Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

417 results about "Dodecanol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dodecanol /ˈdoʊˈdɛkɑːnɒl/, or lauryl alcohol, is an organic compound produced industrially from palm kernel oil or coconut oil. It is a fatty alcohol. Sulfate esters of lauryl alcohol, especially sodium lauryl sulfate, are very widely used as surfactants. Sodium lauryl sulfate, ammonium lauryl sulfate, and sodium laureth sulfate are all used in shampoos. Lauryl alcohol is tasteless and colorless with a floral odor.

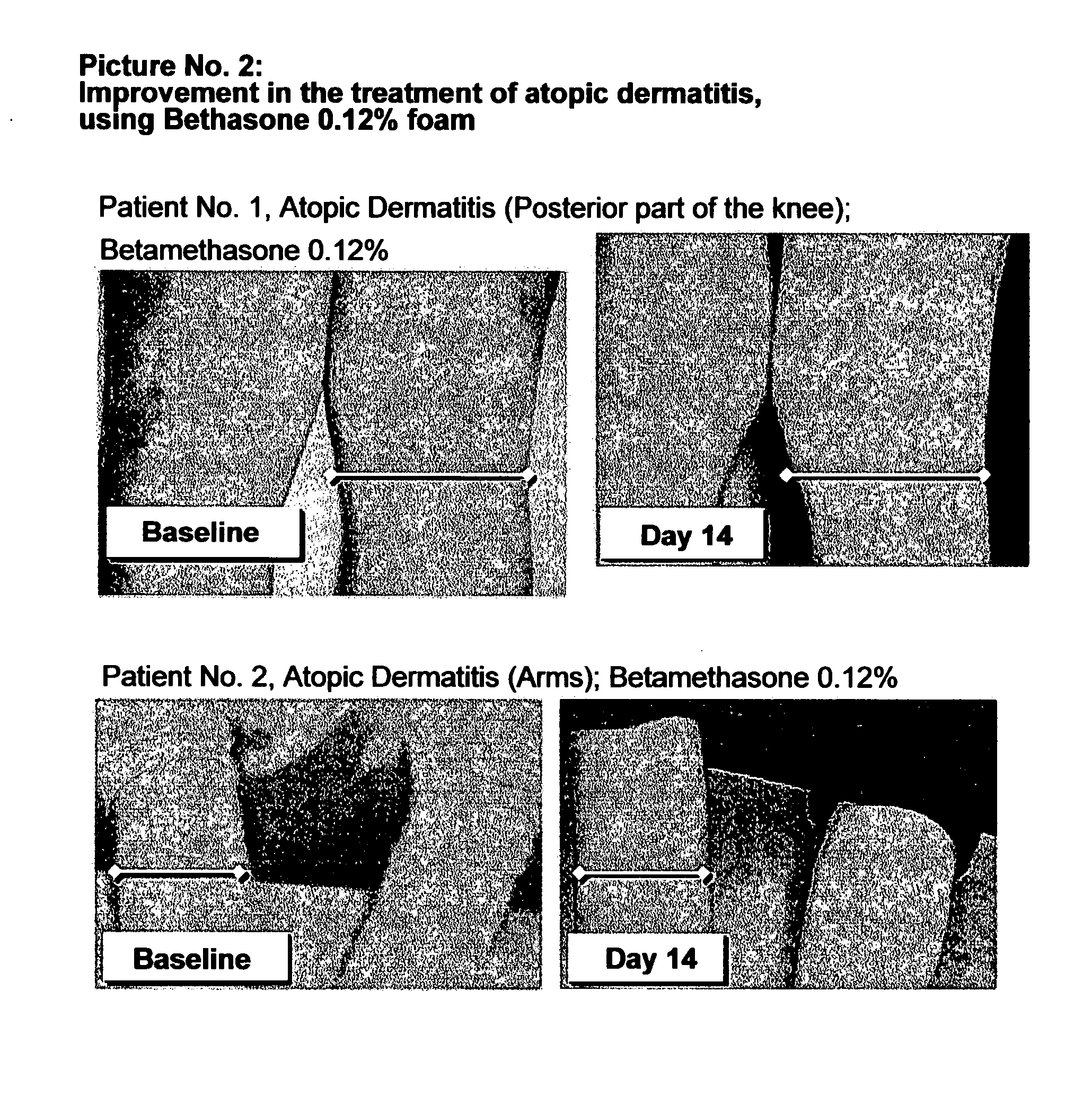

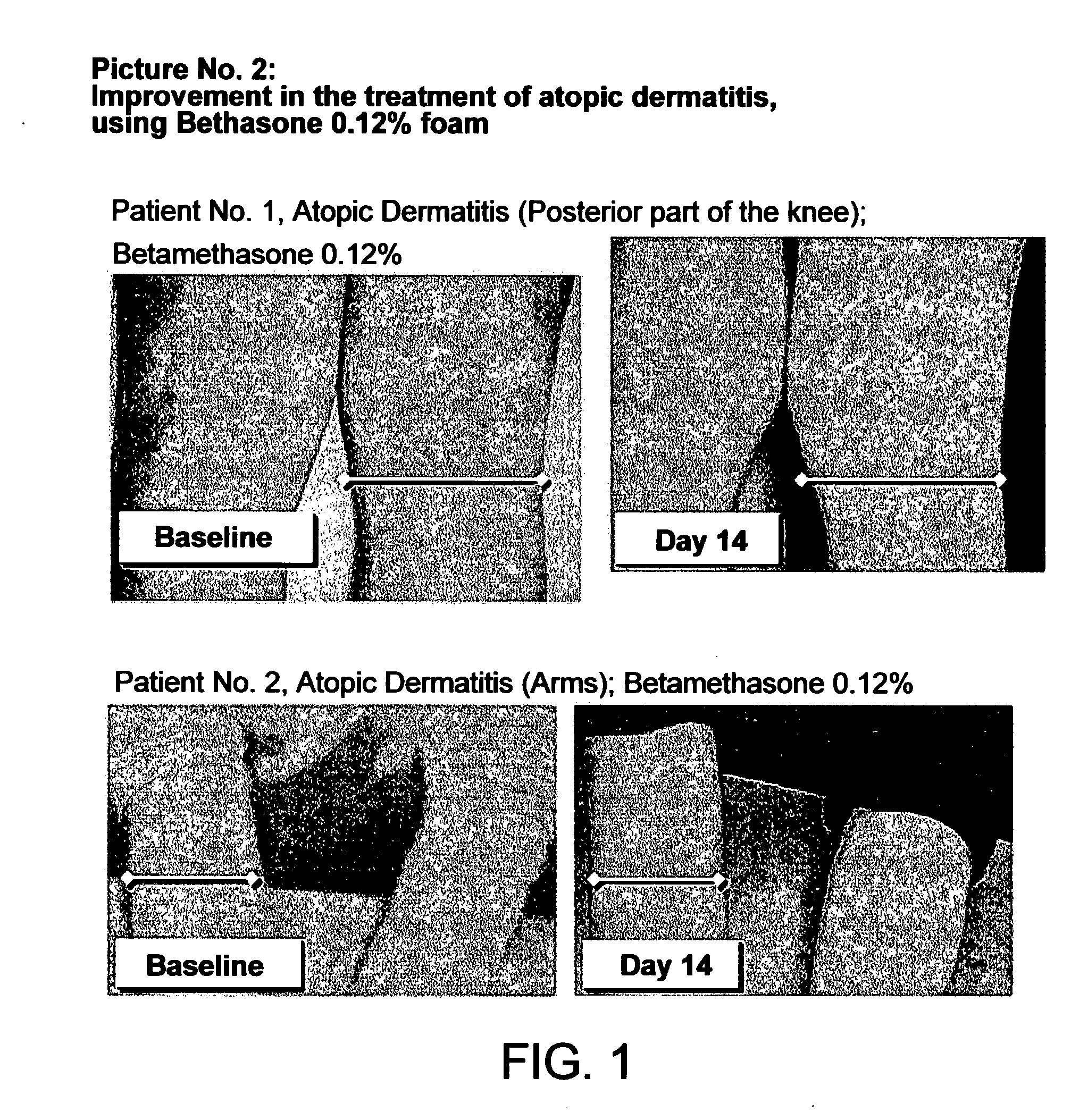

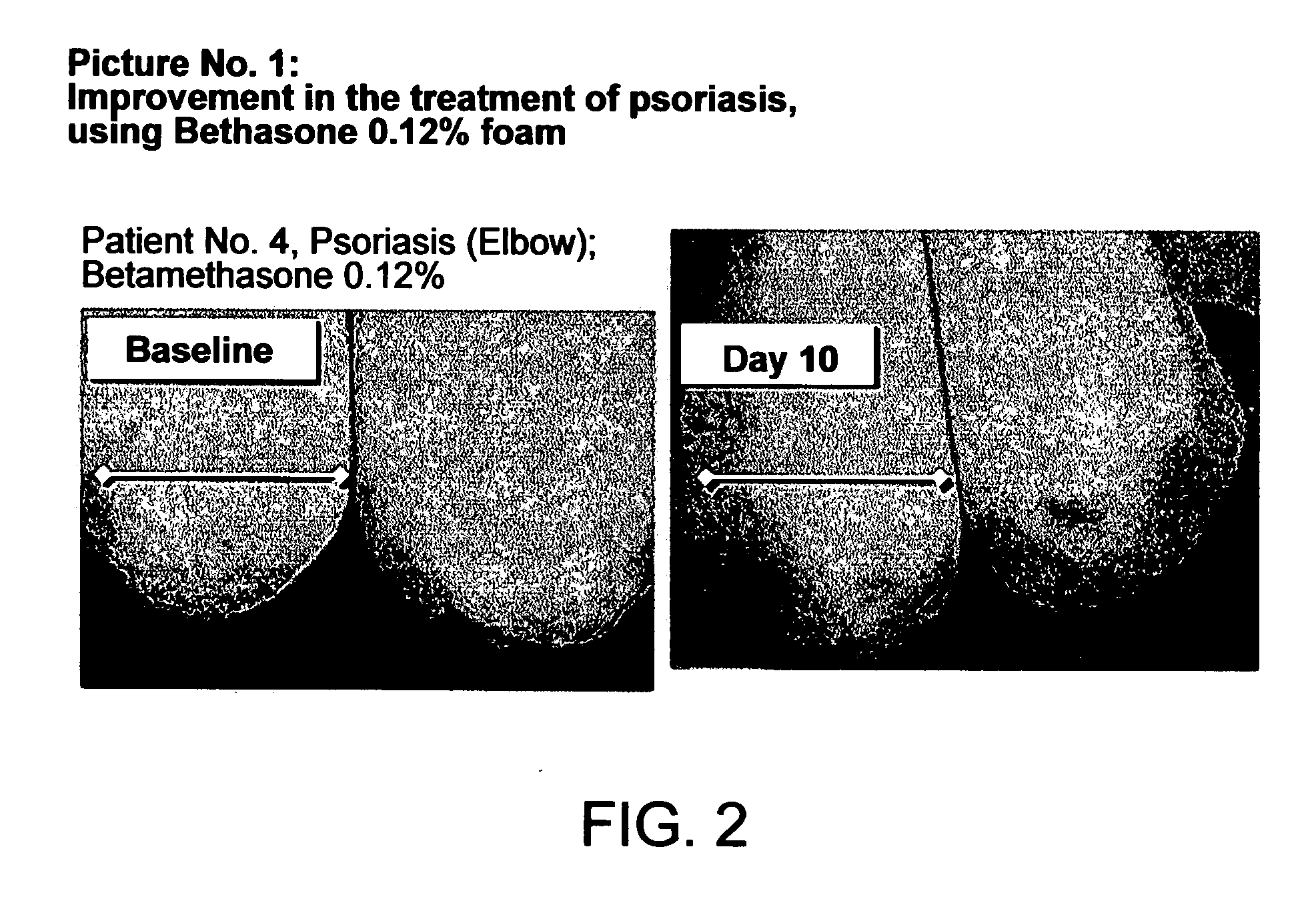

Cosmetic and pharmaceutical foam

InactiveUS20080031907A1Efficient ConcentrationReduce sensitivityAntibacterial agentsBiocideAlcohol freeVegetable oil

The invention relates to uses of an alcohol-free cosmetic or pharmaceutical foam carrier comprising water, a hydrophobic solvent, a foam adjuvant agent, a surface-active agent and a water gelling agent as a flame retardant or flame resistant foam. The hydrophobic solvent is preferably mineral oil; medium chain triglycerides; isopropyl myristearate or octyl dodecanol, silicone oil or vegetable oil or mixtures thereof. The cosmetic or pharmaceutical foam carrier does not contain aliphatic alcohols, also making it non-irritating and non-drying. The alcohol-free foam carrier is suitable for inclusion of both water-soluble and oil-soluble pharmaceutical and cosmetic agents.

Owner:FOAMIX PHARMACEUTICALS LIMITED

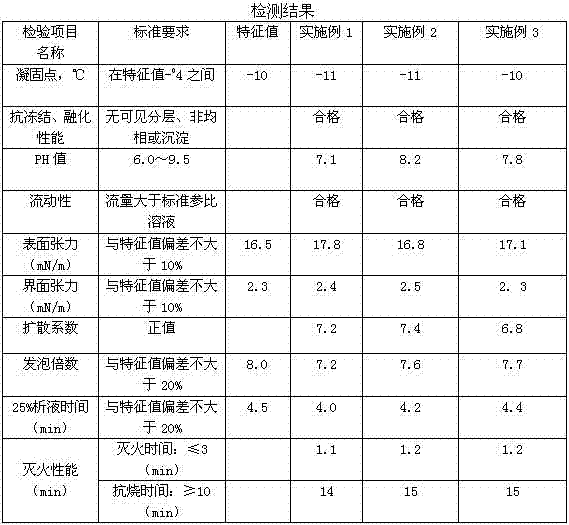

Aqueous film-forming foam extinguishing agent special for fire extinguishing bullet and throwing type fire extinguisher

InactiveCN104117176AImprove fire extinguishing effectPrevent re-ignitionFire extinguisherDiethylene glycol diethyl etherAmmonium dodecyl sulfate

The invention provides an aqueous film-forming foam extinguishing agent special for a fire extinguishing bullet and a throwing type fire extinguisher. The aqueous film-forming foam extinguishing agent has the advantages of being small in additive amount, rapid in fire extinguishing, good in recrudescence resisting effect, environmentally friendly, efficient and the like. The aqueous film-forming foam extinguishing agent comprises, by weight, 8 percent to 12 percent of main foaming agents, 8 percent to 20 percent of auxiliary foaming agents, two percent to 10 percent of antifreeze agents, 12 percent to 22 percent of cosolvents, 0.1 percent to one percent of stabilizers, 8 percent to 20 percent of fire retardants, two percent to five percent of burning-resistance agents and the balance water. The main foaming agents are selected from F1157N, F1203 and F1460, the auxiliary foaming agents are selected from lauryl sodium sulfate, ammonium lauryl sulfate, alkyl glycoside, dodecyl dimethyl betaine and cocamidopropyl betaine. The antifreeze agents are selected from ethylene glycol, glycerol and the like. The cosolvents are selected from dodecanol, n-butyl alcohol and diethylene glycol diethyl ether. The stabilizing agents are selected from xanthan gum, Arabic gum, guar gum and sodium alginate tech grade. The fire retardants are selected from ammonium polyphosphate and ammonium dihydrogen phosphate.

Owner:ANHUI TIANYUAN FIRE PROTECTION TECH

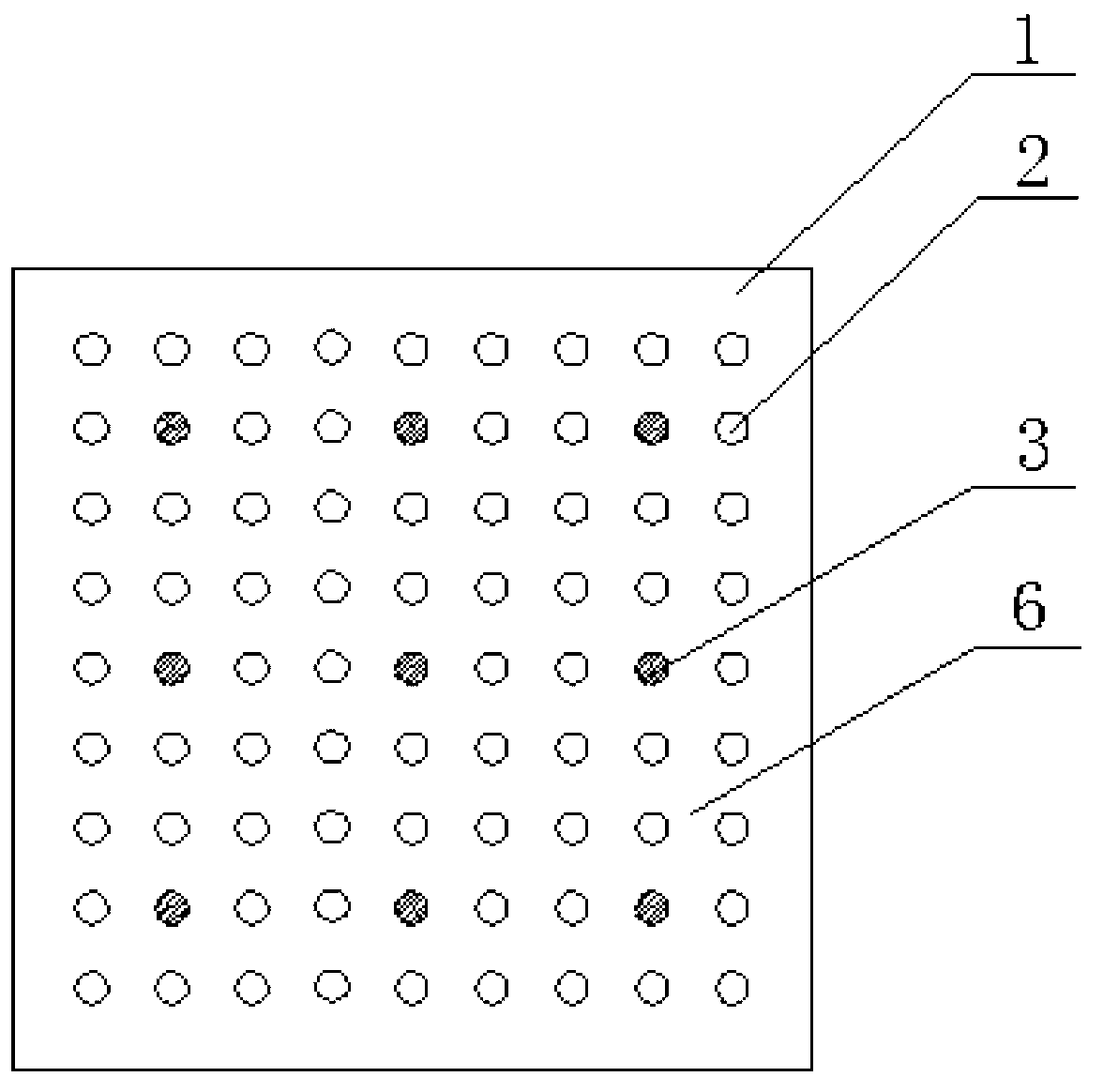

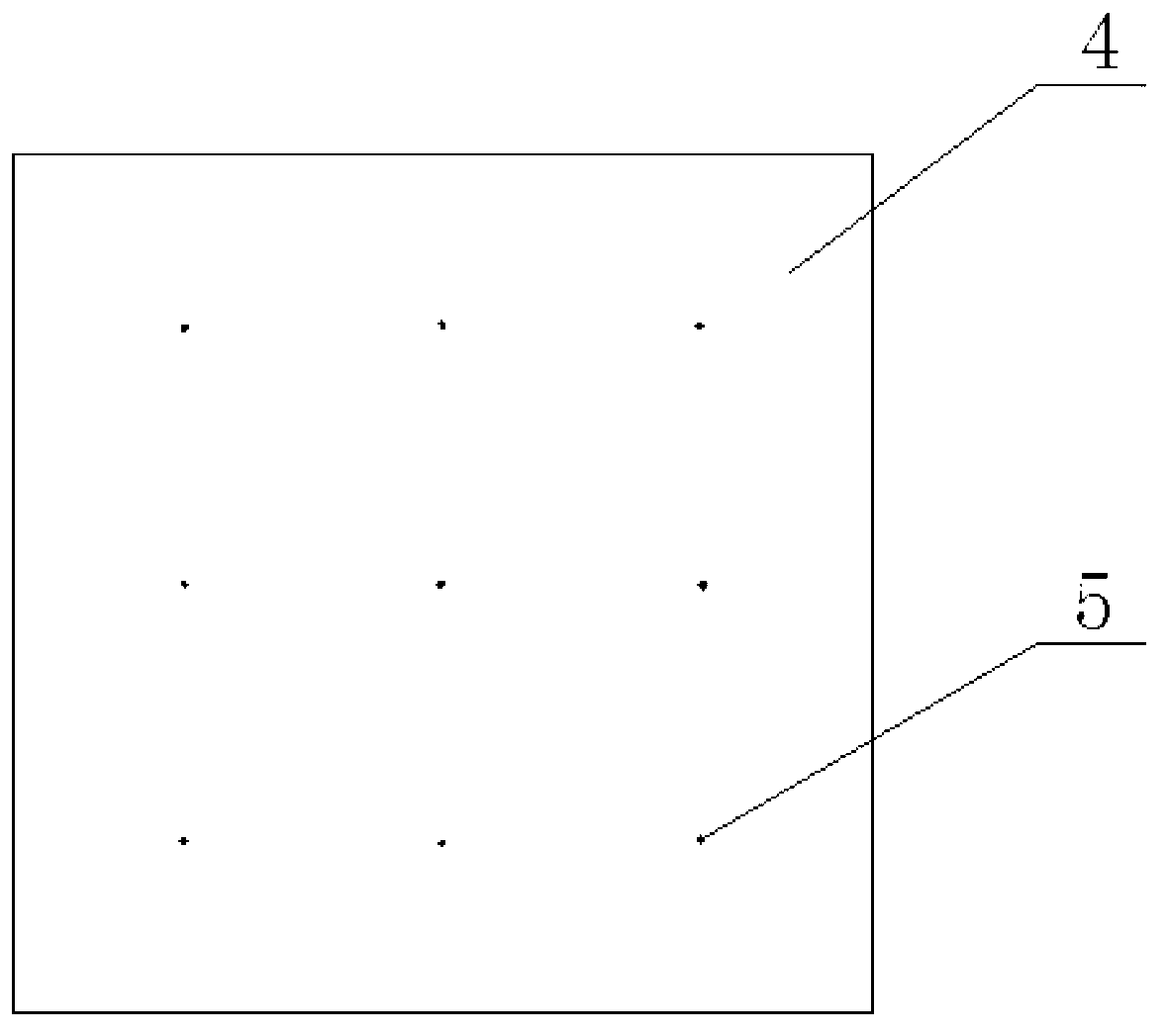

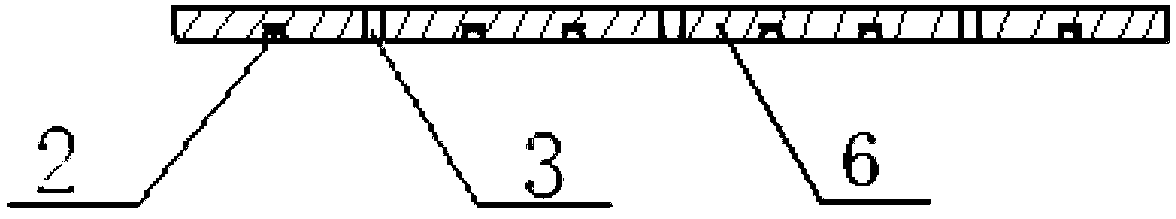

Constructional phase change energy storage plate and manufacturing method thereof

InactiveCN103015540APrevent leakageNo overflowLaminationLamination apparatusEnvironmental resistanceAlcohol

The invention discloses a constructional phase change energy storage plate, consisting of an upper cover plate, a lower bottom plate and a phase change material, wherein the phase change material is a mixture of fatty acid and high carbon alcohols; the fatty acid is n-decylic acid, lauric acid, myristic acid, palmitic acid and stearic acid; the alcohols are dodecanol, tetradecanol, hexadecanol and octadecanol; and the mass percent of the fatty acid to the mass percent of the high carbon alcohols is 46.4%: 53.6% to 97.5%: 2.5%. With the adoption of the constructional phase change energy storage plate and a manufacturing method thereof, the problems such as damages to mechanical performances, environmental protection, safety and the like are fundamentally solved, and meanwhile, the risks existing in actual application are prevented; the constructional phase change energy storage plate is stable in structure; the phase change material is not easy to leak; no irritant gas overflows; the appearance is attractive; and therefore, besides application onto constructed walls, the constructional phase change energy storage plate also can be used as an interior decoration, a suspended ceiling and a laid floor board.

Owner:TIANJIN UNIV

Special high-property coating for chemical equipment

InactiveCN104946082AIncrease viscosityIncrease crosslink densityFireproof paintsEpoxy resin coatingsPyrophylliteMelamine phosphate

The invention discloses a special high-property coating for chemical equipment. The special high-property coating comprises the following raw materials: novolac epoxy resin, phosphorus-containing acrylic resin, boric acid modified organic silicon resin, polytetrafluoroethylene resin, polyvinylidene fluoride, a carbon nano tube, ammonium polyphosphate, pentaerythritol, alumina powder, pyrophyllite powder, graphite, expanded perlite, modified attapulgite, cerium oxide, n-butyl alcohol, n-amyl alcohol, ethanediol, water, amine resin, melamine polyphosphate, N-phenyl-N'-cyclohexyl p-phenylene diamine, dodecanol, dipropylene glycol mono butyl ether, dimethyl phthalate, a coupling agent and an auxiliary agent. The special high-property coating for the chemical equipment, which is disclosed by the invention, has the advantages of good corrosion resistance and high-temperature resistance, high adhesive power and excellent flame-retardant property, can be used for the chemical equipment, is difficult to desquamate, good in protection effect and capable of prolonging the service life of the chemical equipment.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

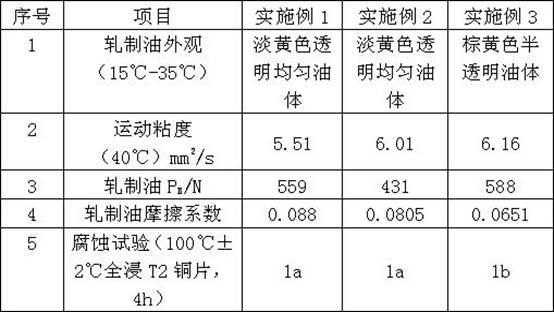

Calendaring copper foil rolled oil and preparation method thereof

ActiveCN102660357AHigh surface finishLong anti-corrosion periodAdditivesPolyethylene glycolCopper foil

The invention relates to the technical field of lubricating agents, in particular to calendaring copper foil rolled oil and a preparation method thereof. The calendaring copper foil rolled oil is used for lubricating in the cold-rolled process of calendaring copper foil. The preparation method is characterized by comprising the following steps of: adding N5 engine oil, butyl stearate, dodecanol, nitrogen-containing borate, fatty alcohol polyethylene glycol phosphate, petroleum sodium sulfonate and benzotriazole into a reaction kettle of which the rotation speed is 80 to 120 revolutions / minute sequentially, heating and stirring; and when the temperature is 80 DEG C, keeping the temperature, stirring continuously for 30 minutes, stopping heating, and stirring continuously to room temperature to obtain uniform and transparent oil, namely the required rolled oil. The minimum rolling thickness of the calendaring copper foil lubricated by the rolled oil is 25 micrometers, so that the calendaring copper foil is high in surface smoothness, long in anti-corrosion period and high in annealing detergency.

Owner:UNIV OF SCI & TECH BEIJING

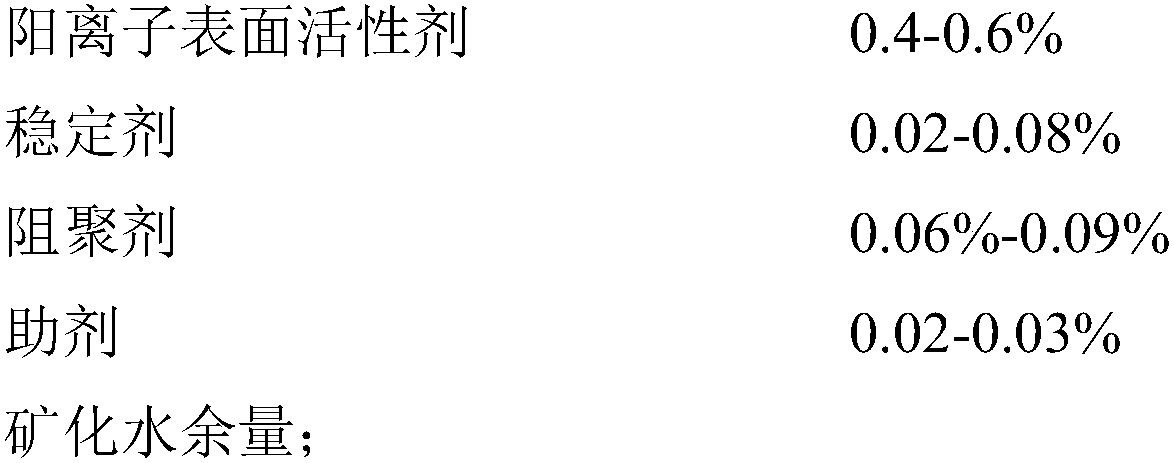

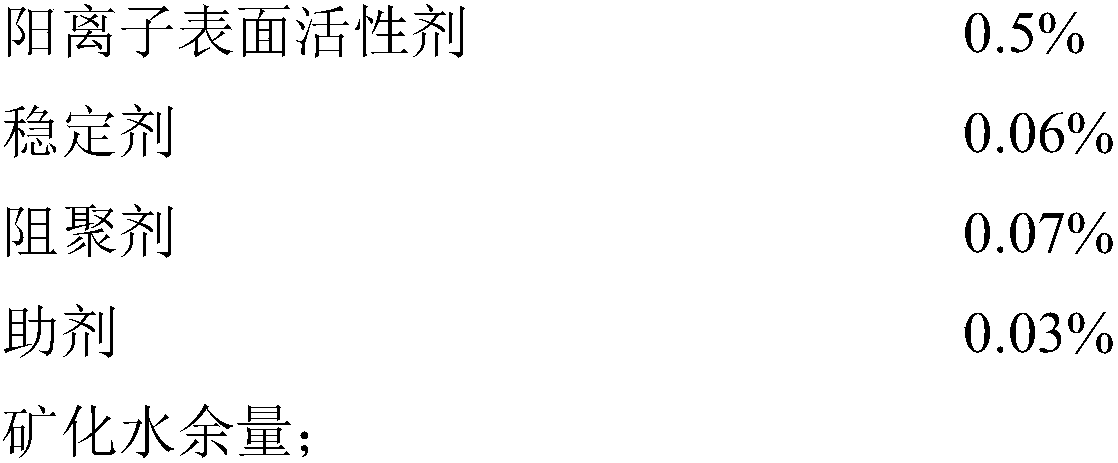

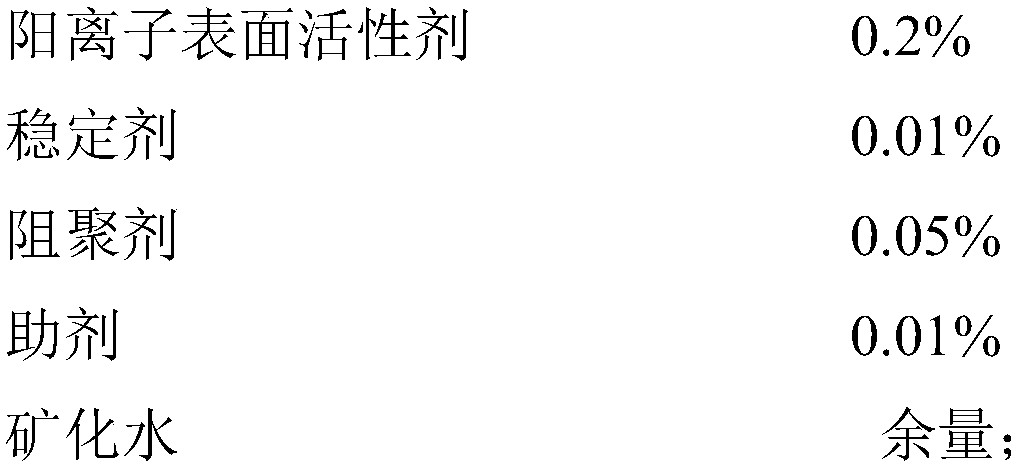

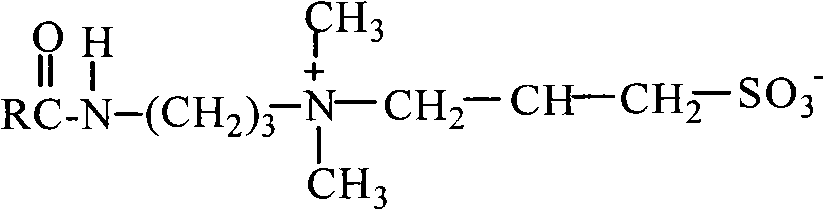

Nanoparticle enhanced low-interfacial-tension foam system and preparation method thereof

InactiveCN107556997AImprove performanceInhibit aggregationDrilling compositionOctadecyltrimethylammonium bromideSurface-active agents

The invention discloses a nanoparticle enhanced low-interfacial-tension foam system and a preparation method thereof. The foam system comprises the following components by weight percent: 0.2-0.8% ofa cationic surface active agent, 0.01-0.1% of a stabilizer, 0.5-1.0% of a polymerization inhibitor, 0.3-1.0% of an additive and the balance of mineralized water, wherein the cationic surface active agent is selected from dodecyl trimethyl ammonium bromide, tetradecyl trimethyl ammonium bromide, hexadecyl trimethyl ammonium bromide and stearyl trimethyl ammonium bromide; the stabilizer is selectedfrom modified nano-SiO2, modified nano-MgO and modified nano-TiO2; the polymerization inhibitor is sodium citrate; the additive is selected from ethylene glycol and dodecanol; the mineralized water isa mixed water solution of sodium chloride, anhydrous calcium chloride and anhydrous magnesium sulfate. The nanoparticle enhanced low-interfacial-tension foam system is good in foaming performance andfoam stabilizing performance, high in interfacial activity, cheap and easily accessible in raw material, simple in preparation method and excellent in foam combination performance.

Owner:YANGTZE UNIVERSITY

Foaming agent used in composite-foam oil flooding

ActiveCN102399548AFunctionalOvercome the shortcoming of gas drive "gas channeling"Drilling compositionSalt resistanceFoaming agent

The invention relates to a foaming agent used in composite-foam oil flooding. The foaming agent comprises materials of, by concentration: 0.2 to 0.4% of hydroxyl-sulfobetaine, 0.1% of 1227, 0.04 to 0.1% of dodecanol, and balance of formation water. The molecular formula of 1227 is C21H38NCl. The molecular formula of dodecanol is C12H26O. The foaming agent provided by the invention has a temperature resistance stabilized at 50 DEG C, and a good salt resistance of 80*10<3>mg / L. Foaming performance and foam stabilizing performance of the foaming agent are detected by using a Ross-mils method (a decanting method). The foaming height of the foaming agent is 14.4cm; the half-life period reaches 16 hours; and the oil-water interfacial tension is 0.192mN / m. According to the invention, advantages of chemical flooding and gas flooding are combined; viscose foam and gas are adopted as oil-flooding agents, such that double functions of profile modifying and oil flooding are achieved, and a defectof gas flooding of gas channeling is avoided. The foaming agent is suitable for oil reservoir with high water content, severe anisotropic, and cracks or large porous channels.

Owner:PETROCHINA CO LTD

Mineral salt toothpaste

InactiveCN101011327ANo side effectsControl inflammationCosmetic preparationsToilet preparationsAdditive ingredientToothpaste

The invention discloses a toothpaste with mineral salts as the main ingredients, which comprises mineral salts 20-40%, calcium carbonate 30-40%, dodecanol sodium sulfate 1.0-2.0%, carboxymethyl cellulose 0.5-1.5%, gourmet powder 0.3-0.8%, glycerin 10-15%, coloring matter 0.2-0.5%, xylitol 1-5% and water 20-30%. The toothpaste can prevent and treat dental caries, gingivitis and periodontal diseases.

Owner:成都卓成健康管理有限公司

Antiseptic disinfectant, and cosmetics and toiletries, medicine or food containing the same

The purpose of the present invention is to provide antiseptic disinfectant, and cosmetics and toiletries, medicine or food containing the same, which enhance the antibacterial activity that 1,2-alkanediol originally have against a broad range of strains by compounding 1,2-alkanediol with 5-10 carbons and a certain fragrance component.The present invention relates to an antiseptic disinfectant, and cosmetics and toiletries, medicine or food containing the same, which include 1,2-alkanediol with 5-10 carbons, and one or more materials selected from a group of citral, geraniol, nerol, perillaldehyde, α-terpineol, dodecanol and L-carvone.

Owner:MANDOM CORP

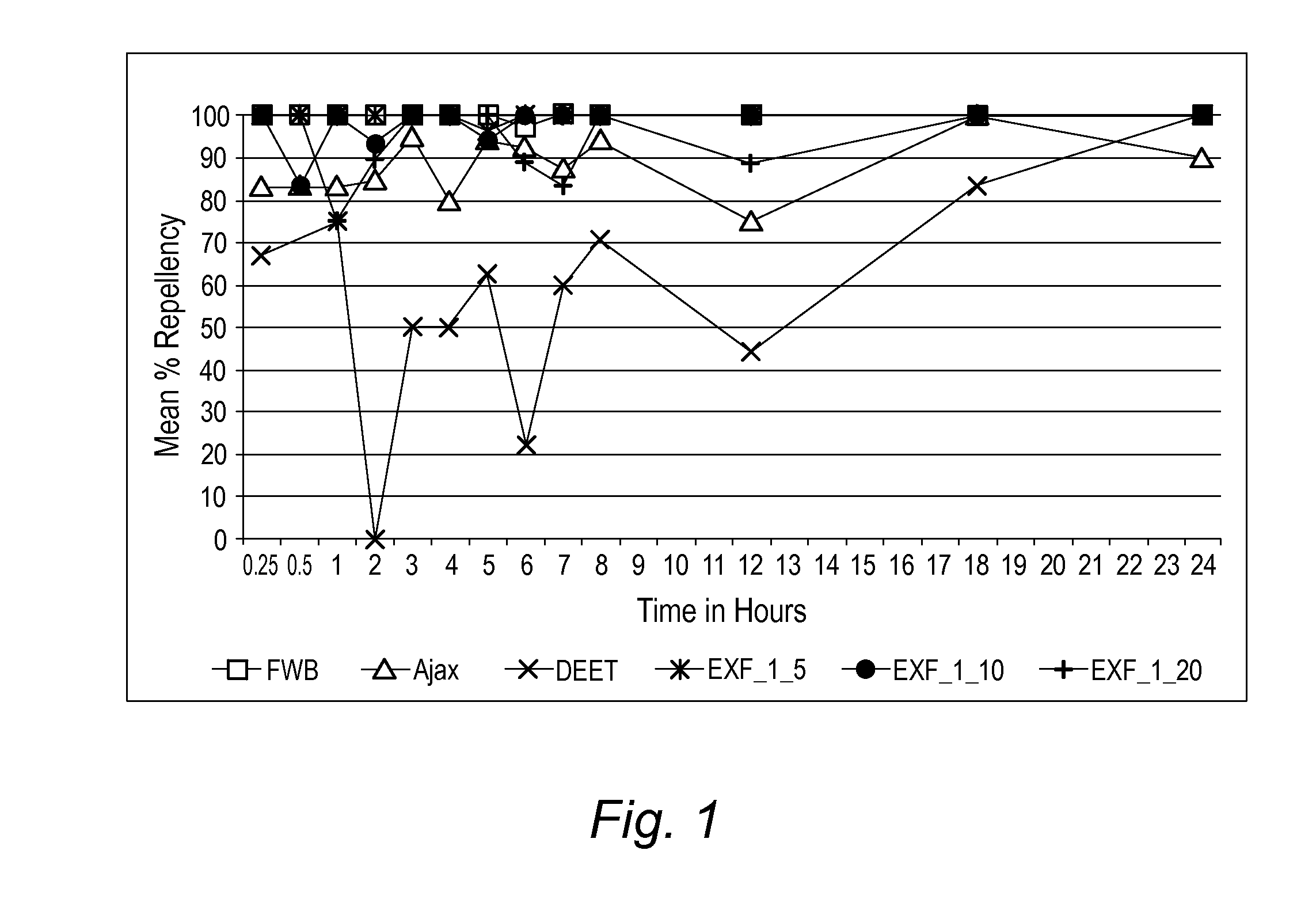

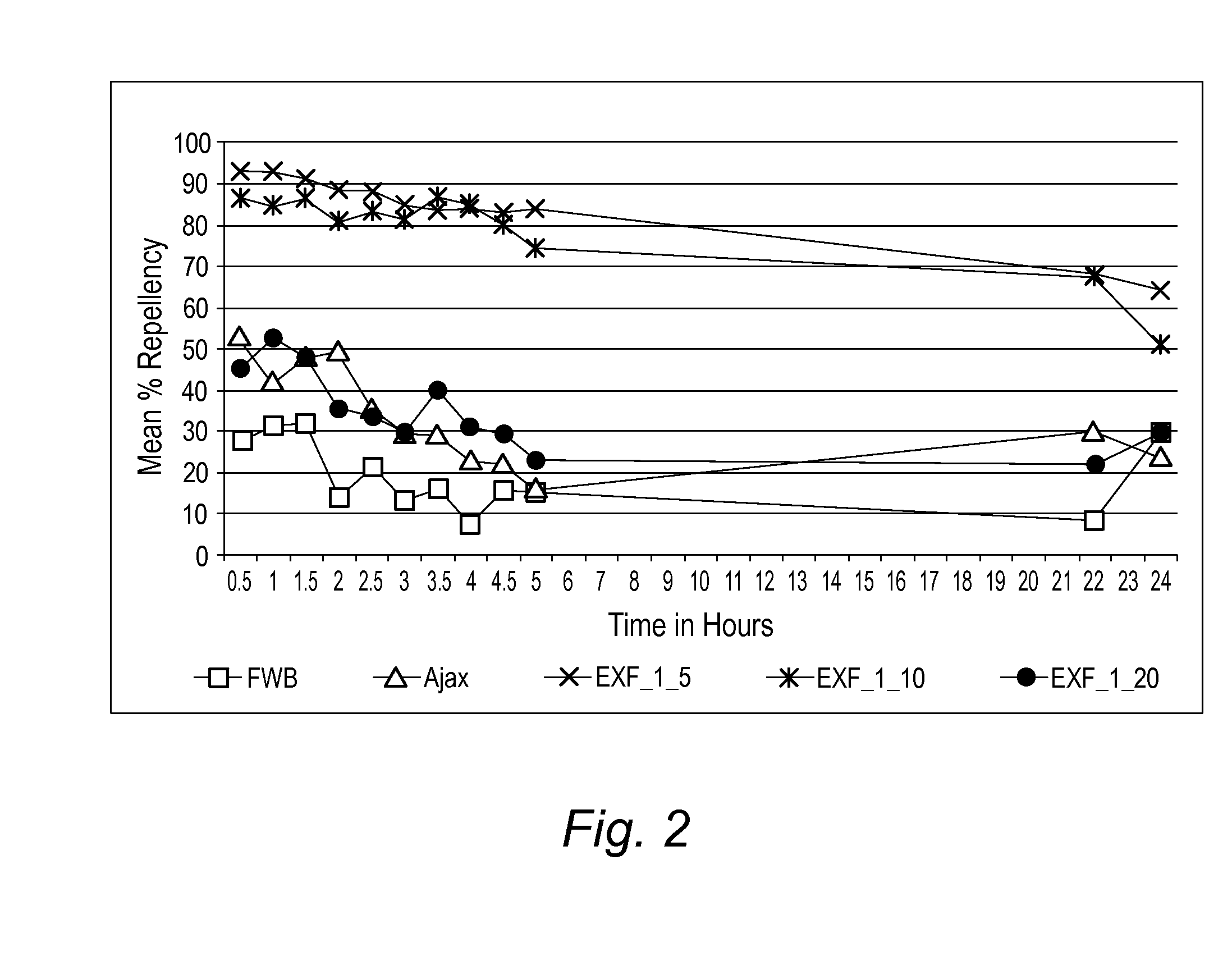

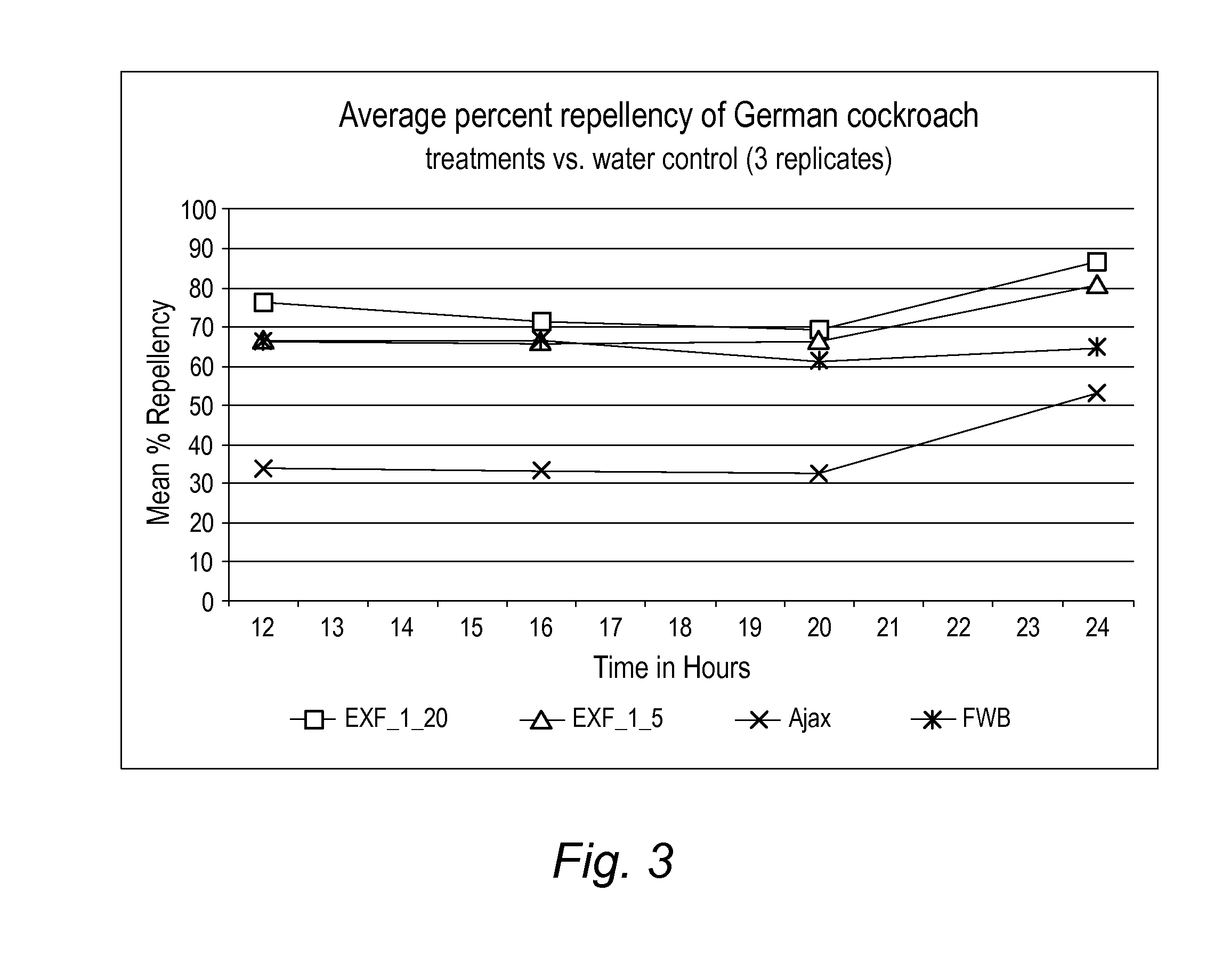

Insect repellent surface composition

Embodiments of the invention relate to a pest-control composition comprising at least one active ingredient and at least two other ingredients; wherein the at least one active ingredient is selected from the group consisting of geraniol, nootketone, amyl cinnamaldehyde, catnip, wintergreen, carvacrol, d-limonene, orange oil, lauric acid, alpha pinene, mint, cornmint oil, lemon oil, eucalyptus, eugenol, peppermint, lemongrass oil, and terpenes; and wherein the at least two other ingredients are selected from the group consisting of 2-propanol, alcohol, ethanol, monobutyl ether, ethylene glycol, terpenes, ethoxylated alcohol, dodecanol, ammonia, soap, lauryl polyglucose, polyethylene glycol, sodium lauryl sulfate, sodium olefin sulfonate, cocamidapropyl betaine, alkylbenzene sulfonate, polyoxyethelene alkylphenol sulfate, sodium dodecyl benzene sulfonate, sodium sterate, potassium sterate, potassium myristate, tomadol, polyglyceryl sterate, glycol monosterate, potassium oleate, polyglyceryl oleate, tween, polymers, acrylic polymers, ethyl cellulous, carboxymethyl cellulose, sodium hydroxide, ammonium hydroxide, polyacrylate polymer, polyvinyl pyrolidane, lauric diethanolamine, dimethyldodecylamine oxide, aspartic acid tetrasodium salt, and sodium citrate.

Owner:ENVANCE TECH LLC

Micro-emulsion cutting fluid for aluminum alloy, and preparation method of micro-emulsion cutting fluid

The invention discloses a micro-emulsion cutting fluid for aluminum alloy and a preparation method of the micro-emulsion cutting fluid. The micro-emulsion cutting fluid comprises the following raw materials in parts by weight: 12-16 parts of paraffin-based oil, 3-5 parts of star anise oil, 4-7 parts of eucalyptus oil, 5-7 parts of sorbitan fatty acid, 3-4 parts of triethanolamine oleate, 3-4 parts of petroleum sodium sulfonate, 7-8 parts of sorbitan monooleate, 3-4 parts of monoethanolamine, 6-7 parts of zinc sulfate, 4-7 parts of sodium oleate, 6-8 parts of dimethicone, 2-4 parts of sodium molybdate, 4-7 parts of octylphenol polyoxyethylene ether, 4-7 parts of chlorinated paraffin, 4-5 parts of ricinoleic acid, 0.5-1.5 parts of dodecanol, 1.2-1.5 parts of imidazolidinyl urea, 10-15 parts of additives and 15-25 parts of deionized water. The micro-emulsion cutting fluid for aluminum alloy also has the outstanding performances on the aspects of corrosion inhibition property, corrosion resistance, lubrication, rust resistance, defoaming property, service life and the like.

Owner:江苏悠谷未来科技有限公司

Highly-efficient blockage remover for sulfur-containing gas well

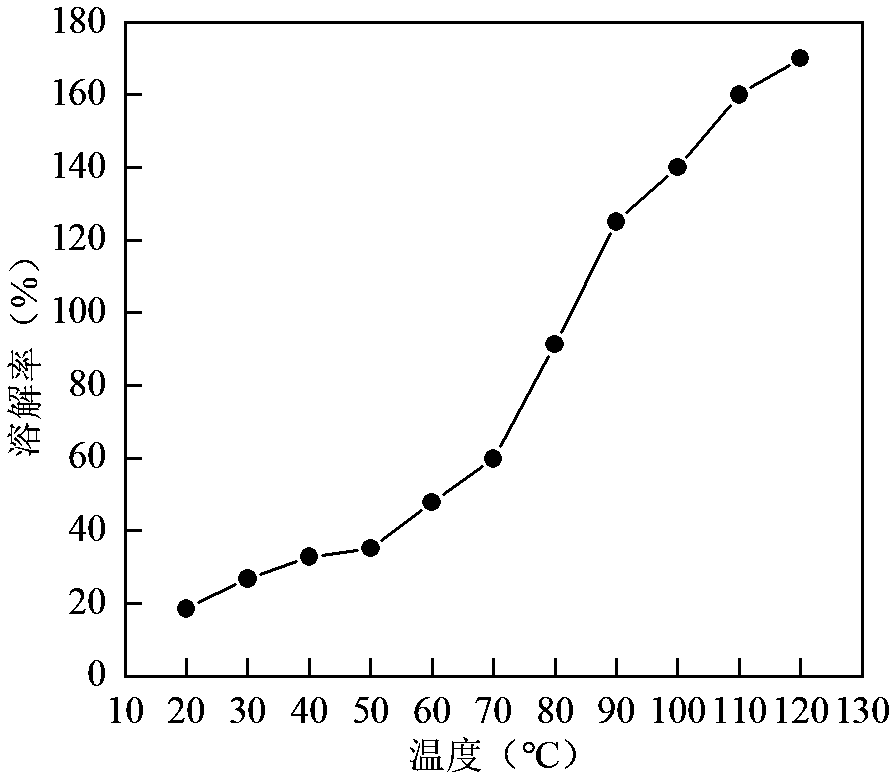

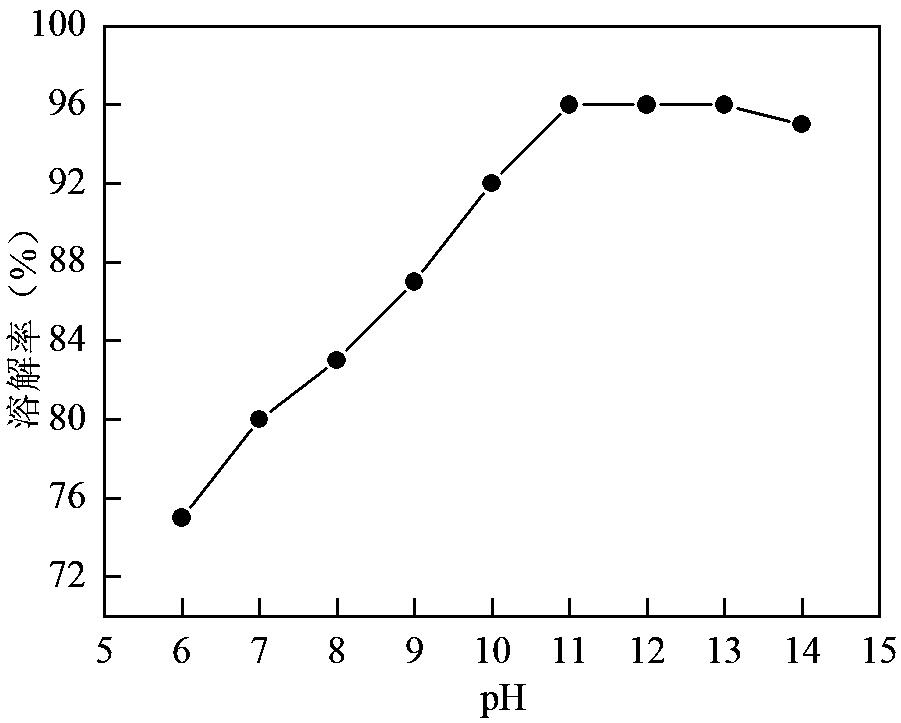

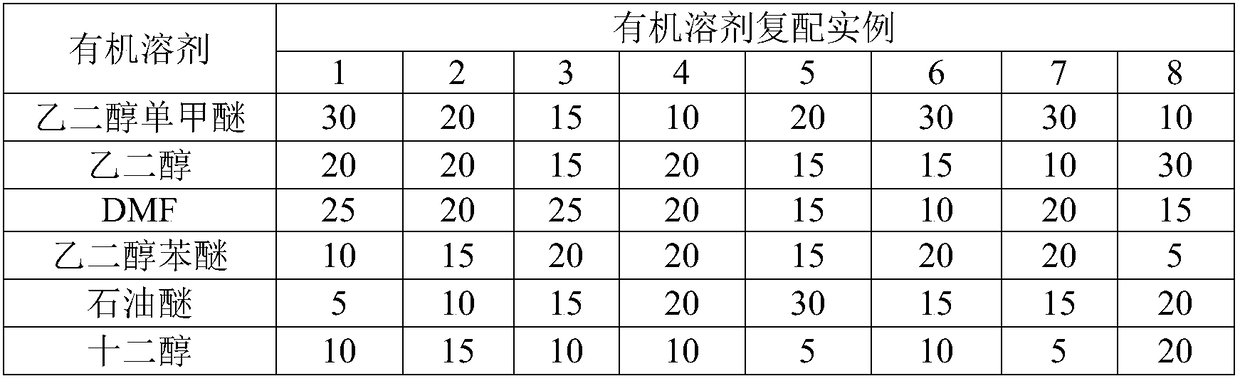

The invention provides a highly-efficient blockage remover for a sulfur-containing gas well. The highly-efficient blockage remover is composed of the following components: 10% to 35% of a high-boiling-point main agent, which is used for dissolving organic obstructions and is composed of ethylene glycol monomethyl ether, ethylene glycol, dimethylformamide, ethylene glycol phenyl ether, petroleum ether and dodecanol; 5% to 10% of an emulsifier, which is compounded from a condensate of fatty alcohol and ethylene oxide, polyoxyethylene sorbitan fatty acid ester and sorbitan fatty acid ester; 7 % to 15% of a surfactant, which is composed of sodium fatty alcohol polyoxyethylene ether sulfate, sodium dodecyl benzene sulfonate, AMALF-32, glyceryl monostearate and polyglyceryl distearate; 5% to 15%of a sulfur-dissolving agent, which is compounded from dimethyl disulfide and diaryl disulfide; 1% to 5% of a metal chelating agent, which is ethylenediaminetetraacetic acid; 8% to 15% of a dispersant, which is a naphthalene sulfonate sodium salt formaldehyde condensate; 3% to 5% of an antioxidant, which is n-octadecanol propionate; 2% to 6% of a scale inhibitor; and a proper amount of an acidity and alkalinity regulator, which is used for regulating a pH value. The blockage remover provided by the invention can resist a temperature of 140 DEG C or above, has an obstruction dissolution rateup to 96%, and has good blockage remover performances to the sulfur-containing gas well in a high-temperature environment.

Owner:SOUTHWEST PETROLEUM UNIV

Gelatin chitosan-nano-silicon dioxide multi-core phase-change energy-storage microcapsule preparation method

ActiveCN107384326AHigh strengthRegular structureHeat-exchange elementsMicroballoon preparationCross-linkHeat conducting

The invention discloses a gelatin chitosan-nano-silicon dioxide multi-core phase-change energy-storage microcapsule preparation method. The preparation method comprises the following steps: respectively preparing chitosan and gelatine into solutions, adding nano-silicon dioxide, performing ultrasonic dispersing to obtain chitosan / SiO2 and gelatine / SiO2 solution, then mixing a phase-change material and chitosan / SiO2, emulsifying with an emulsifying agent to form an emulsion, slowly adding the gelatine / SiO2 and a cross-linking agent into the emulsion dropwise, performing a curing reaction for a certain time, washing and drying to obtain microcapsule powder. According to the preparation method, two phase-change materials, namely, paraffin and dodecanol, are mixed, so that the prepared phase-change material has a wide phase-change temperature; the purpose of introducing nano-SiO2 into the chitosan or the gelatine serving as a microcapsule wall material is to improve the strength of the gelatine-chitosan wall material; meanwhile, the heat conducting performance of the gelatine-chitosan wall material can also be improved.

Owner:YANAN UNIV

Preparation method of clay-based composite phase-change energy storage deicing (snow melting) material

The invention discloses a preparation method of a clay-based composite phase-change energy storage deicing (snow melting) material. The preparation method is characterized in that a composite phase-change energy storage material is prepared from a low-temperature organic phase-change material and a clay material, wherein the low-temperature organic phase-change material is prepared by single-element or multi-element mixing of various organic phase-change materials and is then physically compounded with the treated clay to prepare the clay-based composite phase-change energy storage deicing (snow melting) material. The low-temperature organic phase-change material is selected from polyethylene glycol-300, polyethylene glycol-400, polyethylene glycol-500, polyethylene glycol-600, decyl alcohol, undecanol, dodecanol, heptylic acid, octanoic acid, nonanoic acid, capric acid, methyl laurate, methyl myristate, methyl palmitate, tetradecane, pentadecane, hexadecane, heptadecane, octodecane, nonadecane and the like. The clay material is selected from kaolinite, montmorillonite, bentonite, vermiculite, halloysite, sepiolite, attapulgite, perlite, diatomite, rectorite, zeolite, silicon dioxide, dolomite, calcite and illite. The prepared composite phase-change energy storage deicing (snow melting) material is proper in phase-change temperature (0-5 DEG C), high in phase-change latent heat and high in heat stability.

Owner:CENT SOUTH UNIV

Preparation method of alkanol self-temperature control phase change material

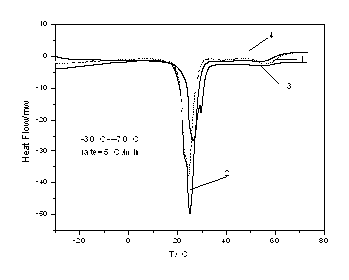

InactiveCN103194183ALarge latent heat of phase changeLow costHeat-exchange elementsPhase change enthalpyParaffin wax

The invention discloses a preparation method of a phase change material. The preparation method is that dodecanol serving as a main phase change agent and paraffin serving as a secondary phase change agent are adopted for preparing a low-temperature phase change material. The low-temperature phase change material has phase change temperature about 22 DEG C, is relatively high in phase change enthalpy value which is about 180J / g, has stable performance, excellent phase change reversibility and little change in size during the phase change, and is safe, nontoxic and non-corrosive.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Color-changing lip protector and preparation method thereof

InactiveCN108888528ASolve the problem of no sense of color and unnatural makeupReduce lip linesCosmetic preparationsMake-upMicrocrystalline waxEthylhexyl palmitate

The invention relates to the technical field of cosmetics, in particular to a color-changing lip protector, which comprises, by weight, the following components: phase A: 19-20 parts of synthetic wax,3-5 parts of beeswax, 1-2 parts of microcrystalline wax, 3-5 parts of polyethylene and 5-7 parts of ground wax; phase B: 7-9 parts of tridecanetriol trimellitate, 7-9 parts of ethylhexyl palmitate, 7-9 parts of polydimethylsiloxane, 12-18 parts of hydrogenated tallow resin, 1-3 parts of squalane, 5-7 parts of meadowfoam seed oil, 9-11 parts of hydrogenated polyisobutene and 2-4 parts of octyl dodecanol, 1.5-2.5 parts of dual bis-diglyceryl polyacyladipate-2; phase C: 2.5-3.5 parts of tocopherol, 0.05-0.15 part of hydroxystyrene-styrene ester, 0.04-0.08 part of CI77891, 0.0.03-0.07 part of CI15850, and 0.04-0.08 part of CI45410. The invention also discloses a preparation method thereof. The color changing lip protector combines the advantages of a lipstick and lip protector, the problem that a single lip protector has no sense of color and unnatural sense of makeup is solved, the lip protector has the advantages of long-lasting adherence, long-acting and lasting and transparent color development.

Owner:广州铭泽恒基生物科技有限公司

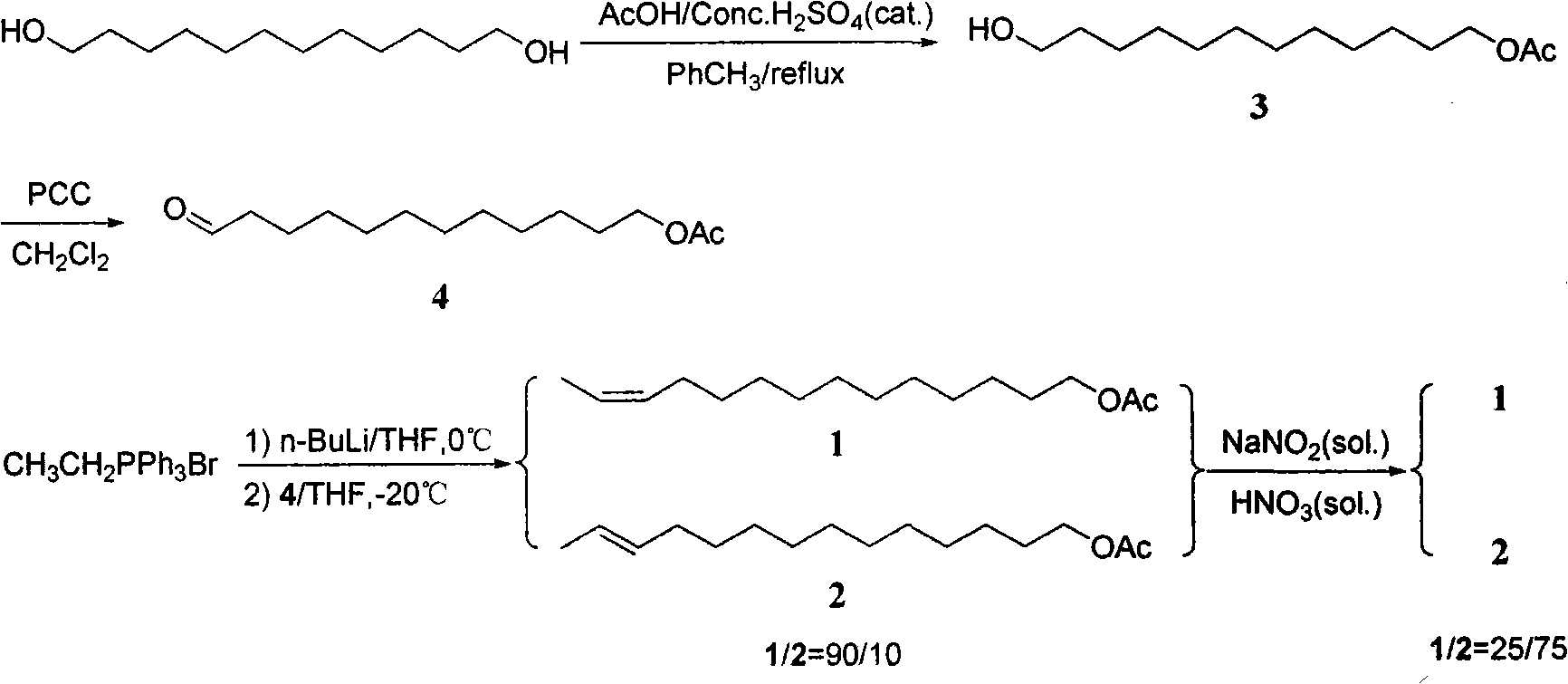

Method for synthesizing tetradecene alcohol acetic ester in ostrinia nubilalis sex pheromone

InactiveCN101665430AIncrease profitHigh yieldOrganic compound preparationCarboxylic acid esters preparationAlcoholWittig reaction

The invention discloses a method for synthesizing tetradecene alcohol acetic ester in ostrinia nubilalis sex pheromone, which takes ethyltriphenylphosphonium bromide and 1, 12-codlemone as starting materials. The method comprises the following steps: the 1, 12-codlemone is subjected to a unilateral transesterification reaction to obtain 12-hydroxy dodecanol acetic ester, and then subjected to an oxidation reaction to obtain 12-oxo dodecanol acetic ester which is in a Wittig reaction with the ethyltriphenylphosphonium bromide to obtain (Z / E)-12 tetradecenoic alcohol acetic ester of high cis-trans ratio in Asian ostrinia nubilalis sex pheromone. The invention has the advantages of simple and reasonable synthesis route, convenient and safe operation, high usage ratio of raw materials, short synthesis time and the like.

Owner:WENZHOU MEDICAL UNIV +1

Gas desulfurizing agent and preparation method thereof

InactiveCN102921282ANo toxicityGood renewabilityDispersed particle separationHydration reactionAcid water

The invention relates to a gas desulfurizing agent, in particular to a renewable sodium phosphate solution to which composite surfactant is added. The formula of the gas desulfurizing agent comprises 3 to 23%(wt) of hydrated sodium phosphate, 0.05 to 0.1%(wt) of dodecanol, a surfactant of which the concentration is 10*10<-5> to 25*10<-5>mol / l based on the total solution, an acid water solution present in an amount capable of enabling the pH (potential of hydrogen) of the desulfurizing solution to be 8.5 to 9.0, and the balance of water. The gas desulfurizing agent disclosed by the invention can be widely applied to the field of gas desulfurization and decarburization such as natural gas desulfurization and flue gas desulfurization.

Owner:CHANGZHOU UNIV

Low-temperature-resistant aqueous polyurethane coating

InactiveCN105860733AImprove low temperature resistanceImprove corrosion resistanceFireproof paintsAntifouling/underwater paintsDimethyl siloxaneDodecylsulfonic acid

The invention discloses a low-temperature-resistant aqueous polyurethane coating which is prepared from, by weight, 70-90 parts of modified polyurethane emulsion, 15-20 parts of water, 3-5 parts of n-Dodecanol ester, 10-15 parts of kaolin, 10-12 parts of titanium dioxide, 2-3 parts of sodium dodecyl sulfate, 1-2 parts of polyacrylamide, 0.05-0.07 part of polyoxyethylene polyoxypropylene pentaerythritol ether, 0.06-0.08 part of polydimethylsiloxane, 0.05-0.07 part of Span60, 0.2-0.3 part of wetting agent BYK-346, 0.2-0.4 part of wetting agent Wet265, 0.1-0.3 part of flatting agent, 0.1-0.3 part of polyvinylpyrrolidone, 0.2-0.3 part of polyoxyethylene and 0.05-0.1 part of mildew preventive. The low-temperature-resistant aqueous polyurethane coating is resistant to high and low temperature, resistant to corrosion, good in sound insulation, good in water resistance and high in mechanical performance.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

Bureau wastepaper composite deinking agent and preparing method thereof

InactiveCN101012344AReduce dosageLow costChemical paints/ink removersStearic acidOleic Acid Triglyceride

The invention discloses a MOW void agent and making method in the void agent technical domain, which comprises the following steps: allocating raw material with 2-5% stearic acid, 10-20% oleic acid, 1-5% acrylic acid, 1-4% maleic anhydride, 3-5% alkyl aliphatic polyoxyethylene ester, 1-2% dodecanol, 2-3% tween, 3-4% sodium benzosulfonate alkyl and water; adding each component into thermostatic autoclave at 75-80 deg.c sequently; stirring at 130-150r / min for 45-60 min; blending evenly; adjusting pH value to 9-10 through NaOH; loading in the barrel; stewing; cooling naturally to indoor temperature; obtaining the product.

Owner:QILU UNIV OF TECH

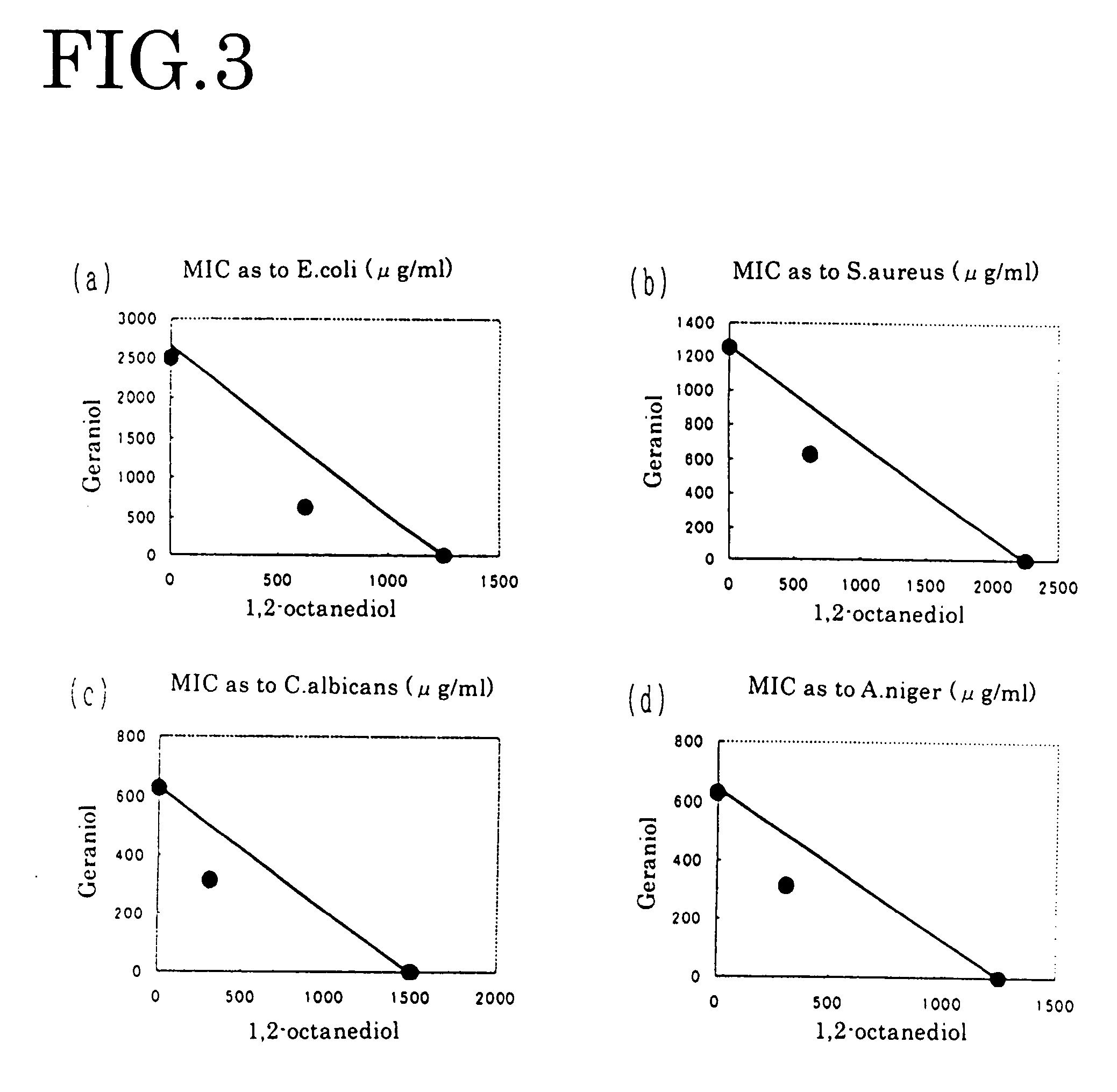

Antiseptic bactericides and cosmetics drugs and food containing the antiseptic bactericides

The purpose of the present invention is to provide antiseptic disinfectant, and cosmetics and toiletries, medicine or food containing the same, which enhance the antibacterial activity that 1,2-alkanediol originally have against a broad range of strains by compounding 1,2-alkanediol with 5-10 carbons and a certain fragrance component. The present invention relates to an antiseptic disinfectant, and cosmetics and toiletries, medicine or food containing the same, which include 1,2-alkanediol with 5-10 carbons, and one or more materials selected from a group of citral, geraniol, nerol, perillaldehyde, α-terpineol, dodecanol and L-carvone.

Owner:MANDOM CORP

Water-based narrow coated paper flexible printing ink and method for preparing same

InactiveCN102964914ALower minimum film forming temperatureHigh glossInksPolymer scienceAcrylic resin

The invention relates to the ink technical field, and in particular relates to water-based narrow coated paper flexible printing ink and a method for preparing the same. The water-based narrow coated paper flexible printing ink comprises the following raw materials in parts weight: 30-45 parts of self-crosslinking water-based acrylic emulsion, 20-28 parts of modified water-based acrylic resin, 15-20 parts of yellow pigment powder, 1-3 parts of pigment dispersant, 0.2-0.8 parts of organic silicon defoamer, 1-4 parts of nonionic organic surfactant, 2-6 parts of dodecanol ester, 3-8 parts of PH stabilizer, 3-5 parts of anionic surfactant and 5-10 parts of water. The water-based narrow coated paper flexible printing ink provided by the invention is environment-friendly and non-toxic, good in use security, stable in performance and good in printing adaptability to coated paper, and has excellent color rendering property, good glossiness and good product quality.

Owner:东莞市佳烨化工科技有限公司

Ultraviolet resistant cold-feeling finishing fabric and processing method, and application of silica coated dodecanol microcapsule to fabric

InactiveCN102720054AUV resistantHas a cooling effectVegetal fibresPolyurethane adhesivePolymer science

The invention discloses an ultraviolet resistant cold-feeling finishing fabric and a processing method thereof, and application of a silica coated dodecanol microcapsule to ultraviolet resistant cold-feeling finishing fabric. The fabric is characterized in that the inner surface and outer surface of the fabric and the interior of the fabric are distributed with silica coated dodecanol microcapsules. The processing method of the fabric comprises the step that the silica coated dodecanol microcapsules are finished to the fabric by using a padding method. The microcapsule particles have size distribution of 0.2-6 mum; in the padding process, rolling waste rate is 80-90%; a capsule dosage is 40-60g / L; drying conditions include a temperature at 80-100 DEG C and a time of 3-5 min; and baking conditions include a temperature at 140-160 DEG C and a time of 1-2 min. A polyurethane adhesive can be used together with the microcapsules. The fabric has ultraviolet resistant and cold-feeling effects.

Owner:SHANGHAI JIALE

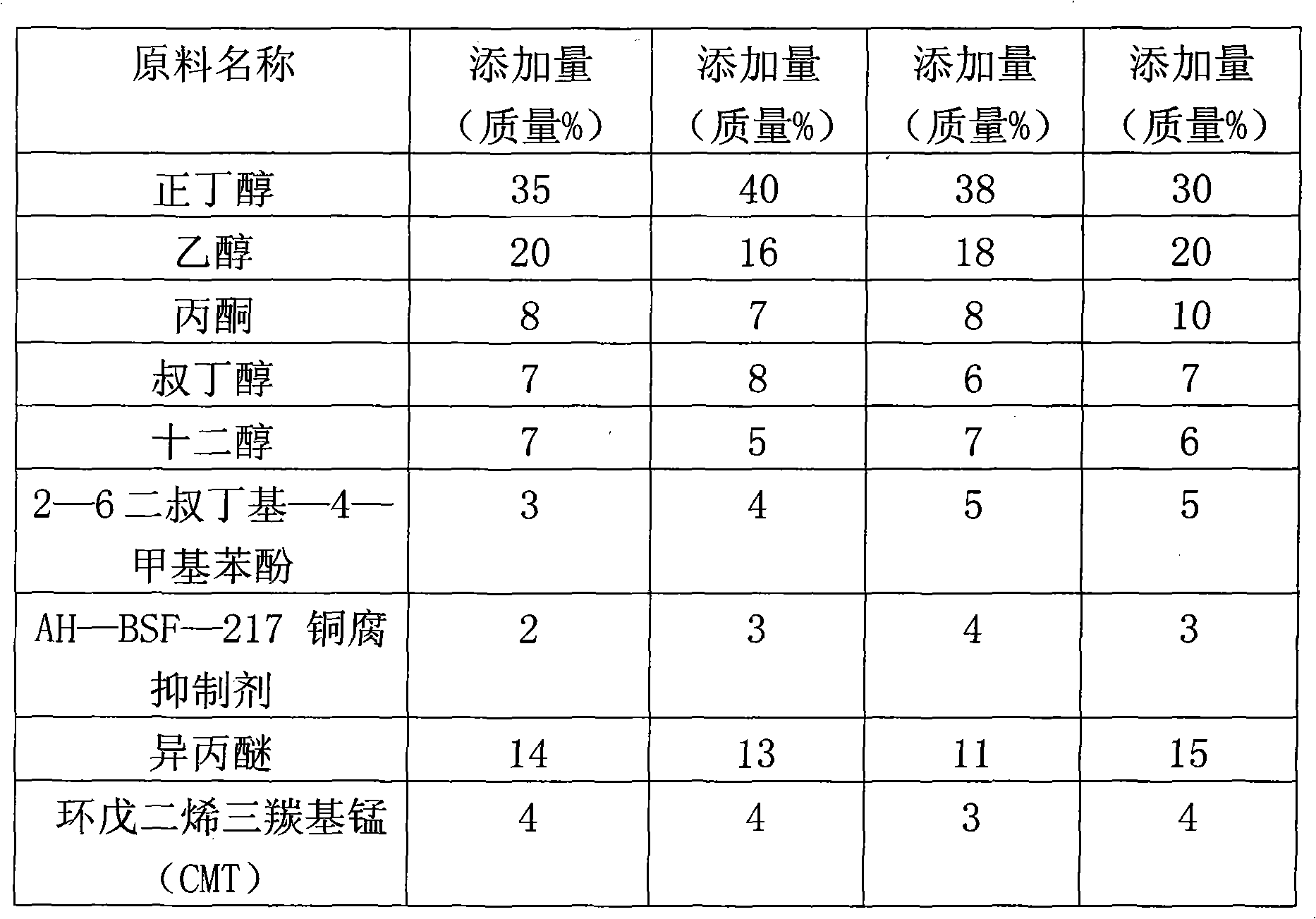

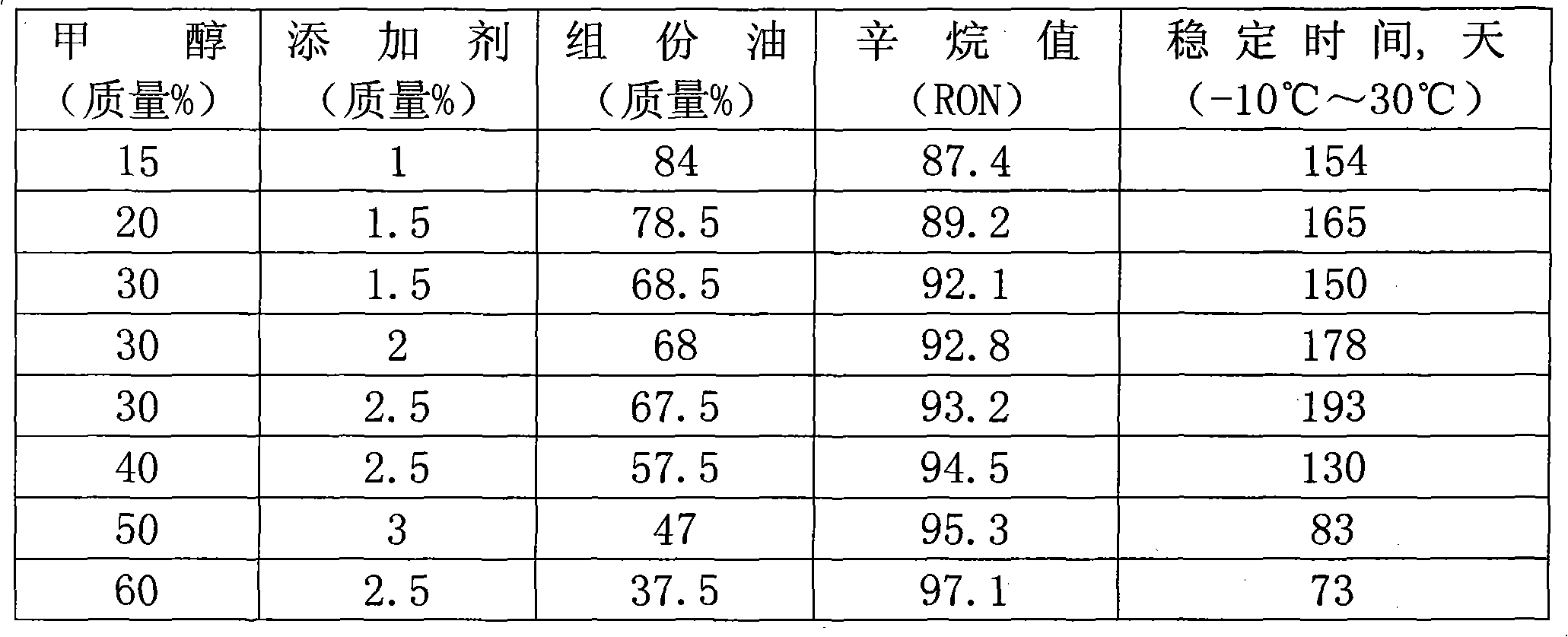

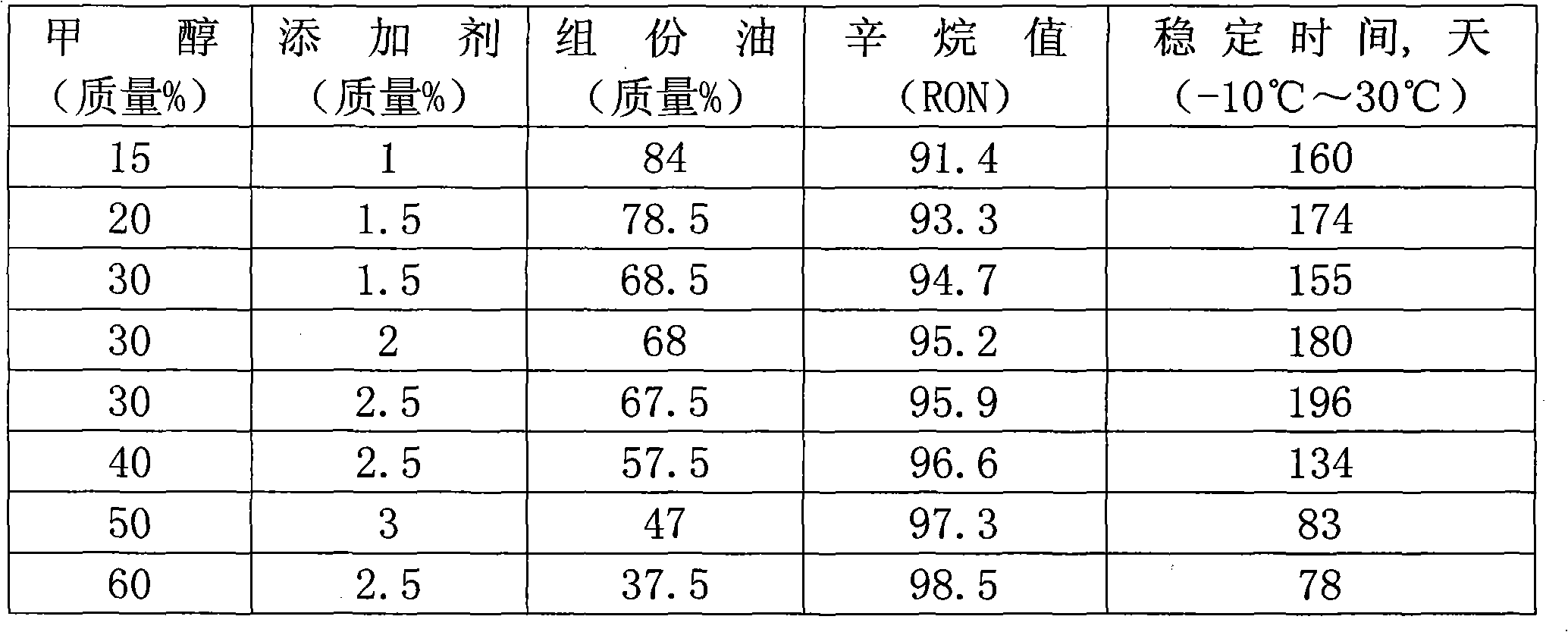

Methanol gasoline additive, methanol gasoline prepared from same and production methods for methanol gasoline additive and methanol gasoline

ActiveCN101886004ABoost octaneExtended storage timeLiquid carbonaceous fuelsFuel additivesOil additiveColor changes

The invention discloses a methanol gasoline additive, methanol gasoline prepared from same and production methods for the methanol gasoline additive and the methanol gasoline. The methanol gasoline additive is prepared from the following components in percentage by mass: 20 to 40 percent of n-butyl alcohol, 5 to 25 percent of ethanol, 3 to 13 percent of acetone, 2 to 10 percent of tertiary butanol, 4 to 9 percent of dodecanol, 2 to 6 percent of 2,6-di-tert-butyl-4-methylphenol, 1.5 to 5 percent of AH-BSF-217 copper corrosion inhibitor, 5 to 15 percent of isopropyl ether and 2 to 4 percent of cyclopentadienyl manganese tricarbonyl. The production method for the methanol gasoline additive comprises the following steps of: adding the raw materials in turn, fully stirring in a reaction kettlefor 30 to 60 minutes, sampling to observe color change, and stopping stirring when the liquid is changed to transparent yellow or rosiness; and putting into a finished product tank. The methanol gasoline is prepared from the following components in percentage by mass: 0.5 to 5 percent of methanol gasoline additive, 15 to 60 percent of methanol and 34.7 to 84 percent of component oil. The methanolgasoline prepared from the methanol gasoline additive has the advantages of high octane number, good anti-explosion, full combustion, reduction of discharge of automobile exhaust, no air blockage, easy cold start of the automobile and the like.

Owner:山东亿源石化有限公司 +1

Color-changeable PP (polypropylene) insulation release film

The invention discloses a color-changeable PP (polypropylene) insulation release film comprising PP, PC, ceramic powder, epoxy resin 6101, furfuryl alcohol furfural resin, melamine, polyacrylamide, polyamide 66, nano-alumina, mica powder, talcum powder, polyvinyl butyral, tetraethyl orthosilicate, ABS, PFA, PBT, PET, polyethylene glycol monomethyl ether, FEP, polymethyl methacrylate, PPO, glass fibers, organic montmorillonite, polyether-ether-ketone fibers, thermochromic red, dodecanol, chitosan, an antioxidant 1010, a light stabilizer 622, nano-TiO2, a PP-g-MAH, a thickener and a coupling agent. The release film has excellent insulativity, heat dissipation, water resistance, corrosion resistance, temperature resistance, weather resistance and adhesiveness, can change colors with heat and has a high-temperature warning effect.

Owner:TAICANG CUSTOM NEW MATERIALS CO LTD

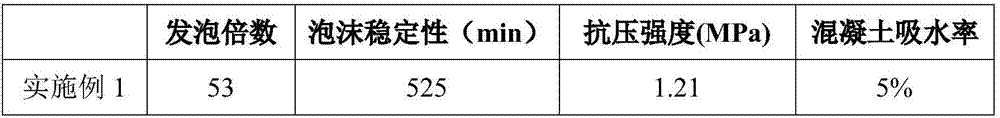

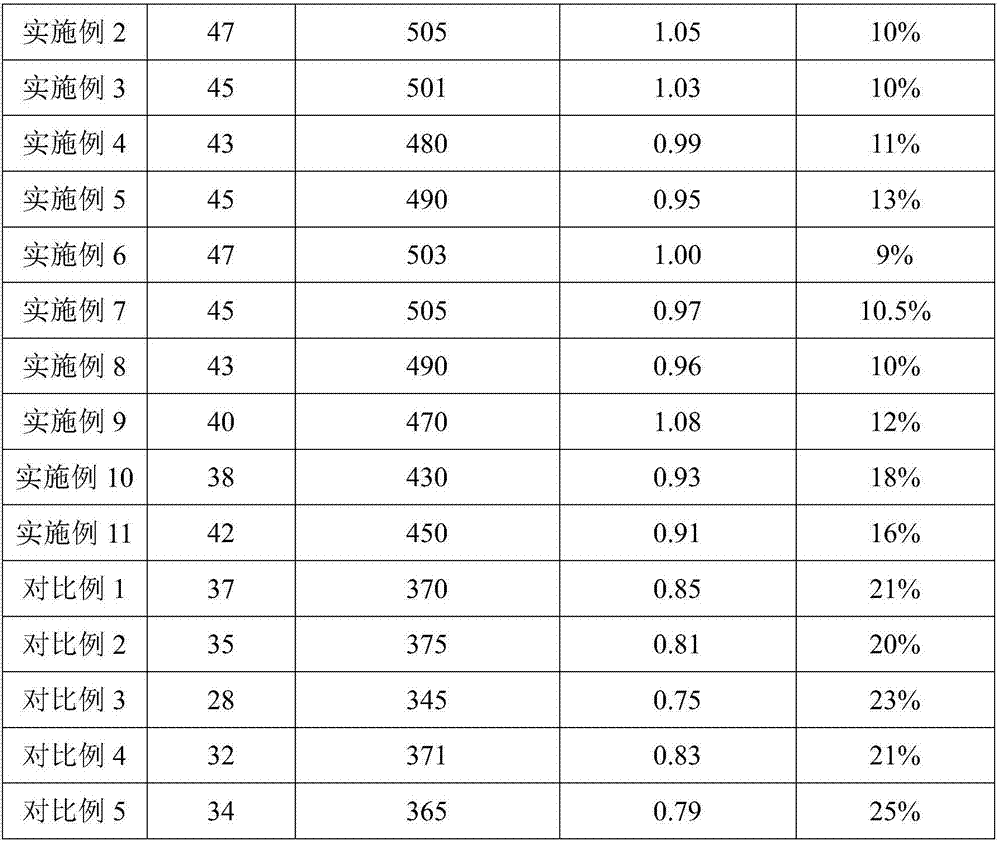

Hydroxyl compound type composite foaming agent and preparation method thereof

The invention relates to a foaming agent, specifically to a hydroxyl compound type composite foaming agent and a preparation method thereof. The hydroxyl compound type composite foaming agent at leastcomprises the following preparation raw materials in parts by weight: 2 to 20 parts of a nonionic surfactant, 1 to 5 parts of an anionic surfactant, 0.1 to 5 parts of a foam stabilizer, 0.5 to 1 partof a thickening agent and 69 to 96.4 parts of water, wherein the nonionic surfactant is one ore more selected from the group consisting of polyether polyol and lignin polyether polyol; and the anionic surfactant is one or more selected from the group consisting of a dodecyl anionic surfactant, lauryl sulfate triethanolamine, secondary alkyl sodium sulfonate, fatty alcohol sodium hydroxyethyl sulfonate, N-sodium lauroyl sarcosine, amide polyoxyethylene ether magnesium sulfate, dodecanol polyoxyethylene ether disodium sulfosuccinate, sodium alpha-olefin sulfonate, sodium fatty alcohol ether sulfate, sulfonates of ethoxylated fatty acid methyl ester, alcohol ether carboxylate, methyl stearate polyoxyethylene ether sodium sulfonate and isooctyl phosphate.

Owner:GUANGDONG SHENGRUI TECH CO LTD

Papermaking waste residue aerated brick and manufacturing method thereof

The invention discloses a papermaking waste residue aerated brick which is characterized by being prepared by the following raw materials by weight: 17-19 parts of papermaking waste residues, 9-13 parts of lime, 15-18 parts of river sand, 14-17 parts of apatite, 6-11 parts of cement, 0.3-0.5 part of aluminium powder, 0.2-0.4 part of sodium dodecanol sulfate, 0.1-0.4 part of methyl polyoxyethylene ether, 0.2-0.5 part of methyl methacrylate, 2-4 parts of milling steel fibers, 7-9 parts of sintering dry-method desulfurized fly ash, 0.15-0.3 part of gellan gum, 0.3-0.6 part of mannan, 1-3 parts of oleic acid, 2-5 parts of manganese dioxide, 0.1-0.3 part of symplocos paniculata, 0.2-0.6 part of chilli seeds, 3-6 parts of auxiliary agents, and a proper amount of water. According to the invention, papermaking waste residues are added into raw materials of aerated bricks, and other routine auxiliary agents are also added; the aerated bricks processed by appropriate technology have the characteristics of low cost, low unit weight, few cracks, high thermal insulation performance, good sound-absorbing effect, and high compressive strength. The circular economy effect of changing waste into valuables is realized, and pollution is reduced.

Owner:ANHUI SHENGREN NEW BUILDING MATERIAL

Bird feather detergent and its producing method

InactiveCN1616626AResidue reductionReduce oxygen consumptionNon-ionic surface-active compoundsDry-cleaning apparatus for textilesCarboxymethyl celluloseAcetic acid

The bird feather detergent is produced through mixing water, EDTA disodium, sodium dodecyl benzene sulfonate, dodecanol polyoxyethylene ether, ethoxyl hendecyl carboxymethyl imidazoline, emulsifier NP and ethyl glycol acetate via stirring; adding sodium carboxymethyl cellulose aqua; and finally adding citric acid to regulate the pH to 5-6. The washed bird feather washed with the detergent has COD lower than 10 mg each 100g, cleanliness higher than 450 mm and fat residue rate lower than 1 %. The detergent has high defatting and detergence efficiency, less foam, antistatic effect, bird feather puffing and softening effect, low cost, convenient use, no toxicity and no environmental pollution.

Owner:YANGZHOU UNIV

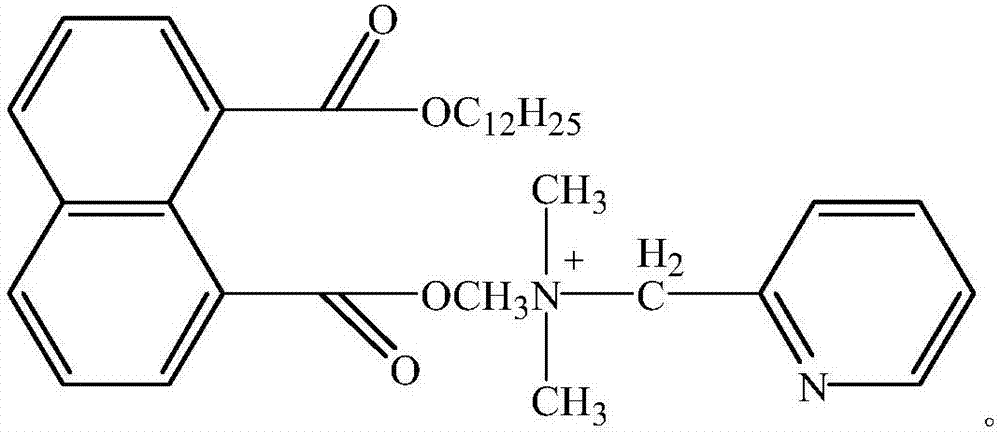

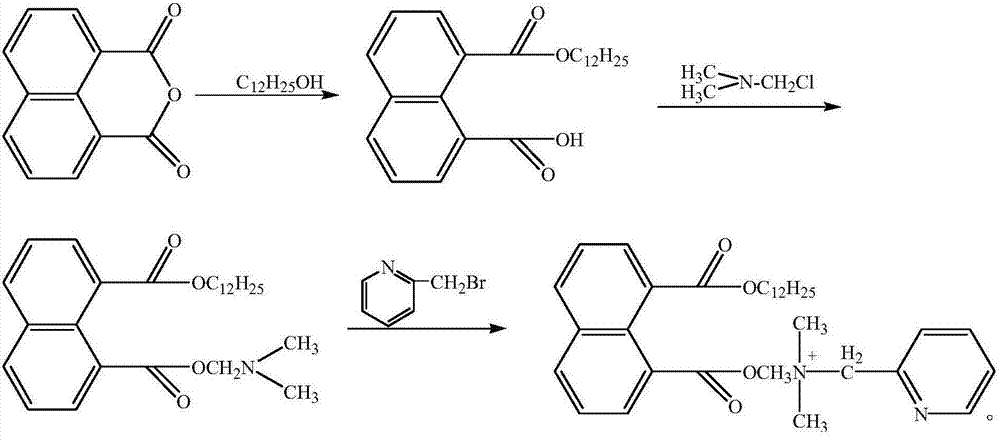

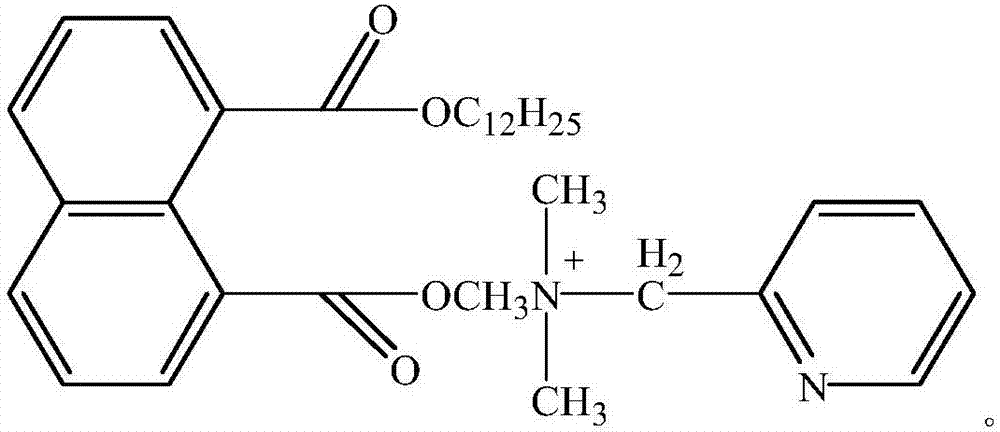

Cation-type anti-swelling clay stabilizer containing N-heterocyclic quaternary ammonium salt and synthesis method thereof

ActiveCN106866506AThe synthesis process is simpleLow costOrganic chemistryDrilling compositionDecompositionSynthesis methods

The invention belongs to the technical field of oilfield development, and in particular relates to a cation-type anti-swelling clay stabilizer containing N-heterocyclic quaternary ammonium salt and a synthesis method thereof. The clay stabilizer is generated by performing reaction between anhydride naphthalene and dodecanol to generate dodecyl anhydride naphthalene half-ester, performing solution polymerization reaction with 2-(dimethylamino)chloromethane hydrochloride to generate an intermediate, and finally performing reaction with 2-bromomethylpyridine, wherein the molar ratio of the anhydride naphthalene to the dodecanol to the 2-(dimethylamino)chloromethane hydrochloride to the 2-bromomethylpyridine is 1:1-1.6:1.1-1.5:0.8-1.7, preferably 1:1.1:1.2:1.5. The clay stabilizer is characterized by wide source of raw materials, simple synthesis process, small usage and high reservoir adaptability. The clay stabilizer is good in temperature resistance and salt resistance, the temperature of 220 DEG C can be resisted, the degree of mineralization of 220000mg / L can be resisted, and the compatibility is excellent. The clay stabilizer can be strongly adhered to the surface of clay, is not prone to decomposition, and is long in duration and high in anti-swelling rate which exceeds 98 percent.

Owner:CHINA PETROLEUM & CHEM CORP +1

Inorganic water-based metallic paint and preparation method thereof

Owner:佛山市南海万磊建筑涂料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com