Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2848 results about "Latent heat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Latent heat is energy released or absorbed, by a body or a thermodynamic system, during a constant-temperature process — usually a first-order phase transition. Latent heat can be understood as energy in hidden form which is supplied or extracted to change the state of a substance without changing its temperature. Examples are latent heat of fusion and latent heat of vaporization involved in phase changes, i.e. a substance condensing or vaporizing at a specified temperature and pressure.

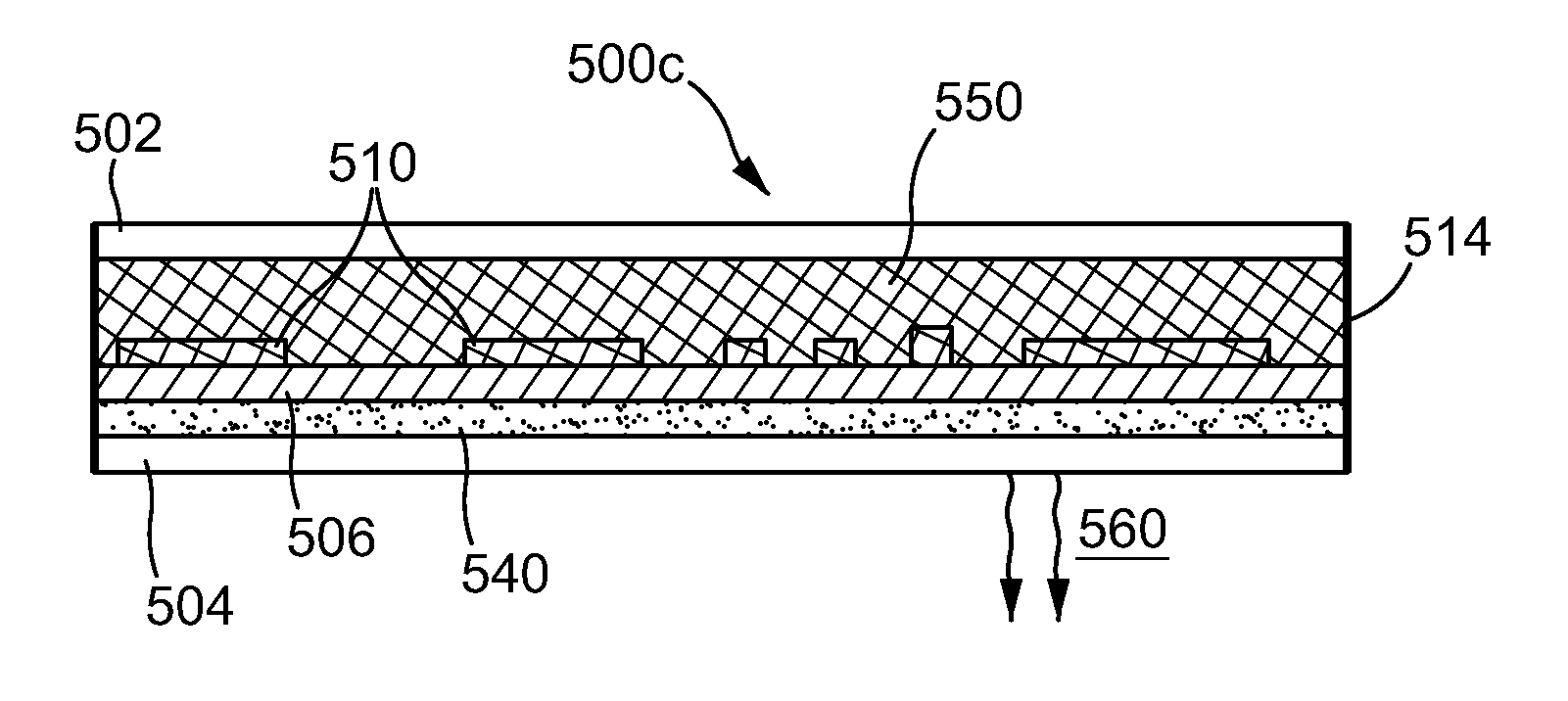

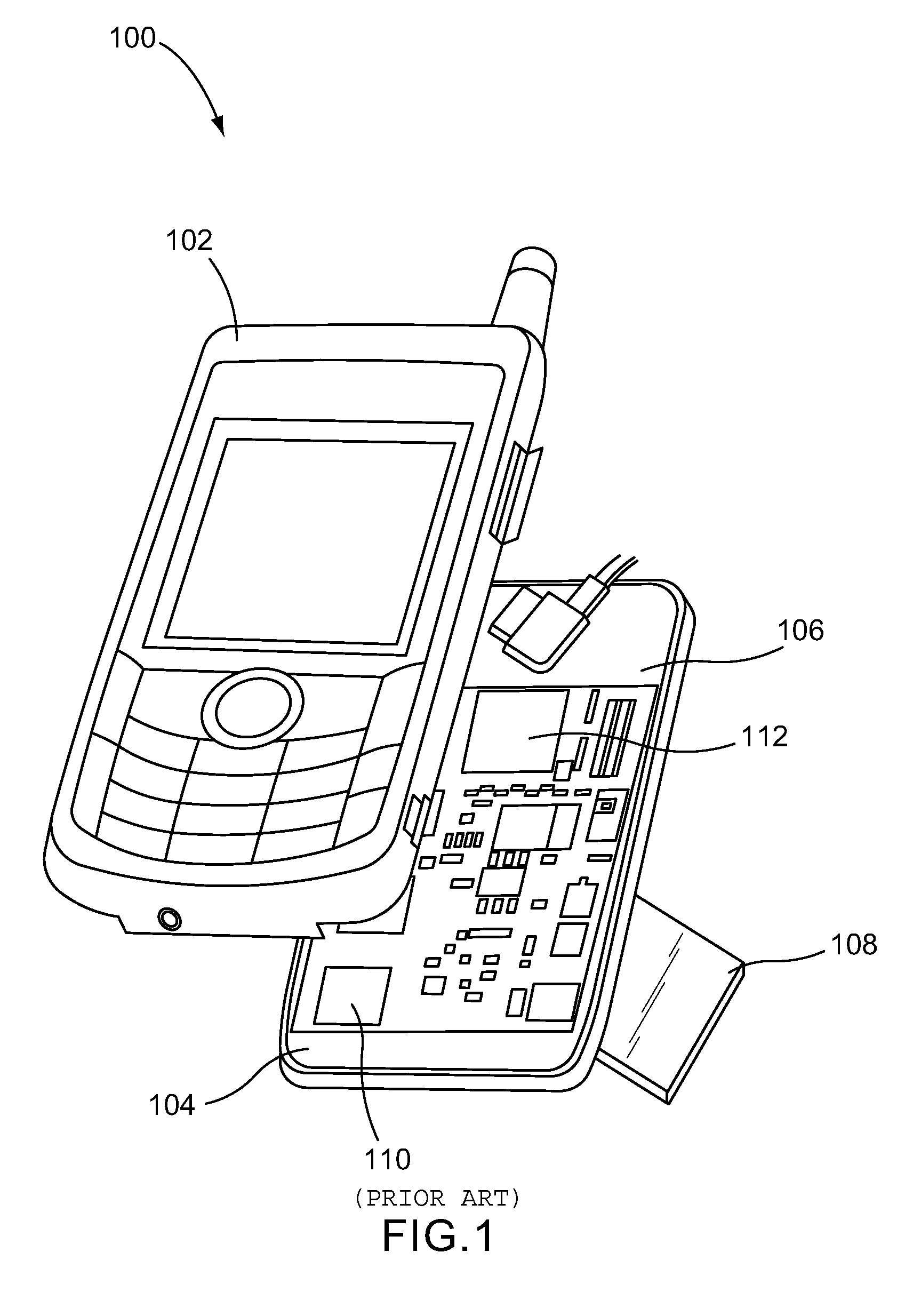

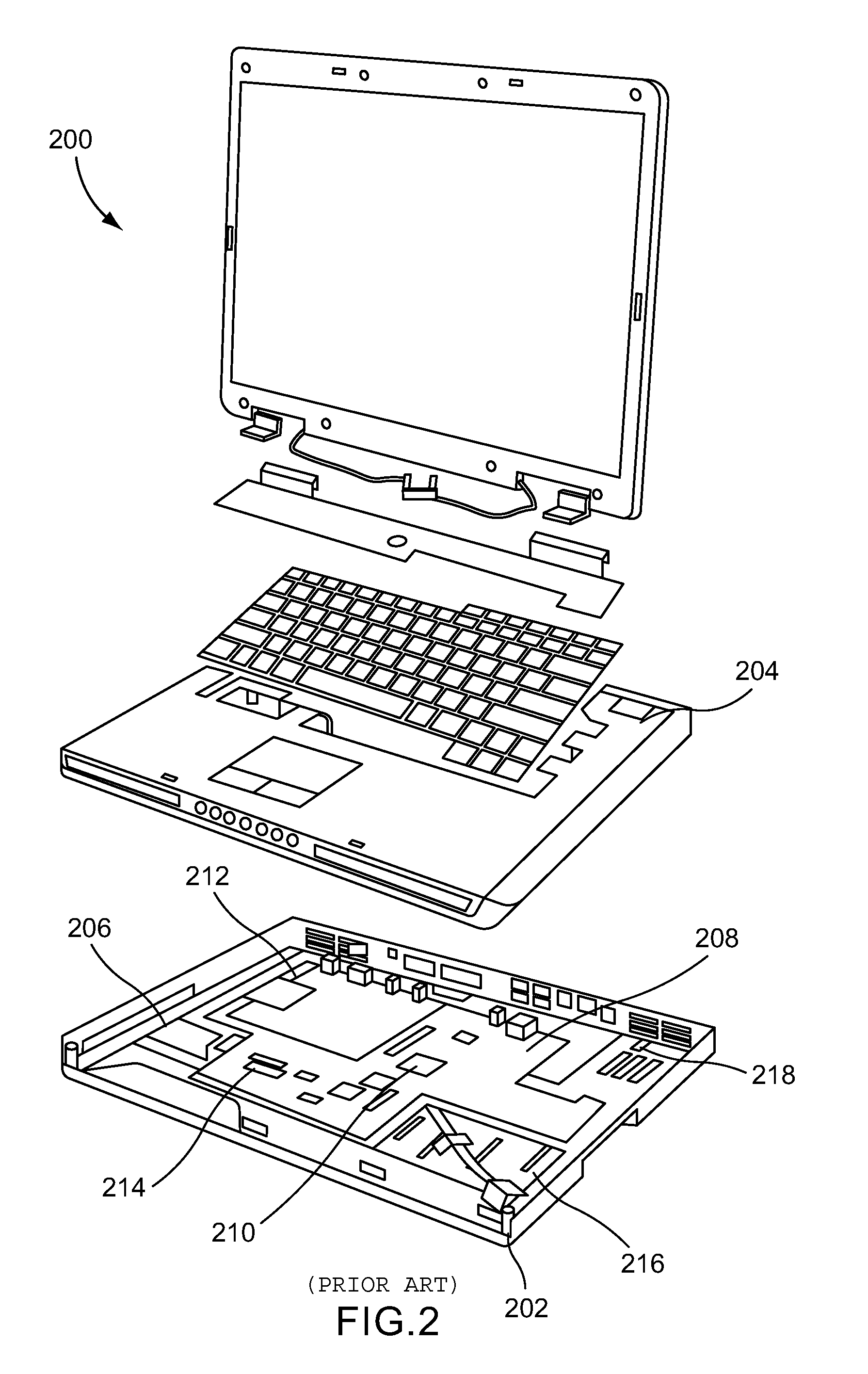

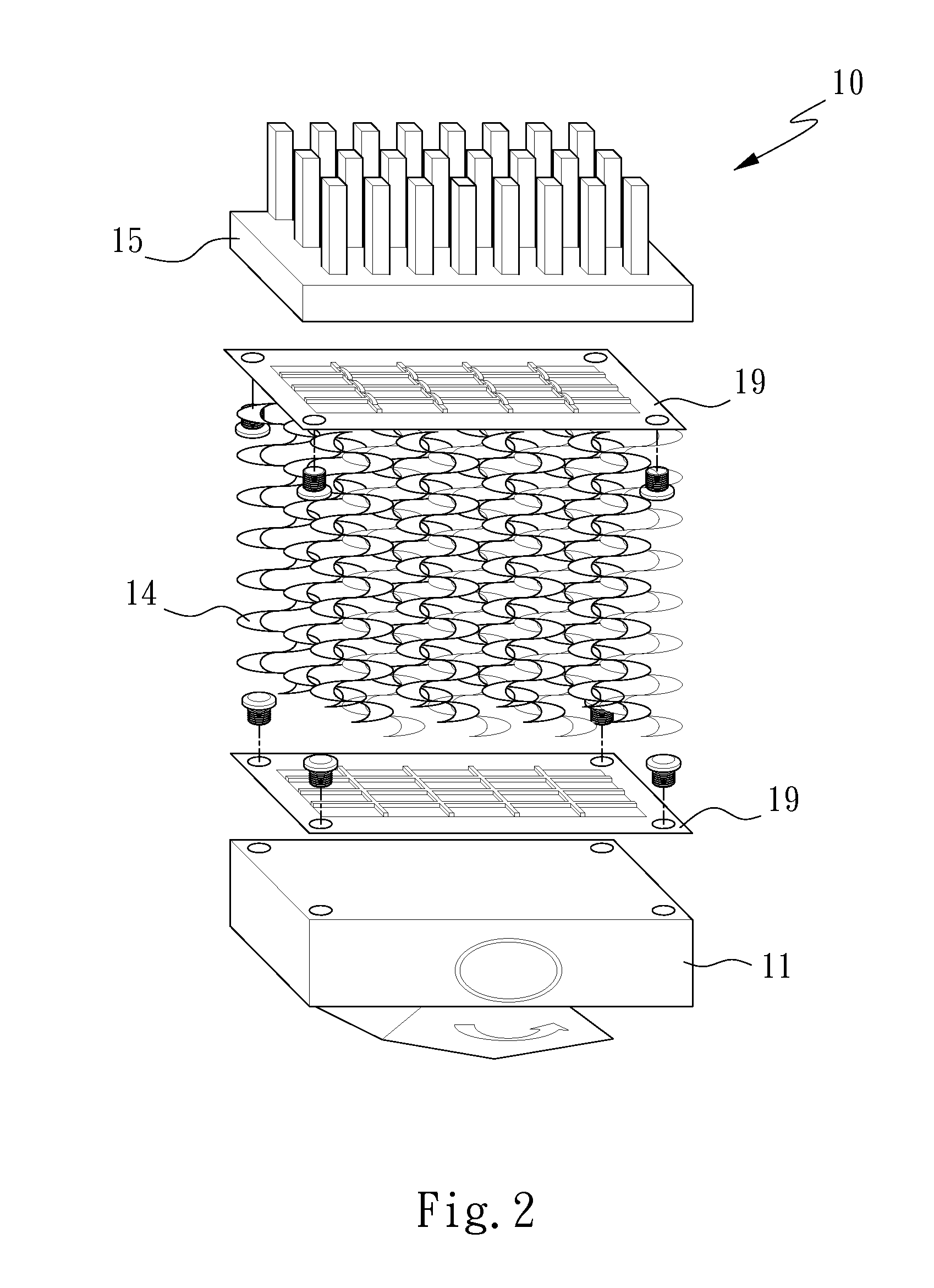

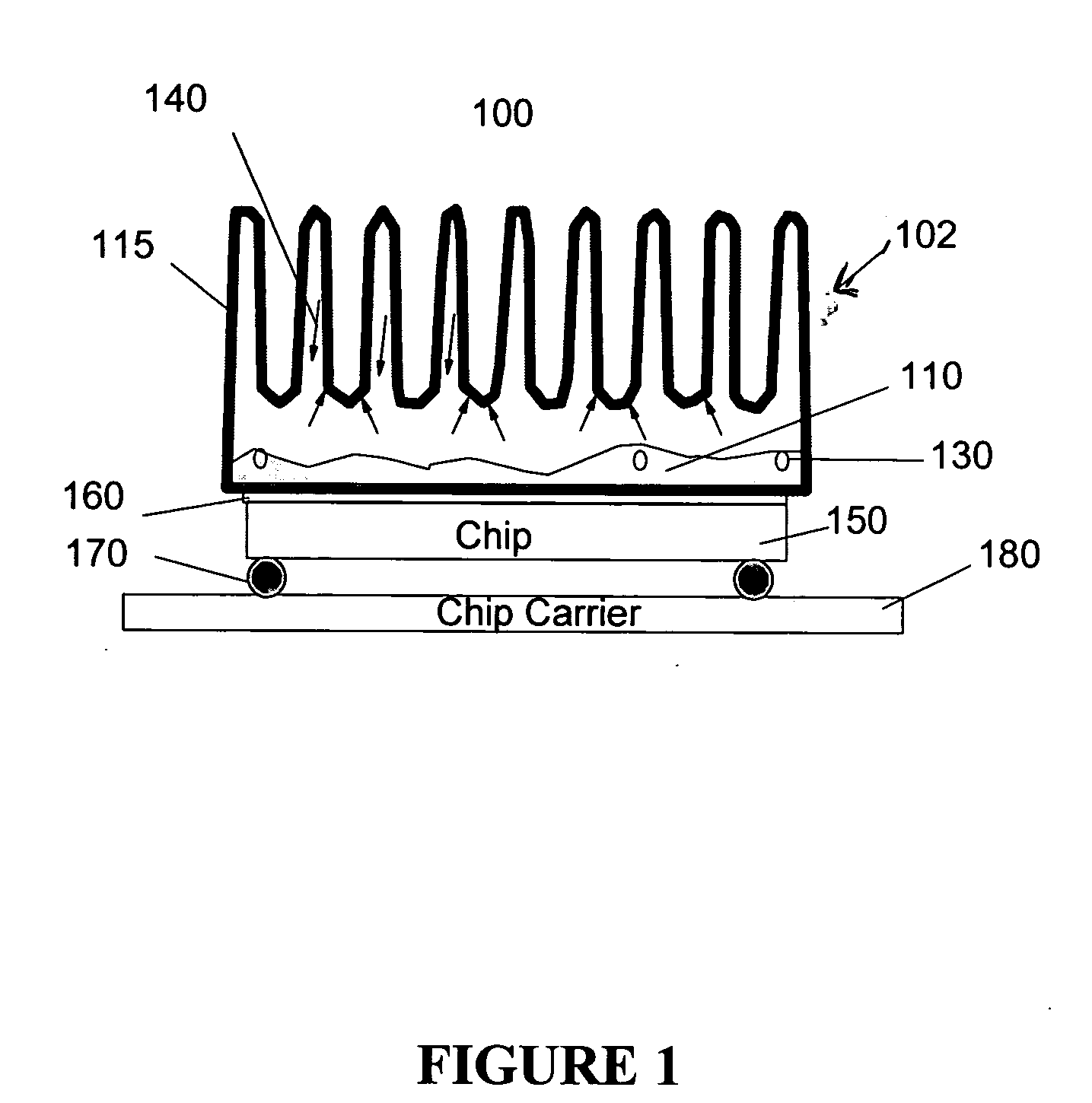

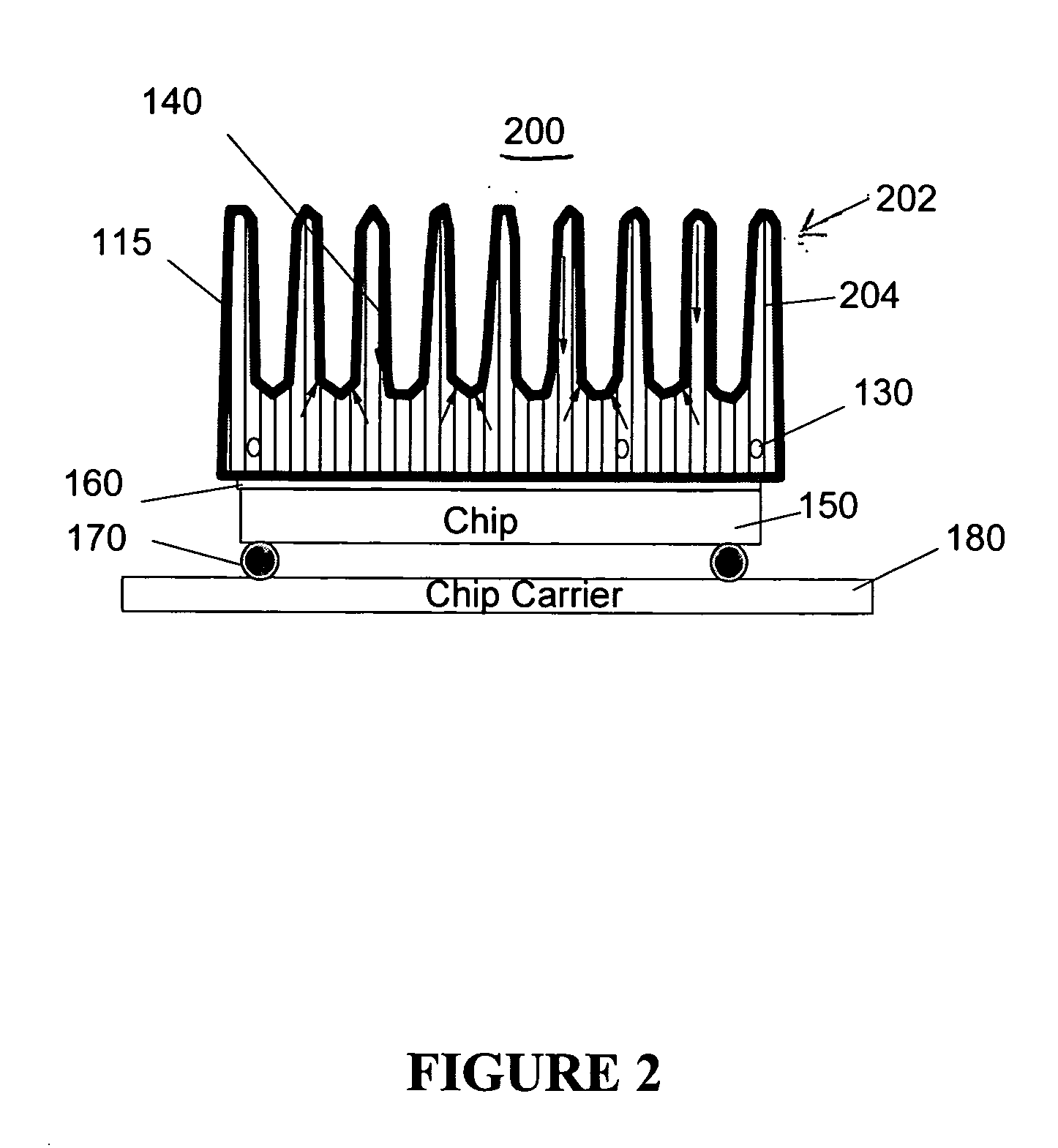

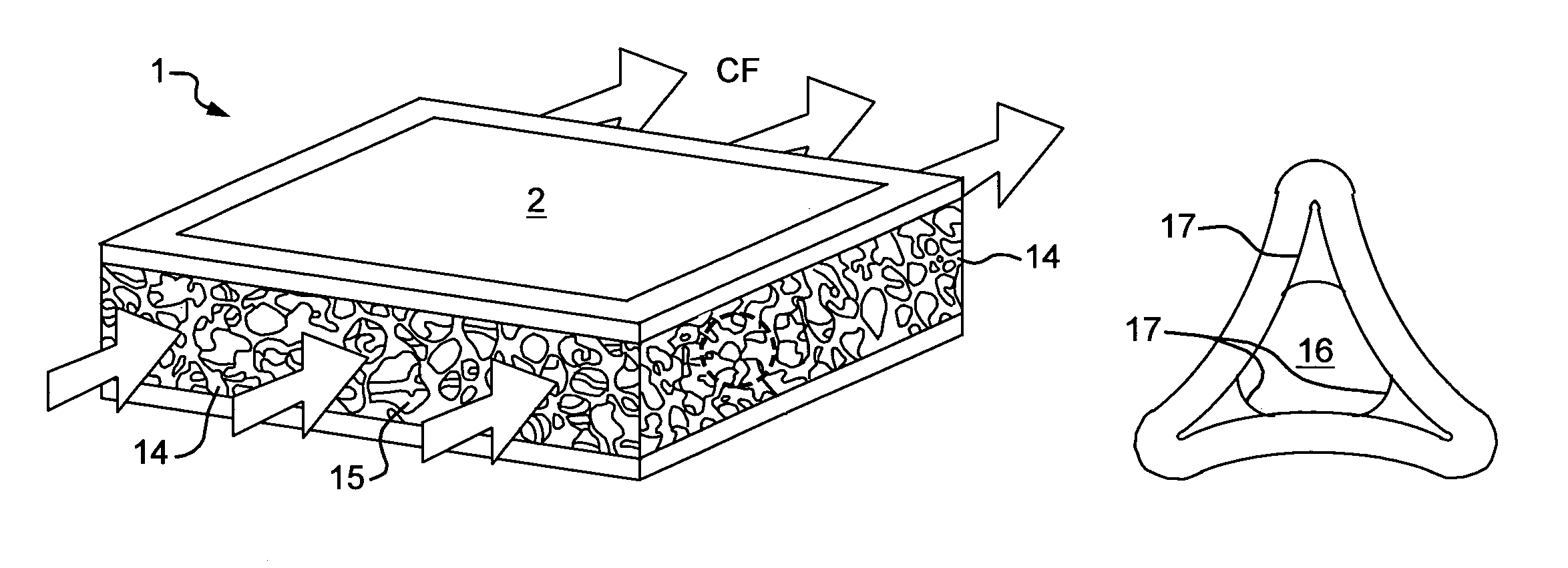

Systems structures and materials for electronic device cooling

An electronic device having one or more components that generate heat during operation includes a structure for temperature management and heat dissipation. The structure for temperature management and heat dissipation comprises a heat transfer substrate having a surface that is in thermal communication with the ambient environment and a temperature management material in physical contact with at least a portion of the one or more components of the electronic device and at least a portion of the heat transfer substrate. The temperature management material comprises a polymeric phase change material having a latent heat of at least 5 Joules per gram and a transition temperature between 0° C. and 100° C., and a thermal conductive filler.

Owner:LATENT HEAT SOLUTIONS LLC

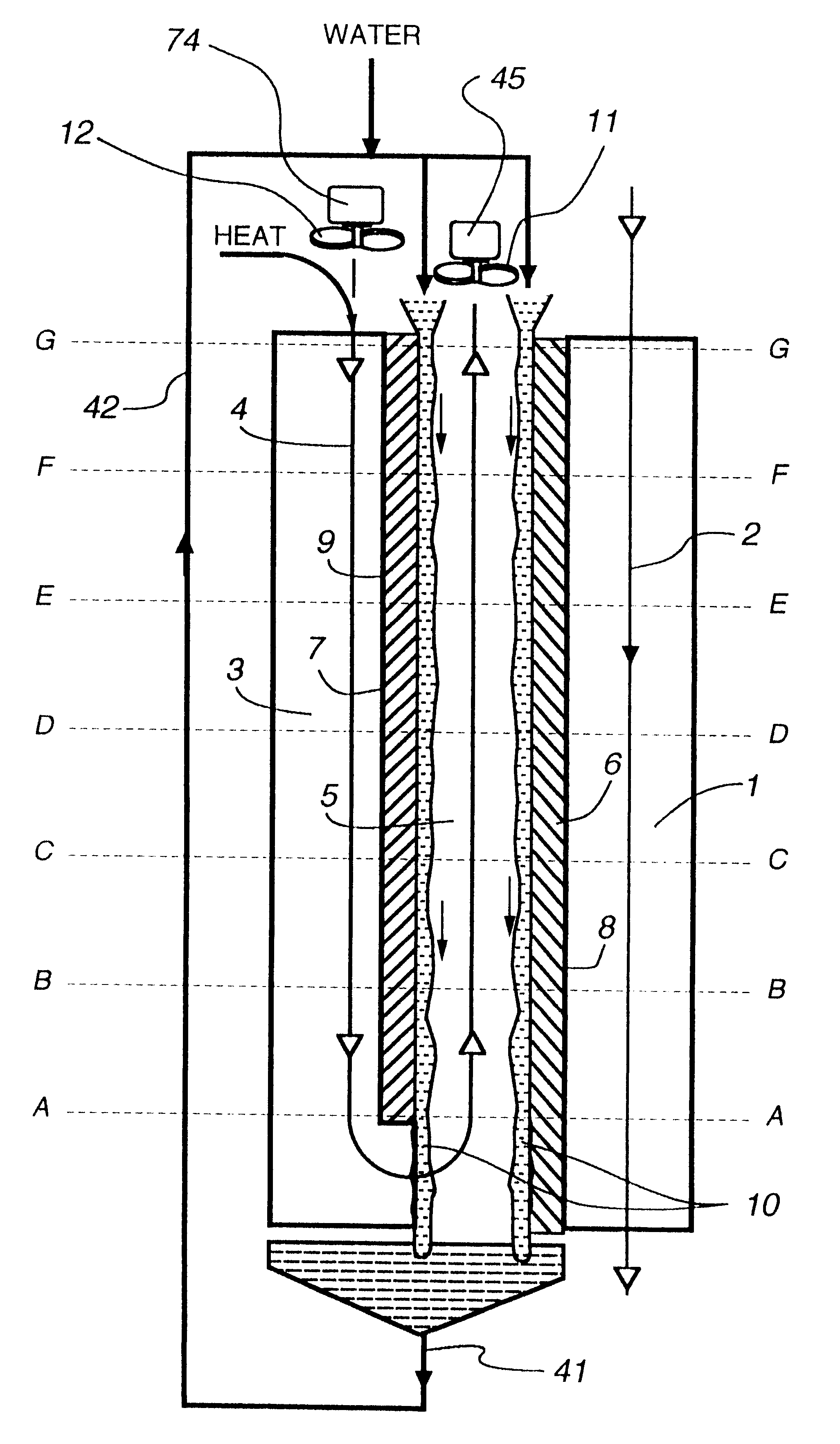

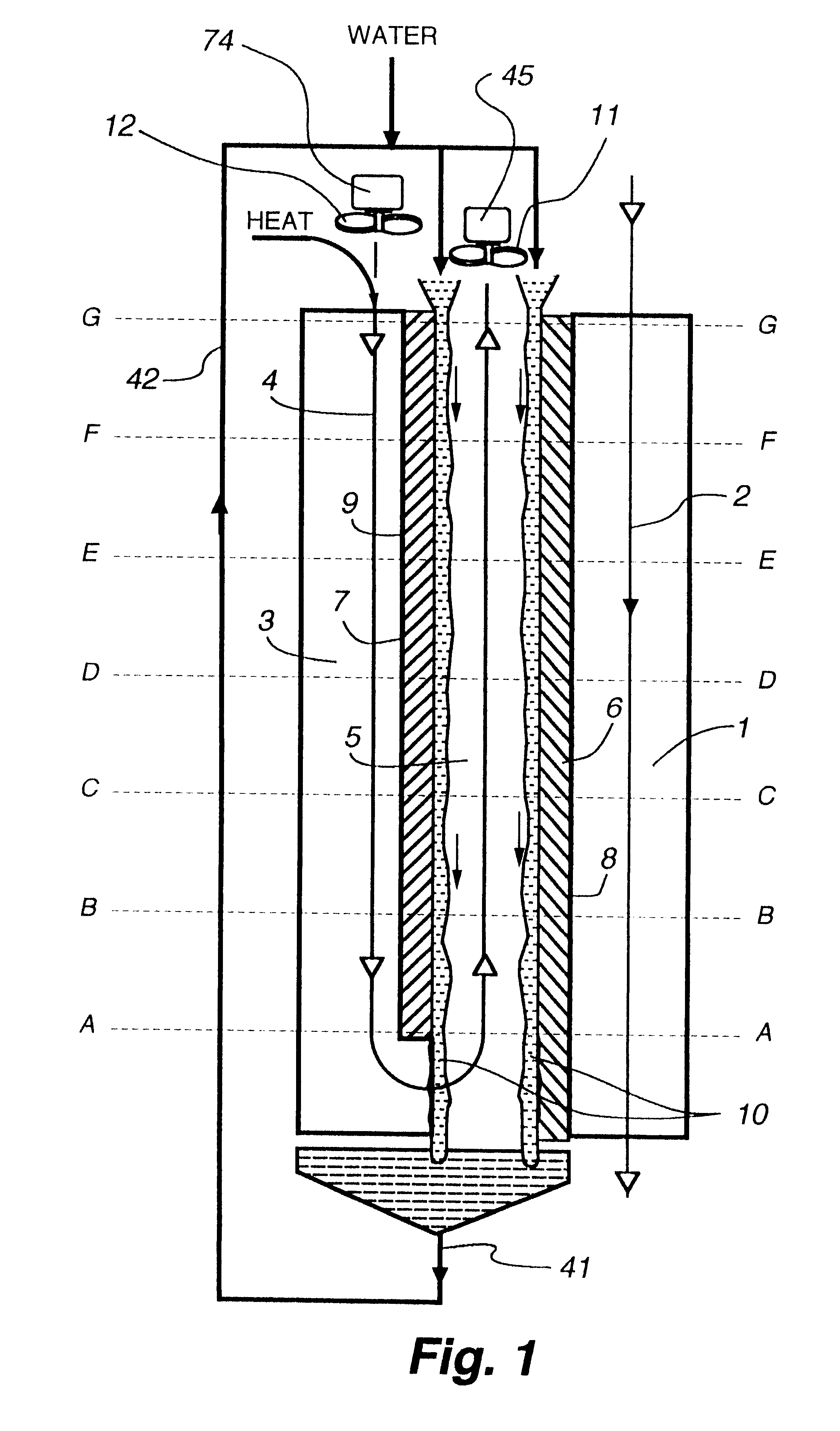

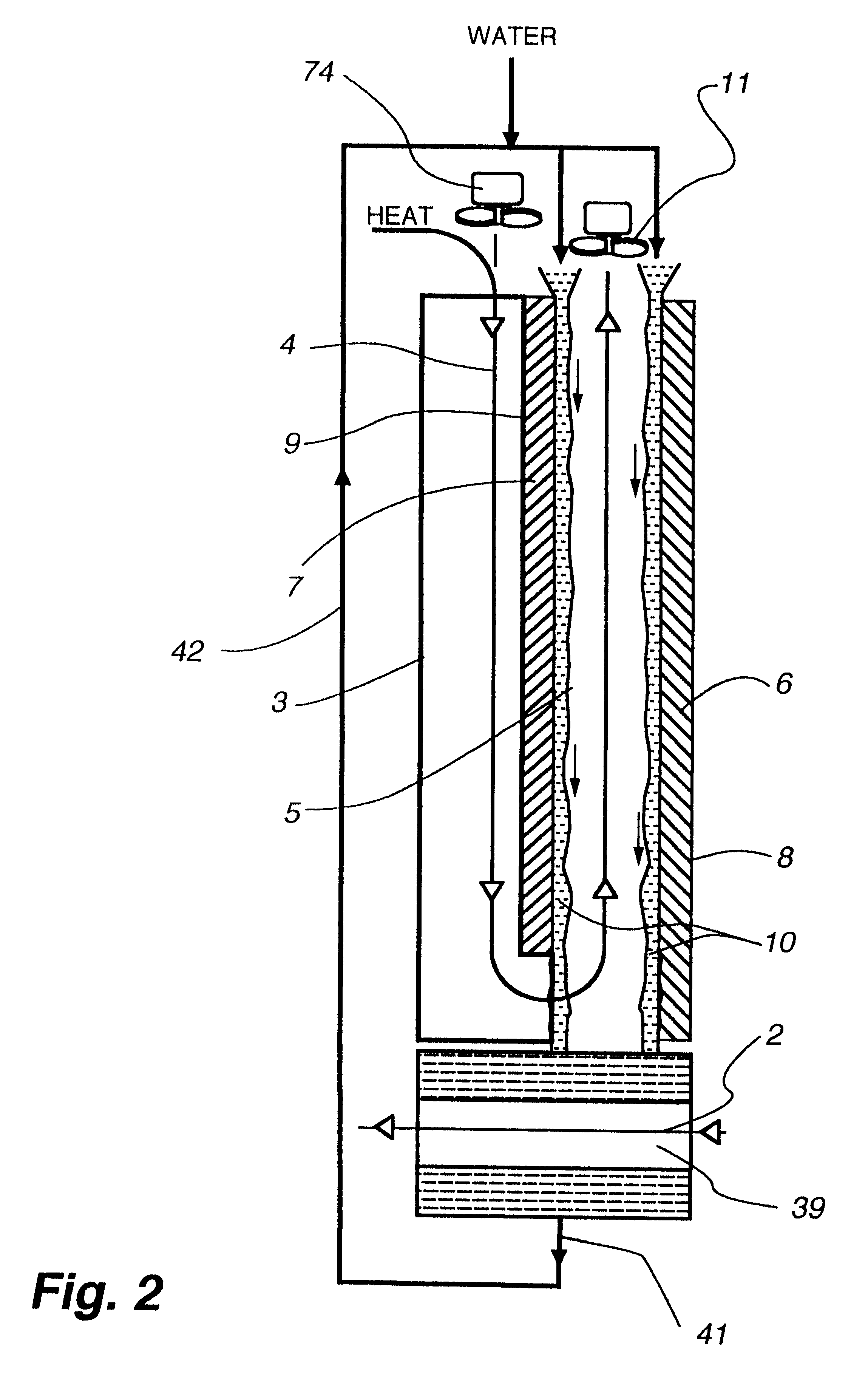

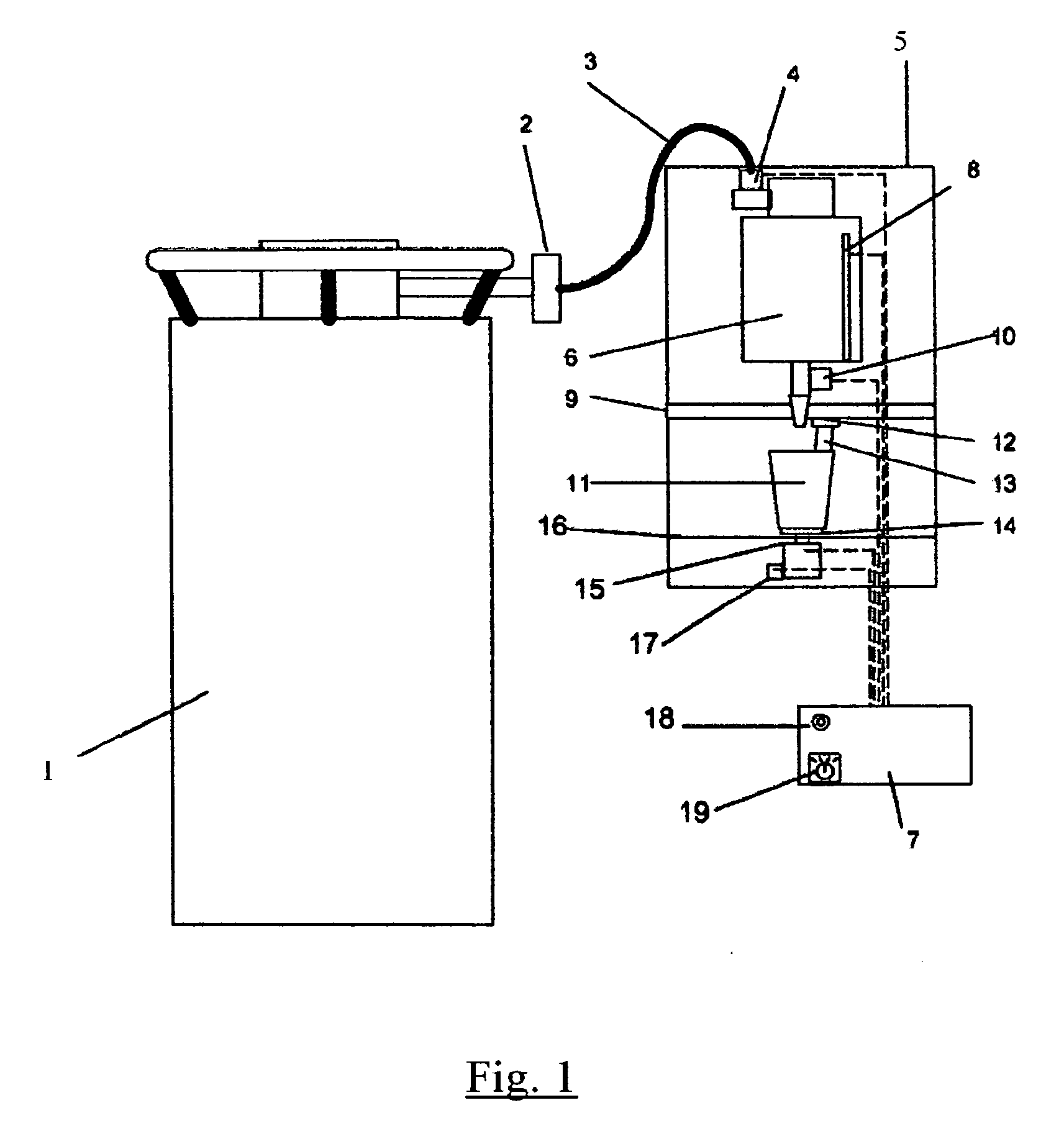

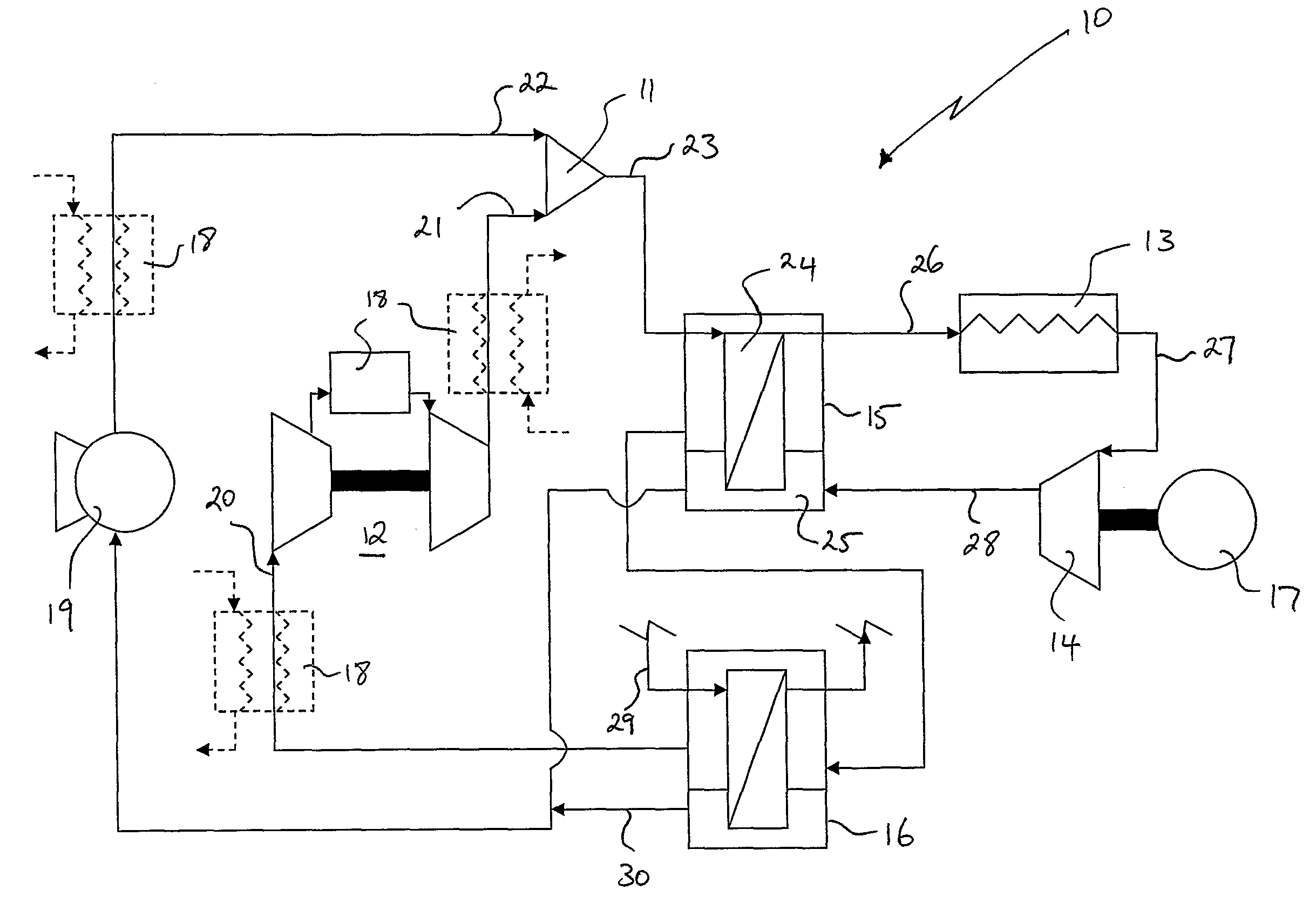

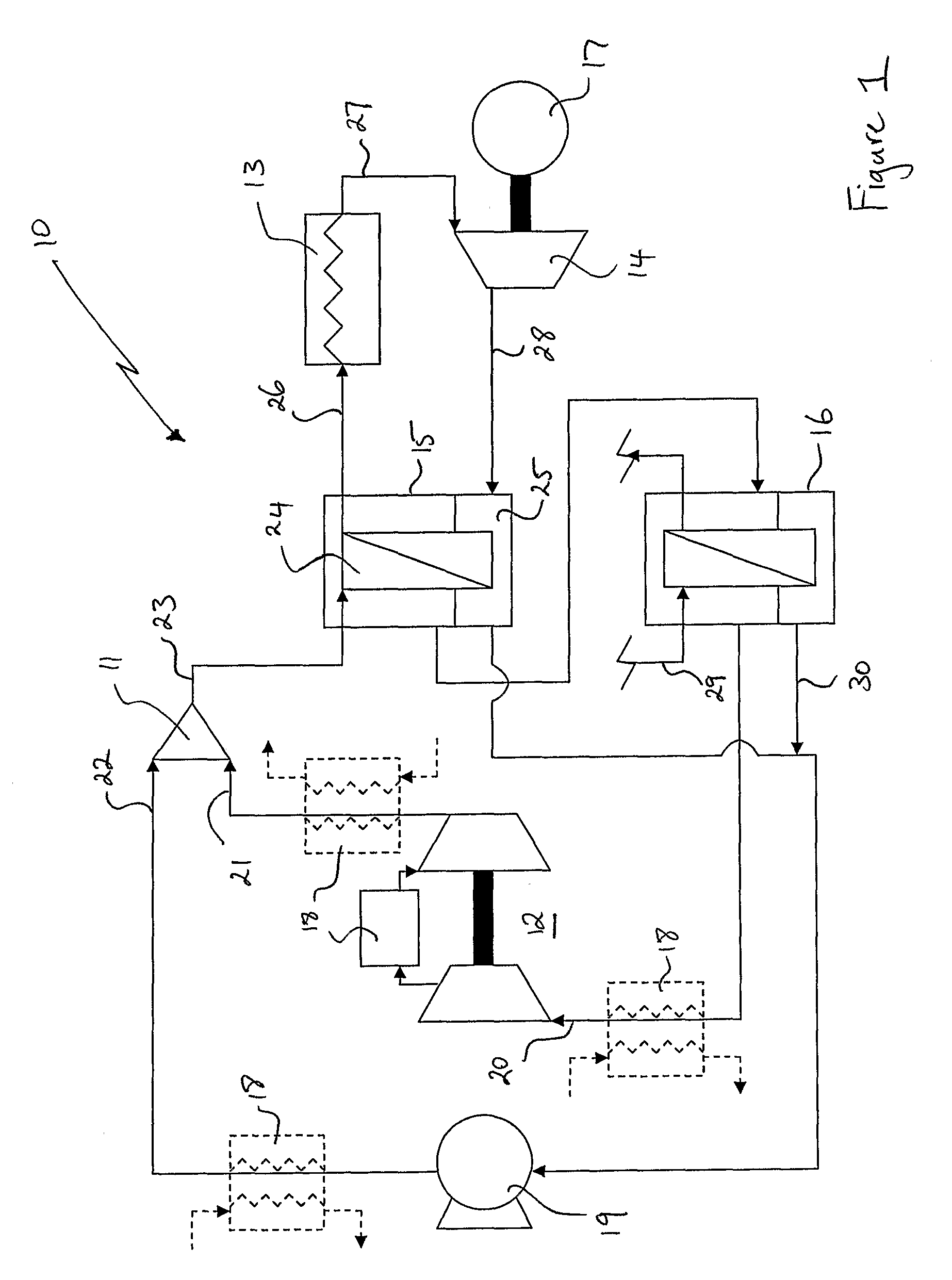

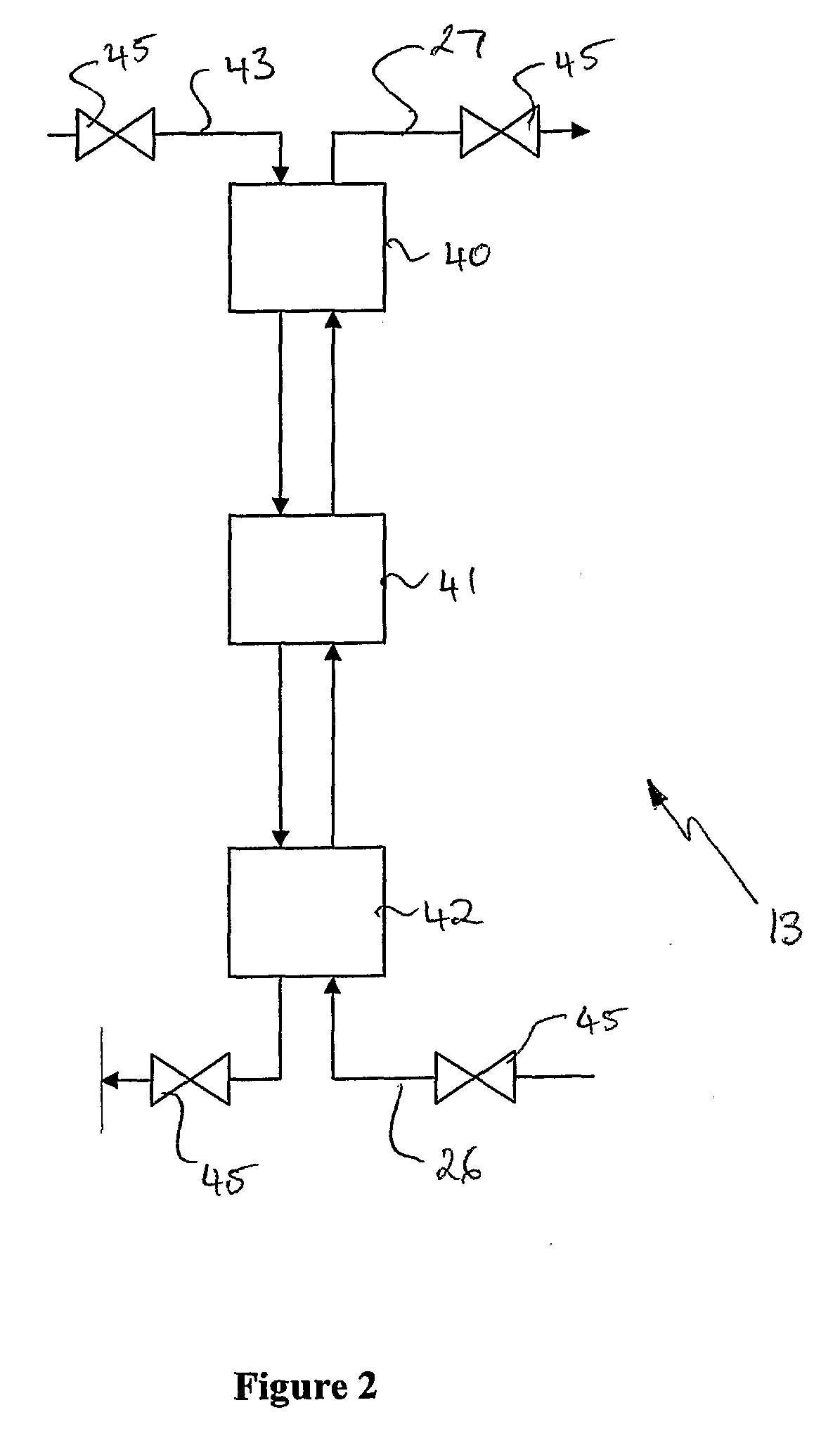

Method and apparatus of indirect-evaporation cooling

InactiveUS6497107B2Less energyHigh energy costFree-cooling systemsStationary conduit assembliesWorking fluidEvaporation

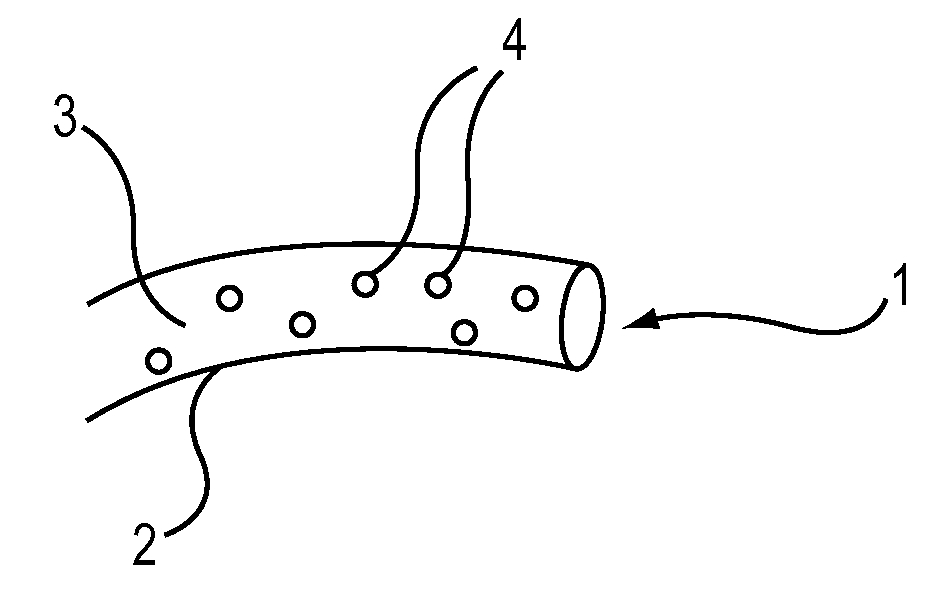

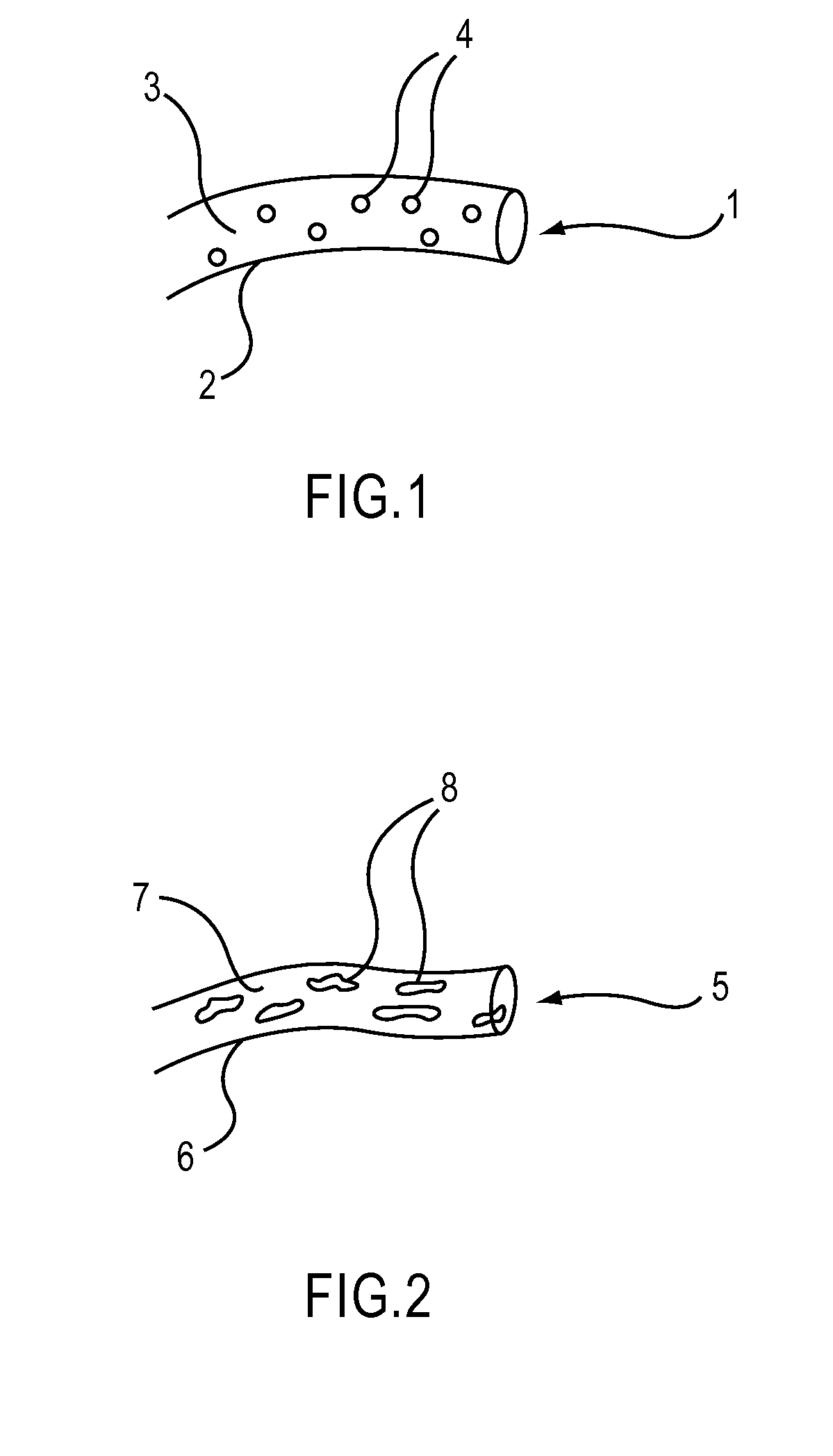

The within invention improves on the indirect evaporative cooling method and apparatus by making use of a working fluid that is pre-cooled with and without desiccants before it is passed through a Wet Channel where evaporative fluid is on the walls to take heat and store it in the working fluid as increased latent heat. The heat transfer across the membrane between the Dry Channel and the Wet Channel may have dry, solid desiccant or liquid desiccant and may have perforations, pores or capillary pathways. The evaporative fluid may be water, fuel, or any substance that has the capacity to take heat as latent heat. The Wet Channel or excess cooled fluid is in heat transfer contact with a Product Channel where Product Fluid is cooled without adding any humidity. An alternative embodiment for heat transfer between adjacent channels is with heat pipes.

Owner:F F SEELEY NOMINEES

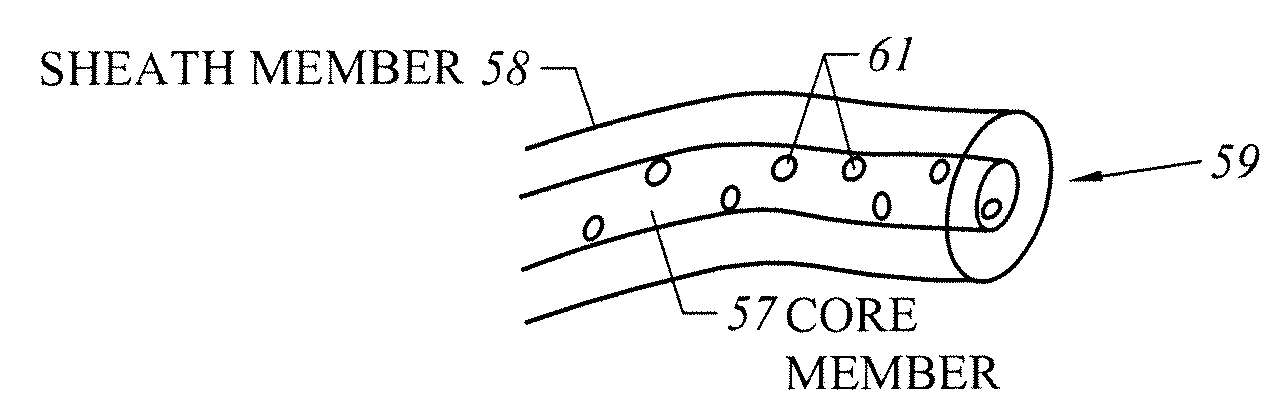

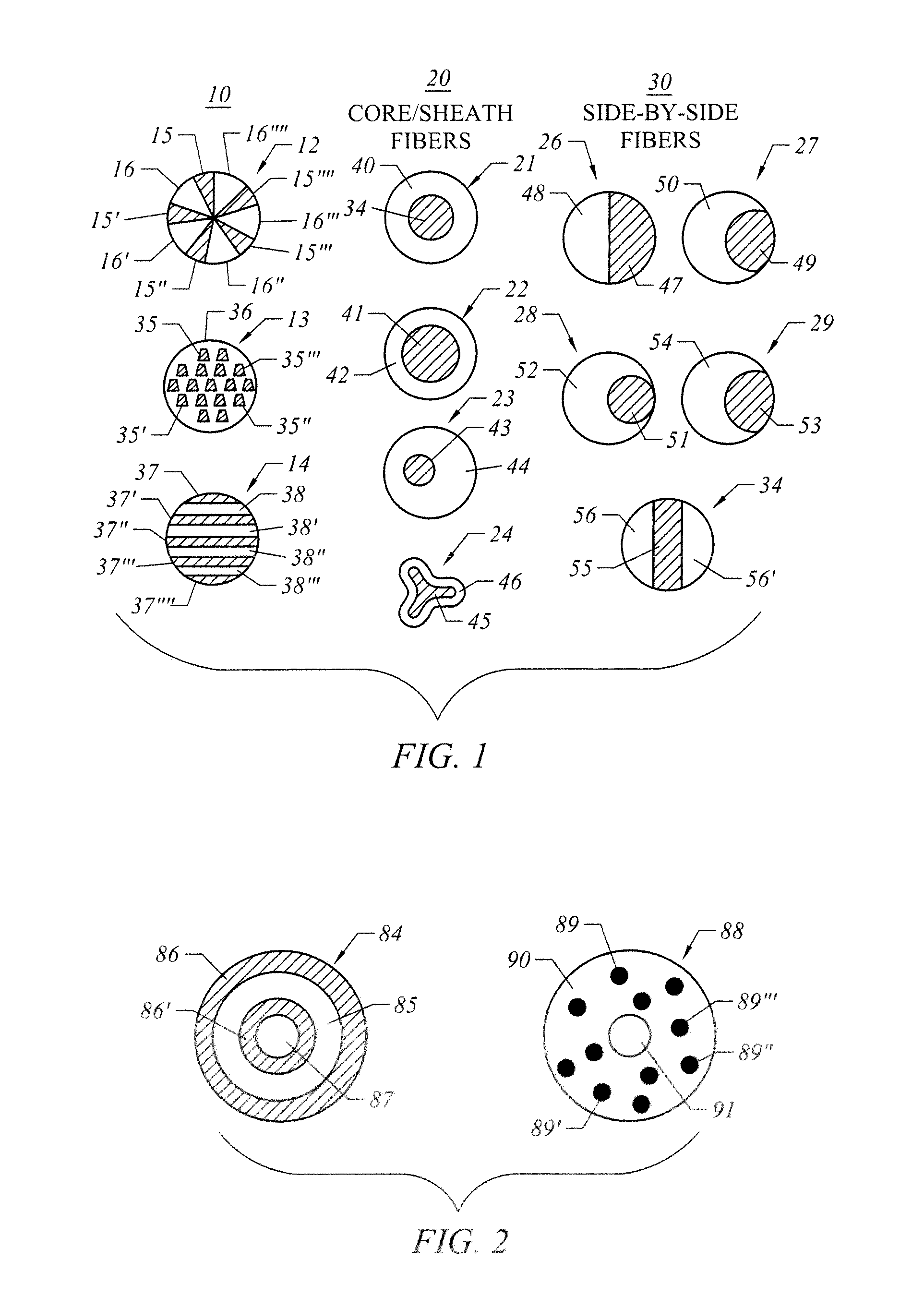

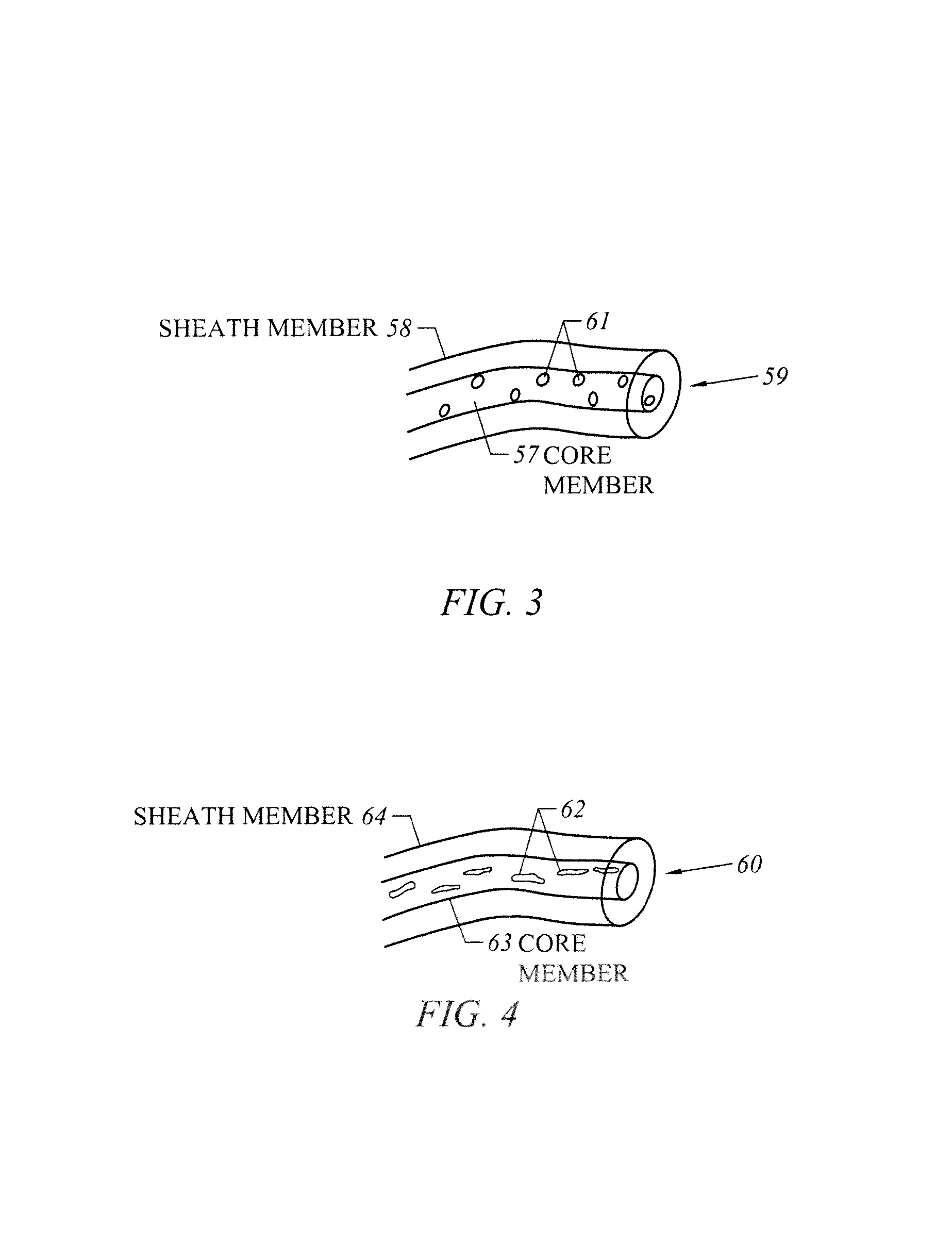

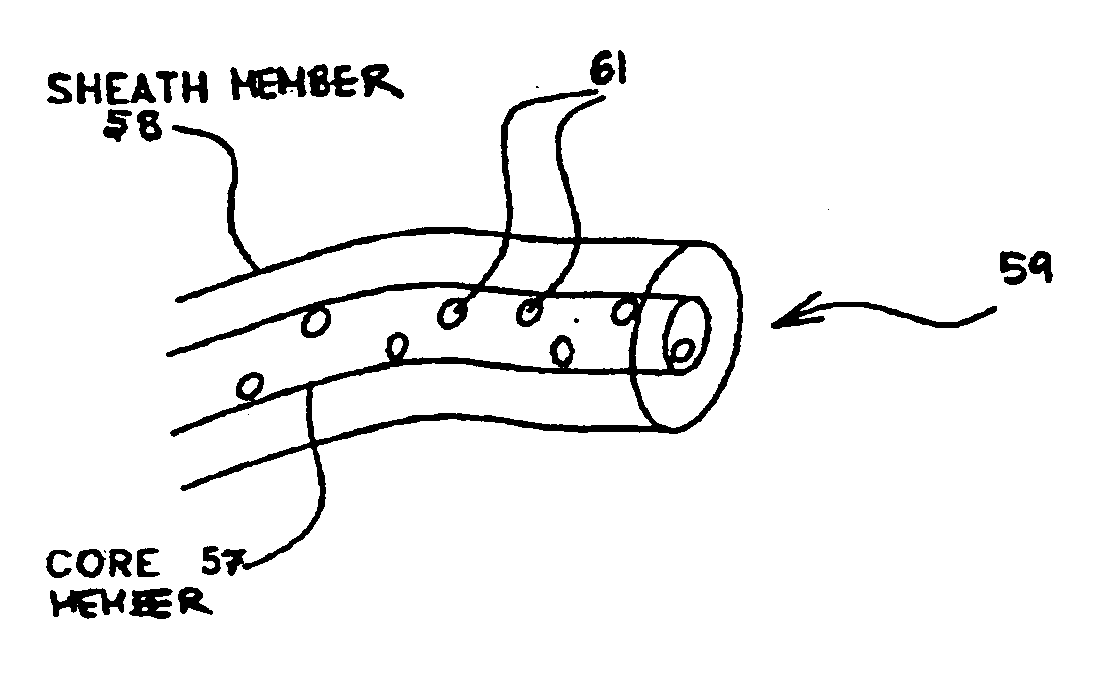

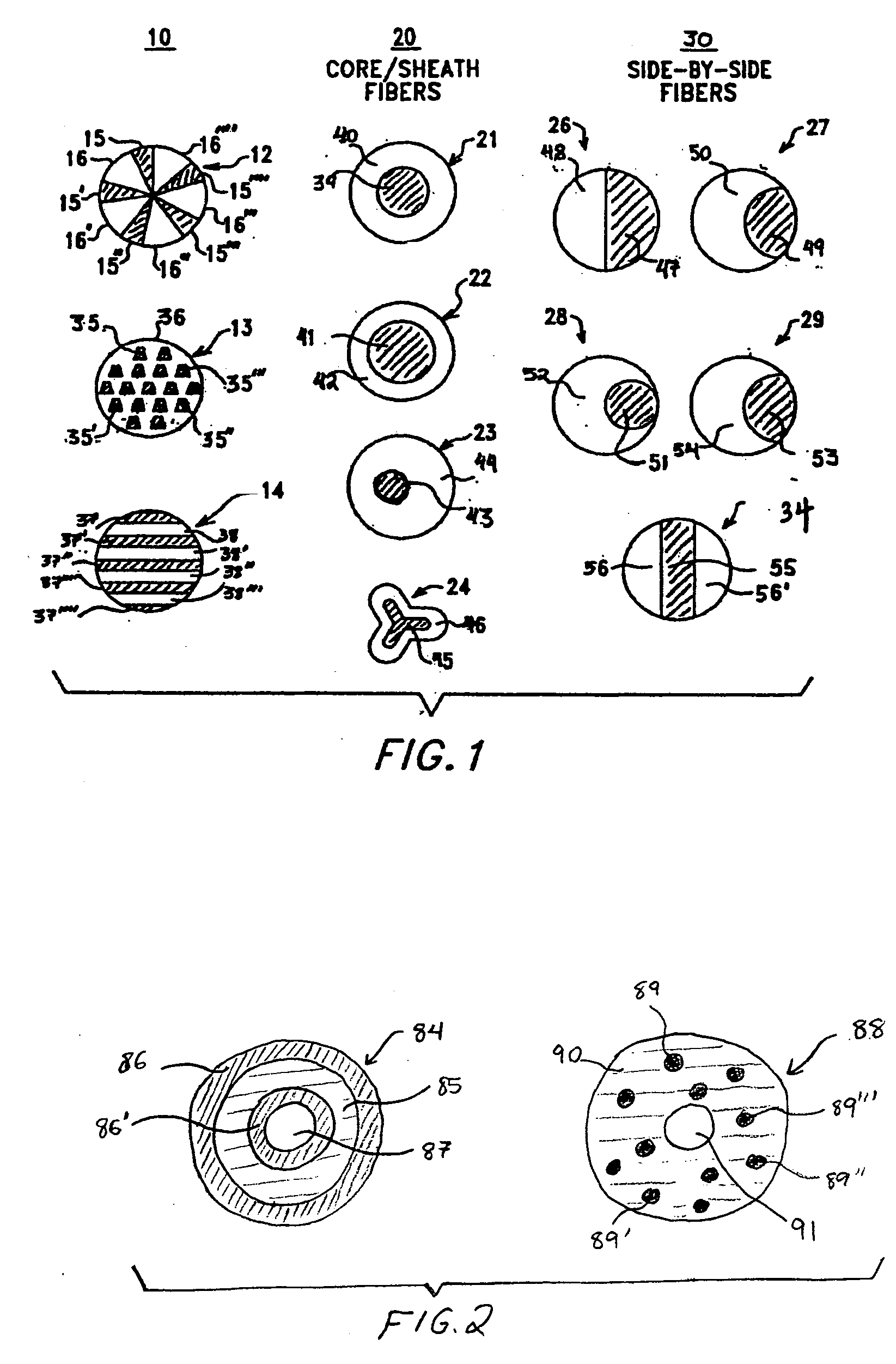

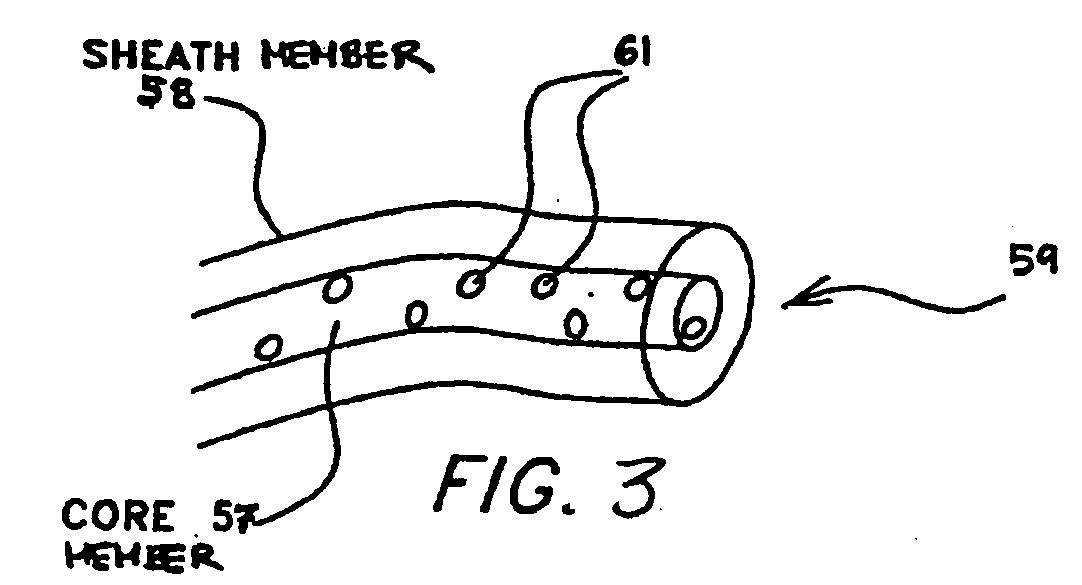

Multi-component fibers having enhanced reversible thermal properties and methods of manufacturing thereof

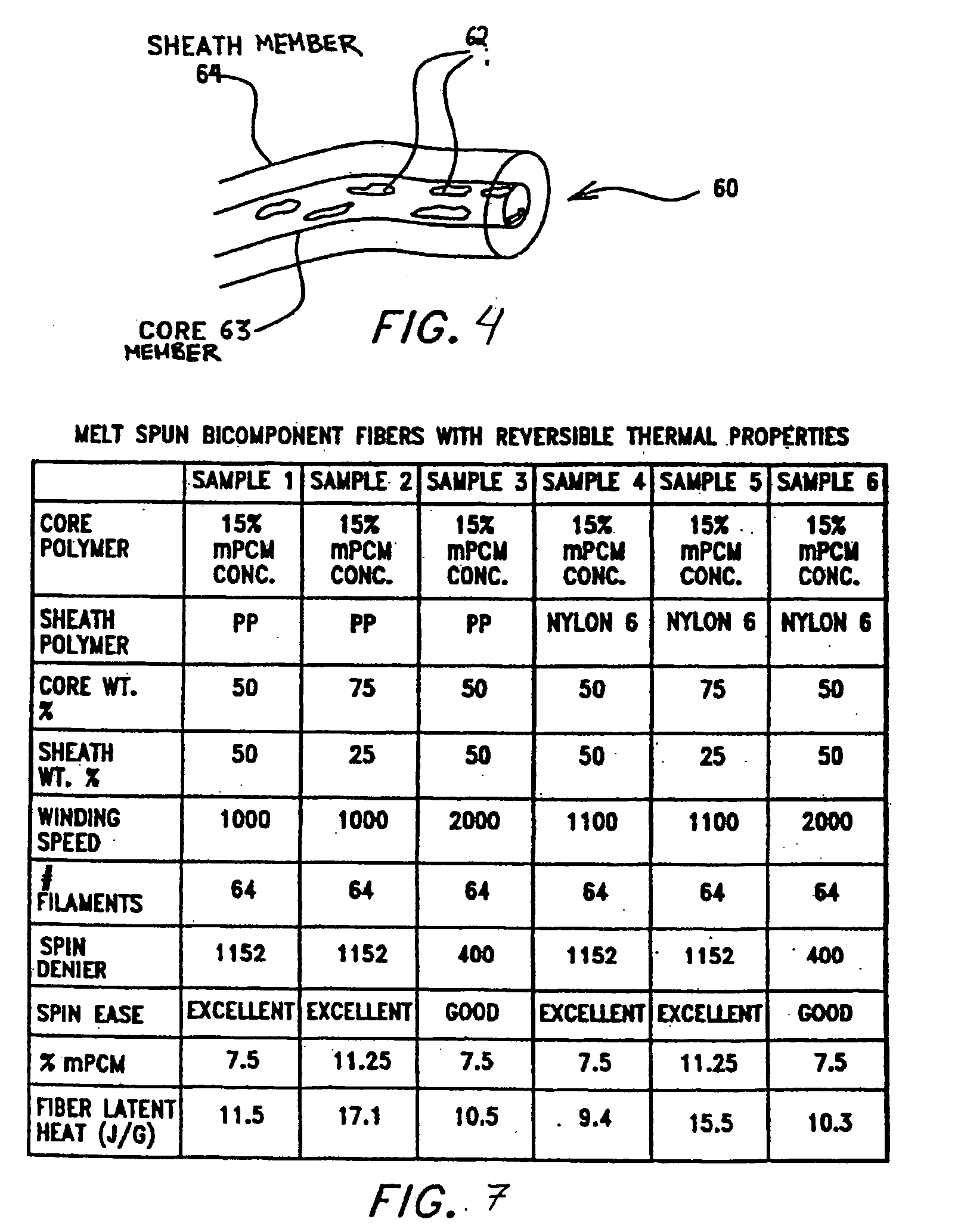

Multi-component fibers having enhanced reversible thermal properties and methods of manufacturing thereof are described. In one embodiment, a multi-component fiber includes a fiber body formed from a set of elongated members, and at least one of the set of elongated members includes a temperature regulating material having a latent heat of at least 40 J / g and a transition temperature in the range of 22° C. to 40° C. The temperature regulating material provides thermal regulation based on at least one of absorption and release of the latent heat at the transition temperature. The multi-component fiber can be formed via a melt spinning process or a solution spinning process and can be used or incorporated in various products where a thermal regulating property is desired. For example, the multi-component fiber can be used in textiles, apparel, footwear, medical products, containers and packagings, buildings, appliances, and other products.

Owner:HILLS CO

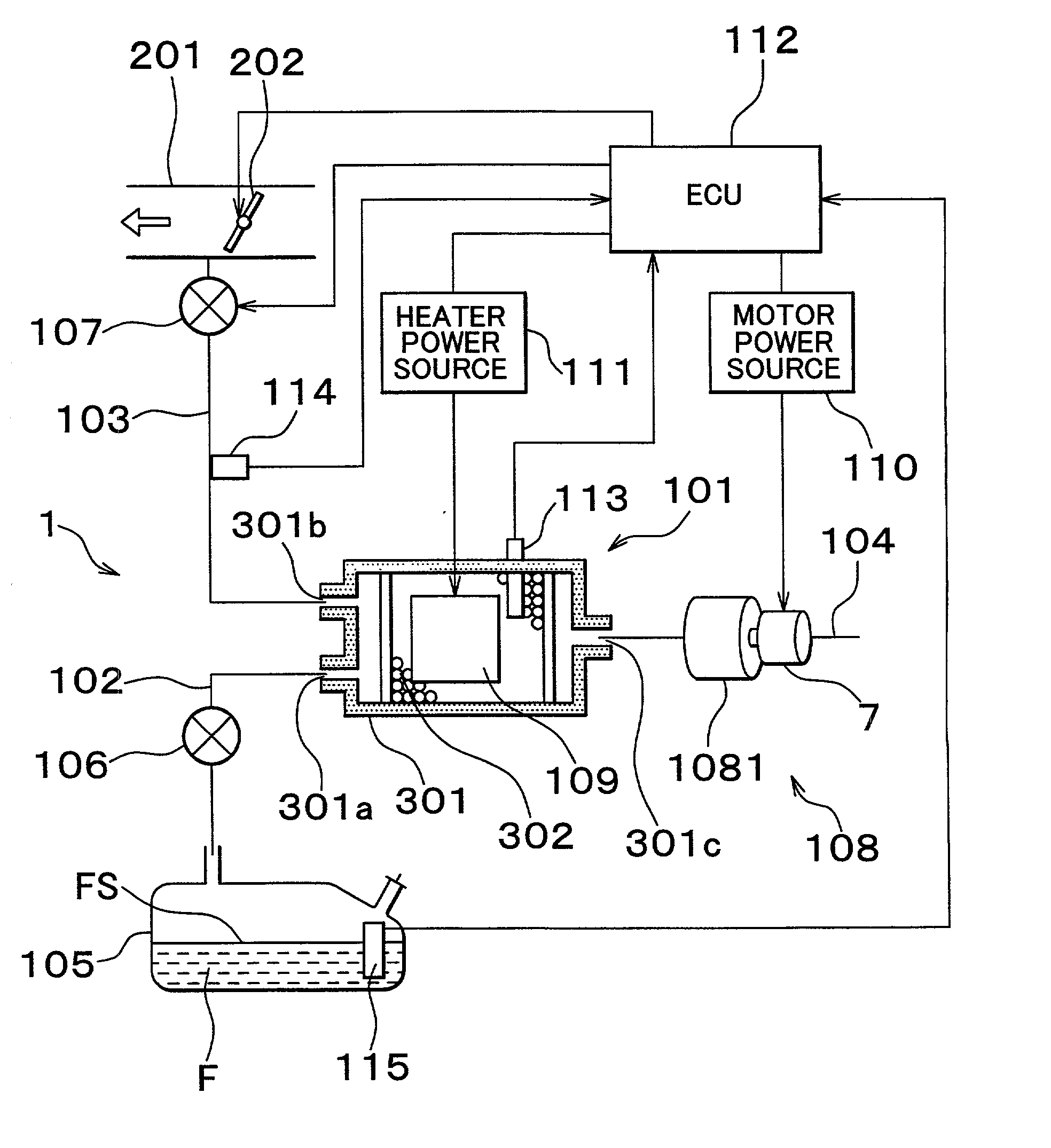

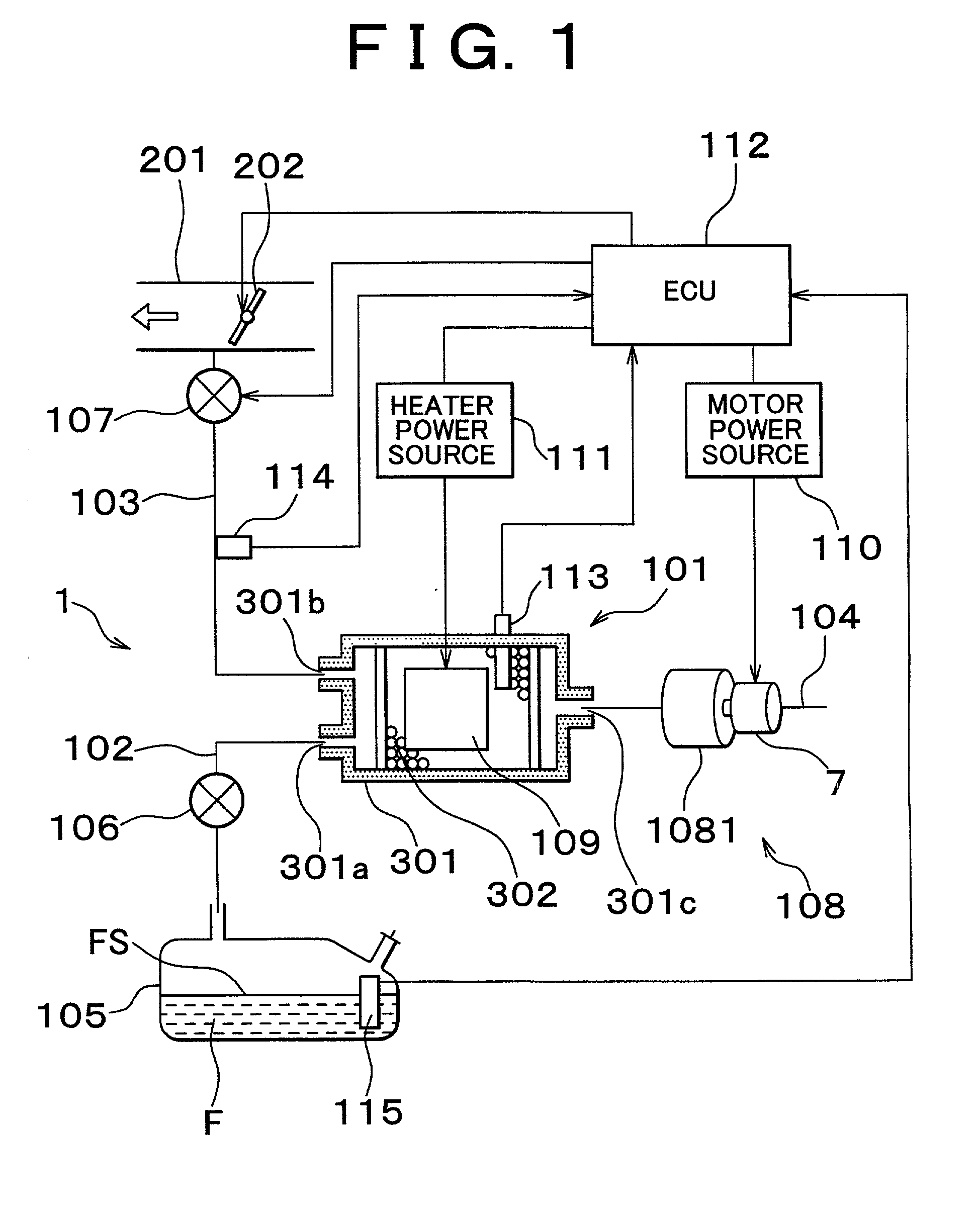

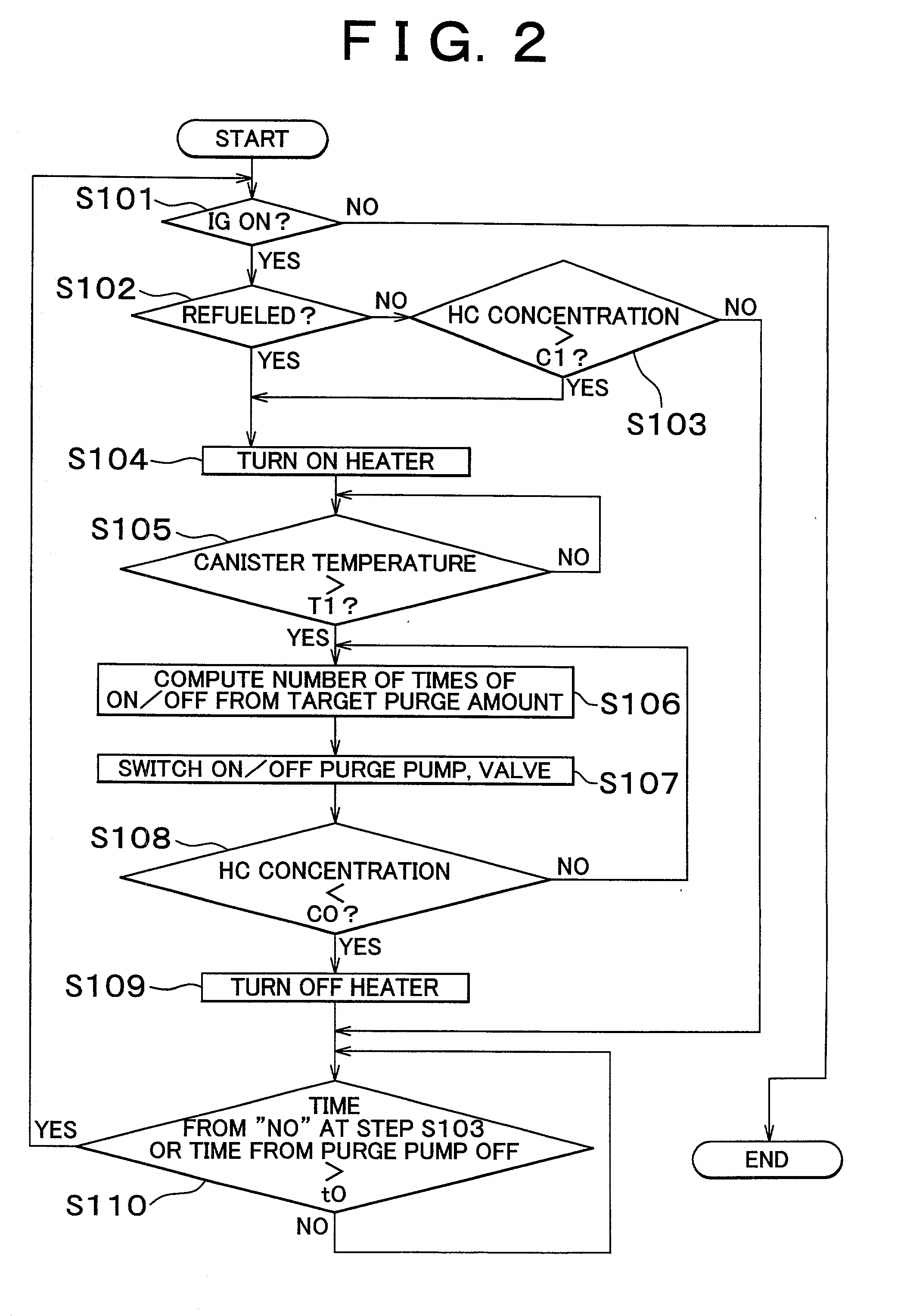

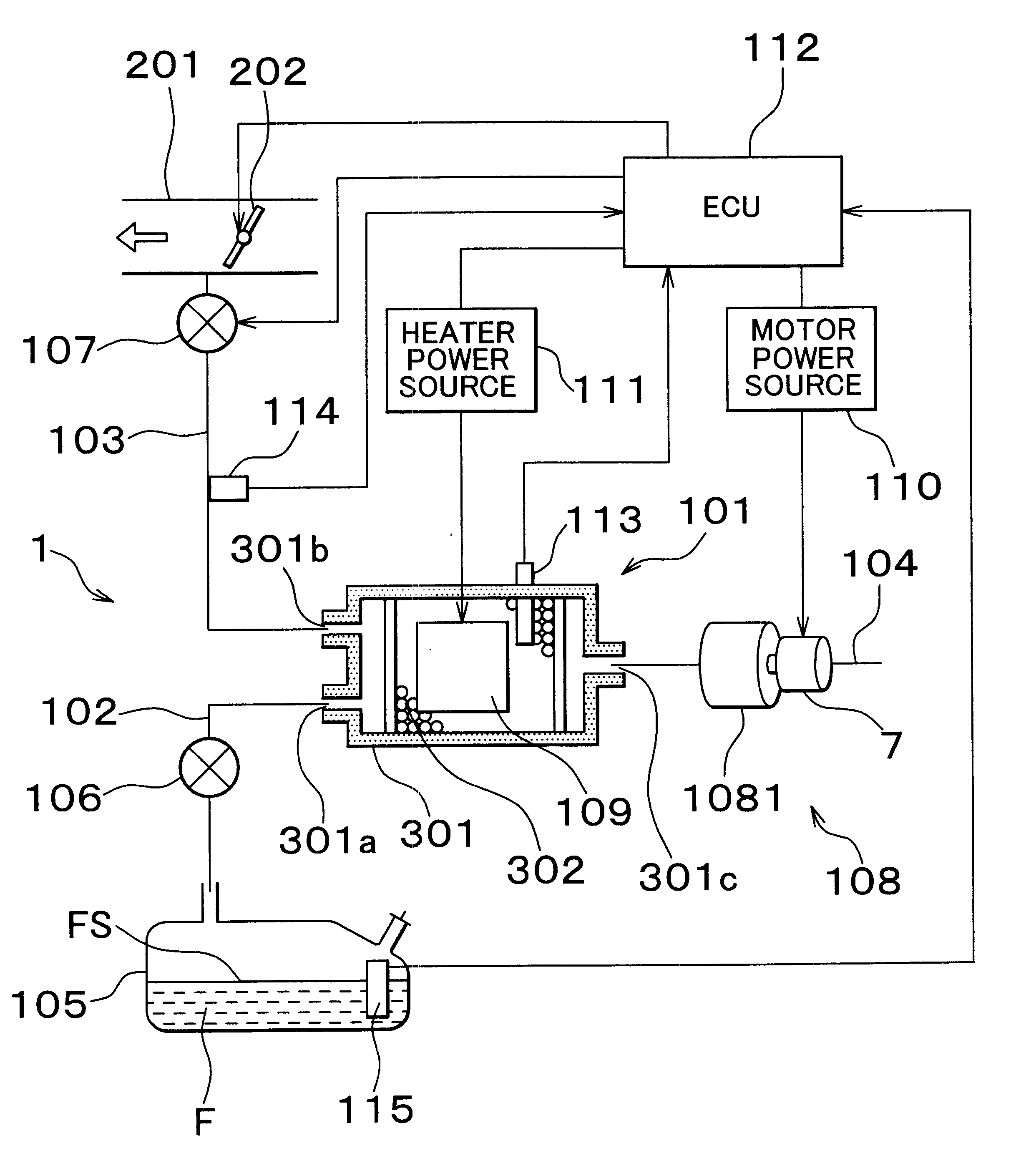

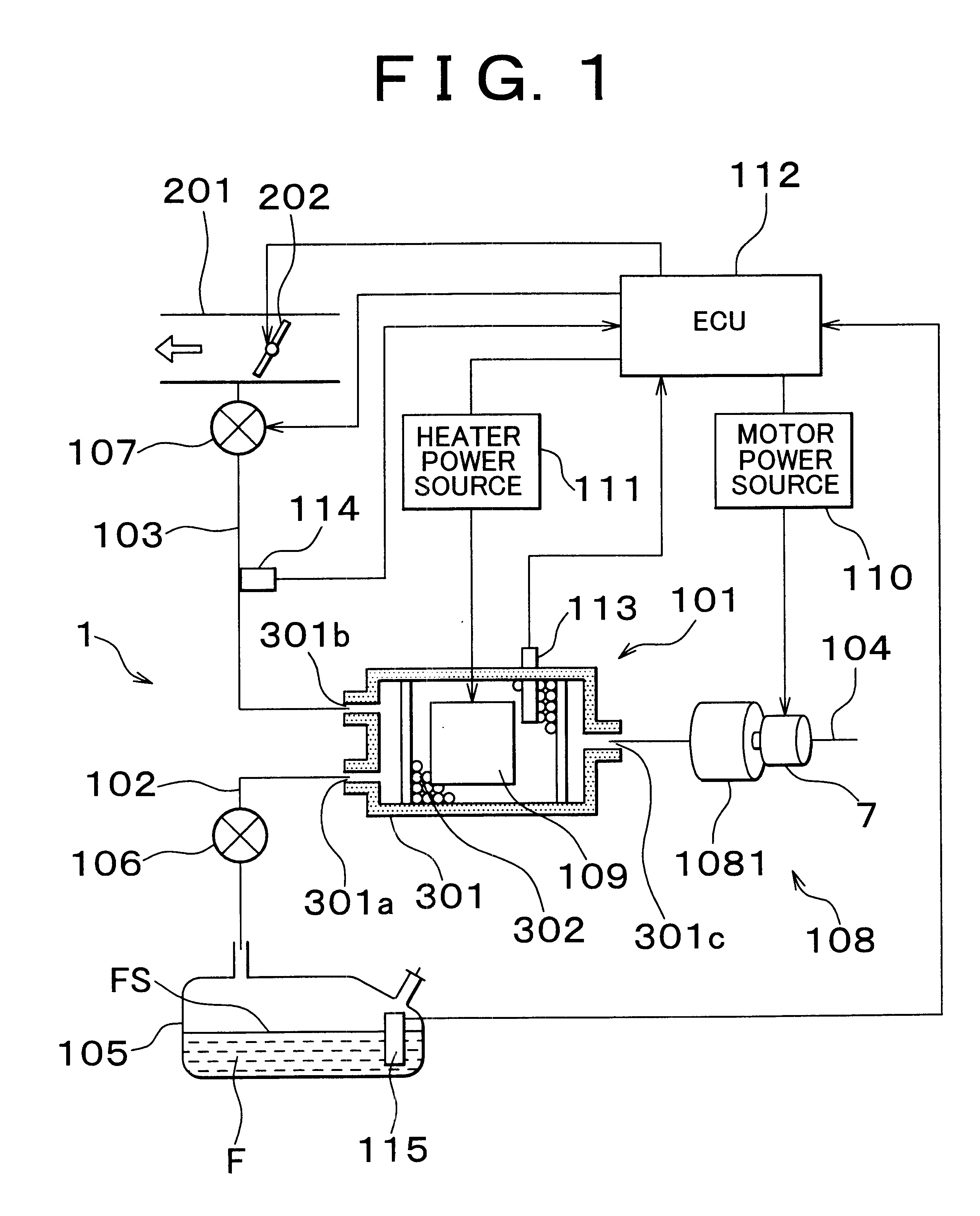

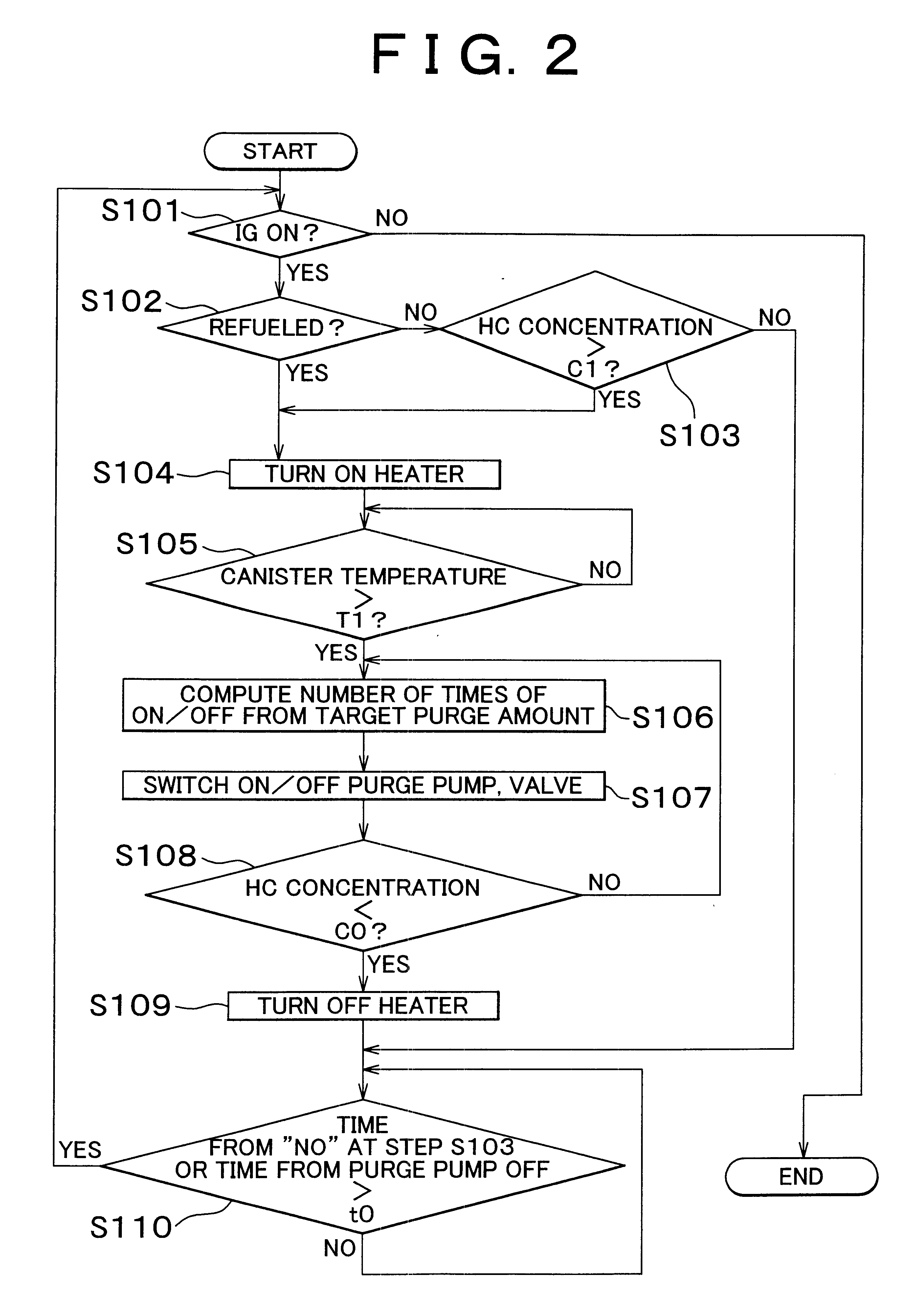

Fuel vapor handling apparatus and diagnostic apparatus thereof

InactiveUS20020162457A1Desorption of fuel is facilitatedFuel can be purged efficientlyNon-fuel substance addition to fuelFuel injection apparatusDesorptionVaporization

A fuel vapor handling apparatus supplies a purging air to a canister by using a purge pump and purges fuel desorbed from the canister into an intake pipe. A controller intermittently operates the purge so that the canister internal temperature recovers from a reduced level caused by the latent heat of vaporization of fuel during an operating period of the purge pump. Therefore, desorption of fuel from the canister during an operating period is facilitated. Since the actual operating time of the purge pump is reduced, the life of a motor that is a power unit of the purge pump becomes longer.

Owner:TOYOTA JIDOSHA KK +1

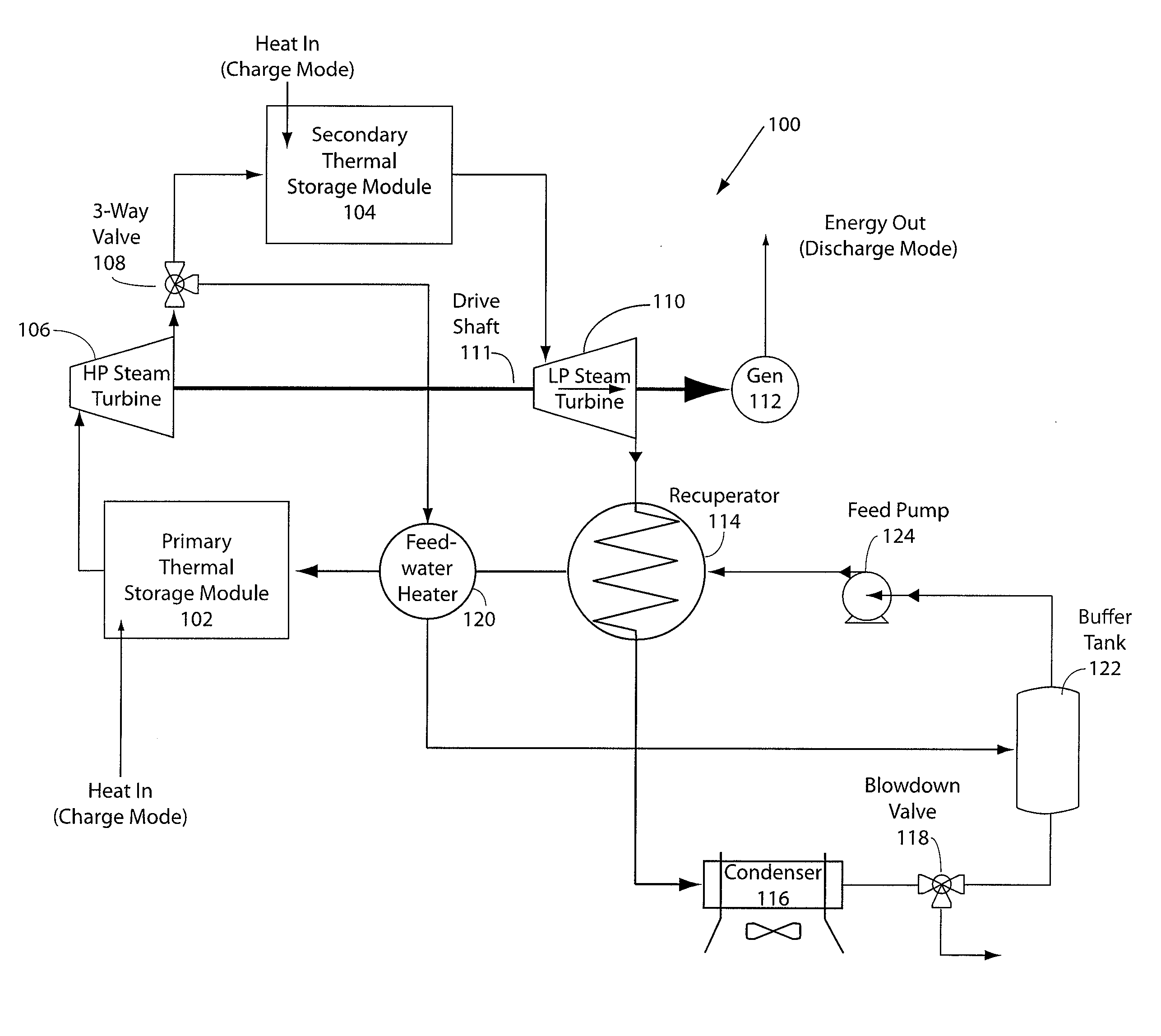

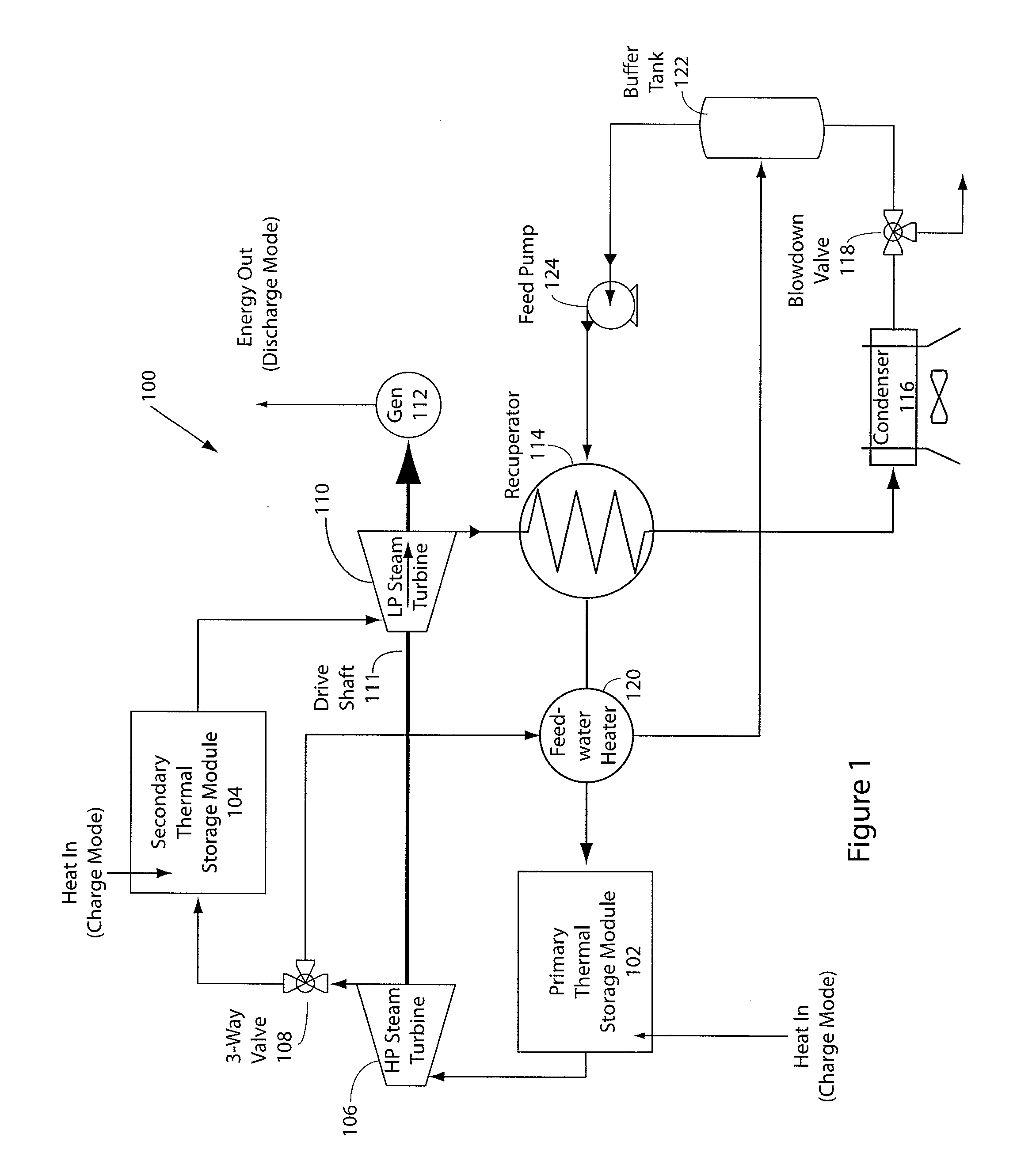

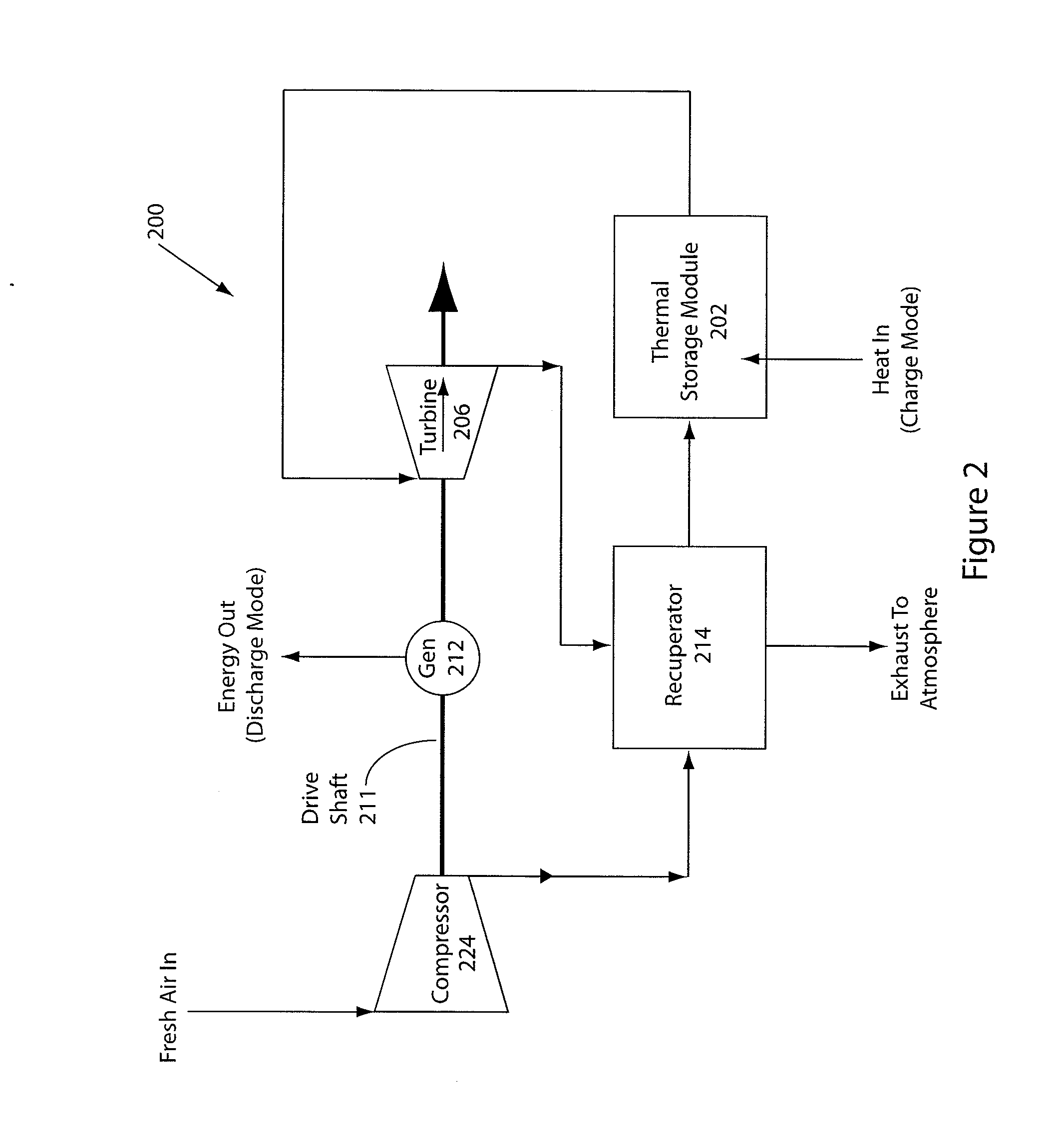

System and method for thermal energy storage and power generation

A thermal energy storage system is proposed in which the latent heat of fusion of common salts is used to store energy within a selectable temperature range, extending both above and below the melting / freezing temperature zone of the salt mixture. The salt mixture occupies interstitial void spaces in a solid endostructure. The solid material remains in the solid state throughout the thermal cycling of the energy storage system, and preferably has properties of thermal conduction and specific heat that enhance the behavior of the salt mixture alone, while being chemically compatible with all materials in the storage system. The storage system is capable of accepting and delivering heat at high rates, thereby allowing power generation using a suitable energy transfer media to power a turbine of an electric generator or a process heat need to provide a relatively local, dispatchable, rechargeable thermal storage system, combined with a suitably sized generator.

Owner:WOODWARD GOVERNOR CO

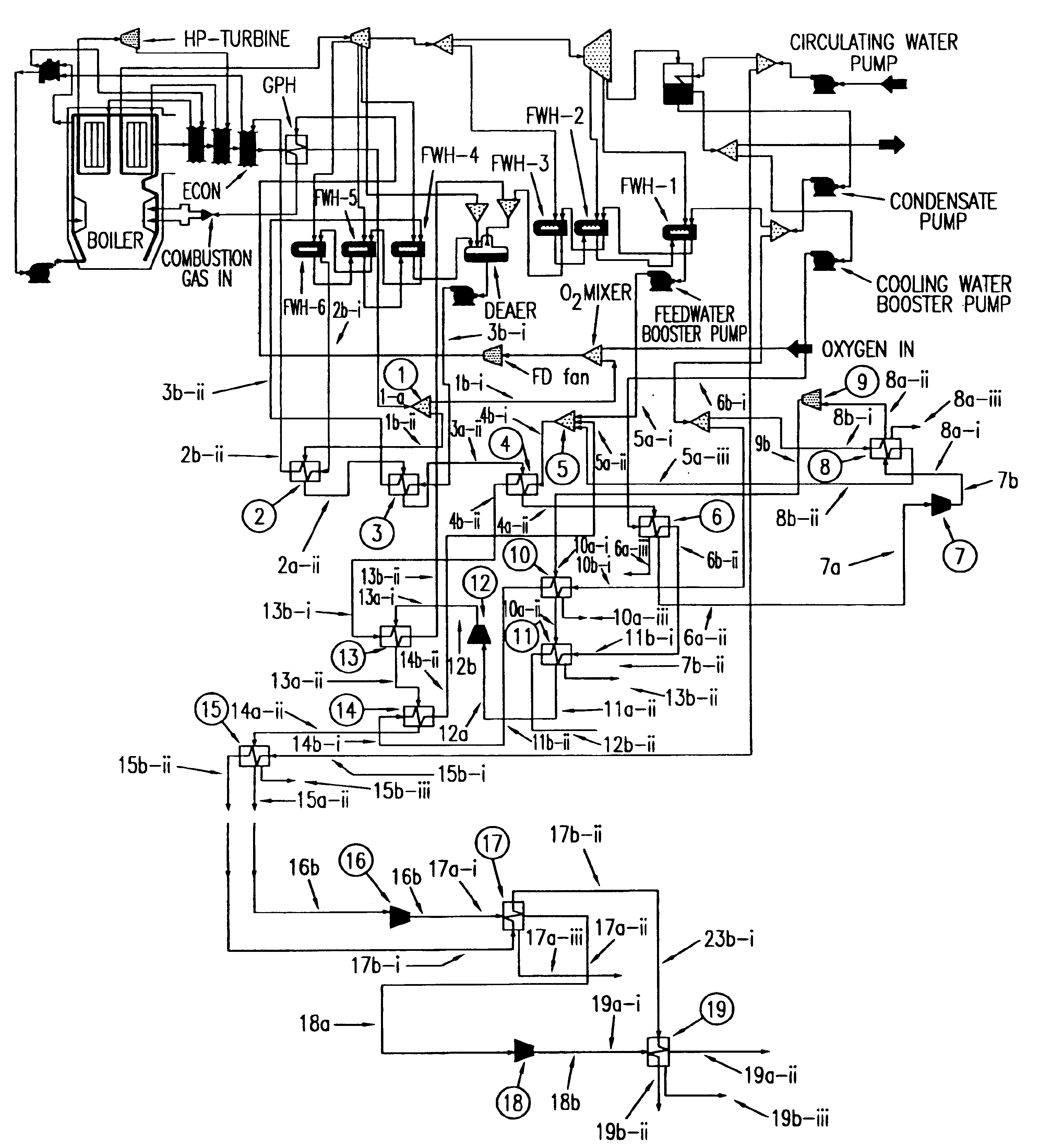

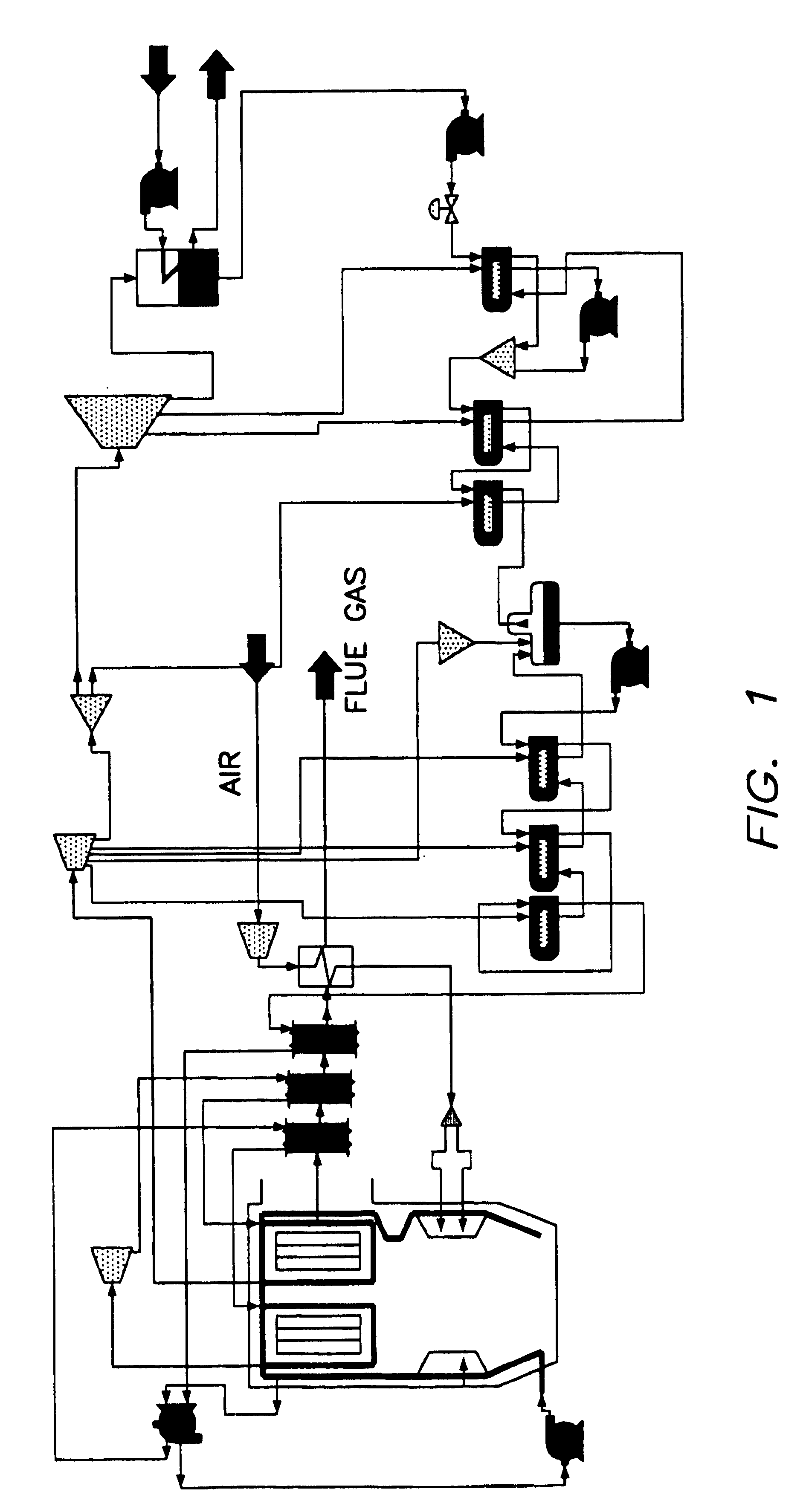

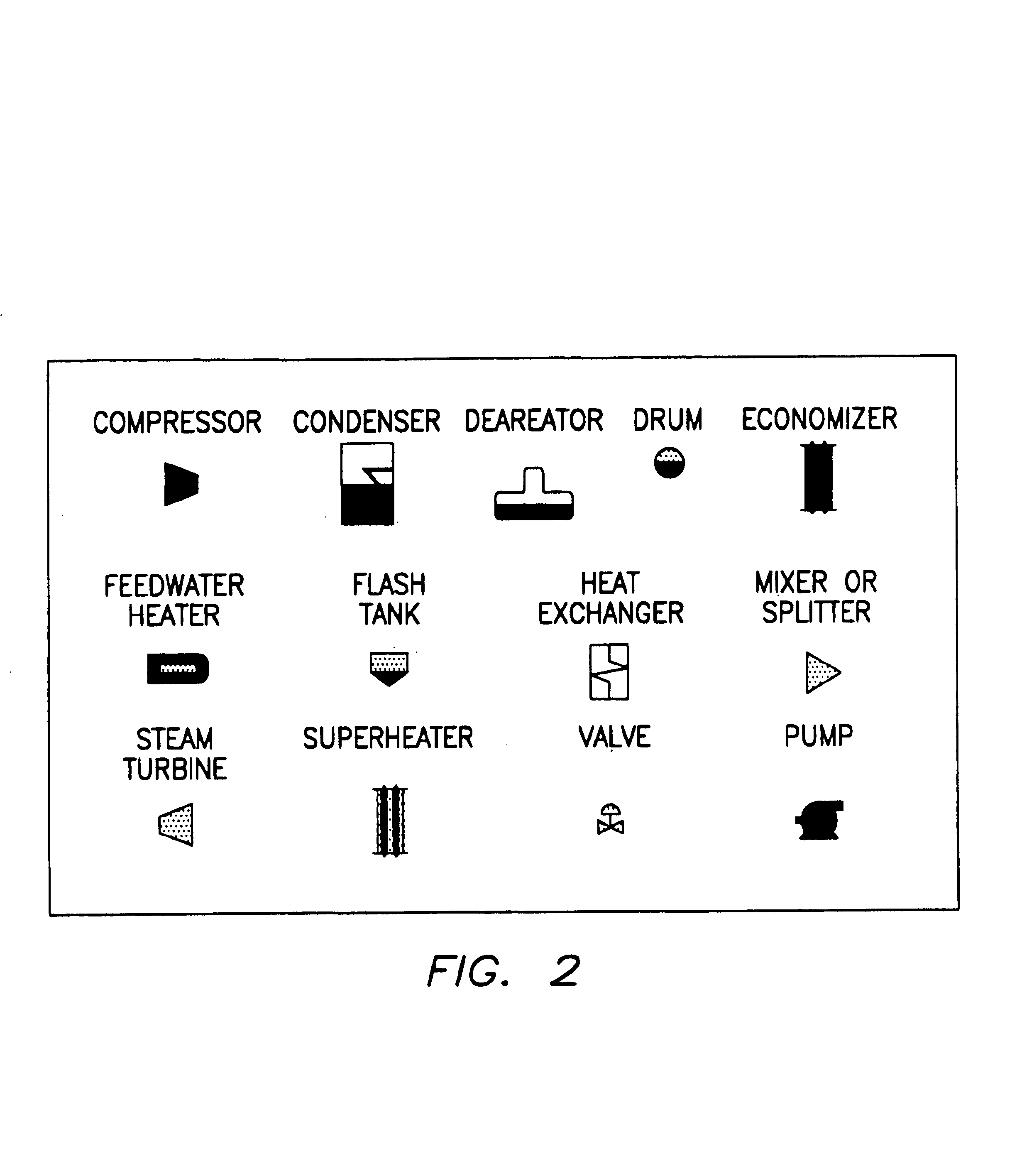

Compression stripping of flue gas with energy recovery

InactiveUS6898936B1Low costReduced Power RequirementsLiquid degasificationSteam regenerationWorking fluidWater vapor

A method of remediating and recovering energy from combustion products from a fossil fuel power plant having at least one fossil fuel combustion chamber, at least one compressor, at least one turbine, at least one heat exchanger and a source of oxygen. Combustion products including non-condensable gases such as oxygen and nitrogen and condensable vapors such as water vapor and acid gases such as SOX and NOX and CO2 and pollutants are produced and energy is recovered during the remediation which recycles combustion products and adds oxygen to support combustion. The temperature and / or pressure of the combustion products are changed by cooling through heat exchange with thermodynamic working fluids in the power generation cycle and / or compressing and / or heating and / or expanding the combustion products to a temperature / pressure combination below the dew point of at least some of the condensable vapors to condense liquid having some acid gases dissolved and / or entrained and / or directly condense acid gas vapors from the combustion products and to entrain and / or dissolve some of the pollutants while recovering sensible and / or latent heat from the combustion products through heat exchange between the combustion products and thermodynamic working fluids and / or cooling fluids used in the power generating cycle. Then the CO2, SO2, and H2O poor and oxygen enriched remediation stream is sent to an exhaust and / or an air separation unit and / or a turbine.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

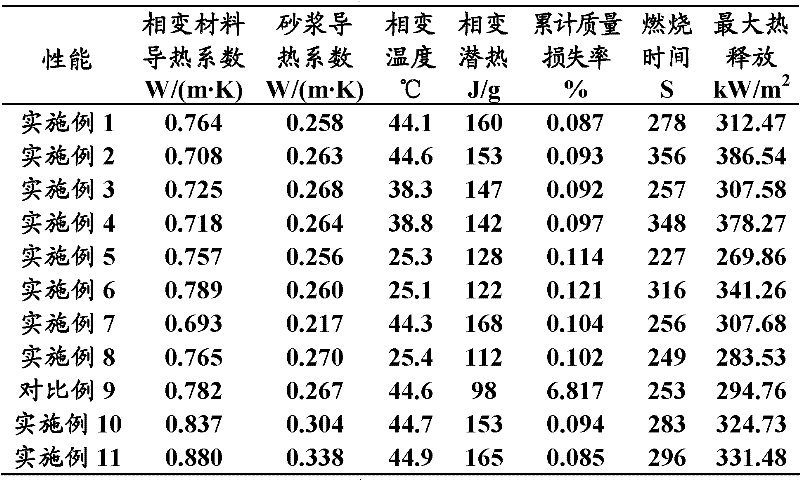

Phase-transition composite material, preparation method and application thereof

ActiveCN102408877APhase transition temperature is suitableLarge latent heat of phase changeClimate change adaptationHeat proofingParaffin waxThermal insulation

The invention relates to a phase-transition composite material which comprises: A) 30-65% of phase-transition materials which are low melting point paraffin with a melting point of 25-45 DEG C and / or dodecanol; B) 25-45% of carrier materials which are high density polyethylane and / or ethane-vinylacetate copolymer; C) 5-15% of inorganic fillers which are porous substances and are selected from one or two of expanded perlite and expandable graphite; D) 1-10% of heat-conduction reinforcing agents; and E) 1-10% of fire retardants. The composite material has an appropriate phase transition temperature which matches the building ambient temperature, has great phase transition latent heat, excellent heat-preservation and heat-insulation performance, is fireproof and flame-retardant, is easy to process, and has greatly reduced phase-transition material leakage. The invention also relates to a method for preparing the phase-transition composite material, which comprises the thermal insulation mortar of the phase-transition composite material and a method of heat preservation of a wall by using the mortar.

Owner:BEIJING UNIV OF CHEM TECH +1

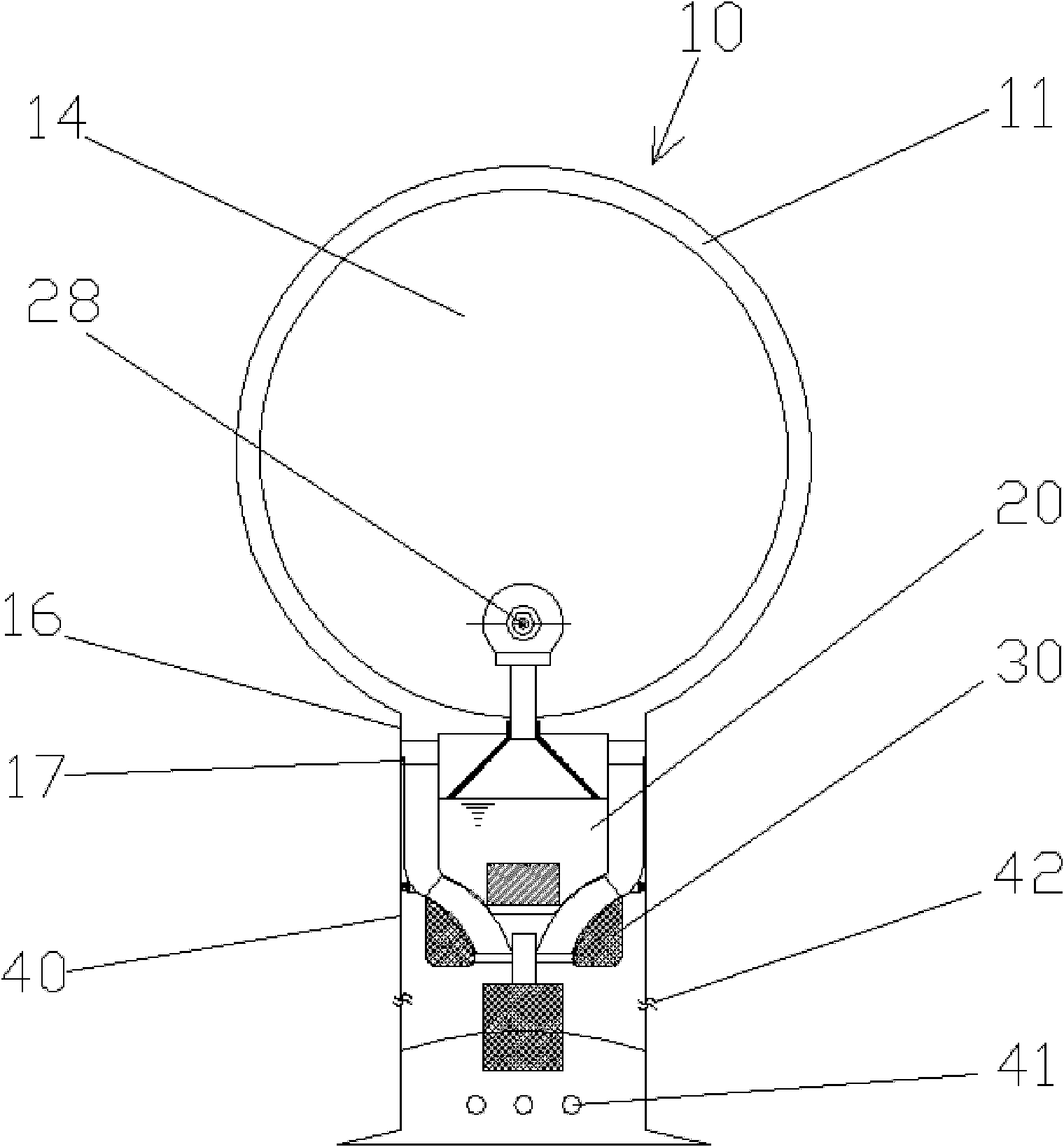

Ventilation device

InactiveCN102095236APromote absorptionImprove cooling effectLighting and heating apparatusJet pumpsWater vaporEngineering

The invention discloses a ventilation device, which aims to solve the problem that the conventional ventilation device does not have an air adjusting function. The device comprises a pedestal, a high-speed air blower and an annular ejector, wherein the high-speed air blower is arranged at the bottom of the pedestal; the annular ejector is arranged at an air outlet of the high-speed air blower and is fixed on the pedestal; and the air inlet or the air outlet of the high-speed air blower is provided with a vapor generator which is fixed on the pedestal for producing water vapor. In the ventilation device, the water vapor is produced through the vapor generator and is ejected through an atomization nozzle at a high speed to produce fog of smaller granularity, so that a hot air flow can more easily absorb the latent heat of vaporization, and the ventilation device has a humidification effect and a heat absorption and temperature reduction effect on a large amount of hot air sucked by the annular nozzle, and brings comfortable cool air similar to air on the shore of a lake or a sea to the surrounding environment. In the ventilation device, an external circulating device is not required to be mounted, so the cost is low; the space is not required to be closed, so that air convection is guaranteed; and the ventilation device is more energy-saving in the same temperature reduction range compared with a fan and an air conditioner, and can be used conveniently and safely.

Owner:曾小颖 +1

In situ method and system for extraction of oil from shale

ActiveUS20070193743A1Easy to moveAvoid insufficient temperatureInsulationFluid removalClosed loopEarth surface

A system and process is disclosed for retorting oil shale and extracting shale oil and other hydrocarbons therefrom, in which a cased heat delivery well is drilled generally vertically through an overburden and then through a body of oil shale to be retorted to the bottom thereof, generally horizontally under the body of oil shale to be retorted, and then back to the earth surface. Heat energy is transmitted conductively to the body of oil shale to be retorted from a closed loop heat delivery module in the well, the module comprising a fluid transmission pipe containing a heating fluid heated to at least a retorting temperature. Heat energy is also transmitted to the body of oil shale to be retorted above the fluid transmission pipe by vapor conduits that conduct retort vapors upward through the body of oil shale to be retorted; the ascending retort vapors condense and reflux, delivering their latent heat of vaporization to the body of oil shale to be retorted, and the condensed retort liquids descend. If not recycled, the retort liquids are collected in a sump at the bottom of a production well and are transmitted to the surface for processing. The vapor conduits communicate at upper ends thereof with the production well, so that vapors that do not reflux are collected in the production well and are transmitted to the surface for processing.

Owner:AMERICAN SHALE OIL

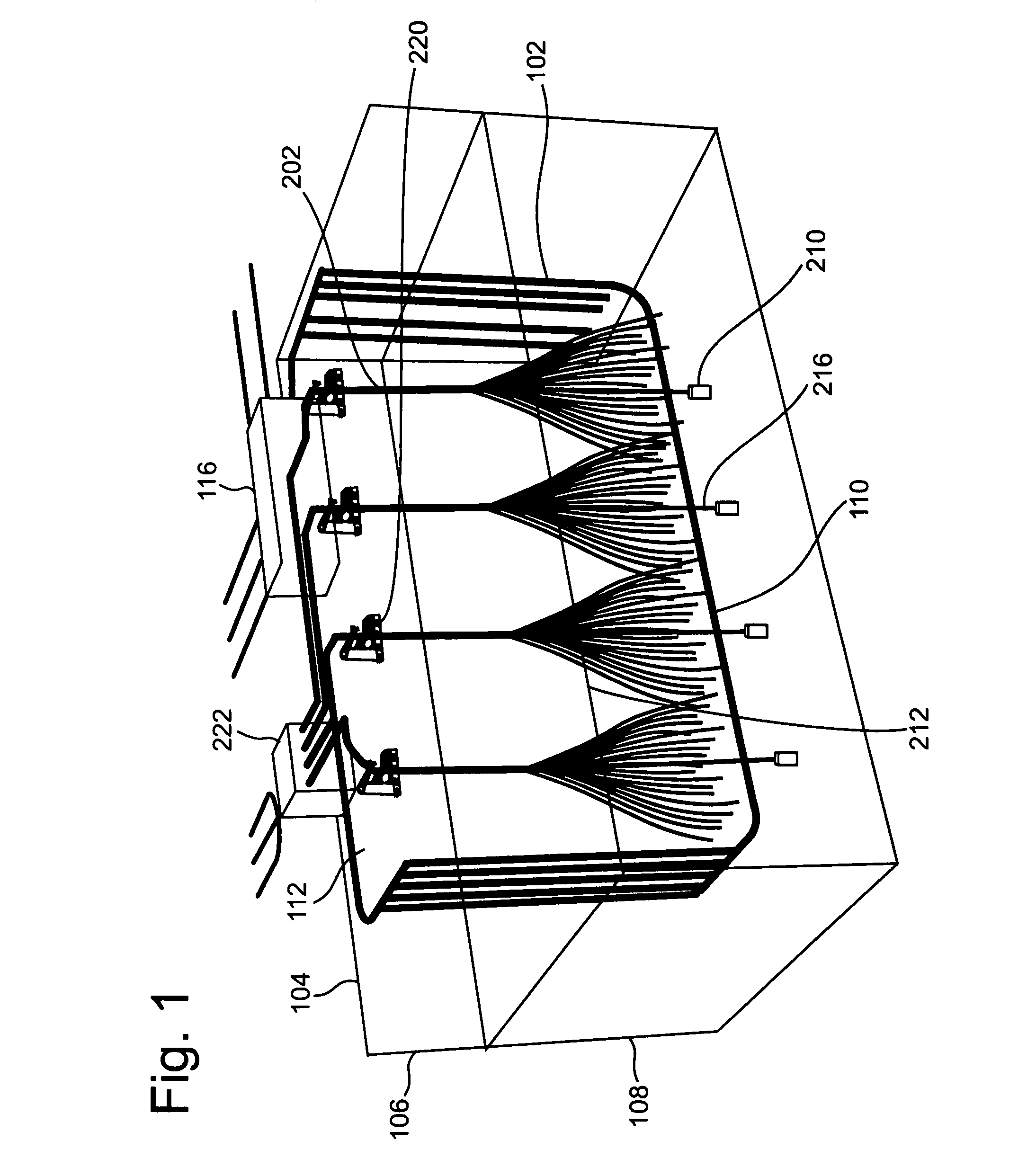

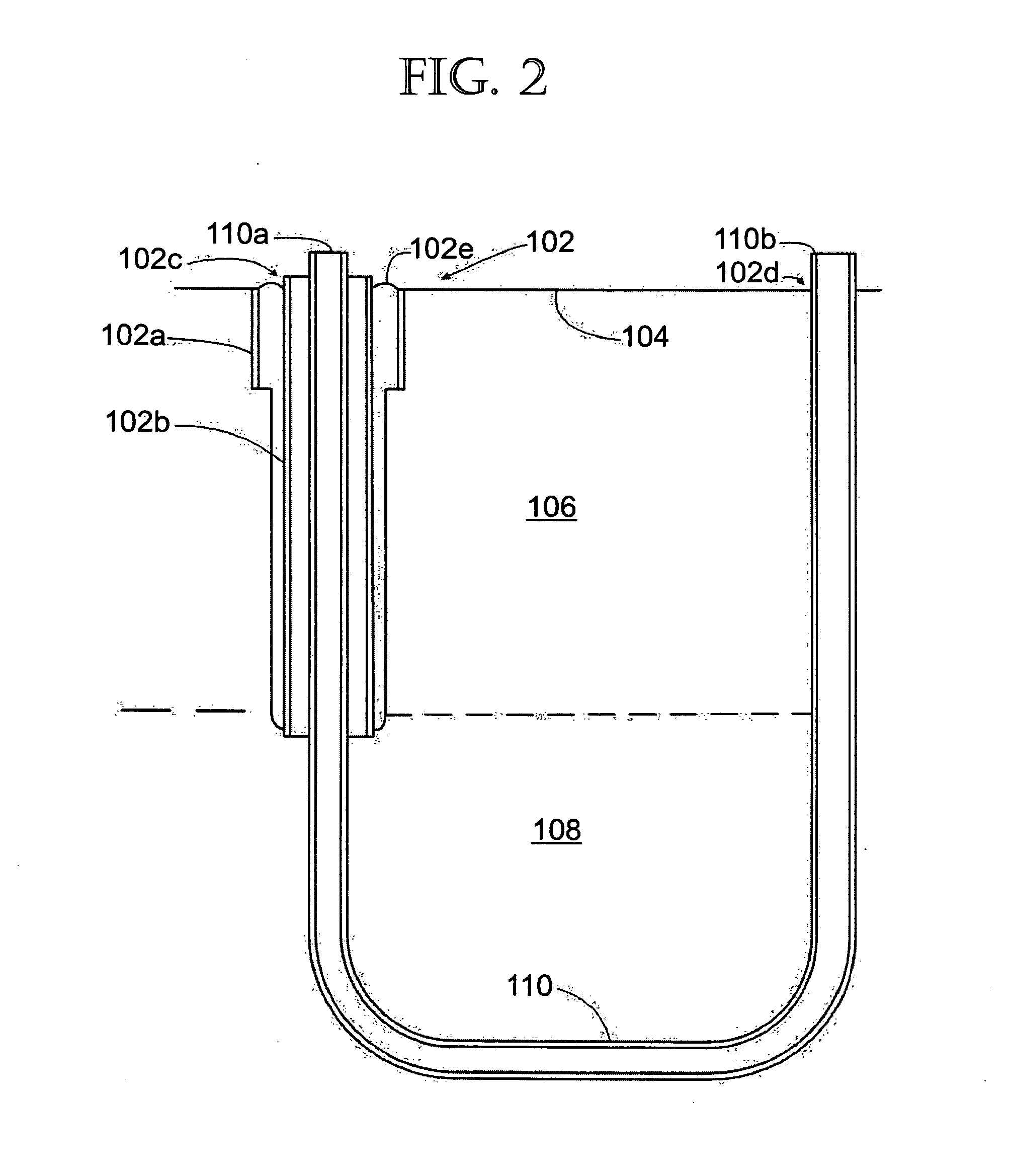

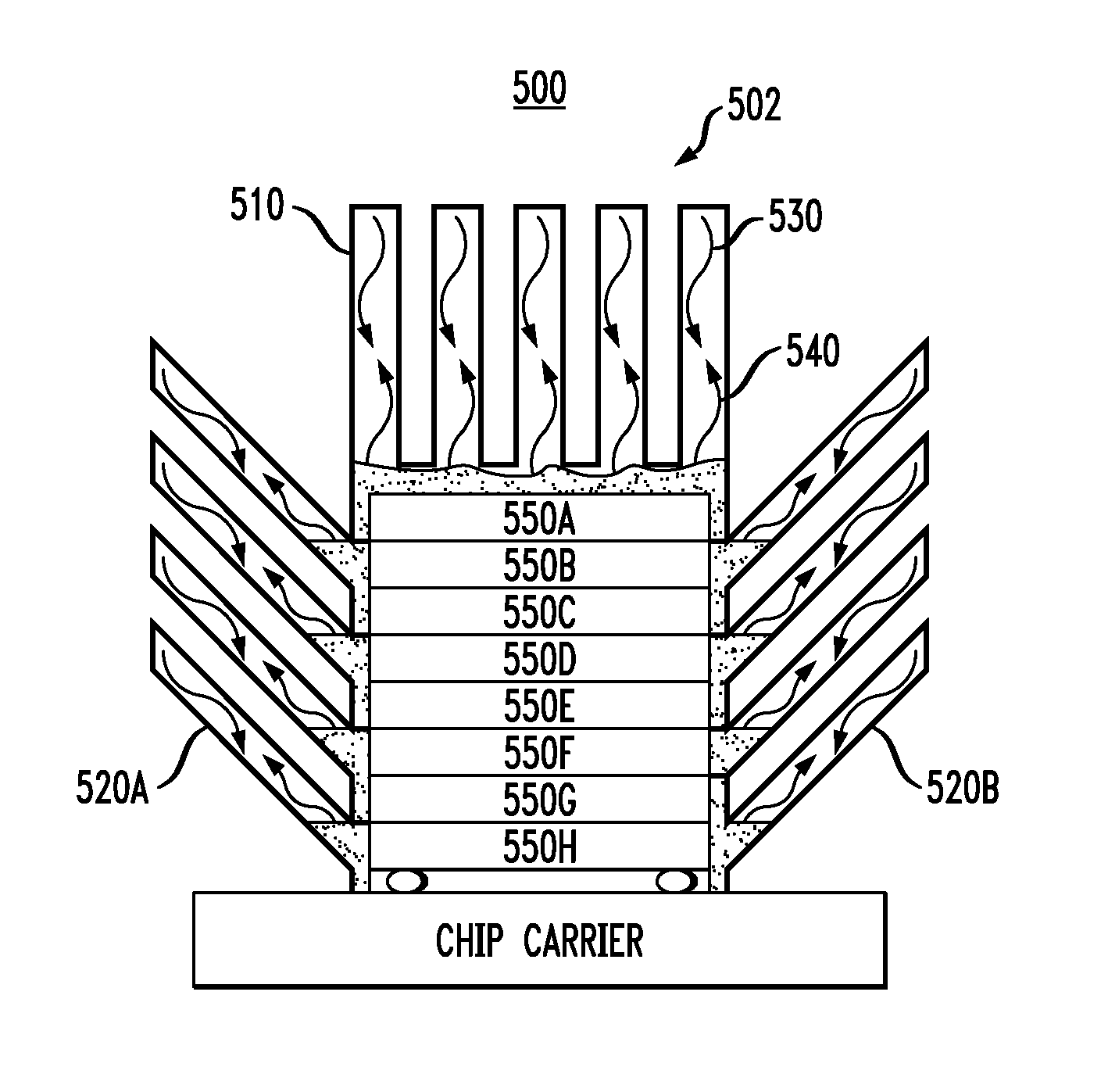

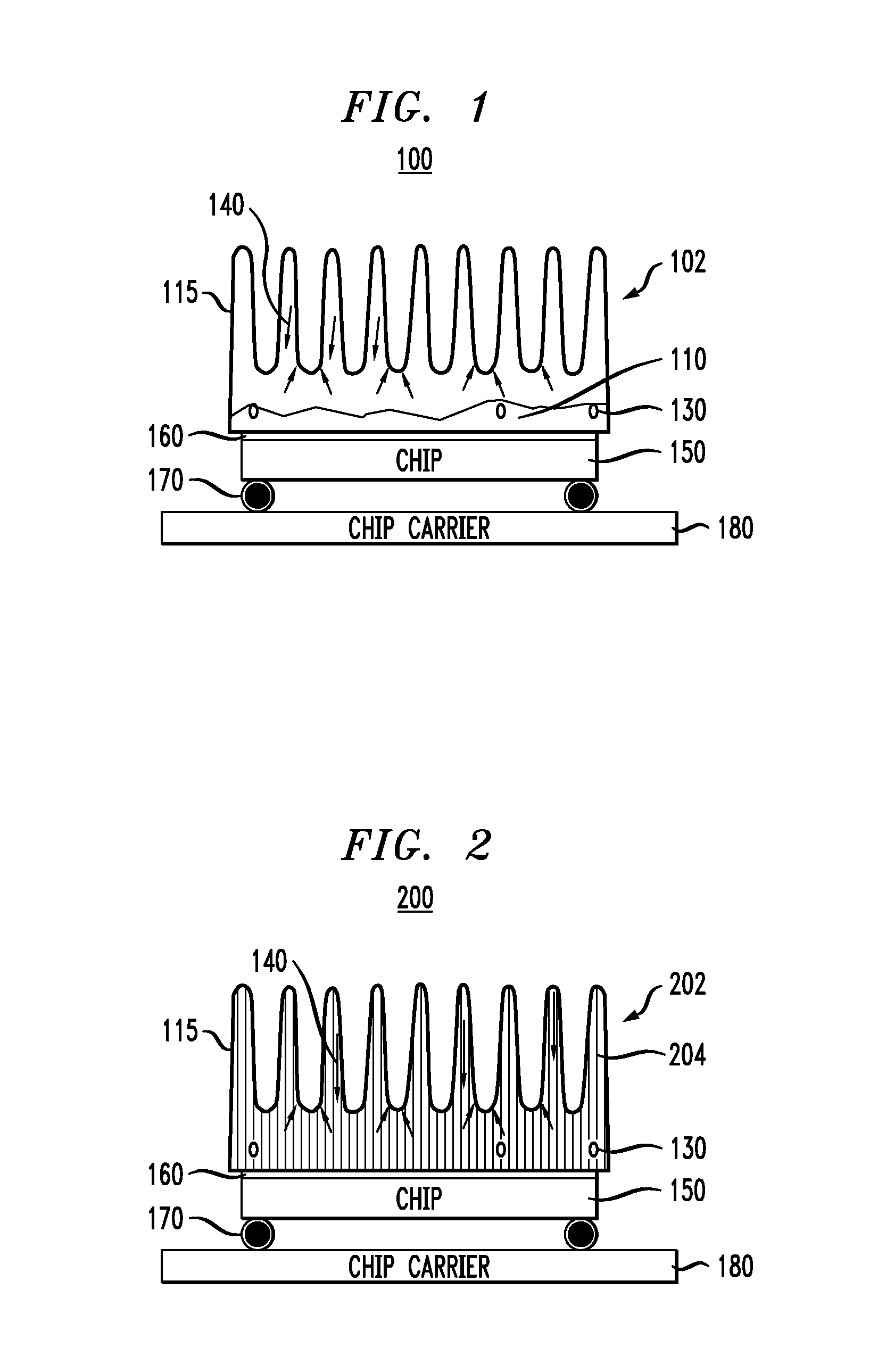

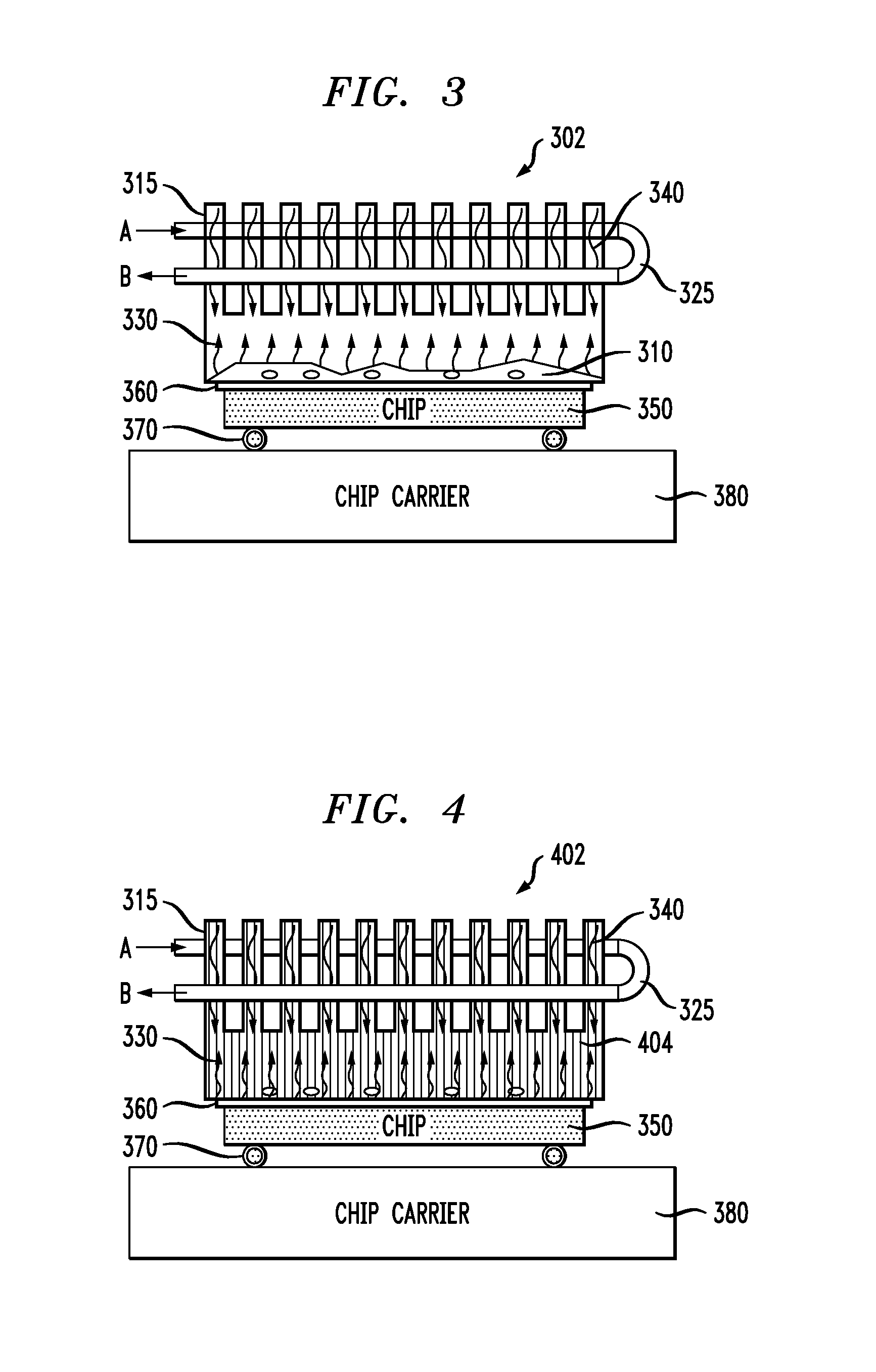

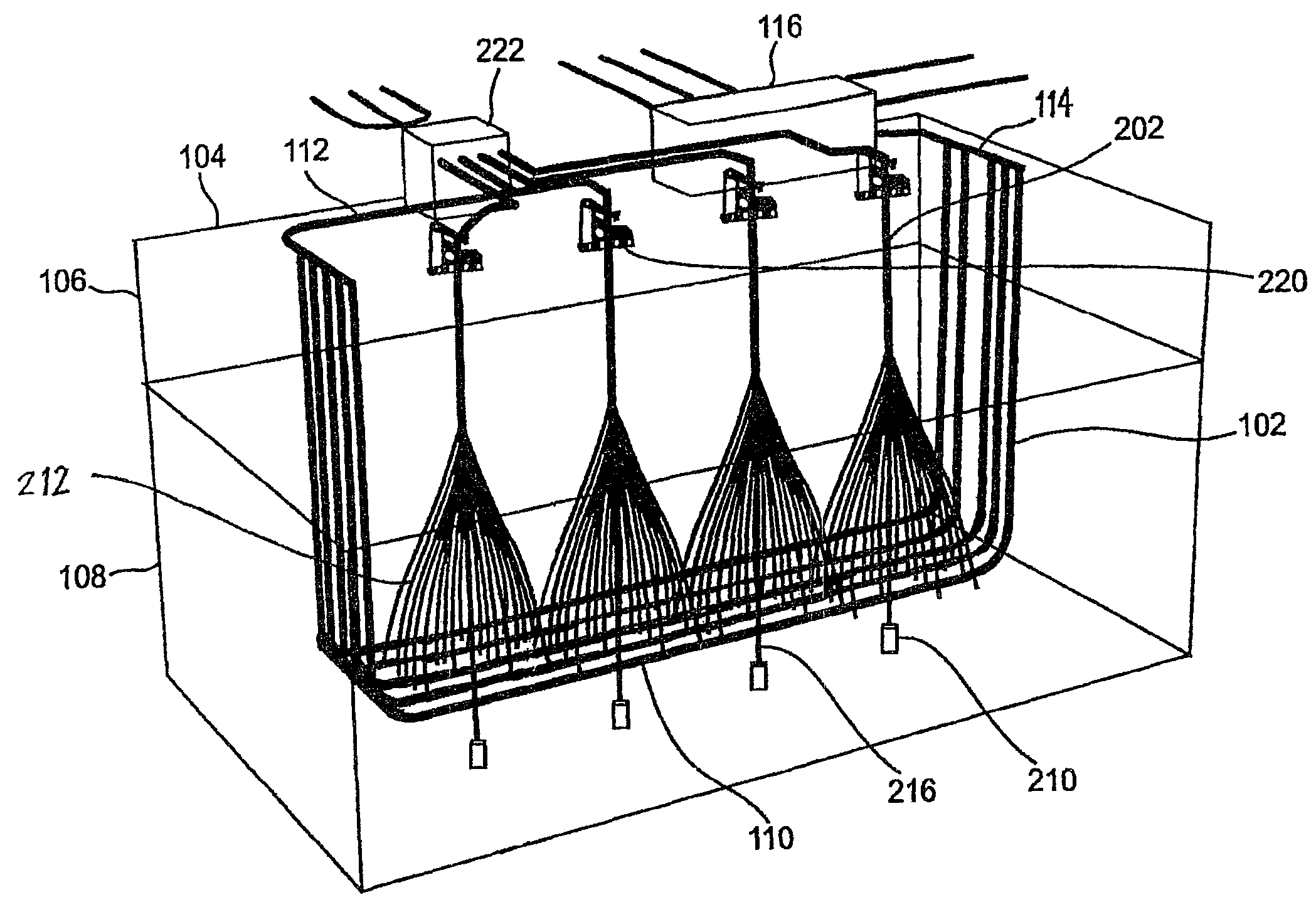

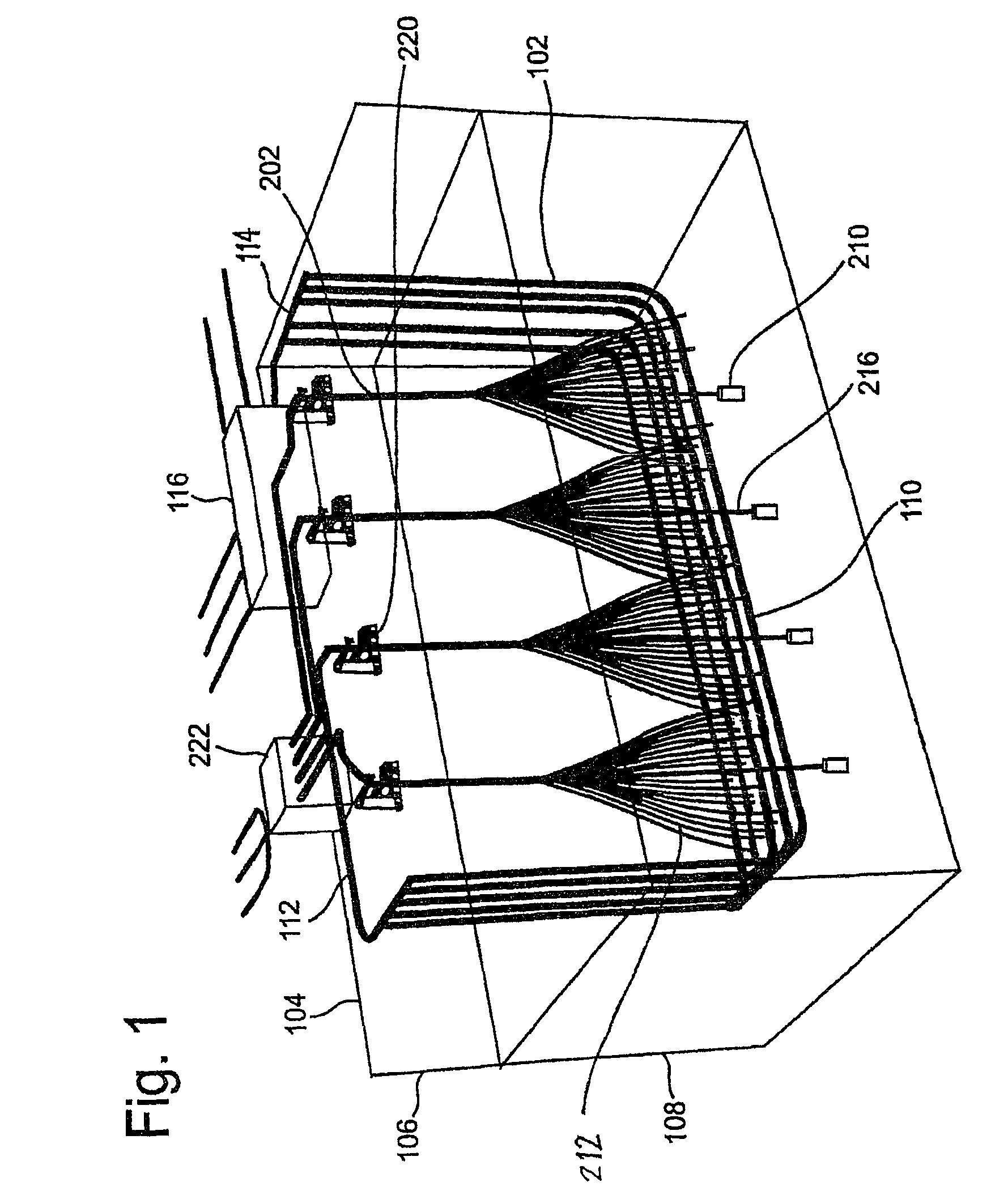

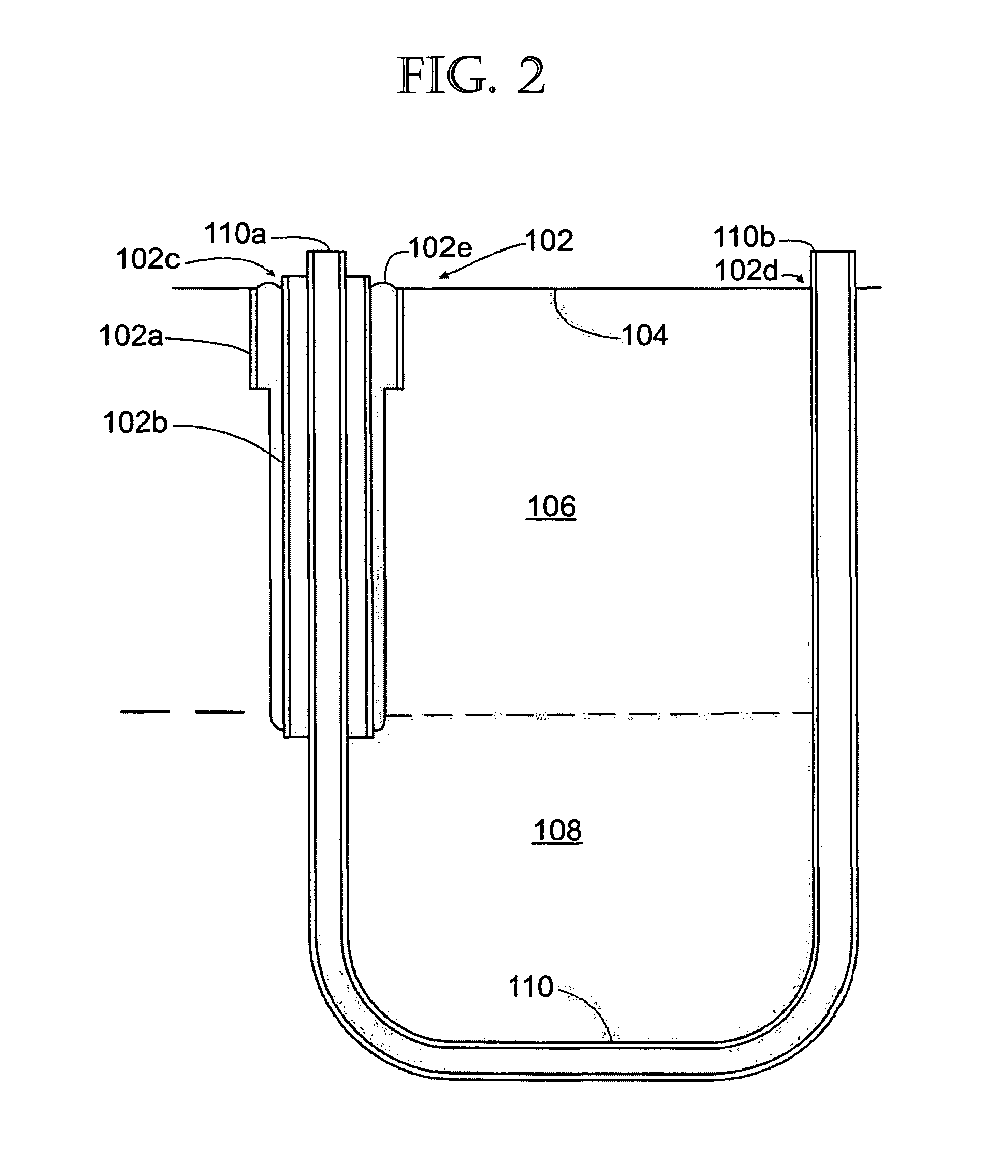

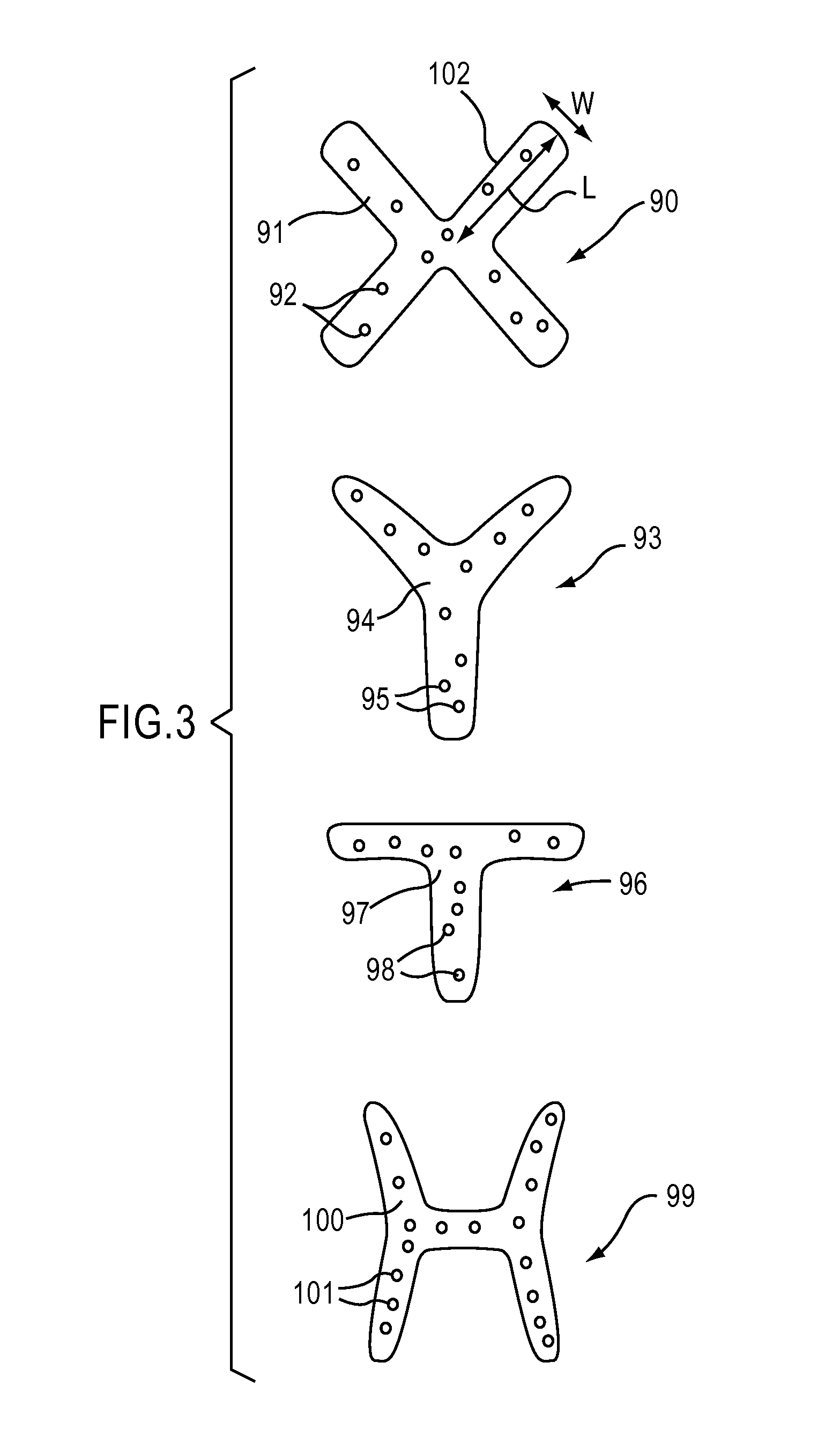

Apparatuses for dissipating heat from semiconductor devices

ActiveUS7369410B2Increase surface areaImprove cooling efficiencySemiconductor/solid-state device detailsSolid-state devices3d shapesEngineering

An apparatus for providing two-phase heat transfer for semiconductor devices includes a vapor chamber configured to carry a cooling liquid, the vapor chamber having base section, and a plurality of three-dimensional (3D) shaped members. The plurality of 3D-shaped members have interior and exterior sidewalls, the 3D-shaped members being connected to the base section so that vapor carrying latent heat can reach the respective interior sidewalls and get transferred to the respective exterior sidewalls configured to be in contact with an external coolant. The vapor chamber is configured to be in contact with a semiconductor device in order to remove heat therefrom.

Owner:GLOBALFOUNDRIES US INC

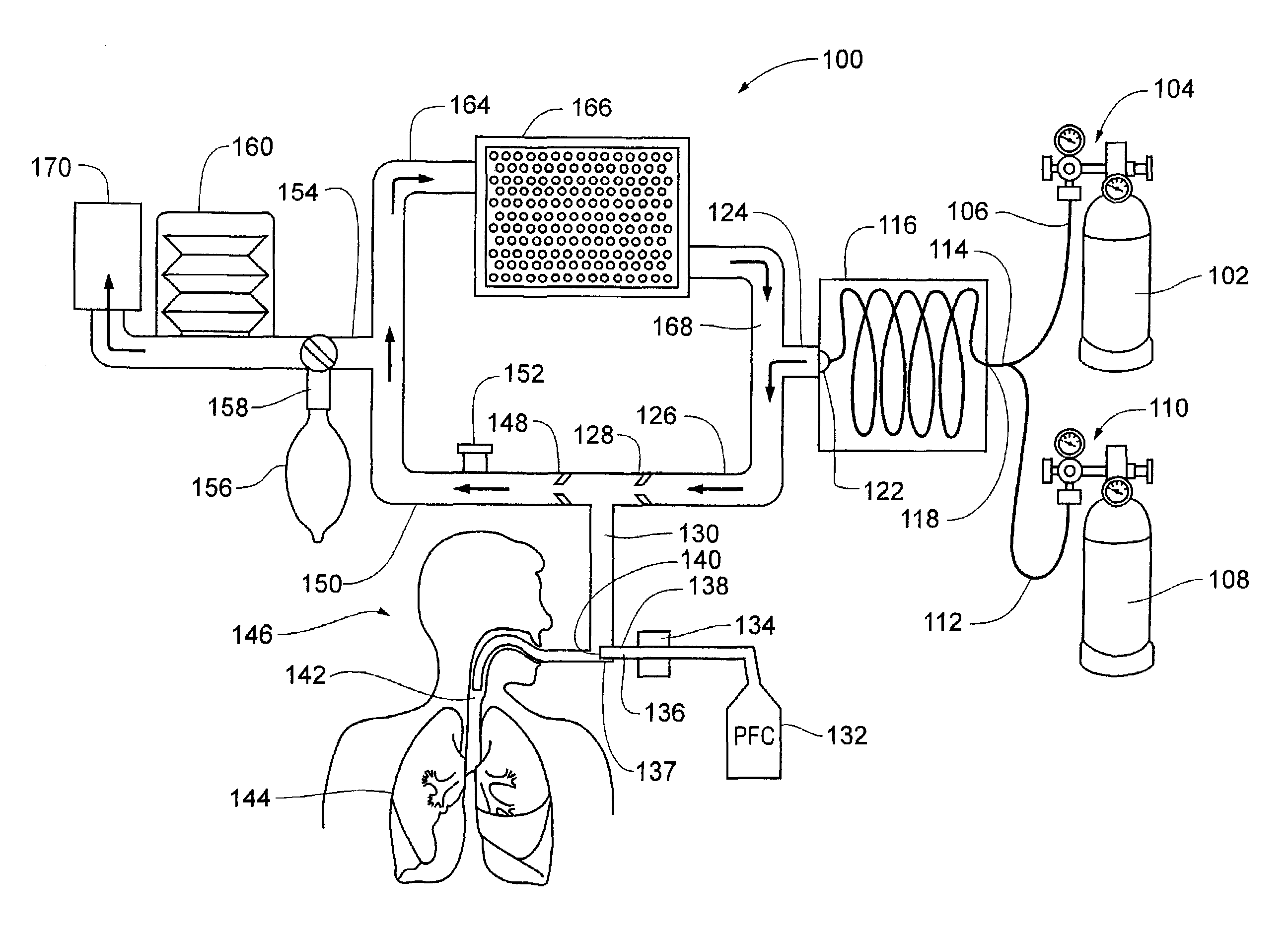

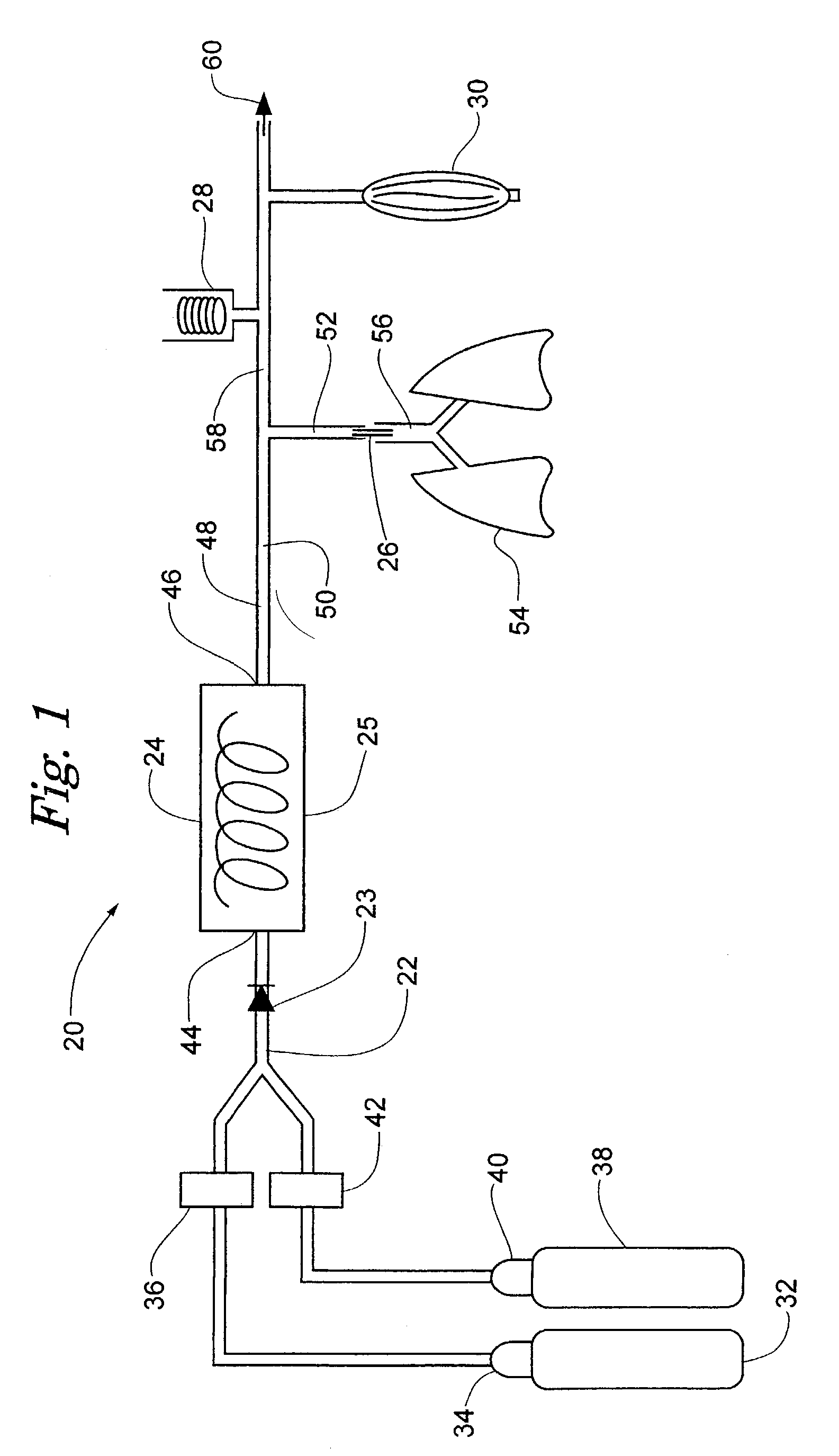

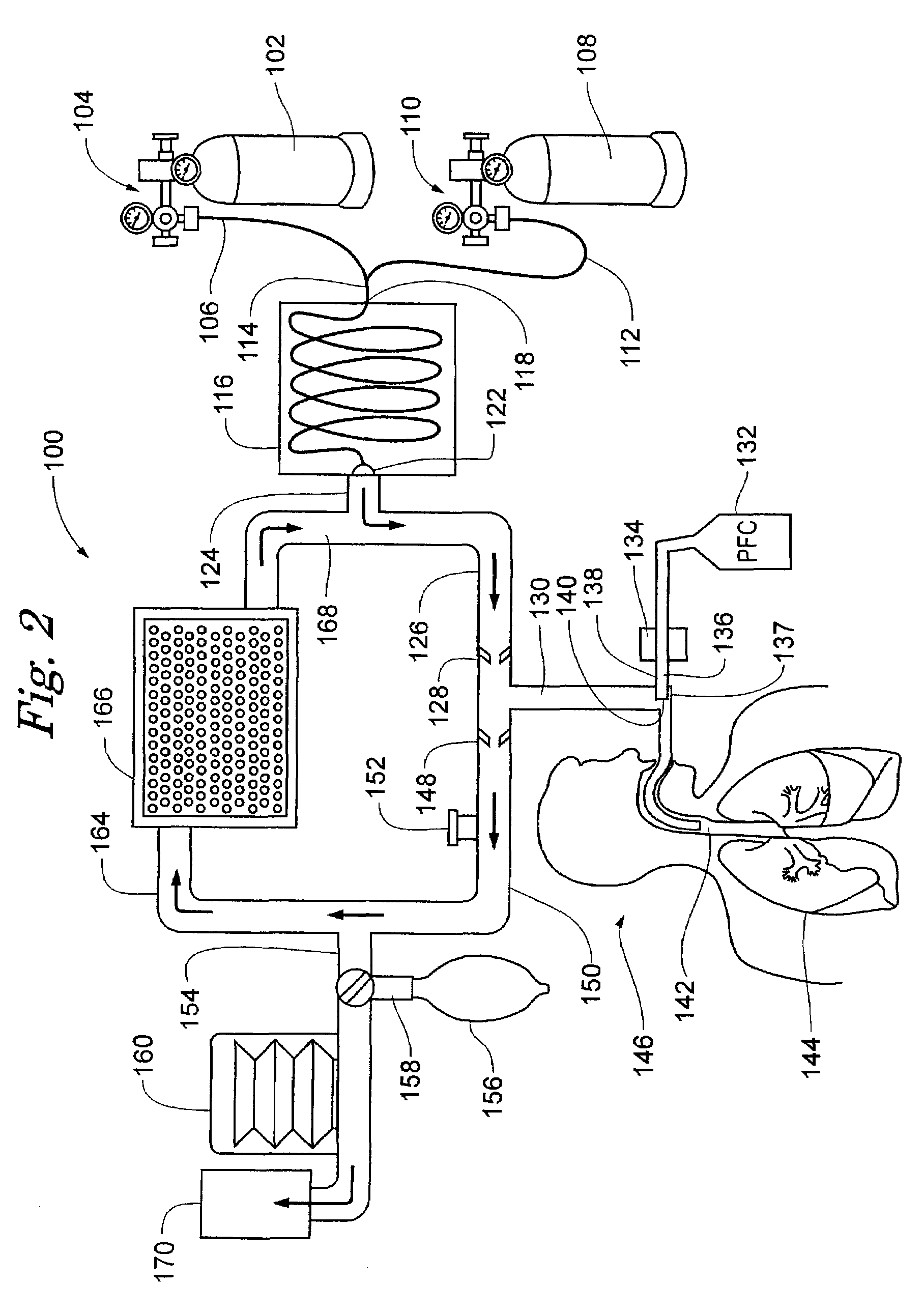

Inducing hypothermia and rewarming using a helium-oxygen mixture

ActiveUS6983749B2Mitigate warmingReduce coolingLighting and heating apparatusInorganic active ingredientsREFLEX DECREASEInspired gas temperature

Devices and methods to heat and cool human beings, including inducing and maintaining hypothermia in human patients. Methods include inducing hypothermia to treat ischemic events, including heart attack and stroke, to limit damage caused by the ischemic event. Methods can include: using the lungs for heat exchange; using cooled gases for ventilation; using helium in the ventilation gas mixture, using medications to control reflex heat production; and injecting a perfluorocarbon mist into the gas stream to increase the cooling rate. The high thermal conductivity and diffusivity of helium results in greater inspired gas temperature equalization toward body temperature. Due to the latent heat of vaporization, addition of even small quantity of phase-change perfluorocarbon dramatically increases the heat carrying capacity of the respiratory gases. Hypothermia may be terminated by discontinuing the medications and warming the patient using a warmed helium-oxygen mixture.

Owner:MINNESOTA HIGH TECH RESOURCES

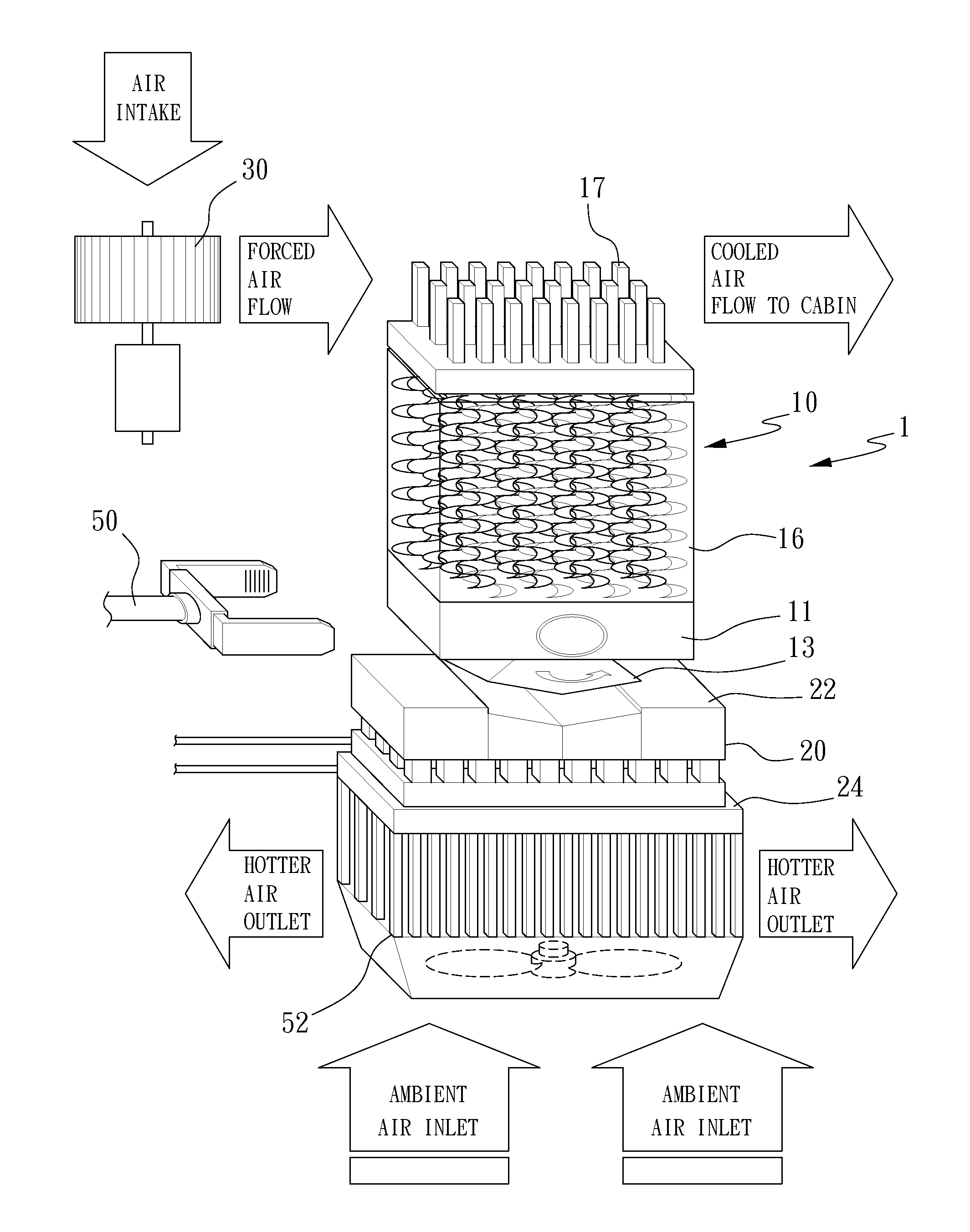

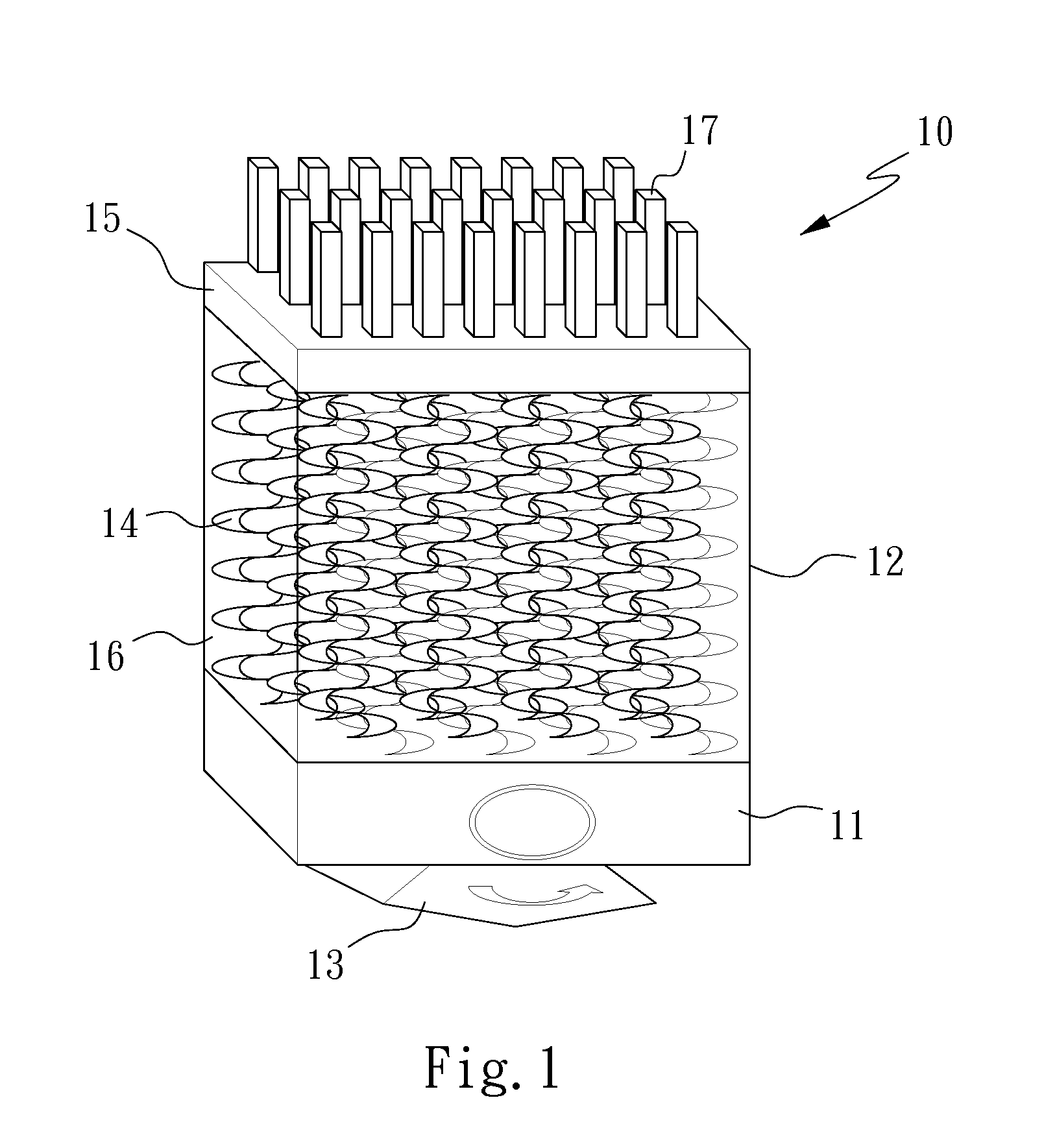

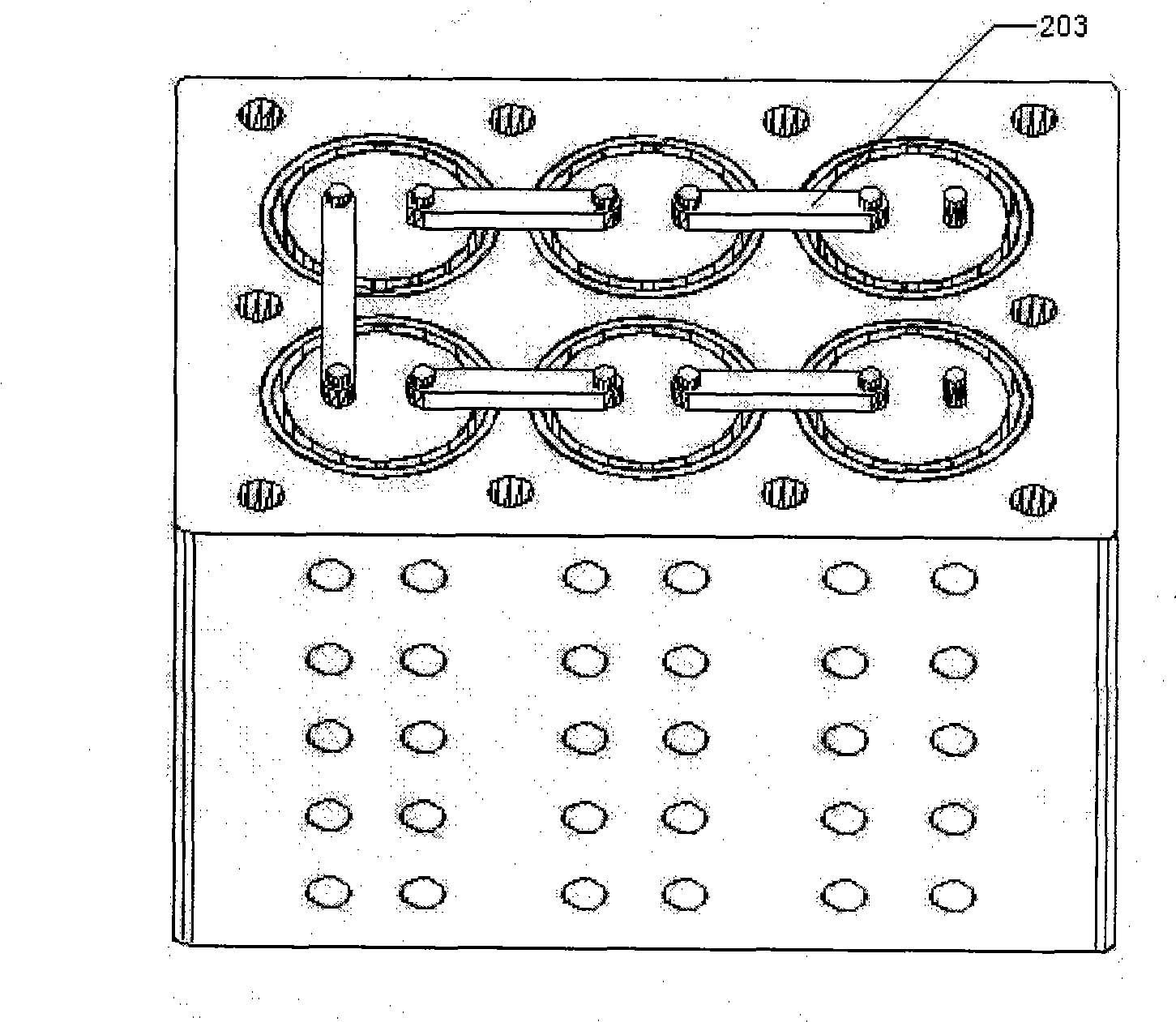

Lhtes device for electric vehicle, system comprising the same and method for controlling the same

InactiveUS20120152511A1Without substantially compromising the trip rangeTemperature regulationAir-treating devicesHeat storage plantsThermal energyThermal energy storage

A latent heat thermal energy storage (LHTES) device for an electric vehicle (EV) comprises a chamber, a plurality of thermal conductivity enhancement units disposed in the chamber, and phase change material (PCM) filled in the chamber, allowing storage of coolness or thermal energy produced when the EV is being charged and retrieval of the coolness or thermal energy when the EV is driven to regulate the temperature of a passenger compartment of the EV. In addition, systems comprising LHTES devices and methods for controlling the same are also introduced.

Owner:SUNNY GENERAL INT +1

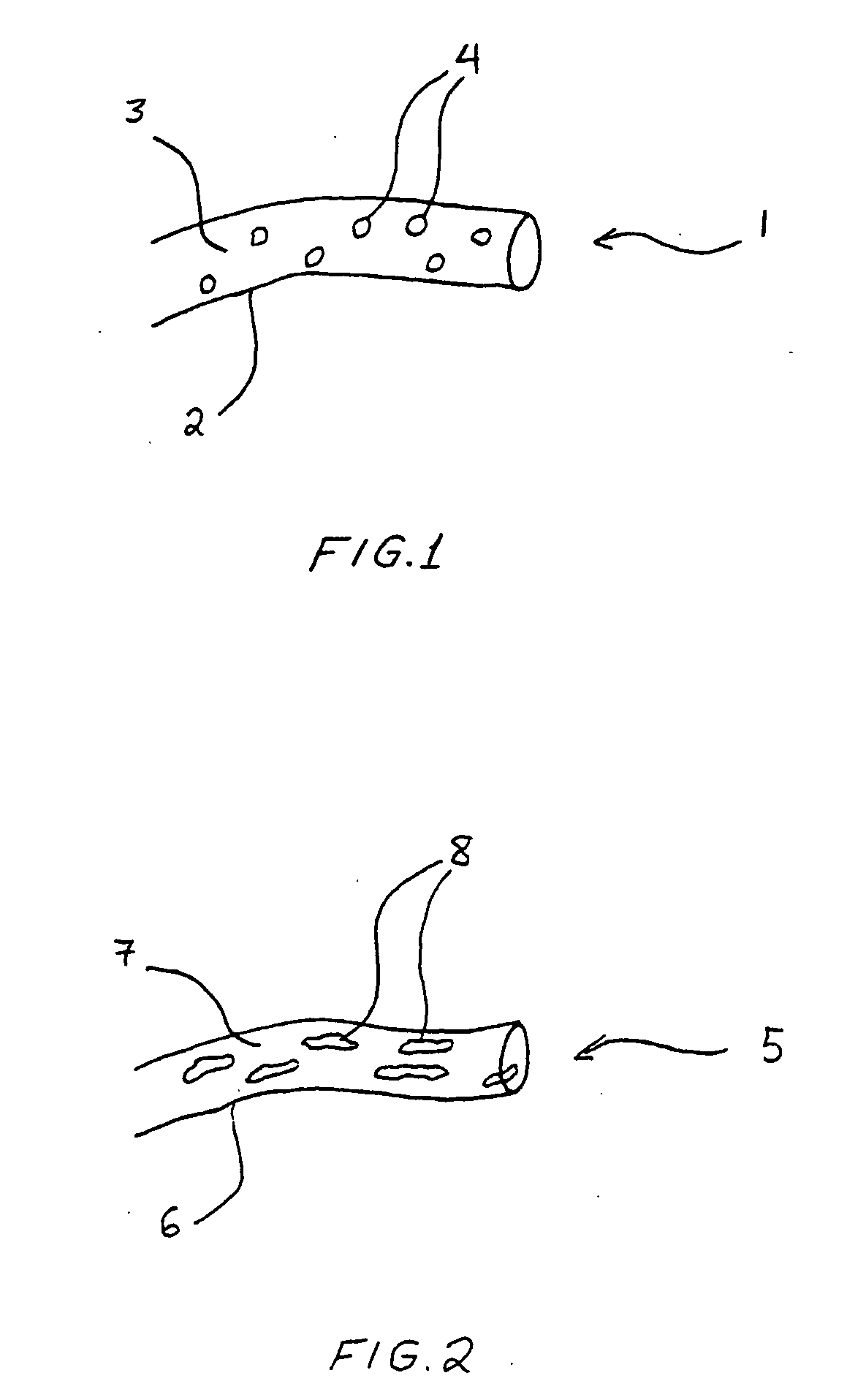

Temperature regulating cellulosic fibers and applications thereof

InactiveUS20070026228A1Monocomponent cellulose artificial filamentGlass/slag layered productsCellulose fiberPhase-change material

Cellulosic fibers having enhanced reversible thermal properties and applications of such cellulosic fibers are described. In one embodiment, a cellulosic fiber includes a fiber body including a cellulosic material and a set of microcapsules dispersed in the cellulosic material. The set of microcapsules contain a phase change material having a latent heat of at least 40 J / g and a transition temperature in the range of 0° C. to 100° C., and the phase change material provides thermal regulation based on at least one of absorption and release of the latent heat at the transition temperature. The cellulosic fiber can be formed via a solution spinning process, and can be used in various products where thermal regulating properties are desired.

Owner:OUTLAST TECH GMBH

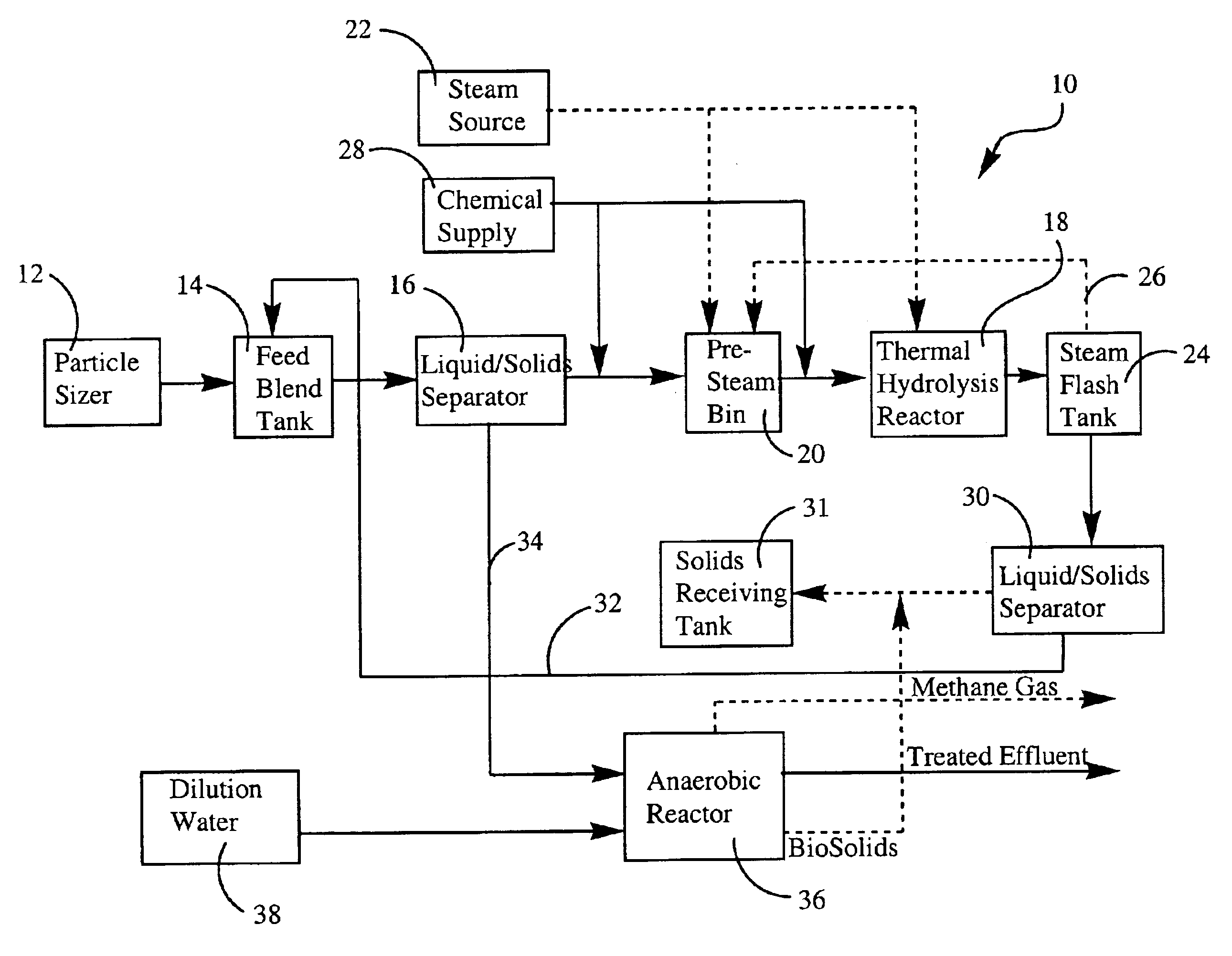

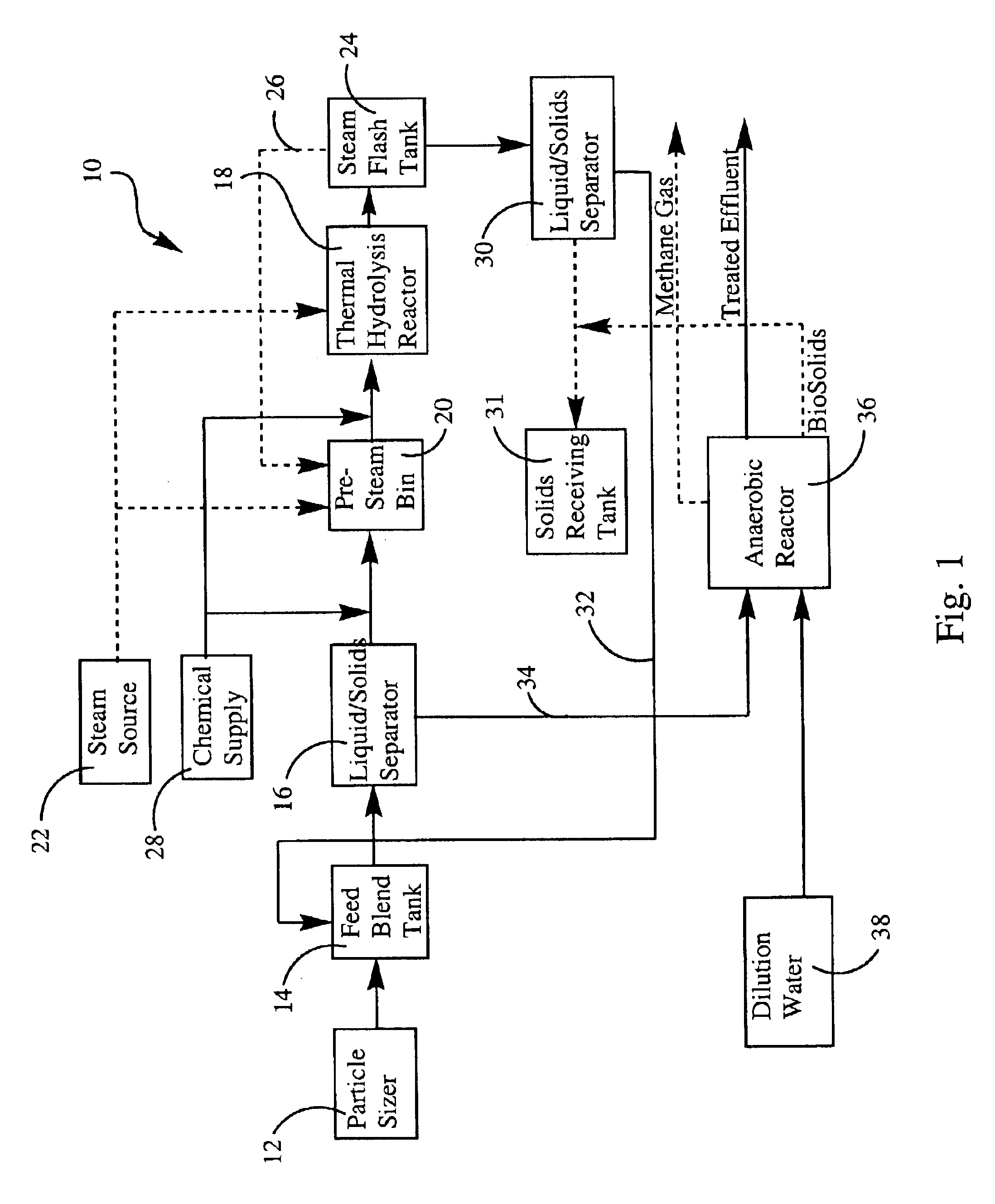

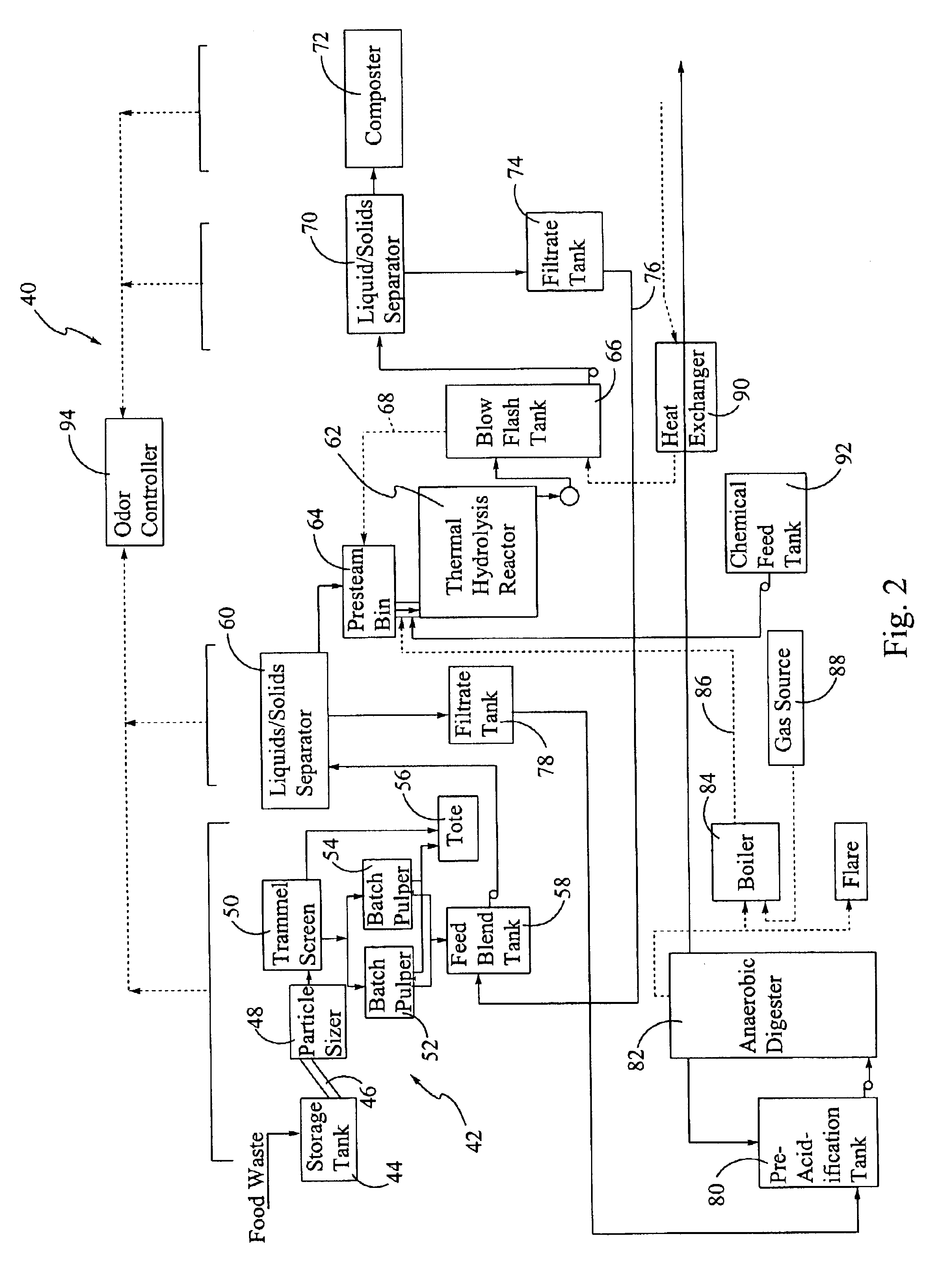

Method and apparatus for the treatment of particulate biodegradable organic waste

InactiveUS6905600B2Lower the volumeSaving in volume requirementBio-organic fraction processingBiological substance pretreatmentsPotassium hydroxideSaturated water vapor

A method for treating particulate biodegradable organic waste includes sizing the waste and adding a base prior to introducing the waste to a thermal hydrolysis reactor and hydrolyzing the waste at a temperature of about 130° C. or greater and a pressure greater than the saturated water vapor pressure to produce a slurry including solubilized organic material and residual solids. The solubilized organic material is separated from the residual solids using a liquid / solid separator and the solubilized organics are subjected to anaerobic digestion to produce a methane gas. The base is preferably potassium hydroxide (KOH) at a concentration of about 1%. The method may further include preheating the particulate biodegradable organic waste with latent heat of the separated solubilized organic material prior to thermal hydrolysis.

Owner:CH2M HILL

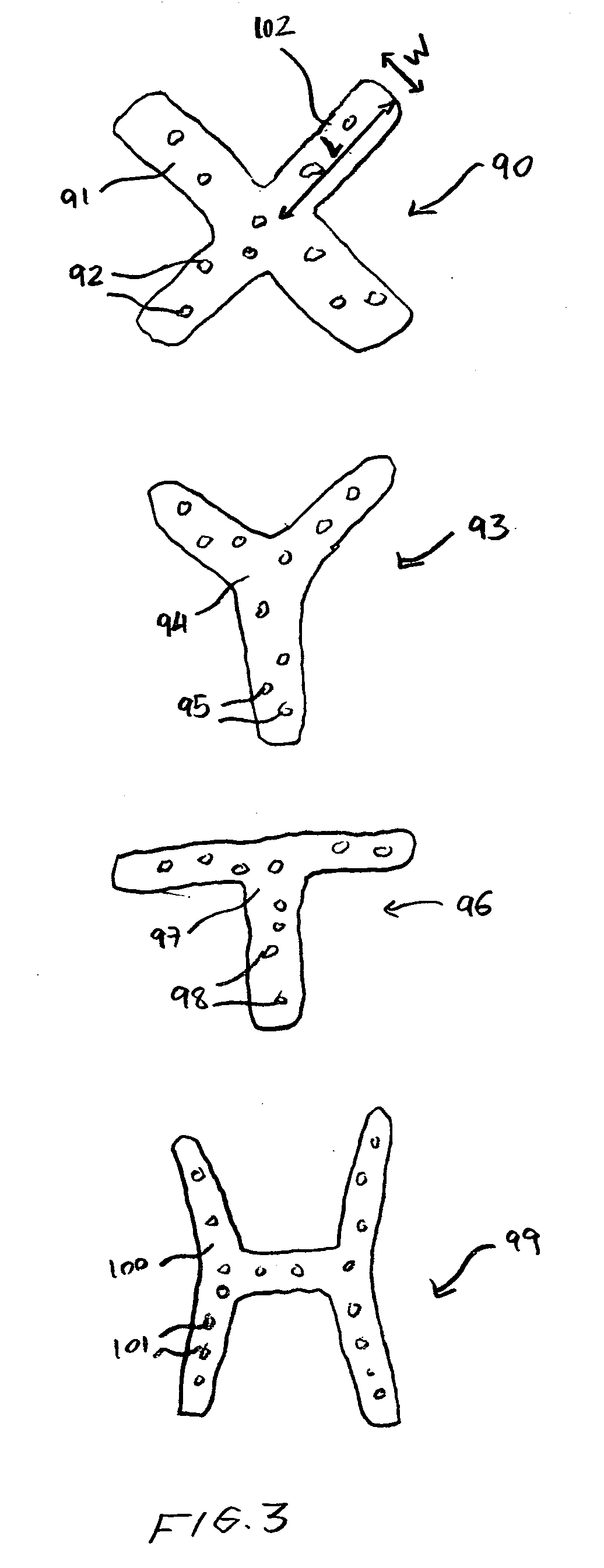

Polymeric composites having enhanced reversible thermal properties and methods of forming thereof

Polymeric composites and methods of manufacturing polymeric composites are described. In one embodiment, a set of microcapsules containing a phase change material are mixed with a dispersing polymeric material to form a first blend. The dispersing polymeric material has a latent heat of at least 40 J / g and a transition temperature in the range of 0° C. to 50° C. The first blend is processed to form a polymeric composite. The polymeric composite can be formed in a variety of shapes, such as pellets, fibers, flakes, sheets, films, rods, and so forth. The polymeric composite can be used as is or incorporated in various articles where a thermal regulating property is desired.

Owner:OUTLAST TECH LLC

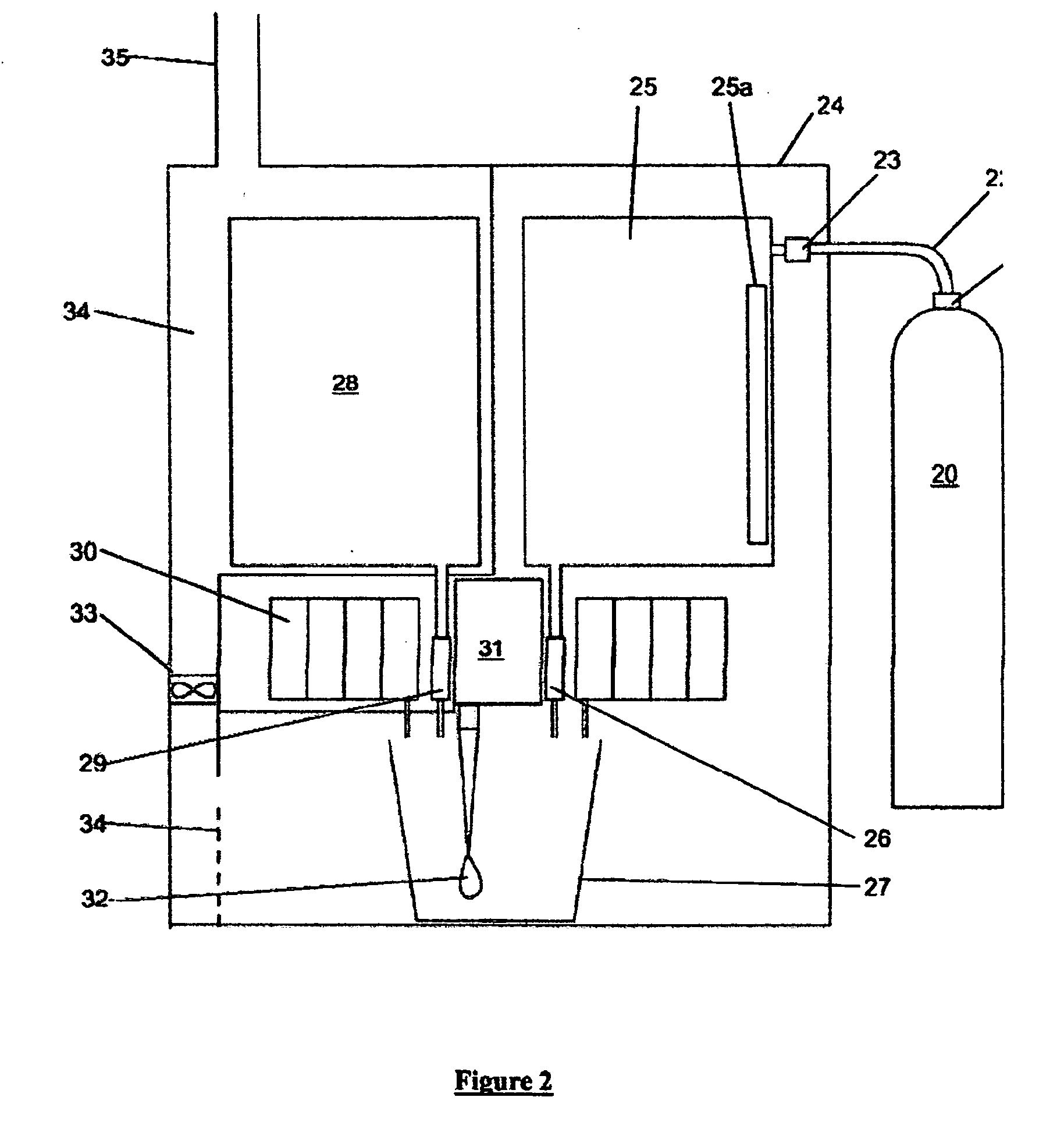

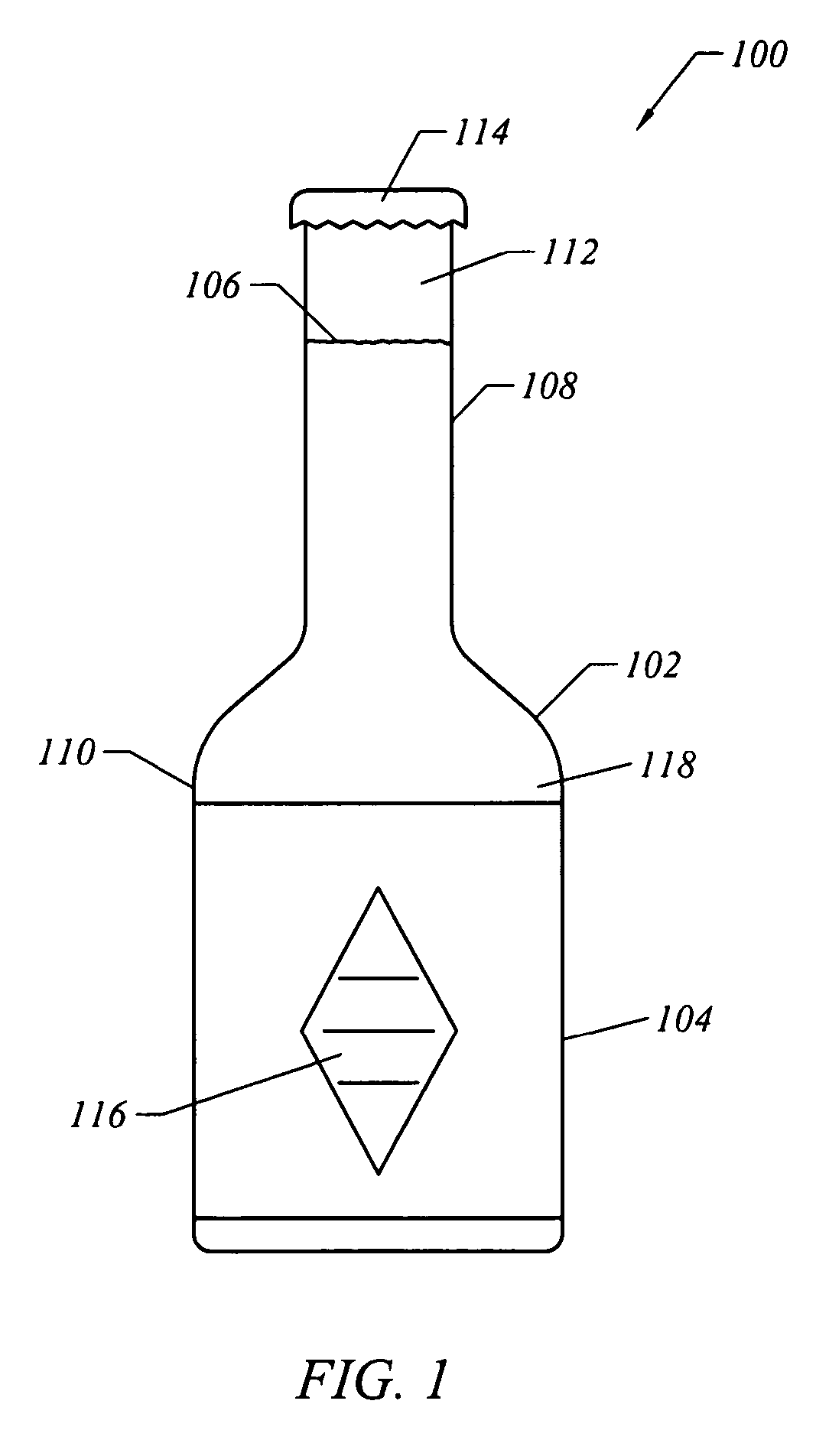

Apparatus for and method of making a frozen confectionery product

ActiveUS20060110515A1Short timeAvoid cross contaminationMilk preservationWort preparationEvaporationRelative motion

Apparatus for producing a serving of frozen confectionery product is characterized by a supply of liquid gas, a support for removably carrying a disposable container that holds a volume of unfrozen confectionery mix, and a holder for releasably holding a disposable agitator, such that the agitator extends into confectionery mix in the container. A valve controllably dispenses liquid gas into the confectionery mix in the container while relative motion is imparted to the container and agitator to agitate and admix the confectionery mix and liquid gas while the liquid gas mix evaporates to cool and freeze the confectionery mix, through a transfer of heat from the confectionery mix to the liquid gas and through the latent heat of evaporation of the liquid gas, to produce the frozen confectionery product.

Owner:SMITTEN VENTURES

Multi-component fibers having enhanced reversible thermal properties and methods of manufacturing thereof

Multi-component fibers having enhanced reversible thermal properties and methods of manufacturing thereof are described. In one embodiment, a multi-component fiber includes a fiber body formed from a set of elongated members, and at least one of the set of elongated members includes a temperature regulating material having a latent heat of at least 40 J / g and a transition temperature in the range of 22° C. to 40° C. The temperature regulating material provides thermal regulation based on at least one of absorption and release of the latent heat at the transition temperature. The multi-component fiber can be formed via a melt spinning process or a solution spinning process and can be used or incorporated in various products where a thermal regulating property is desired. For example, the multi-component fiber can be used in textiles, apparel, footwear, medical products, containers and packagings, buildings, appliances, and other products.

Owner:HILLS CO

Heat Engine System

InactiveUS20100287934A1Increase temperatureImprove heat transfer performanceHeat storage plantsSteam useEnergy transferWorking fluid

A heat engine system for producing work by expanding a working fluid comprising first and second components, the system comprising, an apparatus for combining the second component of the working fluid as a liquid with the first component, the first component being a gas throughout the system, a compressor for compressing the first component, a pump for compressing at least most of the second component, a heater for heating the first and second components, an expander for expanding the first and second components to produce the work, and a recuperator for transferring at least some of the energy of the working fluid from the outlet of the expander, to the working fluid from the outlet of the apparatus, wherein a substantial portion of the energy transferred in the recuperator is at least a portion of the latent heat of the second component from the outlet of the expander.

Owner:COMMONWEALTH SCI & IND RES ORG +1

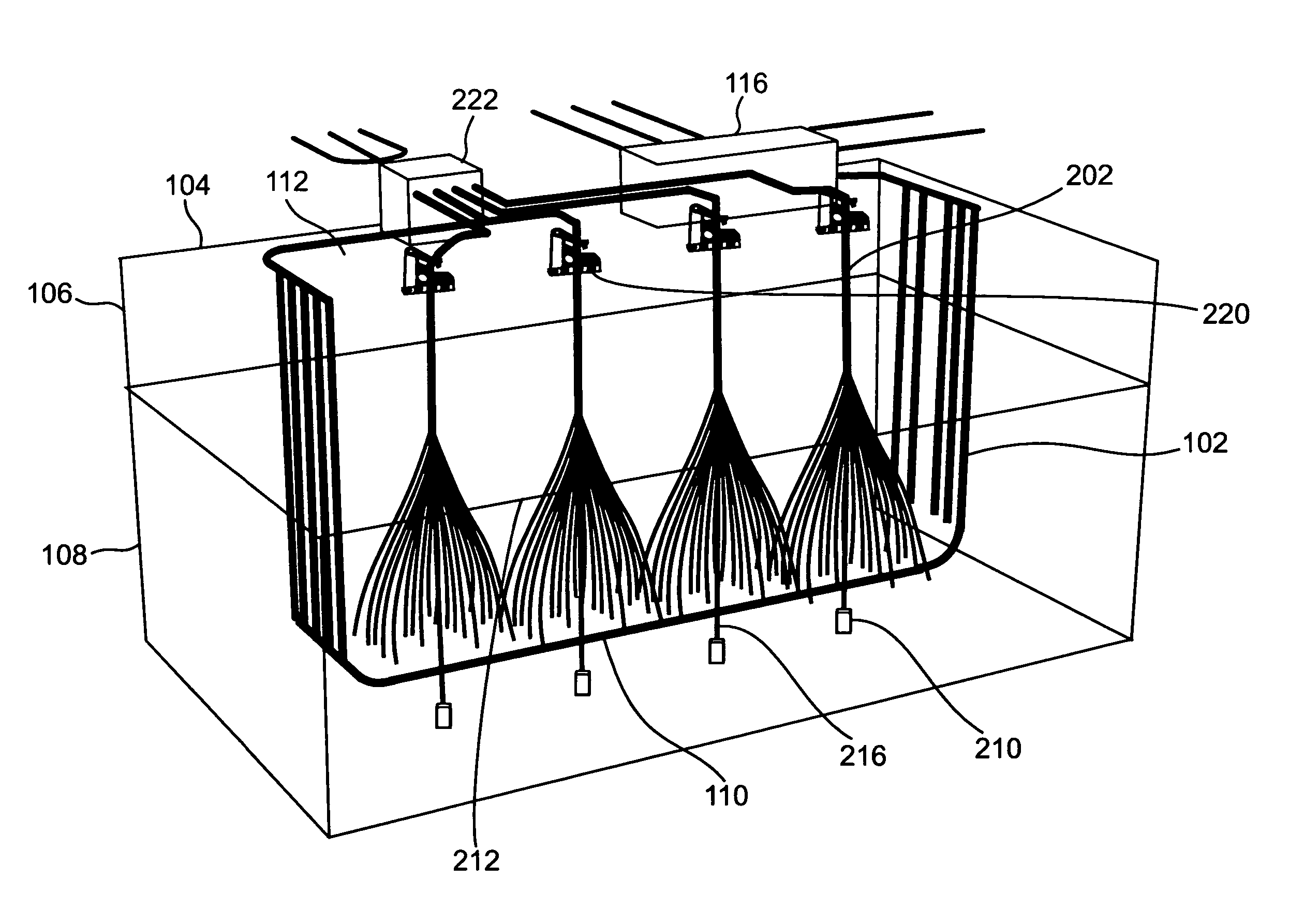

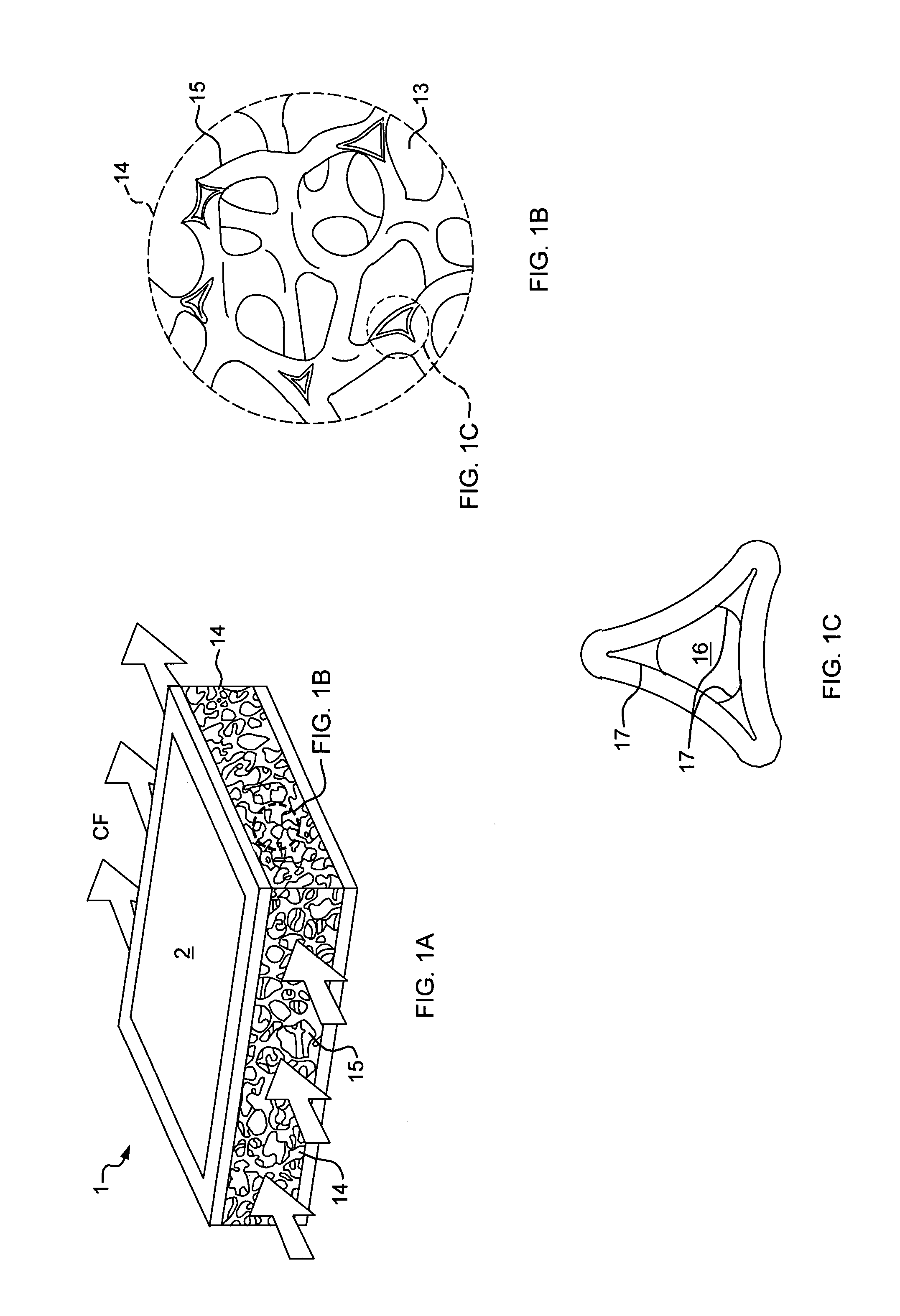

Apparatuses for dissipating heat from semiconductor devices

ActiveUS20070258213A1Increase surface areaImprove two-phase cooling efficiencySemiconductor/solid-state device detailsSolid-state devices3d shapesDevice material

An apparatus for providing two-phase heat transfer for semiconductor devices includes a vapor chamber configured to carry a cooling liquid, the vapor chamber having base section, and a plurality of three-dimensional (3D) shaped members. The plurality of 3D-shaped members have interior and exterior sidewalls, the 3D-shaped members being connected to the base section so that vapor carrying latent heat can reach the respective interior sidewalls and get transferred to the respective exterior sidewalls configured to be in contact with an external coolant. The vapor chamber is configured to be in contact with a semiconductor device in order to remove heat therefrom.

Owner:GLOBALFOUNDRIES US INC

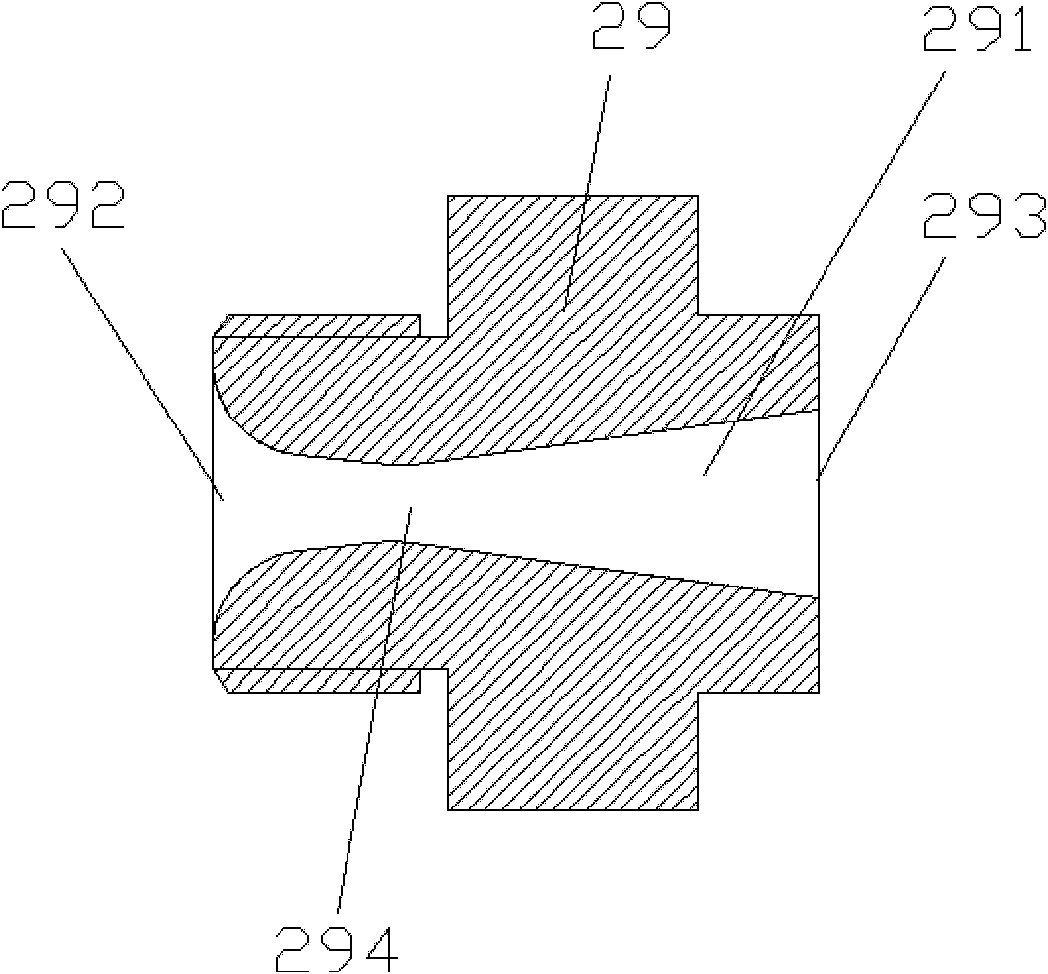

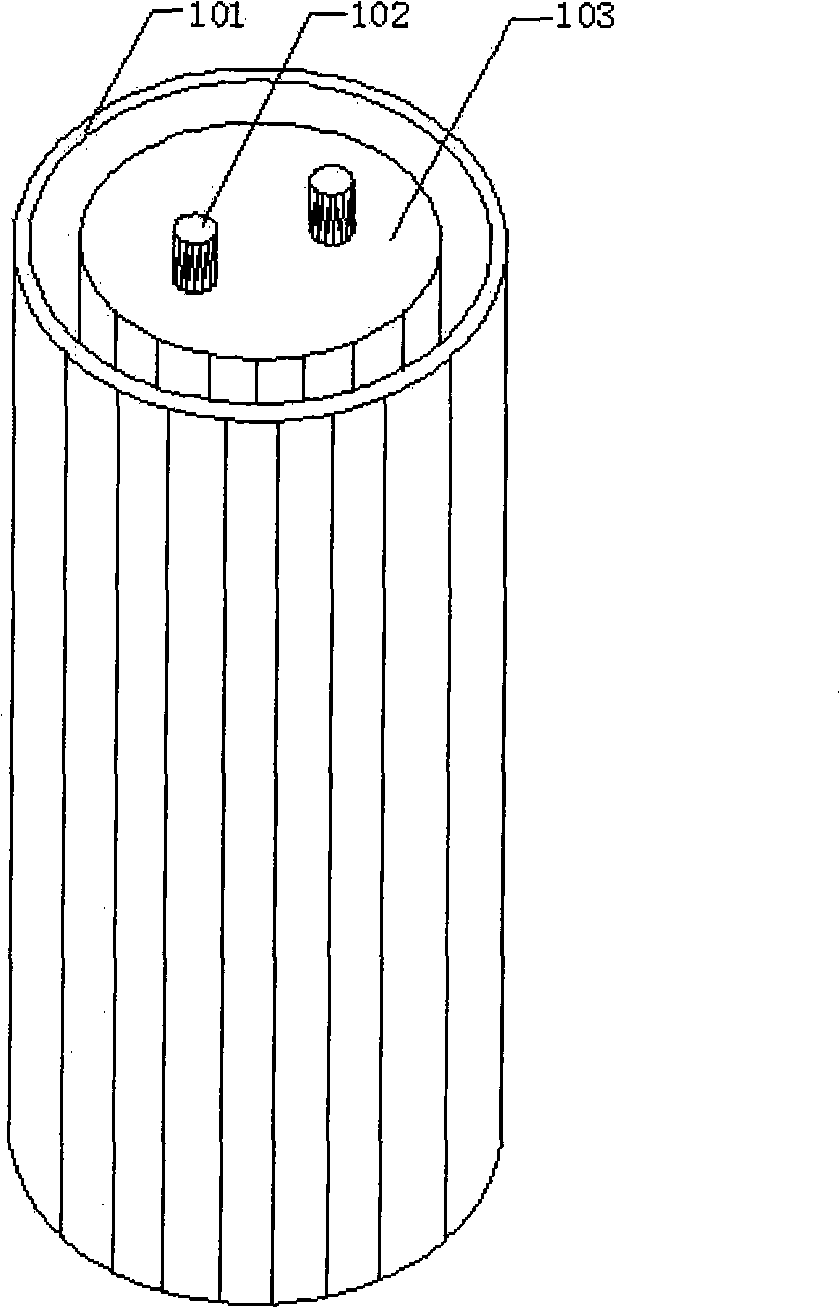

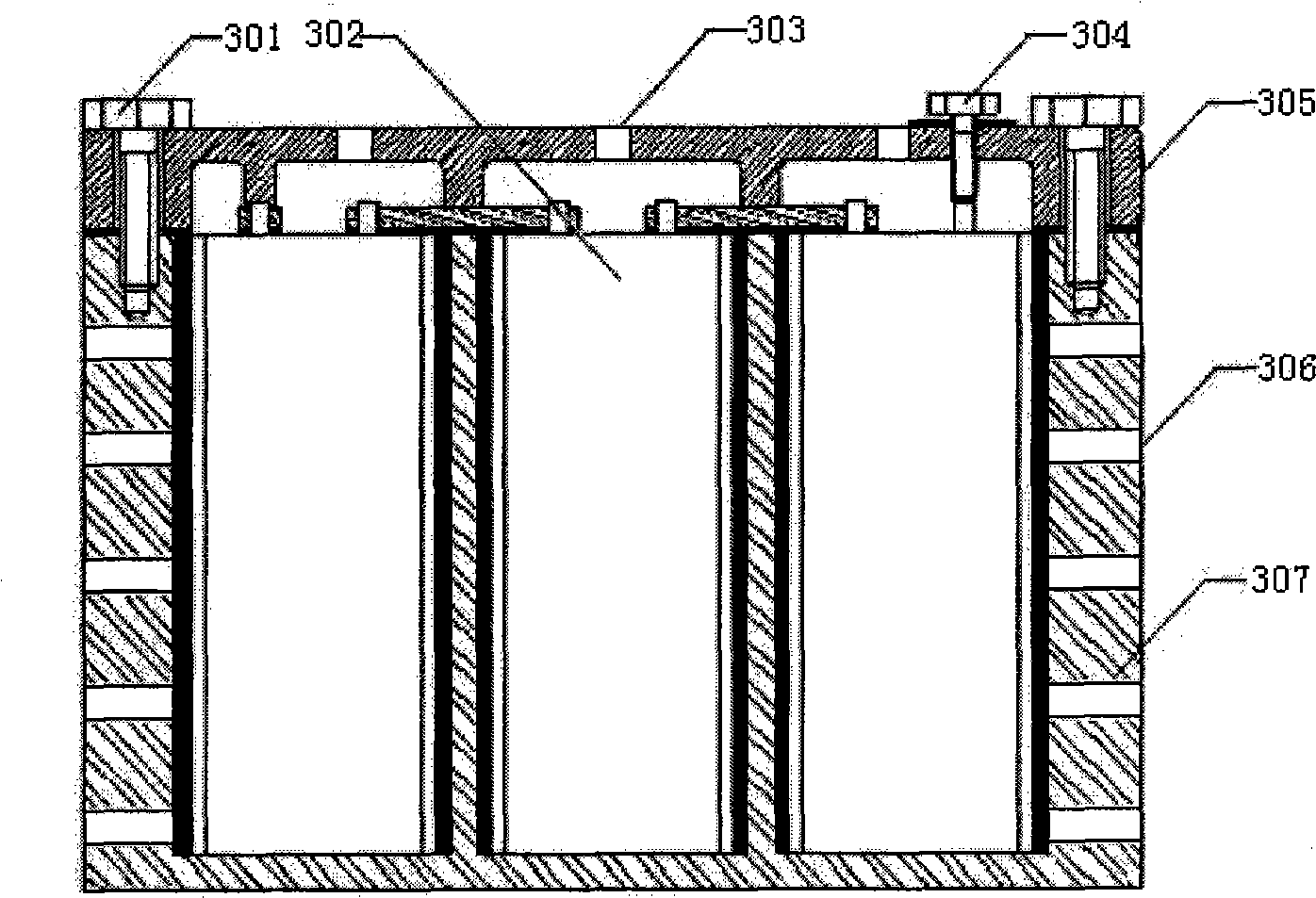

Power battery device with phase-change material cooling system

InactiveCN101546843AEffective coolingExtend your lifeFinal product manufactureSecondary cells manufacturePower batteryEngineering

The invention discloses a power battery device with a phase-change material cooling system, which comprises a bolt, a plurality of battery monomers, a box cover venting hole, an electrode connecting shaft, a box body top cover, a side venting hole and a frame body, wherein the battery monomers use batteries as base bodies, a shell is arranged outside the battery monomers, phase-change material is filled between the batteries and the shell and is sealed by insulating rubber; a battery box body is provided with the venting holes for radiating; the power battery device can realize that the temperature of batteries of a power device can be effectively reduced under more rugged thermal environment and can meet the requirement of the balance of temperature distribution among the battery monomers, thereby achieving the best operation condition of the power device, and prolonging the battery service life and improving the power performance of the power device. The adopted phase-change material has larger latent heat of phase-change, perfect phase-change temperature, economic and safe material, and high recycle utilization efficiency.

Owner:GUANGDONG UNIV OF TECH

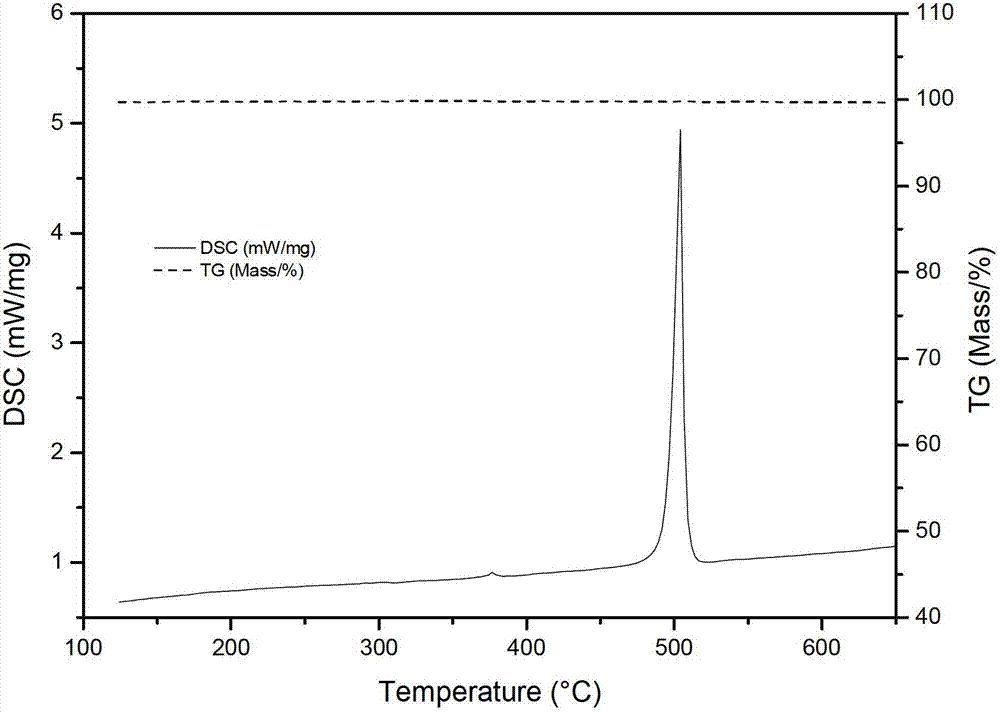

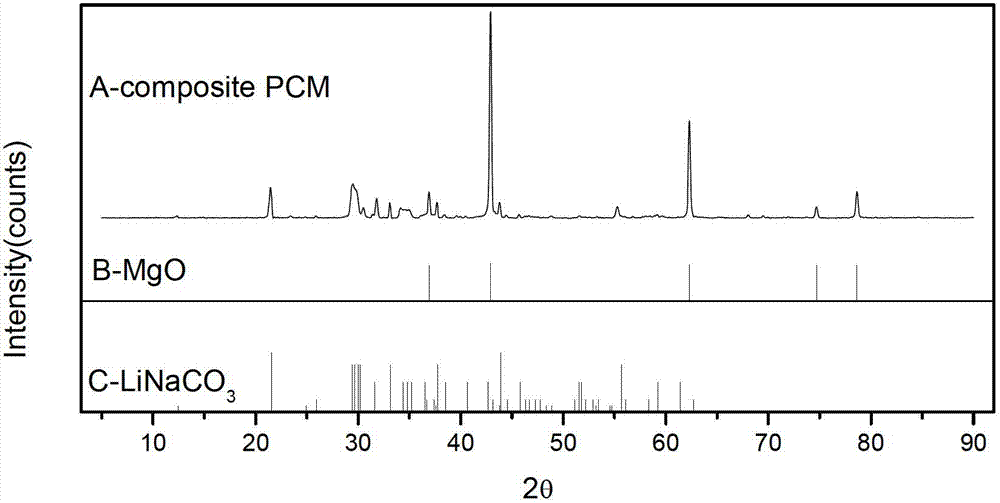

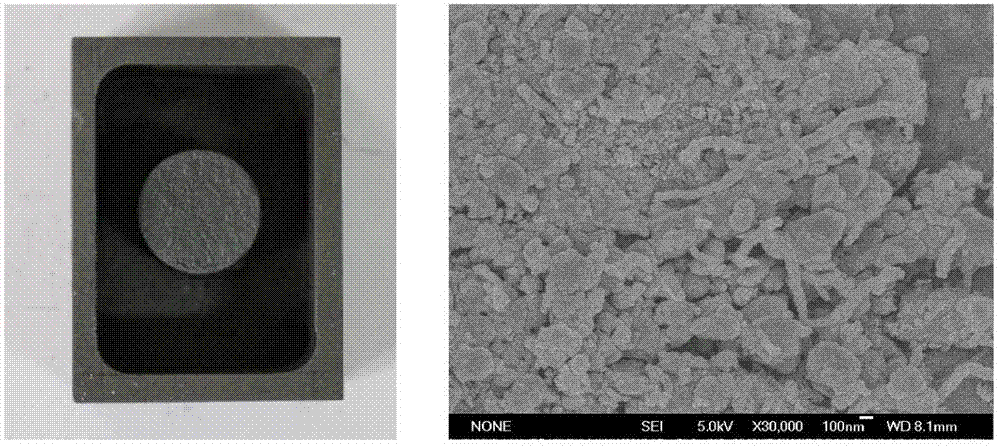

Medium-high temperature composite structural heat storage material, preparation method and application thereof

InactiveCN102888209AHigh phase change enthalpyGood chemical compatibilityHeat-exchange elementsMicro nanoMass ratio

The invention relates to a medium-high temperature (120-1000 DEG C or higher) composite structural heat storage material. The medium-high temperature composite structural heat storage material comprises an inorganic salt phase change latent heat material, a sensitive heat storage material and a heat conduction reinforcing material, wherein the mass ratio of the inorganic salt phase change latent heat material to the sensitive heat storage material is of 1: (0.1-10); and the heat conduction reinforcing material is of 0.0001-1kg / (kg heat storage material) based on mass ratio. The preparation method comprises steps as follows: uniformly mixing the inorganic salt phase change latent heat material with the sensitive heat storage material and the heat conduction reinforcing material; pressurizing to form green blank; and then heating and sintering, so as to obtain the medium-high temperature composite structural heat storage material. The medium-high temperature composite structural heat storage material provided by the invention is capable of obviously reducing the corrosion resistance of the sensitive heat storage material; meanwhile, the thermal conductivity of the composite heat storage material is markedly improved by virtue of the micro-nano doping of the heat conduction reinforcing material; and moreover, high heat storage density is achieved, and wide application prospect is provided.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

In situ method and system for extraction of oil from shale

ActiveUS7743826B2Easy to moveAvoid insufficient temperatureInsulationFluid removalClosed loopEarth surface

A system and process is disclosed for retorting oil shale and extracting shale oil and other hydrocarbons therefrom, in which a cased heat delivery well is drilled generally vertically through an overburden and then through a body of oil shale to be retorted to the bottom thereof, generally horizontally under the body of oil shale to be retorted, and then back to the earth surface. Heat energy is transmitted conductively to the body of oil shale to be retorted from a closed loop heat delivery module in the well, the module comprising a fluid transmission pipe containing a heating fluid heated to at least a retorting temperature. Heat energy is also transmitted to the body of oil shale to be retorted above the fluid transmission pipe by vapor conduits that conduct retort vapors upward through the body of oil shale to be retorted; the ascending retort vapors condense and reflux, delivering their latent heat of vaporization to the body of oil shale to be retorted, and the condensed retort liquids descend. If not recycled, the retort liquids are collected in a sump at the bottom of a production well and are transmitted to the surface for processing. The vapor conduits communicate at upper ends thereof with the production well, so that vapors that do not reflux are collected in the production well and are transmitted to the surface for processing.

Owner:AMERICAN SHALE OIL

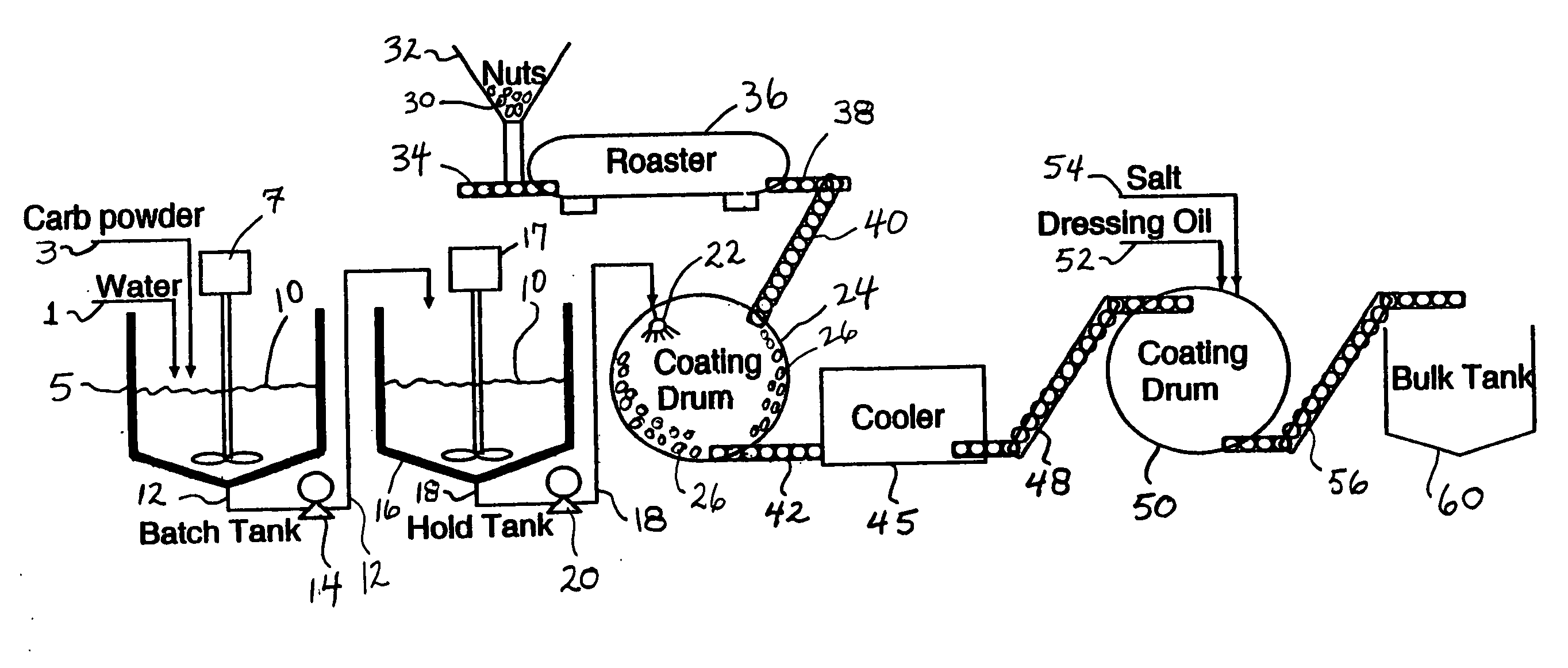

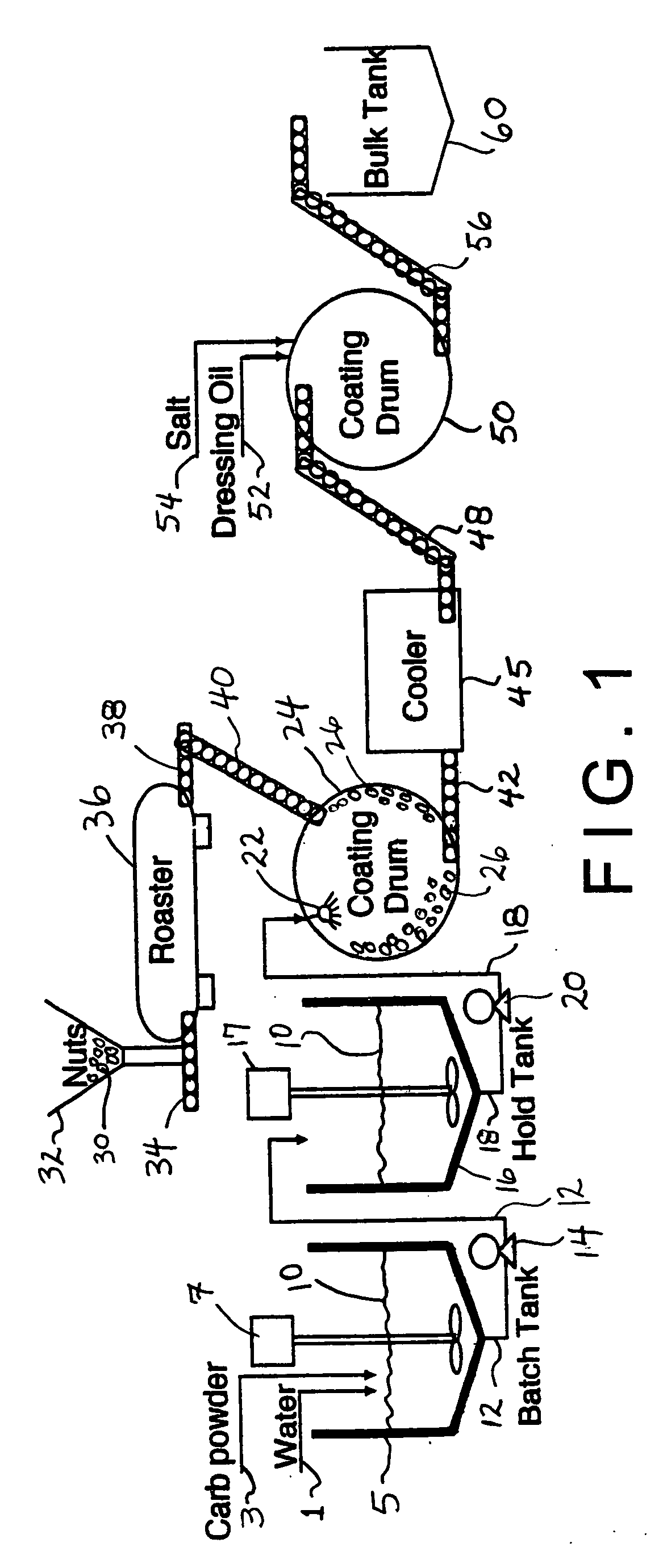

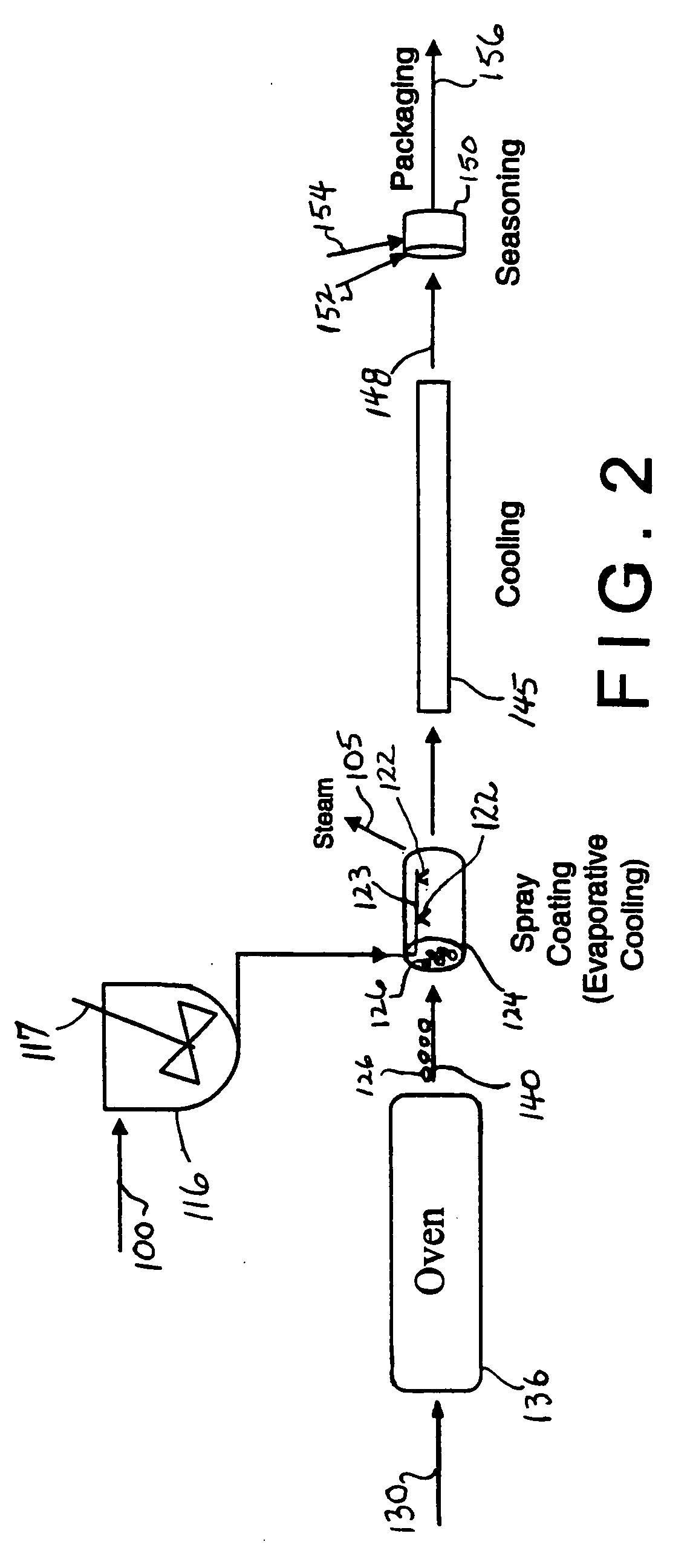

Method and apparatus for applying aqueous coating to cooked foods

A cooked snack food or cooked edible core material, such as roasted nuts, or baked snack chips, while still hot from the cooking step, is tumbled and sprayed with an aqueous solution of a water-soluble, film-forming coating component, such as a maltodextrin. The tumbling and spraying is performed immediately after cooking so that latent heat from the cooked edible core material, reduces the moisture content of the applied aqueous solution to form a dry, thin film coating of the coating component on the edible core material. The need for a separate, subsequent drying step or forced air drying equipment to reduce the moisture content is eliminated by evaporative cooling of the hot cooked snacks and flashing of the applied aqueous coating solution. The dry, coated cooked snack may be cooled to obtain a snack food having a thin, uniform coating which enhances appearance, texture, taste and shelf life.

Owner:KRAFT FOODS GRP BRANDS LLC

Fibers and articles having combined fire resistance and enhanced reversible thermal properties

A fabric, fiber or article comprising a plurality of fiber bodies, the plurality of fiber bodies including a first fiber material and a second fiber material, wherein the first fiber material comprises a cellulosic material and a phase change material dispersed in the cellulosic material, the phase change material forming a plurality of domains dispersed in the cellulosic material, the phase change material having a latent heat of at least 5 Joules per gram and a transition temperature in the range of 0° C. to 100° C., the phase change material providing thermal regulation based on at least one of absorption and release of the latent heat at the transition temperature. Wherein the second fiber material comprises a fire resistant material.

Owner:OUTLAST TECH LLC

Systems, structures and materials for electronic device cooling

Owner:LATENT HEAT SOLUTIONS LLC

Fuel vapor handling apparatus and diagnostic apparatus thereof

InactiveUS6695895B2Desorption of fuel is facilitatedFuel can be purged efficientlyNon-fuel substance addition to fuelFuel injection apparatusDesorptionVaporization

A fuel vapor handling apparatus supplies a purging air to a canister by using a purge pump and purges fuel desorbed from the canister into an intake pipe. A controller intermittently operates the purge so that the canister internal temperature recovers from a reduced level caused by the latent heat of vaporization of fuel during an operating period of the purge pump. Therefore, desorption of fuel from the canister during an operating period is facilitated. Since the actual operating time of the purge pump is reduced, the life of a motor that is a power unit of the purge pump becomes longer.

Owner:TOYOTA JIDOSHA KK +1

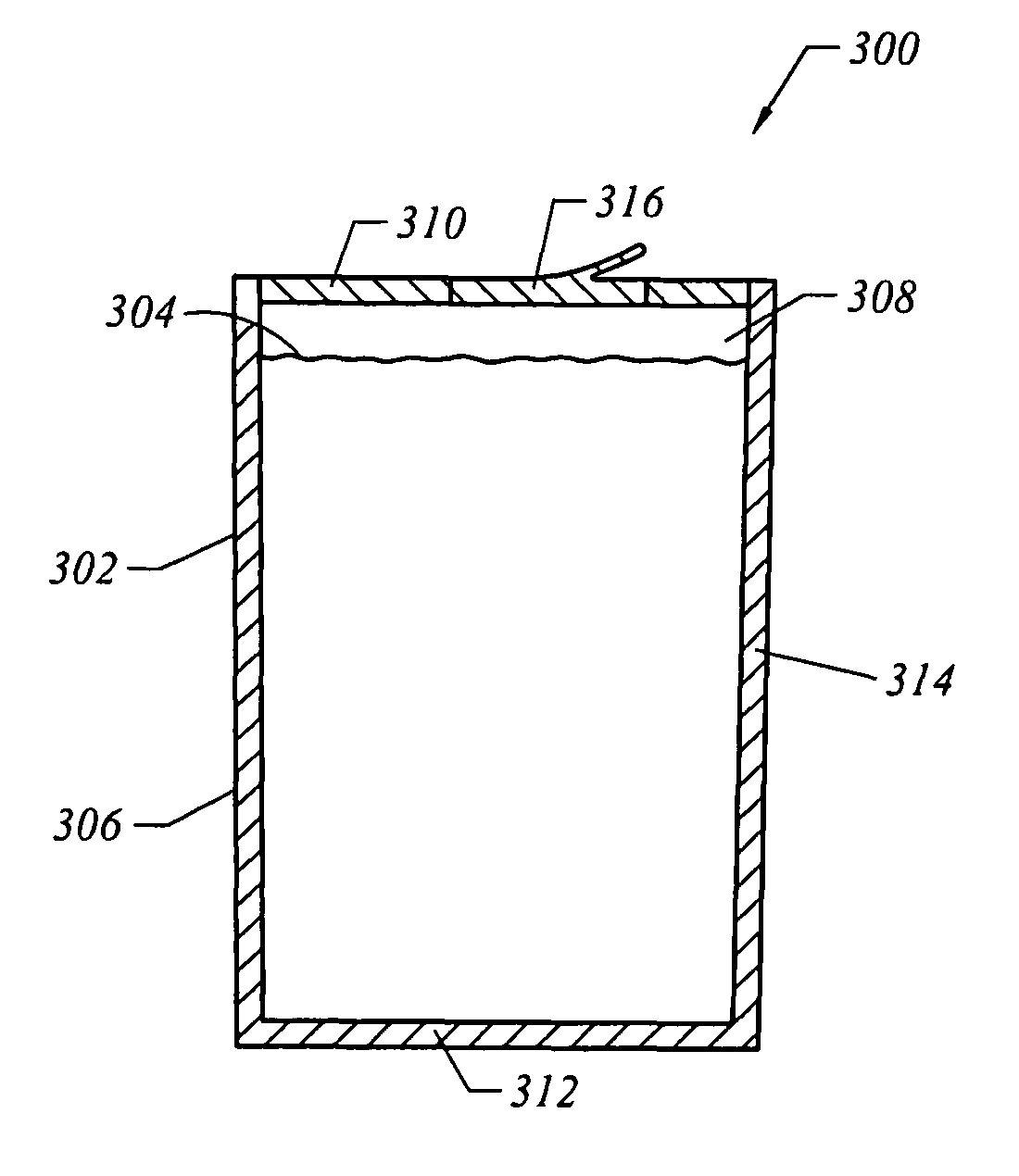

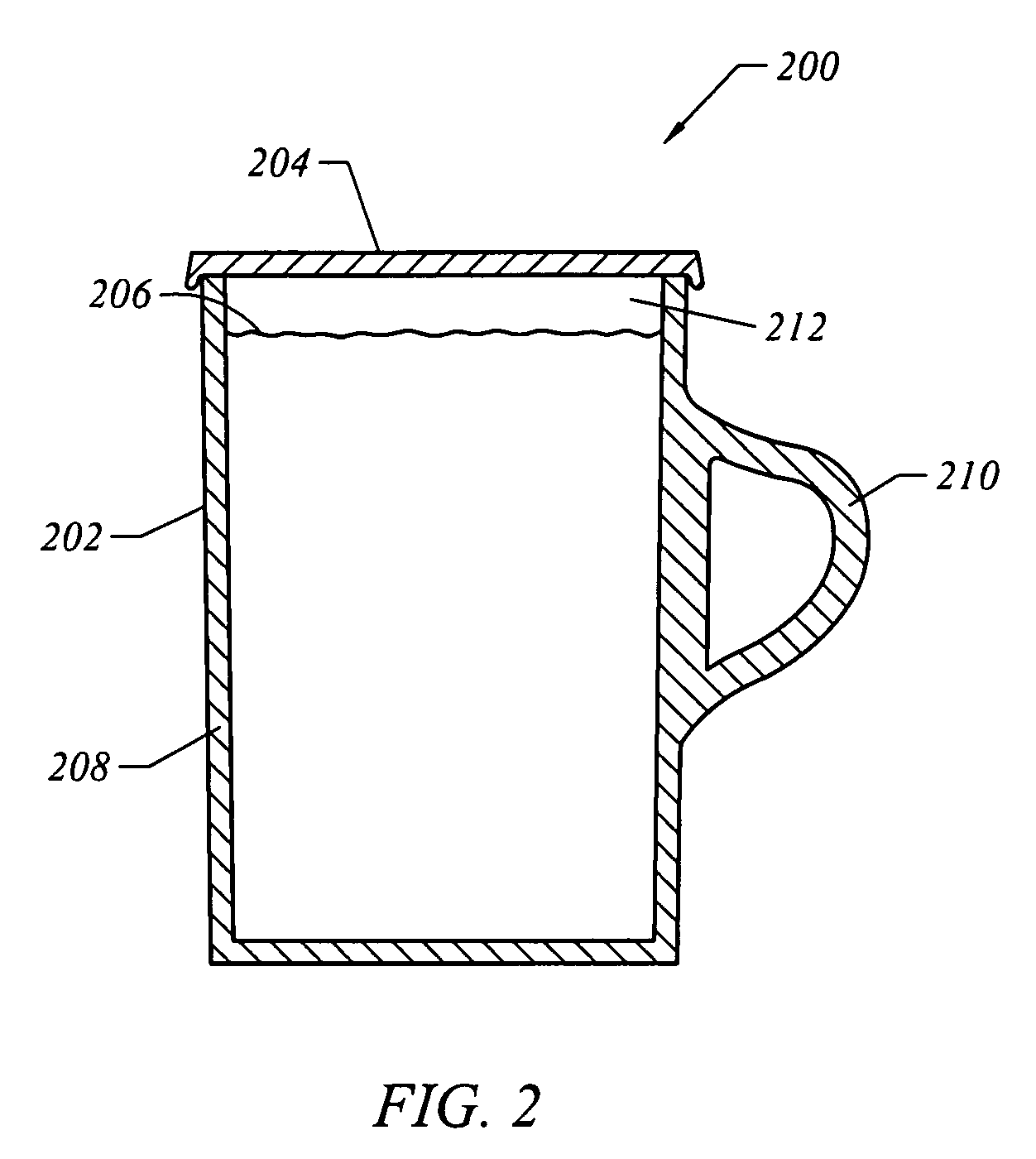

Containers and packagings for regulating heat transfer

InactiveUS7836722B2Exothermal chemical reaction heat productionDomestic cooling apparatusEngineeringLatent heat

A food container includes an upper wall, a lower wall, and a side wall extending between the upper wall and the lower wall. At least one of the upper wall, the lower wall, and the side wall includes a plurality of microcapsules containing a phase change material. The phase change material has a latent heat in the range of 40 J / g to 400 J / g and a transition temperature in the range of 0° C. to 100° C. The phase change material provides thermal regulation based on at least one of absorption and release of the latent heat at the transition temperature.

Owner:OUTLAST TECH LLC

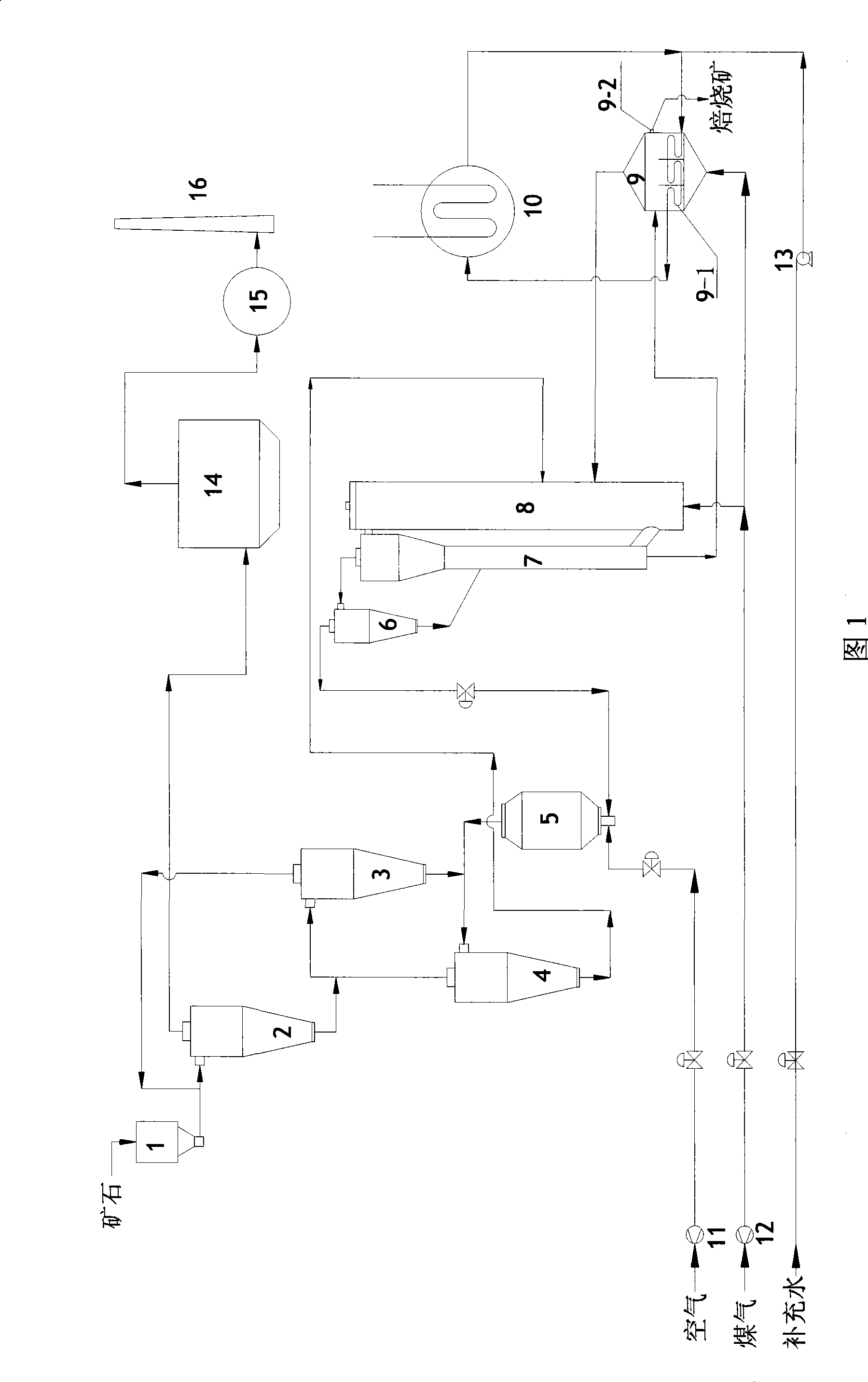

Magnetization roasting technique system for refractory iron ore powder and roasting technology

The invention belongs to the fields of chemical engineering and metallurgy and in particular relates to a process system which adopts a circulating fluid bed to carry out magnetization roasting on limonite, siderite, sedimentary hematite and other refractory iron ore powder bodies. The process system adopts a high-efficiency low-resistance reactor of the circulating fluid bed to carry out the magnetizing roasting to the iron ore powder body; firstly, roasted tail gas in a combustion chamber releases latent heat of unreacted reducing gas through combustion; secondly, the roasted tail gas exchanges heat with the cold iron ore powder body through a multilevel cyclone preheater to reclaim heat; and finally a fluidizing cooler is adopted to reclaim sensible heat of high-temperature roasting ore. The process system has the advantages of high magnetizing roasting efficiency and full heat reclaiming and utilization in the roasting process and the like, can reduce energy consumption of the refractory iron ore powder body in the process of magnetizing roasting and improve the economical efficiency of the refractory iron ore in the process of magnetizing roasting.

Owner:深圳市中科九台资源利用科技产业股份有限公司

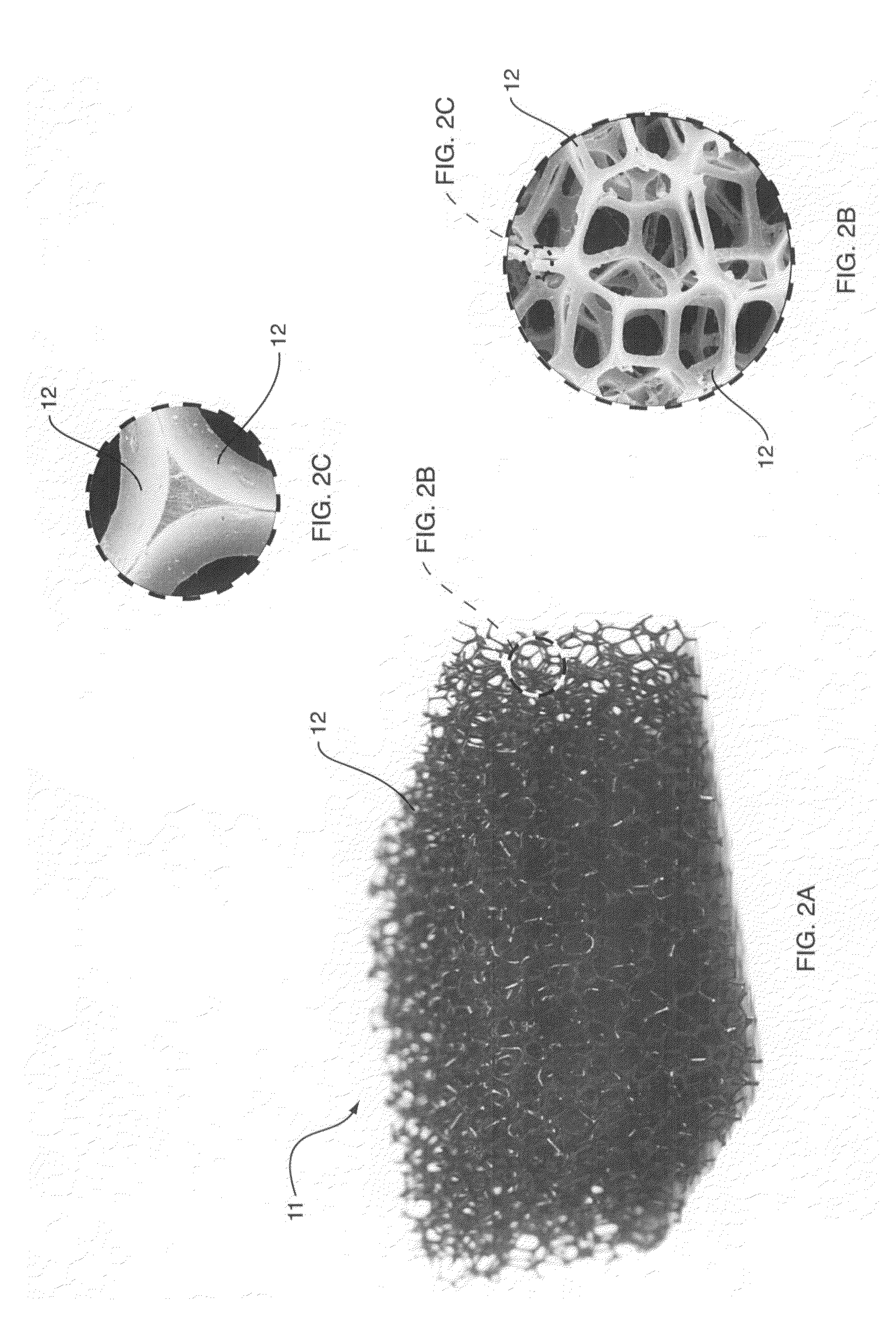

Heat exchange foam

InactiveUS7401643B2Improve efficiencyReduce temperature gradientVacuum evaporation coatingSputtering coatingWorking fluidVaporization

A method and an apparatus for the efficient transfer of heat utilizing micro heat pipes that include a cellular foam or interconnected cellular / truss network having hollow ligaments. A predetermined fraction of the internal volume of the hollow ligaments is filled with a carefully chosen working fluid, and the ends of the hollow ligaments are sealed. In operation, the working fluid evaporates in the region of high heat flux and condenses in regions of lower temperature, resulting in the transfer or redistribution of the fluid's latent heat of vaporization. For open cell foams and interconnected networks, a second fluid flowing through the open cells, separate from the working fluid but also in thermal contact with the hollow ligaments, assists in the transfer of heat from the foam and networks.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

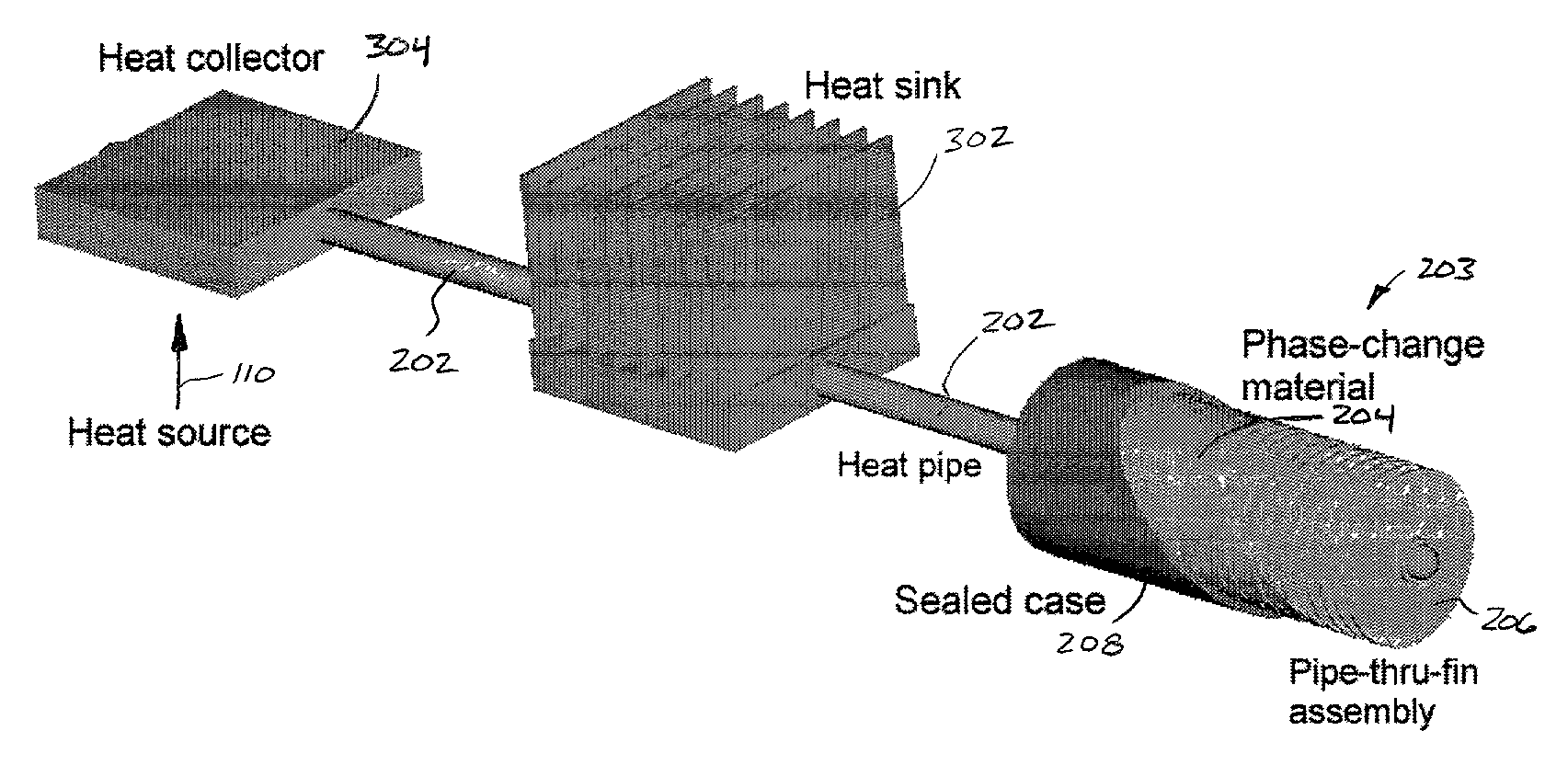

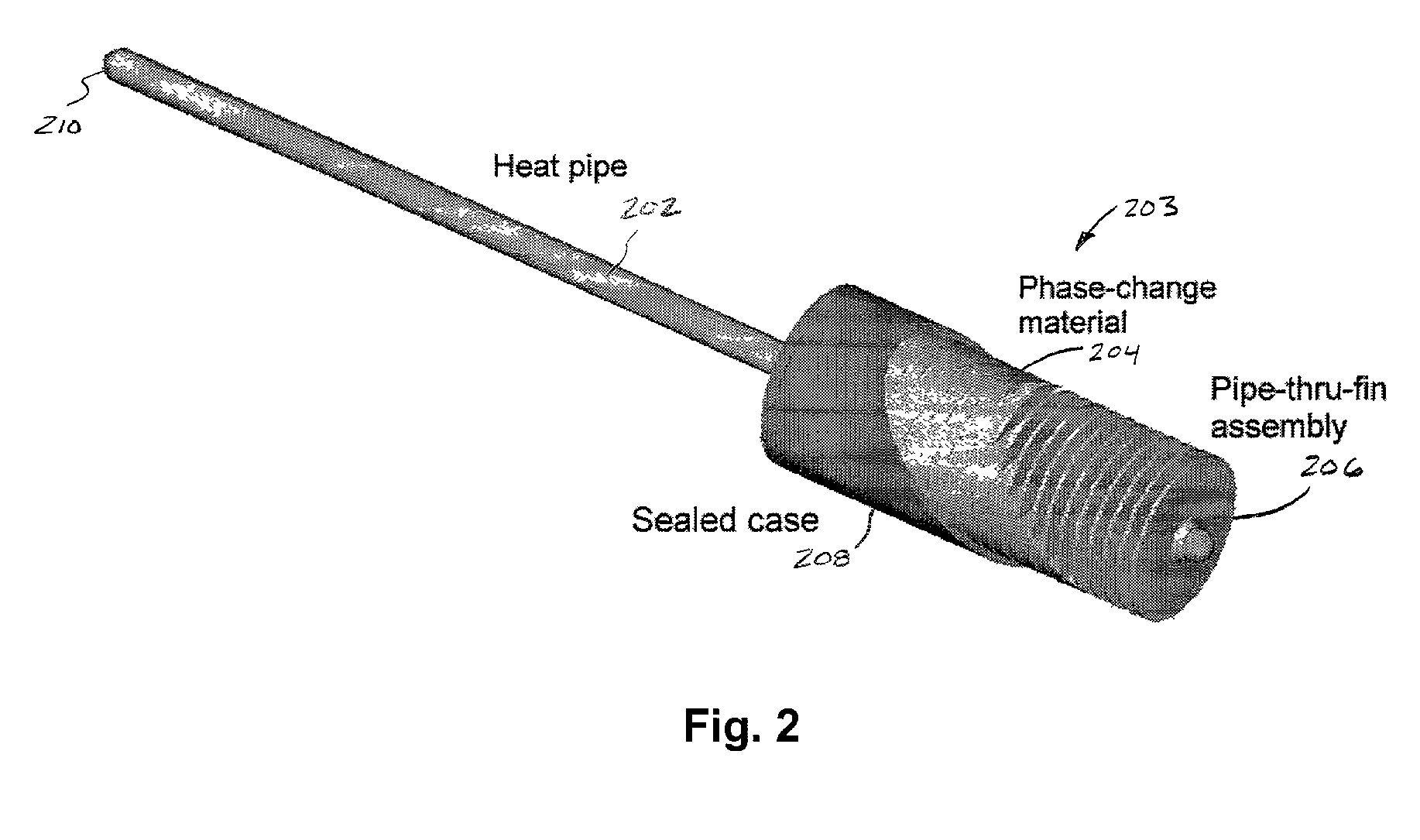

Phase-change heat reservoir device for transient thermal management

InactiveUS6997241B2Good flexibilitySmall sizeCentral heating with accumulated heatHeat storage plantsHeat rejectionThermal solution

A heat transfer system is presented for managing thermal transients, thus providing engineers greater flexibility in designing thermal solutions for applications subject to transient heat-generation. A heat reservoir device for managing a heat input subject to transient conditions includes a heat transfer subsystem having a first end and a second end, where the first end is thermally coupled to the heat input; a heat storage subsystem coupled to the second end of the heat transfer subsystem, where the heat storage subsystem comprises a phase change material responsive to the transient conditions. The excess heat load during transient operation is temporarily absorbed by the latent heat of fusion when the phase change material changes its phase from solid to liquid. Subsequently, the absorbed heat can be released back to the ambient via a heat rejection subsystem. This allows engineers to design smaller heat sinks capable of accommodating given transient conditions. This results in heat sinks which are lower cost and smaller size, or which reduce the requirement to provide higher airflow, thereby also decreasing cost and noise, and increasing reliability.

Owner:ENERTRON INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com