Sludge aerobic mechanical composting method and dynamic roller composting device

A composting method and sludge technology, which are applied in fertilization devices, organic fertilizers, preparation of organic fertilizers, etc., can solve the problems of long composting time, secondary pollution, and poor control of composting conditions, and reduce energy consumption and cost. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] 1) Preparation of composite conditioner for composting

[0031] Take the straw that accounts for 1%-2% of the total weight percentage of the pile, the sun-dried sludge with a weight percentage of 3%-5%, and the compost finished product that accounts for 6%-8% by weight; Sun-dried sludge and compost finished products are laid out to dry outdoors; after drying, the moisture content of straw is about 0.5%, the moisture content of sun-dried sludge is about 4.3%, and the moisture content of compost products is 28%; then crushed and mixed to make compost Composite conditioning agent for use;

[0032] 2) Stacking preparation

[0033] Take the original sludge accounting for 85%-90% of the total weight of the pile, and its water content is about 80%, then mix the original sludge with a compound conditioner for compost, and stir until the particles are uniform and the particle size is ≤ 10mm. ;

[0034] Dynamic Aerobic Mechanical Composting

[0035] Implementation steps of dy...

Embodiment

[0050] The sludge aerobic mechanical composting method is realized through two steps of composting pretreatment and dynamic aerobic mechanical composting:

[0051] specific method:

[0052] Processing before stockpiling:

[0053] Firstly, a compound conditioner for compost is prepared, and the compound conditioner is made by using a mixture of a small amount of straw, raw sludge after drying and finished compost. Before composting, spread the straw, a small amount of raw sludge and the composted sludge products outdoors to dry to control the moisture content (environment temperature 3-30°C is acceptable), and crush them for later use.

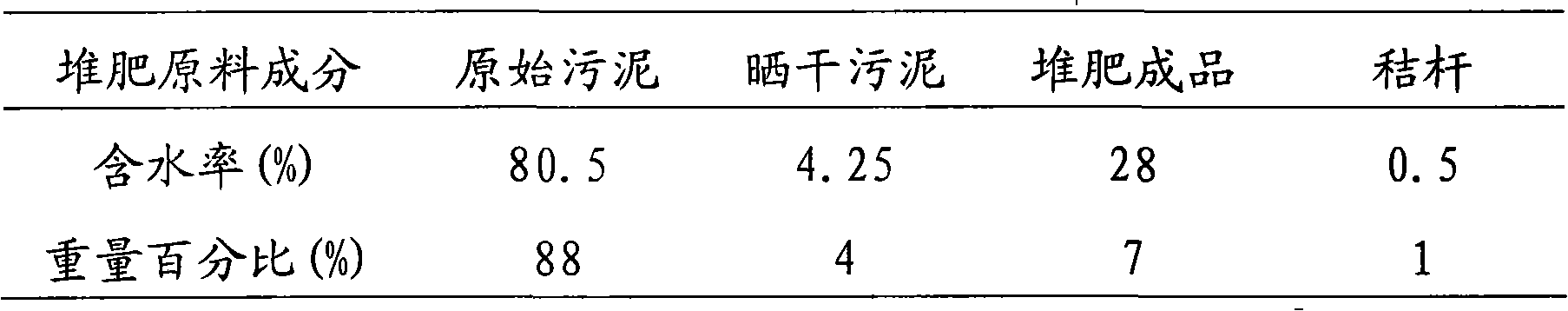

[0054] According to the suitable water content, C / N value, pH value and aeration rate required for the growth and reproduction of aerobic microorganisms, the water content and weight percentage of each component in the sludge raw material and composite conditioner are respectively:

[0055]

[0056] Take the compost raw materials according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com