Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4349 results about "Frost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Frost is a thin layer of ice on a solid surface, which forms from water vapor in an above freezing atmosphere coming in contact with a solid surface whose temperature is below freezing, and resulting in a phase change from water vapor (a gas) to ice (a solid) as the water vapor reaches the freezing point. In temperate climates, it most commonly appears on surfaces near the ground as fragile white crystals; in cold climates, it occurs in a greater variety of forms. The propagation of crystal formation occurs by the process of nucleation.

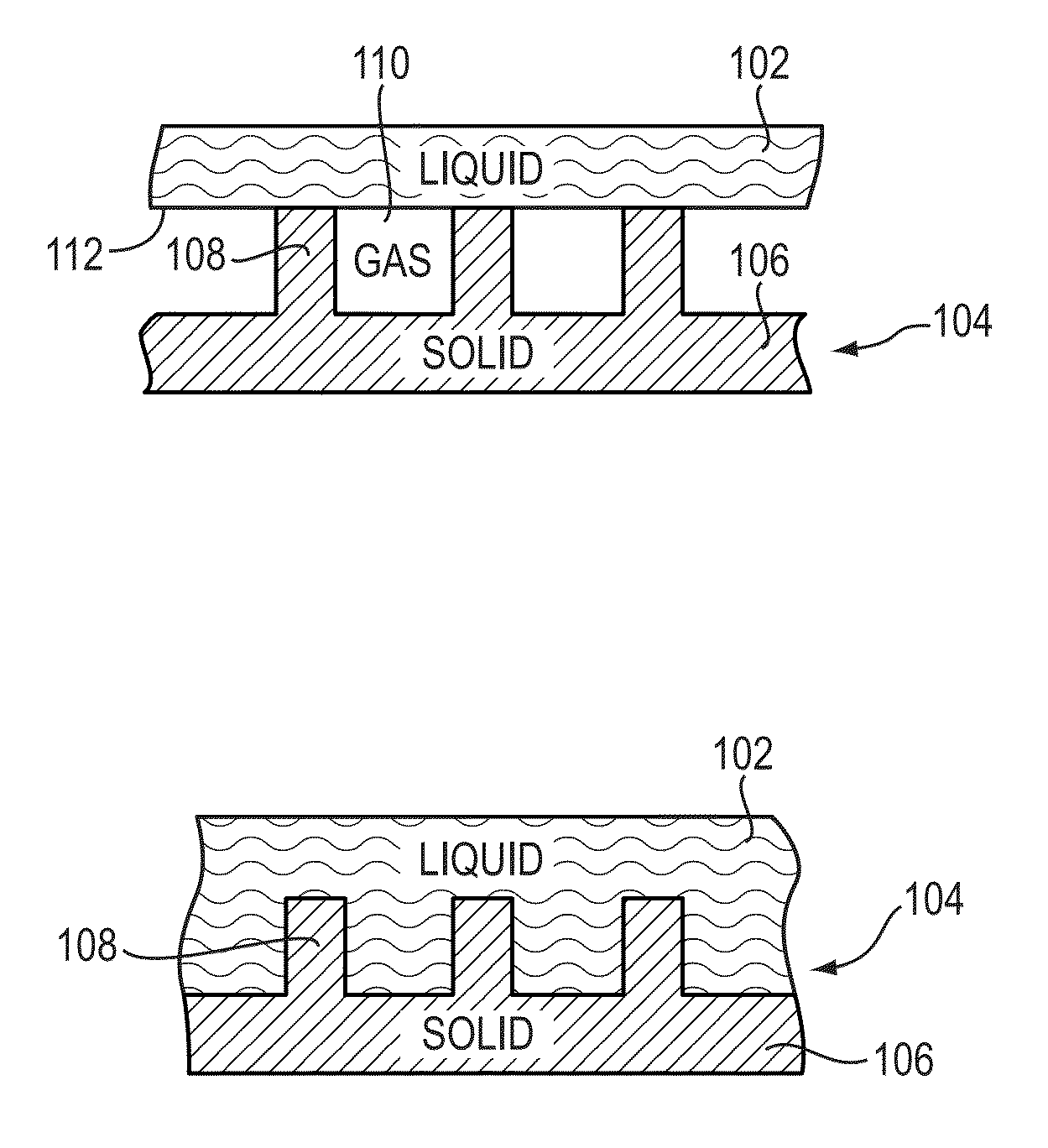

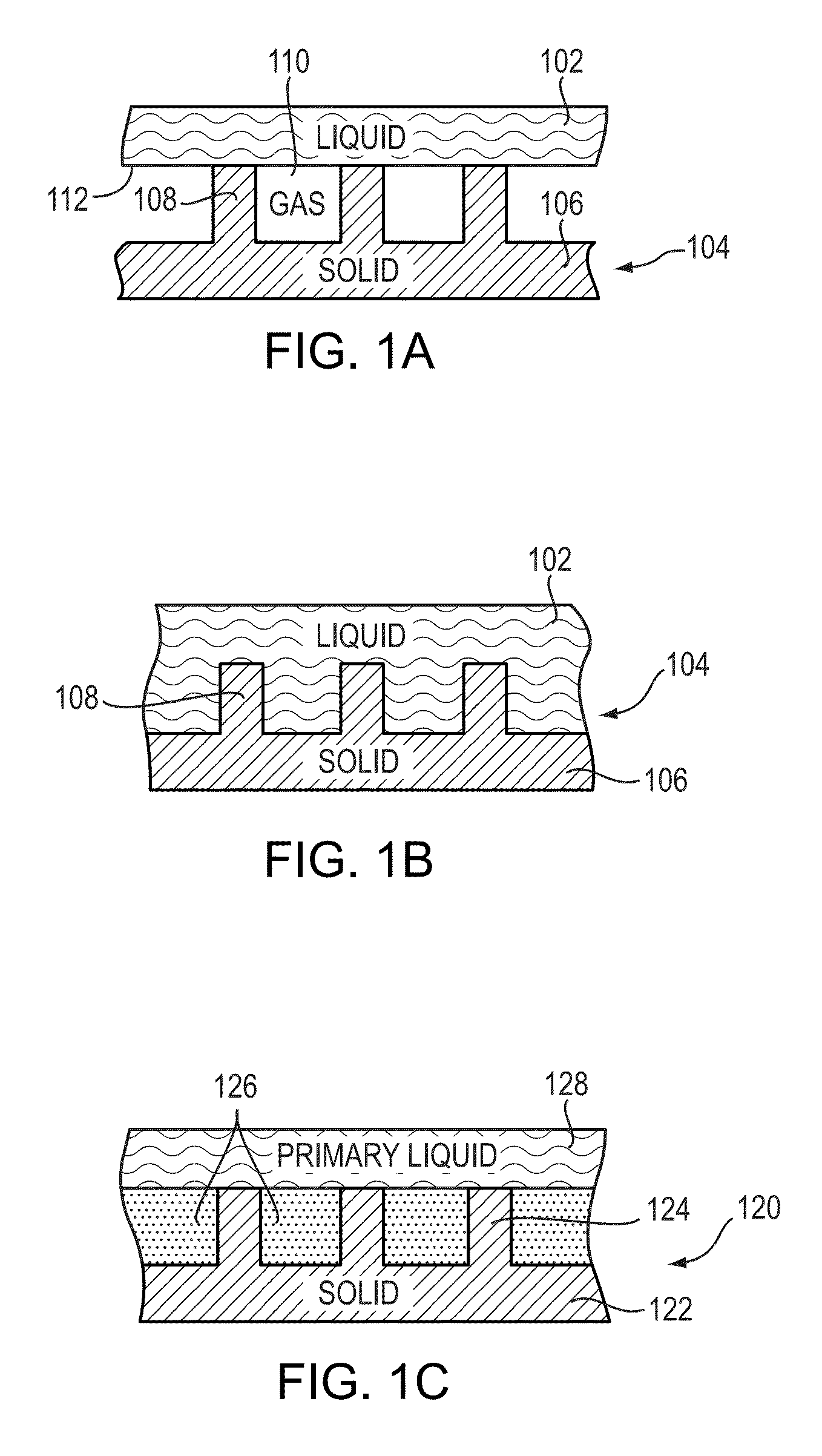

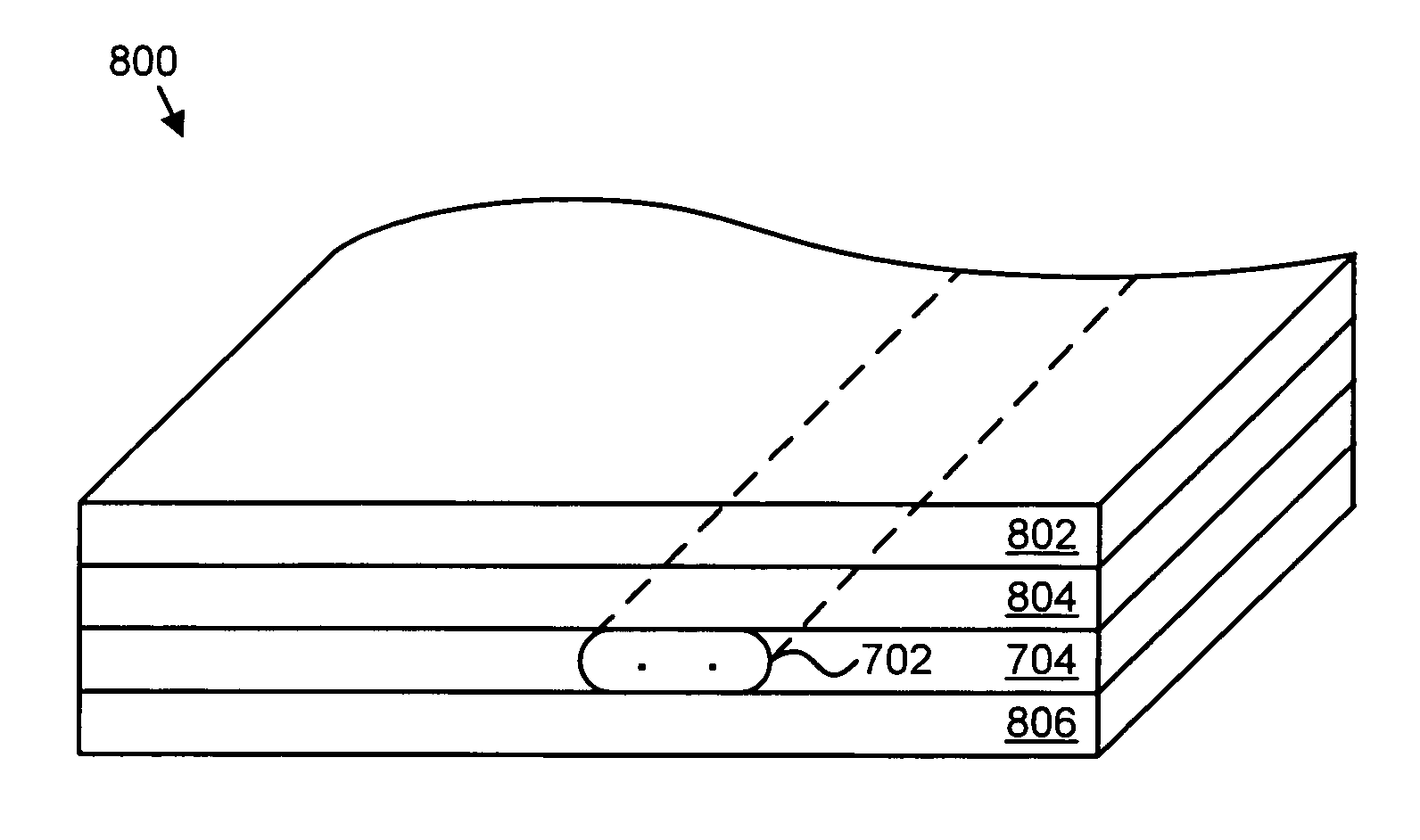

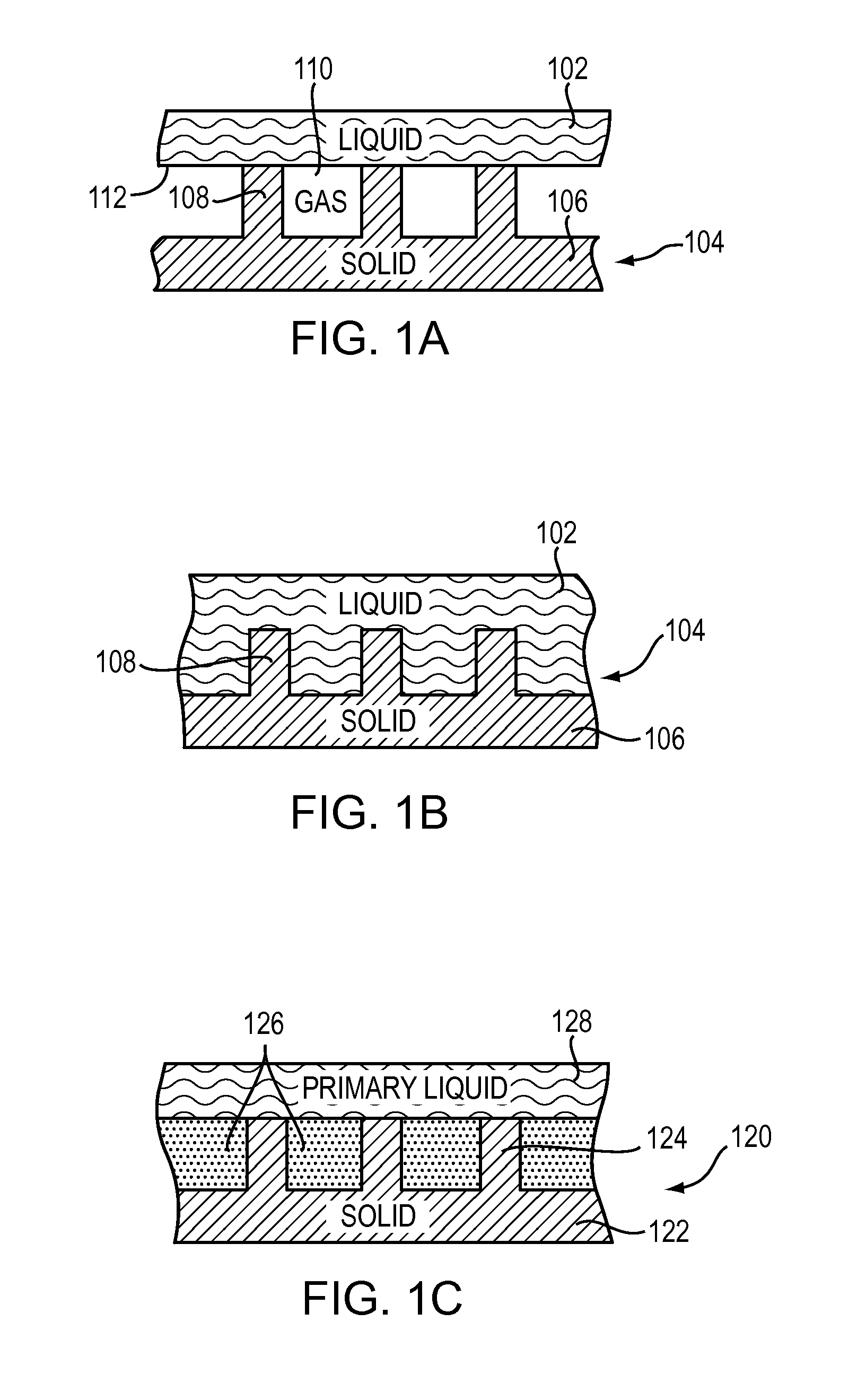

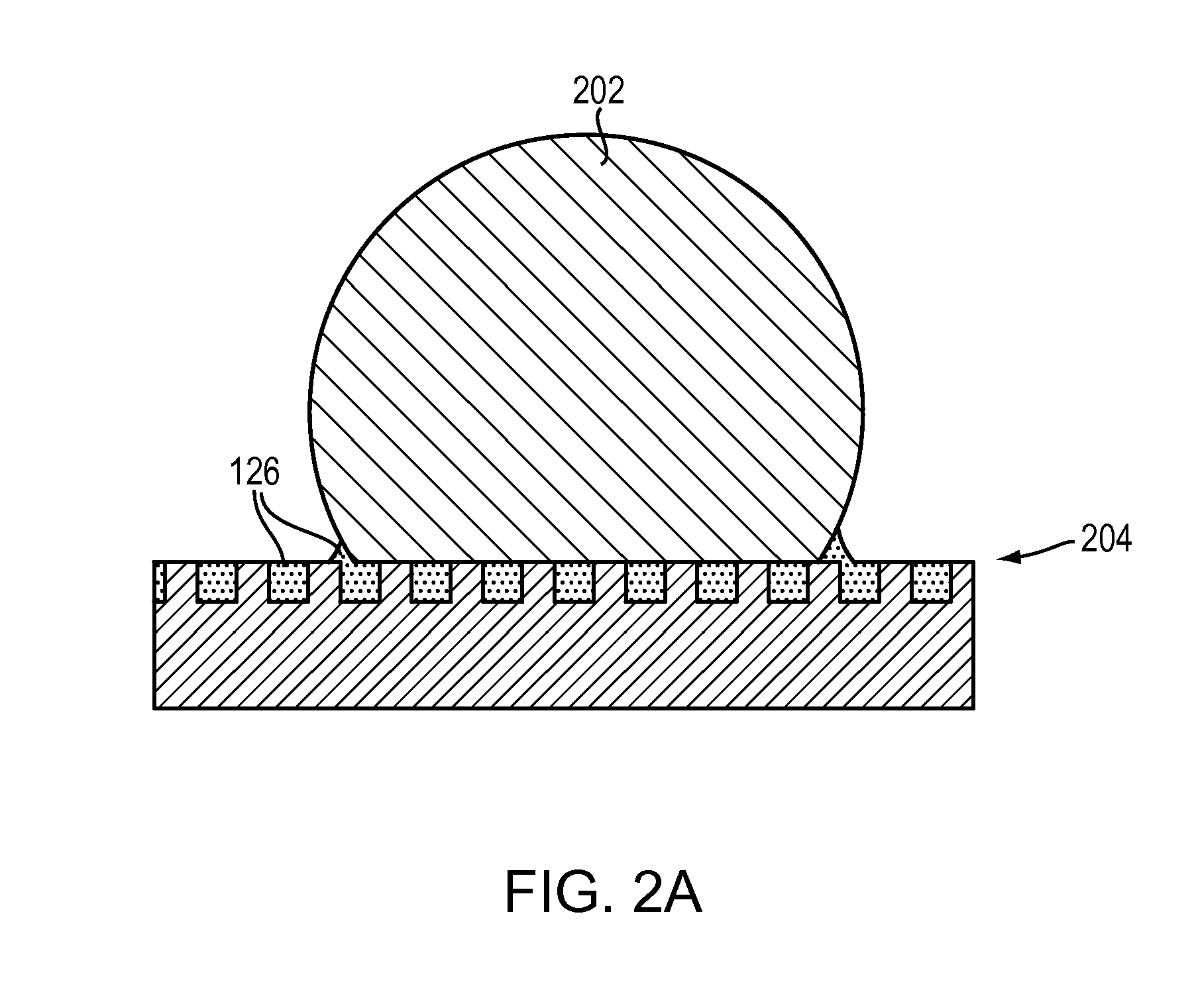

Liquid-Impregnated Surfaces, Methods of Making, and Devices Incorporating the Same

InactiveUS20130032316A1Improve skidReduce resistanceFouling preventionDe-icing equipmentsNon wettingFrost

The invention is directed to an article with a liquid-impregnated surface, the surface having a matrix of features thereupon, spaced sufficiently close to stably contain a liquid therebetween or therewithin, and preferable also a thin film thereupon. The surface provides the article with advantageous non-wetting properties. Compared to previous non-wetting surfaces, which include a gas (e.g., air) entrained within surface textures, these liquid-impregnated surfaces are resistant to impalement and frost formation, and are therefore more robust.

Owner:MASSACHUSETTS INST OF TECH

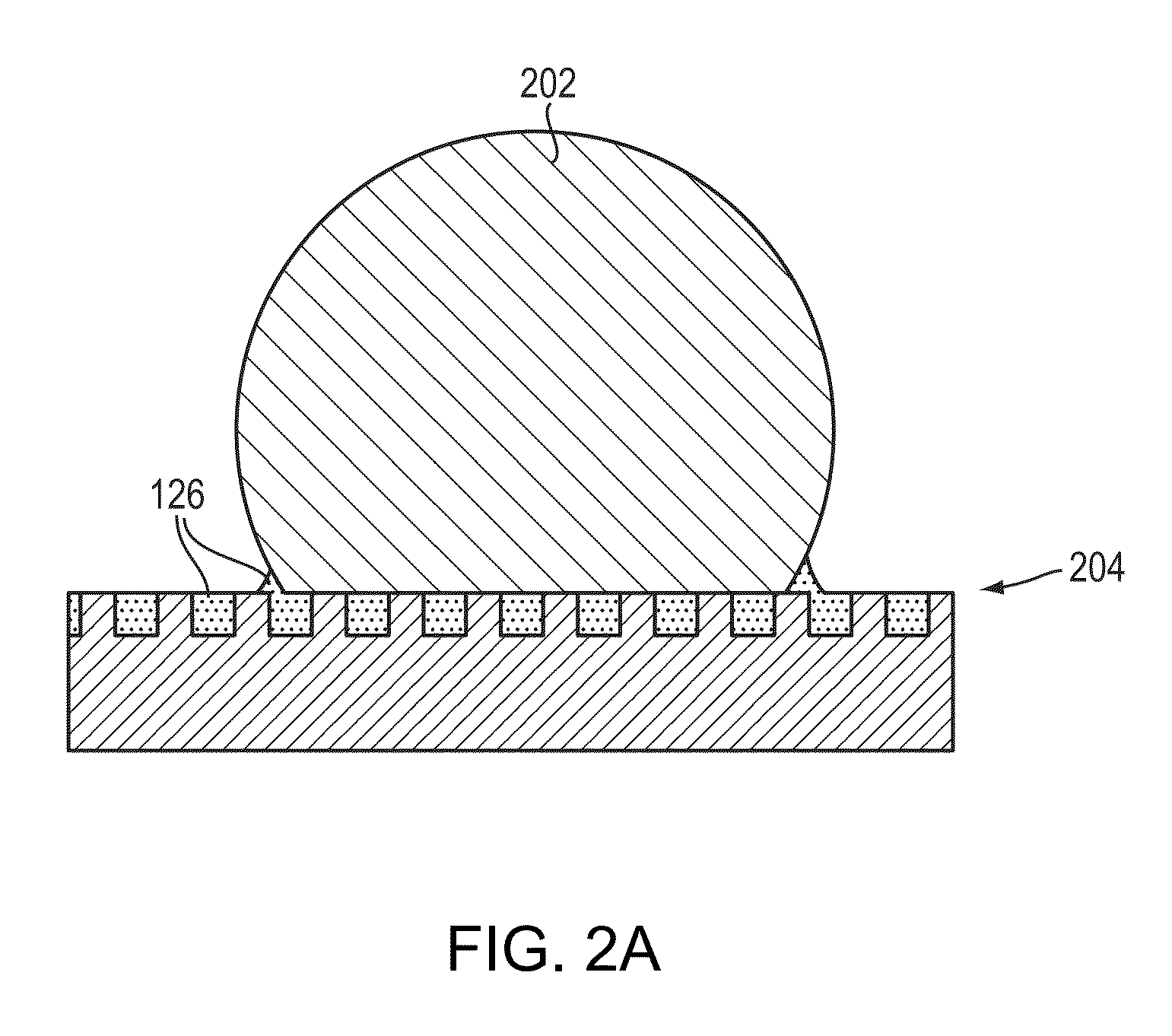

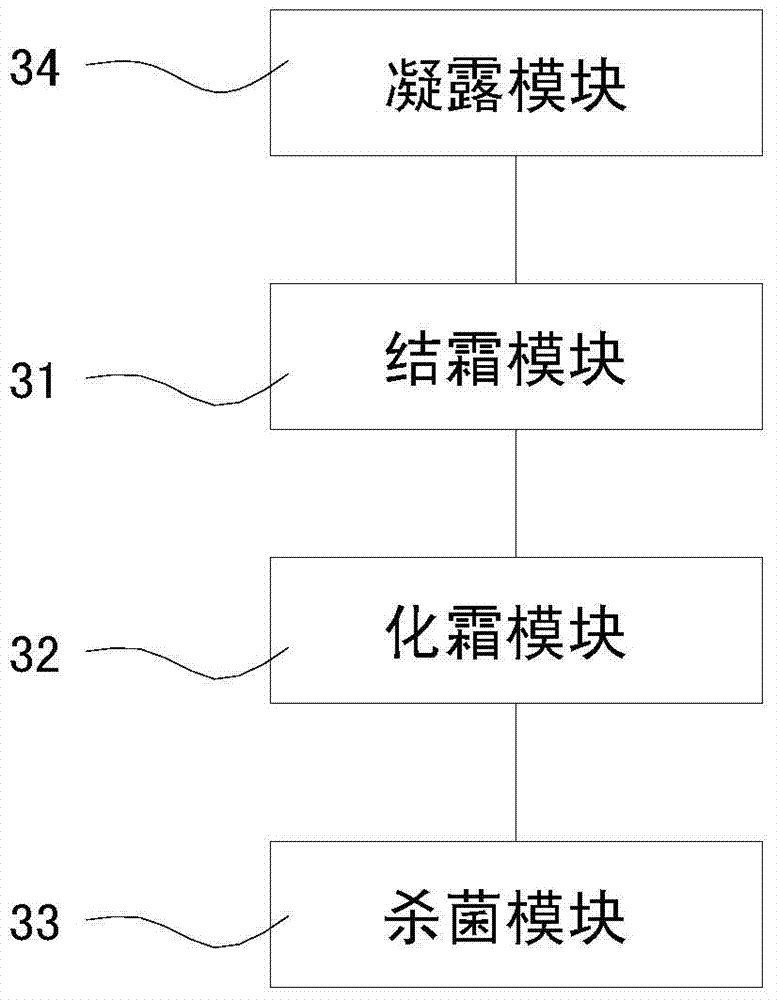

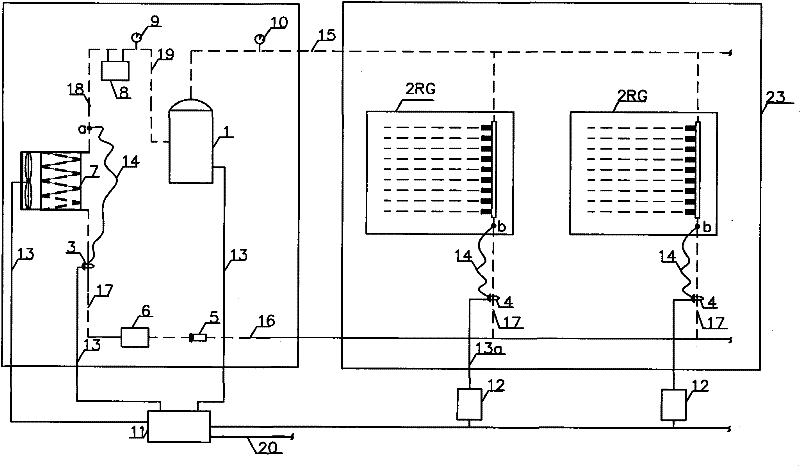

Cleaning method and device for indoor heat exchanger of air conditioner

ActiveCN104848738AAchieve high temperature sterilization functionImprove comfortCleaning heat-transfer devicesSpace heating and ventilation safety systemsFrostEngineering

The invention discloses a cleaning method and device for an indoor heat exchanger of an air conditioner. The cleaning method for the indoor heat exchanger of the air conditioner comprises the steps that 1, the air conditioner is controlled to operate in a refrigerating mode, an indoor draught fan is switched off, the surface of the indoor heat exchanger is frosted, and whether frosting is completed is judged; 2, after frosting is completed, the air conditioner is controlled to operate in a heating mode, the indoor draught fan is switched on, the frost on the surface of the indoor heat exchanger is converted into water, and whether defrosting is completed is judged; 3, after defrosting is completed, the temperature T of an inner tube of the indoor heat exchanger is controlled to be a first preset temperature TS1, the temperature TS1 of the inner tube of the indoor heat exchanger is kept for a first preset time tS1, and cleaning is completed. By the adoption of the cleaning method for the indoor heat exchanger of the air conditioner, cleaning of the indoor heat exchanger of the air conditioner can be achieved, no part is additionally arranged, cost is not increased, the high-temperature sterilizing function is achieved, and the comfort and health of a user are further improved.

Owner:GREE ELECTRIC APPLIANCES INC

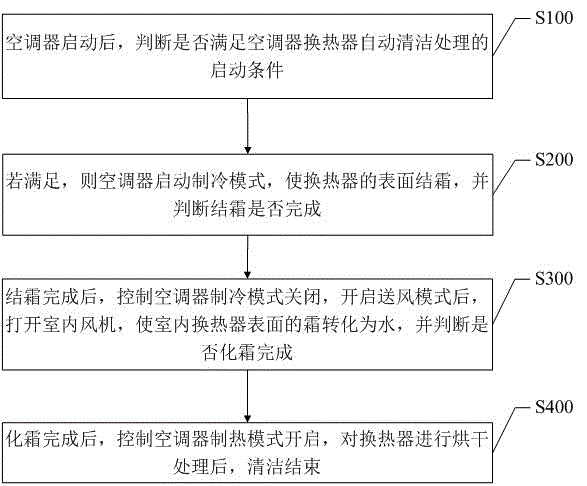

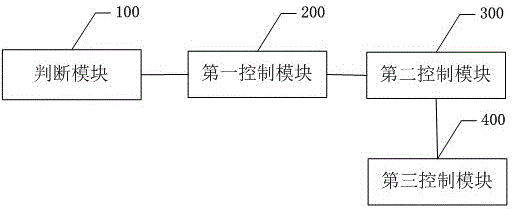

Automatic cleaning treatment method and automatic cleaning treatment system of air-conditioning heat exchanger

The invention discloses an automatic cleaning treatment method and an automatic cleaning treatment system of an air-conditioning heat exchanger. The automatic cleaning treatment method comprises the following steps: after an air-conditioner is started, judging whether the starting condition of automatic cleaning treatment of the air-conditioning heat exchanger is met; if yes, starting the refrigerating mode of the air-conditioner to enable surface of the heat exchanger to frost, and judging whether frosting is finished; after the frosting is finished, controlling the refrigerating mode of the air-conditioner to turn off, starting the air supply mode, then, starting an indoor draught fan to enable frost on the surface of the indoor heat exchanger to melt to water, and judging whether defrosting is finished; and after the defrosting is finished, controlling the heating mode of the air-conditioner to start, drying the heat exchanger, and ending cleaning. According to the invention, the inner side heat exchanger frosts after the temperature is rapidly decreased and covers and wraps dust and germs during frosting, the dust and germs on the heat exchangers are rapidly discharged along with water flow of a large quantity of defrosting water generated during the defrosting process, and automatic cleaning is realized through redrying treatment.

Owner:SHENZHEN SKYWORTH AIR CONDITIONING TECH CO LTD

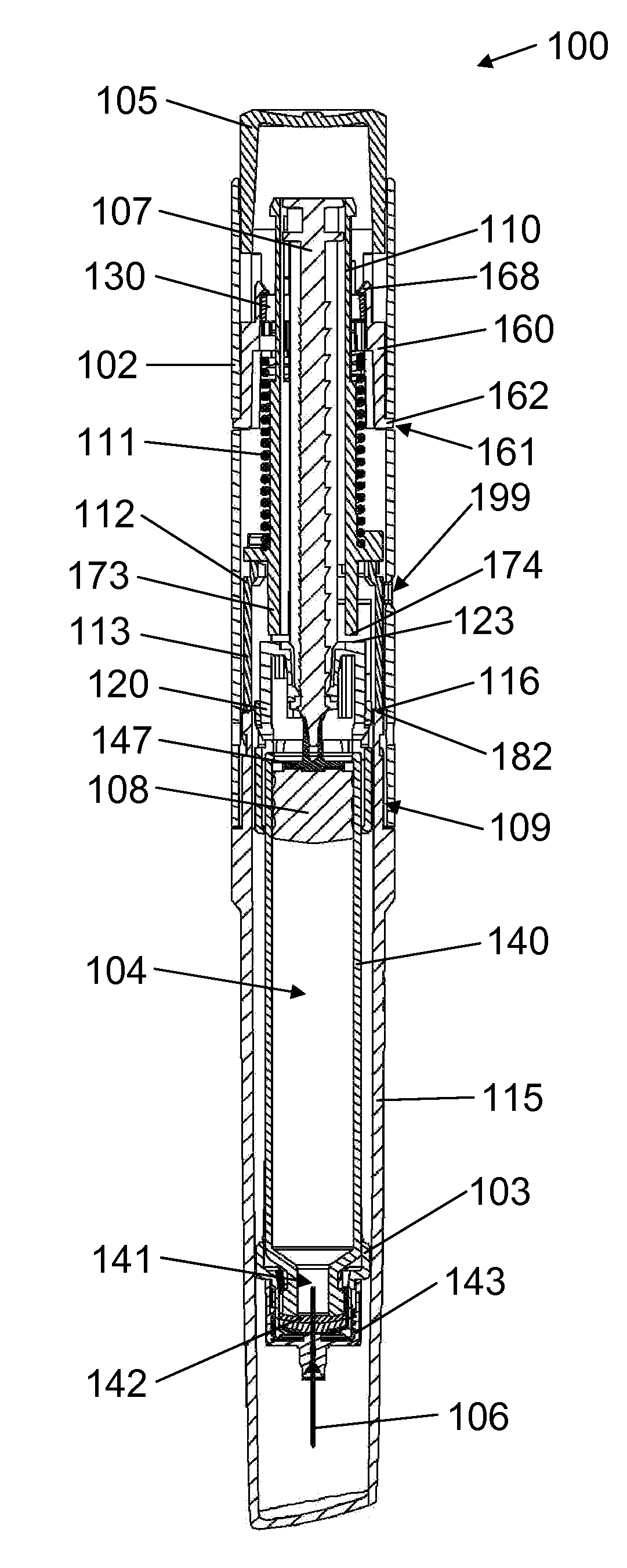

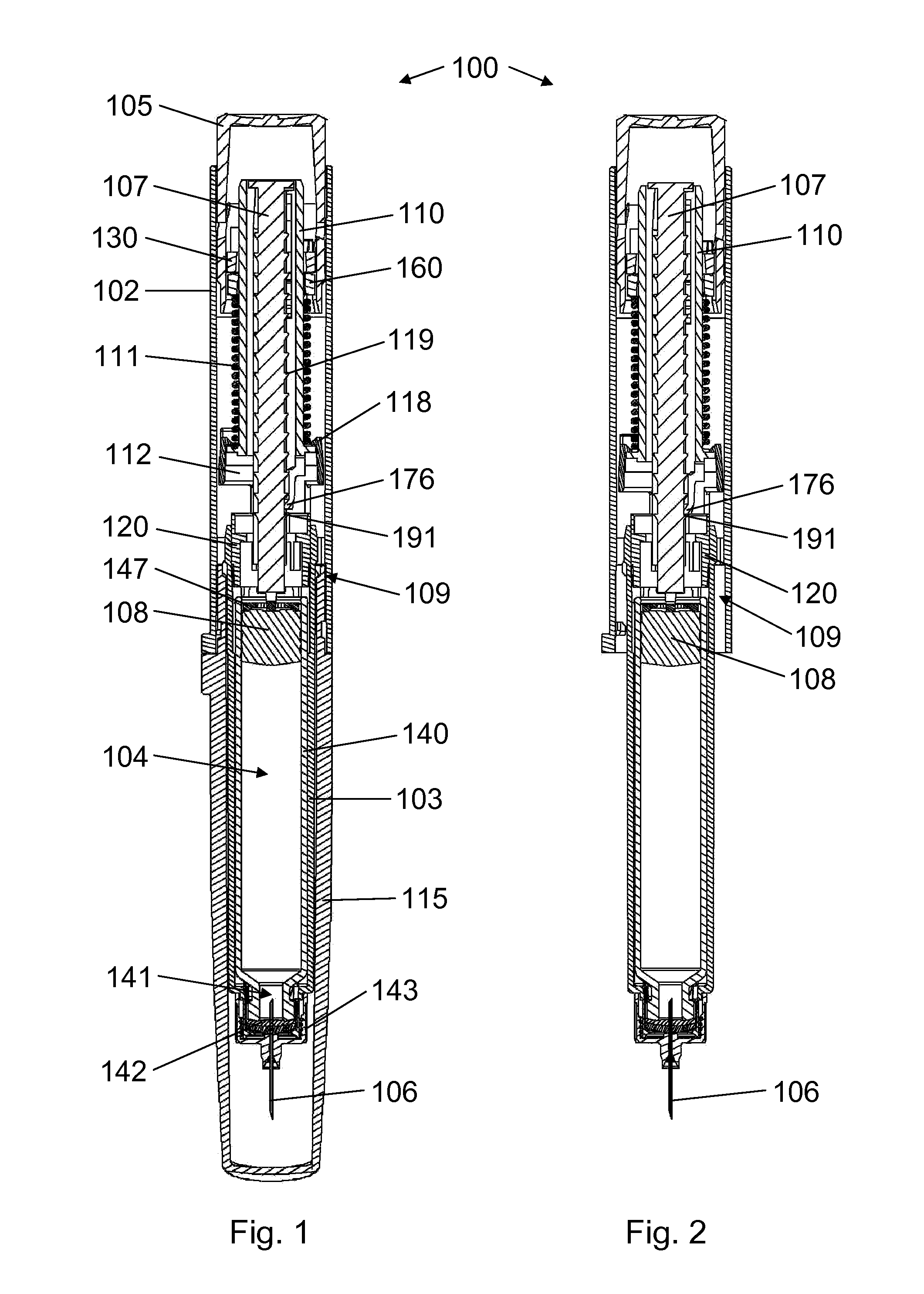

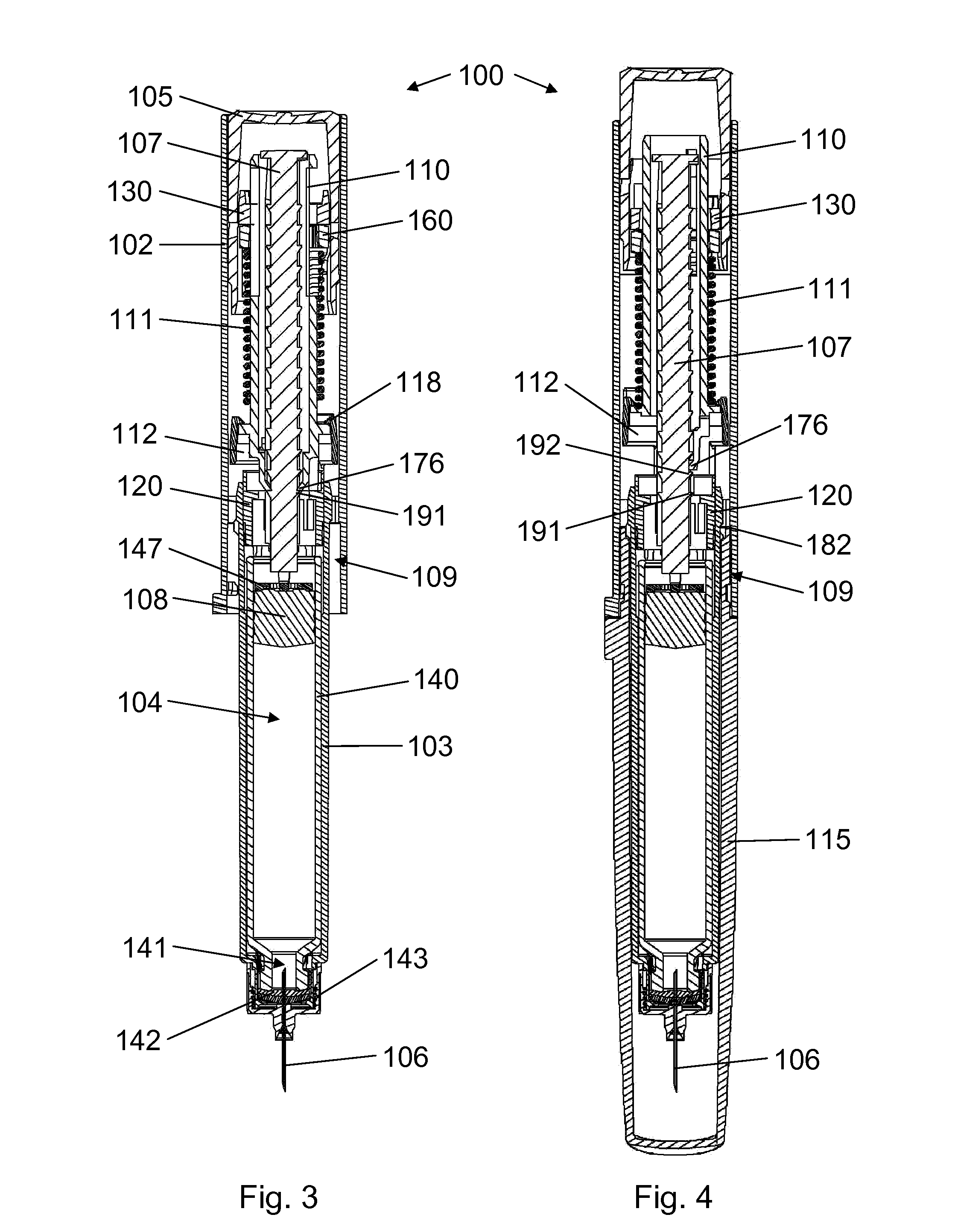

Frost protected injection device

The invention relates to an injection device (100, 200, 300) which is capable of resisting proximal movements of a piston rod (107, 207, 307) relative to a housing (102, 202, 302), when the piston rod (107, 207, 307) is subjected to proximally directed forces below a threshold magnitude, and of allowing reversible proximal movements of the piston rod (107, 207, 307) relative to the housing (102, 202, 302), when the piston rod (107, 207, 307) is subjected to proximally directed forces of or above the threshold magnitude.

Owner:NOVO NORDISK AS

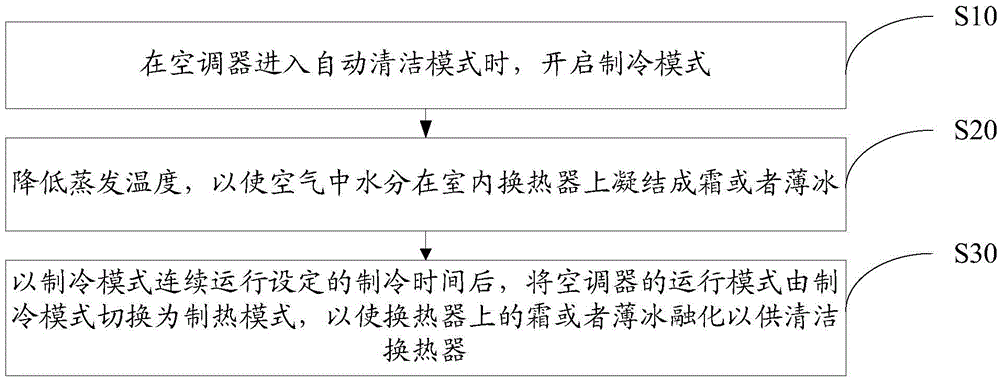

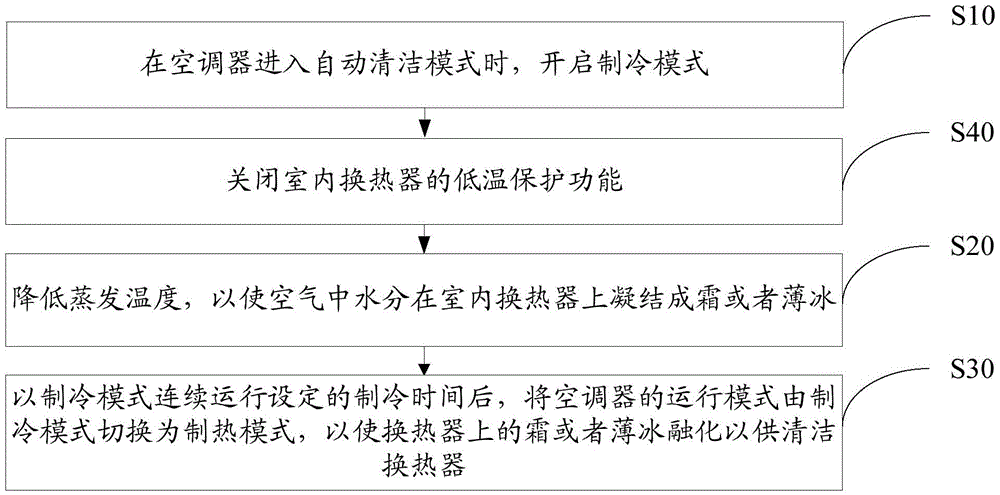

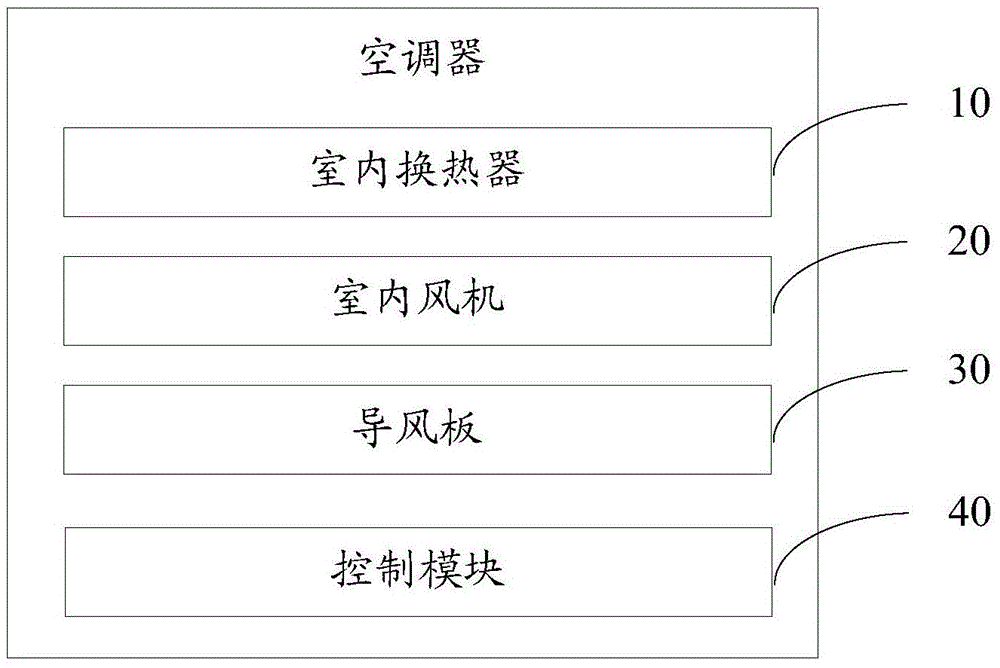

Cleaning control method for indoor heat exchanger of air conditioner and air conditioner

InactiveCN105486164AExpand the scope of cleaningRealize automatic cleaningMechanical apparatusCleaning heat-transfer devicesFrostEngineering

The invention discloses a cleaning control method for an indoor heat exchanger of an air conditioner. The cleaning control method includes the steps that when the air conditioner gets into the automatic cleaning mode, the refrigeration mode is started; evaporating temperature is reduced to enable water in air to be condensed into frost or thin ice on the indoor heat exchanger; after the air conditioner continuously runs in the refrigeration mode for set refrigeration time, the running mode of the air conditioner is switched to the heating mode from the refrigeration mode so that the frost or the thin ice on the heat exchanger can be thawed to clean the heat exchanger. The invention further discloses the air conditioner. By means of the cleaning control method and the air conditioner, automatic cleaning of the indoor heat exchanger of the air conditioner can be achieved, and therefore it can be avoided that the heat exchange efficiency of the heat exchanger is reduced.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

Refrigerated display case having a transparent insulating glazing unit

ActiveUS20060005484A1Improve thermal performanceSeen clearly and easilyShow cabinetsEnvelopes/bags making machineryFrostEngineering

Owner:SAINT-GOBAIN GLASS FRANCE

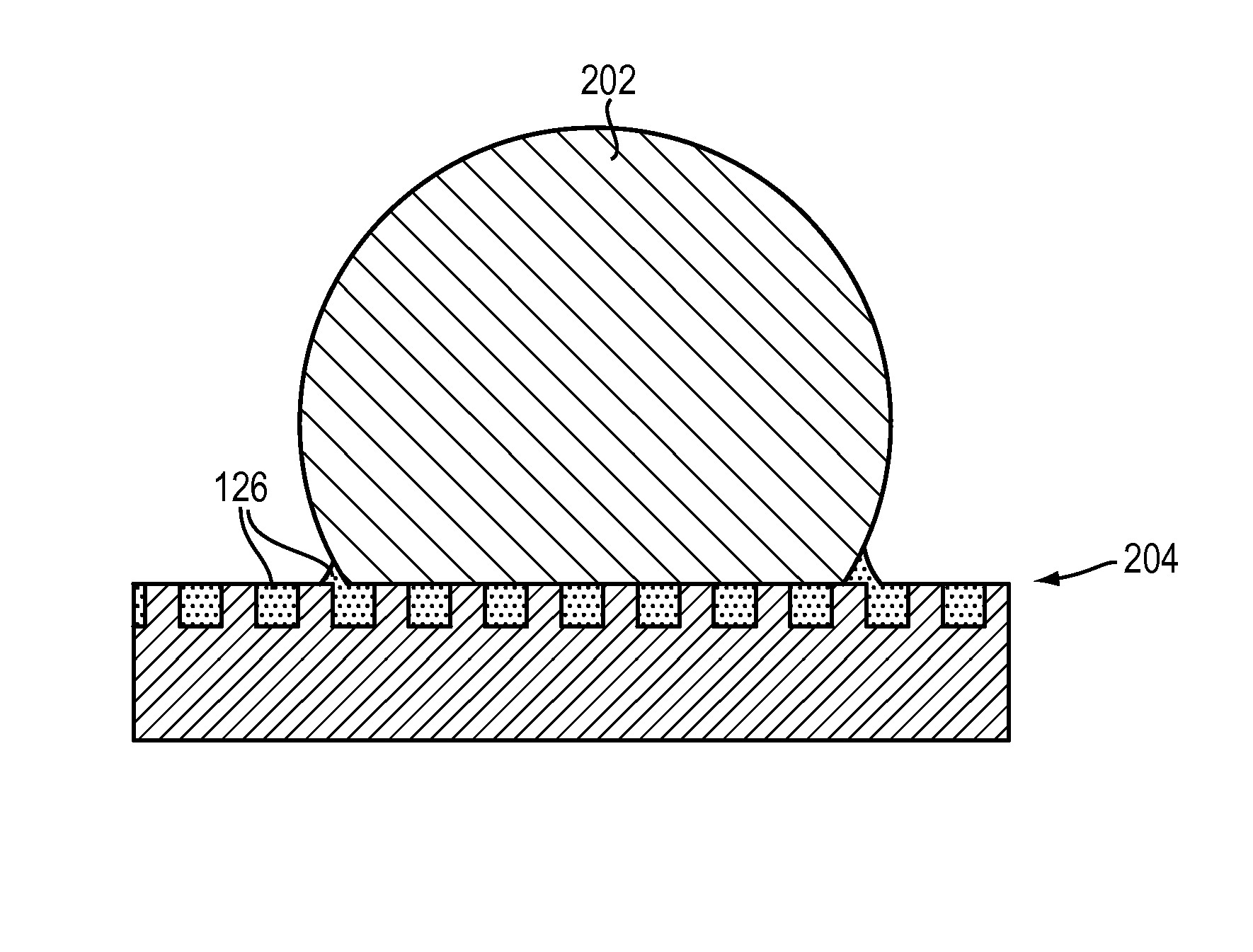

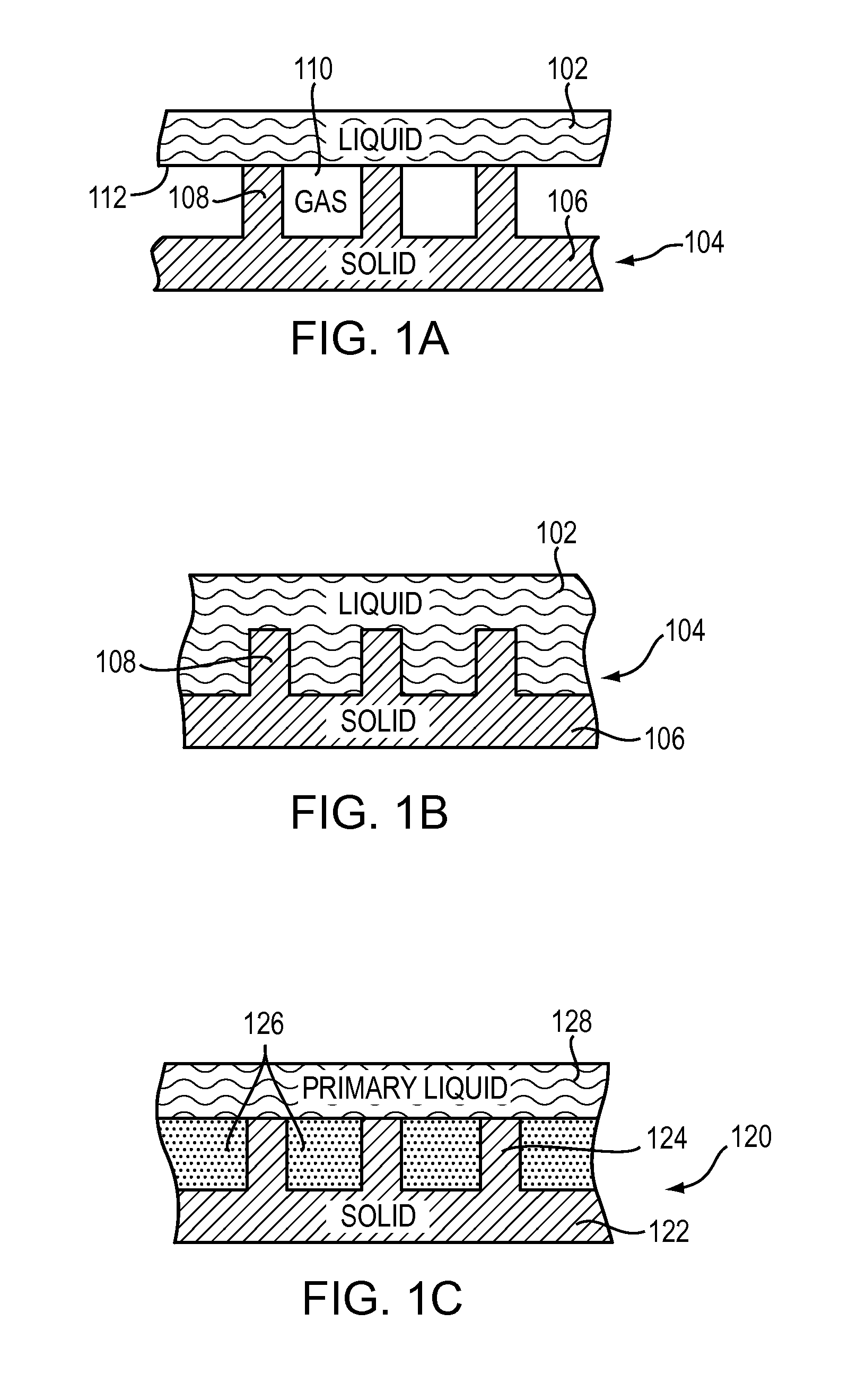

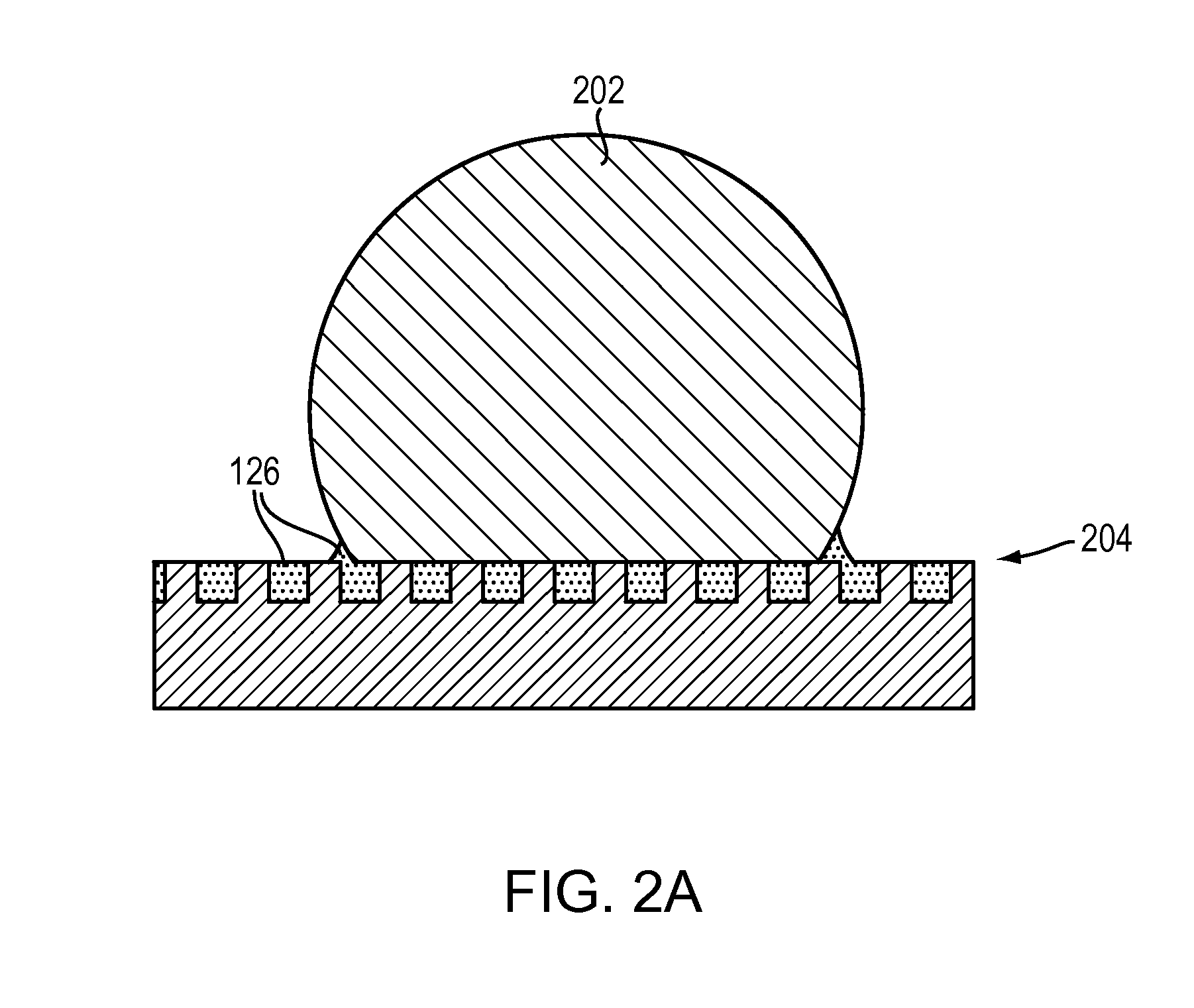

Liquid-impregnated surfaces, methods of making, and devices incorporating the same

ActiveUS8574704B2Reduce viscous dragMinimizes accumulationLayered productsDe-icing equipmentsNon wettingFrost

The invention is directed to an article with a liquid-impregnated surface, the surface having a matrix of features thereupon, spaced sufficiently close to stably contain a liquid therebetween or therewithin, and preferable also a thin film thereupon. The surface provides the article with advantageous non-wetting properties. Compared to previous non-wetting surfaces, which include a gas (e.g., air) entrained within surface textures, these liquid-impregnated surfaces are resistant to impalement and frost formation, and are therefore more robust.

Owner:MASSACHUSETTS INST OF TECH

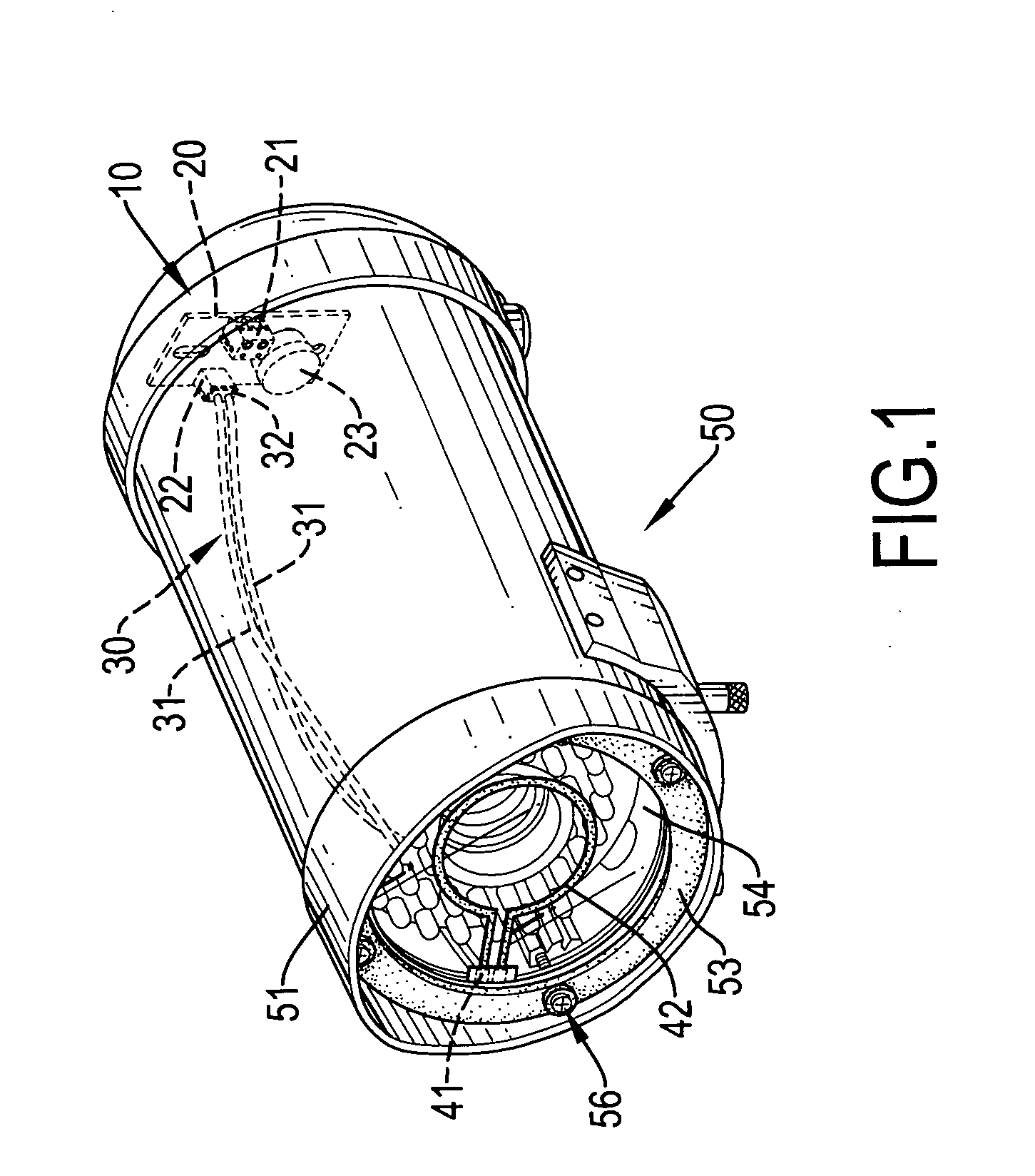

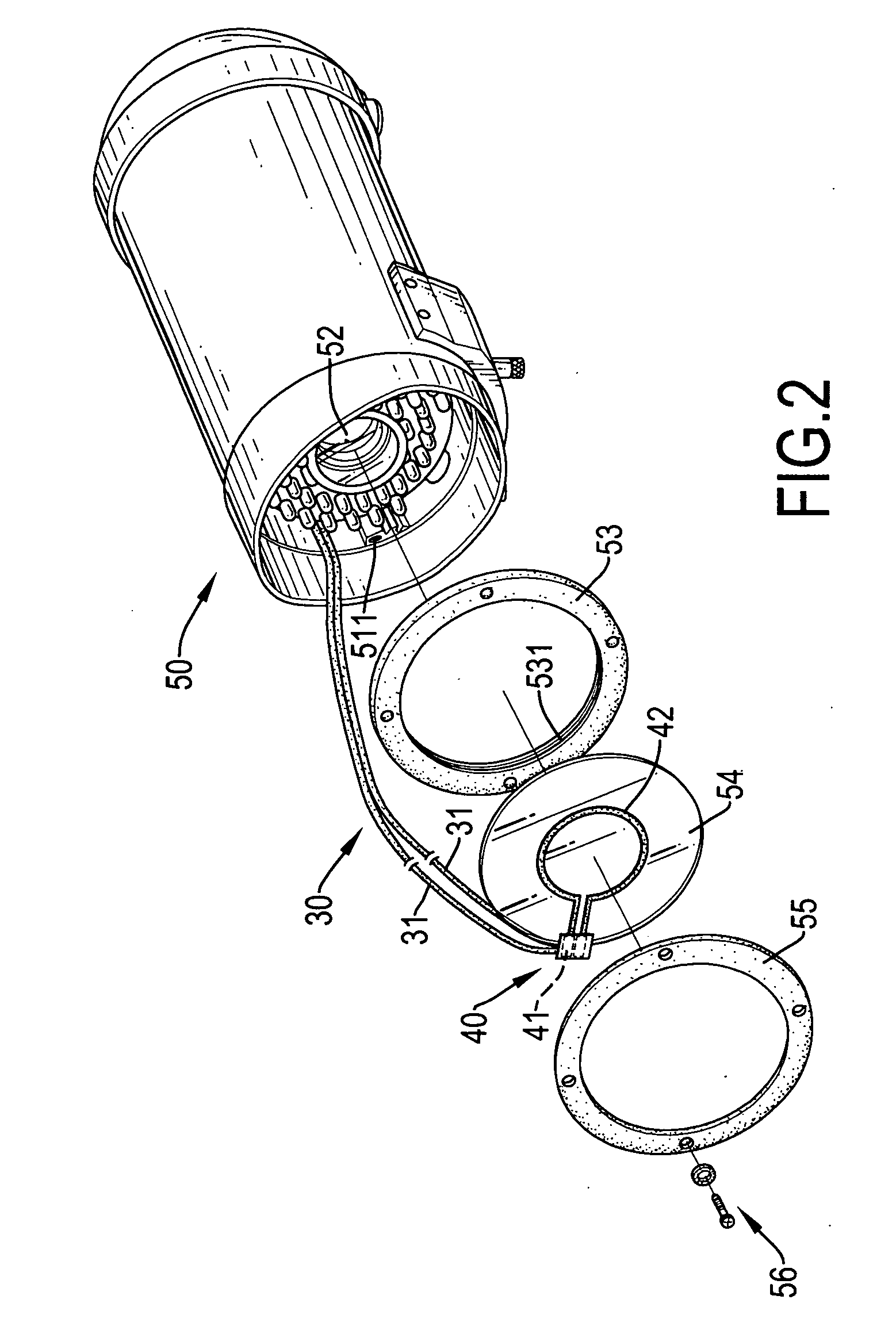

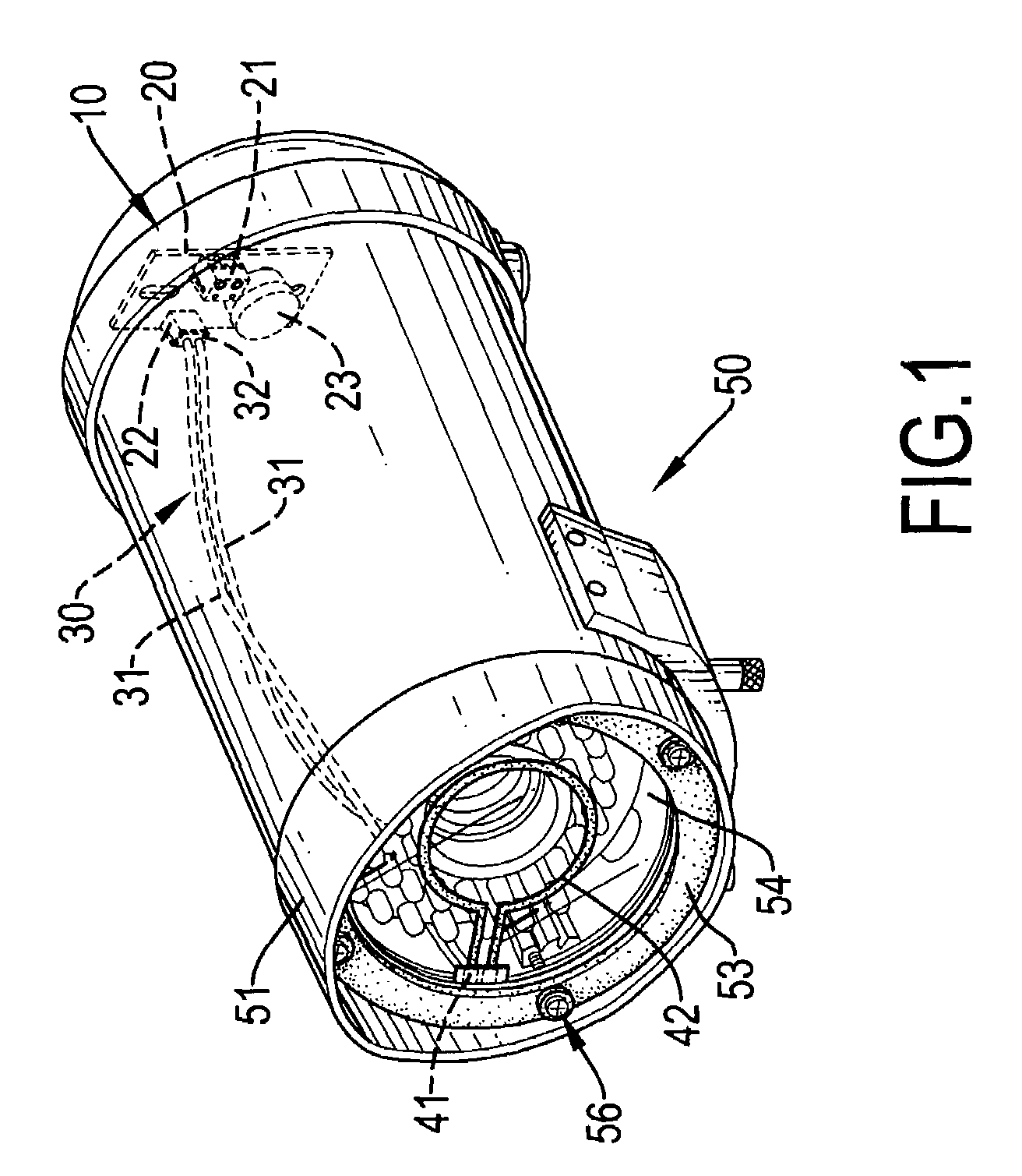

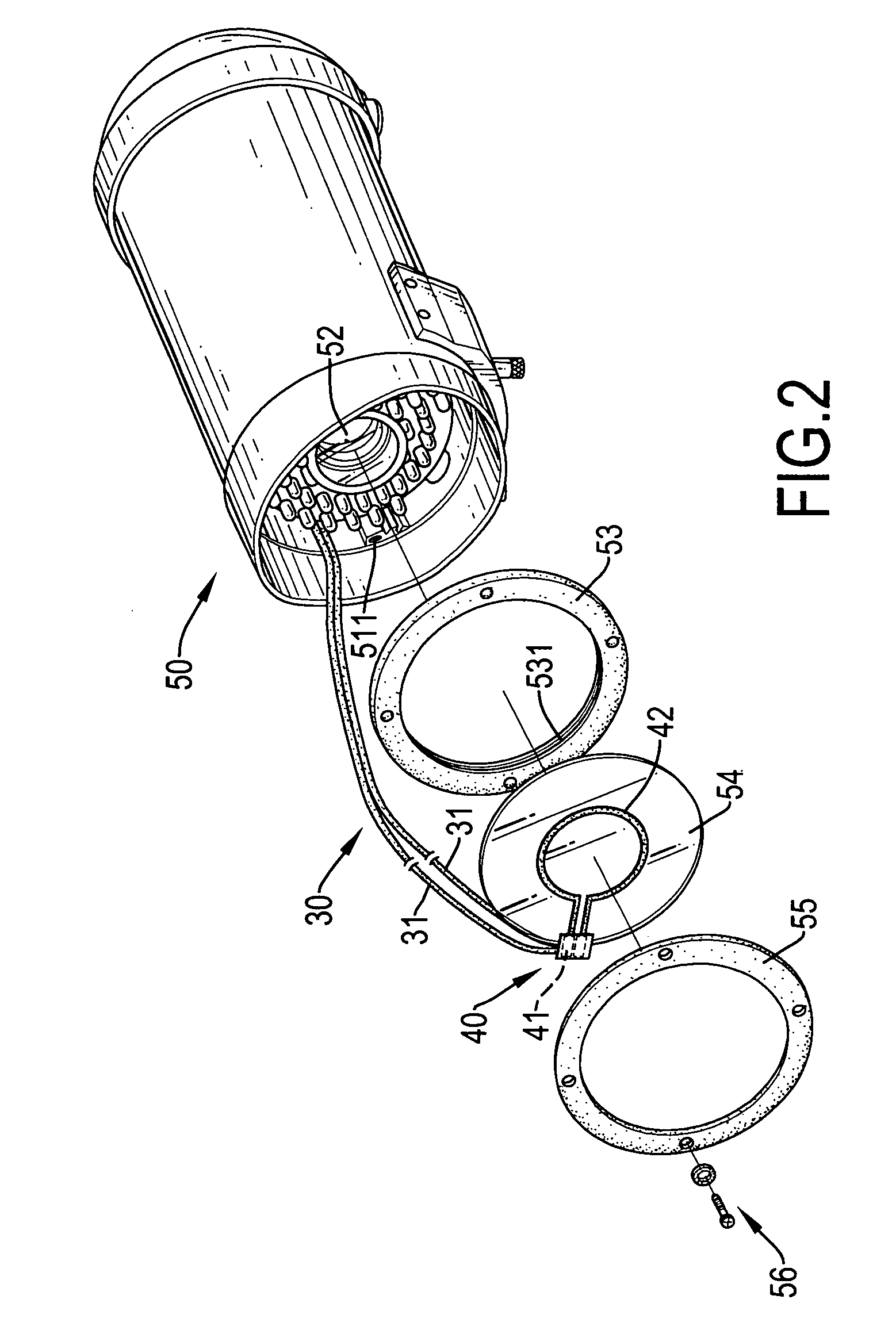

Defogging device for a surveillance camera

InactiveUS20070109441A1Television system detailsCosmonautic condition simulationsFrostTransmitted power

A defogging device for a surveillance camera has a heating element, a circuit board and a power cord. The heating element is mounted over the lens of the surveillance camera. The circuit board compares ambient temperature to a preset temperature, activates the heating element and has a power input terminal, a power output terminal and a temperature sensor. The temperature sensor is mounted between the power input terminal and the power output terminal and senses ambient temperature. When the ambient temperature is above the preset temperature, the circuit board activates the heating element. The power cord is connected to the circuit board and the heating element and transmits power to the heating element from the circuit board. By activating the heating element during periods of cold ambient temperature, the defogging device removes fog and frost from or keeps fog and frost from forming on the lens of the surveillance camera.

Owner:CHENG YI JEN

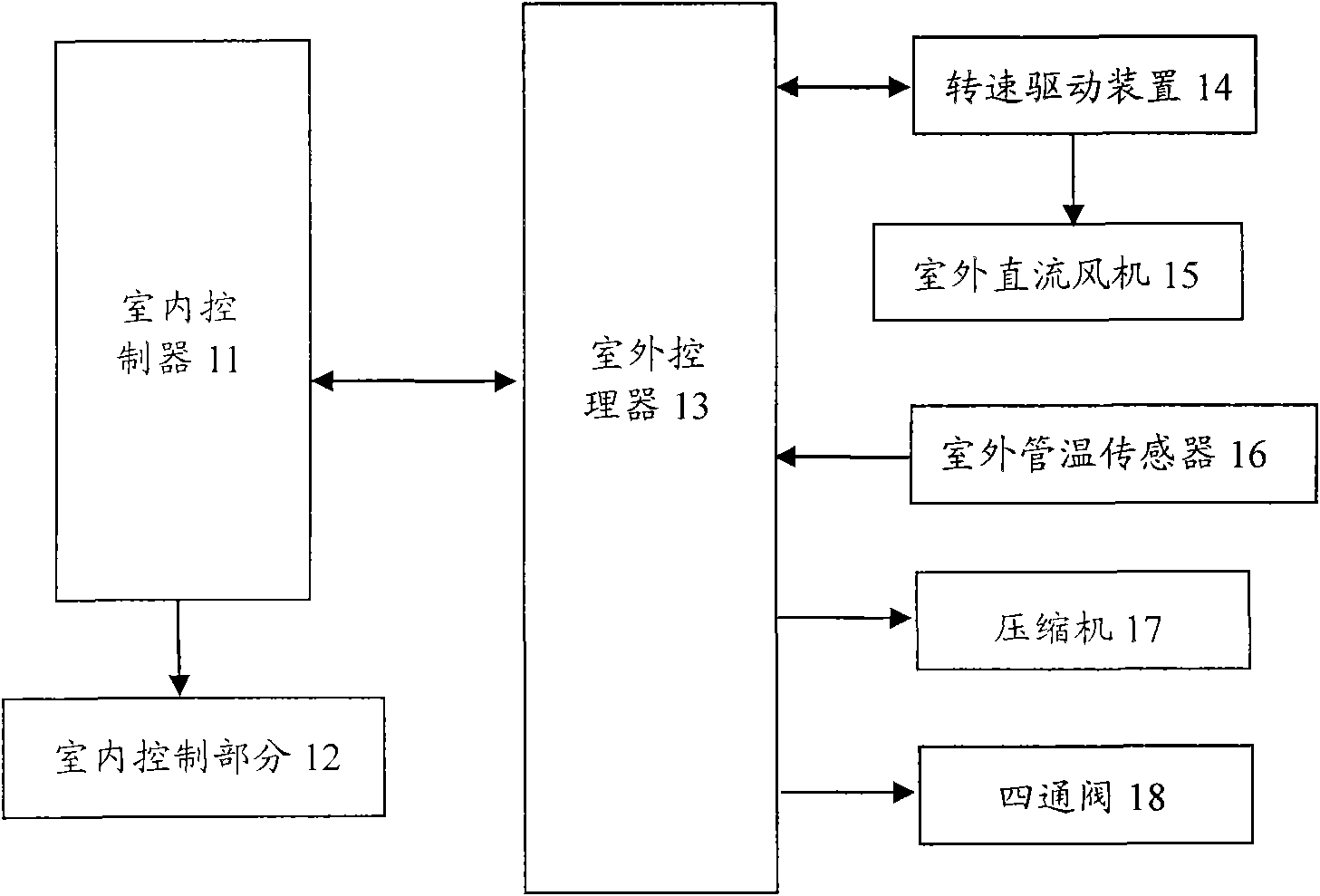

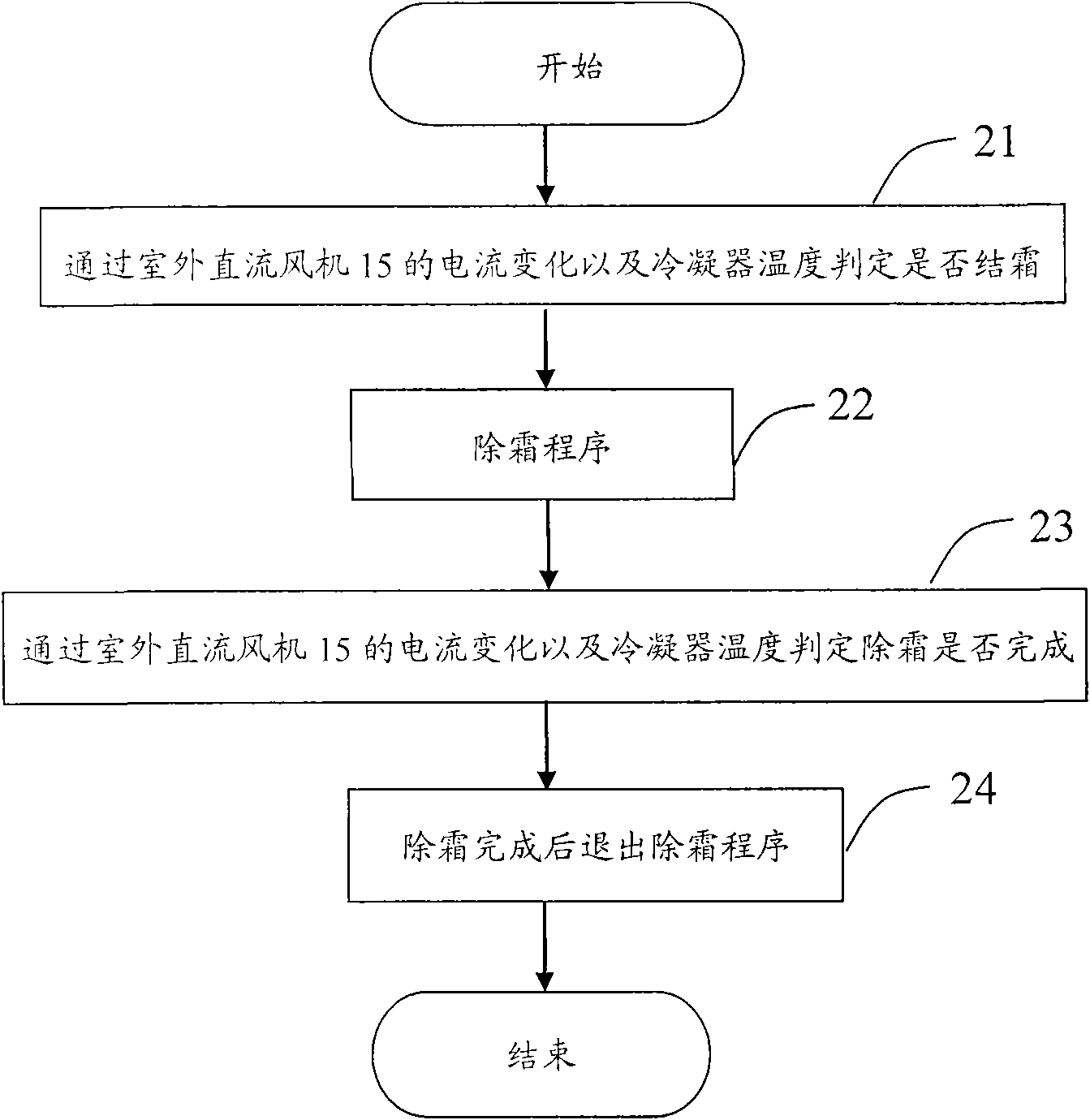

Air conditioner and frost removal control method thereof

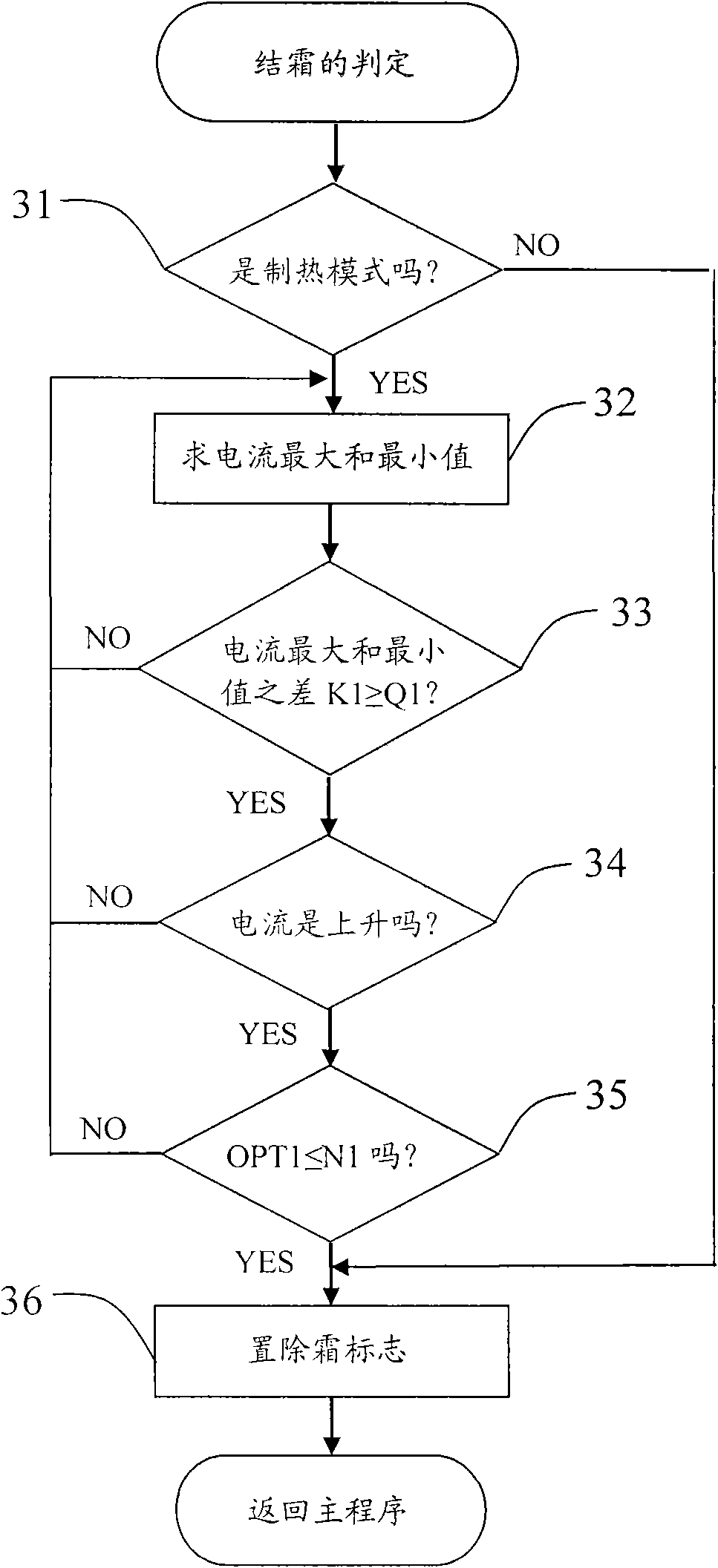

InactiveCN101660808AAccurate and smart defrostingThermometers using value differencesCurrent/voltage measurementFrostPower flow

The invention provides an air conditioner and a frost removal control method of the air conditioner. The air conditioner comprises a controller, an outdoor direct current fan, a condenser and a current detecting unit which detects the current changes of the outdoor direct current fan and feeds the detection result back to the controller. The frost removal control method of the air conditioner comprises the following steps: a, judging whether the air conditioner is frosted through the current changes of the outdoor direct current fan and the temperature of the condenser; and b, judging whetherthe frost removal is finished through the current changes of the outdoor direct current fan and the temperature of the condenser. The conditioner and the frost removal control method of the air conditioner can judge whether the condenser of the air conditioner is frosted and whether the frost removal is finished together by combining the temperature of the condenser with the current changes of theoutdoor direct current fan, and have the advantage of accurate and intelligent frost removal.

Owner:TCL CORPORATION

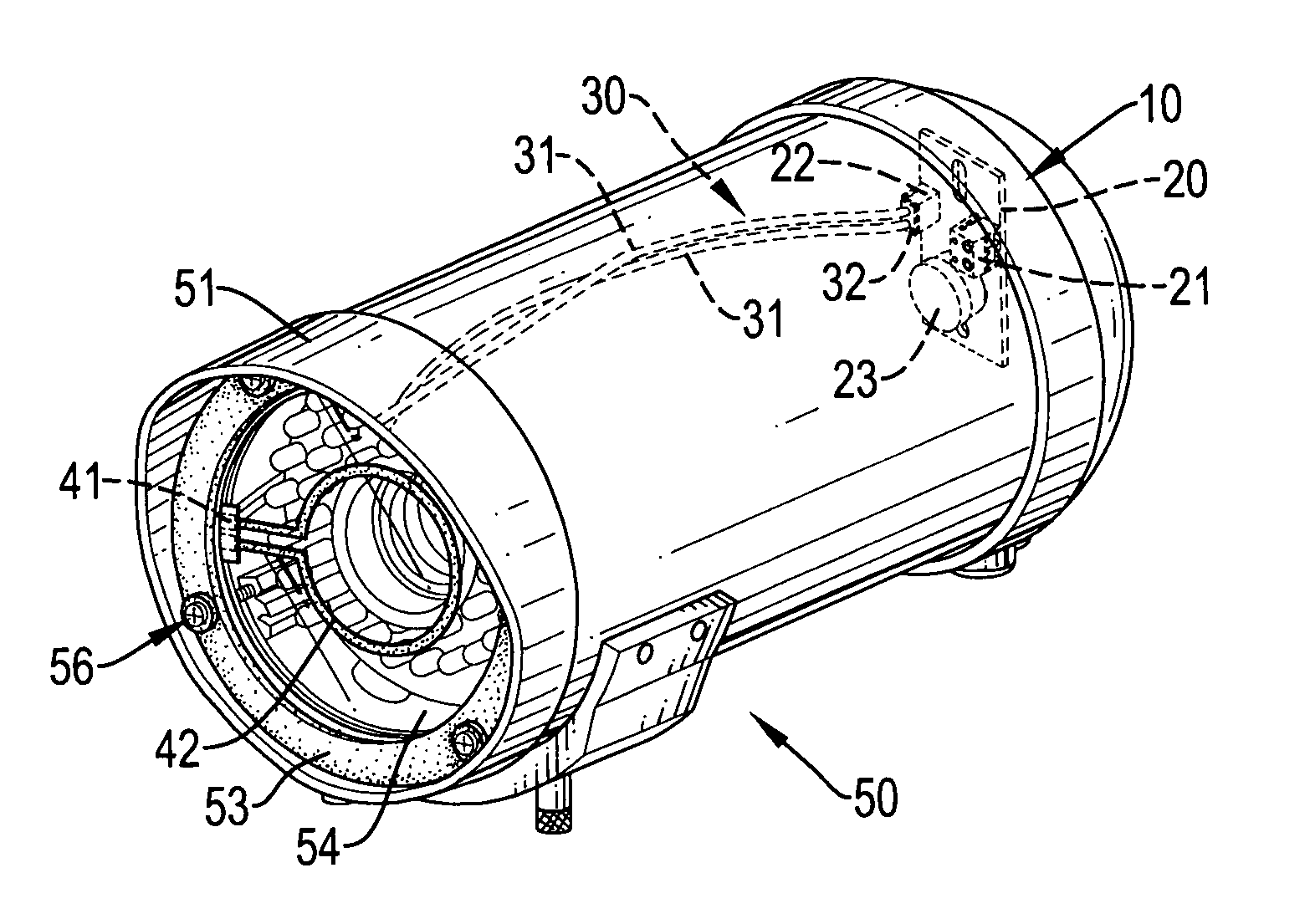

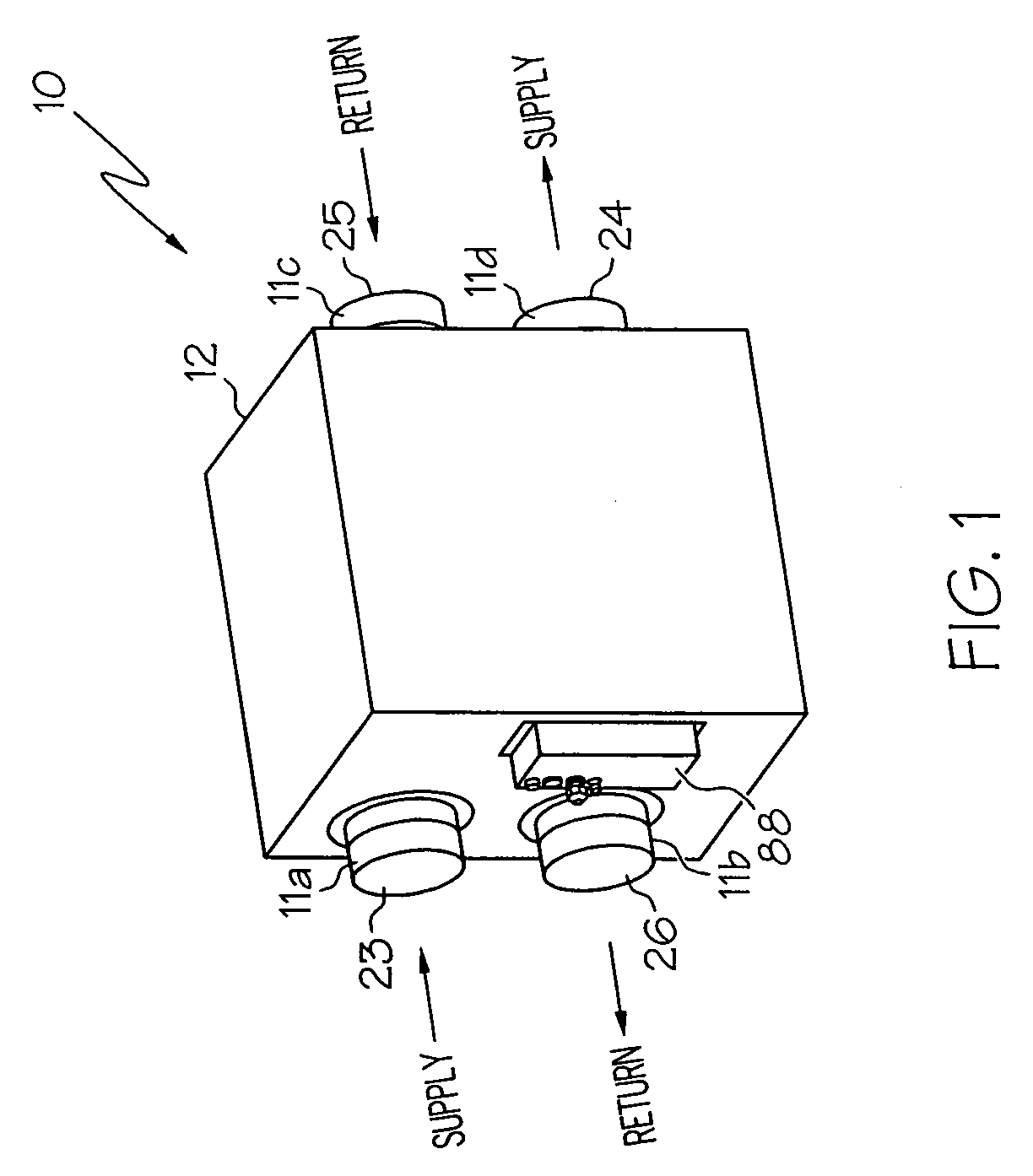

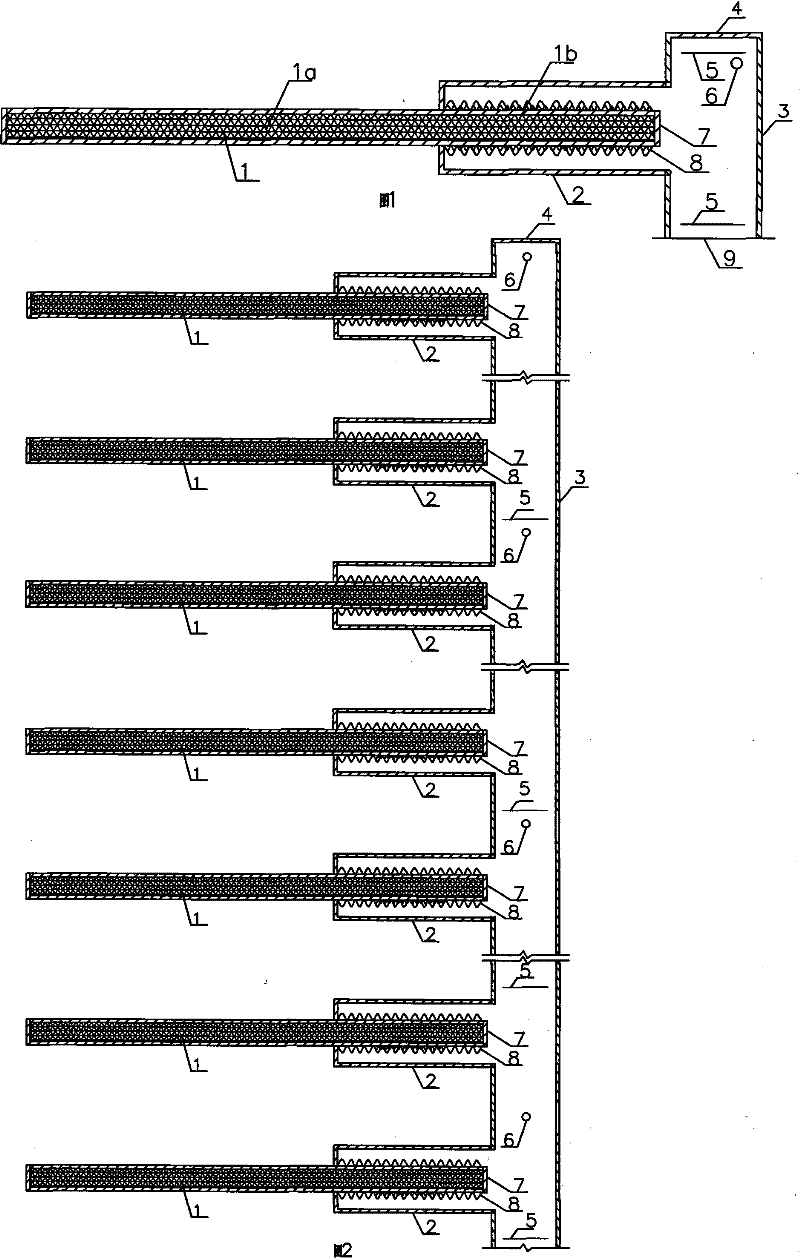

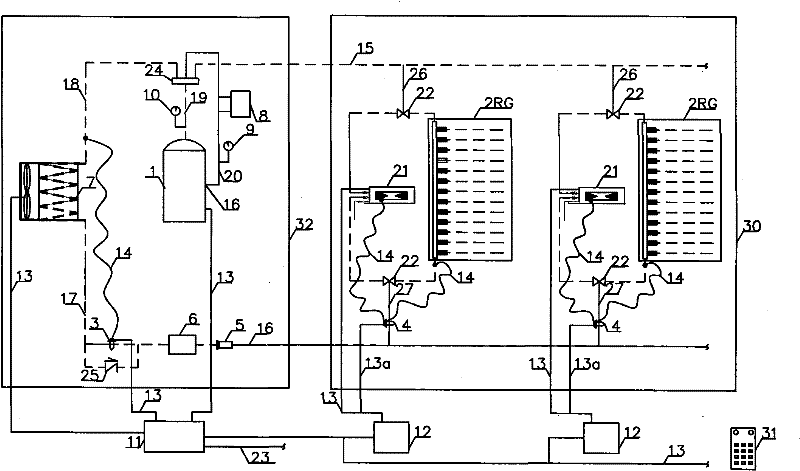

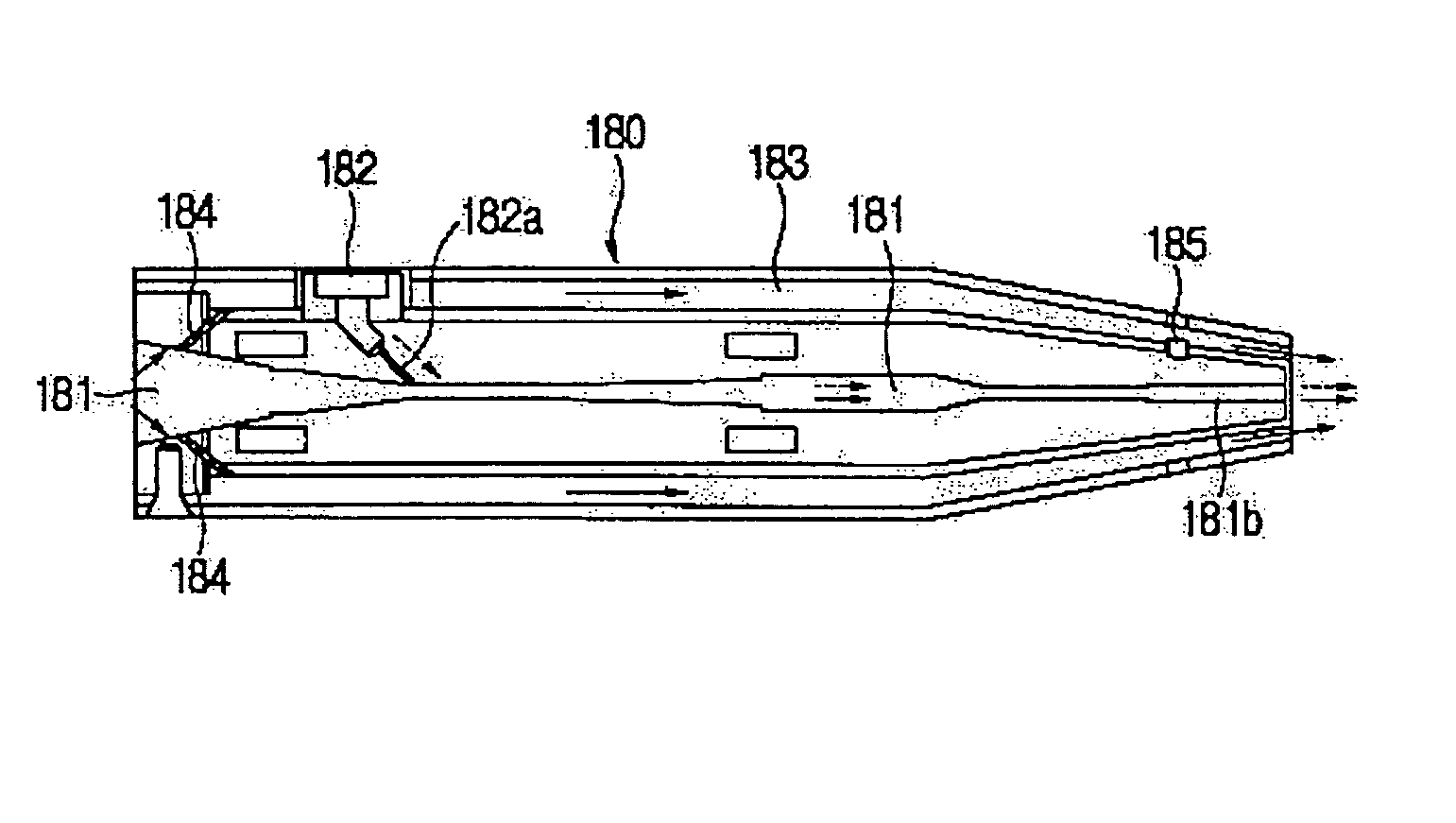

Cryogenic refrigeration unit suited for delivery vehicles

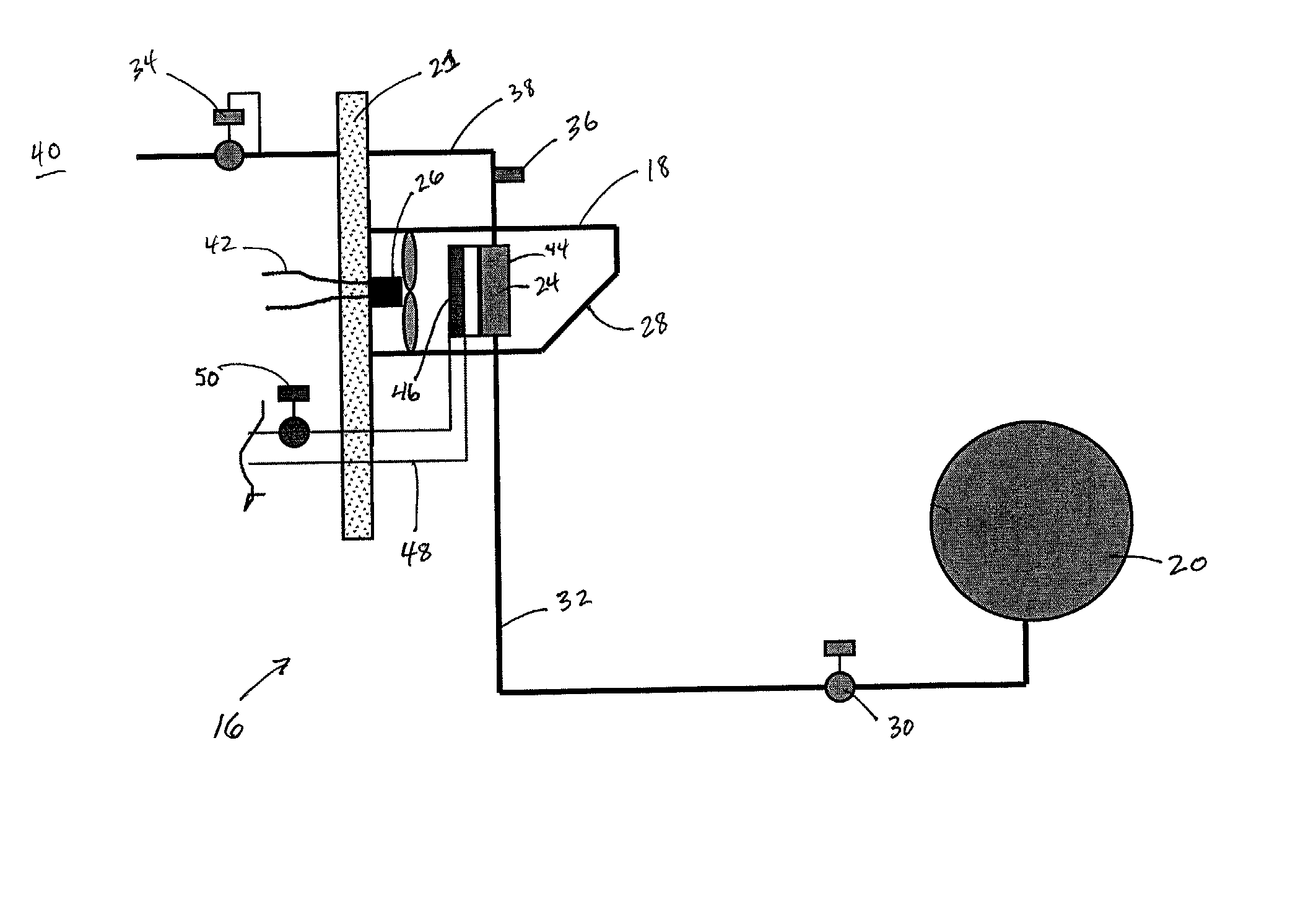

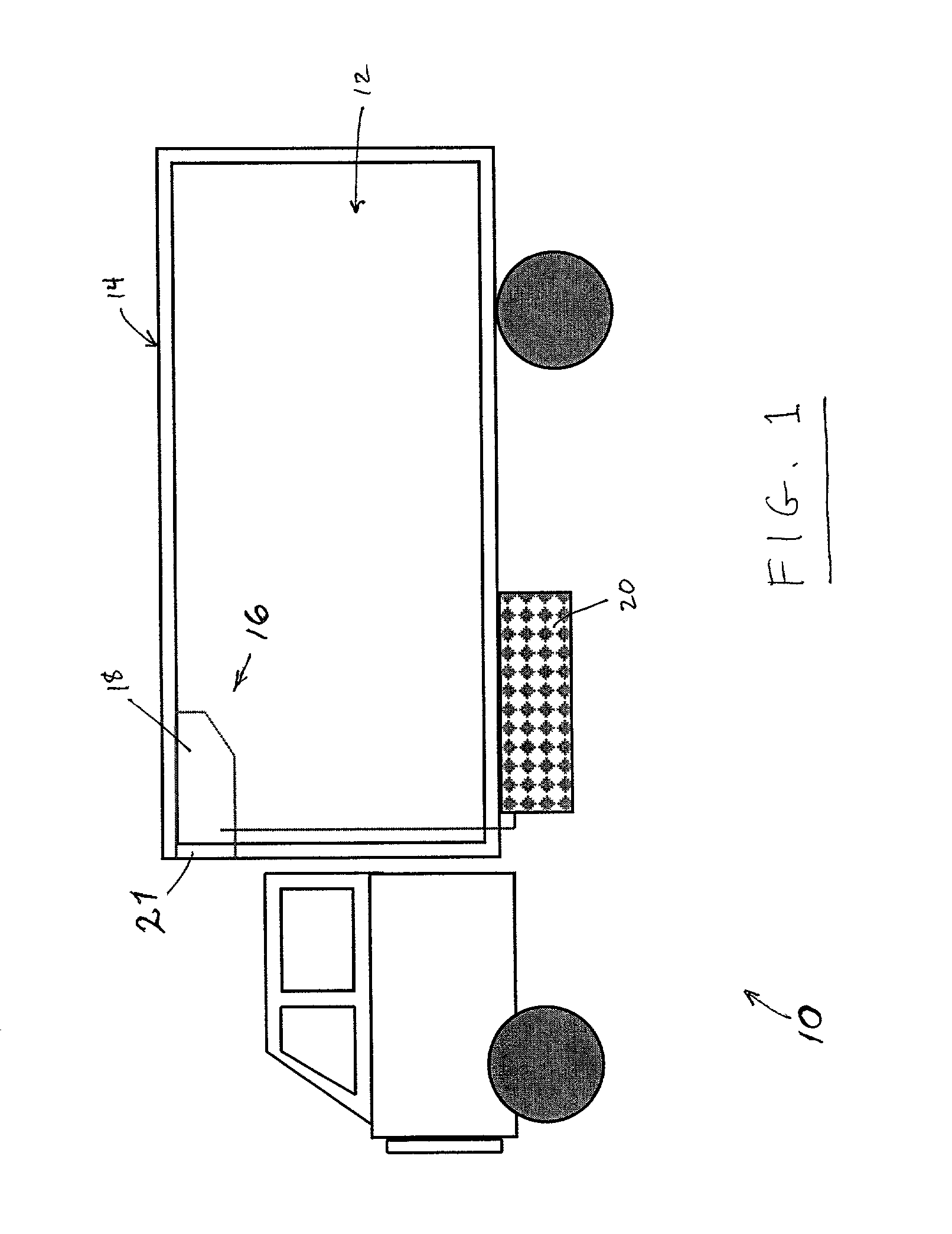

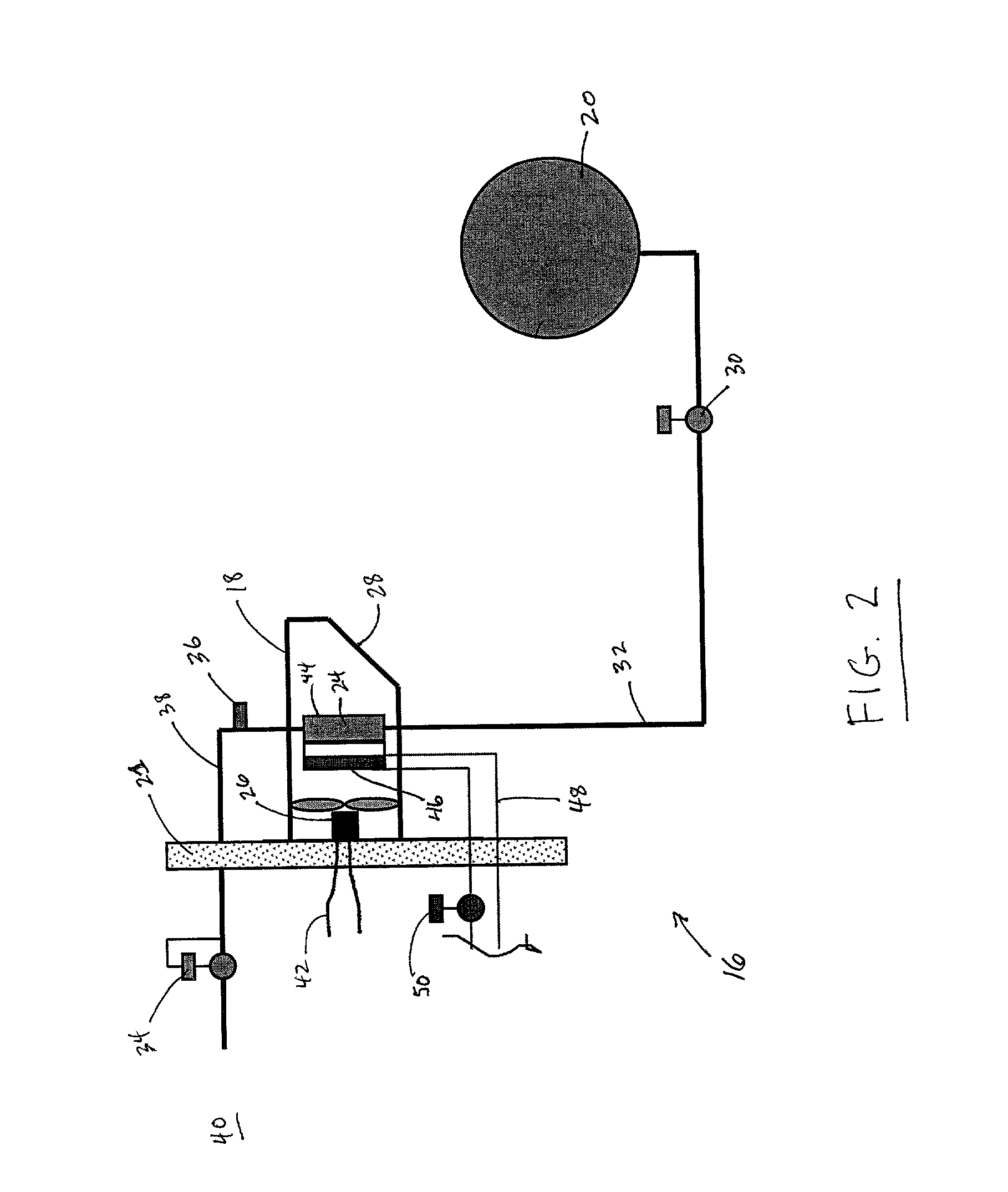

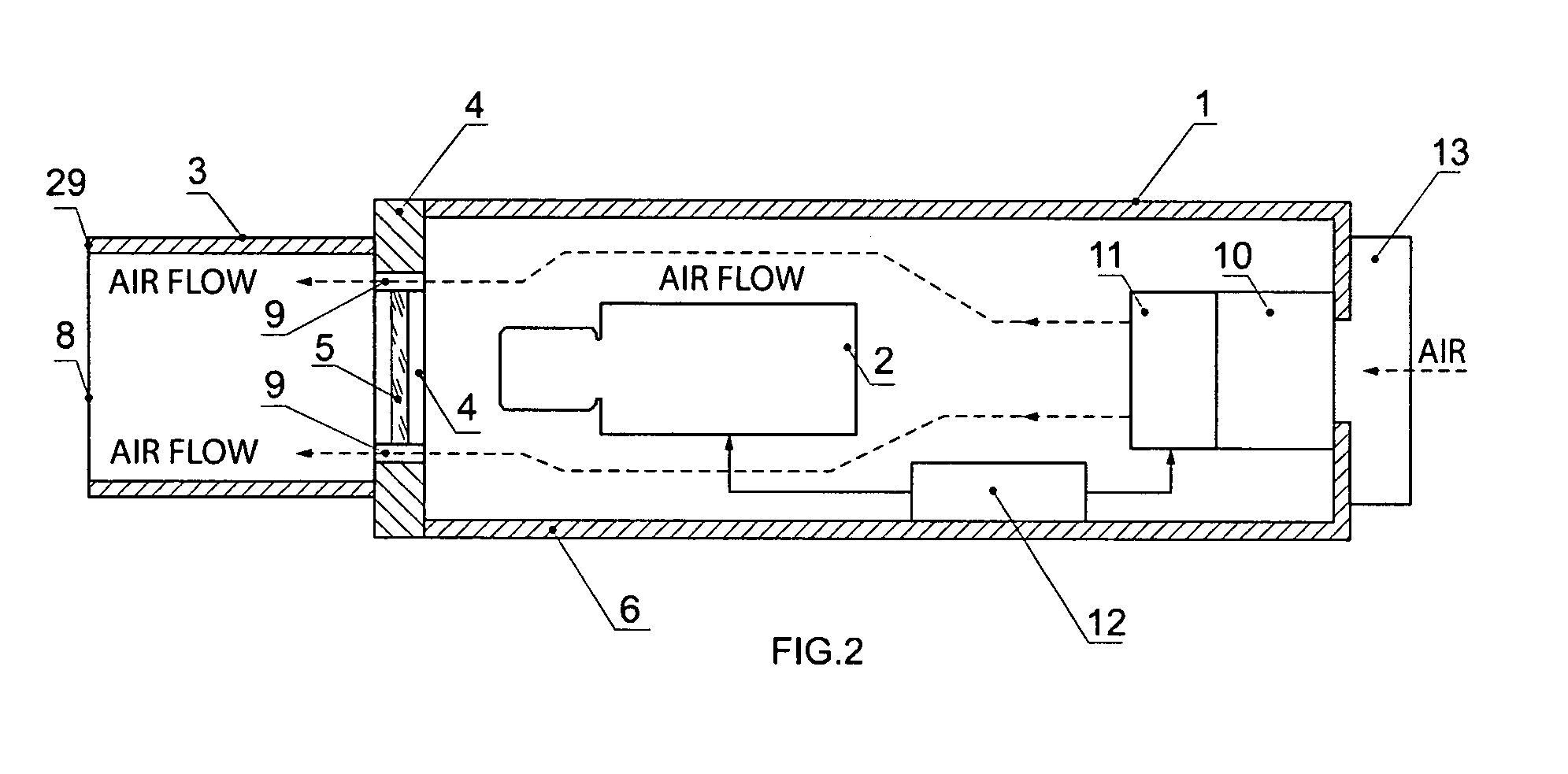

InactiveUS20020129613A1Reduce the temperatureNot contaminate atmosphereAir-treating devicesRefrigerated goods vehicleAir cycleDelivery vehicle

An apparatus to refrigerate the cargo space of delivery vehicles. It provides an environmentally friendly alternative to conventional mechanical a / c and refrigeration units. Cooling is provided by controlled evaporation of a liquefied gas such as CO.sub.2 or nitrogen. Defrost and heating requirements, if needed, are provided by hot engine coolant or by electric heaters powered from the vehicle electrical system. Airflow for the evaporator and for circulation in the temperature controlled space is provided by a blower which is mechanically or electrically driven from vehicle power. This invention can also be applied to multi-temperature control applications. The apparatus is compact and is particularly suited for small inner city delivery vehicles. FIG. 1: The sketch shows an inner city delivery truck for which this invention is most suitable. Refrigerated goods are placed in roller cages that are designed to maximize cargo hauled by use of roller cages that extend to within 2 inches of the ceiling. The evaporator section of this invention is mounted at or near the front wall of the truck and is separated from the cargo by a vertical bulkhead. The conditioned air is delivered at the bottom of the truck to avoid top freeze of perishable cargo that is in close proximity to the ceiling. FIG. 2: This shows the piping schematic and is similar to the invention described in U.S. Application Serial No. 60 / 238,929 (the '929 application) incorporated herein by reference. FIG. 2 shows the engine coolant coil located ahead of the CO.sub.2 coil in the direction of airflow. This prevents the coldest air from coming in contact with the engine coolant--in the cooling mode the air leaving the CO.sub.2 coil can be as low as -50.degree. F. for frozen load applications and this may cause the engine coolant to start freezing. Arrangements must be made to circulate air between the two coils in defrost mode. One means to accomplish this is to place a damper at the outlet of the evaporator section and run the fans. The damper would be closed during defrost. Another method is to place the engine coolant coil on the discharge side of the CO.sub.2 coil and use a cut-out switch if the engine coolant temperature drops below a predetermined value. In this arrangement there is no need for the damper arrangement as the heat will rise to melt any frost on the CO.sub.2 coil. If electric heat is used for defrost and heating freezing of the engine coolant is not a concern and the heaters can be fastened to the discharge side of the CO.sub.2 coil. An electric stand-by mode can be provided to power the system for cooling, heating and defrost when the vehicle is parked with the engine off. A plug-in electrical cable can provide the power needed for the controls, the fans and for heating and defrost. The figure shows the electric heaters attached on the discharge side of the CO.sub.2 coil. Operation: Detailed description is in the '929 application except for the following: The evaporator section is designed for vertical installation to maximize cargo space. Air is discharged at the bottom but may be a conventional top discharge if needed for specific applications. Conventional methods can be used to provide defrost and heating. If engine coolant is used for a heat source, it is preferable to thermally isolate the CO.sub.2 coil from the engine coolant coil to avoid freezing the coolant. The evaporator blower may be located on the inlet side of the coils rather than as shown in the figures. Unique Features: 1. Absence of a conventional condensing section on the exterior of the vehicle makes this an ideal refrigeration unit for small inner city delivery vehicles. Many of the truck cabs are now almost full height (same as the truck body) and there is limited space for the condensing section. 2. Cold plates can be used and still maximize cargo cube. However, this invention has 30-40% less weight than comparable "cold plate" systems. 3. Other features are described in the '929 application.]

Owner:THERMO KING CORP

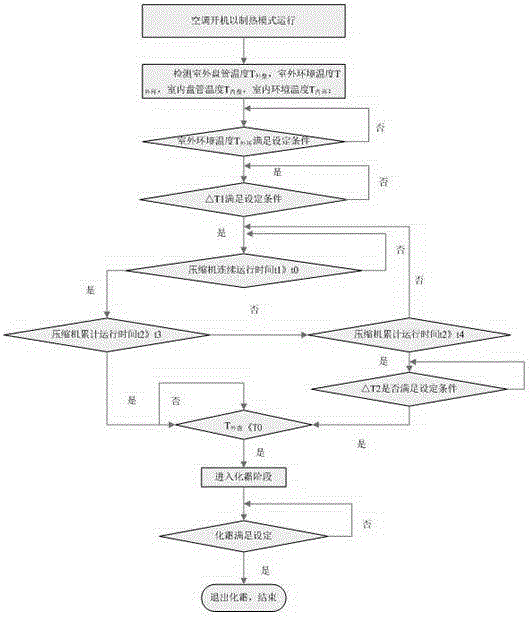

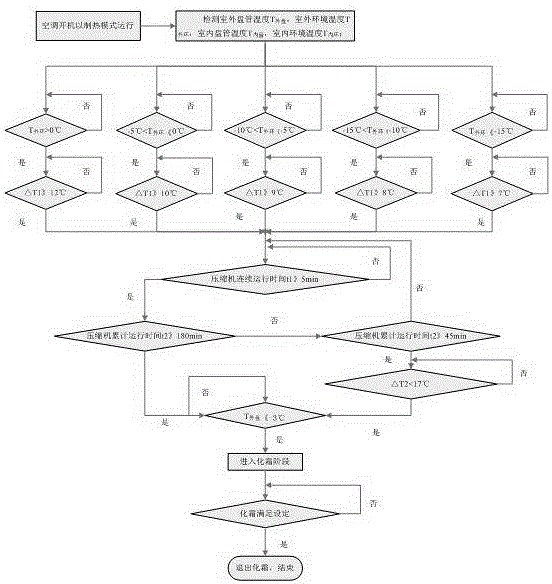

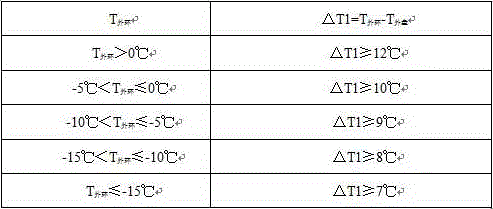

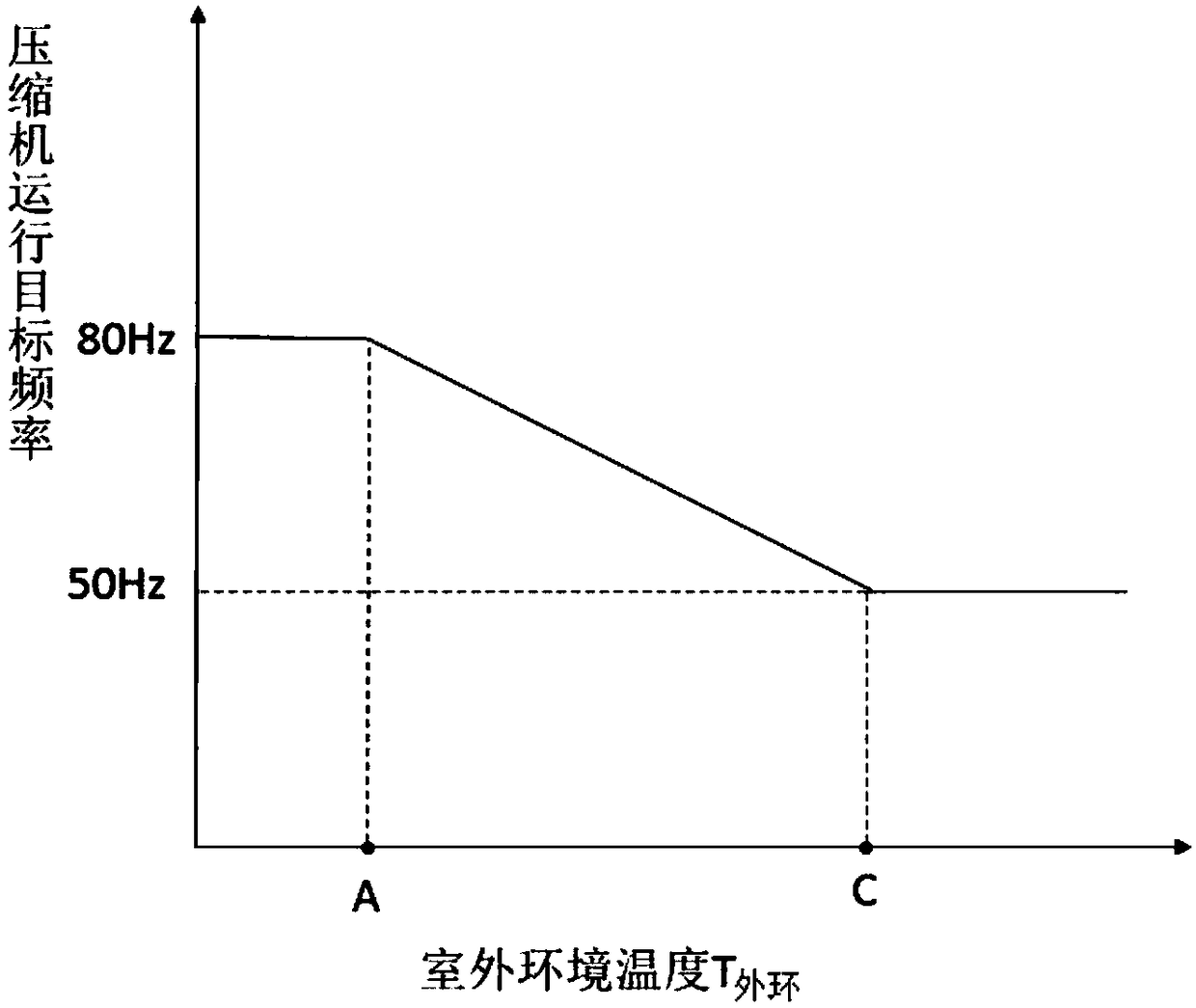

Intelligent defrosting method for frequency-conversion air conditioner

ActiveCN106705347AImprove the efficiency of precision defrostingImprove heating effectMechanical apparatusSpace heating and ventilation safety systemsFrostFrequency conversion

The invention provides an intelligent defrosting method for a frequency-conversion air conditioner. Whether the air conditioner enters a defrosting program or not is judged according to a series of comprehensive factors such as the ranges of the indoor coil temperature, the indoor environment temperature, the outdoor coil temperature and the outdoor environment temperature, differences of the corresponding temperatures and heating running duration and cumulative time, the defrosting exit condition is determined according to the factors such as the defrosting duration and the range of the outer machine coil temperature, and the technical problems that in the prior art, the defrosting condition is simply set, and consequently the phenomena that defrosting is wrongly conducted when frost does not exist, defrosting is frequently conducted when frost is thin, and defrosting is not conducted when frost is thick possibly happen, and the heating effect of the air conditioner is affected can be solved. According to the intelligent defrosting method for the frequency-conversion air conditioner, the intelligent degree of defrosting of the air conditioner can be improved, the effects that defrosting is conducted when frost exists, defrosting is not conducted when frost does not exist, defrosting begins when frosting reaches a certain degree, and defrosting of an outdoor unit is thorough and timely can be improved, the accurate defrosting efficiency of the air conditioner can be effectively improved, and the heating performance of the air conditioner is improved.

Owner:AUX AIR CONDITIONING LTD BY SHARE LTD

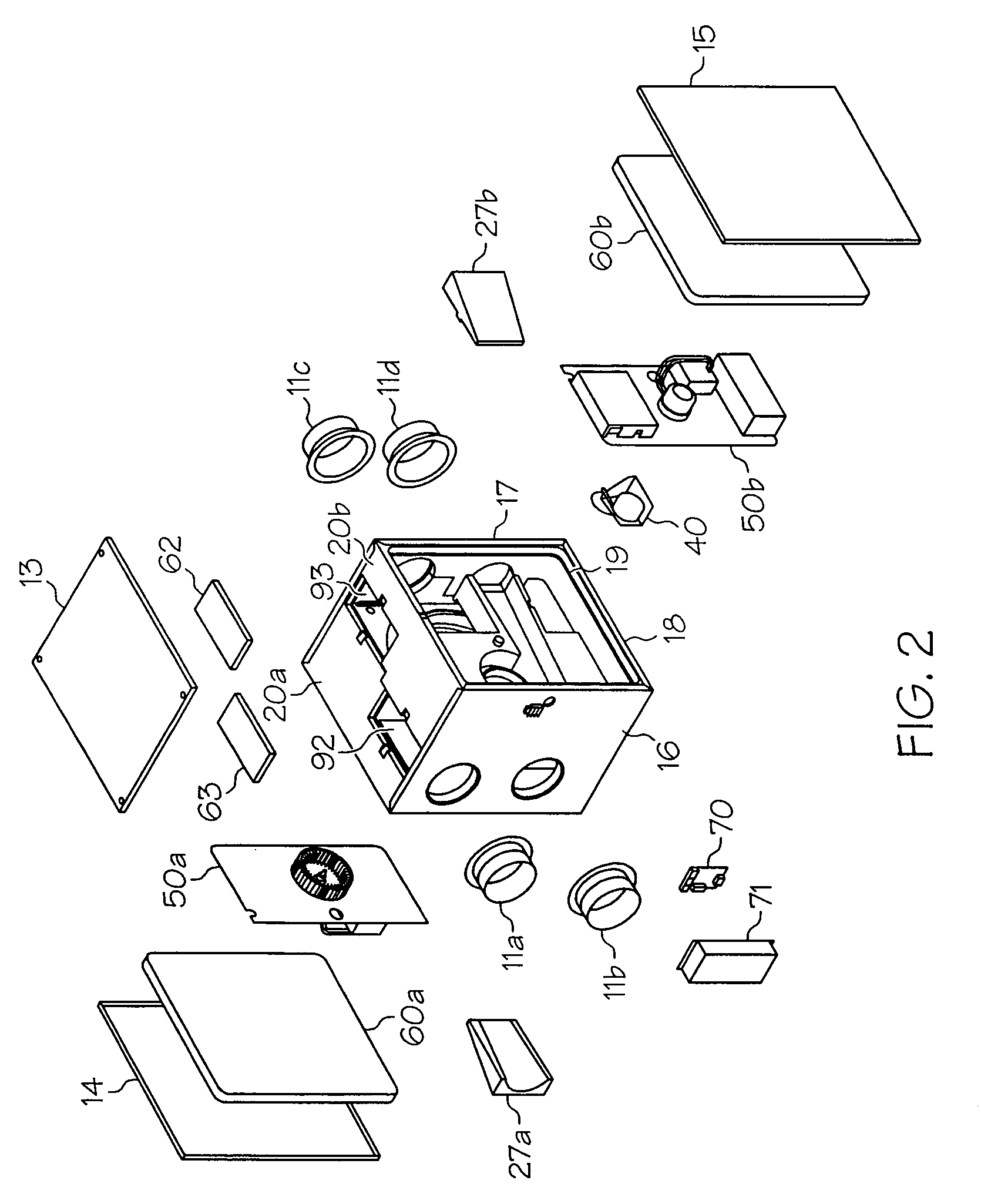

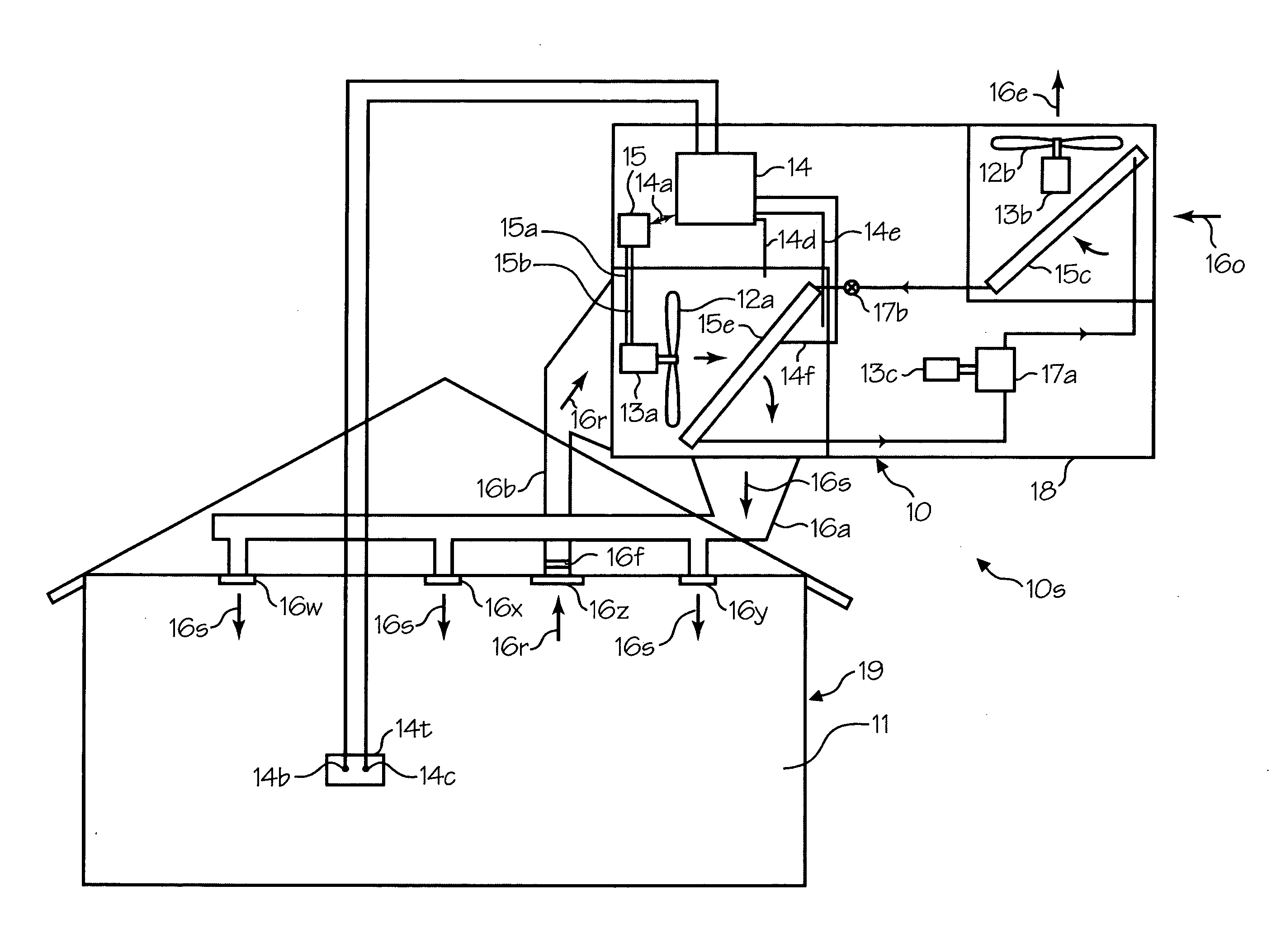

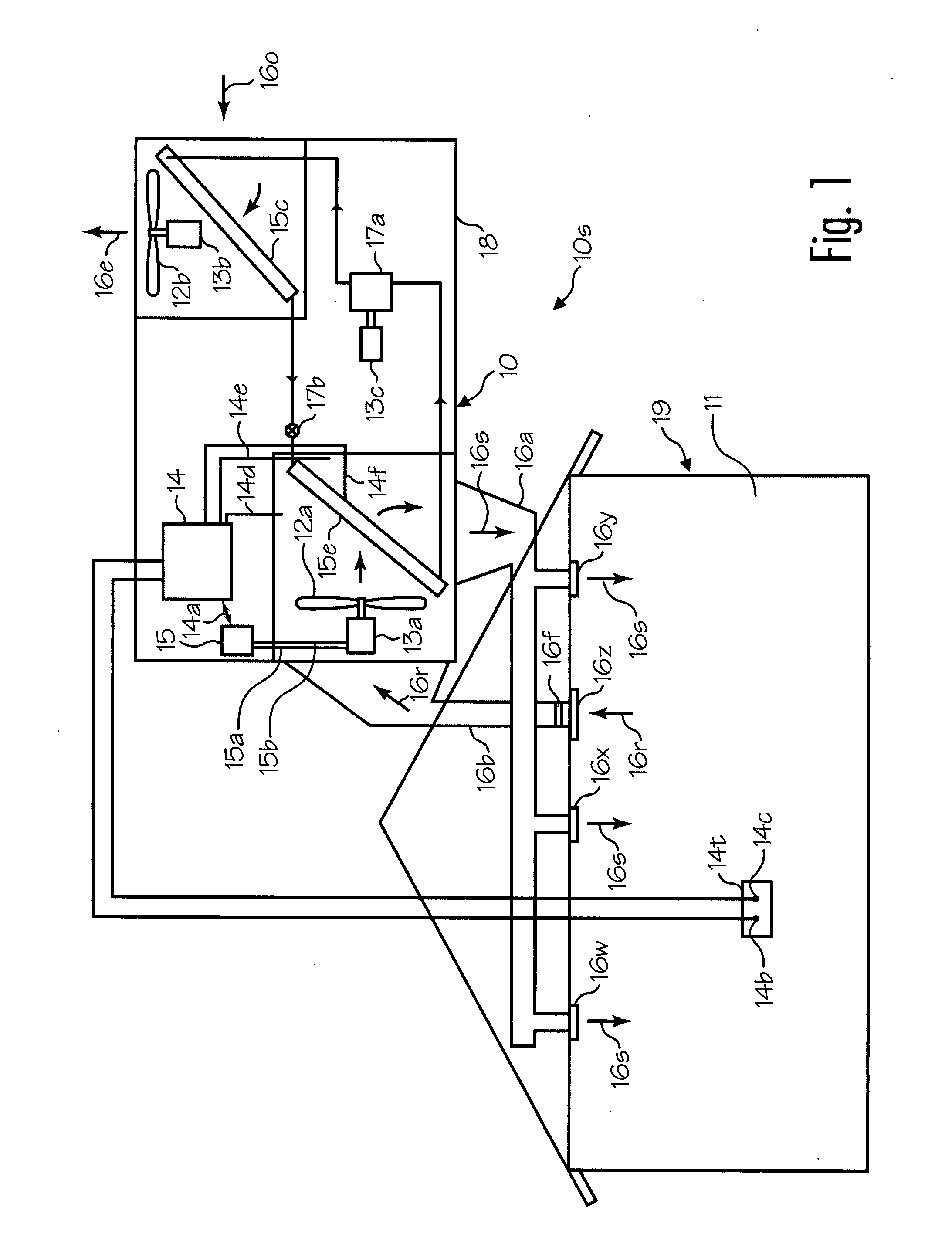

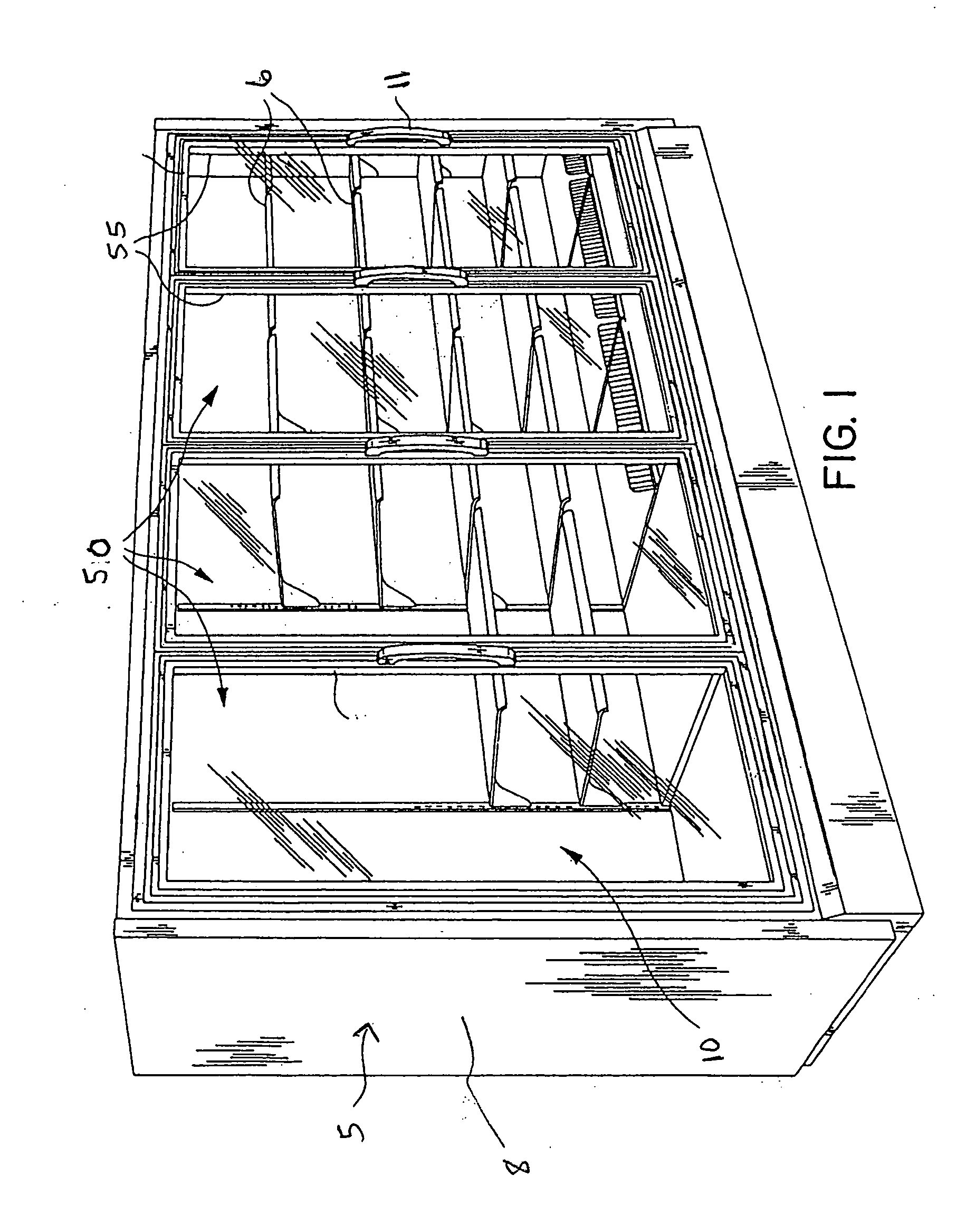

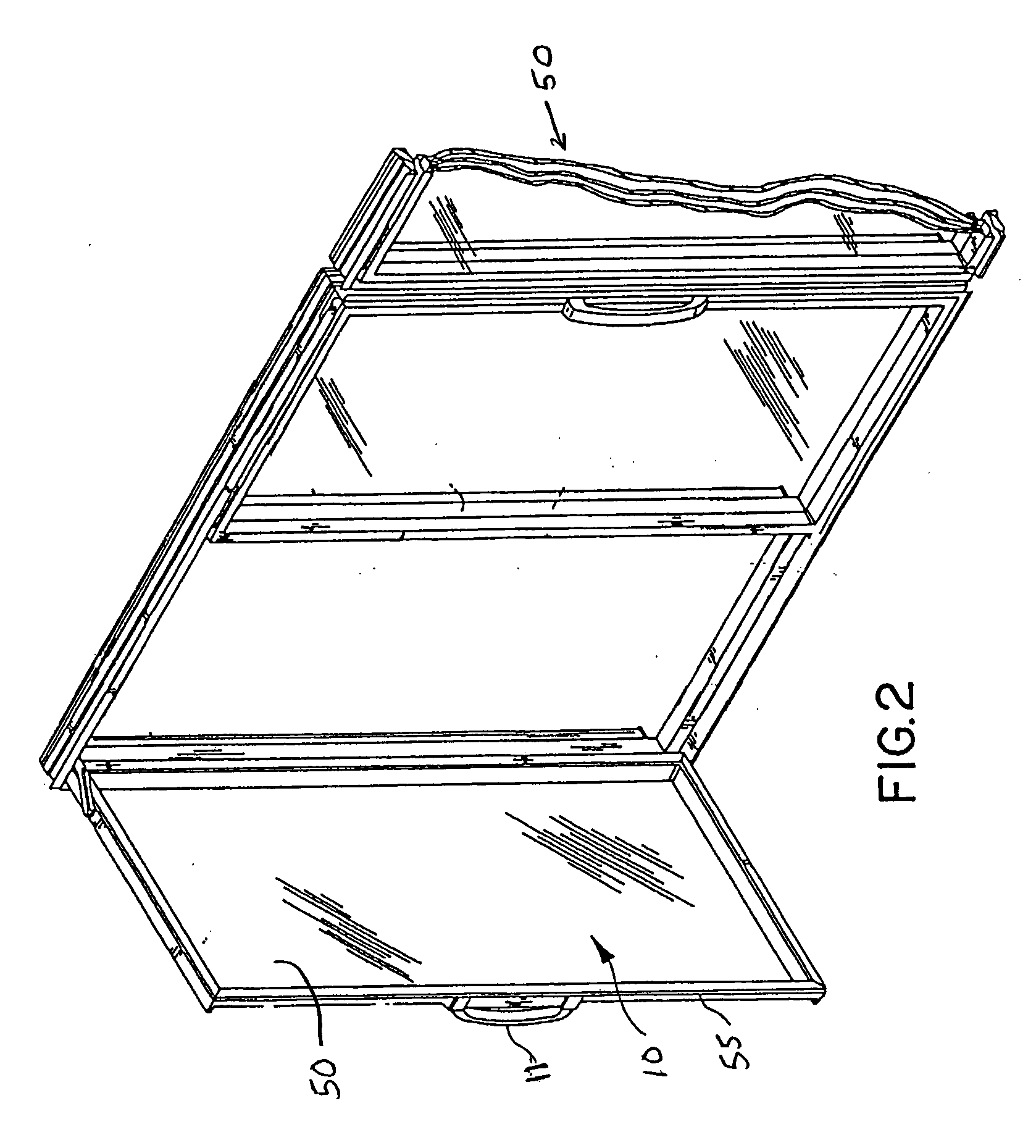

Heat and energy recovery ventilators and methods of use

InactiveUS20050236150A1Increase heightDomestic cooling apparatusHeating and ventilation casings/coversThermal energyMotor drive

An energy recovery ventilator and method for monitoring and maintaining an environmental condition inside a structure such as a house, building, or dwelling is provided. The ventilator may include a housing having mating halves of a molded polymeric material, first and second chambers disposed within the housing to convey separate first and second streams of air, a heat exchanger configured to intersect the first and second chambers, a first fan to circulate the first air stream through the first chamber, a second fan to circulate the second air stream through the second chamber, and a fan motor driving the first and second fans. The ventilator may also be configured to prevent frost build-up in or on the energy ventilator, to provide efficient cooling, and maintain one or more desired environmental conditions.

Owner:STIRLING TECH INC +1

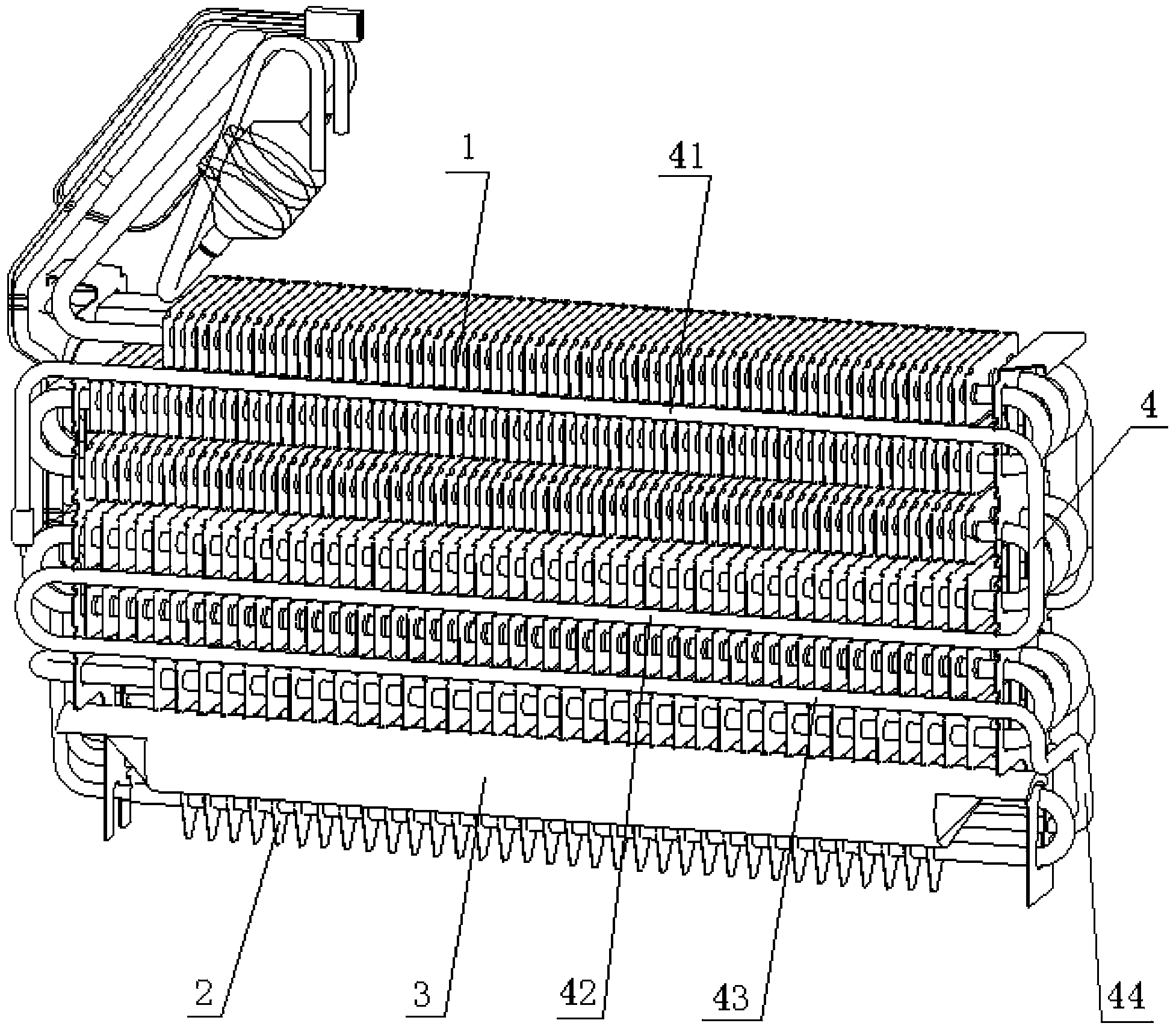

Defrosting system and refrigerator with same

InactiveCN103712401AGuarantee sufficiencyReduce energy consumptionEvaporators/condensersDefrostingFrostHigh humidity

The invention relates to the field of refrigeration defrosting of refrigerators, in particular to a defrosting system and a refrigerator with the defrosting system. The defrosting system comprises an evaporator body and a precooling evaporator, wherein the precooling evaporator is arranged at the bottom of the evaporator body and is used for cooling and dehumidifying high-temperature high-humidity air returning from a return air inlet. One end of the precooling evaporator is communicated with the return air inlet. The other end of the precooling evaporator is communicated with the evaporator body. According to the defrosting system, the precooling evaporator is arranged at the bottom of the evaporator body, after the high-temperature high-humidity air returning from the return air inlet is cooled and dehumidified through the precooling evaporator, cooling and heat exchange are conducted on the cooled and dehumidified air through the evaporator body, and therefore part of frost condenses on the precooling evaporator; in this way, the amount of frost on the evaporator body is obviously reduced, frost is even, and the heat exchange efficiency of the evaporator body is effectively improved.

Owner:HEFEI JINGHONG MITSUBISHI MOTOR HOUSEHOLD ELECTRICAL APPLIANCE TECH DEV

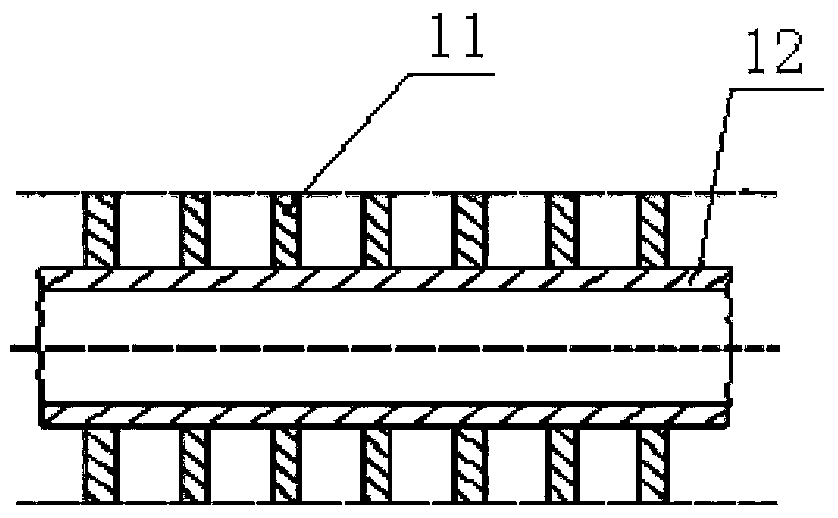

Device capable of extracting heat of phase transformation of compressed steam for radiative heat transfer

InactiveCN102445096AReduce power consumptionPrevent frost crackingIndirect heat exchangersFrostRadiative transfer

A device capable of extracting heat of phase transformation of compressed steam for radiative heat transfer adopts the structure that each group of heat pipe component is composed of a heat pipe and a sleeve; each heat pipe comprises a heating section and a condensation section, one end of the condensation section is sealed, the other end of the condensation section is communicated with one end of the heating section, and an end cover is arranged at the other end of the heating section; one end of each sleeve is welded at the joint of the heating section and the condensation section of the corresponding heat pipe, and the other end is welded together with an air-in communicating pipe; a hydrops baffle, as well as a liquid discharge pipe interface, is arranged in each air-in communicating pipe; and one end of each air-in communicating pipe is connected with the corresponding end cover, and an interface connected with a compressed steam delivery pipe is arranged at the other end. In theinvention, water or other liquid transportation can be avoided, so a huge heat exchange system and a delivery pipe net for heating liquid are prevented, the power consumption during the liquid transportation is also avoided, waterway frost cracking can also be prevented, and the maintenance cost is reduced.

Owner:陈万仁

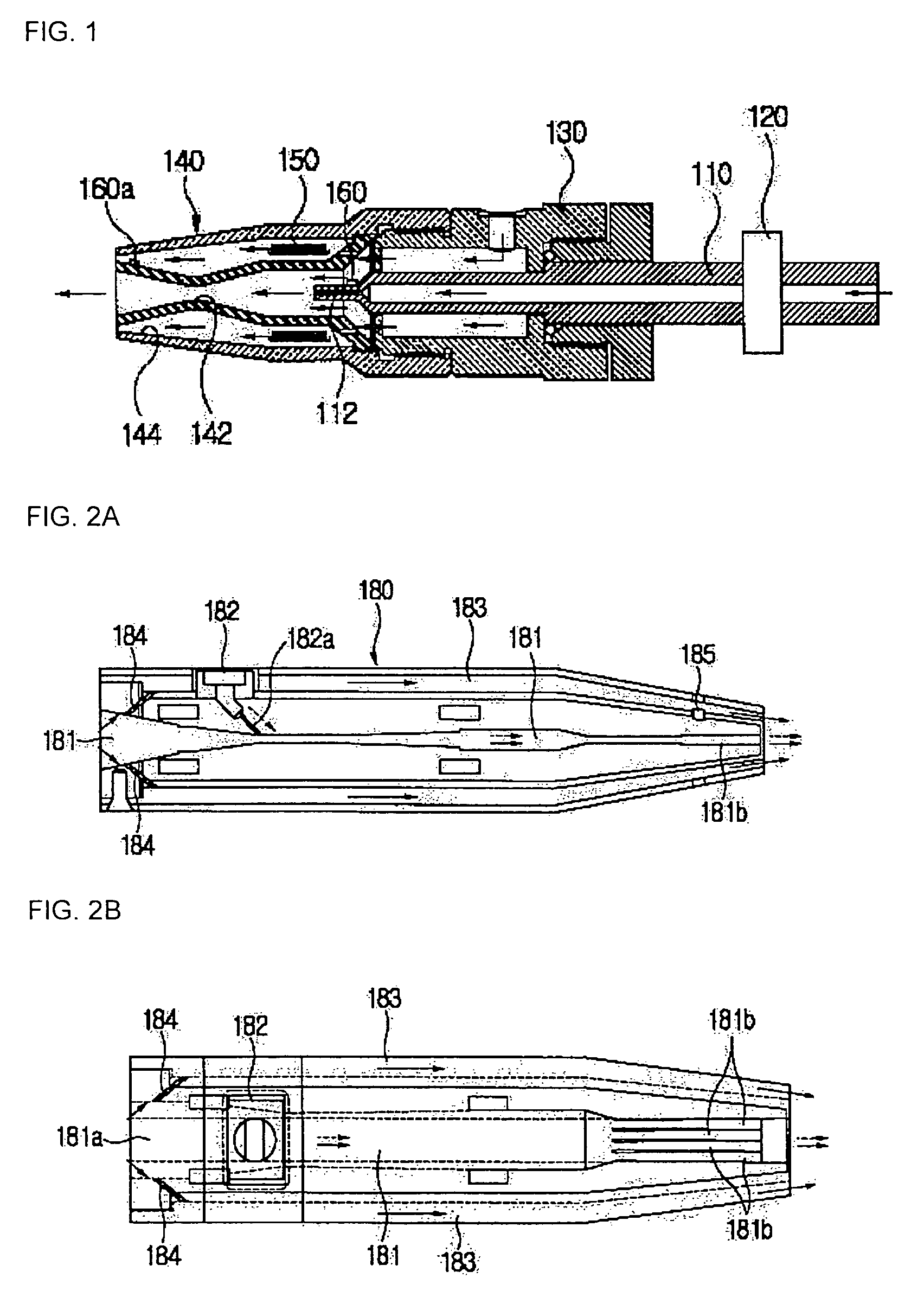

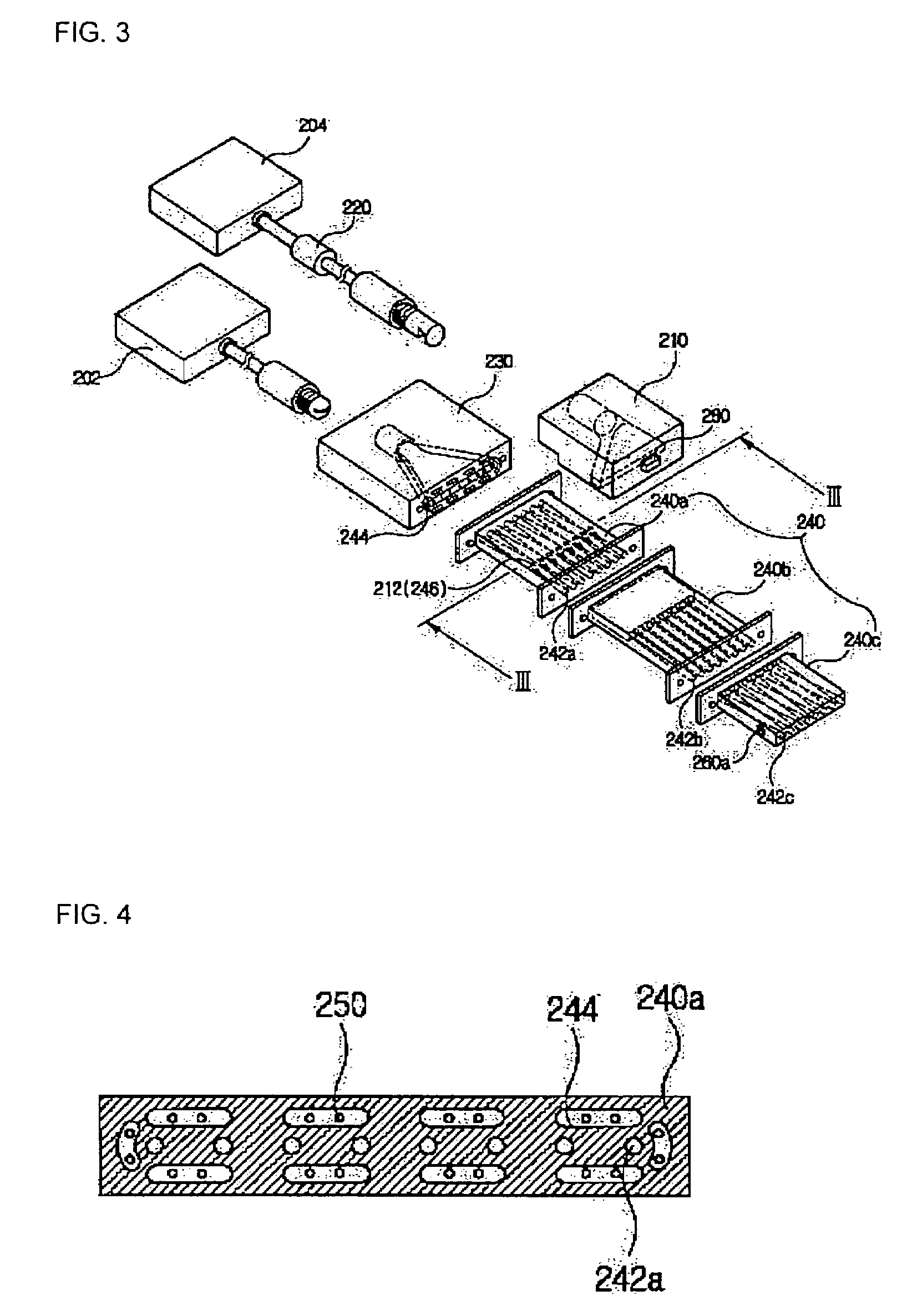

Nozzle for spraying sublimable solid particles entrained in gas for cleaning surface

ActiveUS7442112B2Blast gunsSemiconductor/solid-state device manufacturingSolenoid valveSolid particle

A nozzle for spraying sublimable solid particles and preventing frost from forming at surfaces of the nozzle. The nozzle includes: a cleaning agent block for phase-changing a cleaning agent into a snow containing sublimable solid particles; a nozzle block for growing the cleaning agent snow through adiabatic expansion and spraying the grown cleaning agent snow onto a surface of an object; a carrier gas block for supplying a carrier gas to the nozzle block to mix with the cleaning agent snow; and a heater for heating at least a portion of the carrier gas supplied from the carrier gas supply source. Fine dry ice particles and liquid CO2, passing through a solenoid valve from a CO2 reservoir tank and a pressure drop of a flow rate regulation valve, are introduced into the spray nozzle and then mixed with the carrier gas, such as N2 or purified air, and discharged.

Owner:K C TECH

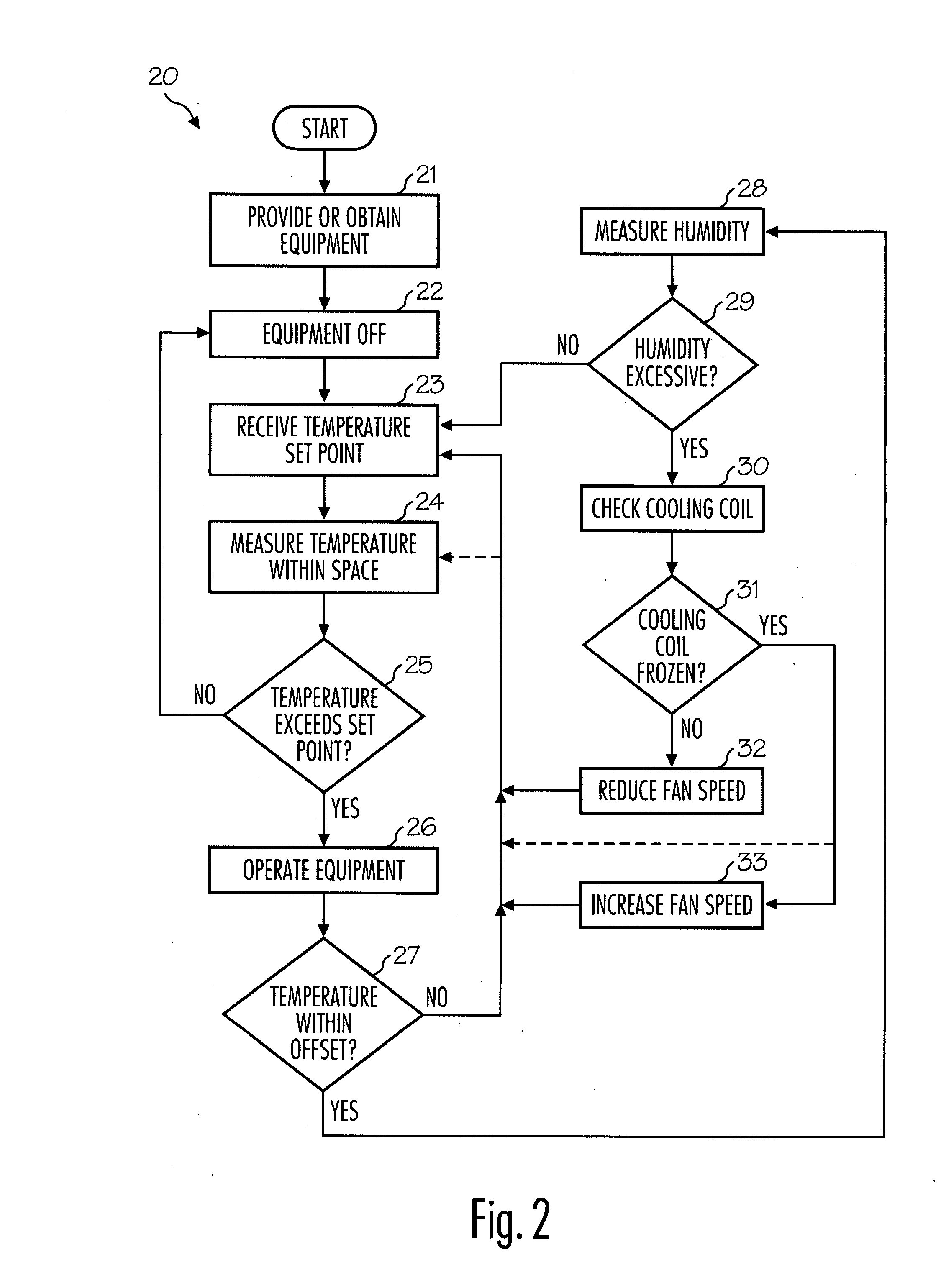

Humidity control and air conditioning

InactiveUS20080307803A1Shorten speedAvoid frostMechanical apparatusCompression machines with non-reversible cycleFrostCooling coil

Air conditioning systems that cool and dehumidify spaces within enclosures, buildings having such systems, and methods of controlling humidity within a space. Embodiments adjust speed of a blower or fan motor based on inputs from sensors within the system, using automated processes, to reduce airflow rates to provide for lower temperatures of the cooling coil and to increase the ratio of latent to sensible heat transfer. Fan speeds may be increased as appropriate to avoid frost formation on the cooling coil, to give priority to cooling when temperatures within the space are high, or periodically to provide for mixing within the space.

Owner:NORDYNE

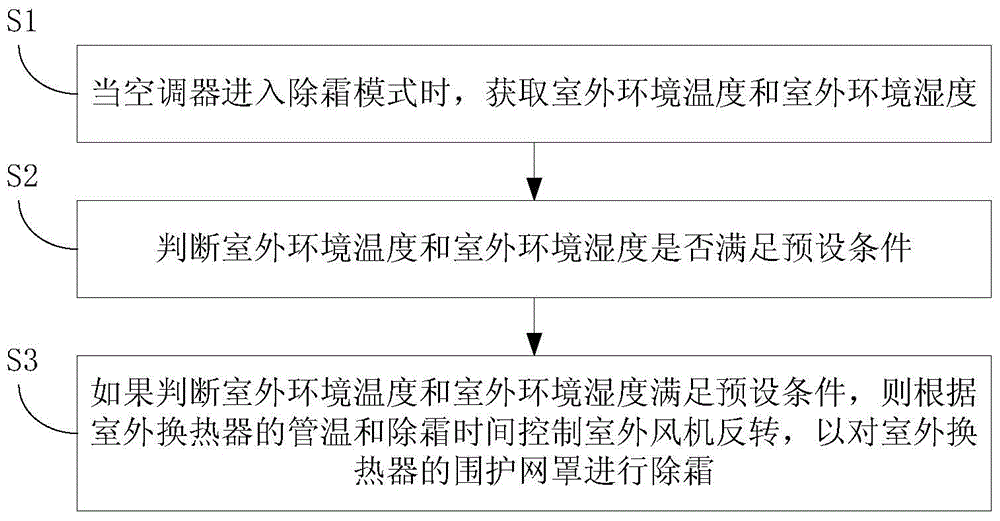

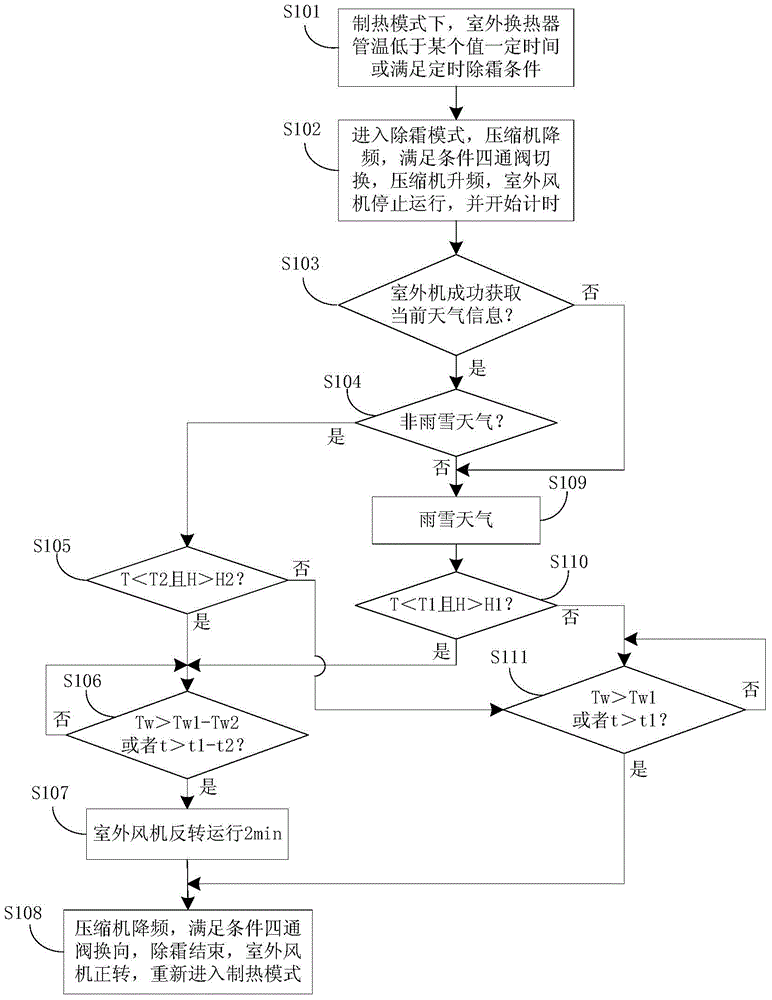

Defrosting control method and device for air conditioner

ActiveCN104833060AEfficient removalMechanical apparatusSpace heating and ventilation safety systemsFrostEngineering

The invention discloses a defrosting control method for an air conditioner. The defrosting control method includes the steps that when the air conditioner enters a defrosting mode, outdoor environment temperature and outdoor environment humidity are obtained; whether the outdoor environment temperature and the outdoor environment humidity meet preset conditions is judged; if yes, an outdoor fan is controlled to rotate reversely according to the pipe temperature and defrosting time of an outdoor heat exchanger so that defrosting can be performed on an enclosure net cover of the outdoor heat exchanger. According to the control method, residual frost on the enclosure net cover of the outdoor heat exchanger can be effectively cleared away. The invention further discloses a defrosting control device for the air conditioner.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

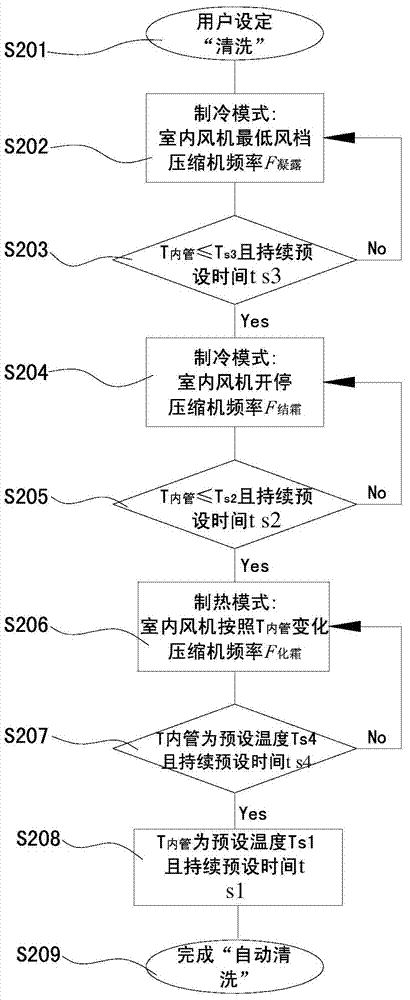

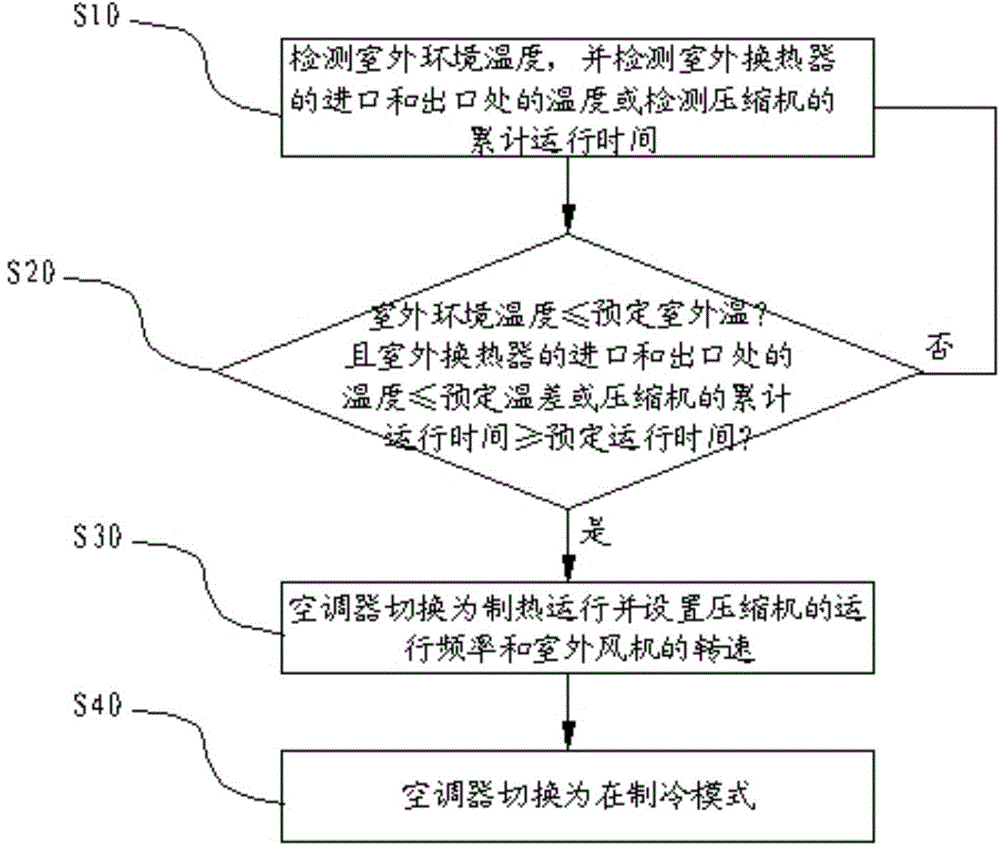

Self-cleaning control method for air conditioners

ActiveCN104949261AImprove heat transfer effectReduce dust accumulationMechanical apparatusSpace heating and ventilation safety systemsFrostTemperature difference

The invention discloses a self-cleaning control method for air conditioners. The self-cleaning control method includes enabling the air conditioners to detect outdoor environmental temperatures, detecting the temperatures of inlets and outlets of outdoor heat exchangers or detecting the cumulative run time of compressors; enabling the air conditioners to carry out heating running to allow frost to condense on the outdoor heat exchangers when the outdoor environmental temperatures are lower than or equal to preset outdoor temperatures and temperature difference between the inlets and the outlets of the outdoor heat exchangers is lower than or equal to preset temperature difference or the cumulative run time of the compressors is longer than or equal to preset run time; switching the air conditioners into a refrigerating mode. The self-cleaning control method for the air conditioners has the advantages that the air conditioners carry out heating running to allow the frost to condense on the outdoor heat exchangers and then are switched into the refrigerating mode to defrost the outdoor heat exchangers, accordingly, dust accumulated on the outdoor heat exchangers can be cleaned by condensed water generated after the outdoor heat exchangers are defrosted and can be effectively reduced, heat exchange effects of the air conditioners can be effectively improved, and energy consumption can be reduced.

Owner:MIDEA GRP CO LTD

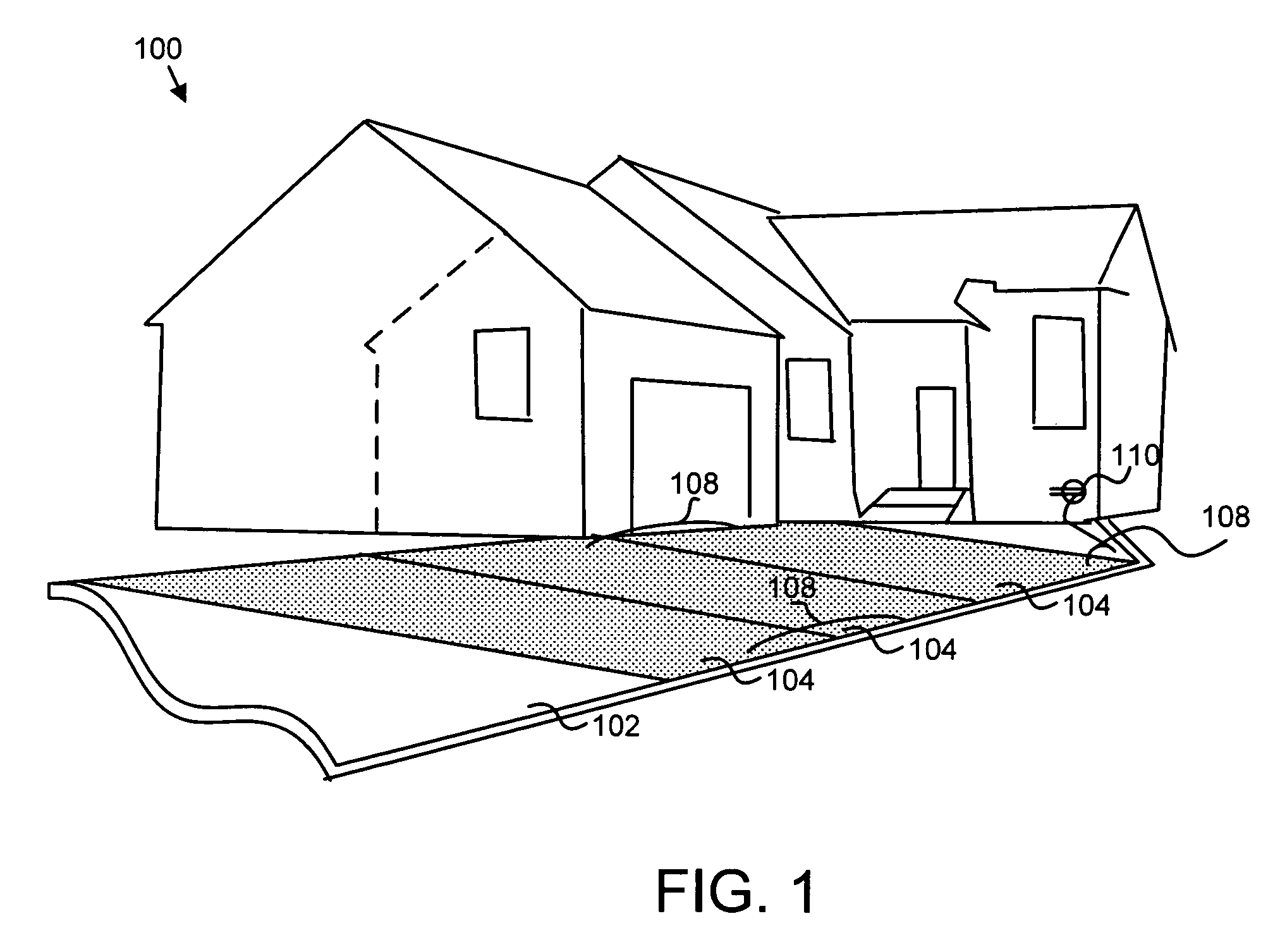

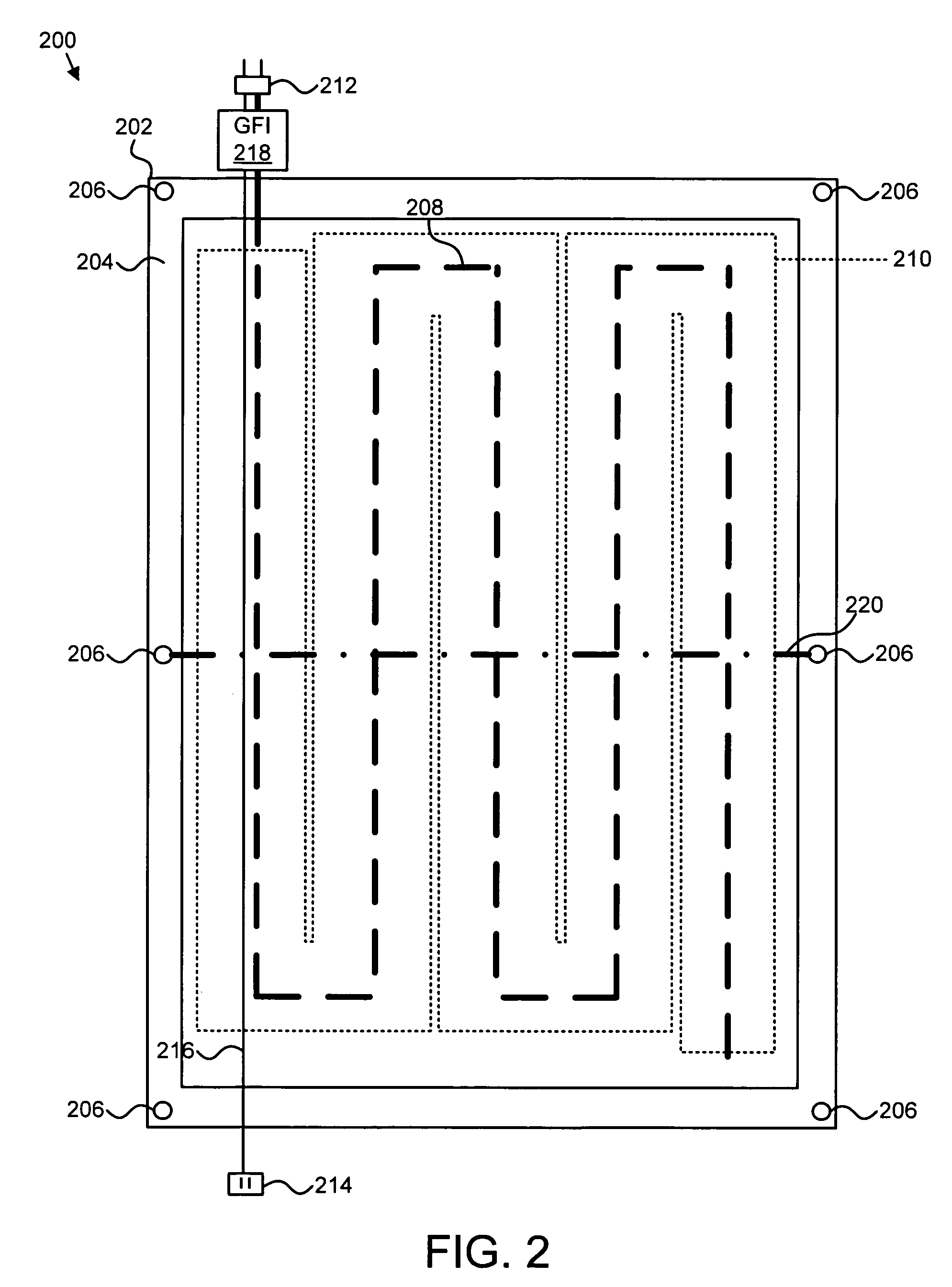

Modular heated cover

The modular heated cover is disclosed with a first pliable outer layer and a second pliable outer layer, wherein the outer layers provide durable protection in an outdoor environment, an electrical heating element between the first and the second outer layers, the electrical heating element configured to convert electrical energy to heat energy, and a thermal insulation layer positioned above the active electrical heating element. Beneficially, such a device provides radiant heat, weather isolation, temperature insulation, and solar heat absorption efficiently and cost effectively. The modular heated cover quickly and efficiently removes ice, snow, and frost from surfaces, and penetrates soil and other material to thaw the material to a suitable depth. A plurality of modular heated covers can be connected on a single 120 Volt circuit or on a single 240 Volt circuit protected by a 20 Amp breaker.

Owner:GREENHEAT IP HLDG LLC

Defogging device for a surveillance camera

A defogging device for a surveillance camera has a heating element, a circuit board and a power cord. The heating element is mounted over the lens of the surveillance camera. The circuit board compares ambient temperature to a preset temperature, activates the heating element and has a power input terminal, a power output terminal and a temperature sensor. The temperature sensor is mounted between the power input terminal and the power output terminal and senses ambient temperature. When the ambient temperature is above the preset temperature, the circuit board activates the heating element. The power cord is connected to the circuit board and the heating element and transmits power to the heating element from the circuit board. By activating the heating element during periods of cold ambient temperature, the defogging device removes fog and frost from or keeps fog and frost from forming on the lens of the surveillance camera.

Owner:CHENG YI JEN

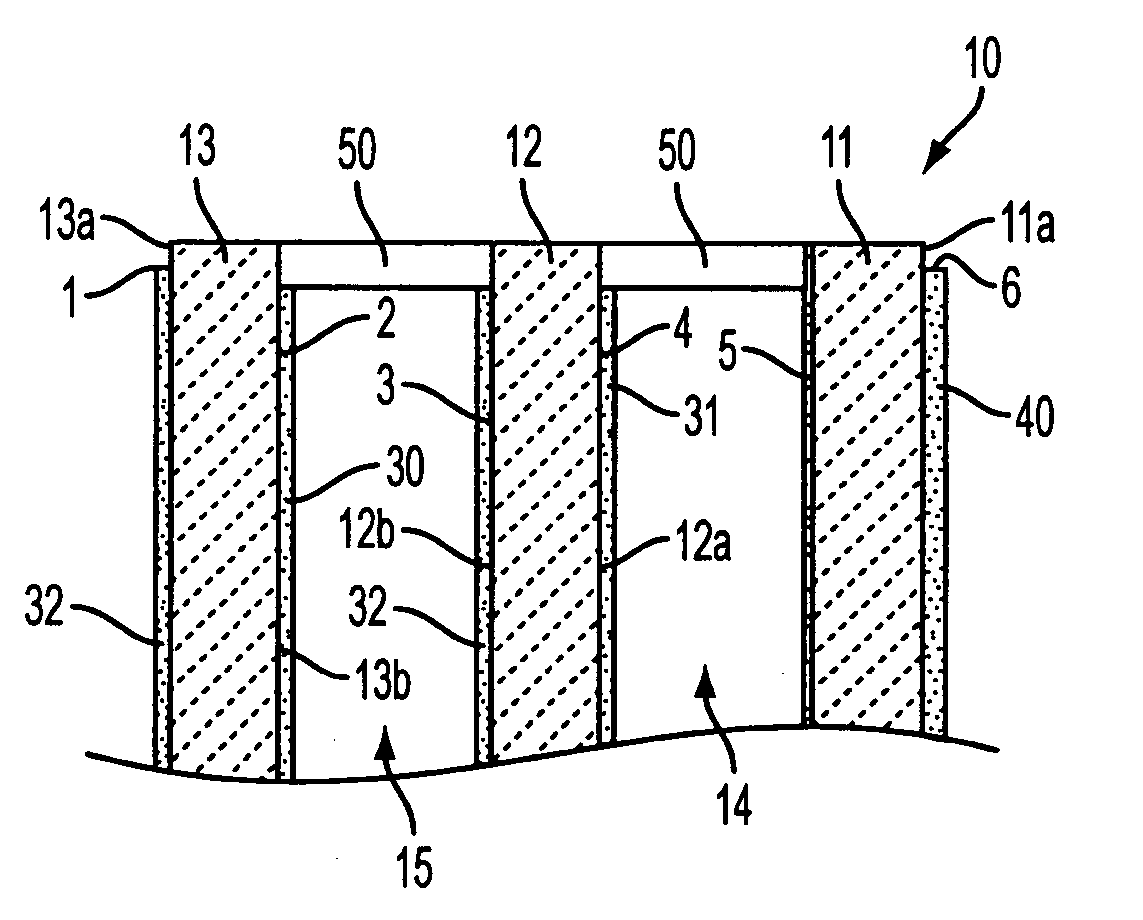

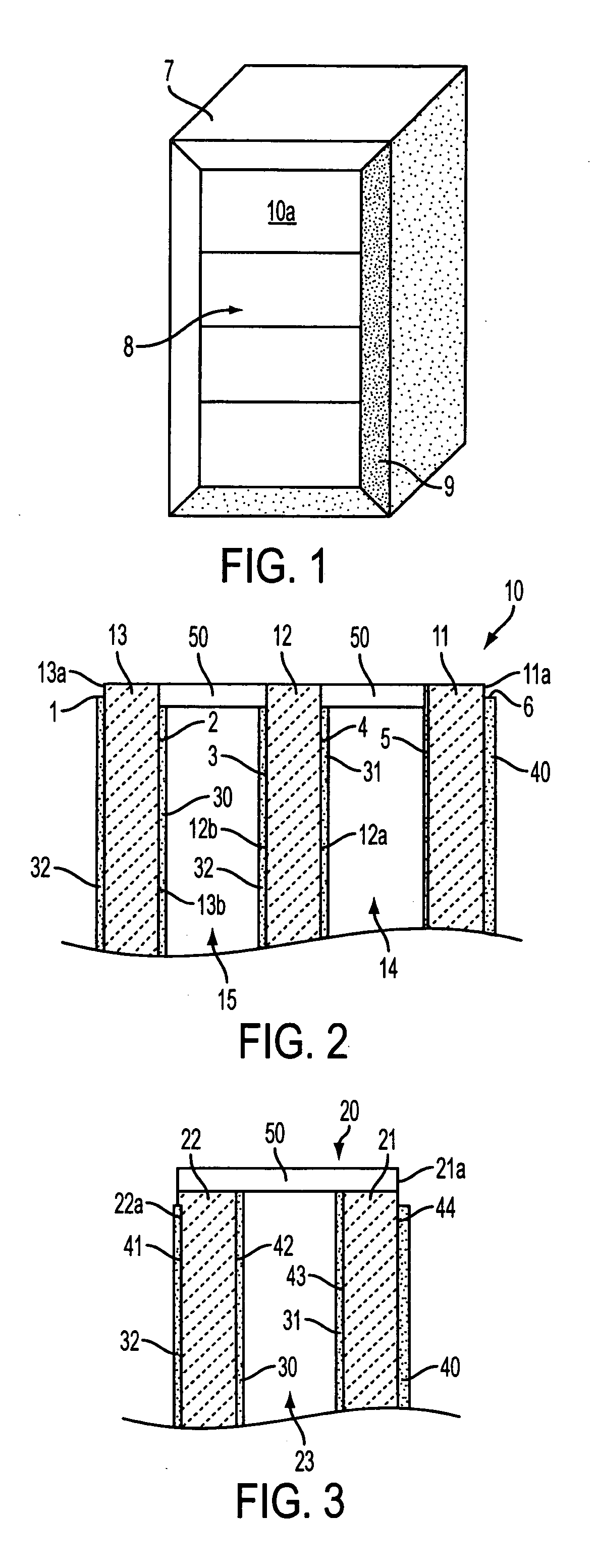

Anti-fog refrigeration door and method of making the same

InactiveUS20060265979A1BurdeningIncreased energy costShow cabinetsRailway roofsThermal insulationLow emissivity

The energy-free refrigeration door of the present application provides a way to control condensation when the door of a refrigeration unit is opened by providing thermal insulation to the door with glass panels which have a low emissivity coating. The door includes a door frame housing and an insulating glass unit comprising inner, middle and outer sheets of glass. A first sealant assembly disposed around the periphery of the inner and middle sheets of glass forms a first chamber between the inner and middle sheets of glass. A second sealant assembly disposed around the periphery of the middle and outer sheets of glass forms a second chamber between the middle and outer sheets of glass. A gas, such as krypton, air, or argon is held in the first and second chambers. The outer sheet of glass and inner sheet of glass each have an unexposed surface that faces the middle sheet of glass. A low emissivity coating is disposed on the unexposed surfaces of the inner and outer sheets of glass so that the glass door as a whole avoids formation of condensation on the outer surface of the outer sheet of the glass door, without the application of electricity to heat the door, while also providing the desired evaporation rate of condensation from the inner side of the inner sheet of the glass door. An anti-fog or anti-frost coating is included on a surface of one of the sheets of glass.

Owner:AGC FLAT GLASS NORTH AMERICA INC

Liquid-impregnated surfaces, methods of making, and devices incorporating the same

ActiveUS20130034695A1Improve skidReduce resistanceDe-icing equipmentsRecord information storageNon wettingFrost

The invention is directed to an article with a liquid-impregnated surface, the surface having a matrix of features thereupon, spaced sufficiently close to stably contain a liquid therebetween or therewithin, and preferable also a thin film thereupon. The surface provides the article with advantageous non-wetting properties. Compared to previous non-wetting surfaces, which include a gas (e.g., air) entrained within surface textures, these liquid-impregnated surfaces are resistant to impalement and frost formation, and are therefore more robust.

Owner:MASSACHUSETTS INST OF TECH

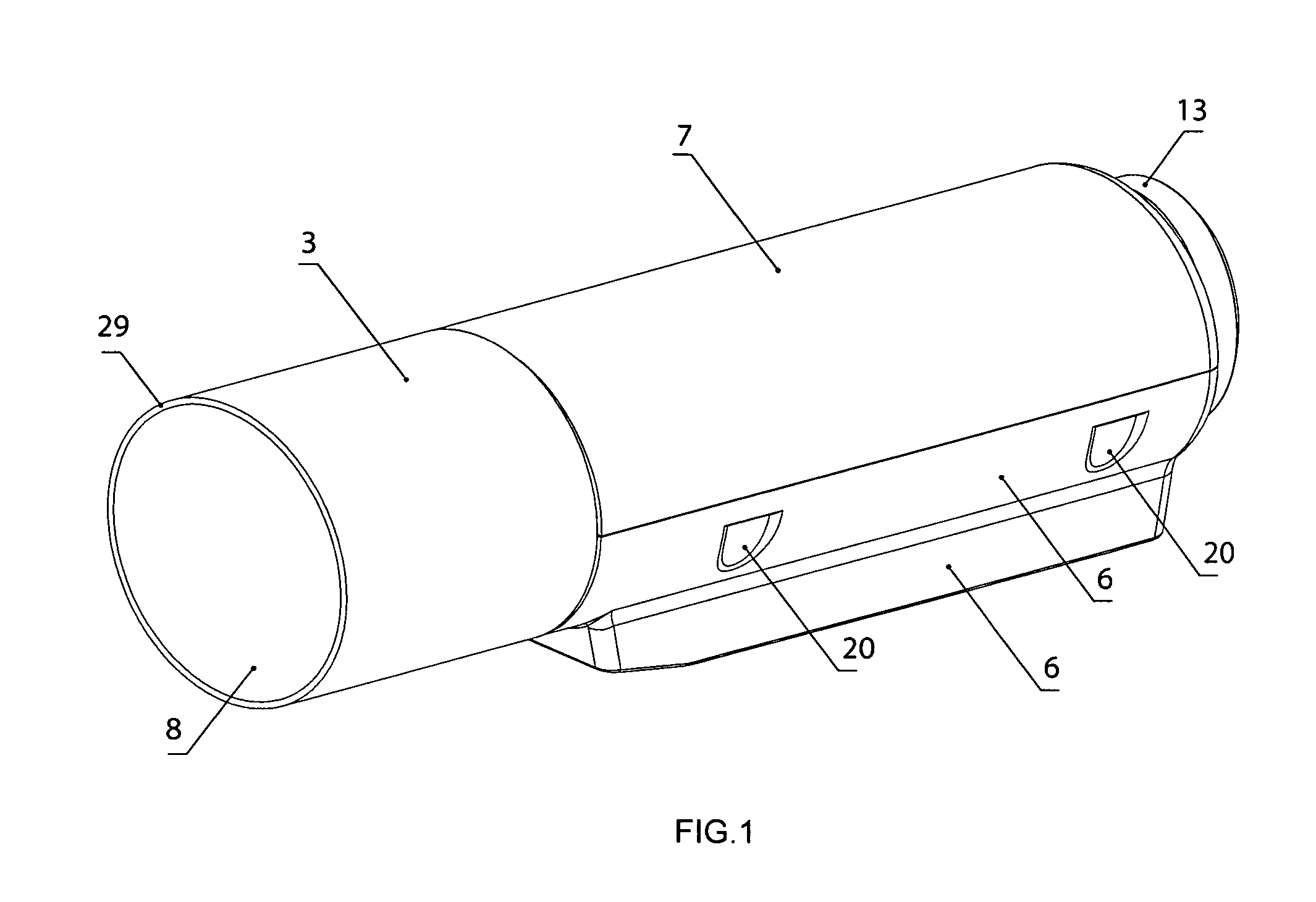

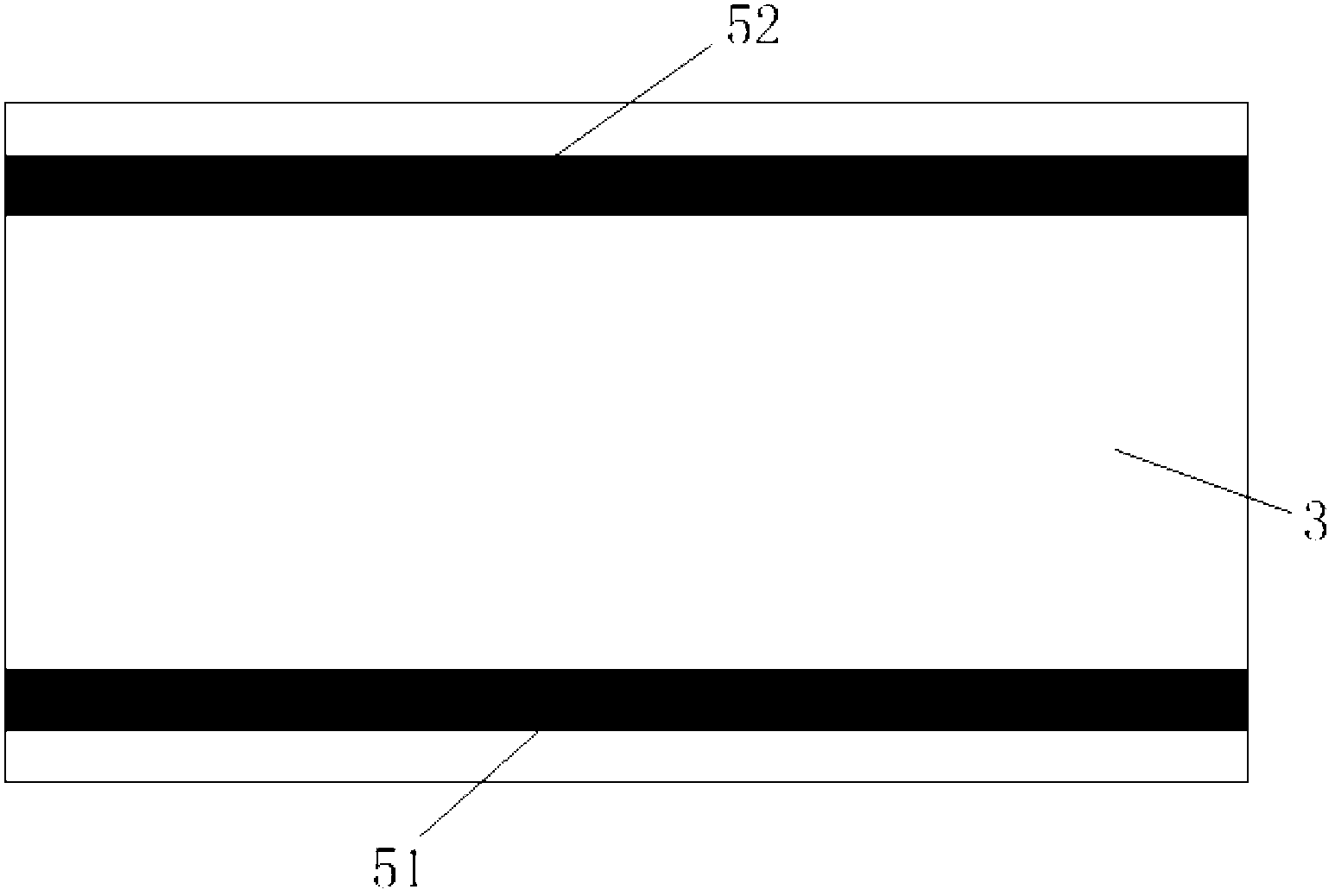

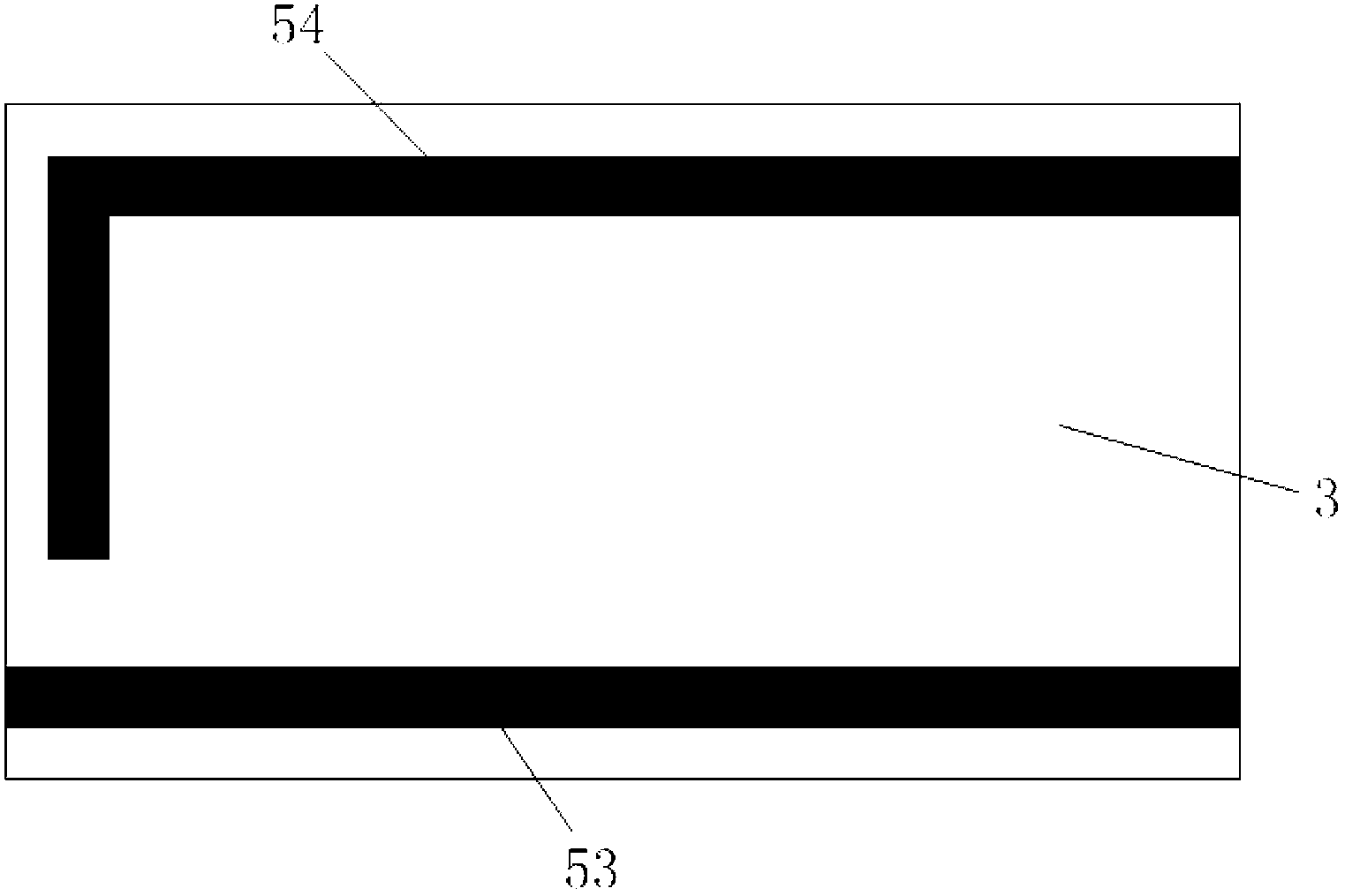

Method for prevention of pollution of the glass of the front window of a housing for an outdoor surveillance camera and a housing for implementation of this method

InactiveUS20130062228A1Convenient and reliable frame designTelevision system detailsFouling preventionFrostSurveillance camera

This invention relates to the methods for preventing pollution of the glass of the front window of a housing for an outdoor surveillance video camera 2 and the housings in which they are implemented. On the external side of this glass 5, a pipe 3 is installed whose first butt end 8 is open to the environment and the second butt end closes the said glass. Using a blowing engine 10 installed in the housing, a pressure is being created in the pipe that exceeds the pressure outside the pipe; using a heater 11, an air flow is being heated in a closed body 1 of the housing and an air supplied to the blowing engine inlet is being cleaned using the filter 13. The microprocessor unit 12 controls the heater, the blowing engine, and the video camera. Technical result: prevention of dust, fogging, water drops, snow from accumulating and frost from depositing on the glass of the front window of the housing for the outdoor surveillance video camera.

Owner:ZAKRYTOE AKTSIONERNOE OBSHCHESTVO STREAM LABS

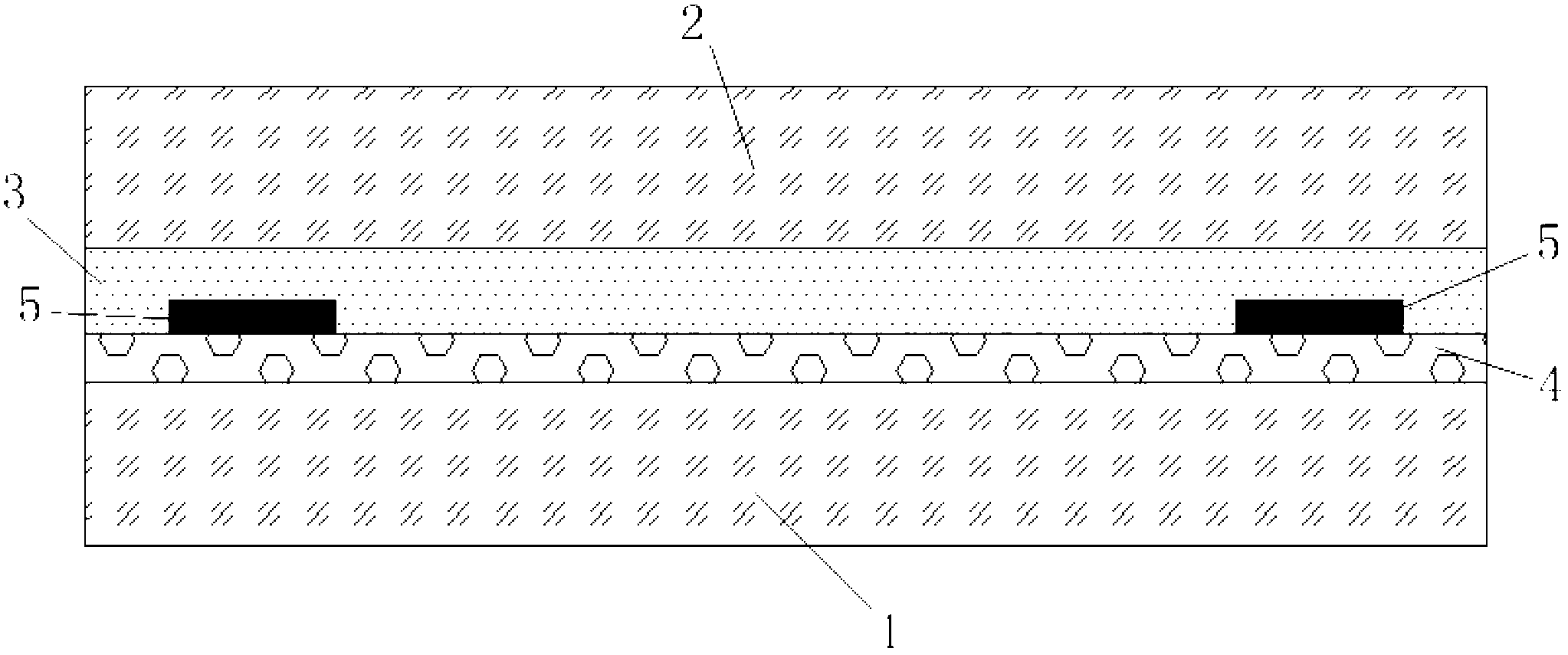

Electrically-heatable low-emissivity coated laminated glass

ActiveCN102795793ALow costSave hot pressing processAnisotropic conductive filmAnisotropic conductive adhesive

The invention relates to the field of laminated glass, particularly a laminated glass with high heat reflectivity and electric heating function applicable to the field of vehicles or construction, more particularly an automobile windshield glass installed on a vehicle. The electrically-heatable low-emissivity coated laminated glass comprises two glass substrates, a middle polymer sandwiched between the two glass substrates, low-emissivity film and a bus, wherein the low-emissivity film is arranged on at least one glass substrate surface in contact with the middle polymer; the bus is distributed on the low-emissivity film; and the bus is a pressure-sensitive adhesive or anisotropic conductive adhesive. According to the electrically-heatable low-emissivity coated laminated glass provided by the invention, the ACF (anisotropic conductive film) or PSA (pressure-sensitive adhesive) is used as the bus in combination with the low-emissivity film to heat the laminated glass, thereby removing frost and melting ice; and thus, compared with the adoption of other buses, the invention simplifies the production technique, is convenient to operate, lowers the material cost and enhances the production efficiency and process yield.

Owner:FUYAO GLASS IND GROUP CO LTD

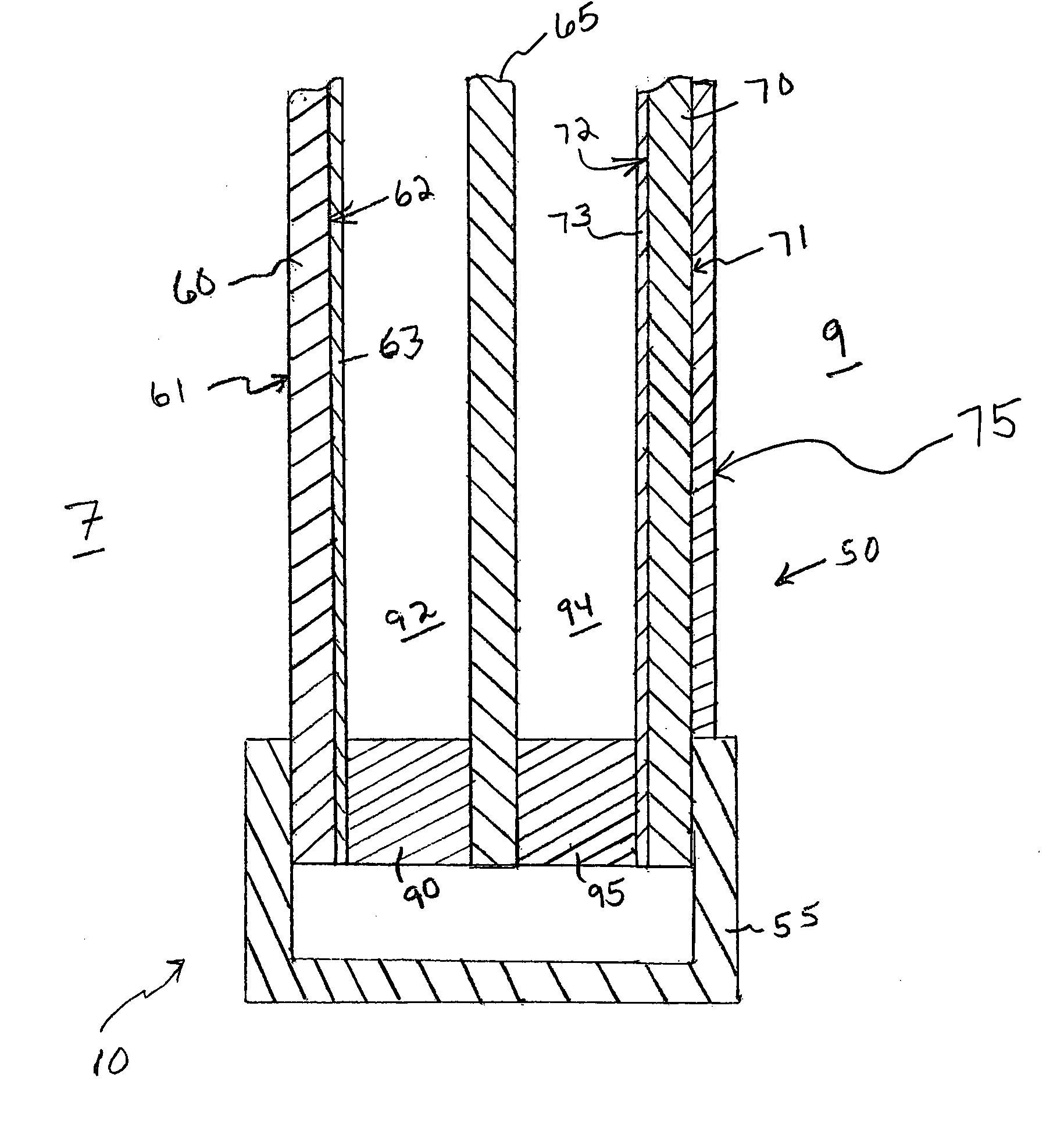

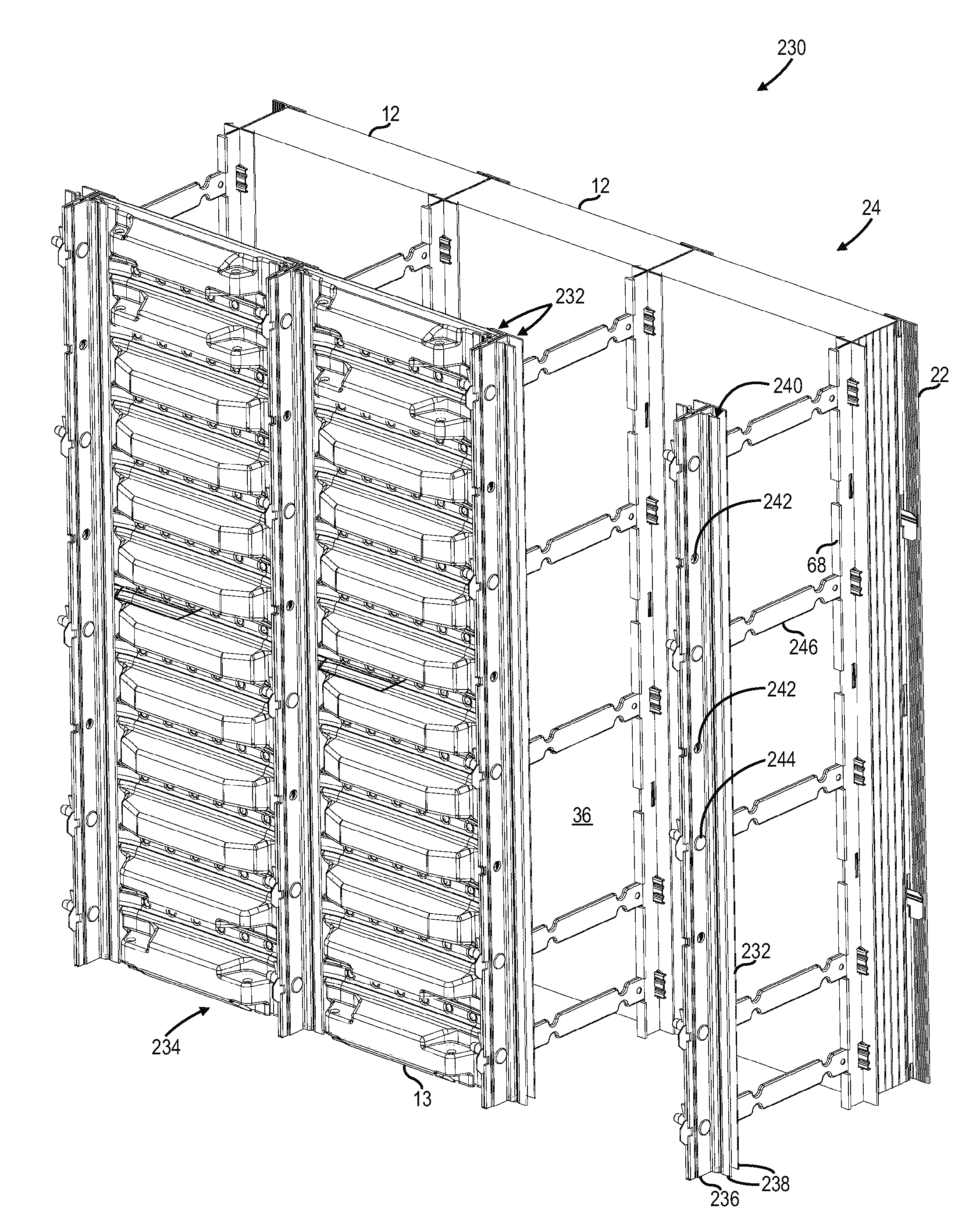

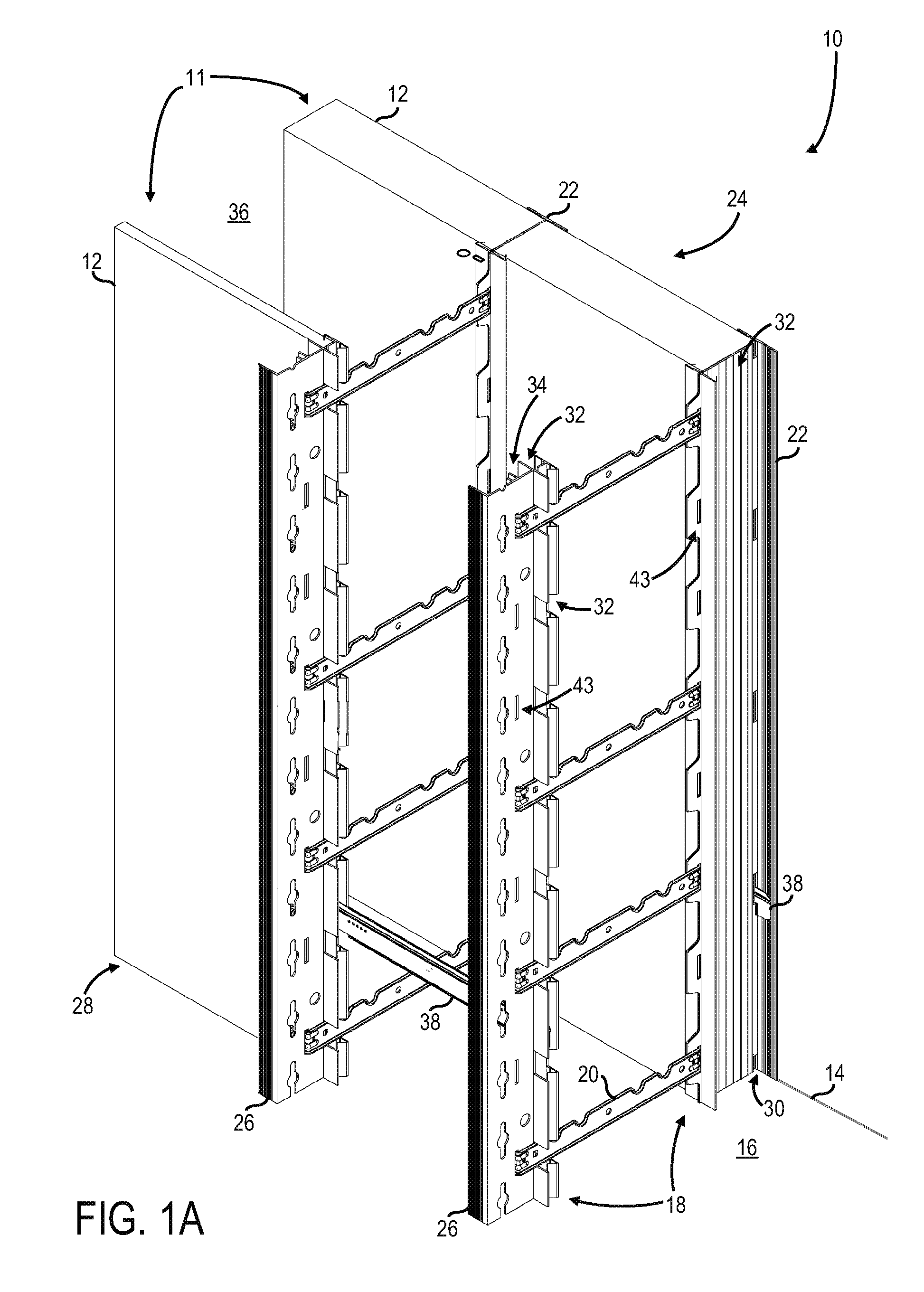

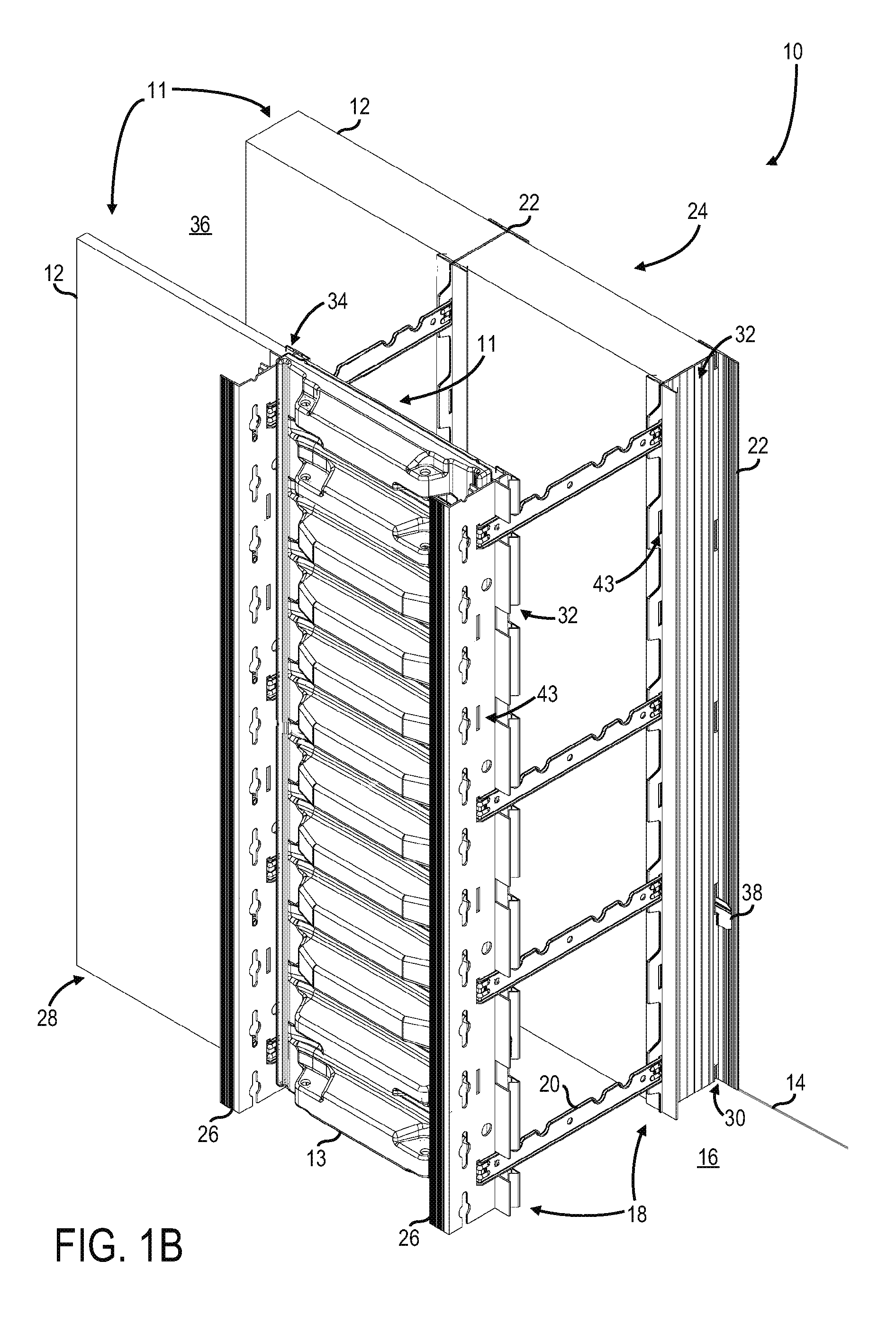

High strength adjustable vertical concrete form

A construction form system for forming concrete walls for use as above grade walls, foundations, frost walls, exterior envelopes, and the like, is disclosed. The system includes a plurality of pairs of opposing vertical forming panels spaced from each other to define a forming cavity disposed to receive a hardenable material. Each pair of opposing forming panels comprises an inner panel forming part of an inner wall and an outer panel forming part of an outer wall. The system also includes an outer rail positioned between each adjacent pair of outer forming panels and an inner rail positioned between each adjacent pair of inner forming panels. The inner forming panels comprise support panels configured to be selectively addable and removable from between each adjacent pair of inner rails prior to and subsequent to a pouring of the hardenable material into the cavity.

Owner:TF FORMING SYST

Washing method of air conditioner

ActiveCN109489189AKeep clean and pollution-freeEasy to cleanMechanical apparatusSpace heating and ventilation detailsFrostProcess engineering

The invention discloses a washing method of an air conditioner. The washing method comprises the steps: S1, dewing is conducted, specifically, refrigeration is conducted to form condensate water for primary washing; S2, frosting is conducted, specifically, refrigeration is conducted to form a frost layer; S3, heating is conducted, specifically, heating is conducted to defrost to washing the surface of a heat exchanger, and sterilization is conducted; and S4, ventilating is conducted, so that the heat exchanger is quickly dried and cooled. The air conditioner comprises a control device, and operations of the rotating speed of a fan and the operating frequency of a compressor of the steps are preset in the control device, wherein the preset operation in the step S3 is that the mapping relation between the pipe temperature T of the heat exchanger and the frequency of the compressor and the mapping relation between the environment temperature and the rotating speed of the fan cooperate tocontrol the pipe temperature of the heat exchanger. According to the washing method, on the one hand, two-step cleaning is achieved, and sterilization is conducted; on the other hand, a system of theair conditioner is utilized to the largest extent; and secondly, through setting of the heating stage, the problems that under the high-temperature working condition, the operating frequency is too high, the air speed is too low, the pipe temperature rises too quickly, when frequency decreasing is triggered, the pressure is too high, and compressor driving protection occurs are avoided.

Owner:AUX AIR CONDITIONING LTD BY SHARE LTD

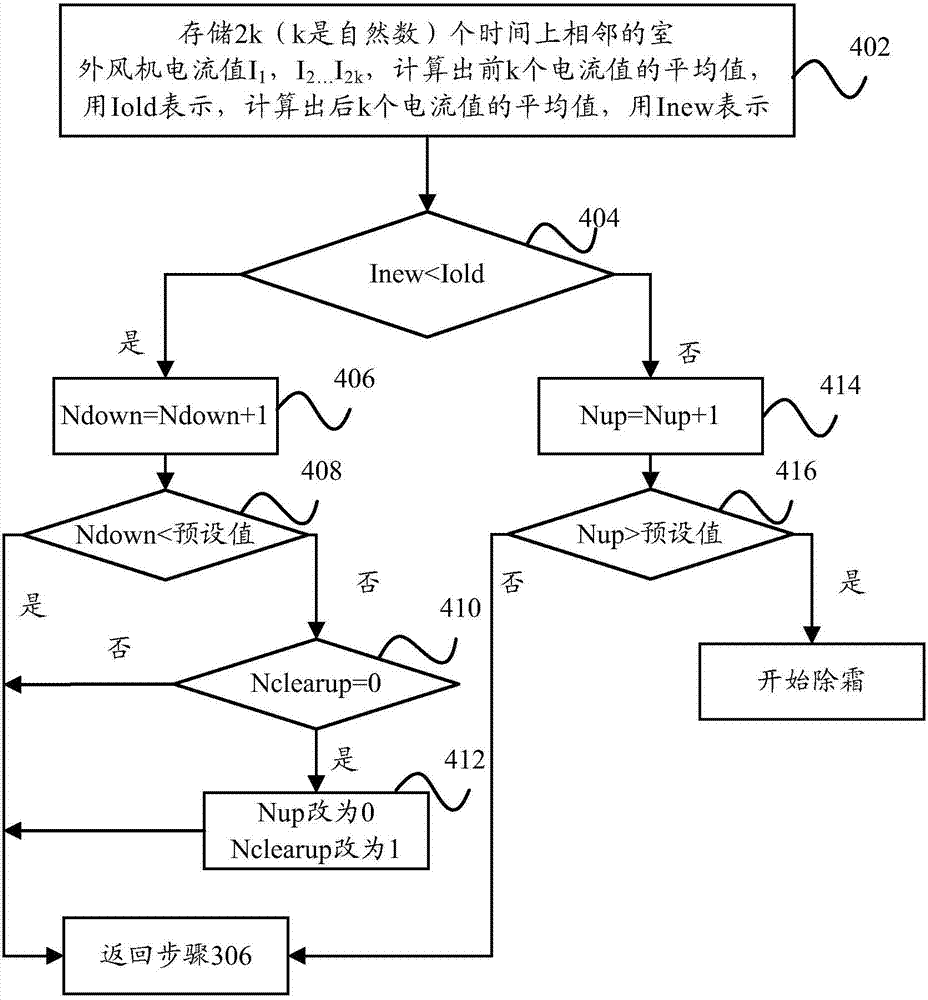

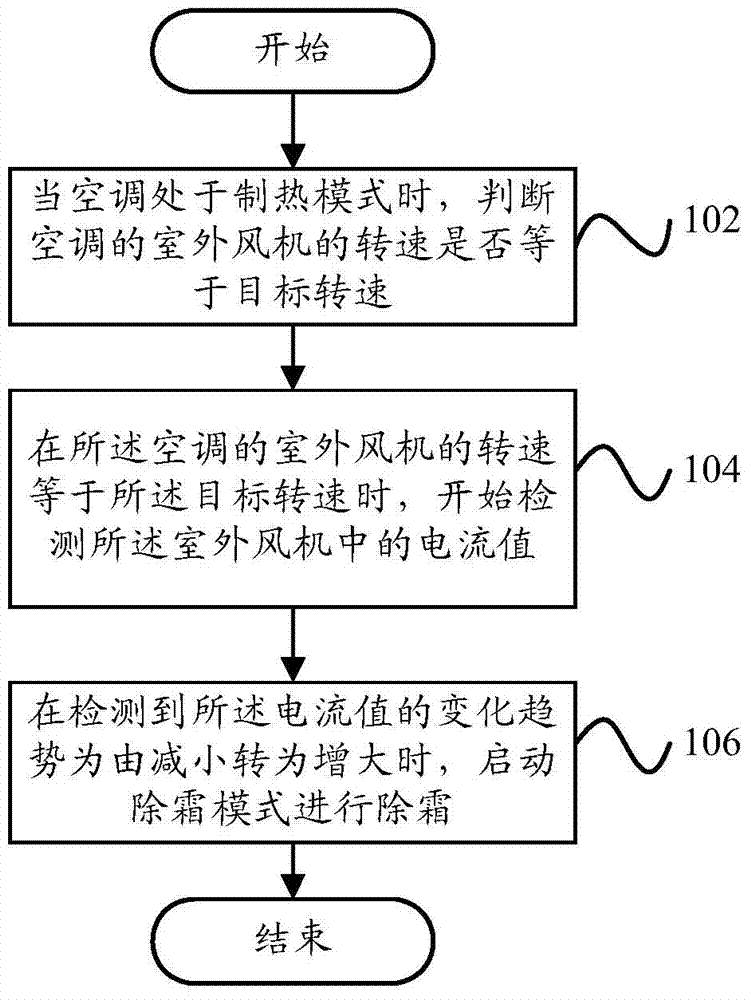

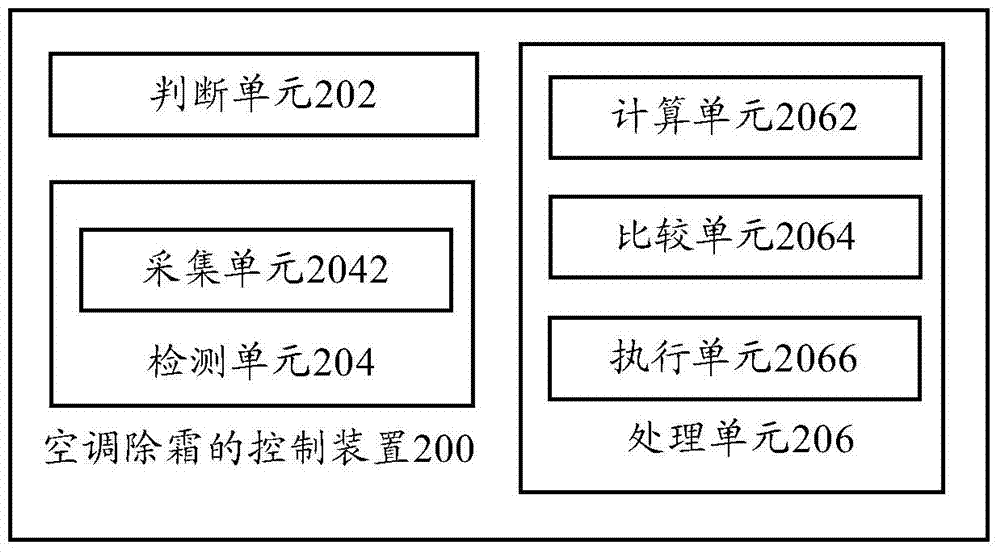

Air conditioner and judgment method and device for air conditioner in defrost mode

ActiveCN103925675AAvoid misjudgmentImprove accuracySpace heating and ventilation safety systemsSpace heating and ventilation control systemsFrostEngineering

The invention provides a control method of an air conditioner in a defrost mode. The control method includes a judgment step, namely judging whether the rotation speed of an outdoor fan of the air conditioner equals to a target rotation speed or not when the air conditioner is in a heating mode; a detection step, namely starting to detect the current value in the outdoor fan when the rotation speed of the outdoor fan of the air conditioner is equal to the target rotation speed; a processing step, namely starting the defrost mode for defrosting when the variation trend of the detected current value increases. Correspondingly, the invention further provides a control device of the air conditioner in the defrost mode. By the technical scheme, timing that the air conditioner starts to defrost can be simply and accurately judged, the shortcomings like frost-free defrost is avoided, and user experience is improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

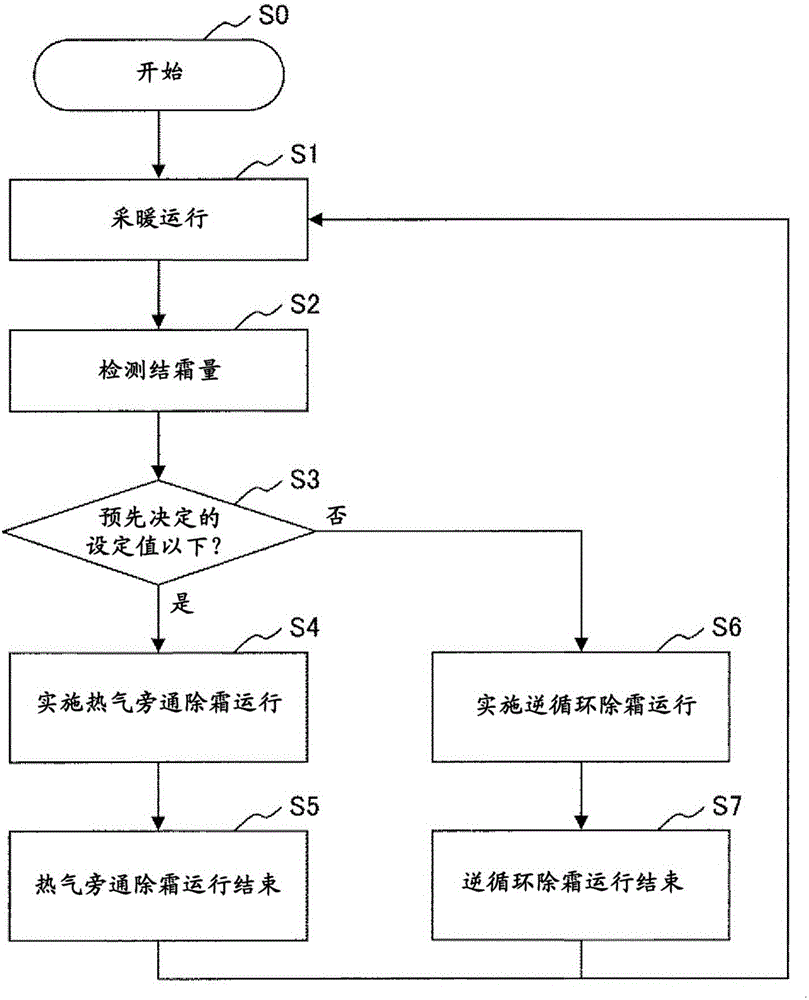

Air conditioner and defrosting operation method therefor

ActiveCN106461253ATotal heating capacity reductionMechanical apparatusSpace heating and ventilation safety systemsPlate heat exchangerFour-way valve

An air conditioner in which a refrigeration cycle is configured by connecting a compressor, a four-way valve, a use-side heat exchanger, an expansion valve, and a heat-source-side heat exchanger. The air conditioner is also provided with: a hot gas bypass circuit that is connected between the discharge side of the compressor and in between the heat-source-side heat exchanger and the expansion valve; an on-off valve that opens / closes the flow path of the hot gas bypass circuit; and a control device that performs control such that either hot gas bypass defrosting operation or inverse cycle defrosting operation is selected according to the amount of frost formation on the heat-source-side heat exchanger, thereby performing defrosting operation. The control device, in the case of executing the hot gas bypass defrosting operation, performs control such that the on-off valve of the hot gas bypass circuit is opened, thereby partially supplying the refrigerant discharged from the compressor to the heat-source-side heat exchanger through the hot gas bypass circuit, and in the case of executing the inverse cycle defrosting operation, performs control to switch the four-way valve so that the refrigerant discharged from the compressor is supplied to the heat-source-side heat exchanger after passing through the four-way valve.

Owner:HITACHI JOHNSON CONTROLS AIR CONDITIONING INC

Throat nourishing health-care type electronic cigarette liquid

InactiveCN102028306APrevent swelling and painPrevention and treatment of hoarsenessTobacco treatmentHydroxy compound active ingredientsDiseasePeppermints

The invention discloses throat nourishing health-care type electronic cigarette liquid, which is used for producing electronic cigarettes, can meet the requirement of smoking addiction, contributes to smoke absorbing and throat nourishing, protects the throat of a human body and maintains health. The electronic cigarette liquid mainly comprises the following components in percentage by weight: 2 to 6 percent of plant cigarette substituting agent, 48 to 55 percent of propylene glycol, 25 to 35 percent of pure water, 4 to 6 percent of tobacco flavor, 0.25 to 1.2 percent of stabilizer, 4 to 9 percent of thickening agent and 3 to 6 percent of Chinese medicinal component, wherein the Chinese medicinal component comprises 3 to 5 types of watermelon frost, peppermint oil, menthol, blumea aromatria, eucalyptus oil and star anise oil according to an equal proportion. The electronic cigarette liquid has the effects of promoting secretion and nourishing throat, clearing sound and eliminating phlegm, and reducing swelling and relieving pain during the enjoyment of smoking, can prevent and treat throat sore, hoarseness, canker sore, stomatitis and gum swelling and pain, and has good curative effect on throat diseases such as dryness, swelling and pain of the throat accompanied by the hoarseness.

Owner:张志军

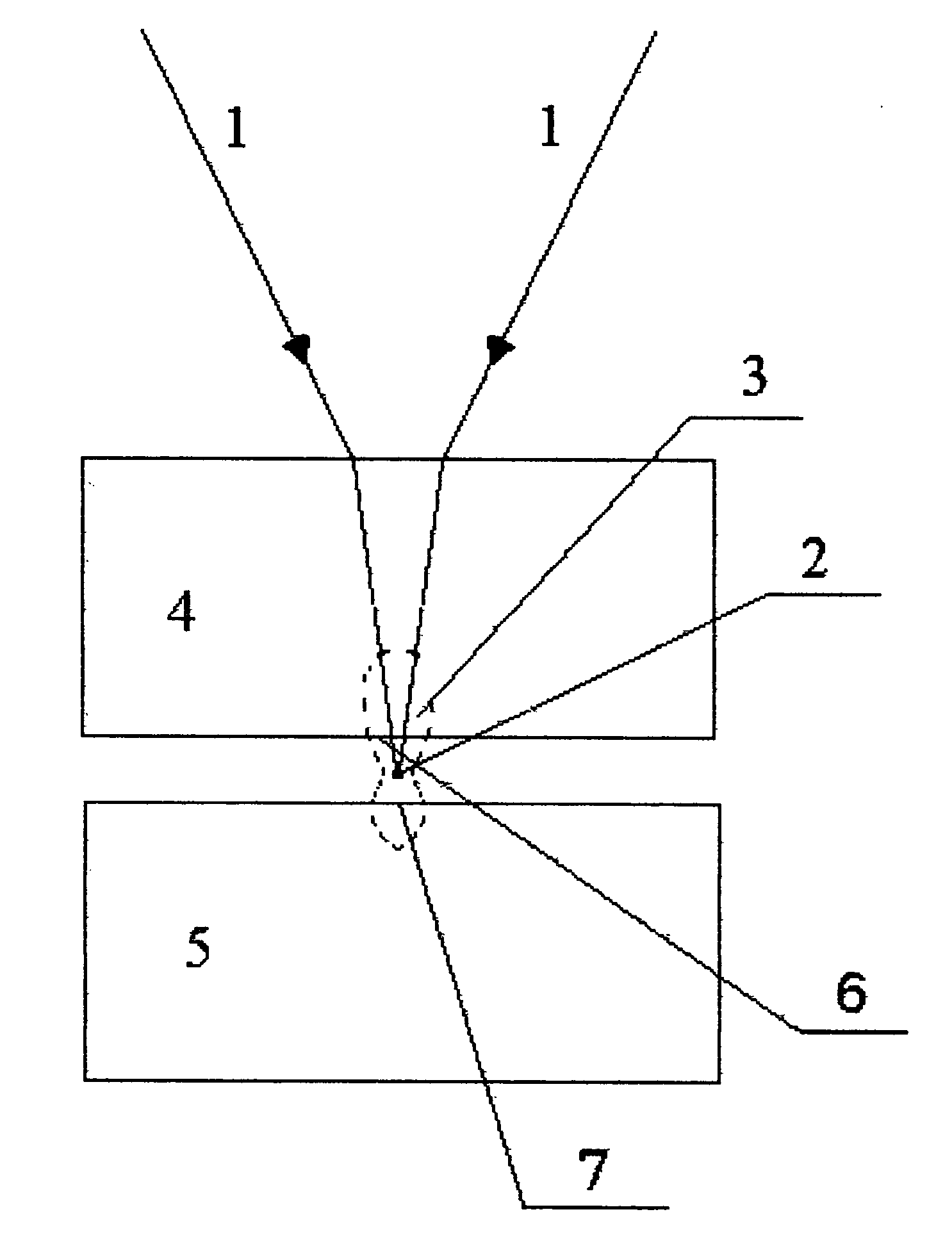

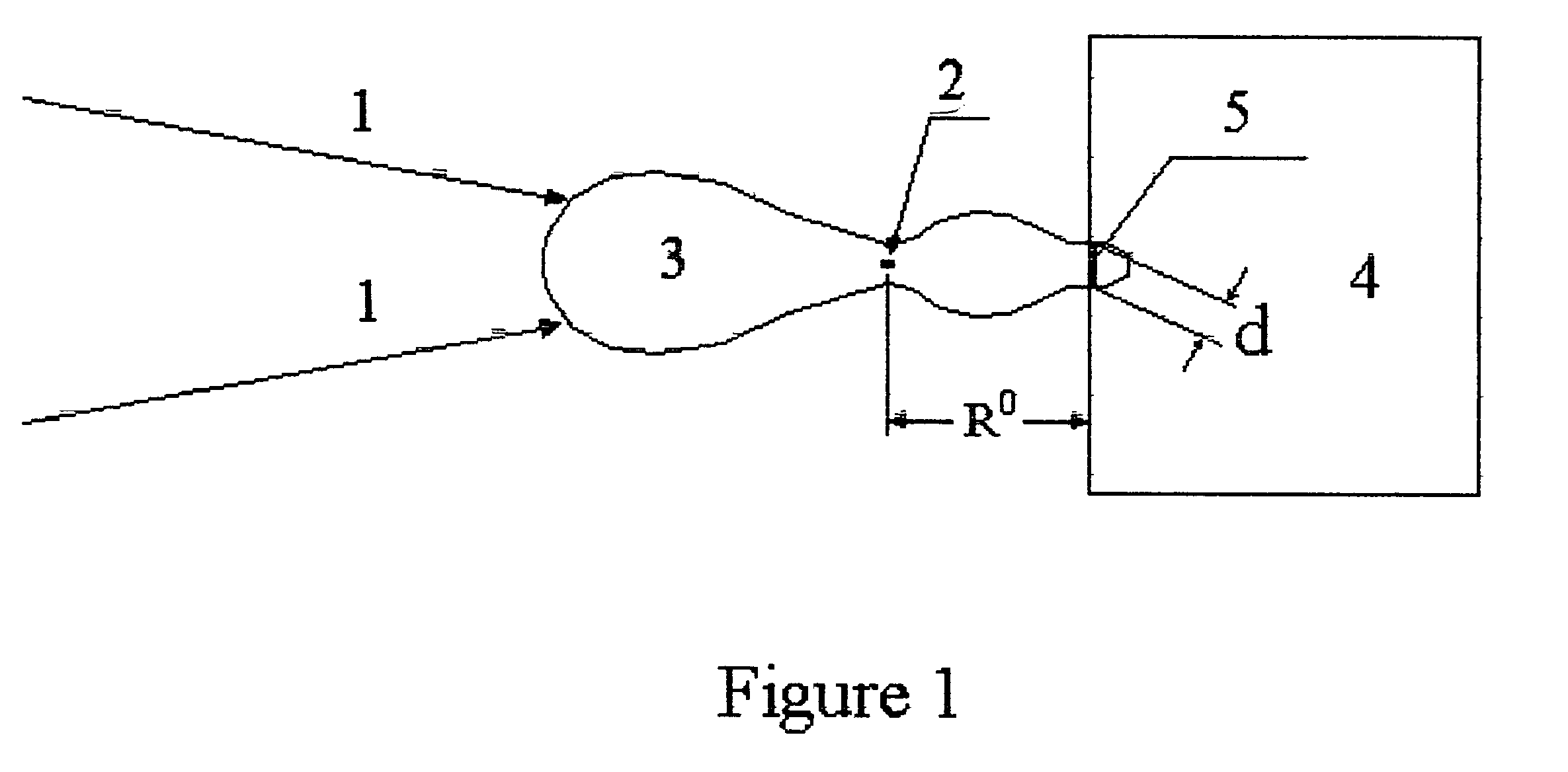

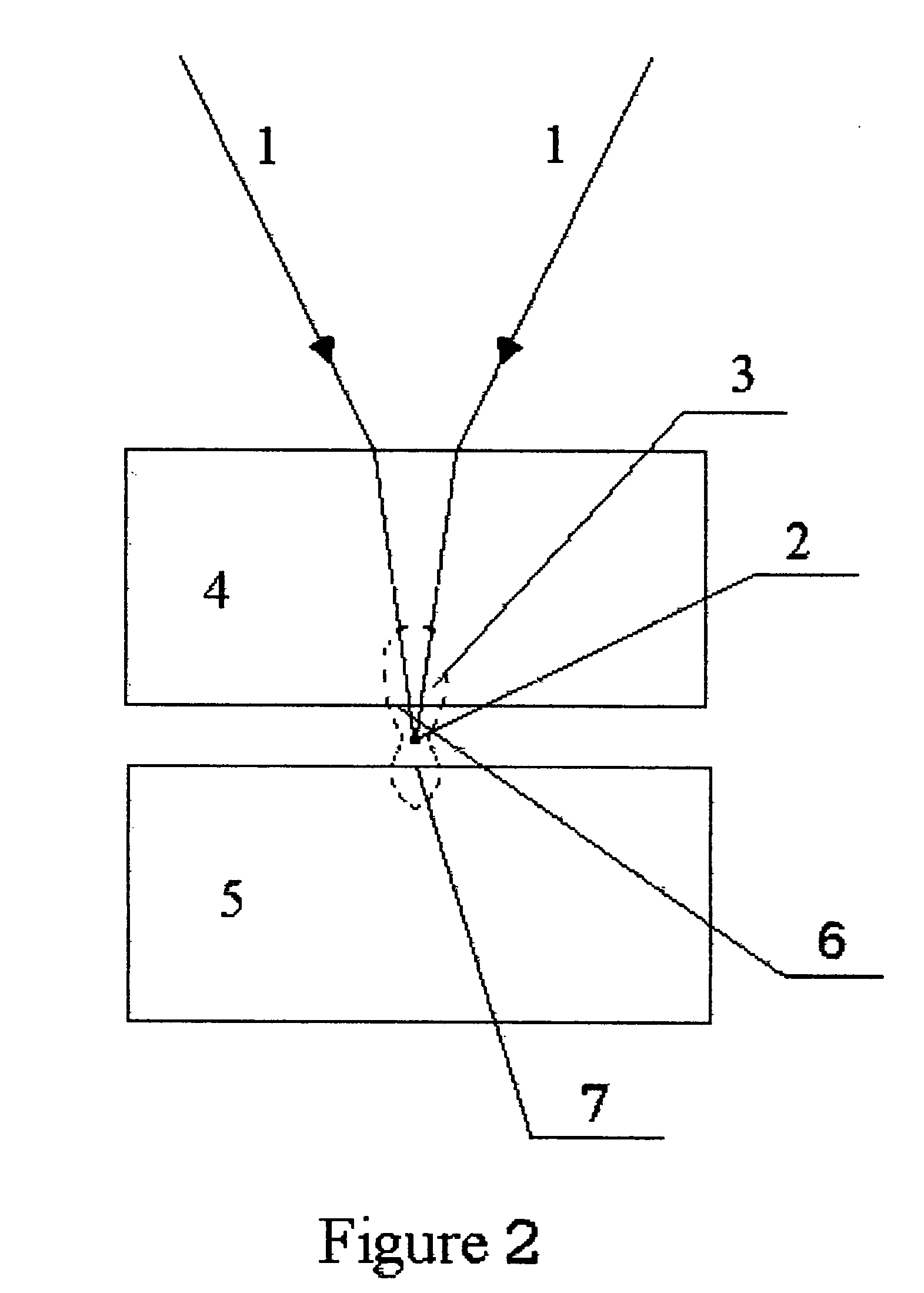

Method and laser system for production of laser-induced images inside and on the surface of transparent material

A method and an apparatus for creating laser-induced images inside transparent materials and on their surfaces are disclosed. The method is founded on the production of etch points by creating breakdowns at the predetermined points inside transparent material and by creating breakdowns at the predetermined points of the air or another environment. Mark areas on the transparent material surfaces are the frost areas and a surface image is an arrangement of the frost areas of different density. Such frost areas on the surface of a transparent material are produced by the plasma generated during breakdowns. A method and a system for controlling characteristics of plasma generated during breakdowns for controlling the parameters of the frost areas arisen under interaction of the plasma with the surface of the transparent material are disclosed.

Owner:TROITSKI IGOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com