Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3541 results about "Heat transmission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

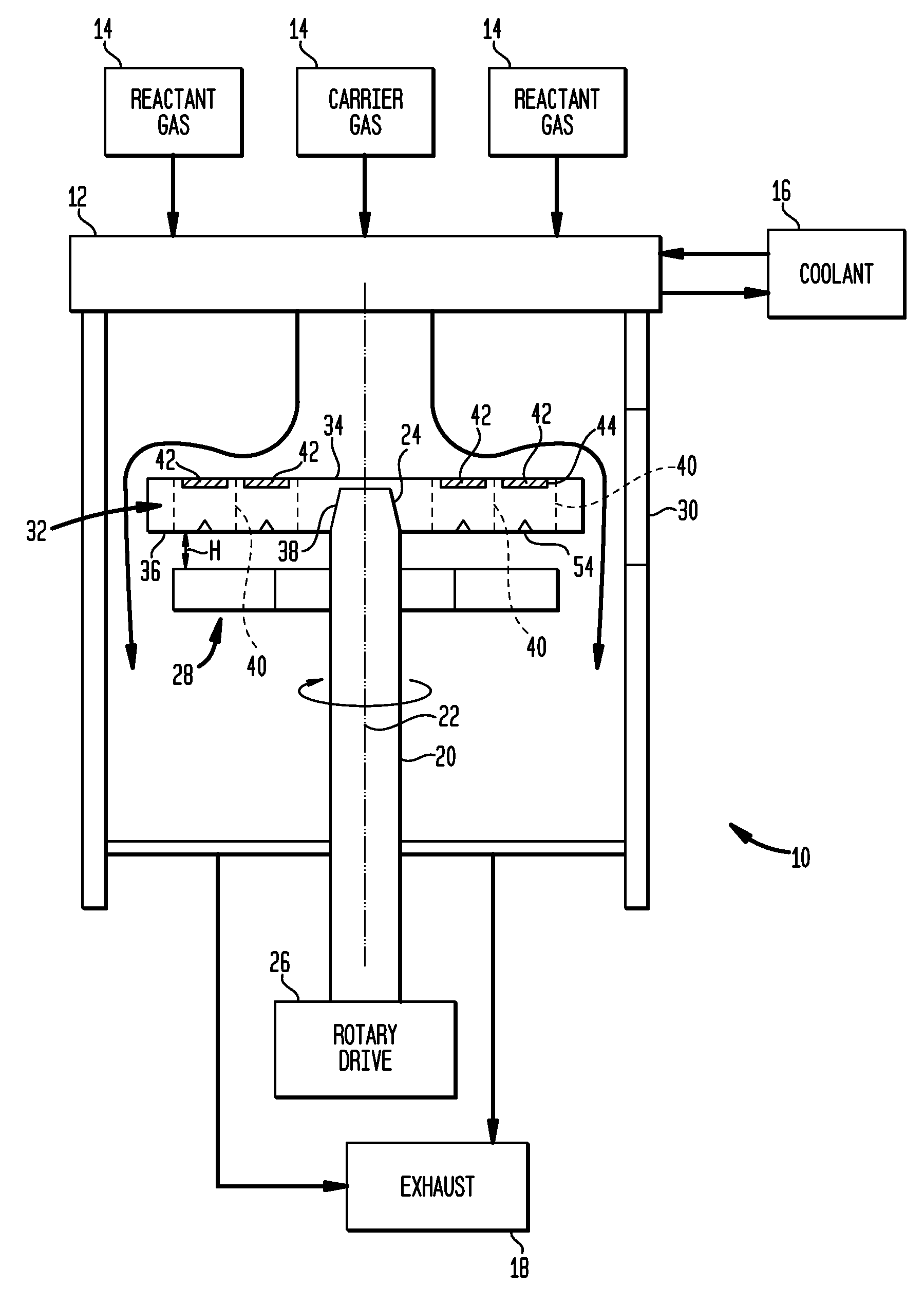

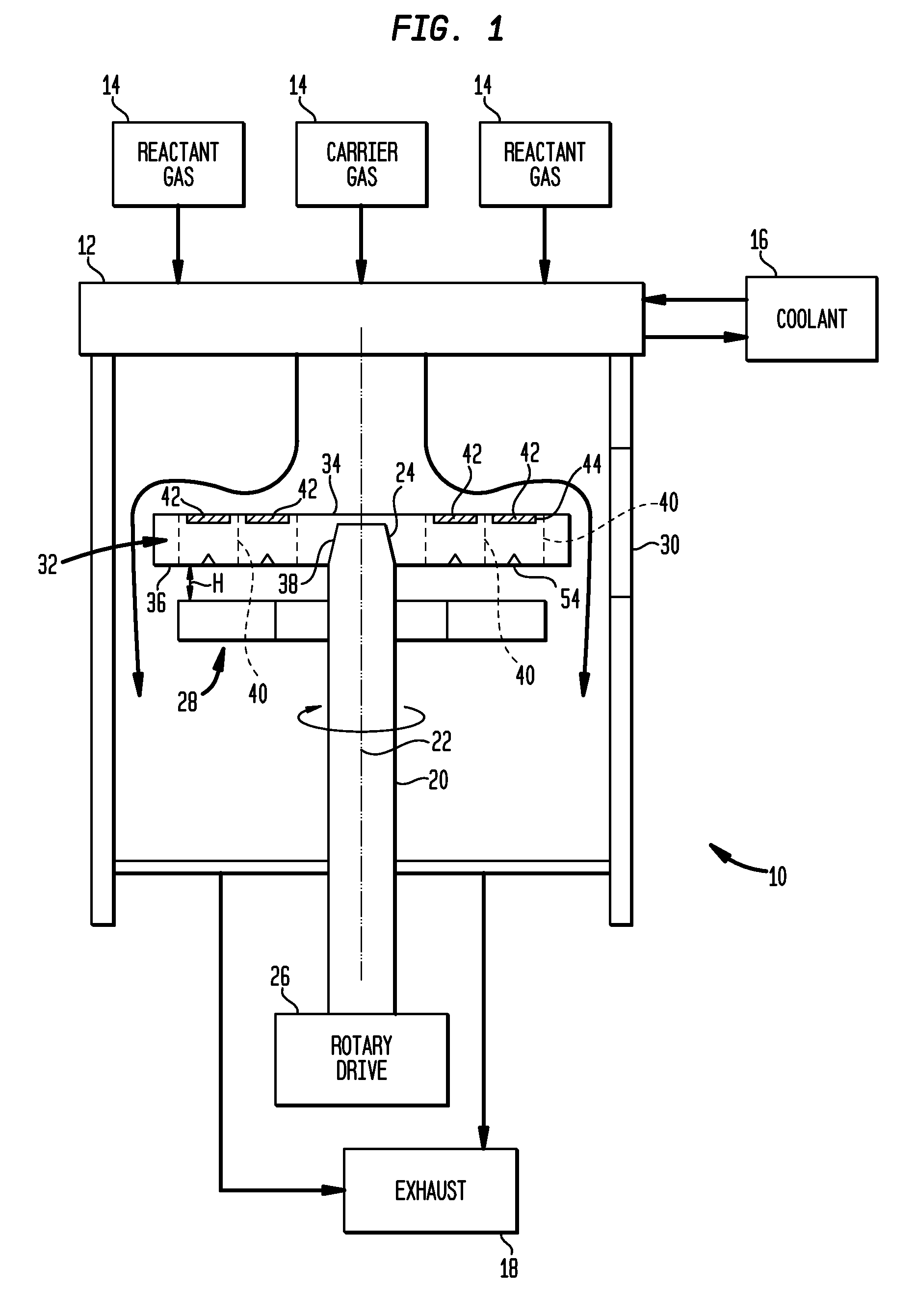

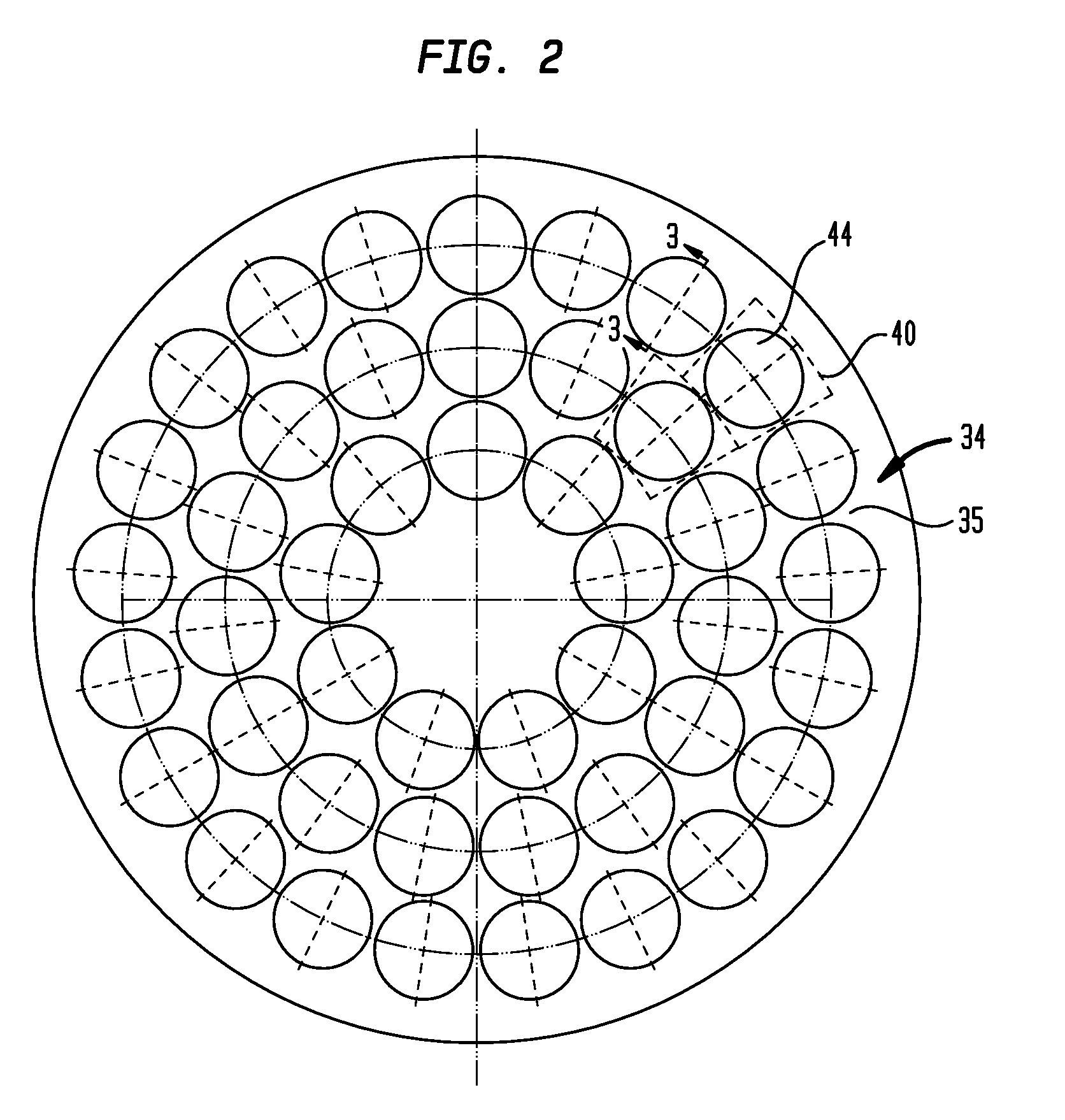

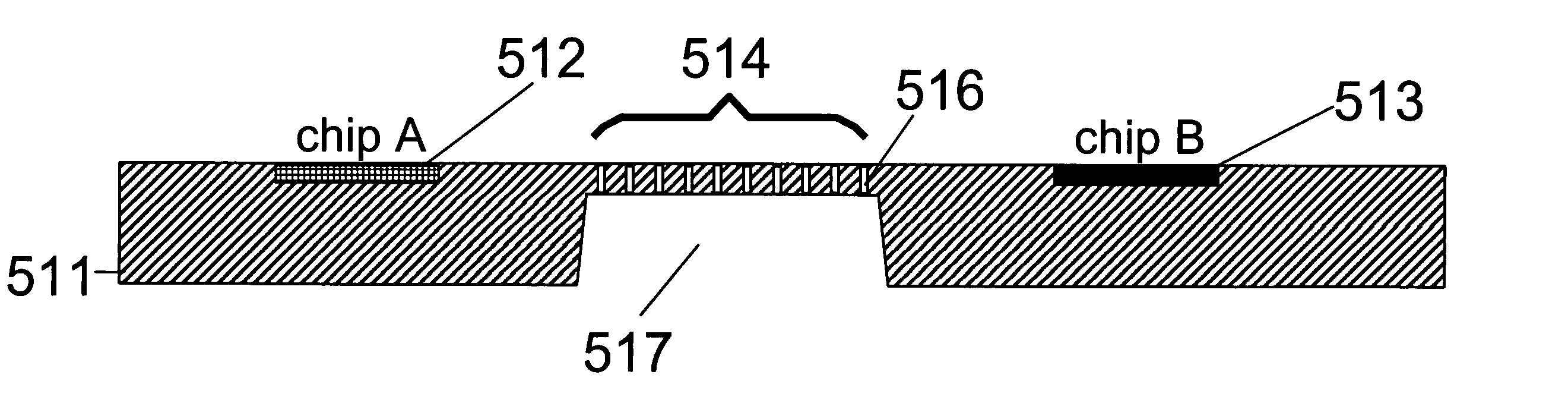

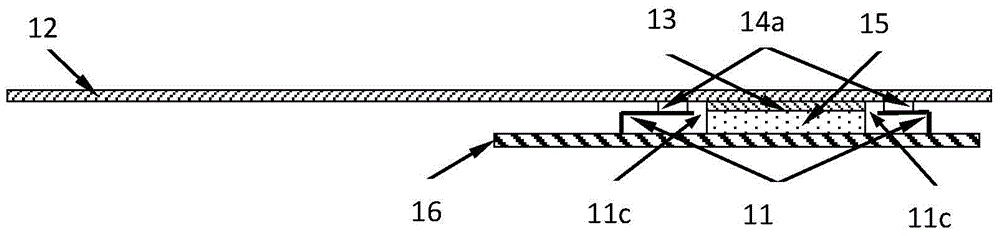

Wafer carrier with varying thermal resistance

InactiveUS20100055318A1Minimize contactImprove temperature uniformityLiquid surface applicatorsSemiconductor/solid-state device manufacturingEngineeringRadiant heat transfer

In chemical vapor deposition apparatus, a water carrier (32) has a top surface (34) holding the wafers and a bottom surface (36) heated by radiant heat transfer from a heating element (28). The bottom surface (36) of the wafer carrier is non-planar due to features such as depressions (54) so that the wafer carrier has different thickness at different locations. The thicker portions of the wafer carrier have higher thermal resistance. Differences in thermal resistance at different locations counteract undesired non-uniformities in heat transfer to the wafer. The wafer carrier may have pockets with projections (553, 853) for engaging spaced-apart locations on the edges of the wafer.

Owner:VEECO INSTR

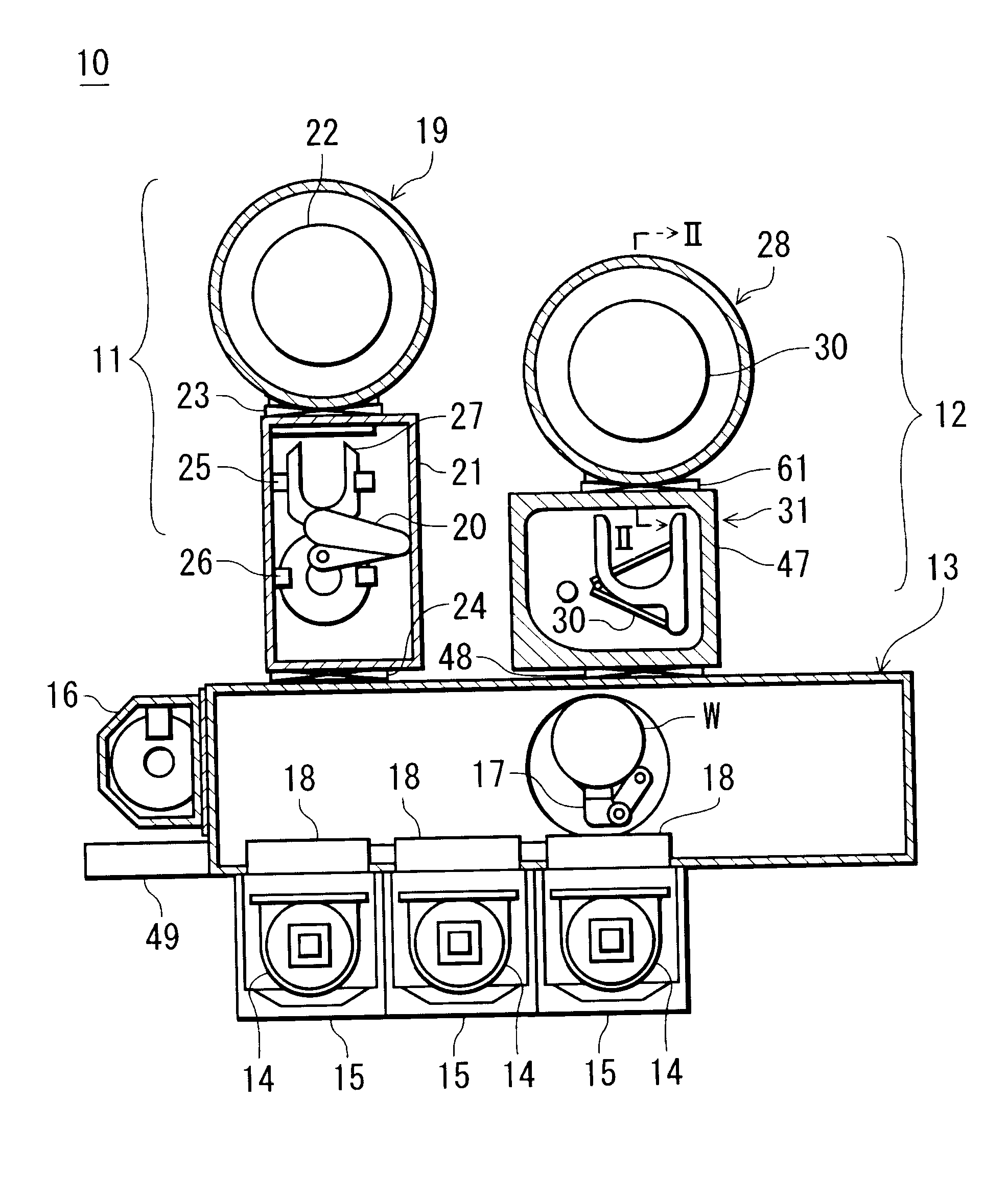

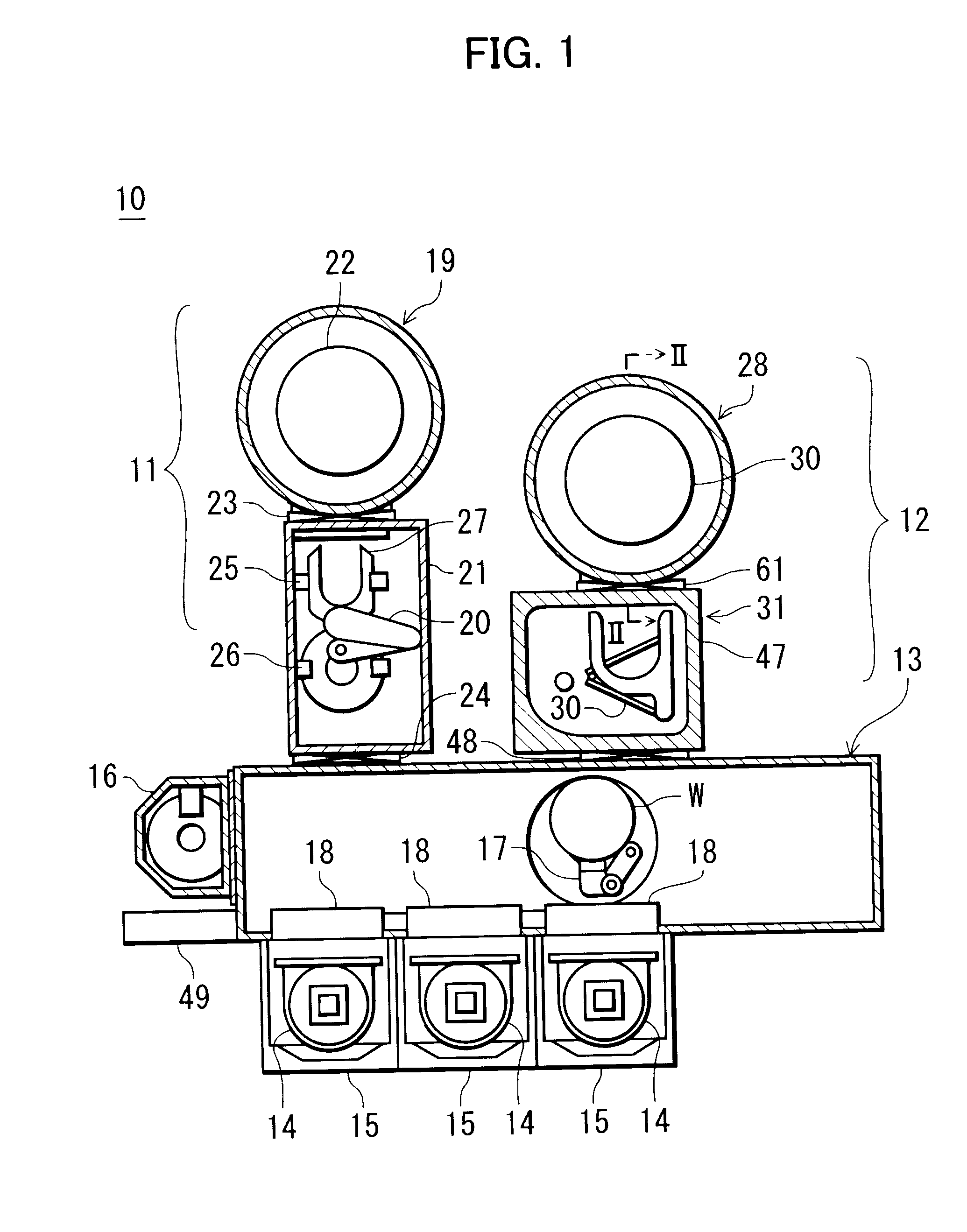

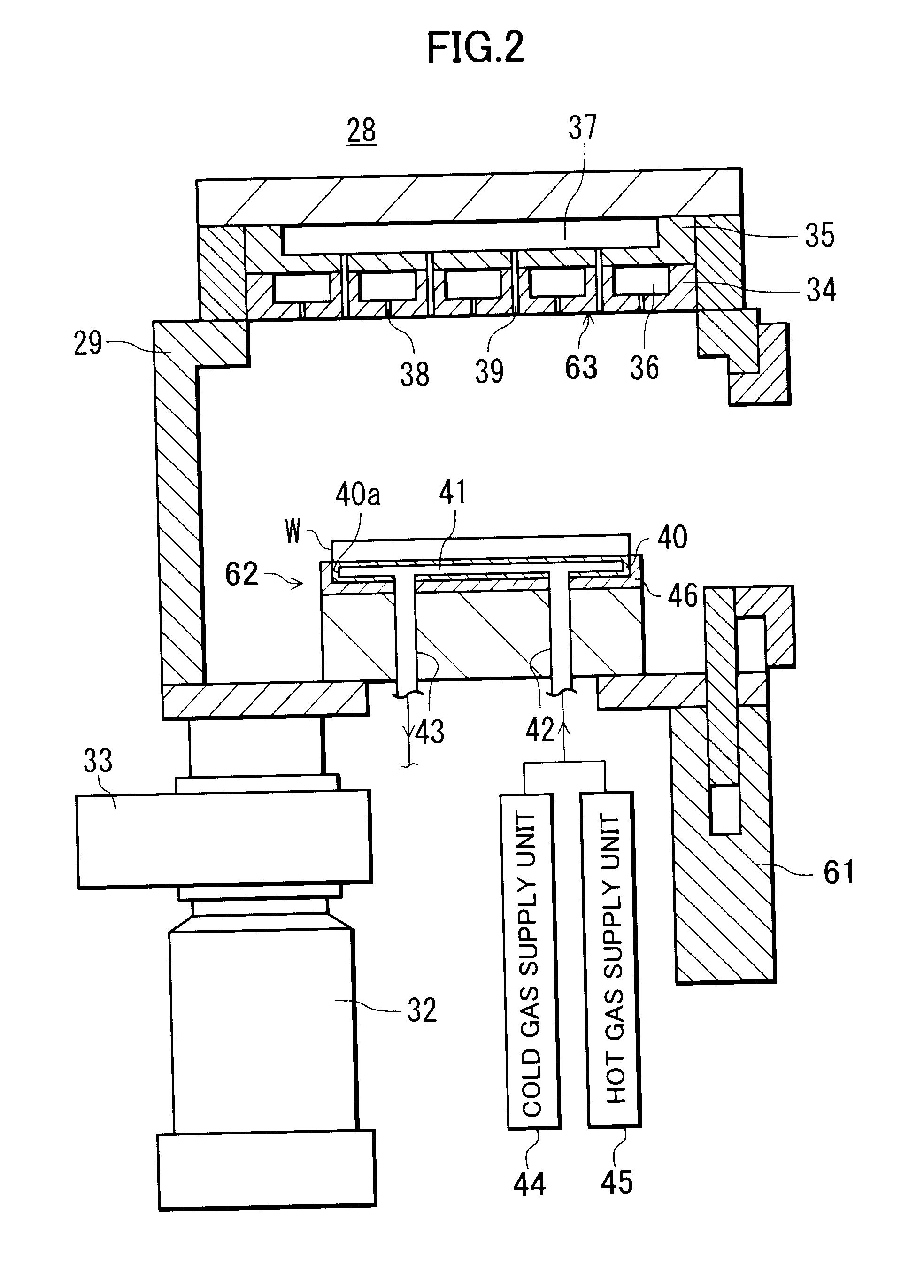

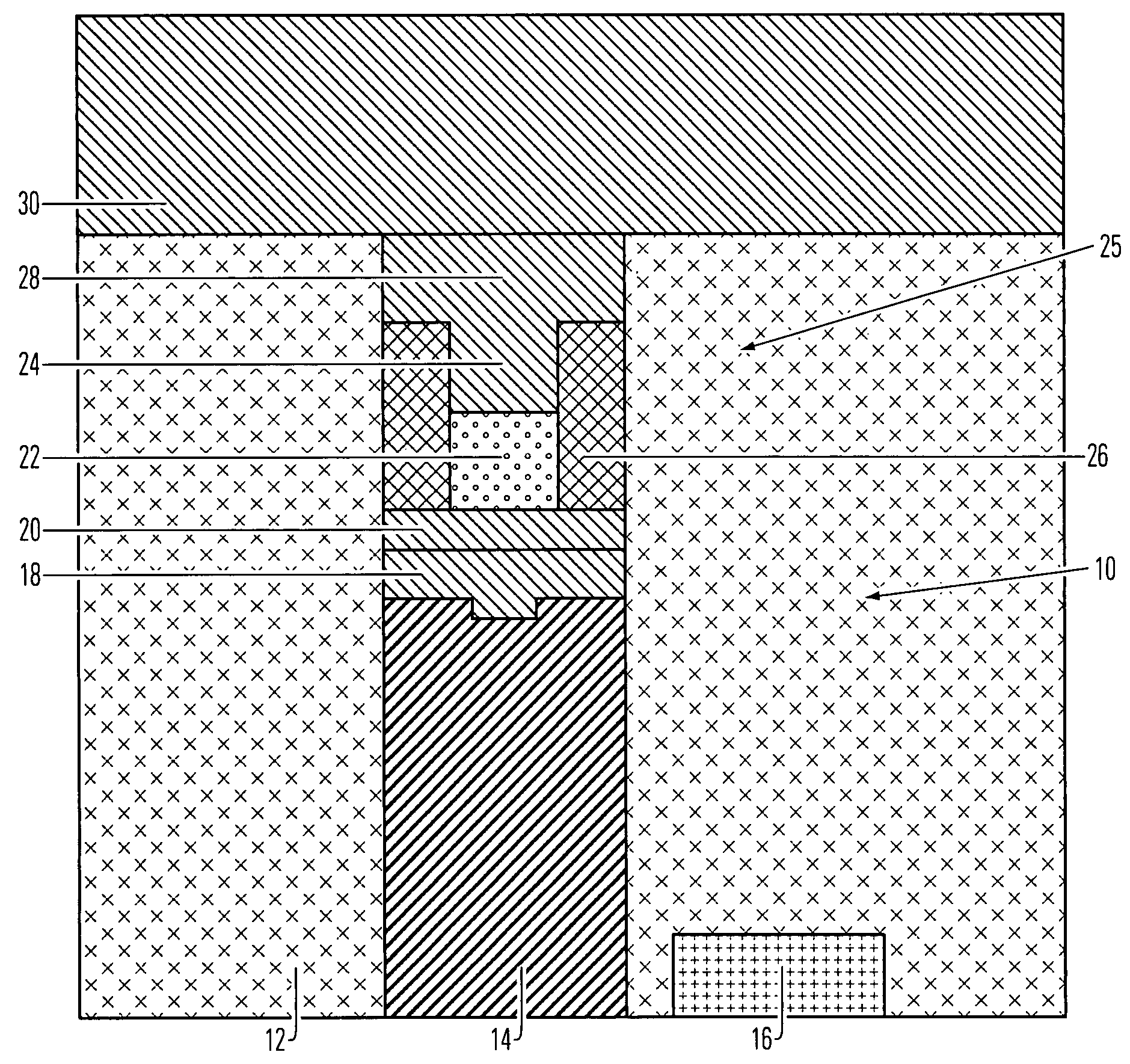

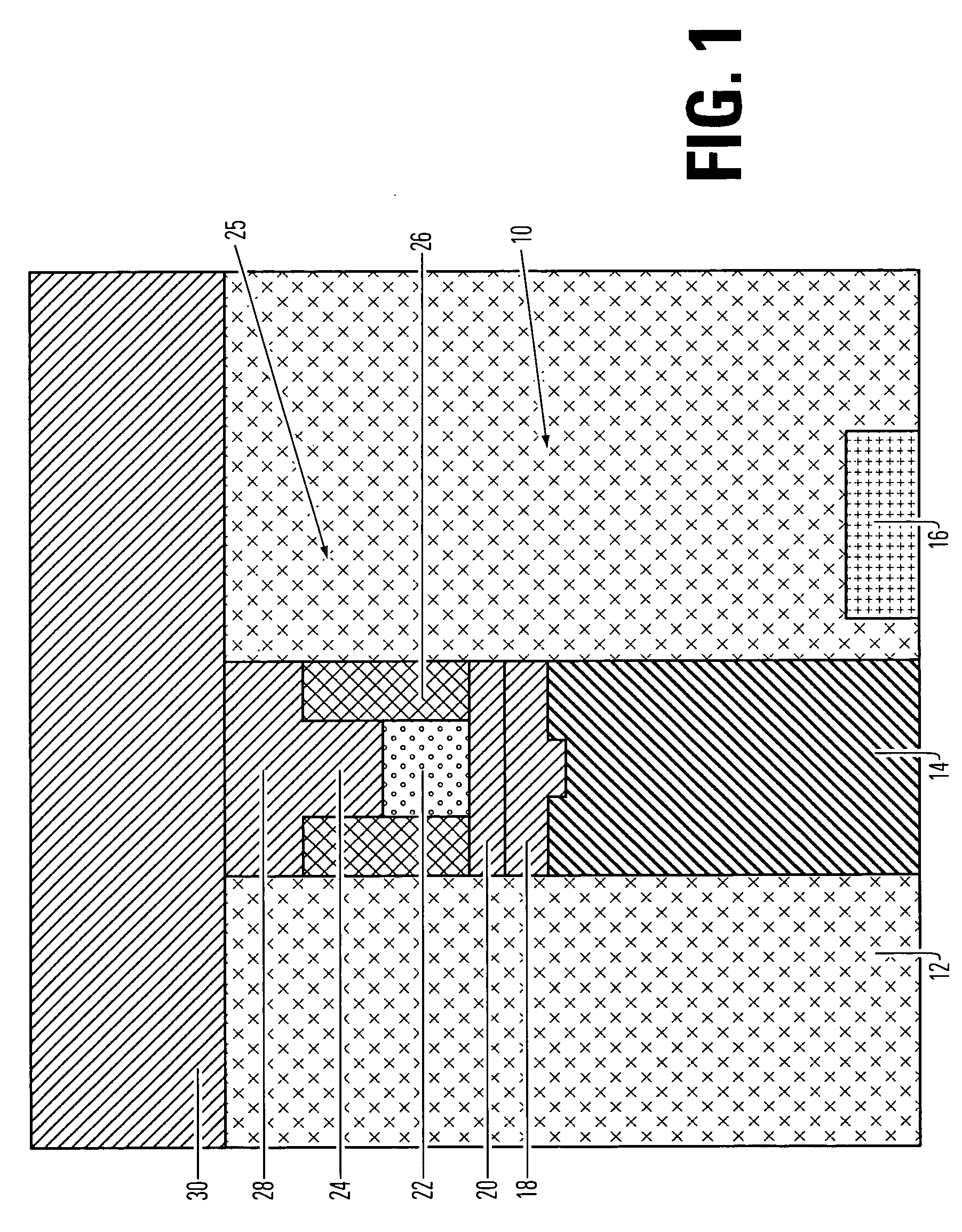

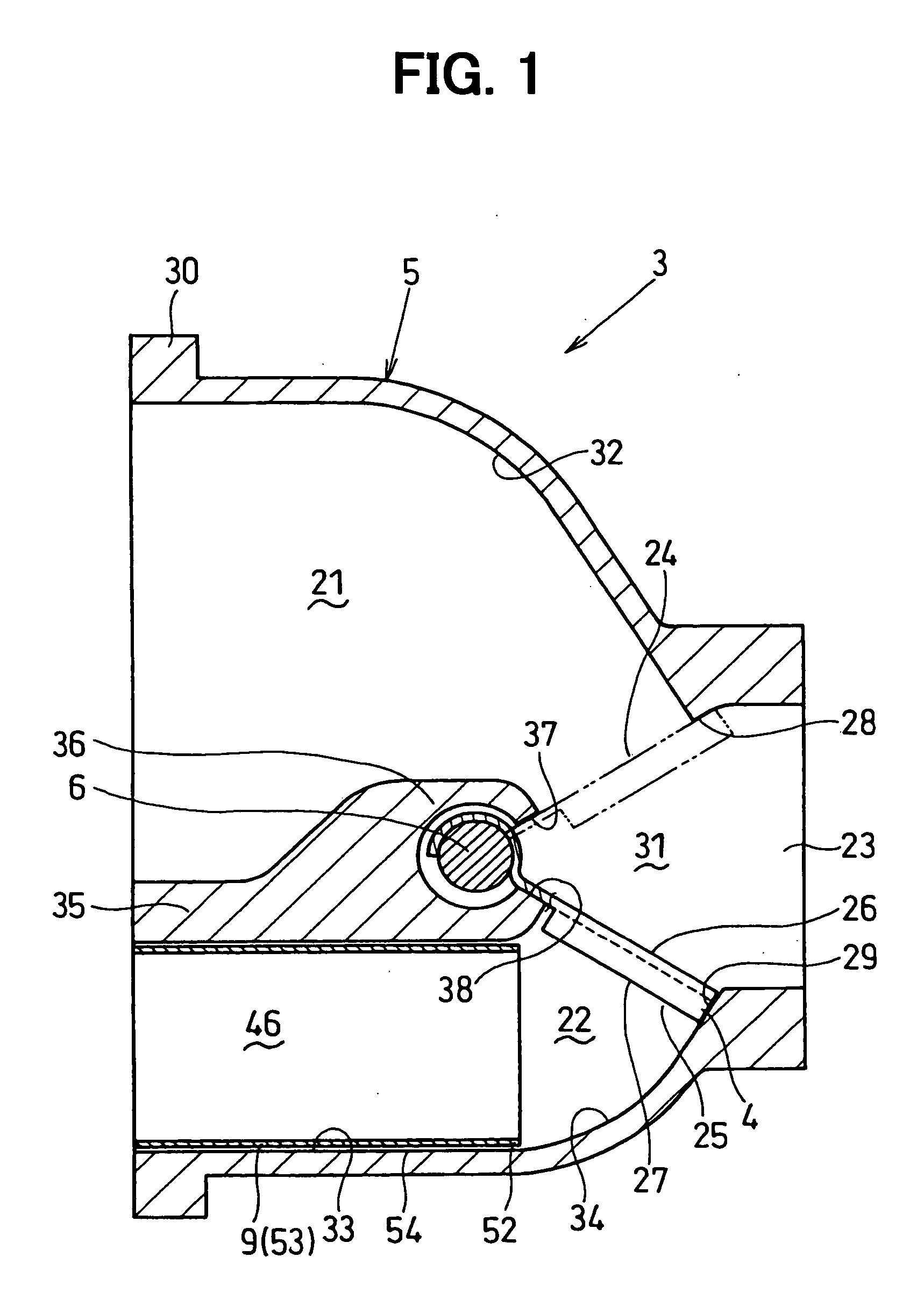

Substrate processing apparatus

InactiveUS20080257494A1Ensure efficient flowRapidly raising and lowering the processing temperature of a substrateElectric discharge tubesSemiconductor/solid-state device manufacturingTemperature controlHeat transmission

A substrate processing apparatus capable of rapidly raising and lowering the processing temperature of a substrate. The substrate processing apparatus has a mounting stage adapted to be mounted with a substrate and to control the processing temperature of the mounted substrate. The mounting stage comprises a temperature control device disposed in a mounting surface of the mounting stage for mounting the substrate thereon, a coolant inflow chamber into which a coolant is flowed, and a heat transmission / insulation switch-over chamber disposed between the temperature control device and the coolant inflow chamber so that a heat-transmitting gas is flowed into and vacuum-exhausted from the heat transmission / insulation switch-over chamber. The temperature control device has therein a gas inflow chamber into which a hot gas is flowed.

Owner:TOKYO ELECTRON LTD

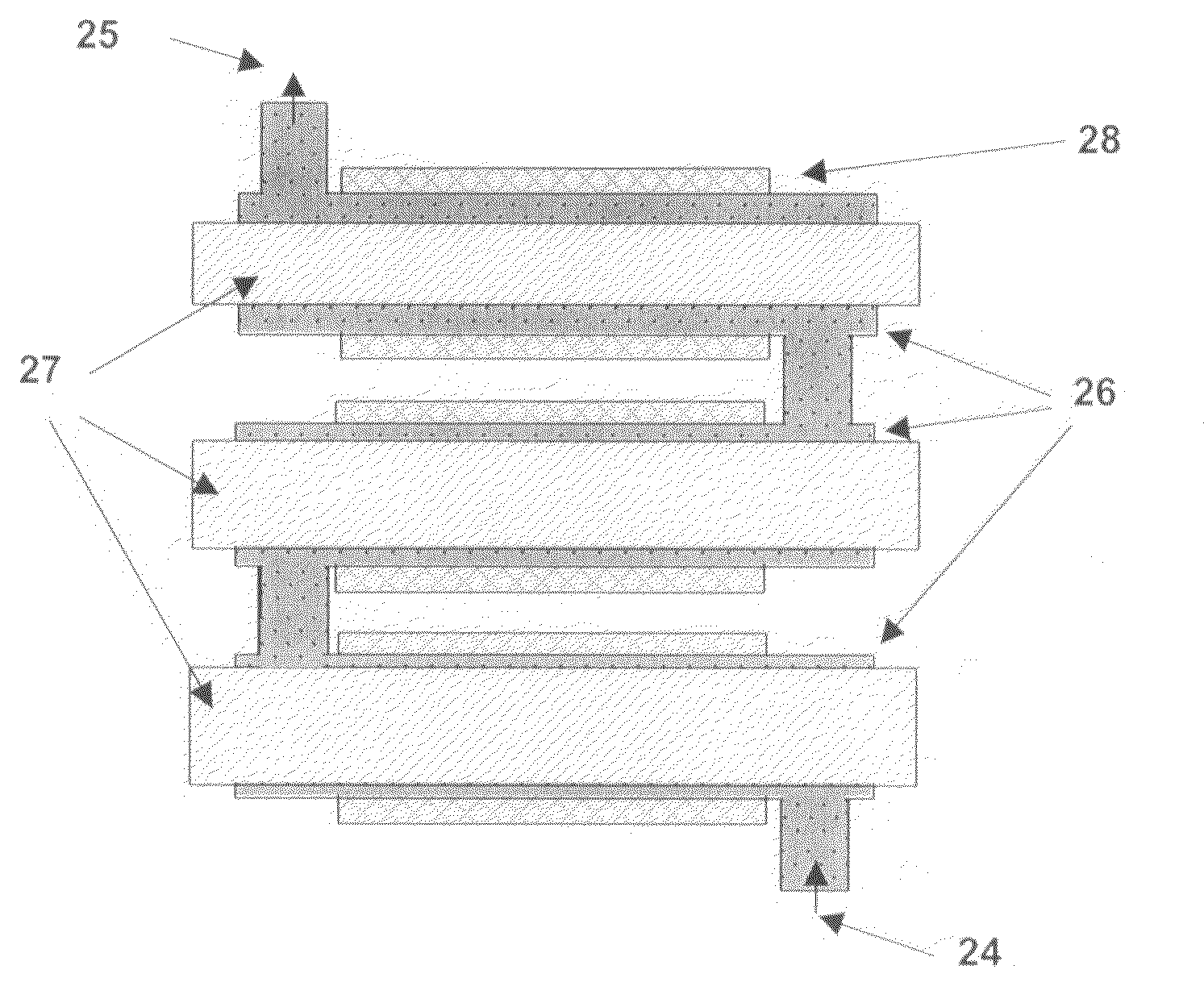

Thermally contained/insulated phase change memory device and method (combined)

ActiveUS20070108430A1Improve heat transfer characteristicsImprove insulation performanceSolid-state devicesBulk negative resistance effect devicesPhase-change memoryDielectric layer

A memory device with improved heat transfer characteristics. The device first includes a dielectric material layer; first and second electrodes, vertically separated and having mutually opposed contact surfaces. A phase change memory element is encased within the dielectric material layer, including a phase-change layer positioned between and in electrical contact with the electrodes, wherein the lateral extent of the phase change layer is less than the lateral extent of the electrodes. An isolation material is positioned between the phase change layer and the dielectric layer, wherein the thermal conductivity of the isolation material is lower than the thermal conductivity of the dielectric material.

Owner:MACRONIX INT CO LTD

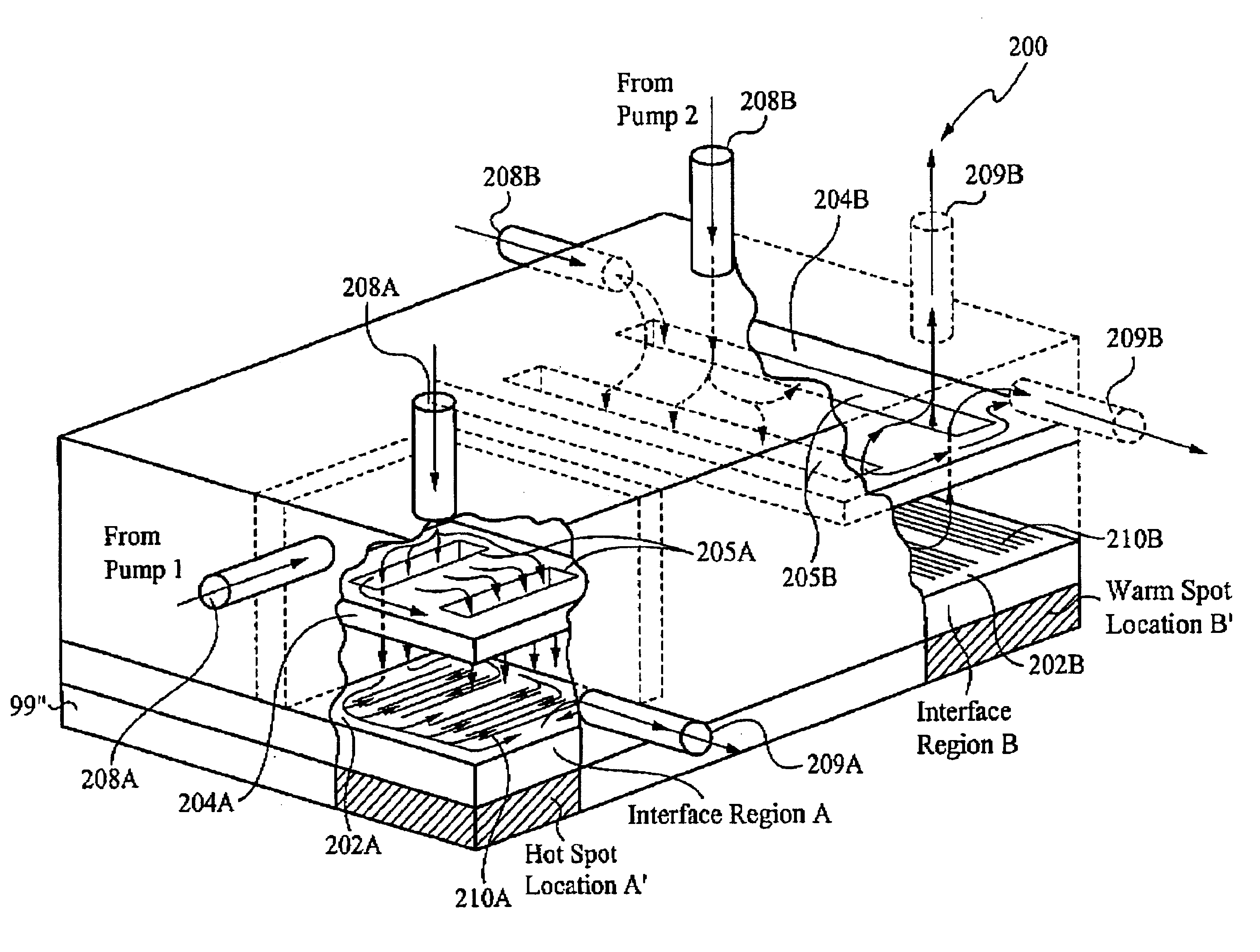

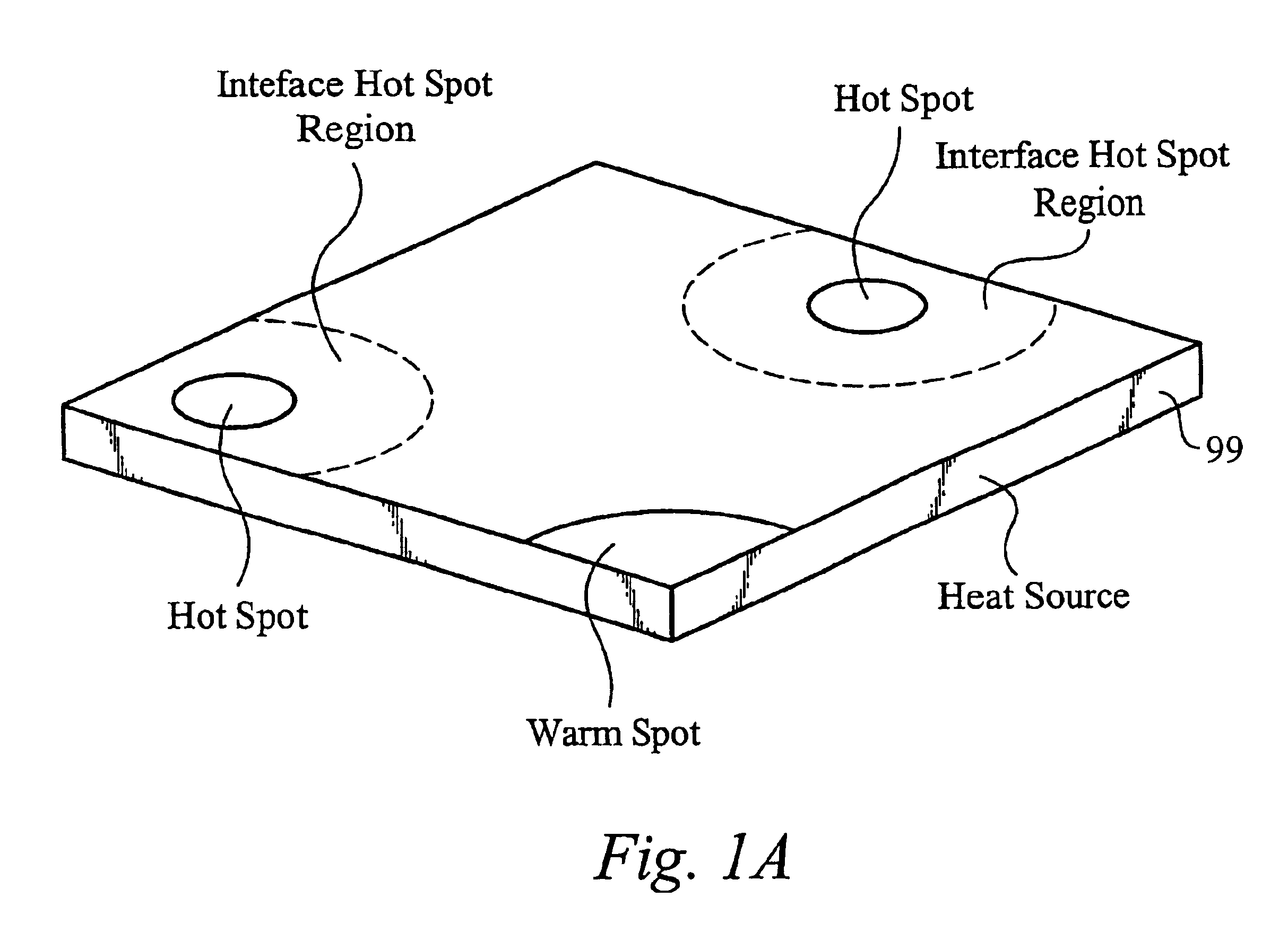

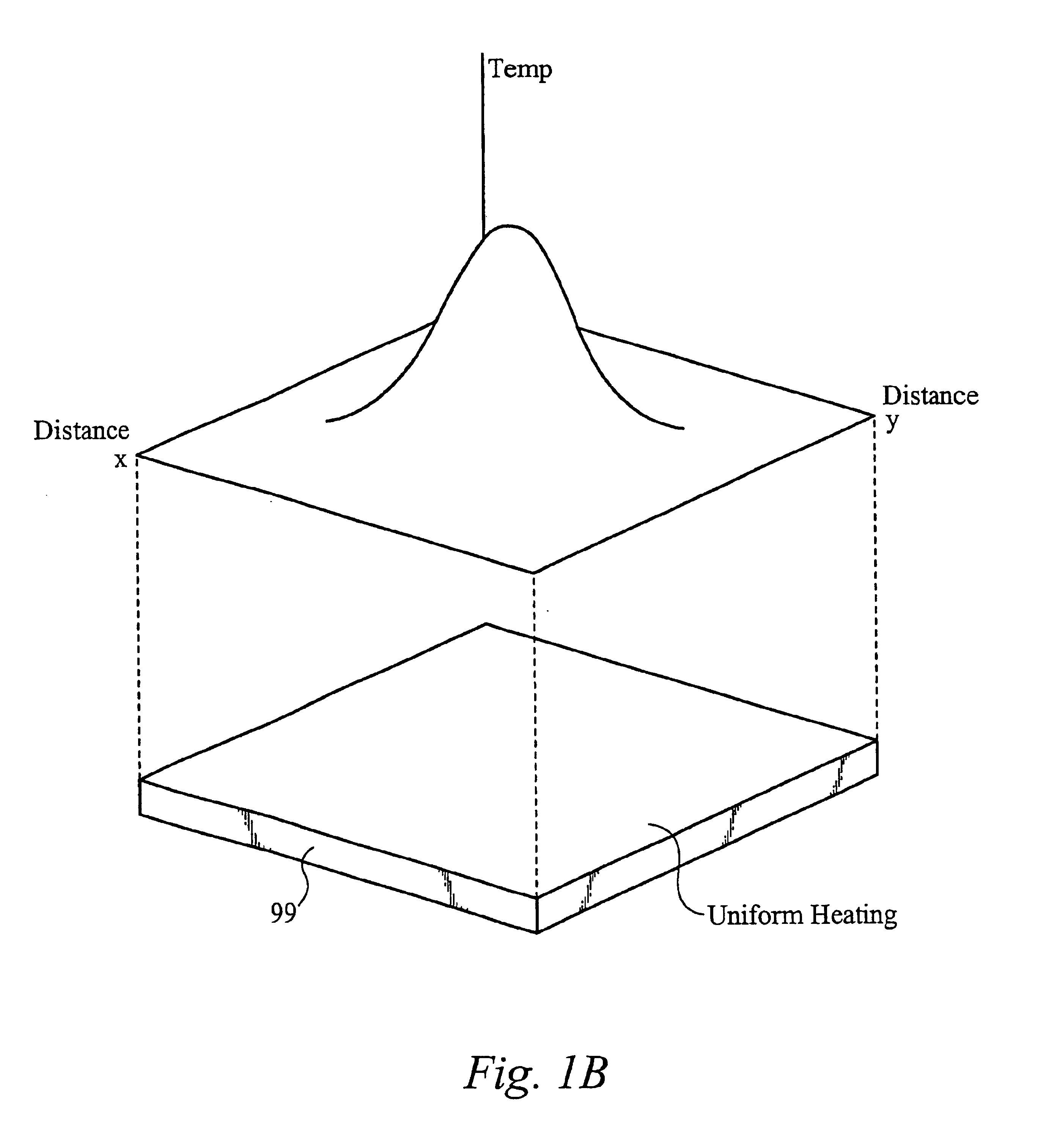

Method and apparatus for achieving temperature uniformity and hot spot cooling in a heat producing device

ActiveUS7104312B2Minimize temperature differenceTemperatue controlSemiconductor/solid-state device detailsTemperature differenceEngineering

A method of controlling temperature of a heat source in contact with a heat exchanging surface of a heat exchanger, wherein the heat exchanging surface is substantially aligned along a plane. The method comprises channeling a first temperature fluid to the heat exchanging surface, wherein the first temperature fluid undergoes thermal exchange with the heat source along the heat exchanging surface. The method comprises channeling a second temperature fluid from the heat exchange surface, wherein fluid is channeled to minimize temperature differences along the heat source. The temperature differences are minimized by optimizing and controlling the fluidic and thermal resistances in the heat exchanger. The resistances to the fluid are influenced by size, volume and surface area of heat transferring features, multiple pumps, fixed and variable valves and flow impedance elements in the fluid path, pressure and flow rate control of the fluid, and other factors.

Owner:VERTIV CORP

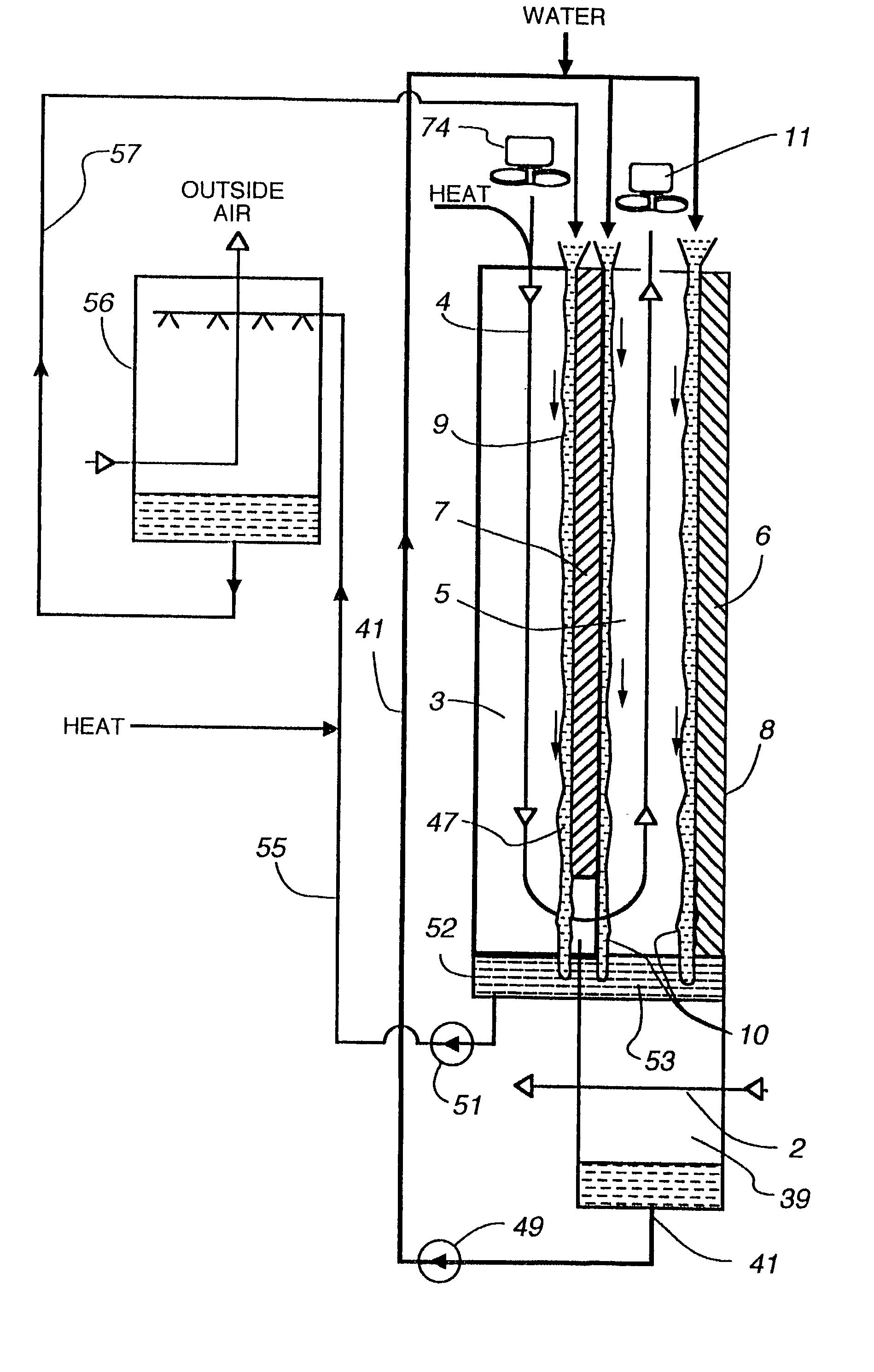

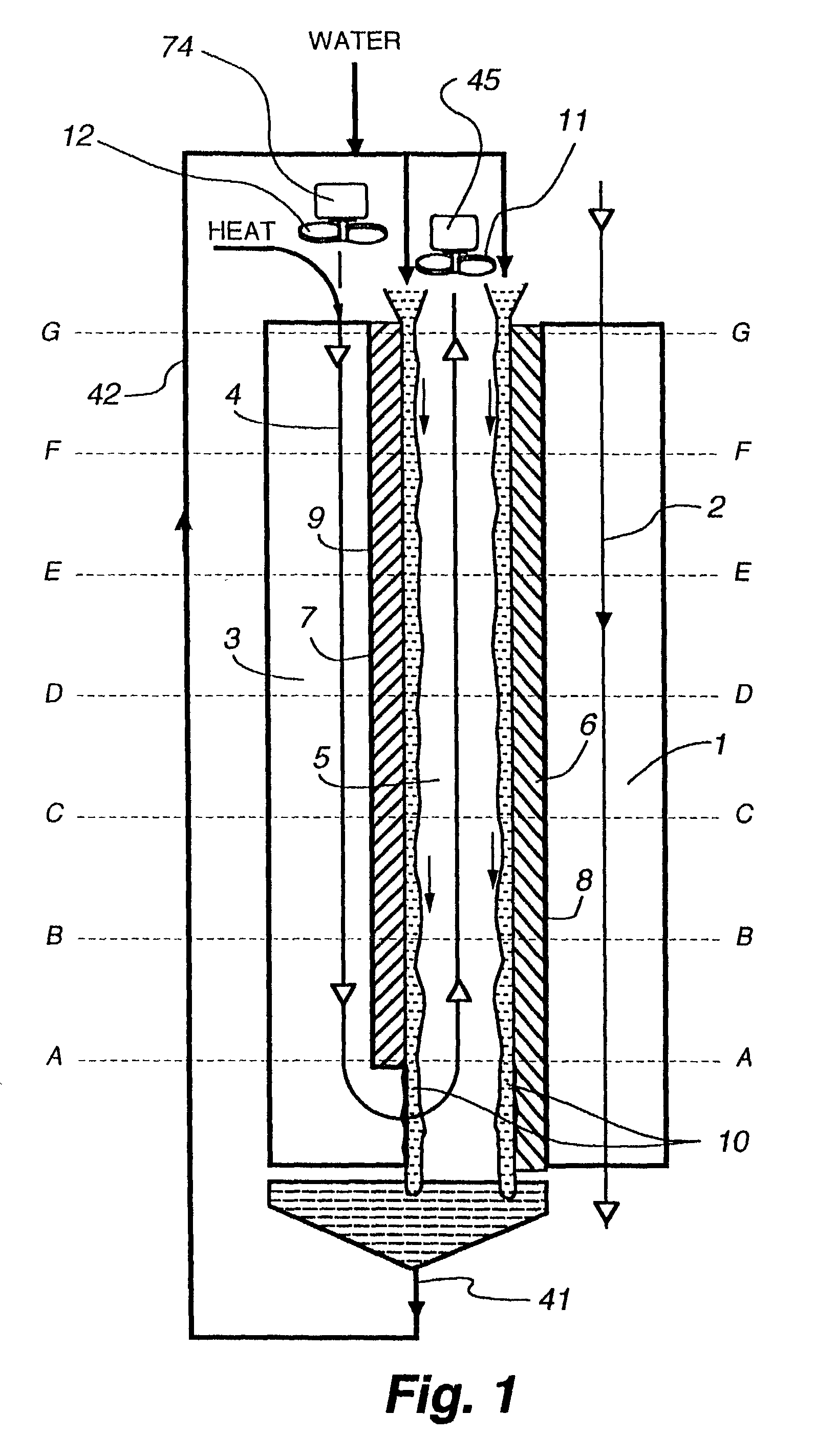

Two-phase heat-transfer systems

InactiveUS6866092B1Prevent freezingImprove the overall coefficientLiquid coolingCasingsLiquid jetInternal pressure

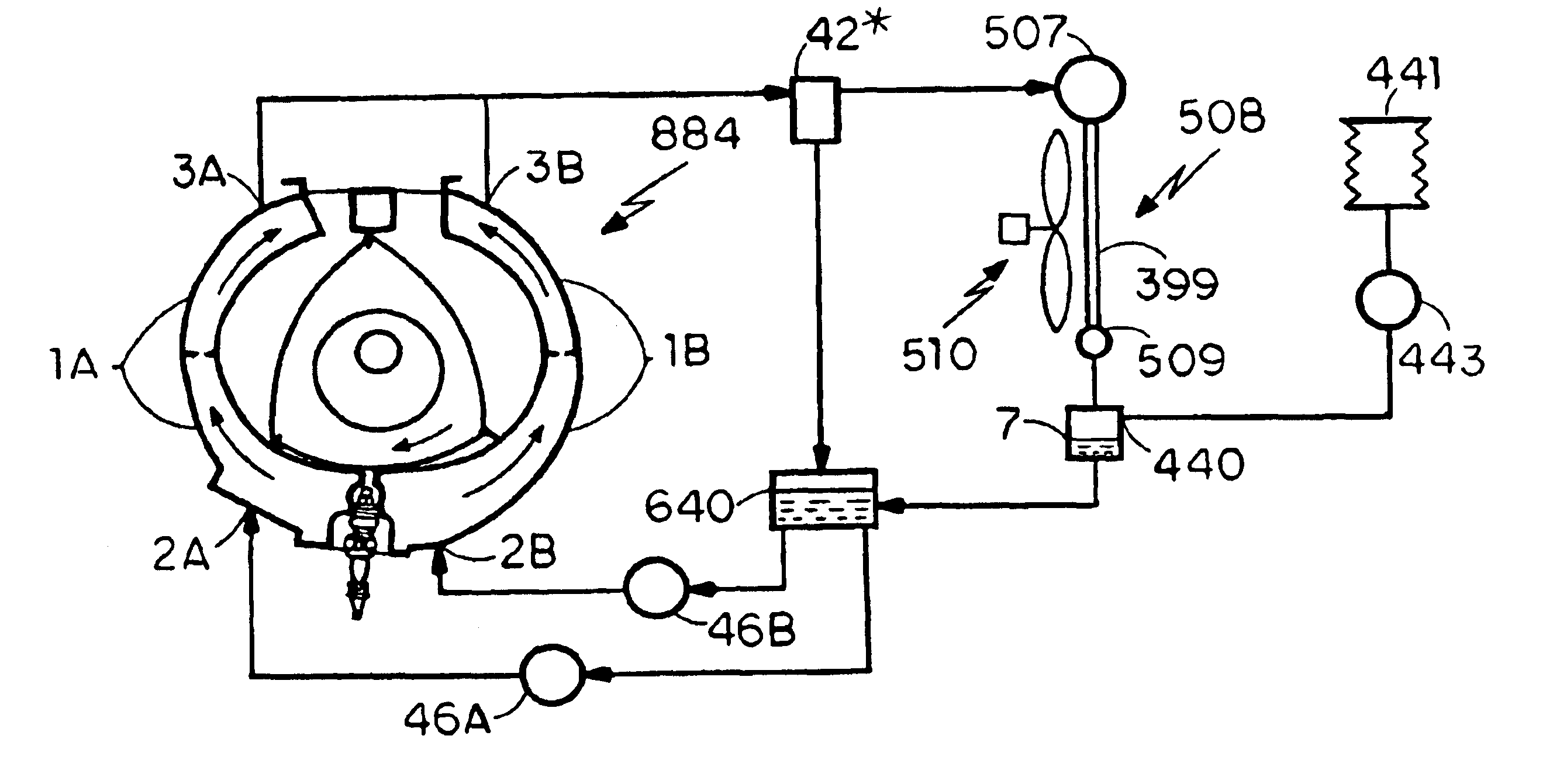

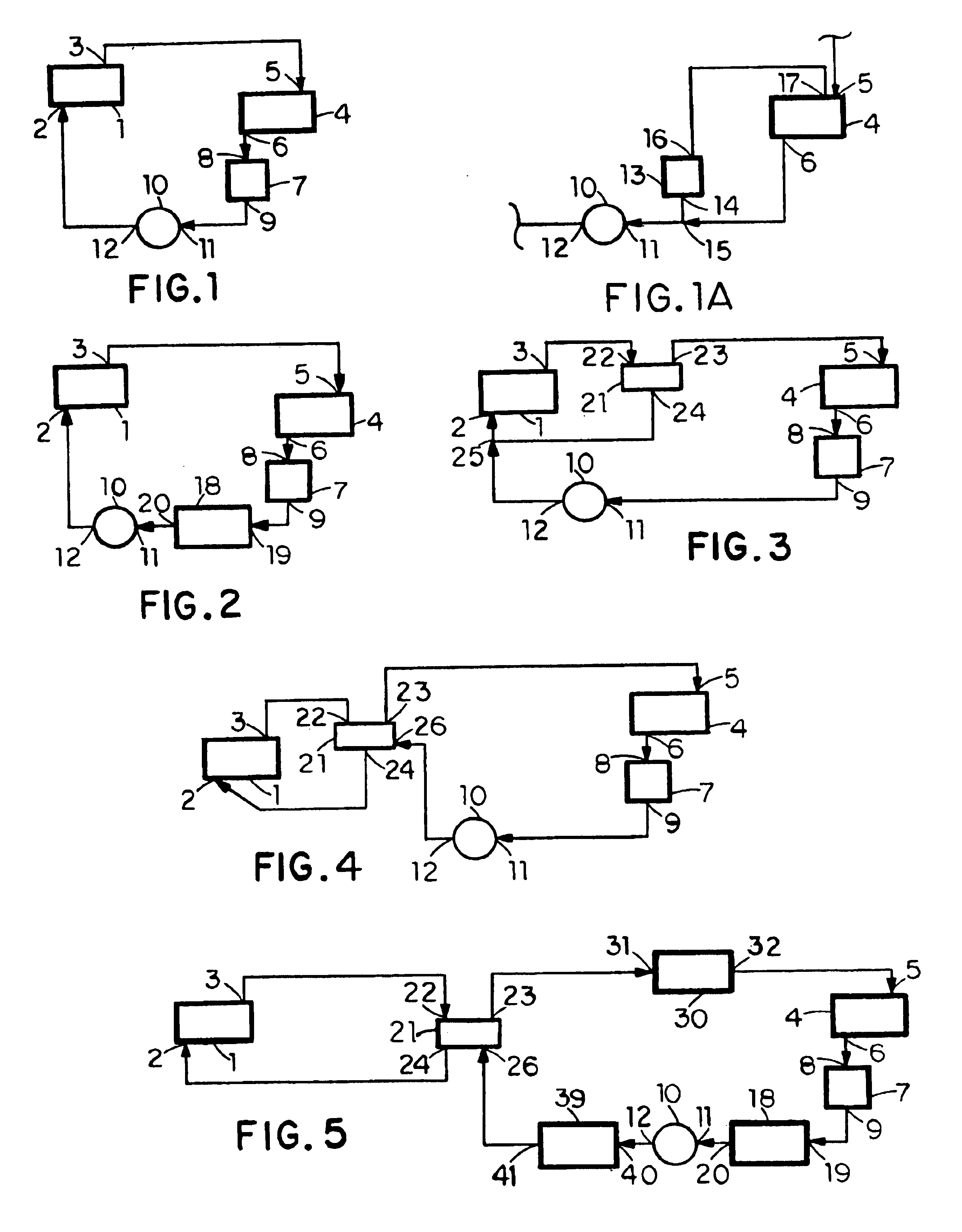

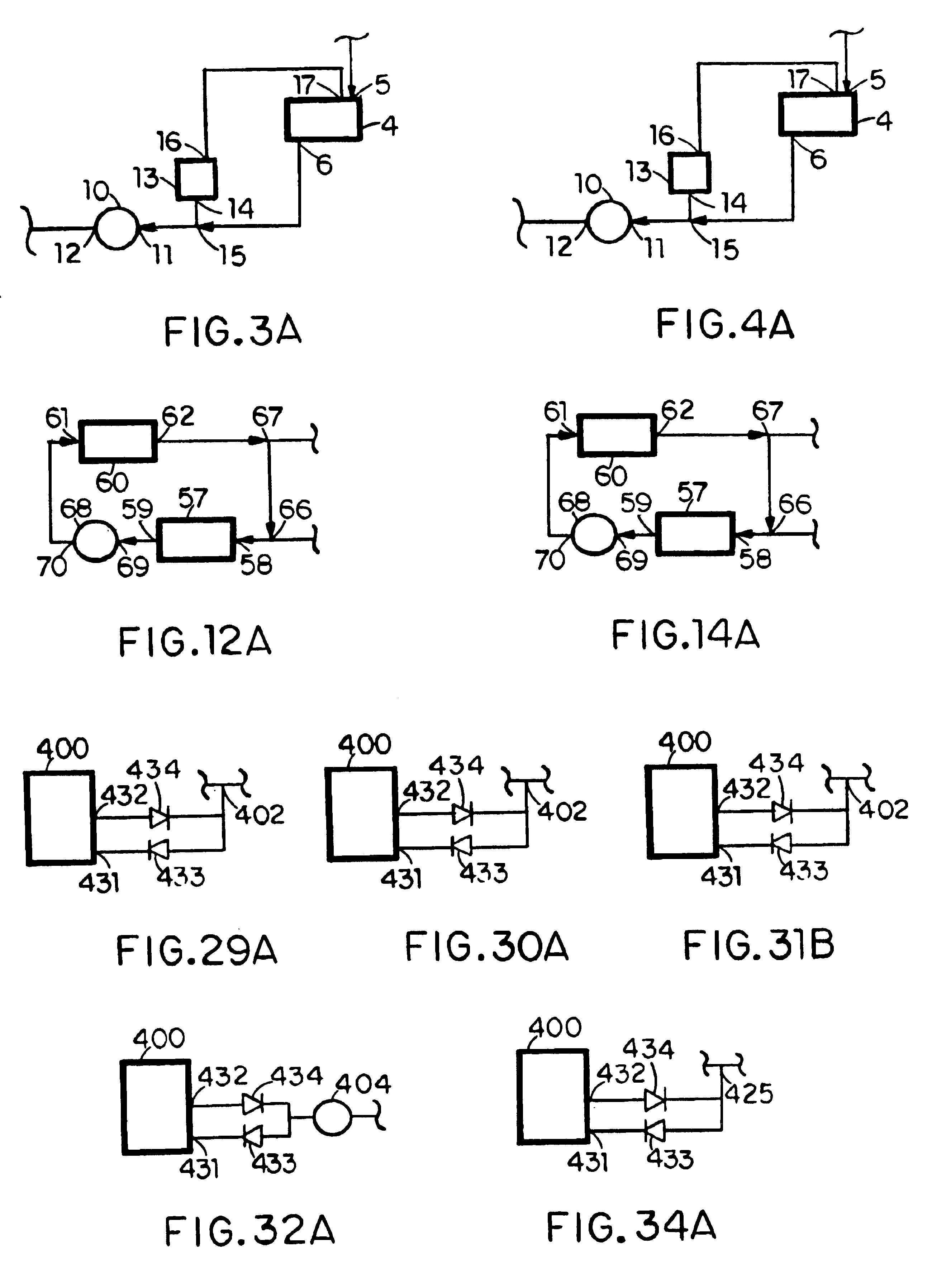

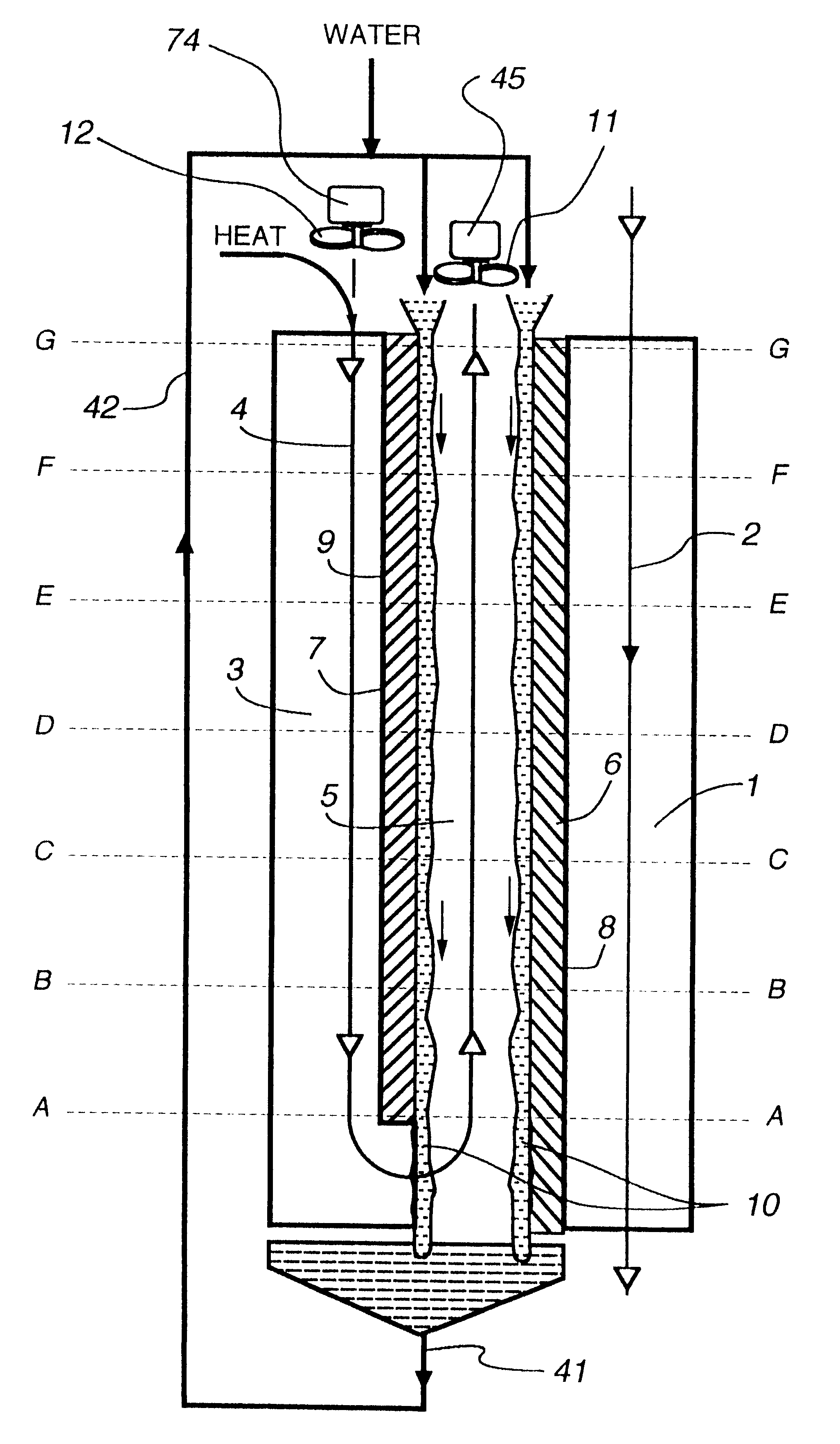

Various techniques are disclosed for improving airtight two-phase heat-transfer systems employing a fluid to transfer heat from a heat source to a heat sink while circulating around a fluid circuit, the maximum temperature of the heat sink not exceeding the maximum temperature of the heat source. The properties of those improved systems include (a) maintaining, while the systems are inactive, their internal pressure at a pressure above the saturated-vapor pressure of their heat-transfer fluid; and (b) cooling their internal evaporator surfaces with liquid jets. FIG. 43 illustrates the particular case where a heat-transfer system of the invention is used to cool a piston engine (500) by rejecting, with a condenser (508), heat to the ambient air; and where the system includes a heat-transfer fluid pump (10) and means (401-407) for achieving the former property.

Owner:MOLIVADAS STEPHEN

Nano carbon materials for enhancing thermal transfer in fluids

InactiveUS6695974B2Improve thermal conductivityImprove heat transfer performanceMaterial nanotechnologyNanostructure manufactureOrganic groupElectrical polarity

A novel fluid heat transfer agent suitable for use in a closed heat transfer system, for example, wherein energy is transferred between an evaporator and a condenser in heat exchange relationship with the heat transfer agent that is caused to flow from one to the other. The novel heat transfer agent is a complex comprising a body of heat transfer fluid, for example, ethylene glycol or water, having suspended therein carbon nanoparticles in a quantity sufficient to enhance the thermal conductivity of the body of heat transfers fluid, per se. The carbon nanoparticles are selected from carbon in the form of sp<2 >type and sp<3 >type bonding and preferably comprise nanotubes or fullerenes and may have a coupling agent bonded thereto or enclosed therein when the nanotube or fullerene forms a hollow capsule. The coupling agent may be a polar organic group covalently bonded to the carbon nanoparticles and miscible in the fluid medium.

Owner:MATERIALS & ELECTROCHEM RES

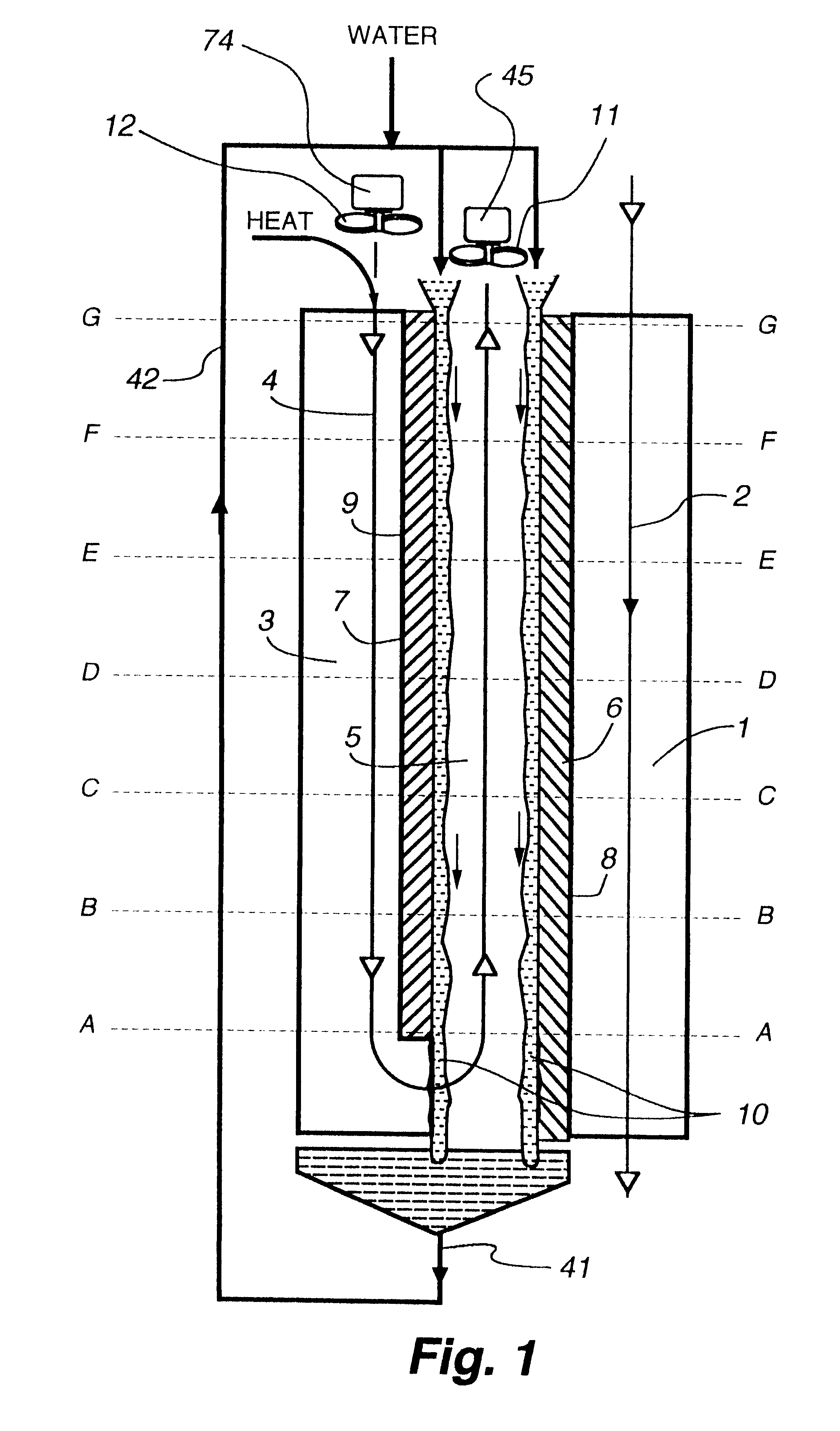

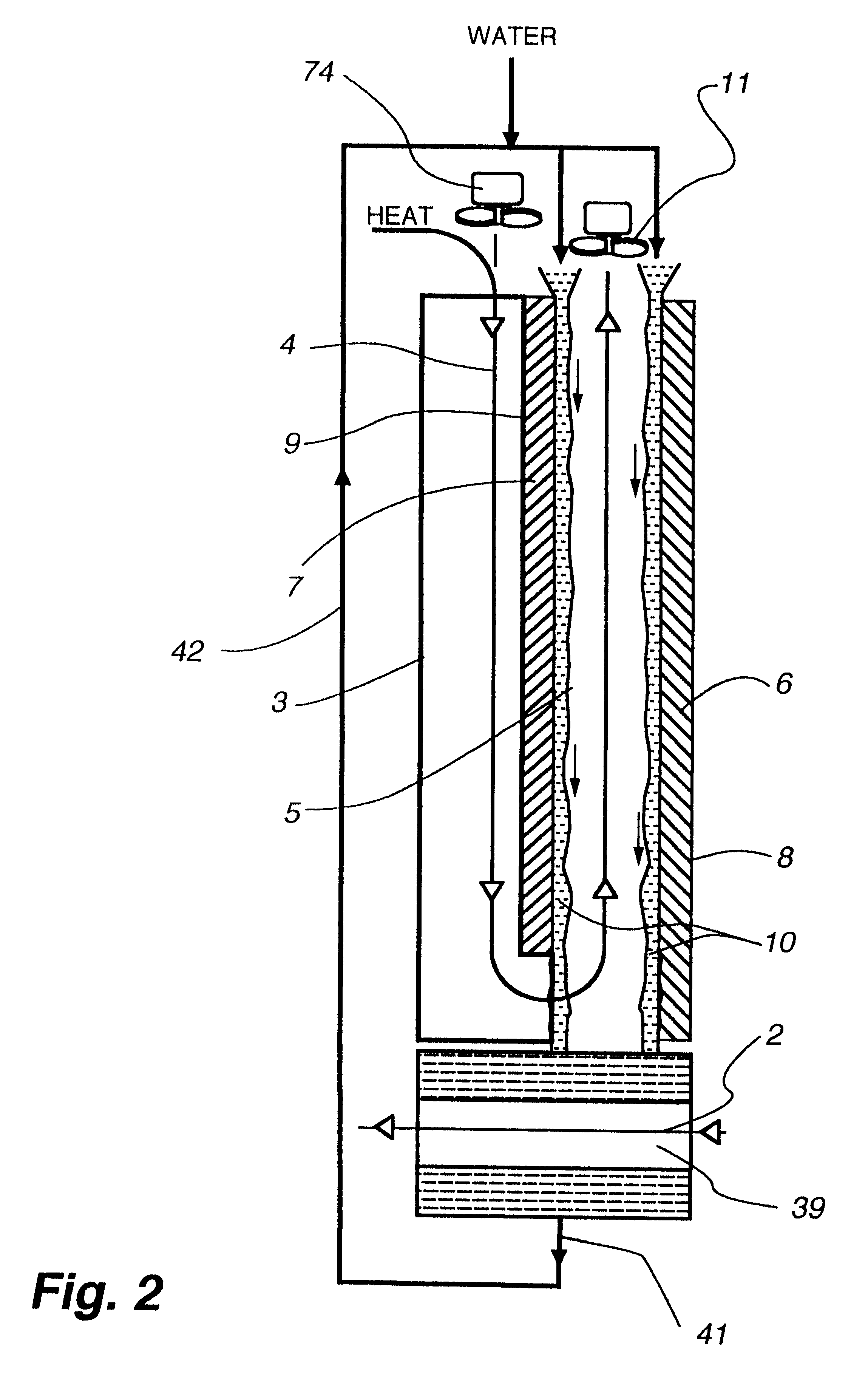

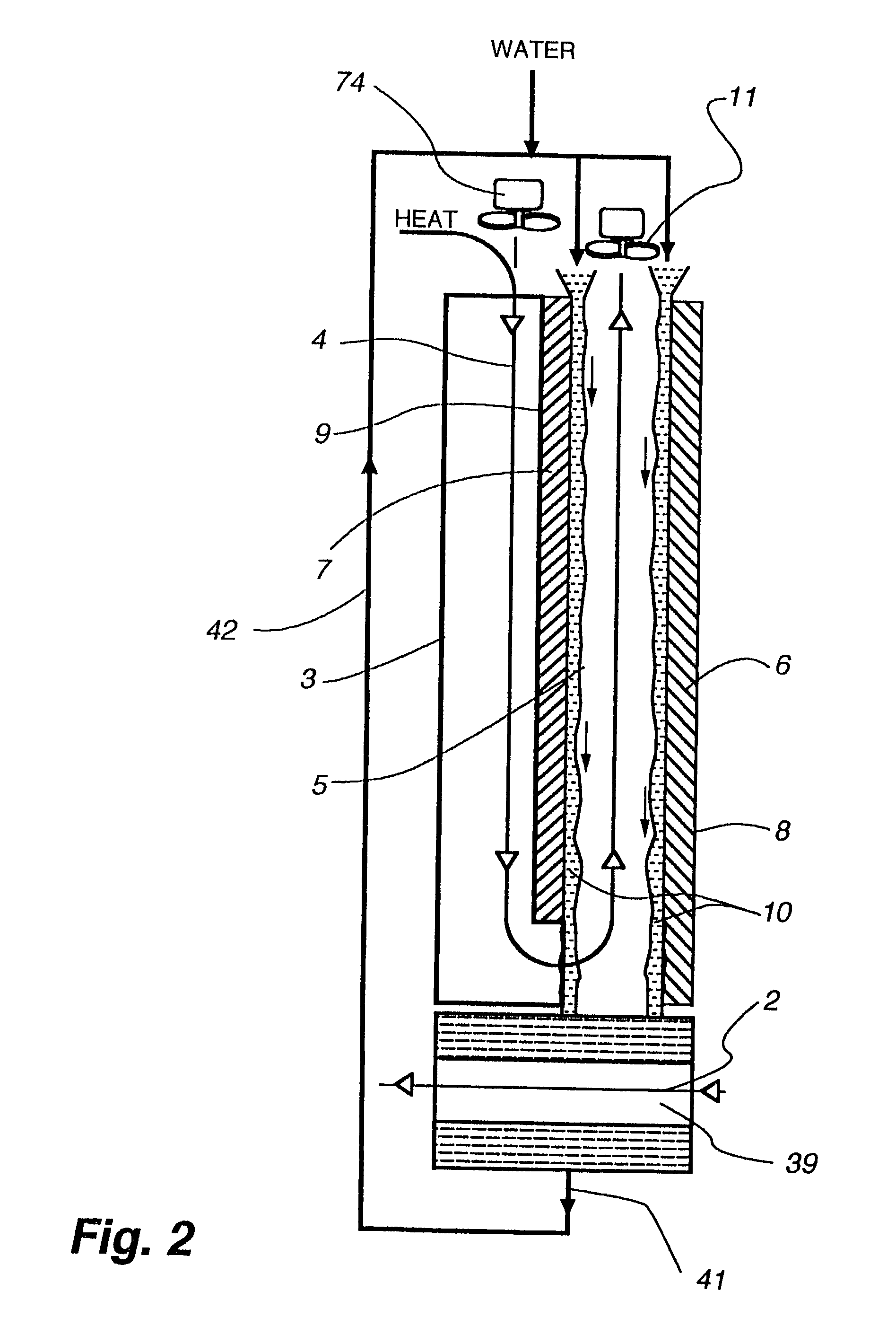

Method and apparatus of indirect-evaporation cooling

InactiveUS6497107B2Less energyHigh energy costFree-cooling systemsStationary conduit assembliesWorking fluidEvaporation

The within invention improves on the indirect evaporative cooling method and apparatus by making use of a working fluid that is pre-cooled with and without desiccants before it is passed through a Wet Channel where evaporative fluid is on the walls to take heat and store it in the working fluid as increased latent heat. The heat transfer across the membrane between the Dry Channel and the Wet Channel may have dry, solid desiccant or liquid desiccant and may have perforations, pores or capillary pathways. The evaporative fluid may be water, fuel, or any substance that has the capacity to take heat as latent heat. The Wet Channel or excess cooled fluid is in heat transfer contact with a Product Channel where Product Fluid is cooled without adding any humidity. An alternative embodiment for heat transfer between adjacent channels is with heat pipes.

Owner:F F SEELEY NOMINEES

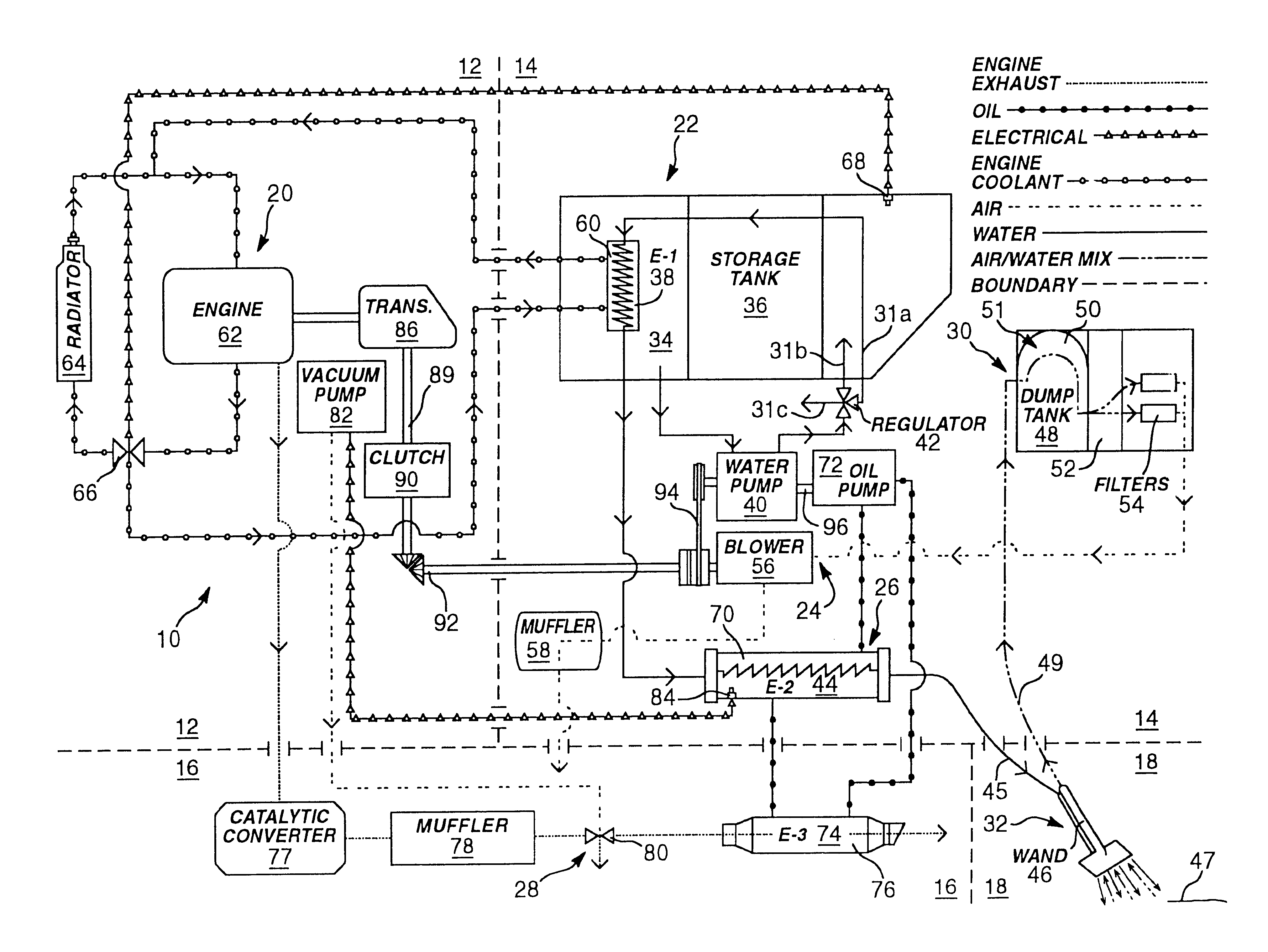

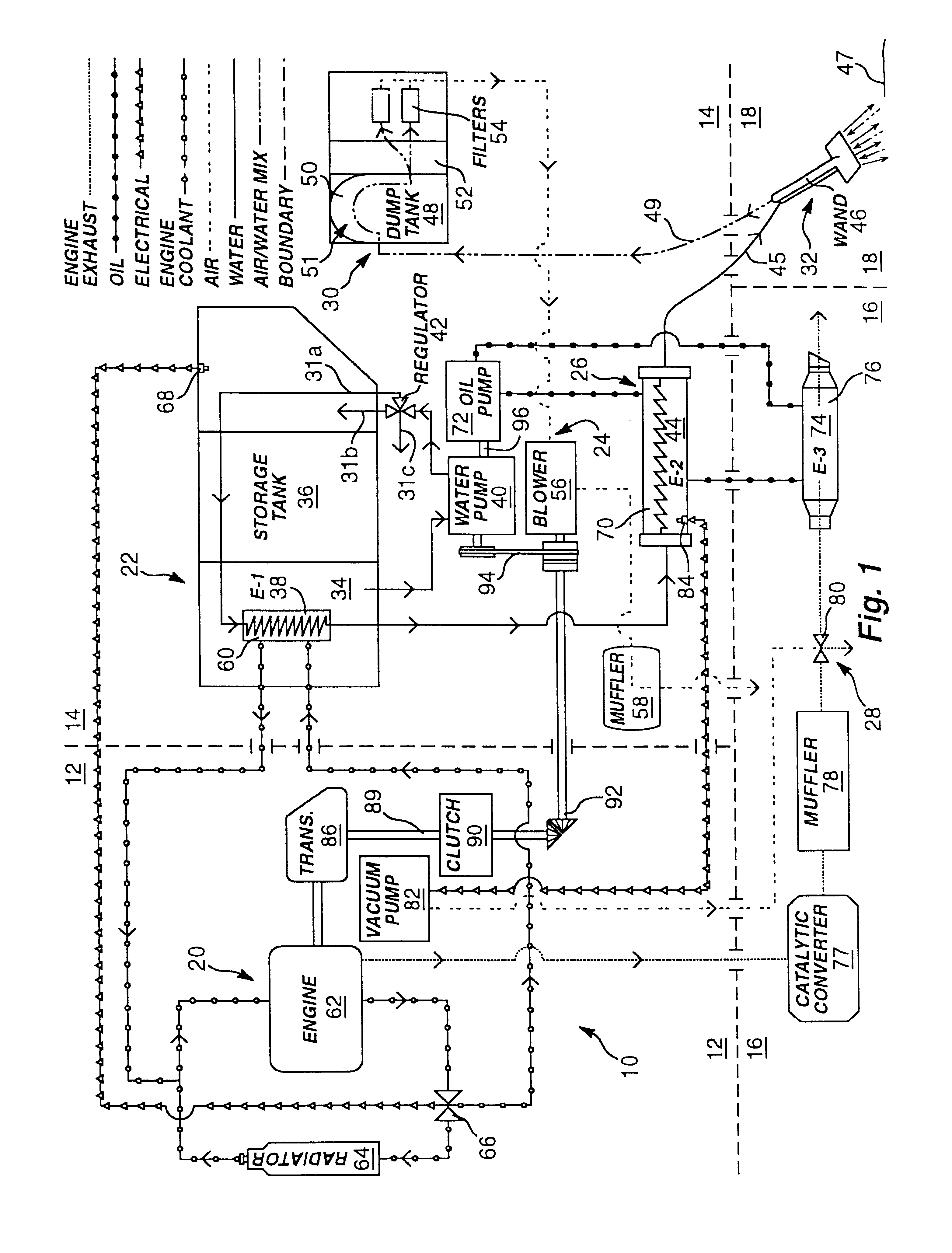

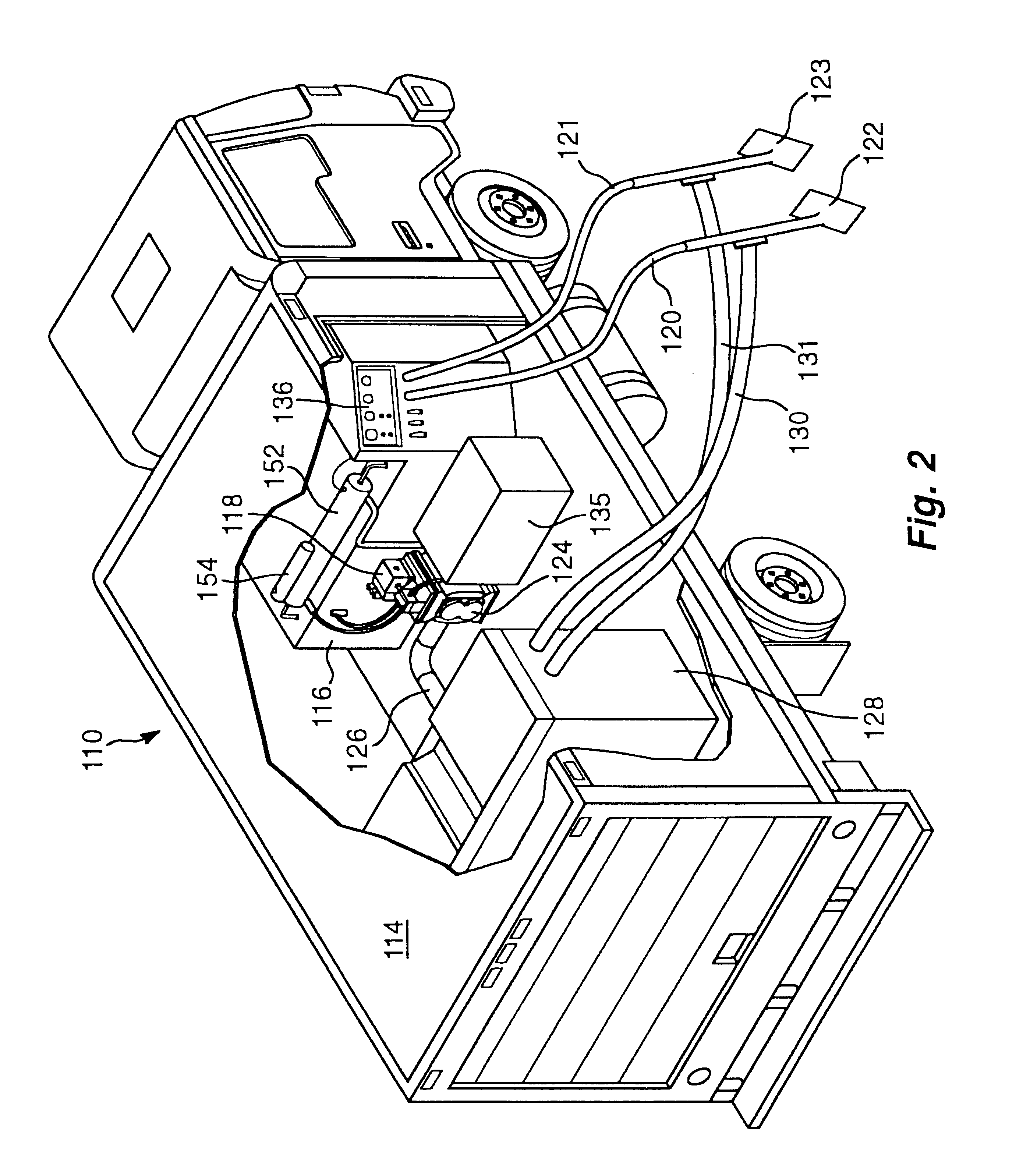

Portable high-temperature, high-pressure washing plant

InactiveUS6675437B1Reliable outputIncrease temperatureInternal combustion piston enginesRecuperative heat exchangersProcess engineeringThermal contact

A washing system for high temperature cleaning applications, such as carpet-cleaning, is disclosed that provides a consistent cleaning fluid temperature. The washing system utilizes multiple heat exchangers and multiple heat paths. The heating and power source is provided by a medium duty, diesel cycle engine. Multi-stage heating involves heat transfer from the engine's coolant to the cleaning fluid and heat transfer from the exhaust of the engine to the cleaning fluid via an intermediate medium. The system also includes a fluid clutch used to engage a power takeoff from the engine to operate the pump and blower of the washing plant. A failsafe source cutoff diverts the exhaust flow from thermal contact with an intermediate heat transfer oil.

Owner:BLUE LINE EQUIP

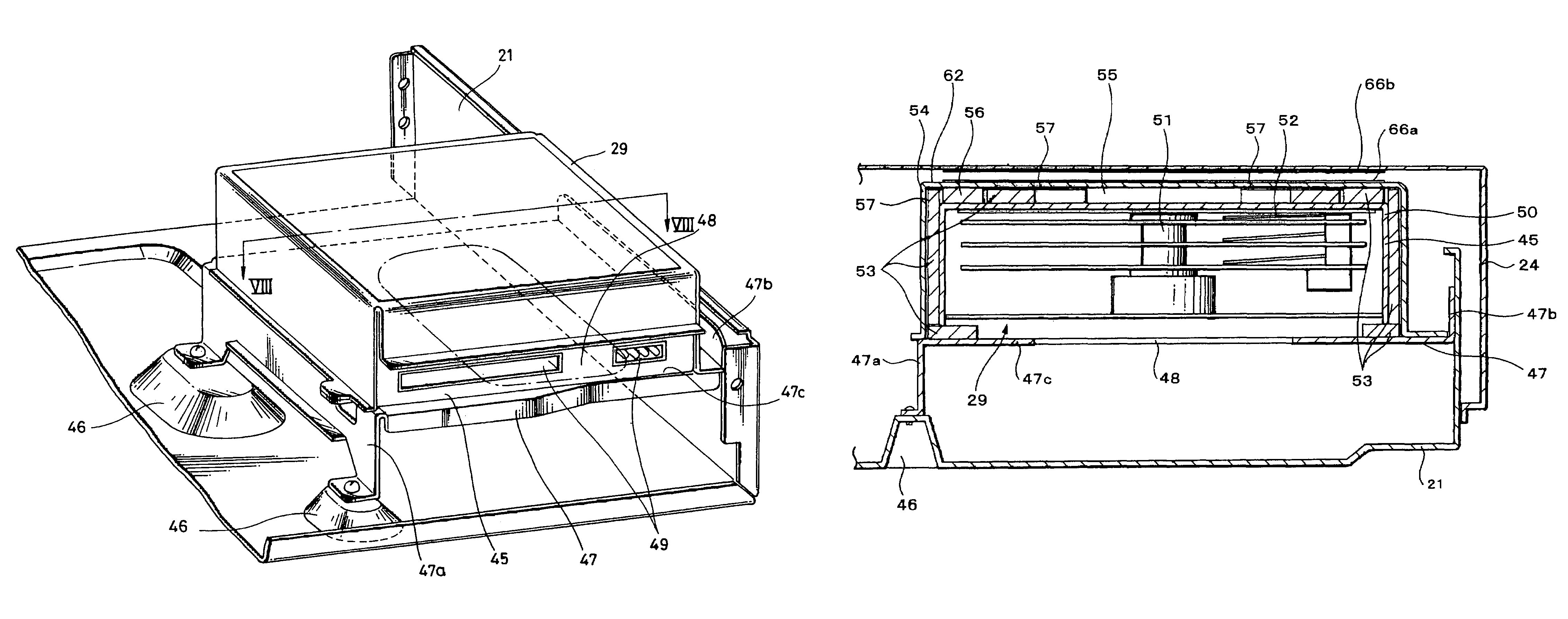

Electronic apparatus and hard disk drive housing apparatus

InactiveUS7315447B2Effective radiationImprove reliabilityApparatus for flat record carriersRecord information storageHard disc driveHeat transmission

A system for mounting a hard disk drive inside an electronic apparatus in such a way that the hard disk drive is isolated from vibration and noise and heat generated by the hard disk dive is radiated to a cover of the electronic apparatus to prevent overheating. A foam heat transmission sheet is placed between the hard disk drive cover and an outer casing that is mounted to the electronic apparatus and far-infrared ray transmitting and receiving sheets are attached to the outside of the outer casing and to the inside of the cover of the electronic apparatus to transmit heat from the hard disk drive to the exterior of the apparatus.

Owner:SONY CORP

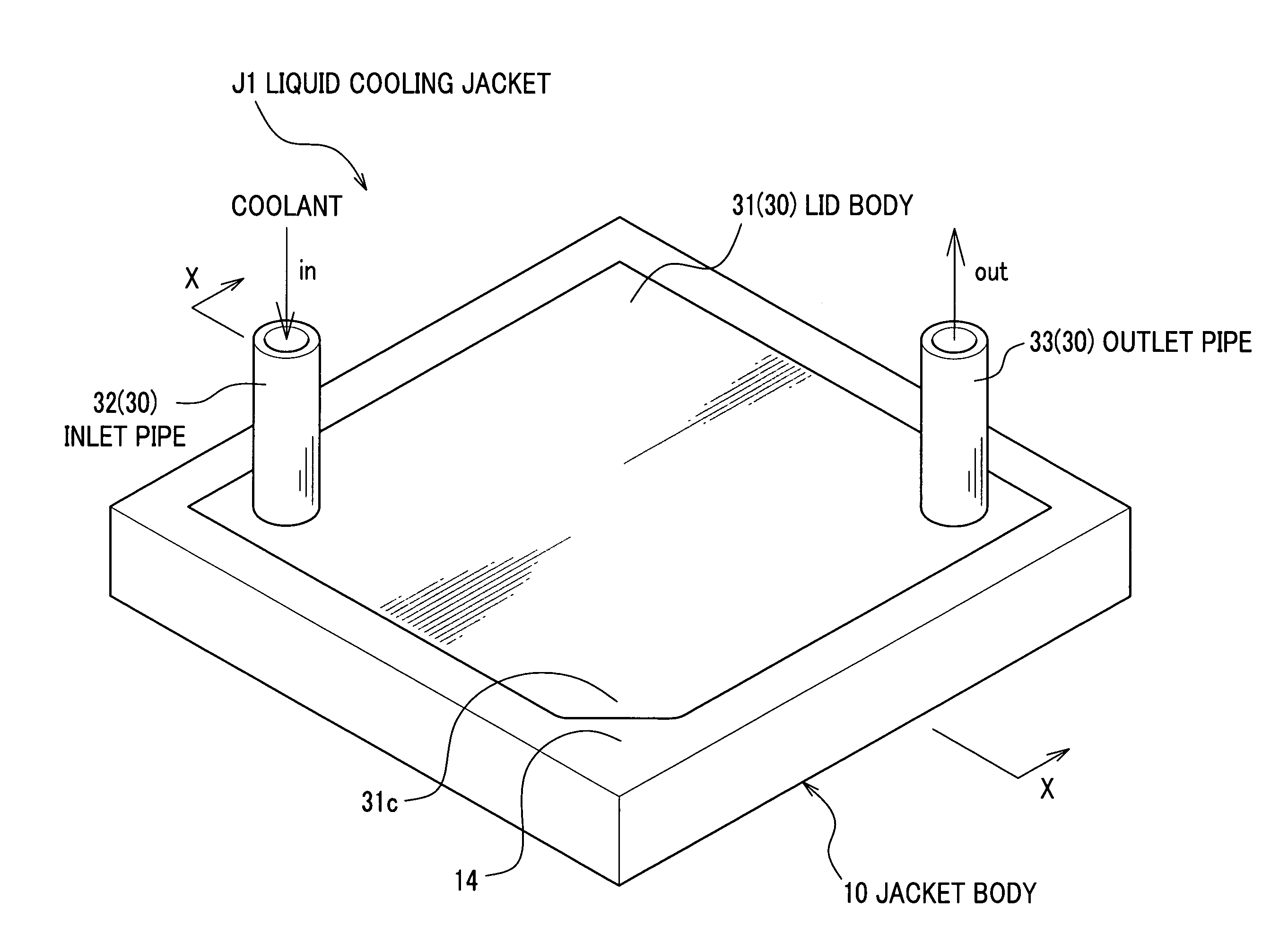

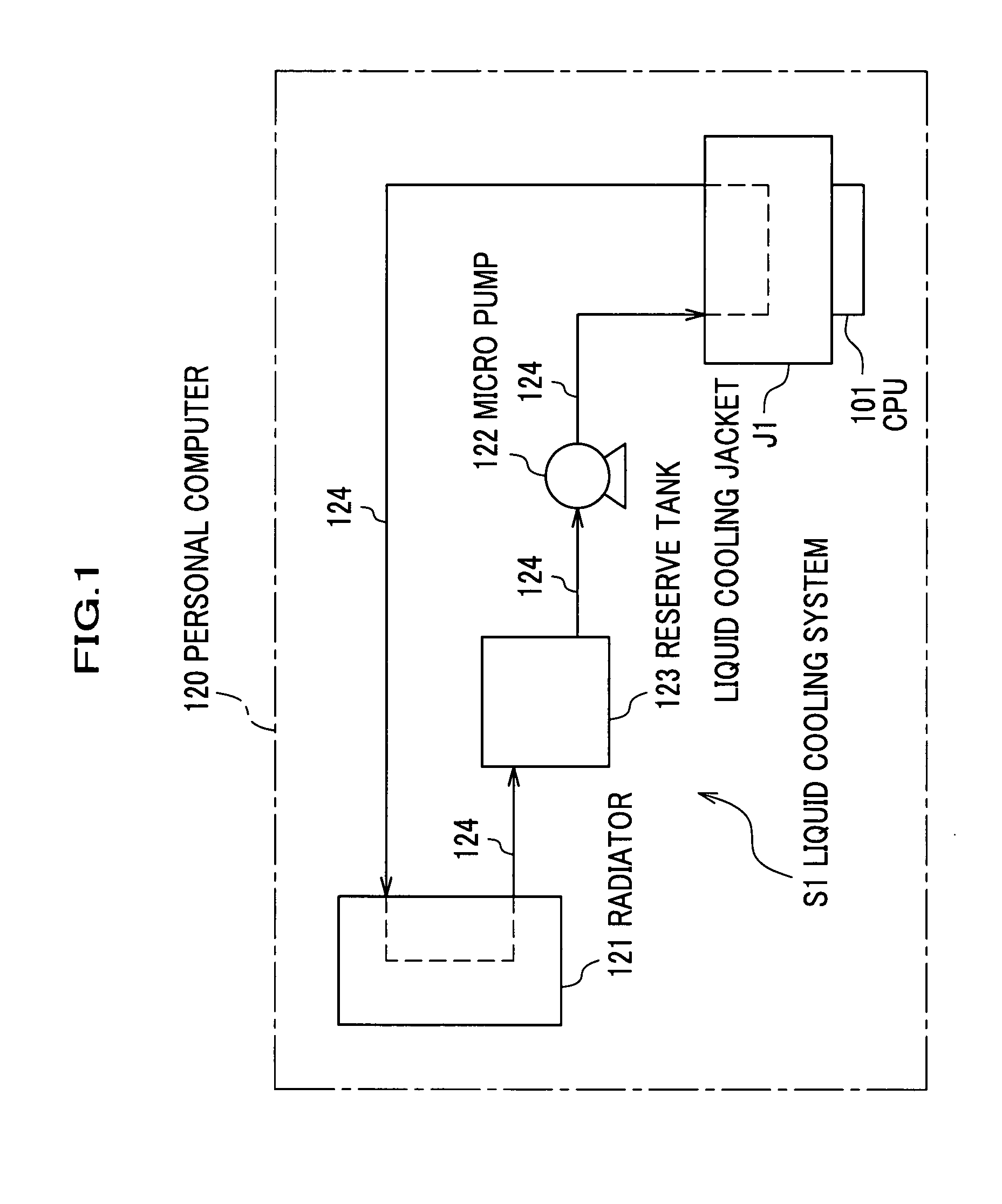

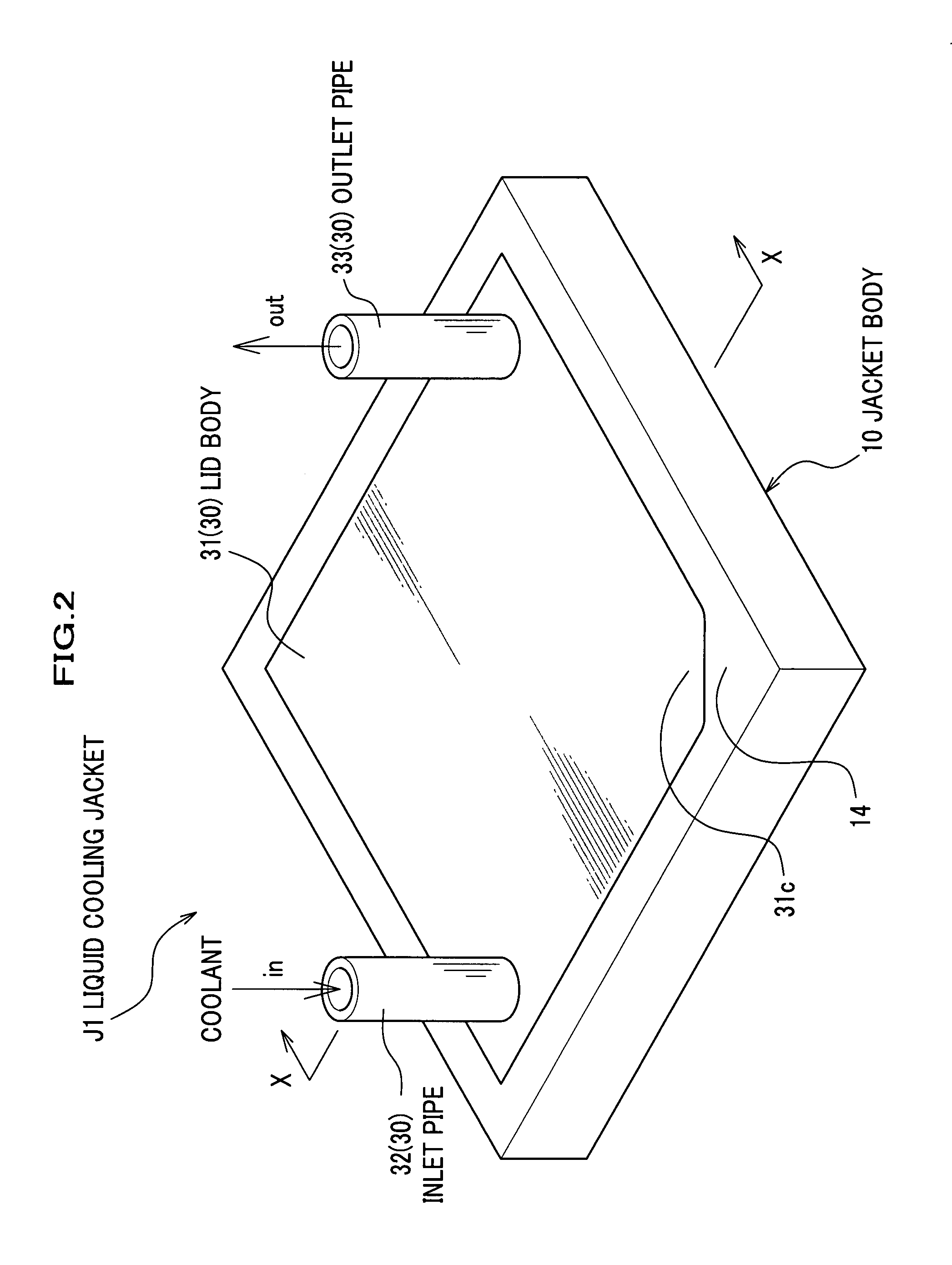

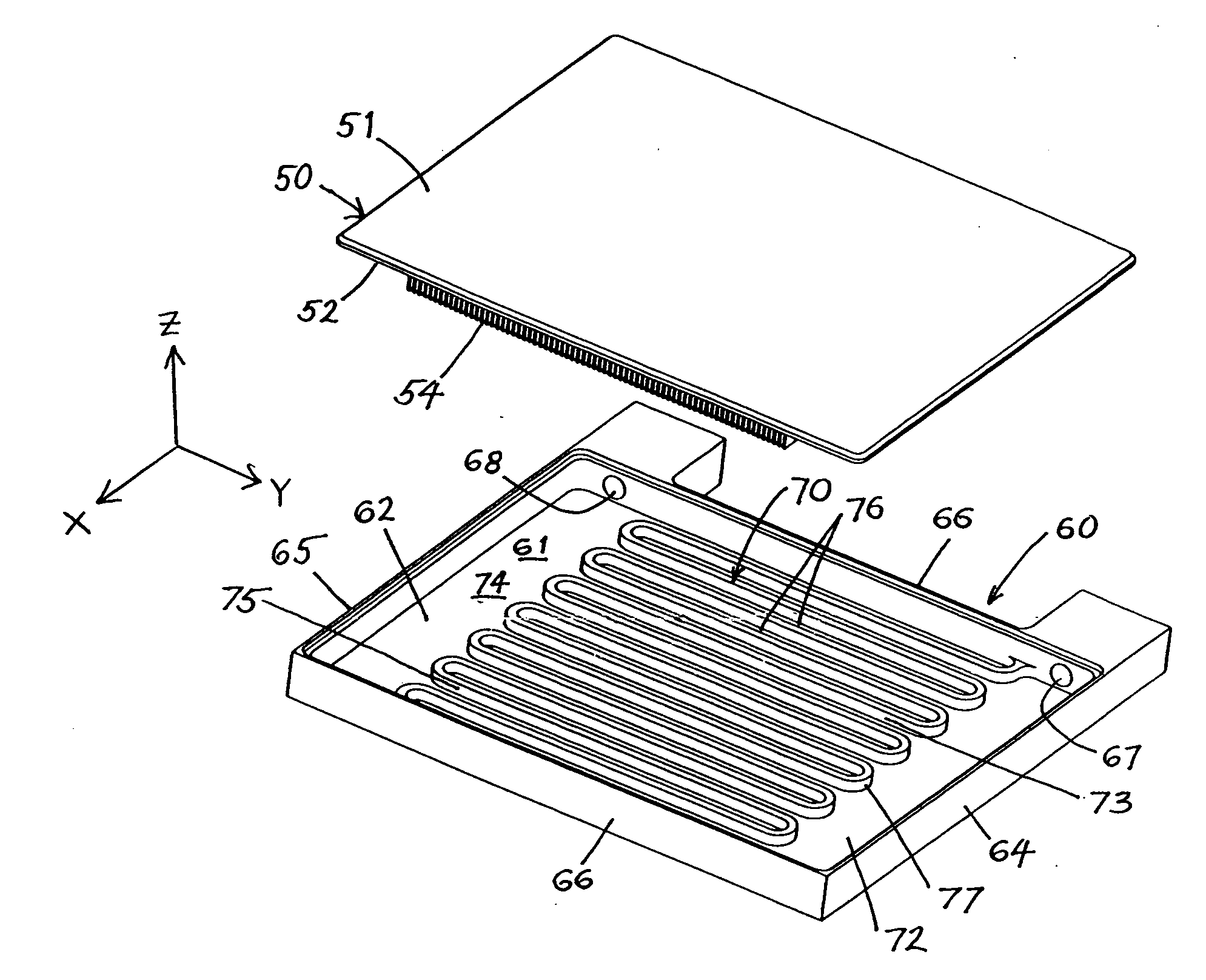

Liquid cooling jacket

InactiveUS20090065178A1Reduce the temperatureHeat dissipationSemiconductor/solid-state device detailsSolid-state devicesHeat transmissionEngineering

A liquid cooling jacket (J1) transmits heat generated by a CPU (101) which is installed at a predetermined position to coolant supplied from an external heat transmission fluid supply means and flowing inside of the liquid cooling jacket. The liquid cooling jacket includes a first flow passage (A1) on a side of the heat transmission fluid supply means, a second flow passage group (B1) including a plurality of second flow passages (B1a) branched from the first flow passage (A1), and a third flow passage (C1) installed at downstream side of the plurality of the second flow passages (B1a), and collecting the plurality of the second flow passages (B1a), wherein the CPU (101) mainly dissipates the heat to the second flow passage group (B1).

Owner:NIPPON LIGHT METAL CO LTD

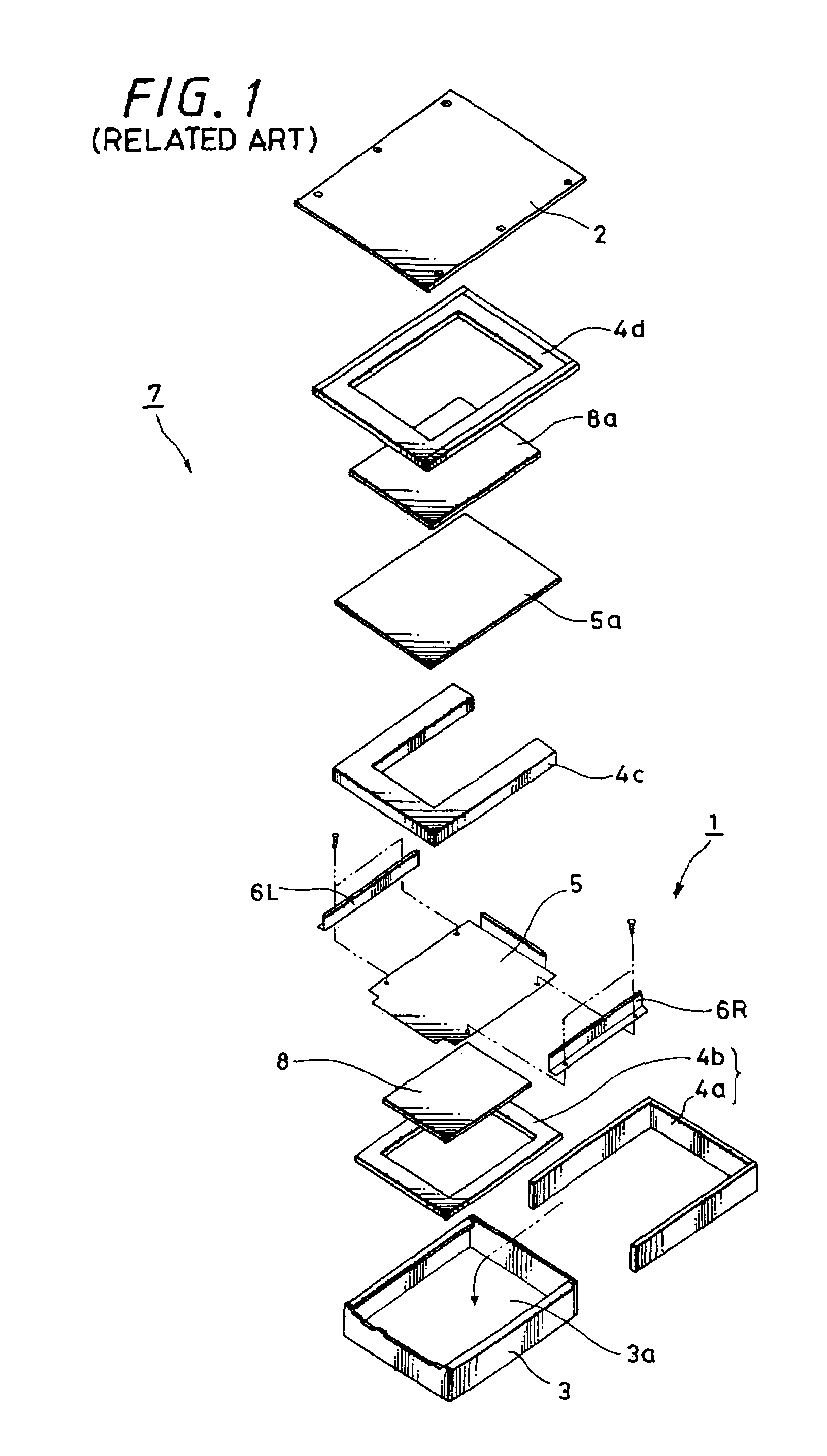

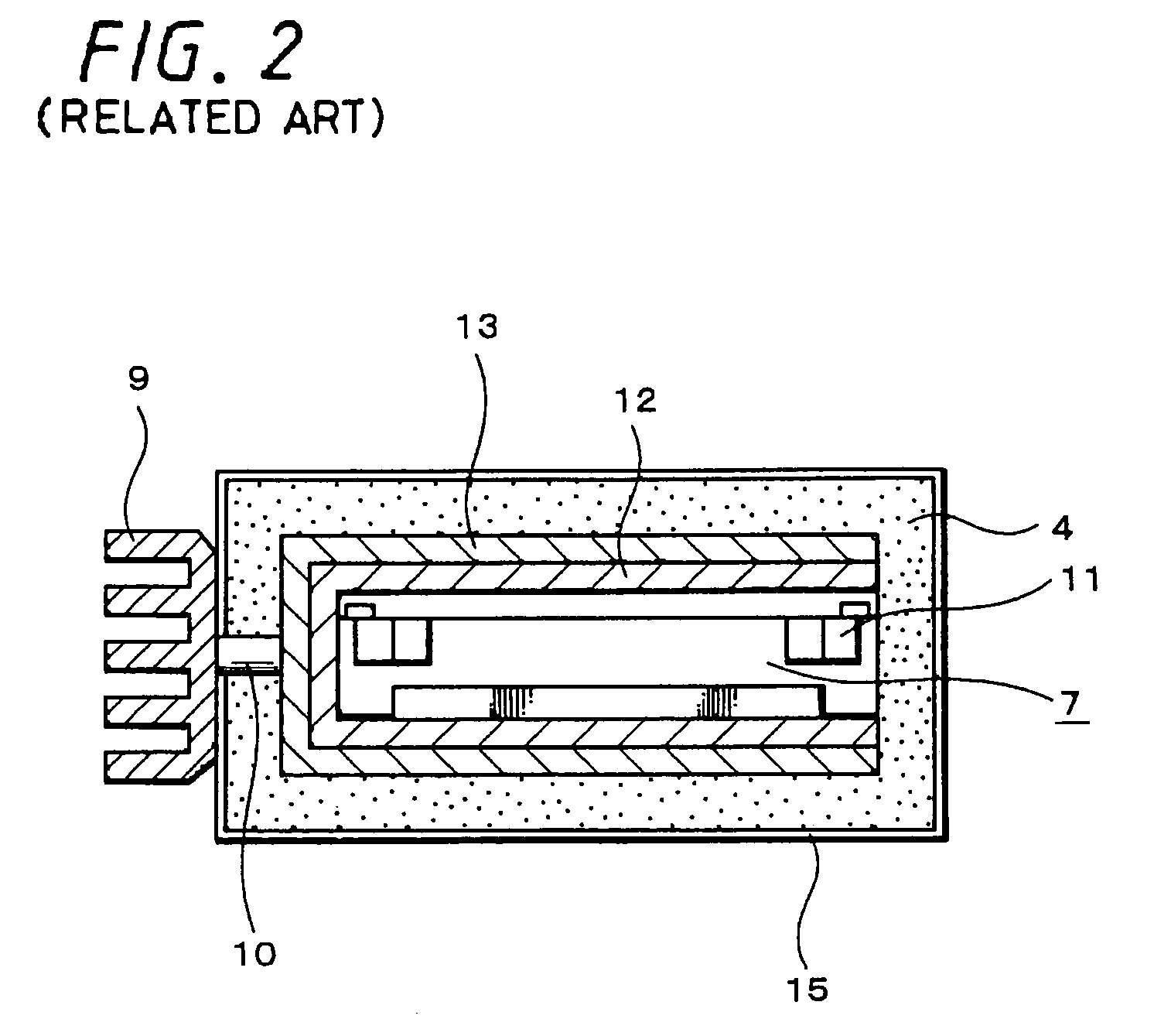

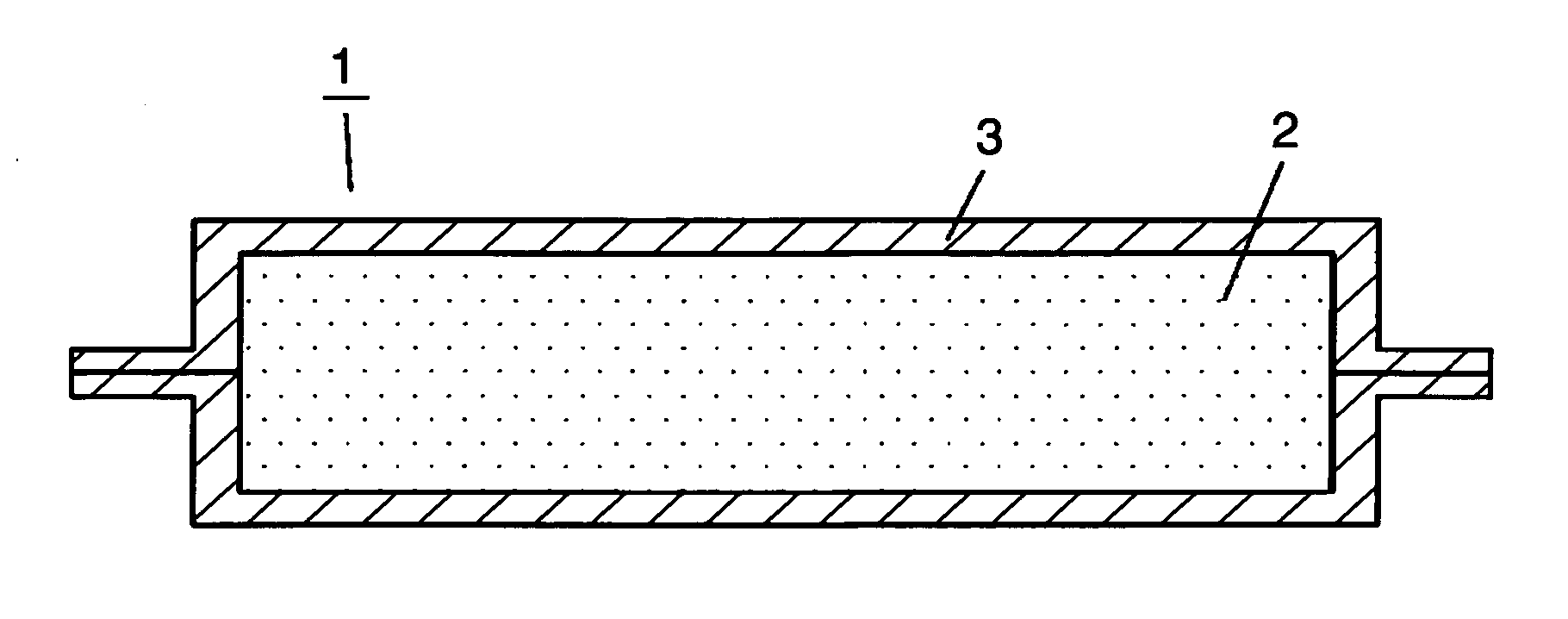

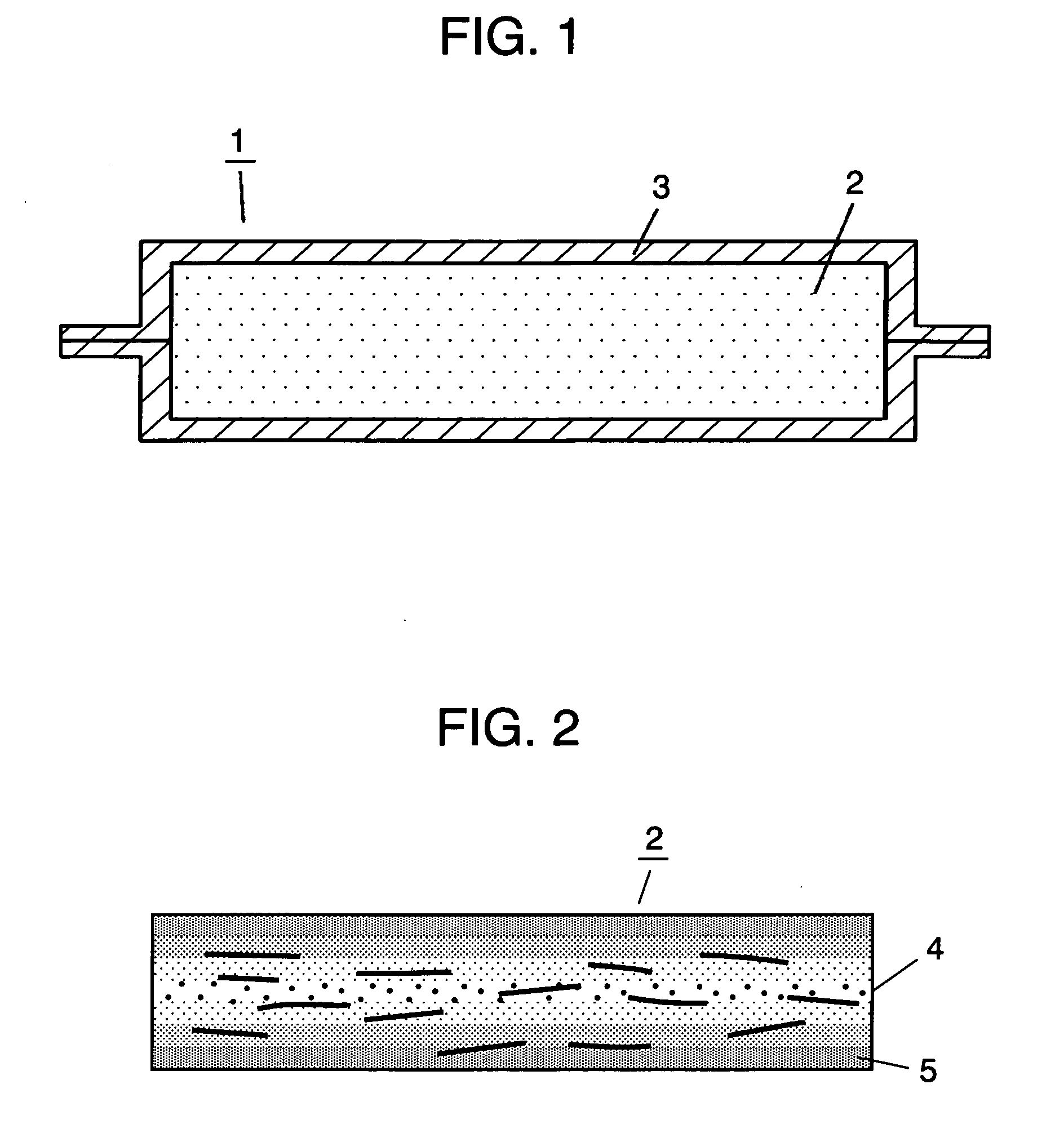

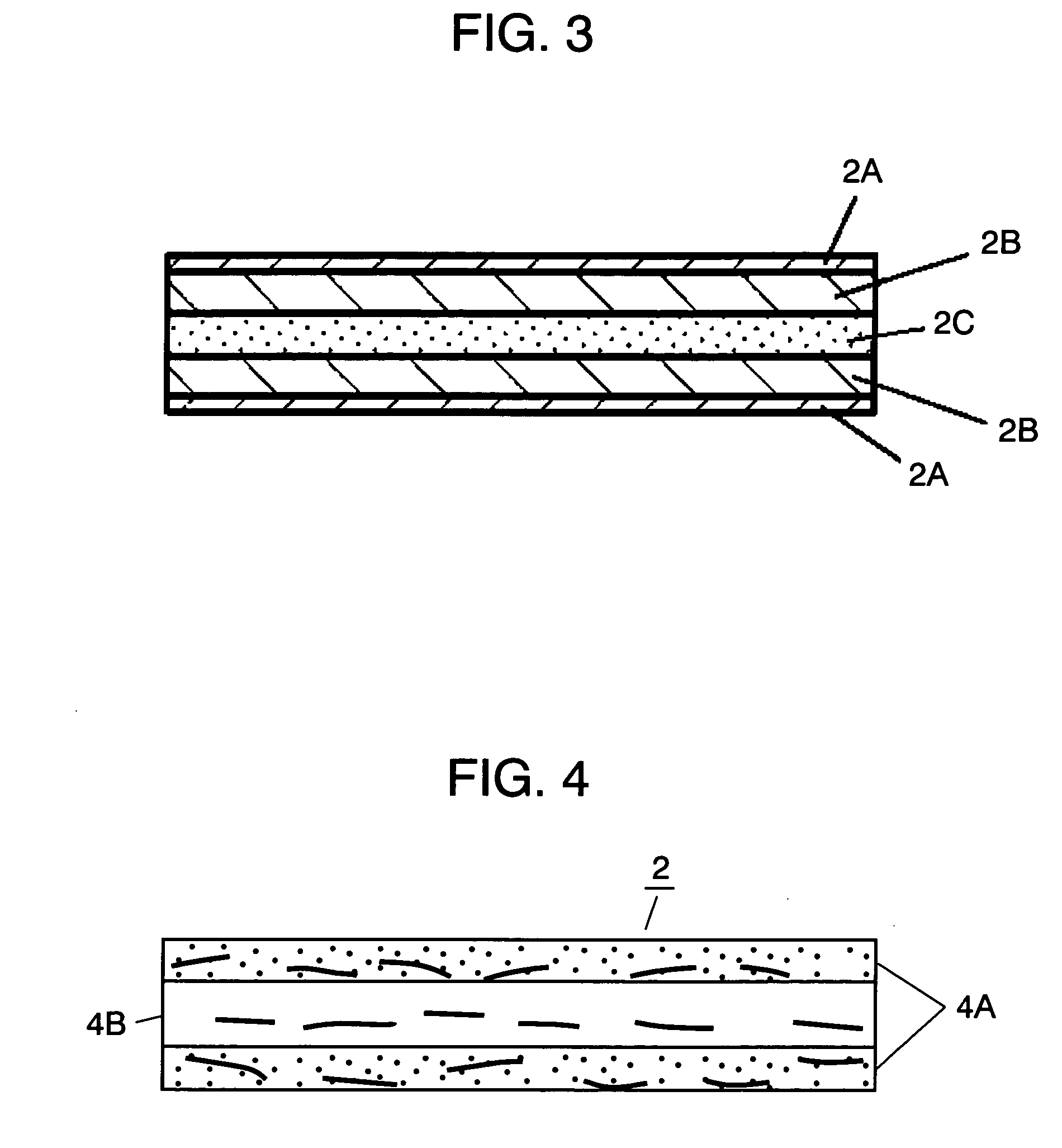

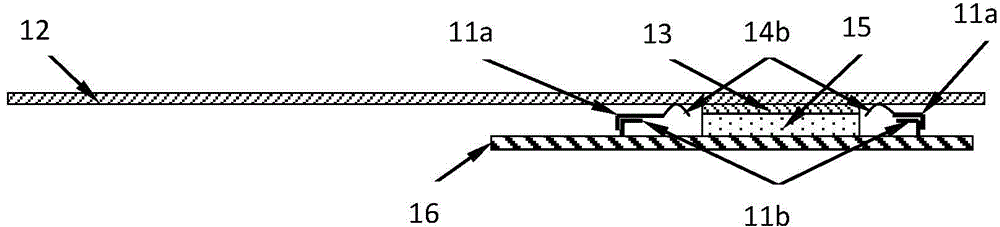

Vacuum thermal insulating material, process for producing the same and refrigerator including the same

A vacuum heat insulator according to the present invention includes a core molded to be plate-shaped with the use of a binding agent. The vacuum heat insulator assumes any one of the following configurations. A) The core is formed by curing a fiber aggregate by means of a binding agent. The fibers have an average fiber diameter of at least 0.1 μm but at most 10 μm, and voids defined by fibers have a void diameter of at most 40 μm. The core has a percentage of the voids of at least 80%. B) The binding agent is varied in concentration in a through-thickness direction of the core. C) A cured layer solidified by the binding agent is formed on at least one side surface of the core. D) The core contains fibers having a length of at most 100 μm. The fibers are oriented perpendicular to a direction of heat transmission. Such vacuum heat insulator is excellent in adiabatic property. Refrigerators, to which such a vacuum heat insulator is applied, are made small in size, or have a large inner volume, or contribute to energy saving.

Owner:PANASONIC CORP

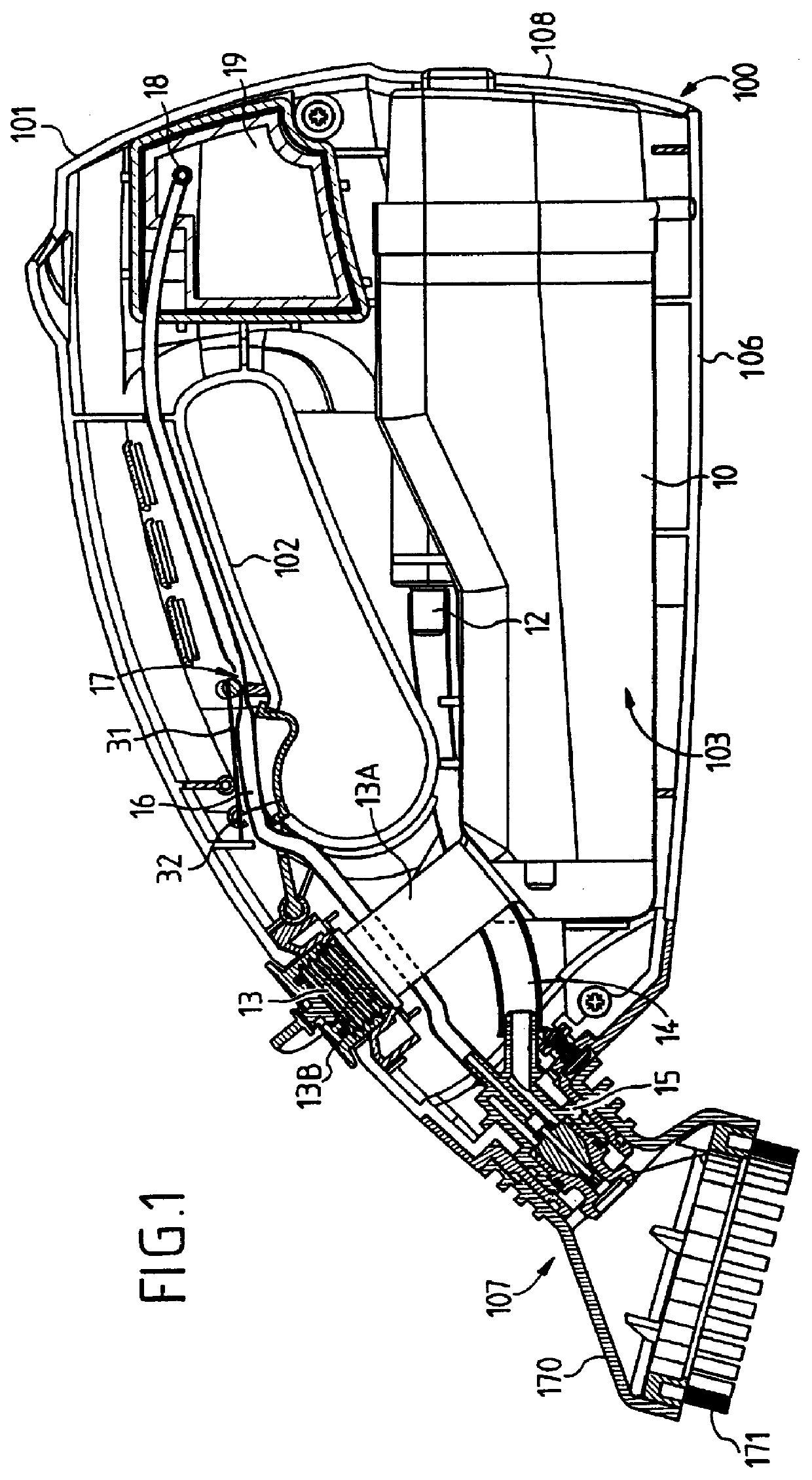

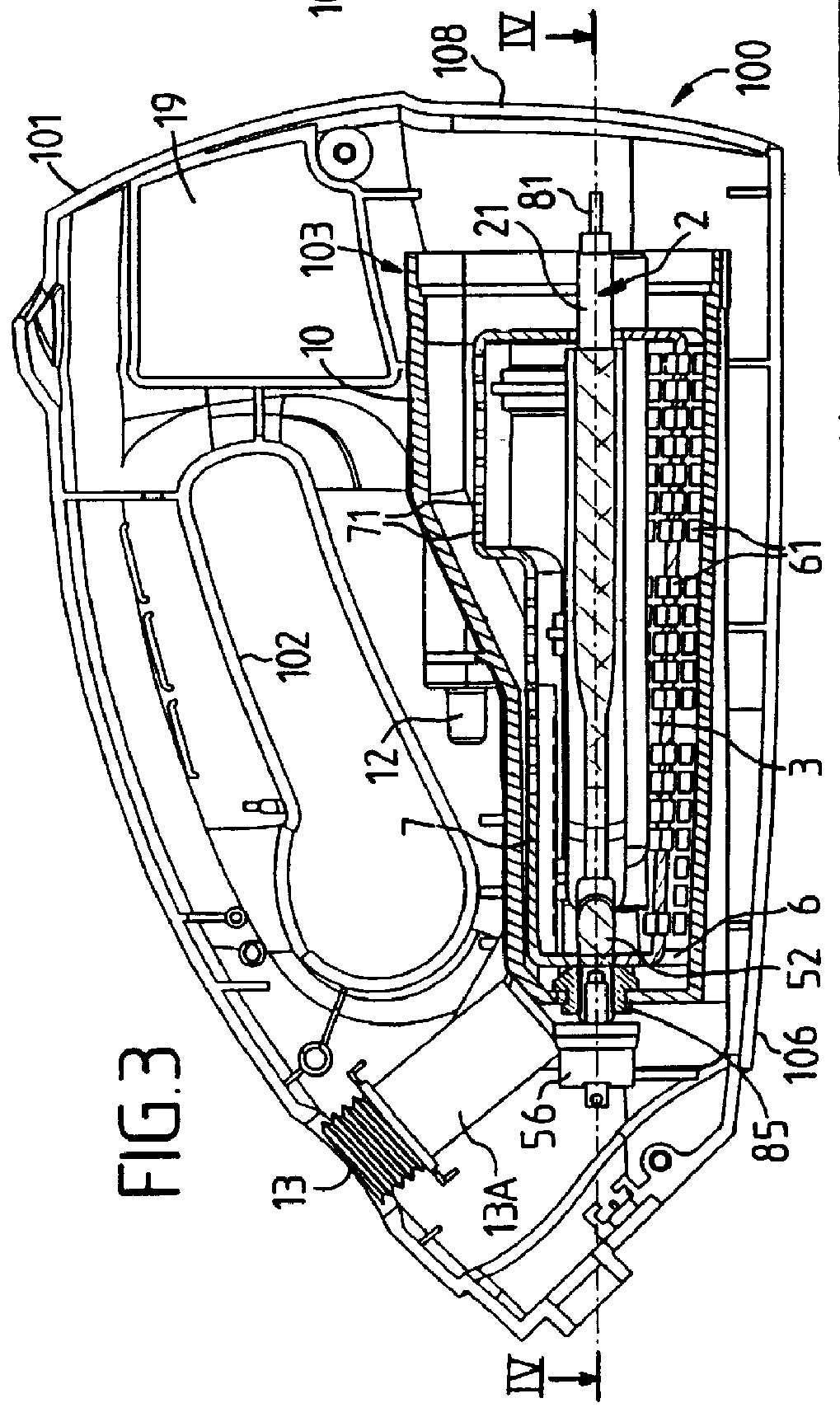

Omnidirectional portable appliance for steam cleaning hard or flexible surfaces

InactiveUS6031969ALow costStart fastUsing liquid separation agentCleaning machinesElectricityElectrical resistance and conductance

The omnidirectional portable appliance for steam cleaning surfaces both hard and flexible, comprises a case provided with a handle, a water feed orifice, an electricity power cord, a cleaning head, a steam generator included in the case and a venturi device [means for selectively] delivering steam to the cleaning head. The instantaneous steam generator having low thermal inertia operates at atmospheric pressure and comprises a capillary body for storing in divided form all of the supply of water to be evaporated, [in divided form] the capillary body being compressed around [the electrical heater means which comprise] a [metal-clad] resistance element and a heater body constituted by a [having a] material that is a good conductor of heat, is overmolded on the resistance element and [thereon to form a heater body which] is associated with at least one heat transmission element connected to [the] a hottest portion of the heater body and provided with a temperature sensor enabling the control of power fed to the [metal-clad] resistance element to be optimized so as to be safe regardless of the orientation in three dimensions of the steam generator.

Owner:SUPERBA SAS

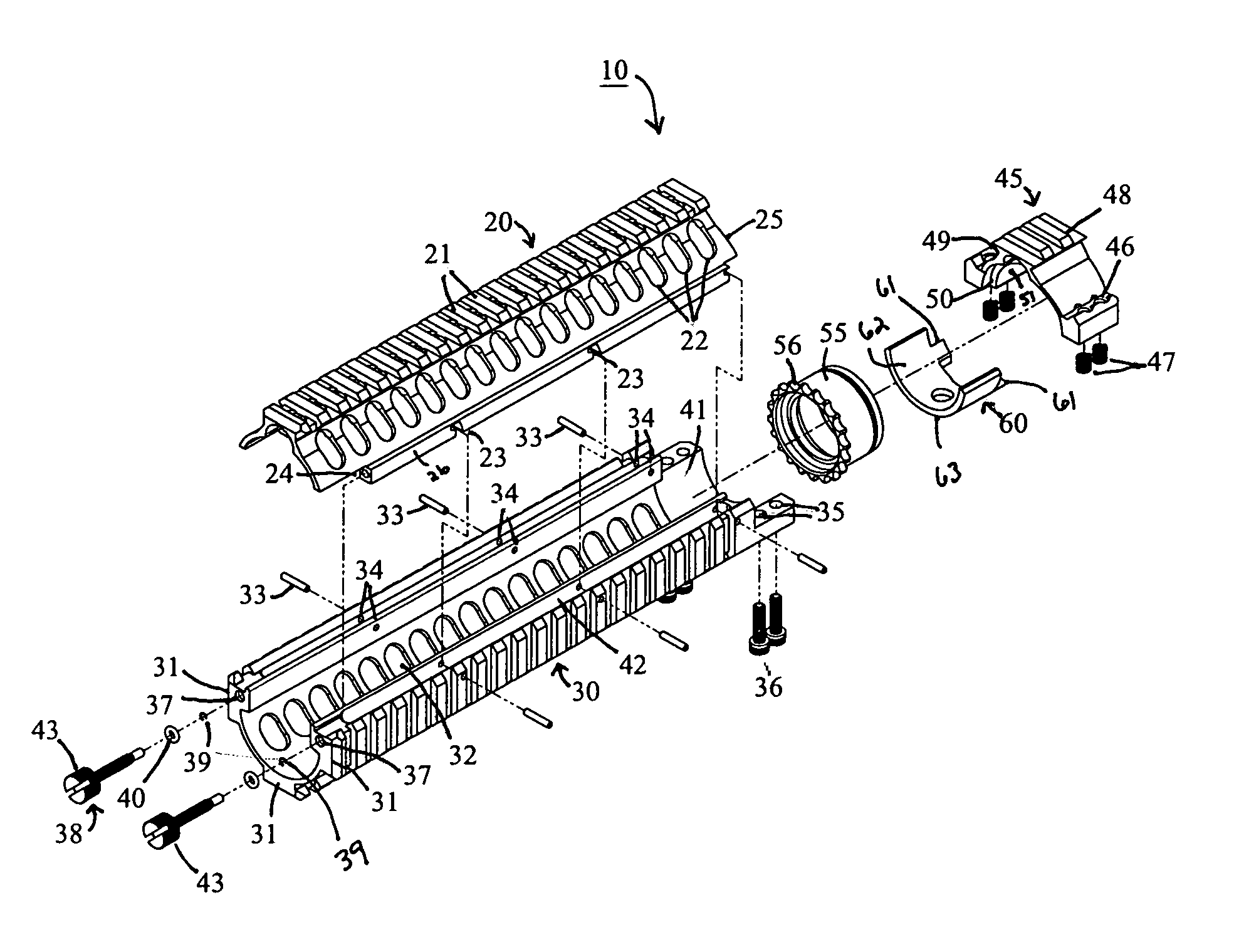

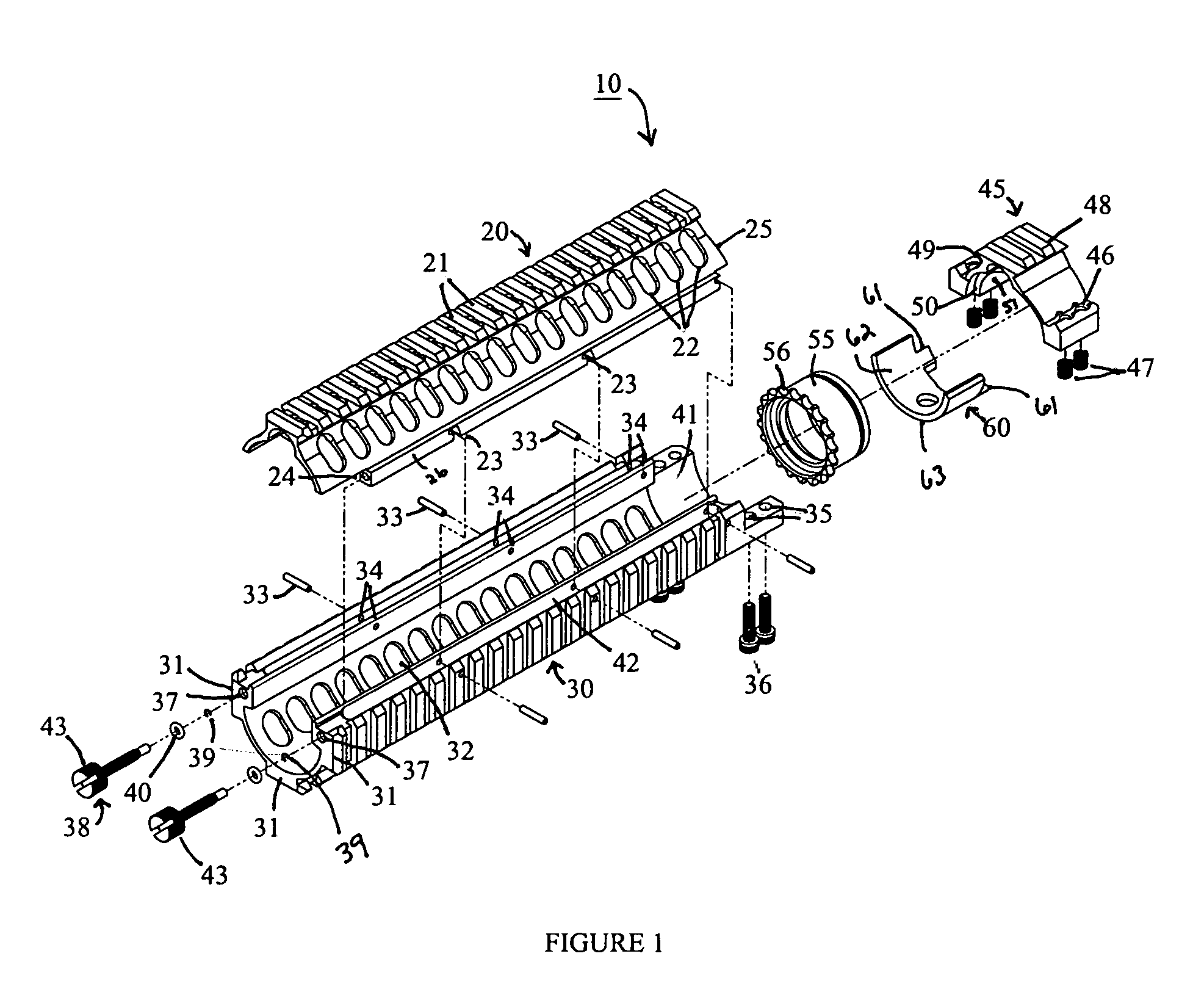

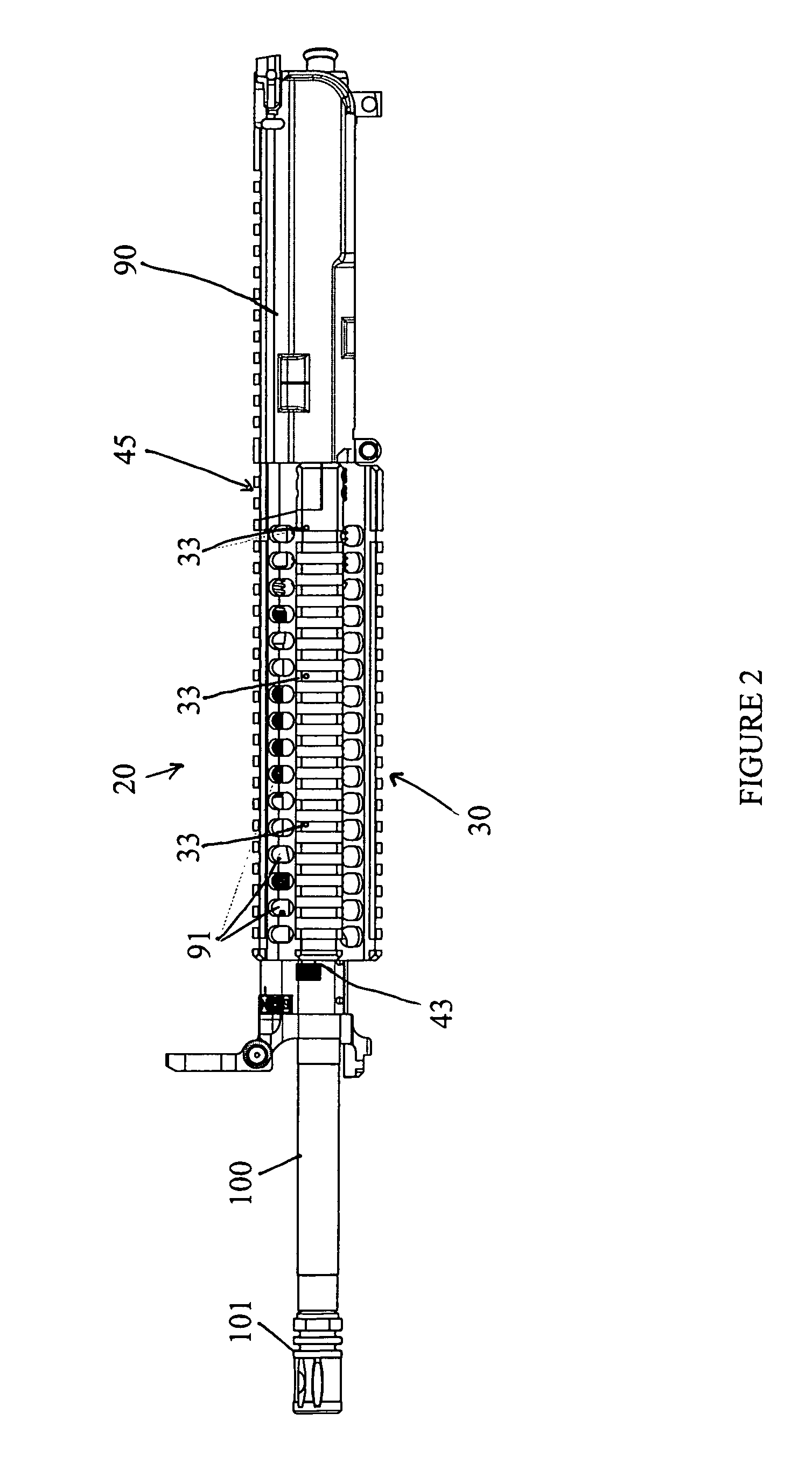

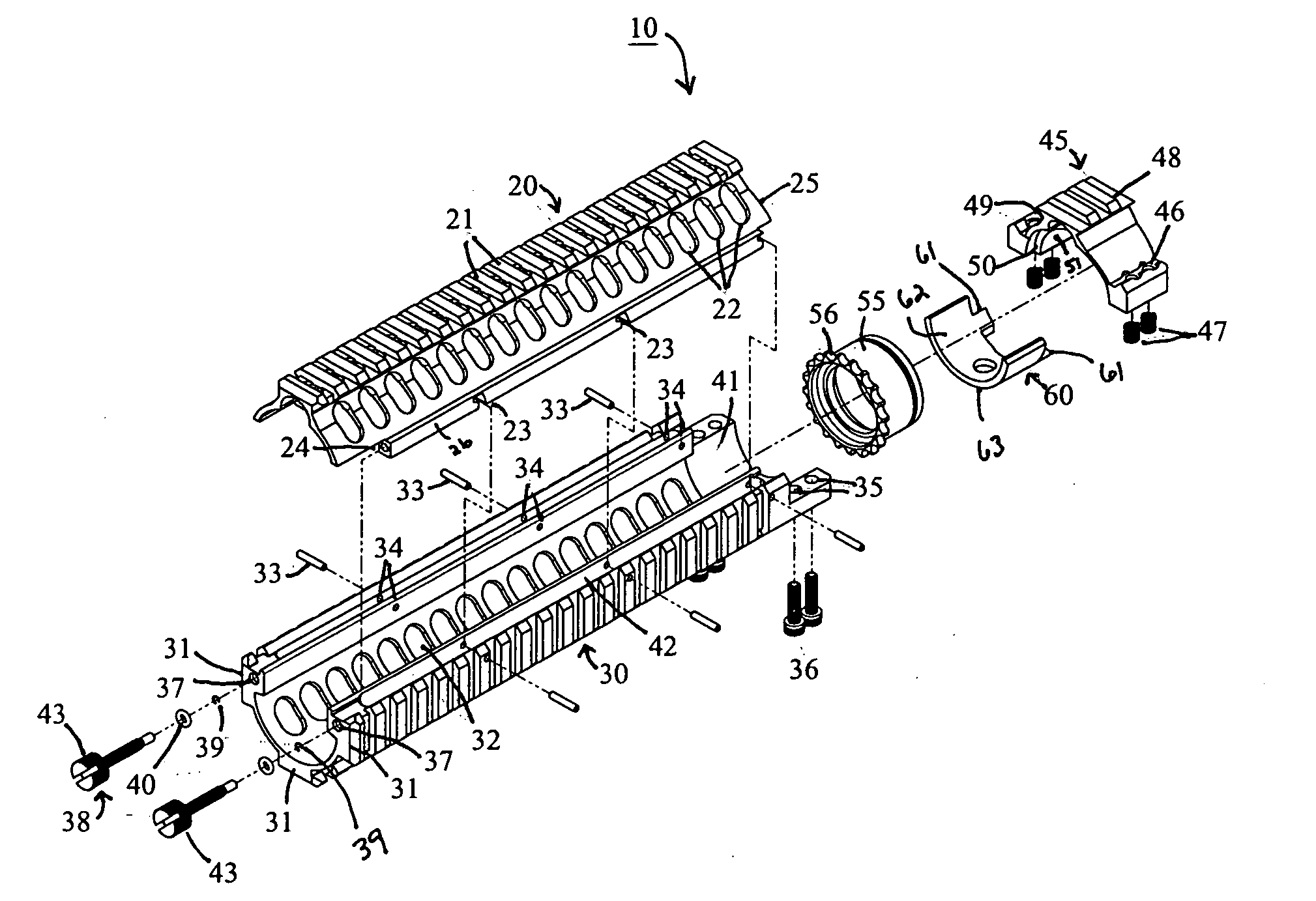

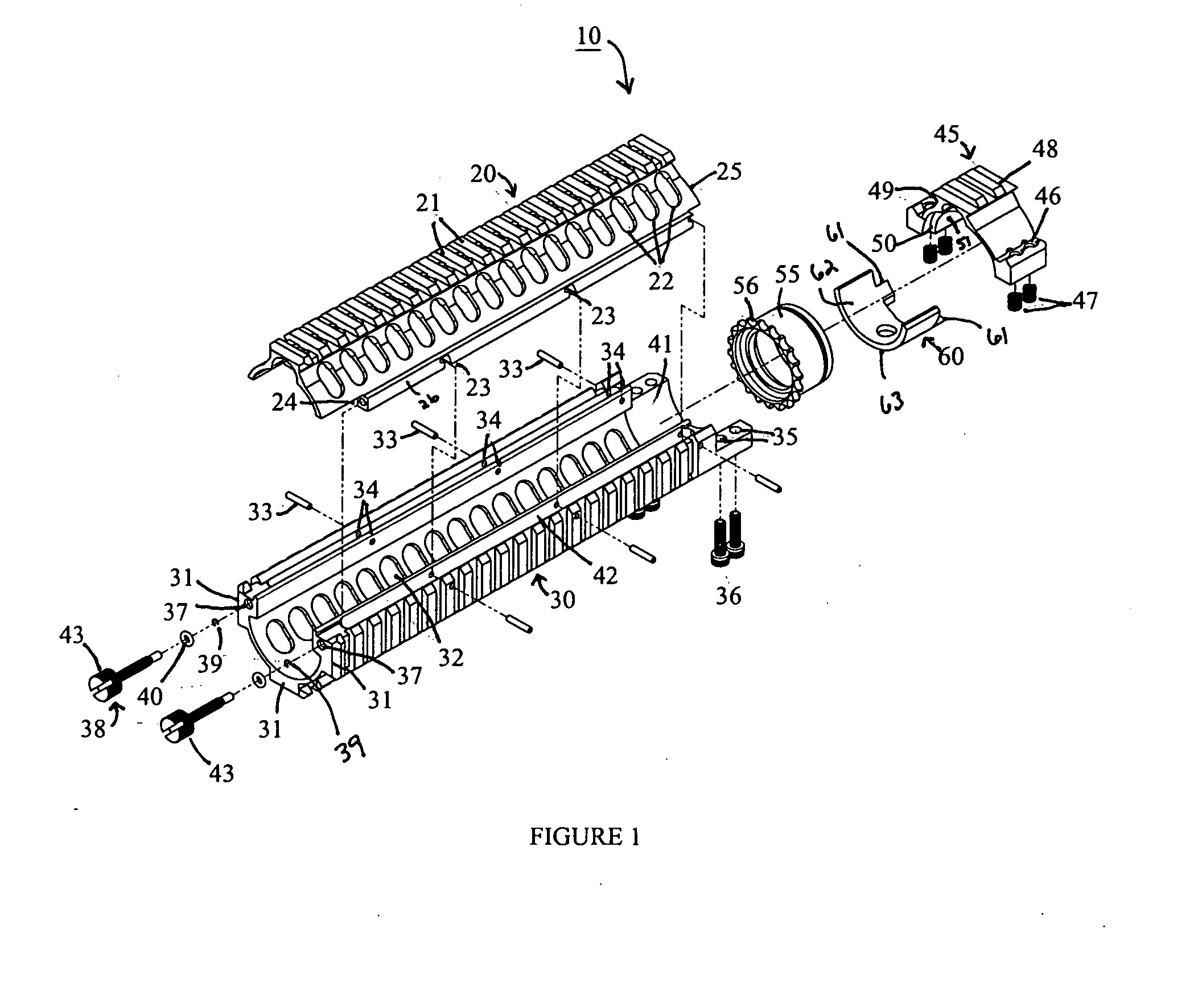

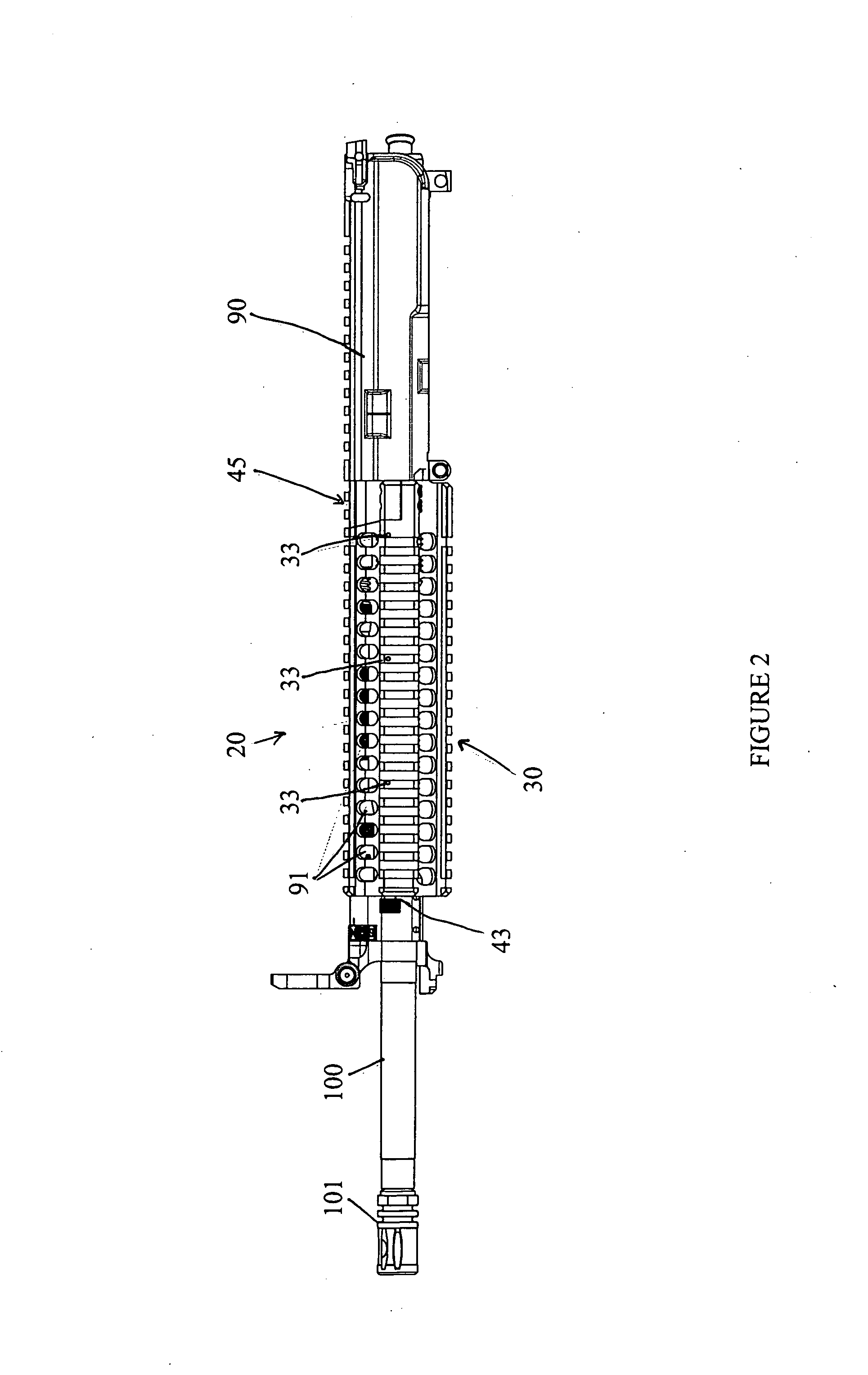

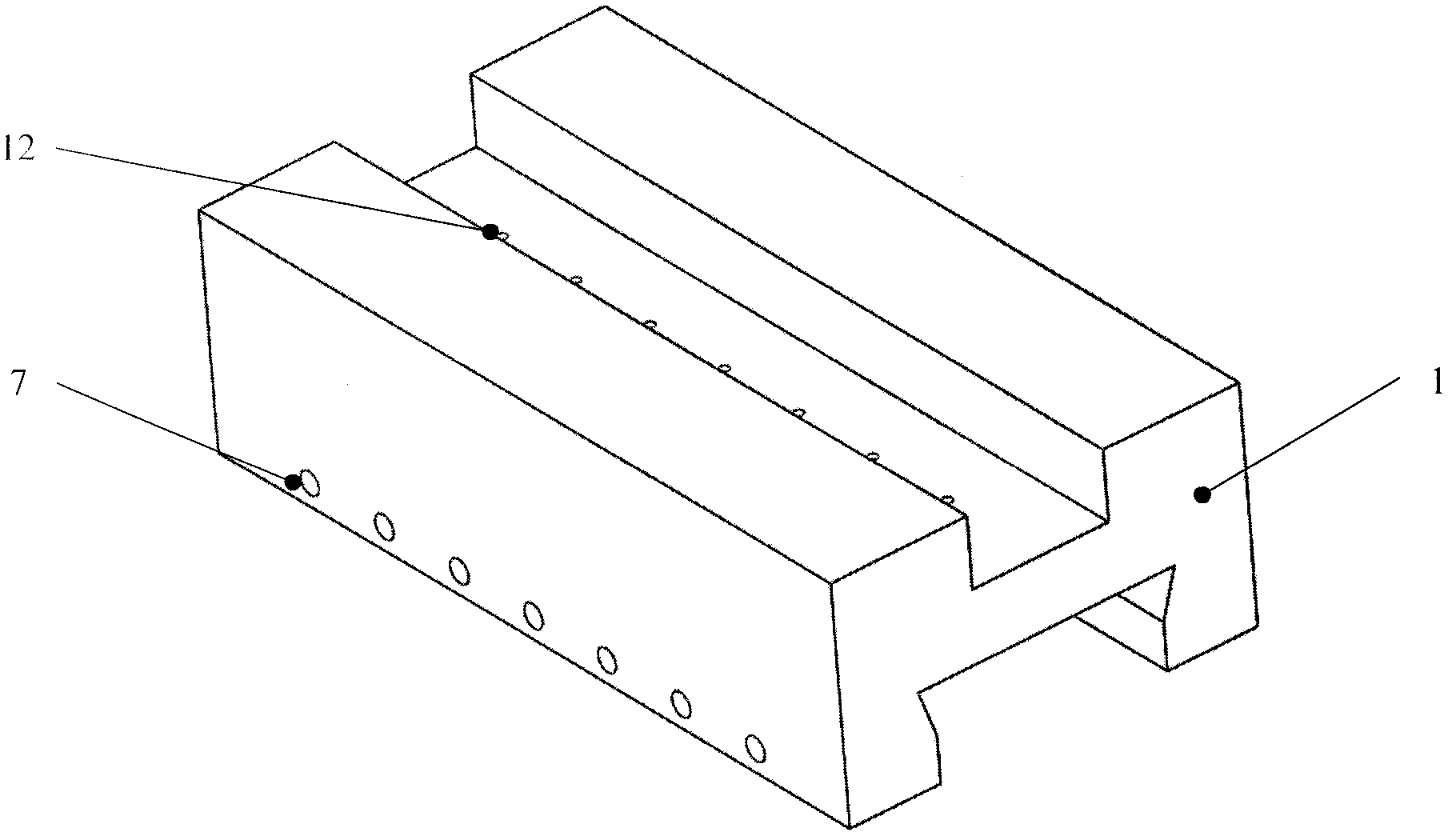

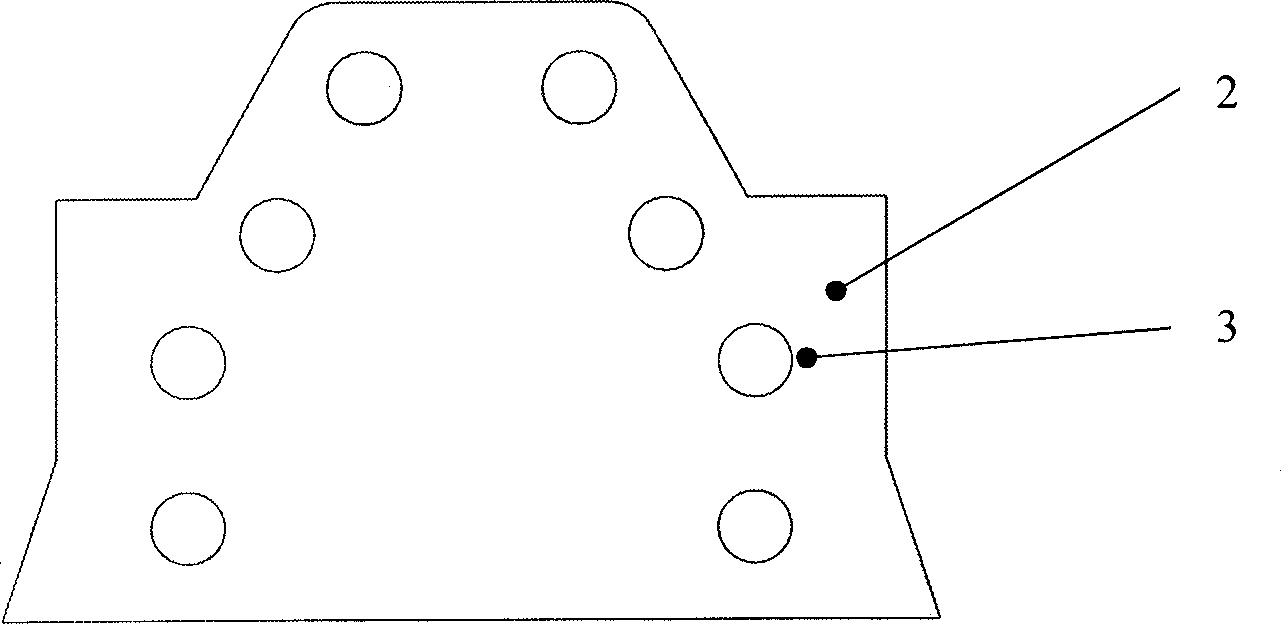

Top opening, modular top rail, multi-rifle adaptable free float rail adaptor system (ARM-R)

An improved Rail Adaptor System / Rail Accessory System (RAS) which attaches to a firearm. The rail is top opening, modular, and free floats the barrel. Provided is a rigid, lightweight, strong platform for mounting firearm accessories. Heat transmission from the barrel assembly to the user is limited. The user is also protected from ventilated gases originating from the operating system. A quick detachable top rail section is provided so that that gas system may be easily accessed. This removable top section of the rail is what makes this device unique because the RAS may be installed without removing the barrel, gas system, front sight base, flash hider or the barrel nut. The herein described RAS is adaptable to a wide variety of firearms with the use of conversion parts. The top rail “returns to zero” on reinstallation allowing the remounting of various optics and electronic gun sites without the need to realign them.

Owner:LWRC INTERNATIONAL

Top opening, modular top rail, multi-rifle adaptable free float rail adaptor system (arm-r)

ActiveUS20120042557A1Minimizing transferImprove ventilationCartridge extractorsWeapon cleaningReturn-to-zeroHeat transmission

An improved Rail Adaptor System / Rail Accessory System (RAS) which attaches to a firearm. The rail is top opening, modular, and free floats the barrel. Provided is a rigid, lightweight, strong platform for mounting firearm accessories. Heat transmission from the barrel assembly to the user is limited. The user is also protected from ventilated gases originating from the operating system. A quick detachable top rail section is provided so that that gas system may be easily accessed. This removable top section of the rail is what makes this device unique because the RAS may be installed without removing the barrel, gas system, front sight base, flash hider or the barrel nut. The herein described RAS is adaptable to a wide variety of firearms with the use of conversion parts. The top rail “returns to zero” on reinstallation allowing the remounting of various optics and electronic gun sites without the need to realign them.

Owner:LWRC INTERNATIONAL

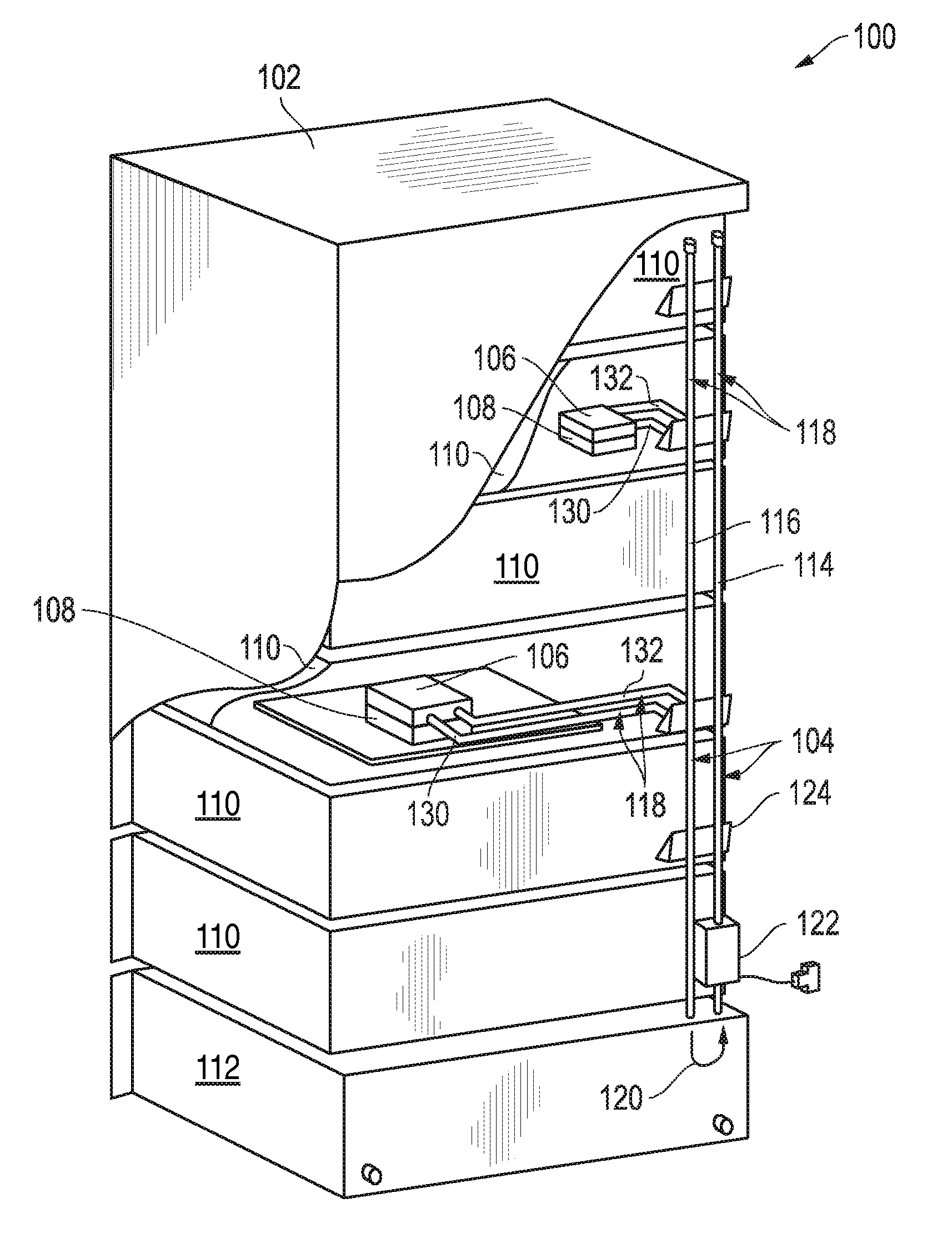

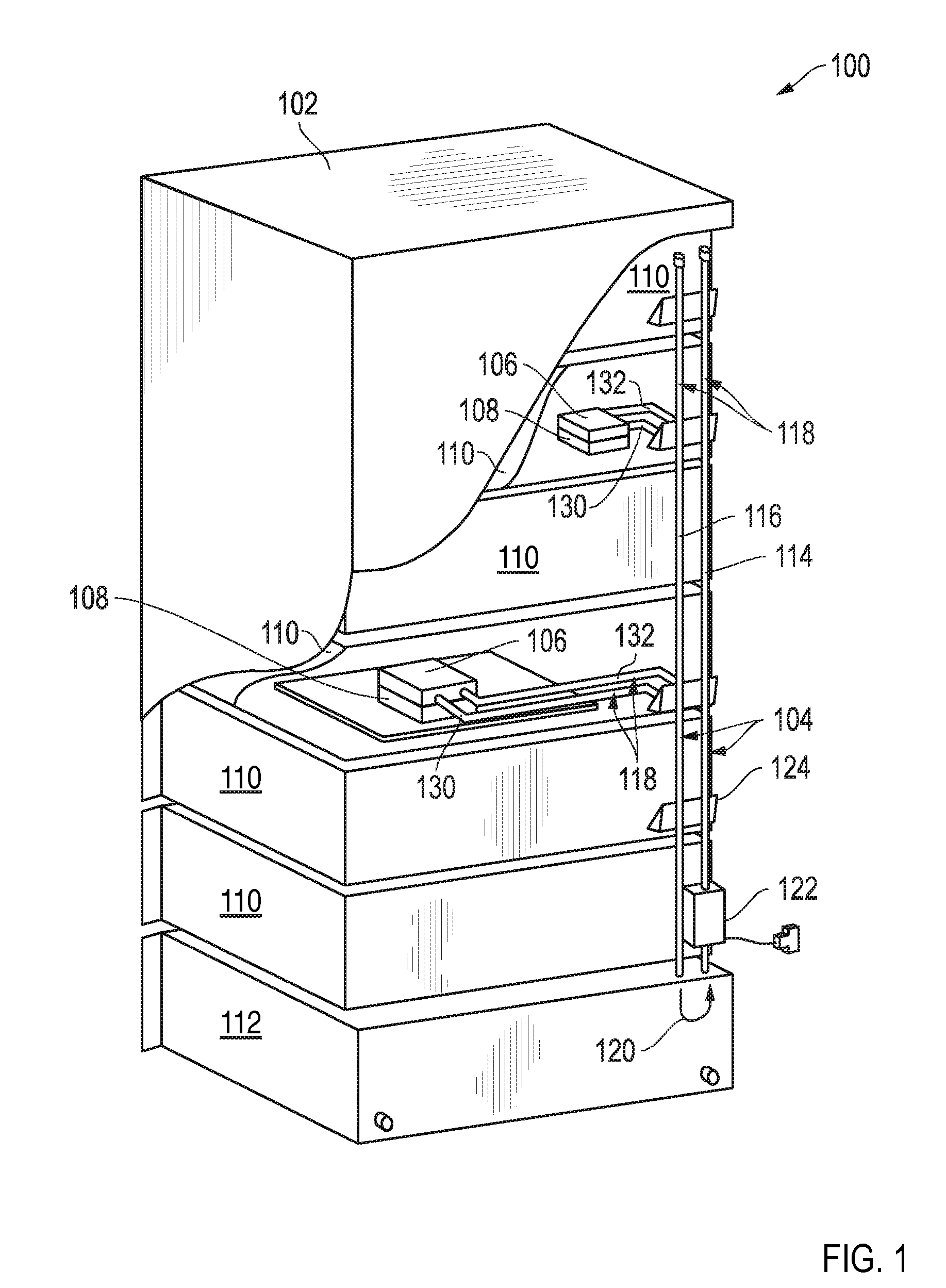

Heat Transfer Systems for Dissipating Thermal Loads From a Computer Rack

Heat transfer systems for dissipating thermal loads from a computer rack are disclosed that include: an expandable heat transfer bus extending along the rack, the expandable heat transfer bus capable of passing a thermal transport; one or more heat sinks connected to the expandable heat transfer bus, each heat sink capable of receiving the thermal transport from the bus and returning the thermal transport to the bus, and each heat sink capable of transferring into the thermal transport a thermal load from an electronic component inside a rack module mounted to the rack; and a heat exchanger connected to the expandable heat transfer bus capable of dissipating the thermal load of the thermal transport.

Owner:IBM CORP

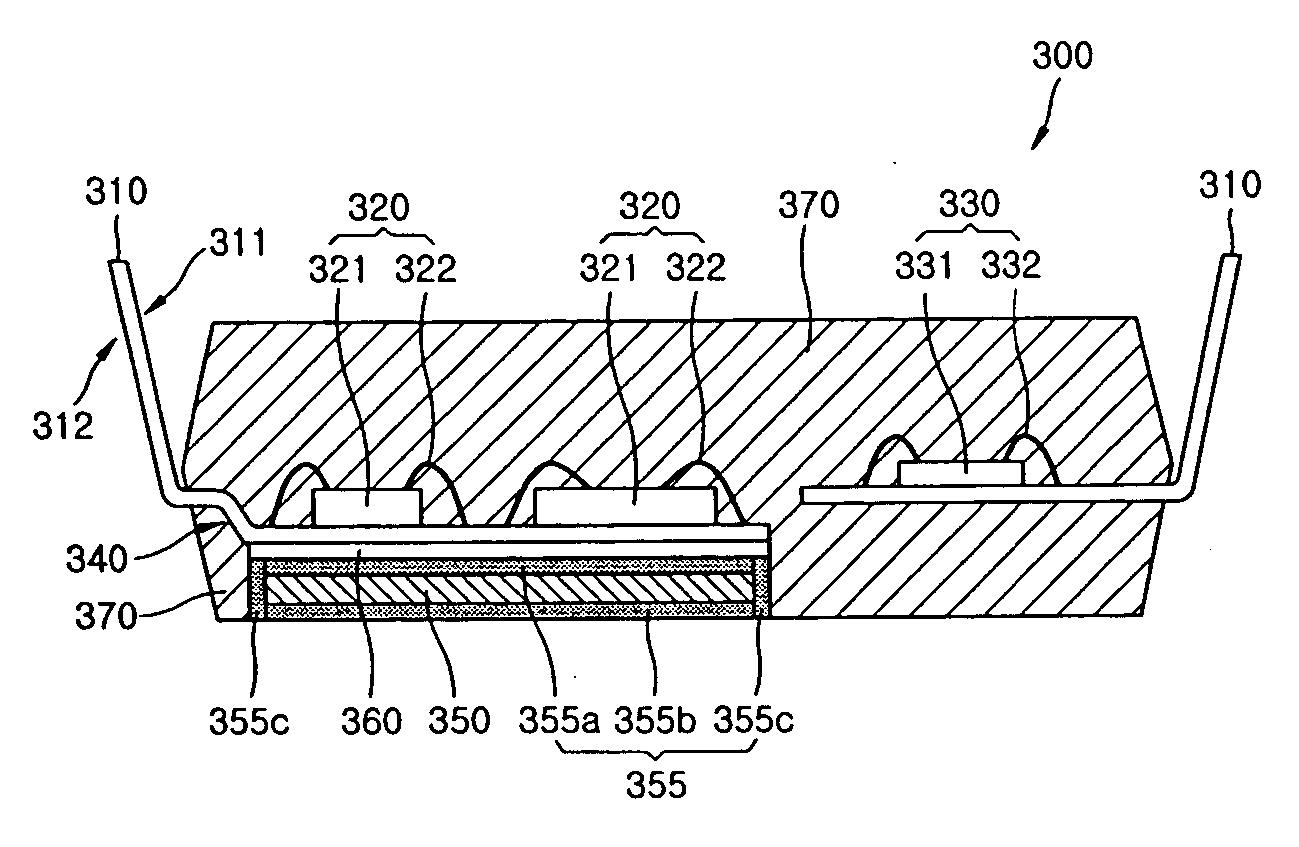

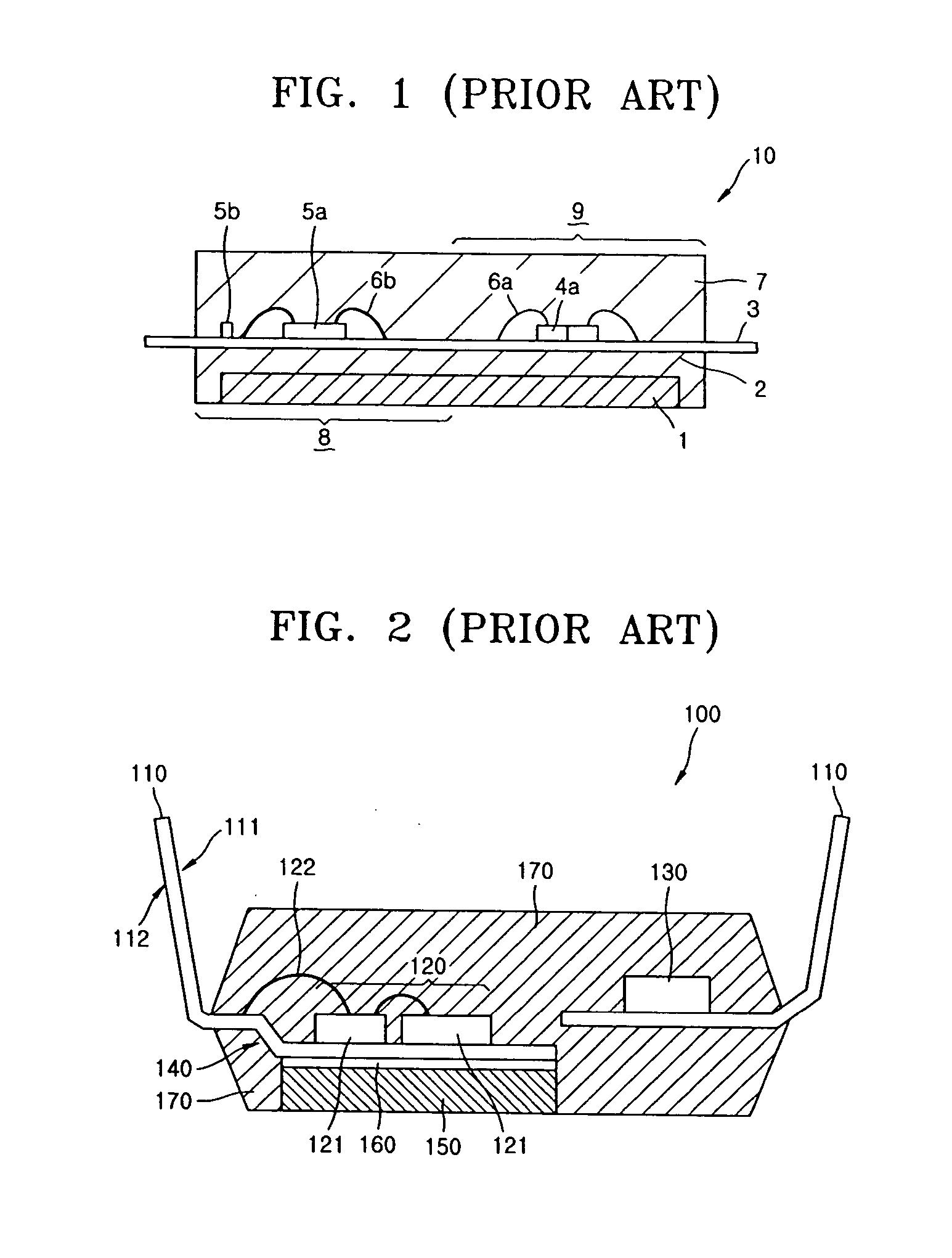

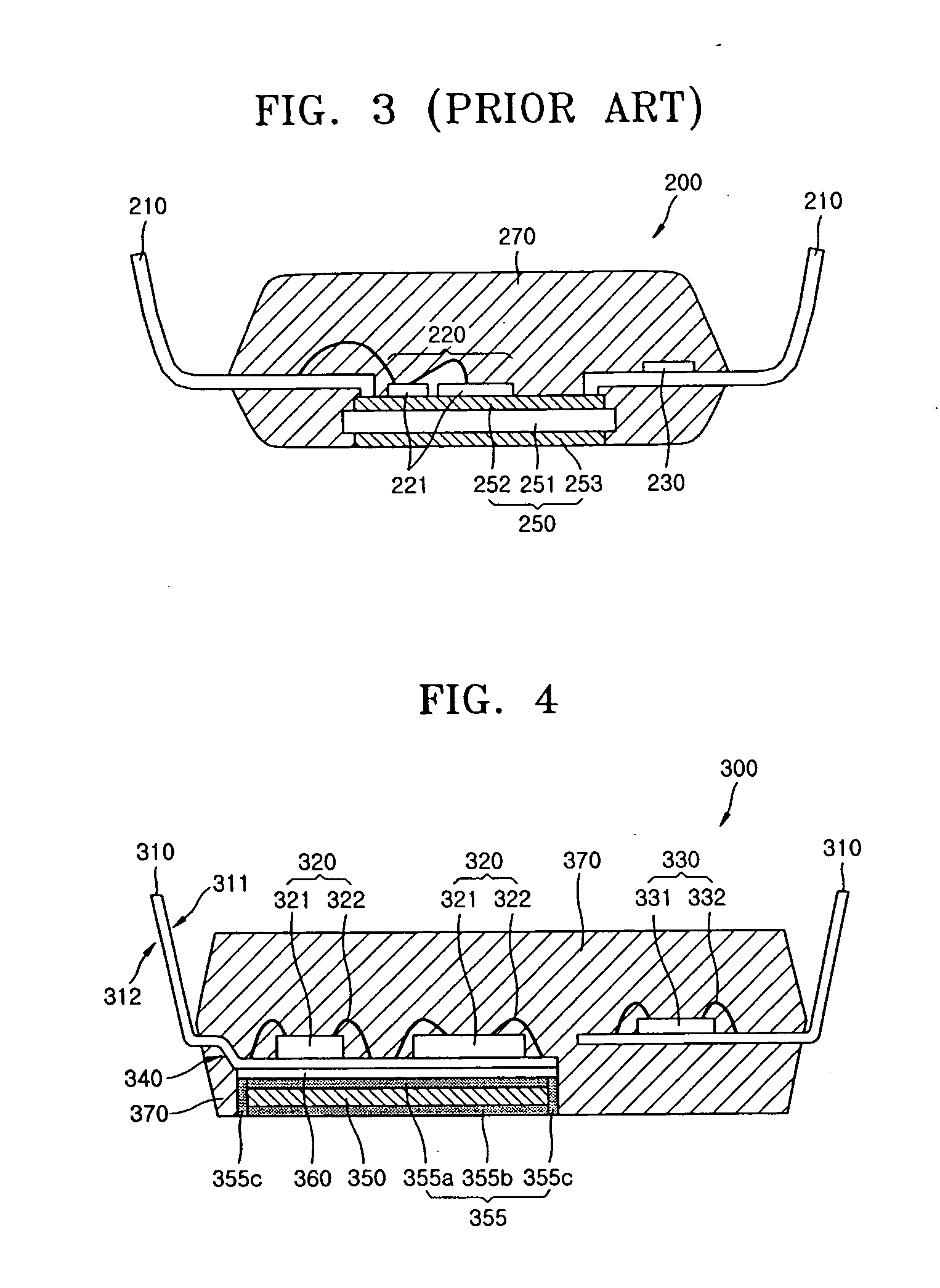

Power module package having excellent heat sink emission capability and method for manufacturing the same

InactiveUS20060056213A1Improve cooling effectLow costSemiconductor/solid-state device detailsSolid-state devicesInsulation layerAdhesive

A power module package includes a power circuit element, a control circuit element, a lead frame, an aluminum oxide substrate having a heat sink and an insulation layer, and a sealing resin. The control circuit element is electrically connected with the power circuit element to control chips within the power circuit element. The lead frame has external connection terminal leads in its edge and has a first surface to which the power circuit element and the control circuit element are attached and a second surface which is used as a heat transmission path. The heat sink is a plate made of metal such as aluminum and the electrical insulation layer is formed at least on an upper surface of the heat sink and made of aluminum oxide. The electrical insulation layer may be formed over an entire surface of the heat sink. Here, the insulation layer is attached to the second surface by an adhesive, on a region below where the power circuit element is attached, to the first surface of the lead frame. In addition, the sealing resin encloses the power circuit element and the control circuit element, the lead frame, and the metal oxide substrate and exposes the external connection terminals of the lead frame.

Owner:FAIRCHILD KOREA SEMICON

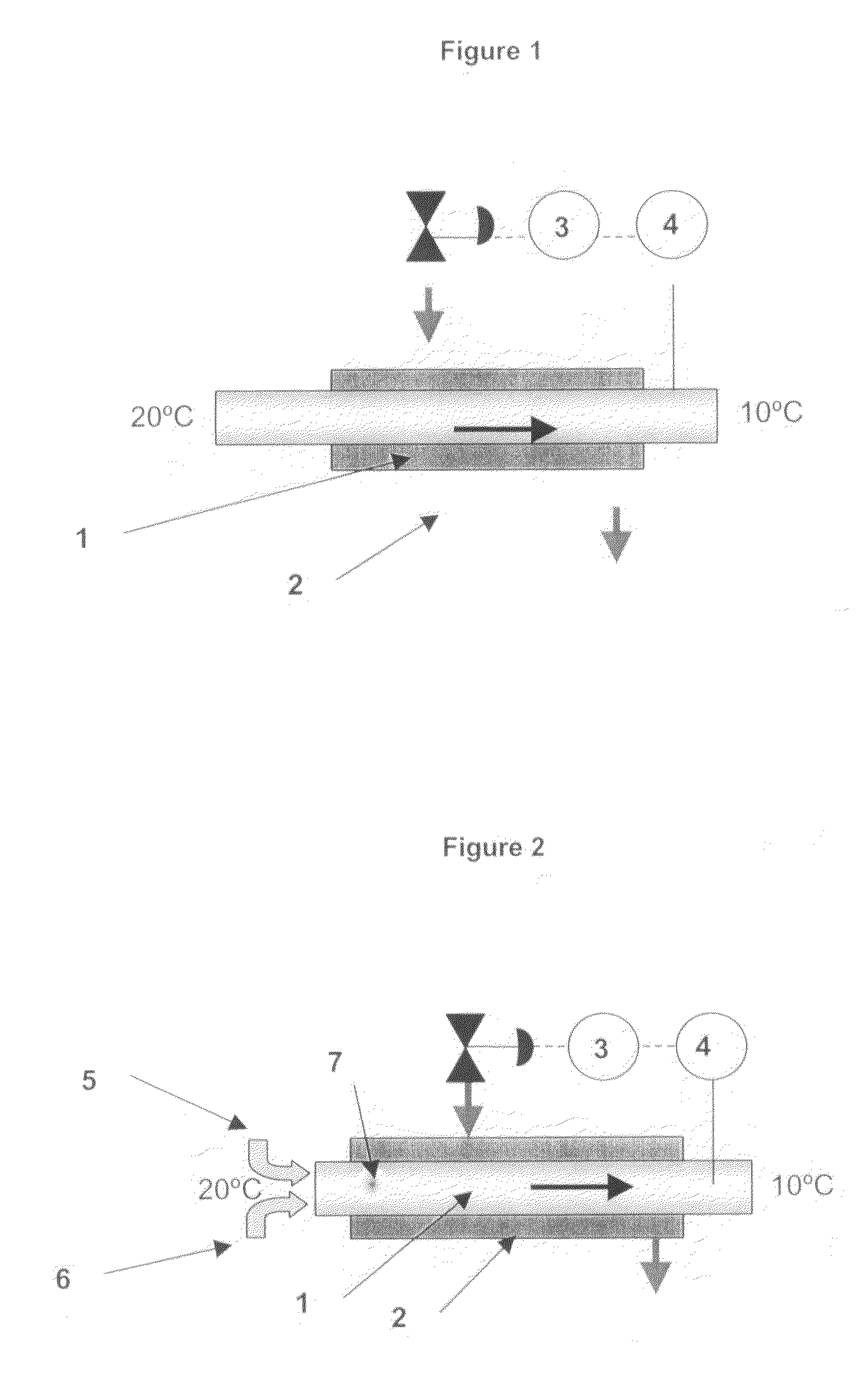

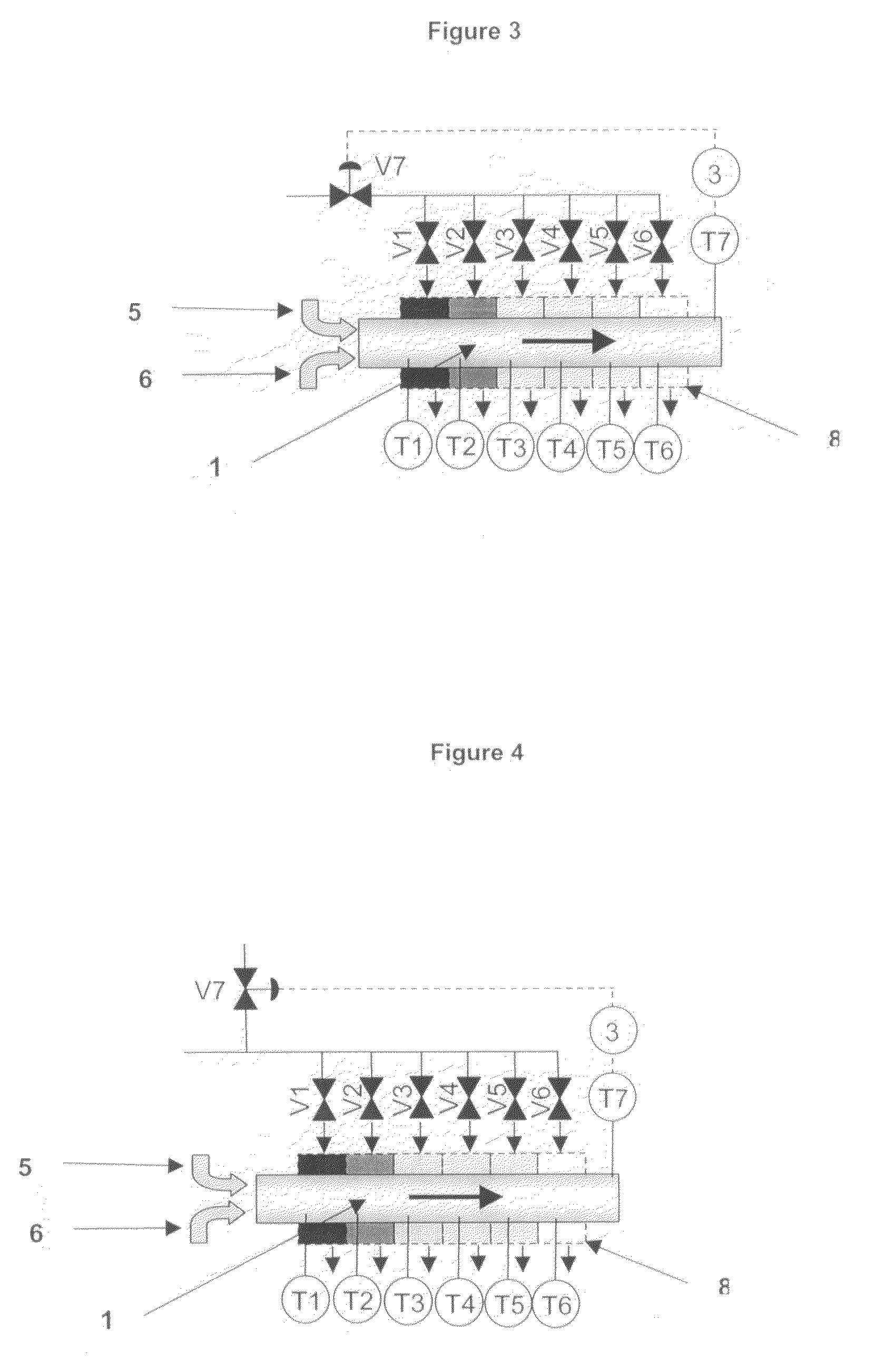

Variable heat flux heat exchangers

InactiveUS20090120629A1Easy to adaptMinimal modificationChemical/physical/physico-chemical processesHeat transfer modificationHeat fluxHeat transmission

A system for heat exchange is provided in which process material flows through a heat exchanger comprising multiple heat transfer stages and the heating and or cooling power applied to each stage can be modified independently. The system comprises a unitary heat exchanger comprising a heat transfer surface comprising a plurality of elements or zones over which a process material can flow wherein each element or zone has independent means to set or control the level of heating or cooling within that zone.

Owner:ASHE MORRIS LTD

Liquid cold plate heat exchanger

InactiveUS20060096738A1Net flow rateReduce the average velocitySemiconductor/solid-state device detailsSolid-state devicesHeat transmissionCooling chamber

A heat exchanger includes a cooling plate having a heat collection surface for fixing against an object to be cooled, an opposed heat transfer surface which may be provided with fins, and a cooling chamber over the heat transfer surface, the cooling chamber having an inlet port and an outlet port for circulating a fluid through the cooling chamber via a flow path between the ports. A flow distributor in the flow path forms a plurality of inlet channels communicating with the inlet port, a plurality of outlet channels alternating with the inlet channels and communicating with the outlet port, and a plurality of flow surfaces which are spaced from the heat transfer surface by gaps. The inlet channels communicate with the gaps so that a fluid entering the inlet channels via the inlet port will flow through the gaps, into the outlet channels, and out of the chamber via the outlet port. The gaps are dimensioned to increase fluid velocity and promote mixing of the fluid, thereby improving heat transfer.

Owner:AAVID THERMALLOY LLV

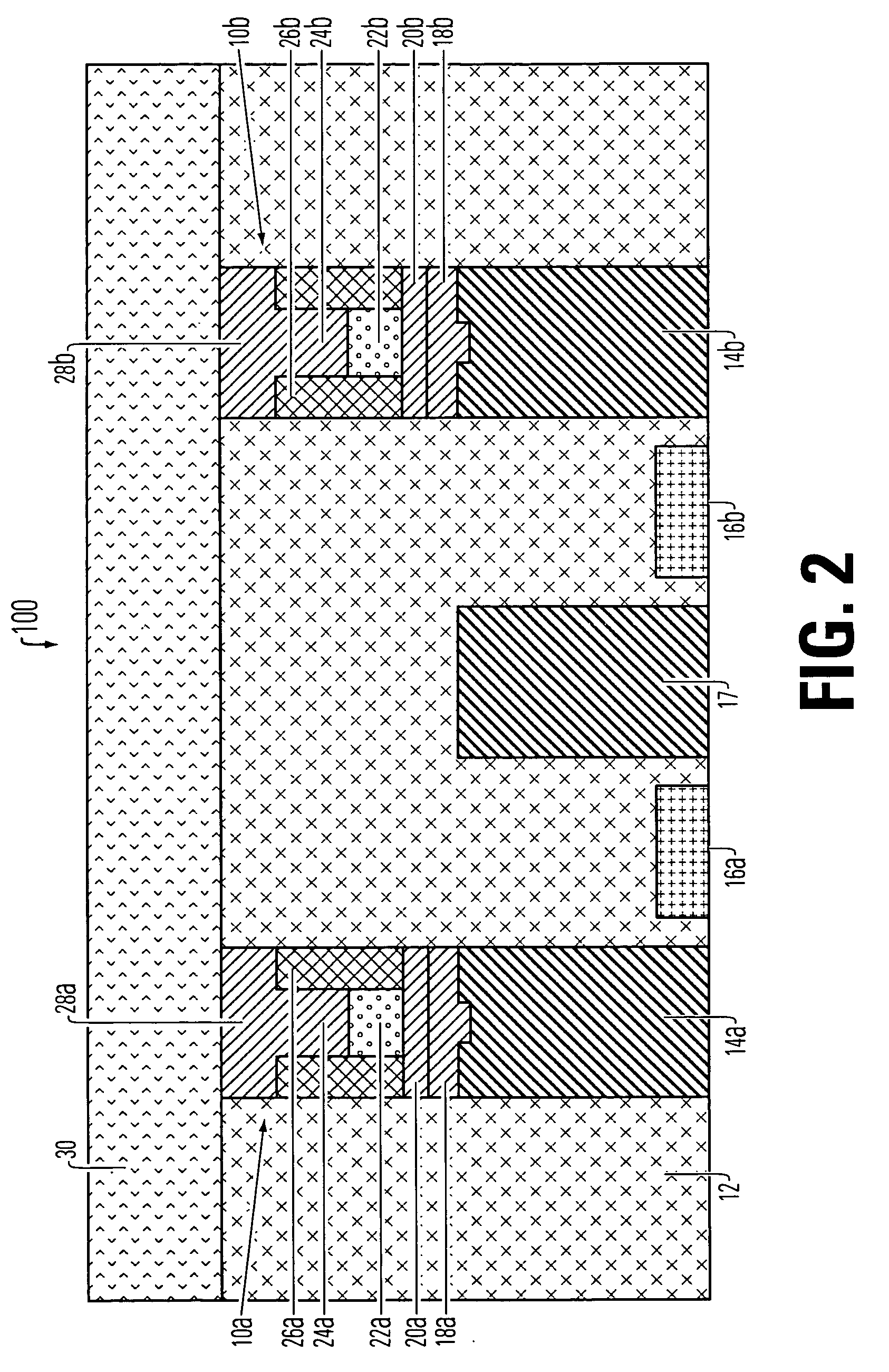

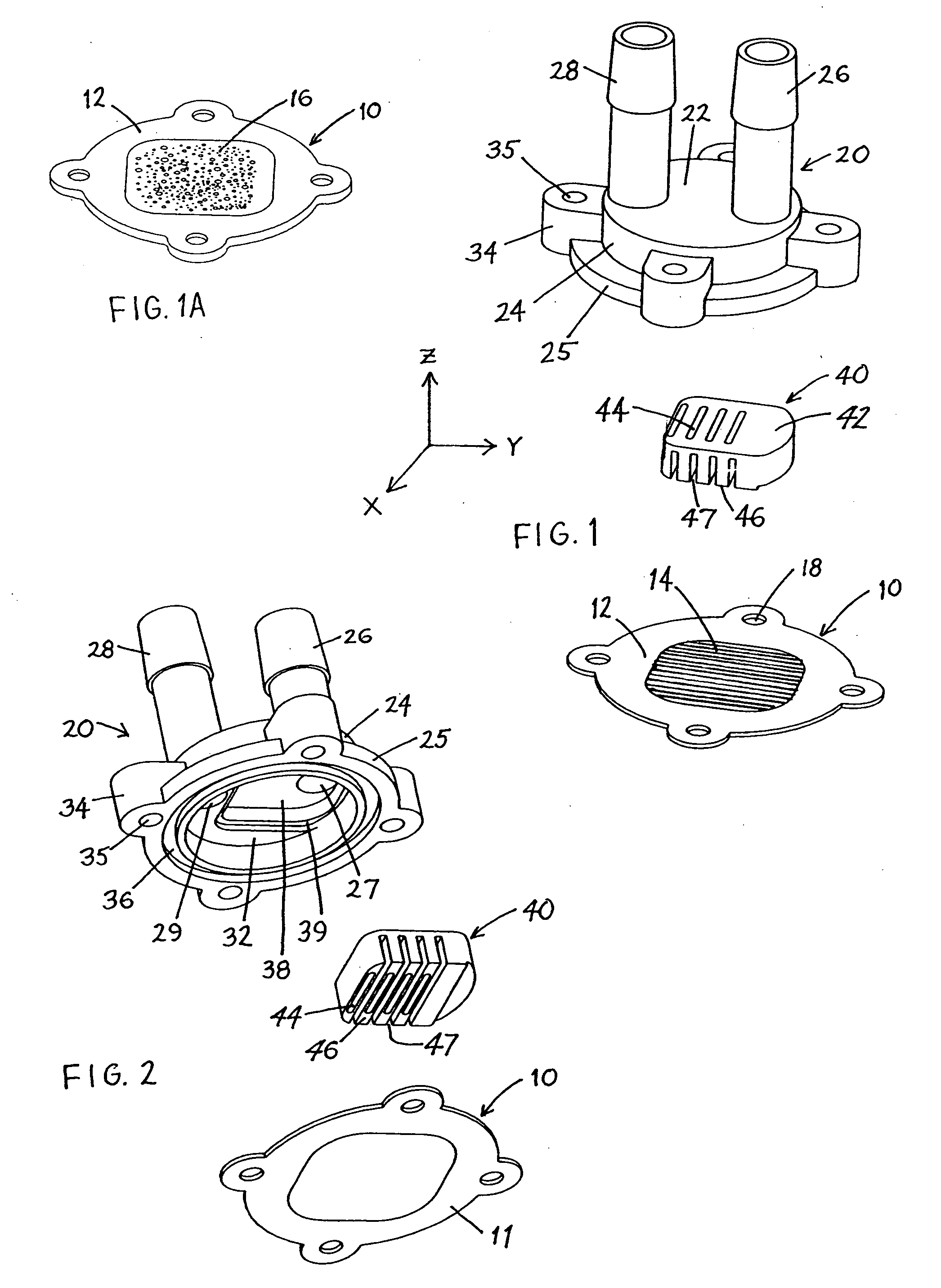

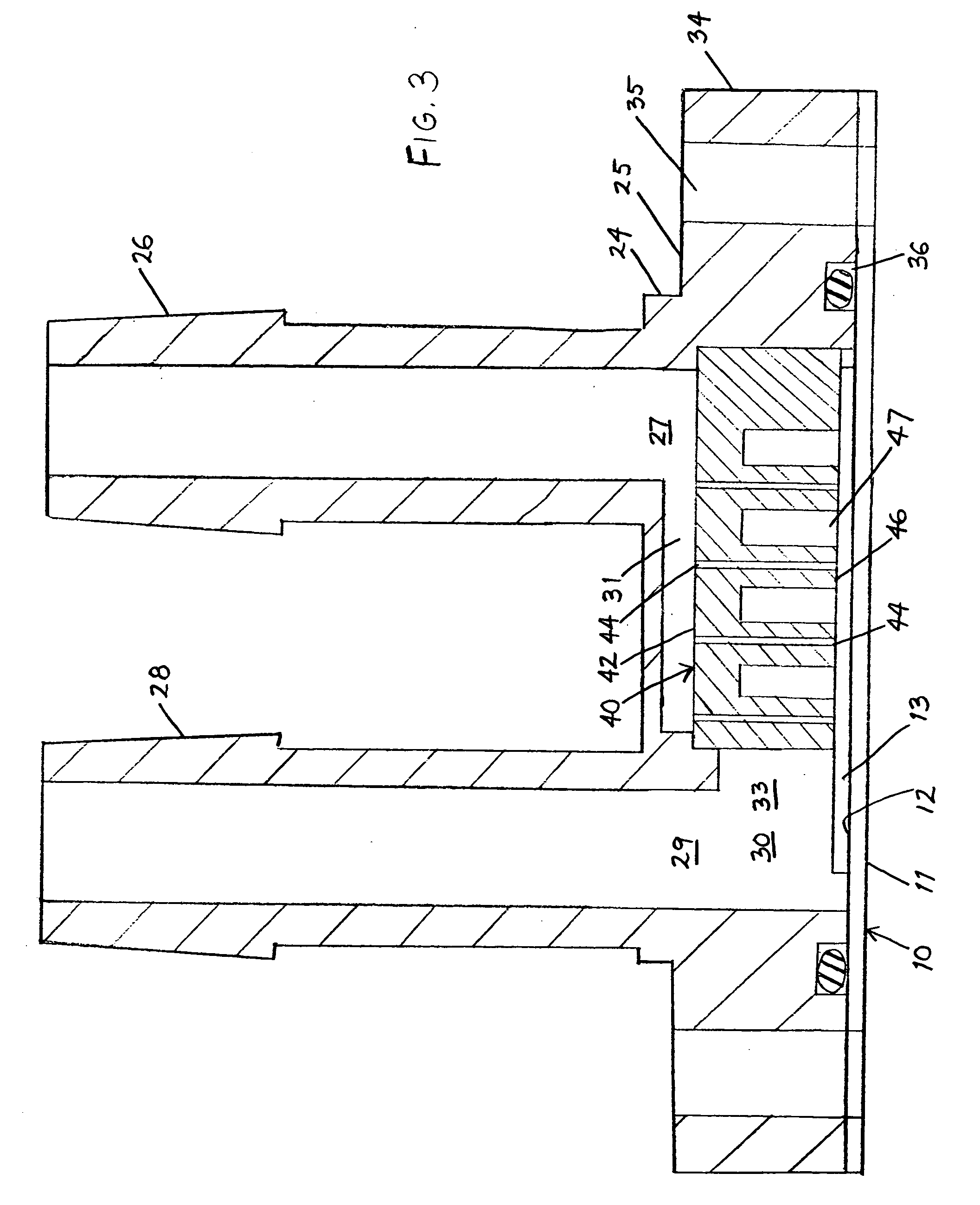

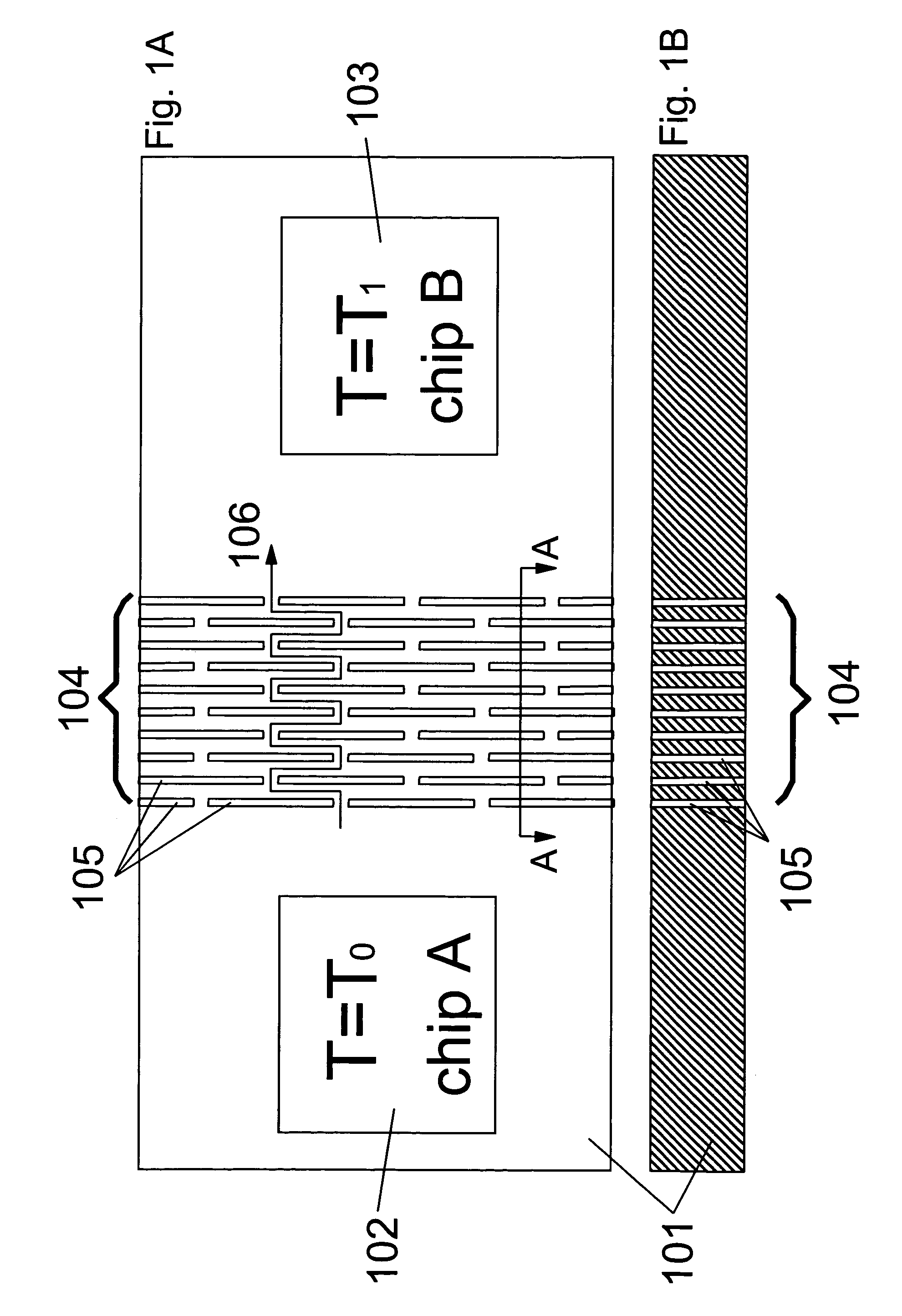

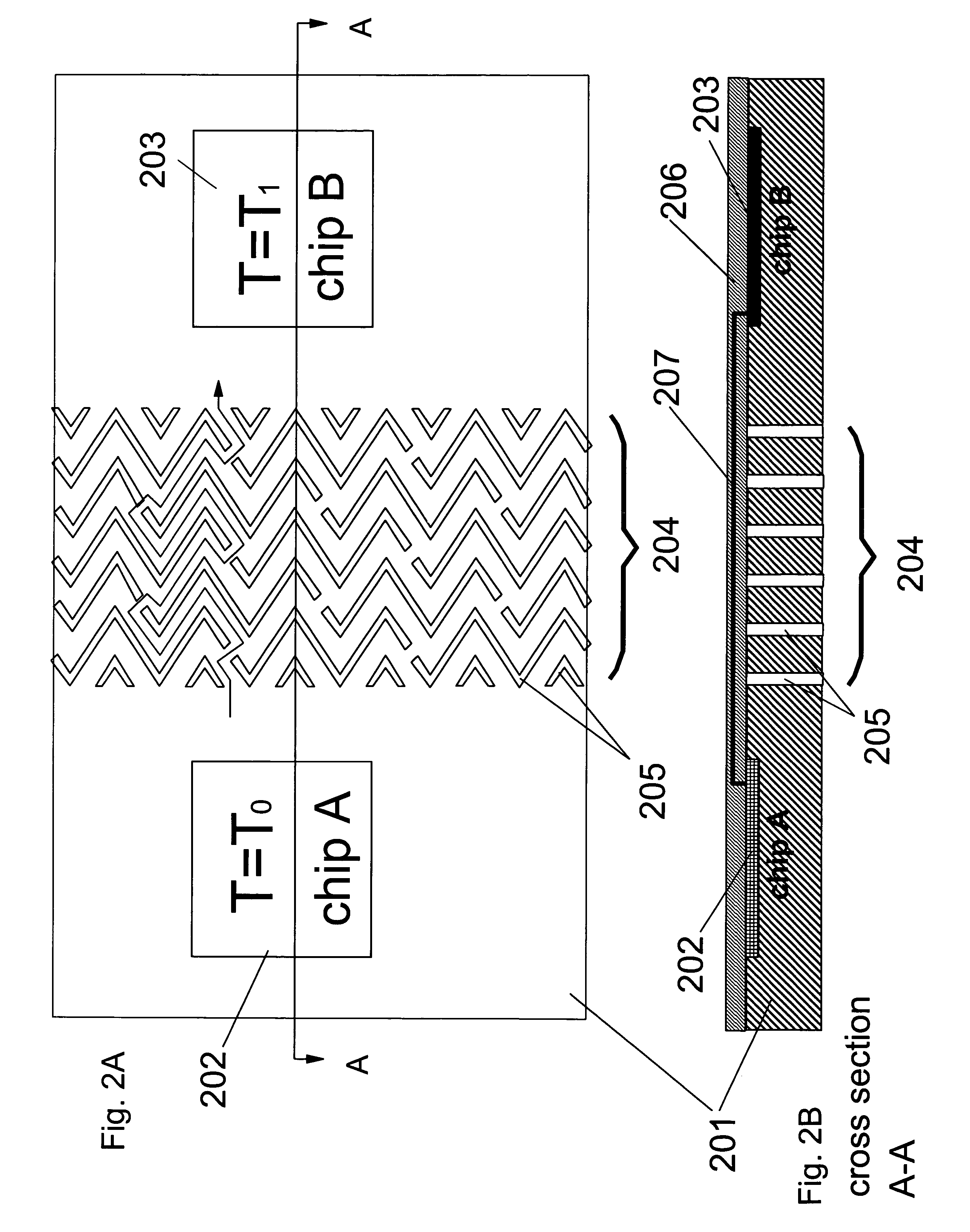

Apparatus and method for thermal isolation, circuit cooling and electromagnetic shielding of a wafer

ActiveUS7033927B2Thermal resistanceIncrease thermal resistanceSemiconductor/solid-state device detailsSolid-state devicesThermal isolationHeat transmission

The disclosure relates to method and apparatus for isolating sensitive regions of a semiconductor device by providing a thermal path or an electromagnetic shield. The thermal path may include vias having different length, depth and configuration such that the thermal path between the two regions is lengthened. In addition, the vias may be fully or partially filled with an insulating material having defined conductive properties to further retard heat electromagnetic or heat transmission between the regions. In another embodiment, electrical isolation between two regions is achieved by etching a closed loop or an open loop trench at the border of the regions and filling the trench with a conductive material to provide proper termination of electromagnetic fields within the substrate.

Owner:TWITTER INC

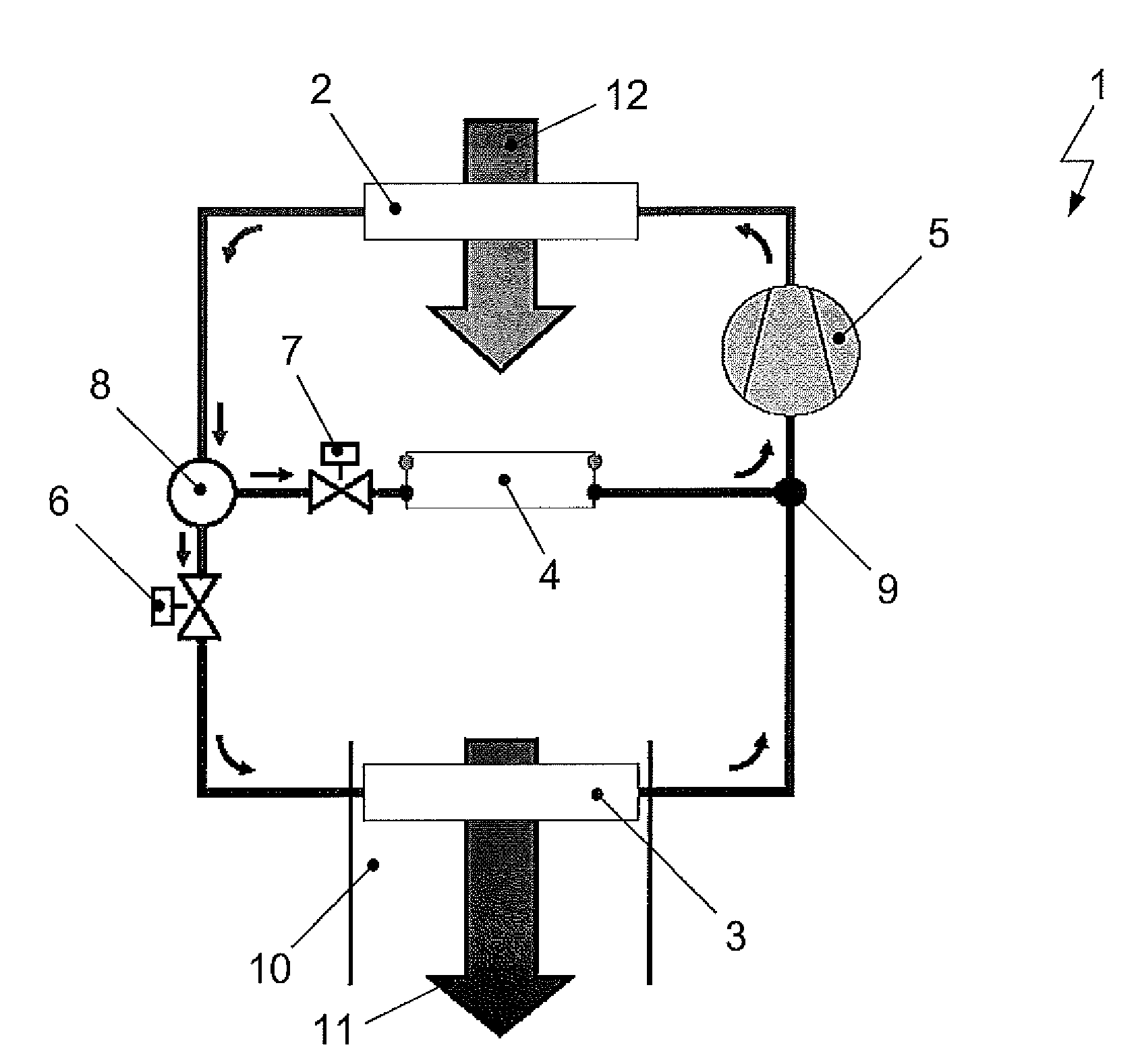

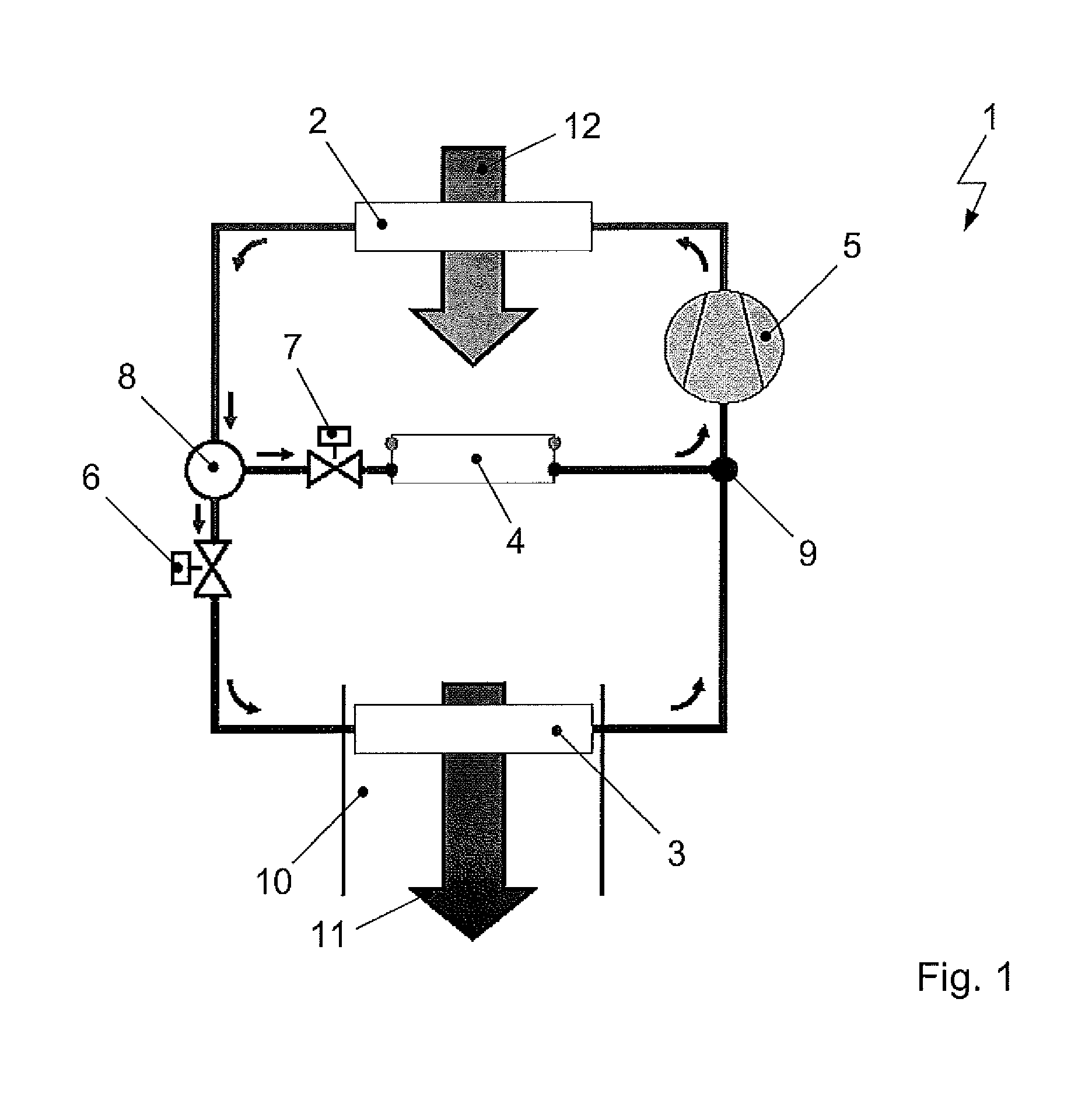

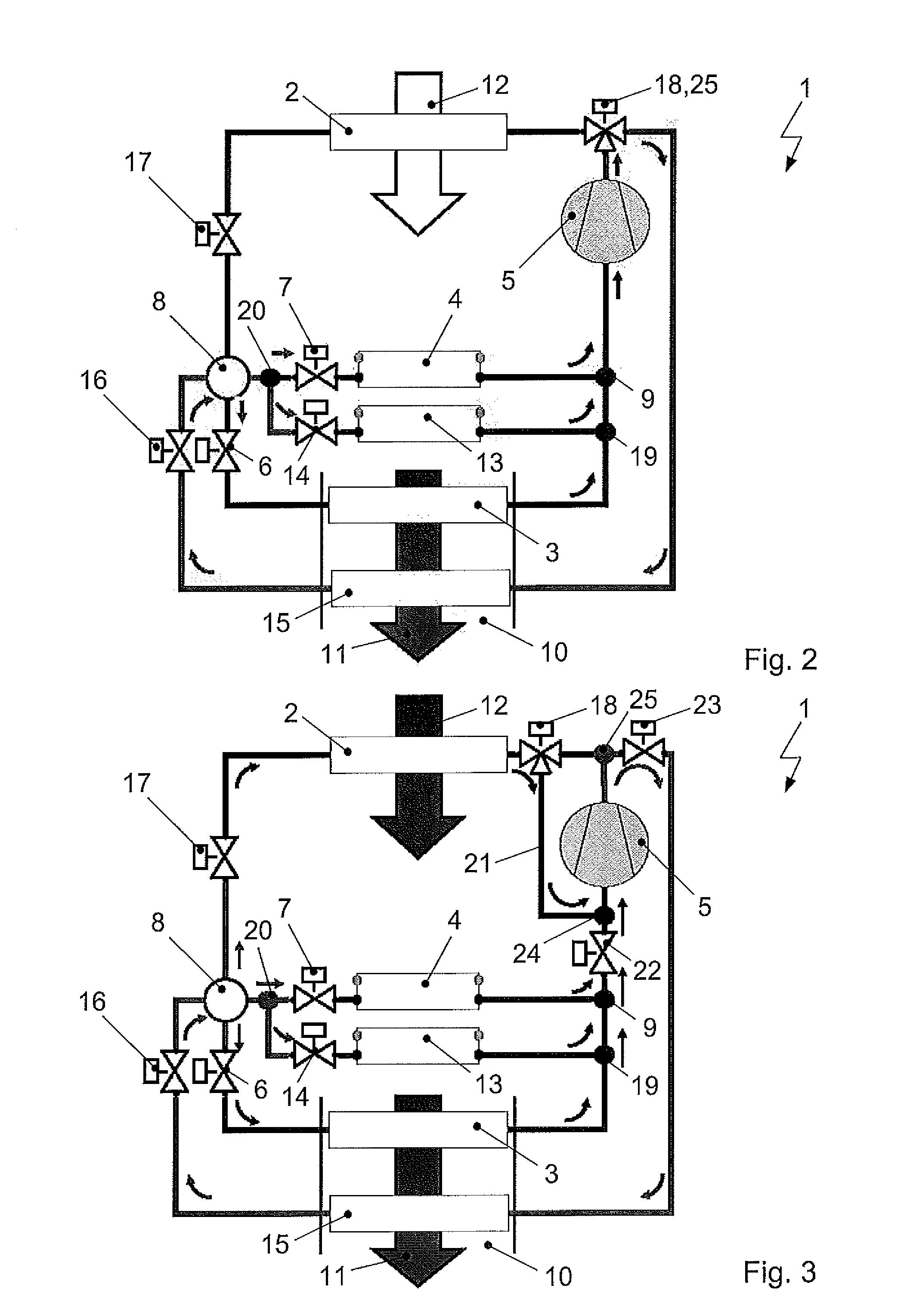

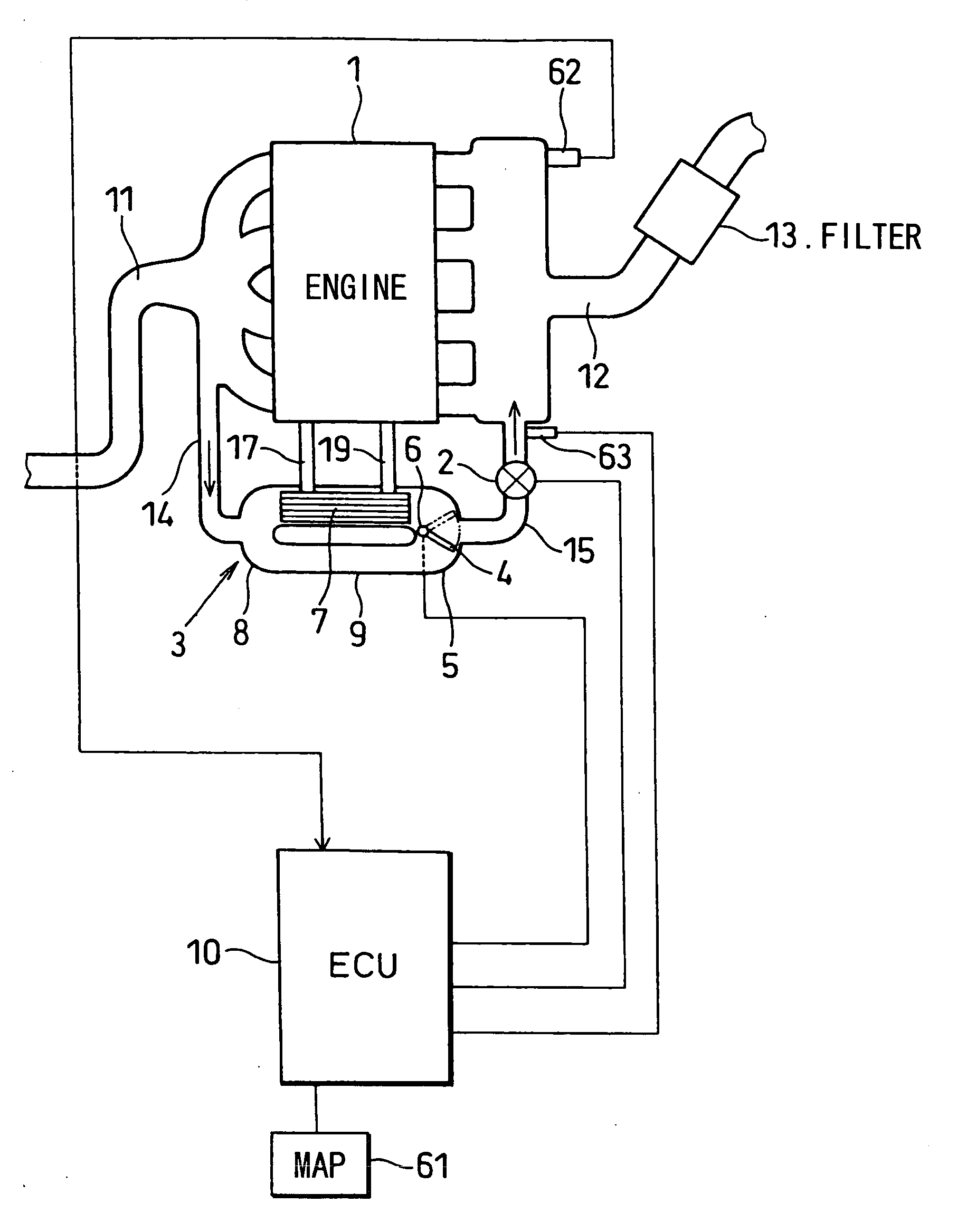

Refrigerant circuit of an HVAC system of a motor vehicle

ActiveUS20120085114A1Improve performanceImprove efficiencyMechanical apparatusCompression machines with several evaporatorsHeat transmissionEngineering

The invention relates to a refrigerant circuit and a process for operation of the refrigerant circuit of an HVAC system of a vehicle, particularly an electric or hybrid vehicle. The refrigerant circuit includes a primary circuit with a compressor, a heat exchanger for heat transmission between the refrigerant and the environment, a collector, a first expansion member, a heat exchanger for supply of heat from the fresh air to be conditioned of the vehicle interior to the refrigerant and a heat exchanger arranged switched in parallel to the heat exchanger. Further, the refrigerant circuit is provided with a secondary train that extends starting from a tapping point positioned between the compressor and the heat exchanger up to a connection point and is provided with a heat exchanger for heat transmission from the refrigerant to the fresh air to be conditioned for the vehicle interior, and a subsequent control valve.

Owner:AUDI AG +1

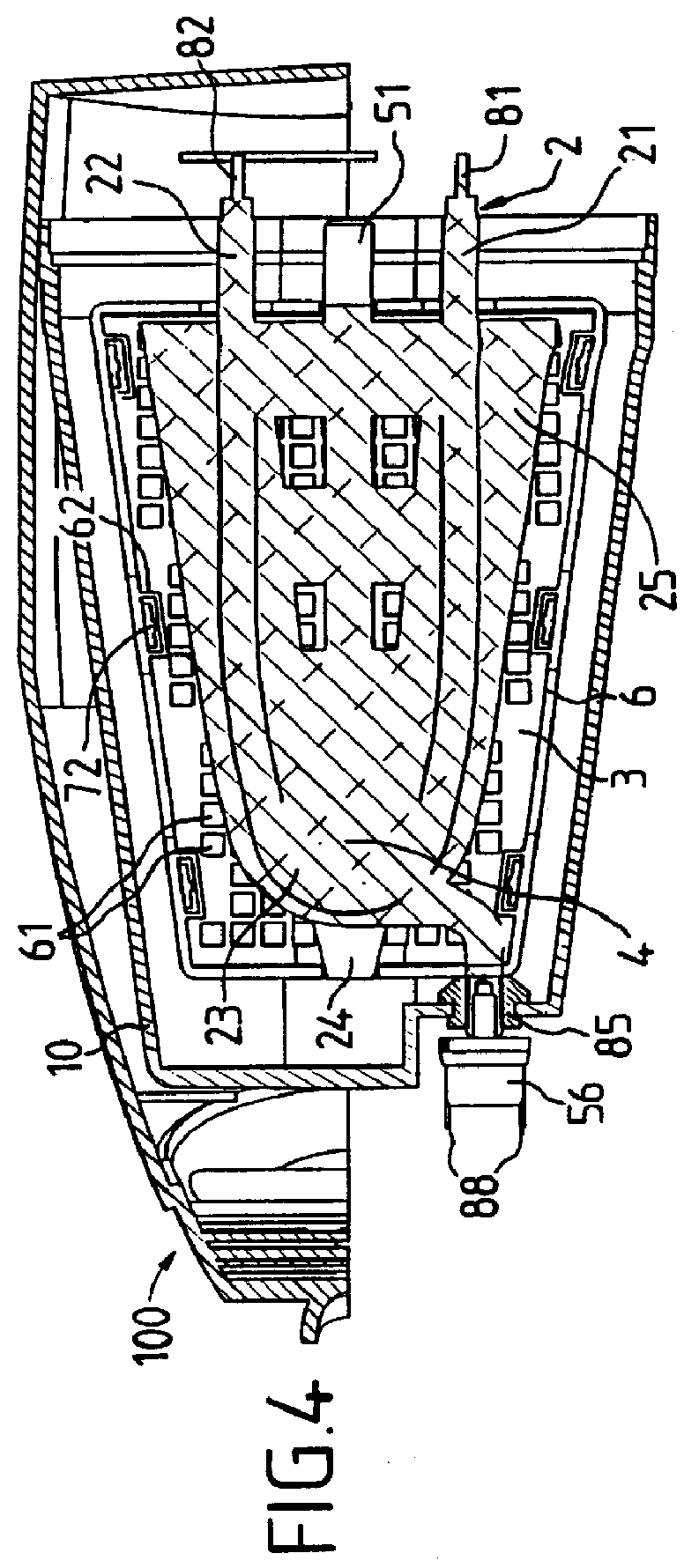

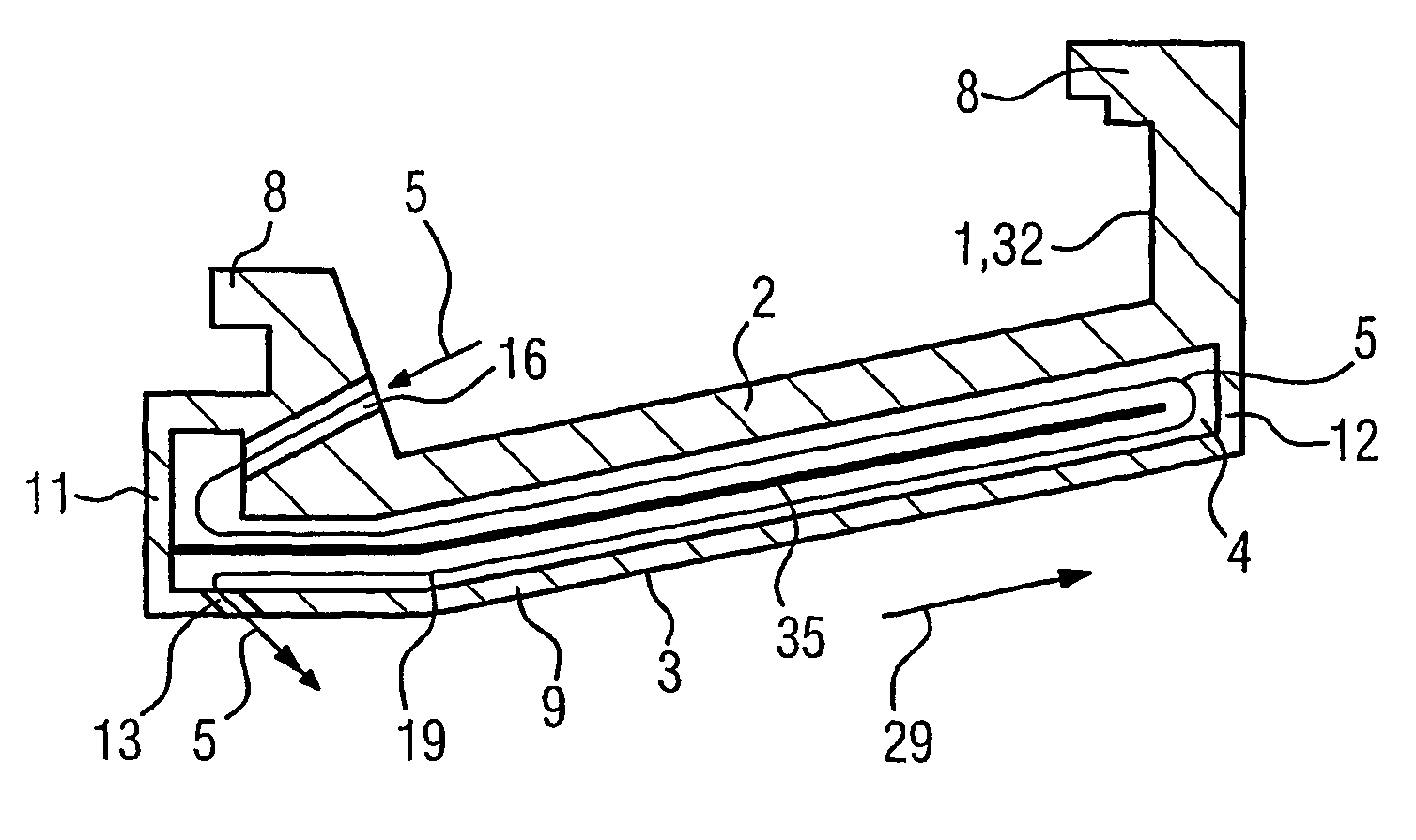

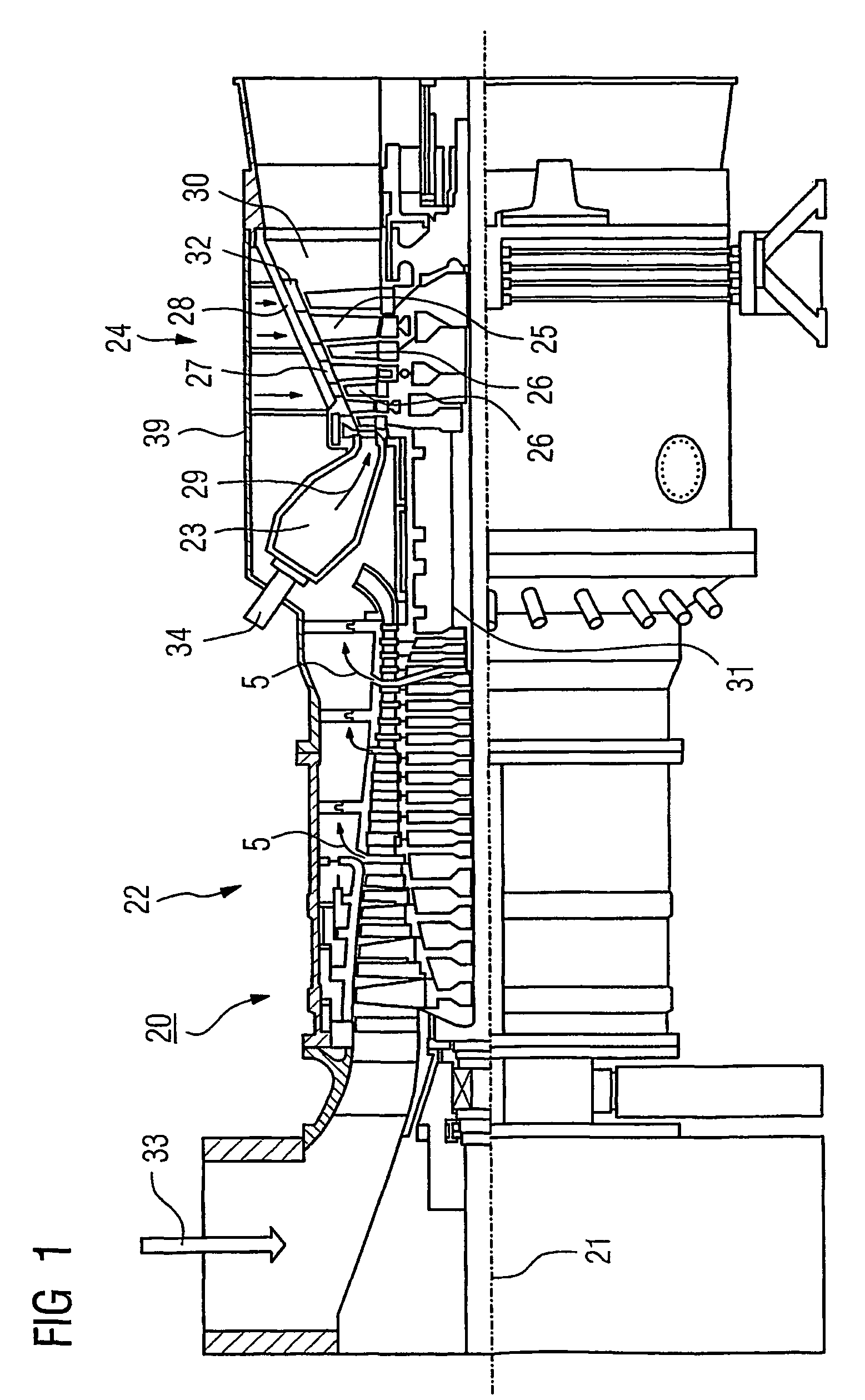

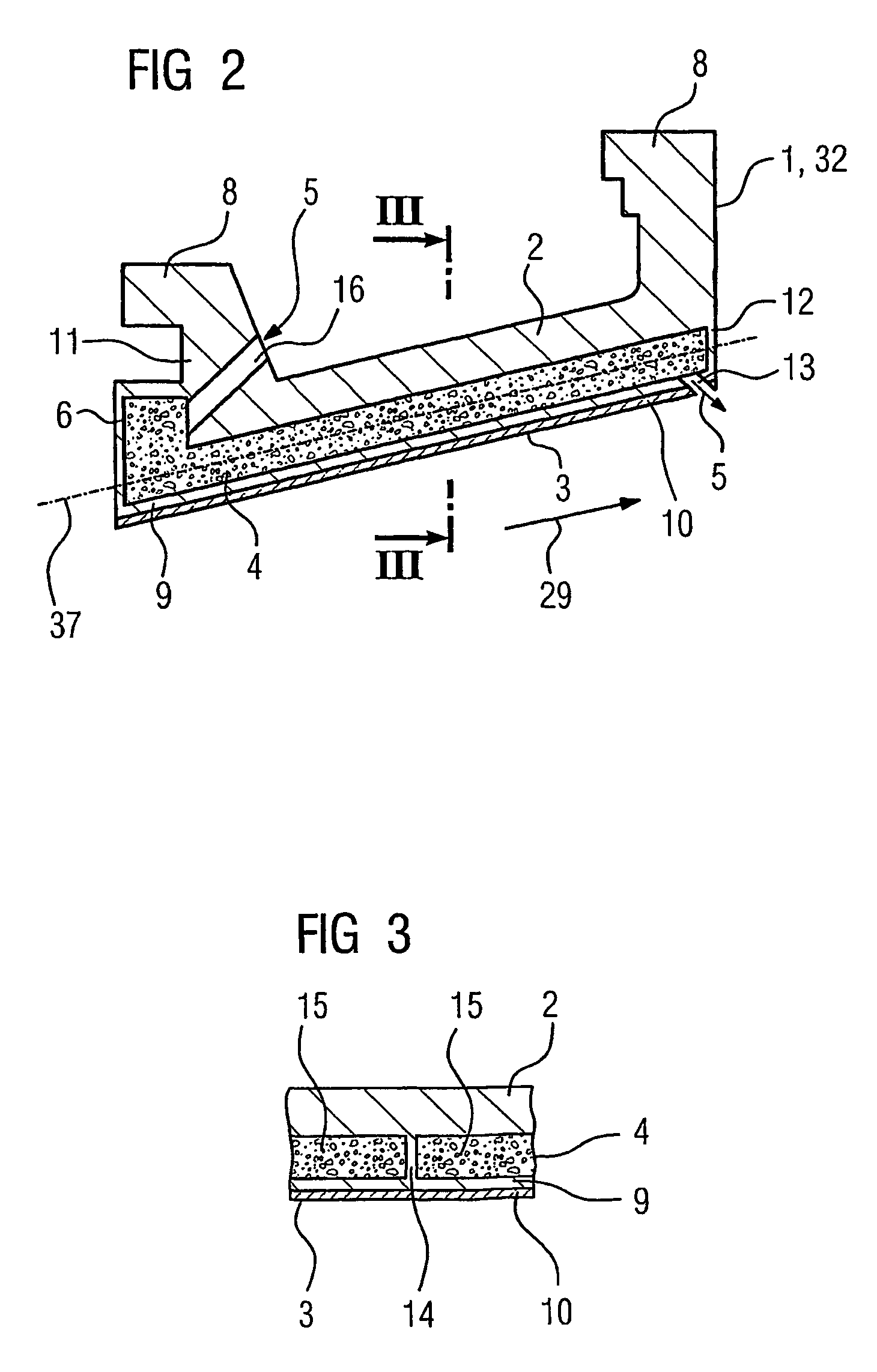

Coolable segment for a turbomachine and combustion turbine

InactiveUS7246993B2Good cooling functionImprove cooling effectPump componentsEngine fuctionsCombustionHeat transmission

A coolable segment for a turbomachine such as a combustion turbine, which turbomachine is operated with a hot fluid. The segment comprises a cooling wall extending in an axial direction and in a circumferential direction orthogonal to the axial direction; a hot fluid surface to be exposed to the hot fluid. Between the wall and the surface a cooling structure is arranged which is permeable to cooling fluid and provides cooling surfaces for cooling by heat transmission through radiation. The cooling structure comprises either a netting, in particular a wire netting or a porous material.

Owner:SIEMENS AG

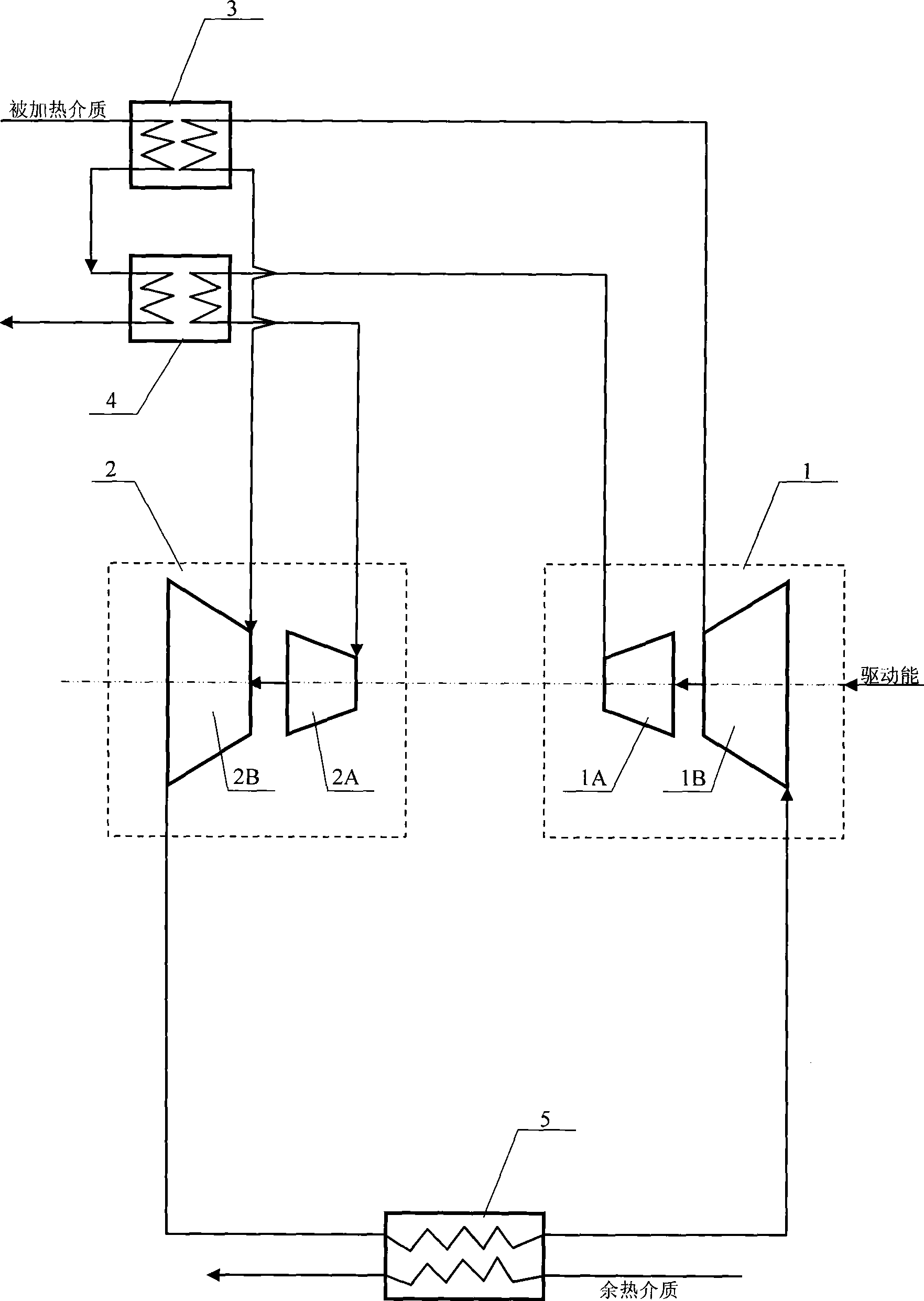

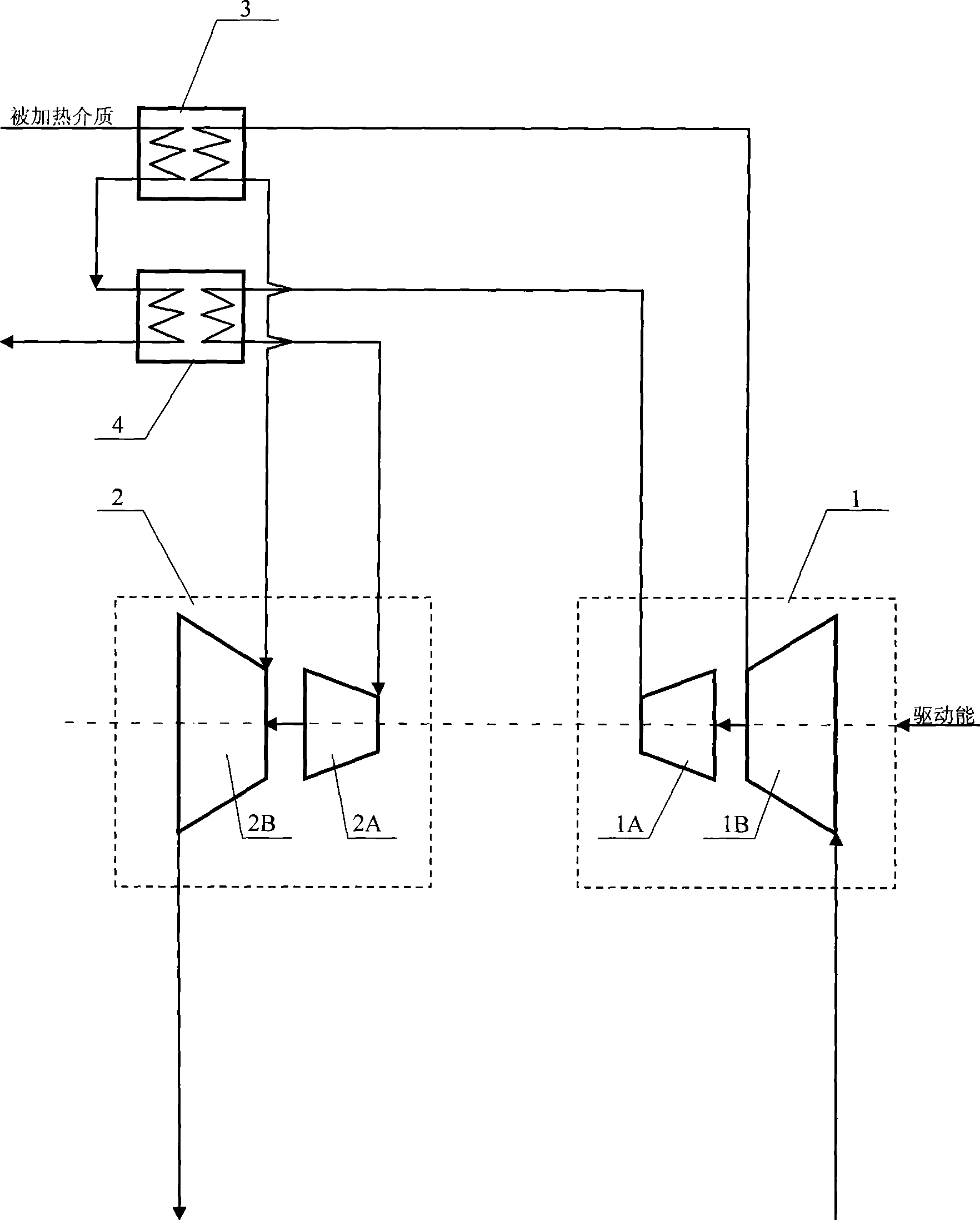

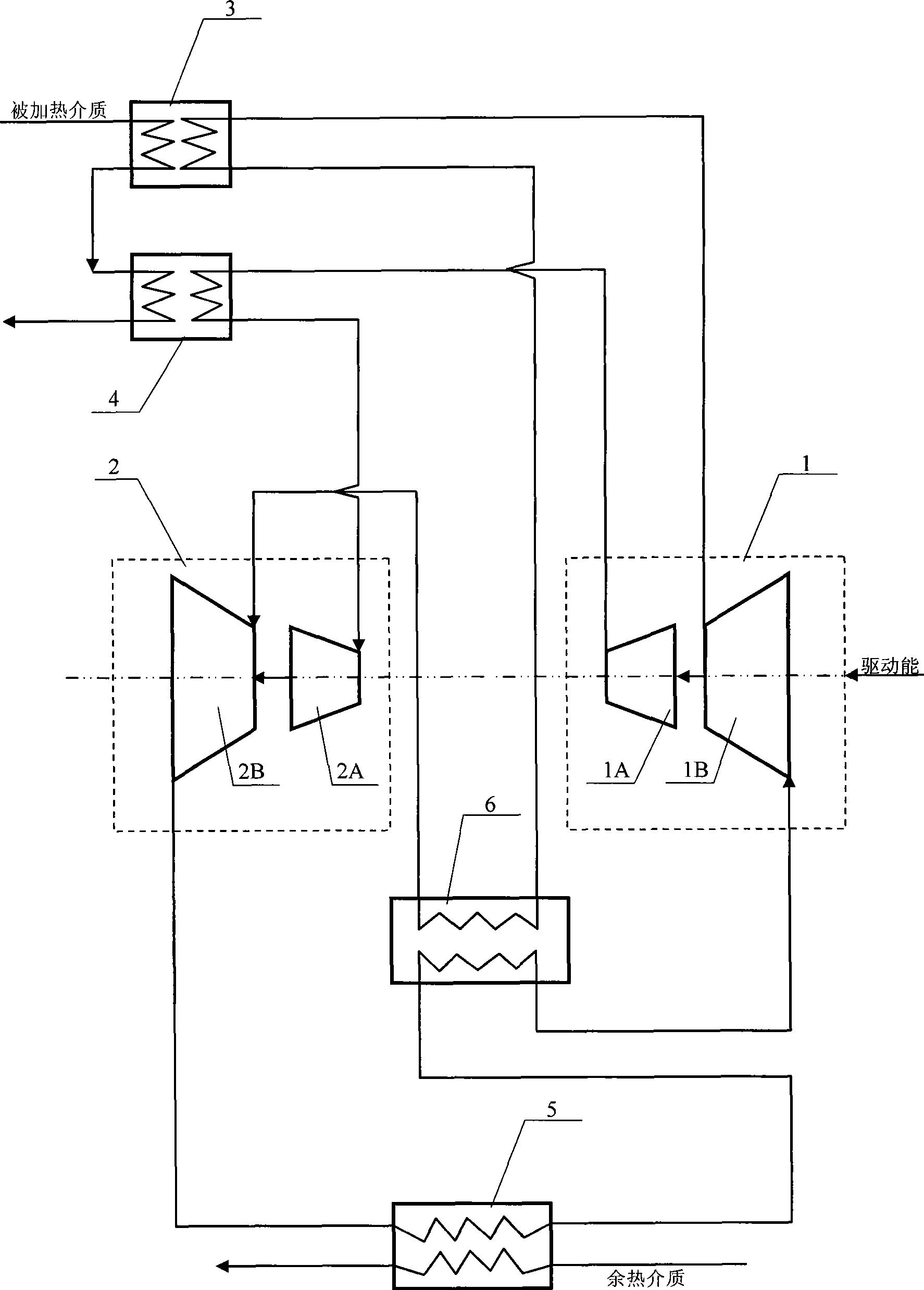

Segmented compression-segmented heat supply-segmented expansion gas compression type units

ActiveCN101504205AReduce power consumptionReduce the compression ratioCompression machines with non-reversible cycleSuperheatersPerformance indexEngineering

A subsection compression-subsection heat supply-subsection gas expanding compression type machine set belongs to the technical field of heat pumps / refrigeration, and consists of a compressor, an expander, a heat exchanger, a second heat exchanger and a low-temperature heat exchanger. Gas working substances absorbing heat from the low-temperature heat exchanger and raising temperature enter the compressor; after the gas working substances are compressed in a low pressure compression section, a part of the gas working substances are provided for the heat exchanger to complete the heating of a heated medium at an initial stage; the part of the gas working substances enter the expander and is expanded at a low pressure expansion section; the other part of the gas working substances are provided for the second heat exchanger to complete the heating of a second stage of the heated medium after continuously passing through the whole compression process and raising temperature, and enter the expander from an inlet of the high pressure expansion section of the expander for expanding; the gas working substances completing the expanding work flow through the low-temperature heat exchanger to absorb the heat and raise the temperature and enter the compressor; and a heat regenerator is added to form a regenerative machine set. The gas expanding compression type machine set reduces temperature difference of heat transmission and improves the performance index; when taken as a heat pump, the gas expanding compression type machine set is particularly suitable for occasions with high heating temperature and wide range; and when used for refrigeration, the gas expanding compression type machine set can reduce power consumption.

Owner:李华玉

Heat radiation assembly and electric device

ActiveCN104813760AReduce thermal resistanceSolve the technical problem of poor heat dissipation performanceSemiconductor/solid-state device detailsSolid-state devicesHeat resistanceHeat transmission

The invention provides a heat radiation assembly and an electric device, wherein the heat radiation assembly comprises: a screening element which is arranged with a through hole thereupon and is in electrical connection with ground copper of PCT board, the PCT board being equipped with heat radiation electrical elements; a heat tube which is positioned on the through hole, the heat tube being in electrical connection with the screening element, together, the heat tube, the PCT board and the screening element constituting an electromagnetic screen cover which can hold a heat radiation electrical element; an elastic thermal interface material which is arranged between the heat tube and the heat radiation electrical element and is cemented to the heat tube and the heat radiation electrical element. In the technical solution herein, the through hole on the screen element cements the thermal interface material on the heat radiation electrical element and the heat tube, which enables heat of the heat radiation electrical element to be transmitted to the heat tube via thermal interface material, thus reducing heat resistance of the heat radiation assembly and shortening heat transmission path between the heat radiation electrical element and the heat tube.

Owner:HUAWEI DEVICE CO LTD

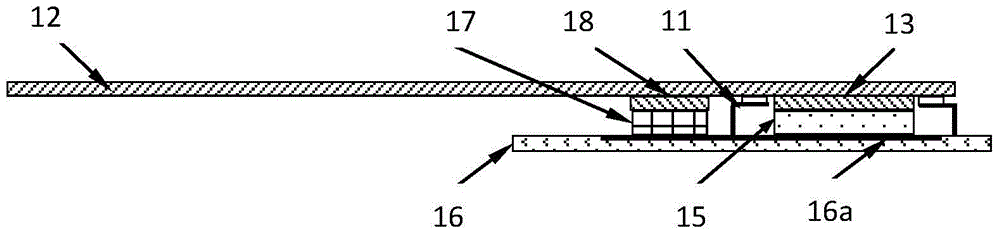

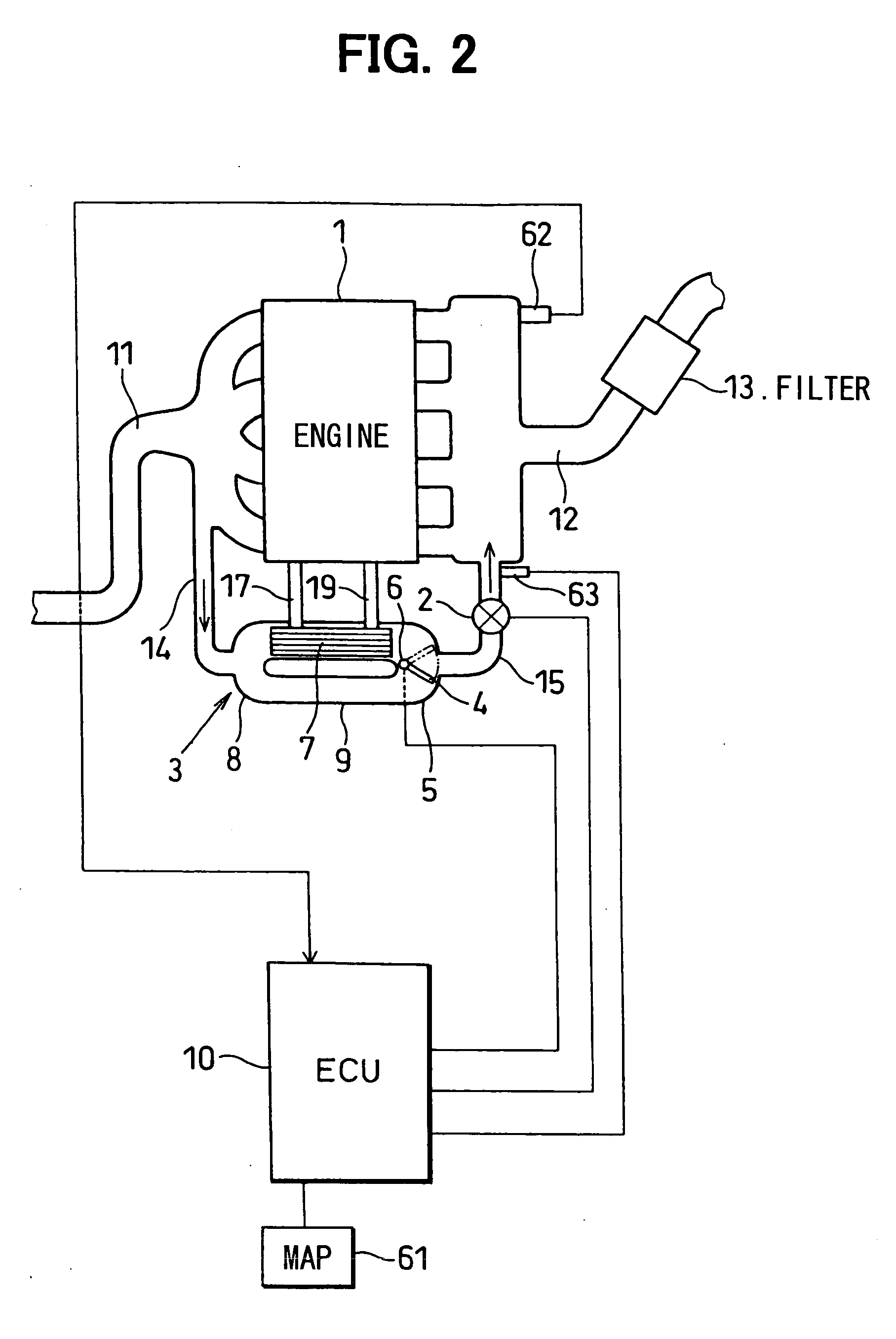

Gas circulating apparatus

InactiveUS20070017489A1Reduce heat transferReducing ability of heatNon-fuel substance addition to fuelInternal combustion piston enginesHeat transmissionEngineering

In a gas circulating apparatus, a bypass pipe extends in parallel with an EGR gas cooler. The aperture end of the bypass pipe is inserted to inside of a housing of a valve device and is positioned adjacent to a valve in the housing. Accordingly, the high-temperature EGR gas heat introduced to a second exhaust gas passage of the housing from the bypass pipe is difficult to be transmitted to a first exhaust gas passage of the housing. Thus, the heat transmission of the high-temperature EGR gas to the EGR gas cooler can be reduced.

Owner:DENSO CORP

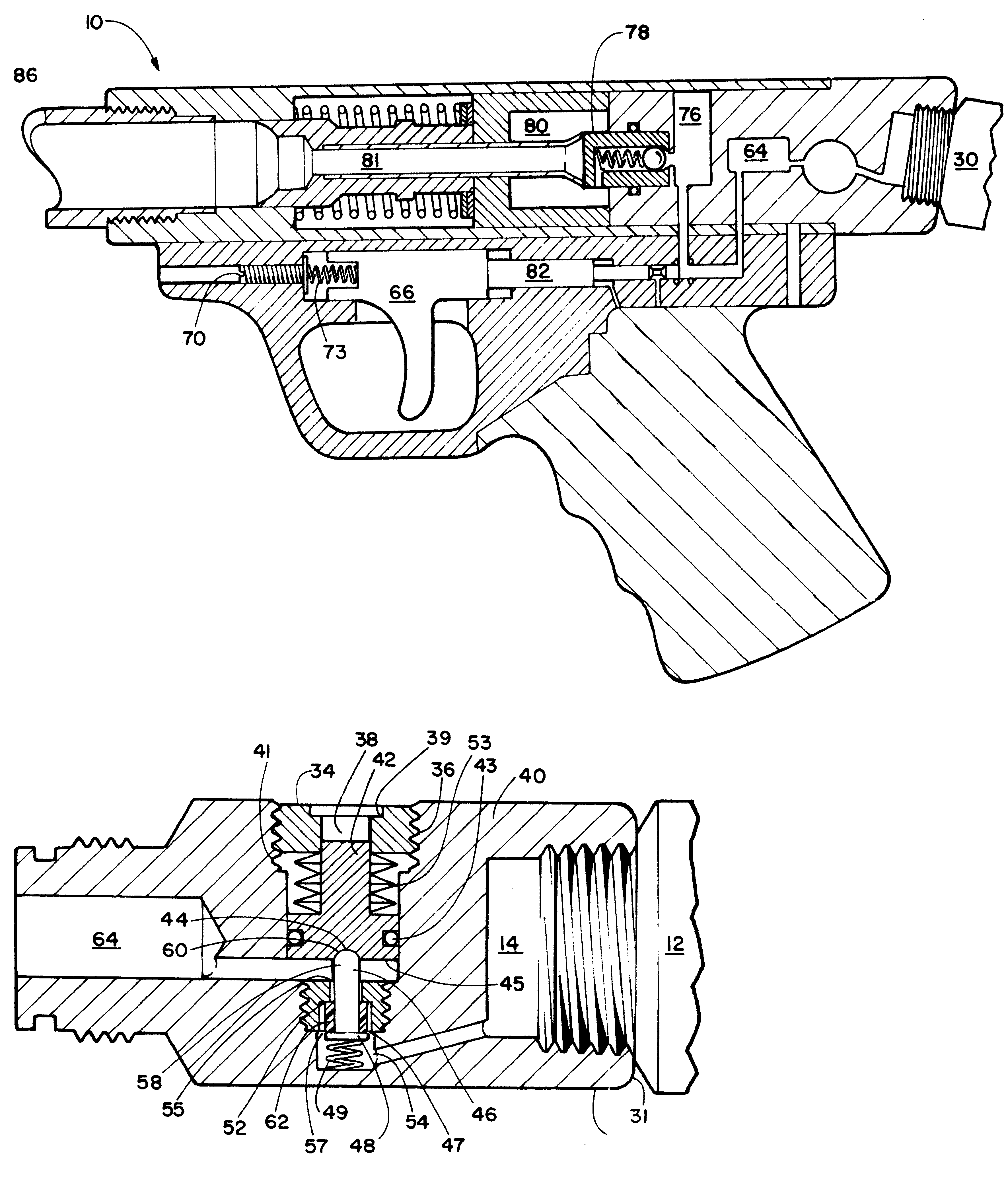

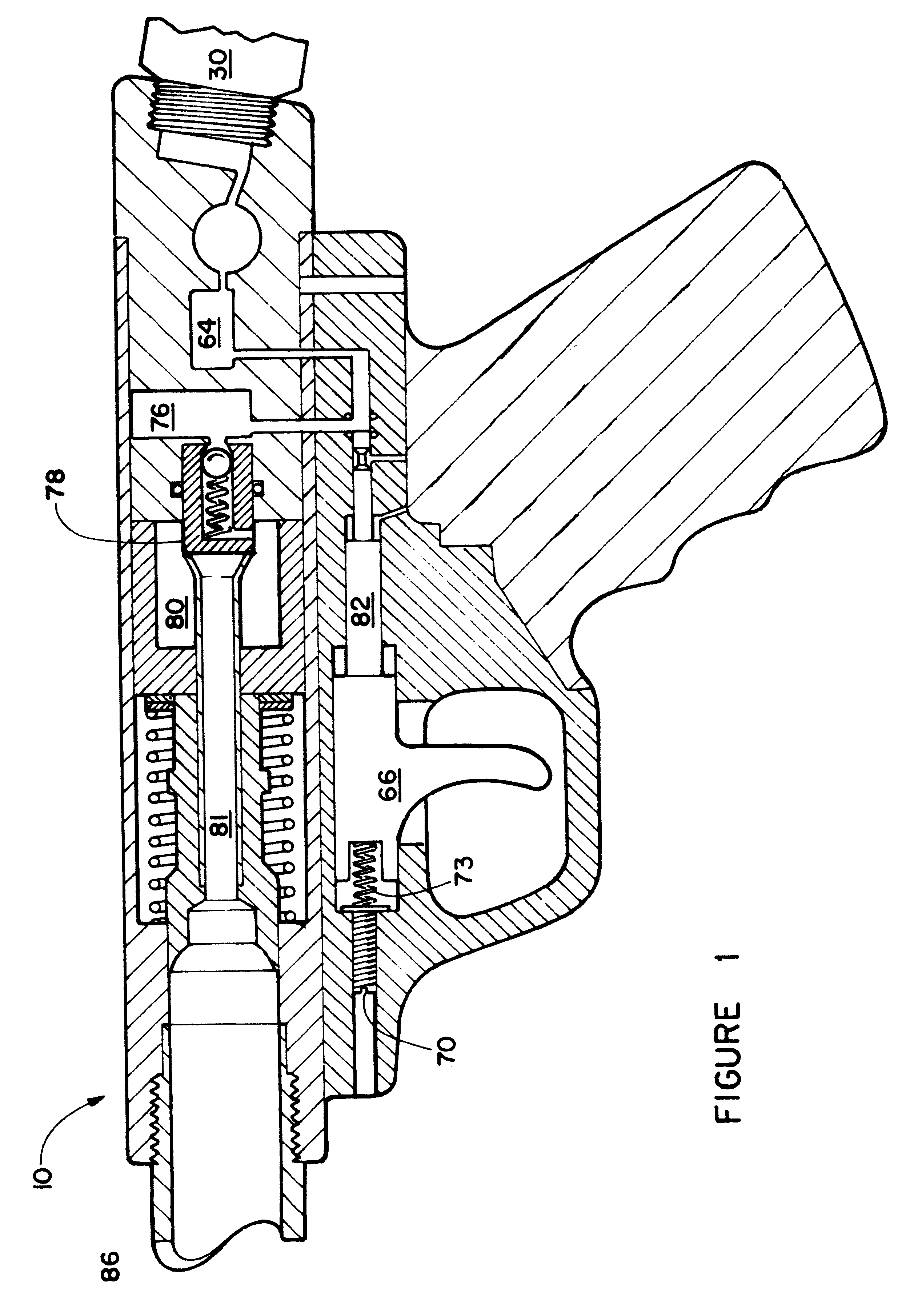

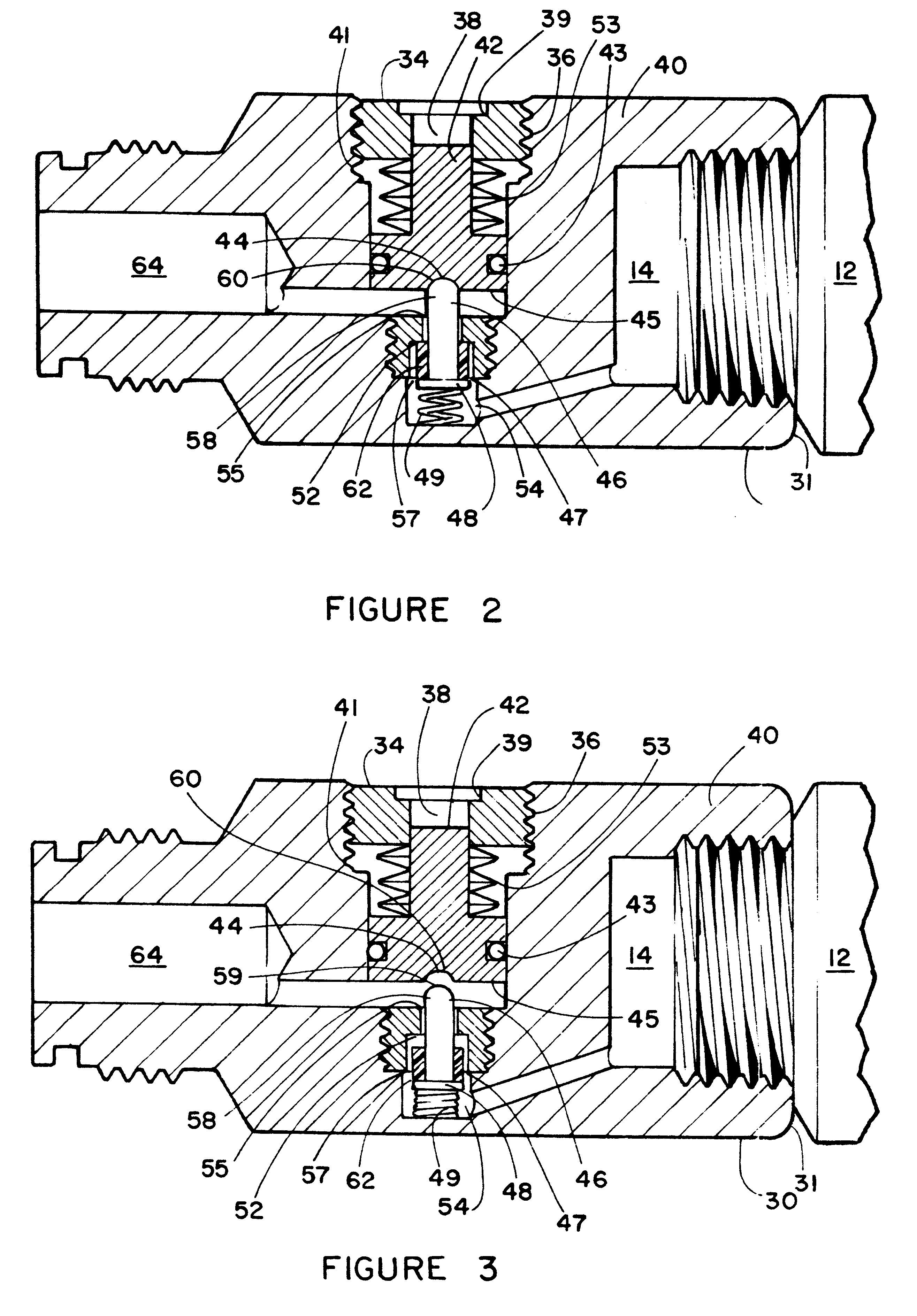

Gas powered gun and assemblies therefor

InactiveUS6276354B1Reduce mechanical complexityJam resistantFiring/trigger mechanismsLiquid ejecting gunsHeat transmissionEngineering

An improved air gun for firing paint balls, pellets,, consisting of a passively venting and freeze resistant regulator, a pressure differential trigger mechanism, and a muzzle break with angled sidewalls. The freeze resistant regulator regulates incoming high pressure gas to a user predetermined pressure to operate the gun while avoiding freezing of the regulator associated with frigid incoming compressed gases and high firing rates. This is accomplished by using a heat transmission component formed by the engagement between a hemispheric shaped tip of a regulating pin and a hemispheric cavity of an adjustment piston. Passive venting of gas from the gun upon removal of the pressurized gas supply is provided by the regulator using a reciprocating regulating pin and adjustment piston which combine to compress a seal into a seat only when pressurized gas is attached to the air gun. Once detached from a pressurized air supply the compressed air in the gun vents through the seat. Firing of the gun is achieved using a pressure differential trigger mechanism capable of fine pull adjustment using a trigger biasing mechanism. Greater accuracy of projectiles leaving the gun is provided by the muzzle break featuring of a plurality of elongated oval slots having angled sidewalls to parse propulsion gases from the projectile which reduces air turbulence encountered by the projectile upon exit from the gun.

Owner:DILLON JOSEPH

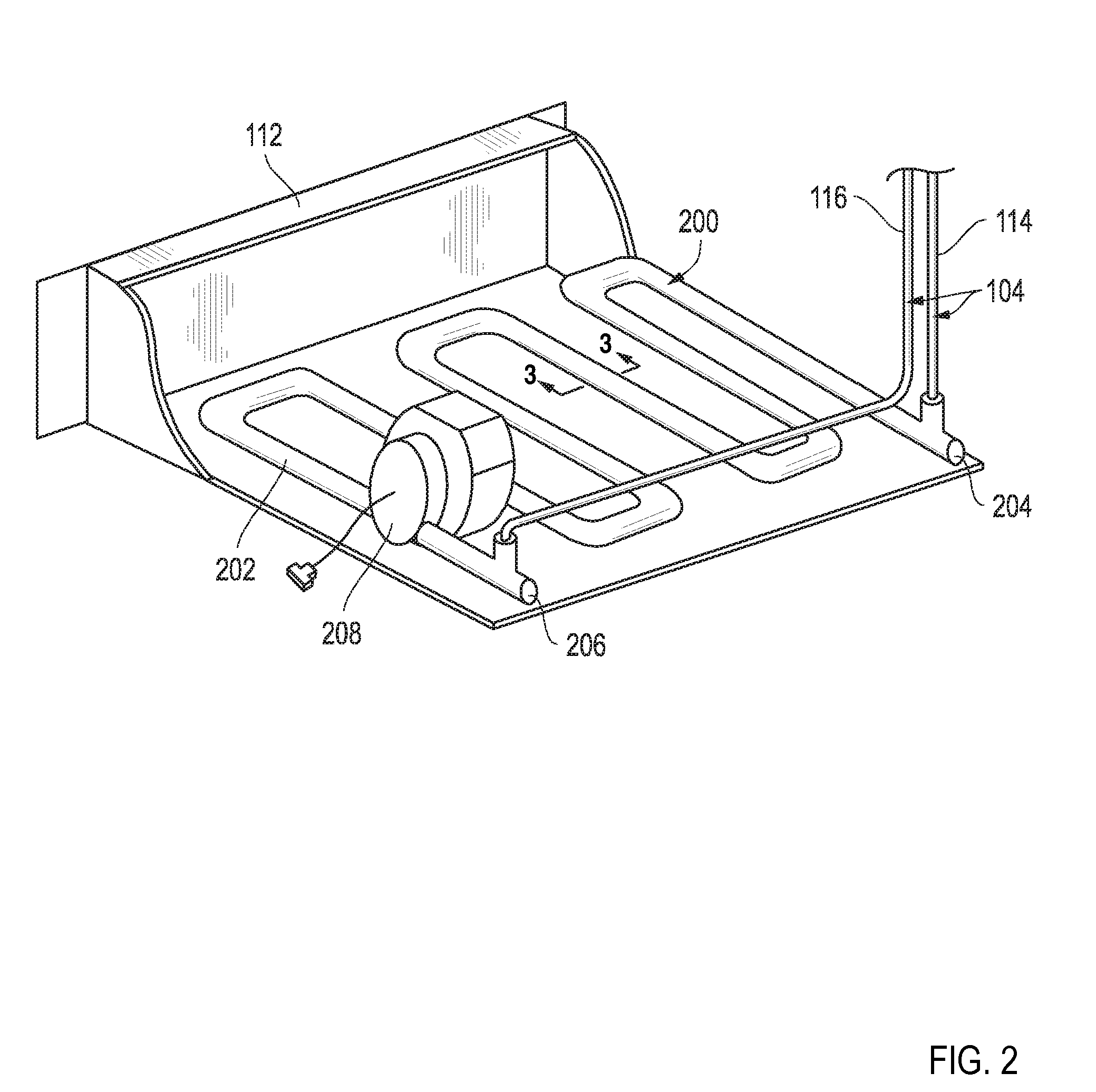

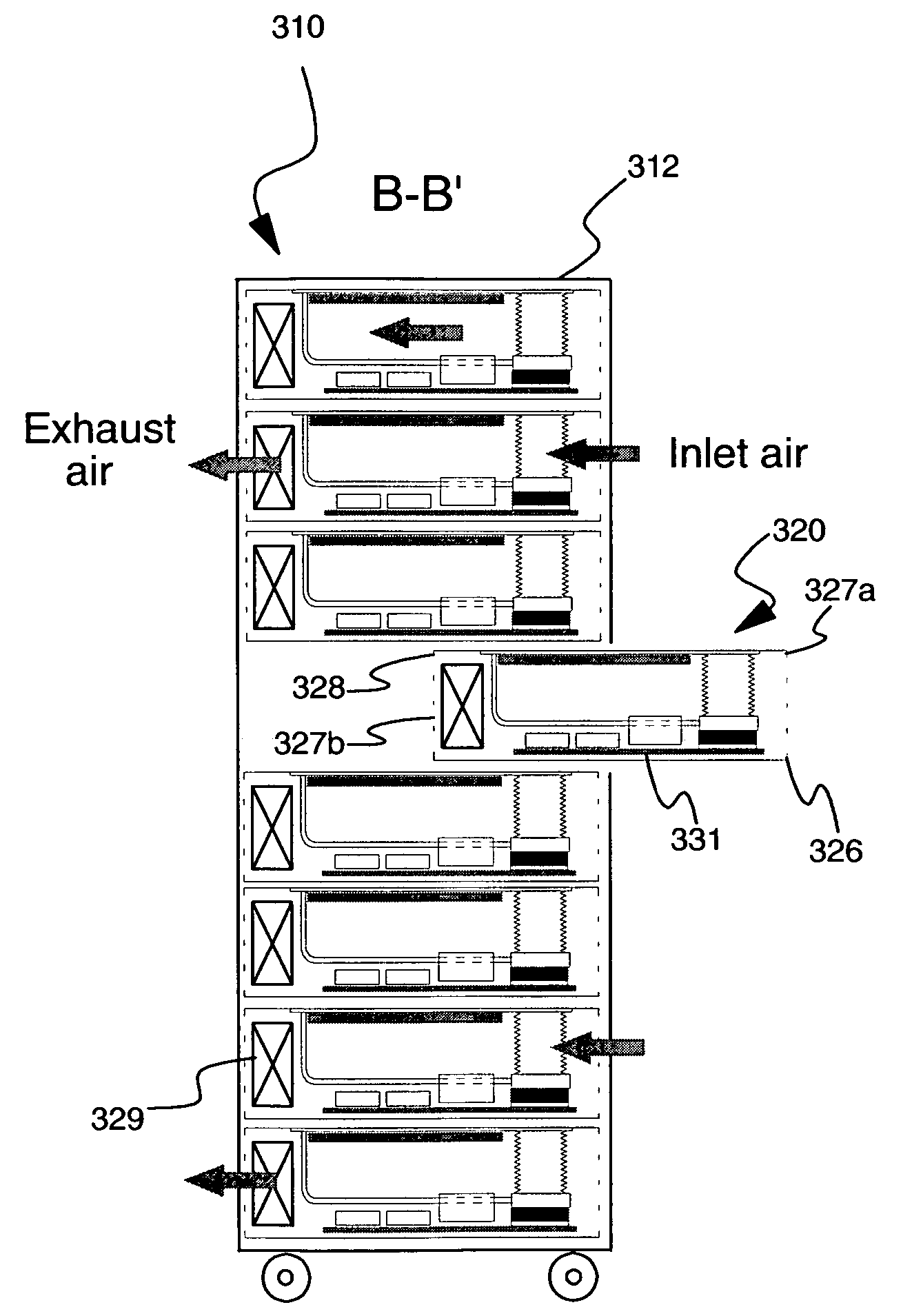

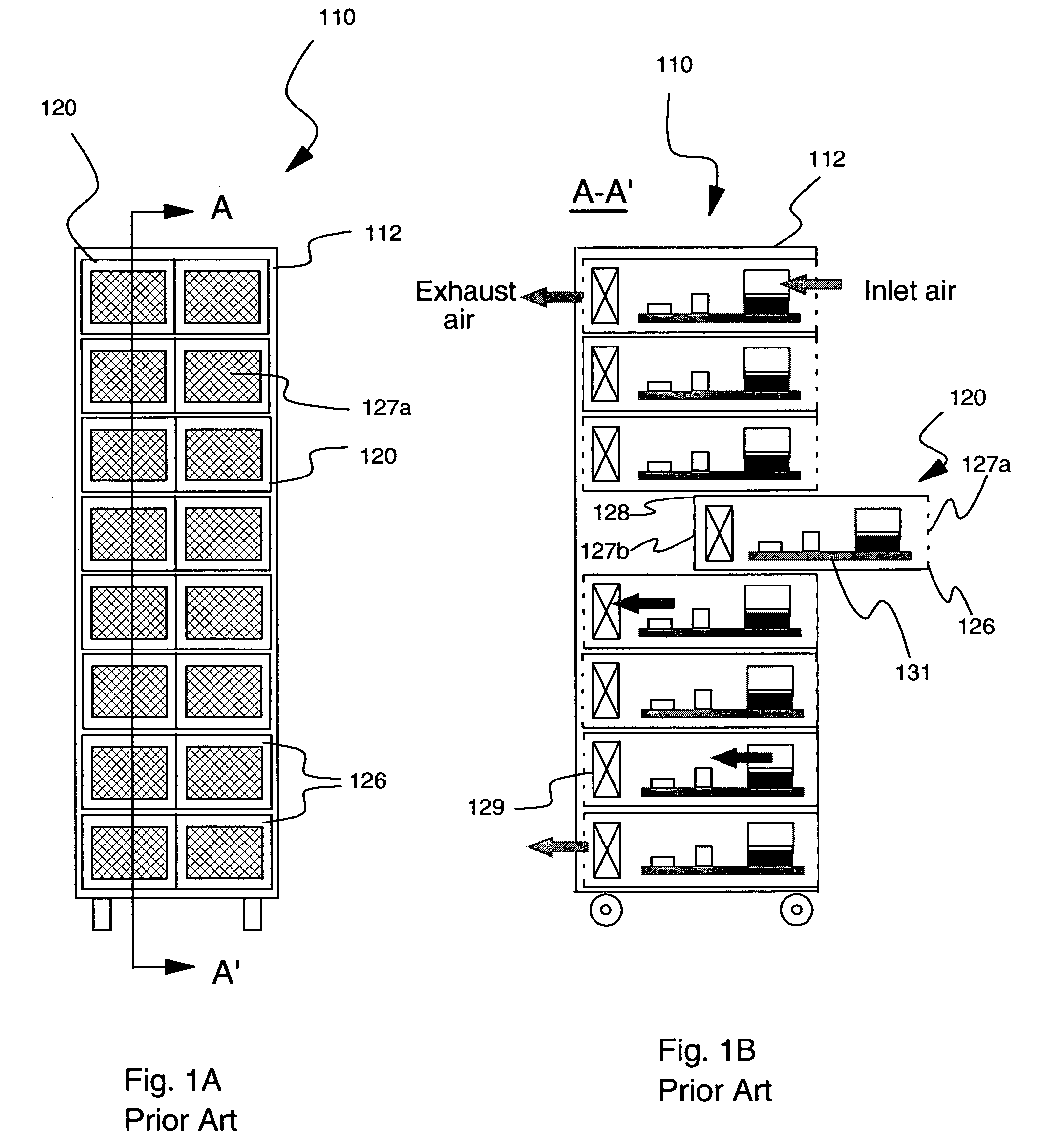

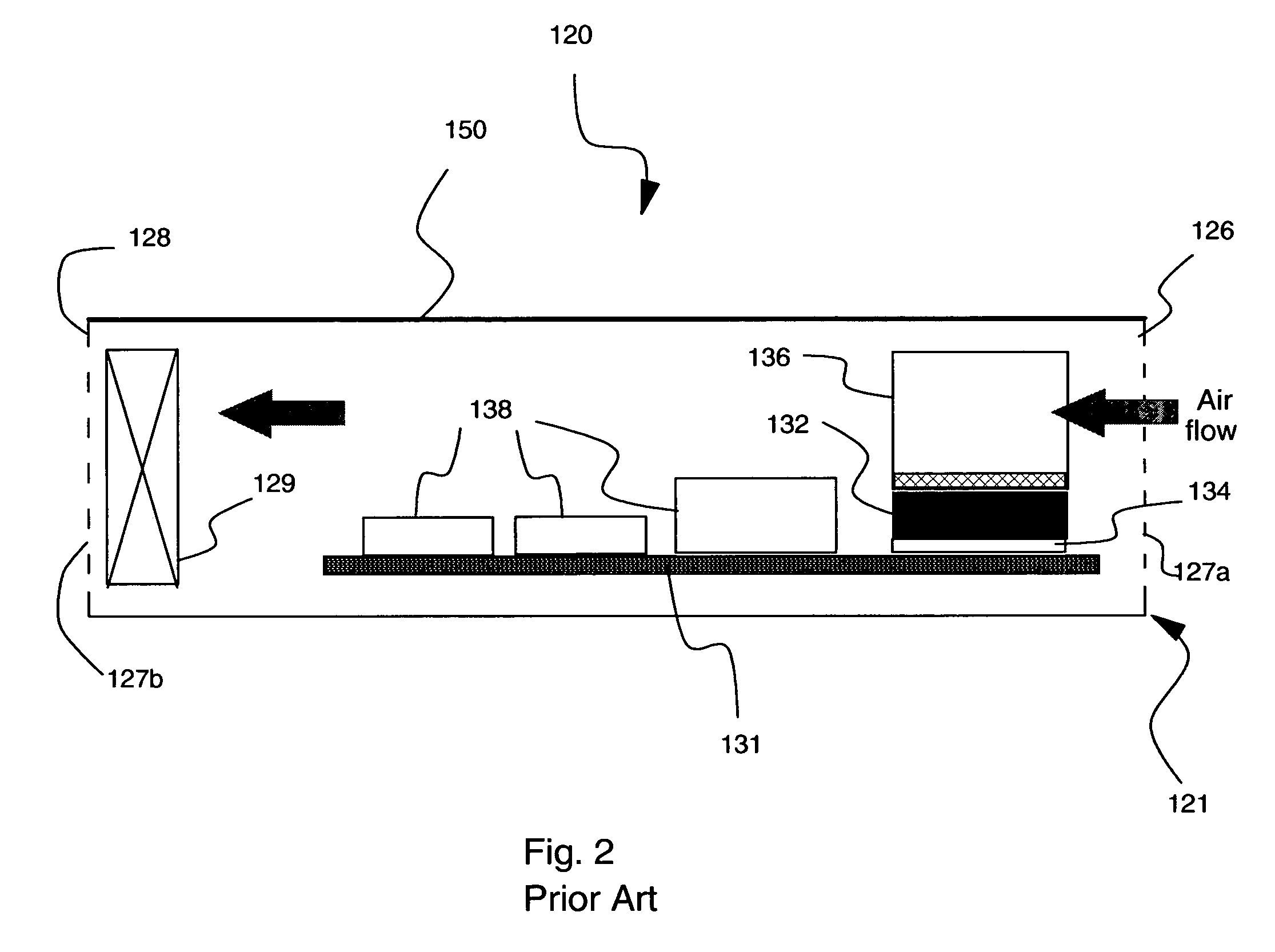

Cooling assembly for electronics drawer using passive fluid loop and air-cooled cover

InactiveUS20050248922A1Increase surface areaOvercomes shortcomingSemiconductor/solid-state device detailsSolid-state devicesHeat transmissionCombined use

A cooling apparatus for electronic drawers utilizing a passive fluid cooling loop in conjunction with an air cooled drawer cover. The air cooled cover provides an increased surface area from which to transfer heat to cooling air flowing through the drawer. The increased cooling surface uses available space within the drawer, which may be other than immediately adjacent to a high power device within the drawer. The passive fluid cooling loop provides heat transfer from the high power device to the air cooled cover assembly, allowing placement of the air cooled cover assembly other than immediately adjacent to the high power device. The cooling apparatus is easily disengaged from the electronics drawer, providing access to devices within the drawer.

Owner:IBM CORP

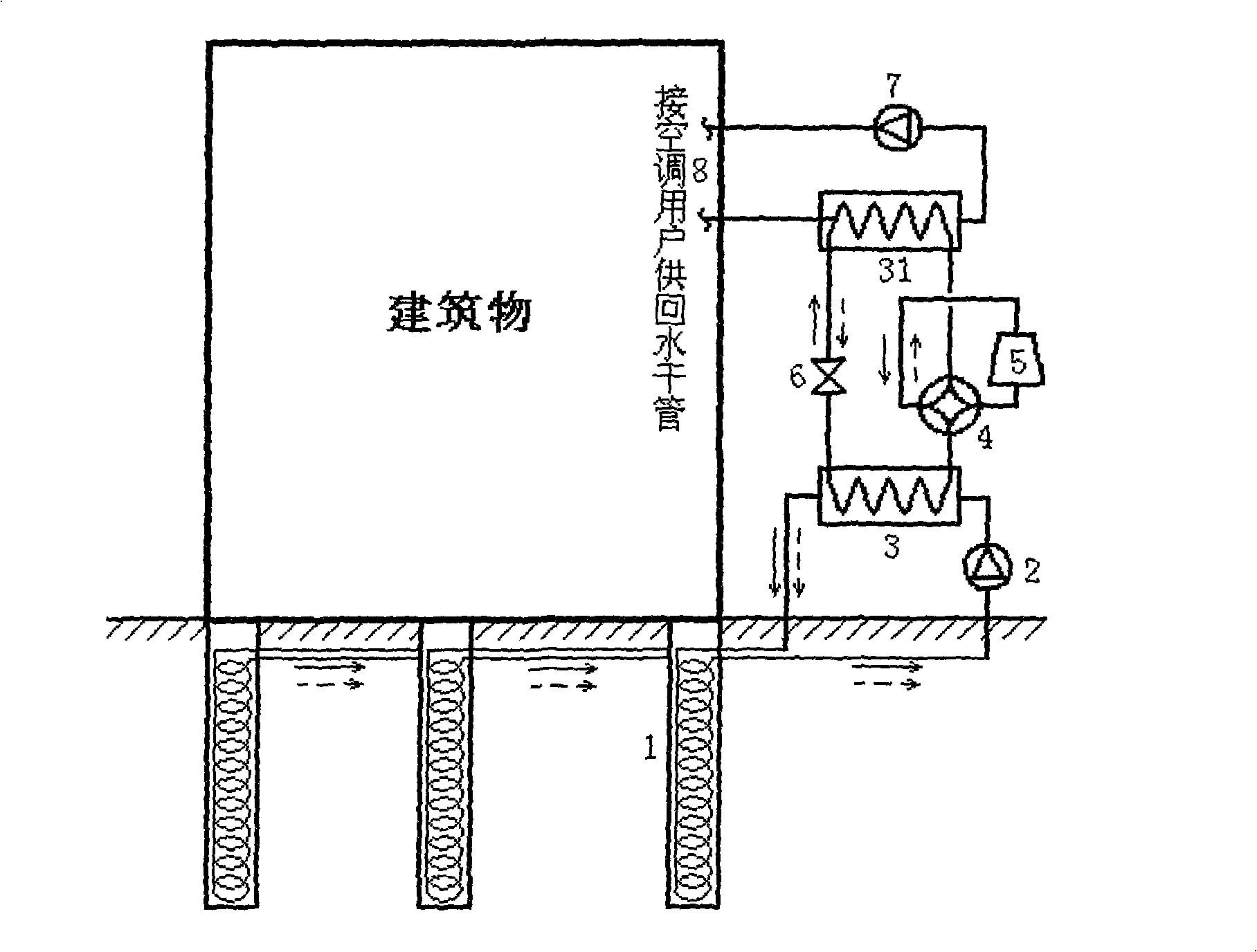

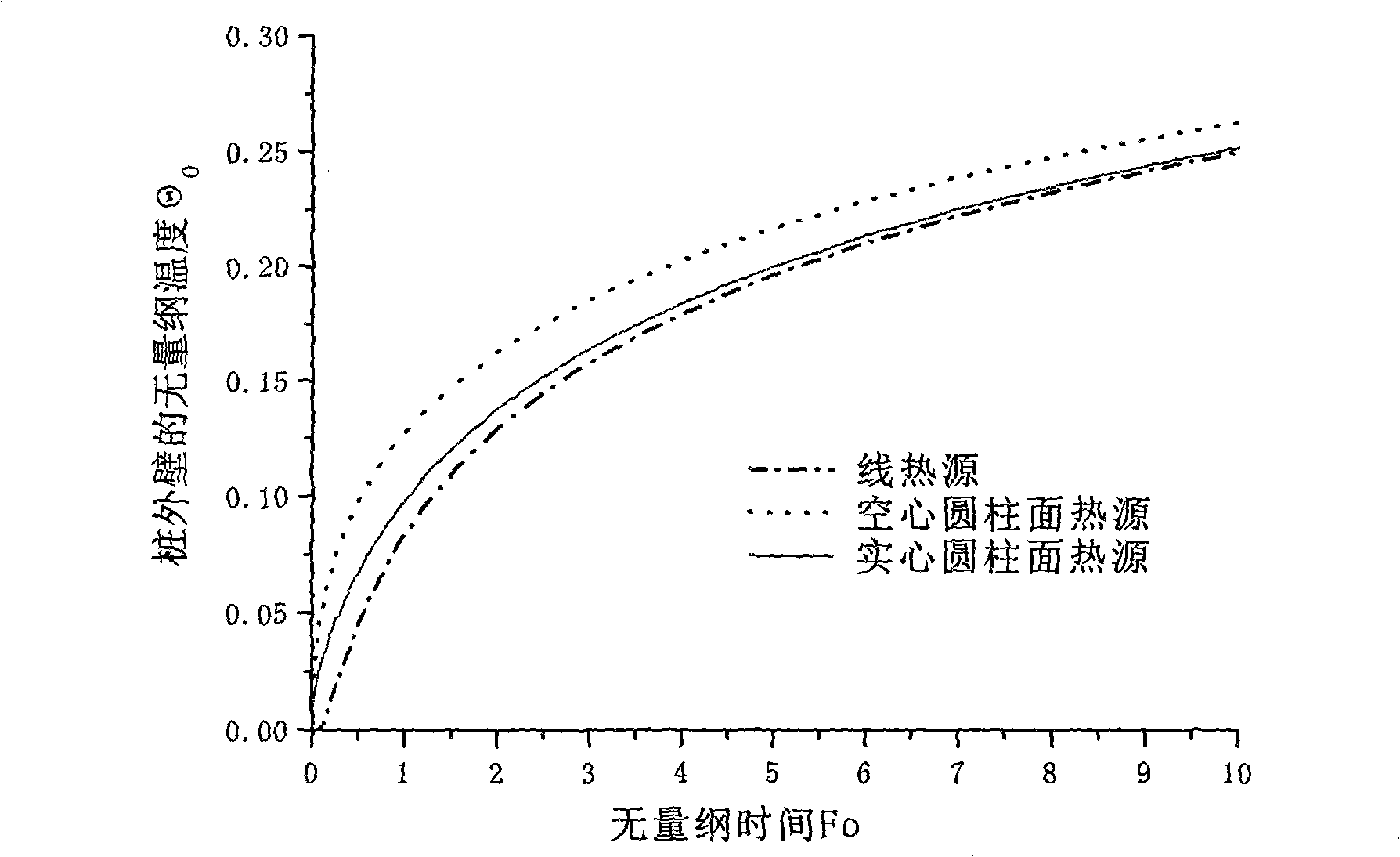

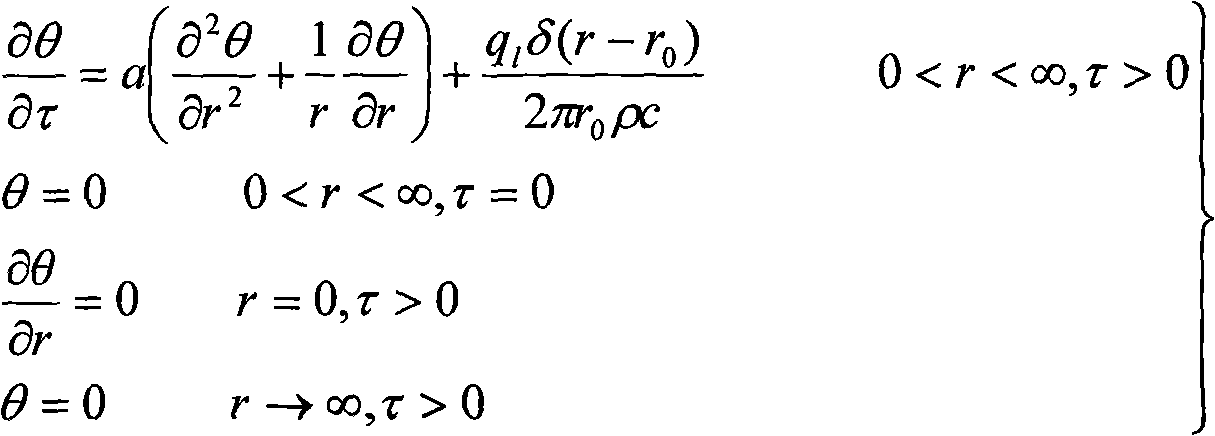

Pile imbedded helix tube type ground source heat pump system and heat transferring model of terrestrial heat exchanger thereof

ActiveCN101408359ASmall footprintReduce initial investmentHeat pumpsOther heat production devicesHeat transmissionEnd system

The invention discloses a pile-embedding spiral pipe typed ground source heat pump system and a heat transmission model of a geothermal heat exchanger thereof. A solid cylindrical surface heat source model is put forward for the first time and two analytic solution expressions of the heat transmission model is worked out by the Green function method. The system can sufficiently utilizes the underground area of a building, saves a great amount of expenses for boring and pipe embedding, reduces the initial investment of the ground source heat pump system, improves the construction efficiency and has convenient and quick construction. Furthermore, the heat transmission model of the pile-embedding spiral pipe geothermal heat exchanger can quantitatively analyze the effects of all parameters of the pile-embedding spiral pipe geothermal heat exchanger on the heat transmission capability and provides a basis for the engineering design. The structure of the pile-embedding spiral pipe typed ground source heat pump system comprises the geothermal heat exchanger which is connected with an air conditioning heat pump system by pipelines; the air conditioning heat pump system is connected with a conveying and end system in the building; the geothermal heat exchangers have the quantity of more than one; and each geothermal heat exchanger forms the pile-embedding spiral pipe-typed geothermal heat exchanger by building pile foundations and spiral pipes which are embedded in the pipe foundations.

Owner:山东中瑞新能源科技有限公司

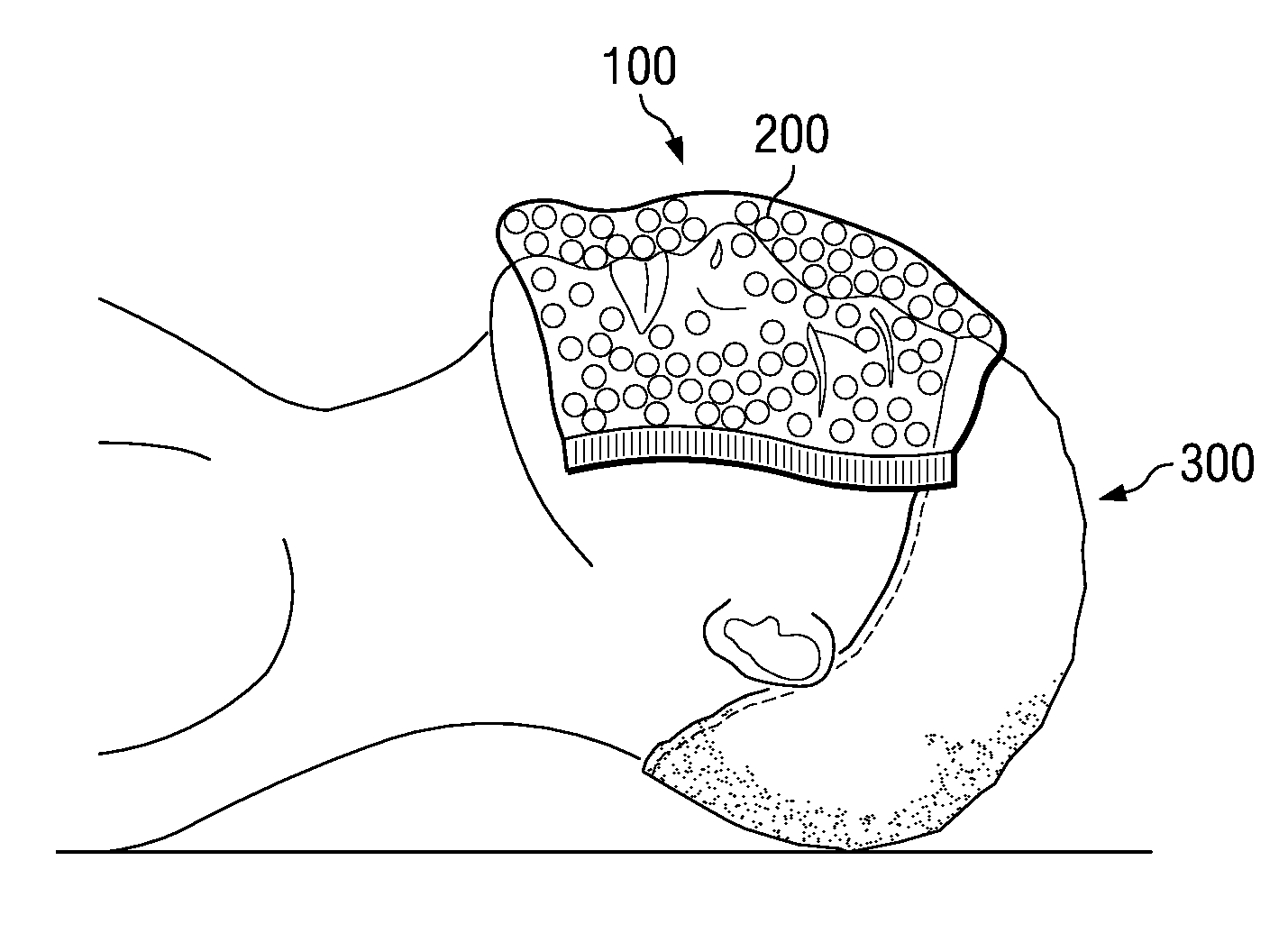

Cold compress for therapeutic cooling

InactiveUS20120165910A1High heat transferIncrease flexibilityTherapeutic coolingTherapeutic heatingCold compressesHeat transfer fluid

A novel cold compress designed for use as a cooling medium. The cold compress comprises a flexible bag having a plurality of spheres. Each sphere contains a heat transfer fluid. As the bag is cooled or frozen, each sphere and the fluid they contain become cool or frozen. The bag is then placed on a body part of the patient who is recovering from surgery or injury. The small spheres allow maximum surface contact with the body part. This allows maximum and efficient heat transfer.

Owner:CHOUCAIR RAMSEY JOE +2

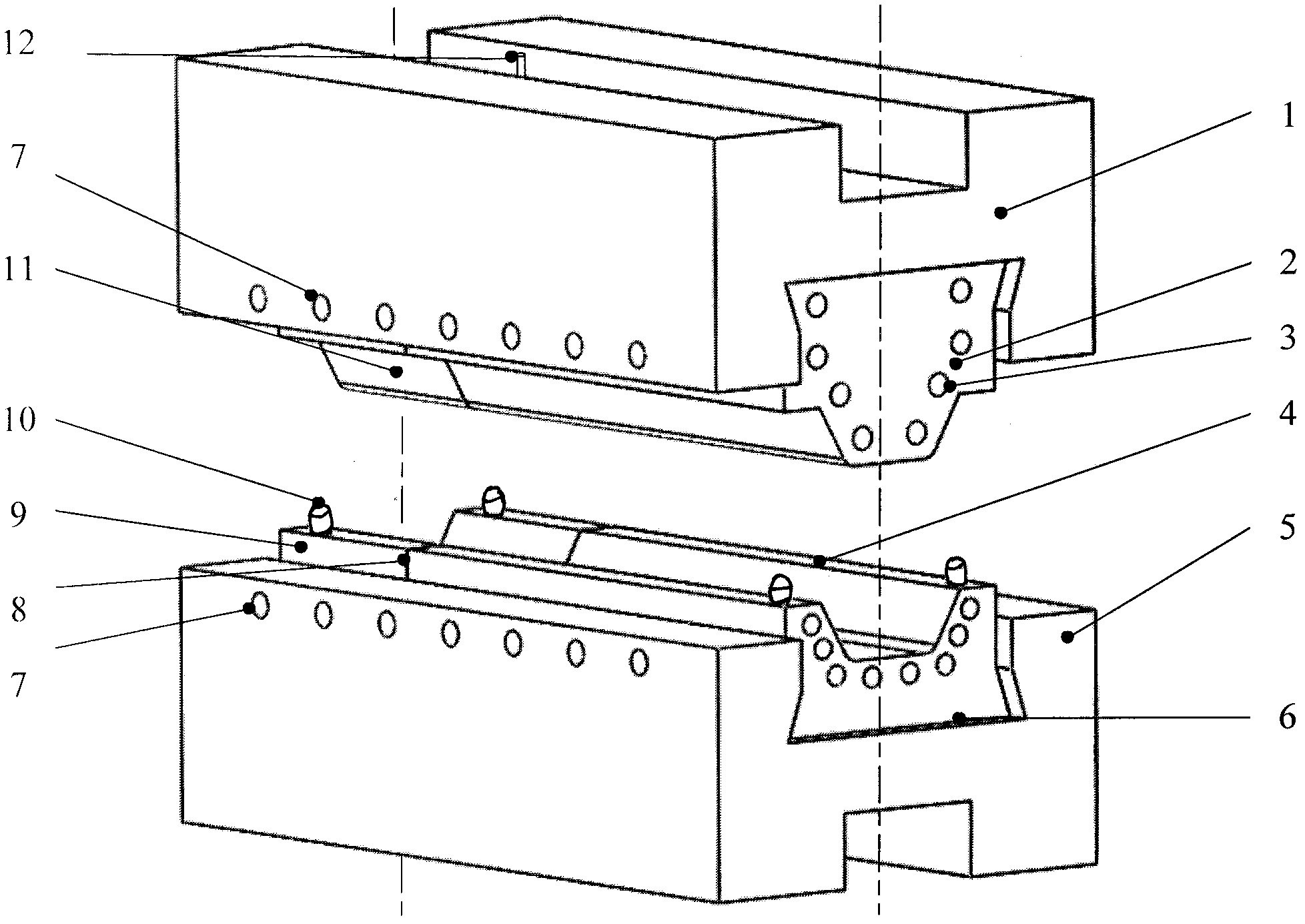

High-temperature splicing and quenching forming process and device of ultrahigh-strength steel

InactiveCN102304612ALess investmentReduce production processHeat treatment process controlHardnessUltimate tensile strength

The invention discloses a high-temperature splicing and quenching forming process of ultrahigh-strength steel. The process is characterized in that heat transfer with different degrees is performed in different regions of a part in forming and in-mold cooling processes, thus the strength and hardness are distributed according to requirements and the random splicing of the high strength and energyabsorption property of the material is achieved. At the same time, the invention also discloses a device for the process. The male mold and female mold of the device are formed by splicing one and more than one insert according to the requirement, and the male mold and the female mold are combined in five different combination modes. The process and device can ensure that the part has different mechanical properties in the different regions after one-time hot forming is finished, and can be applied to the production of automobile anti-collision parts (such as anti-collision beams, pillars A, pillars B, automobile body floor passageway and the like).

Owner:SHANDONG JIANZHU UNIV

Method and apparatus of indirect-evaporation cooling

InactiveUS20030014983A1Economic securityFree-cooling systemsStationary conduit assembliesDesiccantHeat transmission

The within invention improves on the indirect evaporative cooling method and apparatus by making use of a working fluid that is pre-cooled with and without desiccants before it is passed through a Wet Channel where evaporative fluid is on the walls to take heat and store it in the working fluid as increased latent heat. The heat transfer across the membrane between the Dry Channel and the Wet Channel may have dry, solid desiccant or liquid desiccant and may have perforations, pores or capillary pathways. The evaporative fluid may be water, fuel, or any substance that has the capacity to take heat as latent heat. The Wet Channel or excess cooled fluid is in heat transfer contact with a Product Channel where Product Fluid is cooled without adding any humidity. An alternative embodiment for heat transfer between adjacent channels is with heat pipes.

Owner:MAISOTSENKO VALERIY +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com