Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4194results about "Stretch-spinning methods" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wound closure material

Articles are provided having no orientation or a multi-directional orientation. Such articles may be in the form of films, ribbons, sheets, and / or tapes and may be utilized as buttresses with a surgical stapling apparatus or as reinforcing means for suture lines.

Owner:COVIDIEN LP

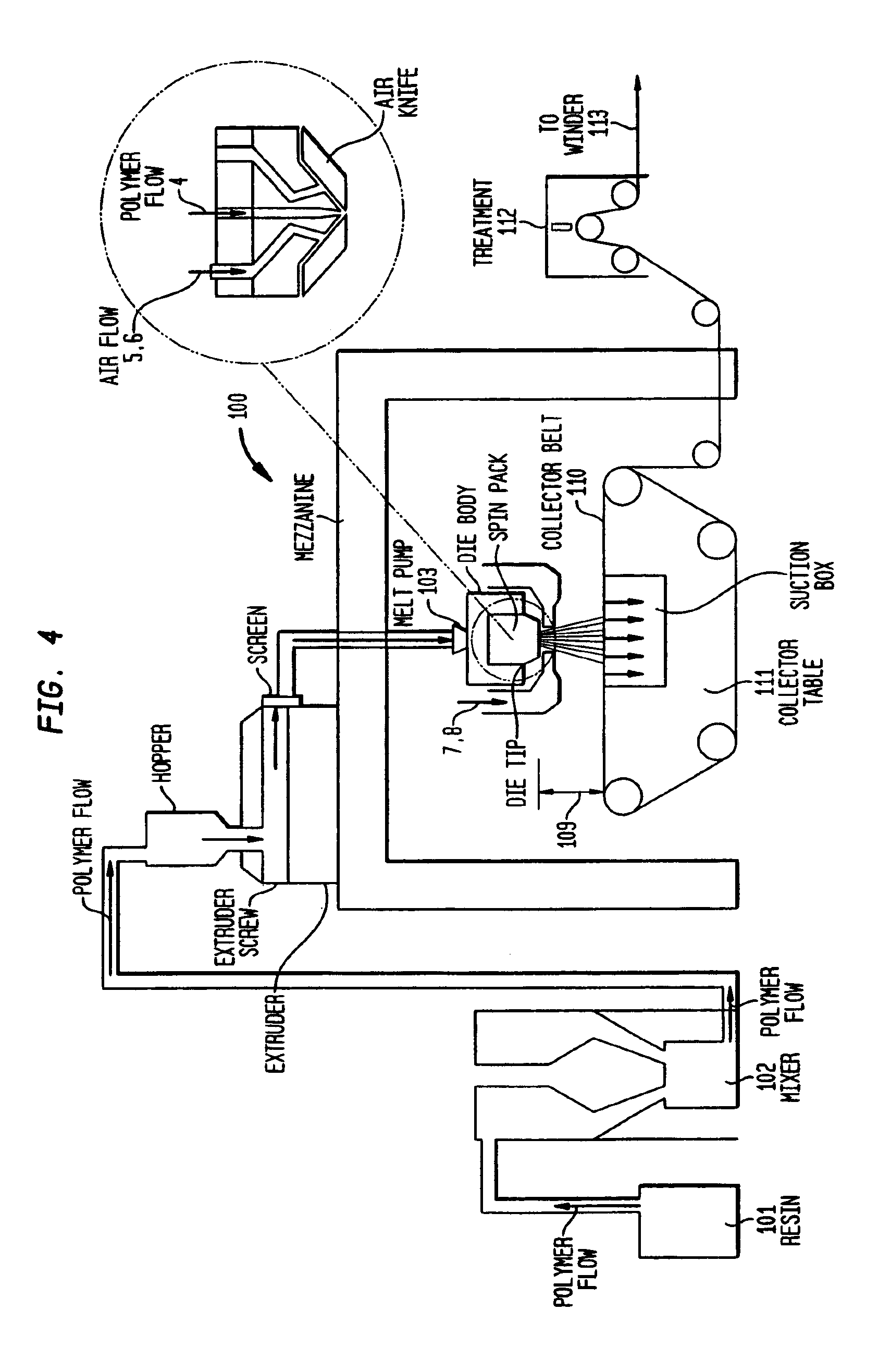

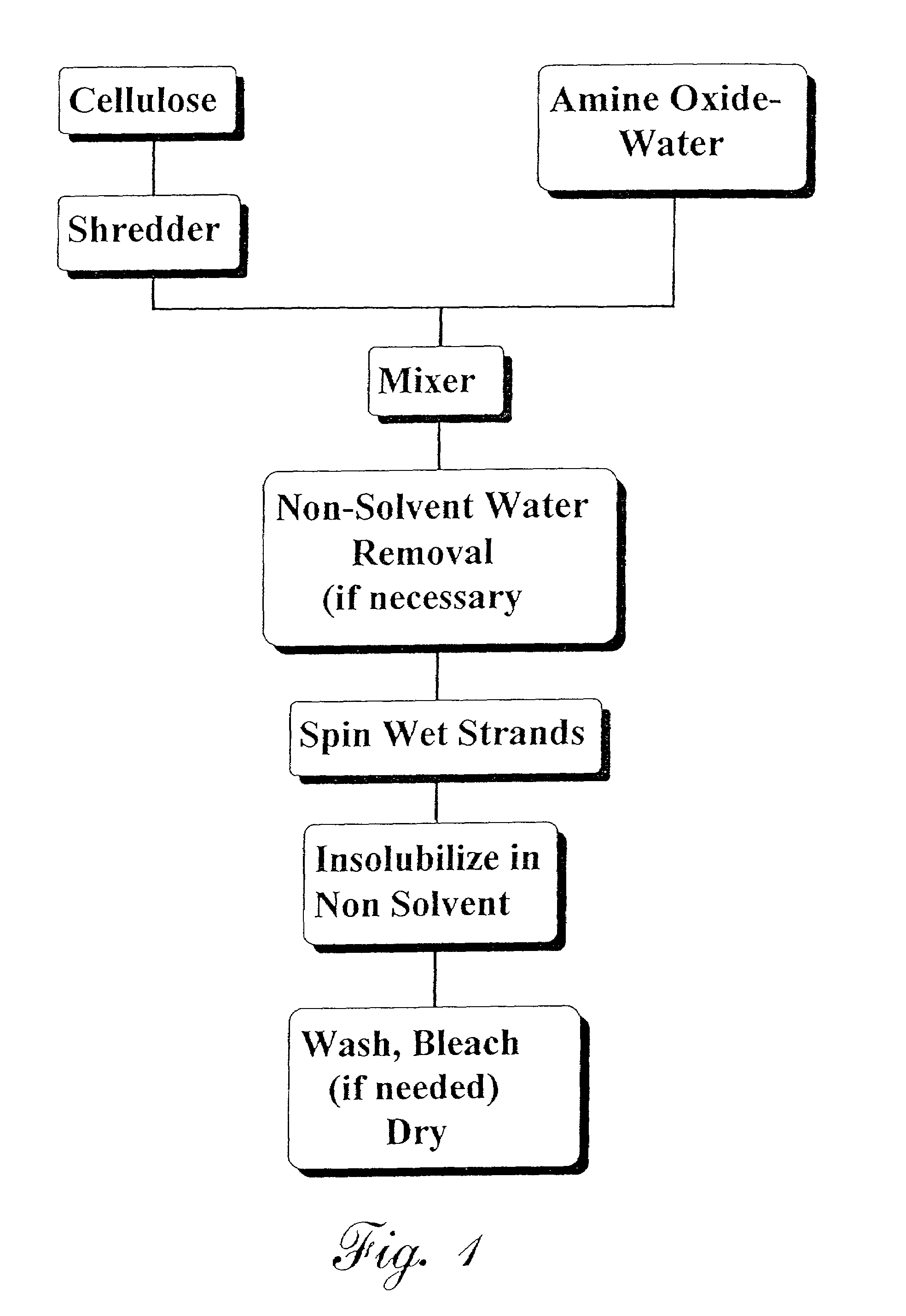

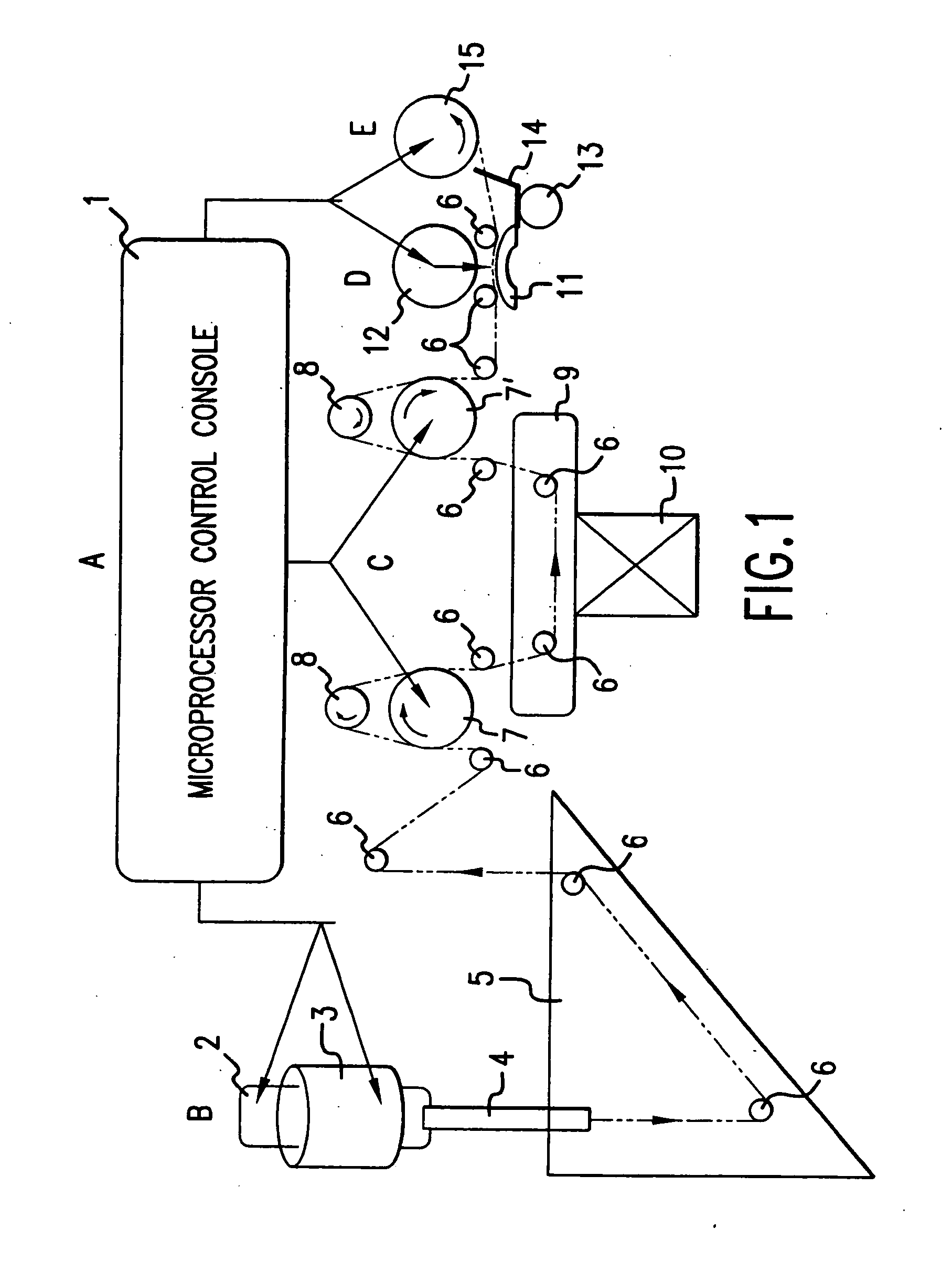

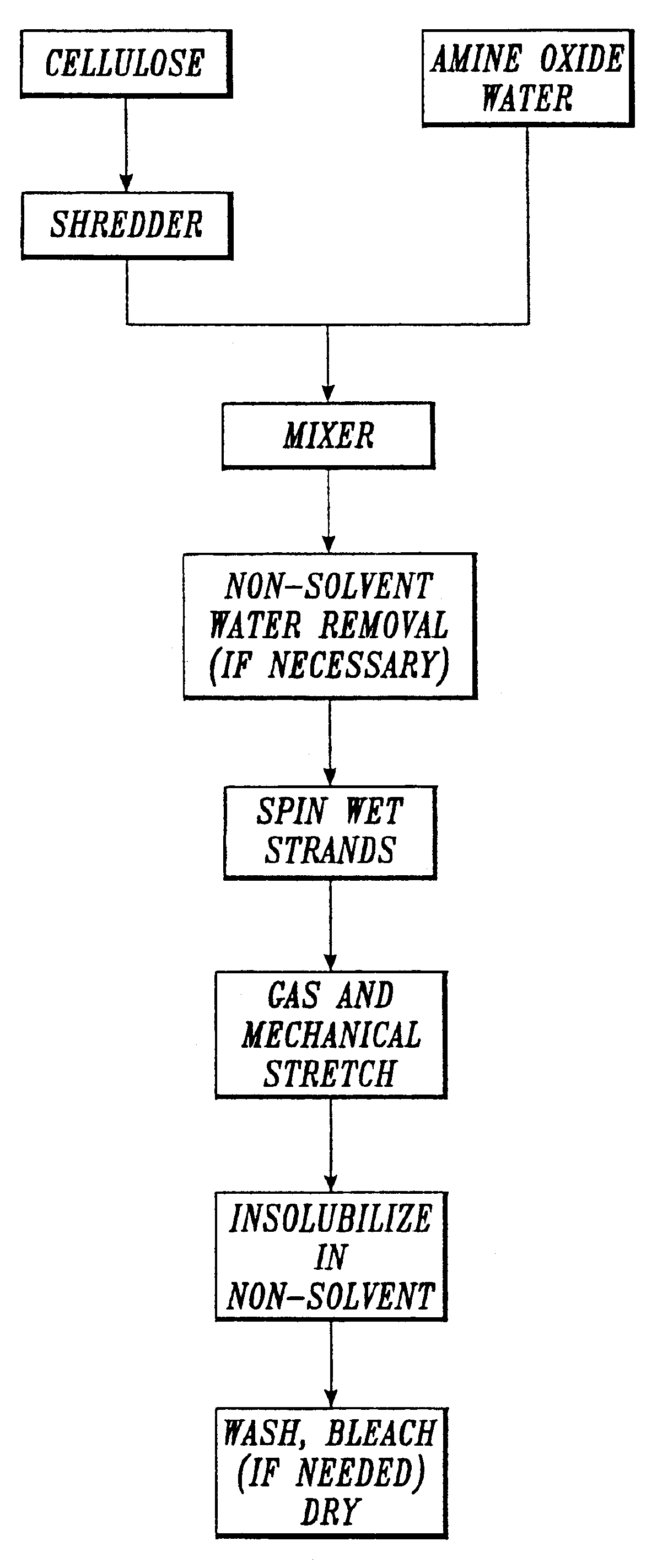

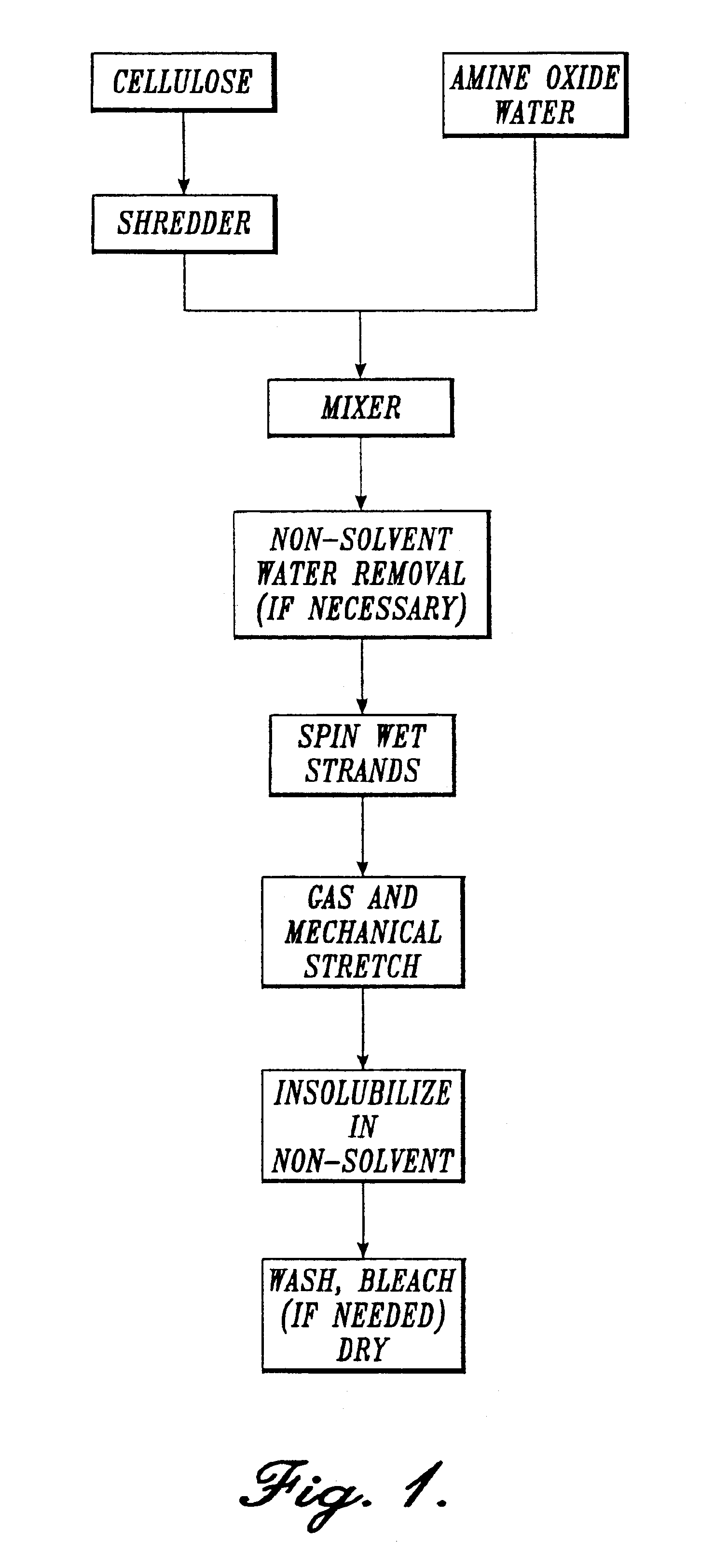

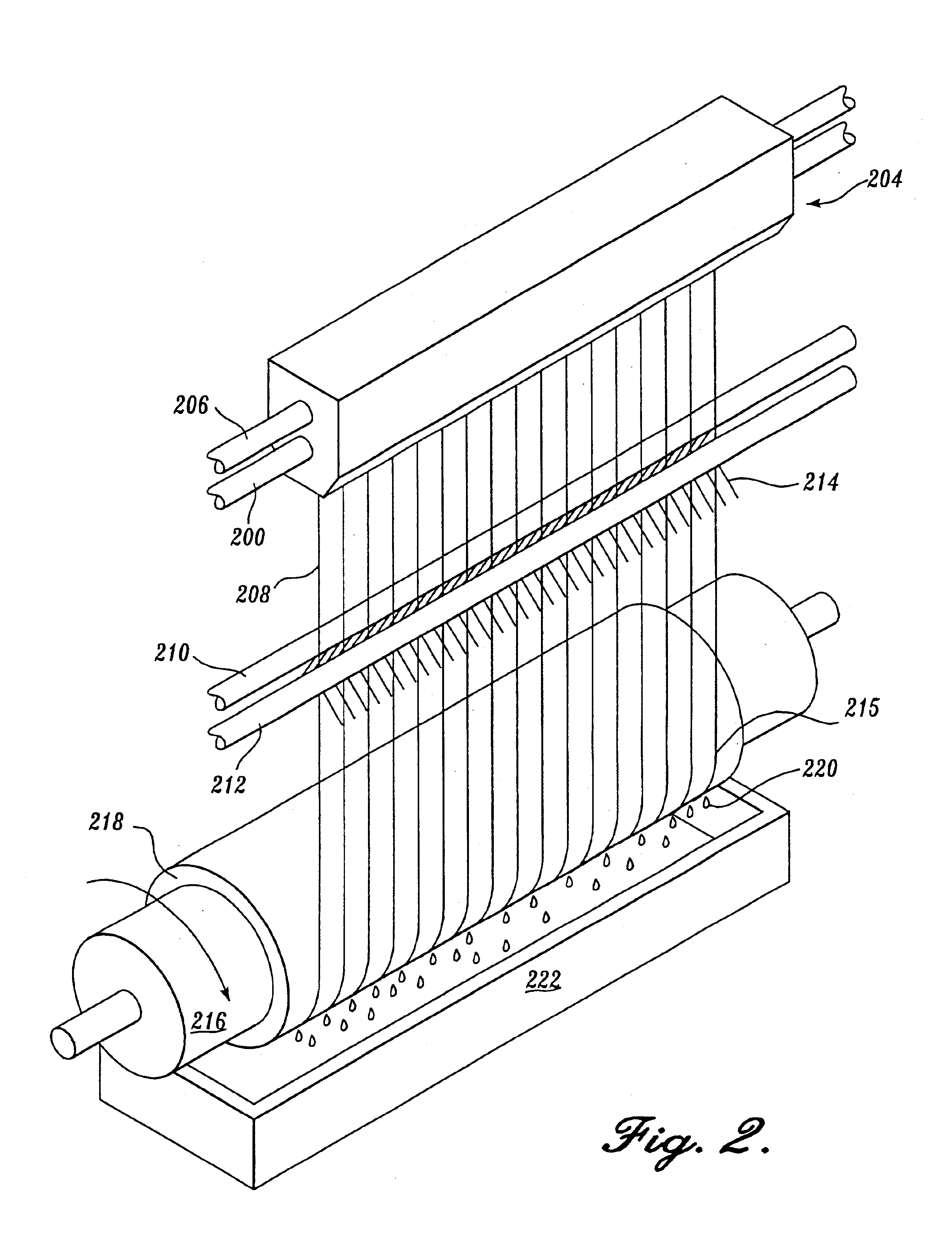

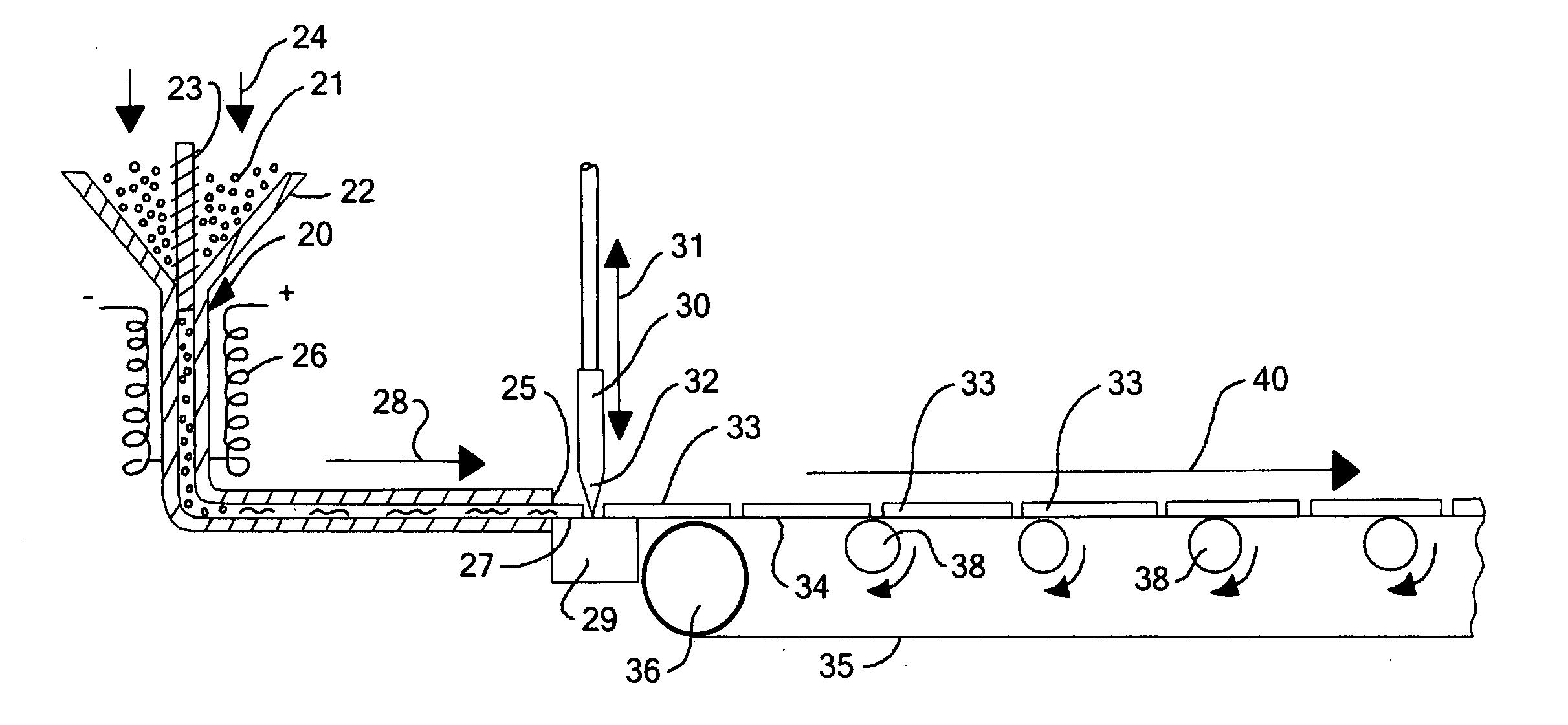

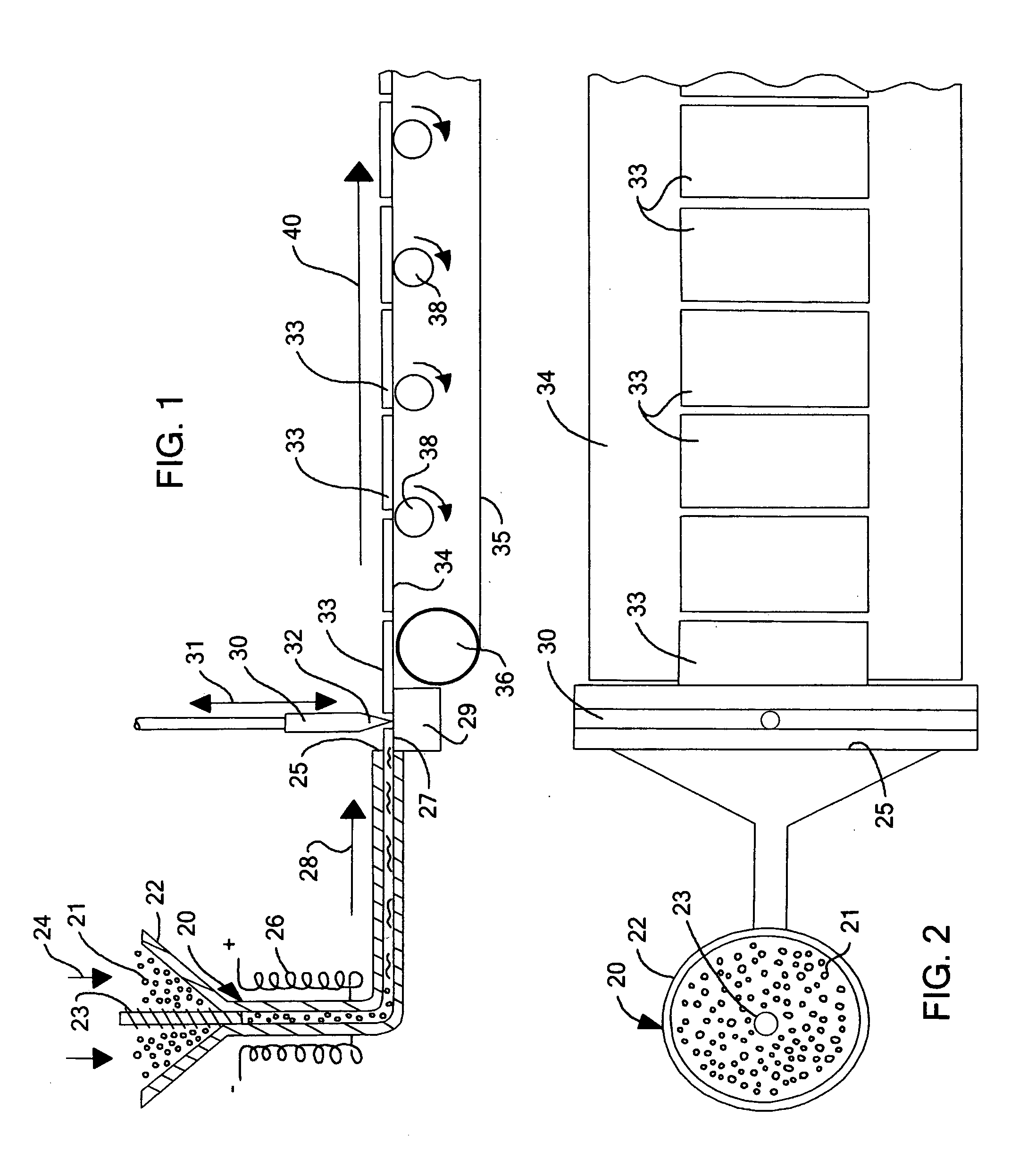

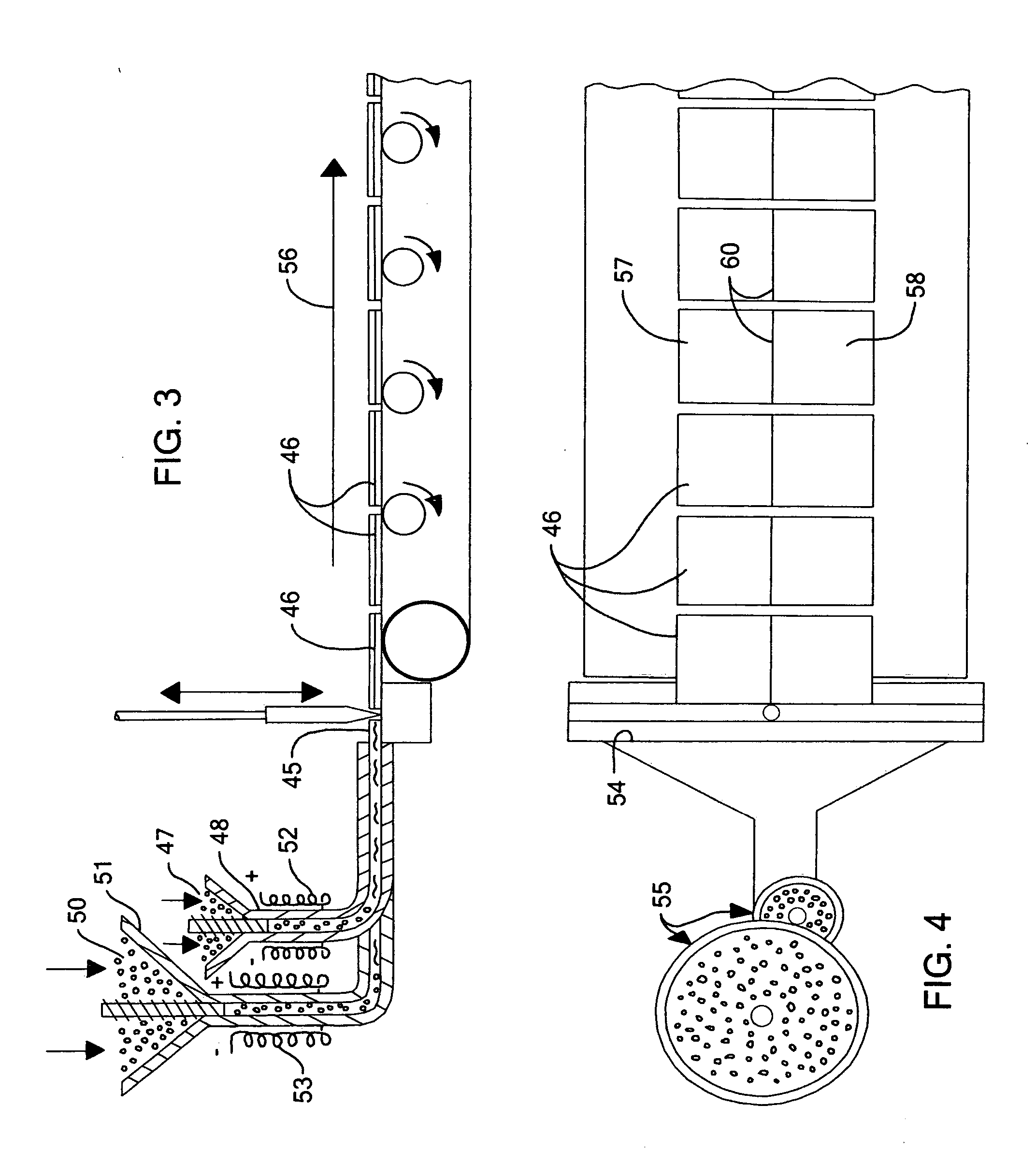

Process for forming micro-fiber cellulosic nonwoven webs from a cellulose solution by melt blown technology and the products made thereby

InactiveUS20050056956A1Artificial filament washing/dryingLoose filtering material filtersNon solventEngineering

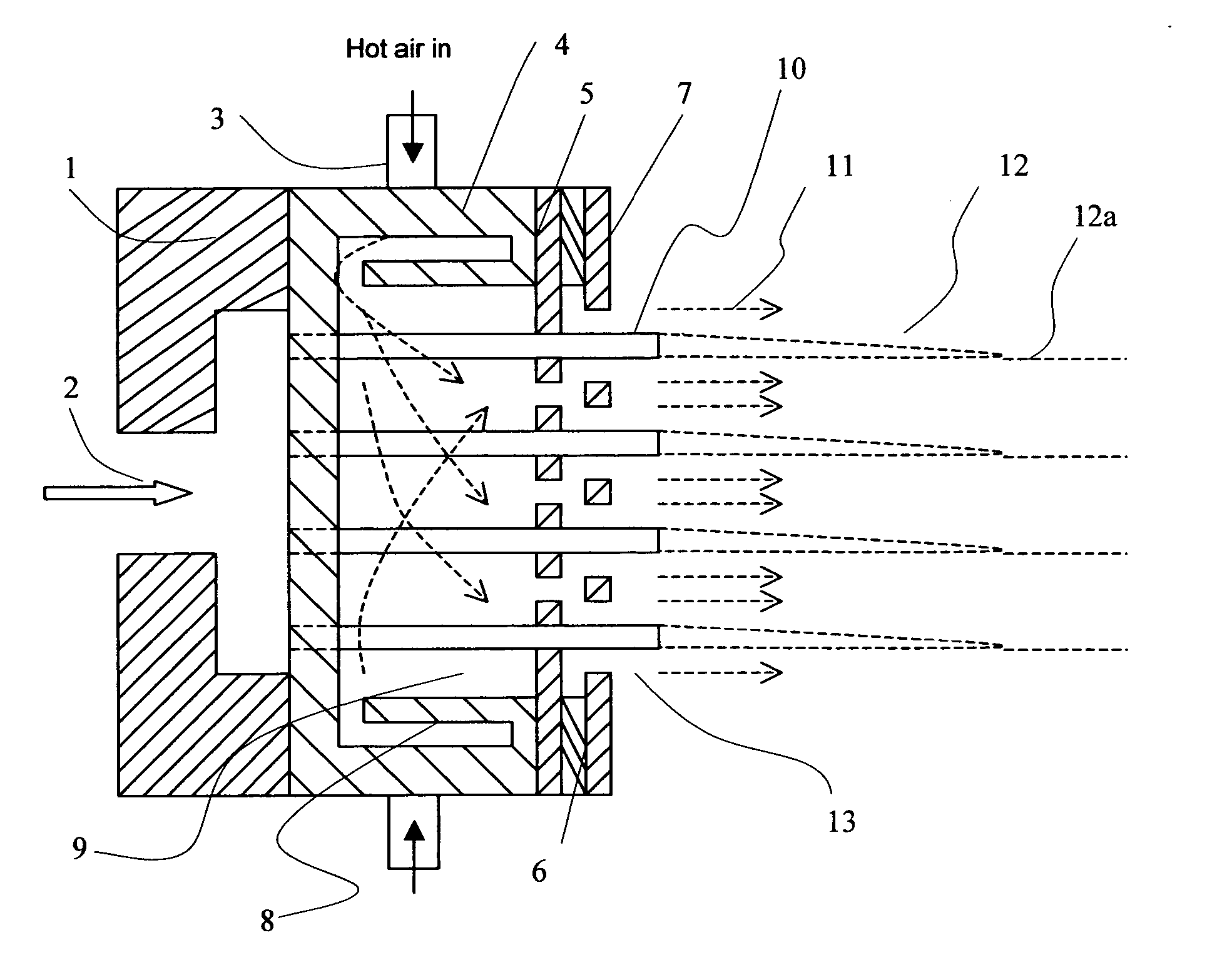

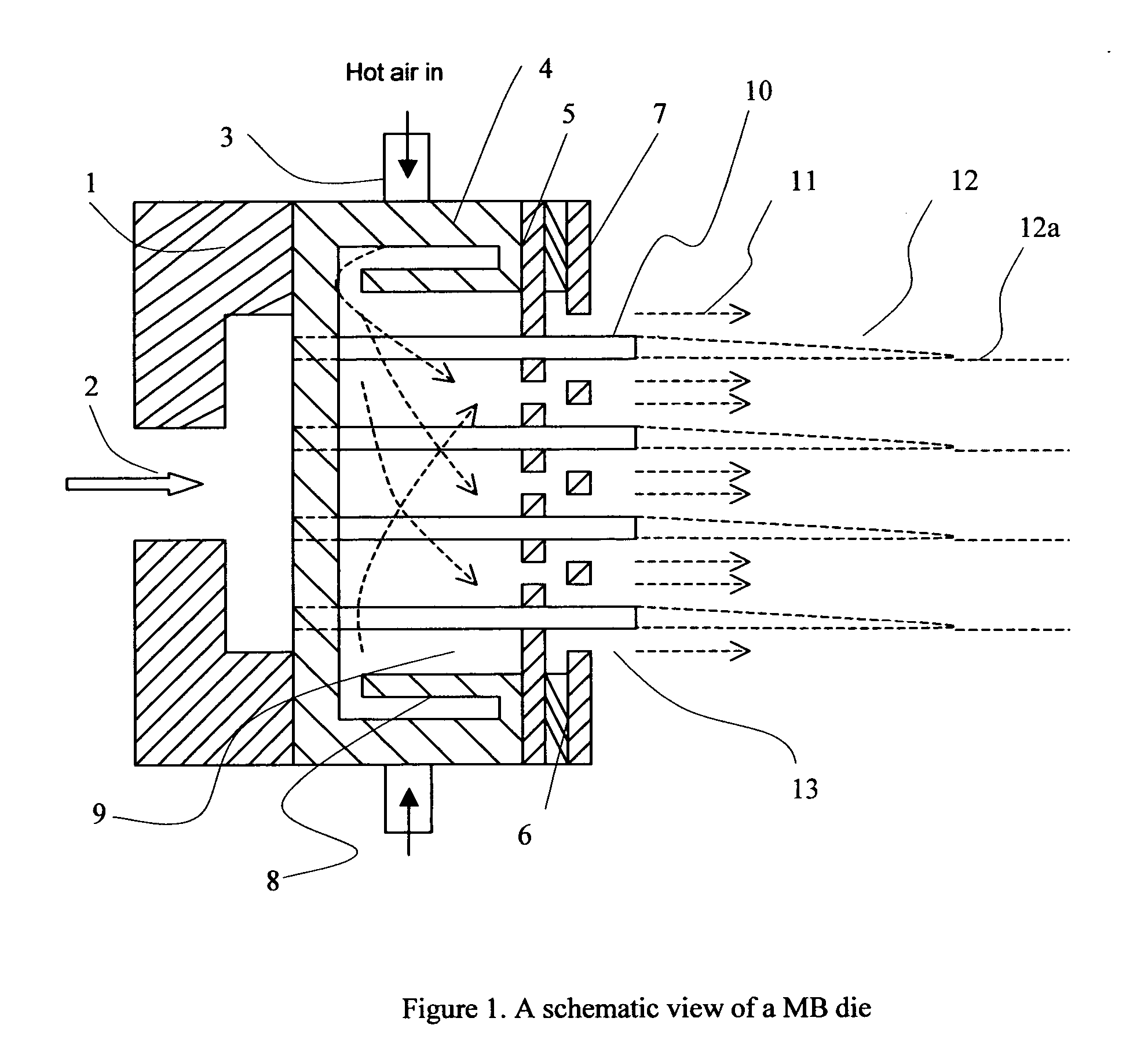

This invention relates to a process of melt blowing a cellulose solution through a concentric melt blown die with multiple rows of spinning nozzles to form cellulosic microfiber webs with different web structures. The process comprises the steps of (a) extruding a cellulose solution (dope) through a melt blown spinneret with multiple rows of spinning nozzles; (b) drawing each individual extrudate filament to fine fiber diameter by its own air jet; (c) coagulating and entangling the fine fibers with a series of pressured hydro needling jets of recycling solution of the mixture of cellulose solvent and non-solvent in the spin-line; (d) collecting the stream of microfibers, air and needling jets on a moving collecting surface to form cellulosic fiber web; (e) hydro-entangling the said pre-bonded web downstream with at least one set of hydro needling jets of recycling solvent / non-solvent solution for forming well bonded nonwoven web; (f) regenerating the fine fibers in at least one bath for at least 5 seconds; (g) further regenerating and washing the fine fibers in another bath for at least 5 seconds; (h) pinching the well bonded melt blown cellulosic nonwoven with pressure rollers to remove major portions of the non-solvent; (i) drying the nonwoven web by heat, or vacuum or both, and (j) winding the nonwoven web into rolls.

Owner:BIAX FIBERFILM CORP

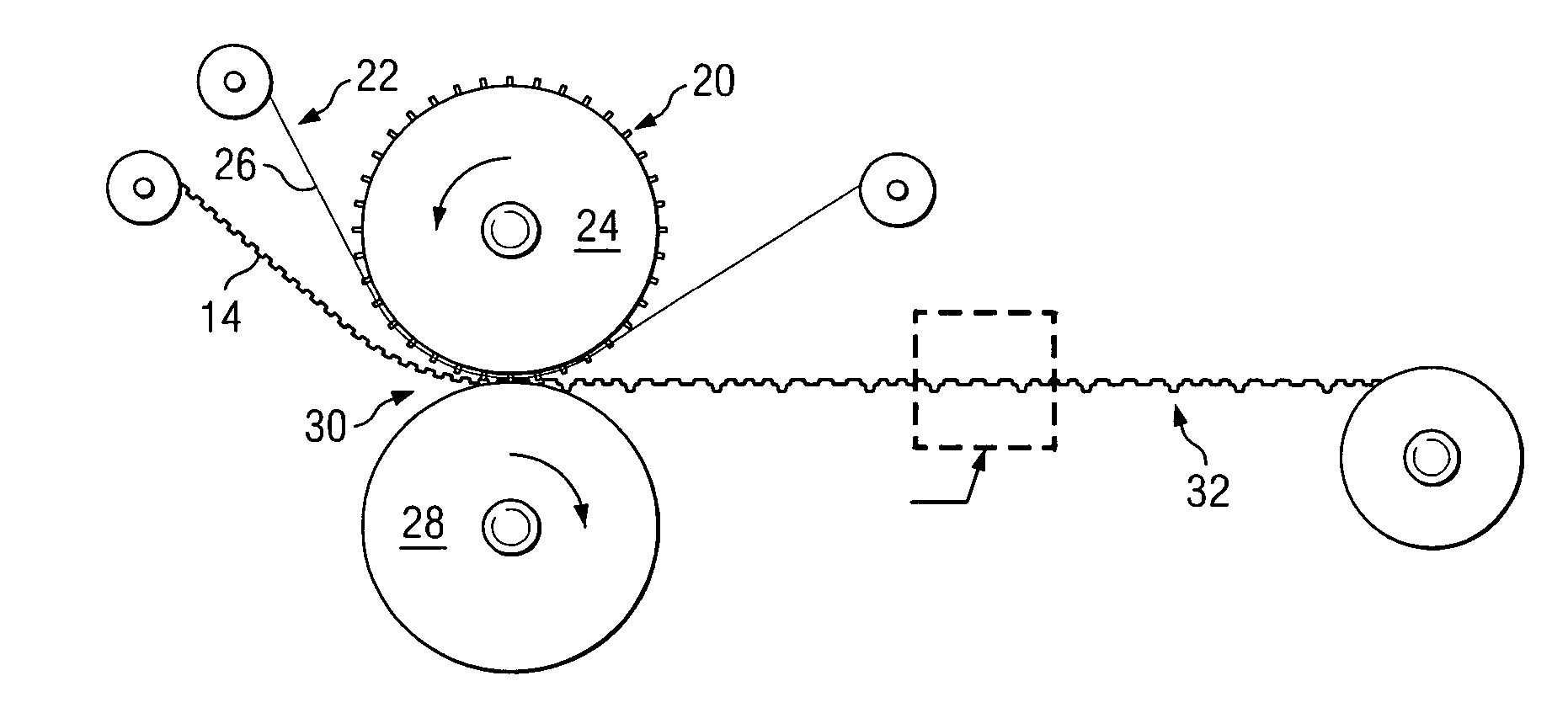

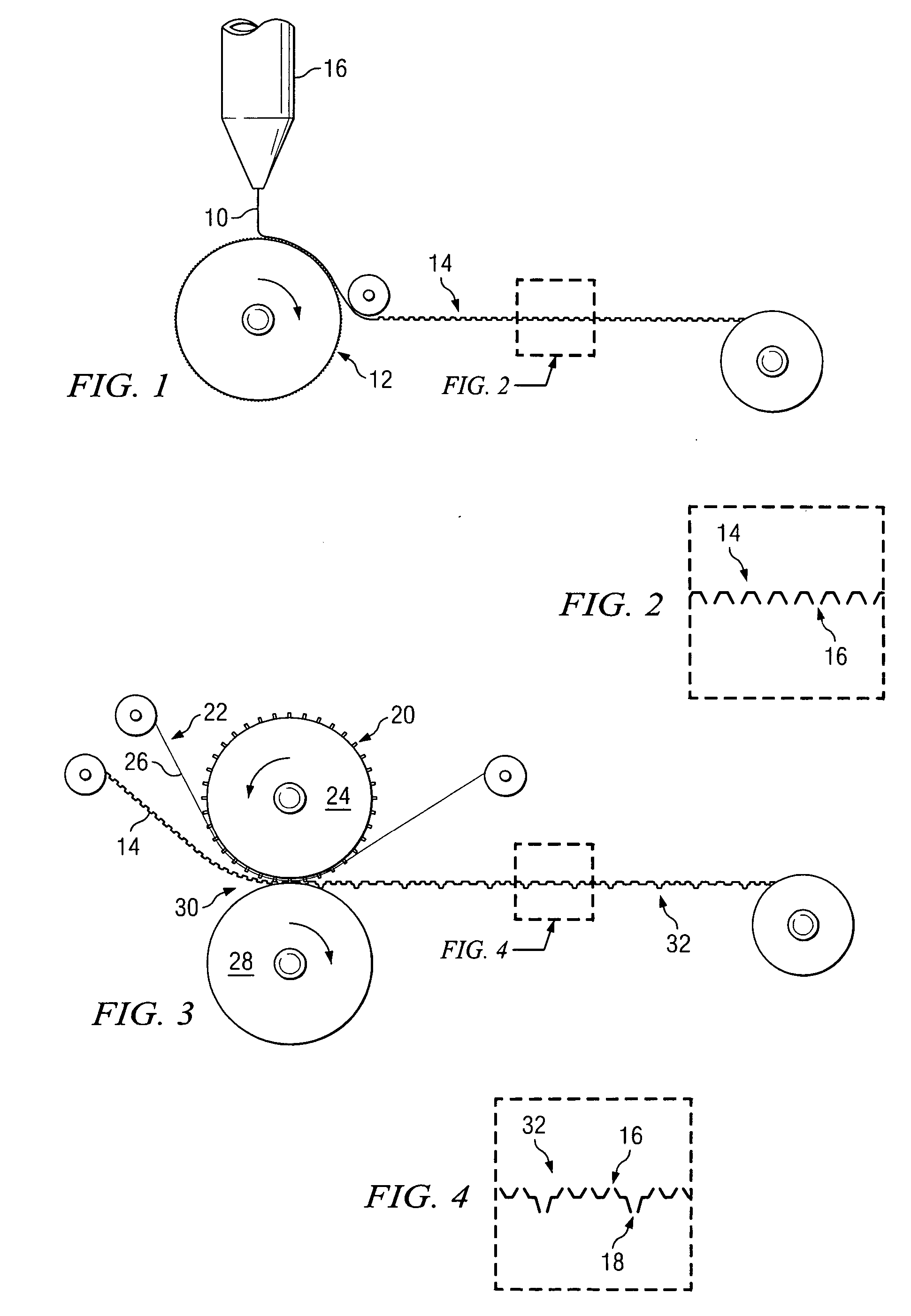

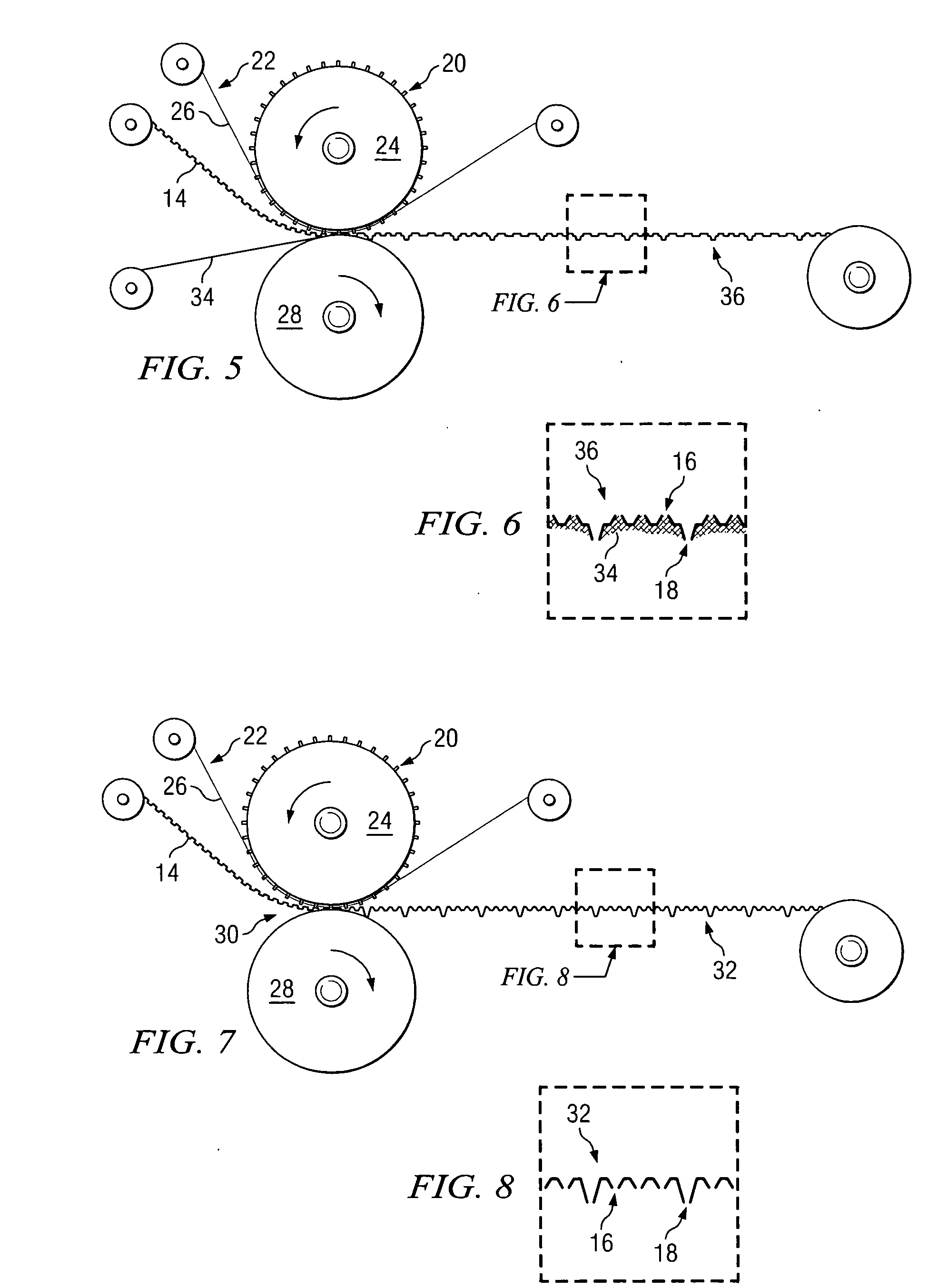

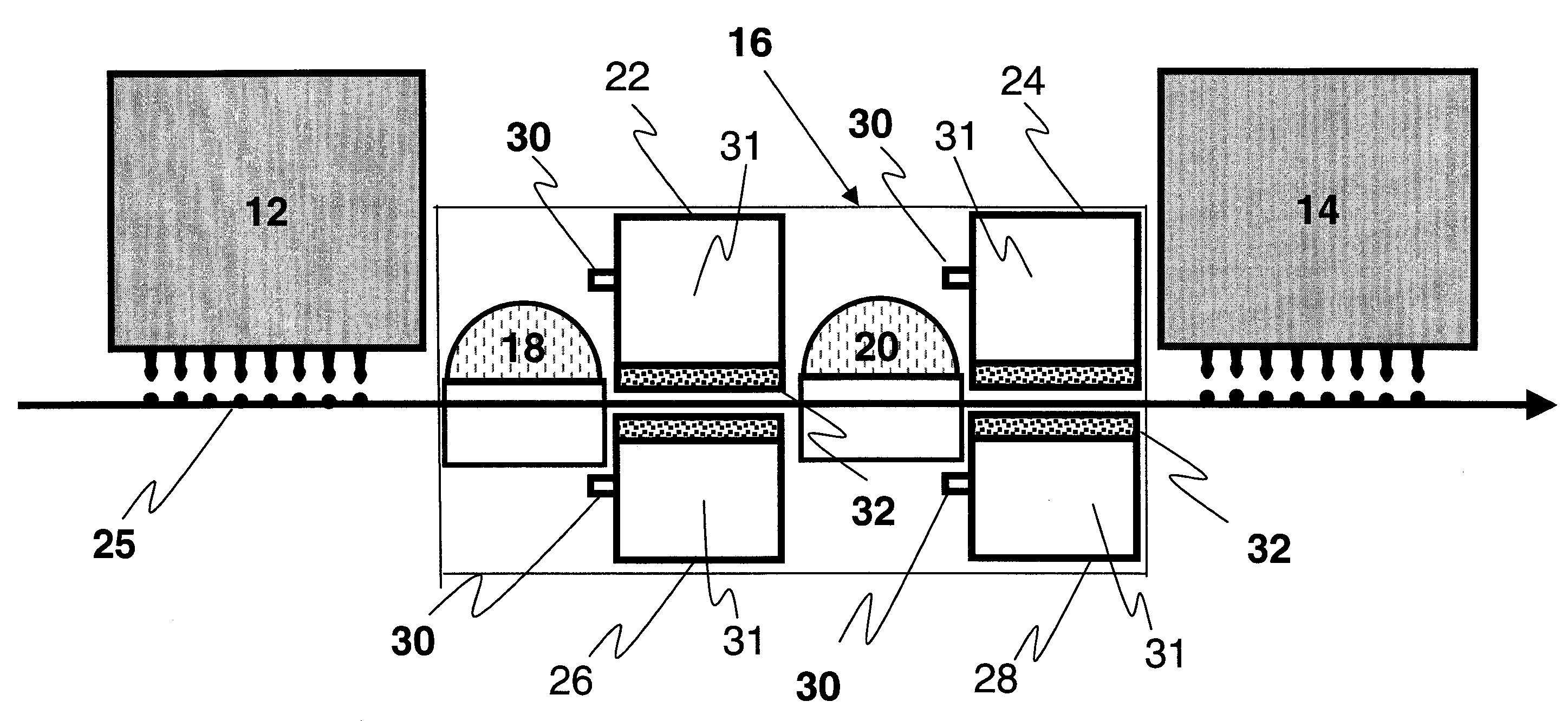

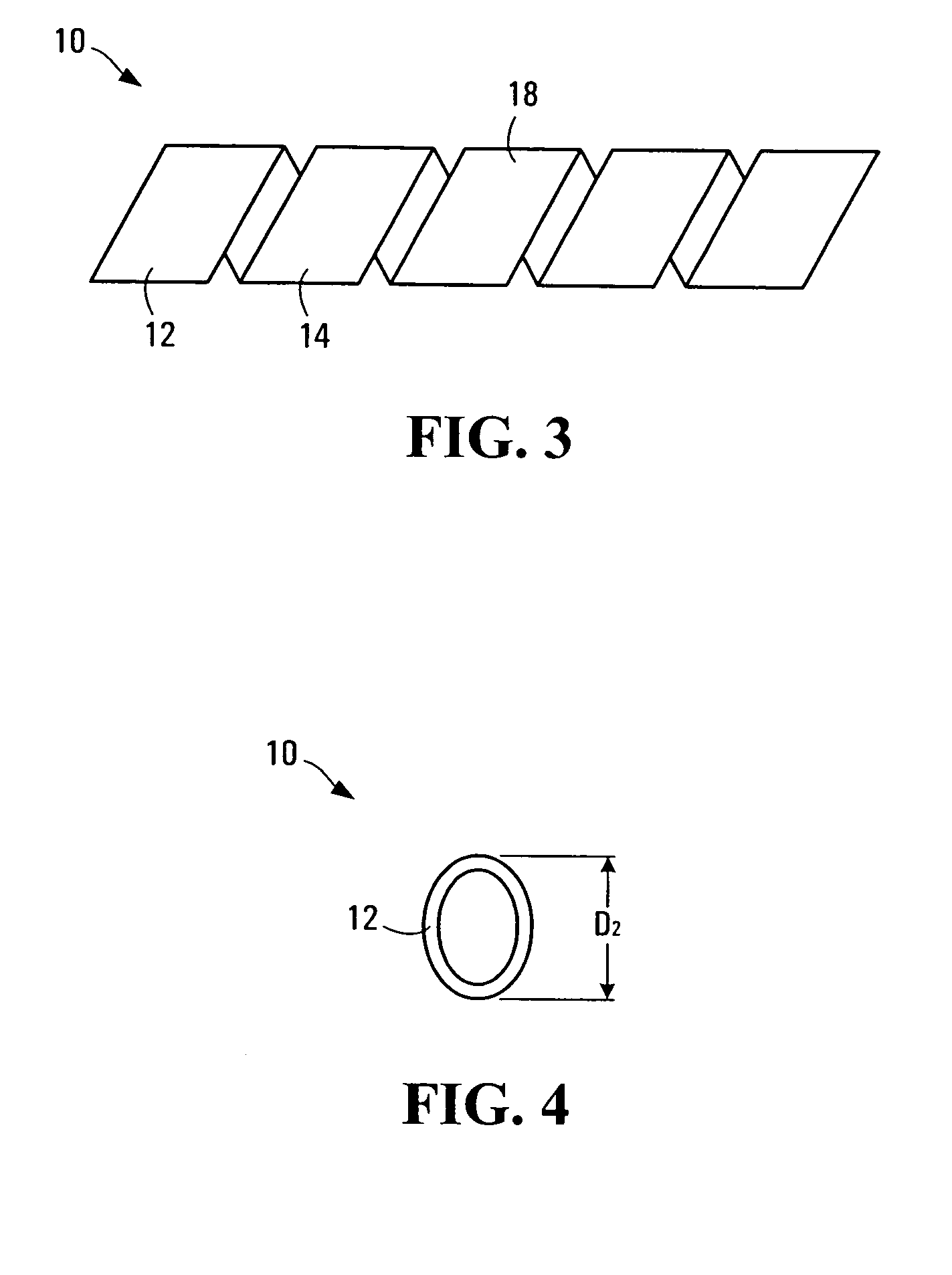

Methods of manufacturing a stretched mechanical fastening web laminate

InactiveUS7897078B2Reduce basis weightSnap fastenersWood working apparatusFiberVolumetric Mass Density

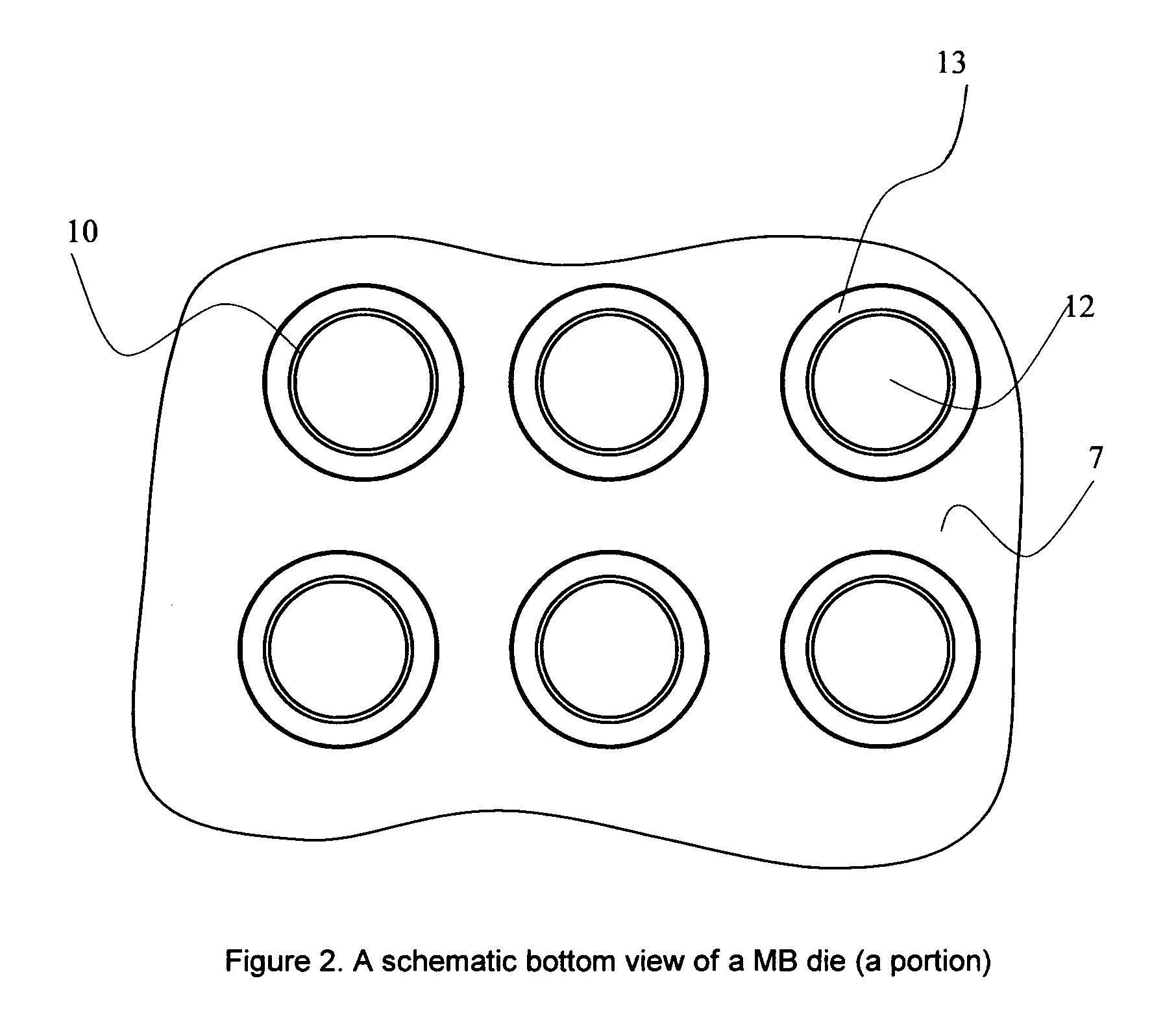

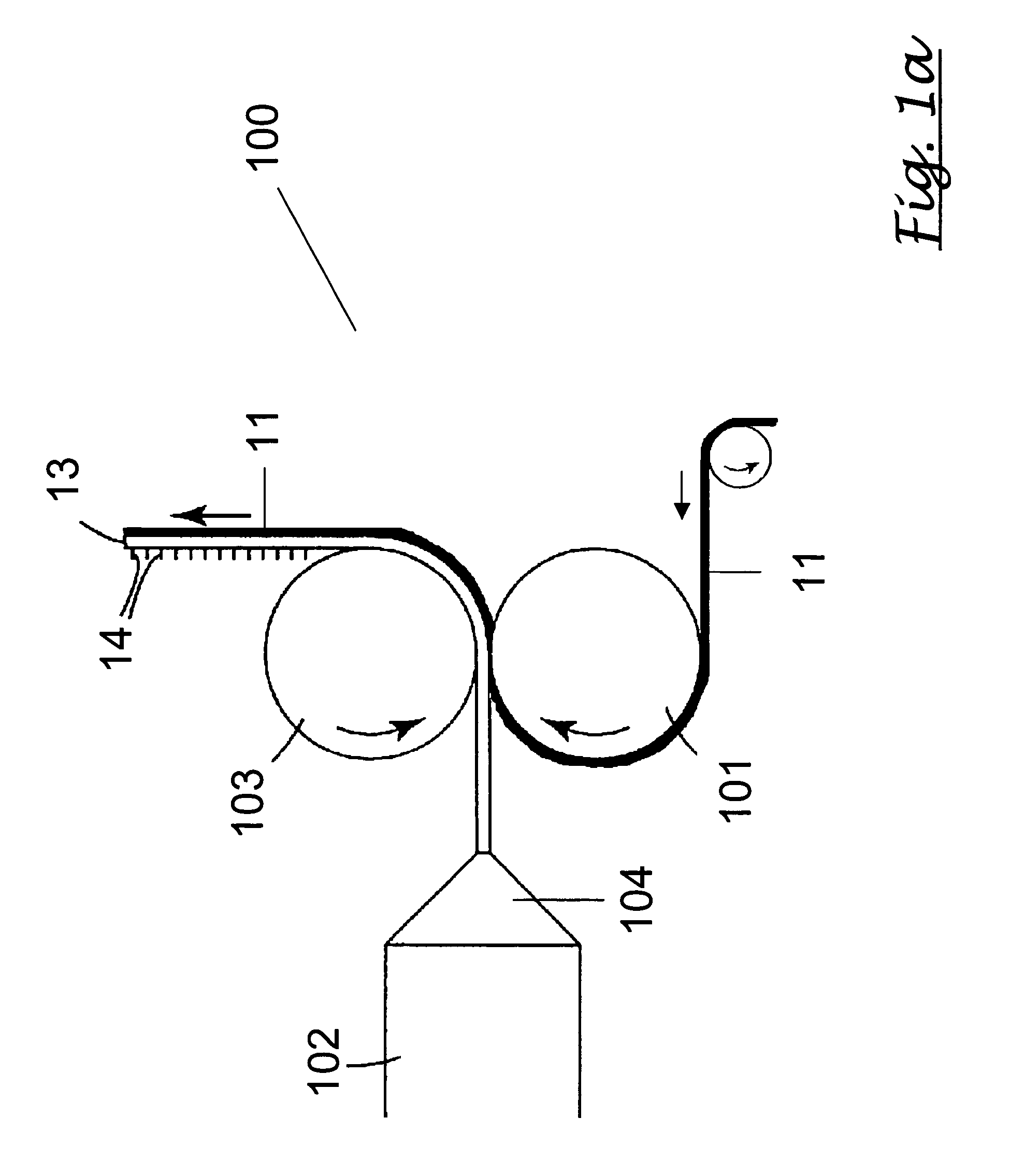

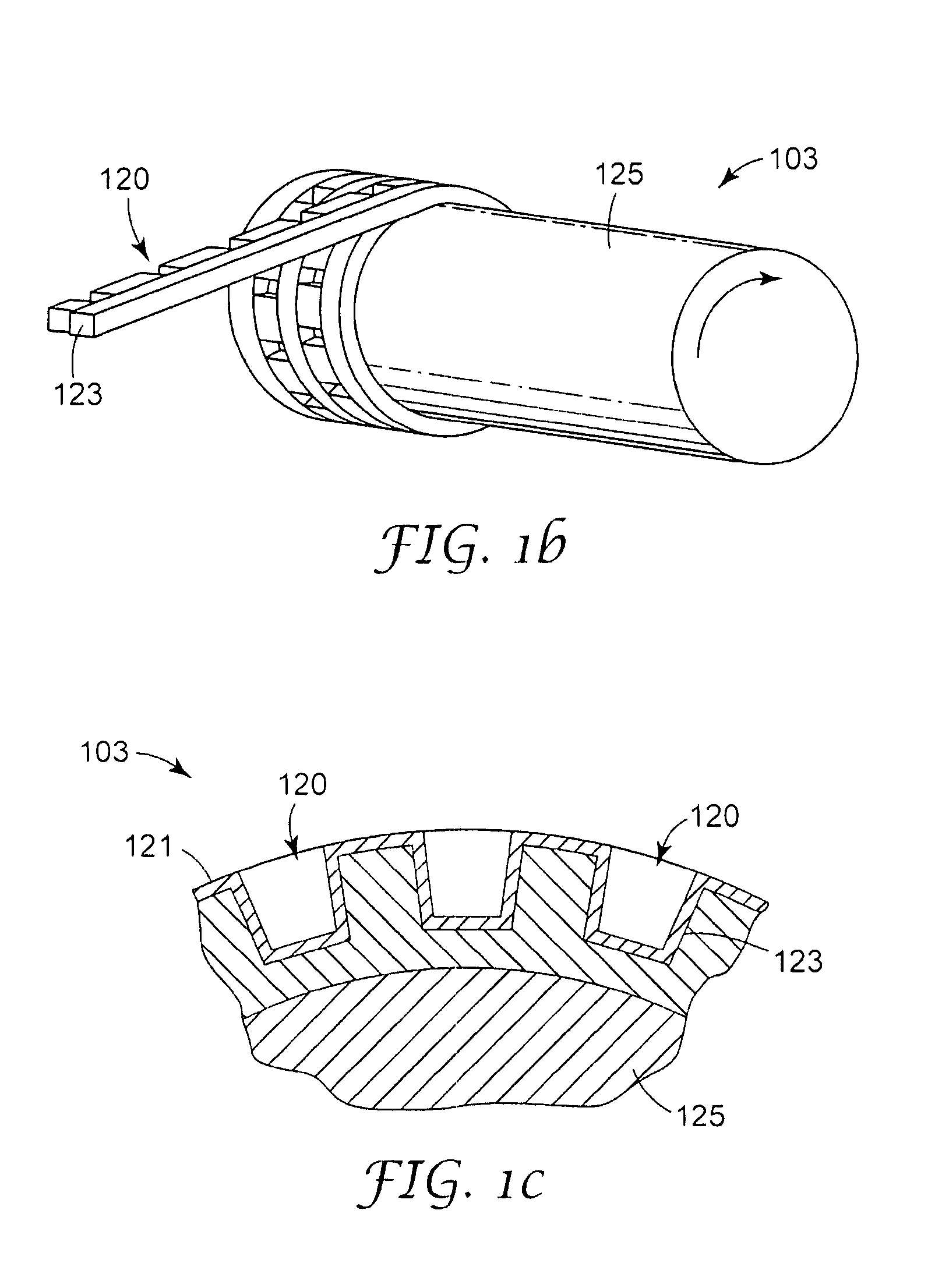

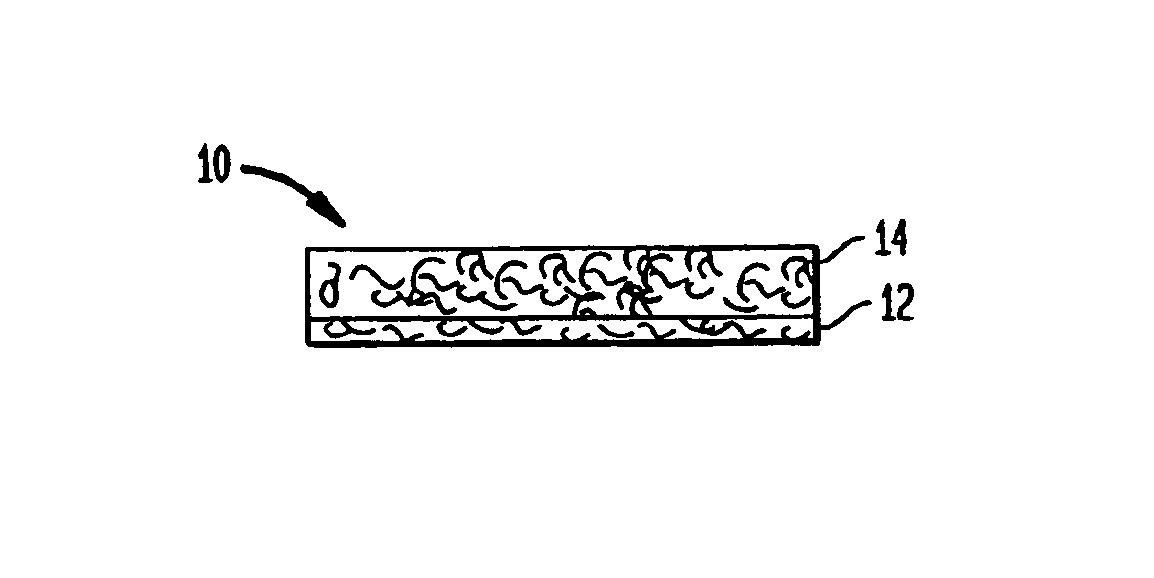

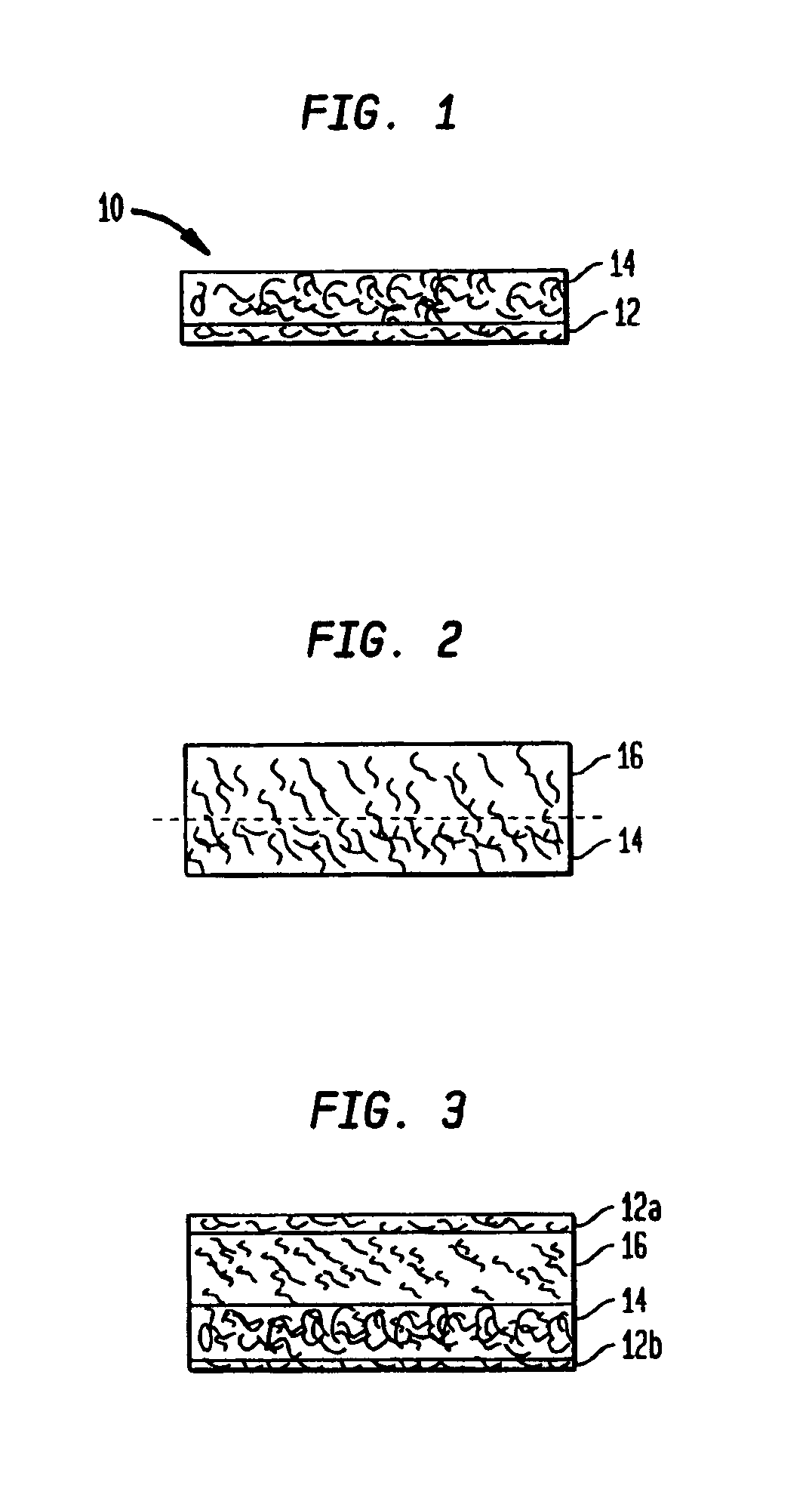

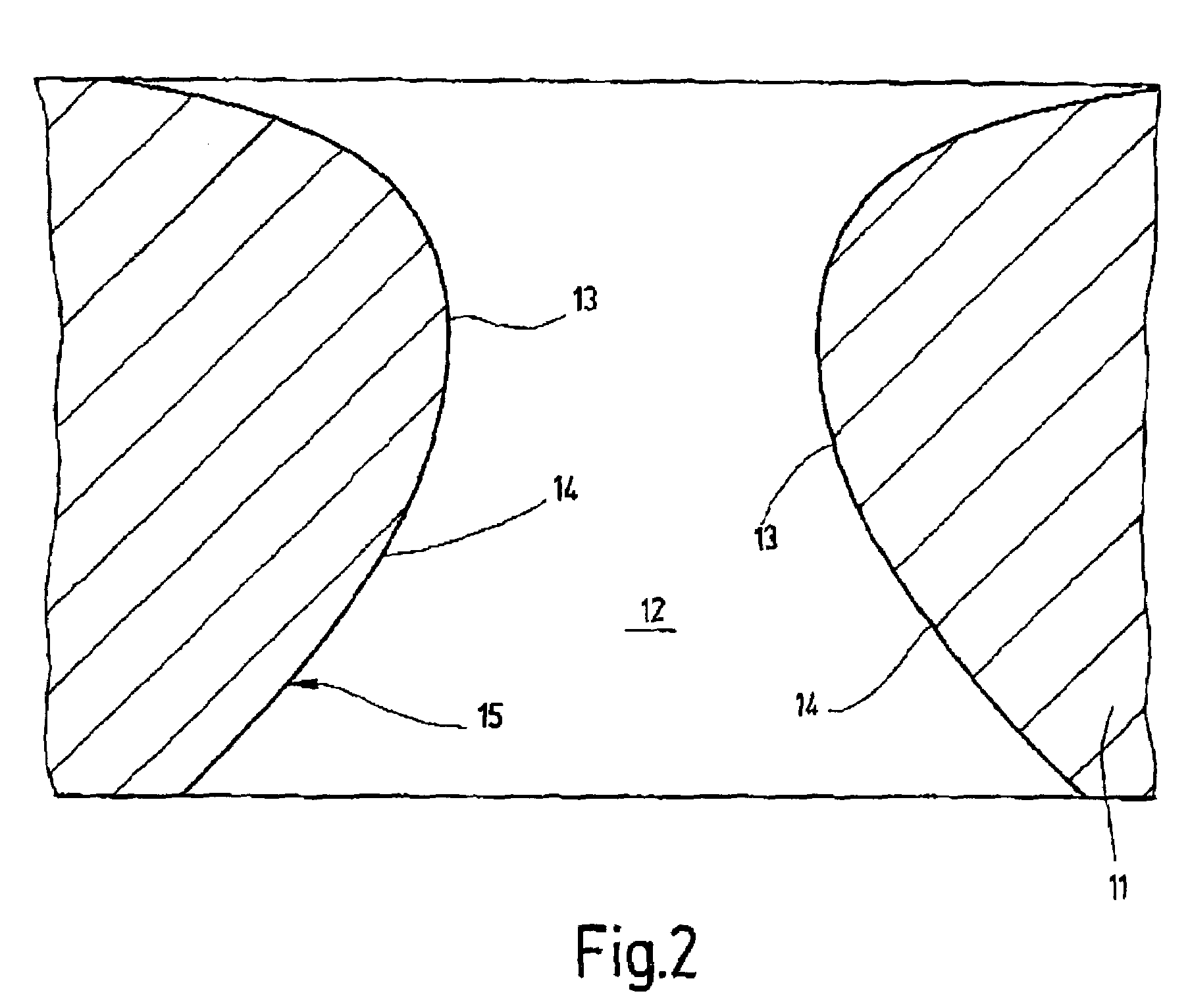

The present invention relates to a method of manufacturing a stretched mechanical fastening web laminate (1) comprising a thermoplastic web layer (13) having two major surfaces, one of the major surfaces bearing a multitude of male fastening elements (14) suitable for engagement with a corresponding female fastening material, and on its other major surface a fibrous web layer (11), said method comprising the steps of(i) providing the fibrous web layer (11) having an initial basis weight,(ii) passing the fibrous web layer (11) through a nip formed by two rolls (101), (103), one of them having cavities (120) that are the negatives of a plurality of male fastening elements (14), introducing a molten thermoplastic resin into the cavities (120) in excess of an amount that would fill the cavities (120) which excess forms the thermoplastic web layer (13), allowing the resin to at least partially solidify and stripping of a precursor web laminate (10) thus formed comprising the fibrous web layer (11) and the thermoplastic web layer (13) bearing a plurality of male fastening elements (14), from the cylindrical roll (103) having cavities (120) whereby the thermoplastic web layer (13) has an initial thickness and an initial hook density, and(iii) stretching the precursor web laminate (10) monoaxially or biaxially thereby decreasing the basis weight of the fibrous web layer (11) and the thickness of the thermoplastic web layer (13) from their respective initial values to provide a stretched mechanical fastening laminate (1) having a basis weight of less than 100 g·m−2.

Owner:3M INNOVATIVE PROPERTIES CO

Filter media

InactiveUS6858057B2Lower performance requirementsEnhanced filtration performance characteristicCombination devicesOther chemical processesFilter mediaEngineering

A filter media comprising a synthetic microfiber polymer fine fiber web wherein the diameter of the fibers is between about 0.8 to about 1.5 microns. The filter media is acceptable for use in ASHRAE applications. Constructions with a low DP backing, support or prefilter layers of coarse fiber provide large area filter webs of high efficiency and a stable and high threshold value of alpha above eleven.

Owner:HOLLINGSWORTH VOSE

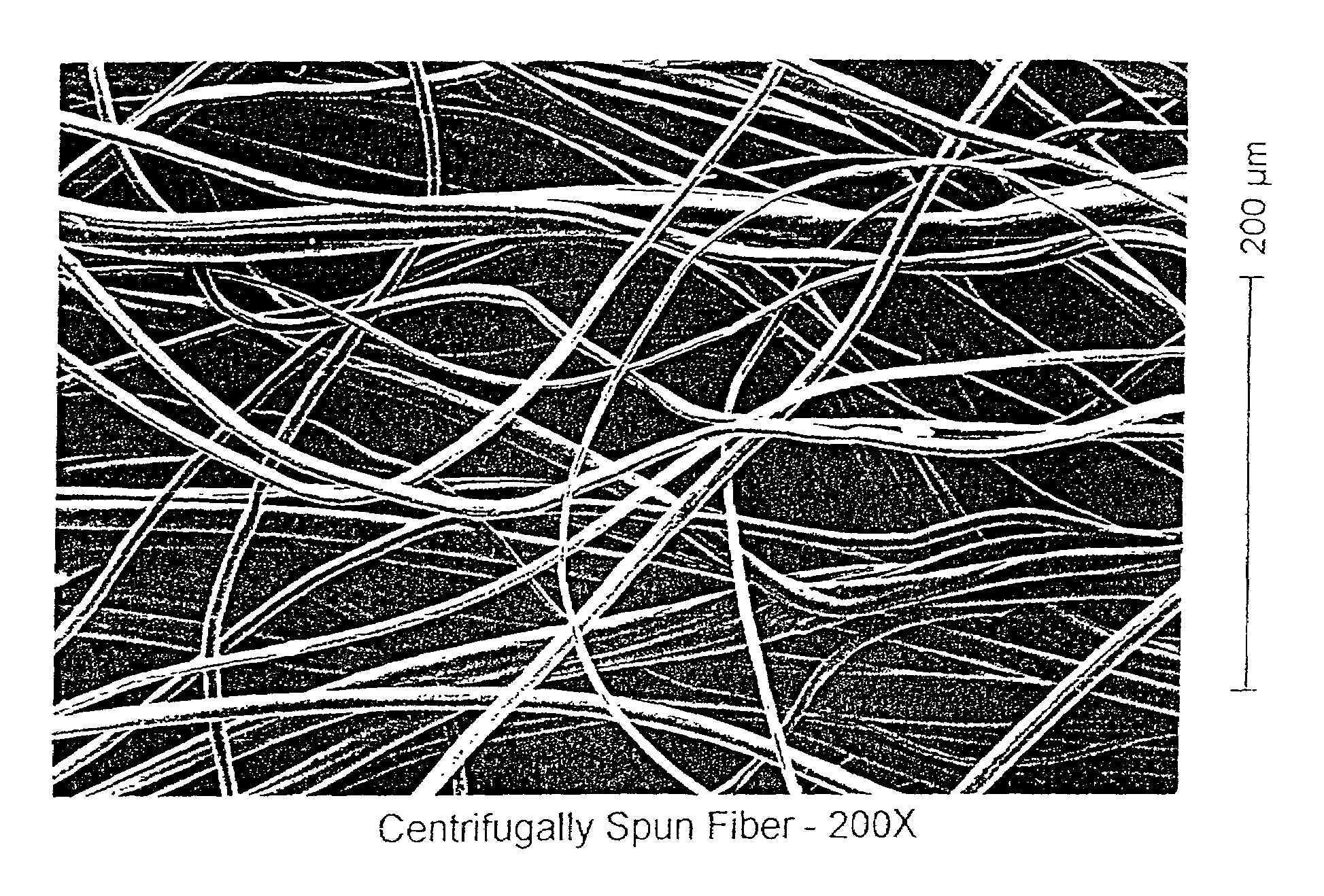

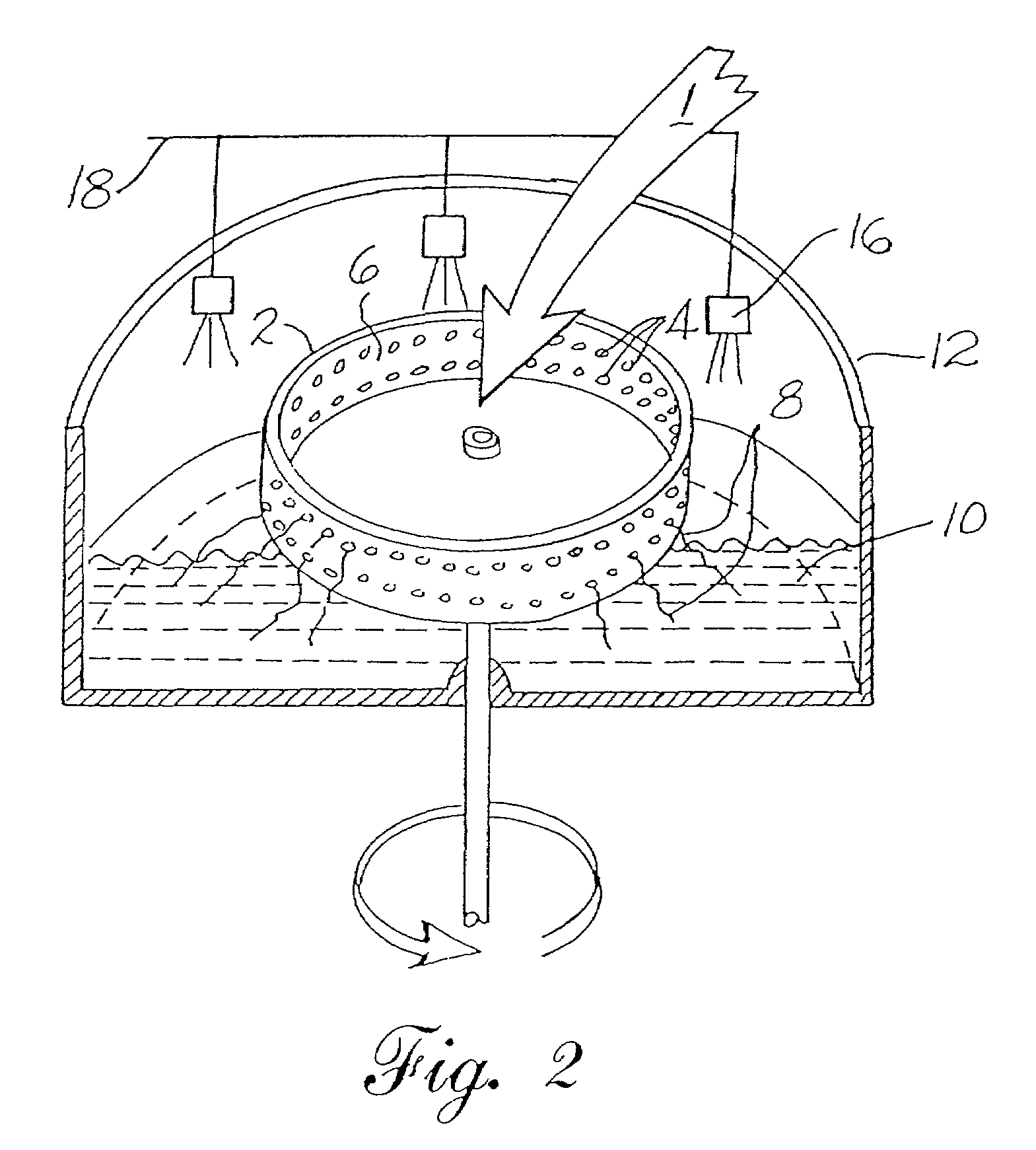

Lyocell nonwoven fabric

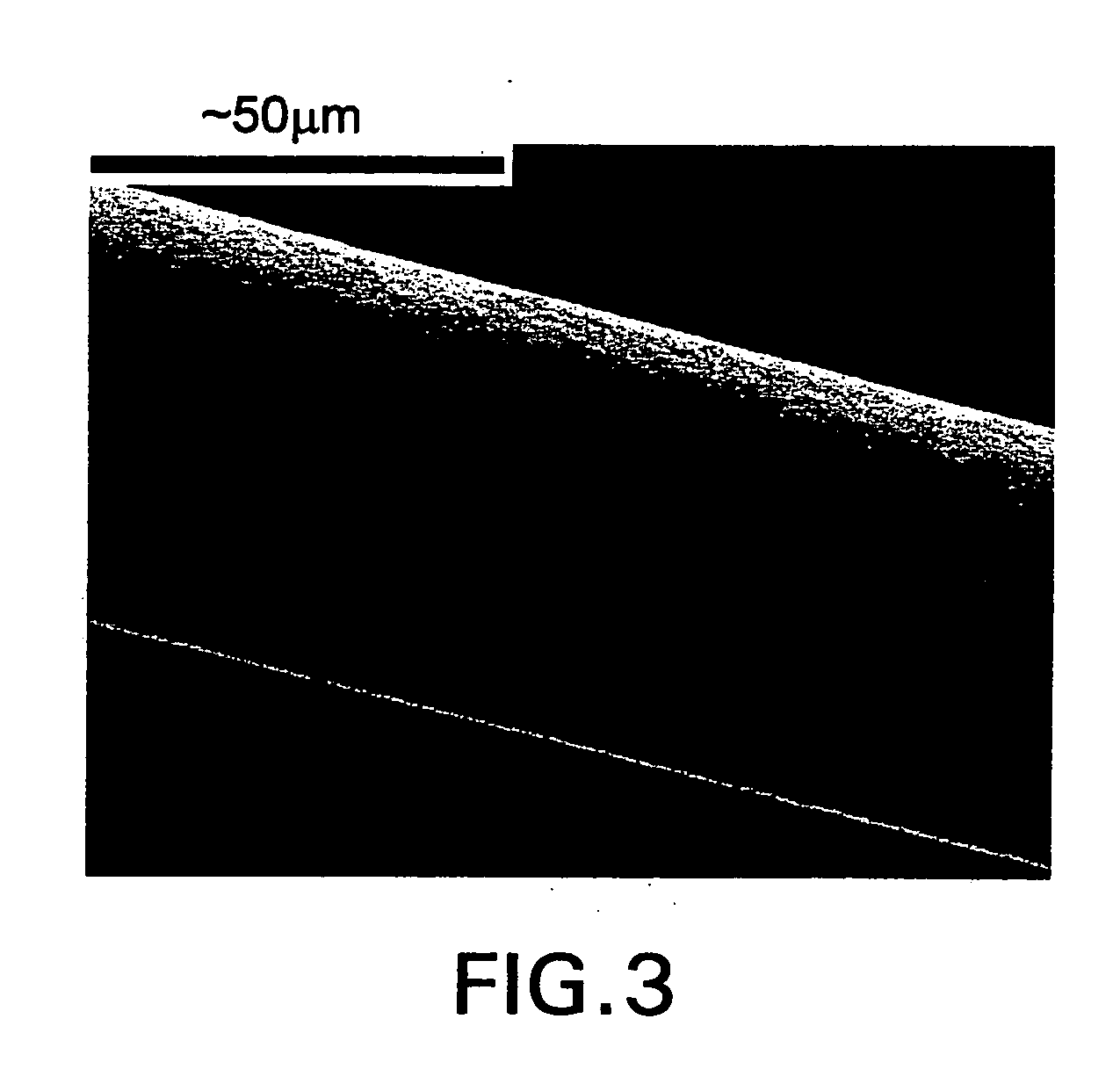

InactiveUS7067444B2Powerful solventLow tendency to fibrillatePulp properties modificationMonocomponent cellulose artificial filamentMelt blowingNonwoven fabric

A lyocell nonwoven fabric having fibers characterized by pebbled surfaces and variable cross sections and diameters along the fibers and from fiber to fiber, is disclosed. The lyocell nonwoven fabric is produced by centrifugal spinning, melt blowing or spunbonding. The lyocell nonwoven fabric has fibers that can be made in the microdenier range with average weights as low as one denier or less. The lyocell nonwoven fabric has fibers with low gloss, a reduced tendency to fibrillate and have enhanced dye receptivity.

Owner:INT PAPER CO

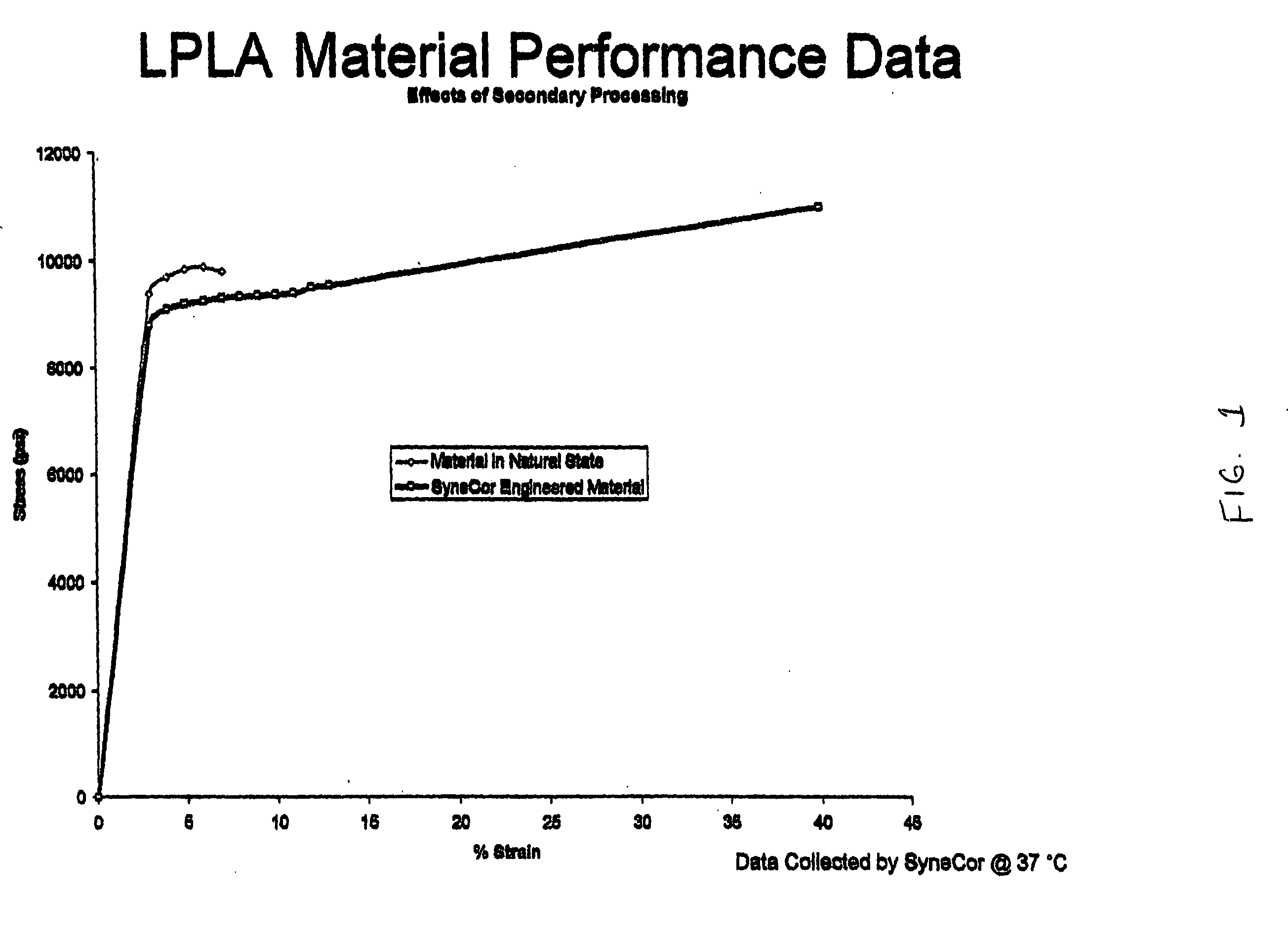

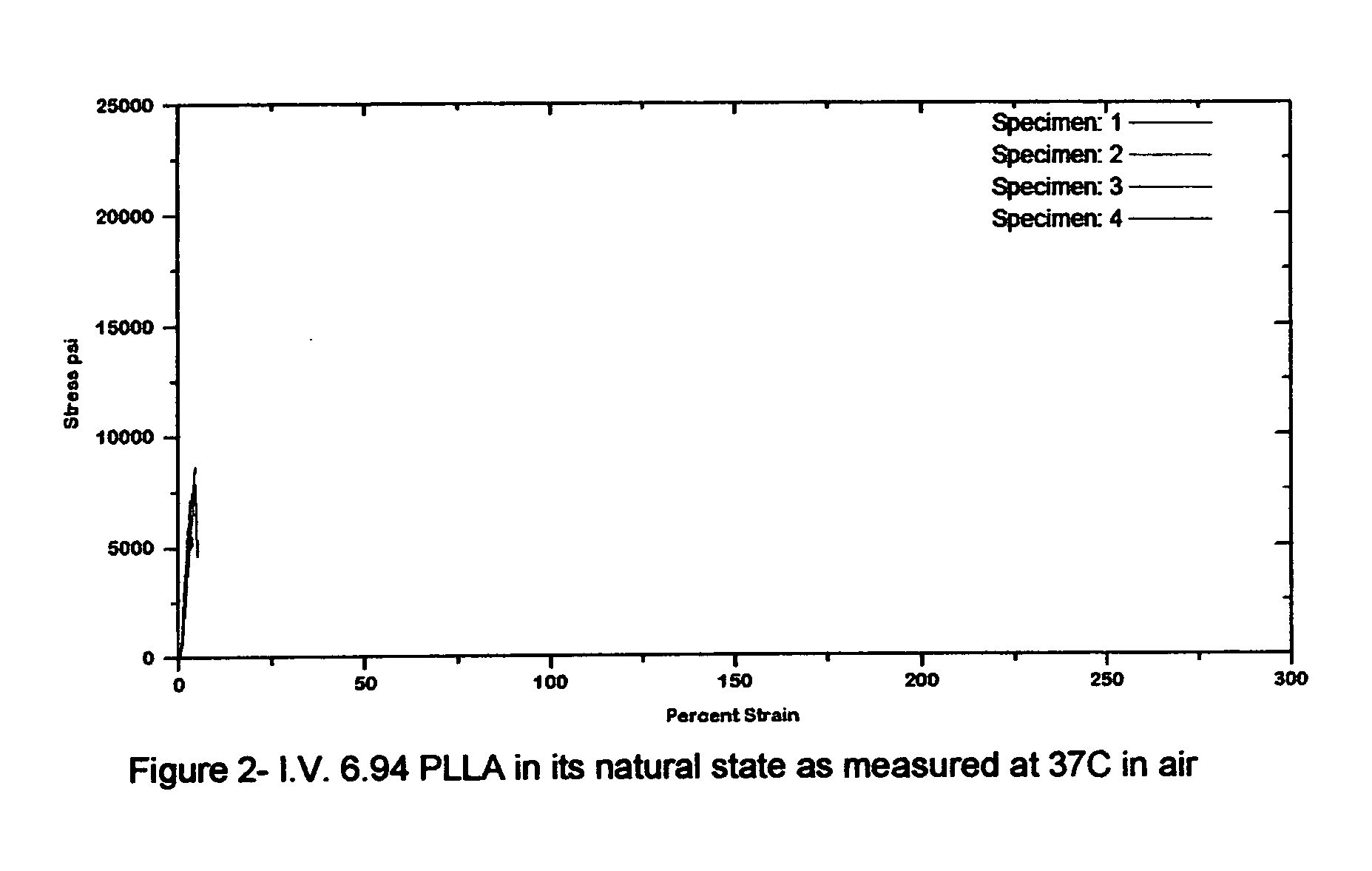

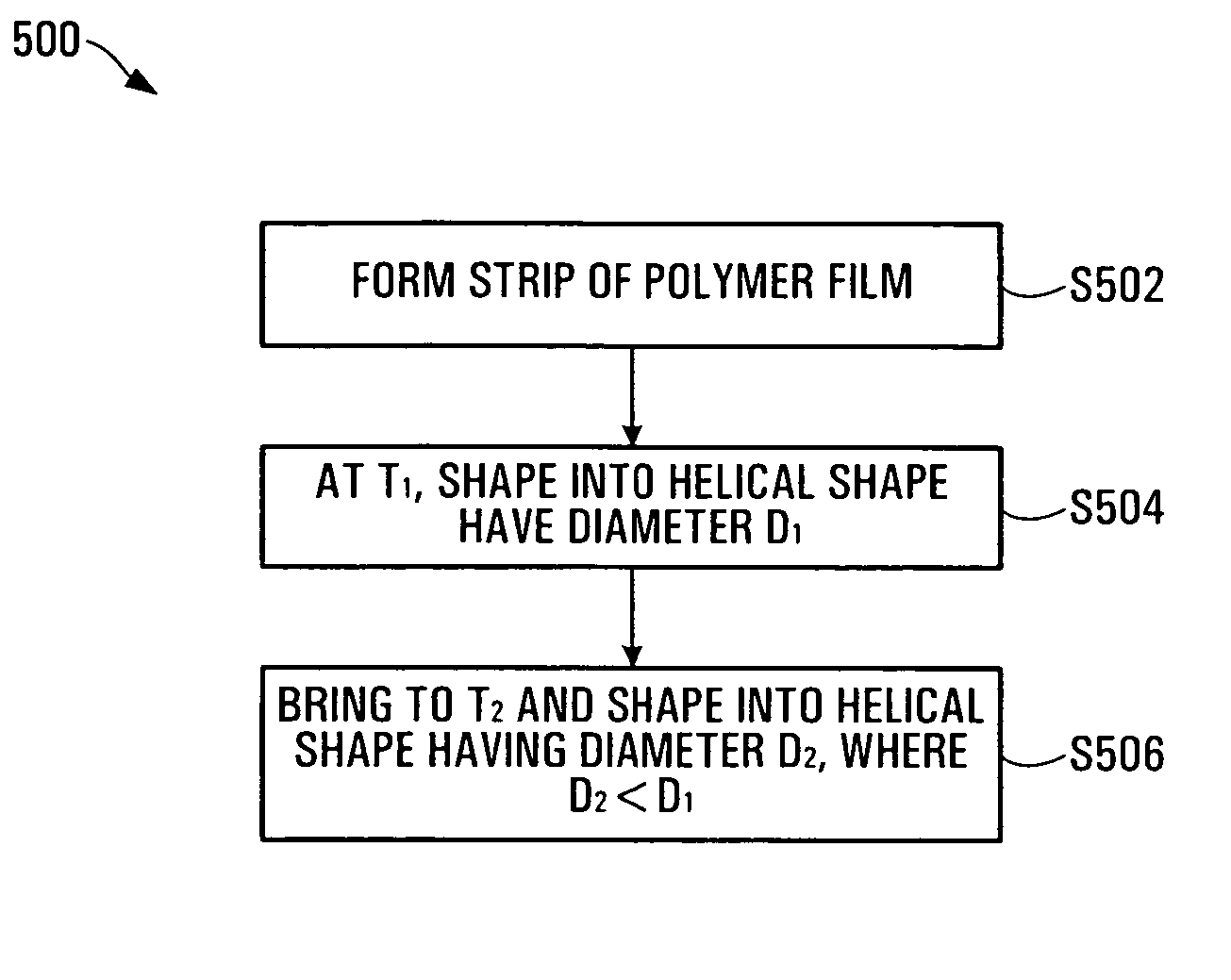

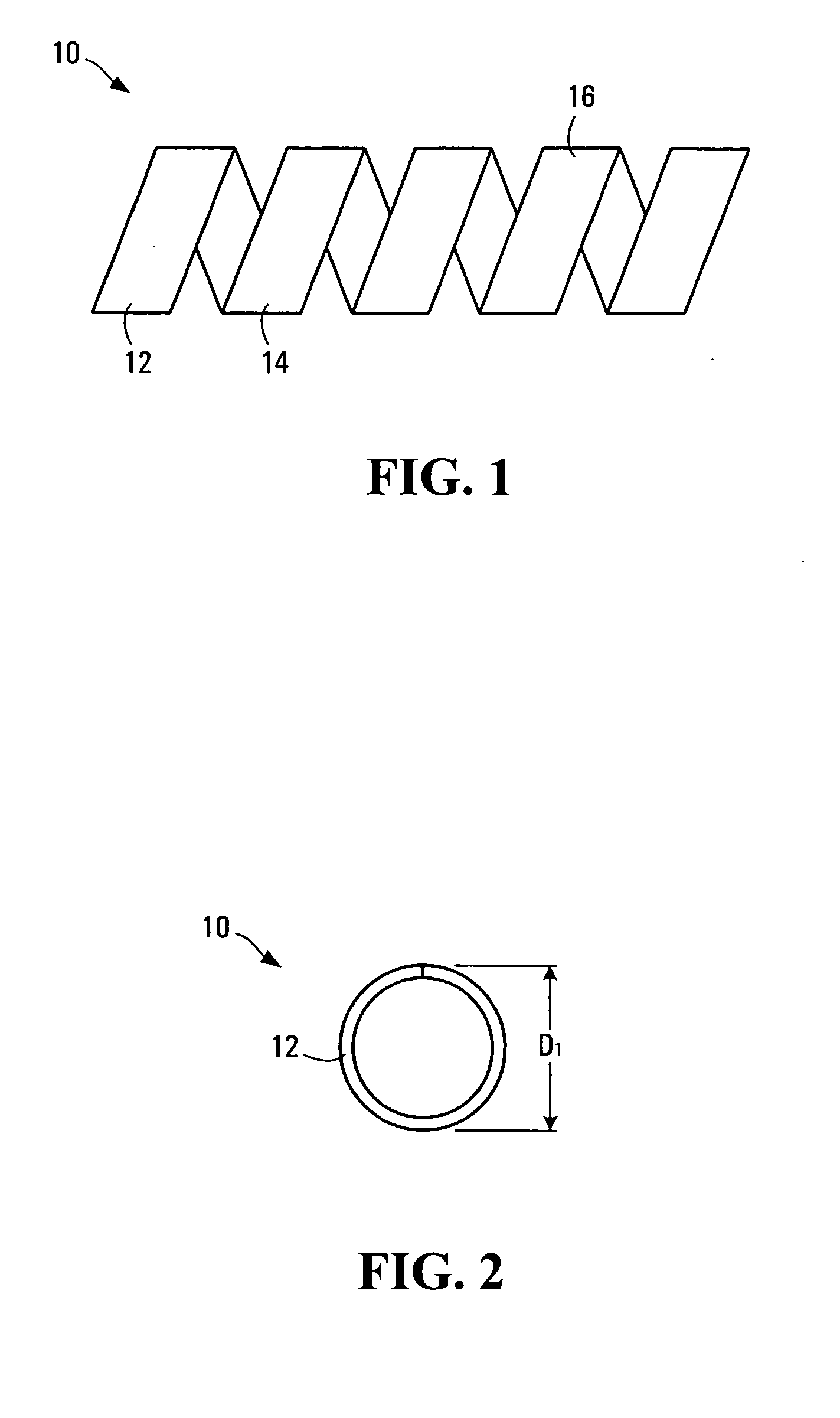

Low profile resorbable stent

A low profile resorbable stent comprising an oriented, resorbable material, wherein said material has Young's Modulus and tensile strength in the oriented state greater than Young's modulus and tensile strength of unoriented material is disclosed. The low profile resorbable stent has a resorbable material with Young's modulus about 2-300 GPa and / or tensile strength 50-200 MPa. The resorbable material of the present invention is oriented such that the tensile strength and modulus are higher than the unoriented materials allowing for the low profile stent design. Also disclosed is a method of manufacturing a low profile resorbable stent. The method comprises providing an extrudate comprising a resorbable material, inducing molecular alignment in the extrudate to form an oriented extrudate and forming the stent from the oriented extrudate. The extrudate of resorbable material can be a sheet, tube or some other form. The sheet extrudate is stretched axially or biaxially to induce molecular alignment. The tubular extrudate is blow-molded to induce molecular alignment.

Owner:MEDTRONIC VASCULAR INC

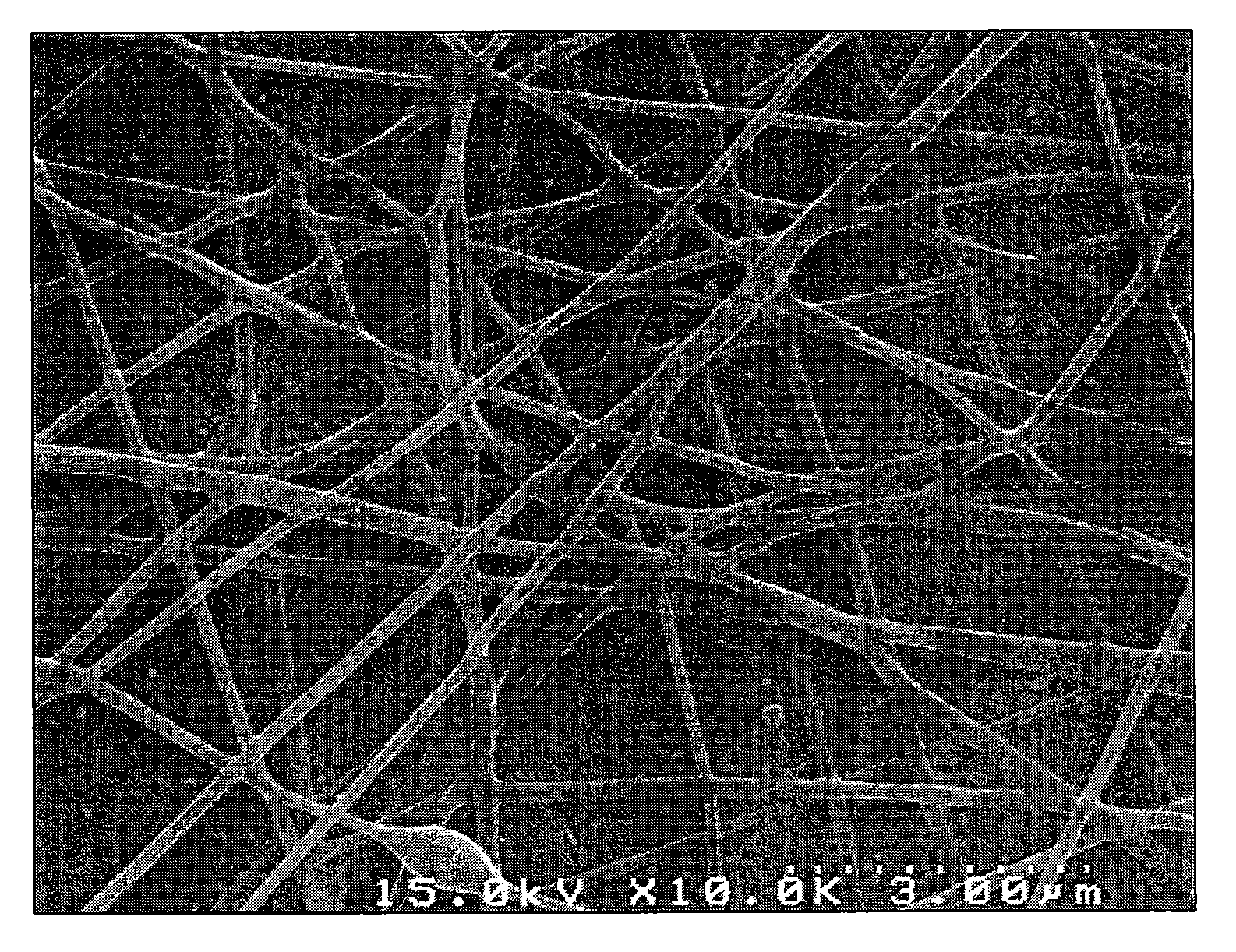

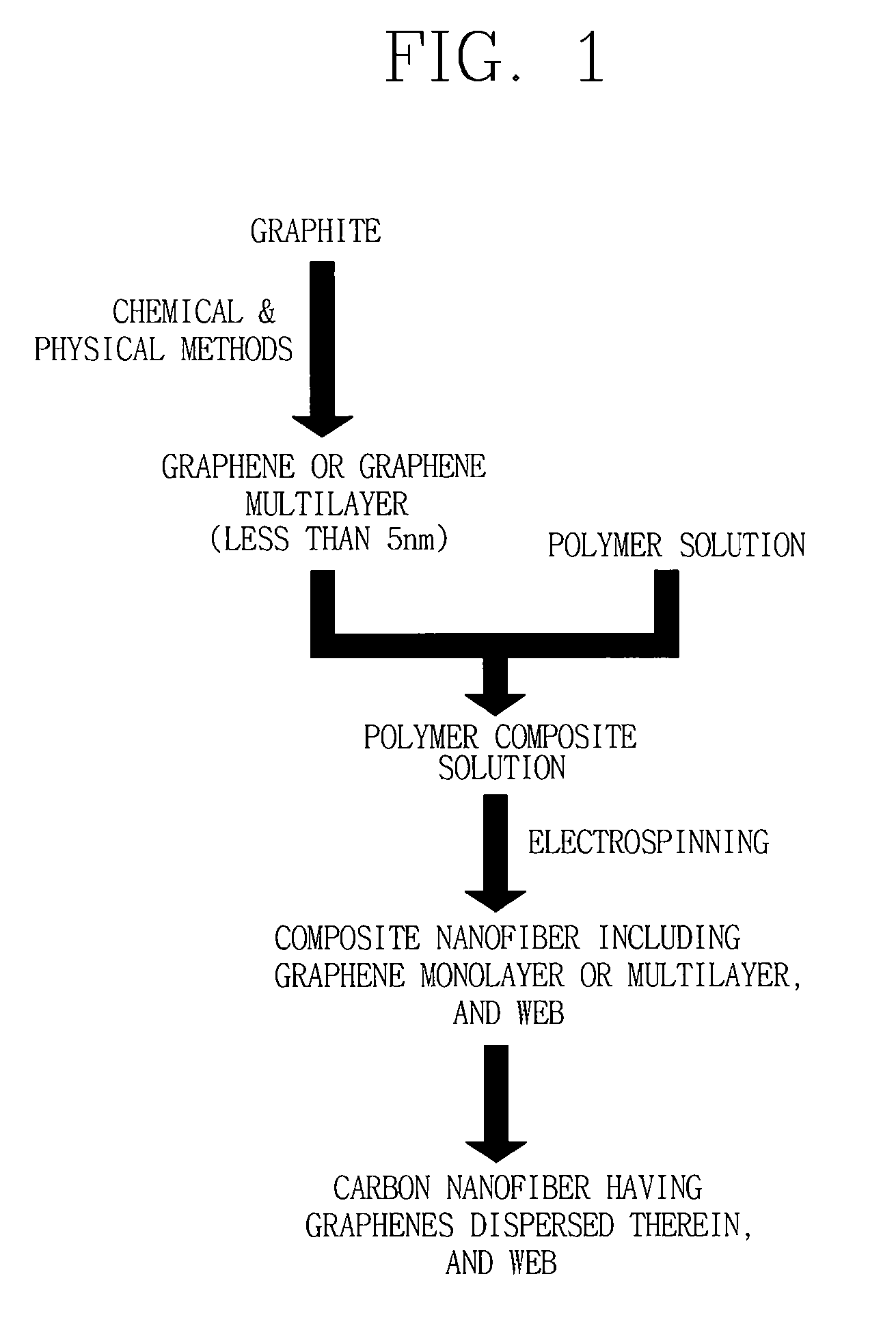

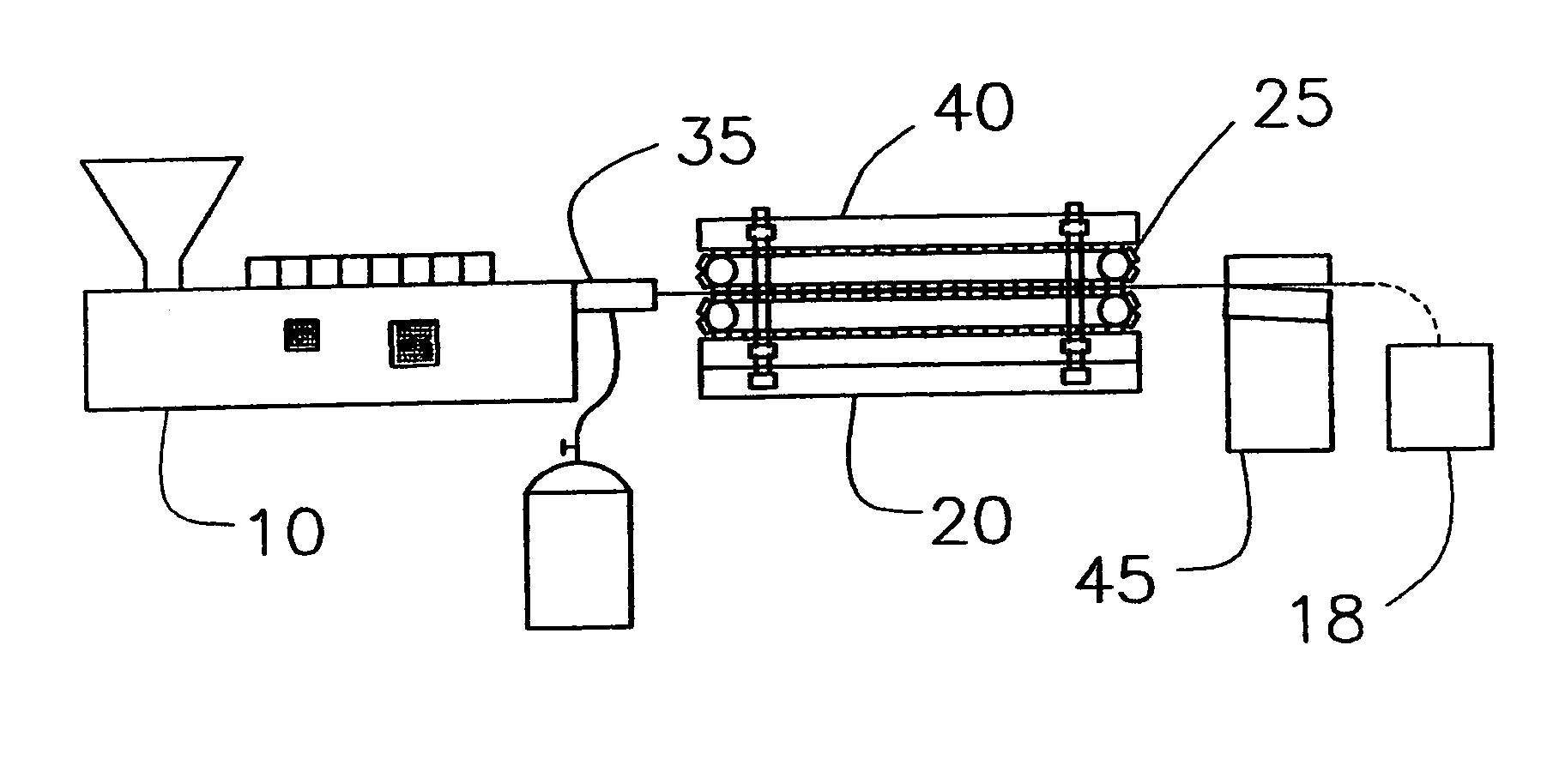

Graphene composite nanofiber and preparation method thereof

Disclosed are a graphene composite nanofiber and a preparation method thereof. The graphene composite nanofiber is produced by dispersing graphenes to at least one of a surface and inside of a polymer nanofiber or a carbon nanofiber having a diameter of 1˜1000 nm, and the graphenes include at least one type of monolayer graphenes, and multilayer graphenes having a thickness of 10 nm or less. The graphene composite nanofiber can be applied to various industrial fields, e.g., a light emitting display, a micro resonator, a transistor, a sensor, a transparent electrode, a fuel cell, a solar cell, a secondary cell, and a composite material, owing to a unique structure and property of graphene.

Owner:KOREA INST OF SCI & TECH

Polymeric endoprostheses with enhanced strength and flexibility and methods of manufacture

InactiveUS20050187615A1Reduce surface roughnessHigh elastic modulusStentsLayered productsPolymer scienceProsthesis

Improved polymeric endoprostheses and methods of manufacturing endoprostheses are disclosed herein. The endoprostheses may comprise one or more polymers wherein the polymer chains are substantially aligned circumferentially, and comprising increased radial strength and flexibility. An endoprosthesis according to the invention may comprise a smooth surface. Endoprostheses disclosed herein may be used in the treatment of strictures in lumens of the body. Alternatively, endoprostheses disclosed herein may be used as anchors to secure medical devices within lumens of the body. The endoprostheses disclosed herein may comprise one or more erodible polymer.

Owner:SYNECOR LLC

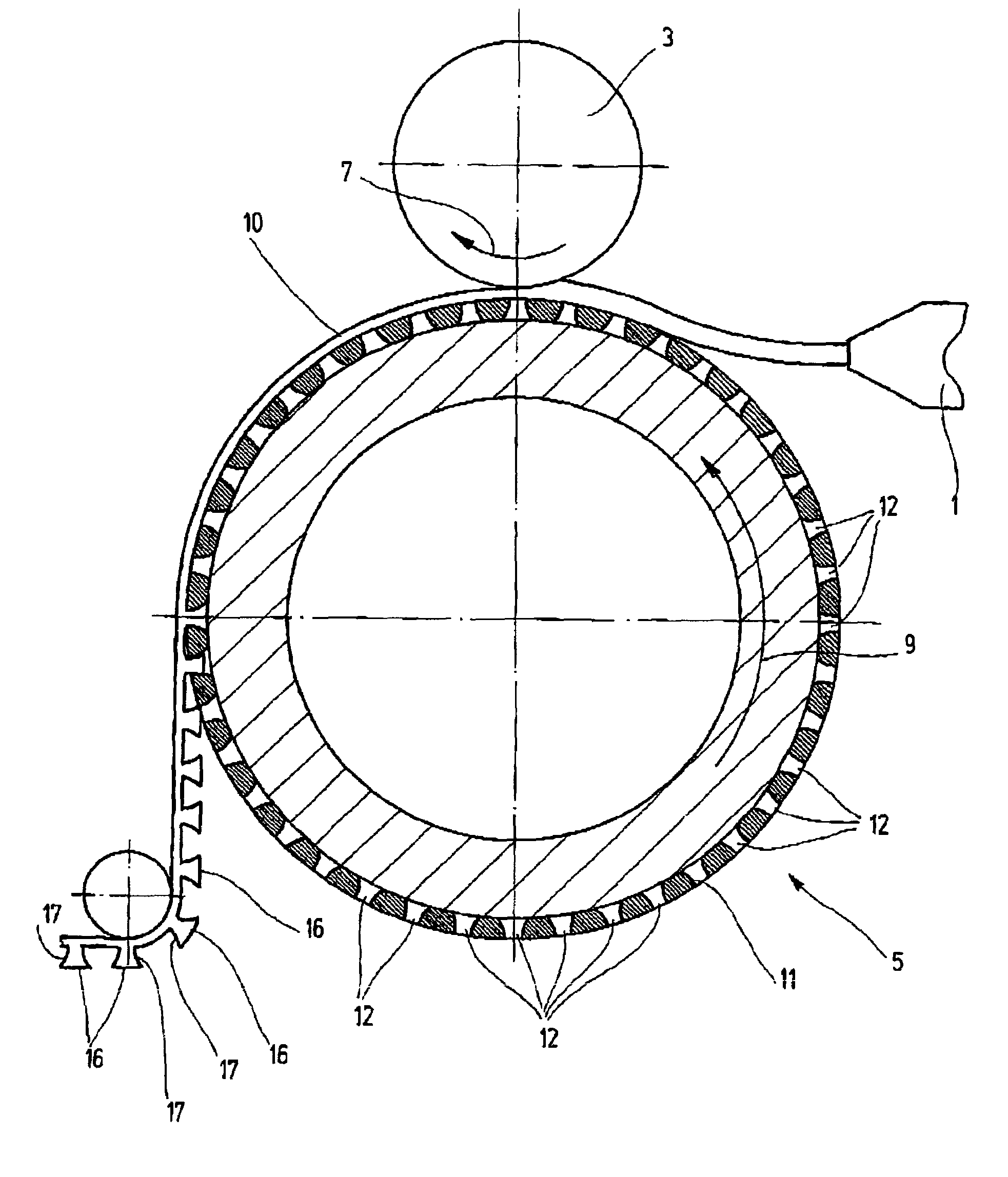

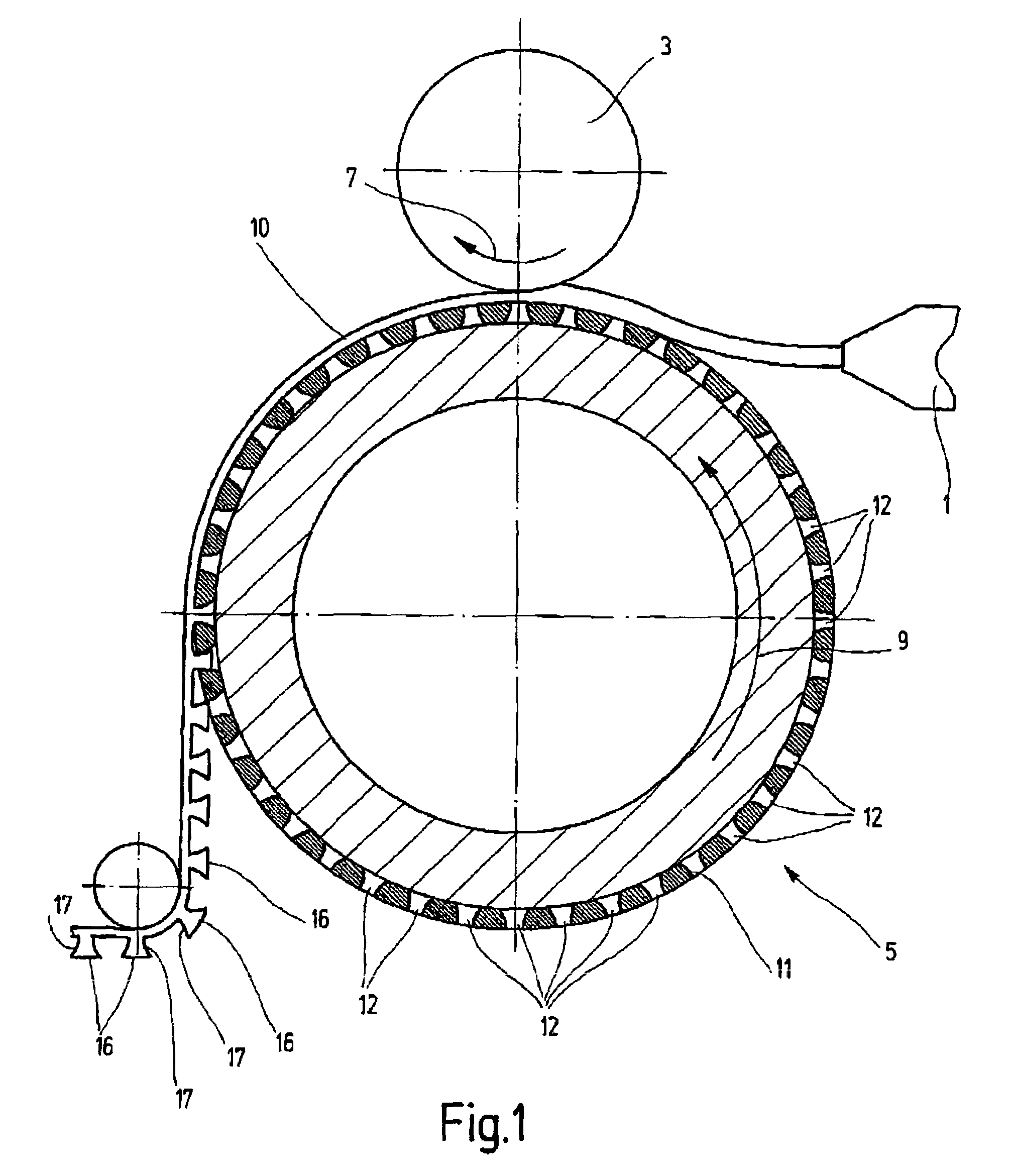

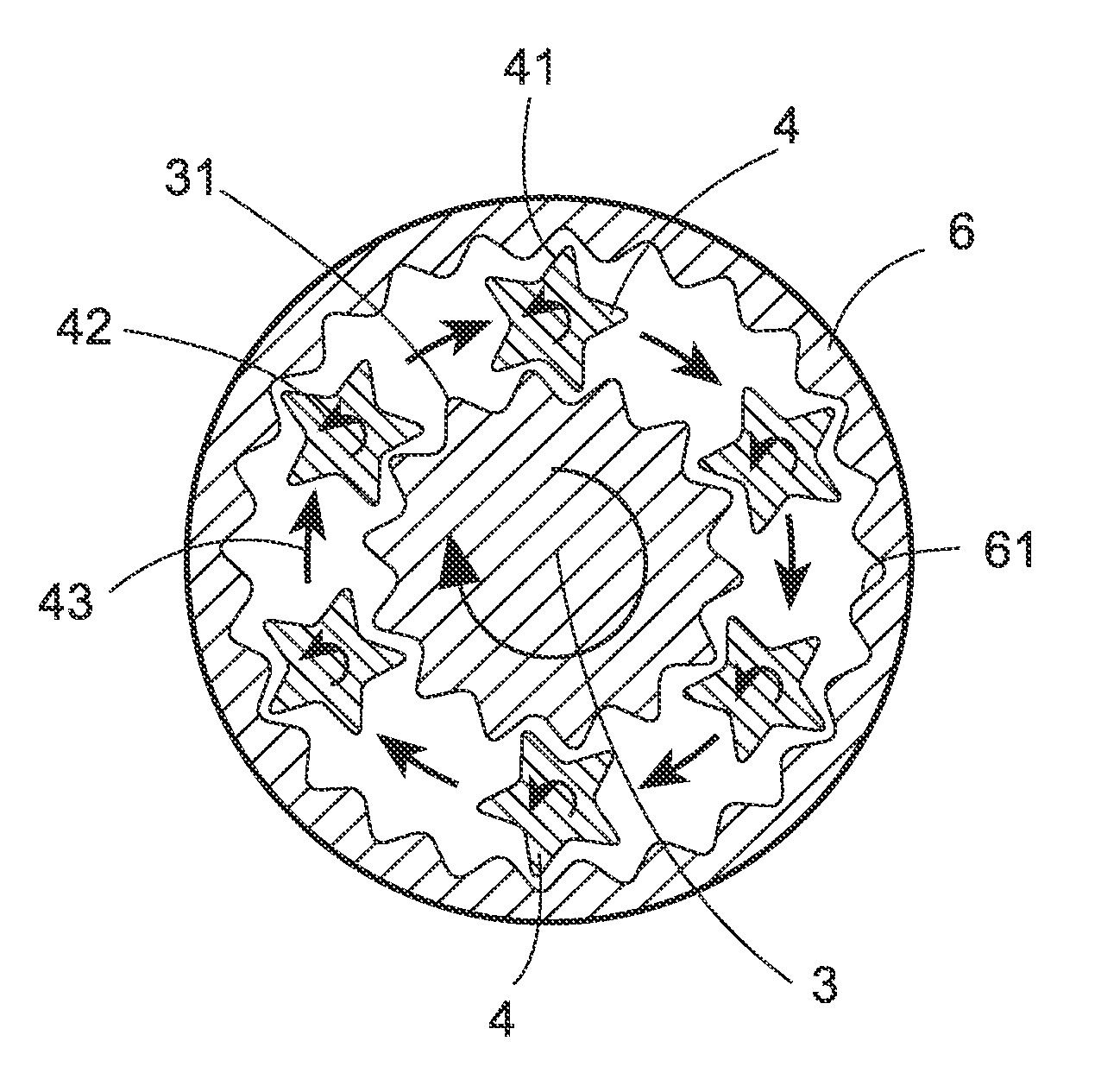

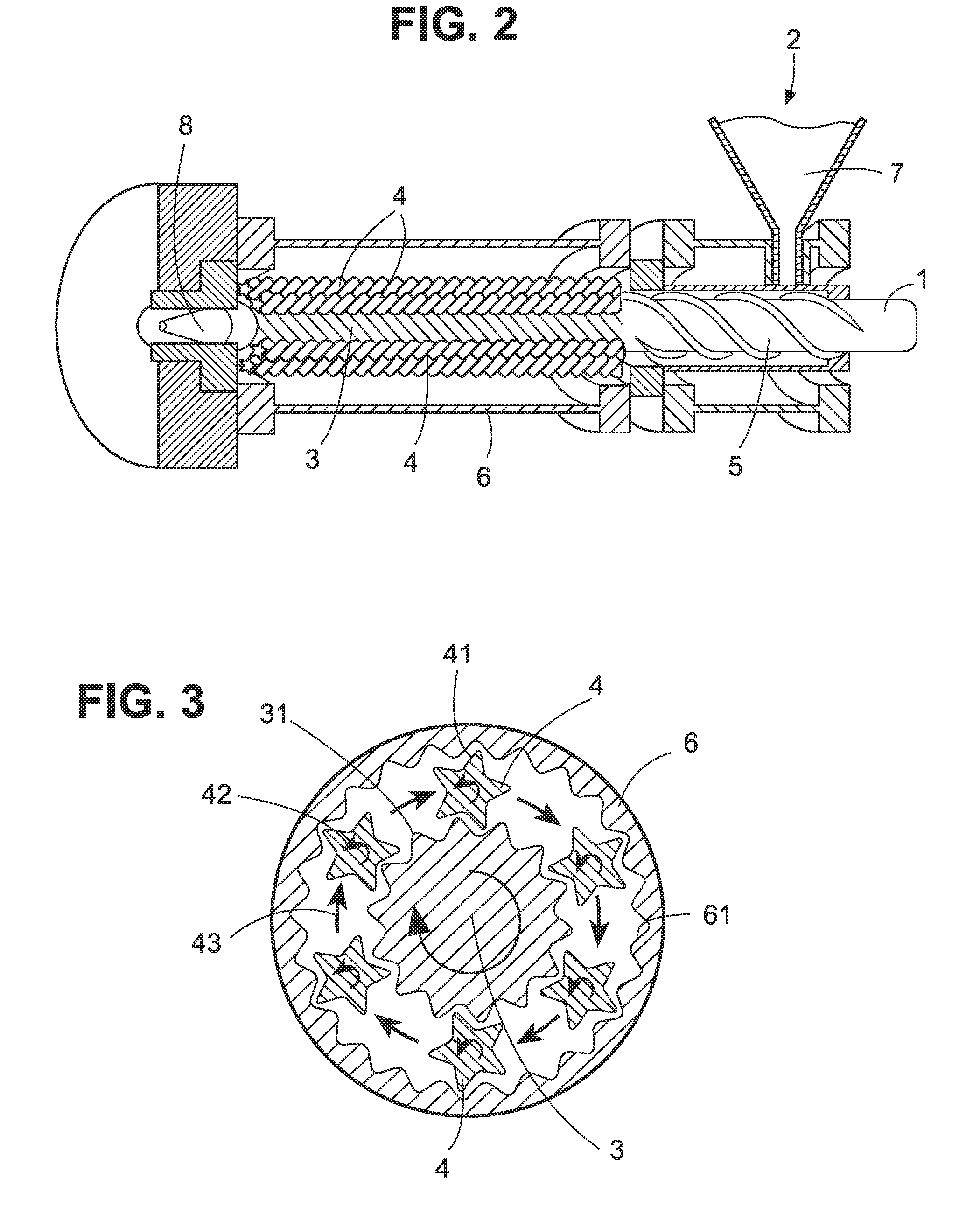

Method for producing an adhesive closing element

InactiveUS7198743B2Easy to demouldFavorable closing behaviorDischarging arrangementArtificial filament physical treatmentEngineeringHooking

A process for produces an adhesive closing element including a plurality of hook elements connected to a backing (10) forming a single piece with the hook elements and being disposed symmetrically thereon. The hook elements are provided in the form of a stem component (17) having a head piece (16). A deformable material is introduced into a forming zone in between a production master (3) and a forming tool (5). The opposite-lying defining walls, at least when seen in a longitudinal section of the respective forming cavity (12), are provided with a continuous convex trajectory. A continuous transition between the cross-sectional forms of the stem component (17) and the head piece (16) is provided for a hooking of the backing (10) resulting in seamless removal.

Owner:GOTTLIEB BINDER

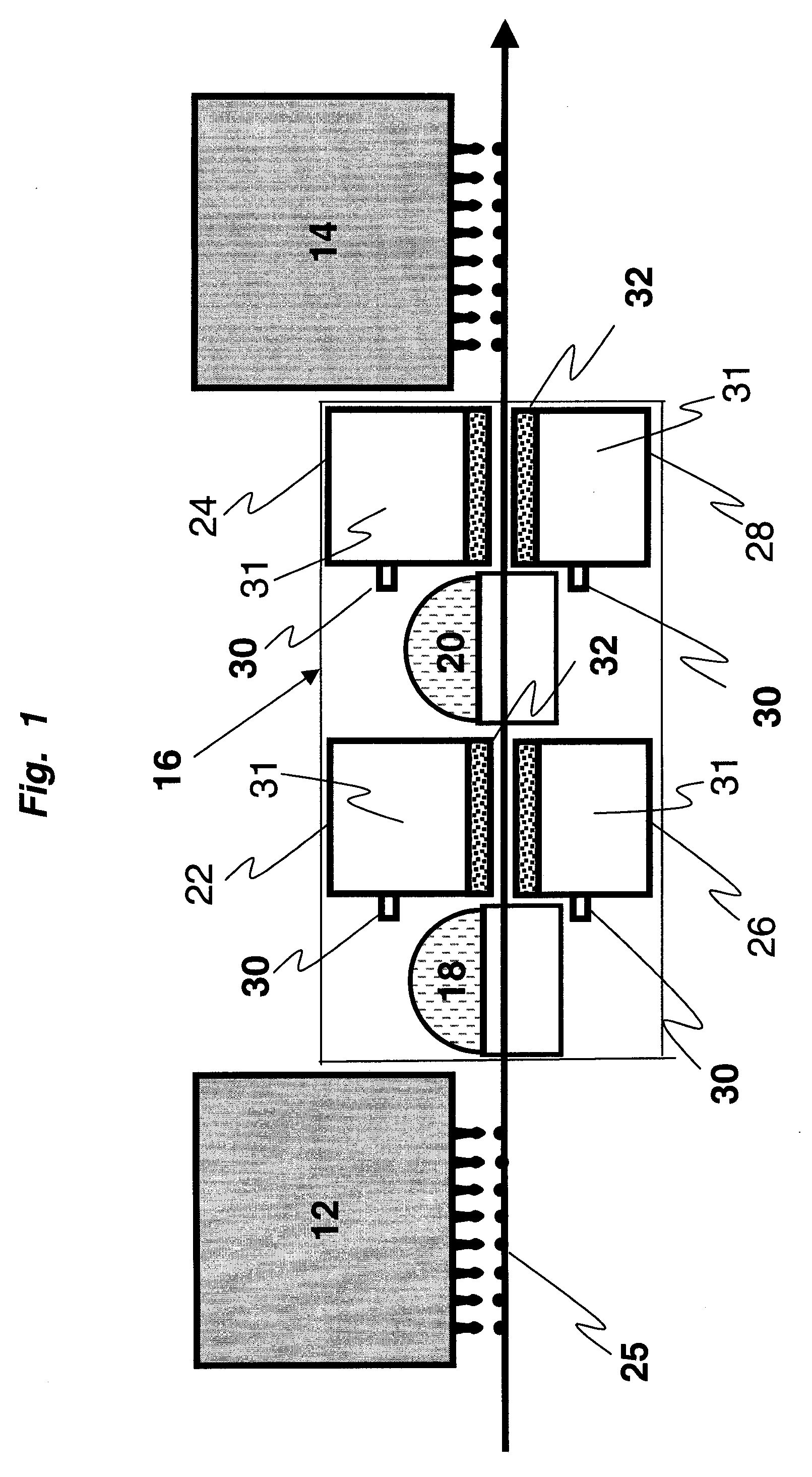

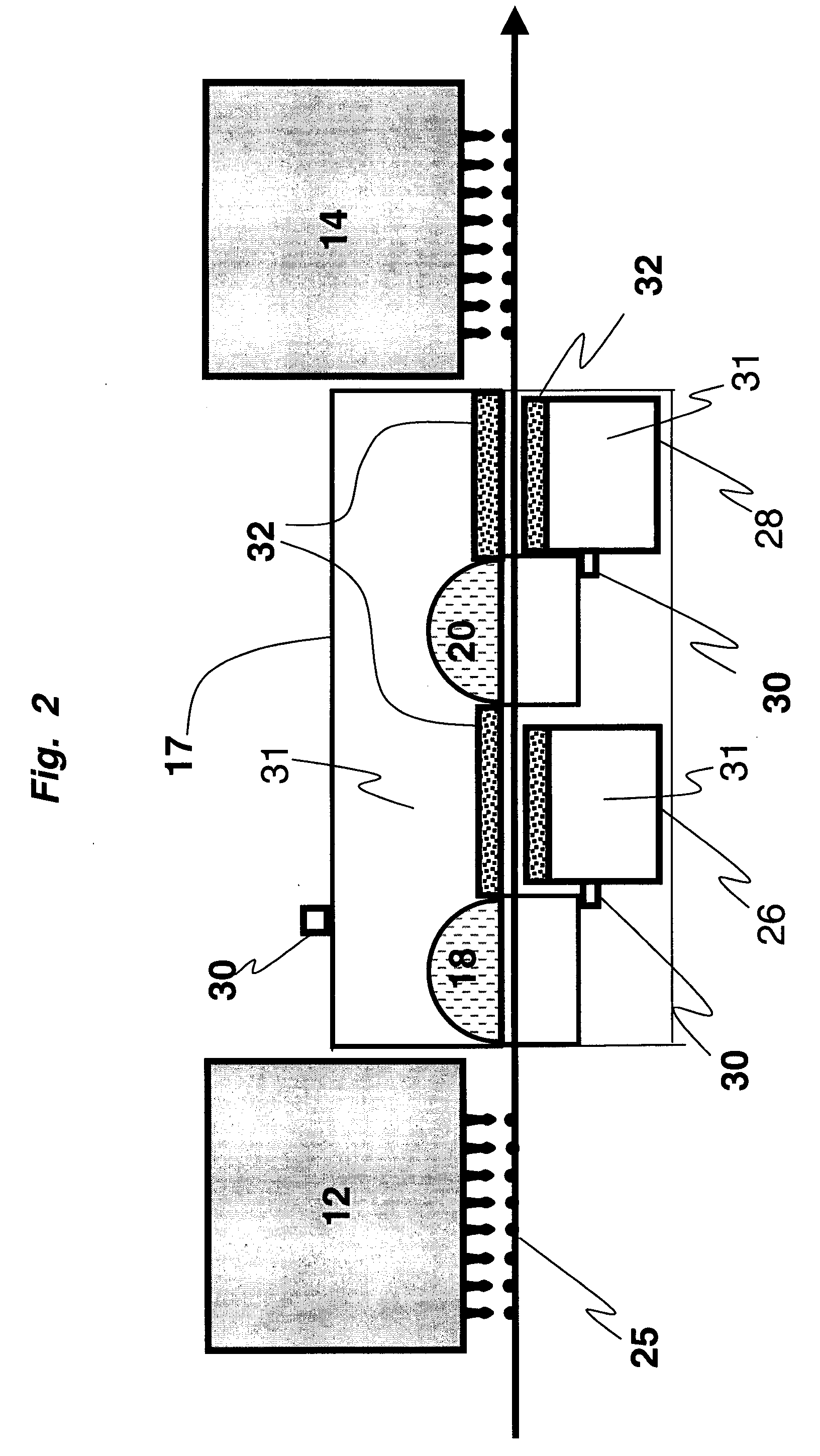

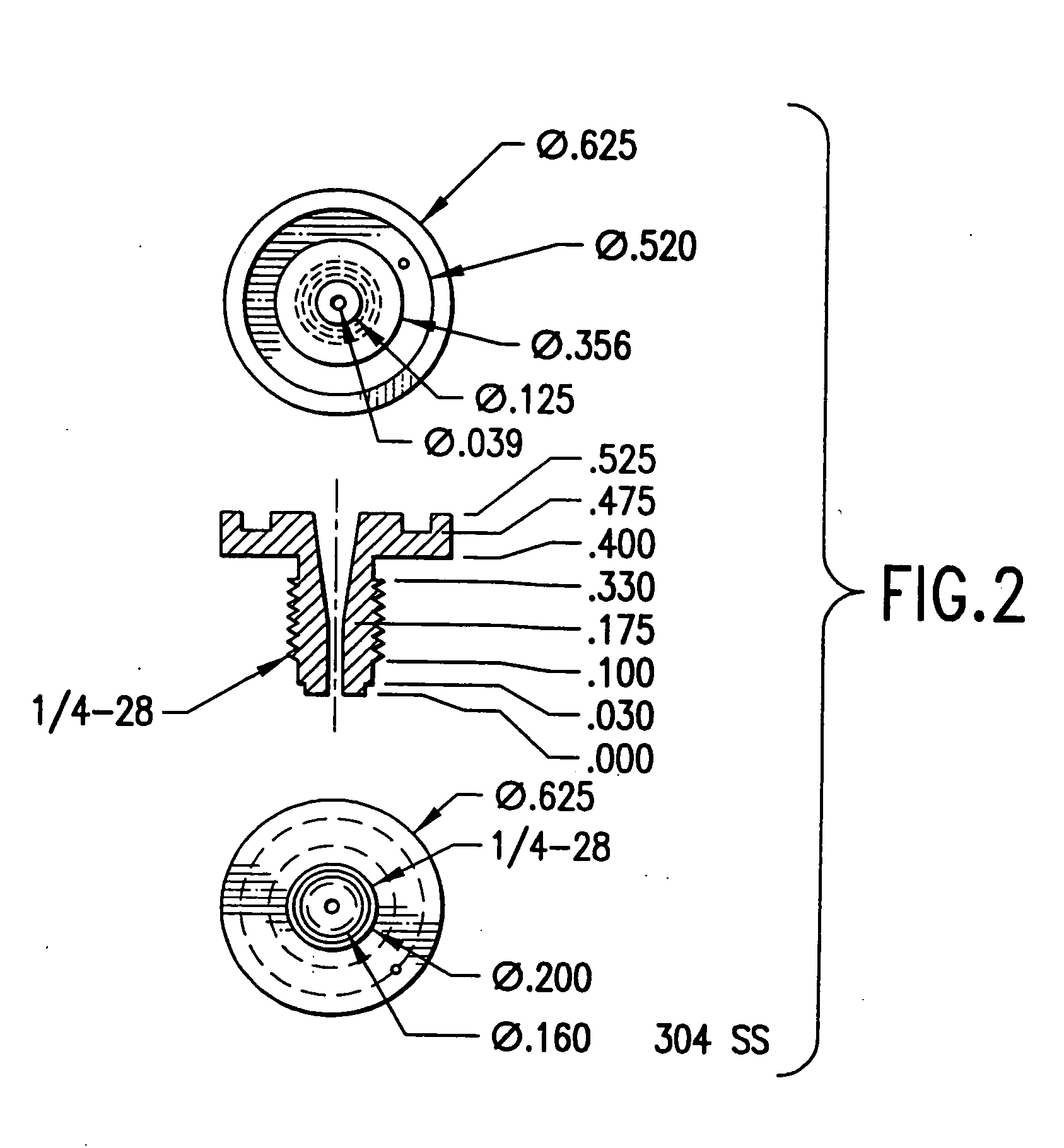

Methods of forming a nebulizing catheter

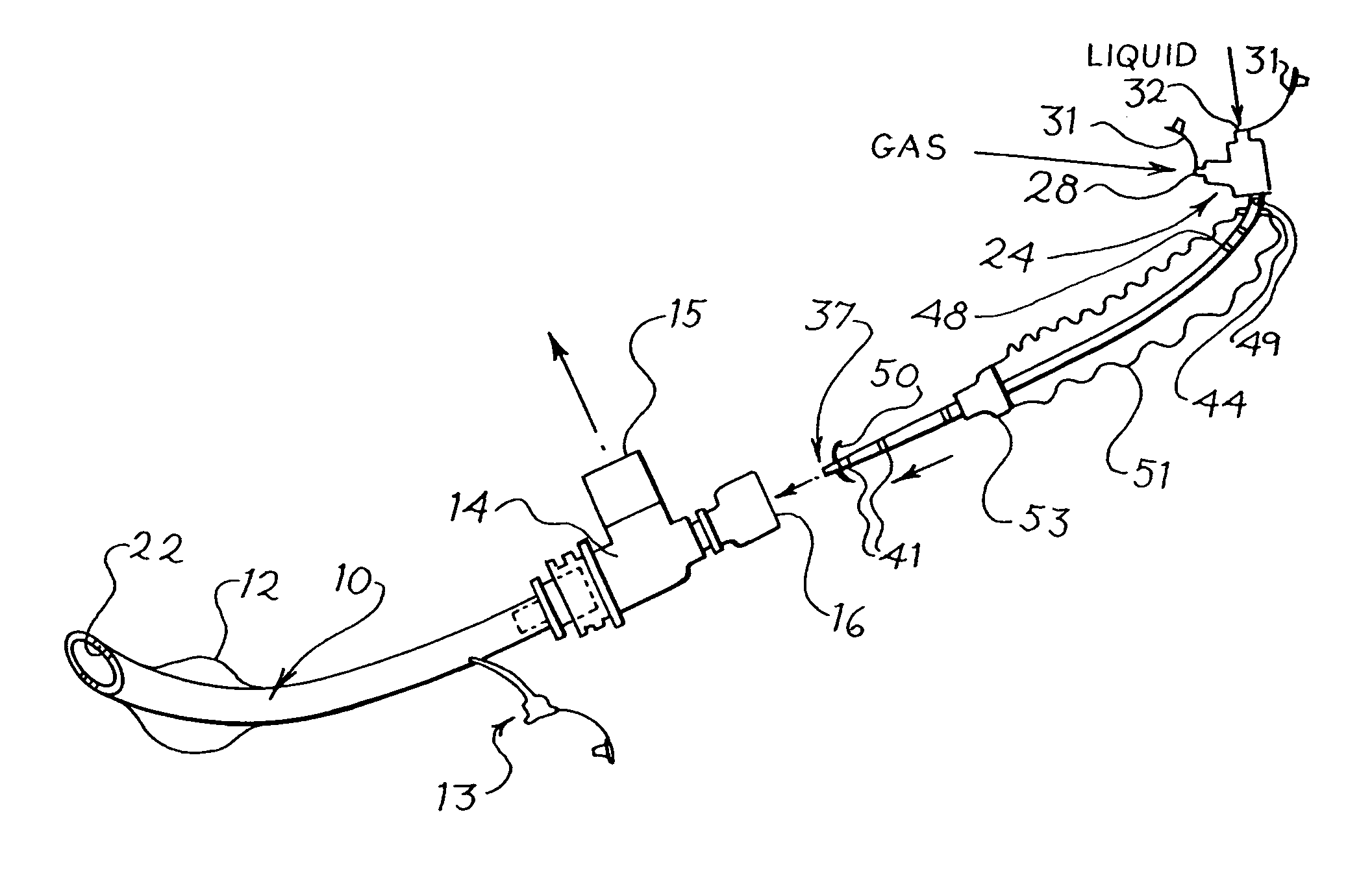

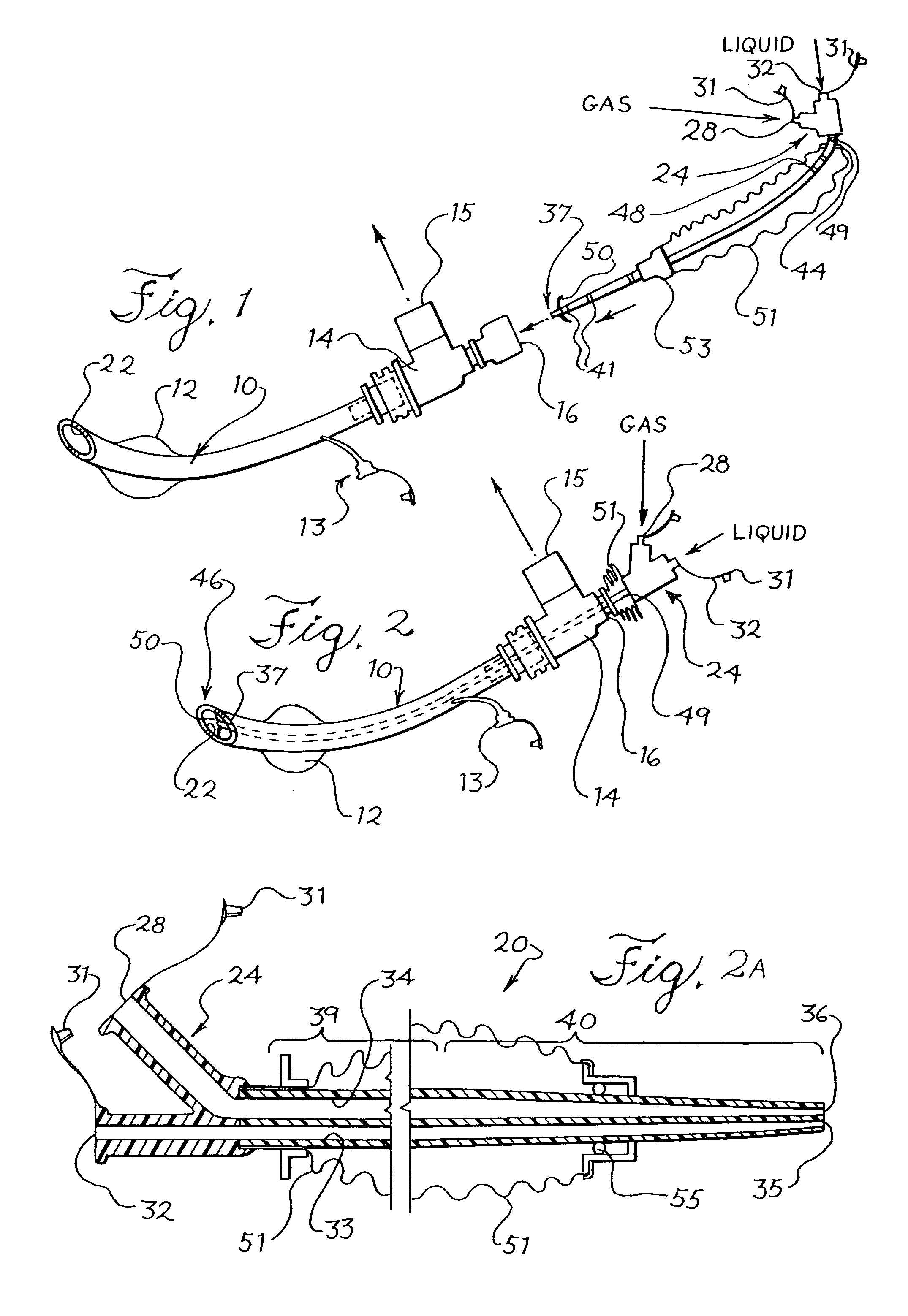

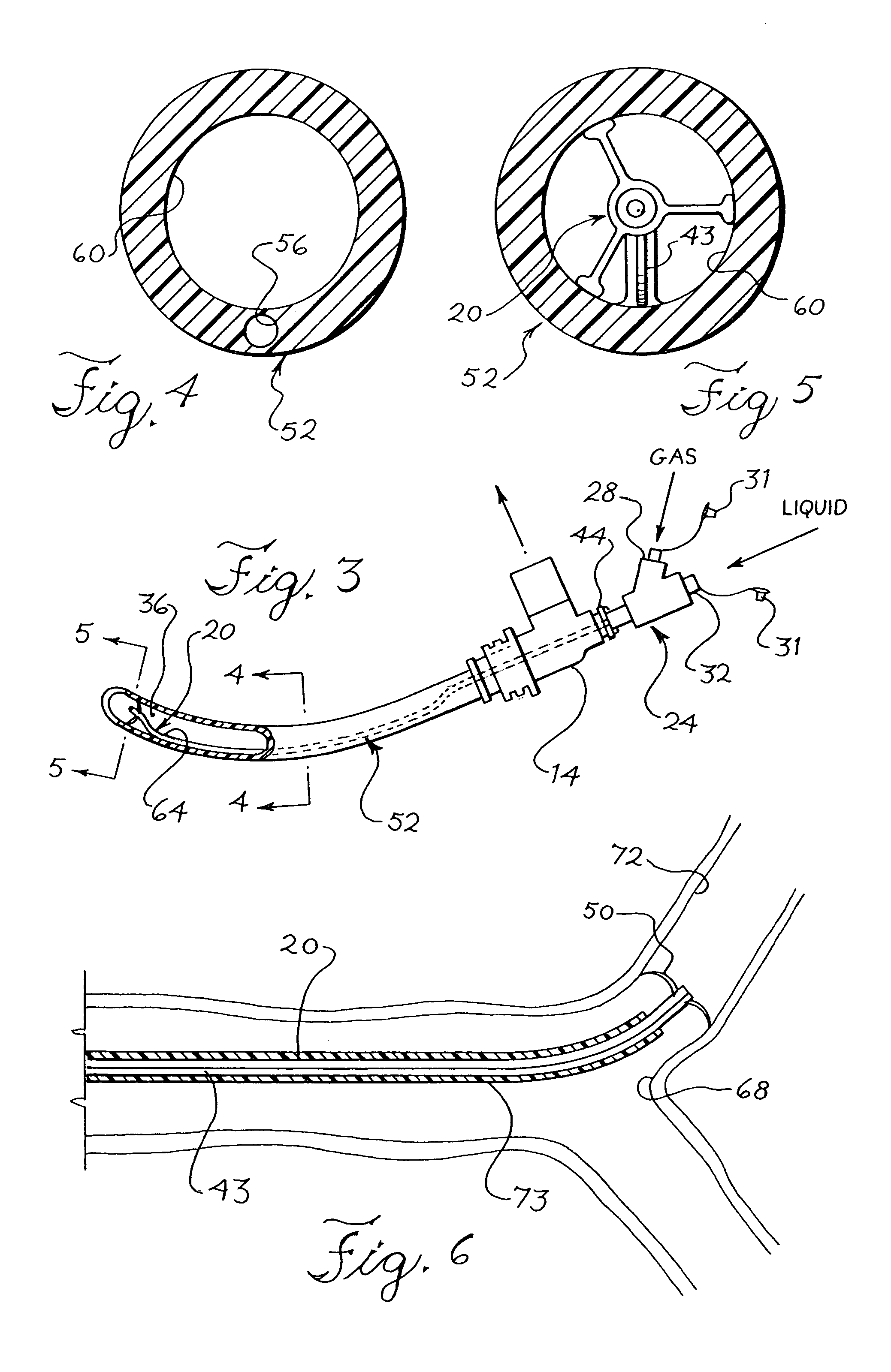

A method and apparatus for delivering a medicine to a patient via the patient's respiratory system with control and efficiency. A nebulization catheter is positioned in the patient's respiratory system so that a distal end of the nebulization catheter is in the respiratory system and a proximal end is outside the body. In a first aspect, the nebulization catheter may be used in conjunction with an endotracheal tube and preferably is removable from the endotracheal tube. The nebulization catheter conveys medicine in liquid form to the distal end at which location the medicine is nebulized by a pressurized gas or other nebulizing mechanism. The nebulized medicine is conveyed to the patient's lungs by the patient's respiration which may be assisted by a ventilator. By producing the aerosol of the liquid medicine at a location inside the patient's respiratory system, the nebulizing catheter provides for increased efficiency and control of the dosage of medicine being delivered. In further aspects of the nebulizing catheter apparatus and method, alternative tip constructions, flow pulsation patterns, centering devices, sensing devices, and aspiration features afford greater efficiency and control of aerosolized medicine dosage delivery.

Owner:TRUDELL MEDICAL

Apertured material for use in absorbent articles and method of making the same

Owner:TREDEGAR FILM PROD CORP

Micro-structured drying for inkjet printers

InactiveUS20090031579A1Improve rigidityImprove protectionCombination devicesDrying solid materials with heatAir bearingDiffuse flow

A dryer operable in close proximity to and in series with an inkjet printhead comprises a heat source and an air bearing structure on one side of the predetermined path and having a pressurized air inlet and an air outlet adjacent to the drying position of the receiver medium. Air flow from the air bearing structure outlet forms an air bearing for the receiver medium. A microporous filter positioned at the outlet and being adapted to convert the air flow from the outlet to a diffuse flow, the microporous filter being formed of an inner layer of very fine screen for optimum air diffusion and an outer layer of courser woven screen to add rigidity and protection from scuffing.

Owner:EASTMAN KODAK CO

Polymeric stent and method of manufacture

InactiveUS20050021131A1Stay flexiblePowerfulStentsHollow filament manufactureInsertion stentBiomedical engineering

A stent formed of polymeric material, useful for the expansion of a lumen and the delivery of one or more therapeutic agents in situ is disclosed. The stent may be multi-layered, and may change shape at a state transition temperature governed by the materials forming the layers. Methods of use and manufacture are also disclosed.

Owner:NANYANG TECH UNIV

Crush resistant delayed-release dosage forms

The invention relates to a dosage form comprising a physiologically effective amount of a physiologically active substance (A), a synthetic, semi-synthetic or natural polymer (C), optionally one or more physiologically acceptable auxiliary substances (B) and optionally a synthetic, semi-synthetic or natural wax (D), wherein the dosage form exhibits a resistance to crushing of at least 400 N and wherein under physiological conditions the release of the physiologically active substance (A) from the dosage form is at least partially delayed.

Owner:GRUNENTHAL GMBH

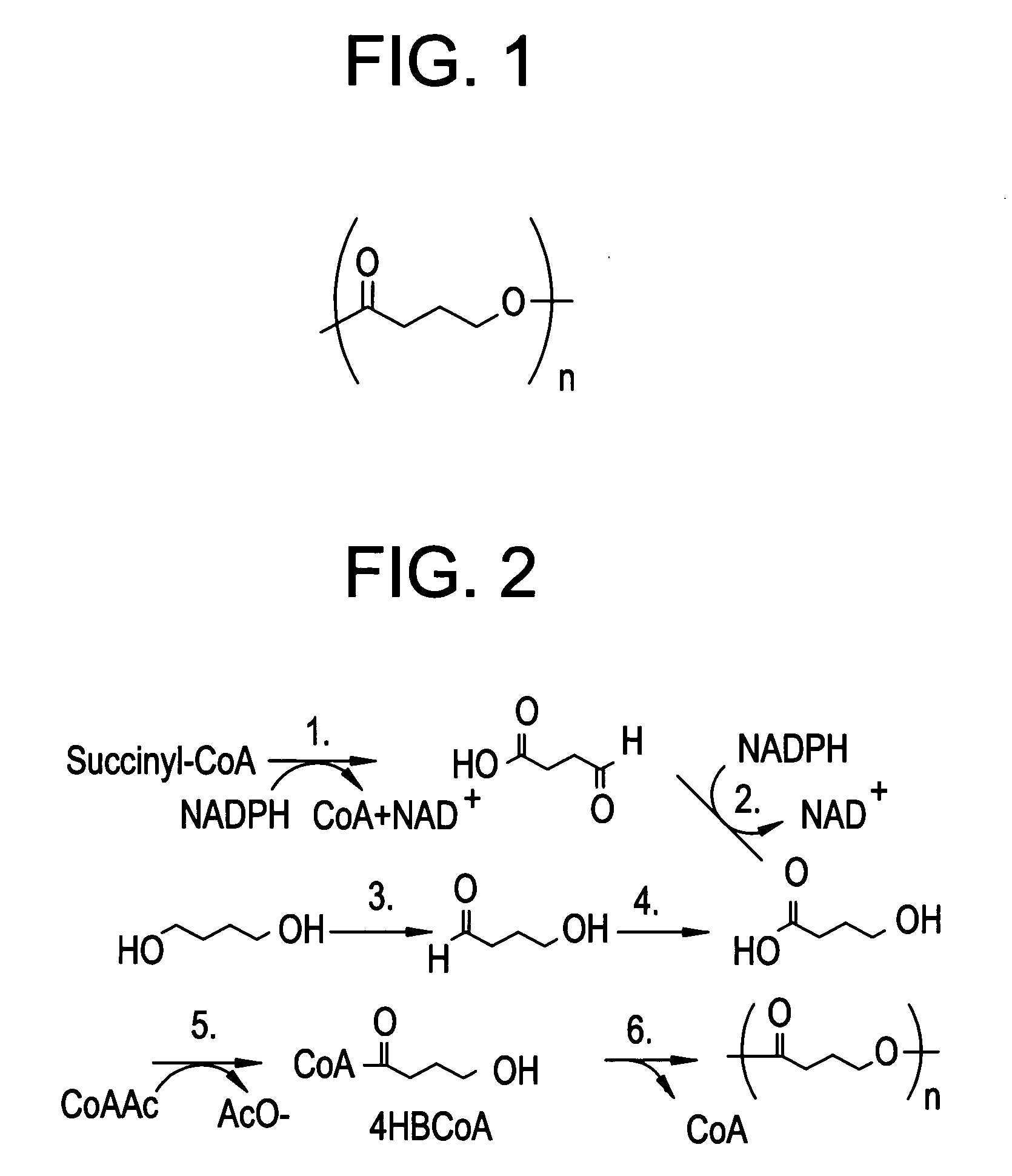

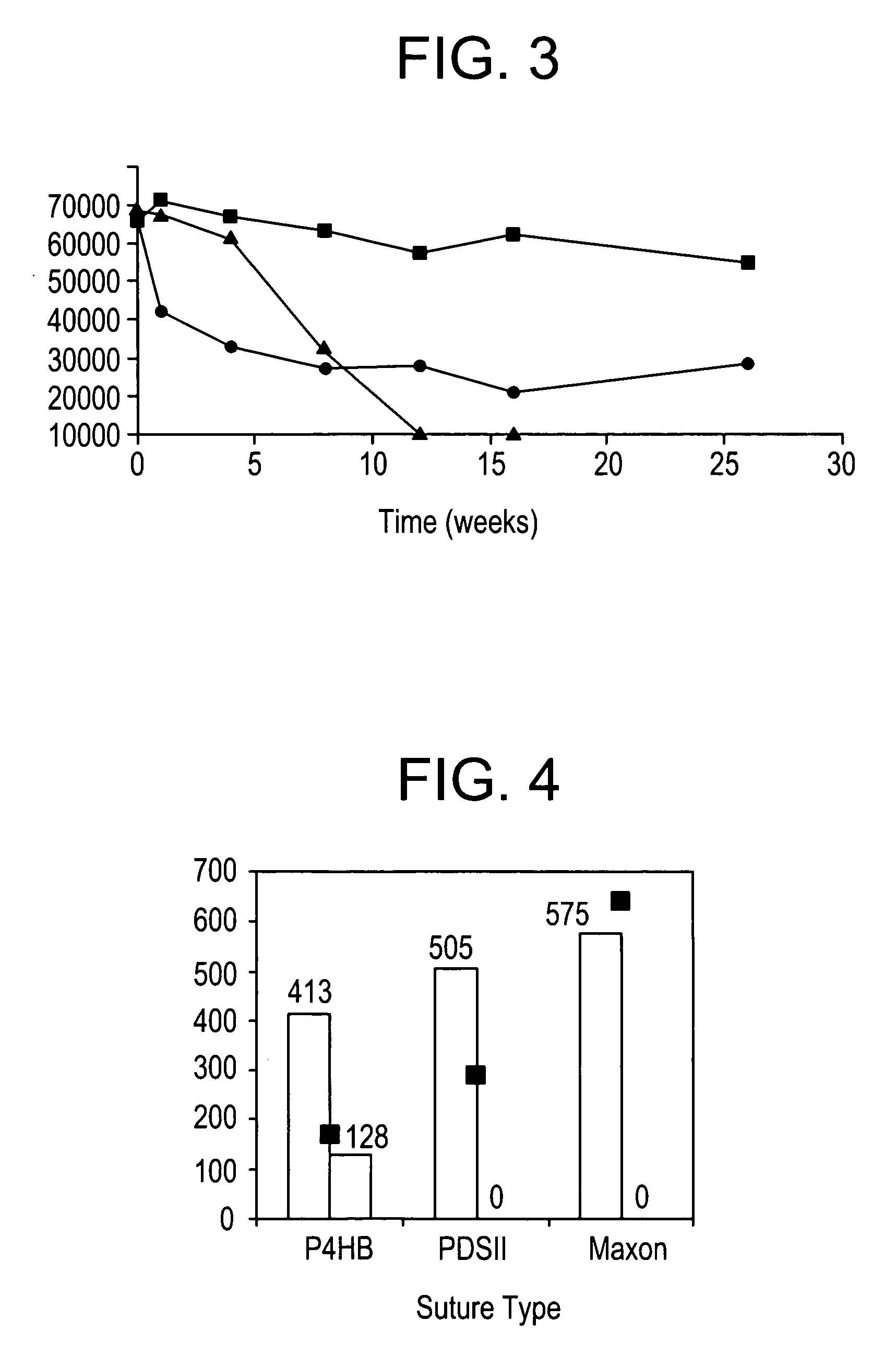

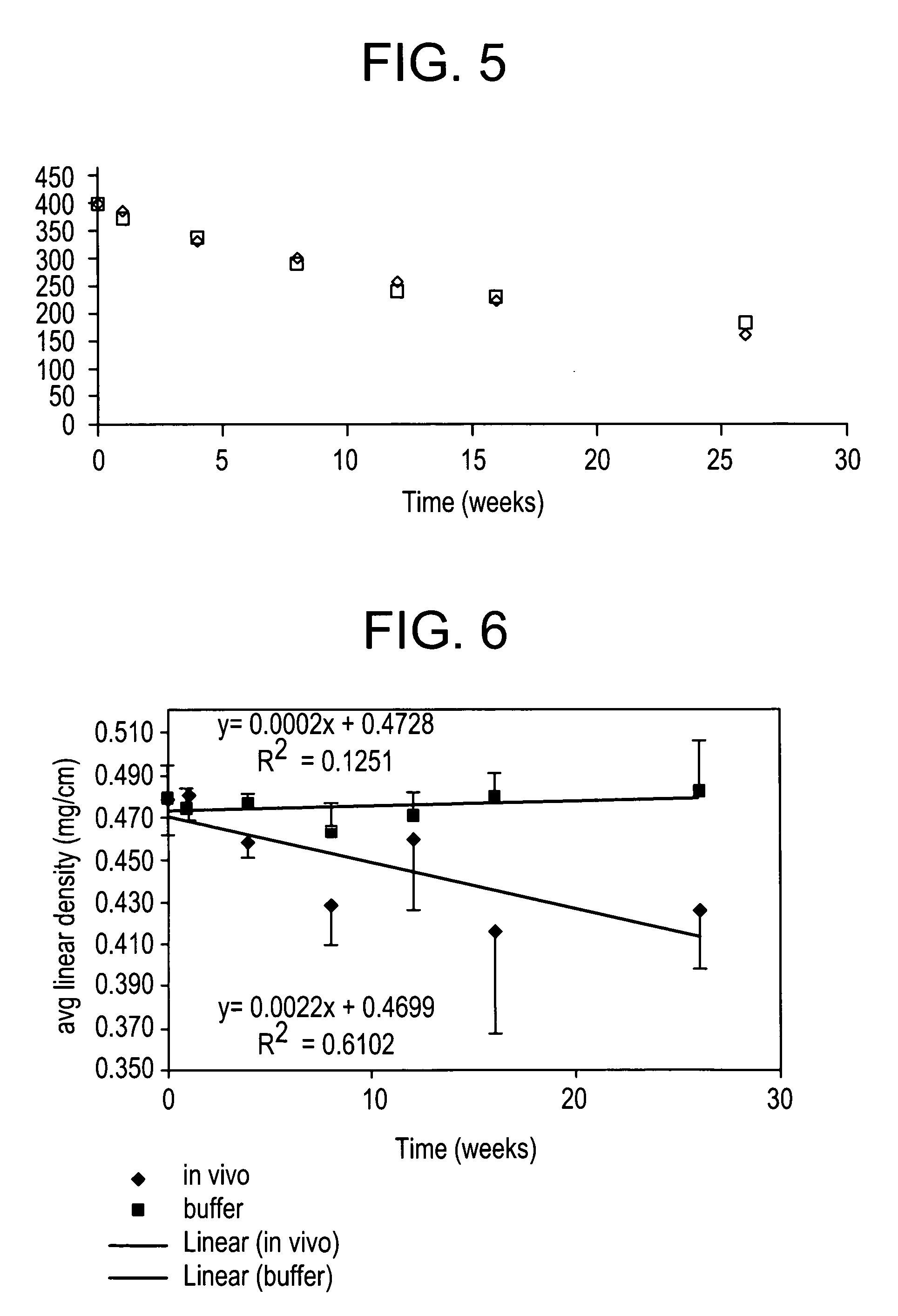

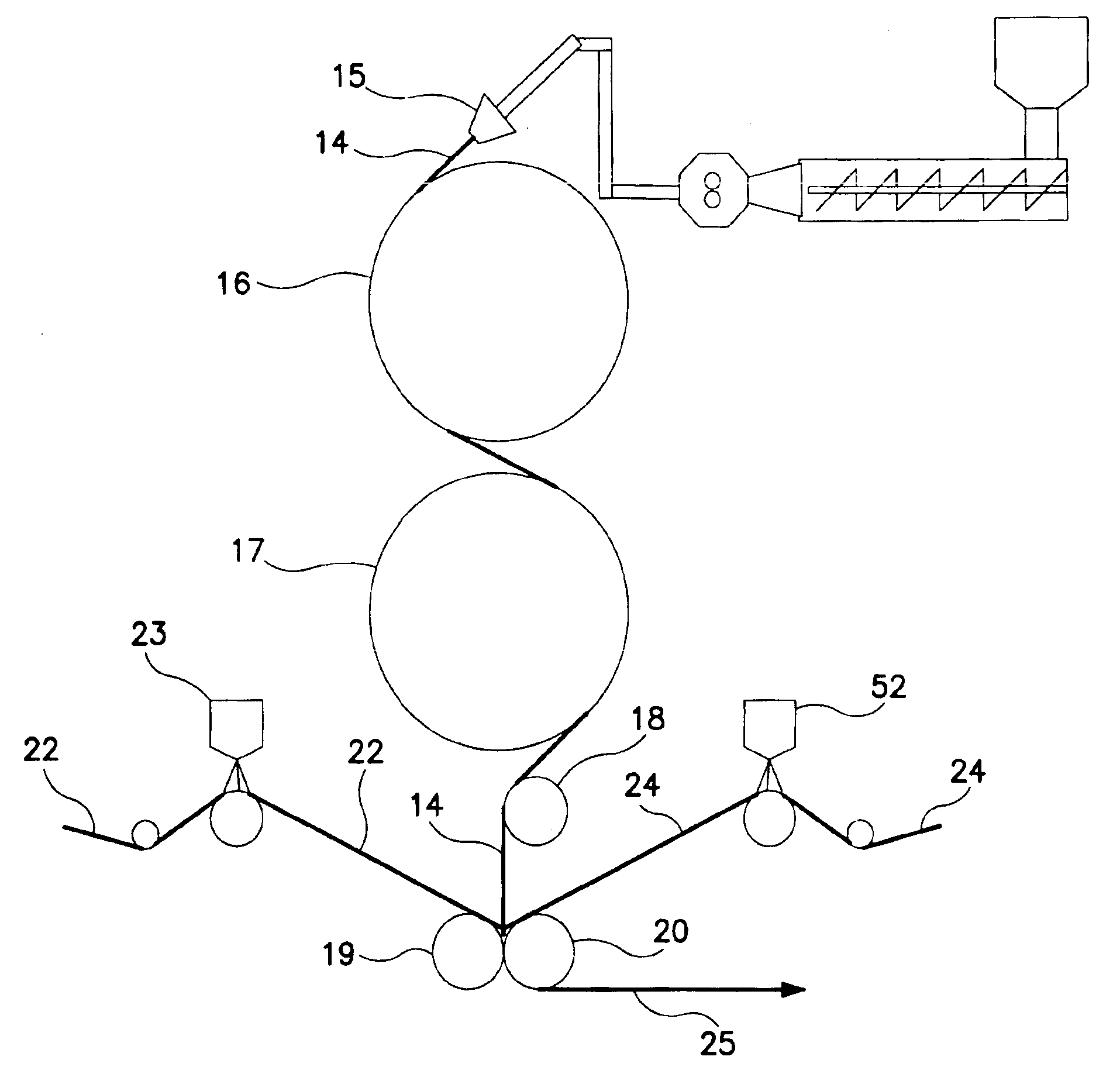

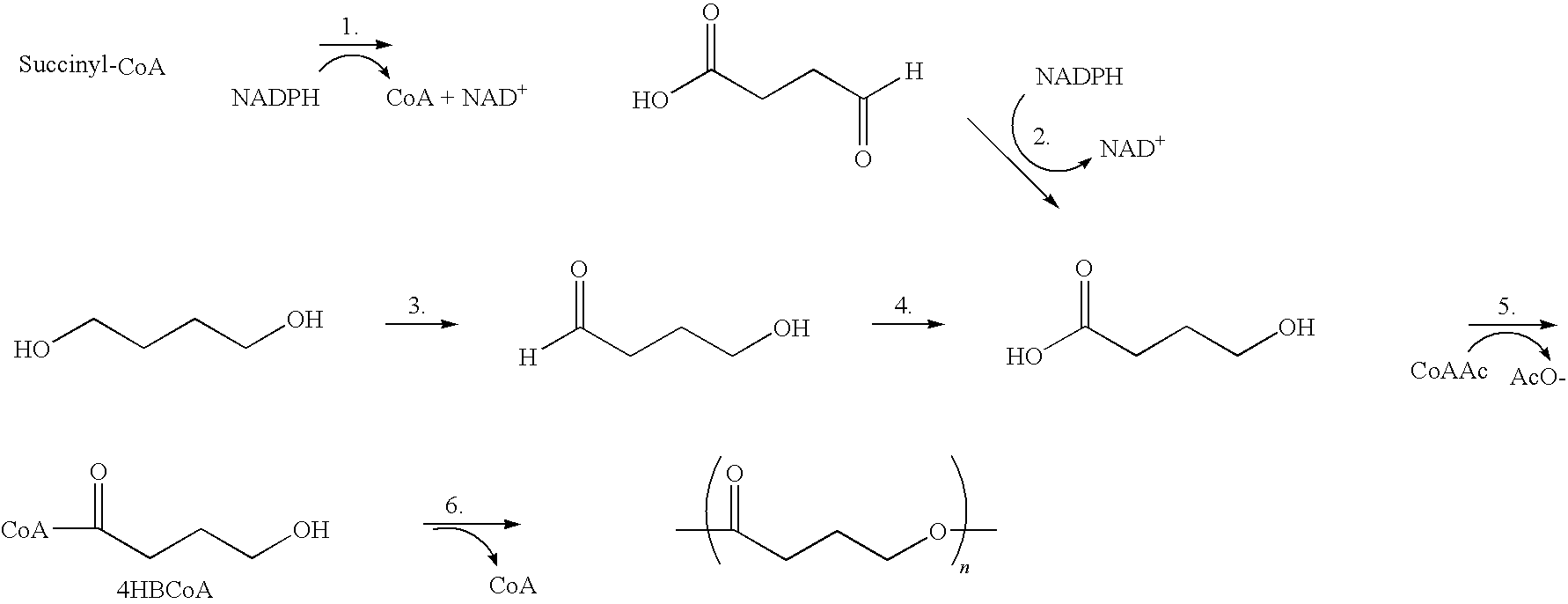

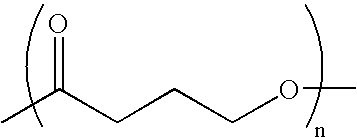

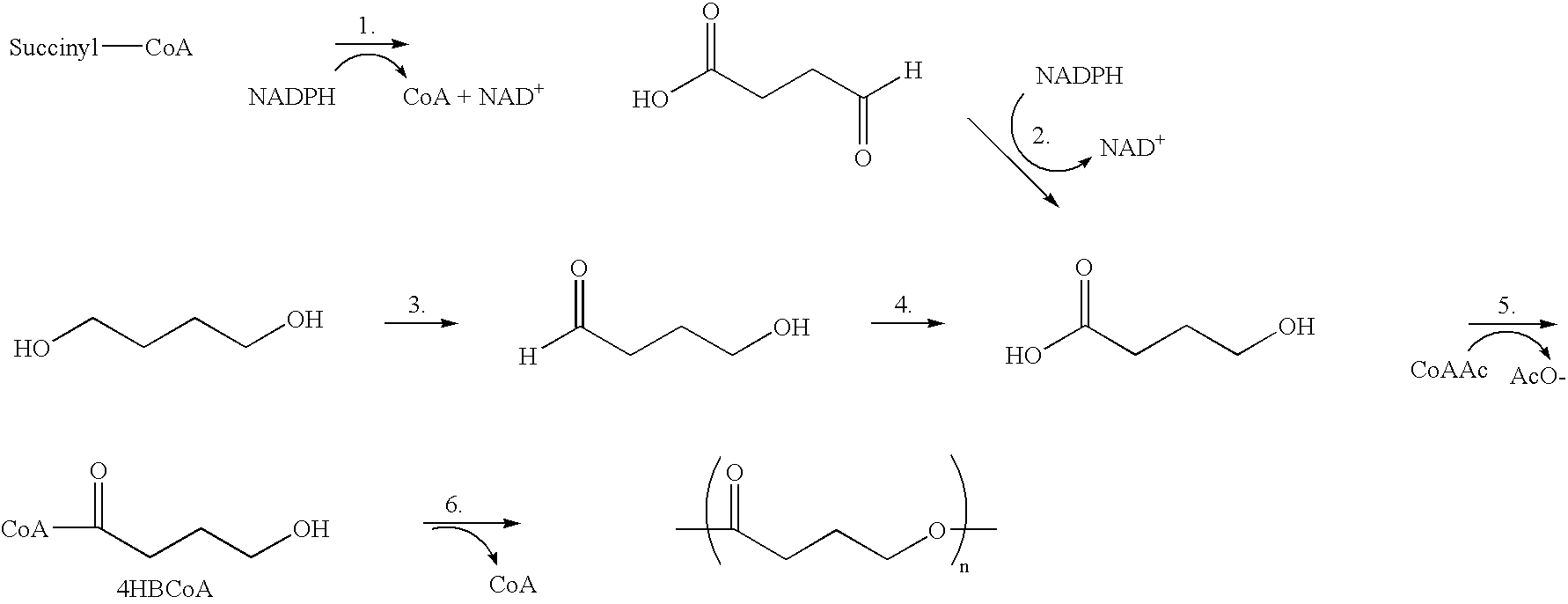

Polyhydroxyalkanoate medical textiles and fibers

ActiveUS8034270B2Easy to operateProlonged strength retentionSurgerySynthetic resin layered productsPolyesterFiber

Absorbable polyester fibers, braids, and surgical meshes with prolonged strength retention have been developed. These devices are preferably derived from biocompatible copolymers or homopolymers of 4-hydroxybutyrate. These devices provide a wider range of in vivo strength retention properties than are currently available, and could offer additional benefits such as anti-adhesion properties, reduced risks of infection or other post-operative problems resulting from absorption and eventual elimination of the device, and competitive cost. The devices may also be particularly suitable for use in pediatric populations where their absorption should not hinder growth, and provide in all patient populations wound healing with long-term mechanical stability. The devices may additionally be combined with autologous, allogenic and / or xenogenic tissues to provide implants with improved mechanical, biological and handling properties.

Owner:TEPHA INC

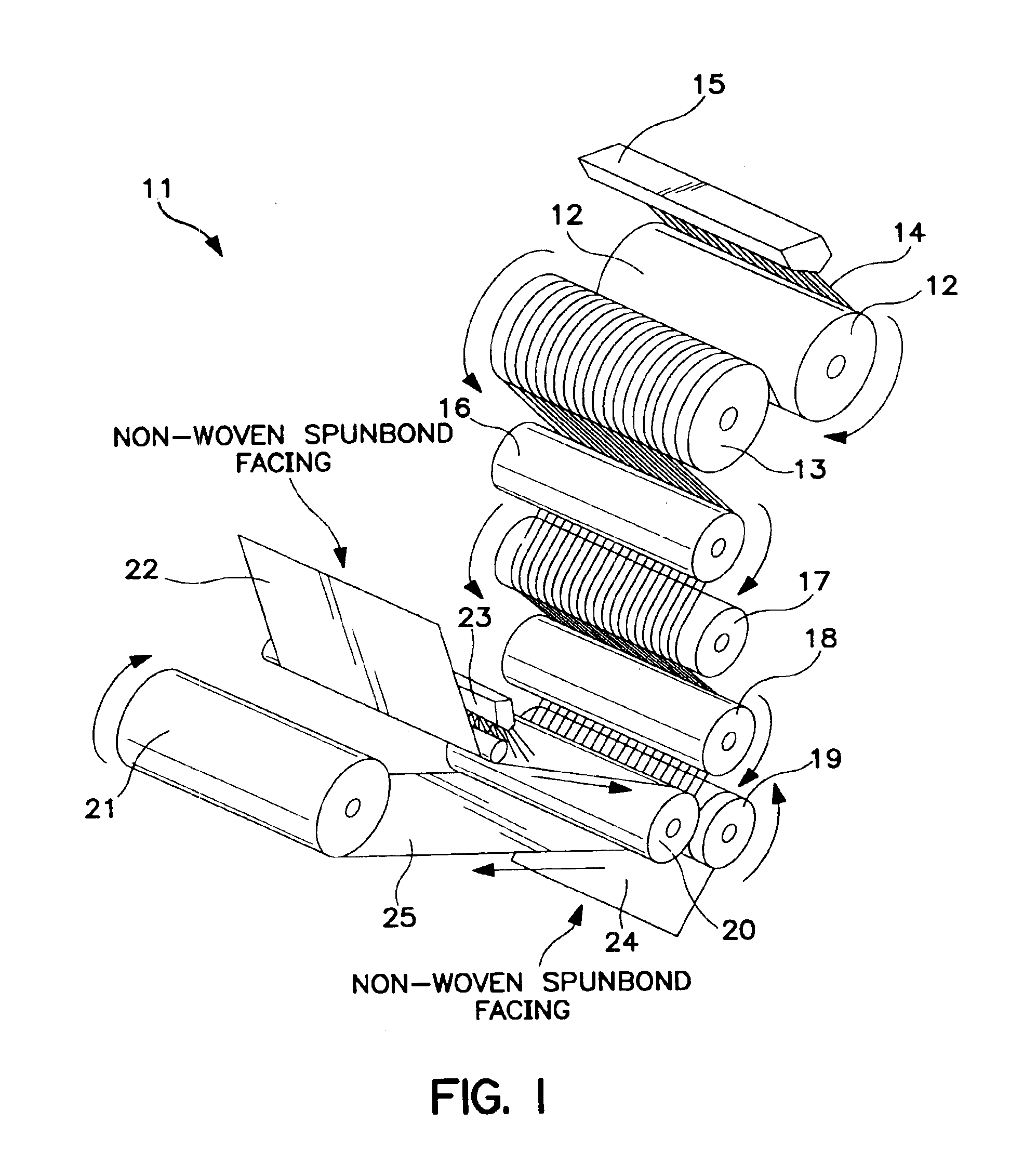

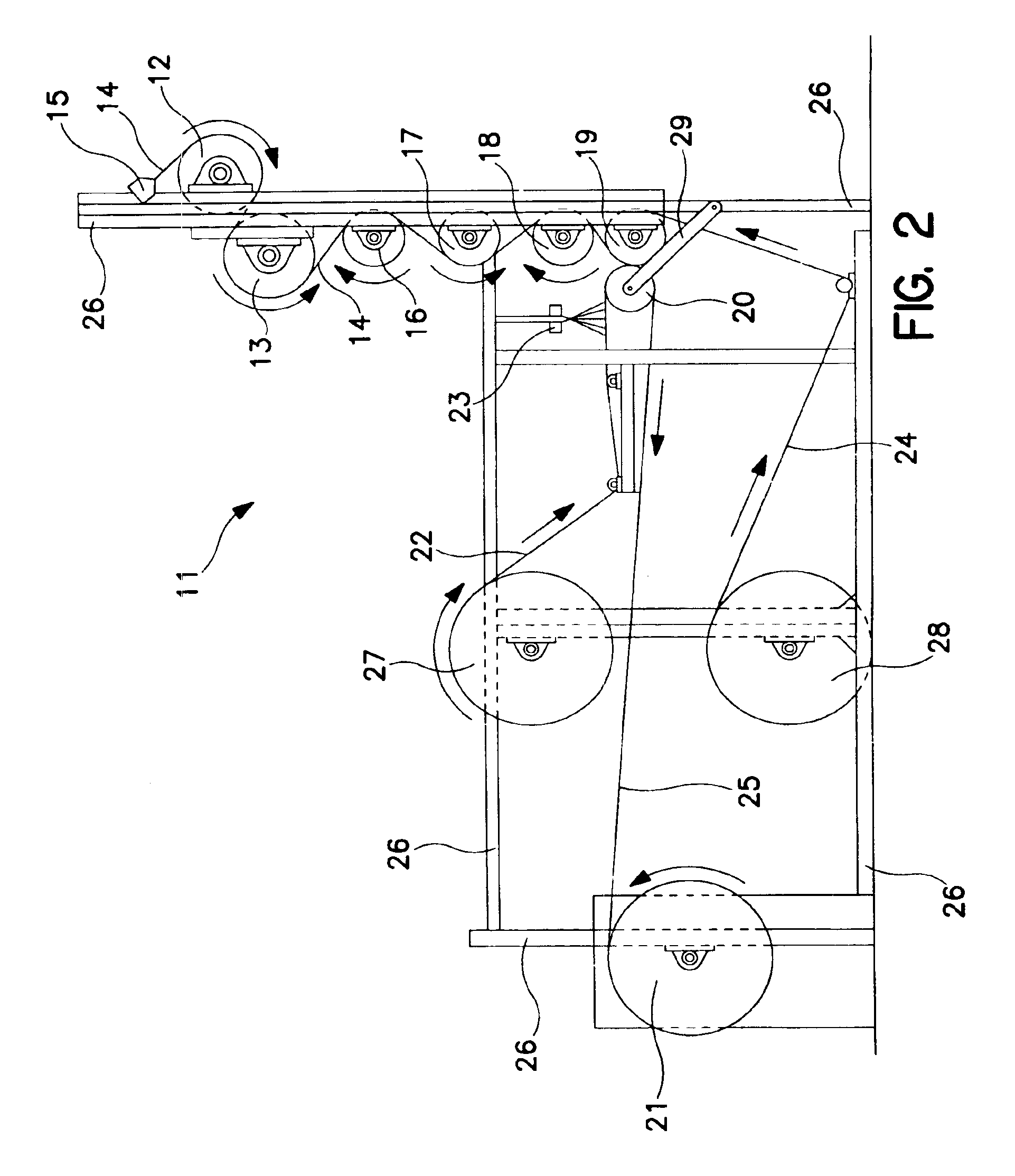

Method and apparatus for producing laminated articles

In the invention, a method is provided for producing a composite nonwoven fabric. A polymer is extruded into heated continuous filaments, possibly elastic, from the die head to a first chilled roller, wherein the extruder is configured to provide the continuous filaments to the chilled roller in a canted direction that is at a tangent or angle to the surface of the first chilled roller. The filaments are conveyed in a downward direction by way of chilled rollers to a nip. In a next step, the nonwoven web is sprayed with an adhesive and is laminated on the continuous filaments in the nip to form a composite nonwoven fabric. The continuous filaments move vertically downward approximately in line with the lamination process, facilitating automatic re-threading of filaments when they are broken or interrupted in their travel downward onto the chilled rolls.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Process for drawing gel-spun polyethylene yarns

A process for drawing essentially diluent-free gel-spun polyethylene multi-filament yarns in a forced convection air oven and the drawn yarns produced thereby, The process conditions of draw ratio, stretch rate, residence time, oven length and feed speed are selected in specific relation to one another so as to achieve enhanced efficiency and productivity. The drawn yarns are useful in armor, composites, fishing line, ropes, sutures, fabrics and other applications.

Owner:HONEYWELL INT INC

Methods and apparatus for spinning spider silk protein

InactiveUS20050054830A1Peptide/protein ingredientsMonocomponent fibroin artificial filamentBiotechnologySpider Proteins

The invention features methods and apparatuses for spinning silk protein fibers (biofilaments) from recombinant biofilament proteins. The methods are particularly useful for spinning fibers of spider silk or silkworm silk proteins from recombinant mammalian cells and may be used to spin such fibers for use in the manufacture of industrial and commercial products.

Owner:NEXIA BIOTECH

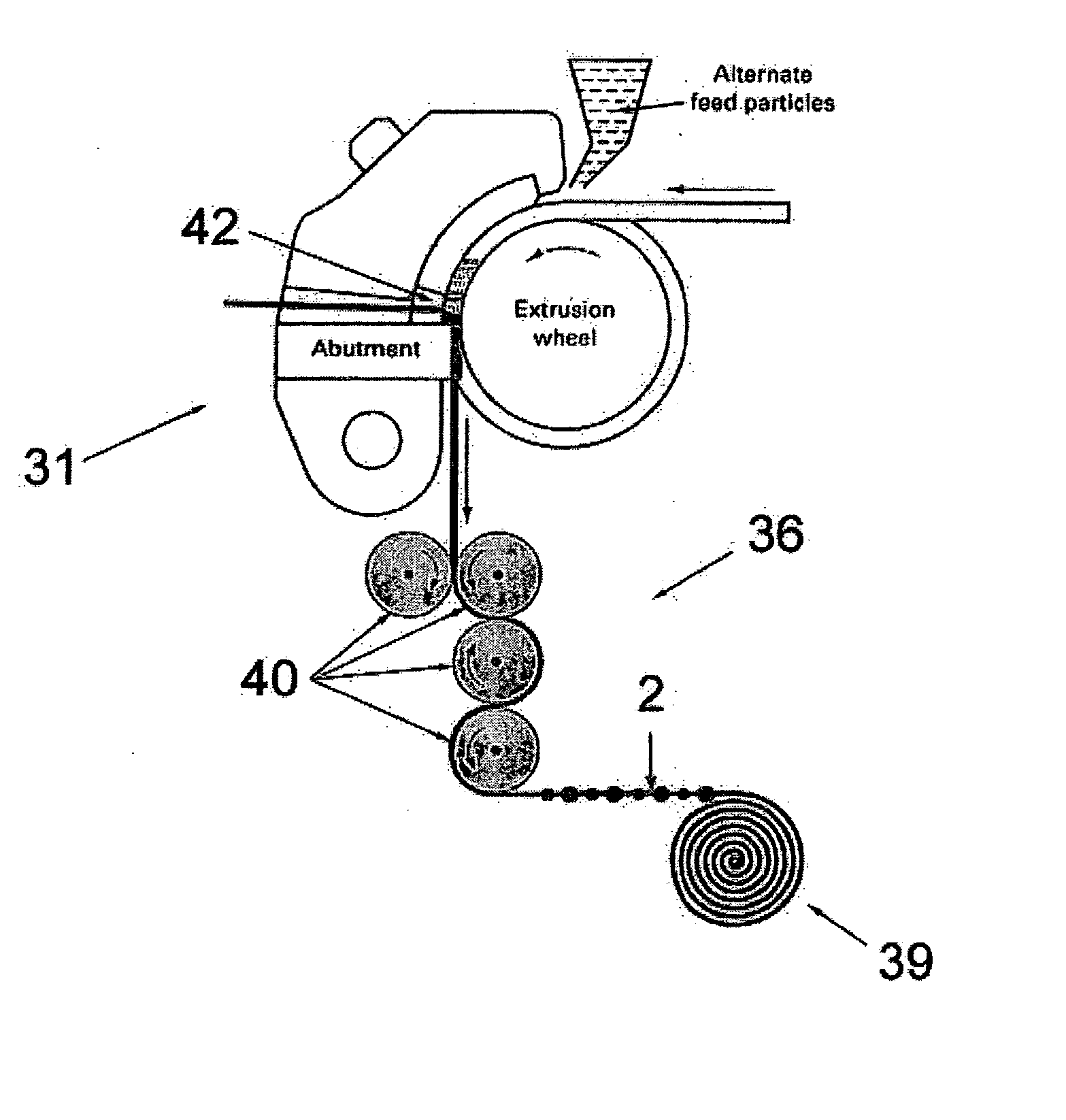

Preform for manufacturing a material having a plurality of voids and method of making the same

InactiveUS20050006803A1Equal thicknessAdditive manufacturing apparatusLayered productsSingle strandBiological materials

A beaded preform includes a plurality of adjacently positioned beads for forming a plurality of voids in an engineered material. The beaded preforms may be comprised of a filaments (single strand of beads) and mats (two-dimensional and three dimensional arrays of beads). The filaments and mats may be coated to become tows and laminates, respectively, which may then be assembled into composite materials. The preforms may be produced using novel manufacturing apparatuses and methods, and incorporated into known manufacturing processes to produce porous structures, including stress-steering structures, in any material including metals, plastics, ceramics, textiles, papers, and biological materials, for example.

Owner:OWENS CHARLES R

Co-extruded, multi-layered battery separator

A battery separator comprises a co-extruded, microporous membrane having at least two layers made of extrudable polymers and having: a uniform thickness defined by a standard deviation of <0.80 microns (μm); or an interply adhesion as defined by a peel strength >60 grams.

Owner:CELGARD LLC

High performance filter media with internal nanofiber structure and manufacturing methodology

ActiveUS20070021021A1Improve performanceImprove efficiencyOther chemical processesIndividual molecule manipulationFiberFilter media

High performance filter media and manufacturing methodology provides nanofibers of diameter less than 1 μm incorporated and processed into internal structure of a filter medium dominantly composed of coarse fibers of diameter greater than 1 μm, to change the internal media structure.

Owner:FLEETGUARD INC

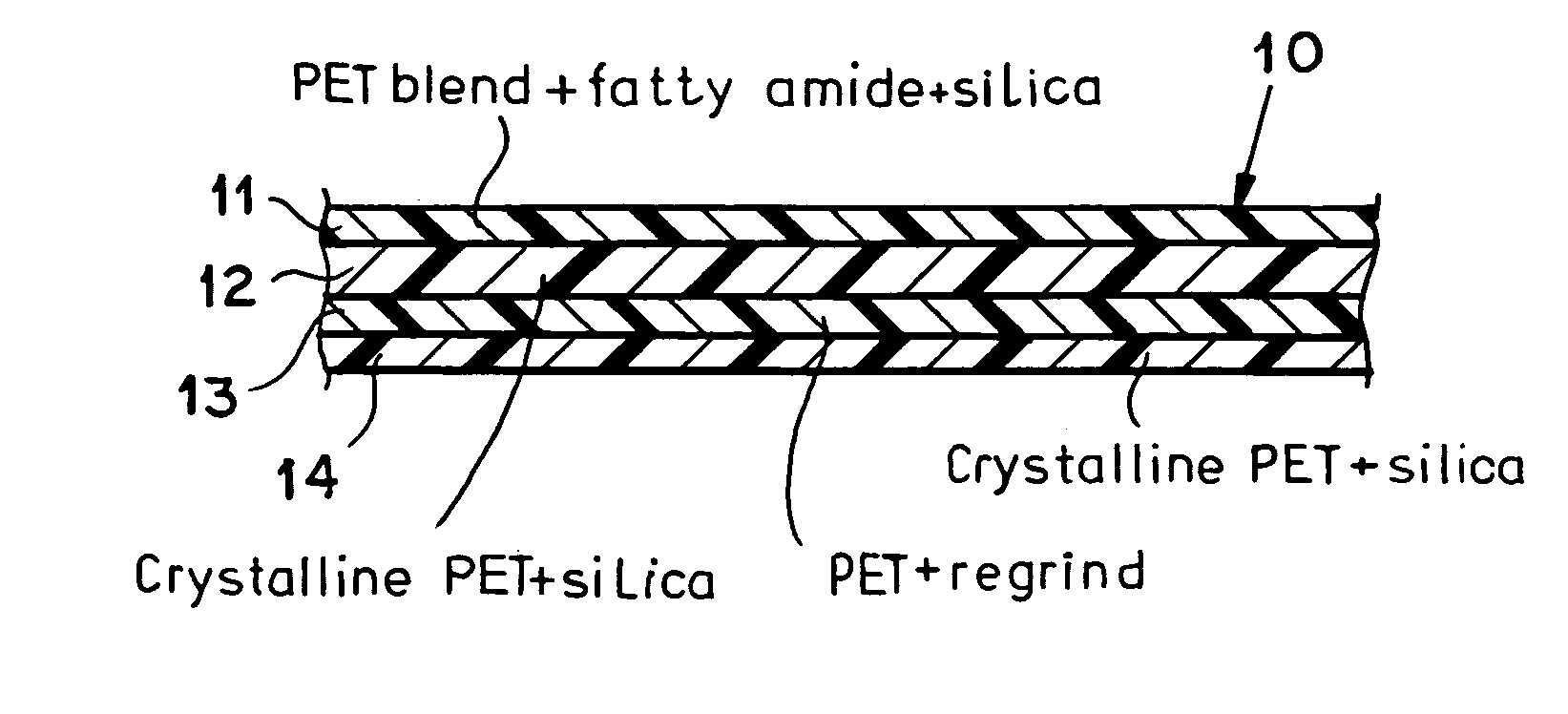

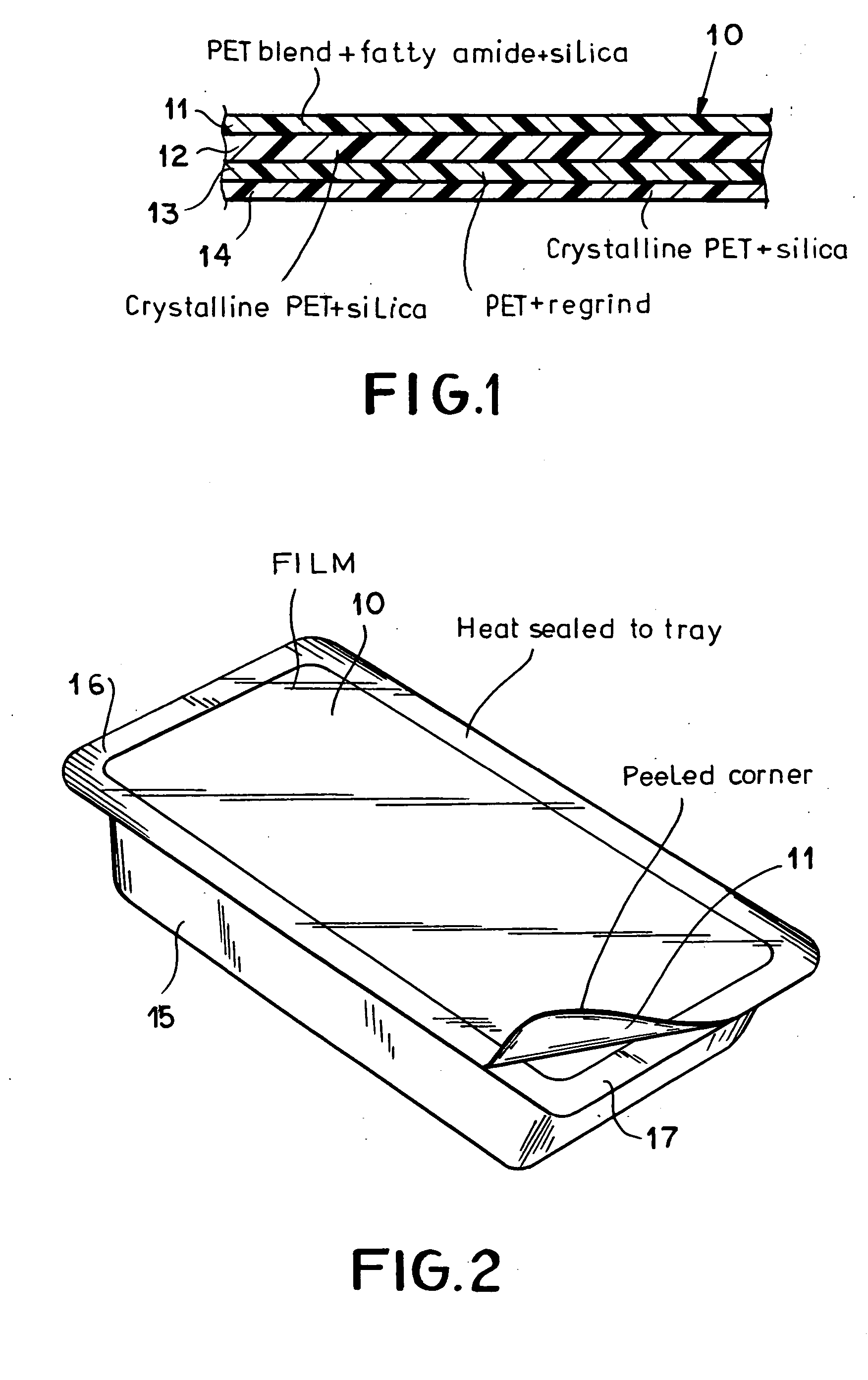

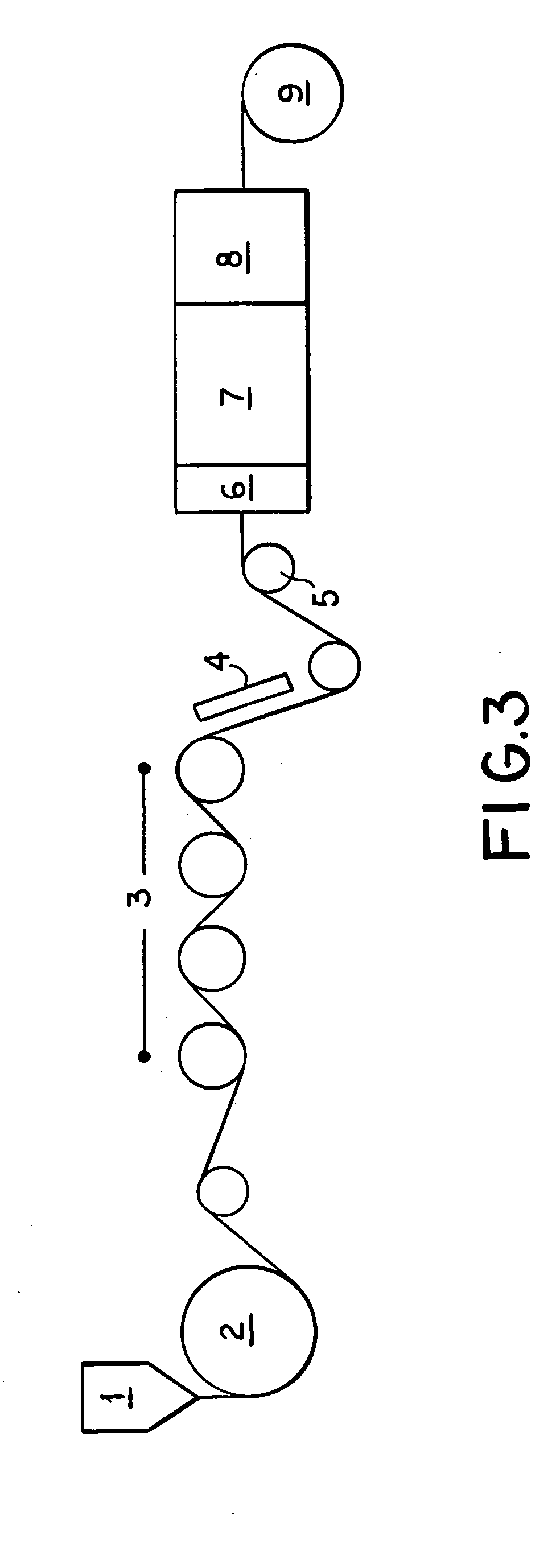

Co-extruded biaxially oriented sealable, peelable film and process for its production

ActiveUS20050208282A1Increase temperatureAvoid stickingLiquid surface applicatorsRecord information storagePolyethylene terephthalatePolyethylene terephthalate glycol

A peelable sealable co-extruded film, comprising: i. a skin layer capable of heat sealing against a rim of a container, to itself, or to another film and adapted to be peeled there from and comprising a hot melt adhesive resin; and ii. a core layer underlying said skin layer and comprising crystalline homopolymer polyethylene terephthalate; and a method for the preparation thereof.

Owner:TERPHANE

Meltblown process with mechanical attenuation

InactiveUS6773648B2High speed spinningImprove productivityPulp properties modificationArtificial filament physical treatmentCelluloseUltrasound attenuation

Owner:WEYERHAEUSER NR CO

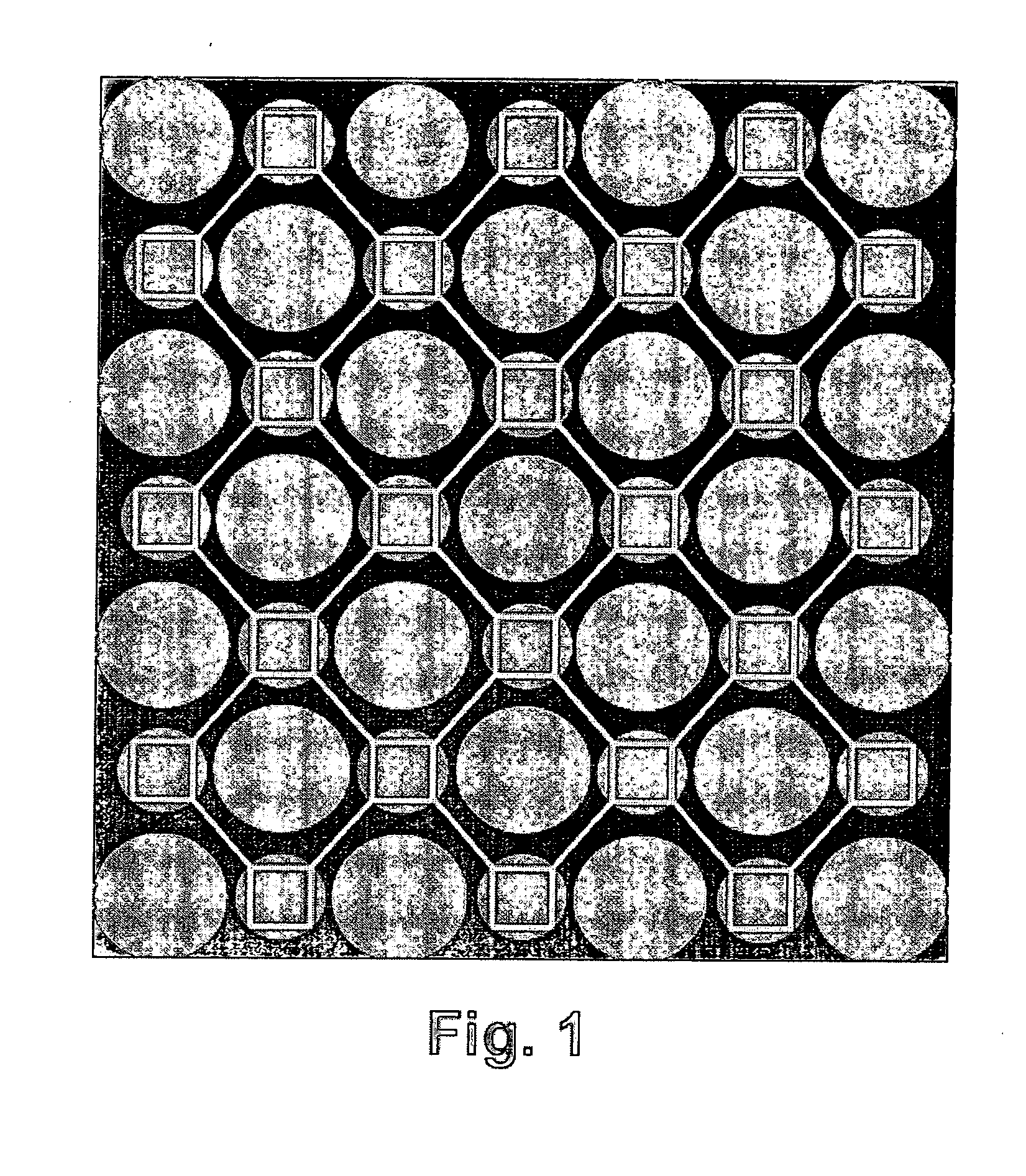

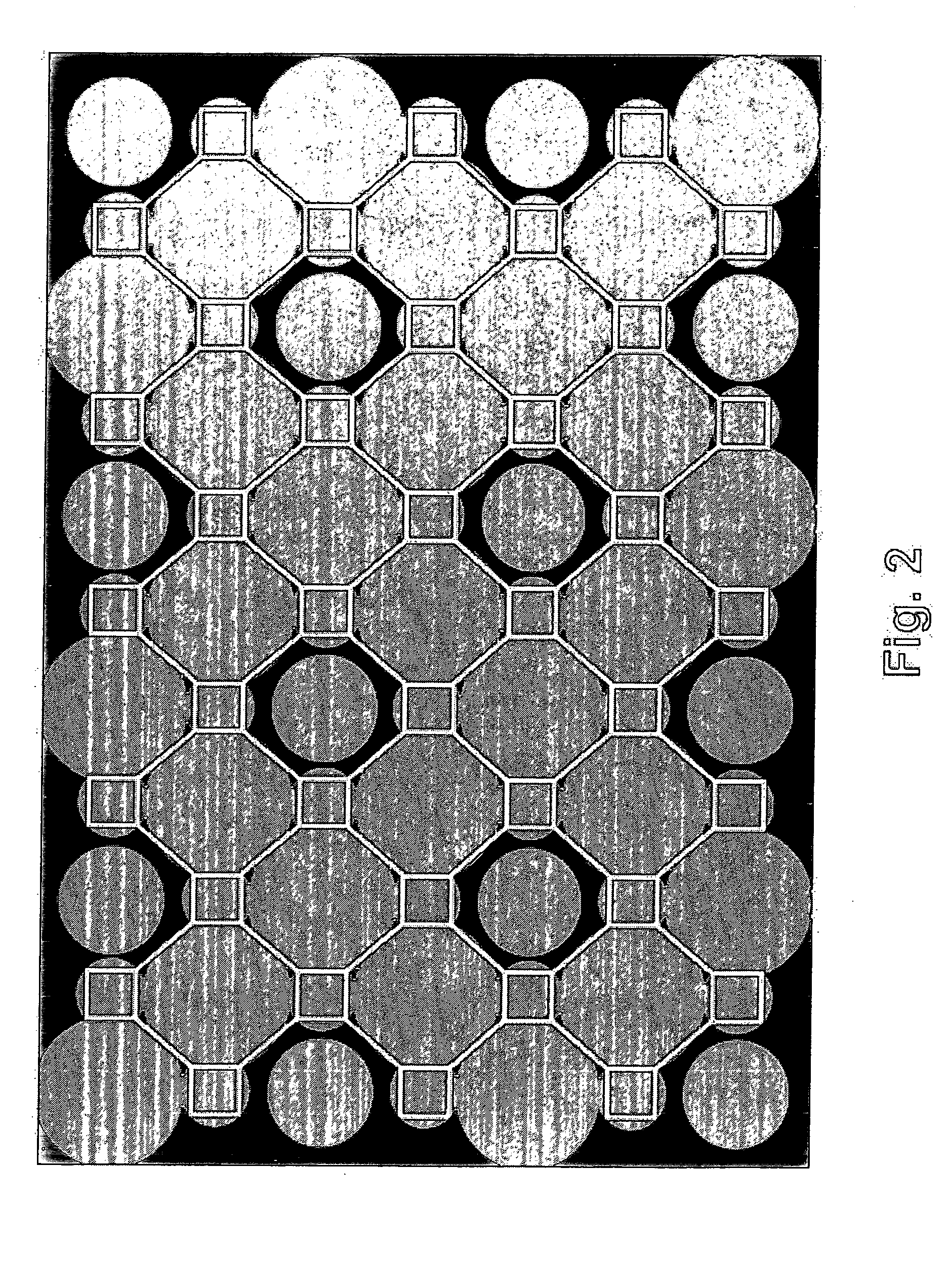

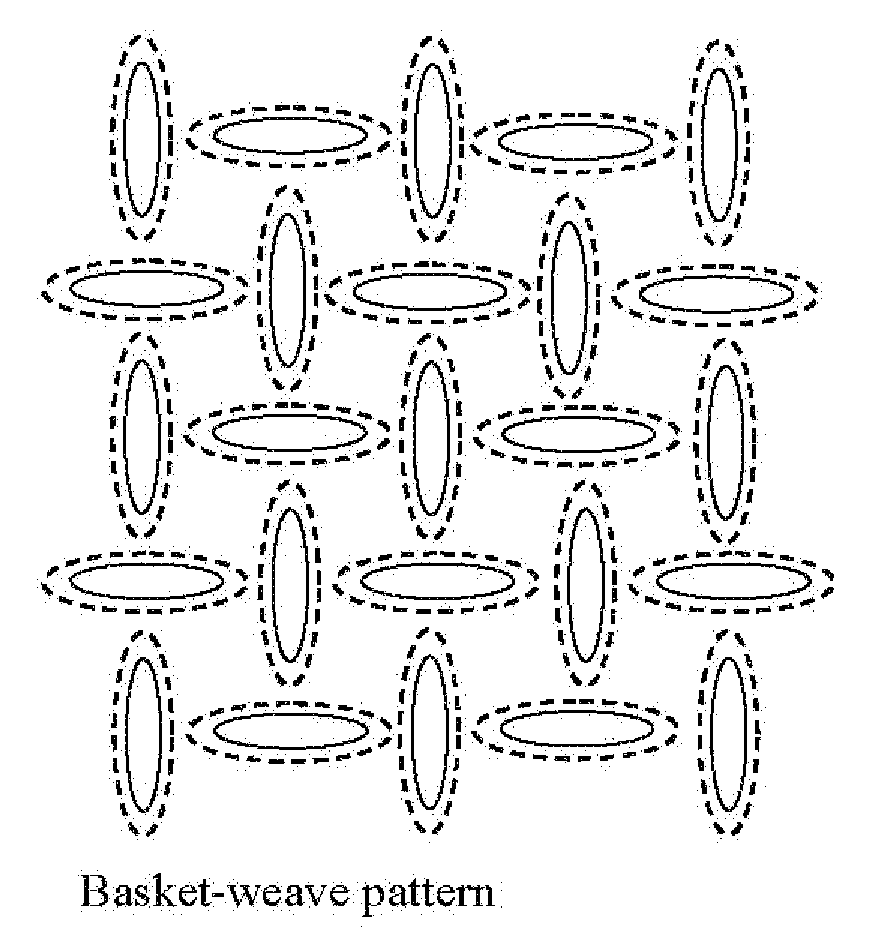

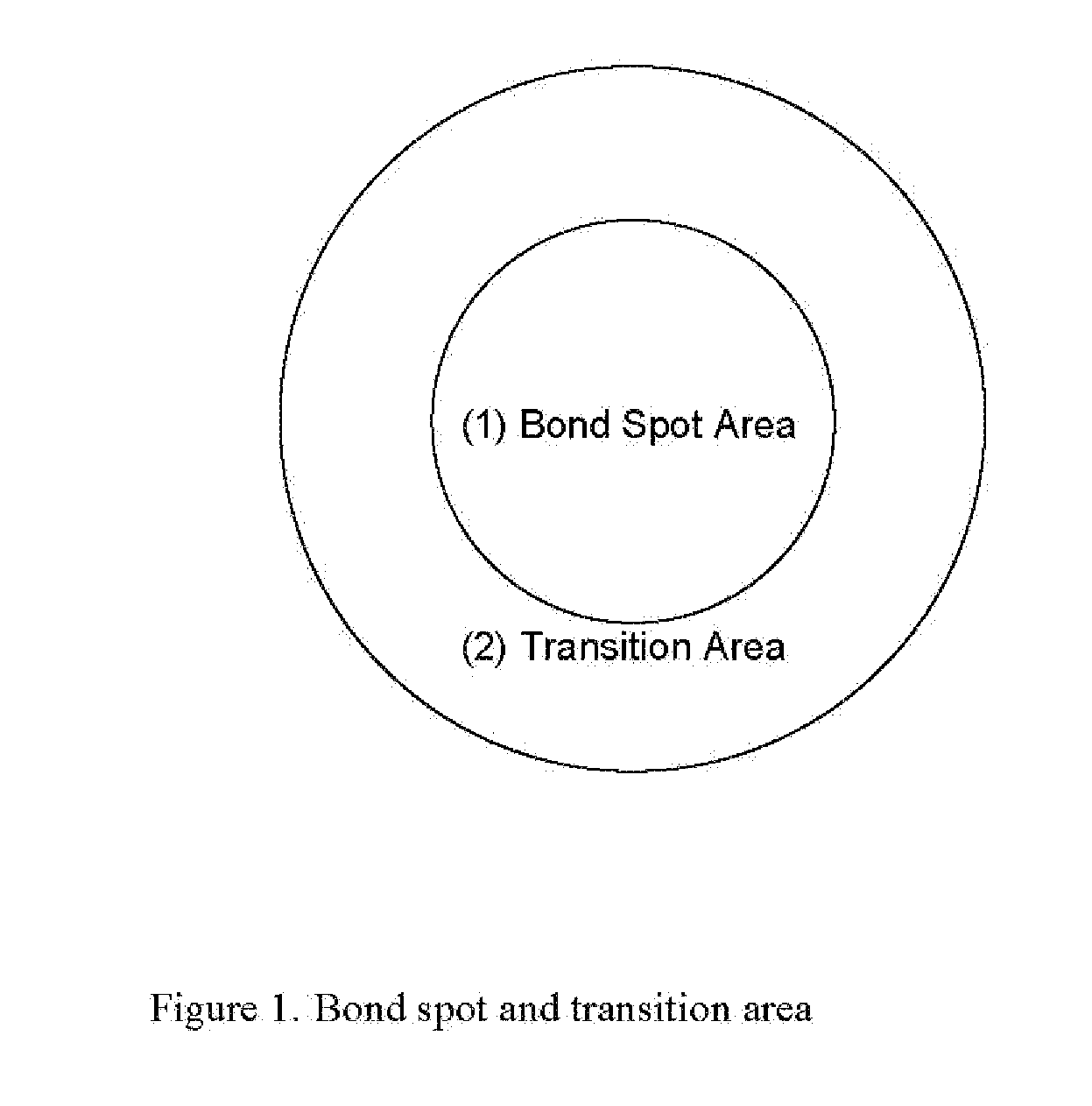

Nonwoven bonding patterns producing fabrics with improved abrasion resistance and softness

ActiveUS20080268194A1Excellent abrasion resistanceHigh strengthStampsWrappersEngineeringNonwoven fabric

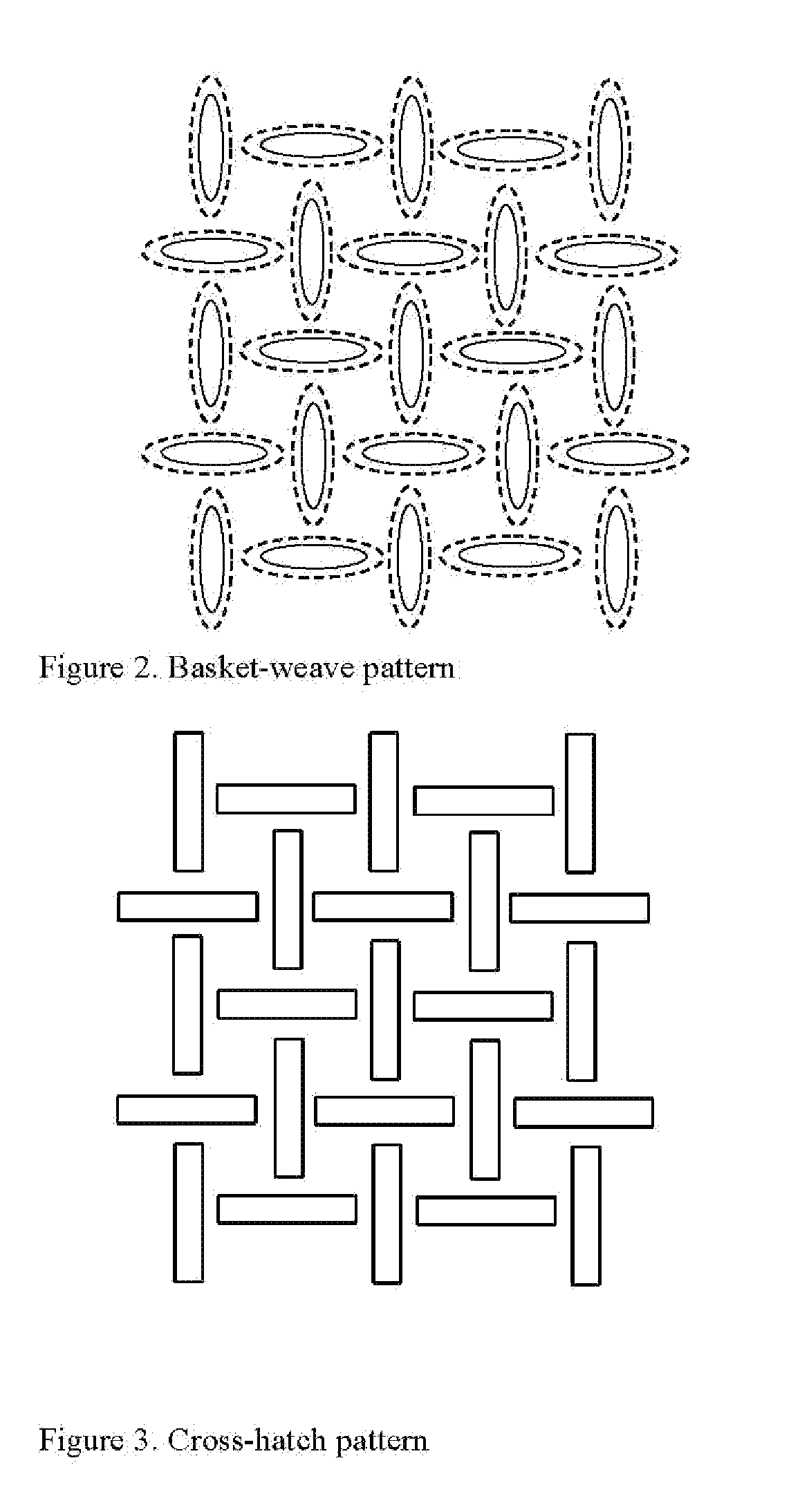

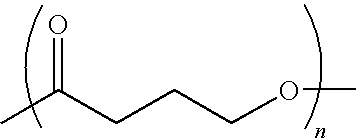

A thermal bonding pattern for nonwoven fabric possessing improved abrasion resistance while retaining softness, comprising a basket-weave pattern or other pattern having a transition area (2) equal to at least 10% of bonding spot area (1) in FIG. 1, more preferably a transition area (2) equal to at least 50% of bonding spot area (1), and most preferably a transition area (2) equal to at least 100% of bonding spot area.

Owner:A AHLSTROM CORP

Method of making a polyhydroxyalkanoate filament

ActiveUS7641825B2Improve handlingImprove methodSuture equipmentsMovable spraying apparatusPolyesterFiber

Absorbable polyester fibers, braids, and surgical meshes with improved handling properties have been developed. These devices are preferably derived from biocompatible copolymers or homopolymers of 4-hydroxybutyrate. These devices provide a wider range of in vivo strength retention properties than are currently available and have a decreased tendency to curl, in the preferred embodiment, due to the inclusion of relaxation and annealing steps following methods are characterized by the following physical properties: (i) elongation to break from about 17% to about 85% (ii) Young's modulus of less than 350,000 psi, (iii) knot to straight ratio (knot strength / tensile strength) of 55-80% or (iv) load at break from 1100 to 4200 grams.

Owner:TEPHA INC

Non-curling polyhydroxyalkanoate sutures

ActiveUS20060058470A1Improve handlingSimple materialSuture equipmentsMovable spraying apparatusPolyesterFiber

Absorbable polyester fibers, braids, and surgical meshes with improved handling properties have been developed. These devices are preferably derived from biocompatible copolymers or homopolymers of 4-hydroxybutyrate. These devices provide a wider range of in vivo strength retention properties than are currently available and have a decreased tendency to curl, in the preferred embodiment, due to the inclusion of relaxation and annealing steps following extrusion and orientation of the fiber. Filaments prepared according to these methods are characterized by the following physical properties: (i) elongation to break from about 17% to about 85% (ii) Young's modulus of less than 350,000 psi, (iii) knot to straight ratio (knot strength / tensile strength) of 55-80% or (iv) load at break from 1100 to 4200 grams.

Owner:TEPHA INC

Process of and apparatus for making a shingle, and shingle made thereby

InactiveUS20060029775A1Shorten the timeMouldsConfectioneryBiomedical engineeringThermoplastic materials

A process and apparatus for making a shingle, together with the shingle made thereby, is provided, in which one or more thermoplastic materials are extruded or co-extruded to form an extrudate, with the extrudate being cut into a preliminary shingle shape, which is allowed to dissipate heat, and then is delivered to a compression mold, wherein the preliminary shingle shape is compression molded to substantially its final dimensions and is then discharged from the mold and allowed to cool.

Owner:CERTAINTEED CORP

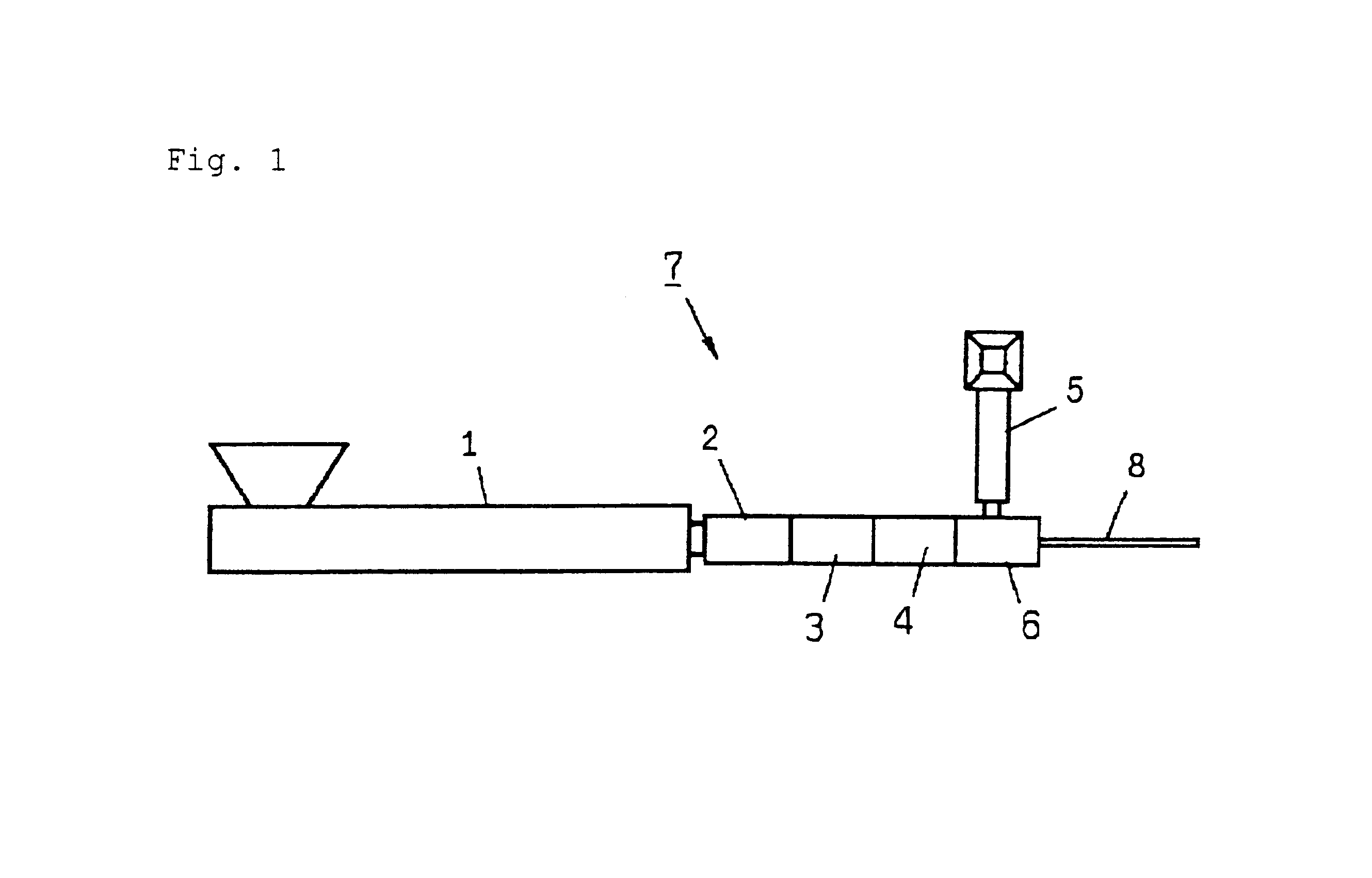

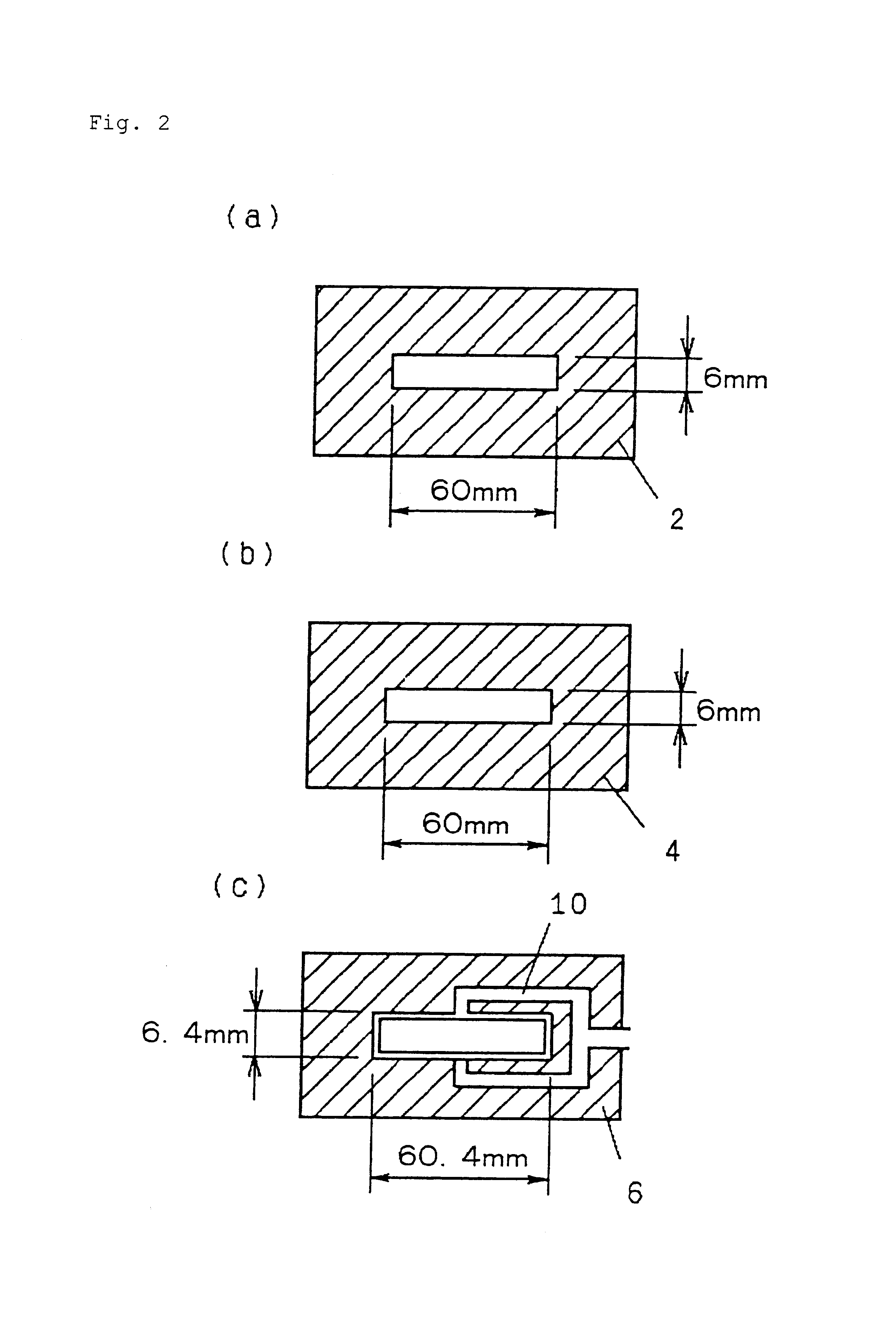

Molded article from thermoplastic composite material and method for producing the same

InactiveUS6716522B2No fading or discolorationIncreased durabilityHair accessoriesToupeesShell moldingThermoplastic composites

The present invention has for its object to provide a molded article of a thermoplastic composite material which is not only durable with little discoloration or fading even on prolonged outdoor exposure and is very satisfactory in physical properties and appearance qualities inclusive of wood-like texture but also has high productivity and good economics.The present invention is a method of producing a molded article of a thermoplastic composite material comprising extruding the thermoplastic composite material containing a thermoplastic resin and a vegetable filler, said vegetable filler content being 50 to 90 weight % of the total weight of said thermoplastic resin and said vegetable filler, wherein extrusion is carried out by means of an extrusion apparatus comprising at least an extruder, a hot shaping die, and a cooling die, said hot shaping die and cooling die being directly coupled.

Owner:SEKISUI CHEM CO LTD

Plastic body provided with a microstructured surface

InactiveUS20060121248A1Lamination ancillary operationsSynthetic resin layered productsThermoplasticPoly methacrylate

The invention relates to a process for the production of a plastics article with a microstructured surface via production of a composite composed of a backing layer composed of a thermoplastic or thermoelastic with one or more structure layers, characterized in that the structure layer(s) is / are composed of from 1 to 100% by weight of a polymethacrylate moulding composition which comprises from 80 to 100% by weight of free-radical-polymerized methyl methacrylate units and from 0 to 20% by weight of other comonomers capable of free-radical polymerization, and which has an average (weight-average) molar mass Mw of from 30 000 g / mol to 70 000 g / mol and, where appropriate, is present in a. mixture with up to 99% by weight of a polymethacrylate moulding composition which is composed of from 80 to 100% by weight of free-radical-polymerized methyl methacrylate units and from 0 to 20% by weight of other comonomers capable of free-radical polymerization, and which has an average (weight-average) molar mass Mw of from 90 000 g / mol to 200 000 g / mol and the structure layer(s) obtain microstructuring via known structuring processes, after production of the composite. The invention further relates to the plastics articles themselves which are capable of production according to the invention, and also to their uses.

Owner:ROEHM GMBH & CO KG

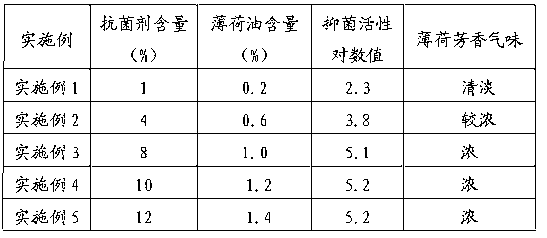

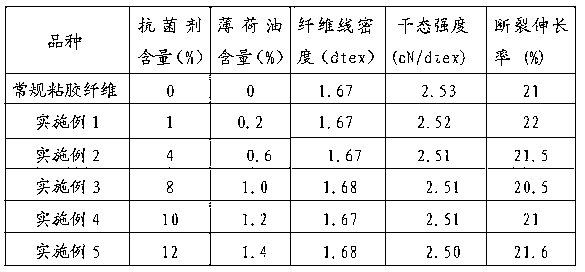

Viscose fiber with plant source anti-bacterial function and aromatic smell, and preparation method thereof

ActiveCN103225123ANo side effectsComfortable to takeArtificial thread manufacturing machinesArtificial filaments from viscoseSide effectMint extract

The invention discloses a viscose fiber with a plant source anti-bacterial function and aromatic smell. The viscose fiber is composed of a viscose spinning solution, an anti-bacterial agent and an aromatic agent, wherein the anti-bacterial agent is mixed powder of a mint extract and a isatis root extract, wherein the weight percentage of the mint extract accounts for 40%-80%; and the weight percentage of the isatis root extract accounts for 60%-20%; the aromatic agent is mint oil coated by microcapsules; the anti-bacterial agent accounts for 1%-8% of the mass of methyl cellulose in the viscose spinning solution; the mint oil accounts for 0.2%-1% of the mass of methyl cellulose in the viscose spinning solution; and the viscose fiber is prepared by adopting a wet spinning method by using the viscose spinning solution, the anti-bacterial agent and the aromatic agent. The plant source extracts and the plant source essential oil are used as the anti-bacterial agent and the aromatic agent; and the anti-bacterial agent and the aromatic agent are uniformly distributed in the fiber, so that the anti-bacterial function and the aromatic smell of the fiber are durable. Since the plant source extracts and the aromatic agent are natural substances extracted from the plants, so that the viscose fiber has no side effect to human body.

Owner:BESTEE MATERIAL (TSINGTAO) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com