Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

695 results about "Polyvinylidene chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyvinylidene chloride or Polyvinylidene dichloride (PVDC) is a homopolymer of vinylidene chloride.

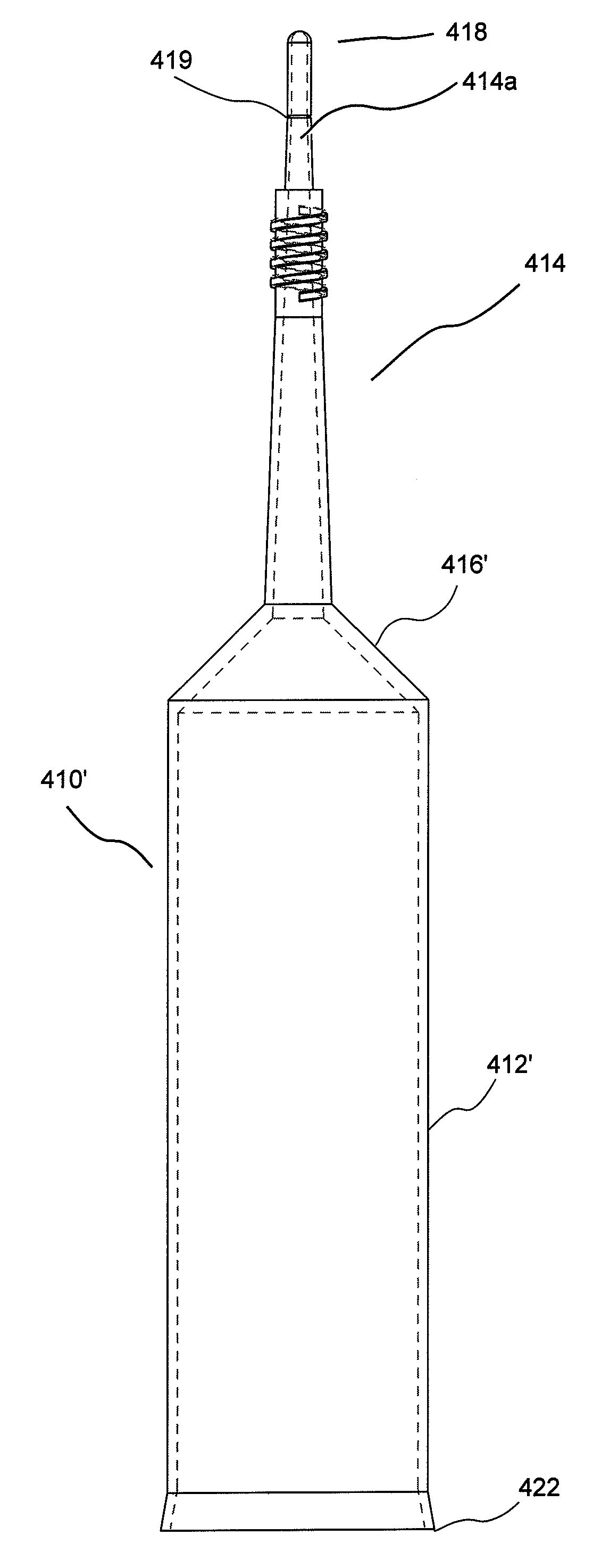

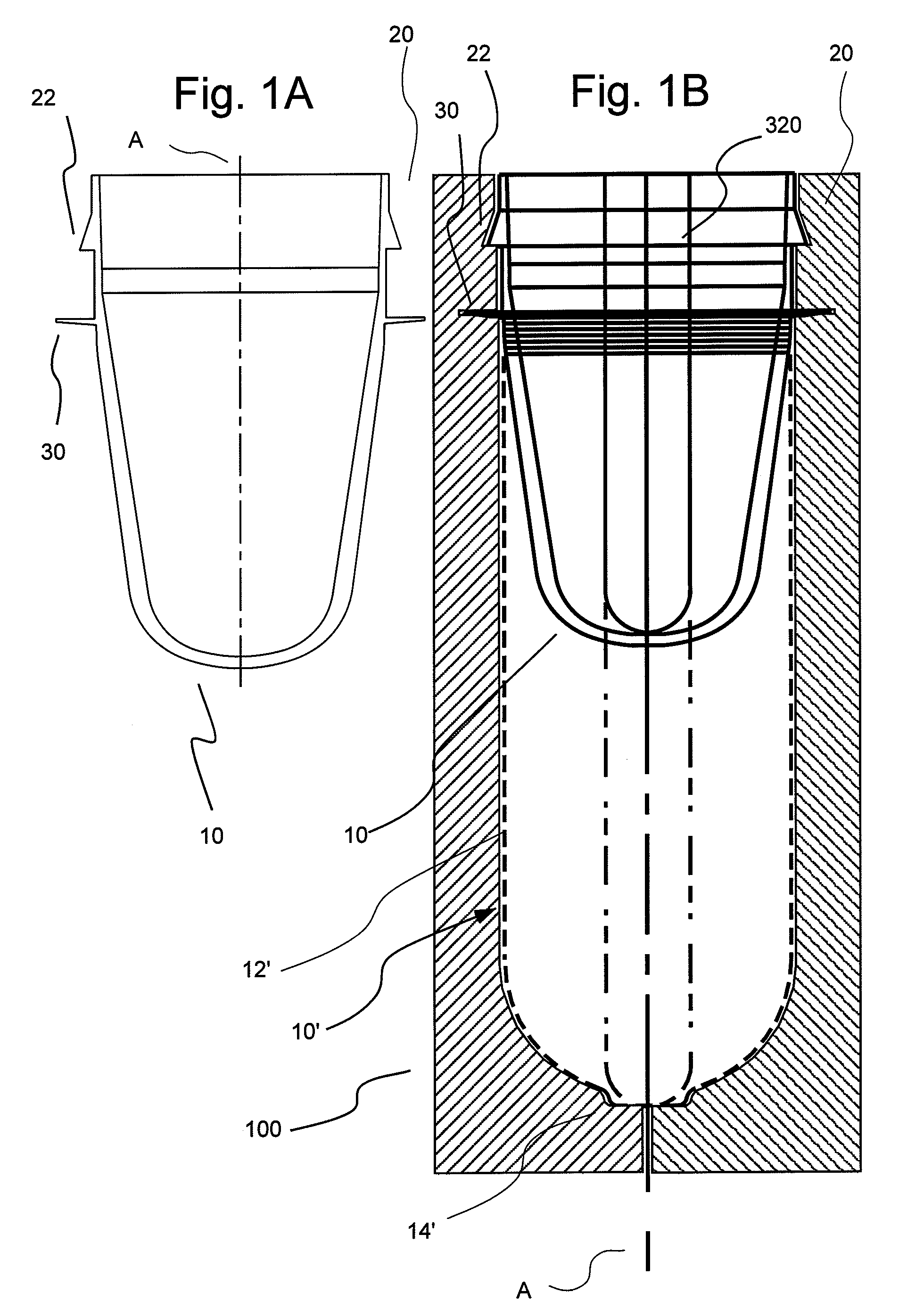

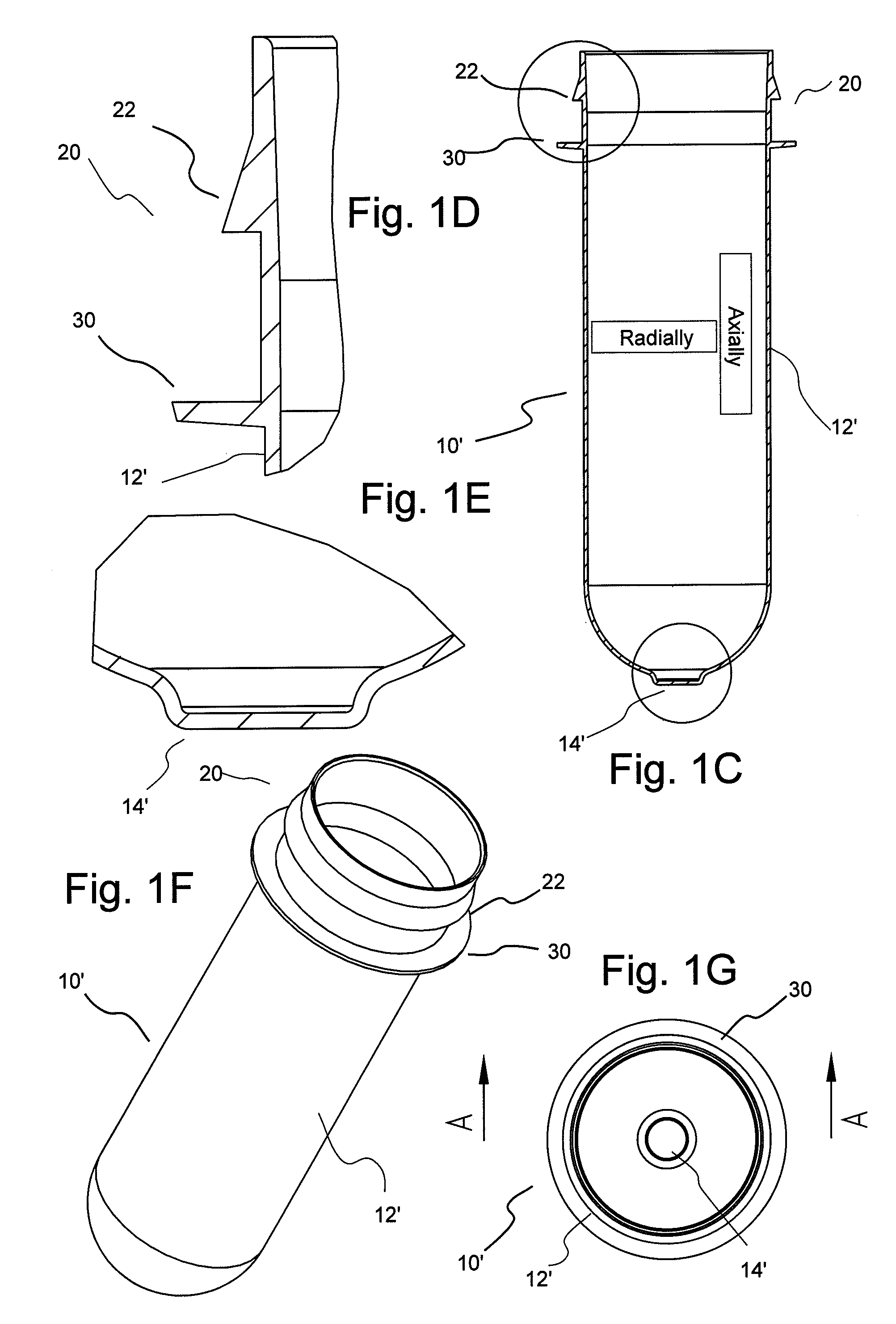

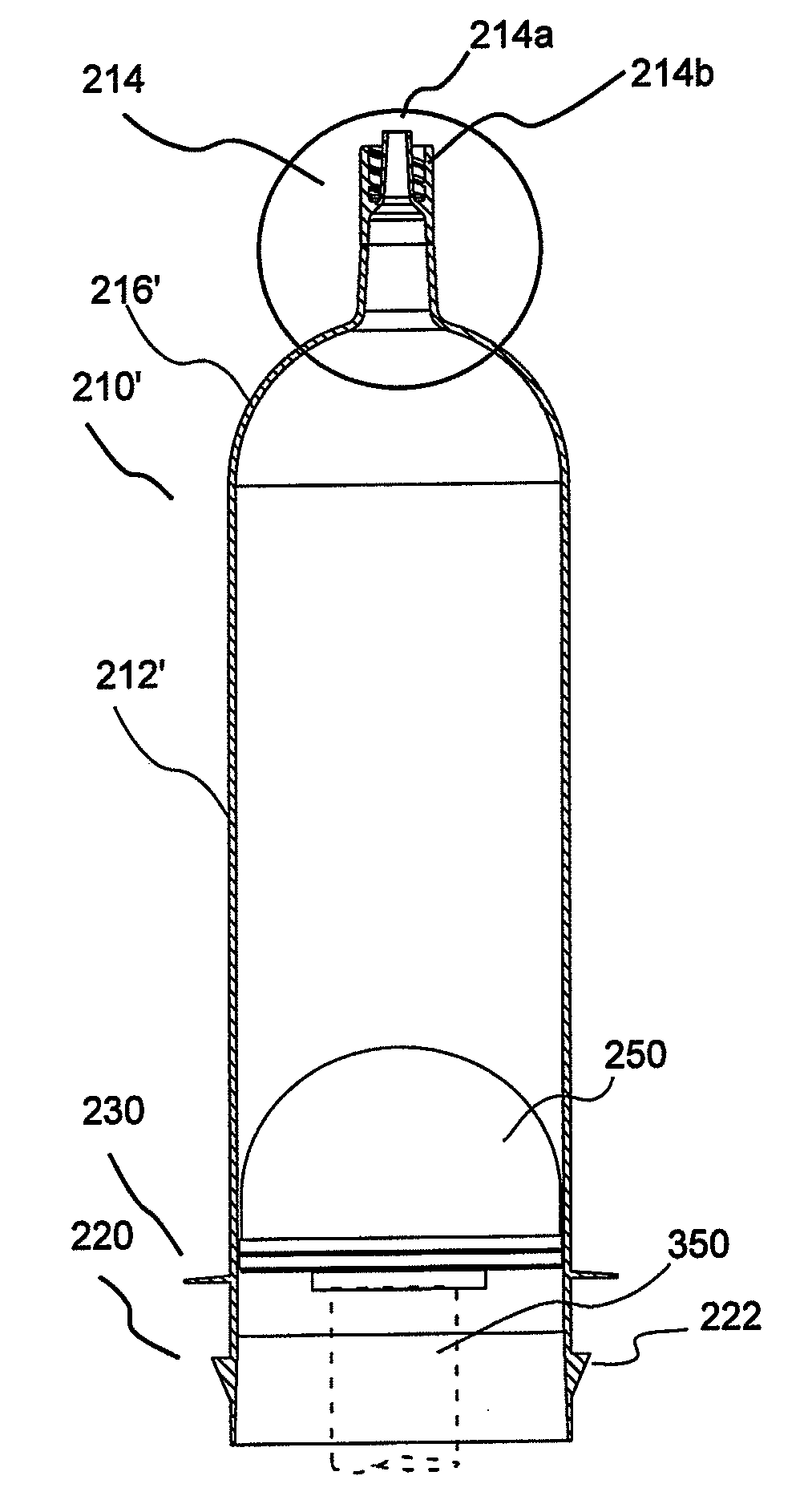

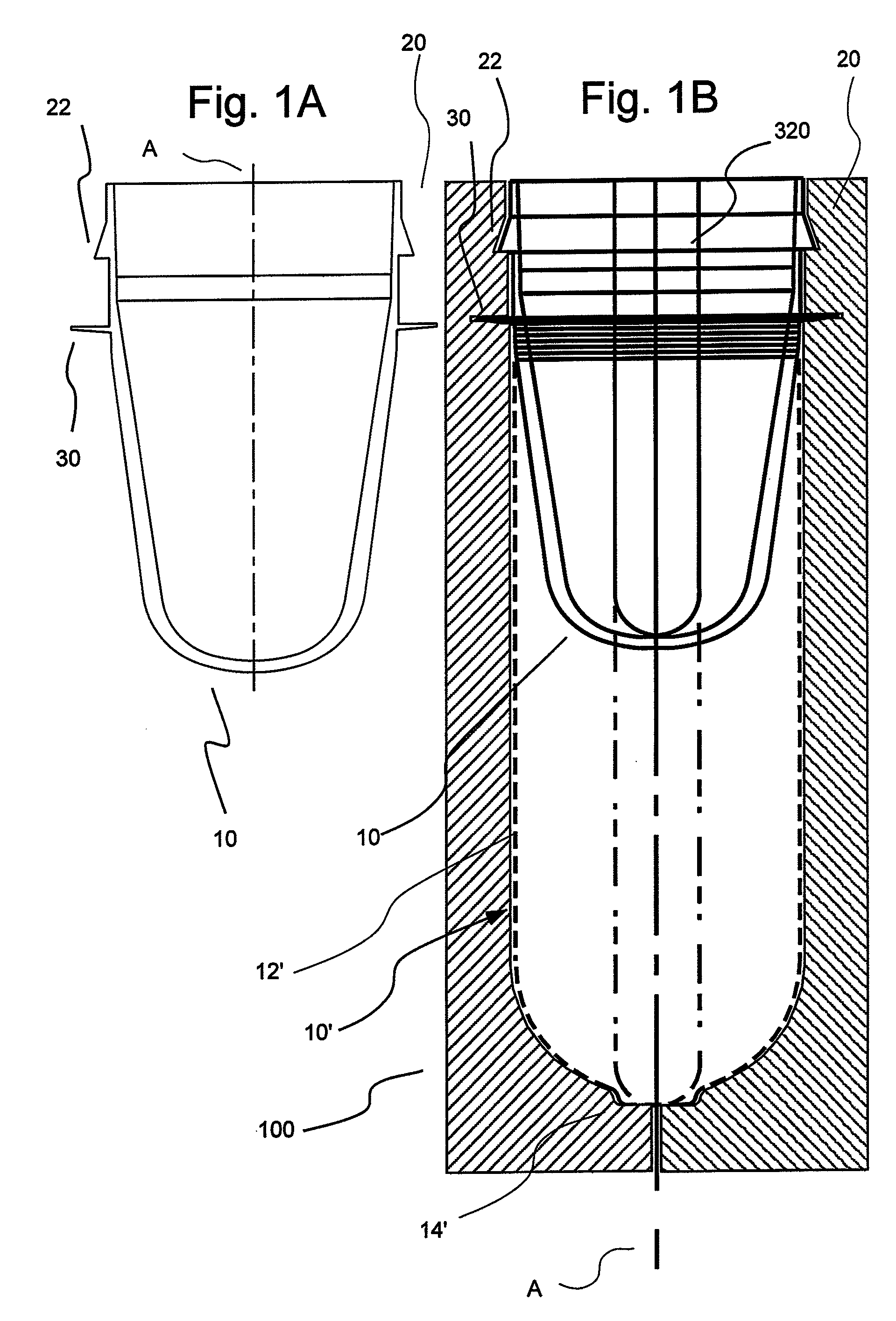

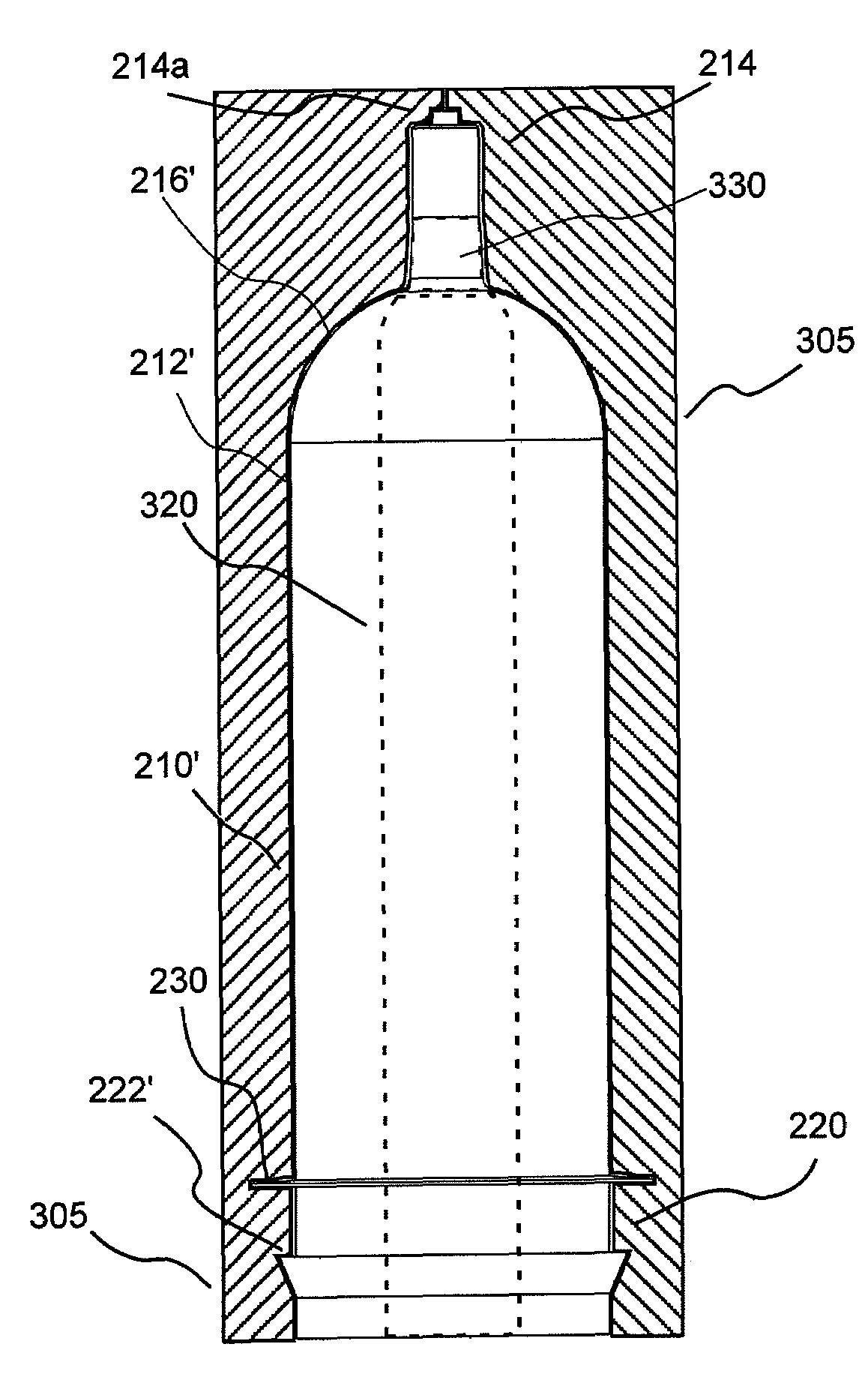

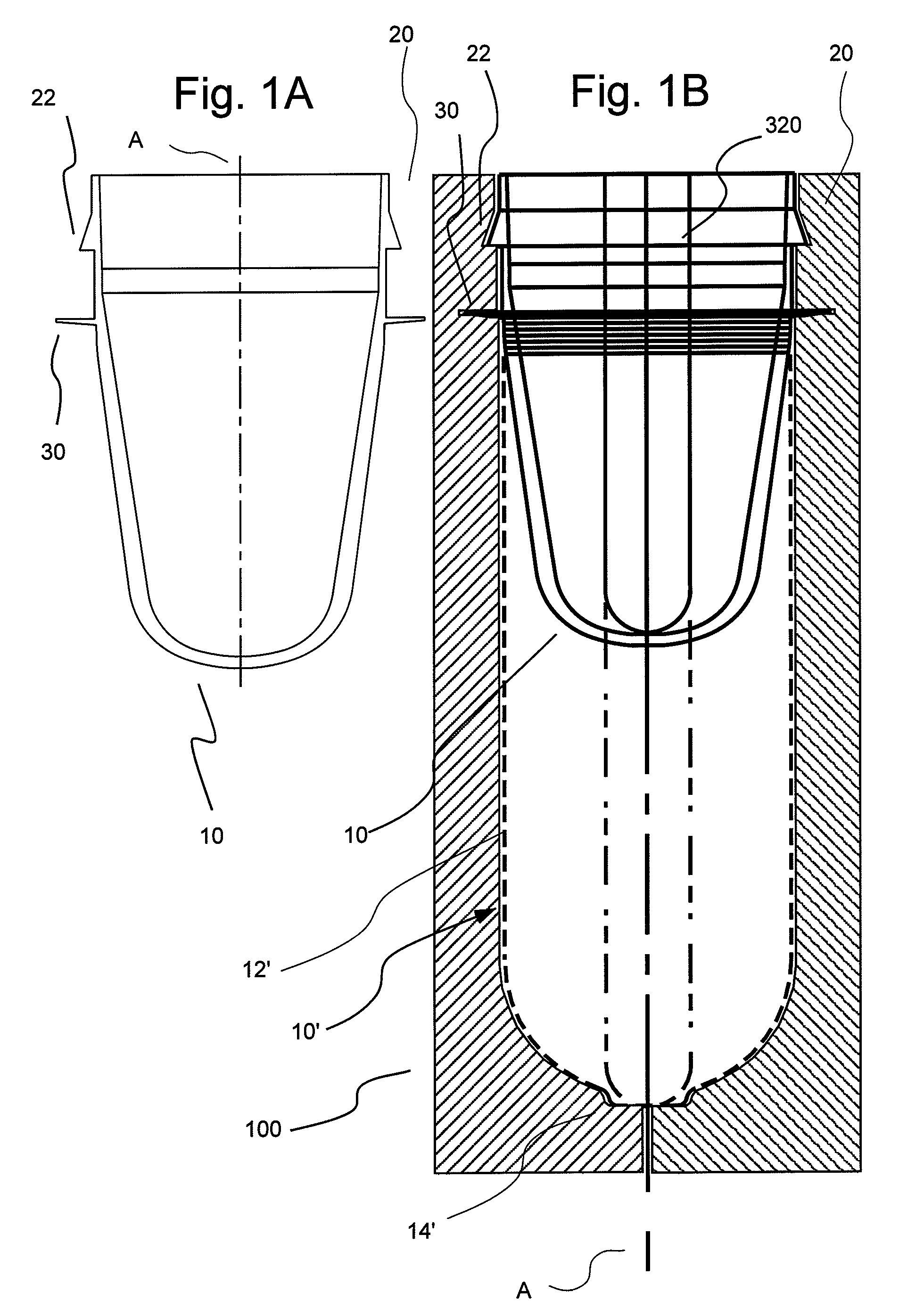

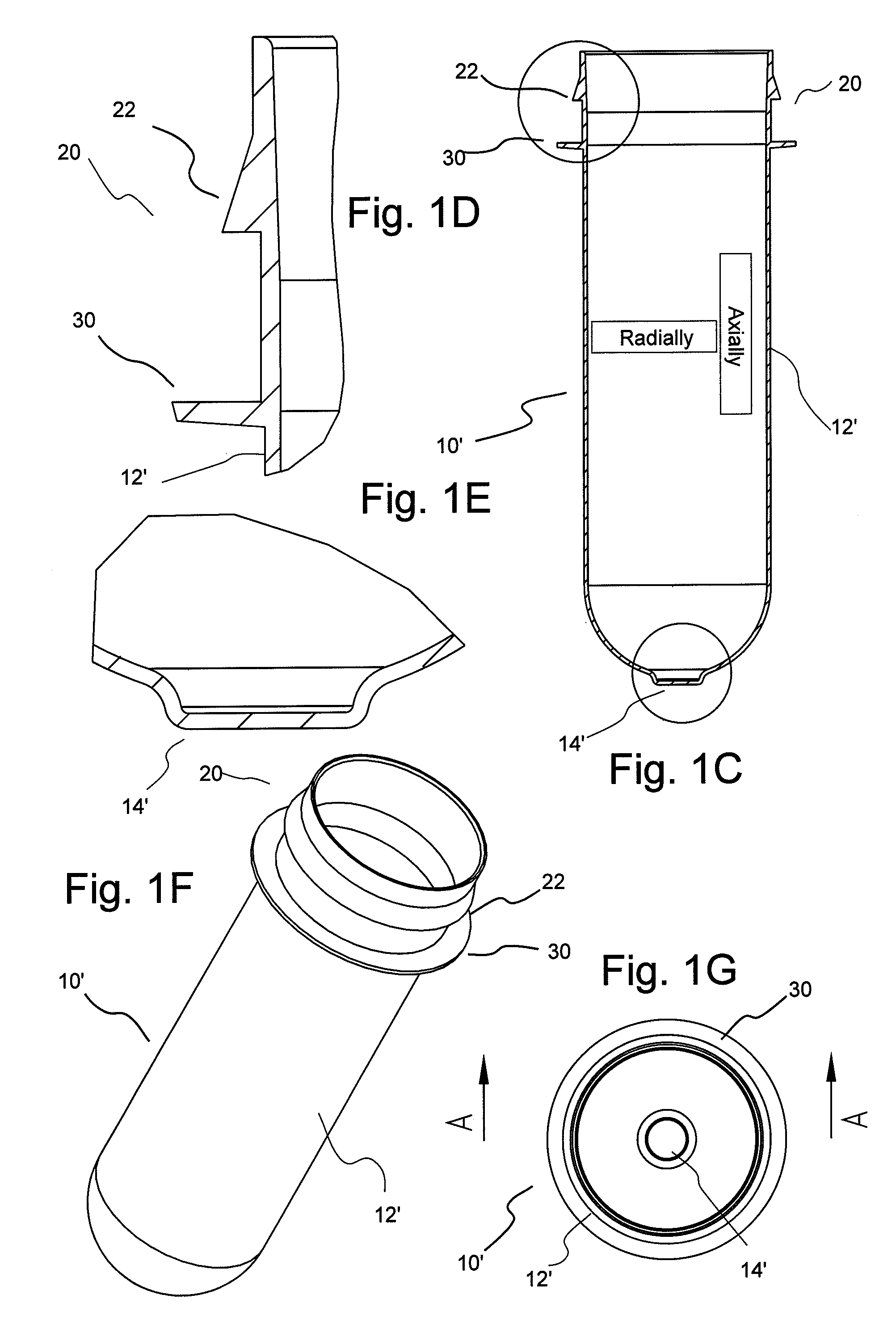

Syringe for use with injectors and methods of manufacturing syringes and other devices

ActiveUS20080033367A1Reduce thicknessInfusion syringesMedical devicesPolystyreneCyclo olefin polymer

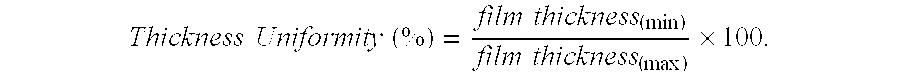

A syringe for use in a pressurized injection of a fluid includes a syringe barrel including a polymeric material having undergone expansion via blow molding. An inner diameter of the syringe barrel can, for example, be sufficiently constant (over at least a portion of the axial length of the syringe) that a plunger slidably positioned within the syringe barrel and in generally sealing contact with an inner wall of the syringe barrel can be used within the syringe barrel to generate a pressure of at least 1 psi within the syringe barrel. In several embodiment, the inner diameter of the syringe barrel is sufficiently constant to generate a pressure of at least 100 psi, at least 300 psi, or even at least 500 psi within the syringe barrel. A method of forming a syringe includes the steps of: injection molding at least one polymeric material to form a preform; placing the preform into an blow mold die; and expanding at least a portion of the preform while heating the preform within the die to form a barrel of the syringe. The syringes can be formed to withstand relatively high pressures as described above. The at least one polymeric material can, for example, be polyethyleneterephthalate, cyclic olefin polymer, polypropylene, polystyrene, polyvinylidene chloride, polyethylene napthalate and / or nylon.

Owner:BAYER HEALTHCARE LLC

Barrier coating for thermoplastic films

The present invention generally relates to a barrier coating composition for application to a thermoplastic film comprising (a) a nano-clay additive in an amount from about 1 wt % to 50 wt % of said barrier coating, wherein said nano-clay additive comprises untreated nano-clay platelets; and (b) a base coating in an amount from about 50 wt % to 99 wt % of said barrier coating, wherein said base coating comprises a polymer selected from the group consisting of polyvinylidene chloride (PVdC), poly(vinyl)alcohol (PVOH), ethylene vinyl alcohol (EVOH), acrylate copolymers and mixtures thereof.

Owner:JINDAL FILMS AMERICAS LLC

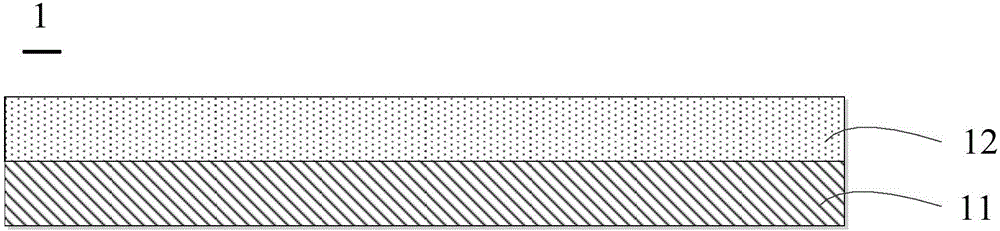

Polymer back panel of solar battery assembly and manufacture method of polymer back panel

ActiveCN102569452AExtend your lifeHigh bonding strengthSynthetic resin layered productsCoatingsPolymer alloyPolyethylene terephthalate glycol

The invention provides a polymer back panel of a solar battery assembly. The polymer back panel comprises a base film layer, binding layers on both sides of the base film layer, a fourth thin film layer and a fifth thin film layer on the other two sides of the binding layers, wherein the base film layers contain at least one of the following components: polyamide polymers, polypropylene and acrylic polymers, polyethylene and ethylene polymers, polyvinylidene chloride, styrene polymers, ABS (acrylonitrile butadiene styrene) resins, liquid crystal polymers, acrylic acid polymers, polyphenyl ether, polycarbonate and polymer alloy of polycarbonate and poly(C2-6 alkal terephthalate). In addition, the invention also provides a manufacture method of the back panel. By adopting a thin film structure made of one or more of the above polymers to substitute for the conventional PET (polyethylene terephthalate) layer, the polymer back panel has excellent processing formation performance, material mechanical performance, barrier performance and anti-aging performance; and a back panel laminated film can be prepared by molten co-extrusion or extrusion composite process, with the advantages of significantly improved bonding strength between the films and simplified production process.

Owner:DSM SUNSHINE SOLAR TECH (SUZHOU) CO LTD

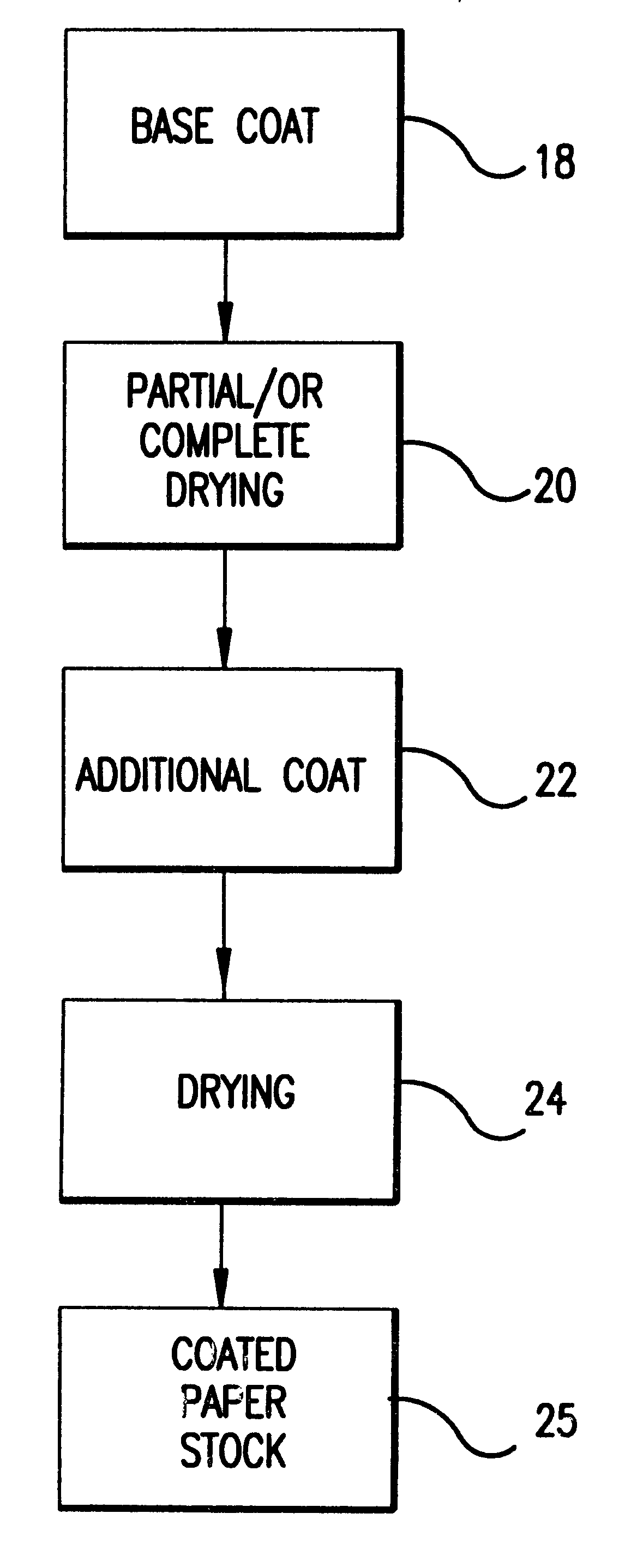

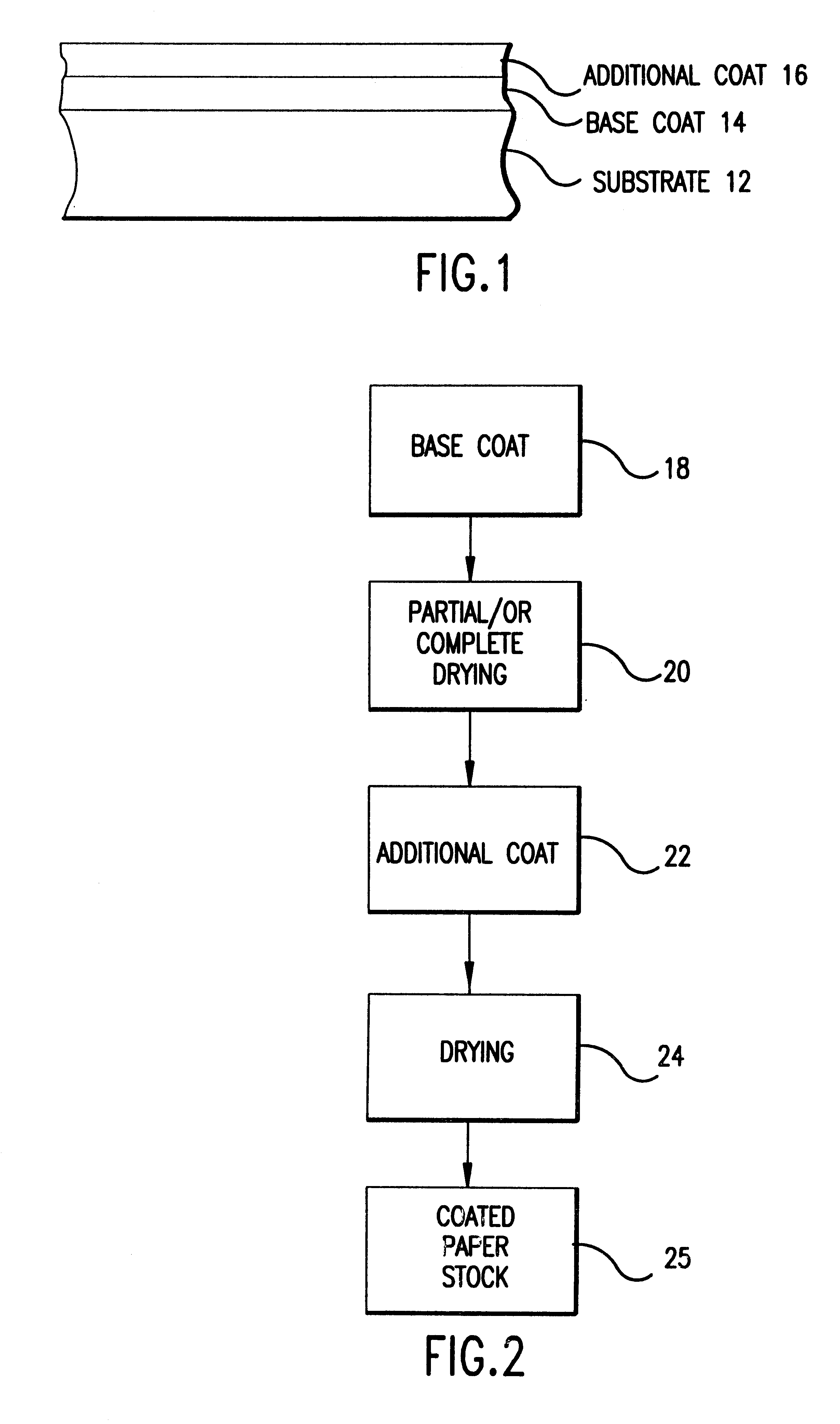

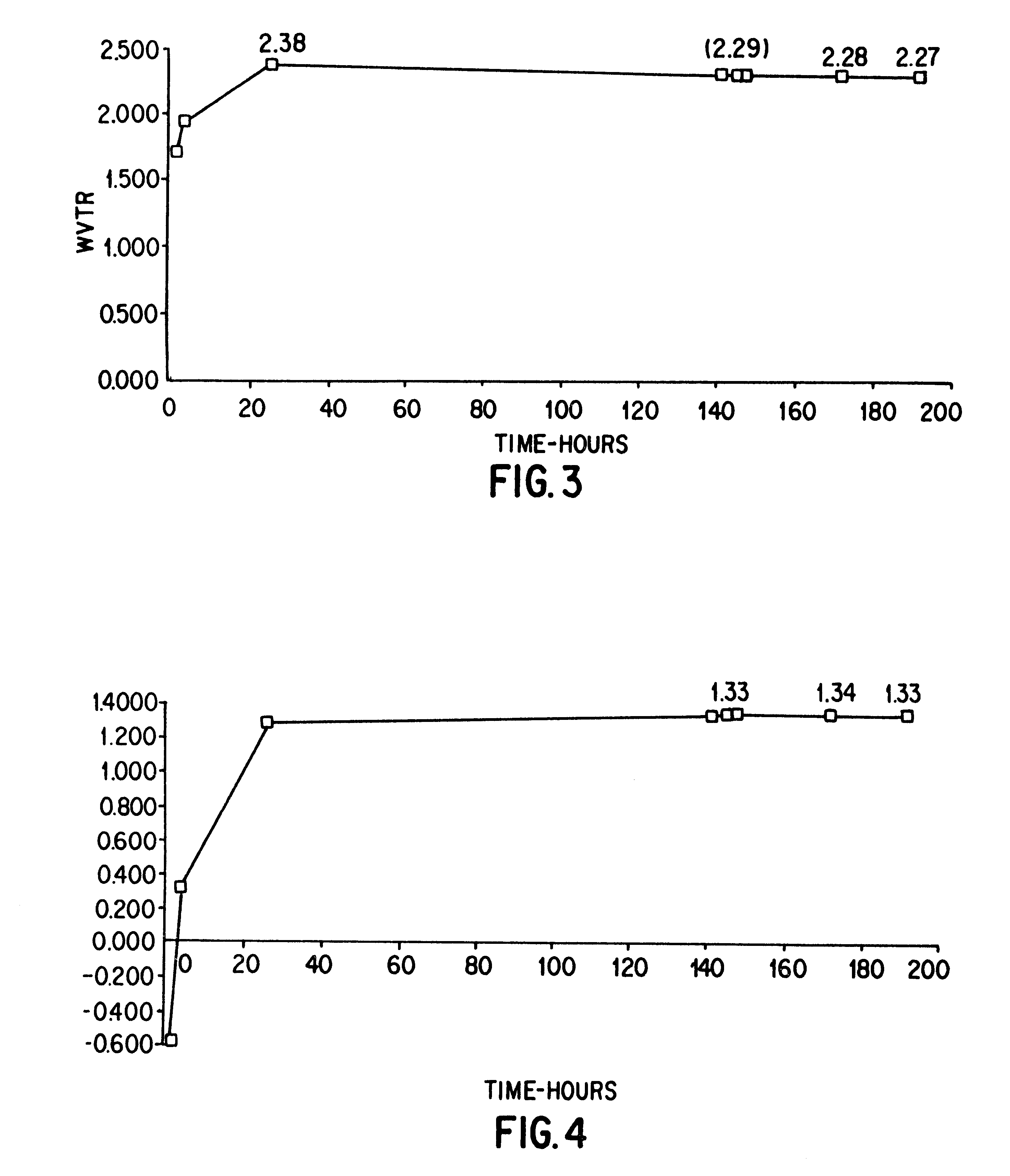

Recyclable and repulpable ream wrap and related methods of manufacture

InactiveUS6548120B1Reduce penetrationReduce drying demandFlexible coversWrappersWater basedPolymer science

Recyclable and repulpable coated paper stock, preferably for use as ream wrap, comprising a substrate coated on at least one surface with a base coat and at least one additional coat over said base coat. Both coats are water based dispersions of a polymer selected from the group consisting of acrylic polymers, acrylic copolymers, polyvinyl acetate, polyvinyl alcohol, ethylene-vinyl acetate, polyvinyl chloride, styrene butadiene copolymers, polyvinylidiene chloride and its copolymers, or starch. The wax free coating forms a pin-hole free continuous film on the substrate which is resistant to water and water vapor. The invention also includes processes for making and recycling the invented coated paper stocks.

Owner:COATING EXCELLENCE INT

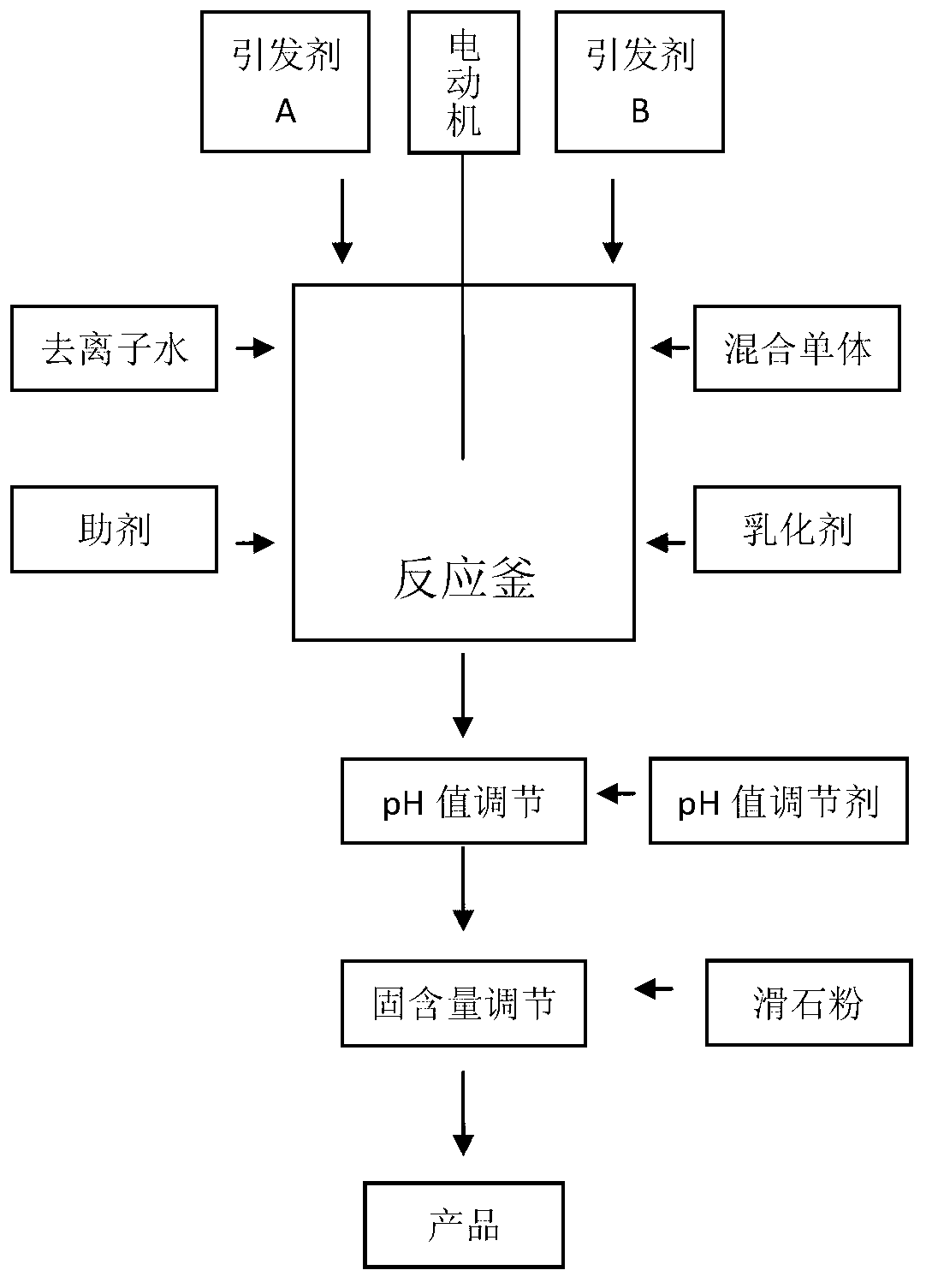

Method for preparing polyvinylidene chloride and acrylic ester copolymerization latex

The invention provides a preparation method of copolymerization latex of polyvinylidene chloride and acrylate, which comprises that reacts raw materials polyvinylidene chloride monomer, second monomer, functional monomer, composite emulsifier, pH adjuster, initiator, seed latex, and water in inertia gas, 0.08-0.12MPa and 50-60DEG C, collects polyvinylidene chloride and acrylate copolymerization latex from reaction product. The inventive PVDC latex is white stably, without changing into yellow after coating, with high stability. The latex can be directly coated on surface of base material as BOPP, BOPET and PVC hard sheet, while the coated or coated and dried film has barrier property, damp proofness, fragrance protectiveness, chemical drug resistance, and fireproof or the like. The film is transparent for long time, without changing into yellow. The inventive product can be used in one-time environment-friend dinnerware and inner layer of paper package, as tobacco, food and drug.

Owner:SHANGHAI CHLOR ALKALI CHEM

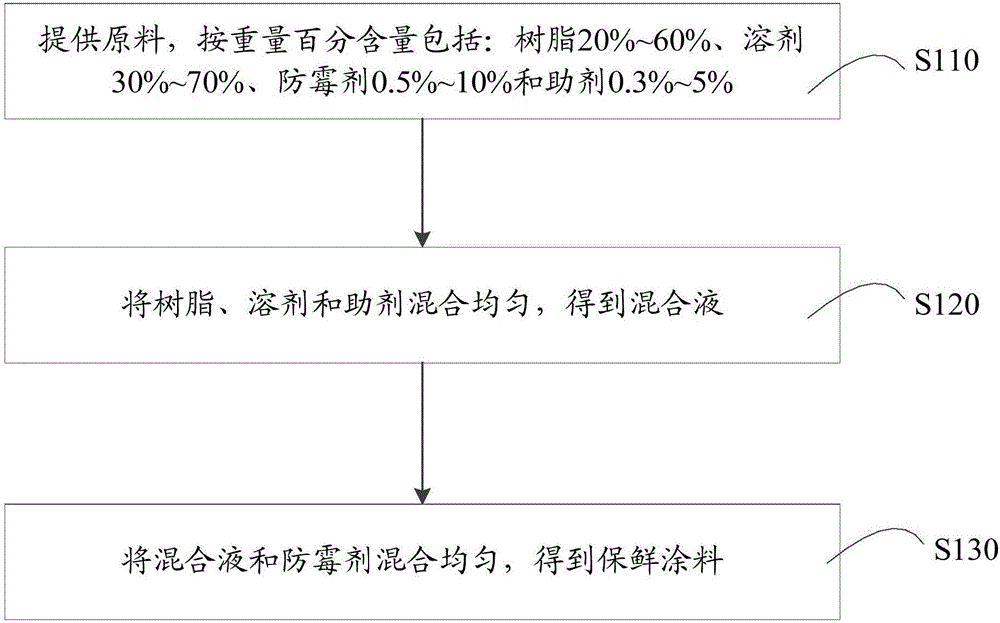

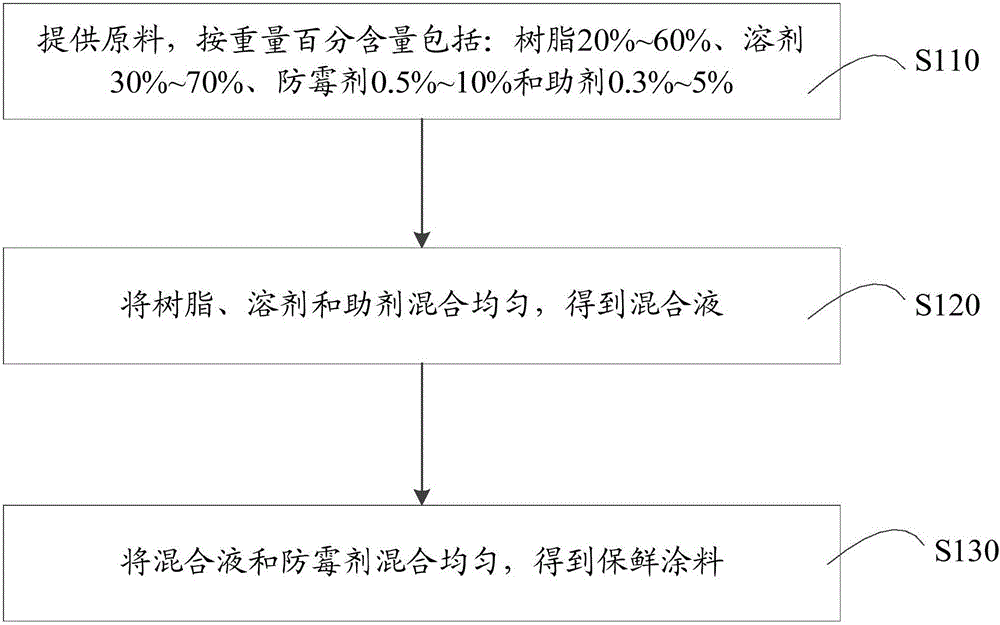

Mildewproof preservative film and preparation method thereof

InactiveCN106634129AIncrease contactNo porosityAntifouling/underwater paintsPaints with biocidesCarvacryl acetateSolvent

The invention discloses a mildewproof preservative film and a preparation method thereof. The mildewproof preservative film comprises a base layer and a mildewproof preservative coating arranged on the base layer, wherein the mildewproof preservative coating is prepared from a mildewproof preservative paint. The mildewproof preservative paint comprises the following components in percentage by weight: 20-60% of resin, 30-70% of solvent, 0.5-10% of mildew preventive and 0.3-5% of aid. The resin is composed of at least one of polyurethane, an acrylate copolymer, polyvinyl alcohol, polyvinylidene chloride, modified polyvinylidene chloride, an ethylene-vinyl acetate copolymer, a polyvinyl acetate copolymer and a vinyl acetate-butyl ester copolymer; and the solvent is composed of at least one of water and ethanol. The mildewproof preservative coating of the mildewproof preservative film has the advantages of compact surface and no void; and by adding the mildew preventive, the mildewproof preservative coating has the favorable effects of keeping the moisture constant and preventing mildewing. The mildewproof preservative film is especially suitable for preserving fruits, bread, tobacco and other foods which have shorter storage period, can easily mildew in a short time and need to be eaten in time.

Owner:CHANGDE JINRUN NEW MATERIAL TECH CO LTD

Method of manufacturing syringes and other devices

Owner:BAYER HEALTHCARE LLC

Method of generating hydrogen in drinking water using an enerceutical product added to magnesium in a hydrogen permeable but solute impermeable container

InactiveUS20100008850A1Increased hydrogen productionImprove usabilityHydrogen productionHydrogen/synthetic gas productionDialysis membranesWater use

Consuming water with increased hydrogen content can provide clinical benefits to humans and animals through a non-mitochondria alternative cellular energy (ACE) pathway and also as an antioxidant. This application discloses that the hydrogen content of drinking water can be safely increased by placing into the water a hydrogen generating device, such as a mixture of metallic magnesium and EH-101 (HB-101) containing solution, whereby the device allows for the selective passage of the generated hydrogen but restricts the passage of magnesium and EH-101 (HB-101) components. This partitioning of hydrogen from EH-101 (HB-101) components is achieved by using either reverse osmosis membrane, low density plastic material such as polyvinylidene chloride (PVDC or Saran), or low molecular weight cutoff dialysis membrane to create a sealed container of the magnesium and magnesium chloride, that can be placed into drinkable water. The EH-101 (HB-101) can be initially placed into a breakable inner compartment within the hydrogen permeable container. This compartment can be easily broken by simple squeezing just prior to placing the device into the water that is intended to have its hydrogen content increased. The increased hydrogen content can be assessed by the capacity of the water to decolorize a potassium permanganate test sample.

Owner:MARTIN WILLIAM JOHN

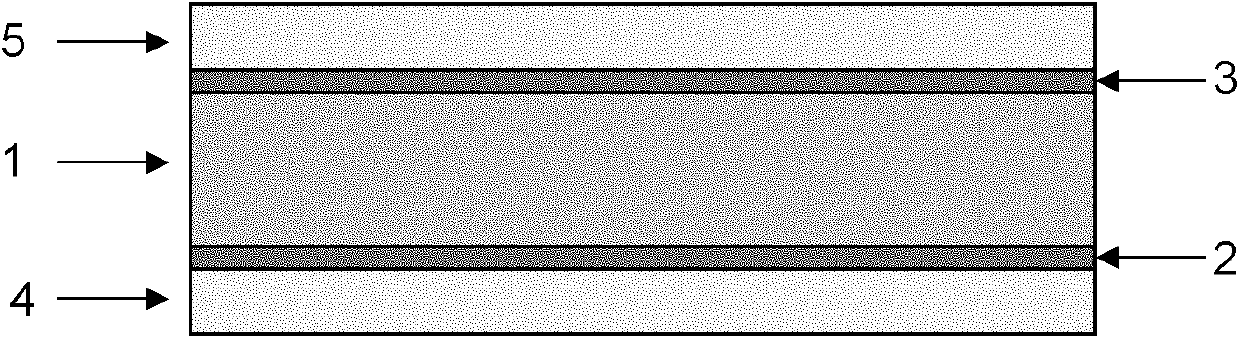

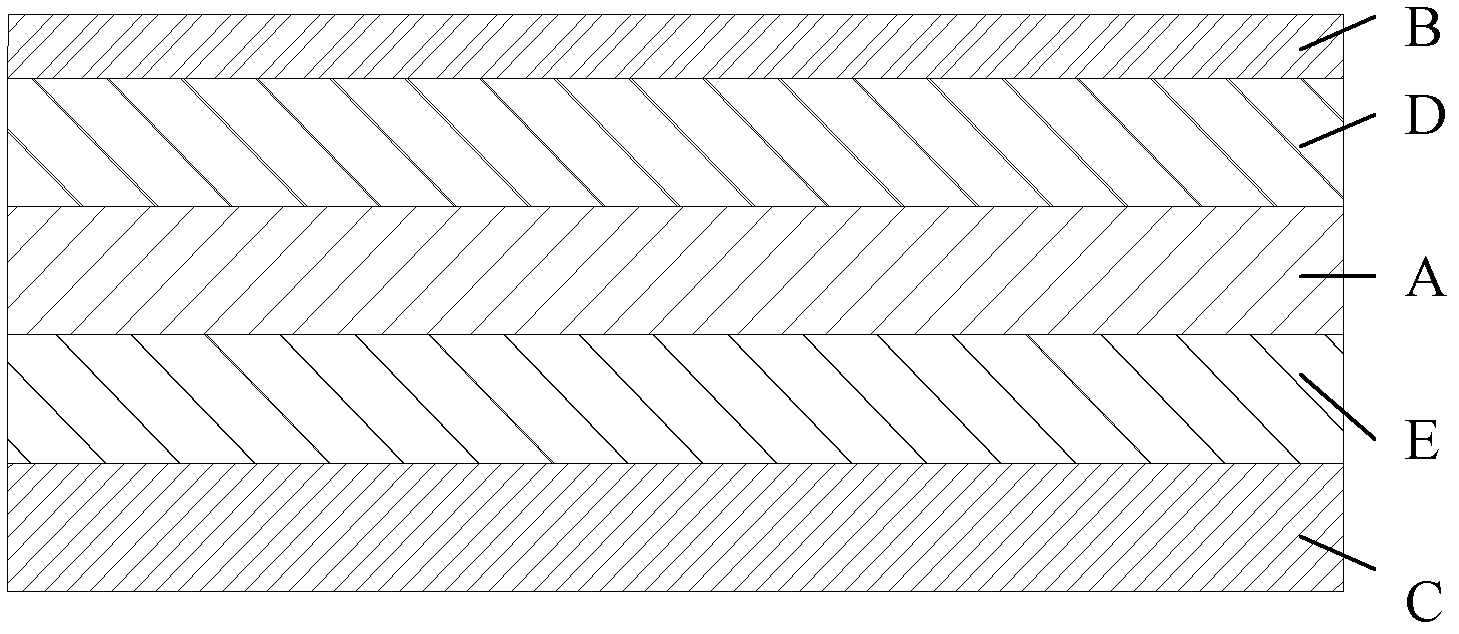

High-separation multilayer joint-extrusion shrink film

InactiveCN102642359AImprove barrier propertiesIncrease oxygenFlexible coversWrappersSurface layerWater vapor

The invention discloses a high-separation multilayer joint-extrusion shrink film, which comprises an outer surface layer, a separation layer, a heat sealing layer and two bonding layers. The two bonding layers are respectively located between the separation layer and the outer surface layer and between the separation layer and the heat sealing layer, the separation layer is made of one of or a combination of two of ethylene vinyl alcohol (EVOH) resin, polyvinylidene chloride resin and modified polyamide resin, the thickness of the separation layer is 10%-45% of the total thickness, the thickness of the outer surface layer is 3%-5% of the total thickness, the thickness of the heat sealing layer is 25%-35% of the total thickness, the thickness of the bonding layers is 10%-30% of the total thickness, and the number of the separation layer is one or three. The outer surface layer of the film is made of high-melting-point resin to overcome the shortcoming that users are easy to burn during a using process of products, simultaneously oxygen and water vapor separation performance are good, the anti-puncturing effect and heat sealing strength are good, and the high-separation multilayer joint-extrusion shrink film can be suitable to vacuum shrink package of chilled pork, cheese products and seafood products.

Owner:张建岭

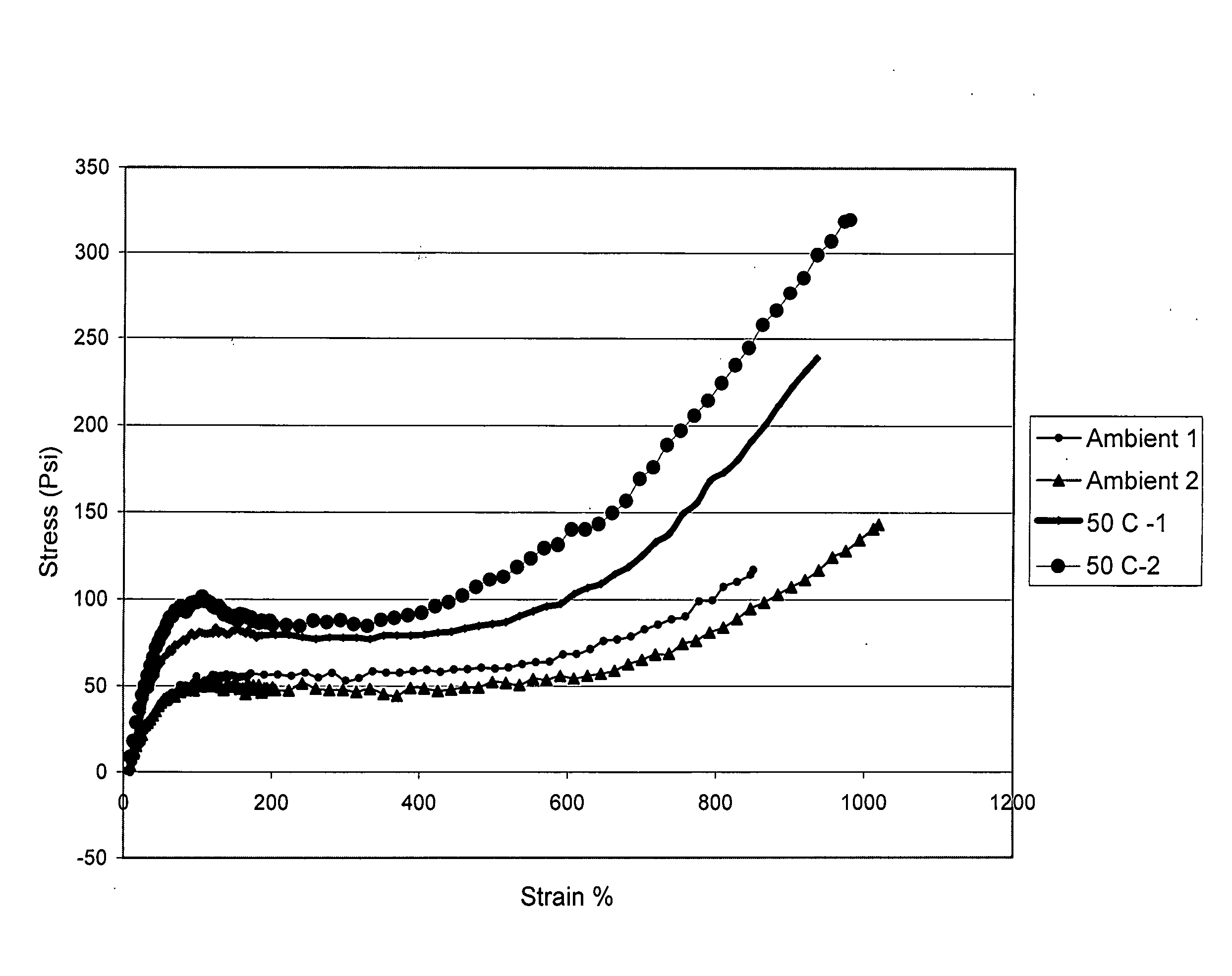

Spray-in latex foam for sealing and insulating

ActiveUS20080160203A1Broaden applicationIncrease shearOther chemical processesWallsSpray foamsButadiene-styrene rubber

A spray latex foam for filling wall cavities to enhance the sealing and insulating properties of a building is provided. The spray latex foam includes a latex system and a gaseous coagulating component. In at least one exemplary embodiment, carbon dioxide is included as a gaseous coagulating agent. One latex suitable for use in the spray foam is polyvinylidene chloride (PVDC), which possesses fire retardancy and environmental durability. However, a preferred latex is styrene-butadiene rubber (SBR). The latex system may also include a thixotropic agent, such as Laponite® RD synthetic clay. The spray latex foam is polyurethane-free. A method of preparing a spray latex foam that includes supplying a latex system and adding a gaseous coagulating component to the latex system is also provided.

Owner:OWENS CORNING FIBERGLAS TECH INC

Chub packaging film

InactiveUS20040157077A1High impact strengthLow production costSynthetic resin layered productsDomestic containersLow-density polyethyleneLinear low-density polyethylene

Owner:FLEXOPACK PLASTICS IND

Cook-in package with tight appearance

InactiveUS6562443B1Increase modulusImprove toughnessWrappers shrinkageLamination ancillary operationsPolyesterPolyamide

Owner:CRYOVAC ILLC

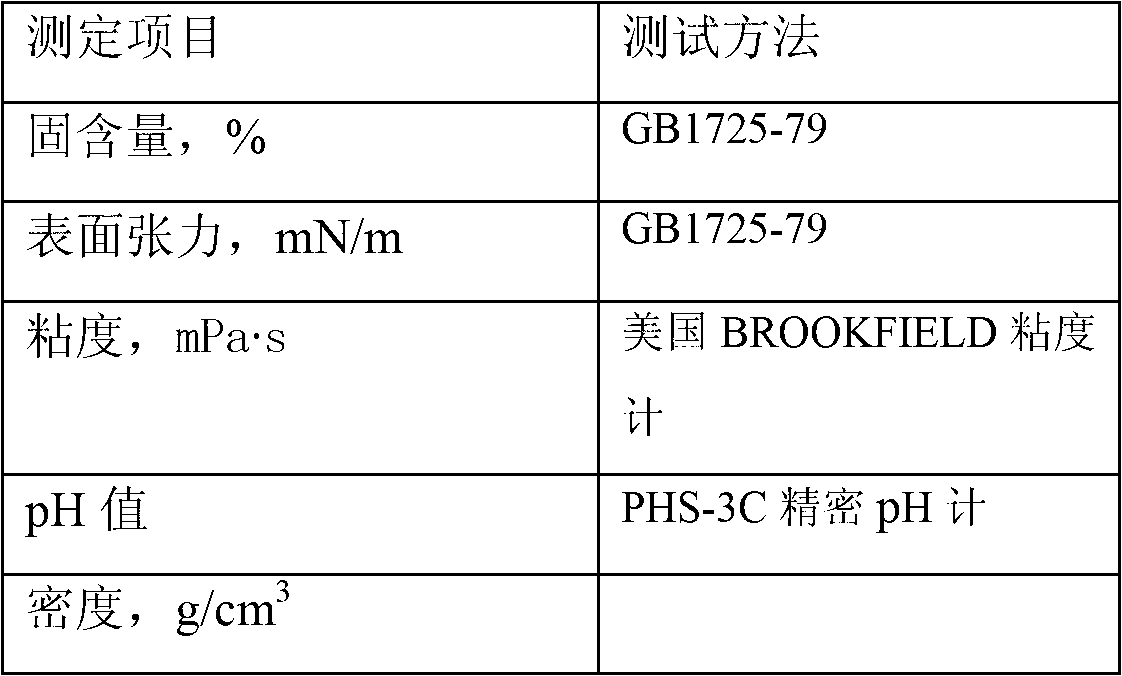

Polyvinyl dichloride (PVDC) latex used for interior and exterior wall coating materials and preparation method thereof and application thereof

The invention discloses a polyvinyl dichloride (PVDC) latex used for interior and exterior wall coating materials and a preparation method thereof and application thereof. The PVDC latex is obtained by a mixed monomer, an auxiliary, an initiating agent and an emulsifying agent through a once polymerization method, wherein the mixed monomer contains a certain amount of vinylidene chloride, vinyl chloride and acrylic ester, and the emulsifying agent contains sodium dodecyl benzene sulfonate and OP-10 or OP-4. The PVDC latex enables a system to be stable, and is free of emulsification breaking and sediment after placed for 24 months under temperature of 30 DEG C and relative humidity (RH) of 70%, and free of damage by calcium and magnesium in use. The interior and exterior wall coating materials obtained by the PVDC latex have the advantages of being environment-friendly, waterproof, damp proof (mildew resistant), coincident with the V-0 grade of the underwriters laboratories (UL) 94 standard in fire resistance, and the like.

Owner:HAINAN BNK WATER BASED NEW MATERIAL CO LTD

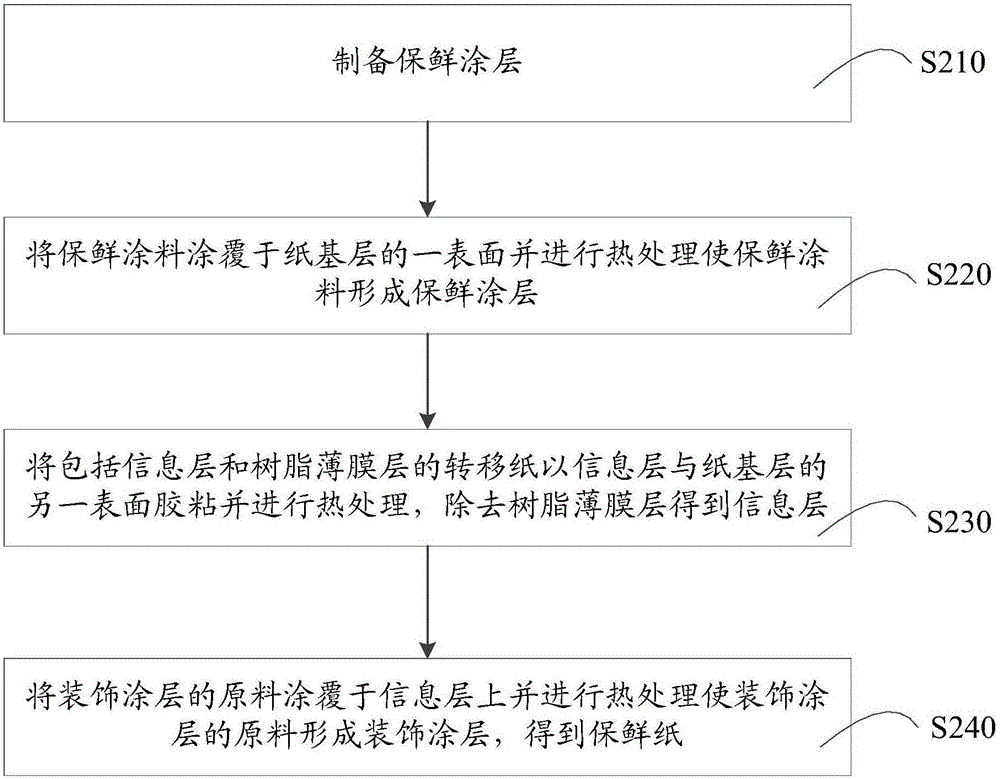

Mildew-proof preservative paper and preparation method and preparation device thereof

InactiveCN106638157AEasy to prepareGood reproducibilityFlexible coversWrappersCarvacryl acetateSolvent

The invention provides a mildew-proof preservative paper and a preparation method and a preparation device thereof. The preparation device comprises a paper-based layer, a decorative coating and a mildew-proof preservative coating, wherein the mildew-proof preservative coating is arranged one surface of the paper-based layer, the decorative coating is arranged on the other surface of the paper-based layer, the mildew-proof preservative coating is made from a mildew-proof preservative coating raw material and is prepared from, by weight, 20%-60% of resin, 30%-70% of solvent, 0.5%-10% of mildew preventive and 0.3%-5% of additive, the resin is at least one of polyurethane resin, acrylic ester copolymer, polyvinyl alcohol, polyvinylidene chloride, modified polyethylene vinylidene chloride, vinyl-vinyl acetate copolymer, polyvinyl acetate copolymer and vinyl acetate-butyl copolymer, and the solvent is at least one of water and ethanol. The surface of the obtained mildew-proof preservative coating is dense and provided with small pores, the mildew-proof preservative coating has the good effect keeping moisture constant, the mildew preventive is dispersed inside resin, mildewing can be also prevented, and further a good preservation effect is reached.

Owner:CHANGDE JINRUN NEW MATERIAL TECH CO LTD

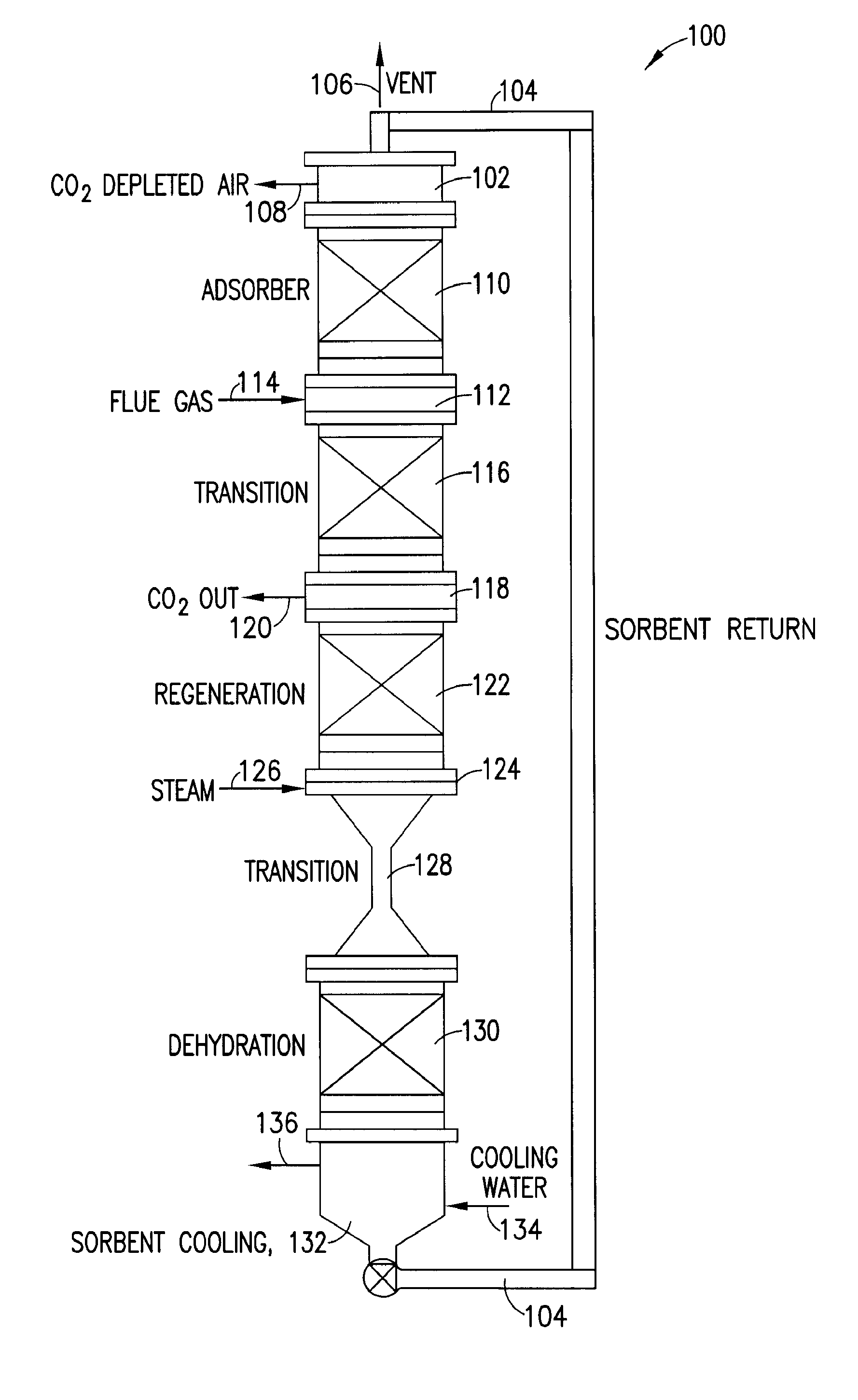

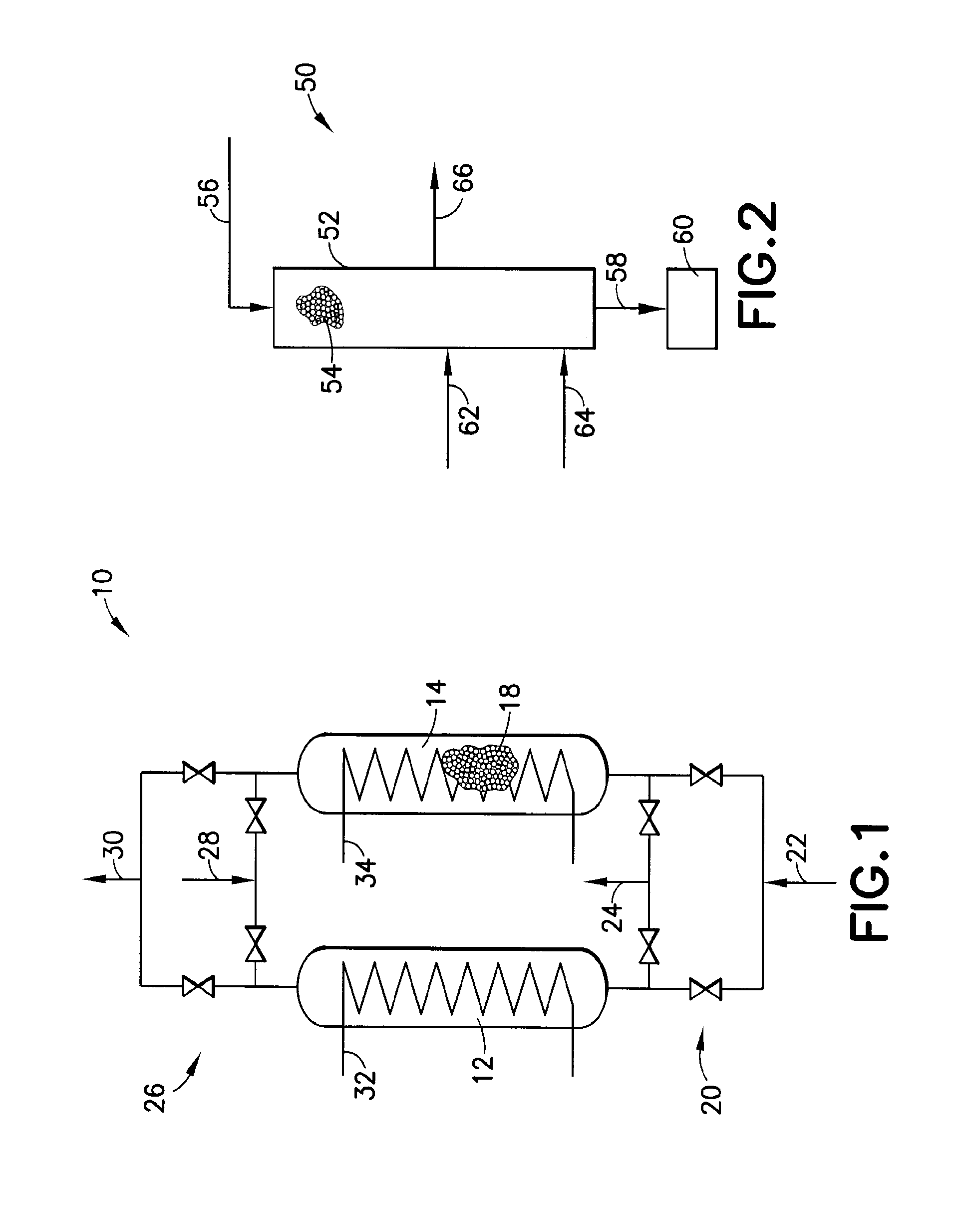

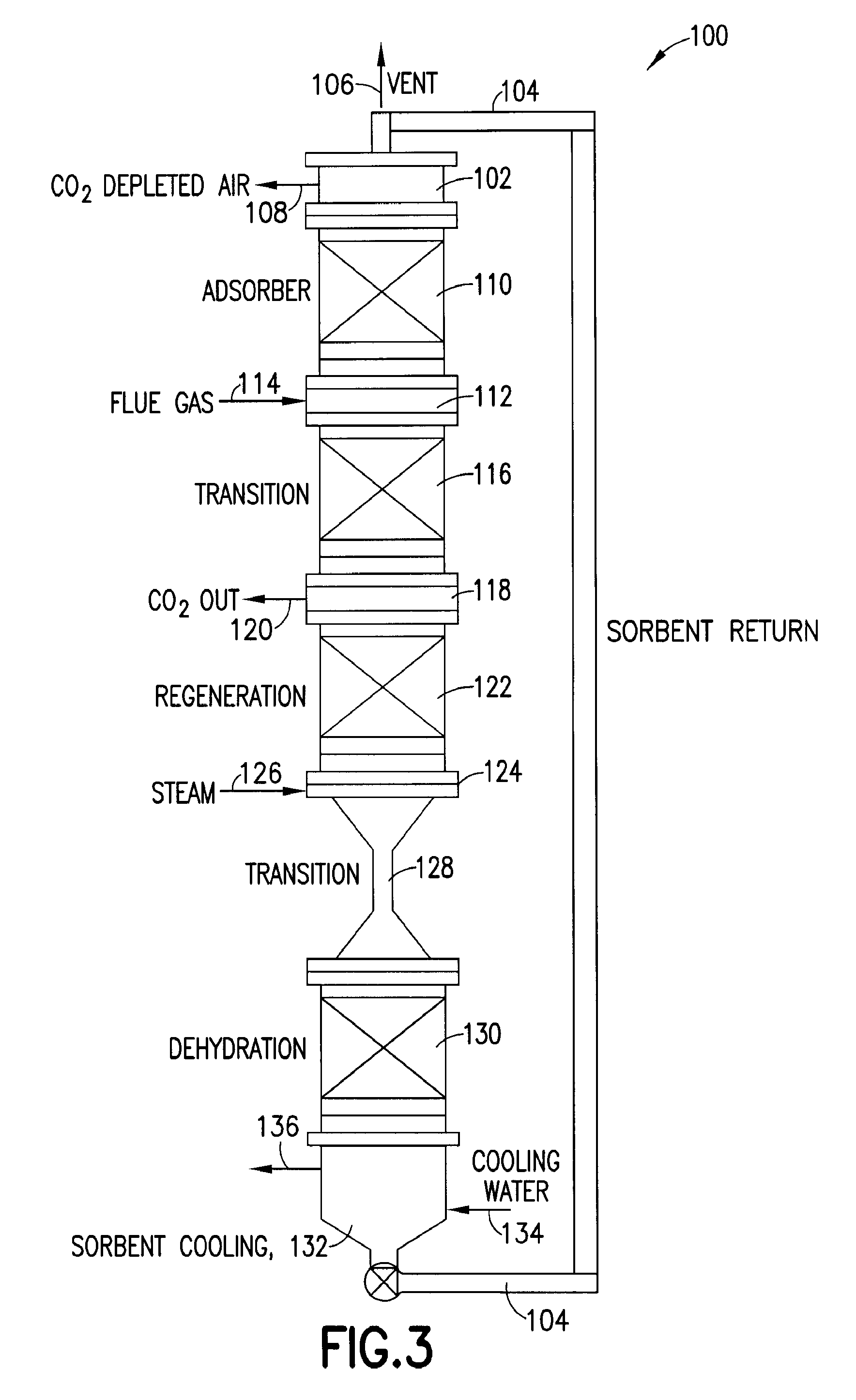

Carbon pyrolyzate adsorbent having utility for co2 capture and methods of making and using the same

A particulate form carbon pyrolyzate adsorbent, having the following characteristics: (a) CO2 capacity greater than 105 cc / gram at one bar pressure and temperature of 273° Kelvin; (b) CO2 Working Capacity greater than 7.0 weight percent; (c) CO2 heats of adsorption and desorption each of which is in a range of from 10 to 50 kJ / mole; and (d) a CO2 / N2 Henry's Law Separation Factor greater than 5. The carbon pyrolyzate material can be formed from a polyvinylidene chloride-based polymer or copolymer, or other suitable resin material, to provide an adsorbent that is useful for carbon dioxide capture applications, e.g., in treatment of flue gases from coal-fired power generation plants.

Owner:ENTEGRIS INC

Polyvinylidene chloride layered silicate nanocomposite and film made therefrom

InactiveUS20060222797A1Increase abuse resistanceIncrease modulusMaterial nanotechnologyDomestic containersBlister packFatty acid

A polymeric film includes at least one layer, the at least one layer including a polyvinylidene chloride layered silicate nanocomposite composition, the composition including 100 parts, by weight of the composition, of a polyvinylidene chloride layered silicate nanocomposite; from 0.1 to 10 parts, by weight of the composition, of a stabilizer; and from 0.1 to 10 parts, by weight of the composition, of a polymeric processing aid. Alternatively, a polymeric film includes at least one layer, the at least one layer including a polyvinylidene chloride layered silicate nanocomposite composition, the composition including 100 parts, by weight of the composition, of a polyvinylidene chloride layered silicate nanocomposite; and from 0.1 to 10 parts, by weight of the composition, of a soap of a fatty acid. A blister pack can be made from either film.

Owner:CISCO TECH INC

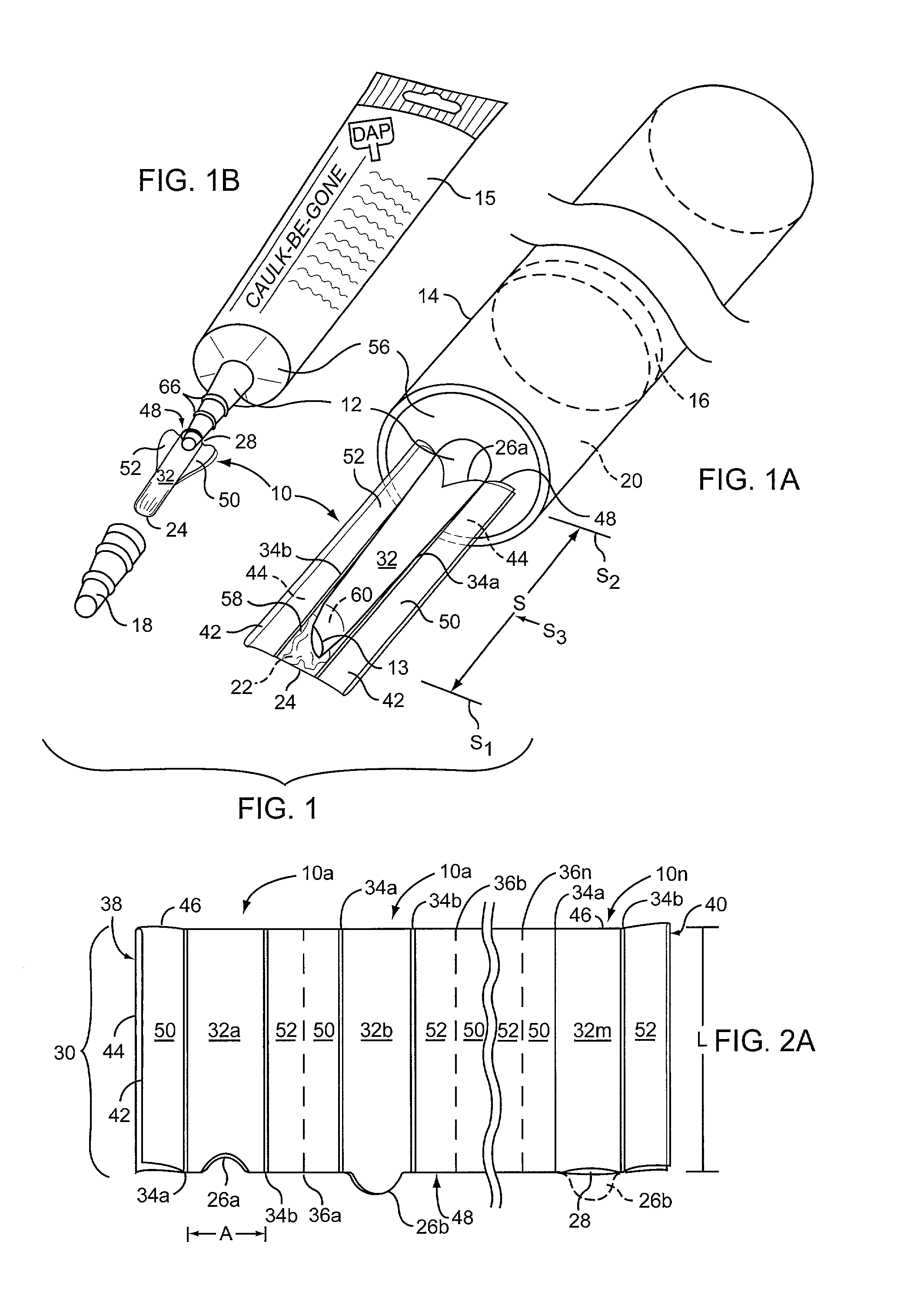

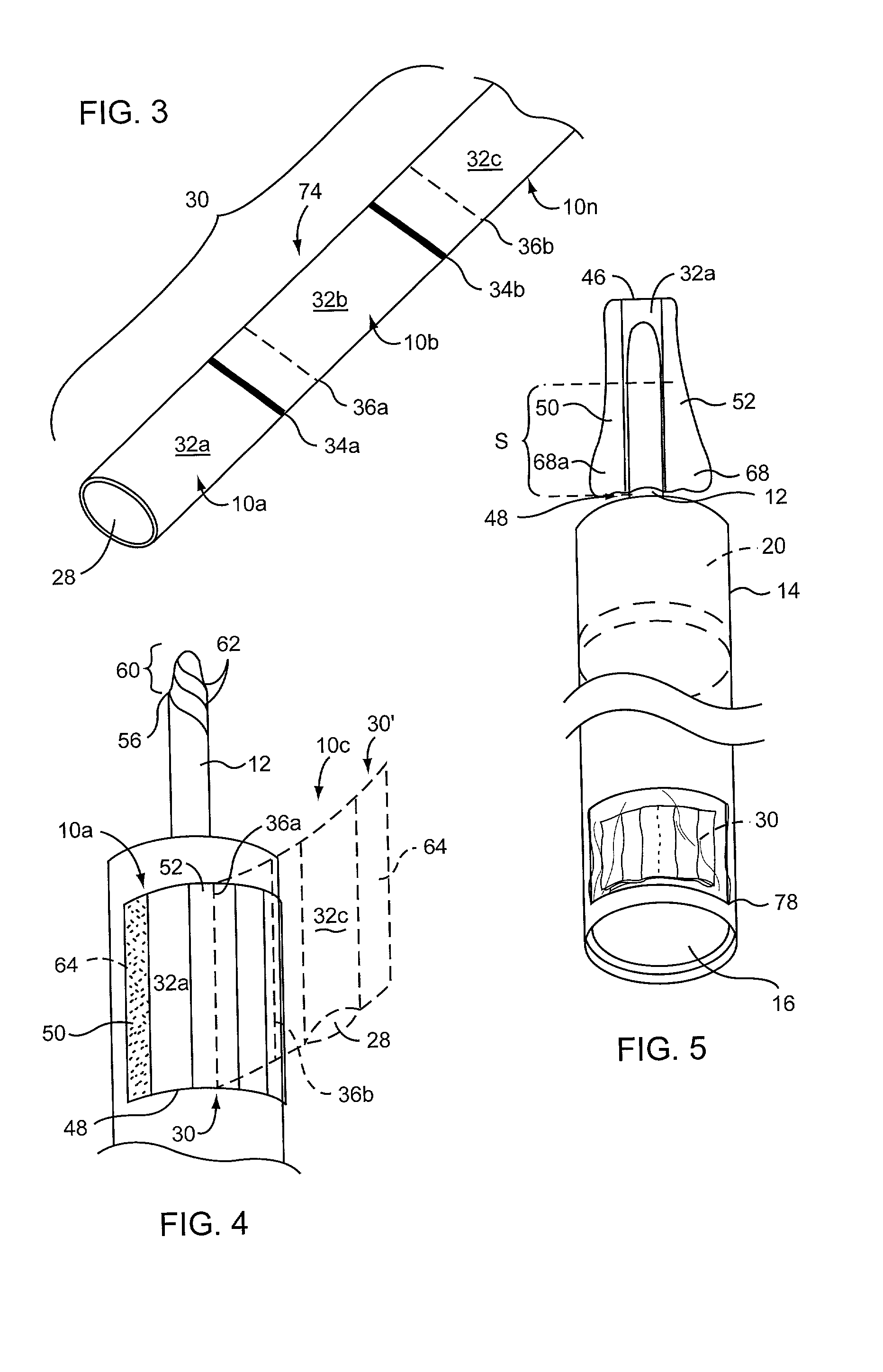

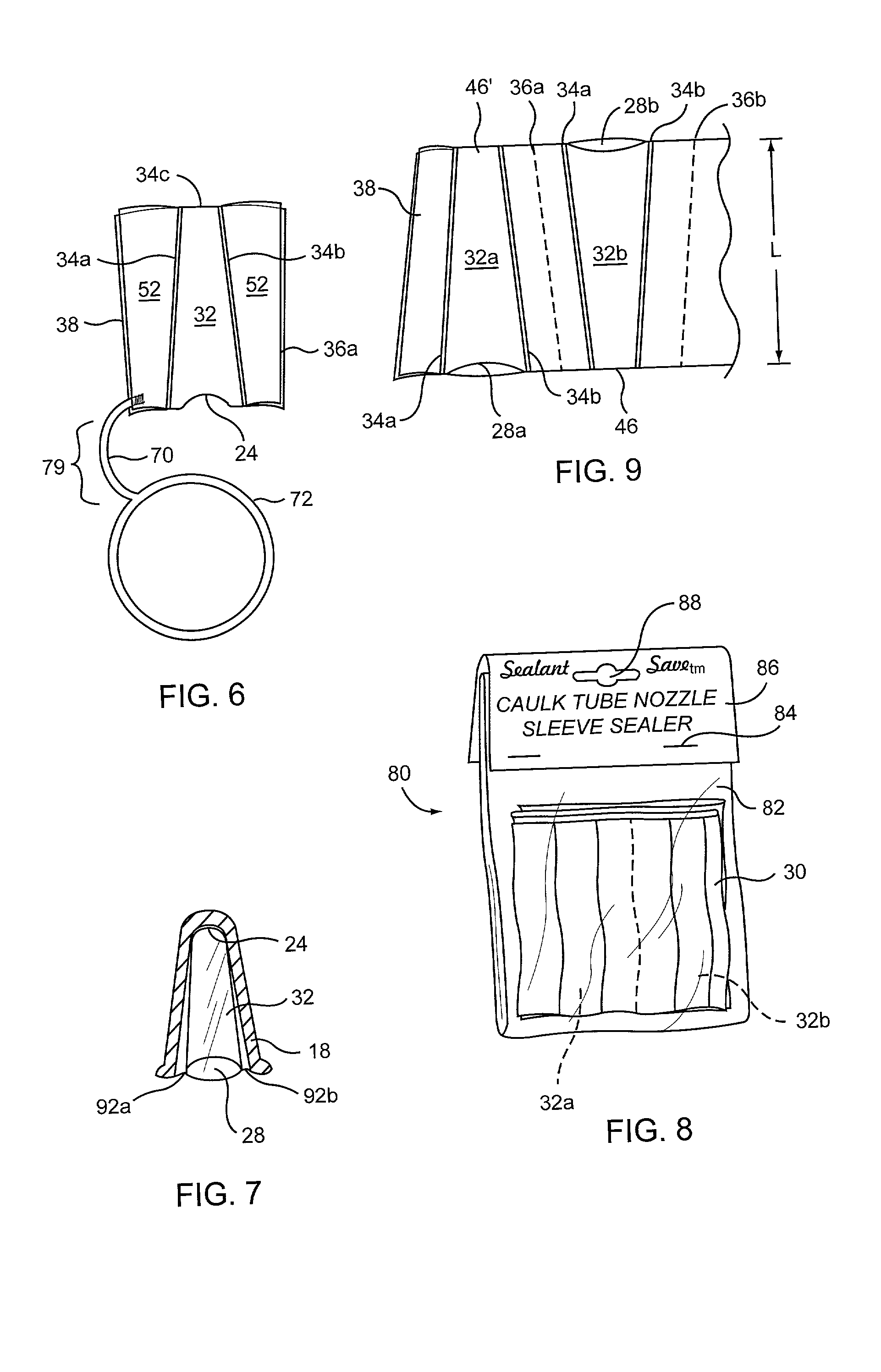

Sleeve-type closures for dispenser nozzles

InactiveUS20010048198A1Improve sealingImprove air tightnessCapsPackage recyclingWater basedVapor barrier

Reusable sleeve closures comprising a flexible thin sleeve of film grade plastic which seals the nozzle of a partially used sealant, mastic or caulk-dispensing cartridge or squeeze tube to substantially retard the hardening of the remaining tube contents. The plastic film provides a vapor barrier against exit of water or organic solvent from the sealant composition, and / or retards diffusion of oxygen that could cause the composition to set. The film is preferably somewhat stretchable and without creep over time, so that the sleeve provides an extremely tight seal for a substantial distance along the nozzle, e.g. film grade polyolefin or polyvinylidene chloride copolymer plastic film. The sleeve length is preferably long enough to provide a head space for a visual and tactile indicator of content condition. Sleeves may be packaged with the cartridge, or provided after-market. A 4-mil film polyolefin sleeve preserves water-based acrylic caulk over 9 months.

Owner:DULIN JACQUES M

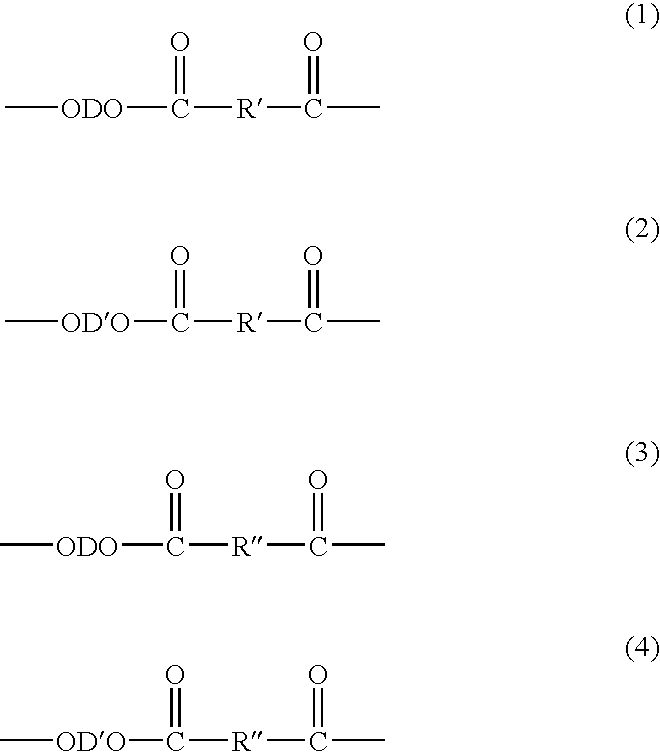

Process for the manufacture of polybutylene terephthalate copolymers from polyethylene terephthalate, and compositions and articles thereof

ActiveUS20100168336A1Improved flow and mechanical propertyEfficient recyclingPlastic recyclingPolymer recoveryPolytetramethylene terephthalatePolymer science

A process comprises depolymerizing, with 1,4-butane diol, a first polymer comprising a polyethylene terephthalate component in the presence of at least one second polymer selected from the group consisting of polyvinyl chlorides, polyvinylidene chlorides, polyamides, polylactic acid, and combinations thereof to produce a molten mixture; and polymerizing the molten mixture under conditions sufficient to form a modified polybutylene terephthalate copolymer. The modified PBT comprises (a) at least one polyethylene terephthalate component residue, and (b) a member selected from the group consisting of (i) the at least one second polymer selected from the group consisting of polyvinyl chlorides, polyvinylidene chlorides, polyamides, polylactic acid, and combinations thereof; (ii) the at least one residue derived from the second polymer; and (iii) combinations thereof.

Owner:SHPP GLOBAL TECH BV

Power cable insulating layer material and preparing method thereof

InactiveCN104140613AGood weather resistanceGood solvent resistancePlastic/resin/waxes insulatorsEpoxyPolyvinyl chloride

The invention relates to a power cable insulating layer material and a preparing method thereof. The material comprises, by weight, 70 parts of polyvinyl chloride, 3 parts of ethylene-vinyl acetate copolymer, 10 parts of polyvinylidene chloride, 10 parts of methyl vinyl silicone rubber, 15 parts of GNA type chloroprene rubber, 5-6 parts of epoxy fatty acid essien ester, 1 part of barium stearate, 10 parts of aluminum hydroxide, 5 parts of compatilizer, 8-10 parts of fire resistant systems and 0.1 part of antioxygen. The prepared fire resistant cable material is obvious in synergistic effect, good in antioxidant effect, high in stability and obvious in fire resistant effect, and has wide application prospects.

Owner:STATE GRID CORP OF CHINA +1

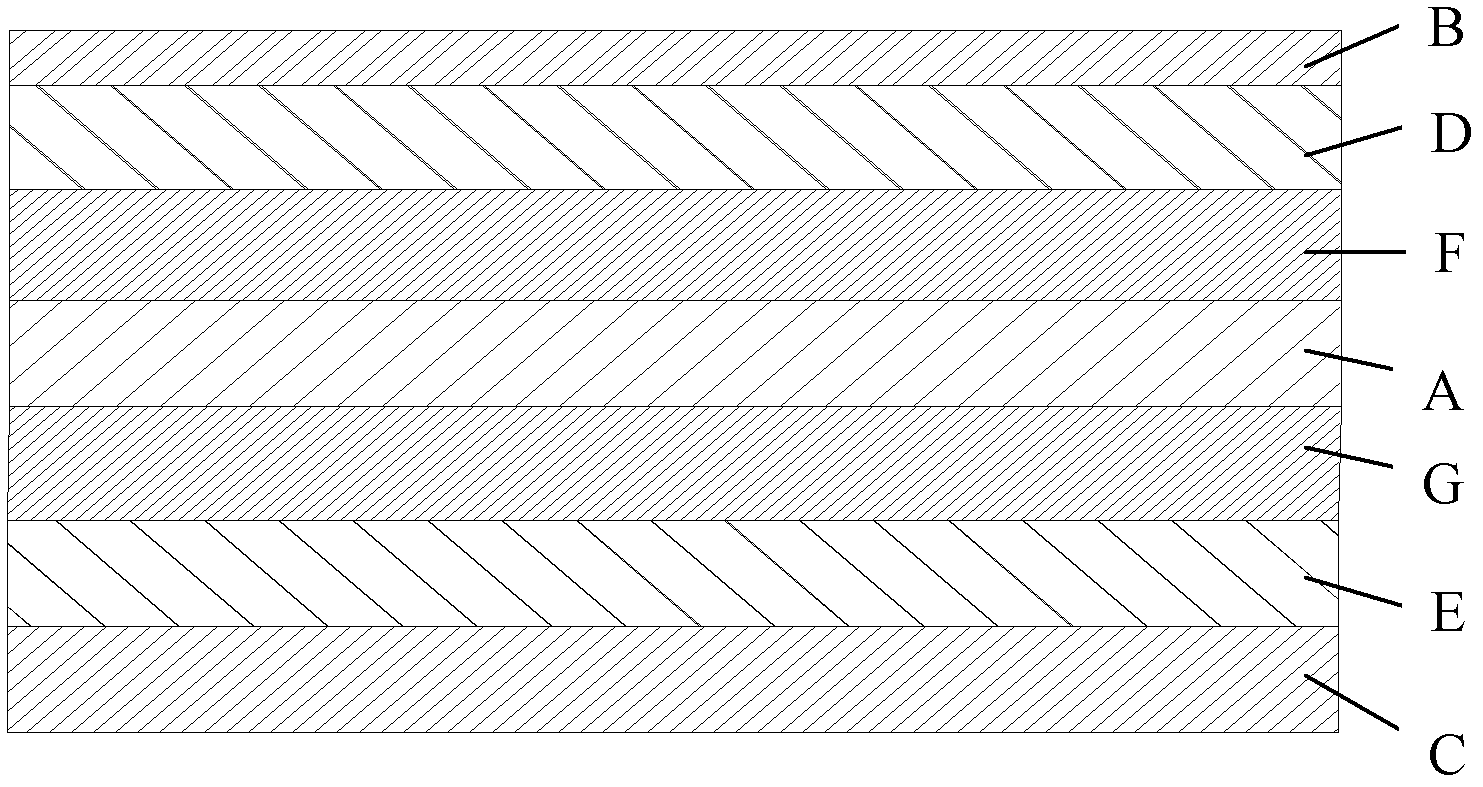

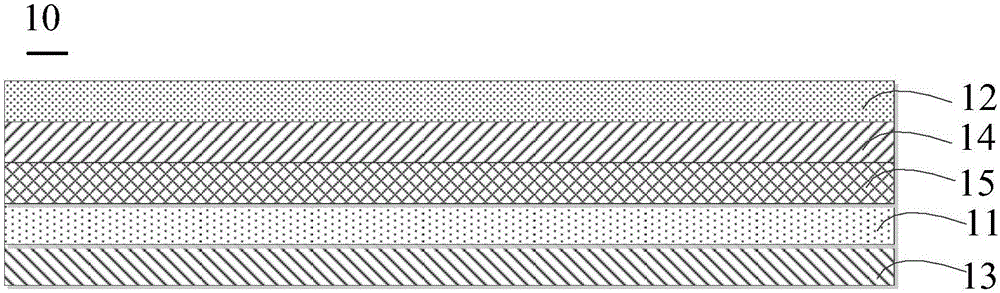

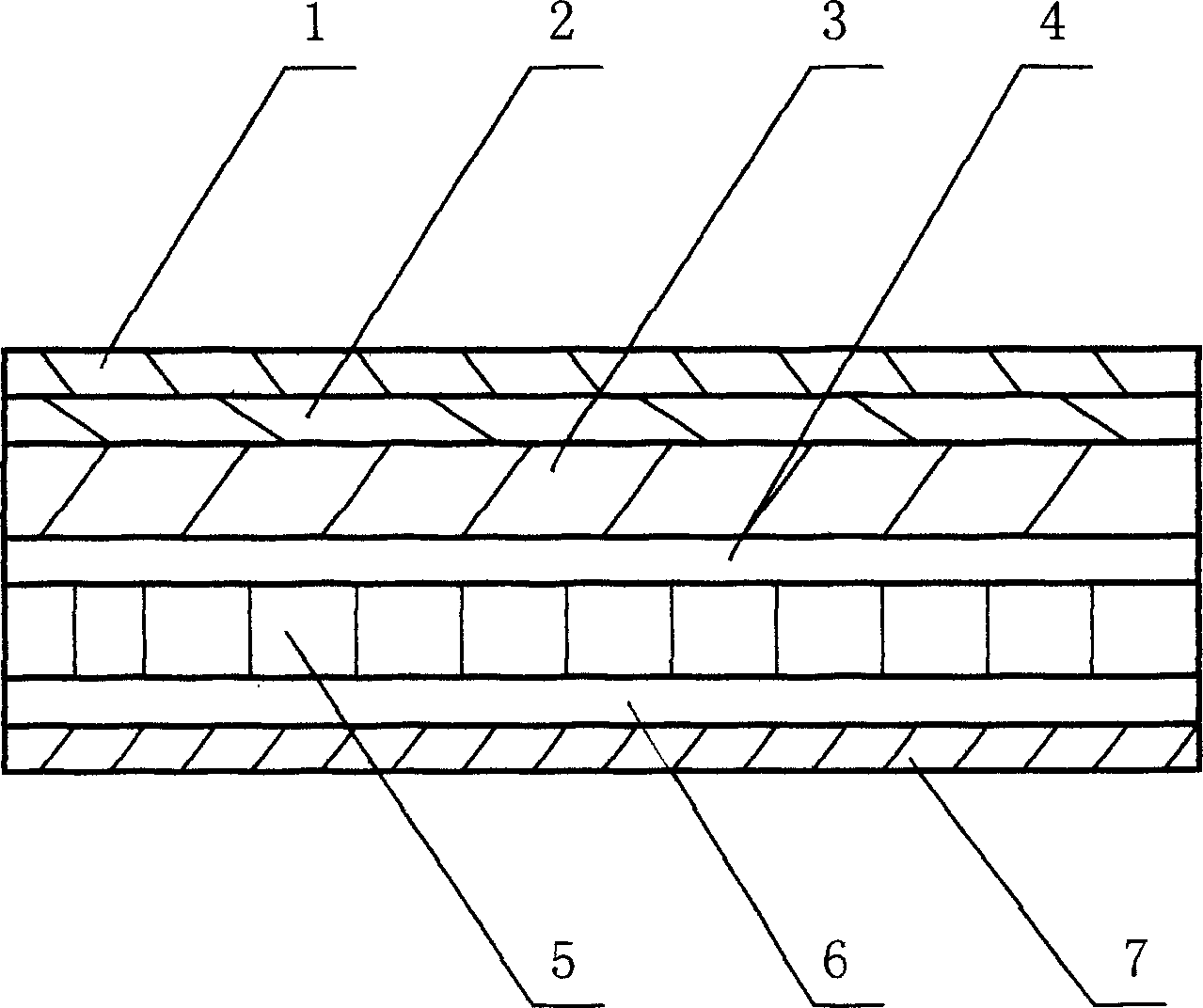

Liquid packaging composite film and manufacturing method thereof

ActiveCN101638159AImprove barrier propertiesHigh composite fastness of coatingFlexible coversWrappersComposite filmPolyvinyl alcohol

The invention relates to a liquid packaging composite film which comprises a film layer, a coating layer and a bonding layer, wherein the film layer and the coating layer are used as base materials; the bonding layer is arranged between the film layer and the coating layer; the coating layer is a polyvinylidene chloride copolymer layer or a polyvinyl alcohol layer; the polyvinylidene chloride copolymer layer comprises polyvinylidene chloride copolymers; and the polyvinyl alcohol layer comprises a polyvinyl alcohol dispersion system. The manufacturing method of the liquid packaging composite film comprises the following steps: treating the base material film by corona discharge; coating the bonding layer on the base material film which is treated by corona discharge, and drying and coolingthe bonding layer; coating the polyvinylidene chloride copolymer dispersion system or the polyvinyl alcohol dispersed system on the base material film which is coated with the bonding layer; and then,drying and cooling the coating layer. The liquid packaging composite film has the characteristics of good barrier property, high firmness of the coating layer and long service life.

Owner:ZHEJIANG BILI PACKAGING

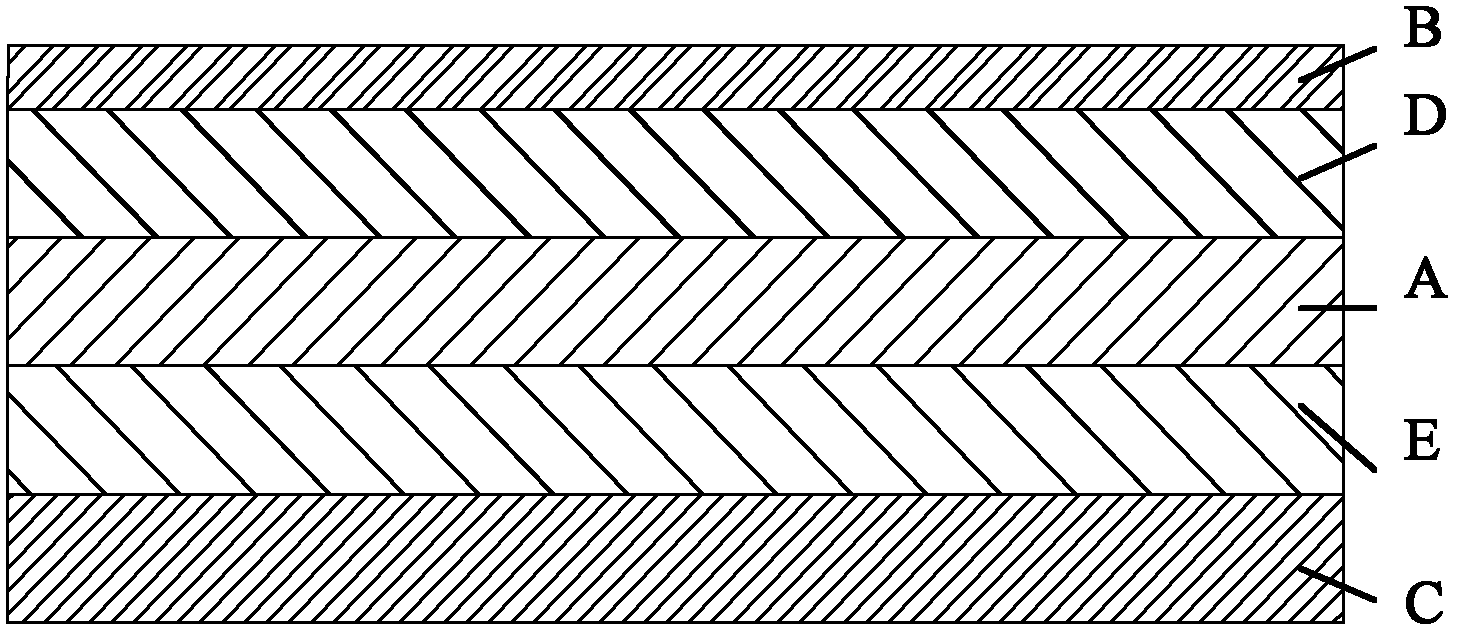

VMPET coated thin film, and production method

InactiveCN101092069AGood heat sealingImprove barrier propertiesFlexible coversWrappersPolyvinyl alcoholRaw material

The invention relates to a novel coated film and the producing method thereof. And it is a VMPET coated film, produced by coating PVDC, PVOH and AC as main raw materials on VMPET.

Owner:海南现代高科实业有限公司

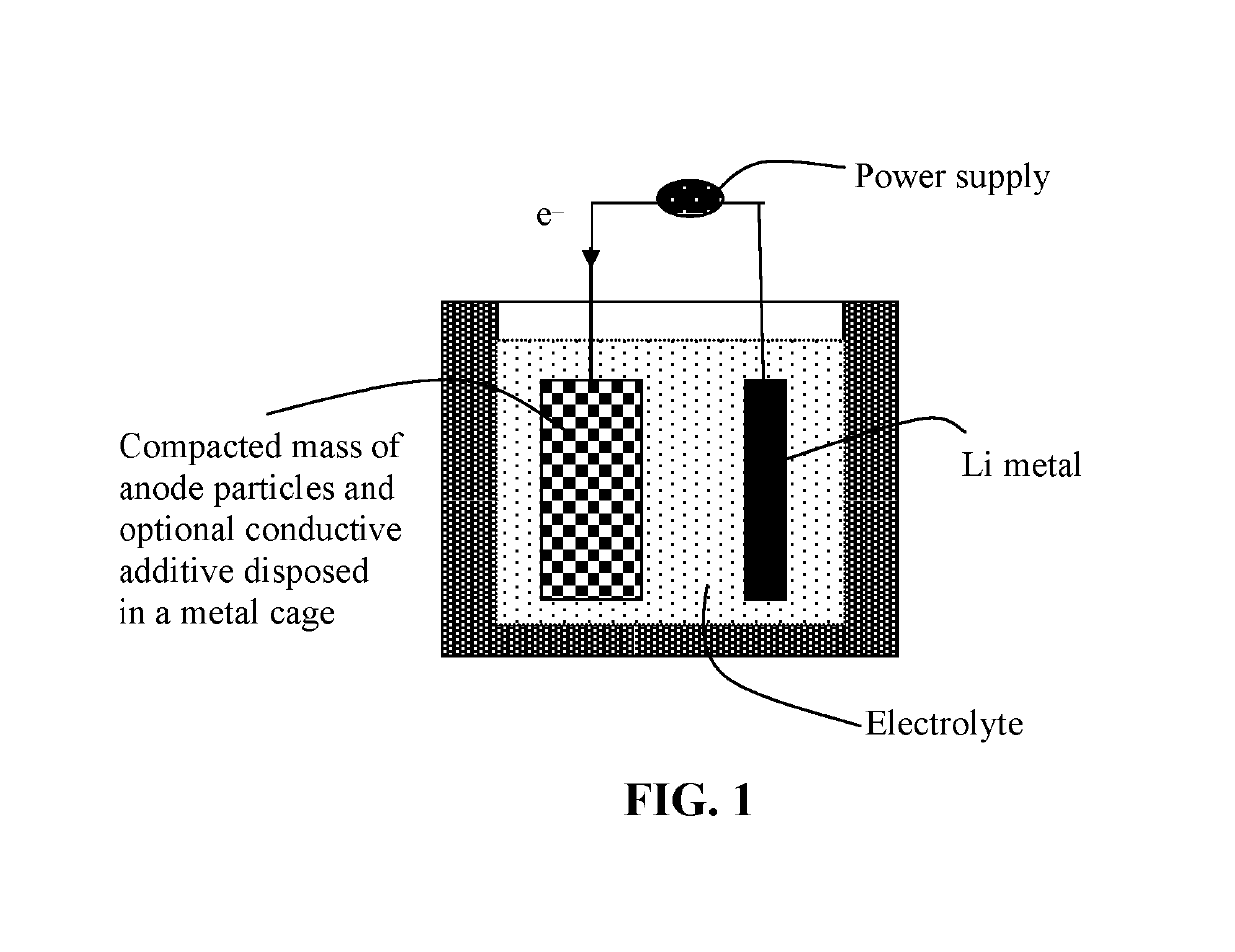

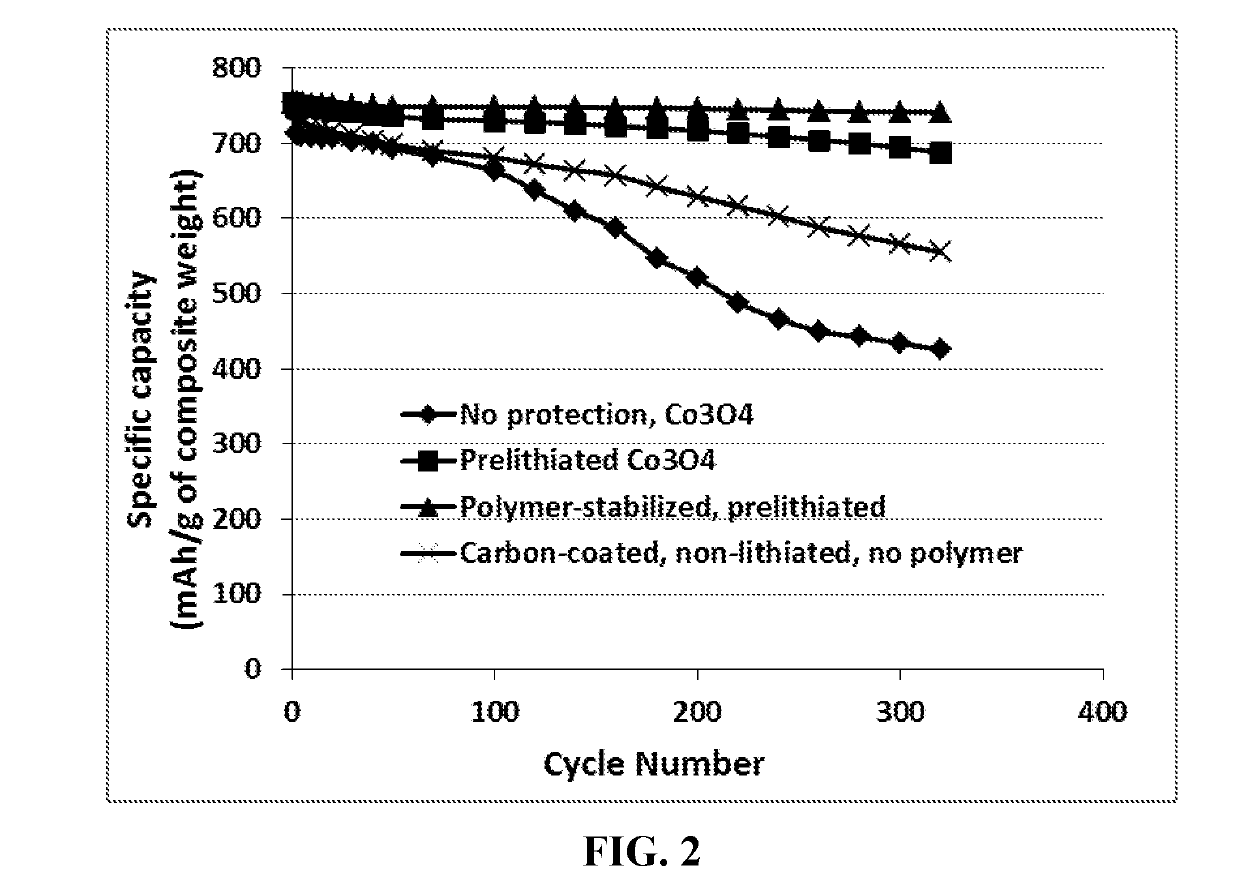

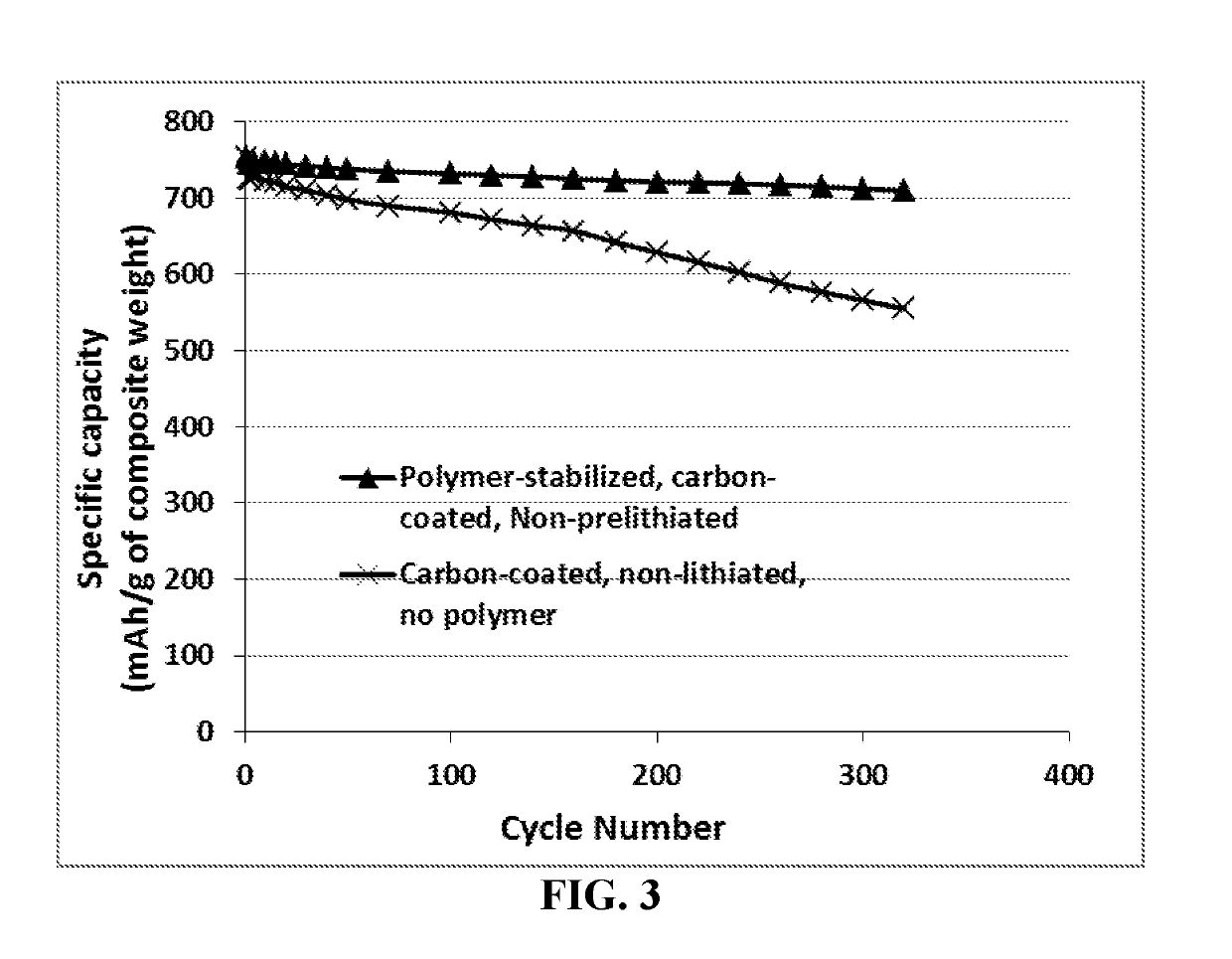

Surface-Stabilized Anode Active Material Particulates for Lithium Batteries and Production Method

ActiveUS20190115617A1High specific capacityLong charge-discharge cycle lifeElectrode manufacturing processesFinal product manufactureParticulatesPoly(ethylene glycol) dimethyl ether

Provided is a surface-stabilized anode active material particulate (for use in a lithium battery), comprising: (a) one or a plurality of prelithiated or un-prelithiated anode active material particles (with or without a coating of carbon, graphene, or ion-conducting polymer); (b) a protecting polymer layer that wraps around, embraces or encapsulates the one or plurality of anode active material particles, wherein the protecting polymer layer has a thickness from 0.5 nm to 5 μm, and a lithium ion conductivity from 10−8 S / cm to 5×10−2 S / cm at room temperature and the protecting polymer layer contains a polymer selected from poly(ethylene oxide) (PEO), polypropylene oxide (PPO), poly(acrylonitrile) (PAN), poly(methyl methacrylate) (PMMA), poly(vinylidene fluoride) (PVdF), poly bis-methoxy ethoxyethoxide-phosphazene, polyvinyl chloride, poly(vinylidene chloride), polydimethylsiloxane, poly(vinylidene fluoride)-hexafluoropropylene (PVDF-HFP), polyethylene glycol (PEG), a PEG derivative, polyethylene glycol methyl ether, polyethylene glycol dimethyl ether, a sulfonated polymer, or a combination thereof.

Owner:GLOBAL GRAPHENE GRP INC

High barrier aluminum-plating composite film for packing liquid dairy product

InactiveCN1880182AHigh gas barrierImprove water resistanceFlexible coversWrappersComposite filmFolding endurance

The invention relates to a high insulated aluminum composite film used to pack liquid milk, wherein it has multilayer structure, from outer to inner, as printing layer, adhesive layer, aluminum layer, adhesive layer, baffle layer, adhesive layer and thermal sealing layer; the baffle layer is made from polyvinylidene chloride polymer or ethane-ethenol polymer. Compared with traditional plastic soft film, the invention avoids the carbon black layer and increases the aluminum layer and oxygen baffle layer, to obtain high waterproof ability and high insulated property, etc.

Owner:ZHEJIANG BILI POLYMER TECH CO LTD

UV-C sensitive composition and dosimeter

InactiveUS7589331B2Efficiently determinedPhotometry using wholly visual meansMaterial analysis by optical meansChloride vinylPhotochemistry

The invention is a UV sensitive composition that undergoes a color change upon exposure to a predetermined dosage of UV-C radiation. The UV-C sensitive composition comprises a halogenated polymer, such as polyvinylidene chloride, that produces an acid upon exposure to UV radiation, and a pH sensitive dye. Upon exposure to UV-C radiation, the halogenated polymer undergoes degradation and produces HCl. The pH sensitive dye changes color as a result in an increase in HCl in the system. The composition may also include an acid scavenging composition and / or a diluent to control the amount of HCl produced in the system. The amount of HCl liberated from UV-C exposure may be selectively controlled so that a color change may be produced at a desired UV-C dosage. In some embodiments, the composition may be used to indicate a UV-C dosage from about 100 to 1600 mJ / cm2.

Owner:CRYOVAC ILLC

Peelable multilayer laminate for packaging

InactiveUS20080145581A1Easy to peelSynthetic resin layered productsThin material handlingPolyesterLiquid crystalline

Multilayer laminate compositions are provided wherein at least one layer of the laminate comprises a blend of a) an organic acid and ethylene / acid copolymer or ethylene / acid that are at least partially neutralized with a metal ion and b) an ethylene homopolymer or copolymer of ethylene and an alpha-olefin form at least one layer of a multilayer laminate. At least one other layer of the laminate is a gas impermeable composition consisting essentially of a material selected from the group consisting of polyvinylidene chloride, ethylene vinyl alcohol polymers, polyamides, metal foils, metallized films or liquid crystalline polyesters and mixtures thereof. The gas permeable layer is easily peelable and may be separated manually from the gas impermeable layer of the laminate. The laminates are useful in packaging applications, including manufacture of lid stock.

Owner:EI DU PONT DE NEMOURS & CO

Articles and methods of making the same

The invention provides an article comprising a first layer and a second layer, and wherein the first layer is formed from a first composition comprising an ethylene / α-olefin / diene interpolymer, an isoprene rubber (synthetic), a natural rubber, a butadiene rubber, a styrene butadiene rubber, a chloroprene rubber, a nitrile rubber, a hydrogenated nitrile rubber, a chlorinated polyethylene, a chlorosulfonated polyethylene, an ethylene / propylene rubber, an ethylene / diene copolymer, a fluoro rubber, a polyurethane, a silicone rubber, or a combination thereof; and wherein the second layer is formed from a second composition comprising a butyl rubber, a halobutyl rubber, polyvinylidene chloride, a brominated polymer derived from a copolymer of isobutylene and p-methyl styrene, a nitrile rubber, a chloroprene rubber, a chlorosulfonated polyethylene, a chlorinated polyethylene, a polyurethane, a fluoro rubber, or a combination thereof.

Owner:DOW GLOBAL TECH LLC

Method of generating hydrogen and of selectively transferring the generated hydrogen to drinking water as a potential source of alternative cellular energy (ACE)

InactiveUS20100008849A1Increased hydrogen productionImprove usabilityHydrogen productionHydrogen/synthetic gas productionAntioxidantReverse osmosis

Consuming water with increased hydrogen content can provide clinical benefits to humans and animals through a non-mitochondria alternative cellular energy (ACE) pathway and also as an antioxidant. This application discloses that the hydrogen content of drinking water can be safely increased by placing into the water a hydrogen generating device, such as a mixture of metallic magnesium and magnesium chloride containing solution, whereby the device allows for the selective passage of the generated hydrogen but restricts the passage of magnesium and magnesium ions. This partitioning of hydrogen from magnesium ions is achieved by using either reverse osmosis membrane or low density plastic material such as polyvinylidene chloride (PVDC or Saran), to create a sealed container of the magnesium and magnesium chloride, that can be placed into drinkable water. The magnesium chloride can be initially placed into a breakable inner compartment within the hydrogen permeable container. This compartment can be easily broken by simple squeezing just prior to placing the device into the water that is intended to have its hydrogen content increased. The increased hydrogen content can be assessed by the capacity of the water to decolorize a potassium permanganate test sample.

Owner:MARTIN WILLIAM JOHN

Using method and product of water polyurethane used for coating prime glue

InactiveCN101147902AReduce manufacturing costPolyureas/polyurethane adhesivesPretreated surfacesPVA - Polyvinyl alcoholPolymer chemistry

The present invention relates to an application method of aqueous polyurethane. It is mainly used as primer coating layer in coated film production using BOPP, PET and nylon film as base material and using polyvinyl dichloride (PVDC), modified polyvinyl alcohol (PVOH) and various acrylic acids (AC) as coating material.

Owner:海南现代高科实业有限公司

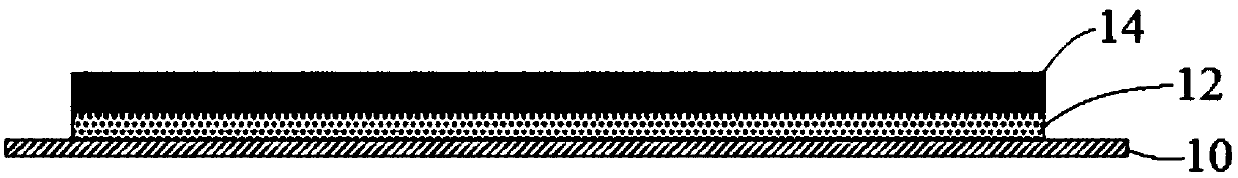

Electrode pole plate, electrochemical device and safety coating layer

ActiveCN109755468AImprove securityImprove electrical performanceProtecting/adjusting hybrid/EDL capacitorHybrid capacitor electrodesConductive materialsEngineering

The invention relates to an electrode pole plate, an electrochemical device and a safety coating layer. The electrode pole plate comprises a current collector, an electrode active material and the safety coating layer, wherein the safety coating layer is arranged between the current collector and the electrode active material layer and comprises a polyvinylidene fluoride and / or polyvinylidene chloride macromolecular substrate, a conductive material and an inorganic filler. A circuit can be rapidly cut off by the electrode pole plate when the electrochemical device (such as a capacitor, a primary battery or a secondary battery) is in a high-temperature condition or internal short-circuit occurs, so that the high-temperature safety of the electrochemical device is improved.

Owner:CONTEMPORARY AMPEREX TECH CO

Method of molding a syringe

A syringe for use in a pressurized injection of a fluid includes a syringe barrel including a polymeric material having undergone expansion via blow molding. An inner diameter of the syringe barrel can, for example, be sufficiently constant (over at least a portion of the axial length of the syringe) that a plunger slidably positioned within the syringe barrel and in generally sealing contact with an inner wall of the syringe barrel can be used within the syringe barrel to generate a pressure of at least 1 psi within the syringe barrel. In several embodiment, the inner diameter of the syringe barrel is sufficiently constant to generate a pressure of at least 100 psi, at least 300 psi, or even at least 500 psi within the syringe barrel. A method of forming a syringe includes the steps of: injection molding at least one polymeric material to form a preform; placing the preform into an blow mold die; and expanding at least a portion of the preform while heating the preform within the die to form a barrel of the syringe. The syringes can be formed to withstand relatively high pressures as described above. The at least one polymeric material can, for example, be polyethyleneterephthalate, cyclic olefin polymer, polypropylene, polystyrene, polyvinylidene chloride, polyethylene napthalate and / or nylon.

Owner:BAYER HEALTHCARE LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com