Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

15972 results about "Crusher" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiated. Crushing is the process of transferring a force amplified by mechanical advantage through a material made of molecules that bond together more strongly, and resist deformation more, than those in the material being crushed do. Crushing devices hold material between two parallel or tangent solid surfaces, and apply sufficient force to bring the surfaces together to generate enough energy within the material being crushed so that its molecules separate from (fracturing), or change alignment in relation to (deformation), each other. The earliest crushers were hand-held stones, where the weight of the stone provided a boost to muscle power, used against a stone anvil. Querns and mortars are types of these crushing devices.

Method for preparing lithium cobaltate by directly using invalid lithium ion battery

InactiveCN102030375AReduce dispersionHigh purityCell electrodesCobalt compoundsElectrical batteryPotassium hydroxide

The invention provides a method for preparing lithium cobaltate by directly using an invalid lithium ion battery. The method comprises the following steps: crushing the invalid lithium ion battery or scraps generated when a lithium cobaltate battery is produced by a mechanical crusher at normal temperature; adding water and one or more of acetic acid, sulfuric acid, hydrochloric acid or nitric acid to produce mixed aqueous solution of the battery scraps and acid; filling the mixed aqueous solution into a hermetic pressure reactor, and controlling the temperature in the reactor to be between 50 and 150 DEG C; introducing or adding one leaching additive of sulfur dioxide or hydrogen, or adding hydrazine hydrate; stirring and leaching, cooling, and filtering; adding one precipitator of sodium carbonate, potassium carbonate and ammonium carbonate, or adding composite precipitator consisting of one of the sodium carbonate, the potassium carbonate and the ammonium carbonate and one of sodium hydroxide and potassium hydroxide to obtain mixture of lithium carbonate, cobalt carbonate and cobalt hydroxide; drying and calcining at high temperature to produce a lithium cobaltate product. The method is particularly suitable for the treatment scale of medium-sized and small enterprises, and is an effective method for directly materializing cobalt secondary resources.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

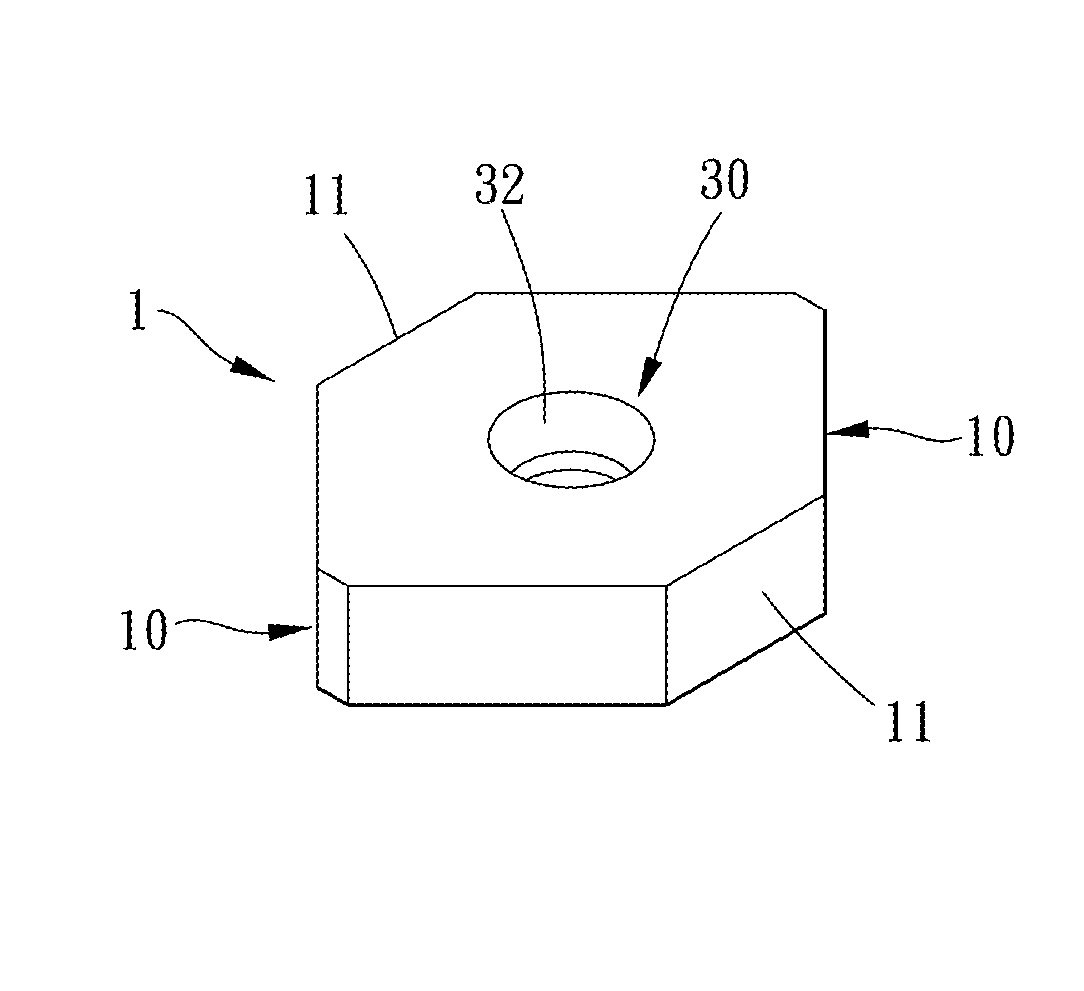

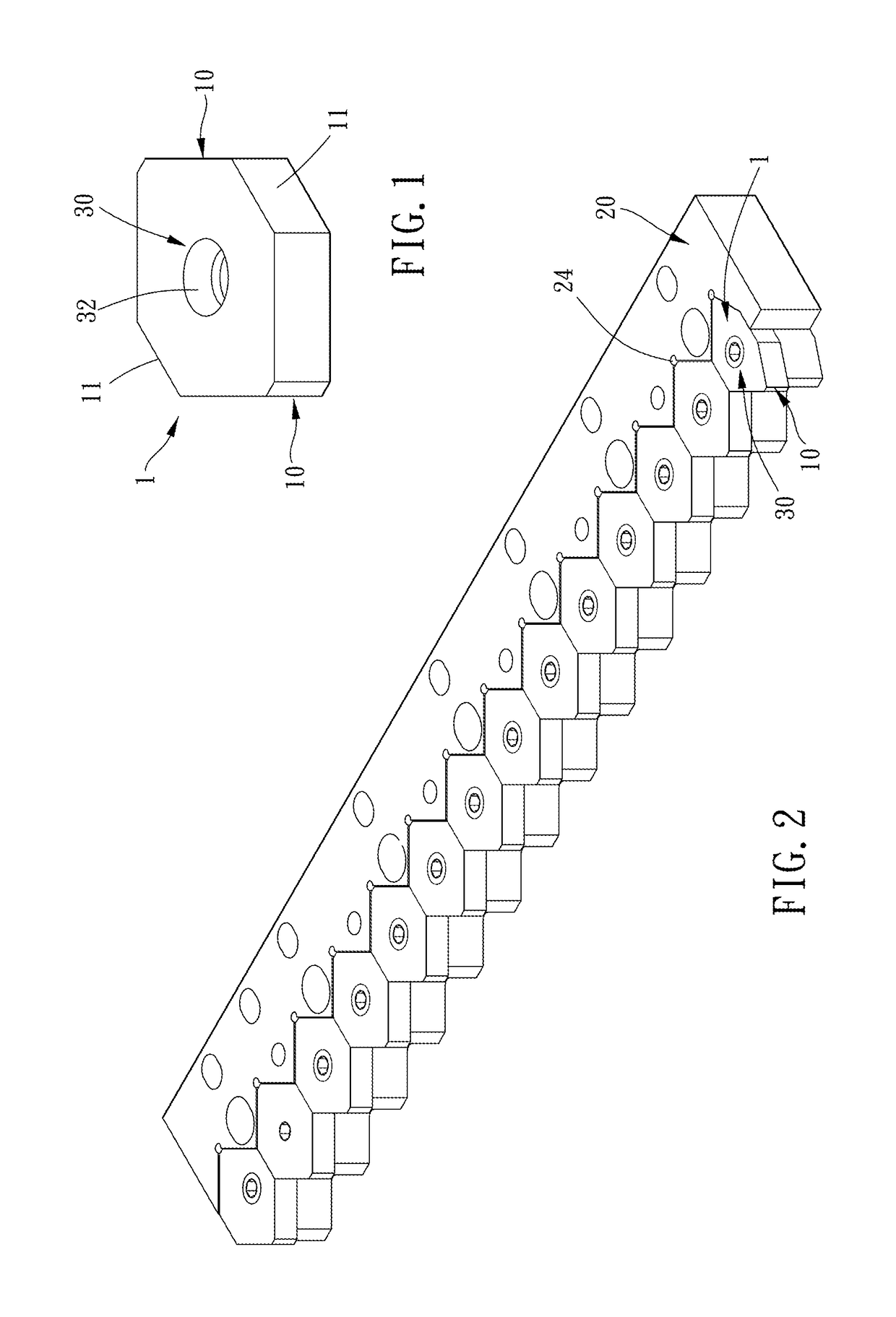

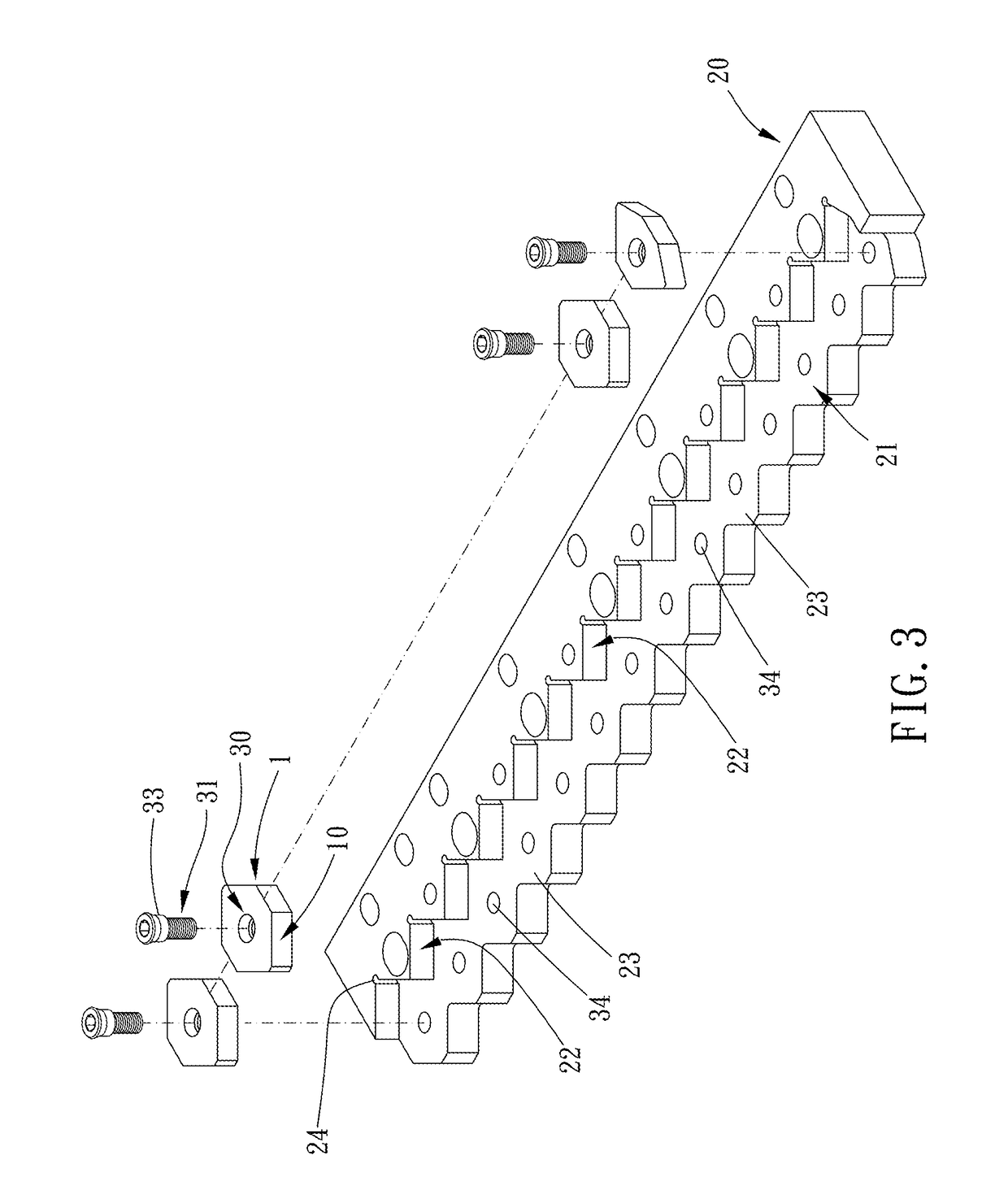

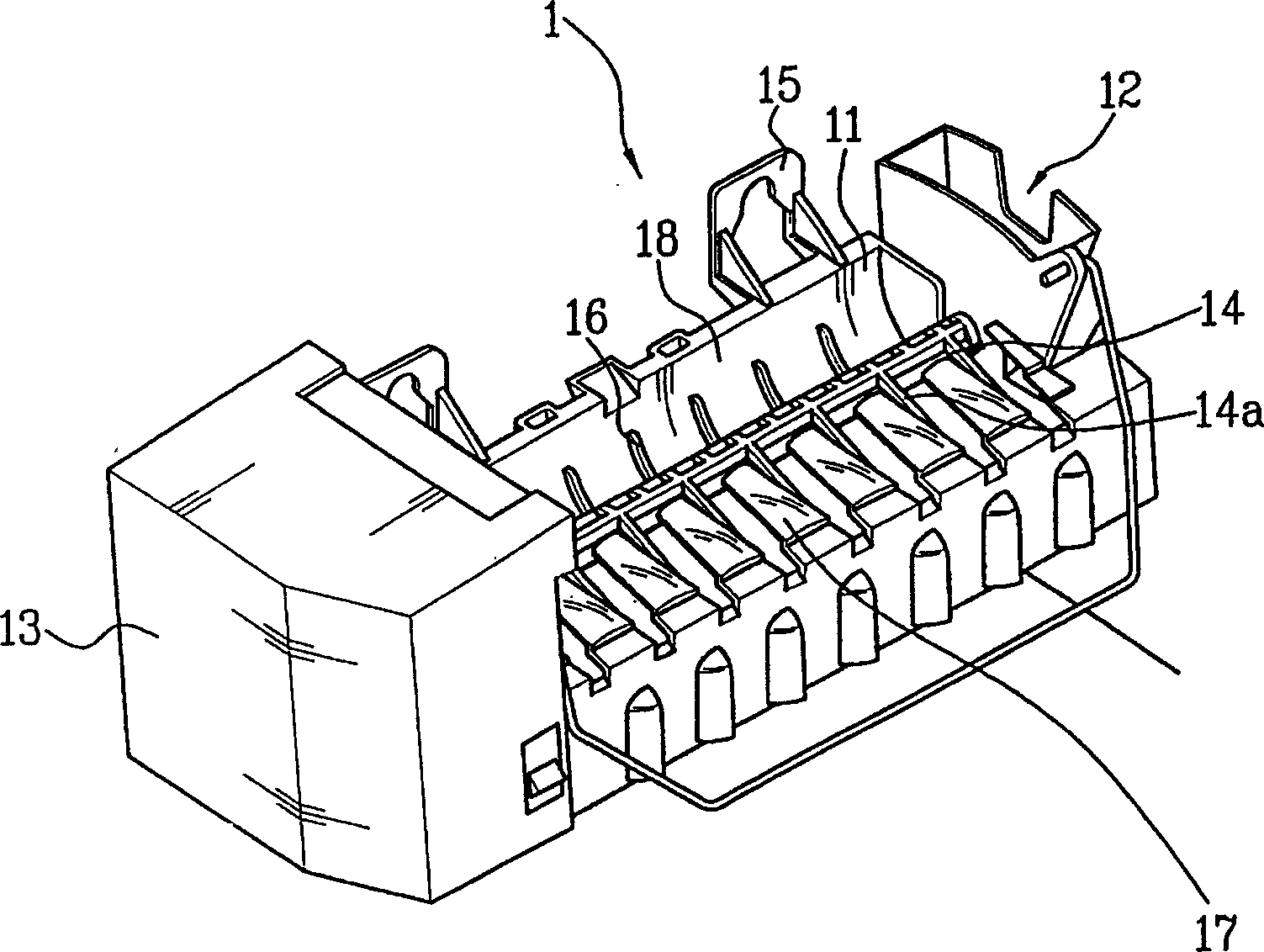

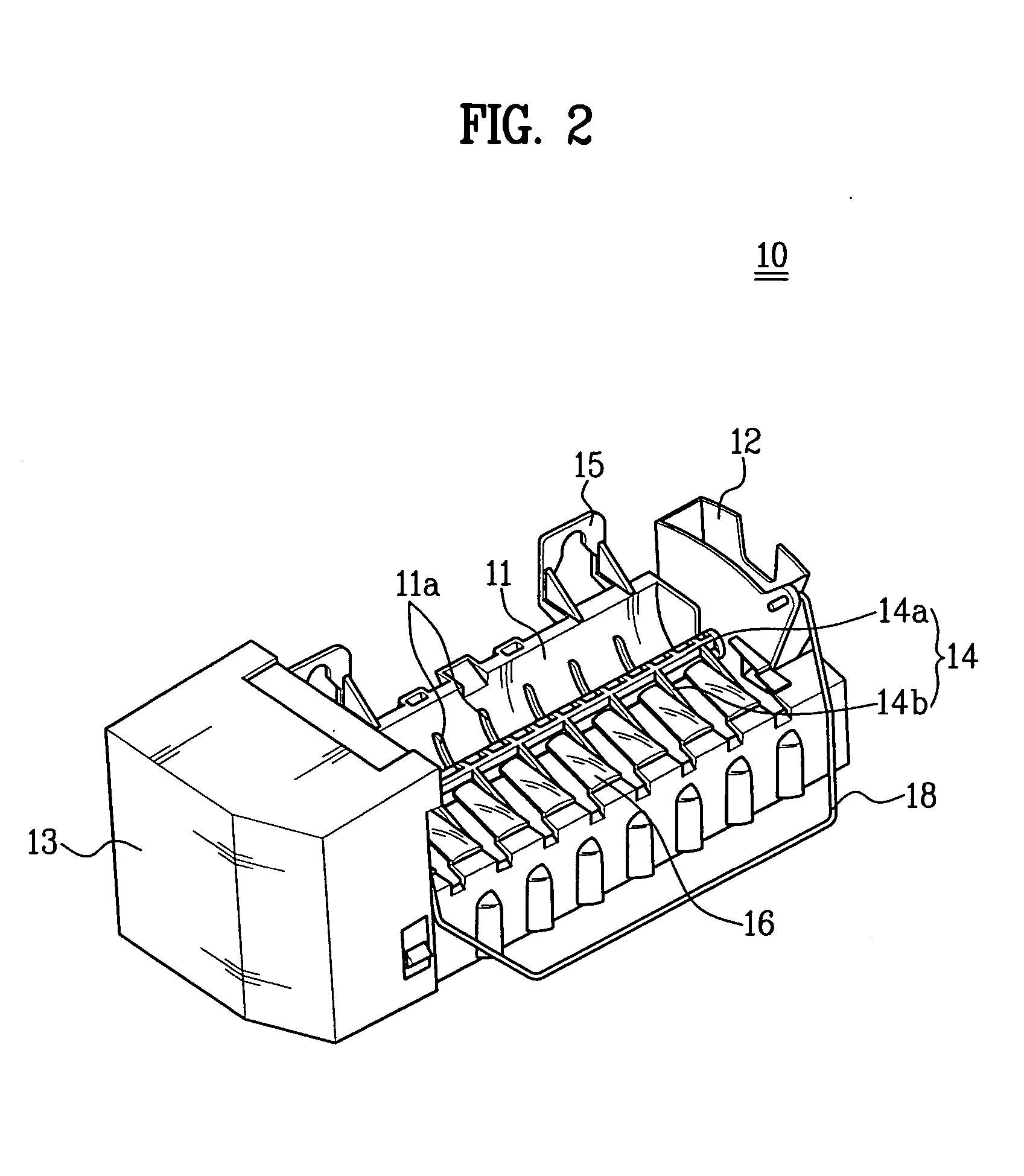

Crusher with cutter assembly and cutter thereof

ActiveUS10124343B2Prevent the crusher cutter from shakingImprove efficiencyGrain treatmentsEngineeringCrusher

A crusher includes a base, a cylinder pivoted to the base, cutting portions arranged on the cylinder. A crusher cutter assembly is further provided, including: a cutter base, for being assembled to the crusher, having receiving slots including an abutting recess and a bottom portion. A crusher cutter is further provided for assembling on the cutter base. The crusher cutter includes: two corner portions, disposed on two sides thereof, for being inserted in the abutting recess and fixed on the cutter base, two sides of the corner portion abutting against the abutting recess; two abutting portions, disposed on two opposite sides of the crusher cutter, for being positionably abutting against another crusher cutter; wherein when the crusher cutter is fixed on the cutter base, a part of the corner portion protrudes beyond the cutter base and is alternatively shifted with a part of the cutting portions.

Owner:KUN SHENG MACHINE

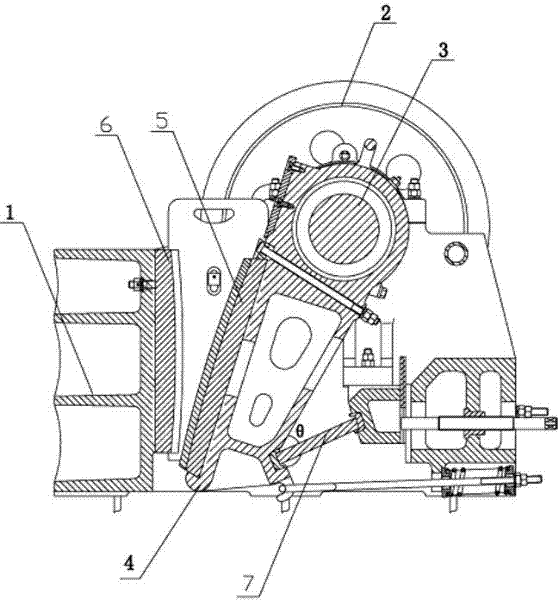

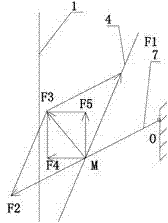

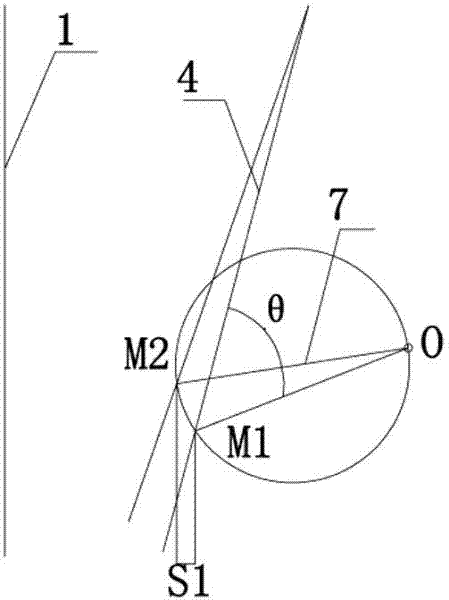

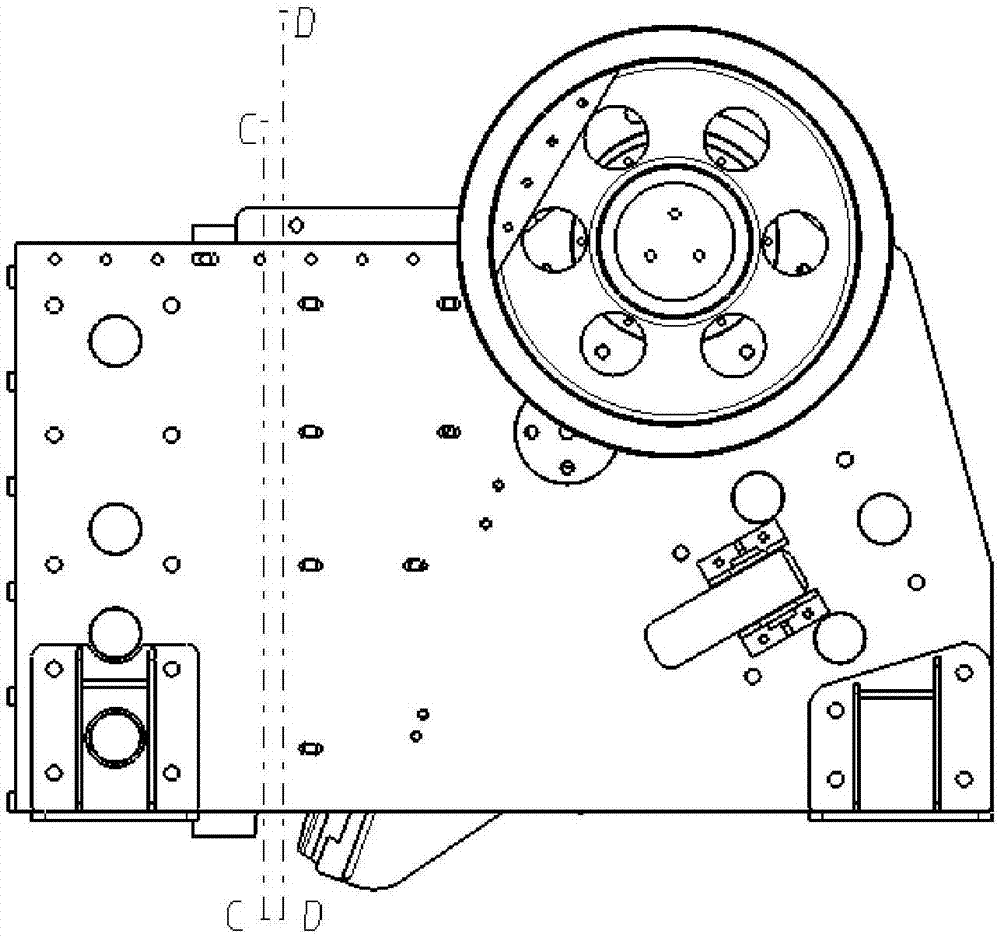

Jaw crusher with double shafts and double crank and rocker mechanisms

The invention discloses a jaw crusher with double shafts and double crank and rocker mechanisms. The jaw crusher comprises a rack, a fixed jaw plate, a movable jaw plate, a front crank and rocker mechanism, a rear crank and rocker mechanism and transmission wheels, wherein the front crank and rocker mechanism comprises a front movable jaw, a front knee plate and a front eccentric driving shaft; the rear crank and rocker mechanism comprises a rear movable jaw, a rear knee plate and a rear eccentric driving shaft; the front and rear jaw plates are respectively pivoted on the front and rear eccentric driving shafts; the front and rear eccentric driving shafts are respectively connected with the transmission wheels; one end of the front knee plate is pivoted below the rear side of the front movable jaw, and the other end of the front knee plate is pivoted below the front side of the rear movable jaw; one end of the rear knee plate is pivoted below the rear side of the rear movable jaw, and the other end of the front knee plate is pivoted on the rack; and the movable jaw plate is fixedly connected to the front movable jaw and faces the fixed jaw plate to form a crushing cavity. The jaw crusher has the advantages that: the function of the lower horizontal motion travel of the movable jaw is improved from material discharge to crushing, so crusher equipment has a secondary-crushing effect.

Owner:义乌市凌丰知识产权服务有限公司

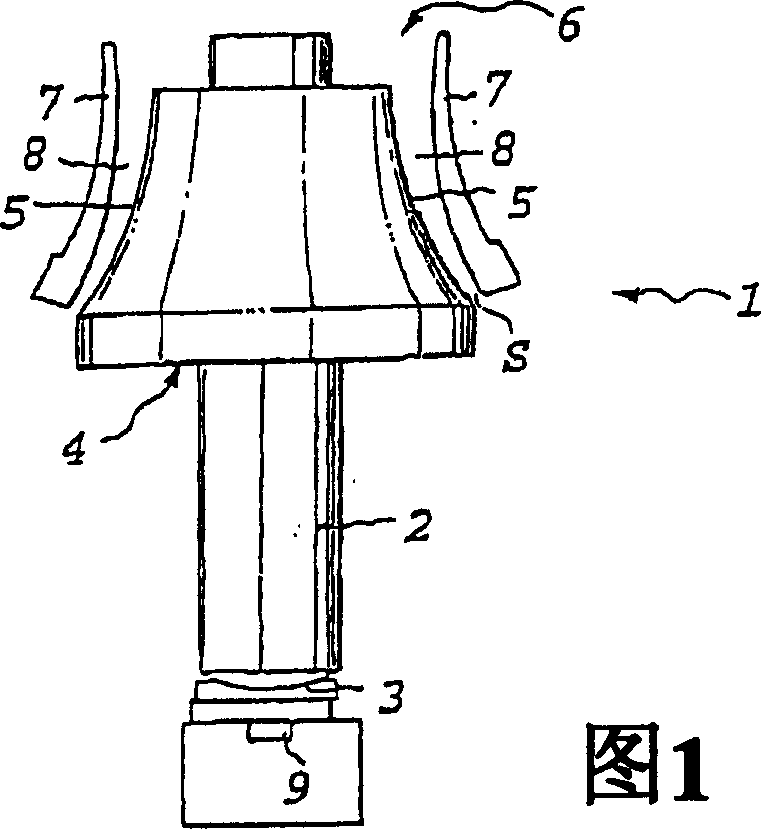

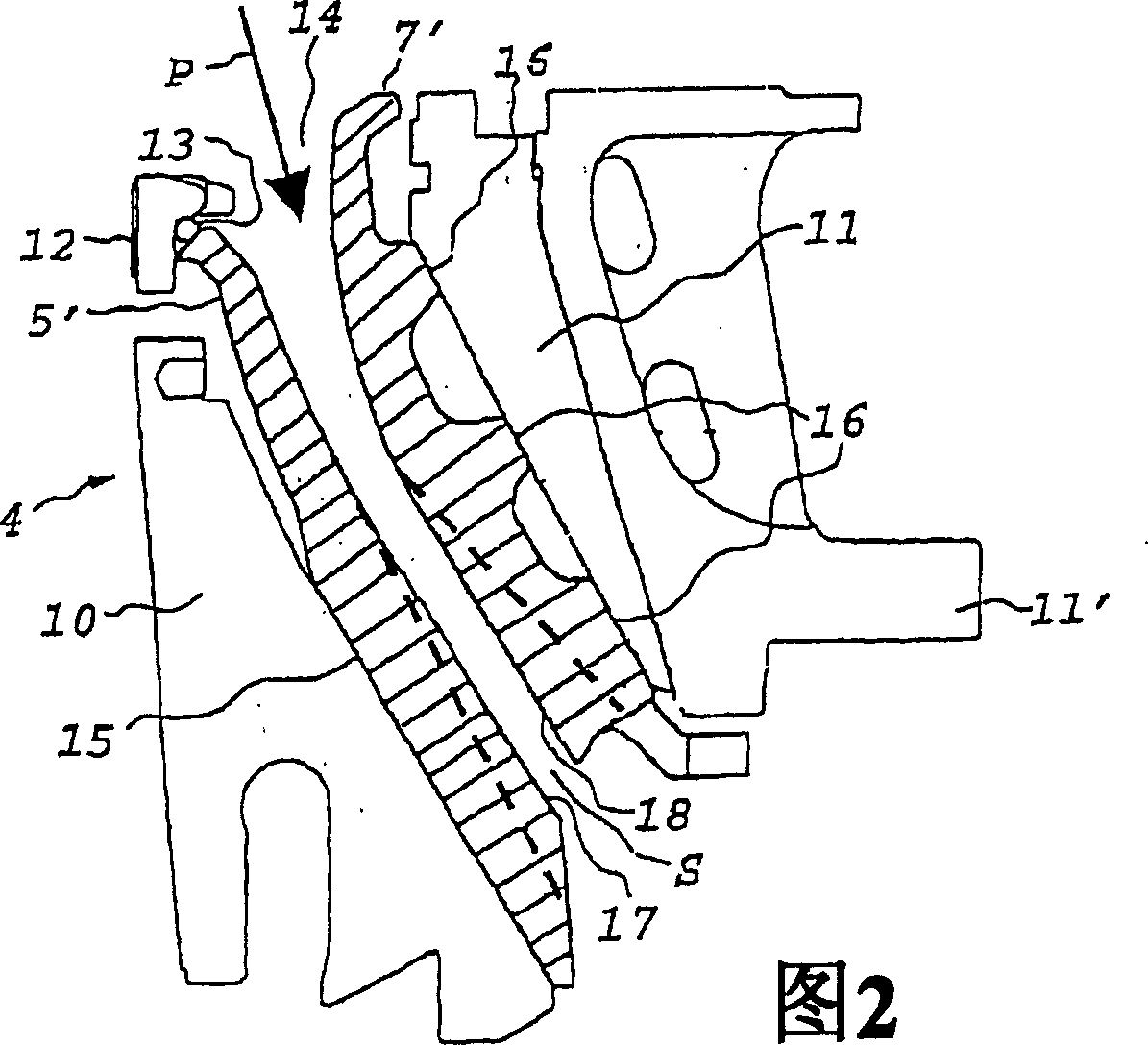

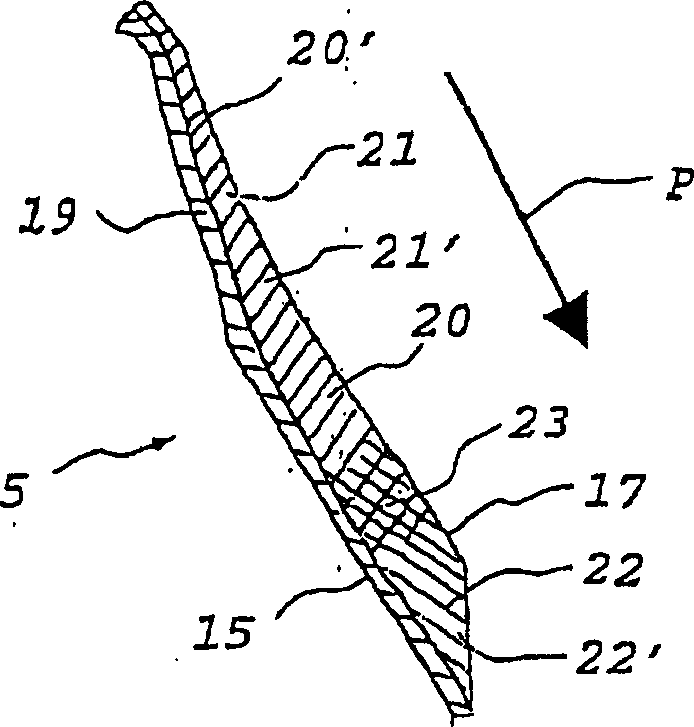

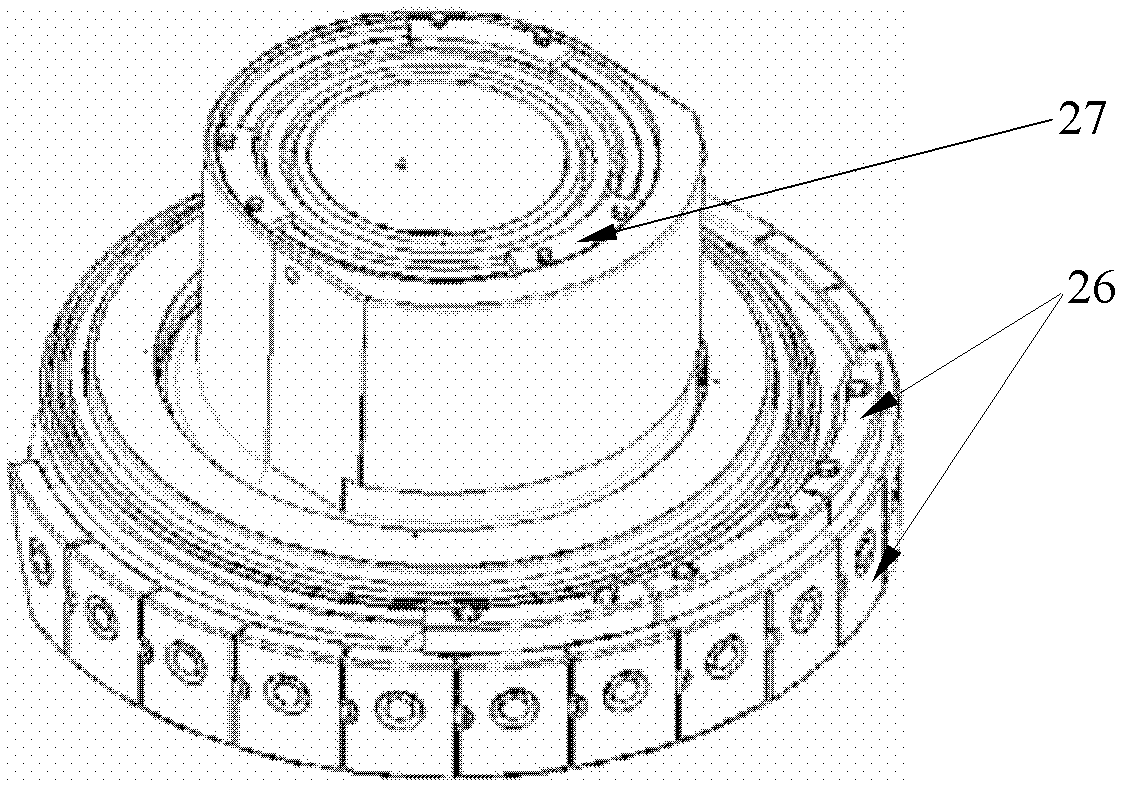

Wear part intended for a crusher and a method of manufacturing the same

A wear part (5) for detachable mounting on a supporting part in an impact-type multi-action crusher is at least partly manufactured by hot isostatic pressing. The wear part (5) has a body (19) for mounting of the wear part (5) on the supporting part and a crushing layer (20) which is attached to the body (19) and which is adapted to be brought, during operation of the crusher, into repeated contact with a raw material that is to be crushed. The body (19) is made of a substance which is easy to machine to narrow tolerances, and the crushing layer (20) is made of a material (27, 28) of high abrasive resistance. In a method of manufacturing the above wear part (5), the following steps are carried out: introducing at least one powder material (27, 28) into a capsule, degassing and sealing the capsule, subjecting the material (27, 28) in the capsule to hot isostatic pressing to form a crushing layer (20), and then after treatment of the wear part (5).

Owner:SANDVIK INTELLECTUAL PROPERTY AB

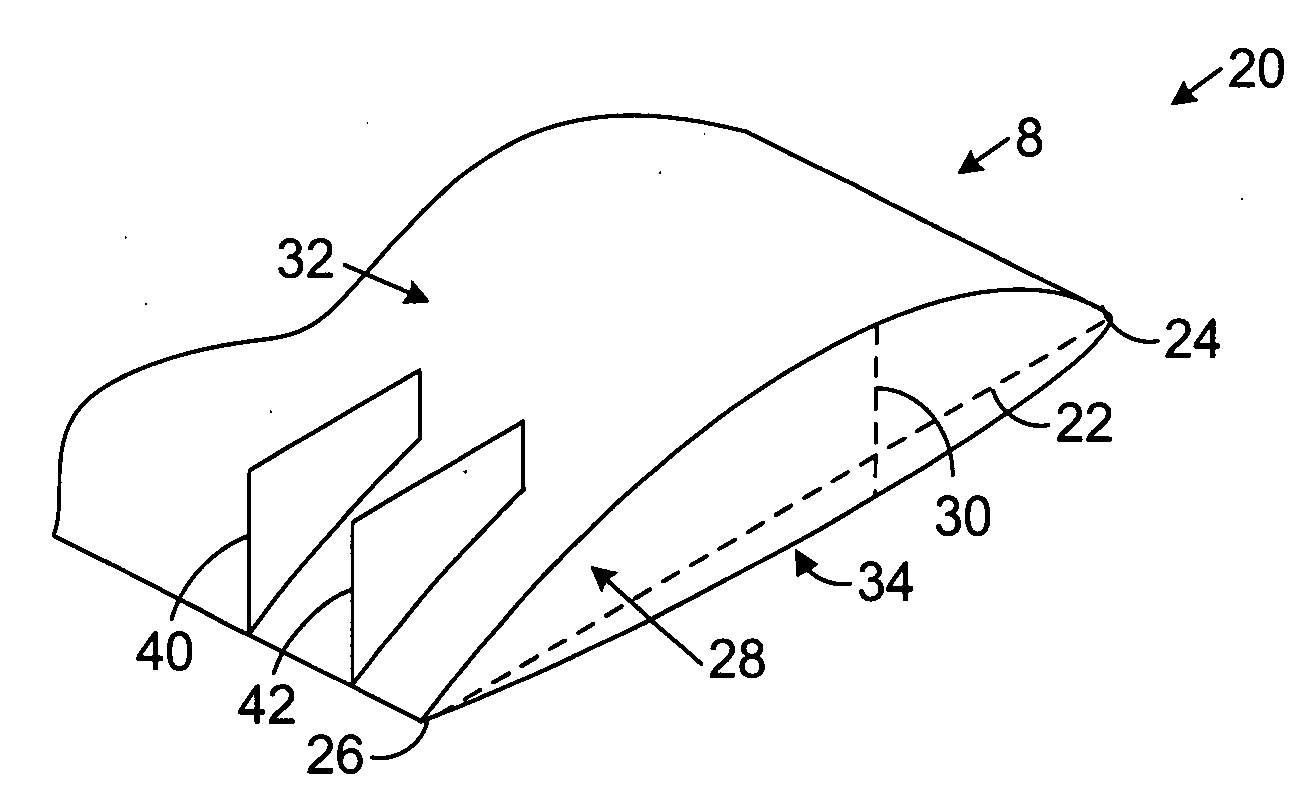

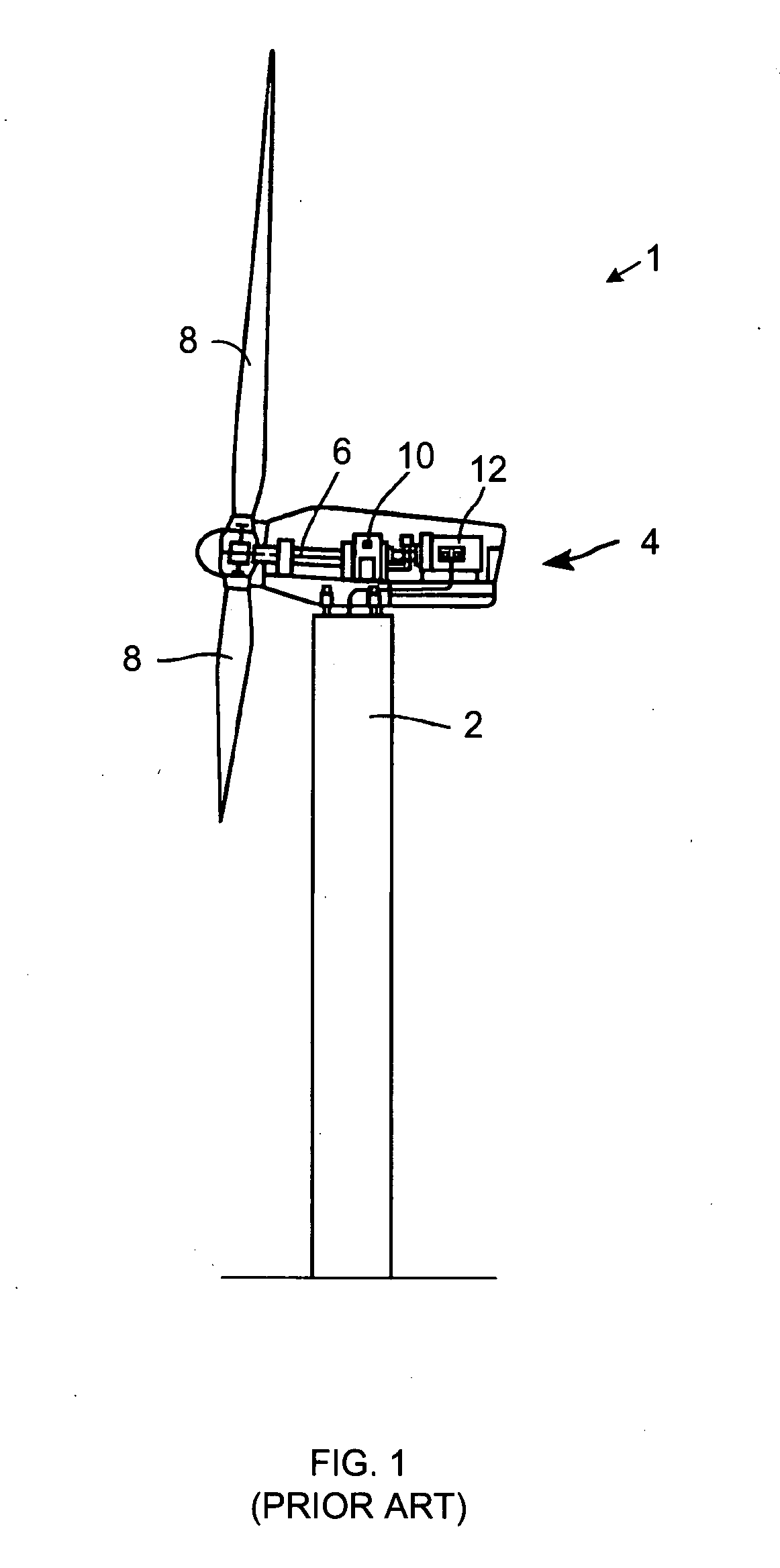

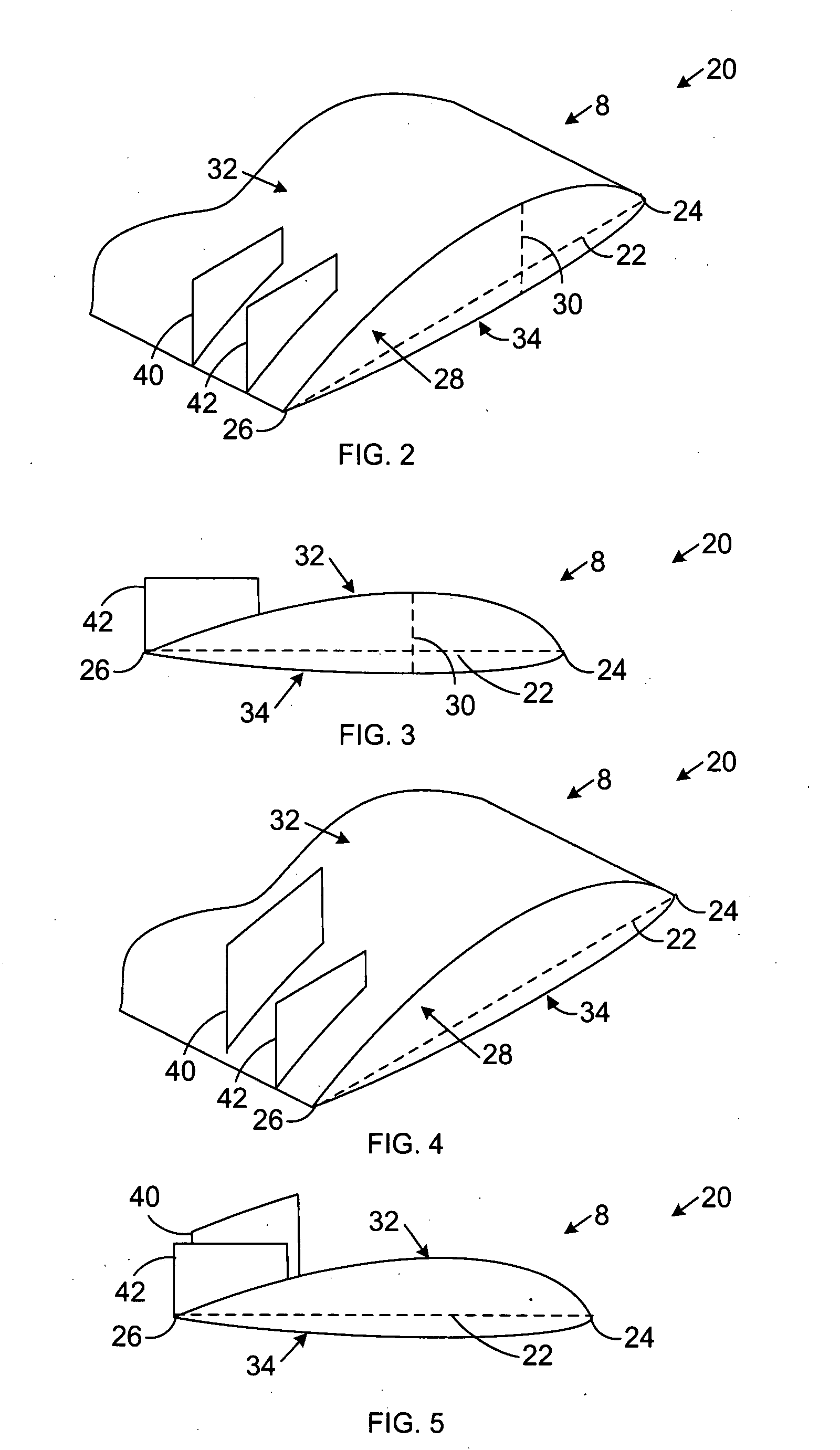

Wind turbine blade tip vortex breakers

A wind turbine includes a tower supporting a drive train with a rotor, at least one blade extending radially from the rotor; and a plurality of substantially flat flaps extending substantially perpendicular from a suction surface of the blade and along different chord lines near a tip of the blade for capturing and directing tip vortices toward a trailing edge of the blade.

Owner:GENERAL ELECTRIC CO

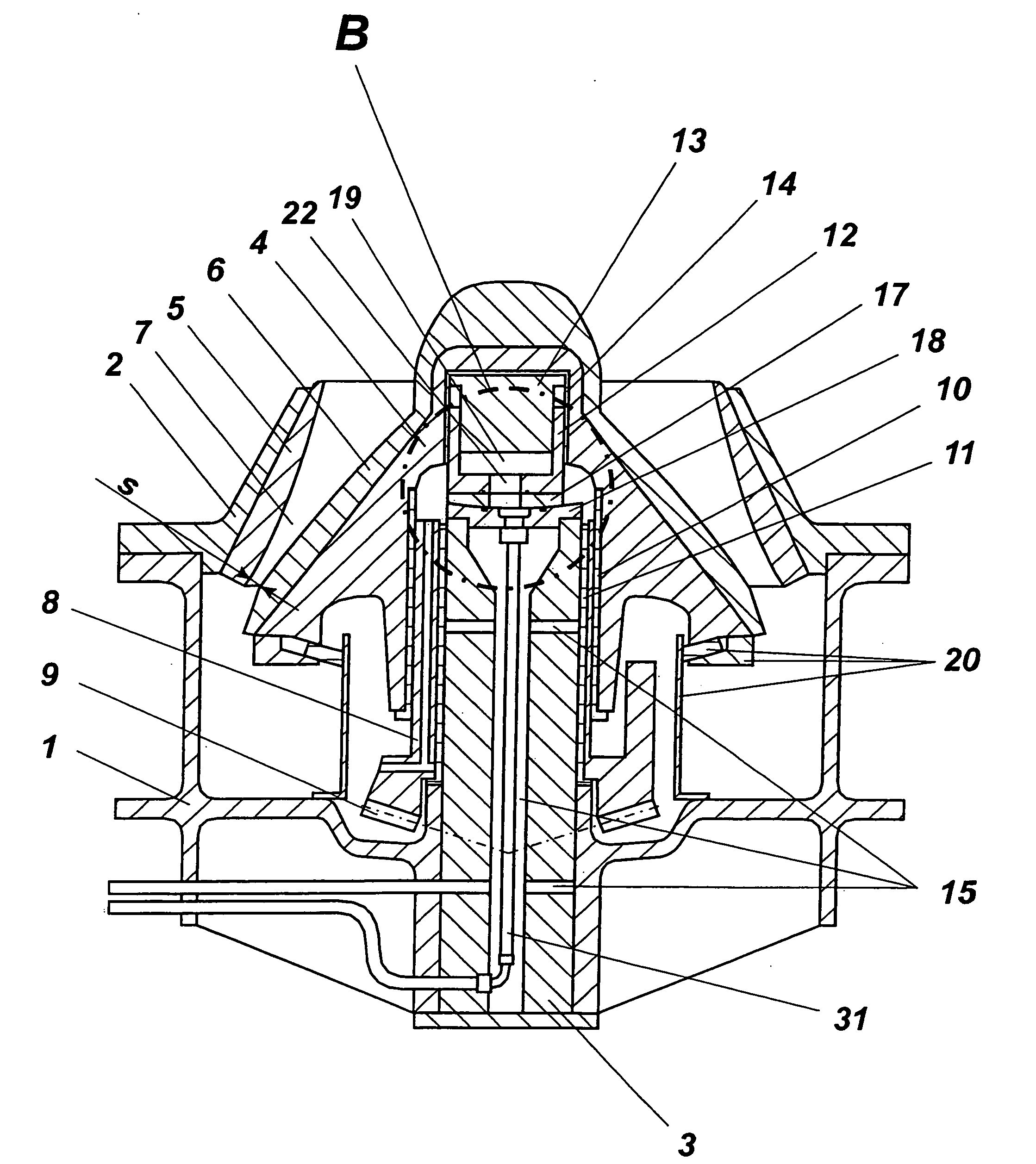

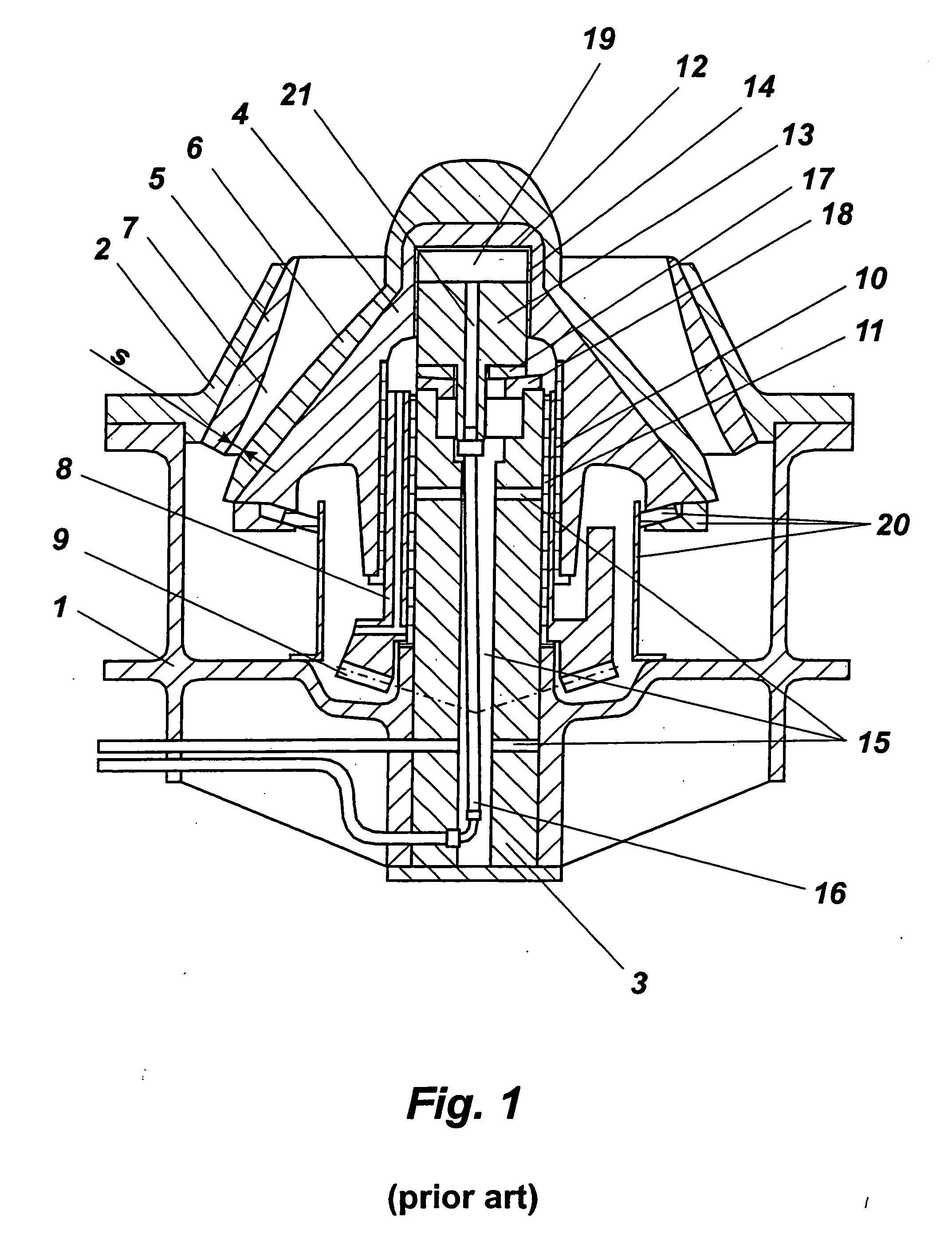

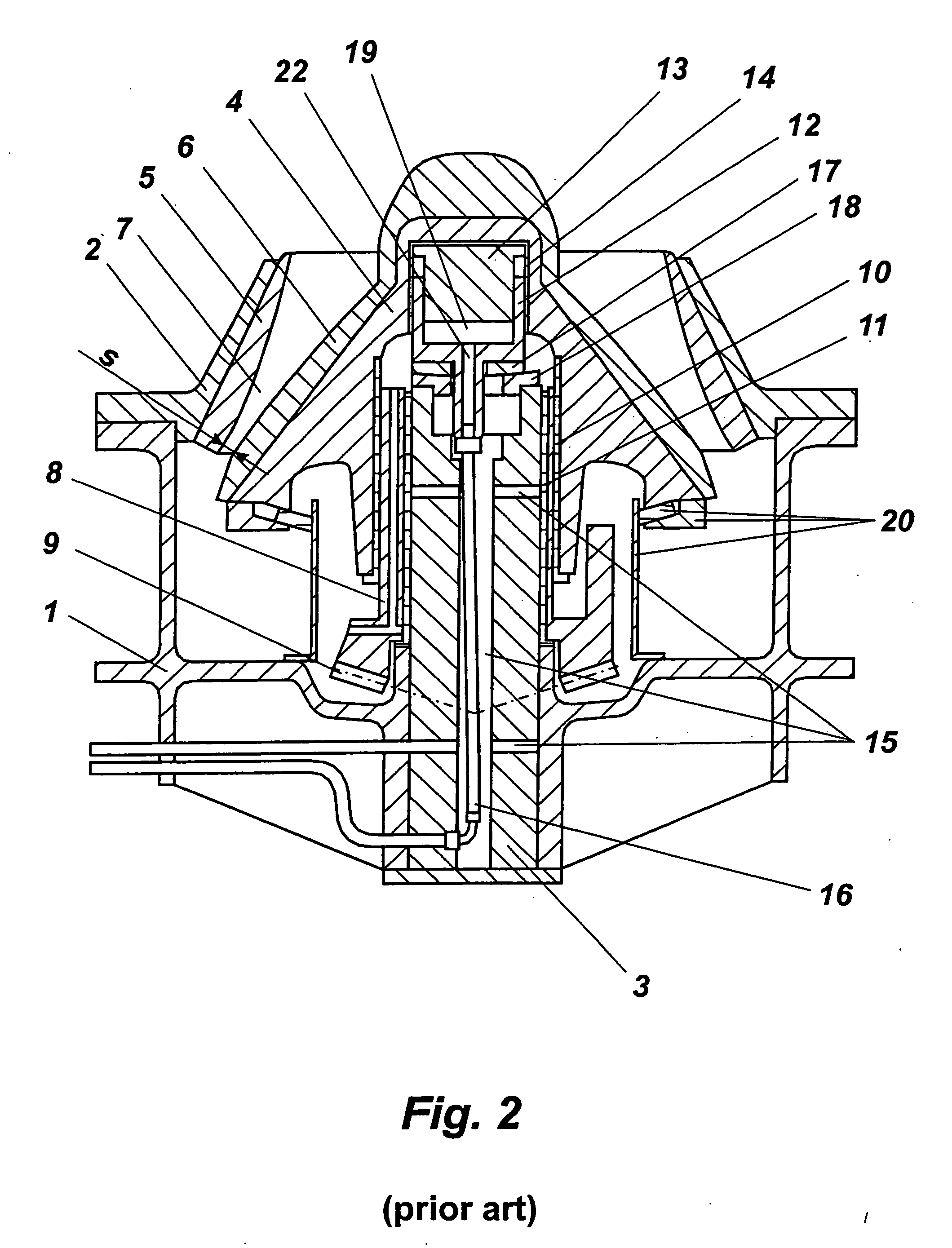

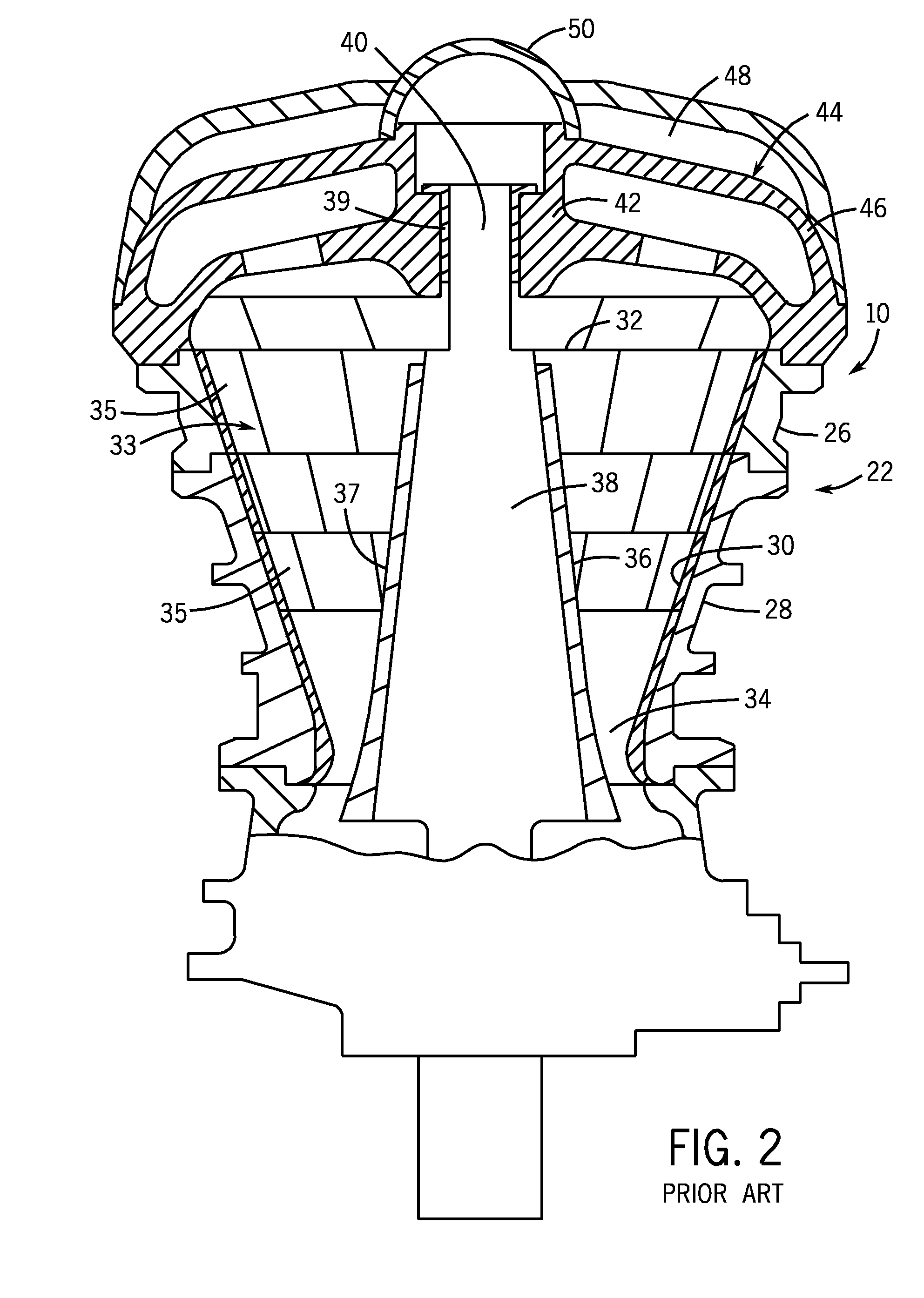

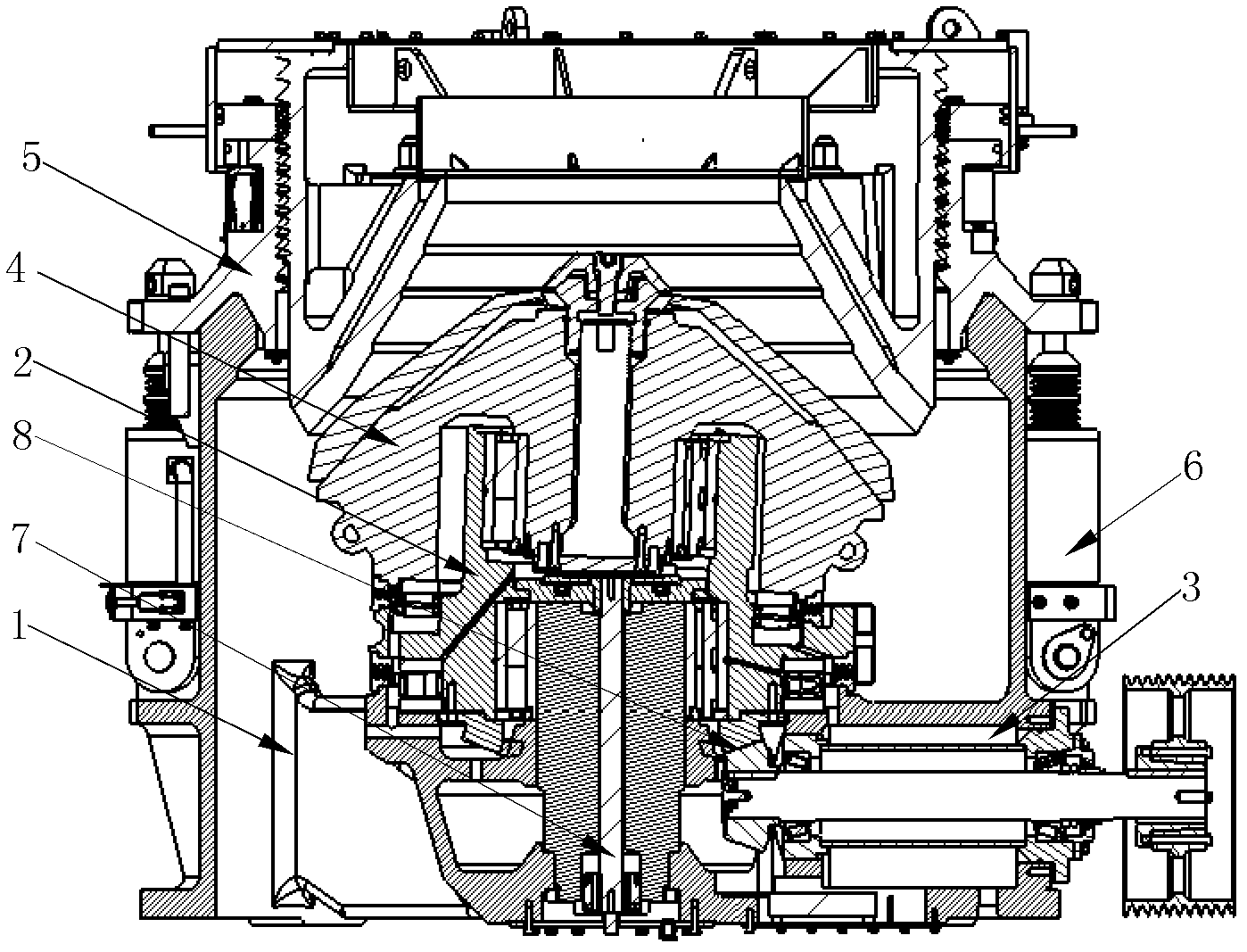

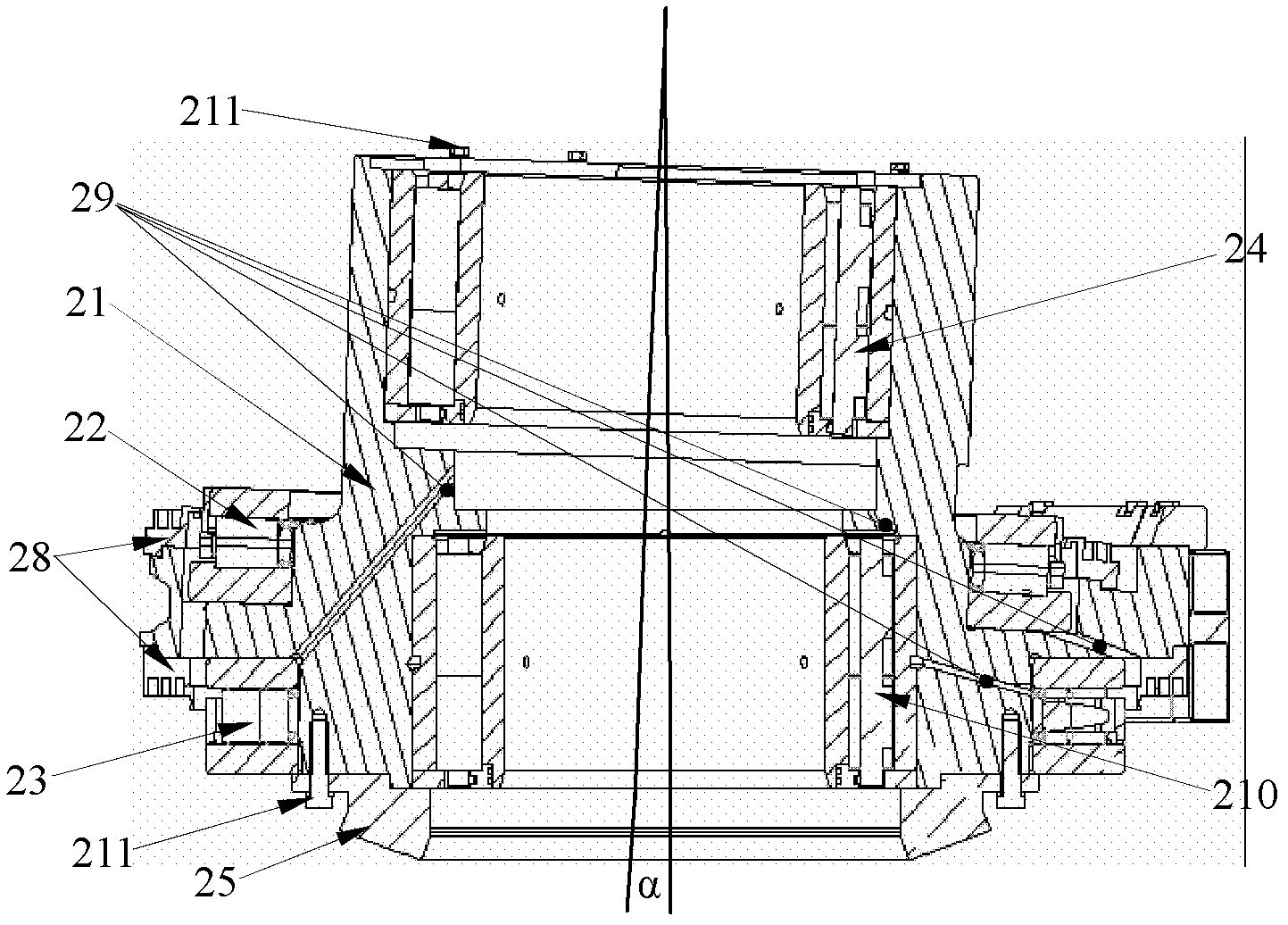

Hydraulically adjustable cone crusher and axial bearing assembly of a crusher

InactiveUS20090008489A1More durableMore reliableBearing componentsGrain treatmentsEngineeringCrusher

A hydraulically adjustable cone crusher and a axial bearing assembly of a cone crusher, which crusher comprises an hydraulic adjustment cylinder / piston assembly mounted in the space formed between the crushing head and the upper surface of the main shaft for adjusting the setting of the crusher. The pressure medium of the hydraulic adjustment system of the crusher is supplied to the pressure medium space formed, except by the adjustment cylinder / piston assembly, also by at least one bearing element.

Owner:METSO MINERALS INC

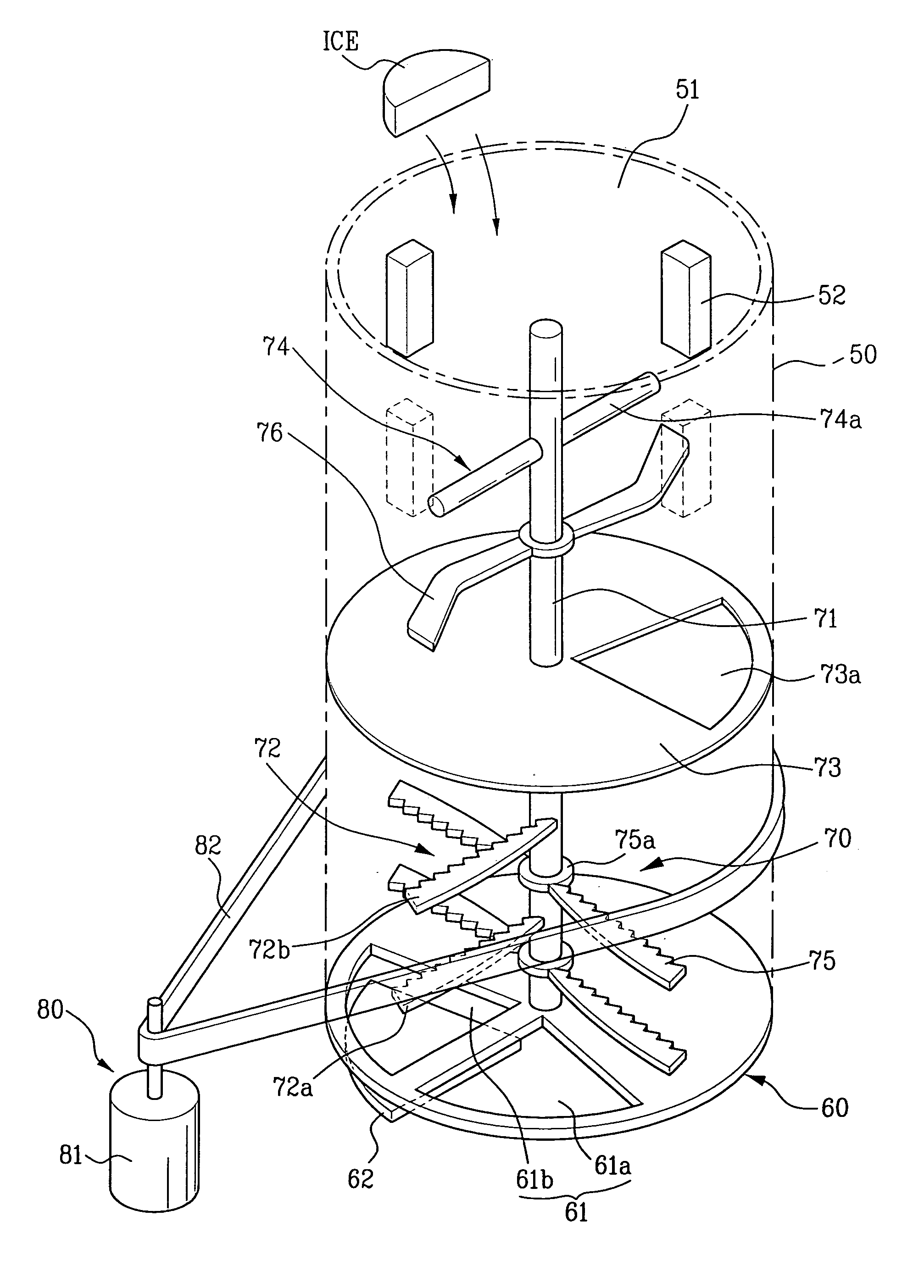

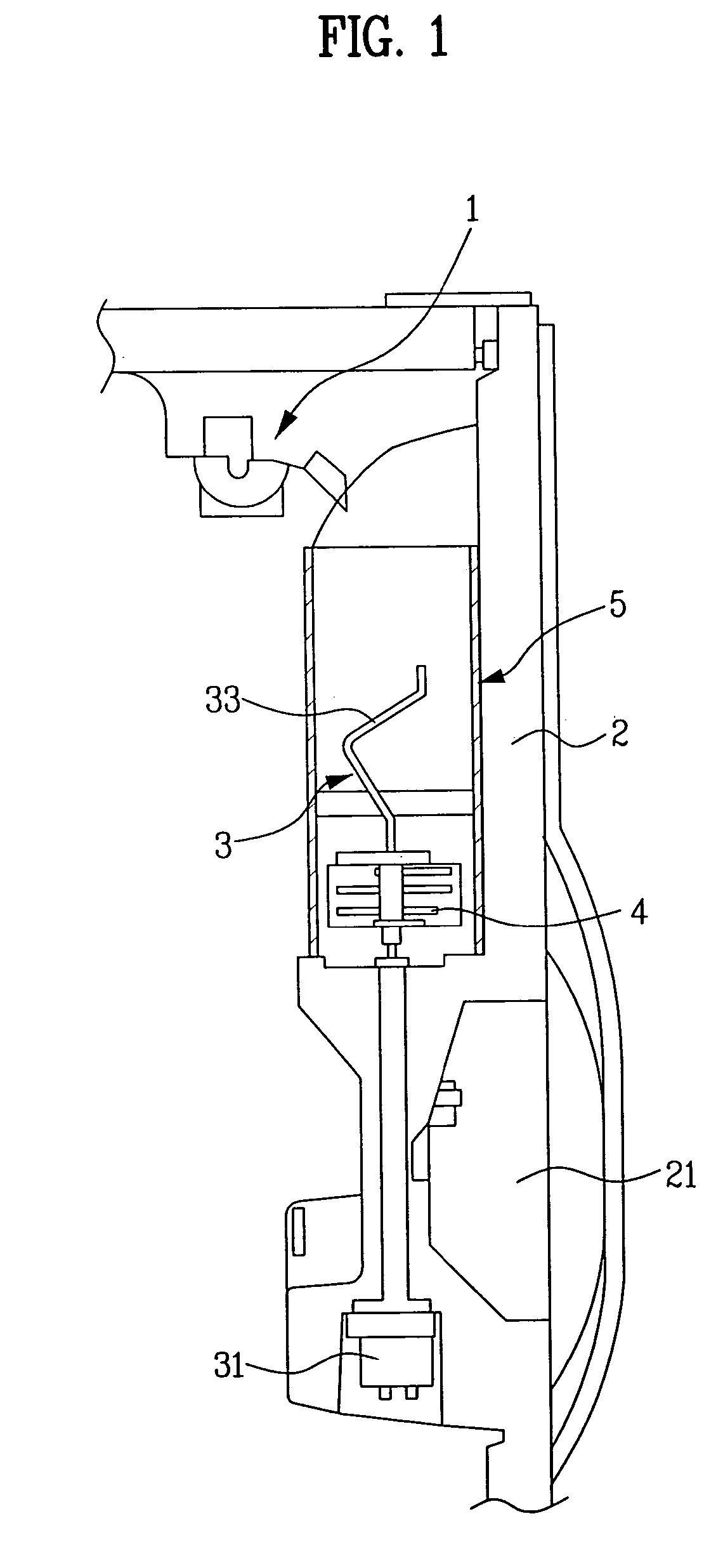

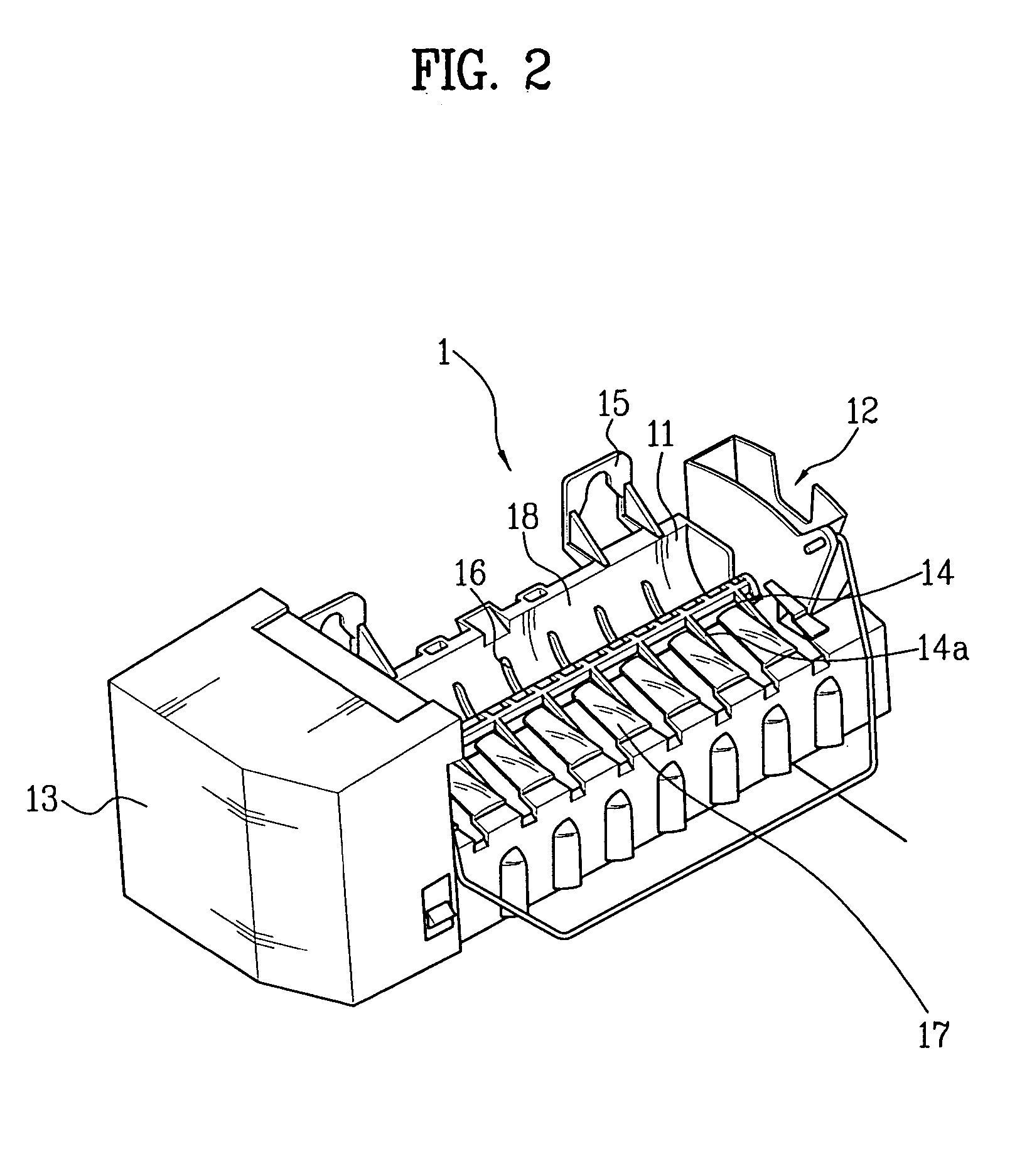

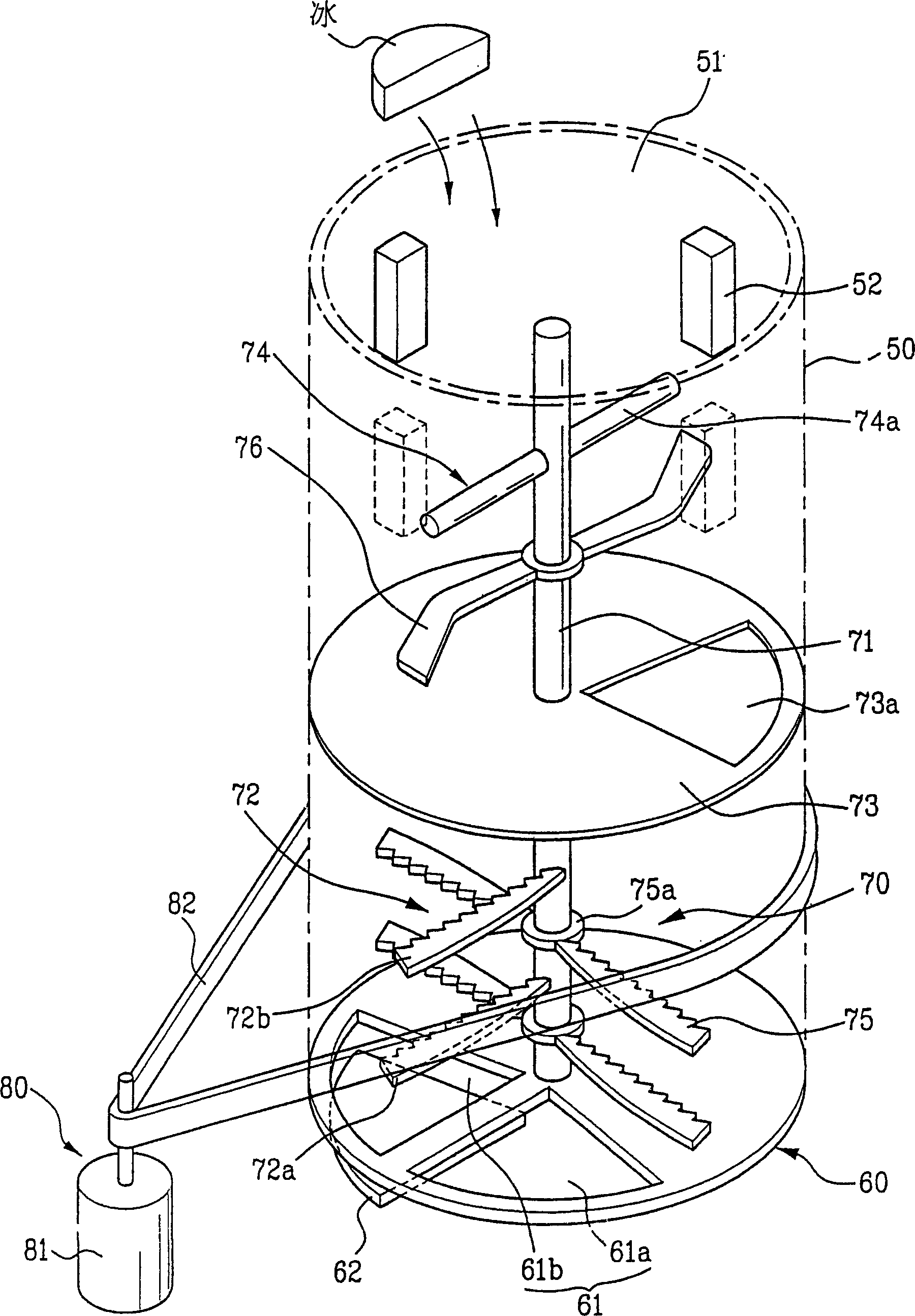

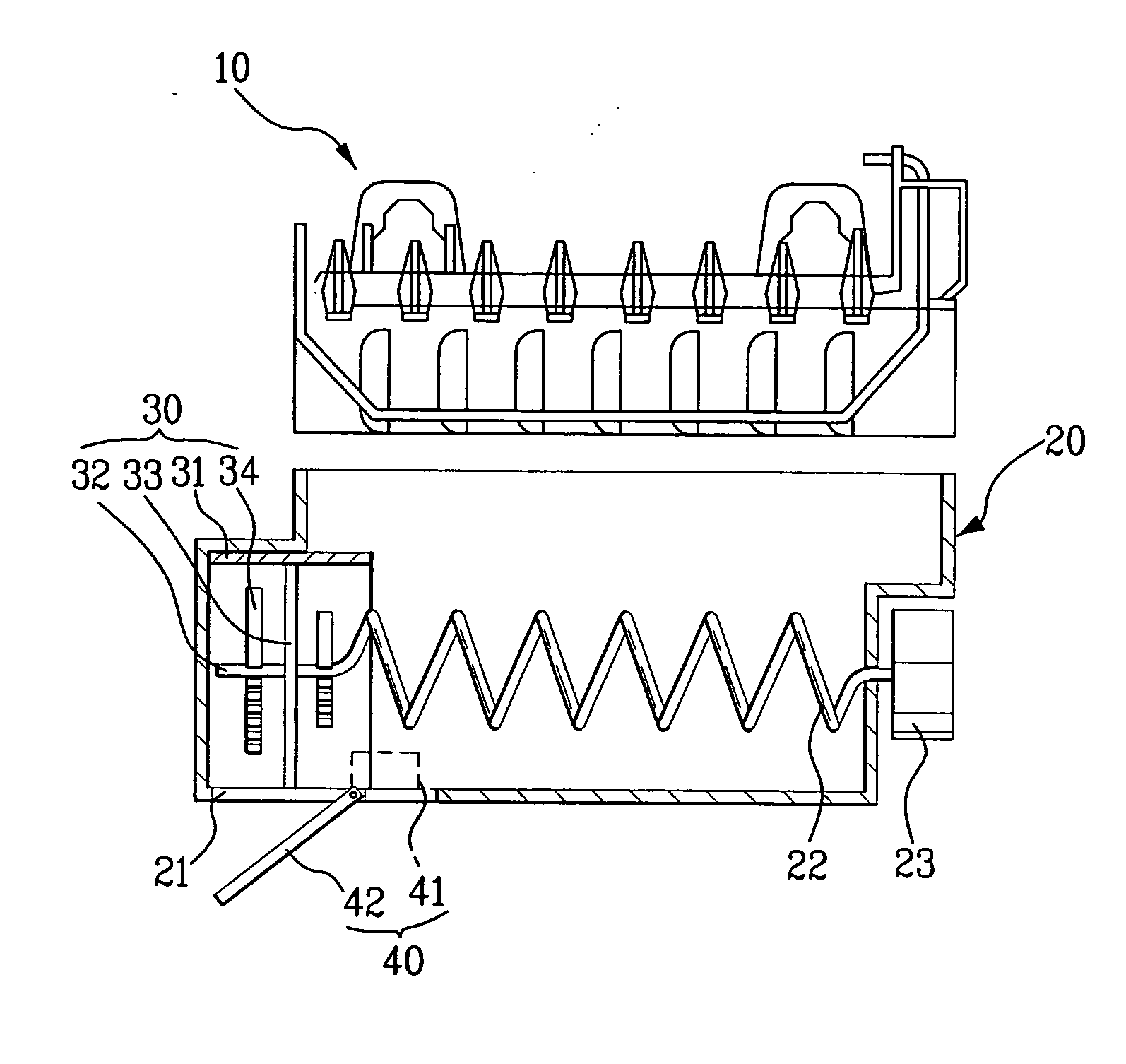

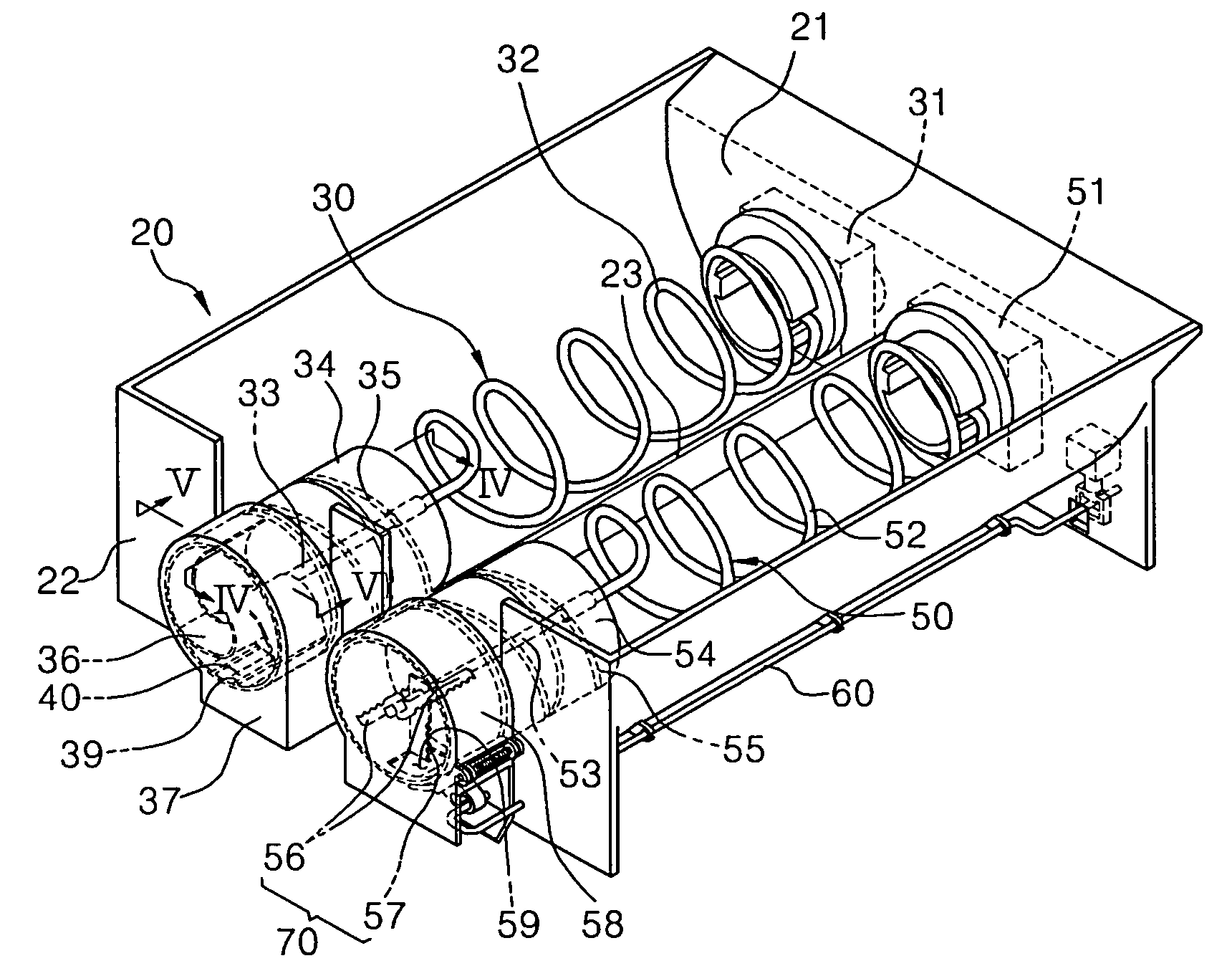

Ice bank of ice-making device for refrigerator

InactiveUS7111473B2Prevent fallingSmooth dischargeLighting and heating apparatusSolid waste disposalEngineeringCrusher

An ice bank of an ice-making device for a refrigerator is disclosed, for smooth crush and discharge of ice, which includes a housing for storing ice made in an icemaker, and provided rotatably to apply the power to the stored ice at a rotation direction; an ice discharger having at least one hole through which the ice is discharge to the external; a crusher provided in the inside of the housing, the crusher guiding the stored ice to the hole of the ice discharge and crushing the ice as a predetermined size before discharging the ice to the hole according to a user's select; and rotating means for rotating the housing. Also, the crusher includes fixed crushing means fixed to the inside of the housing, and rotation crushing means rotated for being synchronized with the housing so as to crush the ice before discharging the ice to the external according to a user's select.

Owner:LG ELECTRONICS INC

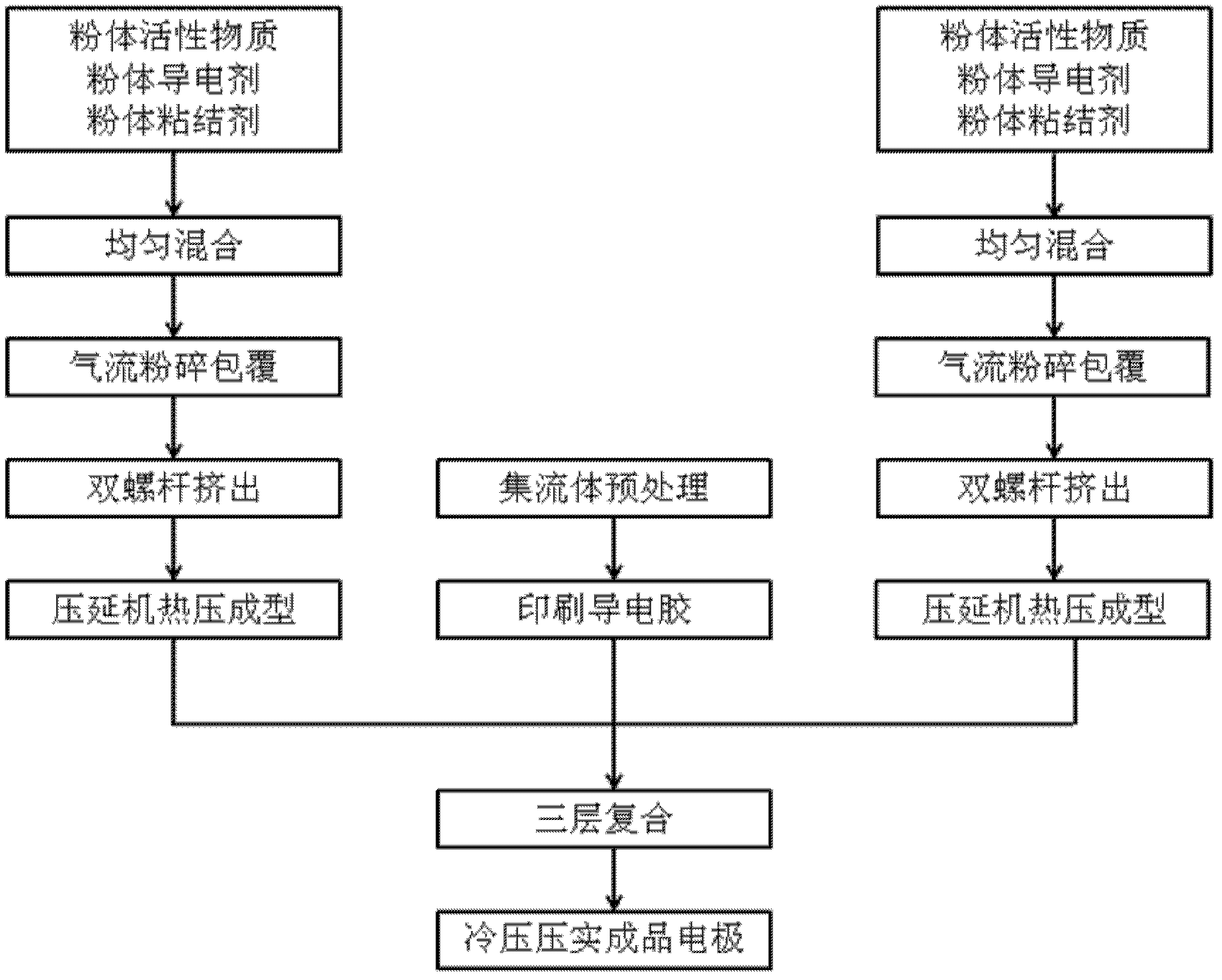

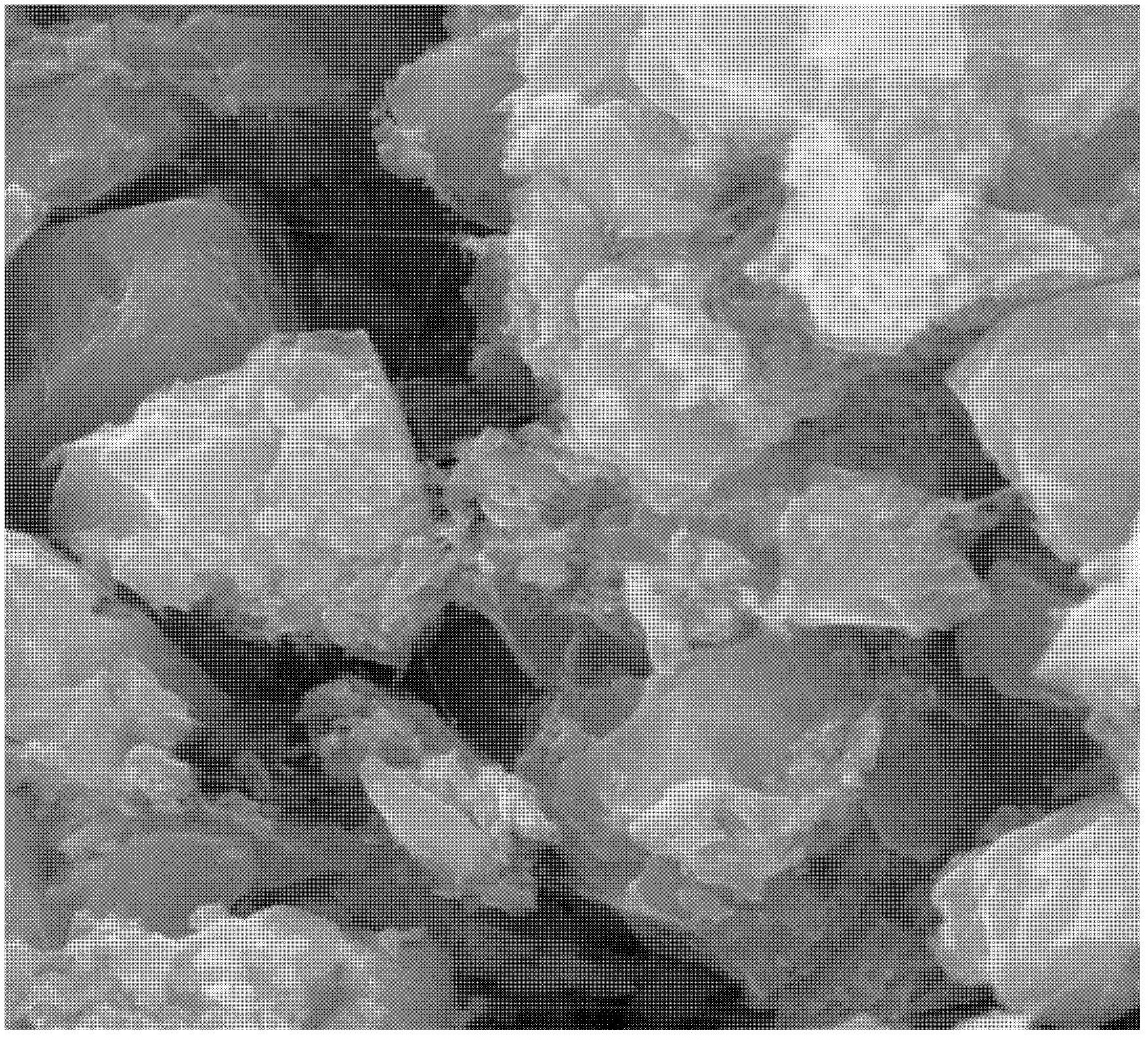

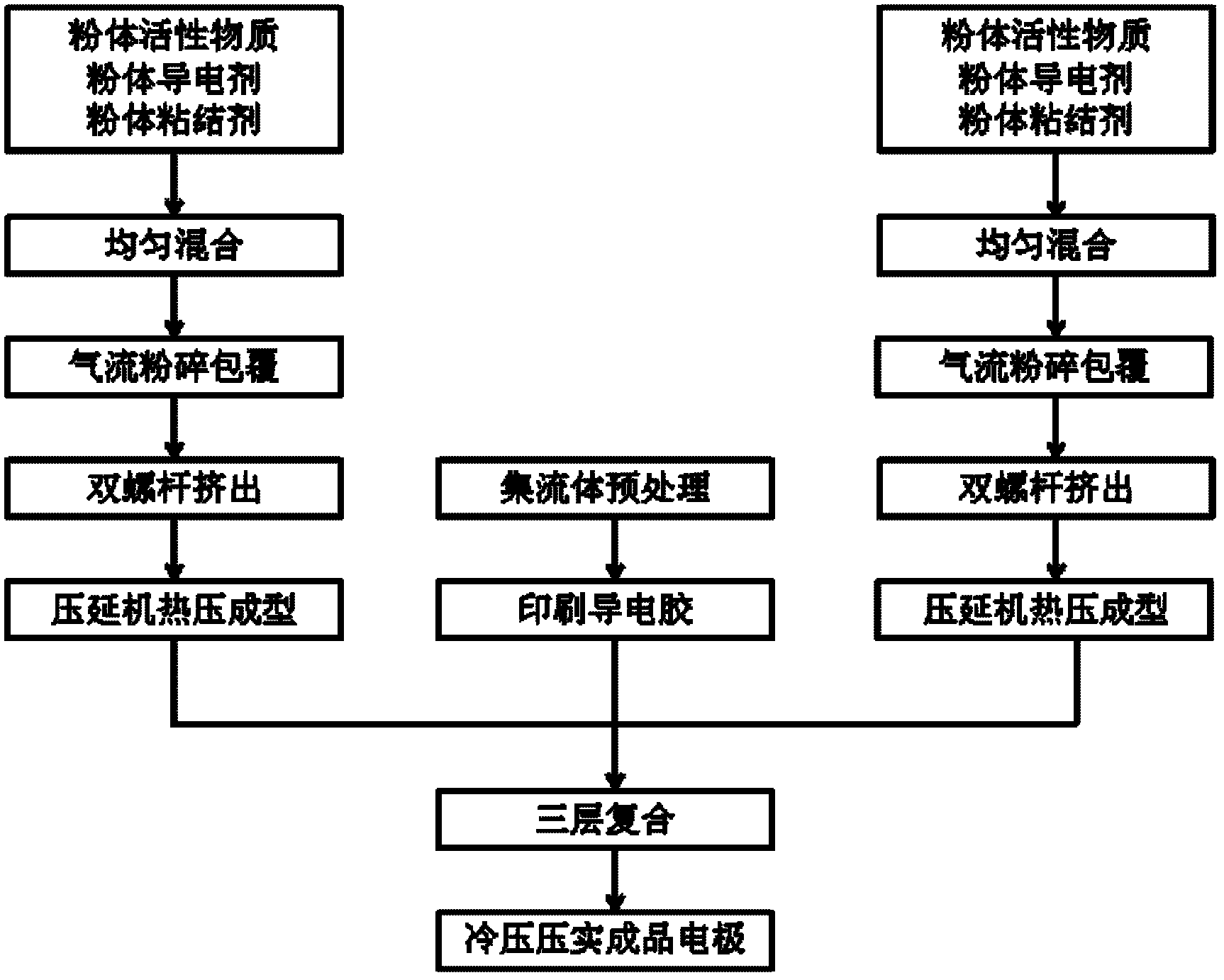

Powder-based electrode forming method

ActiveCN102629681AWell mixedImprove the mixing effectElectrode manufacturing processesHybrid capacitor electrodesAdhesiveCrusher

The invention relates to a powder-based electrode forming method, which comprises the following steps of: uniformly mixing a powder active substance, a powder conductive agent and a powder adhesive through a three-dimensional powder mixer or a zero-gravity powder mixer; crushing through a low-temperature crusher; performing fibrous extrusion forming through a double-screw extruder or an internal mixer / open mill and then achieving target thickness through hot pressing of a calender; and finally performing three-layer compounding with a current collector of a printing conductive adhesive to form an electrode and performing cold rolling to improve the compaction density. According to the powder-based electrode forming method, a method of assisting machining by using a solvent is abandoned, so that the purity of an electrode material is guaranteed to the greatest extent, no energy waste of a drying process or restriction to the time of the drying process exists in a production process, the cost is reduced, the energy loss is reduced, and the working speed is increased.

Owner:GMCC ELECTRONICS TECH WUXI CO LTD

Ice bank of ice-making device for refrigerator

InactiveCN1576760ASmooth dischargeLighting and heating apparatusSolid waste disposalEngineeringCrusher

Owner:LG ELECTRONICS INC

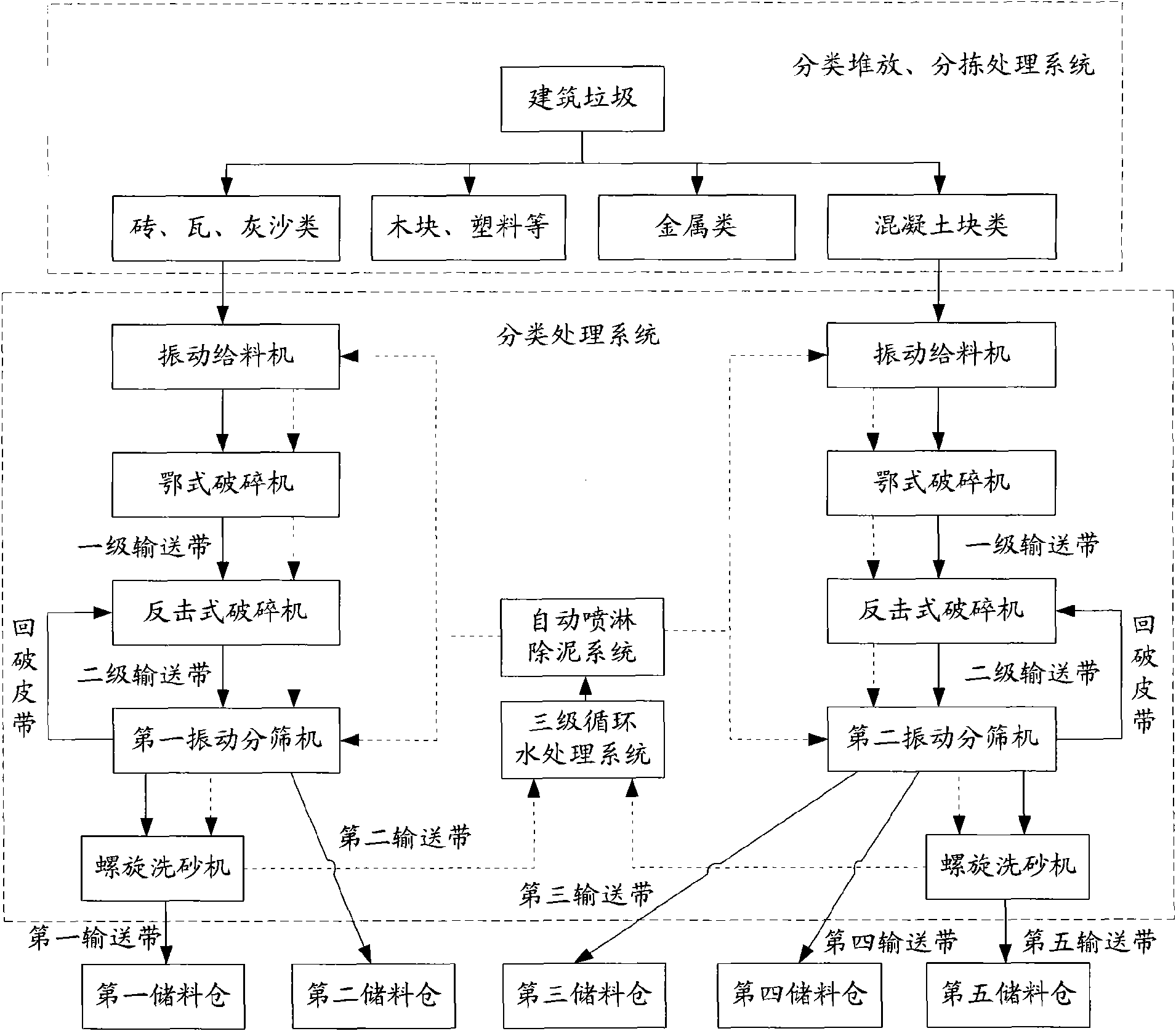

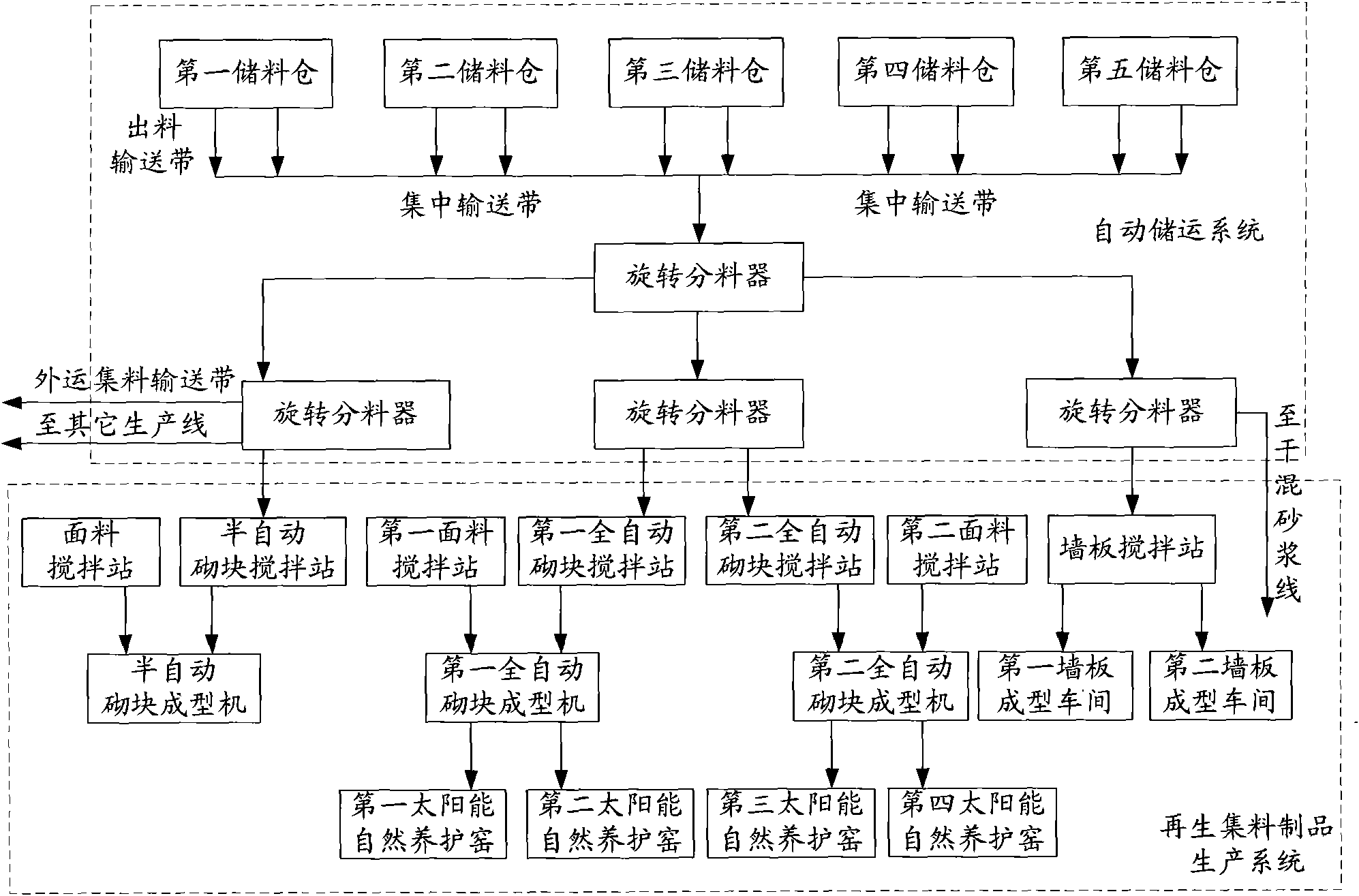

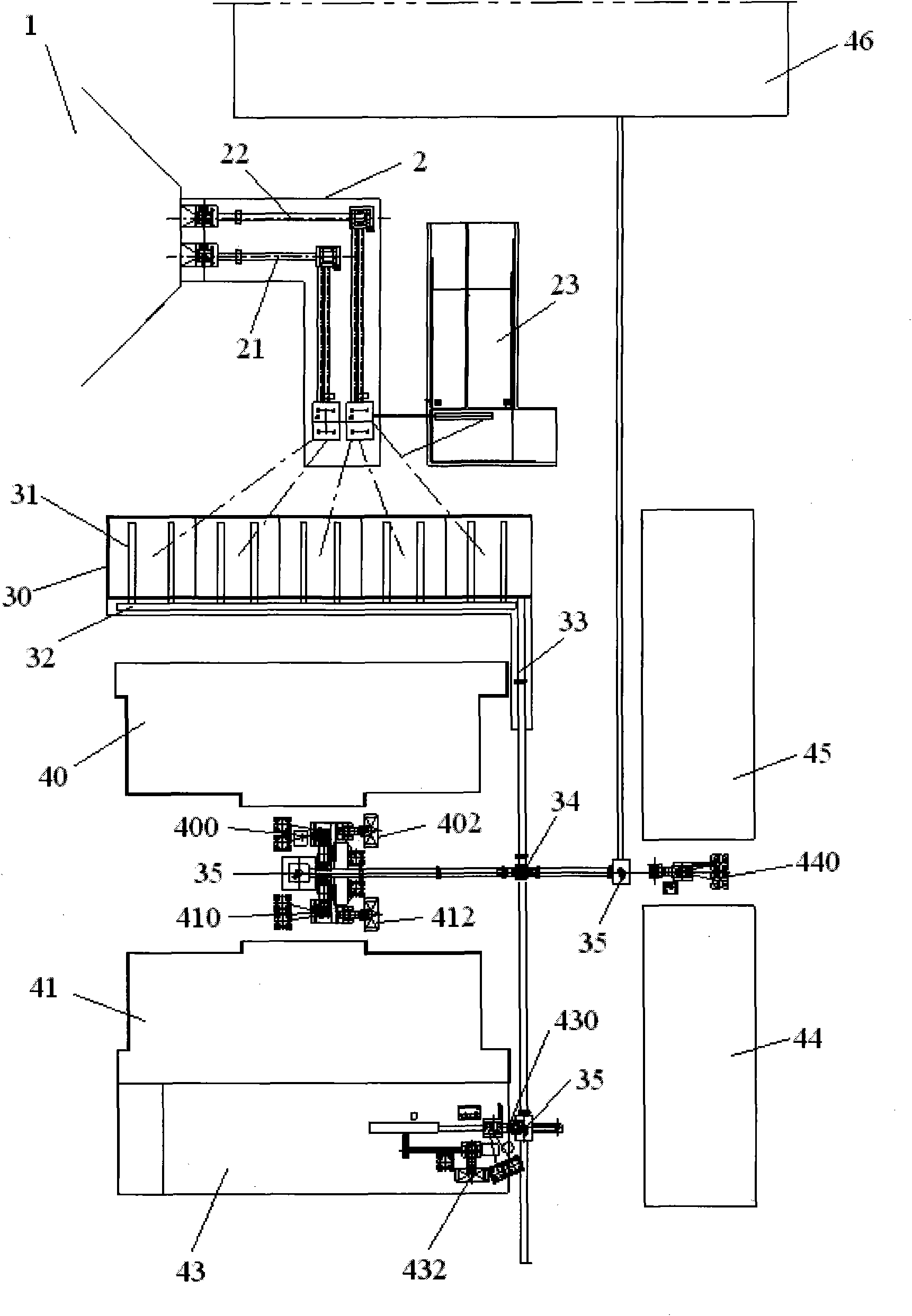

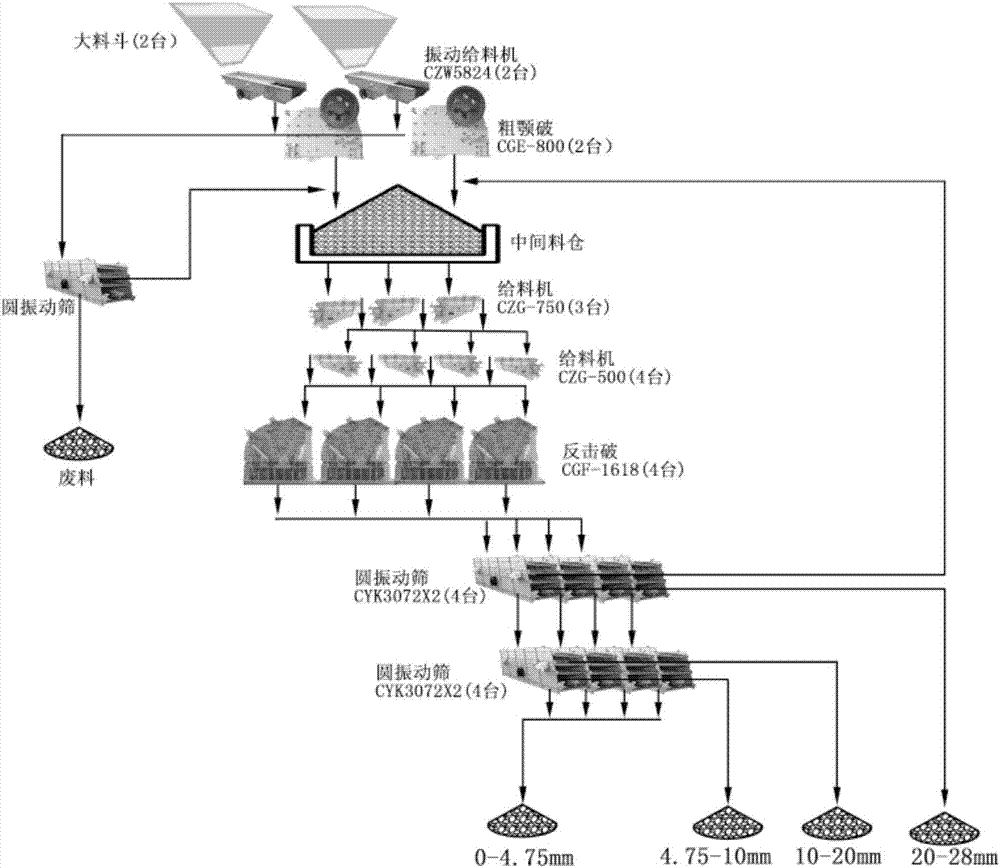

Building refuse treatment regeneration system

The embodiment of the invention discloses a building refuse treatment regeneration system, including a classification stacking, sorting processing system, a classification processing system and a plurality of storage bins, wherein, the classification processing system includes at least two parallel crushing screening process production lines and water circulating systems, each crushing screening process production line includes a feeder, crusher, as well as a screening machine connected in series in sequence, and a plurality of outlets of the screening machine are respectively connected to the plurality of storage bins through conveyor belts. By adoption of the building refuse treatment regeneration system of the embodiment of the invention, bricks, tiles, dust and sand and concrete blocks and the like in the building refuse can be divided into at least two production lines for parallel processing, which greatly enhancing the production efficiency and the purity of recycled aggregates, so that the recycled aggregates can be applied to a variety of uses, reproduced into a variety of high-quality recycled products, reducing the waste of resources and minimizing pollution that will be probably caused to the environment.

Owner:深圳市绿发鹏程环保科技有限公司

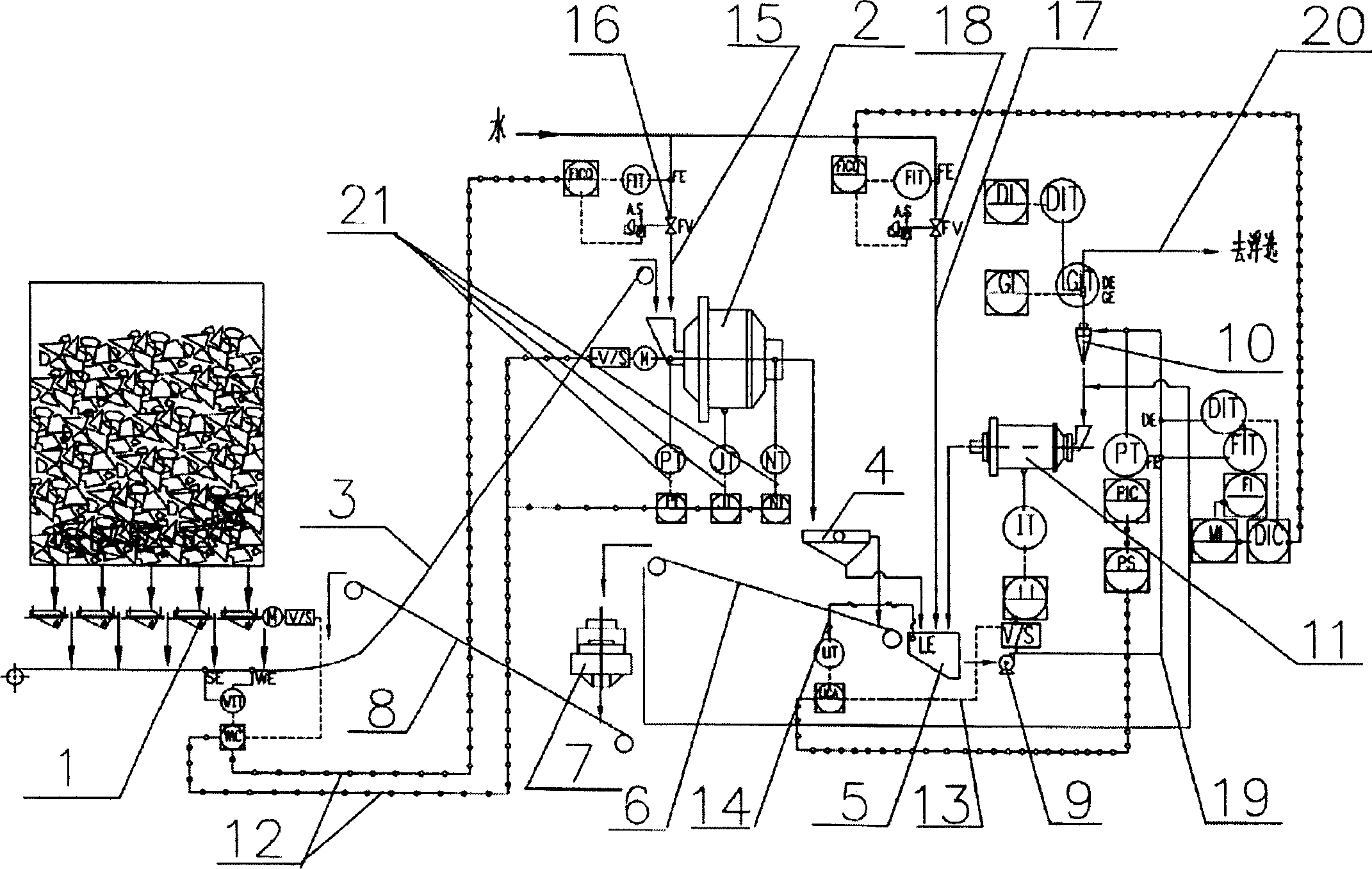

Semi-automill ball-milling type ore grinding system and its control system

A semi-automatic grinder-ball grinder system for grinding ore is composed of a vibration feeder, a semi-automatic grinder with variable-speed driver and load monitor, a vibration sieve, a crusher, a sludge pump, cyclone unit with concentration, flow and granularity detections, and a ball grinder with variable-speed driver. Its control method is also disclosed.

Owner:CHINA ENFI ENGINEERING CORPORATION

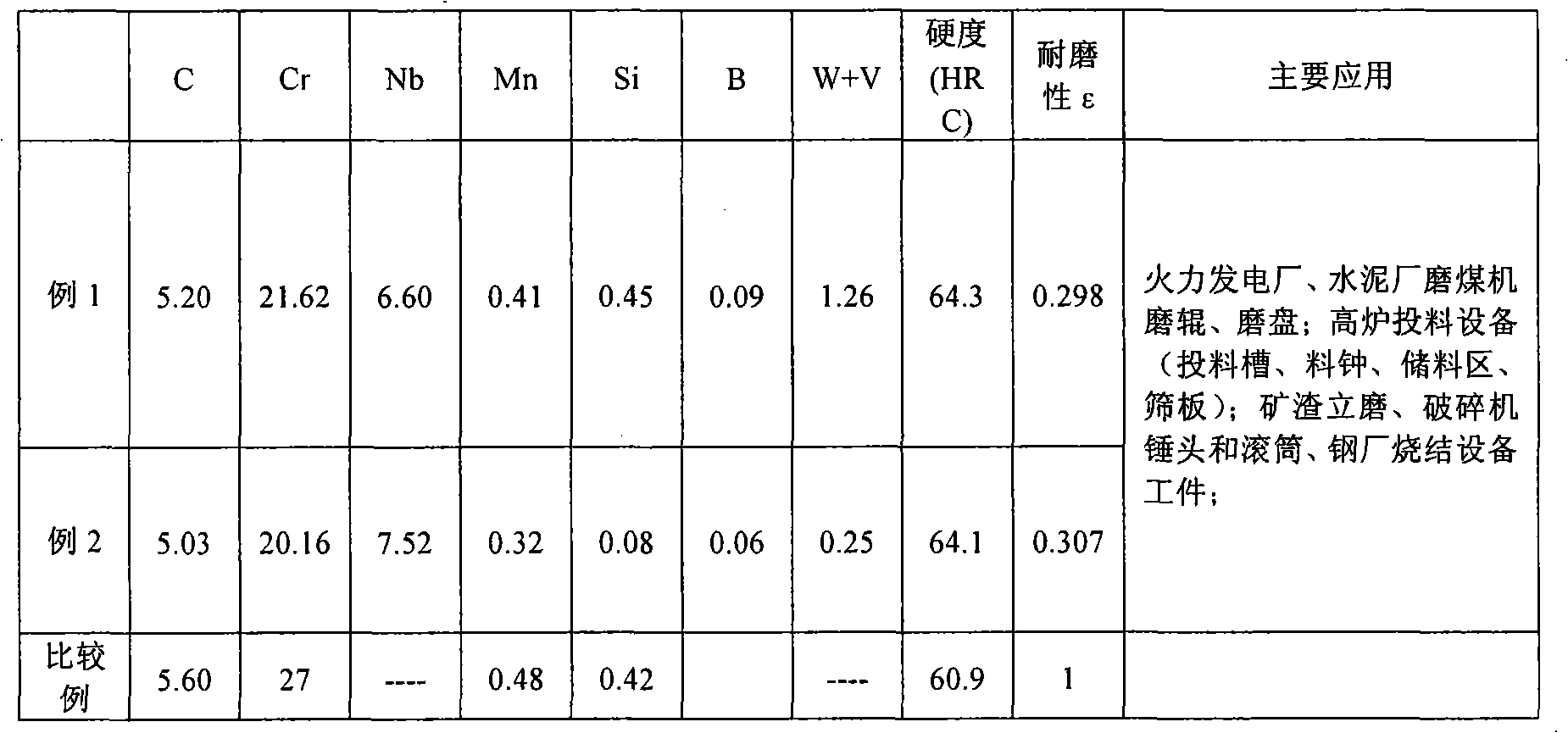

High-carbon high-chromium high-niobium cast iron self-protecting flux-cored wire

InactiveCN101406994AHigh hardnessLow viscosityWelding/cutting media/materialsSoldering mediaHigh carbonNiobium

The invention provides a high-carbon high-chromium high-niobium cast iron self-protection flux-cored wire. The flux-cored wire has a steel belt as an outer skin. The flux core comprises the following components in weight percentage: 10 to 30 percent of ferroniobium, 20 to 30 percent of high carbon ferrochrome, 0.1 to 3 percent of V, 0.2 to 3 percent of W, 0.6 to 0.8 percent of ferromanganese, 0.2 to 0.8 percent of 75 ferrosilicon, 20 to 30 percent of chromium carbide, 5 to 12 percent of graphite, 1 to 10 percent of aluminum-magnesium alloy, 1 to 5 percent of silicon carbide and 1 to 3 percent of ferroboron; and the percentage of a counter weight is between 46 and 54 percent. The high-carbon high-chromium high-niobium cast iron self-protection flux-cored wire has the advantages of high hardness, good wear resistance, good oxidation resistance and strong shock resistance, and is widely applied to grinding rolls and grinding disks of coal grinding machines in thermal power plants and cement plants, material charging equipment in blast furnaces(material charging slots, receiving cones, material storage areas and sieve plates), slag vertical mills, hammer heads and rollers of crushers and sintering equipment workpieces in steel plants.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

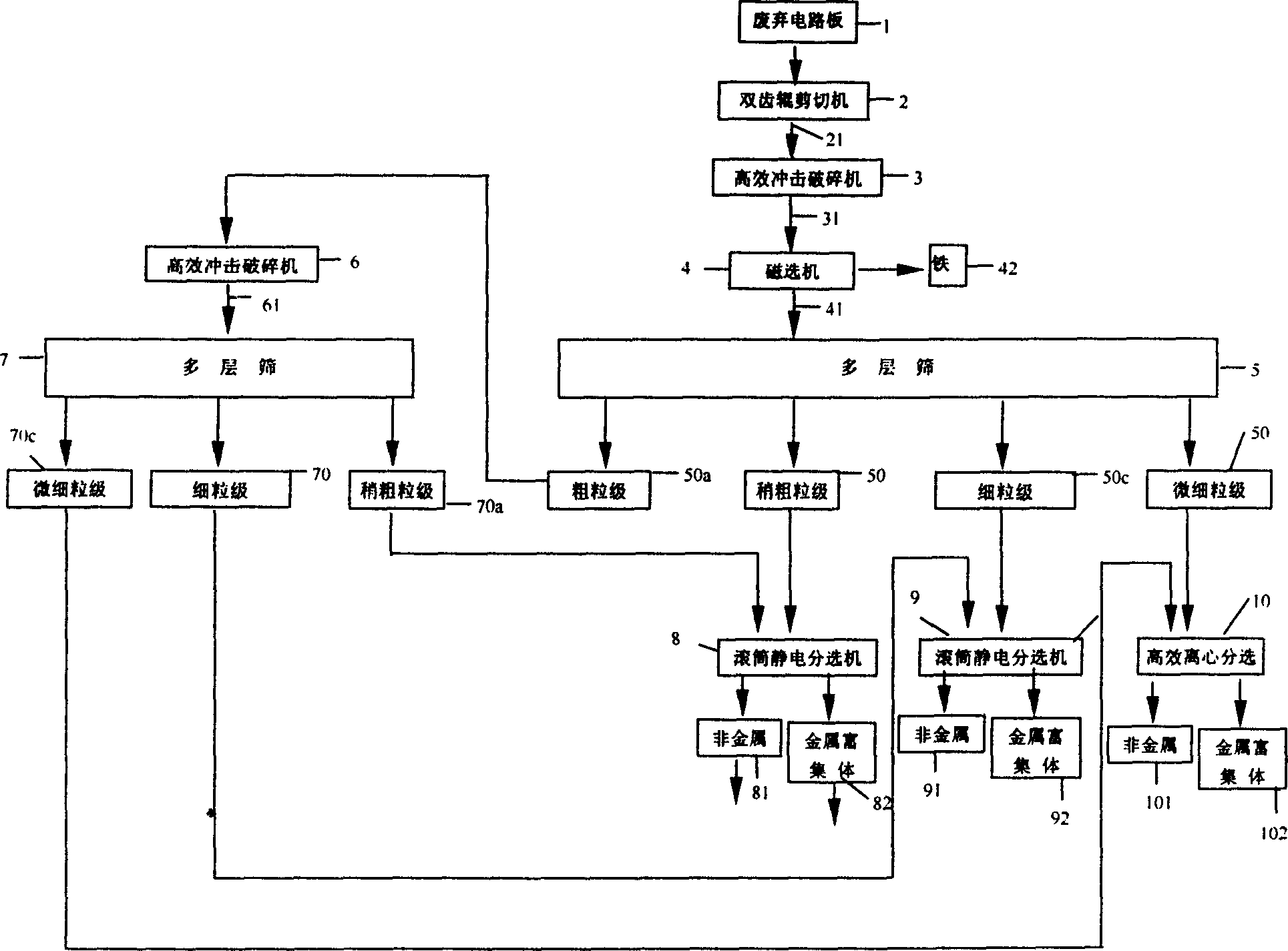

Techhnique for reclaiming metal concentrate in obsolete PCB physically

InactiveCN1563440ASolve resource problemsAchieve recyclingSolid waste disposalProcess efficiency improvementDouble teethMagnetic separator

A physical recovery technology of metal enriched materials from waste CB applies a mechnanical and physical sorting method to cut, crush, screen, sort and separate the waste CB by a double tooth roll shearer, a punch crusher, a magnetic separator, a separating screen, a rotary static separator, high efficient centrifugal separator to get a multicomponent of metal rich collection and a nonmetal enriched material to recover all valuable components from waste CB.

Owner:CHINA UNIV OF MINING & TECH

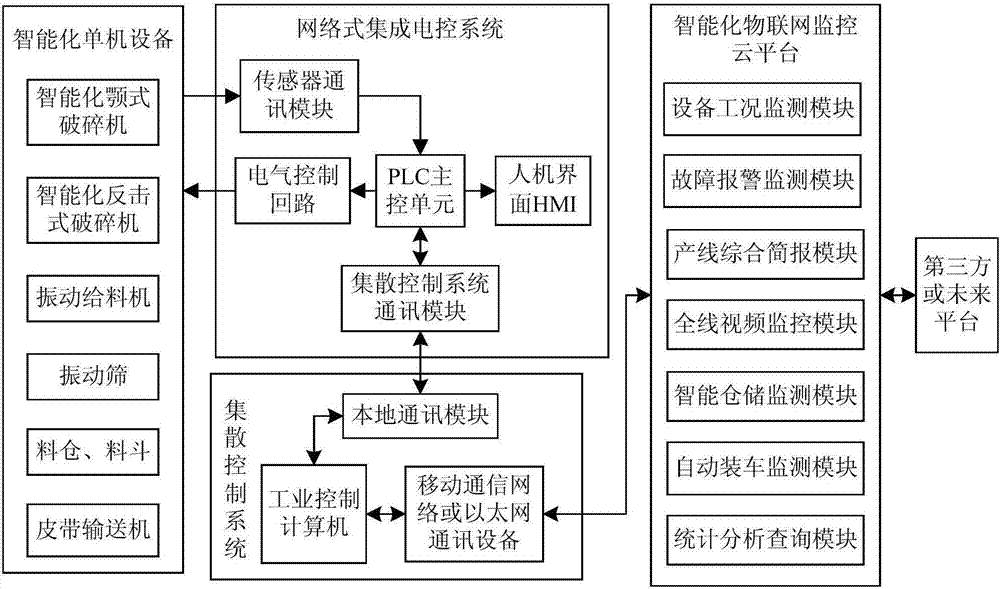

Intelligent gravel aggregate production line

ActiveCN107153410AIncrease the level of automationReduce work intensityTotal factory controlProgramme total factory controlProduction lineDowntime

The invention provides an intelligent gravel aggregate production line, and relates to the technical field of gravel aggregate production. The intelligent gravel aggregate production line comprises an intelligent jaw type crusher, an intelligent impact type crusher, a vibrating screen, a vibrating feeder, a material bin, a hopper, a belt conveyor, a control-related network type integrated electric control system, a distributed control system and an intelligent internet of things monitoring cloud platform, wherein various sensors are additionally arranged on the basis of an original crushing screening production line; sensor information is transmitted to the distributed control system through the network type integrated electric control system, so that automatic regulation and control on the production process is realized, and therefore, the sensor information is transmitted to the intelligent internet of things monitoring cloud platform; and production data storage and safety are managed in a unified mode on the basis of classifying and combing through cloud computation. The intelligent gravel aggregate production line has a fault early-warning function and a real-time alarm function, and quickly increases response speed; internet of things intelligent control and remote monitoring are introduced, the production process is automatically regulated and control, operation is performed with optimal load, the yield is increased, and downtime maintenance is reduced.

Owner:SHANGHAI UNITRUSTON INTELLIGENT TECH CO LTD

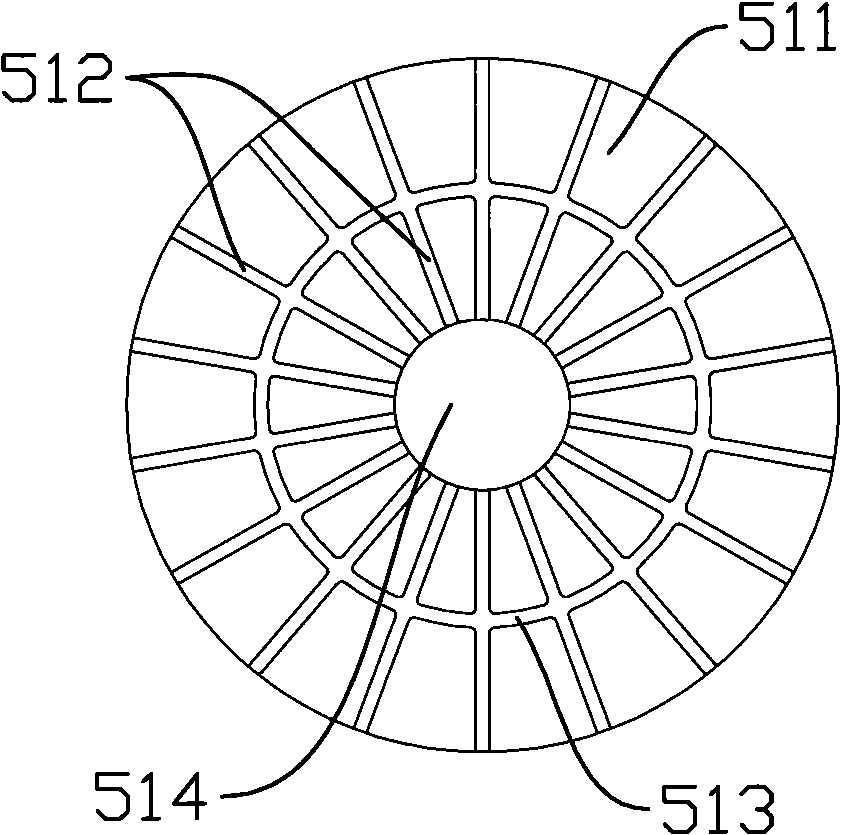

Spider having spider arms with open channel

A spider for use with a gyratory crusher. The spider includes spider arms each formed from two spaced flanges joined by a connecting web to define an open channel having an open top end. The configuration of the spider arms increases manufacturability and provides the required strength and rigidity for the spider. The channel formed in each spider arm is covered by a spider arm shield to reduce abrasive wear to the spider arm.

Owner:METSO OUTOTEC USA INC

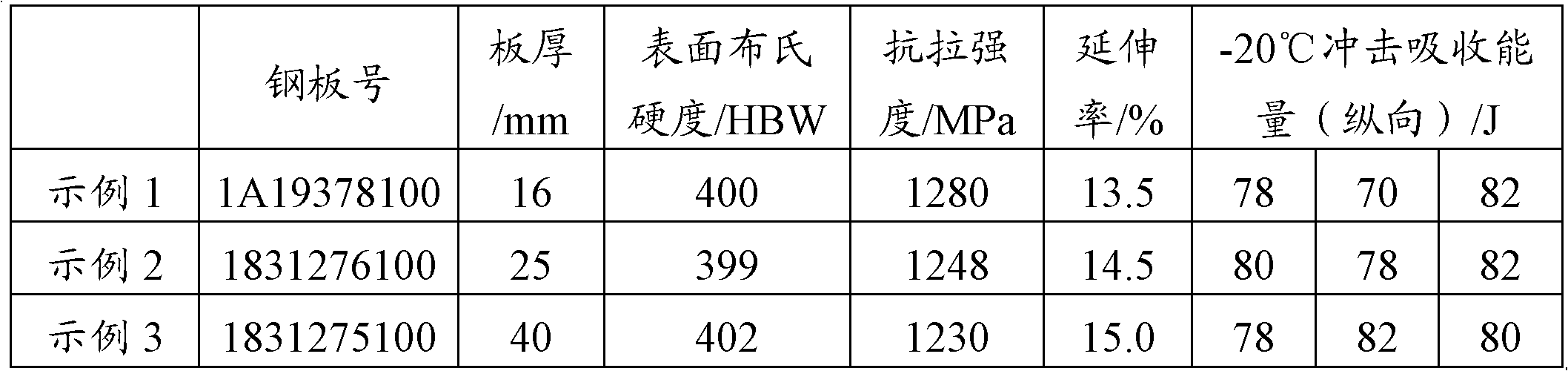

High-strength abrasion-resistant steel for engineering machinery and manufacturing method thereof

InactiveCN102618792ALow costWith superficial Brinell hardnessHigh wear resistanceMechanical products

The invention discloses high-strength abrasion-resistant steel for engineering machinery and a manufacturing method thereof. Components of the steel includes, by weight, 0.05-0.30% of C, 0.20-0.65% of Si, 1.20 to 1.60% of Mn, S<=0.010%, P<=0.020%, 0.0010-0.0040% of B, 0.30-1.00% of Cr, 0.030-0.080% of V, 0.015-0.050% of Al, [N]: 80-(200*10-6), [H]<=2*10-6, [O]<=40*10-6, and the balance Fe and inevitable impurities. The steel has surface brinell hardness no less than 395HBW, tensile strength no less than 1220 MPa, elongation after fracture no less than 13% and -20 DEG C shock absorption energy no less than 70J and is low in cost and capable of being used for manufacturing high-strength and high-abrasion resistance mechanical products in the industries of engineering, mining, building, agriculture, cement production, harbors, electric power and metallurgy. For example, the steel can be used as steel balls and lining plates of a ball grinder, bucket teeth of an excavator, rolling mortar walls, toothed plates and hammers of various crushers, track shoes of a tractor and a tank, scraper knives and relieving teeth for a bulldozer and the like.

Owner:LAIWU IRON & STEEL GRP +1

Method for preparing porcelain granules by using fly ash

InactiveCN101585698AImprove protectionSave natural resourcesFluid removalCeramic materials productionExpanded clay aggregateSlurry

The invention discloses a method for preparing porcelain granules by using fly ash, which comprises the following steps: putting fly ash, potassium feldspar and quartz as raw materials into a ball mill respectively, dry-milling the raw materials, sieving the milled raw materials respectively, removing iron from the sieved fly ash, putting the fly ash after iron removal, the sieved potassium feldspar and quartz and kaolin into the ball mill, and wet-milling and evenly mixing the materials to form mixed slurry; and granulating the mixed slurry by adopting a pressure type spray granulator, putting the granules into an alumina crucible, placing the alumina crucible into a silicon-carbon rod resistance furnace, sintering and naturally cooling the granules, and taking out the granules to obtain the high-strength porcelain granules. The method for preparing the porcelain granules by using the fly ash is not only favorable for saving natural resources and reducing the production cost, but also favorable for environmental protection. The fly ash does not need to be crushed by a high-power crusher, and the fly ash is mixed evenly. The production process is easy to control, and has little energy consumption; the strength of the prepared fly ash porcelain granules can reach 60 to 120MPa; and the porcelain granules have good properties of light weight, high temperature resistance, corrosion resistance and the like, and can be used as a fracturing propping agent for middle and deep layer oil-gas fields.

Owner:SHAANXI UNIV OF SCI & TECH

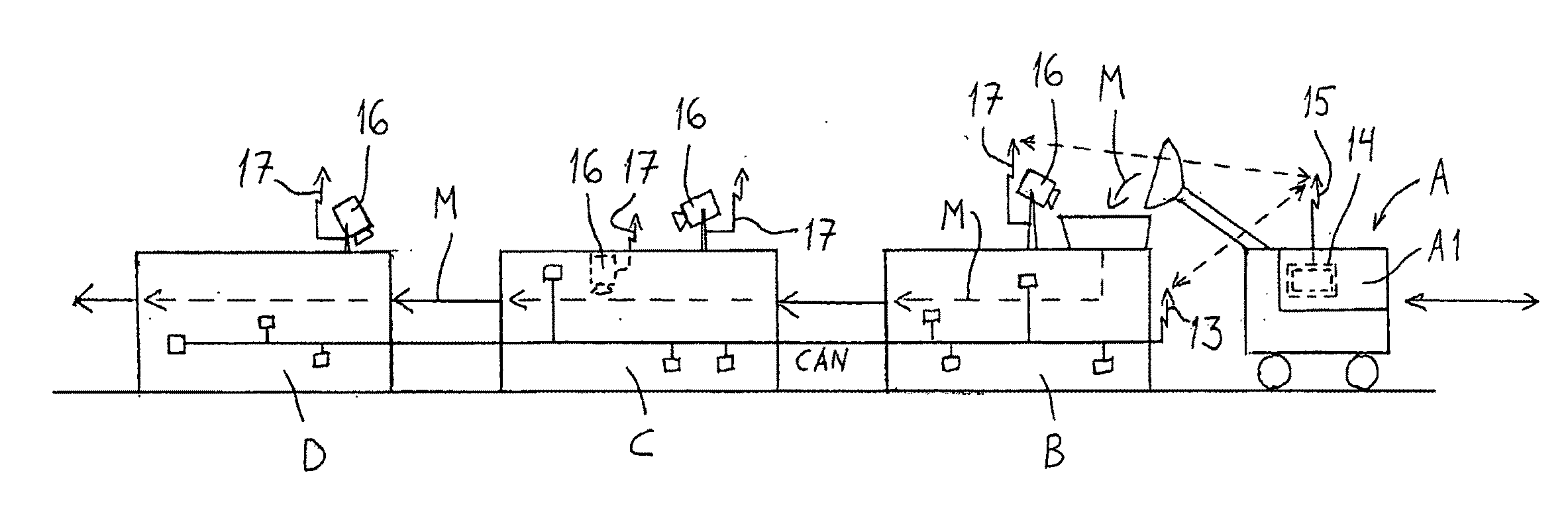

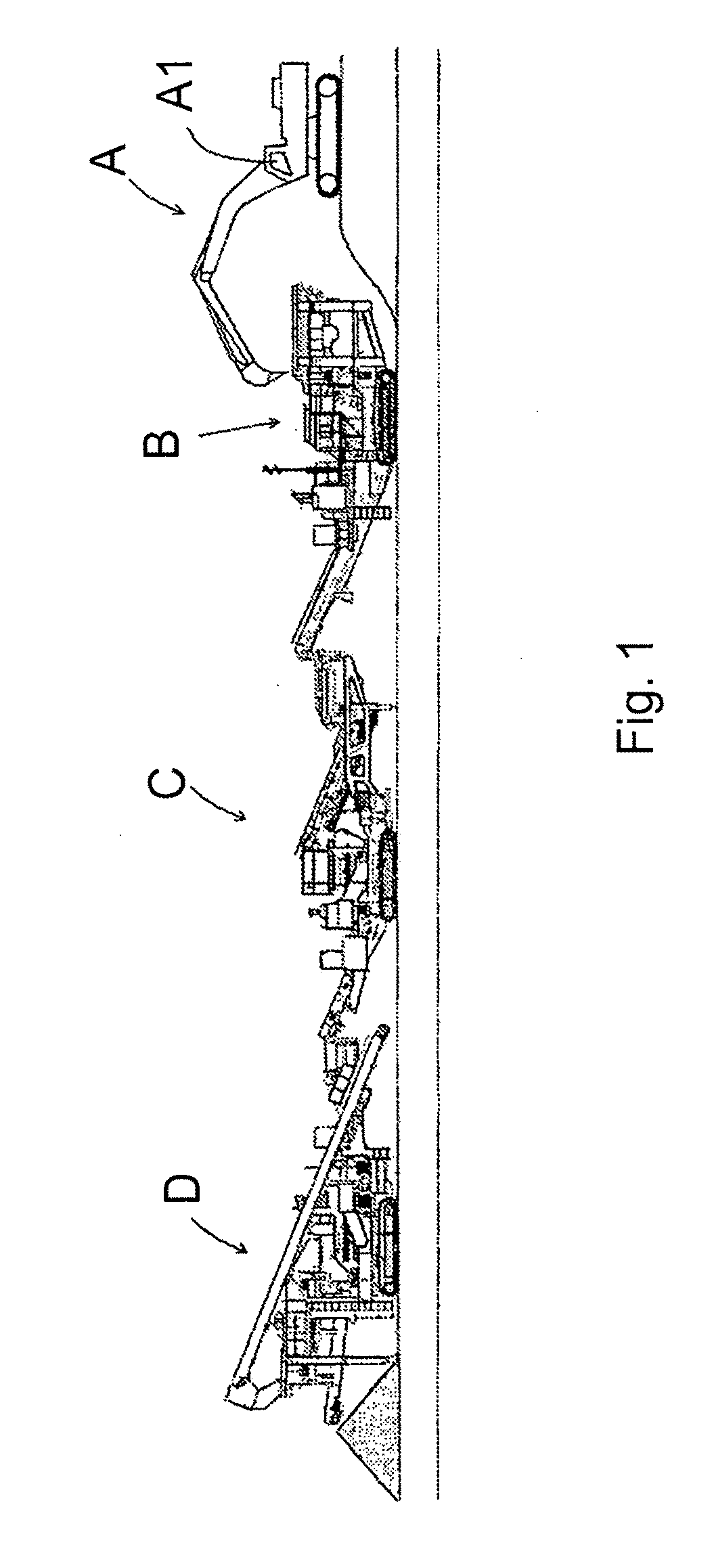

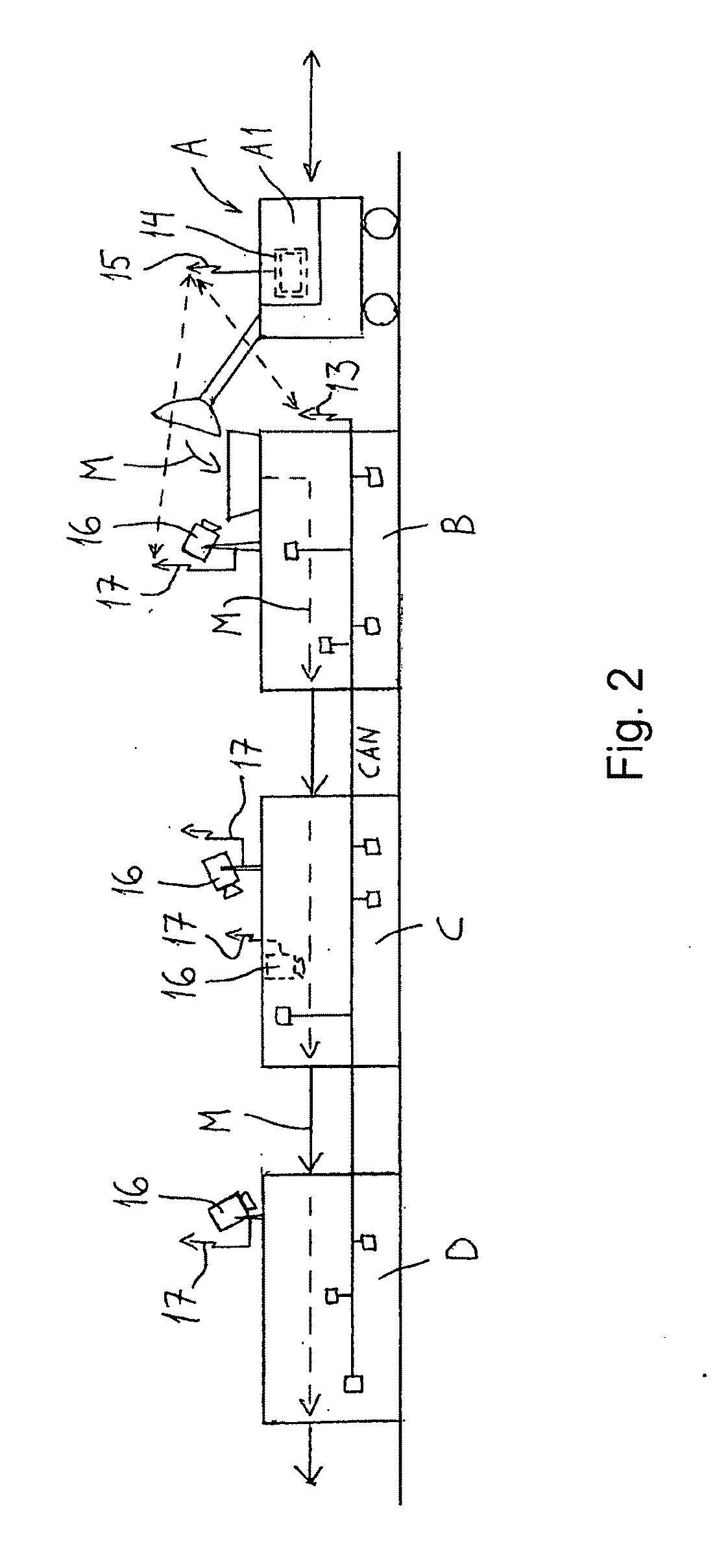

User interface of mineral material processing equipment

InactiveUS20100091103A1Available space is limitedSievingTelevision system detailsTraffic signalActuator

User interface of a mineral processing equipment governs a mineral processing line having several units (crushers, screens) connected in series. The user interface comprises a display screen (14) and control buttons or keys and is connected through a data transmission link to sensors and actuators of the mineral processing equipment for receiving measurement data and sending control commands. The user interface is arranged to show within the display screen (14), by choice of the userstatus of the mineral processing equipment in diagrammatic representation, ora live camera view (21) of at least one point of the equipment.The diagrammatic representations can be in form of a traffic lights (20) indicating the feeding speeds of the units.

Owner:METSO MINERALS INC

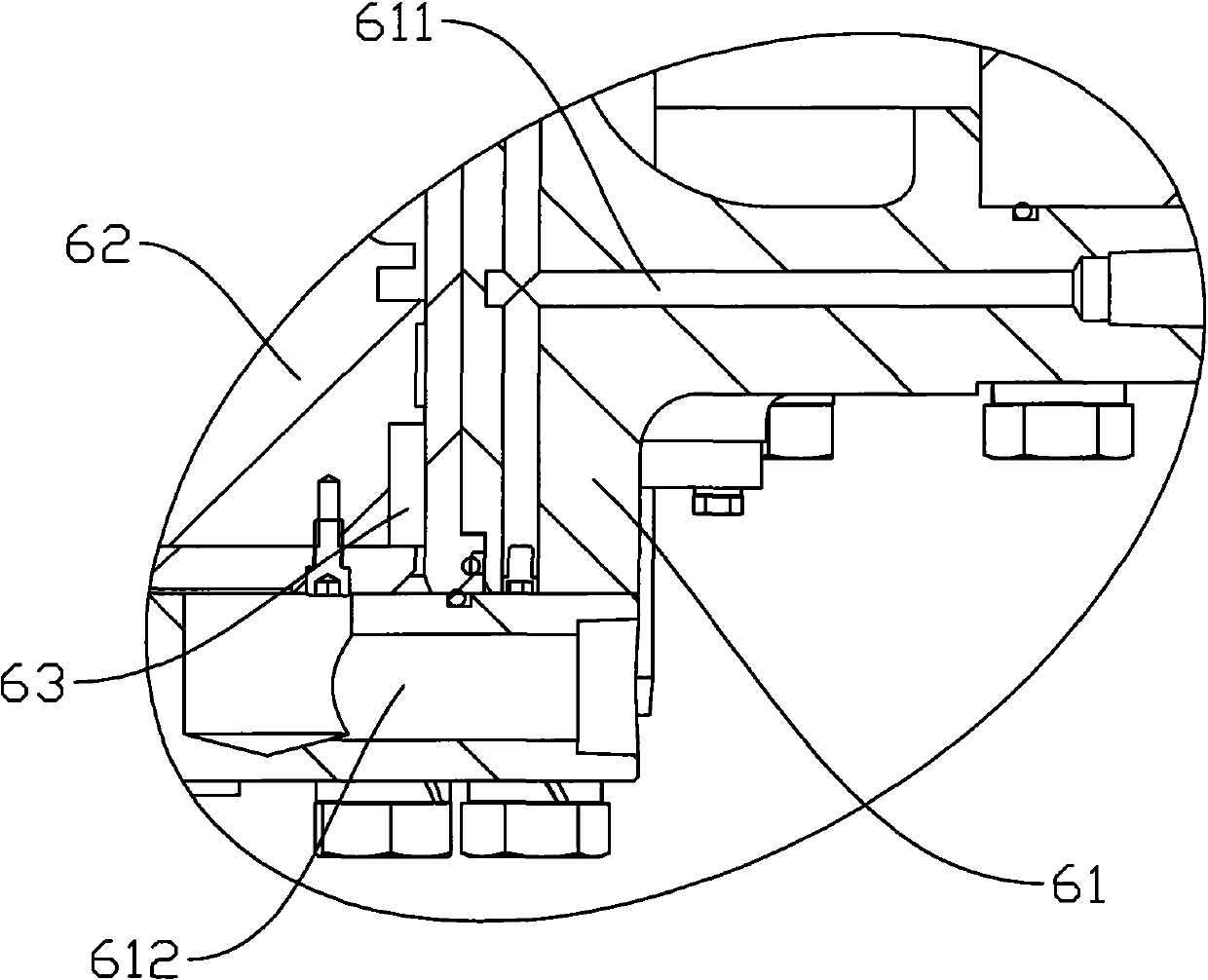

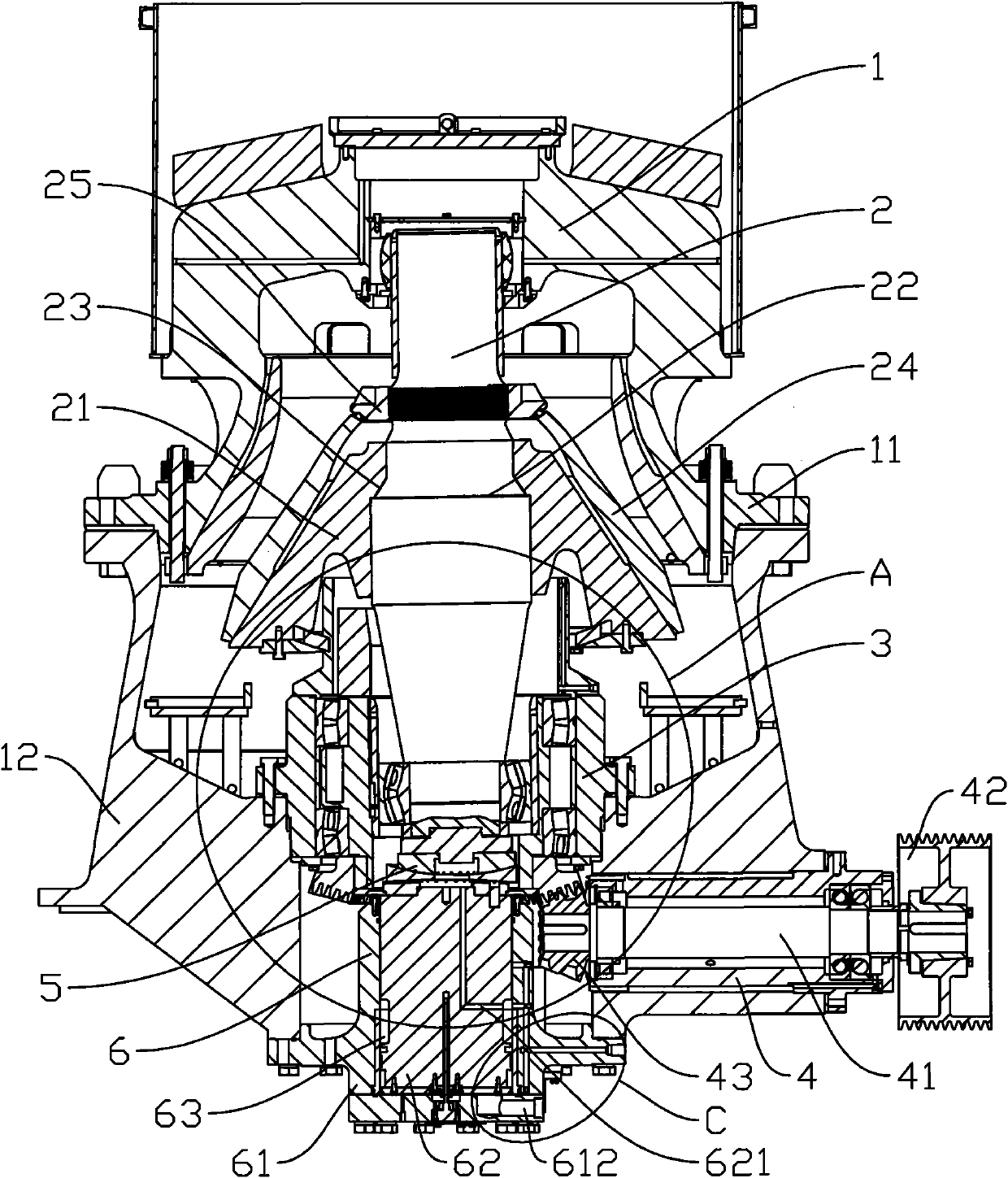

Cone crusher

The invention discloses a cone crusher, which comprises a frame and a movable cone main shaft arranged in the frame, wherein the lower end of the movable cone main shaft is provided with an eccentric mechanism, the eccentric mechanism is in transmission connection with a transmission assembly, a supporting assembly for supporting the movable cone main shaft is arranged below the eccentric mechanism, a hydraulic lifting system for changing the height of the supporting assembly is arranged below the supporting assembly, the hydraulic lifting system comprises a hydraulic cylinder body which is fixed on the lower part of the frame and provided with a cavity and a piston which is arranged in the cavity and moves up and down, the supporting assembly is arranged at the upper end of the piston, and the lower end of the hydraulic cylinder body is provided with a hydraulic oil port which is externally connected with a hydraulic station and communicated with the cavity. The cone crusher has the advantages of novel and unique structure and stable operation, improves the rotational speed of an eccentric sleeve, improves the work efficiency and yield thereof, prolongs the service life of a machine, reduces the use cost and avoids 'teleflex' and running vehicle.

Owner:ZHEJIANG ZHEKUANG HEAVY IND CO LTD

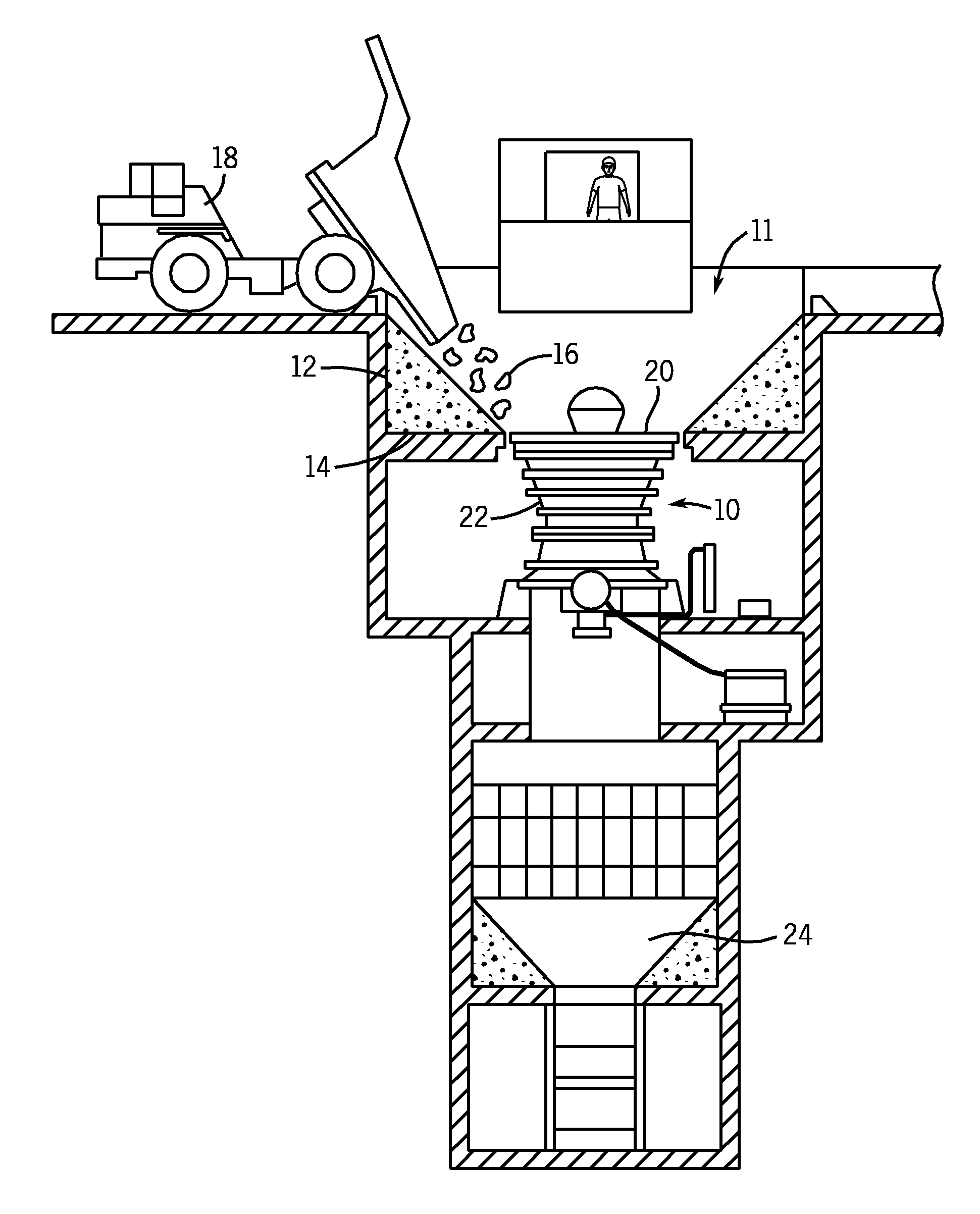

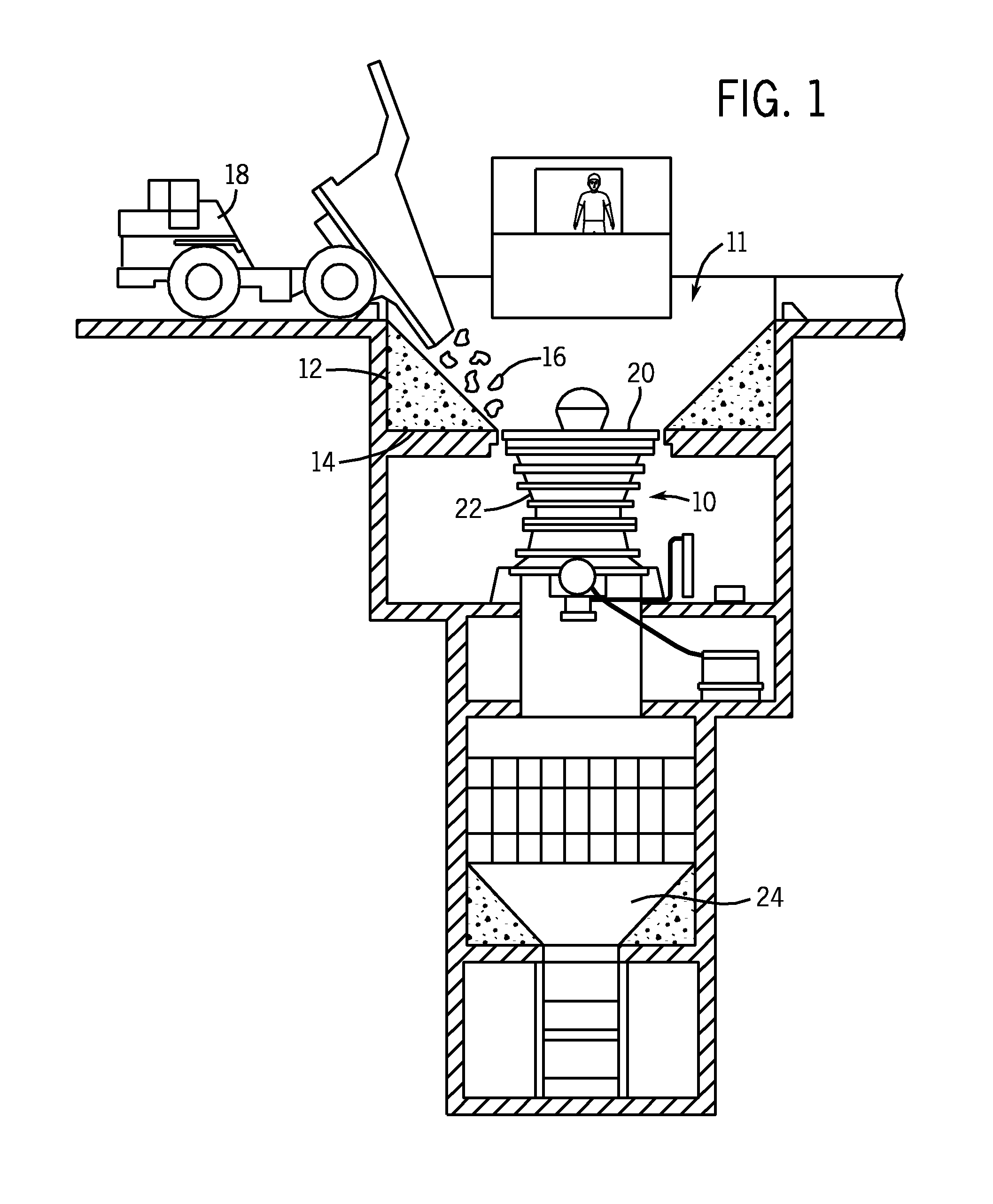

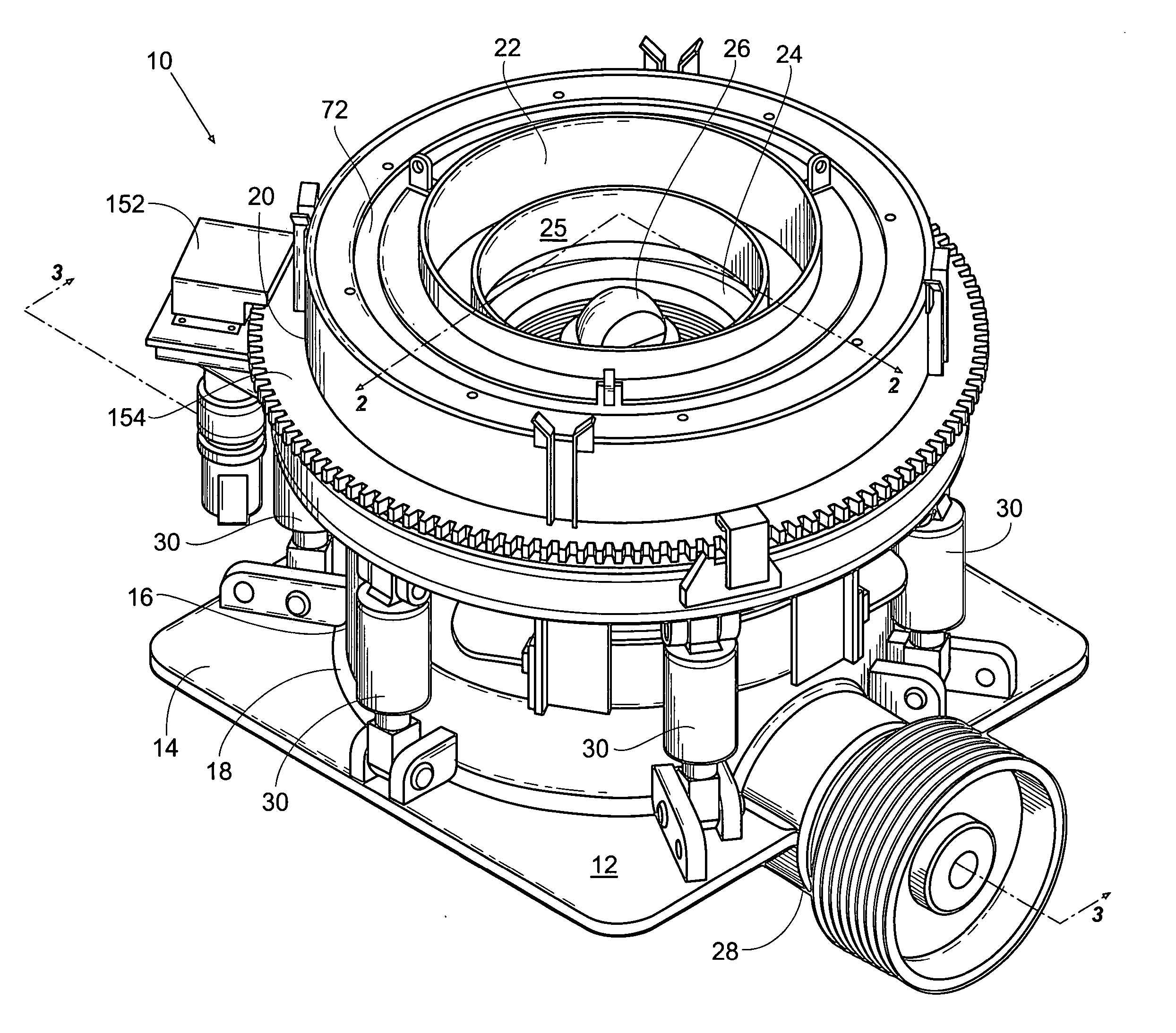

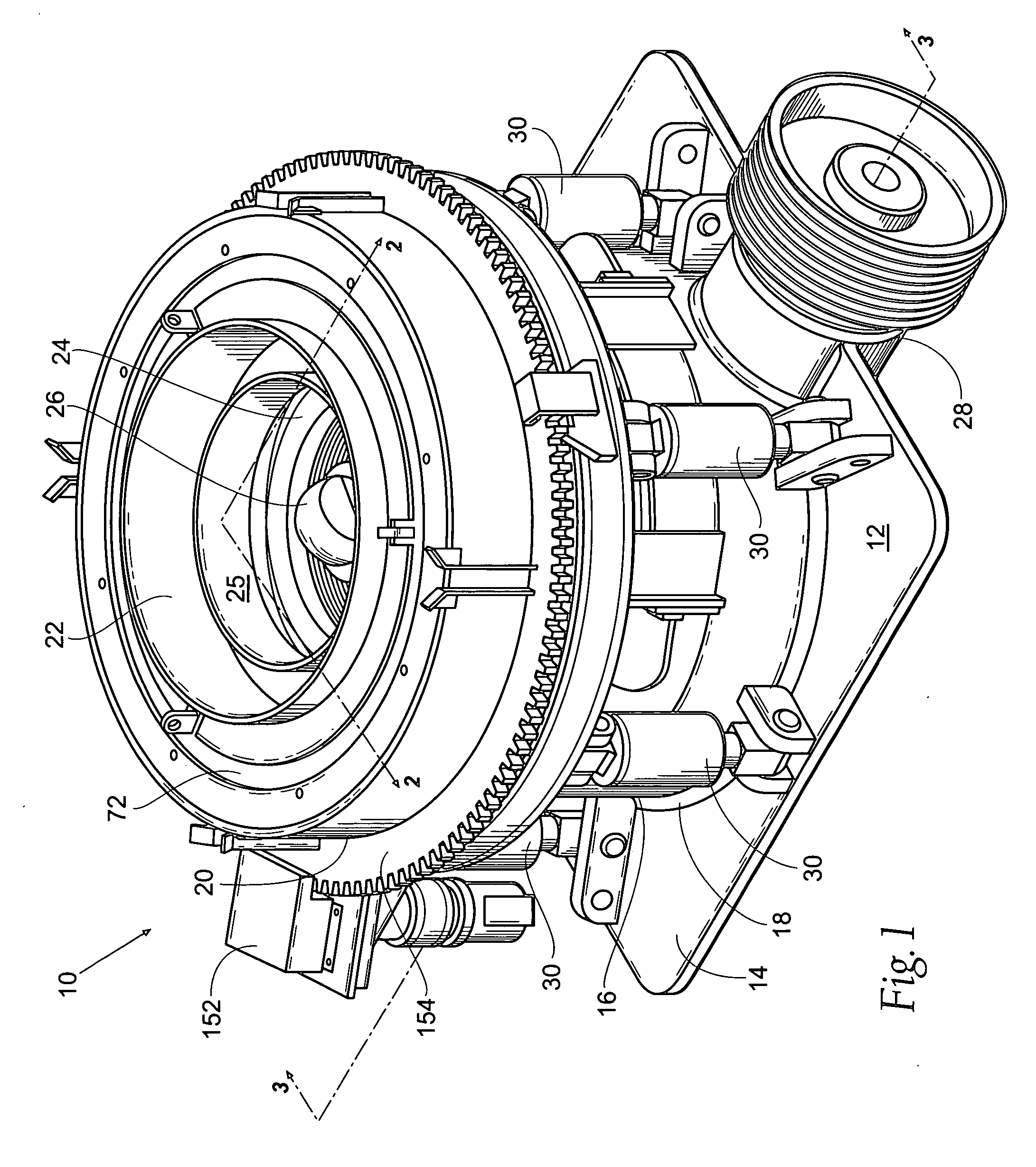

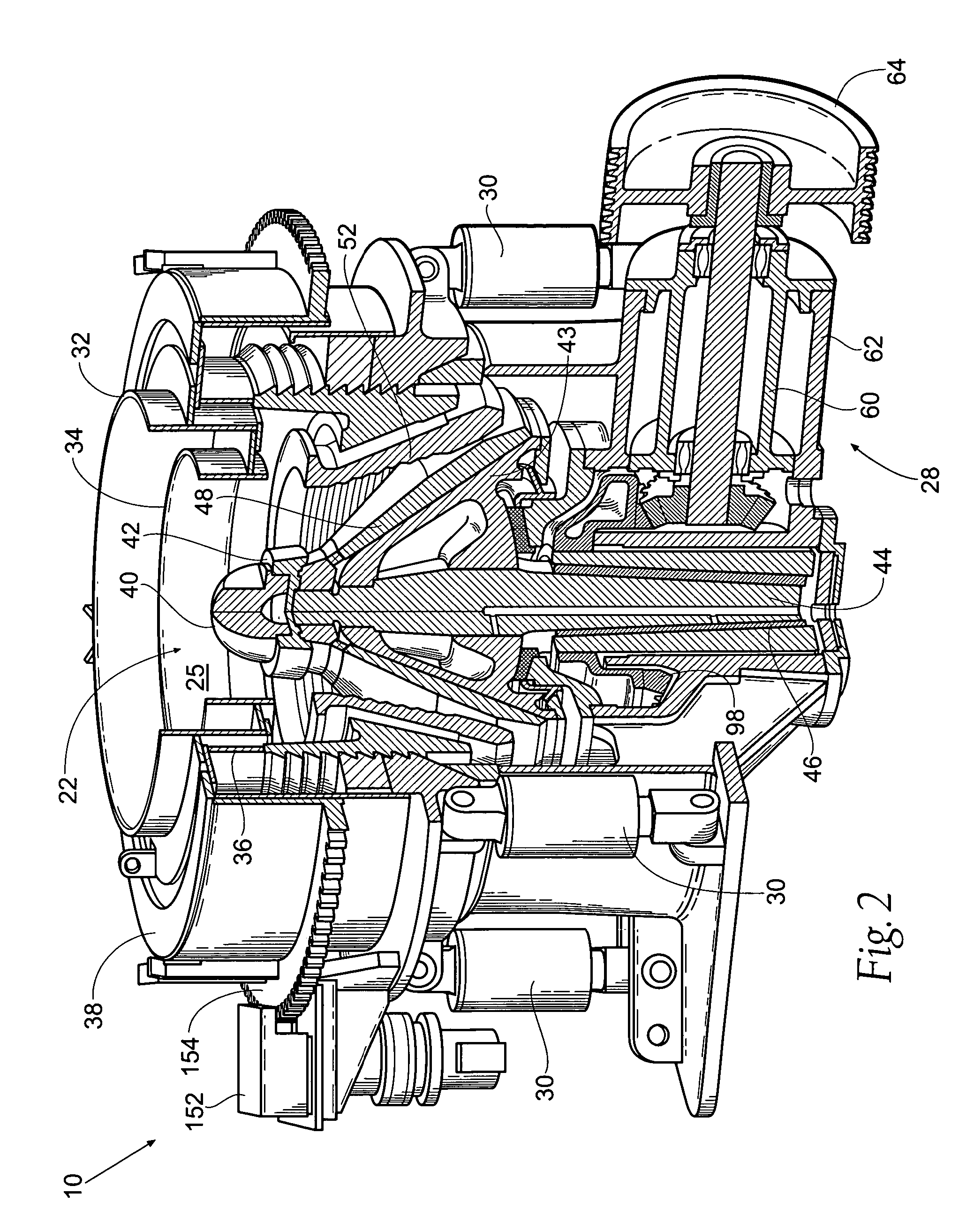

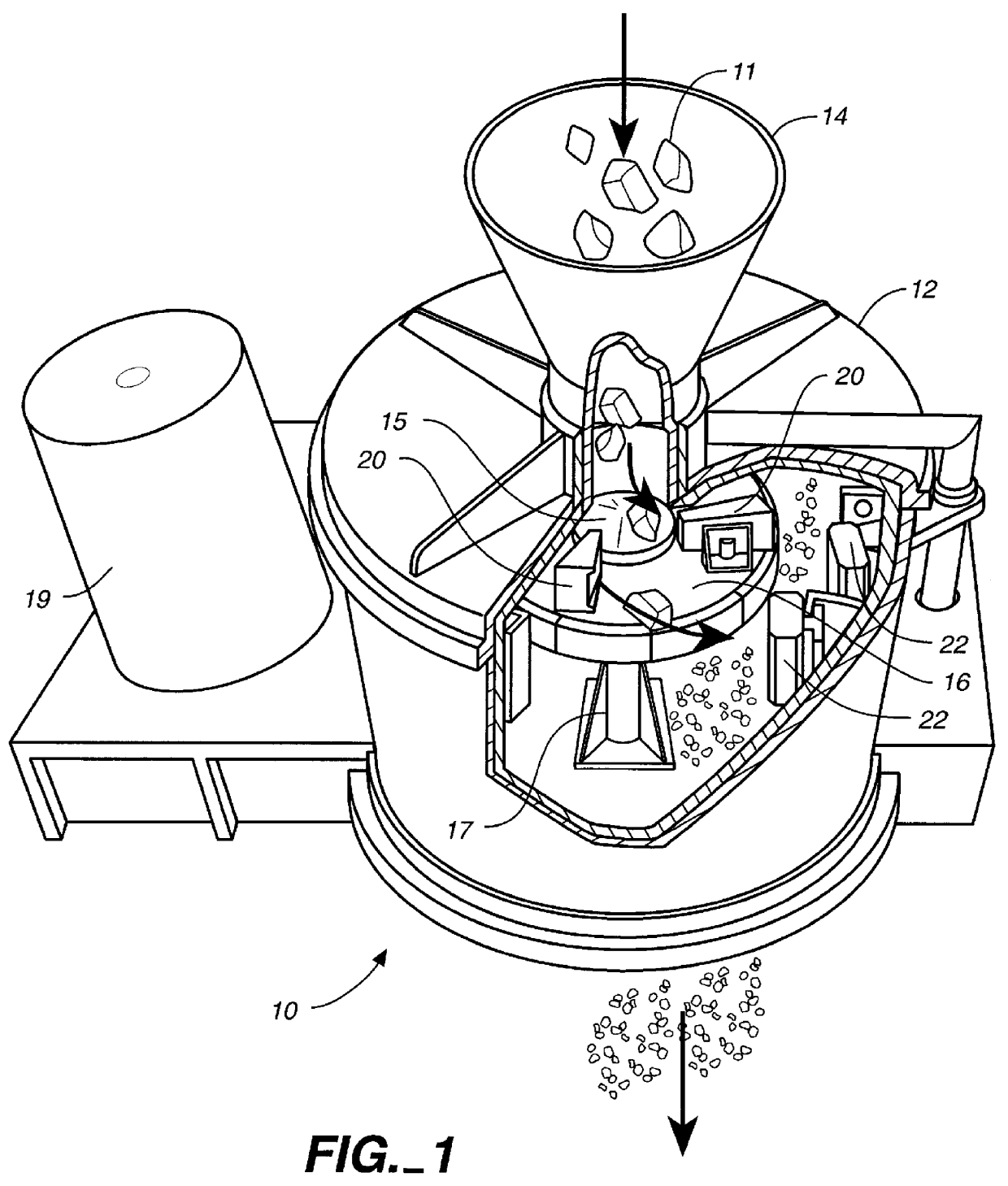

Cone rock crusher

An improved cone-style rock crusher. The rock crusher may be adjusted for varying rock crushing specifications, including different speeds, throws, and liners. The rock crusher comprises a frame that supports a crushing bowl, a crusher head and a shaft, with the shaft being secured to the crusher head. A domed feed plate may be secured onto the crusher head for assistance in secondary rock crushing processes. An eccentric bushing allows the shaft to be aligned properly, regardless of whether there is a load or not within the crushing bowl. The bushing is tapered downwardly, which allows for evenly dispersed contact along the length of the shaft as it gyrates. Furthermore, the thickness of the bushing is asymmetrical. The rock crusher further comprises uniquely designed tramp release cylinders that provide a safeguard that acts as shock absorbers when the rock crusher encounters tramp material.

Owner:INNOTECH SOLUTIONS

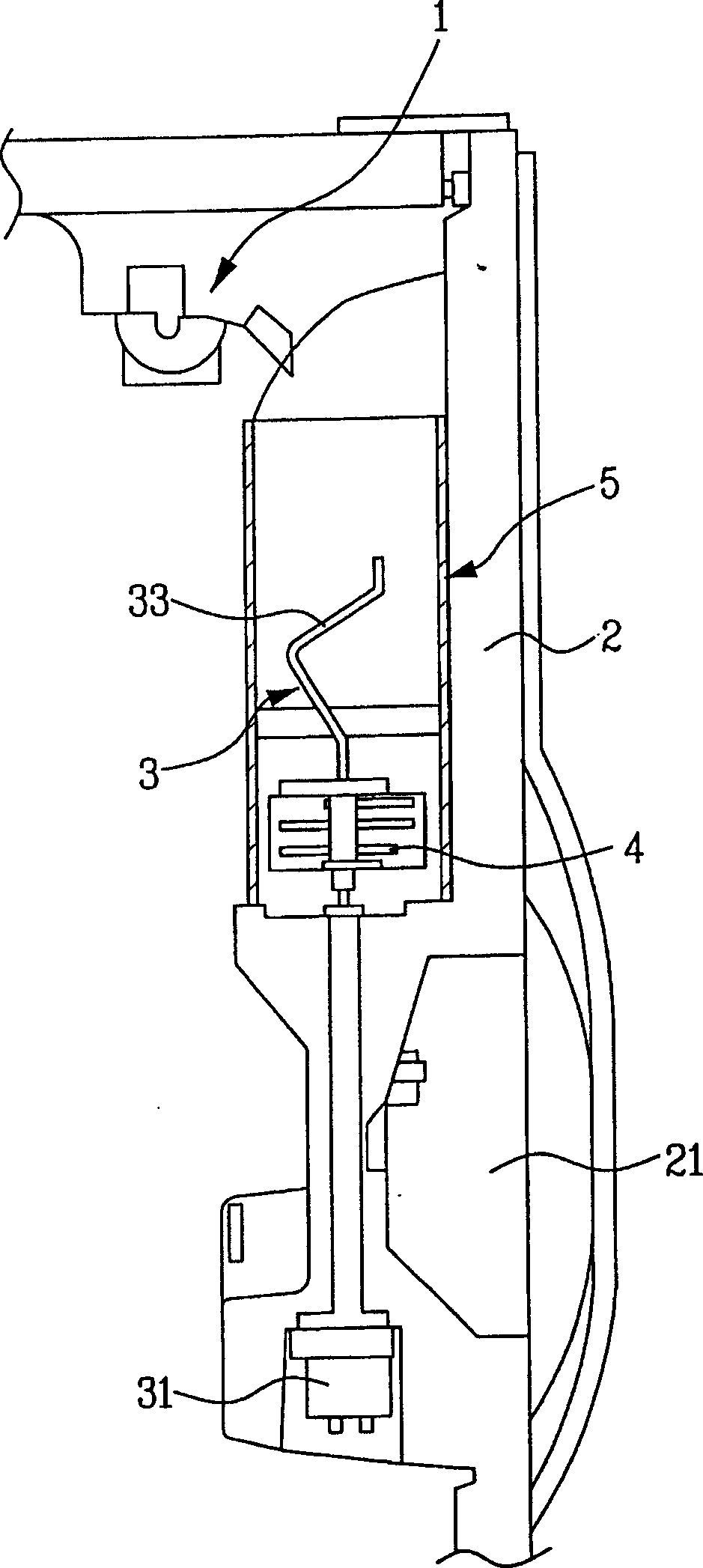

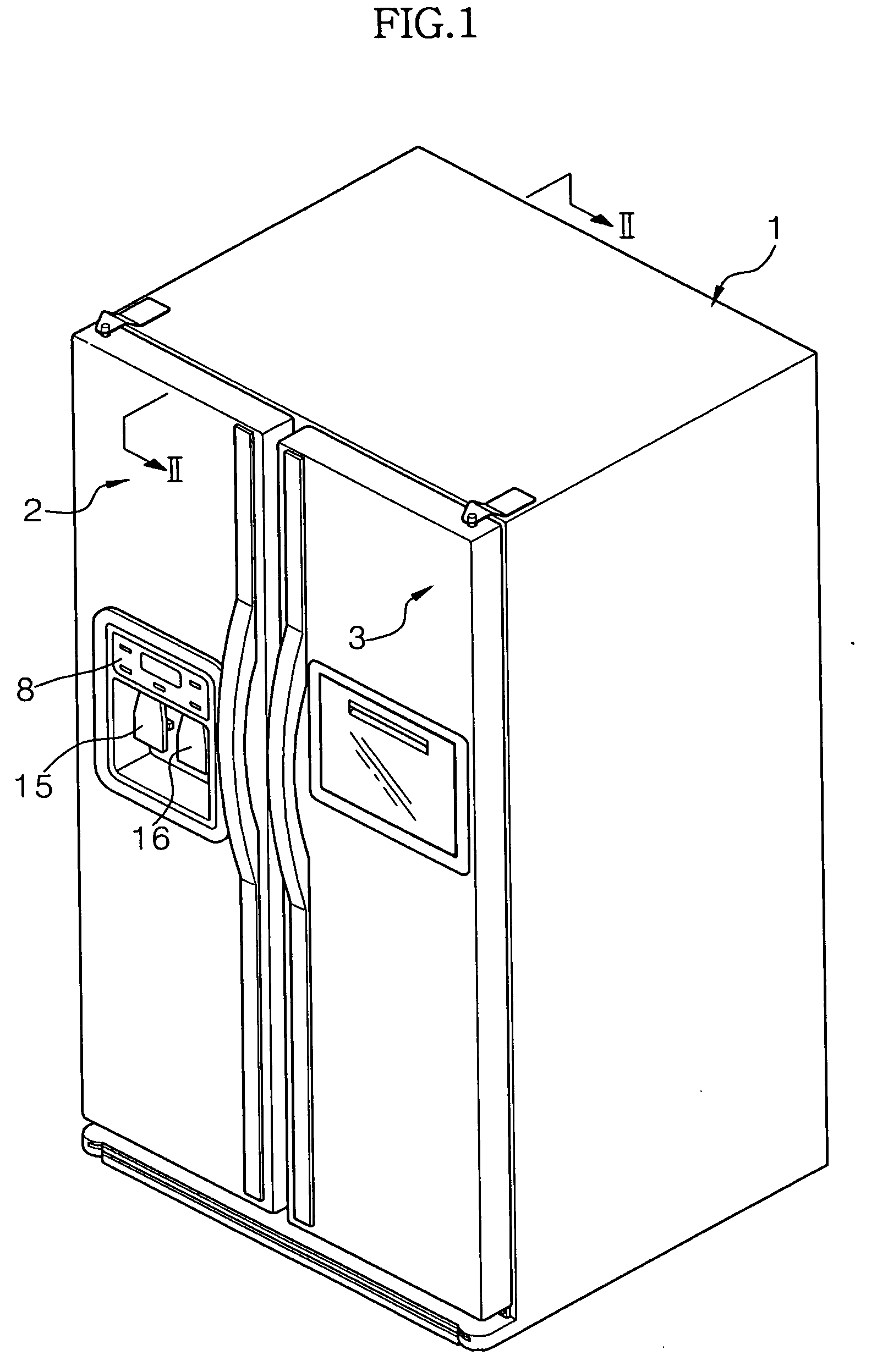

Ice supply system of refrigerator

ActiveUS20050044874A1Smooth slidingSimple structureLighting and heating apparatusIce productionMarine engineeringCrusher

Disclosed is an ice supply system provided at a door and freezer in a refrigerator. The ice supply system of the refrigerator of the present invention includes an icemaker, a container, a crusher and an ice discharger. The icemaker produces the ice by using cool air of the freezer and drops the ice to a lower part of thereof. The container is provided at a lower part of the icemaker, enabling to be inserted into and withdrawn from the door. In this case, the container includes an open top, a first opening provided at a side thereof, a transfer device rotating and transferring the ice to the first opening, and an outlet for discharging the ice. The crusher crushes the ice transferred by the transfer device and the ice discharger is provided for discharging the ice to an ice chute provided at the door by controlling an opening and closing amount of the outlet.

Owner:LG ELECTRONICS INC

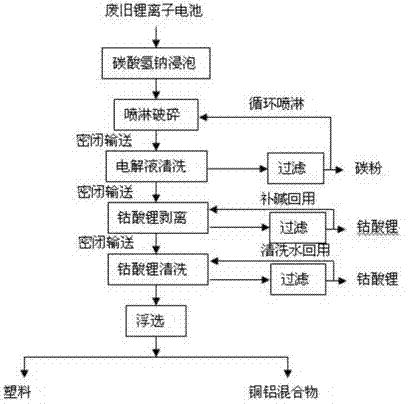

Method for comprehensively recycling waste lithium ion batteries

ActiveCN103943911AAccelerated corrosionAffect healthWaste accumulators reclaimingBattery recyclingSocial benefitsEconomic benefits

The invention discloses a method for comprehensively recycling waste lithium ion batteries, and belongs to the field of recycling of regeneration resource. The method comprises the following steps: a, performing discharging processing on waste lithium ion batteries; b, fragmenting waste lithium ion batteries into sheets with a diameter of 10-20 mm in a closed shearing-type crusher, and spraying during fragmentation to dissolve lithium hexafluorophosphate in the waste lithium ion batteries into a spraying solution; c, peeling carbon powder on the surface of aluminium foils through stirring, dissolving electrolyte into the spraying solution, and recovering carbon powder; d, sending the sheets into a sodium hydroxide solution, peeling lithium cobalt oxide powder on the surface of aluminium foils through stirring, and recovering lithium cobalt oxide powder; e, cleaning the sheets, and recovering lithium cobalt oxide powder; and f, separating and recovering plastic and a copper-aluminium mixture. The method realizes recovery of carbon powder, lithium cobalt oxide powder, the copper-aluminium mixture and plastic through a simple environment-friendly process, and has certain economic benefit and social benefit.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

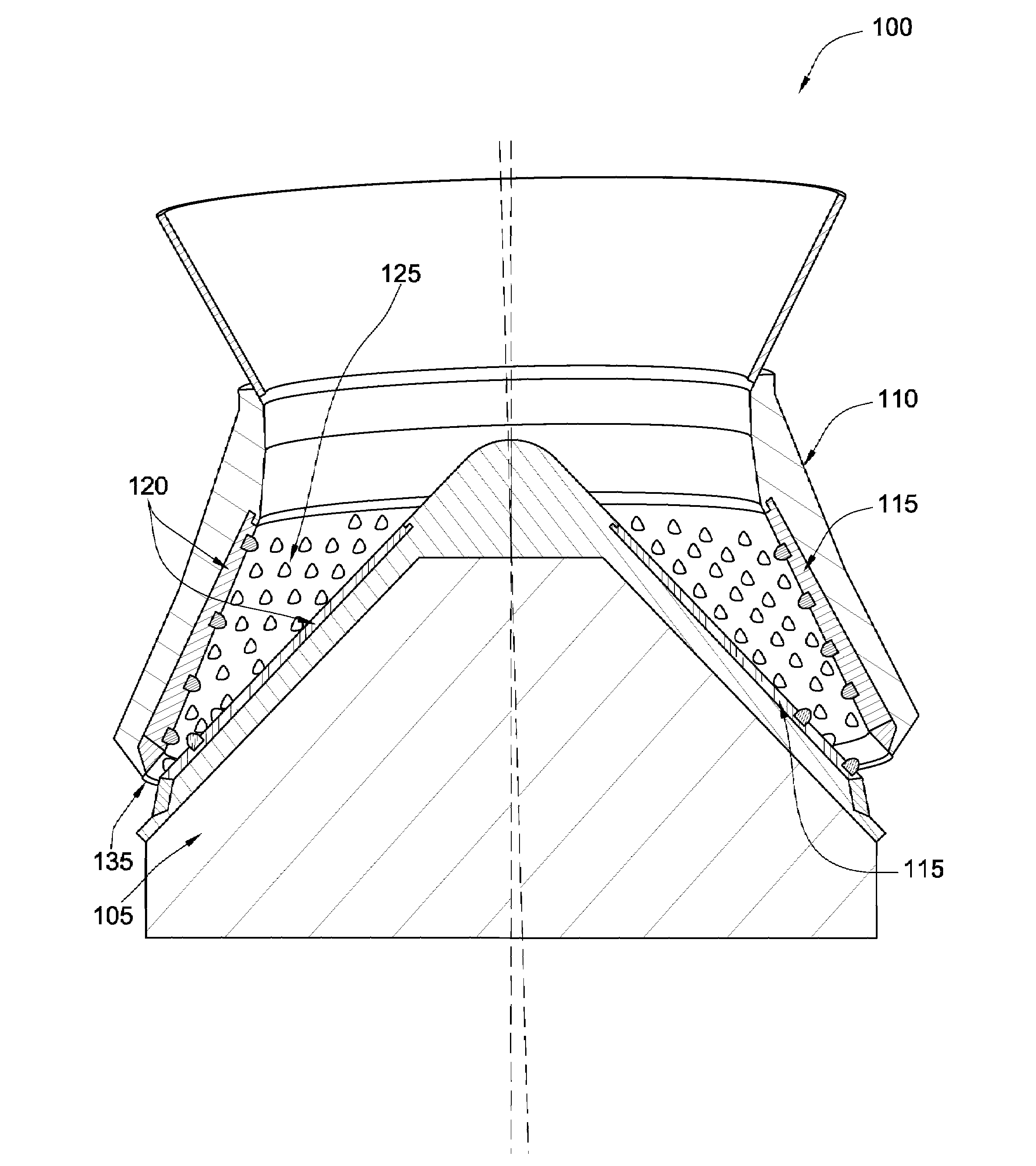

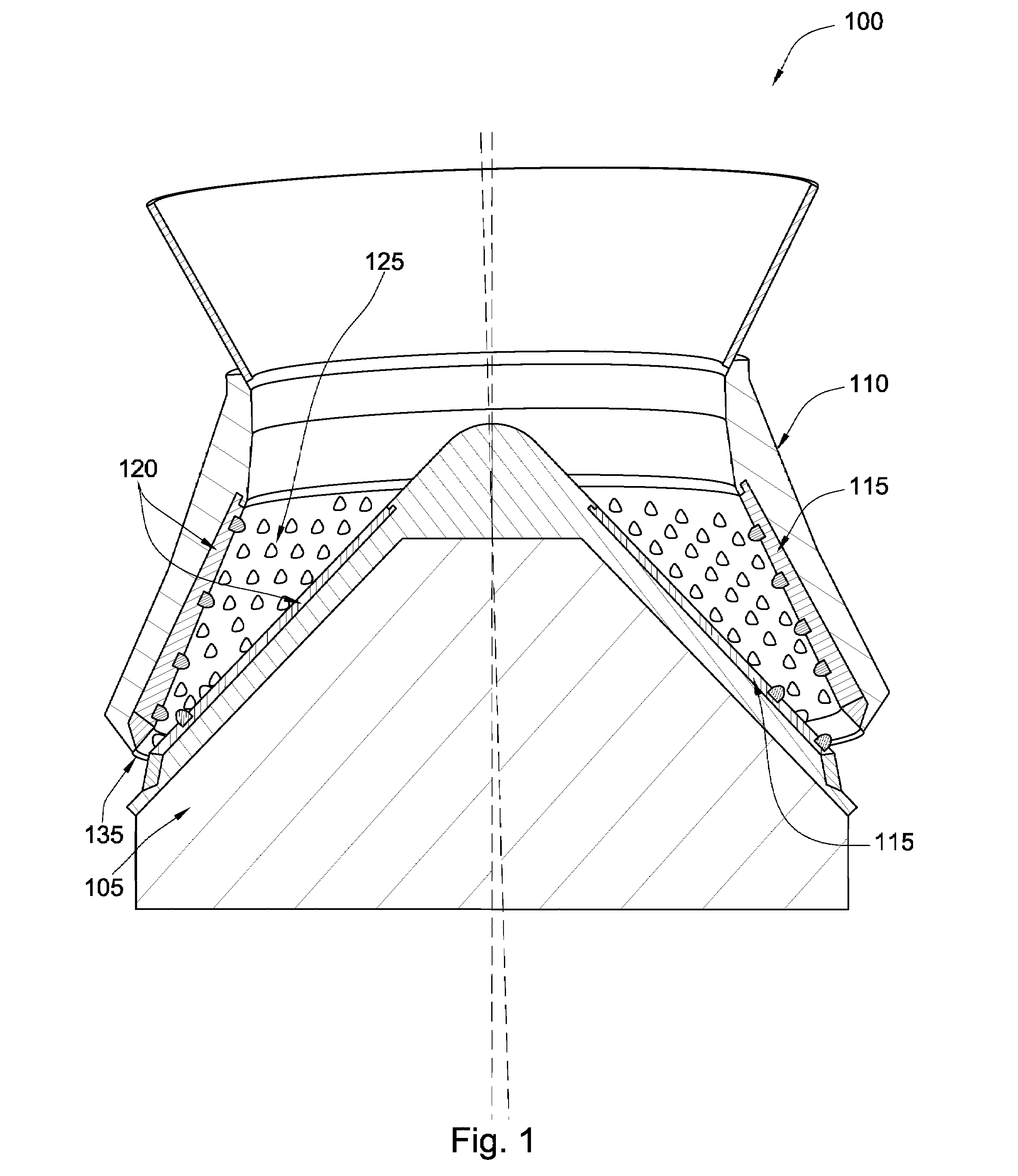

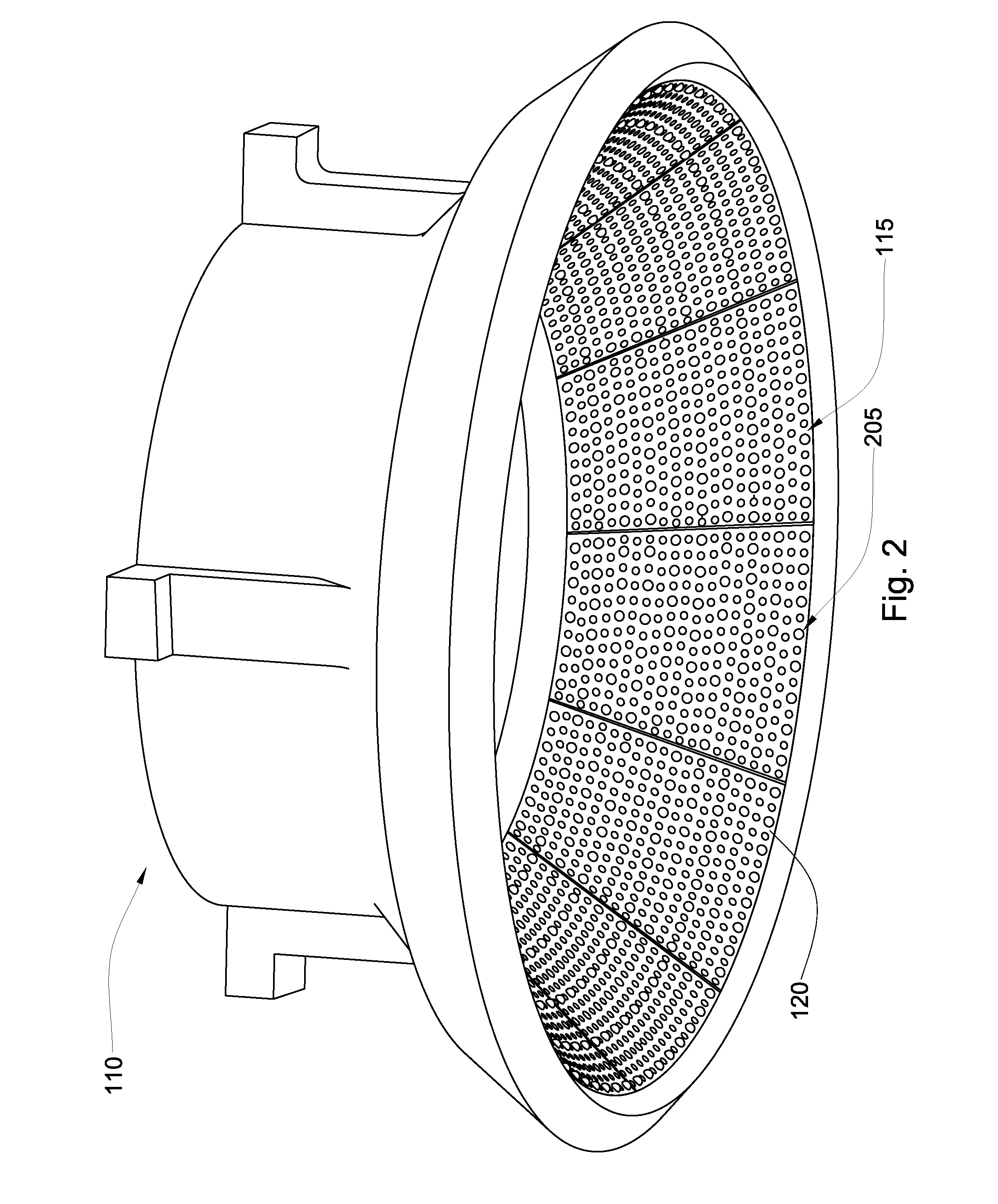

Replaceable Segmented Wear Liner

In one aspect of the invention, a cone crusher comprises a crushing surface comprising a conical head and a concave bowl. At least one of the head or bowl comprises a segmented wear liner wherein at least one segment of the wear liner is held in place by compression.

Owner:NOVATEK IP

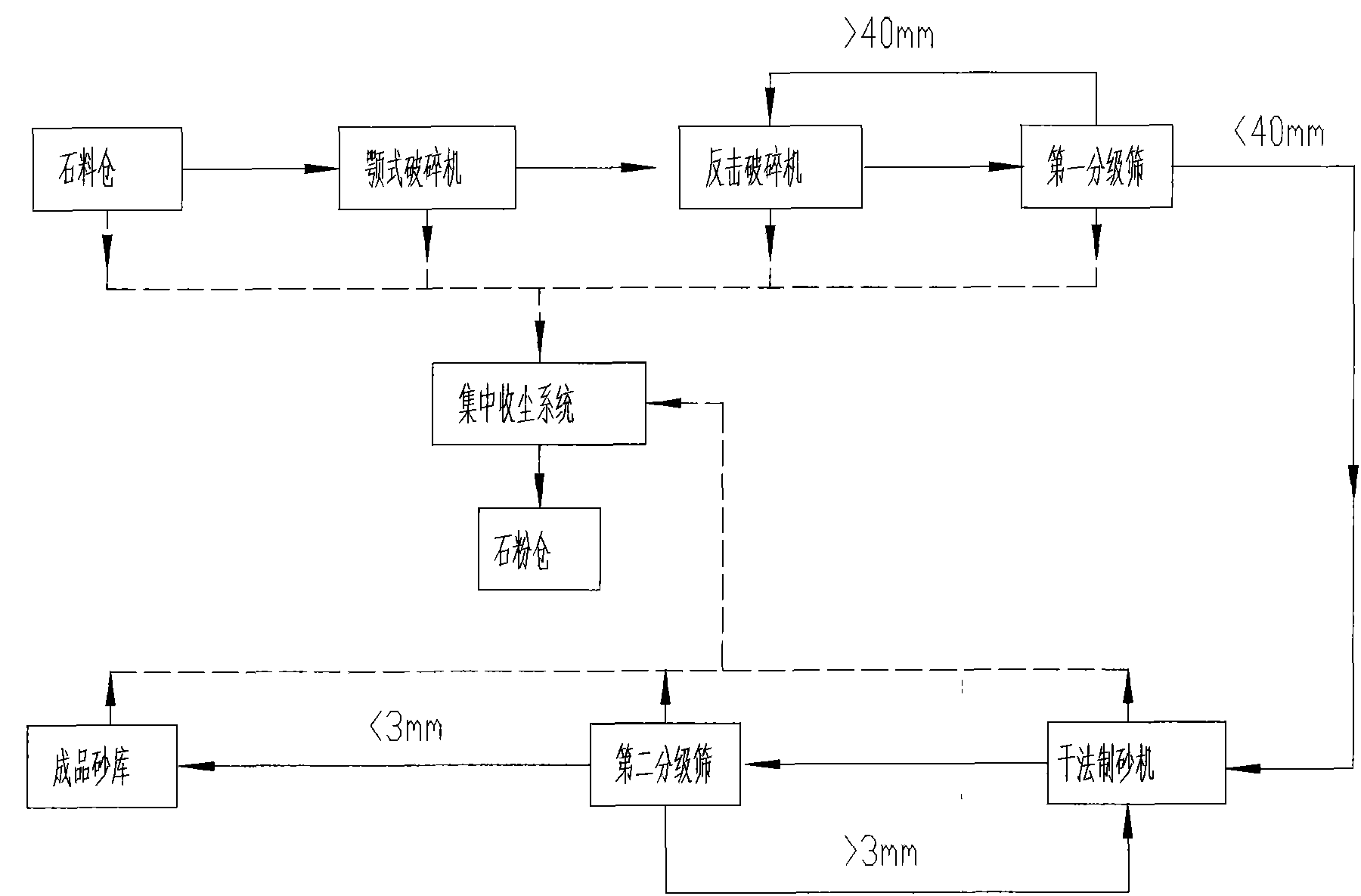

Drying-method sand making device and process

A drying-method sand making device and a process relate to the field of sand making technology. The device includes: a jaw crusher, an impact crusher, a first grading screen, a drying-method sand making machine, a second grading screen and a concentrated dust collecting system. The production process comprises the steps: a stone material in a stone material bin is evenly fed into the jaw crusher through a feeder for a first rough crushing, the crushed material is transported to the impact crusher for a second fine crushing, the crushed material goes into the first grading screen for grading, sandstones with the size of less than 40 mm are fed to the drying-method sand making machine through a conveyor for crushing and sand making, and broken stones with the size of more than 40 mm are returned to the impact crusher; the sandstones going into the drying-method sand making machine are transported to the second grading screen for grading after being crushed by the drying-method sand making machine, sand with the size of less than 3 mm is directly fed into a finished product sand bin, and a stone material with the size of more than 3 mm is afresh returned to the drying-method sand making machine for crushing. The produced machine-made sand has good particle shape and high finished product rate, and can meet the technical index of high-performance concrete on the machine-made sand.

Owner:王燕

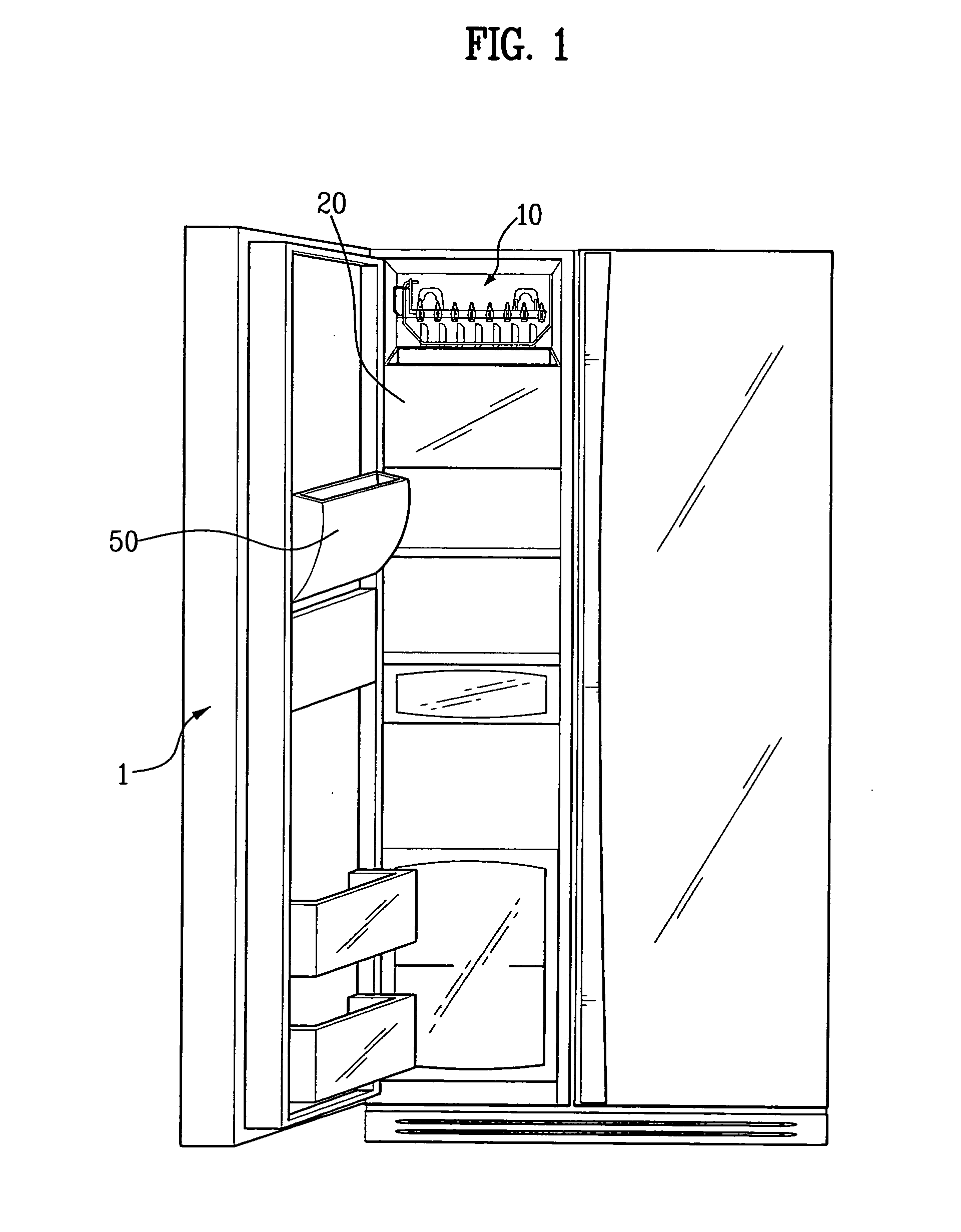

Refrigerator

A refrigerator including a shaved ice dispensing unit, and an ice cube dispensing unit positioned within an ice cube container such that ice cubes, crushed ice, and shaved ice are selectively dispensed to a user. The shaved ice dispensing unit includes a driving motor, a guide barrel having a shaved ice outlet, a plurality of blades disposed at the outlet, a rotational shaft disposed axially within the guide barrel and connected with the driving motor, a compressing wing connected with the rotational shaft above the outlet and extending in a radial direction, and a spiral wing coupled with the rotational shaft at the front of the compressing wing. When the driving motor is driven, the rotational shaft, the spiral wing, and the compressing wing rotate and compress the ice cubes in the ice cube container to produce the shaved ice. The ice cube dispensing unit comprises an ice cube crusher, and an outlet adjusting device to allow the ice cubes to be dispensed or to dispense the crushed ice after producing the crushed ice through the ice cube crusher.

Owner:SAMSUNG ELECTRONICS CO LTD

Municipal sludge expanded ceramsite and preparation method thereof

InactiveCN101618971ALow costSave resourcesCeramic materials productionCeramicwareSludgeExpanded clay aggregate

The invention provides municipal sludge expanded ceramsite and a preparation method thereof. The municipal sludge expanded ceramsite is prepared from the following materials by mass percentage: 20% to 45% of municipal sludge, 50% to 70% of shale, tailings or clay, 1% to 5% of organic matter and 1% to 5% of iron powder, wherein, the tailings is one of pyrite tailings, gold tailings, lead-zinc tailings and aluminum tailings; and the organic matter is sawdust. The preparation method comprises the following steps: feeding the shale, tailings or clay into a crusher, and carrying out the screening treatment; adding and mixing the municipal sludge, the organic matter and the iron powder, feeding into an ageing silo and stirring; then, feeding into a granulating machine, granulating and calcinating in a rotary kiln; and finally, cooling and stacking the calcinated ceramsite by classification. By using a great amount of municipal sludge, the invention is resource-saving and environment-friendly; compared with the original cost, the overall cost of a building is reduced by 5% to 10%; and the prepared expanded ceramsite has the advantages of light weight, fire resistance, sound absorption, good heat insulating and preserving performance, simple process and low cost, so that the invention is suitable for industrialized production.

Owner:XIAN RES & DESIGN INST OF WALL & ROOF MATERIALS CO LTD

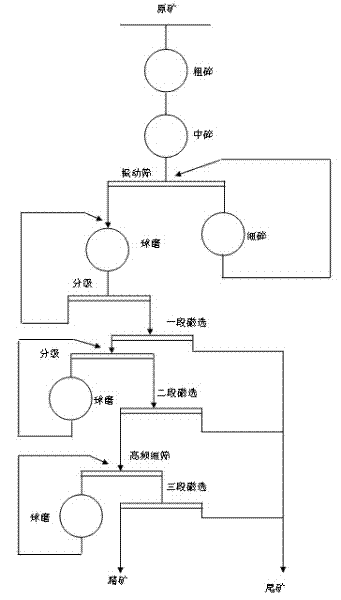

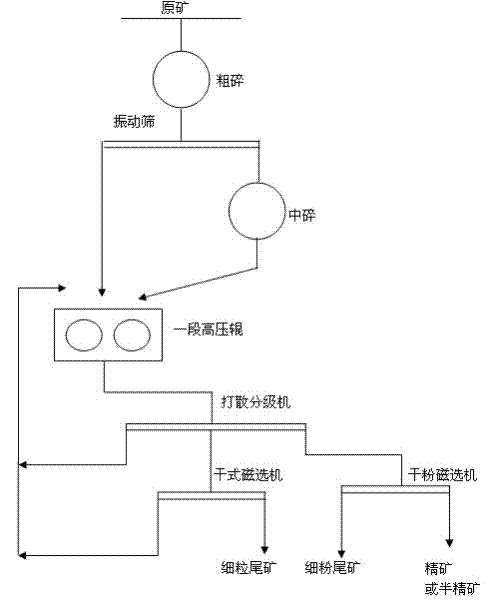

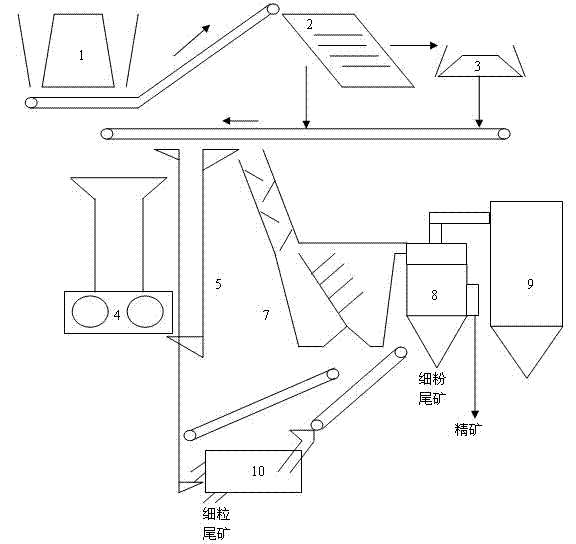

Dry-grinding and dry-separation method of magnetite

ActiveCN102240588ASimplify the crushing processSave moneyGas current separationGrain treatmentsMagnetiteClosed loop

The invention discloses a dry-grinding and dry-separation method of magnetite, which comprises the following steps of: feeding the crude ore of magnetite into a crusher for coarse crushing, and then feeding the crushed magnetite into a vibrating sieve for sieving; controlling the sieve meshes within a range of 35-75 mm; feeding the oversize product to the crusher for intermediate crushing and then feeding the crushed oversize product into a high-pressure roller mill along with the undersize product for fine crushing; breaking and grading the fine-crushed ore by a breaking-grading machine, thereby obtaining the products of three grain grades, i.e. coarse grains, fine grains and fine powder; returning the coarse-grain grade product to the high-pressure roller mill through an elevator, and feeding the fine-grain grade product to a dry type magnetic separator for magnetic separation and discarding tailings, wherein the magnetic field intensity is controlled within a range of 1200-3000 Gs; directly dryly stacking the discarded fine-grain grade tailings, and returning the fine-grain grade concentrate to the high-pressure roller mill through a belt conveyor and the elevator to form a closed loop; and feeding the fine-powder grade product into a cyclone magnetic separator, wherein the magnetic field intensity is controlled within a range of 600-1200 Gs, thereby obtaining concentrate or semi-concentrate. The dry-grinding and dry-separation method is low in power consumption, steel consumption and water consumption, and the tailings are easy to be disposed of.

Owner:CHENGDU LEEJUN IND

Multi-cylinder hydraulic antifriction bearing taper crusher

ActiveCN102357371AIncrease speedImprove crushing efficiencyGrain treatmentsRolling-element bearingWorking pressure

The invention discloses a multi-cylinder hydraulic antifriction bearing taper crusher, which comprises a lower machine frame, an eccentric sleeve mechanism, a transmission set, a movable tapper, an upper machine frame set and an iron passing and cavity clearing device. The upper machine frame set is arranged above the lower machine frame, the transmission set and the eccentric sleeve mechanism are both installed on the lower machine frame, the transmission set is connected with the eccentric sleeve mechanism where the movable tapper is arranged, the iron passing and cavity clearing device is directly installed on the lower machine frame and the upper machine frame set, the eccentric sleeve mechanism adopts an antifriction bearing type eccentric sleeve mechanism, the iron passing and cavity clearing device adopts a relief valve type iron passing and cavity clearing device, and a movable tapper body rotating-proof device is connected to the bottom of the movable tapper. The multi-cylinder hydraulic antifriction bearing taper crusher improves crushing efficiency and output of the taper crusher, and prolongs service life of a machine, reduces using cost of equipment. The iron passing and cavity clearing device can not only bear higher working pressure of a system, but also be safe and reliable, convenient to assemble and capable of controlling a tapper body to rotate according to certain direction, thereby improving production efficiency and saving energy.

Owner:ZHEJIANG ZHEKUANG HEAVY IND CO LTD

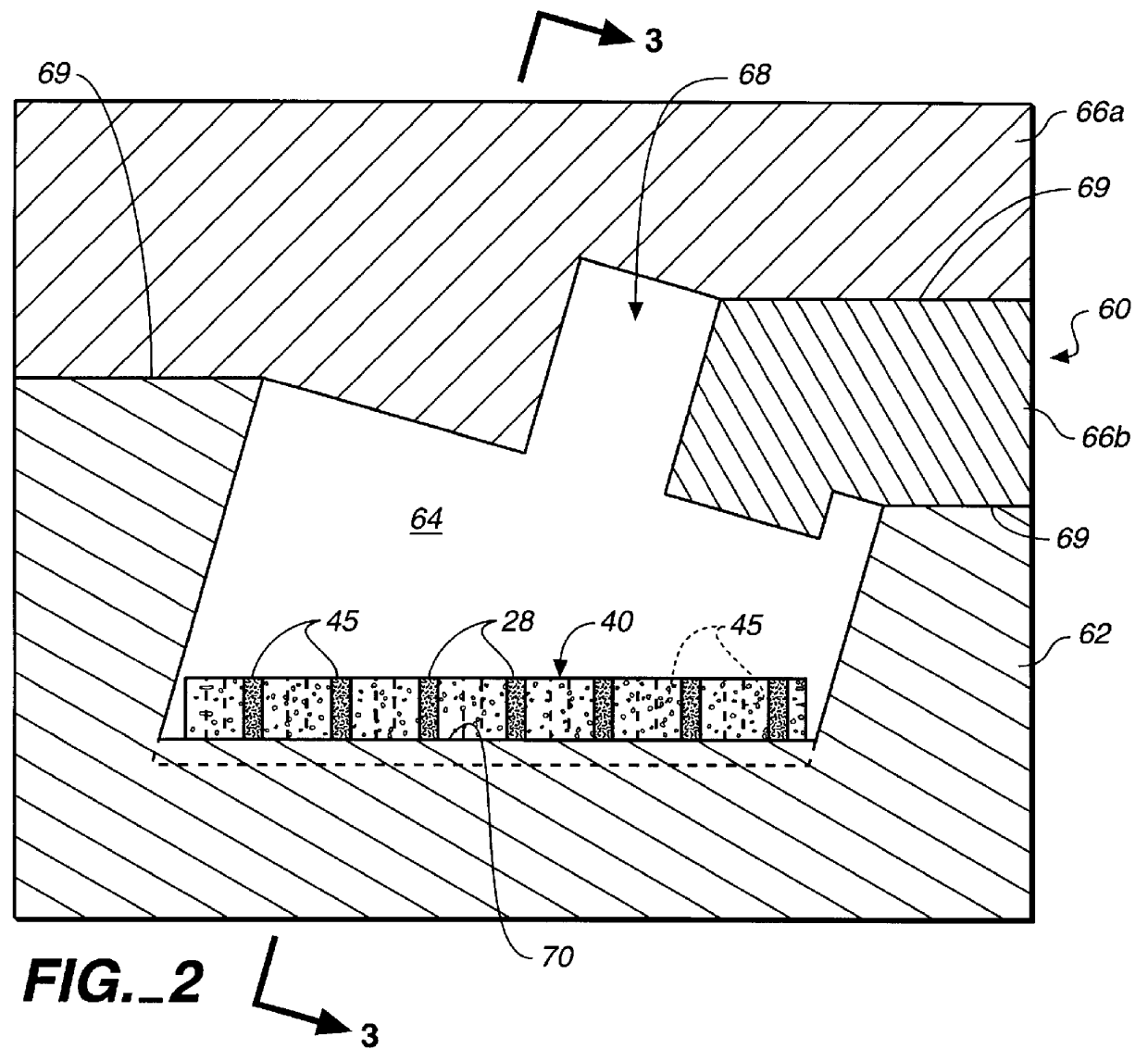

Wear resistant, high impact, iron alloy member and method of making the same

InactiveUS6033791AImprove impact performanceImprove wear resistanceGrain treatmentsThin material handlingShell moldingWear resistant

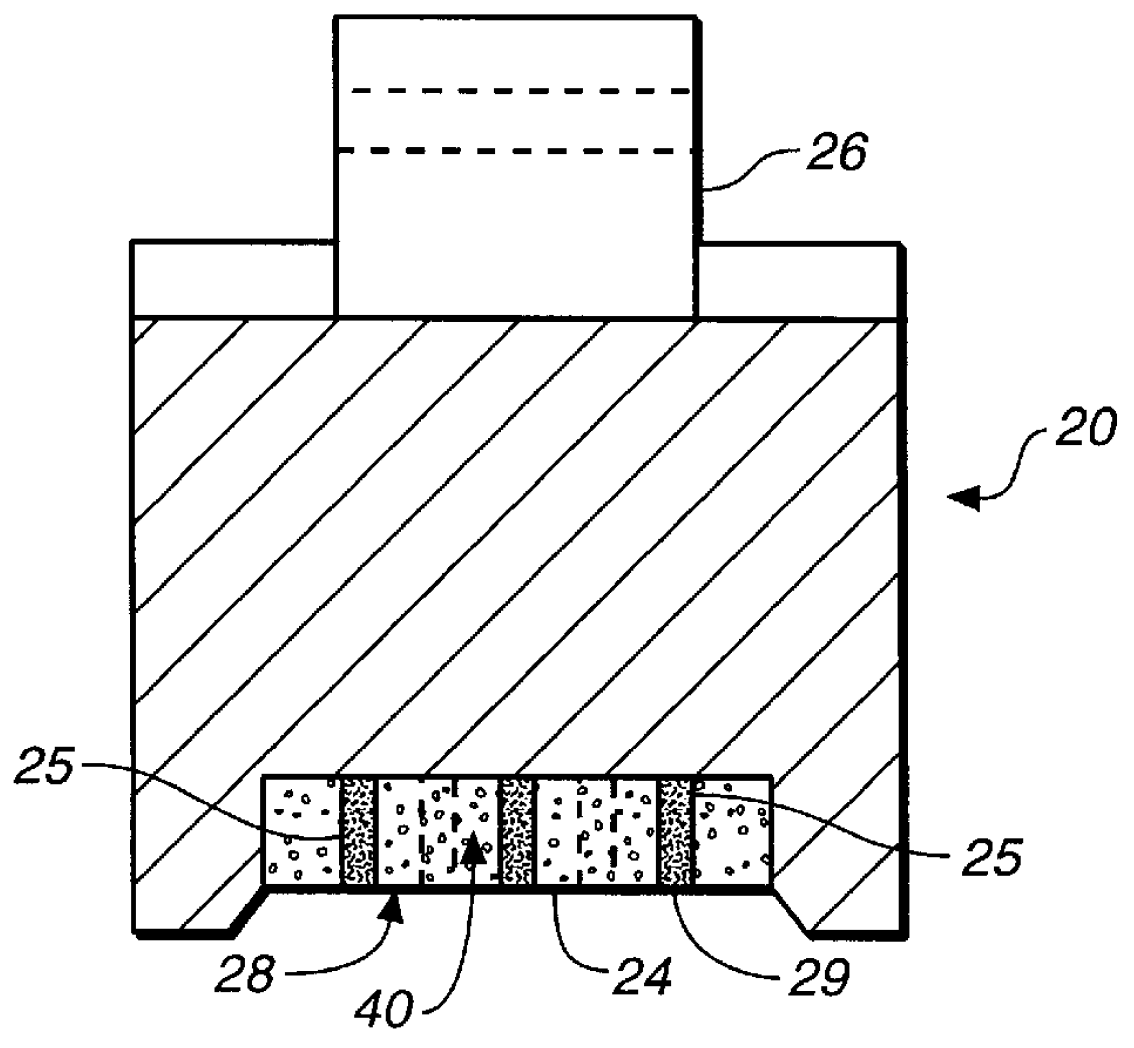

A wear resistant, high-impact iron alloy member (20,22) suitable for use in an impact rock crusher and a method of making the same. The invention provides a white iron alloy member (20,22) having at least one wear surface (24) with carbide granules encapsulated in a matrix (28) of white iron and contained in a selected region adjacent the wear surface (24) of the member (20,22). The iron alloy member is made by a method of casting comprising the steps of: placing a molding insert (35,40) in a mold (60) at a selected location adjacent the wear surface (24); positioning a quantity of carbide granules (29), most preferably tungsten carbide granules 29, in the molding insert (35,40) before pouring; and pouring molten white iron alloy into the mold (60) to form the casting. The tungsten carbide granules (29) are substantially contained at a selected location by the molding insert (35,40), and the resulting casting (20,22) can be heat treated and cooled to provide a component for a rock crusher or the like which exhibits improved resistance to wear.

Owner:DALLESPORT FOUNDRY

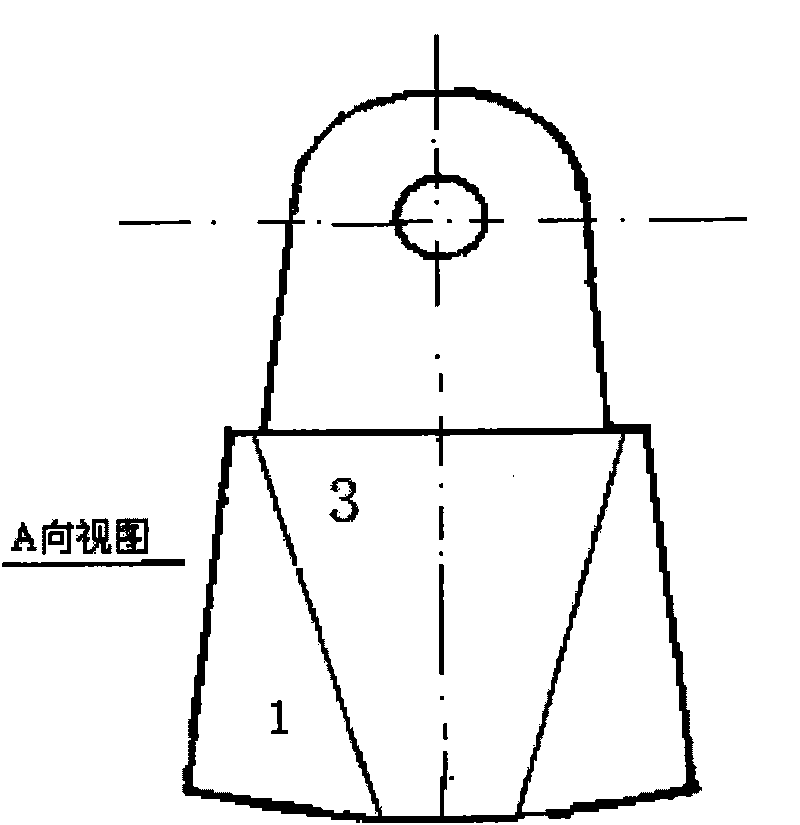

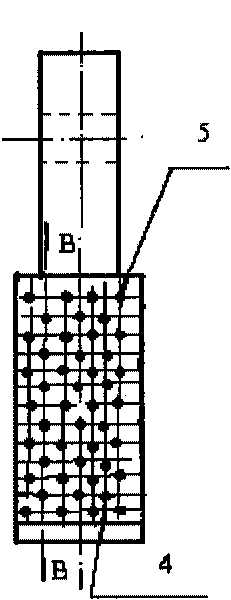

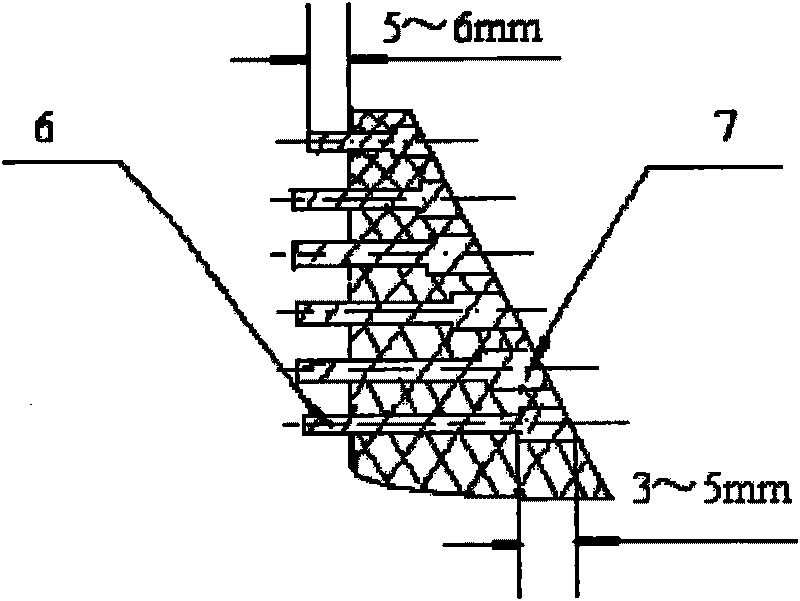

Crusher hammerhead cast of steel bond hard alloy bar and casting method of vanishing mould thereof

InactiveCN101717895AGood effectSimple processFoundry mouldsFurnace typesChemical compositionHardness

The invention discloses a crusher hammerhead cast of a steel bond hard alloy bar and a casting method of a vanishing mould thereof. The hammerhead is cast by low-alloy steel and is cast with the steel bond hard alloy bar in the casting process; the low-alloy steel contains the following chemical components by weight percent: 0.24 wt% to 0.295 wt% of C, 1.32 wt% to 1.56 wt% of Si, 0.028 wt% to 0.035 wt% of S, 0.032 wt% to 0.038 wt% of P, 0.82 wt% to 1.22 wt% of Mn, 1.67 wt% to 2.10 wt% of Cr, 0.42 wt% to 0.51 wt% of Mo, 0.05 wt% to 0.08 wt% of V, 0.05 wt% to 0.07 wt% of Ti, 0.08 wt% to 0.15 wt% of RE and 93.942 wt% to 95.29 wt% of Fe. The casting method of the hammerhead comprises the production process of the low-alloy steel, and the casting process and the thermal treatment process of the vanishing mould. The hammerhead product cast with the steel bond hard alloy bar has the advantages of good strength and toughness and high rigidity and abrasive resistance, is suitable for various working conditions, and can crush objects with different hardness.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com