Method for producing sulphate aluminum cement

A technology of sulfoaluminate cement and calcium sulfate, which is applied in the field of cement to achieve the effects of good grindability, improved utilization rate and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

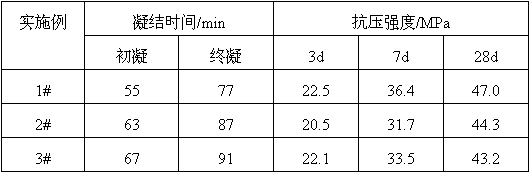

Examples

Embodiment 1

[0032] A preparation method for producing sulphoaluminate cement by partial decomposition of phosphogypsum, the specific implementation steps are as follows:

[0033] a. Preparation of cement raw meal:

[0034] Dosing according to the following parts by mass: 55 parts of limestone, 25 parts of phosphogypsum, 20 parts of low-grade bauxite; then add coke, the consumption of coke is according to the amount of CaSO contained in phosphogypsum in the batching 4 The amount is calculated, namely C: CaSO 4 The molar ratio of the mixture is 0.5; each component is pulverized and mixed until the fineness is 100-200 mesh to obtain cement raw meal;

[0035] b. Preparation of cement clinker:

[0036] Put the raw meal prepared in step a into a rotary kiln for calcining, control the calcining temperature to 1300°C, and calcining time to 30 minutes to obtain cement clinker;

[0037] c. Preparation of cement:

[0038] Add natural dihydrate gypsum with a mass fraction of 5% to the cement c...

Embodiment 2

[0042] A preparation method for producing sulphoaluminate cement by partial decomposition of phosphogypsum, the specific implementation steps are as follows:

[0043] a. Preparation of cement raw meal:

[0044] Dosing according to the following mass parts: 33 parts of limestone, 37 parts of phosphogypsum, 30 parts of low-grade bauxite; then add coke, the consumption of coke is according to the CaSO content of phosphogypsum in the batching 4 The amount is calculated, namely C: CaSO 4The molar ratio of the mixture is 0.5; each component is pulverized and mixed until the fineness is 100-200 mesh to obtain cement raw meal;

[0045] b. Preparation of cement clinker:

[0046] Put the raw meal prepared in step a into a rotary kiln for calcining, control the calcining temperature to 1250° C., and calcining time to 30 minutes to obtain cement clinker;

[0047] c. Preparation of cement:

[0048] Add natural dihydrate gypsum with a mass fraction of 5% to the cement clinker burned ...

Embodiment 3

[0052] A preparation method for producing sulphoaluminate cement by partial decomposition of phosphogypsum, the specific implementation steps are as follows:

[0053] a. Preparation of cement raw meal:

[0054] Dosing according to the following parts by mass: 32 parts of limestone, 50 parts of phosphogypsum, 18 parts of low-grade alumina; 4 The amount is calculated, namely C: CaSO 4 The molar ratio of the mixture is 1.0; each component is pulverized and mixed until the fineness is 100-200 mesh to obtain cement raw meal;

[0055] b. Preparation of cement clinker:

[0056] Put the raw meal prepared in step a into a rotary kiln for calcining, control the calcining temperature to 1300°C, and calcining time to 30 minutes to obtain cement clinker;

[0057] c. Preparation of cement:

[0058] Add natural dihydrate gypsum with a mass fraction of 5% to the cement clinker burned in step b, mix evenly, and grind to a specific surface area of 360m through a ball mill 2 / Kg, made ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition efficiency | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com