Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1359results about How to "Harmless" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Organic-inorganic slow-released fertilizer and method for preparing same

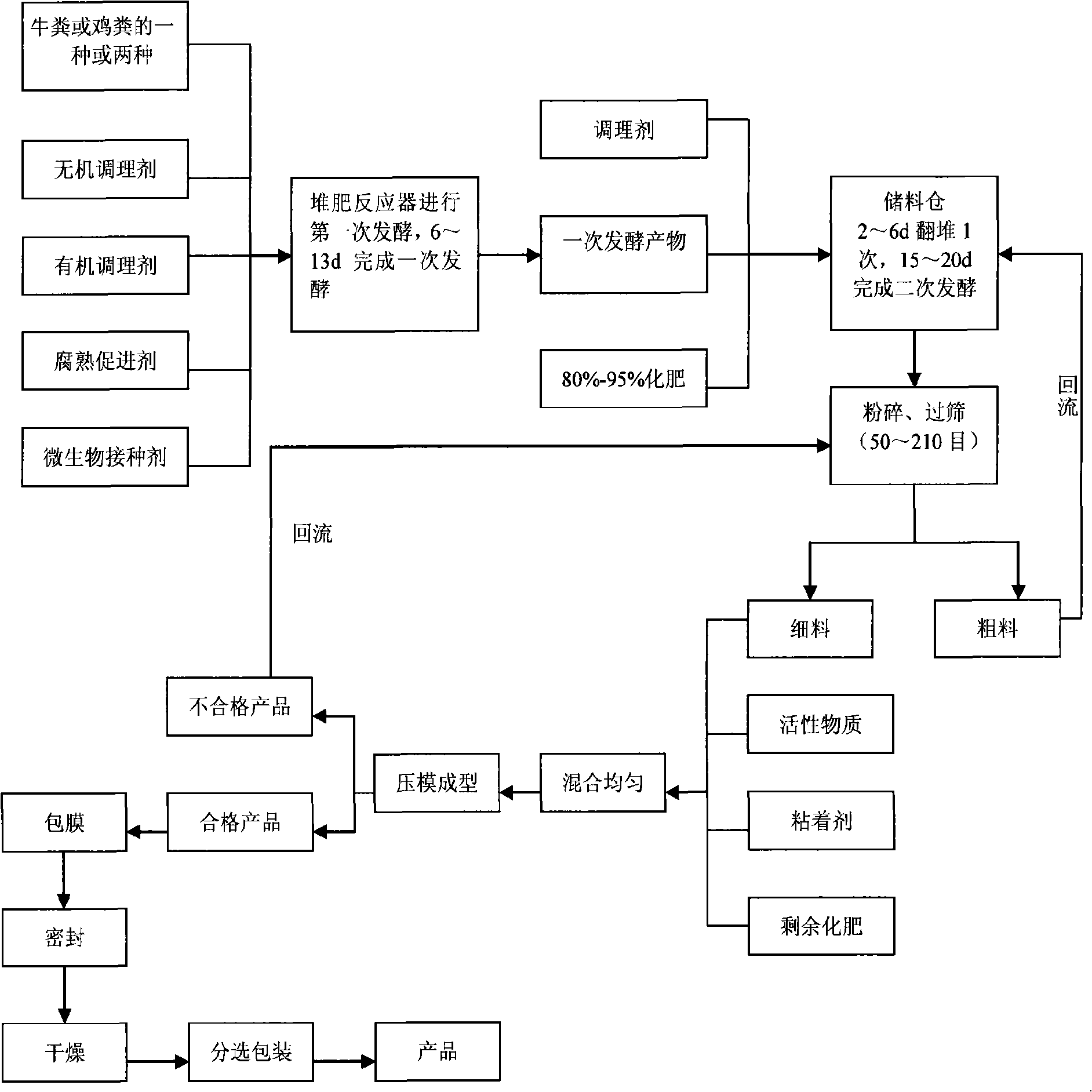

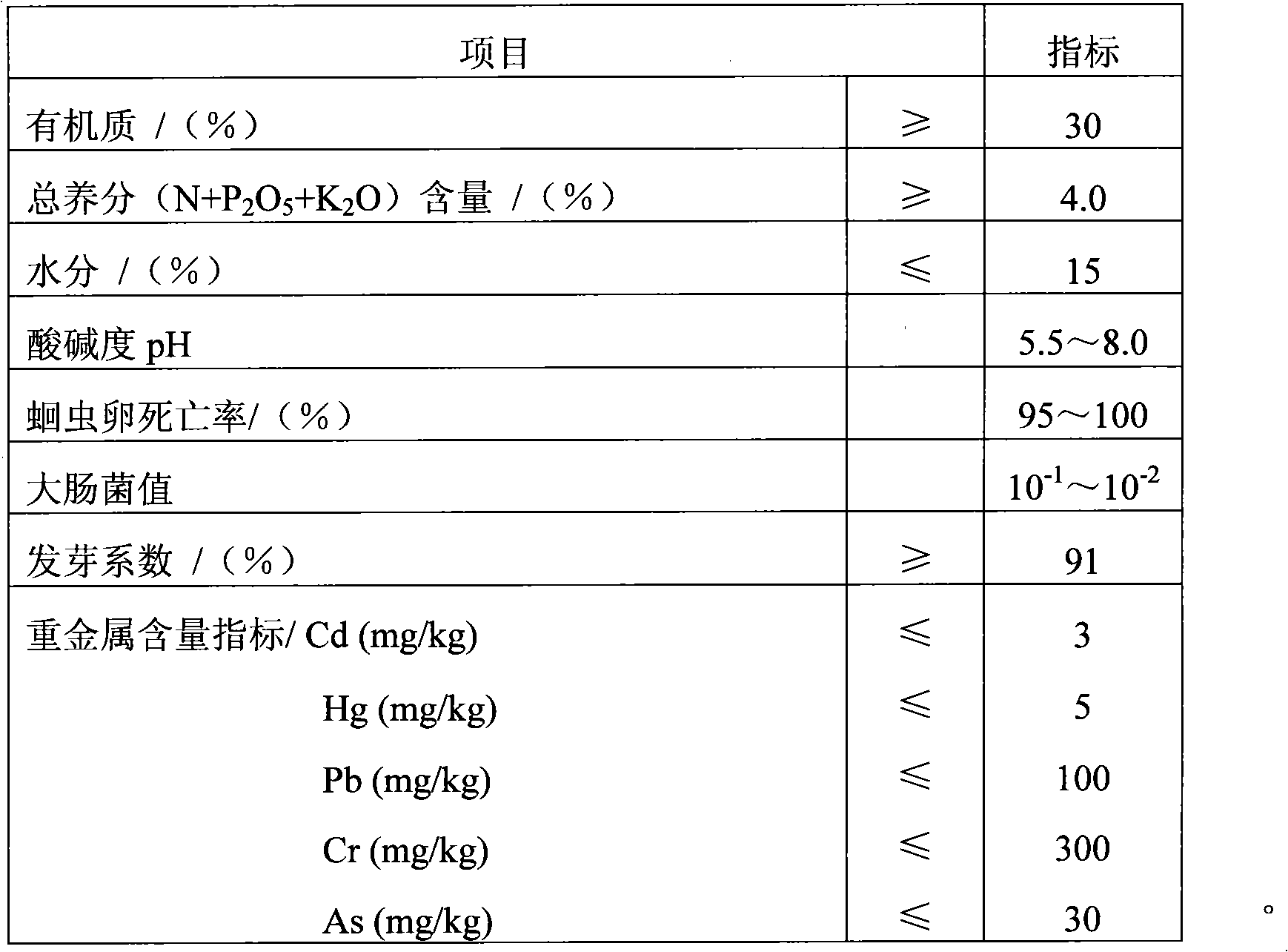

InactiveCN101284747AHarmlessFastBio-organic fraction processingOrganic fertiliser preparationSealantFermentation

The invention discloses a flower organic-inorganic slow-release fertilizer as well as the preparation method thereof. The slow-release fertilizer contains the following materials by weight: primary fermentation products of 45 to 70 percent, chemical fertilizers of 2 to 35 percent, a conditioner of 5 to 30 percent, coating materials of 3 to 25 percent, an agglutinant of 1 to 10 percent, active materials of 0 to 15 percent and a sealant of 0 to 12 percent; the primary fermentation products, the chemical fertilizers and the conditioner are mixed for carrying out the secondary fermentation of composting, and then the products of the second fermentation are crushed for press molding; finally, compound fertilizer particles formed by the press molding are evenly sprayed with the coating materials and the agglutinant, thereby obtaining the flower organic-inorganic slow-release fertilizer; the flower organic-inorganic slow-release fertilizer of the invention has the advantages that the nutrition is rich, the composting process is fast, the rotten degree is good, the fertilizer is prone to be absorbed by flowers, the manufacturing process is simple, and the use is convenient.

Owner:广东省农业科学院土壤肥料研究所

Resource utilization process of organic hazardous waste

ActiveCN111185460AHarmlessAchieve reductionSolid waste disposalTransportation and packagingFluid phaseSlag

The invention discloses a resource utilization process of organic hazardous waste. The resource utilization process includes the steps that classified storage and treatment of solid-phase, solid-liquid mixing and liquid-phase organic hazardous waste are carried out; solid-phase crushing, grinding and screening treatment is carried out; solid-liquid mixing is carried out after solid-liquid separation, solid-phase grinding and liquid-phase sedimentation separation treatment is carried out; direct liquid-phase sedimentation is carried out; then after solid-liquid mixing, a fluxing agent is addedfor stirring, a stabilizer and a dispersing agent are added for slurrying, the slurry is fed into a gasifier, and the obtained gas is used as fuel gas after being subjected to cooling, dedusting, spraying and desulfuration; slag tapping and vitrification slag discharge are carried out; and waste water is recycled. The resource utilization process has the beneficial effects that solid phase, solid-liquid mixing and liquid-phase comprehensive treatment, harmless treatment and slag discharge are realized.

Owner:杰瑞邦达环保科技有限公司

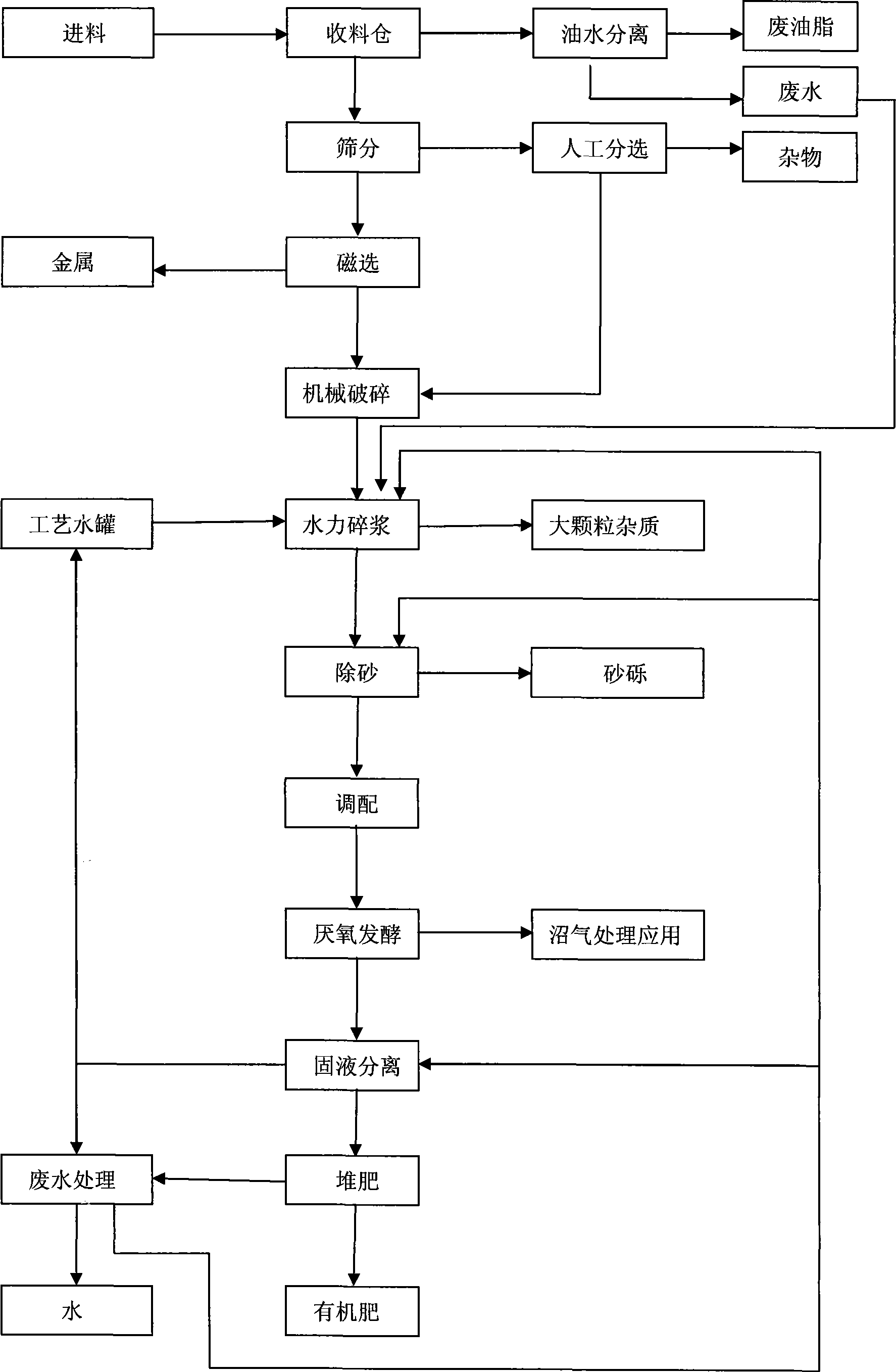

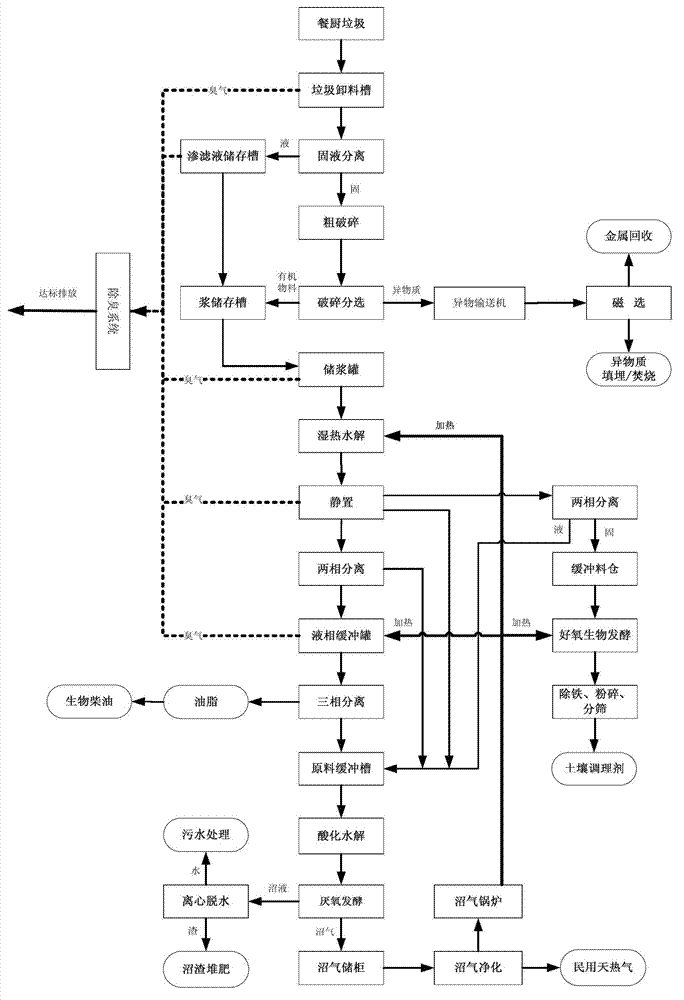

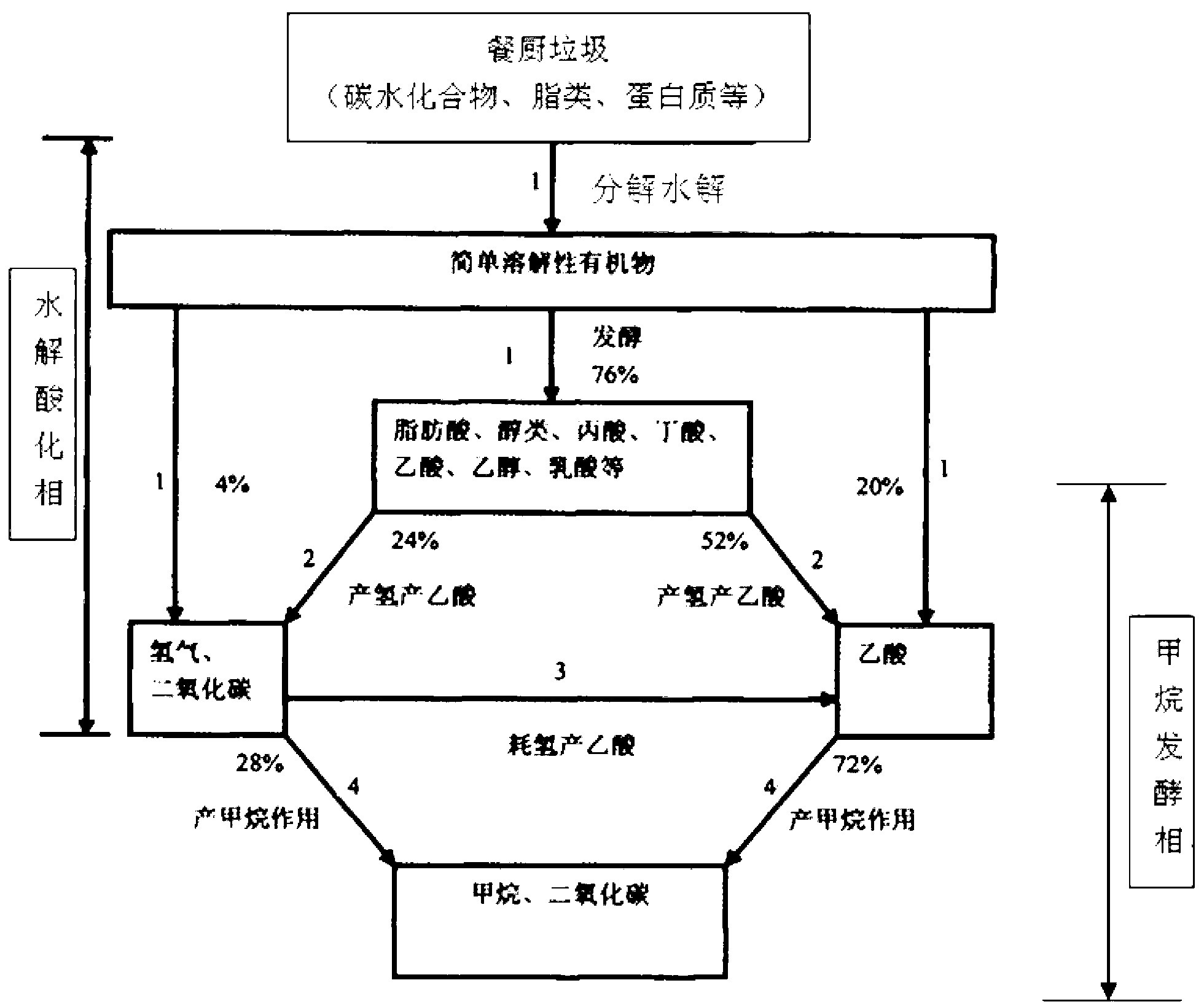

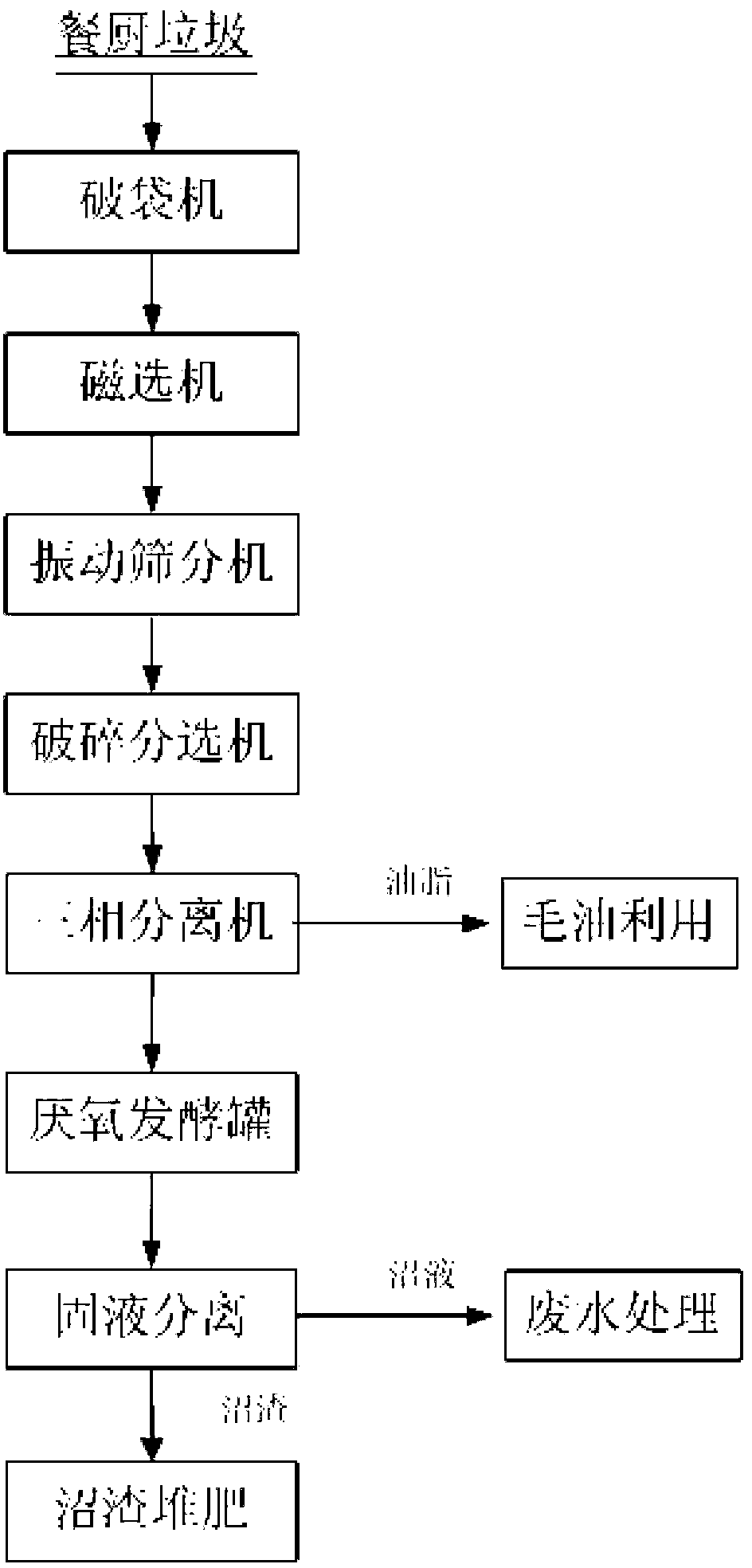

Anaerobic digestion handling method for restaurant garbage

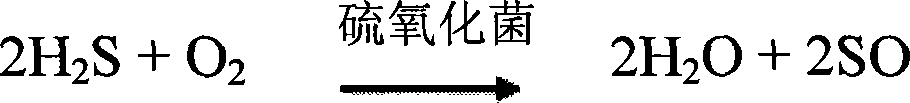

ActiveCN101224999AHarmlessRealize resource processingBio-organic fraction processingClimate change adaptationSlurryOxygen

The invention provides a method for resourceful treatment of restaurant garbage, which is characterized in that the restaurant garbage is completely degraded after treatment with the working procedures of oil separating, preliminary selecting, mechanical crushing, hydraulic pulping, slurry blending, anaerobic fermentation and oxygen-control composting, finally the marsh gas is decomposed via anaerobic digestion and is utilized as energy after desulfurization treatment; the high-quality organic manure is produced from the biogas residues via oxygen-control composting; the separated oil can be recycled as the regenerated industrial raw oil; the wastewater generated in the treatment process can be recycled, and finally the redundant wastewater reaching the standard is discharged after biochemical treatment; and the odor generated by the garbage in the treatment process is directly discharged after reaching the standard via biofiltration treatment, thus the restaurant garbage can be transformed into the clean regenerated energy of electric power and the pollution-free organic manure to completely realize resourceful treatment of restaurant garbage. The resourceful treatment of restaurant garbage has the advantages of innocuity, no peculiar smell, no secondary pollution during the treatment process and realization of harmless and resourceful treatment of restaurant garbage.

Owner:宝林

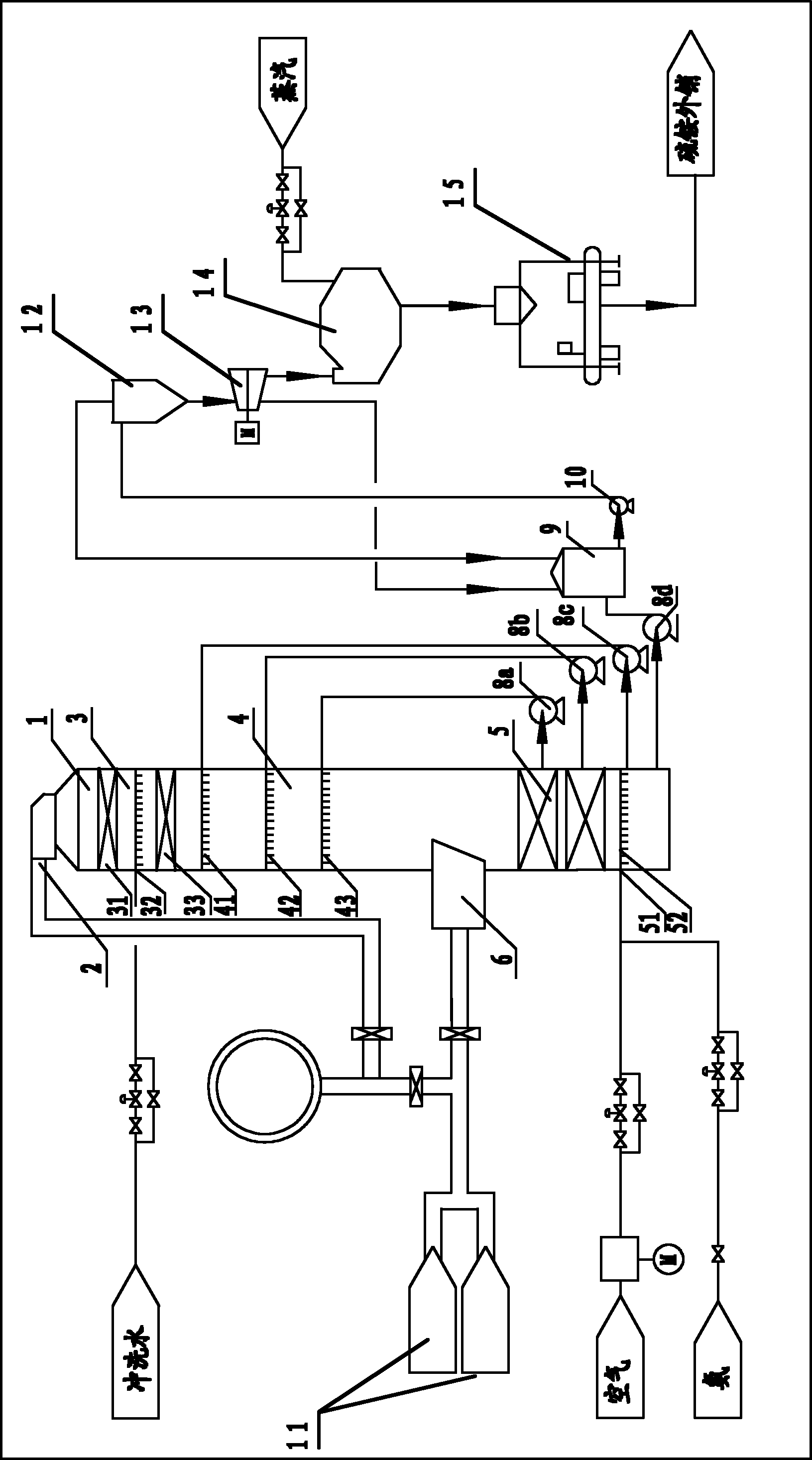

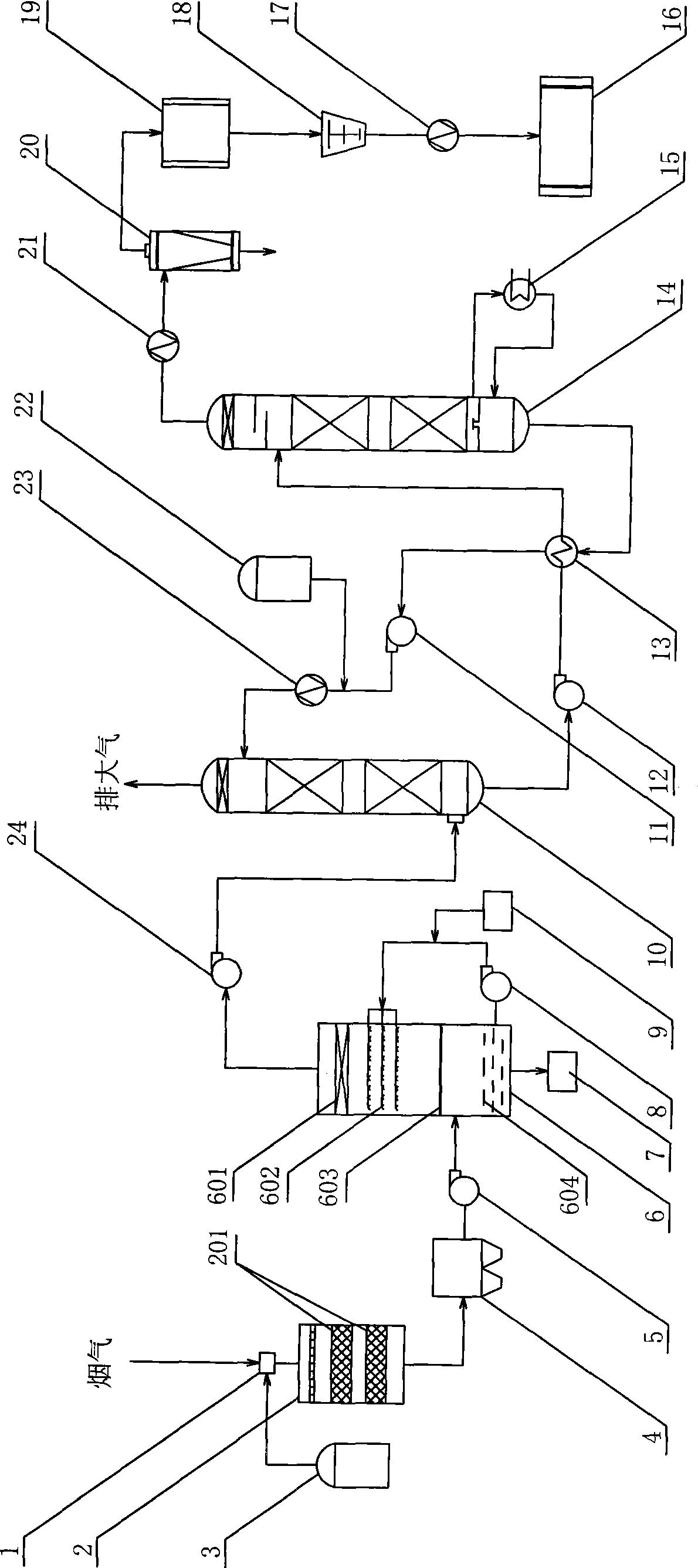

Method for desulfurizing and denitrating smoke simultaneously through ammonia method

ActiveCN101934191AIncrease profitReduce ammonia consumptionDispersed particle separationAmmonia compoundsAmmoniaAmmonium sulfate

The invention relates to a method for desulfurizing and denitrating smoke simultaneously through an ammonia method, which is carried out in a desulfurizing and denitrating system. The desulfurizing and denitrating system comprises a desulfurizing and denitrating tower, the desulfurizing and denitrating tower is provided with a washing demisting segment, an absorption segment and an oxidation segment, wherein the absorption segment is provided with a first desulfurizing spray layer, a second desulfurizing spray layer and a denitrating spray layer from top to bottom; the oxidation segment is provided with a denitrating circulation layer, a desulfurizing circulation layer and an oxidation layer from top to bottom, wherein the denitrating circulation layer, the desulfurizing circulation layerand the oxidation layer are respectively communicated with the denitrating spray layer, the second desulfurizing spray layer and the first desulfurizing spray layer through circulating pipelines positioned outside the desulfurizing and denitrating tower; smoke enters from a smoke inlet, sequentially contacts with the absorption liquid of the denitrating spray layer, the second desulfurizing spraylayer and the first desulfurizing spray layer for denitration and desulfurization, then enters the washing demisting segment and then is exhausted; the absorption liquid of the spray layers descends to the oxidation segment and reacts on the oxidation layer to generate ammonium sulfate; and the absorption liquid of the denitrating circulation layer, the desulfurizing circulation layer and the oxidation layer is respectively delivered to the denitrating spray layer, the second desulfurizing spray layer and the first desulfurizing spray layer through the circulating pipelines positioned outsidethe desulfurizing and denitrating tower.

Owner:NANJING NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION CO LTD

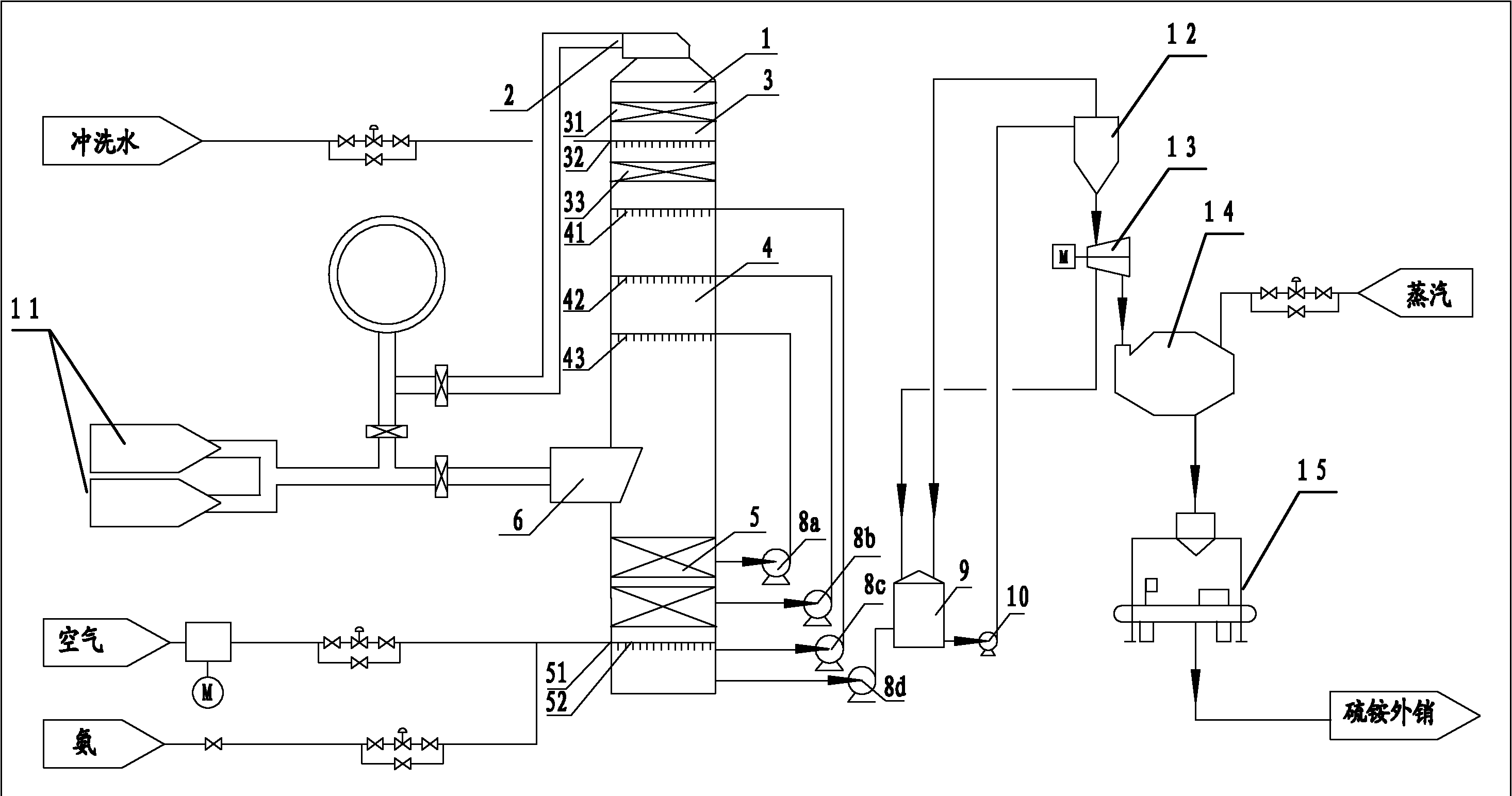

Harmless disposal method of kitchen garbage

InactiveCN102921704AShorten the processing chainPromote engineering applicationSolid waste disposalFurniture waste recoveryOil and greaseEconomic benefits

The invention relates to a harmless disposal method of kitchen garbage, which comprises the following steps of: (1) pretreatment: after unloading the kitchen garbage, performing solid-liquid separation, rough crushing, crushing and sorting and performing magnetic separation, and recycling metal substances mixed in the kitchen garbage; (2) hydrothermal hydrolysis: after the pretreatment, adopting the hydrothermal hydrolysis to fully inactivate viruses and bacteria in the kitchen garbage, separating out animal and vegetable fatty oil from the kitchen garbage, and hydrolyzing organic materials at the same time; (3) using the fatty oil obtained in the step (2) as an industrial fatty oil material or further performing deep processing to obtain fatty acid methyl ester or biodiesel; mixing and proportioning the pasty organic materials and then conveying into an anaerobic fermentation system; and conveying large granular organic materials into an aerobic biological fermentation device. The method provided by the invention realizes harmless disposal of the kitchen garbage mainly by the pretreatment and the hydrothermal hydrolysis process, increases the conversion rate of biological energy of the kitchen garbage and increases the economic benefit of kitchen garbage recycling products.

Owner:CHINA URBAN CONSTR DESIGN & RES INST CO LTD +2

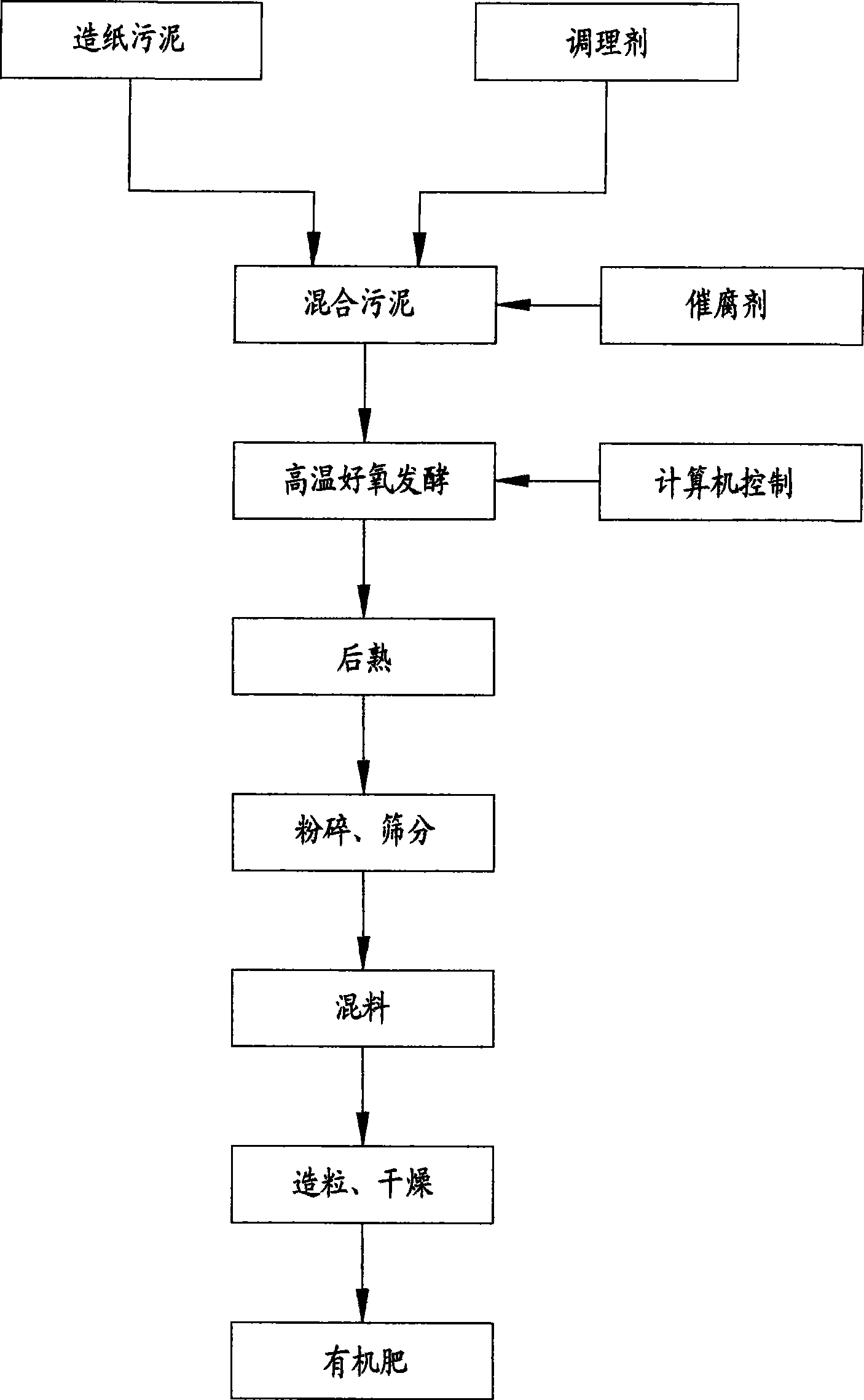

Method for producing fertilizer with papermaking sewage sludge

InactiveCN101429066ARealize comprehensive utilizationSolve processing problemsBio-organic fraction processingOrganic fertiliser preparationSludgePotassium

The invention discloses a method for preparing organic fertilizer from paper-making sludge. The materials such as paper-making sludge, amendment are mixed, subjected to high-temperature aerobic fermentation, post maturation and crushing, screened, and mixed with fertilizer of nitrogen, phosphorus, potassium and the like and medium and micro elements to prepare the organic fertilizer. The method has the advantages of simple process, easy operation, obvious innocuous effect, no environmental pollution and little nutrient loss; and the organic fertilizer prepared by the method is widely applied to industrial crops such as vegetables, fruit trees, Chinese herbal medicines, flowers and field crops such as wheat, corn, paddy rice.

Owner:SHOUGUANG CAILUN ZHONGKE FERTILIZER

Multi-pollutant removing technique and device of fuel coal smoke

InactiveCN101422691ALow flow resistanceReduce investmentProductsCarbon compoundsHigh concentrationDecarburization

The invention discloses a removal technology of removing coal-fired flue gas pollutants and a device thereof. The technology is as follows: an SCR denitration method is first used for removing NOX in the flue gas; then a dust collector is used for removing dusts and ash particles in the flue gas; then a wet calcium-based desulphurization method is used for removing SO2 in the flue gas; then an MEA decarburization process is used for absorbing the SO2 in the flue gas; simultaneously, a pregnant solution of a generated alkanolamine solution is heated, analyzed and regenerated and the generated barren solution of the alkanolamine solution is continuously and cyclically used; and the analyzed CO2 gas with high concentration is produced to be liquid carbon dioxide of industrial grade with high purity after being cooled, gas-liquid separated, dried, compressed and condensed. The device consists essentially of an SCR denitration reactor, the dust collector, a wet calcium-based desulphurization reactor, an MEA decarburization absorption tower, a regeneration tower, a gas-liquid separator, a dryer, a compressor, a condenser and the like which are connected with each other by pipes. The device has simple and compact overall design, low investment and operation costs, and stable and reliable work and can conduct classified integration processing and highly efficient simultaneous removal on every pollutant in the coal-fired flue gas.

Owner:WUHAN KAIDI ELECTRIC POWER ENVIRONMENTAL

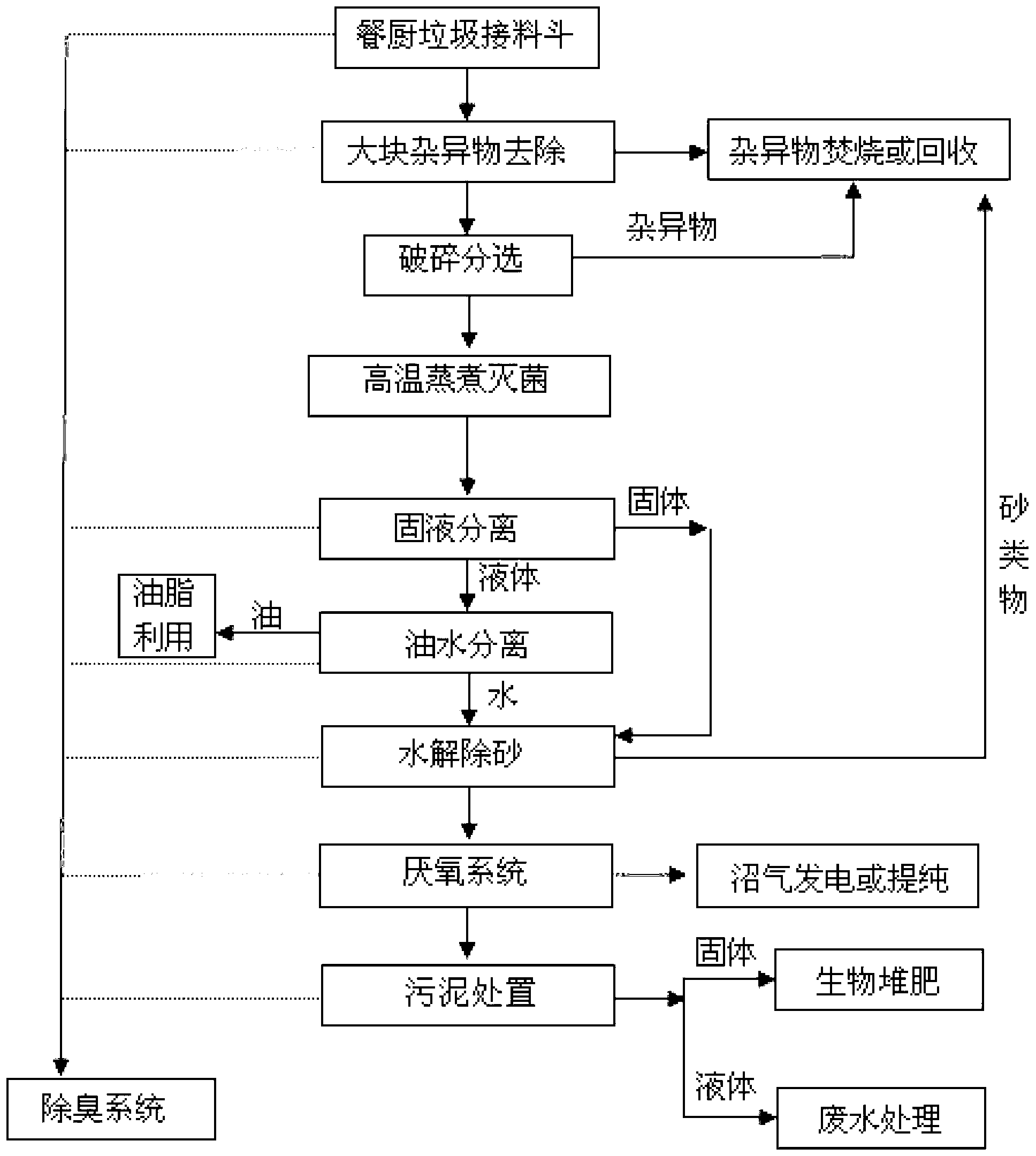

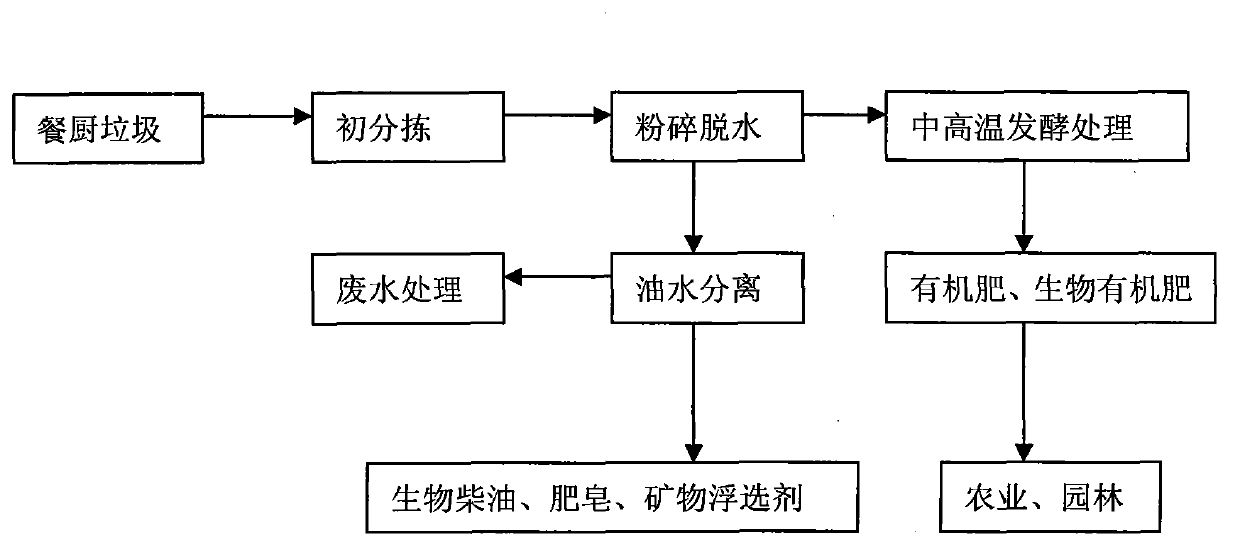

Efficient resourceful treatment method through separation and anaerobic fermentation for kitchen waste

InactiveCN103074381AHarmlessStable in natureFatty oils/acids recovery from wasteBio-organic fraction processingEconomic benefitsOil water

The invention discloses an efficient resourceful treatment method through separation and anaerobic fermentation for kitchen waste. The method includes the steps of firstly performing preliminary bag breaking and leachate collection on original kitchen waste, and removing chunks of miscellaneous and foreign materials; then performing breaking separation, high temperature sterilization, solid-liquid separation and the like; and then performing oil-water separation, hydrolytic sand removal, hydrolytic acidification, anaerobic fermentation and the like. The method has the advantages that not only harmless kitchen waste is achieved, but also extracted crude oil and produced biogas have high economic benefit simultaneously, and the impurity removal rate of the kitchen waste can reach above 90%.

Owner:SOUND ENVIRONMENTAL RESOURCES

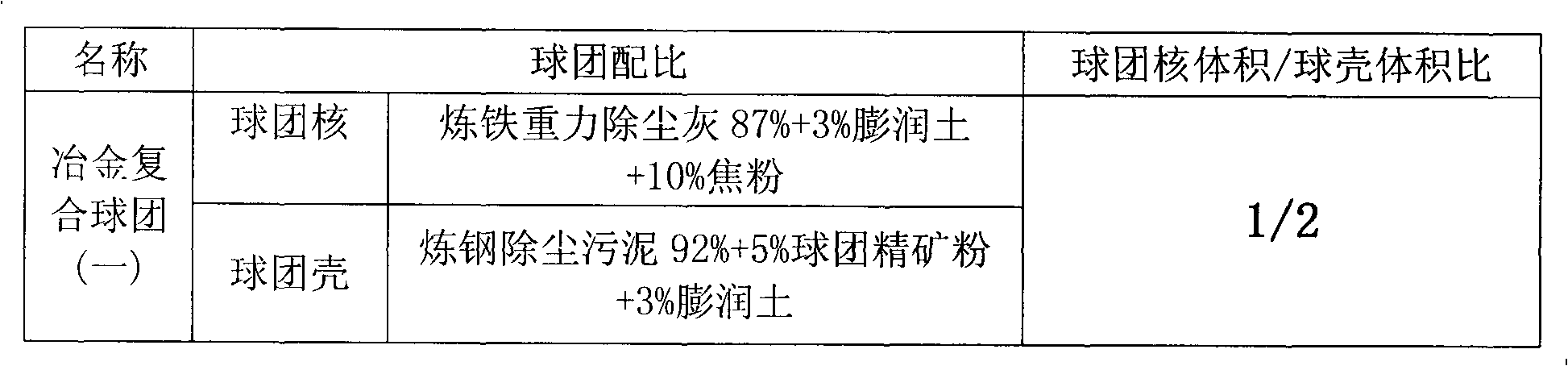

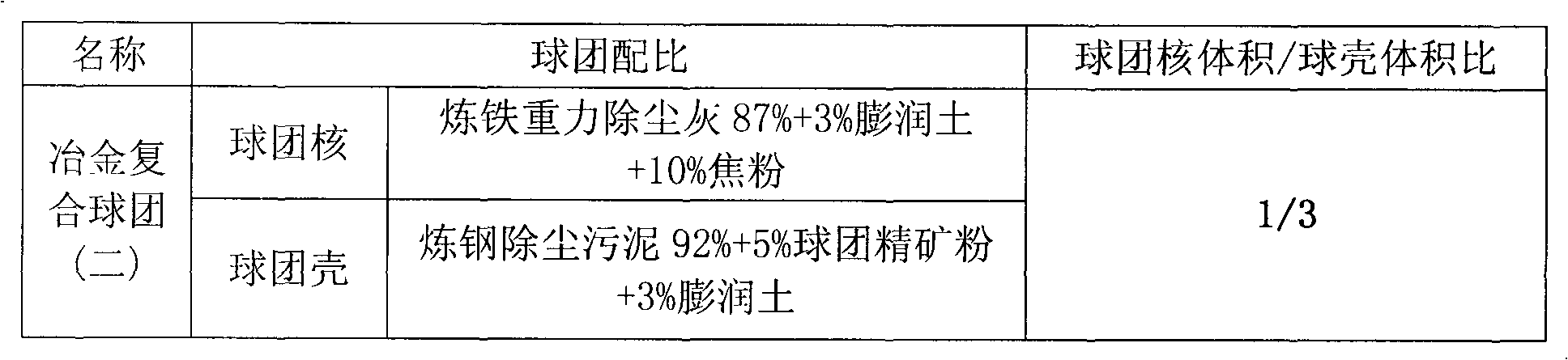

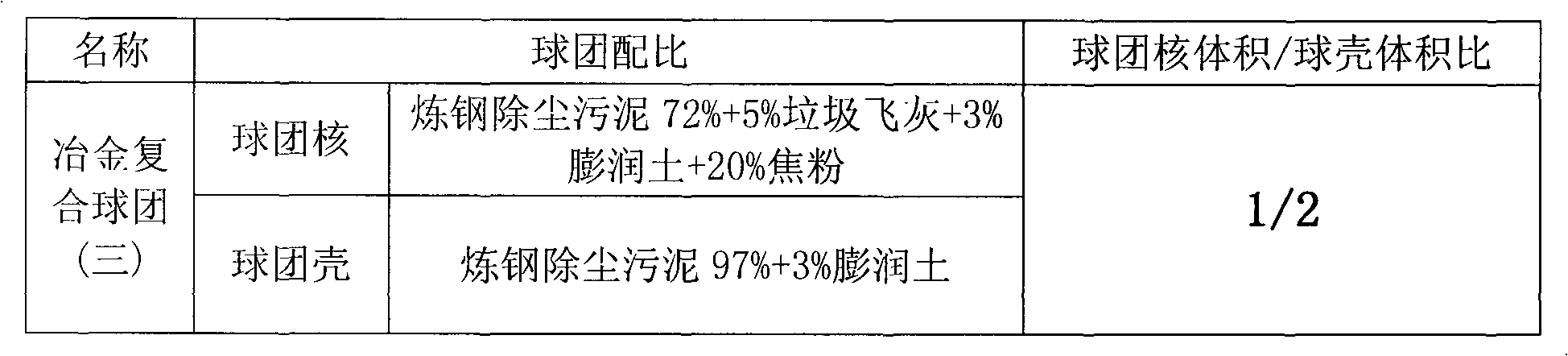

Metallurgical composite pelletizing prepared through twice pelletizing method, as well as preparation method and application thereof

ActiveCN101613800AImprove iron gradeIncrease valueBlast furnace detailsManufacturing convertersSocial benefitsAdhesive

The invention provides a metallurgical composite pelletizing prepared through a twice pelletizing method, as well as a preparation method and an application thereof. The pelletizing is provided with a pelletizing shell formed by a central pelletizing core and a pellet material coating the outside of the pelletizing core. The internal pelletizing core of the formed pelletizing is in a reducing atmosphere, the outside of the formed pelletizing is in an oxidizing atmosphere, and the metallurgical composite pelletizing undergoing twice pelletizing satisfies the metallurgical requirements. The pelletizing core takes an iron-containing material and reducing coal dust or coke powder as raw materials in which adhesive and waste fly dust are added, and is obtained by means of disk pelletization or pressure pelletization. The pelletizing shell takes the iron-containing material and the pelletizing core as raw materials in which the adhesive is added, and is obtained by means of disk pelletization and taking the pelletizing core as the center of the sphere. Various metallurgical performance indexes of the composite pelletizing are highly better than normal pellets. The composite pelletizing not only realizes the harmlessness and the recycling of the waste fly ash, but also can greatly improve the technical and economic indexes of iron making blast furnaces. In addition, the composite pelletizing not only achieves such social benefits as energy conservation, emission reduction, environment protection and environment pollution treatment, but also can create considerable economic benefits.

Owner:CHONGQING ANGRUIYUE SCI & TECH

Comprehensive utilization method of aluminum ash

ActiveCN105347361AHarmlessAvoid pollutionAmmonium salt preparationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAtmospheric dustAluminum industry

The invention belongs to the technical field of comprehensive utilization of waste resources from the aluminum industry and specifically discloses a comprehensive utilization method of aluminum ash. According to the comprehensive utilization method of aluminum ash, metallic aluminium is extracted from aluminum ash through an ore grinding method; the aluminum ash obtained after aluminium extraction undergoes catalytic deamination; the aluminum ash obtained after deamination is mixed with alkali and granulation forming is then carried out; and the granulation product is sintered and the sintered product is finally dissolved out. By the above method, useful components in the aluminum ash can be recovered to the maximum; ammonia gas which has been ignored for a long time is effectively recovered; components such as aluminium oxide, villiaumite and the like are recovered and utilized to the maximum; pollution of aluminum ash processing to the environment is avoided; atmospheric dust pollution is avoided; atmospheric pollution is also avoided due to ammonia gas recovery; pollution of aluminum ash stacking to underground water and soil is avoided due to extraction and recovery of fluoride salt; and environmental safety during the treating process is guaranteed.

Owner:湖南绿脉环保科技股份有限公司

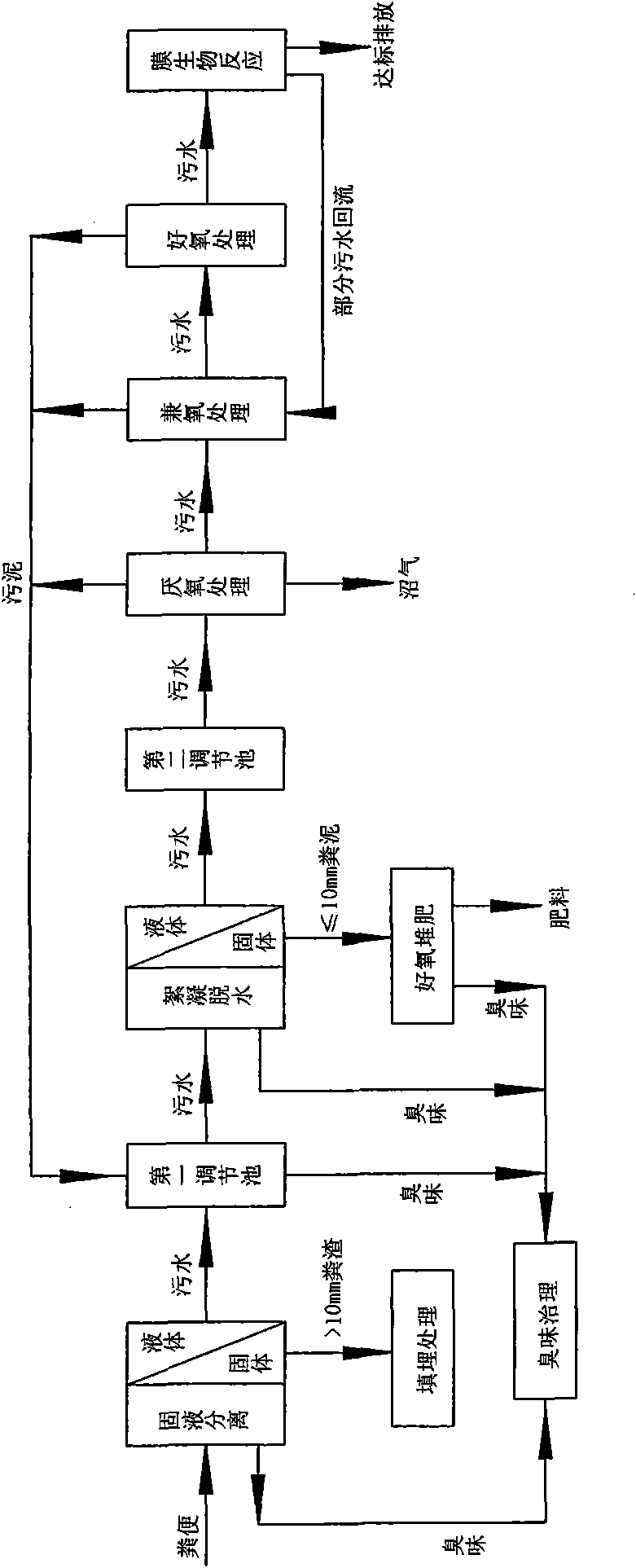

Excrement centralized processing method

ActiveCN101654318AAvoid cloggingCOD removalBio-organic fraction processingSludge treatment by de-watering/drying/thickeningFlocculationFeces

The invention relates to an excrement centralized processing method, comprising the steps of solid-liquid separation, flocculation water removing, aerobic compost treatment, anaerobic sewage treatment, facultative anaerobic sewage treatment, aerobic sewage treatment, membrane anaerobic reacting sewage treatment and odor treatment. Treated with the processing method of the invention, the urban night soil is 100% decontaminated, is 99.7% minimized and the excrement sludge is completely changed into resource.

Owner:北京昊业怡生科技有限公司

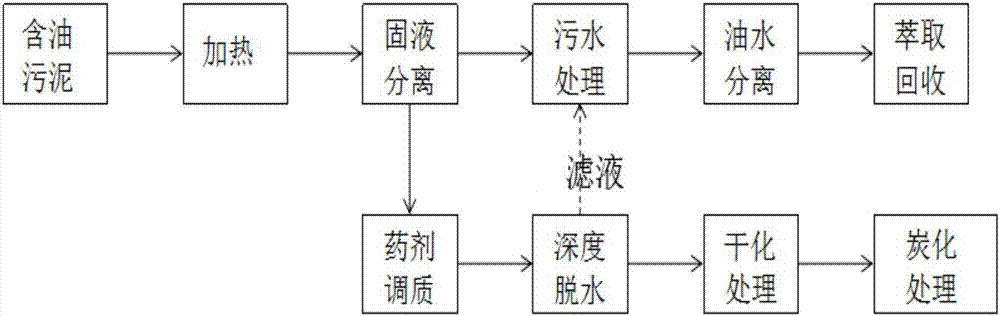

Treating method for oily sludge

InactiveCN106957136AThe treatment method is simple and effectiveSimple processSludge treatment by de-watering/drying/thickeningAgriculture tools and machinesChemistryPyrolysis

The invention provides a treating method for oily sludge and relates to the technical field of oily sludge treatment. The treating method provided by the invention comprises the following steps: heating and stirring oily sludge, standing and then performing solid-liquid separation, thereby acquiring oily mud and oily liquid; introducing the oily liquid into a sewage treatment system for performing oil-water separation, and extracting and purifying the separated oil; adding a reagent into the oily mud for tempering; after tempering, deeply dewatering, thereby acquiring dewatered oily mud and filtrate; performing oil-water separation on the filtrate; performing drying treatment and pyrolysis carbonizing treatment on the dewatered oily mud. The treatment method provided by the invention is simple, convenient and efficient and can realize the reduction, harmless and recycling treatment of the oily sludge, the whole treating process flow operation occupies less area and the investment cost is low.

Owner:安徽省通源环境节能股份有限公司

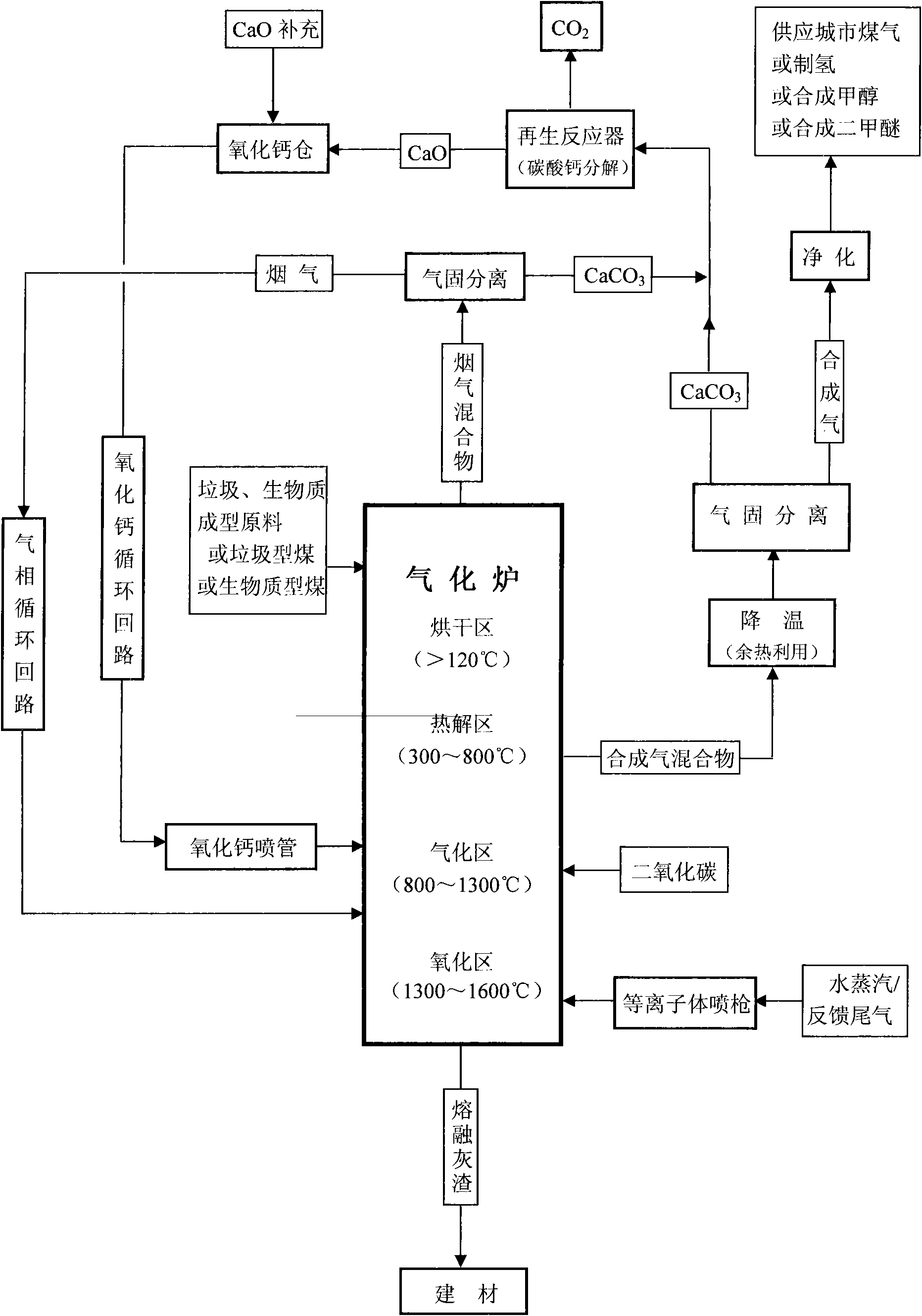

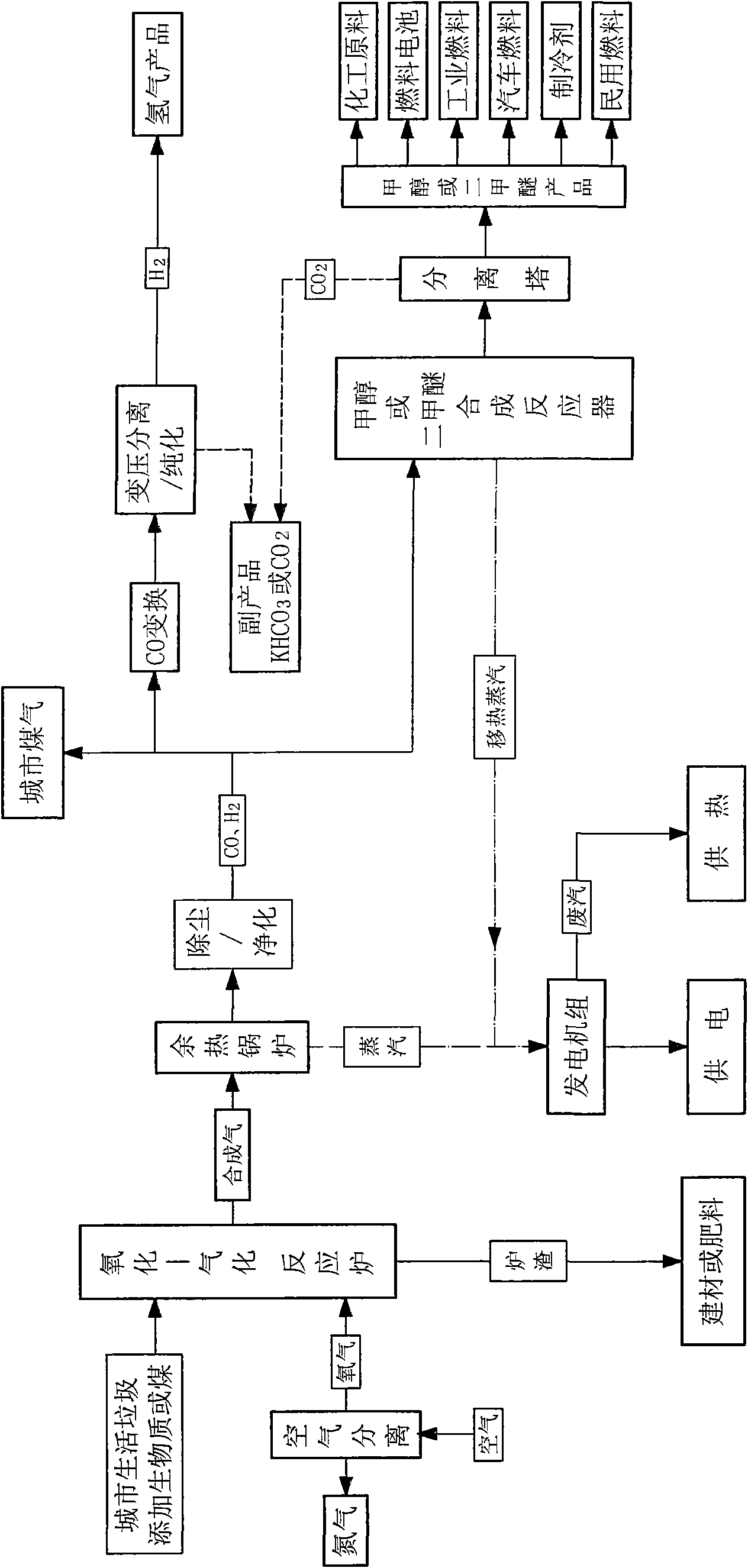

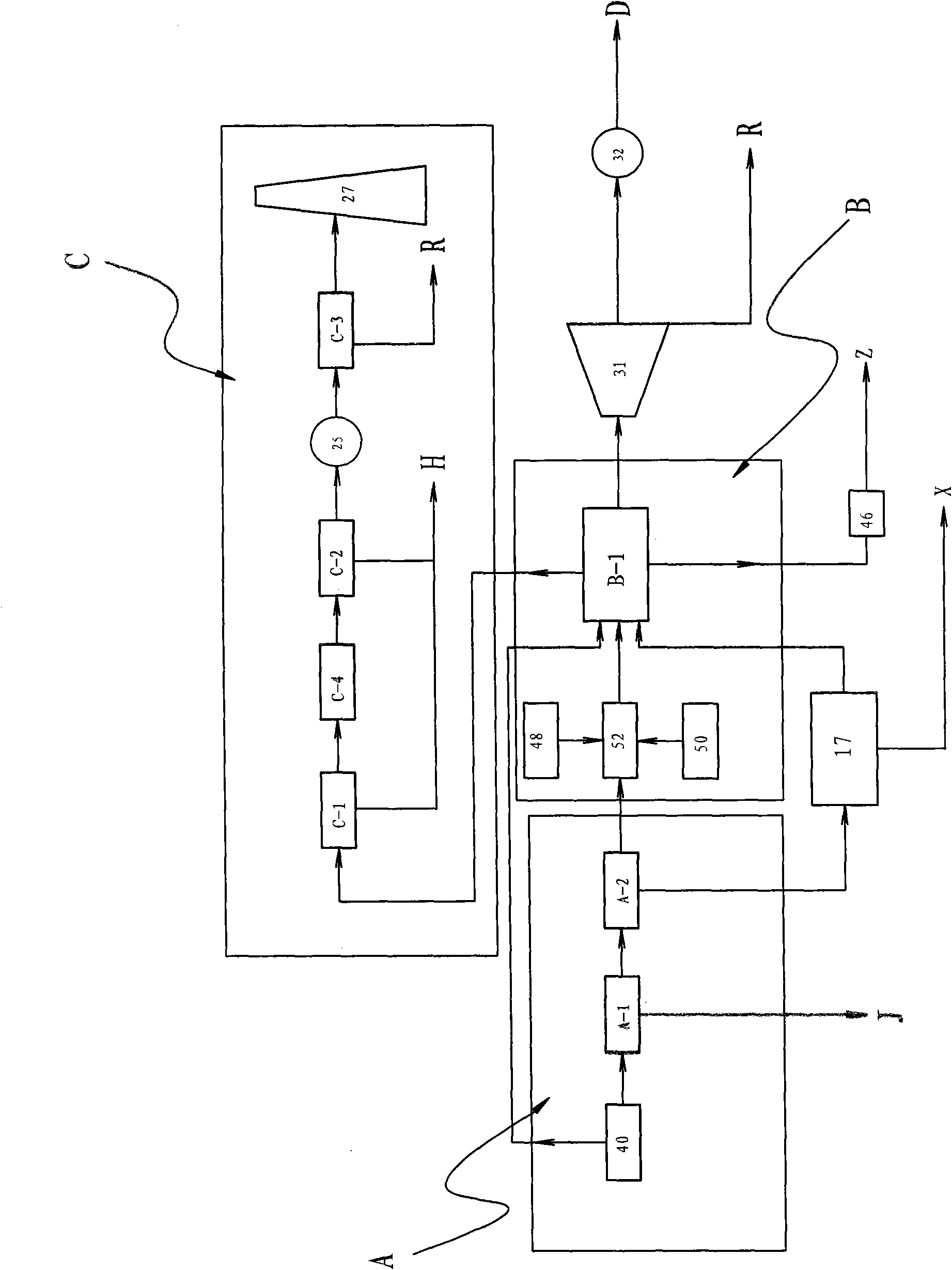

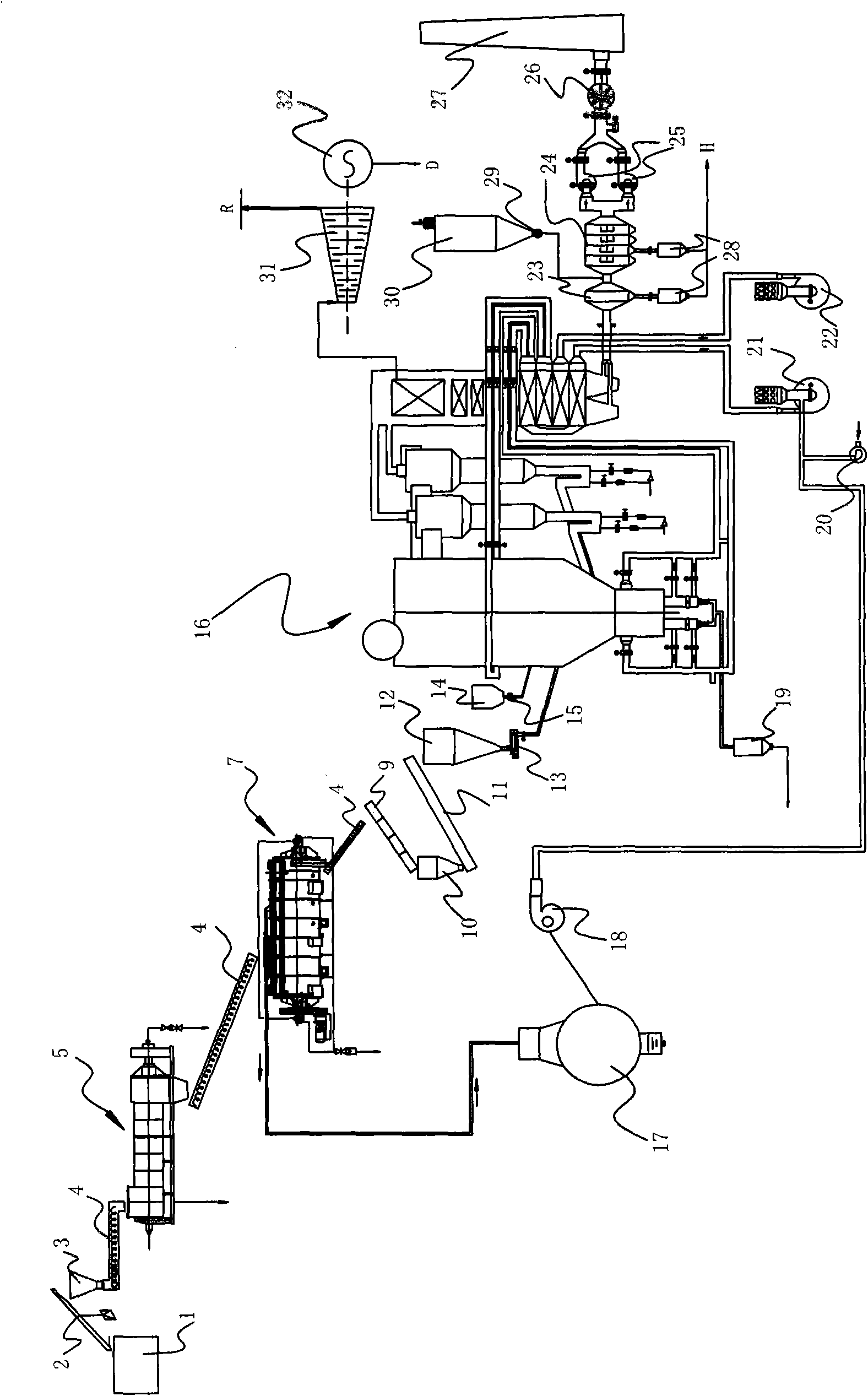

Gasification process for producing synthesis gas from garbage and biomass raw materials

InactiveCN101525118AEliminate pollutionHarmlessHydrogen productionSpecial form destructive distillationGas phaseWater vapor

The invention provides a gasification process for producing synthesis gas from garbage and biomass raw materials, which relates to a gasification processing technique of garbage and biomasses. The gasification process is characterized in that the technological process mainly comprises a raw material solid matter process, a gas phase circulation loop, a calcium oxide circulation loop and a synthesis gas drawing process; one or a mixture of more garbage, the biomasses and coal is sent into a gasification furnace to perform gasification so as to generate the synthesis gas; and simultaneously, calcium oxide is sent into the gasification furnace, an exothermic reaction of absorbing carbon dioxide by the calcium oxide provides the heat required by the gasification reaction in the furnace, and water vapor is sent into a plasma spraying gun and is heated to more than 3,100 DEG C to generate H2, O, O2 and H2O<*> which are sprayed into the gasification furnace to perform reactions with the garbage and the biomasses and supply heat into the furnace. The gasification process adopts a measure to spray the calcium oxide into the furnace to not only greatly reduce the electric energy consumption of the plasma spraying gun, but also improve the quality and the yield of the synthesis gas, thus the aim of transforming the garbage and the biomasses into clean energy can be achieved easily.

Owner:周开根

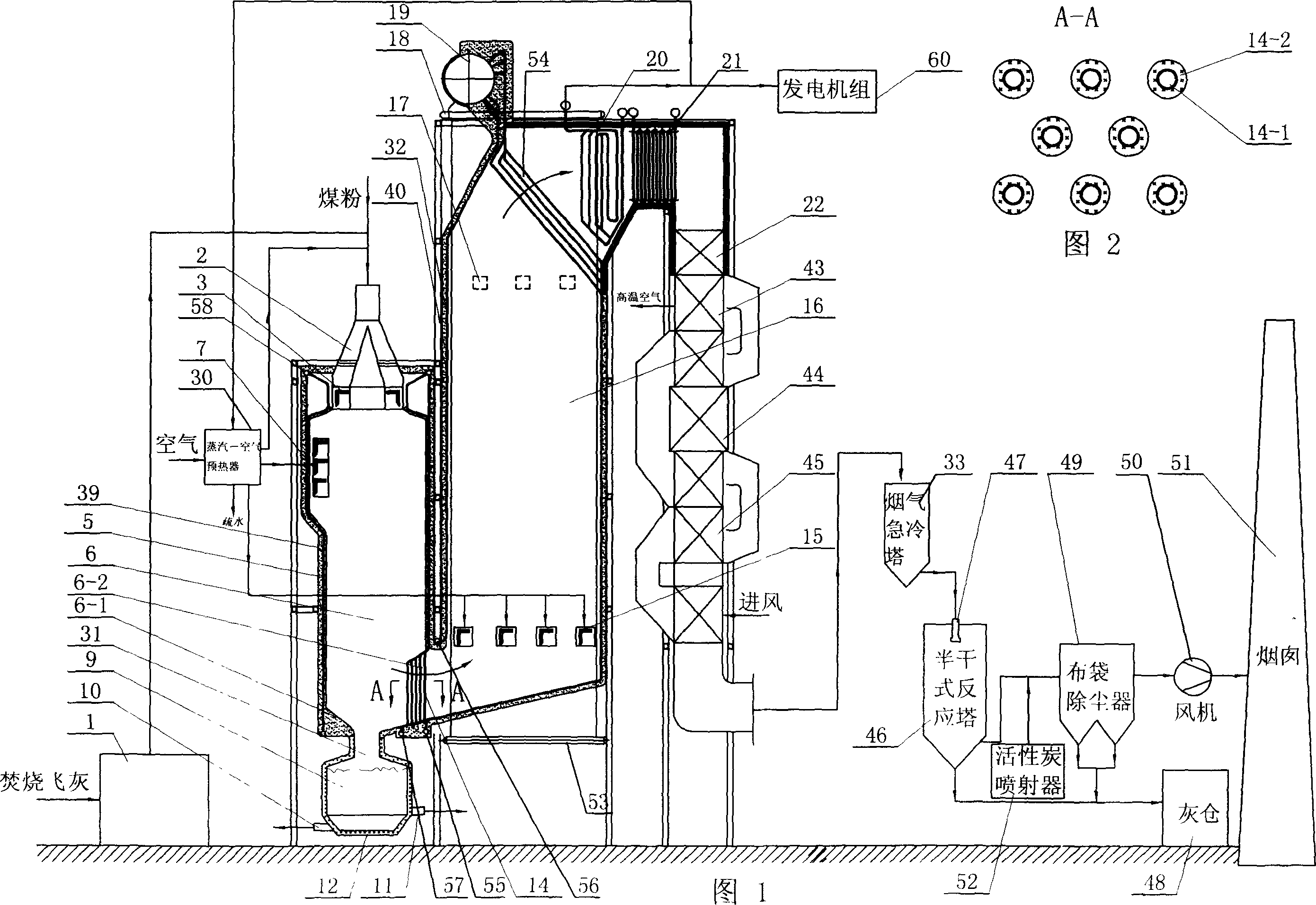

Method of processing refuse burning fly ash through cyclone furnace high temperature melting

The invention relates to a method for processing fly ash after incineration of domestic waste. The high-temperature melting treatment method of fly ash in a garbage incineration is completed by the following steps: 1. The fly ash produced after garbage incineration is mixed with coal powder at a ratio of 15 to 25: 75-85 mixed in a ratio of 75 to 85 and sent to the cyclone furnace 6 for combustion until high-temperature melting; 2. The combustion in the cyclone furnace 6 is in a reduced state; 3. The heavy metals in the fly ash sink to the bottom of the slag pool 9 and are discharged and recovered , and the slag floating on the liquid metal flows out of the slag pool from the slag recovery outlet 11, and is then rapidly cooled by water as cement raw material or building material recycling. The method can not only recover valuable metals in fly ash, decompose dioxin, recover waste heat to generate electricity, but also recycle molten ash as cement raw material or building material after being quenched with water, and has low operating cost. Or the combustion in the cyclone furnace 6 is in an oxidized state, the air excess coefficient is kept at 1.1 to 1.2, and only the quenched glass body is recovered.

Owner:HARBIN INST OF TECH

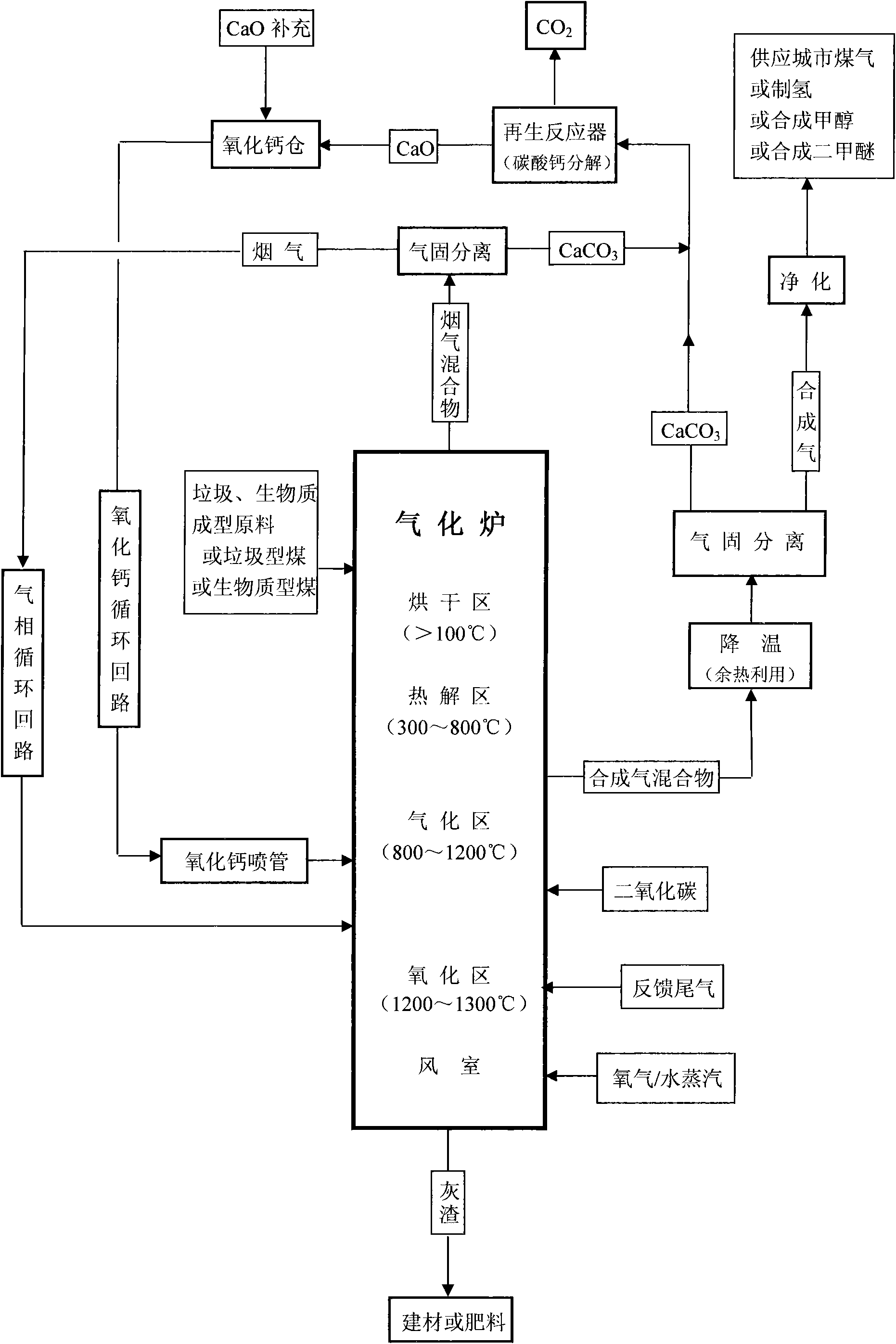

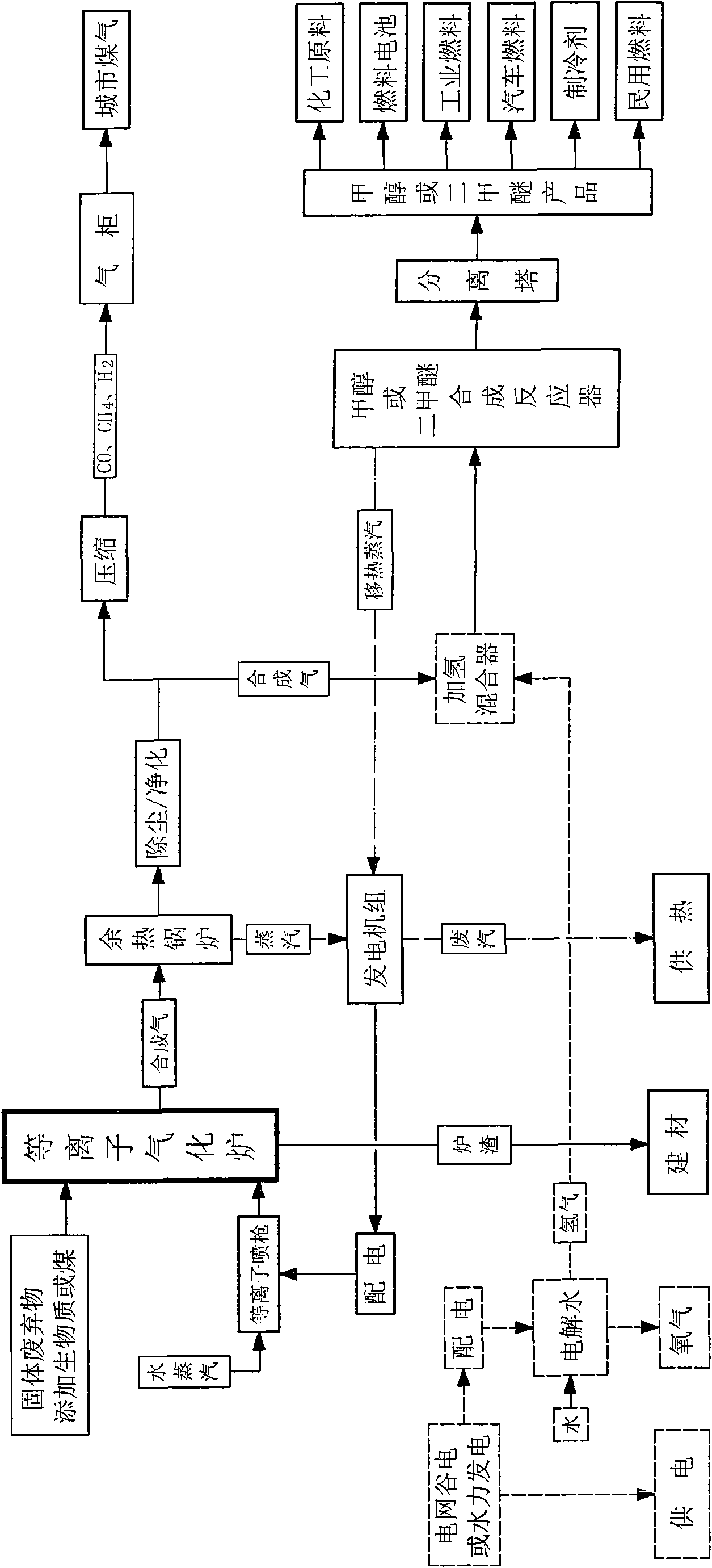

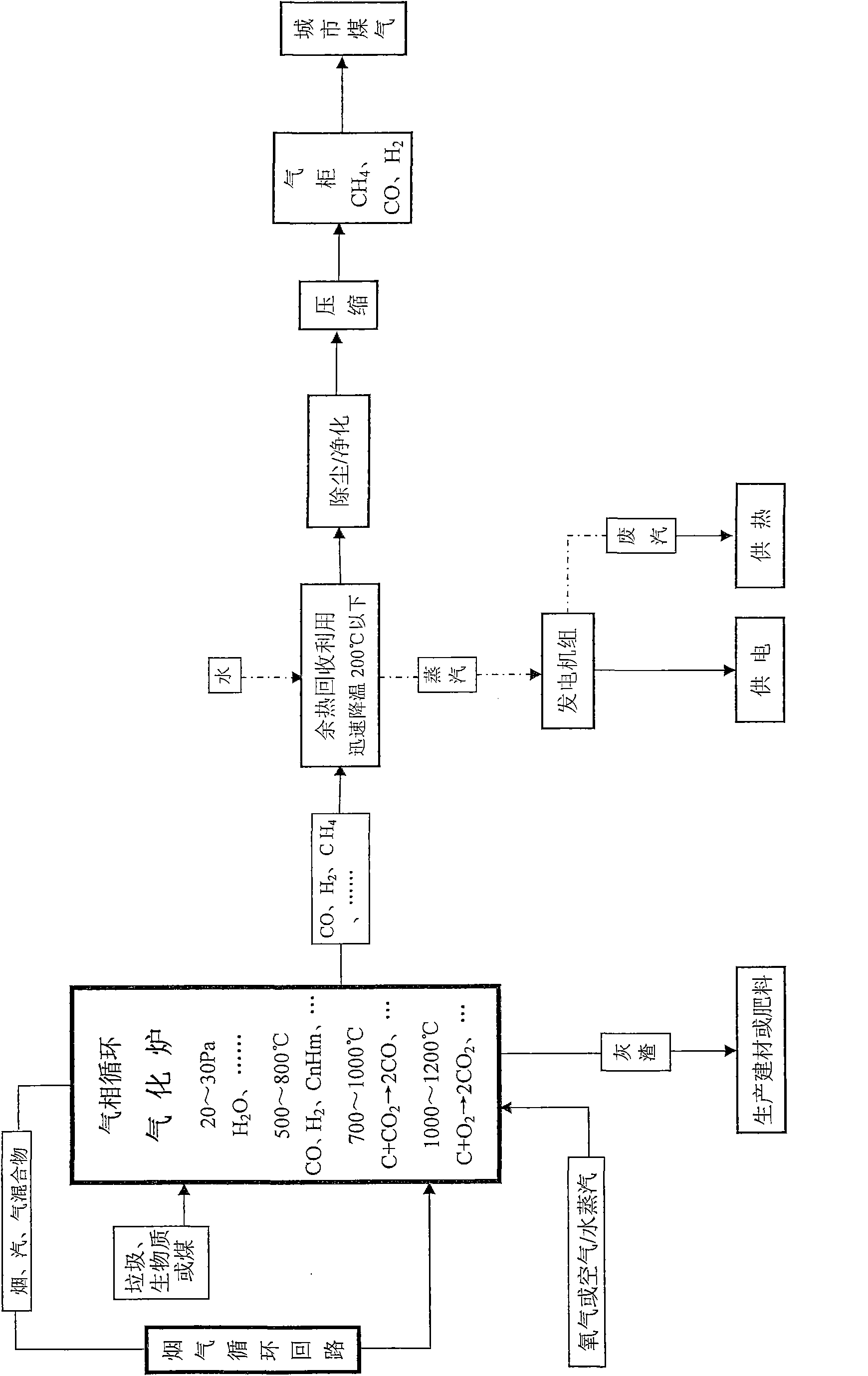

Process, system and device for waste biomass multi-production processing

ActiveCN101565629AEliminate pollutionHarmlessHydrogen separationCombustible gas catalytic treatmentEcological environmentGas phase

The invention relates to a process, a system and a device for waste biomass multi-production processing, in particular to a waste biomass gasification and liquefaction treatment system. The gasification treatment is performed to the waste biomass, the gas is used for producing clean energy and chemical raw materials, the furnace slag is used for producing building materials or fertilizer and the waste heat is used for electric power generation and heat supply so as to realize the environmental-friendly municipal solid waste treatment and the ecological environment protection. The system mainlycomprises a gas-phase circulation gasification furnace, a flue gas circulation air tube, a flue gas circulation fan, a dust-removal / purifying tower and a synthesis reactor and is characterized in that the gas-phase circular reaction is performed to the flue gas in the gasification furnace, the water vapor and the gaseous matter generated during the pyrolysis to obtain hydrogen-rich synthetic gas,and meanwhile, the dioxin (violent in toxicity) is broken up; and the post treatment is performed to the hydrogen-rich synthetic gas to generate city gas, methanol, dimethyl ether or hydrogen. The system has the advantages of full gasification of the solid raw material, no pollutant discharge, extremely low exhaust emission and easy purifying treatment, and the device is flexible in size and is feasible for popularization.

Owner:上海格灵迈环境科技有限公司

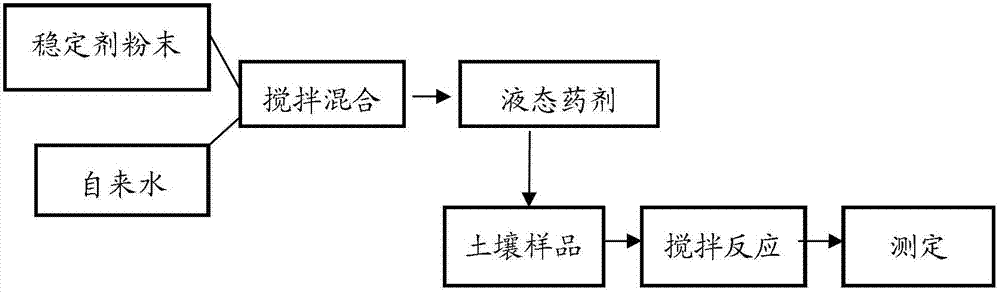

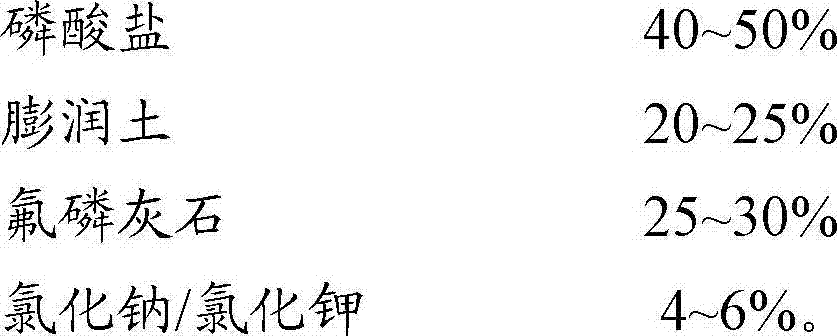

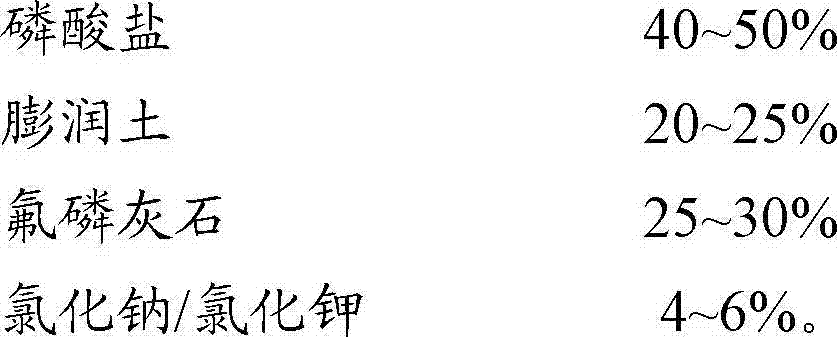

Heavy metal stabilizing agent and method for treating heavy metal contaminated soil by using same

ActiveCN102965116ACaptureHarmlessContaminated soil reclamationOrganic fertilisersSodium BentoniteApatite

The invention discloses a heavy metal stabilizing agent and a method for treating heavy metal contaminated soil by using the heavy metal stabilizing agent. The heavy metal stabilizing agent is prepared from the following raw materials in percentage by weight: 40 to 50 percent of phosphate, 20 to 25 percent of bentonite, 25 to 30 percent of fluor apatite and 4 to 6 percent of sodium chloride / potassium chloride. When the heavy metal stabilizing agent is used for treating the contaminated soil, the heavy metal stabilizing agent and water are mixed together to form a suspension, then the suspension is added into the heavy metal contaminated soil, and the suspension and the heavy metal contaminated soil are fully mixed. The heavy metal stabilizing agent has high stability for treating soil, and the technical problem that the conventional curing agent and curing method cause reverse dissolution easily is solved.

Owner:ENVIRONMENTAL SCI RES & DESIGN INST OF ZHEJIANG PROVINCE

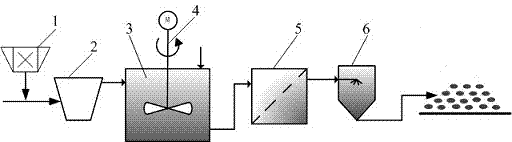

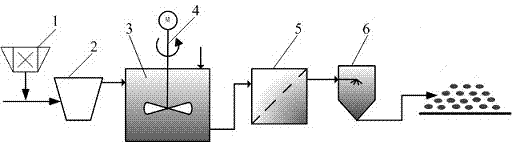

Method and device for preparing formed sludge fuel

InactiveCN102212403AImprove dehydration effectImplement resourcesSludge treatment by de-watering/drying/thickeningBiofuelsSludgeSolid fuel

The invention discloses a process method for preparing a derived solid fuel by using sludge, and the method comprises the following steps: feeding dehydrated wet sludge with the moisture content of 70-85% and biomass at a weight ratio of 50:(1-10) into a tempering kettle, introducing less water, evenly stirring, adding a tempering agent the mass of which is 0-20% of that of dried solid sludge, stirring for 2-10 minutes continuously, removing most of water by a dehydrator, forming, and naturally drying for 24 hours, thus obtaining the derived sludge solid fuel. The invention also discloses a device for preparing a formed sludge fuel. The device comprises a straw crusher, a feeder, the tempering kettle, the stirrer, the fuel hydrator and a fuel forming machine, wherein the stirrer is positioned at the top of the tempering kettle, a stirring shaft is coincident with the axis of the tempering kettle and inserted into the tempering kettle, the outlet of the straw crusher is connected with the inlet of the feeder, the outlet of the feeder is connected with the inlet of the tempering kettle, the outlet of the tempering kettle is connected with the inlet of the fuel dehydrator, and the outlet of the fuel dehydrator is connected with the inlet of the fuel forming machine.

Owner:JIANGSU XINFA ENVIRONMENTAL PROTECTION TECHCO

Method for water plugging and profile controlling of underground polymerization of oil exploitation sludge

The invention relates to a method for water plugging and profile controlling of underground polymerization of oil exploitation sludge, comprising the following steps of: adding 2-7% of crylic acid, 0-3% of acrylamide, 0.2-0.6% of cross linking agent and 0.01-0.05% of initiator into 15-25% of oil exploitation sludge, injecting the mixture together with the oil field water or tap water in the ground; and subsequently generating plugging substances of solid mesh structure wrapping sludge owning to the polymerization reaction under the action of oil pool temperature, thus playing an effect of sealing the underground seams, wherein the oil exploitation sludge is a tank bottom sludge generated during the oil exploitation process of the oil field or the sludge in the sludge pool; the sludge is athin oil sludge; the cross linking agent is a polyol, a glycerin, an N, N-methylene bisacrylamide or N, N-dimethybisacrylamide; and the initiator is the alkali metal salt or the ammonium salt of a persulphuric acid. The method changes the aboveground polymerization process of the oil exploitation sludge grain profile control agent into the underground polymerization process, saves corresponding procedures and the equipment and devices, and generates the water-plugging profile control agent with high intensity and long-term effect by adjusting the concentration of the monomer.

Owner:PETROCHINA CO LTD

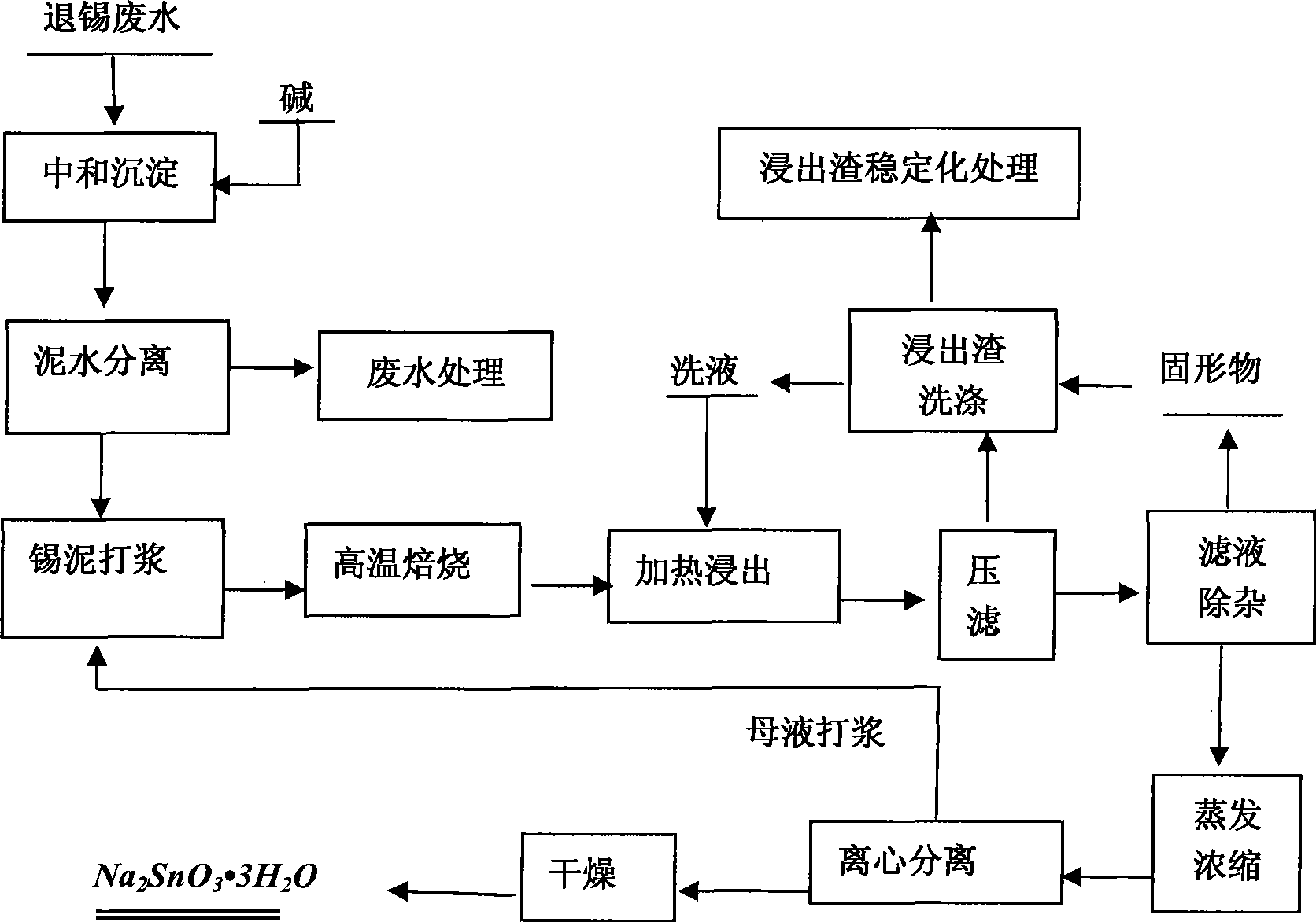

Method for preparing sodium stannate using circuit board tin-stripping wastewater

ActiveCN101497458AReduce manufacturing costRaise the gradeTin compoundsMultistage water/sewage treatmentResource utilizationSludge

The invention relates to a method for preparing sodium stannate by utilizing tin-stripping wastewater of a circuit board. Collected tin-stripping wastewater is neutralized and precipitated by adding alkali to obtain tin sludge with higher tin content; the tin sludge is beat by adding the alkali, and is subjected to high-temperature roasting and countercurrent leaching; then a leachate is subjected to filter pressing; a filtrate is subjected to evaporation, concentration and centrifugal separation after impurity removal; and 10 to 15 percent sodium hydroxide solution is used to wash the obtained product, and thus a crude sodium stannate product can be obtained and then is vacuum dried at a temperature of between 100 and 110 DEG C for 2 to 3.0 hours to obtain a sodium stannate product. The method ensures that the separation rate of tin in the tin-stripping wastewater can reach more than 99 percent, finds a novel treatment way for the tin-stripping wastewater which is produced by printed circuit board industry and is extremely difficult to treat, gives a reasonable fate for all pollutants in the tin-stripping wastewater, and realizes the resource utilization of useful components of the tin-stripping wastewater to the utmost extent when realizing the innoxious treatment of the tin-stripping wastewater.

Owner:江西东江环保技术有限公司

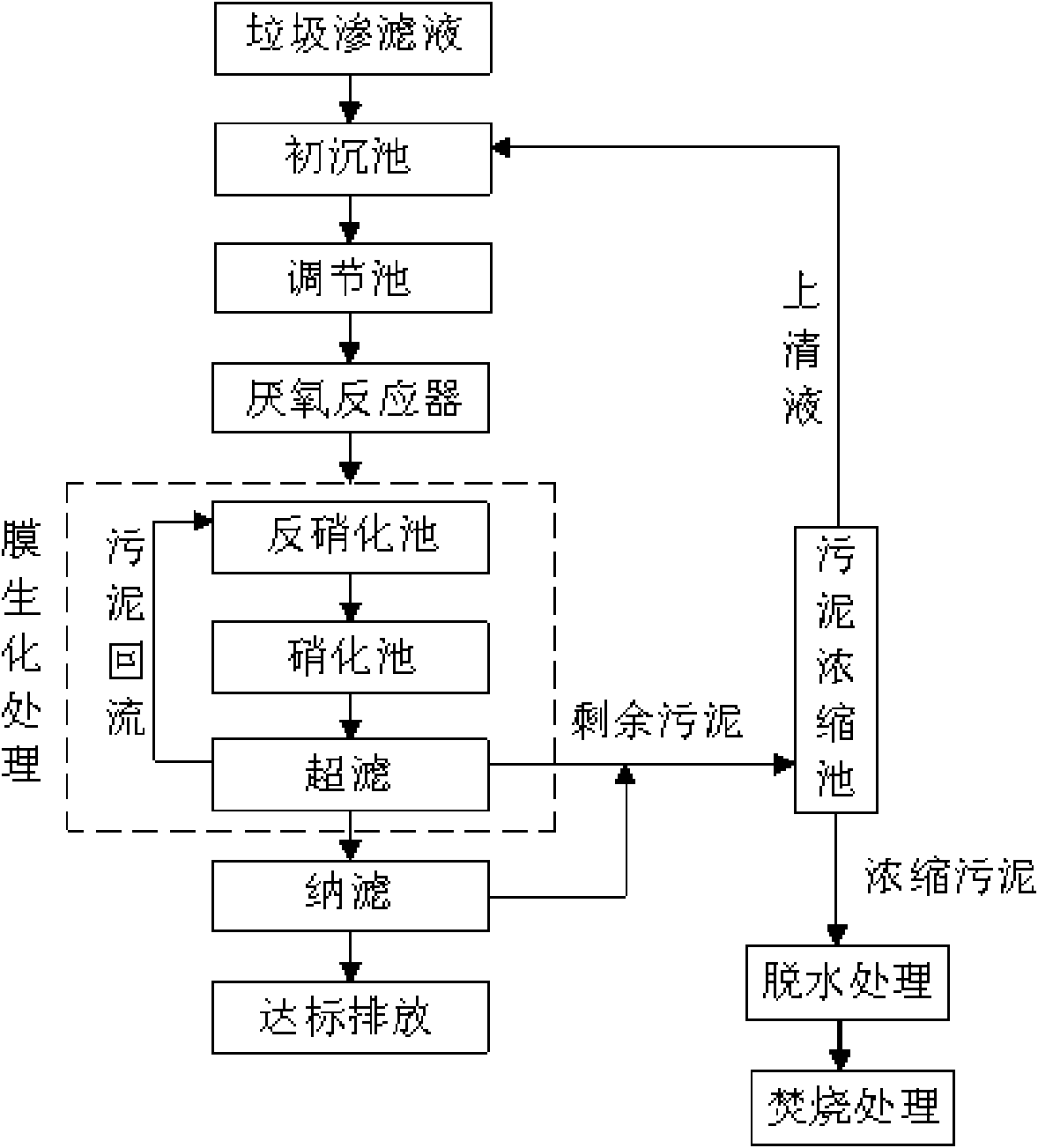

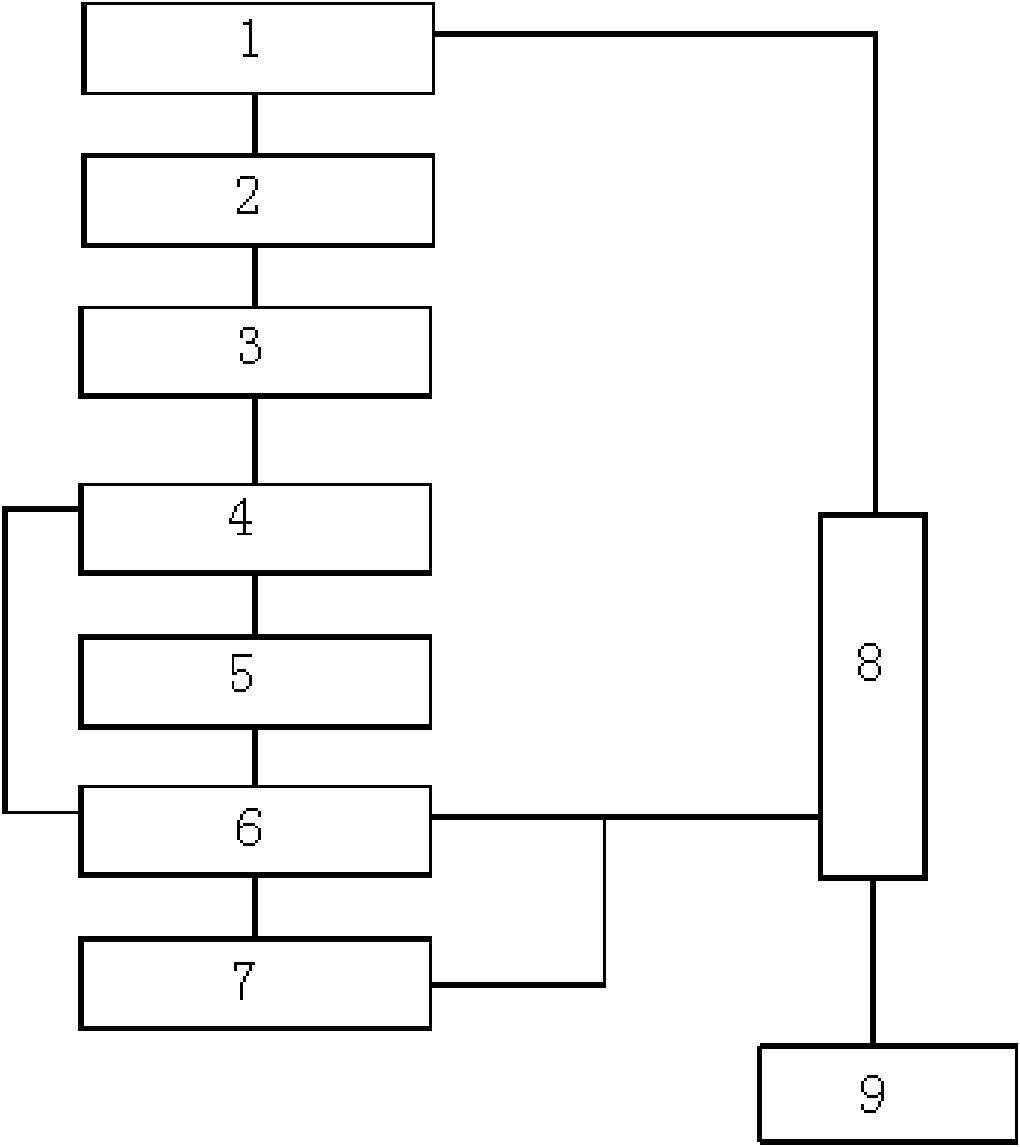

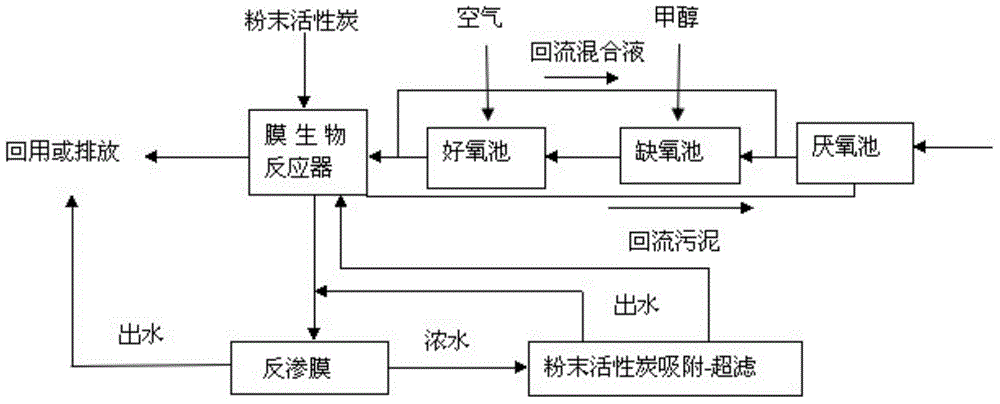

Method and device for treating garbage percolate

ActiveCN101597131AAchieving zero emissionsRelieve stressSludge treatment by de-watering/drying/thickeningTreatment with aerobic and anaerobic processesHigh concentrationAfter treatment

The invention discloses a method and a device for treating garbage percolate, wherein the method comprises the steps of pretreatment, anaerobic treatment, membrane biochemical treatment, nanofiltration treatment, sludge treatment and the like; the device comprises a primary sedimentation tank (1) and an adjusting tank (2), the adjusting tank (2) is connected with an anaerobic reactor (3), the anaerobic reactor (3) is connected with a denitrification tank (4), and the denitrification tank (4) is communicated with a nitrification tank (5); and the nitrification tank (5) is connected with an ultrafiltration apparatus (6), and the ultrafiltration apparatus (6) is connected with a nanofiltration device (7). The method and the device achieve COD degradation of high-concentration wastewater so that the COD of high-concentration COD of 50,000 reaches about 50 after treatment and reaches the standard of industrial reuse water, thus the method and the device achieve zero discharge of the percolate, initiate a new attempt to treat high-concentration percolate, and fill up the domestic blank.

Owner:汕头市澄海洁源垃圾发电厂有限公司

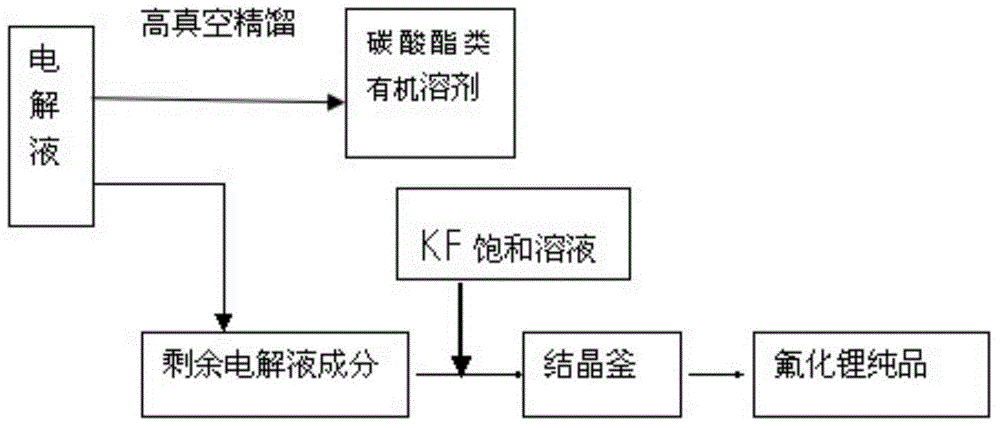

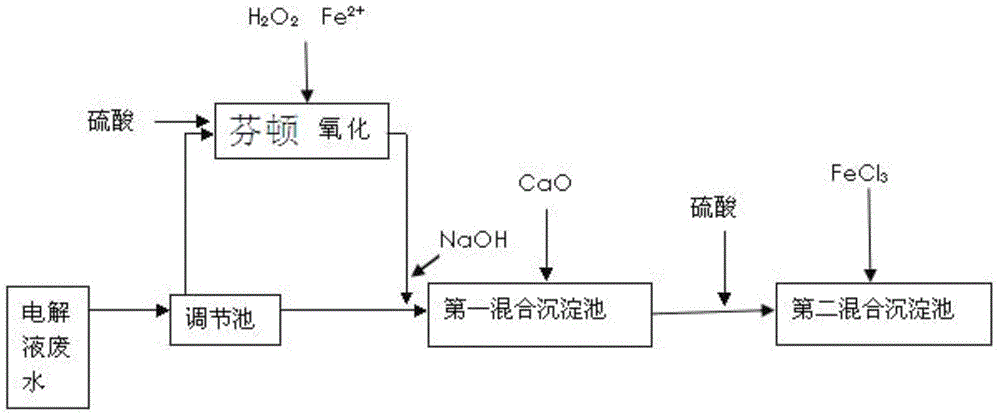

Method for recovery treatment of waste-and-old lithium battery electrolyte and treatment of electrolyte wastewater

InactiveCN104628217AImprove biodegradabilityOvercome incompletenessDispersed particle separationWater/sewage treatmentUltrafiltrationFiltration

The invention discloses a method for recovery treatment of a waste-and-old lithium battery electrolyte and treatment of electrolyte wastewater. Three treatment units are employed for treatment. Firstly, the waste-and-old electrolyte is treated. Then, waste gas resulting from the reaction of the electrolyte is pumped into the waste water for absorption, so that the waste gas can be removed during a waste water treatment process; the lithium battery waste water is treated by a Fenton agent through oxidation to obtain improved biodegradability of the waste water; and reaction precipitates are removed through flocculent sedimentation and the obtained water is treated through combination of A2 / O and MBR membrane separation. Finally, the outlet water goes through a RO reverse osmosis unit to ensure the quality of the outlet water. Combination technology of active carbon powder adsorption and ultra-filtration is employed to remove organic pollutants of the concentrated water resulting from the RO unit, so that the water after treatment can meet the requirements of RO high-quality reuse water. According to the invention, imperfection of an existing technical method of waste-and-old lithium battery recovery and treatment is overcome, and quantitative reduction, harmlessness, and reutilization of waste water treatment of the waste-and-old electrolyte are realized.

Owner:天津卡特化工技术有限公司

Kitchen waste on-site treatment method

ActiveCN103121859AAchieve reductionHarmlessBio-organic fraction processingClimate change adaptationOil and greaseSites treatment

The invention relates to a kitchen waste on-site treatment method which comprises the following steps of: (1) primary sorting of kitchen waste: when the kitchen waste is collected, sorting out hard waste such as plastic, metals, ceramic pieces, big bones and the like; (2) grinding and dehydration: feeding the kitchen waste after primary sorting into a grinding and dehydration system, separating out water and oil in the kitchen waste by a spiral extrusion draining system, feeding the water and oil into an oil-water separation system, grinding solid matters in the kitchen waste at the same time, and feeding the ground product into a fermentation treatment system; (3) medium and high-temperature fermentation treatment: conveying the solid matters extruded and ground in step (2) into a fermentation bin, treating for 15-25 days to end the fermentation, and discharging; and (4) oil-water separation: conveying the water and oil separated out from the kitchen waste into a waste liquid collection tank, and separating oil from wastewater under the effect of gravity. The method provided by the invention solves the problem of high energy consumption of a high-temperature technology, and realizes reduction, harmlessness and resource treatment of the kitchen waste.

Owner:北京世纪阿姆斯生物工程有限公司

Sludge treatment method and sludge treatment system

ActiveCN102153256AHarmlessAchieve reductionCombination devicesSludge treatment by de-watering/drying/thickeningCombustionTreatment system

The invention provides a sludge treatment method which comprises the following steps: drying: drying sludge through a drying device; combusting: feeding the sludge dried in the drying step to a combustion furnace, mixing a combustion improver with the dried sludge, and carrying out mixed combustion; and tail gas treatment: treating the tail gas generated in the combustion step, and discharging. The sludge treatment system comprises the combustion furnace and a tail gas treatment device, wherein the combustion furnace is used for burning the sludge; and the tail gas treatment device is used for treating the tail gas generated after the sludge is burned by the combustion furnace. The sludge treatment system is characterized by further comprising a sludge drying device and a sludge conveyer, wherein the sludge drying device is arranged in front of the combustion furnace and is used for drying the sludge to be burned by the combustion furnace; and the sludge conveyer is convenient for delivery of the sludge in the sludge drying device. The method and system provided by the invention have the advantages that the cost is low, and effect is good.

Owner:JIAXING NEW JIES THERMAL POWER +1

Ceramsite prepared by using smelting wastes, and preparation method thereof

ActiveCN103922698AHarmlessAchieve reductionCeramic materials productionClaywaresSocial benefitsSludge

The invention relates to the technical field of harmlessness treatment of smelting wastes, and especially relates to a ceramsite prepared by using smelting wastes, and a preparation method thereof. The ceramsite comprises 10-90% of smelting waste powder, 5-40% of municipal sludge, 4-20% of fly ash, 0-20% of gangue and 0.1-10% of a curing agent. The preparation method of the ceramsite comprises the following steps: 1, crushing the smelting wastes by using a crusher to prepare the smelting waste powder; 2, weighing the smelting waste powder, the municipal sludge, the fly ash, gangue and the curing agent, mixing, and uniformly stirring to prepare ceramsite powder; 3, conveying the ceramsite powder to a ball forming granulation machine, and carrying out granulation molding to prepare ceramsite balls; 4, drying the ceramsite balls; and 5, calcining he dried ceramsite balls to prepare the finished ceramsite. The ceramsite prepared in the invention has the advantages of light weight, environmental protection and wide uses; and the preparation method recycles the smelting wastes, and has good economic and social benefits.

Owner:DONGGUAN YICHENG ENVIRONMENTAL TECH

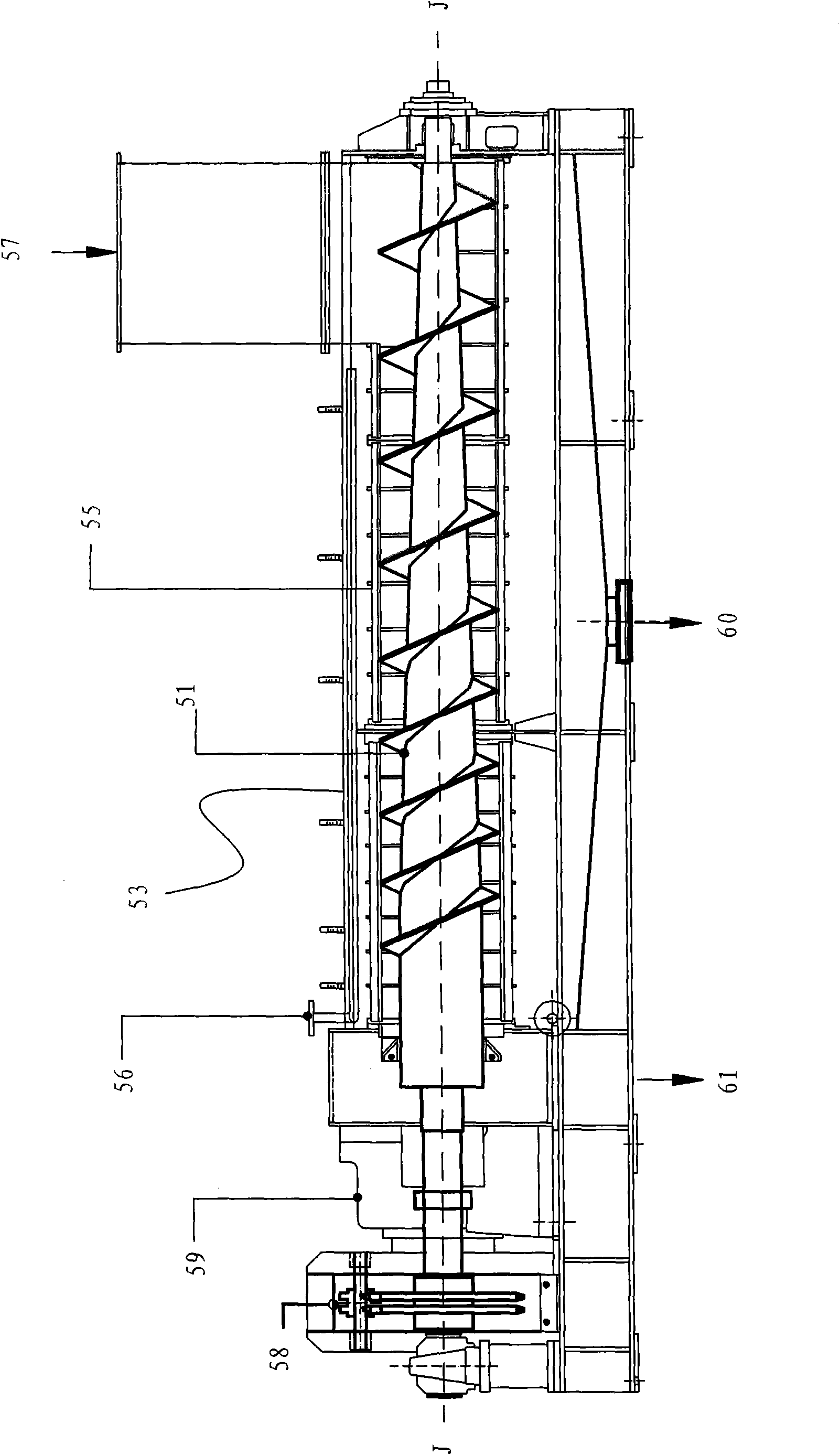

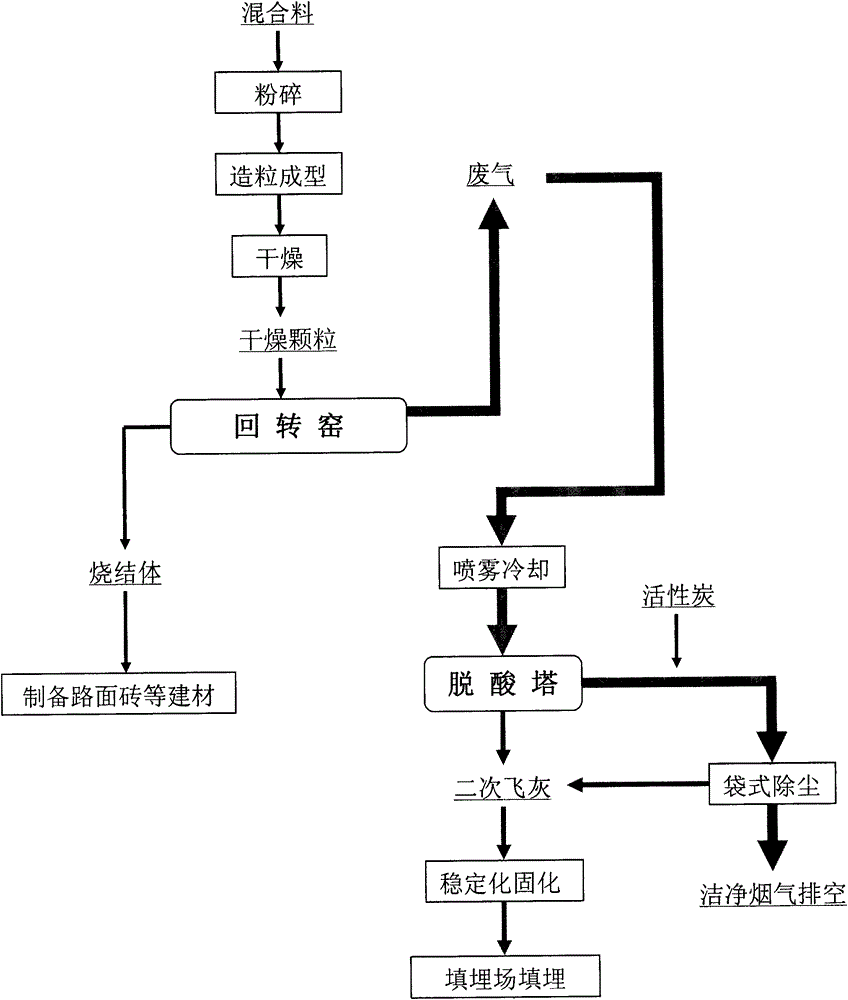

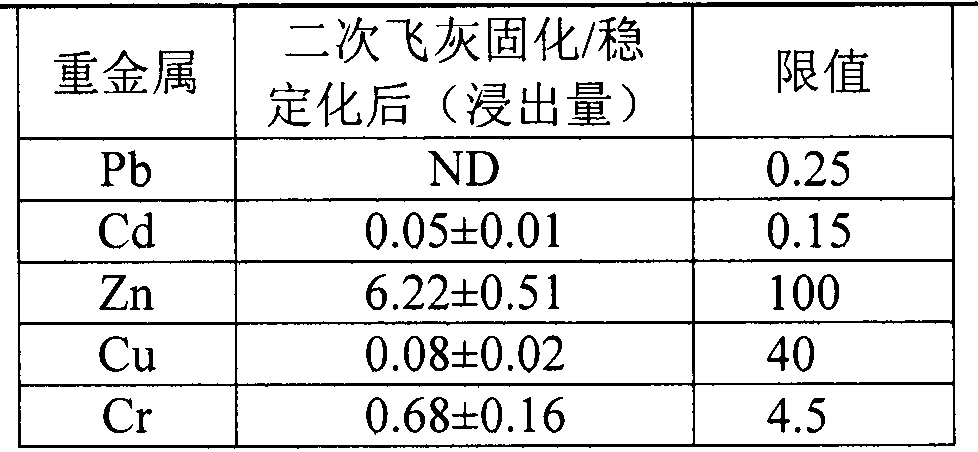

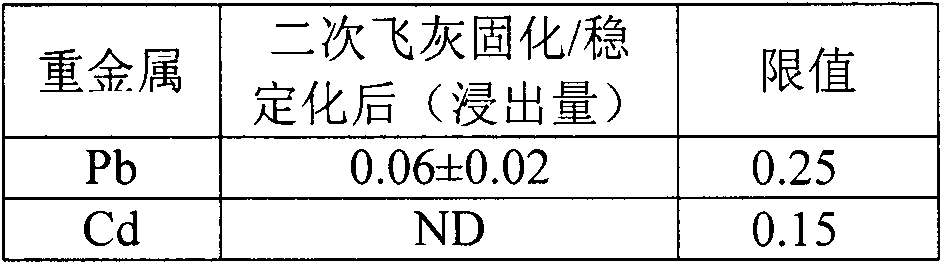

Garbage burning fly ash sintering harm-eliminating resource-utilization treatment system

The invention relates to a garbage burning fly ash sintering harm-eliminating resource-utilization treatment technology. According to the invention, garbage burning fly ash is mixed with premixed coal and auxiliary materials; the mixture is granulated and shaped; and the material is dried and is sintered in a rotary kiln. During the sintering process, when the temperature is increased and a coal ignition point is reached, the premixed coal is spontaneously combusted. Therefore, external coal dose can be reduced. Initial combustion of the premixed coal can provide a reductive atmosphere, such that dechlorination and detoxification of dioxin in fly ash can be benefited. Large amount of gas is produced by subsequent combustion, such that dust pores and holes are produced on inner and outer parts of the sintered body, and heavy metal volatilization can be promoted, and fly ash sintered body with low heavy metal content and leaching amount can be obtained. The sintered body has no potential harm to the environment, such that fly ash harm-eliminating and resource-utilization are sufficiently realized. During the processing process, smoke and secondary fly ash production amounts are low, and heavy metal and acidic component contents are high. In deacidification and heavy metal stabilization processes, agent utilization rate is improved. Compared with a traditional original fly ash curing / stabilizing process, a landfill amount can be reduced by 80-90%, such that pressure caused by serious landfill space shortage can be effectively relieved.

Owner:TIANJIN YIMING ENVIRONMENTAL TECH CO LTD

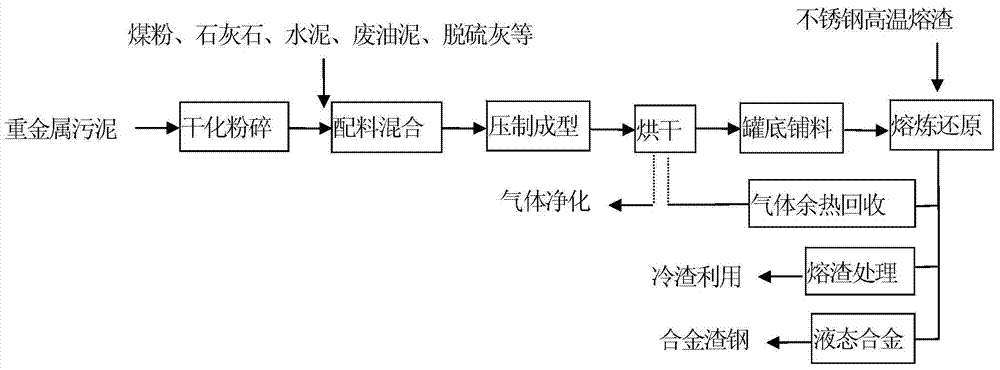

Method for treating heavy metal sludge by using stainless steel molten slag

InactiveCN104512988AIncrease productionIncrease temperatureSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSludgeMetallurgy

The present invention discloses a method for treating heavy metal sludge by using stainless steel molten slag. The method comprises drying crushing, material matching mixing, pressing molding, drying, tank bottom material spreading, smelting reduction, gas purification, molten slag treating, metal recovery and other steps, and specifically comprises that: after heavy metal sludge is subjected to pre-treatment, a certain proportion of ingredients are matched, and the sludge agglomerate is adopted as the bottom spreading material and is placed into a stainless steel molten slag tank to carry out a harmless treatment on the sludge agglomerate. According to the present invention, the characteristics of high production amount, high temperature and rich sensible heat resource of the stainless steel molten slag are adopted, and the stainless steel molten slag is adopted to treat the heavy metal sludge, such that the harmless treatment on the hazardous components and the resource on the valuable material are achieved, the method is the new attempt crossing the industry, and the waste heat resource can be effectively utilized so as to achieve the waste treatment adopting the waste.

Owner:BAOSHAN IRON & STEEL CO LTD +1

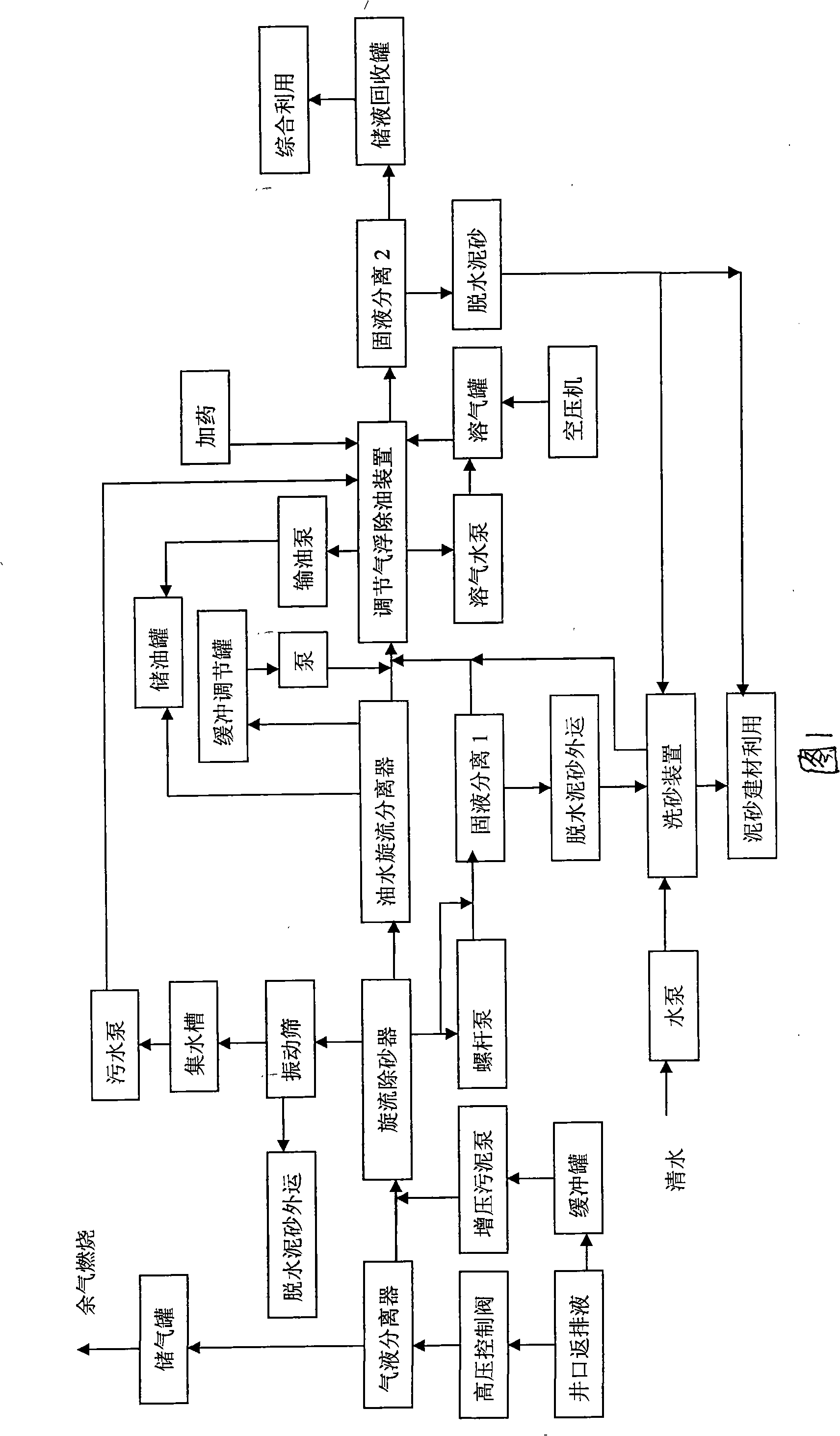

Method for no-grounding treatment and comprehensive utilization of oil-gas field downhole operation output solution

The invention relates to a treatment and integrated utilization method for preventing the liquid output from the oil field and gas field underground operation from dropping on the ground, so that the liquid output from the oil field and gas field underground operation is received and enters into the process of the method to be treated through a sealing process when returning at the well head; after the oil, the gas, the sand and the mud contained in the output liquid are classified, refined and separated through the processes of gas-liquid separation, whirling sand removal, oil-water separation, regulating addition emulsion breaking air floating, and solid-liquid separation, the oil-gas overflows and is utilized; quite large water containing sand particles are cleaned with clean water and then used as building material after the solid-liquid separation process, and the mud with small grain size is made into cake shapes through pressure filtration for brick manufacturing, so that the output liquid can be recycled after being regulated and purified, so as to thoroughly solve the problems of preventing the liquid output from underground operation from dropping on the ground and the resource utilization, and does not bring any potential pollution.

Owner:PUYANG TIANDIREN ENVIRONMENTAL PROTECTION TECH CO LTD

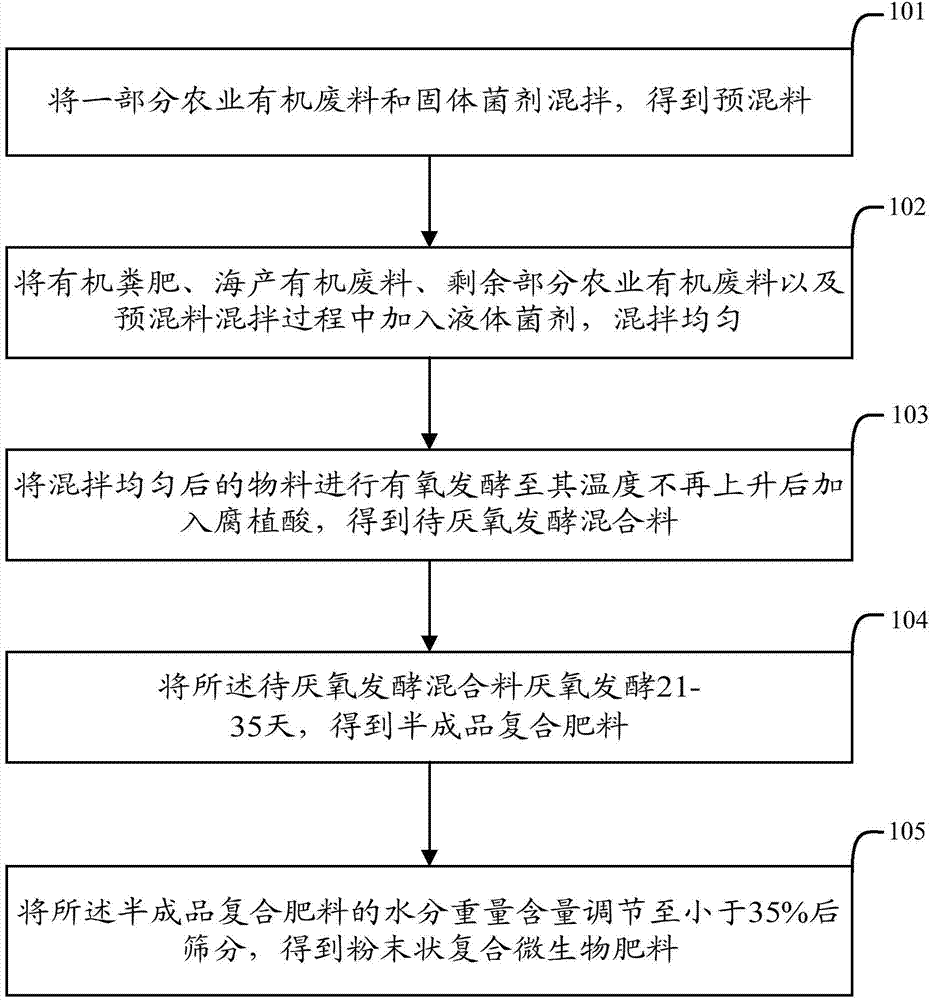

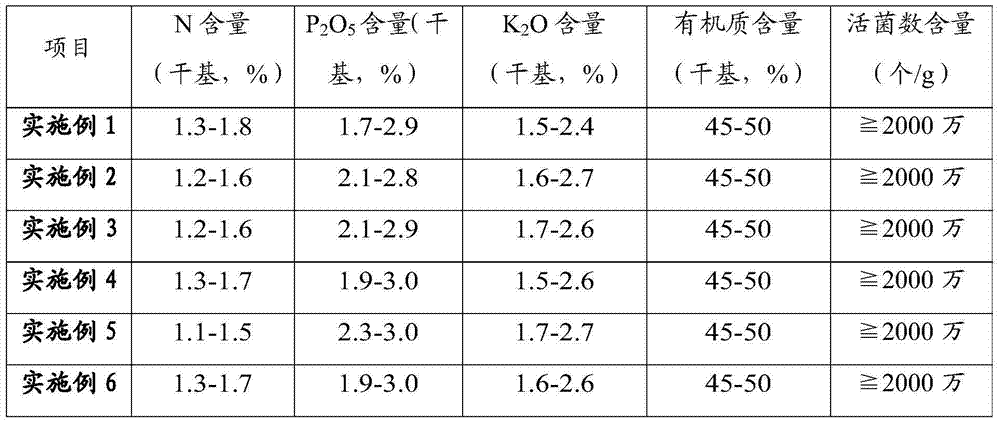

Composite microbial fertilizer and preparation method thereof

InactiveCN104496577APromote absorptionRich strainsBio-organic fraction processingAnimal corpse fertilisersEnvironmental resistancePlant growth

The invention provides a composite microbial fertilizer and a preparation method thereof, and belongs to the field of composite microbial fertilizers. The composite microbial fertilizer is prepared form the following raw materials in parts by weight: 4-6 parts of organic manure, 2-4 parts of humic acid, 0.7-3 parts of agriculture organic waste, 0.2-0.4 part of marine organic waste, 0.01-0.02 part of a liquid inoculant and 0.005-0.01 part of a solid inoculant. According to the composite microbial fertilizer, on one hand, comprehensive, balanced and easy-to-absorb nutrients are provided for crops, healthy growth of the crops is accelerated, and the produced fulvic acid can be used for adjusting the crop growth as a plant growth regulator, and on the other hand, a lot of beneficial microorganisms are generated. Due to balanced and sufficient fermentation substrates, the produced microorganisms are not easy to die; the composite microorganisms are large in viable number; the composite microbial fertilizer is significant in fertilizer efficiency, environmental friendly, and harmless after being applied; and due to large content of microorganisms and organic matters, the soil structure is also improved.

Owner:刘长生 +2

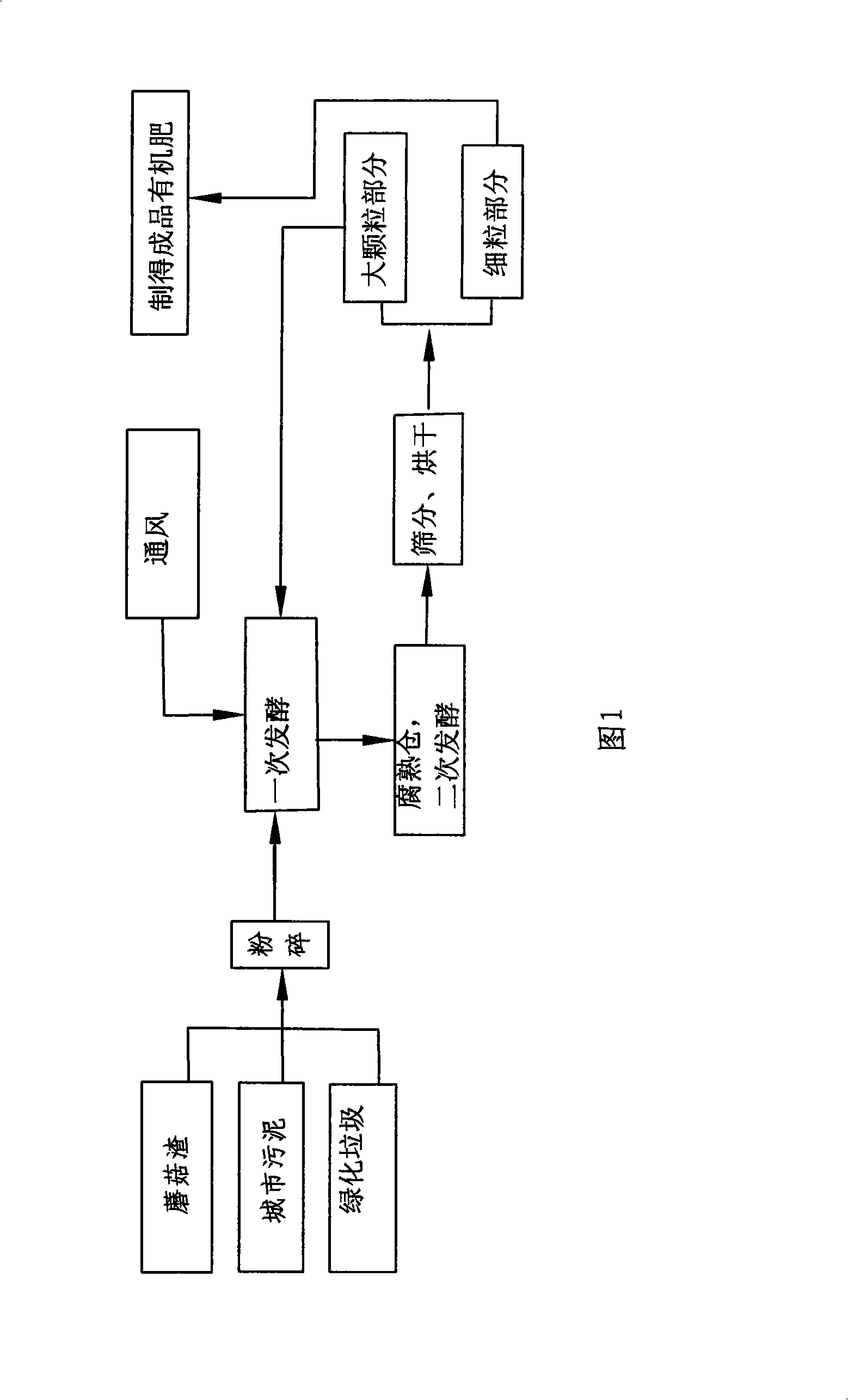

Process for reclaiming city domestic sludge

ActiveCN101333123ASolve processing problemsRelieve pressureBio-organic fraction processingOrganic fertiliser preparationMushroomBiology

The invention relates to the technical field of sludge resource technology, in particular to a technology which uses aerobic biological-physical-chemical jointed rapid fermentation technology to treat the urban living sludge resources; municipal sludge, mushroom dregs and green garbage are mixed based on a proper proportion; then an appropriate amount of quicklime is added to the mixture for fermentation through the aerobic biological-physical-chemical jointed technology; the fermentated product is screened and sorted to form the refined organic fertilizer. The technology can make fast treatment to three waste resources including the municipal sludge, the urban green garbage and the mushroom dregs; the technology can also adjust the material proportion of the mixture based on the nutritional characteristics of various gardens and fruit trees, as well as the resource conditions in different areas, so that the obtained organic fertilizer can achieve best effect. The organic fertilizer has full nutrients, good fertilizer efficiency, long fertilizer effect period and high utilization rate, which has the functions of improving the soil activity, resisting drought, saving water, preventing disease and improving crop yield and quality so as to eventually reduce the municipal sewage sludge and realize harmless treatment to the municipal sewage sludge resource.

Owner:DONGGUAN SHENGYIN BIO ORGANIC FERTILIZER

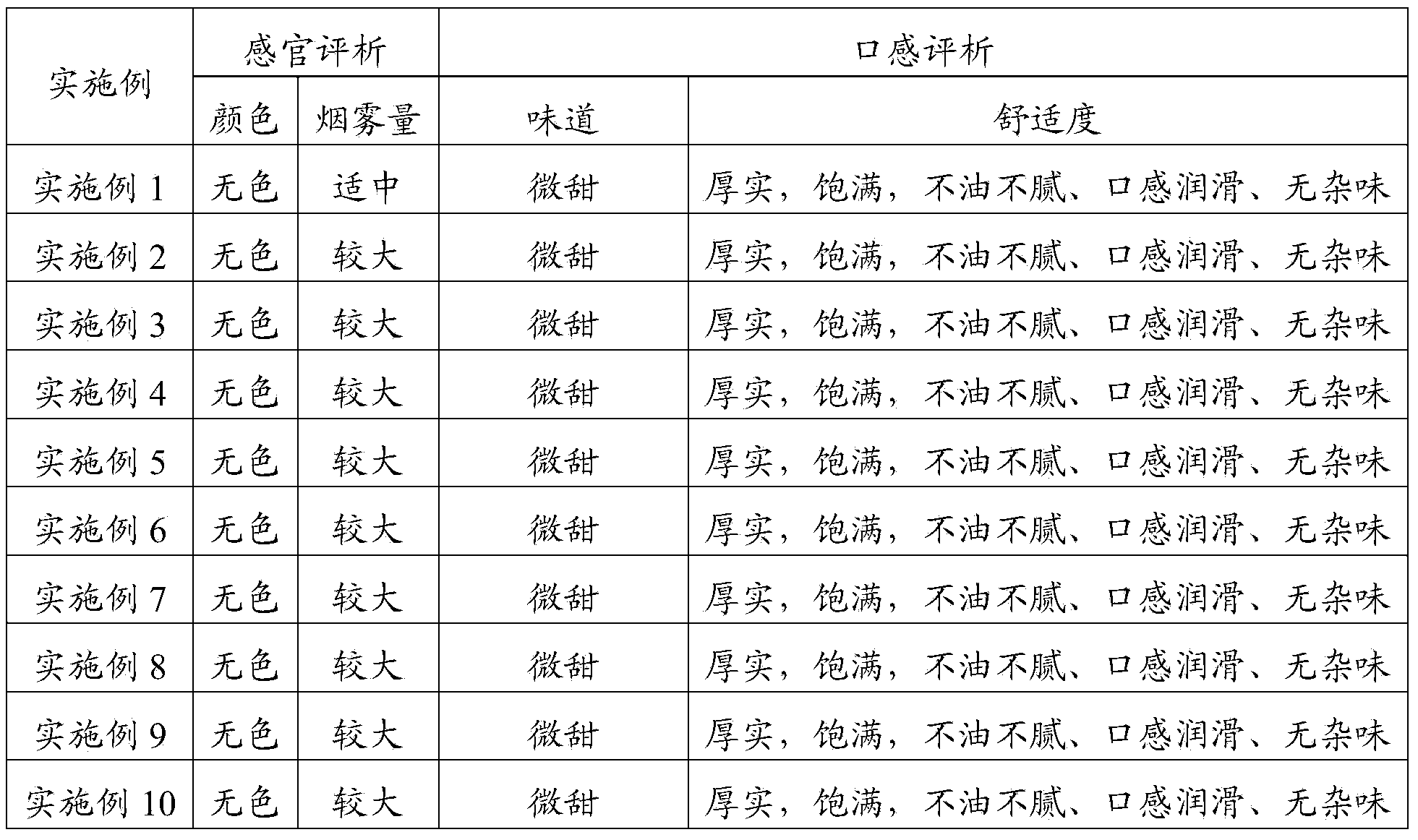

Electronic cigarette tobacco juice solvent and electronic cigarette tobacco juice

InactiveCN103622161ATasting experience is not greasyStrong tasting experienceTobacco treatmentTobacco devicesFlavorLiquid smoke

The invention provides an electronic cigarette tobacco juice solvent comprising sorbitol. The sorbitol is used as the electronic cigarette tobacco juice solvent. As for electronic cigarette tobacco juice made of the electronic cigarette tobacco juice solvent, smoking experience is not greasy, foreign flavor is avoided, and higher smoking comfort is achieved. Furthermore, the electronic cigarette tobacco juice comprises one or more of propylene glycol, glycerin and mannitol, the sorbitol is reacted with the propylene glycol, the glycerin and the mannitol so that a large amount of smoke can be generated when the electronic cigarette tobacco juice made of the electronic cigarette tobacco juice solvent is smoked, smoking experience of a smoker is enhanced, smoking experience is dense and flush, mouth feel is smooth and free of the foreign flavor, and the higher smoking comfort is achieved. In addition, the electronic cigarette tobacco juice solvent is composed of food solvents and has no harm to the smoker.

Owner:HUIZHOU KIMREE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com