Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

278results about How to "Improve grindability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyester Resin for Toner, Toner Composition and Resin Particle

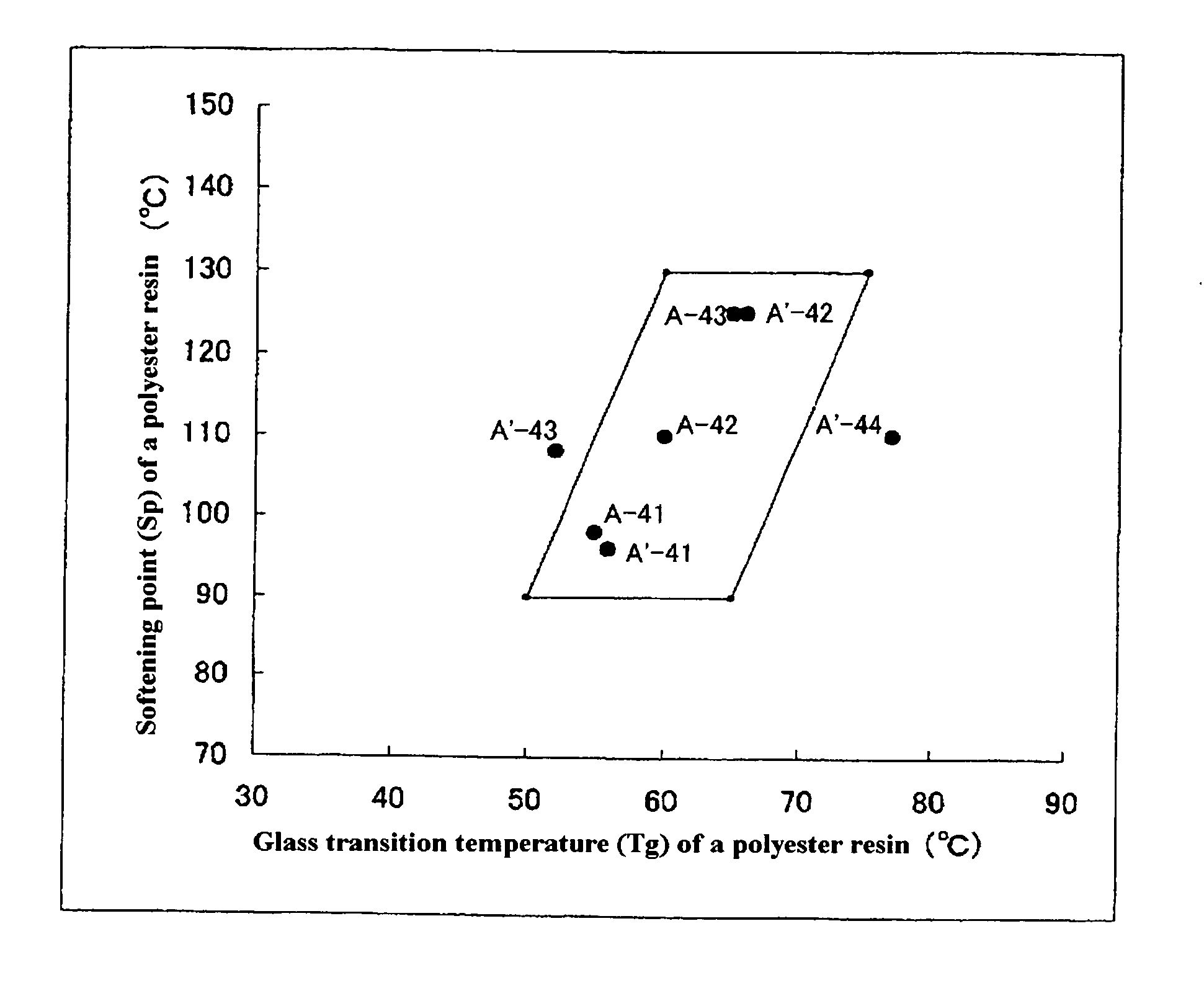

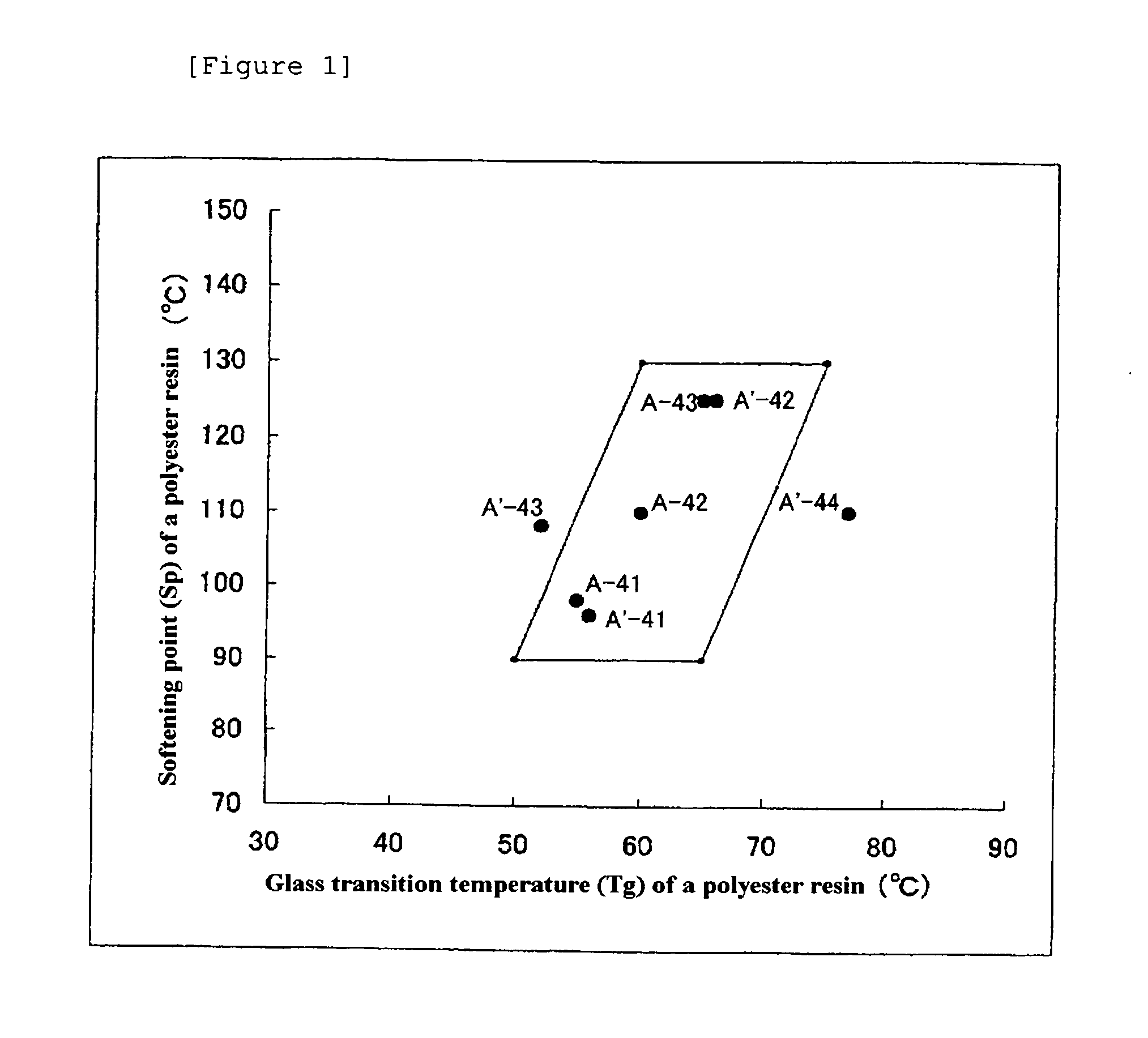

ActiveUS20070281235A1Excellent low-temperatureExcellent grindabilityMixingDevelopersChemistryPolyester

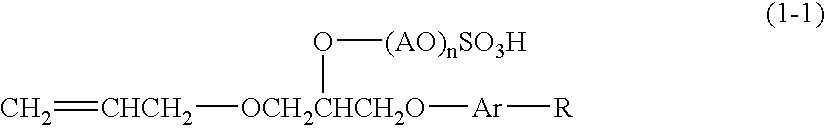

[PROBLEMS] Disclosed is a heat-fusible electrostatic image developing toner which has an excellent balance between fixability at low temperatures and grindability and is excellent in glossiness after fixing. Also disclosed is a resin for toners. [MEANS FOR SOLVING PROBLEMS] A polyester resin for toners which is obtained by polycondensing a polyol component and a polycarboxylic acid component is characterized by containing 20-100 weight % of one or more polyester resins (A1) having a storage elastic modulus from 2.5×103 Pa to 5×106 Pa at 150° C. wherein the molar average cohesive energy of the polyol component is between 7.0×104 and 1.4×105 J.

Owner:SANYO CHEM IND LTD

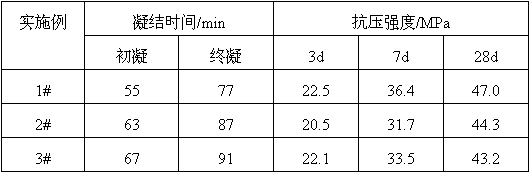

Method for producing sulphate aluminum cement

The invention relates to a method for producing sulphate aluminum cement. The method comprises the following steps: preparing cement raw meal by proportioning limestone, phosphogypsum, low grade alumina and coke; uniformly grinding and calcining at high temperature; in the calcining process, promoting phosphogypsum to be decomposed as much as possible; replacing partial limestone by calcium oxide generated by decomposition; collecting sulfur dioxide to prepare sulfuric acid; and adding natural dihydrate gypsum in the cement clinker and grinding to prepare a cement product. Compared with the existing conventional production methods, according to the method, the utilization of phosphogypsum can be greatly improved, the utilization concentration of sulfur dioxide discharged by decomposition of little gypsum in the production process can be guaranteed to be reached, the use level of limestone is further reduced and emission of carbon dioxide is reduced. Cement calcined is wide in adaptability, can be widely applied to production of sulphate aluminum cement by phosphogypsum, and further can be suitable for producing high early strength cement, expansive cement and the like.

Owner:CHONGQING UNIV

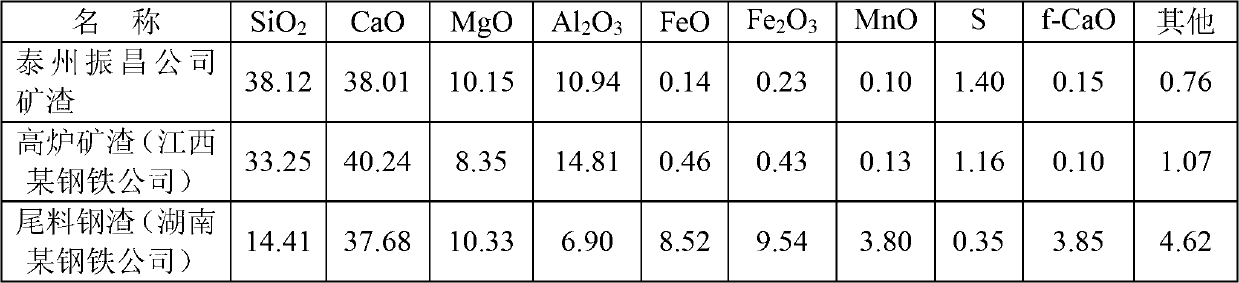

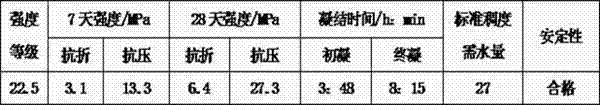

Aerated concrete block produced through using specially-made mineral waste residue and tailings steel slag and production method of aerated concrete block

The invention provides an aerated concrete block produced through using specially-made mineral waste residue and tailings steel slag and a production method of the aerated concrete block. The aerated concrete block is produced through the following steps: adding an additive A, an additive B and water in components as follows: 40 to 50% of specially-made mineral waste residue obtained in a such way that cinder is obtained through the production process of recycling steel slag discharged from Taizhou Zhenchang Industrial Waste Residue Comprehensive Utilization LTD and metallurgical and chemicalferrous waste residue, and then is water-quenched, 35 to 45% of tailings steel slag, 2 to 4% of cement clinker, 1 to 3% of gypsum, and 8 to 12% of modified wood, wherein the grain size of the specially-made mineral waste residue is less than or equal to 5 mm, the grain size of the tailings steel slag is less than or equal to 20 mm, the additive A accounts for 1% of the total weight of the components, the additive B accounts for 0.05% of the total weight of the components, and water accounts for 0.5 to 0.6 times of the total weight of the components; and conducting mixing, heating, air-entrapping, steaming and pressing, and curing in sequence. The aerated concrete block produced by adopting the production method is high in strength, and small in drying shrinkage value, and can meet the block standards of the A3.5 grade and the B09 grade in the JC1062-2007 foam concrete block standard.

Owner:TAIZHOU ZHENCHANG IND RESIDUE COMPREHENSIVE UTILIZATION +1

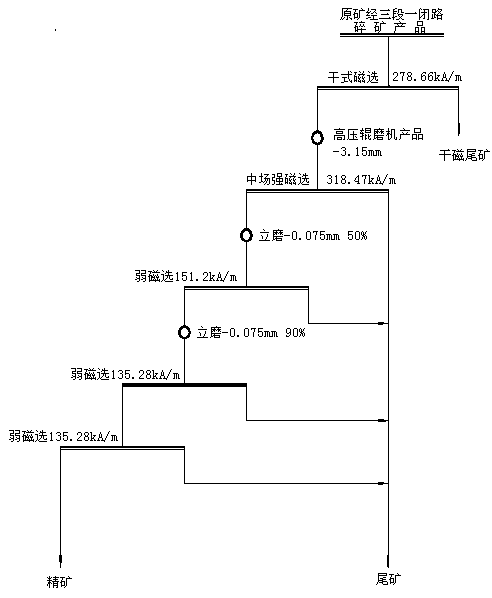

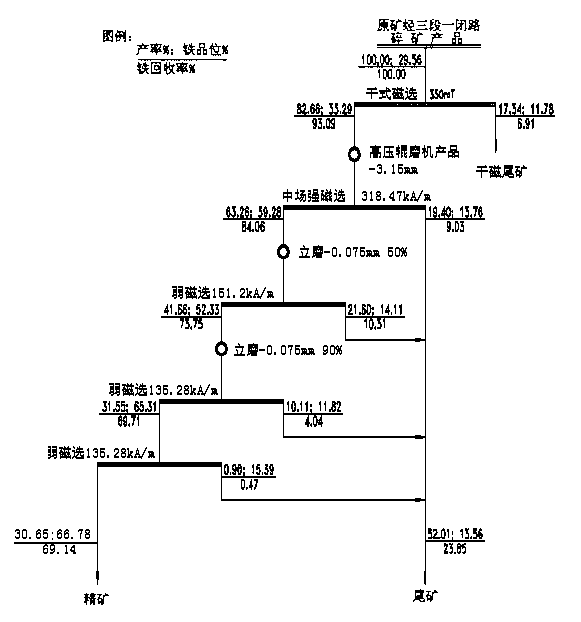

High-efficiency and energy-saving new lean magnetite combined milling magnetic separation method

ActiveCN104162475AReduce consumptionReduce energy consumptionMagnetic separationGrain treatmentsMagnetiteSteel ball

The invention discloses a high-efficiency and energy-saving new lean magnetite combined milling magnetic separation method. A high pressure roller mill is used as an ultrafine crushing device, and a vertical mill substitutes a ball mill. The method comprises the following steps: crushing, screening, carrying out dry pre-concentration, milling through the high pressure roller mill, carrying out medium field intensity wet magnetic separation, carrying out vertical coarse milling, carrying out weak magnetic roughing, carrying out vertical fine milling, and carrying out low intensity magnetic separation. The method allows a large number of coarse grain waste ores to be abandoned before milling, so the milling amount is reduced, the over milling problem during mineral liberation is effectively solved, and the consumption of steel balls and lining plates of the ball mill is significantly reduced, thereby the operation cost of the whole process is reduced. The method improves the grade of raw ores by above 2% after the weak magnetic dry separation, improves the relative grindability of roller mill products by above 30%, and reduces the energy consumption by 35-50% by adopting the vertical stirred mill to substitute the ball mill; and the power consumption of per unit of the raw ores and the consumption of the steel balls and the lining plates of the method in the invention are 65.37% and 59.26% lower than those of with routine three stage closed loop + two stage ball milling + two stage weak magnetic separation milling technologies in ore separation work respectively.

Owner:马钢集团设计研究院有限责任公司

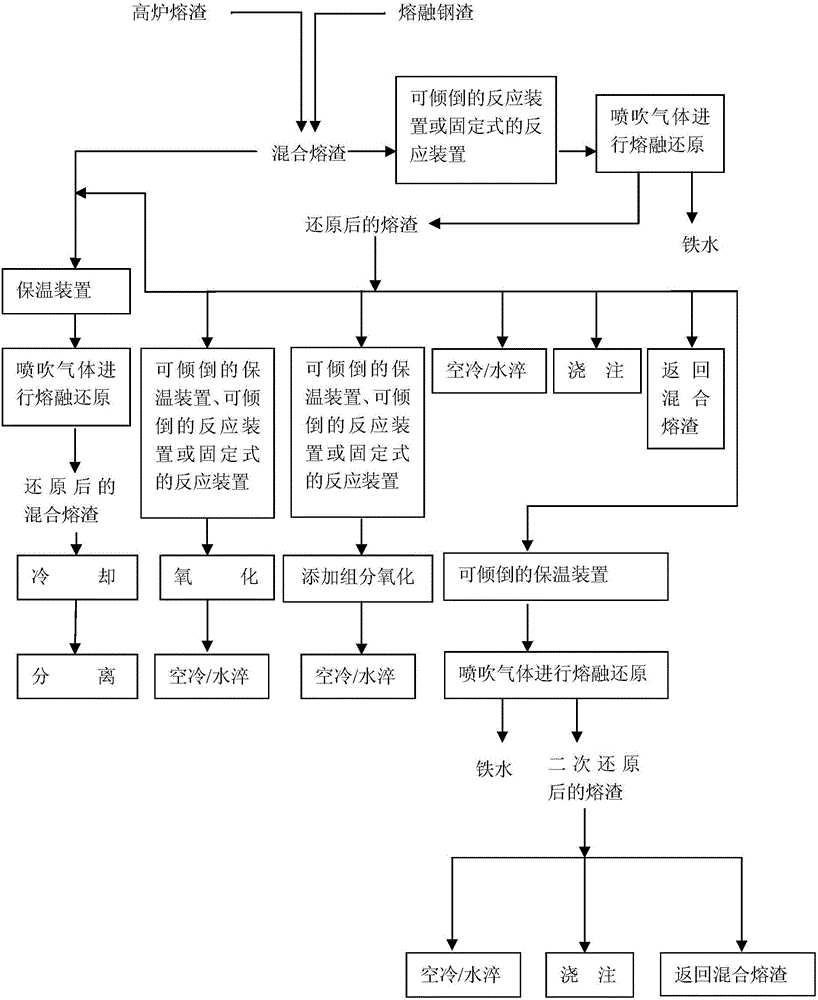

Mixed slag smelting reduction production and thermal refining method

ActiveCN106191344AEasy to removeTake advantage ofRecycling and recovery technologiesProcess efficiency improvementMolten stateReducing agent

The invention discloses a mixed slag smelting reduction production and thermal refining method, and belongs to the field of non-blast furnace iron smelting and comprehensive utilization of resources. The method comprises the following steps: 1) an iron-contained material and a reducing agent are added in mixed slag of blast furnace slag and molten steel slag for heating to reach a molten state; and oxide gas is sprayed for iron smelting by smelting reduction to treat most iron-contained material; and 2) an iron component, a calcium silicon component and a phosphorus component in the mixed slag are separated and recovered according to a reaction device. After smelting reduction, the reduced slag can serve as a cement additive, a cement regulator, a cement clinker or a cement clinker with high production additional value, so that the method realizes efficient comprehensive utilization of the resources, and is a new smelting reduction iron making method. The method uses smelting reduction of the mixed slag for production of pig iron or steel and phosphorus-enriched phases and thermal refining, is short in reaction time, high in metal recovery rate, low in production cost, high in raw material adaptability, high in handling quantity, environment-friendly and high in economic benefit, and can effectively achieve the goal of efficient recycling of metallurgic resources and heat energy.

Owner:NORTHEASTERN UNIV

Ecotypic cementing material

ActiveCN102515588AIncreases hydration activityImprove grinding efficiencyCement productionSodium metasilicateBrick

The invention relates to an ecotypic cementing material, which comprises the components of: 40-60 parts of building waste brick powder, 15-30 parts of slag, 10-20 parts of steel plant semi-dry sintering flue gas desulfurization ash, and 10-15 parts of a composite grinding aid activator, which is prepared by raw materials in the following weight ratio: 70-85 parts of calcination modified desulfurization gypsum, 5-10 parts of sodium metasilicate pentahydrate, 5-10 parts of sodium aluminate, 1-5 parts of a naphthalene-based water reducer, 0.1-0.5 part of triethanolamine, 0.05-0.1 part of potassium humate, and 0.05-0.1 part of glycerol. The cementing material of the invention utilizes the synergetic and complementary effects of component materials, realizes resource utilization of building waste brick powder and semi-dry desulphurization ash as well as other solid wastes, thus making waste profitable.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Autoclaving-free prestressed high-strength tube pile concrete and tube pile manufacturing method

The invention relates to autoclaving-free prestressed high-strength tube pile concrete and a tube pile manufacturing method. The concrete is prepared from the following components in parts by mass: 300-420 parts of PI or PII 52.5 cement, 5-80 parts of mineral powder, 5-100 parts of lithium slag powder, 5-40 parts of glass microbead powder, 680-720 parts of sand, 1125-1170 parts of broken stones, 125-135 parts of water, 4-5 parts of a polyocarboxy acid water reducing agent and 2-5 parts of an exciting agent. After stirring and shaping are performed, only constant-pressure steaming is performed for 6-8 hours, the strength requirement of C80 can be met, the energy consumption is reduced, and besides, the lithium slag powder which is industrial waste is utilized for the autoclaving-free concrete tube pile, so that the problem of resource wasting and the problem of environmental pollution are solved to a certain extent.

Owner:SOUTHEAST UNIV

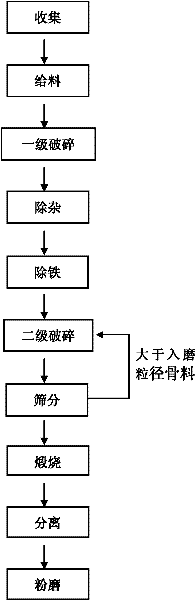

Method for recycling waste clay

InactiveCN102218435AGive full play to the role of materialImprove grindabilityConstruction waste recoverySolid waste disposalLitterIron removal

The invention provides a method for recycling waste clay, which comprises the following steps of: removing impurities from construction waste materials through treatment processes such as crushing, impurity removal, iron removal, sieving and the like, and preparing the materials into a recycled aggregate meeting the requirement of grinding equipment on particle size; burning up combustibles in the recycled aggregate through a calcining process to reduce ignition loss and water content; separating a concrete component from a clay brick component in the recycled aggregate; and grinding the clay brick component to obtain regenerated powder. By the method, waste clay brick resources can be fully utilized by a simple process; moreover, the regenerated clay powder obtained in the production has good performance, wide application range and high added value.

Owner:上海德滨环保科技有限公司

Retarding superplasticizer composition for roller compacted concrete

InactiveCN102659342AVC value loses quicklyVC value loss is smallRoller-compacted concreteSuperplasticizer

The invention relates to a retarding superplasticizer composition for roller compacted concrete, which is prepared from 40-80 percent of barium-containing naphthalene based superplasticizer, 10-30 percent of modified lignosulfonate, 3-7 percent of plastic retaining agent, 5-15 percent of composite retarder, 1-7 percent of layer silicate mineral material, 0.1-0.5 percent of polysiloxane and 0.1-0.2 percent of air entraining agent. The retarding superplasticizer composition does not contain alkali harmful to alkali-aggregate reaction, has a better inhibition effect to the alkali-aggregate reaction, and has the advantages of high water reducing rate, strong VC value retaining capacity, good water retaining property, small bleeding rate, remarkable retarding effect and the like, so that the prepared roller compacted concrete mixture has the characteristics of good workability, small VC value loss, small bleeding rate, long setting time, greatly reduced early hydration heat and delayed occurrence time of a hydration heat peak, so as to have better construction property, mechanical property and durability.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

High-strength prestressed concrete pipe-styled pile blended with ground river sands and production method thereof

InactiveCN101672035ARich sources of river sandGood wearabilityMixing operation control apparatusShaping reinforcementsRebarRiver sand

The invention discloses a high-strength prestressed concrete pipe-styled pile blended with ground river sands, which is composed of binding material, sands, stones, water reducers, water, ground riversands and reinforcing steel bars, wherein the binding material : sands : stones : water reducers : water : ground river sands is equal to 1:1.45-1.62:2.65-2.82:0.0065-0.0068:0.28-0.3:0.1-0.45 by weight ratio. The invention aims at overcoming the disadvantages in the prior art and provides a high-strength prestressed concrete pipe-styled pile blended with ground river sands, which has plentiful raw materials, low production energy consumption and low production cost. The invention also aims at providing a method for producing the high-strength prestressed concrete pipe-styled pile, and the property of the high-strength prestressed concrete pipe-styled pile can reach and exceed the property of PHC piles without being blended with additives and the concrete; the source of river sands is plentiful, cement with high price can be saved and the production cost is reduced greatly.

Owner:广东建华管桩有限公司

Method for mixed slag smelting reduction recycling and thermal refining

ActiveCN106048109ARealize smelting reduction ironmakingEasy to removeCement productionRecycling and recovery technologiesThermal energyEconomic benefits

The invention discloses a method for mixed slag smelting reduction recycling and thermal refining, and belongs to the field of non-blast furnace iron making and comprehensive utilization of resources. With the method, pig iron or steel and a phosphorus-rich phase are recycled from mixed slag, and slag thermal refining is carried out. The method comprises the following steps that (1) blast furnace slag and molten steel slag are mixed; (2) gas blowing is carried out to carry out smelting reduction; and (3) separation and recycling are carried out. According to the method, blast furnace slag and the molten steel slag are mixed, then, oxidizing gas is blown to carry out molten reduction iron making, the iron in the mixed slag is recycled, phosphorus-rich phase recycling and slag thermal refining are achieved, and the reduced slag can serve as slag cement or a cement regulator or an additive in cement production or cement clinker, or be used for producing high-value-added cement clinker. The method for mixed slag smelting reduction recycling and thermal refining is short in reaction time, high in metal recycling rate, low in production cost, high in material adaptability, high in handling capacity, friendly to the environment, high in economic benefit, and capable of effectively achieving the purpose of high-efficiency recycling of metallurgical resources and thermal energy, and is a new smelting reduction technology.

Owner:NORTHEASTERN UNIV

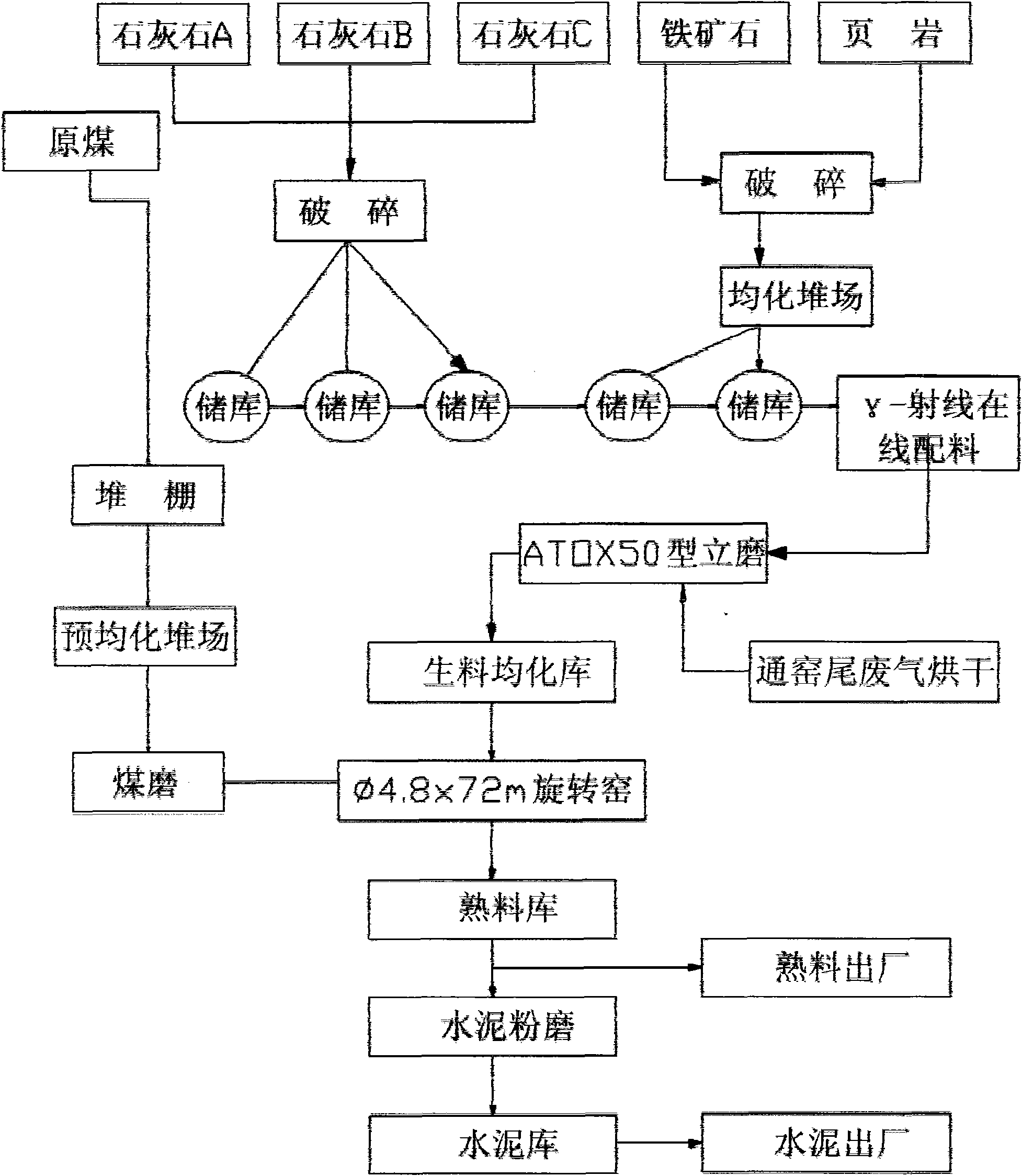

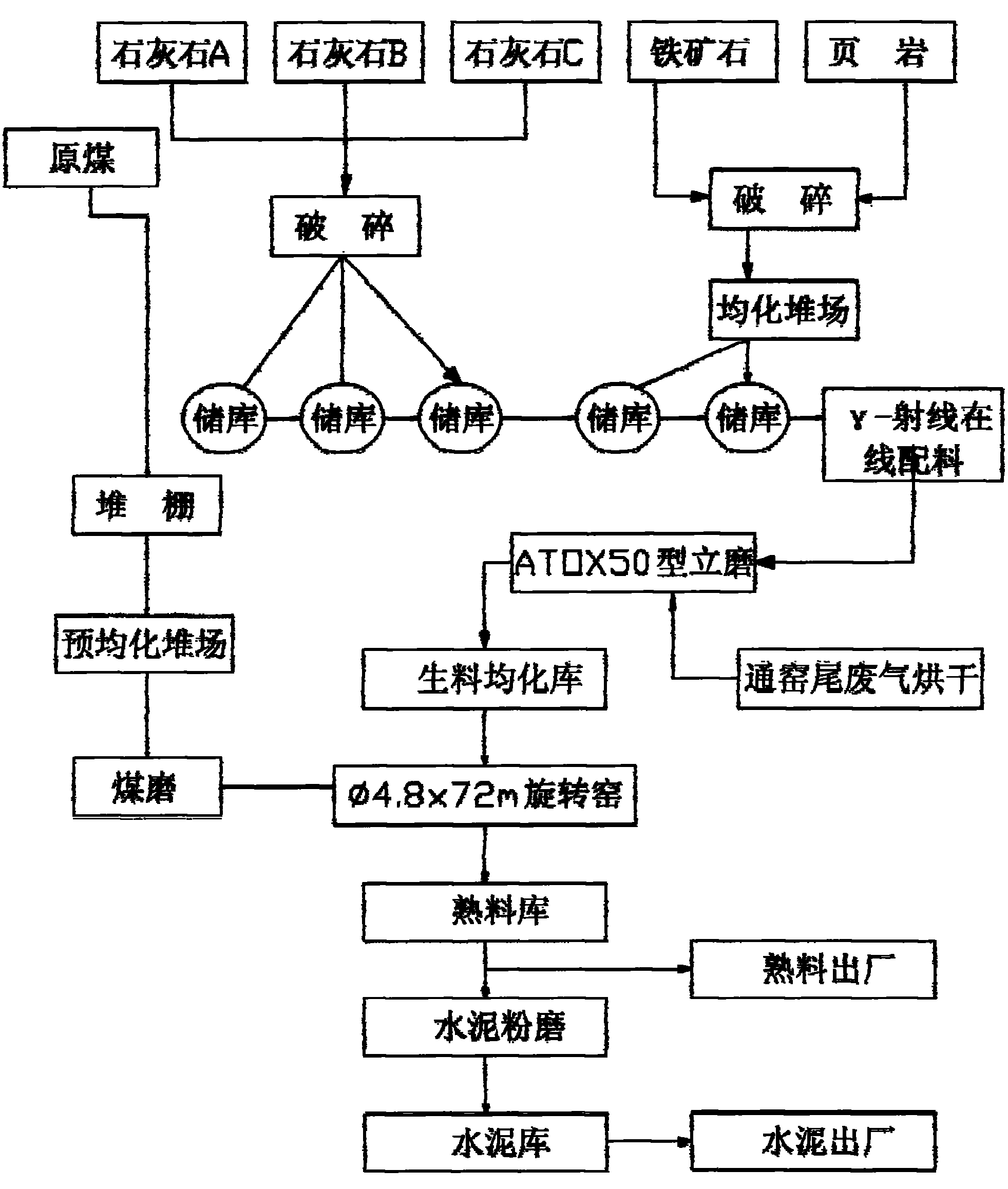

Method for producing cement by utilizing high-silicon low-calcium limestone

InactiveCN101781096AIt has the characteristics of "low calcium and high free silicon"Rich reservesIronstoneMining engineering

The invention relates to a method for producing cement by utilizing high-silicon low-calcium limestone. The cement comprises the following raw materials in percentage by weight: 48 to 50 percent of low-grade high-silicon limestone with CaO content between 42 and 45 percent and f-SiO2 content between 10 and 18 percent, 31 to 33 percent of high-magnesium limestone, 16 to 18 percent of matched limestone, 3 to 6 percent of shale and 2 to 4 percent of ironstone. The method is technology which utilizes low lime saturation ratio and ore of high silicon rate and high alumina rate and has an attribute of low silica modulus; online detection is performed on the mixture ratio of the raw materials by using a gamma ray instrument and a formula is adjusted by using one minute as a cycle; and a plate hammer counterpunch type crusher is used for crushing, a roller-type vertical grinding mill is used for grinding and waste gas at the tail of a kiln is used for drying the raw materials. The method has the advantages of capability of developing and utilizing low-grade limestone resource, accurate material burdening, timely regulation of the mixture ratio, and capability of reducing homogenization facilities and storage yard; and high quartziferous rock ore can be used in vertical milling and has high grindability. The method is suitable for utilizing high-dissociative silicon low-calcium limestone.

Owner:SINOMA TIANSHAN YUNFU CEMENT

Application of coal modifier in shaft kiln incineration and producing technique thereof

A 'SHENZHOUSHENGLONG' coal modifier mainly consists of a grinding aid, a catalyst, an oxidant, a smoke suppressor and combustion improver, a smoke suppressor and igniter, a sulfur fixation agent, a bulking agent, a penetrating agent, etc. The coal modifier is a powdery material and can be added into coal (at a ratio of 0.1% the actual coal weight) to improve the combustion temperature and the combustion speed of the coal, thus achieving catalytic combustion and improving the coal combustion effect as well as the coal utilization rate. Accordingly, the invention performs the functions of saving coal, substituting high-quality coal by poor-quality coal, improving the hourly output of cement clinker stage, improving the grade of cement clinker, fixing sulfur and reducing the discharge of harmful gases such as SO2 in the smoke, thus protecting environment and indeed achieving the green production of cement.

Owner:哈尔滨绿万家环保科技有限公司 +5

Preparation method and application method of calcium sulphosilicate mineral

InactiveCN104609434AThe synthesis process is simpleSynthetic raw materials are abundant and easy to obtainAlkaline-earth metal silicatesCalcium silicateAluminate

The invention discloses a preparation method of a calcium sulphosilicate mineral. The preparation method is characterized by comprising the steps of respectively finely grinding a calcium oxide raw material, a silicon oxide raw material and gypsum and uniformly mixing; calcining at a high temperature, maintaining the temperature for a period of time to obtain mixed mineral constituents mainly including calcium sulphosilicate; and grinding the mixture to a certain fineness so as to obtain the calcium sulphosilicate mineral. The invention further discloses an application method of the calcium sulphosilicate mineral. The application method is characterized in that the calcium sulphosilicate mineral is applied to a sulphate aluminum cement additive so as to increase the later strength of the sulphate aluminum cement. According to the application method, the later strength of the sulphate aluminum cement can be effectively improved, and the quality of a concrete structure of a final product is improved; meanwhile, the preparation method has the advantages that the preparation is simple, the implementation is convenient and the cost is low.

Owner:CHONGQING UNIV

Method for smelting reduction production of zinc smelting slag

InactiveCN107699699ASolve the accumulationTake advantage ofProcess efficiency improvementIndiumBismuth

The invention discloses a method for smelting reduction production of zinc smelting slag. The method for smelting reduction production of the zinc smelting slag comprises the following steps that S1,the zinc smelting slag is added into an insulation device or a smelting reaction device allowing slag to flow out, calcium minerals and additives are added, all the components are heated to be in themolten state, one or more of copper oxide minerals, copper sulfide minerals and copper-containing materials are added into the insulation device or the smelting reaction device at the moment, reactionslag is monitored in real time, and molten slag is obtained by regulating and controlling the temperature and the CaO / SiO2 basicity ratio of the reaction slag; and S2, the molten slag is obtained, aferrum-containing silicate mineral phase, a copper-rich phase, a ferrum-rich phase and dust containing zinc, lead, bismuth and smoke are obtained through settlement separation, gold and silver are migrated and enriched to enter the copper-rich phase, and all the phases are separated. According to the method for smelting reduction production of the zinc smelting slag, the slag copper content (lowerthan 0.1 wt%) can be decreased, efficient recovery of components such as copper, ferrum, gold, silver, lead, zinc, indium, bismuth, sodium and potassium can be achieved, and low-copper ferrum-containing materials are obtained; and the metal recovery rate is high, the production cost is low, environmental friendliness is achieved, and economic benefits are high.

Owner:NORTHEASTERN UNIV

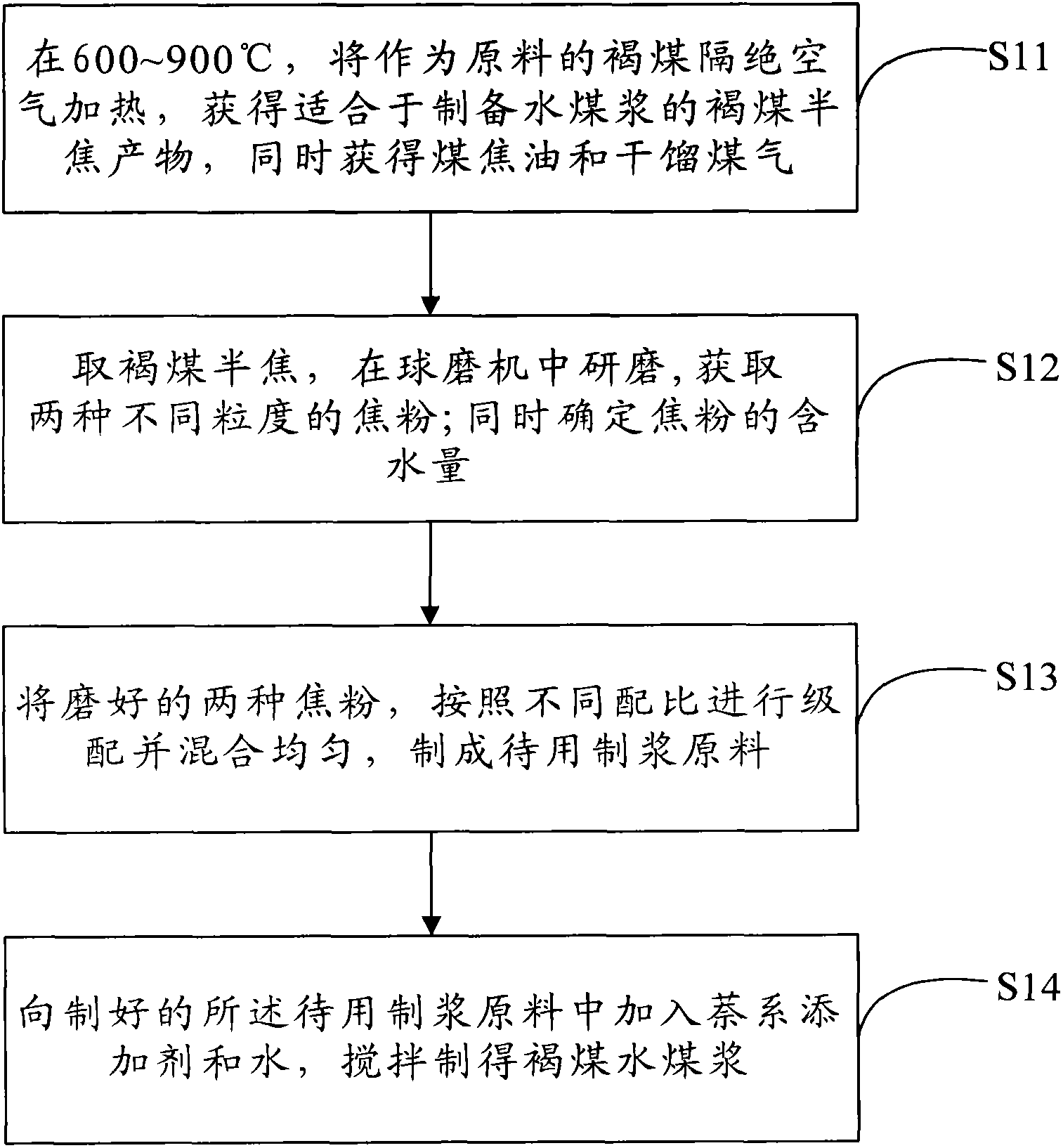

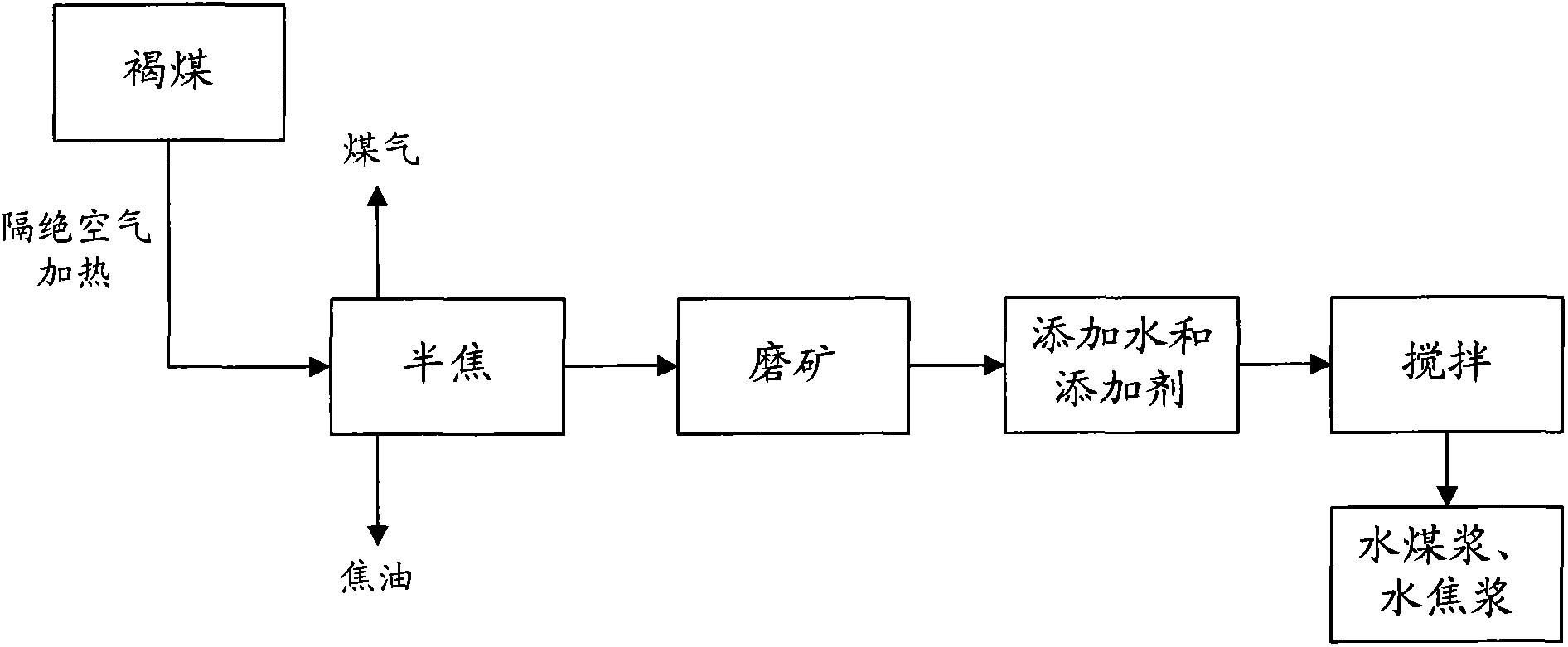

Method for preparing gasified coal water slurry by utilizing lignite

InactiveCN101914401AReduce moistureReduce volatilityLiquid carbonaceous fuelsSpecial form destructive distillationCoal waterBrown coal

The invention discloses a method for preparing gasified coal water slurry by utilizing lignite, comprising the following steps: isolating the lignite which is taken as a raw material from air and heating at the temperature of 600-900 DEG C to obtain a lignite semicoke product suitable for preparing the coal water slurry, coal tar and retort gas; taking the lignite semicoke; grinding the lignite semicoke in a ball grinding mill into two kinds of coke powders with different particle sizes; grading the two kinds of ground coke powers in different proportion and evenly mixing to prepare a stand-by pulping raw material; adding naphthalene additive and water in the stand-by pulping raw material; and stirring to prepare the lignite coal water slurry. In the method of the invention, dry distillation process is utilized, firstly tar with high addition value in the lignite is extracted to obtain high-quality retort gas and simultaneously obtain lignite semicoke the structure and the performanceof which are beneficial for pulping, thus improving the utilization value of the lignite and realizing the comprehensive utilization of the lignite.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Ultrahigh-toughness alkali-activated shotcrete and preparation method thereof

The invention discloses ultrahigh-toughness alkali-activated shotcrete and a preparation method thereof. The shotcrete consists of the following components in parts by mass: 200 to 400 parts of ultrafine lithium slag powder, 100 to 200 parts of slag powder, 50 to 100 parts of stone powder waste, 30 to 60 parts of Portland cement, 10 to 70 parts of sodium hydroxide solution, 15 to 50 parts of sodium silicate solution, 1 to 10 parts of aluminum sulfate, 1 to 5 parts of nanometer aluminum oxide, 400 to 900 parts of nickel slag sand, 300 to 600 parts of copper slag sand, 3 to 6 parts of a thickening agent, 1 to 20 parts of fiber, 3 to 10 parts of a water-reducing agent and 200 to 350 parts of water. The problems that the existing ordinary ultrahigh-property shotcrete has large use amount of cement and low durability are effectively solved.

Owner:南京绿色增材智造研究院有限公司

Method for recycling valuable components from copper-containing slag

InactiveCN107699702ARealize comprehensive utilizationTake advantage ofProcess efficiency improvementHeavy metalsCalcium

The invention relates to a method for recycling valuable components from copper-containing slag. The method includes the steps that S1, clinker is mixed, wherein copper slag is added in a smelting reaction device, calcium-series mineral and an additive are added, mixed slag is formed, the mixed slag is heated to the molten state to be used as reaction slag and is evenly mixed, the reaction slag ismonitored in real time, the mixed reaction slag is made to meet the condition a and the condition b at the same time through regulation and control, and slag subjected to reaction is obtained; and S2, separation and recycling are conducted. By means of the method, hot-state slag can be processed, molten copper slag physical heat resources and hot-state metallurgy flux are sufficiently utilized, cold-state clinker can also be processed; by adjusting the physicochemical property of the slag and using the mature physicochemical property of the copper-containing slag, the copper-containing slag metallurgy process is achieved, and the problem that because a large amount of clinker is stacked at present, environment pollution is caused and the problem of heavy metal element pollution are solved.

Owner:NORTHEASTERN UNIV

Method And Apparatus For Pelletizing Blends Of Biomass Materials For Use As Fuel

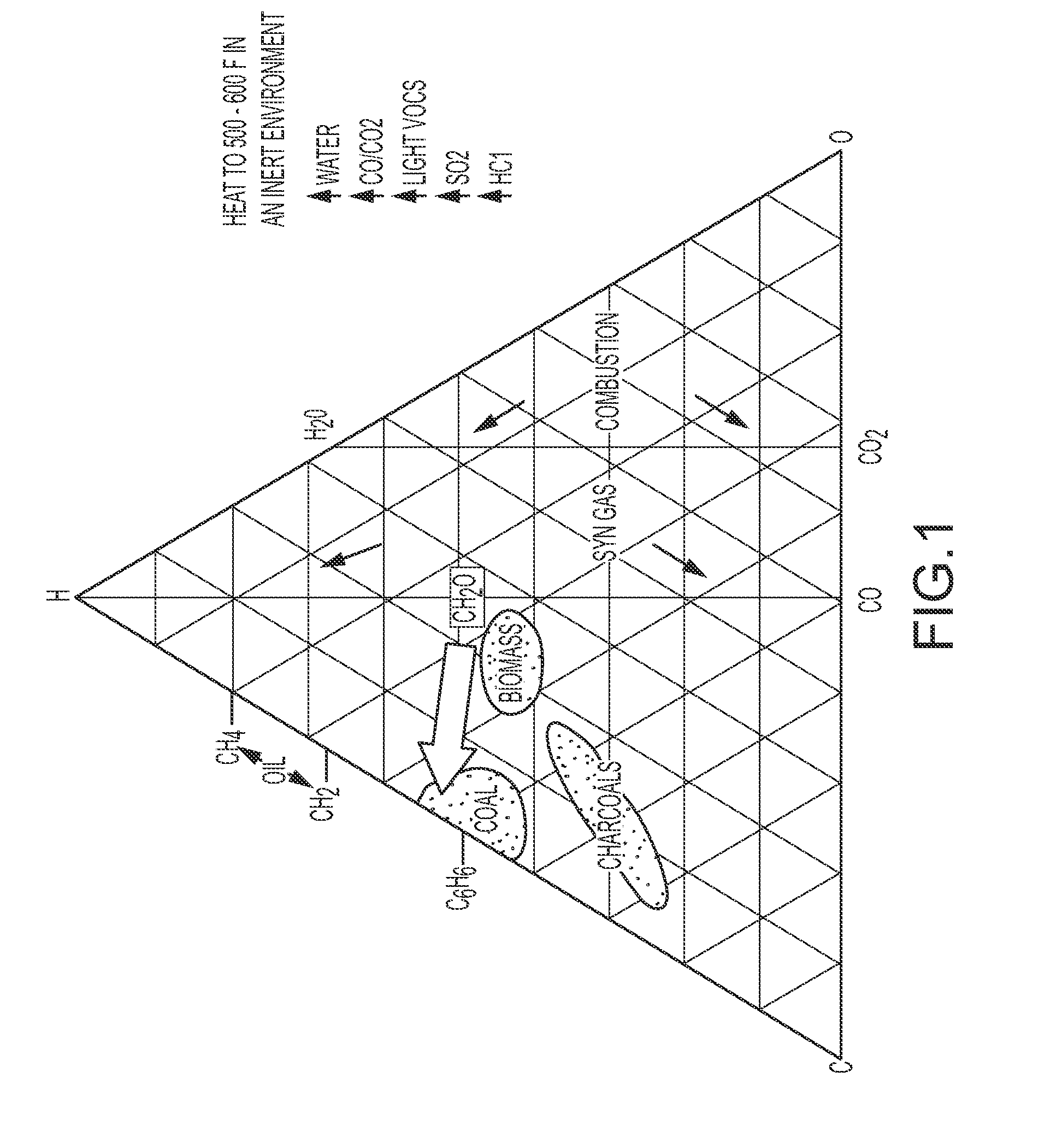

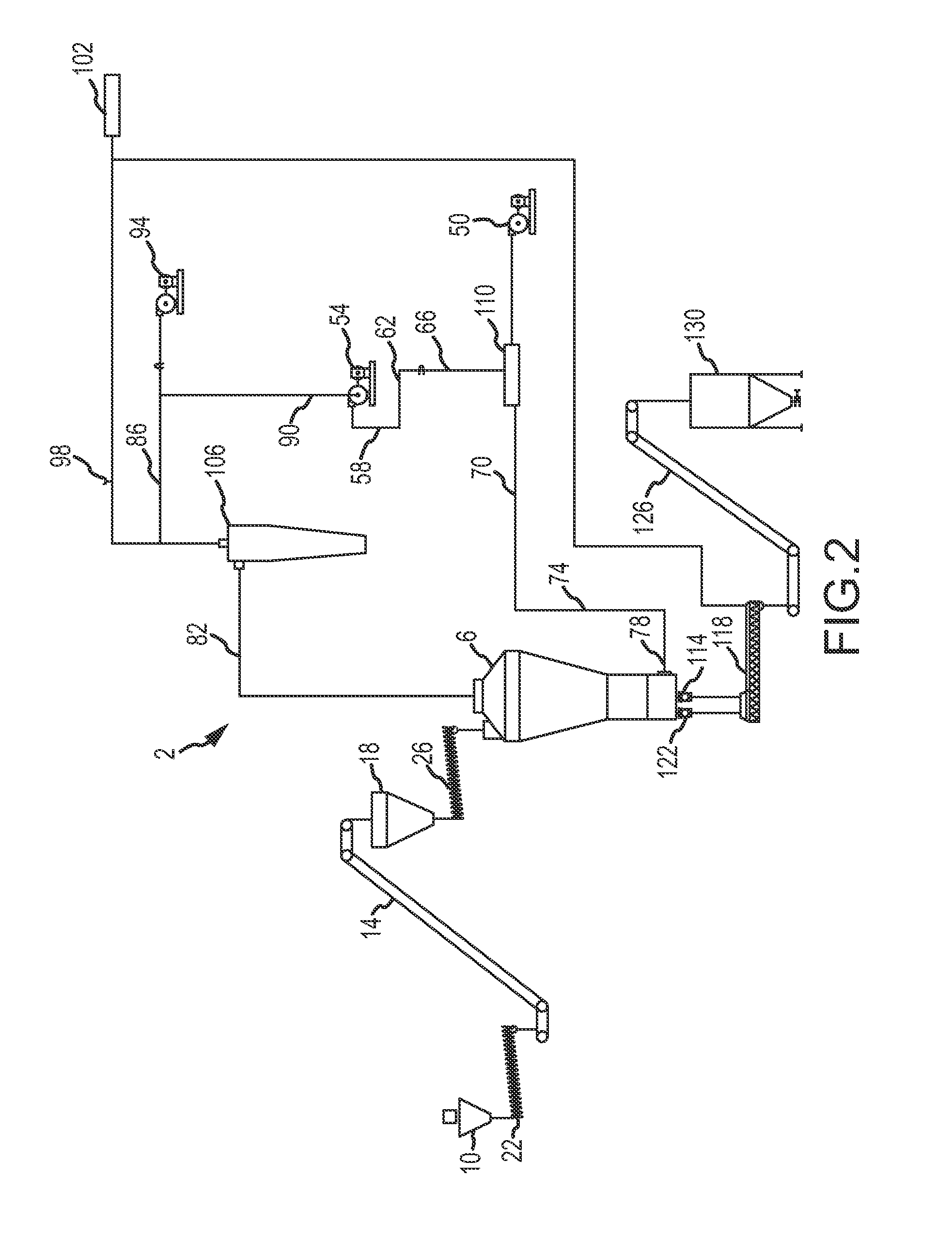

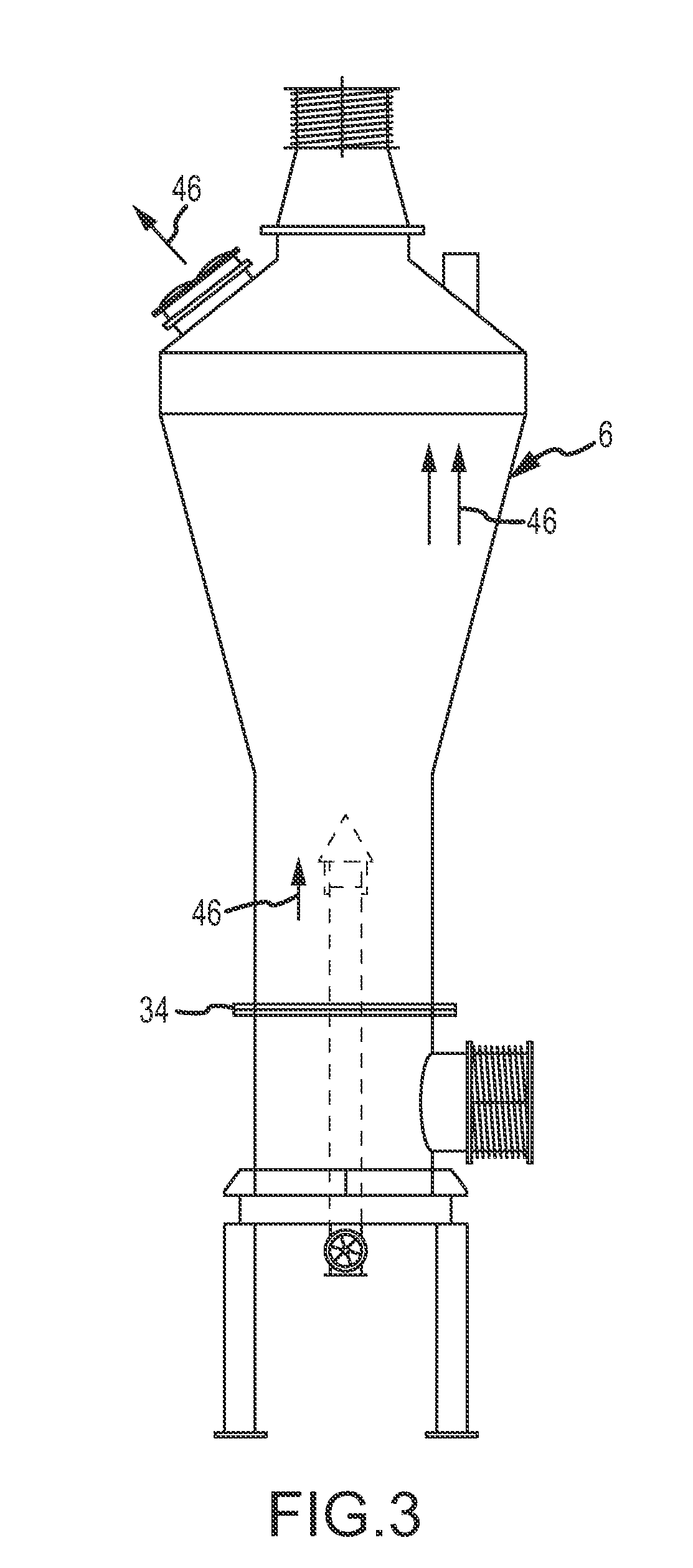

ActiveUS20140082998A1Minimization requirementsImprove grindabilityBiofuelsSolid fuelsProcess engineeringTorrefaction

An assembly for processing green biomass materials from two separate feed sources for use as a fuel pellet includes a drying assembly, a torrefaction assembly and a heating assembly. The drying assembly is adapted to convert the green biomass material obtained from a first source to white biomass material. The torrefaction assembly is adapted to convert green biomass material obtained from a second source to torrefied biomass material. The heating assembly provides heat for both the drying assembly and the torrefaction assembly.

Owner:ASTEC

Preparation method and application of PD composite mineral admixture containing silica fume

The present invention provides a preparation method and application of a PD composite mineral admixture containing silica fume. The PD composite mineral admixture comprises components of, by weight percentage, 0%-95% of volcano ash, 0%-95% of mountain flour, 5%-30% of silica micropowder (silica fume) and 0-8% of gypsum, wherein the volcano ash content and mountain flour content can not be zero at the same time, and the gypsum content can be zero according to the requirements. A double-mixing admixture, a ternary-mixing admixture and a quaternary-mixing admixture are prepared by utilizing superimposed effect and interaction effect generated by a quaternary system of ''volcano ash-mountain flour-silica fume-gypsum''. Admixtures with different performance characteristics can be prepared by only adjusting the proportion of the components in the PD composite mineral admixture provided by the invention; the admixture can substitute 15%-50% of cement in concrete and mortar, with equal or excessive amount, and realizes a better effect than an admixture mixed with single volcano ash or mountain flour; and the admixture can be prepared by using local raw materials, or waste stone slag and mountain flour. Therefore, the admixture has good application prospect and promotion value in places lack of conventional admixture.

Owner:张仲 +1

High-alumina refractory castable and preparation method thereof

The invention belongs to the technical field of refractory materials, in particular to a high-alumina refractory castable and a preparation method thereof. The high-alumina refractory castable is prepared from the following raw materials in parts by weight: 50-70 parts of high bauxite, 8-13 parts of andalusite, 11-23 parts of floating bead, 15-20 parts of silicon carbide, 10-15 parts of silicon nitride, 7-12 parts of alpha-Al2O3 micro powder, 3-9 parts of silica-alumina colloid powder, 1-5 parts of attapulgite clay, 10-25 parts of calcium aluminate cement, water reducer and aluminium silicatefiber, wherein the water reducer occupies 0.1-0.3% of total mass of the above raw materials, and the aluminium silicate fiber occupies 0.05-0.12% of total mass of the above raw materials. The high-alumina refractory castable has the advantages of high Al2O3 content, light weight, low heat conductivity and high castable strength.

Owner:黎文泰

Composite material and method of manufacturing the same

InactiveUS20090295048A1Improve grindabilityImprove rigidityMaterial nanotechnologyCeramic shaping apparatusBoron carbideSilicon

A composite material according to the invention includes X parts by volume of boron carbide, Y parts by volume of silicon carbide, and Z parts by volume of silicon as main components, wherein 10<X<60, 20<Y<70, and 5<Z<30 are satisfied, and grains of 10 μm or more of the boron carbide and the silicon carbide are 10-50 parts by volume.

Owner:TOTO LTD

Method for recycling valuable components from mixed slag containing nickel and iron

InactiveCN107663589ASolve pollutionAchieve recyclingProcess efficiency improvementLead smeltingIron alloys

The invention relates to a method for recycling valuable components from mixed slag containing nickel and iron. The method comprises the following steps: S1, mixing slag, namely adding nickel smeltingslag into a smelting reaction device, and adding one or more of lead smelting slag, blast furnace slag, steel slag and iron alloy slag, thus forming mixed slag; heating the mixed slag to be in a smelting state to be taken as reaction slag, mixing uniformly, monitoring the reaction slag in real time, and meanwhile, regulating to enable the mixed slag containing nickel and iron to meet conditions aand b simultaneously, thus obtaining the reacted slag; and S2, separating for recycling. According to the method, the mixed slag containing nickel and iron can be treated efficiently, so that the problems that a great amount of slag is accumulated to result in environment pollution and heavy metal pollution are solved, and the heavy metal components can be recycled.

Owner:NORTHEASTERN UNIV

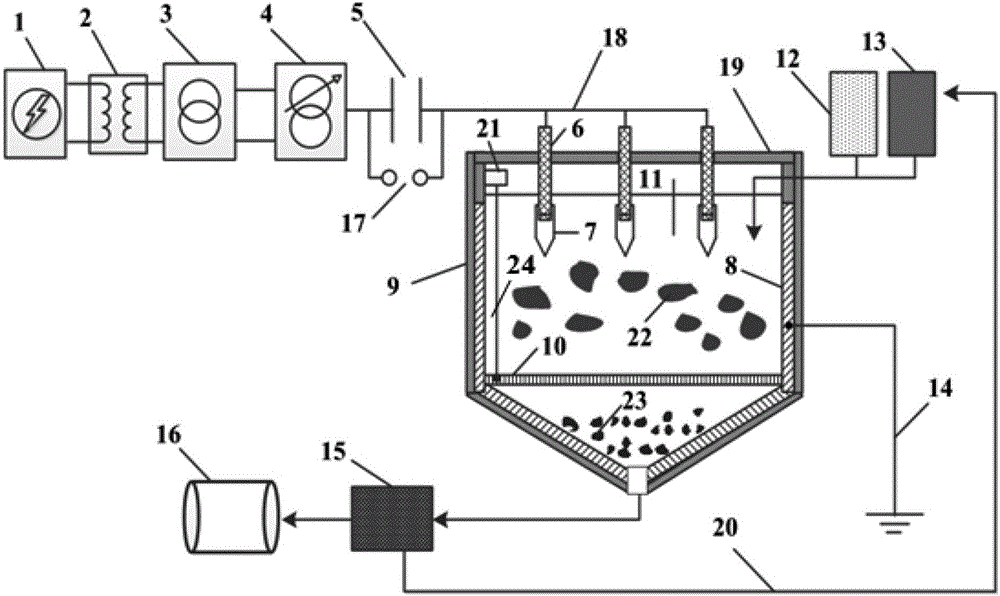

High-voltage electric pulse pretreatment method for intensifying leaching of difficult-to-treat gold ore

ActiveCN106824454AIncrease the content of useful mineralsIncrease monomer dissociationGrain treatmentsPretreatment methodMineral particles

The invention discloses a high-voltage electric pulse pretreatment method for intensifying the leaching of difficult-to-treat gold ore, and belongs to the technical field of the processing of minerals of gold ore. According to the method, the high-voltage electric pulse crushing pretreatment is realized by utilizing the differences of the dielectric properties of different minerals in ore; a high-voltage electric pulse discharge crushing device is used for carrying out selective crushing on gold-containing ore; gold and a gangue mineral in a gold-containing material are prompted to generate a micro crack and a running crack at an interface; a crystal of a gold-containing mineral is completely dissociated into monomer mineral particles; in this way, the exposed surface area of the gold is increased; therefore, the contact probability of cyanide and a gold grain is increased, so that the sufficient improvement of the leaching rate of the gold is facilitated.

Owner:NORTHEASTERN UNIV

Method for recovering valuable components from zinc smelting slag

InactiveCN107674985ASolve pollutionRealize comprehensive utilizationProcess efficiency improvementMolten stateIndium

The invention discloses a method for recovering valuable components from zinc smelting slag. The method comprises the following steps that S1, the zinc smelting slag is added to a heat insulating device or a smelting reaction device in which slag can flow out, calcium-based minerals and additives are added, and mixed slag is formed; the mixed slag is heated to a molten state, reaction slag is formed, the reaction slag is monitored in real time, and by regulating and controlling the temperature of the reaction slag and the specific value of alkalinity CaO / SiO2, the slag obtained after a reaction is completed is obtained; and S2, the obtained slag is subjected to sedimentation separation, smoke dust containing a ferrous silicate mineral phase, a copper-rich phase and an iron-rich phase and smoke dust containing zinc, lead, bismuth and indium are obtained, and gold and silver components are migrated and enriched and enter the copper-rich phase; and all the phases are recovered. By the adoption of the method, the copper-containing slag (copper-containing slag smaller than 0.1wt%) can be lowered, besides efficient recovery of the components of copper, iron, gold, silver, lead, zinc, indium, bismuth, sodium, potassium and the like can be achieved, low-copper materials containing iron are obtained, the metal recovery rate is high, the production cost is low, environmental friendlinessis achieved, and the economic returns are high.

Owner:NORTHEASTERN UNIV

Smelting reduction production and thermal refining method for titanium-containing slag mixture

ActiveCN106048107AAchieve growthAchieve settlementRecycling and recovery technologiesProcess efficiency improvementMolten stateMaterials science

The invention provides a smelting reduction production and thermal refining method for a titanium-containing slag mixture. The smelting reduction production and thermal refining method for the titanium-containing slag mixture comprises the following steps of (1) adding a reduction agent, a vanadium-titanium-containing mineral and / or an iron-containing material into the titanium-containing slag mixture and performing heating to a set temperature to enable the slag mixture to be in a molten condition, and then injecting oxidative gas for smelting reduction and oxidation, and controlling the temperature range of the slag mixture and the alkalinity ratio range of CaO / SiO<2>; and (2) performing separation and recovery according to different reaction devices. According to the method, the titanium component, the iron component, the vanadium component, the phosphorus component and the free calcium oxide component in the slag mixture can be recycled efficiently; solid-state materials containing vanadium, titanium and iron can be processed massively by using a smelting reduction ironmaking technology for the production of high-grade titanium slag and vanadium-enriched slag, and at the same time the method is the novel smelting reduction ironmaking technology which is capable of realizing thermal refining of the slag and efficient and comprehensive utilization of resources. The method is short in reaction time, high in metal recovery rate, low in production cost, strong in raw material adaptability, large in processing capacity and capable of solving the problem of efficient recovery and use of multi-metal complex ore metallurgical resources and heat energy effectively.

Owner:NORTHEASTERN UNIV

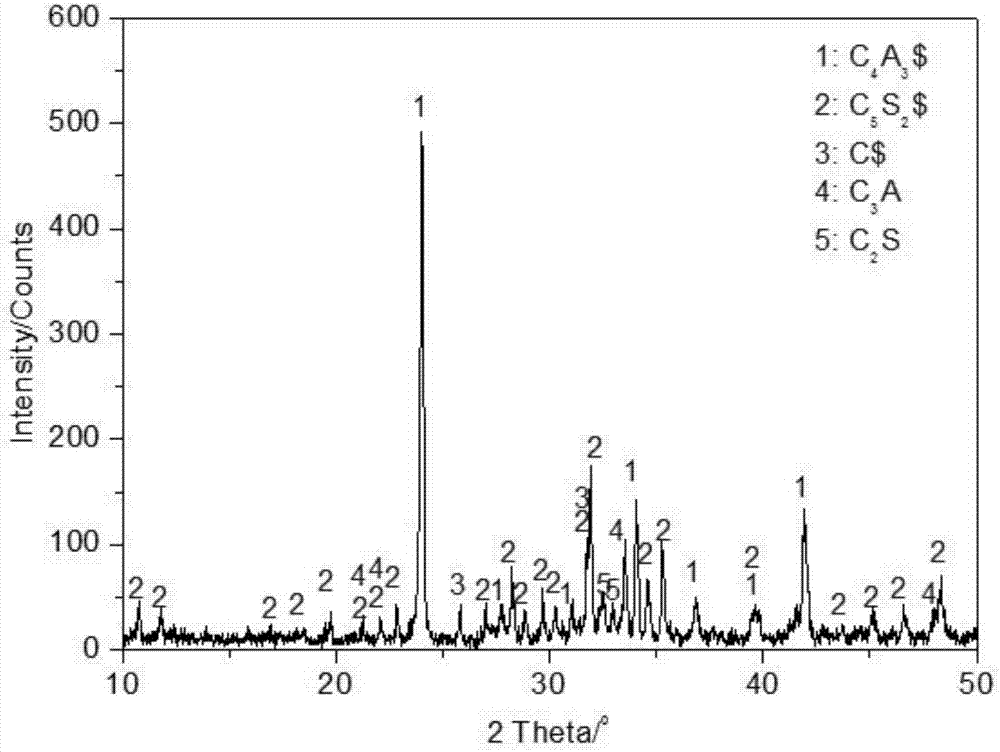

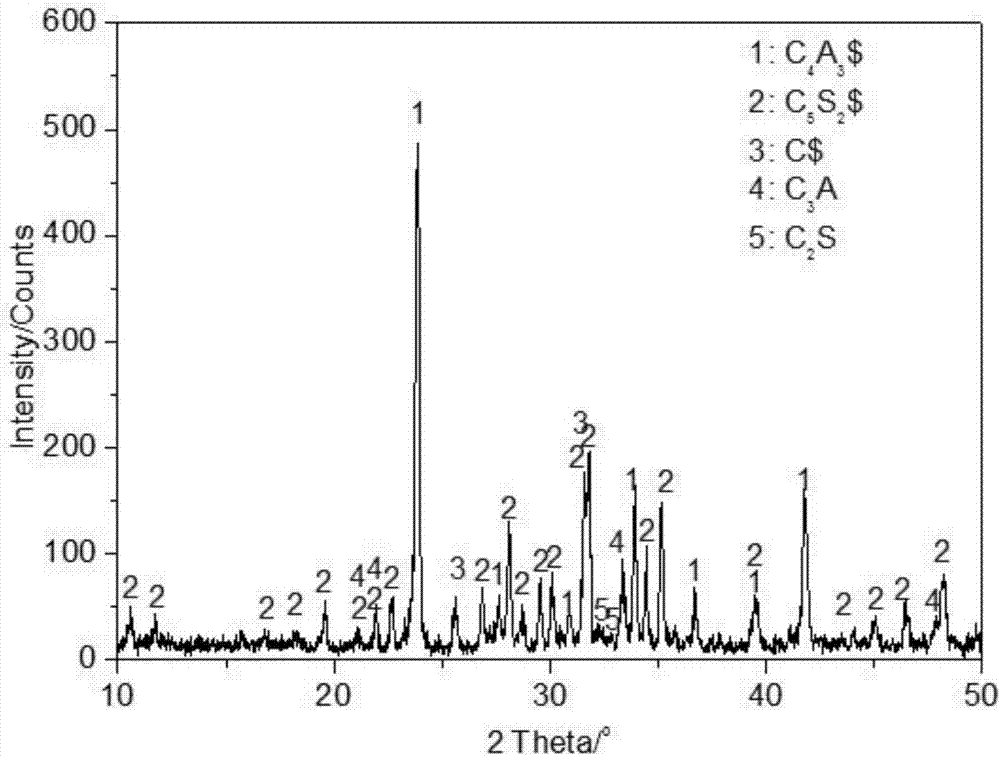

Calcium sulfo-silicate sulfo-aluminate cement and preparation method thereof

ActiveCN107021654ACalcination temperature is lowReduce CO2 emissionsClinker productionGypsumAluminate

The invention discloses calcium sulfo-silicate sulfo-aluminate cement and a preparation method thereof. A main mineral phase of clinker of the cement comprises the following ingredients in parts by mass: 5-40 parts of C4(AxF1-x)3$, 20-65 parts of C5S2$, 5-15 parts of C$ and 5-20 parts of C3A. The preparation method comprises the steps of calcining crude materials of the cement once at the temperature of 1,050 DEG C to 1,200 DEG C, and carrying out heat preservation for 1 hour or less, thereby preparing the cement. According to the calcium sulfo-silicate sulfo-aluminate cement and the preparation method thereof, the energy consumption and CO2 discharge of preparation of the cement clinker are lowered to a large extent, and the calcined clinker has good grindability. The calcium sulfo-silicate sulfo-aluminate cement presents good early mechanical properties, calcium sulfoaluminate minerals are basically hydrated completely at a seventh day, and calcium sulfo-silicate minerals already start to hydrate at a seventh day, so that the problem of sulfo-aluminate cement that later strength is lowered is solved; dihydrate gypsum generated from the hydration of calcium sulfo-silicate can be converted into mono-sulfur calcium sulfo-aluminate hydrate from tri-sulfur calcium sulfo-aluminate hydrate.

Owner:CHONGQING UNIV

Method for preparing ceramic tiles from calcium silicate slag

InactiveCN103641446ARealize mass utilizationReduce consumptionCeramic materials productionClaywaresCalcium silicatePyrophyllite

The invention relates to a method for preparing ceramic tiles from calcium silicate slag, belonging to the field of comprehensive utilization of resources and novel technologies for ceramic preparation. The ceramic tiles contain the following raw materials in percentage by weight: 30-60% of calcium silicate slag, 10-30% of clay, 2-25% of quartz, 0-20% of feldspar, 0-10% of pyrophyllite, 0-10% of green coke and 0-10% of talc. According to the method, ceramics are produced from calcium silicate slag, so that the stacked discharge of calcium silicate slag is reduced, the aim of resource recycling is achieved, and a new way for the high-added-value utilization of calcium silicate slag is added; the utilization ratio of calcium silicate slag in calcium silicate slag ceramics can reach 60%; by using the characteristic that a great deal of alkali metal ions are contained, a feldspar raw material can be replaced partially or totally, and the ceramic tiles are produced under the low-temperature condition of 1,130-1,180 DEG C; all properties of the ceramic tiles prepared by the method disclosed by the invention are better than the national ceramic standards.

Owner:UNIV OF SCI & TECH BEIJING

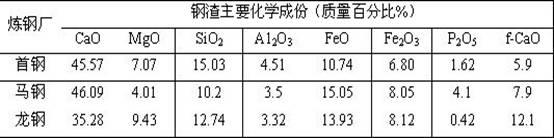

Method for modifying high-temperature steel slag by using compound materials of tailings

ActiveCN102605113AChange compositionChange physical stateIncreasing energy efficiencyCalcium in biologySteelmaking

The invention relates to method for modifying steel slag, in particular to a method for modifying high-temperature steel slag discharged in the final steelmaking stage by using a large amount of mining tailings with low cost, comprising the following steps: mixing 15-30 parts by weight of high alumina silicate tailings, 60-80 parts by weight of high calcium silicate tailings and 5-15 parts by weight of calcium carbonate tailings to obtain compound materials of the tailings; granulating to prepare agglomerated blocks of 3-5cm; adding the compound materials of the tailings into steel slag pot or disc by batches according to the proportion of (70-80%):(20-30%) of the discharged steel slag and the compound materials of the tailings; carrying out steel slag splashing for furnace maintenance, wherein the left steel slag is not poured into the steel slag pot or disc for modifying the steel slag; preserving the temperature of the steel slag at 1,200-1,400 DEG C for 30-60min; quenching by using water, applying heat or covering by heat when the temperature is below 1,200-1,400 DEG C; breaking; and carrying out magnetic separation. Due to the adoption of the method, the separation effect of the steel slag can be improved significantly, the grindability of the separated steel slag can be improved, the total recovery rate of the scrap steel can be up to 95-100%, the components of the separated steel slag are controllable and have high activity, and the separated steel slag contain less than 1.5% by weight of the free calcium oxide, has the grinding work index of 14-17kw.h / t and can replace the portland cement clinker.

Owner:迁安金隅首钢环保科技有限公司

Method of drying biomass

InactiveUS20120023813A1Reduce moisture contentHigh calorific valueProductsReagentsFluidized bedEnvironmental engineering

A process for torrefaction of biomass is provided in which biomass are passed into a fluidized bed or a non-fluidized bed reactor and heated to a predetermined temperature in an oxidizing environment. The dried biomass is then fed to a cooler where the temperature of the product is reduced to approximately 100 degrees Fahrenheit.

Owner:BIOMASS SECURE POWER INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com