Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1540 results about "Cold plate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A cold plate is a popular dish with origins in rural Newfoundland, Canada. It is generally served as a mid-day or evening meal. Often in Newfoundland cold plates are served at weddings and large gatherings. The ability to prepare this dish almost entirely in advance makes it amenable to such purposes.

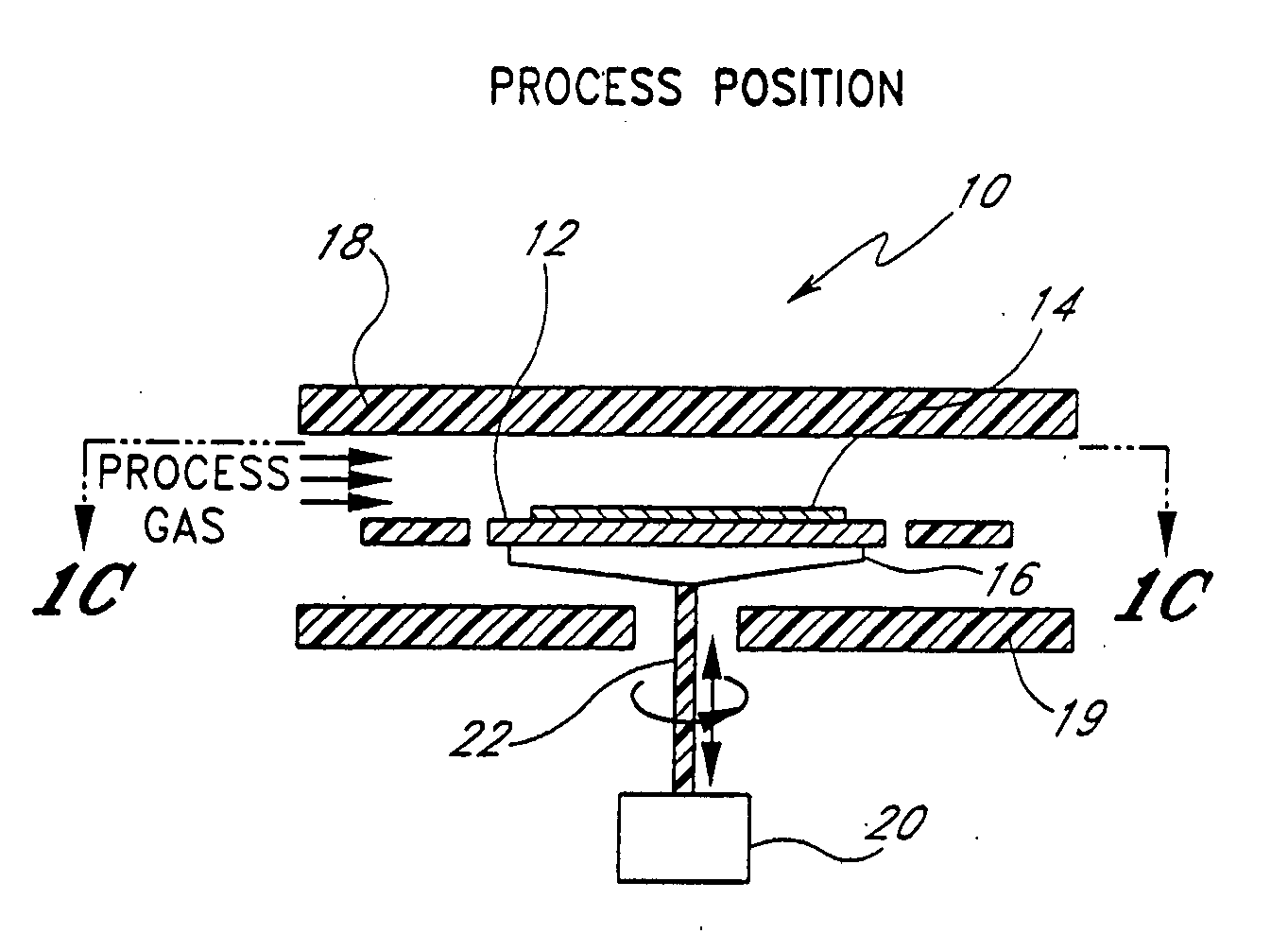

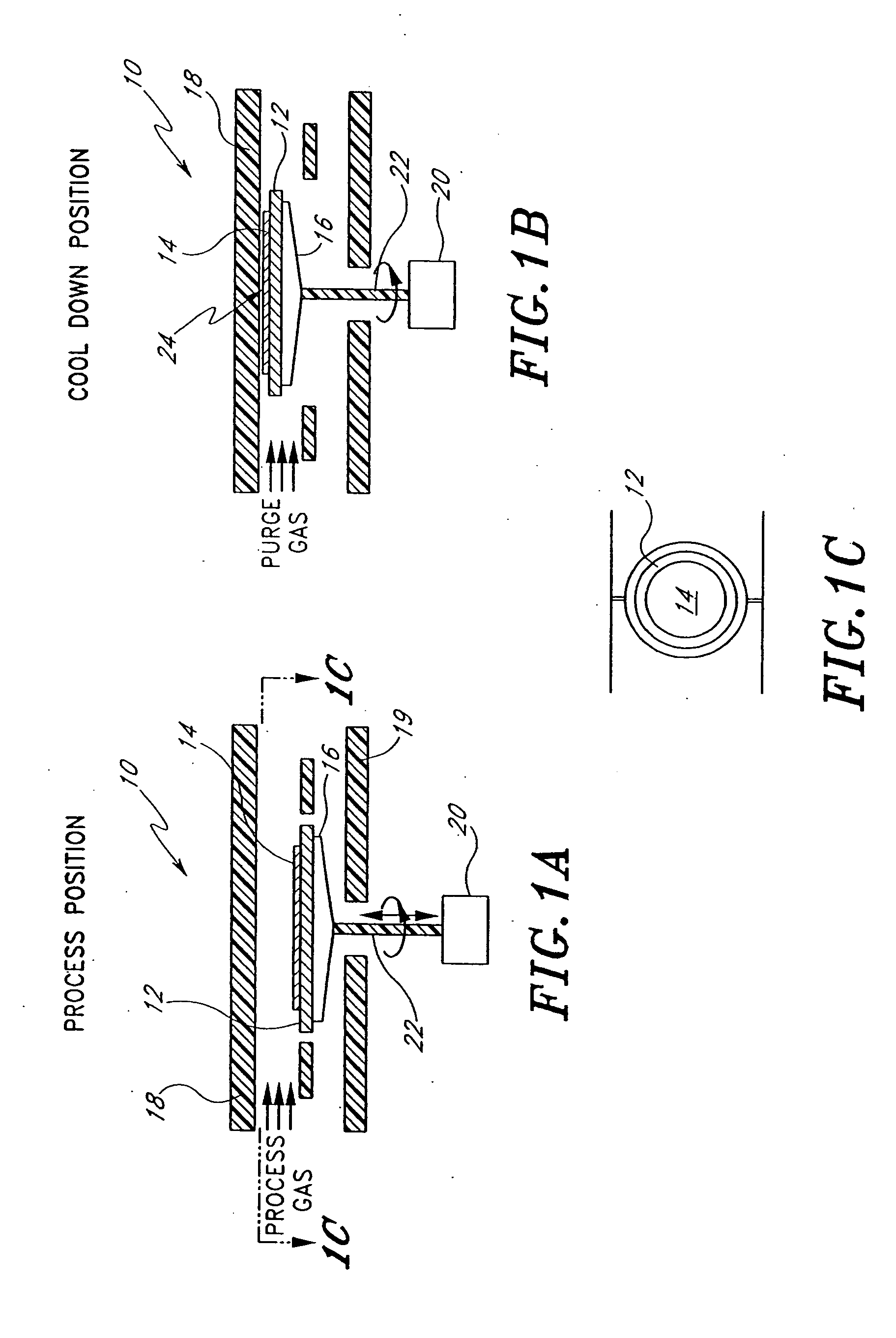

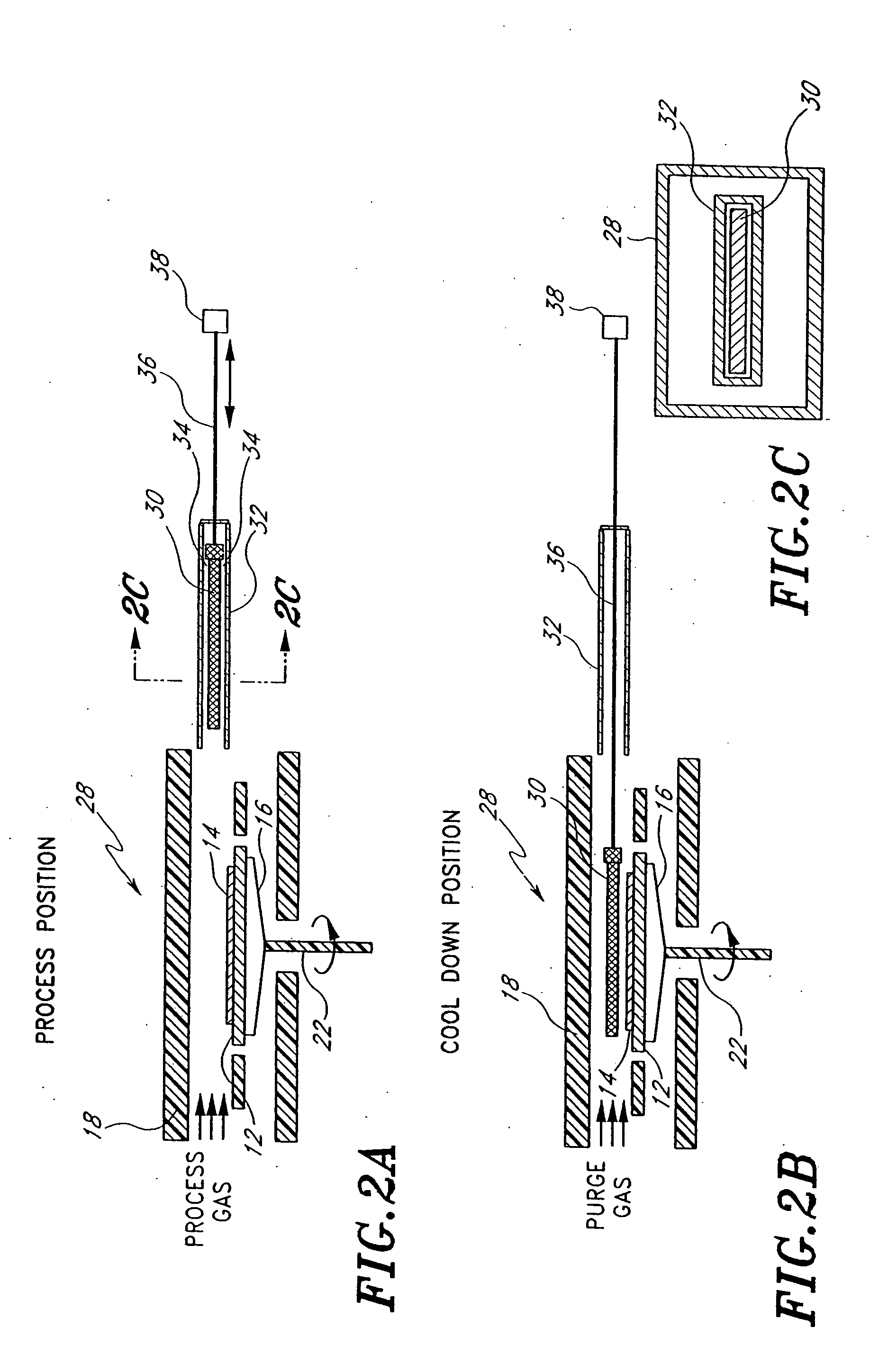

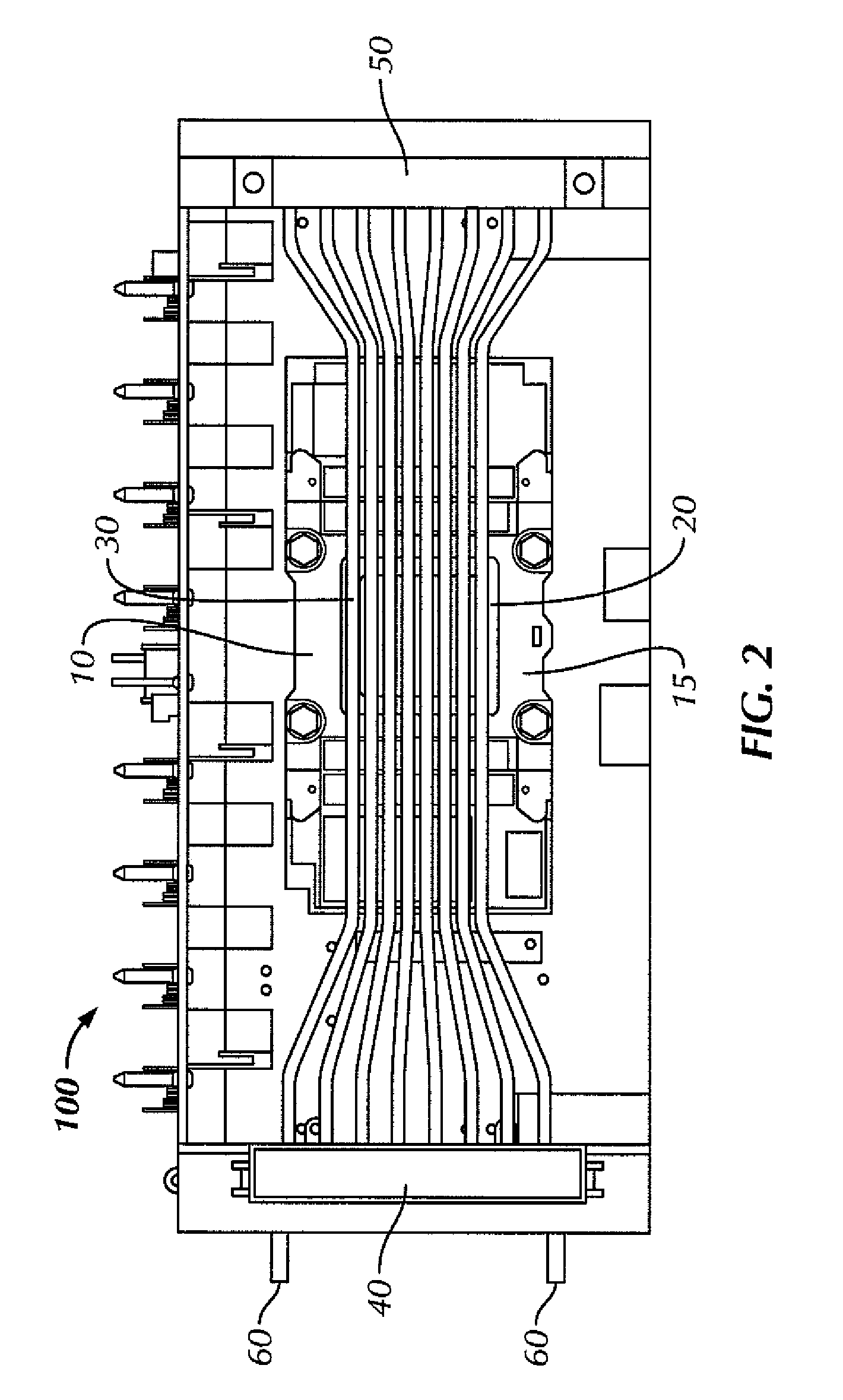

Apparatus for thermal treatment of substrates

InactiveUS20050229855A1Short timeIncrease wafer throughputSemiconductor/solid-state device manufacturingFrom chemically reactive gasesEngineeringCold plate

Methods and apparatuses are provided for cooling semiconductor substrates prior to handling. In one embodiment, a substrate and support structure combination is lifted after high temperature processing to a cold wall of a thermal processing chamber, which acts as a heat sink. Conductive heat transfer across a small gap from the substrate to the heat sink speeds wafer cooling prior to handling the wafer (e.g., with a robot). In another embodiment, a separate plate is kept cool within a pocket during processing, and is moved close to the substrate and support after processing. In yet another embodiment, a cooling station between a processing chamber and a storage cassette includes two movable cold plates, which are movable to positions closely spaced on either side of the wafer.

Owner:RAAIJMAKERS IVO

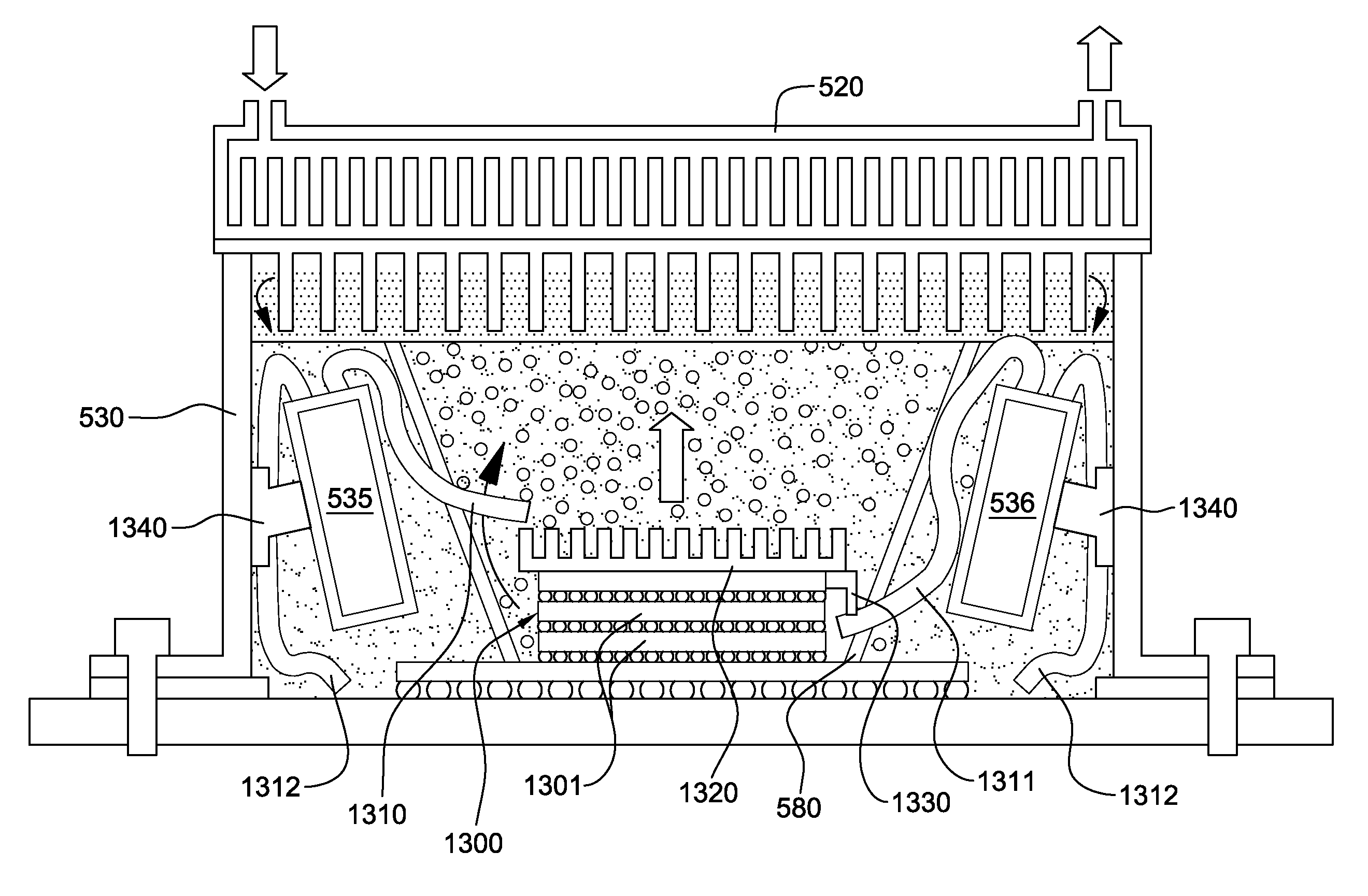

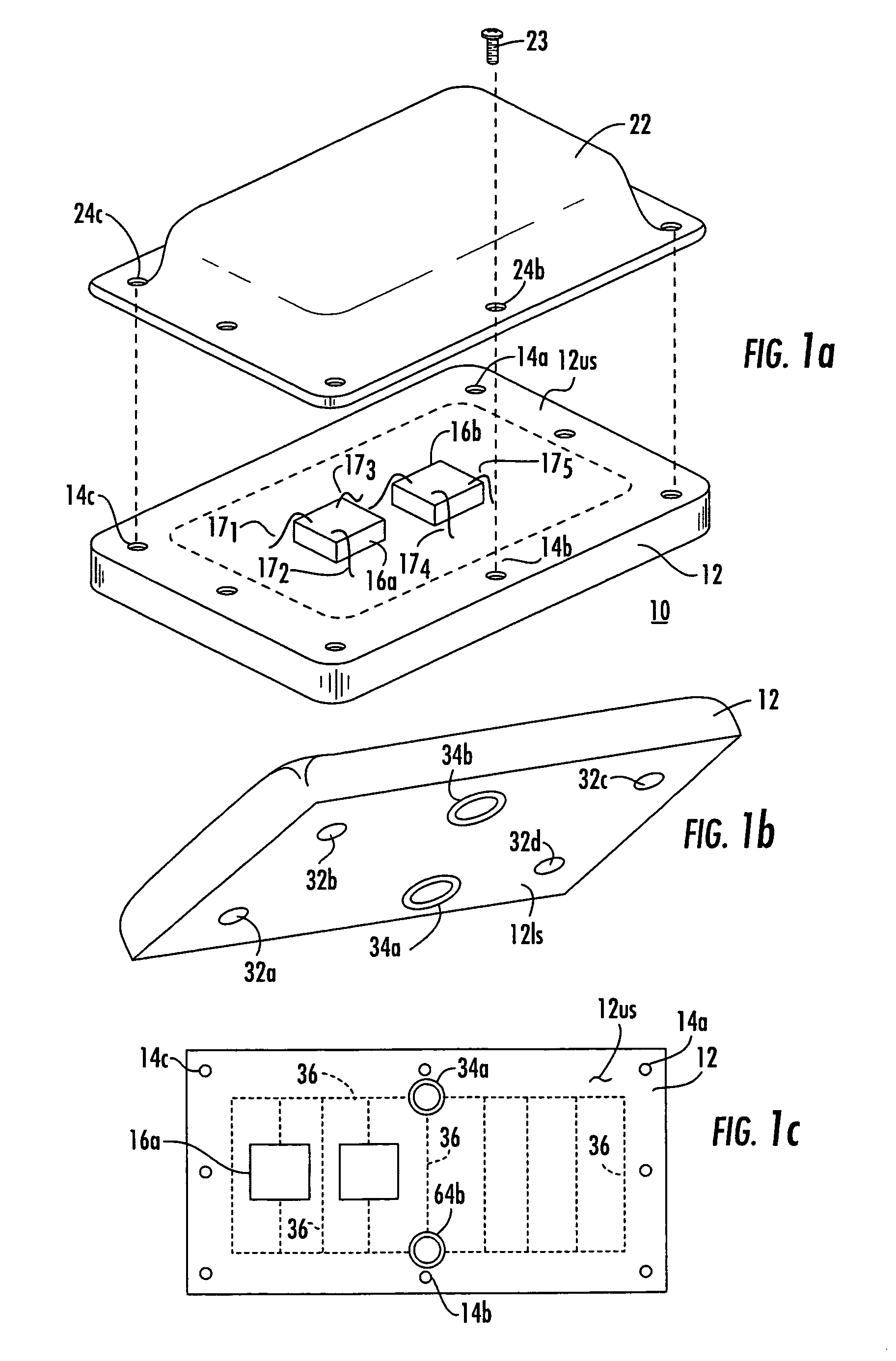

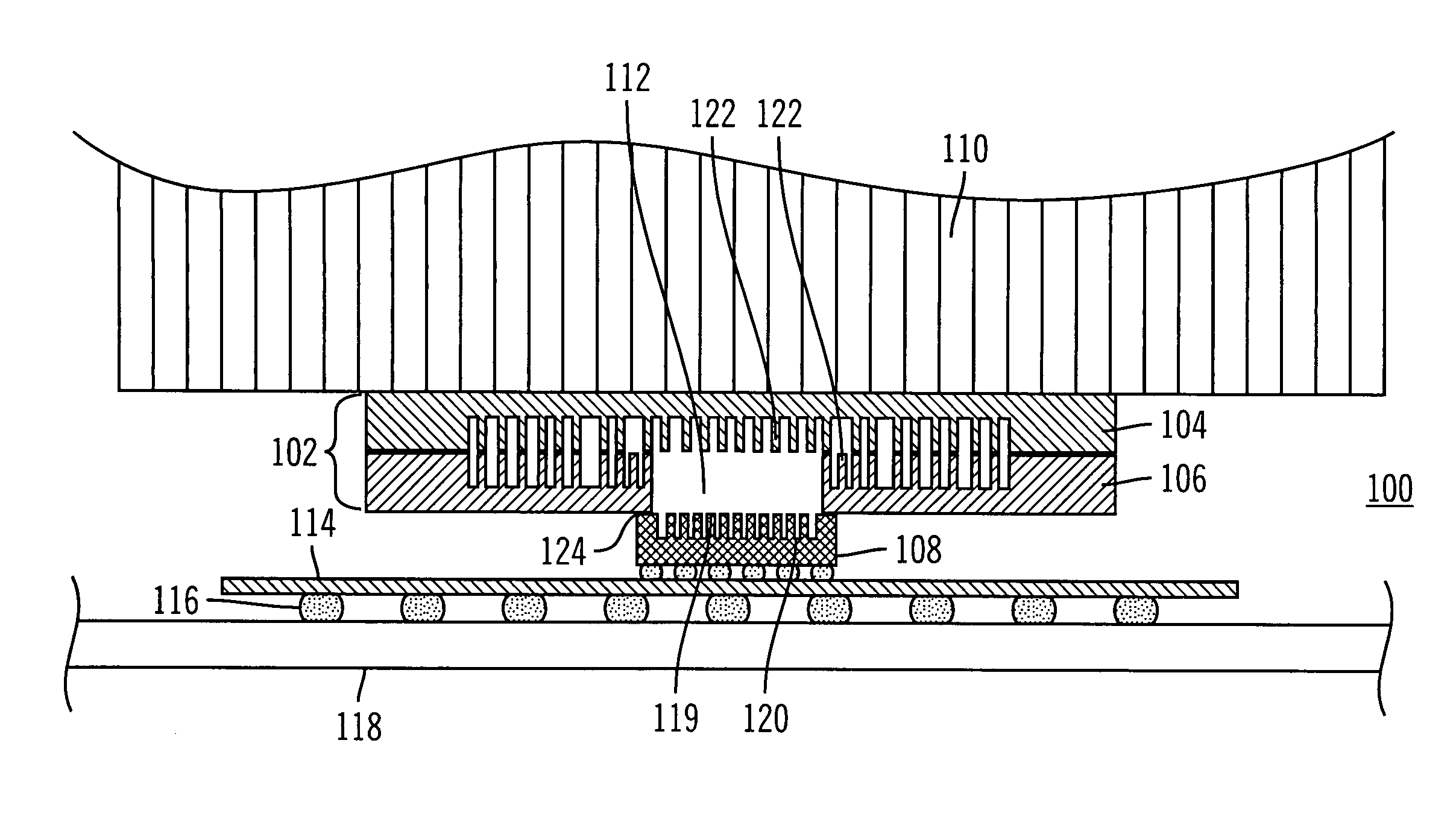

Cooled electronic module with pump-enhanced, dielectric fluid immersion-cooling

ActiveUS8014150B2Facilitating cooling of a heat-generating electronic deviceImprove cooling effectDigital data processing detailsSemiconductor/solid-state device detailsDielectricComputer module

Cooled electronic modules and methods of fabrication are provided with pump-enhanced, dielectric fluid immersion-cooling of the electronic device. The cooled electronic module includes a substrate supporting an electronic device to be cooled. A cooling apparatus couples to the substrate, and includes a housing configured to at least partially surround and form a sealed compartment about the electronic device. Additionally, the cooling apparatus includes dielectric fluid and one or more pumps disposed within the sealed compartment. The dielectric fluid is in direct contact with the electronic device, and the pump is an impingement-cooling, immersed pump disposed to actively pump dielectric fluid within the sealed compartment towards the electronic device. Multiple condenser fins extend from the housing into the sealed compartment in an upper portion of the sealed compartment, and a liquid-cooled cold plate or an air-cooled heat sink is coupled to the top of the housing for cooling the condenser fins.

Owner:INT BUSINESS MASCH CORP

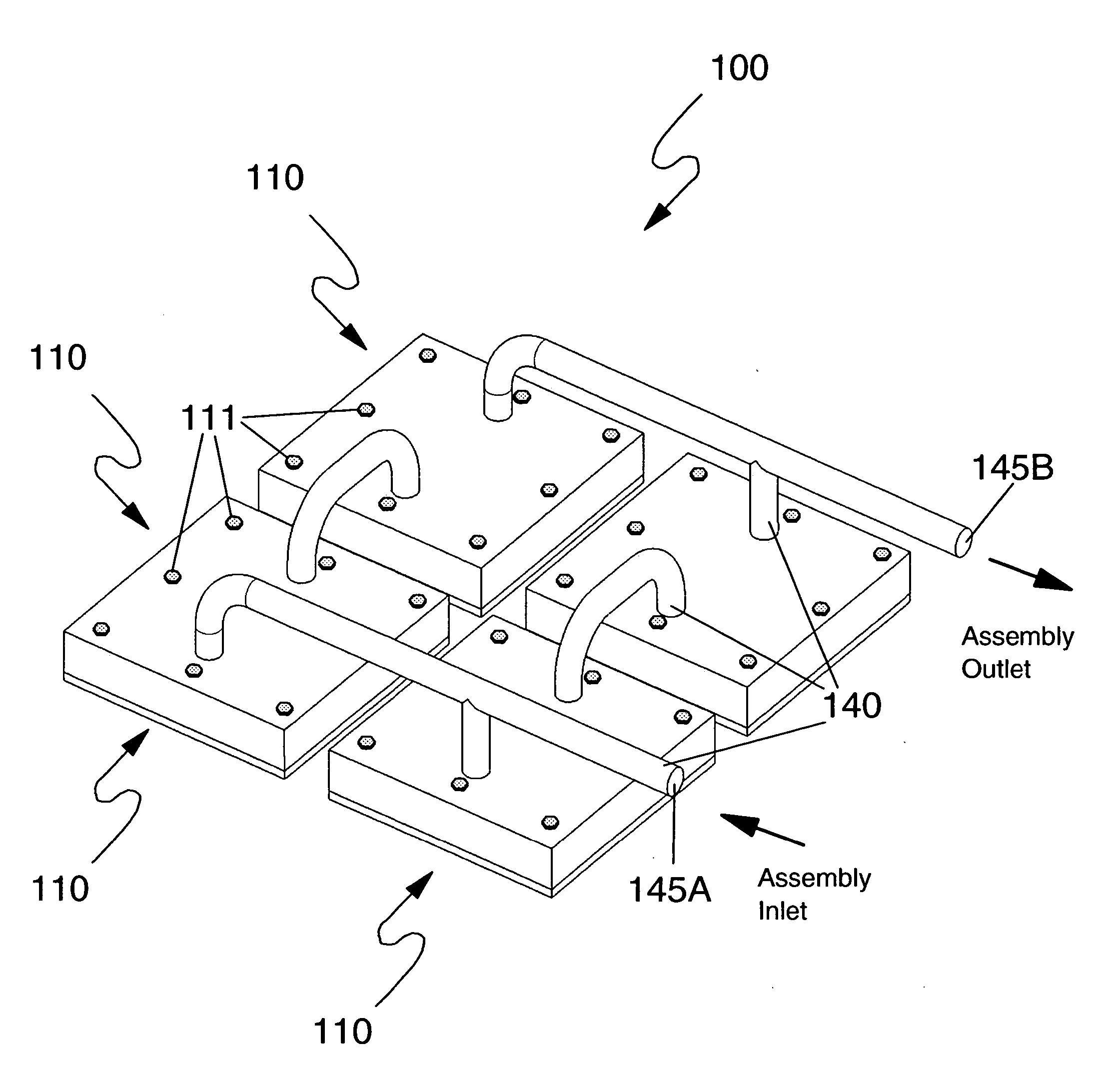

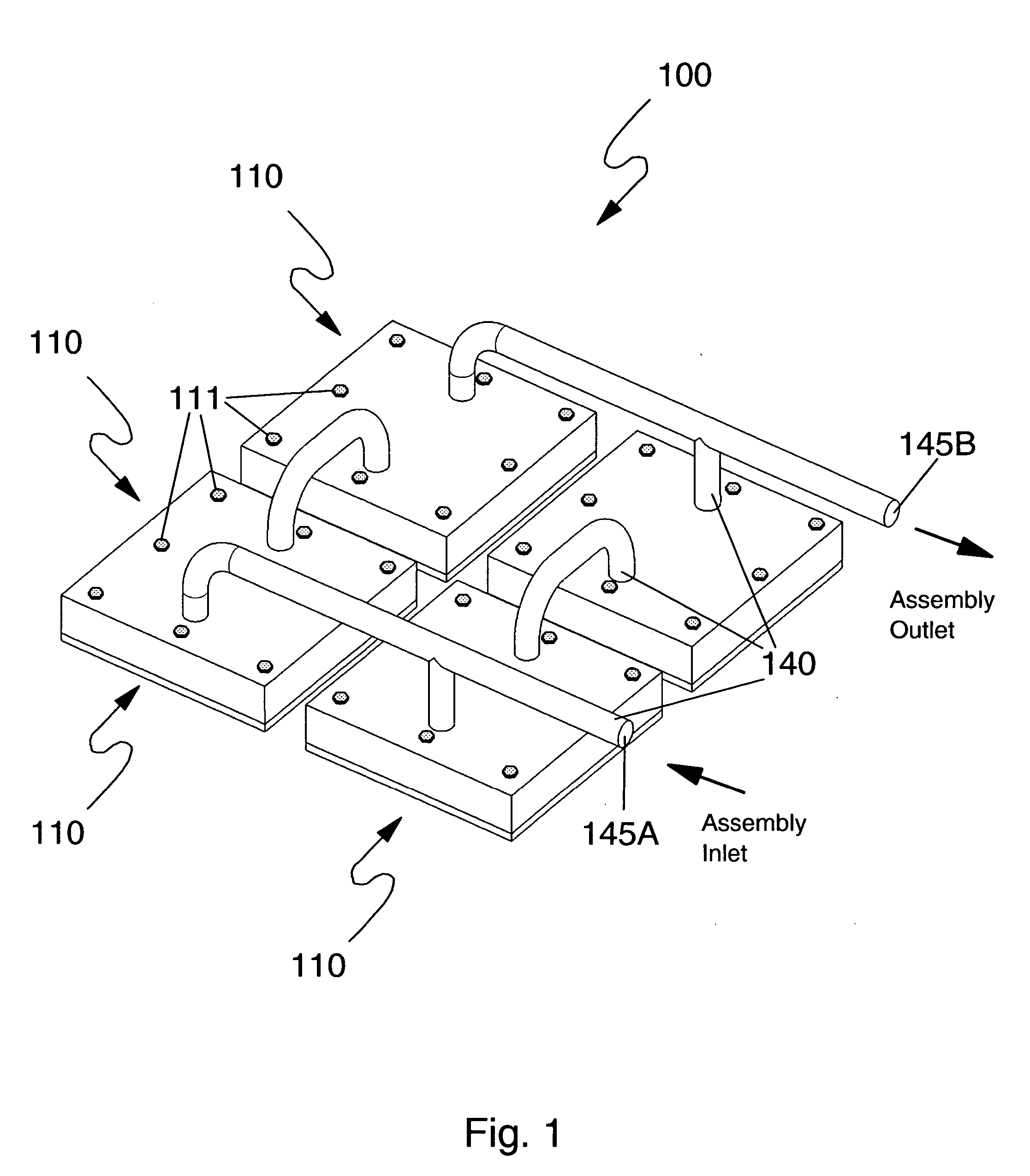

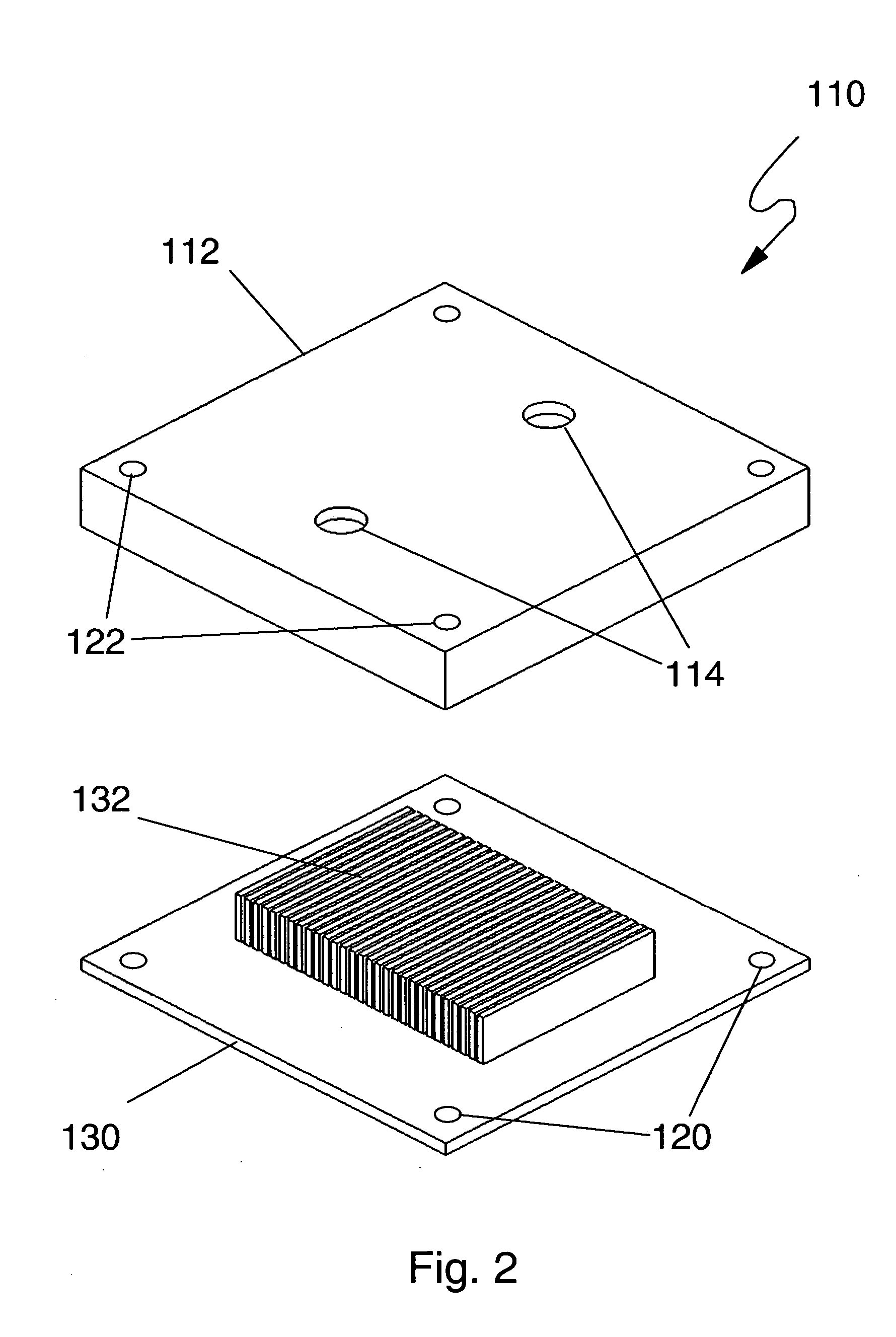

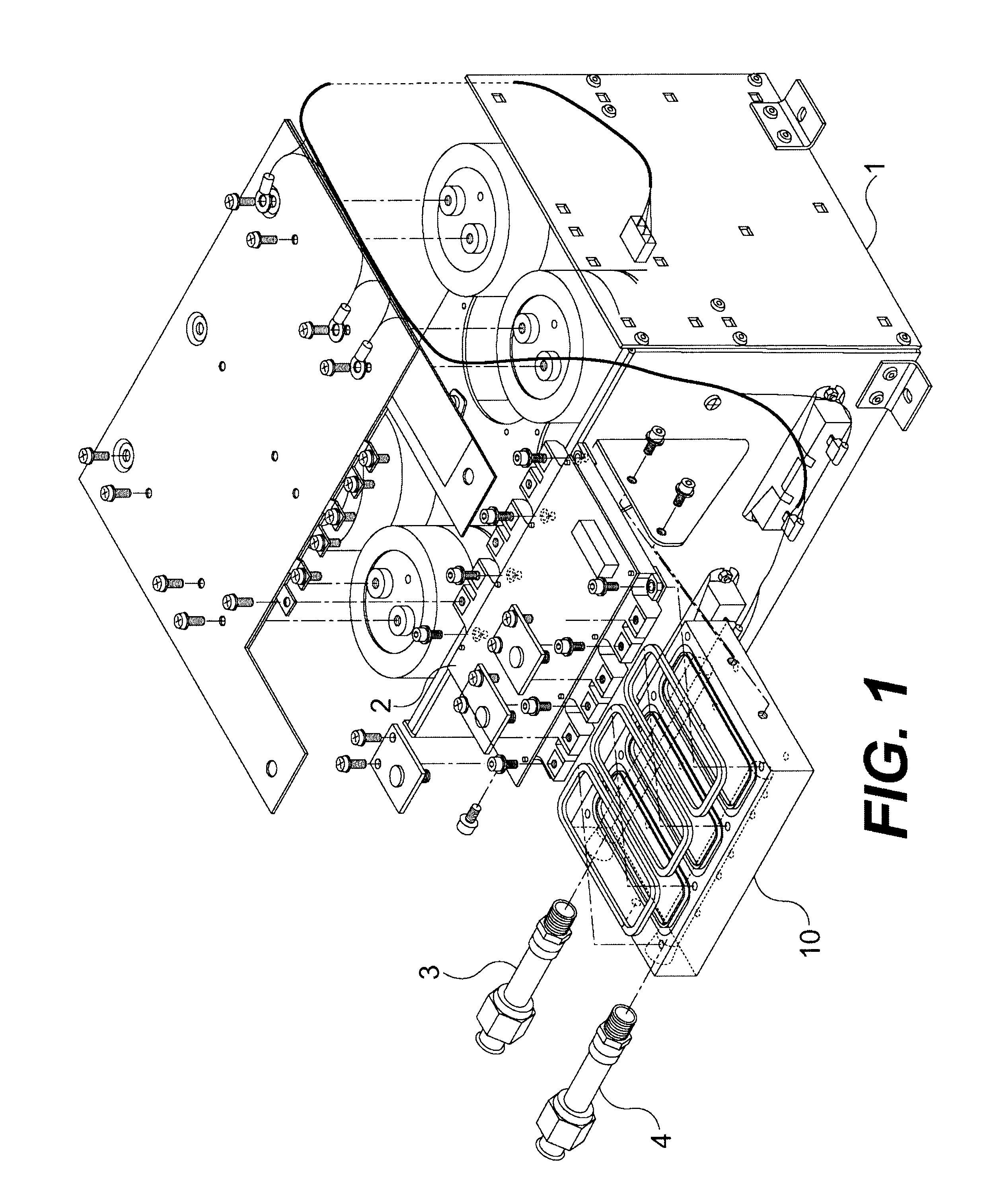

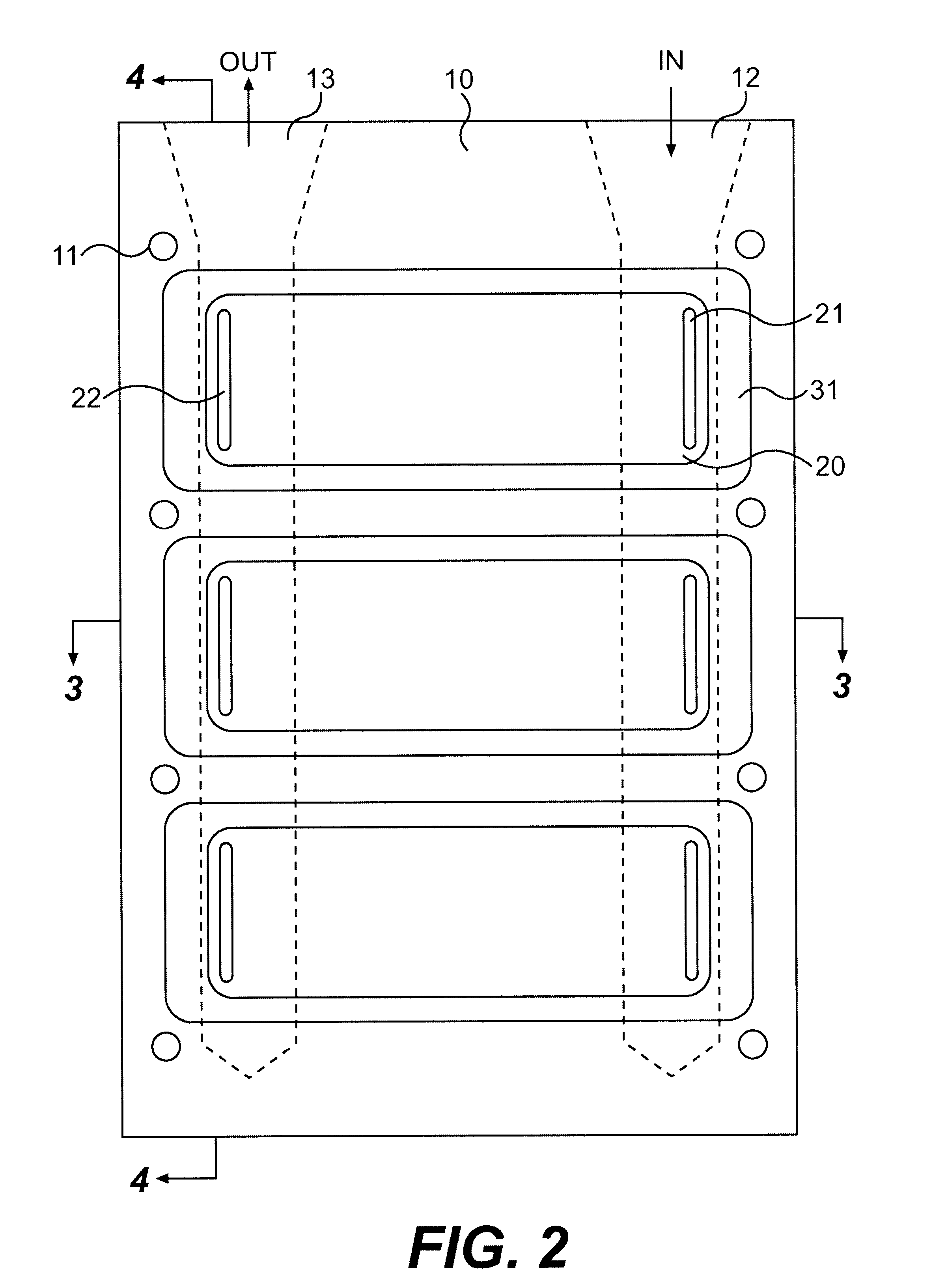

Composite cold plate assembly

InactiveUS20050128705A1Reduce connectionsSolve the lack of flexibilitySemiconductor/solid-state device detailsSolid-state devicesEngineeringCold plate

A cooling fluid distribution assembly for a plurality of electronic modules, using a composite cold plate structure. One cold plate is associated with each electronic module requiring liquid cooling. Each cold plate includes a high thermal conductivity base sealably fastened to a cover, the cover having at least one fluid inlet and at least one fluid outlet. Cover fluid inlets and outlets are connected via a plurality of flexible, nonmetallic conduits, the conduits being bonded to the cover inlets and outlets. Each cold plate cover is formed of a material that is capable of being bonded to the flexible, nonmetallic conduits, covers are therefore formed of a different material than the material comprising the cold plate base. Cold plate structures preferably include internal fluid distribution structures. The resulting cooling fluid distribution assembly provides reliable fluid connections and is sufficiently flexible to adjust for variances in module height etc.

Owner:IBM CORP

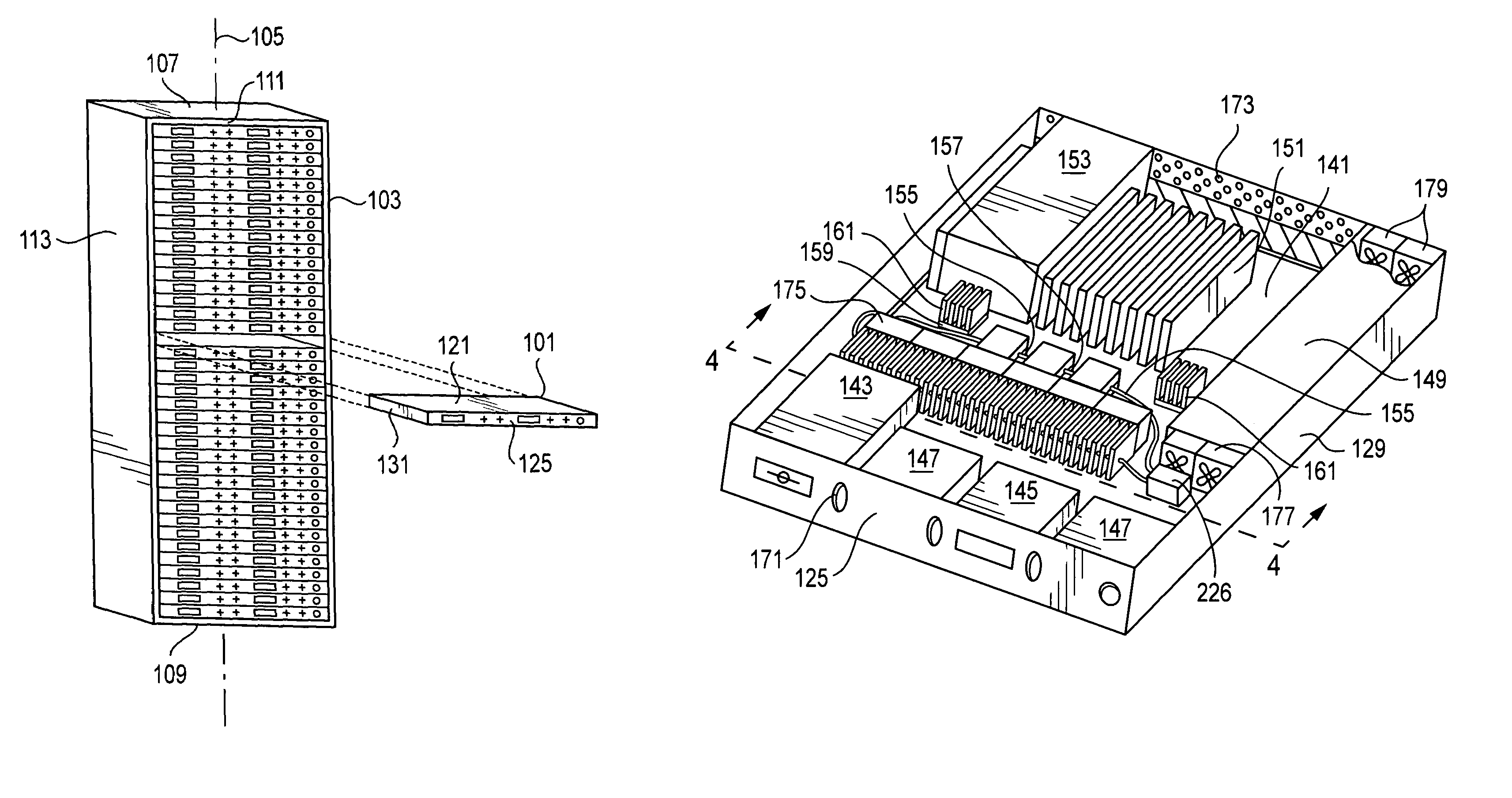

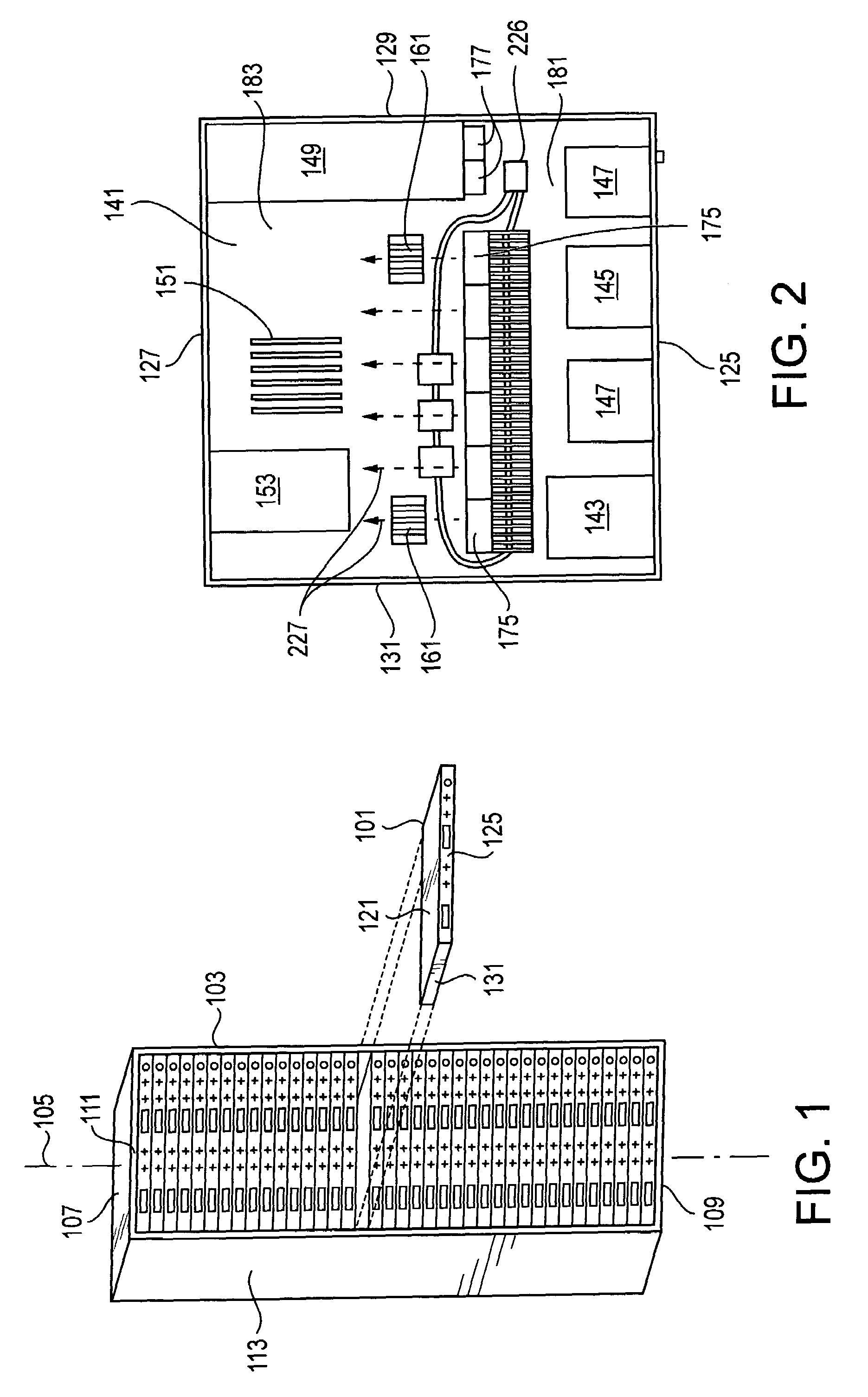

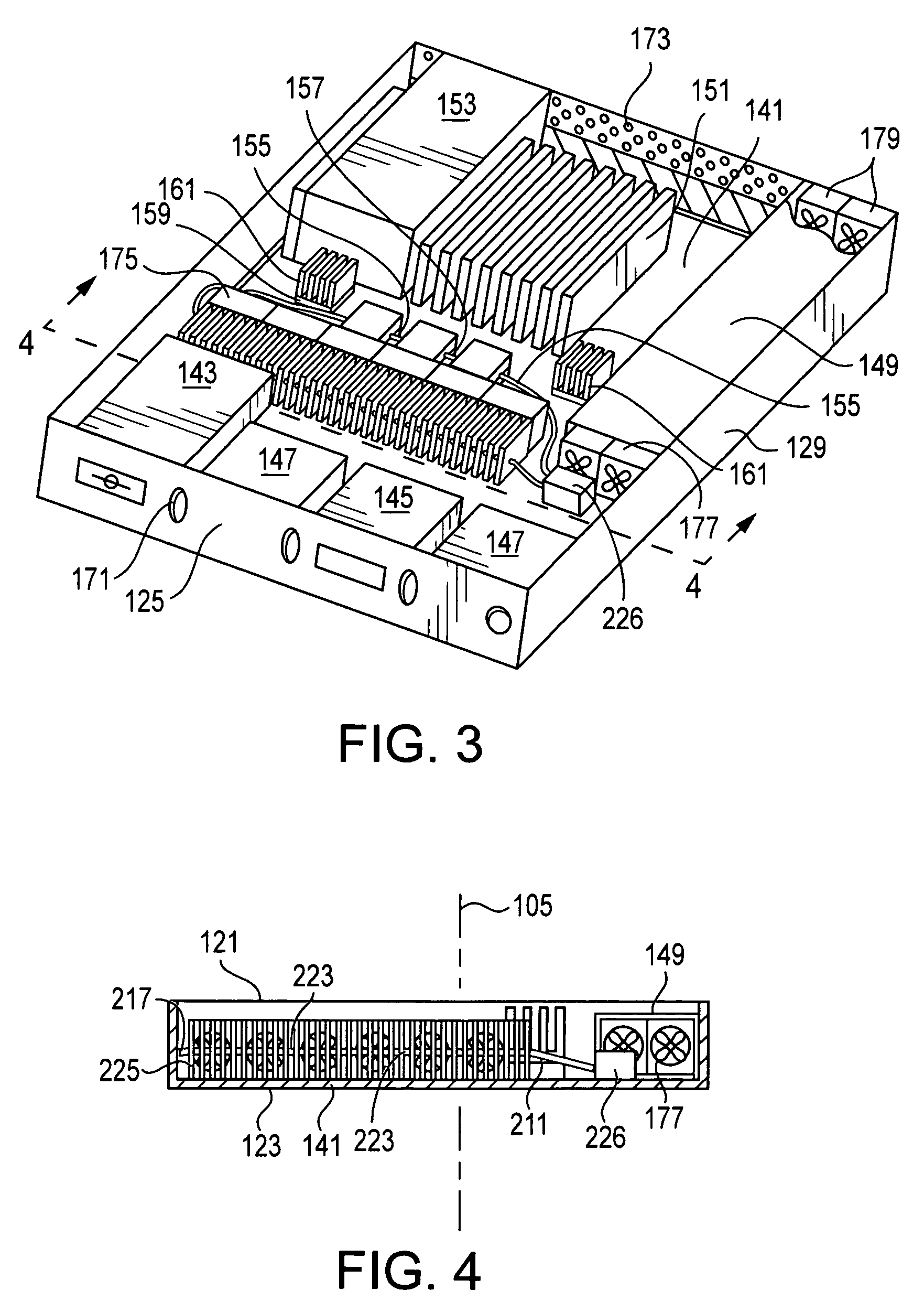

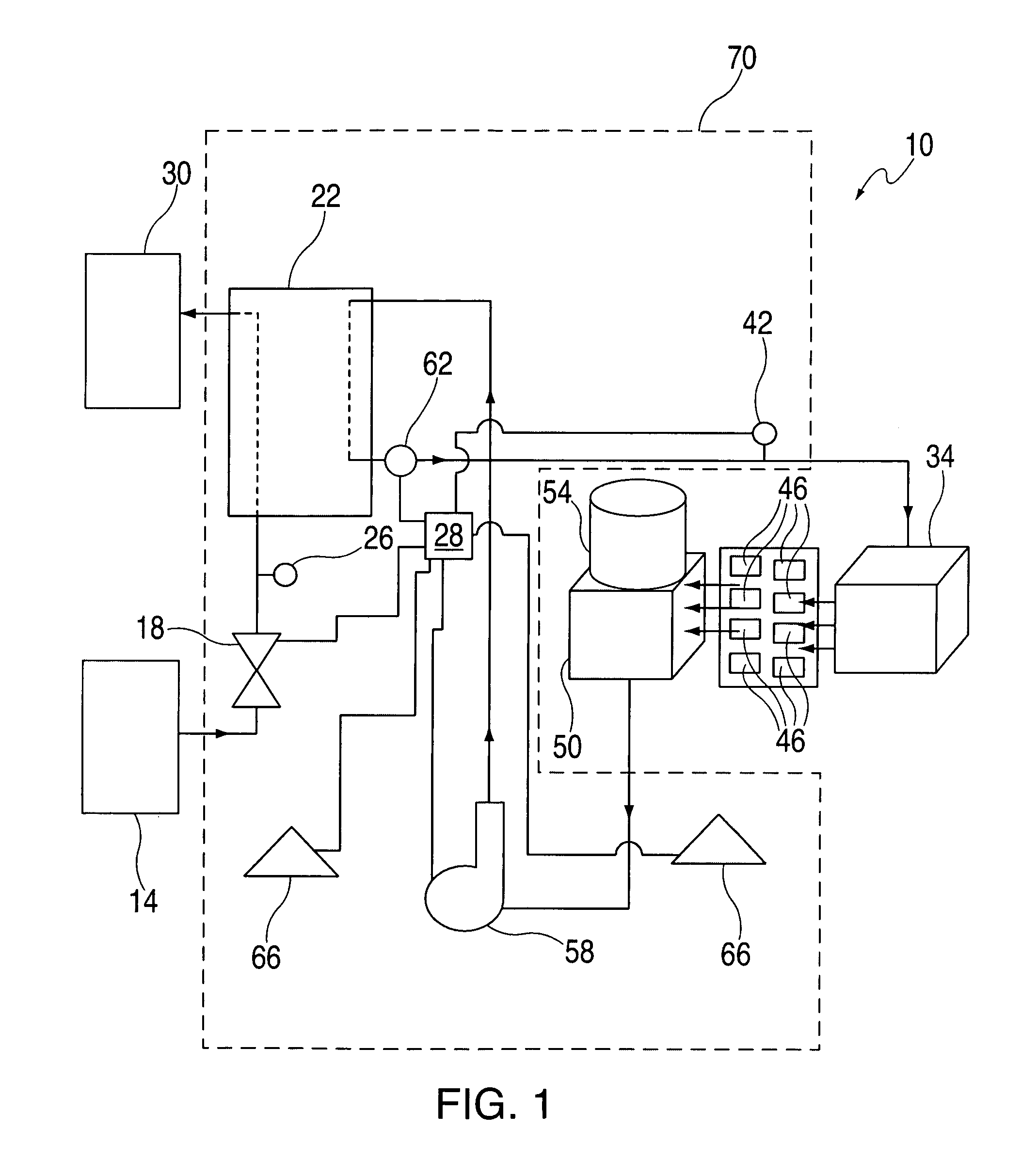

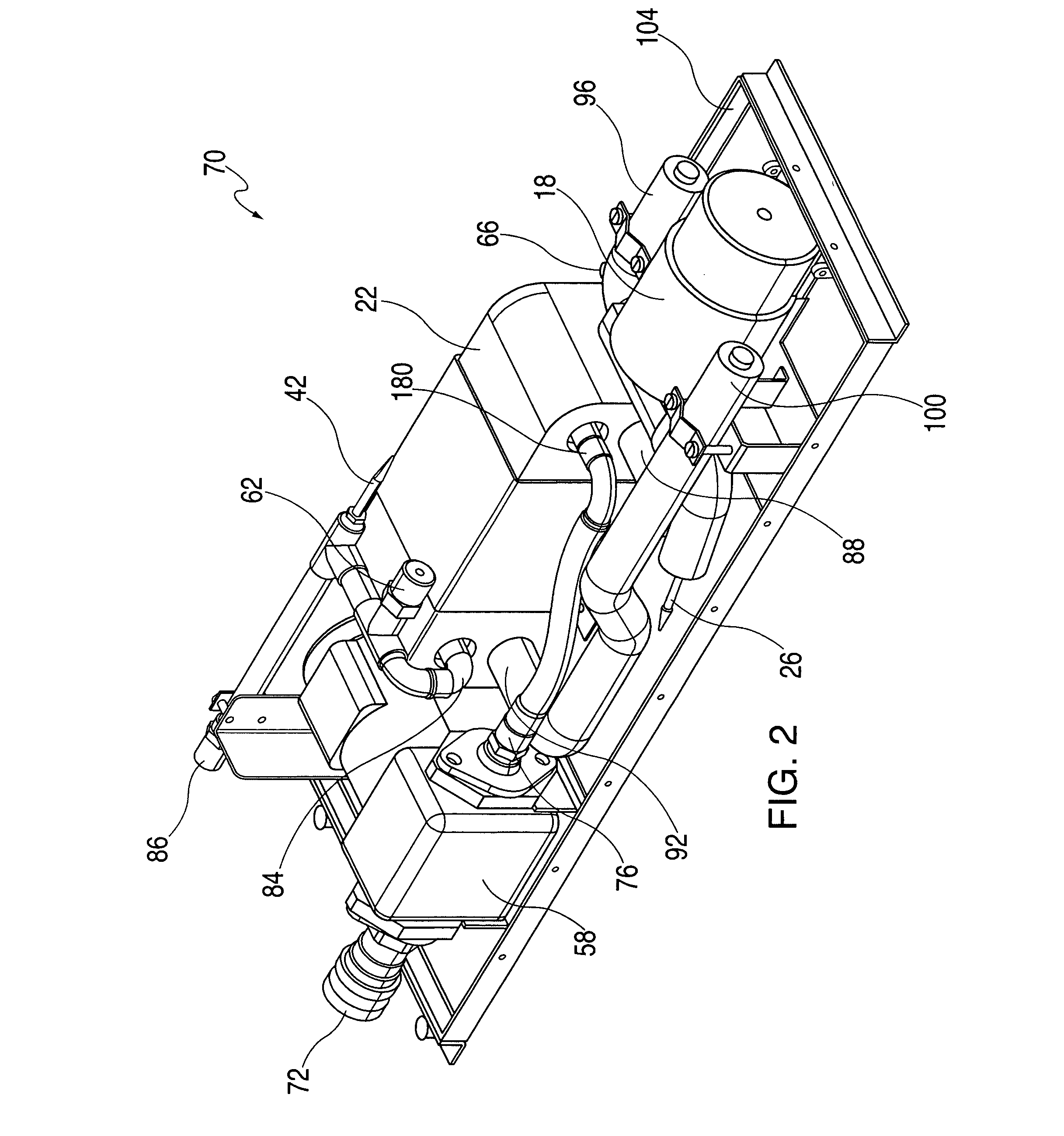

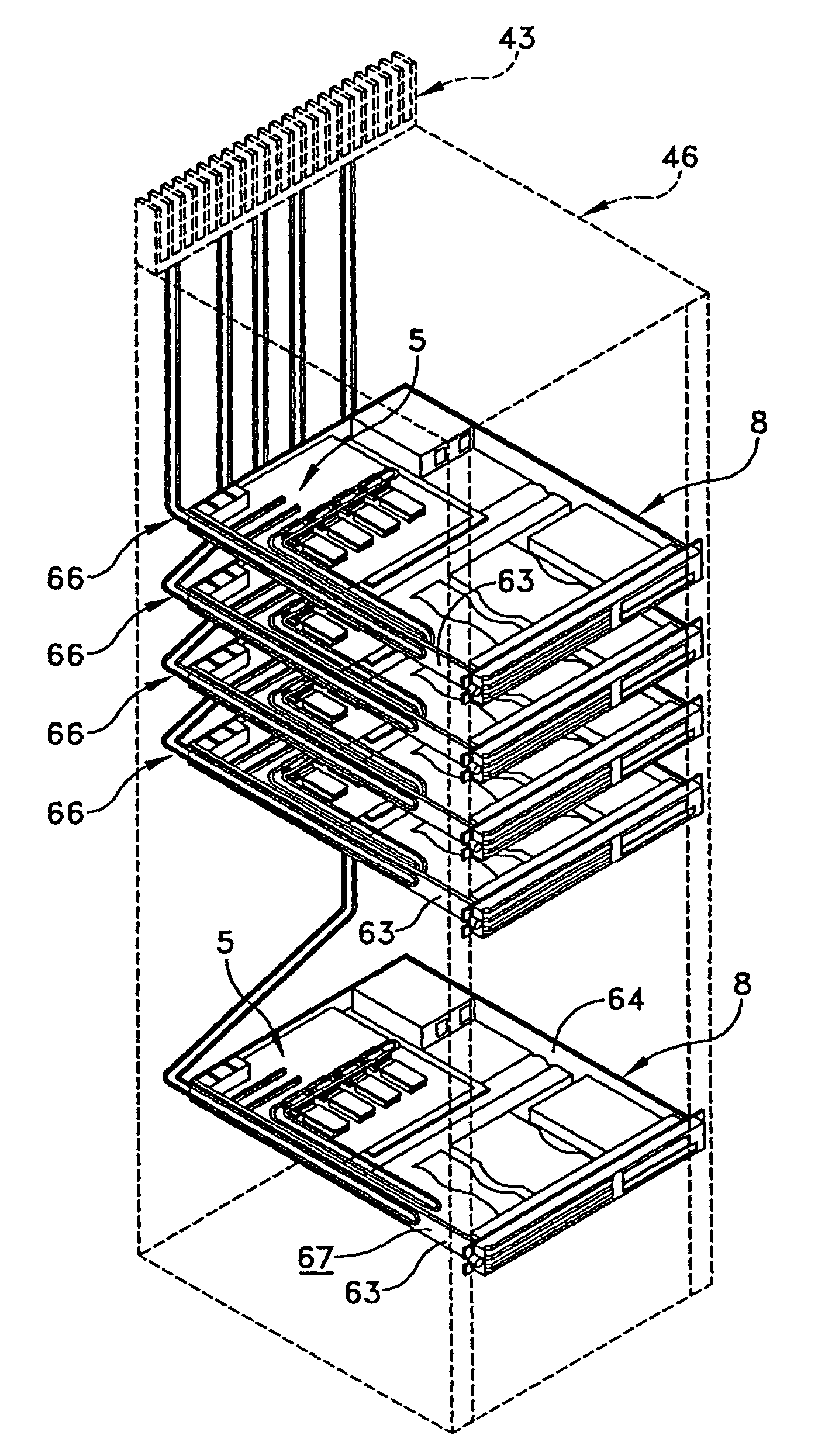

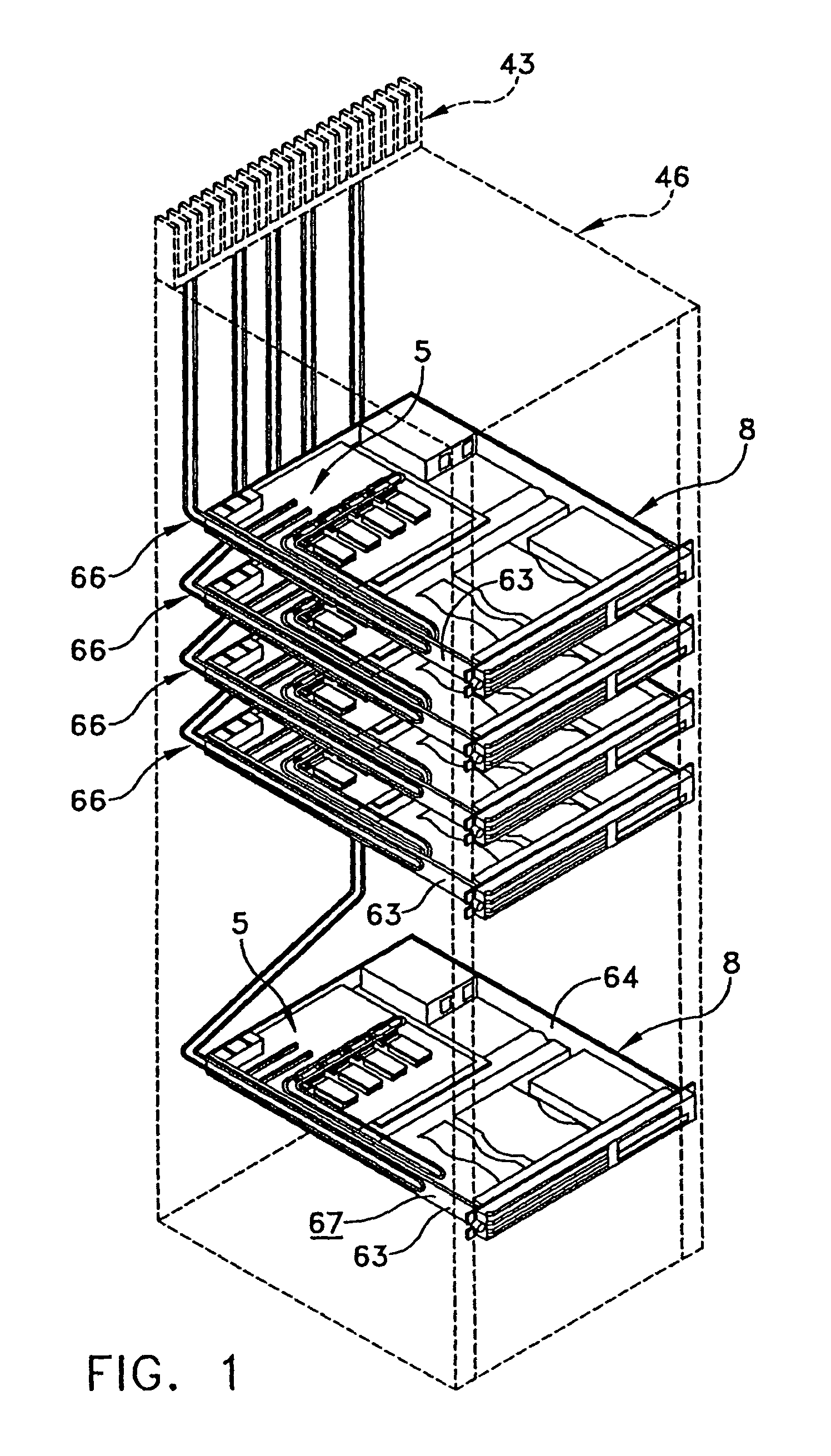

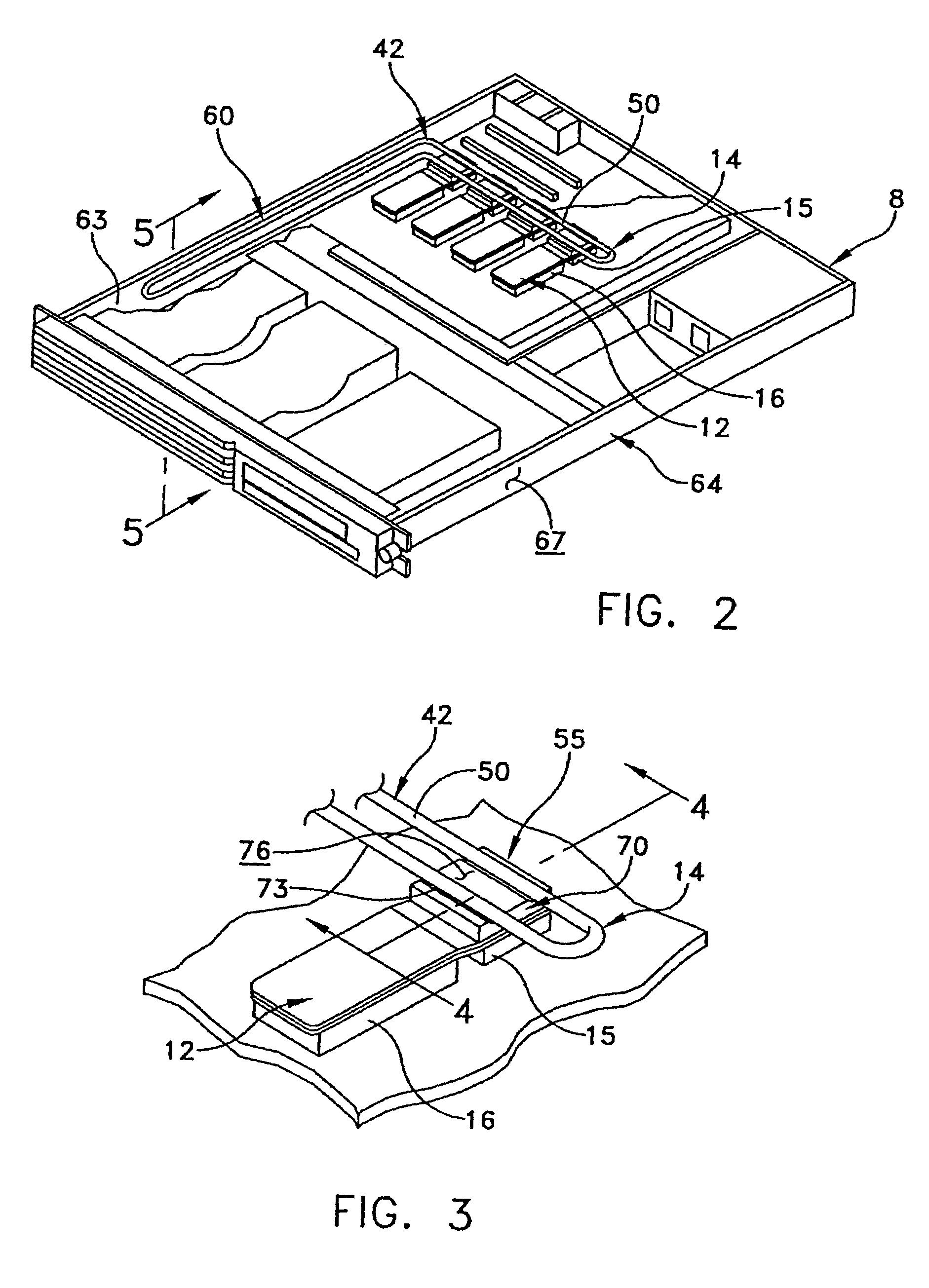

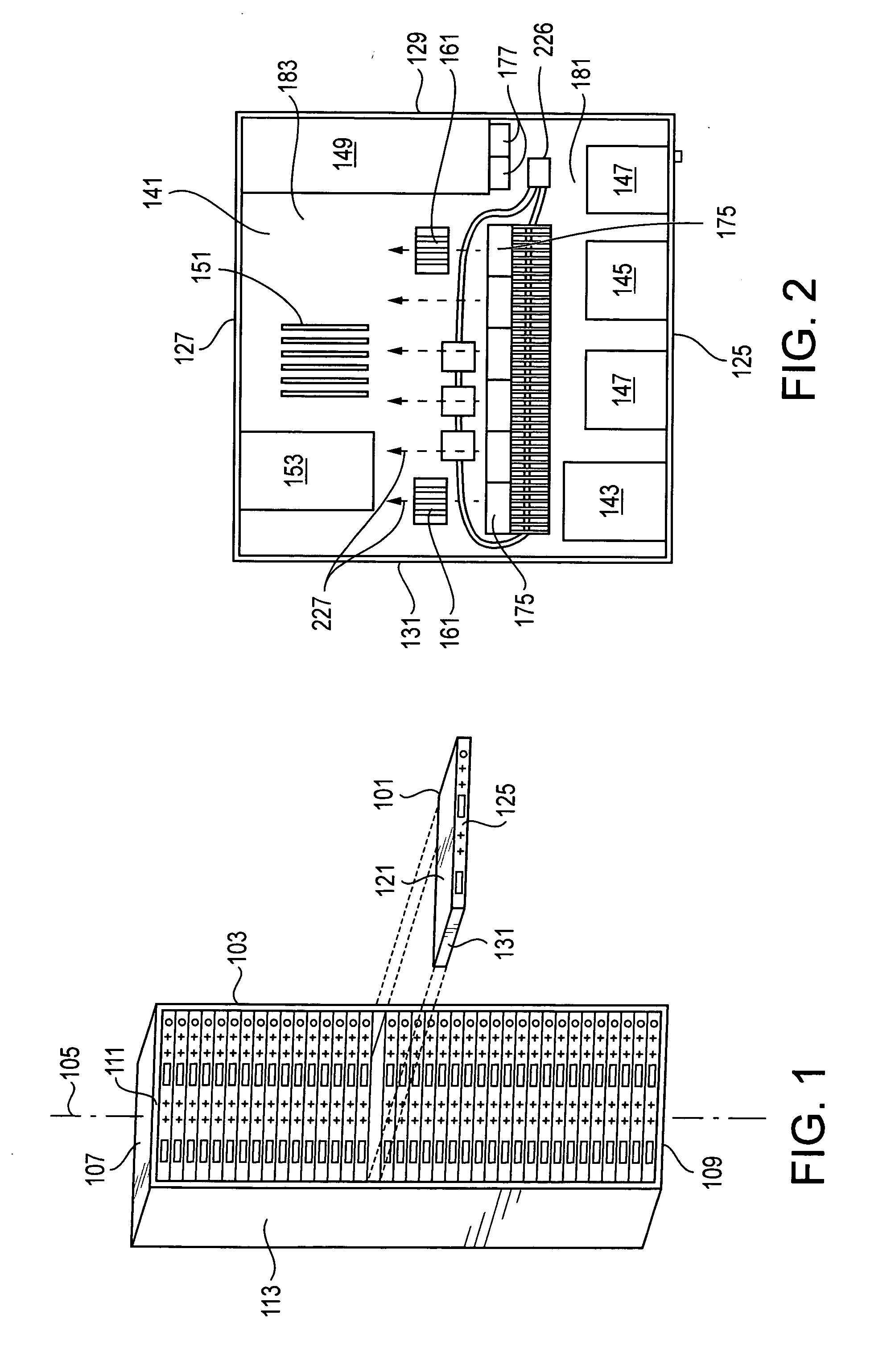

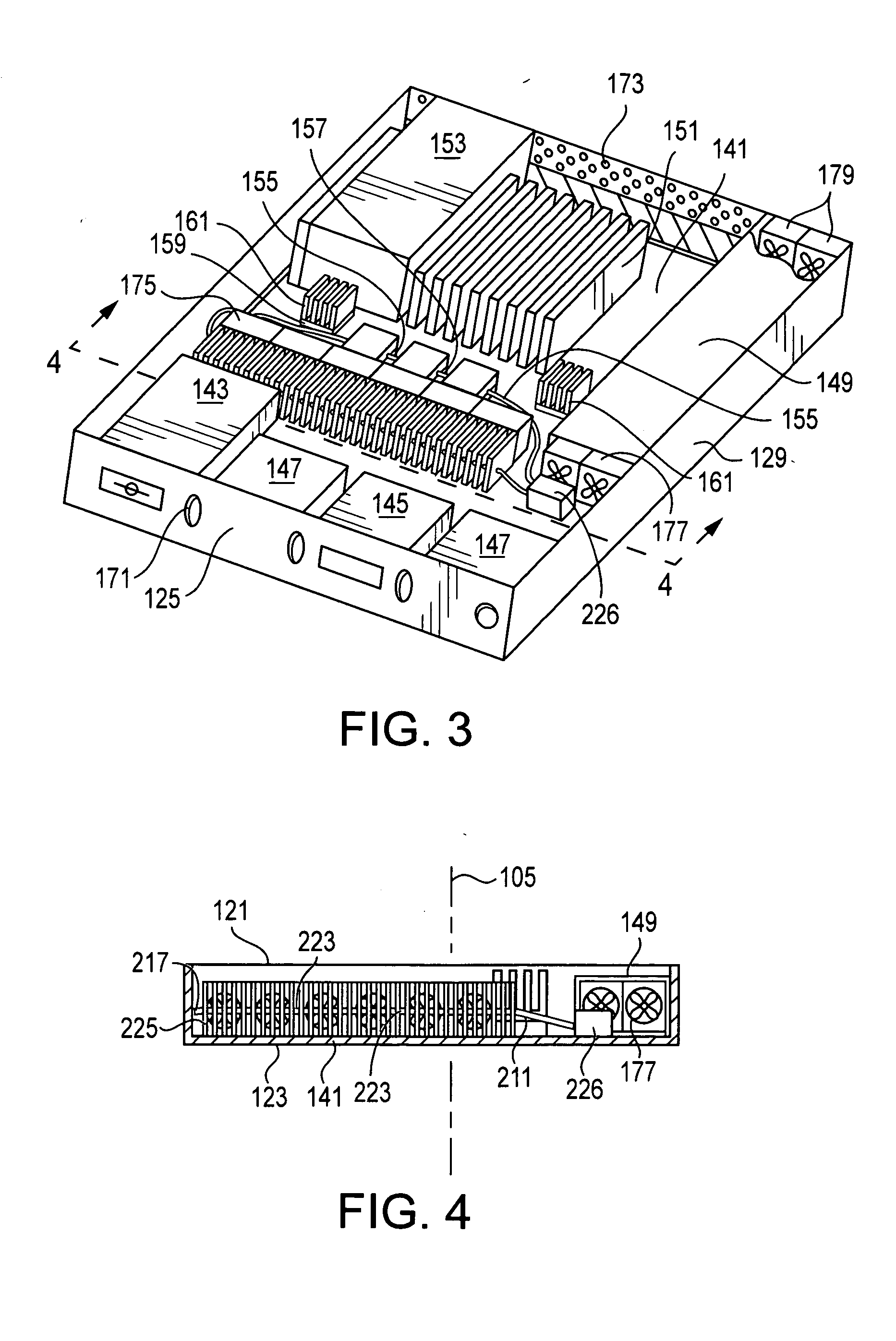

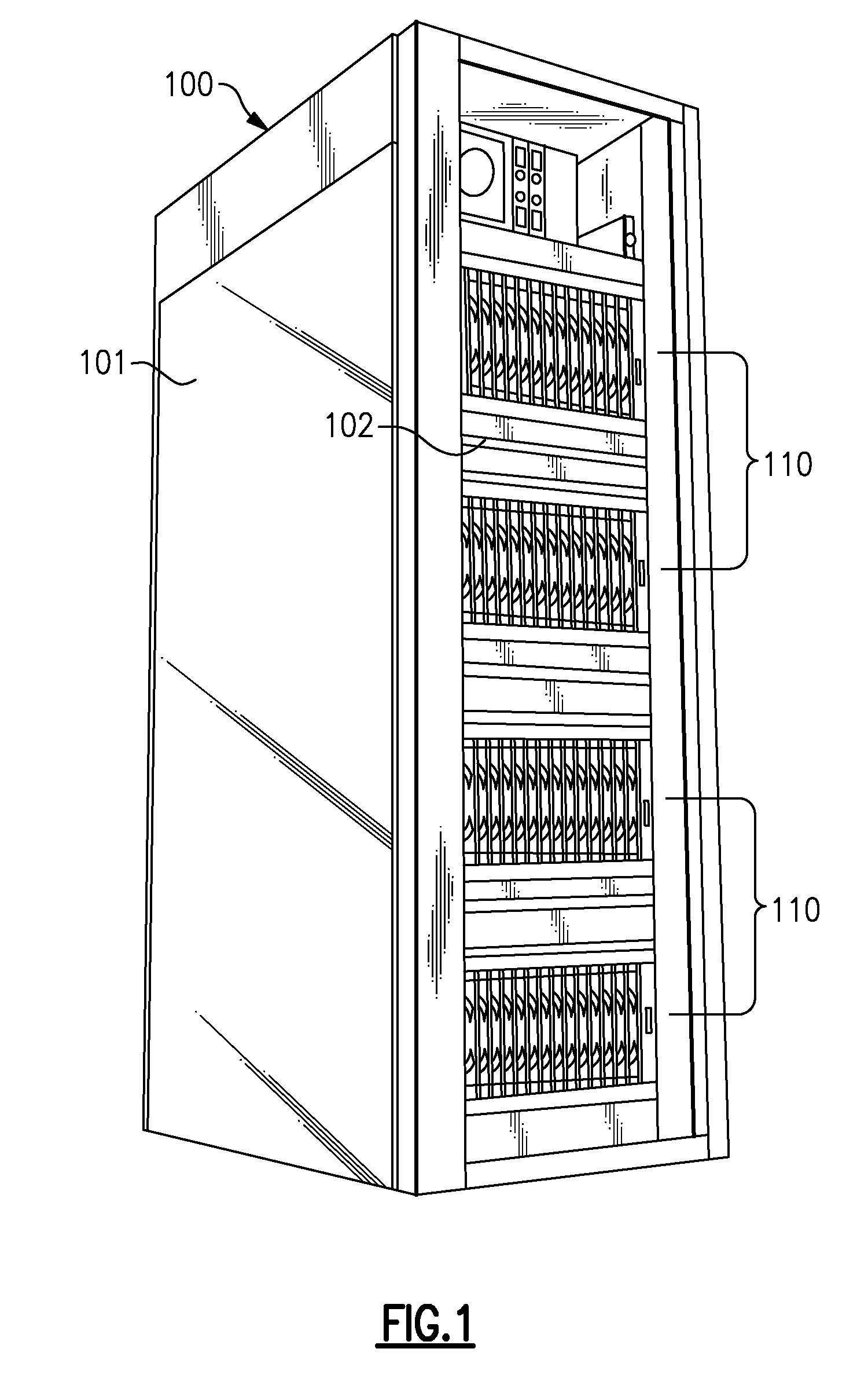

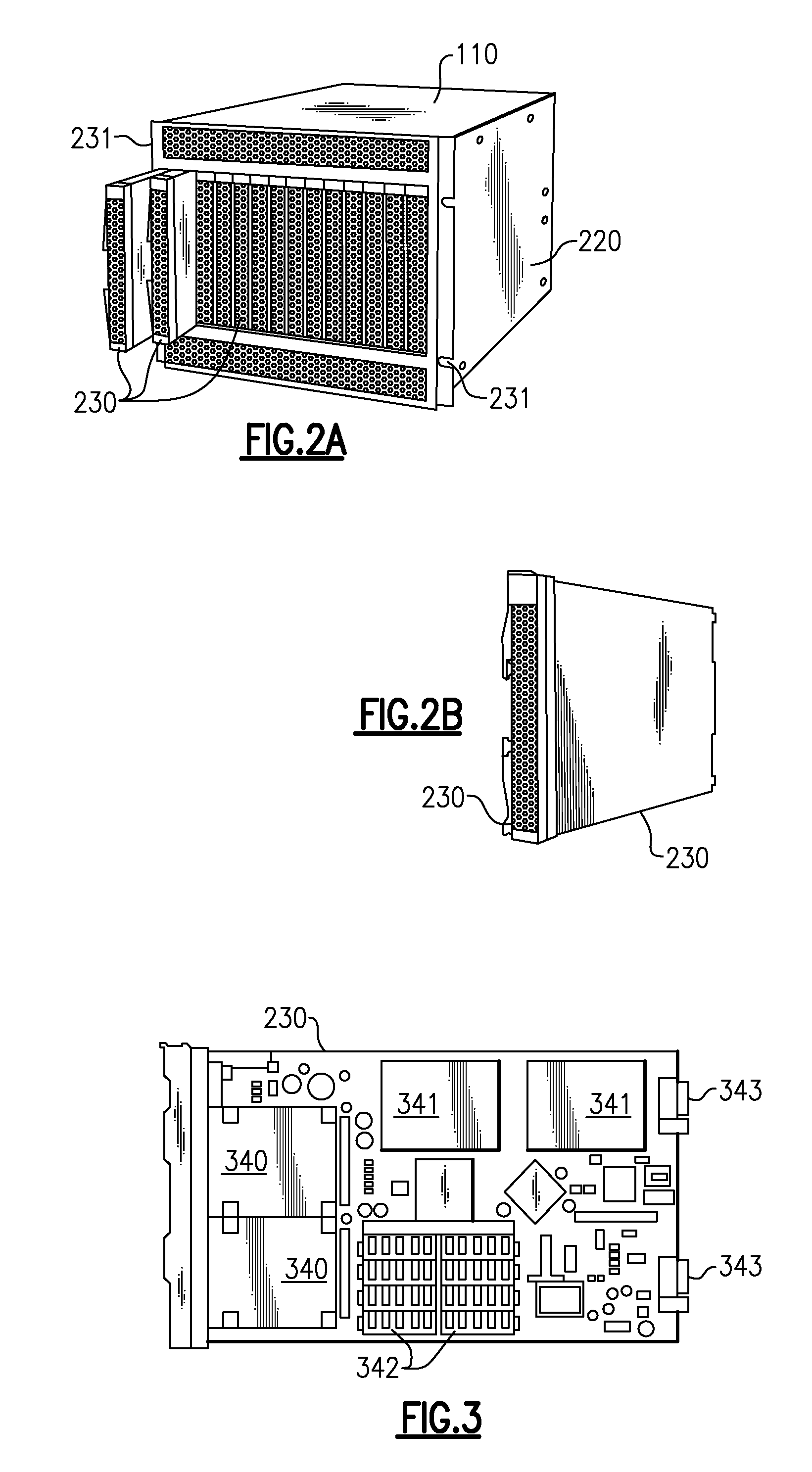

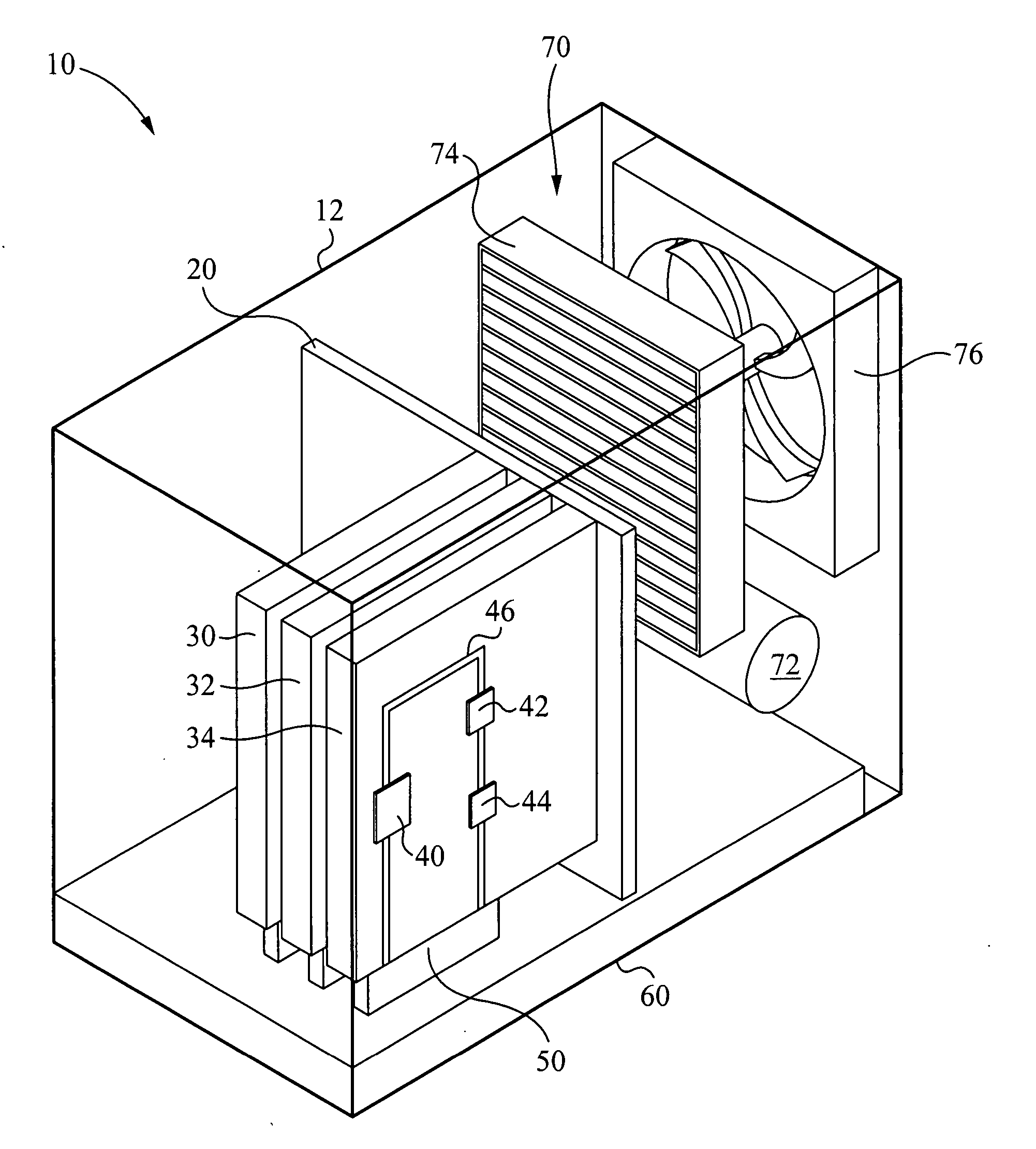

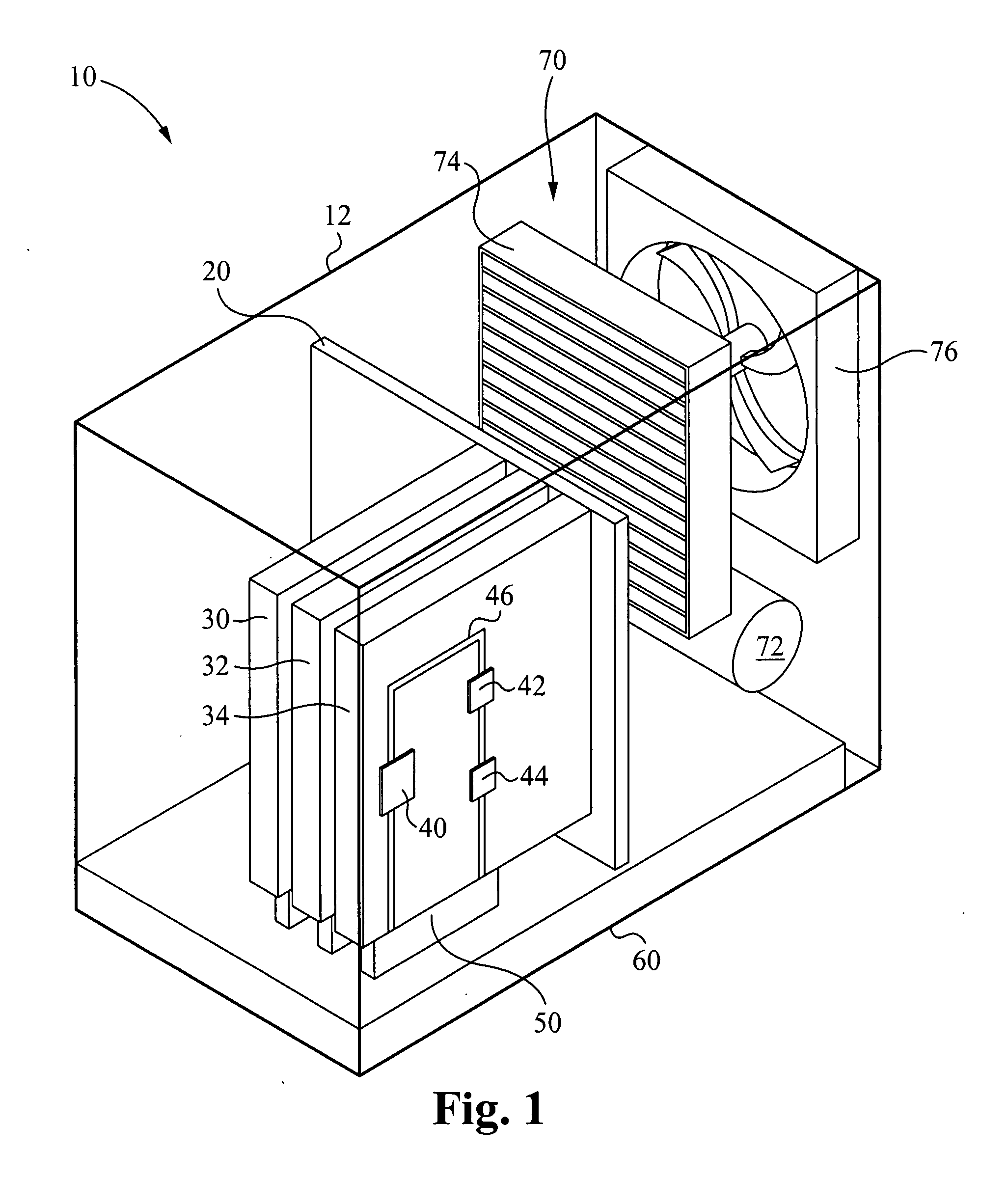

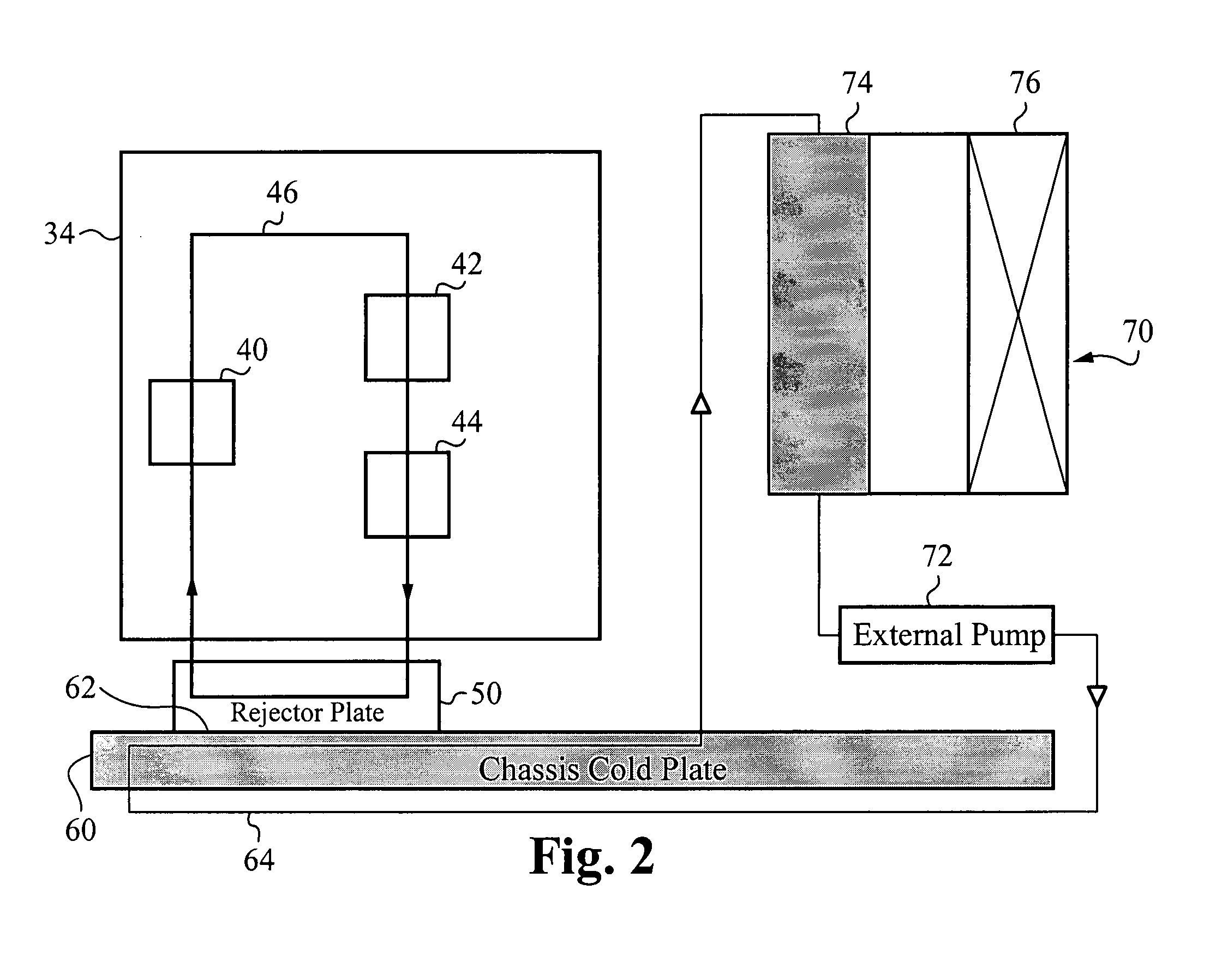

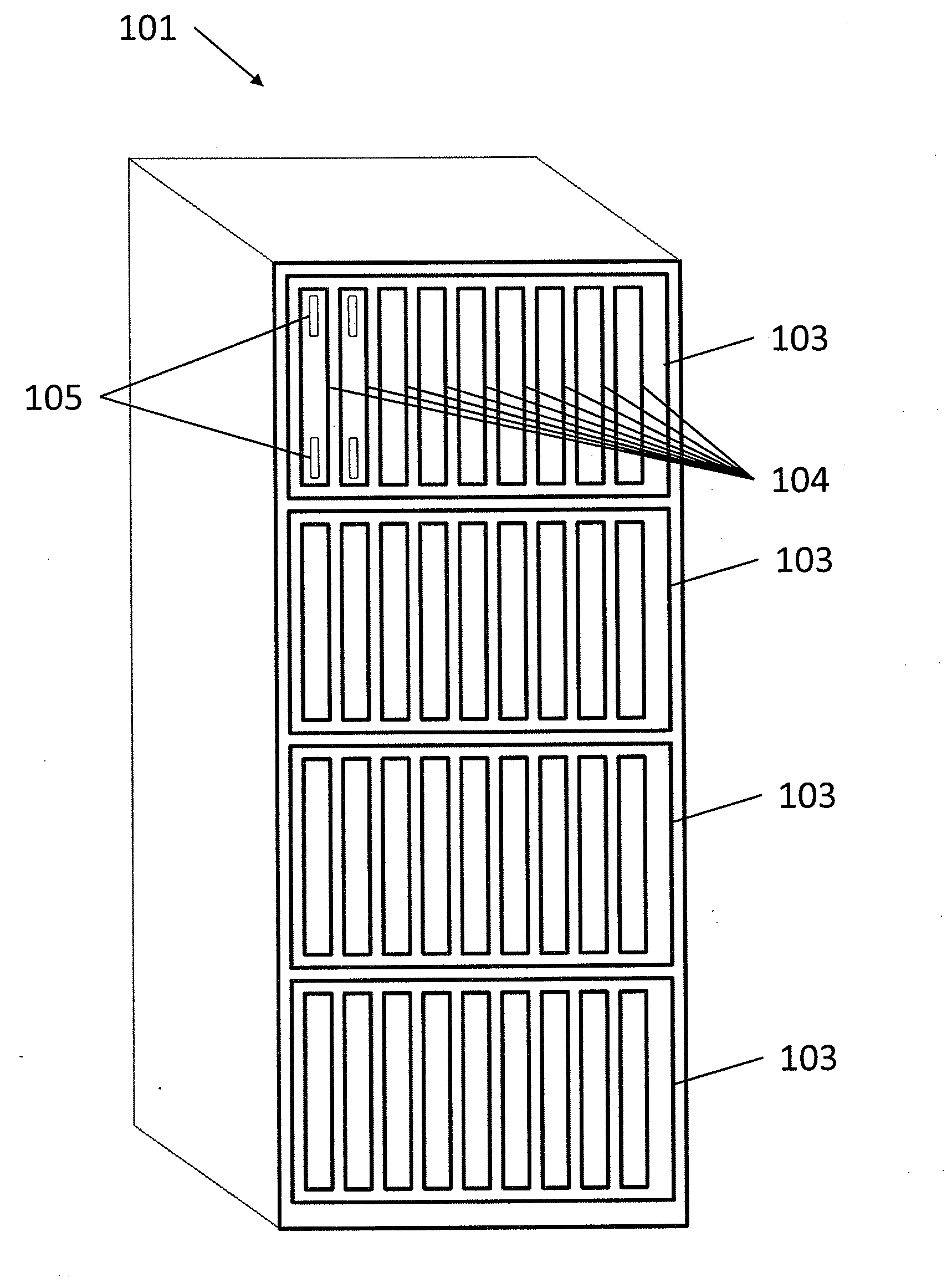

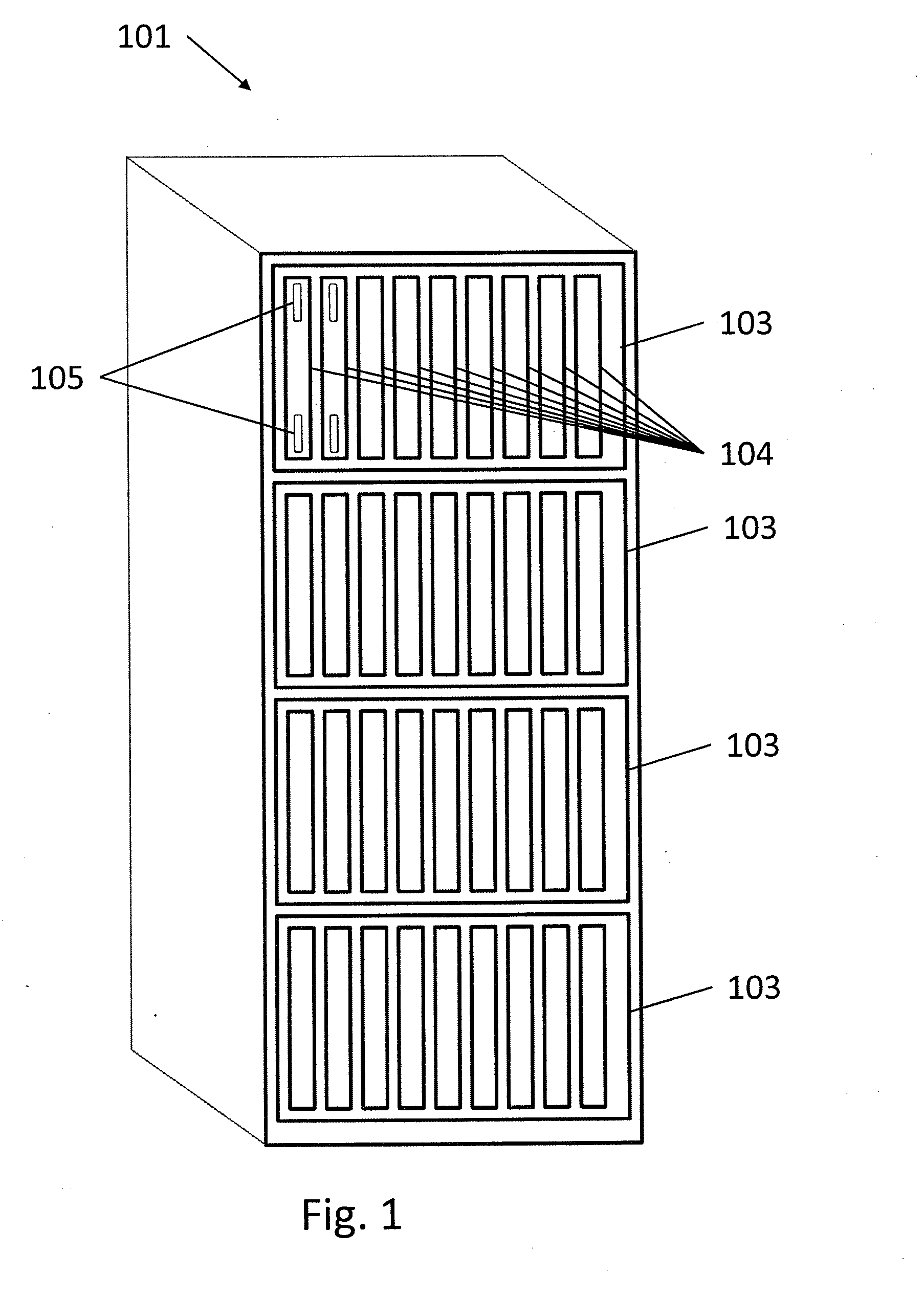

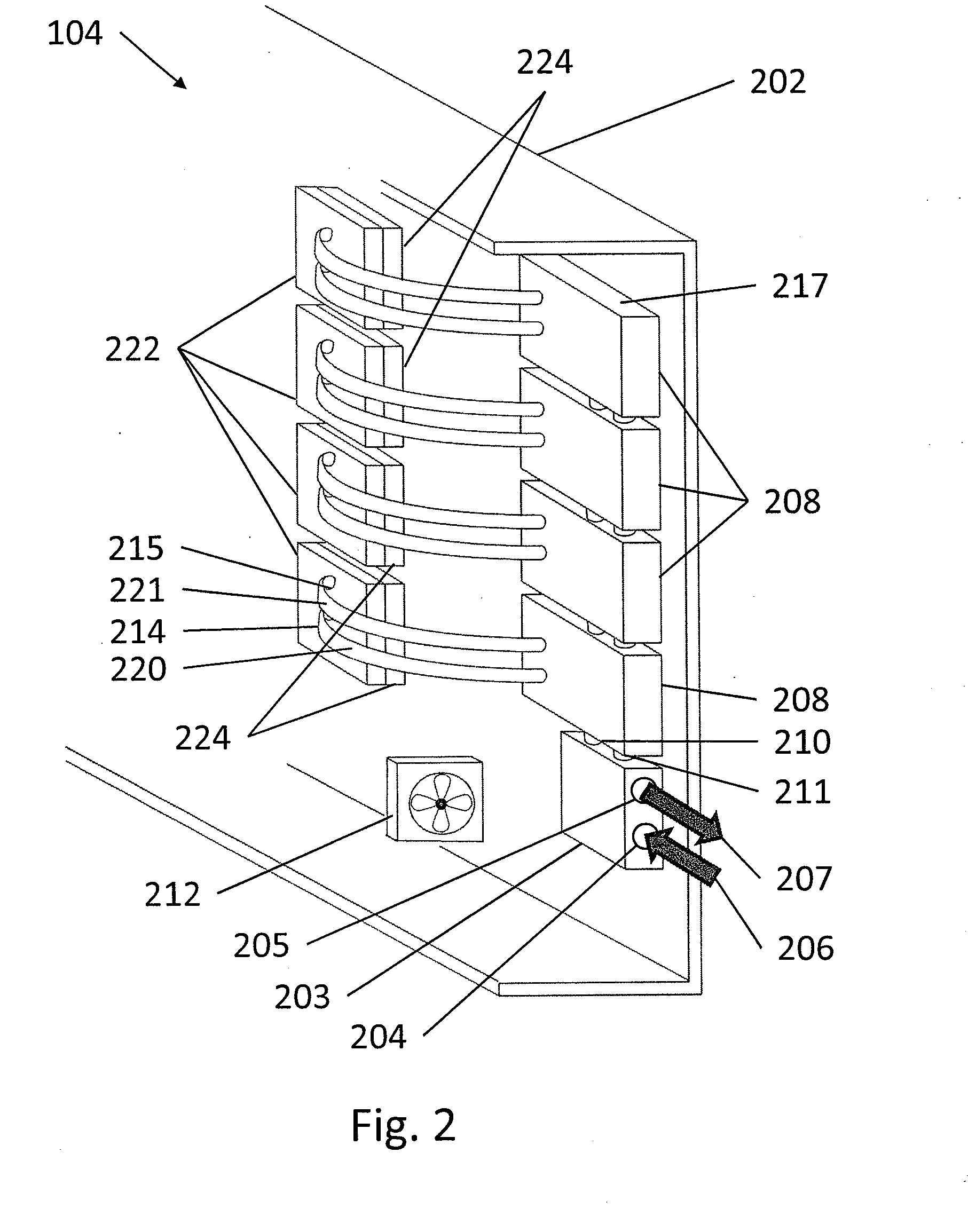

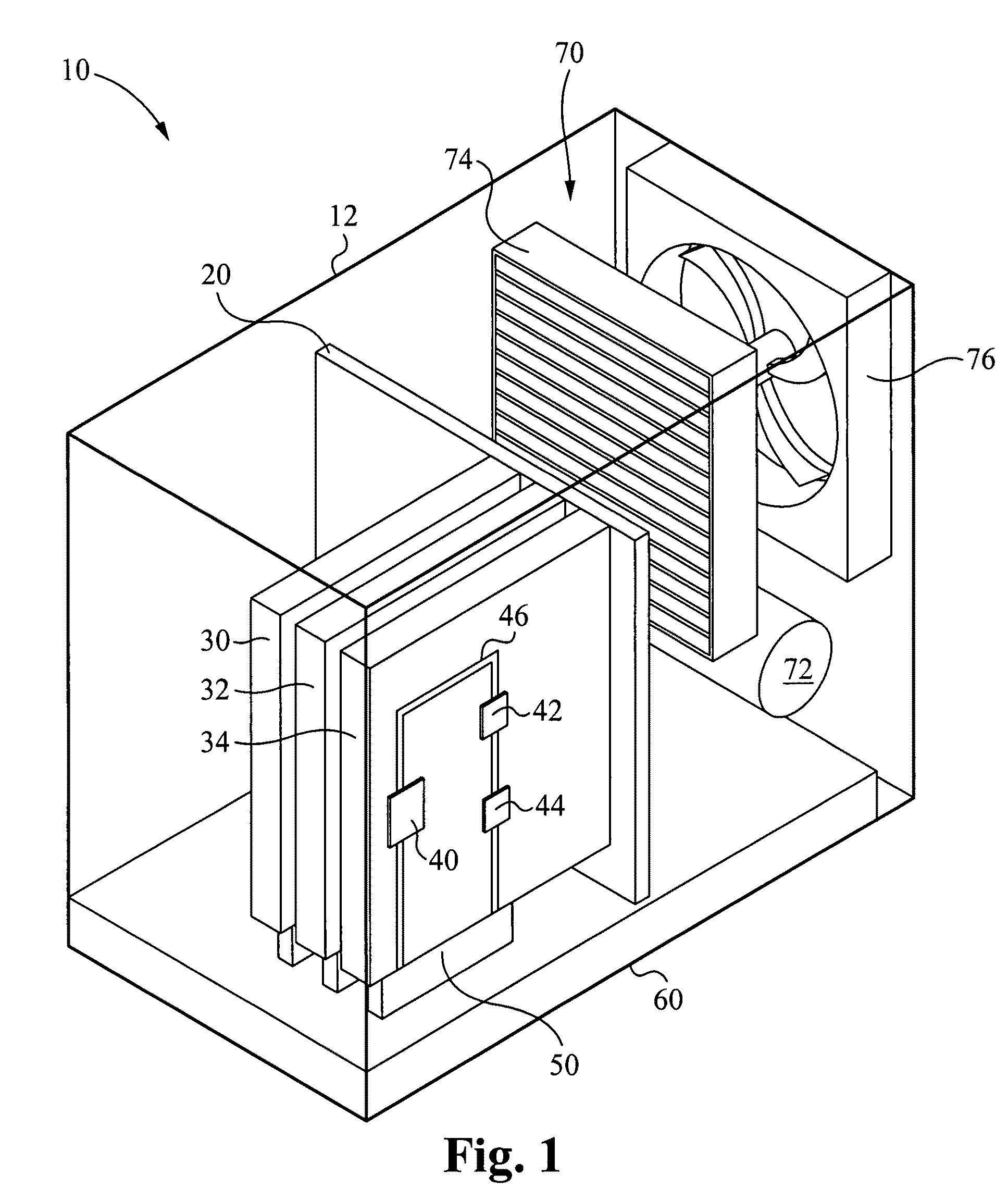

Small form factor liquid loop cooling system

ActiveUS7203063B2Easy to useDigital data processing detailsIndirect heat exchangersSmall form factorComputerized system

An enclosure forms a plurality of tiers vertically stacked in a longitudinal dimension. Each tier is a 1U modular computer system having a computer chassis configured for mounting in the multi-tiered support, and computer components that need cooling within the computer chassis. A cold plate is in thermal communication with at least one of the computer components, and convectively removes heat from that component using a liquid coolant. A heat exchanger dissipates heat from the liquid coolant, and provides liquid coolant back to the cold plate. An air mover within the chassis cools the heat exchanger, blows air across other components needing cooling, and removes heated air from the chassis. The air mover may extend substantially across the chassis, or it may blow crosswise from an outlet-ventilating direction.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

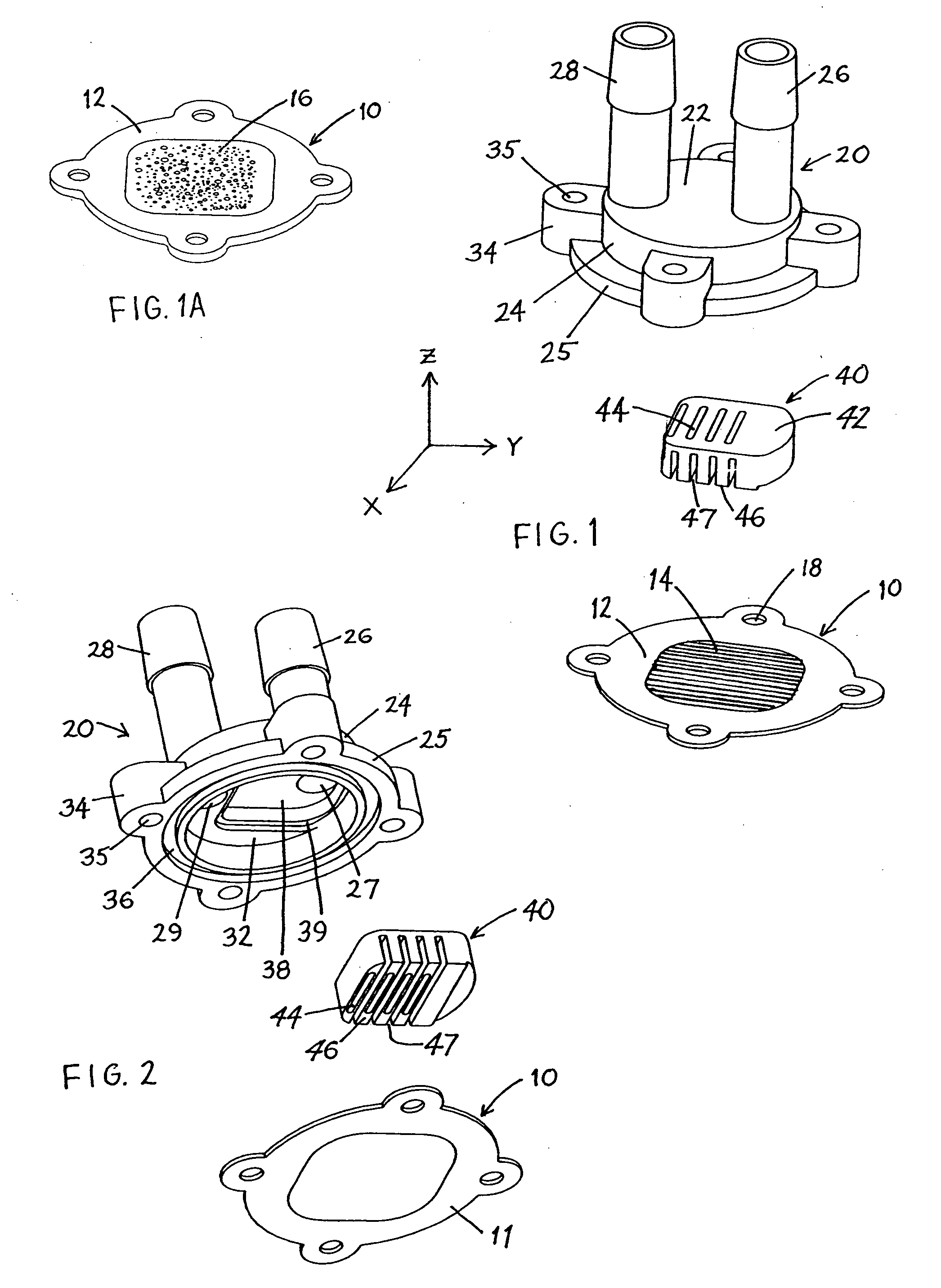

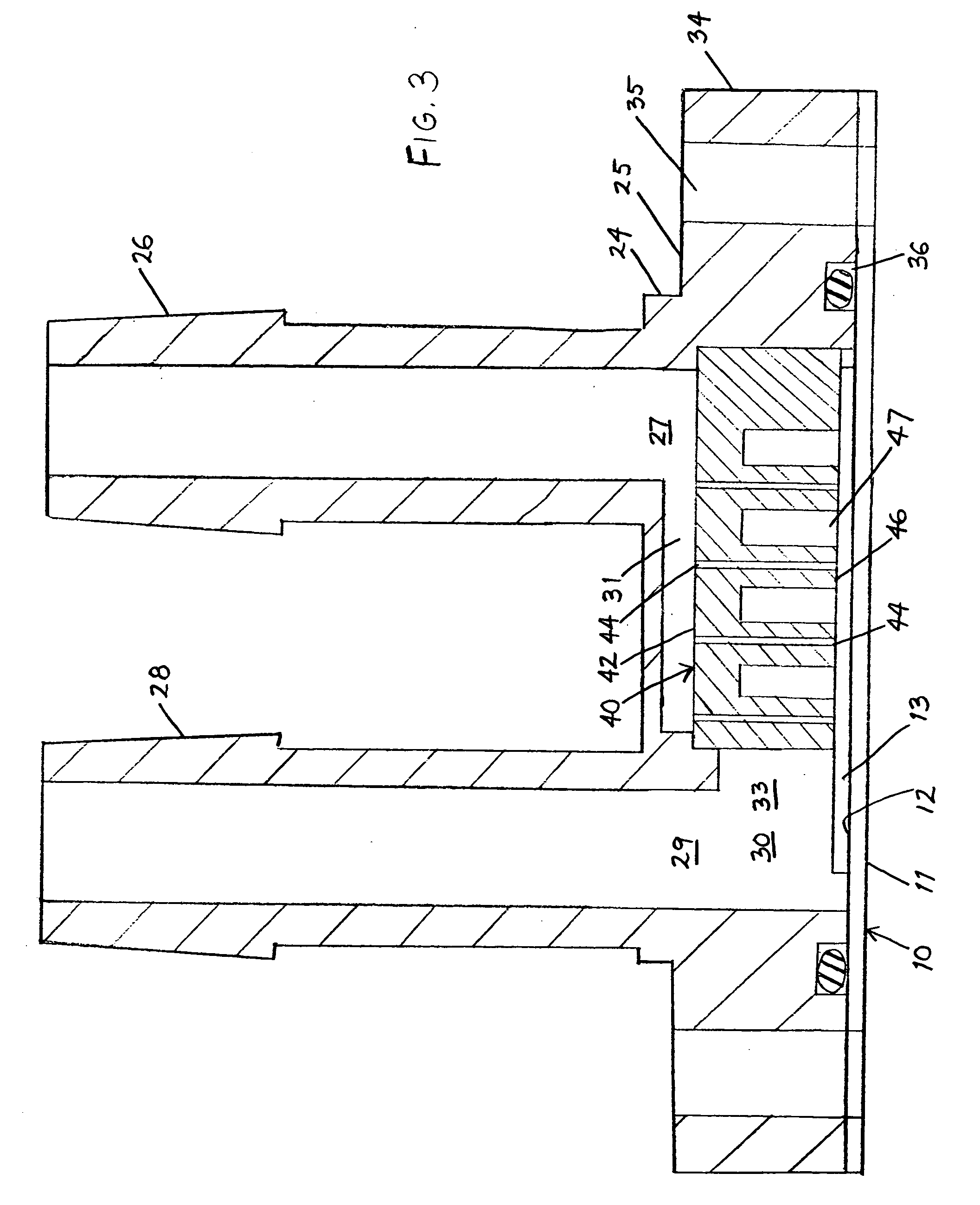

Device and method for piercing a patient's skin with an injector whilst reducing pain caused by the piercing

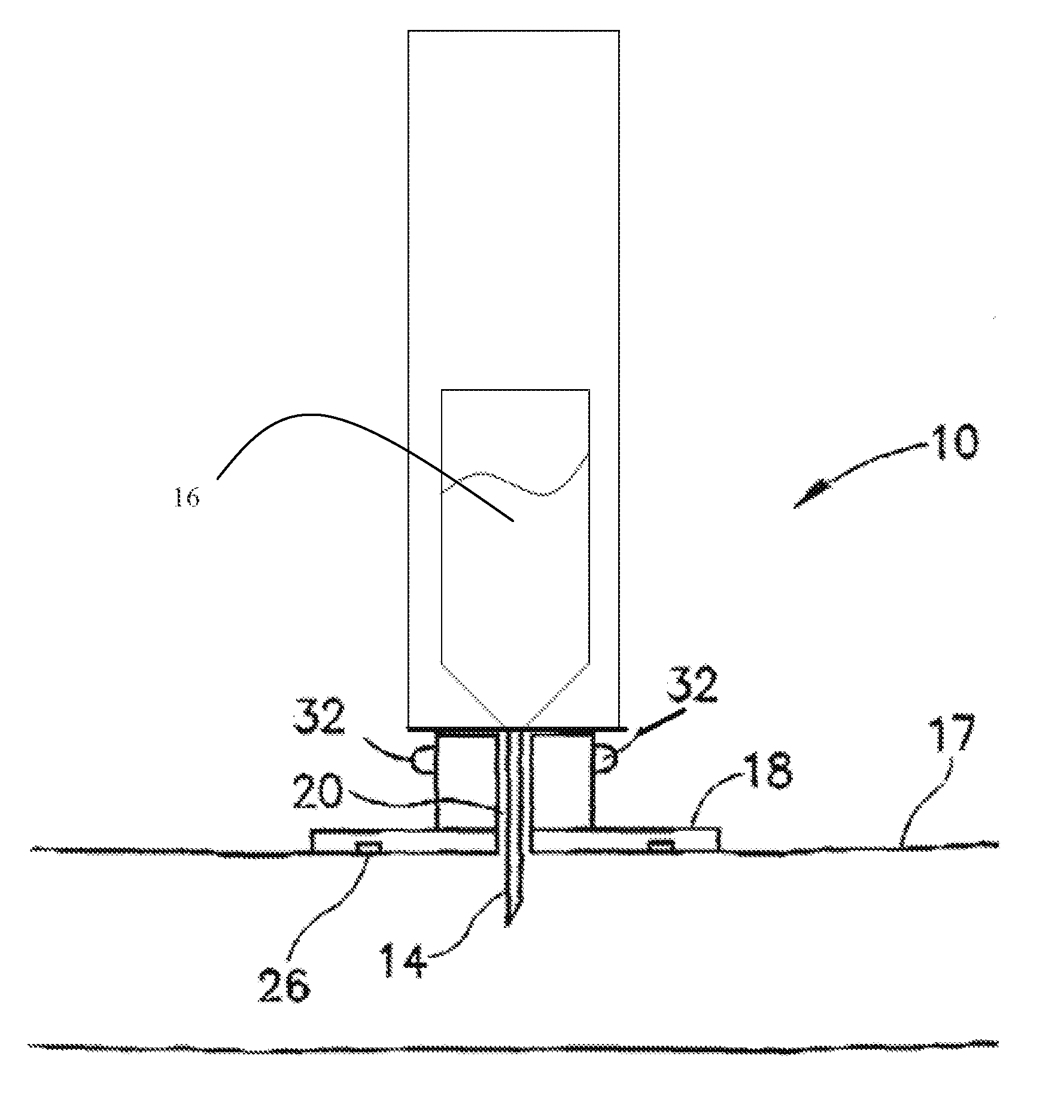

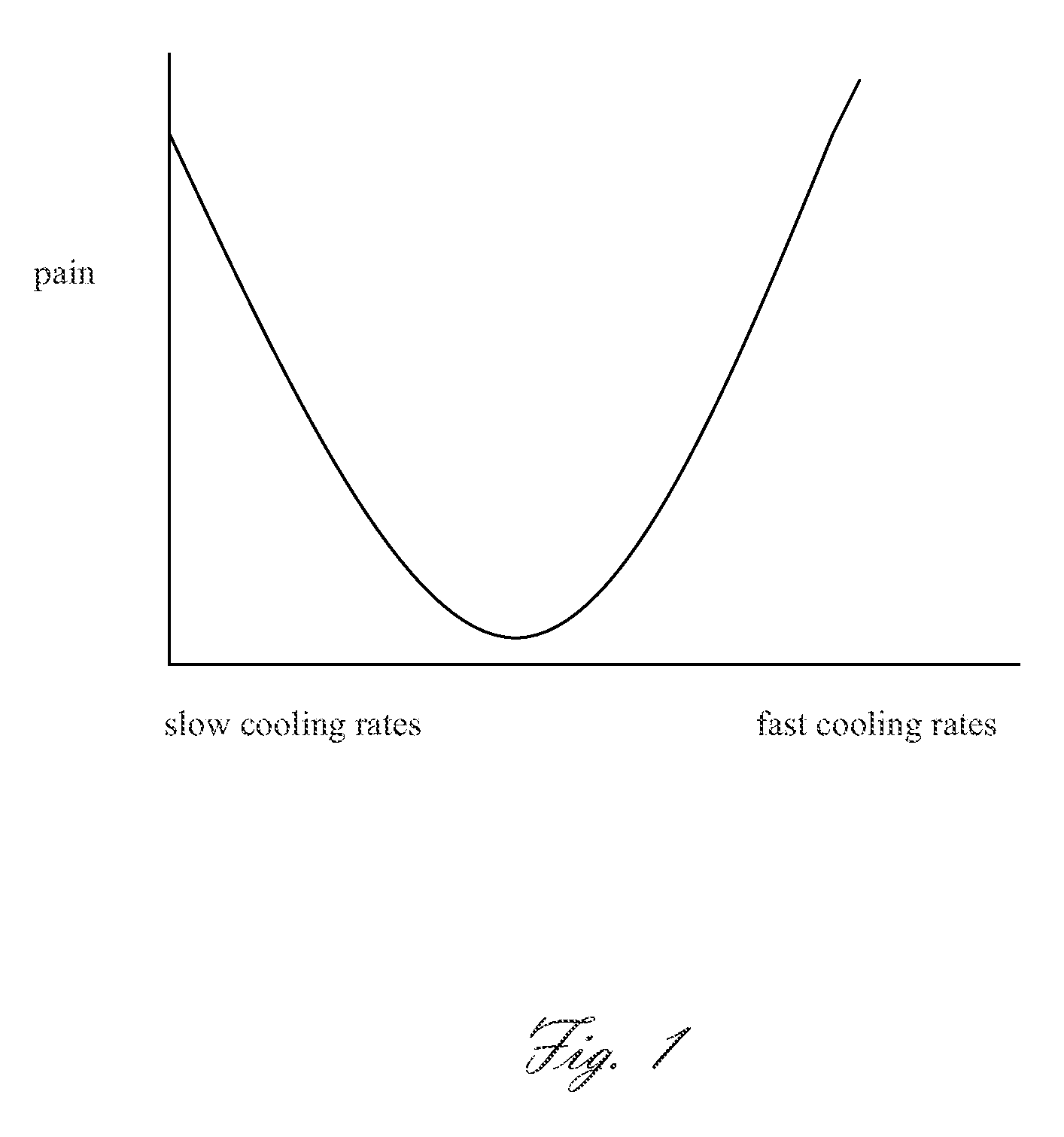

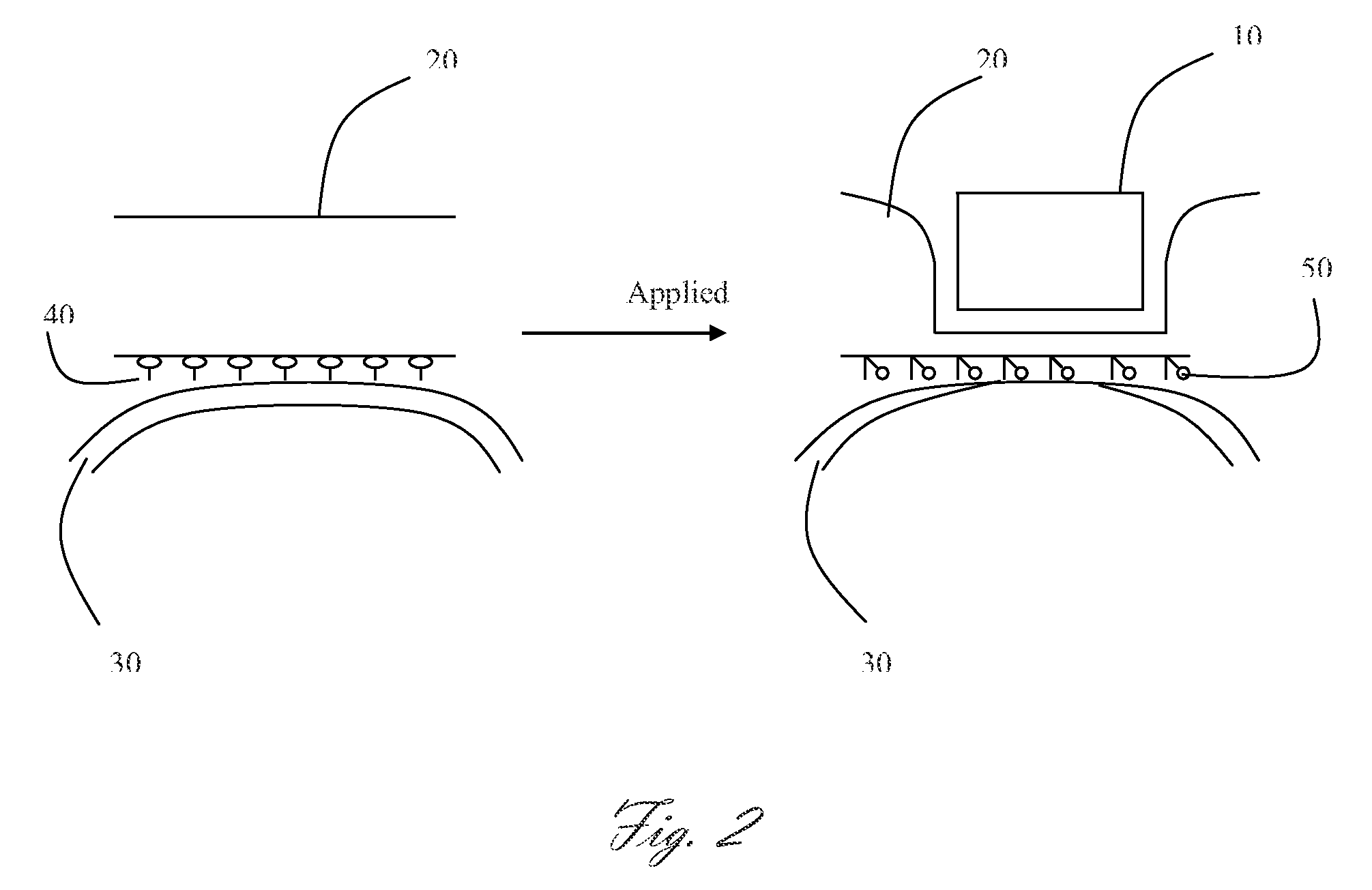

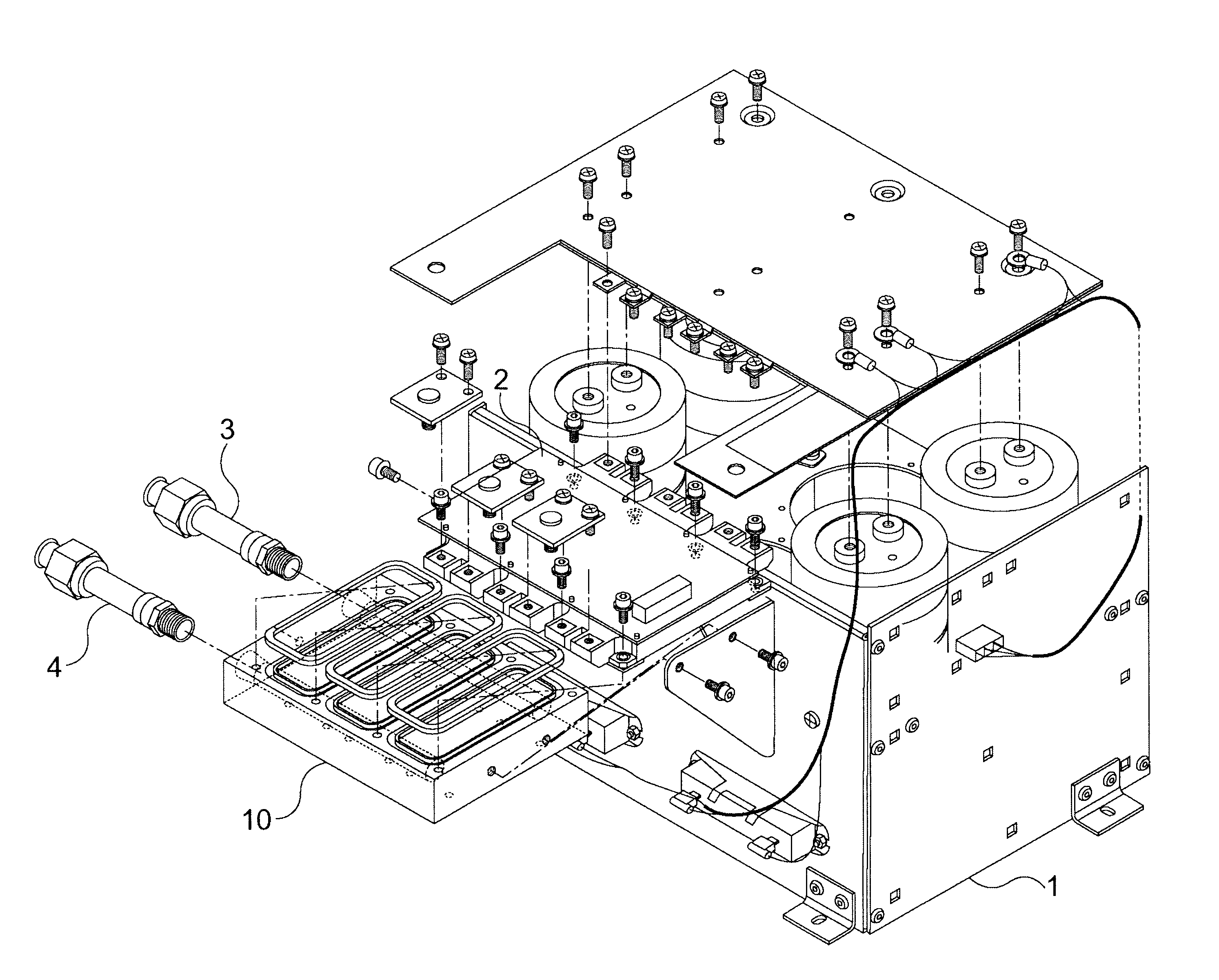

This invention generally relates to an injector for painlessly piercing a region of a patient's skin. The injector comprises (a) piercing mechanism, comprises: (i) at least one reciprocating needle; said at least one needle is characterized by diameter K; said needle penetrates to depth D in said skin; said depth D is characterized by an initial temperature T; (ii) at least one container having a medicament to be delivered to said patient. The injector further comprises (b) cooling mechanism, comprises at least one attachable cooling means, especially a Peltier Cooled Cold Plate (PCCP), in connection with a radiator and sufficient DC power supply; said PCCP is characterized by an effective surface area S; said effective surface S is optimized such that said pain caused by said piercing is eliminated; said PCCP is characterized by temperature TiPCCP; said PCCP adapted for cooling a portion of said skin prior to and / or during and / or after piercing thereof by said piercing mechanism such that the cooling is obtained at said depth D; said depth D is cooled from said initial temperature T to a final temperature TD(ΔT) in a period of time t (dt) by said PCCP; said final temperature TD Of said depth D is higher than about 0 and lower than about 13 degrees C.; said ΔT / dt is optimized such that said pain caused to said patient is eliminated. The injector further comprises (c) at least one aperture through which said needle is reversibly piercing said skin.

Owner:SINDOLOR MEDICAL

Liquid-cooled power semiconductor device heatsink

InactiveUS6434003B1Semiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceEngineering

The present invention relates to a cold plate for cooling electronic components comprising a base having a top surface onto which at least one electronic component is to be placed; a cooling well formed in the top of the base and open at the top; a feed channel formed in the base for carrying fluid into the cooling well; a drain channel formed in the base for carrying cooling fluid away from the cooling well; cooling well inlets and outlets formed in the cooling well and in communication with the feed channel and drain channels, respectively. The feed and drain channels are sufficiently large relative to the size and flow characteristics of the well and cooling well inlets and outlets such that when the cooling fluid flows through the device, the pressure drop across the feed channel is substantially less than the pressure drop across the well.

Owner:YORK INT CORP

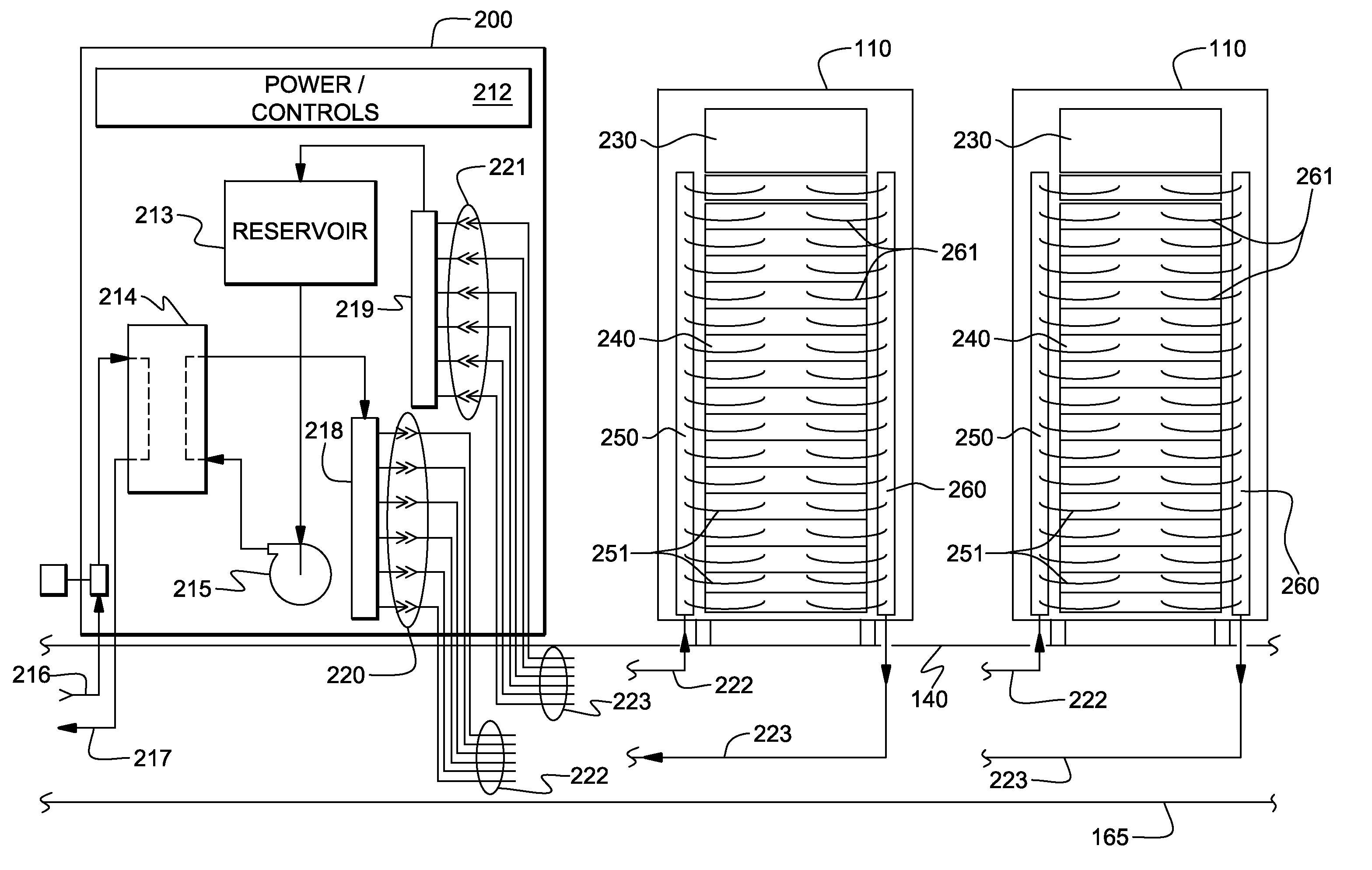

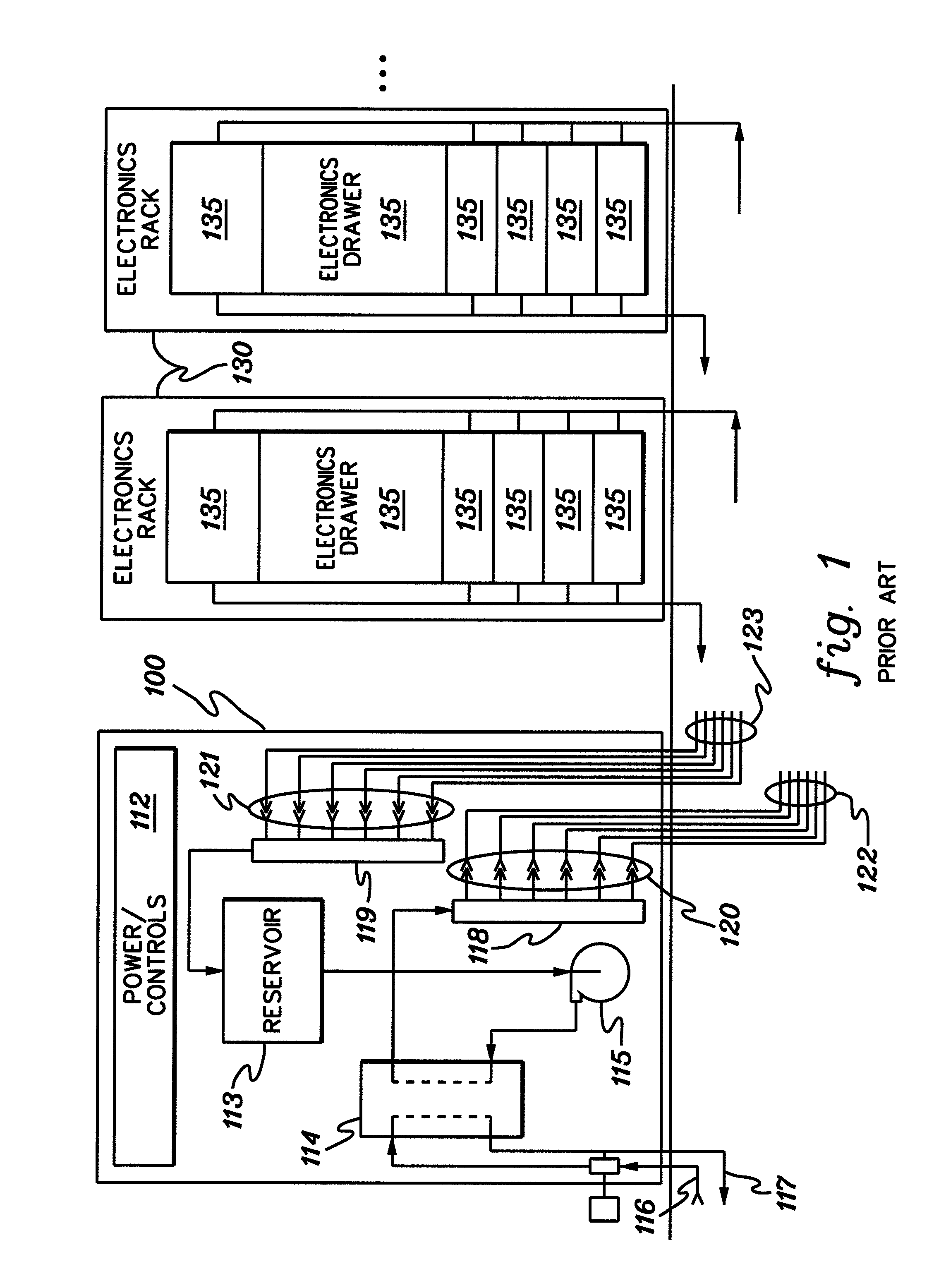

Method and apparatus for cooling electronic components

A modular fluid unit for cooling heat sources located on a rack, the modular fluid unit comprising: a heat exchanger in fluid communication a pump; and wherein the modular fluid unit is mountable within the rack and is configurable to be in fluid communication with a cold plate return manifold, a cold plate supply manifold, and an end-user fluid supply. A method for cooling electronic components in a rack, the method comprising: circulating a first liquid from a cold plate to one of a plurality of heat exchangers mounted within the rack; circulating a second liquid from a second liquid supply to the one of a plurality of heat exchangers; and transferring heat from the first liquid to the second liquid at the one of a plurality of heat exchangers.

Owner:IBM CORP

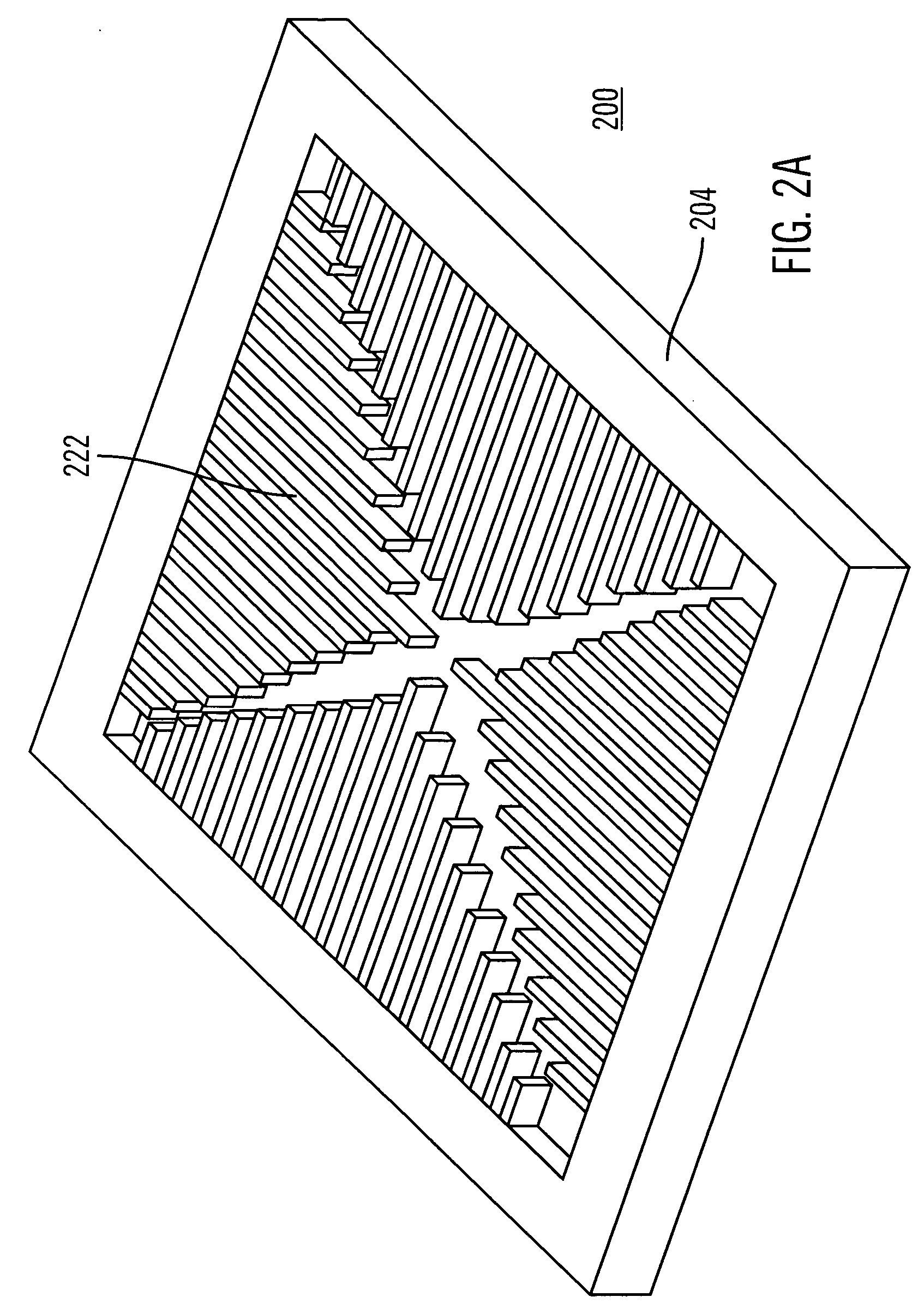

Enhanced clad metal base plate

ActiveUS20120320529A1Semiconductor/solid-state device detailsPrinted circuit aspectsCold plateElectron

The current invention comprises a base plate made of at least a first metal and a second metal clad together with a metallurgical bond, where the first and second metals are different metals. The base plate includes an enhanced surface that is entirely contained within the second meta where the enhanced surface comprises fins, pins, or other structures. The tip of the enhanced surface extends above the outer surface of the second metal, and the enhancements are monolithic with the second metal. The base plate can form one component of a cold plate for cooling electronics.

Owner:WIELAND MICROCOOL LLC

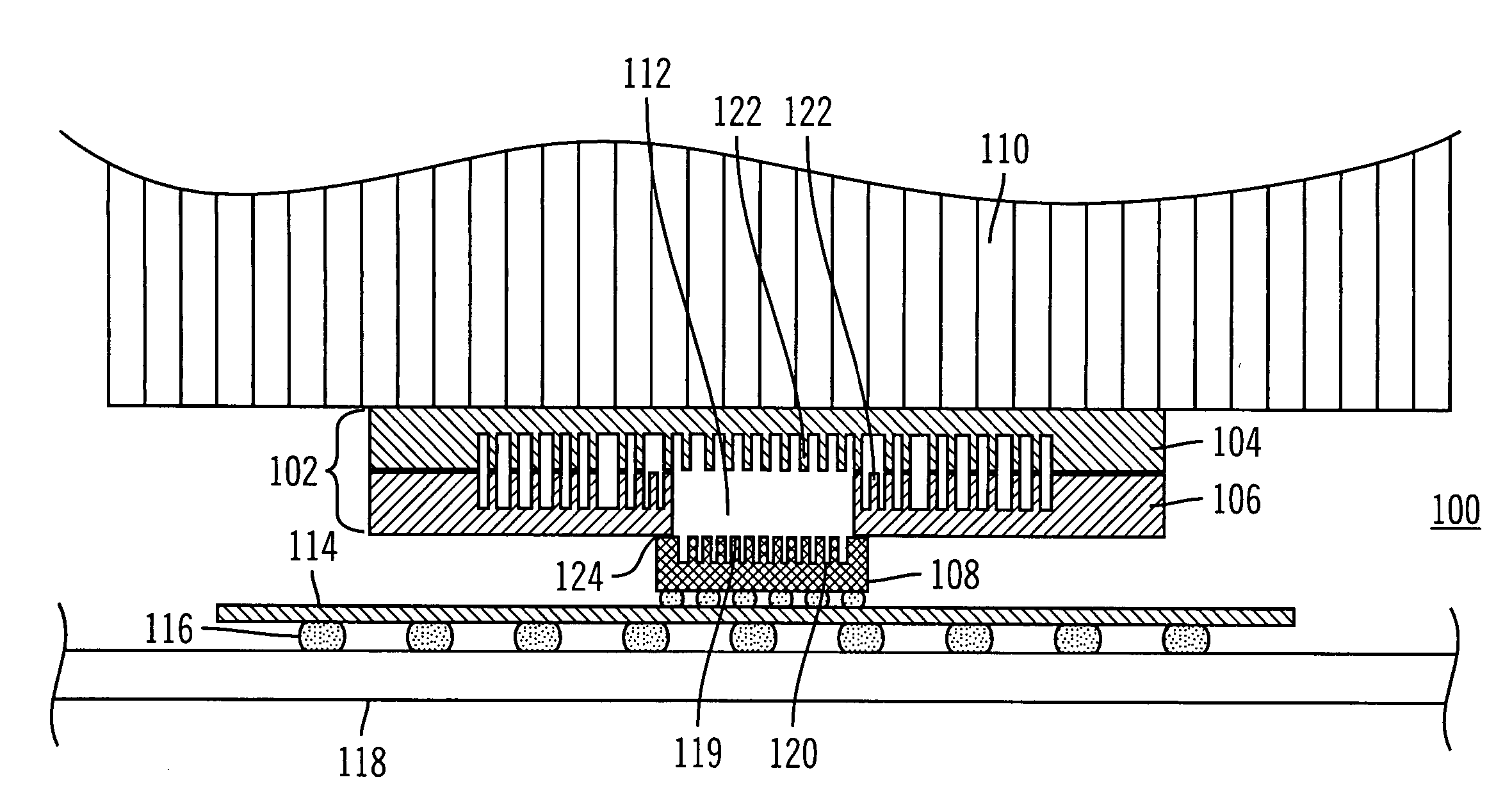

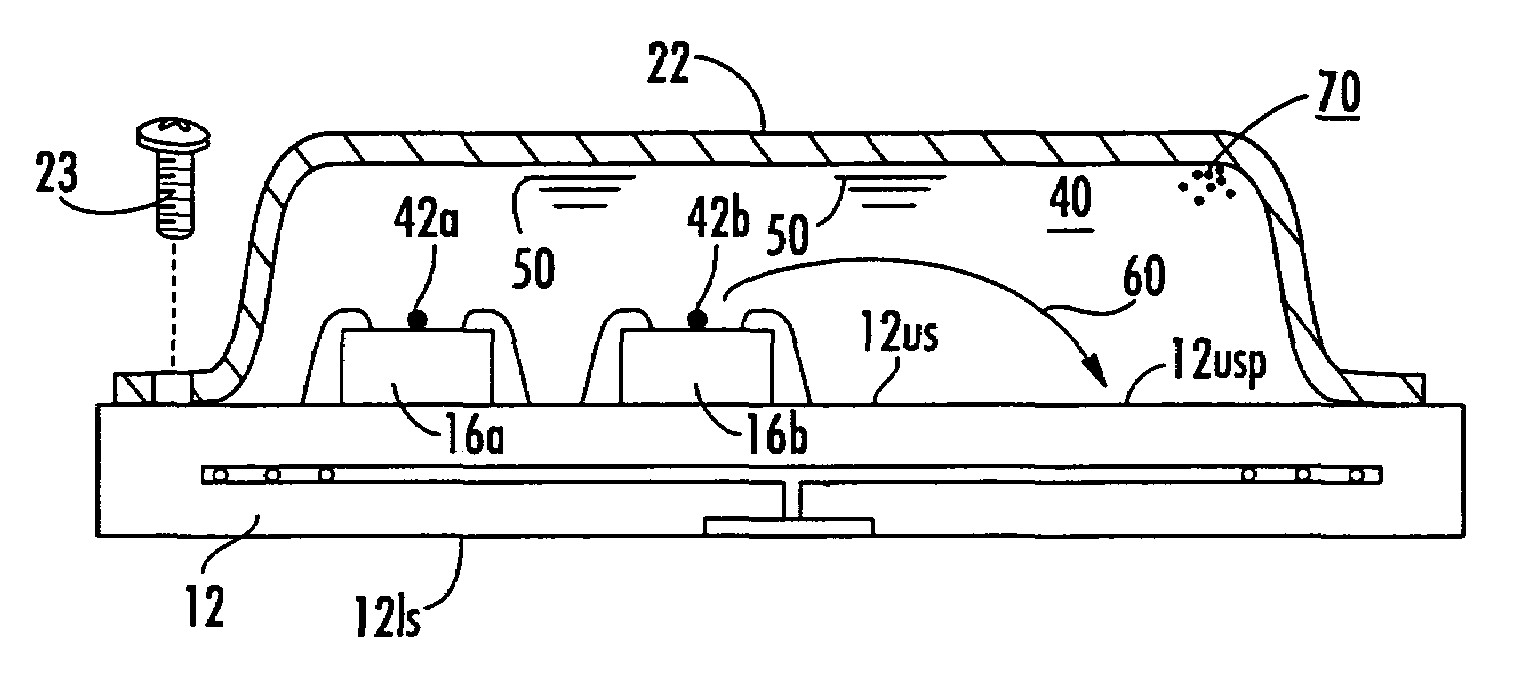

Cooled electronic module with pump-enhanced, dielectric fluid immersion-cooling

ActiveUS20100328889A1Facilitating cooling of a heat-generating electronic deviceImprove cooling effectWave amplification devicesDigital data processing detailsDielectricComputer module

Cooled electronic modules and methods of fabrication are provided with pump-enhanced, dielectric fluid immersion-cooling of the electronic device. The cooled electronic module includes a substrate supporting an electronic device to be cooled. A cooling apparatus couples to the substrate, and includes a housing configured to at least partially surround and form a sealed compartment about the electronic device. Additionally, the cooling apparatus includes dielectric fluid and one or more pumps disposed within the sealed compartment. The dielectric fluid is in direct contact with the electronic device, and the pump is an impingement-cooling, immersed pump disposed to actively pump dielectric fluid within the sealed compartment towards the electronic device. Multiple condenser fins extend from the housing into the sealed compartment in an upper portion of the sealed compartment, and a liquid-cooled cold plate or an air-cooled heat sink is coupled to the top of the housing for cooling the condenser fins.

Owner:IBM CORP

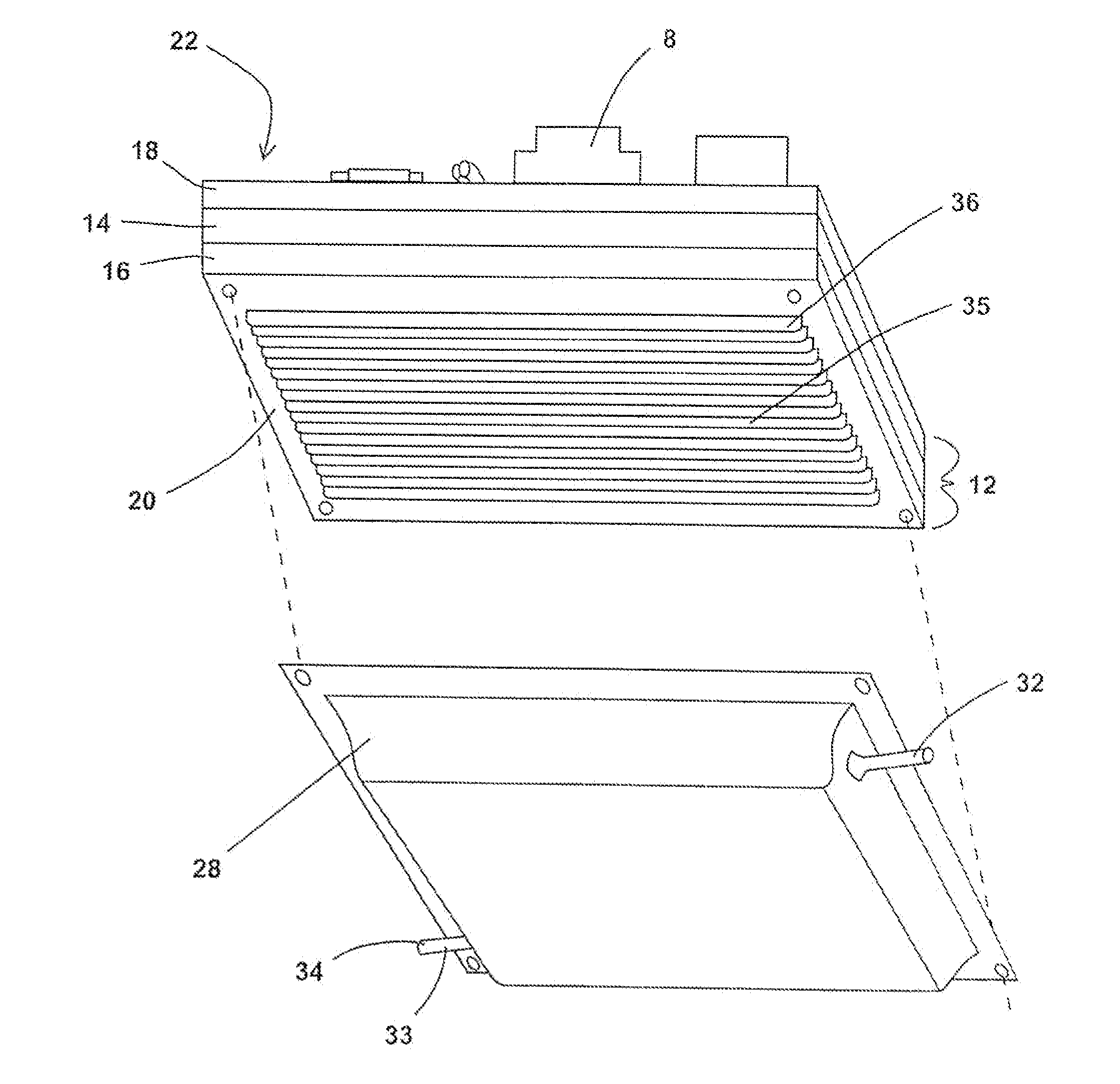

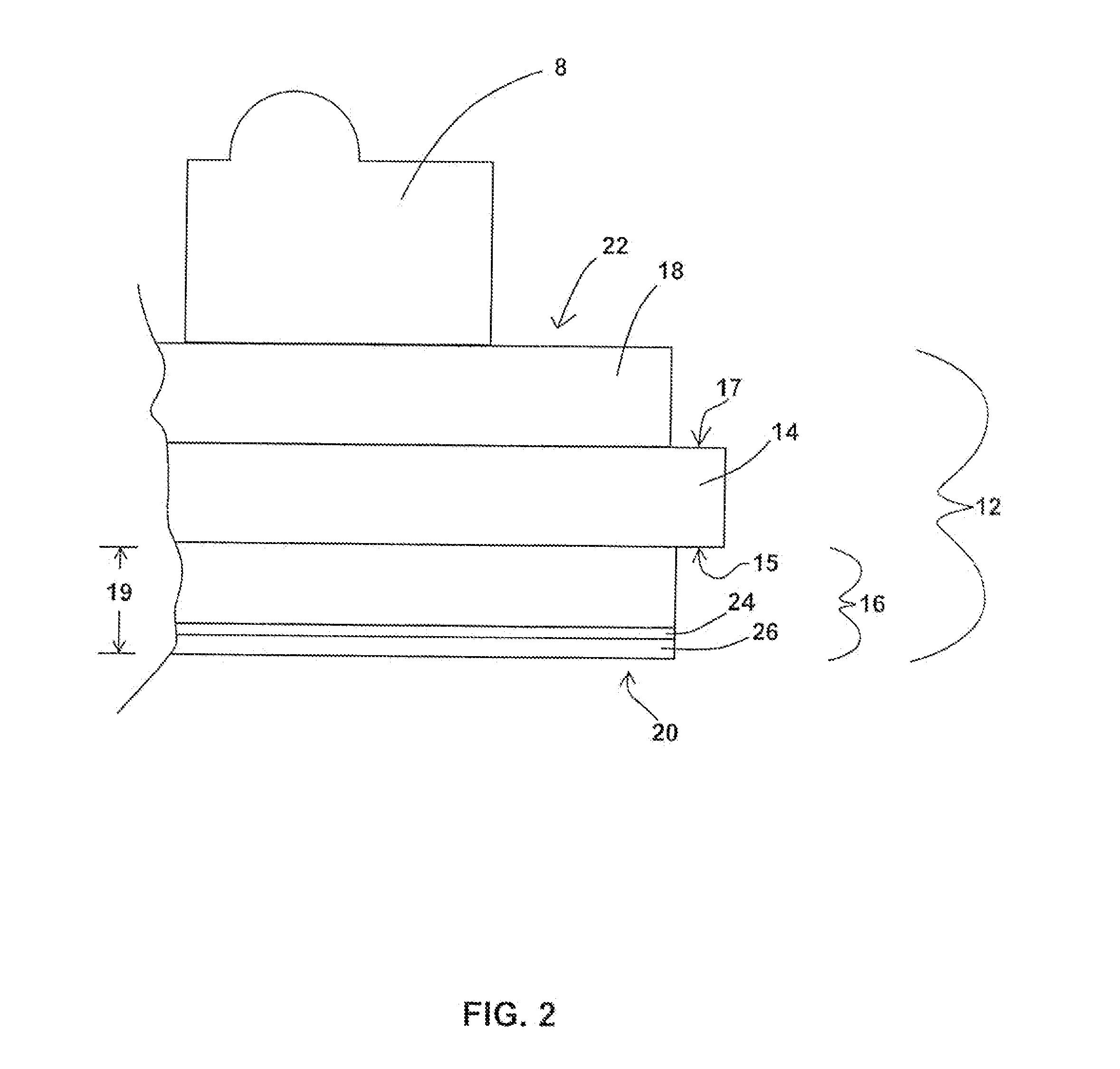

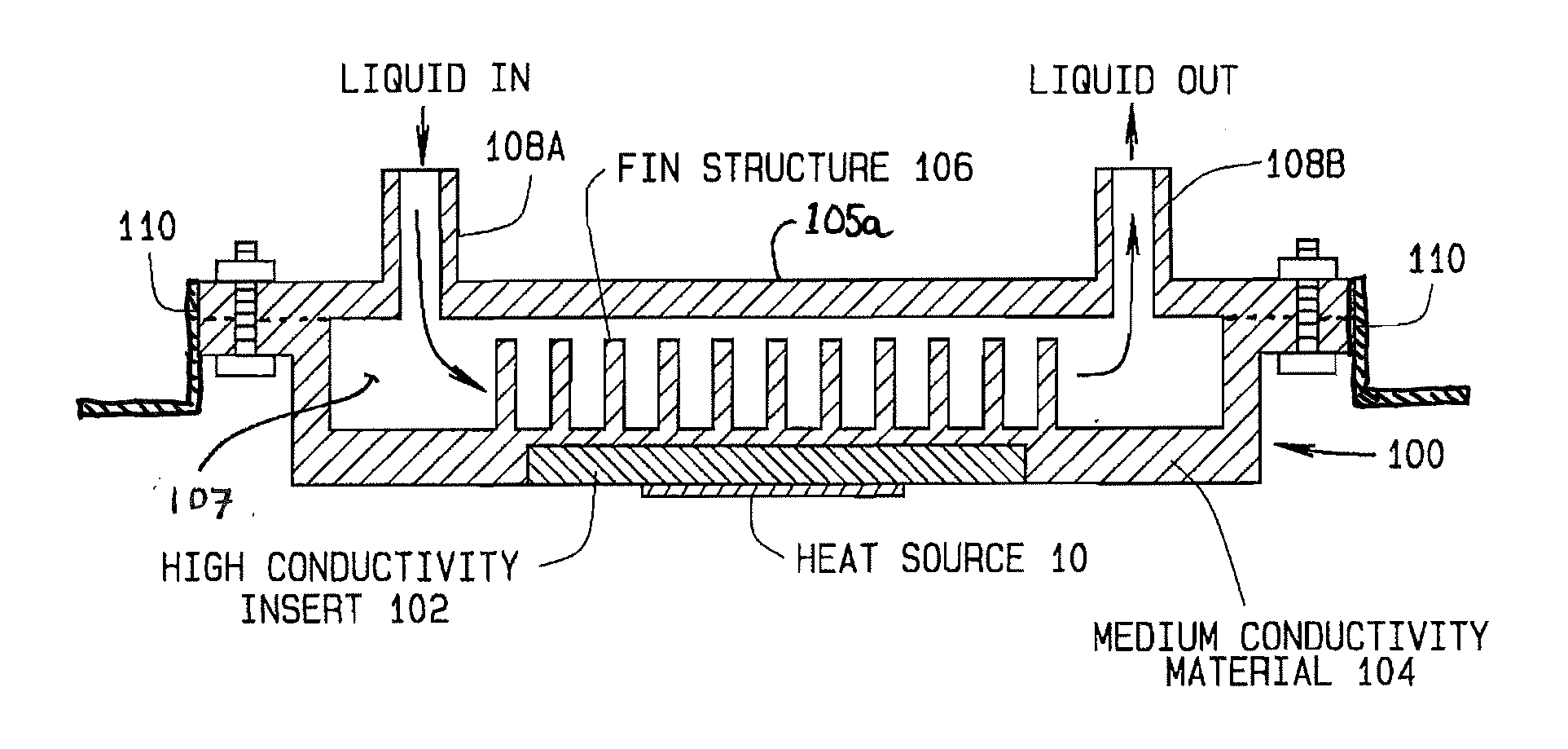

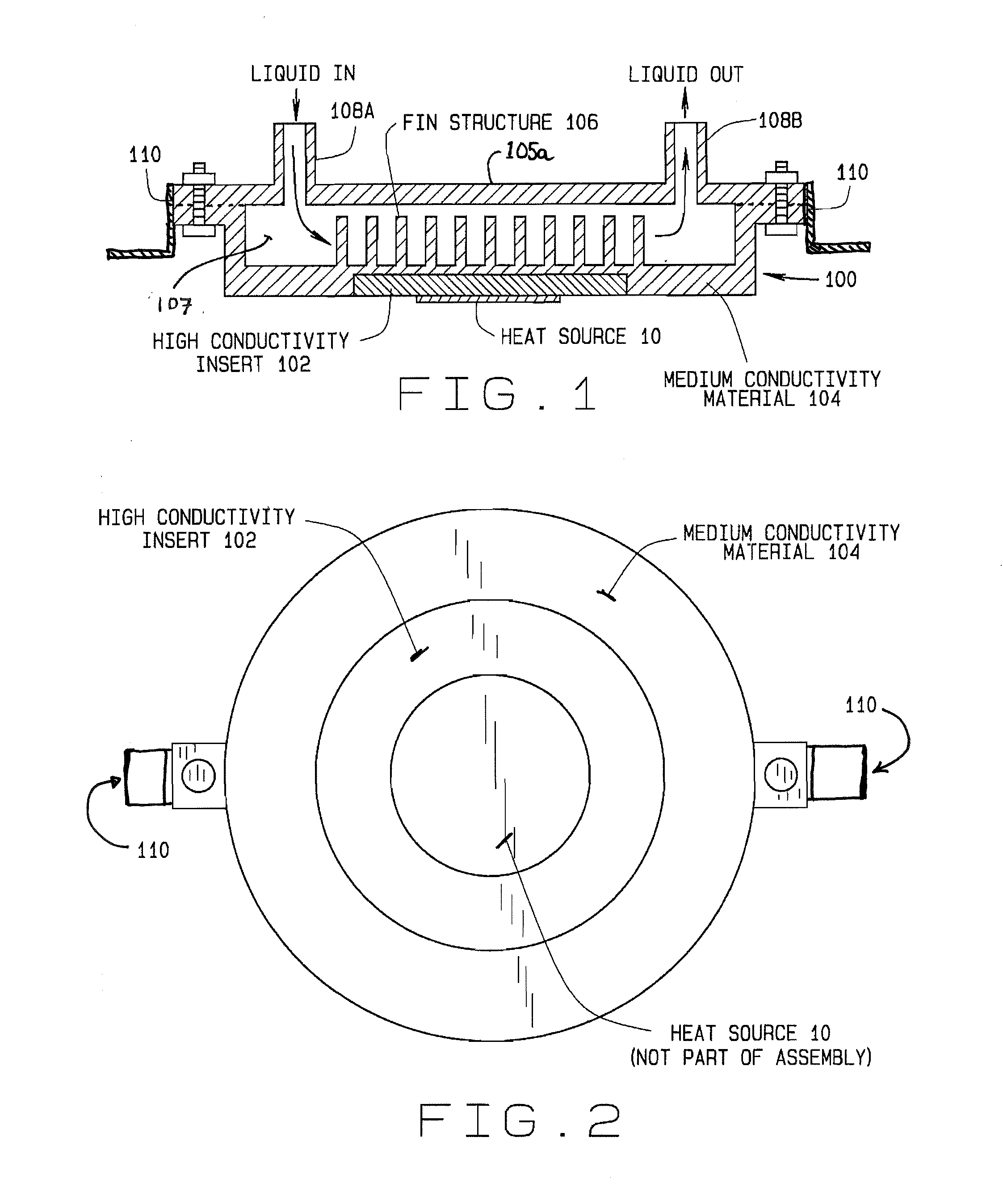

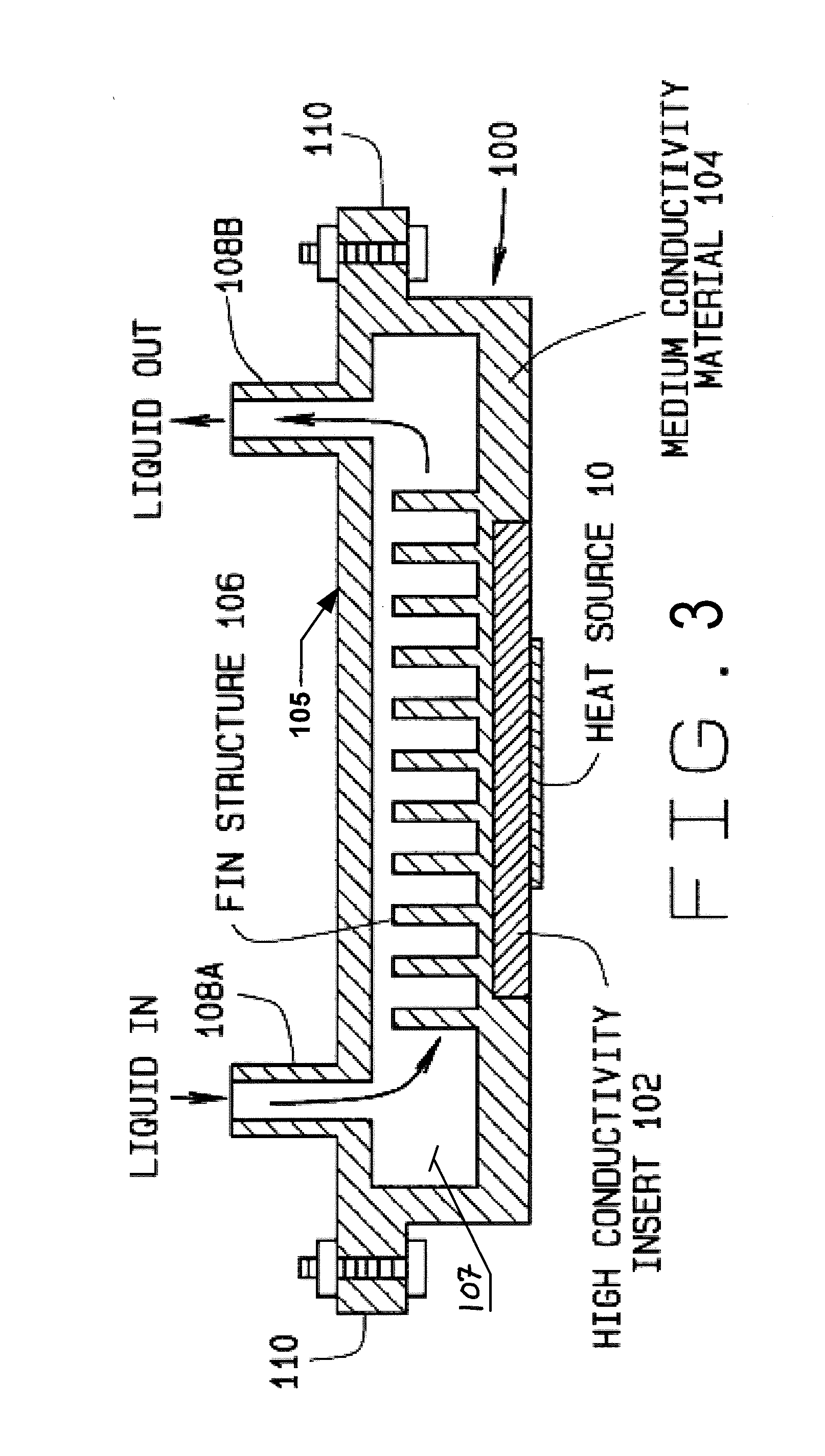

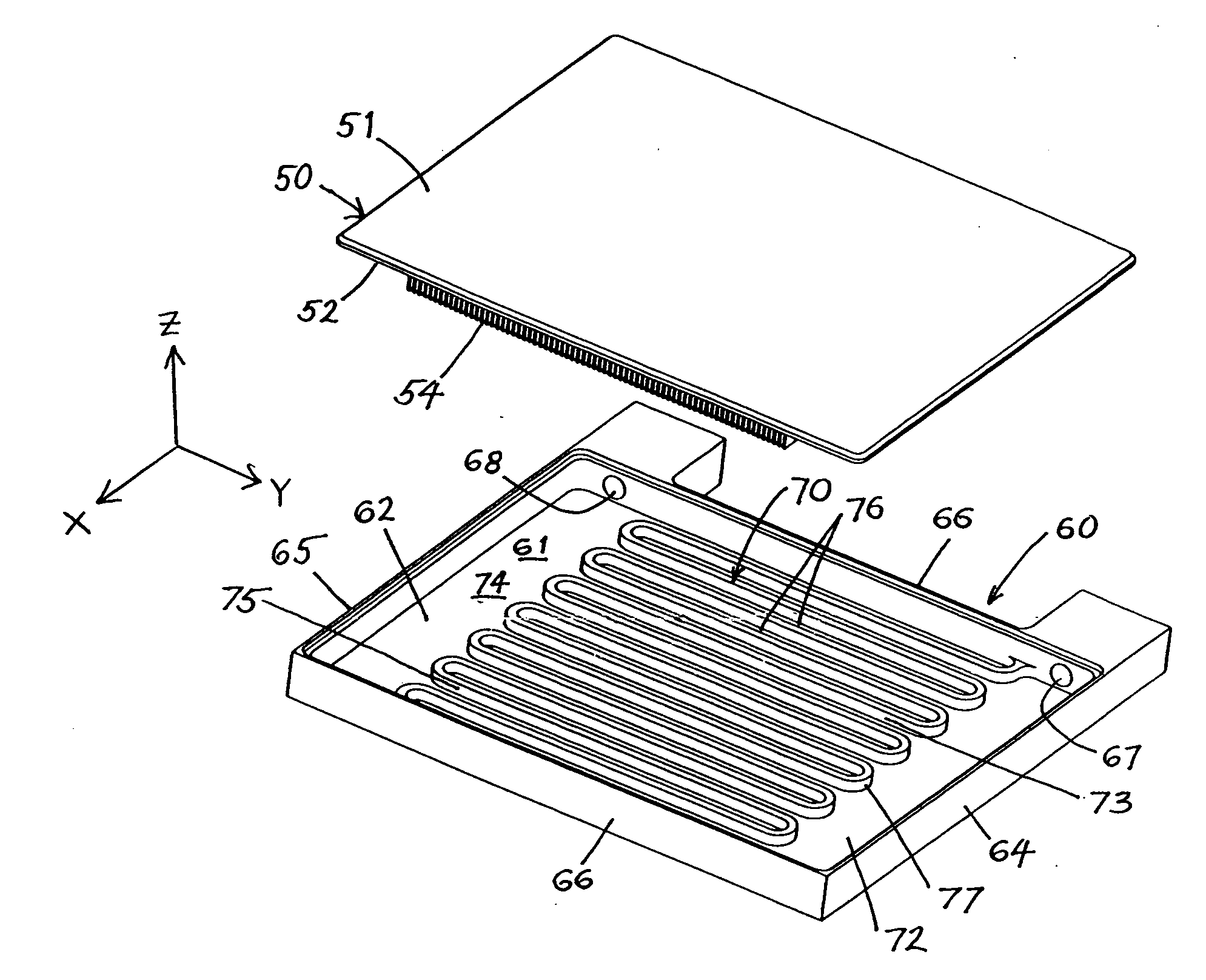

Liquid Cooling System Cold Plate Assembly

InactiveUS20120175094A1Convenient and efficient transferSemiconductor/solid-state device detailsSolid-state devicesThermal energyLiquid cooling system

A cold plate assembly consisting of a thermally conductive base component with an insert having a high thermal transfer characteristic adapted for contacting the surface of a heat source on one side. The surface of the base component opposite from the insert is surrounding by a housing defining an enclosed volume through with a flow of liquid coolant is directed. Inlet baffles adjacent to a fluid inlet in the housing direct the incoming flow of liquid coolant towards the surface of the base component in proximity to the insert, facilitating an efficient transfer of thermal energy from the heat source to the liquid coolant through the insert and base component. Optional extensions or fins extending into the liquid coolant contained in the enclosed volume from the surface of the base component further facilitate the transfer of thermal energy from the heat source.

Owner:ASETEK DANMARK

Thermal management system and method for electronics system

InactiveUS6972365B2Lighting and heating apparatusSemiconductor/solid-state device detailsThermal energySemiconductor chip

A thermal energy management system is provided having a heat spreading device that is operatively engaged with at least one semiconductor chip and a thermal bus operatively engaged with the heat spreading device so as to transport thermal energy from the heat spreading device to a heat sink. The heat spreading device includes a heat pipe and the thermal bus includes a loop thermosyphon. A second thermal bus may be operatively engaged with the first thermal bus so as to transport thermal energy from the first thermal bus to a heat sink. The second thermal bus may also include a loop thermosyphon. A method of managing thermal energy in an electronic system is also provided that includes spreading thermal energy generated by one or more devices over a surface that is relatively larger than the devices, thermally coupling an evaporator portion of a loop thermosyphon to the surface, and thermally coupling a condensing portion of the loop thermosyphon to a thermal energy sink, e.g., a second loop thermosyphon, convection fin, or cold plate.

Owner:THERMAL

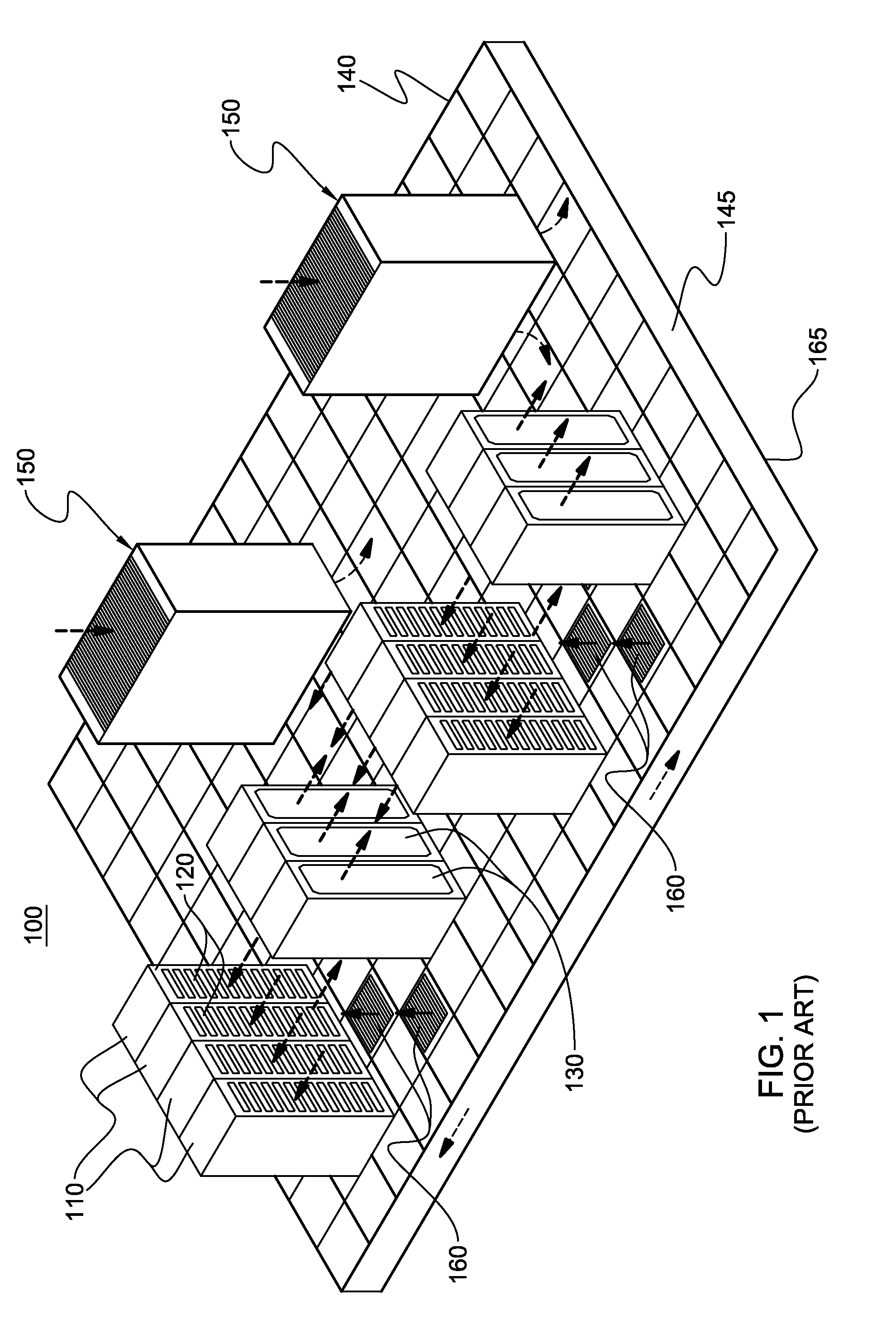

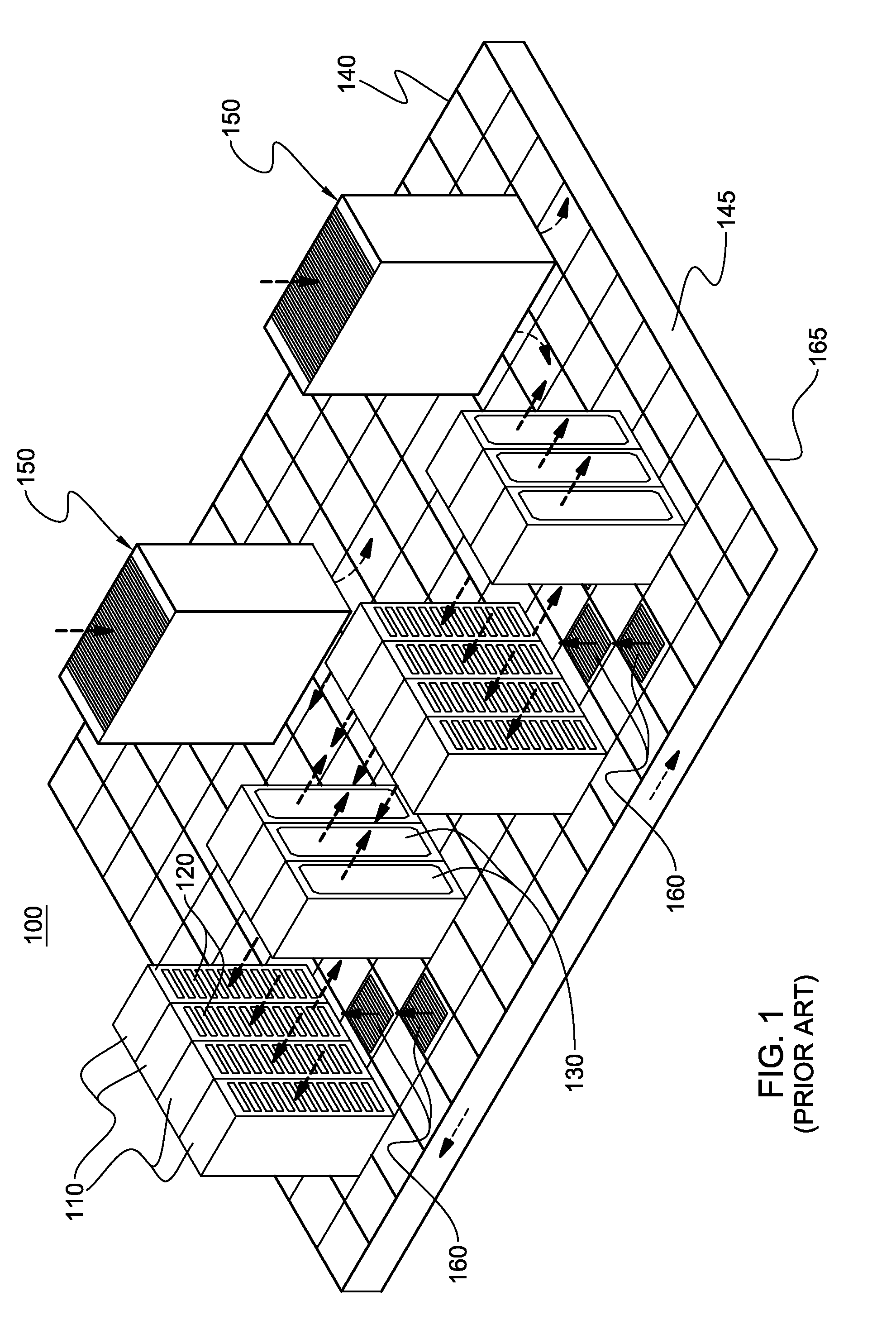

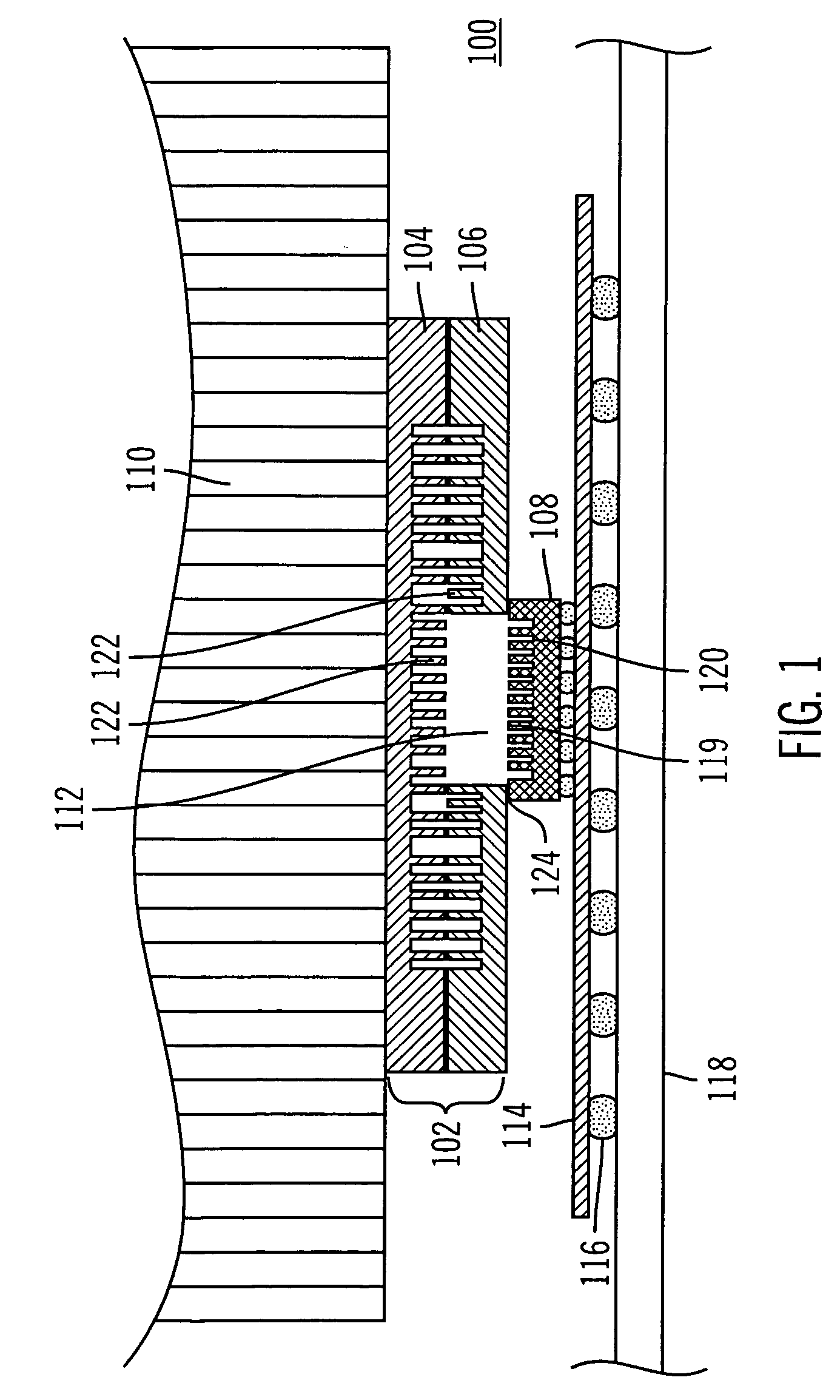

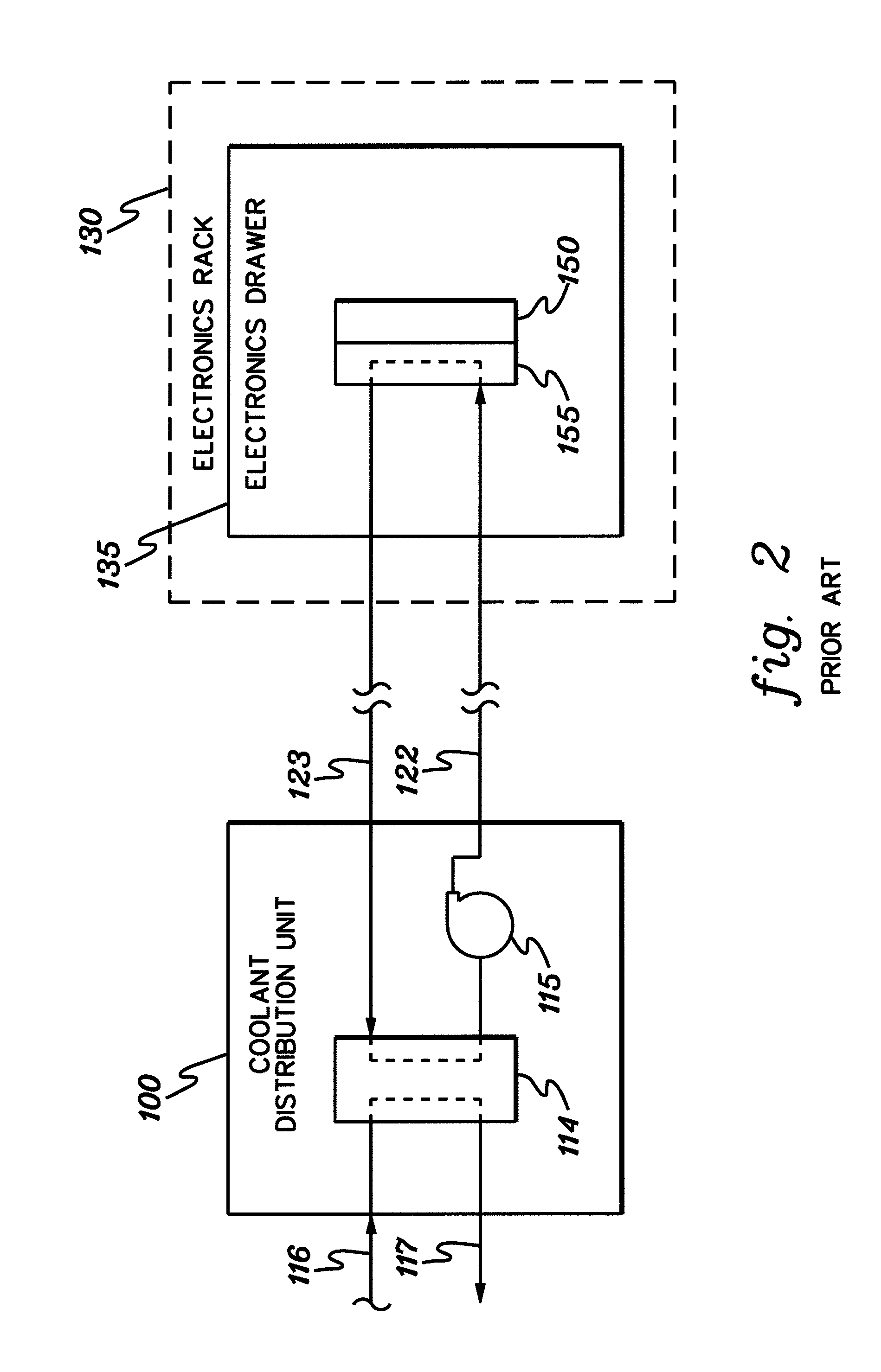

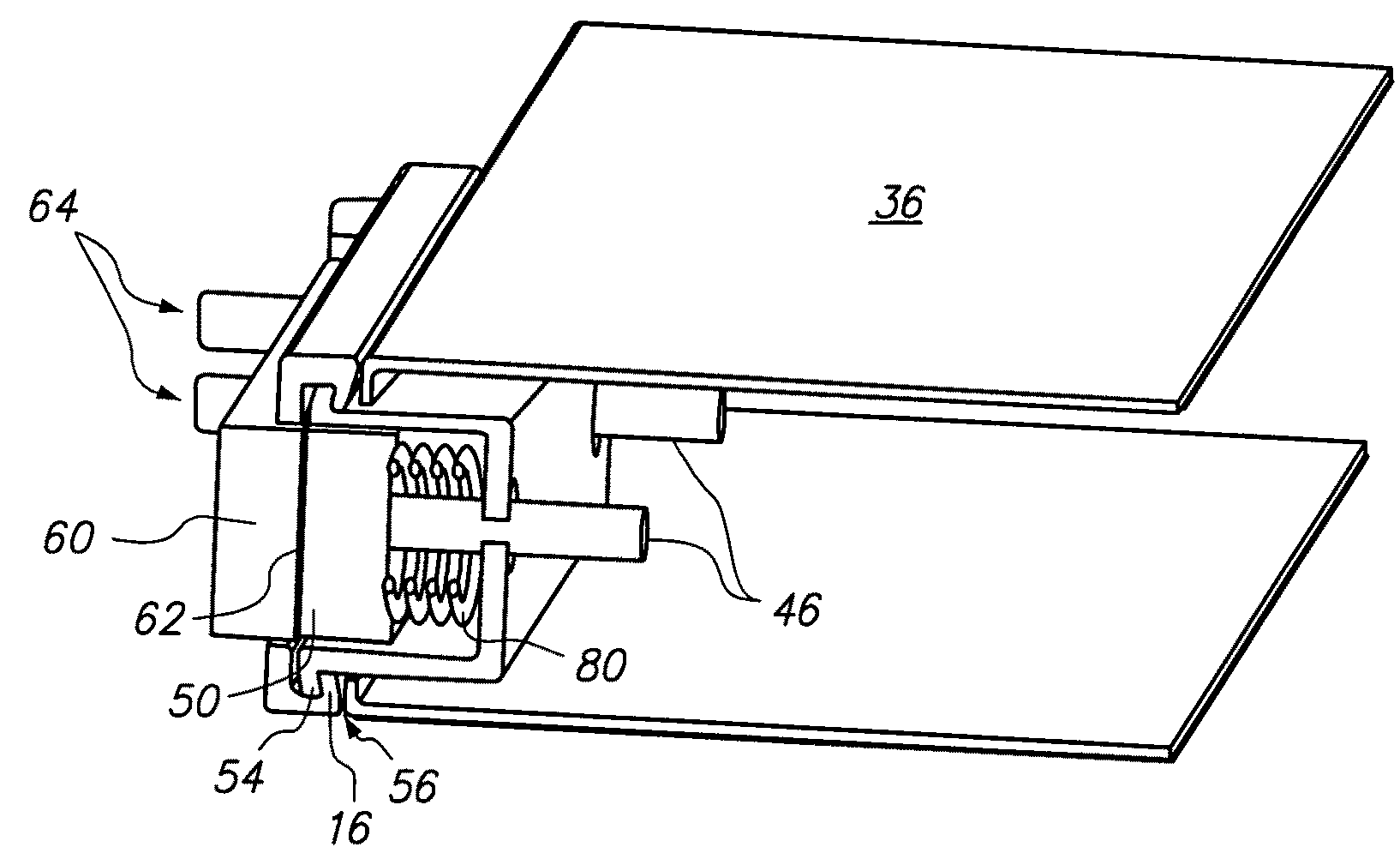

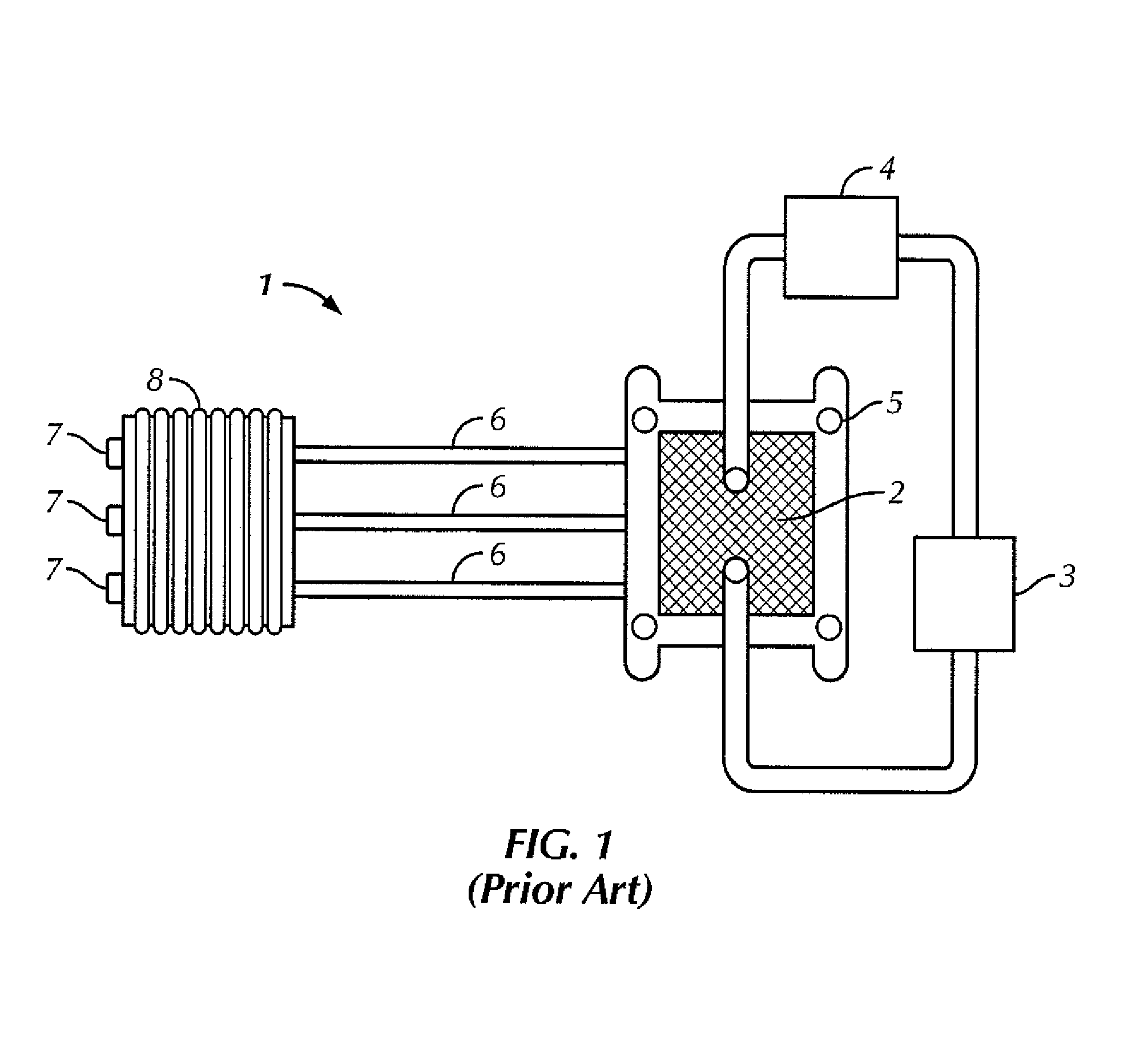

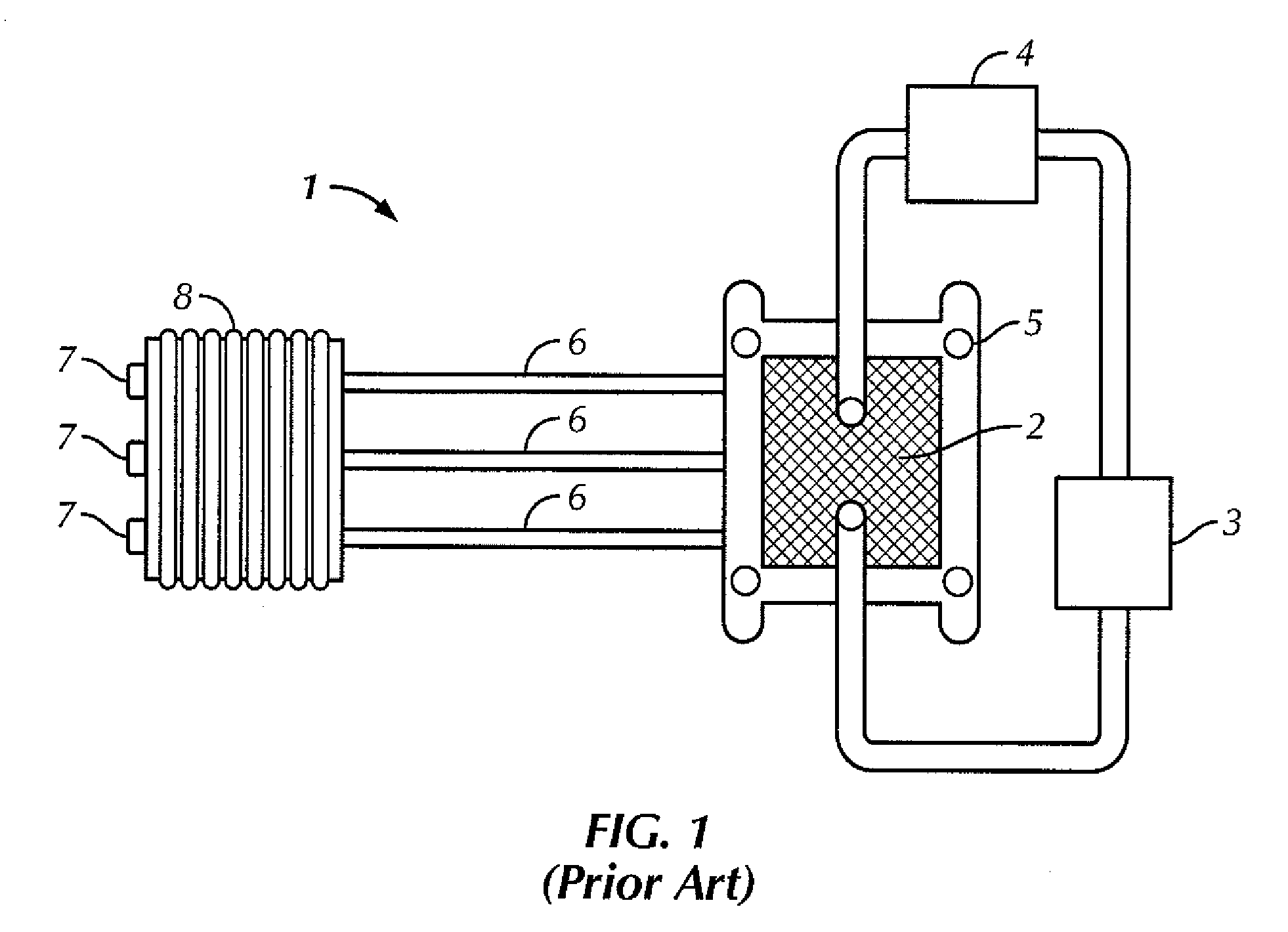

Cooling apparatus and method employing discrete cold plates disposed between a module enclosure and electronics components to be cooled

InactiveUS7298617B2Improve cooling effectSemiconductor/solid-state device detailsSolid-state devicesComputer moduleElectronic component

Cooling apparatuses and methods are provided for cooling an assembly including a substrate supporting multiple electronics components. The cooling apparatus includes: multiple discrete cold plates, each having a coolant inlet, a coolant outlet and at least one coolant chamber disposed therebetween; and multiple coolant-carrying tubes, each tube extending from a respective cold plate and being in fluid communication with the coolant inlet or outlet of the cold plate. An enclosure is provided having a perimeter region which engages the substrate to form a cavity with the electronics components and cold plates being disposed within the cavity. The enclosure is configured with multiple bores, each bore being sized and located to receive a respective coolant-carrying tube of the tubes extending from the cold plates. Further, the enclosure is configured with a manifold in fluid communication with the tubes for distributing coolant in parallel to the cold plates.

Owner:IBM CORP

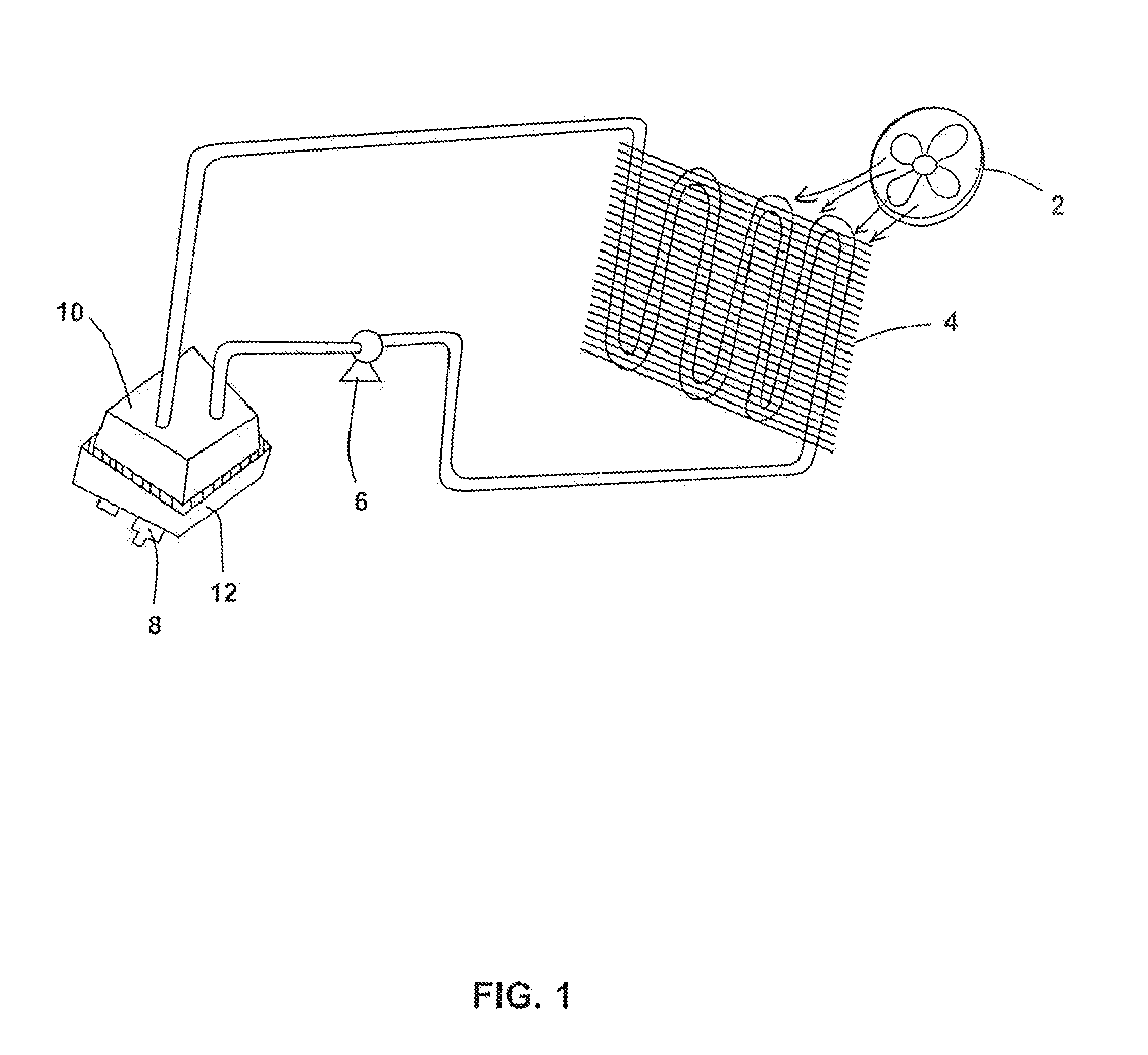

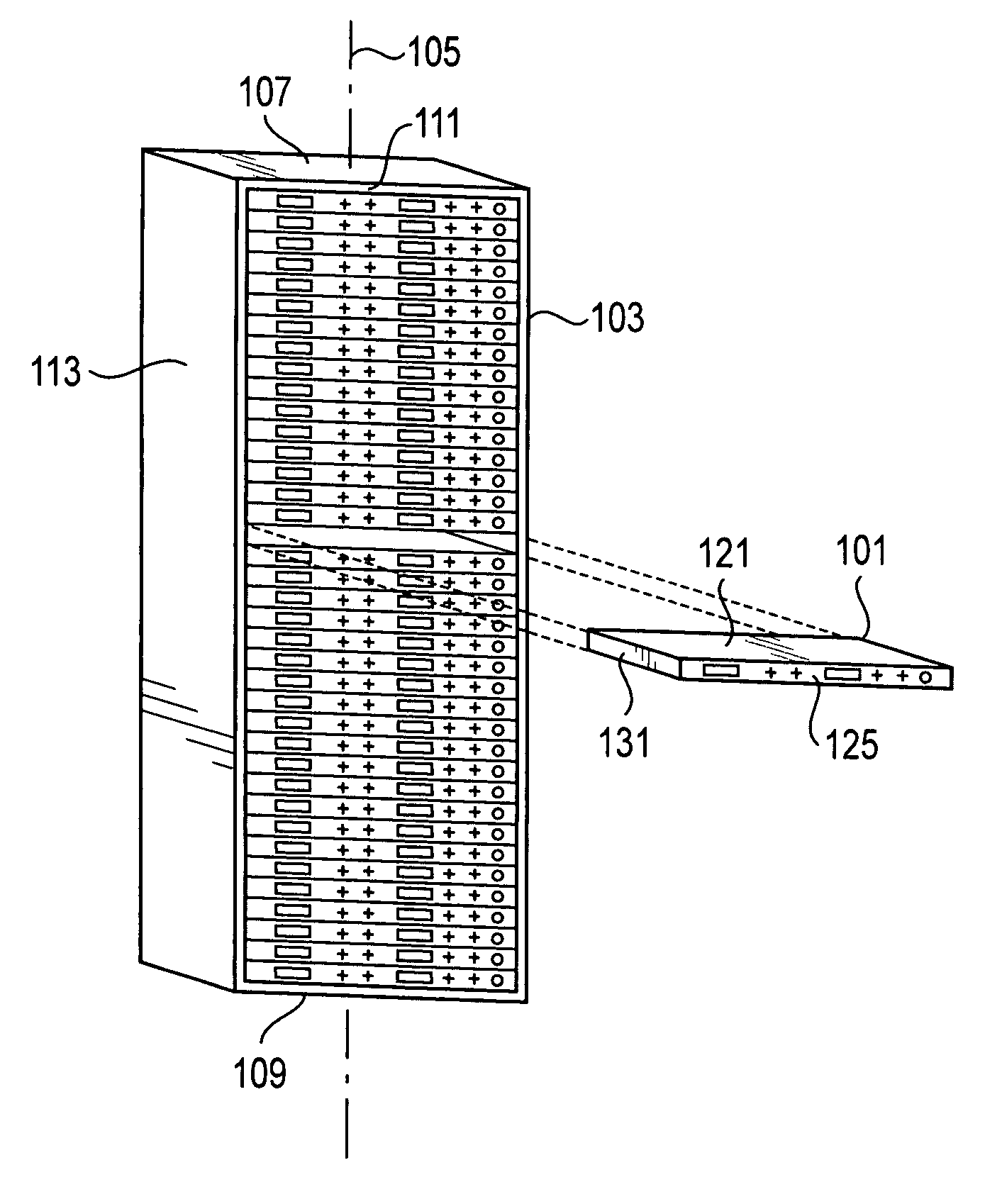

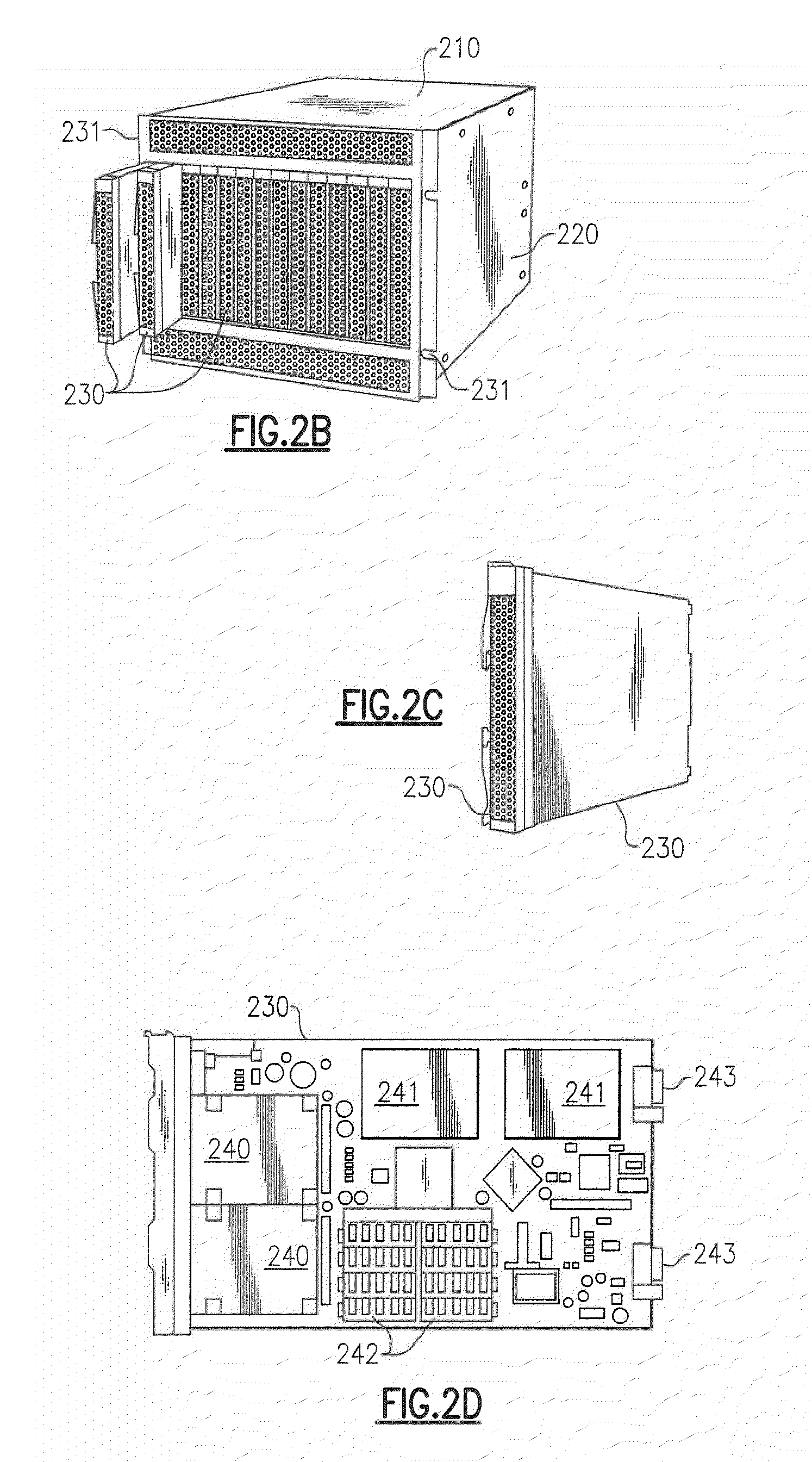

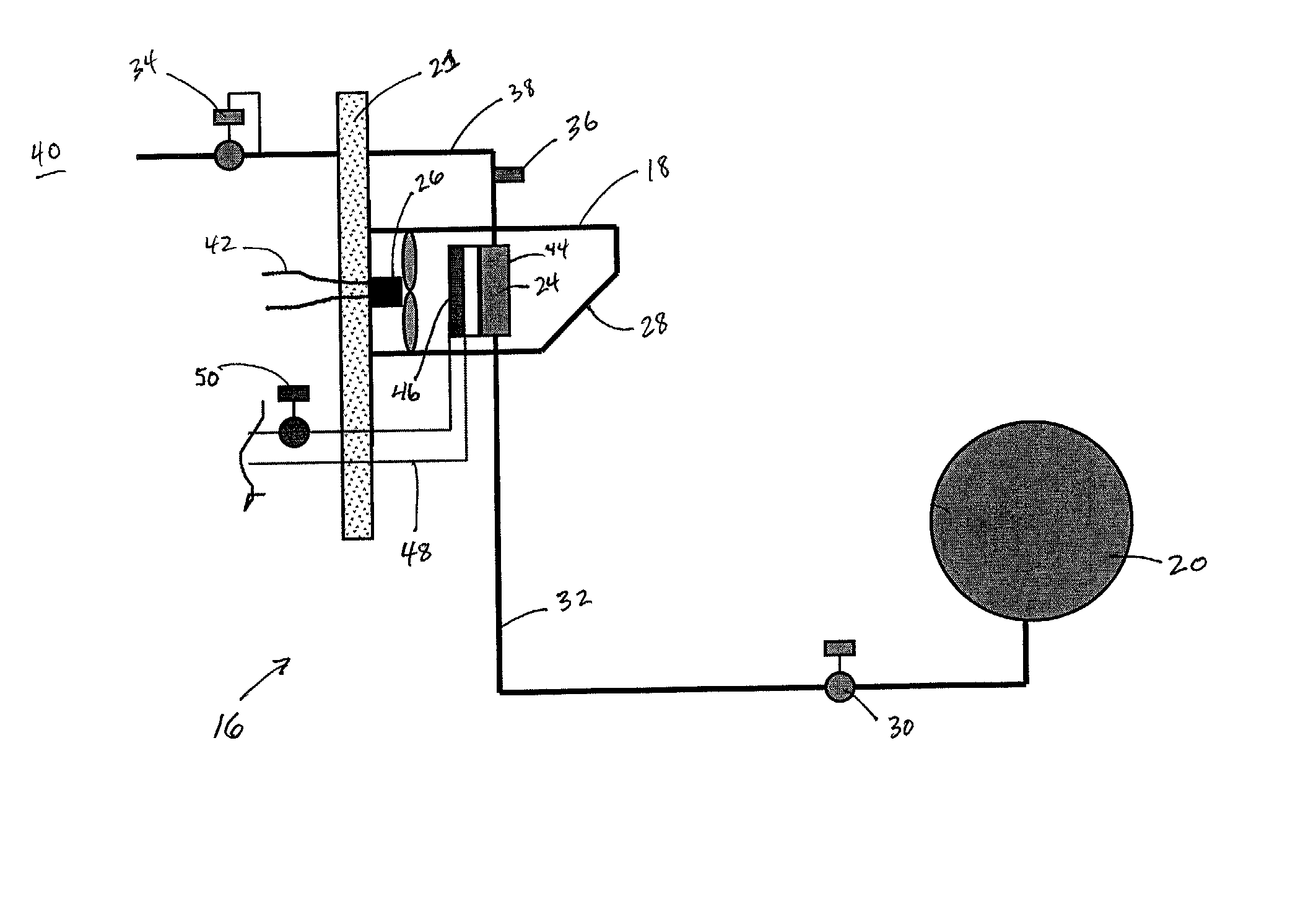

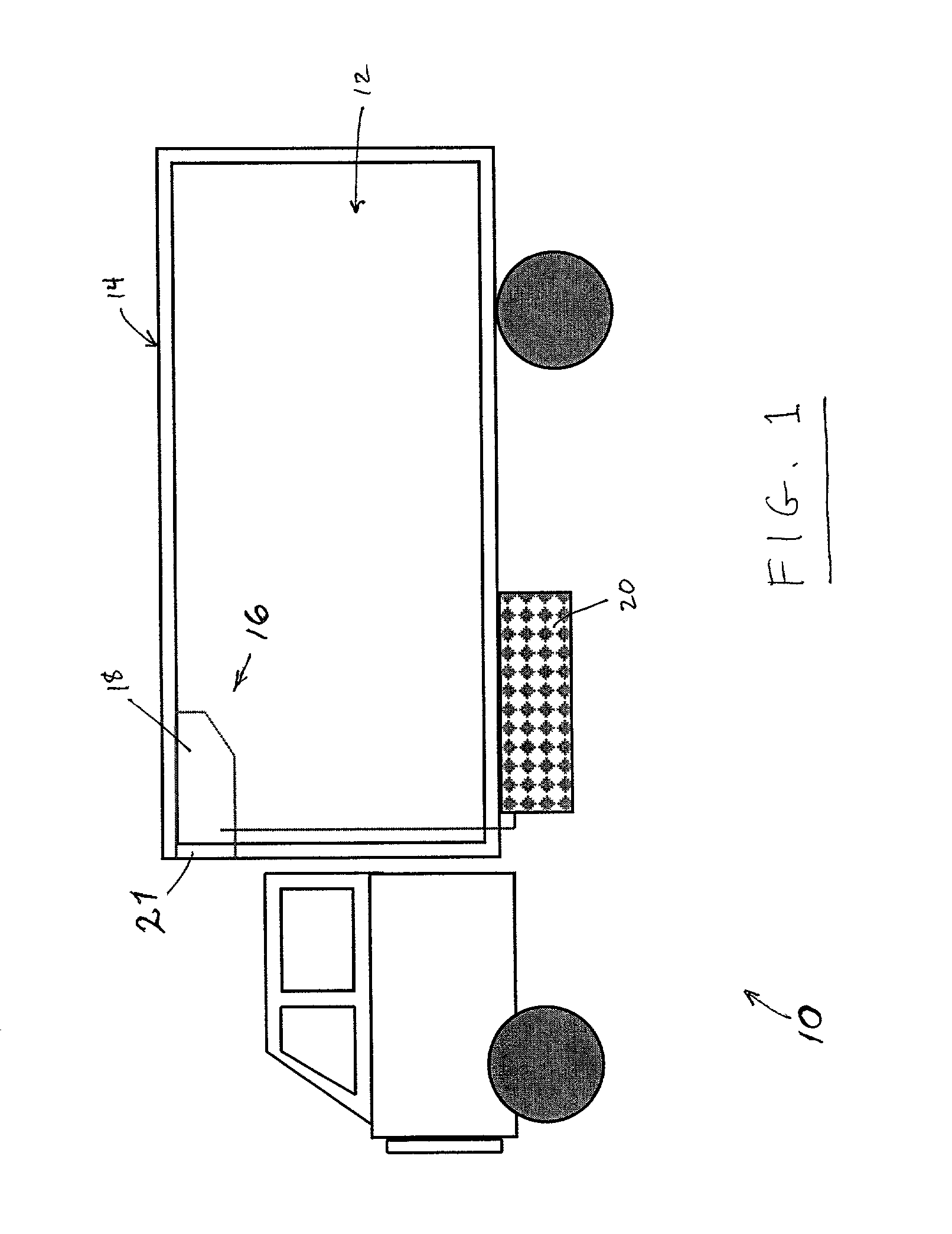

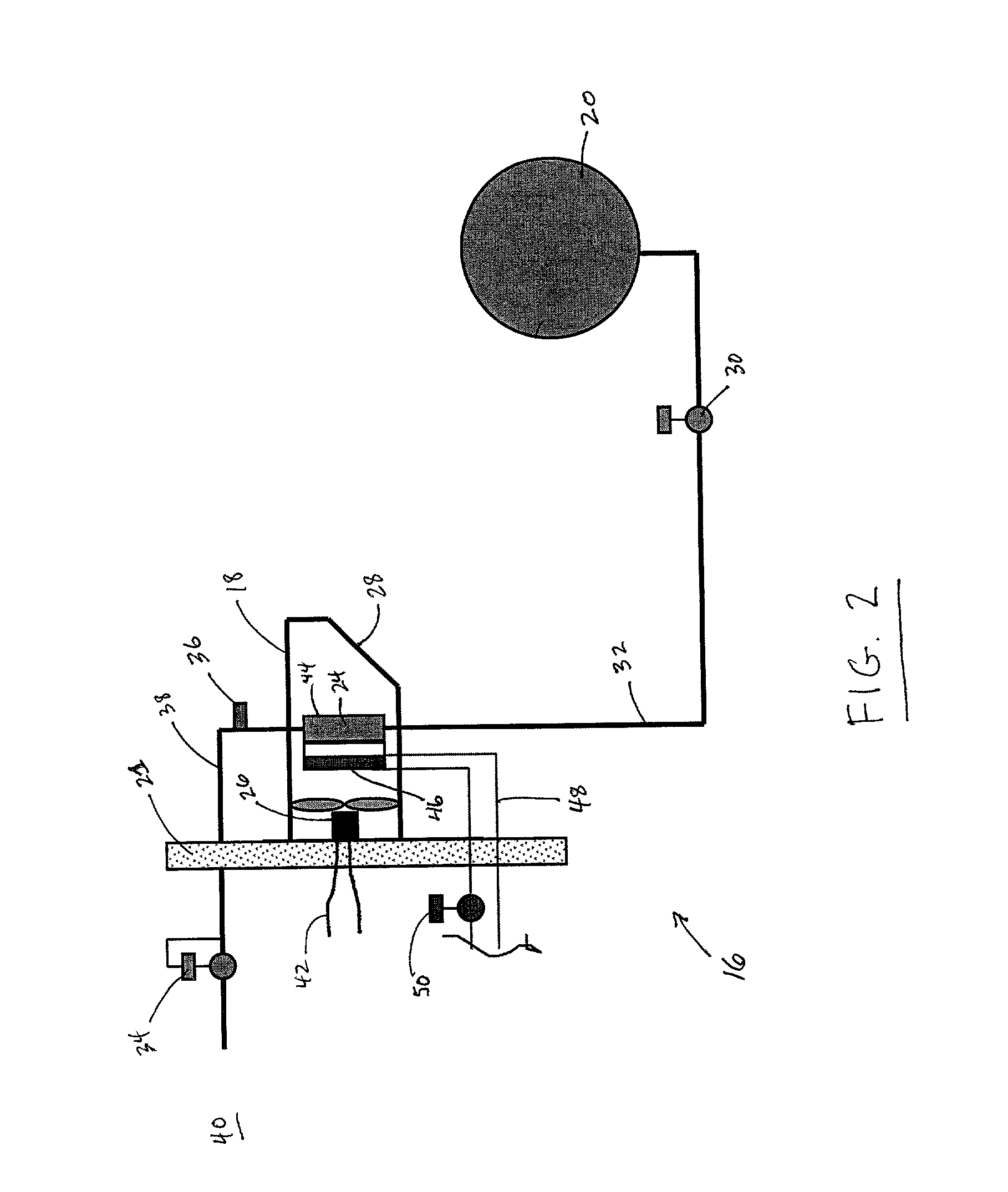

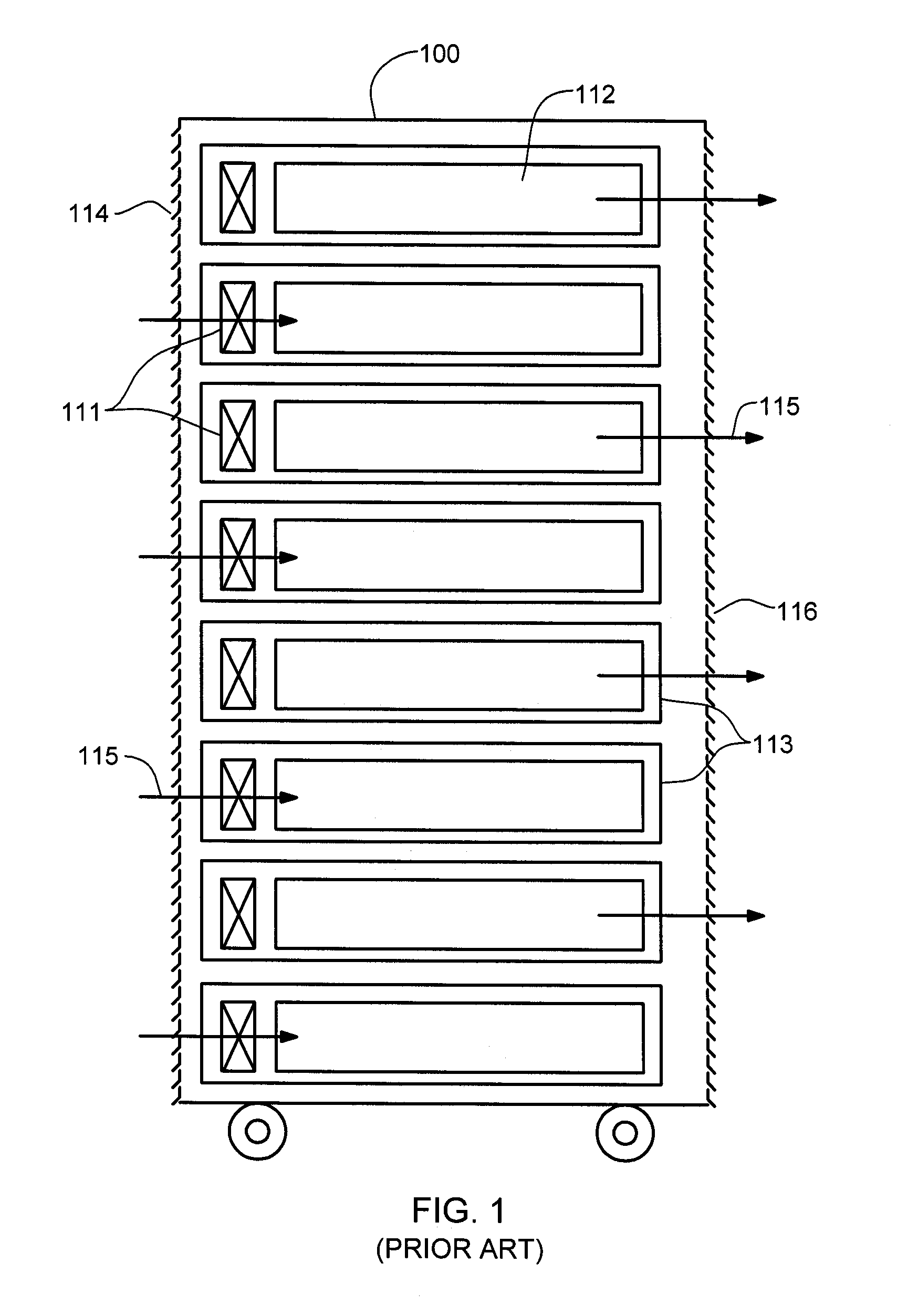

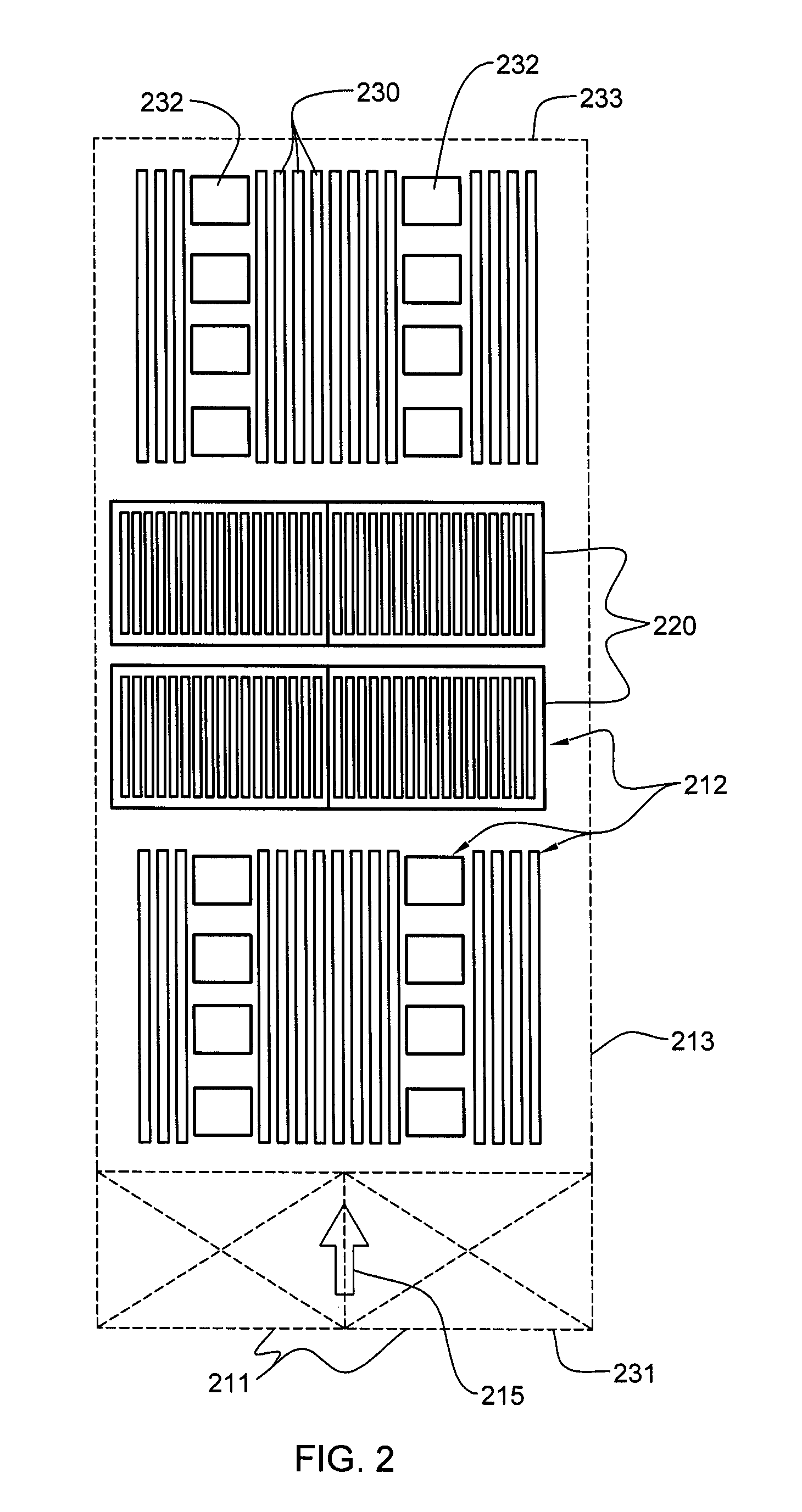

Small form factor liquid loop cooling system

ActiveUS20050259397A1Easy to useDigital data processing detailsPower cablesSmall form factorEngineering

An enclosure forms a plurality of tiers vertically stacked in a longitudinal dimension. Each tier is a 1U modular computer system having a computer chassis configured for mounting in the multi-tiered support, and computer components that need cooling within the computer chassis. A cold plate is in thermal communication with at least one of the computer components, and convectively removes heat from that component using a liquid coolant. A heat exchanger dissipates heat from the liquid coolant, and provides liquid coolant back to the cold plate. An air mover within the chassis cools the heat exchanger, blows air across other components needing cooling, and removes heated air from the chassis. The air mover may extend substantially across the chassis, or it may blow crosswise from an outlet-ventilating direction.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

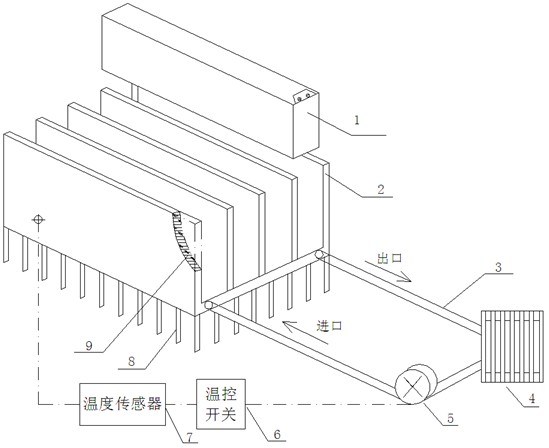

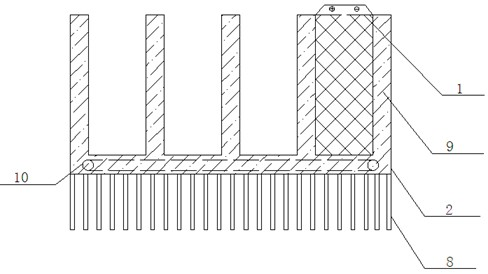

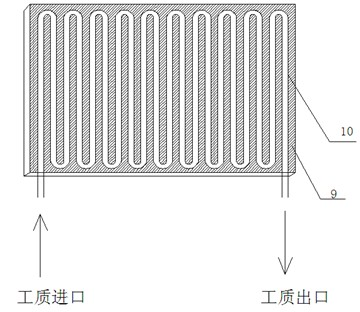

Radiating and cooling device for power battery

InactiveCN102664292ATemperature controlImprove energy efficiencySecondary cellsTemperature controlPower battery

The invention relates to a radiating and cooling device for a power battery. An aluminum hollow cold plate shell is in the form of a radiating fin; the inside of the shell is hollow; a plurality of groove spaces are formed on the aluminum shell; power batteries can be embedded into grooves; the aluminum hollow cold plate shell is filled with a phase change material; radiating fins are arranged on an aluminum hollow cold plate shell bottom plate; a snakelike copper tube is arranged at the bottom of an aluminum shell cavity, and is contacted with the phase change material; a liquid cooling working medium is introduced into the snakelike copper tube; the snakelike copper tube, a pump and an external heat exchanger are connected in series, so that an active liquid cooling system is formed; a temperature sensor is arranged on the surface of the power battery; and a temperature switch is connected in series with a pump body power supply. The flow of the cooling working medium can be adjusted according to different requirements of battery temperature control; the using amount of a metal is reduced by adding the phase change material on the premise of ensuring the battery radiating effect, so that the cost of a battery radiating device is reduced effectively; and the requirements of different power batteries are met.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

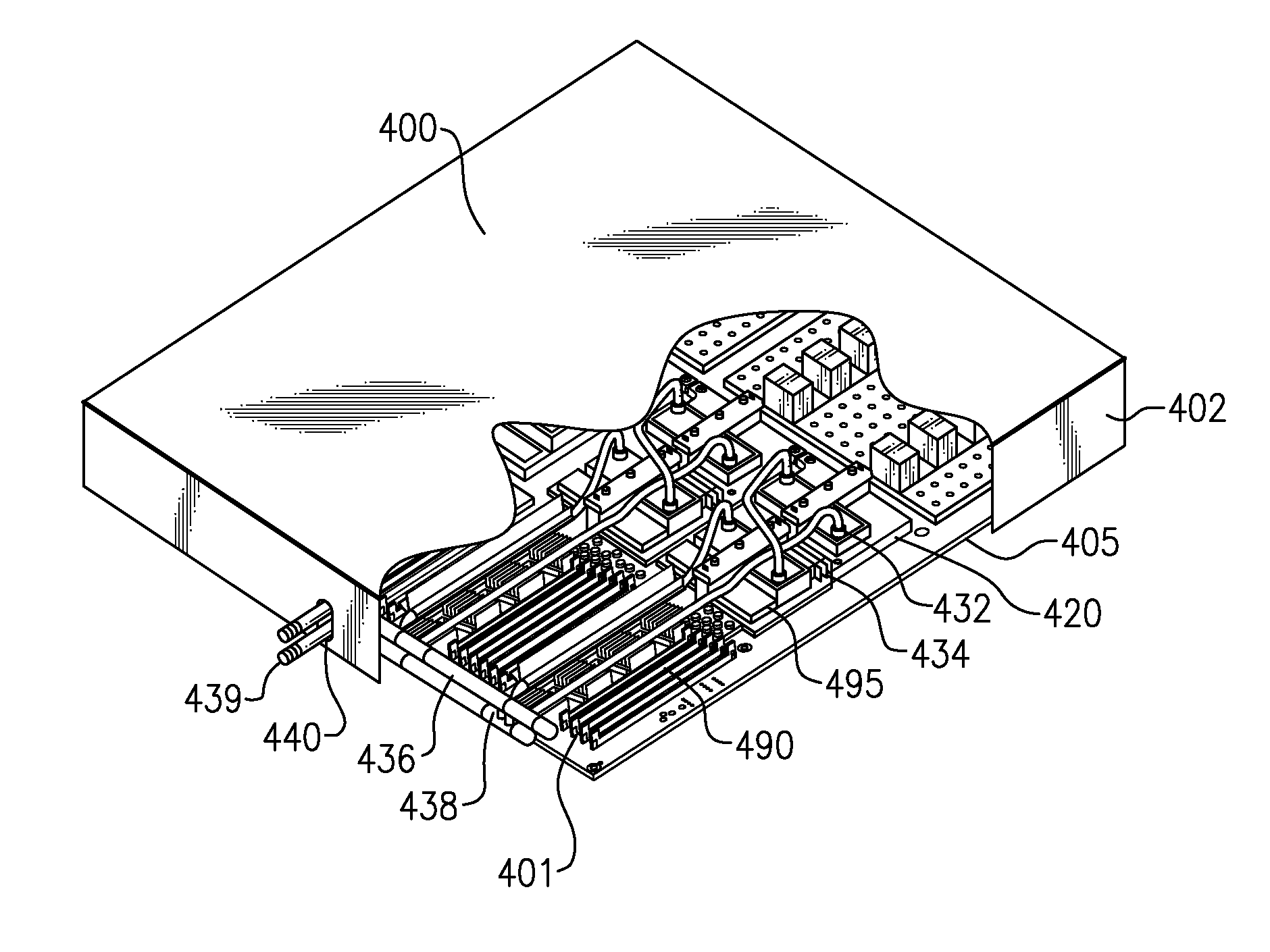

Hybrid immersion cooled server with integral spot and bath cooling

InactiveUS7724524B1Digital data processing detailsIndirect heat exchangersNuclear engineeringElectronic component

A hybrid immersion cooling apparatus and method is provided for cooling of electronic components housed in a computing environment. The components are divided into primary and secondary heat generating components and are housed in a liquid sealed enclosure. The primary heat generating components are cooled by indirect liquid cooling provided by at least one cold plate having fins. The cold plate is coupled to a first coolant conduit that circulates a first coolant in the enclosure and supplies the cold plate. Immersion cooling is provided for secondary heat generating components through a second coolant that will be disposed inside the enclosure such as to partially submerge the cold plate and the first coolant conduit as well as the heat generating components.

Owner:IBM CORP

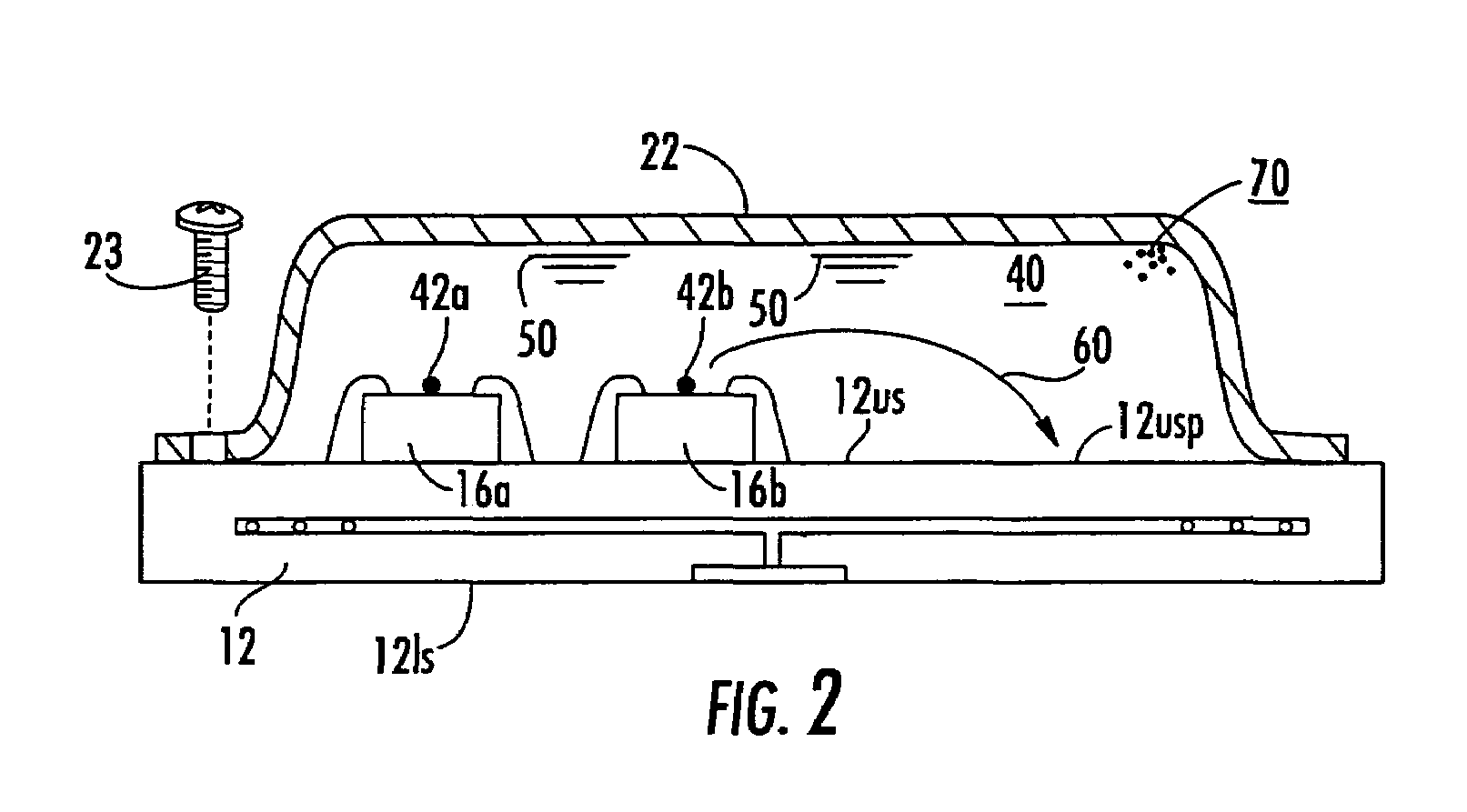

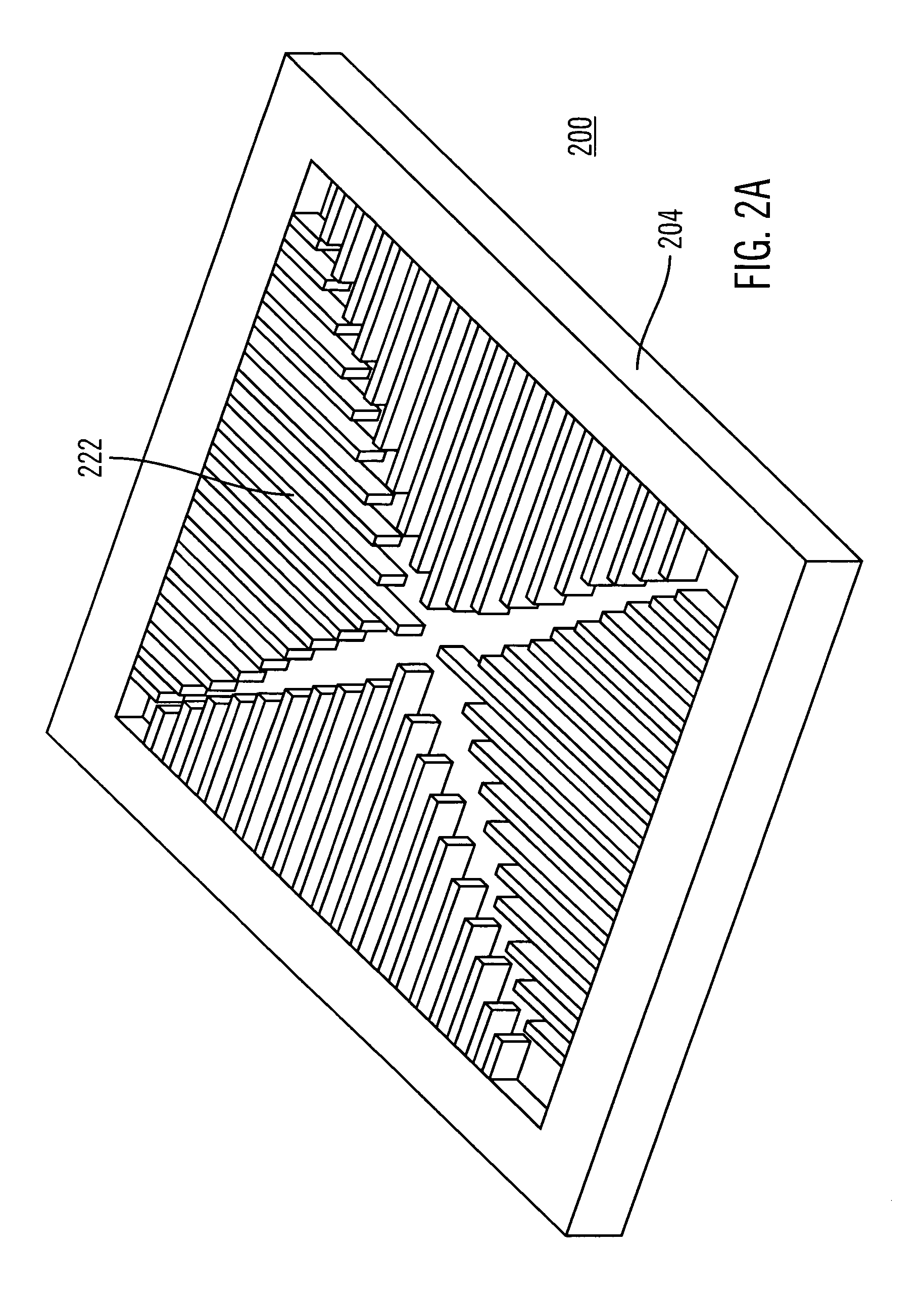

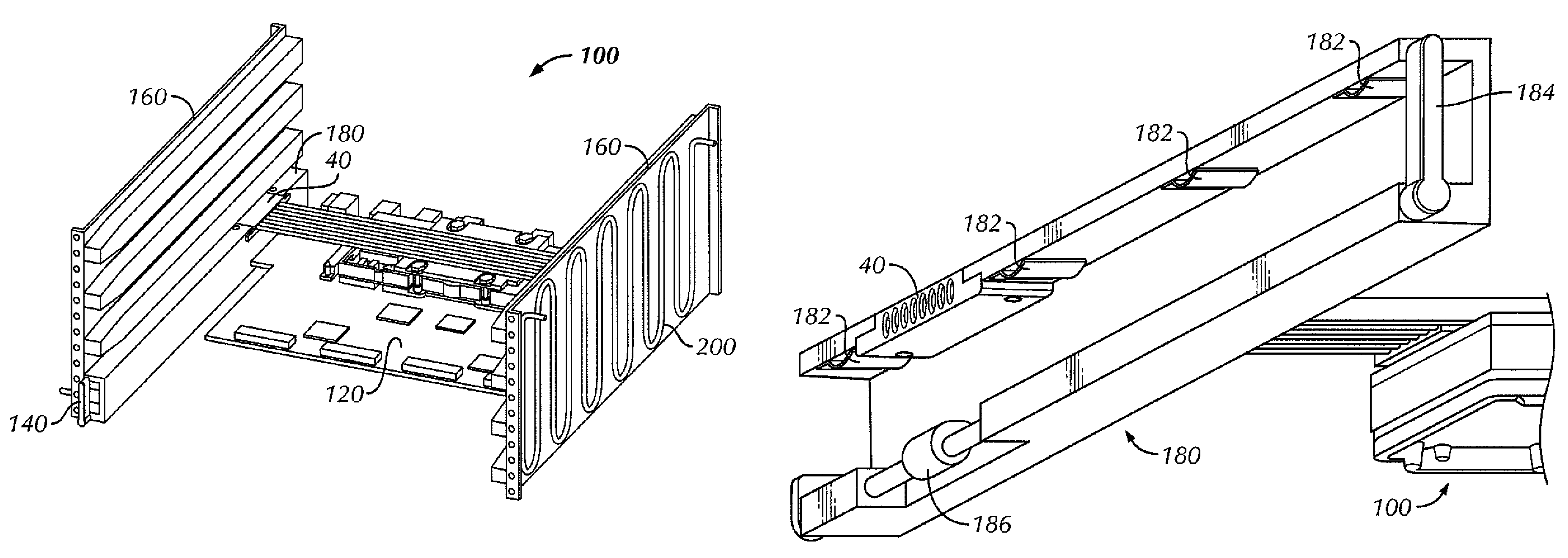

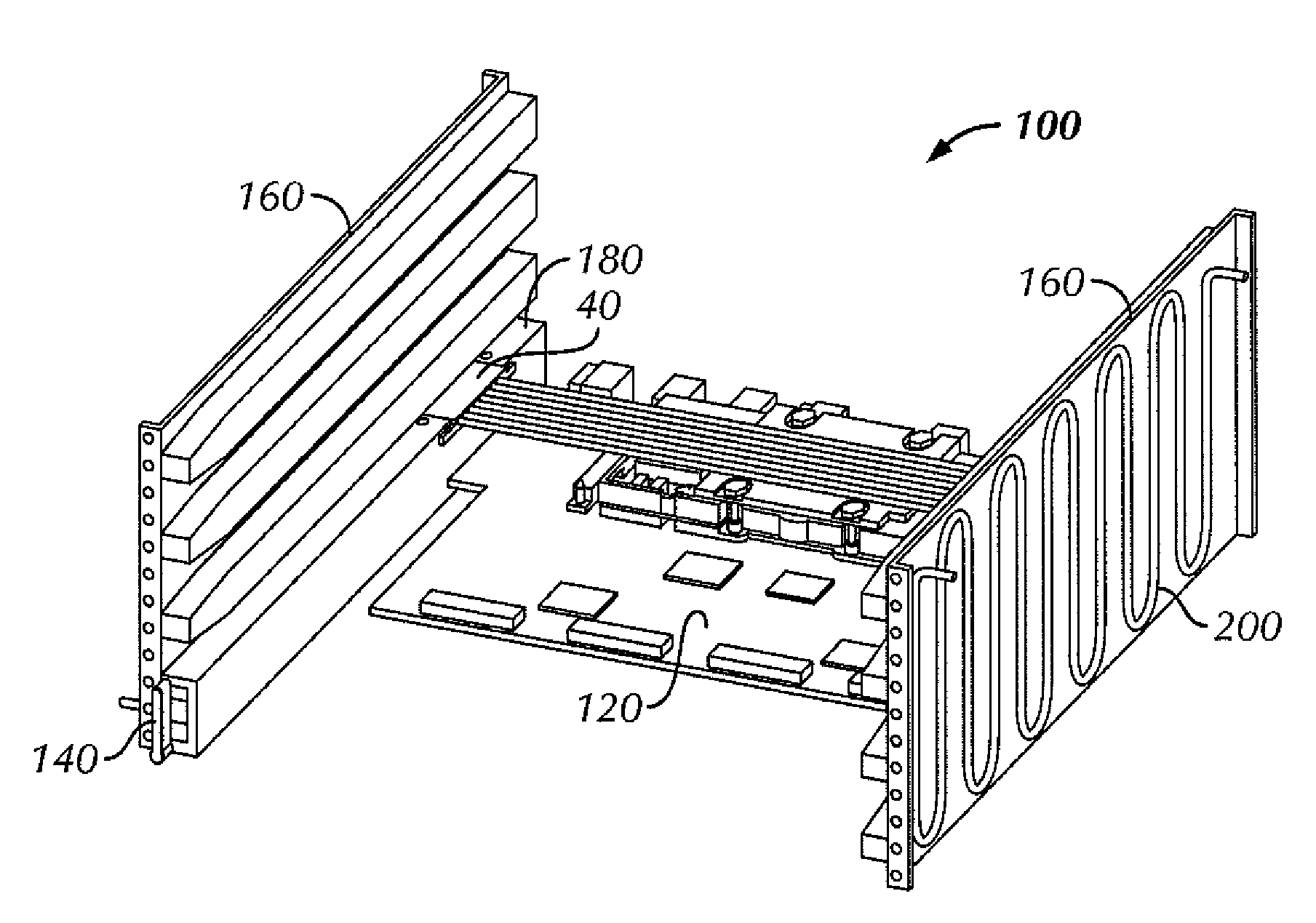

Liquid cooling loops for server applications

ActiveUS20070201210A1Reduce thermal resistanceIncrease surface areaSolid-state devicesFurniture partsElectricityLocking mechanism

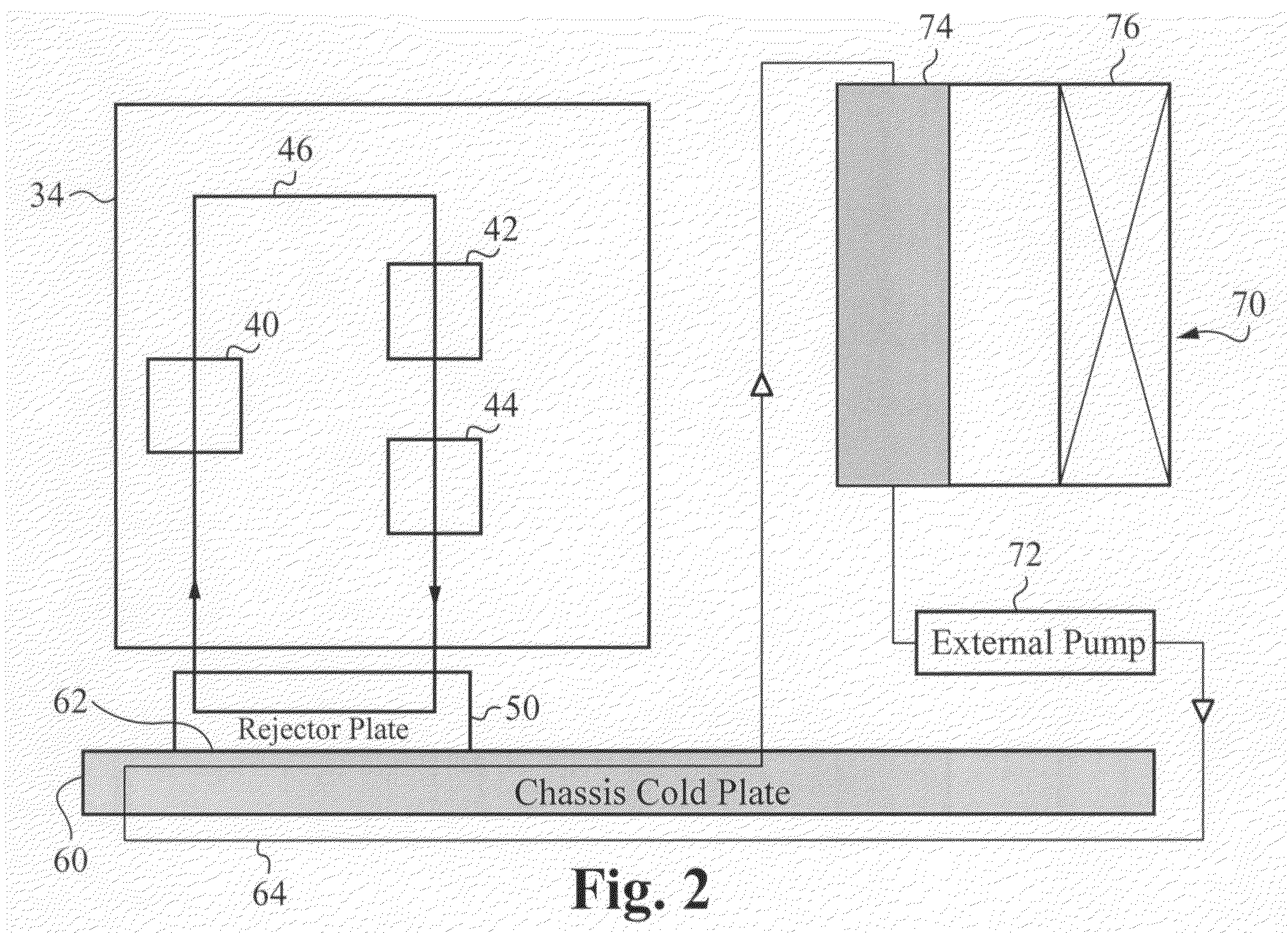

A mounting system provides mechanisms and form factors for bringing a heat exchanger from a server rack into thermal contact with a heat exchanger from a electronics server. To ensure good thermal contact, pressure is applied between the two heat exchangers, the rejector plate and the chassis cold plate. The mounting mechanism used to engage and disengage the heat exchangers is configured to isolate the force applied to the two heat exchangers. The mounting mechanism includes an interlocking mechanism that prevents transfer of the applied force to the rest of the electronics server. Without isolating this force, the force is applied to the electronics server and / or the rack chassis, possibly disconnecting the electrical connections between the electronics server and the rack, as well as providing mechanical stress to the electronics server and the rack chassis. The mounting mechanism is also coupled to the electronics server locking mechanism such that the action of locking the electronics server into the rack causes the heat exchangers to engage in thermal contact. This is a fail safe procedure since no separate process is required to engage the electronics server cooling loop.

Owner:LIEBERT

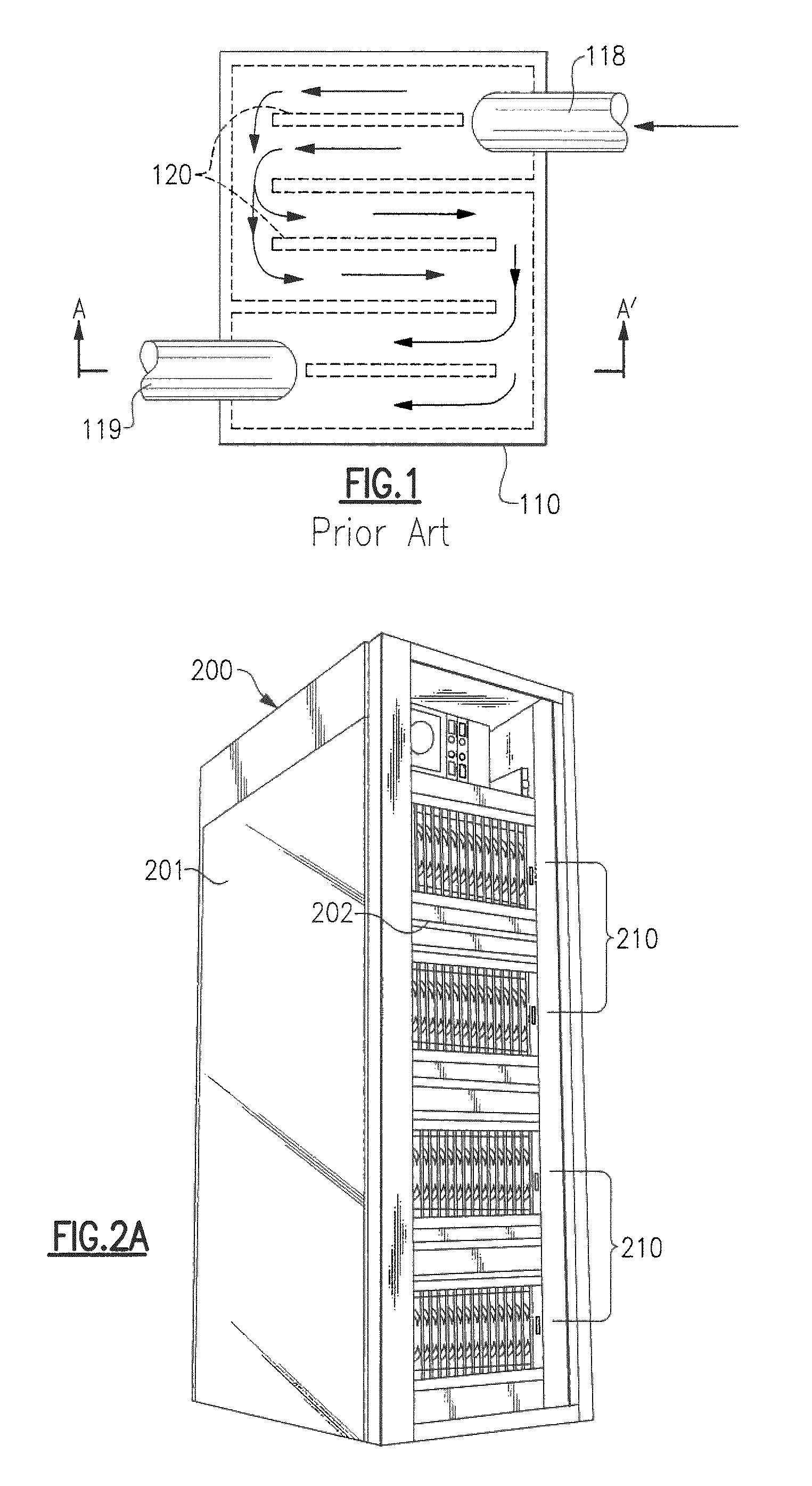

Liquid-Based Cooling System For Data Centers Having Proportional Flow Control Device

InactiveUS20110240281A1Efficient use ofMaximize engine efficiencyTemperature control using digital meansDigital data processing detailsProportional controlAdsorption chiller

A liquid-based cooling system provides a method of supplying a heated coolant fluid at a relatively constant temperature and pressure to one or more heat driven engines, such as adsorption chillers or heat pumps, by utilizing a proportional flow control device in association with each of a plurality of heat-producing electronic components to optimize the output of a plurality of liquid-cooled cold plates operatively mounted on such plurality of heat-producing electronic components. The proportional flow control devices may be electro-mechanical or solid state proportional control valves for water flow control. The proportion flow control devices are operatively connected to be actuated based upon the electrical signals typically generated to control the variable cooling fans of the electronic components.

Owner:INDAL IDEA PARTNERS

Open flow cold plate for liquid cooled electronic packages

ActiveUS7916483B2Digital data processing detailsSemiconductor/solid-state device detailsCoolant flowDirect liquid cooling

A method and associated assembly is provided for cooling of a computing embodiment having electronic components. The heat generating components are disposed in the vicinity of at least one cold plate providing direct liquid cooling. Coolant is provided to the cold plate which will eventually exit it through one or more ports or orifices placed on the sides or both side and bottom of the cold plate. The placement, size and number of port(s) or orifice(s) can be selectively adjusted to control amount of coolant flow. Effluent flow from the cold plate flows over the remaining immersion cooled components and then exits the liquid tight enclosure which houses the electronic components.

Owner:LENOVO GLOBAL TECH INT LTD

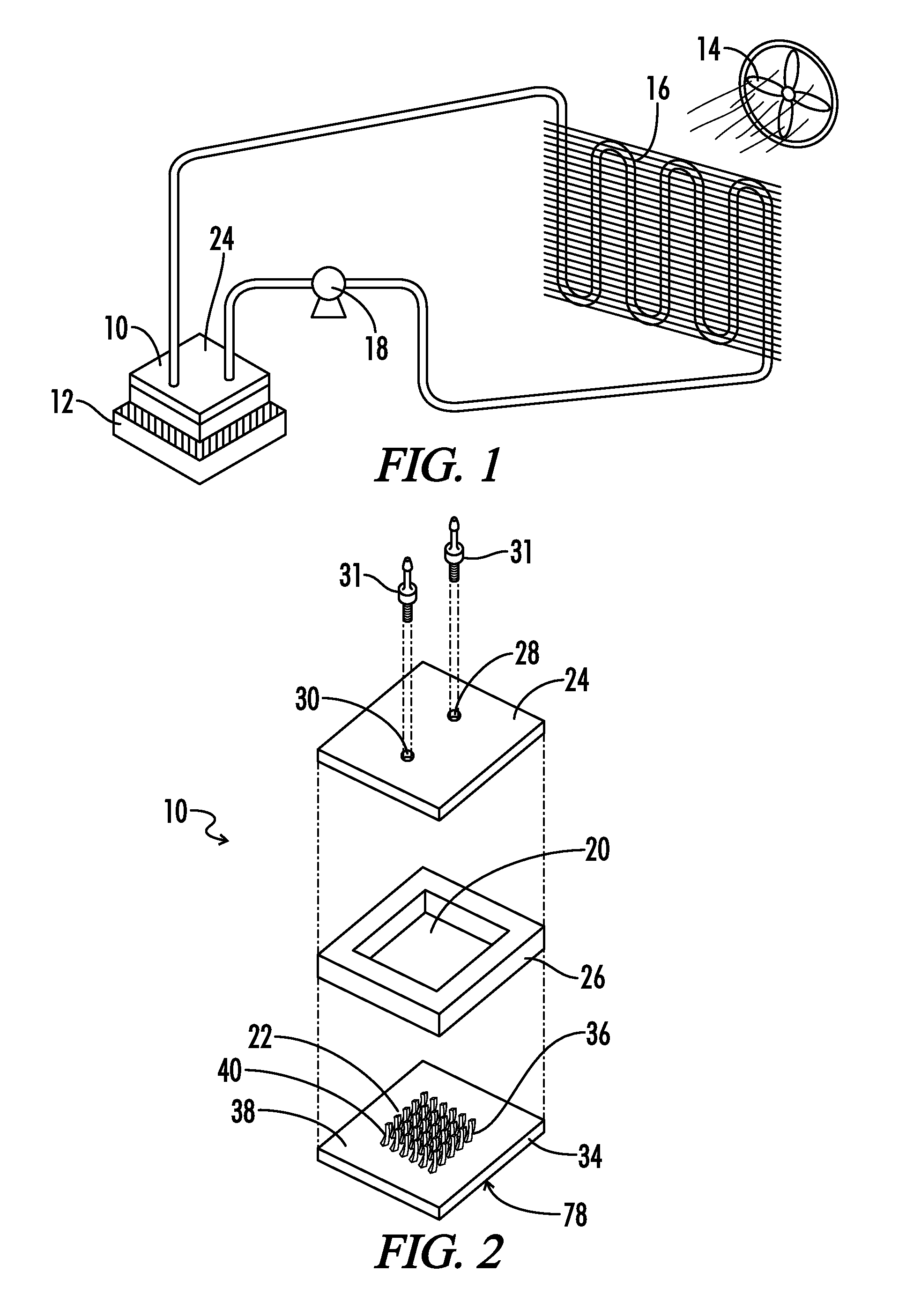

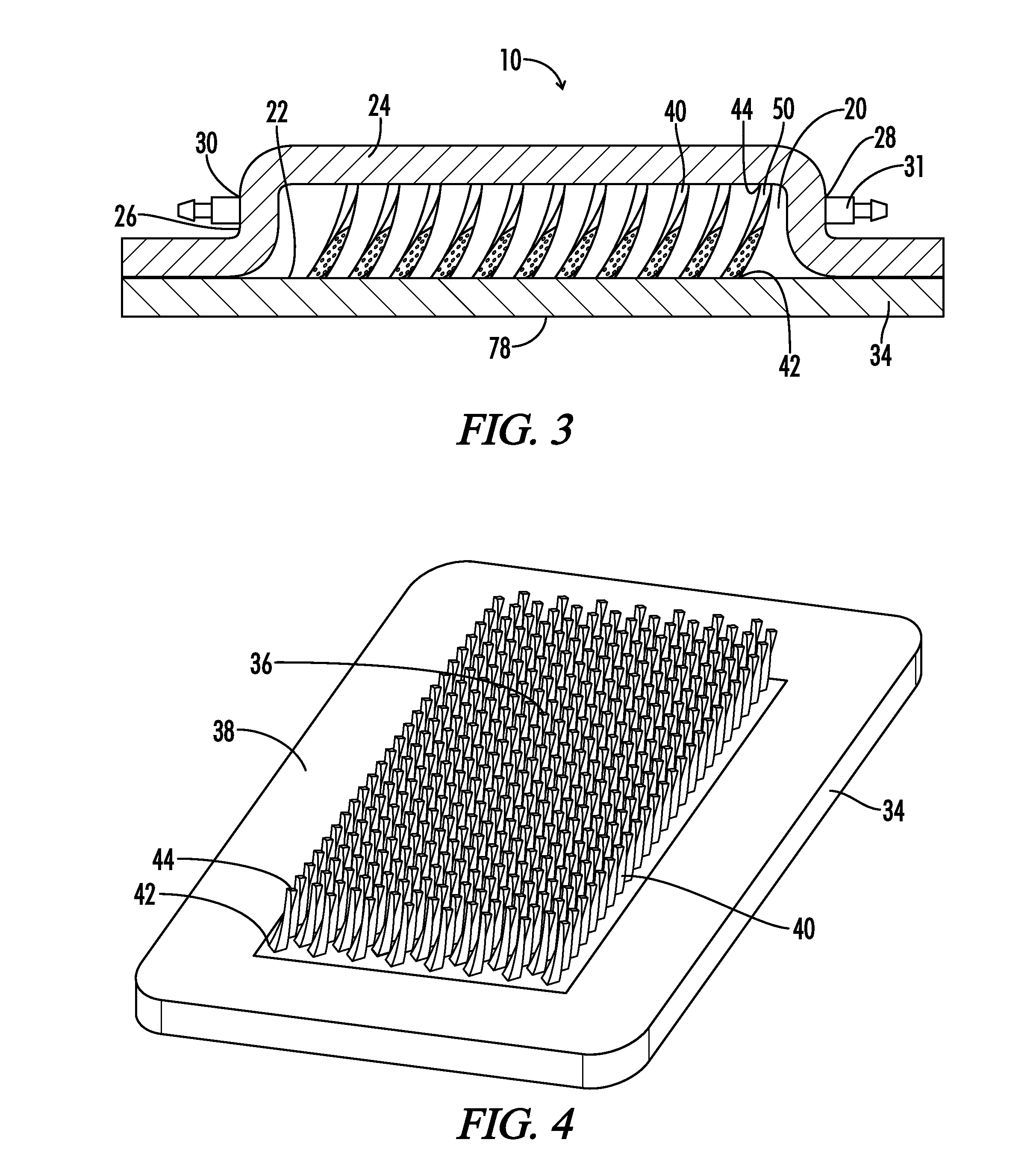

Cold plate with pins

InactiveUS20110079376A1Semiconductor/solid-state device detailsMetal-working apparatusEngineeringCold plate

A cold plate includes an enclosure with an inlet, an outlet, a base and a lid. The inlet and outlet are in fluid communication, so fluid can flow from the inlet though the enclosure to the outlet. The base is formed from a base plate, and the base plate includes an island facing into the enclosure. A plurality of pins extends from the island toward the lid. The pins can have a spiral shape, where the cross sectional profile of the pins change along the length of the pin.

Owner:WOLVERINE TUBE INC

Liquid cold plate heat exchanger

InactiveUS20060096738A1Net flow rateReduce the average velocitySemiconductor/solid-state device detailsSolid-state devicesHeat transmissionCooling chamber

A heat exchanger includes a cooling plate having a heat collection surface for fixing against an object to be cooled, an opposed heat transfer surface which may be provided with fins, and a cooling chamber over the heat transfer surface, the cooling chamber having an inlet port and an outlet port for circulating a fluid through the cooling chamber via a flow path between the ports. A flow distributor in the flow path forms a plurality of inlet channels communicating with the inlet port, a plurality of outlet channels alternating with the inlet channels and communicating with the outlet port, and a plurality of flow surfaces which are spaced from the heat transfer surface by gaps. The inlet channels communicate with the gaps so that a fluid entering the inlet channels via the inlet port will flow through the gaps, into the outlet channels, and out of the chamber via the outlet port. The gaps are dimensioned to increase fluid velocity and promote mixing of the fluid, thereby improving heat transfer.

Owner:AAVID THERMALLOY LLV

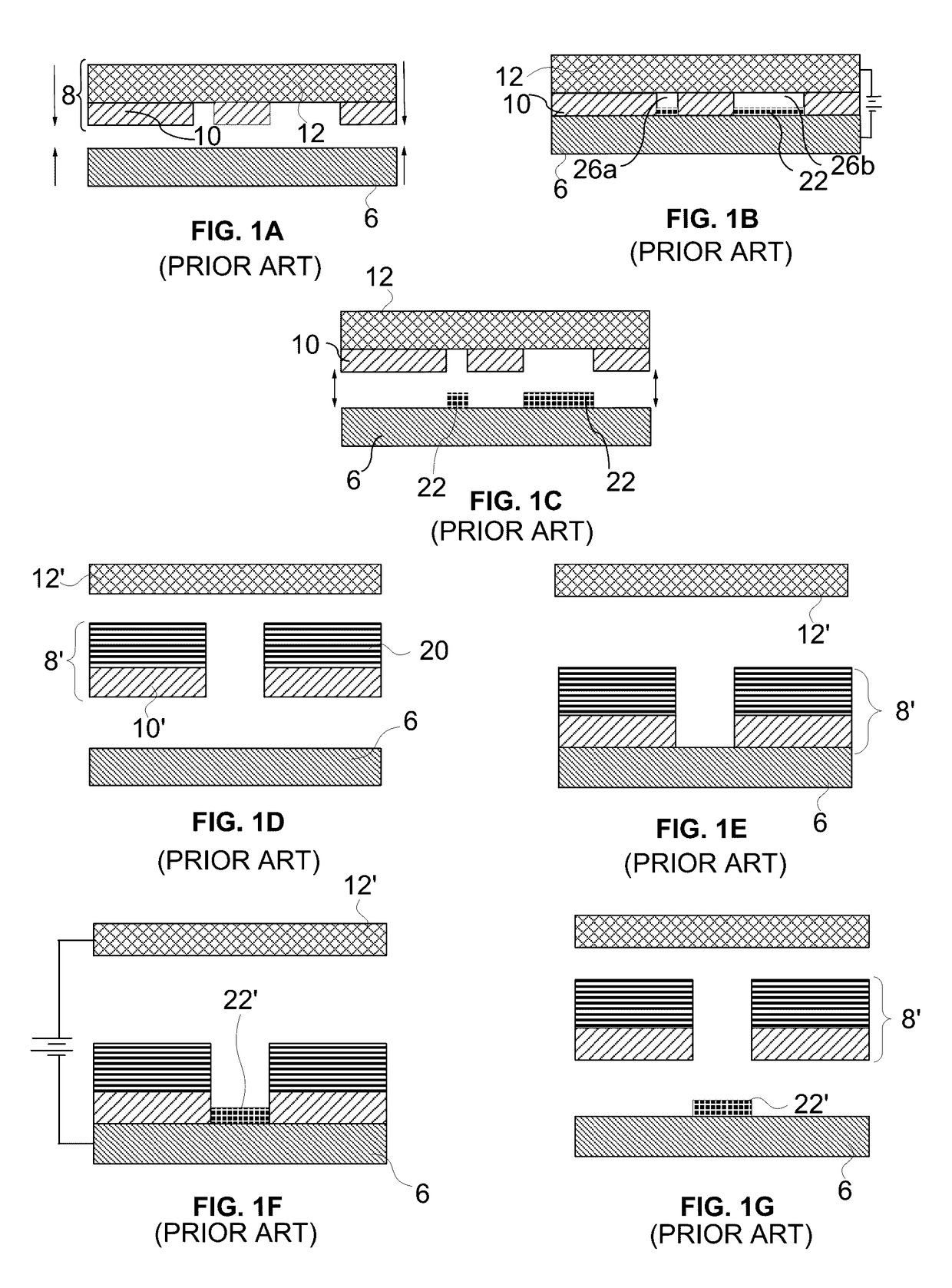

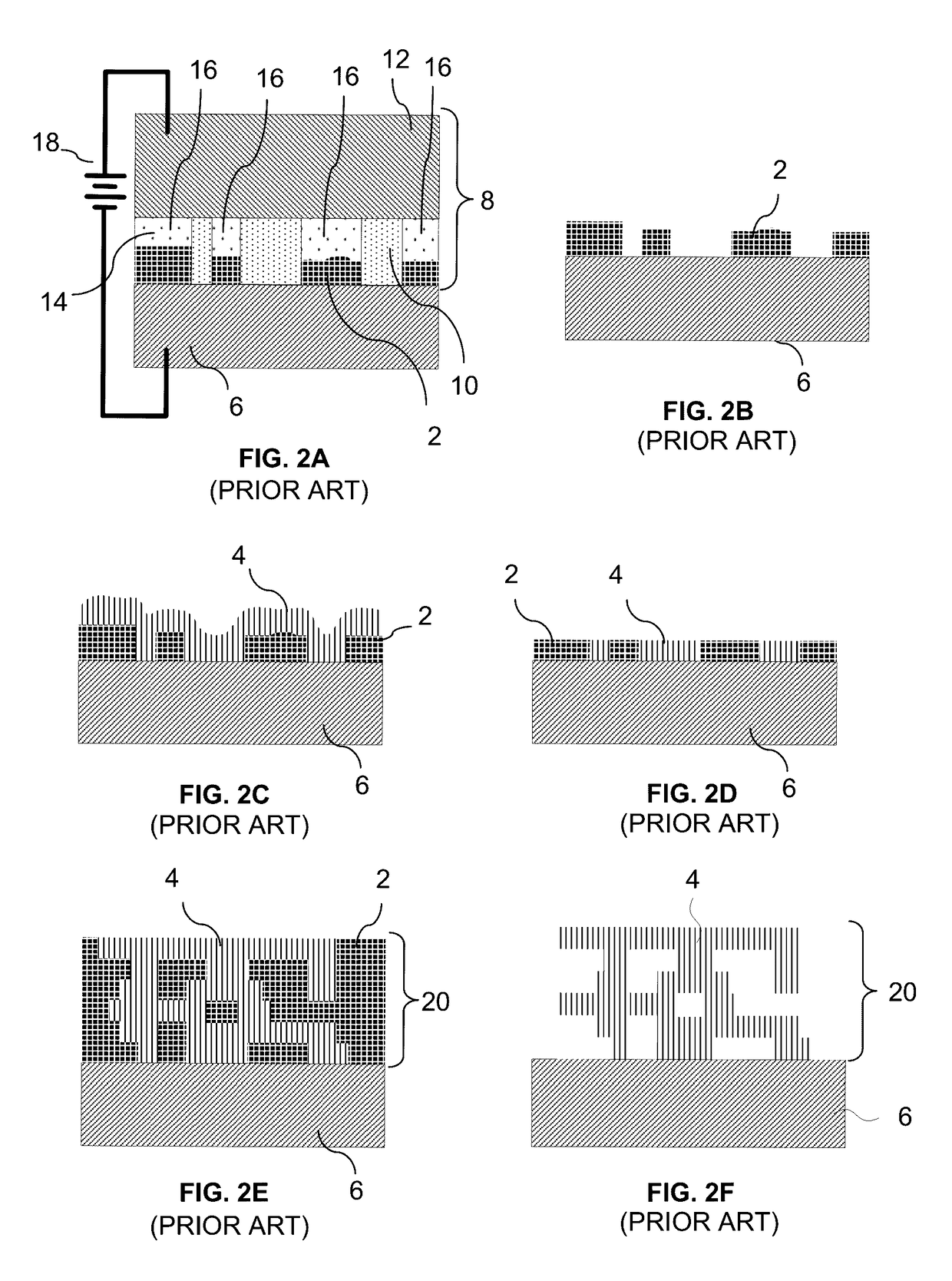

Thermal interposer for thermal management of semiconductor devices

InactiveUS20050280162A1Semiconductor/solid-state device detailsSolid-state devicesDevice materialInterposer

A thermal interposer is provided for attachment to the back surface of a semiconductor device so as to give a very low thermal resistance. In one preferred embodiment, the thermal interposer has two plates containing wick structures such as grooves. The thermal interposer is integrated with a semiconductor device so as to form a vapor chamber. In particular, the back surface of the semiconductor chip is in direct contact with the interior sealed volume of the vapor chamber, so as to greatly reduce the thermal resistance from the combination of the chip and the vapor chamber. Further, the upper plate is thermally coupled to a heat-sinking fixture such as a heat sink or a cold plate.

Owner:IBM CORP

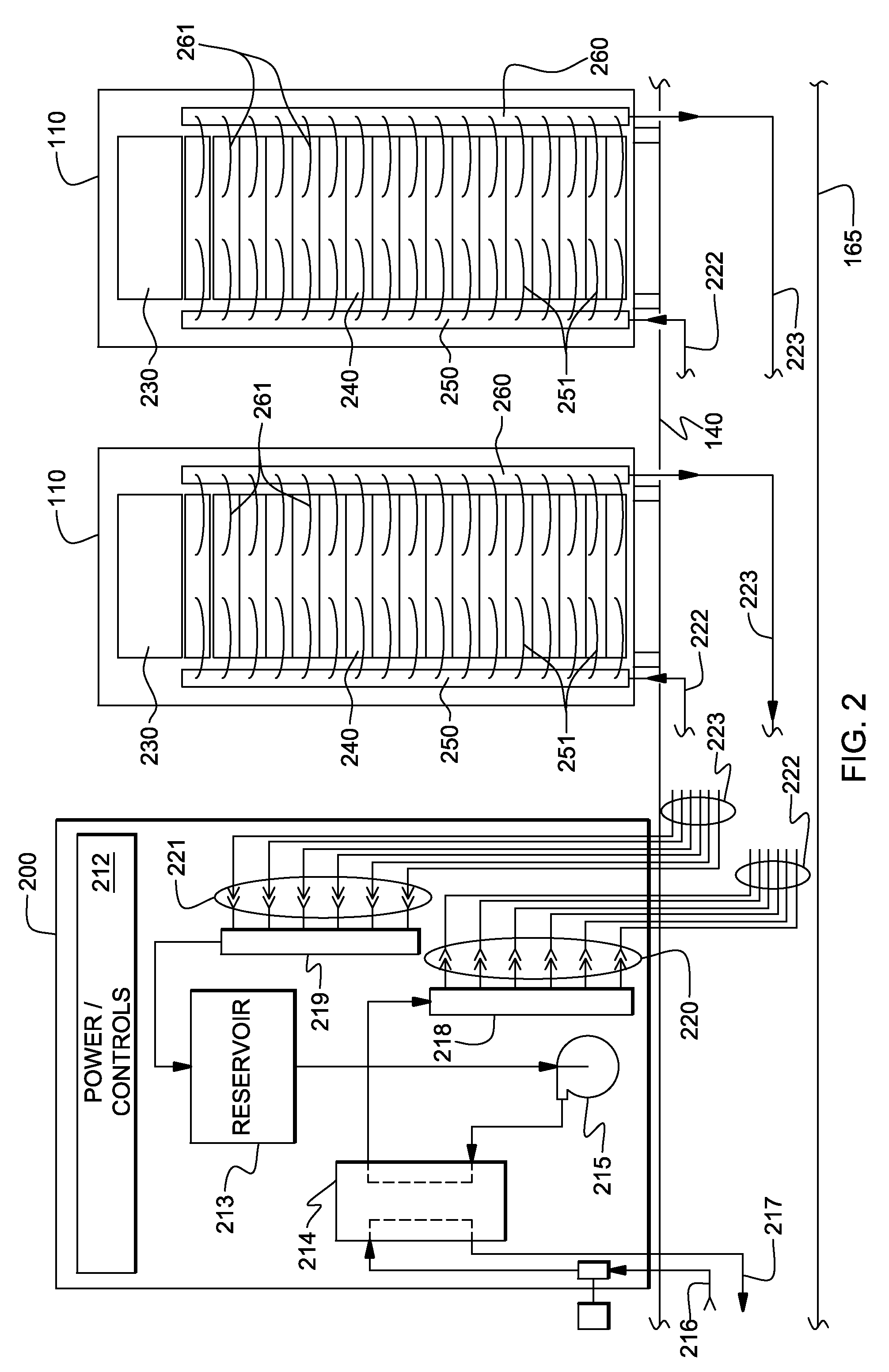

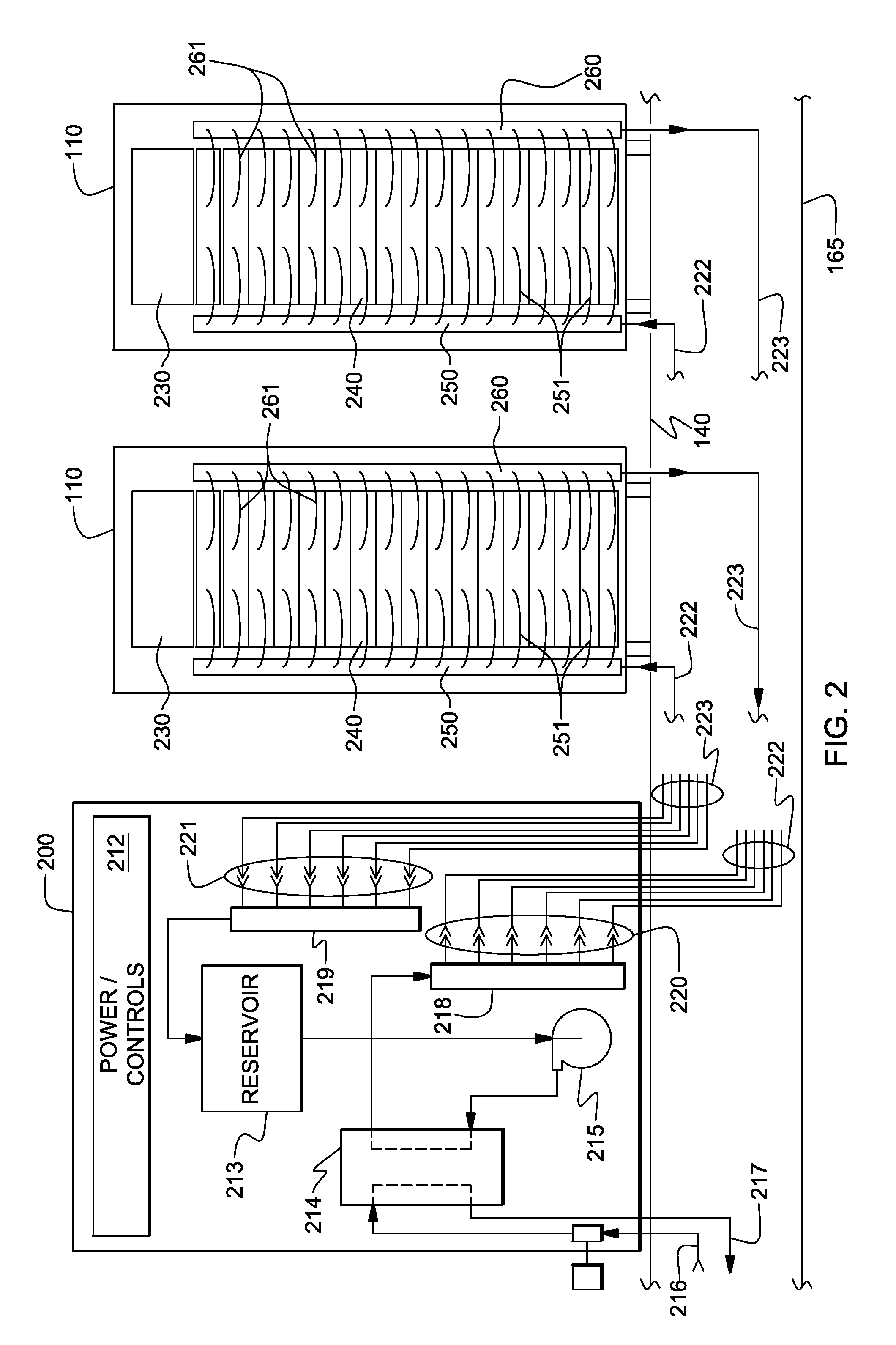

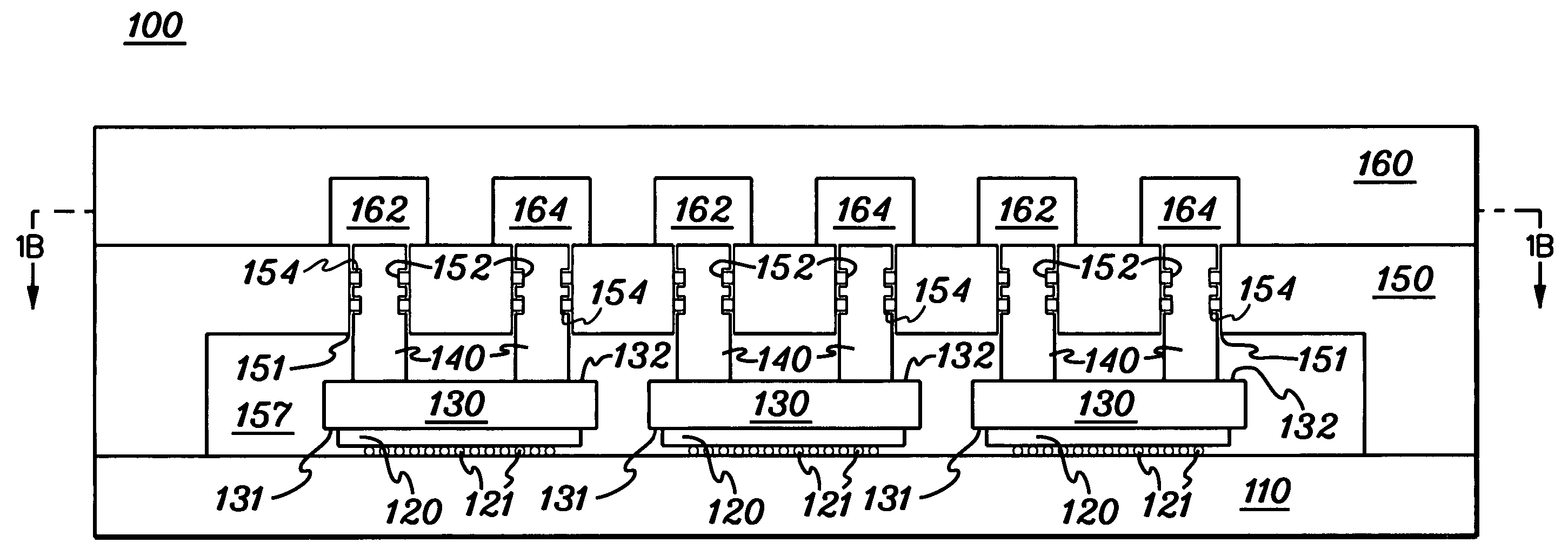

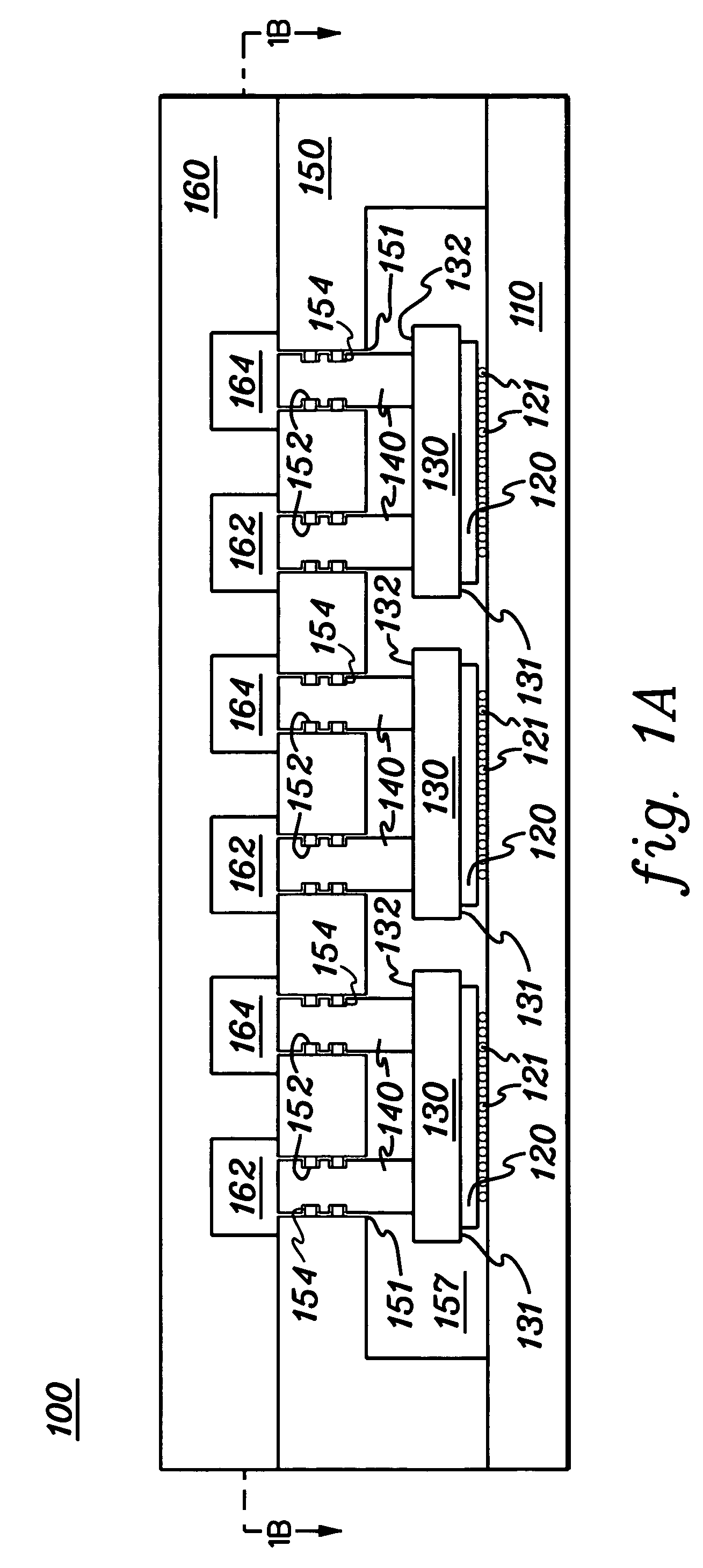

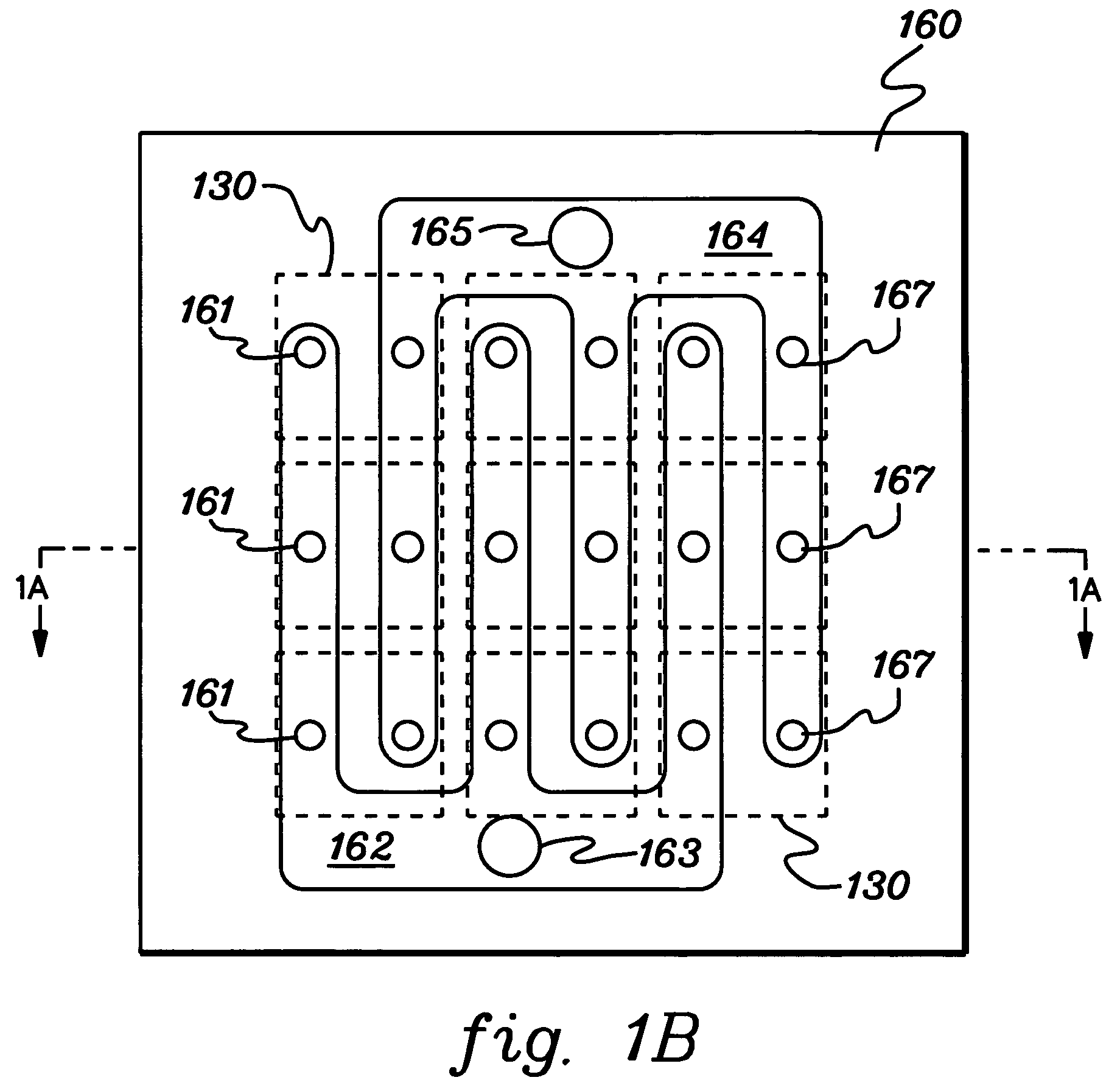

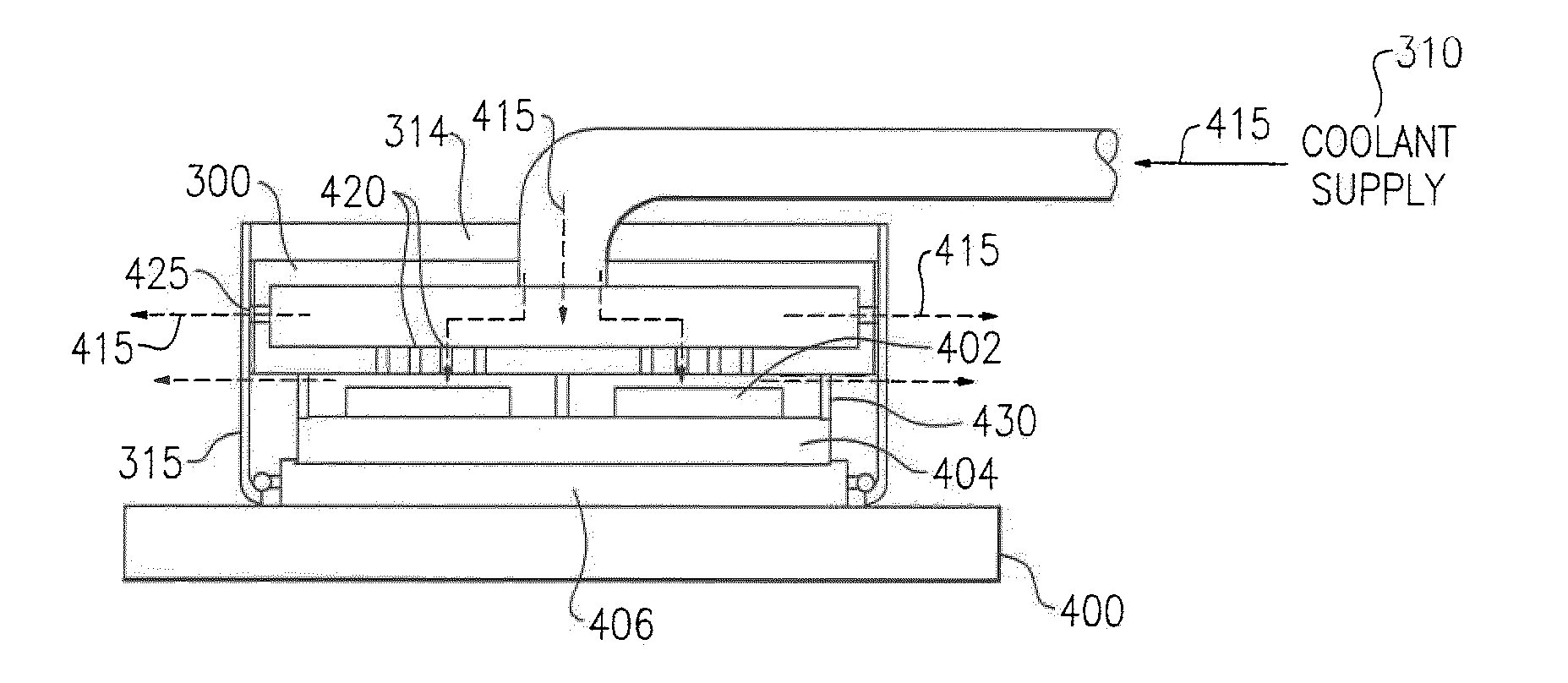

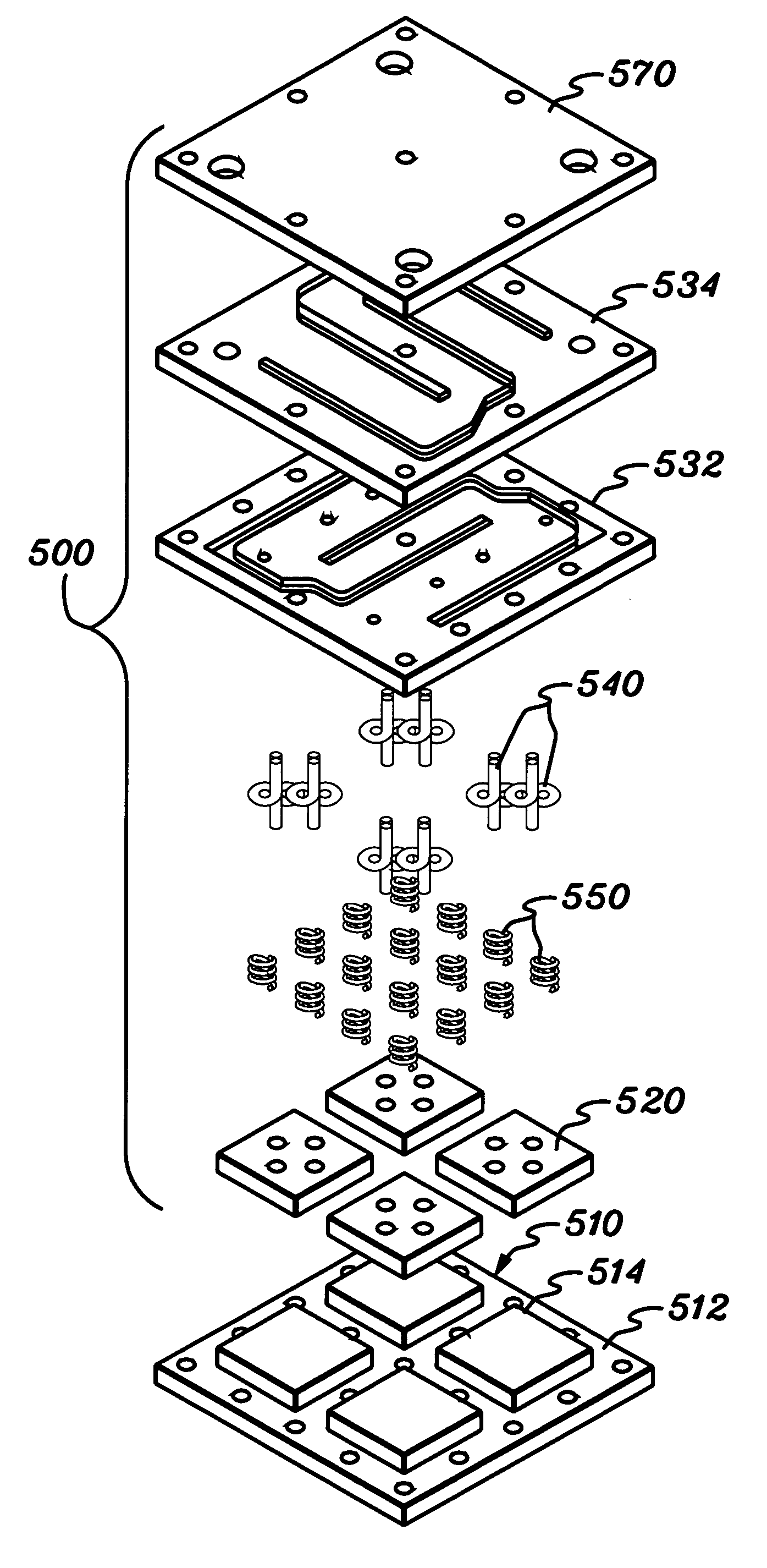

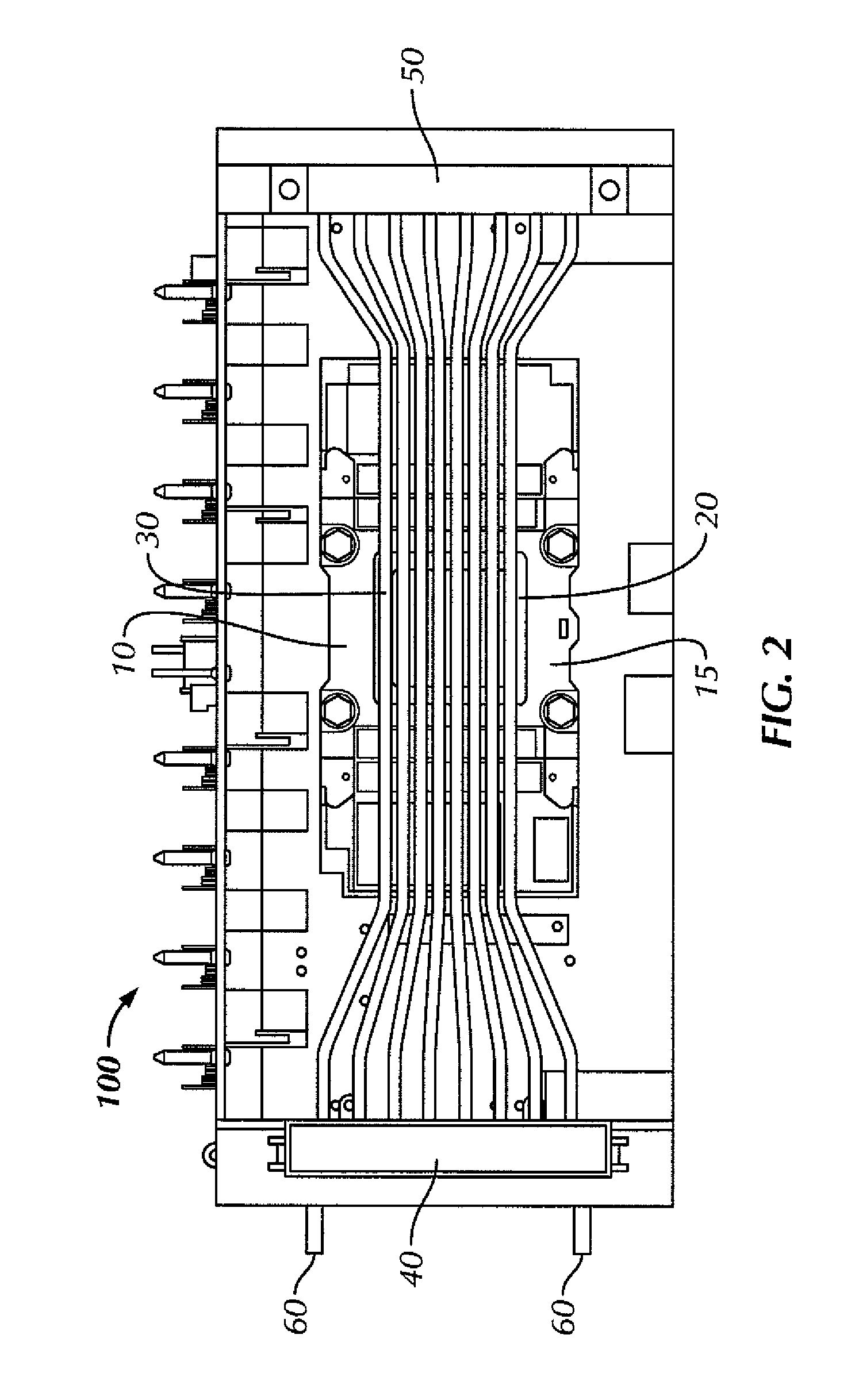

Cooling apparatuses and methods employing discrete cold plates compliantly coupled between a common manifold and electronics components of an assembly to be cooled

ActiveUS7298618B2Digital data processing detailsSemiconductor/solid-state device detailsEngineeringElectronic component

Cooling apparatuses and methods are provided for cooling an assembly including a planar support structure supporting multiple electronics components. The cooling apparatus includes: multiple discrete cold plates, each having a coolant inlet, coolant outlet and at least one coolant carrying channel disposed therebetween; and a manifold for distributing coolant to and exhausting coolant from the cold plates. The cooling apparatus also includes multiple flexible hoses connecting the coolant inlets of the cold plates to the manifold, as well as the coolant outlets to the manifold, with each hose segment being disposed between a respective cold plate and the manifold. A biasing mechanism biases the cold plates away from the manifold and towards the electronics components, and at least one fastener secures the manifold to the support structure, compressing the biasing mechanism, and thereby forcing the parallel coupled cold plates towards their respective electronics components to ensure good thermal interface.

Owner:LENOVO GLOBAL TECH INT LTD

Cryogenic refrigeration unit suited for delivery vehicles

InactiveUS20020129613A1Reduce the temperatureNot contaminate atmosphereAir-treating devicesRefrigerated goods vehicleAir cycleDelivery vehicle

An apparatus to refrigerate the cargo space of delivery vehicles. It provides an environmentally friendly alternative to conventional mechanical a / c and refrigeration units. Cooling is provided by controlled evaporation of a liquefied gas such as CO.sub.2 or nitrogen. Defrost and heating requirements, if needed, are provided by hot engine coolant or by electric heaters powered from the vehicle electrical system. Airflow for the evaporator and for circulation in the temperature controlled space is provided by a blower which is mechanically or electrically driven from vehicle power. This invention can also be applied to multi-temperature control applications. The apparatus is compact and is particularly suited for small inner city delivery vehicles. FIG. 1: The sketch shows an inner city delivery truck for which this invention is most suitable. Refrigerated goods are placed in roller cages that are designed to maximize cargo hauled by use of roller cages that extend to within 2 inches of the ceiling. The evaporator section of this invention is mounted at or near the front wall of the truck and is separated from the cargo by a vertical bulkhead. The conditioned air is delivered at the bottom of the truck to avoid top freeze of perishable cargo that is in close proximity to the ceiling. FIG. 2: This shows the piping schematic and is similar to the invention described in U.S. Application Serial No. 60 / 238,929 (the '929 application) incorporated herein by reference. FIG. 2 shows the engine coolant coil located ahead of the CO.sub.2 coil in the direction of airflow. This prevents the coldest air from coming in contact with the engine coolant--in the cooling mode the air leaving the CO.sub.2 coil can be as low as -50.degree. F. for frozen load applications and this may cause the engine coolant to start freezing. Arrangements must be made to circulate air between the two coils in defrost mode. One means to accomplish this is to place a damper at the outlet of the evaporator section and run the fans. The damper would be closed during defrost. Another method is to place the engine coolant coil on the discharge side of the CO.sub.2 coil and use a cut-out switch if the engine coolant temperature drops below a predetermined value. In this arrangement there is no need for the damper arrangement as the heat will rise to melt any frost on the CO.sub.2 coil. If electric heat is used for defrost and heating freezing of the engine coolant is not a concern and the heaters can be fastened to the discharge side of the CO.sub.2 coil. An electric stand-by mode can be provided to power the system for cooling, heating and defrost when the vehicle is parked with the engine off. A plug-in electrical cable can provide the power needed for the controls, the fans and for heating and defrost. The figure shows the electric heaters attached on the discharge side of the CO.sub.2 coil. Operation: Detailed description is in the '929 application except for the following: The evaporator section is designed for vertical installation to maximize cargo space. Air is discharged at the bottom but may be a conventional top discharge if needed for specific applications. Conventional methods can be used to provide defrost and heating. If engine coolant is used for a heat source, it is preferable to thermally isolate the CO.sub.2 coil from the engine coolant coil to avoid freezing the coolant. The evaporator blower may be located on the inlet side of the coils rather than as shown in the figures. Unique Features: 1. Absence of a conventional condensing section on the exterior of the vehicle makes this an ideal refrigeration unit for small inner city delivery vehicles. Many of the truck cabs are now almost full height (same as the truck body) and there is limited space for the condensing section. 2. Cold plates can be used and still maximize cargo cube. However, this invention has 30-40% less weight than comparable "cold plate" systems. 3. Other features are described in the '929 application.]

Owner:THERMO KING CORP

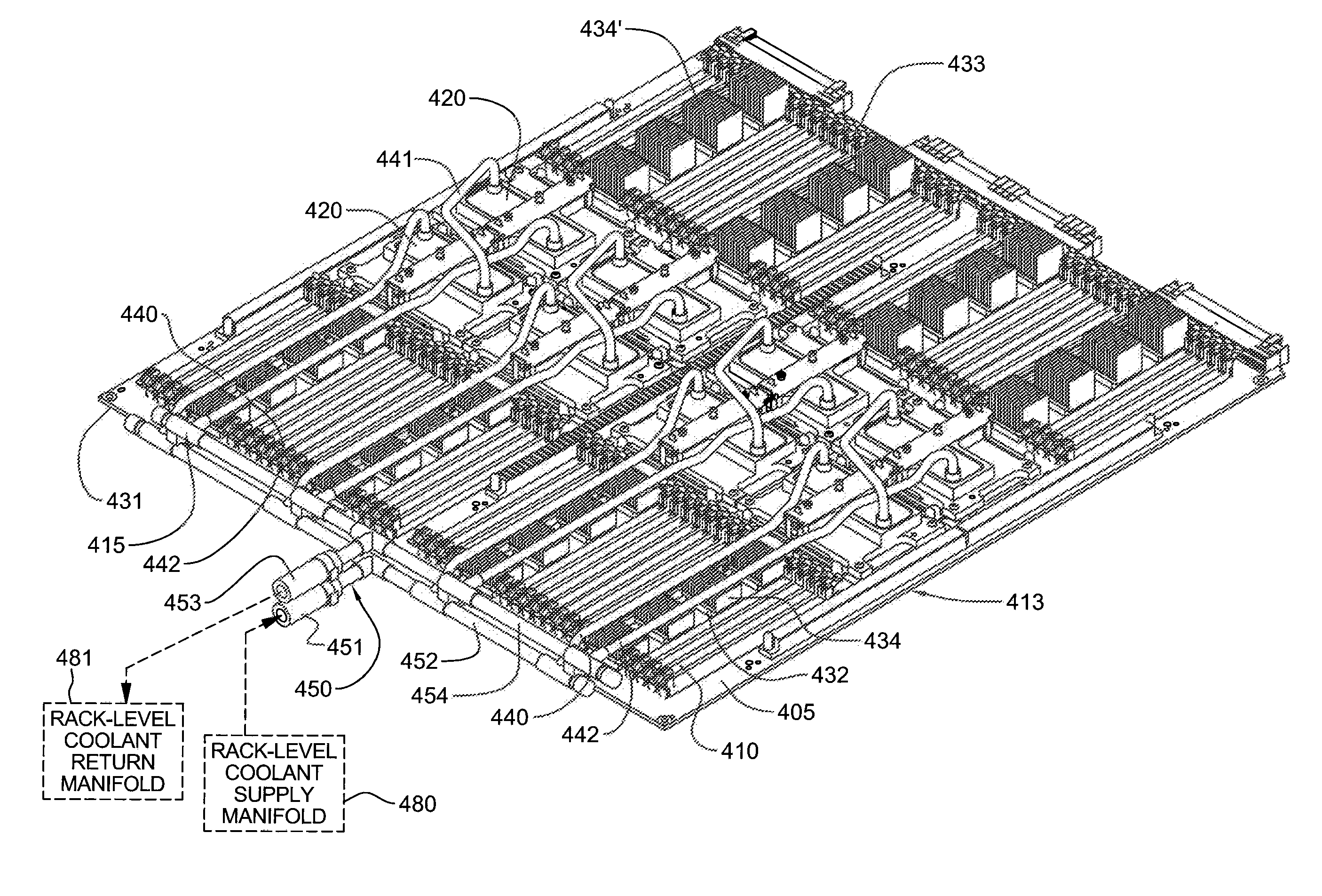

Method of assembling a cooling system for a multi-component electronics system

InactiveUS7641101B2Easy to transportEasy to assembleHeat exchange apparatusModifications using gaseous coolantsElectronic systemsEngineering

A cooling system assembly method including: providing a support fixture having a multi-level support surface and multiple positioning dowels extending therefrom; positioning multiple liquid-cooled cold plates on the support surface employing the multiple dowels, the dowels providing relative positioning and alignment of the cold plates for facilitating subsequent coupling thereof to electronic components to be cooled; sealing multiple coolant-carrying tubes in fluid communication with the cold plates; and sealing a header subassembly to the coolant-carrying tubes to provide an assembled liquid-based cooling system. In operation, the support fixture facilitates shipping of the assembled cooling system by maintaining the components in fixed relation. A transfer fixture is employed in removing the cooling system from the support fixture and placing the cooling system in engagement with the electronics system. The transfer fixture includes multiple clips engaging and holding components of cooling system in fixed relation when removed from the support fixture.

Owner:IBM CORP

Parallel cooling of heat source mounted on a heat sink by means of liquid coolant

InactiveUS6992888B1Semiconductor/solid-state device detailsSolid-state devicesBoiling pointEngineering

A module includes a cold plate. Solid-state heat sources are thermally mounted on the cold plate in a chamber defined by the cold plate and a lid. Cooling of the heat sources is enhanced by a dielectric liquid within the chamber. The liquid has a boiling point slightly below the temperatures of “hot” spots, to form small bubbles during operation, which enhance convection flow. The liquid may be a mixture of fluorocarbons of different boiling points. The liquid may contain diamond particles.

Owner:LOCKHEED MARTIN CORP

Liquid cooling loops for server applications

A mounting system provides mechanisms and form factors for bringing a heat exchanger from a server rack into thermal contact with a heat exchanger from a electronics server. To ensure good thermal contact, pressure is applied between the two heat exchangers, the rejector plate and the chassis cold plate. The mounting mechanism used to engage and disengage the heat exchangers is configured to isolate the force applied to the two heat exchangers. The mounting mechanism includes an interlocking mechanism that prevents transfer of the applied force to the rest of the electronics server. Without isolating this force, the force is applied to the electronics server and / or the rack chassis, possibly disconnecting the electrical connections between the electronics server and the rack, as well as providing mechanical stress to the electronics server and the rack chassis. The mounting mechanism is also coupled to the electronics server locking mechanism such that the action of locking the electronics server into the rack causes the heat exchangers to engage in thermal contact. This is a fail safe procedure since no separate process is required to engage the electronics server cooling loop.

Owner:LIEBERT

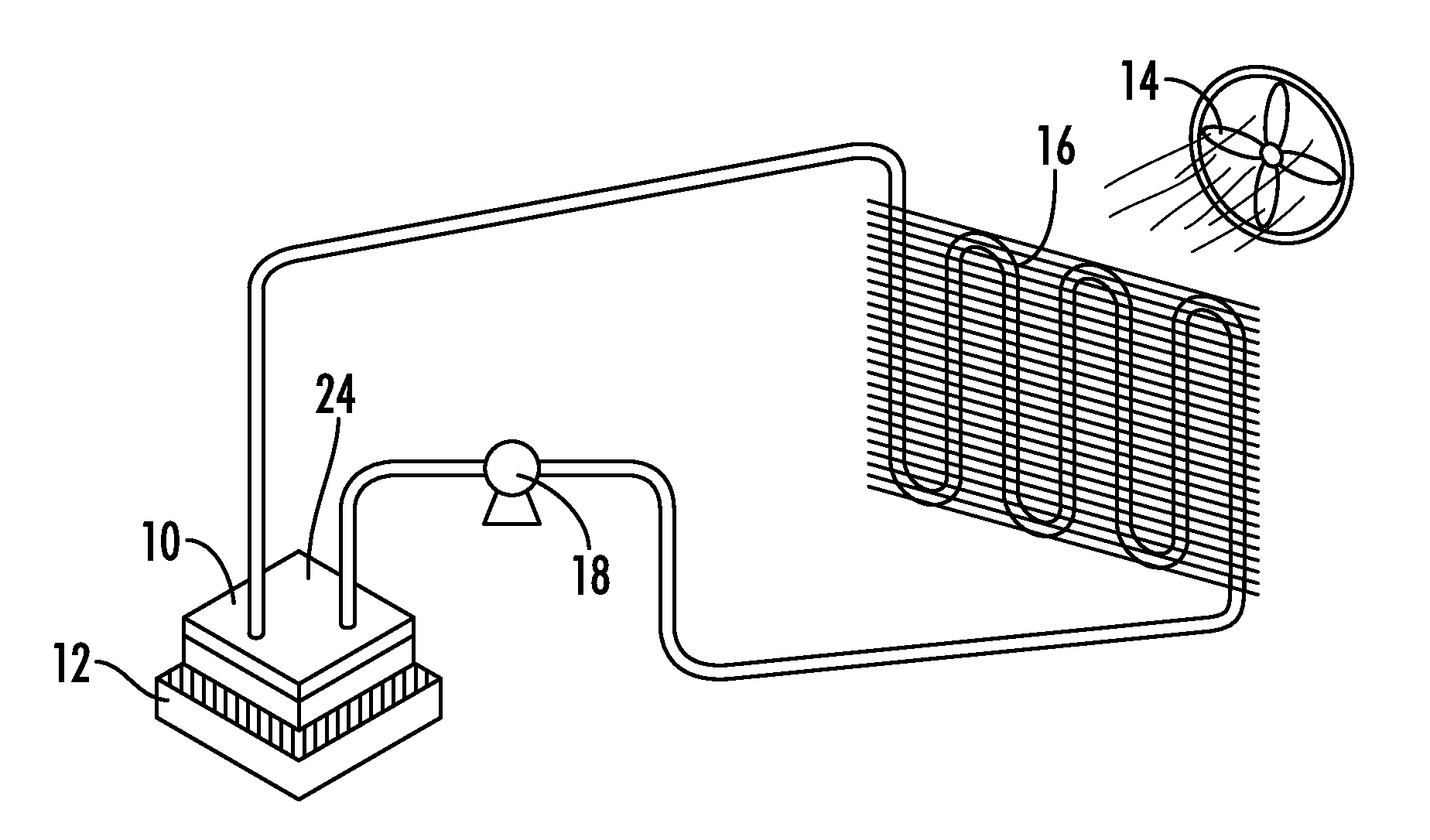

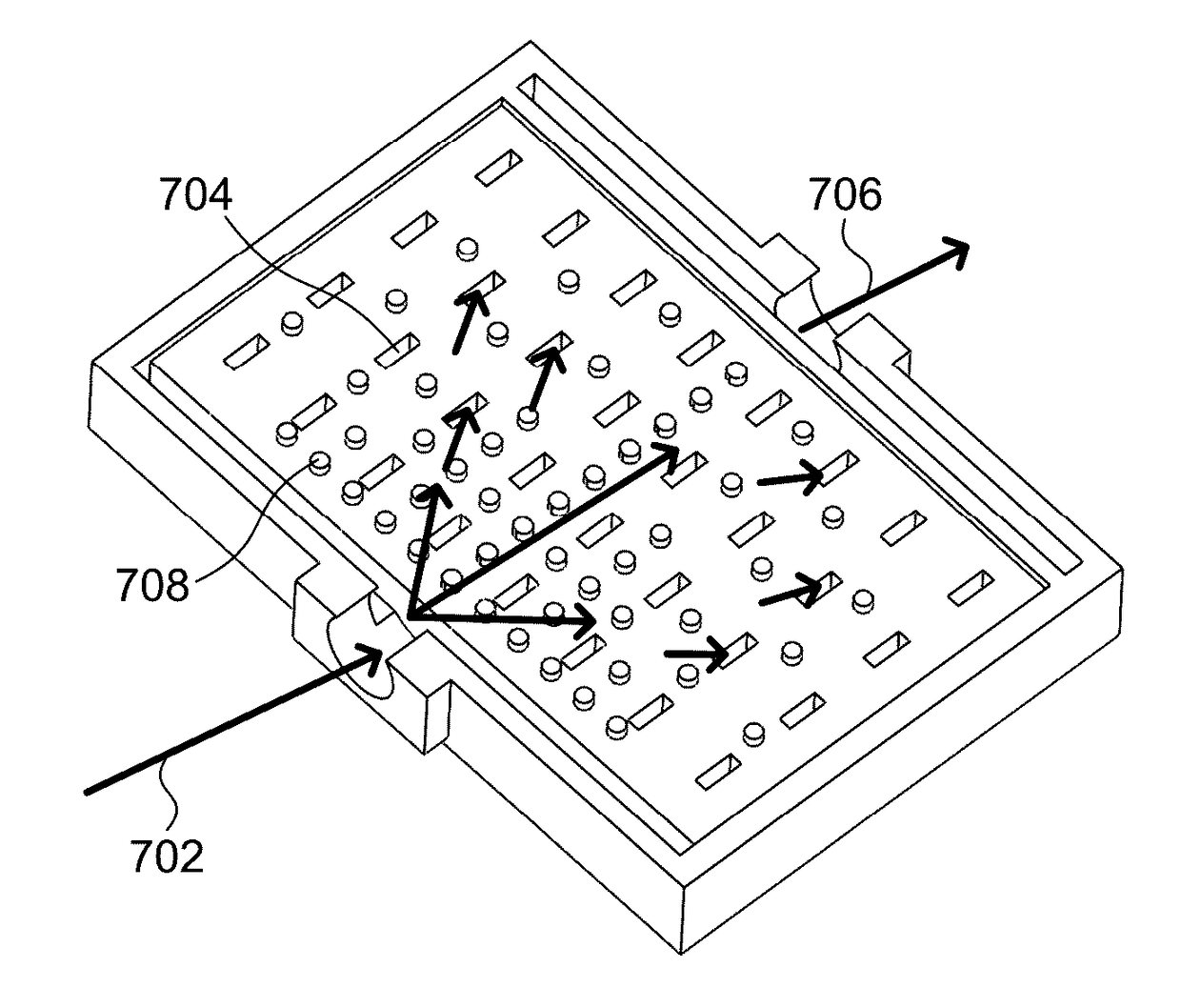

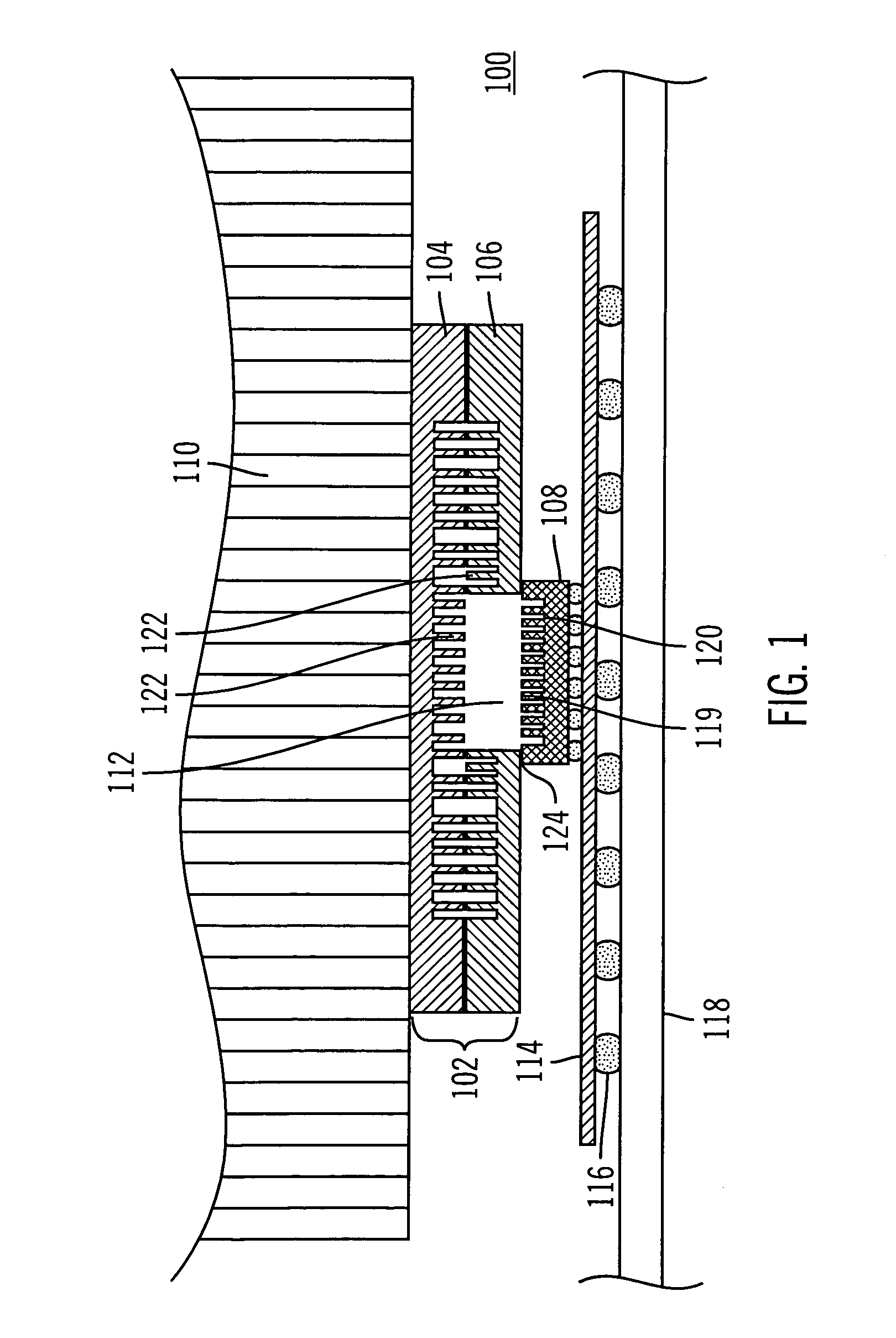

Micro Heat Transfer Arrays, Micro Cold Plates, and Thermal Management Systems for Cooling Semiconductor Devices, and Methods for Using and Making Such Arrays, Plates, and Systems

ActiveUS20170092565A1Large specific surface areaSemiconductor/solid-state device detailsSolid-state devicesSpray nozzleEngineering

Embodiments of the present invention are directed to heat transfer arrays, cold plates including heat transfer arrays along with inlets and outlets, and thermal management systems including cold-plates, pumps and heat exchangers. These devices and systems may be used to provide cooling of semiconductor devices and particularly such devices that produce high heat concentrations. The heat transfer arrays may include microjets, microchannels, fins, and even integrated microjets and fins.

Owner:MICROFAB

Thermal interposer for thermal management of semiconductor devices

InactiveUS7002247B2Semiconductor/solid-state device detailsSolid-state devicesSemiconductor chipInterposer

Owner:IBM CORP

Thermal transfer technique using heat pipes with integral rack rails

ActiveUS7626820B1Indirect heat exchangersCooling/ventilation/heating modificationsWorking fluidEngineering

A thermal transfer apparatus for cooling a heat-producing electronic component includes an evaporator disposed over the heat-producing electronic component and thermally coupled to the heat-producing electronic component, a plurality of heat pipes carrying a working fluid therein disposed over the evaporator and thermally coupled to the evaporator, a cold plate thermally coupled to a first end of the plurality of heat pipes, and a condenser thermally coupled to a second end of the plurality of heat pipes. The heat pipes extend over the evaporator such that the first end and the second end of the heat pipes couple to the cold plate and condenser at a location not over the heat-producing electronic component. The cold plate and the condenser are supplied with a coolant from outside the thermal transfer apparatus.

Owner:ORACLE INT CORP

Thermal transfer technique using heat pipes with integral rack rails

A thermal transfer apparatus for cooling a heat-producing electronic component includes an evaporator disposed over the heat-producing electronic component and thermally coupled to the heat-producing electronic component, a plurality of heat pipes carrying a working fluid therein disposed over the evaporator and thermally coupled to the evaporator, a cold plate thermally coupled to a first end of the plurality of heat pipes, and a condenser thermally coupled to a second end of the plurality of heat pipes. The heat pipes extend over the evaporator such that the first end and the second end of the heat pipes couple to the cold plate and condenser at a location not over the heat-producing electronic component. The cold plate and the condenser are supplied with a coolant from outside the thermal transfer apparatus.

Owner:ORACLE INT CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com