Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

545 results about "Butyl Stearate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Butyl stearate. C17H35COOC4H9 A liquid that solidifies at approximately 19°C; mixes with vegetable oils and is soluble in alcohol and ethers but insoluble in water; used as a lubricant, in polishes, as a plasticizer, and as a dye solvent.

Drilling fluid lubricating agent

ActiveCN101486896AMeet the requirements of lubricating performanceImprove the lubrication effectDrilling compositionStearateTrimethylolpropane

The invention relates to a lubricant for drilling fluid, which essentially solves the problems of the prior art that the lubricant for drilling fluid has poor lubricating property in the high-density drilling fluid. The lubricant for drilling fluid comprises the following components calculating by weight percentage: a) 1 to 35 percent of long-chain organic acid oiliness agent; b) 1 to 35 percent of synthetic ester oiliness agent; c) 0.1 to 8 percent of emulsifier; and d) 25 to 90 percent of base oil; in which the synthetic ester oiliness agent is selected from at least one of isooctyl stearate, butyl isostearate, trimethylolpropane trioleate, trimethylolpropane palm kernel ester, trimethylolpropane ethylhexoate, neopentyl glycol oleate, methyl laurate or pentaerythritol caproate, therefore, the technical proposal solves the problem preferably, and can be used in the industrial production of lubricant for drilling fluid.

Owner:CHINA PETROLEUM & CHEM CORP

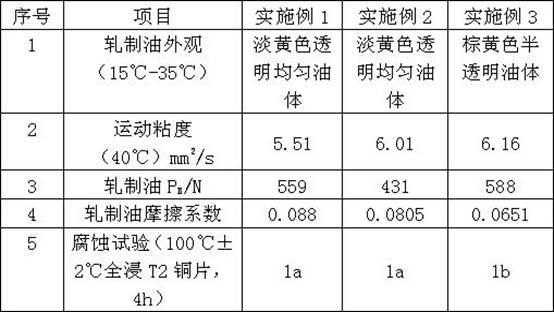

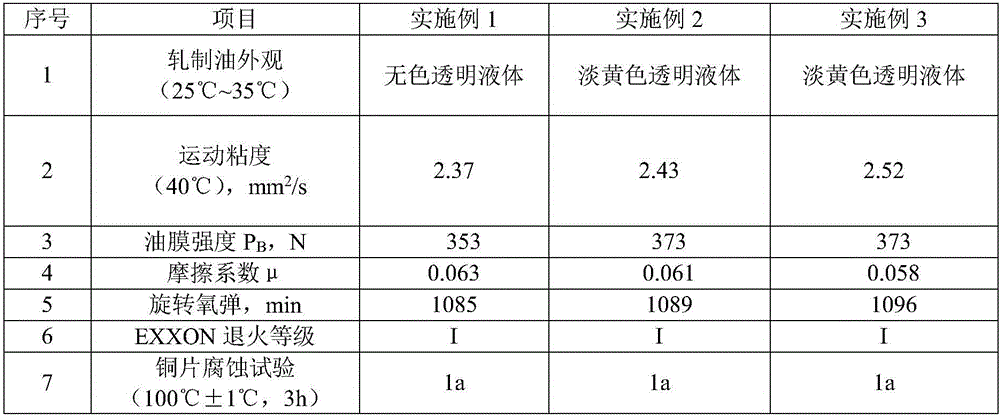

Calendaring copper foil rolled oil and preparation method thereof

ActiveCN102660357AHigh surface finishLong anti-corrosion periodAdditivesPolyethylene glycolCopper foil

The invention relates to the technical field of lubricating agents, in particular to calendaring copper foil rolled oil and a preparation method thereof. The calendaring copper foil rolled oil is used for lubricating in the cold-rolled process of calendaring copper foil. The preparation method is characterized by comprising the following steps of: adding N5 engine oil, butyl stearate, dodecanol, nitrogen-containing borate, fatty alcohol polyethylene glycol phosphate, petroleum sodium sulfonate and benzotriazole into a reaction kettle of which the rotation speed is 80 to 120 revolutions / minute sequentially, heating and stirring; and when the temperature is 80 DEG C, keeping the temperature, stirring continuously for 30 minutes, stopping heating, and stirring continuously to room temperature to obtain uniform and transparent oil, namely the required rolled oil. The minimum rolling thickness of the calendaring copper foil lubricated by the rolled oil is 25 micrometers, so that the calendaring copper foil is high in surface smoothness, long in anti-corrosion period and high in annealing detergency.

Owner:UNIV OF SCI & TECH BEIJING

PE wood/plastic composite sectional material and manufacturing method thereof

The invention discloses a PE wood / plastic composite sectional material and relates to the technical field of composite materials. The PE wood / plastic composite sectional material is made from the following raw materials in parts by weight: 10-70 parts of wood flour, 20-50 parts of polyethylene, 3-20 parts of calcium carbonate powder or talc powder, 0.1-1 part of stearic acid or n-butyl stearate, 0.4-1.5 parts of one or a combination of more than one of calcium stearate, lead stearate, barium stearate, cadmium stearate, lanthanum stearate, zinc stearate, PE wax, or oxidized polyethylene wax OPE or 0.1-1.5 parts of paraffin, 0.5-3 parts of a coupling agent, 0.5-2 parts of an antioxidant, 0.05-2 parts of a UV absorbent, a light shielding agent, quencher or free radical scavenger, and 3-12 parts of titanium pigment. The PE wood / plastic composite sectional material provided by the invention has the advantages of water resistance, insect resistance, rust corrosion resistance, convenience for fabrication, safety in use, strong plasticity, energy conservation, environmental friendliness and no formaldehyde, benzene or other poisonous substances.

Owner:LINYI KANGYIJIA ECOLOGY WOOD

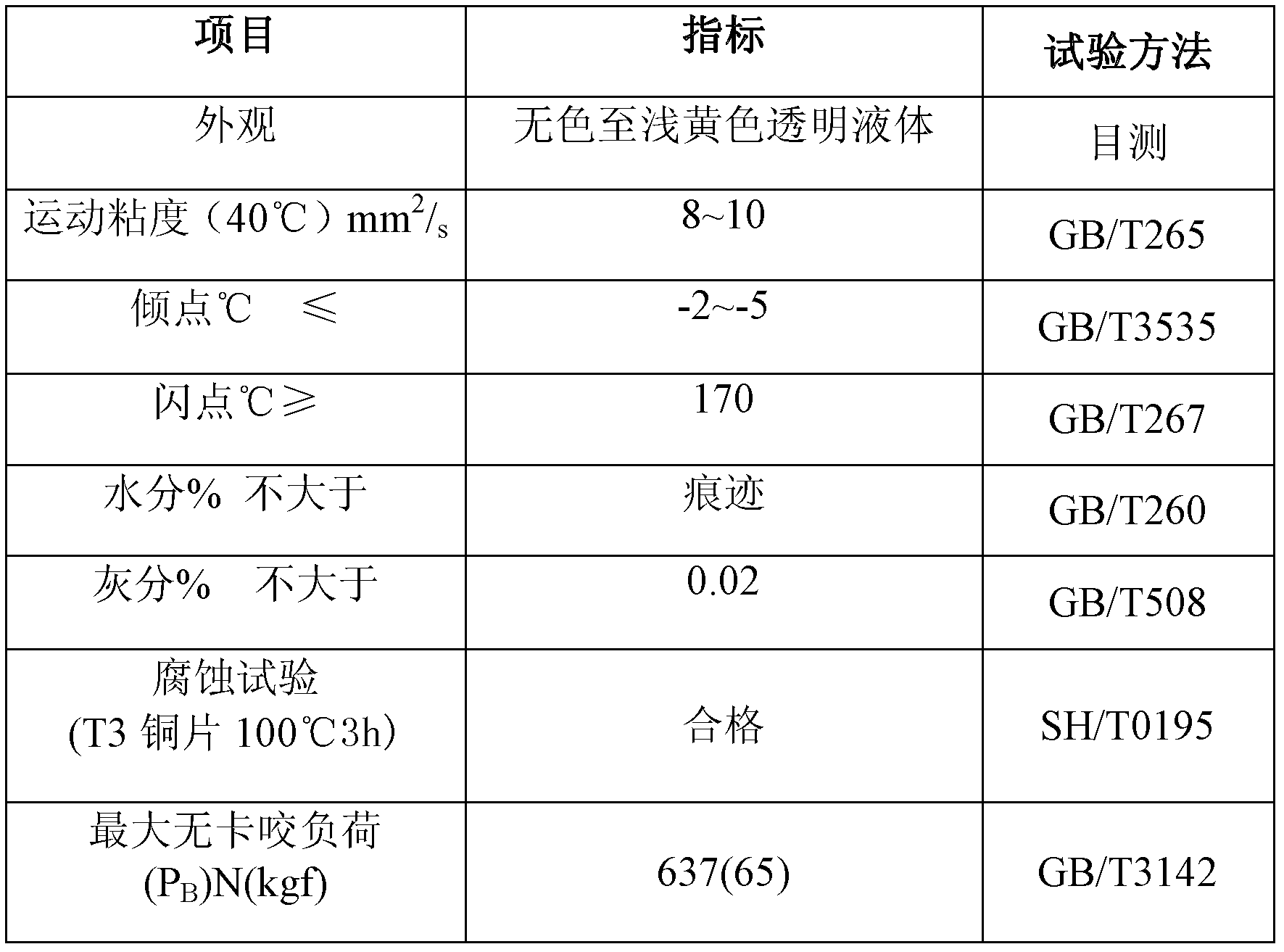

Rolling oil for stainless steel

ActiveCN102504919ALow viscosityExtended service lifeLubricant compositionWater sourceChlorinated paraffins

The invention relates to a rolling oil for a stainless steel, which is prepared by the following raw materials by weight: 64.5-79.9% of white oil, 5-15% of neopentyl polyol ester, 5-10% of pentaerythritol aliphatic ester, 2-5% of isooctyl stearate or butyl stearate, 0.5-1.2% of mixed-type high temperature antioxygen, 0.05-0.2% of phenol-type antioxygen, 0.05-0.1% of ethylenediaminetetraacetic acid (EDTA) dipotassium salt, 0.4-0.8% of antirust additive, 0.1-0.5% of metal passivator and 2-3% of antiwear agent. The invention uses synthetic ester to replace chlorinated paraffin, which prevents environmental pollution of chlorinated paraffin, meanwhile avoids using large quantity of water for cooling, saves massive water source and also converts the processing oil into recyclable oil, thereby prolonging the service life of the processing oil greatly. The invention has the features of excellent lubrication performance, cooling performance, rust resistance, cleanness, energy conservation andenvironmental friendliness. The waste liquid is less in volume and can be recycled. Therefore the rolling oil provided by the invention is the preferred processing oil for finishing rolling of stainless steel to obtain high-gloss surface.

Owner:彭美东

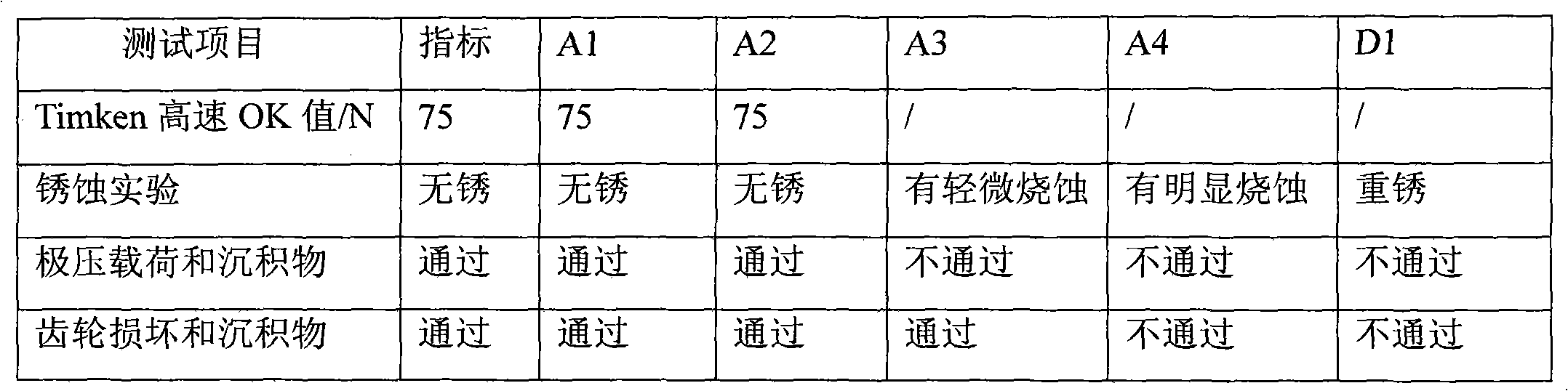

Gear oil composition for automobile

InactiveCN101993763AImprove antioxidant capacityExtend your lifeAdditivesPolymer scienceWear resistant

The invention discloses a gear oil composition for an automobile. The gear oil composition for the automobile comprises viscosity blend base oil, a sulfur-containing extreme pressure additive, a phosphorus-containing wear-resistant additive, an antirust additive, a metal passivator and a synthetic ester oiliness additive, wherein the synthetic ester oiliness additive may be one or more of trimethylolpropane trioleate, octyl stearate, butyl stearate, isooctyl stearate and isooctyl palmitate; and the synthetic ester oiliness additive accounts for 2 to 10 percent of the total weight of the gear oil composition. The gear oil has the advantages of high wear resistance, high maximum non-seizure load, high load-bearing capacity, high viscosity index, high low-temperature flowability, high lubricating property and the like, is suitable for the lubrication of an automobile manual gearbox and a rear drive axle gear and is also suitable for an automobile automatic gearbox.

Owner:SUZHOU SHIHAO BUILDING MATERIAL NEW TECH ENG

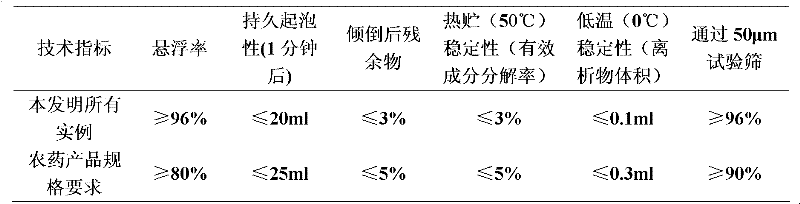

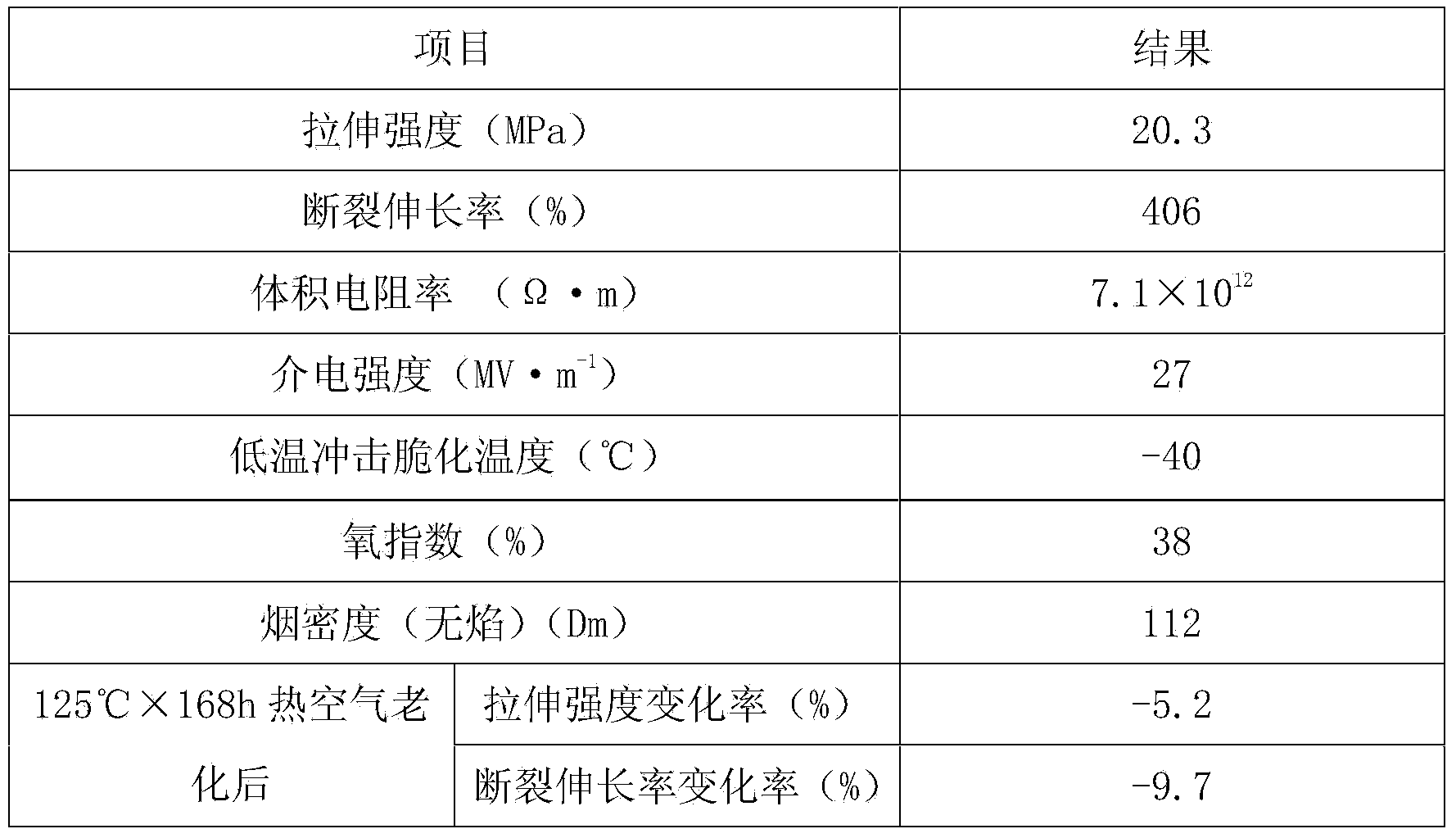

Oil and low-temperature resistant low-smoke and halogen-free flame retardant cable material for boats, and its preparation method

ActiveCN102977609AImprove flame retardant performanceExcellent non-flammabilityInsulated cablesInsulated conductorsMeth-Carbamate

The invention provides an oil and low-temperature resistant low-smoke and halogen-free flame retardant cable material for boats. The cable material is prepared from the following raw materials, by weight, 20-30 parts of polyurethane, 60-80 parts of methyl vinyl silicone rubber, 8-10 parts of acrylonitrile-butadiene rubber, 8-10 parts of magnesium hydroxide, 0.5-1.0 part of butyl stearate, 1-3 parts of barium stearate, 8-12 parts of triglycol dioctate, 4-6 parts of copper oxide, 0.5-1.0 parts of molybdenum trioxide, 30-50 parts of fumed silica, 10-13 parts of modified argil, 0.5-1.0 part of an antioxidant H, 0.1-0.3 parts of an antioxidant AW, 0.5-1.5 parts of a promoter NOBS, 0.2-0.5 parts of a vulcanizing agent DCBP, 8-10 parts of triphenyl phosphate, 12-15 parts of antimony (III) oxide and 6-8 parts of zinc borate hydrate. The cable material has the advantages of excellent flame retardation, very less smoke in combustion, no generation of toxic gases or corrosive gases, good low temperature resistance, good oil resistance, and good abrasion resistance.

Owner:广东蓝宇塑料制品有限公司

Zero-halogen and low-smoke flame retardant cable material for computers, and its preparation method

ActiveCN102977611AImprove flame retardant performanceExcellent non-flammabilityInsulated cablesInsulated conductorsPolymer scienceAluminium hydroxide

The invention provides a zero-halogen and low-smoke flame retardant cable material for computers. The cable material is prepared from the following raw materials, by weight, 20-30 parts of polypropylene, 60-80 parts of methyl-vinyl silicone rubber, 10-20 parts of an EVA resin, 8-10 parts of aluminum hydroxide, 0.5-1.0 part of butyl stearate, 1-3 parts of zinc stearate, 8-12 parts of epoxy soybean oil, 4-6 parts of zinc oxide, 0.5-1.0 part of molybdenum trioxide, 30-50 parts of fumed silica, 10-13 parts of modified argil, 0.5-1.0 part of an antioxidant H, 0.1-0.3 parts of an antioxidant AW, 0.5-1.5 parts of a promoter NOBS, 0.2-0.5 parts of a vulcanizing agent DCBP, 8-10 parts of ammonium polyphosphate, 12-15 parts of antimony (III) oxide and 6-8 parts of zinc borate hydrate. The cable material has the advantages of excellent flame retardation, very less smoke in combustion, no generation of toxic gases or corrosive gases, good weather resistance, good abrasion resistance and good insulation property.

Owner:蚌埠尚维知识产权运营有限公司

Long glass fiber-reinforced polyvinyl chloride sheet as well as preparation method of on-line mixing of polyvinyl chloride sheet

The invention discloses a long glass fiber-reinforced polyvinyl chloride (PVC) sheet as well as a preparation method of on-line mixing of the polyvinyl chloride sheet. The long glass fiber-reinforced polyvinyl chloride sheet comprises the following components by weight: 100 parts of PVC; 2-3 parts of dibutyltin mercaptide; 0.5-1 parts of calcium stearate; 0.2-0.5 parts of zinc stearate; 1-2 parts of butyl stearate; 1-2 parts of higher fatty acid; 0.5-1.5 parts of paraffin; 0.3-1 parts of poly(ethylene oxide) with high melting point; 2-5 parts of polyethylene-graft-maleic aldehyde (PE-g-MAH); 5-30 parts of glass fiber; 0.1-0.5 parts of a coupling agent and 10-30 parts of active calcium carbonate. The preparation method of on-line mixing of the polyvinyl chloride sheet comprises the steps of feeding PVC, various additives and fillers into a first-stage co-rotating two-screw extruder, mixing on line, and preplasticizing; transferring into a second-stage counter-rotating parallel two-screw extruder, introducing the surface-treated glass fiber into the second-stage extruder and mixing with the materials, cutting, opening, homogenizing, plasticizing, building pressure and extruding from a coat-hanger die; and packaging after being processed by using a three-roll calender, a forming machine and a cutting machine.

Owner:安徽福美达新材料科技有限公司 +1

High-lubricating rolling oil composition and application thereof

ActiveCN106318568AImprove the lubrication effectMeet lubrication needsLubricant compositionPhosphateButylated hydroxytoluene

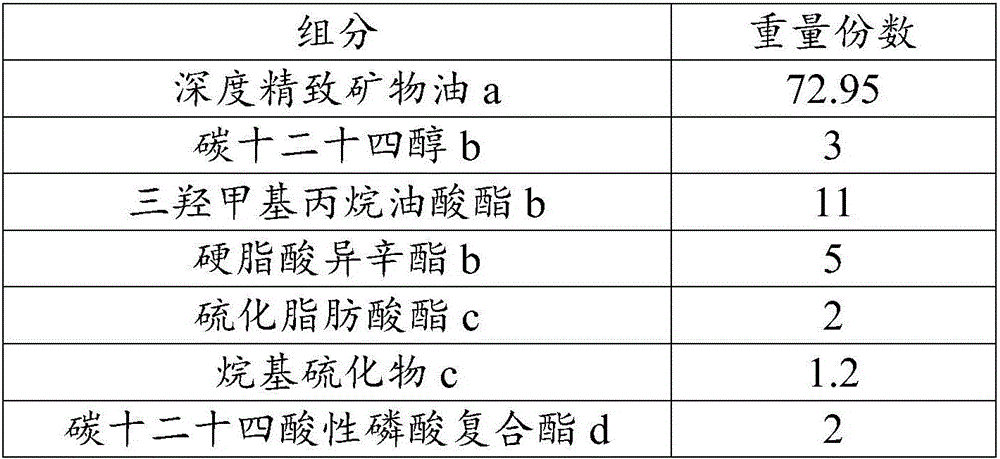

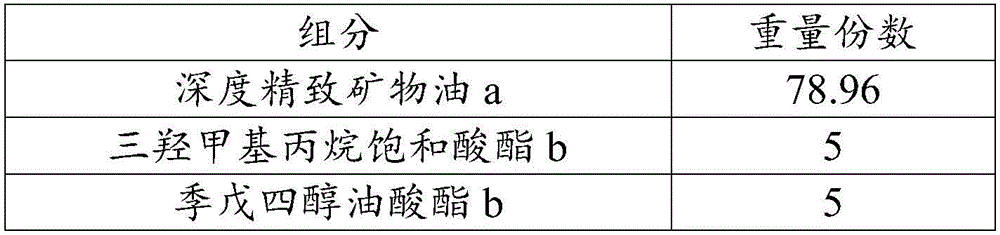

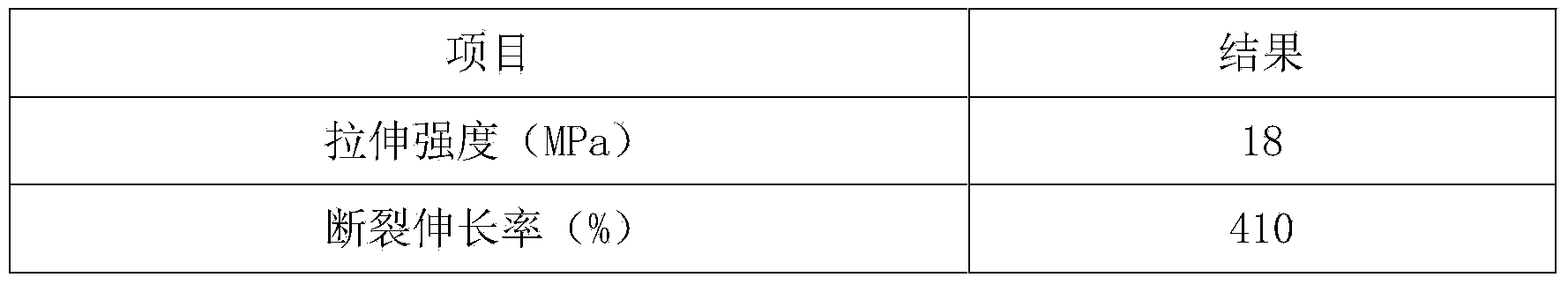

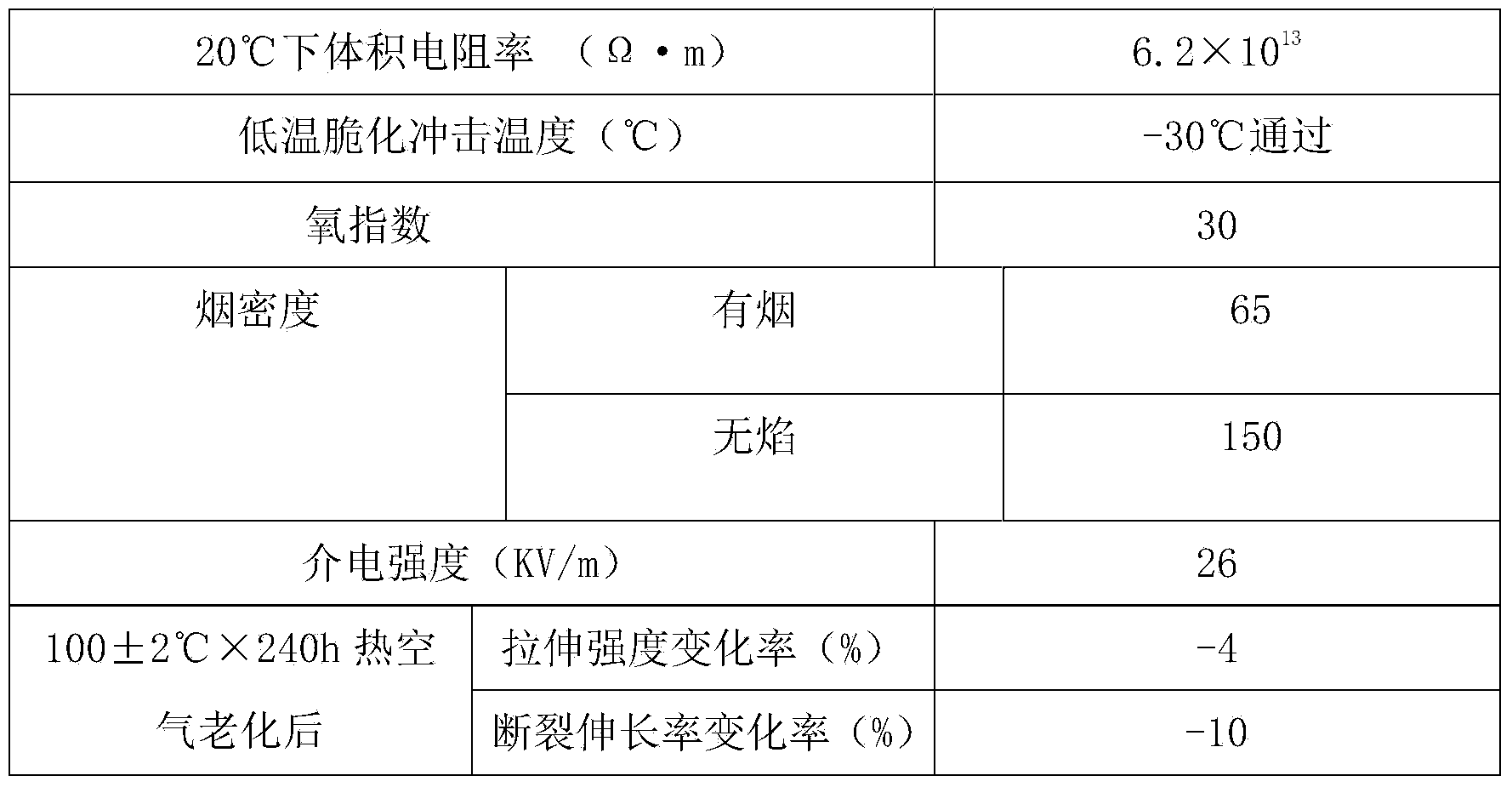

The invention relates to a high-lubricating rolling oil composition and application thereof. The composition is prepared from 40-90 parts of highly refined mineral oil, 10-30 parts of carbon dodecanol tetradecyl alcohol, isotridecyl alcohol, n-octanol, pentaerythritol oleate, trimethylolpropane trioleate, diisooctyl phthalate, 2-ethylhexyl palmitate, isooctyl stearate, methyl palmitate or butyl stearate, 1-5 parts of ZDTP, octadecyl zinc dithiophosphate, sulfurized olefin, sulfide aliphatic acid ester, sulfurized animal oil, alkyl sulfide or sulfur phosphorus molybdenum, 0.5-5 parts of amine thiophosphate, isooctyl acidic phosphate octadecylamine, tricresyl phosphate, tributyl phosphate, dibutyl phosphate and carbon-12 to carbon-14 acid phosphate compound ester, 0.1-5 parts of 2,6-butylated hydroxytoluene, N-phenyl naphthylamine, thioether phenol or alkyl diphenylamine and 0.01-2 parts of 1H-benzotriazole, thiadiazole derivative and benzotriazole.

Owner:CHINA PETROLEUM & CHEM CORP

Environment-friendly cold-resistant polyvinyl chloride cable material

InactiveCN103509293AStrong impact resistanceSolve environmental problemsWear resistantDecabromodiphenyl ether

The invention provides an environment-friendly cold-resistant polyvinyl chloride cable material. The polyvinyl chloride cable material is prepared with the following components and raw materials by weight: 60-70 parts of polyvinyl chloride, 10-15 parts of polysiloxane, 8-10 parts of silicon rubber, 12-15 parts of dioctyl terephthalate, 5-10 parts of triethylene glycol di-2-ethylhexoate (triglycol dioctate), 3-5 parts of epoxy triglyceride, 8-10 parts of tributyl acetocitrate, 1-2 parts of cobalt naphthenate, 0.2-0.3 part of ethyl silicon oil, 2-5 parts of chlorinated polyethylene, 10-15 parts of aluminum hydroxide, 5-6 parts of triphenyl phosphate, 4-6 parts of decabromodiphenyl ether, 8-10 parts of light activated calcium carbonate, 5-8 parts of bentonite, 1-2 parts of zinc oxide, 1-2 parts of titanium dioxide, 5-6 parts of cinerite, 6-8 parts of highly wear-resistant carbon black, 2-3 parts of Ca-Zn compound stabilizer, 0.1-1 part of antioxidant 1076, 0.1-0.3 part of dicumyl peroxide (DCP), 0.2-0.3 part of butyl stearate, 1-2 parts of barium stearate, 0.1-0.5 part of zinc stearate, and 8-10 parts of modified filler. The cable material is of good shock resistance at low temperature and environment-protection property, thereby solving the problem that the existing polyvinyl chloride cable material is not environment-friendly, and bad in the shock resistance at low temperature.

Owner:东莞虎塑塑胶科技有限公司

Fire-proof paint

InactiveCN103881433AEffective fire and water resistanceSimple materialFireproof paintsAcrylonitrilePetroleum

The invention relates to a fire-proof paint. The fire-proof paint comprises the following components in parts by weight: 8-13 parts of dehydrated castor oil, 12-15 parts of acrylonitrile, 6-11 parts of butyl stearate, 3-5 parts of methyl methacrylate, 20-25 parts of petroleum, 5-10 parts of pigment, 7-14 parts of fireproof raw materials and 3-6 parts of mixture additives. The fireproof paint can be applied to retarding flame when furniture or wall ornaments catch a fire, and also can be used for repairing a wall on which the paint is prone to fall; meanwhile, the fireproof paint is capable of effectively achieving the fireproof and waterproof effects; the fireproof paint is simple in material, low in manufacturing cost and wide in application range.

Owner:江门市彩信化工有限公司

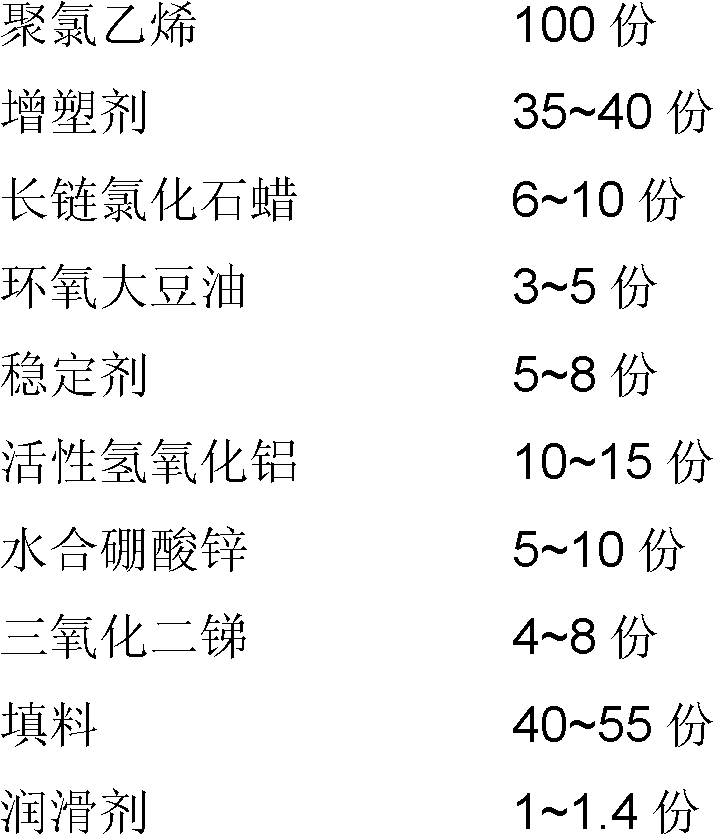

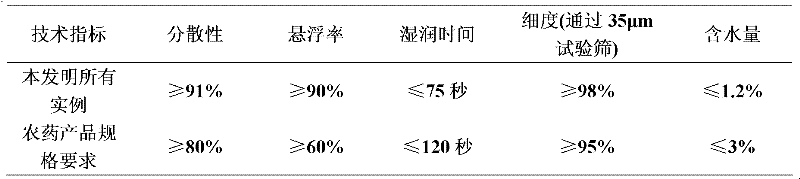

Environment-friendly flame-retardant polyvinyl chloride cable insulating material and preparation method thereof

InactiveCN102675768AOvercoming Harmful FlawsPlastic/resin/waxes insulatorsPolyvinyl chlorideStearic acid

The invention discloses an environment-friendly flame-retardant polyvinyl chloride cable insulating material and a preparation method thereof. The cable insulating material comprises the following components in parts by weight: 100 parts of polyvinyl chloride, 35-40 parts of a plasticizing agent, 5-8 parts of a stabilizing agent, 6-10 parts of long-chain chlorinated paraffin, 3-5 parts of epoxy soybean oil, 4-8 parts of antimonous oxide, 10-15 parts of active aluminum hydroxide, 5-10 parts of hydrated zinc borate, 1-1.4 parts of a lubricating agent, 10-20 parts of calcined kaolin and 30-45 parts of a filler, wherein the filler is a composition of active ground limestone and nano calcium carbonate; and the lubricating agent is a composition of stearic acid and butyl stearate. The oxygen index of the insulating material can be over 33, and is accordant with RoSH and REACH regulations. The preparation method of the insulating material comprises the following steps of: mixing raw materials in a high-speed mixing machine; and extruding and pelletizing with a dual-step screw extruder.

Owner:江苏凯诺电缆集团有限公司

Glass oil paint

ActiveCN103897564AEconomical to makeStrong adhesionShellac coatingsPolyester coatingsLacquerOil paint

The invention relates to an glass oil paint which comprises the following components in parts by weight: 20-27 parts of modified dry oil, 12-17 parts of hydroxyethyl cellulose, 3-6 parts of butyl stearate, 12-15 parts of water-soluble resin, 5-8 parts of lac resin, 3-6 parts of lacquer resin, 12-15 parts of zinc phosphate, 4-6 parts of zinc molybdate, 11-16 parts of mica powder, 1-4 parts of citric acid, 2-4 parts of antiseptic antirust emulsion and 5-8 parts of thinners. According to the glass oil paint, raw materials are common in the market, so that the production cost is low, and the glass oil paint has strong adhesive force, acid and alkali resistance and water resistance, can effectively remove and prevent iron rust due to addition of the antiseptic antirust emulsion, and can be smeared on glass, so as to meet the demands of people.

Owner:SHANGHAI DABAO CHEM PROD

Alcohol-free fountain solution and preparation method thereof

The invention discloses an alcohol-free fountain solution. The alcohol-free fountain solution is characterized by consisting of following raw materials in parts by weight: 2-10 parts of alginic acid propylene glycol alginate, 1-5 parts of epoxy butyl stearate, 1-3 parts of glycine, 1-3 parts of arginine, 1-8 parts of sodium dodecyl sulfate, 1-5 parts of hydroxyethyl urea, 0.5-1 part of hydrogen peroxide, 1-3 parts of tannin, 1-2 parts of vanillin, 1-3 parts of EDTA (Ethylene Diamine Tetraacetic Acid), 0.2-1 part of organic silicon defoamer, 5-10 parts of additive and 30-50 parts of water. According to the alcohol-free fountain solution disclosed by the invention, IPA (Iso Propyle Alcohol) or other alcohol additives do not need to be added during a using process of the alcohol-free fountain solution, the cost is reduced, and the alcohol-free fountain solution is mild and harmless to a human body and environment and adapts to the requirements of energy conservation, environmental protection and safety.

Owner:宋睿

Anti-corrosive coating for surface layer of electrical equipment and preparation method ofanti-corrosive coating

InactiveCN108395785AImprove ductilityUniform coatingAnti-corrosive paintsPolyurea/polyurethane coatingsLateriteElectric power

The invention discloses an anti-corrosive coating for the surface layer of electrical equipment and a preparation method thereof, and relates to the field of anti-corrosive coatings. The anti-corrosive coating is prepared form the following raw materials in part by weight: 25-35 parts of epoxy resin, 15-25 parts of polyurethane resin, 30-40 parts of polyacrylic resin, 5-10 parts of polydimethylsiloxane, 4-8 parts of dibutyl phthalate, 6-10 parts of mica, 3-6 parts of laterite, 5-10 parts of bentonite, 4-8 parts of talcum powder, 4-8 parts of graphene, 3-6 parts of zinc powder, 3-6 parts of zinc oxide, 3-6 parts of aluminum oxide, 4-8 parts of glass fibers, 3-6 parts of nano titanium dioxide, 3-6 parts of nano silicon carbide, 2-4 parts of microcrystalline wax, 2-4 parts of butyl stearate,10-15 parts of acetone and the like. The coating has the advantages of being good in ductility, capable of being easily applied uniformly, good in cohesiveness, not liable to fall off, and excellent in heat resistance and ageing resistance, a coating layer is not liable to crack, the raw material cost is low, the preparation method is simple, and the operation is easy.

Owner:合肥励仙电力工程有限公司

Furan resin self-hardening sand for casting and preparation method thereof

The invention discloses furan resin self-hardening sand for casting and a preparation method thereof. The furan resin self-hardening sand is prepared from the following raw materials in parts by weight: 20-30 parts of fresh sand, 70-80 parts of old sand, 1-1.5 parts of self-hardening furan resin, 10-15 parts of phosphoric acid, 8-12 parts of p-toluenesulfonic acid, 5-10 parts of ethyl sulfate, 0.5-1.5 parts of N-2-(amino ethyl group)-3-aminopropyl trimethoxy silane, 4-8 parts of tricresyl phosphate, 3-6 parts of waste syrup, 2-4 parts of activated carbon, 3-5 parts of sepiolite, 4-6 parts of zeolite, 5-10 parts of dibutyl phthalate, 2-3 parts of sodium alginate, 3-5 parts of butyl stearate and 4-6 parts of composite powder. The furan resin self-hardening sand has the advantages of being non-toxic, high in strength, small in smell, low in gas evolution and thermal expansivity, good in gas permeability and collapsibility, proper in viscosity, smooth and clean in surface, easy to clean and the like. The prepared casting is high in degree of precision and good in surface quality. The furan resin self-hardening sand is suitable for casting various cast steels, cast iron and non-ferrous castings.

Owner:TONGLING JINGWEI FLUID SCI & TECH

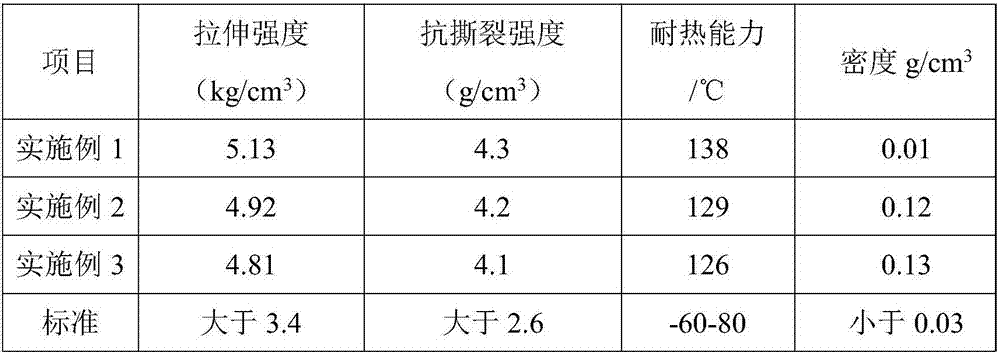

Lightweight plastic-wood composite sheet and preparation method thereof

The invention relates to a lightweight plastic-wood composite sheet and a preparation method thereof. The preparation method comprises the following steps of: firstly stirring PVC particles and tribasic lead sulfate evenly in a stirred tank, and then adding wood flour, LDPE-g-GMA, hollow glass beads, chlorinated polyethylene, ethylene bisstearamide and hard fatty acid butyl ester to the tank, heating up and stirring evenly, cooling and taking out the mixture, and then stirring the mixture evenly with baking soda and citric acid at room temperature, extruding out and molding. The lightweight plastic-wood sheet has the advantages of convenient production and manufacture, high degree of mechanization in the production process, low production cost, low density, light weight, easy installation and maintenance, less use of timber and plastic, turning waste into treasure, being recyclable and not destroyed by insects, no aging and discoloration as well as cracking, no buckling deformation and high impact strength, with the function of adsorbing gas. The lightweight plastic-wood sheet can be applied to a plurality of occasions such as office buildings, hotels and home offices, can be made into products such as photo frames, picture frames, foot lines, and hoisting and fastening boards, and can also be used as suspended beams, pergolas, and the like.

Owner:江苏森诺塑胶科技有限公司

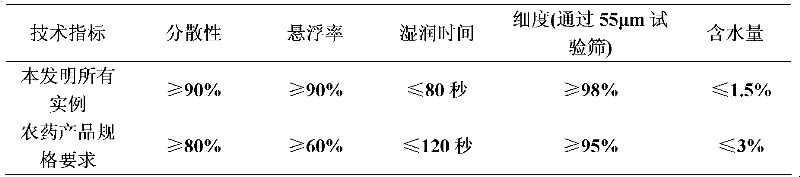

Environment-friendly flame-retardant polyvinyl chloride cable sheath material and preparation method thereof

InactiveCN102634127AOvercoming Harmful FlawsPlastic/resin/waxes insulatorsInsulated cablesPolyvinyl chlorideOxygen

The invention provides environment-friendly flame-retardant polyvinyl chloride cable sheath material and a preparation method thereof. The environment-friendly flame-retardant polyvinyl chloride cable sheath material comprises the following components: by weight, 100 parts of polyvinyl chloride, 35-40 parts of plasticizer, 5-8 parts of stabilizer, 6-10 parts of long-chain chlorinated paraffin, 3-5 parts of epoxidized soybean oil, 4-8 parts of antimony trioxide, 10-15 parts of active aluminum hydroxide, 5-10 parts of hydrated zinc borate, 1-1.4 parts of lubricant and 40-55 parts of filler, wherein the filler is composition of active heavy-weight calcium carbonate and nano calcium carbonate, and the lubricant is composition of stearic acid and butyl stearate. Oxygen index of the cable sheath material can reach 33 or above, and accords with RoSH and REACH regulations. The preparation method of the cable sheath material includes mixing the components in a high-speed mixer and then extruding and pelleting in a double-step screw extruder.

Owner:江苏凯诺电缆集团有限公司

Antibacterial engineering plastic

InactiveCN105623046AImprove antibacterial propertiesHigh hardnessLithium carbonateEngineering plastic

The invention discloses antibacterial engineering plastic.The antibacterial engineering plastic is prepared from polyvinyl plastic, an antibacterial agent, a filling agent, a lubricating agent, a bridging agent, an impact-resistant modifying agent and a dispersing agent; lithium carbonate is adopted as the antibacterial agent, silicon carbide is adopted as the filling agent, silicon carbide is adopted as the lubricating agent, caprolactam blocked aromatic isocyanate is adopted as the bridging agent, chlorinated polyethylene is adopted as the impact-resistant modifying agent, and carboxymethylcellulose is adopted as the dispersing agent.The antibacterial engineering plastic is prepared from polyvinyl plastic, the antibacterial agent, the filling agent, the lubricating agent, the bridging agent, the impact-resistant modifying agent and the dispersing agent, and the prepared antibacterial engineering plastic has the advantages of being good in antibacterial effect, high in hardness and strength, low in cost, good in quality, high in impact-resistant strength and long in service life.

Owner:TAICANG CHENZHOU PLASTIC

Pesticide composite containing picoxystrobin and triazole compound

InactiveCN102210308AImprove protectionGood treatment effectBiocideFungicidesTriazole antifungalsFlusilazole

The invention provides a pesticide composite containing picoxystrobin and triazole compound, comprising an effective active ingredient A and an effective active ingredient B, wherein the effective active ingredient A is the picoxystrobin; the effective active ingredient B is selected from one of epoxiconazole, flusilazole, tetraconazole, triazole and propiconazole. The pesticide composite disclosed by the invention comprises the following ingredients in percentage by weight: 1-60wt% of effective active ingredient A- picoxystrobin, 1-50wt% of effective active ingredient B selected from one of epoxiconazole, flusilazole, tetraconazole, triazole and propiconazole and the balance of accessory ingredient and butyl stearate. The pesticide composite disclosed by the invention is used for preventing and curing various diseases, such as crop powdery mildew, Septoria nodorum, leaf blight, downy mildew, smut, leaf spot, banana freckle, epidemic diseases, rust diseases, leaf mold, rice blast, banded sclerotial blight and anthracnose of grape and has obvious synergy.

Owner:陕西汤普森生物科技有限公司

Glass paint

InactiveCN102942825AStrong adhesionStrong acid and alkali resistance and water resistanceCoatingsWater solubleButanol

The invention discloses glass paint. The glass paint comprises the following raw materials by weight: 8 to 10 parts of hydroxyethyl cellulose, 4 to 6 parts of talcum powder, 1 to 2 parts of bismuth oxychloride, 2 to 4 parts of water-soluble resin, 5 to 7 parts of butanol, 7 to 9 parts of butyl stearate, 1 to 2 parts of petroleum, and 30 to 40 parts of water. The glass paint disclosed by the invention is high in adhesive force, and high in resistance to acid, alkali and water, and meets the demands of people.

Owner:HAIAN SUHAI FINE CHEM

Pathological tissue transparentizing and dewaxing solution and preparation method thereof

ActiveCN104655460ANo irritating smellWon't become brittlePreparing sample for investigationAlkaneEther

The invention discloses a pathological tissue transparentizing and dewaxing solution and a preparation method thereof. The pathological tissue transparentizing and dewaxing solution comprises 92.5-98 parts by weight of highly branch chain saturated alkane, 0.5-5 parts by weight of a stabilizing agent and 0.1-2.5 parts by weight of synergist, wherein the highly branch chain saturated alkane is one or a mixture of more of naphthenic oil, quadricyclane, cis-1-isopropyl-4-methyl cyclohexane, and contra-1-isopropyl-4-methyl cyclohexane; the stabilizing agent is one or a mixture of more of epoxy soybean oil, trimethylolpropane, and epoxy butyl stearate; the synergist is one or a mixture of more of polyether modified heptamethyltrisiloxane, butyl ether polydimethylsiloxane, and dimethyl-3-hydroxypropyl methyl (siloxane and polysiloxane). The technical problems that a pathological tissue transparentizing and dewaxing solution is toxic and has pungent smell, and tissue becomes brittle and shrinks to be unfavorable for slicing after being soaked in the solution for a long time in the prior art are solved.

Owner:无锡市江原实业技贸有限公司 +1

Chlorosulfonated polyethylene cable sheath material and preparation method thereof

InactiveCN103265764AImprove aging resistanceImprove heat resistancePlastic/resin/waxes insulatorsInsulated cablesPolymer scienceSilanes

The invention discloses a chlorosulfonated polyethylene cable sheath material and a preparation method thereof. The cable sheath material comprises the following raw materials: chlorosulfonated polyethylene, impact-resistant polystyrene, nano calcium carbonate, siliceous rock powder, modified zinc borate, ethyl carbamate, an accelerant CZ, a silane coupling agent KH550, epoxidized butyl stearate, thiodipropionate, alkylphenol polyoxyethylene and diisobutyl phthalate. By taking the chlorosulfonated polyethylene as a main material, the cable sheath material is excellent in aging resistance, heat resistance, low-temperature resistance, oil resistance and electrical-insulation resistance. By taking the nano calcium carbonate as a reinforcing agent and modifying the zinc borate serving as a fire retardant, the fire resistance of the cable sheath is improved greatly, so that the cable sheath is obvious in fire resistance.

Owner:ANHUI CHANGYUAN ZHIHAO ELECTRIC POWER SCI & TECH

Phthalate-free medical polrvinyl chloride (PVC) plastic

The invention discloses phthalate-free medical polrvinyl chloride (PVC) plastic. The plastic is prepared by blending the following components in part by weight: 100 parts of PVC resin, 25 to 95 parts of eco-friendly plasticizer, 0.1-8 parts of polyolefin and chloroethylene function modifier, 4.5-9 parts of high-efficiency heat stabilizer and 0.3-1.5 parts of lubricant, wherein the eco-friendly plasticizer is cyclohexane1,2-diisononyl phthalate, SOFT-N-SAFE, EPN or acetyl tributyl citrate; the polyolefin and chloroethylene function modifier is more than two of styrene, maleic anhydride, diethyl maleate and chloroethylene; the chloroethylene is more than one of powdery, pasty and liquid calcium and zinc heat stabilizer; and the lubricant is butyl stearate or oxidized polyethlene wax. The phthalate-free medical PVC plastic is used for producing disposable medical supplies and is safe because the plastic is phthalate-free.

Owner:欧阳伟

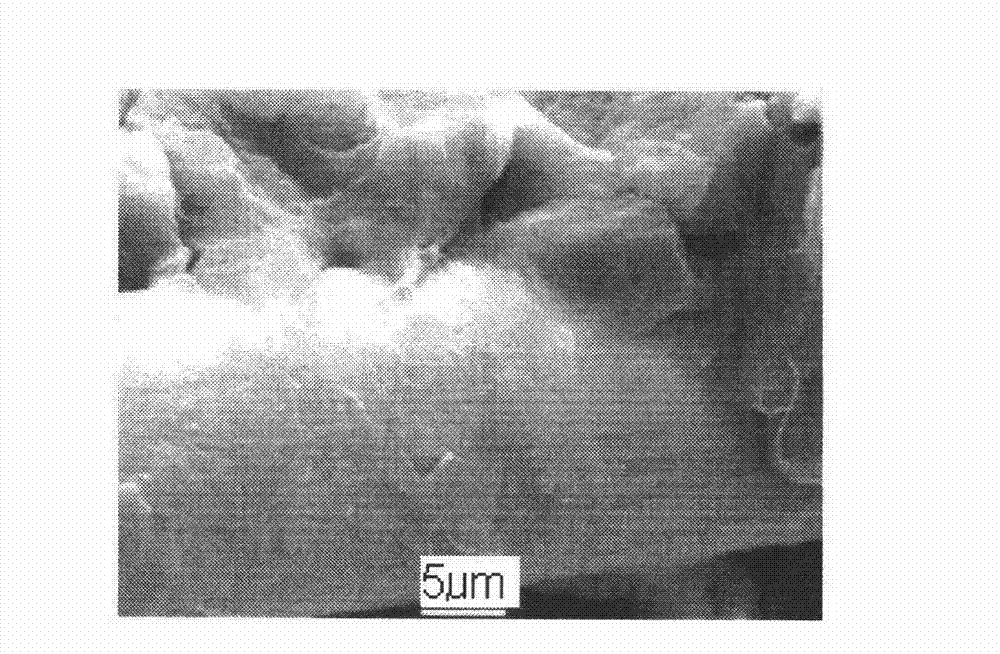

Universal nonferrous metal and stainless steel cold rolling oil composite additive and preparation method thereof

ActiveCN106566598AImprove anti-friction and anti-wear effectImprove anti-wear and anti-friction performanceAdditivesAntioxidantSolvent

The invention provides a universal nonferrous metal and stainless steel cold rolling oil composite additive and a preparation method thereof and belongs to the field of lubricating agents. According to the universal nonferrous metal and stainless steel cold rolling oil composite additive, lauryl alcohol, butyl stearate, pentaerythritol oleate and lauric acid are selected as oily agents; 2,6-di-tert-butyl-4-methylphenol is selected as an antioxidant; benzotriazole and thiadiazole derivatives are used as metal deactivators; dialkyl phosphorodithioate serves as an antiwear agent; and hydrogenated base oil serves as a solvent. The alcohol-ester type oily agents are mainly used for compounding with a little amount of acid oily agents as supplementation; a little amount of dialkyl phosphorodithioate is used as the antiwear agent to reinforce an oil film so as to improve the surface quality of a rolled stock; the service life of rolling oil is prolonged through a little amount of the antioxidant and the metal deactivators, the cyclic use frequency is increased, and rolled pieces are protected against corrosion. The universal nonferrous metal and stainless steel cold rolling oil composite additive is convenient to use, low in cost and little in dosage, and has the characteristics of high oil film strength, good antiwear and antifriction effect, high oxidation resistance and excellent annealing performance.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method for three-layer co-extruded composite high barrier blown film

InactiveCN104385565AReduce melt viscosityImprove melt fluidityLow-density polyethyleneLinear low-density polyethylene

The invention relates to a preparation method for a three-layer co-extruded composite high barrier blown film. The method includes: taking polyvinylidene chloride as the basic raw material, adding metallocene linear low density polyethylene, an ethylene-octene block copolymer, tributyl citrate, a rare earth calcium zinc composite stabilizer and butyl stearate, and carrying out a three-layer coextrusion blow molding process so as to obtain the film. The formula of the film surface layer involves: 80-88 parts by weight of metallocene linear low density polyethylene and 12-20 parts by weight of the ethylene-octene block copolymer. The interlayer comprises: 77-85 parts by weight of polyvinylidene chloride, 12-18 parts by weight of tributyl citrate, 2-3 parts by weight of the rare earth calcium zinc composite stabilizer, and 1-2 parts by weight of butyl stearate. The film prepared by the method provided by the invention has excellent oxygen obstruction and aqueous vapor permeation performance, good physical and mechanical properties and sanitation properties, and is suitable for packaging of cooked food, oily food, chilled fresh meat, dairy products, tea and drugs, etc.

Owner:FUJIAN NORMAL UNIV

Irradiation crosslinking low-smoke and halogen-free flame retardant cable material and its preparation method

InactiveCN102977468AImprove flame retardant performanceExcellent non-flammabilityElastomerPolymer science

The invention provides an irradiation crosslinking low-smoke and halogen-free flame retardant cable material. The cable material is prepared from the following raw materials, by weight, 100 parts of ethylene propylene diene monomer, 60-80 parts of high-density polyethylene, 9-11 parts of a maleic anhydride grafted polyolefin elastomer, 0.2-0.4 parts of an ultraviolet ray absorber UV-9, 10-20 parts of an EVA resin, 8-10 parts of aluminum hydroxide, 0.5-1.0 part of butyl stearate, 1-3 parts of zinc stearate, 0.2-0.5 parts of dicumyl peroxide (DCP), 1-2 parts of TAIC, 4-6 parts of zinc oxide, 0.5-1.0 part of molybdenum trioxide, 30-50 parts of carbon black N3393, 10-13 parts of nanometer calcium carbonate, 0.5-1.0 part of an antioxidant 4020, 0.1-0.3 part of an antioxidant MB, 8-10 parts of triphenyl phosphate, 12-15 parts of antimony (III) oxide and 6-8 parts of zinc borate hydrate. The cable material has the advantages of excellent flame retardation, very less smoke in combustion, no generation of toxic gases or corrosive gases, good weatherability, good abrasion resistance, good insulation property, and ultraviolet resistance.

Owner:武汉爱邦高能技术有限公司

Aerial insulation cable material

InactiveCN104109302AQuality improvementImprove performancePlastic/resin/waxes insulatorsLow-density polyethyleneAerial cable

The present invention discloses an aerial insulation cable material made from the following raw materials by weight: 60-80 parts of SG-3 type PVC (polyvinyl chloride), 20-30 parts of low density polyethylene, 15-25 parts of ethylene-vinyl acetate copolymer, 10-15 parts of bisphenol A type polycarbonate, 15-20 parts of magnesium hydroxide, 5-10 parts of butyl stearate, 4-8 parts of rapeseed oil, 1-2 parts of barium stearate, 2-3 parts of calcium stearate, 3-5 parts of diphenyl isooctyl phosphate, 4-6 parts of 2,2'-ethylenedioxydiethyl bis(2-ethylhexanoate), 8-12 parts of nano sepiolite powder, 15-25 parts of carbon black N660, 5-8 parts of a composite filler, 1-2 parts of catechol, 1-2 parts of dibutyltin dichloride and 5-10 parts of dibutyl isophthalate. The aerial insulation cable material is stable in quality, reliable in performance, excellent in weather resistance, aging resistance and electrical properties, good in toughness, tensile strength, and high temperature resistance, excellent in machining performance, and suitable for 1KV and below aerial cable insulating layers.

Owner:朱六璋

Toughening-modified organic glass plate and preparation method thereof

The invention discloses a toughening-modified organic glass plate, which comprises the following raw materials in part by weight: 90 to 110 parts of methyl methacrylate, 10 to 20 parts of butyl acrylate, 0.2 to 0.3 part of azodiisobutyronitrile and 0.3 to 0.8 part of butyl stearate. The invention has the advantages that: the impact strength of the toughening-modified organic glass plate is improved by about 80 percent to 24KJ / m<2> compared with the common organic glass plate; the elongation at break is increased by about 30 percent to over 4 percent; and the toughening effect is desirable, and the reduction in tensile strength is little.

Owner:713 RES INST OF CHINA SHIPBUILDING IND CORP

EPE pearl wool and preparation method thereof

InactiveCN107880347AEasy to operateShorten the timeLow-density polyethyleneLinear low-density polyethylene

The invention provides EPE pearl wool. The EPE pearl wool is prepared from the following raw materials in parts by weight: 70-80 parts of low density polyethylene, 30-40 parts of high density polyethylene, 10-15 parts of an ethylene-vinyl acetate copolymer, 12-16 parts of azodicarbonamide, 3-5 parts of dicumyl peroxide, 3-5 parts of zinc oxide, 20-30 parts of titanate modified calcium carbonate, 5-7 parts of isobutyl triethoxysilane, 1-2 parts of magnesium stearate, 4-6 parts of butyl stearate, 4-5 parts of hexamethylenetetramine, 3-5 parts of polycarbonate, 5-7 parts of aluminum hydroxide, 8-9 parts of bamboo charcoal powder, 6-8 parts of dioctyl adipate, 3-5 parts of ethanol amine, 8-9 parts of dicyclohexyl phthalate and 7-9 parts of kaolin. The EPE pearl wool provided by the invention has good elasticity, buffering capability, thermal stability and mechanical properties. The invention also provides a preparation method of the EPE pearl wool.

Owner:HEFEI LANGSHENG NOVEL MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com