Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

136results about "Polymer recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

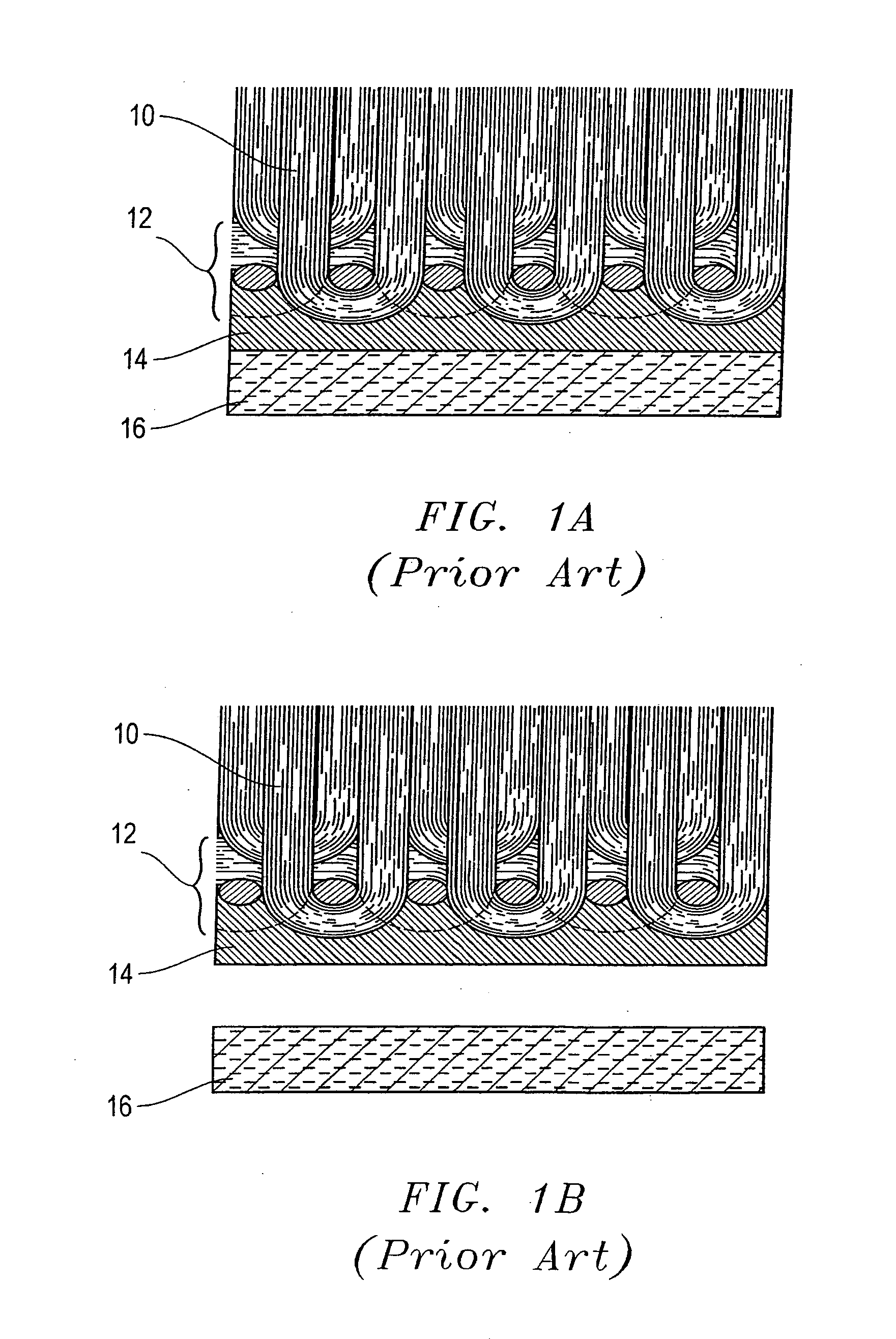

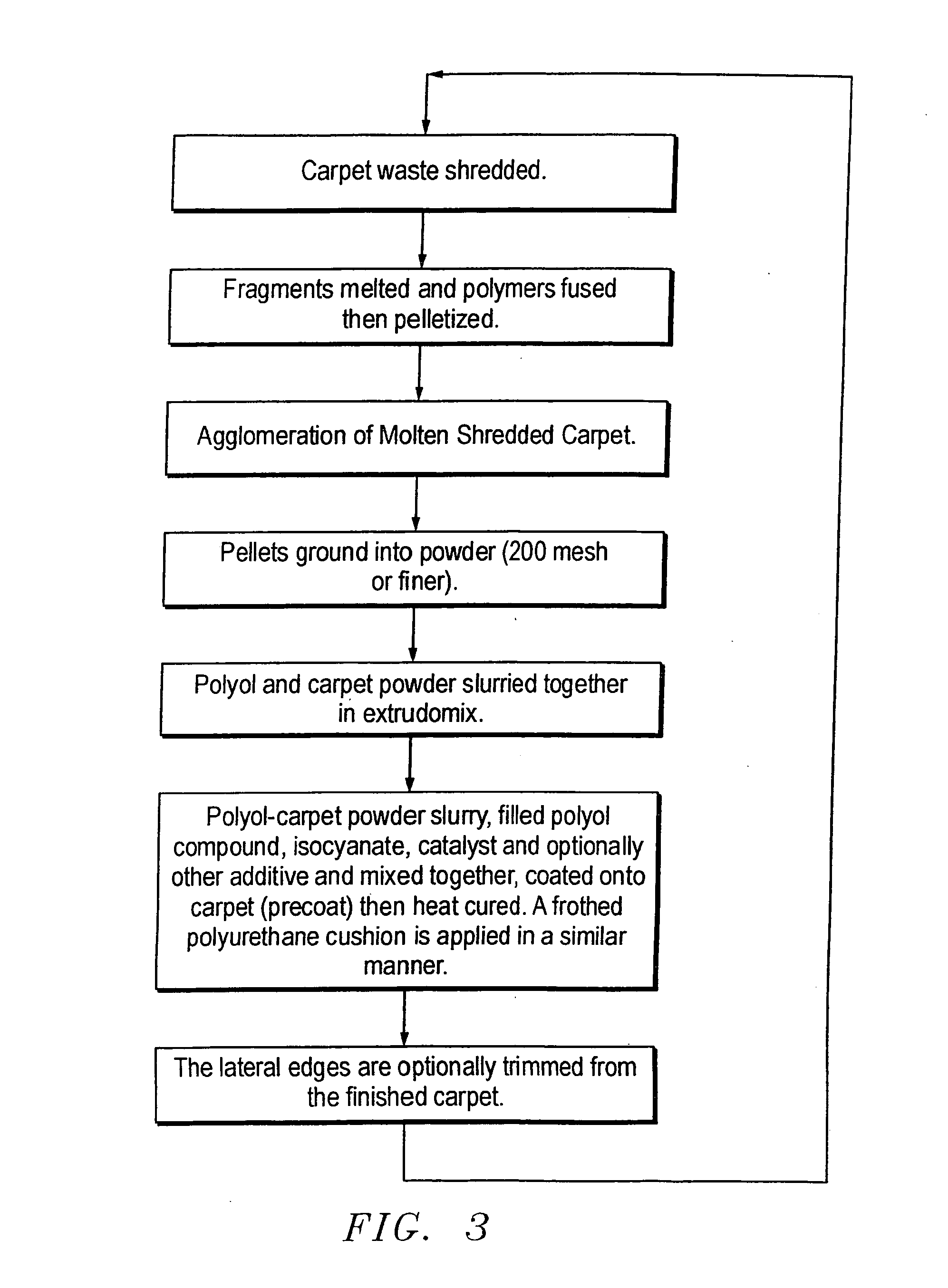

Method of preparing carpet backing using recycled carpet scrap

InactiveUS20070043128A1Reduces and eliminates dumpingReduce manufacturing costPlastic recyclingTextile/flexible product manufactureEmulsionSlurry

Carpet backing is prepared from carpet scrap by first comminuting the carpet scrap into fragments and then melting and fusing the carpet scrap fragments together to render molten fragments. The resulting molten fragments containing synthetic resins are then formed into agglomerates. The pellets are then ground into a fine powder. A slurry may be prepared from the ground powder and a carrier. The ground powder may, alternatively, be mixed with a polyurethane reactive mixture, aqueous polymer containing emulsion or a thermoplastic composition such as bitumen, polypropylene or polyethylene. The resulting polymeric coating is coated onto a substrate. The coated substrate is then hardened.

Owner:JENKINES RANDALL C +3

Process for production of biaxially oriented films based on crystallizable thermoplastics, using recycled material whose molecular weight has been increased by condensation processes

ActiveUS7700015B2Not impair property of filmGood orientationOther chemical processesPlastic recyclingThermoplasticCondensation process

Owner:MITSUBISHI POLYESTER FILM

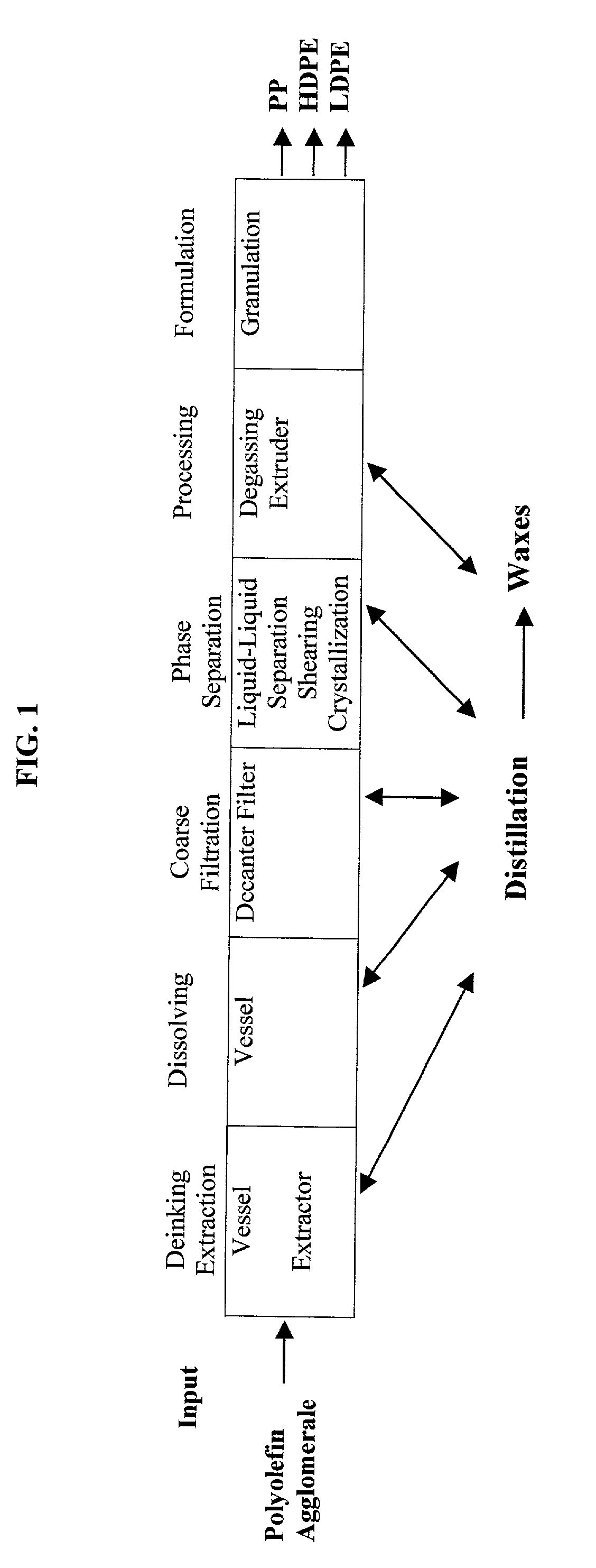

Method for the production of a polypropylene blend

InactiveUS20020128394A1Faster cycle timeMechanical characteristicPlastic recyclingPolymer recoveryOrganic solventPlastic packaging

A method for producing a polypropylene blend from a plastic packaging materials containing high molecular weight polypropylene, other high molecular weight polymers such as polyethylene, low molecular weight polymers and other contaminants. The method includes extraction, solid-liquid separation and liquid-liquid phase separation using various organic solvents. The polypropylene blend has a purity of 95% and has favorable melt flow characteristics, while retaining satisfactory mechanical properties.

Owner:DER GRUNE PUNKT DUALES SYST DEUTLAND

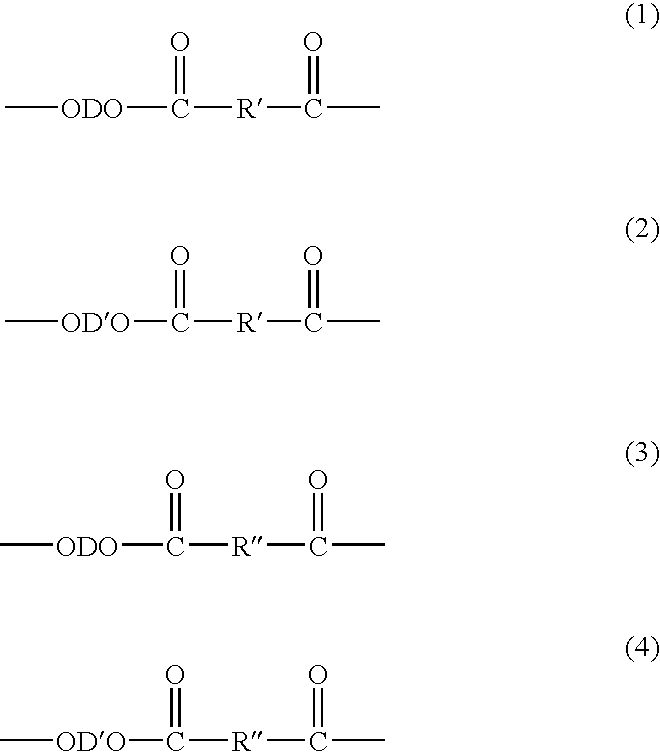

Process for the manufacture of polybutylene terephthalate copolymers from polyethylene terephthalate, and compositions and articles thereof

ActiveUS20100168336A1Improved flow and mechanical propertyEfficient recyclingPlastic recyclingPolymer recoveryPolytetramethylene terephthalatePolymer science

A process comprises depolymerizing, with 1,4-butane diol, a first polymer comprising a polyethylene terephthalate component in the presence of at least one second polymer selected from the group consisting of polyvinyl chlorides, polyvinylidene chlorides, polyamides, polylactic acid, and combinations thereof to produce a molten mixture; and polymerizing the molten mixture under conditions sufficient to form a modified polybutylene terephthalate copolymer. The modified PBT comprises (a) at least one polyethylene terephthalate component residue, and (b) a member selected from the group consisting of (i) the at least one second polymer selected from the group consisting of polyvinyl chlorides, polyvinylidene chlorides, polyamides, polylactic acid, and combinations thereof; (ii) the at least one residue derived from the second polymer; and (iii) combinations thereof.

Owner:SHPP GLOBAL TECH BV

Method for recovering useful components from dyed polyester fiber

InactiveUS7959807B2Efficient and economical componentHigh purityArtificial filament recoveryPreparation by ester-hydroxy reactionFiberRecovery method

To establish an efficient and economical useful component recovery method capable of recovering high purity useful components from a dyed polyester fiber.A method for recovering useful components from a dyed polyester fiber, includes a dye extraction step, a solid liquid separation step, a depolymerization reaction step, an ester interchange reaction step, and a useful component separation step, for recovering useful components from the dyed polyester fiber, wherein the dye extraction step includes a step of extracting and removing a dye at the glass transition temperature of the polyester or higher and at 220° C. or less with a xylene extracting solvent and an alkylene glycol extracting solvent in combination.

Owner:TEJIN FIBERS LTD

Methods and materials for depolymerizing polyesters

ActiveUS9255194B2Plastic recyclingPreparation from carboxylic acid esters/lactonesCyclic processPolyester

Provided is a method of depolymerizing polyesters from post-consumer products, such as beverage bottles, to produce a high purity reaction product. For the depolymerization reaction, the polyesters are reacted with an alcohol and an amine organocatalyst at a temperature of about 150° C. to about 250° C. In one application, the use of an organocatalyst with a boiling point significantly lower than the boiling point of the reactant alcohol allows for the ready recycling of the amine organocatalyst. In another application, performing the depolymerization reaction under pressure at a temperature above the boiling point of the alcohol allows for accelerated depolymerization rates and the recovery of the organocatalyst with no further heat input. In a further application, glycolytic depolymerization of poly(ethylene terephthalate) (PET) produces a reaction product of bis(2-hydroxyethyl)terephthalate (BHET), which may in turn be used to produce high purity beverage bottle grade PET, in a closed loop process with minimal waste.

Owner:INT BUSINESS MASCH CORP

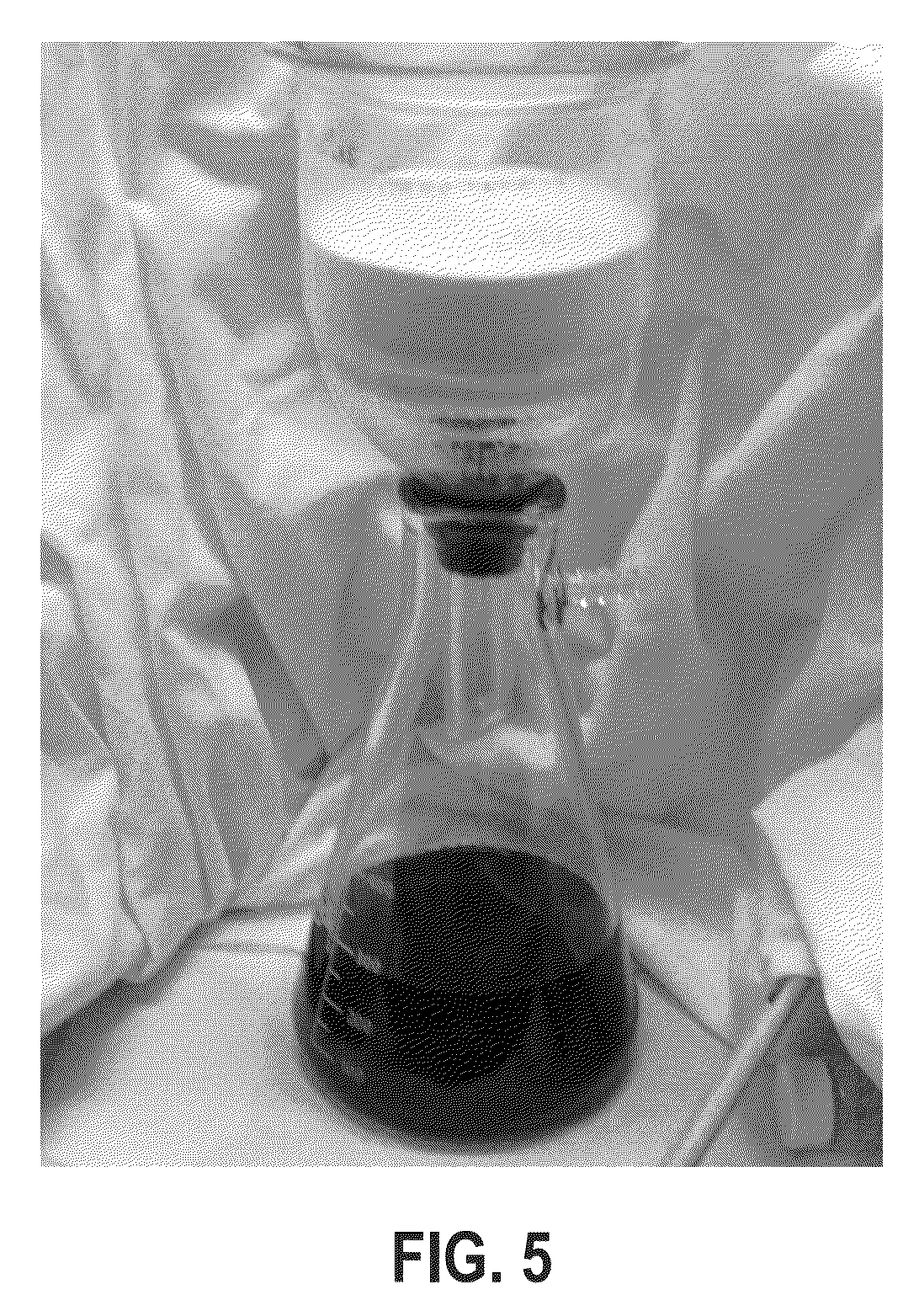

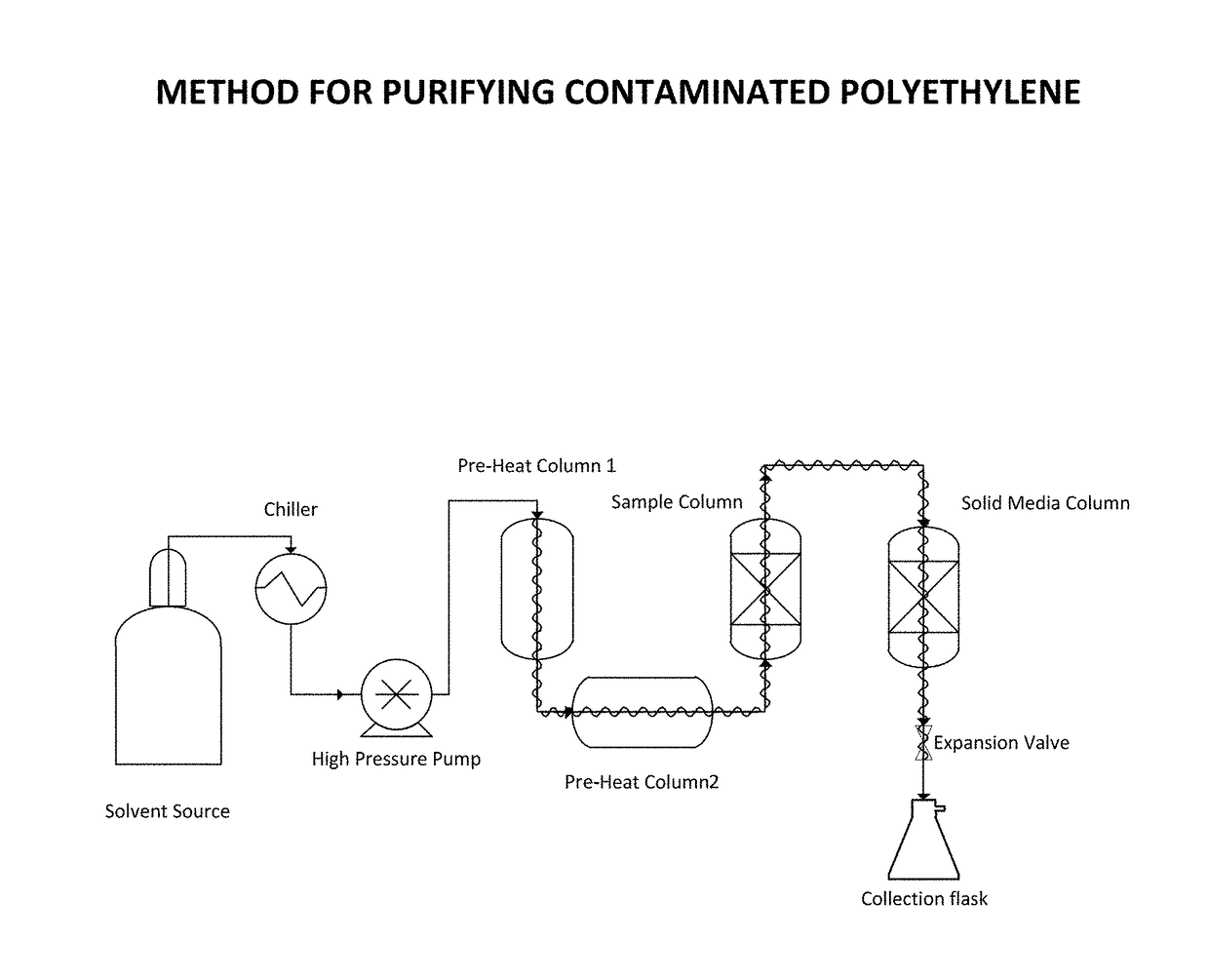

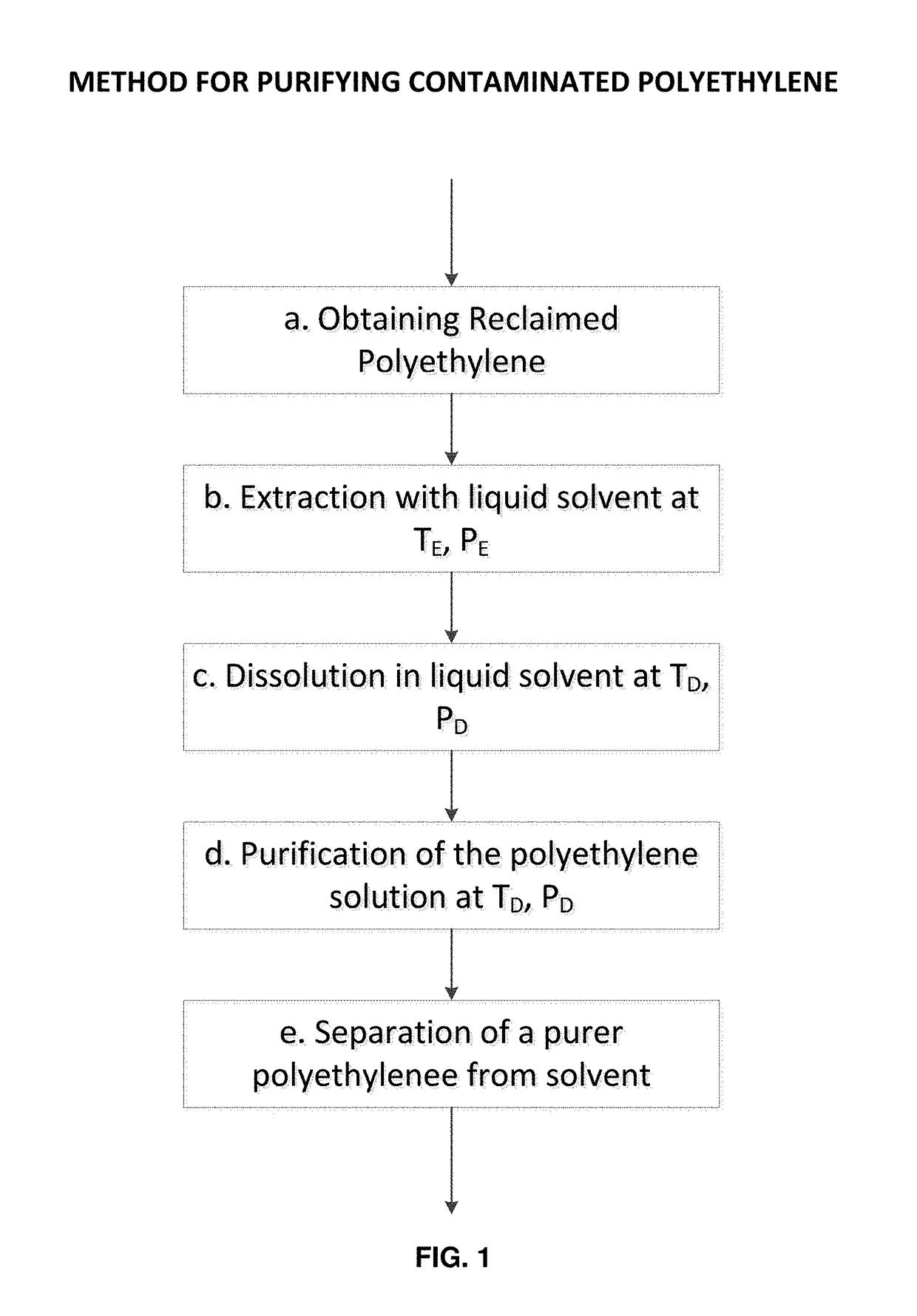

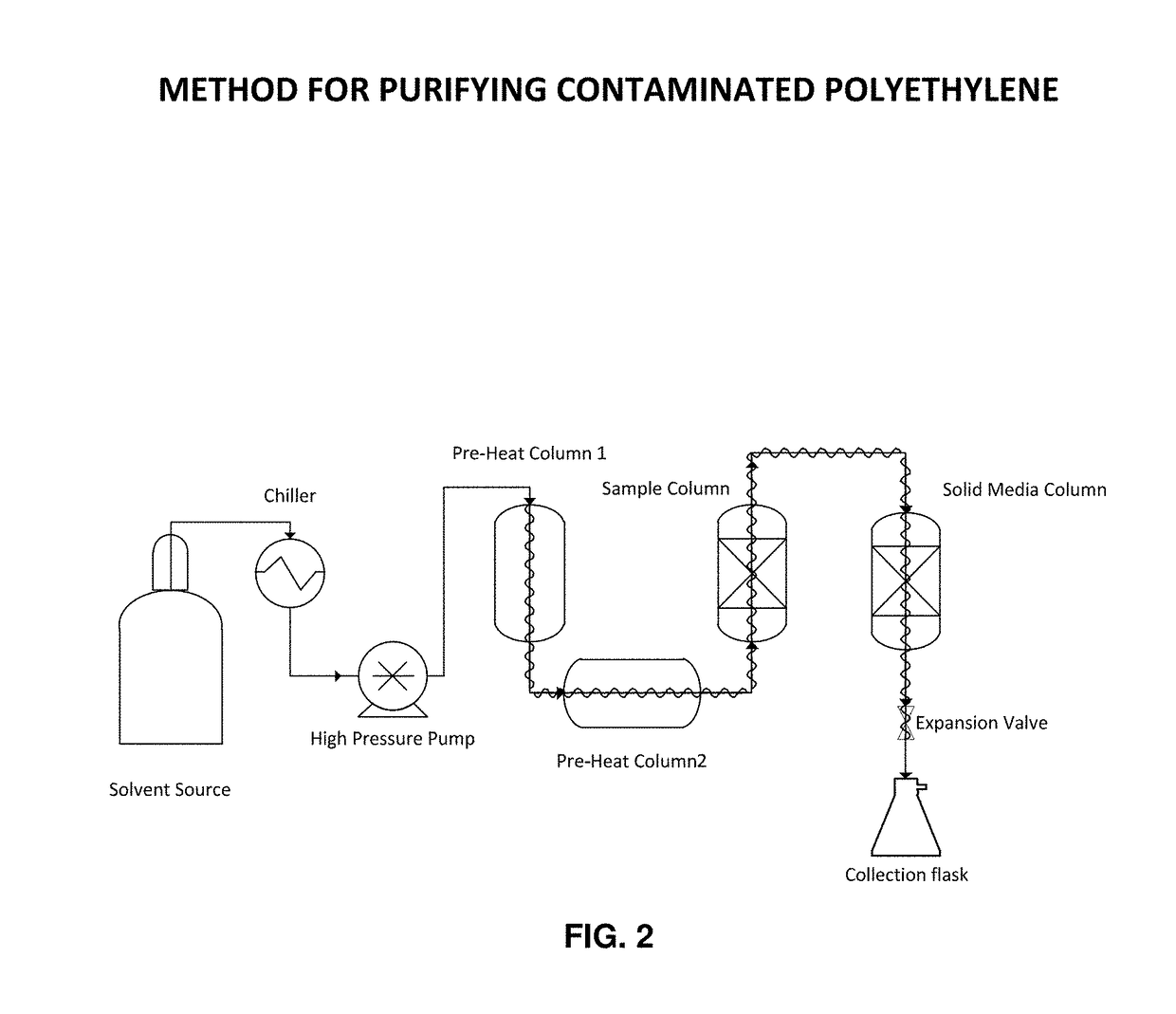

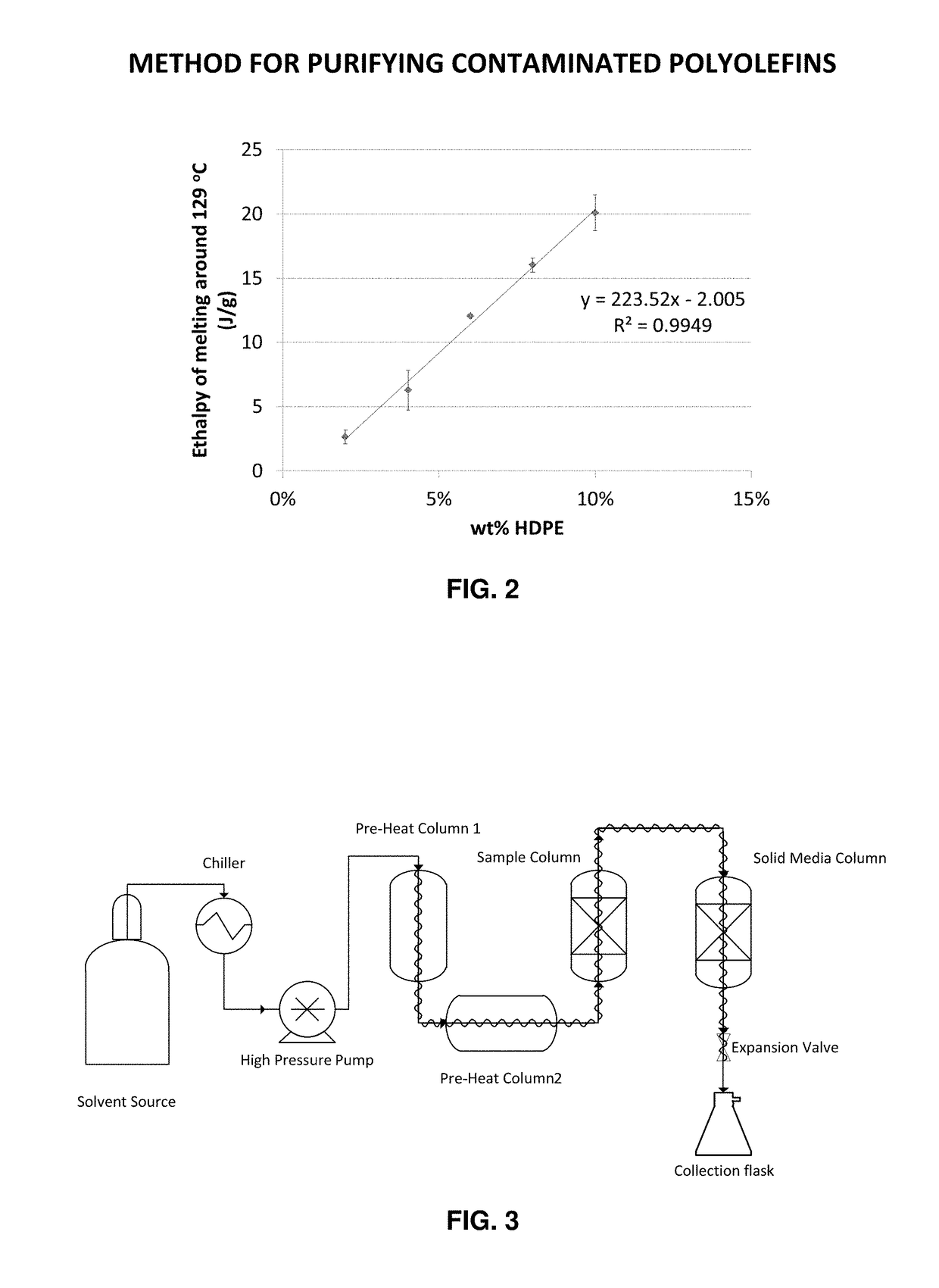

Method for purifying contaminated polyethylene

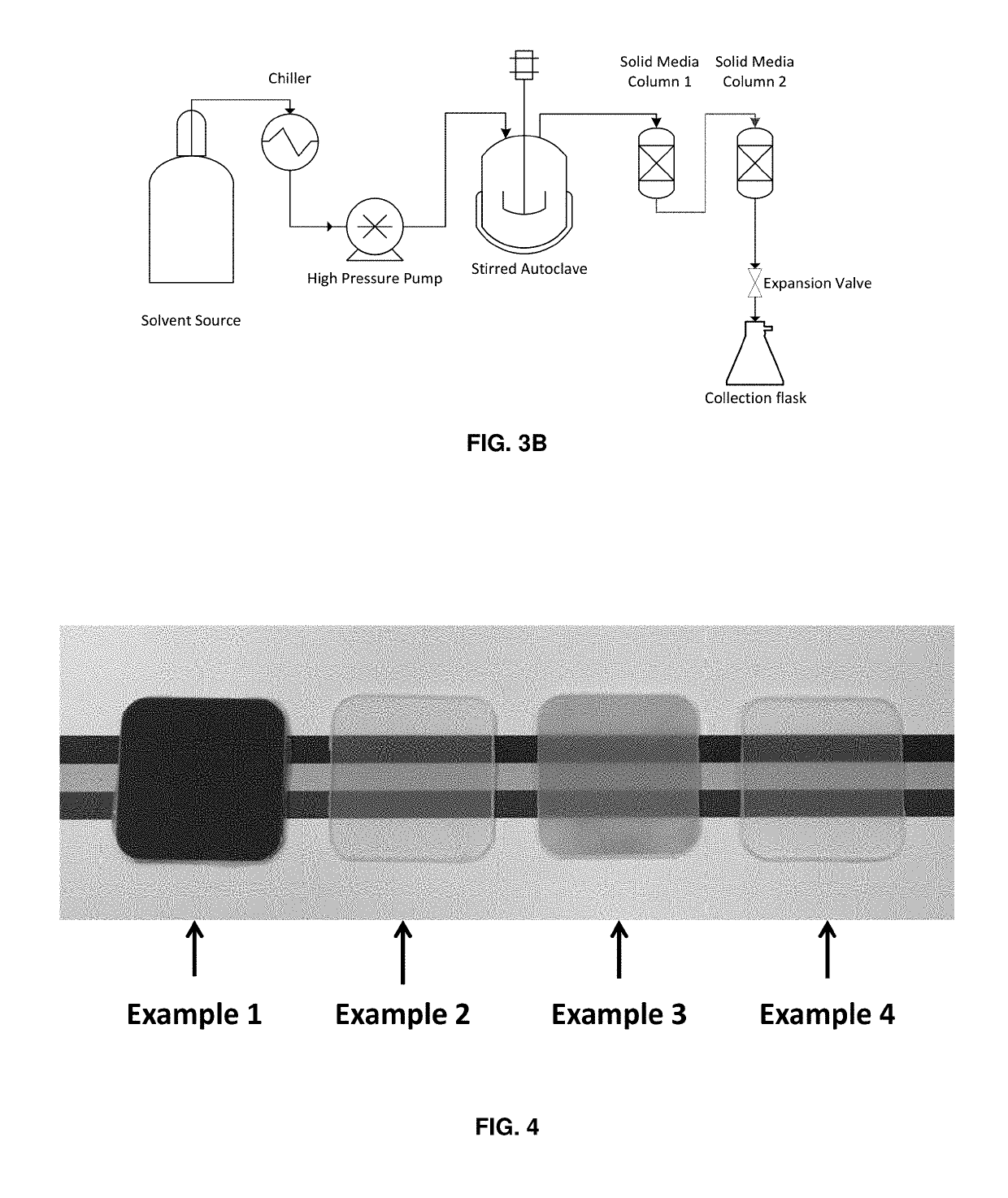

A method for purifying reclaimed polyethylene, such as polyethylene reclaimed from post-consumer use or post-industrial use, is disclosed. The method involves obtaining the reclaimed polyethylene and contacting it at an elevated temperature and pressure with a fluid solvent to produce an extracted reclaimed polyethylene. The extracted reclaimed polyethylene is dissolved in a solvent at an elevated temperature and pressure to produce a polyethylene solution, which is purified at an elevated temperature and pressure by contacting the polyethylene solution with solid media to produce a purer polyethylene solution. A purer polyethylene is then separated from the purer polyethylene solution.

Owner:PROCTER & GAMBLE CO

Method for recycling plastic products

The invention relates to a method for recycling at least one plastic product, the method comprising degrading at least one polymer of the plastic product to monomers using an enzyme and recovering the resulting monomers. The method of the invention may be used for degrading, simultaneously or sequentially at least two different polymers of the plastic product, and / or for recycling at least two plastic products.

Owner:卡比欧斯公司

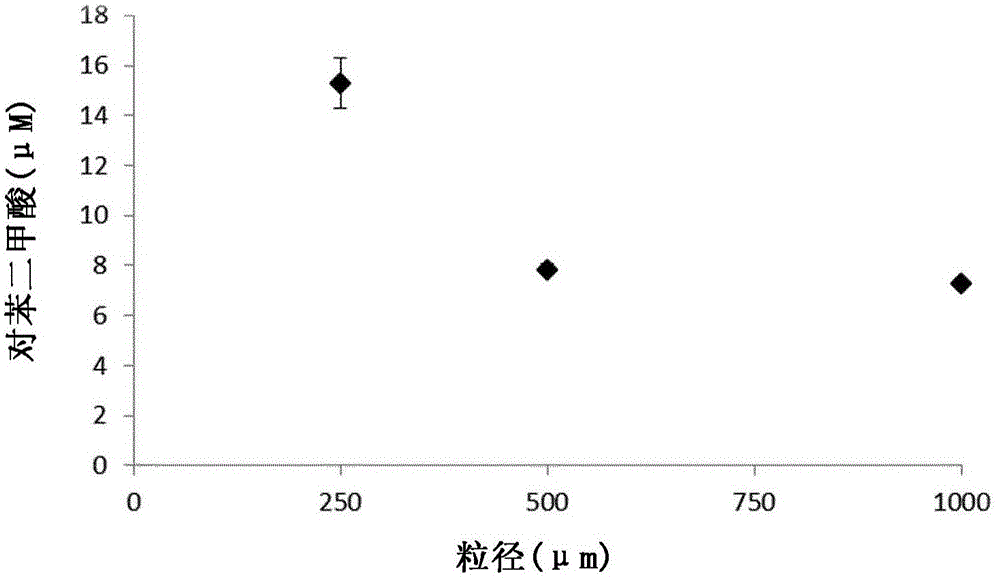

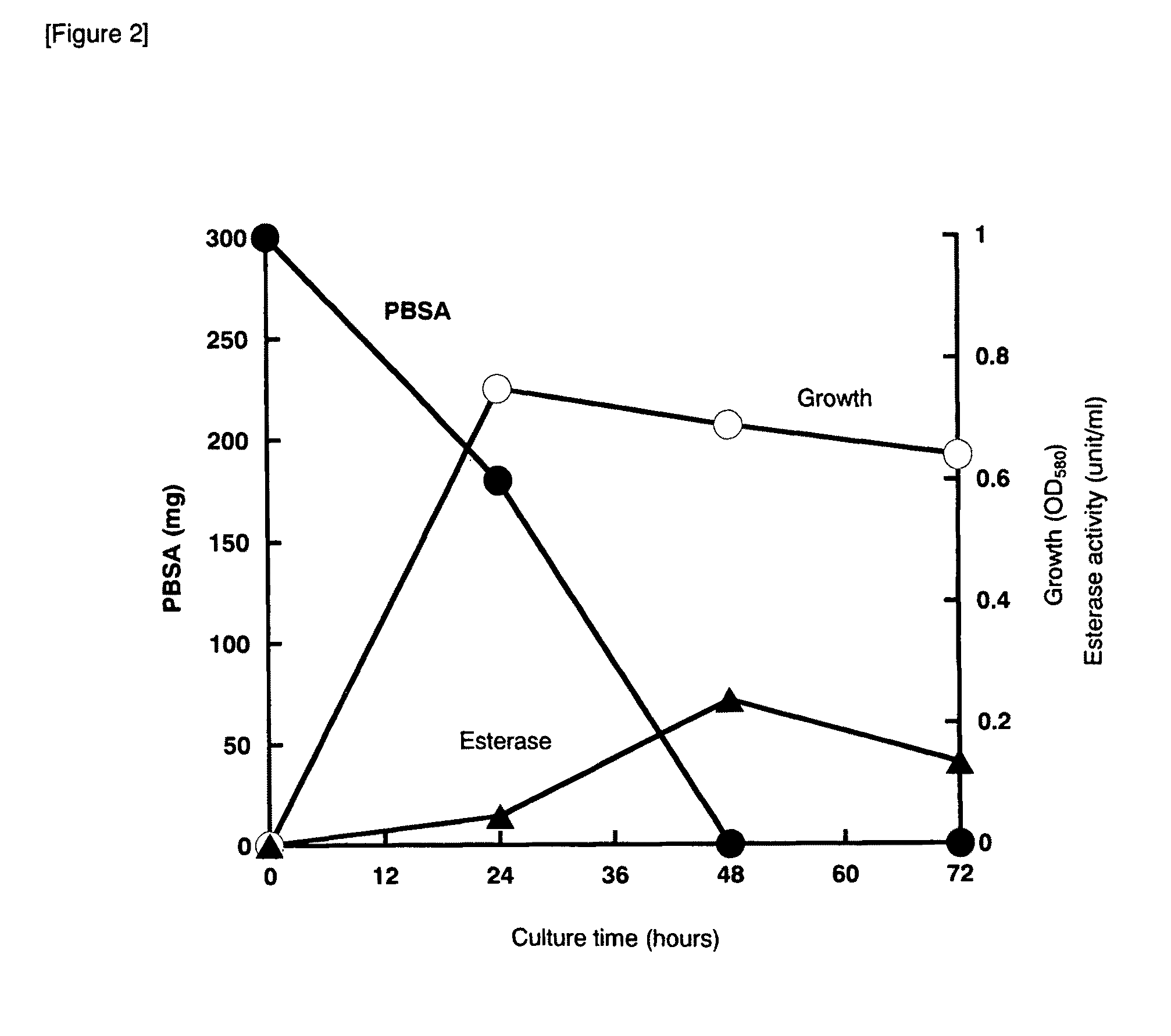

Polyester-based-plastic-degrading bacteria, polyester-based-plastic-degrading enzymes and polynucleotides encoding the enzymes

Owner:JAPAN SCI & TECH CORP

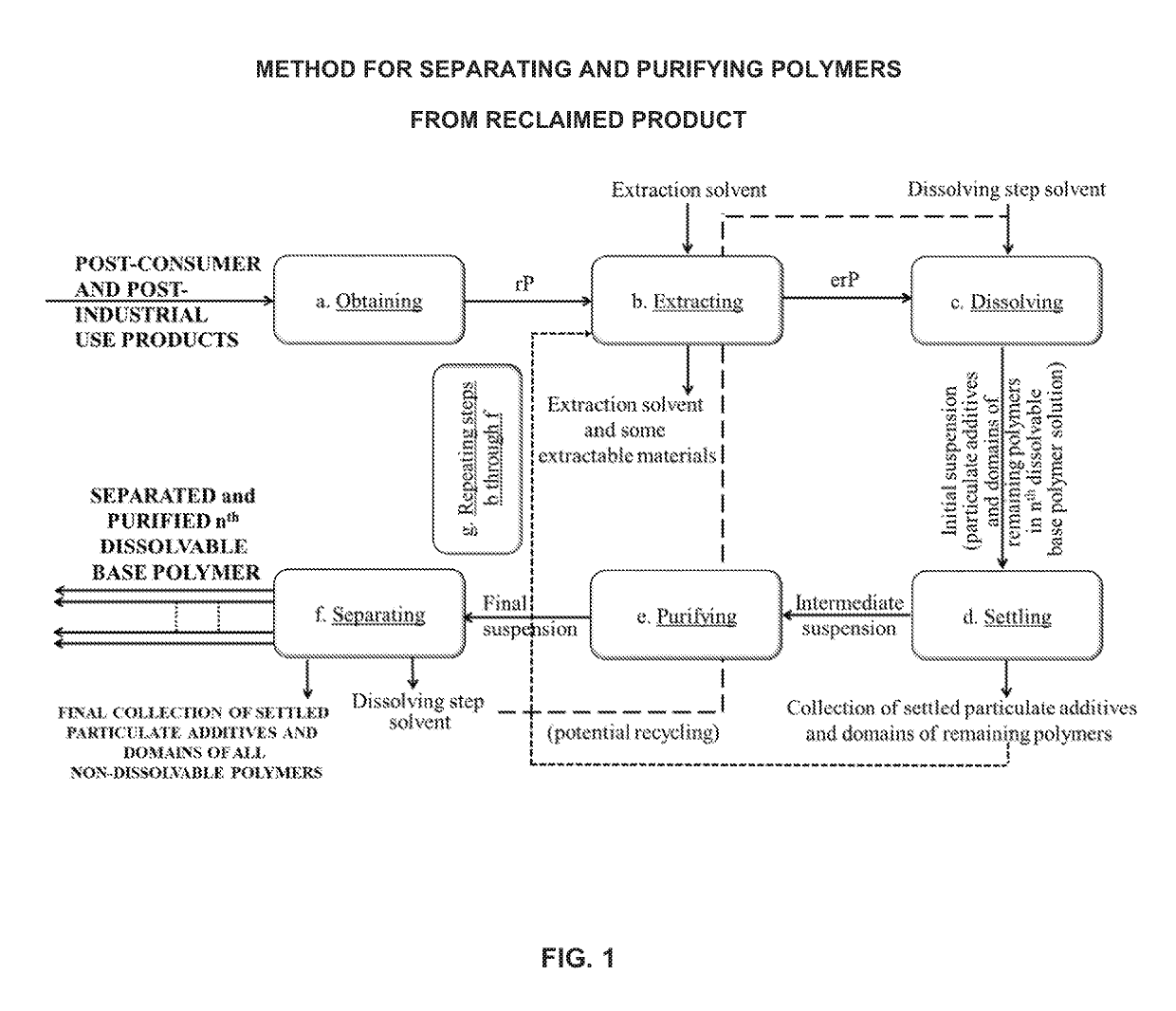

Method for purifying reclaimed polymers

A method for purifying a reclaimed polymer is provided. The method involves obtaining reclaimed polymer, contacting it with a first fluid solvent to produce an extracted reclaimed polymer then dissolving the extracted reclaimed polymer in a solvent to produce a first solution comprising polymer and suspended contaminants. The first solution is settled to produce a second solution comprising polymer and remaining contaminants. The second solution is purified by contacting the second solution with solid media to produce a third solution comprising purer polymer. Finally, the purer polymer is separated from the third solution.

Owner:THE PROCTER & GAMBLE COMPANY

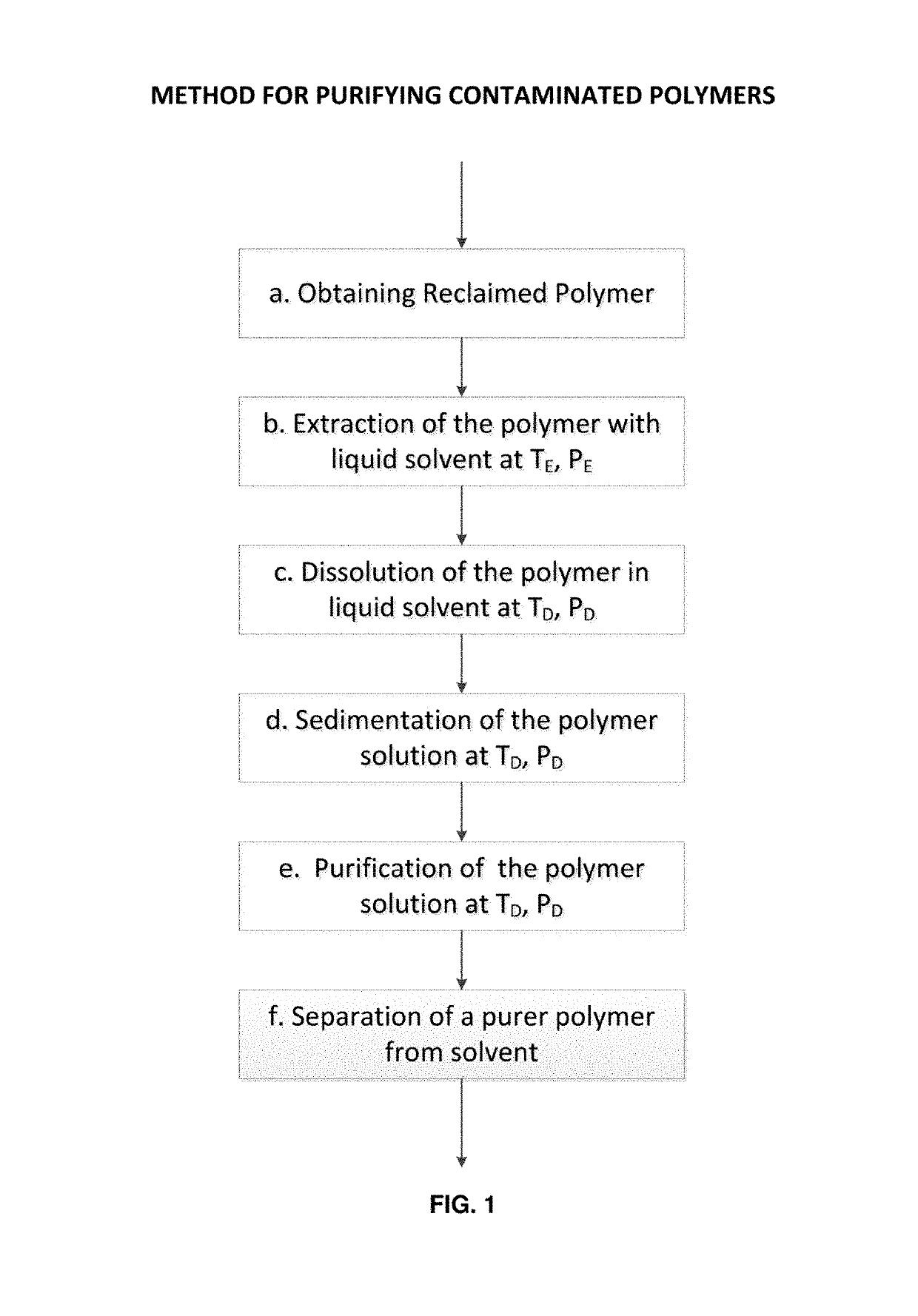

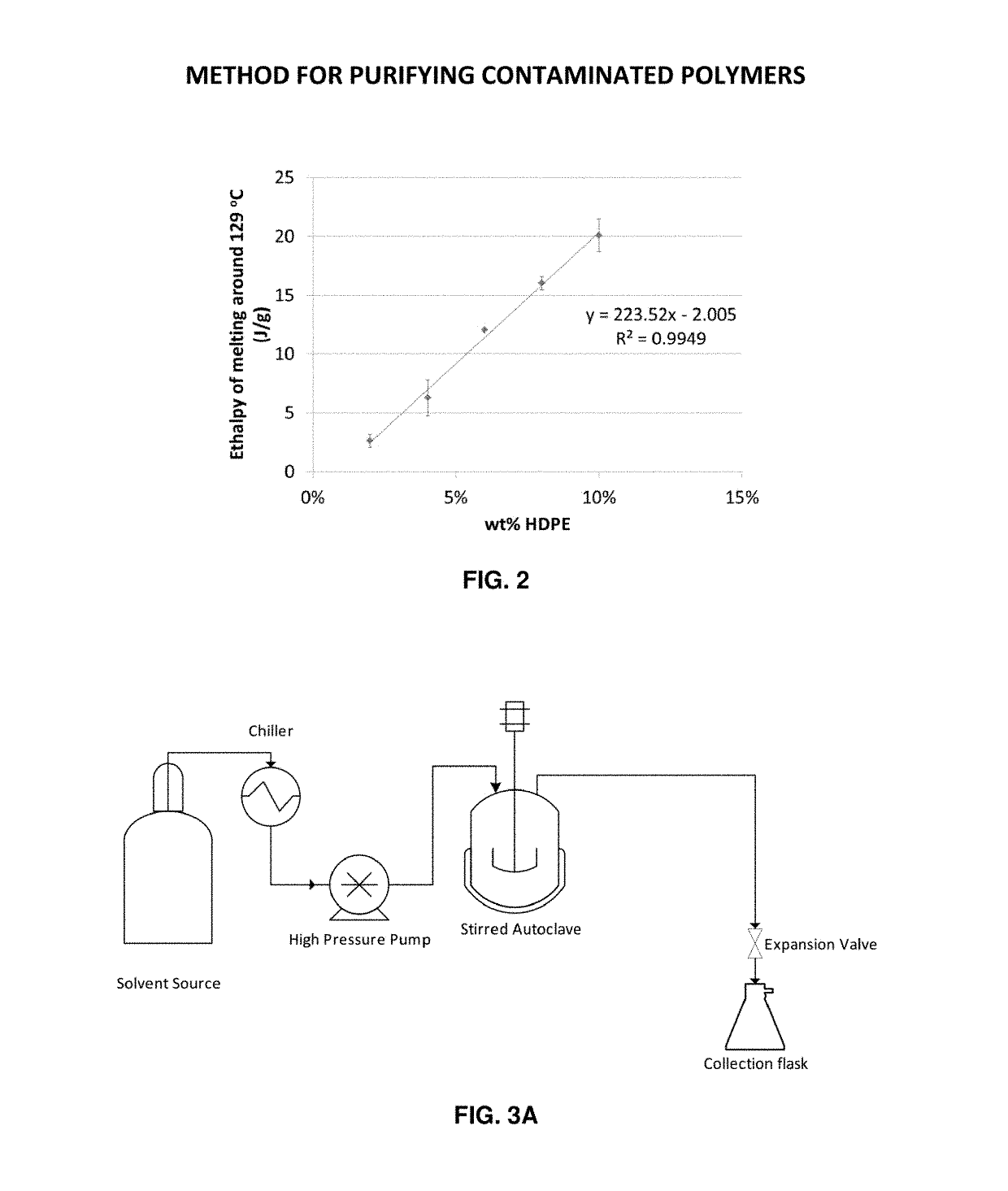

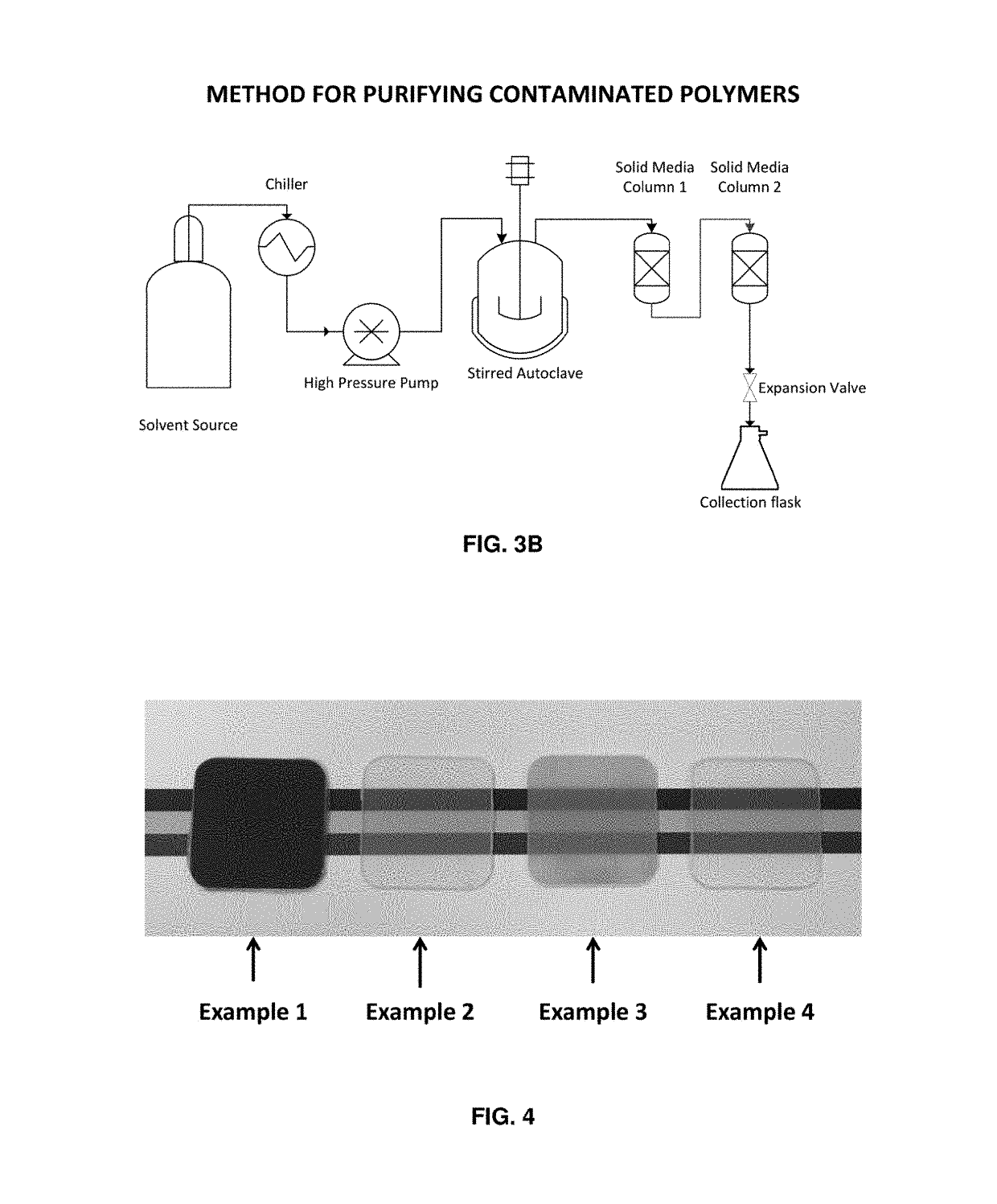

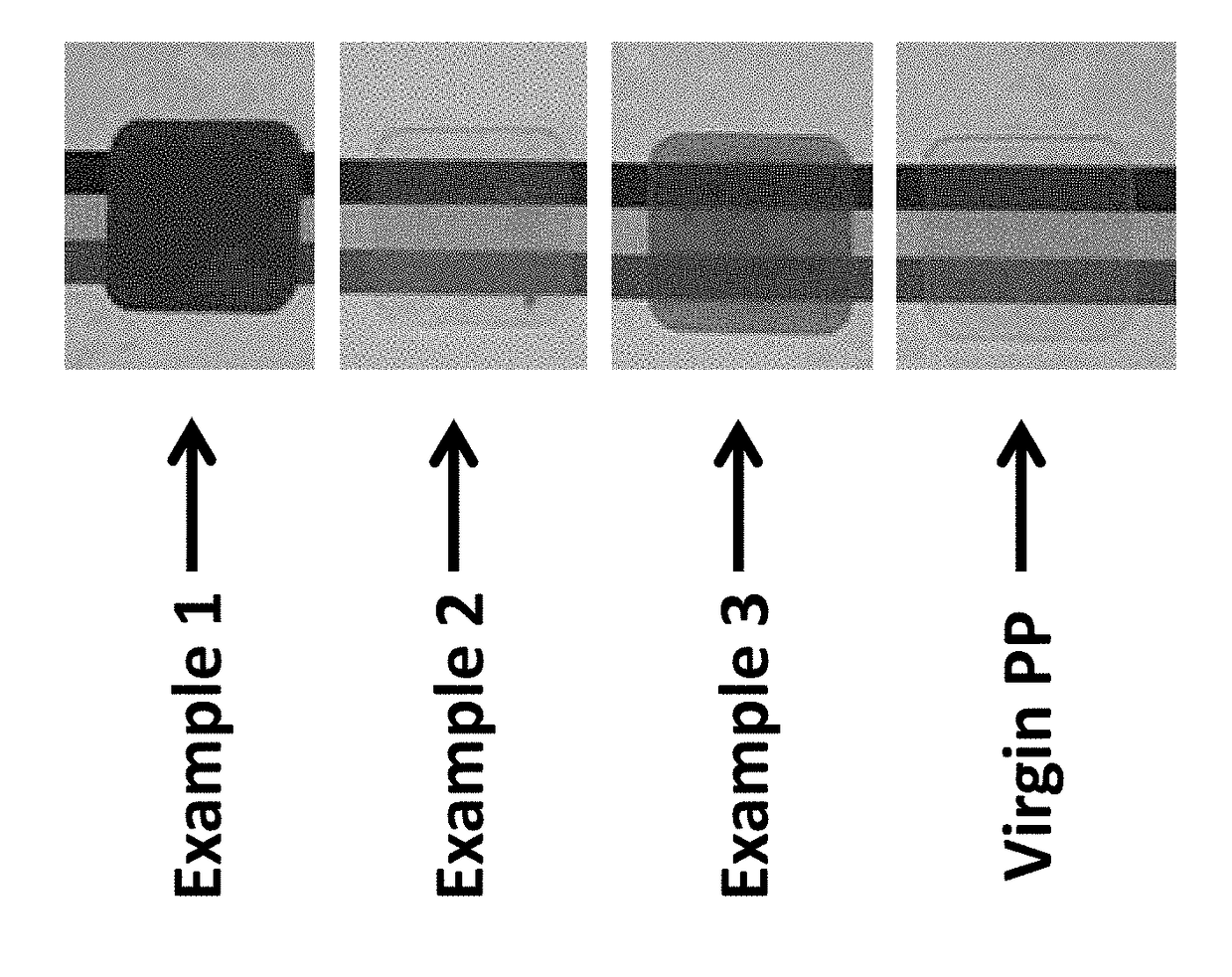

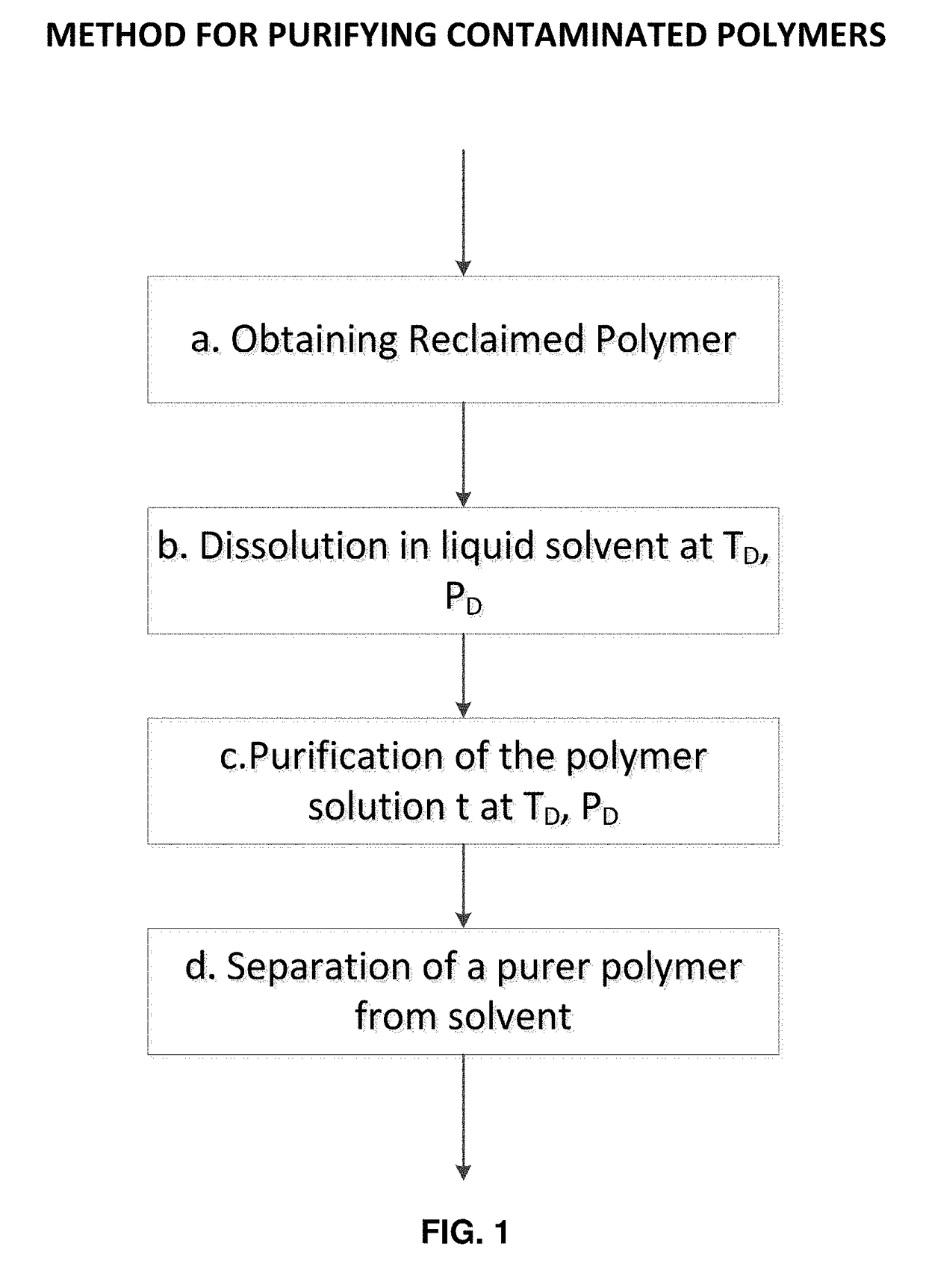

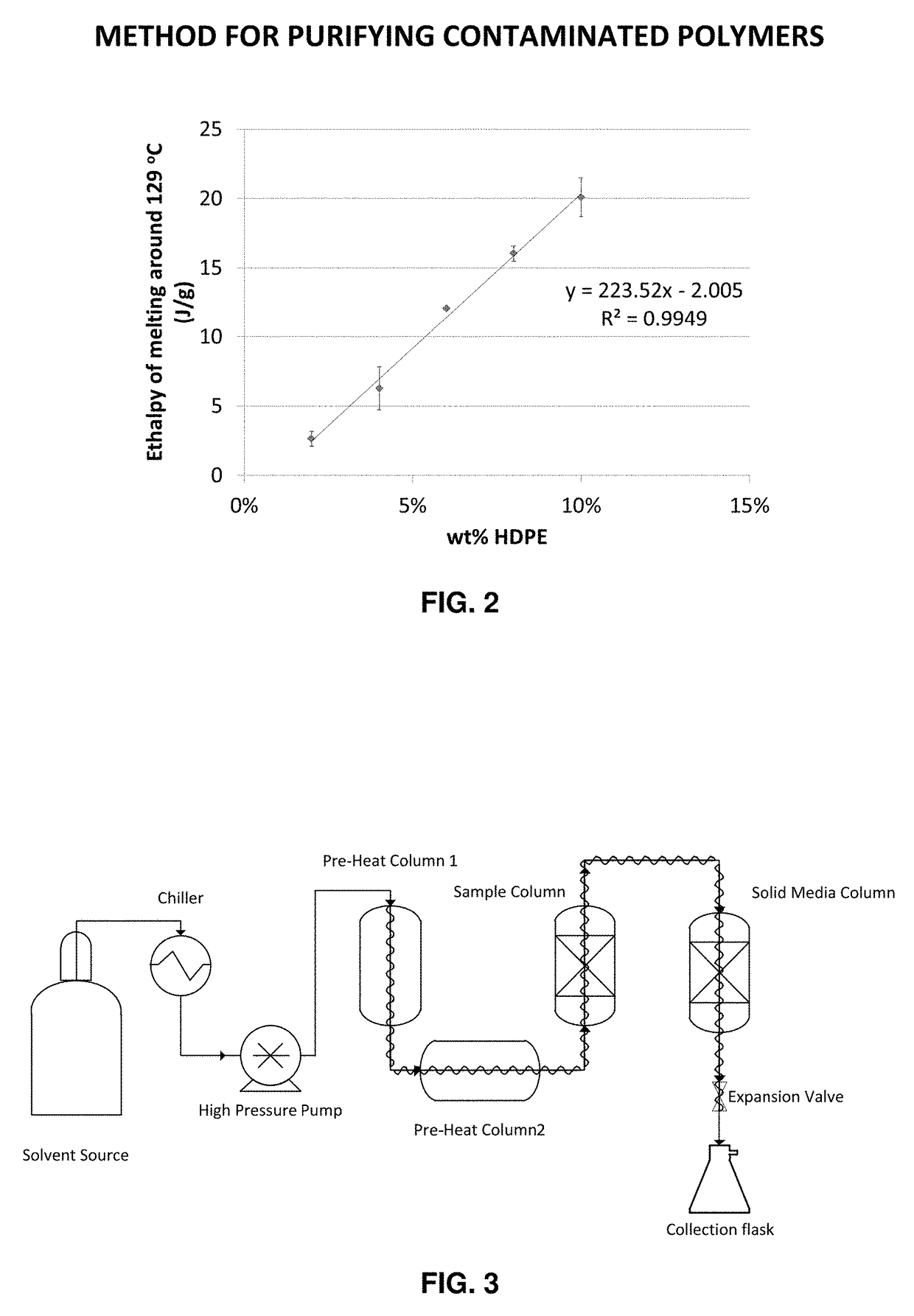

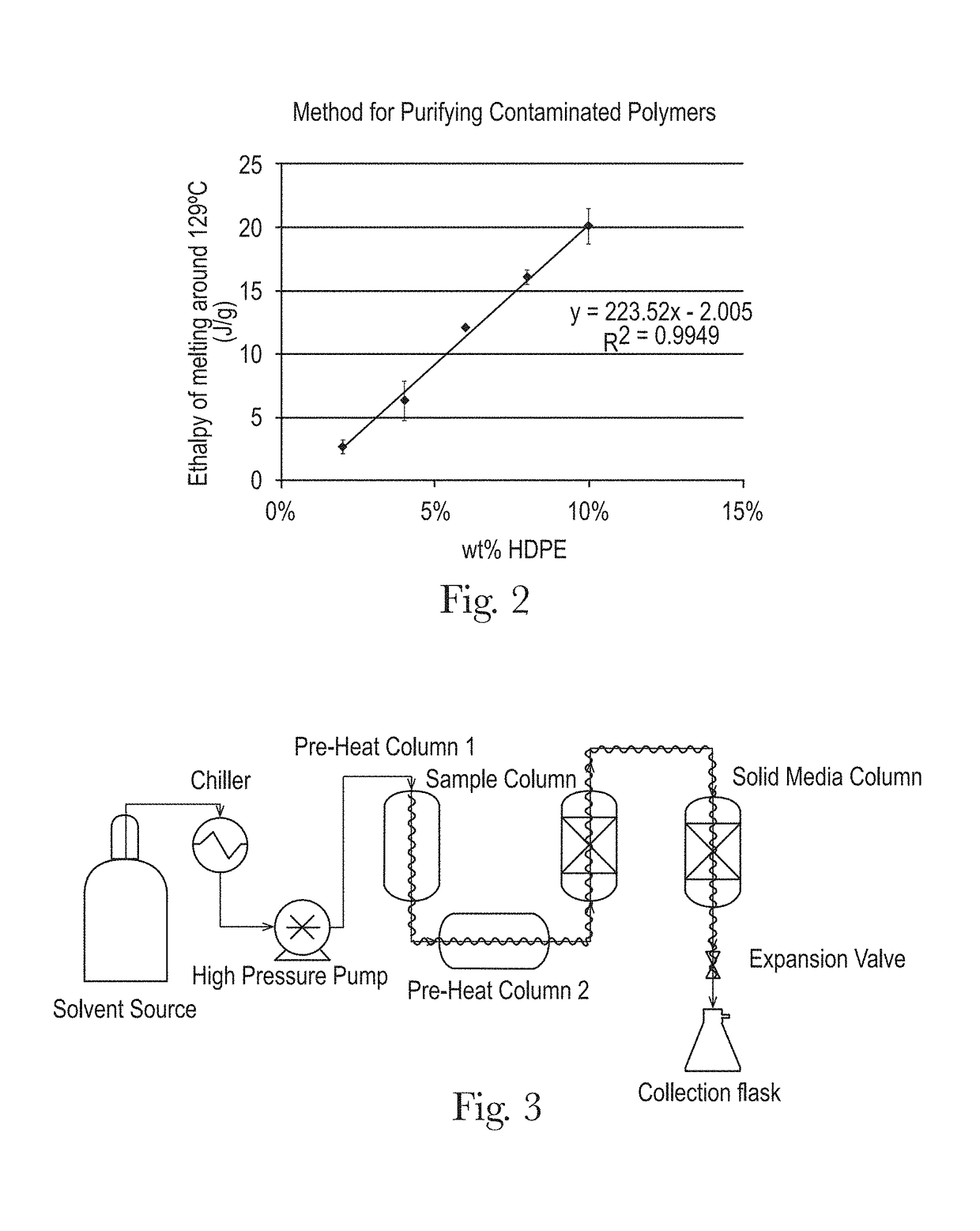

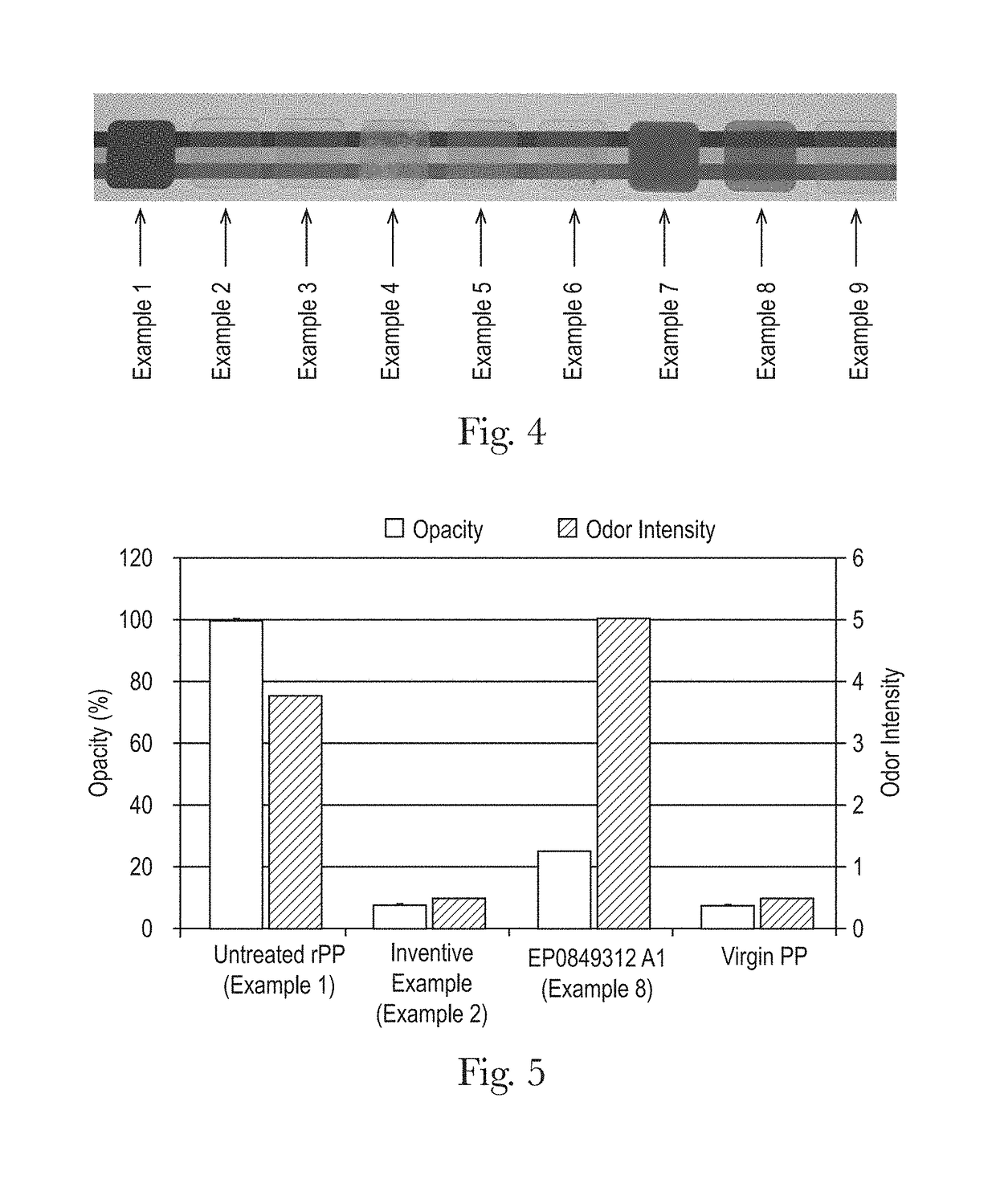

Method for purifying contaminated polymers

A method for purifying a reclaimed polymer, such as a polymer reclaimed from post-consumer use or post-industrial use, is disclosed. The method involves obtaining the reclaimed polymer and dissolving it in a solvent at an elevated temperature and pressure to produce a polymer solution, which is purified at an elevated temperature and pressure by contacting the polymer solution with solid media to produce a purer polymer solution. A purer polymer is then separated from the purer polymer solution.

Owner:PROCTER & GAMBLE CO

Method for extracting nylon from waste materials

InactiveUS7659320B2Increase pressureHead heightPlastic recyclingSolution crystallizationSolventWaste material

The invention relates to a method for recovering nylon from a nylon-containing material by contacting the nylon-containing material with an alkanol-containing solvent at elevated temperature and at a pressure higher than the equilibrium pressure of the alkanol-containing solvent at the elevated temperature, thereby dissolving the nylon in the alkanol-containing solvent, removing the alkanol-containing solvent containing dissolved nylon from any undissolved solids, and decreasing the temperature of the alkanol-containing solvent containing dissolved nylon to precipitate the dissolved nylon.

Owner:INTERFACE INC

Method for purifying contaminated polymers

A method for purifying a reclaimed polymer, such as a polymer reclaimed from post-consumer use or post-industrial use, is disclosed. The method involves obtaining the reclaimed polymer and contacting it at an elevated temperature and pressure with a fluid solvent to produce an extracted reclaimed polymer. The extracted reclaimed polymer is dissolved in a solvent at an elevated temperature and pressure to produce a polymer solution, which is purified at an elevated temperature and pressure by contacting the polymer solution with solid media to produce a purer polymer solution. A purer polymer is then separated from the purer polymer solution.

Owner:THE PROCTER & GAMBLE COMPANY

Method for purifying reclaimed polypropylene

A method for purifying a reclaimed polypropylene is provided. The method involves obtaining reclaimed polypropylene, contacting it with a first fluid solvent to produce an extracted reclaimed polypropylene then dissolving the extracted reclaimed polypropylene in a solvent to produce a first solution comprising polypropylene and suspended contaminants. The first solution is settled to produce a second solution comprising polypropylene and remaining contaminants. The second solution is purified by contacting the second solution with solid media to produce a third solution comprising purer polypropylene. Finally, the purer polypropylene is separated from the third solution.

Owner:THE PROCTER & GAMBLE COMPANY

Chemical process for recycling polyethylene terephthalate (PET) waste

InactiveUS7893122B2Improve efficiencyIncrease conversion ratePreparation from carboxylic acid saltsPlastic recyclingPolyethylene terephthalate glycolCompanion animal

Owner:UNIV IBEROAMERICANA A C

Non-chemical, mechanical procedure for the devulcanization of scrap rubber and/or elastomers and apparatus therefor

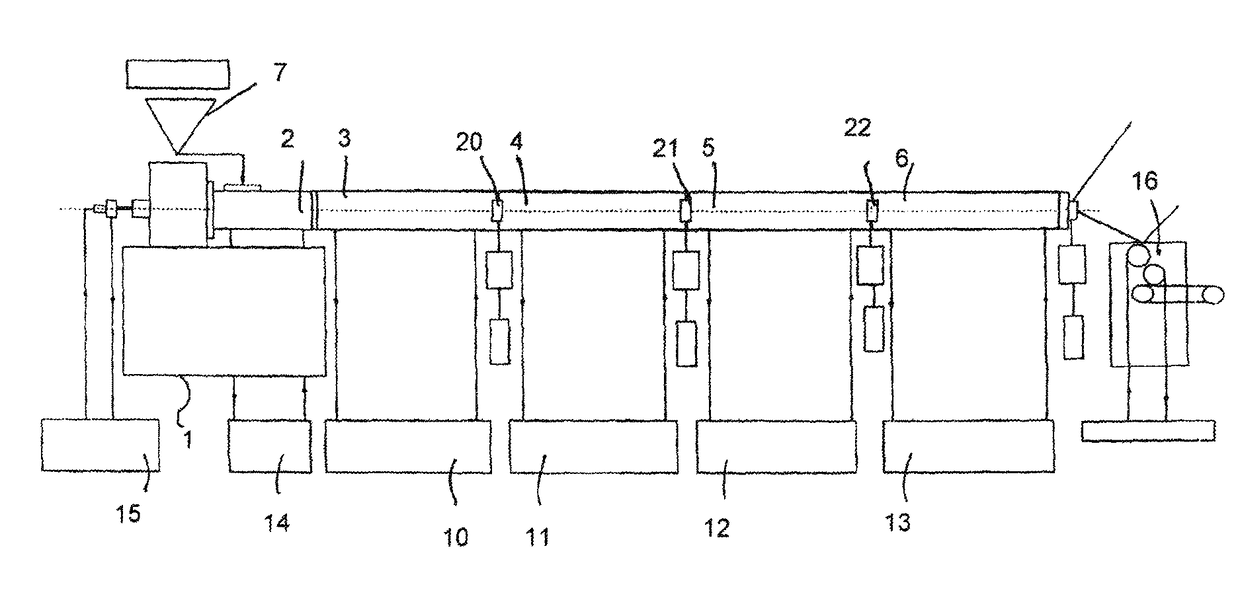

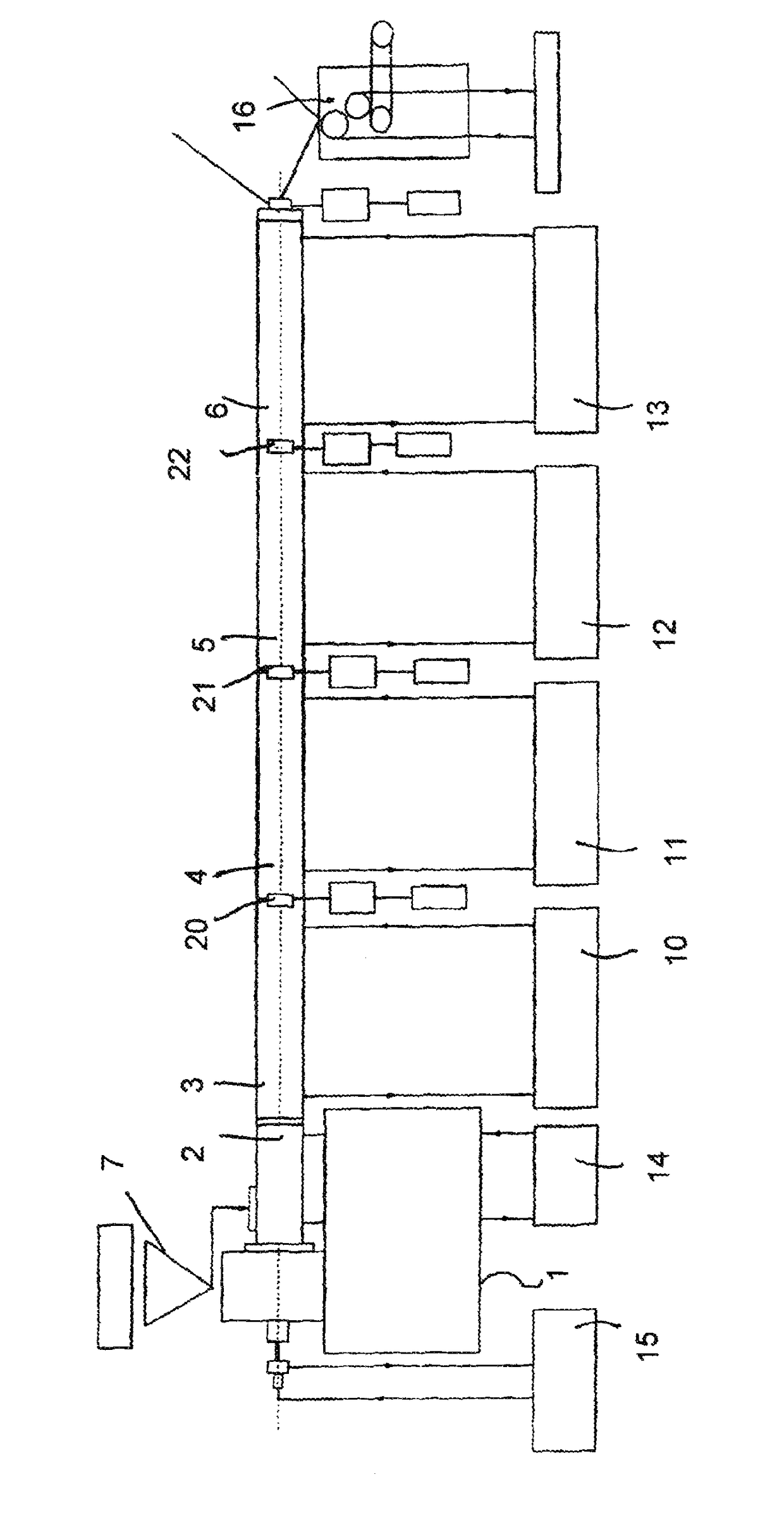

Method of devulcanizing rubber and / or elastomers without the need for a chemical agent, in which method the vulcanized rubber and / or elastomers are fed into a planetary roller extruder, which planetary roller extruder has a housing, a central spindle, and at least one group of planetary spindles. Mechanical and thermal stress is generated on the vulcanized rubber and / or elastomers by kneading and / or crushing the vulcanized rubber and / or elastomers using the central spindle and the planetary spindles. The mechanical and thermal stress alone is sufficient to break or destroy the molecular chains or bonds of the vulcanized rubber and / or elastomers.

Owner:ENTEX RUST & MITSCHKE

Method for the degrading of synthetic polymers and device for carrying out said method

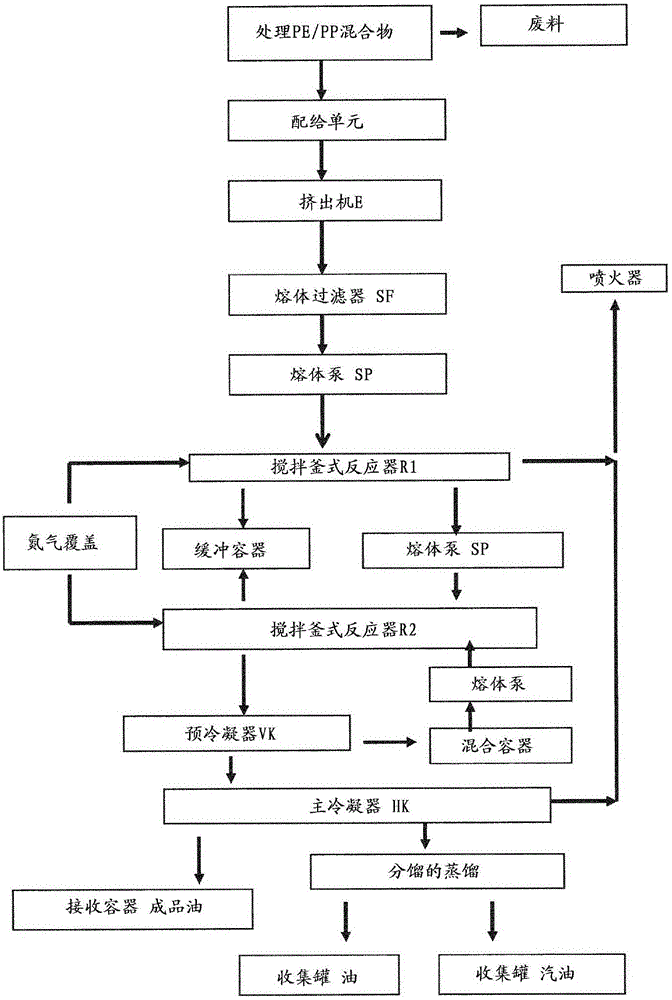

The present invention relates to a method for degrading synthetic polymers, in particular polyolefines, comprising the following steps a) the synthetic polymers, in particular dried, synthetic polymers, are melted in at least one extruder (E), b) the polymer melt is purified by guiding said polymer melt through at least one melt filter (SF), c) the purified polymer melt is transferred into at least one first reactor (R1), said purified polymer melt in the at least one first reactor (R1) is guided from a lower region into an upper region of the reactor (R1) by heating to temperatures of between 300 and 370° C, preferably 330° C to 360° C, in particular 350° C, the polymers in the at least one first reactor (R1) are cleaved into oligomers, d) the oligomer mixture formed in the at least one first reactor (R1) is transferred into at least one second reactor (R2), the oligomer mixture in the at least second reactor (R2) is guided from a lower region into an upper region of the reactor (R2) by heating to a temperature of between 380 to 450° C, preferably 400° C to 430° C, in particular 410° C, the oligomers in the at least one second reactor (R2) being degraded into short-chained hydrocarbons, in the presence of at least one clay mineral as a depolymerisation catalyst, e) the short-chained hydrocarbons formed in the at least one second reactor (R2) are discharged into at least one precondenser (VK), the short-chained hydrocarbons emerging from the at least one second reactor (R2) are cooled in the at least one precondenser (VK); and f) the short-chained hydrocarbons cooled in the at least one precondener (VK) are guided into at least one main condenser (HK), the short-chained hydrocarbons emerging from the at least one precondenser (VK) are liquefied in the at least one main condenser (HK). The invention also relates to a system for carrying out said method and to the product oil produced according to said method.

Owner:ACHIM METHLING JOSEF RANFTL

Process of recycling mixed PET plastic articles

ActiveUS10385183B2Increase productionInexpensive and durablePlastic recyclingPolymer recoveryPolymer scienceOligomer

The invention relates to a method for recycling at least one mixed PET plastic article, the method comprising degrading at least PET of the mixed PET plastic article to monomers and / or oligomers using an enzyme and recovering the resulting monomers and / or oligomers. The method of the invention may be used for depolymerizing, simultaneously or sequentially at least two different polymers of the mixed PET plastic article, and / or for recycling at least two mixed PET plastic articles.

Owner:CARBIOS

Polyester polyols from recycled polymers and waste streams

The present invention relates to polyester polyols made from aromatic polyacid sources such as thermoplastic polyesters. The polyols can be made by heating a thermoplastic polyester such as virgin polyethylene terephthalate, recycled polyethylene terephthalate, or mixtures thereof, with a glycol to give a digested intermediate which is then reacted with a digestible polymer, which can be obtained from various recycle waste streams. The polyester polyols comprise a glycol-digested polyacid source and a further digestible polymer. The polyester polyols provide a sustainable alternative to petrochemical or biochemical based polyester polyols.

Owner:RESINATE MATERIALS GRP

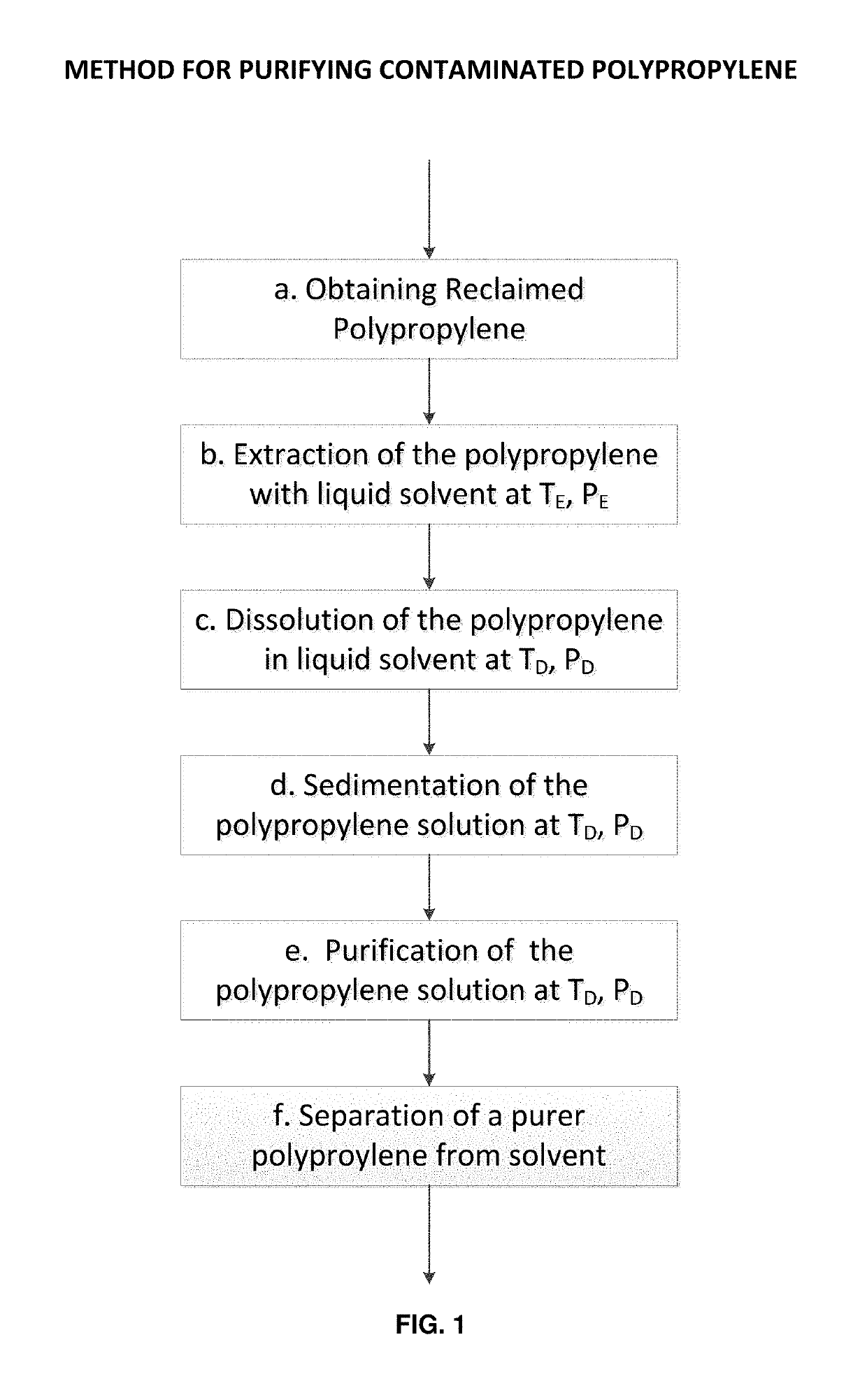

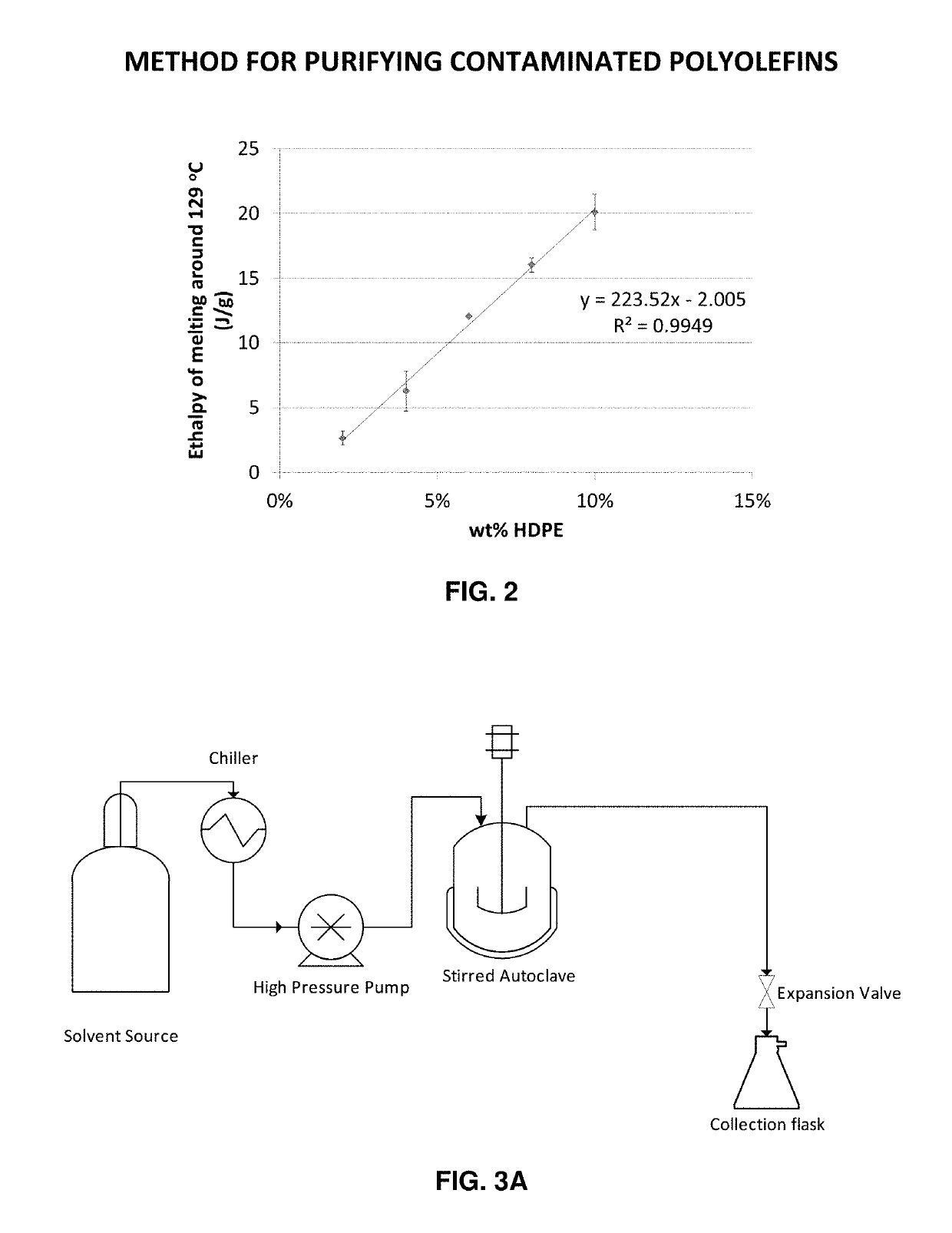

Method for purifying contaminated polypropylene

A method for purifying reclaimed polypropylene, such as a polypropylene reclaimed from post-consumer use or post-industrial use, is disclosed. The method involves obtaining the reclaimed polypropylene and contacting it at an elevated temperature and pressure with a fluid solvent to produce an extracted reclaimed polypropylene. The extracted reclaimed polypropylene is dissolved in a solvent at an elevated temperature and pressure to produce a polypropylene solution, which is purified at an elevated temperature and pressure by contacting the polypropylene solution with solid media to produce a purer polypropylene solution. A purer polypropylene is then separated from the purer polypropylene solution.

Owner:PROCTER & GAMBLE CO

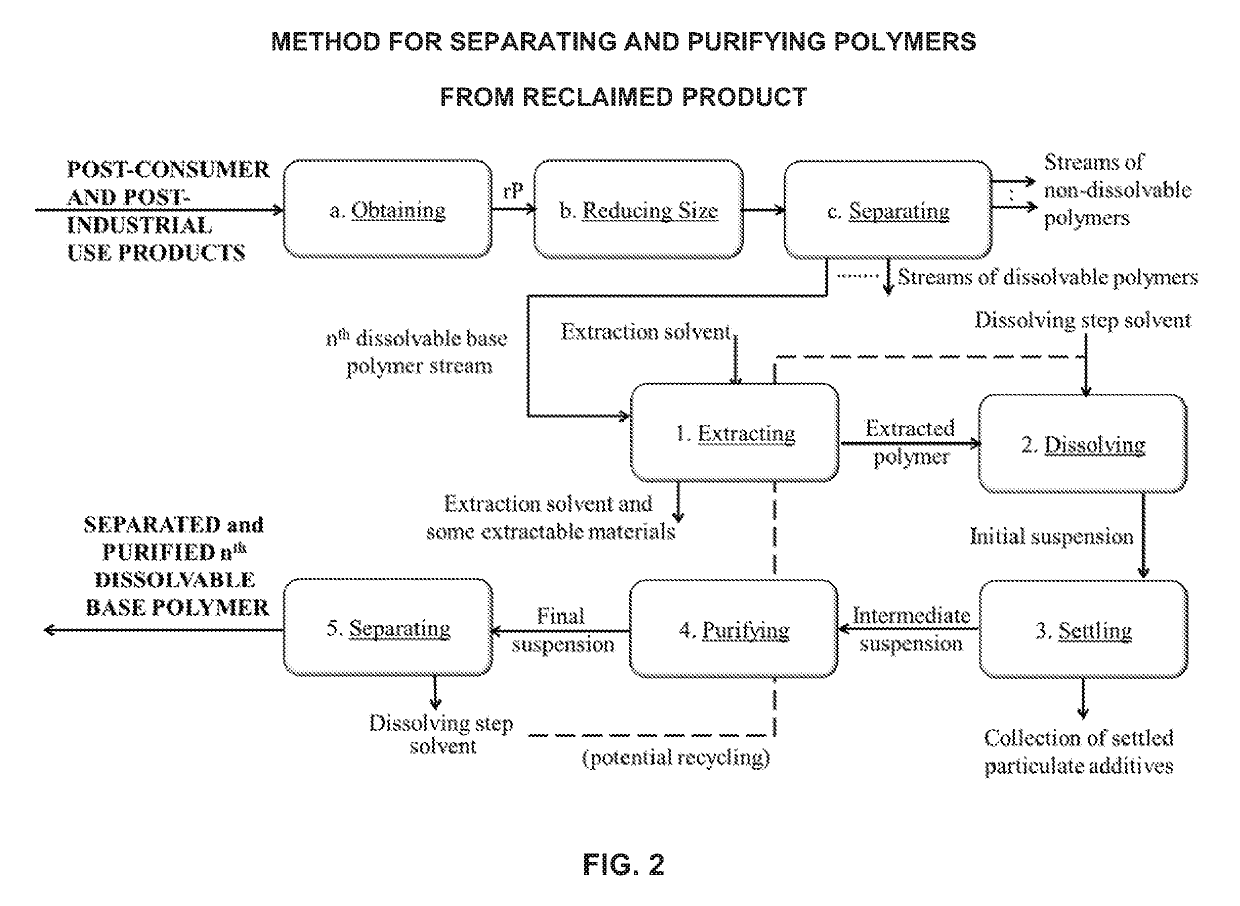

Method for separating and purifying materials from a reclaimed product

Owner:PROCTER & GAMBLE CO

Separation of Polyolefins from Nylons

InactiveUS20050272913A1Economical acceptablePractical acceptableLayered productsPlastic recyclingNylon materialPolyolefin

In the recycling of Nylon 6 and Nylon 6,6 polyamides from post-consumer or post-industrial waste, a process is disclosed to separate Nylon 6 and Nylon 6,6 polyamides from commingled polyolefin waste components, particularly polypropylene, by admixing the waste with an ester solvent composition and heating the admixture to a temperature above the melting temperature of the contained polyolefins to form an ester solvent composition further containing dissolved polyamide polymer and a separate immiscible liquid polyolefin phase. The ester solvent composition preferably contains ethylene carbonate, propylene carbonate, butylene carbonate, or mixtures thereof.

Owner:CHEM PROD CORP

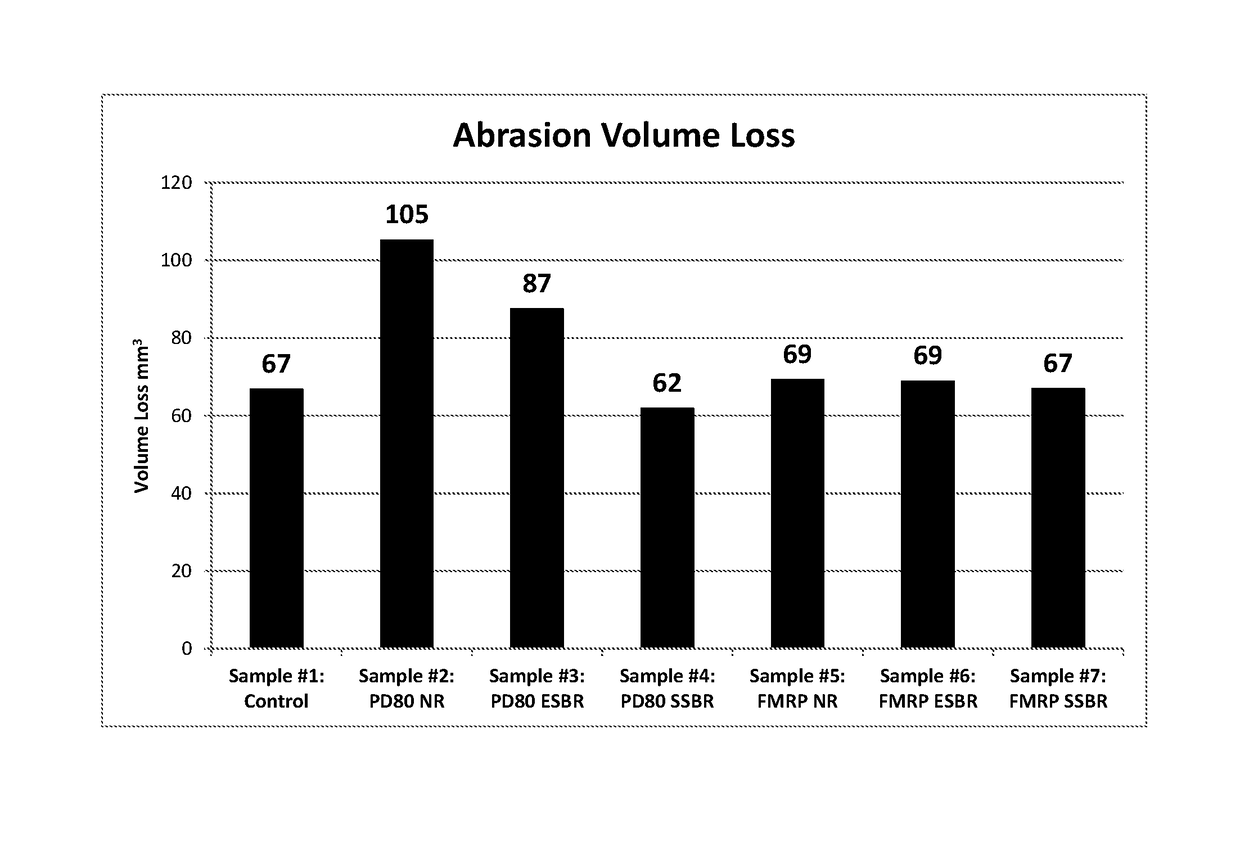

Recycled micronized rubber formulation having improved abrasion resistance

ActiveUS9815974B2Without significantly compromising the abrasion resistance of the rubber formulationSeverely abrasion resistanceProductsConveyorsEngineeringSynthetic rubber

This invention is based upon the discovery that micronized solution styrene-butadiene rubber from postconsumer sources can be included in rubber formulations without severely compromising abrasion resistance. The micronized solution styrene-butadiene rubber utilized in the rubber formulations of this invention can be made by cryogenic grinding postconsumer rubber products using conventional procedures. For instance, it can be made by cryogenically grinding a tire tread containing a high level of solution styrene-butadiene rubber. The micronized solution styrene-butadiene rubber can then be blending into desired virgin rubbers and cured without significantly compromising the abrasion resistance of the rubber formulation. The rubber formulation of this invention is comprised of a natural or synthetic rubber and from 1 weight percent to 30 weight percent of a micronized rubber composition containing at least 10 weight percent solution styrene-butadiene rubber and having a particle size of 40 mesh to 200 mesh.

Owner:LEHIGH TECH INC

Recovery of additive manufacturing support materials

The inventions is directed to a method for recovering support materials used in an additive manufacturing process. The method comprises exposing a precursor additive manufactured article comprised of a water soluble support polymer and an insoluble material to water. The water soluble support polymer is dissolved in the water. The remaining article is then removed from the water. The dissolved water soluble polymer is precipitated from the water. The precipitated polymer is separated from the water and any remaining water removed to recover the water soluble support polymer. The recovered water soluble support polymer may then be re-used to make further additive manufactured articles.

Owner:DOW GLOBAL TECH LLC

Manufacture of dihydroxy aromatic compounds by alcoholysis of polycarbonate-containing compositions

A method to produce a purified dihydroxy aromatic compound from a polycarbonate-containing composition is provided. The method includes depolymerizing the polycarbonate by alcoholysis using a titanium-based catalyst producing a dihydroxy aromatic compound and a dialkyl carbonate, recovering the dihydroxy aromatic compound as a crude dihydroxy aromatic compound; and contacting the recovered crude dihydroxyl aromatic compound with an acid in the presence of a solvent at an elevated temperature. Alternatively, the method comprises dissolving the recovered crude dihydroxyl aromatic compound in a solvent; contacting the dissolved crude dihydroxy aromatic compound with a base; and neutralizing the combination of the dissolved crude dihydroxy aromatic compound and the base with an acid.

Owner:SAUDI BASIC IND CORP SA

Method and related arrangement for devulcanization of vulcanized rubber

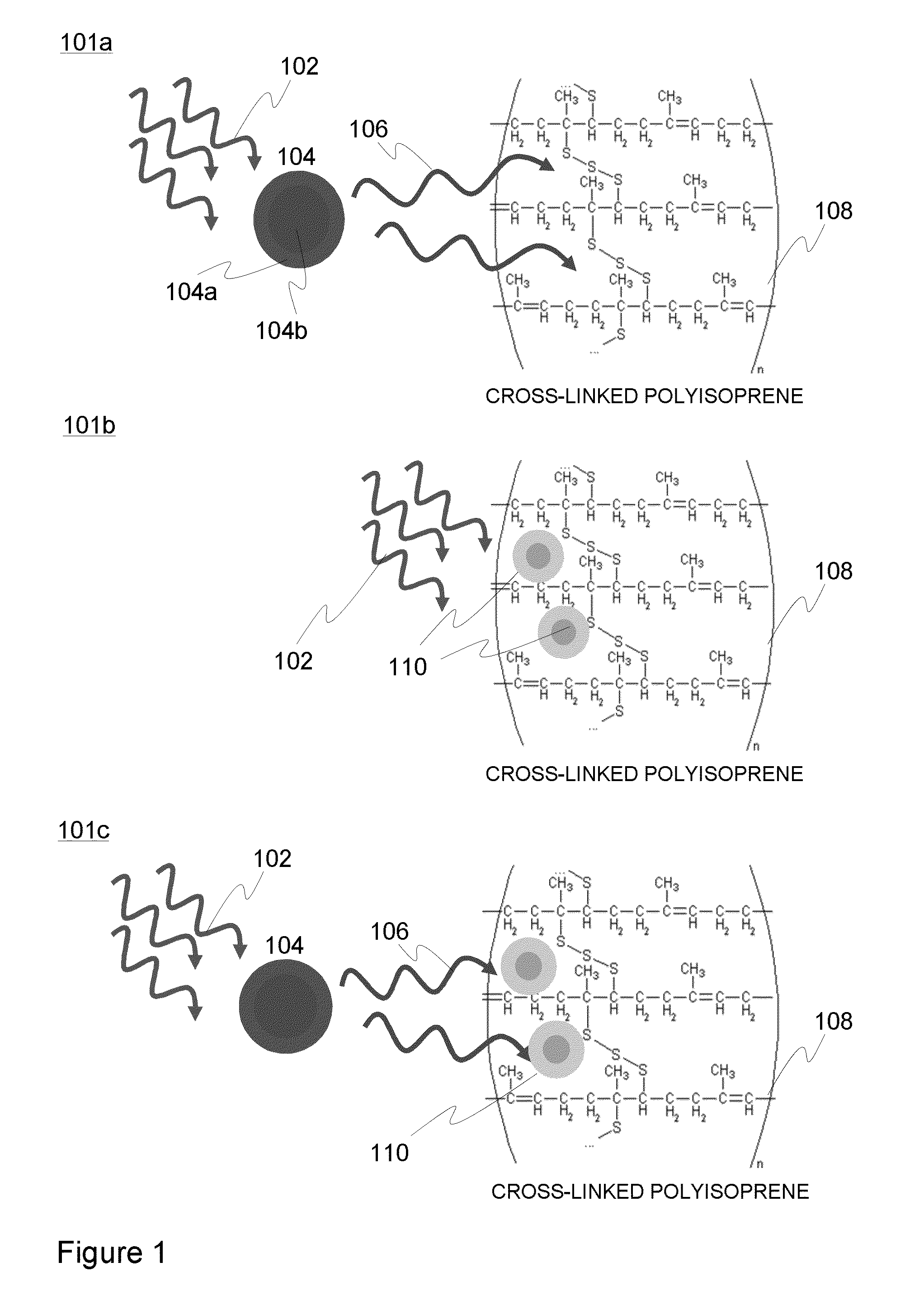

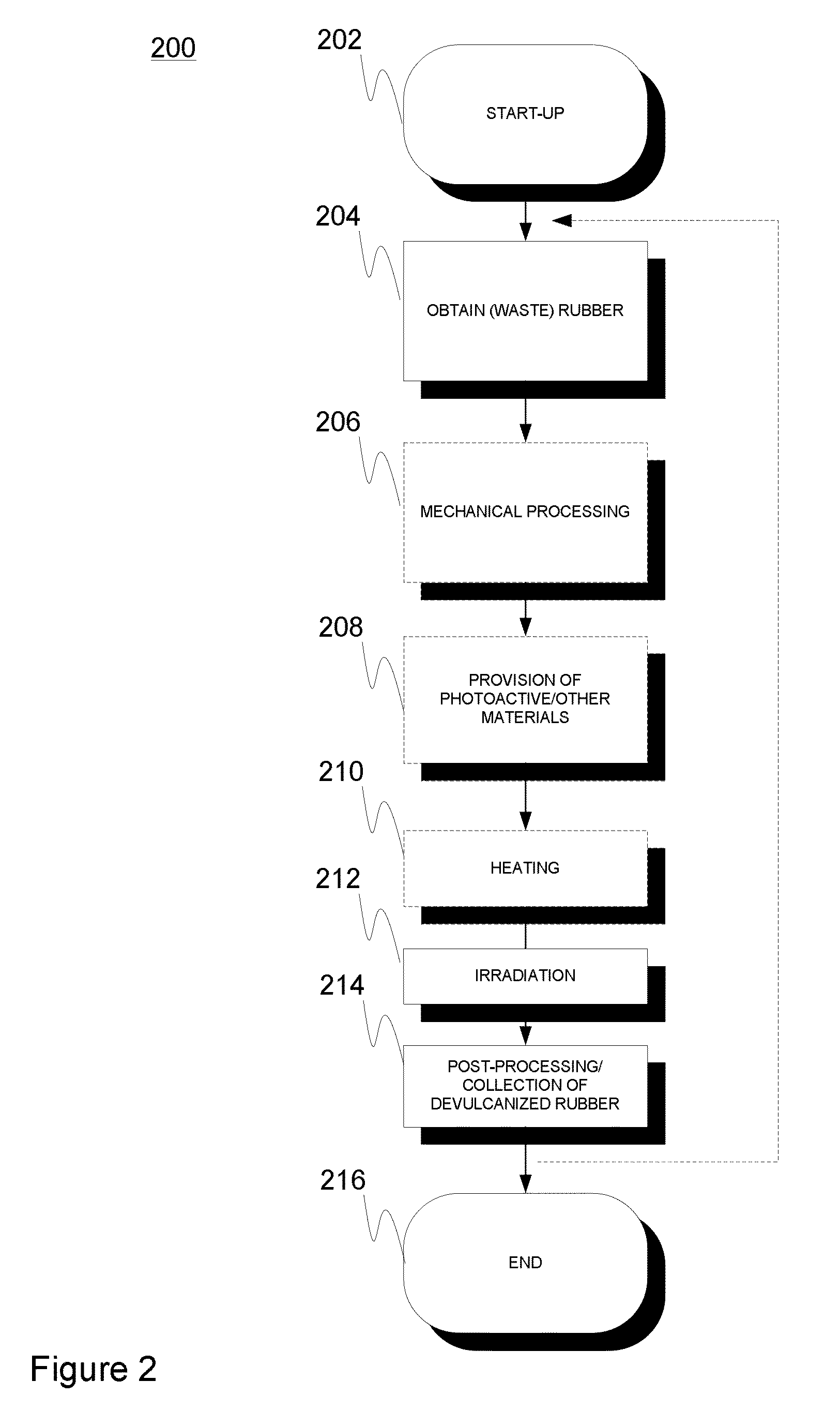

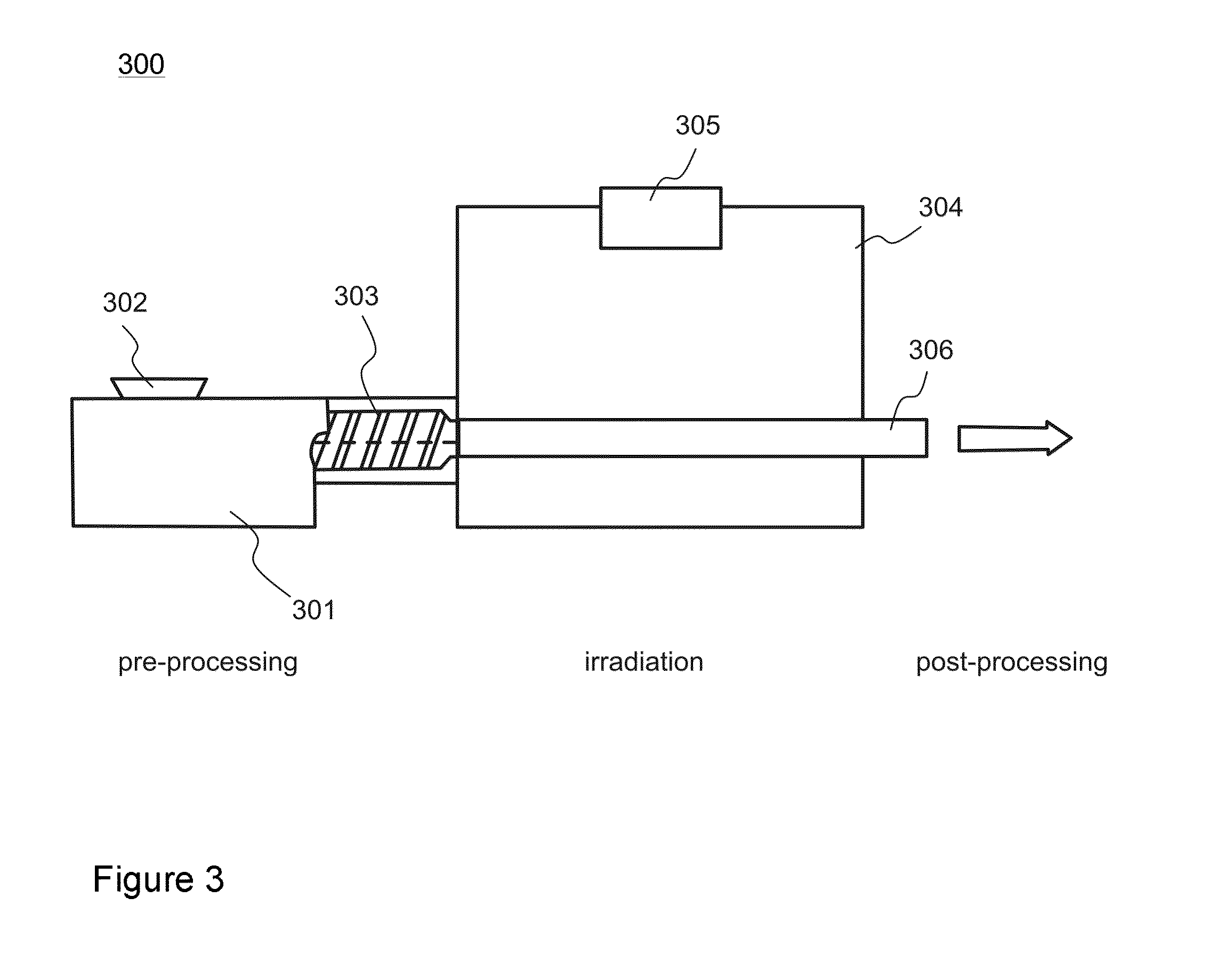

InactiveUS20150005400A1Reduce problemsSimple and rapid devulcanizationPlastic recyclingPolymer recoveryElastomerChemical reaction

A method for devulcanization of rubber feedstock and a related arrangement are provided. The method includes doping rubber feedstock with a photoactive substance (104, 110), configured to activate upon exposure thereof to external radiation of a predetermined wavelength; and further exposing cured rubber feedstock to the external radiation of the predetermined wavelength. Radiation exposure results, upon photoactive substance activation, in initiation of selective scission of intermolecular crosslinks, such as sulfur crosslinks, in the vulcanized rubber elastomers. The photoactive substance may be configured to initiate an excitation emission response and / or chemical reaction. The photoactive substance is preferably selected from semiconducting nanocrystals, such as quantum dots. An arrangement for carrying out the method is presented.

Owner:KALLIOPUSKA JUHA +2

Plastic compound and preparation process

The invention relates to a plastic compound comprising at least one polyolefin and a biological entity that degrades said polyolefin. The invention further relates to a process for preparing a plastic article wherein at least one polyolefin and one biological entity that degrades said polyolefin are mixed at a temperature at which the polyolefin is in a partially or totally molten state.

Owner:CARBIOS +2

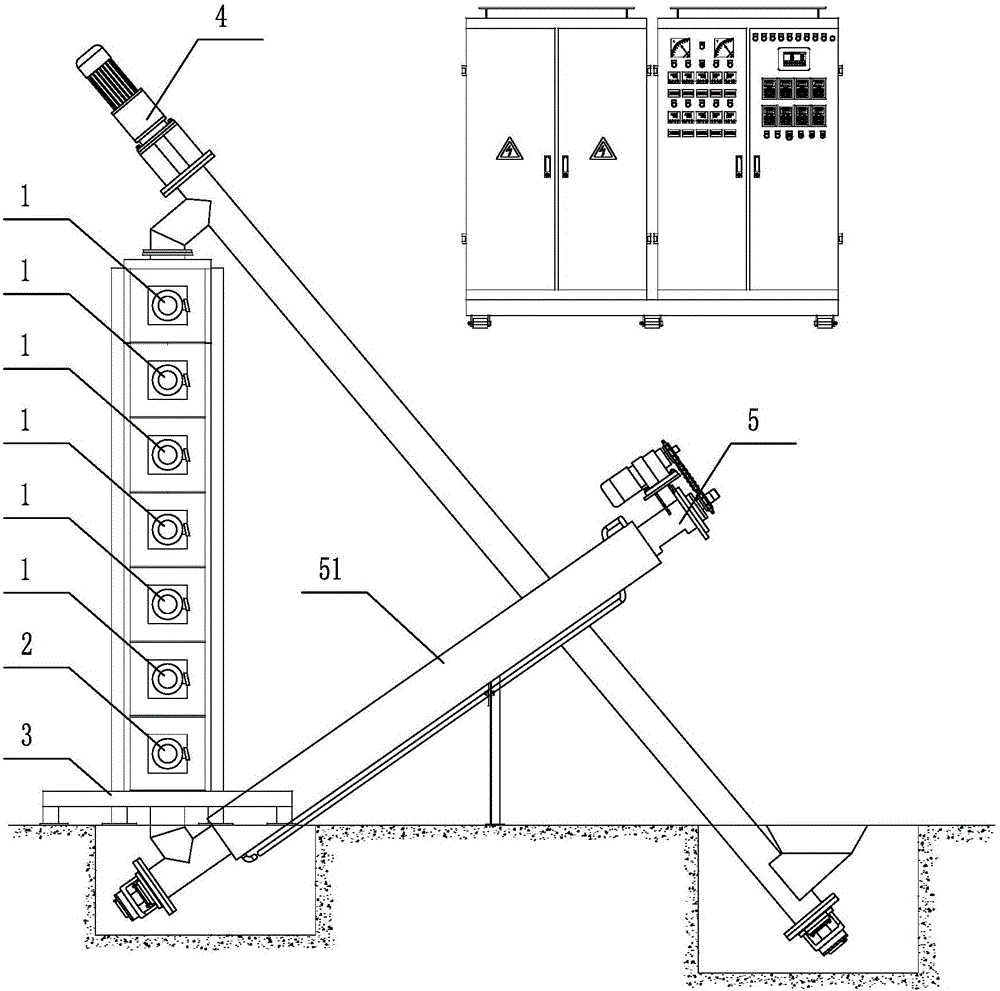

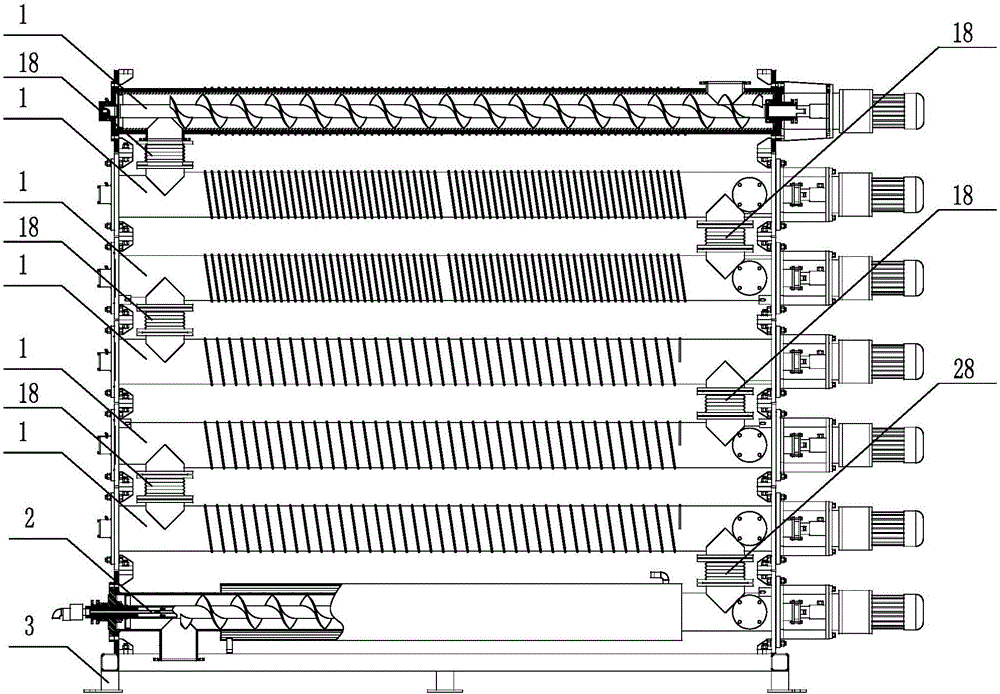

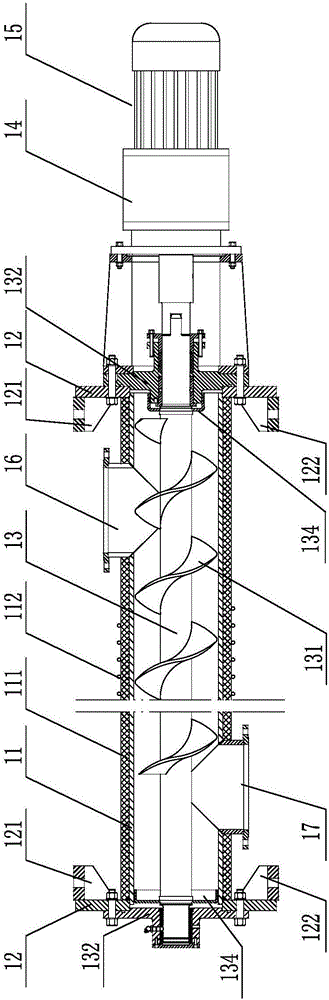

Continuous high temperature and atmospheric pressure desulfurizer

ActiveCN103665428BRapid coolingAvoid destructionPlastic recyclingPolymer recoveryWaste rubberEngineering

The invention discloses a continuous high-temperature atmospheric-pressure desulphurization machine which comprises at least three desulphurization cylinder units and one or more cooling cylinder units, wherein each desulphurization cylinder unit as well as each cooling cylinder unit is provided with an independent frequency modulation motor as a power driving device. According to the reaction process of rubber power desulphurization, the reaction time of rubber power in each desulphurization cylinder unit can be controlled in a segmented mode, and the production accidents of blocking and insufficient desulphurization can be prevented. The cooling cylinder unit can rapidly cool the desulphurized recycled rubber powder, and high-temperature steam of the rubber powder, a softener and an activator can be changed into liquid to permeate the recycled rubber powder, so that damage to the environment is avoided, and the prominent technical problem during waste rubber powder desulphurization is solved. According to the invention, the continuous high-temperature atmospheric-pressure desulphurization machine does not need a rack, has a compact structure and occupies a small space; different types of desulphurization devices can be combined at will to provide convenience for processing different rubber powders; during maintenance, a user only needs to replace a faulted unit; the transportation cost, equipment cost and maintenance cost are greatly reduced.

Owner:山东阳光盛世机械装备有限公司

Shape-memory resin performing remoldability and excellent in shape recovering property, and molded product composed of the cross-linked resin

It is possible to provide a shape-memory molded product having excellent shape-memory properties and recycling efficiency by using a shape-memory resin having a glass transition temperature (Tg) within the range of 40° C. to 200° C. and a dissociation temperature (Td) of a thermo-reversible reaction within the range of 50° C. to 300° C. and satisfying the relationship: Tg+10° C.≦Td,wherein the resin is deformed at a temperature of Tg to less than Td, and cross-linked through a thermo-reversible reaction in which a covalent bond is formed by cooling and dissociated by heating.

Owner:NEC CORP

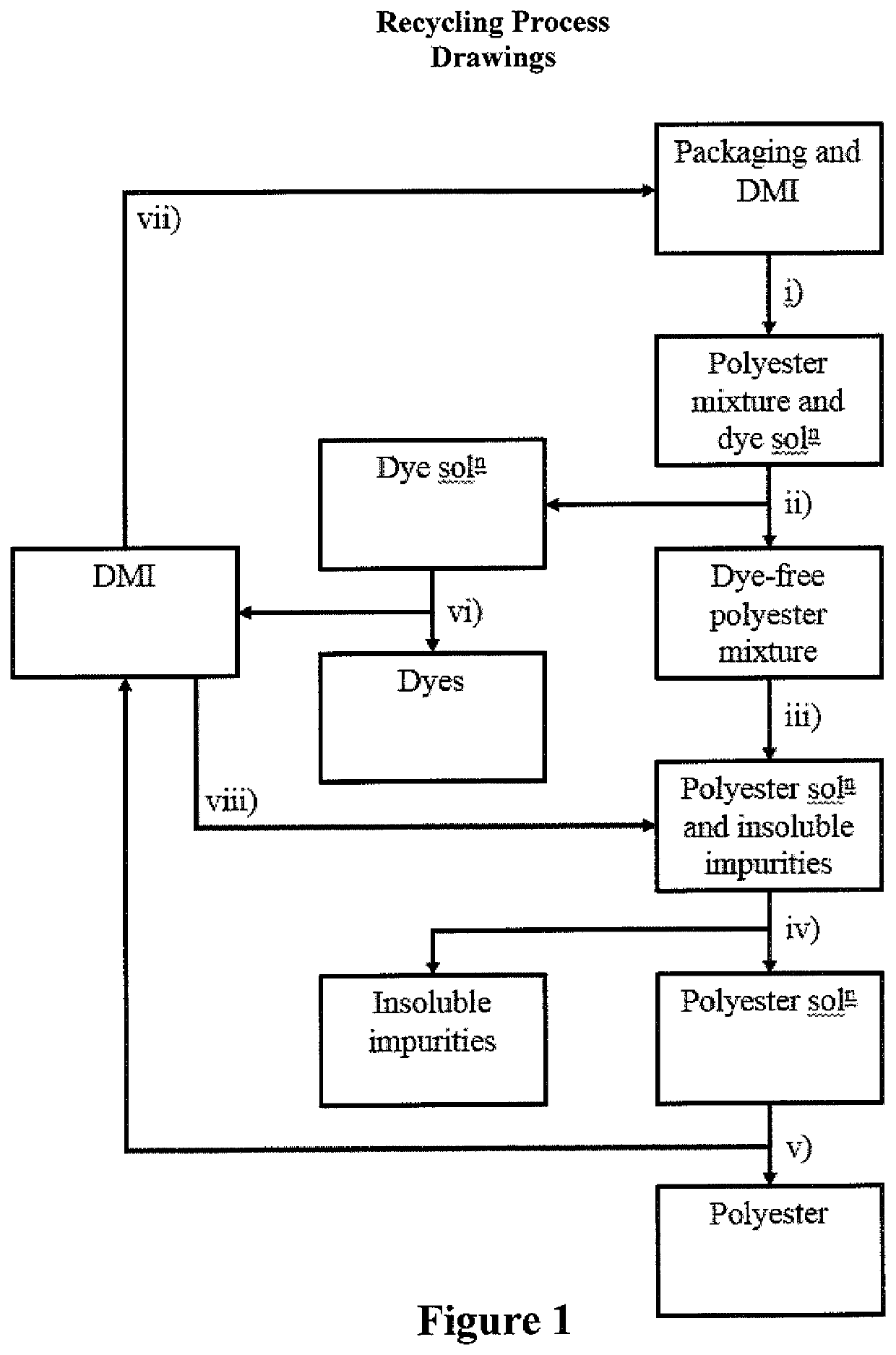

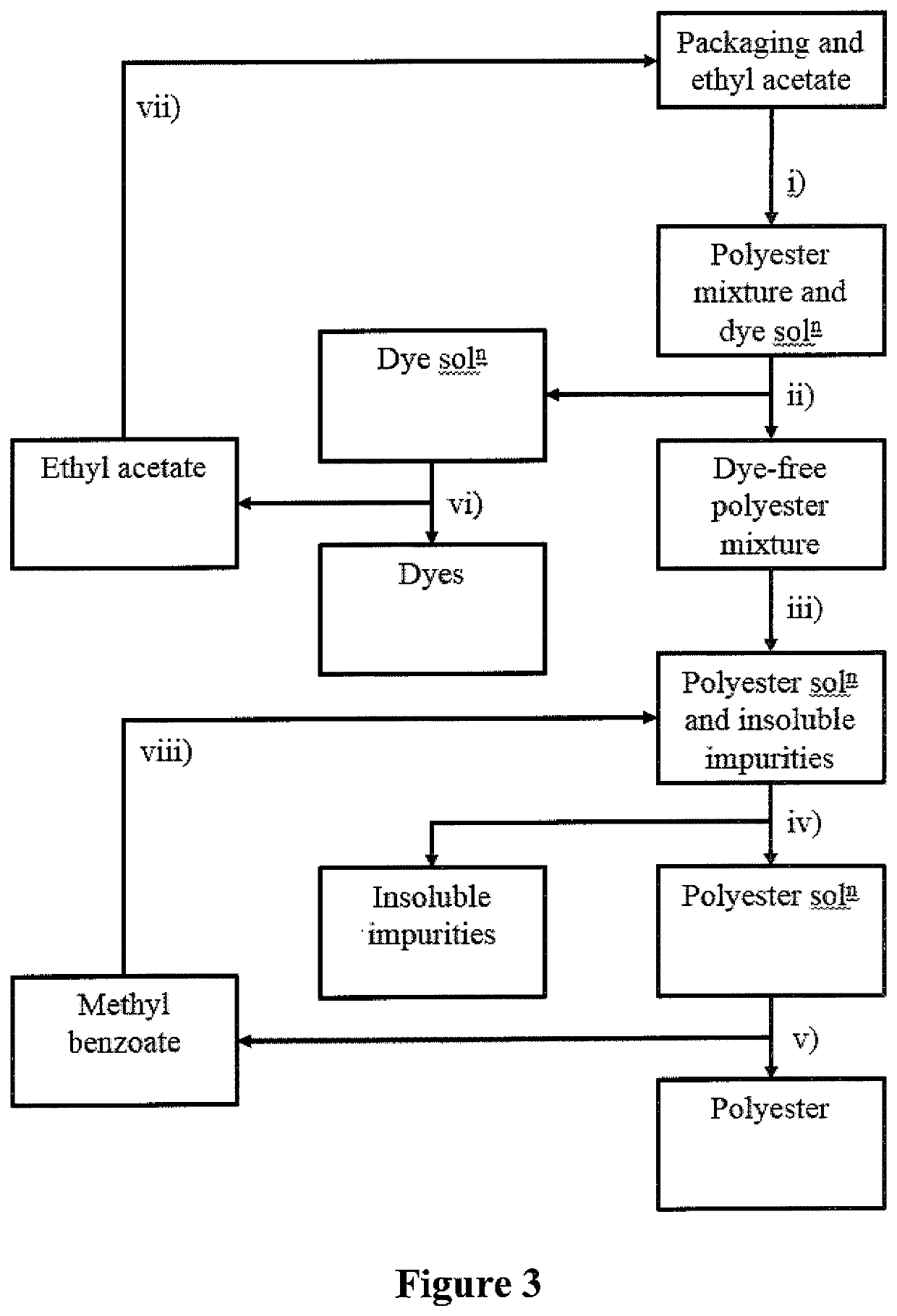

Recycling process

InactiveUS20190345306A1Minimizing temperatureIncrease surface areaPlastic recyclingPolymer recoveryPolyesterChemistry

The invention relates to a process for extracting polyester from packaging. In particular, the invention relates to packaging comprising one or more dyes such as black packaging. The claim process uses a two stage extraction process to convert waste polyester in clean, reusable polyester.The invention relates to a process for extracting polyester from fabric. In particular, fabric comprising polyester and one or more dyes. The claimed process uses a multistage mechanism to separate dyes from polyester containing garments and reconstitute the polyester.

Owner:WORN AGAIN FOOTWEAR & ACCESSORIES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com