Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5012 results about "Filter media" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fine particle liquid filtration media

The present invention provides a filter media comprising (a) a nonwoven composite material comprising a stabilized mixture of thermoplastic microfibers and at least about 50%, by weight, of a secondary fibrous material such as pulp or polymeric staple fibers; (b) a first outer nonwoven web comprising a substantially uniform nonwoven web of autogenously bonded multicomponent fibers; and (c) a second outer nonwoven web wherein the nonwoven composite material is positioned between the first outer nonwoven web and second outer nonwoven web. The filter material is well suited to filtering liquid borne particulate matter ranging in size from 5.mu. to about 25.mu..

Owner:KIMBERLY-CLARK WORLDWIDE INC

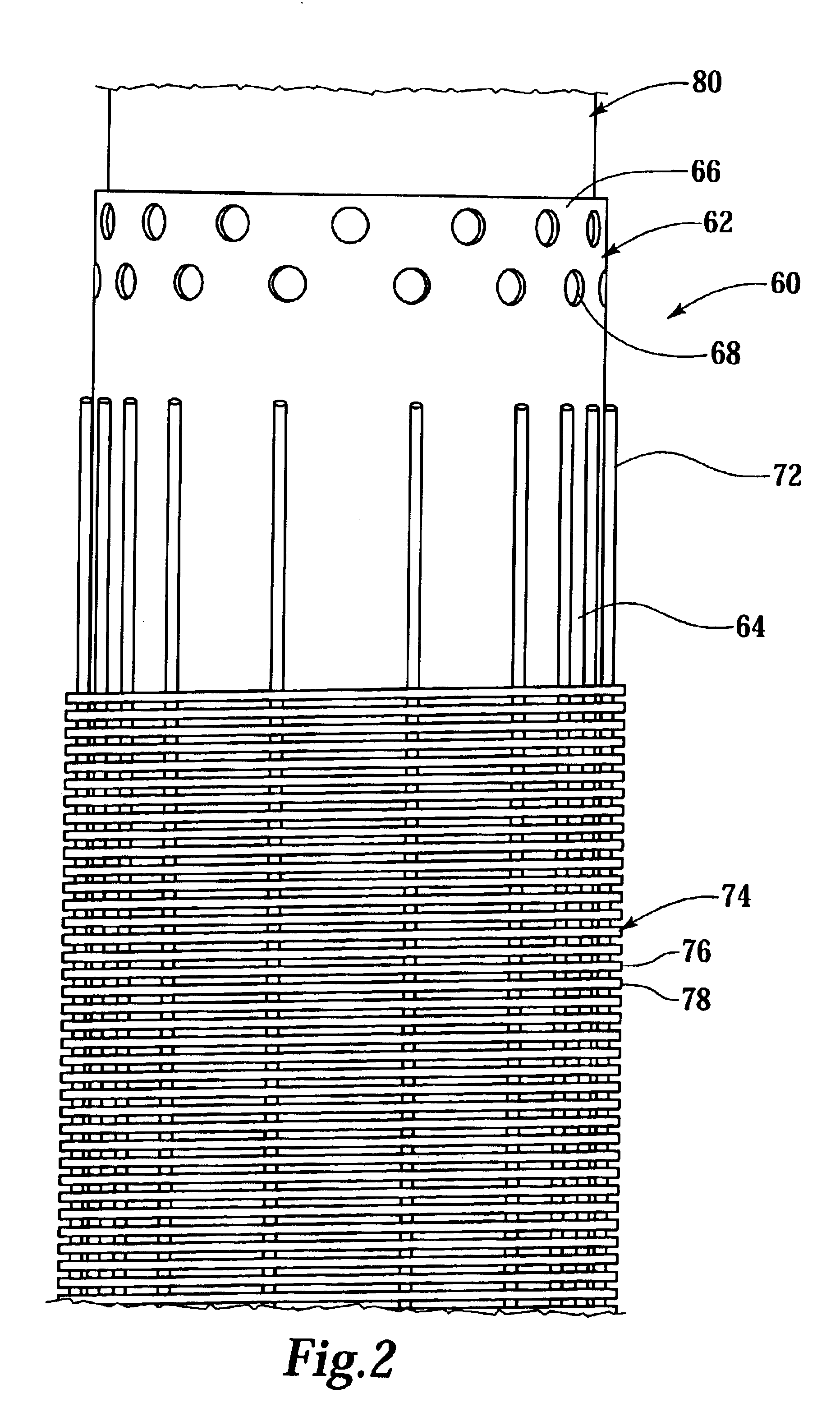

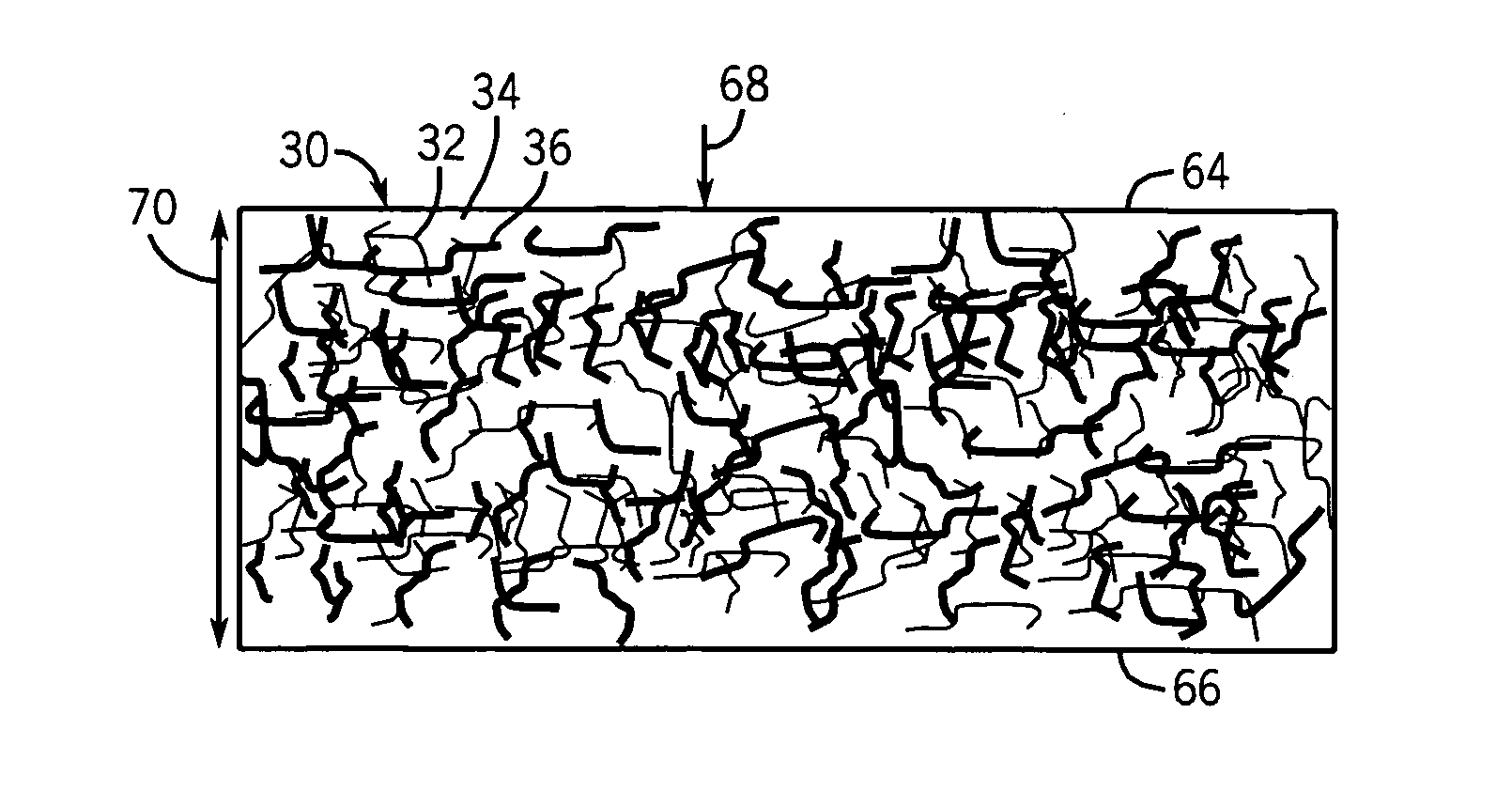

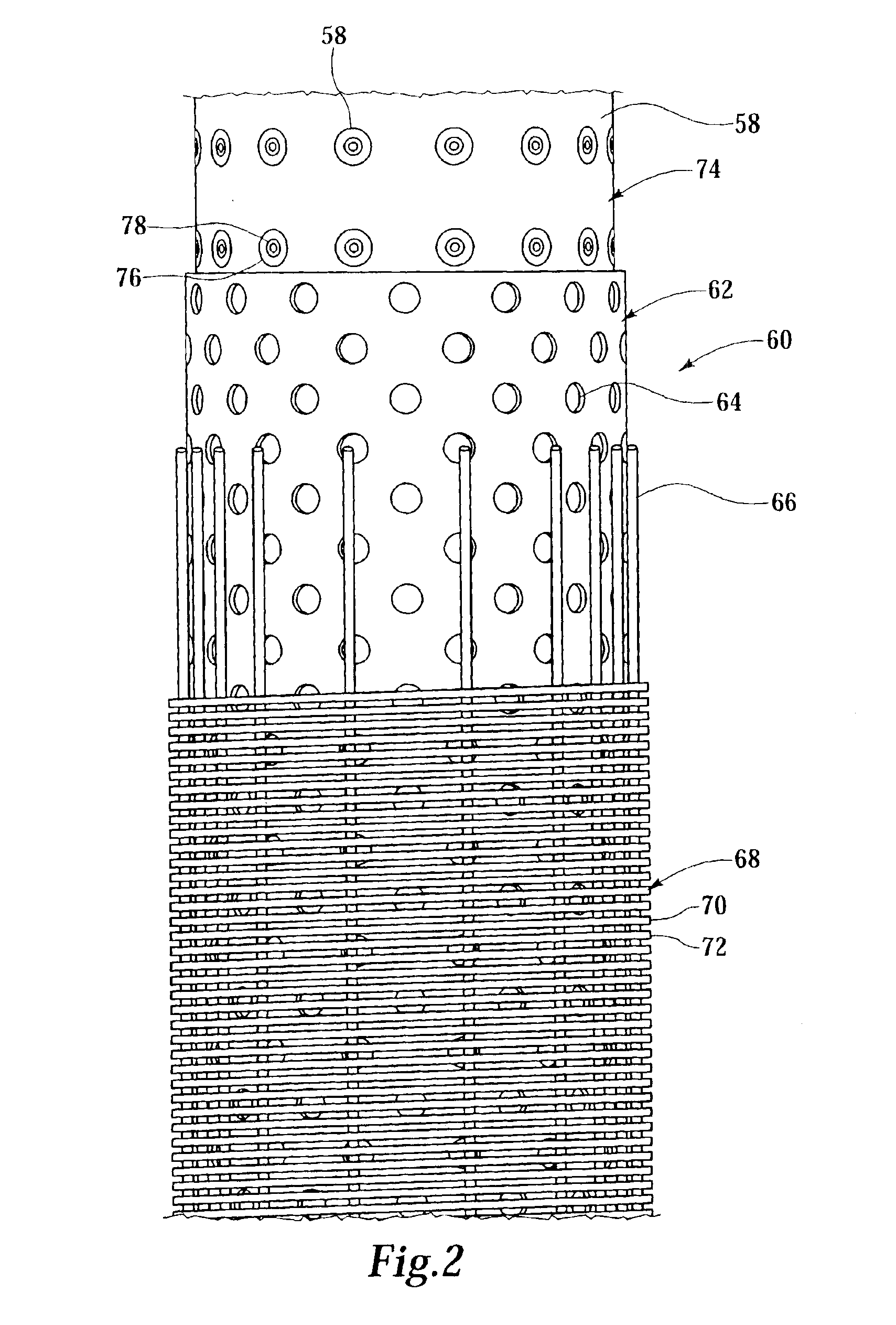

Low density composite proppant, filtration media, gravel packing media, and sports field media, and methods for making and using same

InactiveUS6582819B2Low densityEasy to transportGranule coatingPretreated surfacesFiltrationArtificial turf

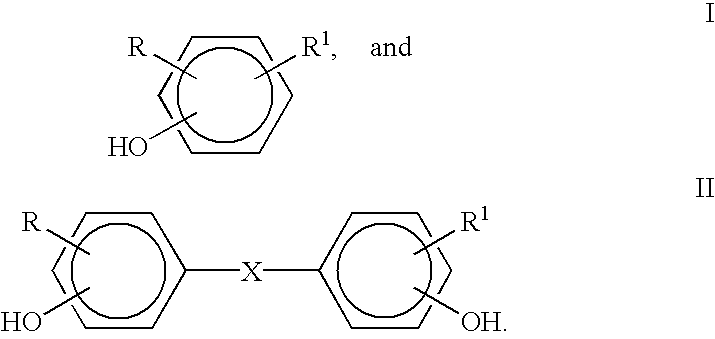

Low density composite particles made of a binder and filler material are provided for use in subterranean formations. The filler includes low density filler and optionally other filler. The binder includes a polymer and optionally cement. The particles may be employed as proppants useful to prop open subterranean formation fractures. The particles are also useful for gravel packing in subterranean formations, water filtration and artificial turf for sports fields. Methods of making the composite particles are also disclosed.

Owner:HEXION INC

Filter element, air cleaner, and methods

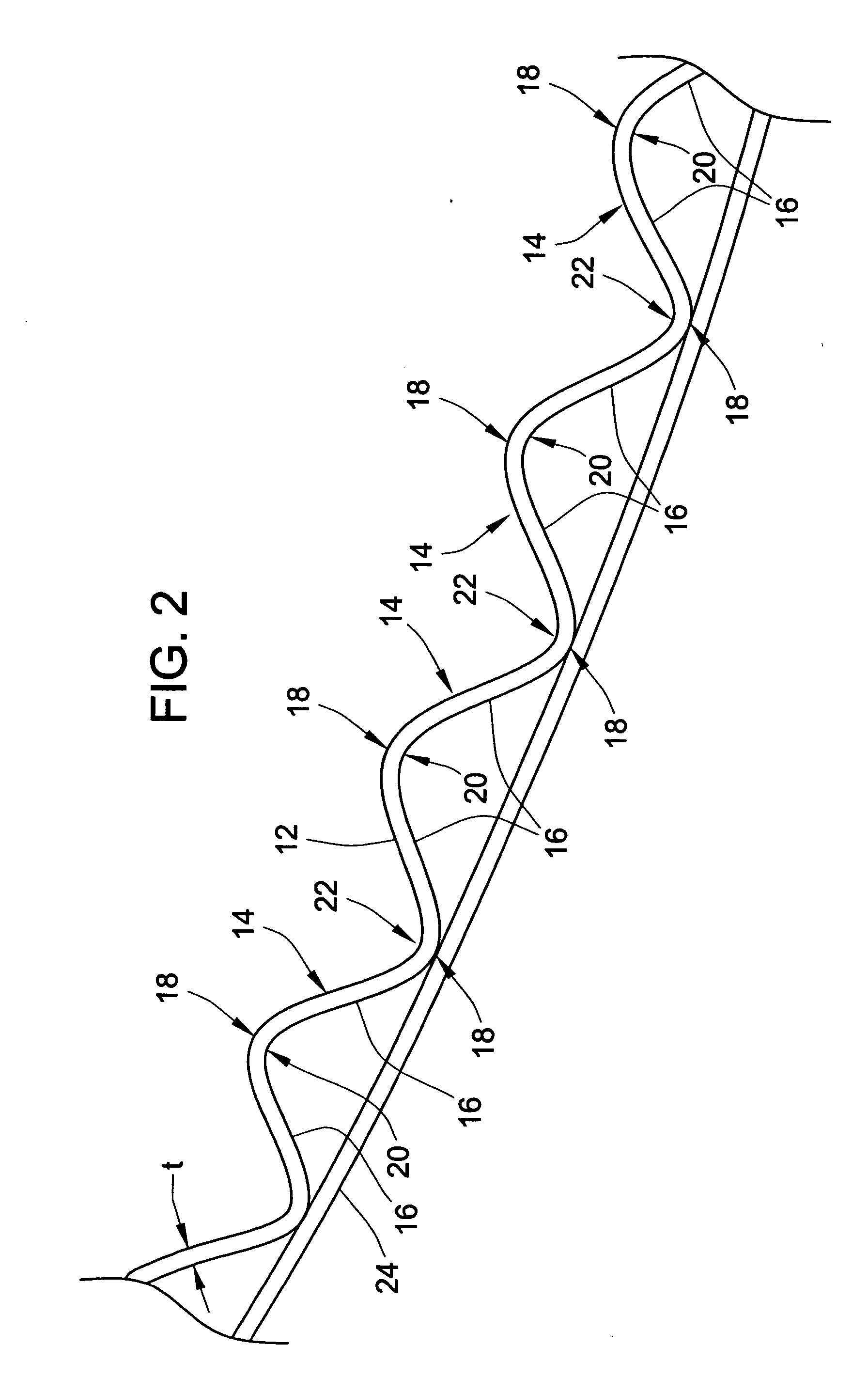

A filter arrangement includes a filter element, a frame construction secured to the filter element, and a handle member secured to the filter element. In preferred embodiments, the handle member is secured to the frame construction. Preferably, the filter element includes a central core member, wherein fluted filter media is coiled around the central core member. Preferably, the central core member includes a plurality of corrugations, wherein the corrugations mateably engage at least some flutes. Preferably, the handle member is integral with the central core member, and also includes a fastening member for connection to a frame construction on the filter element. Methods for cleaning air and servicing an air cleaner preferably include constructions as described herein.

Owner:DONALDSON CO INC

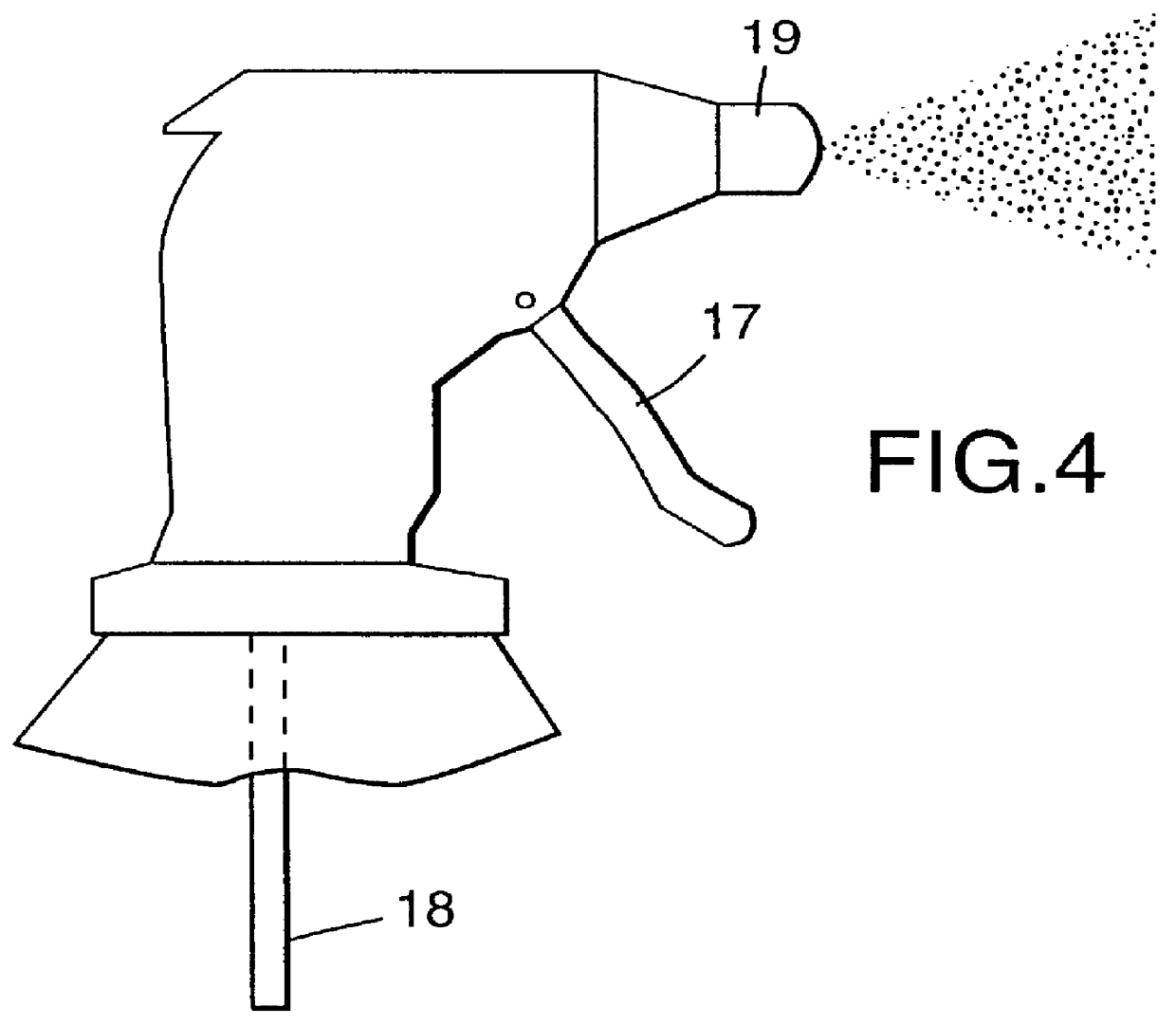

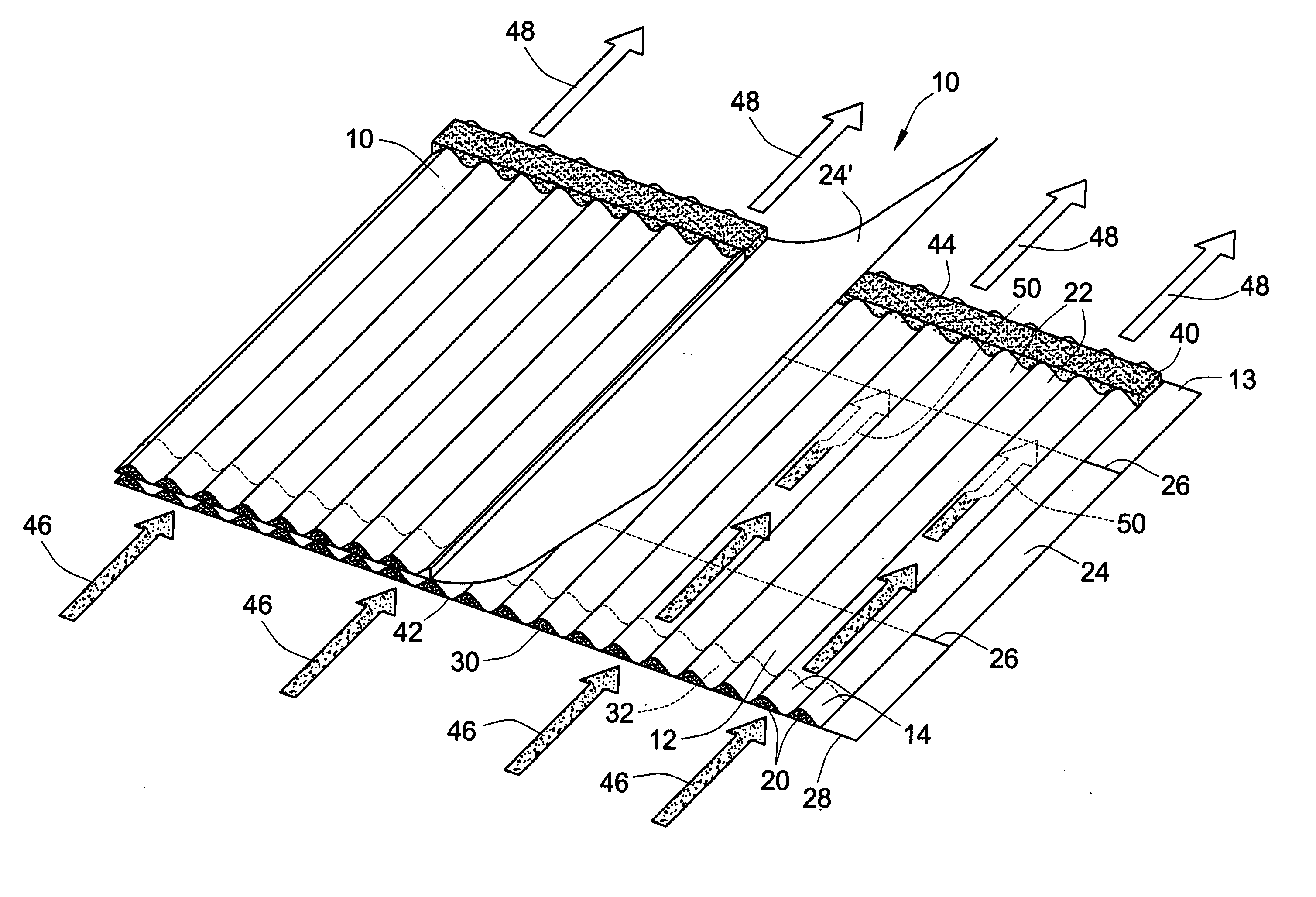

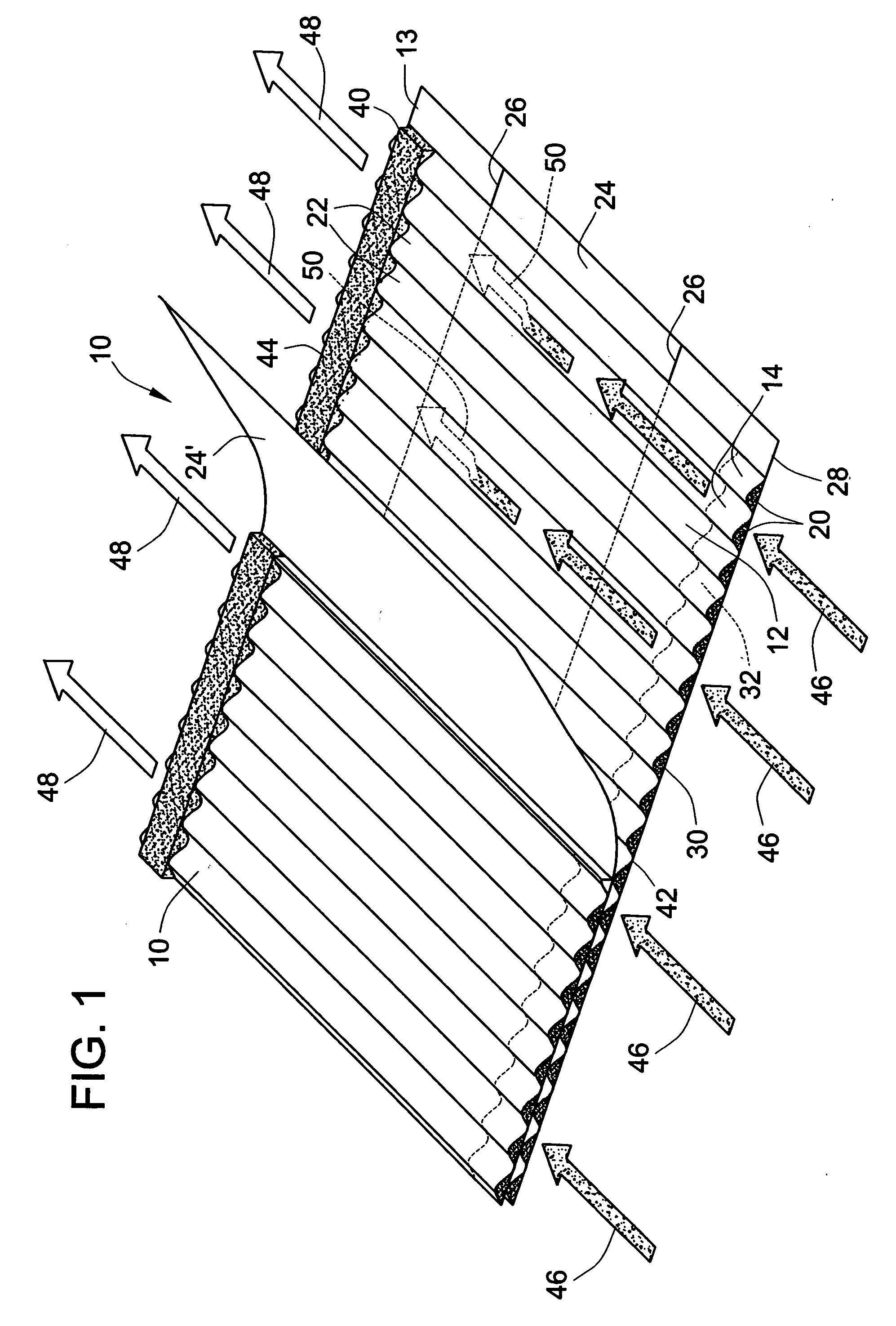

Cleanable high efficiency filter media structure and applications for use

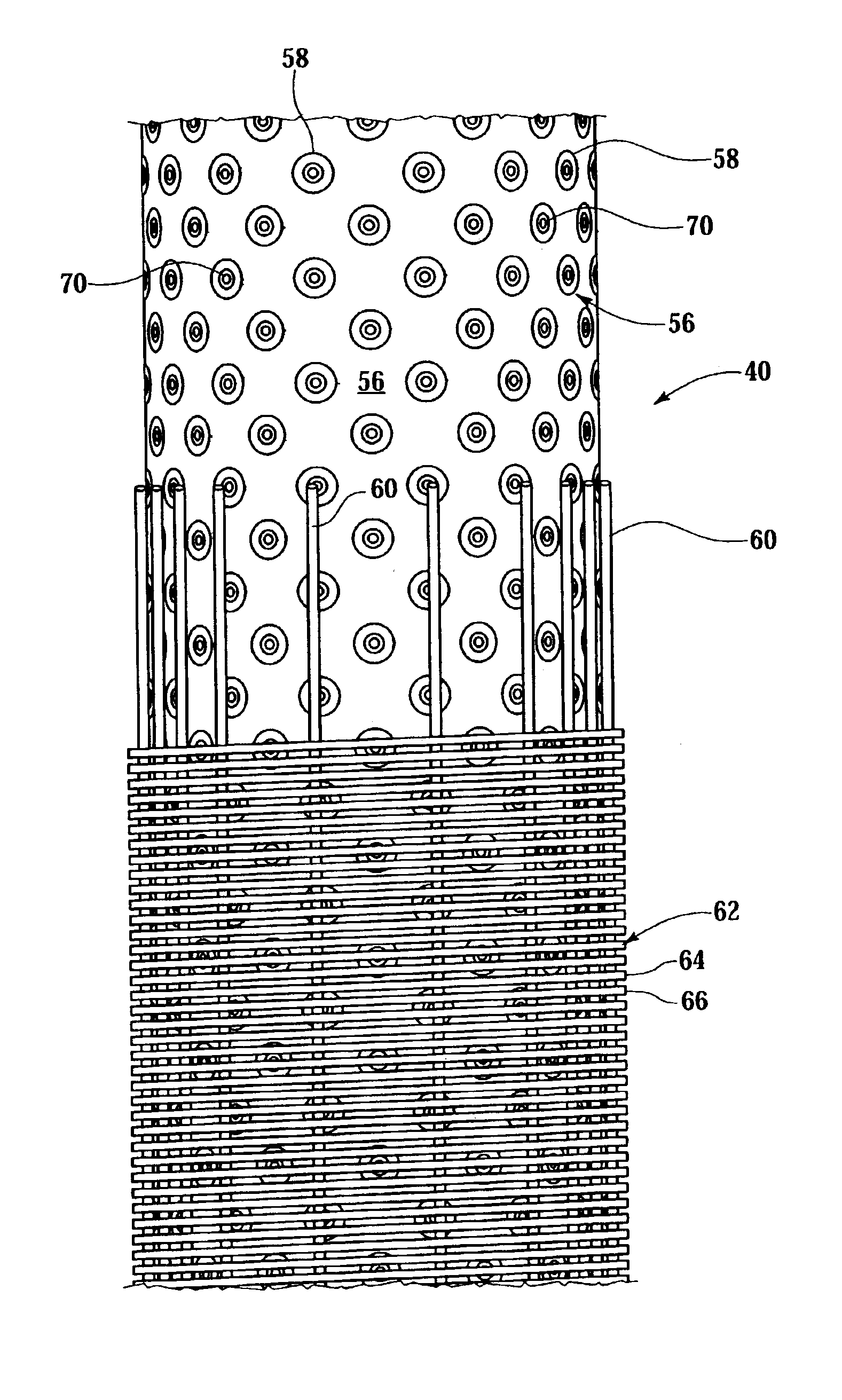

ActiveUS7008465B2Improve filtering effectHigh particle captureCombination devicesAuxillary pretreatmentParticulatesFiber

An improved cartridge, typically in cylindrical or panel form that can be used in a dry or wet / dry vacuum cleaner. The cartridge is cleanable using a stream of service water, or by rapping on a solid object, or by using a compressed gas stream, but can provide exceptional filtering properties even for submicron particulate in the household or industrial environment. The cartridge has a combination of nanofiber filtration layer on a substrate. The nanofiber and substrate are engineered to obtain a maximum efficiency at reasonable pressure drop and permeability. The improved cartridge constitutes at least a substrate material and at least a layer including a non-woven, fine fiber separation layer.

Owner:DONALDSON CO INC

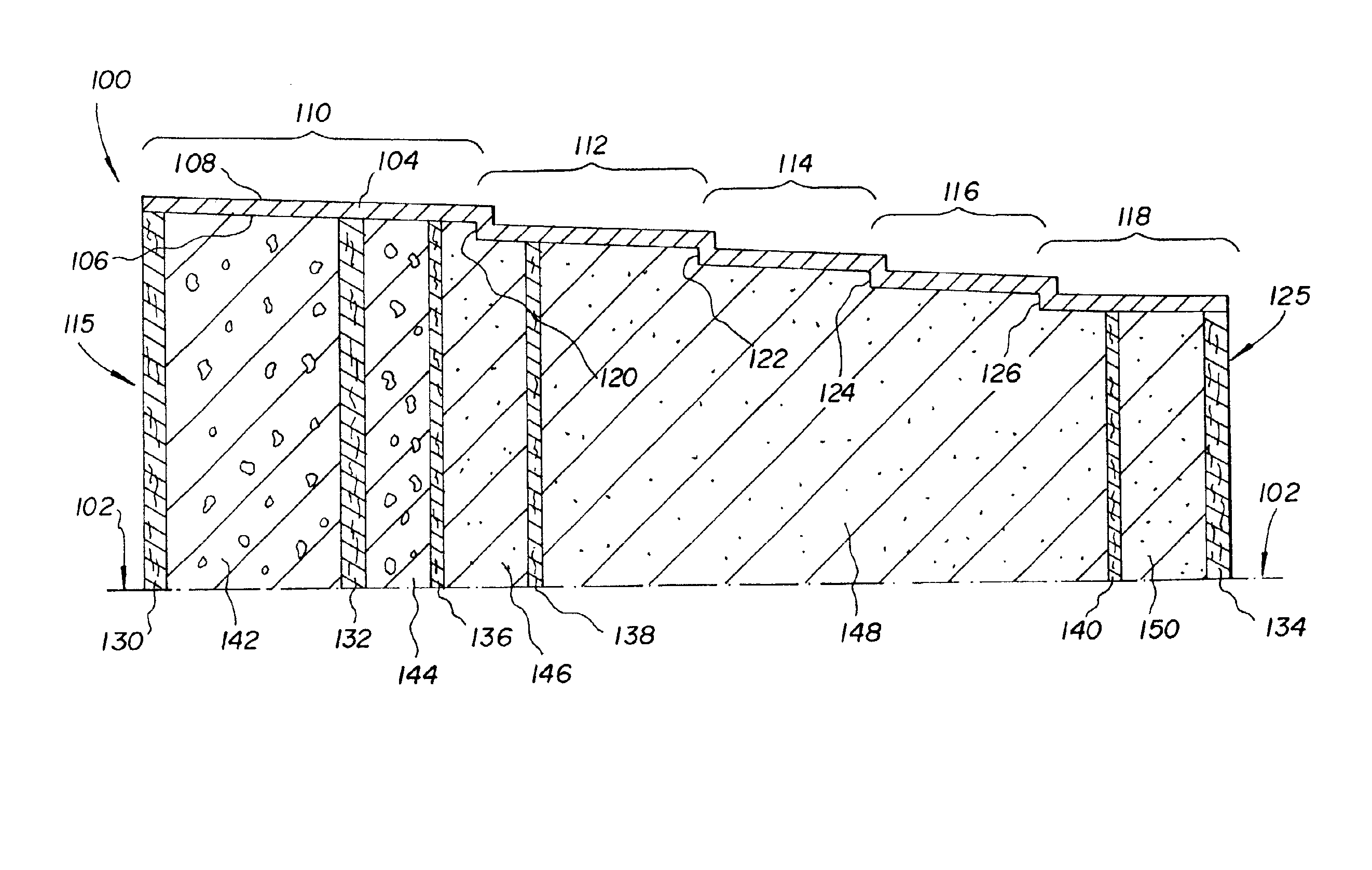

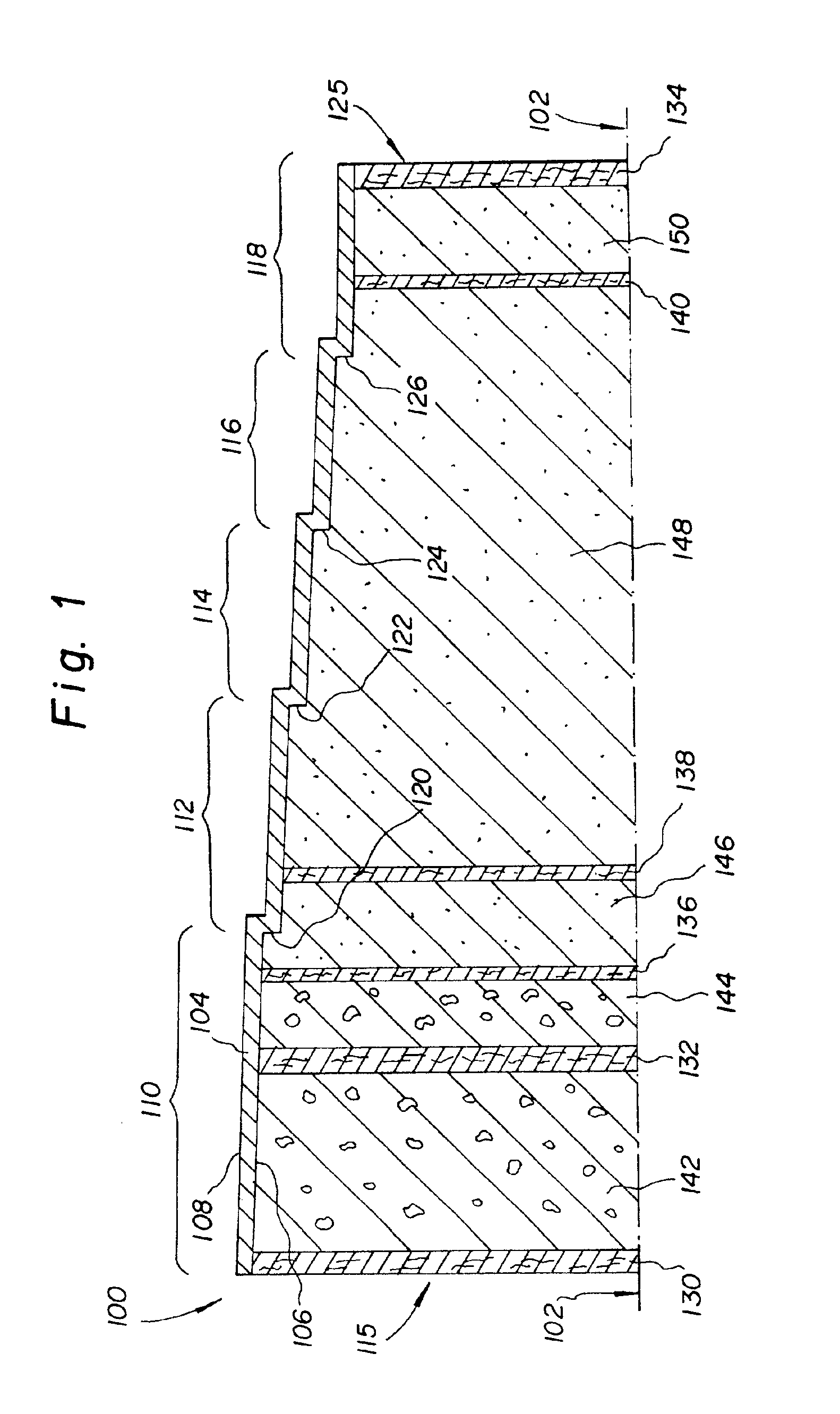

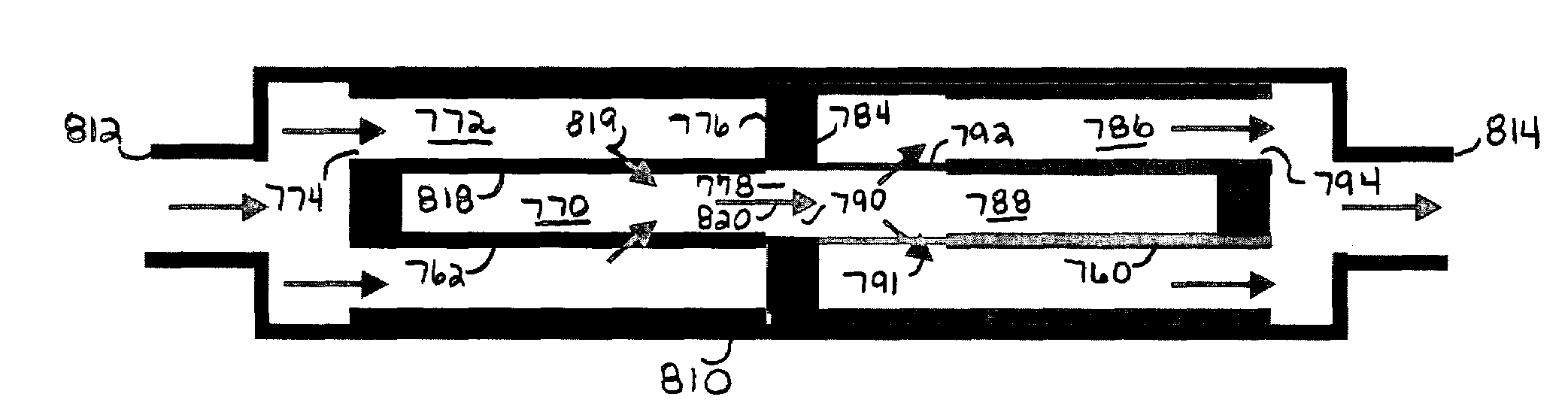

Filter cartridge assemblies and methods for filtering fluids

Filter cartridge assemblies and housings are provided and include a tubular housing having an inner wall, an outer wall, a first end, and a second end. The housings include inner walls with shoulders or other radially-inwardly extending flow directors at the intersections of adjacent sections of the tubular body. The assemblies include a plurality of filter media sections within the housing, and each of the plurality of filter media sections preferably has a different filter media composition. One or more of the filter media sections traverses one or more of the shoulders or other radially-inwardly extending flow directors such that the flow directors evenly direct the flow of fluid through the assembly. The assemblies find particular applicability in dialysis systems.

Owner:RENAL SOLUTIONS

Low density composite proppant, filtration media, gravel packing media, and sports field media, and methods for making and using same

InactiveUS20020048676A1Point becomes highImprove interfacial organic-inorganic adhesionPigmenting treatmentDead plant preservationFiltrationArtificial turf

Low density composite particles made of a binder and filler material are provided for use in subterranean formations. The filler includes low density filler and optionally other filler. The binder includes a polymer and optionally cement. The particles may be employed as proppants useful to prop open subterranean formation fractures. The particles are also useful for gravel packing in subterranean formations, water filtration and artificial turf for sports fields. Methods of making the composite particles are also disclosed.

Owner:HEXION INC

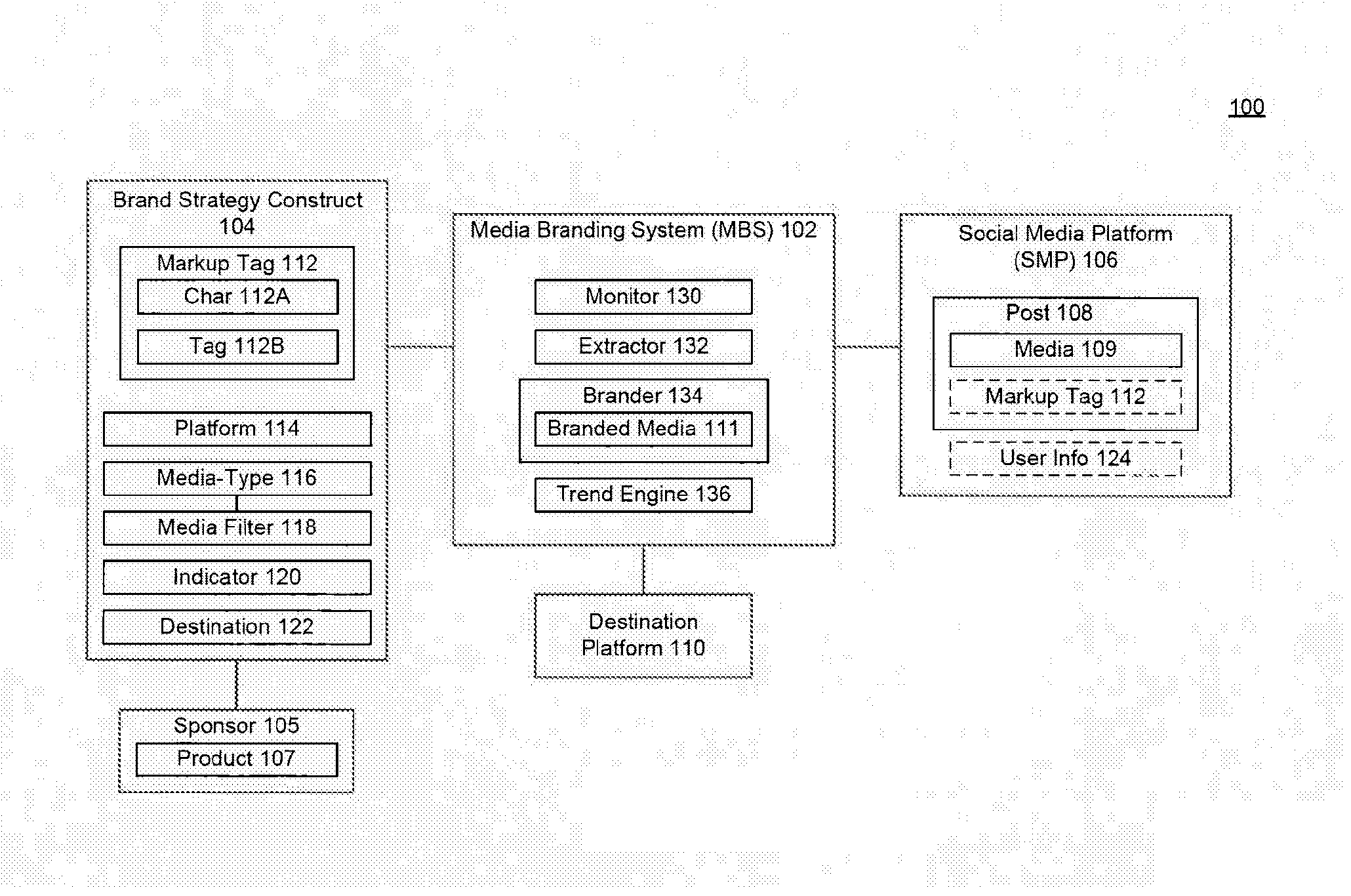

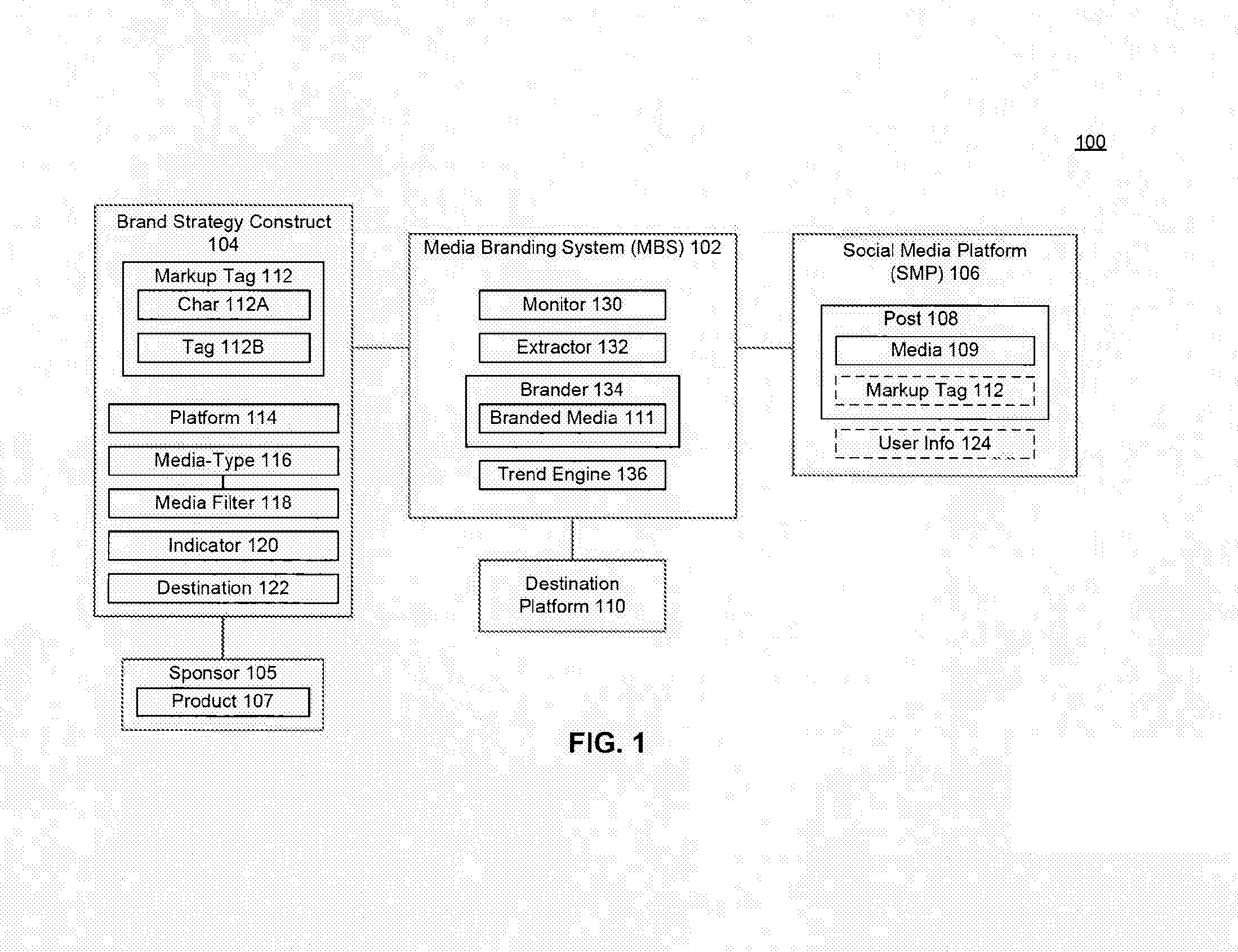

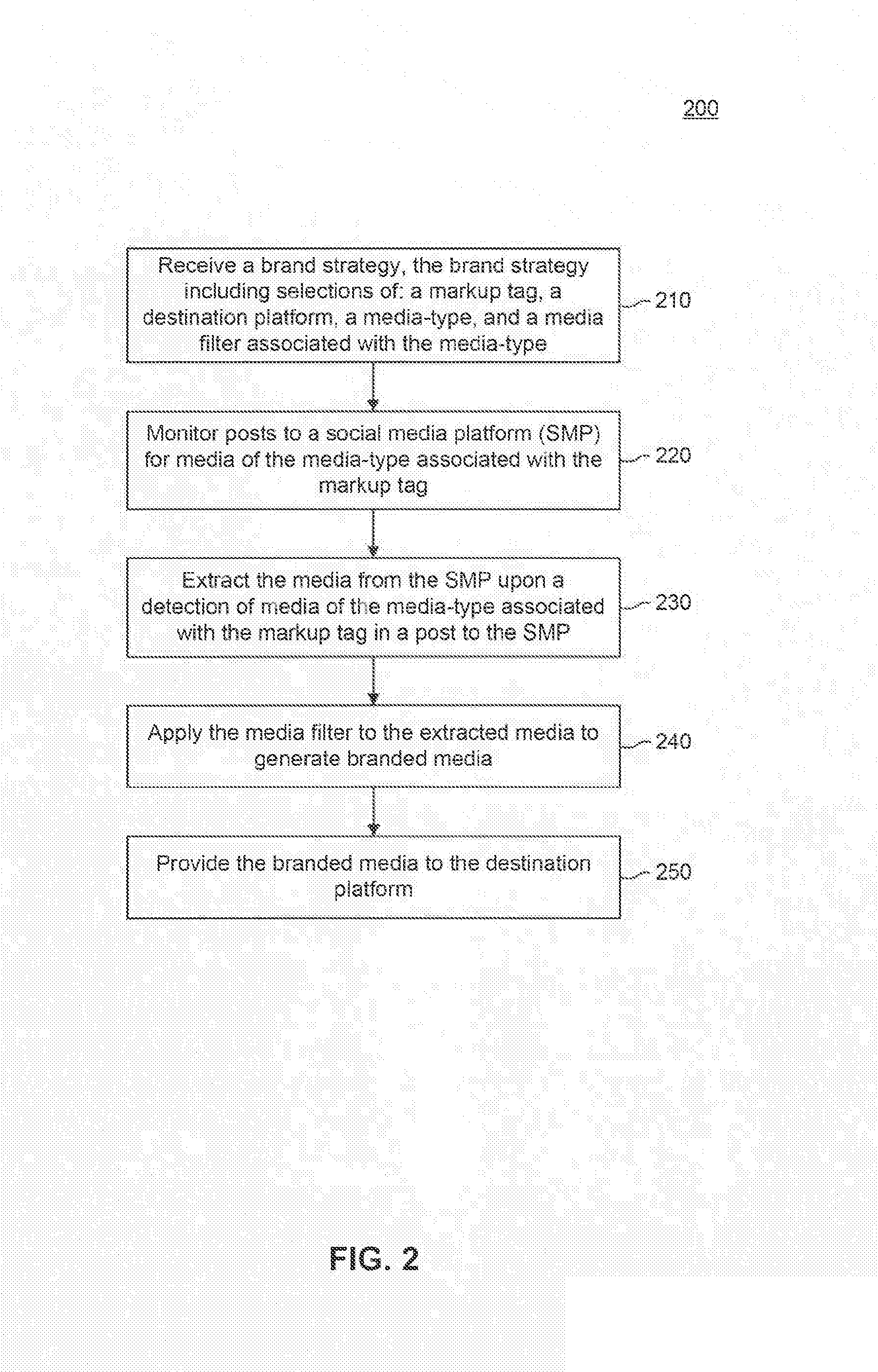

Social Media Branding

Methods, systems and computer-readable storage mediums encoded with computer programs executed by one or more processors for providing social media branding are disclosed. A brand strategy construct including a markup tag, a destination platform, a media-type, and a media filter associated with the media-type is received. Posts to a social media platform (SMP) are monitored for media of the media-type associated with the markup tag. Media is extracted from the SMP upon a detection of media of the media-type associated with the markup tag in a post to the SMP. The media filter is applied to the extracted media to generate branded media. The branded media is provided to the destination platform.

Owner:RAPP WORLDWIDE

Electret filter media

InactiveUS6119691AReduce filtration efficiencyImprove filtering effectSynthetic fibresBreathing filtersMicrometerFilter media

An electret filter media, and mask, that is made of a nonwoven web of thermoplastic microfibers. The thermoplastic microfibers are of substantially the same composition, are nonconductive, and have an effective fiber diameter less than about 15 micrometers. The nonwoven web also has sufficient unpolarized trapped charge to exhibit an initial filtration quality factor of at least 0.31 when measured under the DOP Penetration and Pressure Drop Test.

Owner:3M CO

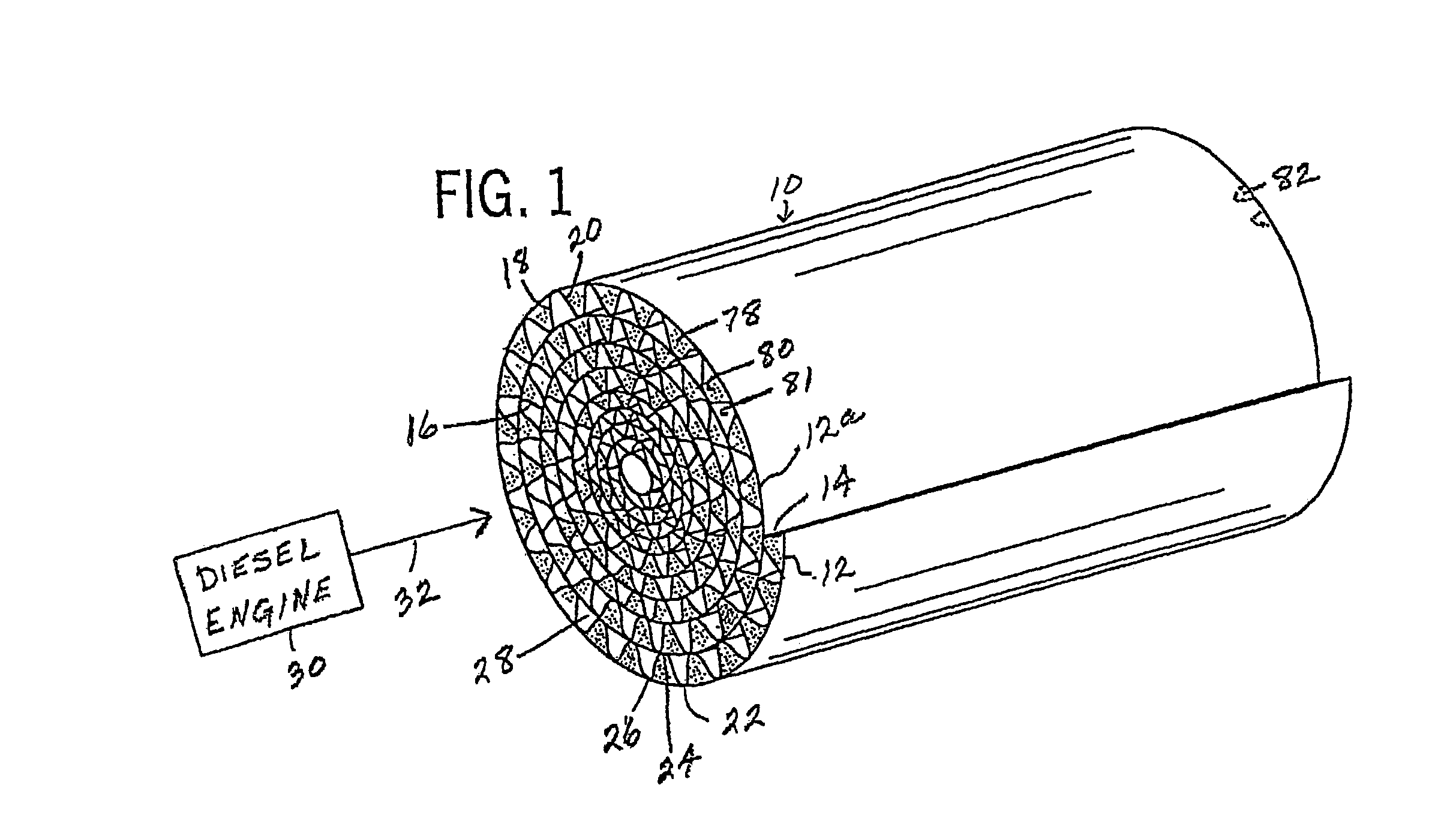

High temperature nanofilter, system and method

InactiveUS7052532B1More laminar flowShort pleat heightDispersed particle filtrationTransportation and packagingFiberNanoparticle

A filter, system and method is provided for filtering nanoparticles in a hot gas, namely particles <about 1 micron in a gas >about 200° C. and further particularly >about 450° C. including diesel exhaust. The filter includes filter media material composed of fibrous filter media having a plurality of fibers and granular filter media having a plurality of granules extending from the surfaces of the fibers. The filter is characterized by a permeability >about 3×10−12 m2 and an inertial resistance coefficient <about 1×106 m−1. The filter captures particles in the Most Penetrating Region (MPR). A filter system includes a nanoparticle filter in series with a diesel exhaust treatment element.

Owner:3M INNOVATIVE PROPERTIES CO +1

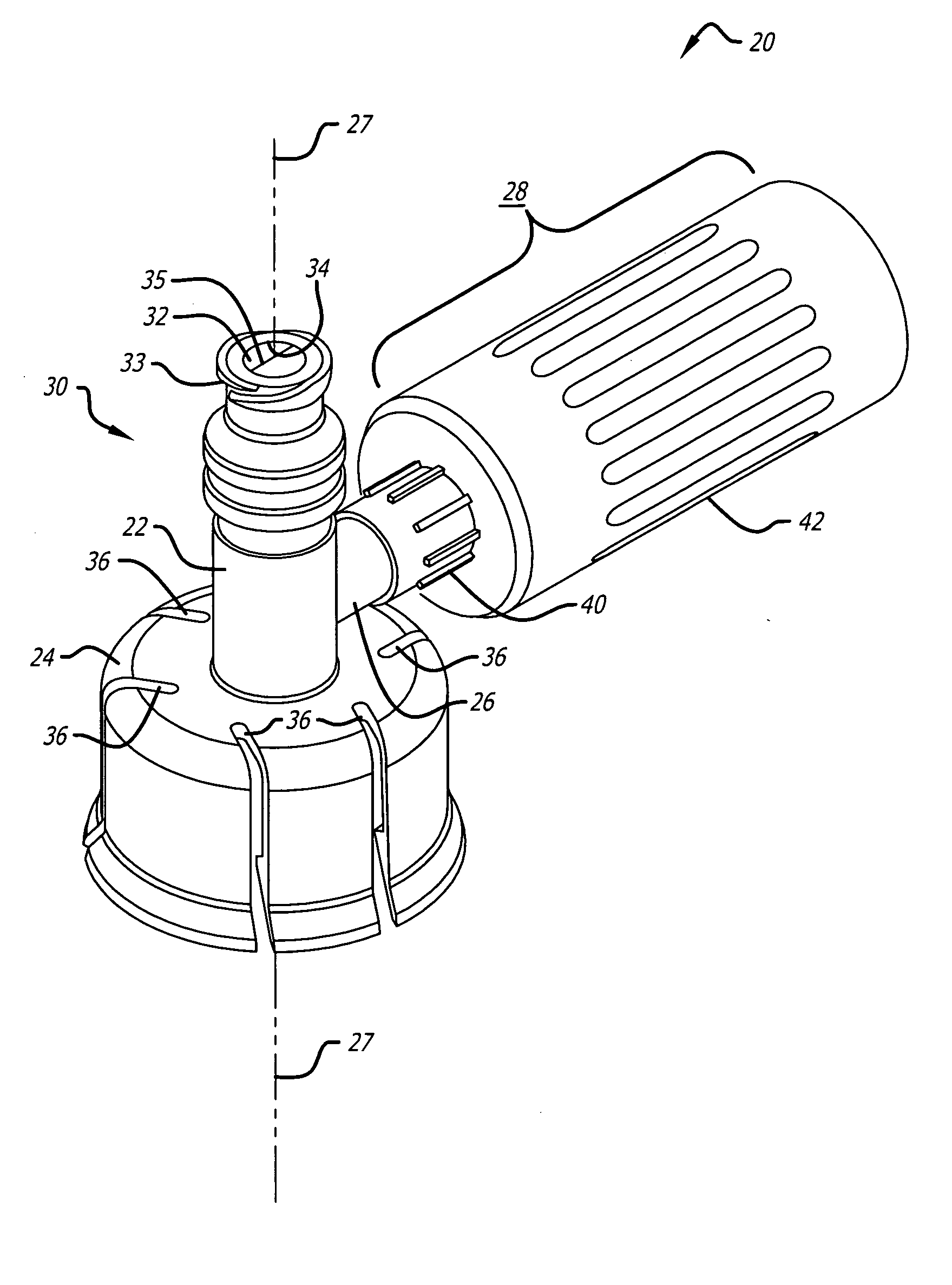

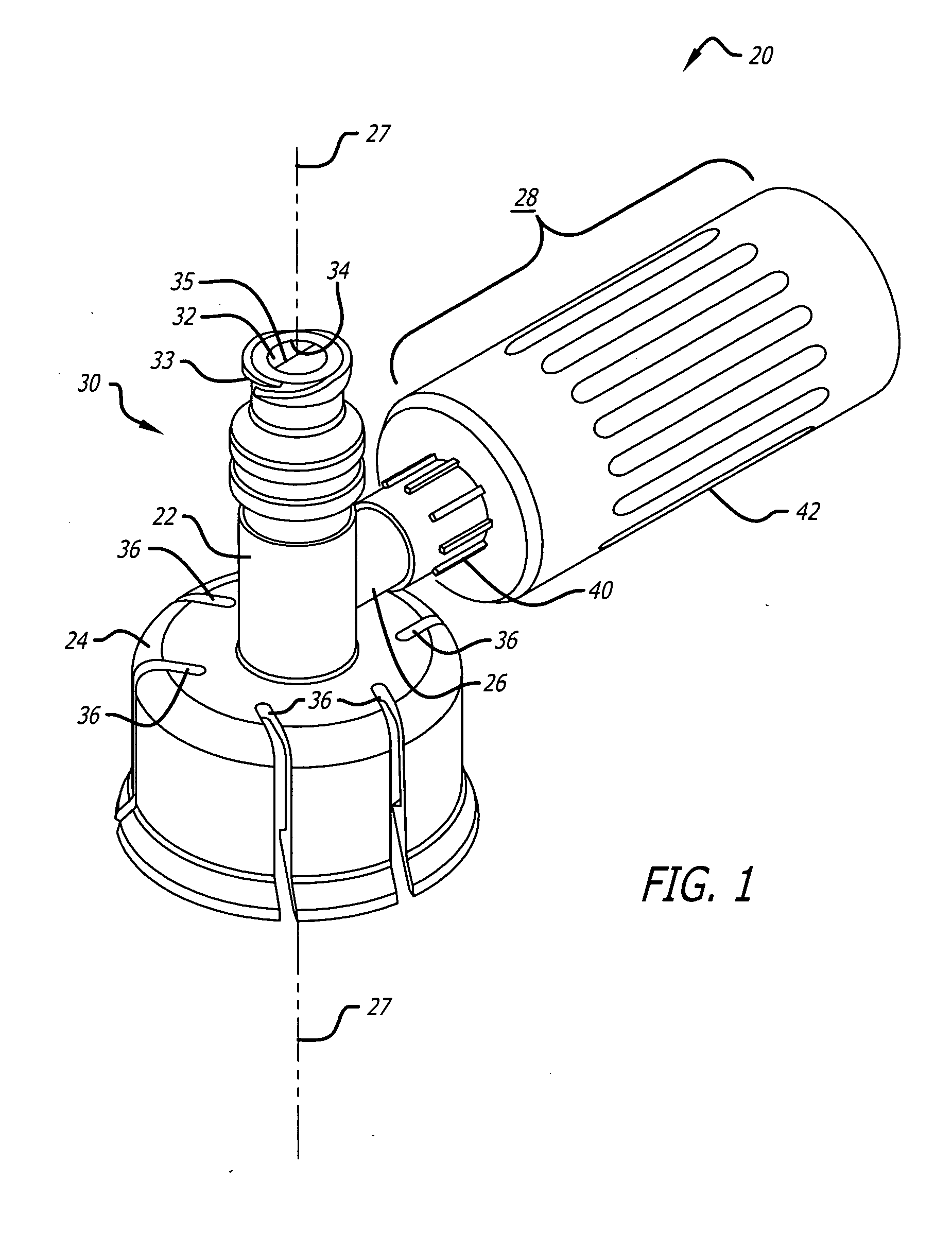

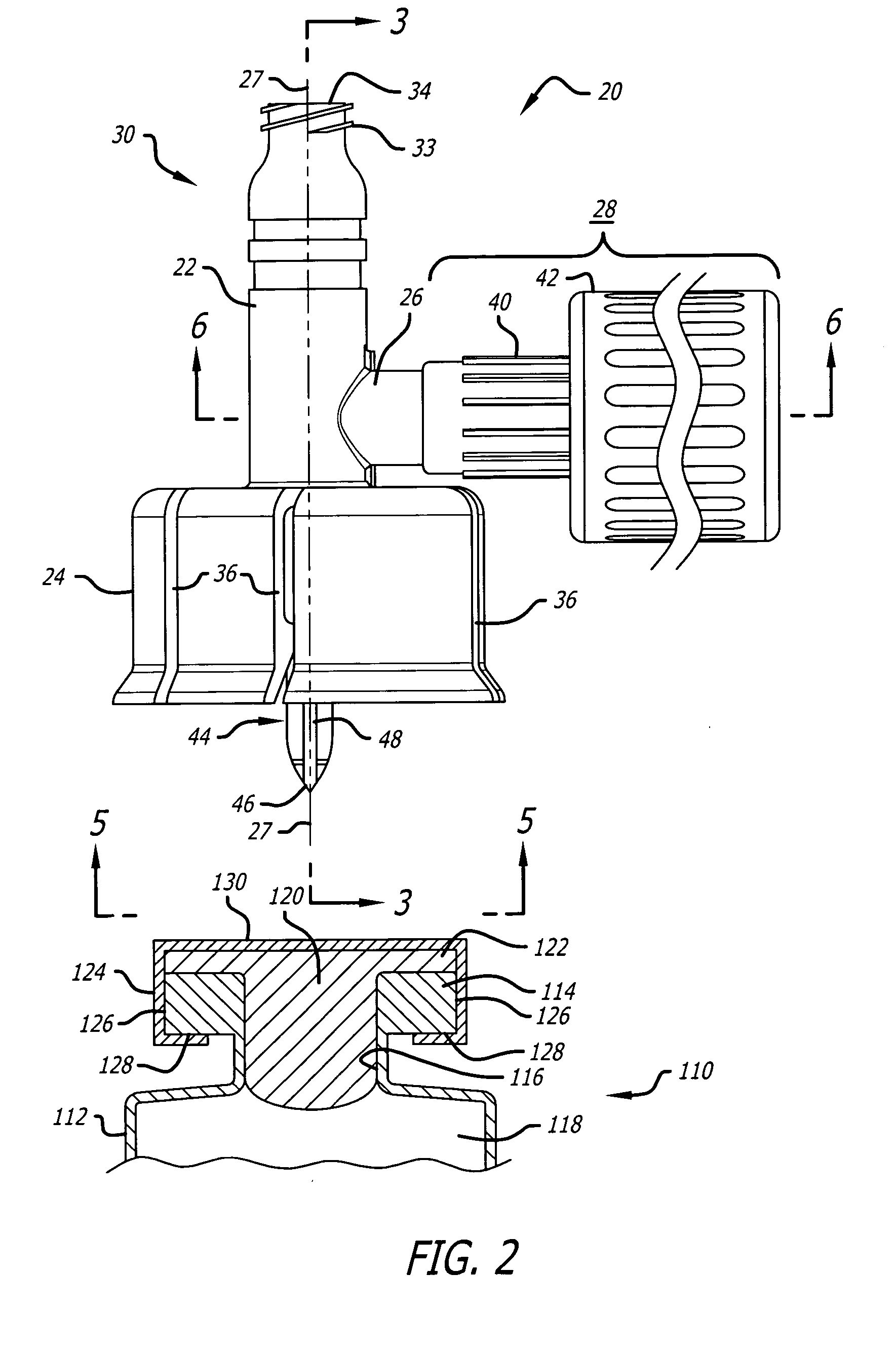

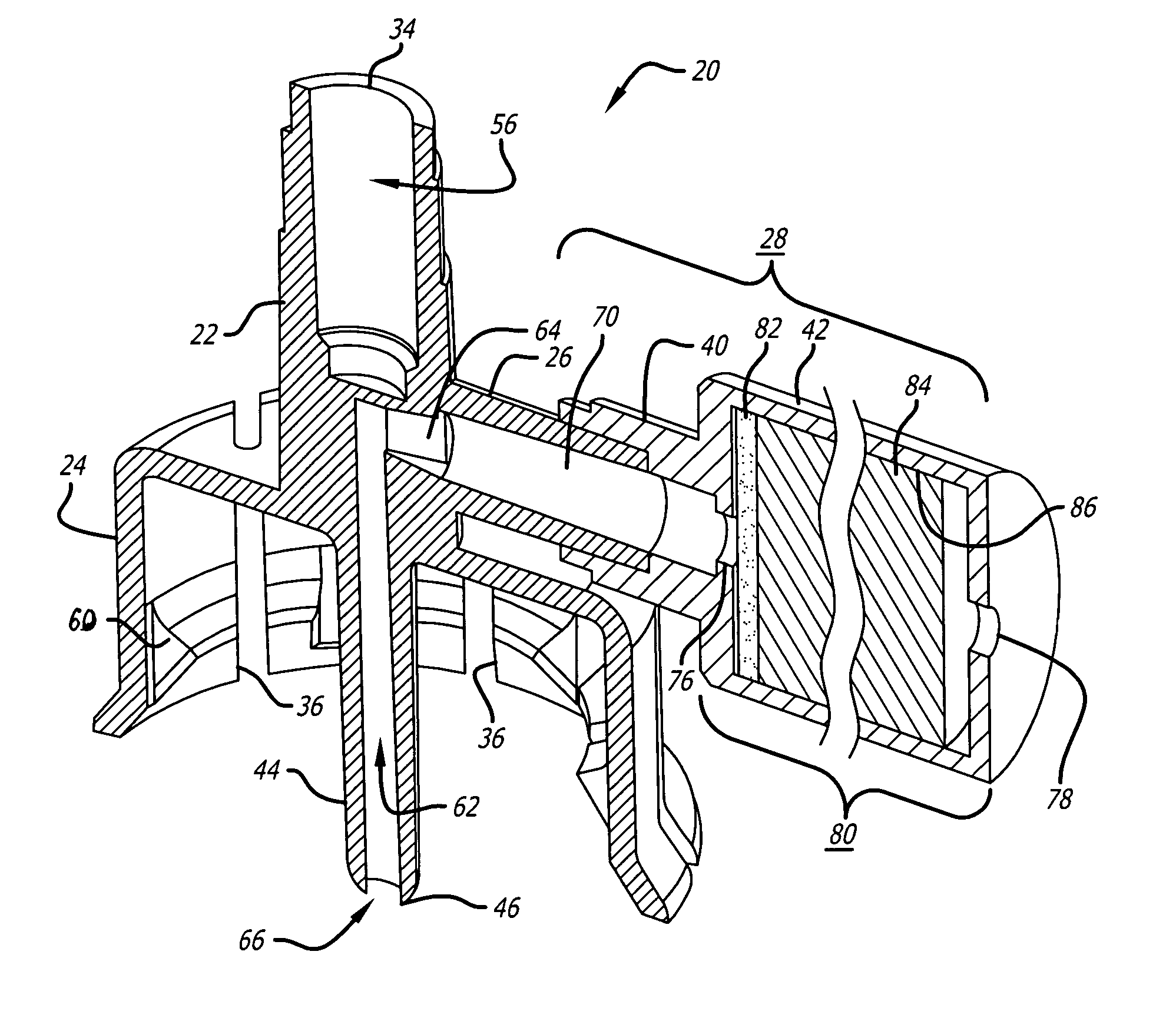

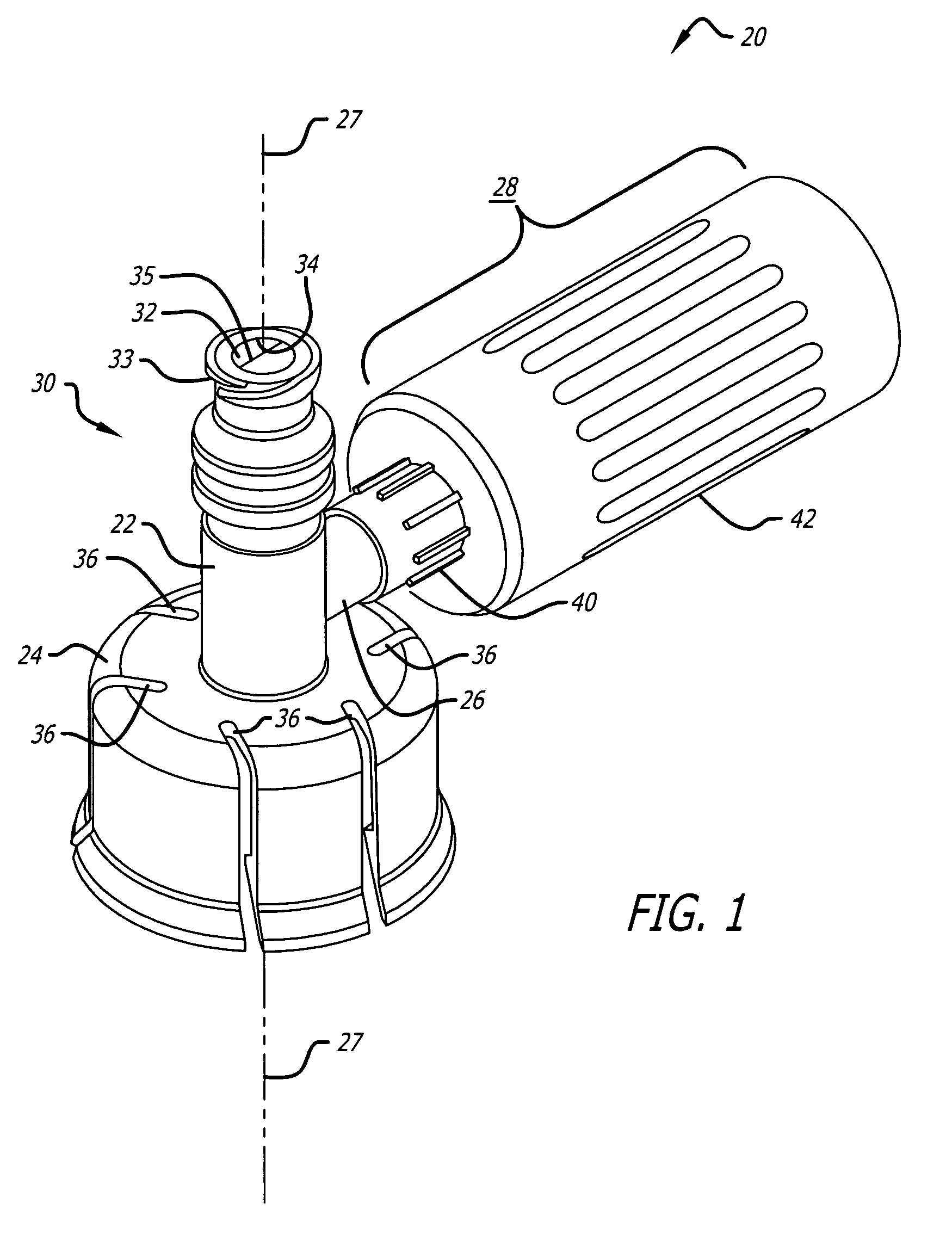

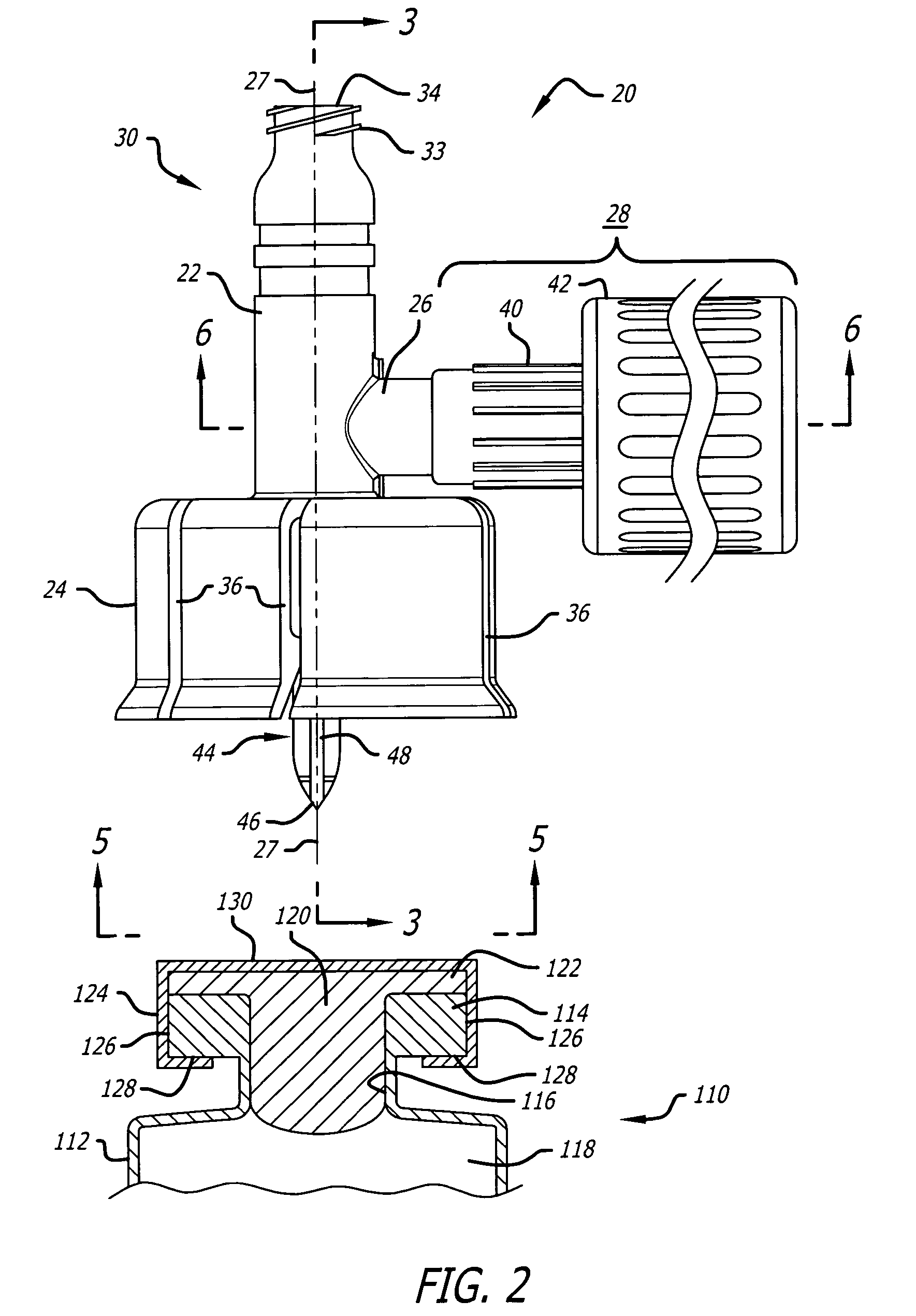

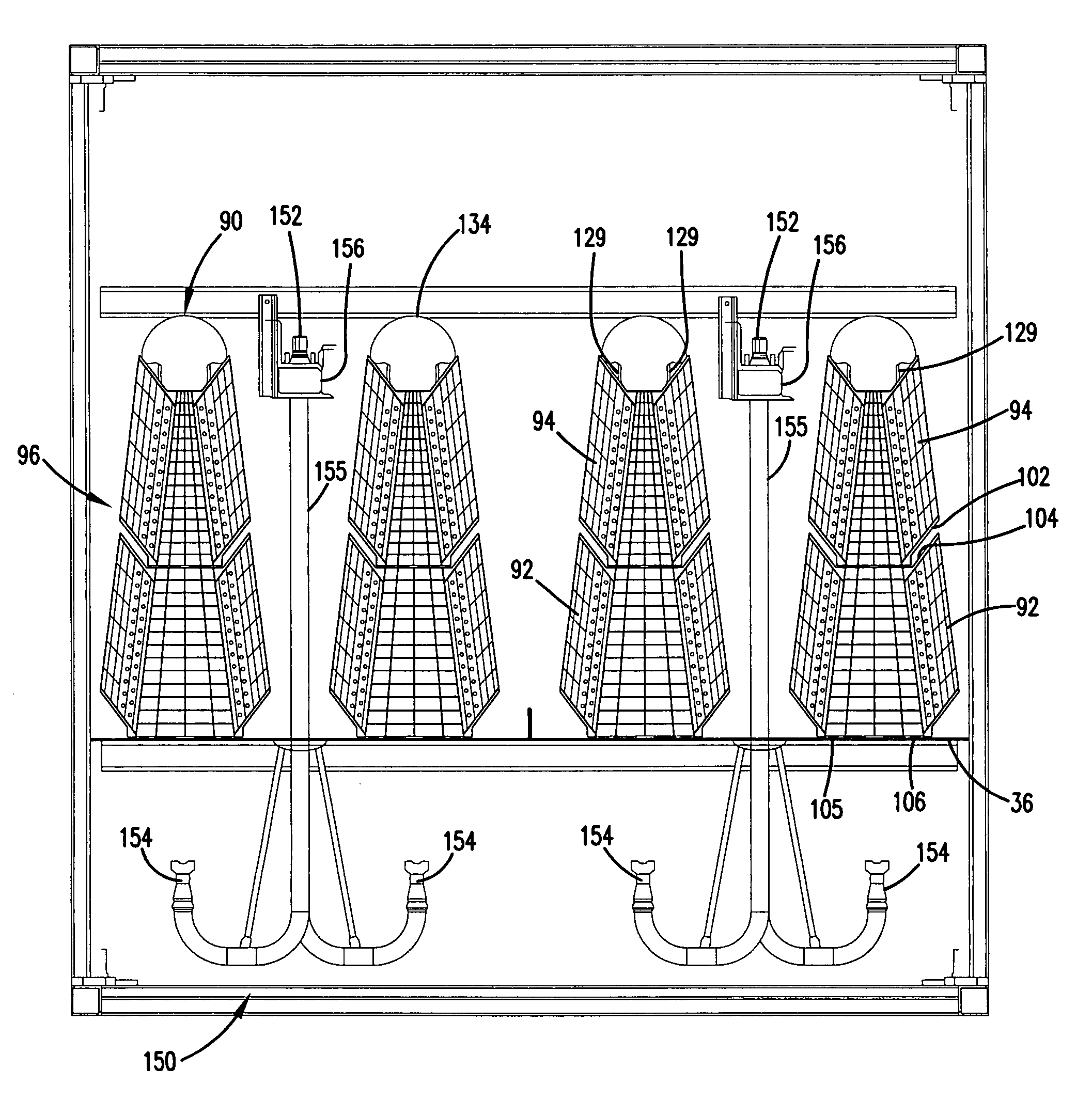

Vented vial adapter with filter for aerosol retention

A vented vial adapter has a filter attached to a vent arm that includes at least two filter media for suppressing aerosolized medicaments from leaving the vial and suppressing bacteria and other contaminants from entering the vial during reconstitution activities of the medication in the vial. The filter media allows the passage of air to the atmosphere outside the vial for pressure equalization. In another aspect, a third filter medium is used in the vent of the adapter to allow gas to pass in either direction through it, but prevents bacteria and particulate matter in the atmosphere from reaching the second filter device. A first filter is hydrophobic and prevents non-dispersed liquid from reaching the second filter, while conducting liquid dispersed in gas. The second filter absorbs the liquid dispersed in gas.

Owner:CAREFUSION 303 INC

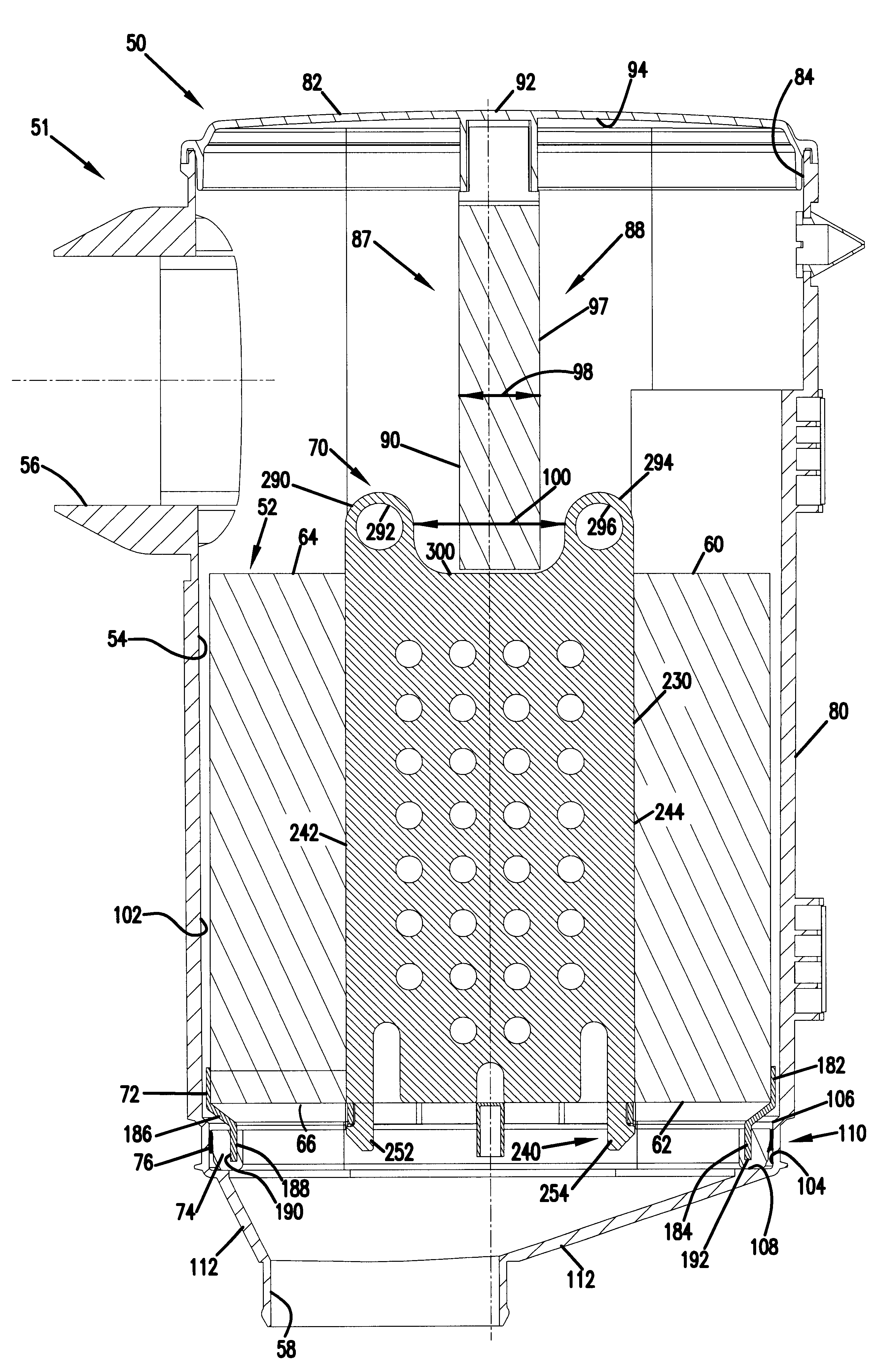

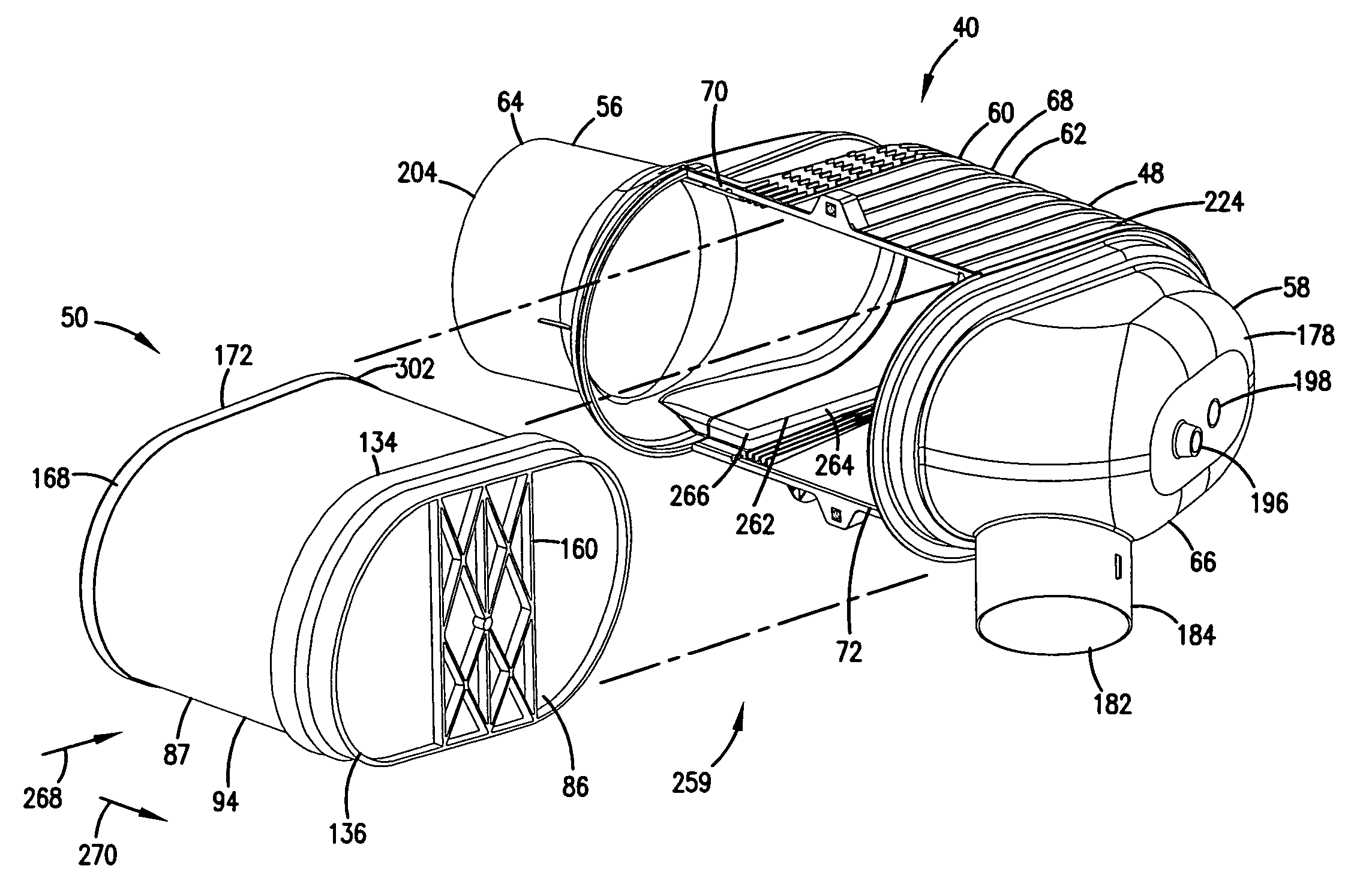

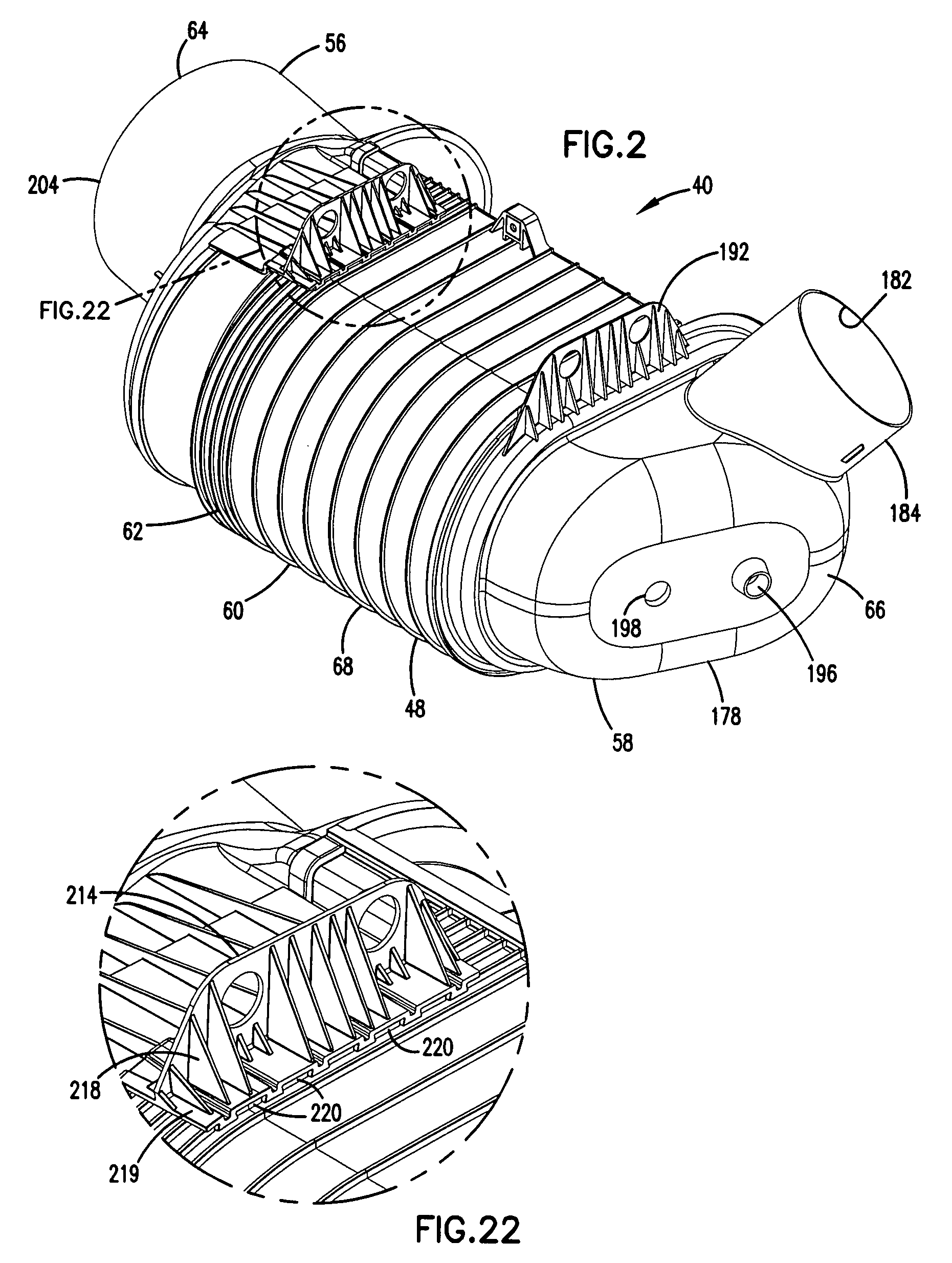

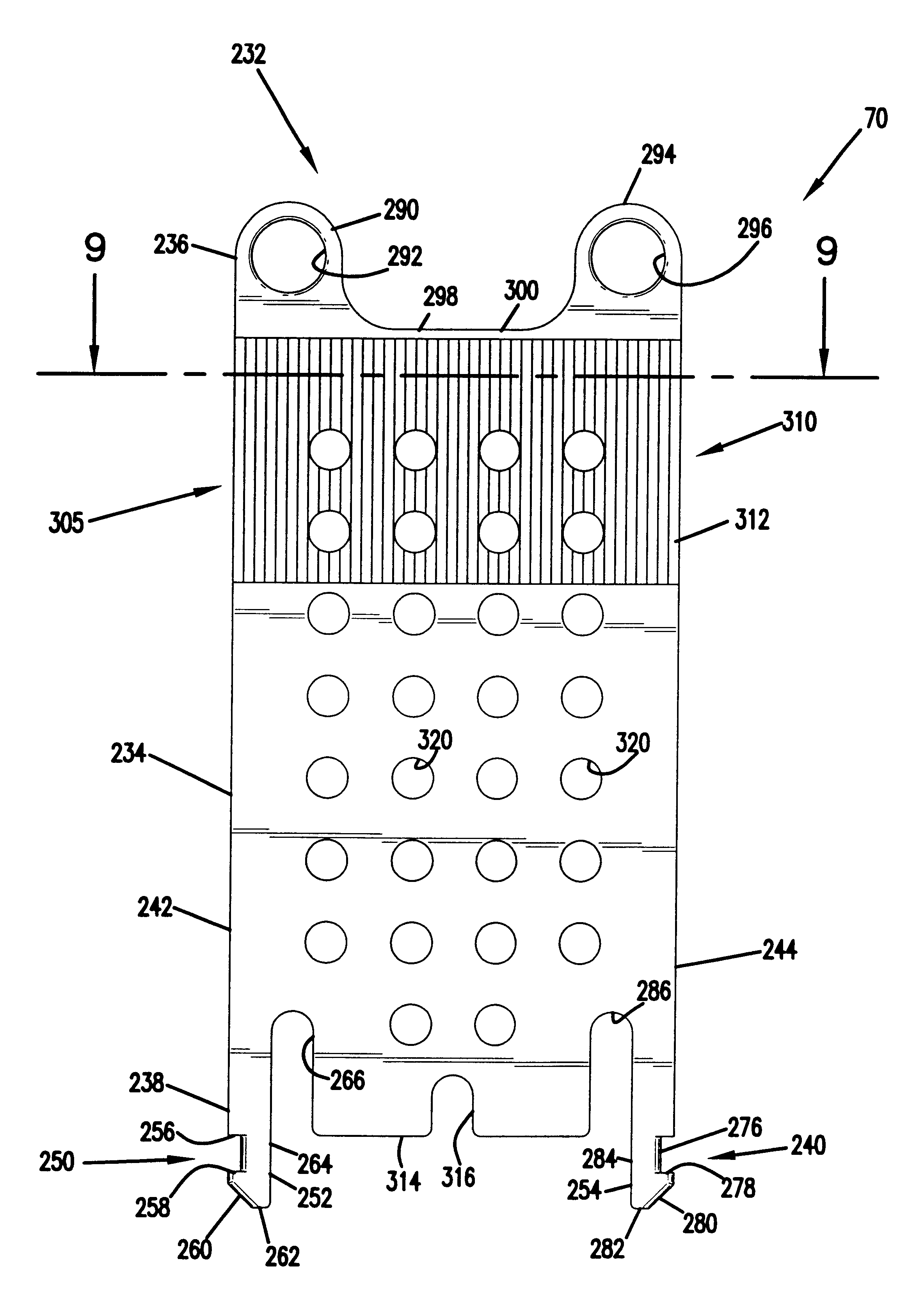

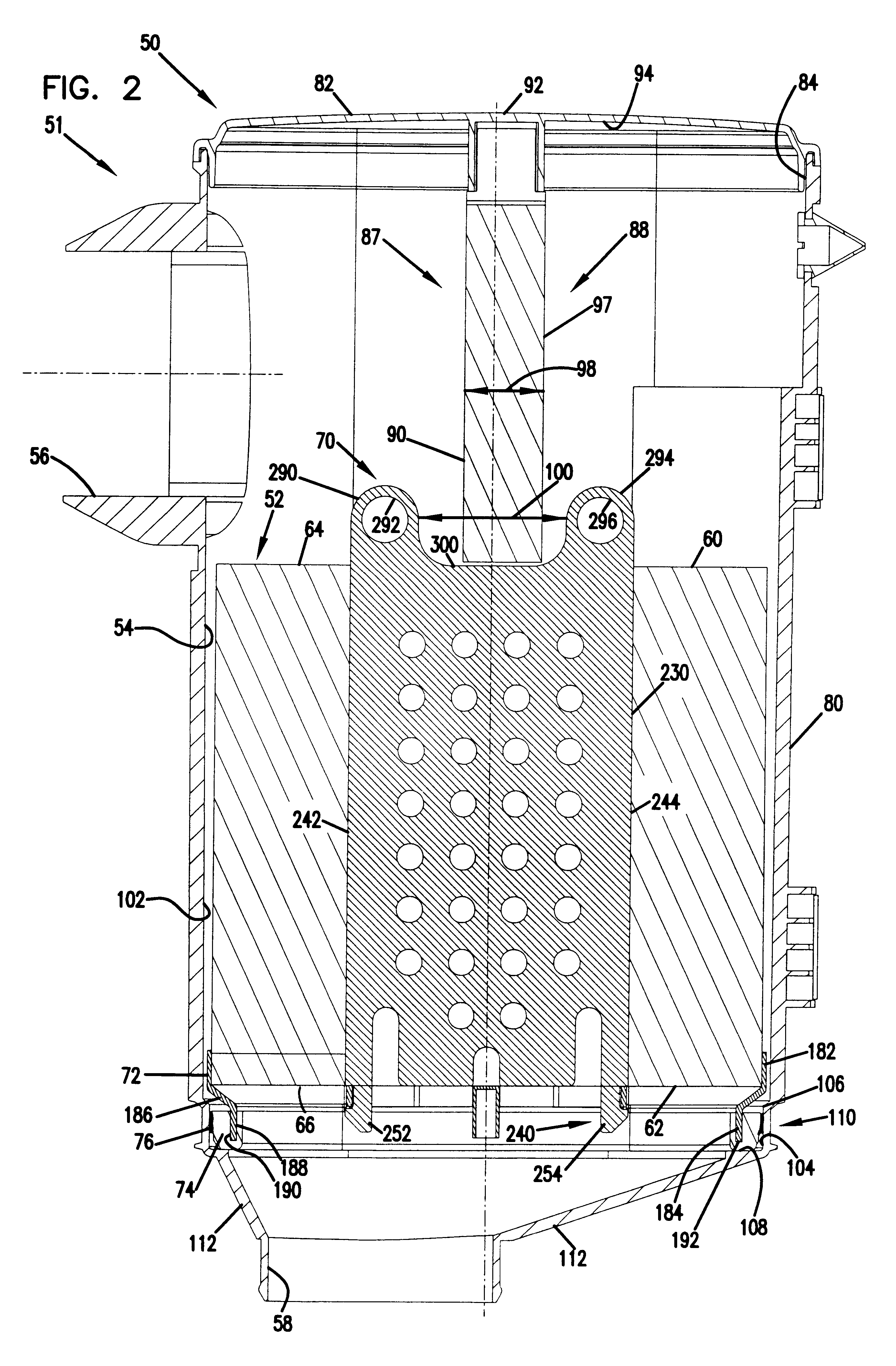

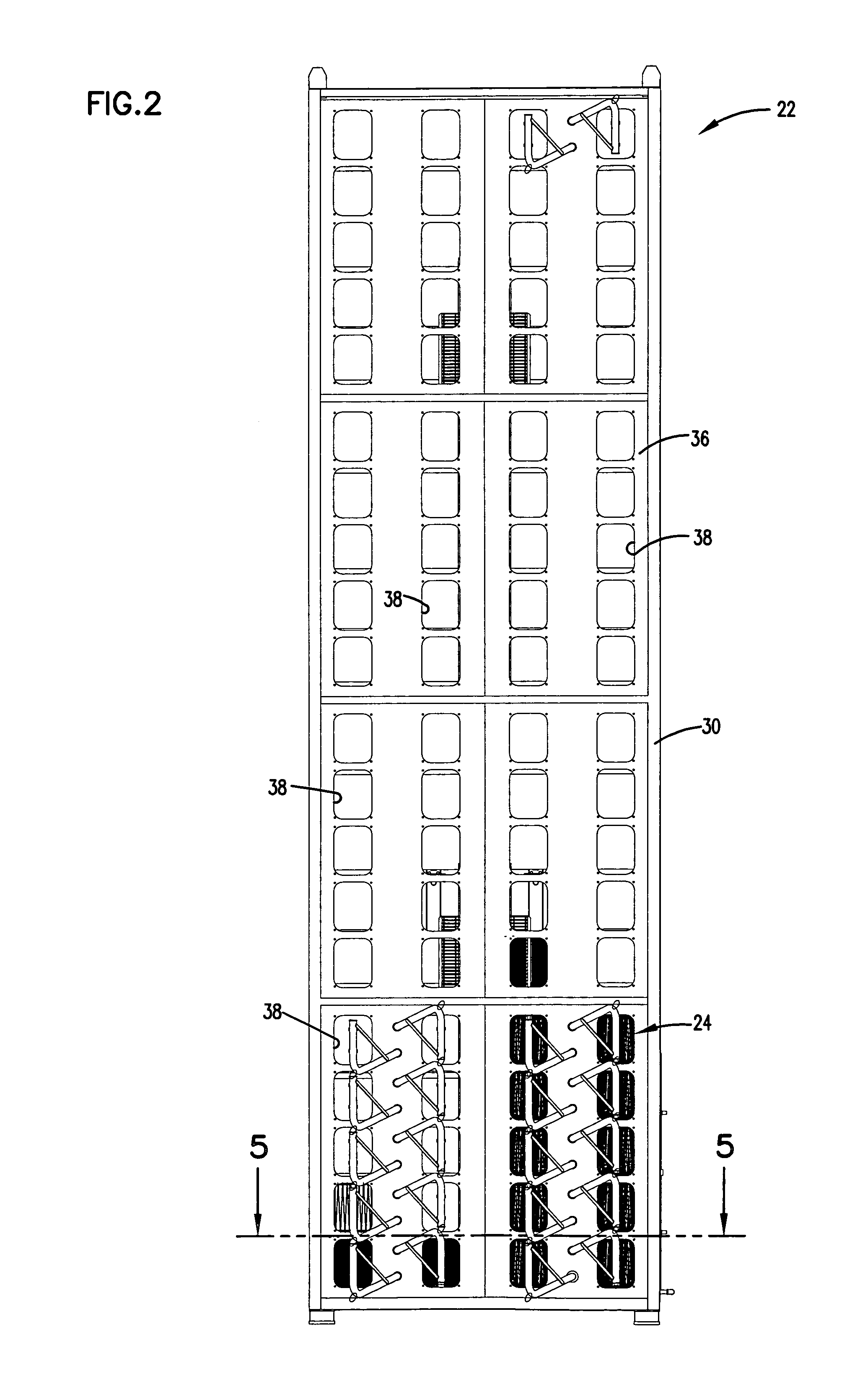

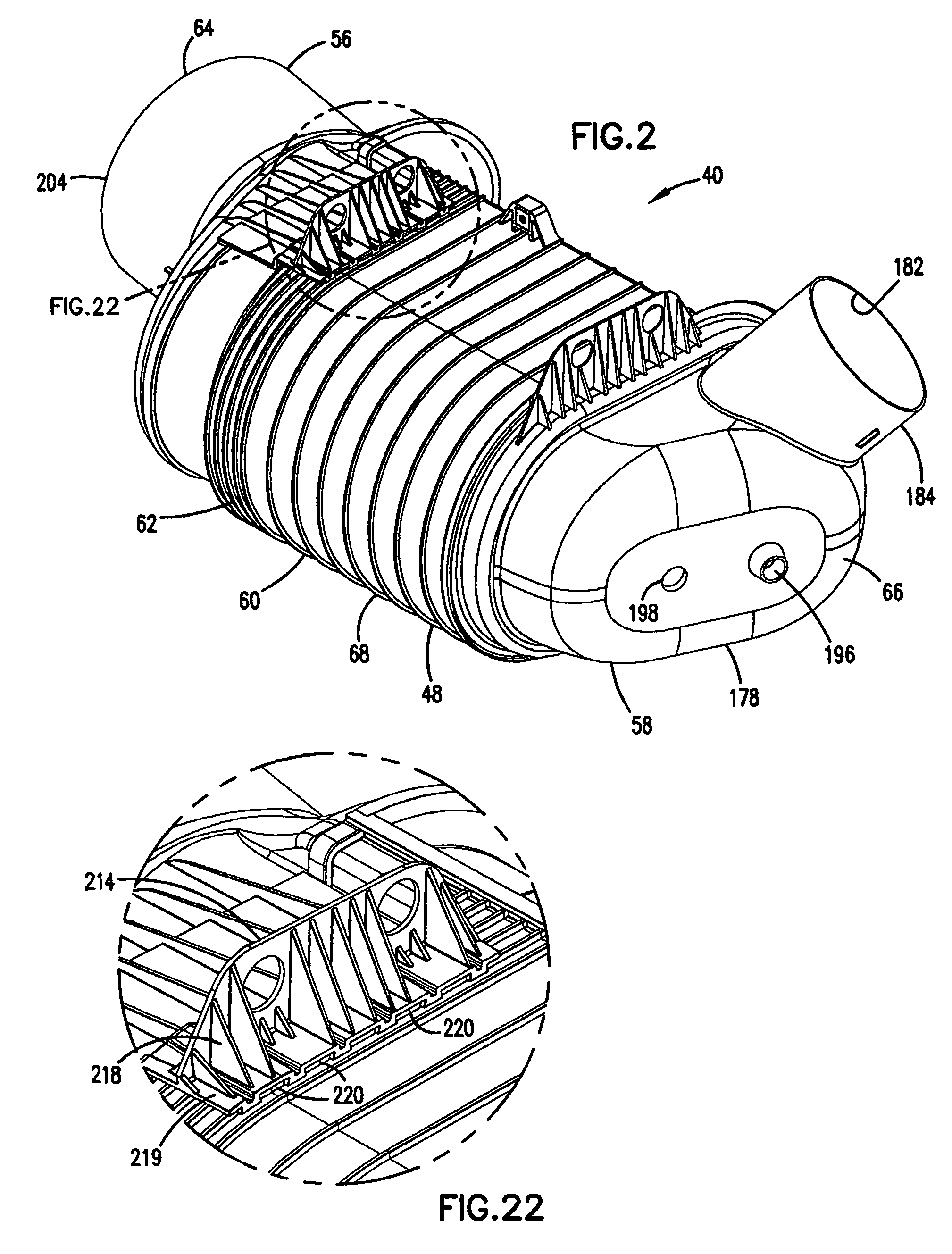

Air filter having fluted filter media

An air cleaner (40) includes a housing (48) and an access cover. The internal volume of the housing (48) can be reached through an opening (70) in a side wall of the housing. A filter element (50) having fluted filter media is removable and replaceable from the air cleaner (40). The housing is constructed and arranged to cam the element (50) into sealing engagement with the housing (48). The access cover includes structure to help support and ensure proper seating of the filter element within the housing. A method of installing the filter element in the air cleaner includes sliding a portion of the filter element against a slide surface in the housing. A method of servicing an air cleaner includes tilting the filter element against a tilt surface in the housing to release a seal between the filter element and the housing. The filter element can have a handle to assist in servicing of the air cleaner. The housing can have a window to allow visual inspection of the internal component of the housing and to determine visually whether a filter element is installed therein.

Owner:DONALDSON CO INC

Electret filter media and filtering masks that contain electret filter media

InactiveUS6783574B1Reduce filtration efficiencyImprove filtering effectSynthetic fibresBreathing filtersFilter mediaRespiratory mask

Electret filter media comprising a nonwoven web of thermoplastic nonconductive microfibers having trapped charge, said charge provided by (1) subjecting the nonwoven web to a corona treatment, followed by (2) impingement of jets of water or a stream of water droplets on the web at a pressure sufficient to provide the web with filtration enhancing electret charge and (3) drying the web. This electret filter media may be used in a respiratory mask to provide extraordinarily good filtration properties.

Owner:3M CO

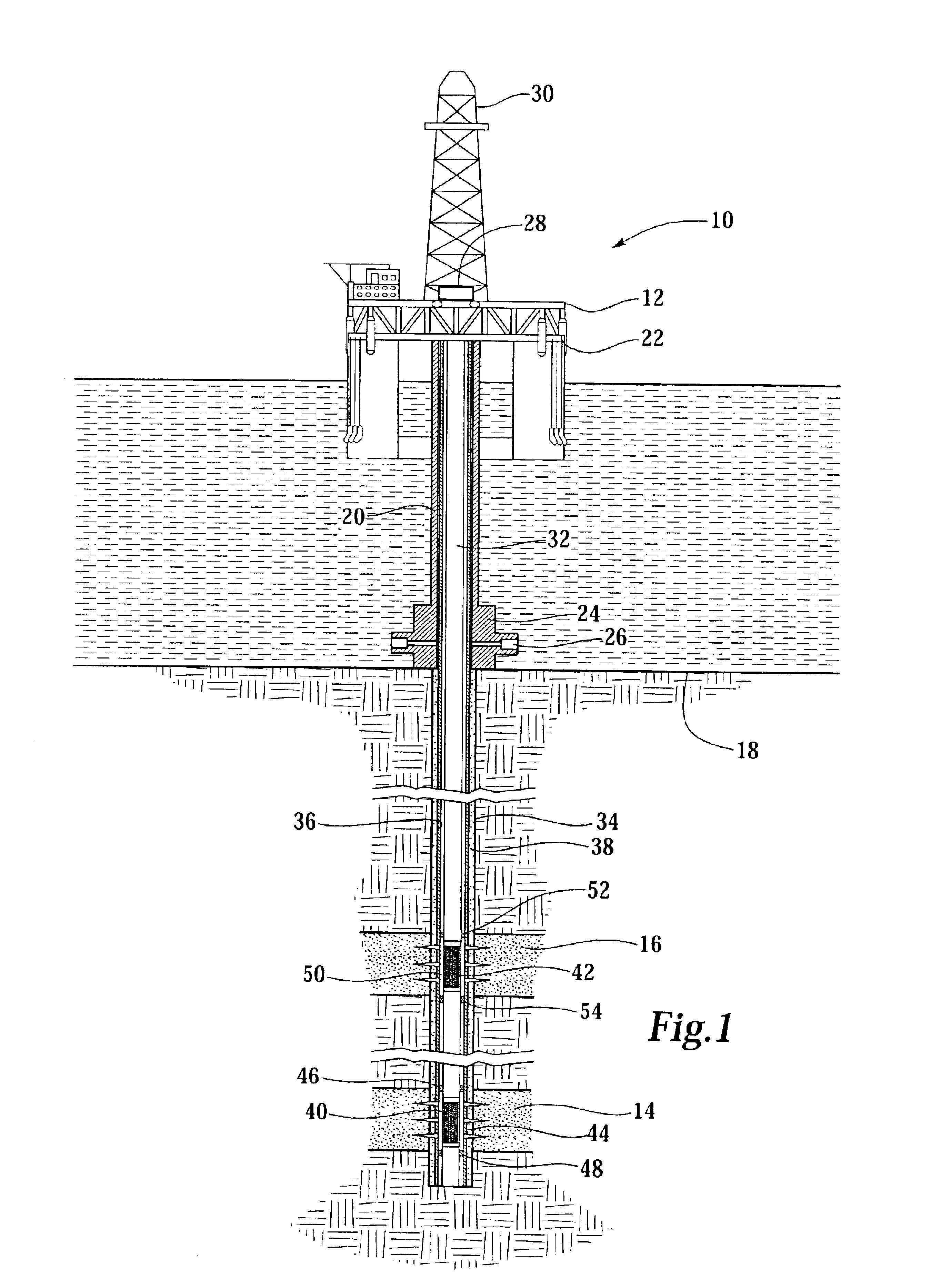

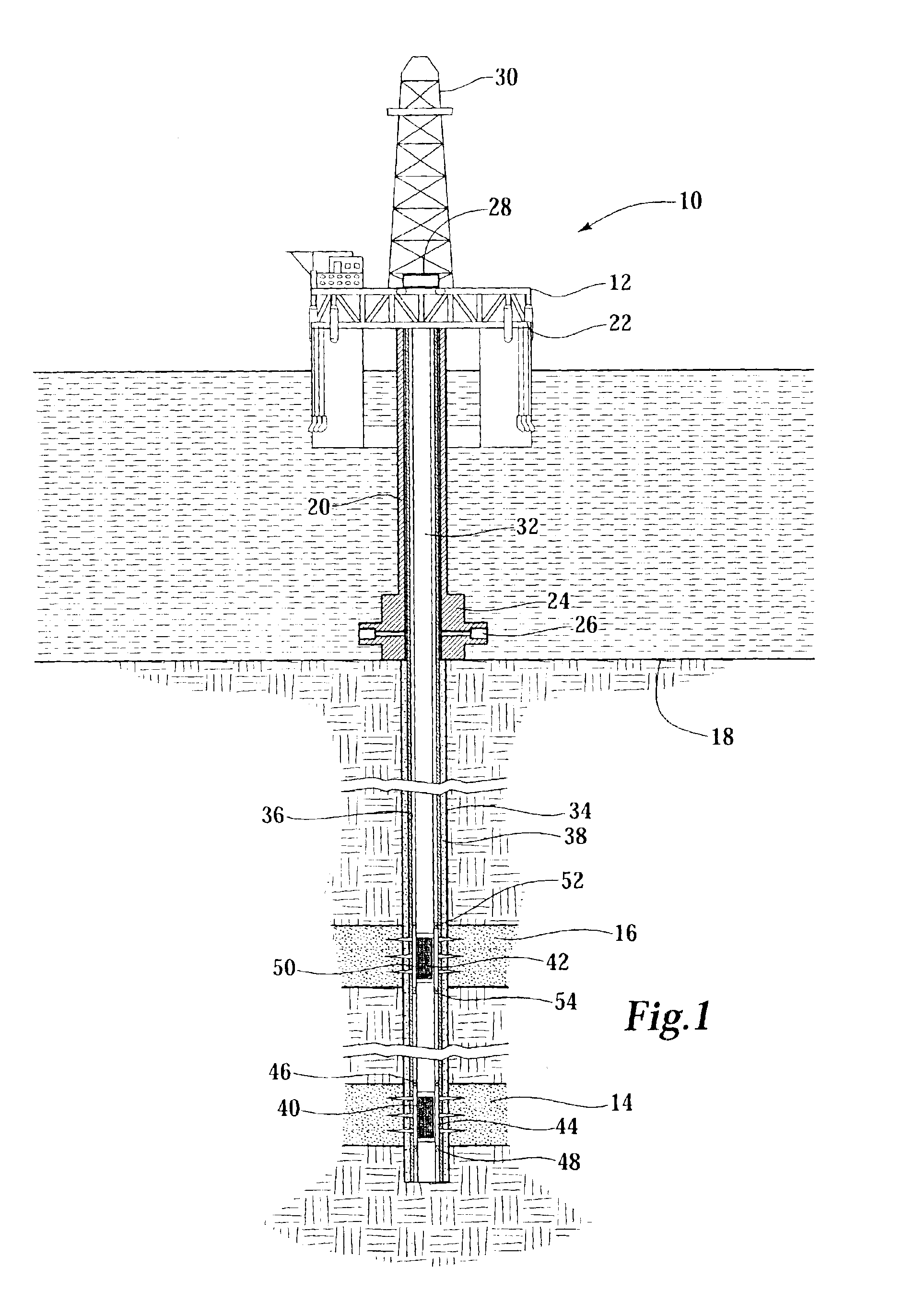

Sand control screen assembly and treatment method using the same

A sand control screen assembly (200) positionable within a production interval of a wellbore that traverses a subterranean hydrocarbon bearing formation comprises a base pipe (202) having openings (204) in a sidewall section thereof that allow fluid flow therethrough. A filter medium (210) is positioned about the exterior of at least a portion of the base pipe (202). The filter medium (210) selectively allows fluid flow therethrough but prevents the flow of particulate of a predetermined size therethrough. A seal member (218, 220, 222) is operably associated with the base pipe (202). The seal member (218, 220, 222) has a one-way valve configuration and a valve open configuration such that the seal member (218, 220, 222) controls fluid flow through the openings (204) of the base pipe (202).

Owner:HALLIBURTON ENERGY SERVICES INC

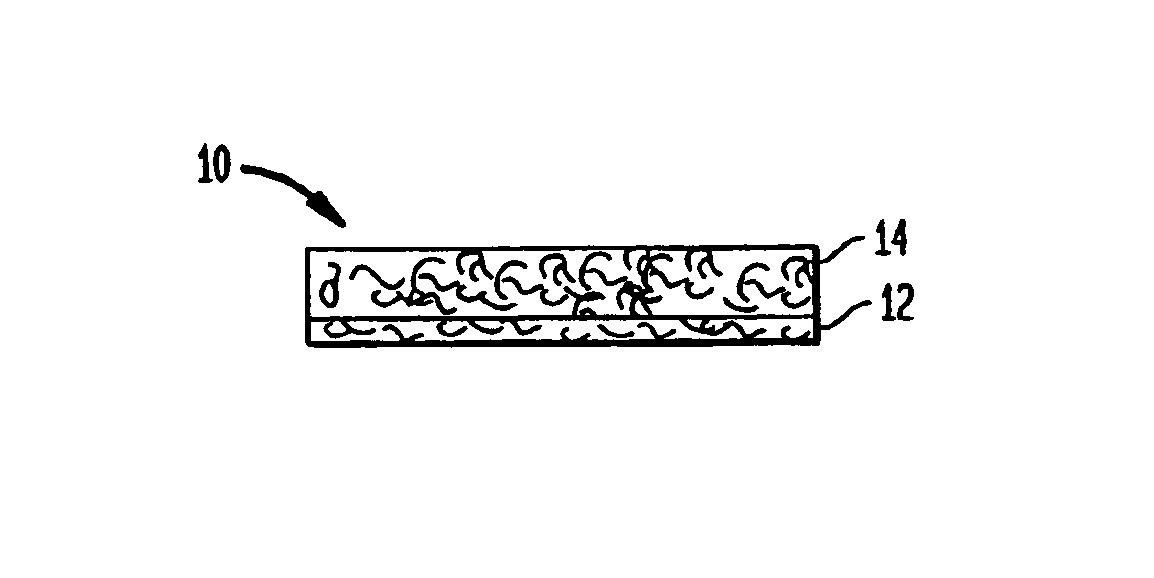

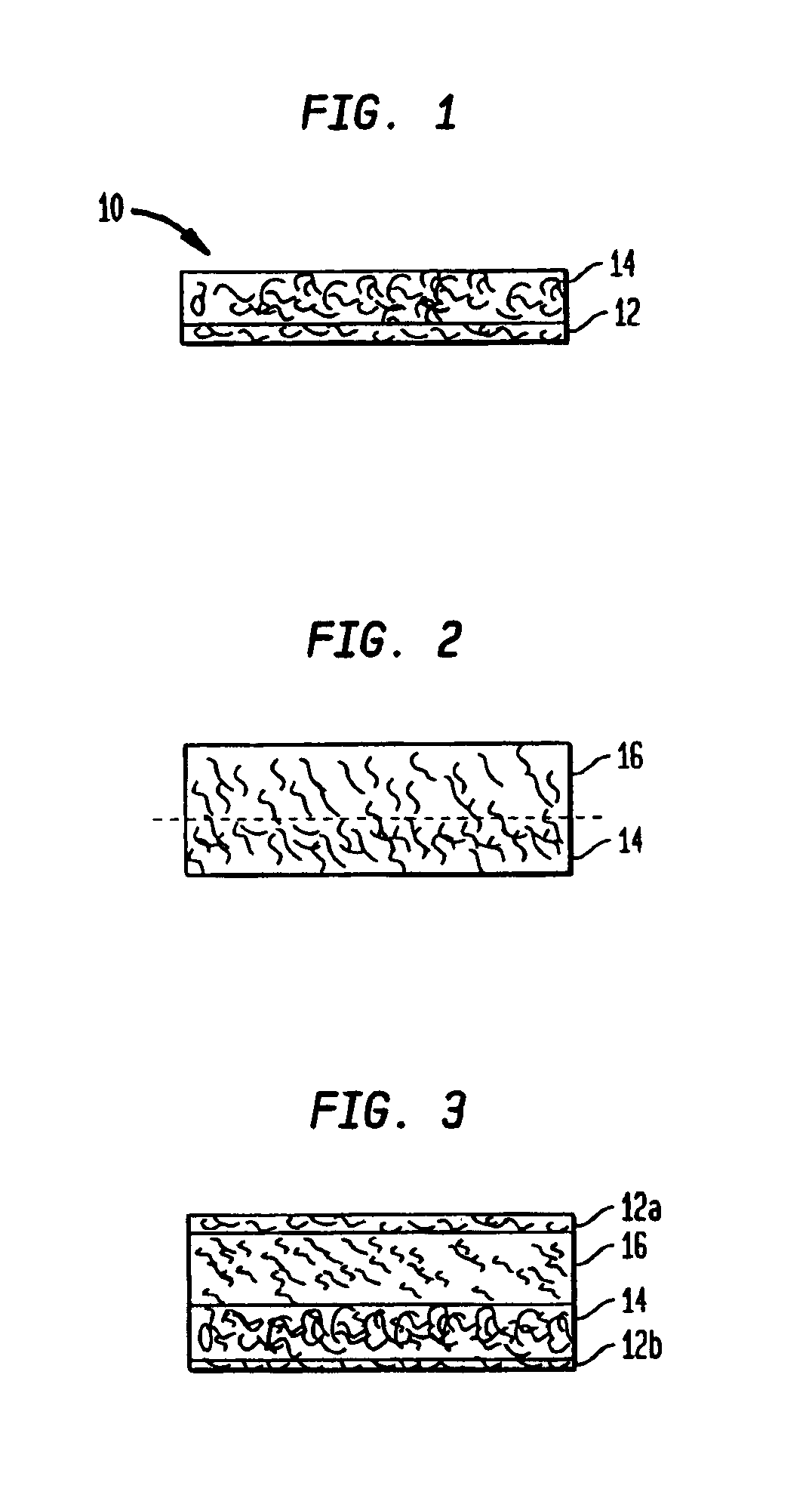

Filter medium and structure

ActiveUS20060096263A1Efficient removalHigh strengthDispersed particle filtrationTransportation and packagingFiberParticulates

Thermoplastic bicomponent binder fiber can be combined with other media, fibers and other filtration components to form a thermally bonded filtration media. The filtration media can be used in filter units. Such filter units can be placed in the stream of a mobile fluid and can remove a particulate load from the mobile stream. The unique combination of media fiber, bicomponent binder fiber and other filtration additives and components provide a filtration media having unique properties in filtration applications.

Owner:DONALDSON CO INC

Filter medium and breather filter structure

Thermoplastic bicomponent binder fiber can be combined with other media, fibers and other filtration components to form a thermally bonded filtration media. The filtration media can be used in filter units, such as breather caps. Such filter units can be placed in the stream of a mobile fluid and can remove a particulate and / or fluid mist load from the mobile stream. The unique combination of media fiber, bicomponent binder fiber and other filtration additives and components provide a filtration media having unique properties in filtration applications.

Owner:DONALDSON CO INC

Filter medium and structure

Owner:DONALDSON CO INC

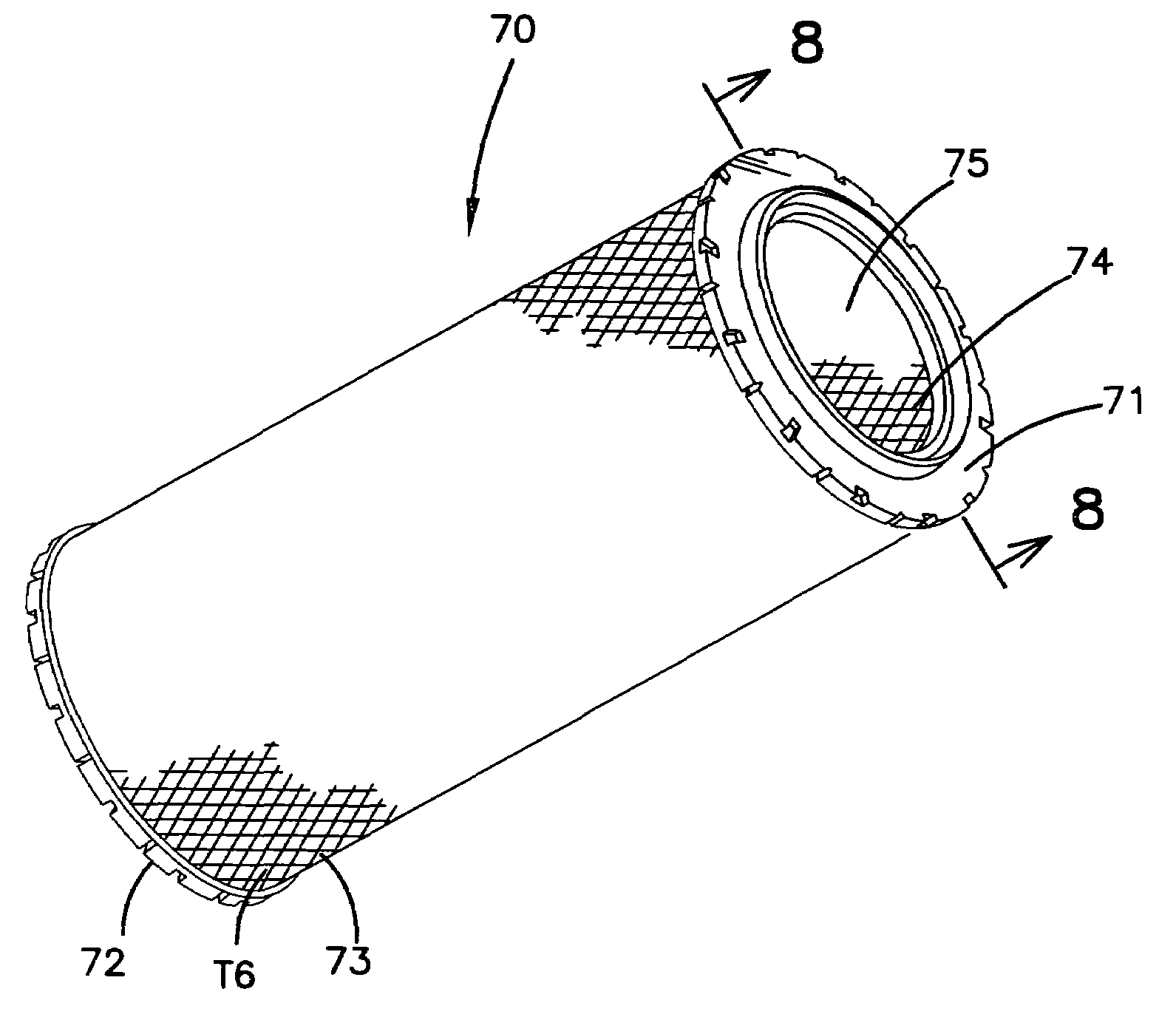

Filter element, air cleaner, and methods

InactiveUS6547857B2High strengthCombination devicesAuxillary pretreatmentClassical mechanicsFilter media

A filter arrangement includes a filter element, a frame construction secured to the filter element, and a handle member secured to the filter element. In preferred embodiments, the handle member is secured to the frame construction. Preferably, the filter element includes a central core member, wherein fluted filter media is coiled around the central core member. Preferably, the central core member includes a plurality of corrugations, wherein the corrugations mateably engage at least some flutes. Preferably, the handle member is integral with the central core member, and also includes a fastening member for connection to a frame construction on the filter element. Methods for cleaning air and servicing an air cleaner preferably include constructions as described herein.

Owner:DONALDSON CO INC

Vented vial adapter with filter for aerosol retention

A vented vial adapter has a filter attached to a vent arm that includes at least two filter media for suppressing aerosolized medicaments from leaving the vial and suppressing bacteria and other contaminants from entering the vial during reconstitution activities of the medication in the vial. The filter media allows the passage of air to the atmosphere outside the vial for pressure equalization. In another aspect, a third filter medium is used in the vent of the adapter to allow gas to pass in either direction through it, but prevents bacteria and particulate matter in the atmosphere from reaching the second filter device. A first filter is hydrophobic and prevents non-dispersed liquid from reaching the second filter, while conducting liquid dispersed in gas. The second filter absorbs the liquid dispersed in gas.

Owner:CAREFUSION 303 INC

Fiber containing filter media

InactiveUS20040038014A1Efficient removalLow efficiencySynthetic resin layered productsUltrafiltrationPolymer scienceFilter media

Improved filtration media or filter bodies can be made from fine fiber and can be formed into a filtration structure having no internal defects. The filter media or filter body comprises a collection of spot in fiber with defined fiber diameter, layer thickness and media solidity. The fine fiber is formed into a media body and obtains substantial flux and filtration efficiency. The filtration media or body can comprise single or multiple layers of fine fiber combined into the improved filter body.

Owner:DONALDSON CO INC

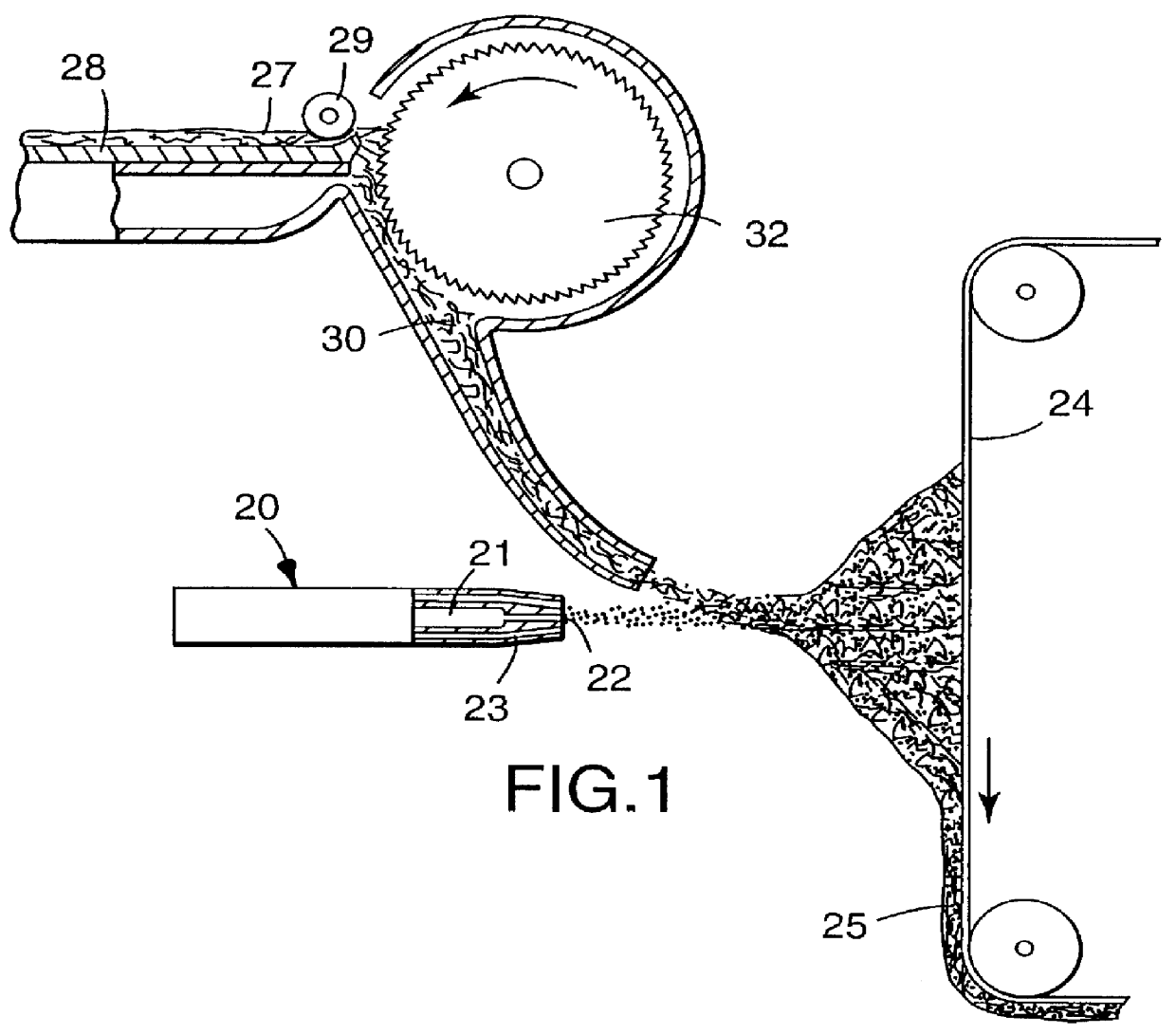

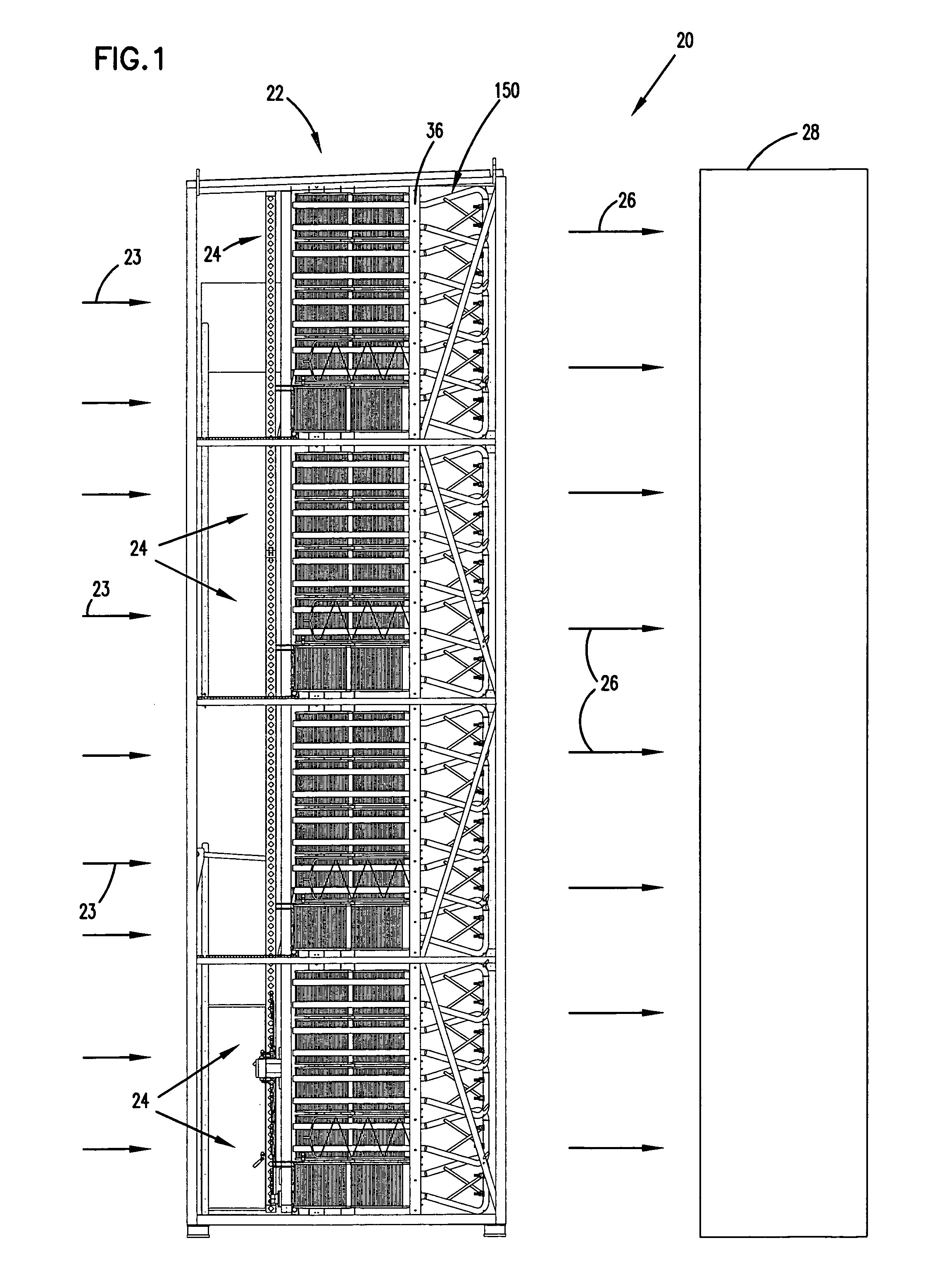

Z-filter media with reverse-flow cleaning systems and methods

A method for cleaning a filter having Z-media includes providing a filter having Z-media and cleaning the media construction by directing a pulse of compressed gas into the media construction through the downstream flow face. Filter elements useable with such methods include elements made of Z-media. An example system utilizing the method includes a gas turbine air intake system.

Owner:DONALDSON CO INC

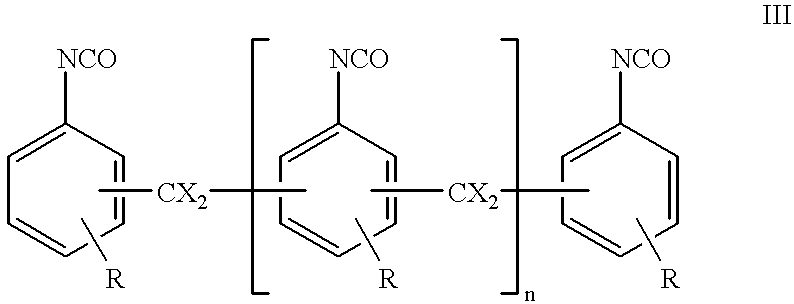

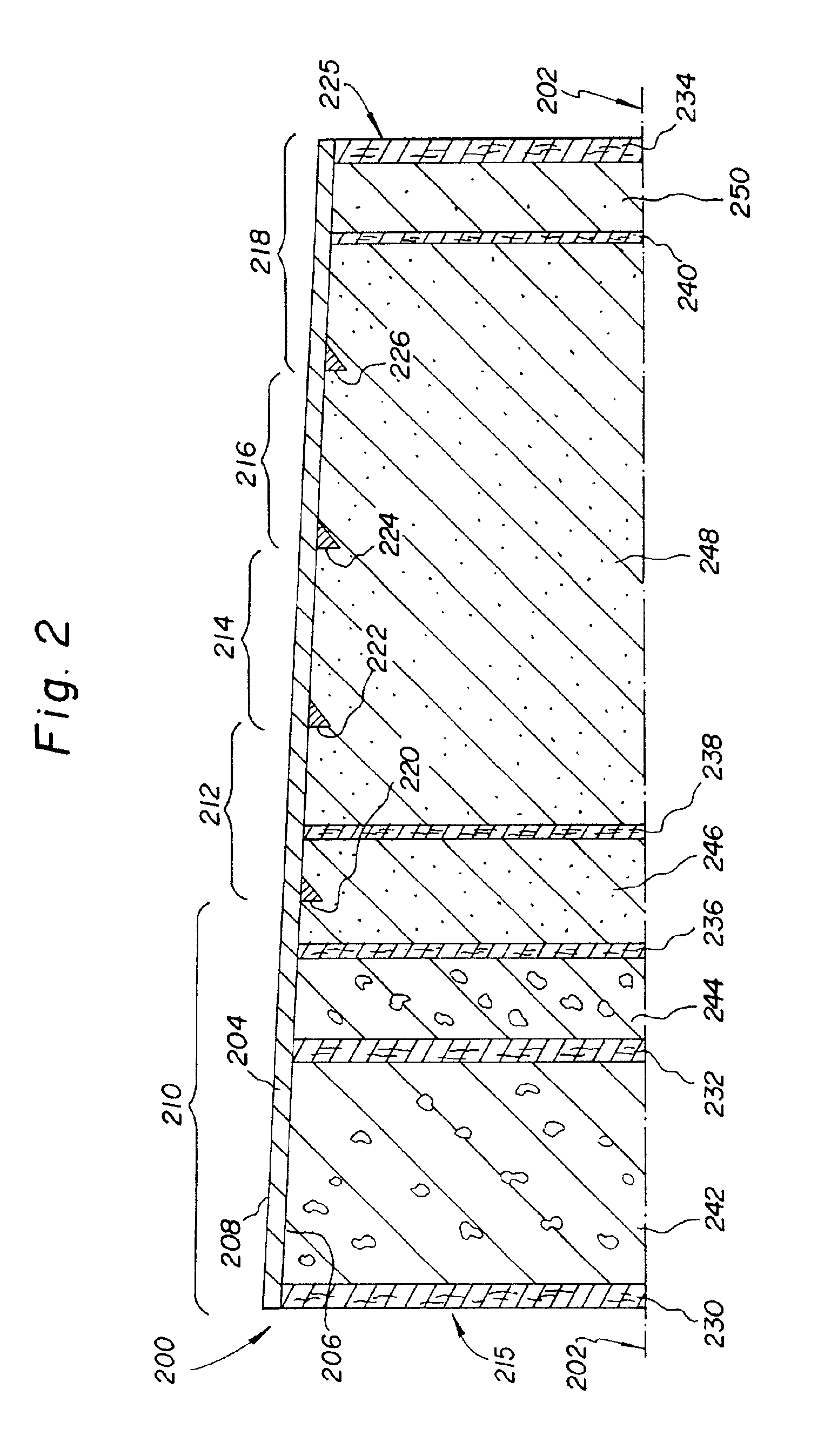

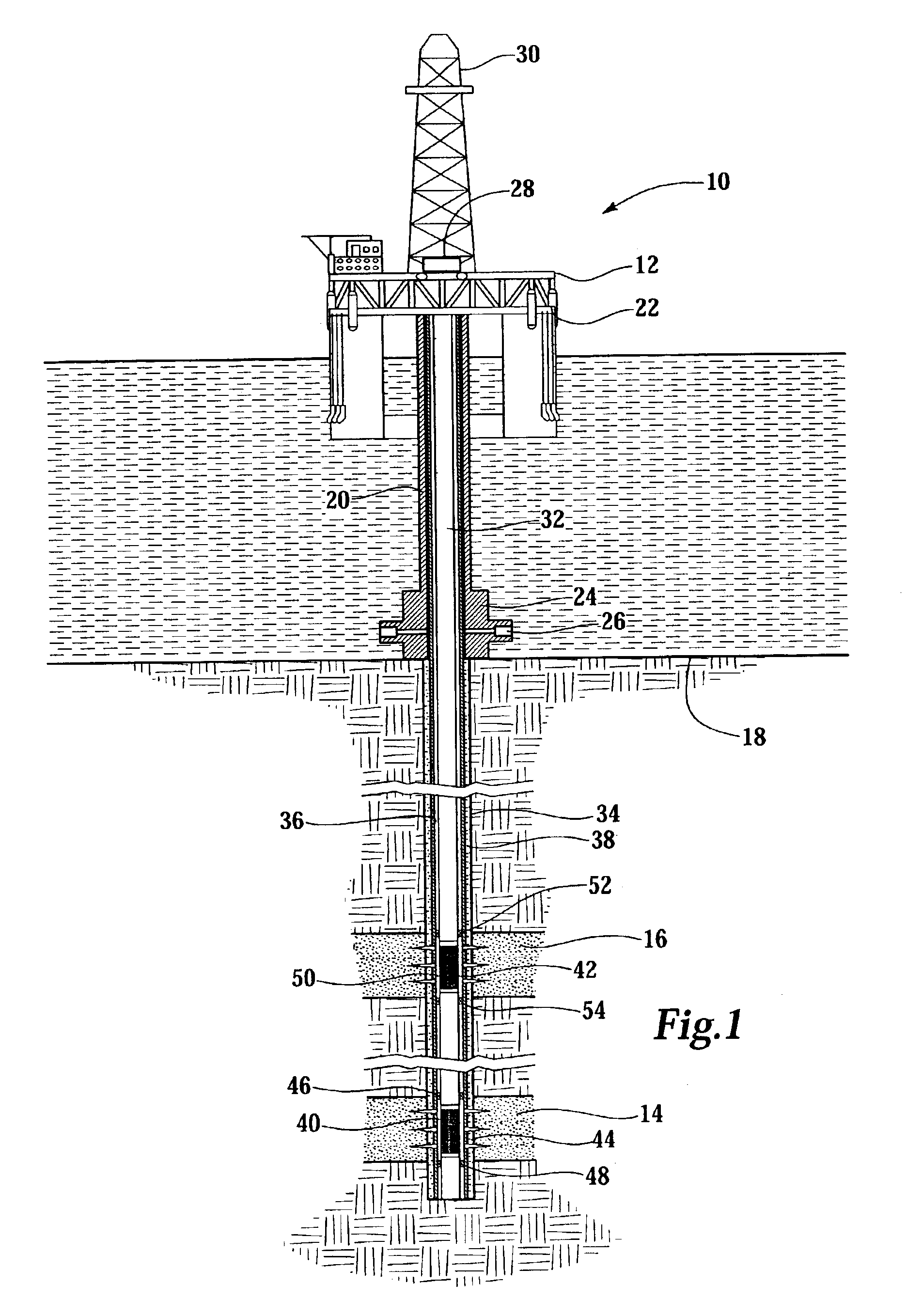

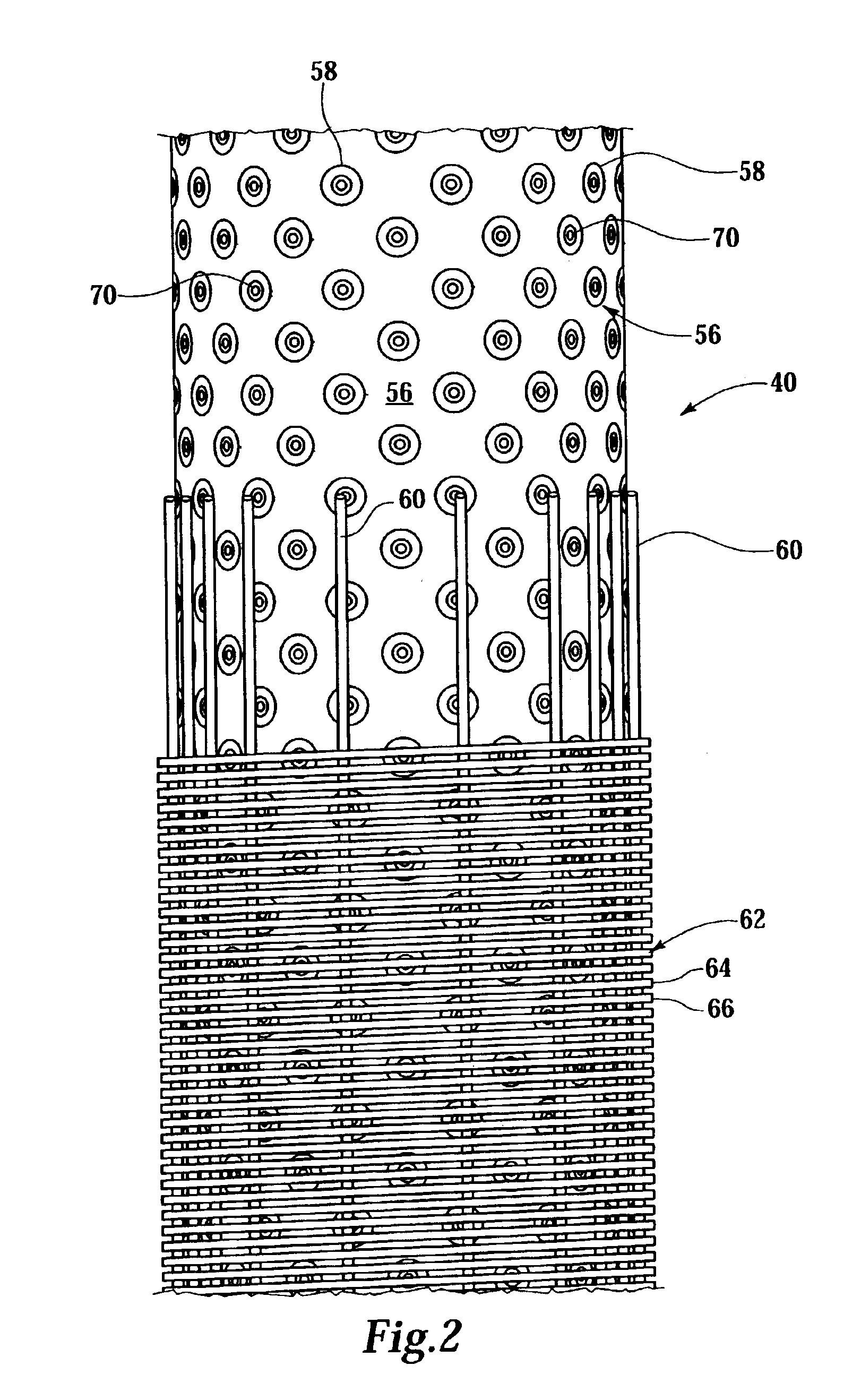

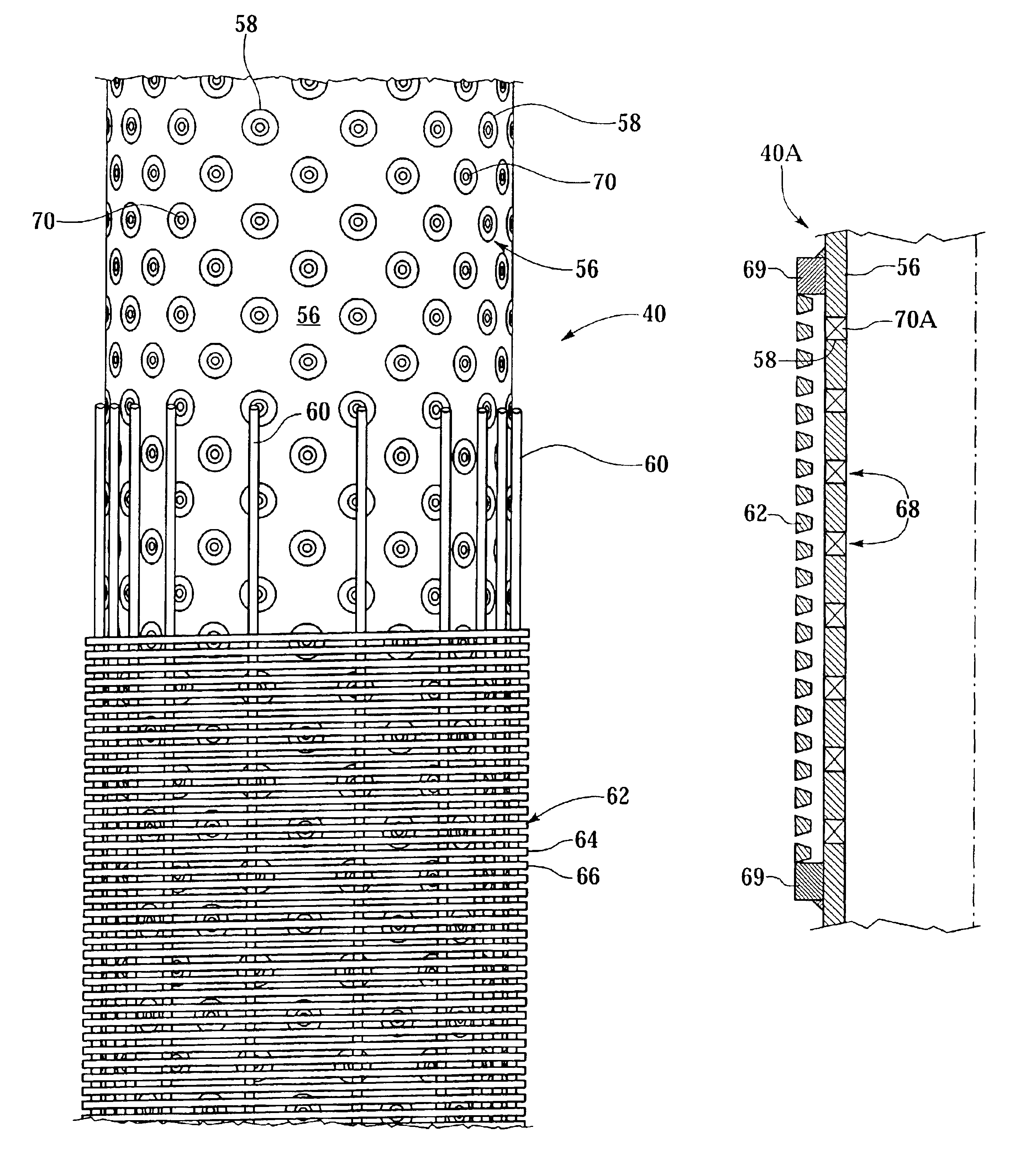

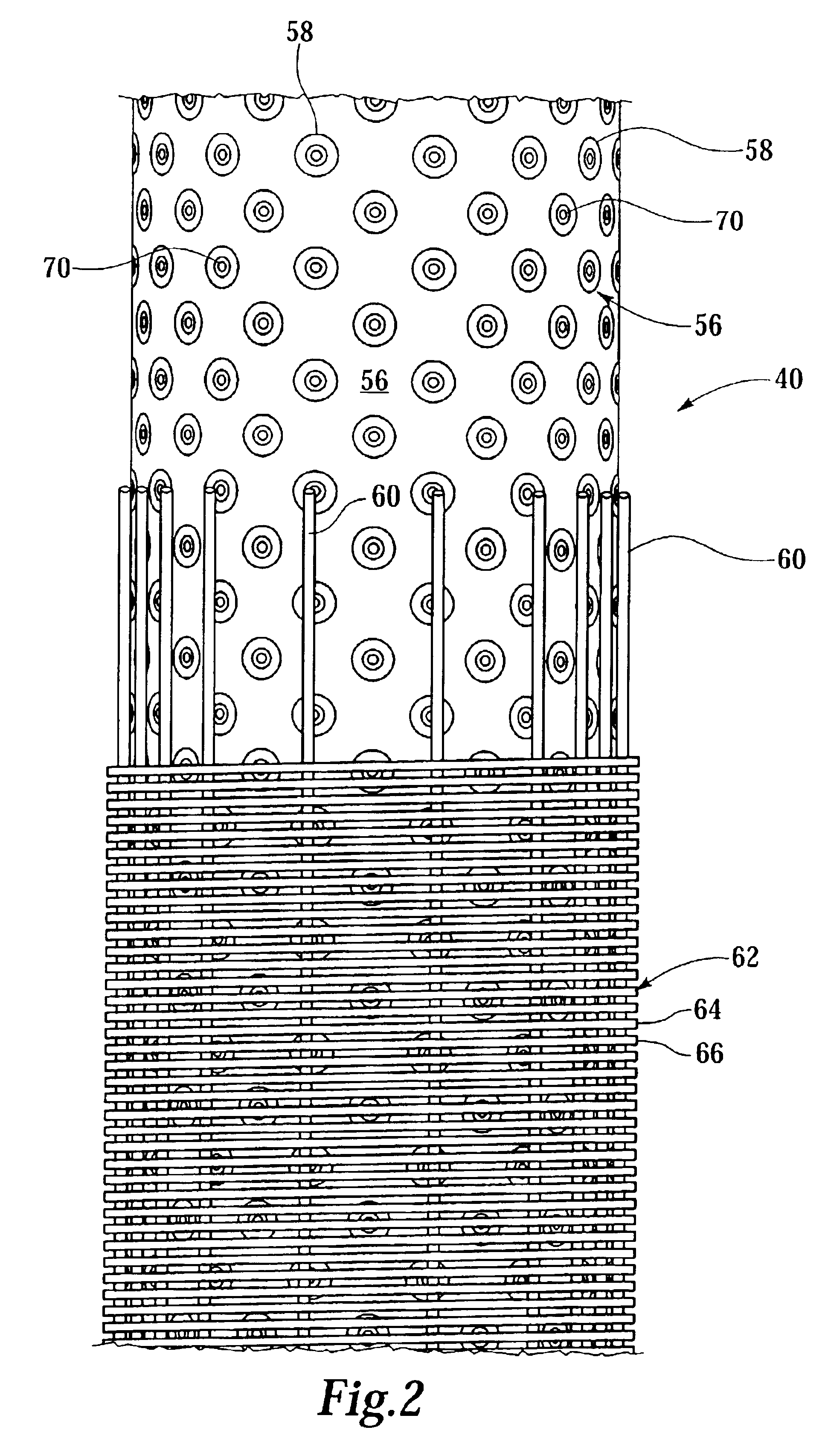

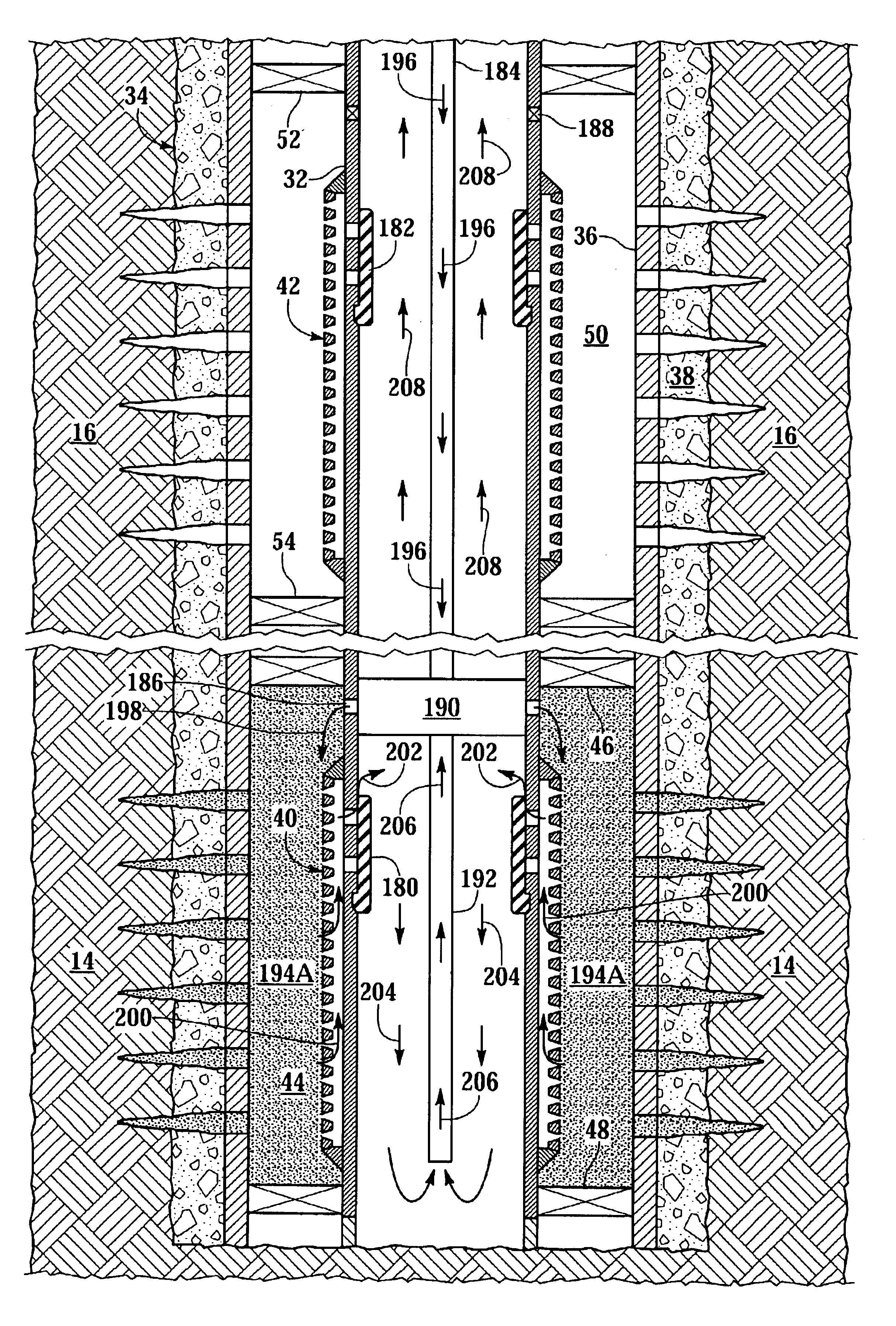

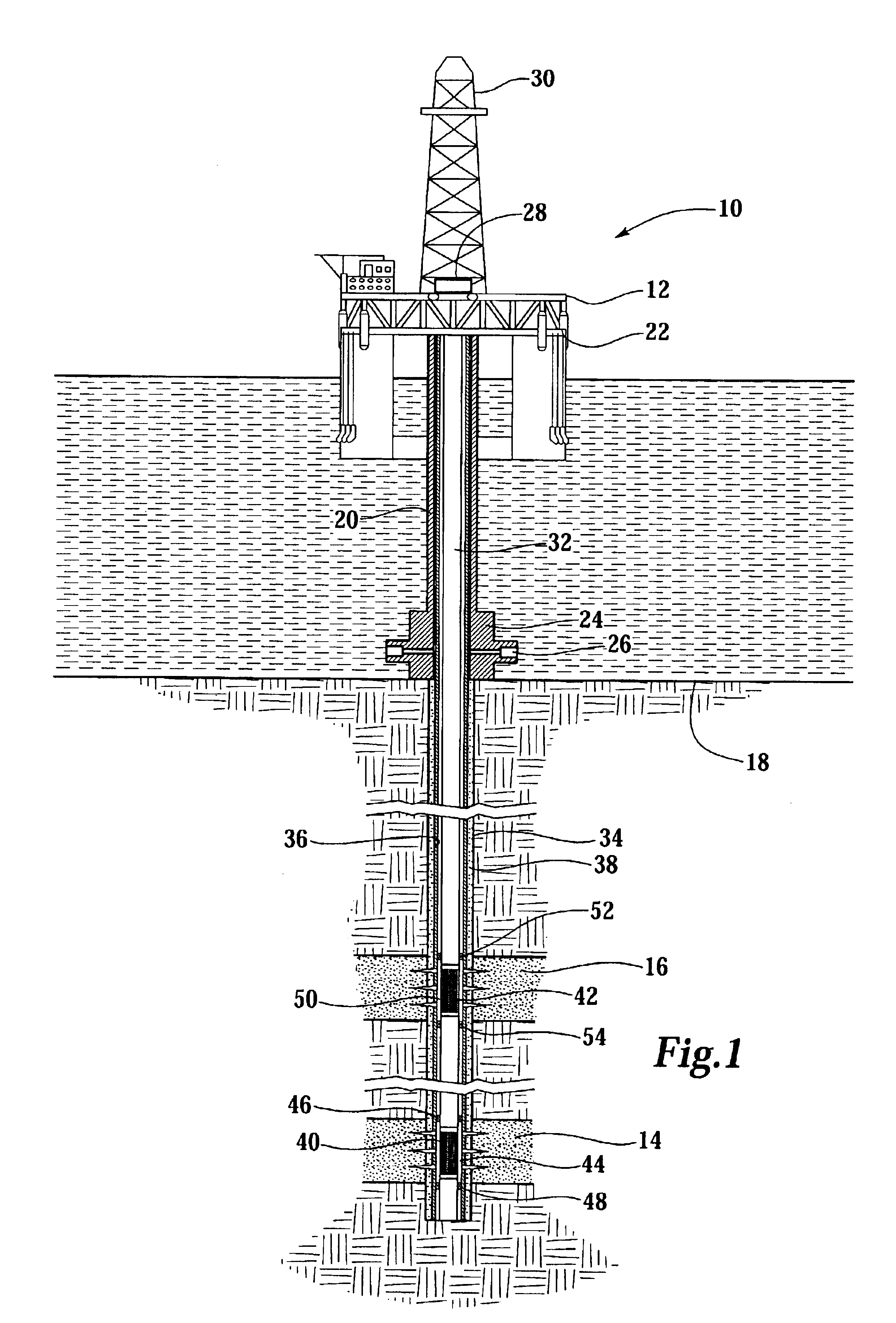

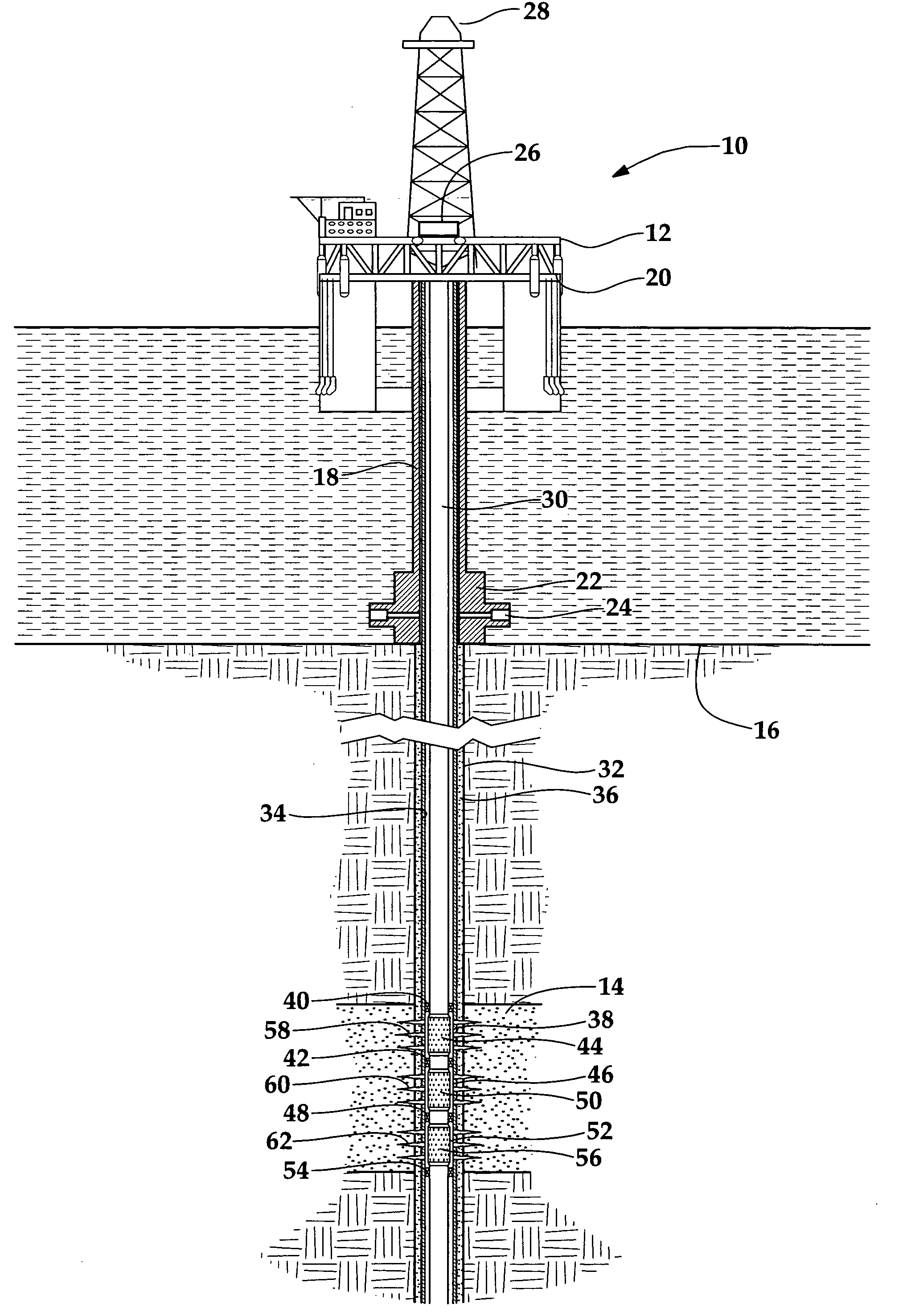

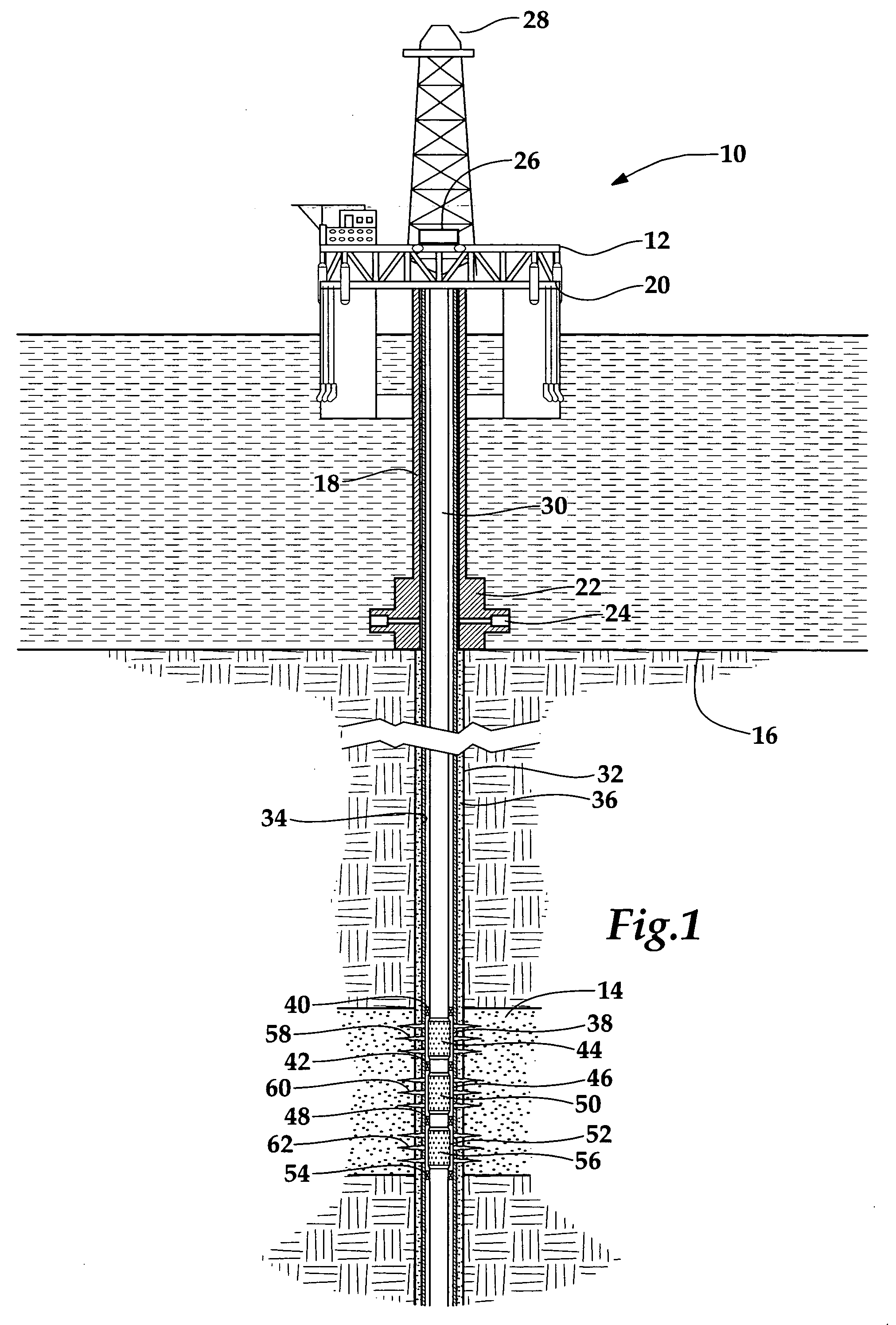

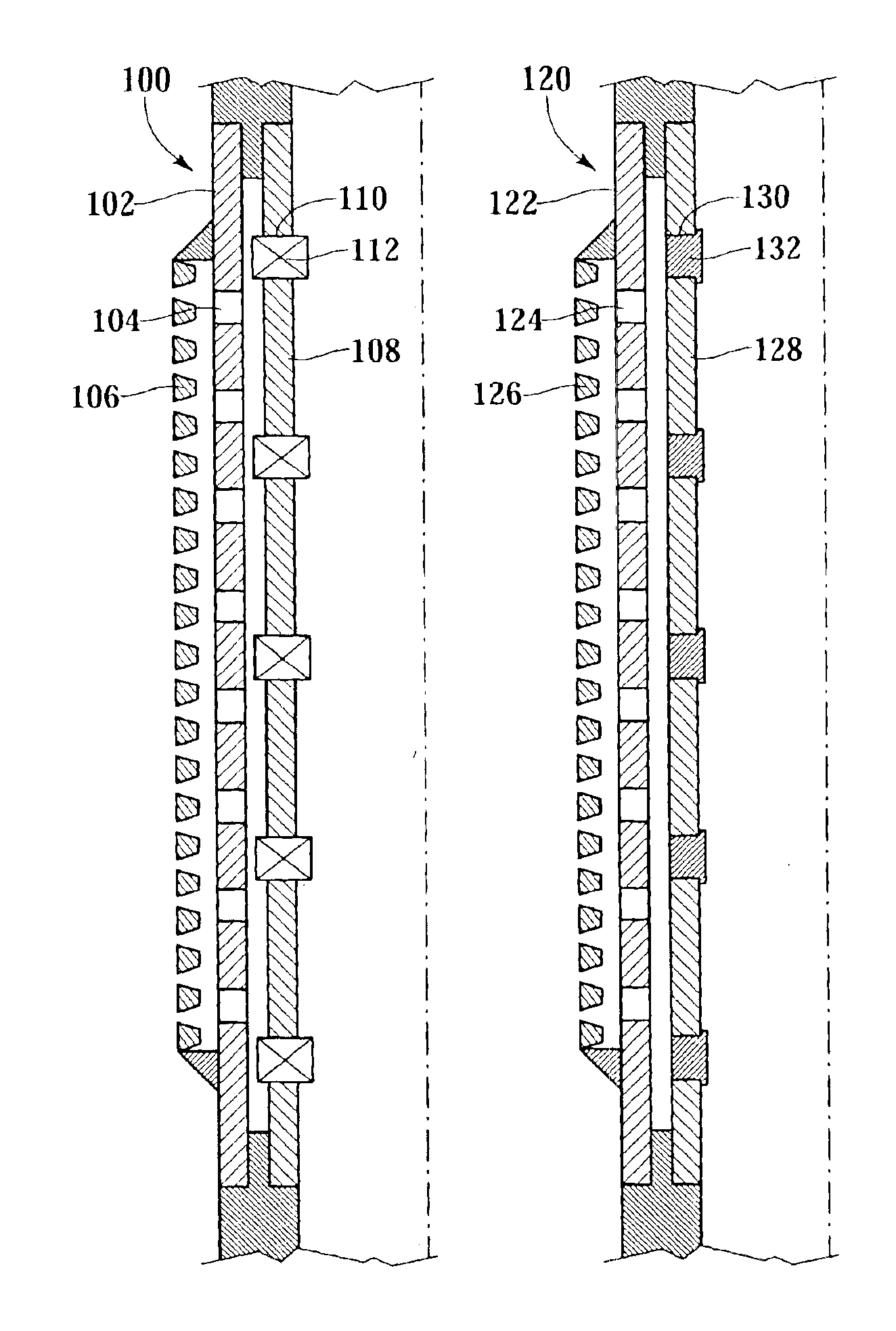

Sand control screen assembly and treatment method using the same

A sand control screen assembly (40) and method for treating formations traversed by a wellbore (34) in a single trip are disclosed. The sand control screen assembly (40) includes a base pipe (56) with a plurality of openings (58) that allow fluid flow therethrough. A filter medium (62) is positioned about the exterior of the base pipe (56) to filter particulate matter out of the production fluids. One-way valves (70) are operably associated within the openings (58) of the base pipe (56) to prevent fluid flow from the interior of the base pipe (56) to the exterior of the base pipe (56) during a treatment process. The one-way valves (70), however, are actuatable to allow fluid flow from the exterior of the base pipe (56) to the interior of the base pipe (56) to allow production of fluids from the formation (14).

Owner:HALLIBURTON ENERGY SERVICES INC

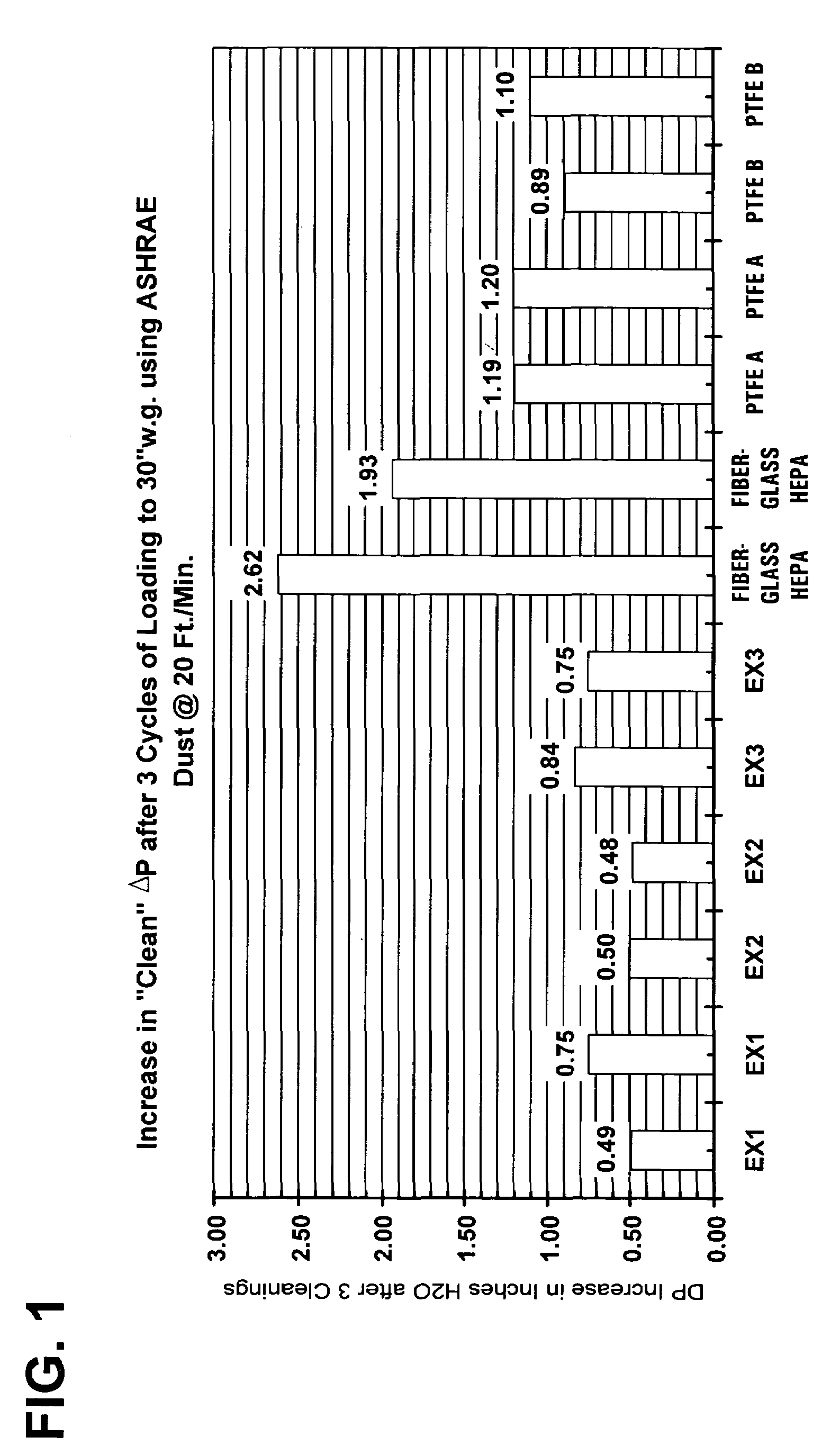

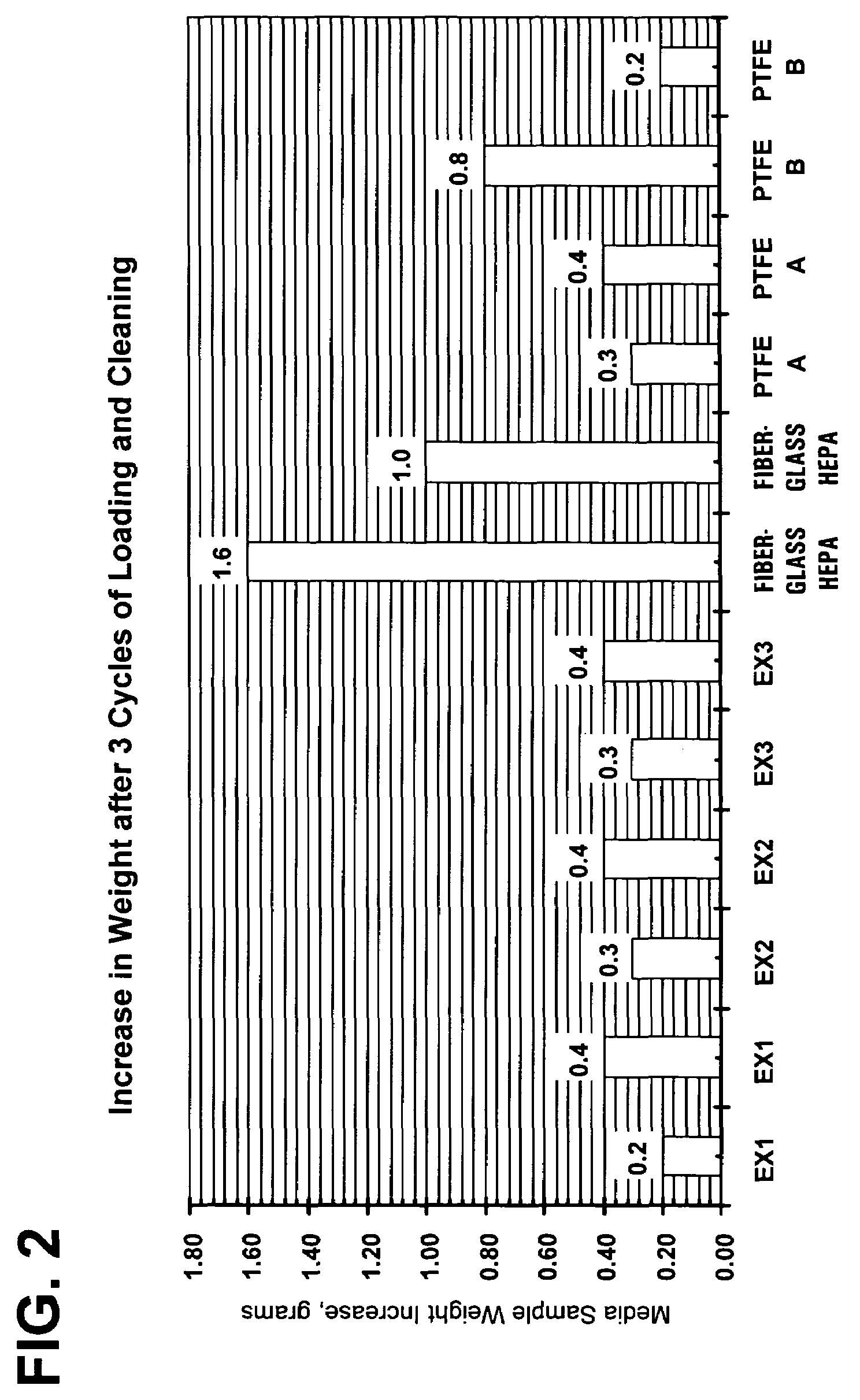

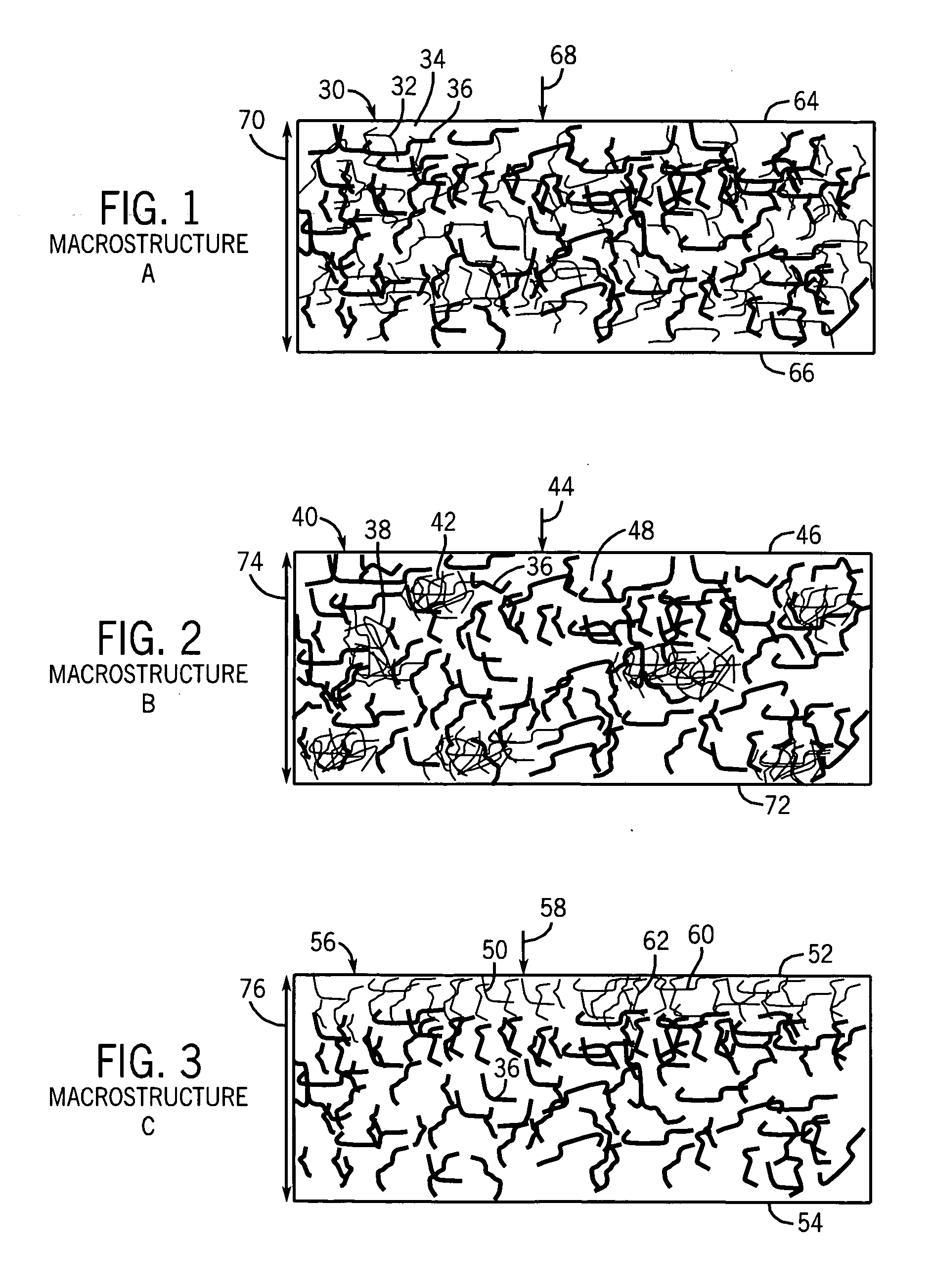

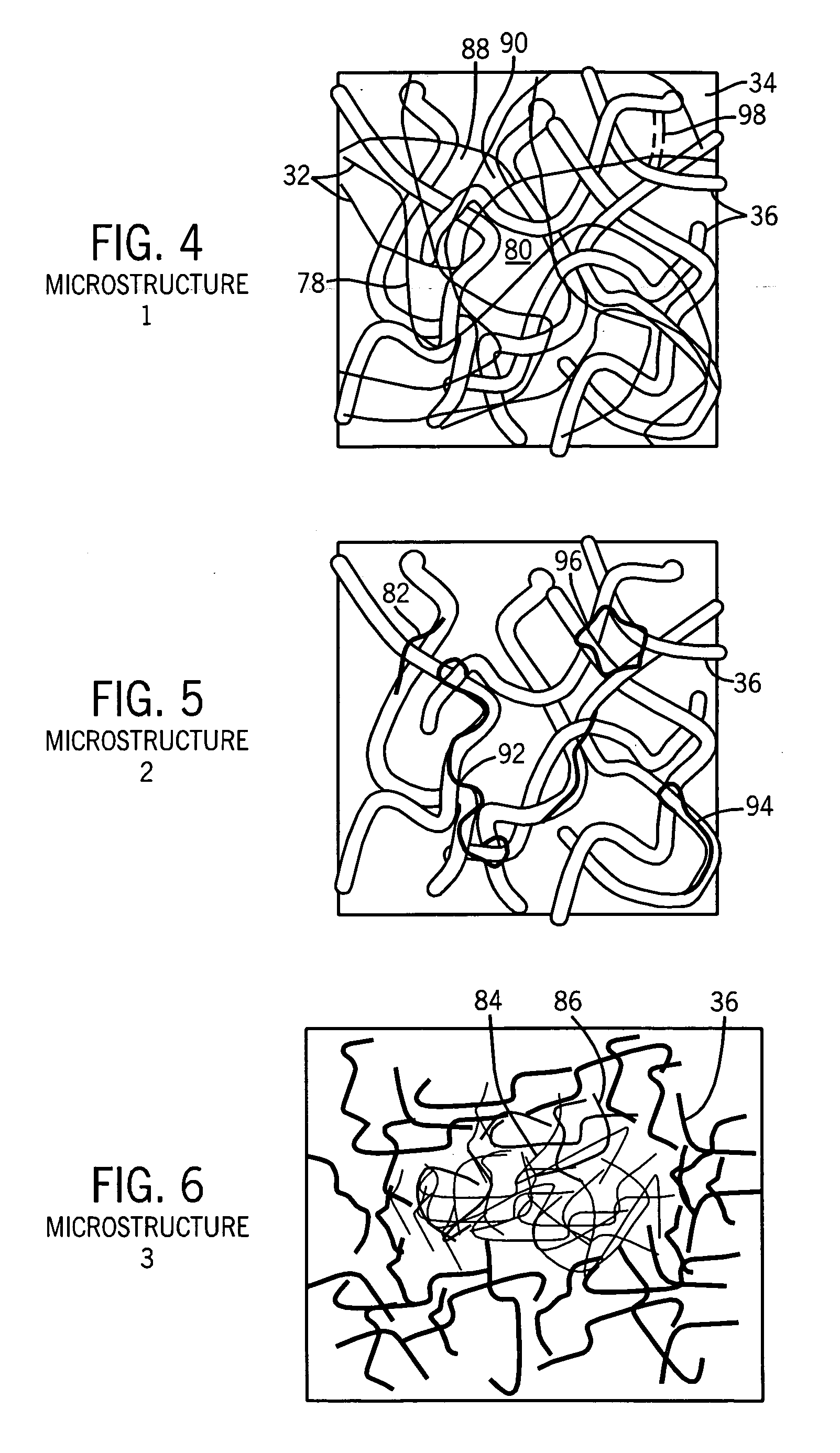

Filter media

InactiveUS6858057B2Lower performance requirementsEnhanced filtration performance characteristicCombination devicesOther chemical processesFilter mediaEngineering

A filter media comprising a synthetic microfiber polymer fine fiber web wherein the diameter of the fibers is between about 0.8 to about 1.5 microns. The filter media is acceptable for use in ASHRAE applications. Constructions with a low DP backing, support or prefilter layers of coarse fiber provide large area filter webs of high efficiency and a stable and high threshold value of alpha above eleven.

Owner:HOLLINGSWORTH VOSE

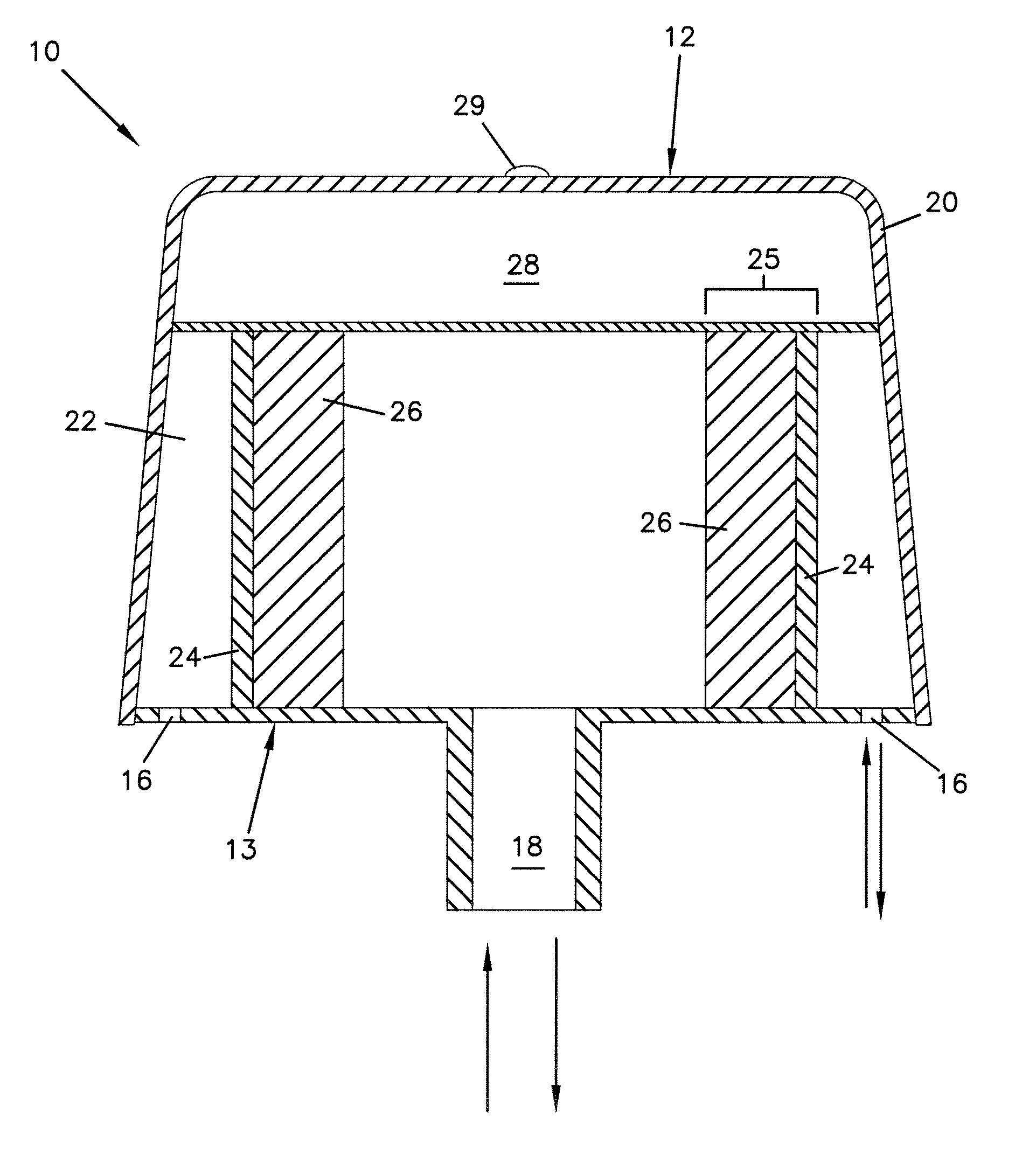

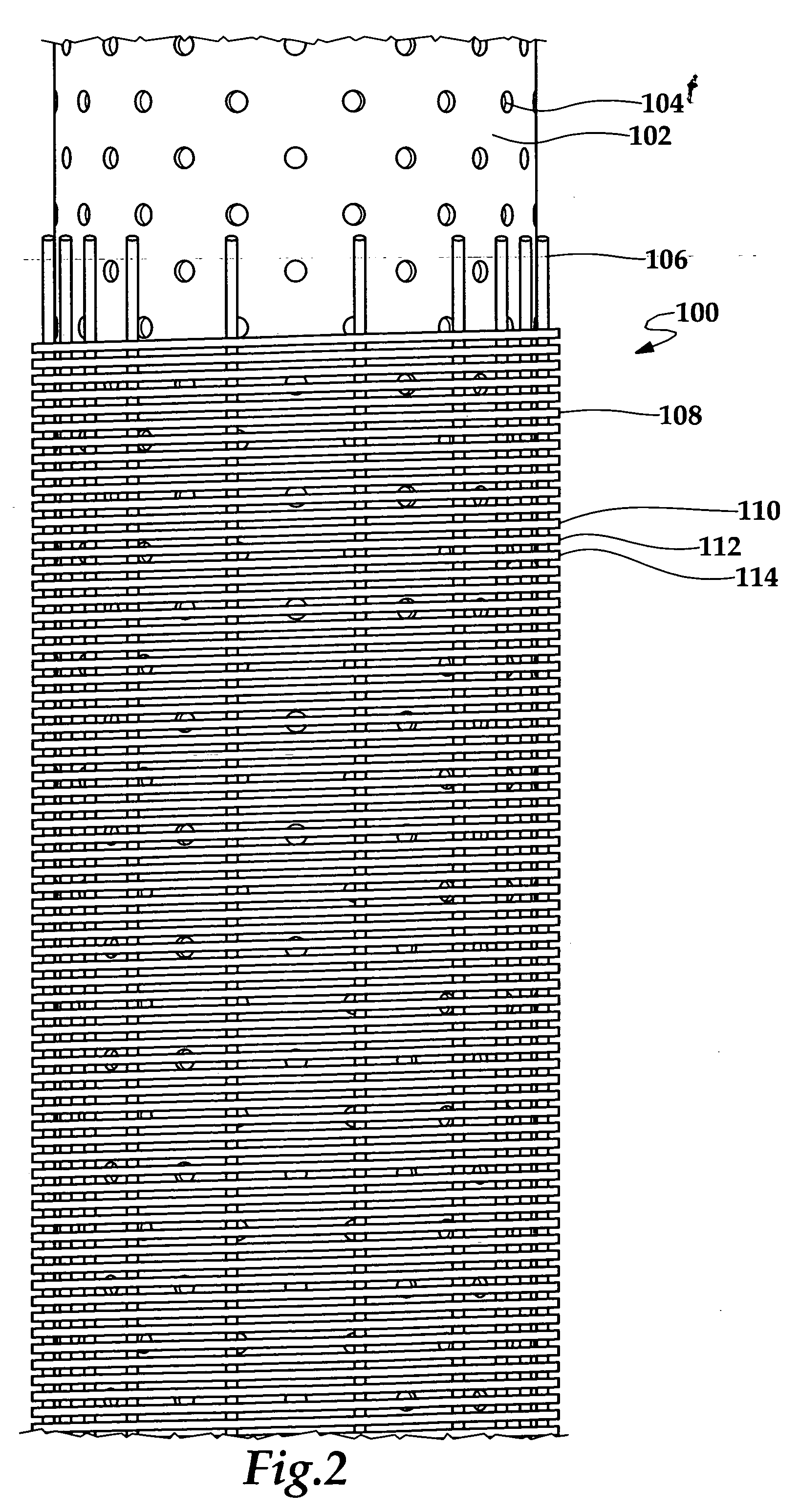

Sand control screen assembly having an internal seal element and treatment method using the same

InactiveUS6857476B2Avoid flowAvoid lostFluid removalDrinking water installationParticulatesFilter media

A sand control screen assembly (90) that is positionable within a wellbore comprises a base pipe (92) having a blank pipe section (94) and a perforated section (96) having at least one opening (98) that allows fluid flow therethrough. A filter medium (100) is positioned about the exterior of the base pipe (92) that selectively allows fluid flow therethrough and prevents particulate of a predetermined size from flowing therethrough. An internal seal element (104) is positioned at least partially within the perforated section (96) of the base pipe (92). The internal seal element (104) controls the flow of fluid through the opening (98) of the base pipe (92) such that fluid flow is prevented from the interior to the exterior of the sand control screen assembly (90) but is allowed from the exterior to the interior of the sand control screen assembly (90).

Owner:HALLIBURTON ENERGY SERVICES INC

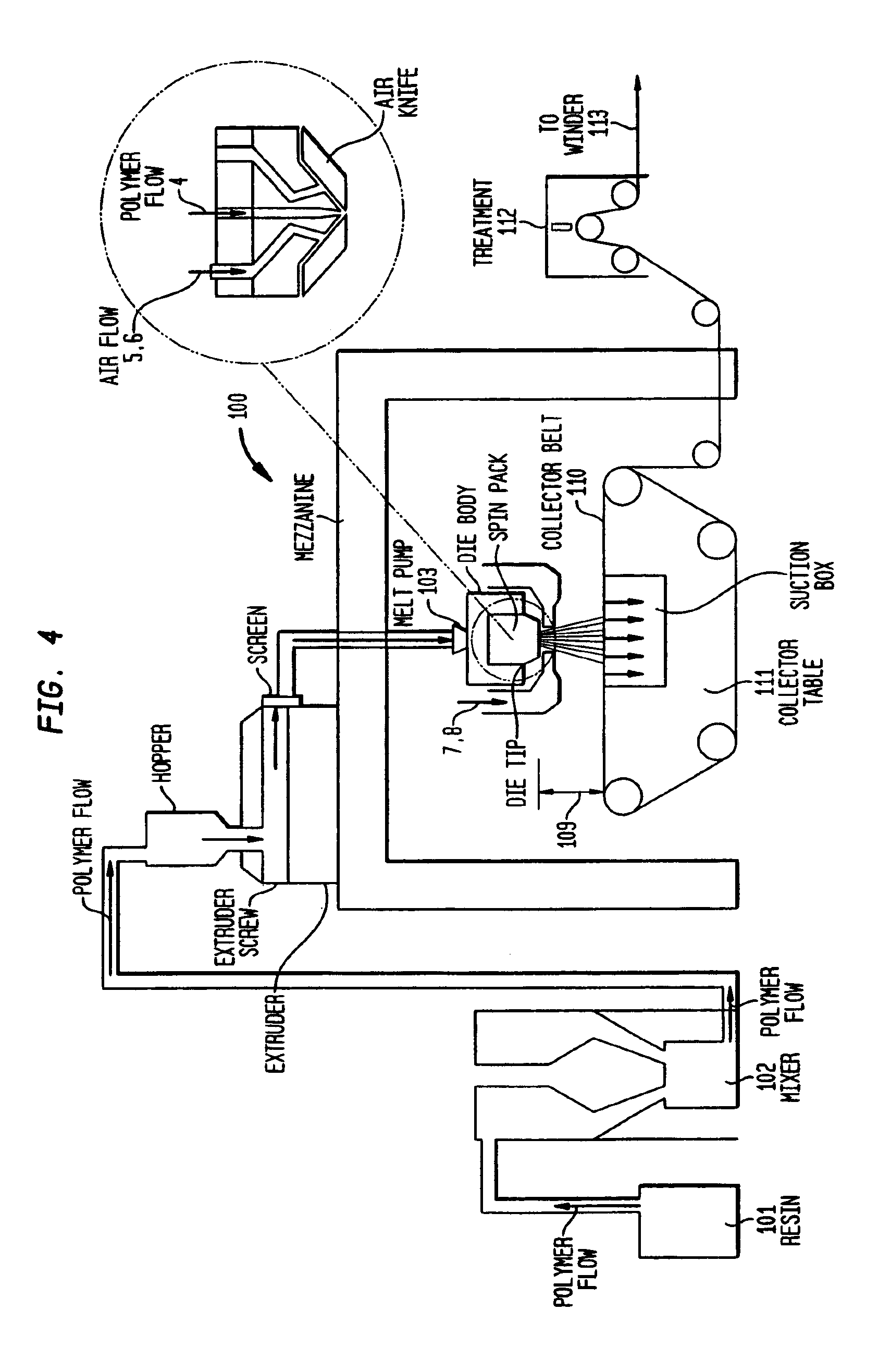

High performance filter media with internal nanofiber structure and manufacturing methodology

InactiveUS20050026526A1Improve performanceImprove efficiencyOther chemical processesIndividual molecule manipulationFiberNanofiber

High performance filter media and manufacturing methodology provides nanofibers of diameter less than 1 μm incorporated and processed into internal structure of a filter medium dominantly composed of coarse fibers of diameter greater than 1 μm, to change the internal media structure.

Owner:FLEETGUARD INC

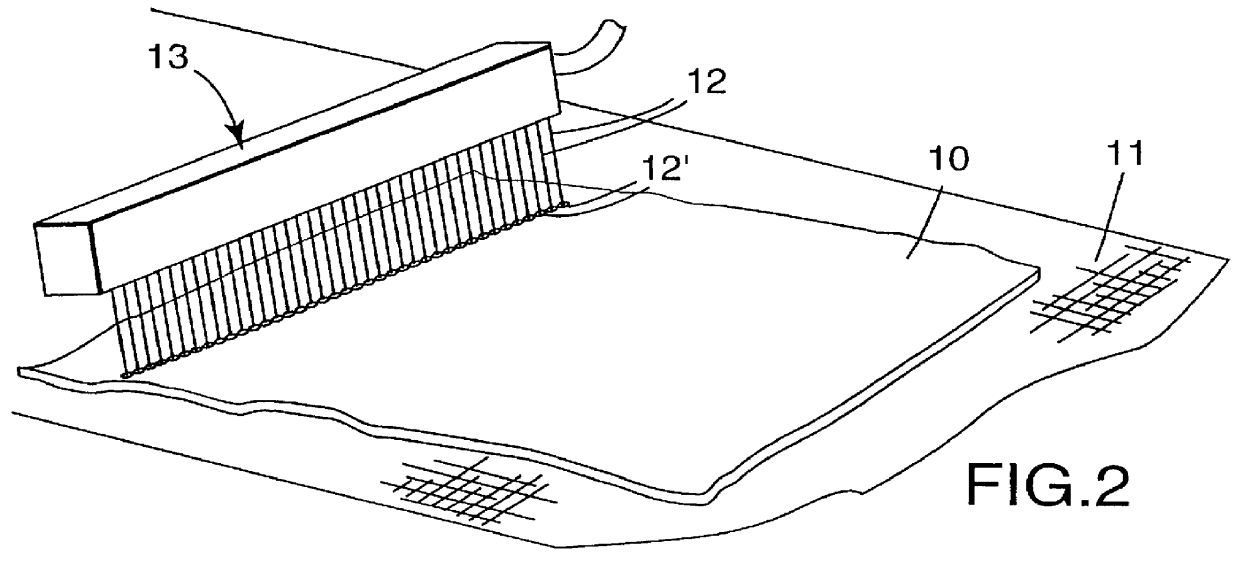

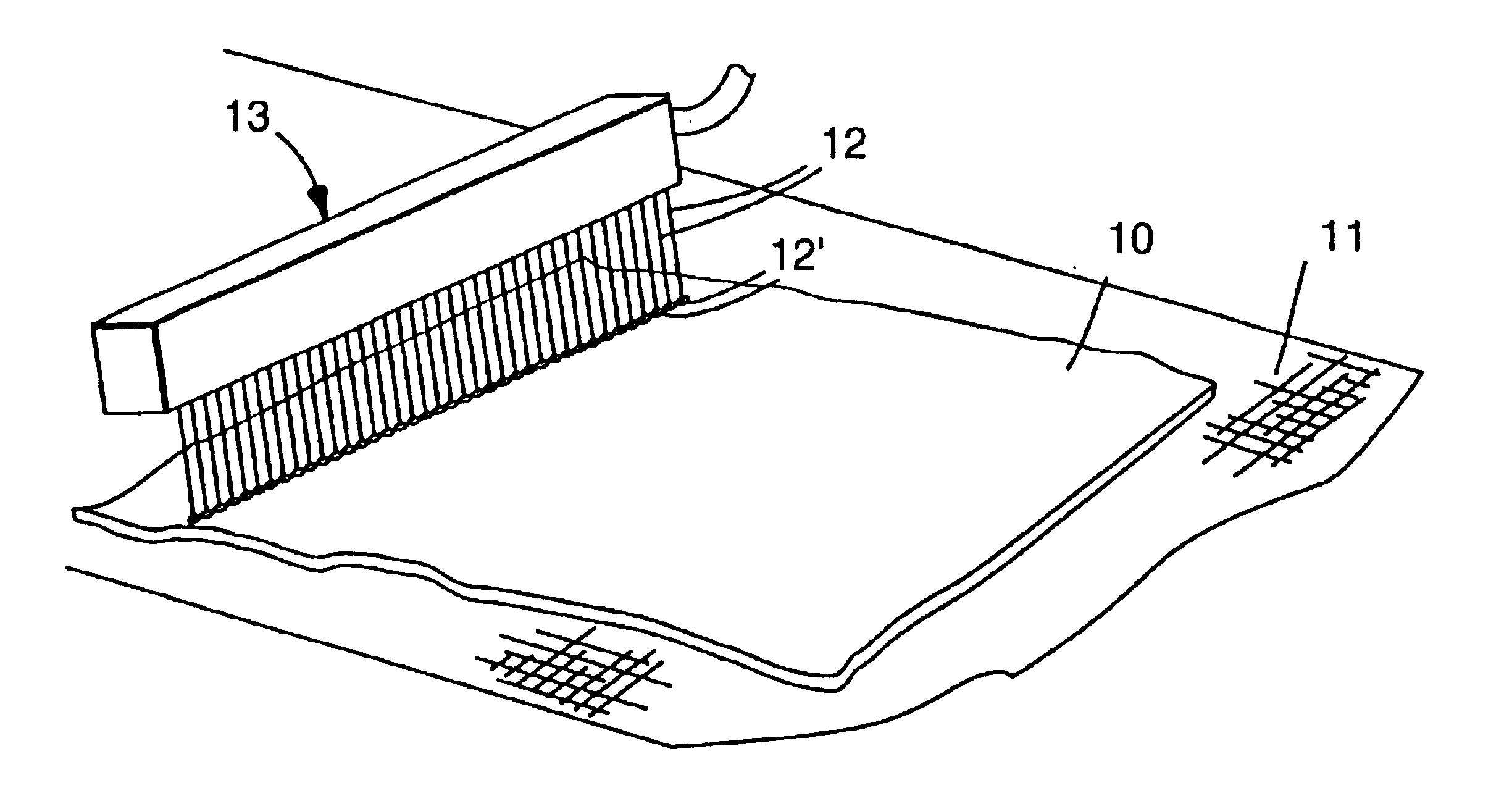

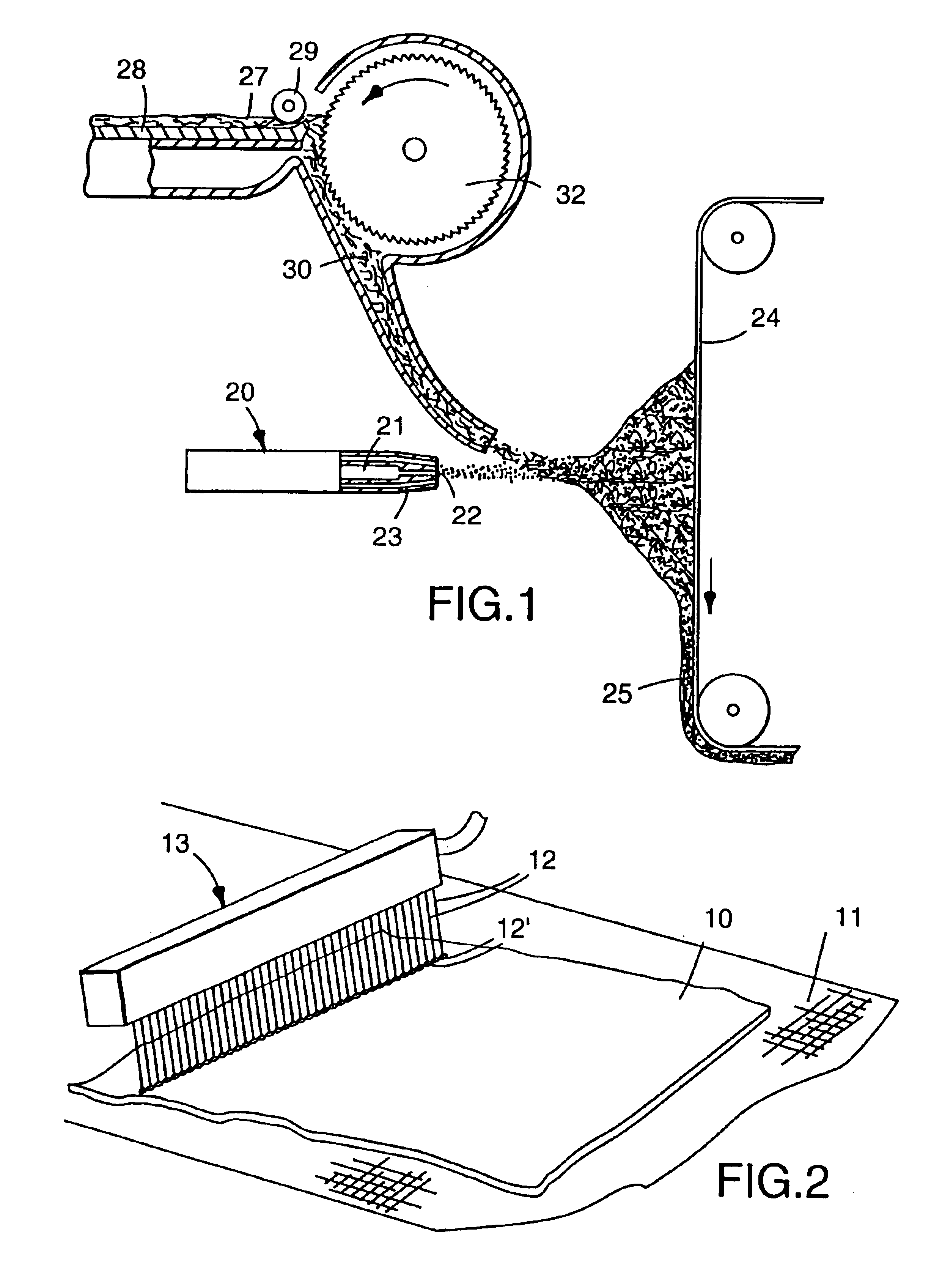

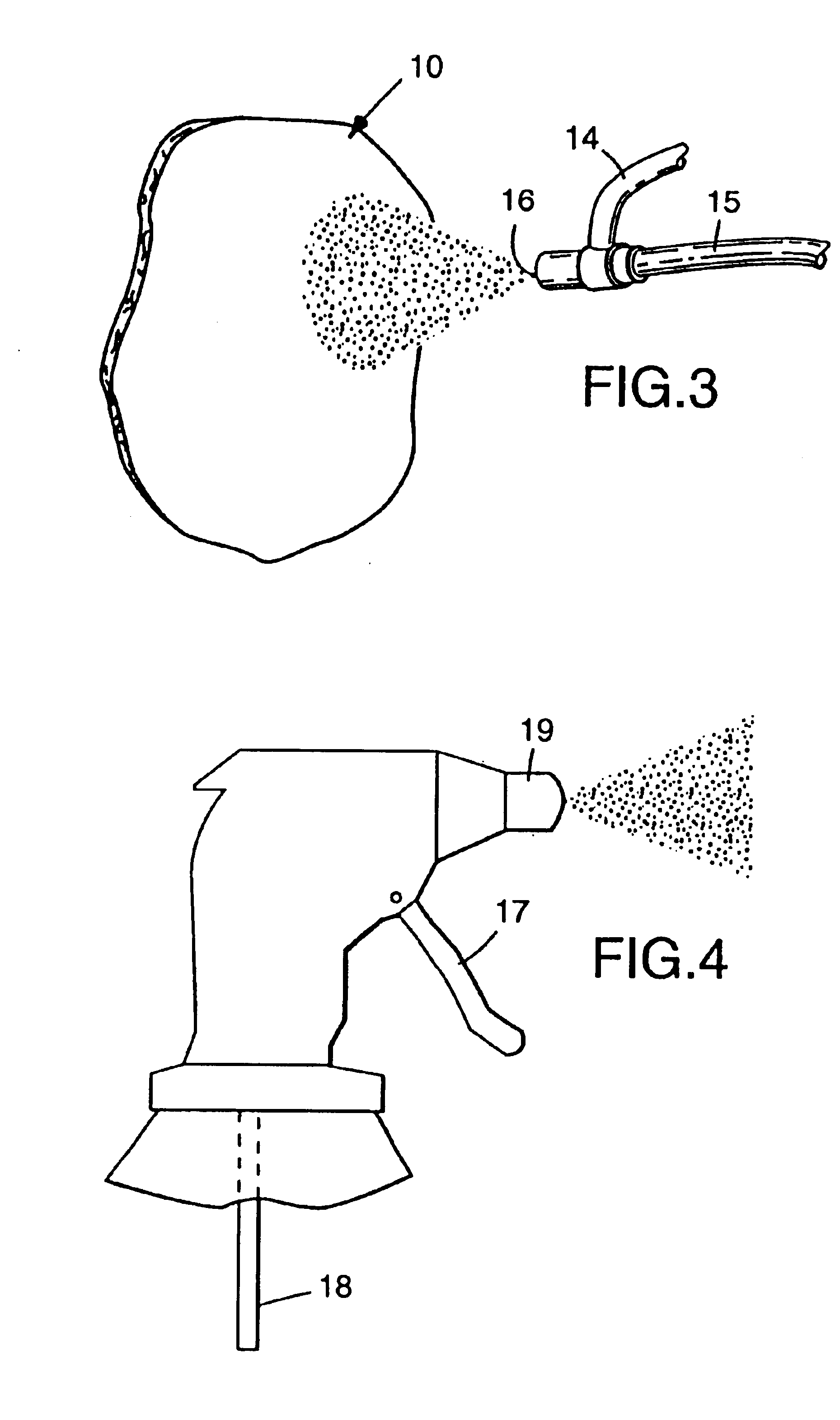

Gathered filter media for an air filter and method of making same

ActiveUS20060091066A1Reduce complexityReduce manufacturing costGas treatmentMechanical working/deformationAir filterFilter media

A filter media including a gathered sheet of porous filter material, is provided, together with an apparatus and method for fabricating such a gathered sheet of porous filter material. An improved filter apparatus incorporating such gathered porous filter material is also provided. By gathering the porous filter material, rather than forming convolutions through corrugating or pleating, as was done in the past, a desirable convoluted shape is achieved with little or no compression of the filter media.

Owner:BALDWIN FILTERS

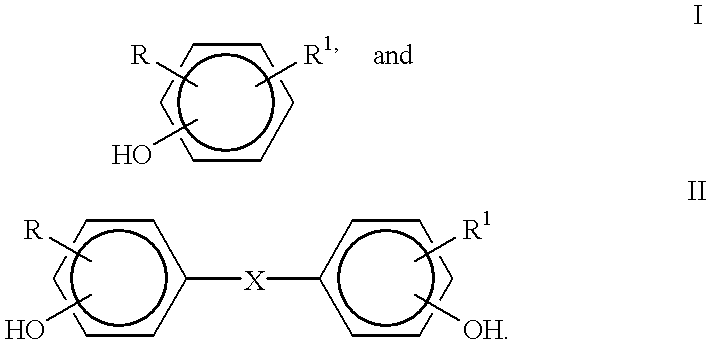

Coated filter media

InactiveUS20060231487A1Fine surfaceImprove abilitiesSemi-permeable membranesIsotope separationPolymer scienceFilter media

The invention relates to a coating composition on the surface of a filtration media. In particular, the invention relates to a coating composition for a filtration media comprising at least one polymer; at least one crosslinking agent; and optionally at least one compatabilizing agent.

Owner:THE LUBRIZOL CORP

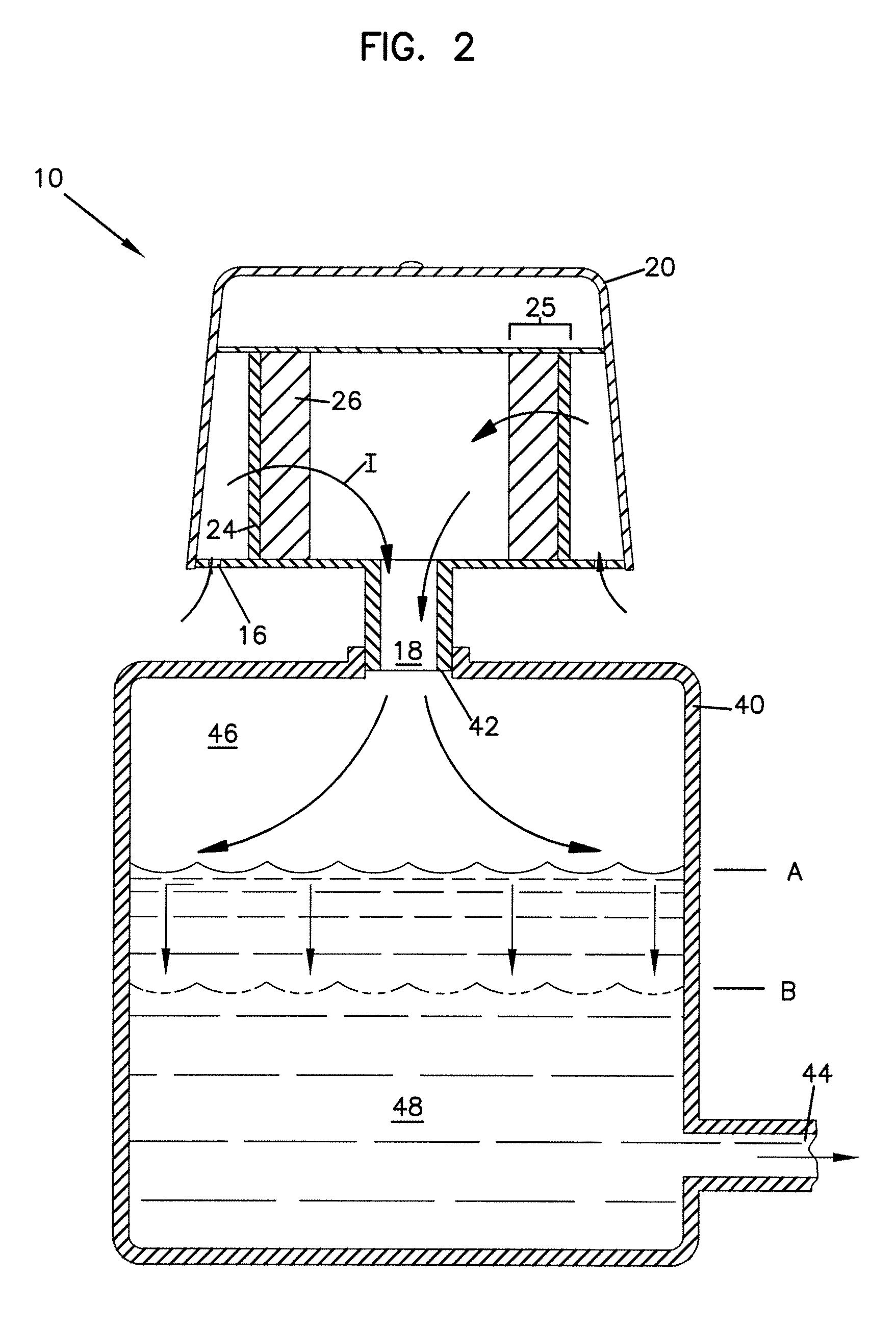

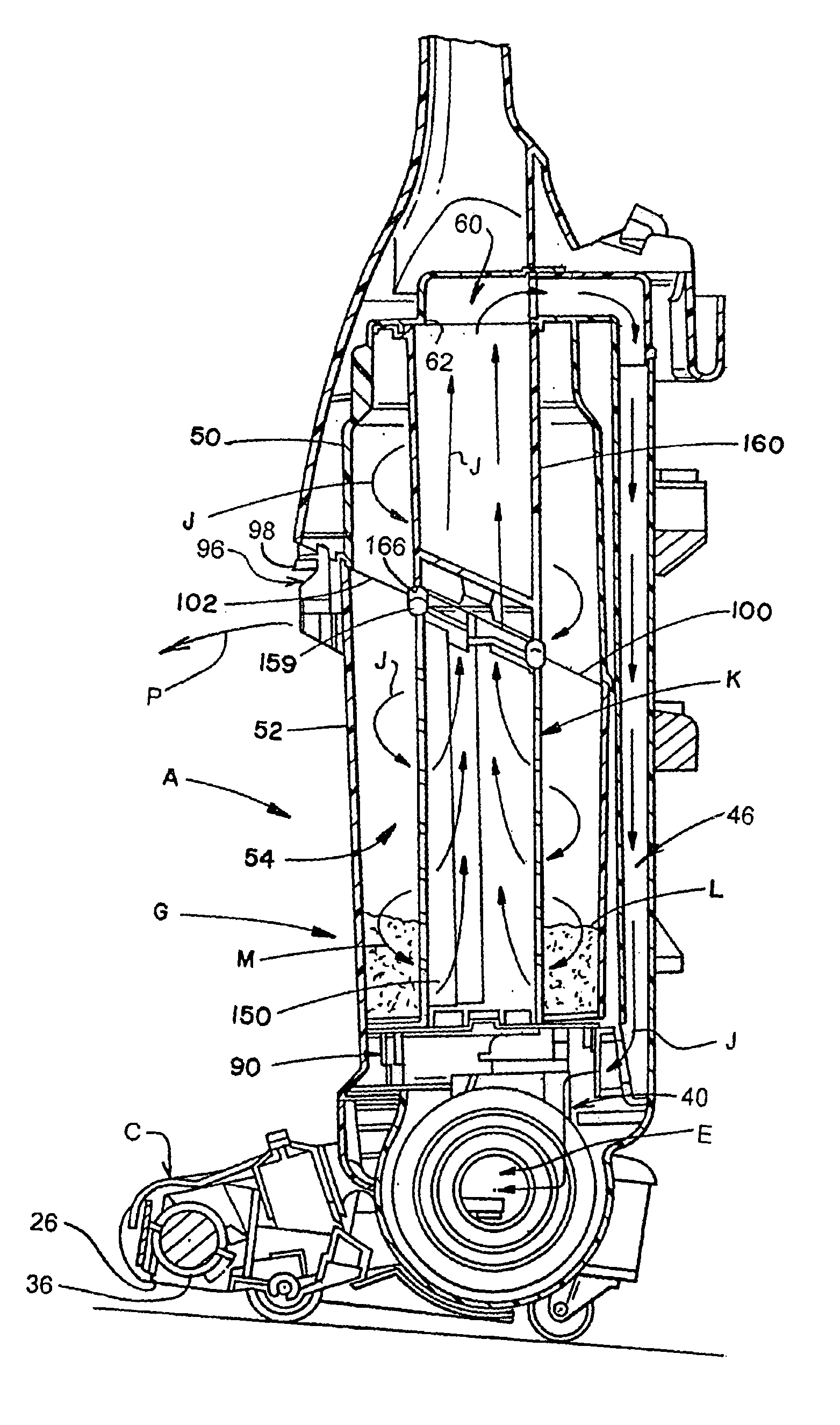

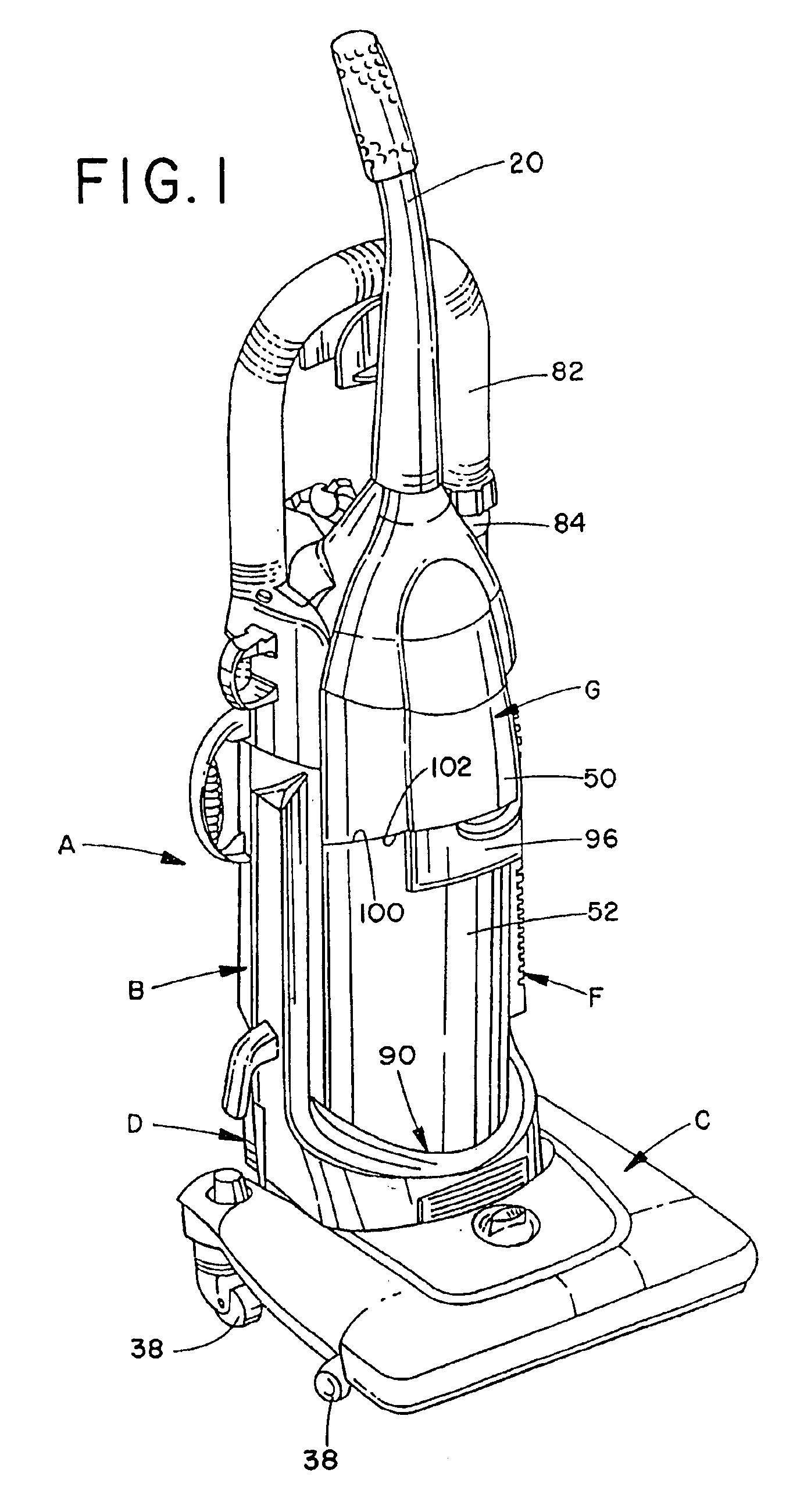

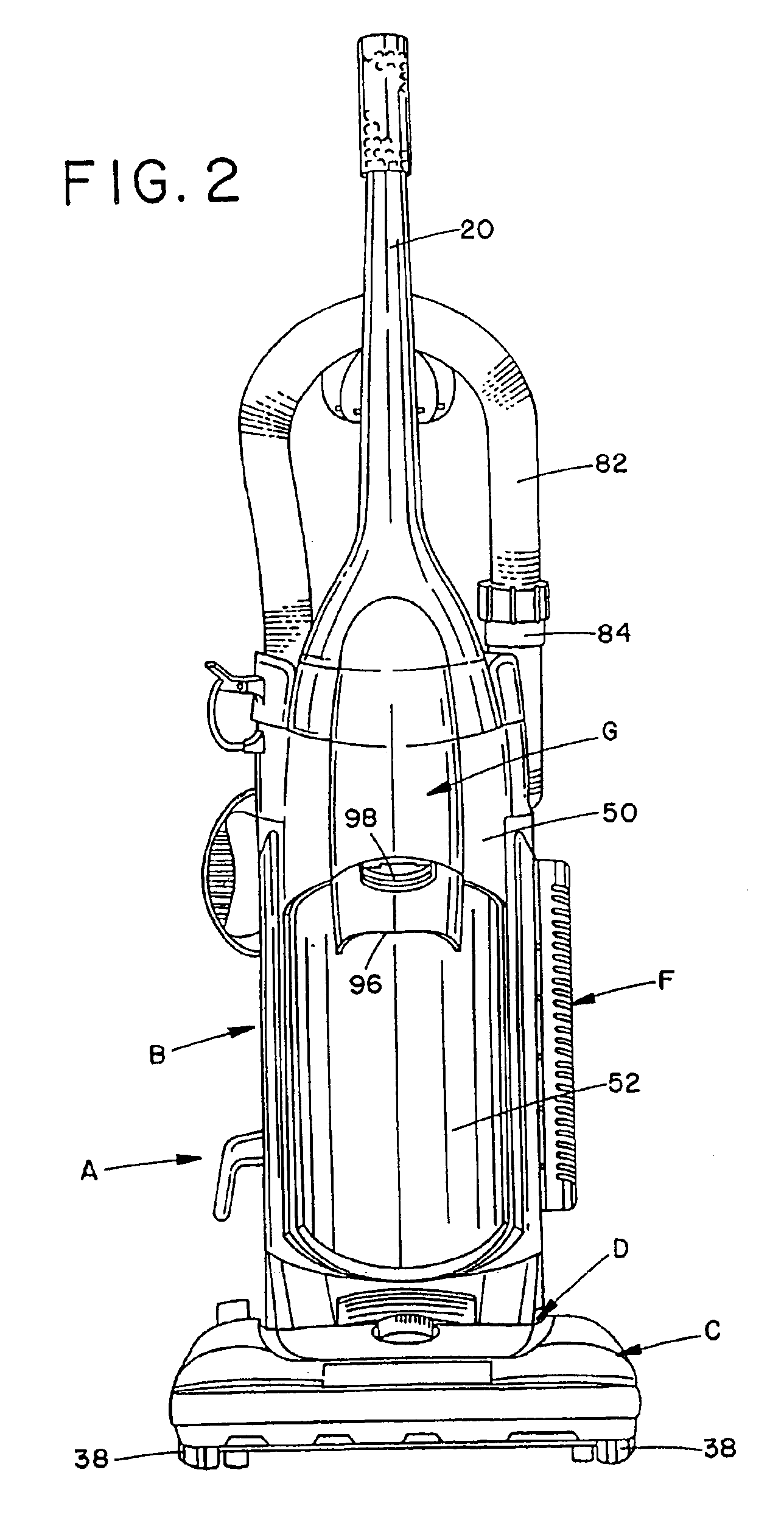

Upright vacuum cleaner with cyclonic airflow

InactiveUS6848146B2Easily and conveniently emptied dirt cupEffective filteringCleaning filter meansCombination devicesHEPACyclone

A vacuum cleaner includes a first housing defining a cyclonic airflow chamber and a second housing defining a main suction opening that is in communication with an inlet of the cyclonic chamber. A suction source has a suction airstream inlet in communication with an outlet of the cyclonic chamber, and establishes a suction airstream that enters said main suction opening, passes through said cyclonic chamber, and passes to an outlet of said suction source. A substantial portion of particulates entrained in the suction airstream are separated therefrom when said suction airstream moves in a cyclonic fashion through the cyclonic chamber. A main filter assembly, preferably including filter medium comprising polytetrafluoroethylene (PTFE), is located in the cyclonic chamber so that a suction airstream moving from the main suction opening to the inlet of said suction source by way of the cyclonic airflow chamber passes through the filter medium thereof after said airstream moves in a cyclonic fashion within the cyclonic airflow chamber to remove residual particulates from the suction airstream before it leaves the cyclonic chamber. A HEPA filter can be provided to filter the suction airstream exhausted through the outlet of the suction source prior to the airstream being discharged from the vacuum.

Owner:ROYAL APPLIANCE MFG

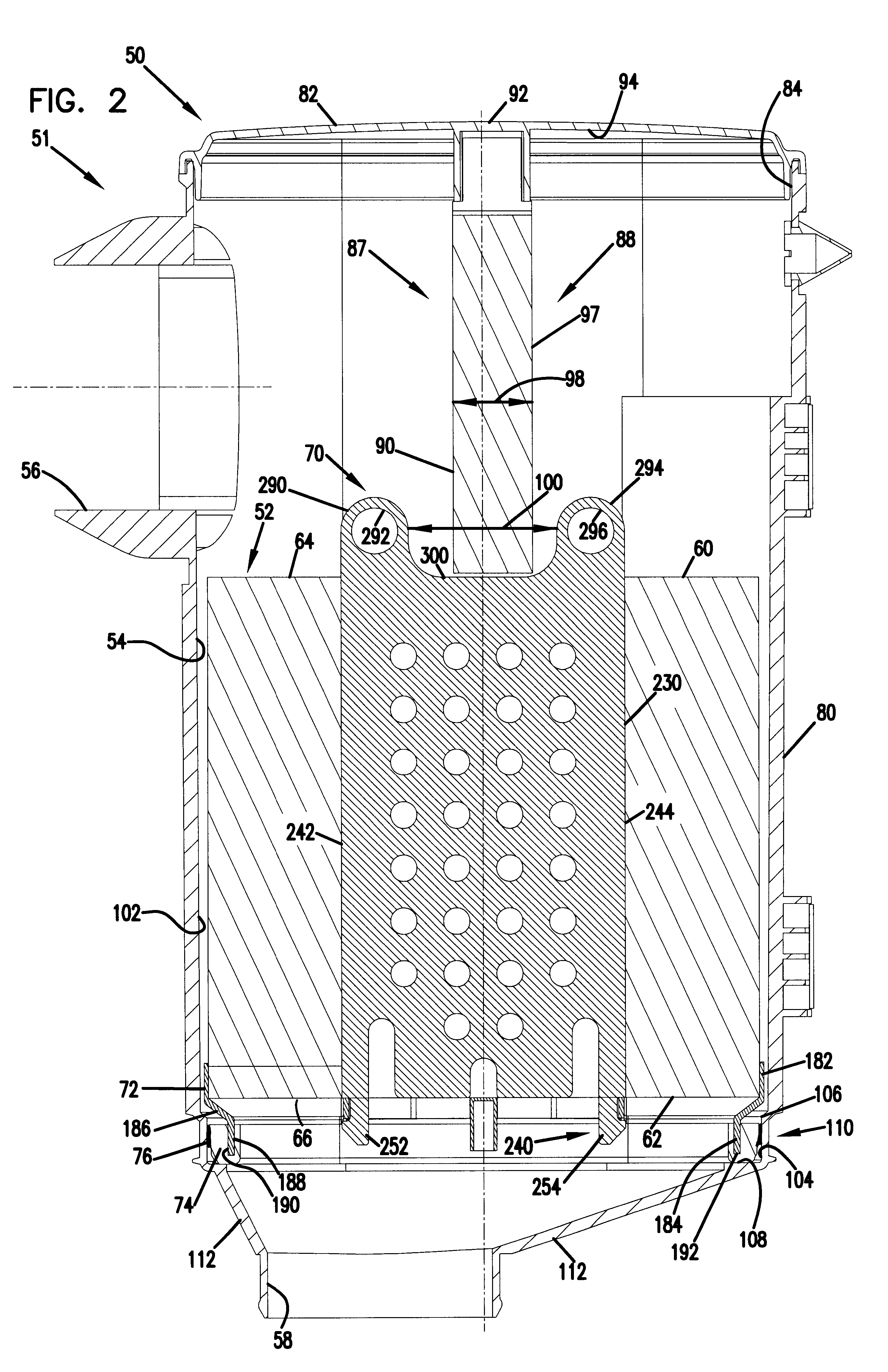

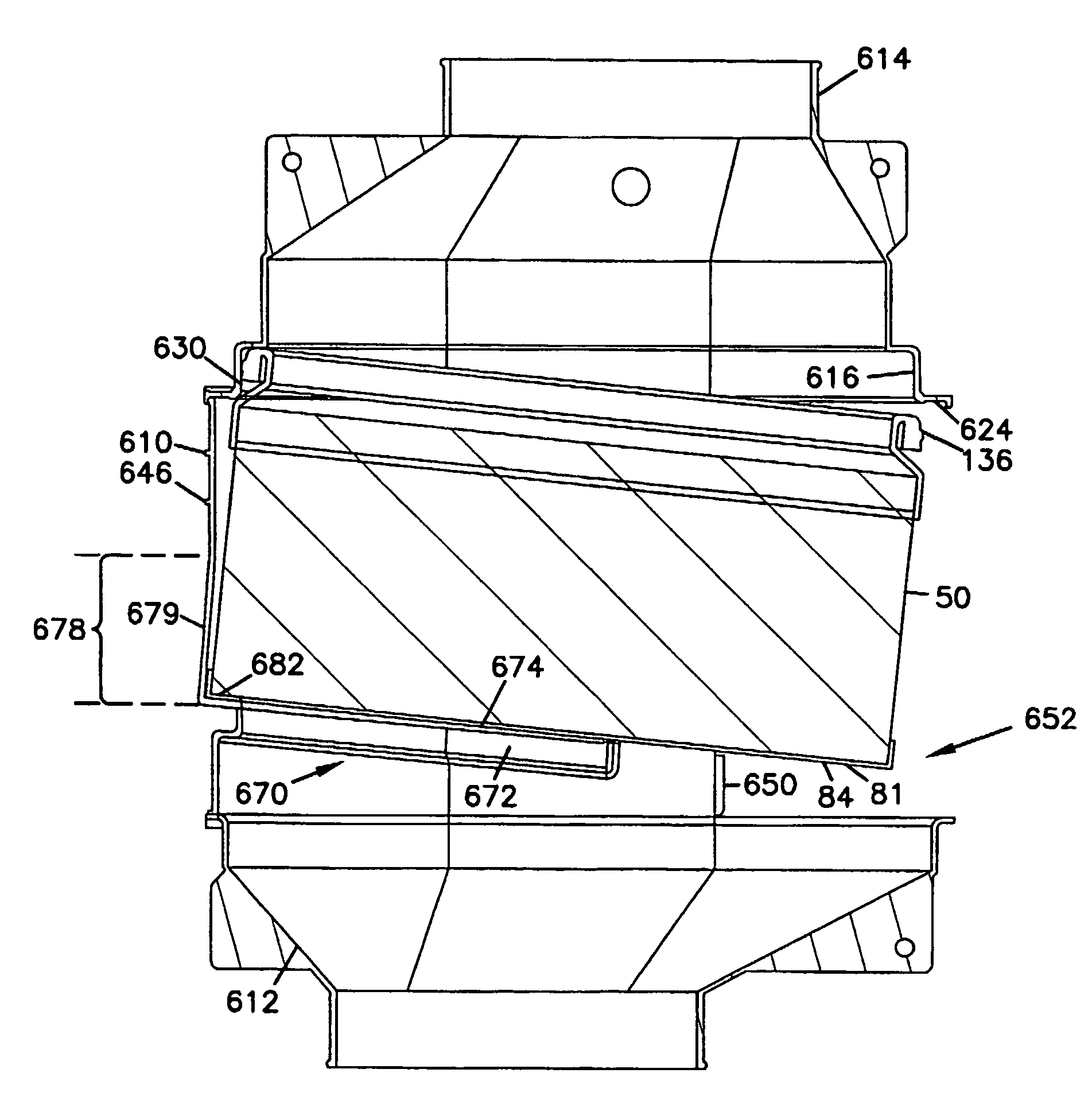

Filter arrangements; side-entry housings; and methods

An air cleaner (40) includes a housing (48) and an access cover. The internal volume of the housing (48) can be reached through an opening (70) in a side wall of the housing. A filter element (50) having fluted filter media is removable and replaceable from the air cleaner. The housing (48) is constructed and arranged to cam the element (50) into sealing engagement with the housing (48). The access cover includes structure to help support and ensure proper seating of the filter element within the housing. A method of installing the filter element in the air cleaner includes sliding a portion of the filter element against a slide surface in the housing. A method of servicing an air cleaner includes pushing the filter element against a pivot region in the housing to release a seal between the filter element and the housing.

Owner:DONALDSON CO INC

Apparatus and method for reducing water production from a hydrocarbon producing well

InactiveUS20070012444A1Reduce water productionReduce penetrationFluid removalSealing/packingHydrophilic monomerWater production

A filtering apparatus for use in a hydrocarbon producing well for reducing water production therein includes a filtering medium treated with a relative permeability modifier such that the relative permeability modifier reduces the permeability of the filtering medium if the relative permeability modifier contacts water production. The relative permeability modifier may be used to treat a metal portion of the filtering medium in the case of a wire wrap screen or a wire mesh screen or may be use treat a metal portion or the prepacked component of a prepacked screen. The relative permeability modifier may be a polymer of at least one hydrophilic monomer and at least one hydrophobically modified hydrophilic monomer, a hydrophobically modified polymer, a hydrophobically modified water-soluble polymer, hydrophobically modified copolymers thereof or the like.

Owner:HALLIBURTON ENERGY SERVICES INC

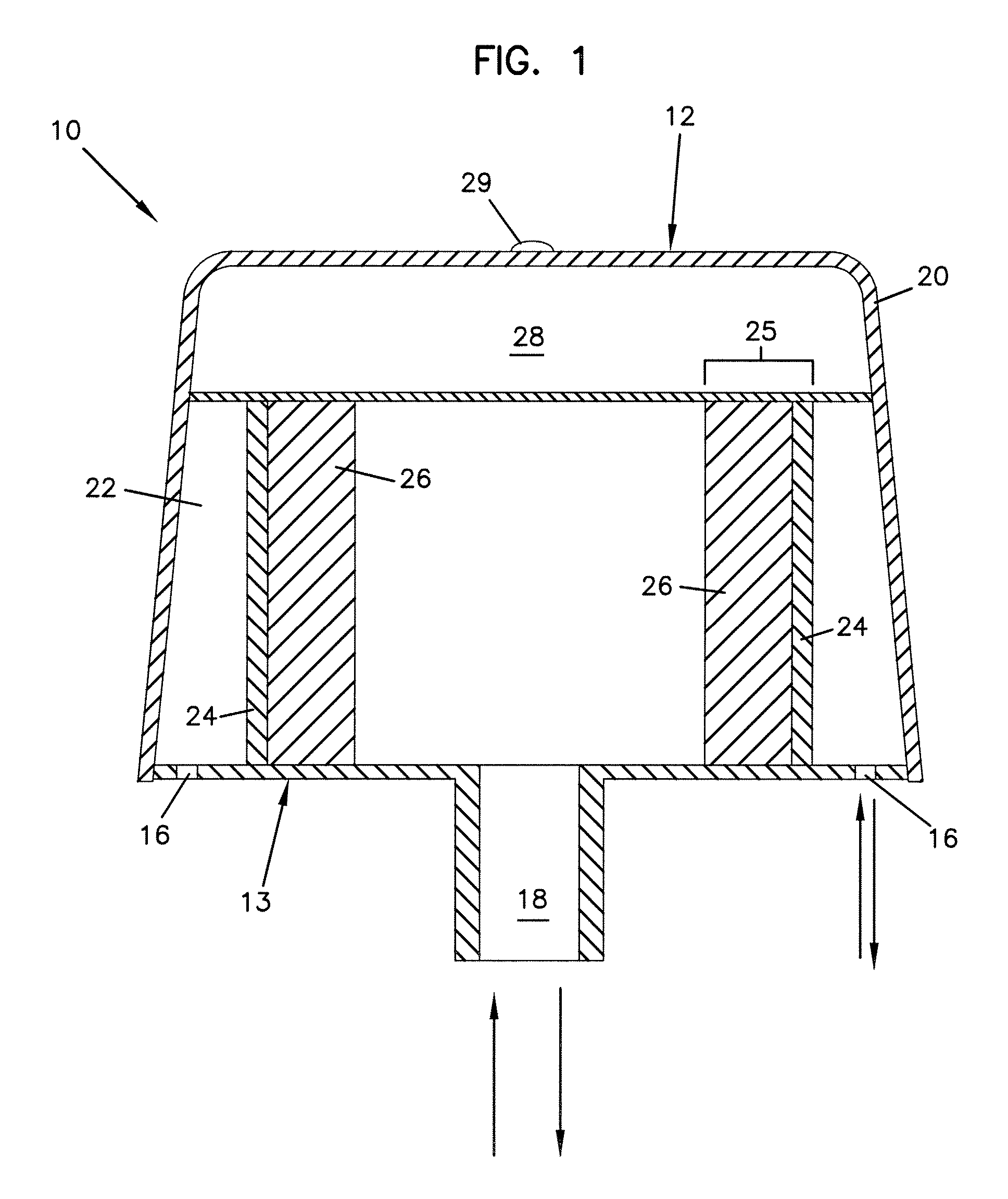

Sand control screen assembly having an internal isolation member and treatment method using the same

InactiveUS6886634B2Avoid flowAvoid lostFluid removalDrinking water installationParticulate flowFilter media

A sand control screen assembly (80) that is positionable within a wellbore comprises a base pipe (82) having at least one opening (84) that allows fluid flow therethrough and a filter medium (86) positioned about the exterior of the base pipe (82) that selectively allows fluid flow therethrough and prevents particulate flow of a predetermined size therethrough. An internal isolation member (88) that has at least one opening (90) is positioned within the base pipe (82). A one-way valve (92) is operably associated with the opening (90) of the internal isolation member (88). The one-way valve (92) controls the flow of fluid through the opening (90) of the internal isolation member (88) such that fluid flow is prevented from the interior to the exterior of the sand control screen assembly (80) but is allowed from the exterior to the interior of the sand control screen assembly (80).

Owner:HALLIBURTON ENERGY SERVICES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com