Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1284results about "Construction waste recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

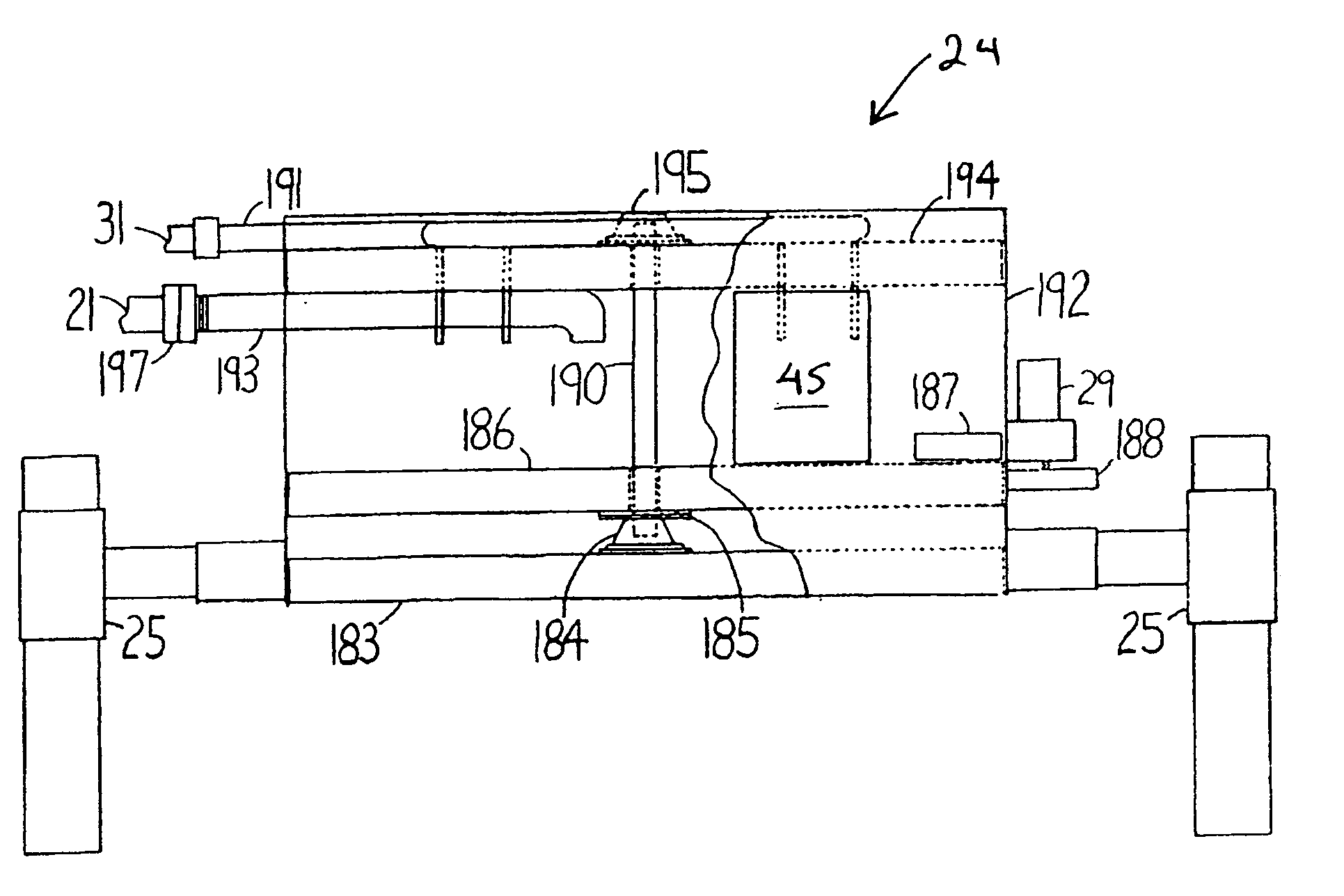

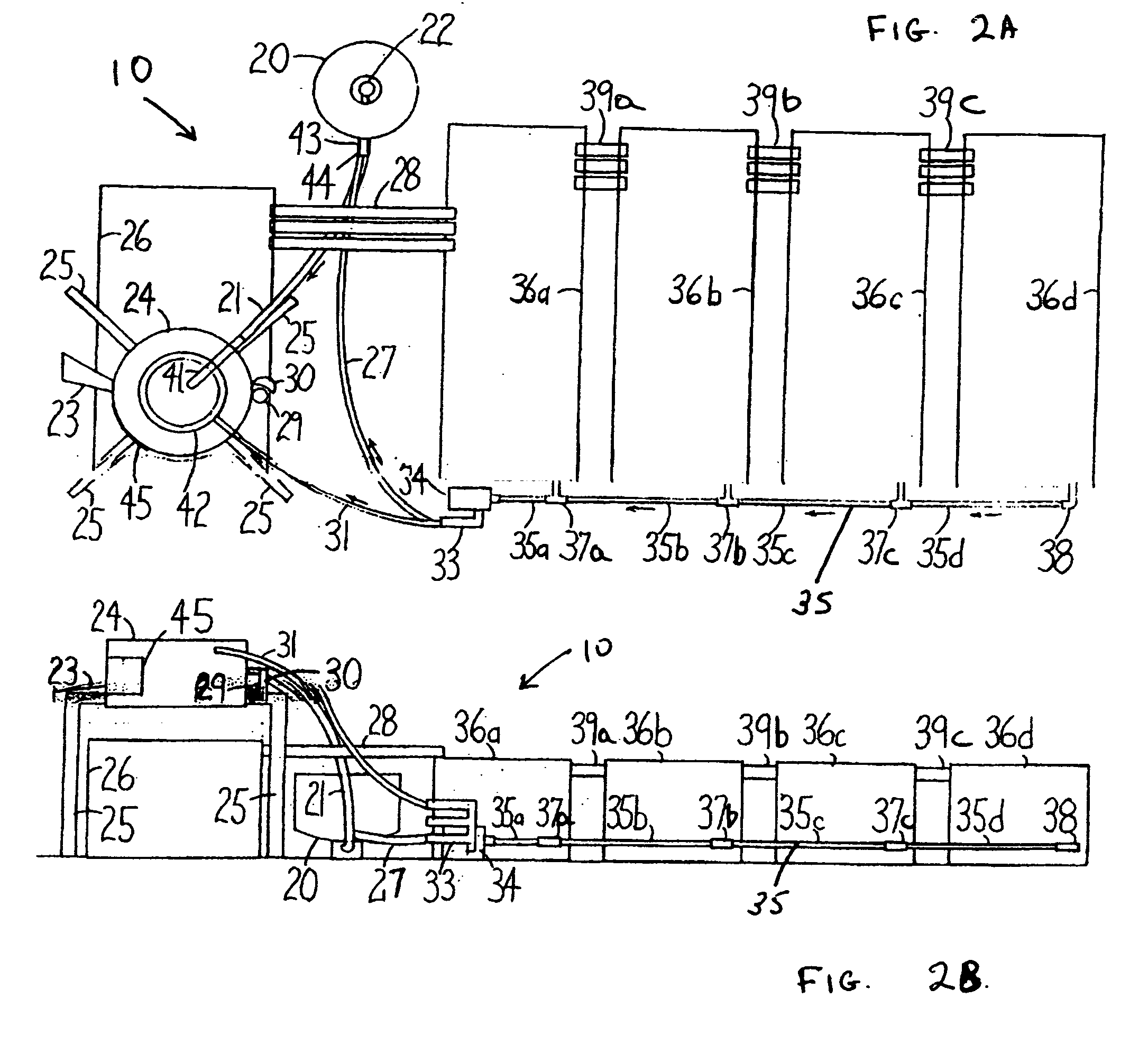

Method and Apparatus for Microwave Reduction of Organic Compounds

InactiveUS20070102279A1Maximum protectionElectrical coke oven heatingSolid waste disposalEngineeringVolumetric Mass Density

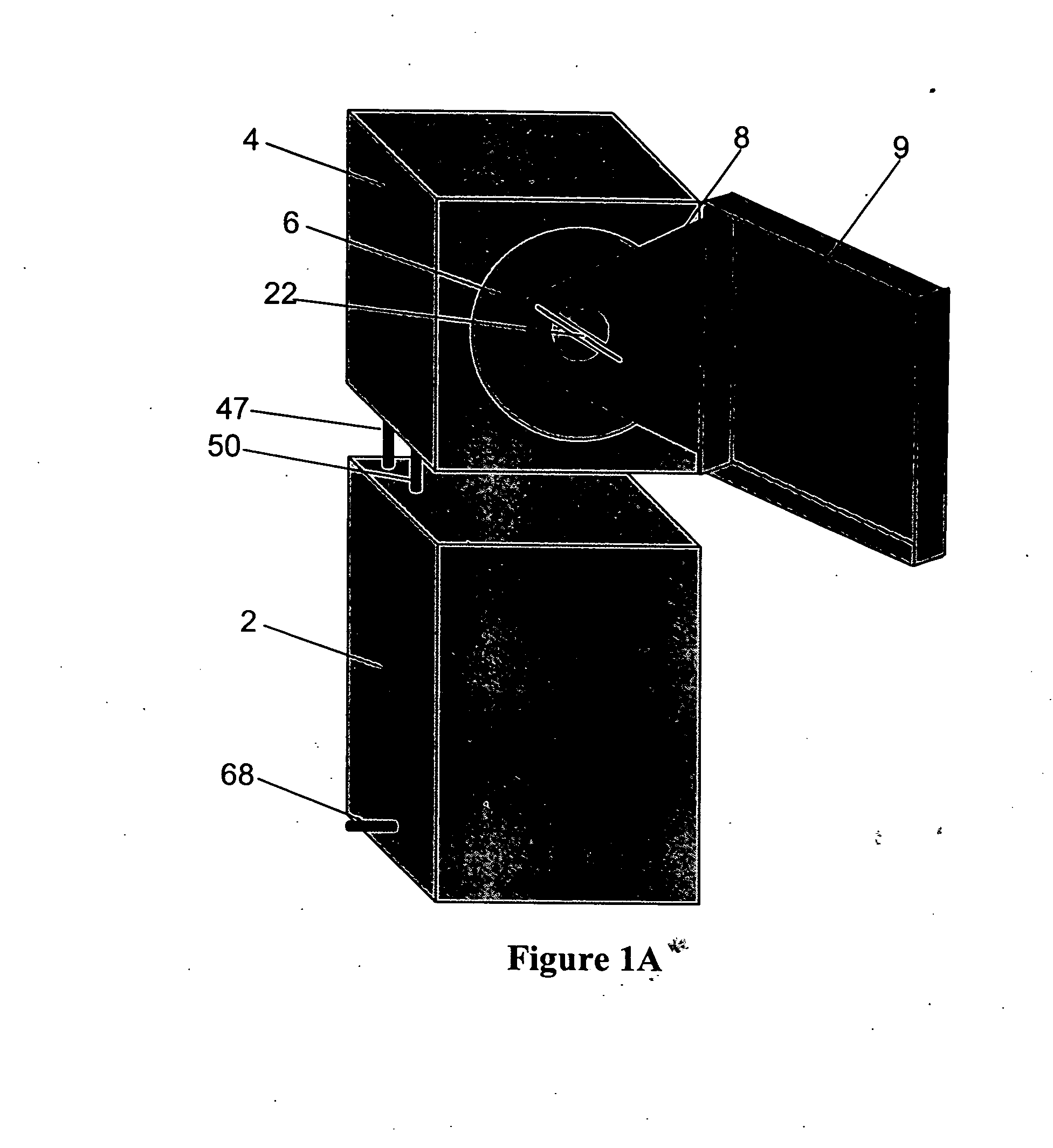

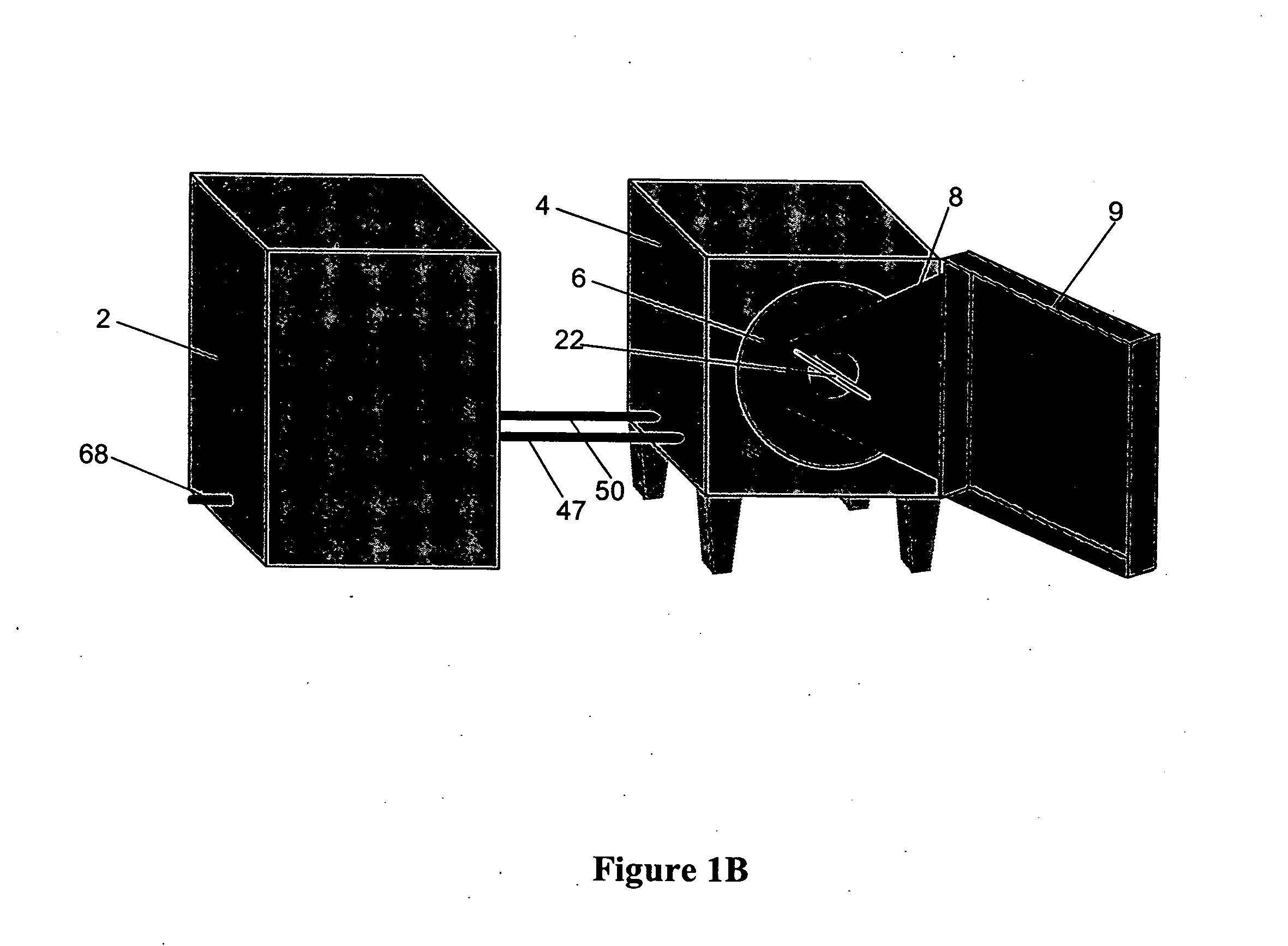

The invention described herein generally pertains to utilization of high power density microwave energy to reduce organic compounds to carbon and their constituents, primarily in a gaseous state. The process includes, but is not limited to, scrap tires, plastics, asphalt roofing shingles, computer waste, medical waste, municipal solid waste, construction waste, shale oil, and PCB / PAH / HCB-laden materials. The process includes the steps of feeding organic material into a microwave applicator and exposing the material to microwave energy fed from at least two linear polarized sources in non-parallel alignment to each other, and collecting the material. The at least two sources of microwave energy are from a bifurcated waveguide assembly, whose outputs are perpendicular to each other and fed through waveguide of proper impedance, such that the microwave sources are physically and electrically 90° out of phase to each other. The microwave frequency is between 894 and 1000 MHz, preferably approximately 915 MHz.

Owner:NOVAK JUDITH

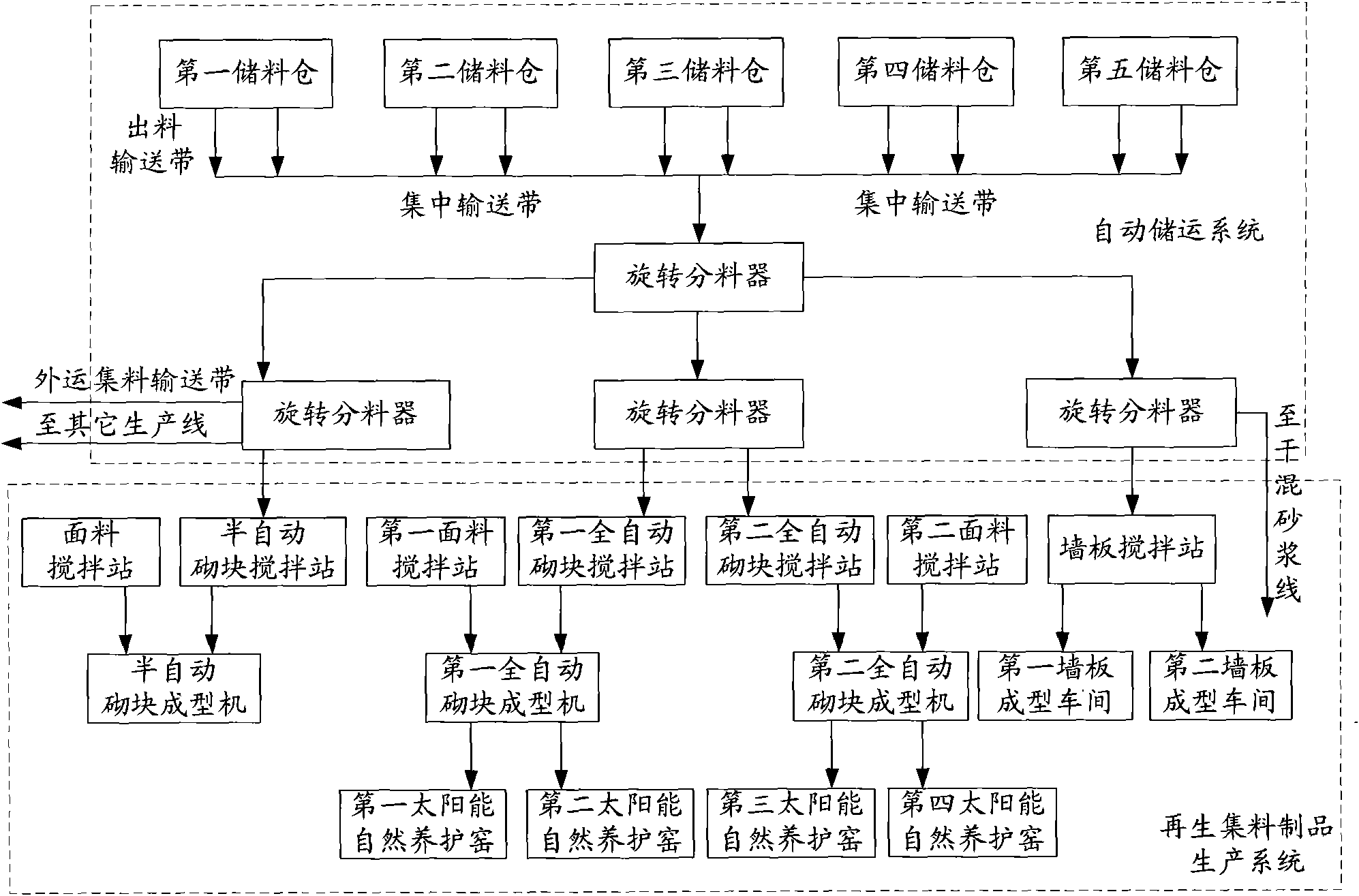

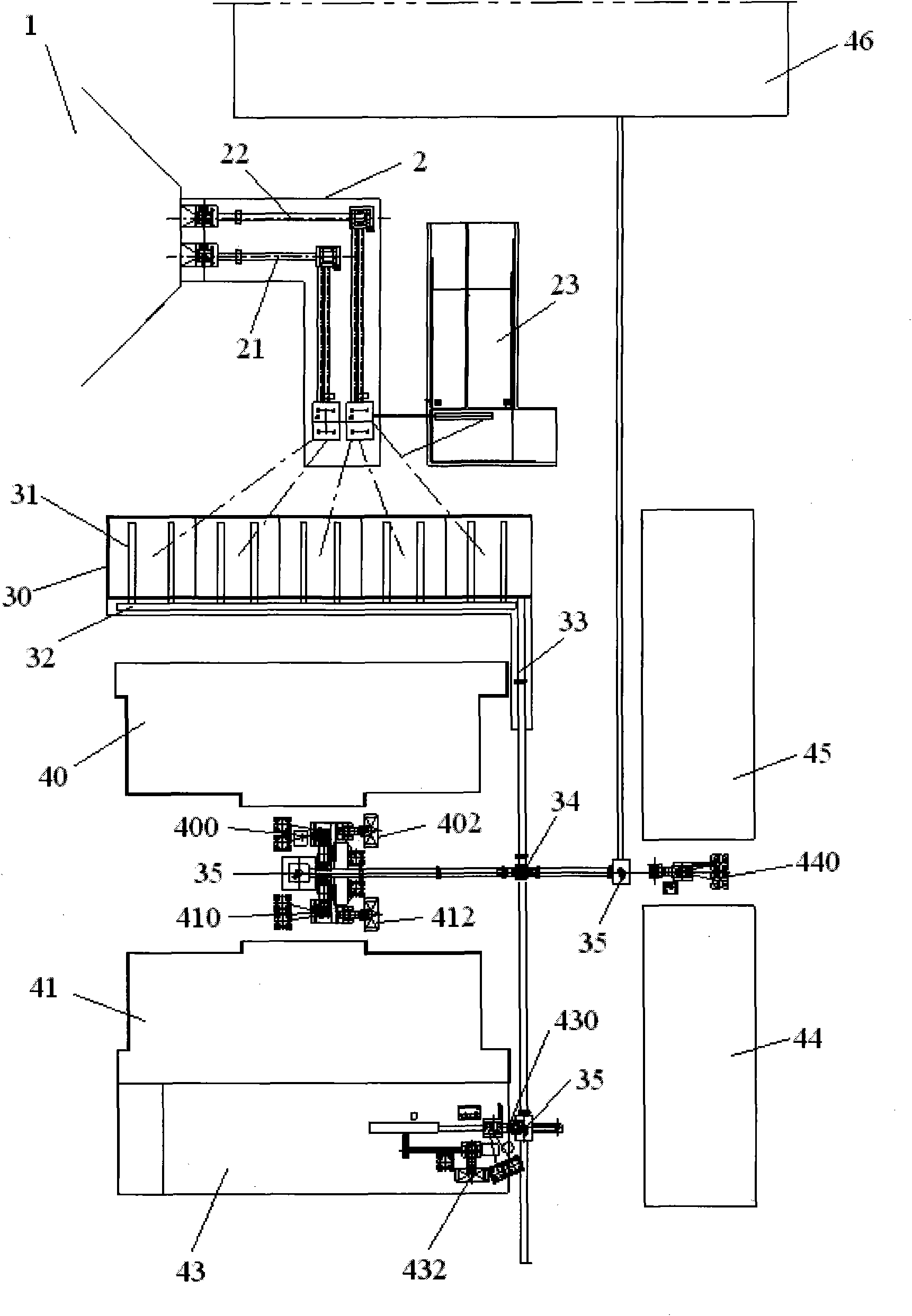

Building refuse treatment regeneration system

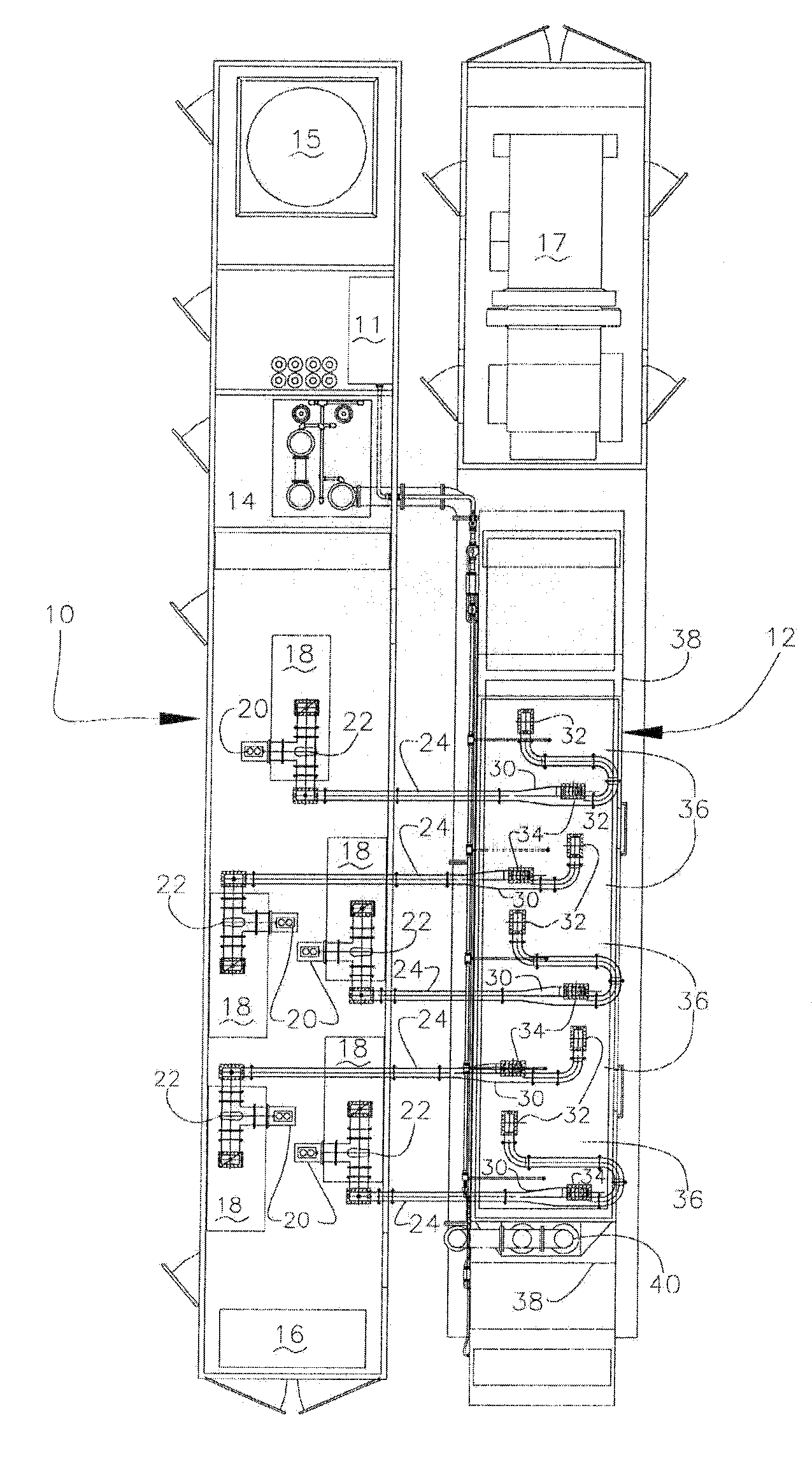

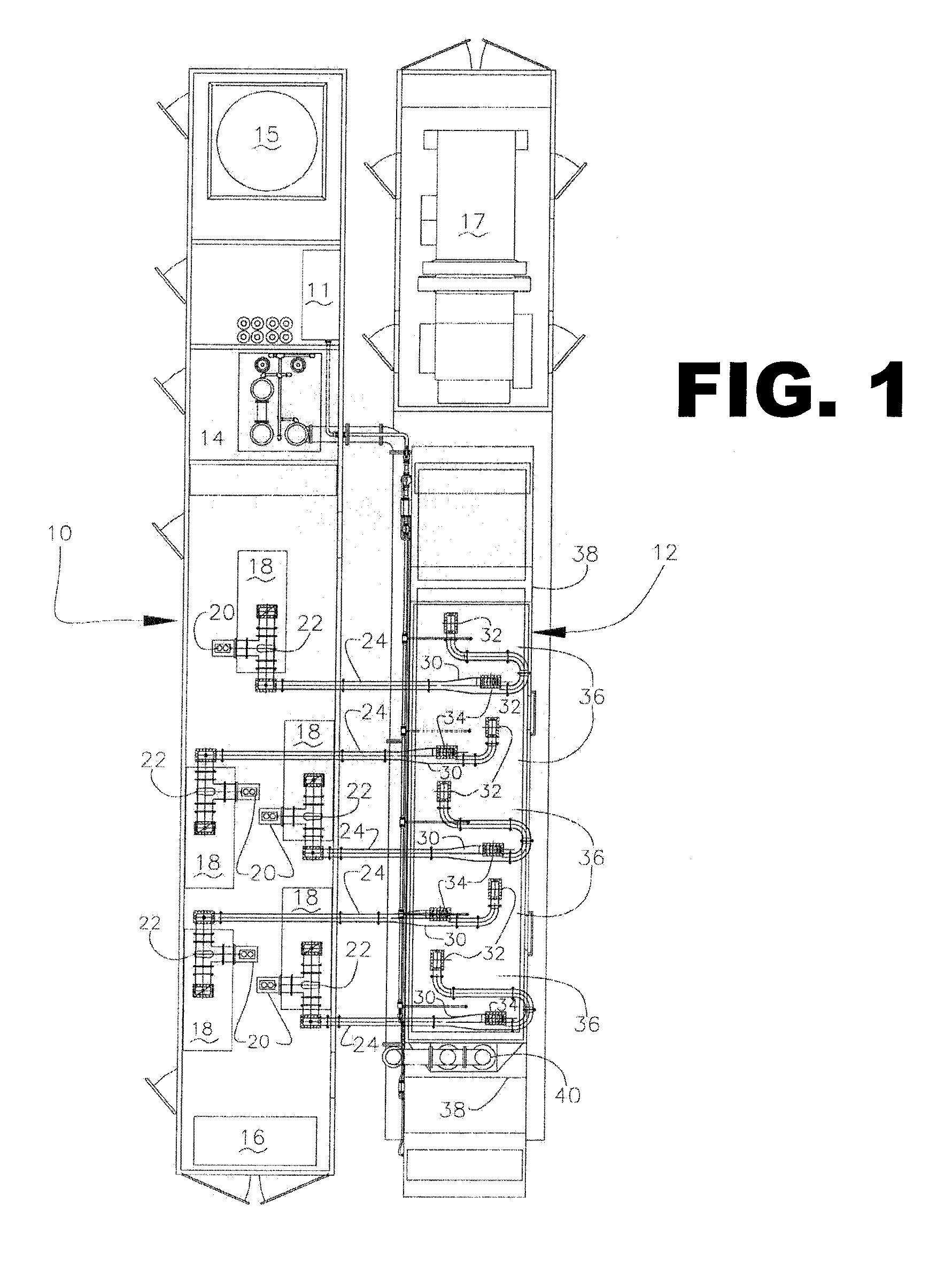

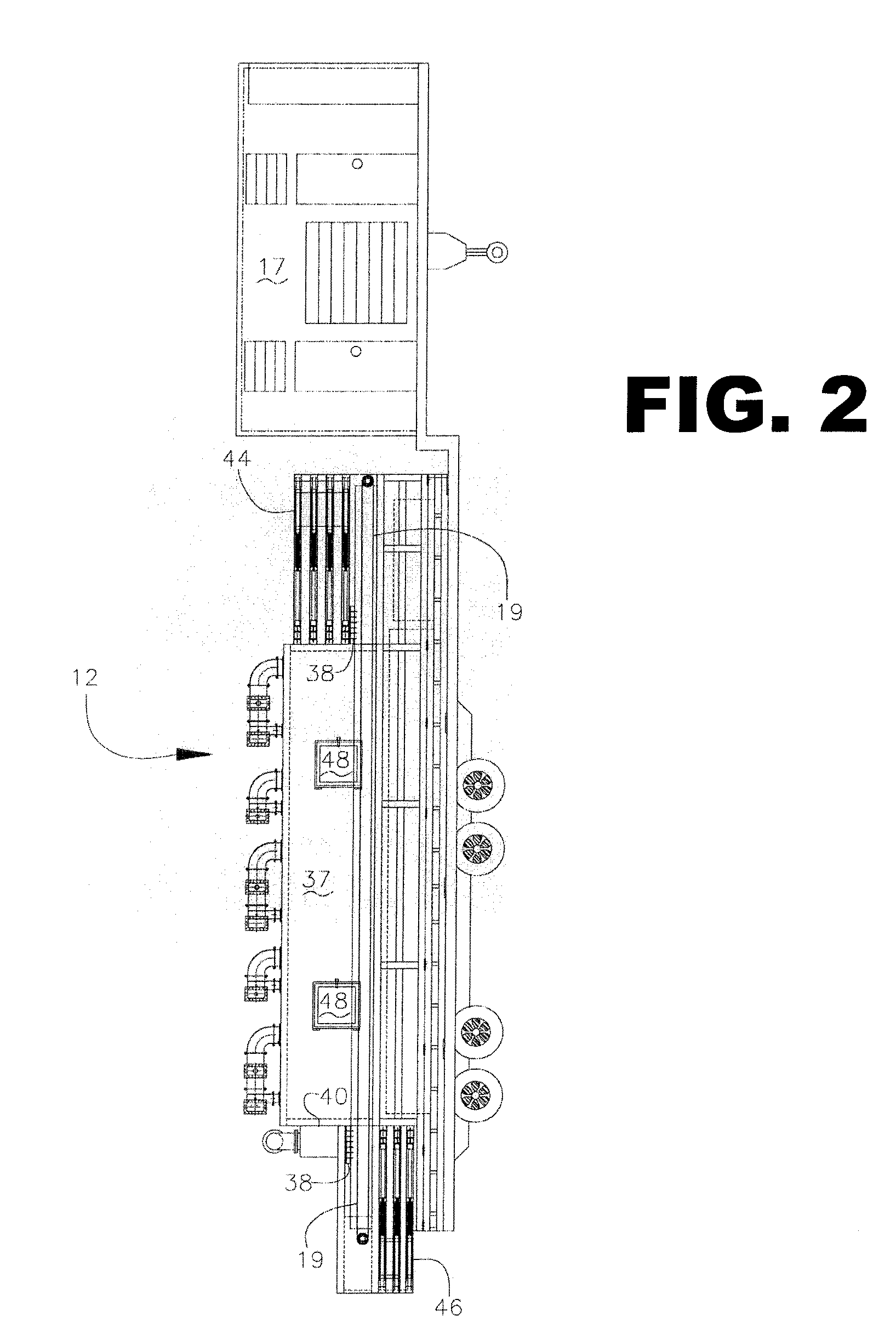

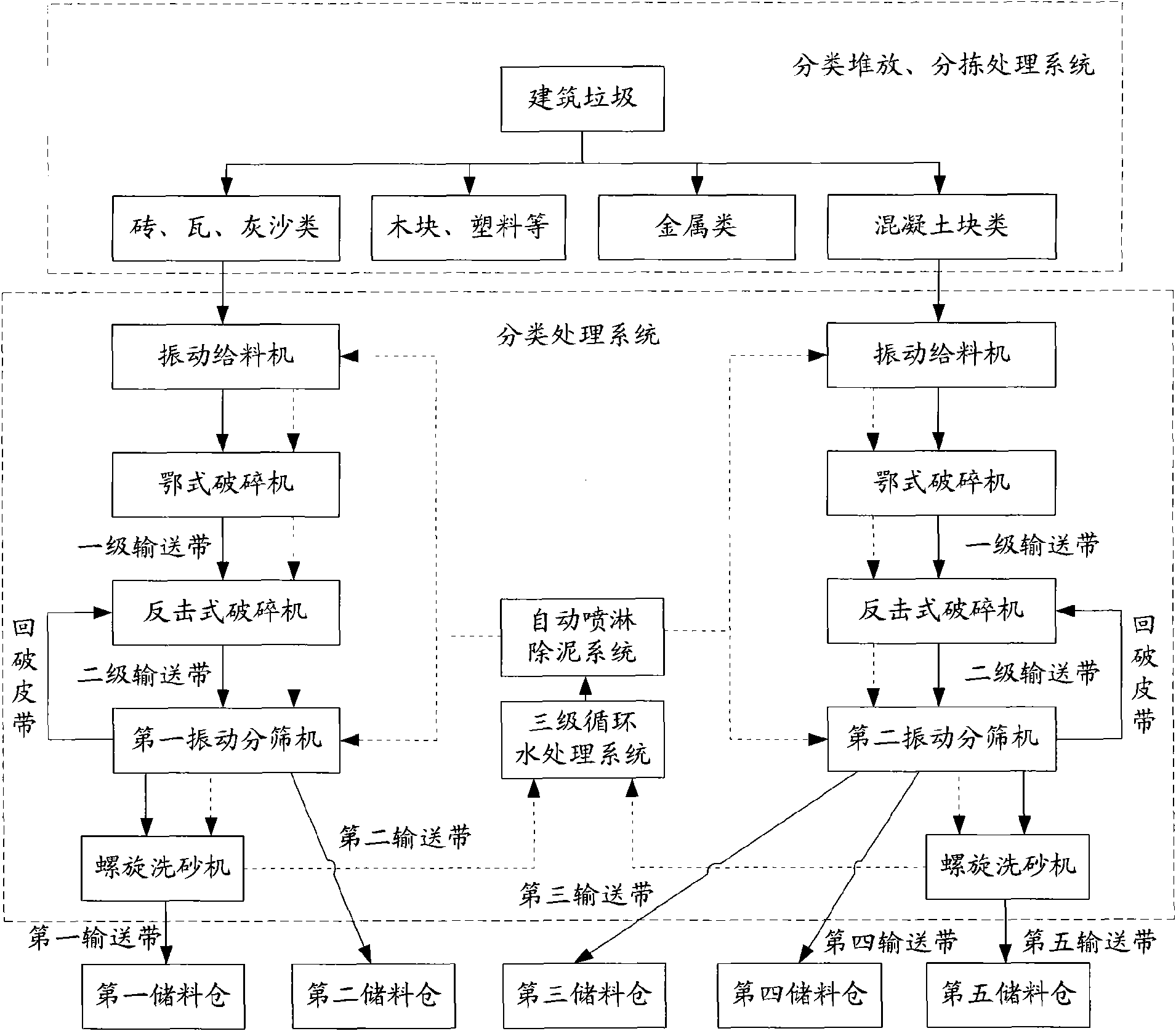

The embodiment of the invention discloses a building refuse treatment regeneration system, including a classification stacking, sorting processing system, a classification processing system and a plurality of storage bins, wherein, the classification processing system includes at least two parallel crushing screening process production lines and water circulating systems, each crushing screening process production line includes a feeder, crusher, as well as a screening machine connected in series in sequence, and a plurality of outlets of the screening machine are respectively connected to the plurality of storage bins through conveyor belts. By adoption of the building refuse treatment regeneration system of the embodiment of the invention, bricks, tiles, dust and sand and concrete blocks and the like in the building refuse can be divided into at least two production lines for parallel processing, which greatly enhancing the production efficiency and the purity of recycled aggregates, so that the recycled aggregates can be applied to a variety of uses, reproduced into a variety of high-quality recycled products, reducing the waste of resources and minimizing pollution that will be probably caused to the environment.

Owner:深圳市绿发鹏程环保科技有限公司

Appliance for converting household waste into energy

ActiveUS20070099039A1Reduce the total massEliminating garbage requiring landfillsFuel cell heat exchangeSolid waste disposalSteam reformingNuclear engineering

A method and reactor system is configured as an appliance for the destruction of residential and building waste to form hydrogen-rich syngas. This syngas is used to power a fuel cell for the generation of electric power, steam and heat or cooling for use in residences and buildings as well as hydrogen fuel for vehicles. The waste conversion rector that carries out the endothermic reactions of steam reforming is heated with the waste heat and electrical power. Alternatively, this reactor can be heated by a natural gas burner. This reactor is designed as a rotary drum, into which are placed bags of waste that can consist of normal garbage as well as toilet solid waste. Glass and metal are not melted in this drum and are recovered as completely sterilized at the end of the process cycle.

Owner:RAVEN SR INC

Construction waste treatment device

InactiveCN107214179AEfficient crushingPromote fragmentationConstruction waste recoverySolid waste disposalWater storageArchitectural engineering

The invention discloses a construction waste treatment device, which comprises a crushing chamber, an atomizing nozzle is arranged on the upper side of the crushing chamber, a water suction pipe is arranged on the upper side of the atomizing nozzle, a water storage chamber is arranged inside the upper end of the suction pipe, and a water storage chamber is arranged on the left upper side of the crushing chamber. There is a feeding pipe, the lower end of the right side of the feeding pipe is provided with a drainage plate, the lower side of the drainage plate is provided with a crushing plate, the lower left end of the crushing chamber is provided with a connecting pipe, the right side of the connecting pipe is provided with a rebar storage chamber, and the upper end of the rebar storage chamber is provided with a There is an electromagnet, there is a discharge port on the lower side of the crushing chamber, a crushing chamber is provided on the lower side of the discharge port, a screen is provided at the lower end of the crushing chamber, a discharge pipe is provided in the middle of the lower side of the crushing chamber, and a discharge pipe is provided on the lower side of the discharge pipe. There is a grinding chamber, the four corners of the lower side of the crushing chamber are provided with support columns, the lower side of the grinding chamber is provided with a discharge pipe, the lower side of the support column is provided with a base, the inside of the base is provided with a vibration-damping pad, and the upper middle of the base is provided with a pulley. The construction waste is crushed, separated, crushed, screened, ground and transported, which can effectively protect the environment and save resources.

Owner:彭利辉

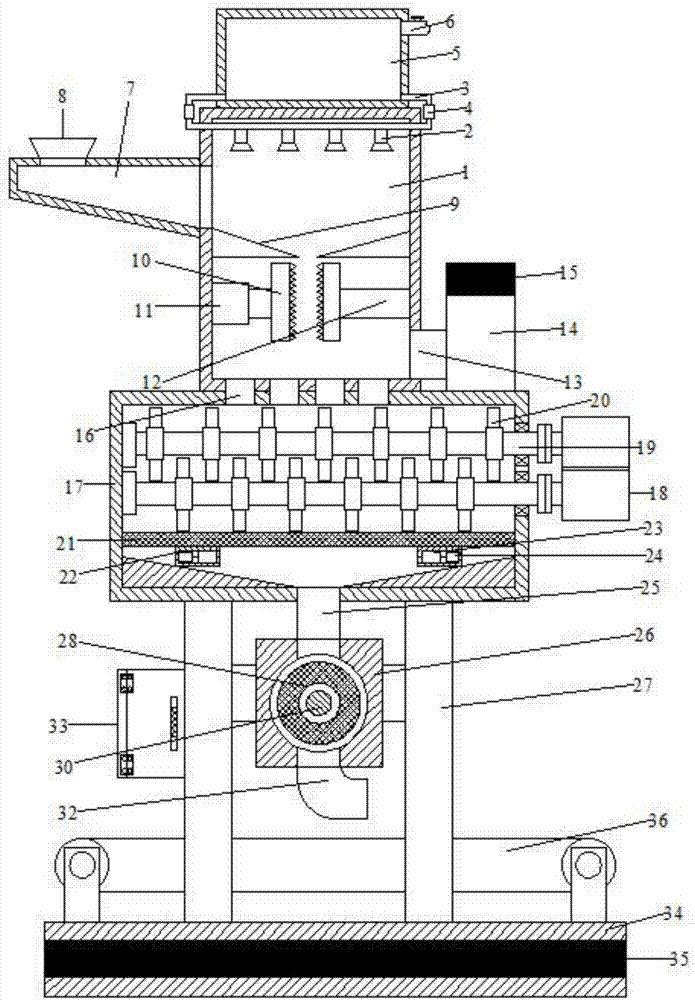

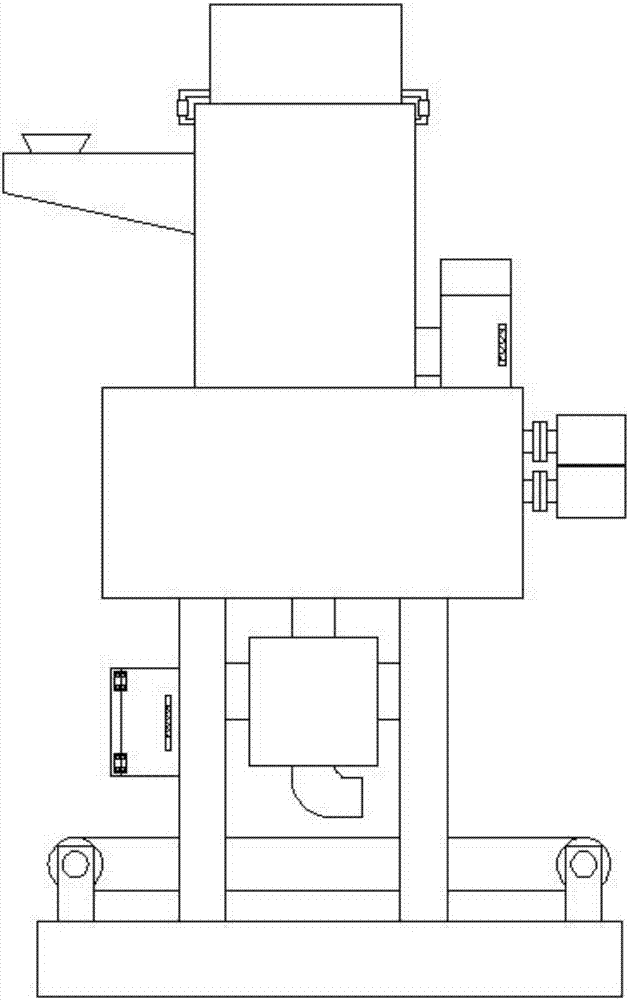

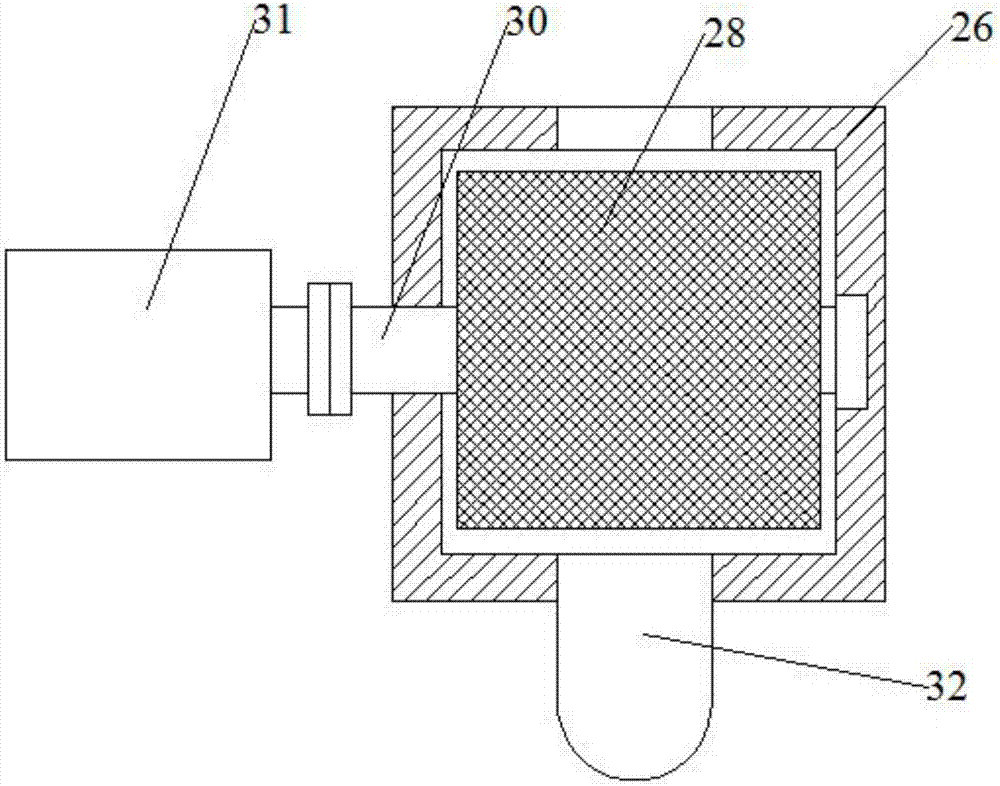

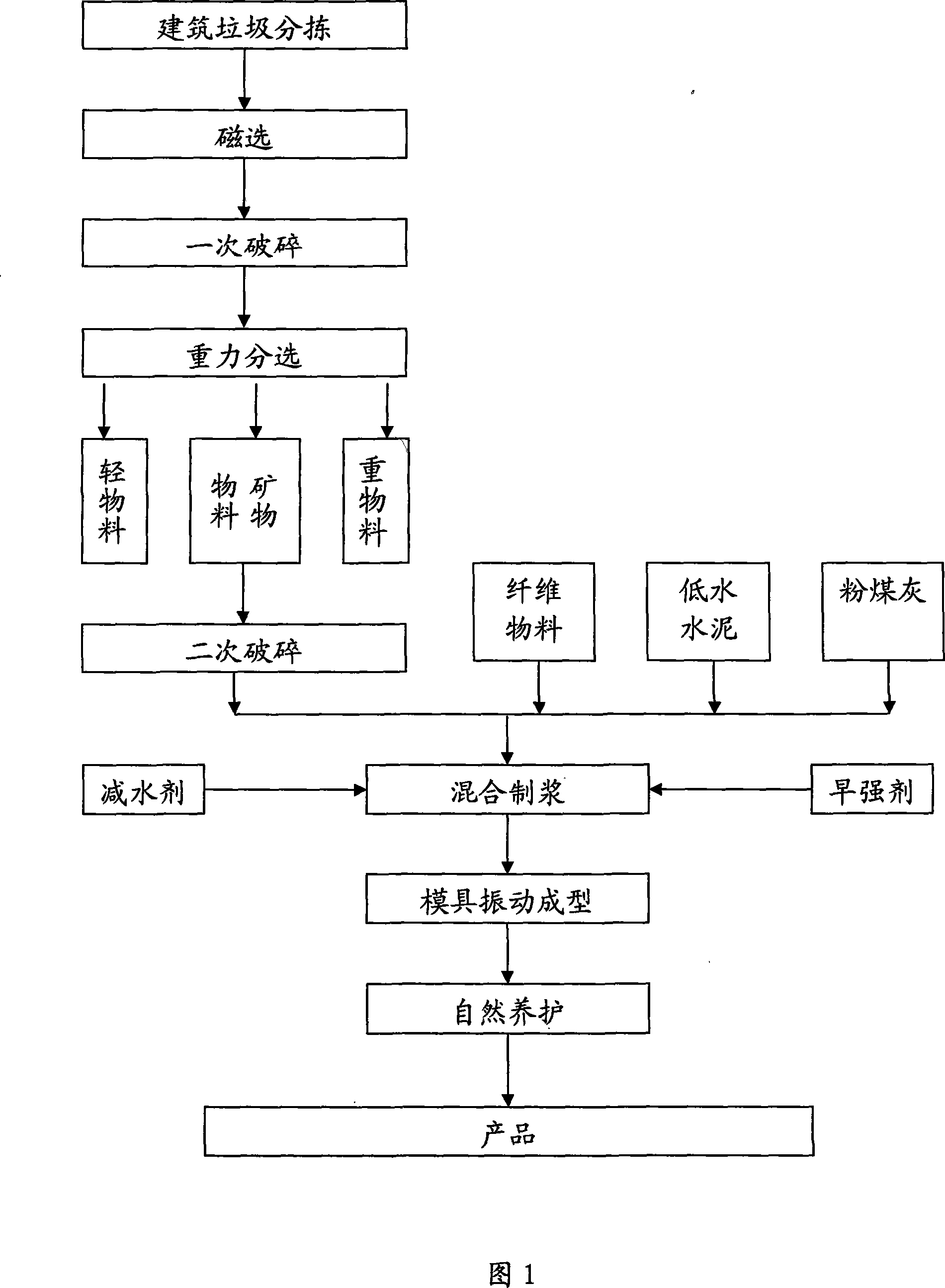

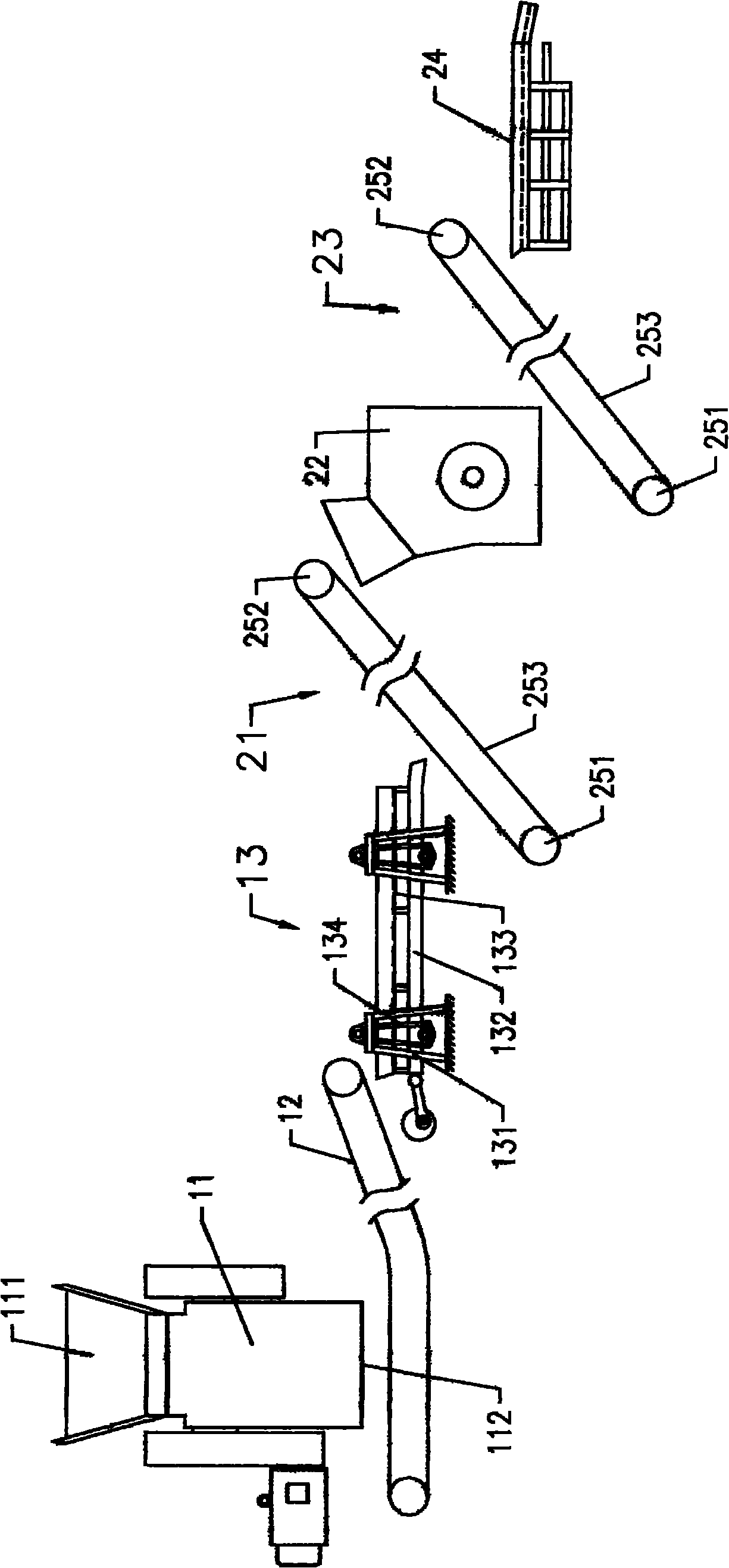

Method for manufacturing building material from building garbage

InactiveCN101239804AReduce final emissionsReduce dosageConstruction waste recoveryTransportation and packagingFiberBrick

The present invention relates to a method for manufacturing the building material with the building garbage, the method executes sorting, magnetic separation, primary crushing and gravity sorting to the city building material, and the building material is separated to heavy material, light material and mineral material, the mineral material is used for manufacturing the building material after the secondary crushing, and the raw material of the building material comprises the following components: fiber material 5-10 parts, mineral material 40-60 parts, low-water cement 20-30 parts and other material 0-30 parts, the production process of the building material comprises the steps of mixing the fiber material, mineral material and other material to uniform, then adding the low-water cement for mixing to uniform, adding water and stirring to slurry, placing into the mold for jolt molding or extrusion molding, and forming the building used sheet material after natural curing. The method of the invention has the advantages of full utilization of the mineral material comprising the major component of the building garbage, saving the material resource, reducing the final discharging amount of the building garbage, and the method can be used for manufacturing the building materials such as hollow brick, hollow block, partition plate and the like.

Owner:BEIJING HENGYECUN S&T

Construction waste comprehensive treatment method

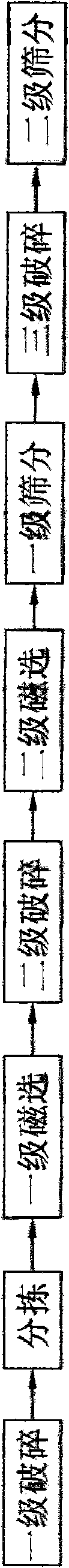

InactiveCN102009059AReduce pollutionLow costConstruction waste recoverySolid waste disposalForeign matterSocial benefits

The invention discloses a construction waste comprehensive treatment method which comprises the following steps: primary crushing, sorting, primary magnetic separation, secondary crushing, secondary magnetic separation, primary screening, tertiary crushing and tertiary screening. The construction waste comprehensive treatment method can be used for thoroughly sorting foreign matters in the construction waste, thereby enhancing the quality of the regenerative aggregate. The invention has the advantages of reasonable procedure arrangement, low labor consumption and high efficiency, and is simple to operate. When being used for treating construction waste, the method has the social benefits of saving land resources and reducing environmental pollution.

Owner:潍坊大于环保建材有限公司

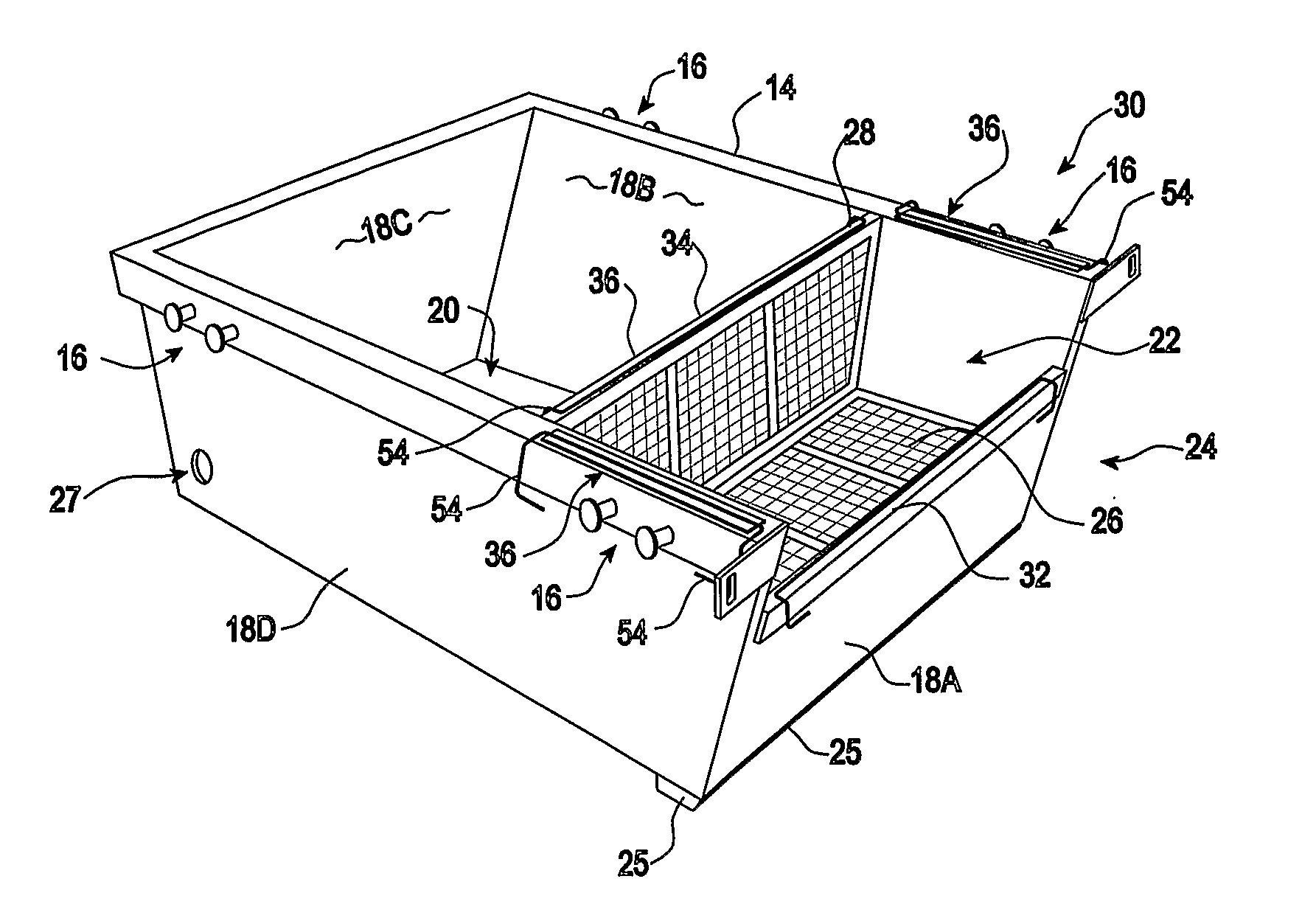

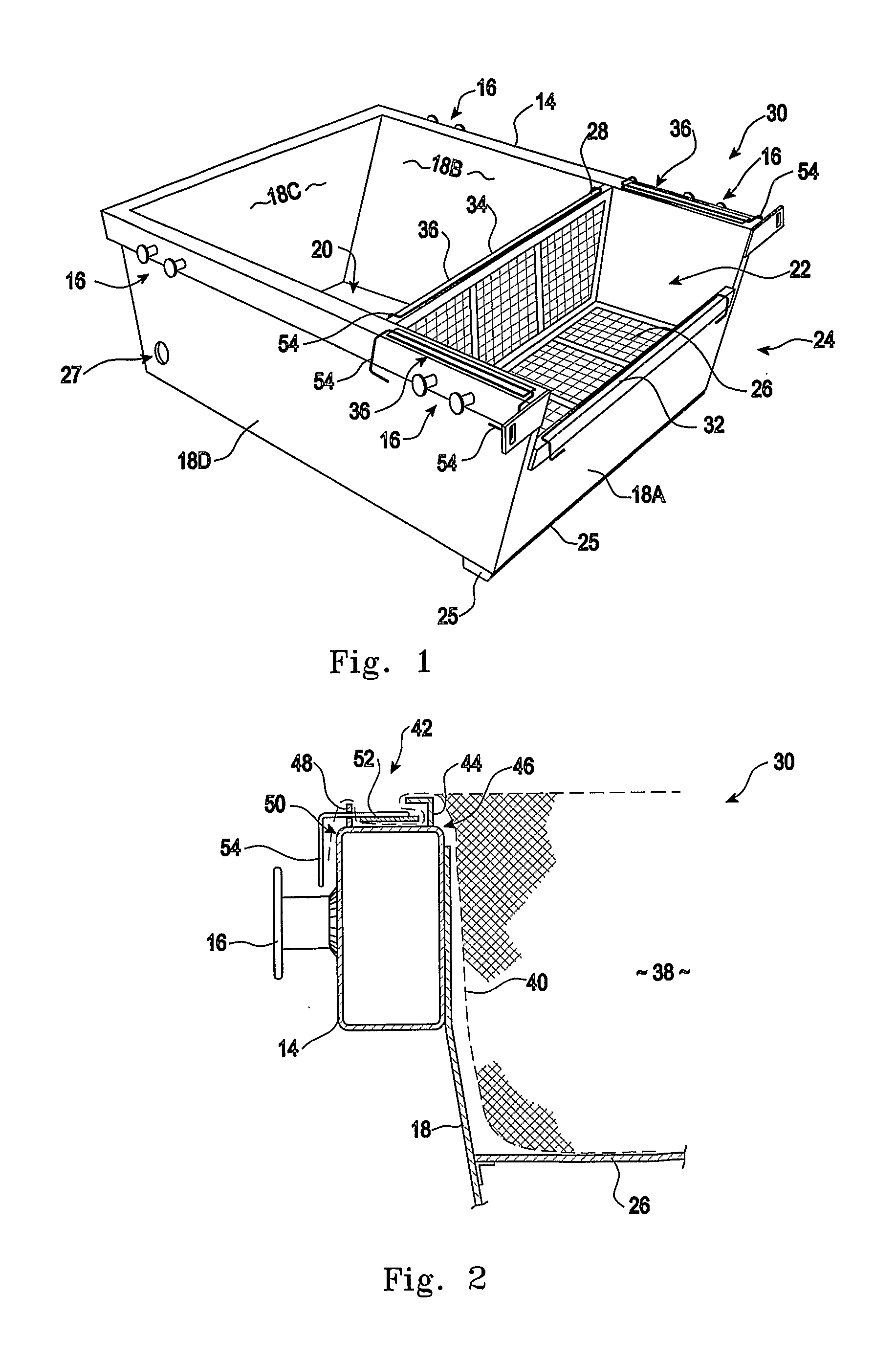

Waste bin

A slurry handling and disposal system is provided for waste slurry and particulates. The system includes a waste bin provided with support structures for retaining a flexible removable filter element with a filter element supported above a floor of the waste bin. The particulate matter component of a volume of the waste slurry and particulates deposited in the filter element is retained in said filter element while the liquid component of the waste slurry and particulates are collected in a base portion of the waste bin.

Owner:WESTON OWEN CHARLES

Method for treating urban domestic refuse by cement kiln

InactiveCN101028628AEliminate pollutionAdaptableConstruction waste recoverySolid waste disposalCombustionAdhesive

A method for reclaiming the city life garbage by cement kiln includes such steps as separating the building garbage from city life garbage, dewatering, breaking, regulating lime saturation coefficient, adding modified combustion promoter and adhesive, shaping, and clacining in cement kiln to obtain cement clinker.

Owner:尹小林

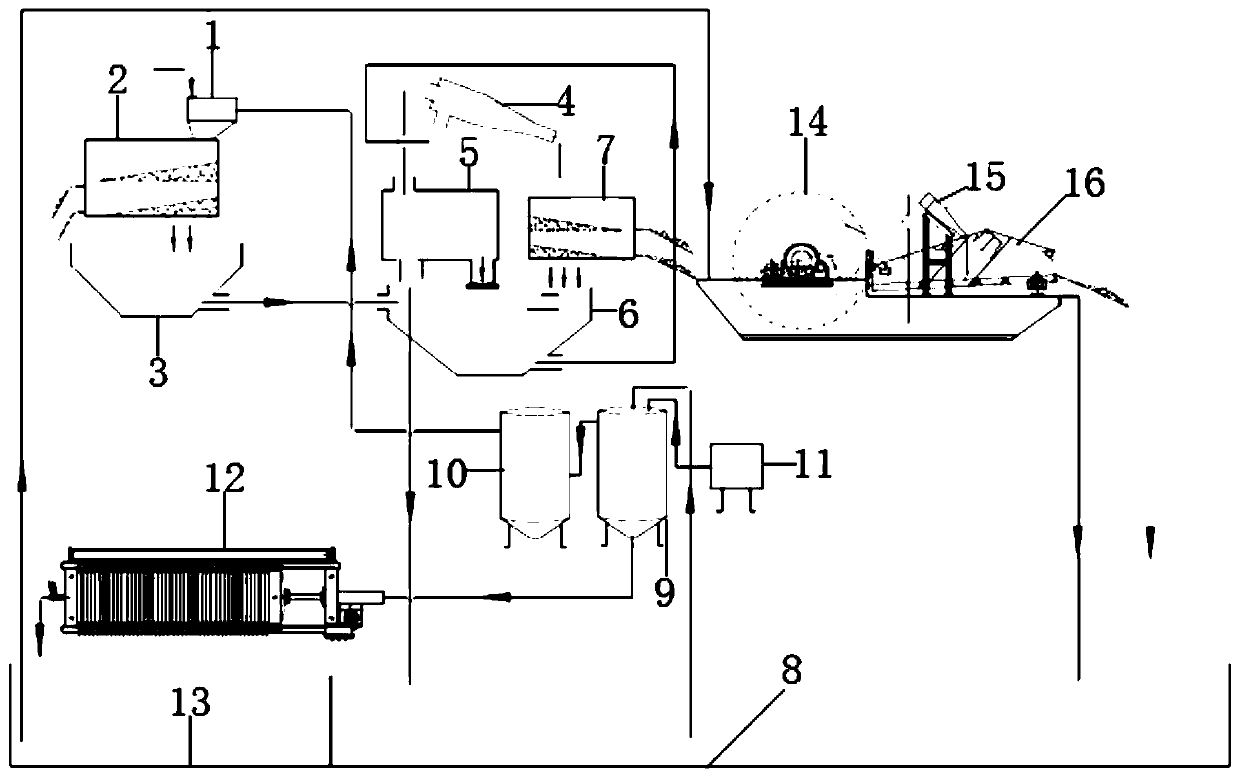

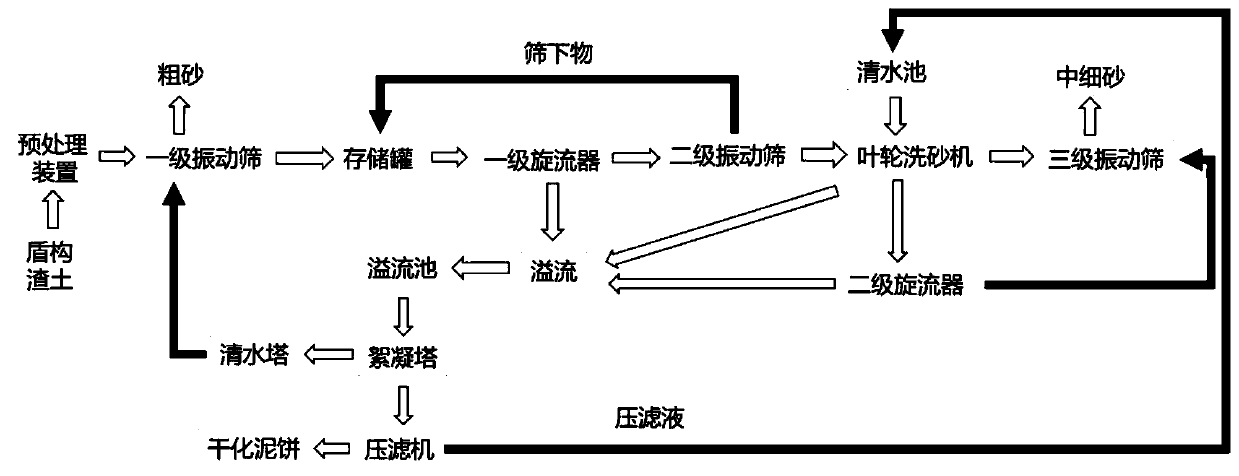

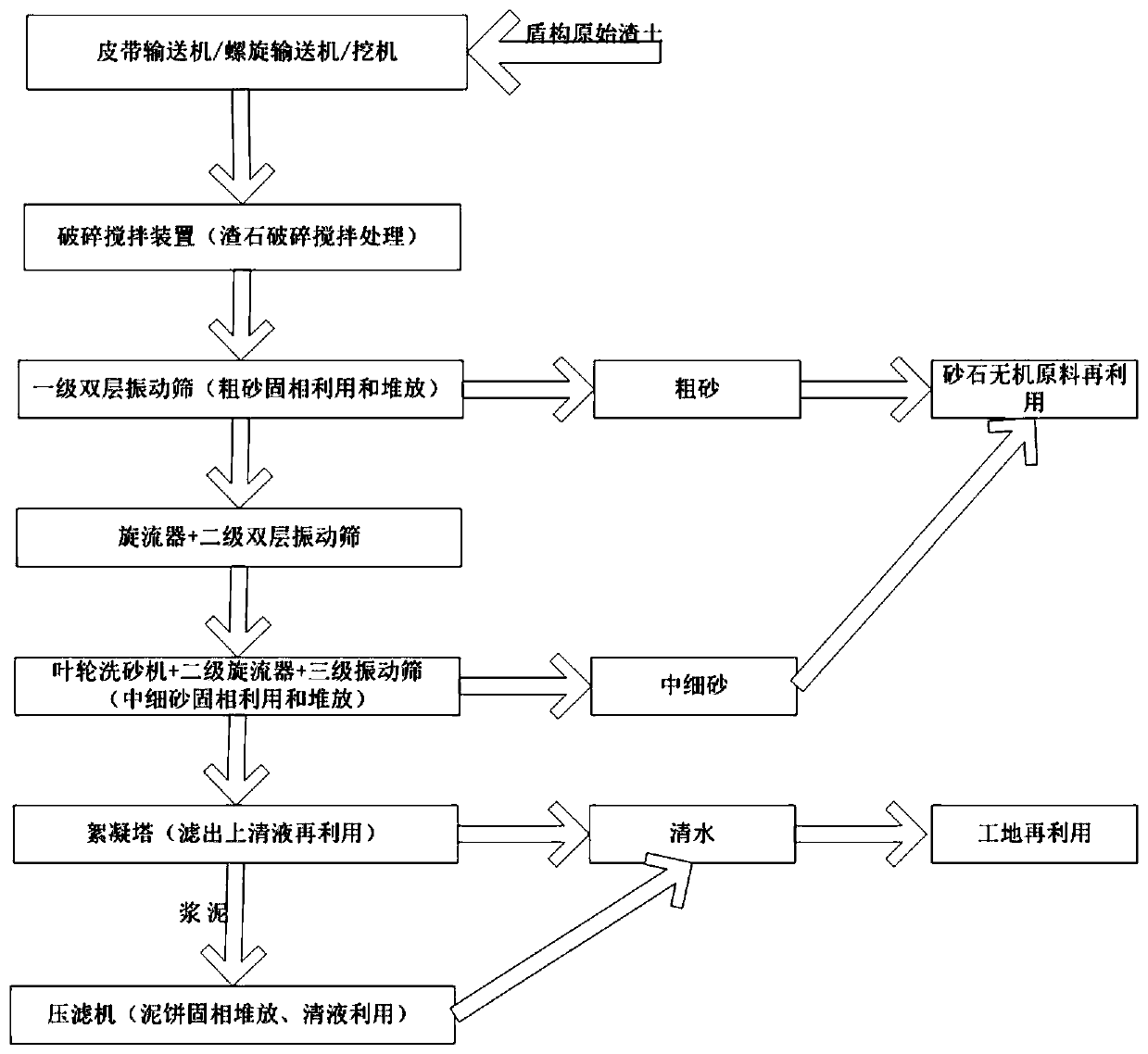

Shield construction muck treatment system and method

ActiveCN110303033AAchieve graded solid-liquid separationReduce transport volumeSievingConstruction waste recoveryEngineeringSlurry

The invention relates to the technical field of shield construction muck treatment, in particular to a shield construction muck treatment system and method. The muck generated by shield construction is crushed and stirred by a crushing and stirring device and then enters a primary-stage double-layer vibrating screen, oversize products are discharged out of the system, undersize products enter a sieve cone tank, the sieve cone tank is connected with a swirler through a pump, an intermediate tank is connected to an overflow port of the swirler, a discharge port of the intermediate tank is connected to an overflow tank through a pipeline, the slurry in the overflow tank is pumped to a flocculation tower through a pump, the flocculation tower is connected with an automatic dosing device, a flocculation medicament is pumped into the flocculation tower, the slurry in the flocculation tower is pumped to a filter press through a pump, drying mud cake treatment is carried out through the filterpress, the treated clear water flows into a clear water tank for reutilization, the dried mud cake is discharged out of the system, so that classified solid-liquid separation of different particle size components and water in the shield muck is realized, reutilization of inorganic raw materials and water resources of the shield muck is formed, and huge economic benefits are generated while the social resources are saved.

Owner:CHINA RAILWEY ENG SERVICE CO LTD

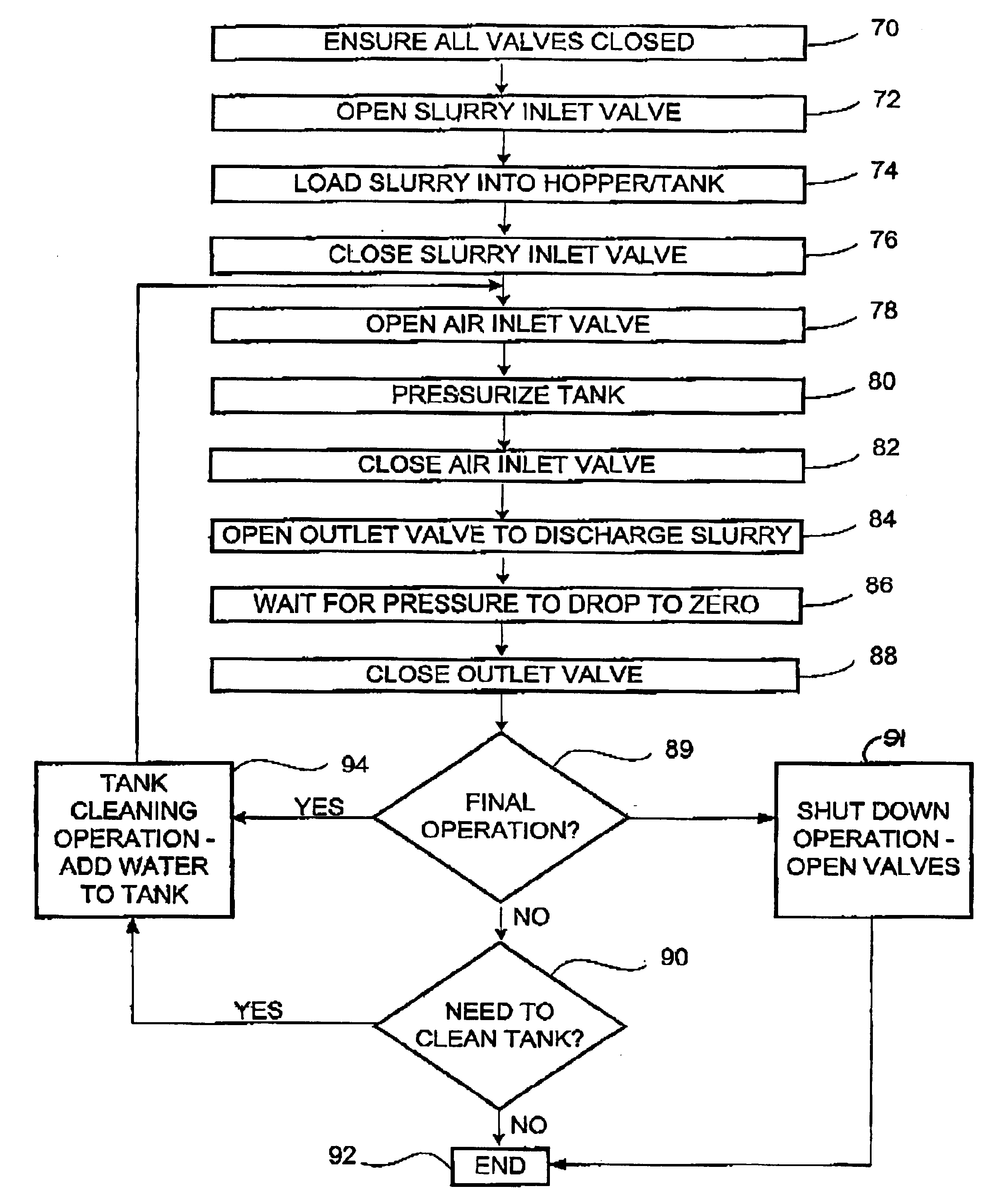

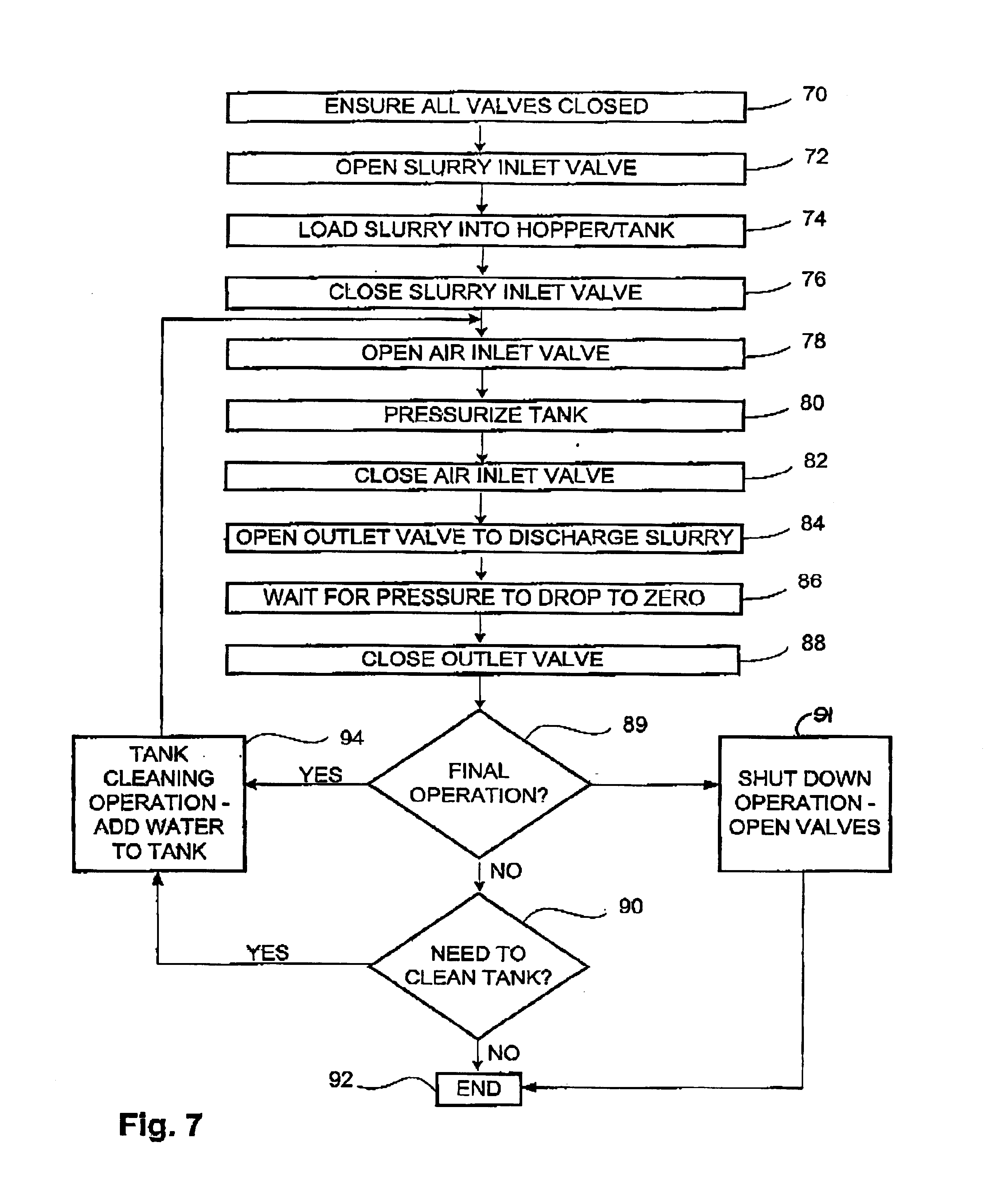

Concrete recovery method and system

According to certain embodiments of the present invention, there is disclosed herein a method and system of recovering concrete which includes admitting a concrete slurry to a tank, pressurizing the tank with a fluid under pressure, discharging through a discharge line the pressurized fluid-slurry from the tank, cleaning the tank by admitting a cleaning liquid into the tank after discharging fluid-slurry therefrom, and discharging the cleaning liquid from the tank through the discharge line for cleaning purposes.

Owner:FE HLDG LLC

Method for reclaiming concrete

A method and apparatus for reclaiming uncured concrete are disclosed. Uncured concrete containing gravel, sand and cement is mixed with water in a concrete hopper and the resultant slurry flows to a screen where the gravel is separated from the rest of the slurry material. The gravel free material flows to a separator where the sand is removed by gravity from the remaining cement water mixture. The cement water mixture flows to a tank where the cement settles out of the water by gravity. Water containing unsettled cement is recirculated to mix it with uncured concrete in the concrete hopper.

Owner:DEHART MICHAEL ROBERT +1

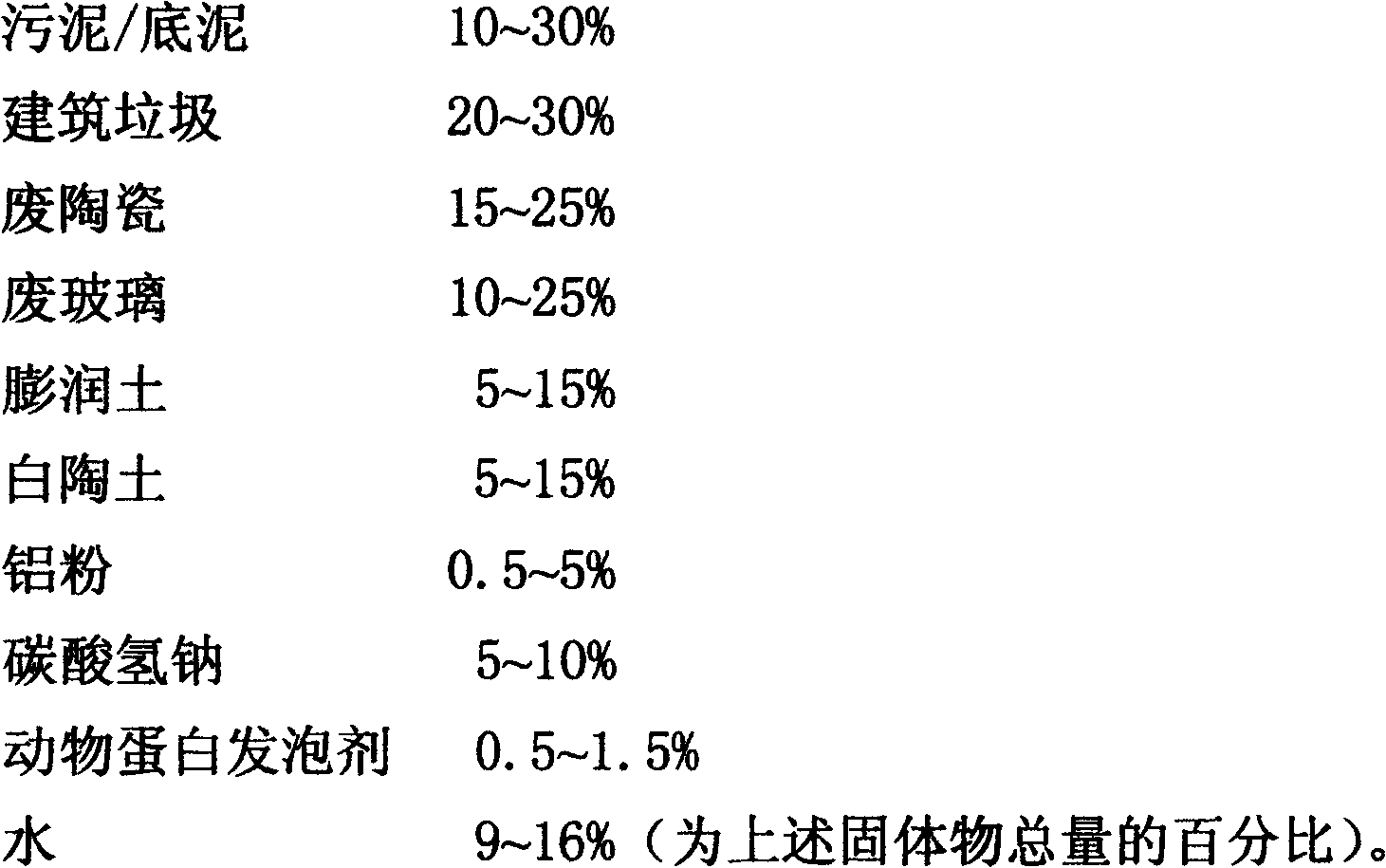

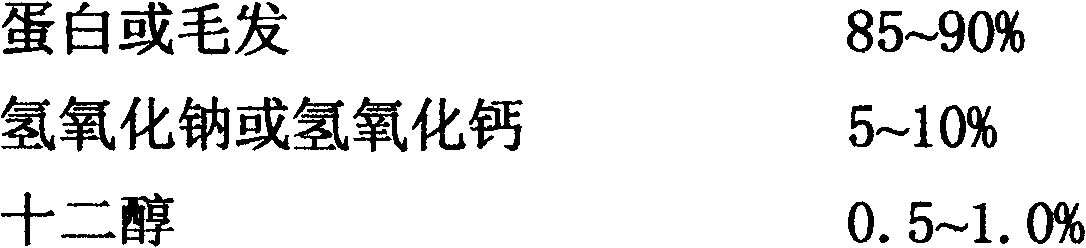

High-strength light foam ceramic plate and manufacturing method thereof

InactiveCN102627469AEasy accessLow priceConstruction waste recoverySolid waste disposalEnvironmental resistanceSodium bicarbonate

The invention discloses a high-strength light foam ceramic plate and a manufacturing method thereof, and belongs to the field of building material manufacturing. The ceramic plate comprises the following materials in percentage by weight: 10-30 percent of sludge / bottom mud, 20-30 percent of building waste, 15-25 percent of waste ceramic, 10-25 percent of waste glass, 5-15 percent of bentonite, 5-15 percent of kaolin, 0.5-5 percent of aluminum powder, 5-10 percent of sodium bicarbonate, 0.5-1.5 percent of animal albumen foaming agent and 9-16 percent (percentage of total amount of the solid matters) of water. The manufacturing method comprises the following steps of: mixing and crushing the main raw material; adding the animal albumen foaming agent and water; granulating; filling a granular material into a refractory combined mould; leveling; filling in a kiln; firing; and performing cold processing to produce a ceramic plate finished product. The high-strength light foam ceramic plate has the advantages of high product strength, small volume weight, fire proofing, excellent freeze proofing, long-term water proofing, readily available main raw material which basically comes from environmental solid waste, has a wide source and is low in cost and adoption of the animal albumen foaming agent of small using amount and wide source; the manufacturing process has the advantages of simplicity, high efficiency, energy conservation, environmental friendliness, no secondary pollution; and the high-strength light foam ceramic plate can be used as thermal insulation decorative materials, fire barriers and the like of exterior walls of buildings.

Owner:SICHUAN UNIV

Comprehensive treatment method of architectural garbage

InactiveCN1868597AReduce processing costsMethod securitySievingConstruction waste recoveryStone particleLitter

A comprehensive treating method for the building garbage includes such steps as proper breaking, separating metals, bamboo, wood and plastics out, adding the rest into a washing pool with three-class layered sieve, washing with water while stirring to separate silt sludge, sand and stone particles and big blocks from each other, multi-stage mechanical separation of silt sludge to obtain sludge and sand-stone particles, depositing sludge to become water and clay, drying clay, and cyclic use of water.

Owner:GUANGZHOU ZHENGLV ENVIRONMENTAL PROTECTION TECH CO LTD

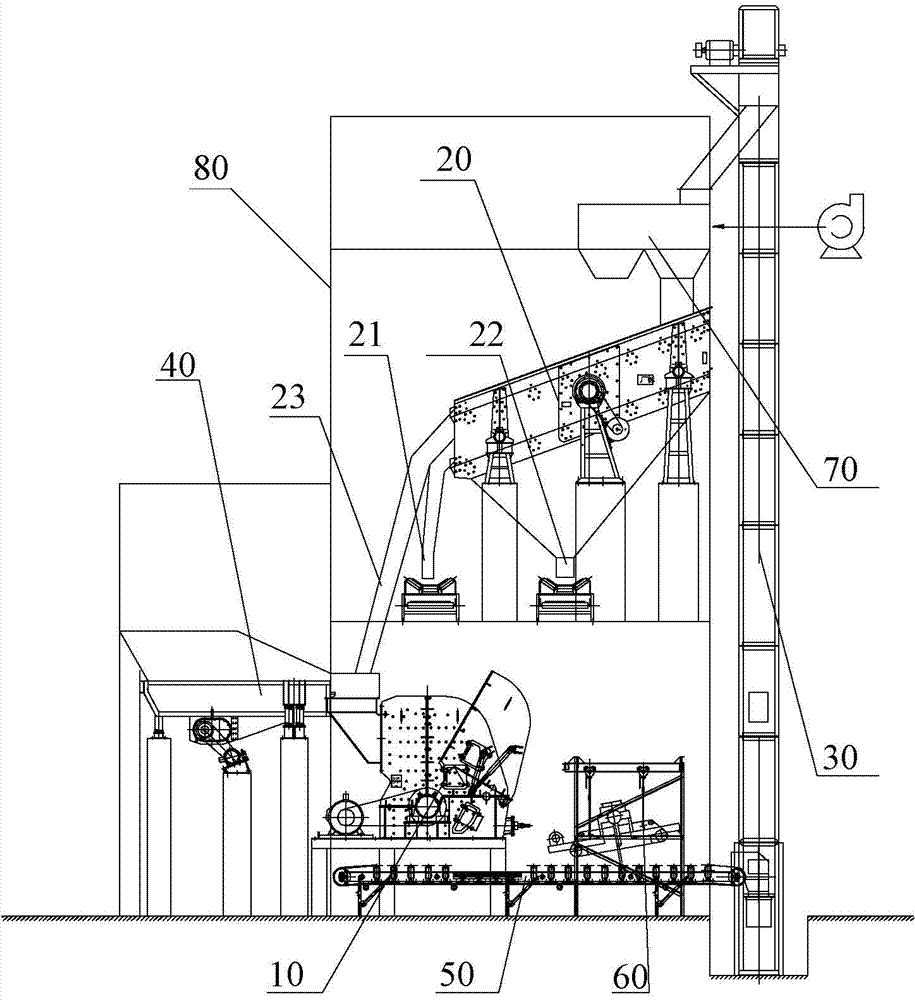

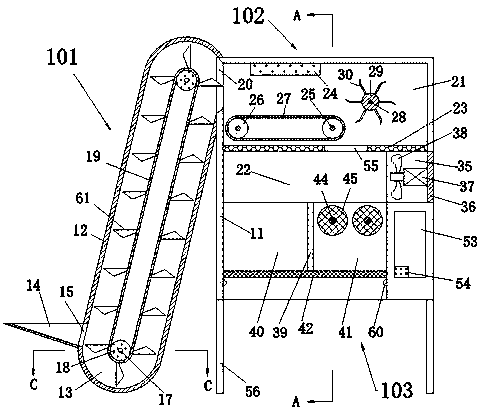

Building garbage treatment system

InactiveCN103586257ASmall footprintReduce conveying equipmentConstruction waste recoverySolid waste disposalTreatment systemConstruction waste

The invention provides a building garbage treatment system. The building garbage treatment system comprises crushing equipment, sieving equipment and material lifting equipment, wherein the sieving equipment is arranged above the crushing equipment and is provided with a downwardly arranged material slideway; the material lifting equipment is used for lifting the discharged material of the crushing equipment to the sieving equipment. According to the building garbage treatment system provided by the invention, the sieving equipment is arranged above the crushing equipment, so that the occupied area of the whole treatment system is effectively reduced. In addition, height fall exists between the sieving equipment and other equipment, so that the return material of the sieving equipment automatically slides downwards through the material slideway under the action of gravity, conveying equipment is reduced and efficiency is improved.

Owner:ZOOMLION MATERIAL HANDLING EQUIPMENT CO LTD +1

Construction waste treatment method

InactiveCN106111665AReduce consumptionReduce pollutionConstruction waste recoverySolid waste disposalSewagePollution

The invention discloses a construction waste treatment method. The construction waste treatment method comprises the following steps of 1, manual sorting and robot sorting, 2, primary crushing, 3, iron removing and winnowing, 4, secondary crushing, 5, screening and 6, joint powder grinding. According to the construction waste treatment method, the problems that a lot of land is consumed, and air dust, sewage pollution and the like are produced due to landfill of construction waste are solved, and construction waste recycled materials are produced.

Owner:HANGZHOU ENVIRONMENTAL GROUP

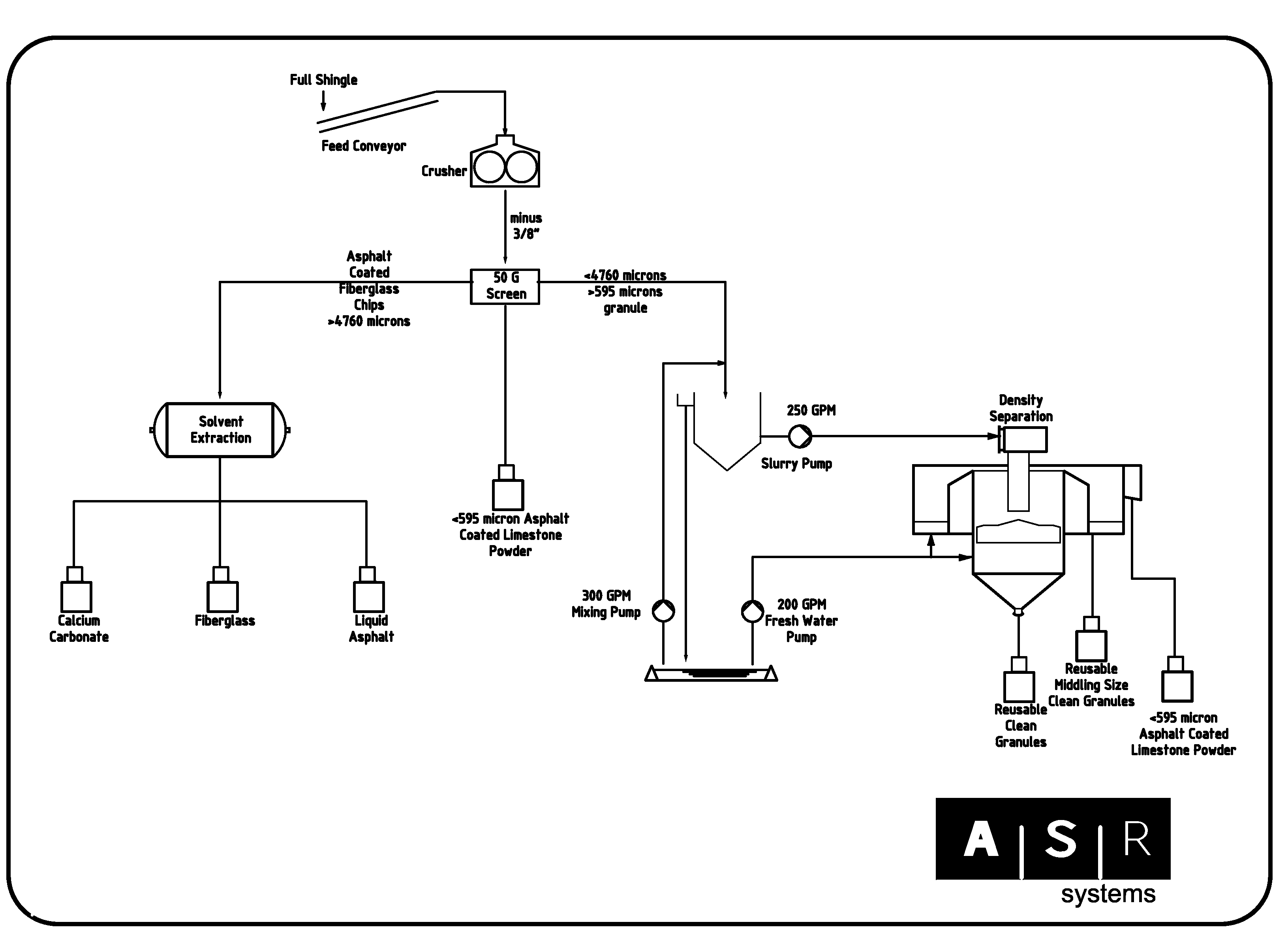

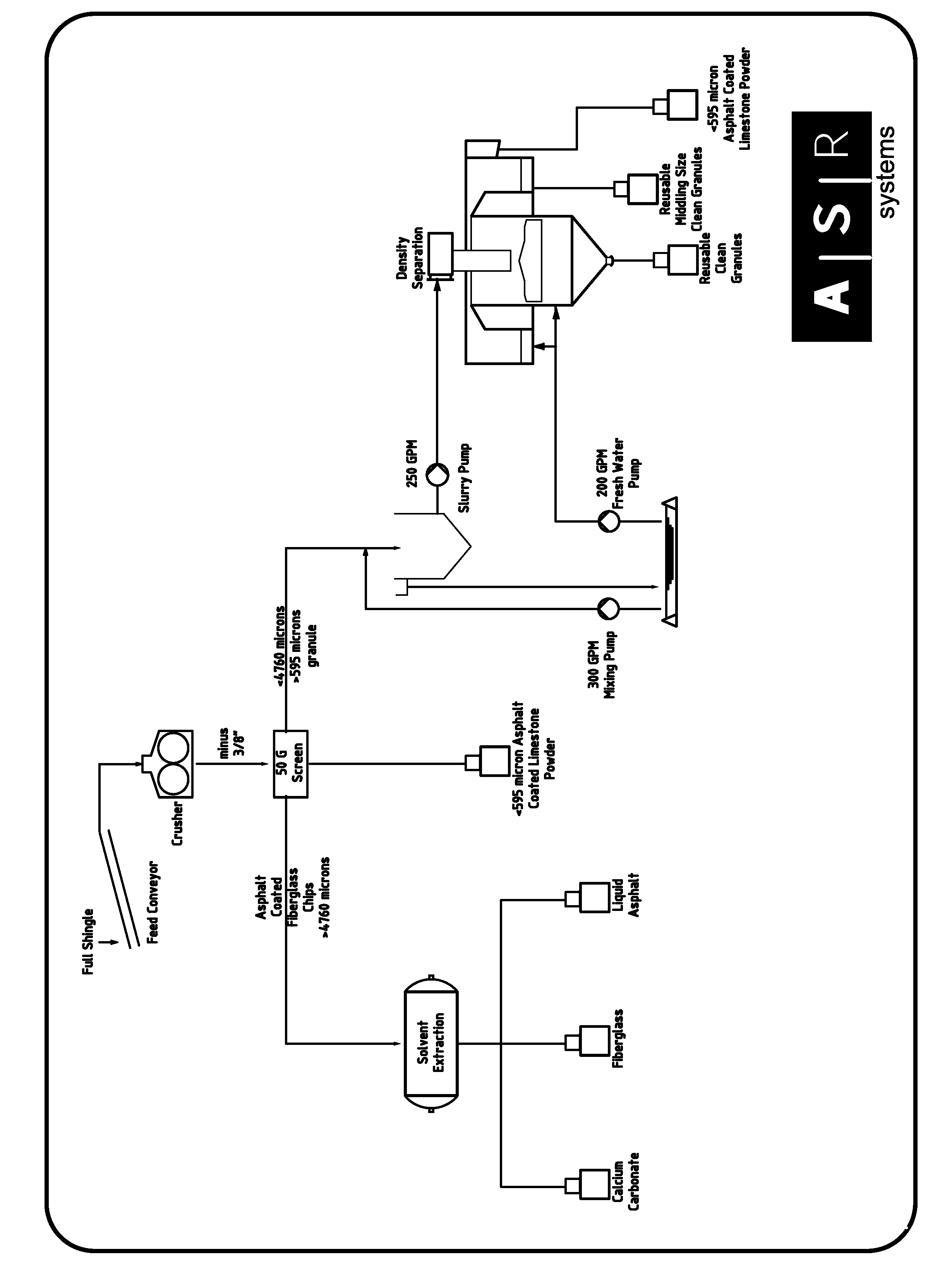

Method for progressive separation and extraction of raw materials from residential roofing products

This invention relates to a progressive method of separating and extracting raw materials from residential roofing products for re-use as ingredients for asphalt and fiberglass related products, including roofing materials. The method includes reduction, separation and then extraction of raw materials. The resulting products are alternative roofing granules, asphalt coated limestone, limestone, recycled asphalt and recycled fiberglass strand powders.

Owner:ASR HLDG

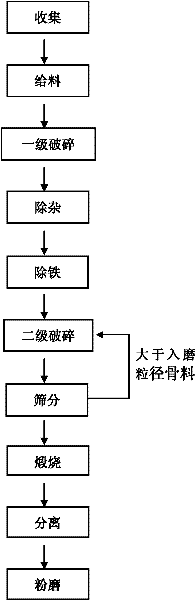

Method for recycling waste clay

InactiveCN102218435AGive full play to the role of materialImprove grindabilityConstruction waste recoverySolid waste disposalLitterIron removal

The invention provides a method for recycling waste clay, which comprises the following steps of: removing impurities from construction waste materials through treatment processes such as crushing, impurity removal, iron removal, sieving and the like, and preparing the materials into a recycled aggregate meeting the requirement of grinding equipment on particle size; burning up combustibles in the recycled aggregate through a calcining process to reduce ignition loss and water content; separating a concrete component from a clay brick component in the recycled aggregate; and grinding the clay brick component to obtain regenerated powder. By the method, waste clay brick resources can be fully utilized by a simple process; moreover, the regenerated clay powder obtained in the production has good performance, wide application range and high added value.

Owner:上海德滨环保科技有限公司

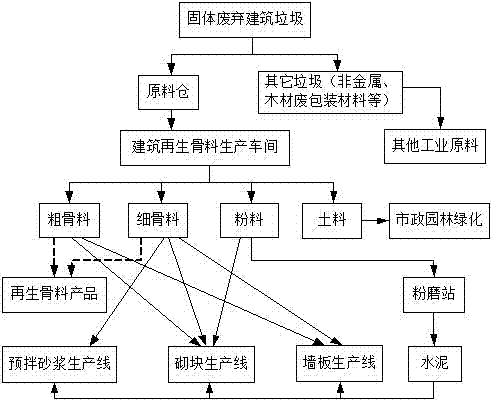

Construction waste recycling technology

InactiveCN104261715AImprove land occupationAvoid pollutionConstruction waste recoveryWaste processingMixed materialsRenewable resource

The invention discloses a construction waste recycling technology. The technology comprises an aggregate production technology, a premixed mortar production technology, a building block production technology, and a wallboard production technology. The construction wastes are graded, grinded, and sieved to produce aggregate that can replace the natural sand and stones. Part of the aggregate can be used to produce premixed mortar, cement mixed material, and concrete products. The residual aggregate is packed as commercial aggregate for sale, and can be used in concrete mixing plants, premixed mortar plants, and road structural foundation backfilling. The produced powder can be used to product concrete products, and the produced soil can be directly used as greening soil. The construction wastes are graded, removed, or grinded, and then subjected to a series of technological procedures, so that the wastes are converted into renewable resources and reutilized, and the economic profit is prominent. The sprayed dusts and sands which cause severe environmental pollution during the transportation and storage process are avoided. Solved is the problem that plants cannot grow on the soil that is used to bury construction wastes.

Owner:GUANGDONG XINGU TECH

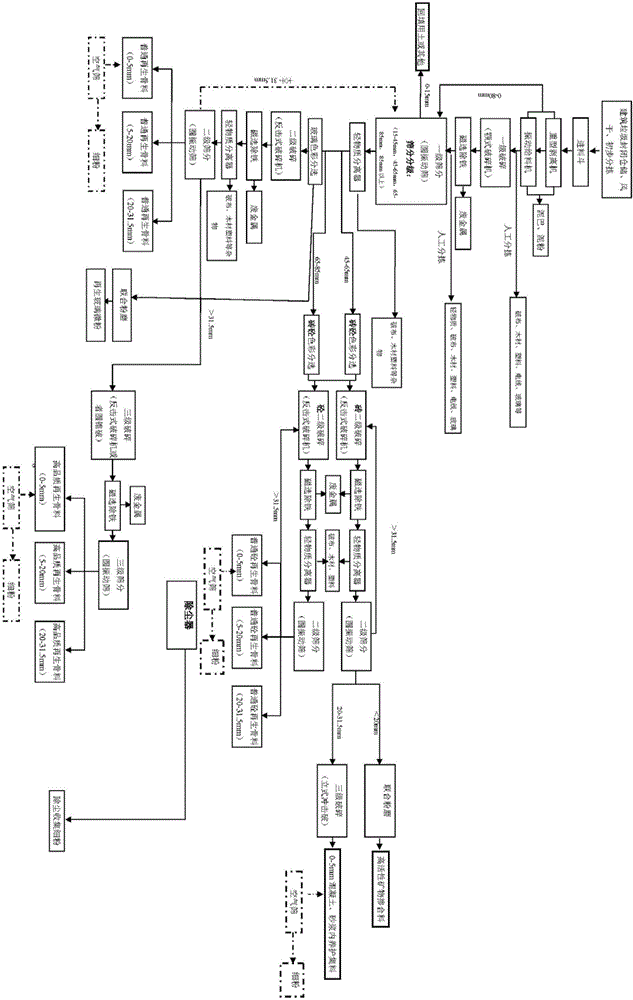

Fine treatment process for building solid waste

ActiveCN106830728ARealize refined classificationRealize resource utilizationConstruction waste recoverySolid waste disposalThree stageResource utilization

The invention discloses a fine treatment process for building solid waste, mainly comprising the following steps: pretreatment in a storage yard of building solid waste, including airing and manual sorting; stripping of mud powder and mud blocks, three-stage crushing, three-stage screening, manual sorting, air separation, magnetic separation, color separation, screening of different-hardness solid waste by different sorting techniques and combined grinding and dry type sand washing techniques, thereby preparing 2 kinds of novel green mineral aggregate, namely common recycled aggregate with particle sizes of 0-5mm, 5-20mm and 20-31.5mm, and high-strength high-quality recycled aggregate with particle sizes of 0-5mm, 5-20mm and 20-31.5mm, 5 types of high-quality, high-added value recycled products such as mortar and concrete curing aggregate, inertia micropowder and other sorted products. The fine treatment process for building solid waste realizes fine, high-added value treatment of building solid waste, achieves 100% resource utilization, and makes a great breakthrough in fine treatment in the resource utilization industry of building solid waste.

Owner:中建西部建设西南有限公司 +1

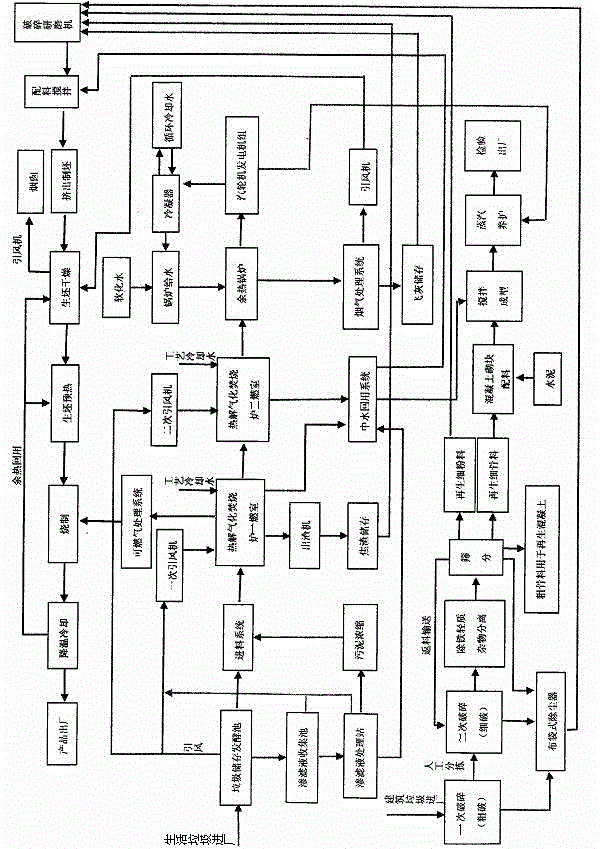

Resourceful cyclic utilization technology for household and building rubbish

InactiveCN105983567AAvoid secondary pollutionSolving RecyclingConstruction waste recoverySolid waste disposalTunnel kilnBrick

The invention discloses a resourceful cyclic utilization technology for household and building rubbish. The technology comprises the steps that firstly, the rubbish is fermented, percolate treatment is conducted, the rubbish is conveyed into a pyrolysis gasifier, and methane is used for supporting combustion; secondly, the rubbish is combusted, and coke residues are stored and left for use; thirdly, high-temperature smoke is subjected to heat absorbing and recycled to be guided into a tunnel kiln for air drying of sintered green bricks; fourthly, the coke residues and fly ash are conveyed to the tunnel kiln for brick sintering; fifthly, recycled water and process cooling water are used for green brick manufacturing and stirring, and high-temperature steam is used for power generation; sixthly, the building rubbish is roughly broken, impurity removing is conducted, secondary fine breaking is conducted, impurity removing is conducted, and recycled aggregate is screened and used; seventhly, the recycled aggregate with the particle size being 3 mm-10 mm is used for manufacturing hollow blocks; and eighthly, recycled fine powder with the particle size being smaller than 3 mm is used for brick sintering. The resourceful cyclic utilization technology has the beneficial effects that the household rubbish, the building rubbish and the brick sintering technology are organically combined, waste water reaching the standard, the coke residues, the fly ash, the high-temperature smoke, steam and generated electricity are utilized in rubbish treatment and brick sintering, the rubbish is thoroughly utilized, secondary pollution is eliminated, the household rubbish and the building rubbish are cyclically utilized, and waste is turned into wealth.

Owner:于继林

Charcoal production from house refuse

InactiveCN1644492AReasonable designNo pollutionConstruction waste recoverySolid waste disposalLitterMetallic materials

Carbon production by domestic refuse is carried out by: 1.transporting the domestic refuse to pre- treating pool, conveying it by conveyer belt and first sizing, and reutilizing the sized metal materials, glass and building refuse; 2 roughly breaking the sized domestic refuse with 3-5cm grain, magnetic separating and removing fine iron; 3.drying, shining and extruding the magnetic separated refuse to make, the water content <3-20%, and fine breaking with 1-2cm grain; 4. press shaping the fine refuse; 5. transporting the compressed refuse to carbonized apparatus, high-temperature treating at 300-1200deg.C for 0.5-1.5hrs to obtain semi-coke.

Owner:彭立军 +1

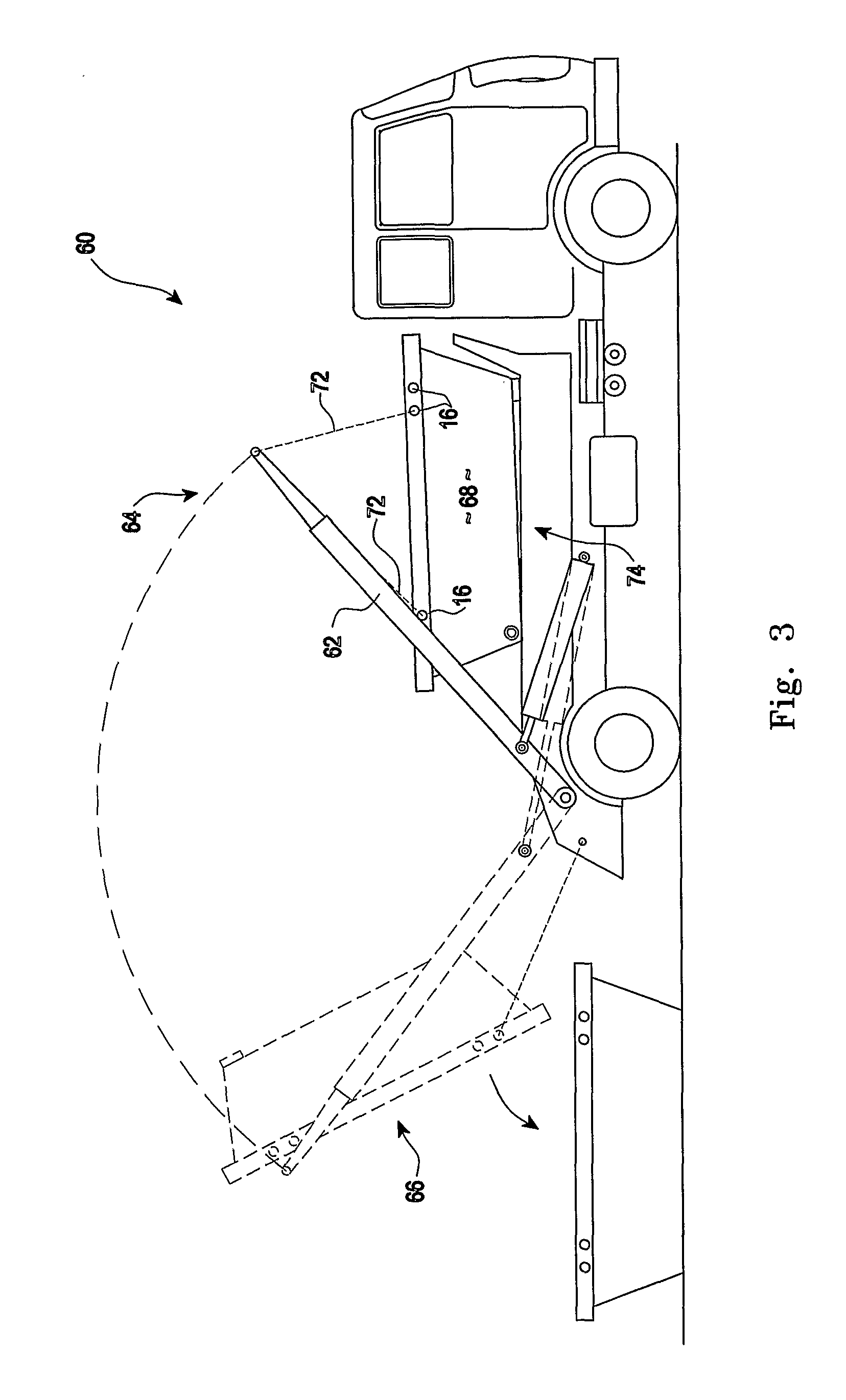

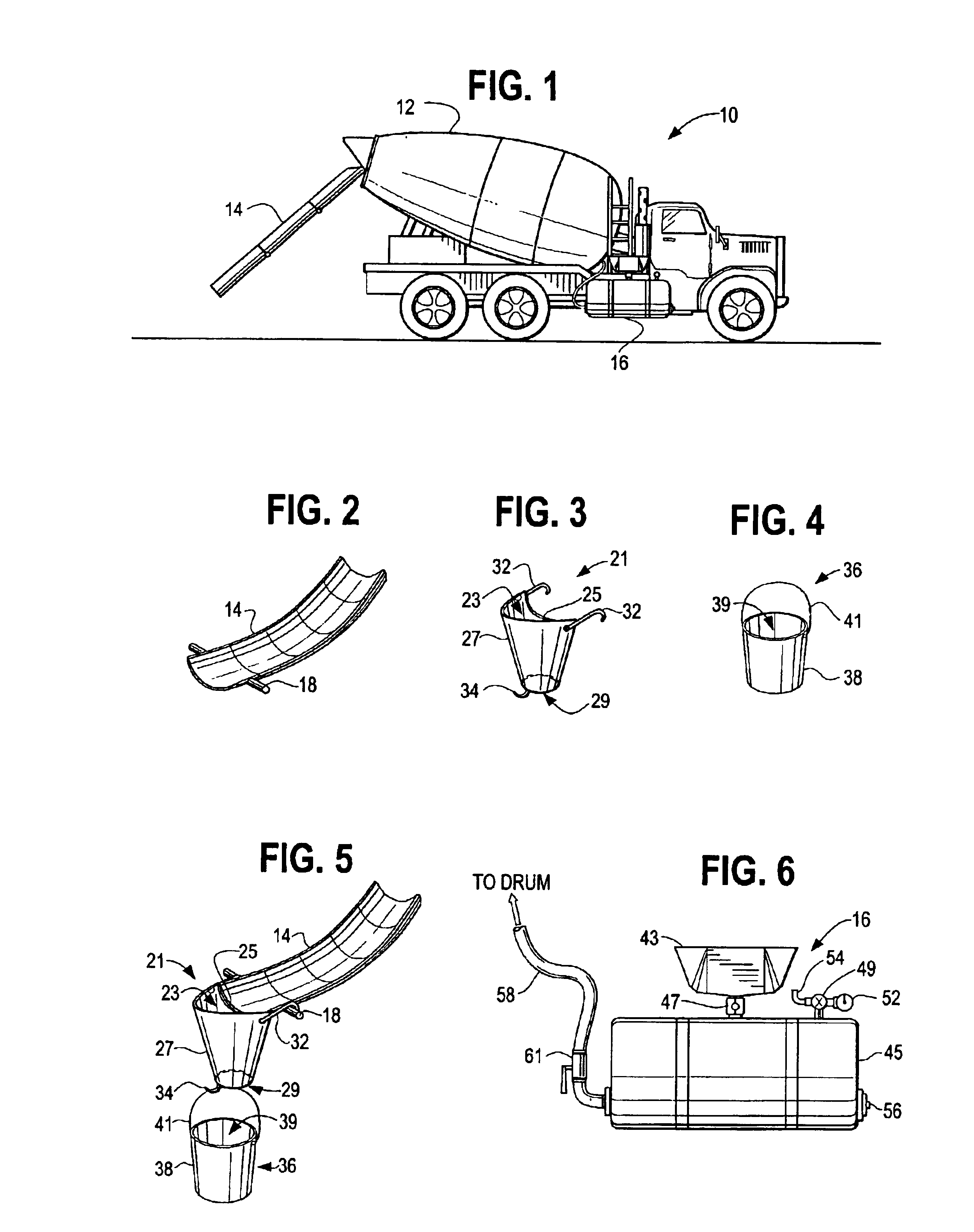

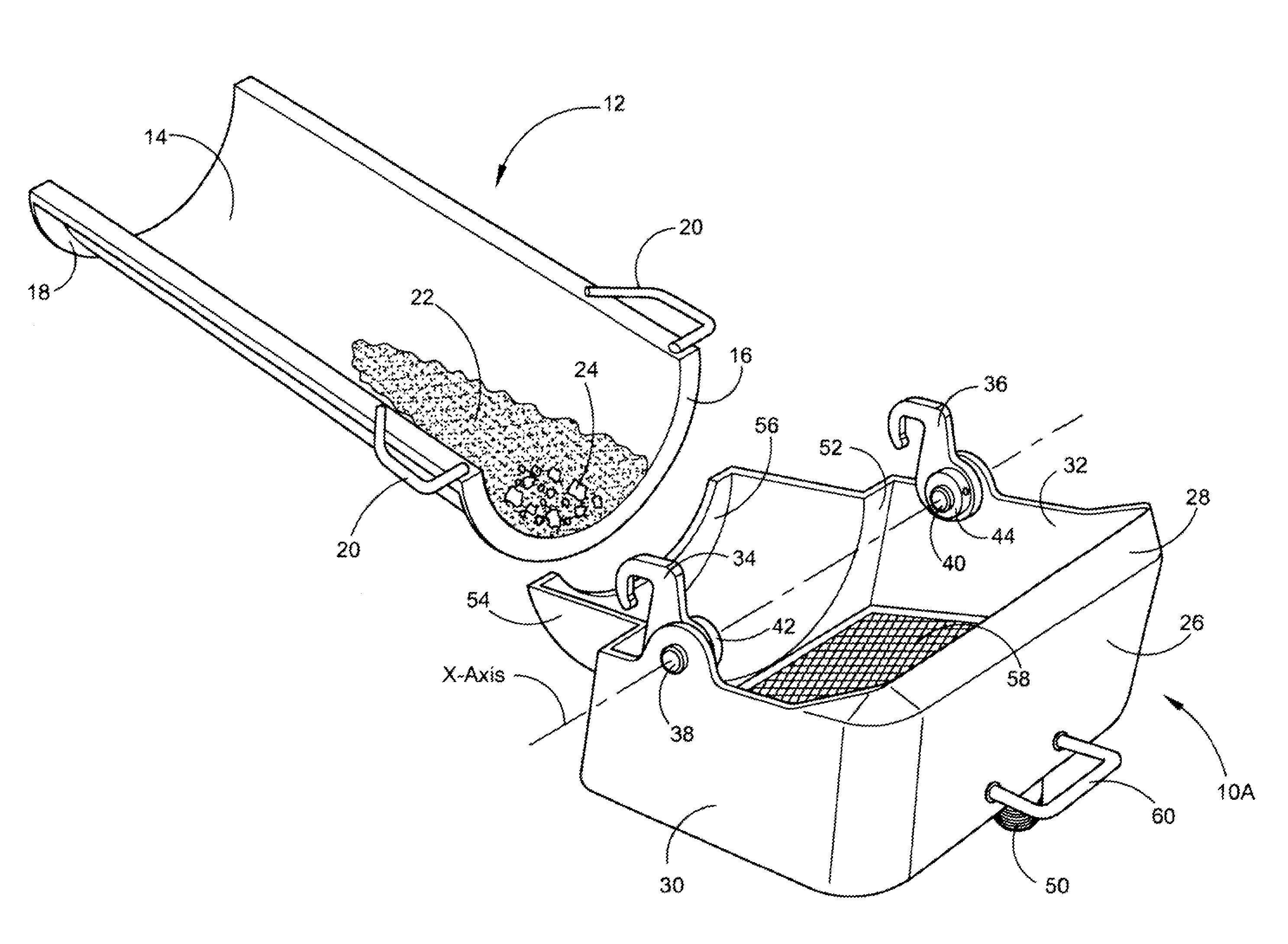

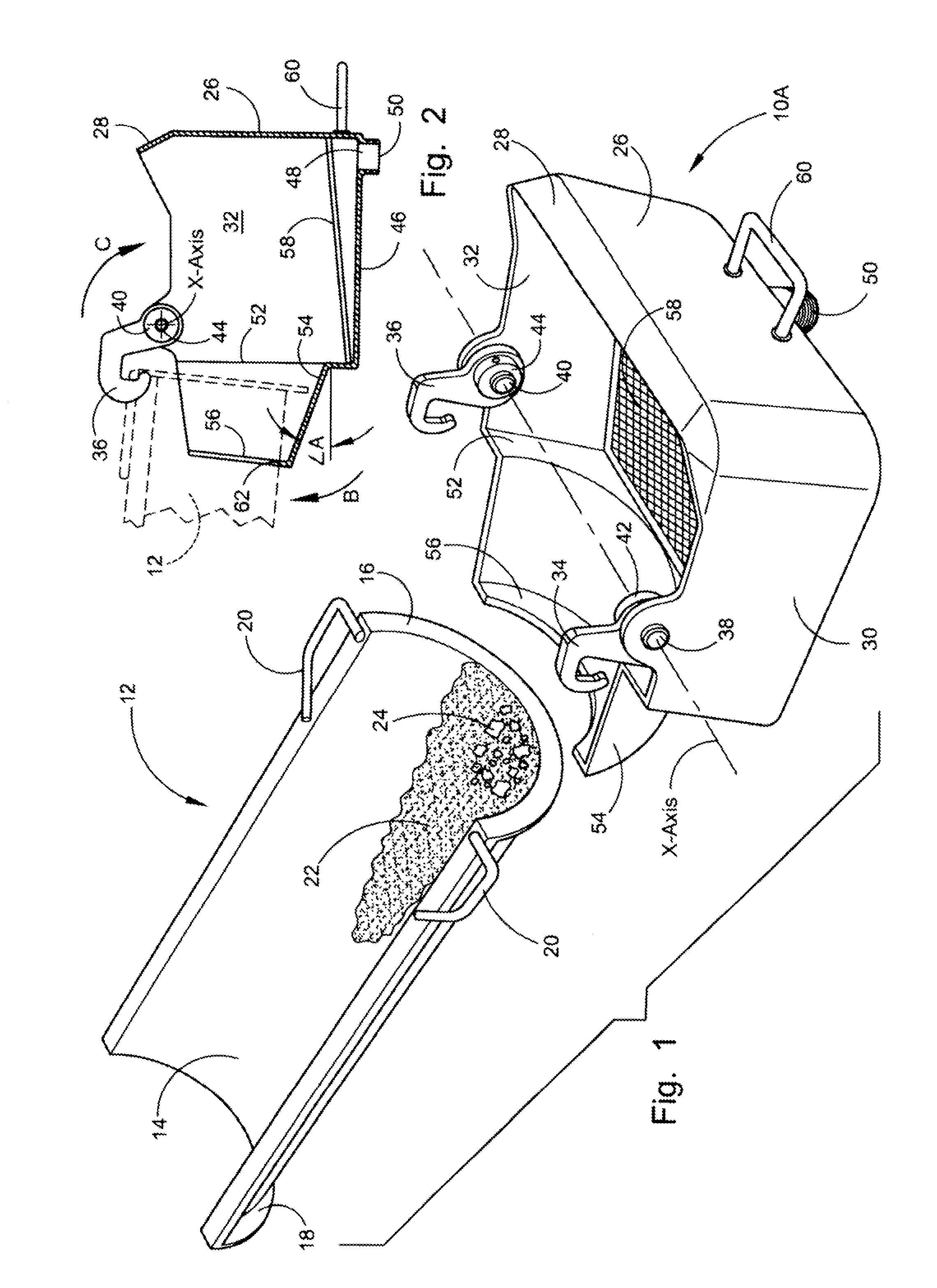

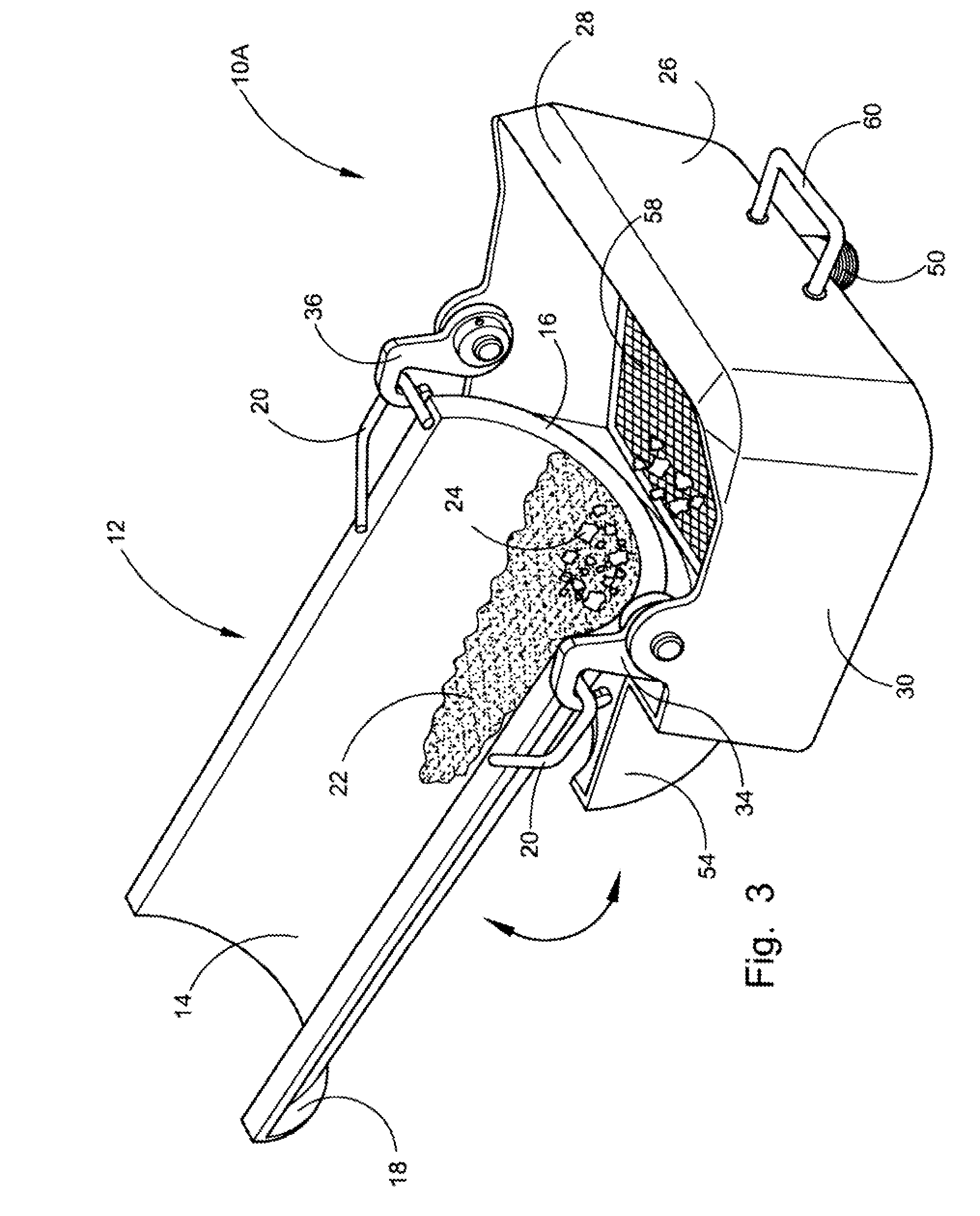

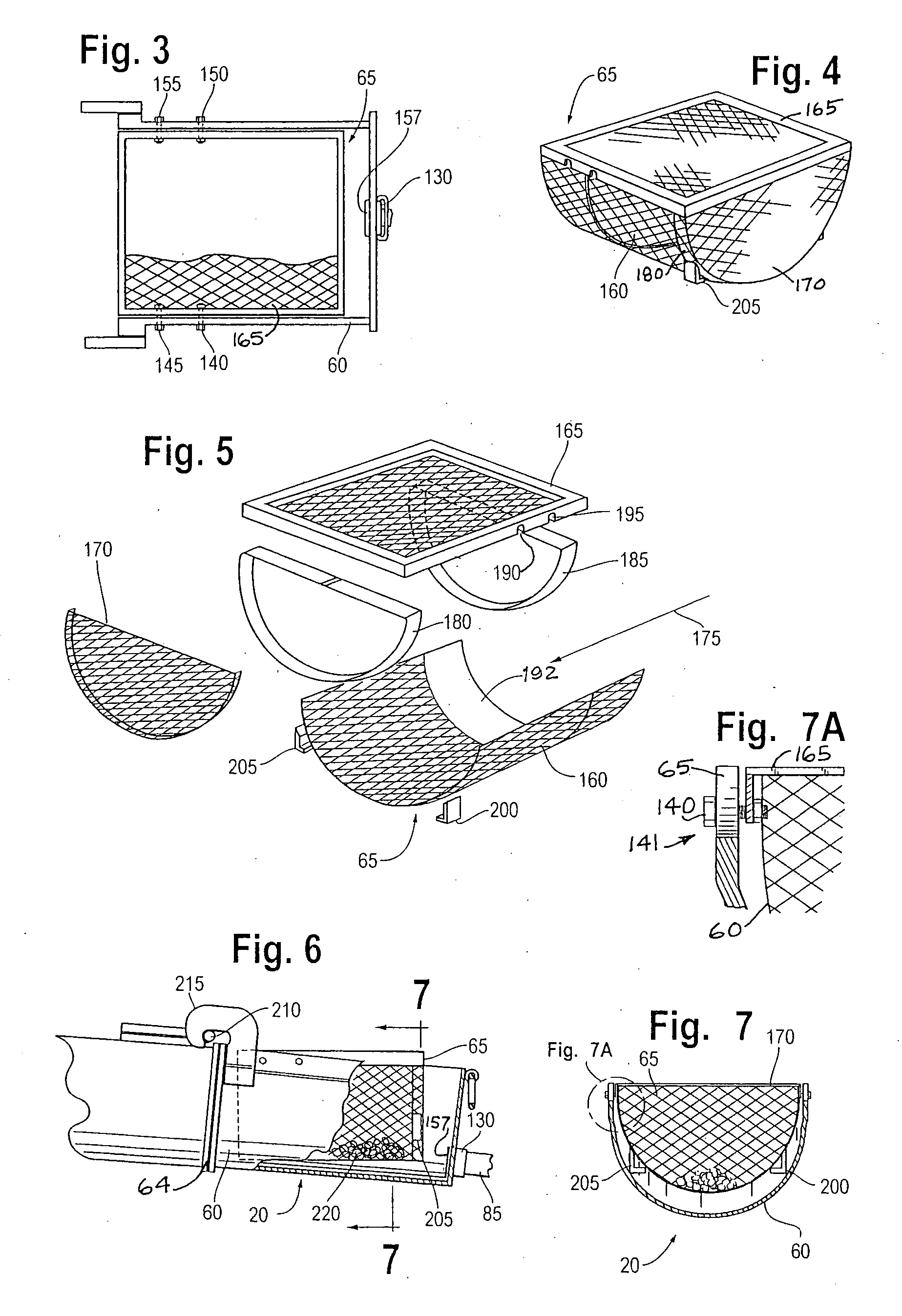

Cement slurry collection chute basin

The present application is directed at a cement slurry collection chute basin that incorporates a leak proof means, no matter what the size or condition of the end of the concrete flop chute. By using a forward angled entry trough with a square large basin area having the attachment hooks in a forward position, the weight is put in the rear and the forward edge of the device is held forward of the end flange and tight against the lower surface of the concrete chute. A screen separates the aggregate from the cement slurry, which flows out a drain orifice in the bottom. An alternate embodiment is constructed from “half-pipe” housing. This alternate embodiment cement slurry collection chute basin will be much more efficient and economical to manufacture because of the “half-pipe” construction and the ease with which it could he welded and fabricated into form.

Owner:MANNO JOSEPH J

Construction waste sorting device

ActiveCN110433959AFast and accurate sortingReduce flyingConstruction waste recoveryUsing liquid separation agentMaterial SeparationSubgrade

The invention discloses a construction waste sorting device, which comprises a sorter body, wherein a lifting device is arranged to the left side of the sorter body; a first sorting chamber is arranged on the upper side in the sorter body; a second sorting chamber having an opening downward is disposed on the lower side; a partitioning plate is fixedly disposed between the first sorting chamber and the second sorting chamber; the right side of the partitioning plate is provided with a drop port running through the upper and lower sides; a first sorting device is disposed in the first sorting chamber; a second sorting device is disposed in the second sorting chamber. The construction waste sorting device can be used for sorting construction wastes quickly and accurately, automatically liftsthe dumped garbage into a sorting component, separates and piles recyclables materials in the dumped garbage, crushes gravel and the like for paving roadbeds, reduces the blowing of the generated dust by spraying water to the utmost extent to ensure the air quality in the area nearby.

Owner:谢秀英

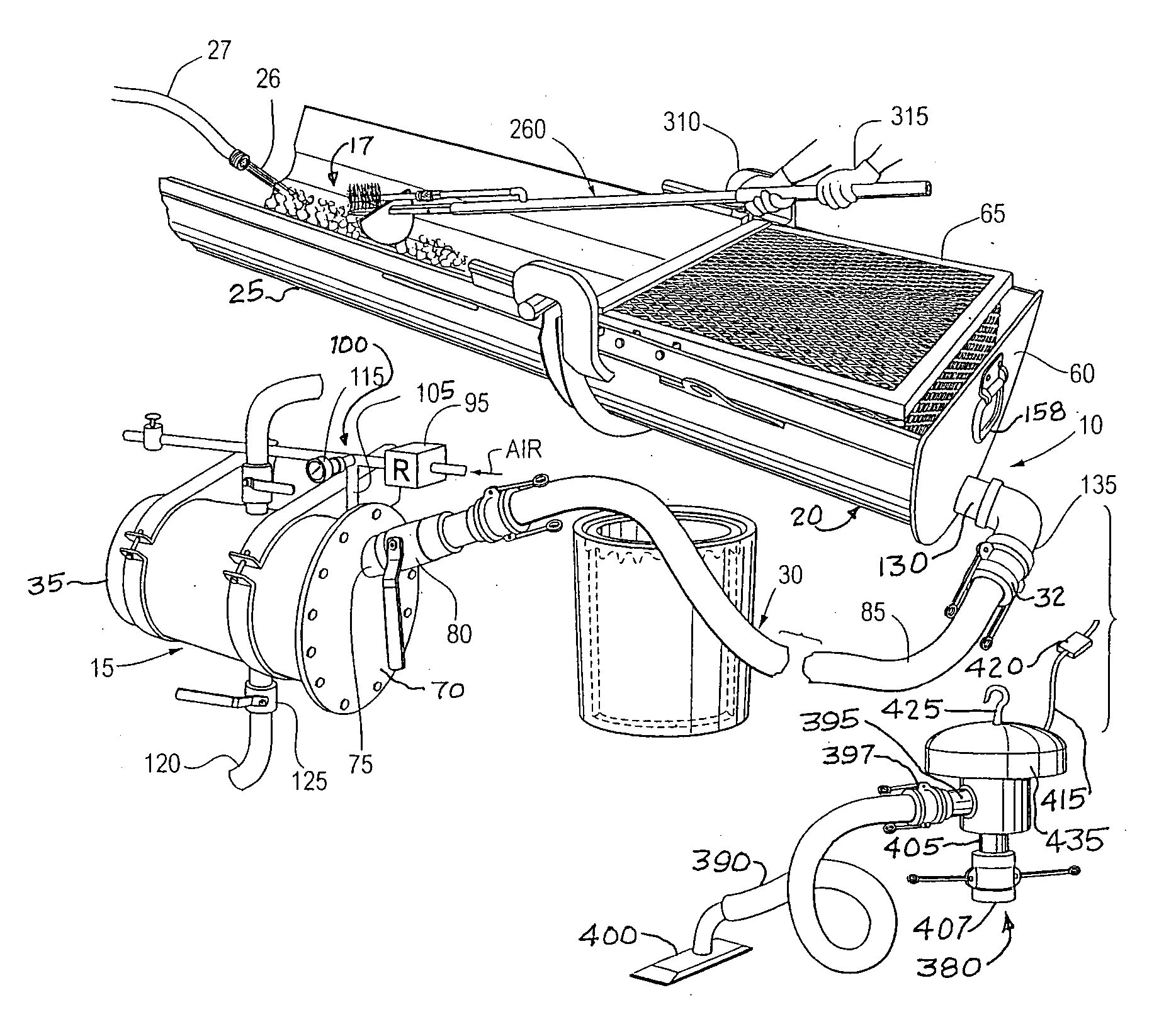

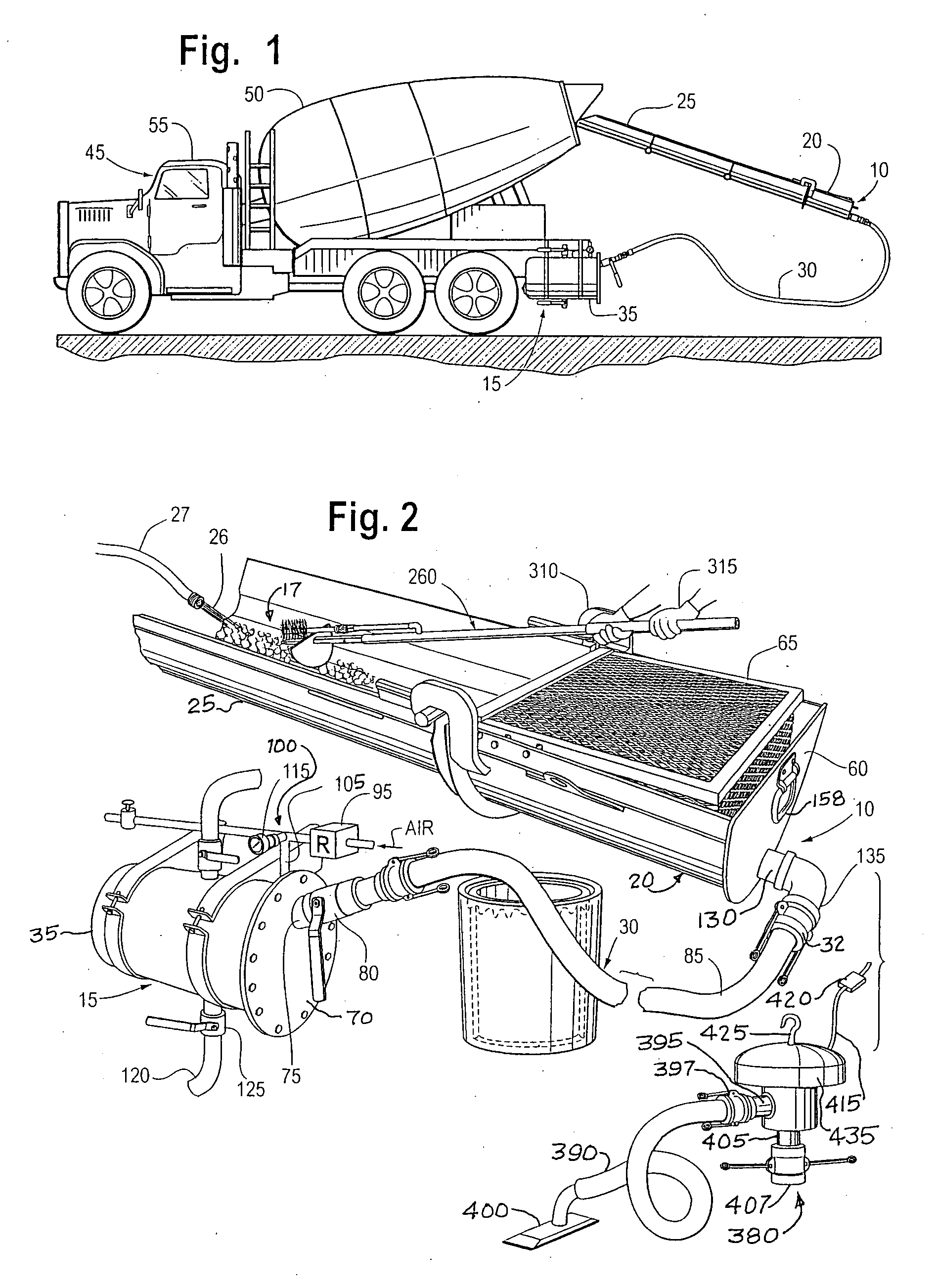

Concrete wash out and slurry capture method and system

A slurry capture system and kit, and methods of using them, are disclosed for facilitating the recovery of a concrete residue, such as from a chute of a cement mixer truck. The system includes a collector for attaching to the chute of the cement mixer truck and for collecting the concrete residue therefrom. The system further includes a container for storing the collected residue and a conduit in fluid communication between the collector and the container for transferring the residue collected in the collector to the container for subsequent disposal.

Owner:FE HLDG LLC

Method for on-site treatment and resource utilization of architectural ornament rubbish

InactiveCN106694526AConvenient operation and managementStrong adaptability to engineering applicationsConstruction waste recoverySolid waste disposalSites treatmentShortest distance

The invention discloses a method for on-site treatment and resource utilization of architectural ornament rubbish. The method comprises the following steps that front end pre-treatment module treatment is conducted, specifically, a torn-down and built site is subjected to leveling and planning firstly, then the architectural ornament rubbish which is distributed in a scattered mode is transshipped to a centralized stacking area of materials at a short distance through a professional vehicle, and part of the light materials which are sorted is subjected to classified stacking through a pre-treatment facility; middle end movable crushing treatment module treatment is conducted, specifically, raw materials which are sorted through manual work are sent to a combined movable crusher to be subjected to processing treatment through an excavator or a loader, and produced aggregates with different specifications are stacked to a finished material stacking area; and rear end resource utilization module treatment is conducted, specifically, the light materials sorted by the front end and the aggregates crushed by the middle end are directly used or treated or subjected to regeneration treatment on site, so that the requirement of resource utilization is met. According to the method for on-site treatment and resource utilization of the architectural ornament rubbish, reasonable and effective resource utilization of the architectural ornament rubbish can be achieved, and the environmental pollution problem caused by random storing of the architectural ornament rubbish is avoided.

Owner:SHANGHAI PUDONG ROAD & BRIDGE GRP CO LTD +1

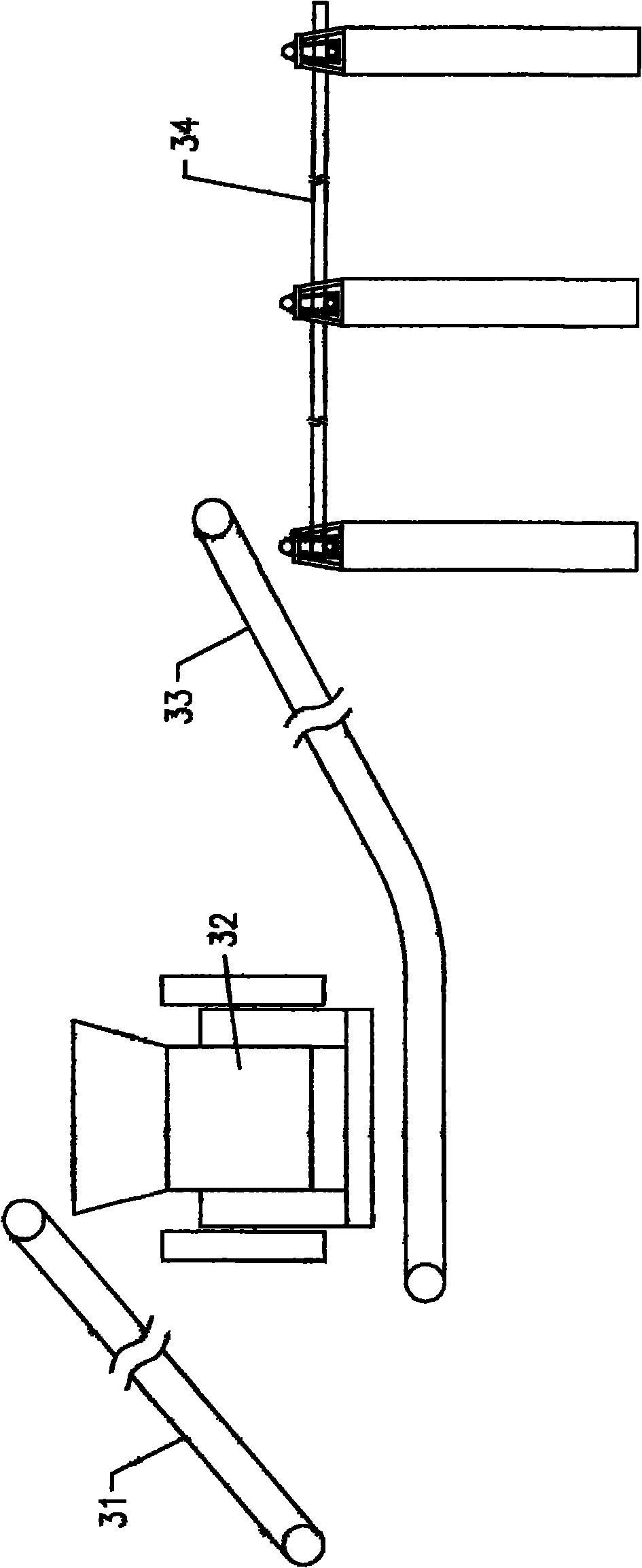

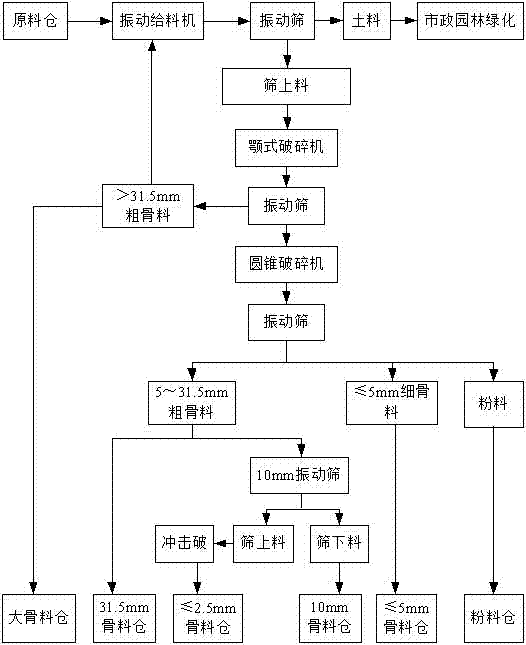

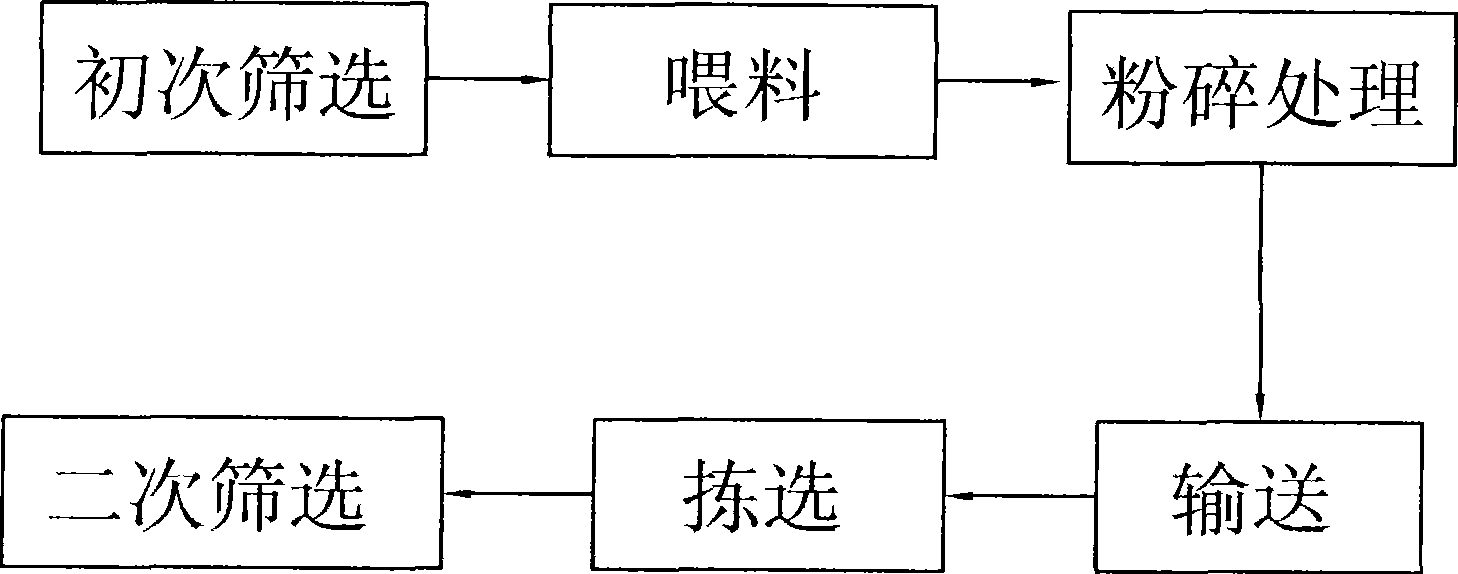

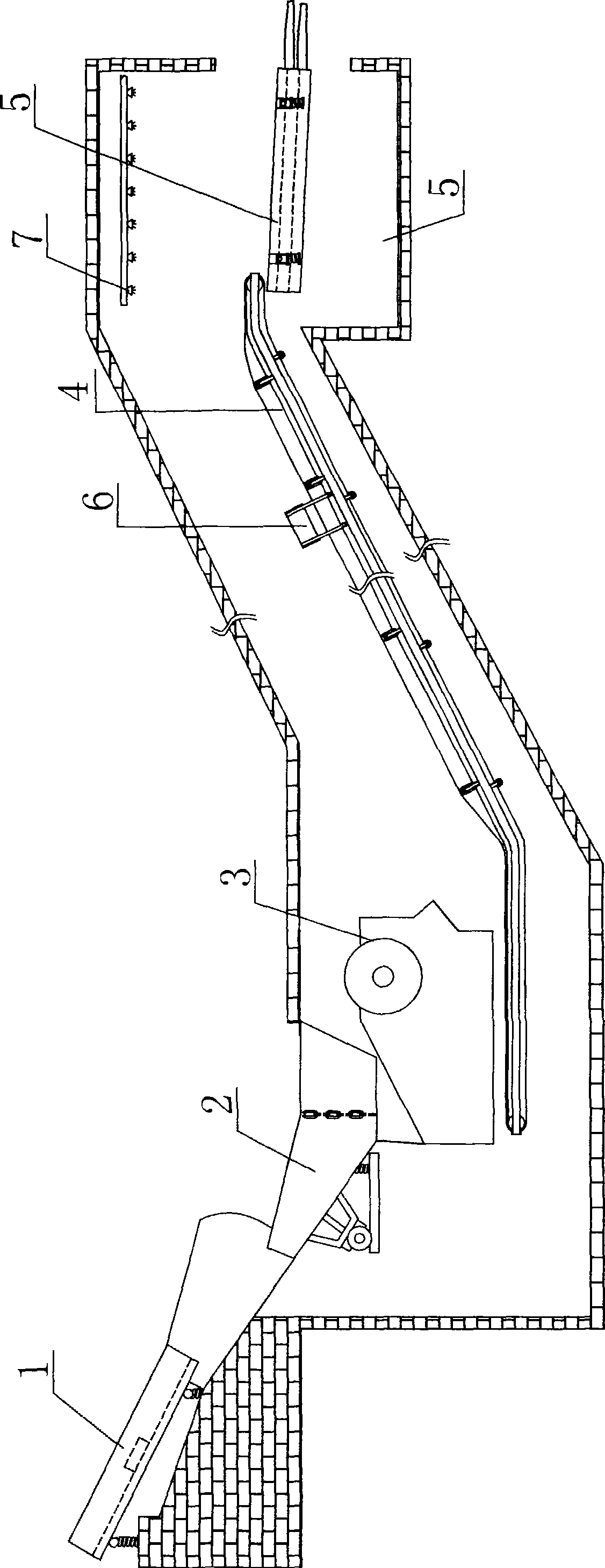

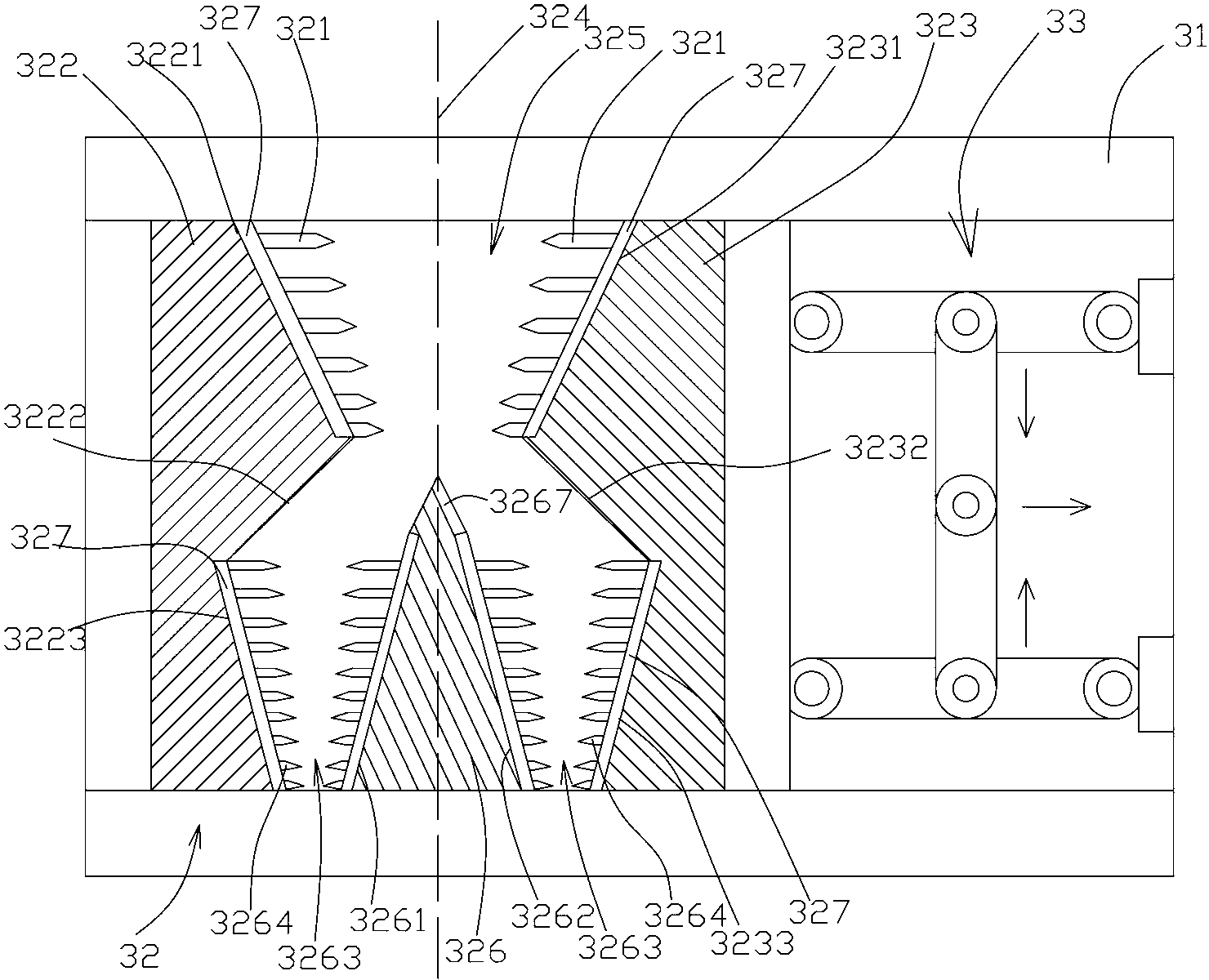

Method for producing renewable aggregate by using construction waste

InactiveCN101544483AReduce flyingReduce pollutionConstruction waste recoveryWaste processingPollutionConstruction aggregate

The invention discloses a method for using construction waste to produce renewable aggregate. Through the steps of primary selection, material feeding, crushing, conveying, selection, secondary selection, and the like, the construction waste is crushed into a construction aggregate mixture from which the renewable aggregate with a regulated particle size is selected, so that the discarded construction waste can be recycled. Except a small amount of earth, all construction waste can be fully used, so that the secondary pollution is prevented, the environment is protected and the land is conserved. The method realizes actual comprehensive utilization rate of the construction waste close to 100 percent and achieves the utilization of the city construction waste as a resource.

Owner:潍坊三建滨海建筑材料有限公司

Solid construction waste processing and treating system

InactiveCN102989747ASimple structureLow costConstruction waste recoverySolid waste disposalPrillBrick

The invention discloses a solid construction waste processing and treating system which comprises a compound crusher, a double-cone crusher, a high-frequency vibrating screen, a water separator and a stone surface treatment machine, wherein solid construction waste with the rated size is crushed into the size less than that of preset particles by the compound crusher and enters the double-cone crusher to be further crushed into particles with the size less than that of another preset particles; the crushed particles are fed into the high-frequency vibrating screen and are separated to be in grades which are smaller than or equal to a large grade, a middle grade and a small grade, the particles of different grades are fed into the water separator to separate out stones, red bricks, pure concrete particles, as well as remove floating matters; and finally, the stones with different particle sizes are fed into the stone surface treatment machine, and the concrete layers on the surfaces of the stones are removed. The system is simple in structure, the stones and other building materials which accord with the building standard can be treated, waste materials can be changed into valuable materials, and the system is environment-friendly.

Owner:何德裕

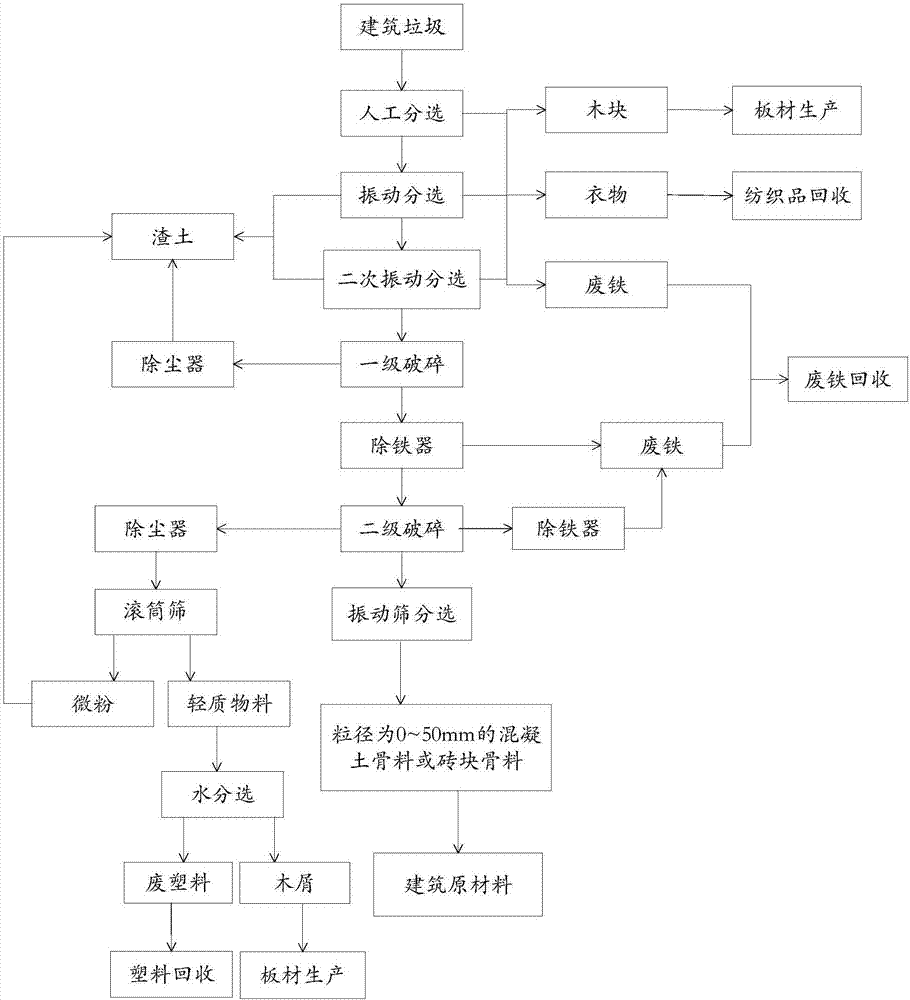

Method for recycling construction wastes

InactiveCN107377584AIncrease profitQuality improvementConstruction waste recoverySolid waste disposalEnvironmental resistancePrill

The invention discloses a method for recycling construction wastes. The method comprises the following steps: artificial sorting, vibratory sorting, primary crushing, iron removing, secondary crushing and sorting through a vibrating screen. According to the method for recycling the construction wastes, steps are reasonable and orderly, selected equipment is advanced, and the running cost is low. By the method, the sorting efficiency is high, a large quantity of recycled aggregates which are good in quality and are fine-grained can be produced, and the recycled aggregates which are produced by the method do not contain other impurities, and belong to high-quality recycled materials. Meanwhile, residue soil, scrap iron, clothes, wood blocks, plastics, micro-powder and the like in the construction wastes can further be recycled and are fully utilized, the construction wastes are sorted thoroughly, the utilization rate of raw materials is high, and therefore, the method has high benefit of environmental protection and marketization popularization prospect.

Owner:赵长强

Fine crushing device for construction waste

InactiveCN110340111AAvoid cloggingImprove screening efficiencyConstruction waste recoverySolid waste disposalArchitectural engineeringSieve

The invention discloses a fine crushing device for construction waste. The fine crushing device for construction waste comprises a box body. A grinding drum is arranged in the box body, uniformly formed sieve pores are formed in a cone-shaped surface of the grinding drum, and a grinding head is embedded into the grinding drum. By arranging a grinding head capable of rotating up and down and the grinding drum provided with the sieve pores, preliminarily crushed construction waste is ground rotatably and screened. By arranging a grinding plate at the bottom of the grinding head, the constructionwaste accumulated at the bottom of the grinding drum is ground and crushed and pulled and screened outward. By arranging a supporting shaft, the grinding drum rotates to screen the construction waste, so that the screening efficiency is improved and the sieve pores are prevented from being blocked.

Owner:李星来

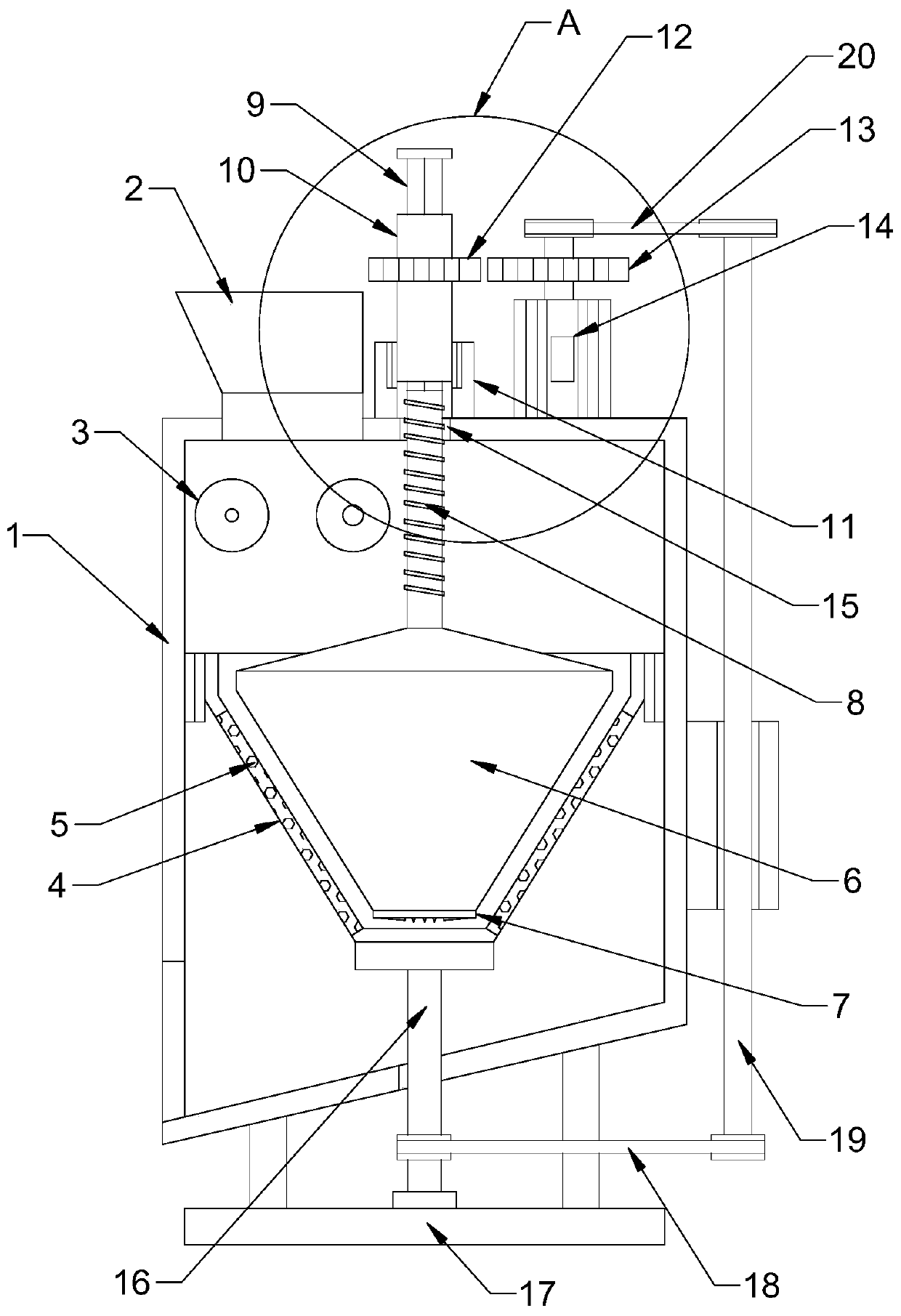

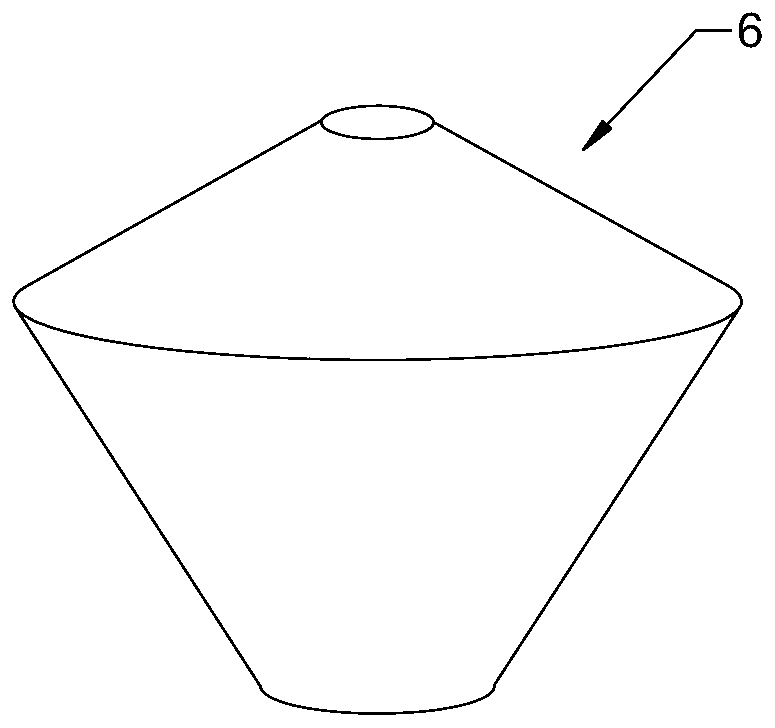

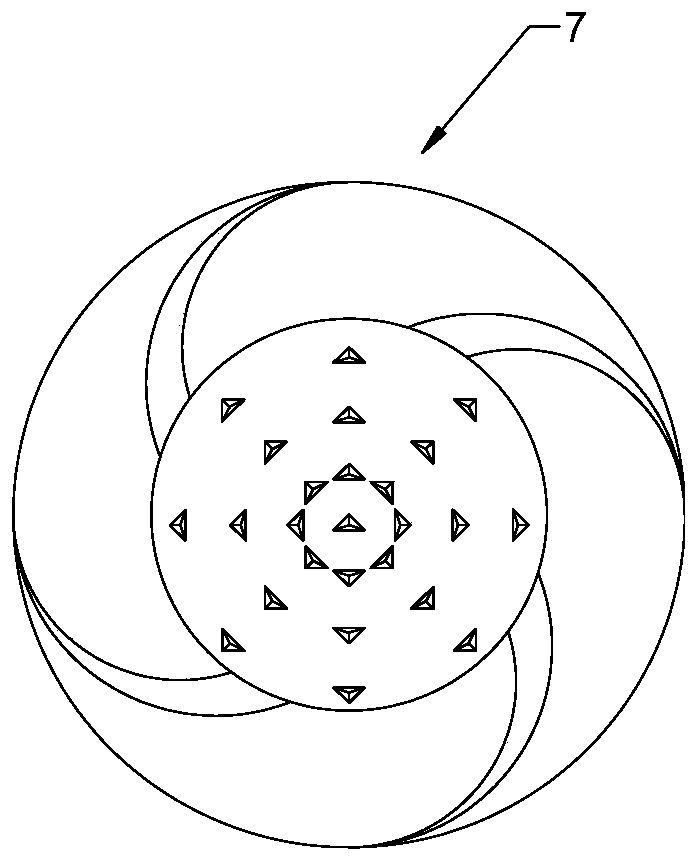

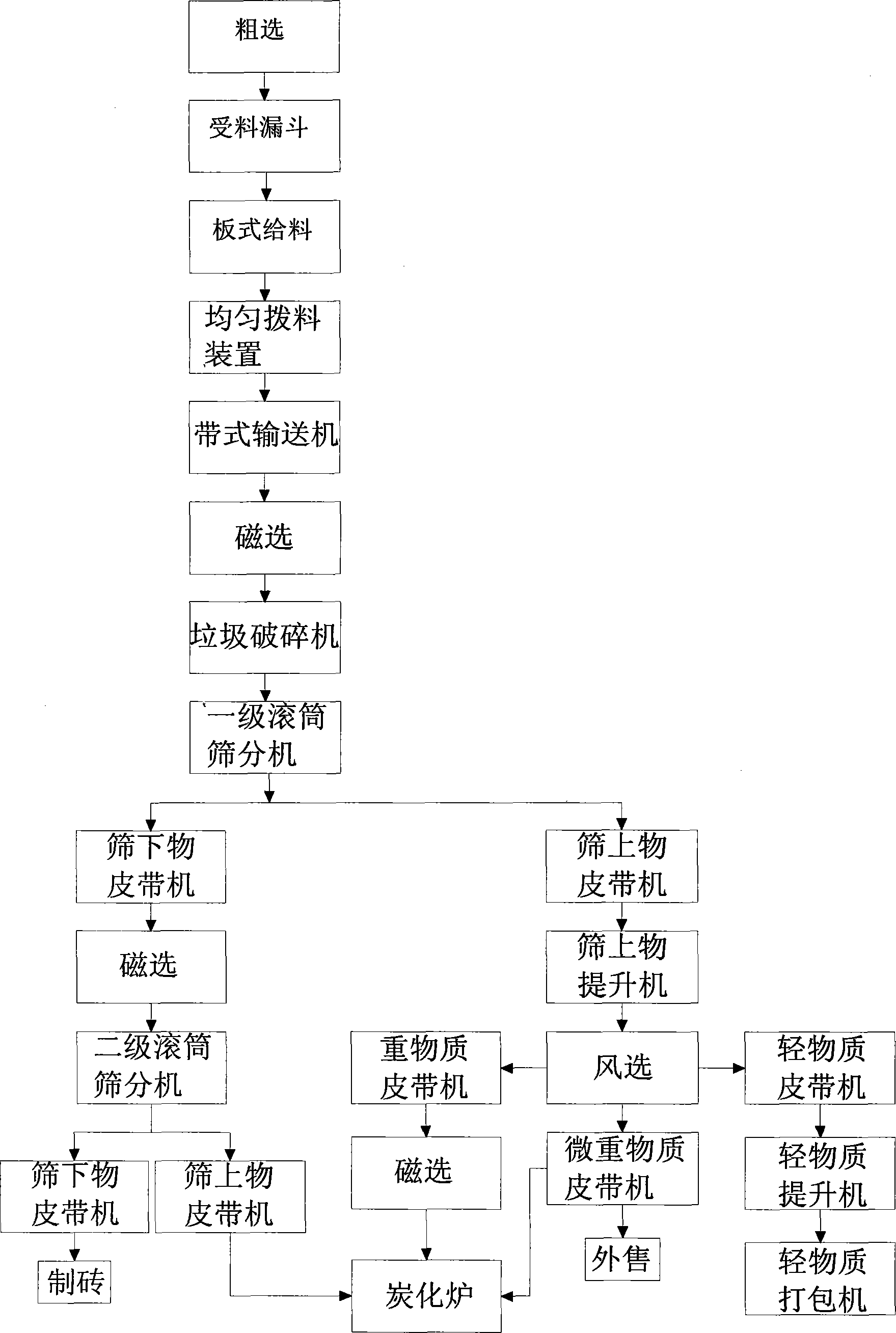

Integrated household garbage treatment method

ActiveCN103909085AImprove efficiencyRealize the effect of turning waste into treasureConstruction waste recoverySolid waste disposalMagnetic separatorCarbonization

The invention relates to an integrated household garbage treatment method. According to the integrated household garbage treatment method, household garbage is subjected to rapid innocent treatment by virtue of procedures of rough selection, loading, magnetic separation, crushing screening, winnowing, secondary magnetic separation and anaerobic carbonization; a first-stage drum sieving machine, a second-stage drum sieving machine, a strong-magnetism iron separator and an anaerobic carbonization furnace are utilized for carrying out mechanization treatment on the household garbage, and the household garbage is sequentially subjected to crushing screening and magnetic separation, so that the utilization efficiency of the strong-magnetism iron separator is greatly increased, and the innocent treatment of the household garbage is realized by virtue of the anaerobic carbonization furnace; meanwhile, the household garbage can be made into coal and building materials and can be converted into heat energy by virtue of the method, so that an effect of recycling of the garbage is realized.

Owner:DEZHOU QUNFENG MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com