Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

960 results about "Breather" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In physics, a breather is a nonlinear wave in which energy concentrates in a localized and oscillatory fashion. This contradicts with the expectations derived from the corresponding linear system for infinitesimal amplitudes, which tends towards an even distribution of initially localized energy.

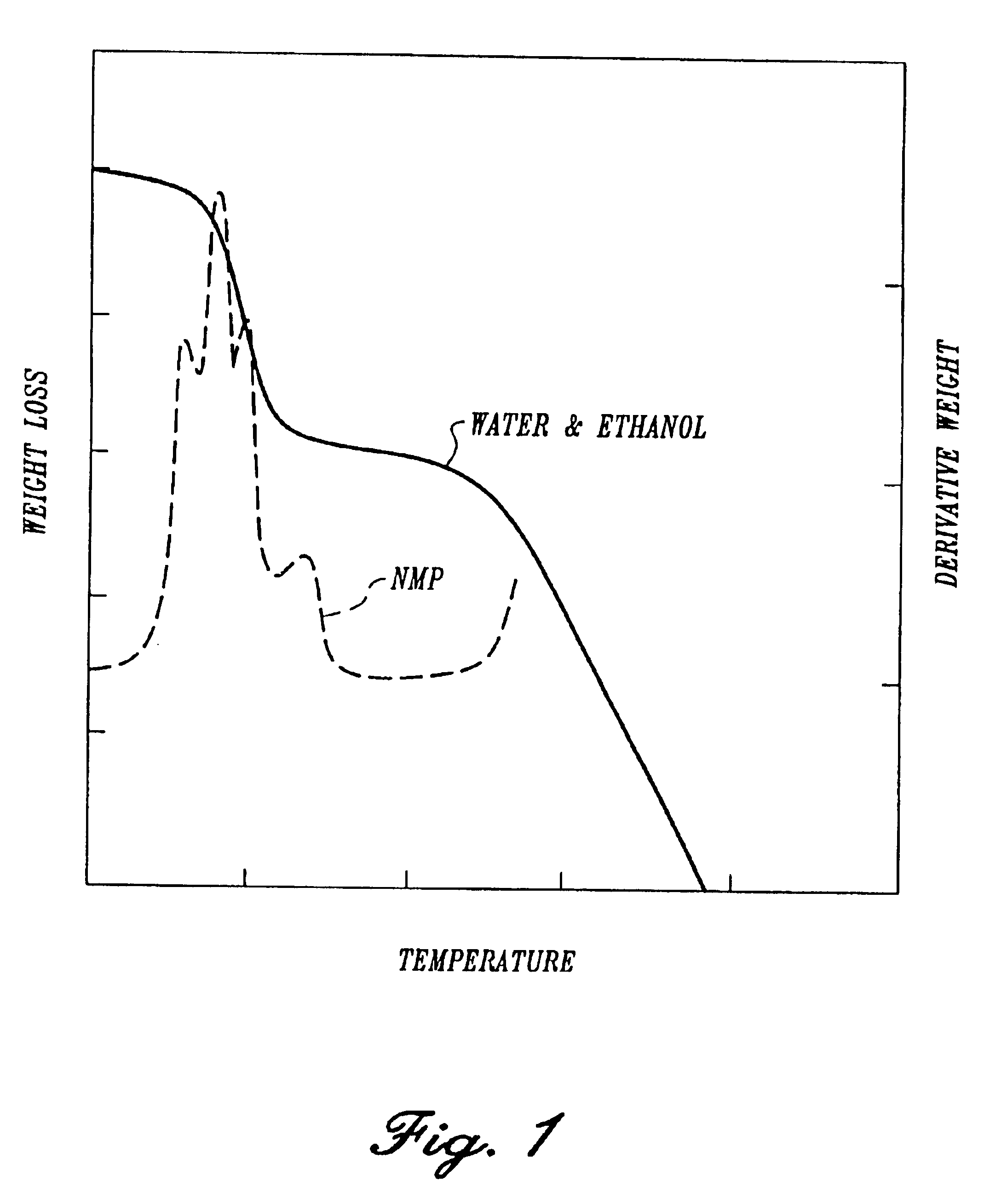

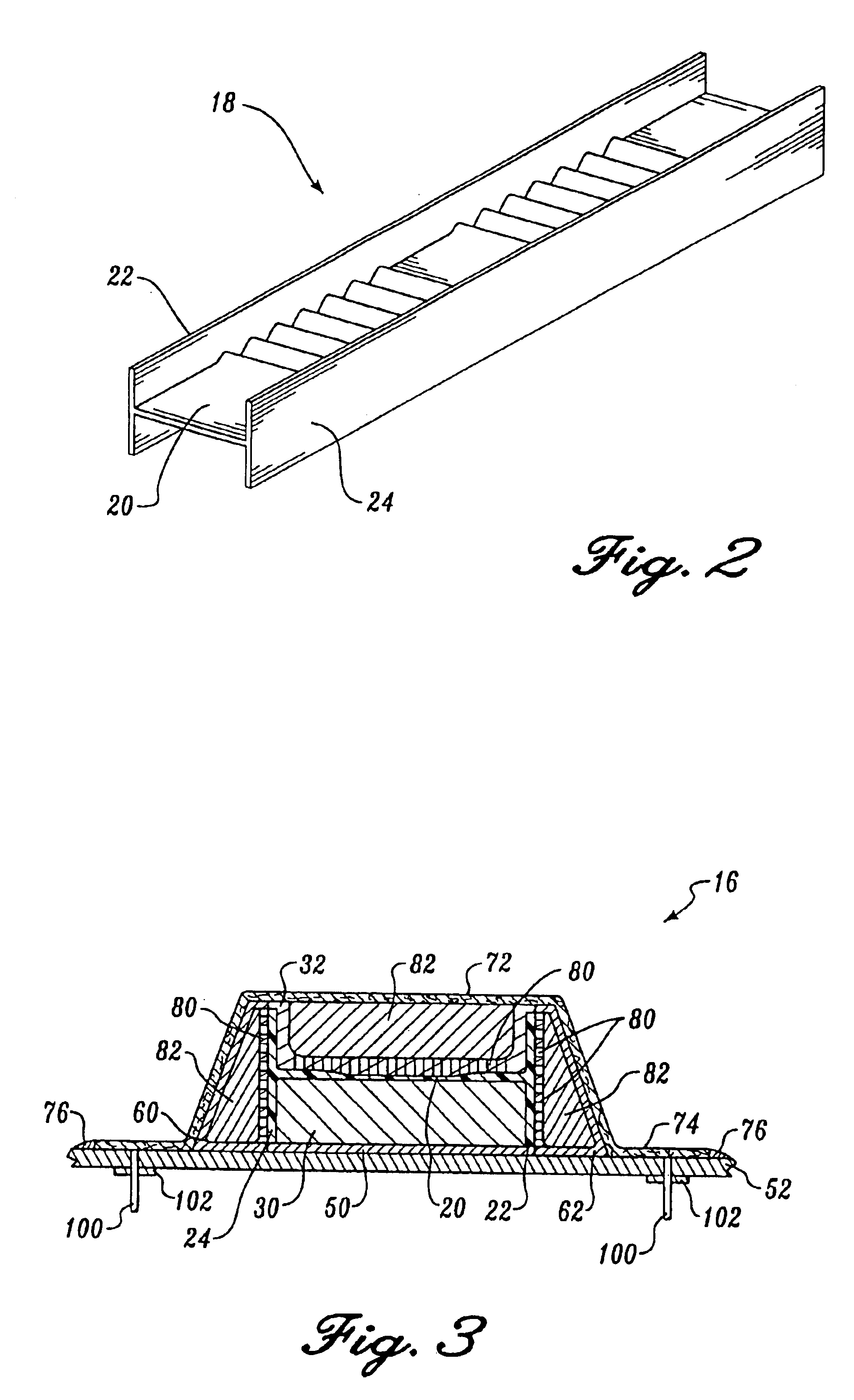

Filter medium and breather filter structure

Thermoplastic bicomponent binder fiber can be combined with other media, fibers and other filtration components to form a thermally bonded filtration media. The filtration media can be used in filter units, such as breather caps. Such filter units can be placed in the stream of a mobile fluid and can remove a particulate and / or fluid mist load from the mobile stream. The unique combination of media fiber, bicomponent binder fiber and other filtration additives and components provide a filtration media having unique properties in filtration applications.

Owner:DONALDSON CO INC

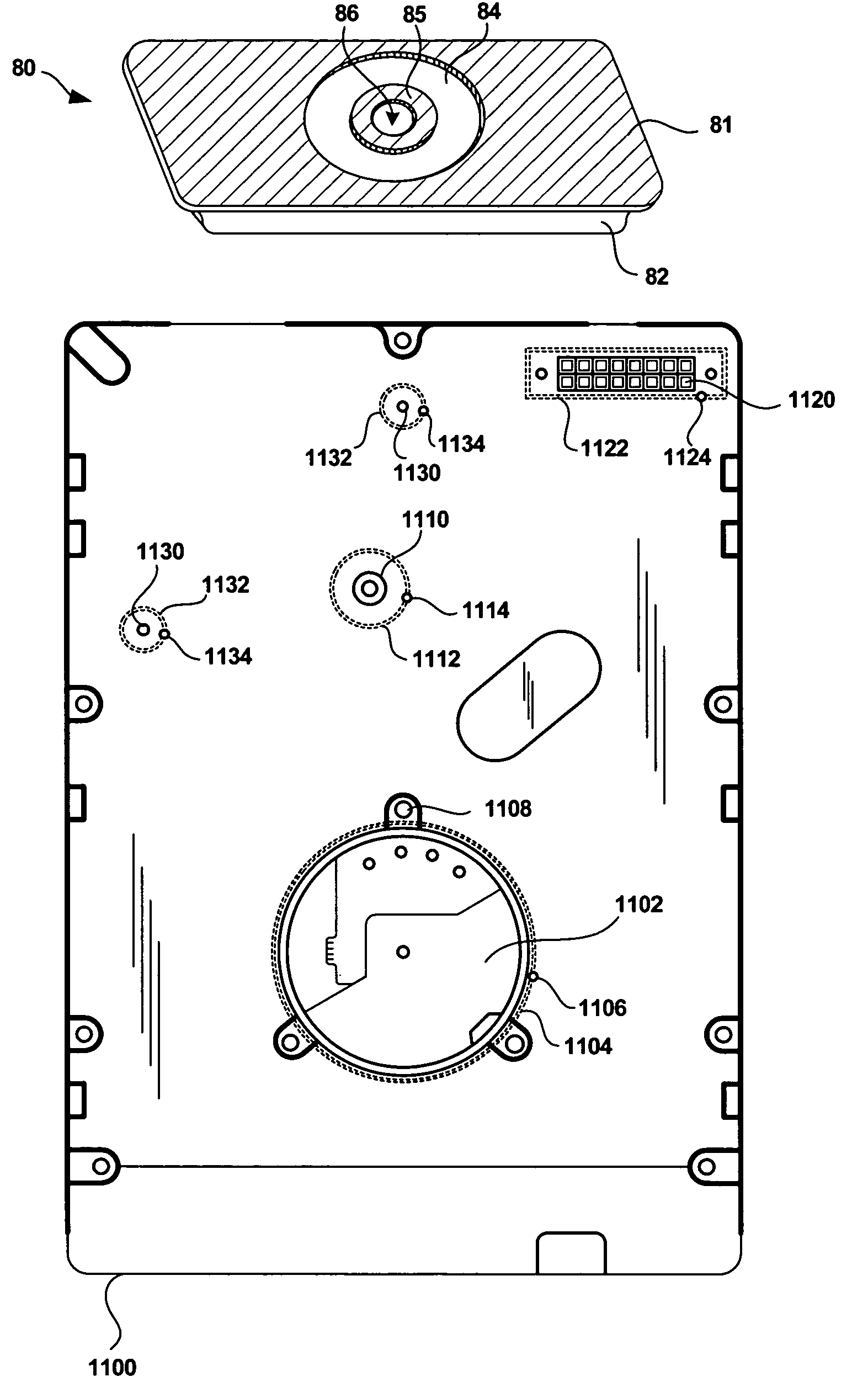

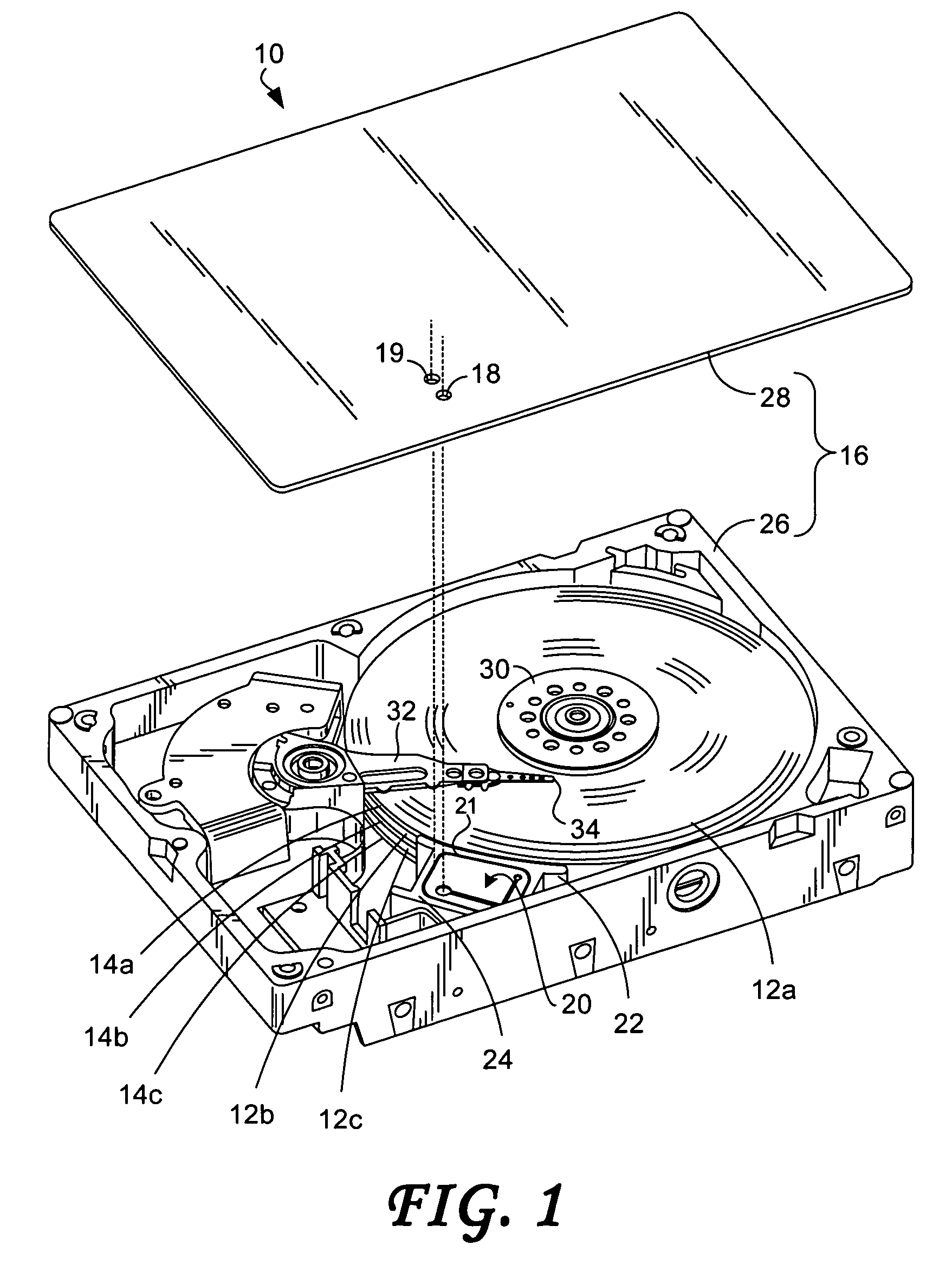

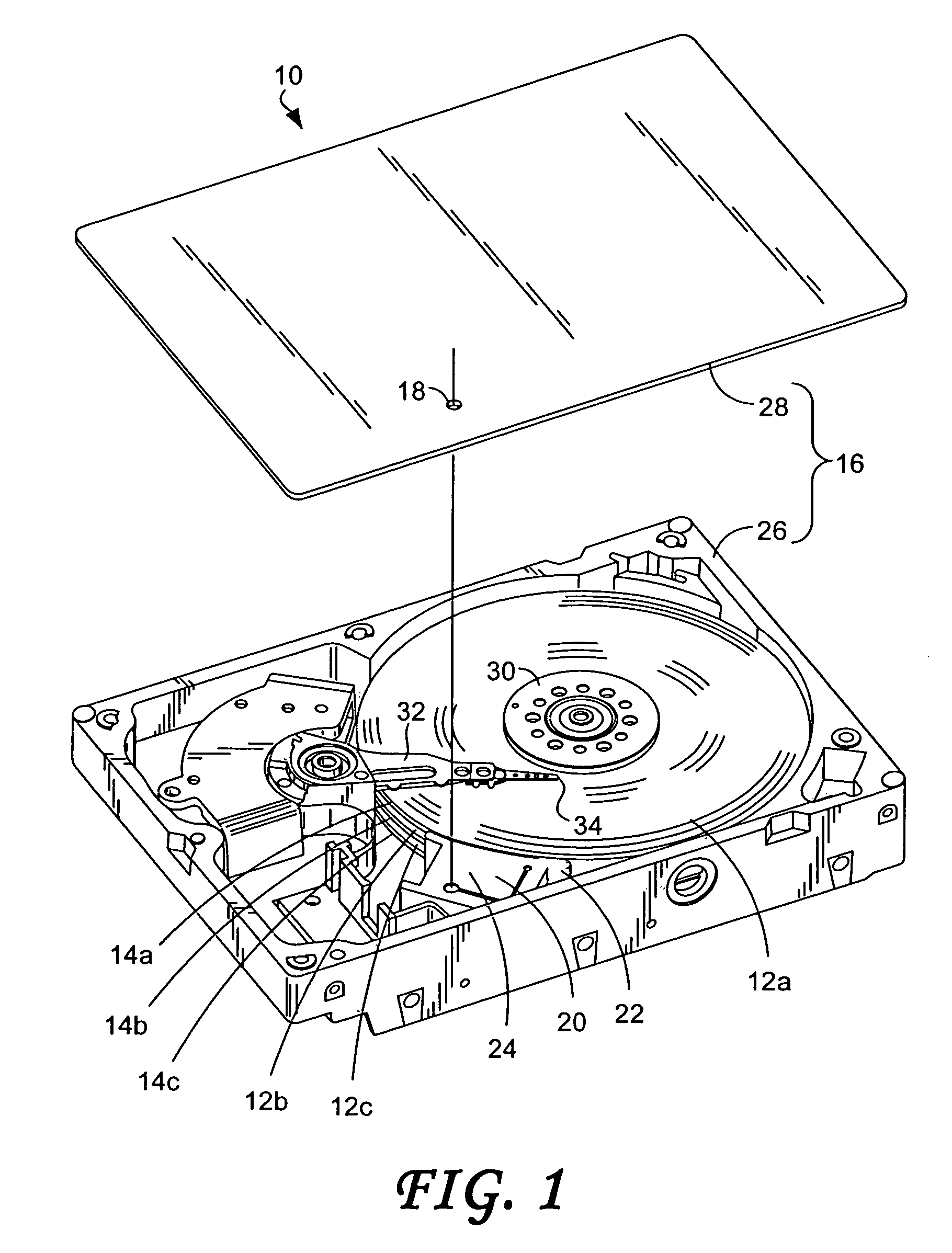

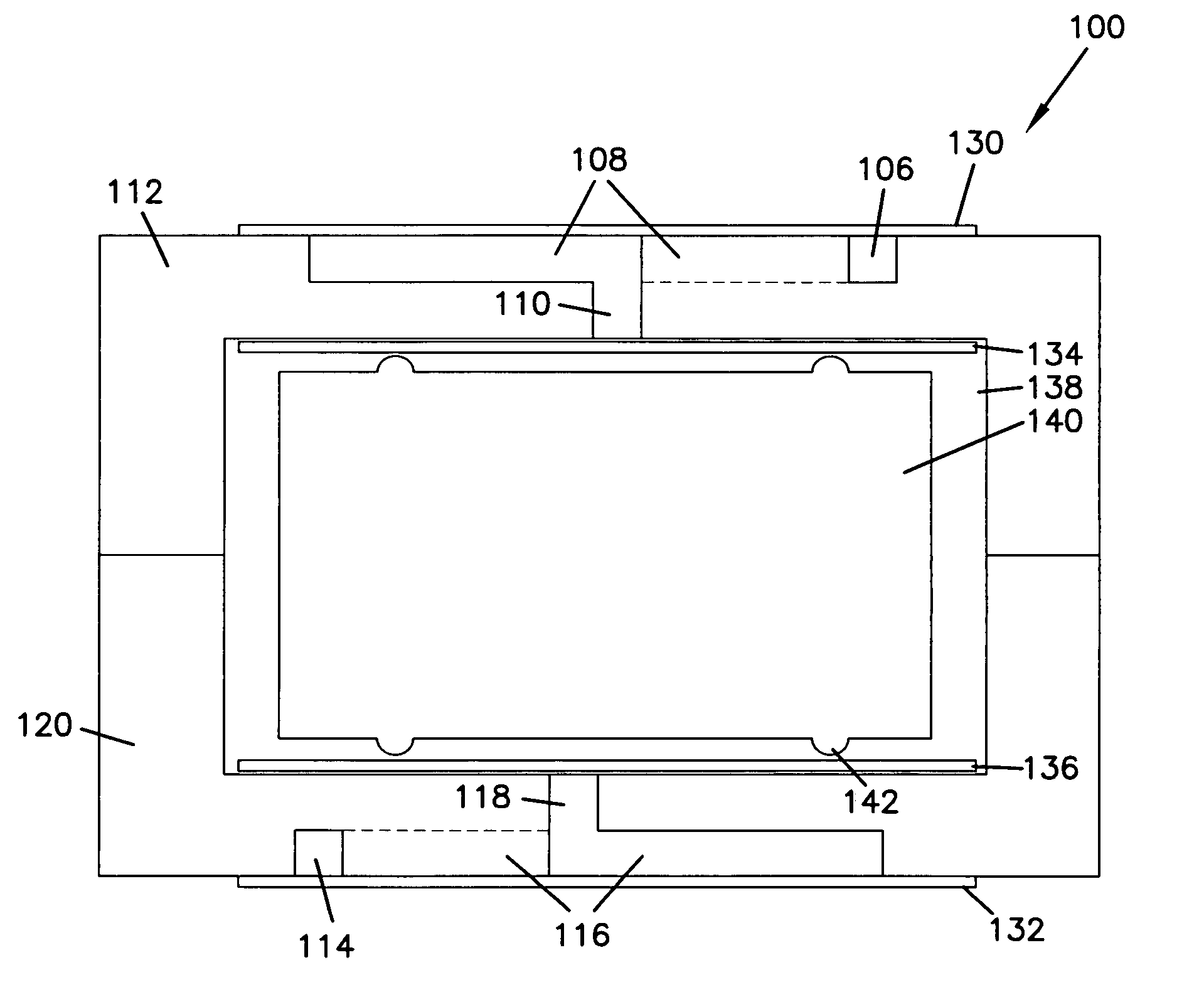

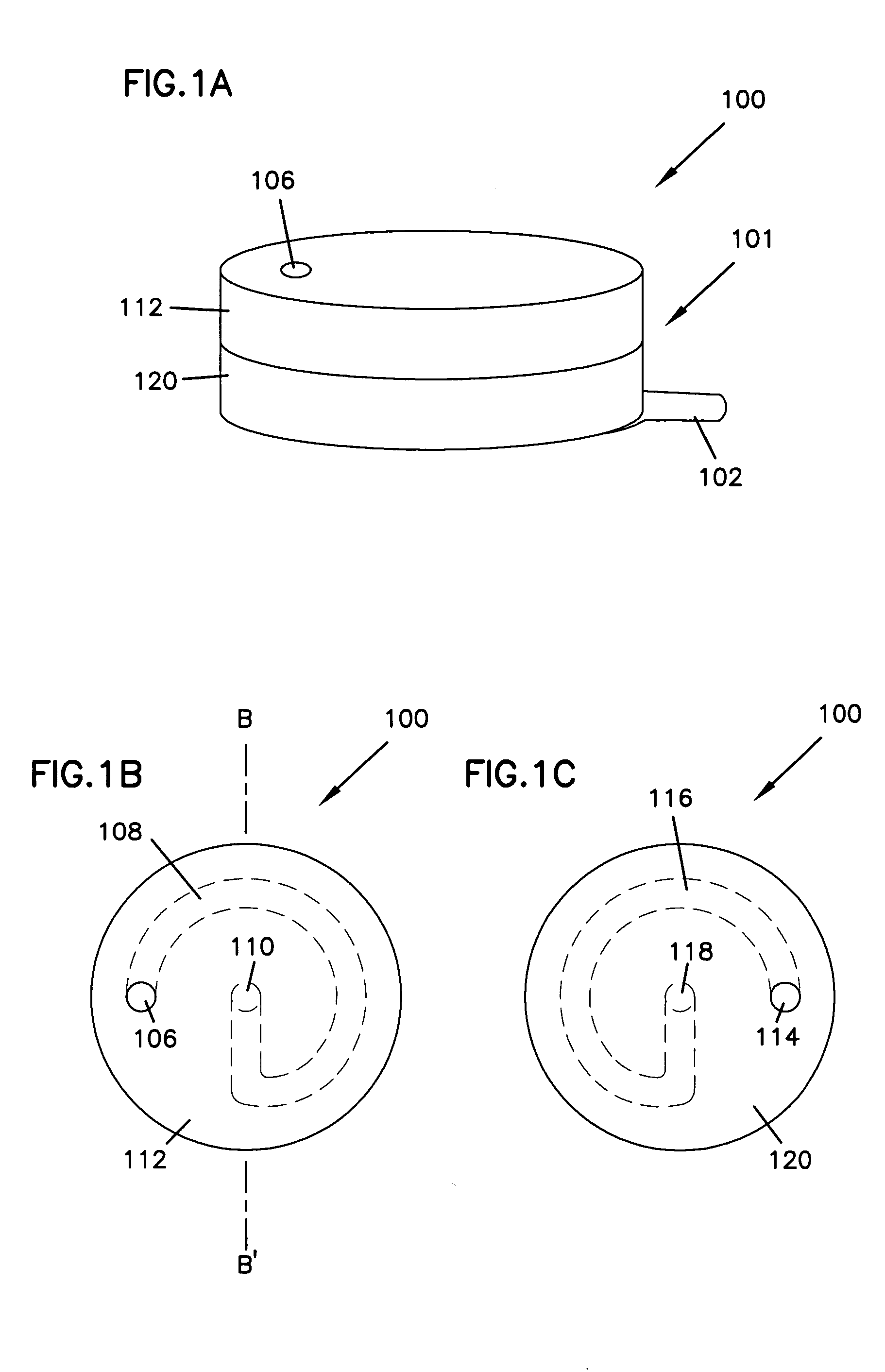

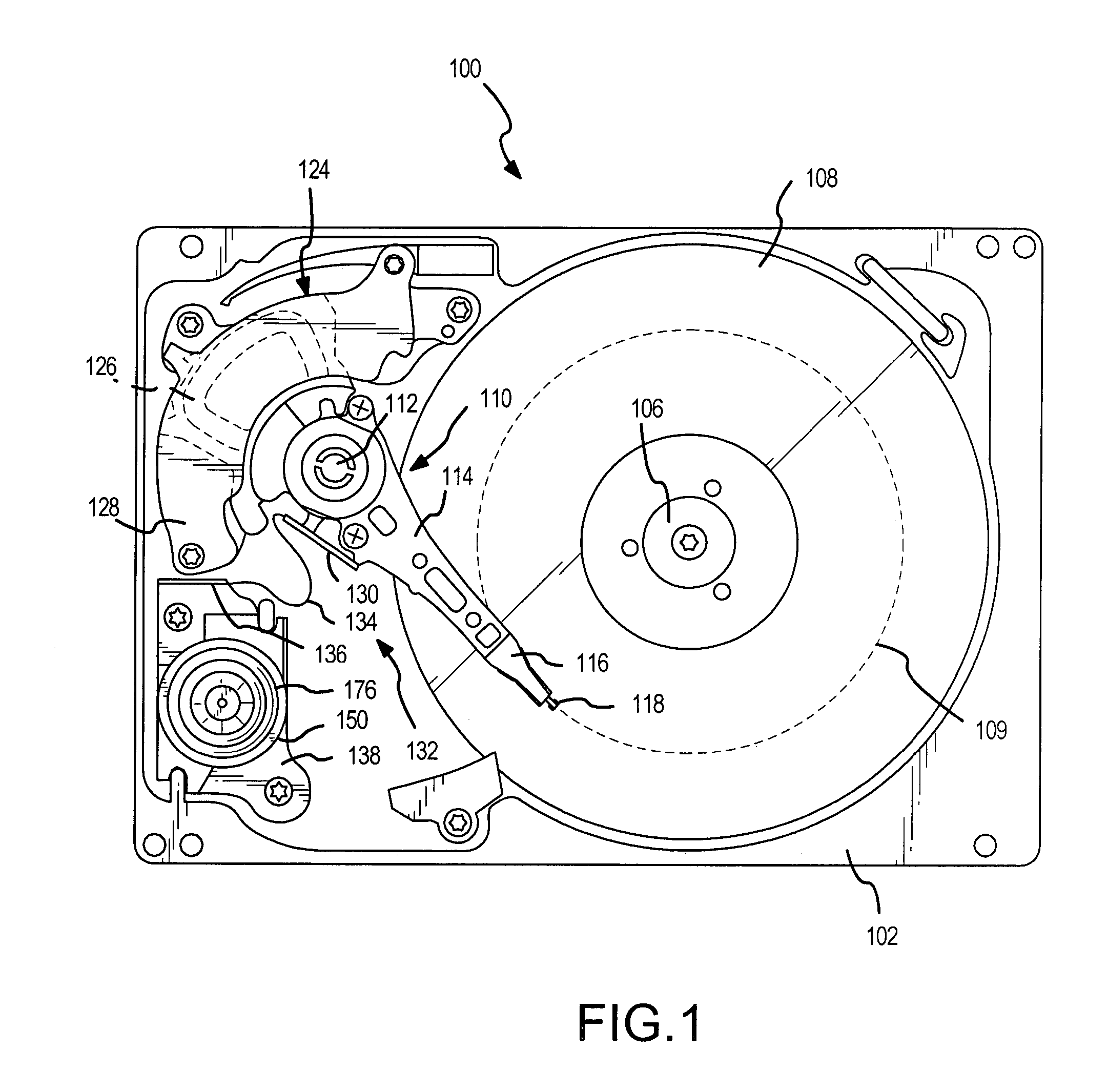

Disk drive configured to enable non destructive leak detection at the interface between a drive sub-component and the disk drive housing

ActiveUS7274534B1Undesired vibrations/sounds insulation/absorptionRecord information storageTest channelNon destructive

A disk drive includes a disk drive housing having a breather hole and a separate leak testing hole, both the breather hole and the leak testing hole being formed through the disk drive housing, and a drive sub-component attached to a surface of the disk drive housing so as to form an interface between the sub-component and the surface of the housing. The interface defines an interface outer perimeter and a sealed airflow testing channel in fluid communication only with the leak testing hole to enable a non-destructive detection of leaks at the interface. The airflow testing channel may be disposed within the interface outer perimeter.

Owner:WESTERN DIGITAL TECH INC

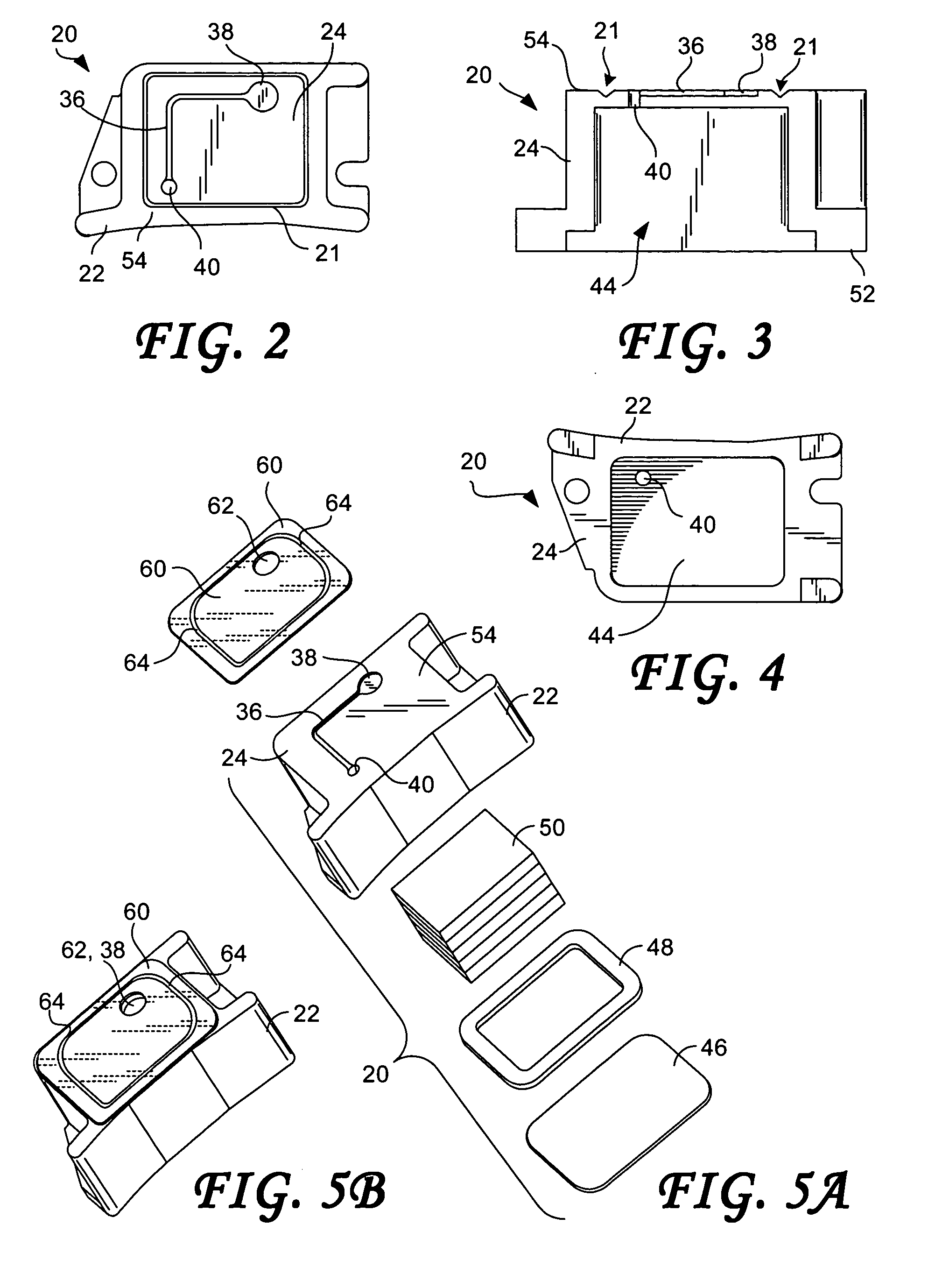

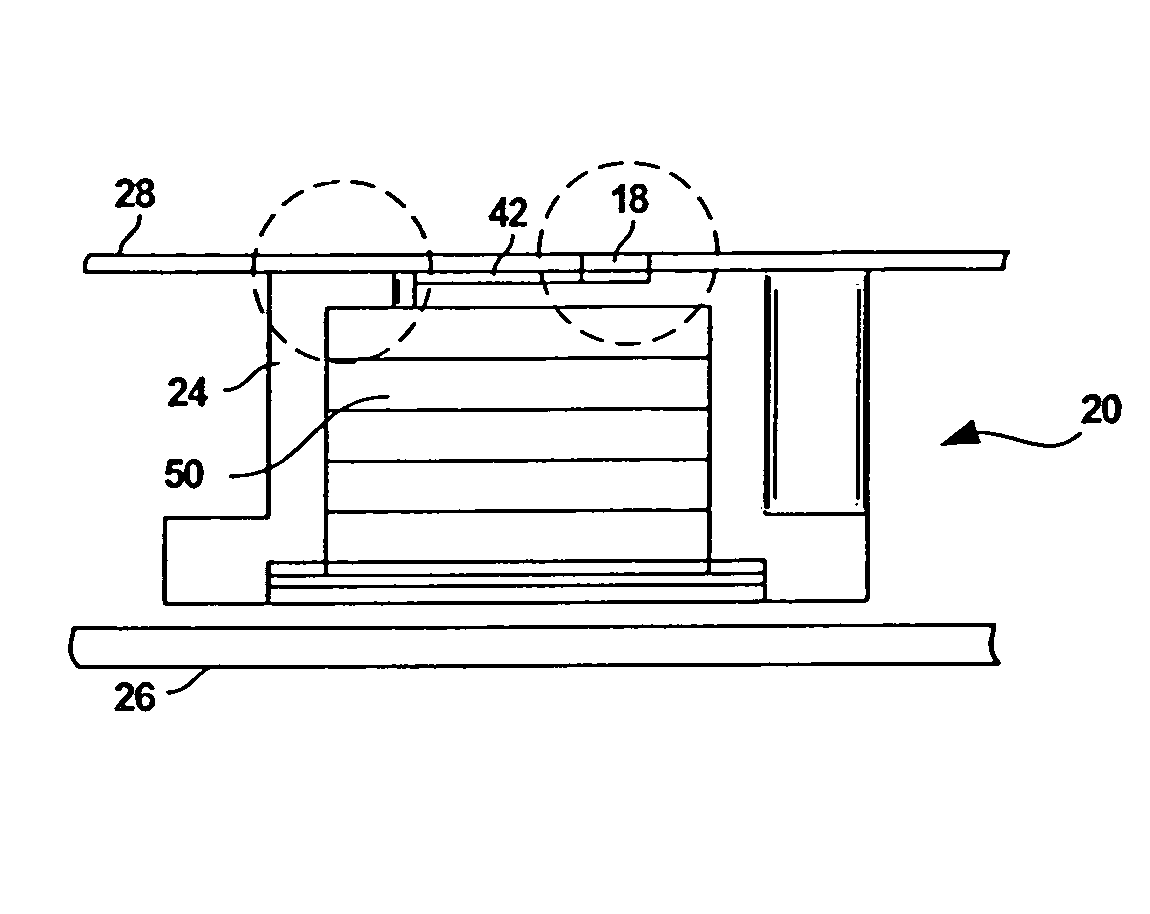

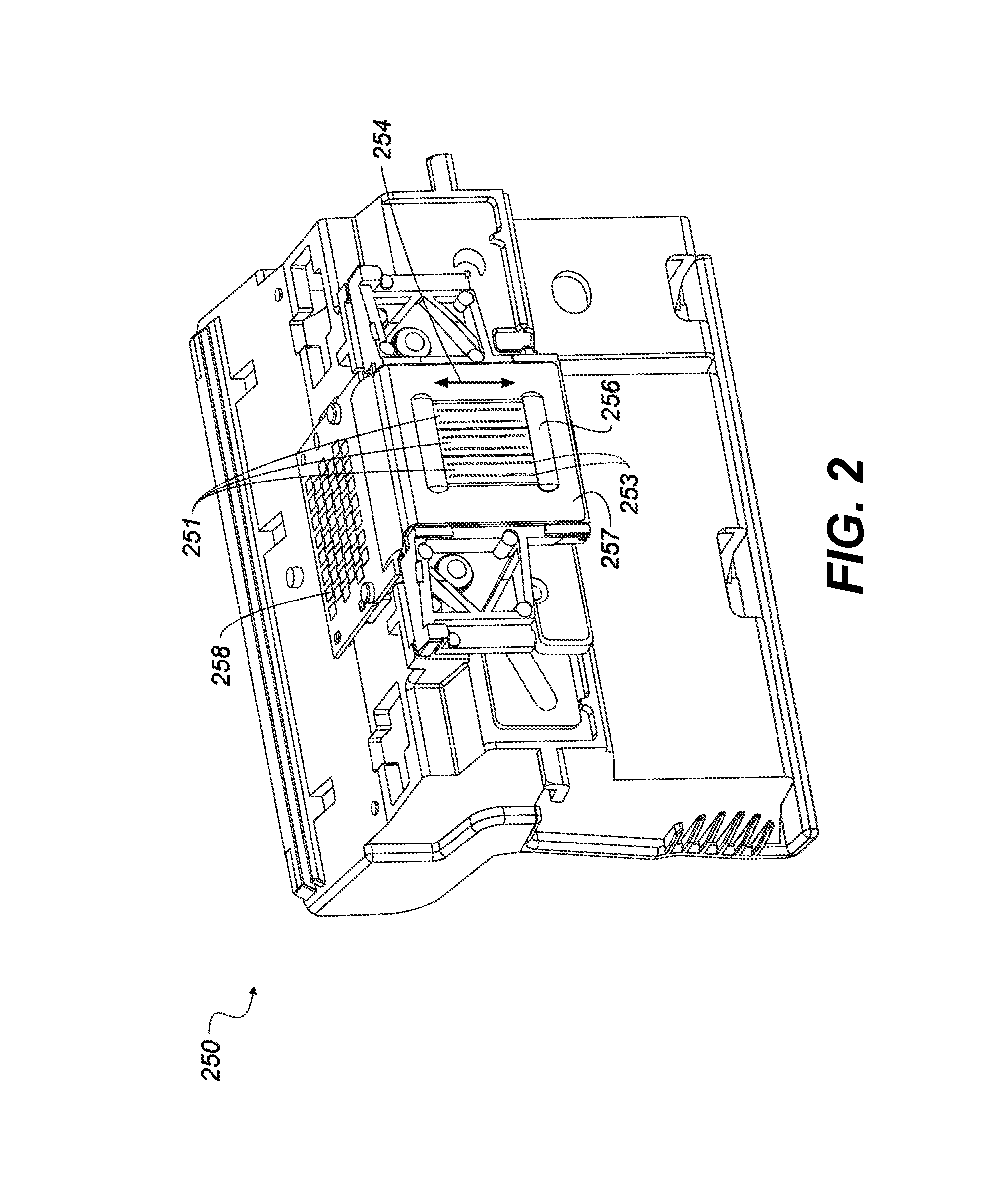

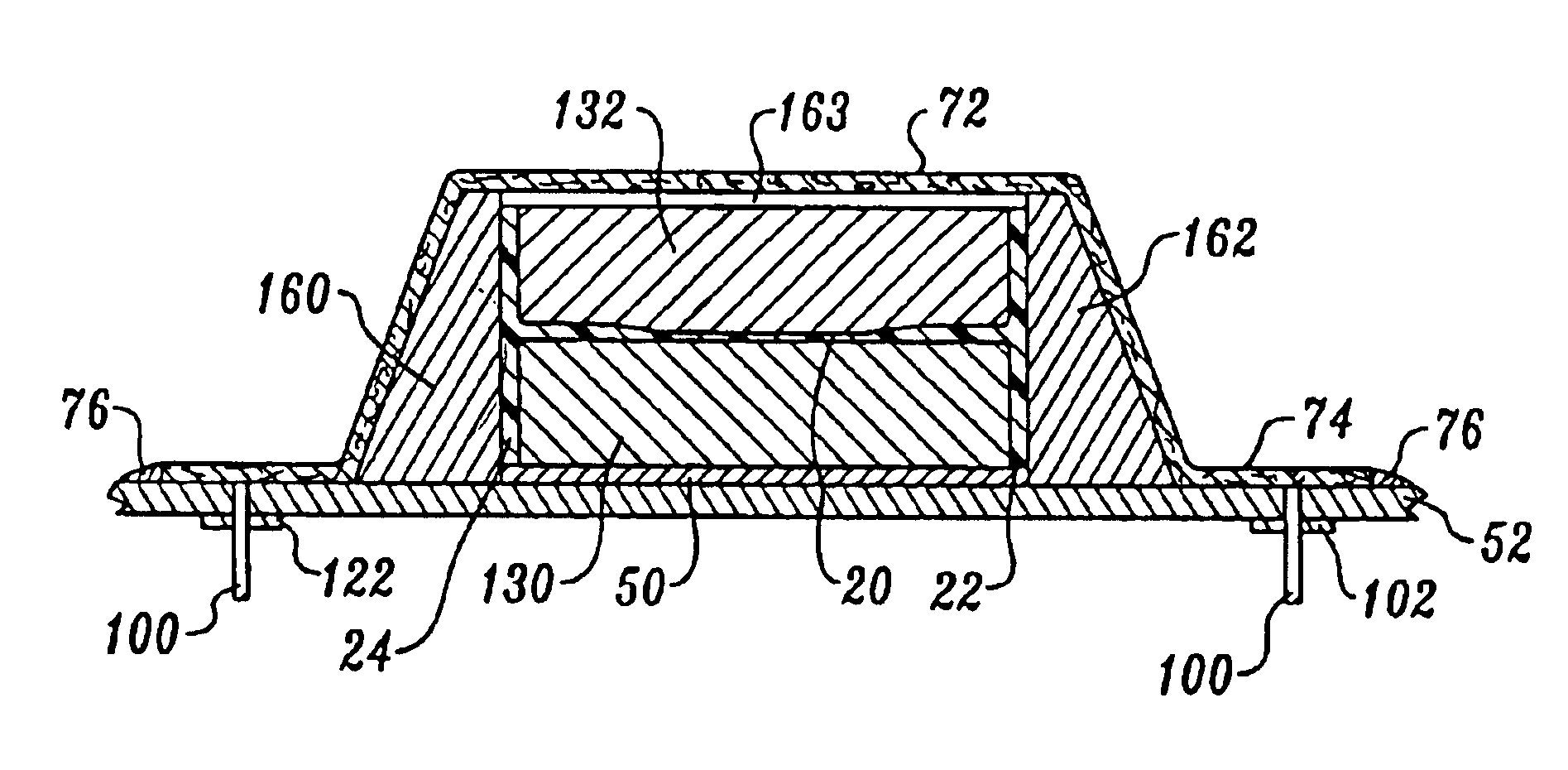

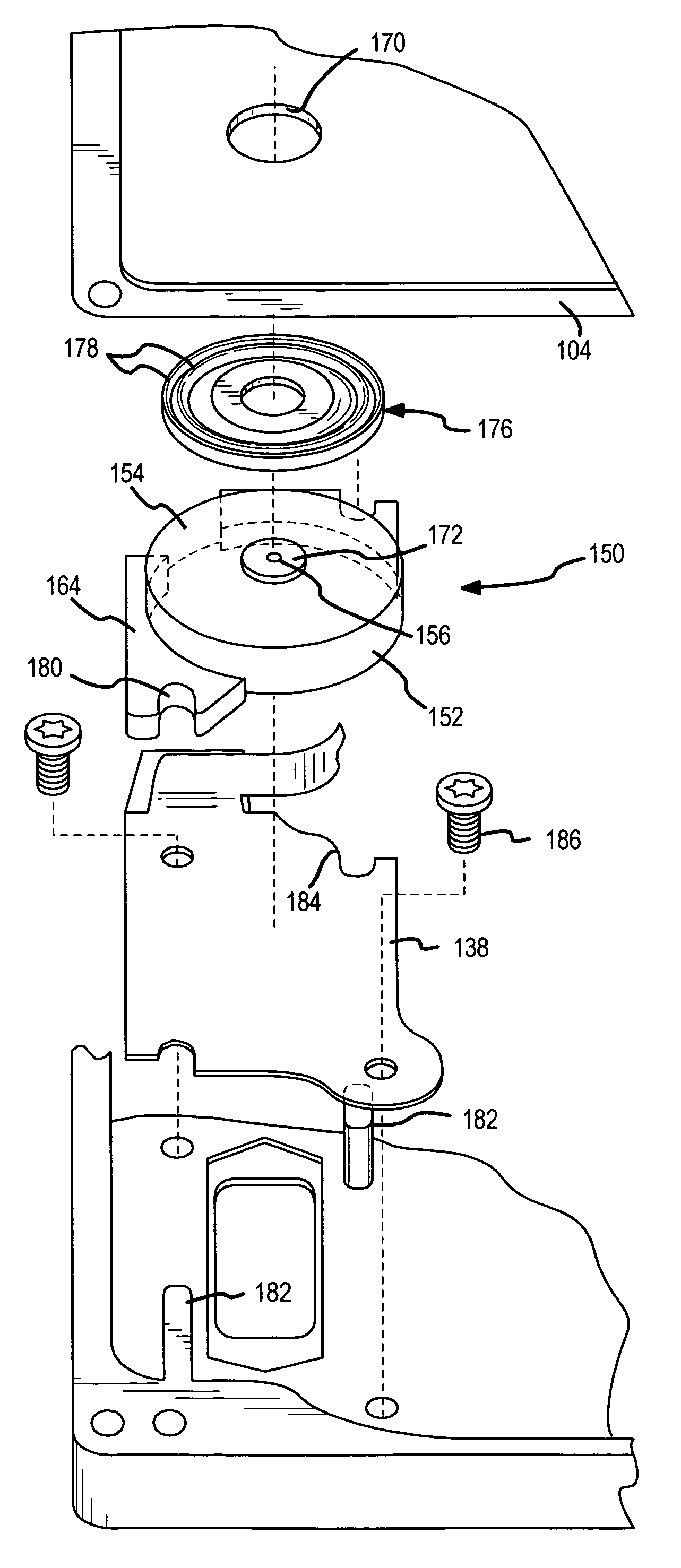

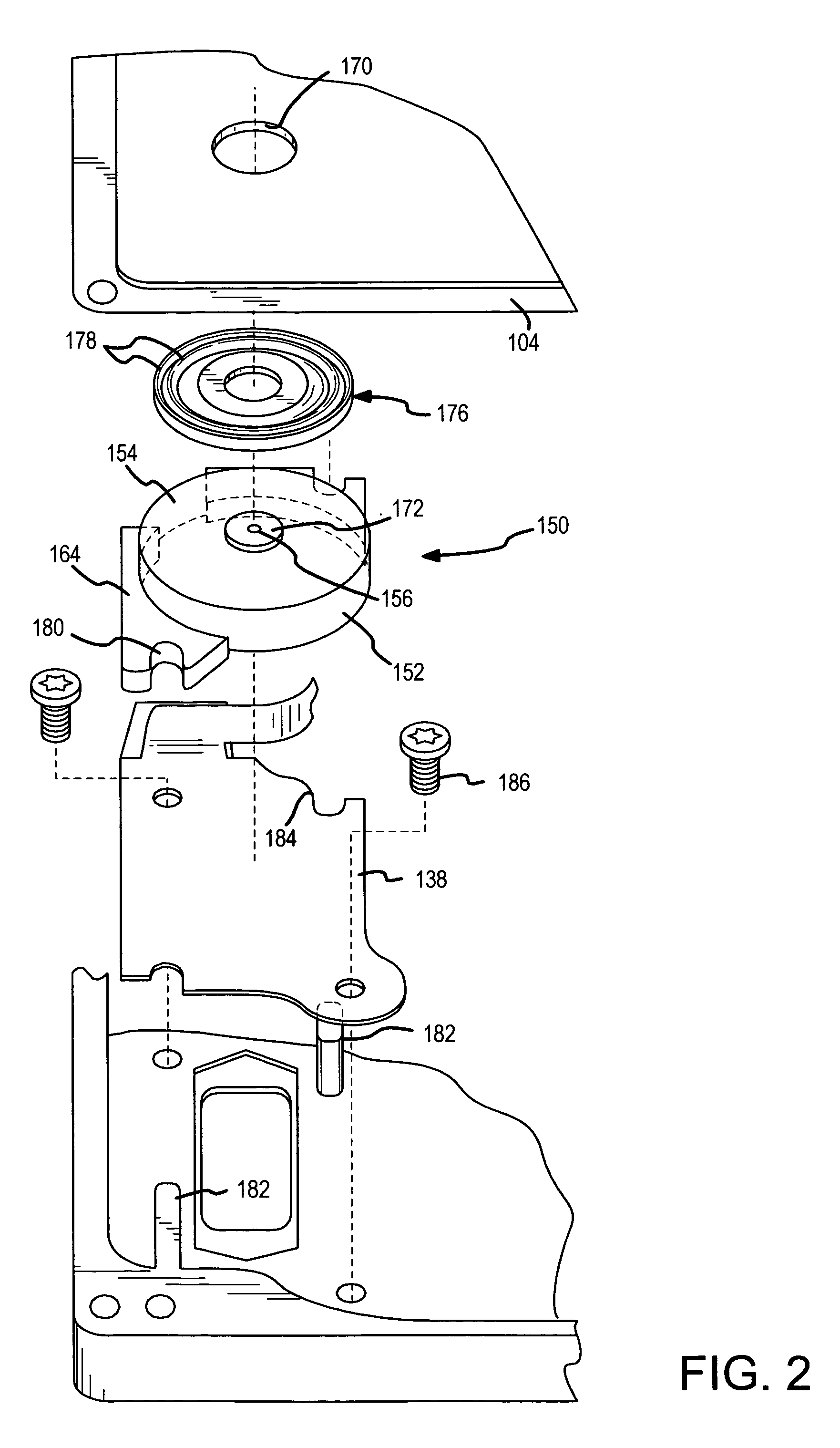

Disk drive having a disk drive component adhered to the disk drive housing via an adhesive assembly having a leveling layer

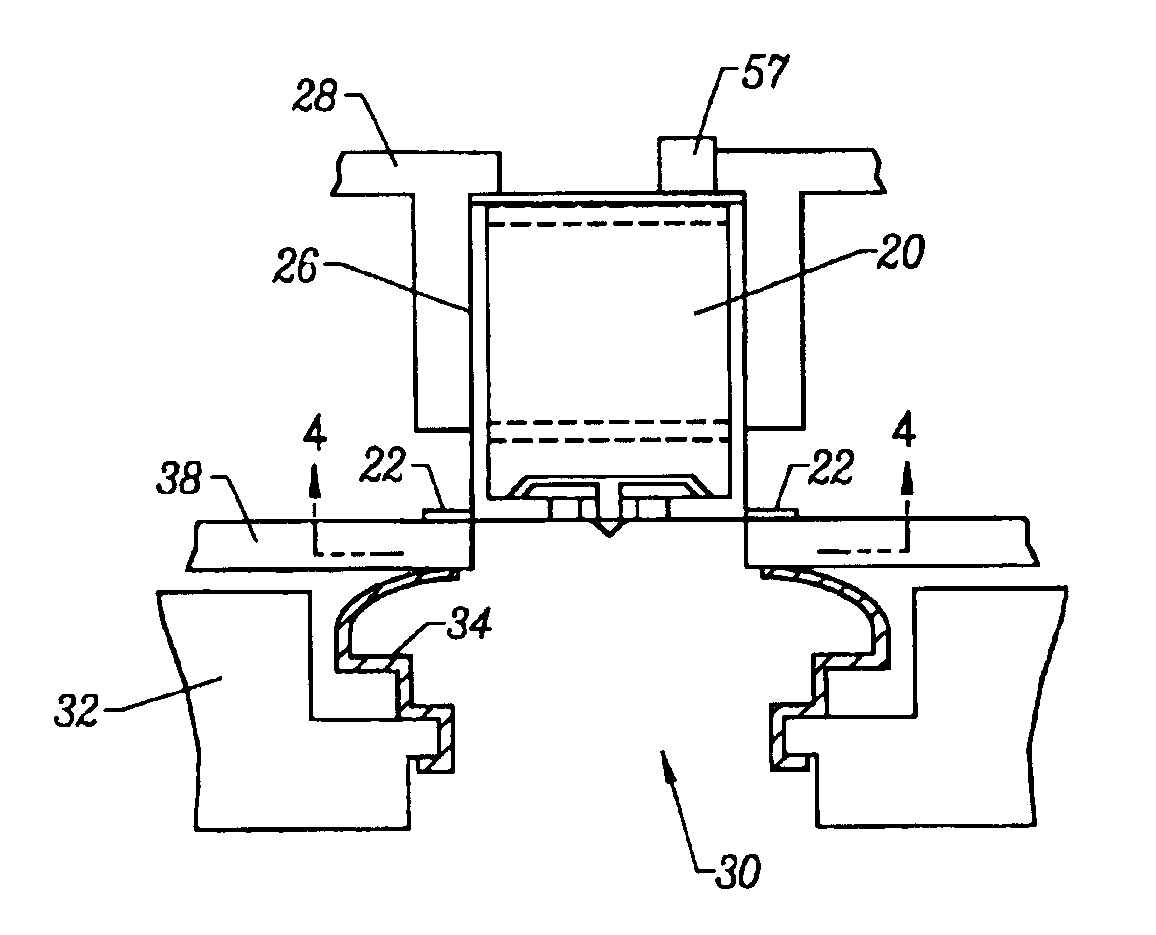

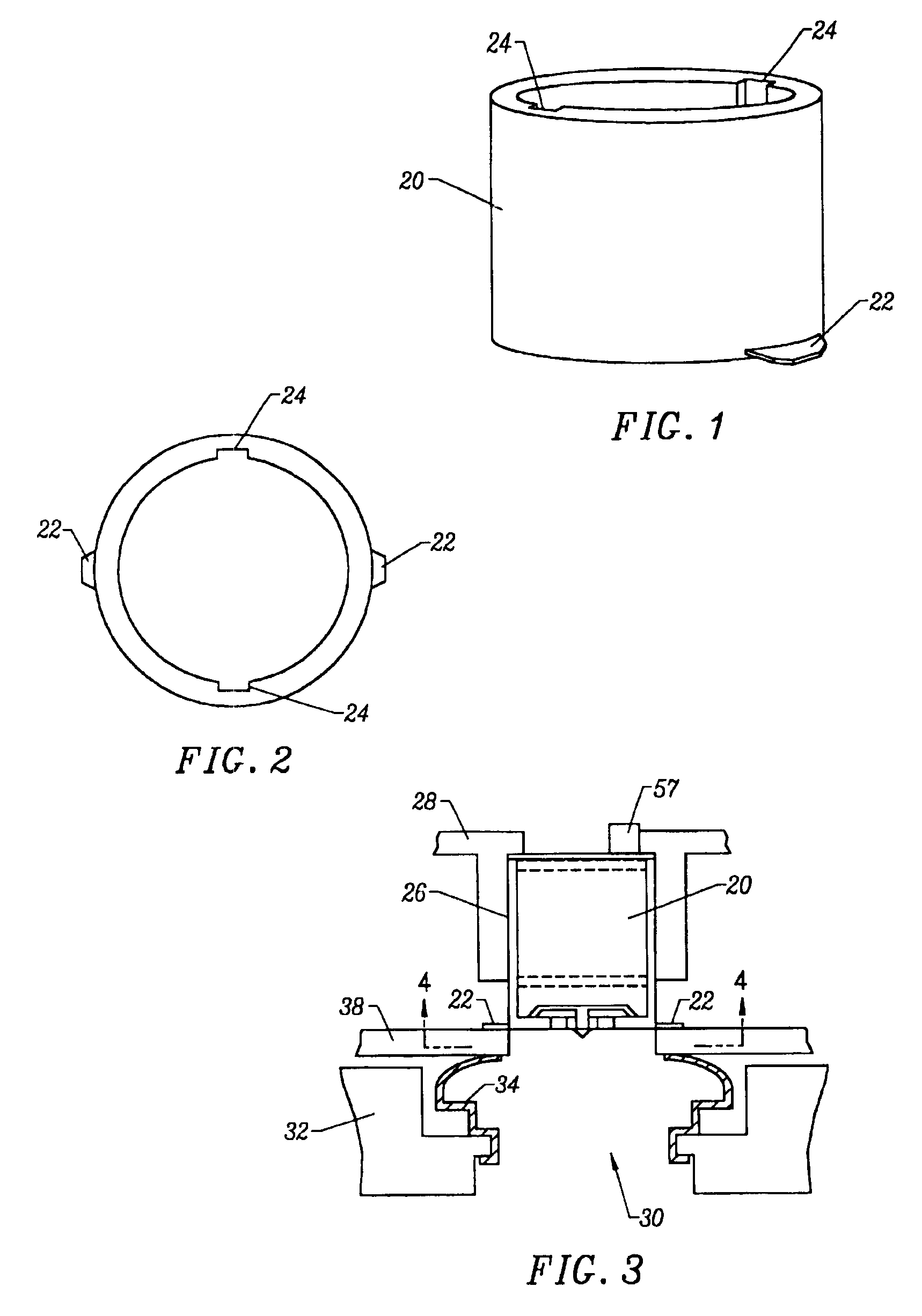

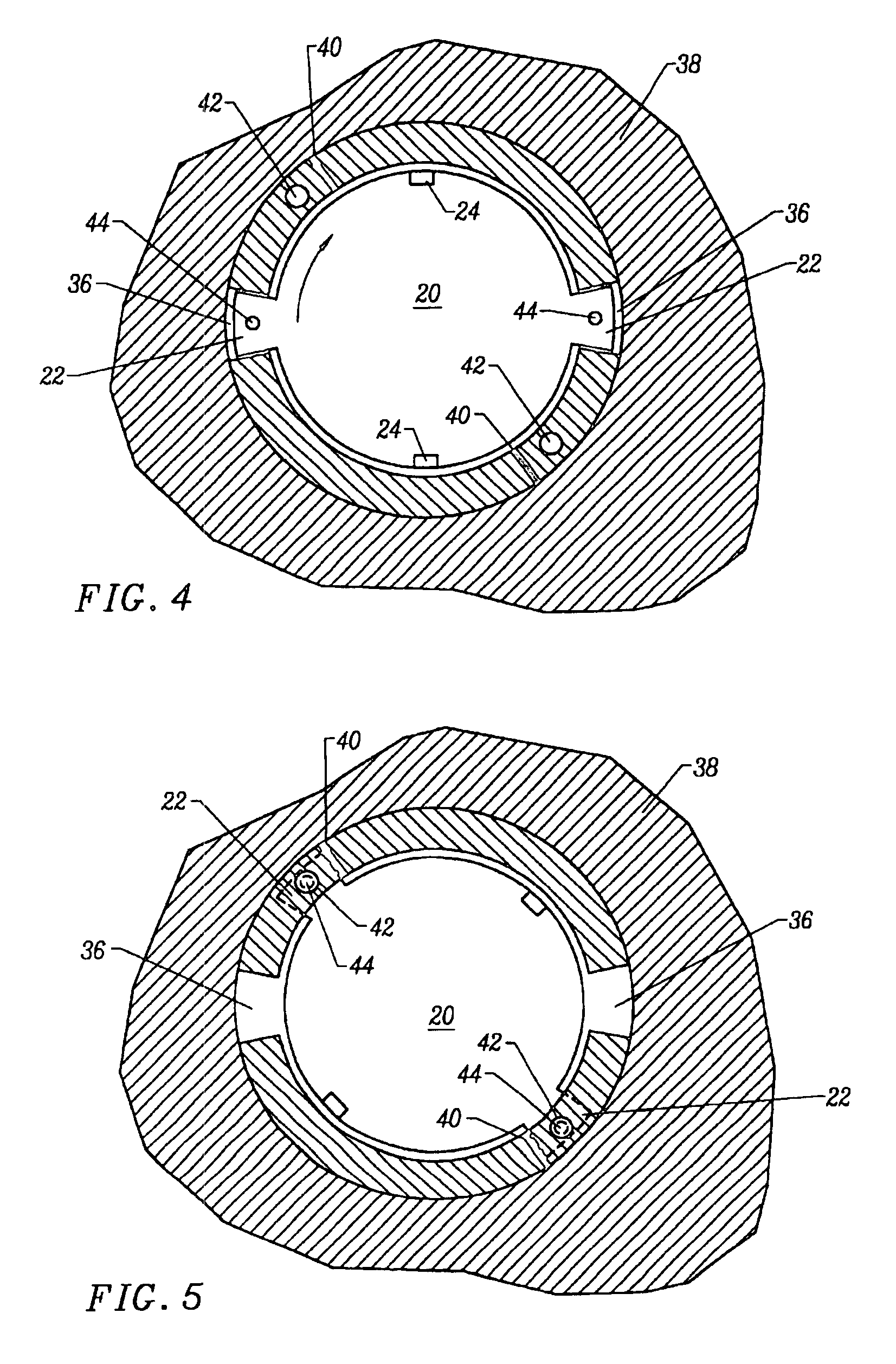

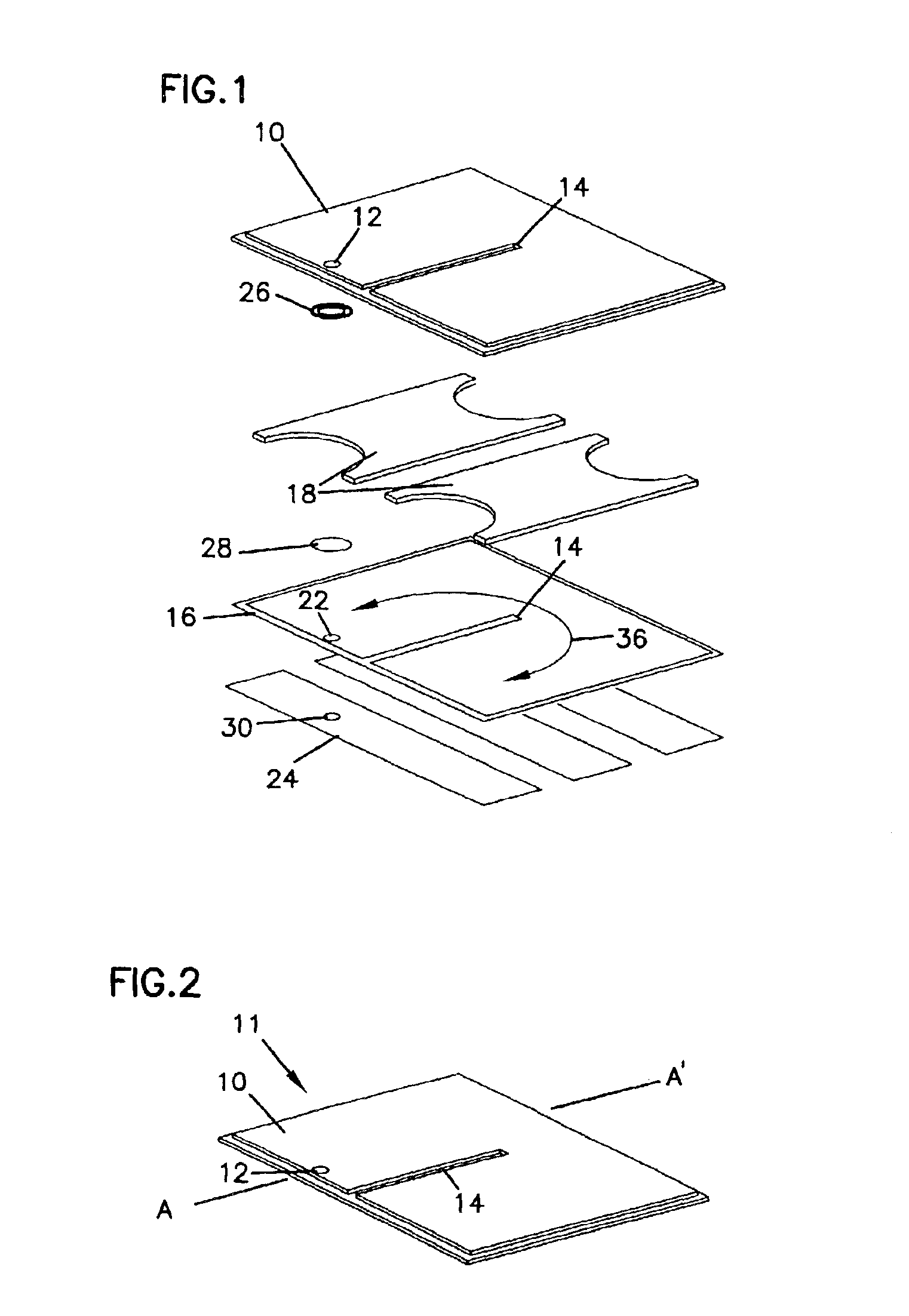

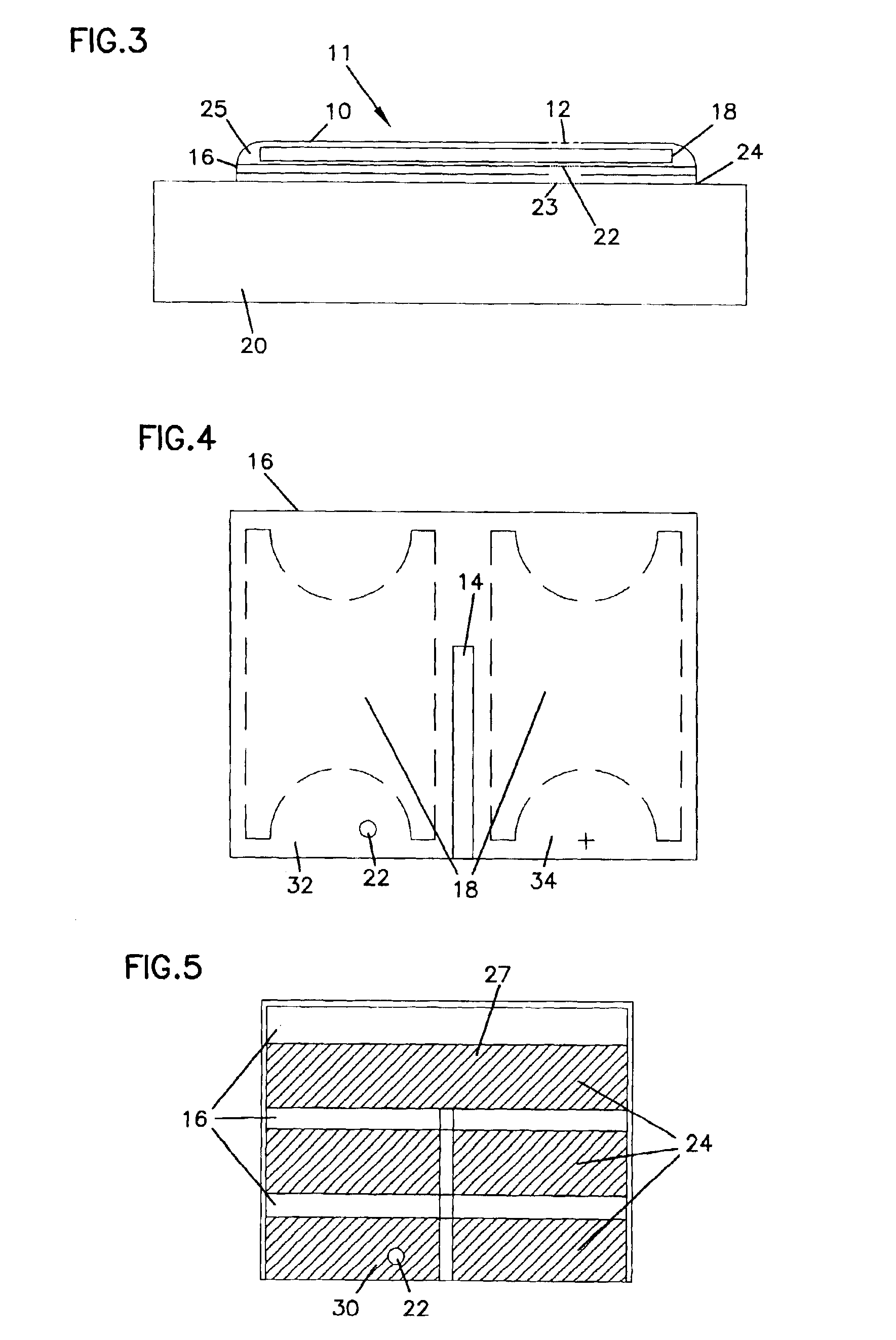

InactiveUS7209319B1Avoid insufficient thicknessUndesired vibrations/sounds insulation/absorptionRecord information storageBreatherEngineering

A disk drive includes a disk drive housing having a breather hole formed through the disk drive housing. A breather filter is configured for attachment to the disk drive housing and for limiting and filtering airflow into the disk drive housing. The breather filter includes a breather filter housing portion having a breather filter housing surface that defines a filter housing hole. The filter housing hole is configured to align with the breather hole formed in the disk drive housing. A filter portion is fitted within the filter housing portion. A leveling layer is provided that defines a first leveling layer surface and a second leveling layer surface. The leveling layer is formed of a material that is impermeable to air. A first adhesive layer is provided to adhere the breather filter housing surface to the first leveling layer surface. A second adhesive layer 40 is also provided to adhere the second leveling layer surface to the disk drive housing. The leveling layer and the first and second adhesive layers further define respective openings that are aligned with the filter housing hole and the breather hole to collectively form a delimited and sealed airflow inlet to the disk drive.

Owner:WESTERN DIGITAL TECH INC

Filter medium and structure

Thermoplastic bicomponent binder fiber can be combined with other media, fibers and other filtration components to form a thermally bonded filtration media. The filtration media can be used in filter units, such as breather caps. Such filter units can be placed in the stream of a mobile fluid and can remove a particulate and / or fluid mist load from the mobile stream. The unique combination of media fiber, bicomponent binder fiber and other filtration additives and components provide a filtration media having unique properties in filtration applications.

Owner:DONALDSON CO INC

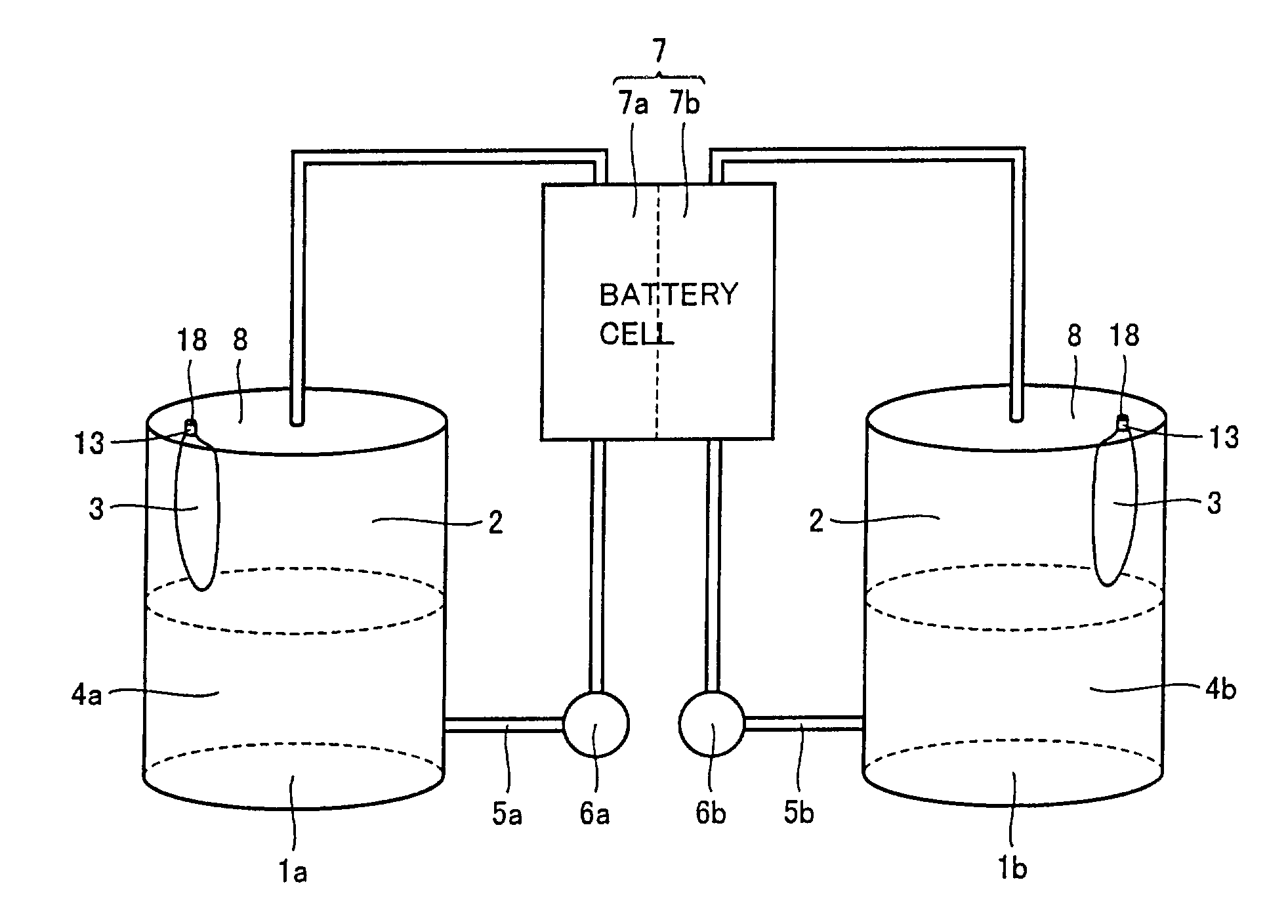

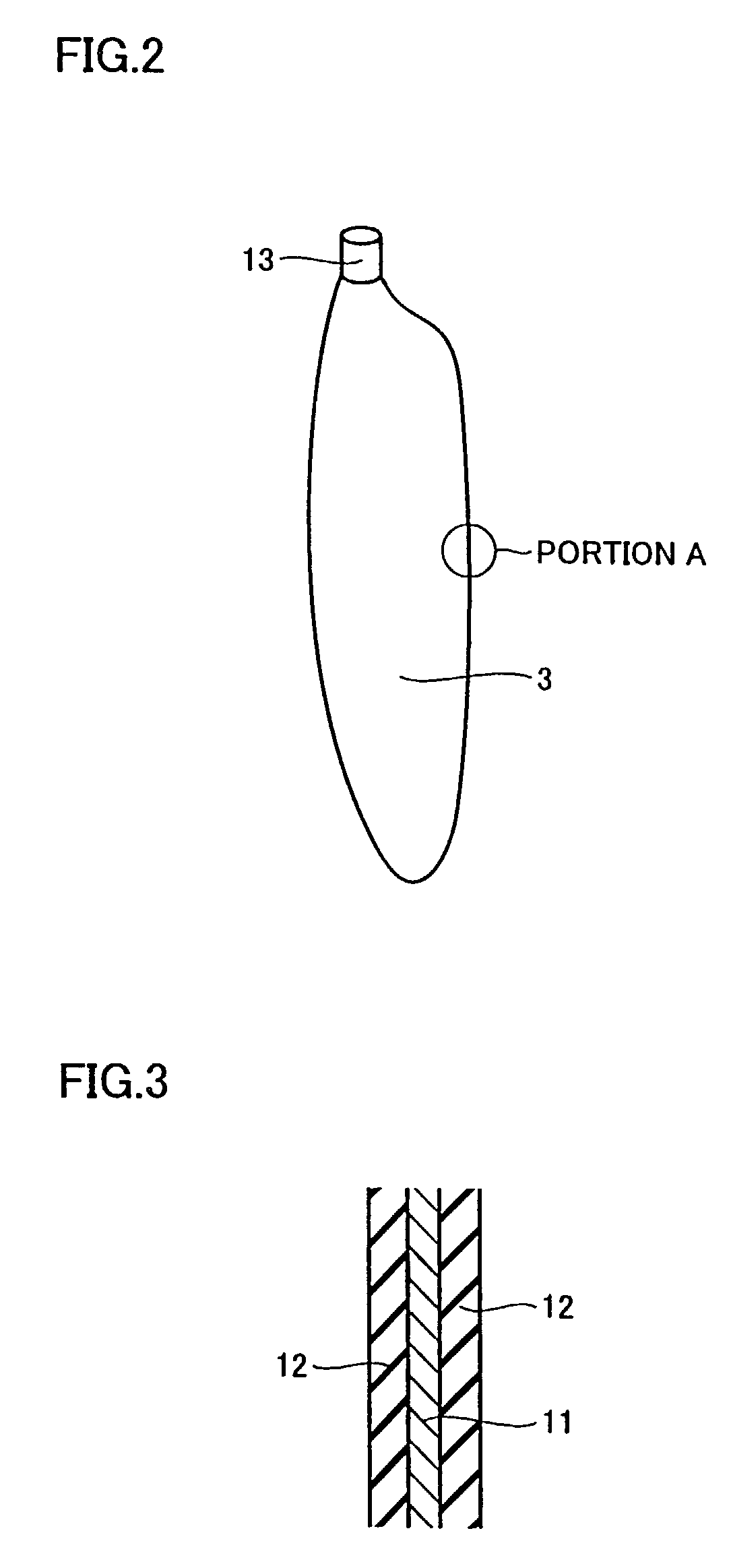

Pressure fluctuation prevention tank structure, electrolyte circulation type secondary battery, and redox flow type secondary battery

A simplified, pressure-variation preventing tank structure capable of preventing pressure variations in a gas phase portion resulting from temperature variations, without bringing stored liquid into contact with air. This pressure-variation preventing structure includes a breather bag arranged in a gas phase portion of a tank and inflating / deflating in communication with outside air, and a manhole to which the breather bag is attached to suspend in a gas phase portion, including a communication hole for the breather bag to communicate with outside air. The breather bag has air-blocking, acid-resistant and expandable characteristics.

Owner:SUMITOMO ELECTRIC IND LTD +1

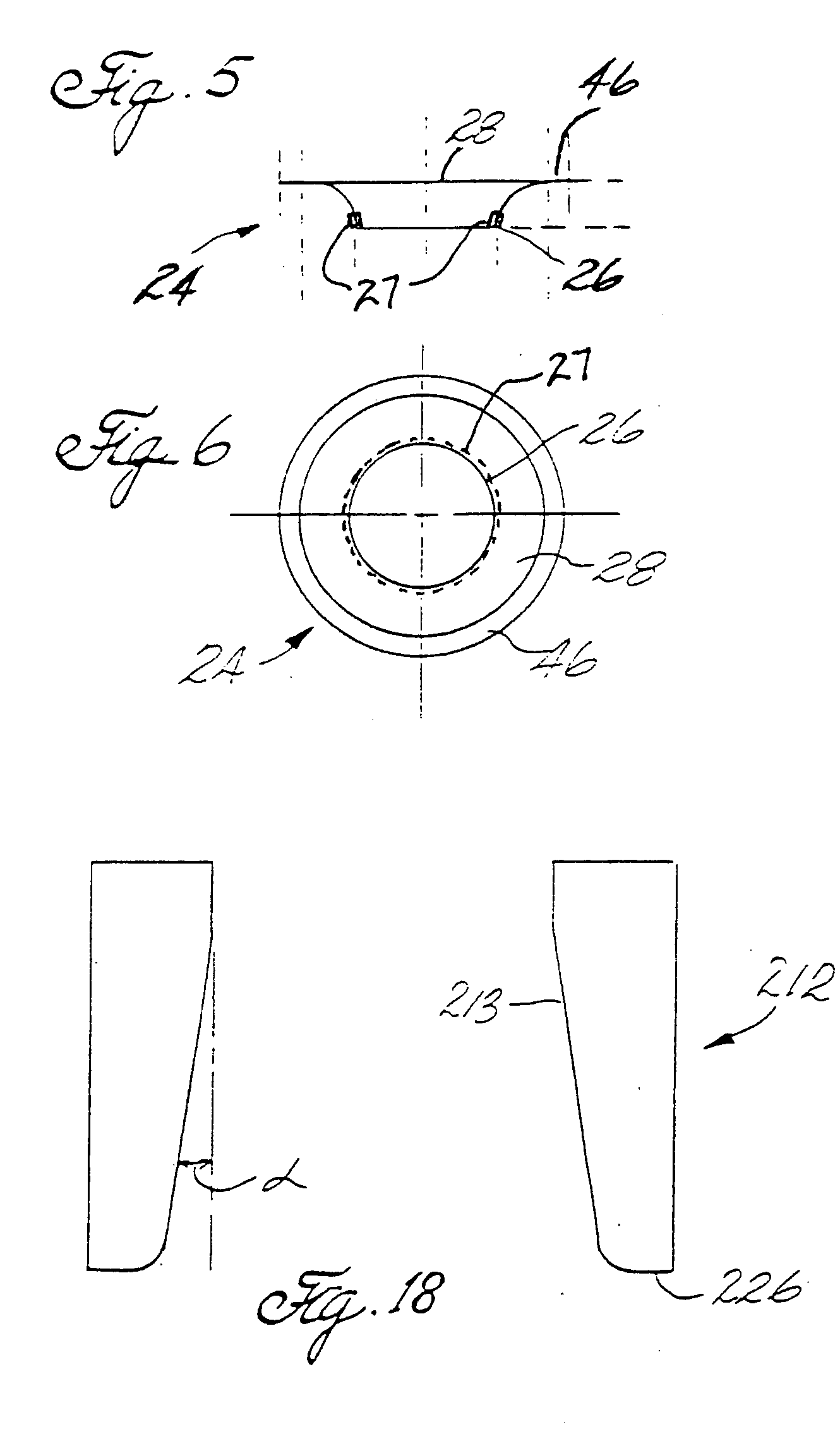

Flat speaker with a flat membrane diaphragm

InactiveUS20050286729A1Reduce the possibilityHigh quality soundPlane diaphragmsTransducer casings/cabinets/supportsMembrane stretchBreather

A flat loudspeaker having a back plate, a driver responsive to an electrical signal, an enhancer having a neck and a mouth, the neck attached to the driver and movable in accordance with the movement of the driver, a thin film membrane, the membrane attached to the enhancer, the membrane stretched over the frame, a frame for supporting the membrane and maintaining it in a taut state, and a rubber type adhesive for dampening the membrane resonances and for adhering the membrane to the frame. Clarity of sound can be further improved by including a plurality of sound breathers in the back plate of the speaker. For improved sound radiation capability, the size and the shape of the enhancer can be modified in various ways, including a frustoconical, parabolic, or bell-shaped enhancer. Dampening material may be provided in the space below or affixed to the membrane to improve sound quality.

Owner:DIGITAL SONICS

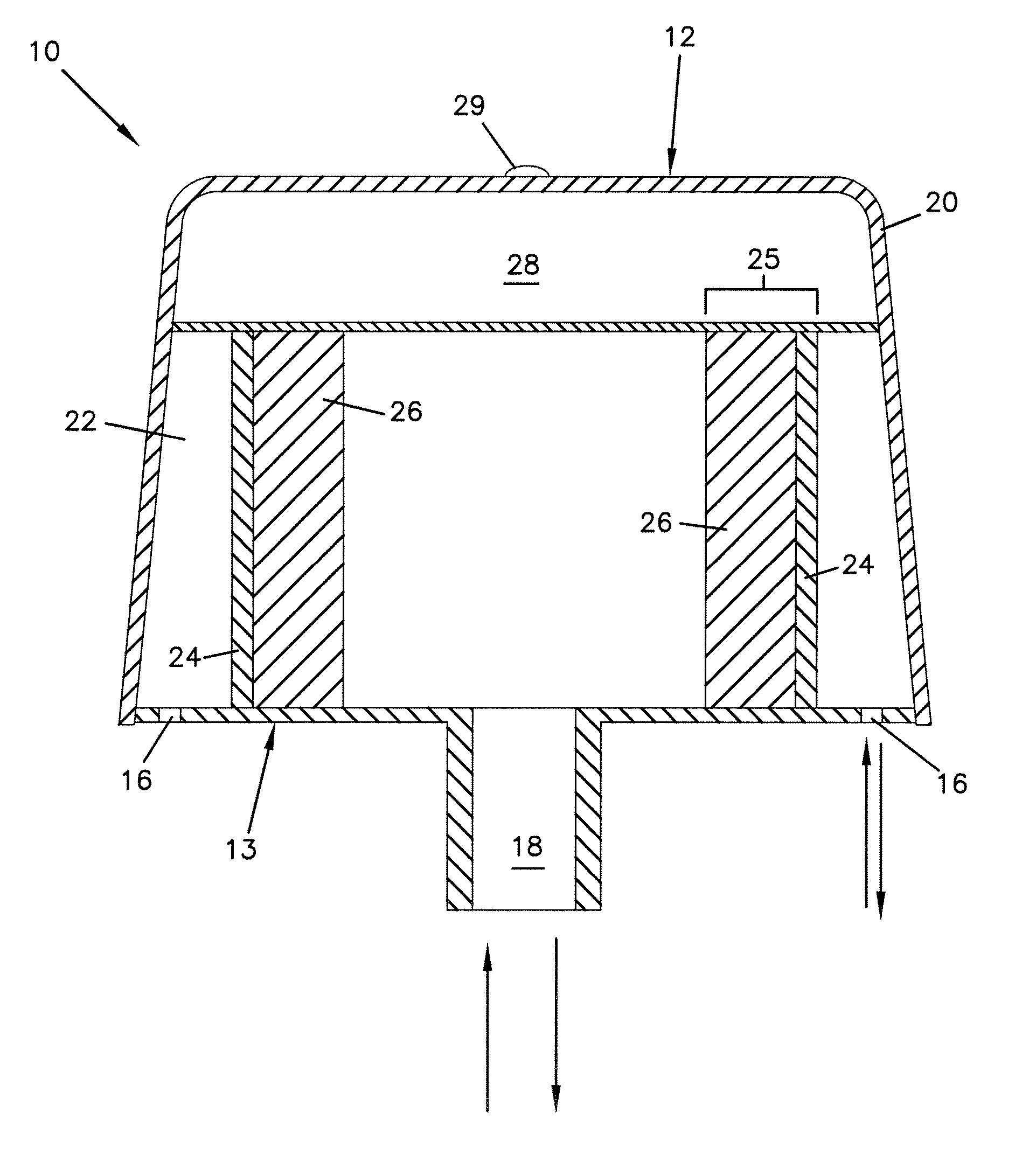

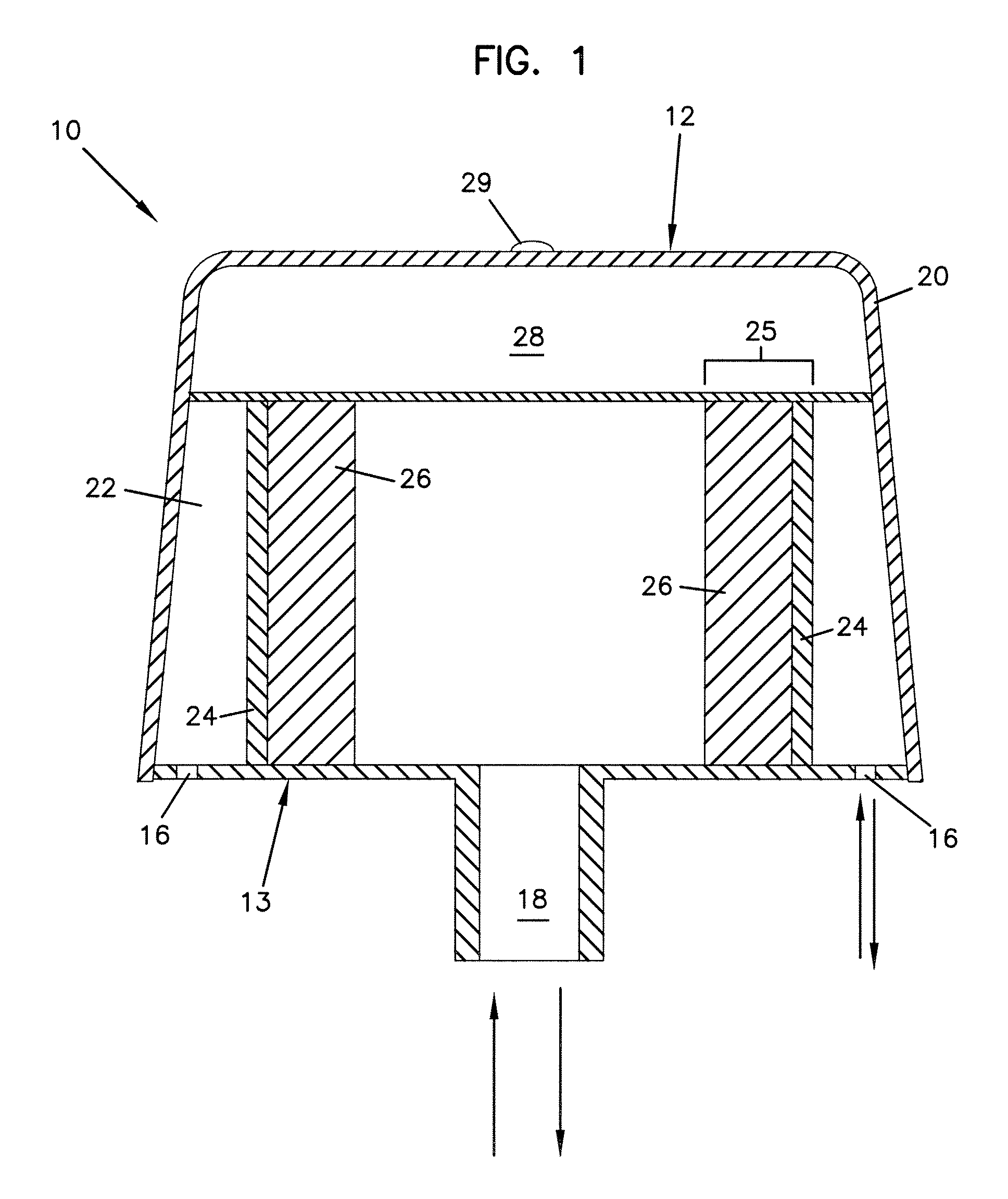

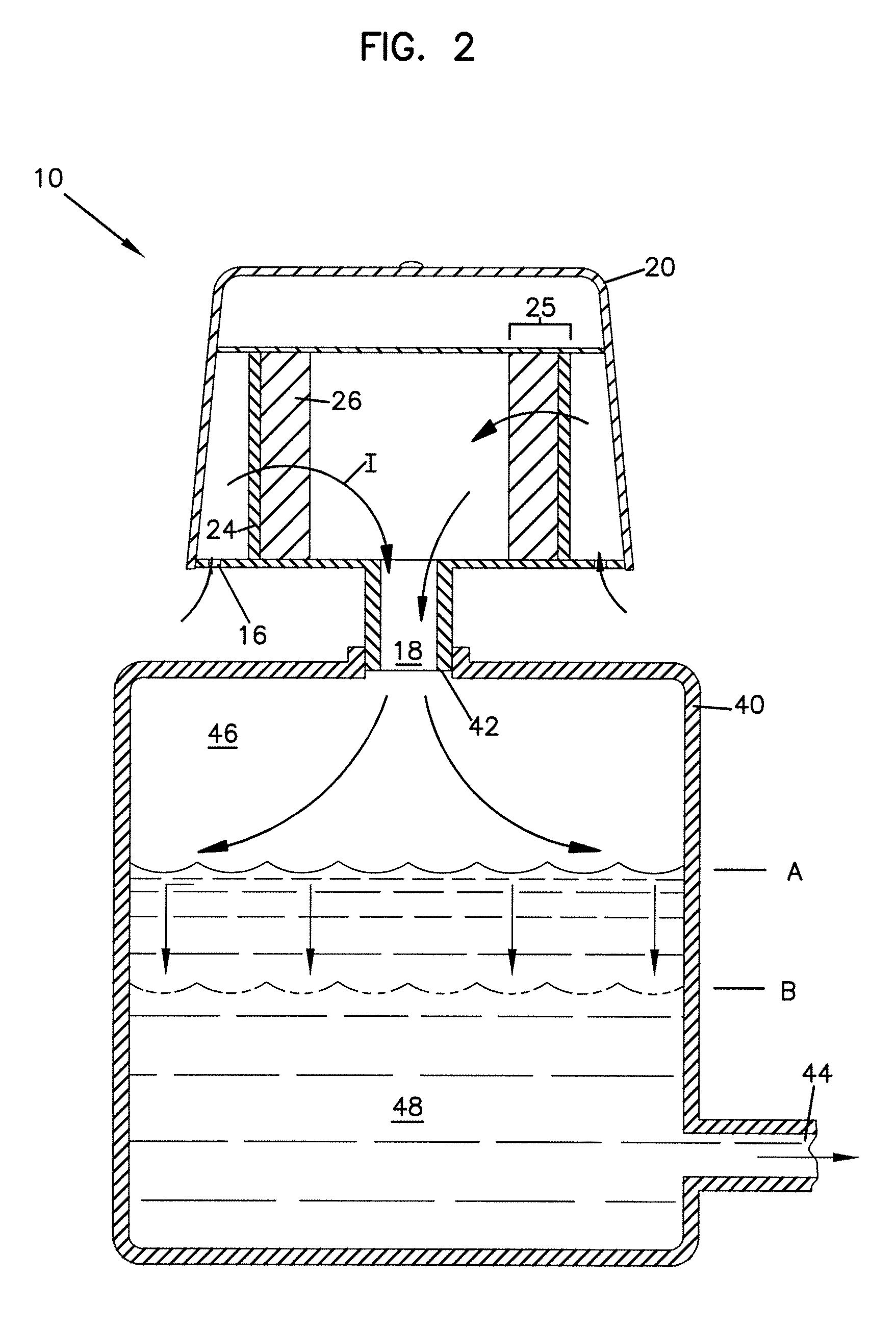

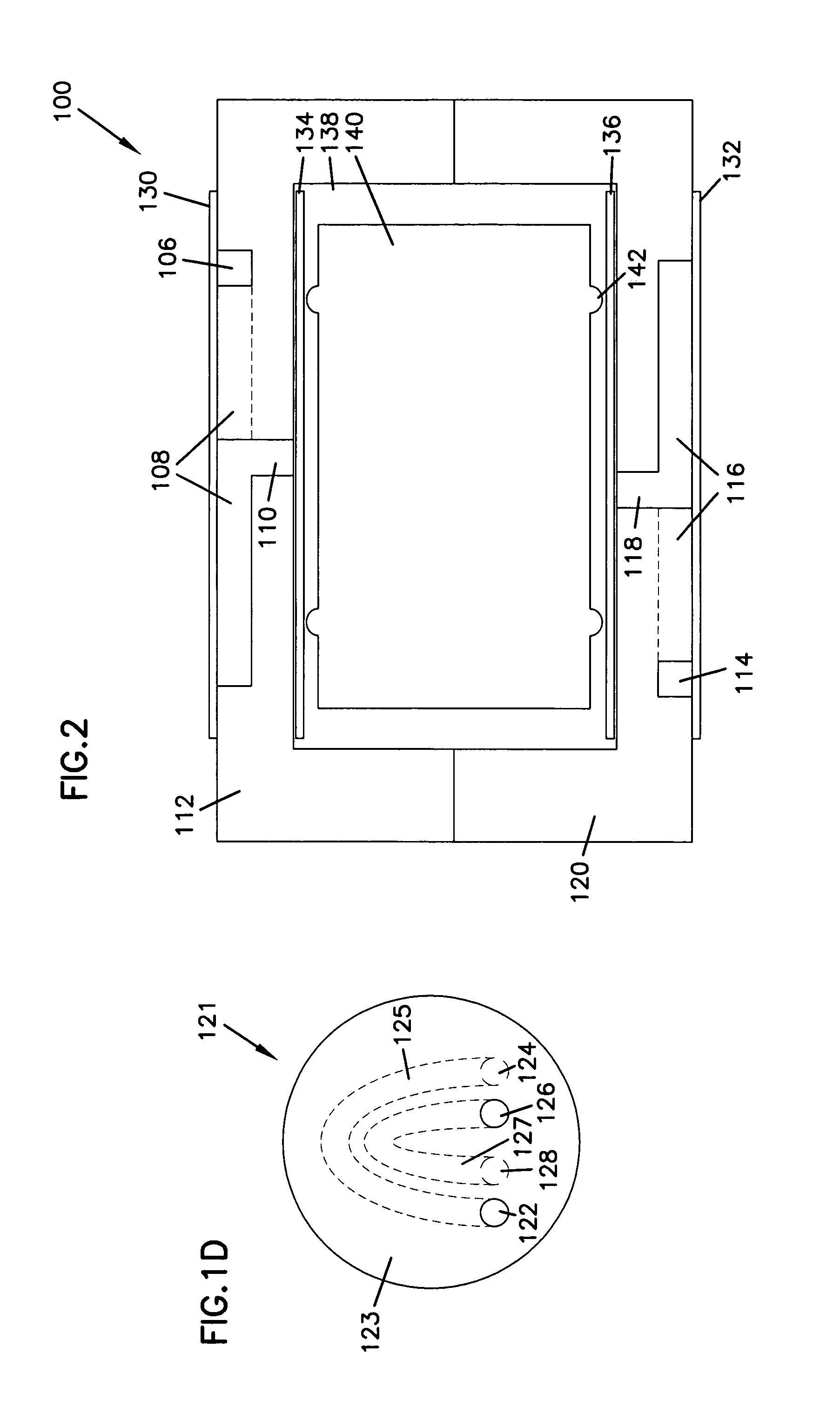

Filter constructions containing breather and recirculation filter elements

Filters and filtering methods for placement in an electronic enclosure, such as a hard disk drive housing, are disclosed. In one embodiment the filter includes a housing having a top, a base, and at least one sidewall extending from the top to the base, the housing defining an inlet port and an outlet port through the sidewall, and a breather port in the base, the housing further defining an internal volume. Adsorbent filter media is disposed within the internal volume of the housing such that the housing defines a first path for flow of fluid through the breather port in the base to the filter media and a second path for flow of fluid through the inlet port, into contact with the filter media, and out the outlet port.

Owner:DONALDSON CO INC

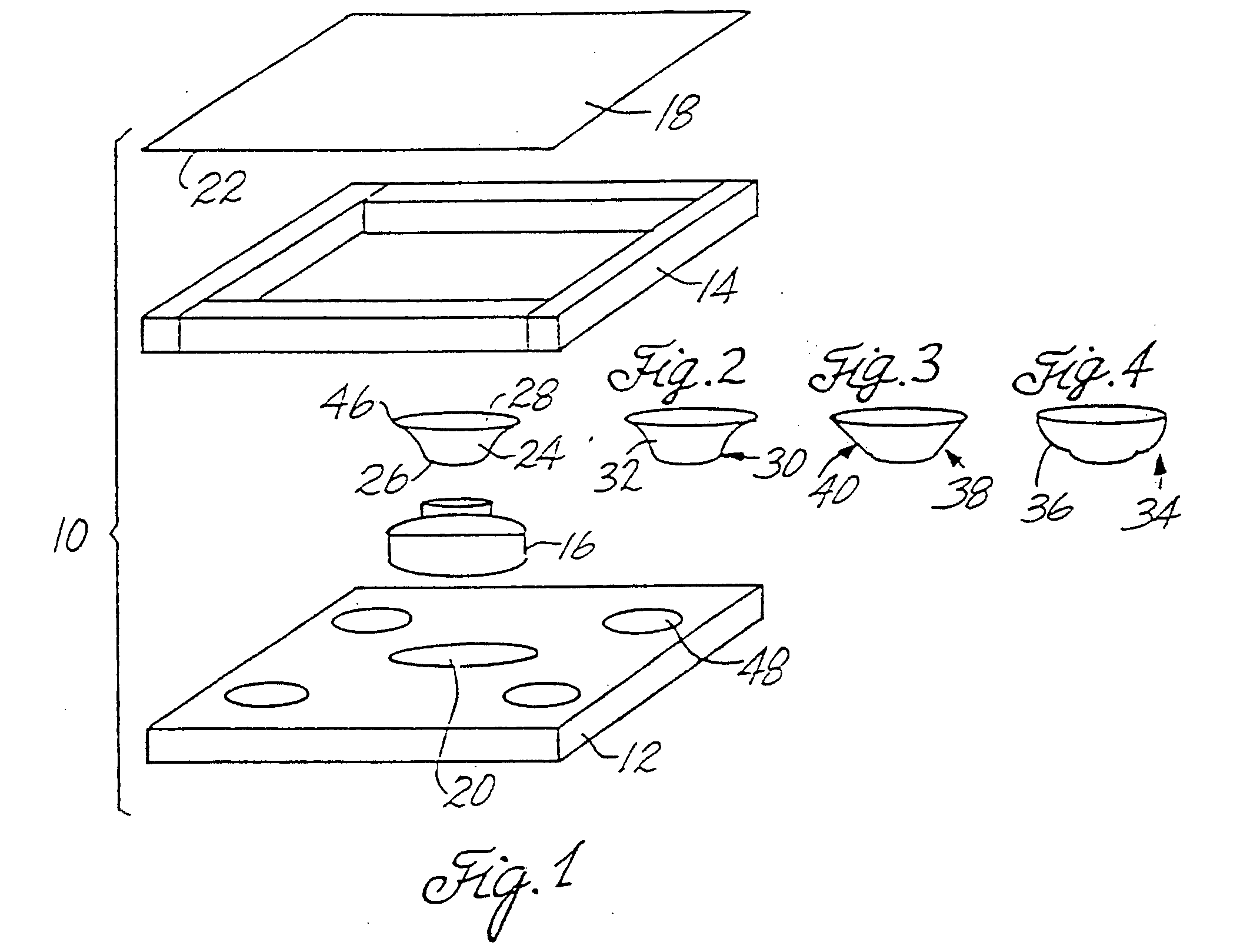

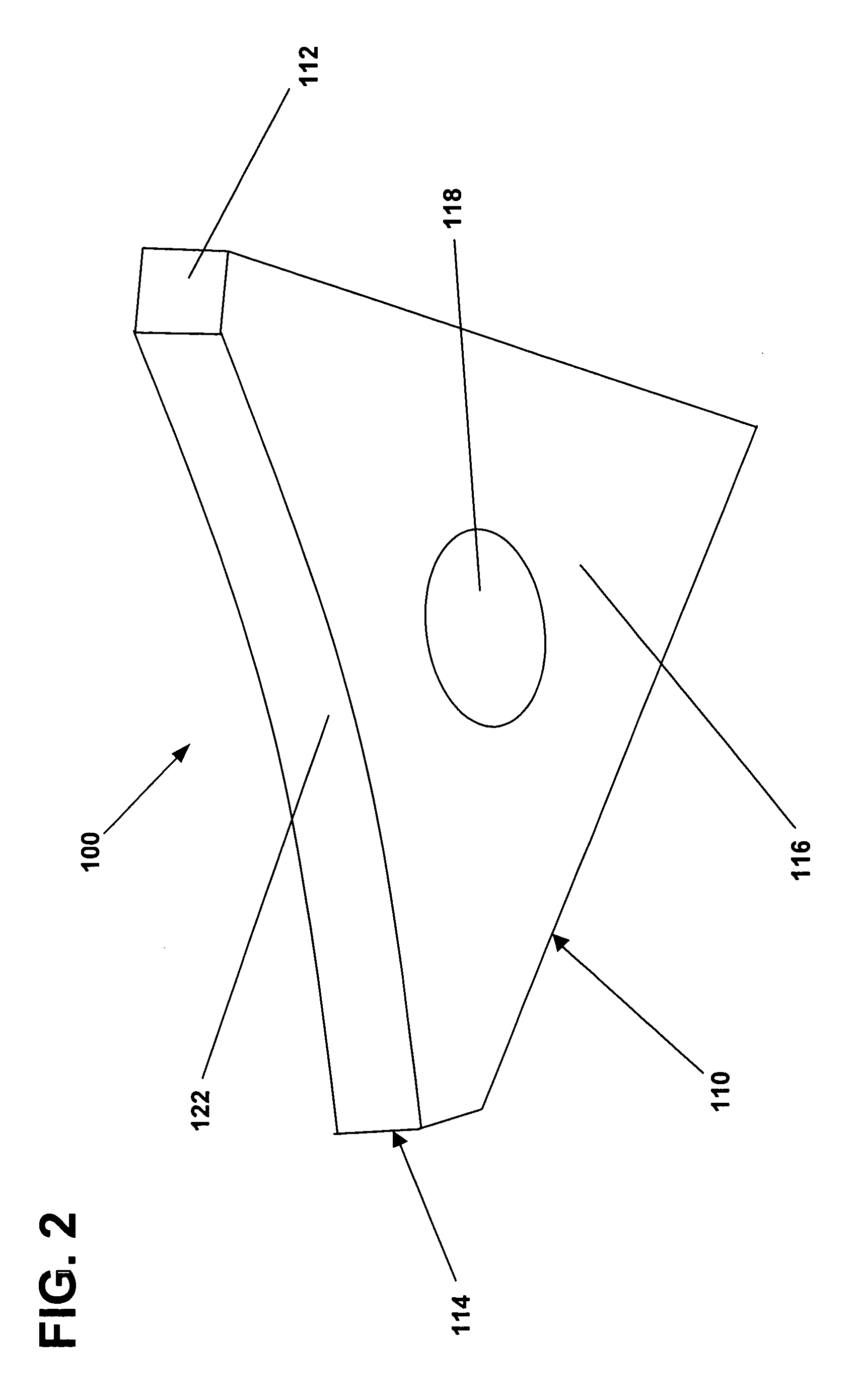

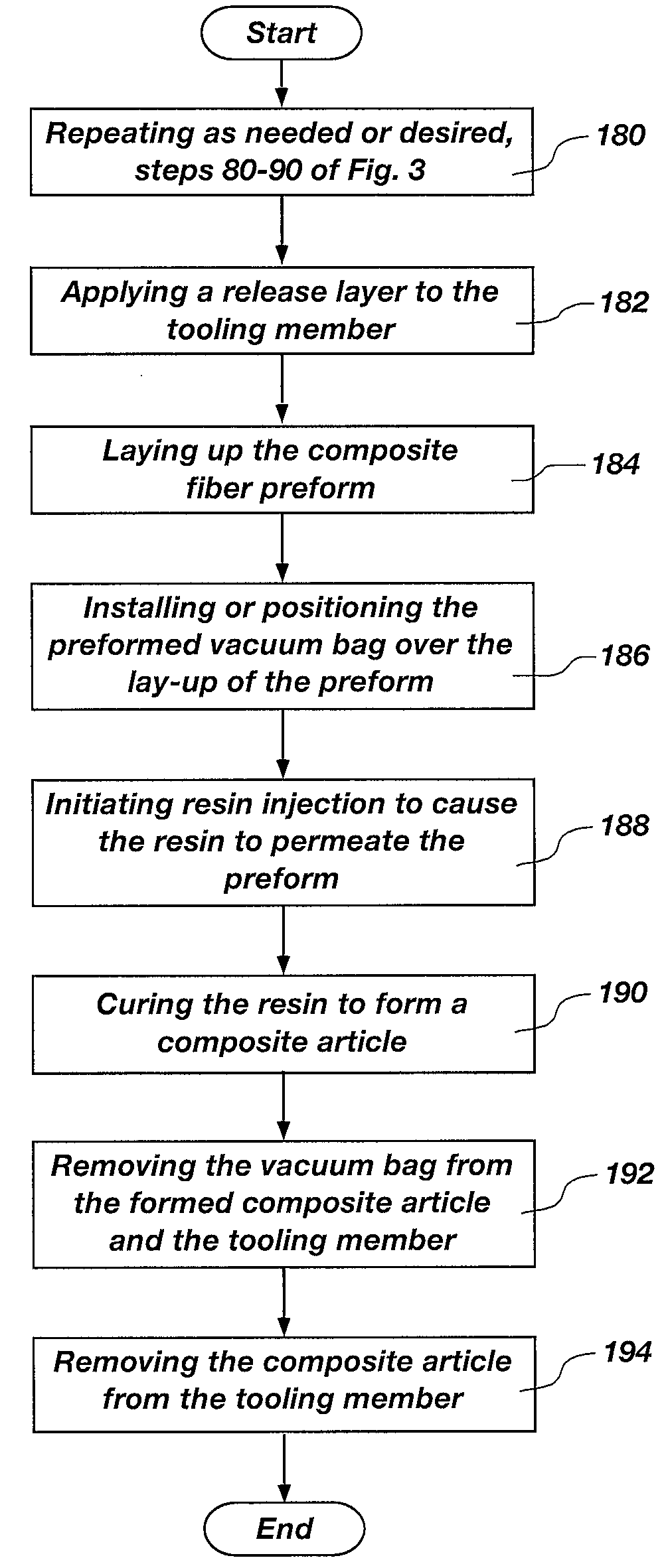

Multi-function vacuum bag for composite part manufacture

A multi-function vacuum bag for use in the manufacture of composites, wherein the vacuum bag may be configured to provide all-in-one capabilities, namely to function as the vacuum bag, a caul or caul sheet, release layer and / or a breather, as well as to provide other functions. Specifically, the multi-function vacuum bag allows a separate breather or breather material, a separate caul or caul layer, and a release or release layer all to be eliminated, if desired, as the multi-function vacuum bag is capable of performing the functions of each of these once formed. Furthermore, the multi-function vacuum bag may be used with various composite manufacturing process, such as VARTM or resin infusion processes, various vacuum bagging processes, filament winding processes, and others.

Owner:AMERICAN CONSULTING TECH

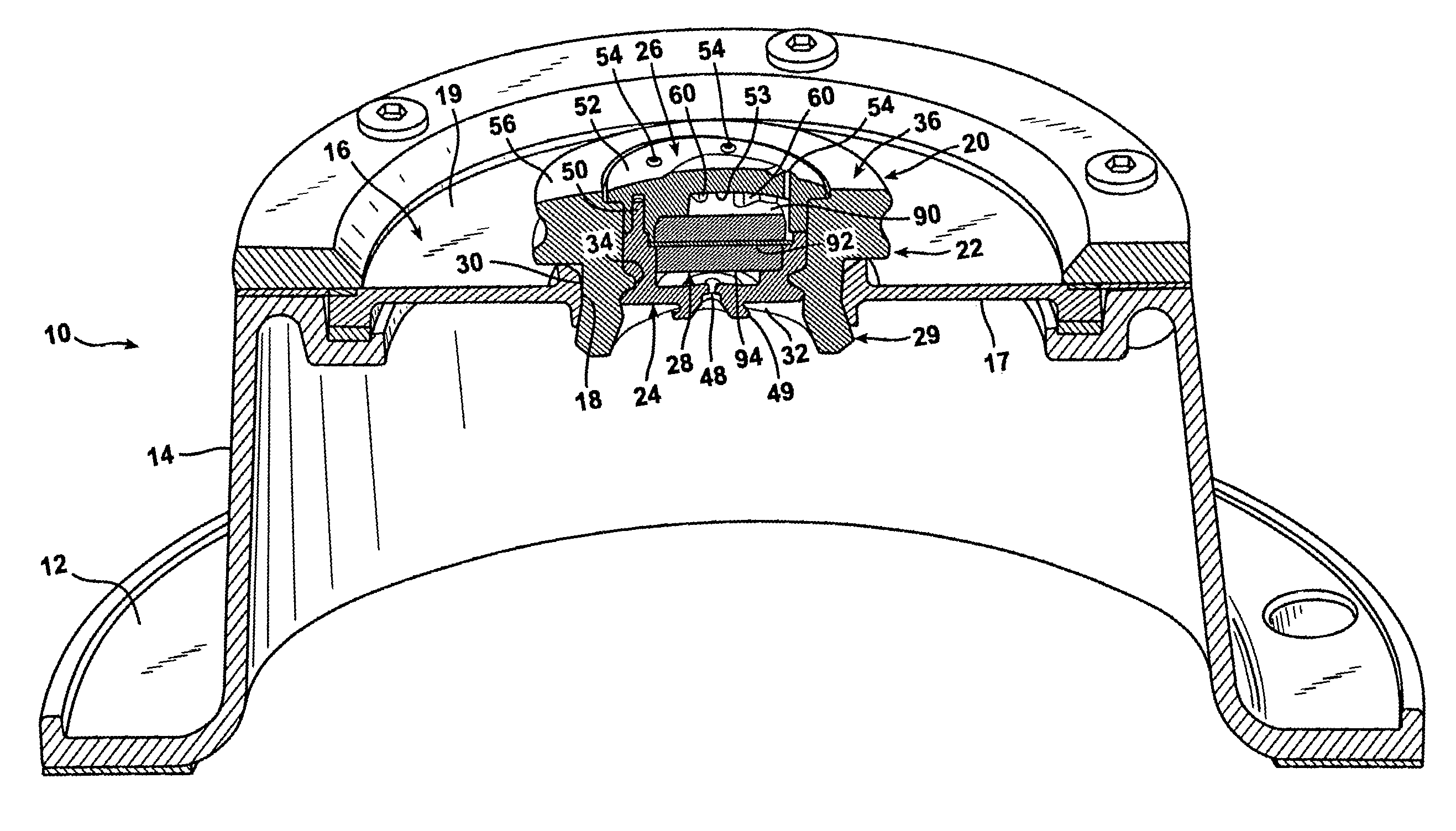

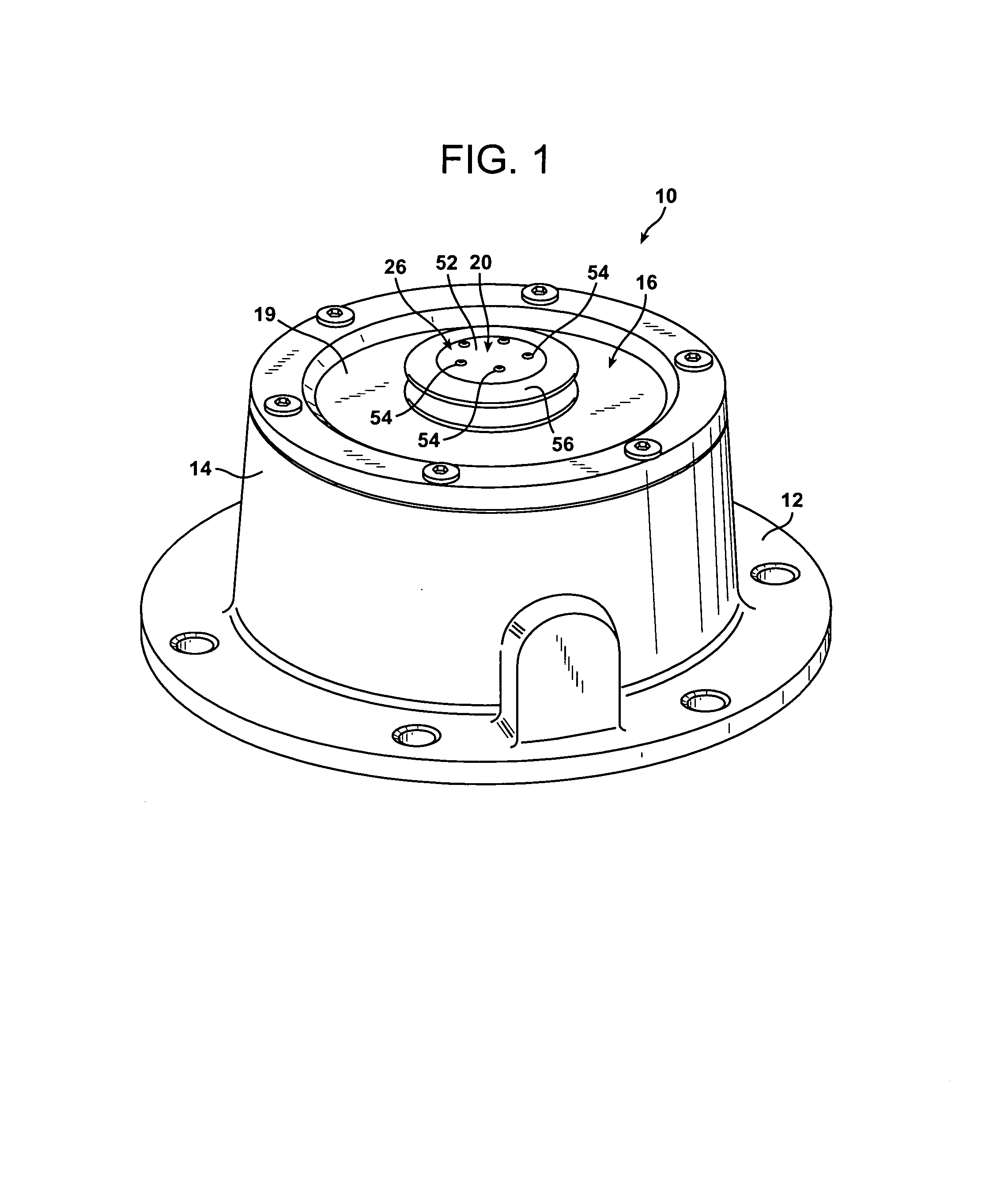

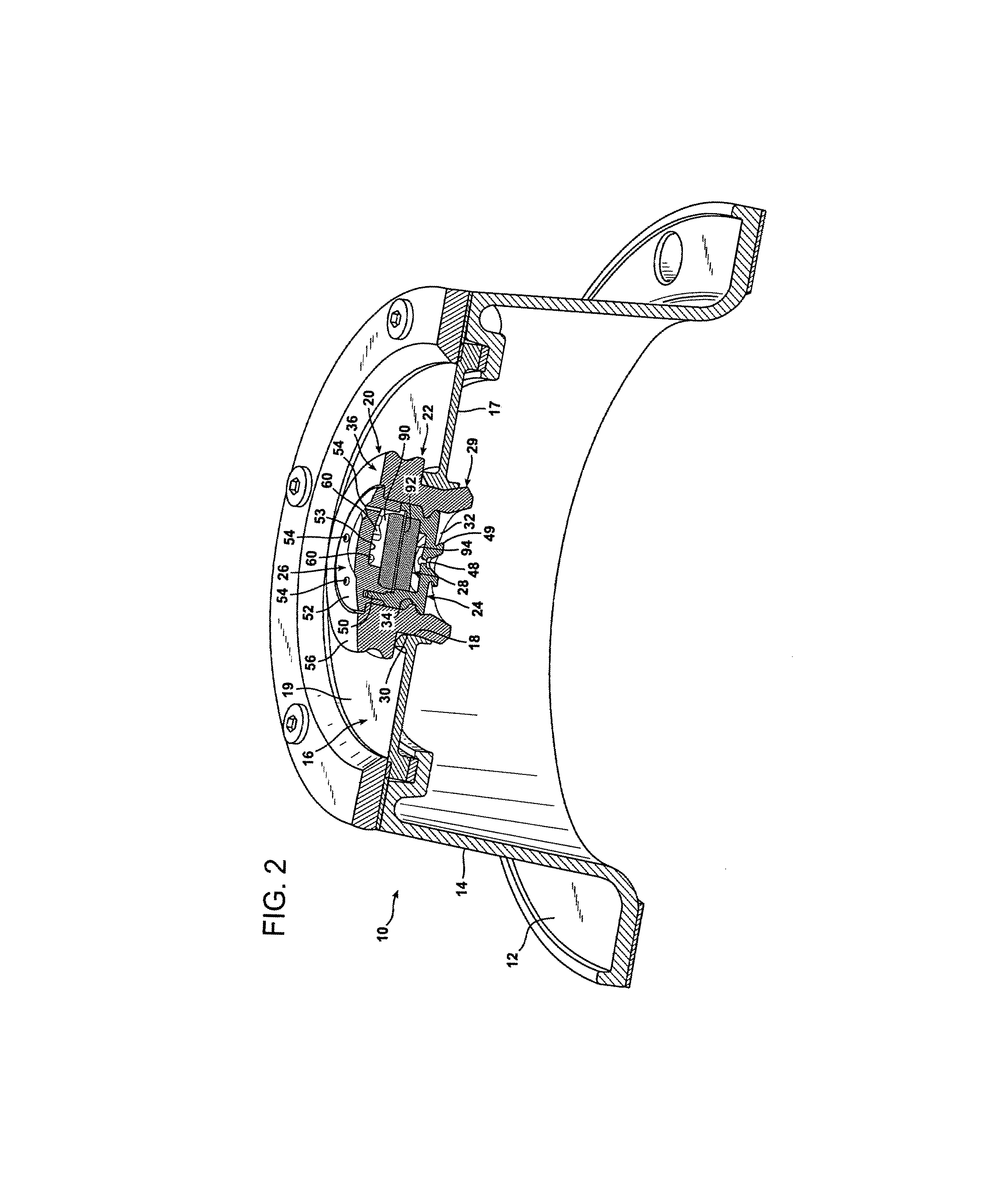

Hubcap filter

ActiveUS7156890B1Effective preventionExtended seal lifeCombination devicesGas treatmentMobile vehicleBreather

A hubcap breather assembly is provided for a hubcap housing lubricated wheel bearings in an automotive vehicle. The breather assembly includes a resilient, annular collar that fits into an access opening in a hubcap end wall, a filter cartridge cup, and a filter cartridge lid which fit together to hold a filter therebetween in a filter cartridge chamber. The filter is a hydrophobic, gas-permeable, particular matter filter that is disposed within and extends entirely across the filter cartridge chamber. Ambient air entering the hubcap through the hubcap breather assembly is filtered to exclude both particulate matter and water before entering the wheel bearing chamber. The filter is preferably formed of three layers, including an outboard porous layer of sintered polypropylene plastic, an intermediate hydrophobic layer of polytetrafluoroethylene, and an inboard porous layer of sintered polypropylene plastic. The filter can be replaced by separating the filter cartridge lid from the filter cartridge cup.

Owner:BENDIKS SPAJSER FAUNDEJSHN BREJK LLK

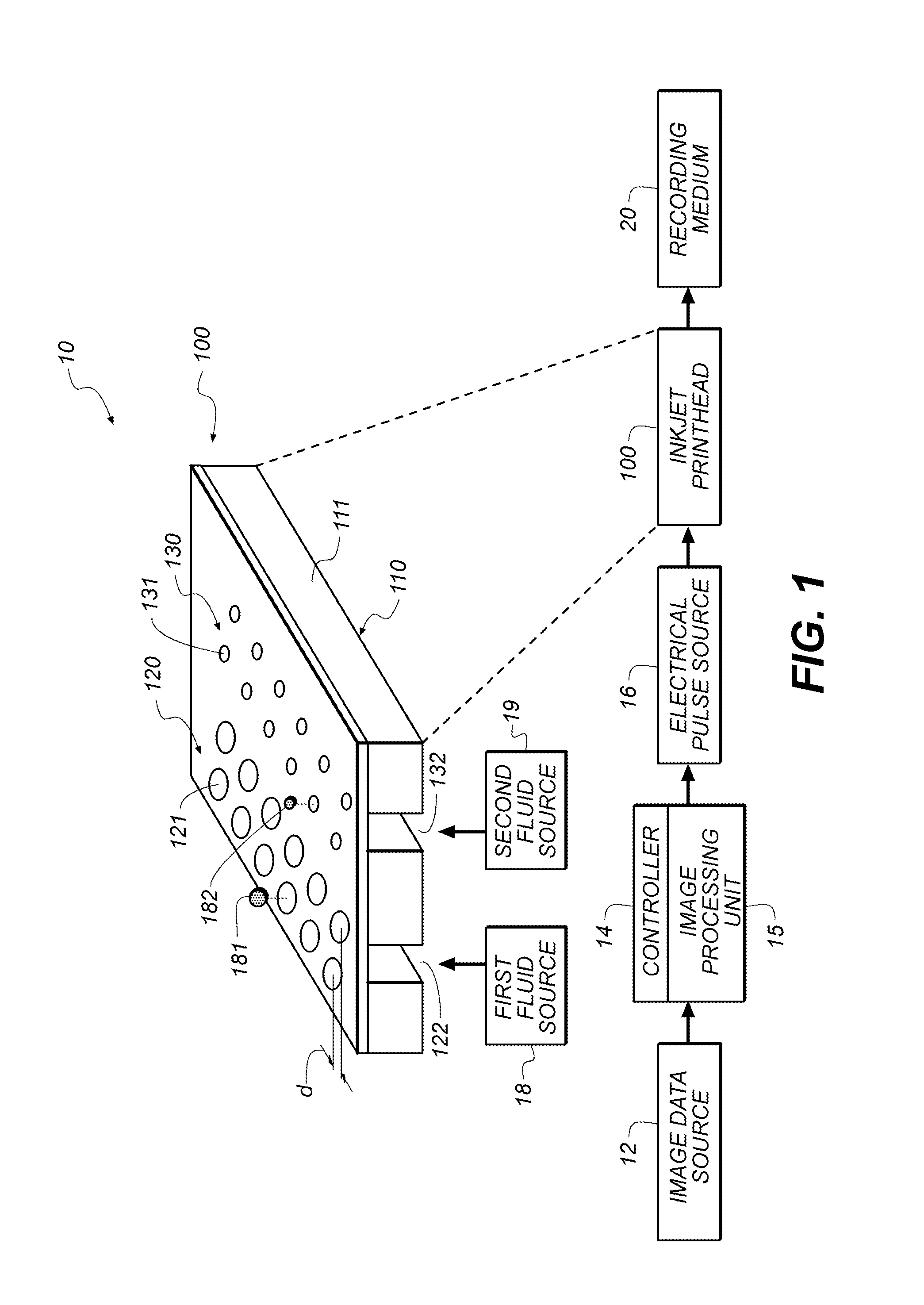

Biased wall ink tank with capillary breather

An ink tank including a reservoir for holding ink, the reservoir including a flexible wall for adjusting an internal volume of the reservoir; a biasing element for applying a force to the flexible wall that tends to increase the internal volume of the reservoir; an ink supply port for delivering ink from the reservoir to a printhead; and a breather element, at least a portion of which is disposed inside the reservoir, including a capillary material in contact with ink in the reservoir, wherein the breather element is configured to allow air to enter the reservoir in response to an internal pressure of the reservoir being less than atmospheric pressure outside the ink tank by an amount that is related to a property of the biasing element and a capillary pressure of the breather element.

Owner:EASTMAN KODAK CO

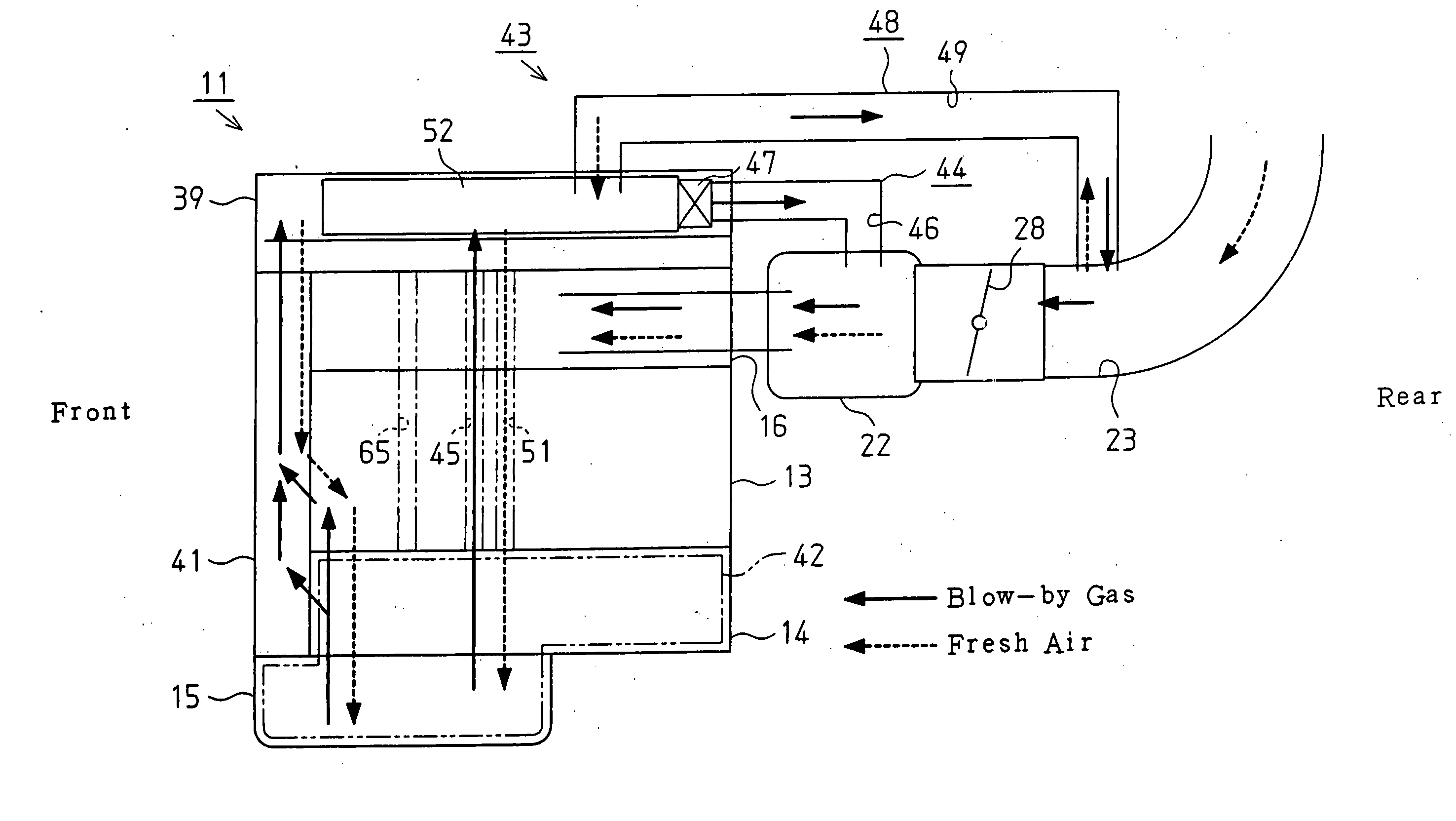

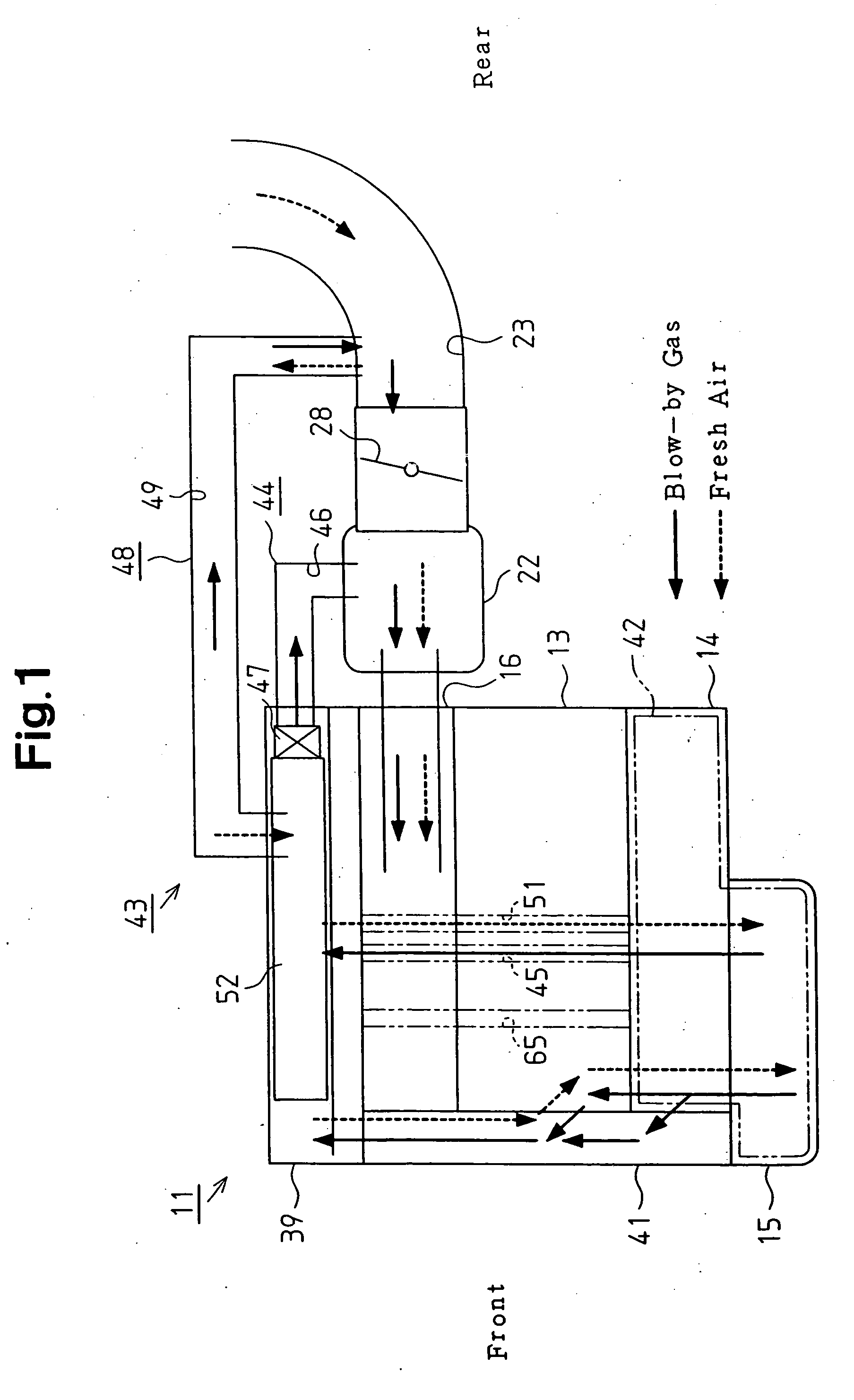

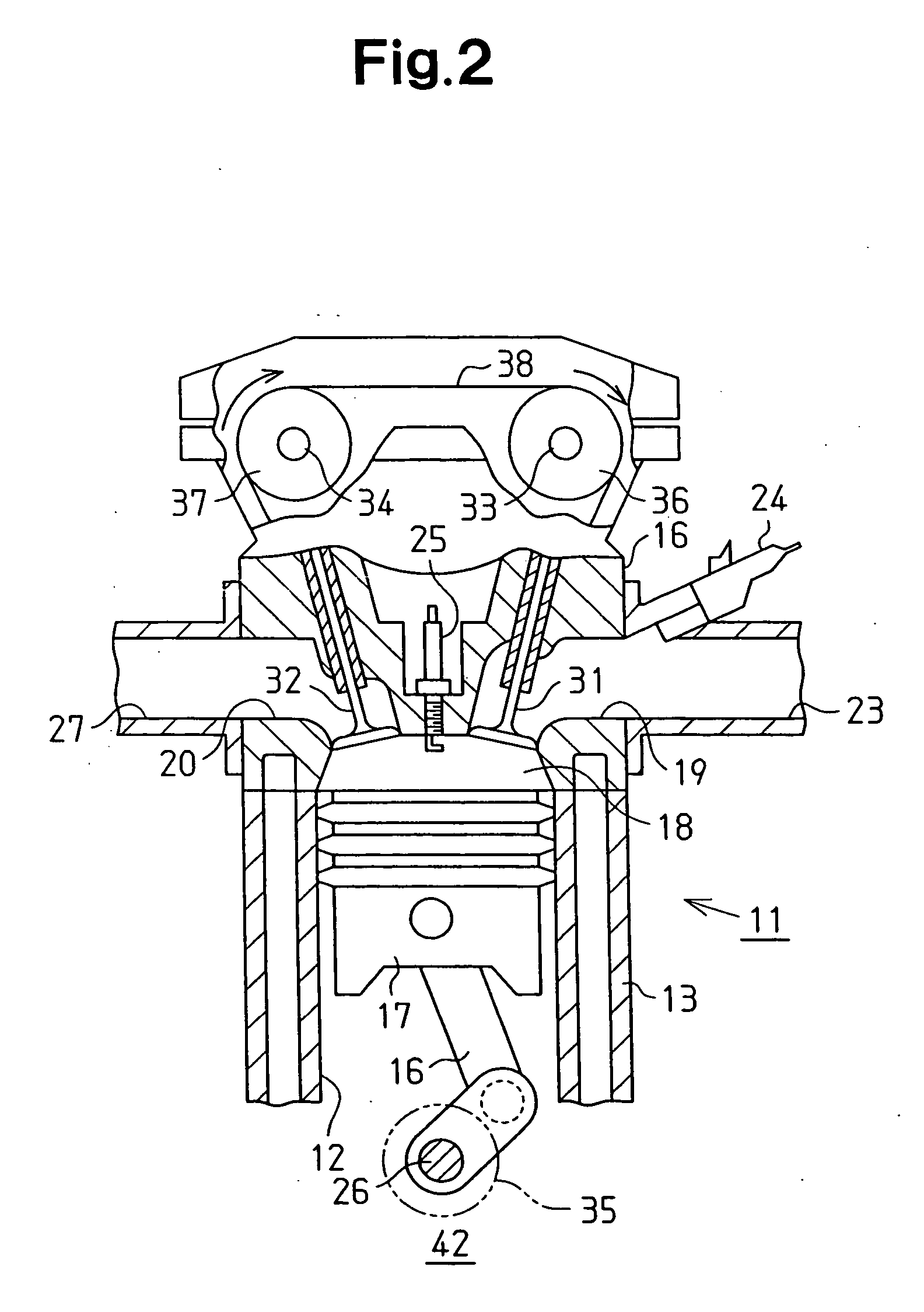

Breather chamber structure for internal combustion engine and internal combustion engine

InactiveUS20050005921A1Internal combustion piston enginesNon-fuel substance addition to fuelBreatherEngineering

A breather chamber is located in a blow-by gas passage to separate oil from blow-by gas. A partitioning member partitions the interior of the breather chamber into a plurality of spaces. The partitioning member is arranged such that the spaces extend along the flowing direction of the blow-by gas and that an adjacent pair of the spaces are connected at ends in the flowing direction. A separating member is provided in at least one of the spaces. The separating member obstructs the flow of the blow-by gas in the associated space, thereby separating oil from the blow-by gas. Therefore, oil is separated from the blow-by gas securely and is prevented from being brought out of the breather chamber.

Owner:TOYOTA JIDOSHA KK

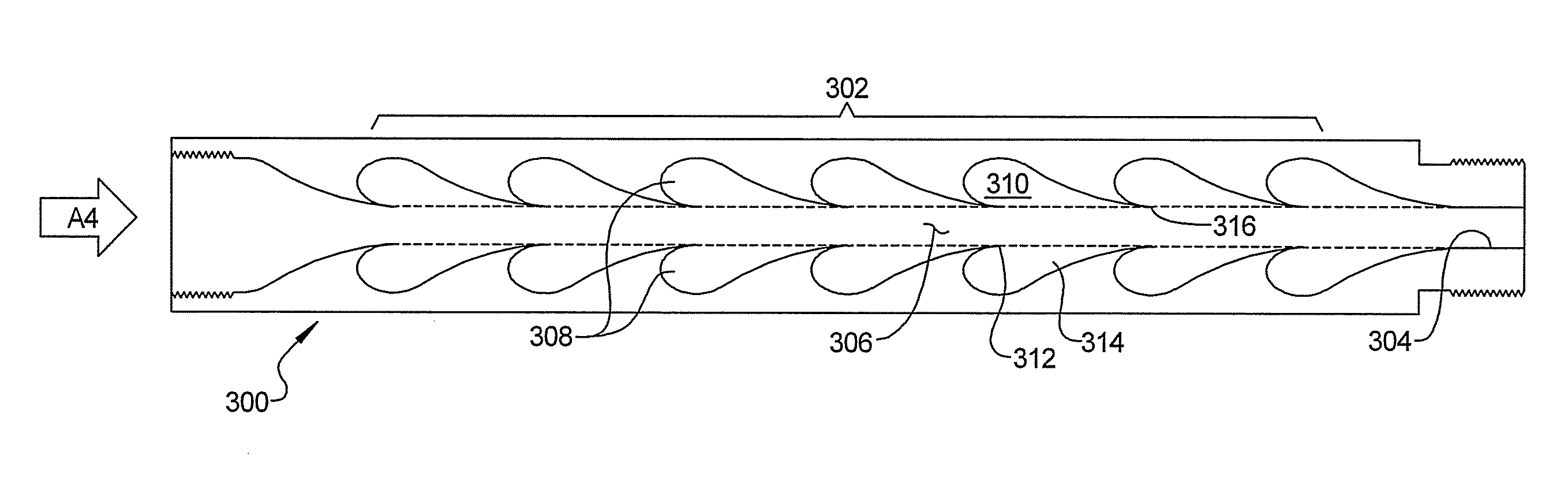

Engine Crankcase Breathing Passage With Flow Diode

InactiveUS20150059718A1Shorten speedStable flow patternCombustion enginesCrankcase ventillationBreatherCrankcase

An internal combustion engine is disclosed which includes an improved crankcase drain back system. A set of drain flow diodes are disposed in each of the drain lines to direct fluid flow in a direction from the head portion to the crankcase. Likewise, a set of breather flow diodes are disposed in the breather lines to direct fluid flow in a second direction from the cylinder portion to the head portion. The flow diodes include a series of stacked flow diode elements which allow flow in one direction, while resisting flow in the opposite direction.

Owner:GM GLOBAL TECH OPERATIONS LLC

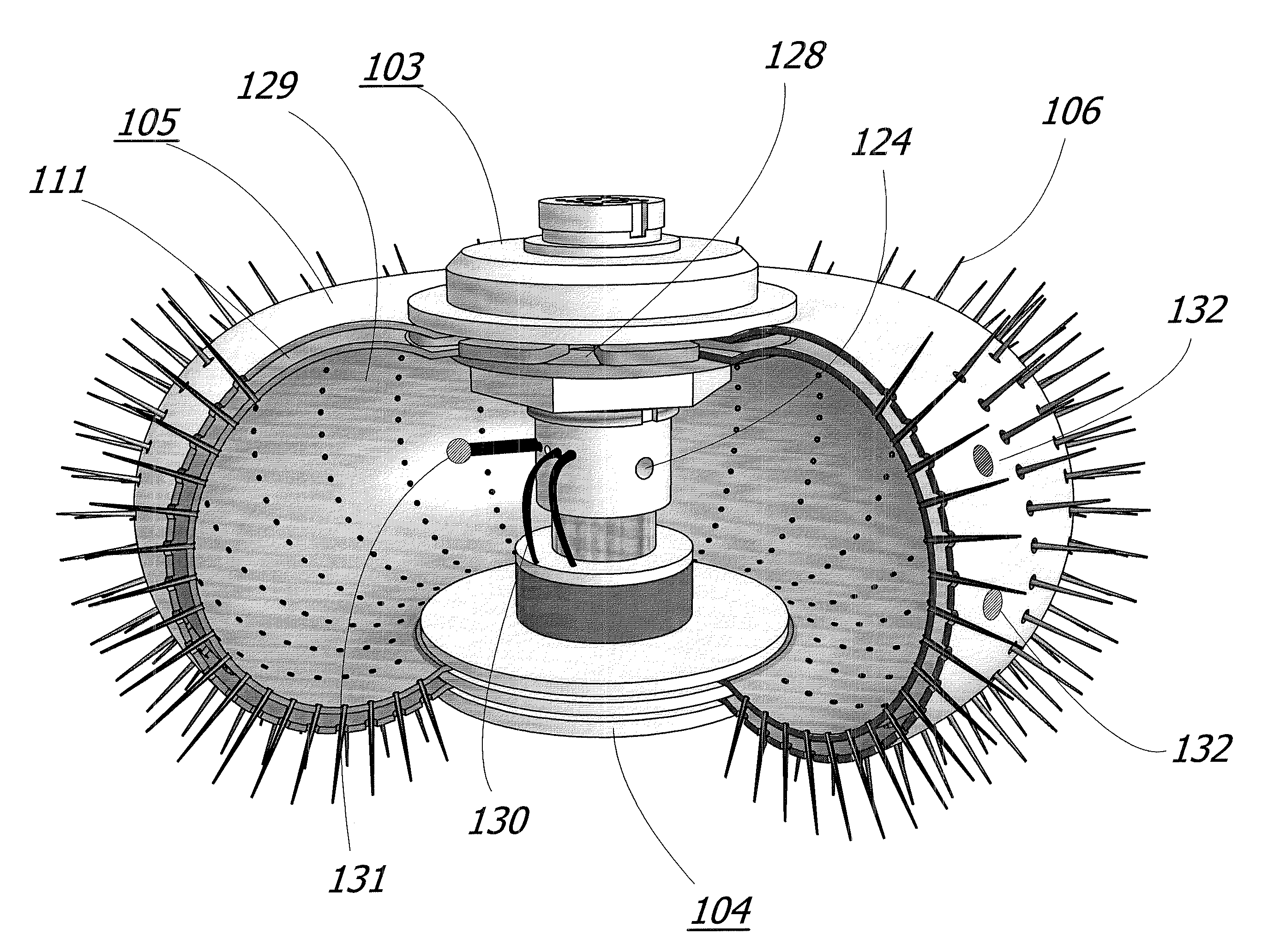

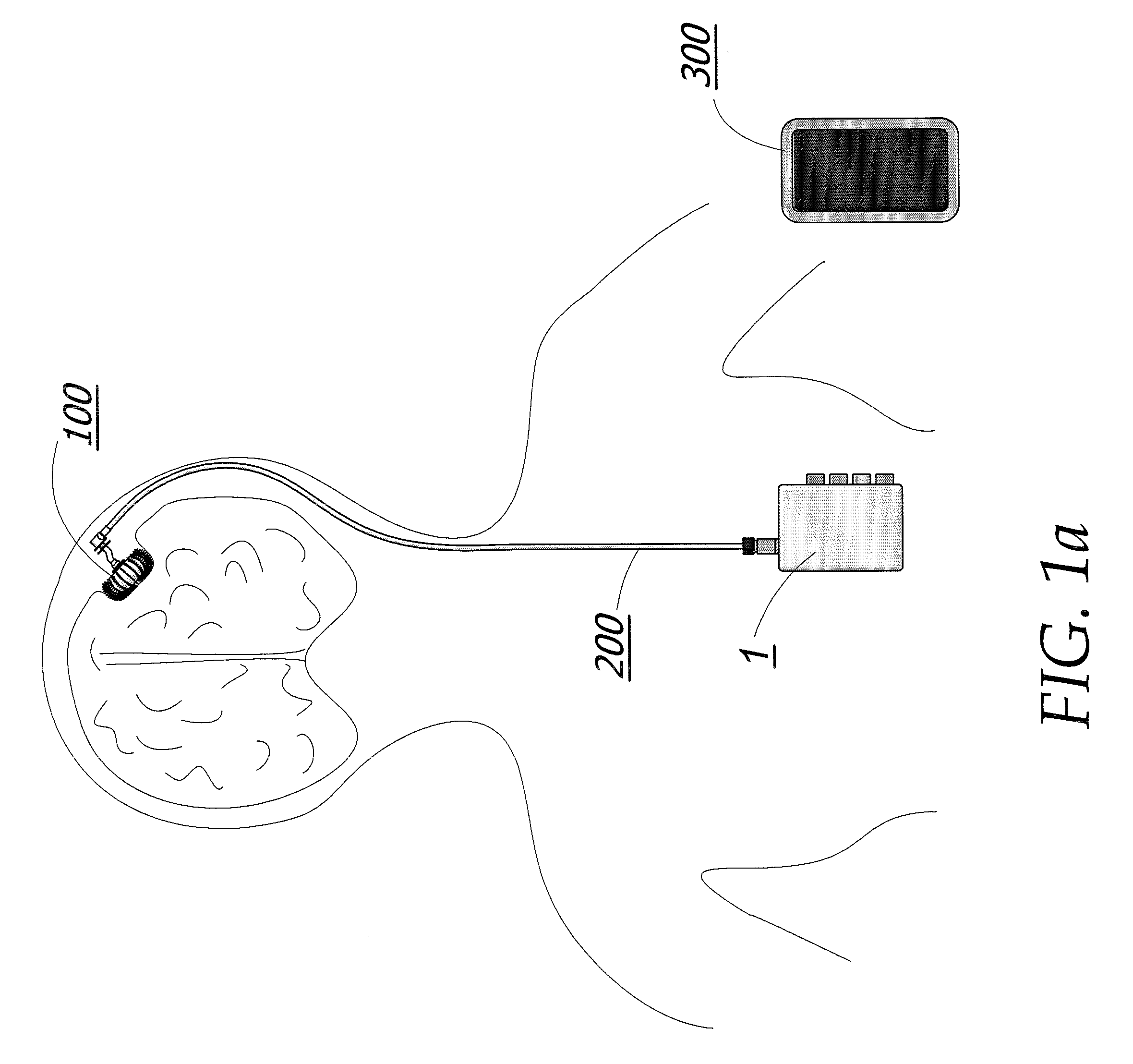

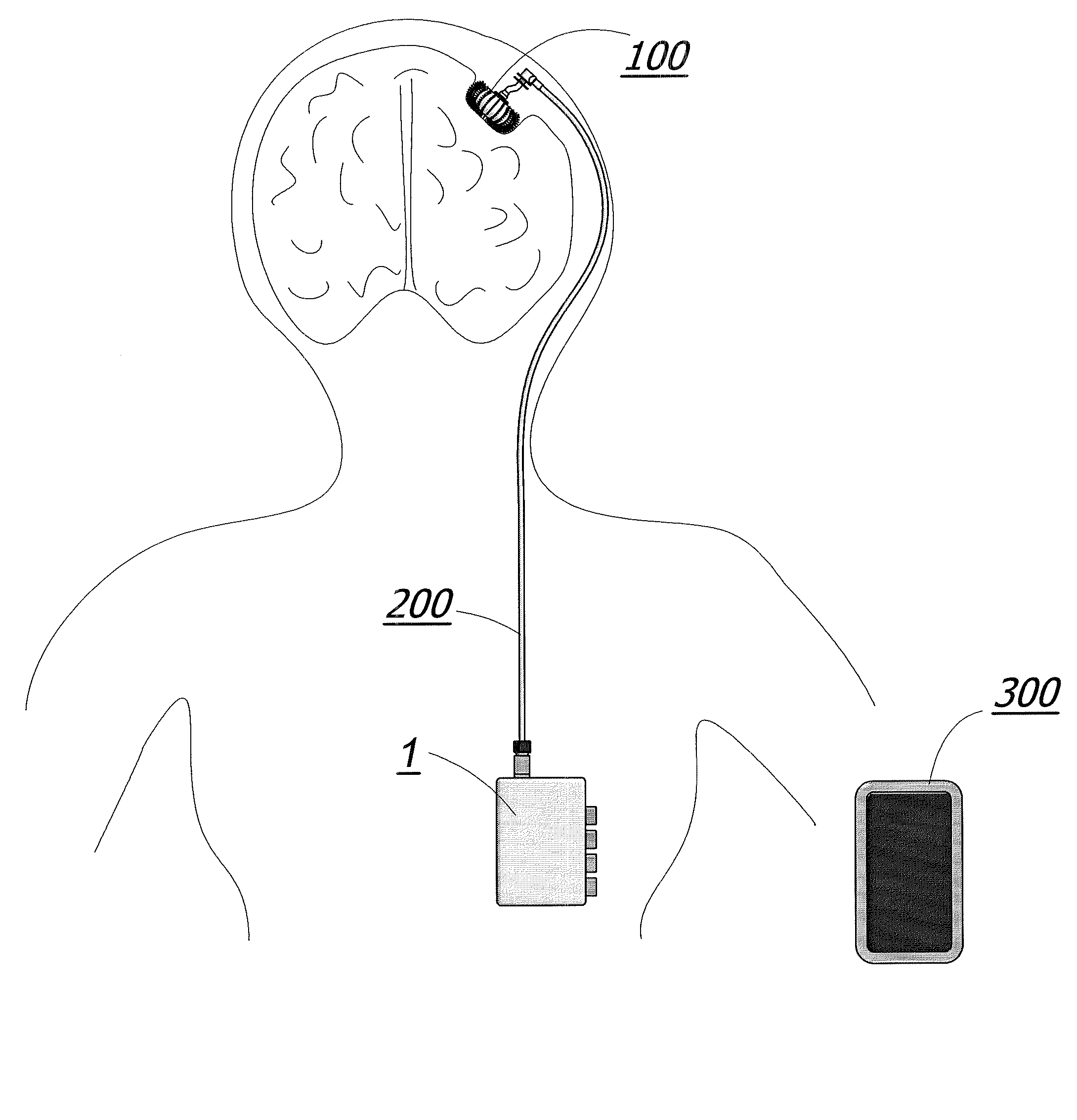

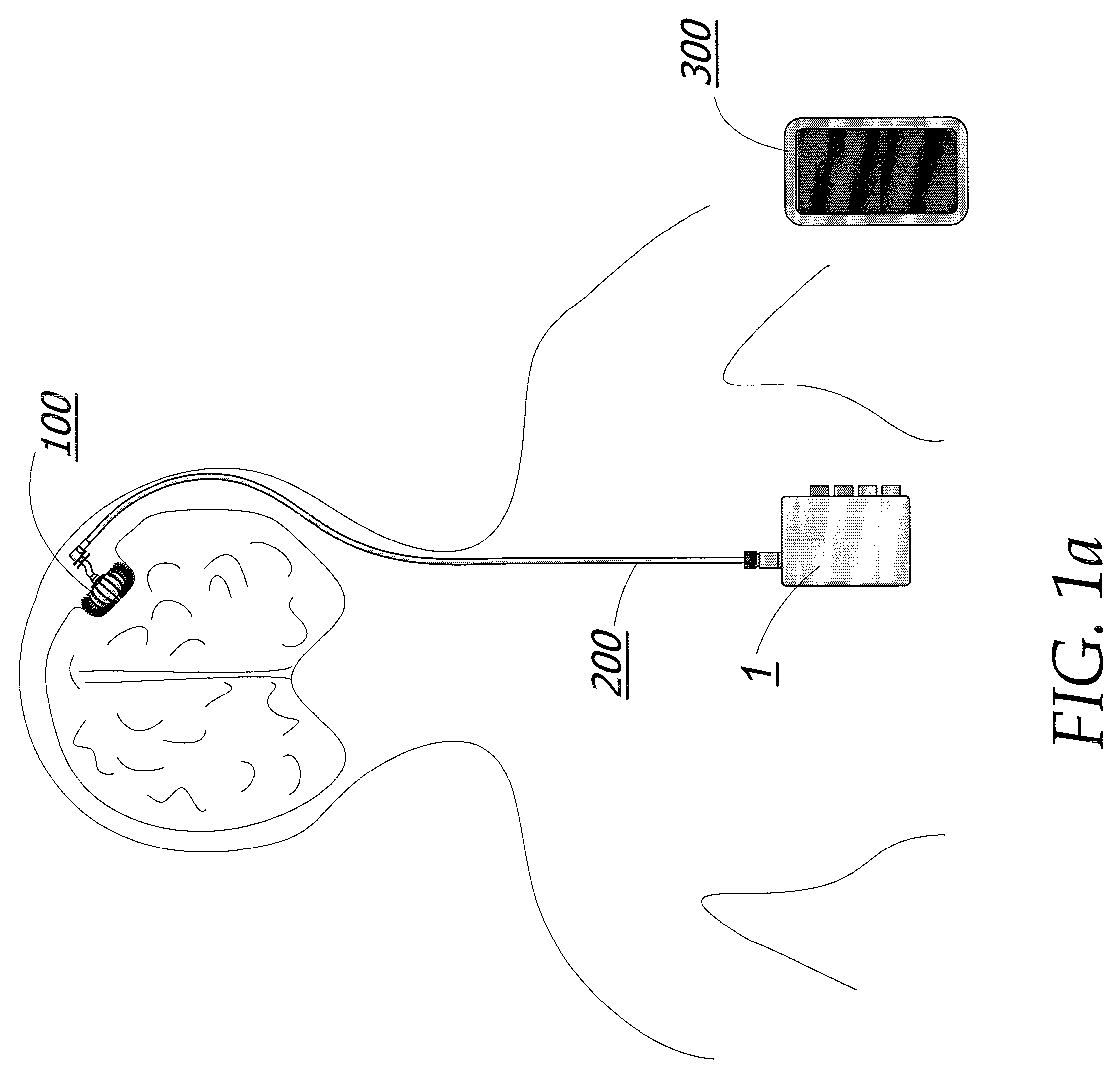

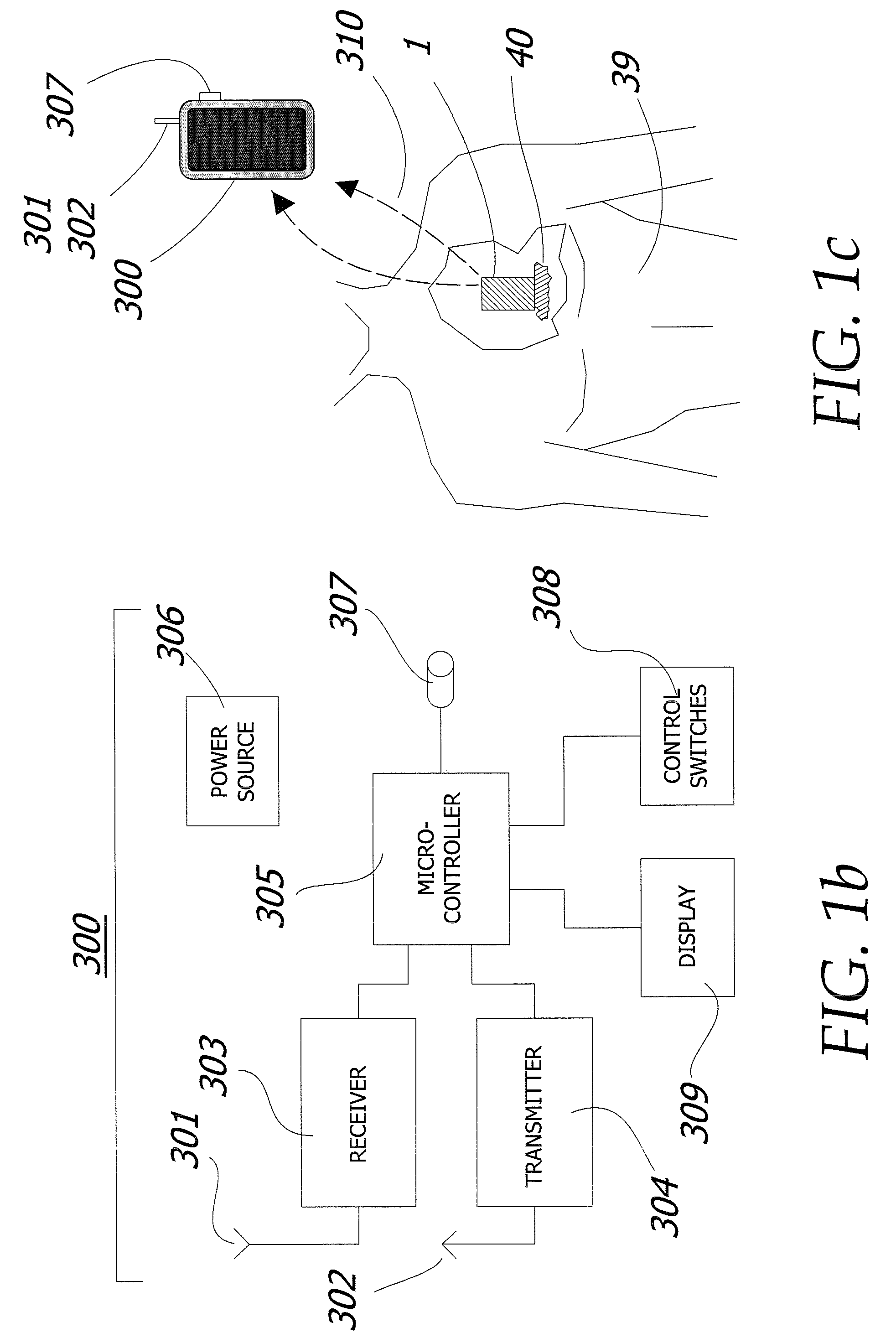

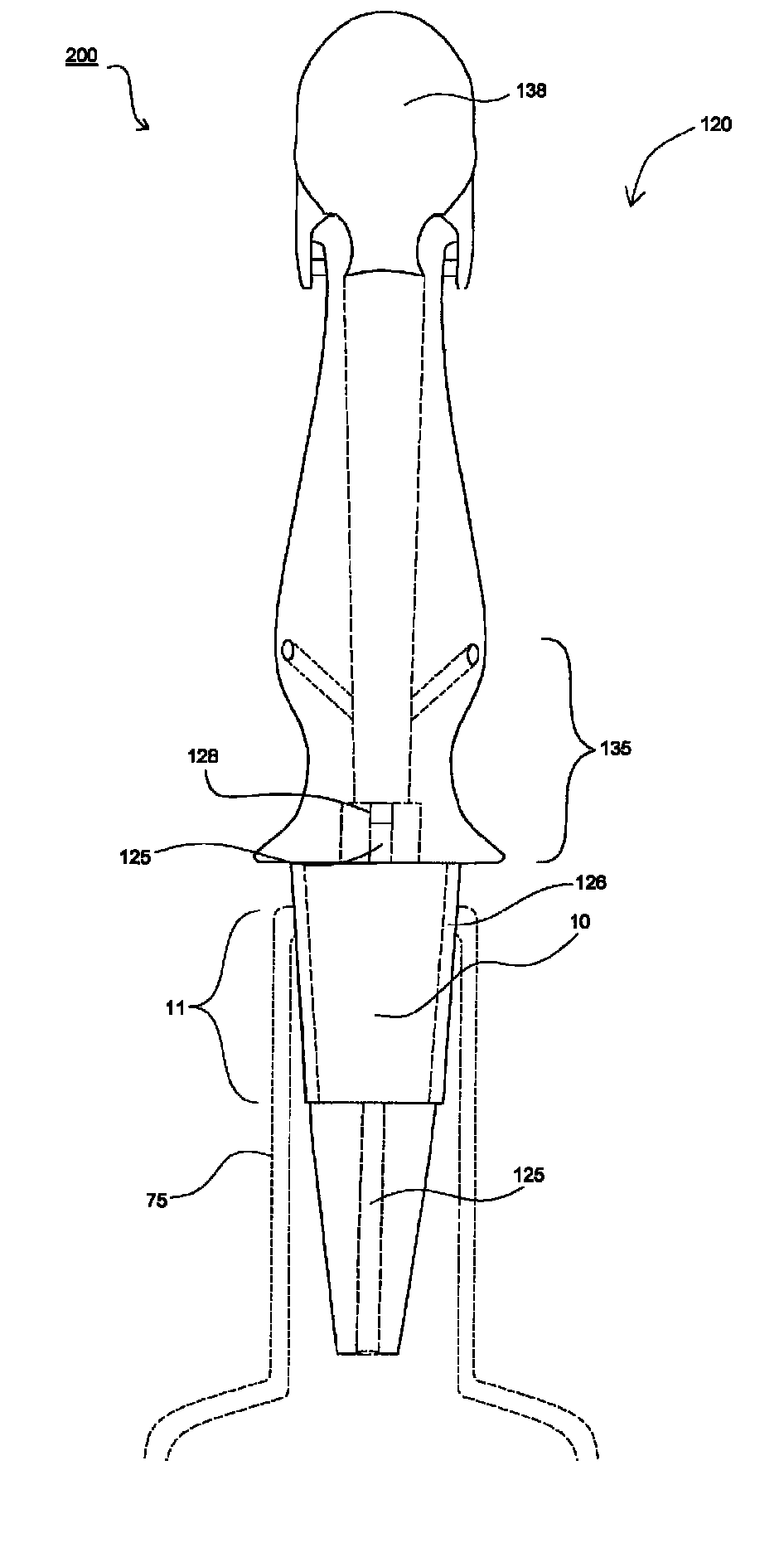

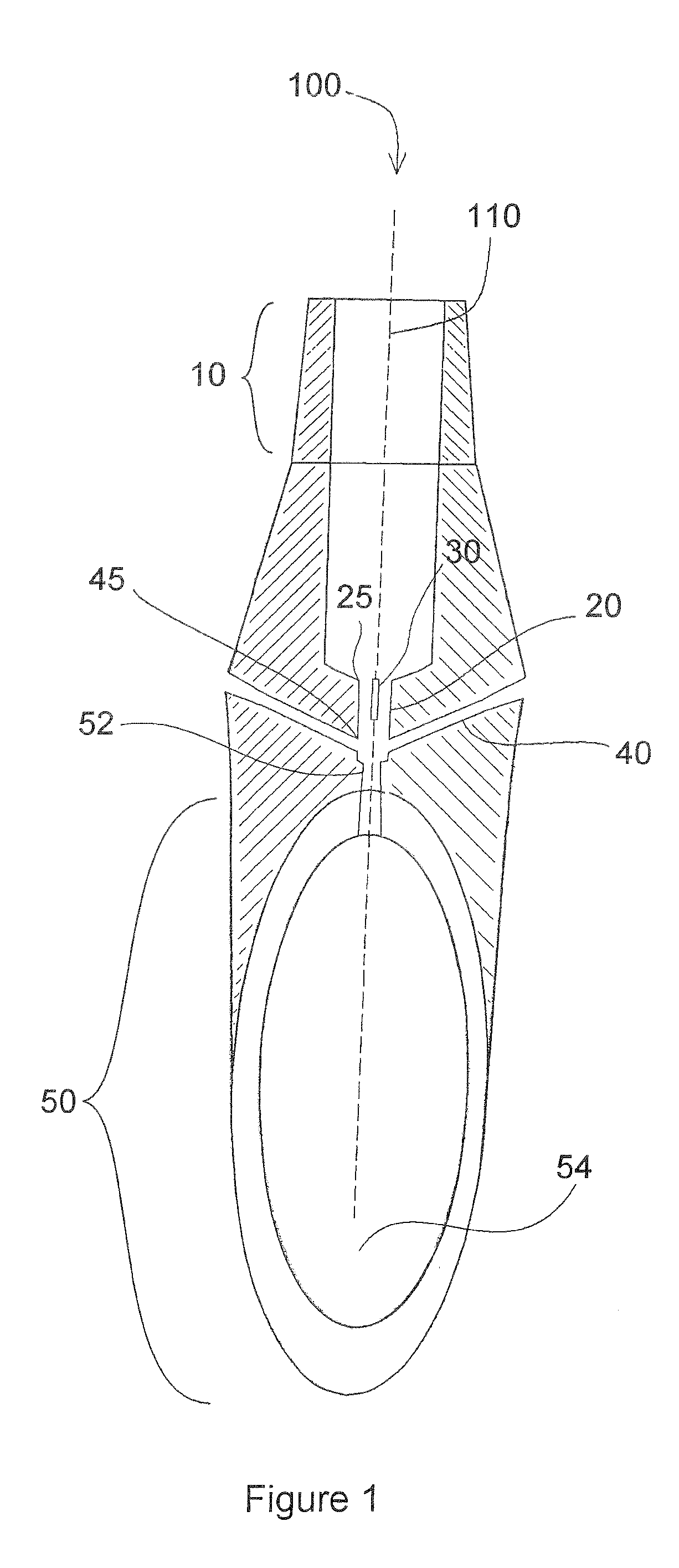

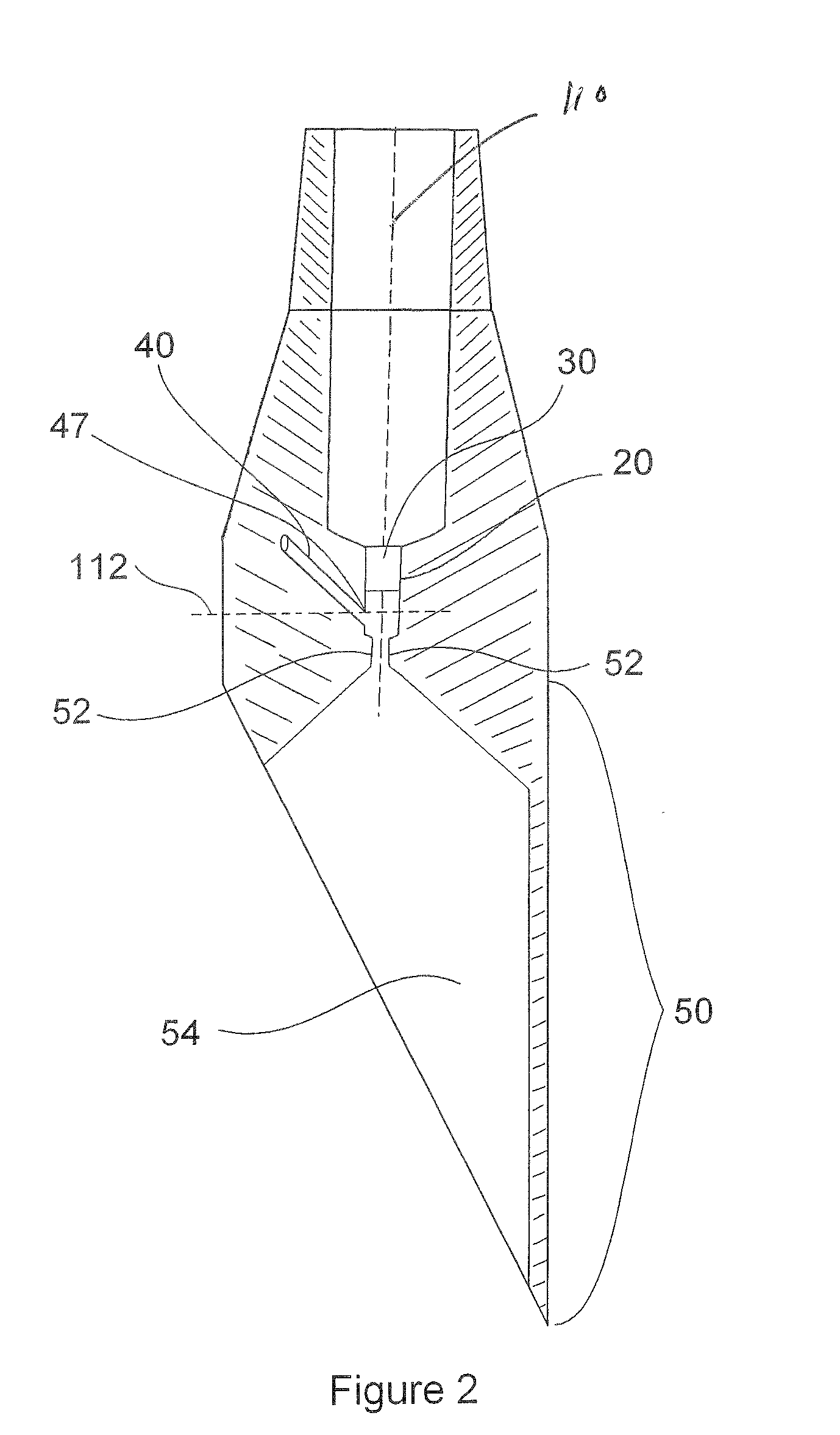

Magnetic breather pump and a method for treating a brain tumor using the same

Owner:COGNOS THERAPEUTICS INC

Magnetic breather pump and a method for treating a brain tumor using the same

Owner:COGNOS THERAPEUTICS INC

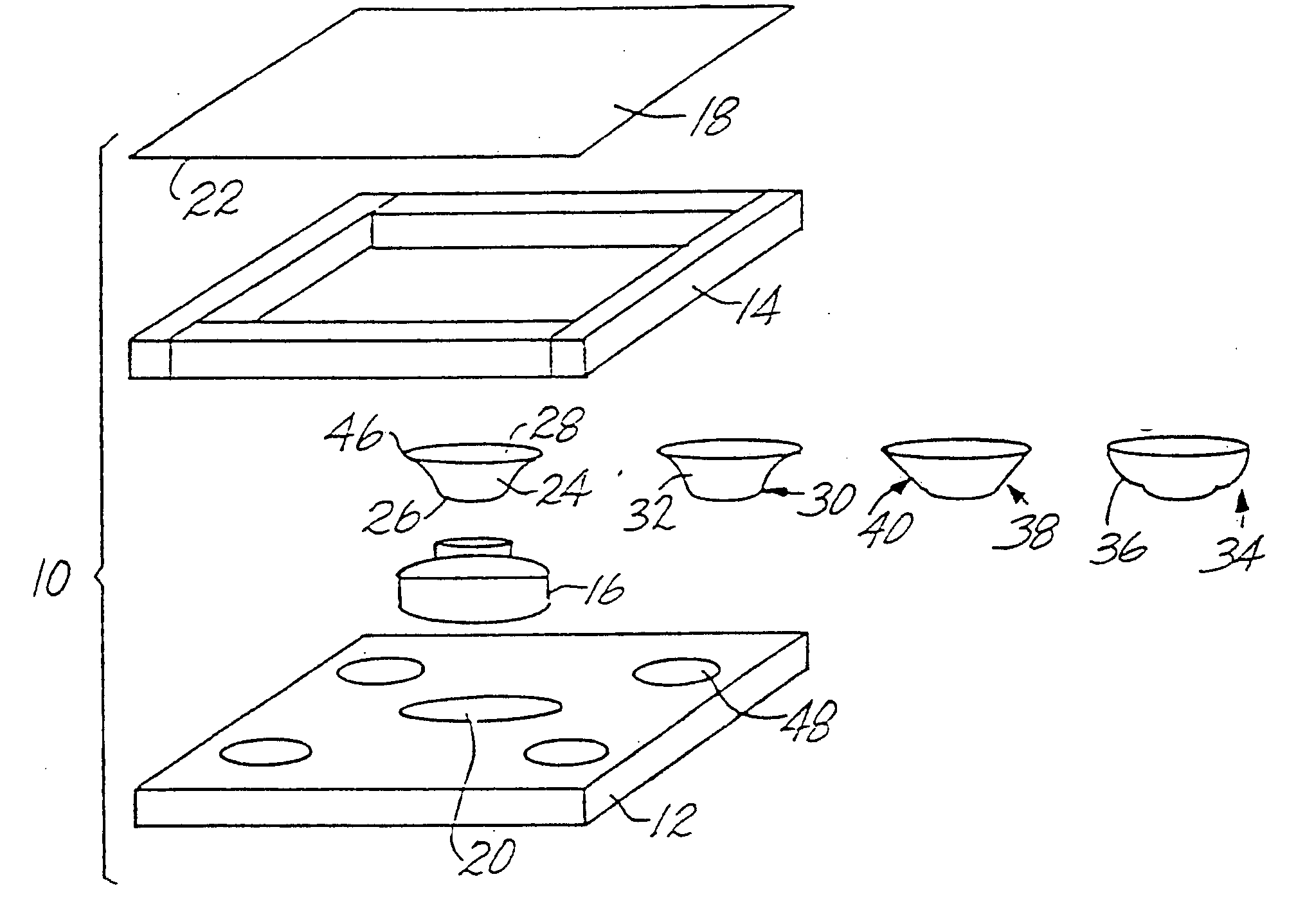

Modular SMIF pod breather, adsorbent, and purge cartridges

InactiveUSRE39241E1Easily and quickly inserted intoEasy to removeCombination devicesLiquid fillingBreatherMarine engineering

Modular cartridges which may be inserted into and removed from a well or receptacle on the bottom of a pod. The cartridges may be configured to include various types and combinations of valves, filters, and / or conditioning agents. A standalone cartridge replacement station may be provided for inserting and removing various cartridges from one or more of the receptacles on the bottom of a pod while wafers are seated within the pod. The standalone replacement unit may decouple an existing cartridge from the pod by rotating the cartridge from a locked to an unlocked position and then lowering the cartridge out of the pod. Thereafter, the replacement station may insert a new cartridge up into the appropriate receptacle and rotate the cartridge into a locked position in the pod.

Owner:ENTEGRIS INC

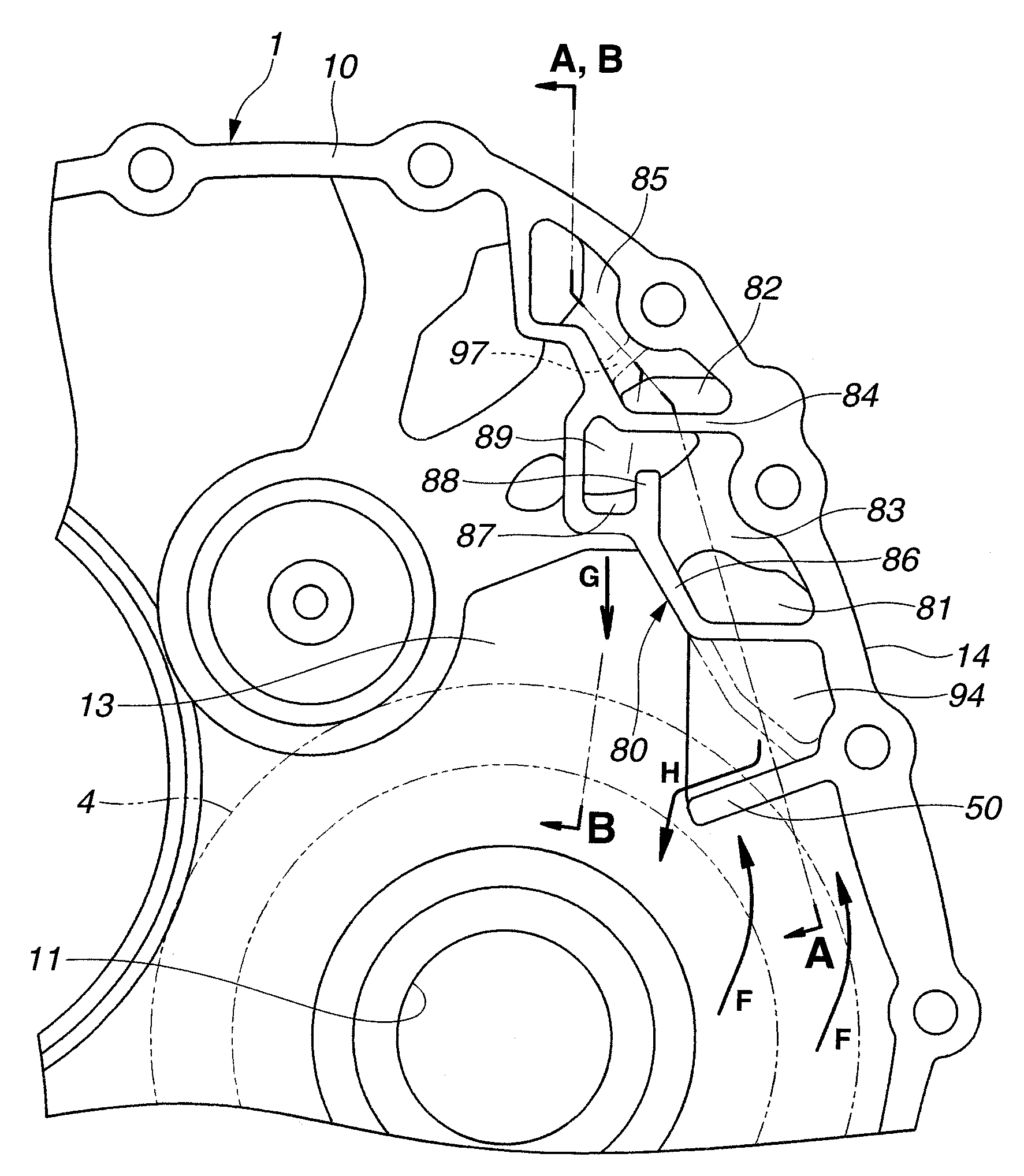

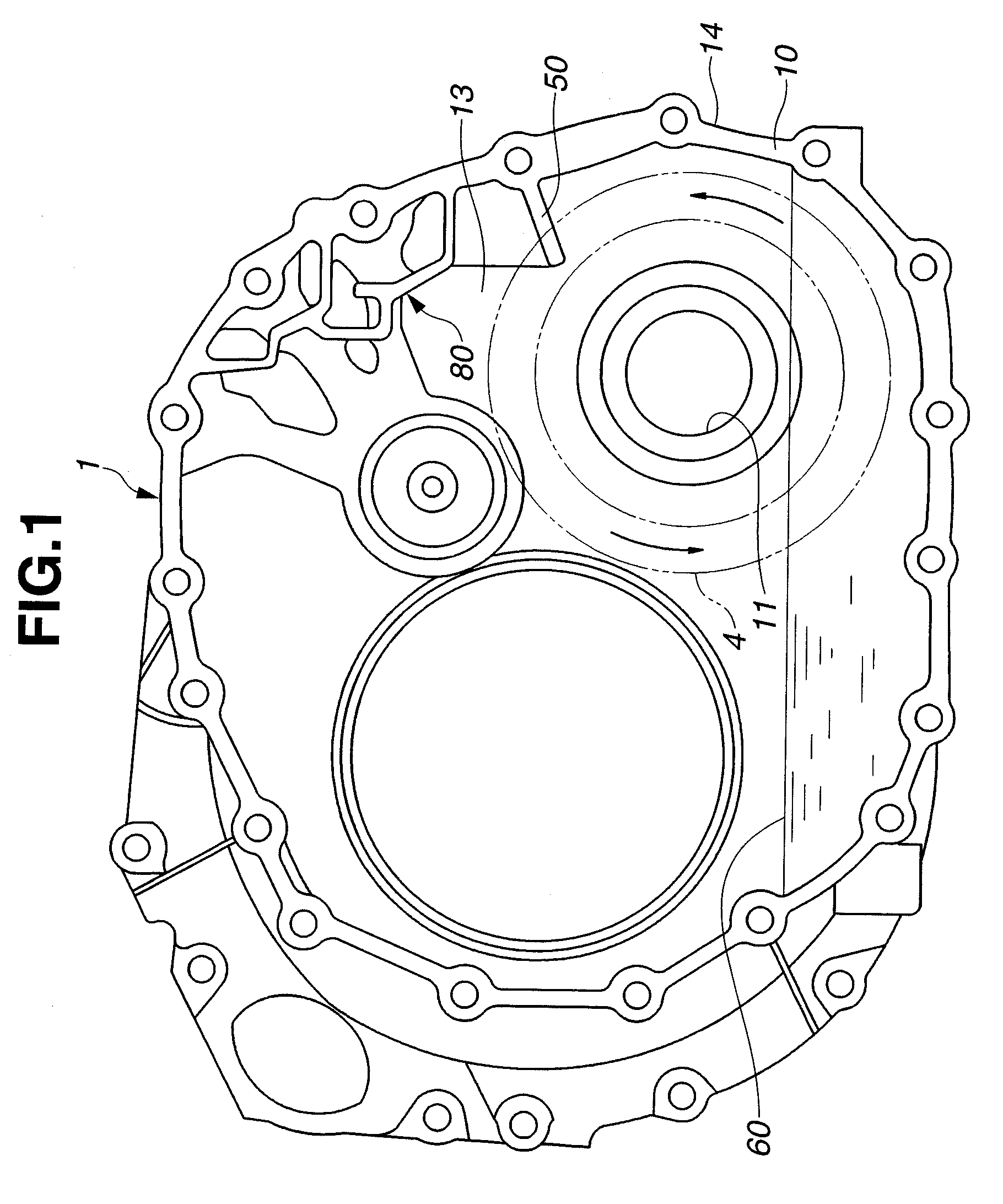

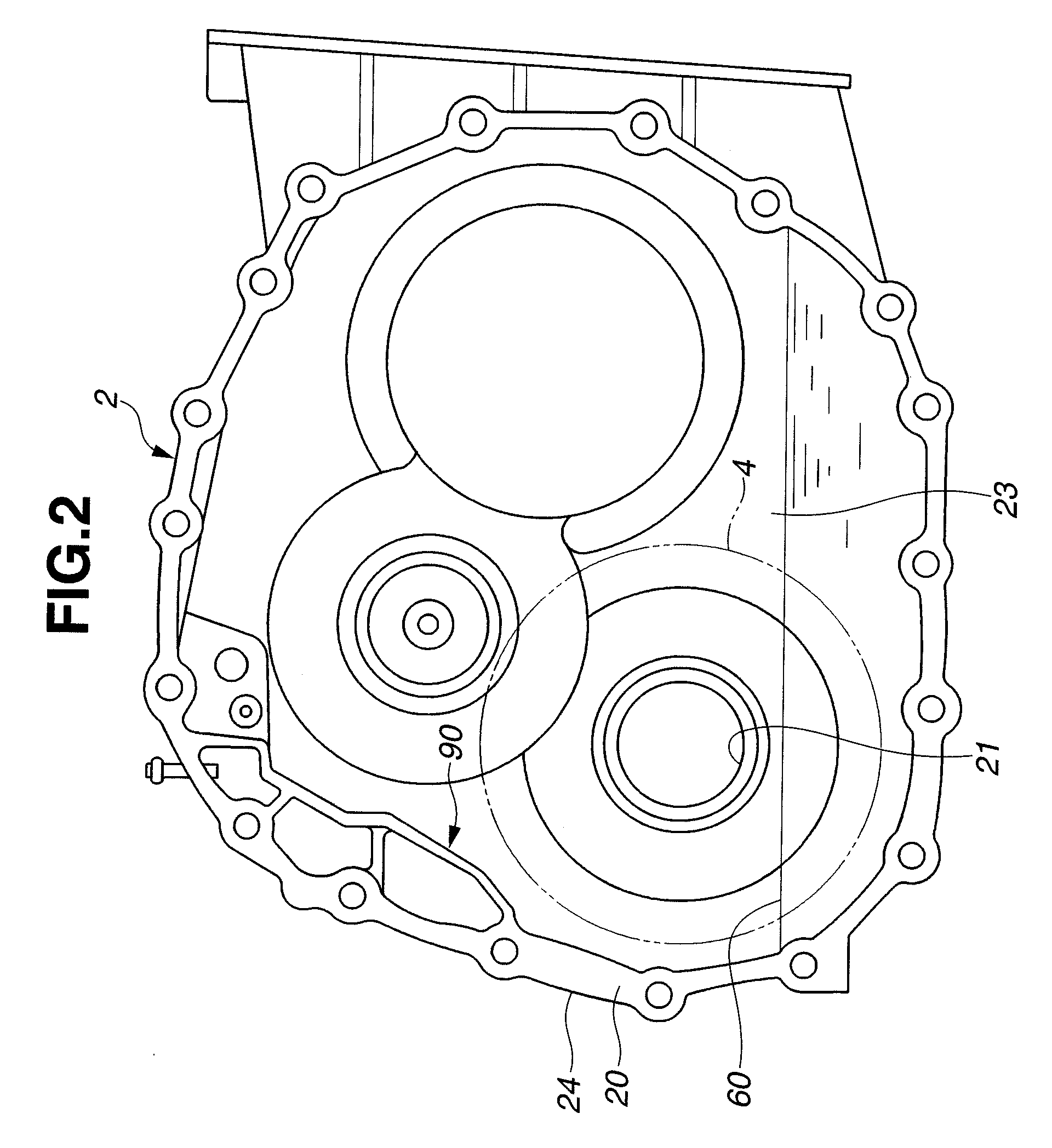

Automatic transmission

InactiveUS20080041179A1Efficient supplyPrevented from reachingGearboxesGear lubrication/coolingBreatherAutomatic transmission

In an automatic transmission having an air breather chamber for separating oil and air, entering the air breather chamber as oil bubbles, a shielding rib is located below an air-breather opening serving as an inlet-and-return port, for preventing oil, stored in a transmission casing assembly and splashed by rotary motion of a transmission rotating component part, from directly reaching the air-breather opening. An upside of the shielding rib is configured to be inclined downwardly with respect to a horizontal line in such a manner as to be oriented toward the transmission rotating component part, for receiving oil dripping through the air-breather opening with the upside of the shielding rib and for rapidly delivering the received oil toward the transmission rotating component part, using the inclined upside of the shielding rib.

Owner:JATCO LTD

Dual diffusion channel filter

ActiveUS7125433B2Reduce the amount requiredExtended service lifeCombination devicesGas treatmentInterior spaceBreather

A multiple diffusion channel filter assembly is disclosed. The filter assembly provides filtration of air entering and exiting an electronic enclosure through a breather hole. In one implementation, the filter assembly contains a housing with an adsorbent component and a first diffusion channel and a second diffusion channel. In another implementation, the filter assembly contains a first layer and a second layer which surround an adsorbent component and a first and a second diffusion channel that are in fluid communication with the interior space defined by the first and second layers. In yet another implementation, the invention, includes a filter accessory containing a diffusion channel configured to work in conjunction with a separate filter assembly thereby adding an additional diffusion channel to the existing design.

Owner:DONALDSON CO INC

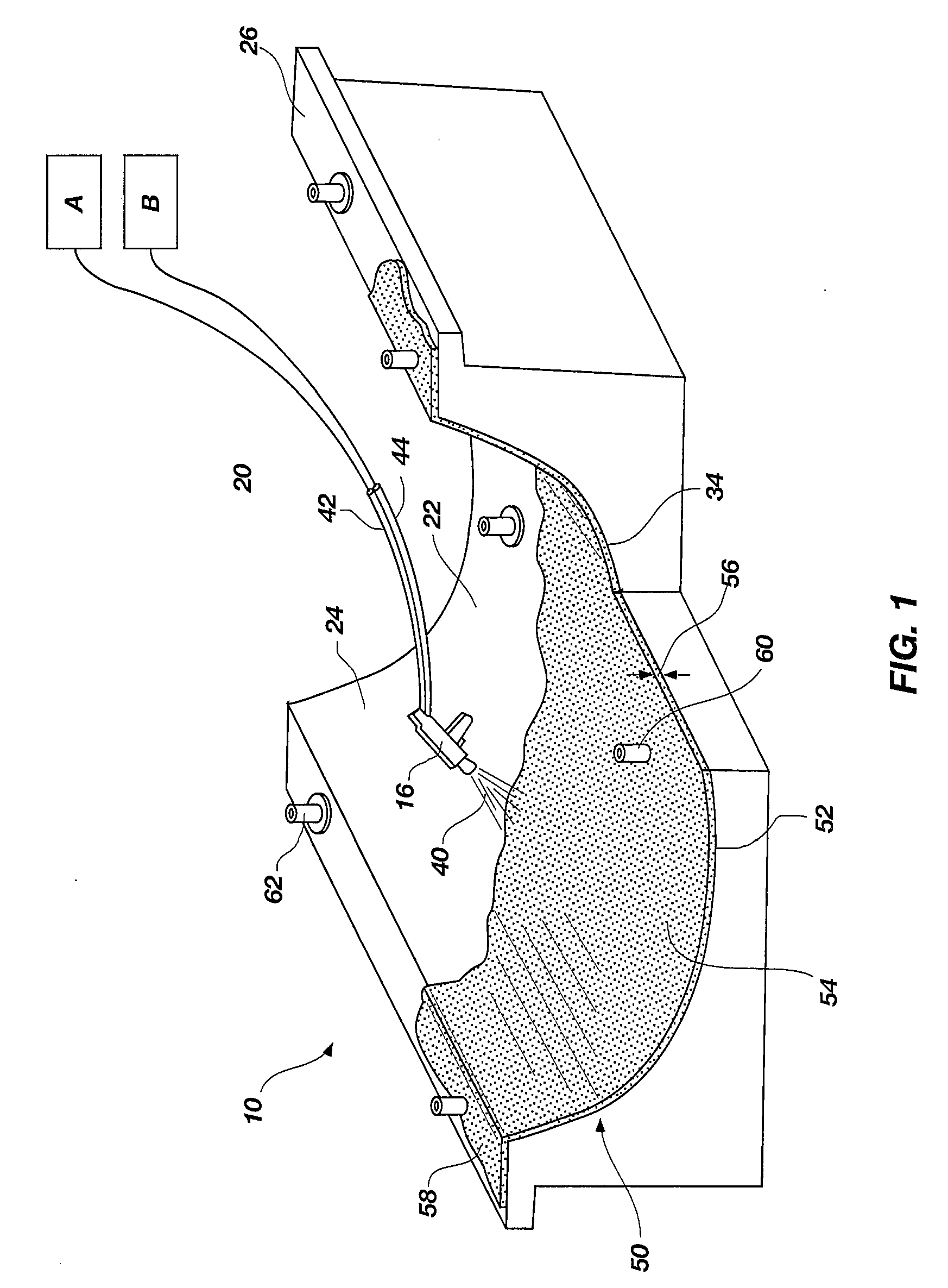

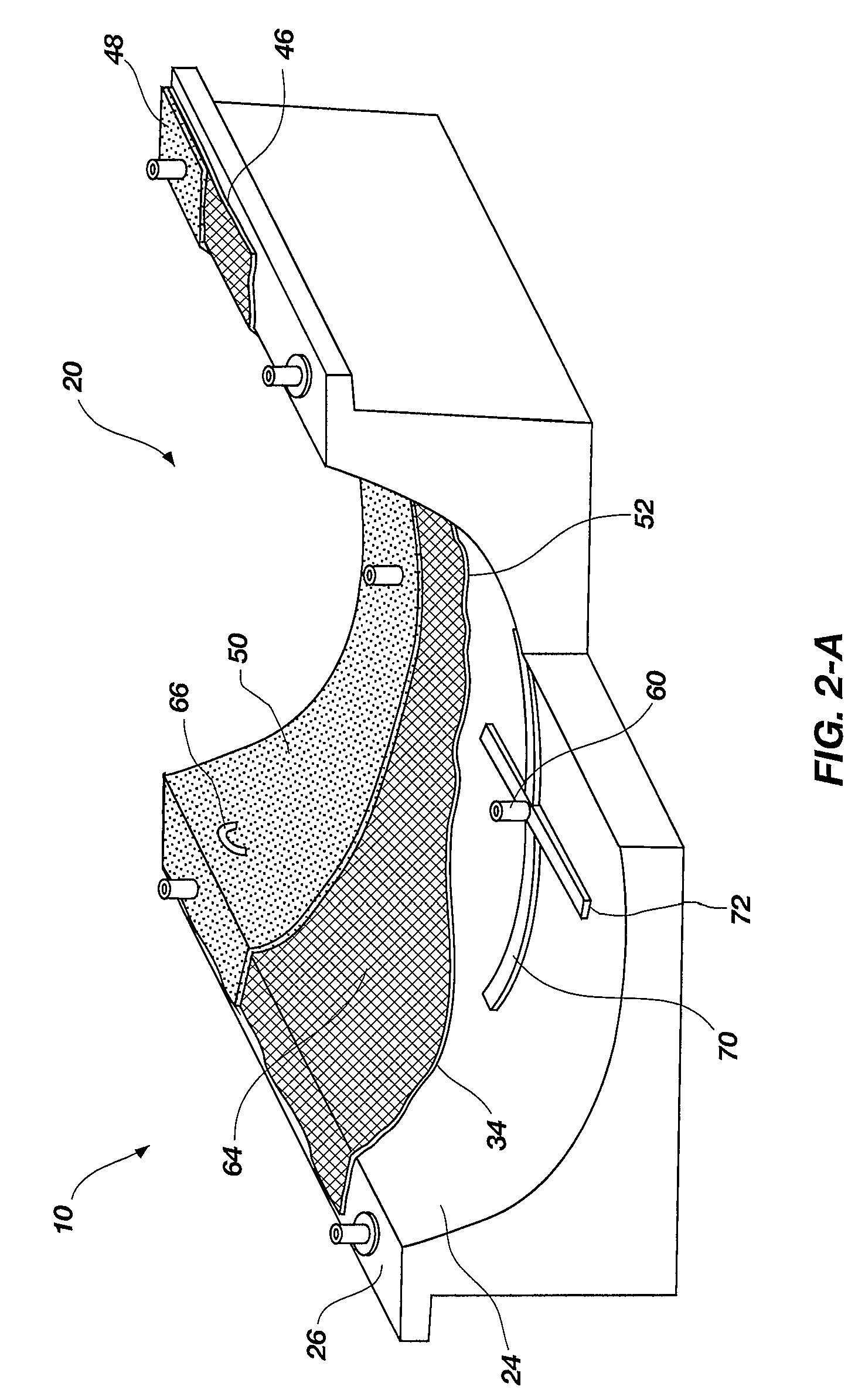

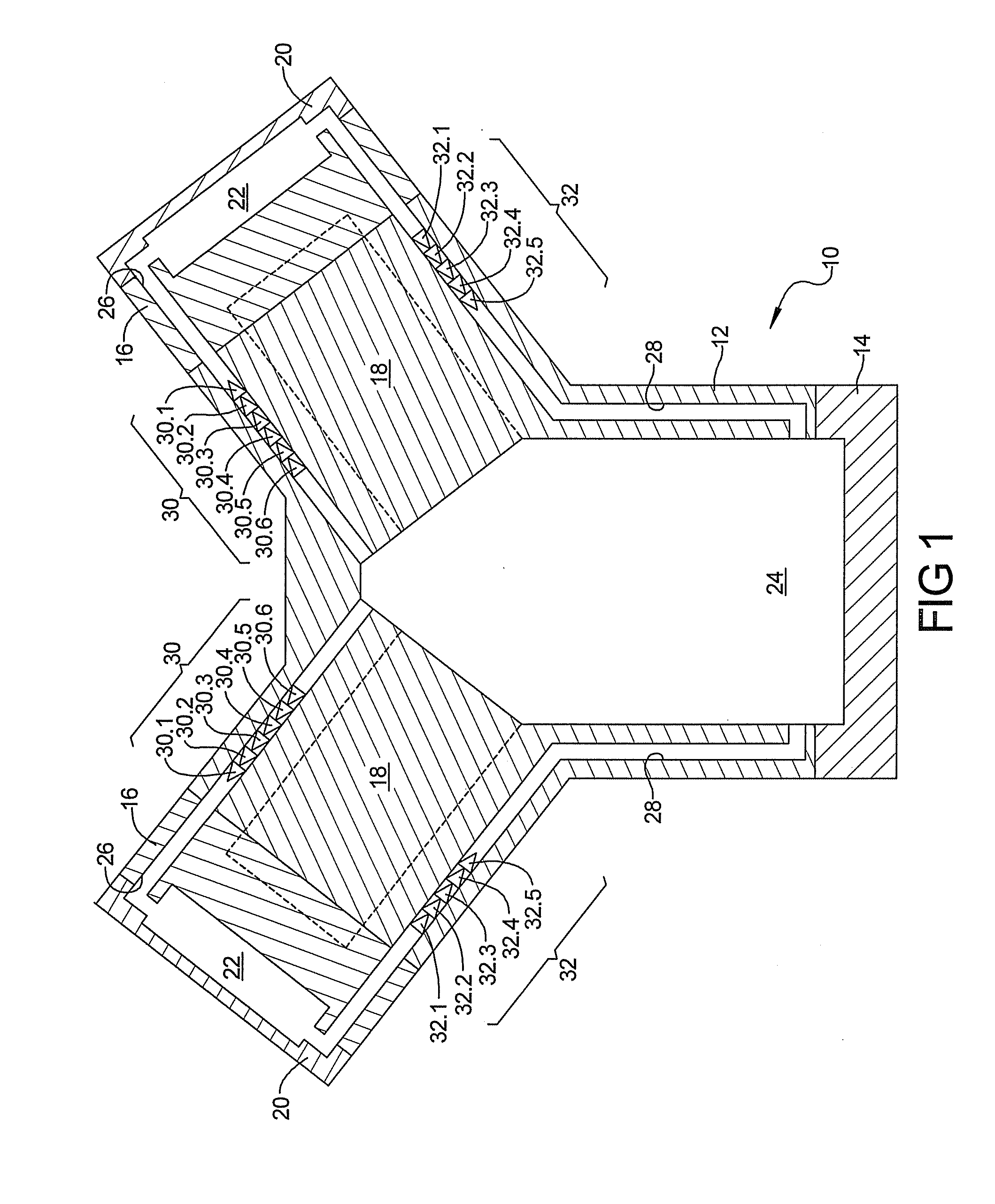

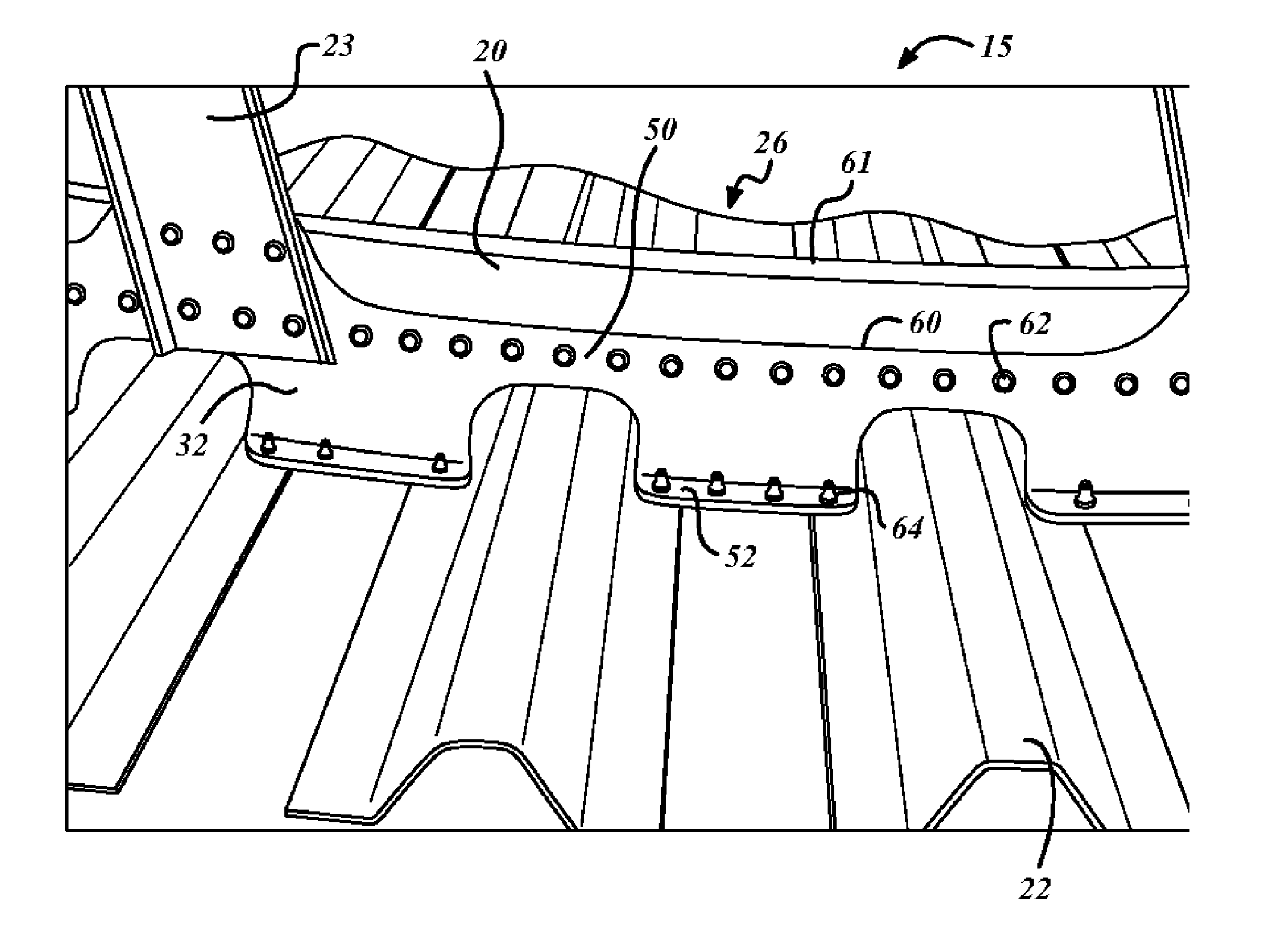

Method for forming composite parts from volatile-emitting materials using breathable tooling

A method and apparatus for curing composite materials that emit large volumes of volatiles during processing. The apparatus includes tooling having a rigid forming surface contoured to the shape of the formed composite part. A plurality of passages extend from the forming surface through the tooling. The passages are in fluid contact with an exhaust port. A composite workpiece is laid up and placed adjacent the forming surface. The apparatus includes a heater that heats the composite workpiece to temperatures at which volatiles are emitted. An evacuation system draws the volatiles away from the composite workpiece through the passages in the tooling and out of the exhaust port. One embodiment of tooling according to the invention is used to form a sine wave spar. The tooling includes upper and lower tool inserts upon which U-shaped composite channels are formed. The upper and lower tools are placed adjacent to each other to form the web of the spar. Cap strips are placed on either side of the joined U-shaped channels. Side rail tools are then placed adjacent the cap strips. A breather cloth is placed over the tools and the entire assembly is placed within a vacuum bag. The assembly is then placed within an autoclave and connected to the vacuum exhaust of the autoclave. During processing, volatiles are drawn away from the composite workpiece through the passages in the tooling using the vacuum exhaust.

Owner:THE BOEING CO

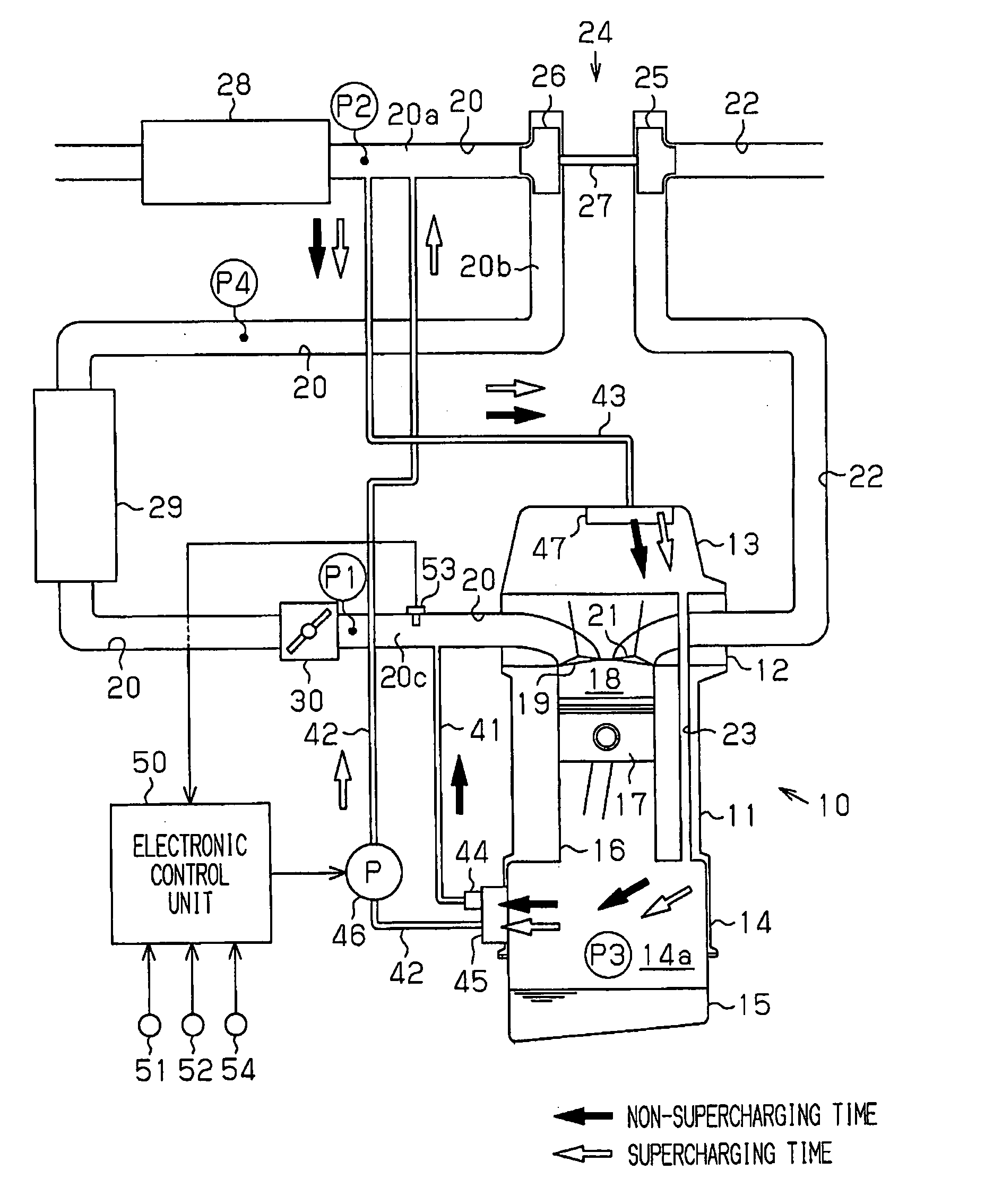

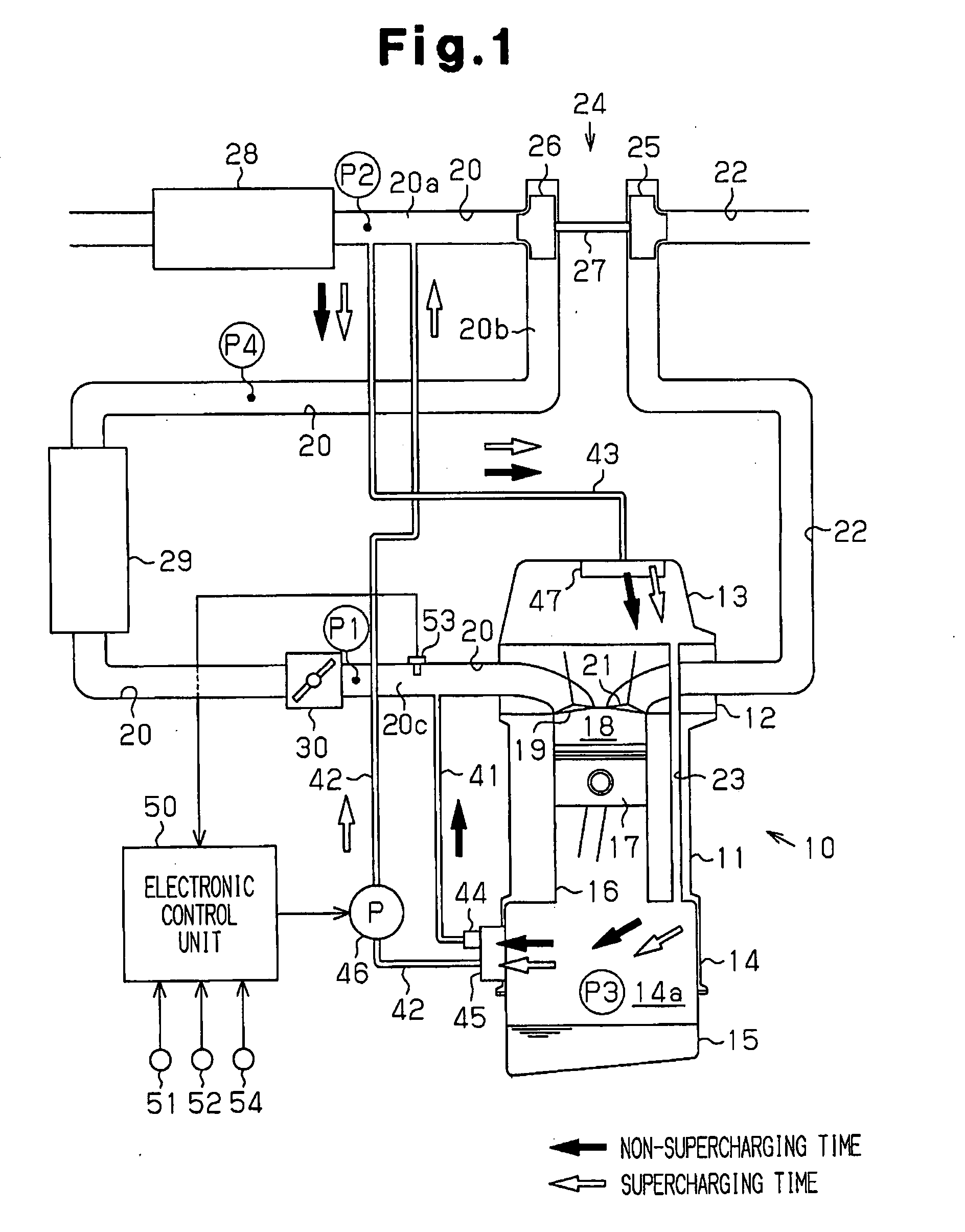

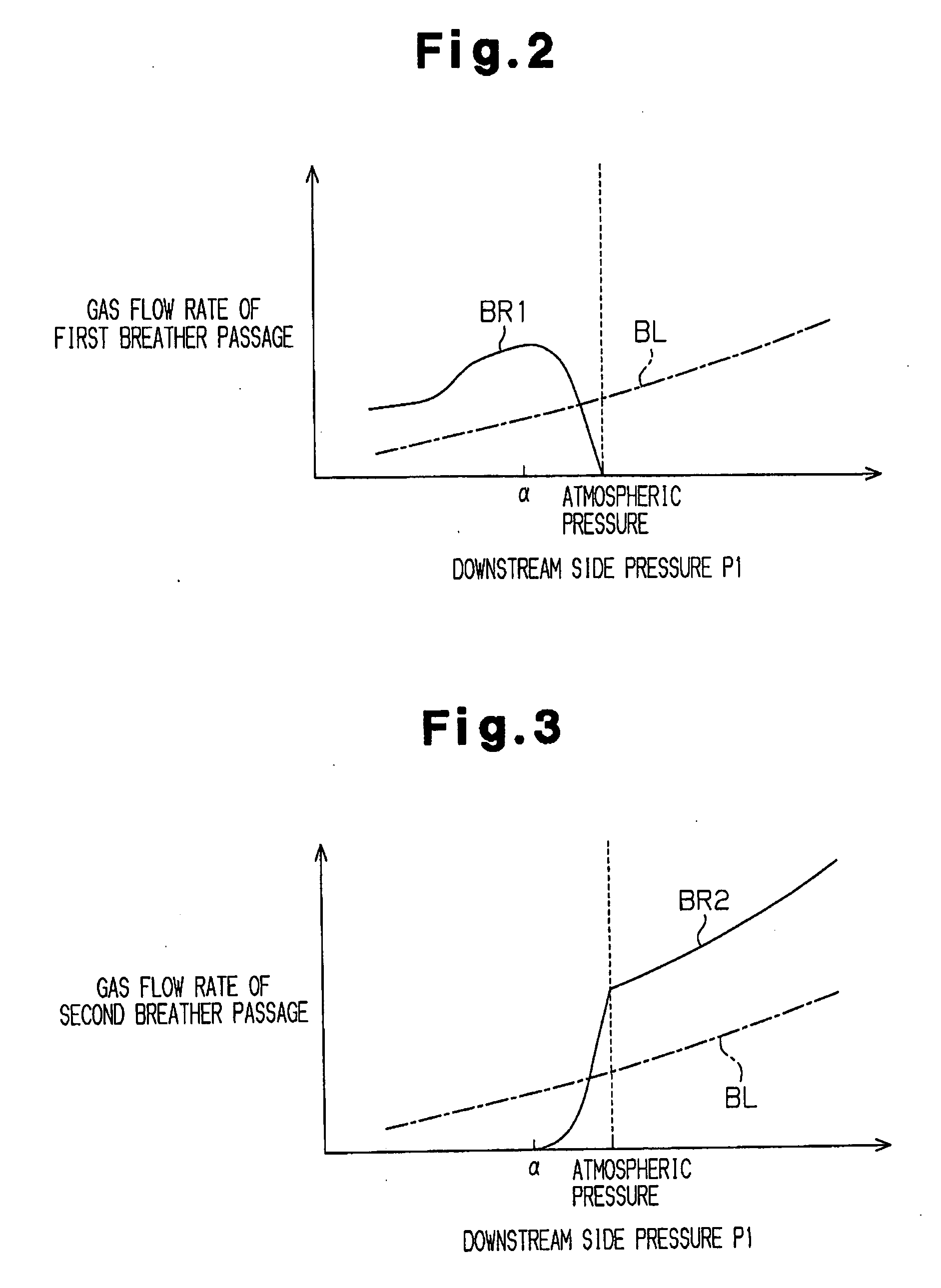

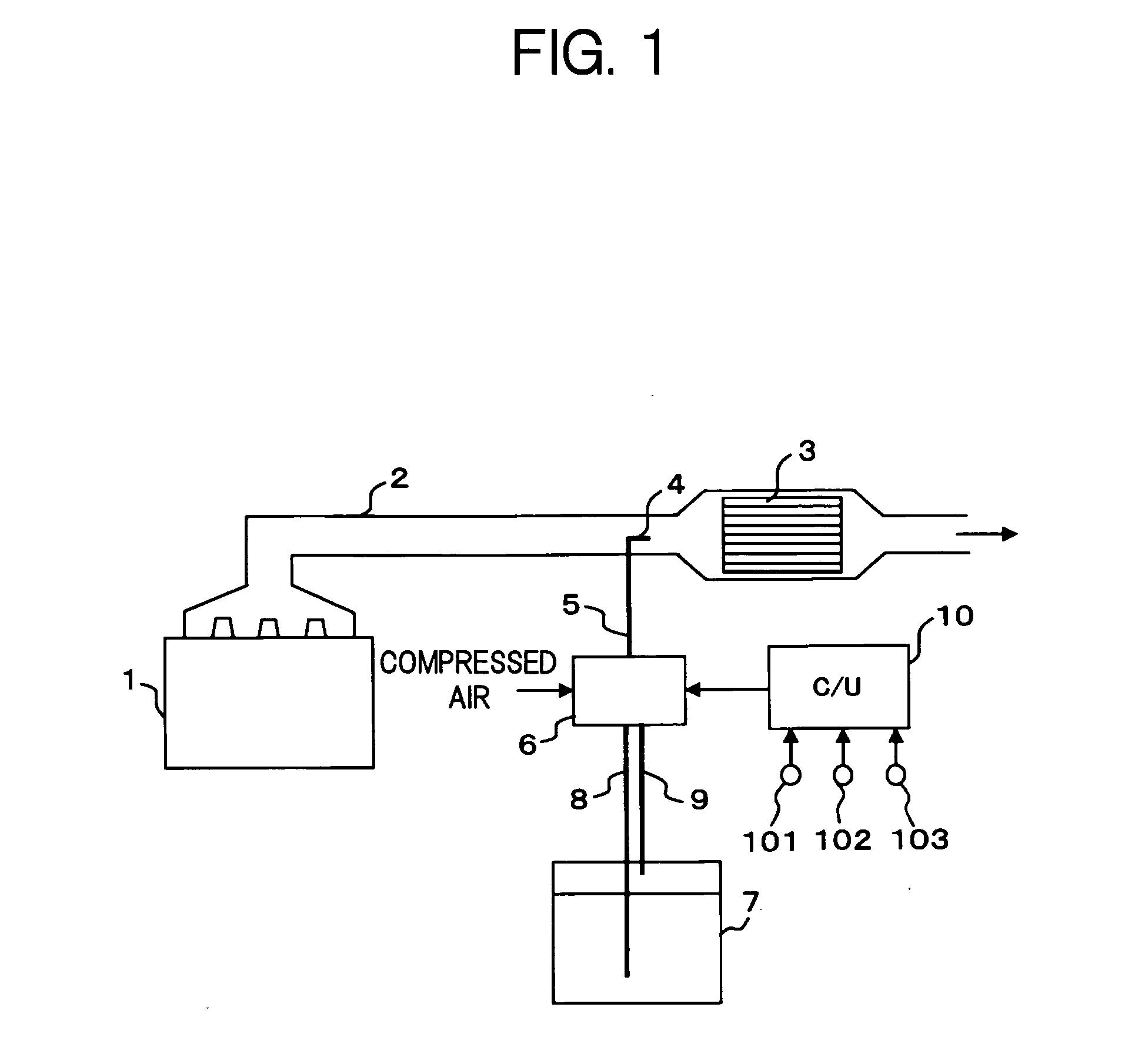

Blow-by gas processing apparatus

An upstream portion of an intake passage is positioned upstream of a supercharger. An intermediate portion is positioned between the supercharger and a throttle valve. A downstream portion is positioned downstream of the throttle valve. A blow-by gas processing apparatus has a first breather passage, a second breather passage, and an introduction passage. The first breather passage connects an interior of the engine with the downstream portion. The second breather passage has a pump that pressure feeds gas from the interior of the engine to the intake passage. The introduction passage connects at least one of the upstream portion and the intermediate portion with the interior of the engine. Accordingly, the interior of the engine is efficiently ventilated.

Owner:TOYOTA JIDOSHA KK

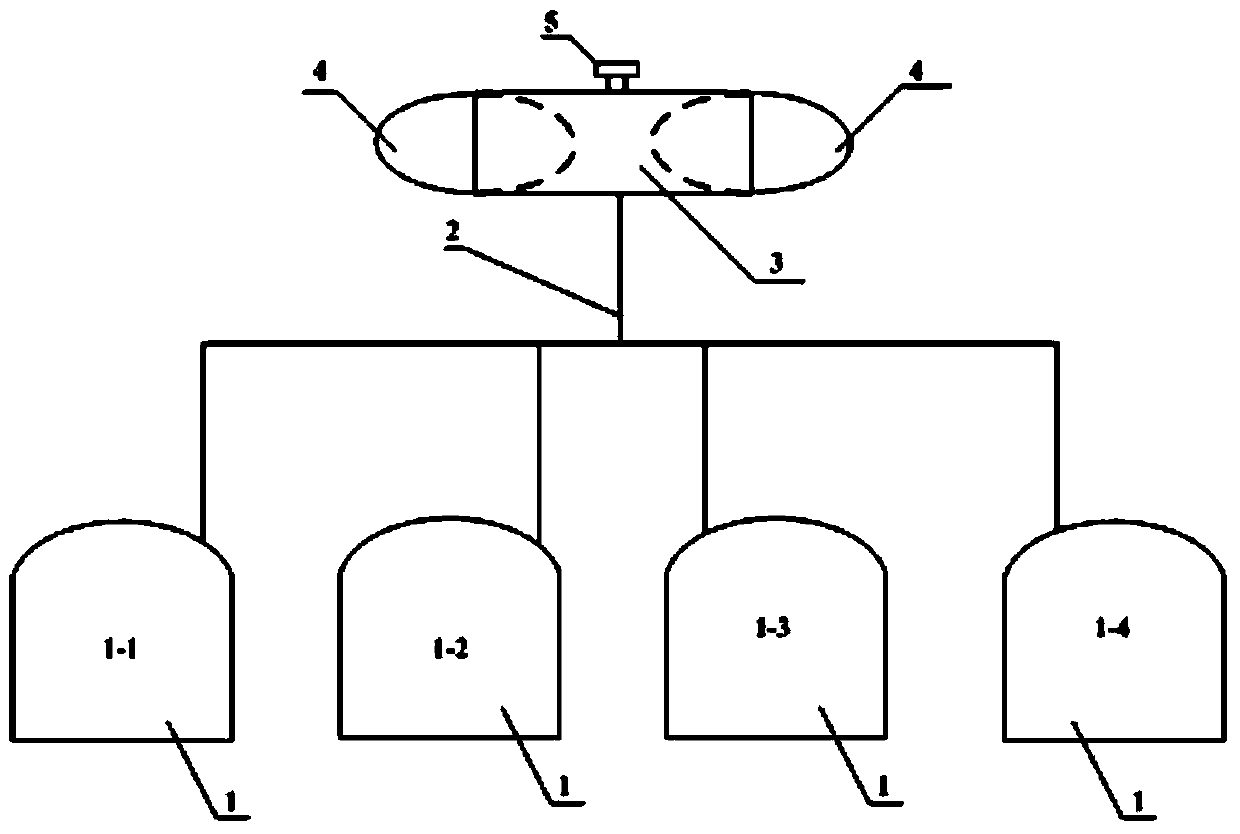

Storage tank area integrated breathing apparatus

The invention relates to a storage tank area integrated breathing apparatus. The problem that breather valves of multiple storage tanks stored with the same media in the prior art are excessive, small in buffering capacity and large in waste gas emission load is mainly solved. The storage tank area integrated breathing apparatus comprises at least two storage tanks 1, at least one storage tank gas connecting pipe 2, a buffer 3, at least one air bag 4 and a breather valve 5. The storage tanks 1 are connected with an inlet of the buffer 3 through the storage tank gas connecting pipe 2, the air bag 4 is arranged on the buffer 3, and an outlet of the buffer 3 is connected with the breather valve 5. The problem is well solved by adopting the technical scheme, and the storage tank area integrated breathing apparatus can be used for various tank areas.

Owner:CHINA PETROLEUM & CHEM CORP QINGDAO RES INST OF SAFETY ENG +1

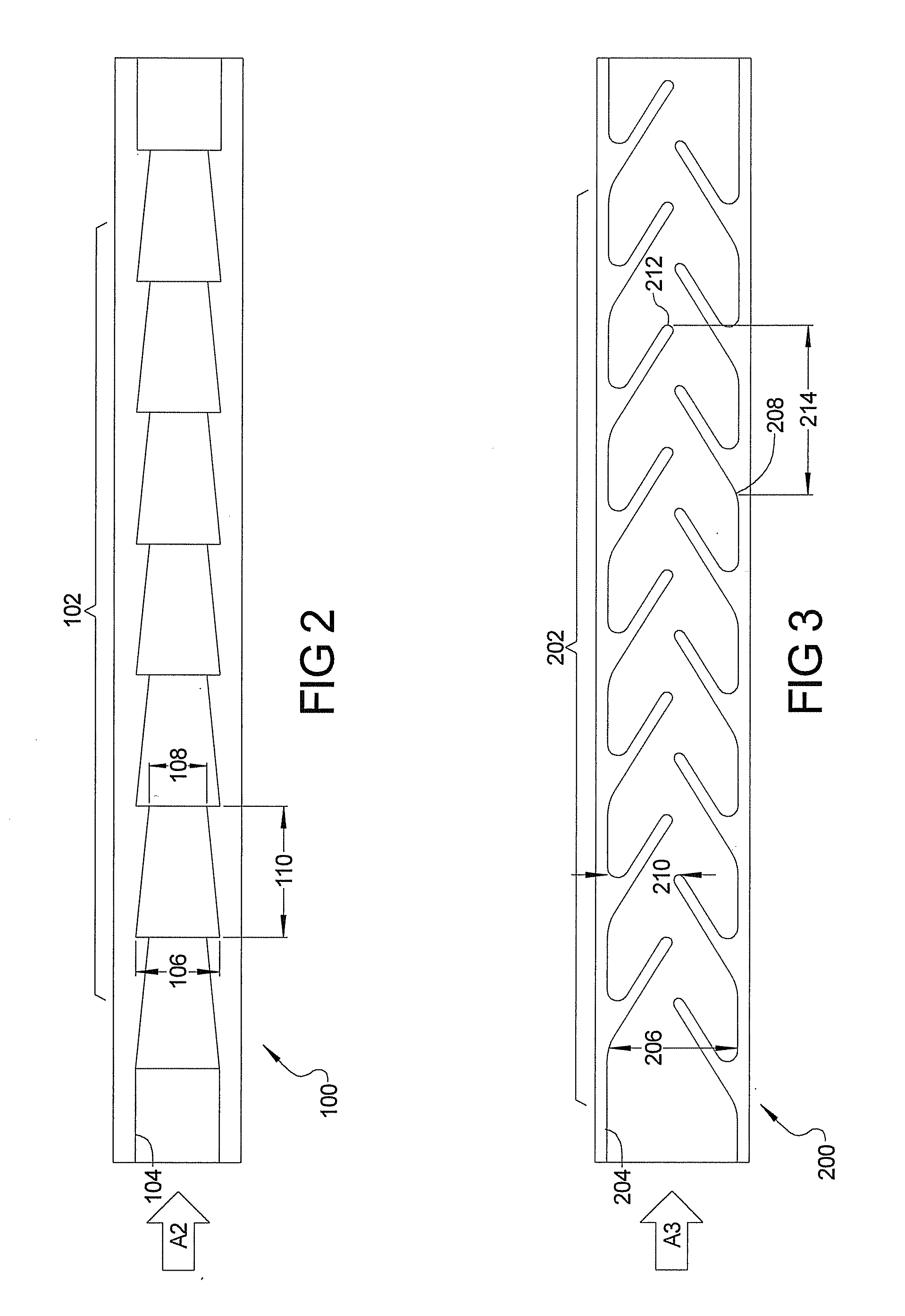

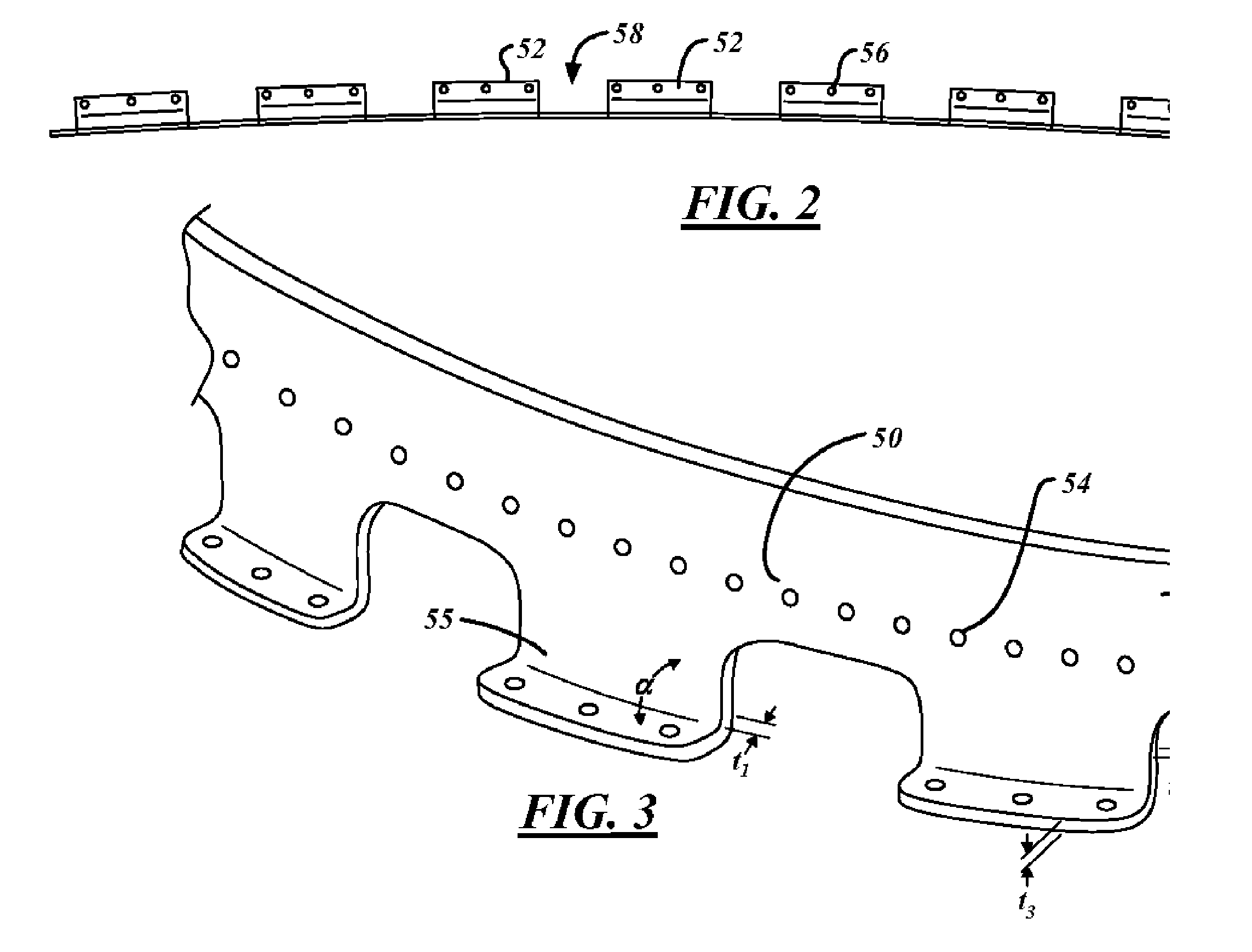

Method to control thickness in composite parts cured on closed angle tool

ActiveUS20070102839A1Improve uniformityUniform thicknessHollow wall articlesBeltsJet aeroplaneAviation

The present invention provides a method for controlling the thickness of composite laminates cured on closed angel tools. The invention utilizes a peel ply rather than a breather during the preparation for cure of laminate parts having a substantially uniform initial thickness. This method allows composite parts to be formed with greater uniformity and without the need for extra hardware. The composite part formed by the above method may find use in a wide variety of applications, including, for example, automotive and aerospace applications. Thus, for example, a composite part formed in accordance with the present invention is ideally suited for use as a shear tie in a commercial aircraft, which are used to secure the inner framework of the aircraft to the airplane skin.

Owner:THE BOEING CO

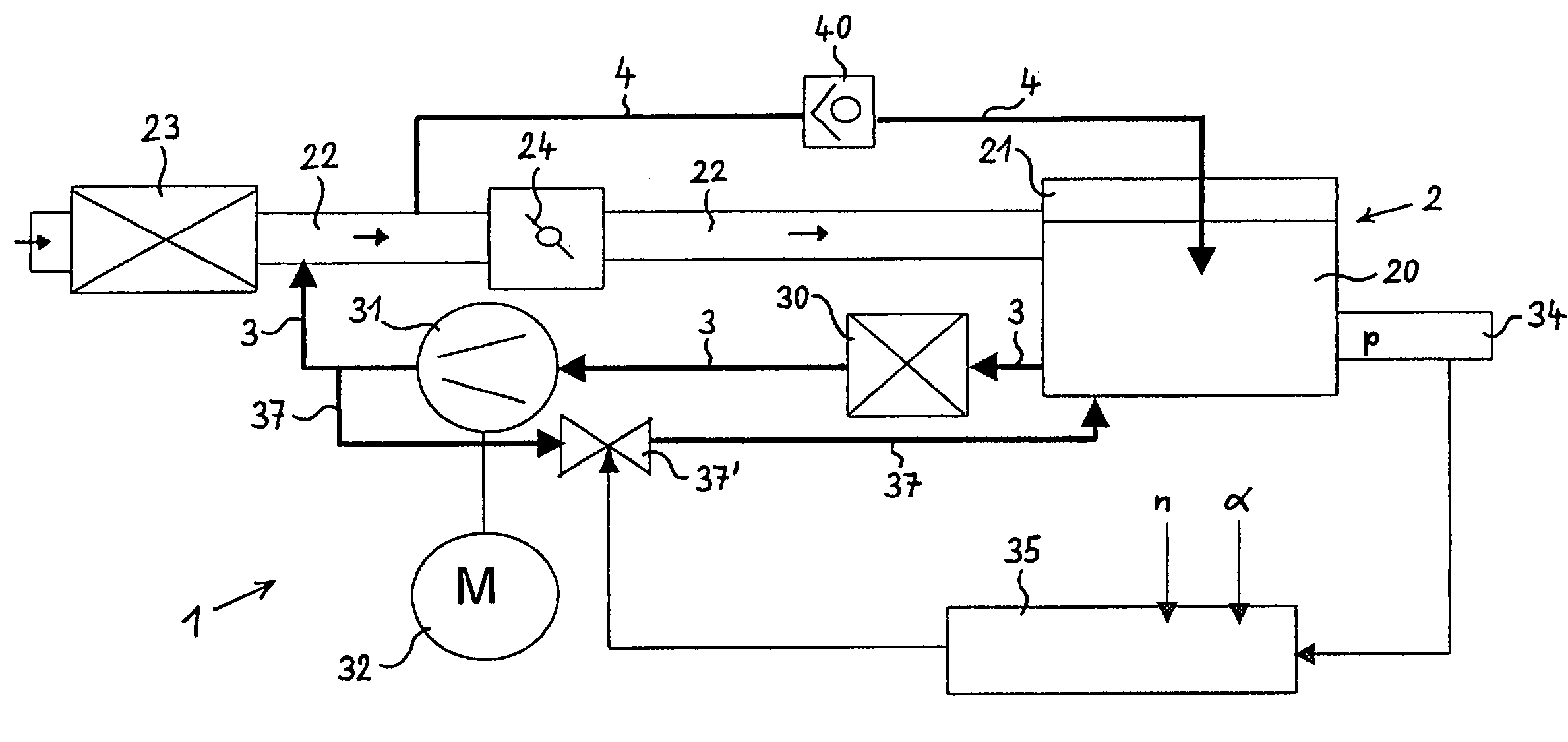

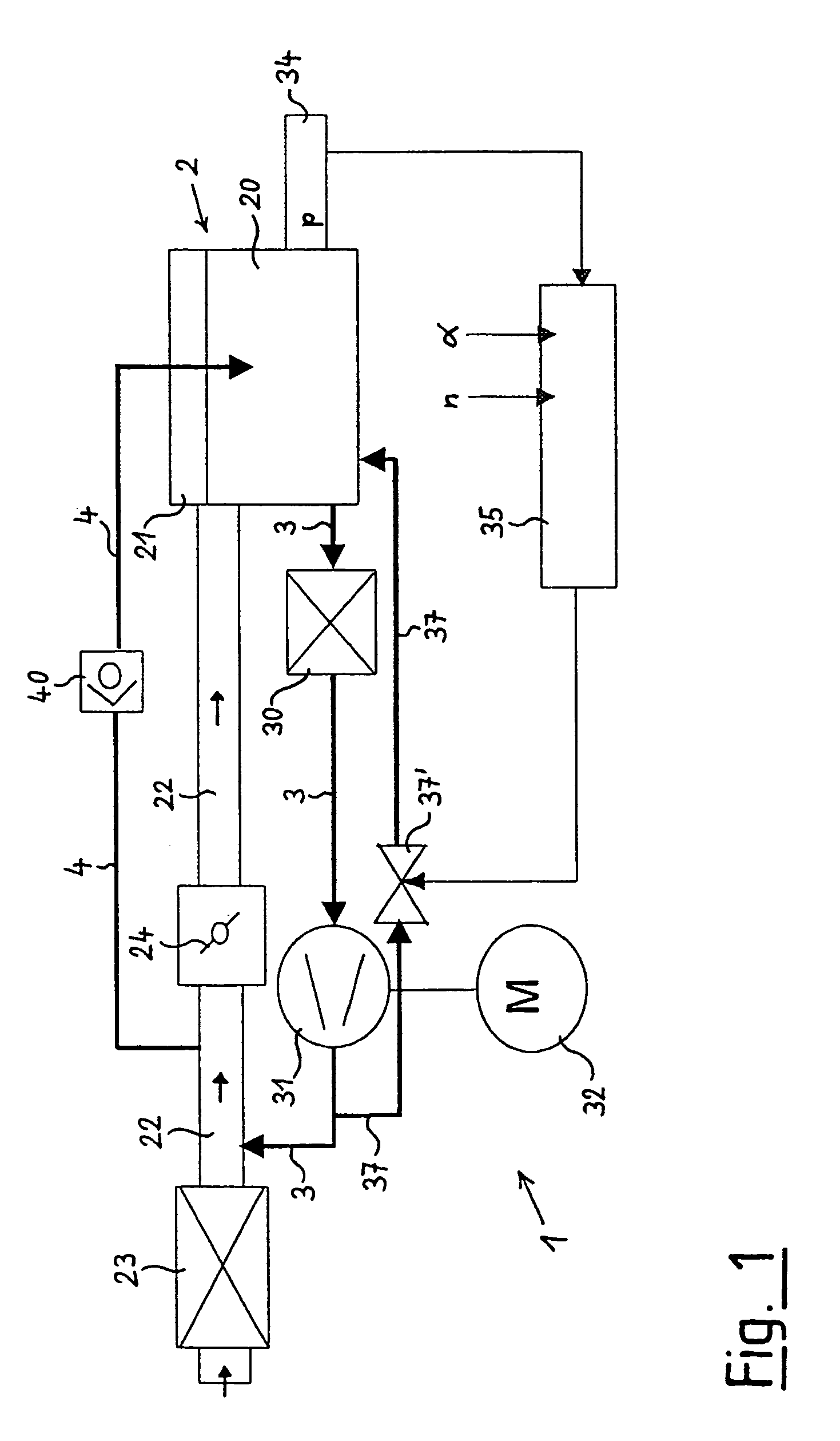

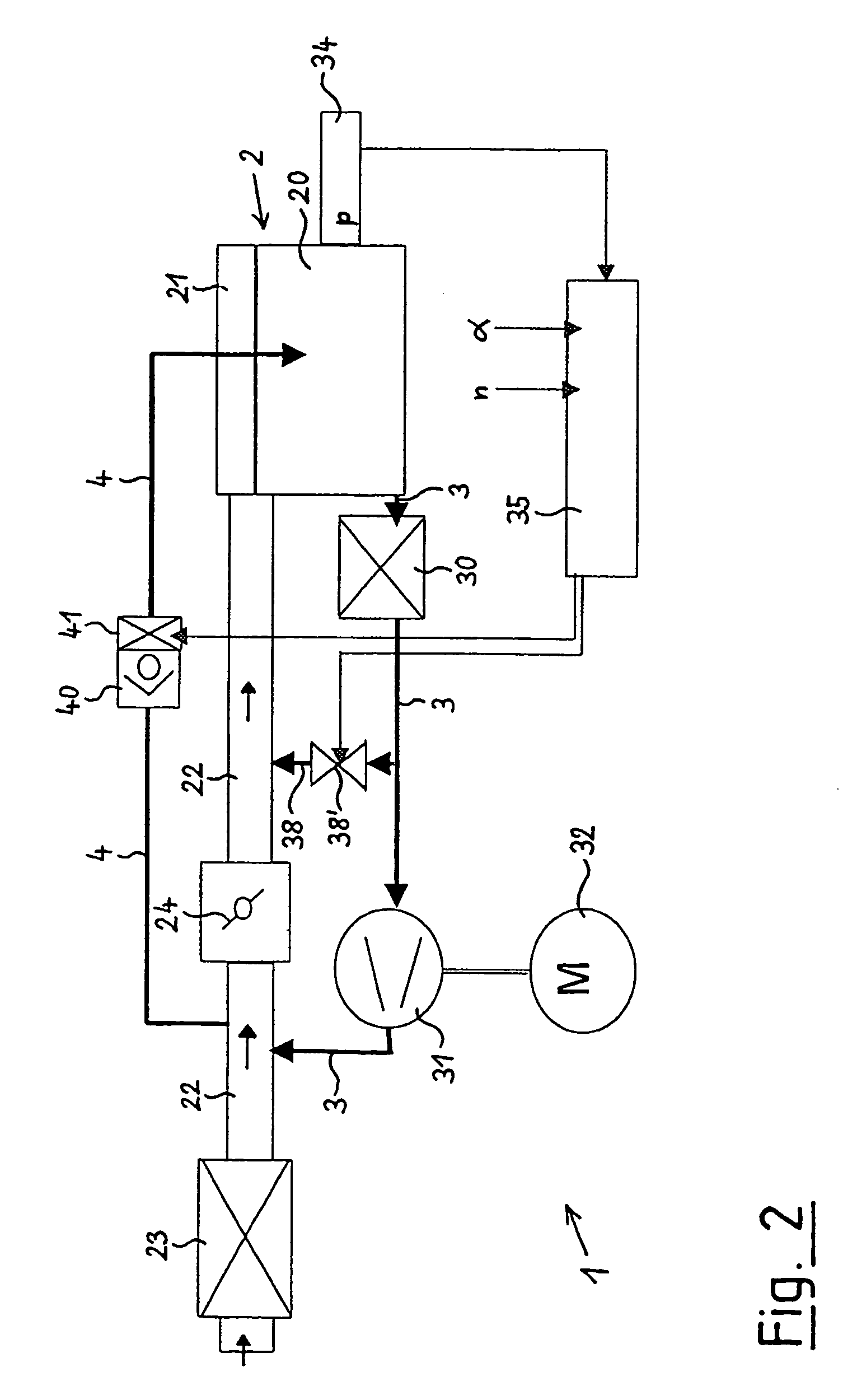

Device for the ventilation of the crankcase of an internal combustion engine

InactiveUS7100587B2Increase volumeImprove efficiencyNon-fuel substance addition to fuelInternal combustion piston enginesBreatherAmbient pressure

The invention relates to a device (1), for the ventilation of the crankcase (20) of an internal combustion engine (2), with a breather tube (3), running from the crankcase (20) to an inlet manifold (22) on the internal combustion engine (2), in the course of which an oil-mist separator (30) is arranged. The novel device is characterized in that in the course of the breather line (3), a pump device is arranged, by means of which a reduced pressure may be generated in the crankcase (20) relative to ambient pressure.

Owner:HENGST WALTER

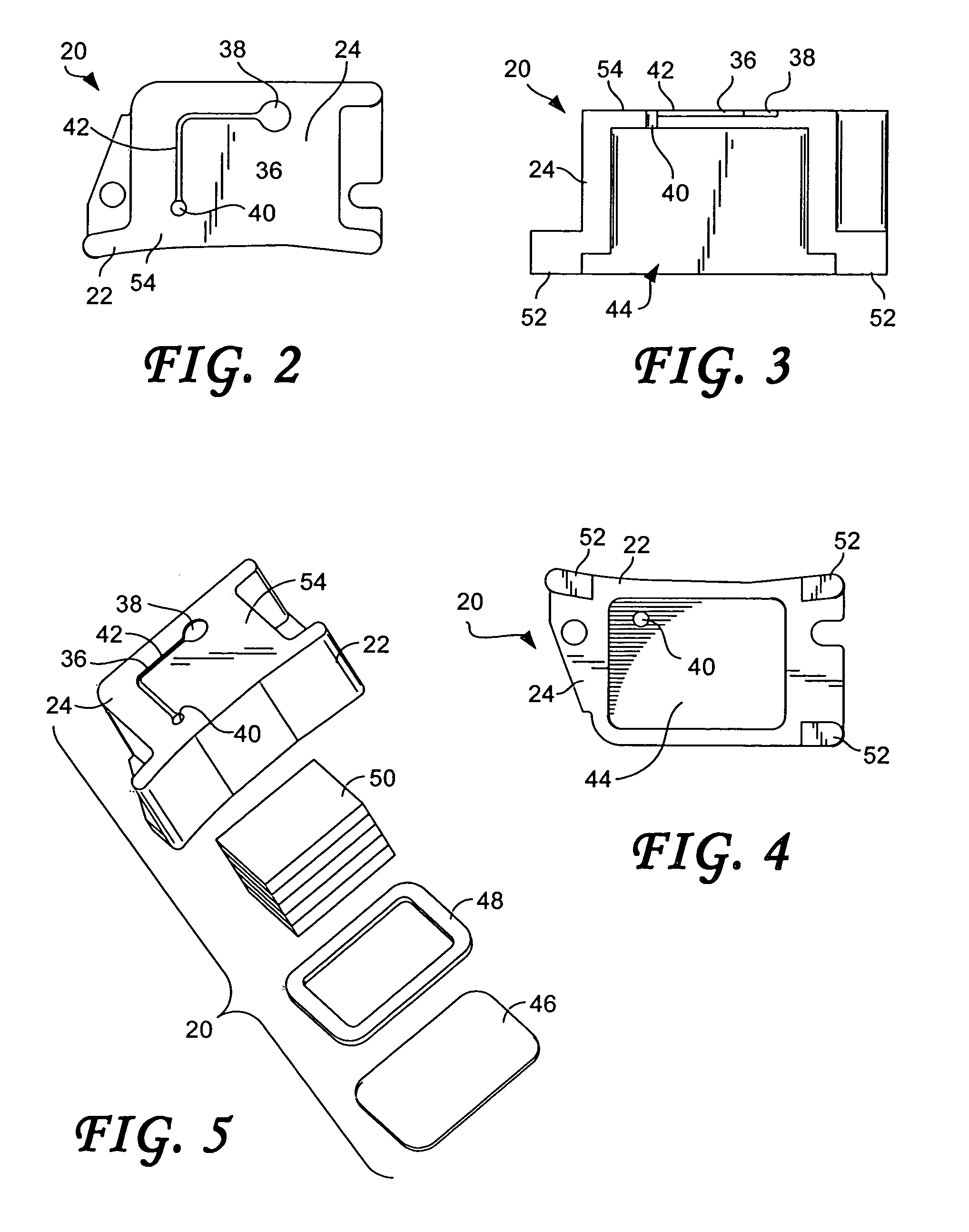

Disc drive breather filter mounted to a flex circuit bracket

ActiveUS7082012B2Prevent leakageEasy to fixDisposition/mounting of recording headsApparatus for flat record carriersBreatherFlexible circuits

A breather filter is assembled within a disc drive by positioning the filter atop a flex circuit bracket on a base plate of the drive. A breather port is formed through a top cover of the disc drive, and an inlet of the breather filter is sealed against the top cover of the drive. Compressing the top cover against the top of the breather filter helps to retain the filter in position between the flex circuit bracket and the top cover without an adhesive connection to the top cover. The connection of the breather filter to the flex circuit bracket allows a top-down assembly of the disc drive so that an adhesive connection between the filter and the top cover of the drive is not required.

Owner:SEAGATE TECH LLC

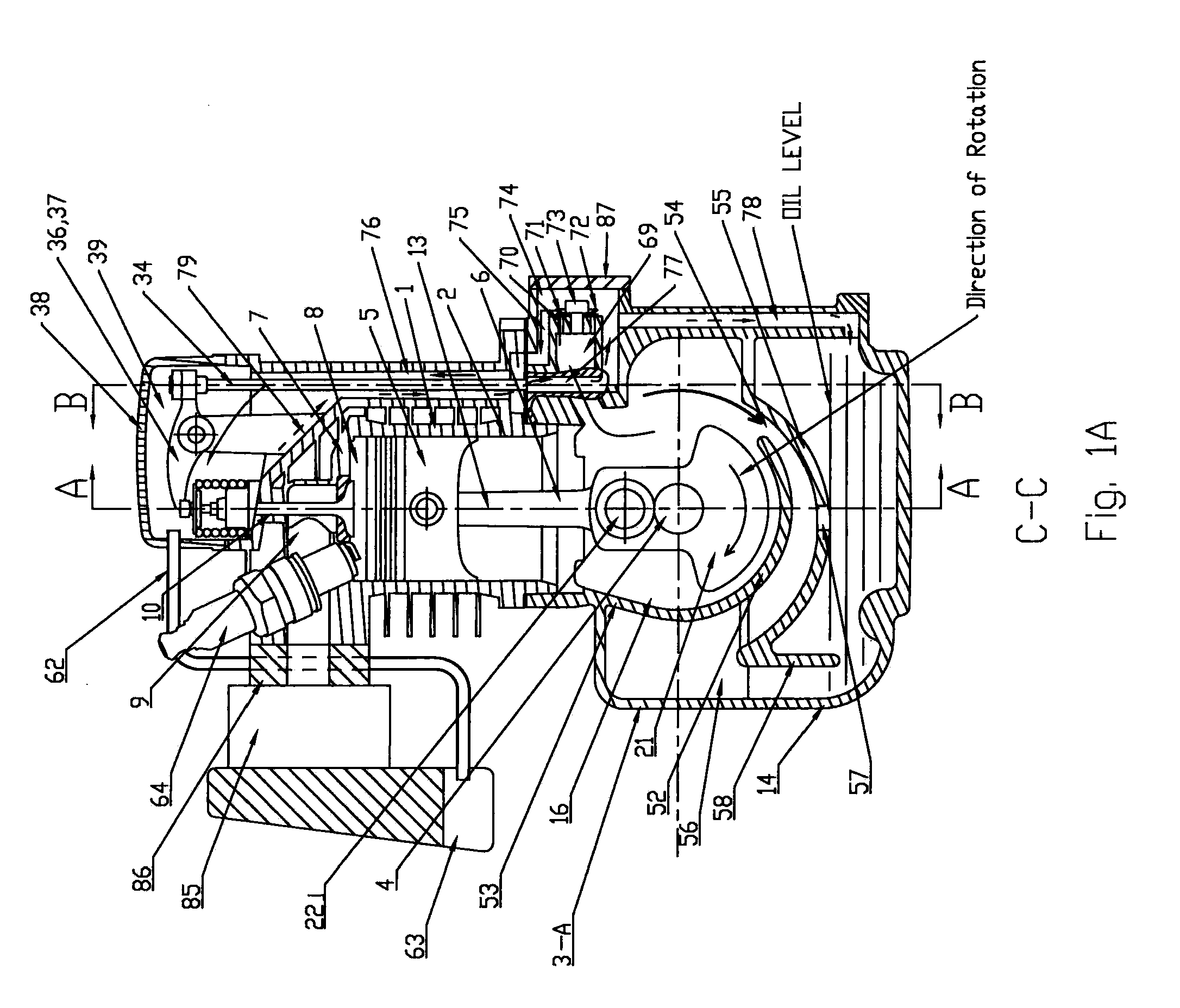

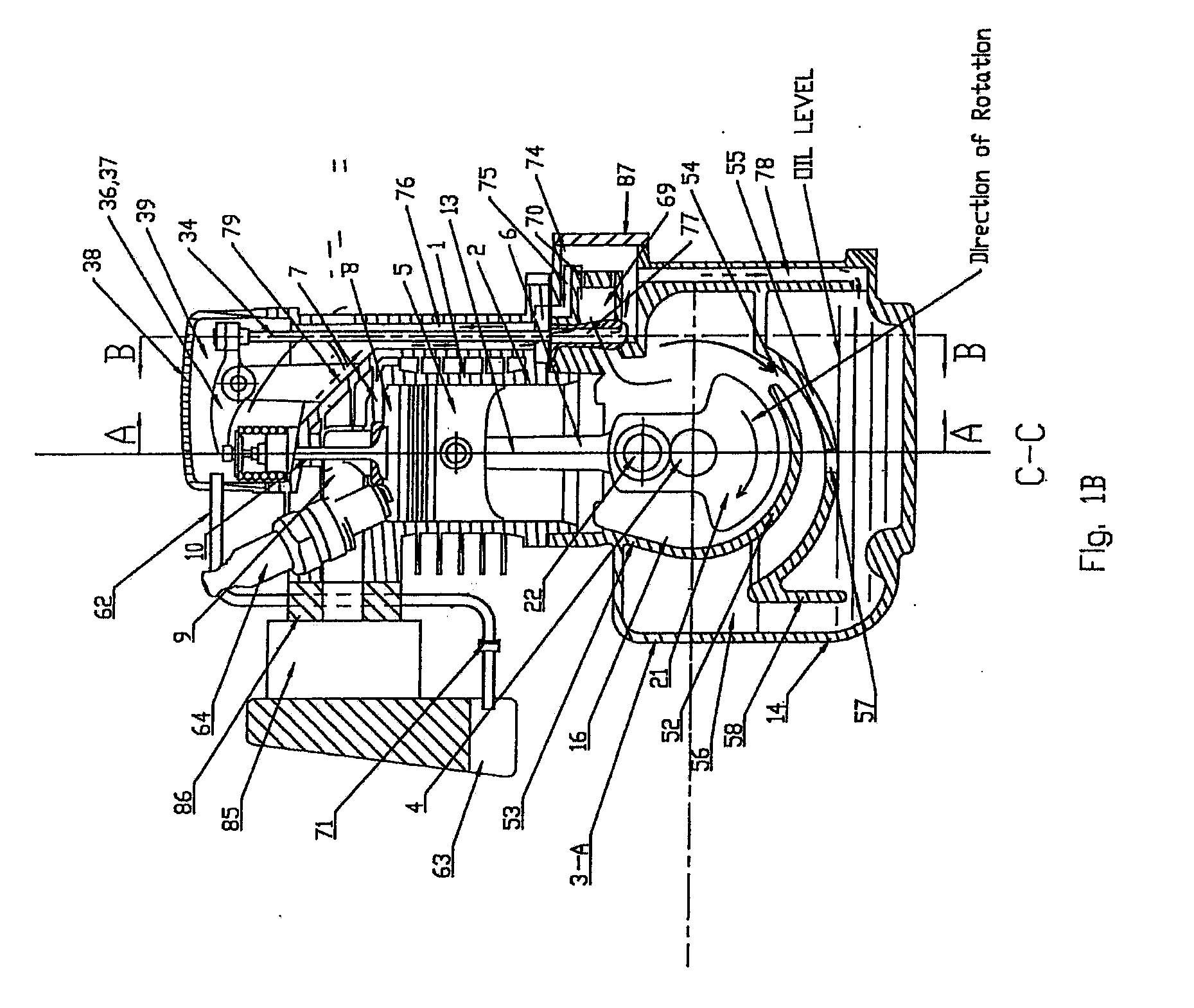

Engine lubrication method

An engine lubrication method is provided. The four-cycle engine has a lightweight aluminum alloy engine block having a cylindrical bore and an enclosed oil reservoir formed therein. A crankshaft is rotatably mounted in the engine block for rotation about a crankshaft axis. A piston reciprocates within the bore and is connected to the crankshaft by a connecting rod. A cam shaft is rotatably mounted in the crank shaft chamber for rotation about a cam shaft axis, parallel to the crank shaft axis. An oil pump driven by the cam shaft, which mates by cam gear with crank gear that is driven by crank shaft, inhales the oil from the oil reservoir to splash lubricate into the crank shaft chamber. The engine is provided with a cylinder head assembly defining a compact combustion chamber having a pair of overhead intake and exhaust ports and cooperating intake and exhaust valves. A lightweight, high-powered engine is thereby provided having relatively low HC and CO emissions. A circular arc wall surrounds around web of the crankshaft with a slight distance from the web. A scroll-shaped wall has gradually increased distance from said wall to the direction of rotation of the web and has partial overlap with the circular arc wall. The check valve splashes breathing mist oil from crank shaft room to breather room and causes the oil to supply to lubricate engine parts in valve chamber and the oil, after lubricating the parts, is returned into the oil reservoir.The oil in crank shaft chamber, after lubricating engine parts, is returned to oil reservoir guided by scroll-shaped wall and a hole provided on the scroll-shaped wall.In case of stock of engine oriented power take off side up or down, oil is prevented to flow from oil reservoir to combustion chamber by a weir which is provided between circular wall and scrolled or extended wall.

Owner:ETG

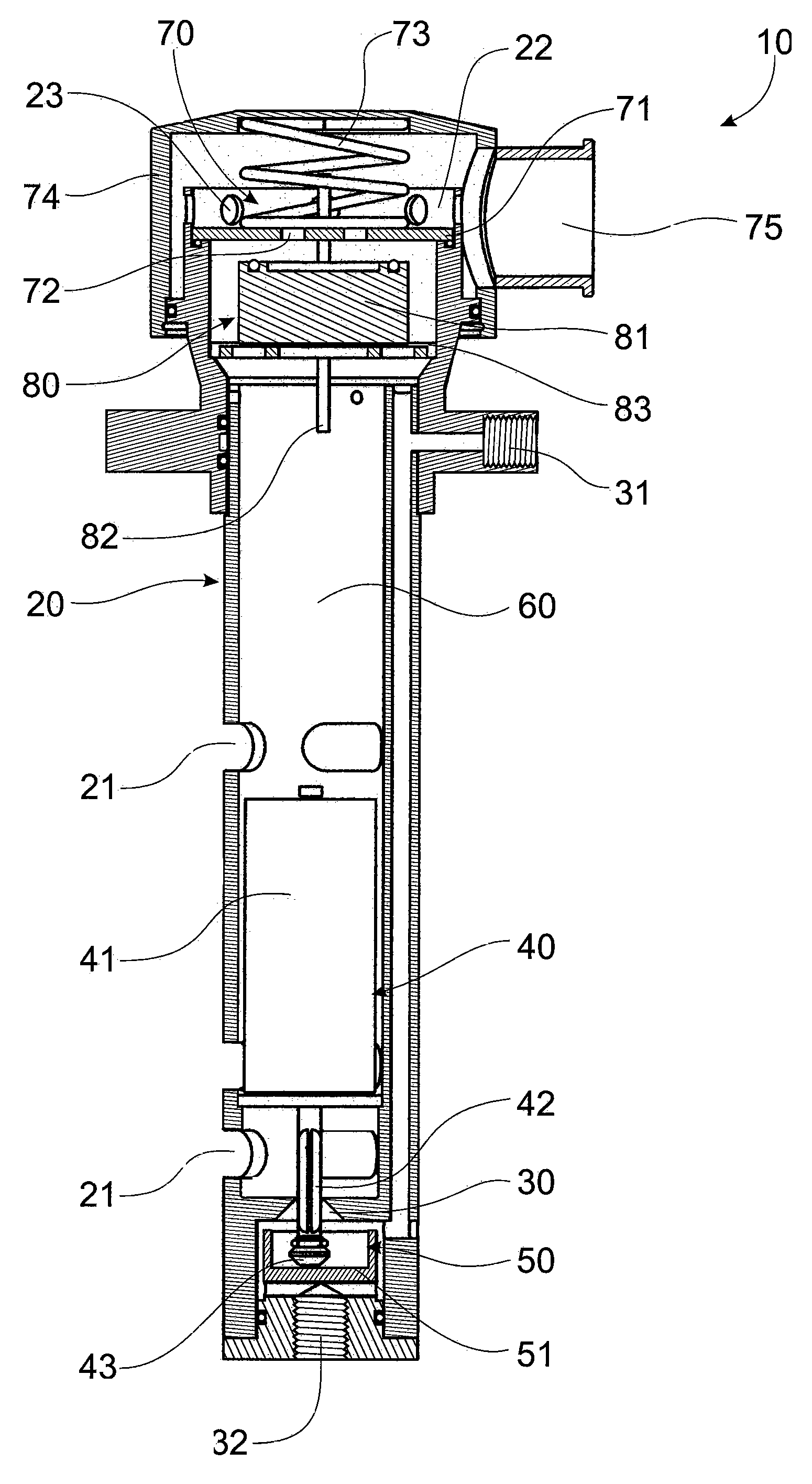

Valve assembly

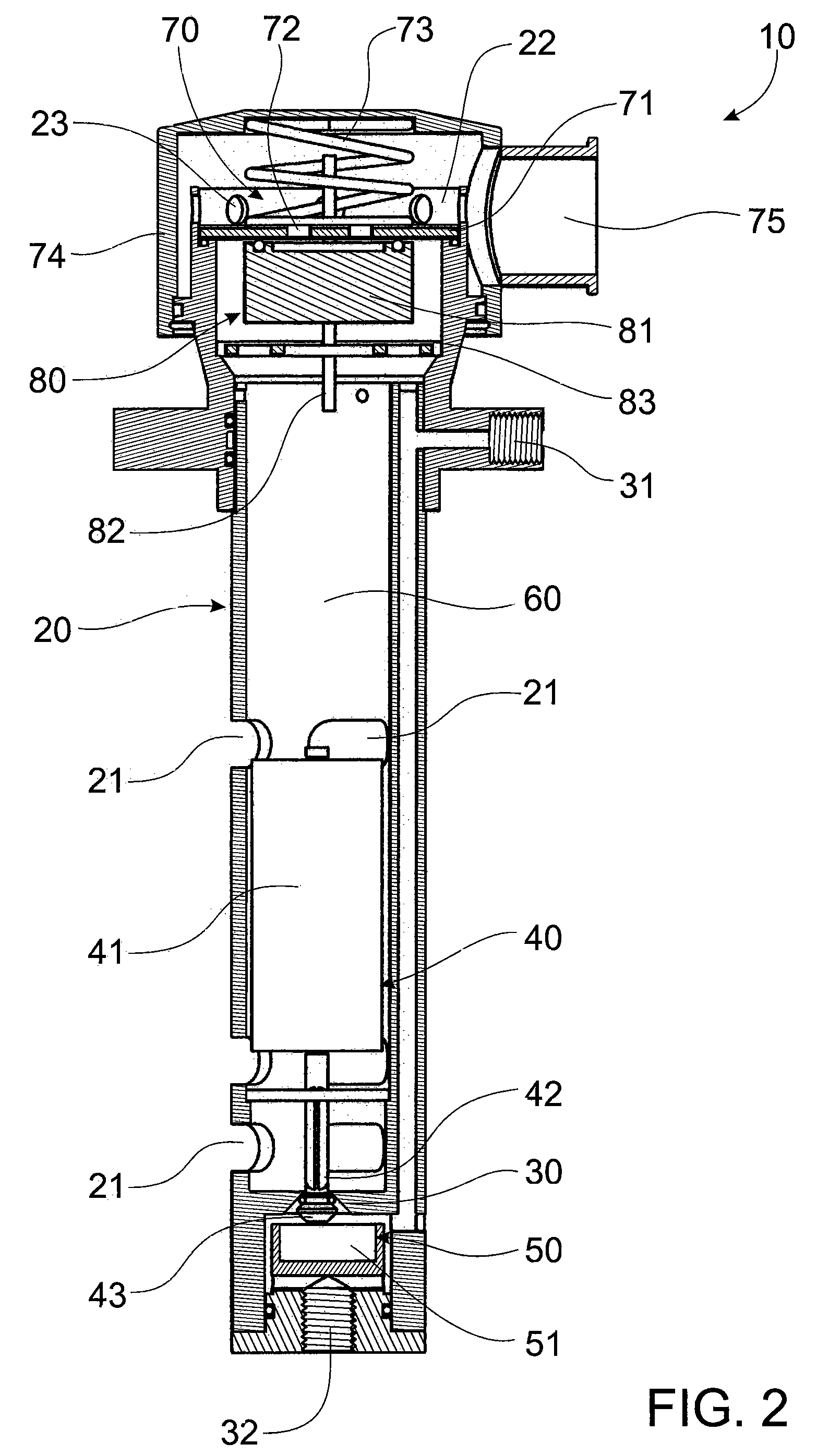

A valve assembly (10) able to be mounted with a liquid container, the valve assembly comprising: a housing (20) having a passageway (60) that extends through the housing; a breather float valve (80) mounted within the housing, the breather float valve movable between an open position to allow gas to pass through the passageway and a closed position that prevents liquid from passing through the passageway; a liquid inlet (30), forming part of the housing, the liquid inlet allowing fluid to pass into the housing; and an inlet float valve (41) mounted within the housing, the inlet float valve movable between an open position that permits the flow of liquid through the liquid inlet and a closed position that prevents the flow of fluid through the liquid inlet.

Owner:WEIR MINERALS AUSTRALIA LTD

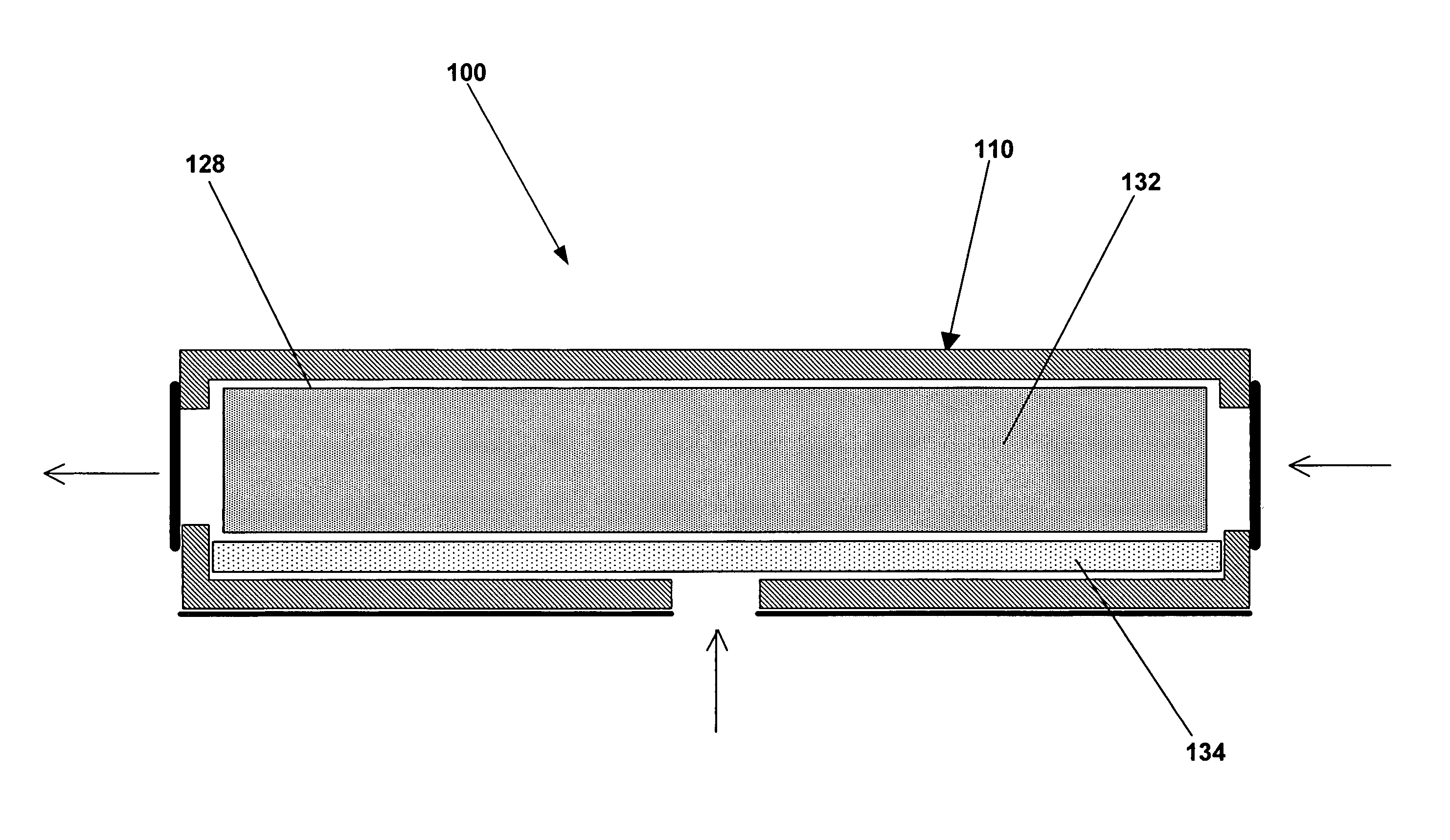

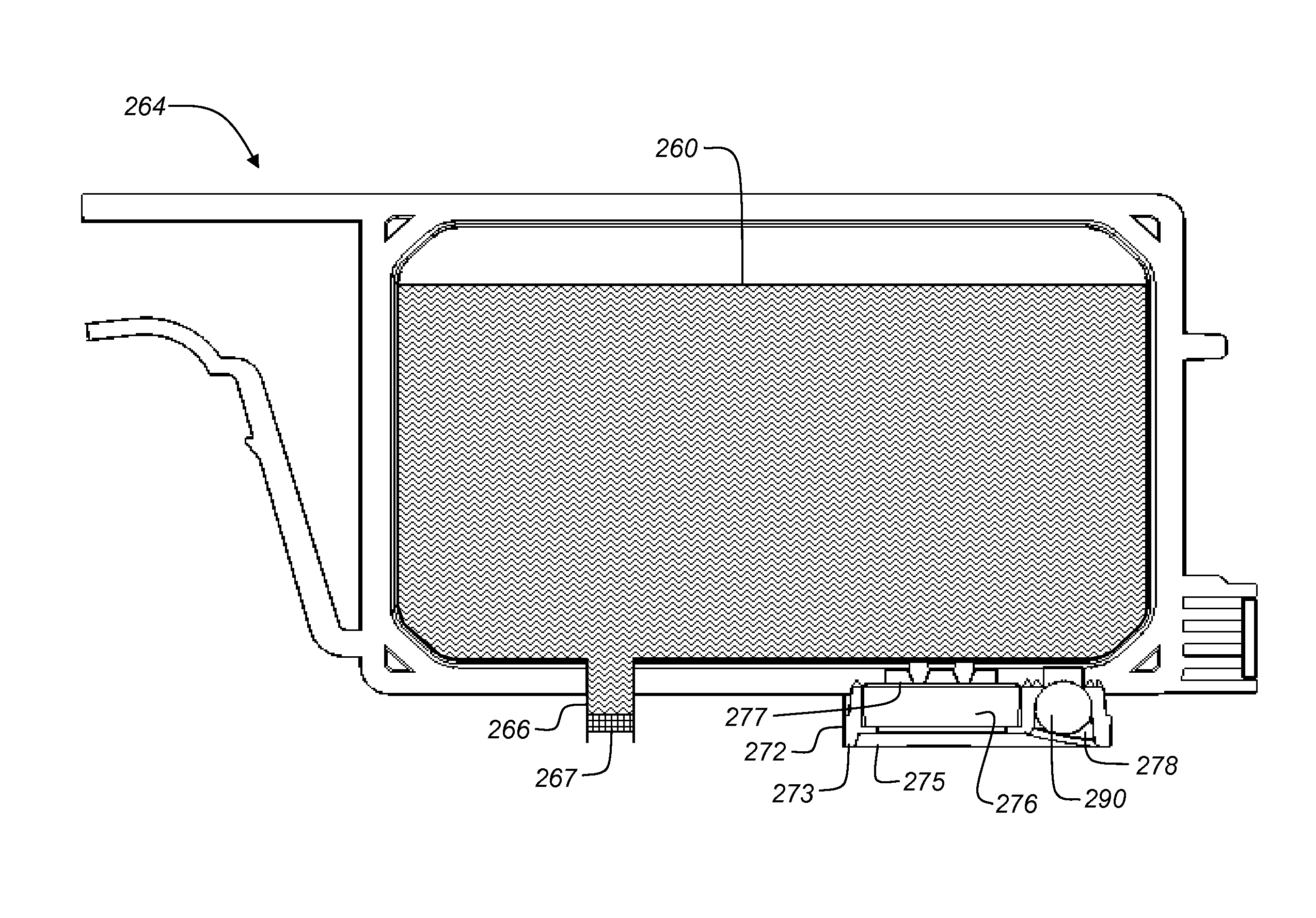

Electronic breather bag filter

A breather bag filter assembly for use with an electronic enclosure, such as a hard disk drive enclosure containing a rotating disk, is disclosed. The filter assembly provides filtration of air entering and exiting an electronic enclosure through a breather hole. The filter assembly is a deformable sealed cavity that exchanges air with the drive enclosure as the air pressure inside the drive enclosure fluctuates. In one implementation of the invention the filter assembly contains three layers of material. Two layers of material form the exterior of the filter assembly surrounding a third layer that is composed of an adsorbent material.

Owner:DONALDSON CO INC

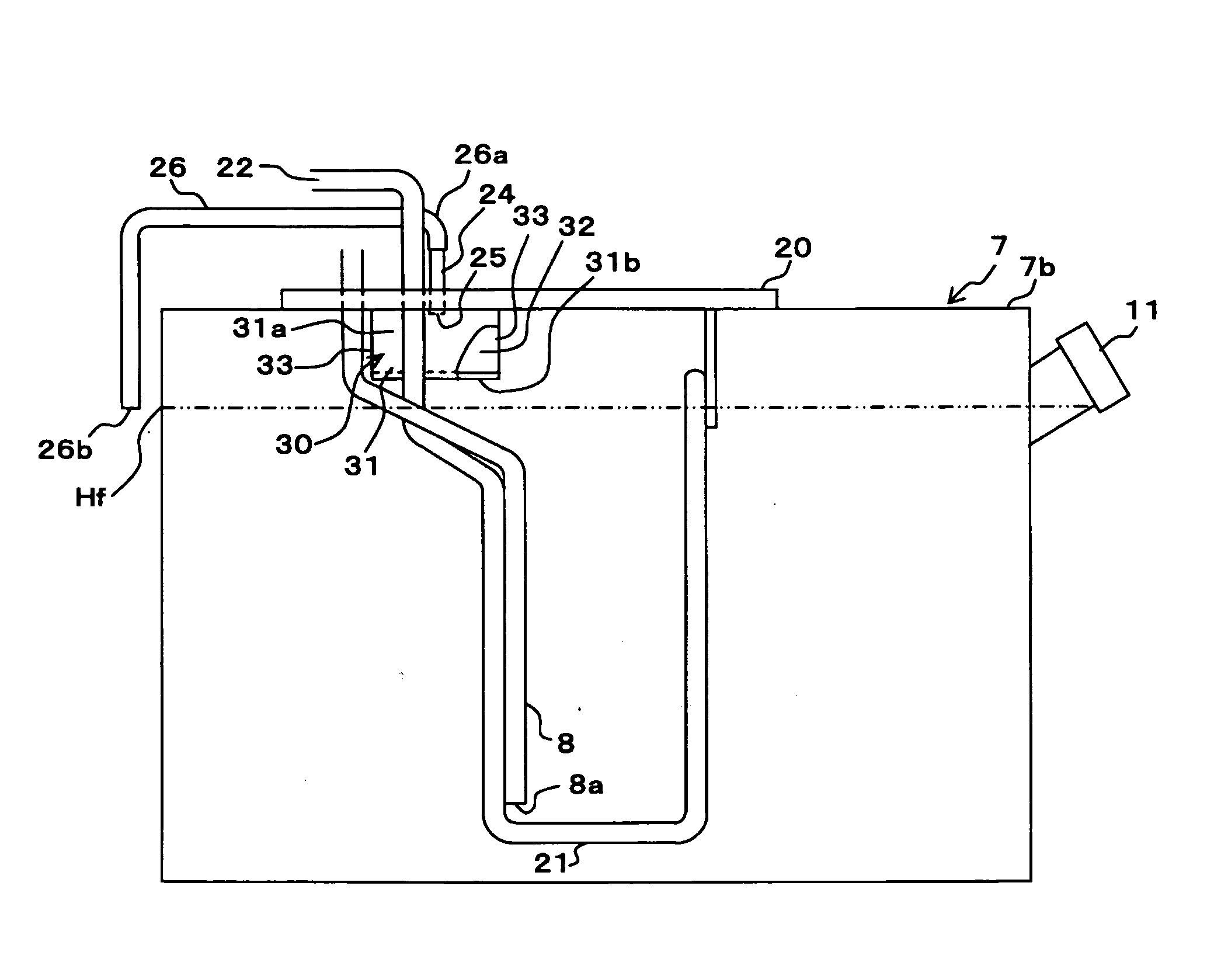

Liquid tank, breather device, and exhaust gas purification device for engine

InactiveUS20090038296A1Prevent outflowLiquid outflow via the vent hole can be preventedInternal combustion piston enginesExhaust apparatusInterior spaceBreather

In a liquid tank provided with a pressure relief vent hole, a shielding member surrounding the vent hole is disposed. The shielding member forms an isolated chamber communicated with the vent hole. In a portion located to the side of the vent hole, the shielding member allows communication between the isolated chamber and an inner space in the liquid tank excluding the isolated chamber. On the other hand, in a portion located below the vent hole, the shielding member blocks movement of the liquid between the isolated chamber and the inner space.

Owner:NISSAN DIESEL MOTOR CO

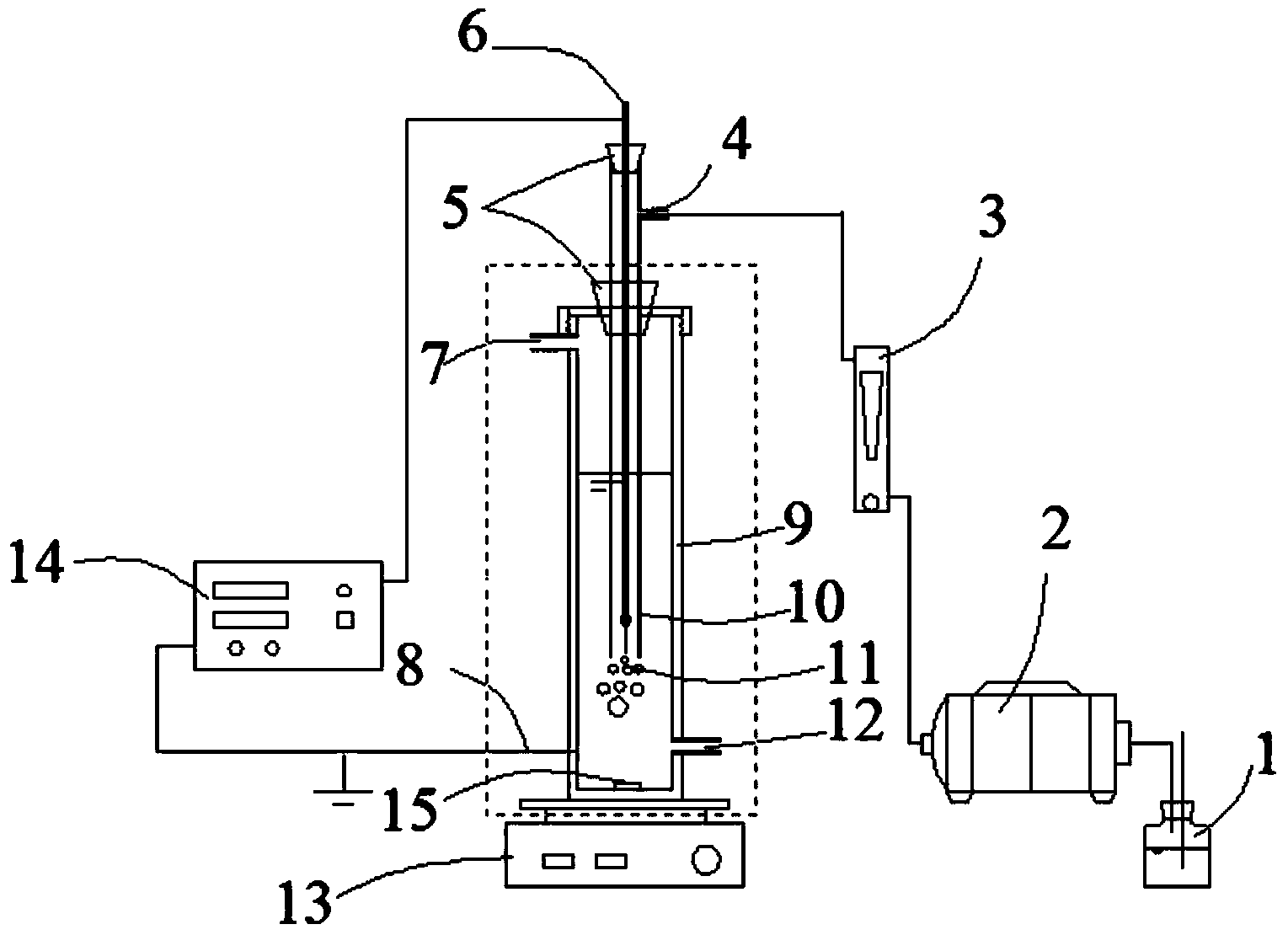

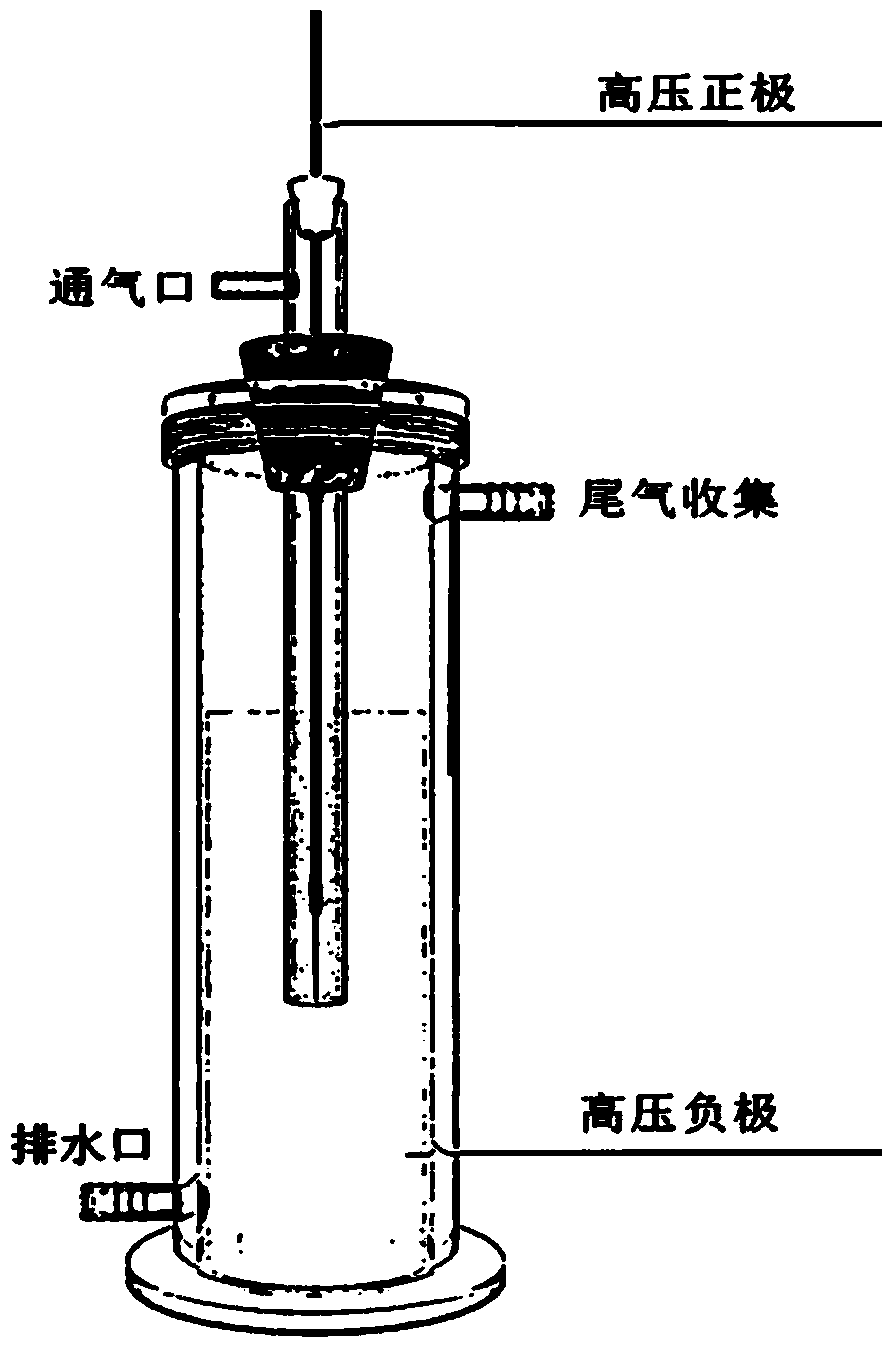

Device and method for degrading antibiotic wastewater by utilizing low temperature plasma in coordination with bismuth molybdate catalyst

InactiveCN103848484AImprove degradation rateHigh removal rateWater/sewage treatment using germicide/oligodynamic-processMetal/metal-oxides/metal-hydroxide catalystsCatalyst degradationBreather

The invention discloses a device and a method for treating antibiotic wastewater by utilizing low temperature plasma in coordination with a bismuth molybdate catalyst. The device for treating the antibiotic wastewater by utilizing the low temperature plasma in coordination with the bismuth molybdate catalyst comprises a barrel-shaped reactor, a breather pipe, a high voltage electrode, an alternating current high voltage power supply, an air pump and a stirrer, wherein the breather pipe is arranged inside the barrel-shaped reactor and is coaxial with the barrel-shaped reactor, the high voltage electrode is suspended inside the breather pipe, the lower port of the breather pipe is arranged at the lower bottom part inside the barrel-shaped reactor, the upper part of the breather pipe is arranged outside the barrel-shaped reactor, an air inlet is formed in the side wall of the upper part of the breather pipe, the air inlet is communicated with the outlet of the air pump by virtue of a pipeline; the alternating current high voltage power supply is respectively connected to the high voltage electrode and grounded, and the stirrer is arranged at the lower part of the barrel-shaped reactor. The device for treating the antibiotic wastewater by utilizing the low temperature plasma in coordination with the bismuth molybdate catalyst has the characteristics of simple design, low equipment investment and no secondary pollution and can be applied to the filed of treatment on antibiotic wastewater and organic wastewater difficult to be biochemically degraded, wherein a degradation reaction temperature can be increased by fully utilizing heat produced in a discharge process.

Owner:NANJING UNIV

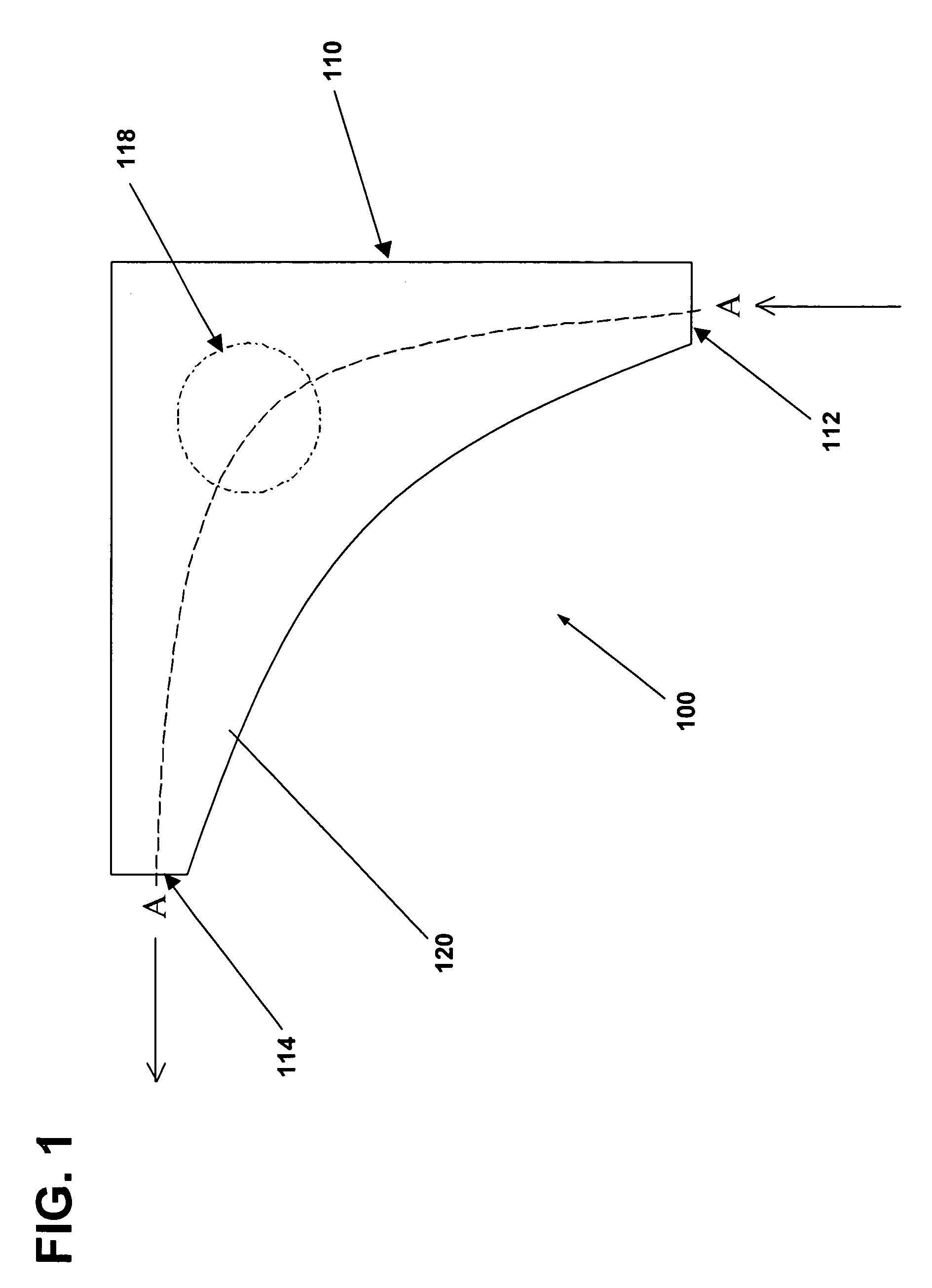

Venturi apparatus for pouring and aereating beverages

ActiveUS8251352B2Maximize flowEasy to introduceFlow mixersUsing liquid separation agentBreatherAcute angle

An improved venturi apparatus for the incorporation of air into a liquid. The preferred embodiment of the invention comprises an entry section, a cylindrical section, and an outflow section. Lateral tubes extend from the cylindrical section so as to form an acute angle relative to both the central and cross-sectional axes of the cylindrical section, thereby preventing leakage of liquid out through the lateral tubes during use and subsequent handling. The entry section includes a breather tube connected to the cylindrical section.

Owner:FRANMARA INC

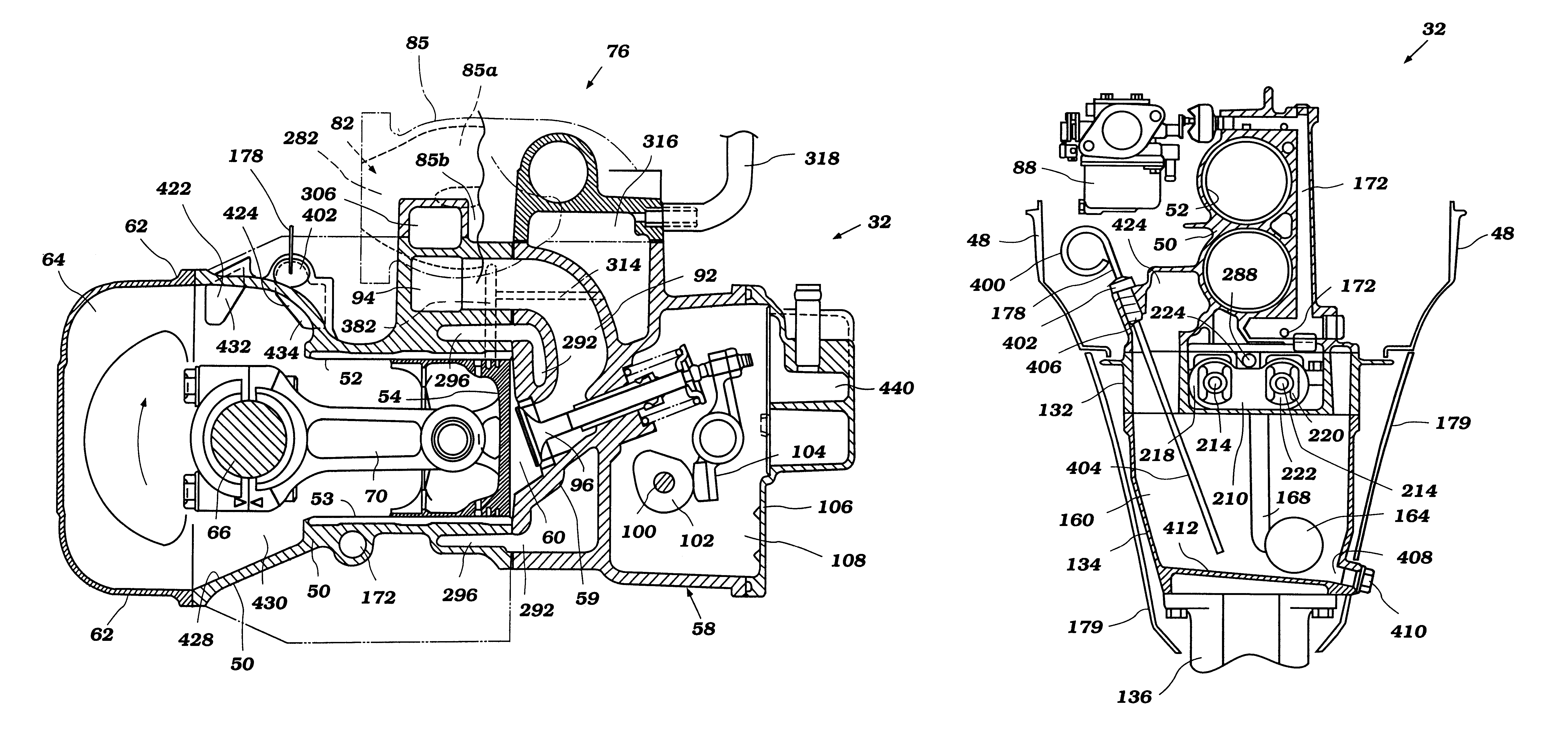

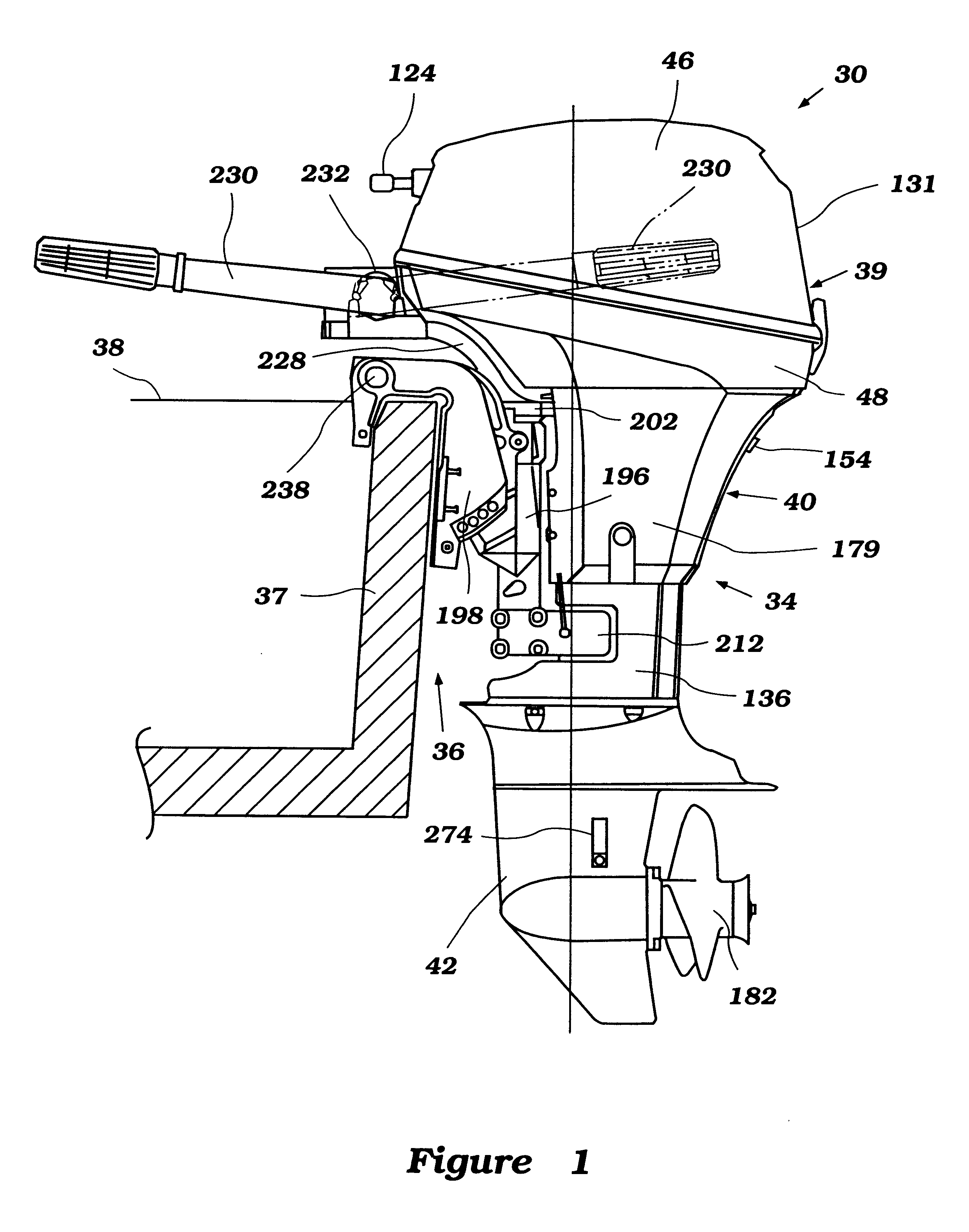

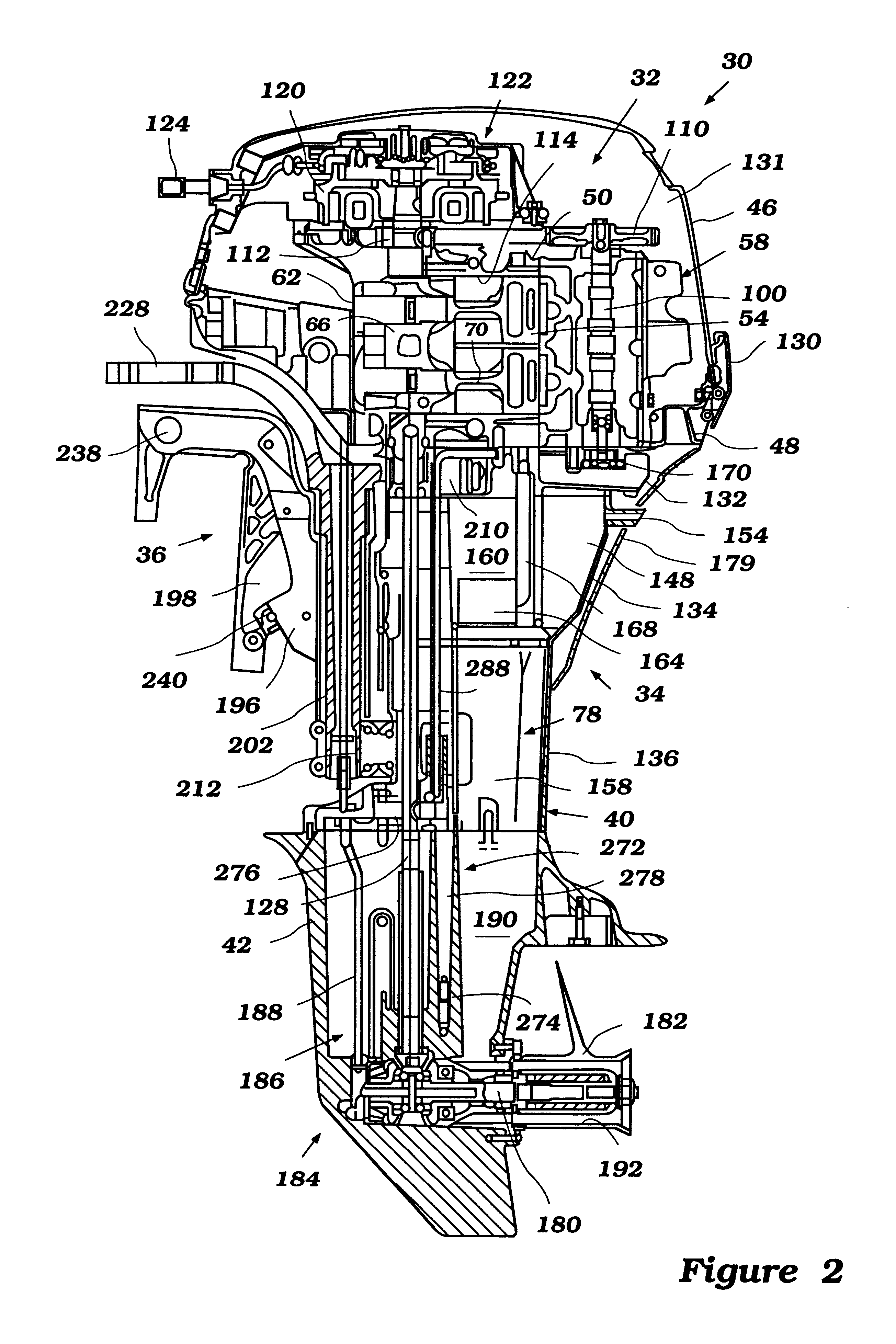

Engine layout for outboard motor

An improved arrangement of an outboard motor reduces the size of the outboard motor and improves a lubrication system of the outboard motor. Intake and exhaust passages are located along a side of a cylinder body. A crank case lubricant return passage is located on the same side of the cylinder body as the intake and exhaust passages. The return passages have openings located on an inner surface of the crank case. A breather passage connecting a cam chamber and an lubricant reservoir are located on a side of the cylinder body opposite the intake and exhaust passage. The lubricant reservoir including a drain and an insertion port. The insertion port being pointed towards the drain.

Owner:SANSHIN KOGYO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com