Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

353results about "Drip or splash lubrication" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

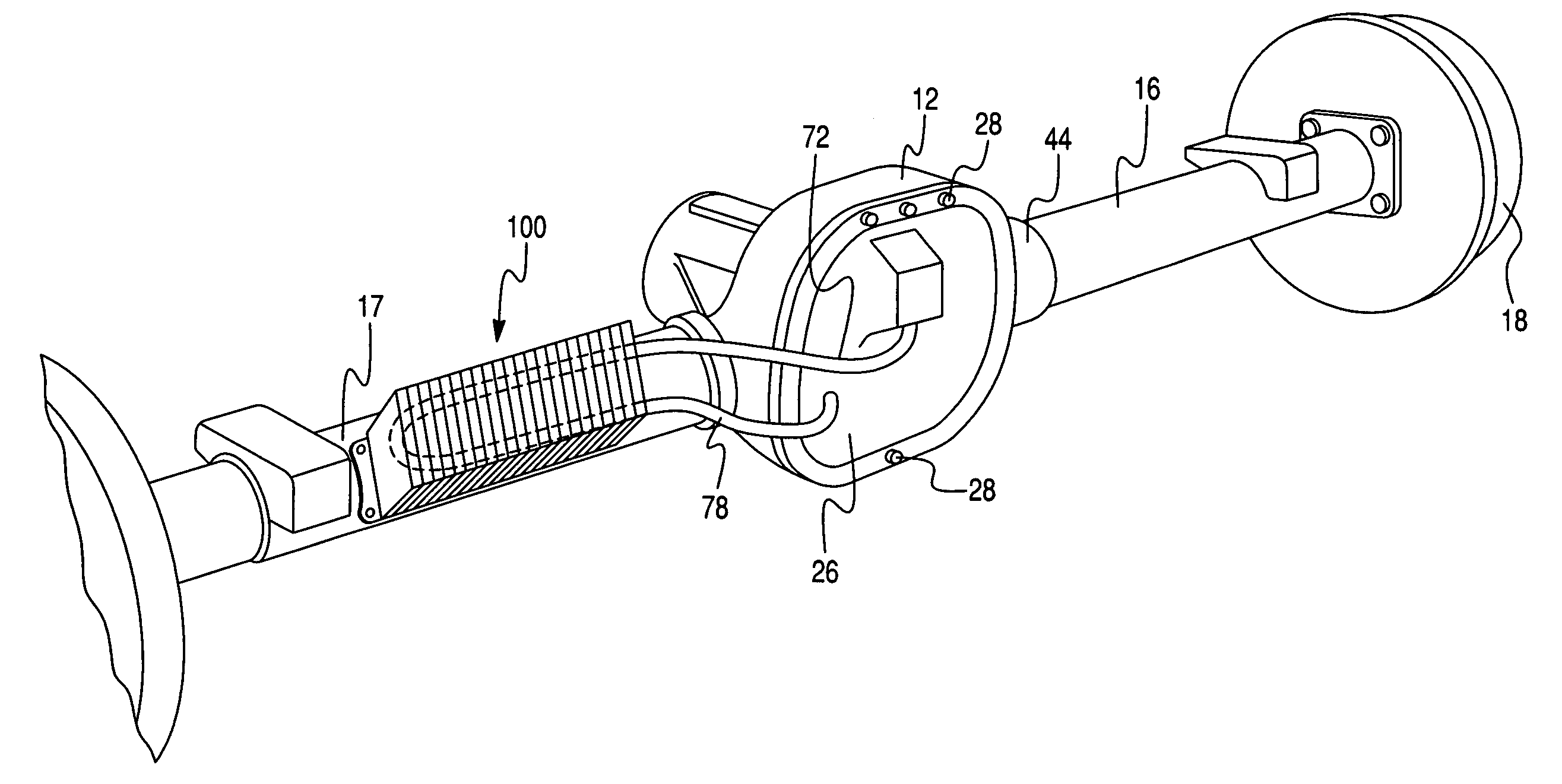

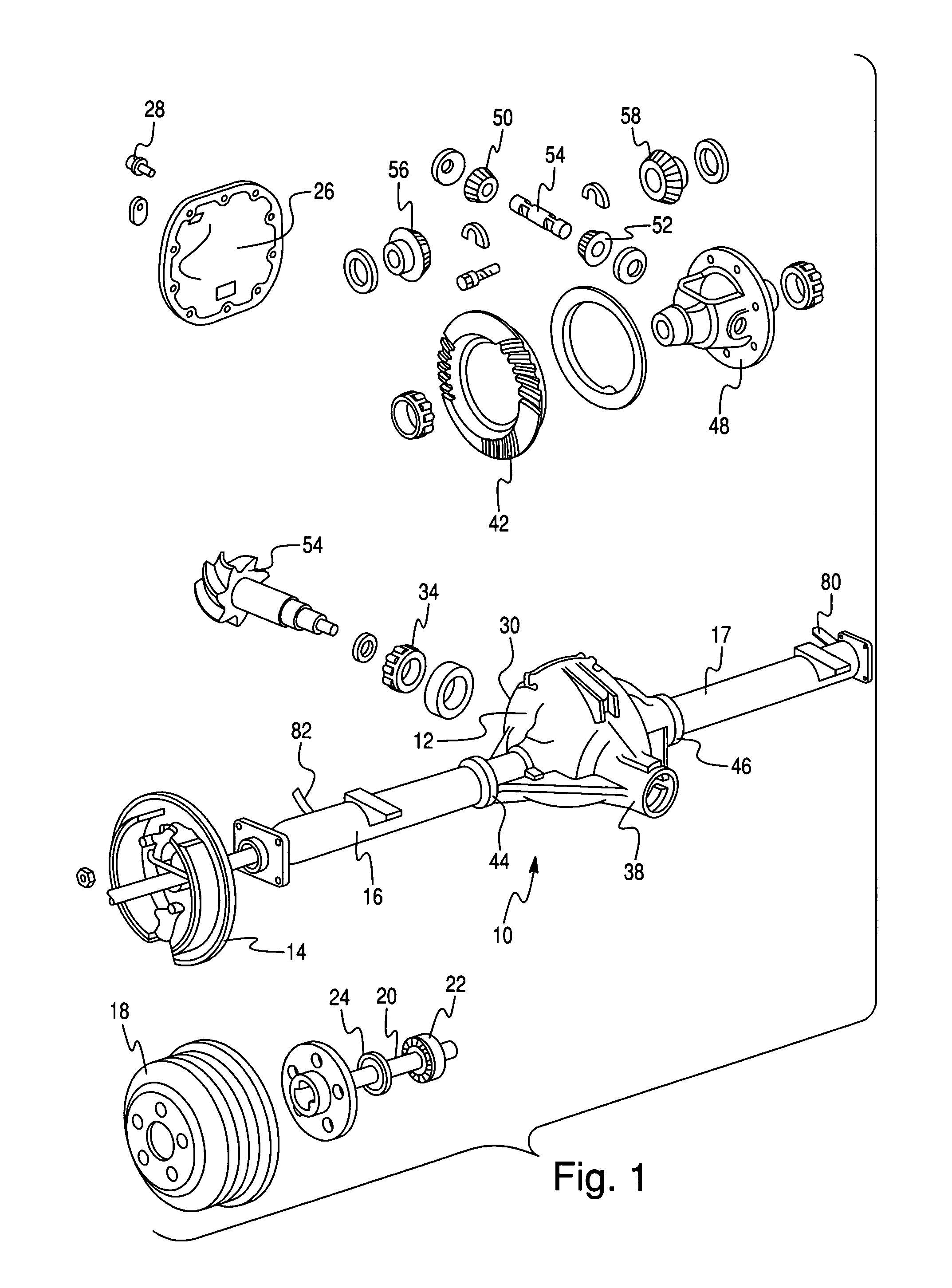

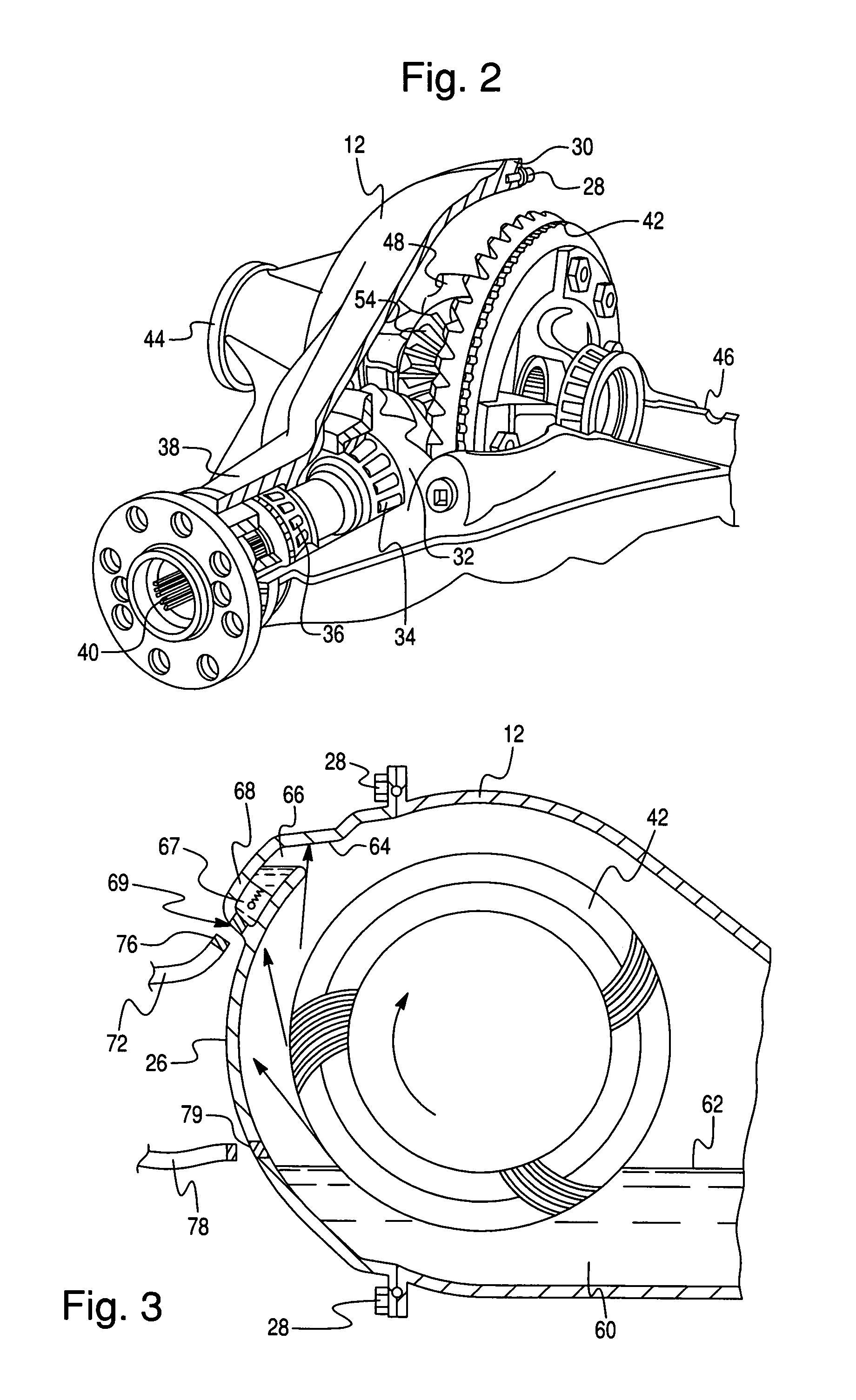

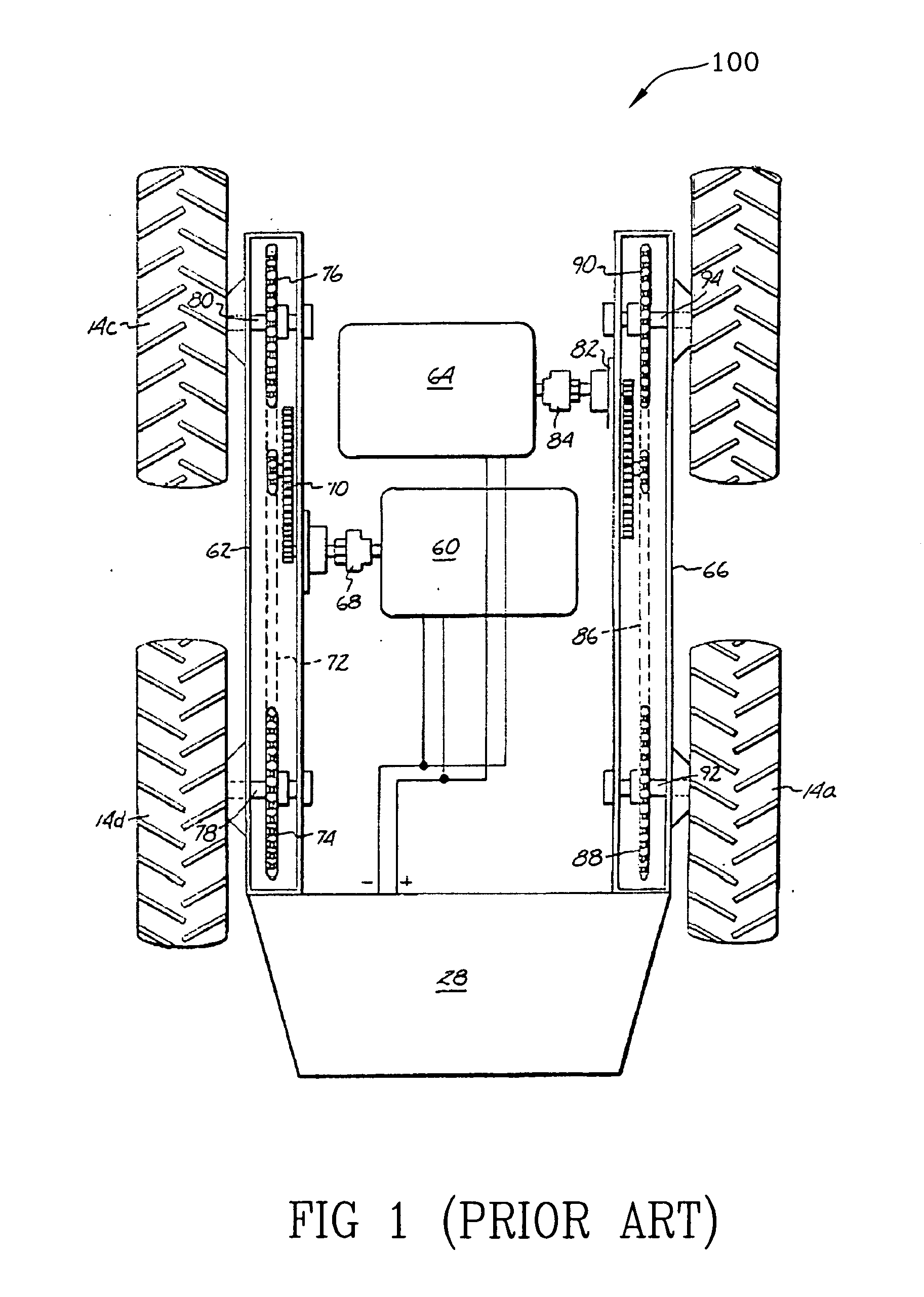

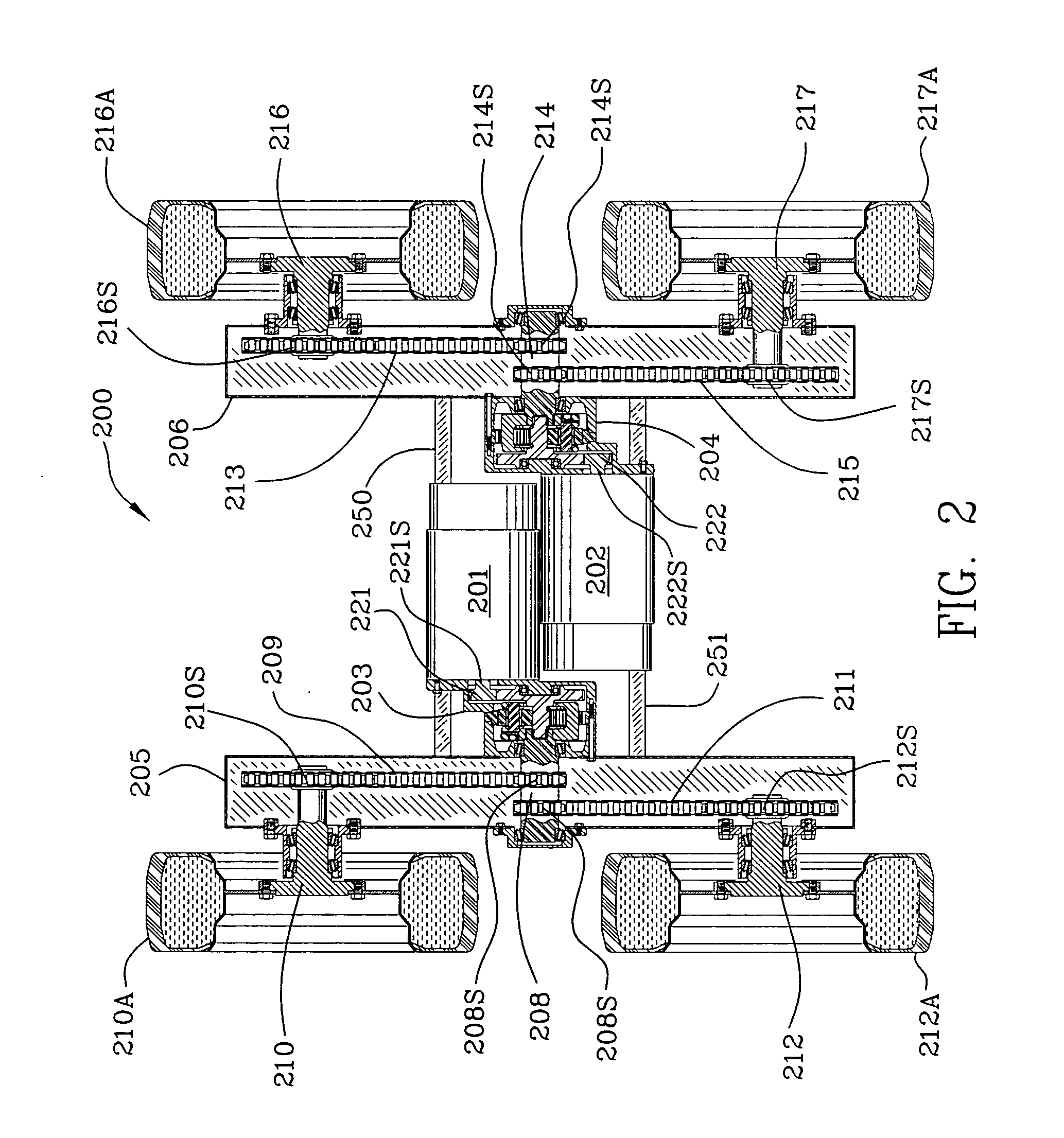

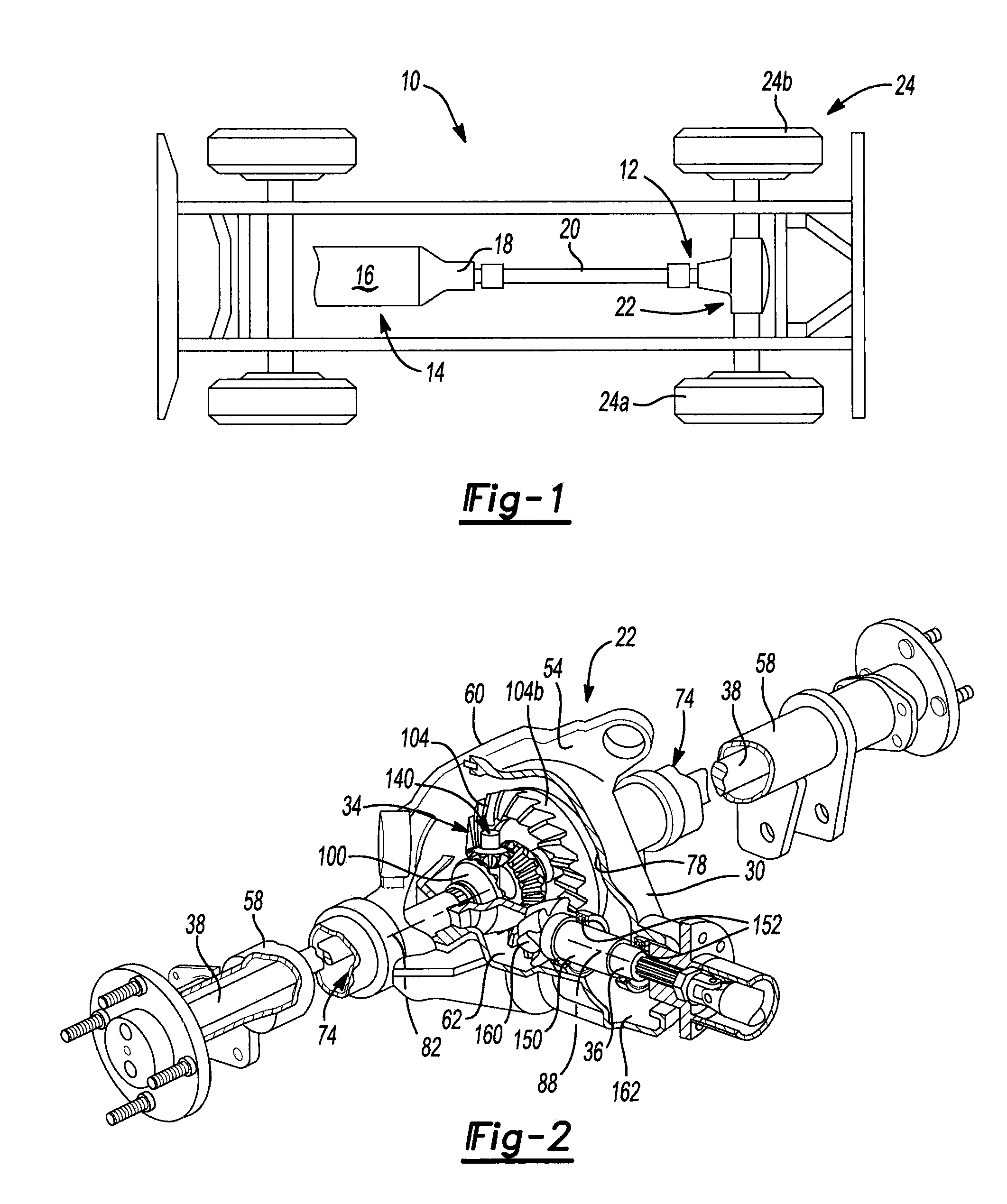

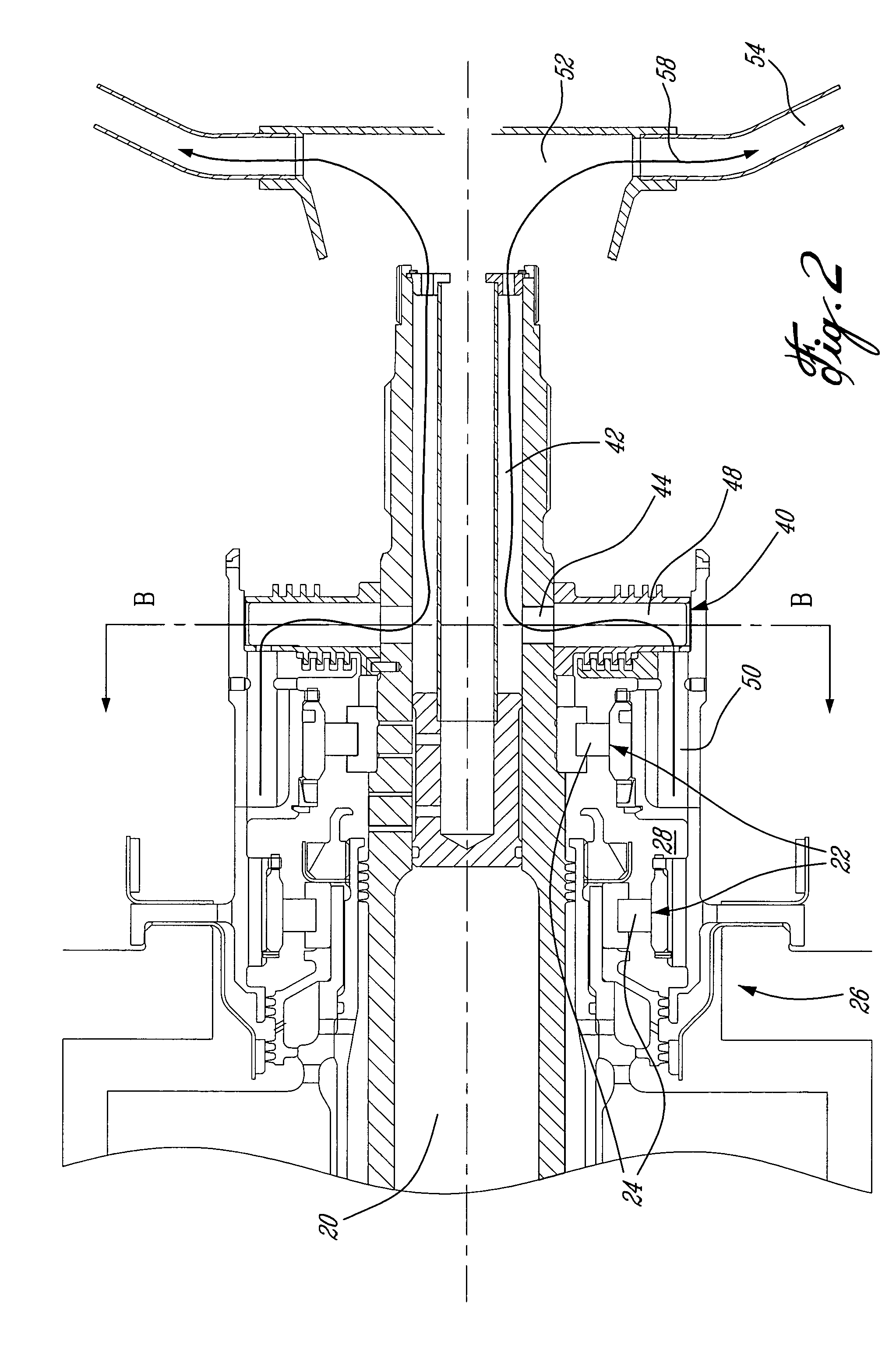

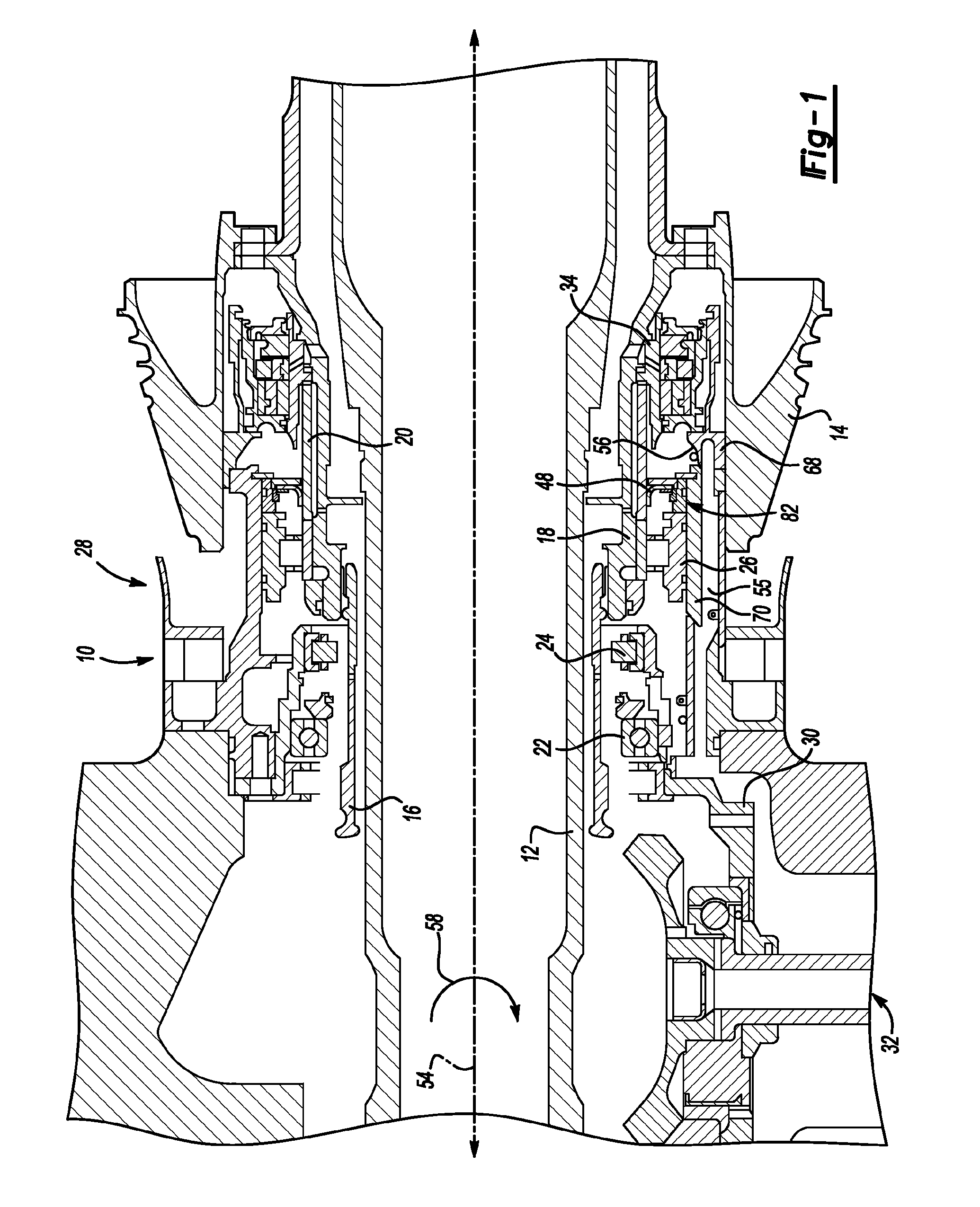

Lubricant cooling system for a motor vehicle axle

In a driven axle assembly (12) for a motor vehicle that includes a differential housing located substantially in the center of the axle and tubes (16, 17) extending laterally from the differential, surrounding axle shafts (20) and opening into a lubricant reservoir (60) in the differential housing, a system for circulating and cooling axle lubricant includes a cover (26) for closing and sealing the housing having a first aperture into the housing where a ring gear rotates through the lubricant reservoir. The aperture in the cover opens to a chamber that holds lubricant carried through the aperture by the rotating ring gear. Conduit (72) connected by a hydraulic fitting to the chamber has its opposite end connected to an oil cooler mounted on the axle tube. Conduit (78) returns the lubricant to the reservoir in the differential housing. Lubricant flows via a gravity feed through the first conduit into the cooler and back to the housing reservoir via the second conduit, effectively cooling the lubricant without the addition of a pump.

Owner:DANA AUTOMOTIVE SYST GRP LLC

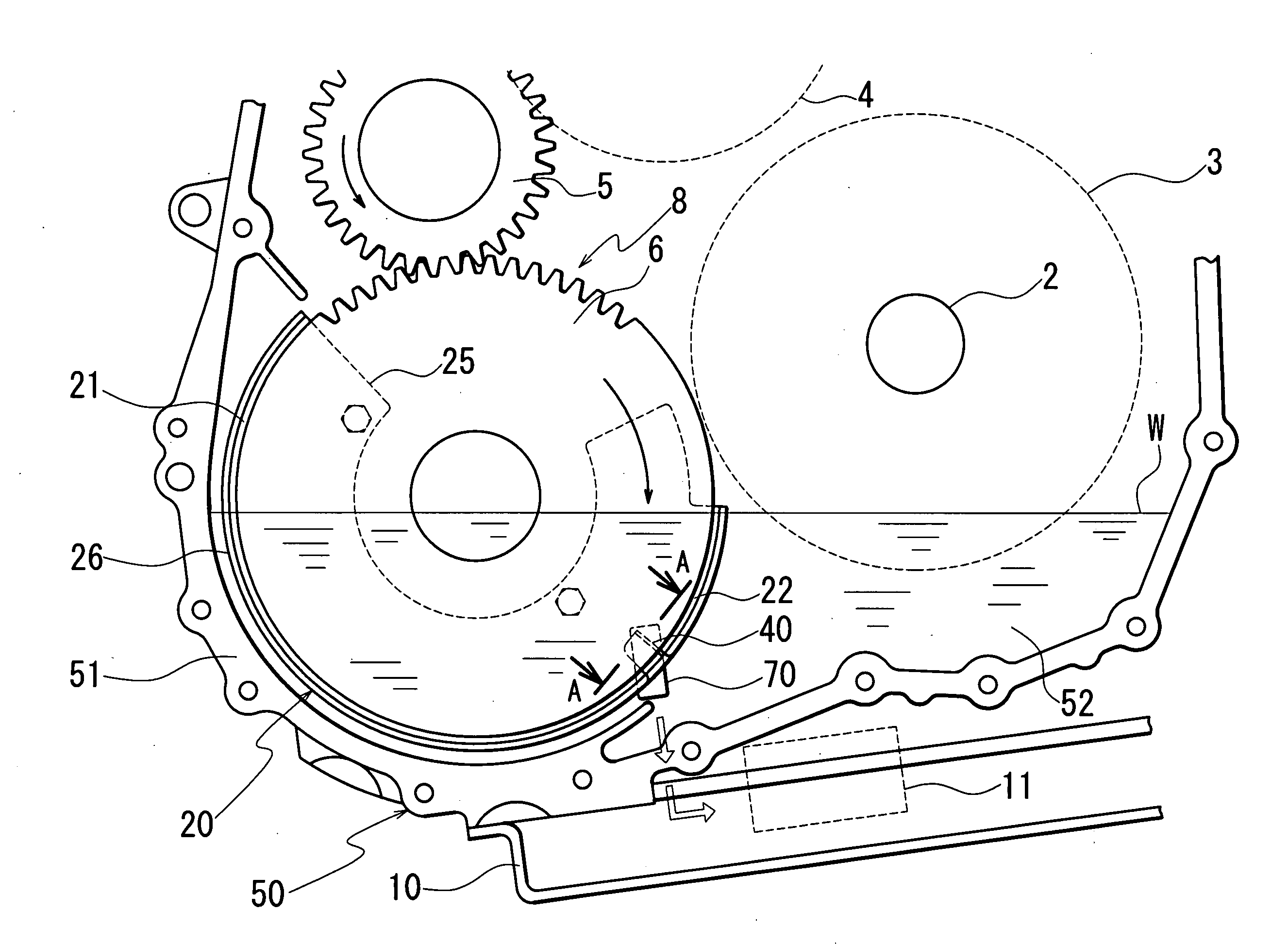

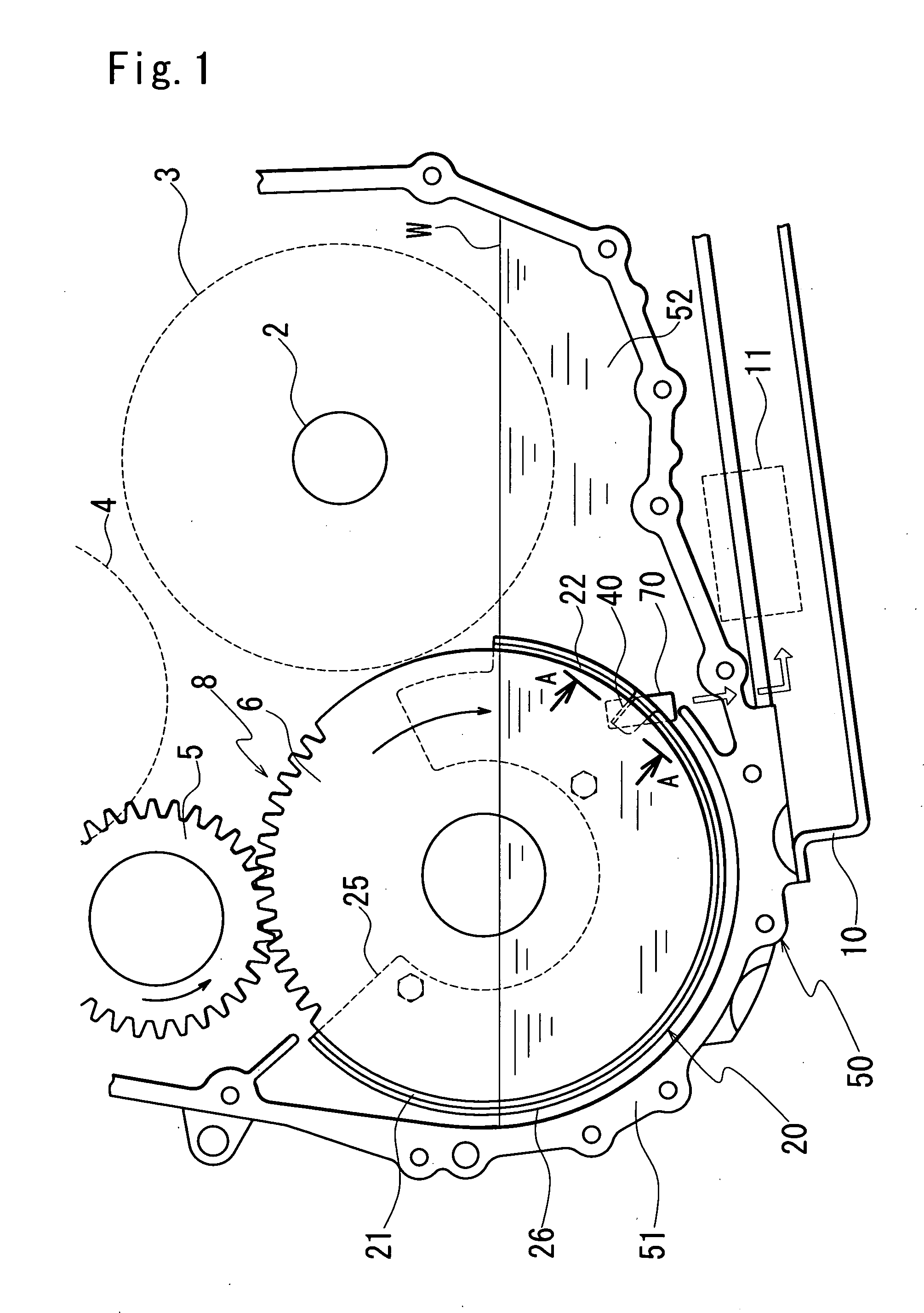

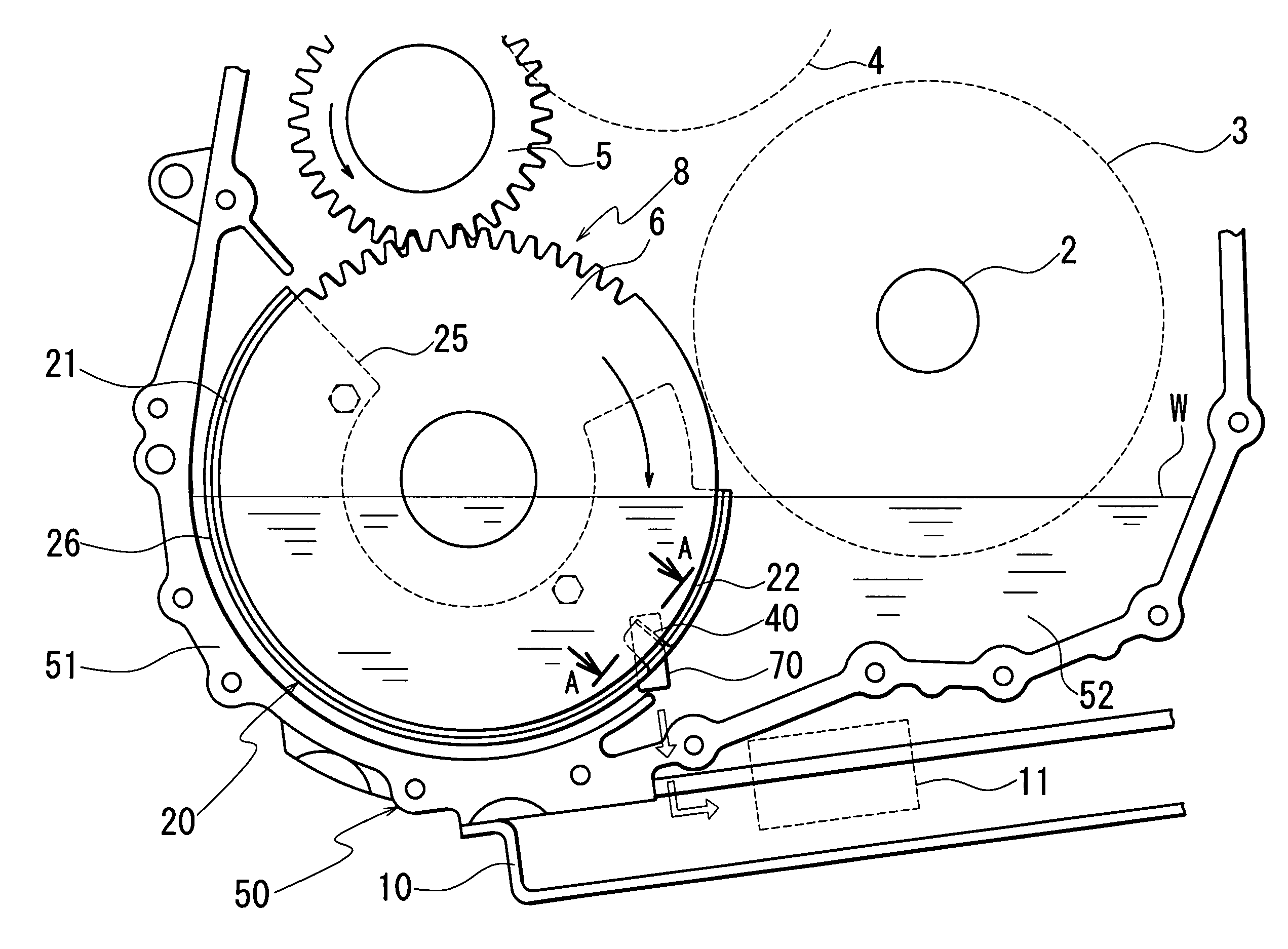

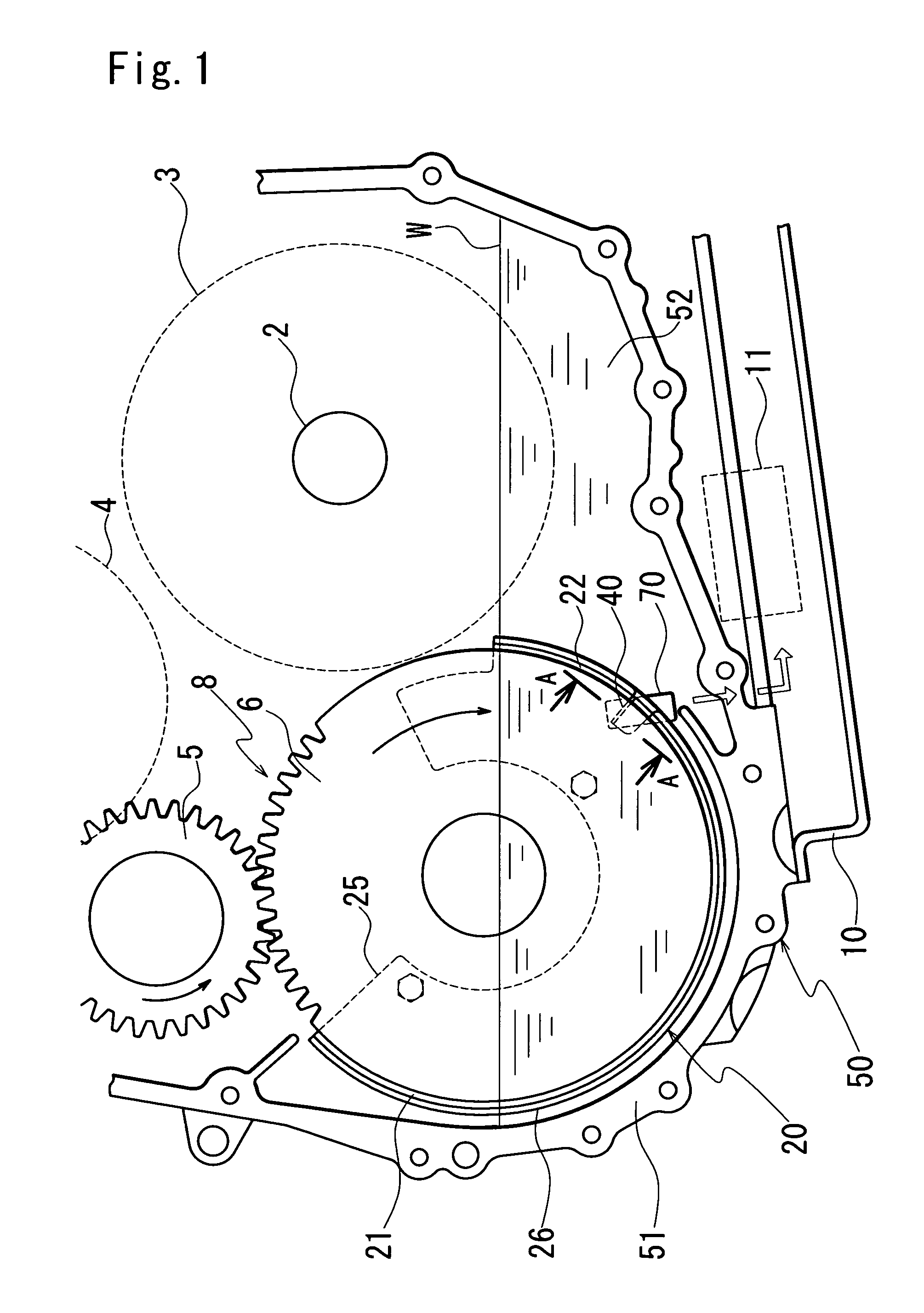

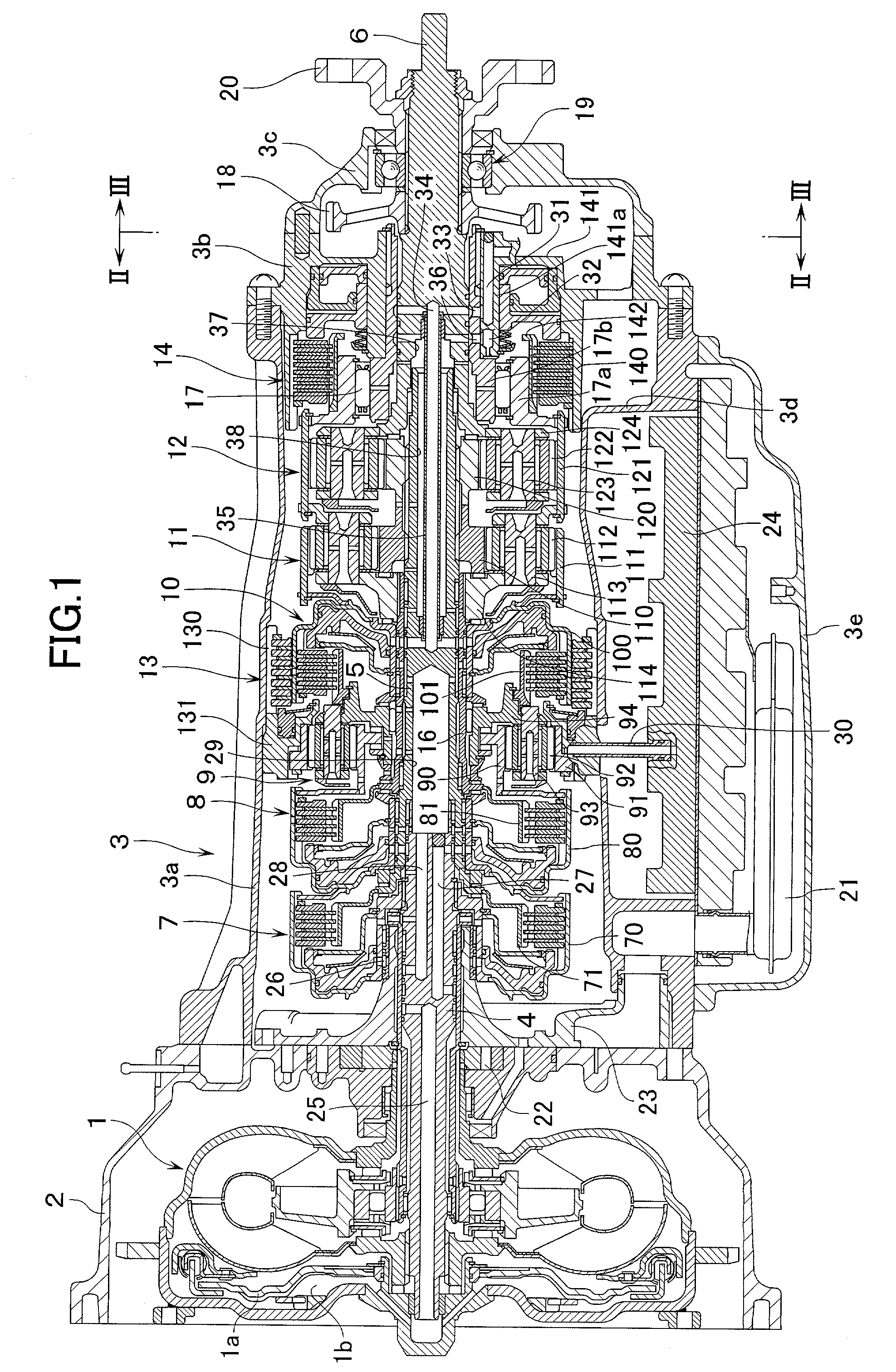

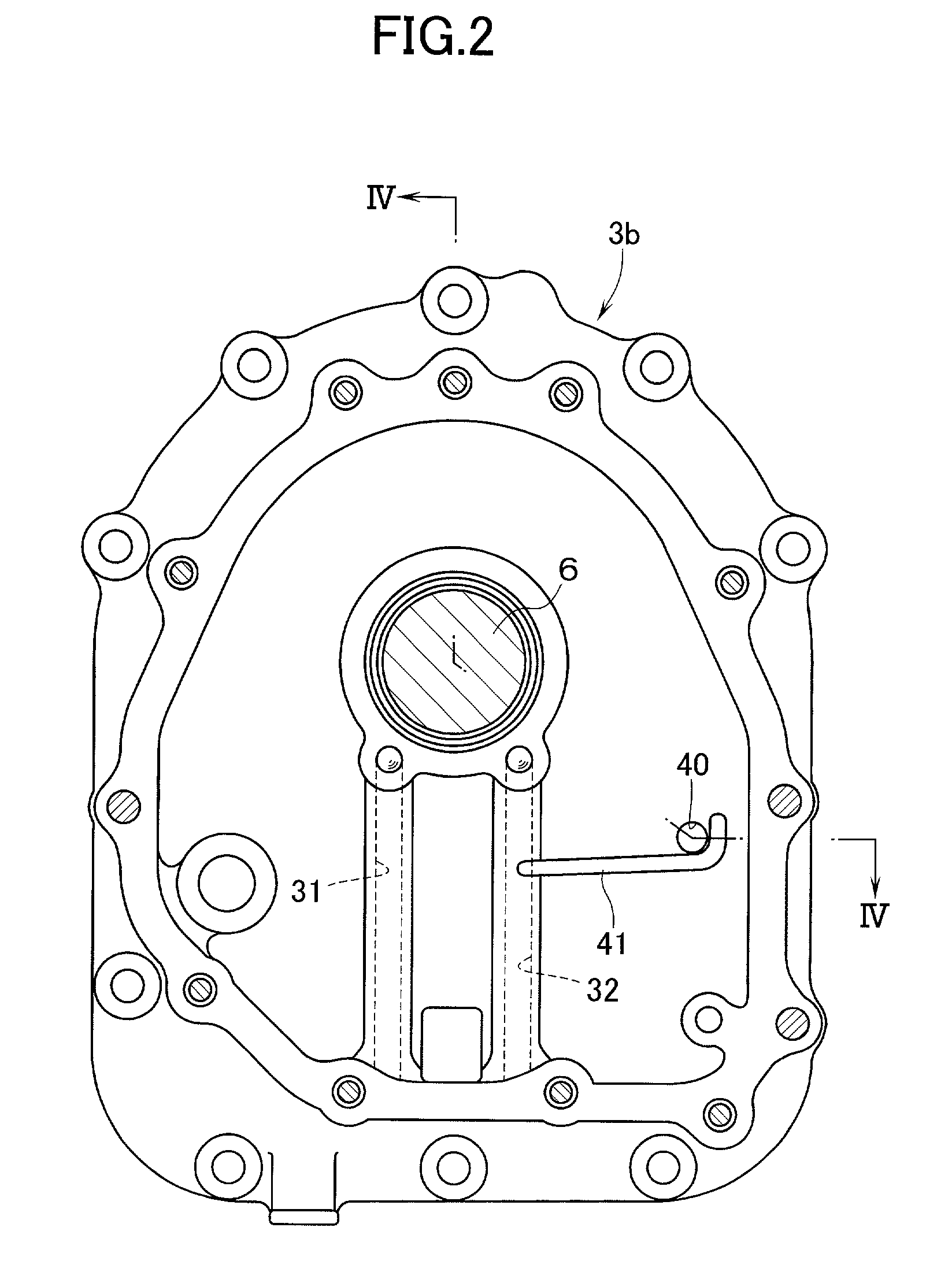

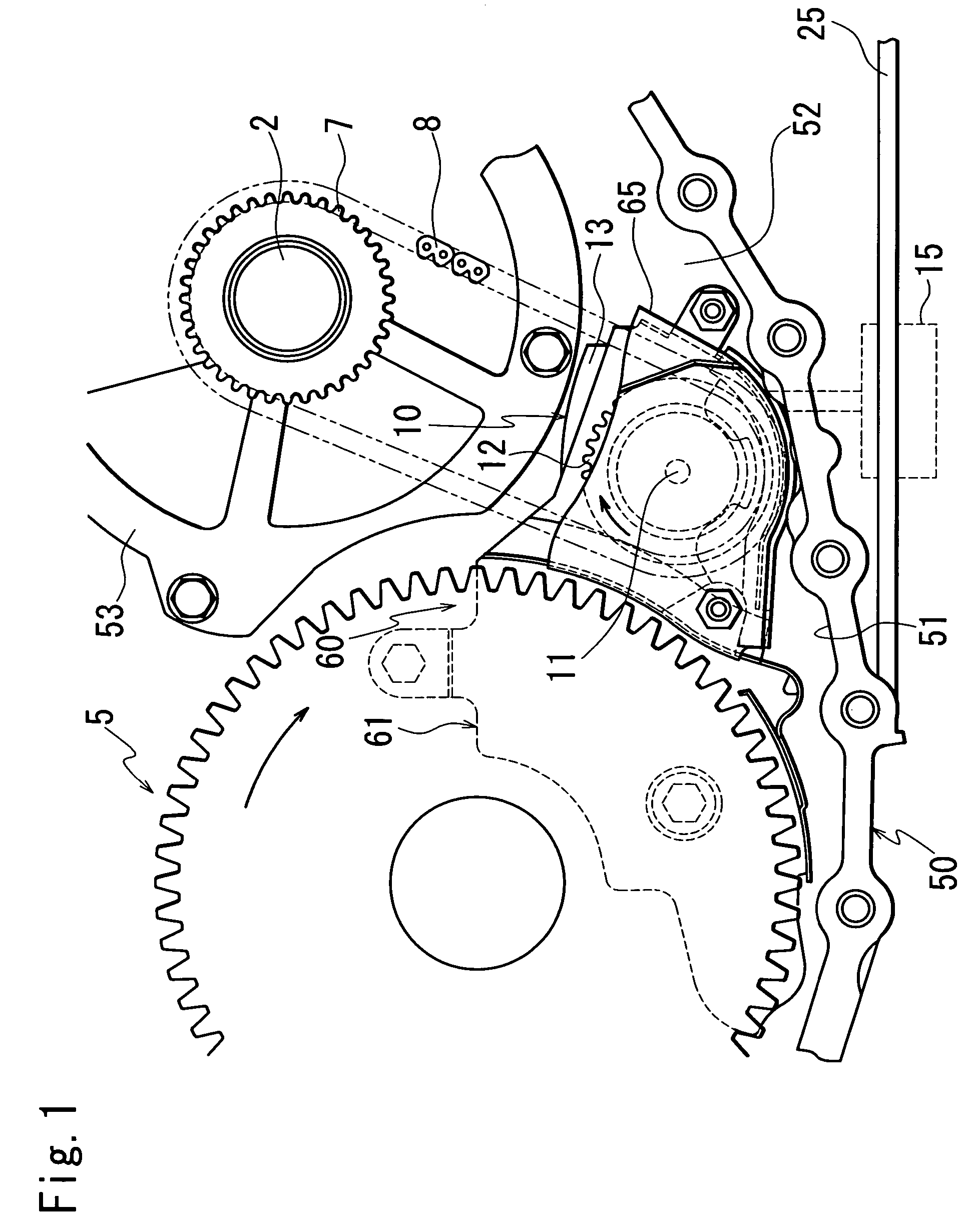

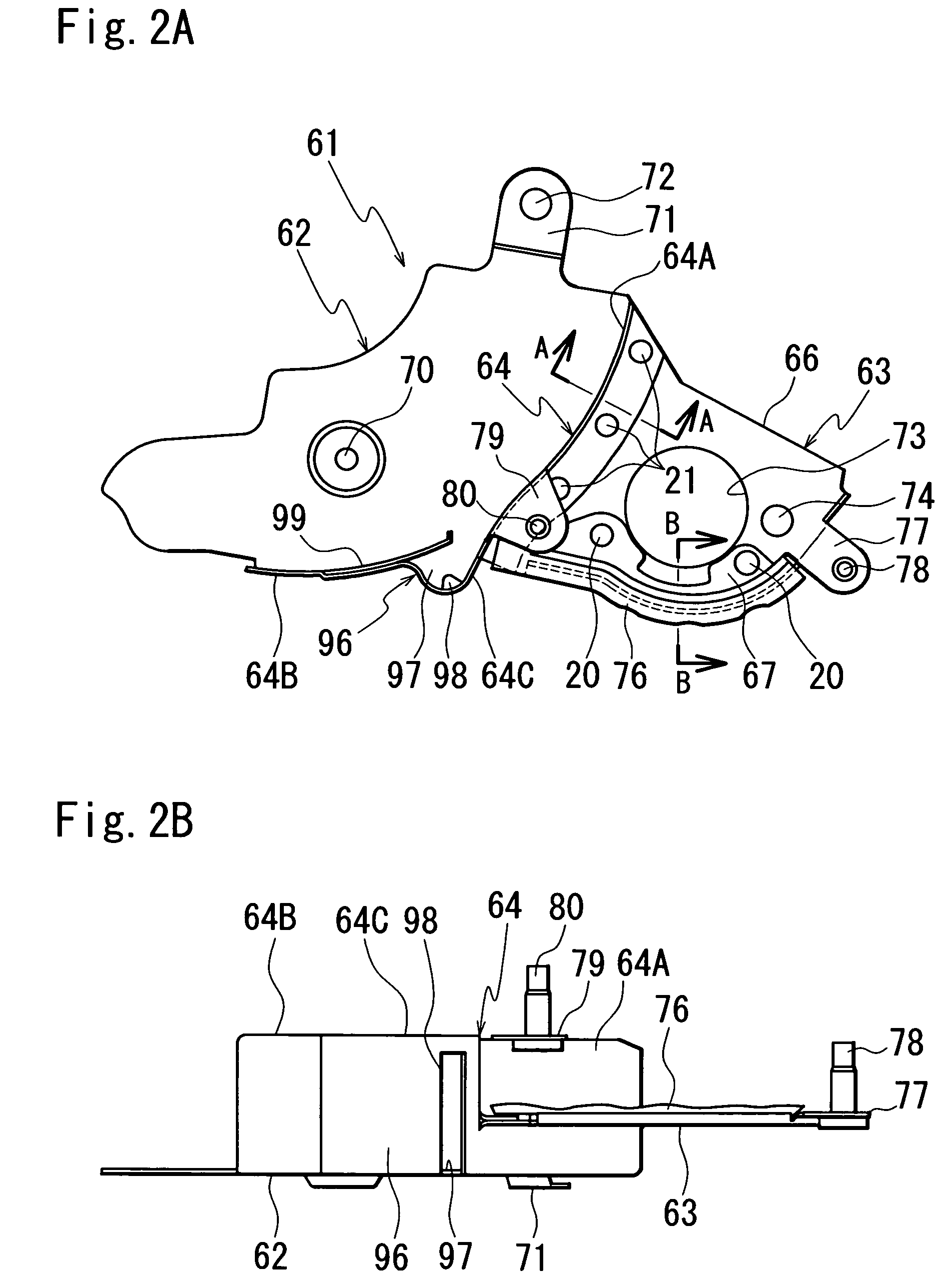

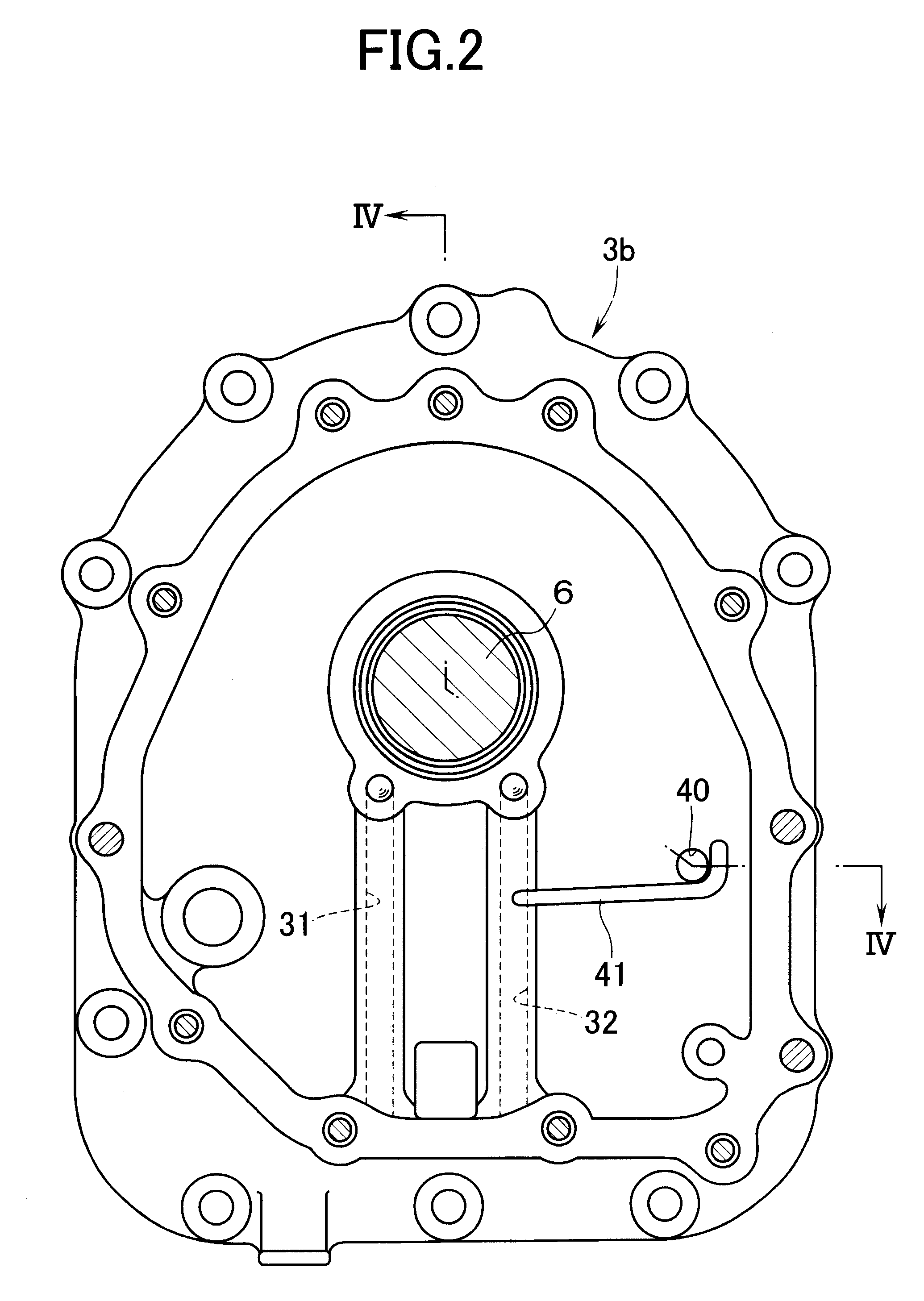

Oil discharge structure of baffle plate

An oil discharge structure of a baffle plate for discharging oil from a space of a gear side to a space of a transmission side with a space-saving design is provided. A slit is formed in a side face plate facing a final gear of a case side baffle plate to discharge the oil from an oil volume X in the circumference of the final gear to an oil volume Y stored in a clearance between the case side baffle plate and the transmission case, and in a clearance between the housing side baffle plate and the housing. This provides a compact structure that is not larger in a radial direction of the final gear and discharges the oil in the oil volume X.

Owner:JATCO LTD

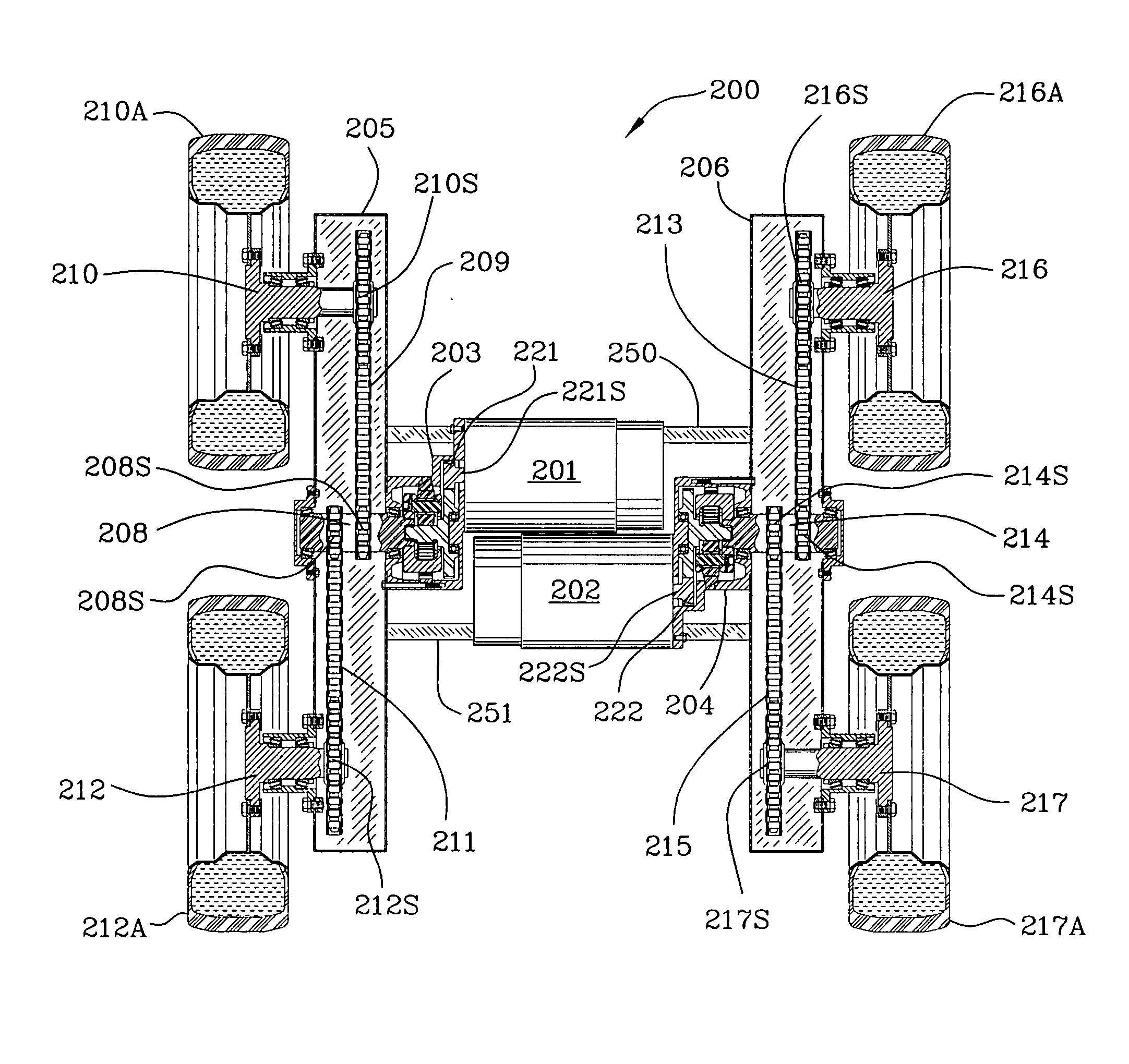

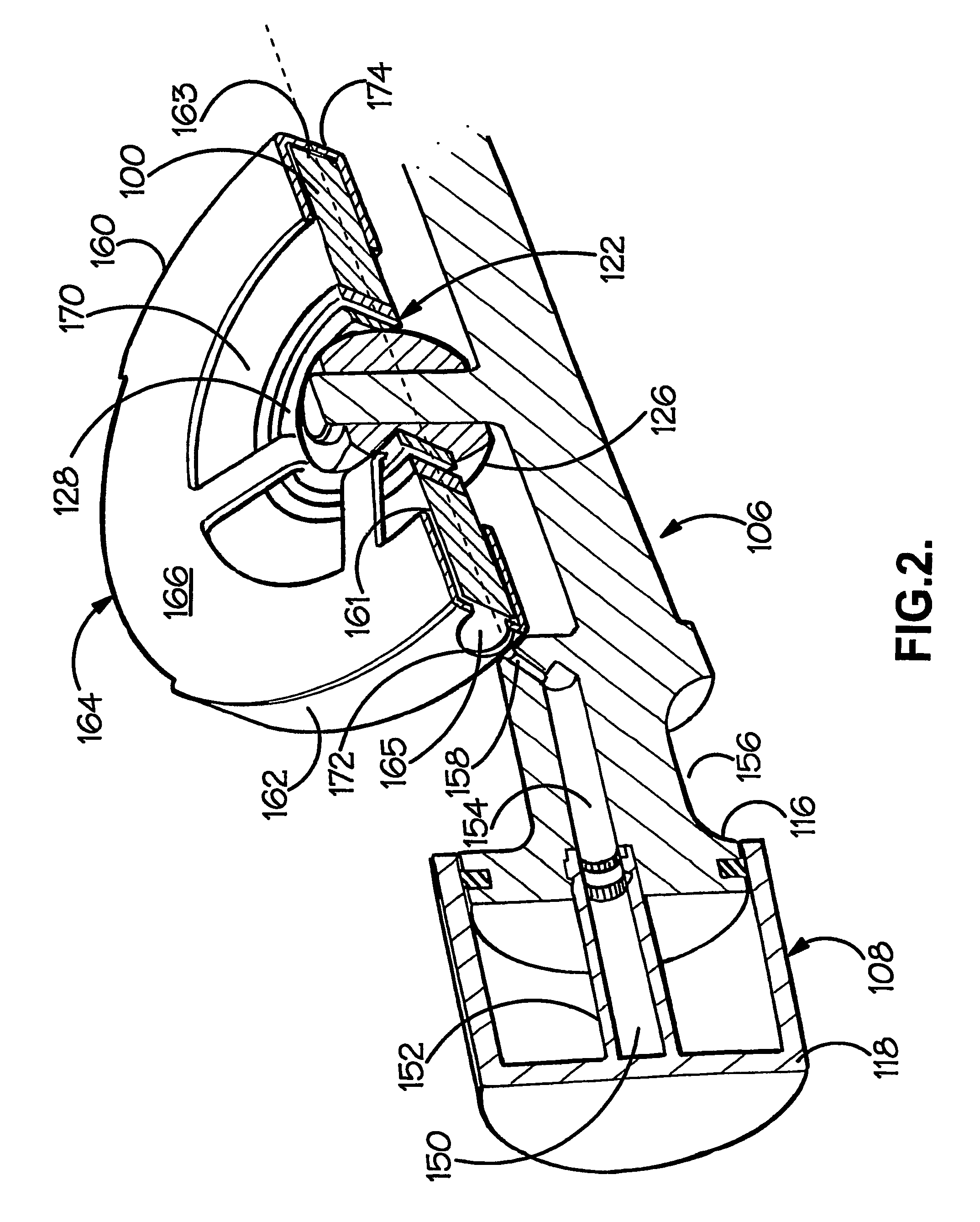

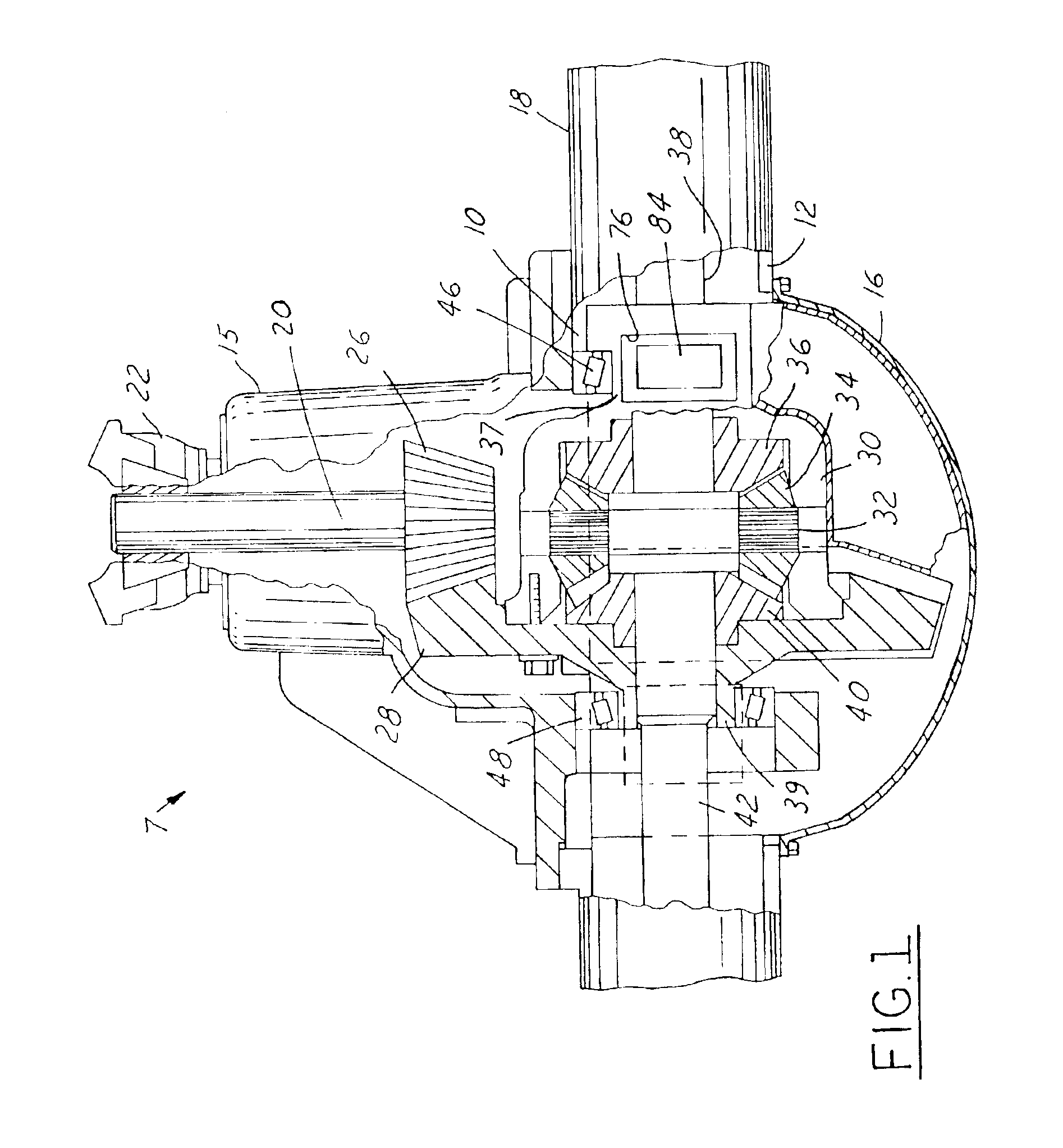

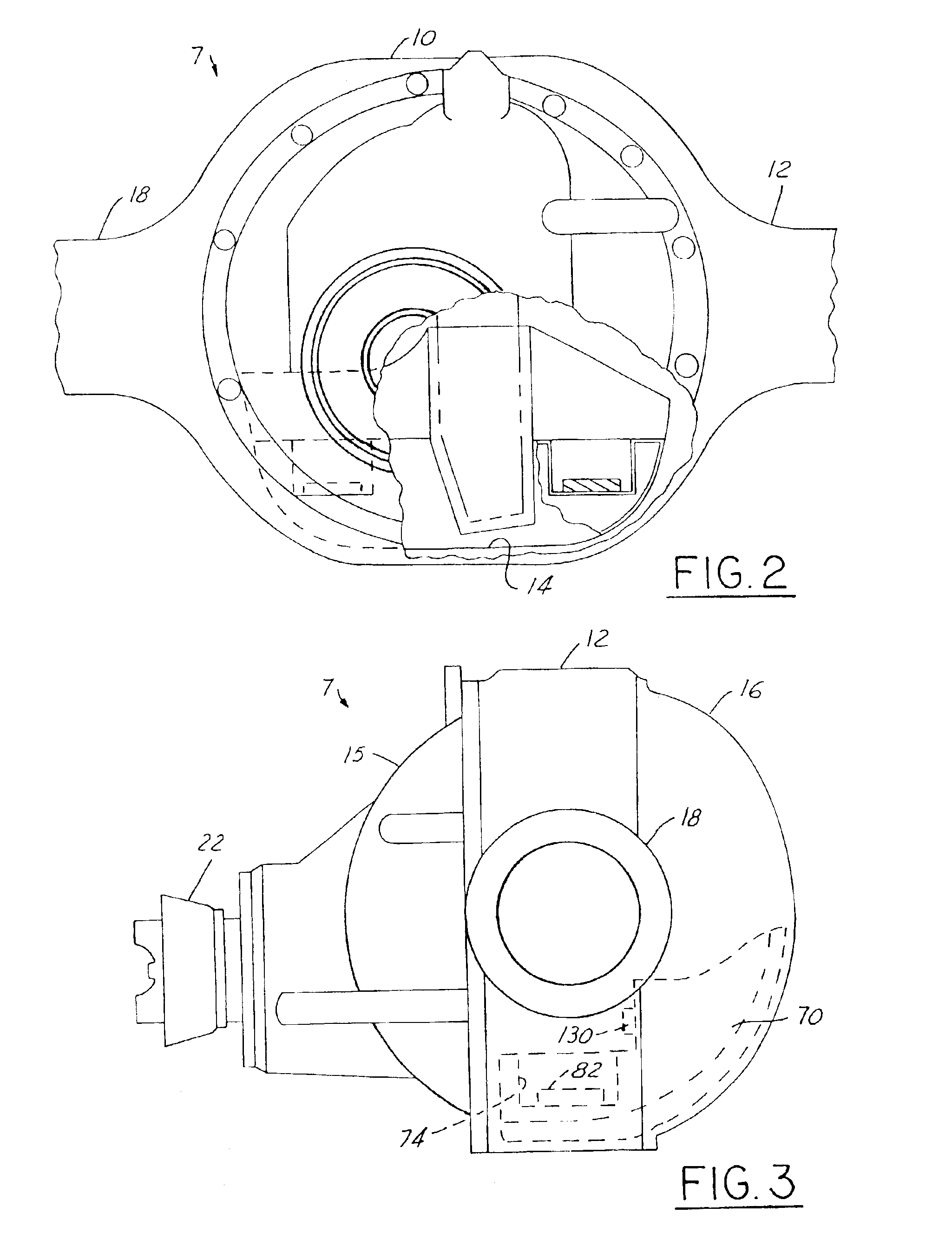

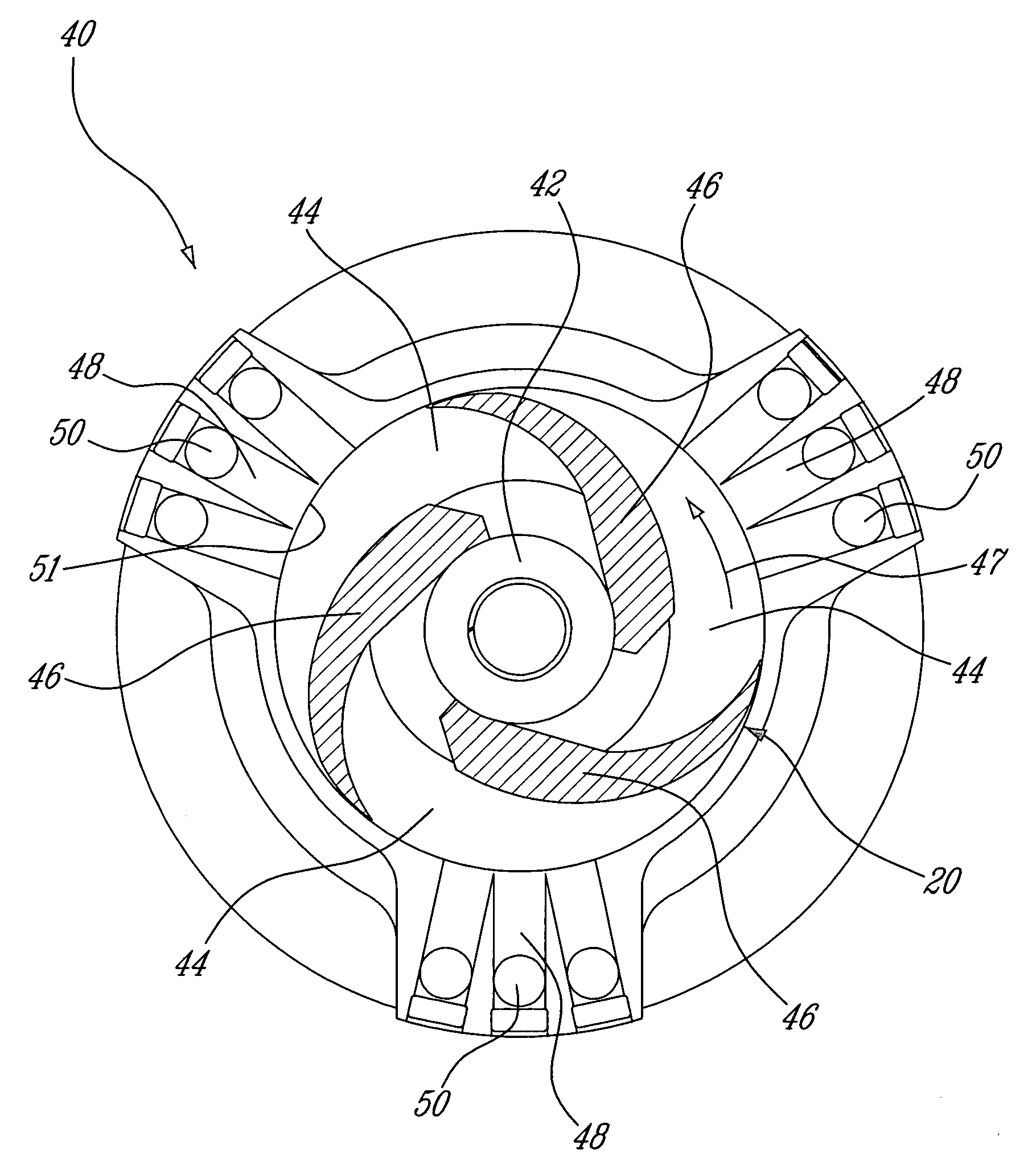

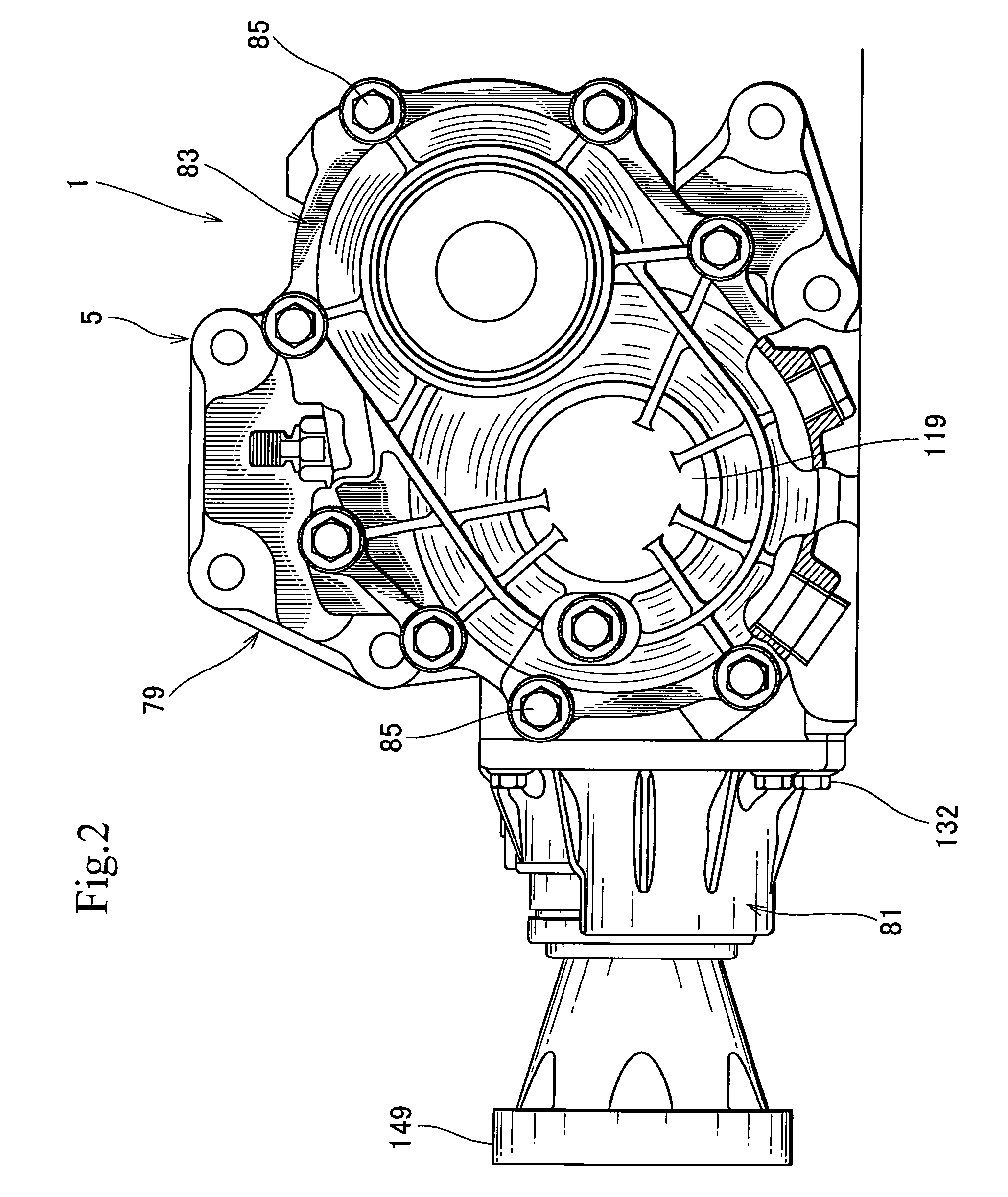

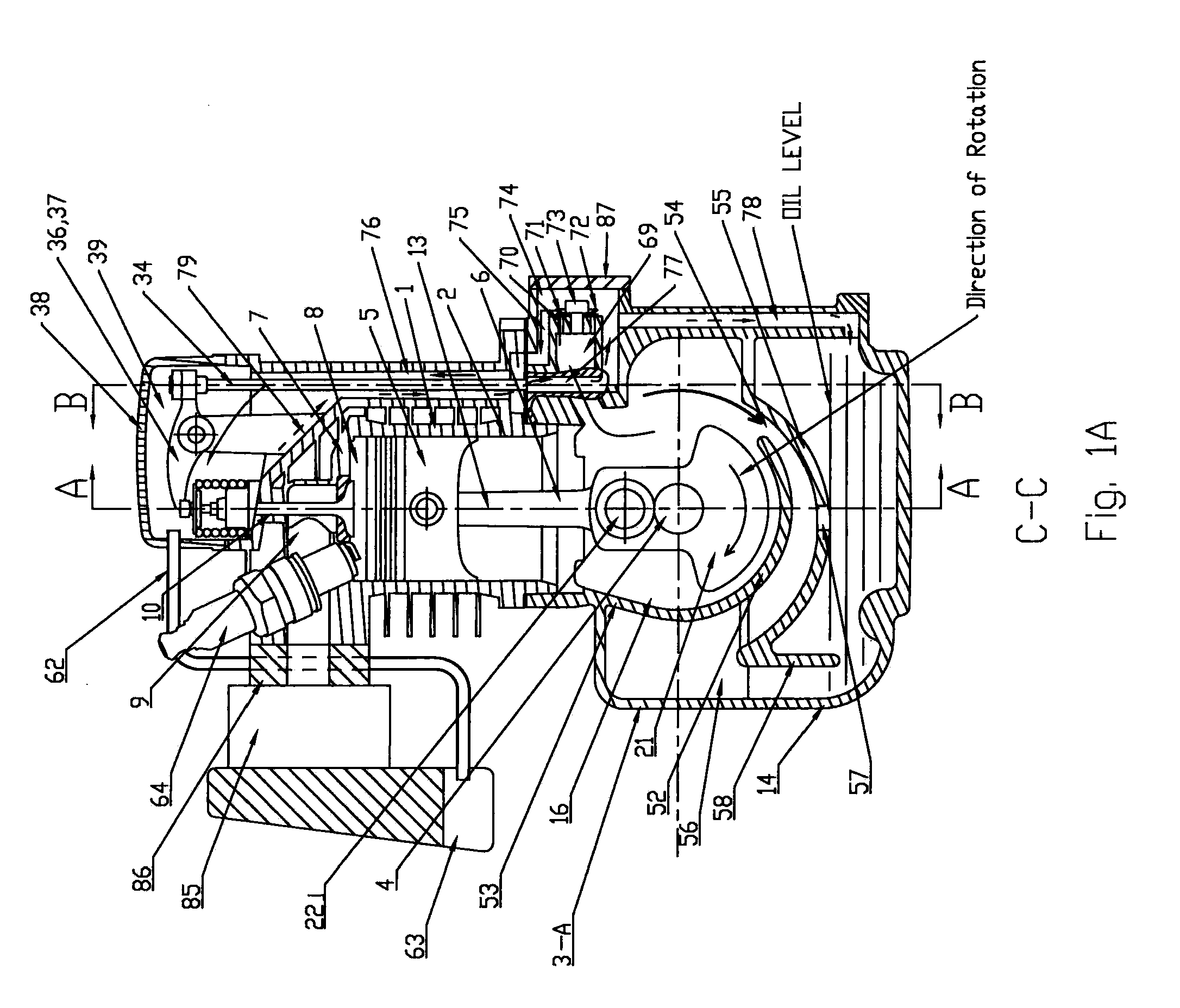

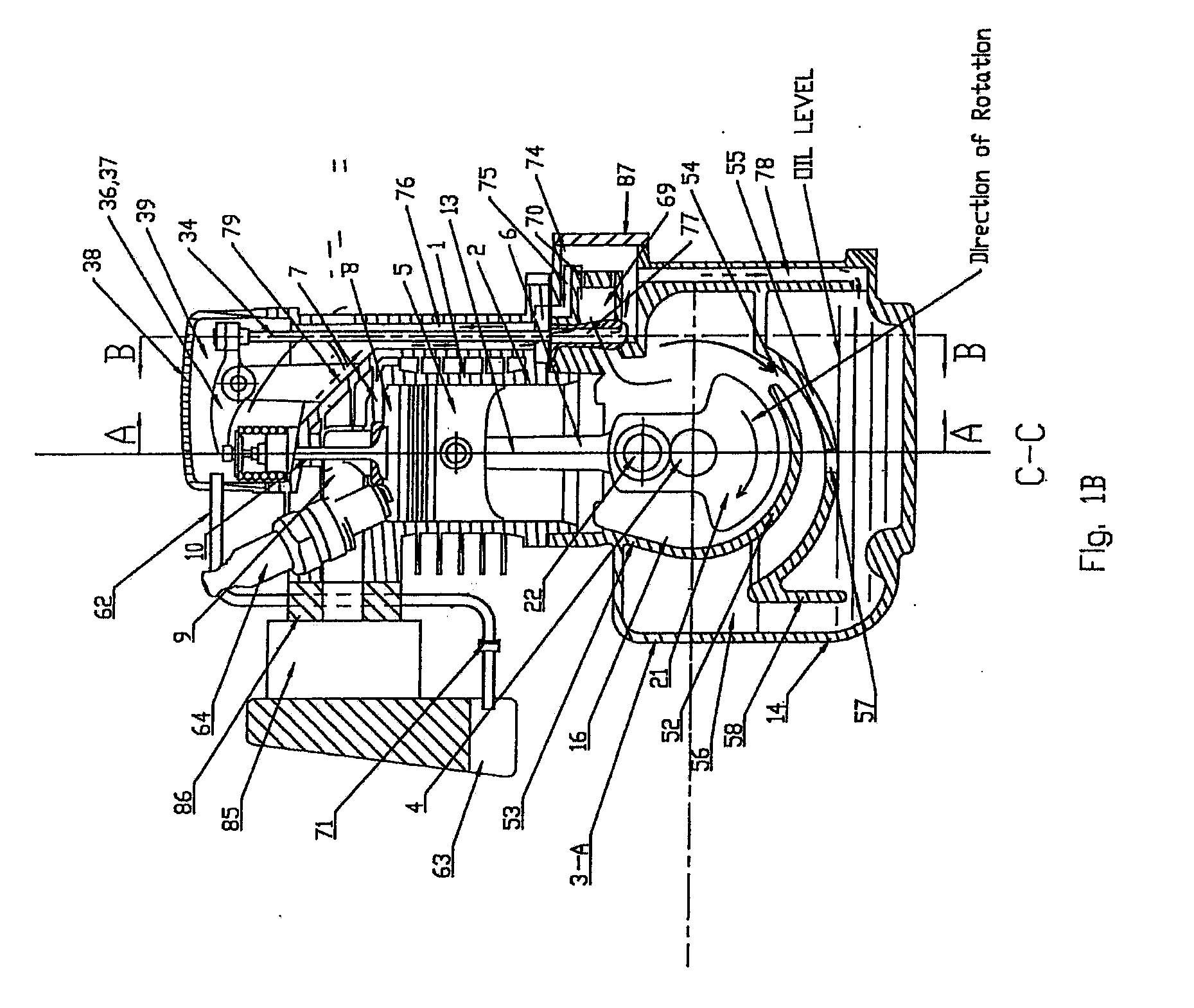

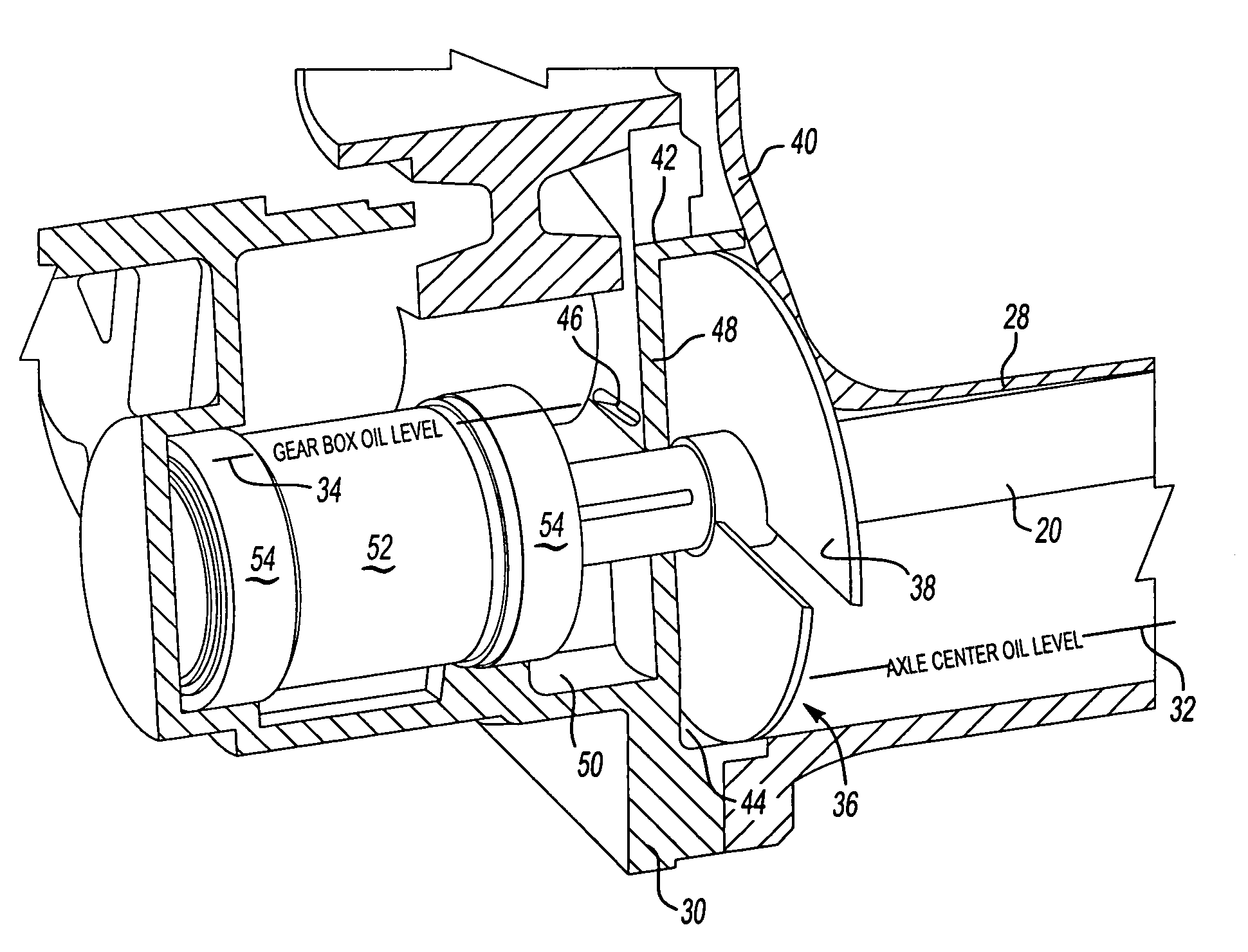

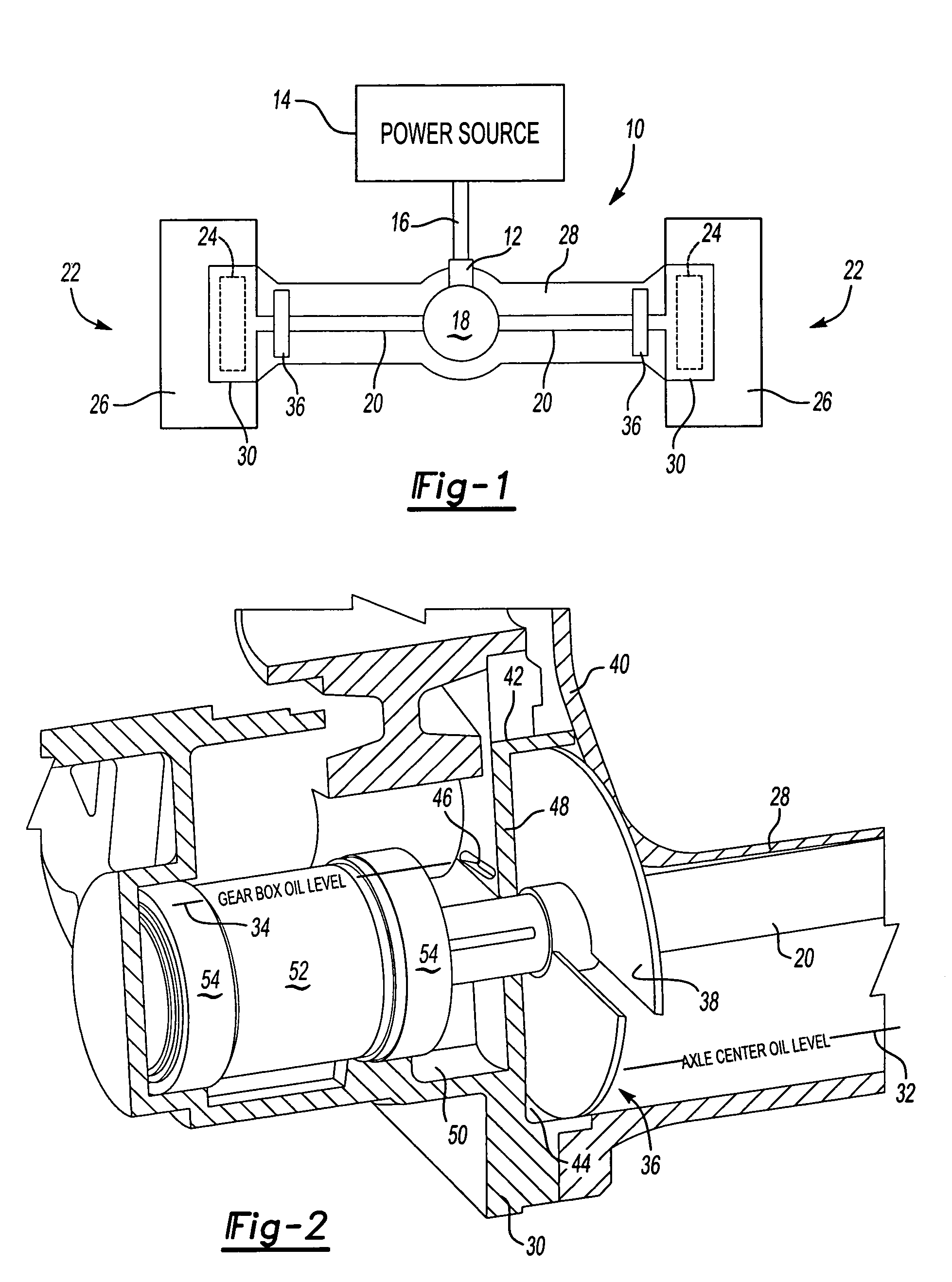

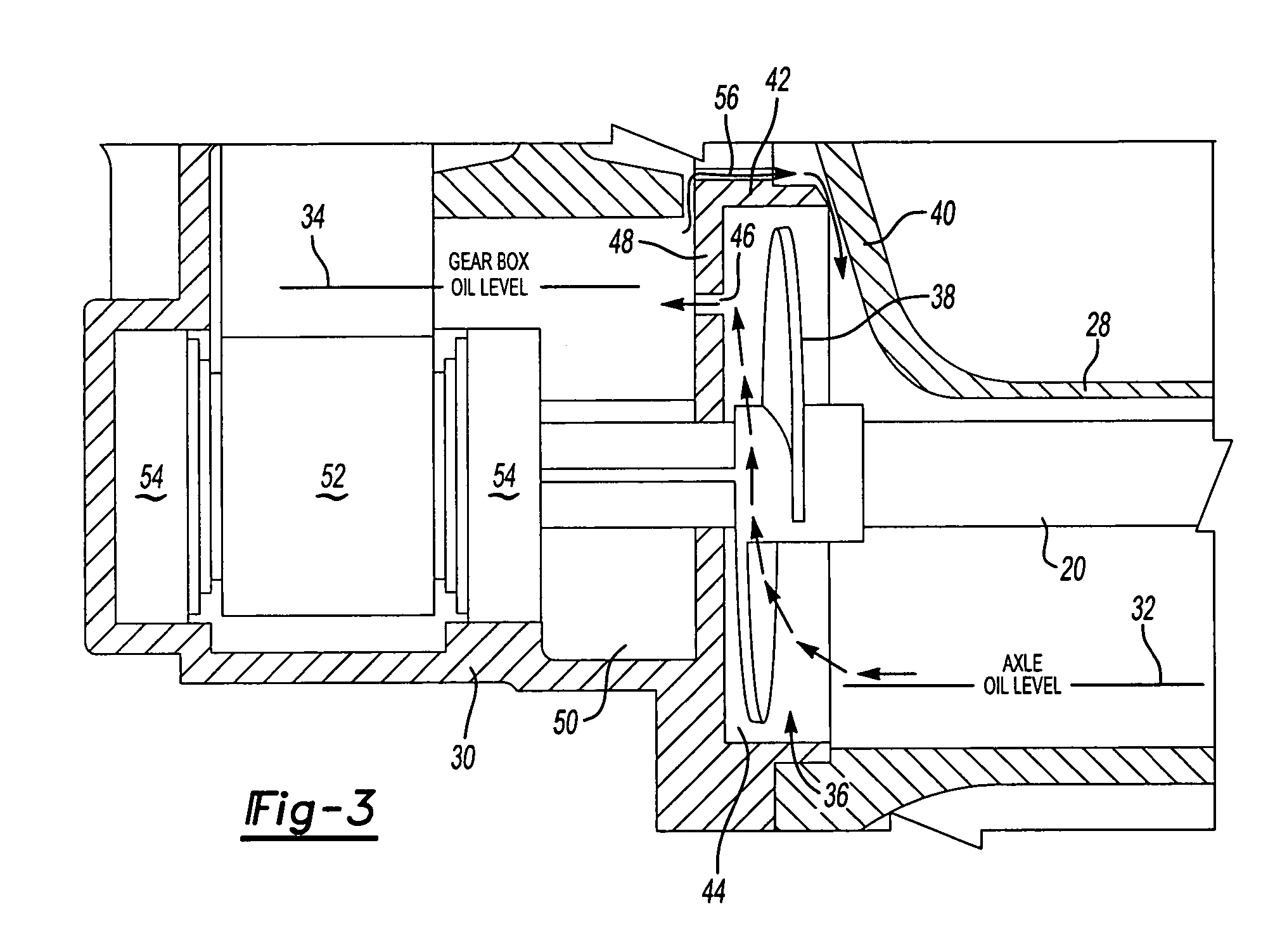

Lubrication system for right-angle drives used with utility vehicles

ActiveUS20080230289A1Closely spacedMinimizes numberDrip or splash lubricationElectric propulsion mountingReducerEngineering

A bearing lubrication device in a right angle gear reducer includes a gear housing having an interior portion and a lubricating fluid reservoir therein. An oil slinger, rotating pinion shaft, pinion shaft housing, and bearings for supporting the pinion shaft within the pinion shaft housing work together to provide a continuous supply of oil to the bearings. The pinion shaft includes two radially and longitudinally extending passageways therethrough which supply oil from a recess in one end of the pinion shaft to the bearings. Oil is slung from the reservoir into the recess of the rotating pinion shaft where it is forced outwardly and through the passageways to a chamber formed by the rotating pinion shaft, shaft housing and bearings. The roller bearings pump the oil from the chamber back to the fluid reservoir. Oil passageways in the shaft housing enable the return of oil from one bearing set.

Owner:FAIRFIELD MFG CO INC

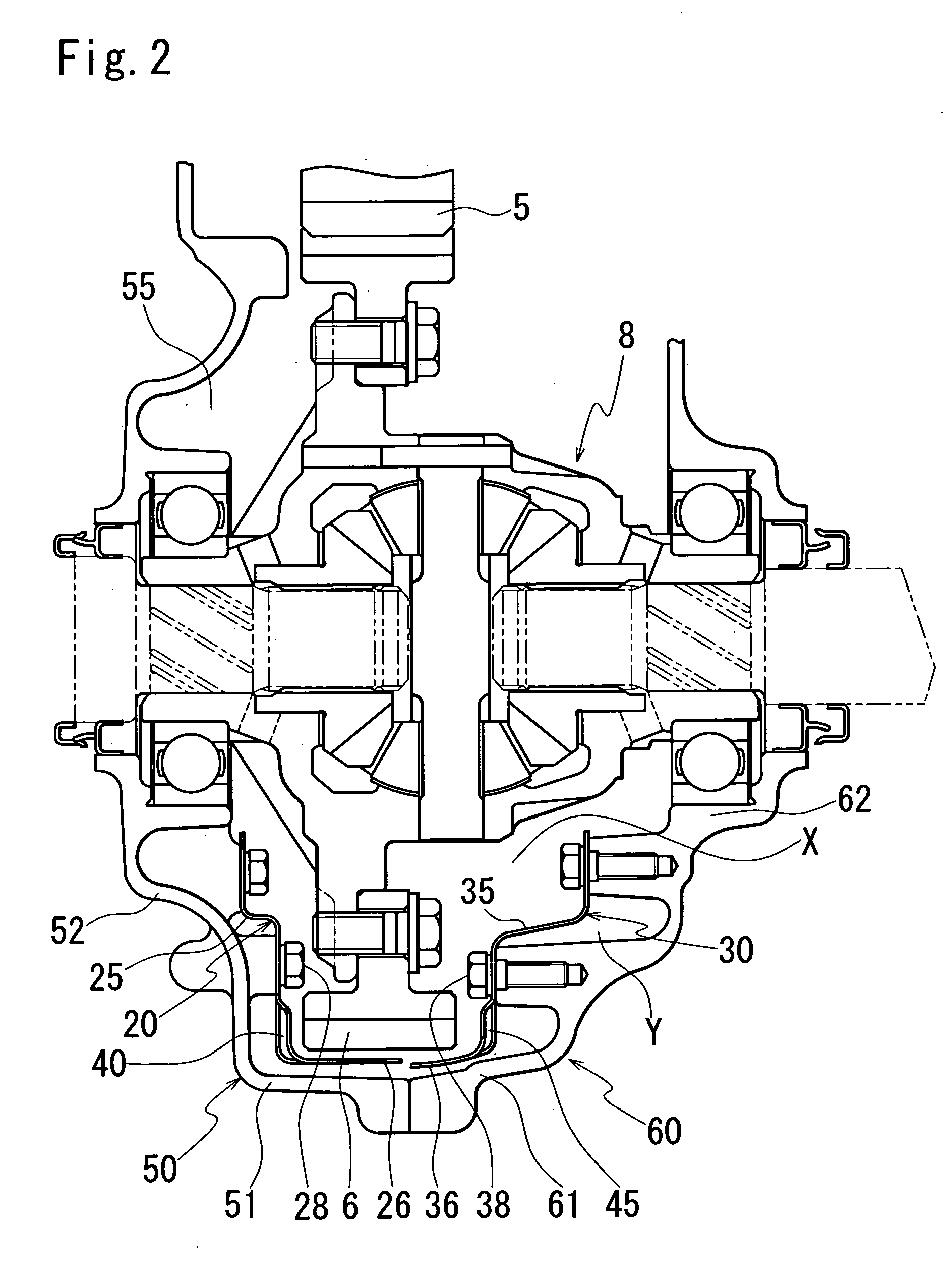

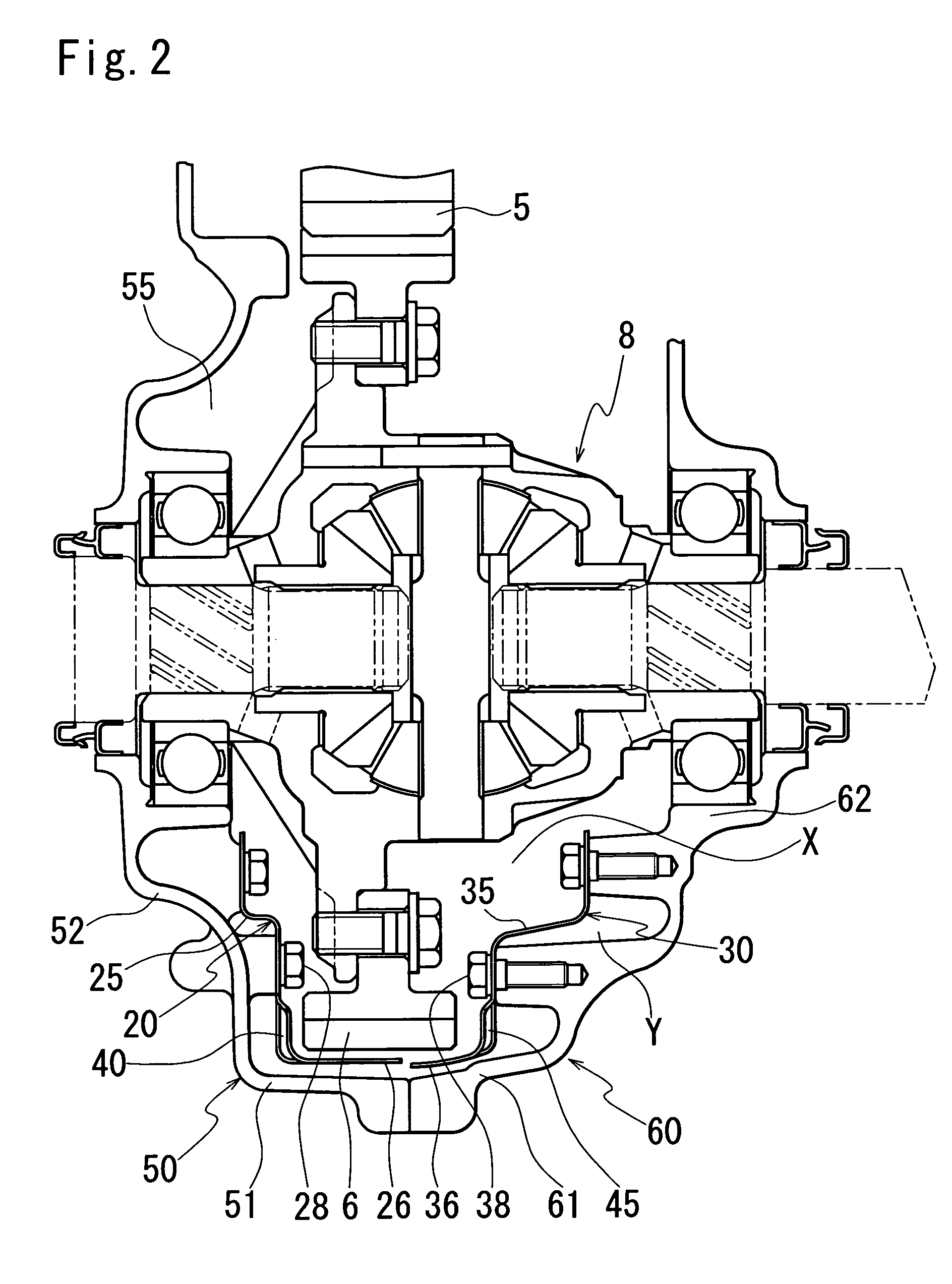

Oil discharge structure of baffle plate

ActiveUS7984791B2Reduce friction lossReduce the amount requiredGearboxesDrip or splash lubricationGear wheelEngineering

An oil discharge structure of a baffle plate for discharging oil from a space of a gear side to a space of a transmission side with a space-saving design is provided. A slit is formed in a side face plate facing a final gear of a case side baffle plate to discharge the oil from an oil volume X in the circumference of the final gear to an oil volume Y stored in a clearance between the case side baffle plate and the transmission case, and in a clearance between the housing side baffle plate and the housing. This provides a compact structure that is not larger in a radial direction of the final gear and discharges the oil in the oil volume X.

Owner:JATCO LTD

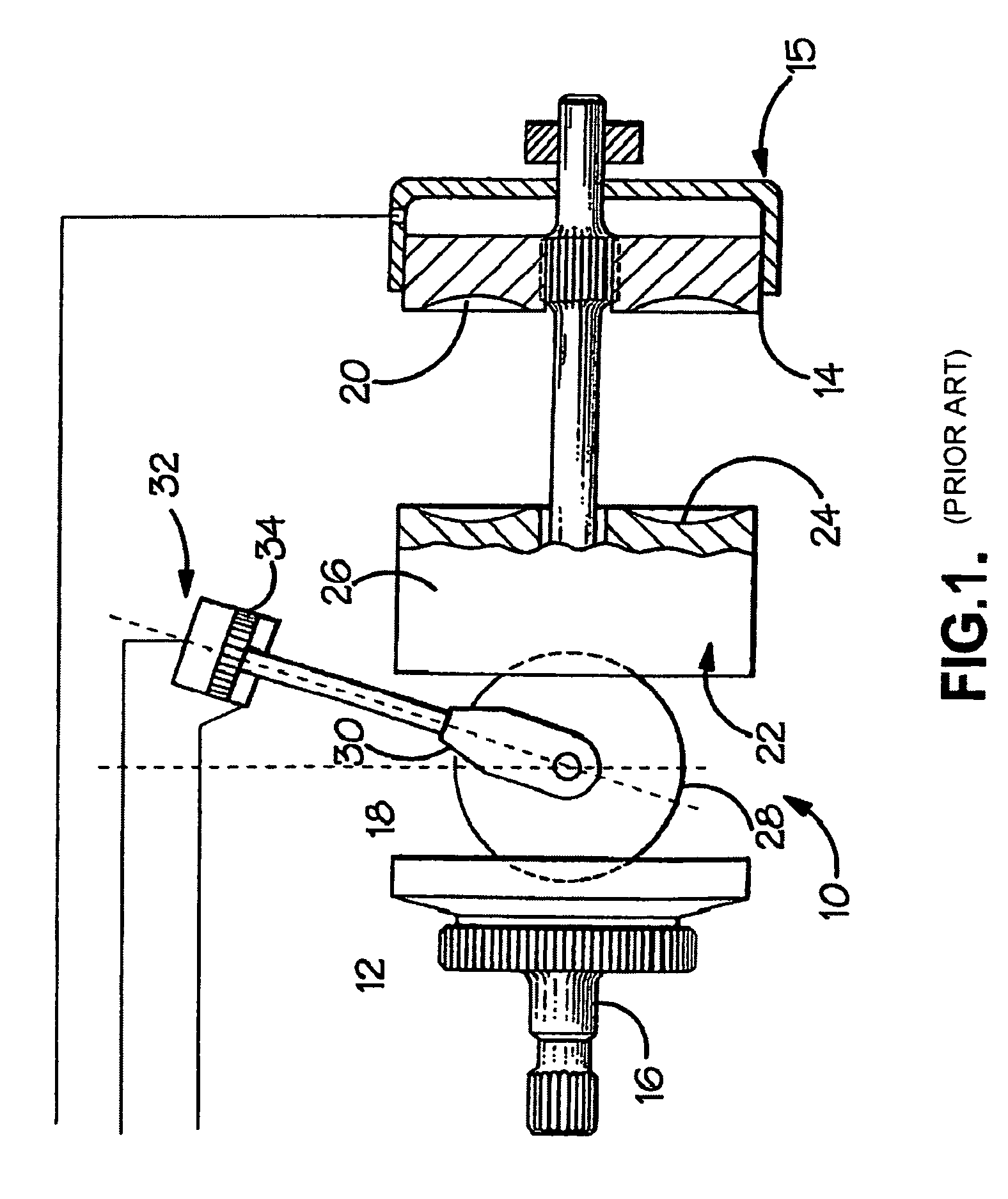

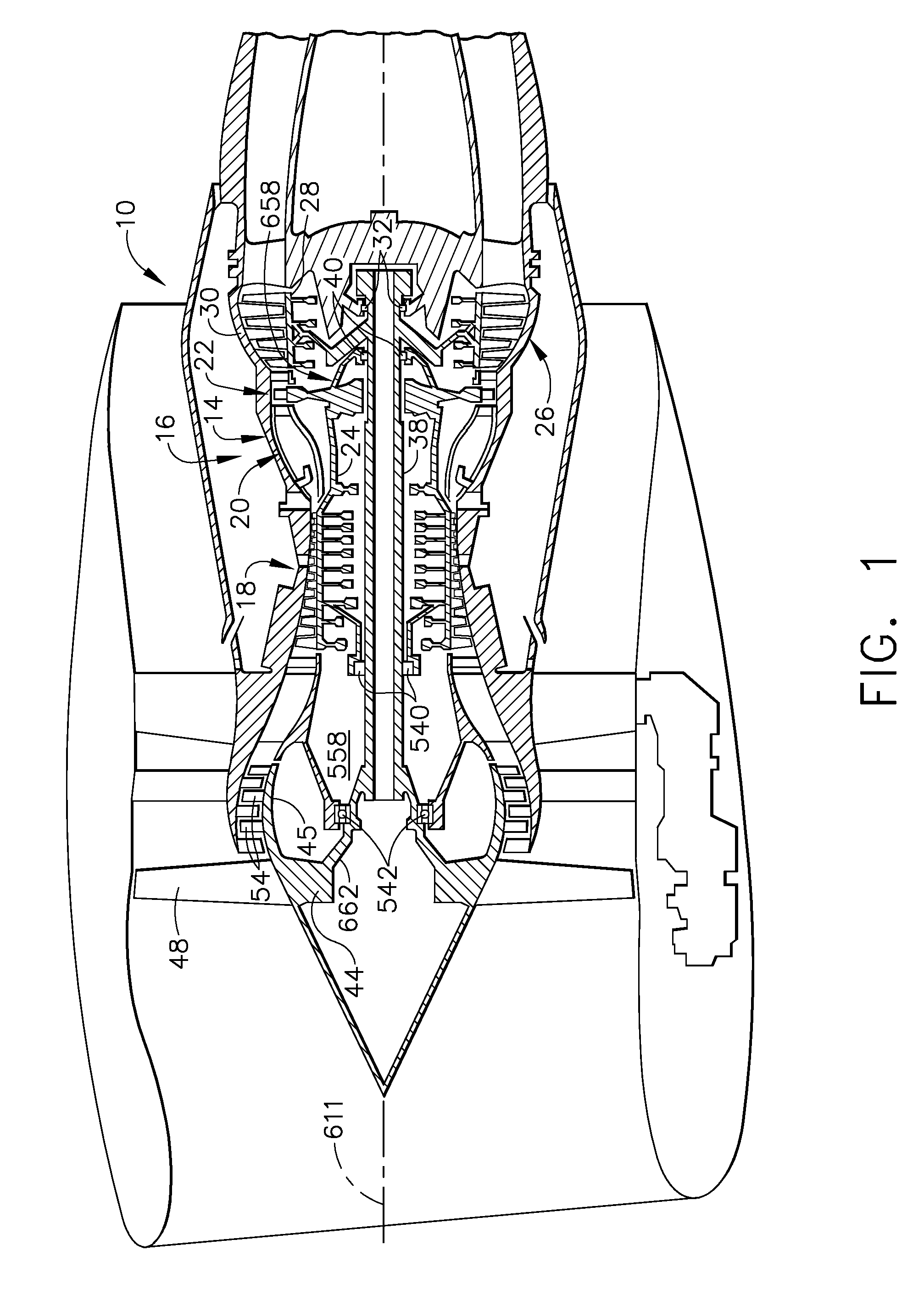

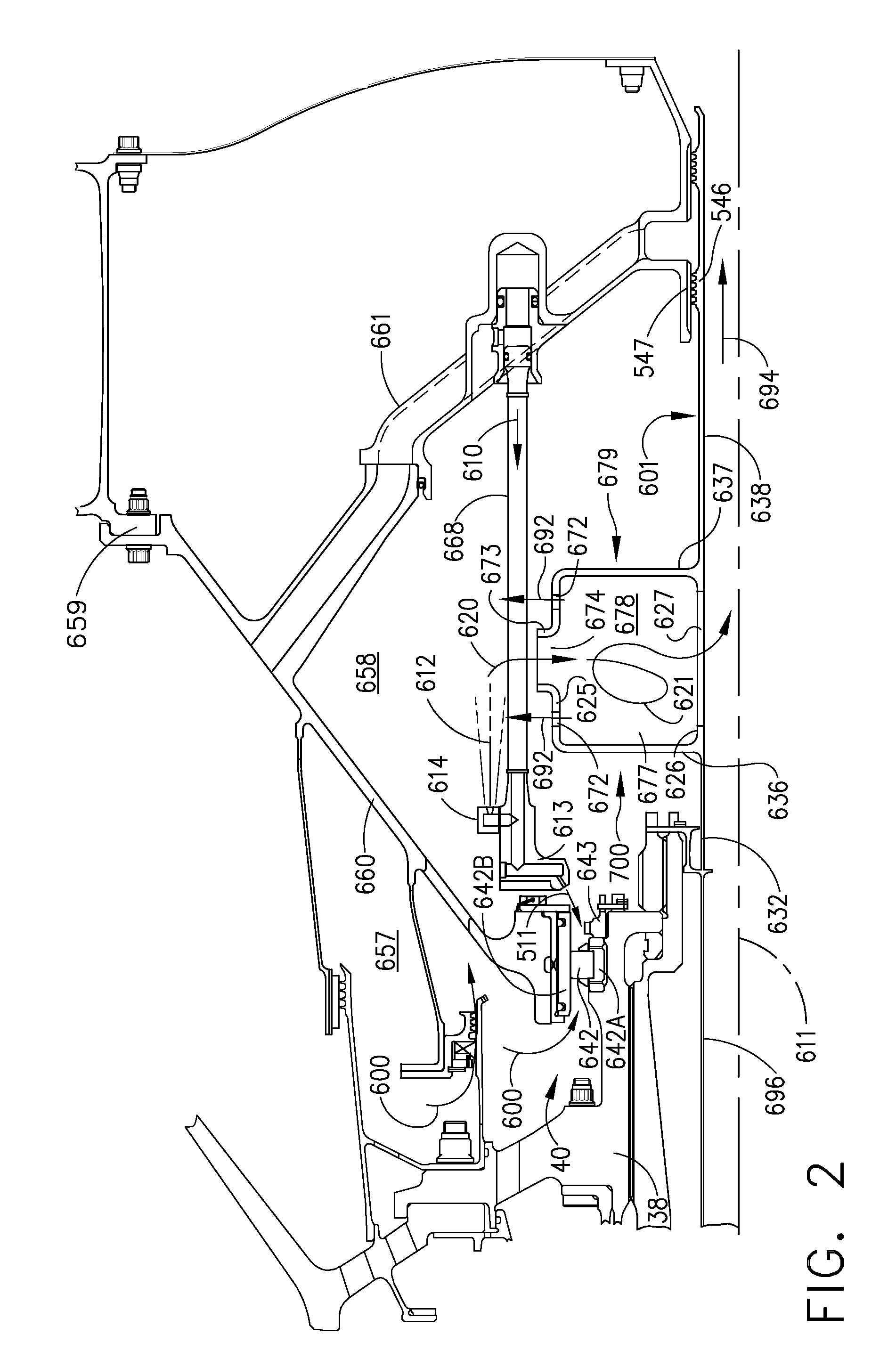

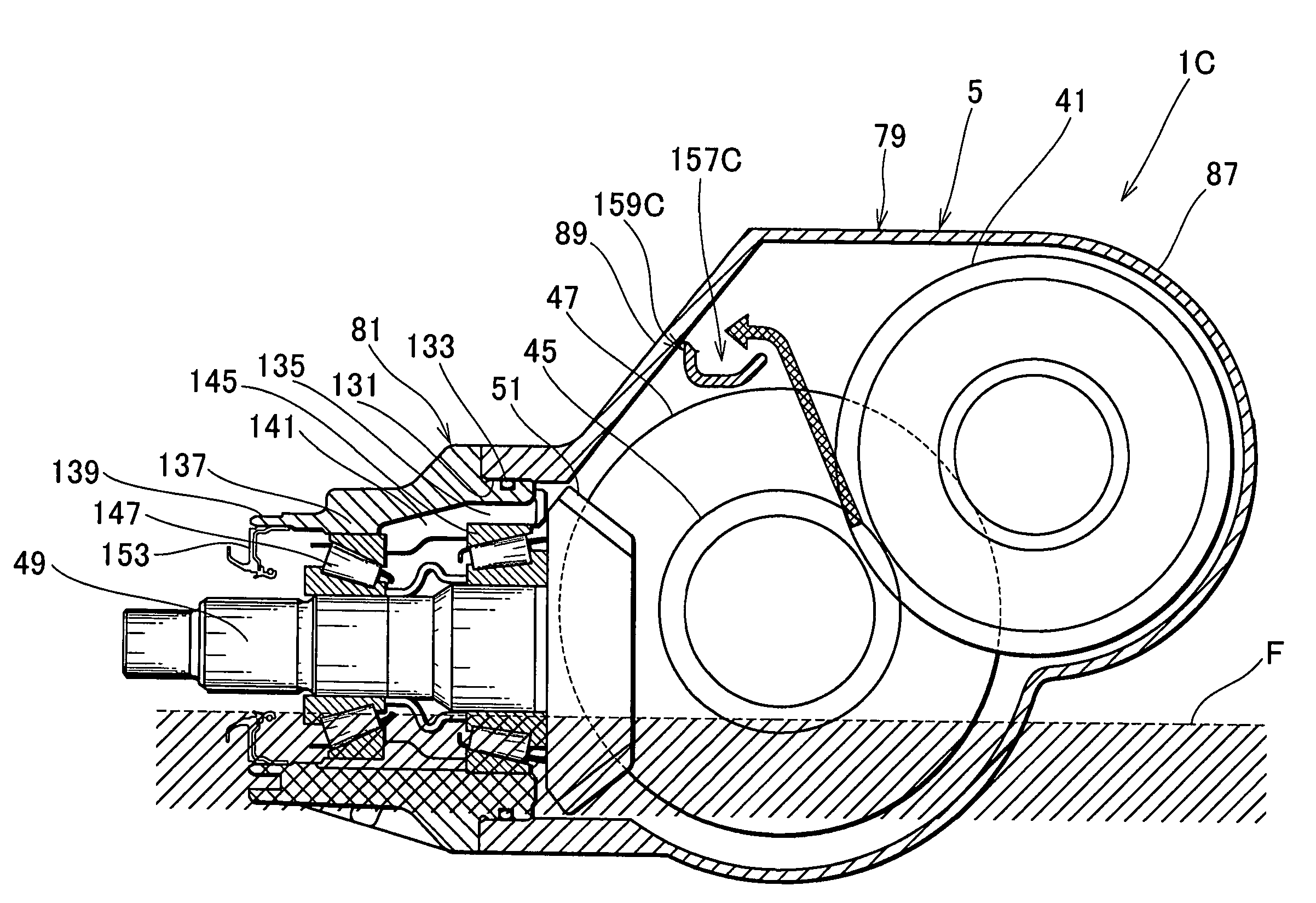

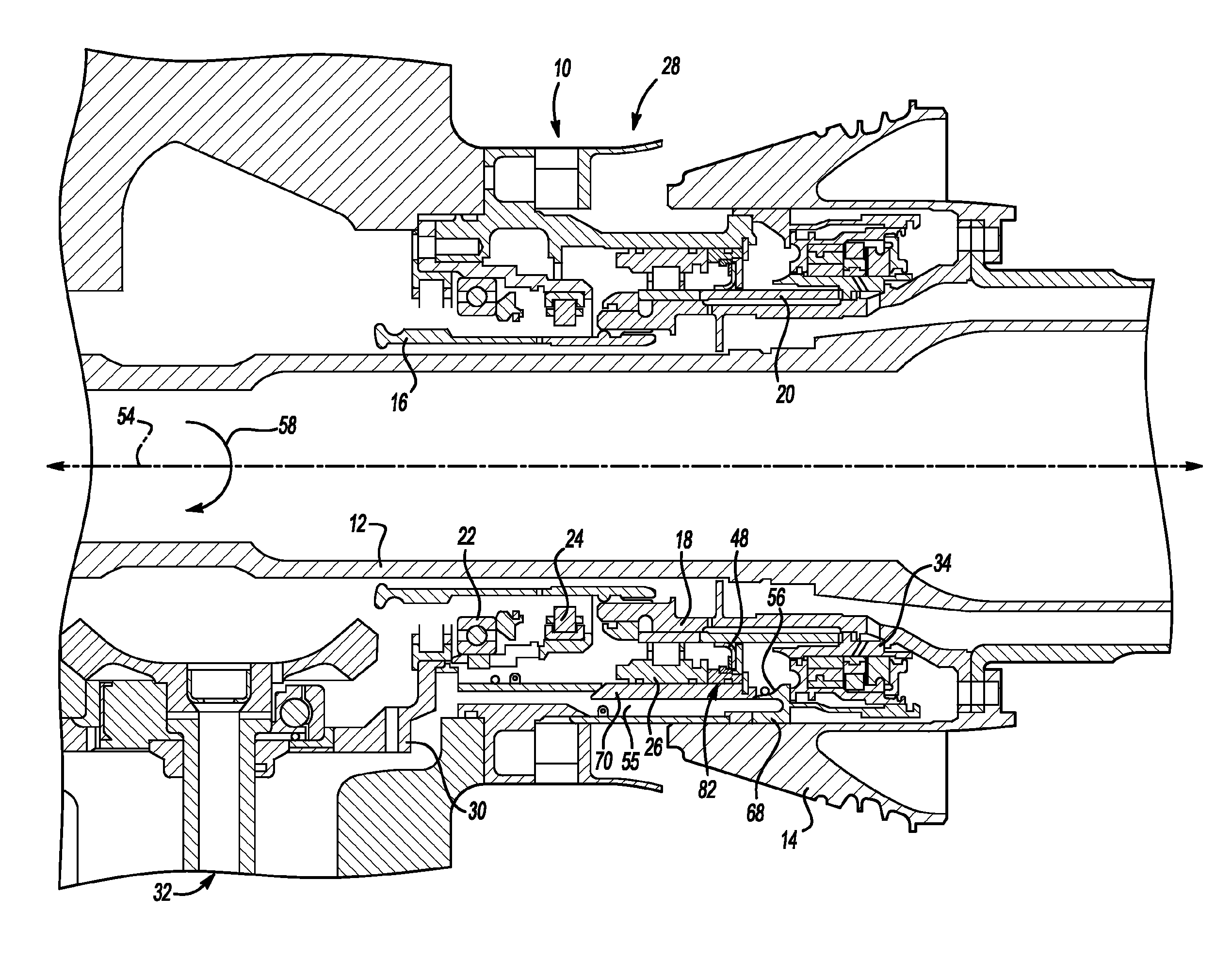

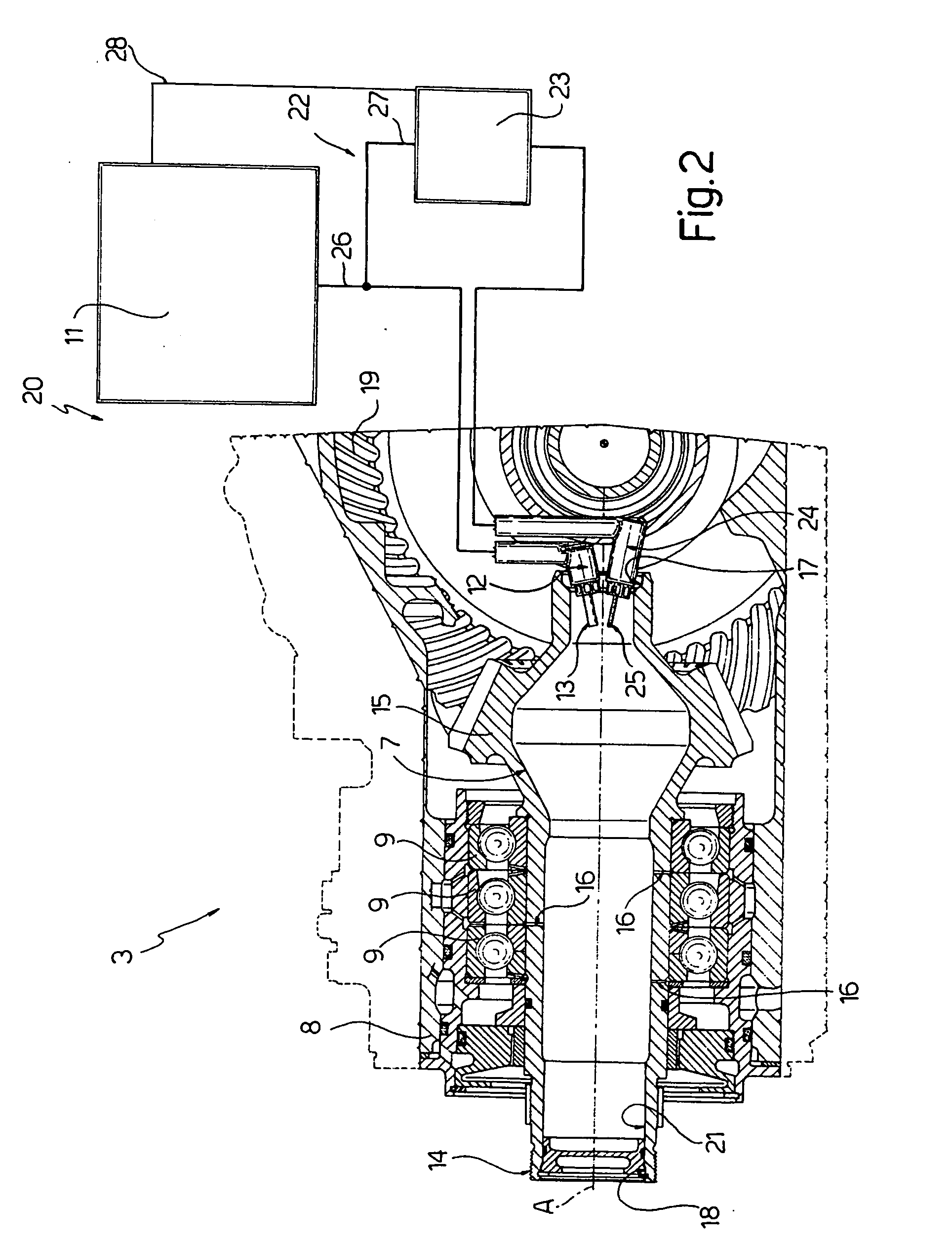

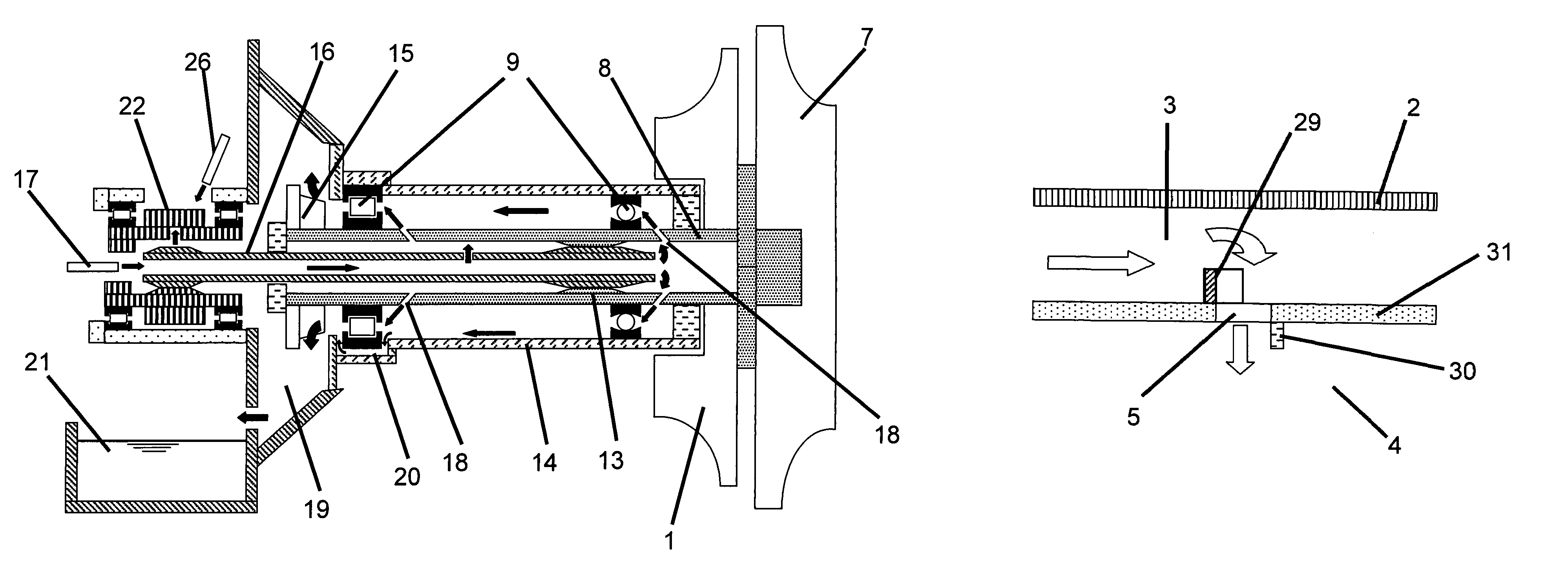

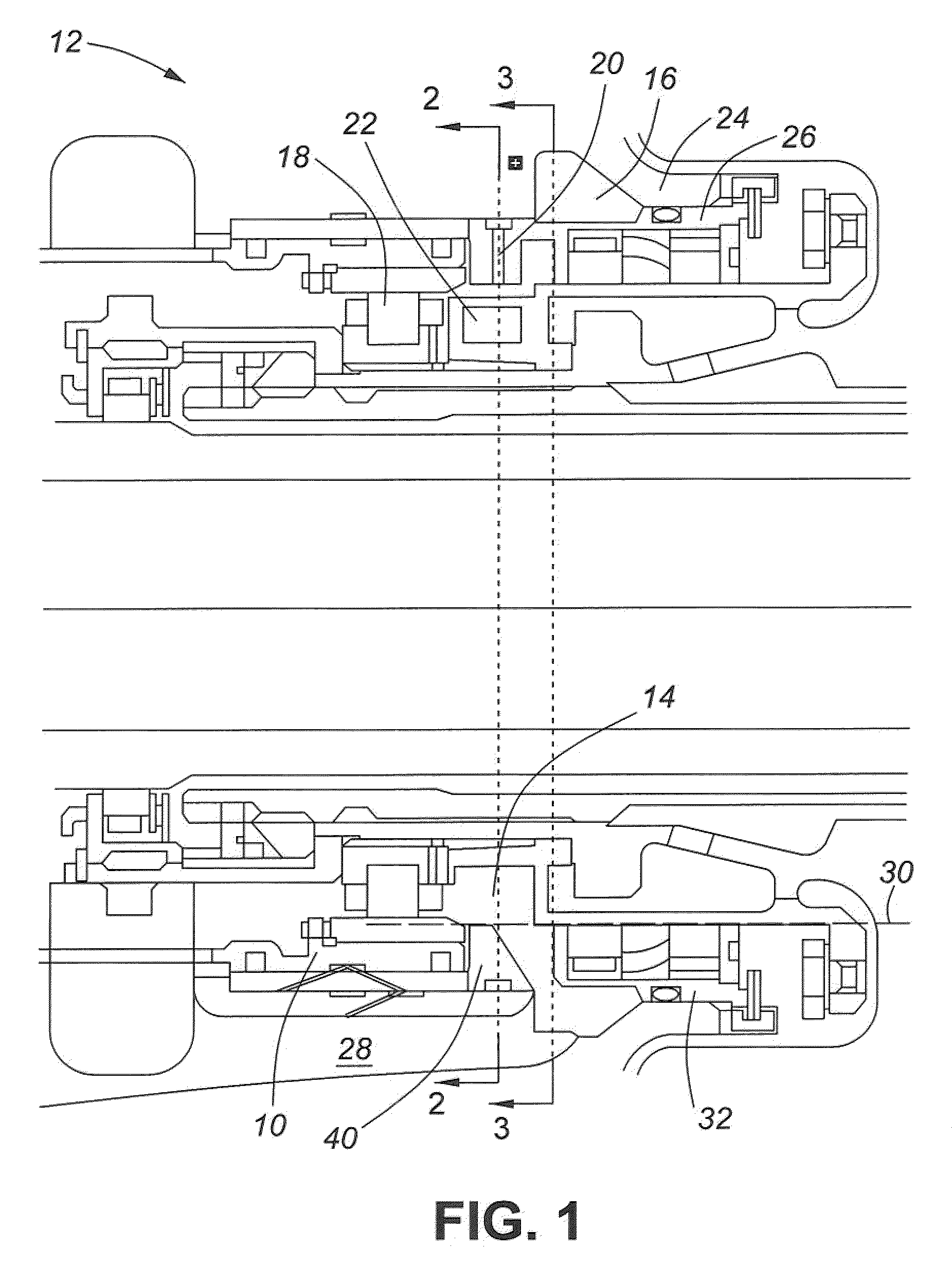

Fluid supply arrangement for a rolling-traction continuously variable ratio transmission unit

A fluid display arrangement is disclosed for a rolling-traction continuously-variable ratio transmission unit in which drive is transmitted from one race to another by at least one rotating roller whose outer circumference engages the races, the fluid supply arrangement comprising a shroud mounted in proximity to the roller and a fluid supply conduit, and being characterised in that the shroud has an inner surface providing a circumferential portion adjacent the roller's outer circumference and two radially extending portions adjacent respective flanks of the roller, a fluid receiving chamber being thereby defined between the roller and the shroud, and the fluid supply conduit being arranged to deliver fluid into the fluid receiving chamber.

Owner:ALLISON TRANSMISSION INC

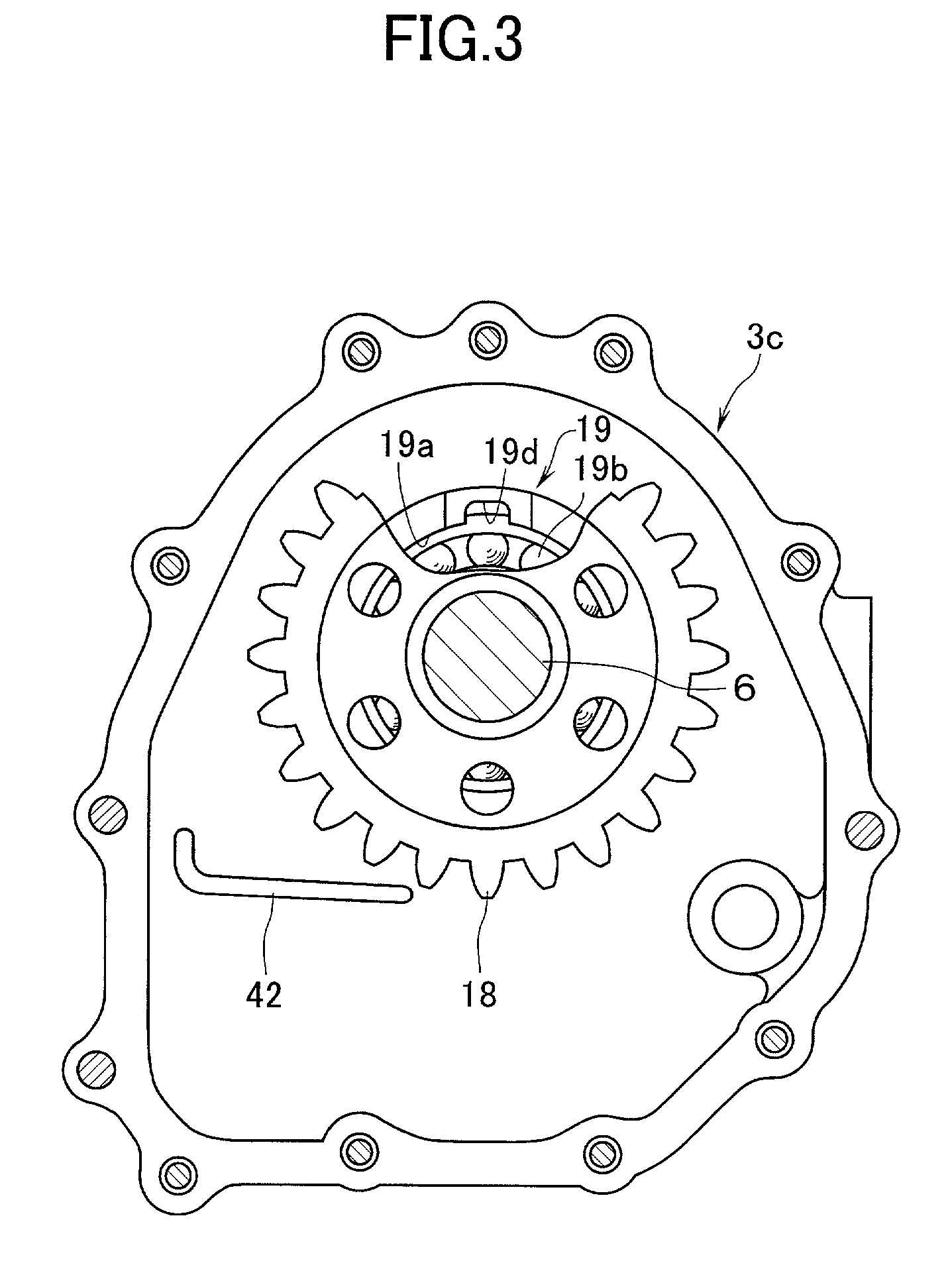

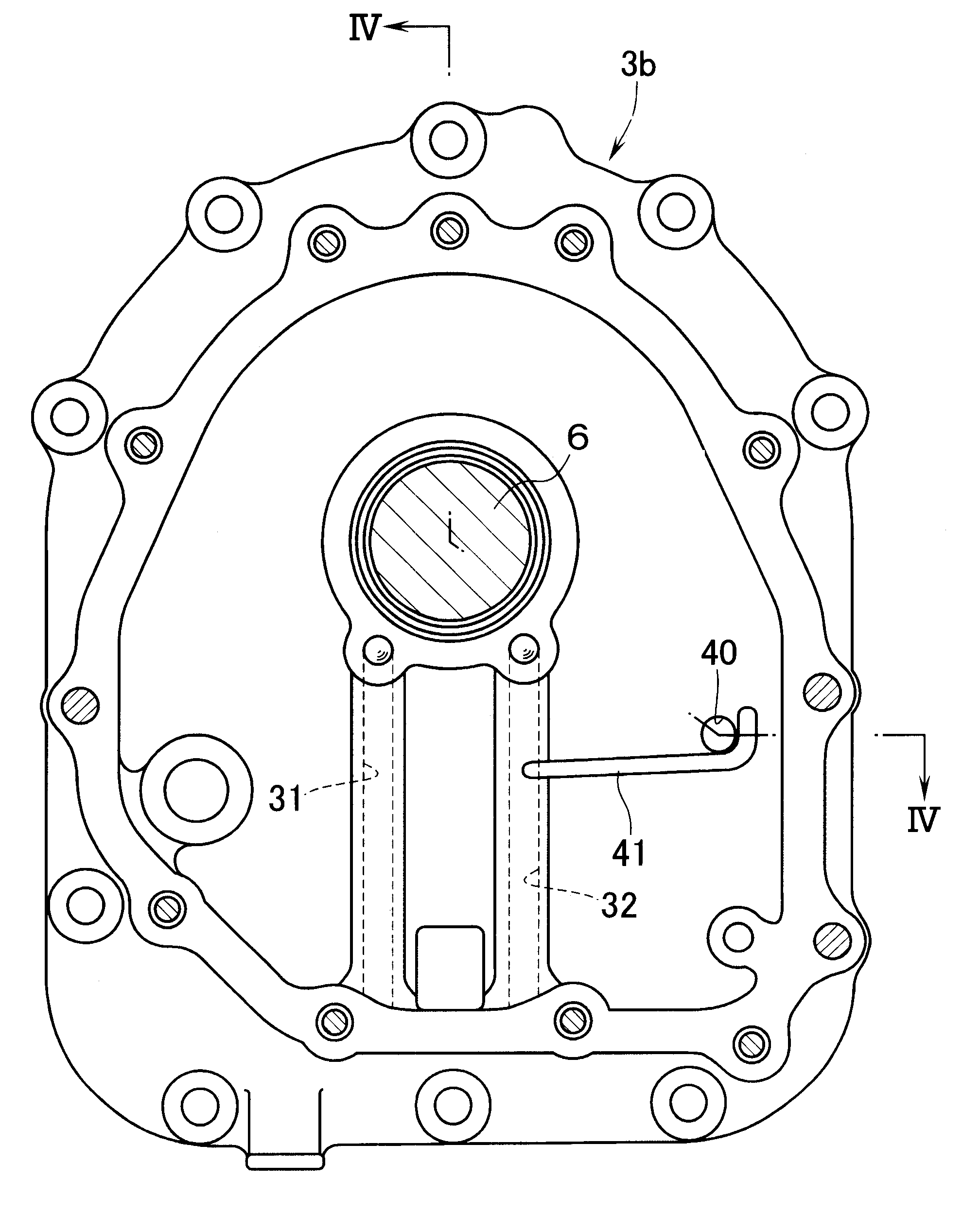

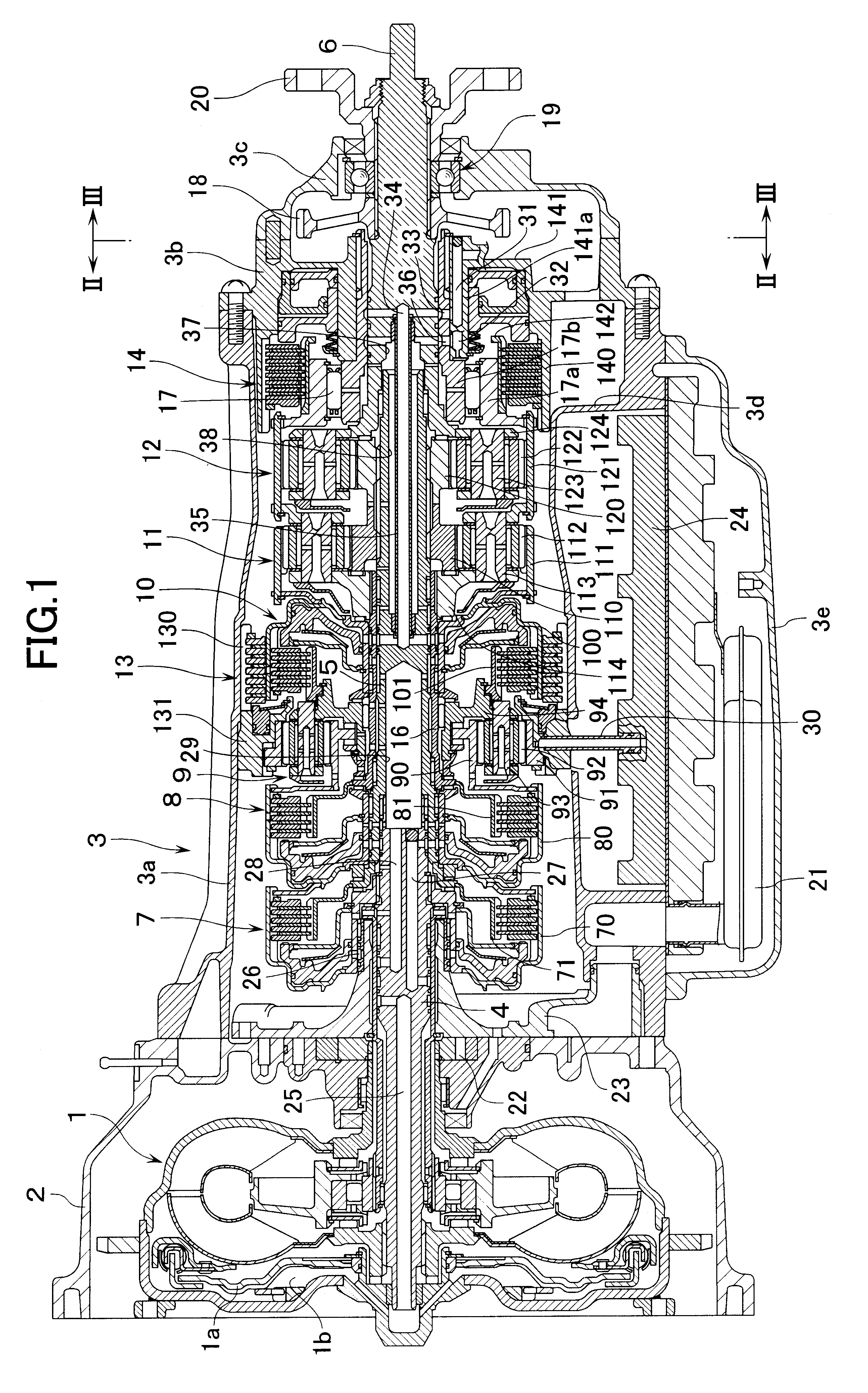

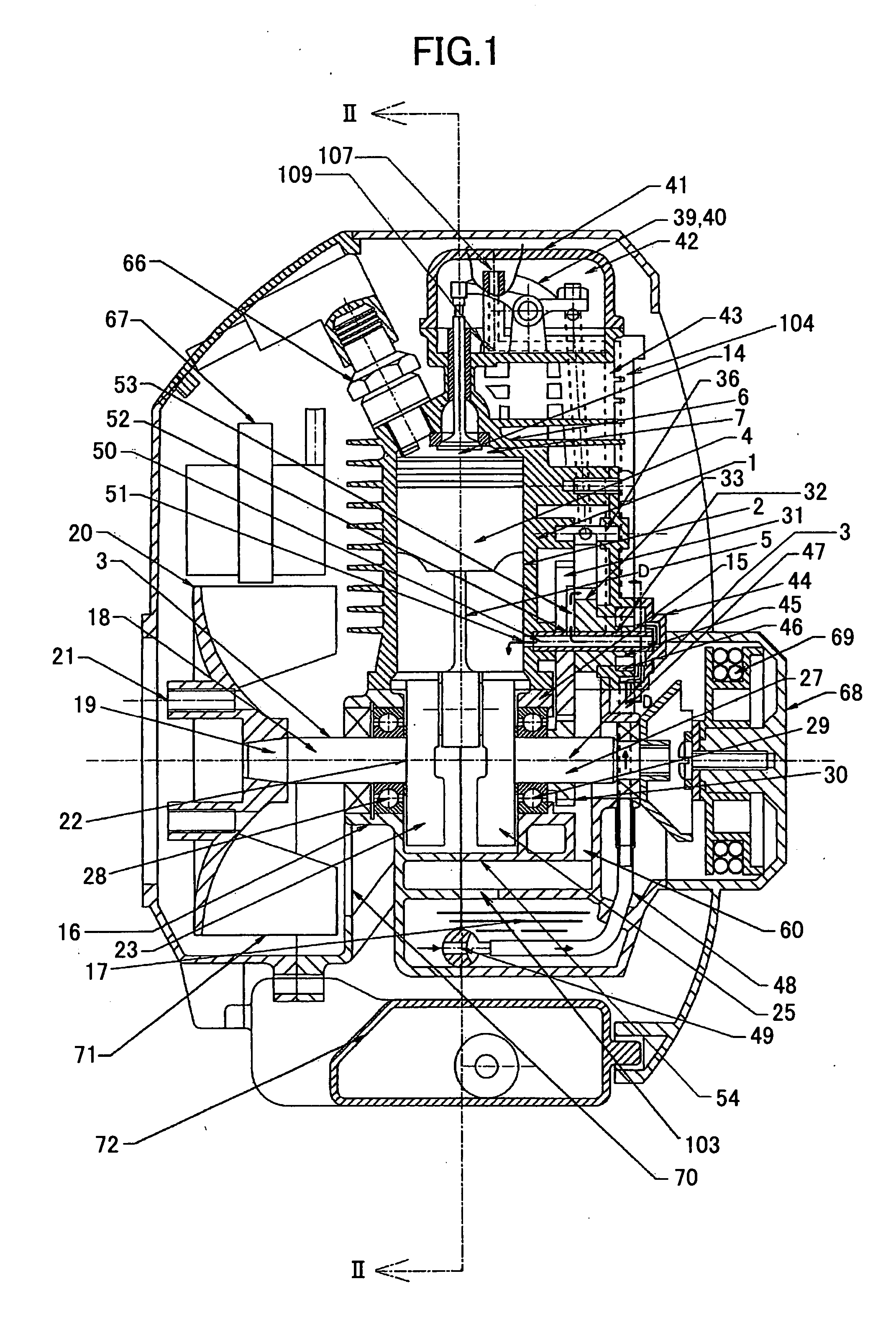

Lubricating structure for output shaft bearing portion in transmission

An output shaft bearing portion which is provided in an extension housing to be attached to an outside of an end wall portion of a casing main body of a transmission casing is lubricated by lubrication oil which is supplied to lubricating portions inside the casing main body. In the end wall portion there is formed an oil guide passage which guides the lubrication oil supplied to the lubricating portions inside the casing main body. Inside the extension housing, there is formed a rib which guides the lubrication oil flown from the oil guide passage, into a position in which the lubrication oil can be scraped by a gear wheel provided inside the extension housing. The lubrication oil scraped by the gear wheel is supplied to the output shaft bearing portion.

Owner:HONDA MOTOR CO LTD

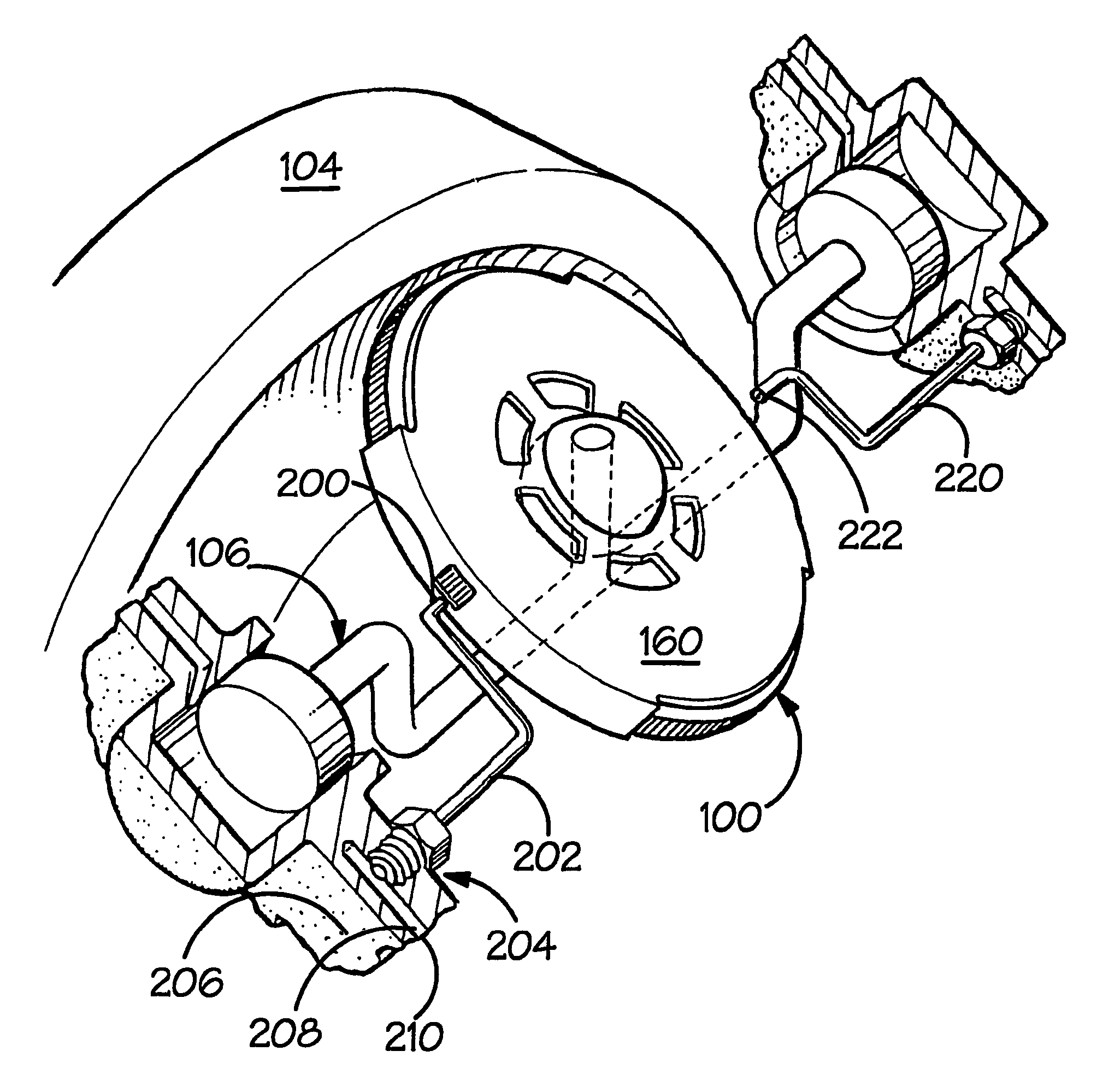

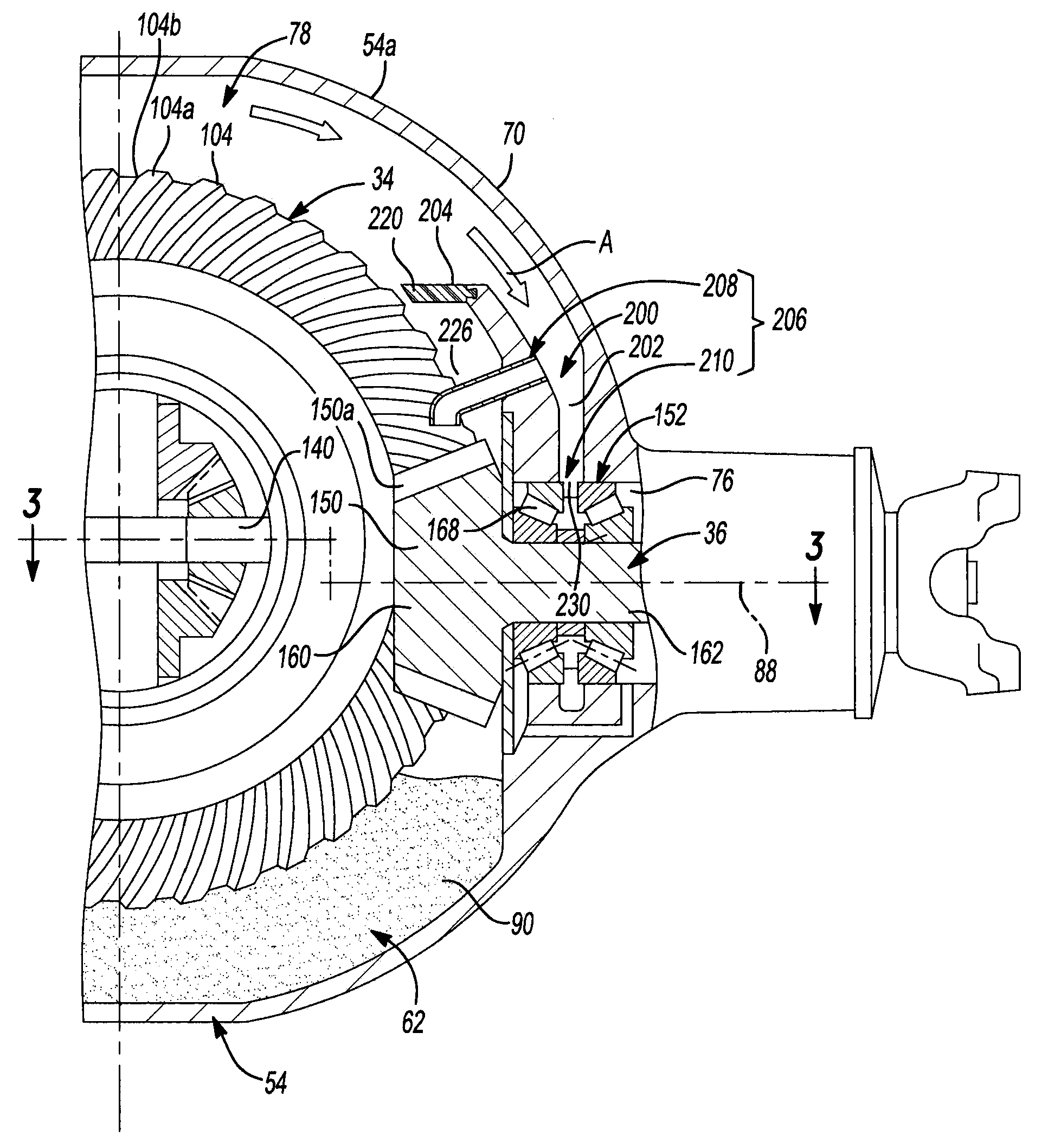

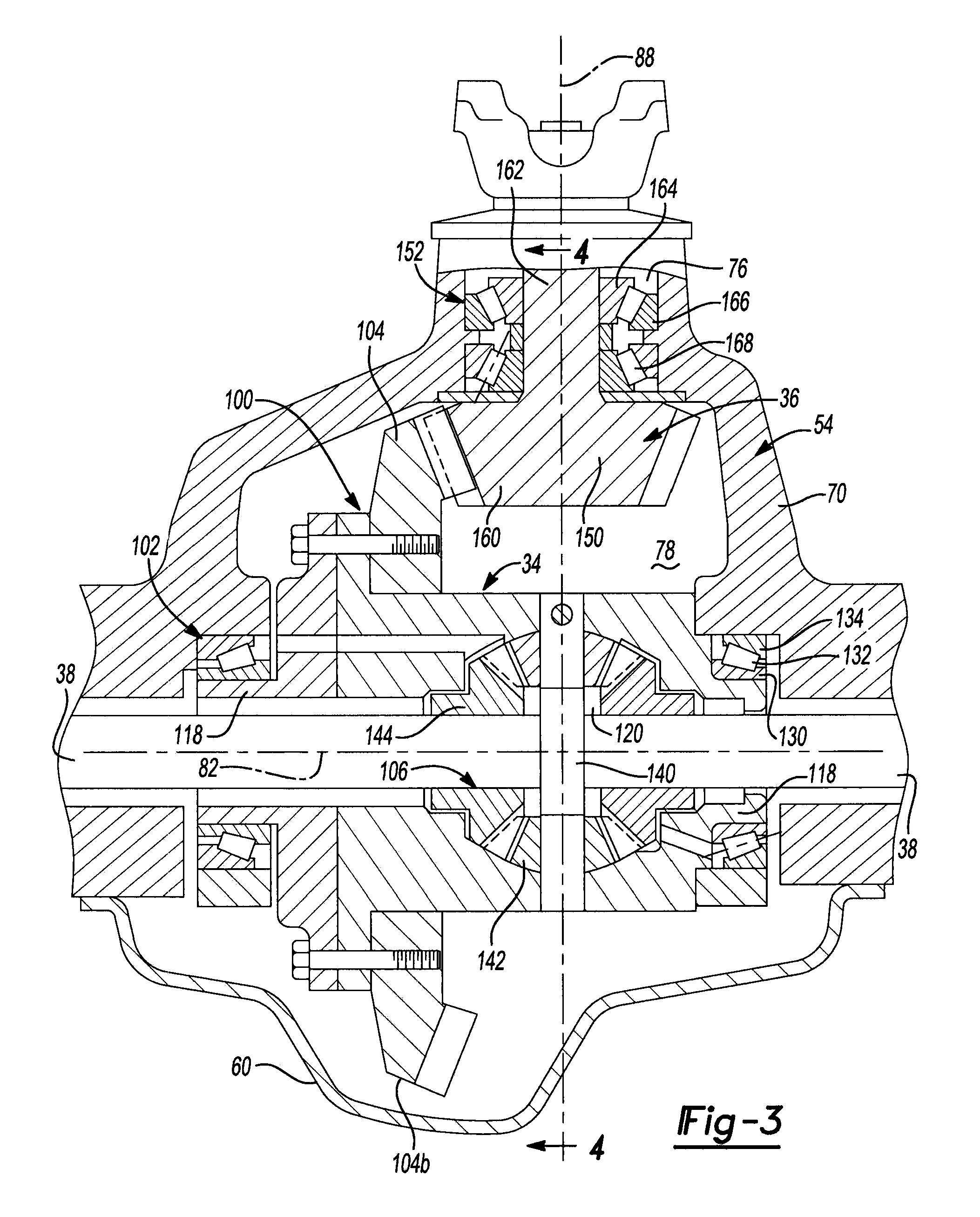

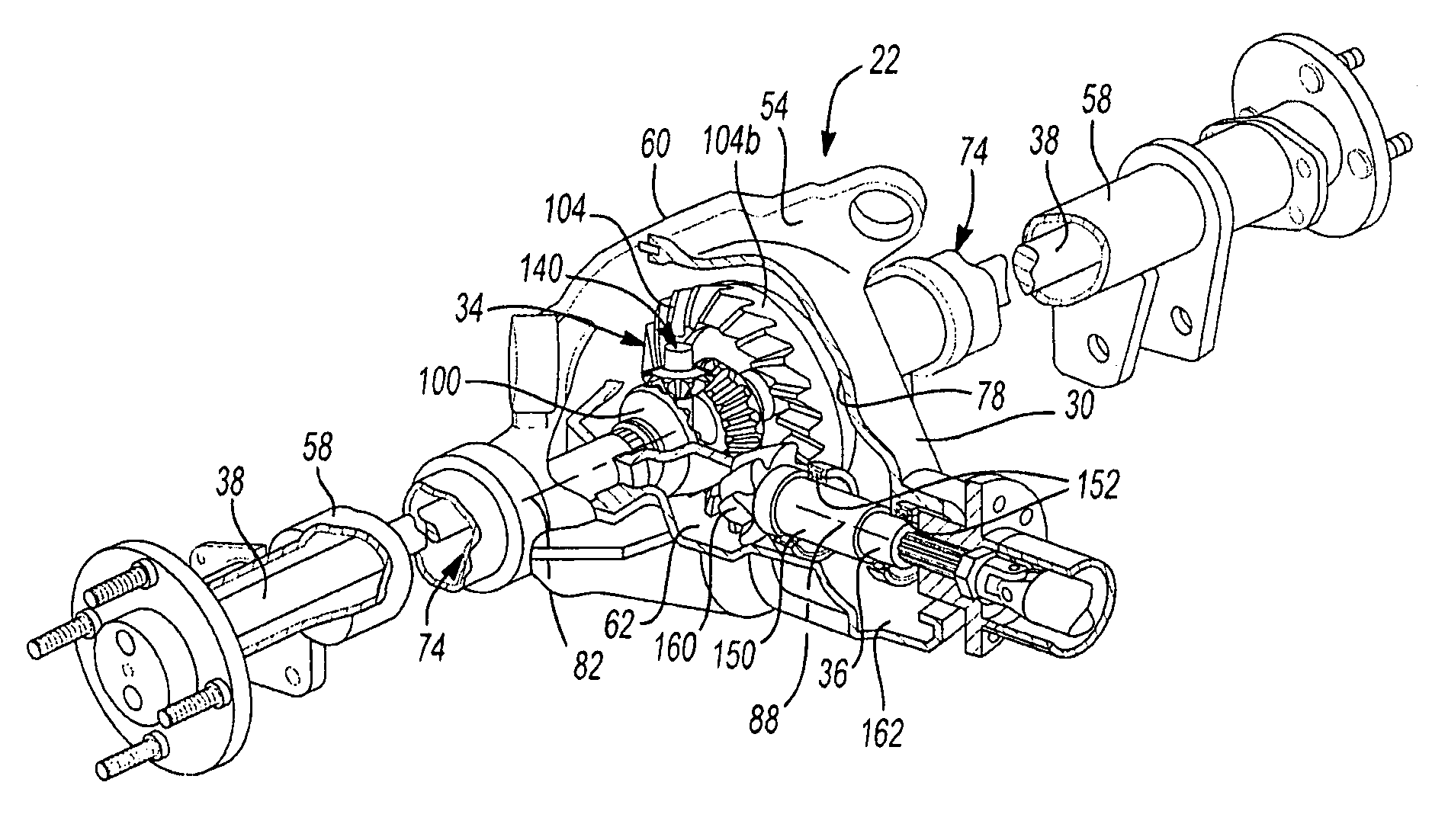

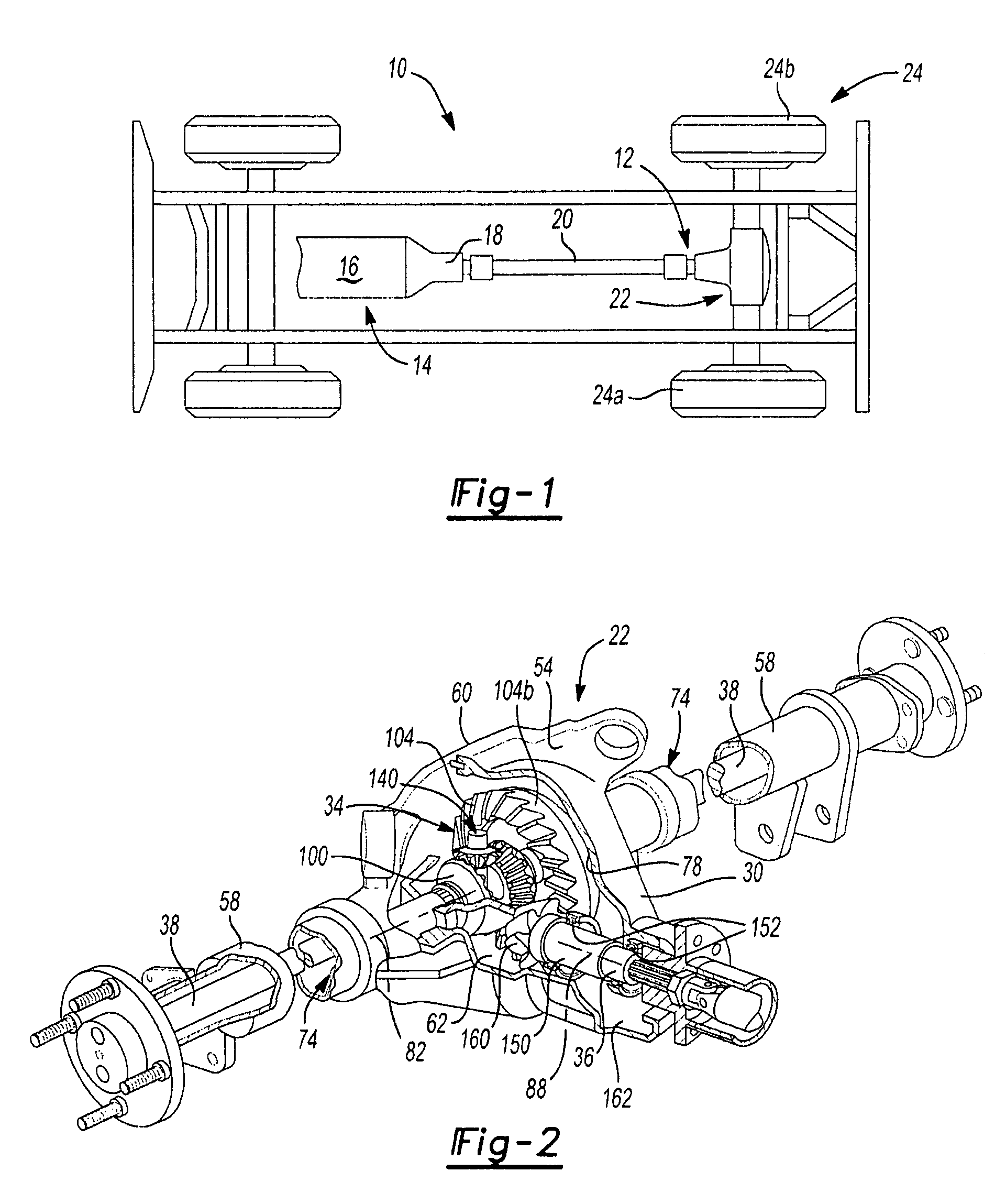

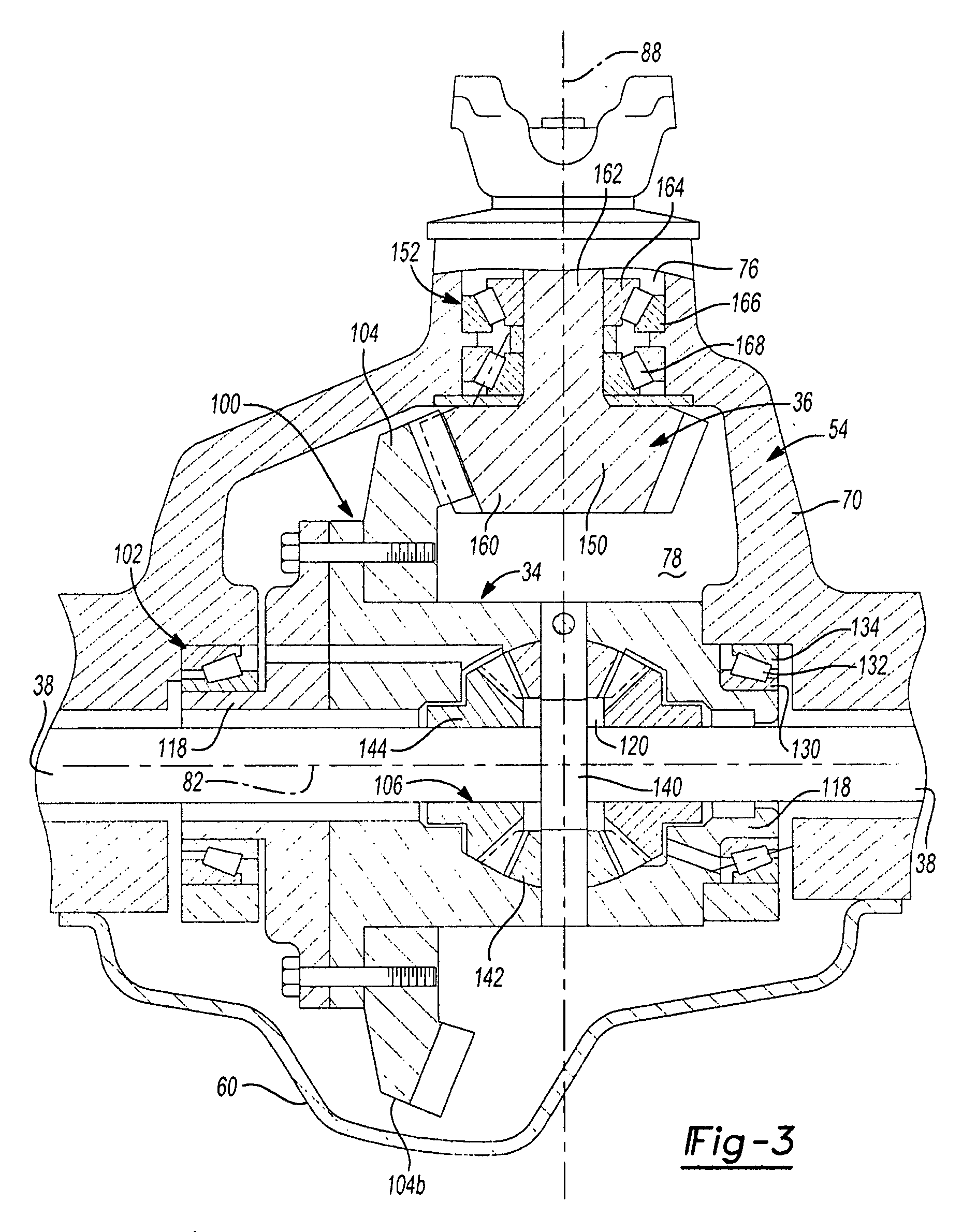

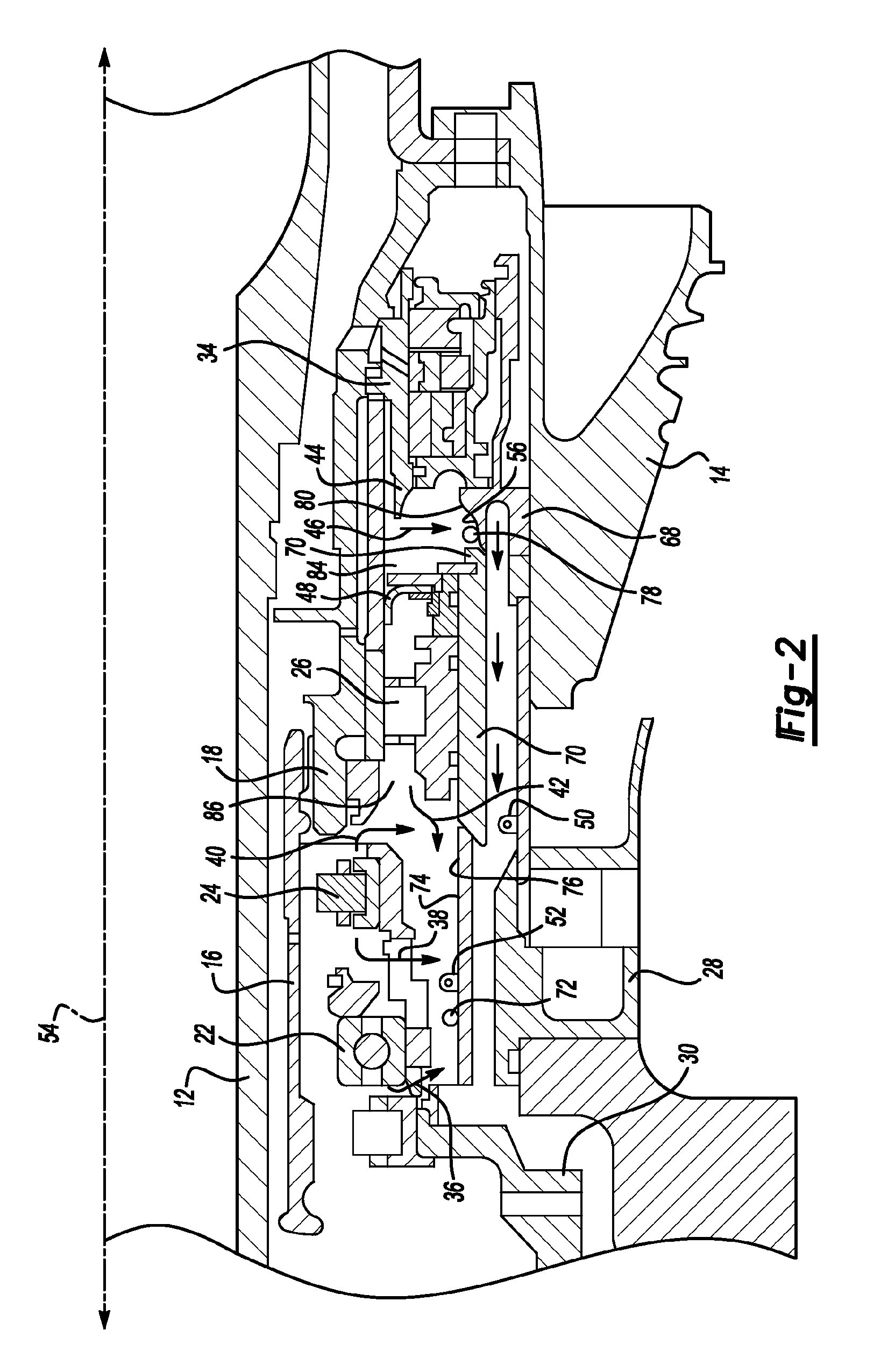

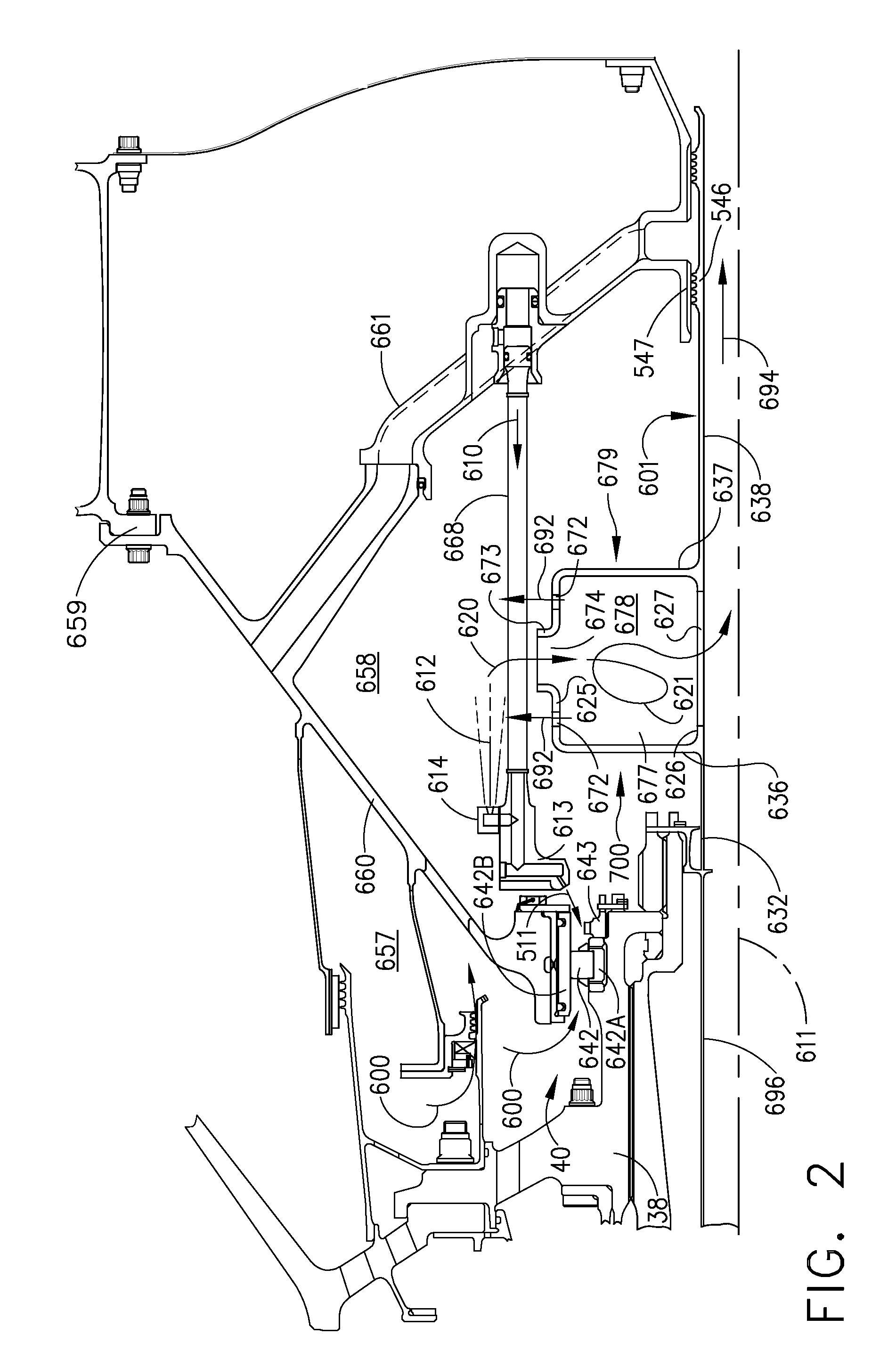

Drive axle assembly with gear mesh lubrication systems for lubricating gear mesh and/or differential bearings

An axle assembly having an axle assembly with first and second sumps for holding a lubricant. A rotating ring gear associated with a differential can rotate through the lubricant in the first sump to cause a portion of the lubricant to cling to the ring gear. A portion of the lubricant that has clung to the ring gear can be removed from the ring gear and transferred to the second sump. The lubricant in the second sump can be drained to lubricate teeth of a pinion that is in meshing engagement with the ring gear and / or to lubricate bearings that support the pinion. A related method is also provided.

Owner:AMERICAN AXLE & MFG

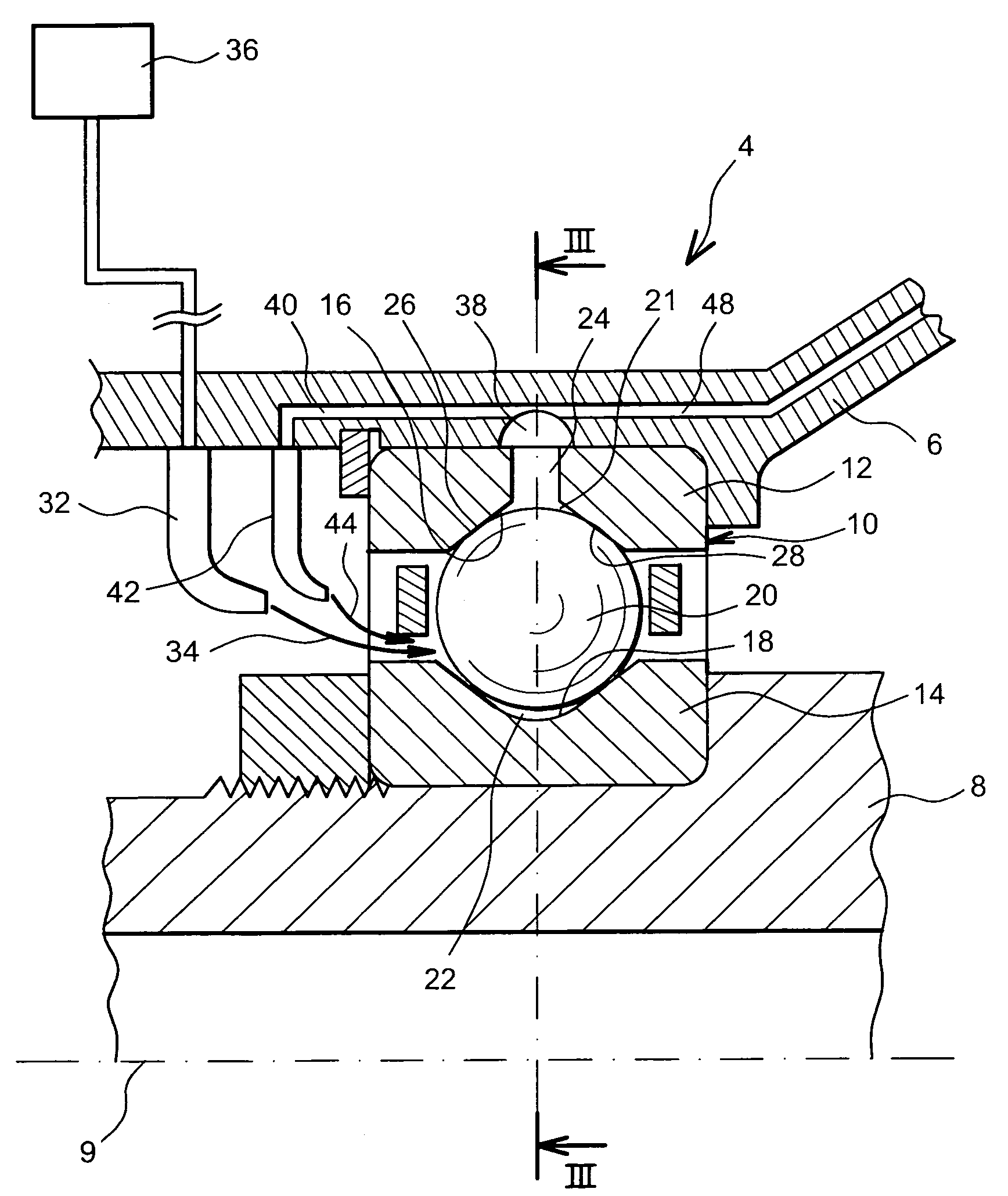

Fluid pump mechanism for use in existing helical gearsets

A fluid pump cowling for attachment to at least a pair of helical drivetrain gears having teeth and lands. The cowling has a pair of sidewalls adapted to extend at least partially over the lands of a first of the pair of drivetrain gears and a curved sump wall extending between the sidewalls that corresponds generally to the outermost circumference of the first gear. A sump channel is defined between the sidewalls on the sump wall adjacent a distal end of the sump wall. The sump channel has a generally frustoconical shape and leads to a fluid outlet opening defined in one of the sidewalls. The cowling is positioned such that the teeth of the pair of helical gears mesh in an area in fluid communication with the sump channel to create an area of high fluid pressure upon rotational movement of the gears with a fluid.

Owner:FORD GLOBAL TECH LLC

Drive axle assembly with gear mesh lubrication systems for lubricating gear mesh and/or differential bearings

An axle assembly having an axle assembly with first and second sumps for holding a lubricant. A rotating ring gear associated with a differential can rotate through the lubricant in the first sump to cause a portion of the lubricant to cling to the ring gear. A portion of the lubricant that has clung to the ring gear can be removed from the ring gear and transferred to the second sump. The lubricant in the second sump can be drained to lubricate teeth of a pinion that is in meshing engagement with the ring gear and / or to lubricate bearings that support the pinion. A related method is also provided.

Owner:AMERICAN AXLE & MFG

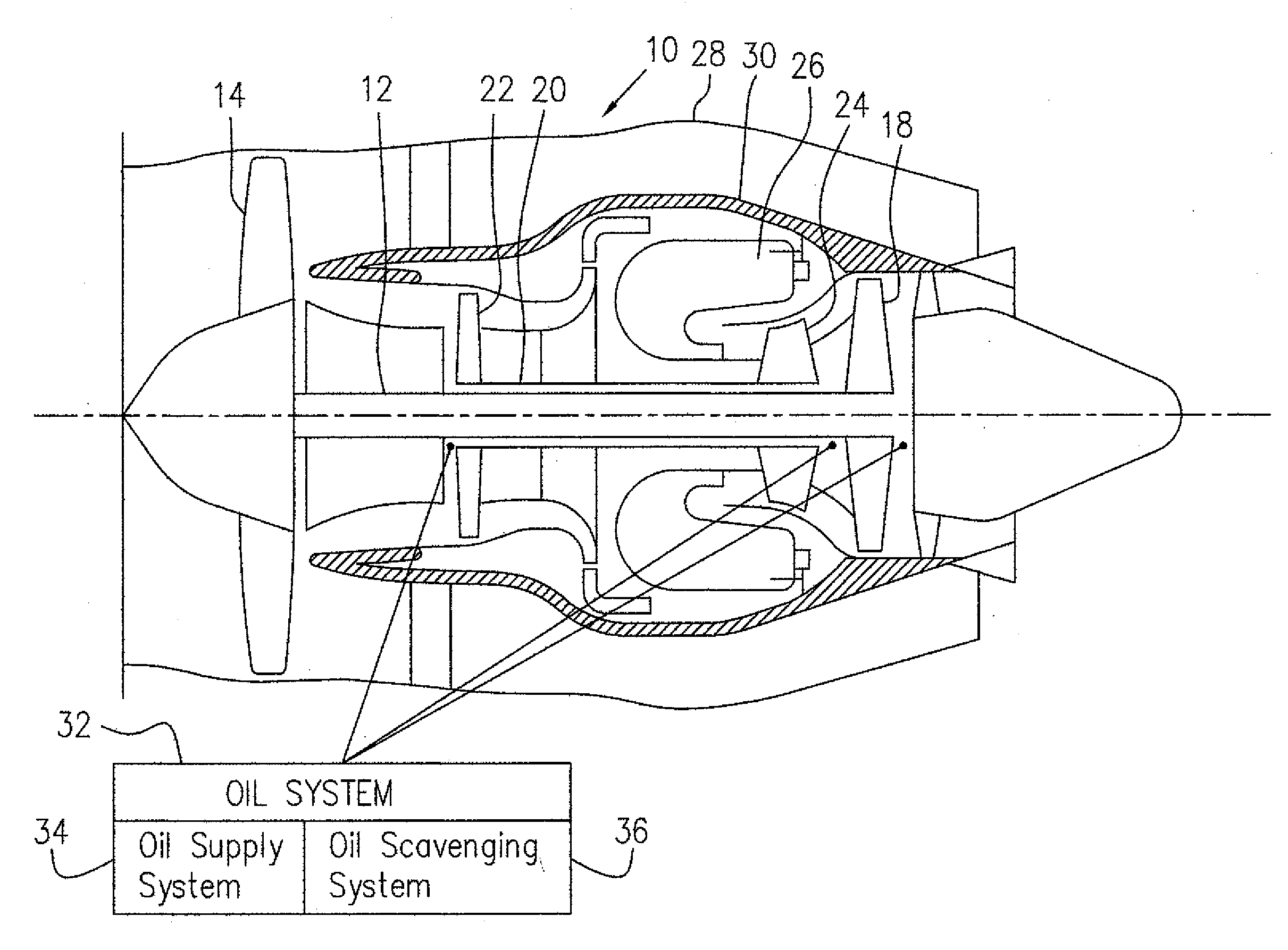

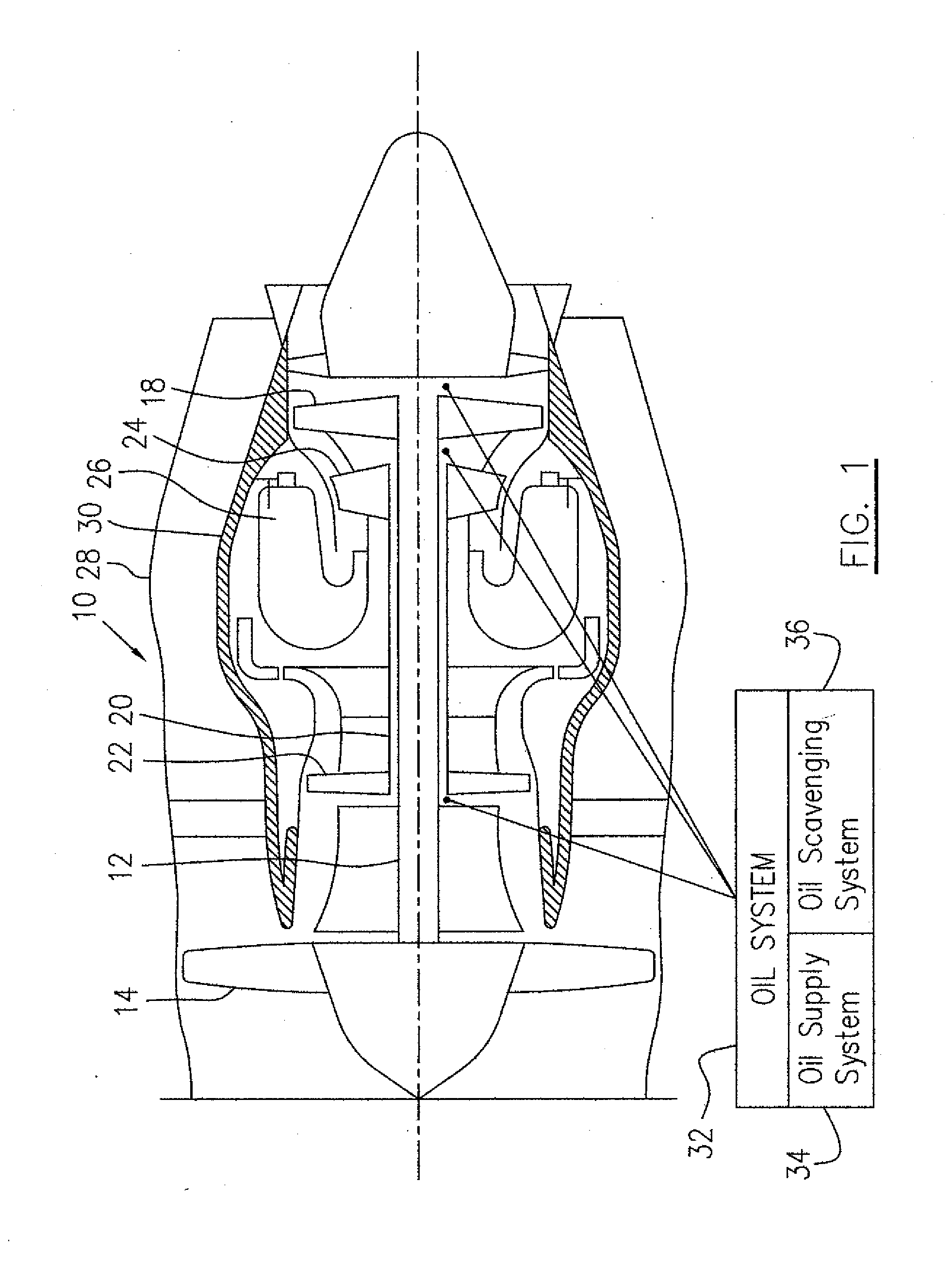

Gas turbine oil scavenging system

ActiveUS20090101444A1Low levelLow engine powerTurbinesDrip or splash lubricationFuel tankGas turbines

A method for scavenging oil in a gas turbine engine comprises using a driving fluid flow to drive a flow of a fluid collected in an oil system of the engine to pass through an ejector and then the driven flow of the fluid is directed to be discharged into an oil tank.

Owner:PRATT & WHITNEY CANADA CORP

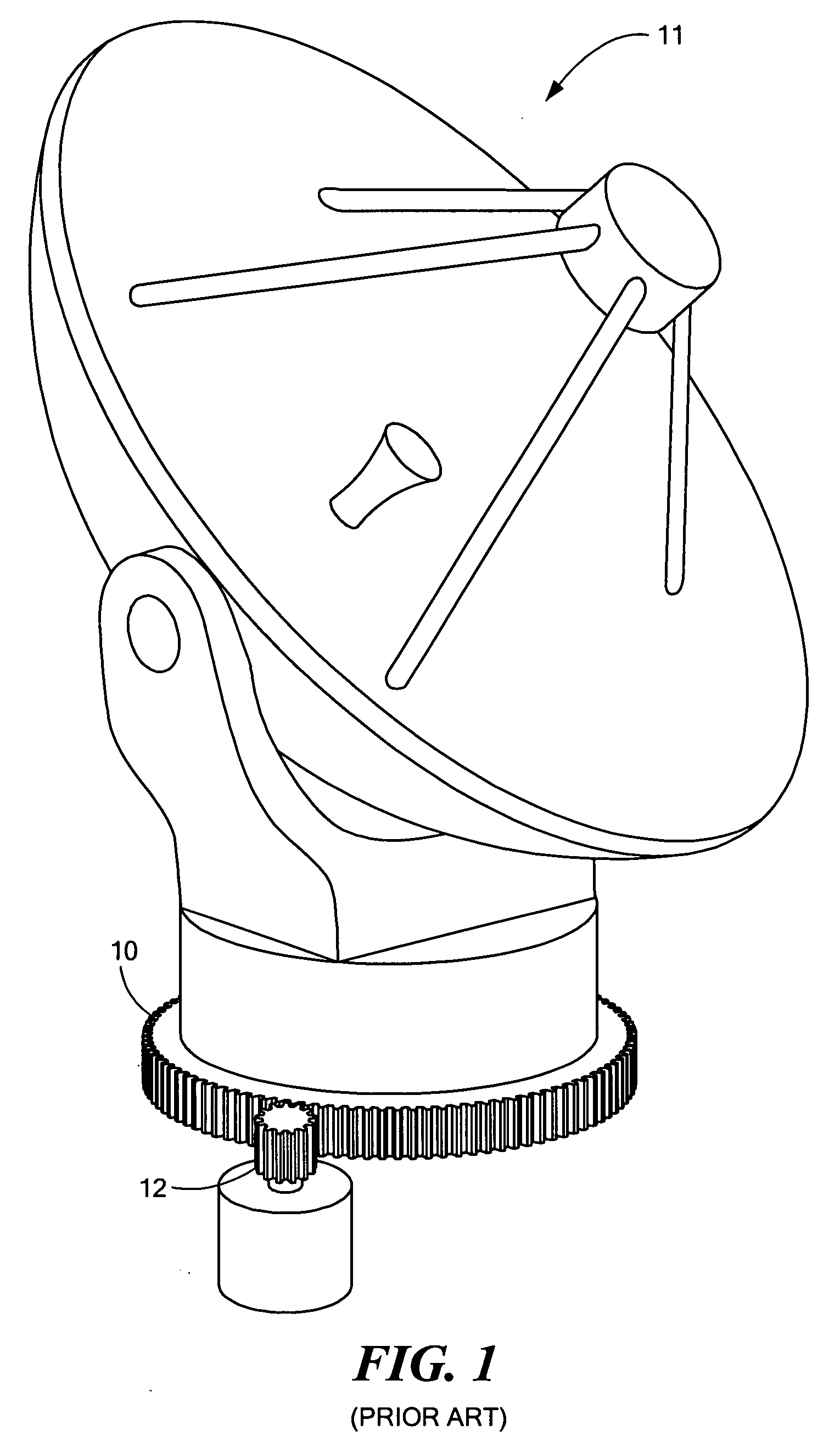

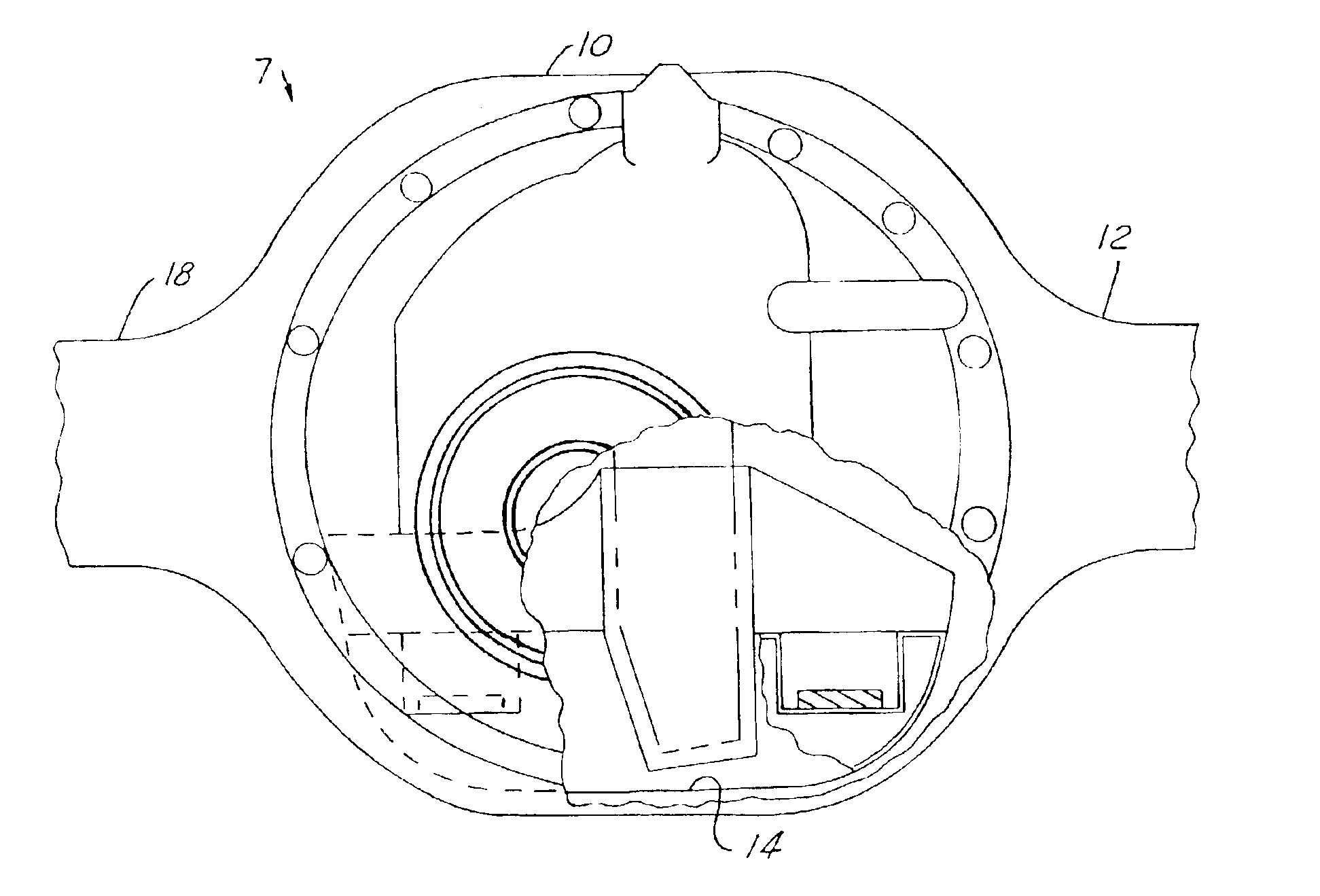

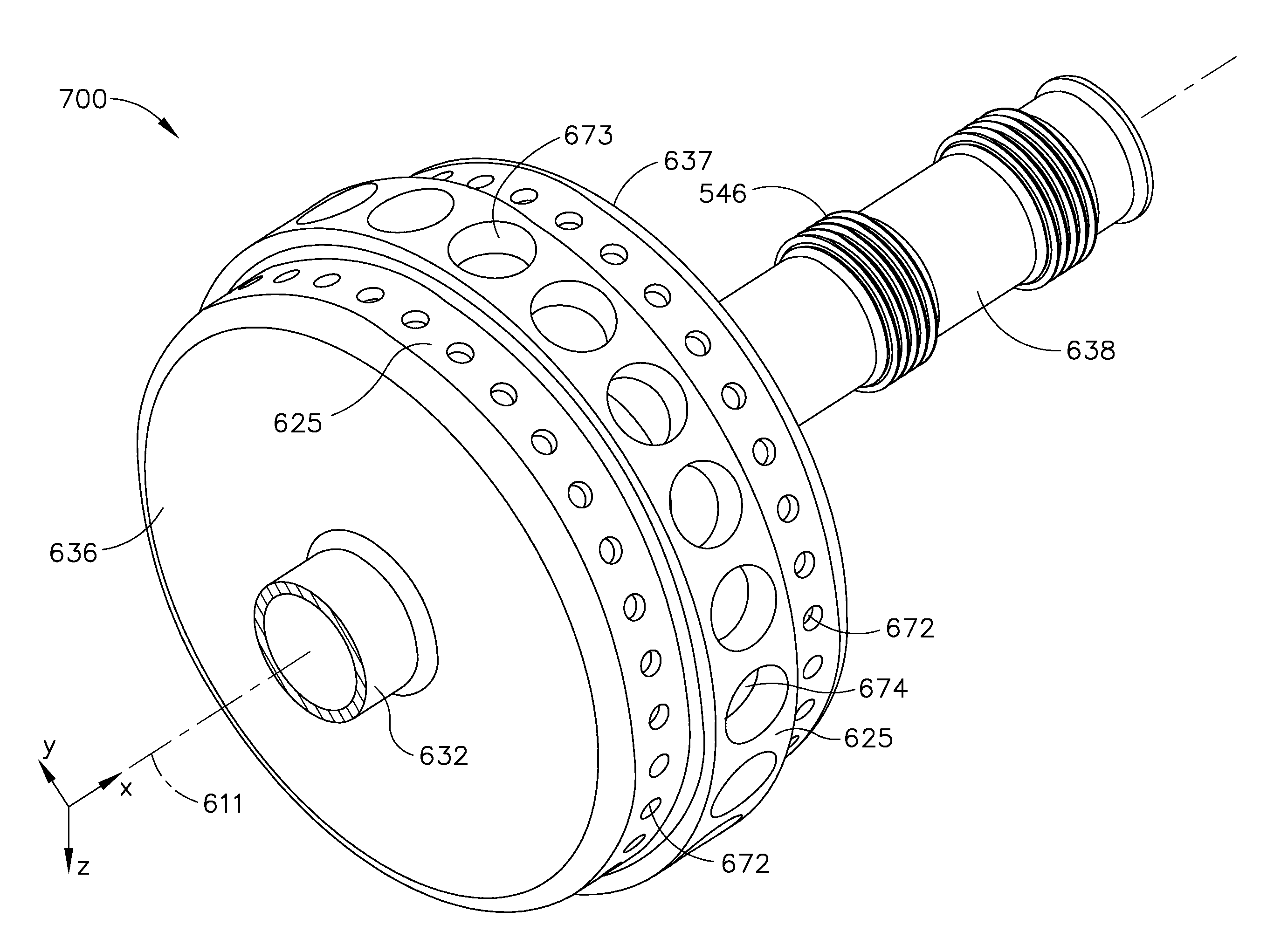

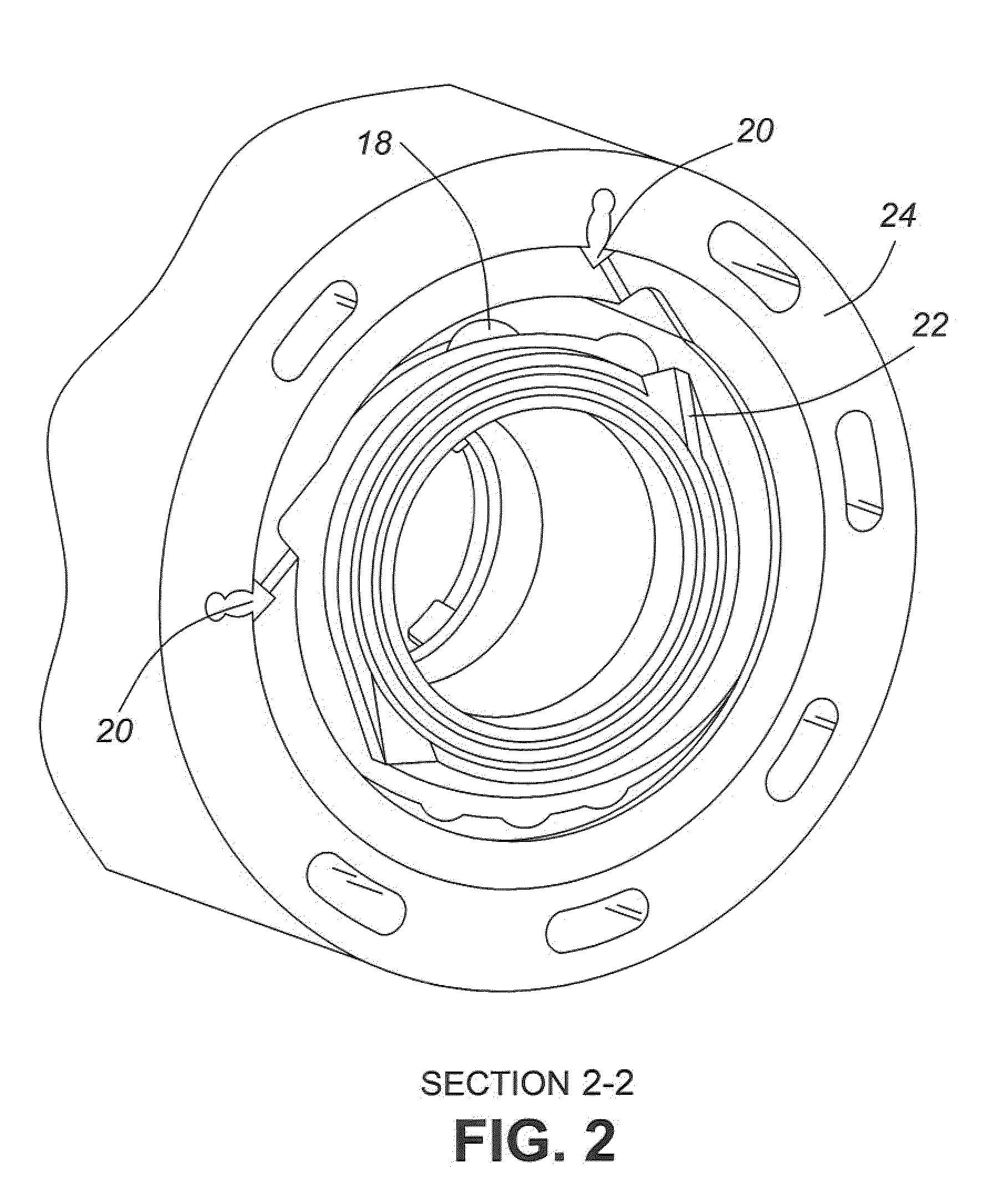

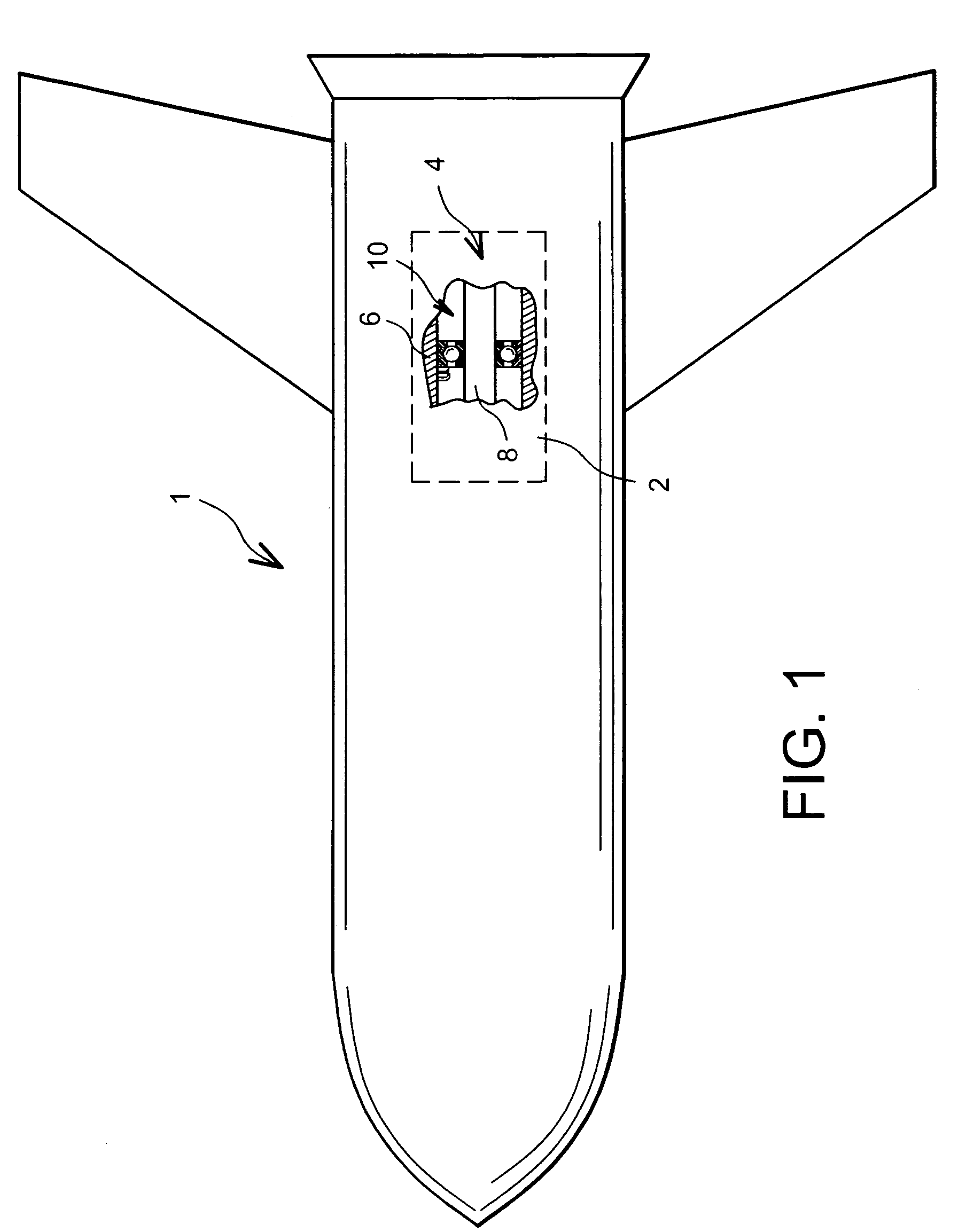

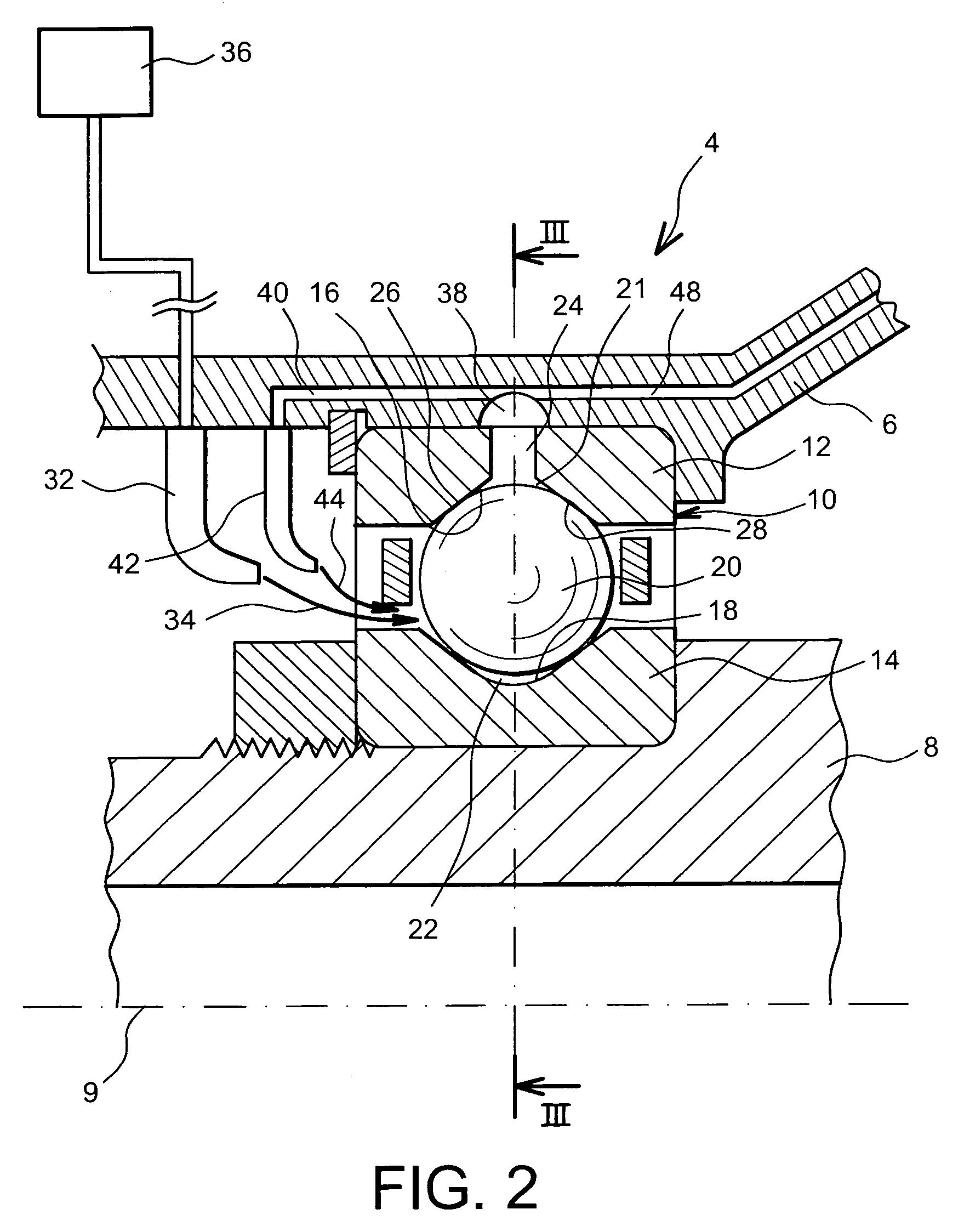

Direct grease injection for large open gearing

ActiveUS20080276743A1Minimize messReduce wearRoller bearingsDrip or splash lubricationGear driveGear wheel

A drive gear includes a plurality of internal radial channels extending between the axial bore and the periphery of the gear, and an axial bore includes a lubricant distribution structure therein to provide lubrication where the teeth of the drive gear mesh with the teeth of a gear driven by the drive gear.

Owner:RAYTHEON CO

Rotating shaft scavenging scoop

A bearing scavenge system comprises a scavenging passage extending axially through a rotating shaft supported by the bearing assembly. Oil and air are drawn from an oil cavity of the bearing assembly and evacuated through the rotating shaft as the shaft rotates.

Owner:PRATT & WHITNEY CANADA CORP

Free vortex air-oil separator

Owner:GENERAL ELECTRIC CO

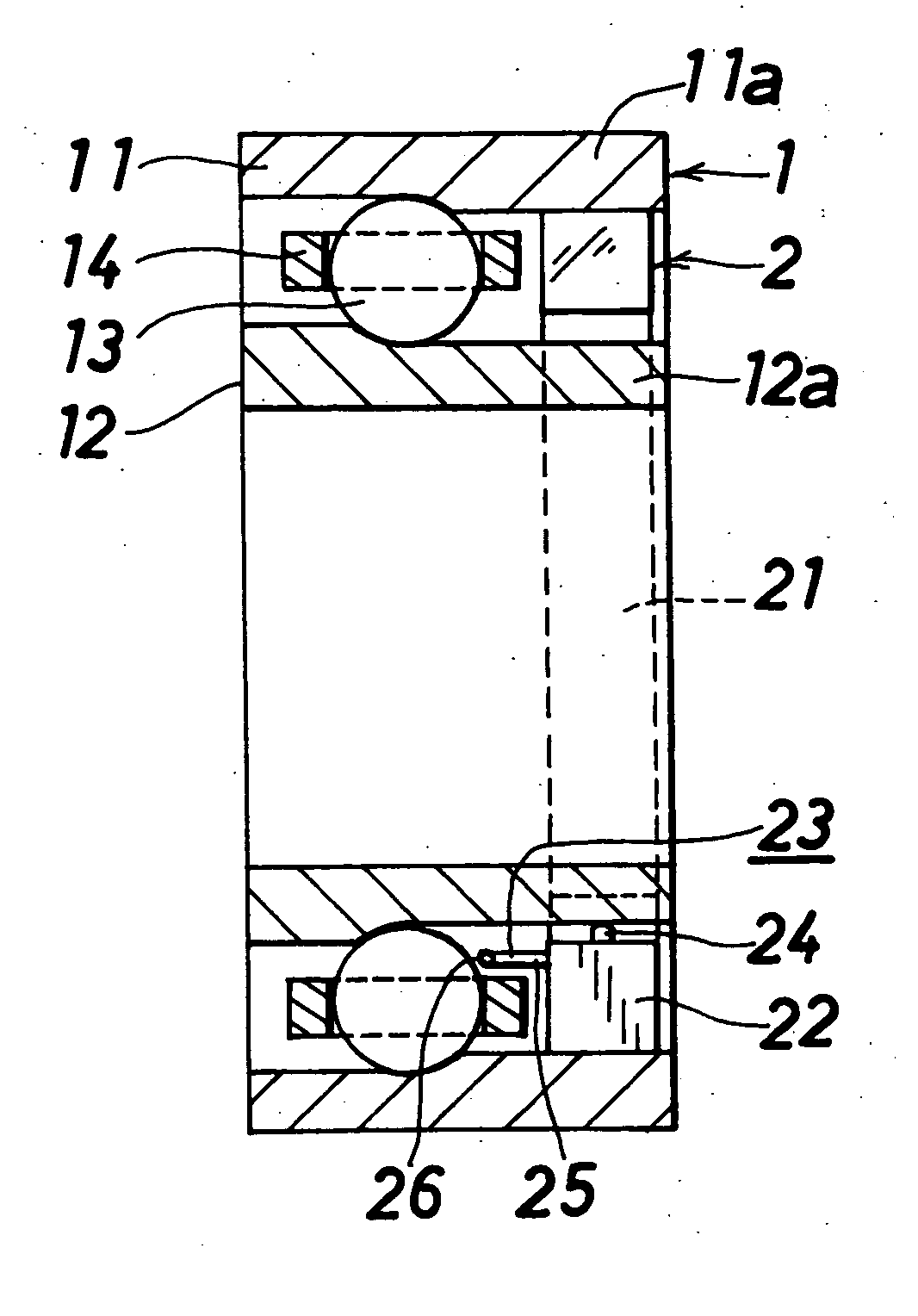

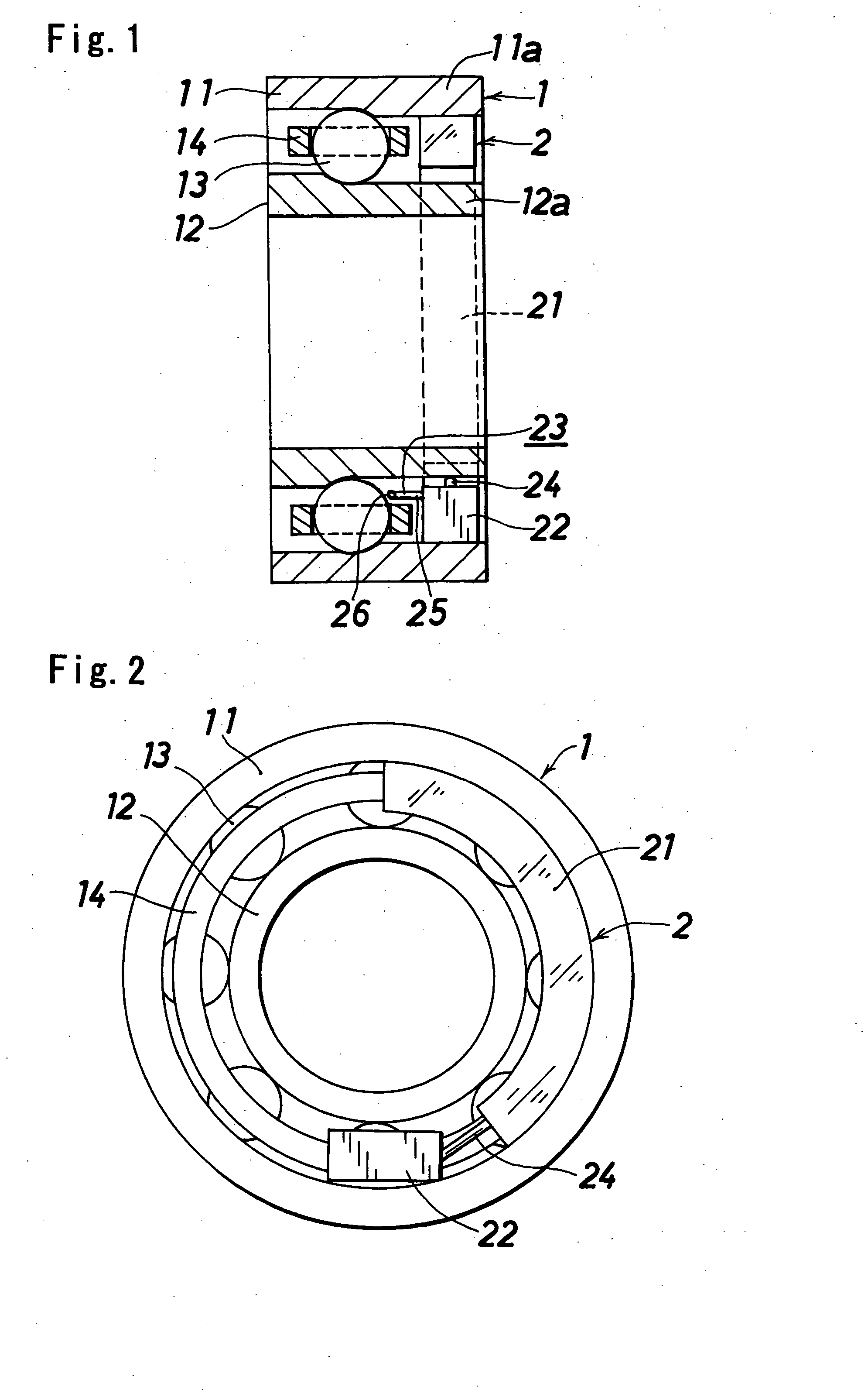

Rolling bearing apparatus

InactiveUS20070071382A1Reduce maintenance frequencyReduce noiseRolling contact bearingsDrip or splash lubricationRolling-element bearingCentre of rotation

An oil supply unit provided in a rolling bearing apparatus has a lubricating oil discharge nozzle in which an opening is faced to a cage portion of the rolling bearing. An opening direction of the nozzle is inclined to a rotating direction with respect to a direction of a center axis of rotation.

Owner:JTEKT CORP

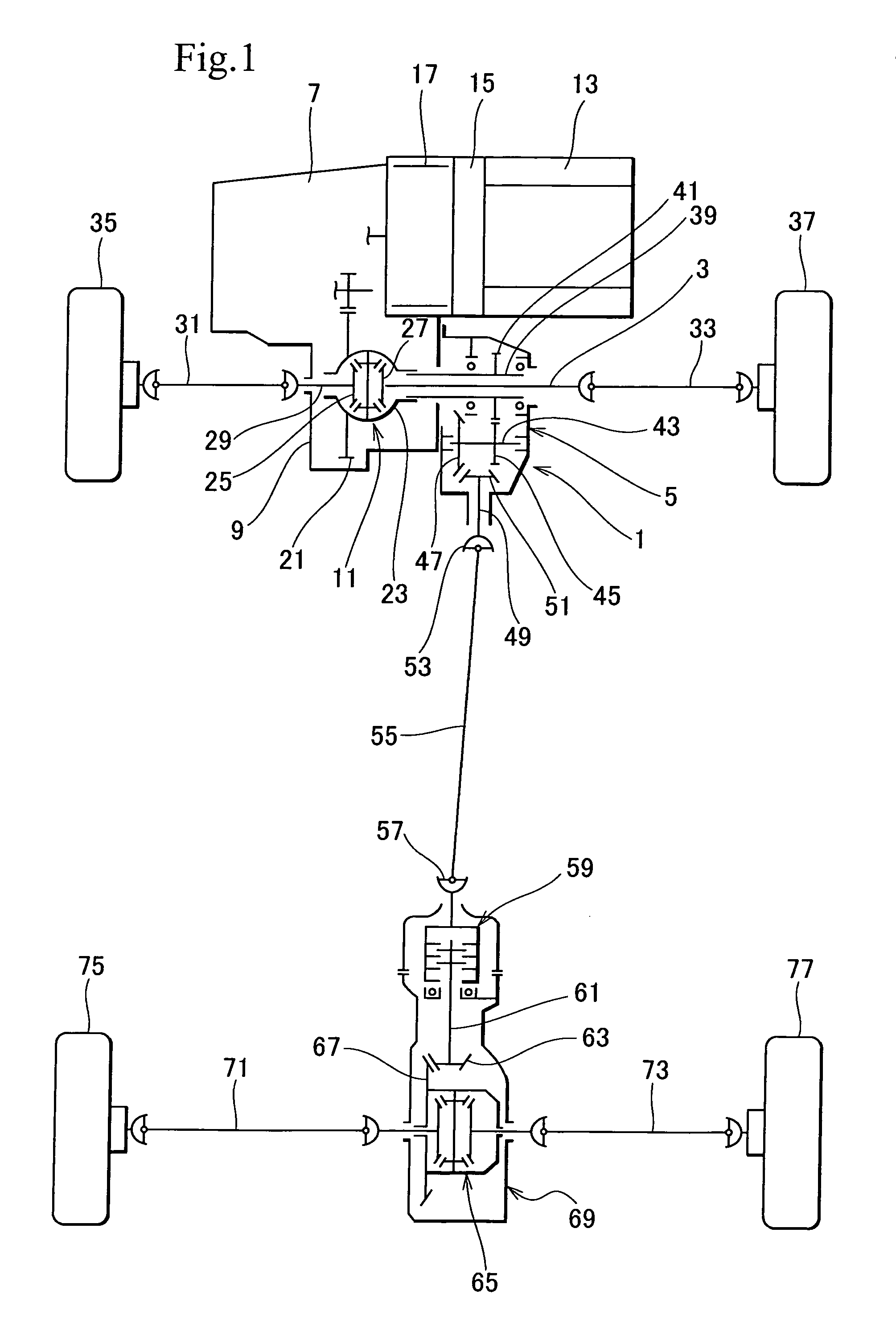

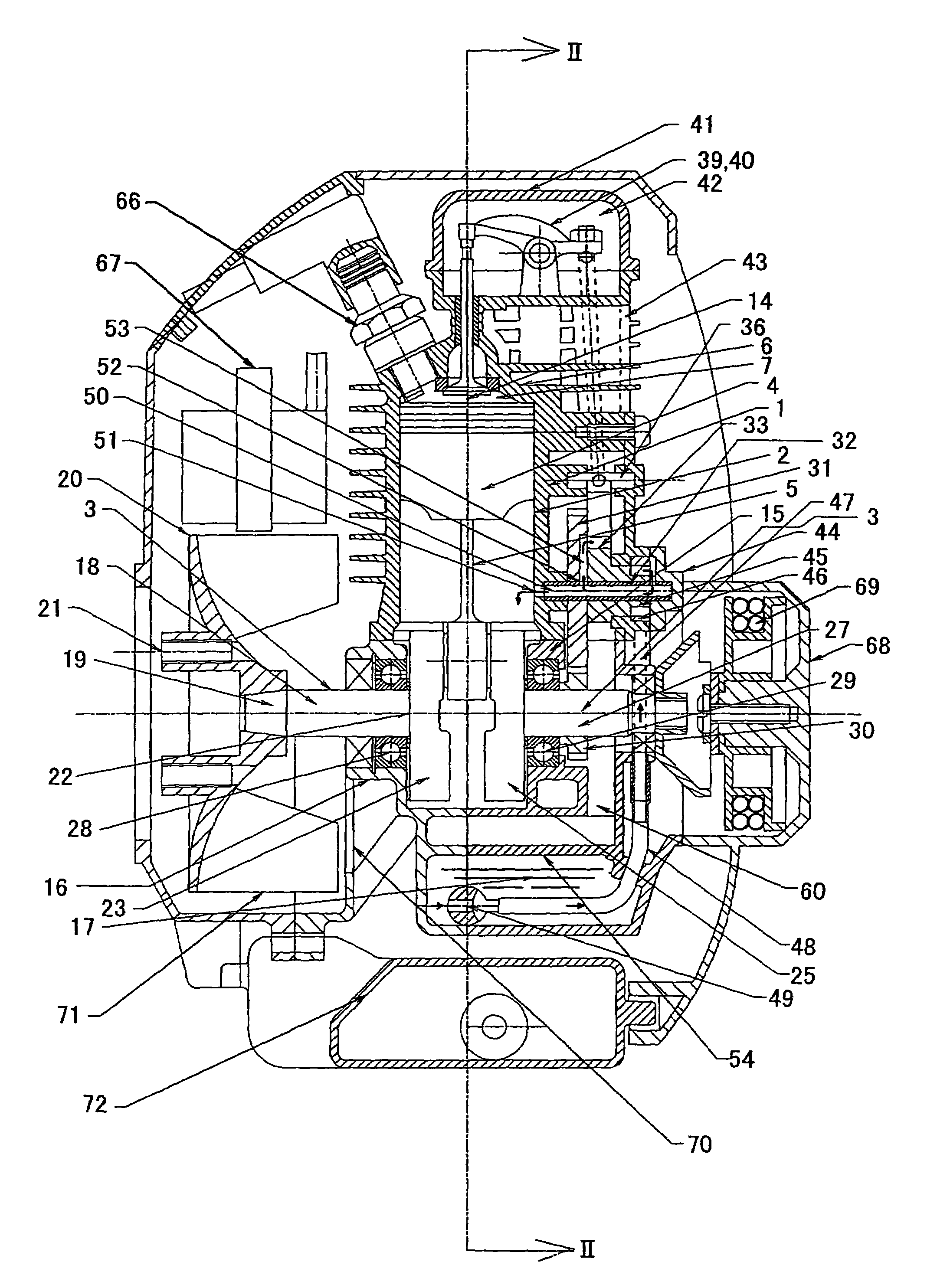

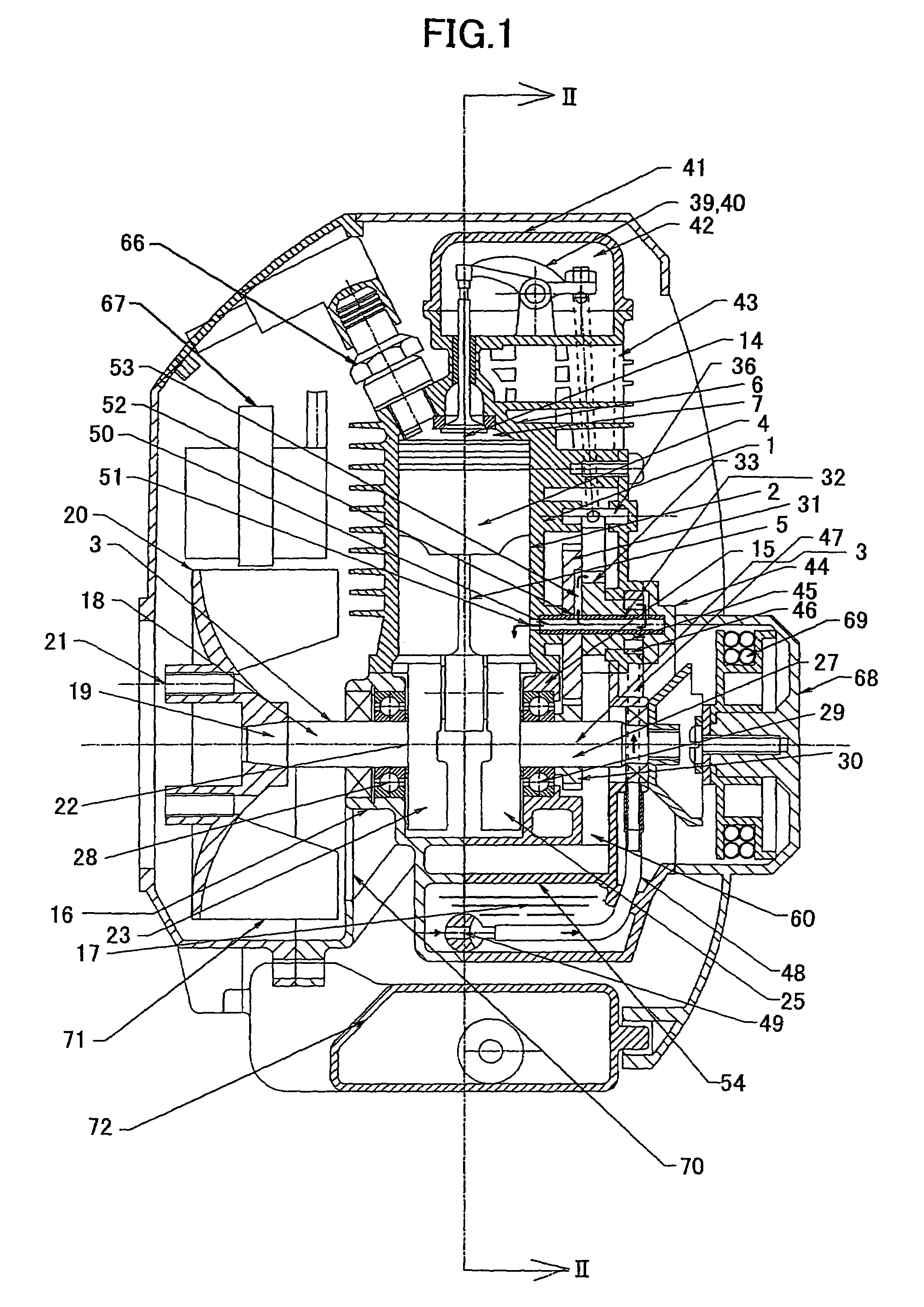

Power transmission apparatus

InactiveUS8657073B2Accurate supplyDrip or splash lubricationGear lubrication/coolingElectric power transmissionTransfer case

A power transmission apparatus is capable of easily passing lubricant toward a seal arranged between a higher shat and an opening of a case of the apparatus. The apparatus includes the higher shaft, i.e., a hollow connecting shaft that faces the outside of the transfer case through the opening of the transfer case. The oil seal is arranged between the hollow shaft and the opening of the transfer case. The hollow shaft meshes, through helical spur gears, with an intermediate transferring shaft that is positioned lower than the hollow shaft. A lubricant guide is arranged to receive lubricant splashed up by the ring gear and helical spur gear of the intermediate shaft and guide the received lubricant toward the oil seal and a ball bearing.

Owner:GKN DRIVELINE TORQUE TECHNOLOGY KK

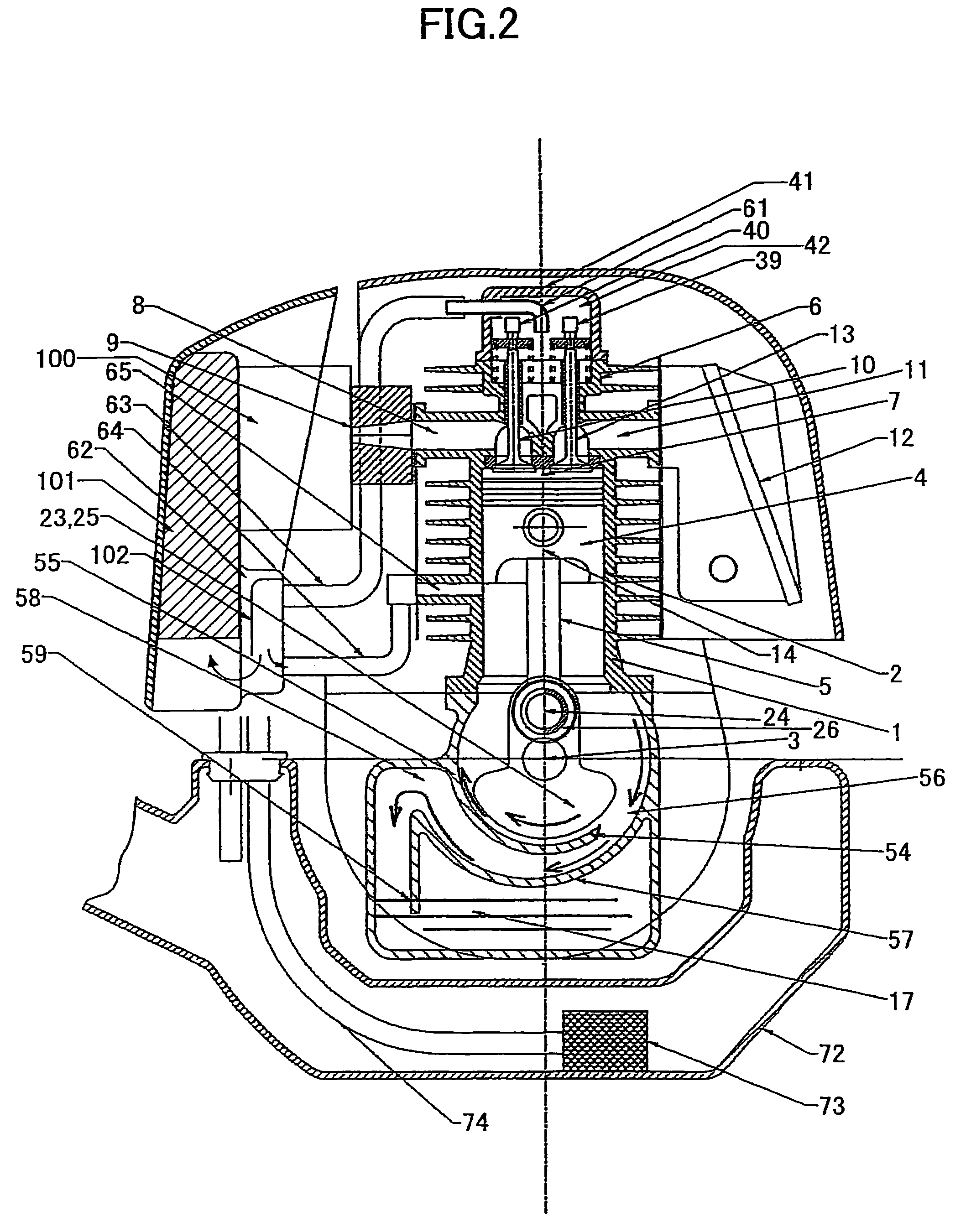

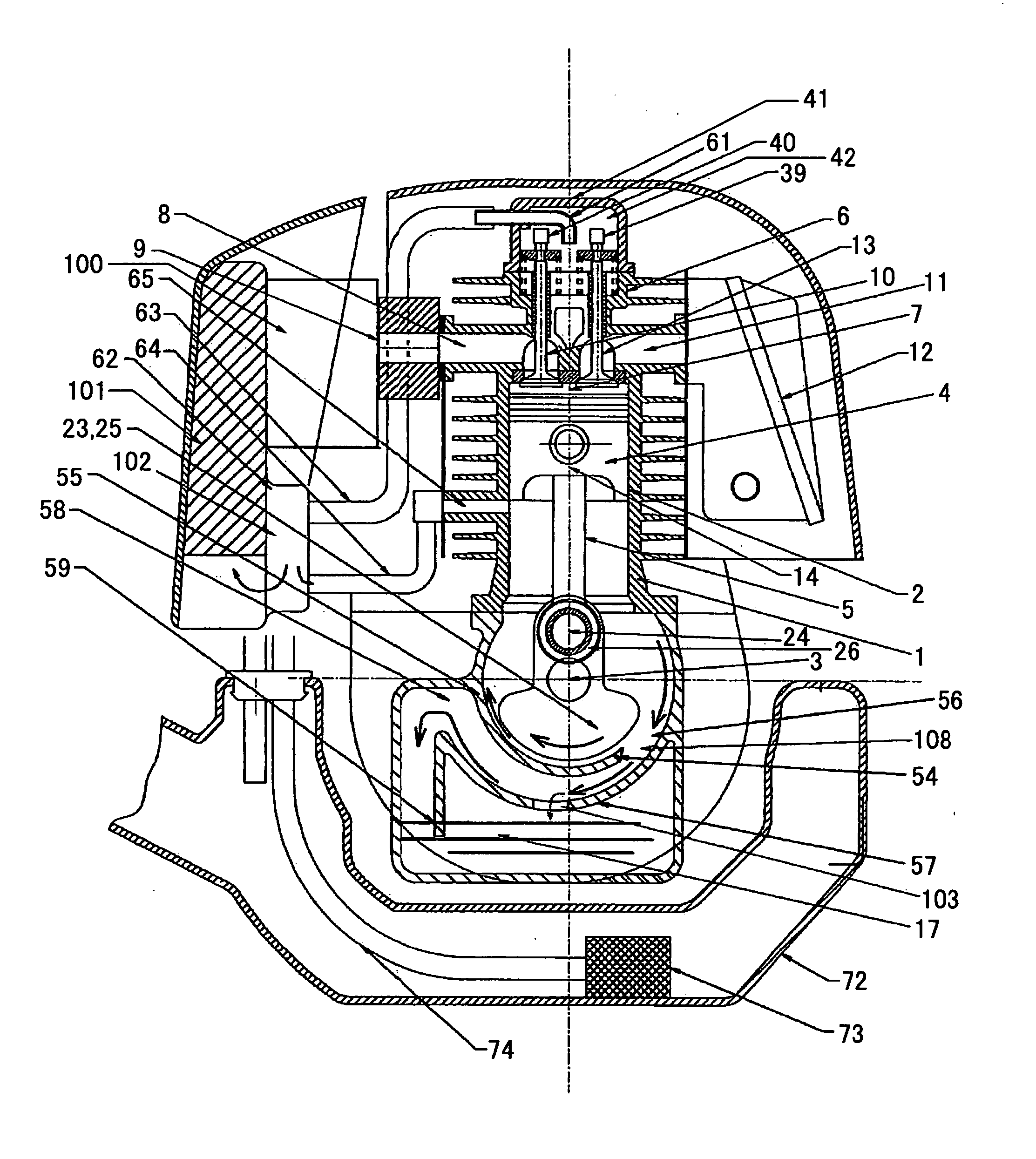

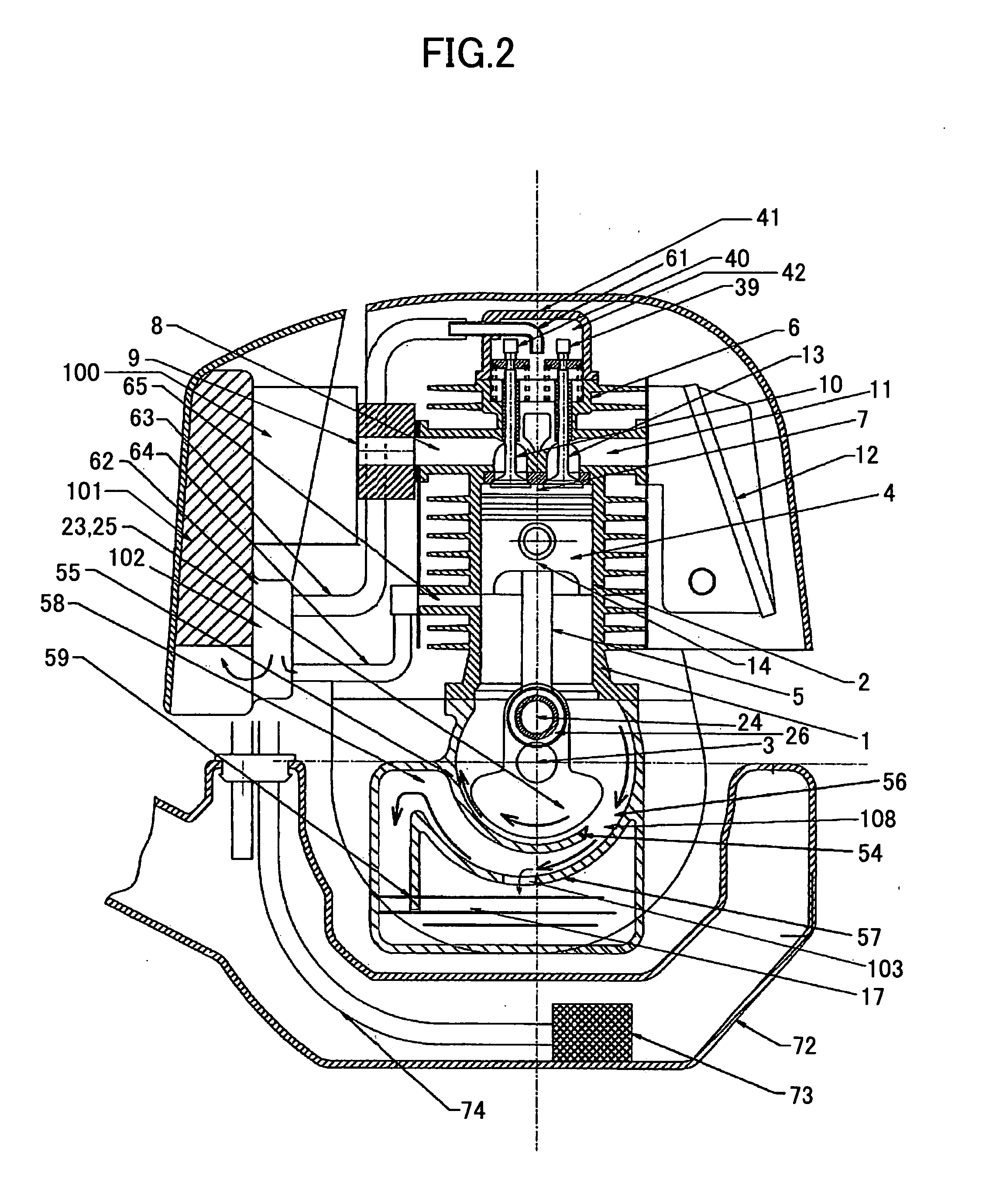

Engine lubrication method

An engine lubrication method is provided. The four-cycle engine has a lightweight aluminum alloy engine block having a cylindrical bore and an enclosed oil reservoir formed therein. A crankshaft is rotatably mounted in the engine block for rotation about a crankshaft axis. A piston reciprocates within the bore and is connected to the crankshaft by a connecting rod. A cam shaft is rotatably mounted in the crank shaft chamber for rotation about a cam shaft axis, parallel to the crank shaft axis. An oil pump driven by the cam shaft, which mates by cam gear with crank gear that is driven by crank shaft, inhales the oil from the oil reservoir to splash lubricate into the crank shaft chamber. The engine is provided with a cylinder head assembly defining a compact combustion chamber having a pair of overhead intake and exhaust ports and cooperating intake and exhaust valves. A lightweight, high-powered engine is thereby provided having relatively low HC and CO emissions. A circular arc wall surrounds around web of the crankshaft with a slight distance from the web. A scroll-shaped wall has gradually increased distance from said wall to the direction of rotation of the web and has partial overlap with the circular arc wall. The check valve splashes breathing mist oil from crank shaft room to breather room and causes the oil to supply to lubricate engine parts in valve chamber and the oil, after lubricating the parts, is returned into the oil reservoir.The oil in crank shaft chamber, after lubricating engine parts, is returned to oil reservoir guided by scroll-shaped wall and a hole provided on the scroll-shaped wall.In case of stock of engine oriented power take off side up or down, oil is prevented to flow from oil reservoir to combustion chamber by a weir which is provided between circular wall and scrolled or extended wall.

Owner:ETG

Lubrication scavenge system

A method and apparatus for scavenging lubricant is disclosed herein. In the invention, a rotating structure is encircled within a sump housing and subjected to lubrication. The sump housing collects high-momentum lubricant flow and low-momentum lubricant flow. The interior of the sump housing is separated into a plurality of chambers with at least one dynamic seal. The at least one dynamic seal extends between the sump housing and the rotating structure to isolate the high-momentum lubricant flow from the low-momentum lubricant flow.

Owner:ROLLS ROYCE CORP

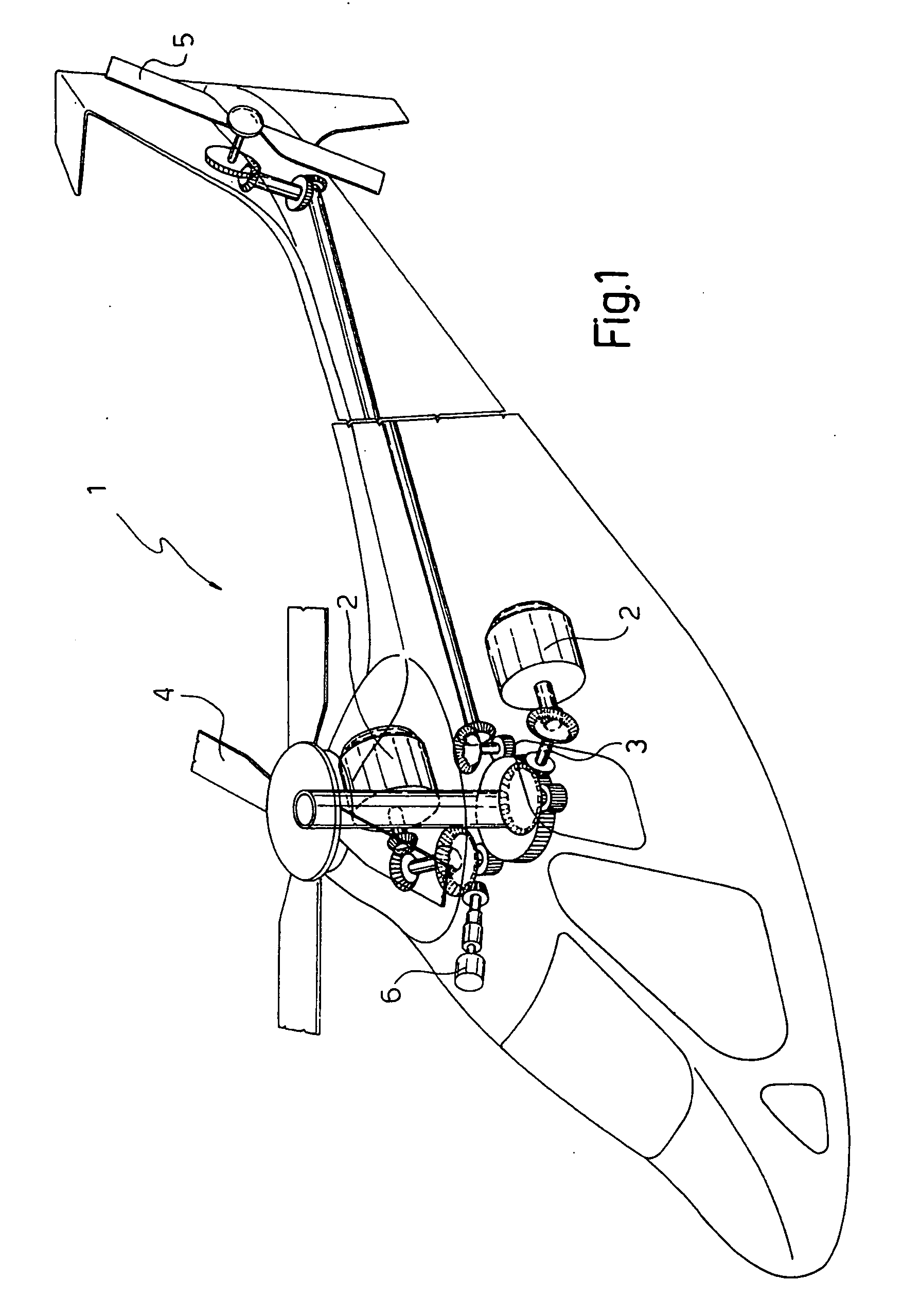

Helicopter with an auxiliary lubricating circuit

ActiveUS20090071753A1Meet the requirementsDrip lubricationDrip or splash lubricationAuxiliary memoryEngineering

Owner:LEONARDO FINMECCANICA SPA

Engine lubrication method

InactiveUS7287508B2Emission reductionSufficient lightingLubrication of auxillariesDrip or splash lubricationExhaust valveCombustion chamber

An engine lubrication method is provided. The four-cycle engine has a lightweight aluminum alloy engine block having a cylindrical bore and an enclosed oil reservoir formed therein. A crankshaft is rotatably mounted in the engine block for rotation about a crankshaft axis. A piston reciprocates within the bore and is connected to the crankshaft by a connecting rod. An oil pump driven by the cam gear, which mates with crank gear that is driven by crank shaft, inhales the oil from the oil reservoir to splash lubricate into the cylinder bore. The engine is provided with a cylinder head assembly defining a compact combustion chamber having a pair of overhead intake and exhaust ports and cooperating intake and exhaust valves. A lightweight, high-powered engine is thereby provided having relatively low HC and CO emissions. A circular arc wall surrounds around web of the crankshaft with a slight distance from the web. A scroll shaped wall has gradually increased distance from said wall to the direction of rotation of the web and has partial overlap with the circular arc wall. The crankshaft web splashes and flies the oil to lubricate engine parts and the oil after lubricating the parts is forced to return into the oil reservoir guided by scroll shaped wall.

Owner:ETG

Dual level oil impeller for drive axle assembly

InactiveUS6991574B2Reduce the amount requiredFully lubricatedDrip or splash lubricationGear lubrication/coolingImpellerTransaxle

Owner:ARVINMERITOR TECH

Free vortex air-oil separator

Owner:GENERAL ELECTRIC CO

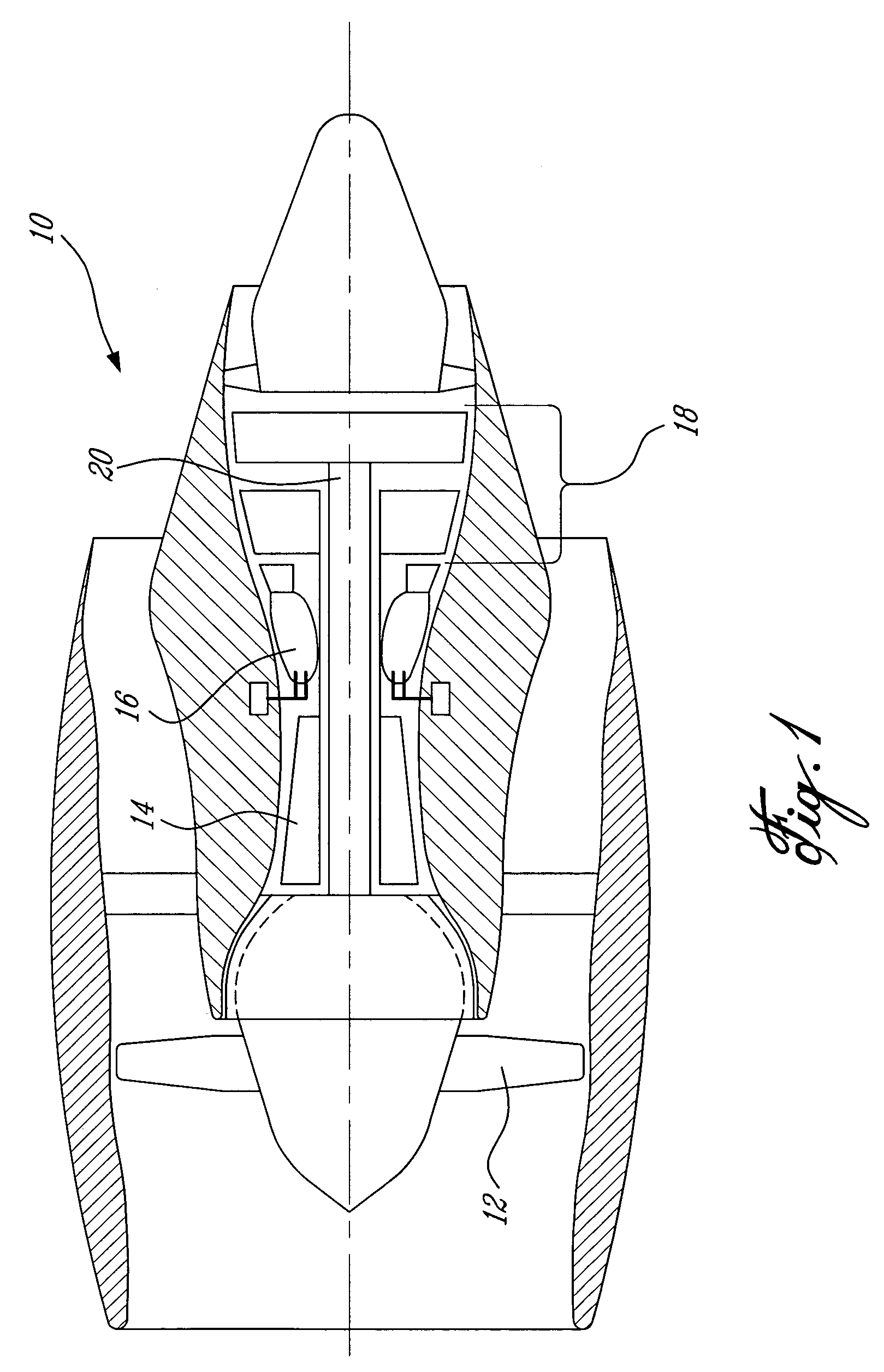

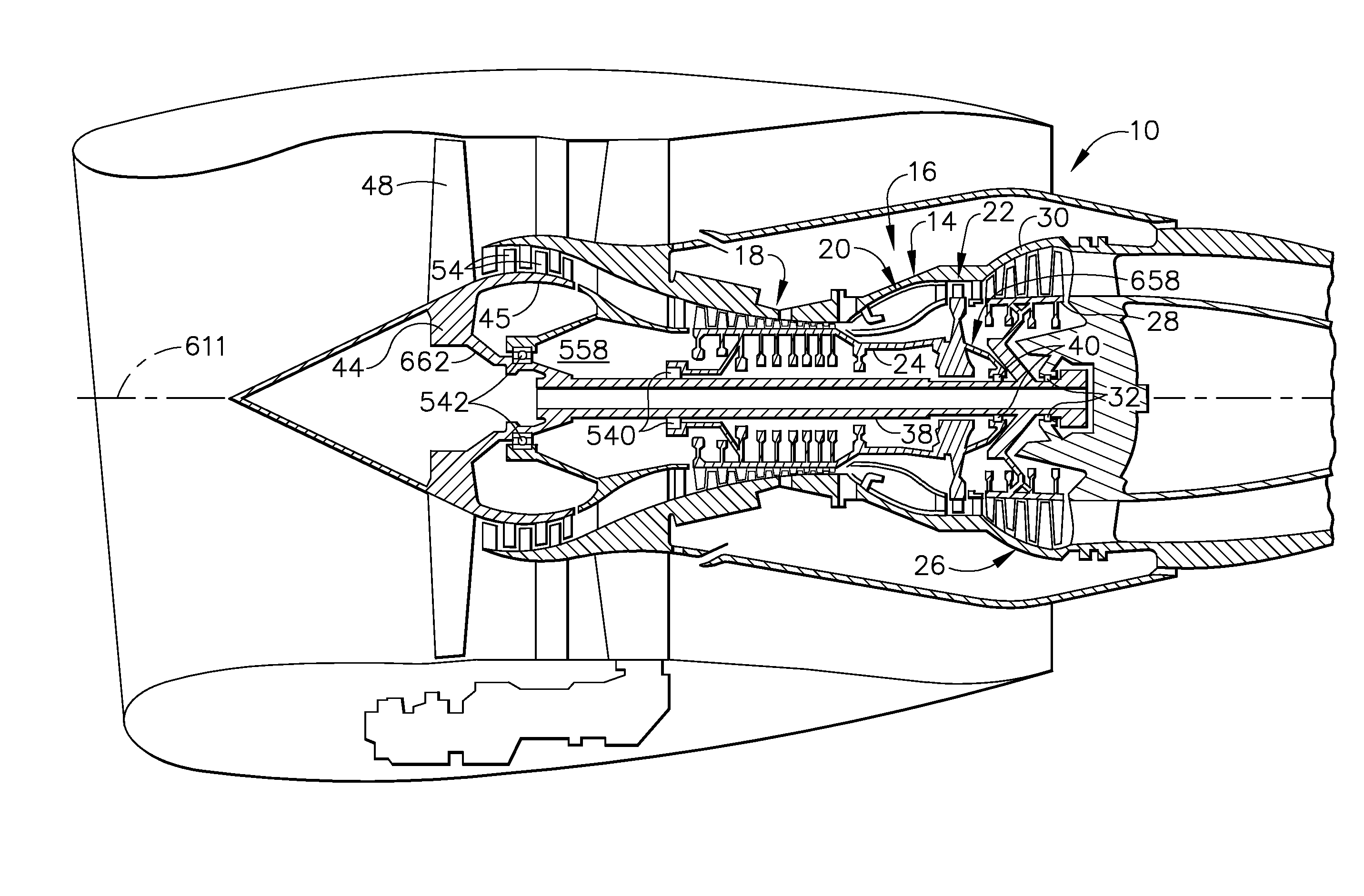

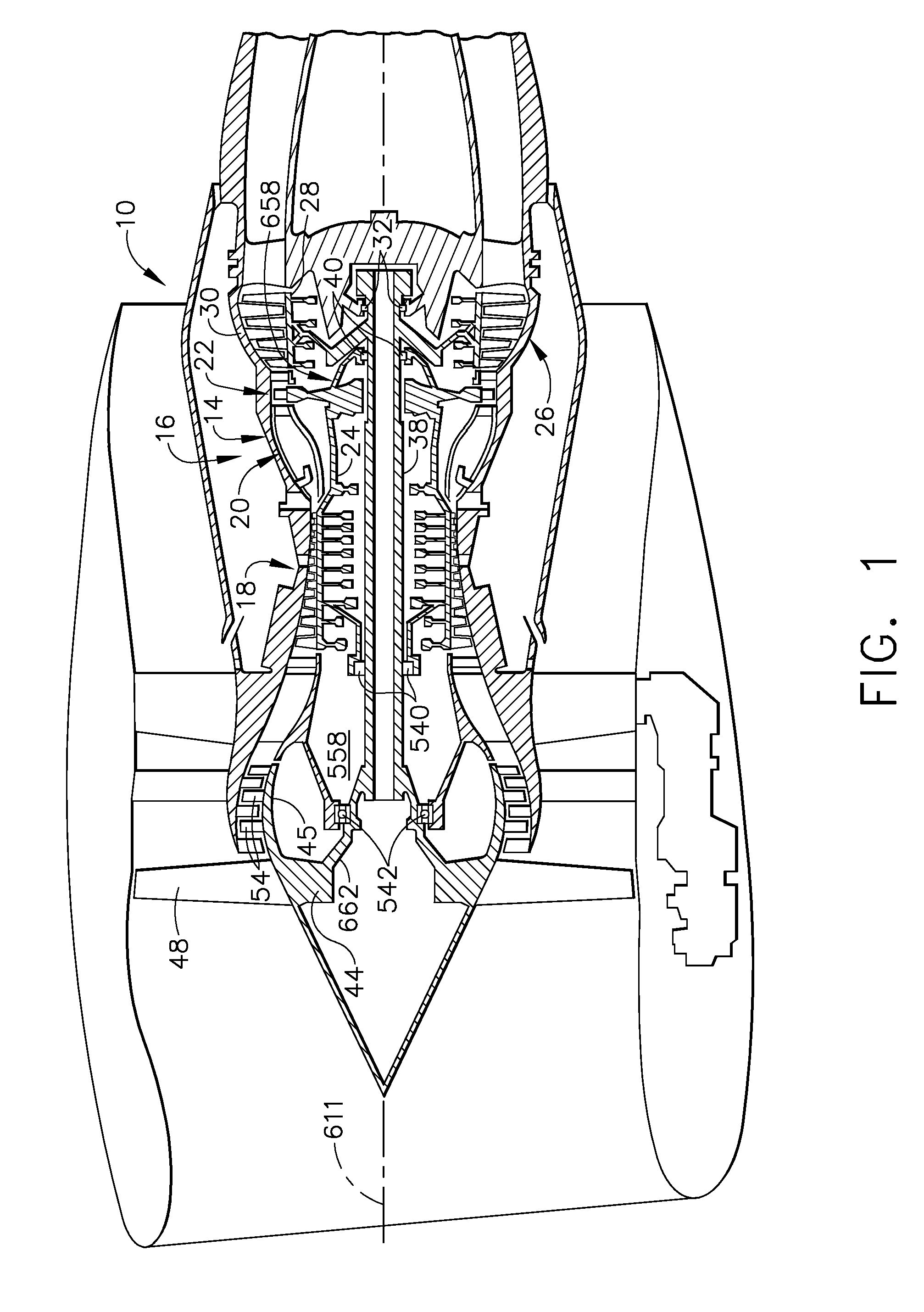

Turbine, particularly useful for small aircraft

ActiveUS7065954B2Reducing weight and quantityImprove efficiencyRotary bearingsTurbine/propulsion fuel supply systemsLow speedCombustion chamber

A turbine includes a combustion chamber with deflectors generating vortices in a secondary gas flow into the combustion chamber, thereby confining the flame front from penetrating into the cold region of the chamber under variable operating conditions, simplifying cooling of the chamber walls. The turbine further includes devices for decoupling vibrations between the high- and low-speed shafts, including a loosely mounted spline coupling the high-speed shaft to the step-down system and disk dampening means coupling the step-down system to the low-speed output shaft.

Owner:FLORESTAN TECH PTY LTD

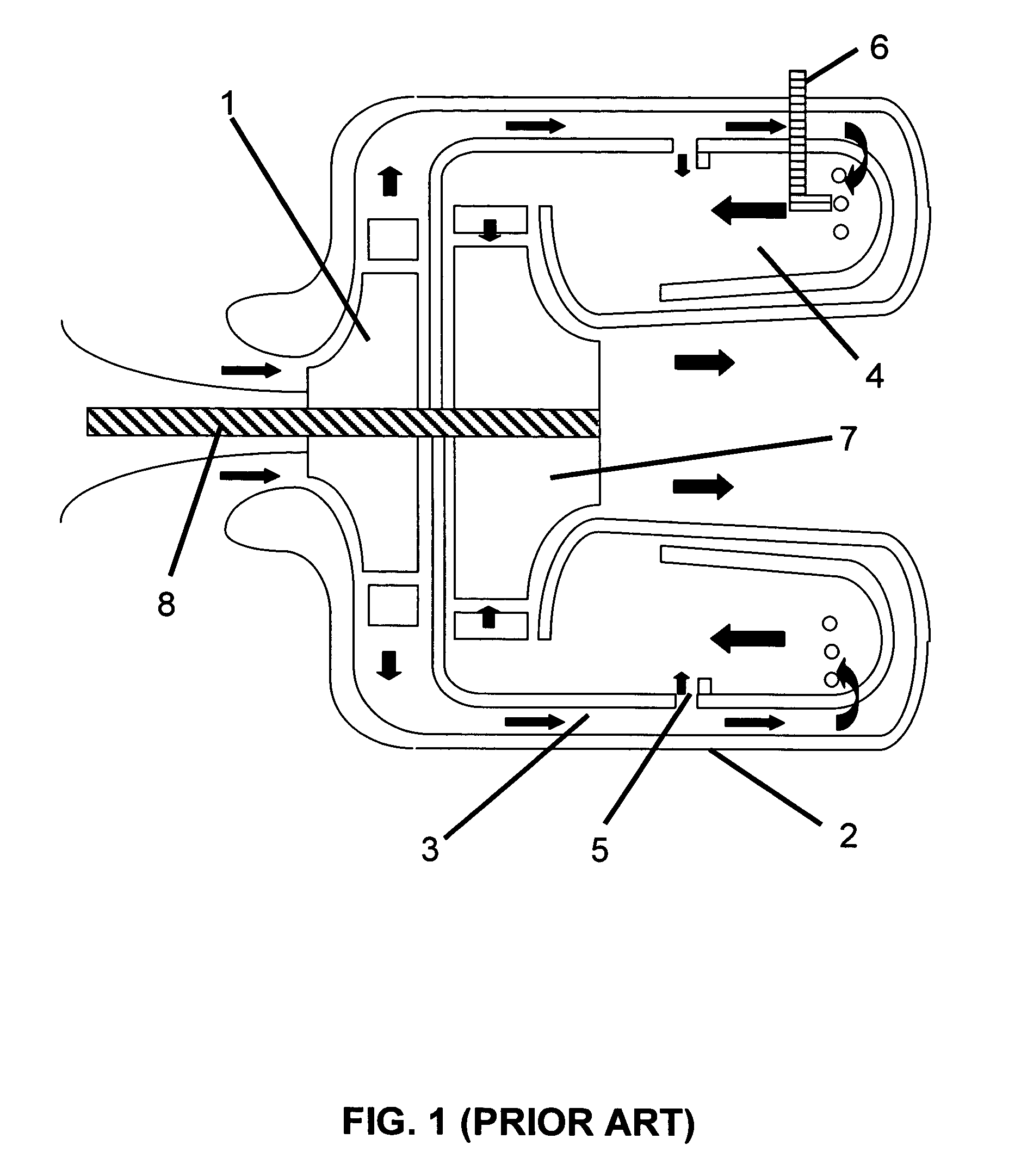

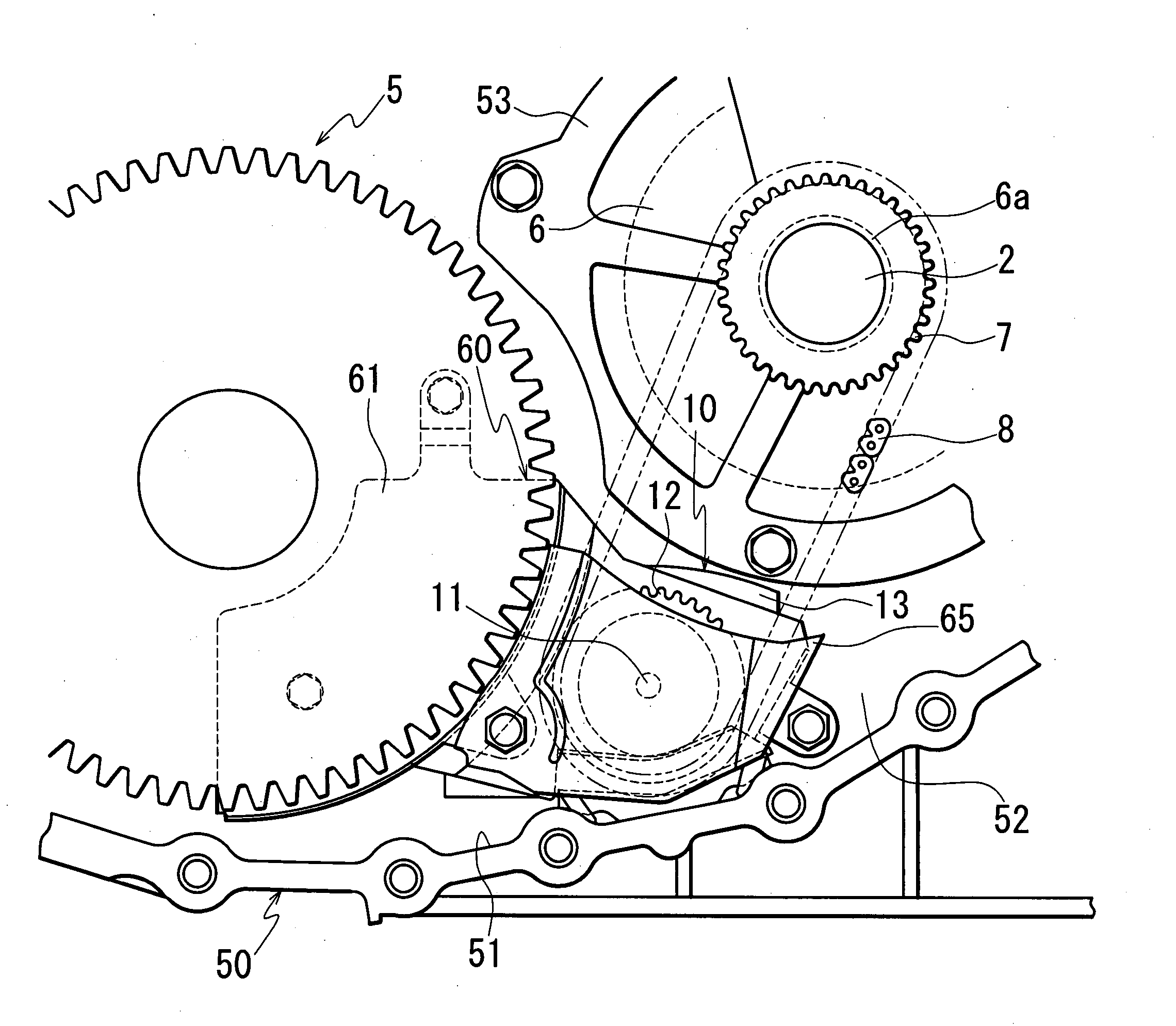

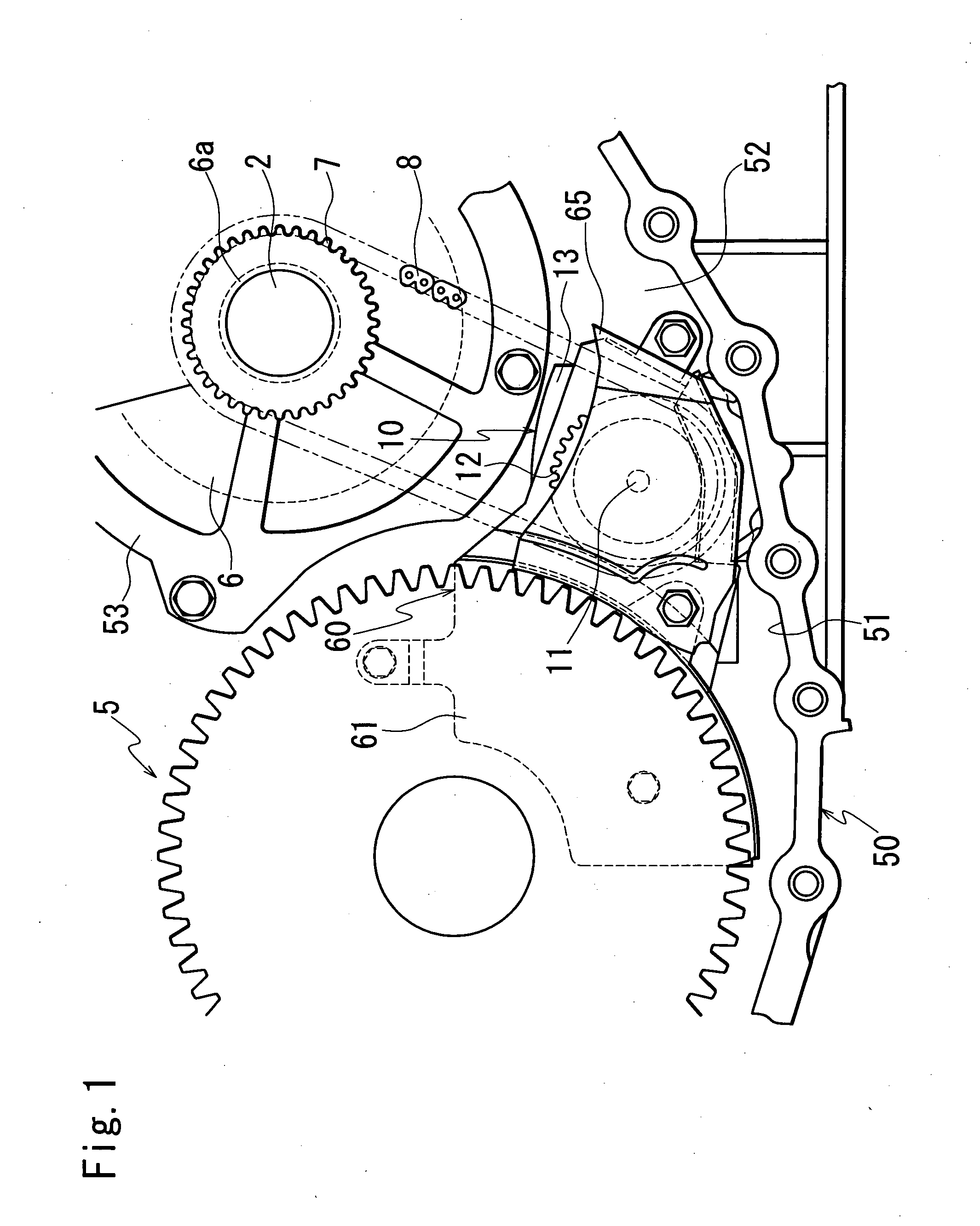

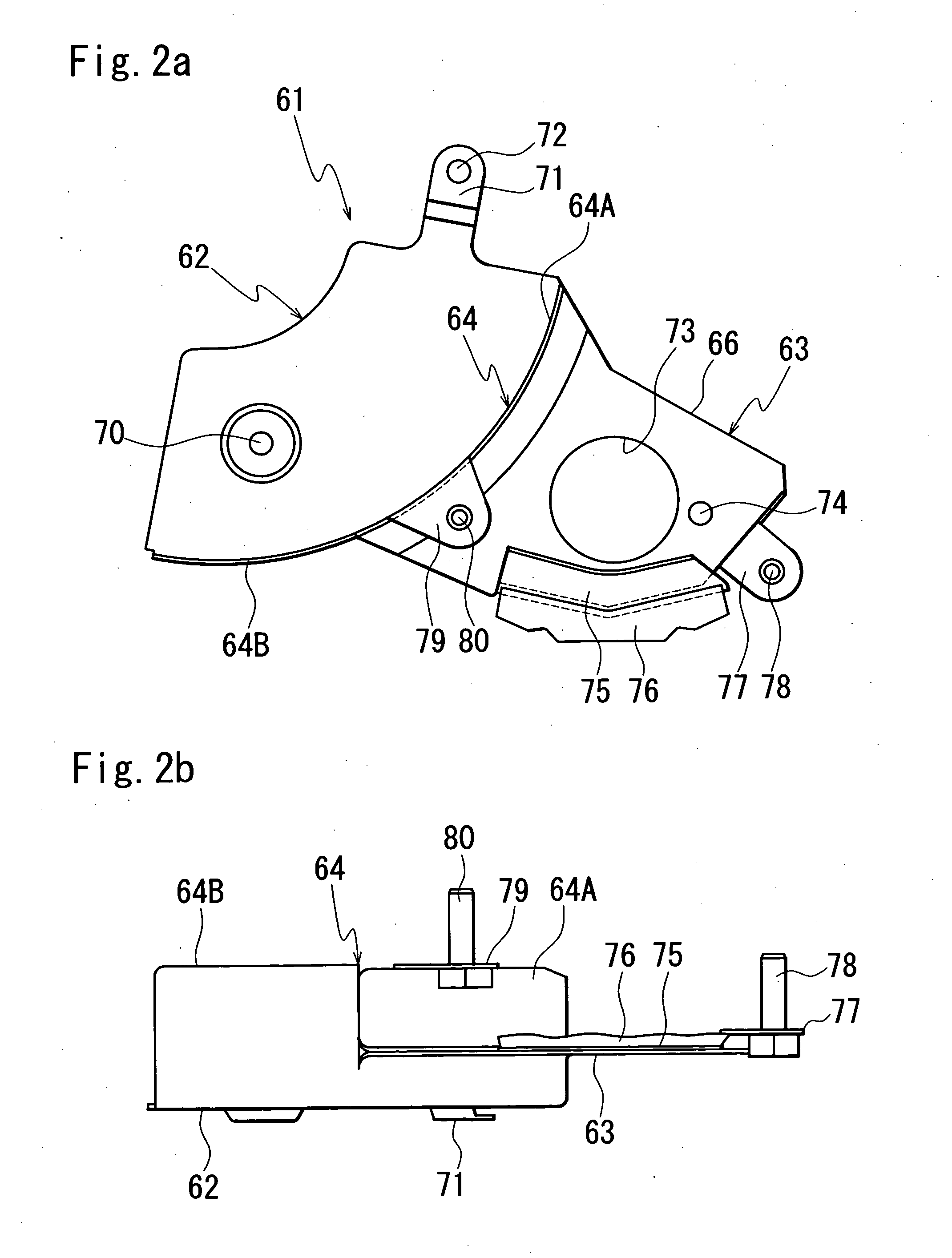

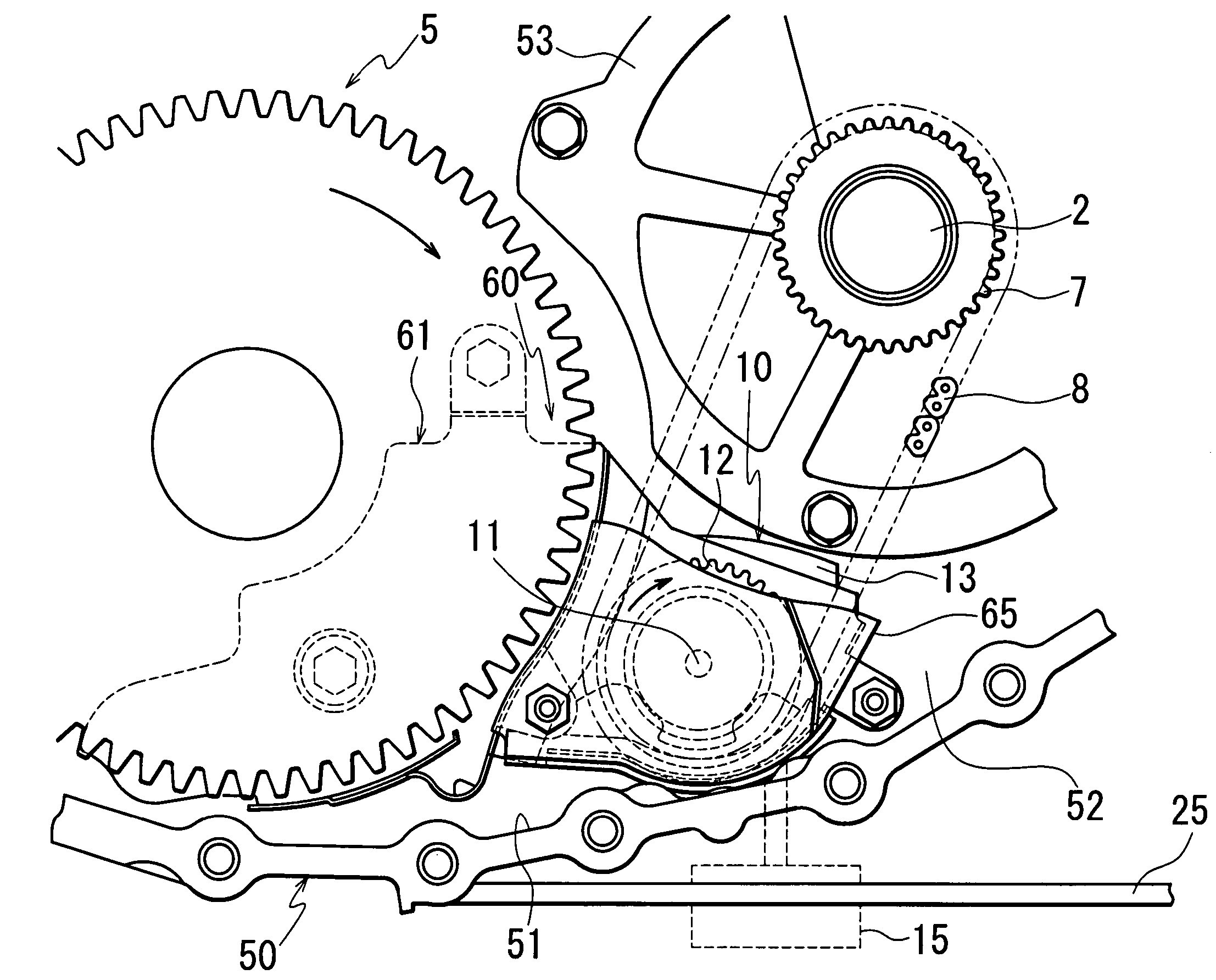

Baffle plate

InactiveUS20060060424A1Simple designEasy to manufactureGearboxesDrip or splash lubricationEngineeringSprocket

There is provided a baffle plate which conforms to the shape of the inner peripheral surface of a transmission case and can be easily brought into contact with the inner peripheral surface of the transmission case, making it easier to design and manufacture the baffle plate. Rubber plates are arranged on a side of the baffle plate in proximity to the bottom wall of the transmission case. The baffle plate encloses both sides of the rotating surface of the driven sprocket. Therefore, even if the inner peripheral surface of the bottom wall of the transmission case has a complex shape, the side of the baffle plate in proximity to the case bottom wall can be closely attached to the inner peripheral surface of the transmission case. And, the baffle plate can be easily designed and manufactured. Also, oil agitating resistance during rotation of the driven sprocket can be reduced.

Owner:JATCO LTD

Oil separating structure of automatic transmission

There is provided an oil separating structure of an automatic transmission, which makes it difficult for an oil strainer of an oil pump to draw oil containing air bubbles. A baffle plate base separates a space around the oil strainer and a space around a driven sprocket as well as a final gear, and therefore, oil containing air bubbles formed as a result of agitation by the driven sprocket, chain, and final gear does not flow directly into the oil strainer. As a result, the oil strainer is unlikely to draw oil containing air bubbles.

Owner:JATCO LTD

Lubricating structure for output shaft bearing portion in transmission

An output shaft bearing portion which is provided in an extension housing to be attached to an outside of an end wall portion of a casing main body of a transmission casing is lubricated by lubrication oil which is supplied to lubricating portions inside the casing main body. In the end wall portion there is formed an oil guide passage which guides the lubrication oil supplied to the lubricating portions inside the casing main body. Inside the extension housing, there is formed a rib which guides the lubrication oil flown from the oil guide passage, into a position in which the lubrication oil can be scraped by a gear wheel provided inside the extension housing. The lubrication oil scraped by the gear wheel is supplied to the output shaft bearing portion.

Owner:HONDA MOTOR CO LTD

Engine lubrication method

ActiveUS20080083392A1Suitable for useDrip or splash lubricationMachines/enginesExhaust valveGear wheel

An engine lubrication method is provided. The four-cycle engine has a lightweight aluminum alloy engine block having a cylindrical bore and an enclosed oil reservoir formed therein. A crankshaft is rotatably mounted in the engine block for rotation about a crankshaft axis. A piston reciprocates within the bore and is connected to the crankshaft by a connecting rod. An oil pump driven by the cam gear, which mates with crank gear that is driven by crank shaft, inhales the oil from the oil reservoir and the valve chamber to splash lubricate into the cylinder bore. The engine is provided with a cylinder head assembly defining a compact combustion chamber having a pair of overhead intake and exhaust ports and cooperating intake and exhaust valves. A lightweight, high-powered engine is thereby provided having relatively low HC and CO emissions. A circular arc wall surrounds around web of the crankshaft with a slight distance from the web. A scroll-shaped wall has gradually increased distance from said wall to the direction of rotation of the web and has partial overlap with the circular arc wall. The crankshaft web splashes and causes the oil to fly to lubricate engine parts and the oil, after lubricating the parts, is forced to return into the oil reservoir guided by scroll-shaped wall and a hole provided on the scroll-shaped wall.

Owner:ETG

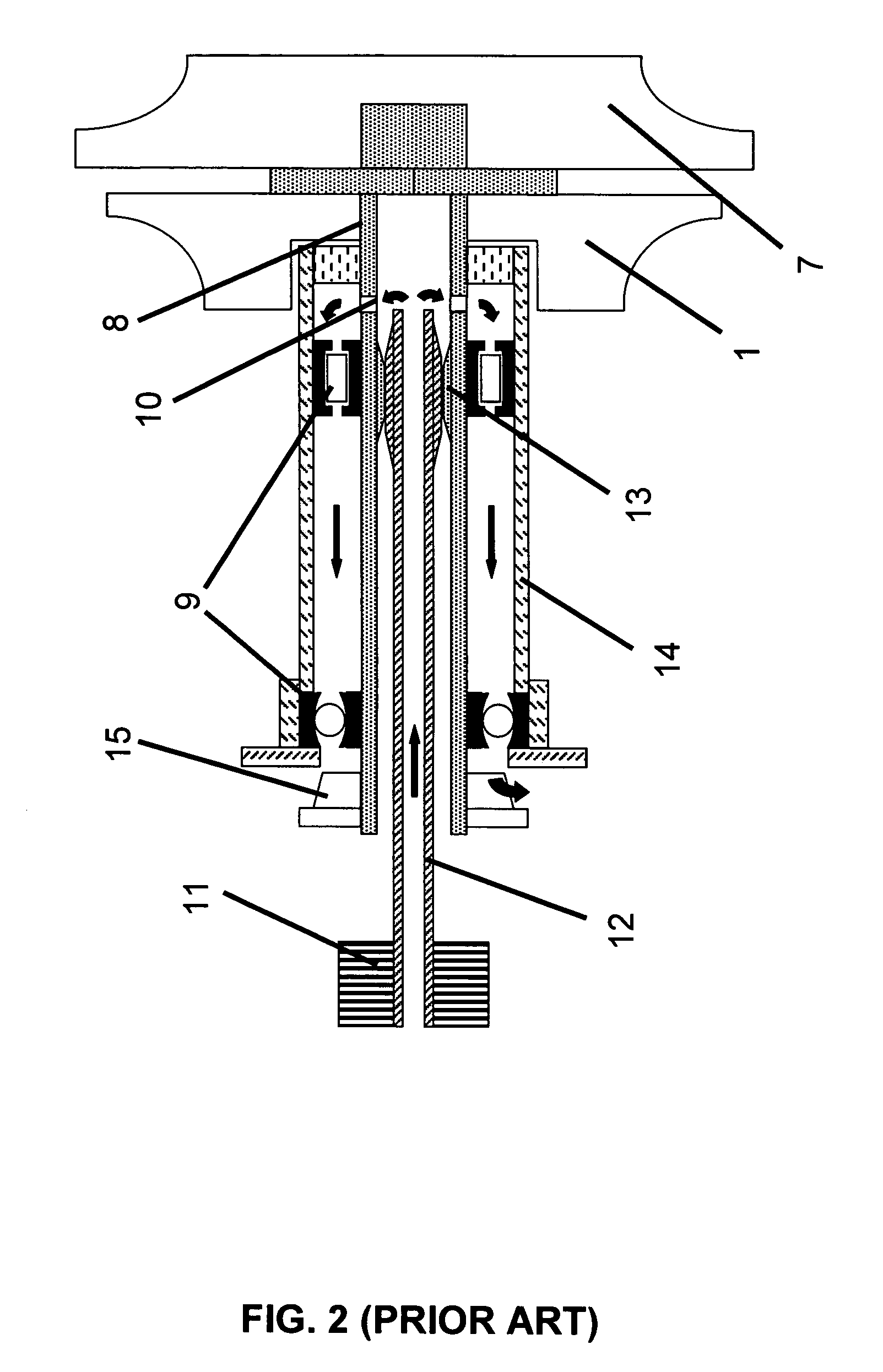

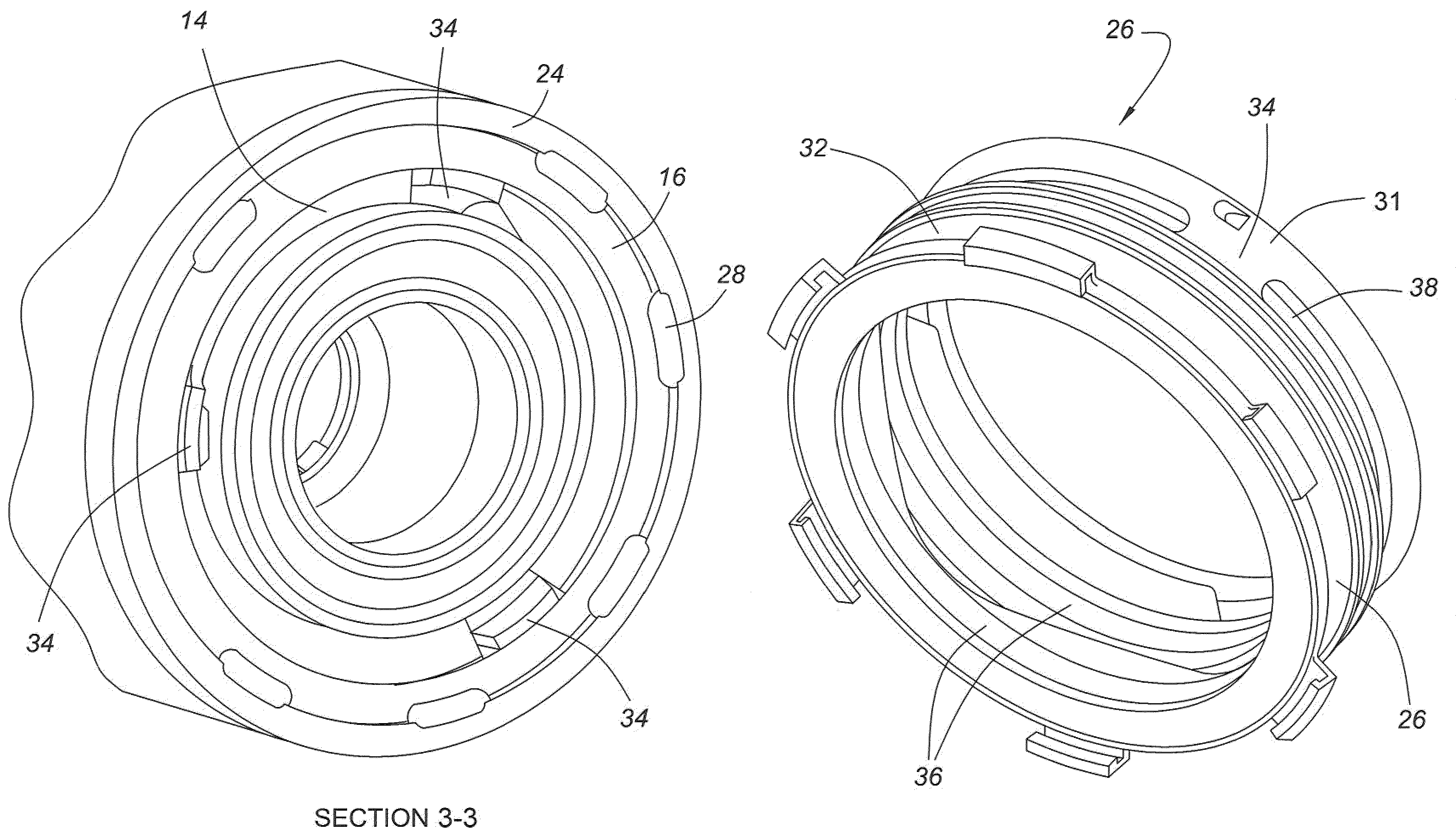

Oil scavenge system for gas turbine engine bearing cavity

An oil scavenging system and method suitable for use in a gas turbine engine having a bearing housing. The bearing housing provides for arcuate slots within the housing and a plurality of peripherally arranged apertures disposed for cooperation with the arcuate slots. During rotation of the bearing and shaft, the rotational momentum induces rotation of the oil which distributes the oil to the peripheral circumference of the housing for eventual passage through the slots and apertures. The arrangement maximizes the use of the circumferential space of the bearing for efficient oil distribution.

Owner:PRATT & WHITNEY CANADA CORP

Bearing assembly comprising double injection of liquid lubricant, and aeronautical vehicle comprising at least one such assembly

A bearing assembly includes a first liquid lubricant injector designed to be fed exclusively with non-recycled liquid lubricant to lubricate a bearing. A plurality of drain orifices passes through a bearing ring fixed to a fixed part, and the assembly also includes a second liquid lubricant injector fed with liquid lubricant drained through a collection device for collecting liquid lubricant drained from the orifices, the collection device communicating firstly with a reinjection circuit connected to the second injector, and with a bypass circuit designed to evacuate surplus drained liquid lubricant.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Gear type of manual transmission for automotive vehicle

An output reduction gear type of manual transmission having a reduction gear chamber formed by partitions disposed on opposite sides of a reduction gear unit, an oil inflow structure comprising an oil inflow passage formed at a lower end of the reduction gear unit and tapered roller bearings supporting an output shaft and a counter shaft which are coupled by the reduction gear unit, an oil outflow structure comprising an oil tray which collects oil splashed by the counter shaft and the reduction gear unit and an oil outflow passage formed at an upper part of the reduction gear unit.

Owner:MAZDA MOTOR CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com