Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5062results about "Friction gearings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

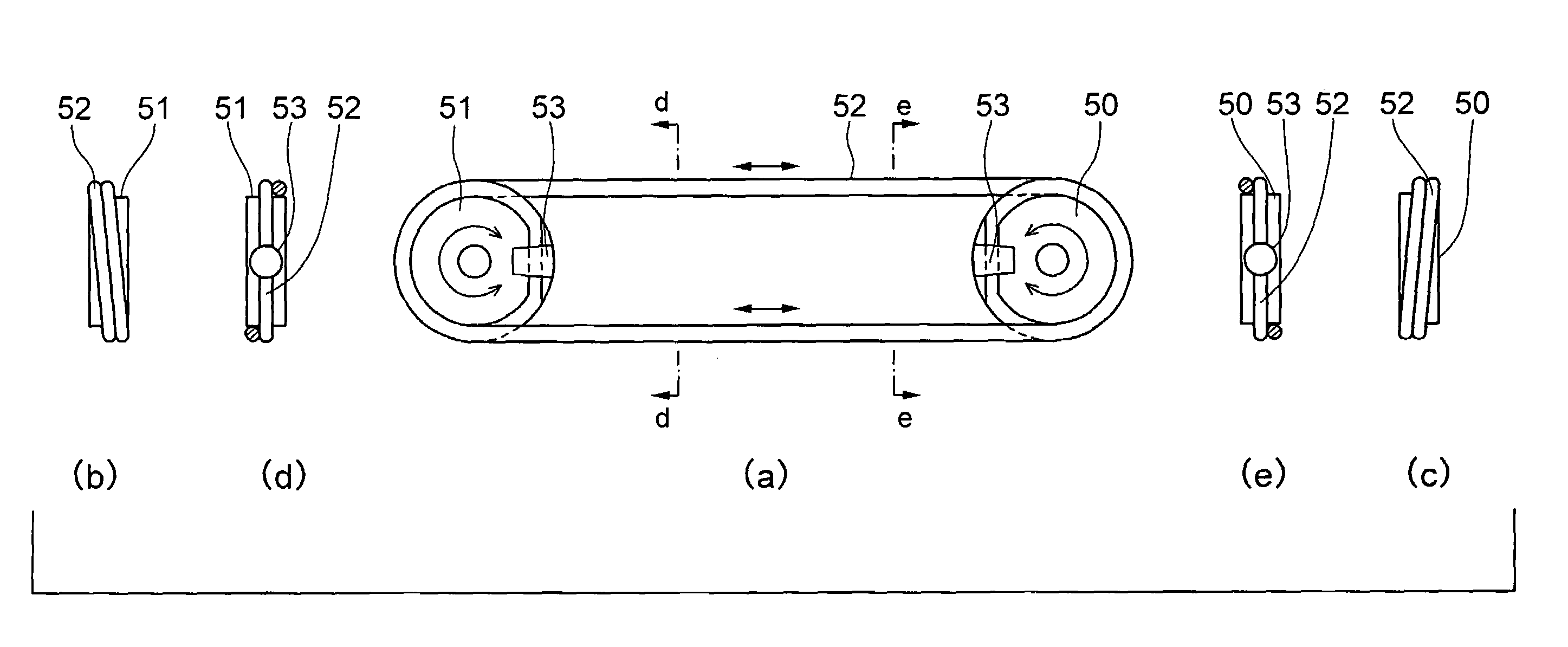

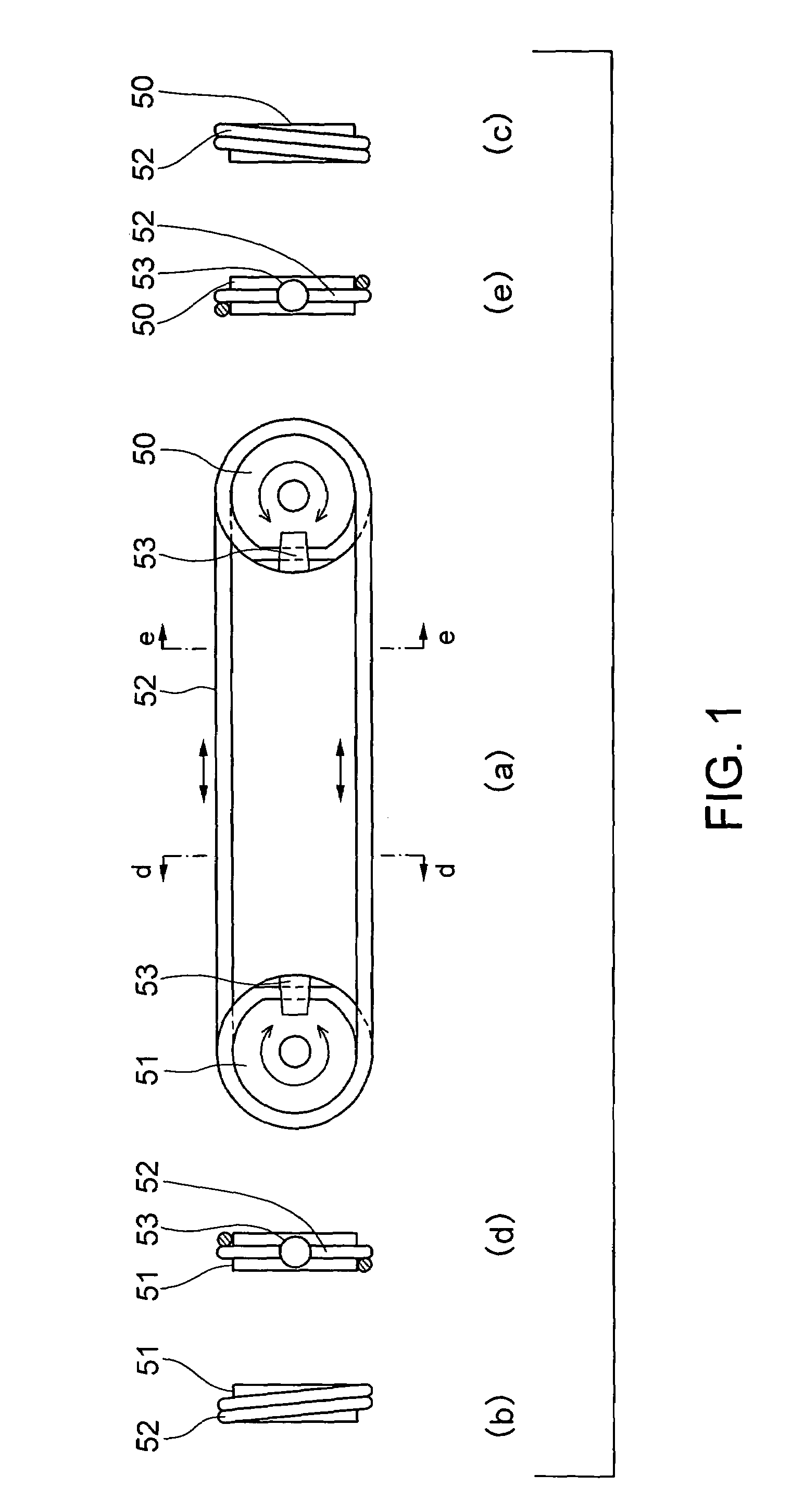

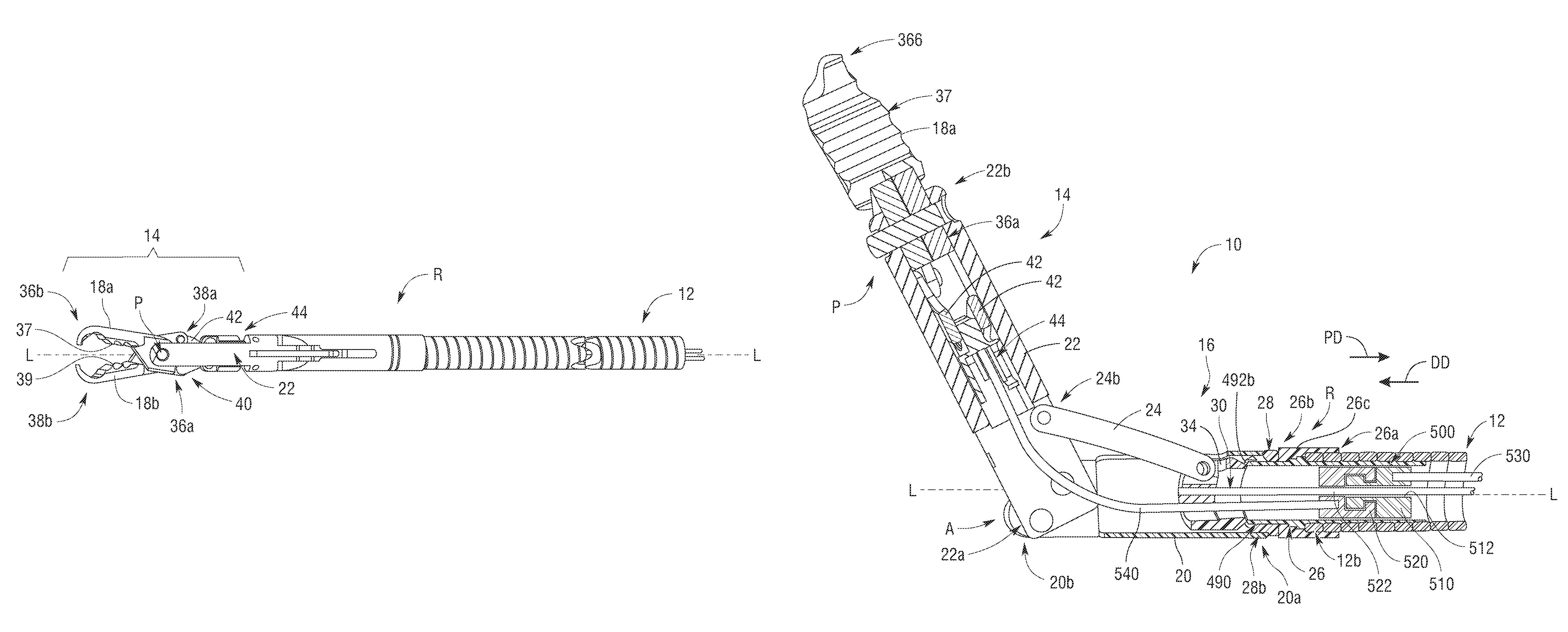

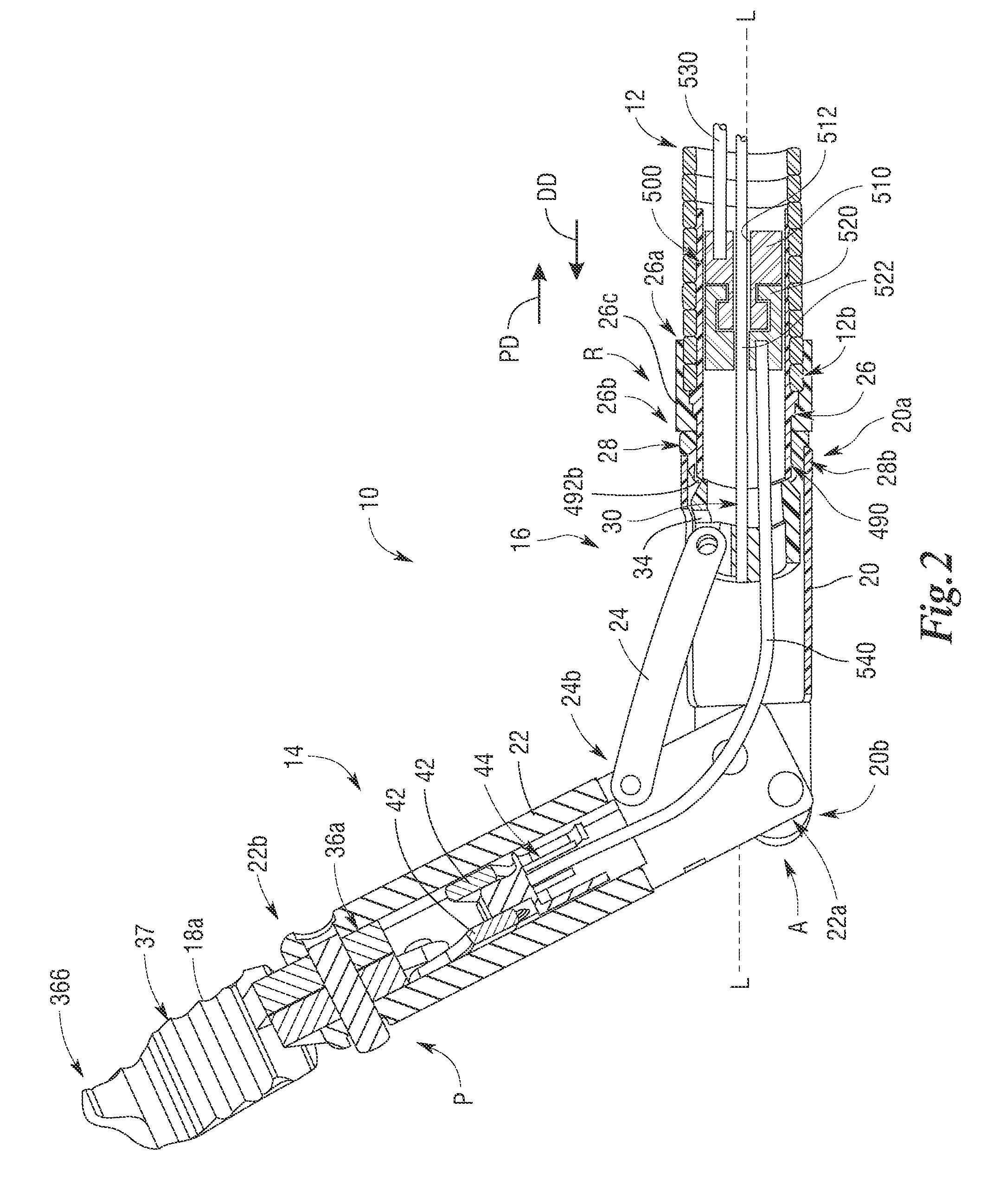

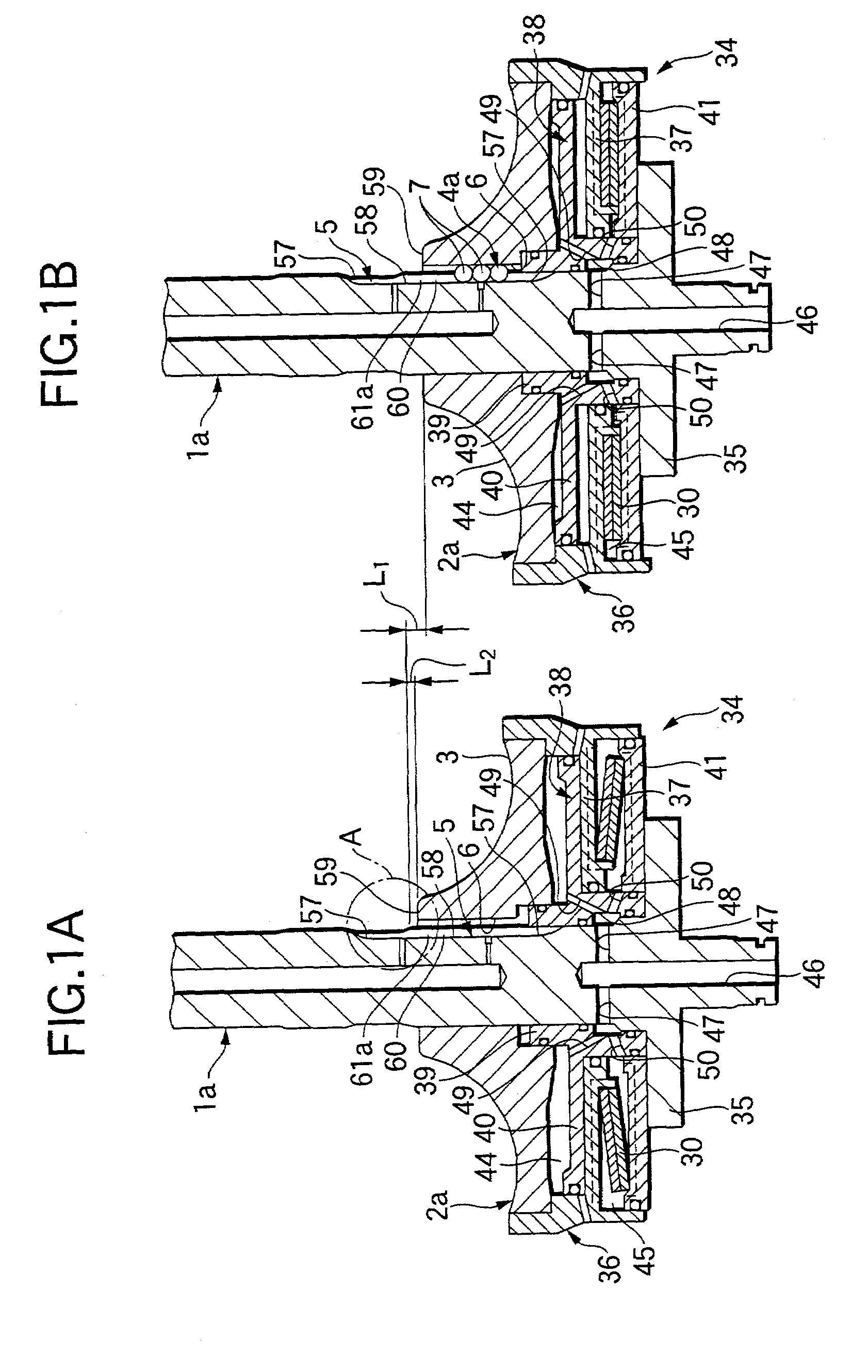

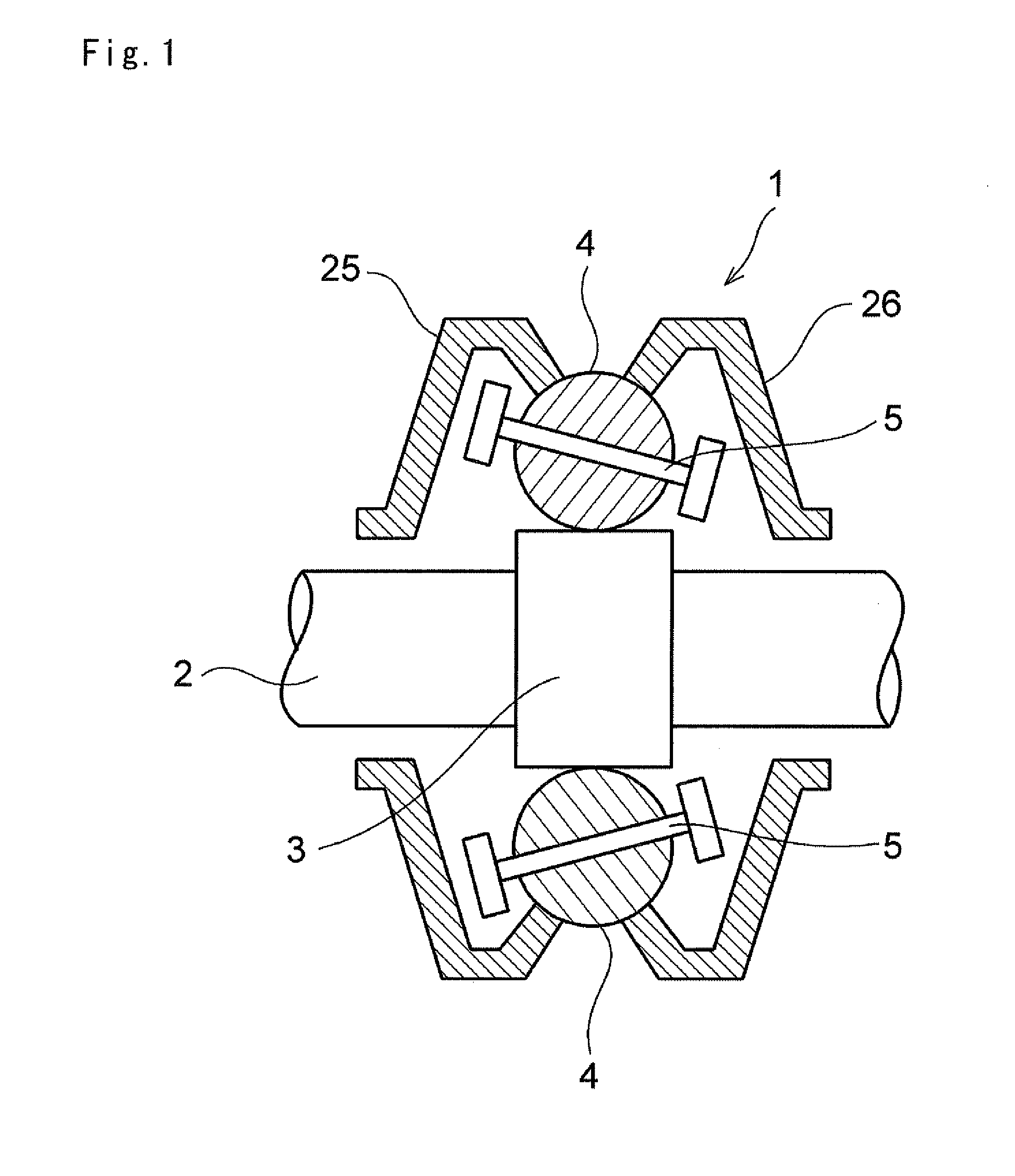

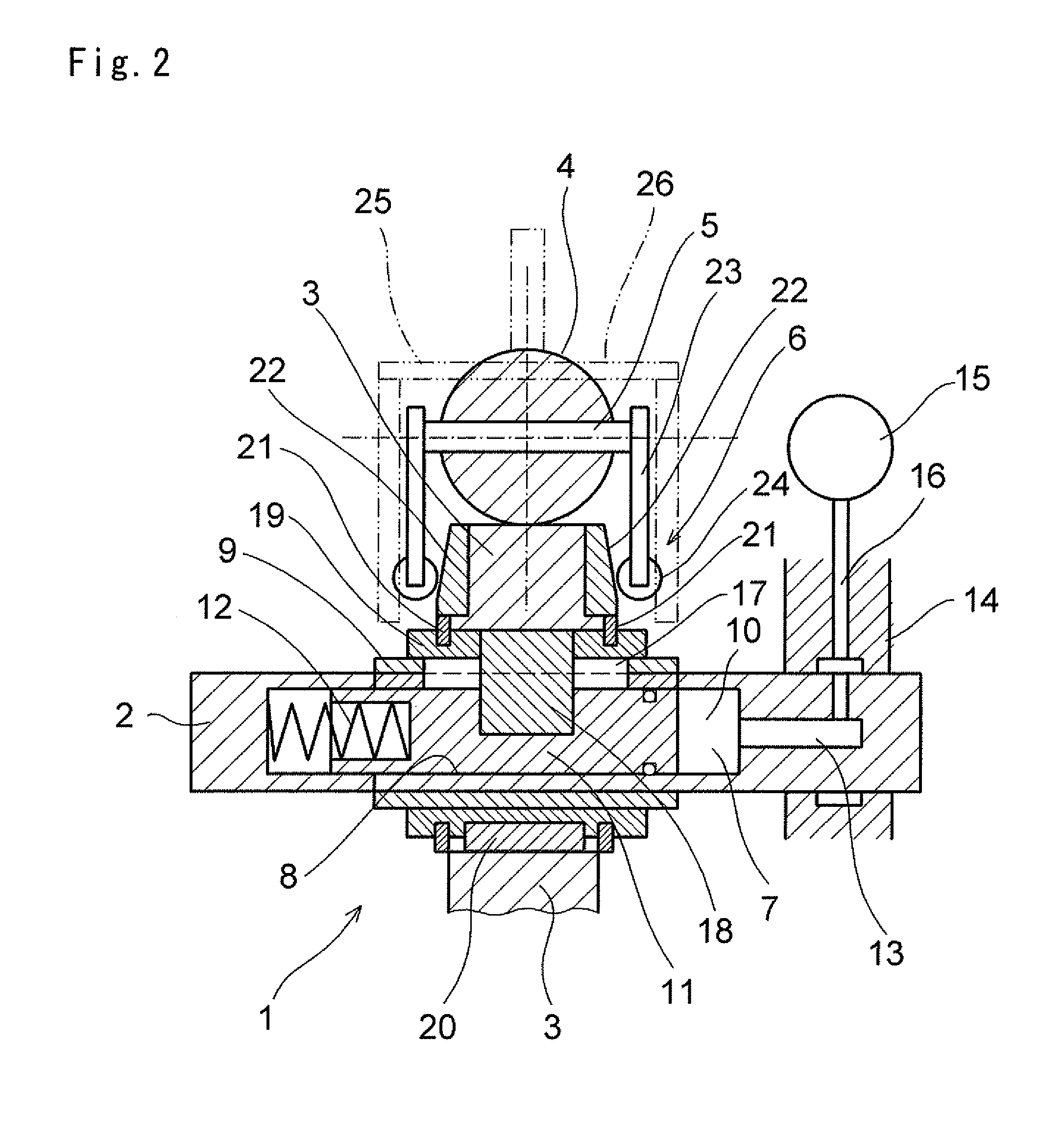

Power transmission mechanism and manipulator

ActiveUS7300373B2Small sizeEnhance reliability and rigidity and controllabilitySuture equipmentsProgramme-controlled manipulatorElectric power transmissionEngineering

A power transmission mechanism comprising: a flexible power transmission element; a pair of a drive pulley and a driven pulley on which the flexible power transmission element is wound, each the pulley having a pin-embedding hole formed to extend from the outer circumferential thereof toward the center thereof, and a slit elongated in the circumferential direction of the pulley to extend to opposite sides of the embedding hole and communicating with the embedding hole; and a pair of columnar or tapered anchor pins each having a path hole penetrating the anchor pin across the lengthwise direction thereof to receive the flexible power transmission element inserted therein, wherein each the anchor pin receiving the flexible power transmission element in the path hole thereof is embedded in the embedding hole of the associated pulley under pressure, and the flexible power transmission element is thereby held on the pulley.

Owner:TERUMO KK

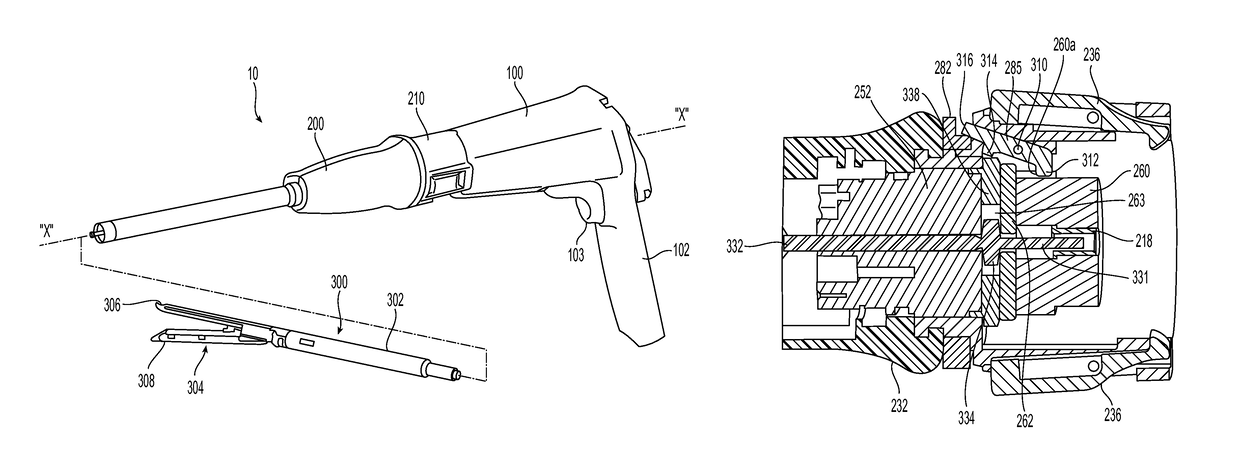

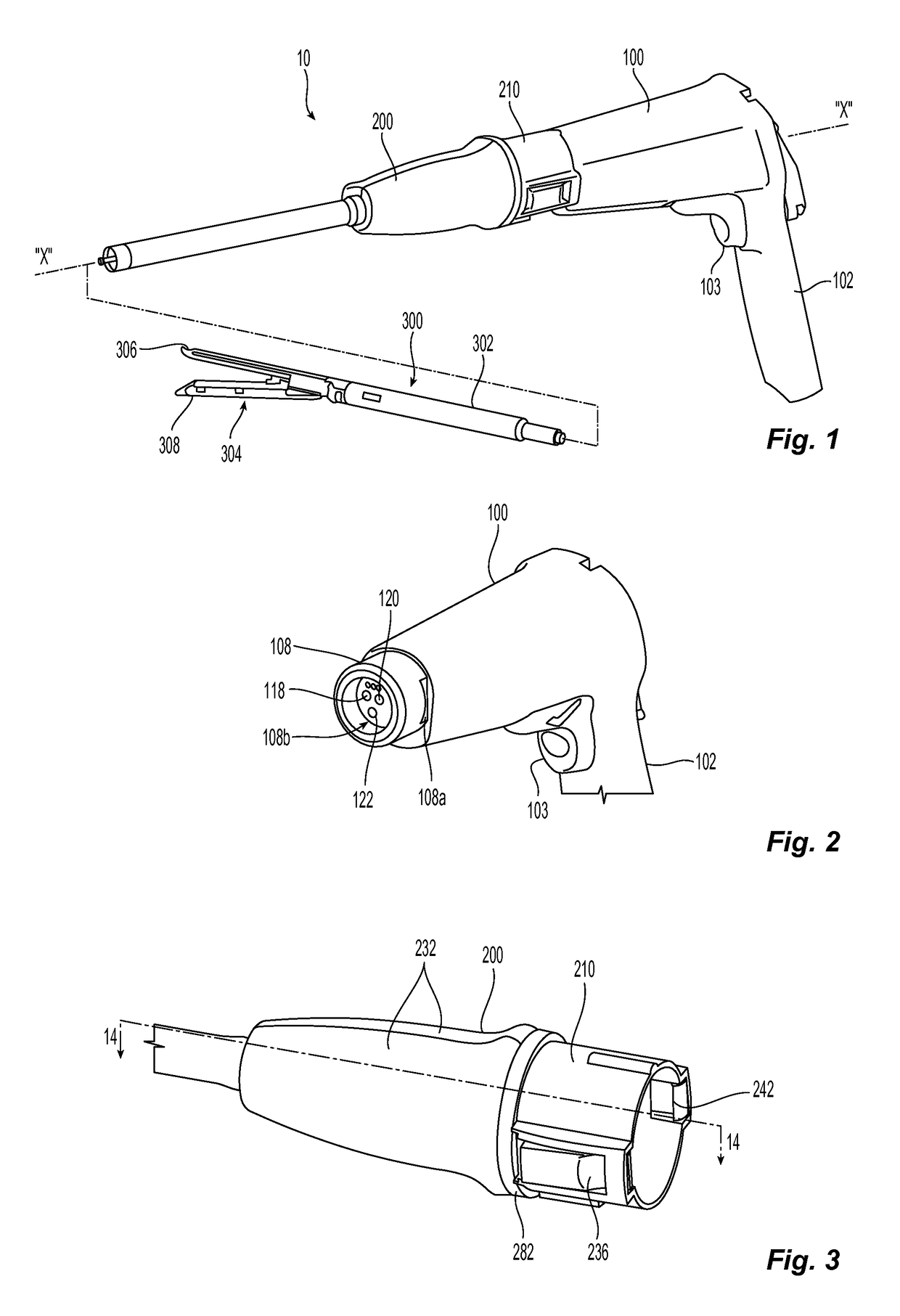

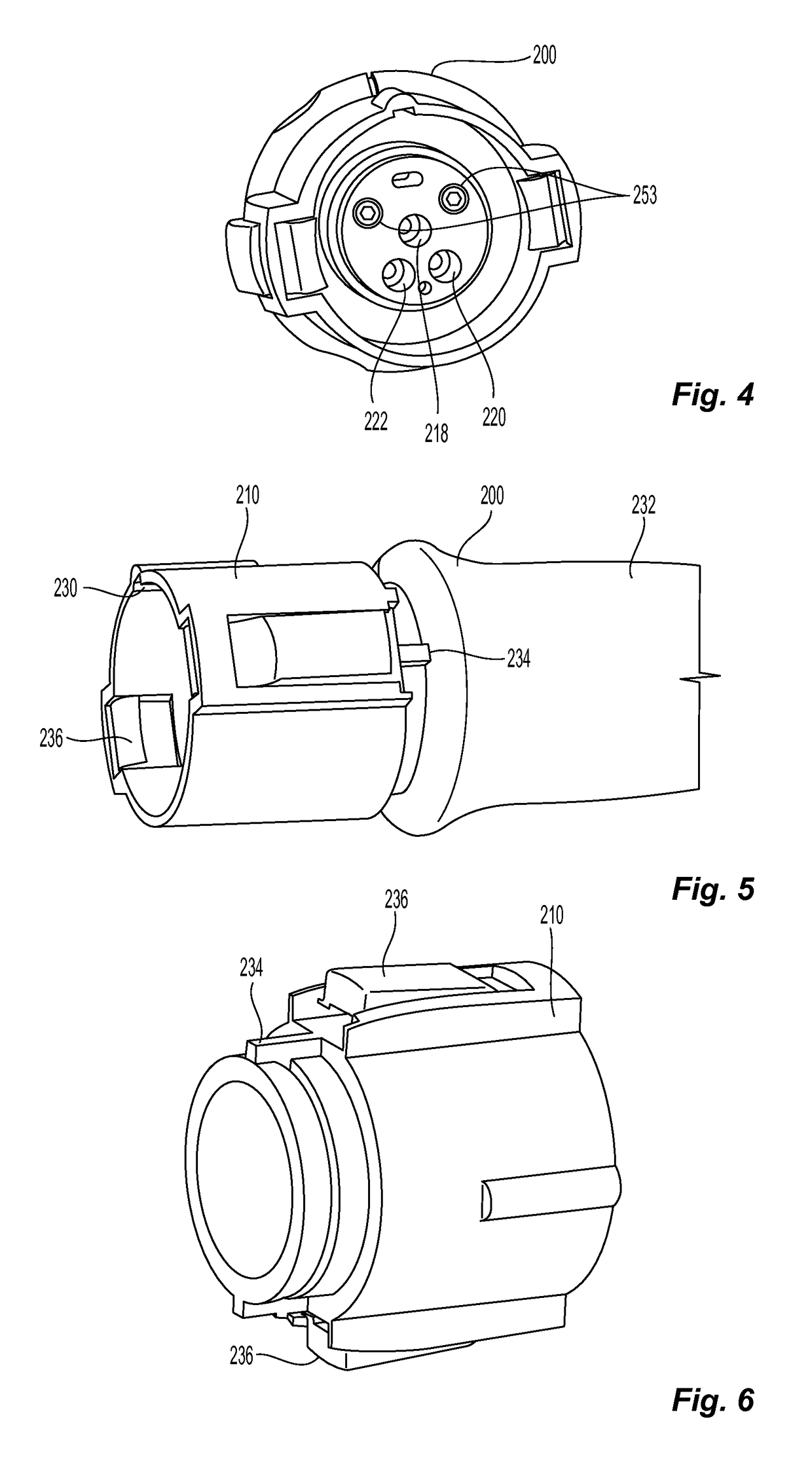

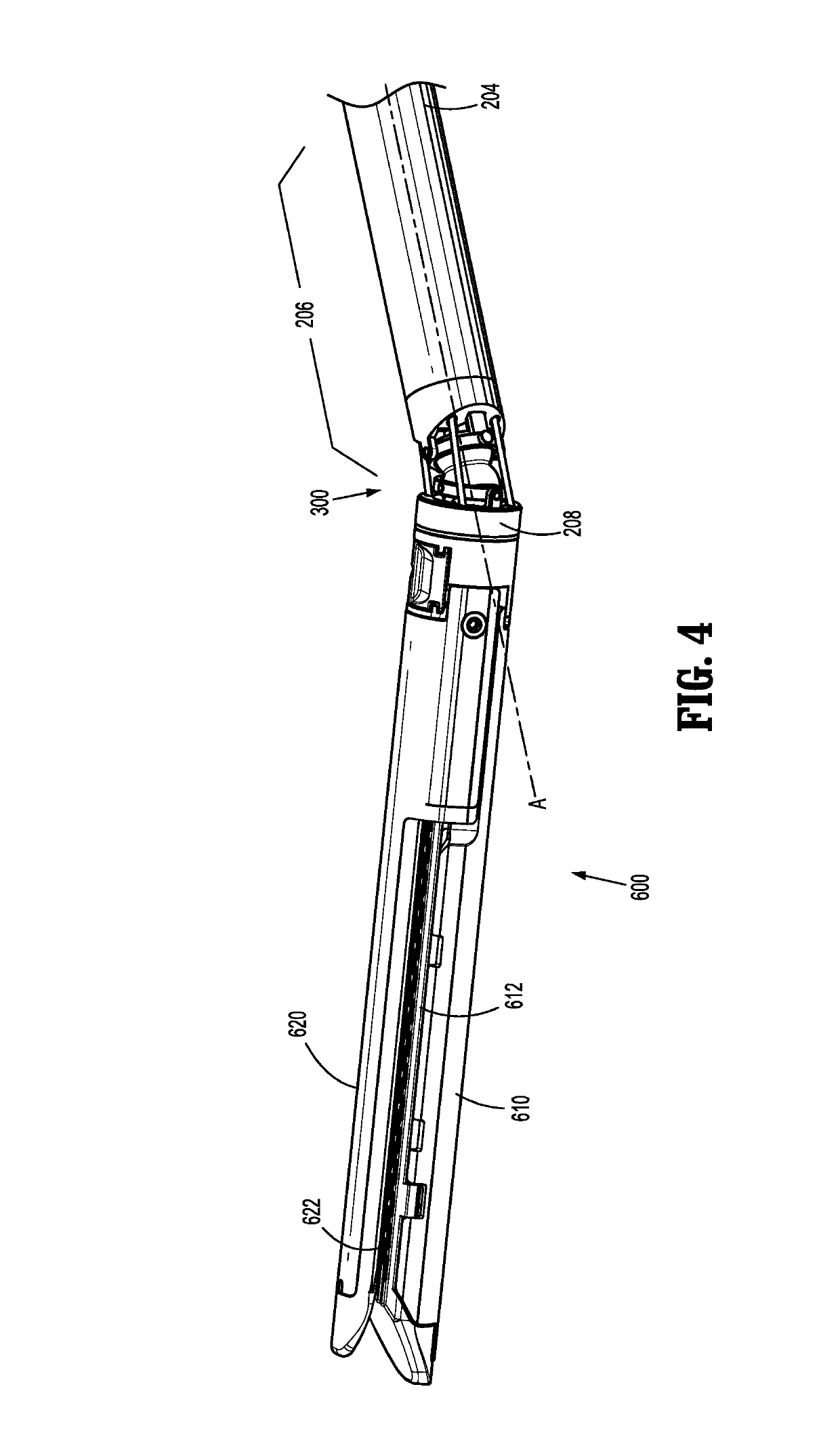

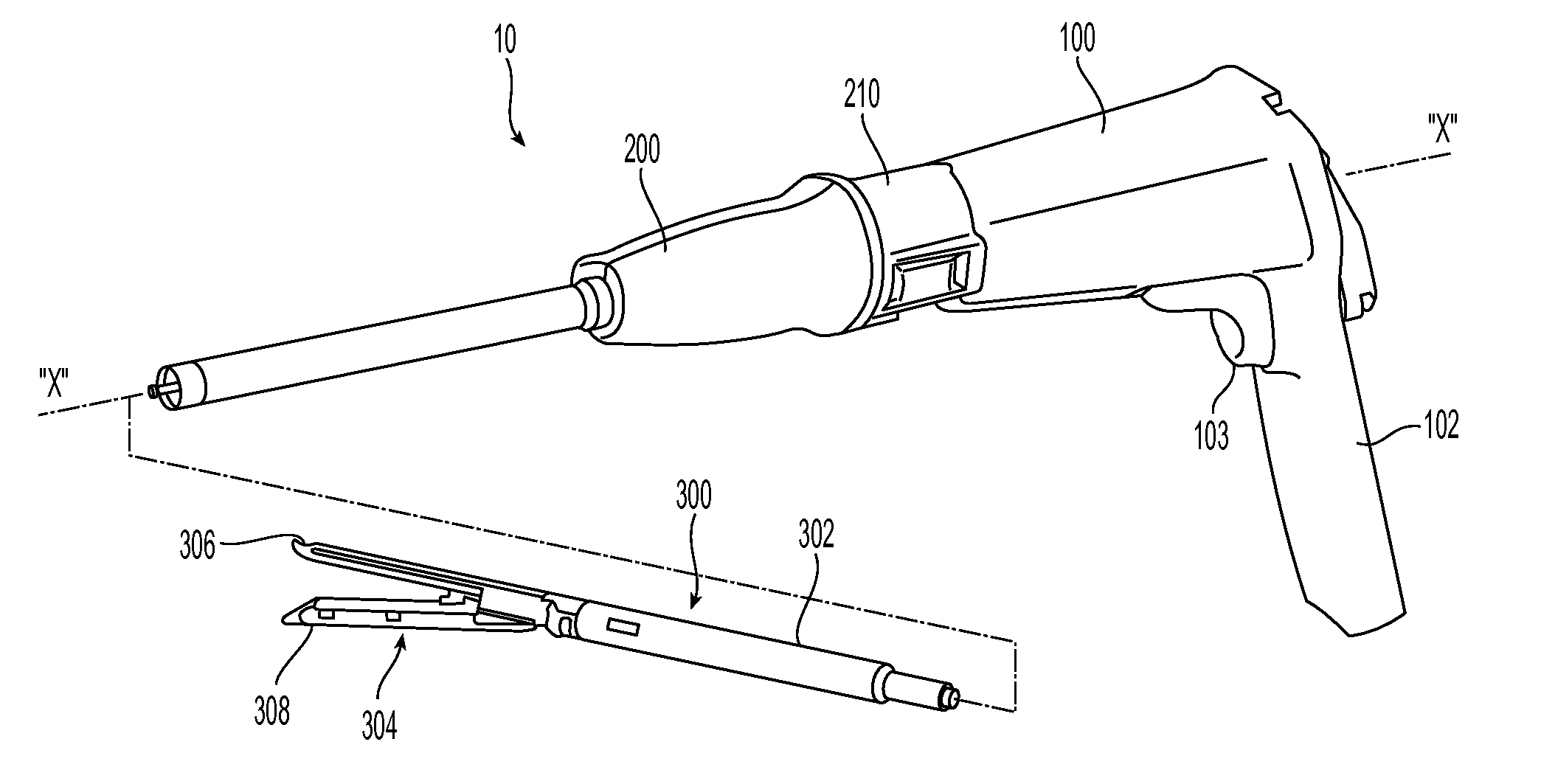

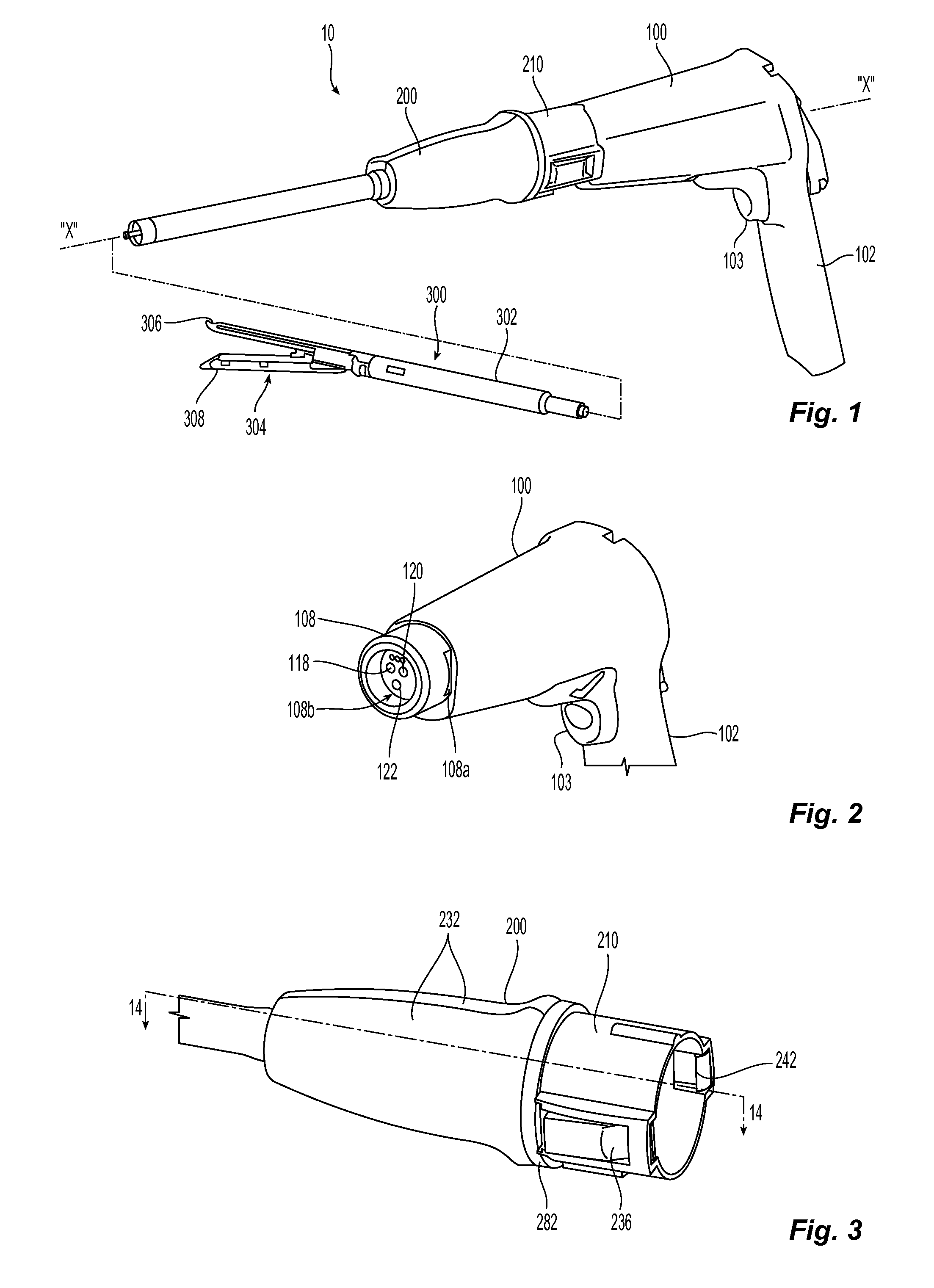

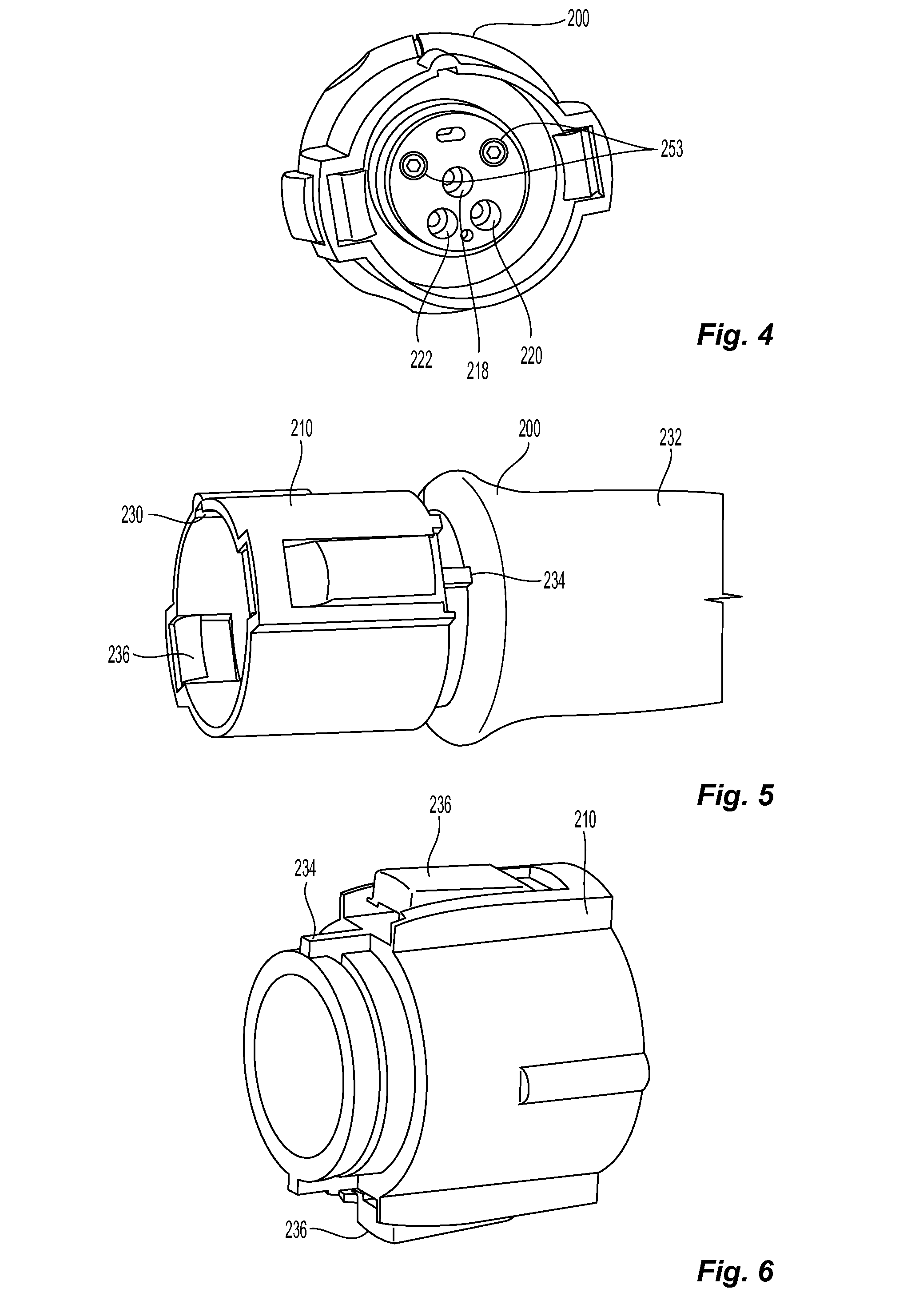

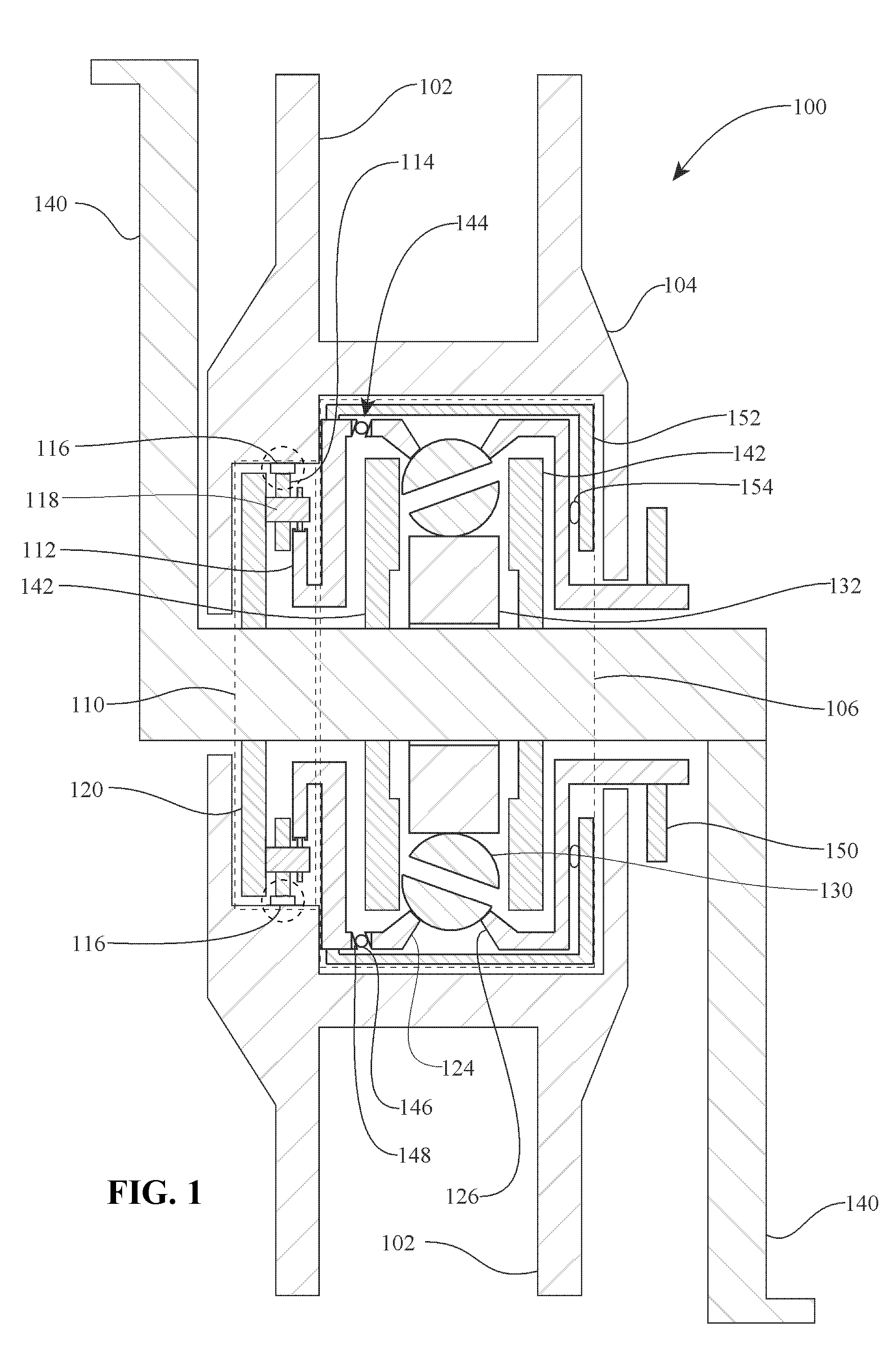

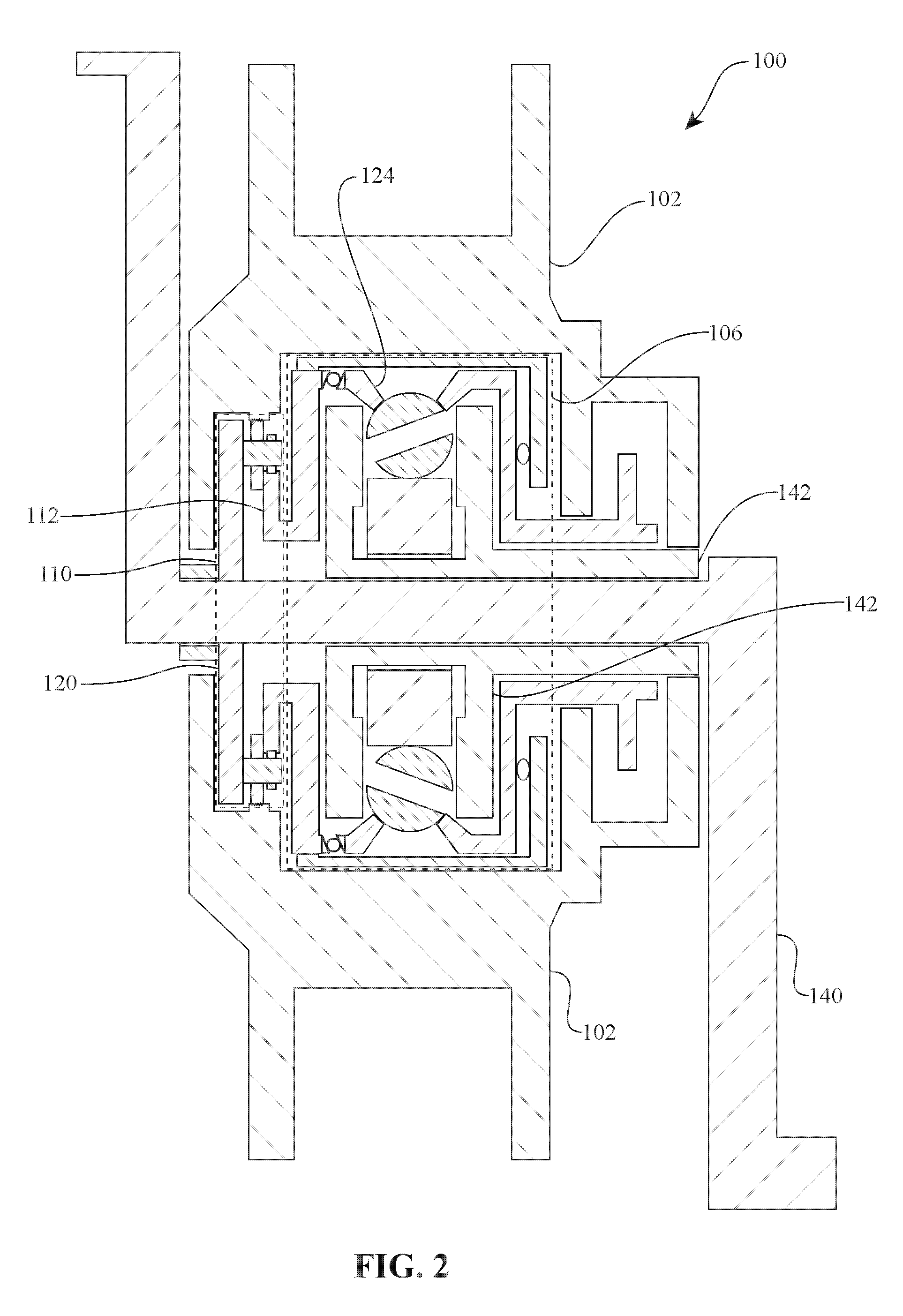

Adapter direct drive with manual retraction, lockout and connection mechanisms

A surgical device adapter for coupling an end effector to a handle assembly is disclosed. The surgical device adapter includes: a housing; a drive mechanism disposed within the housing and couplable to the handle assembly and the end effector; and a drive coupling assembly coupled to the surgical device adapter and selectively couplable to the handle assembly, the drive coupling assembly including a retraction assembly selectively couplable to the drive mechanism such that rotation of the drive coupling assembly about a longitudinal axis defined by the surgical device adapter and relative to the housing actuates the drive mechanism.

Owner:COVIDIEN LP

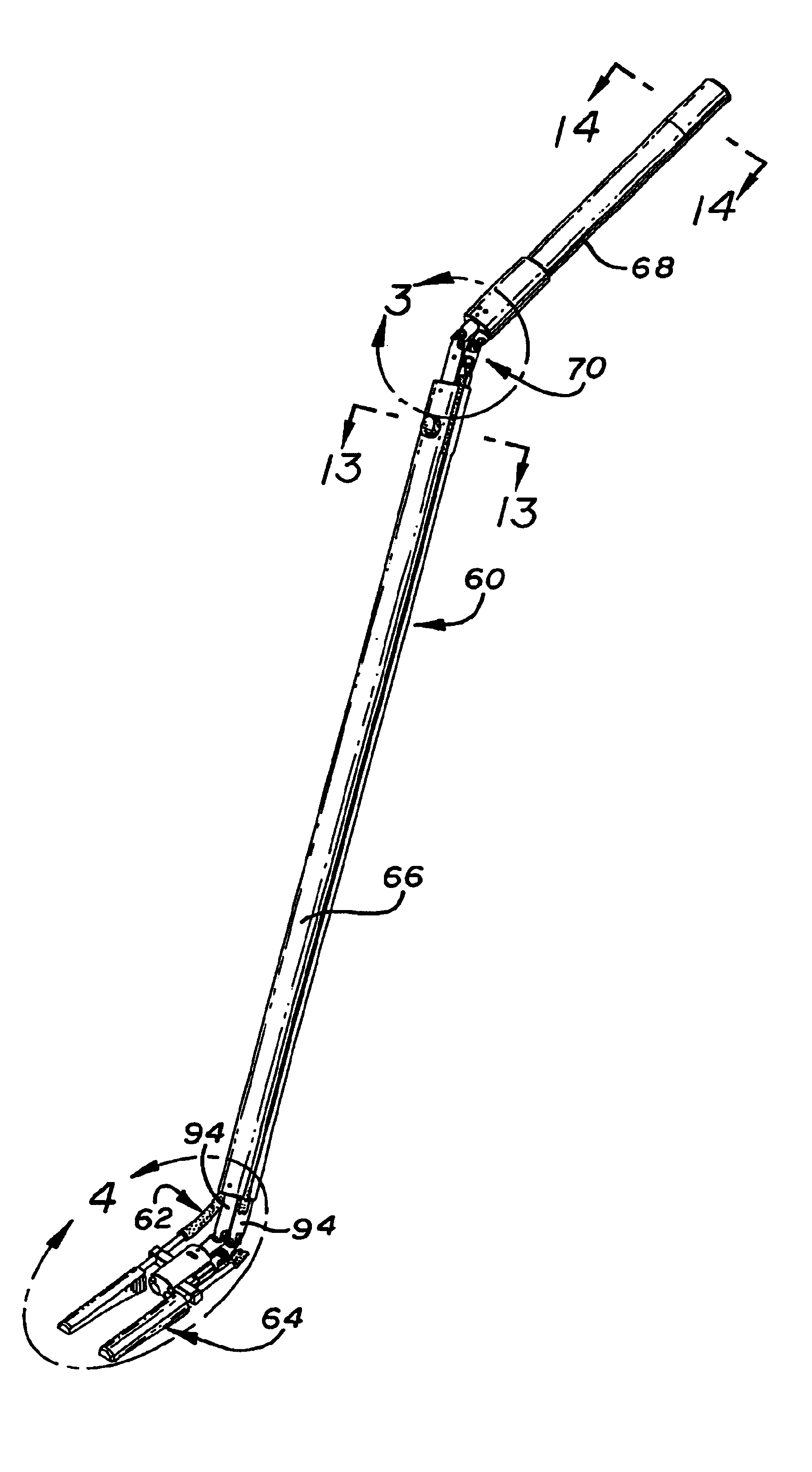

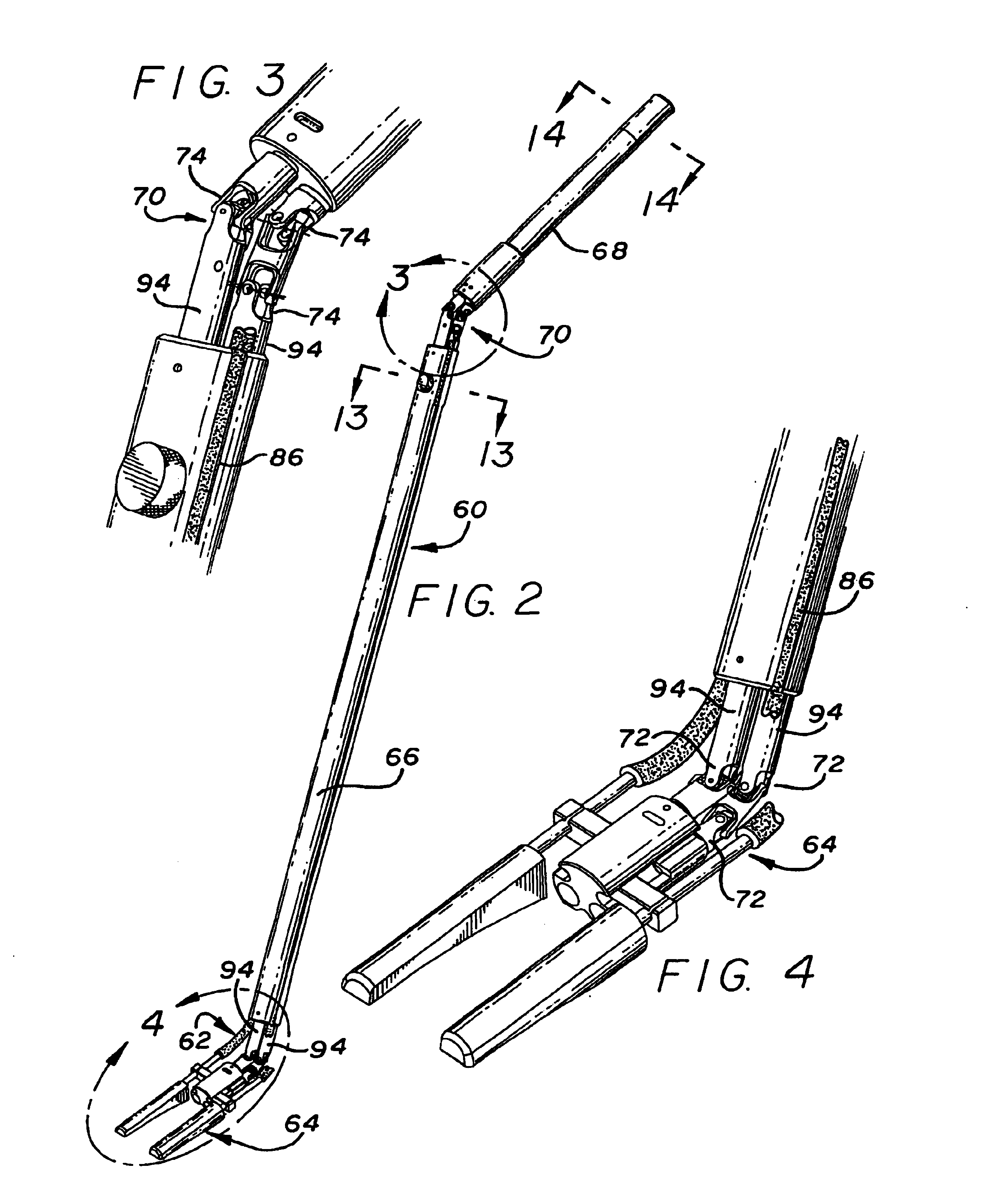

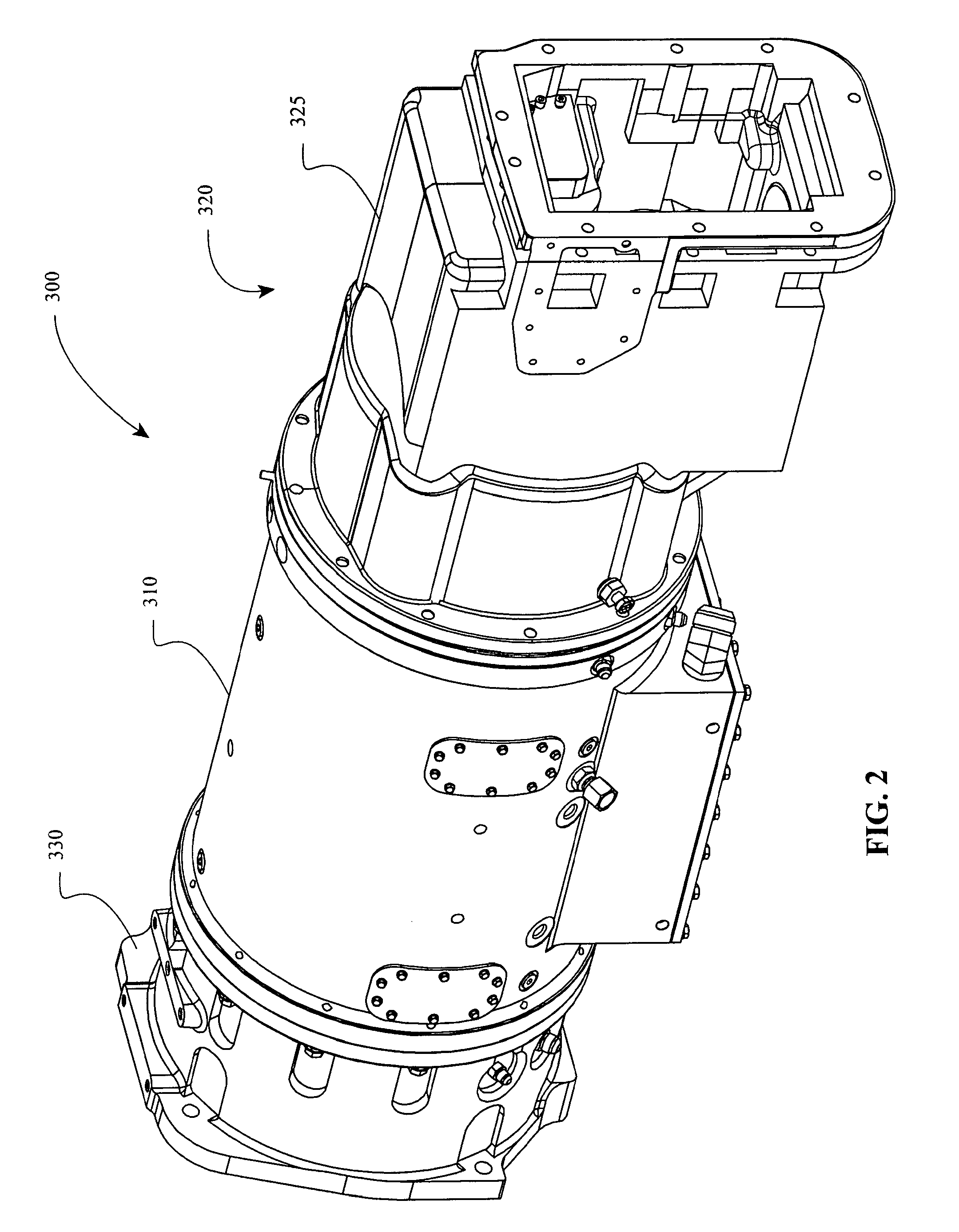

Adapter with centering mechanism for articulation joint

A joint assembly of an adapter defines a first longitudinal axis and includes first and second hinges, first and second rings, a joint cover, and a biasing mechanism. The joint cover has first and second cover portions. The first ring is pivotally coupled to the first hinge and the first cover portion is pivotally coupled to the first hinge to define a first joint center. The second ring is pivotally coupled to the second cover portion and the second hinge is pivotally coupled to the second ring to define a second joint center that is spaced from the first joint center. The first and second joint centers define a cover axis of the joint cover. The biasing mechanism is engaged with the first ring and the joint cover to bias the joint cover towards an aligned configuration in which the cover axis is aligned with the first longitudinal axis.

Owner:TYCO HEALTHCARE GRP LP

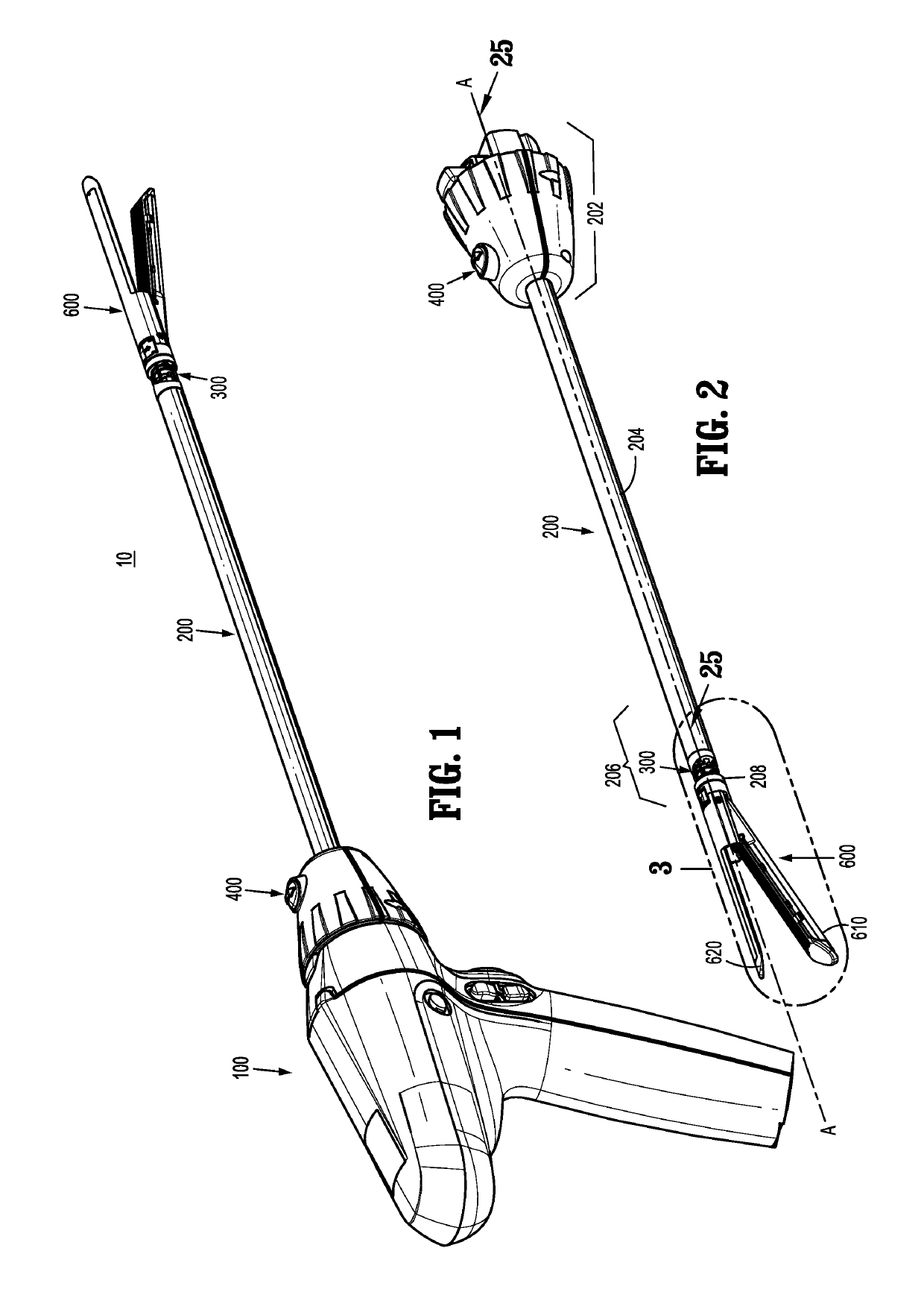

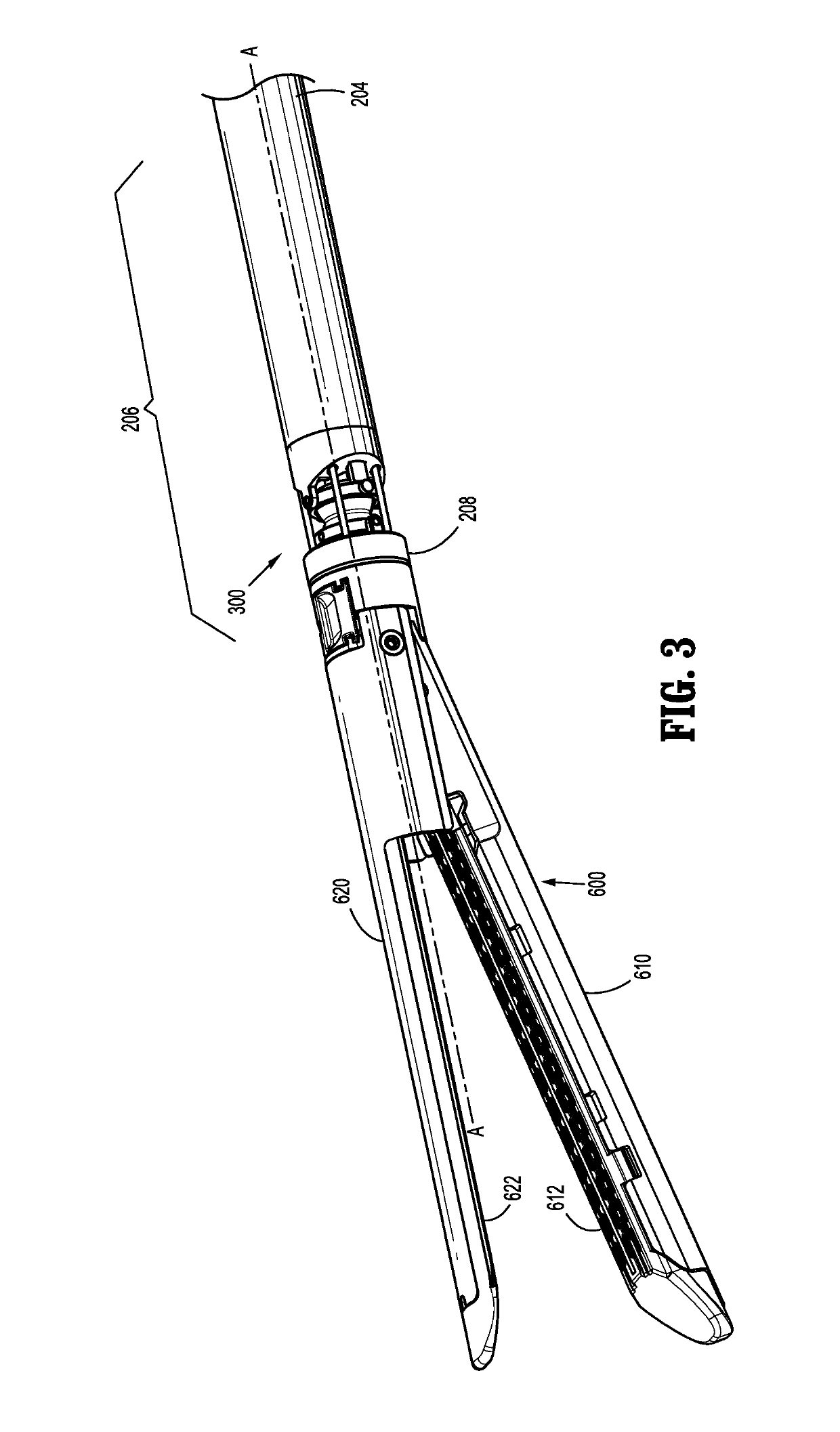

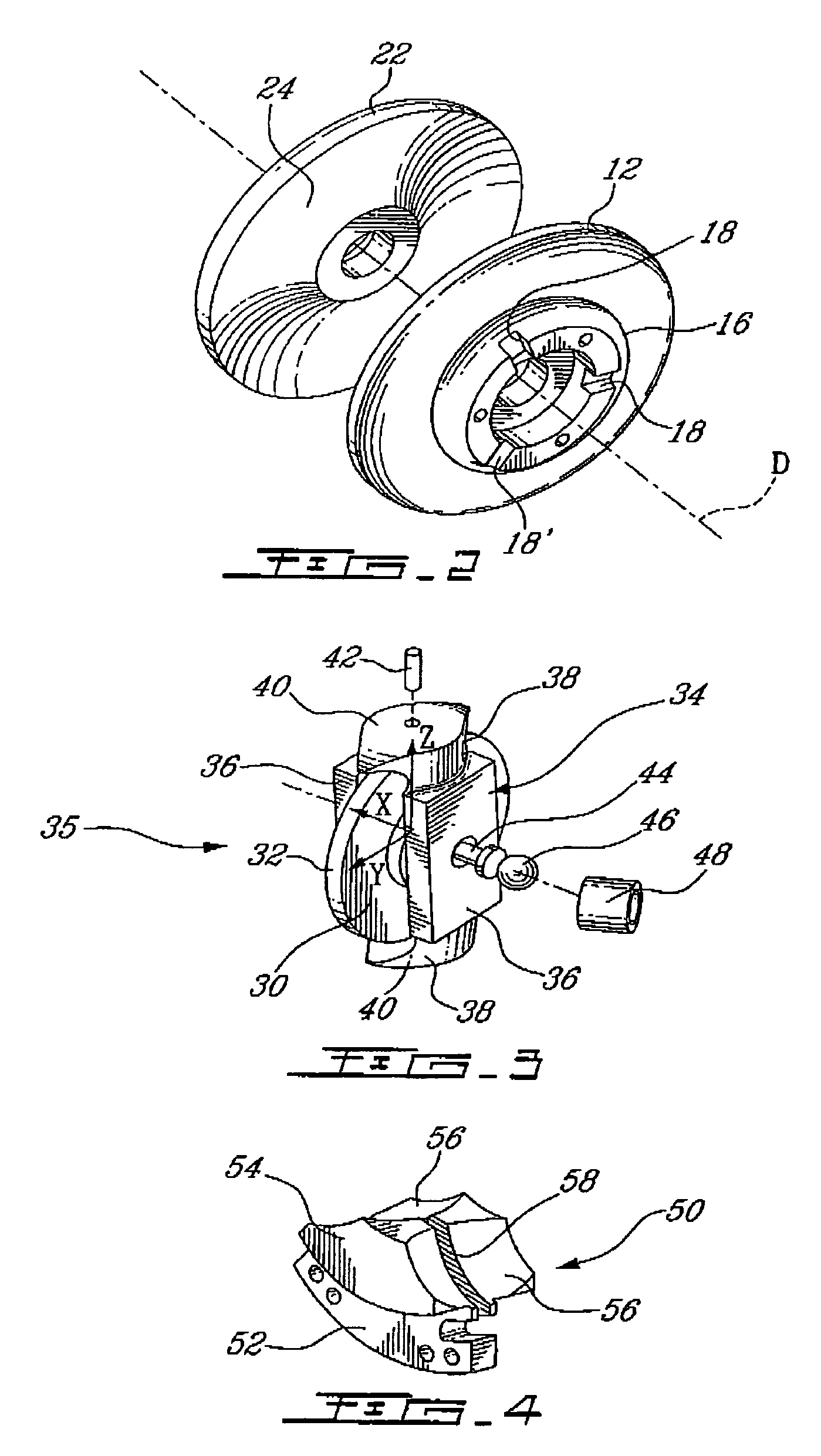

Rotational coupling device for surgical instrument with flexible actuators

Rotational couplers for use with surgical devices that are actuated by semi-flexible actuators such as wires and the like. The couplers enable the actuators to apply various actuation motions to actuation features on the surgical device as well as other actuators to apply axial and rotational motions to the surgical device to manipulate the device into various orientations relative to an elongate shaft to which the device is movably attached.

Owner:CILAG GMBH INT +1

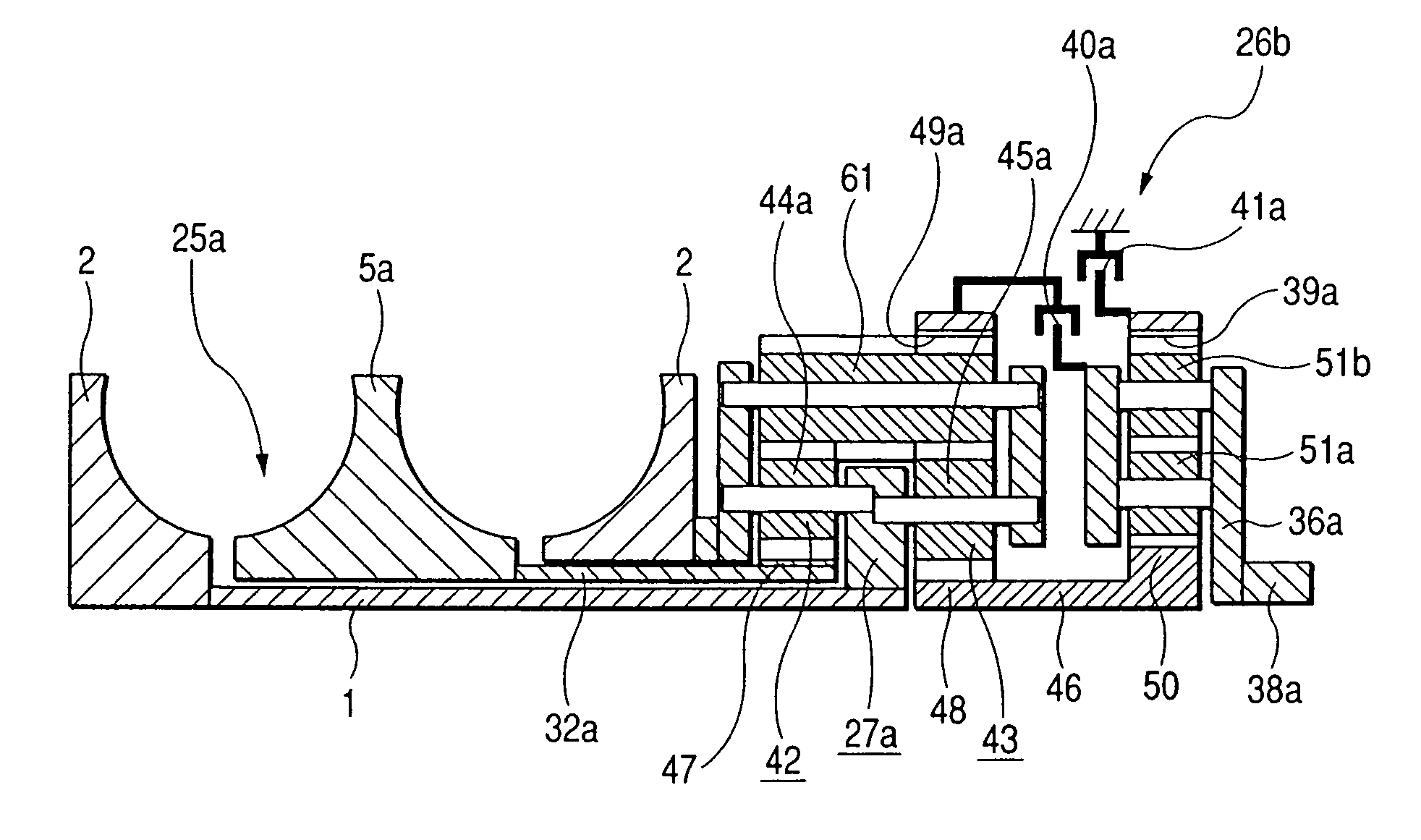

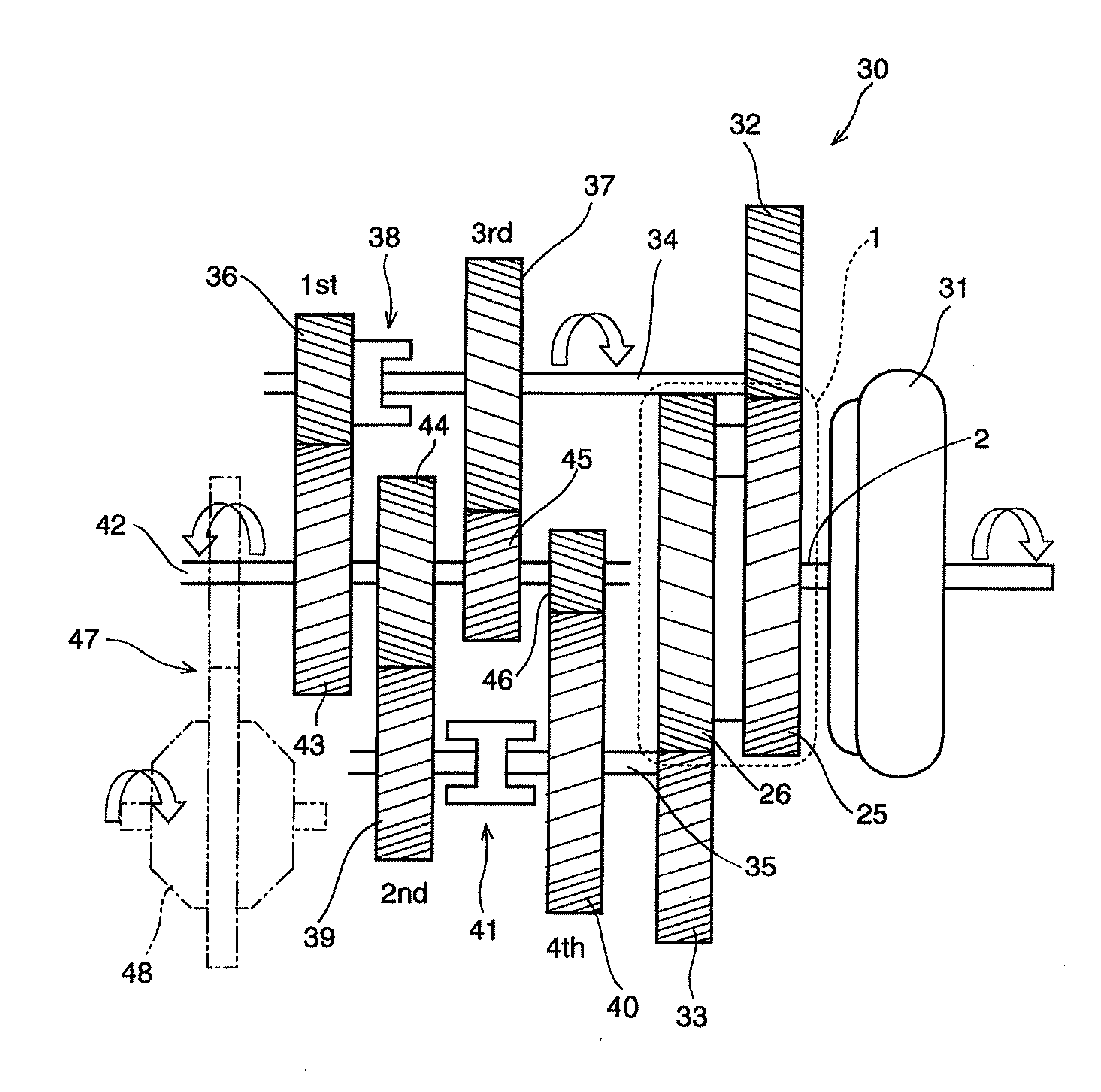

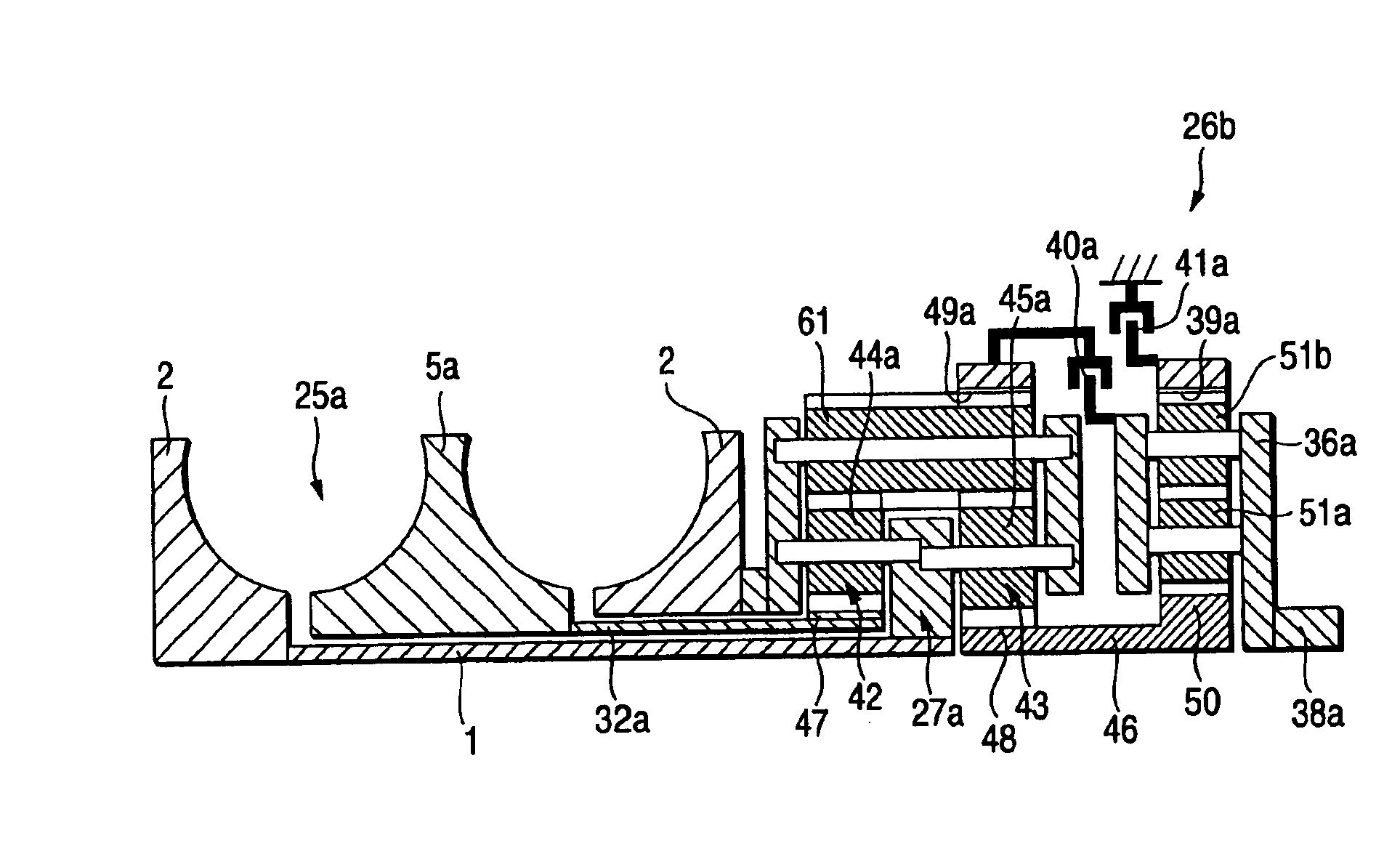

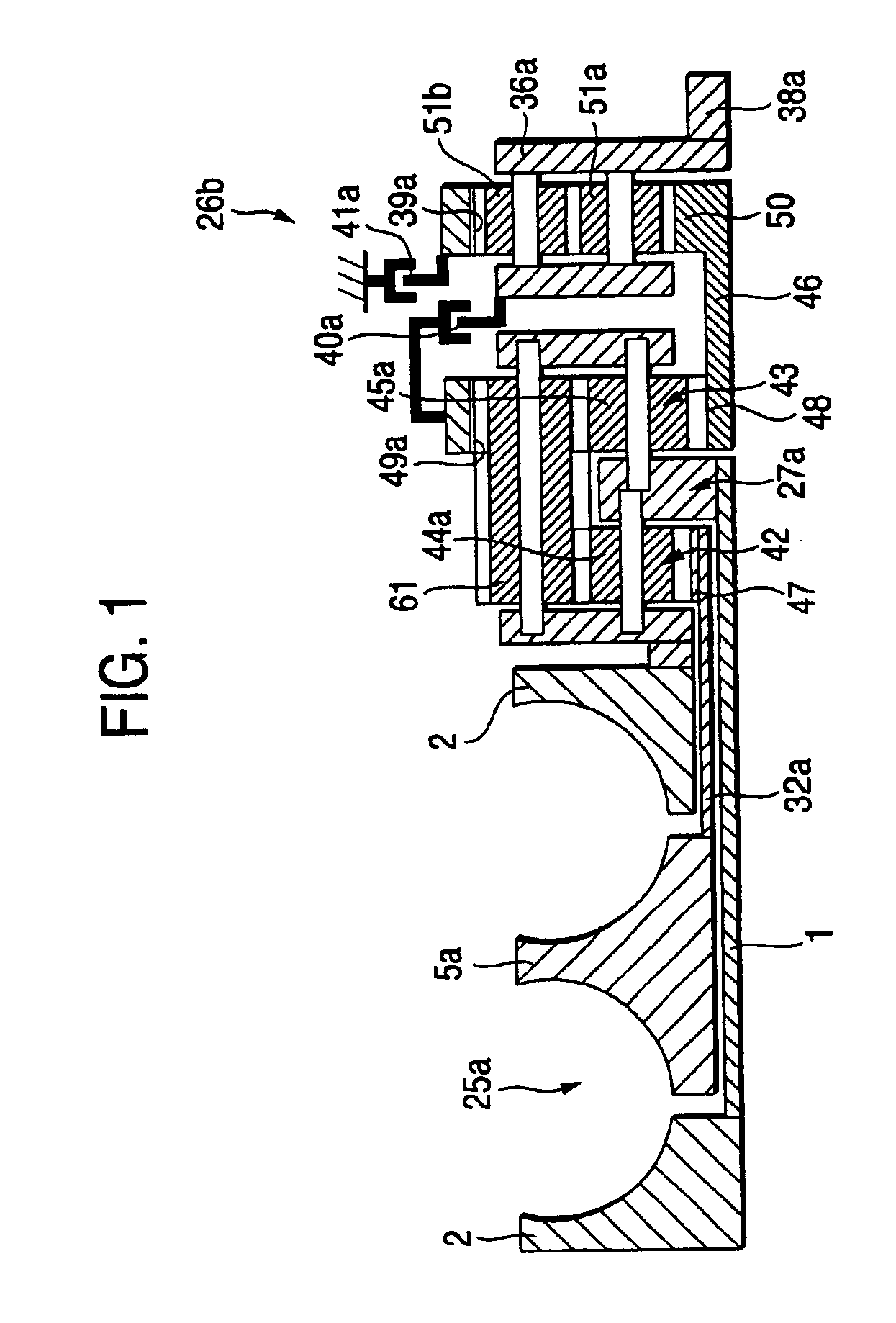

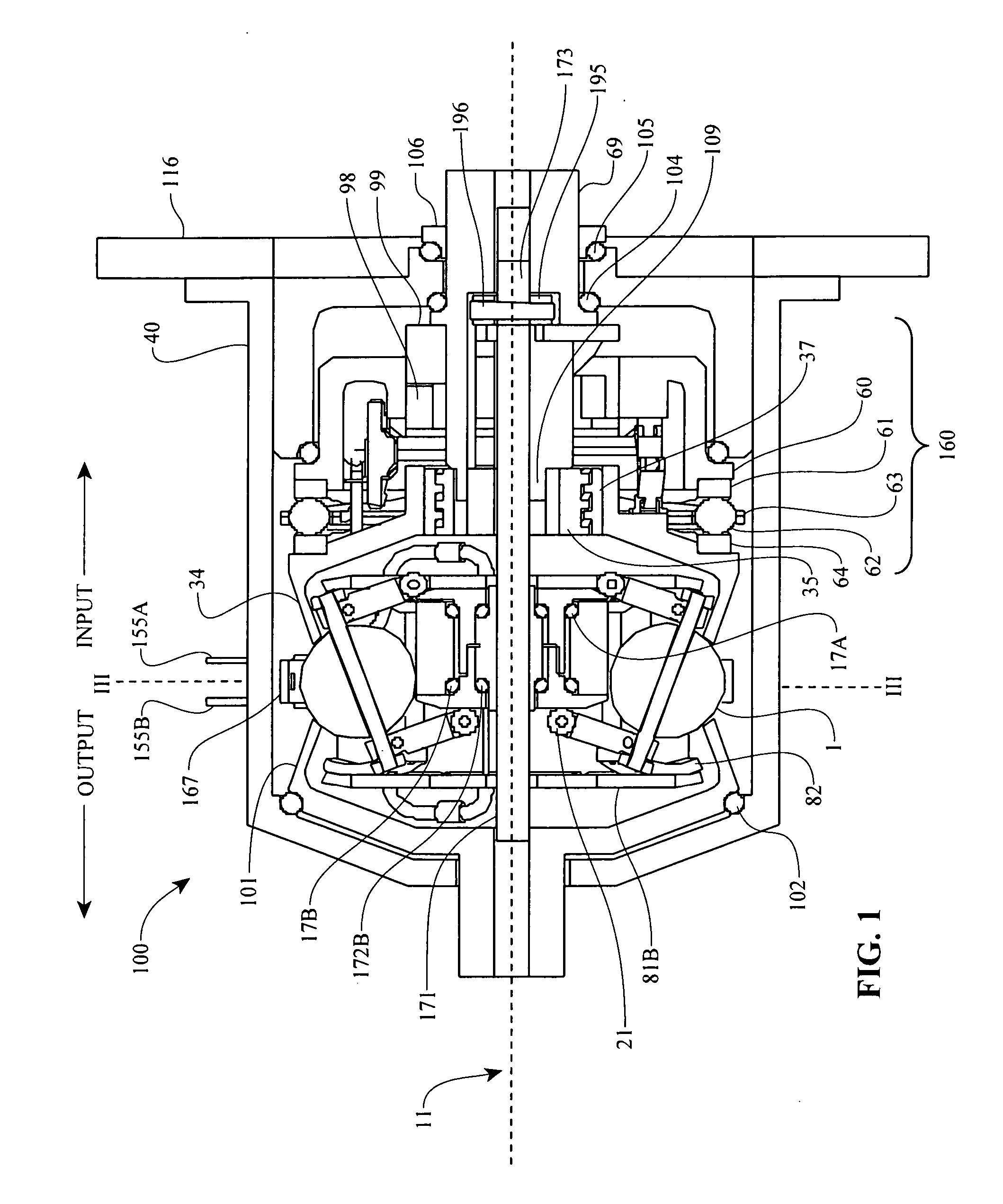

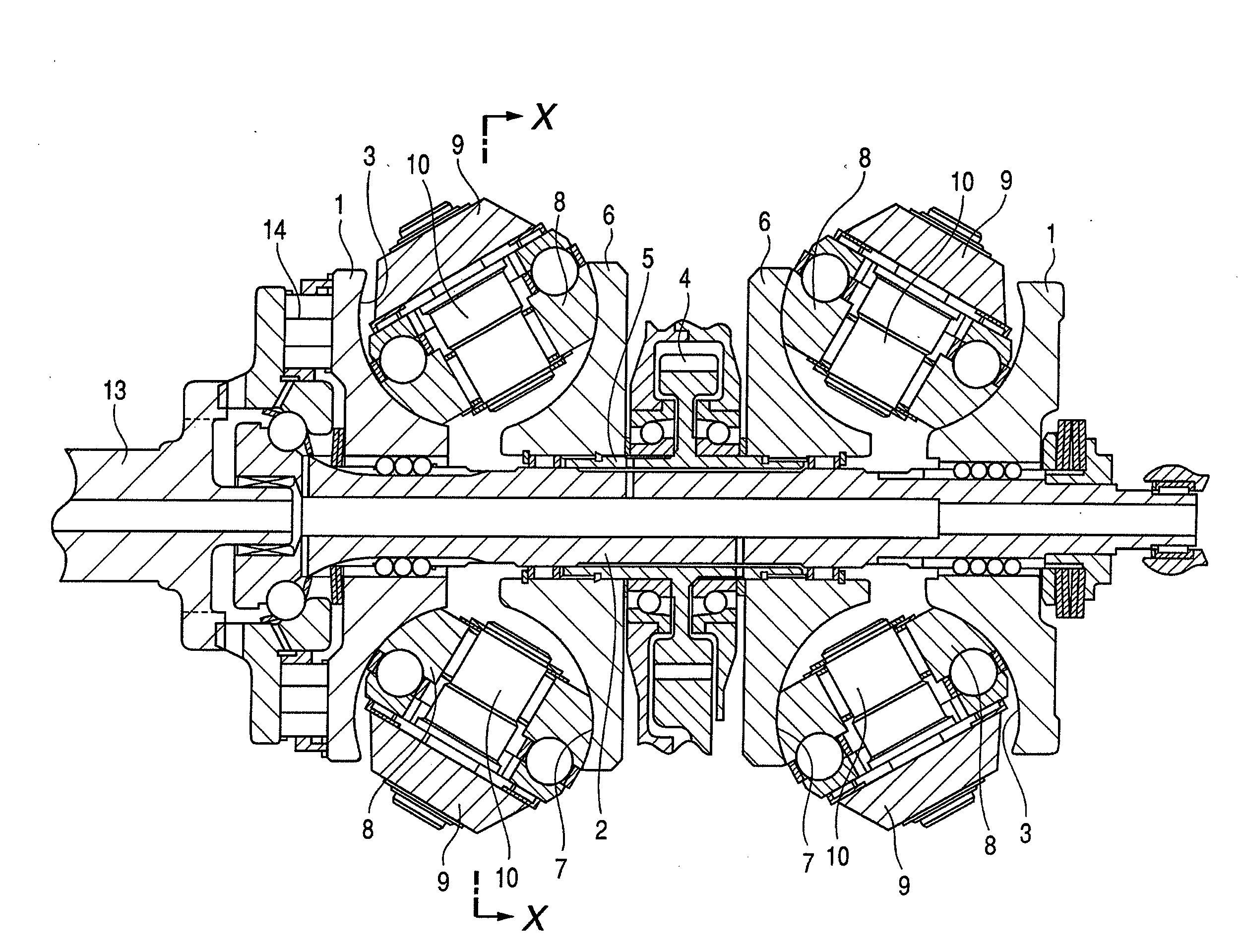

Toroidal type continuously variable transmission

A toroidal type continuously variable transmission having first and second discs supported around a rotating shaft and receiving power rollers therebetween includes a ball spline having a first spline groove formed in an outer circumferential surface of the rotating shaft, a second spline groove formed in an inner circumferential surface of the first disc, and balls provided between the first spline groove and the second spline groove rollably. An axial position of an end portion of an effective groove portion of the first spline groove is located to correspond to an axial position of an inner end portion of the second spline groove or more closely to the second disc than the axial position thereof when a pressing unit, a preload spring and the first disc are installed around the rotating shaft, pressure oil is not fed to the pressing unit, and the preload spring is not elastically deformed.

Owner:NSK LTD

Adapter direct drive with manual retraction, lockout and connection mechanisms

A surgical device adapter for coupling an end effector to a handle assembly is disclosed. The surgical device adapter includes: a housing; a drive mechanism disposed within the housing and couplable to the handle assembly and the end effector; and a drive coupling assembly coupled to the surgical device adapter and selectively couplable to the handle assembly, the drive coupling assembly including a retraction assembly selectively couplable to the drive mechanism such that rotation of the drive coupling assembly about a longitudinal axis defined by the surgical device adapter and relative to the housing actuates the drive mechanism.

Owner:TYCO HEALTHCARE GRP LP

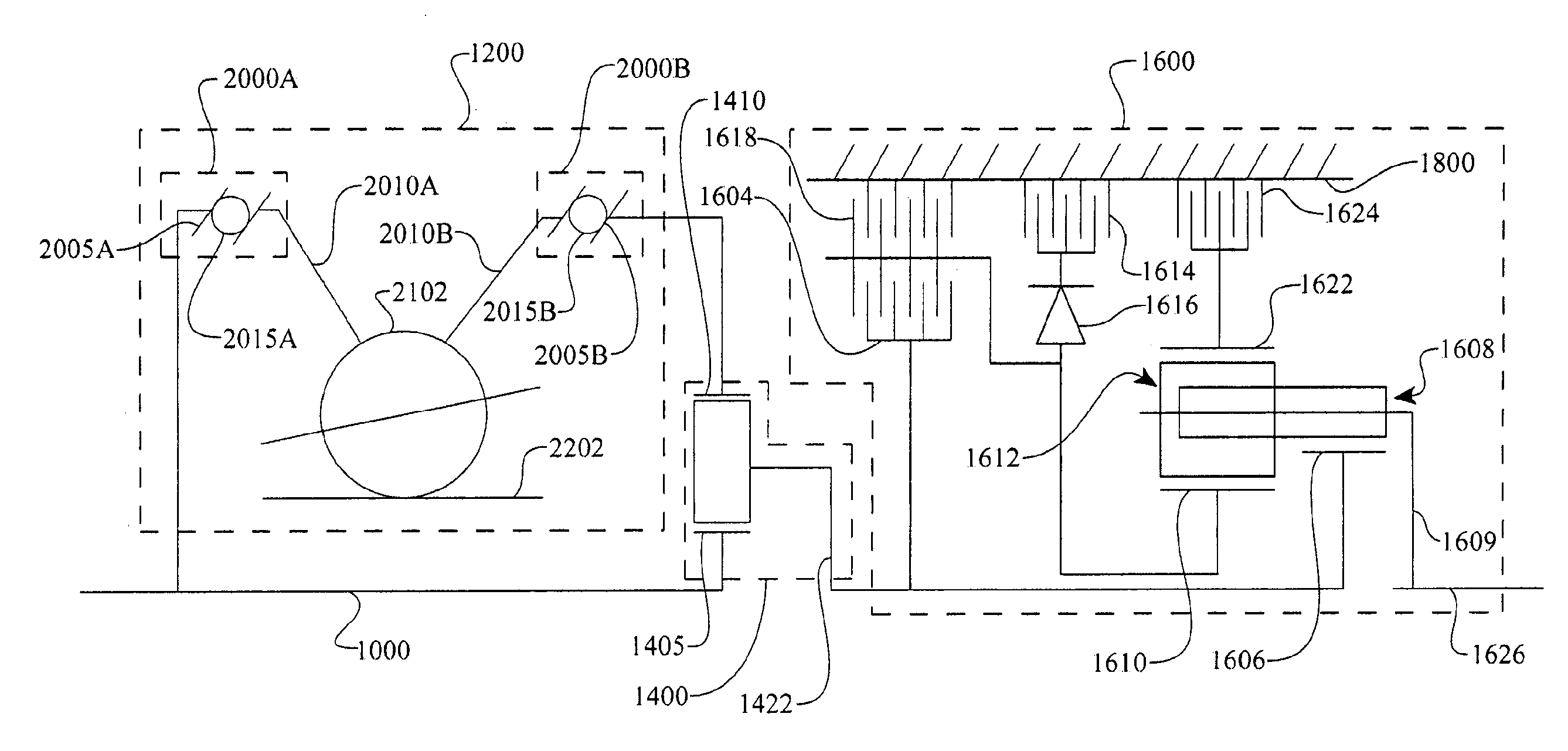

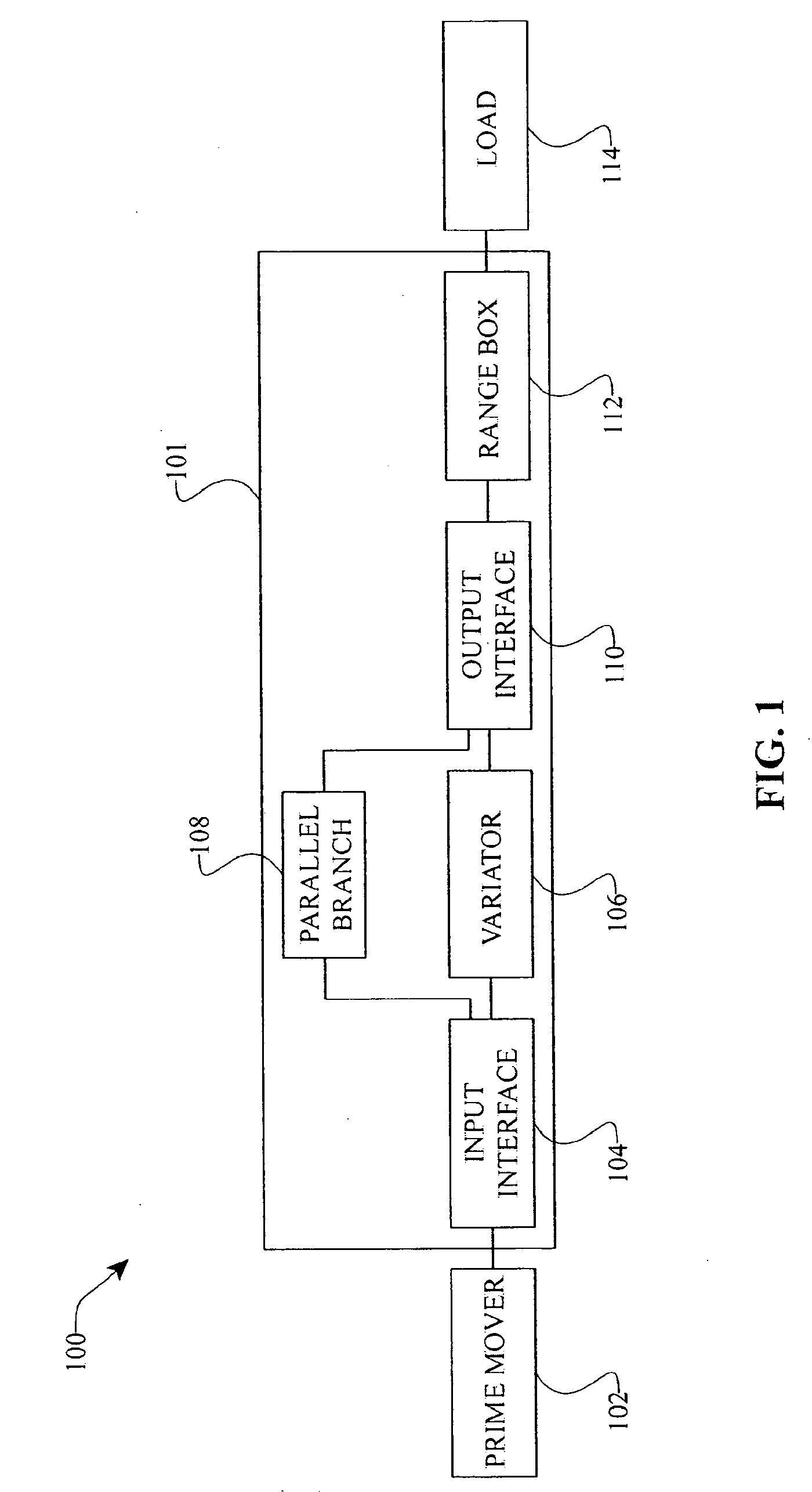

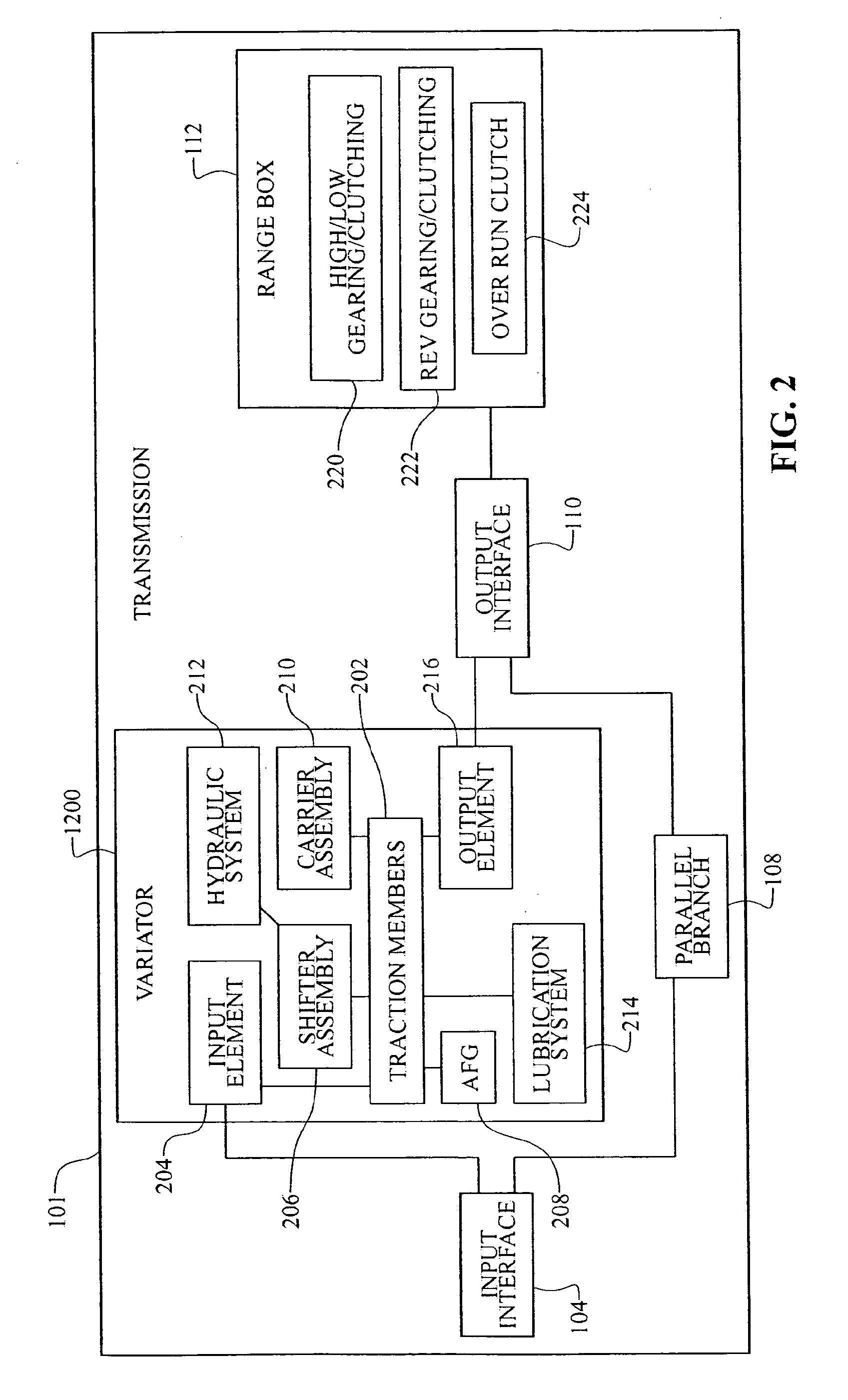

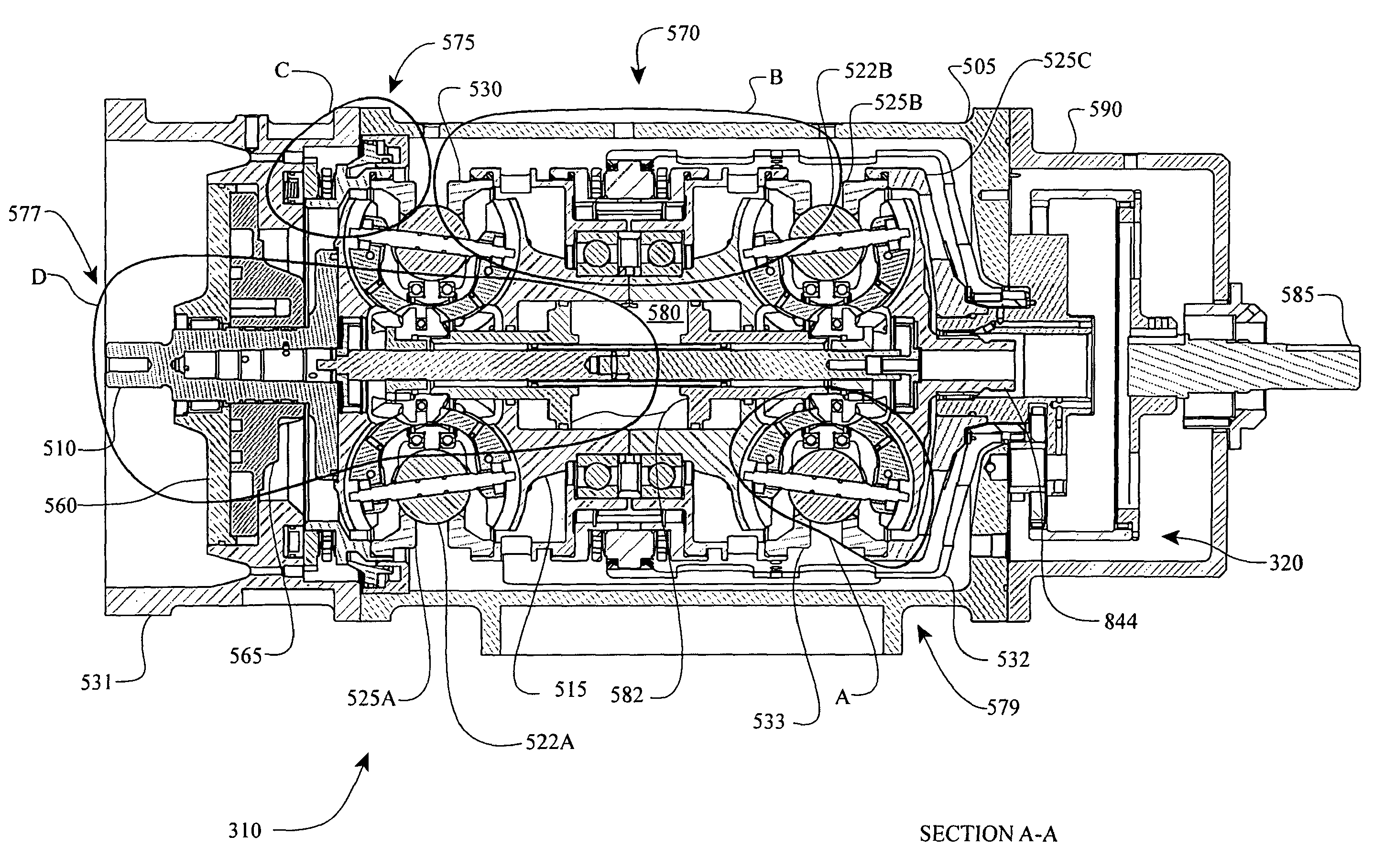

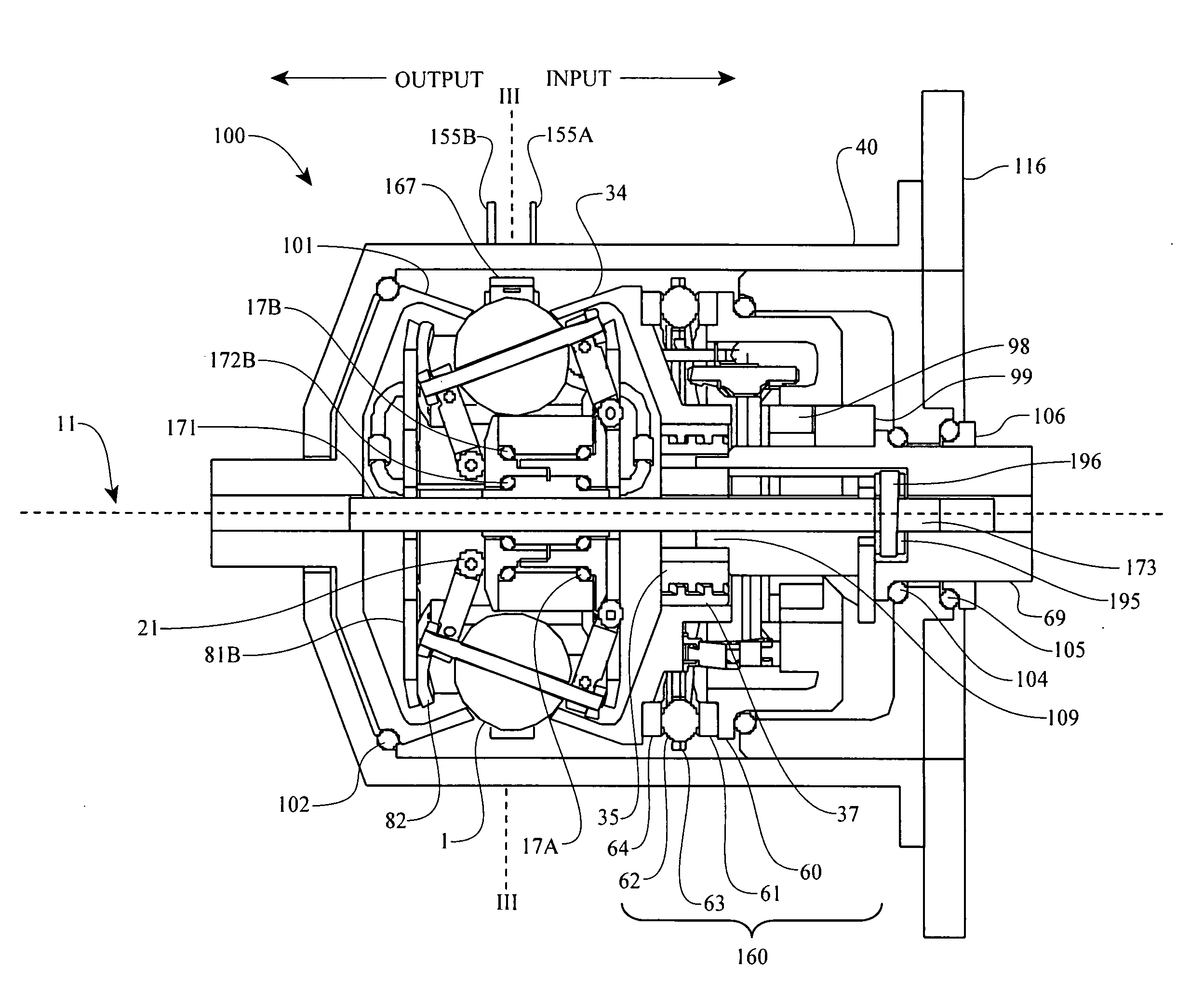

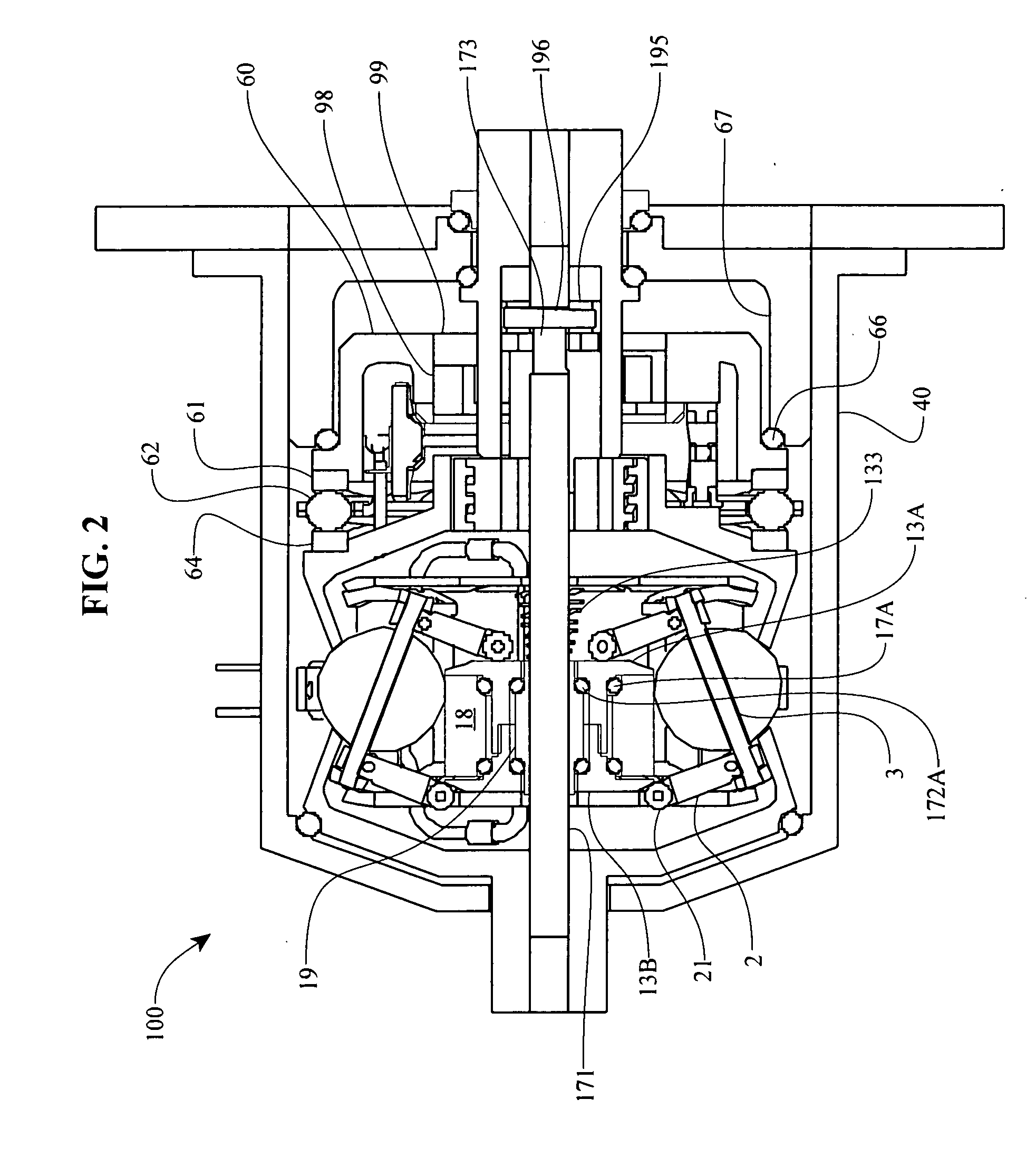

Continuously variable transmissions and methods therefor

Inventive embodiments are directed to components, subassemblies, systems, and / or methods for continuously variable transmissions (CVT) having a variator provided with a plurality of tilting, traction planets and traction rings. In one embodiment, a variator is coupled to a rangebox to provide multiple operating modes. In another embodiment, a hydraulic system is configured to control the transmission ratio of the variator and the rangebox. Various inventive shift-cam-and-sun subassemblies can be used to facilitate shifting of the transmission ratio of a CVT. Embodiments of a transmission housing and bell housing are adapted to house components of a CVT and, in some embodiments, to cooperate with other components of the CVT to support operation and / or functionality of the CVT. Various related devices include embodiments of, for example, a pivot arm, a control feedback mechanism, axial force generation and management mechanisms, a control valve integral with an input shaft, a pivot pin hub, and a rotatable carrier configured to support planet-pivot arm assemblies. FIG. 72 shows a torque-split ball-type rolling traction CVT with a ball-type rolling traction variator (1200) and planetary gearset (1400) which is followed by a rangebox (1600).

Owner:FALLBROOK INTPROP COMPANY

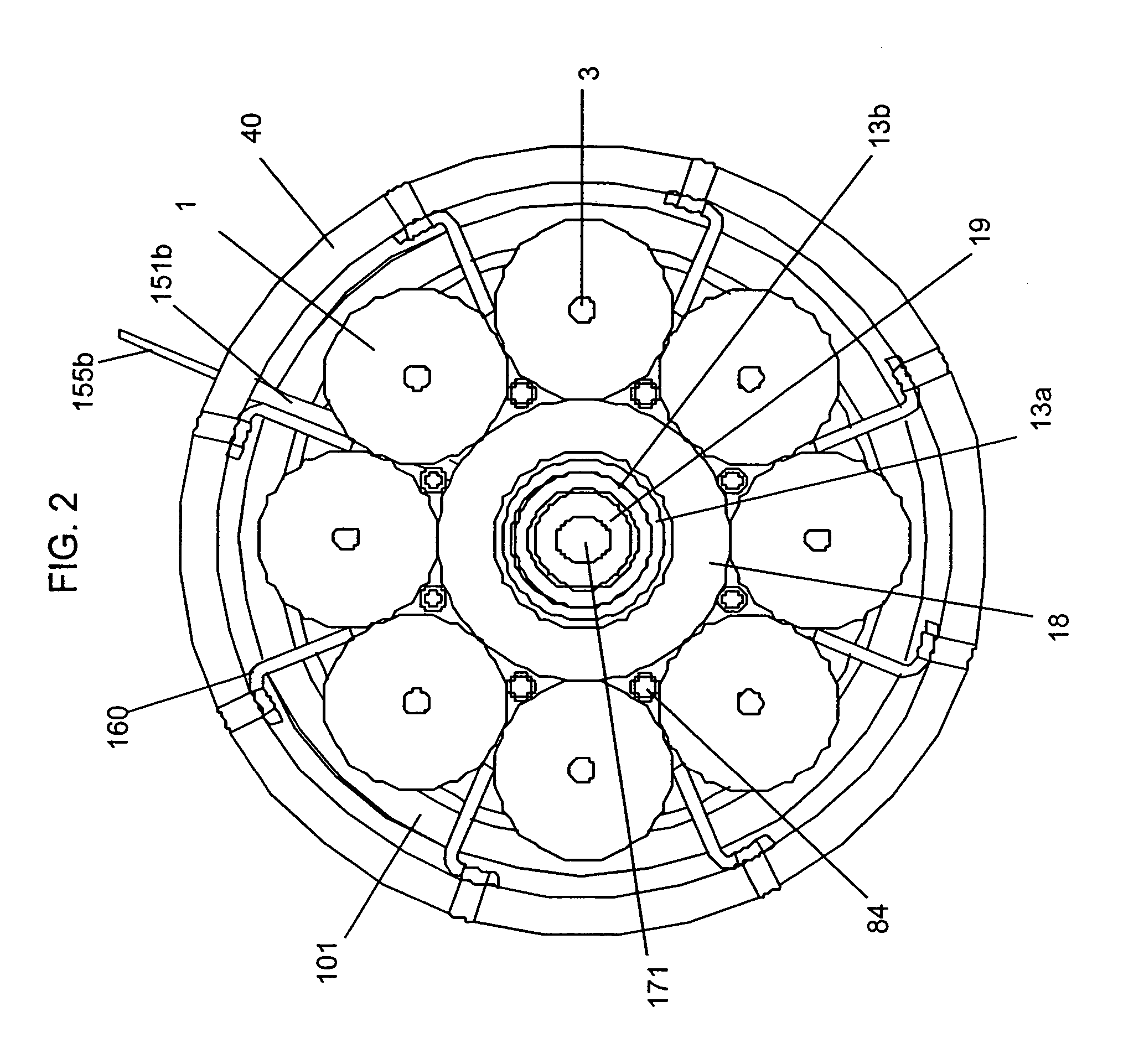

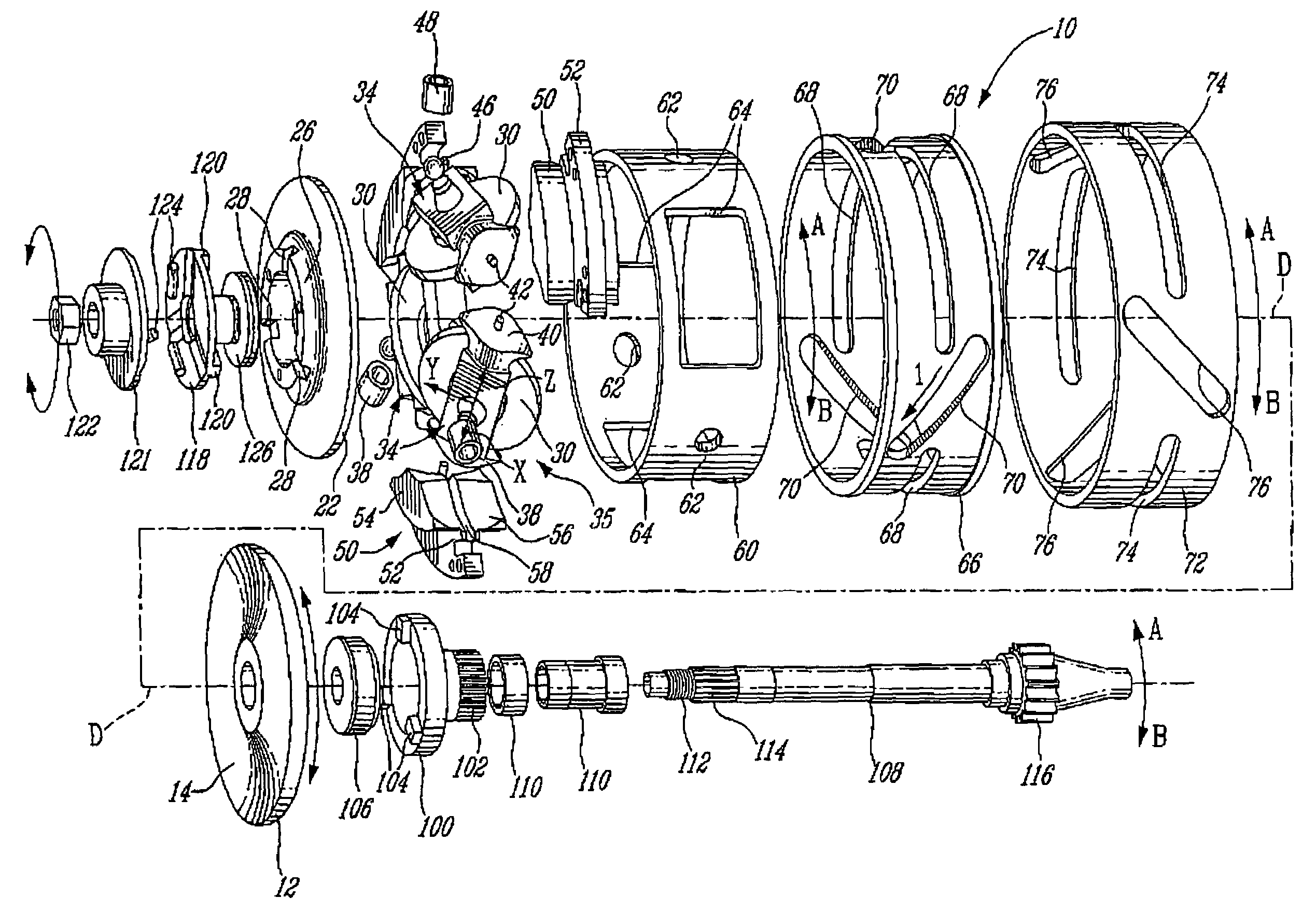

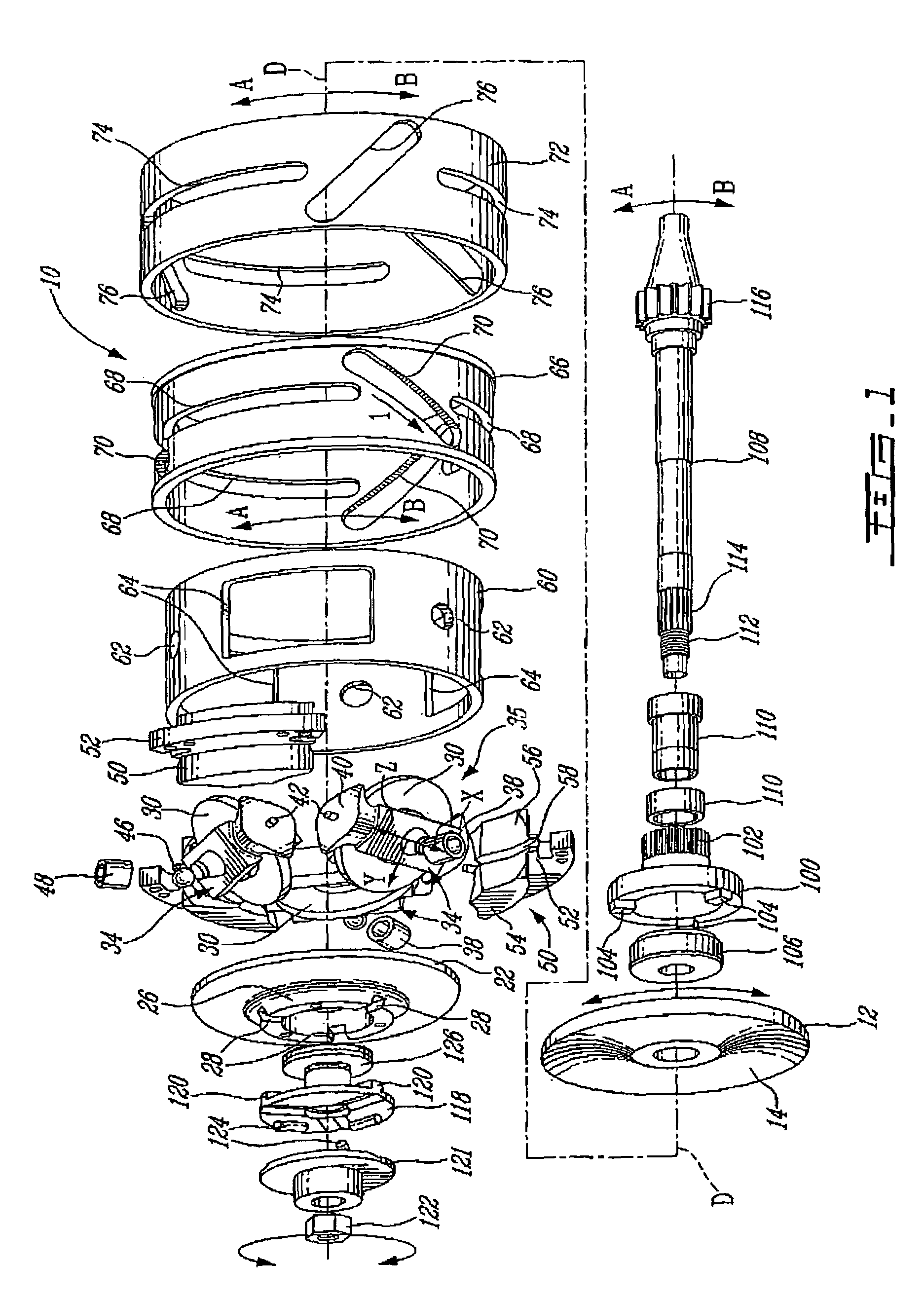

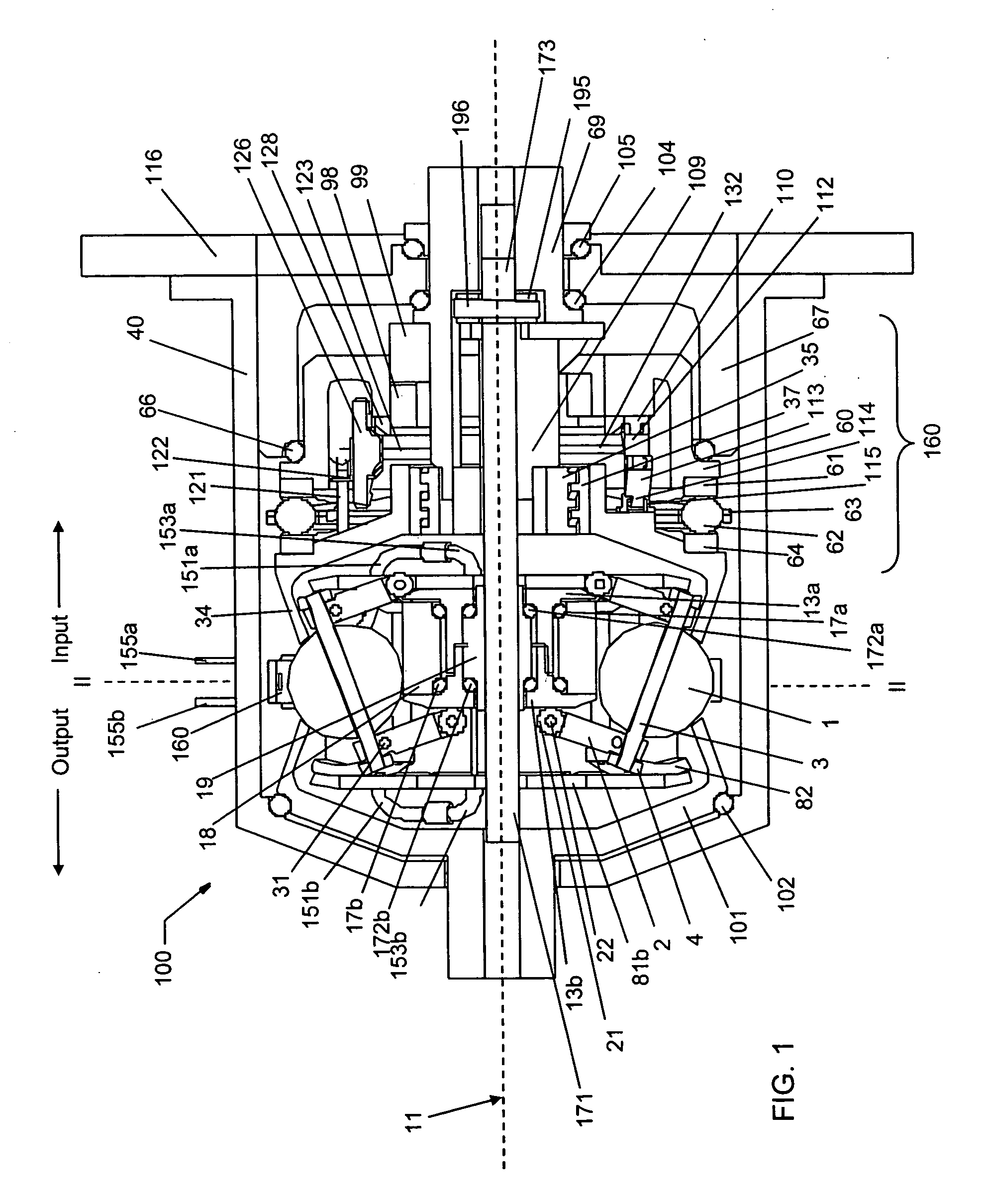

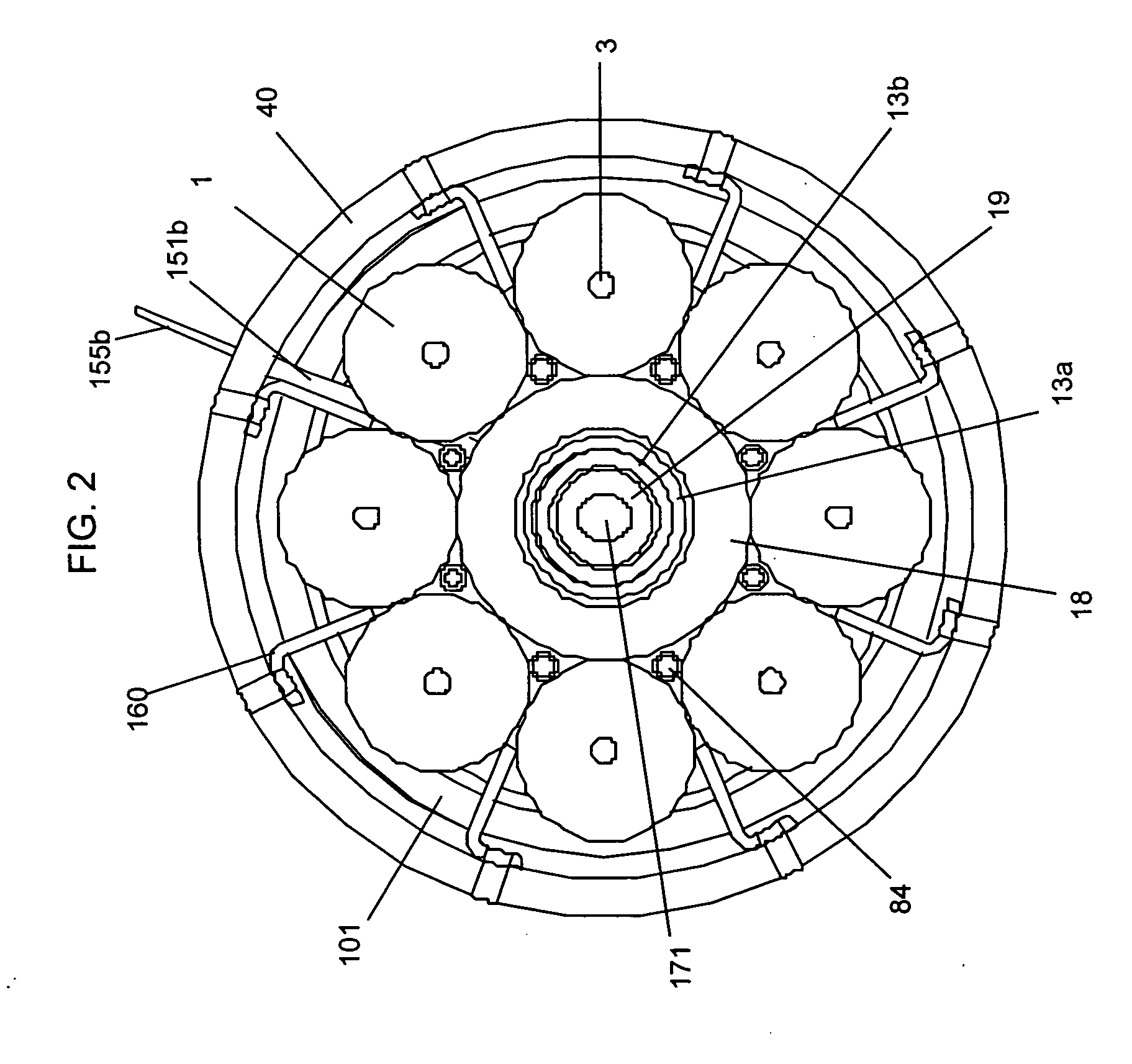

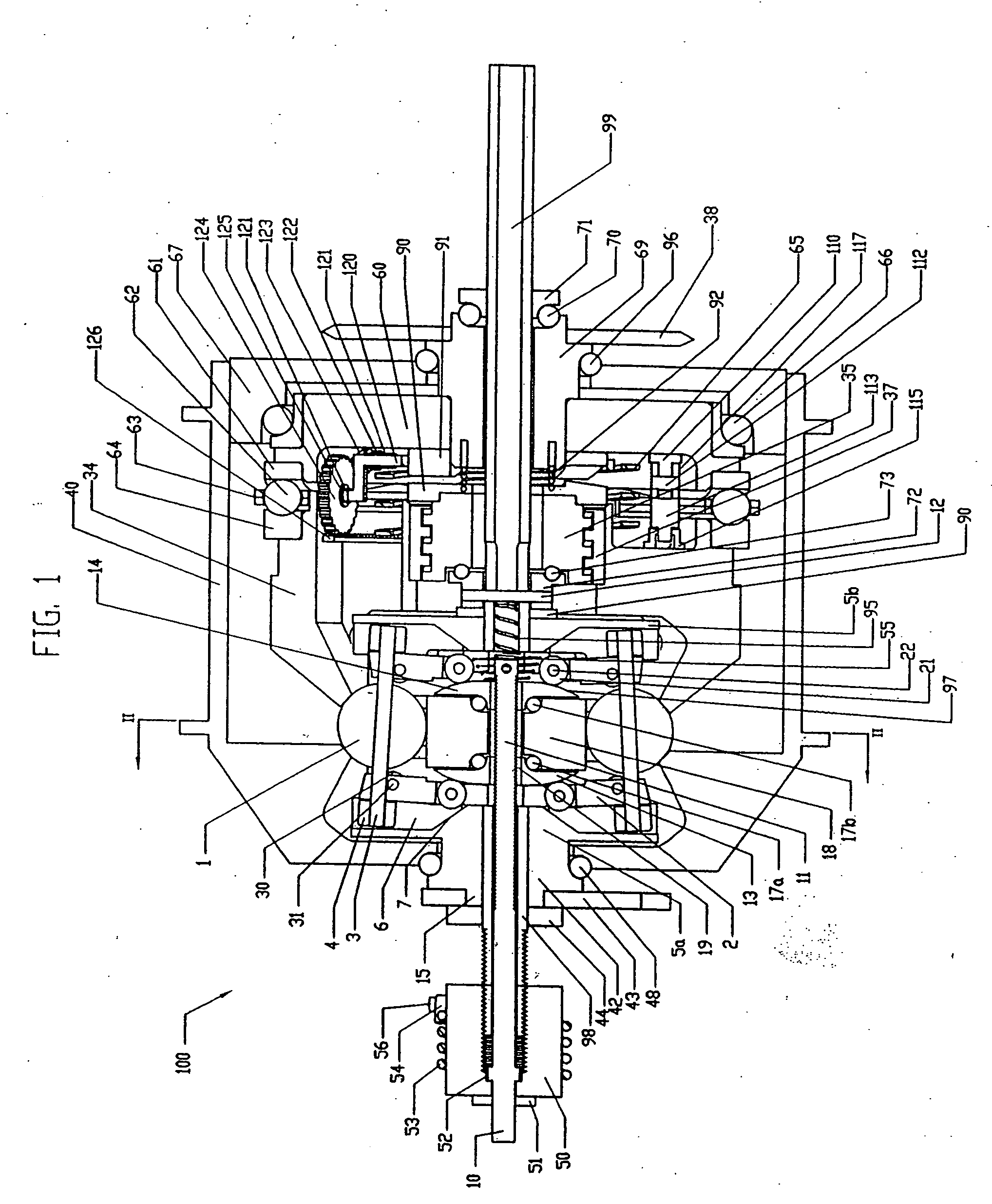

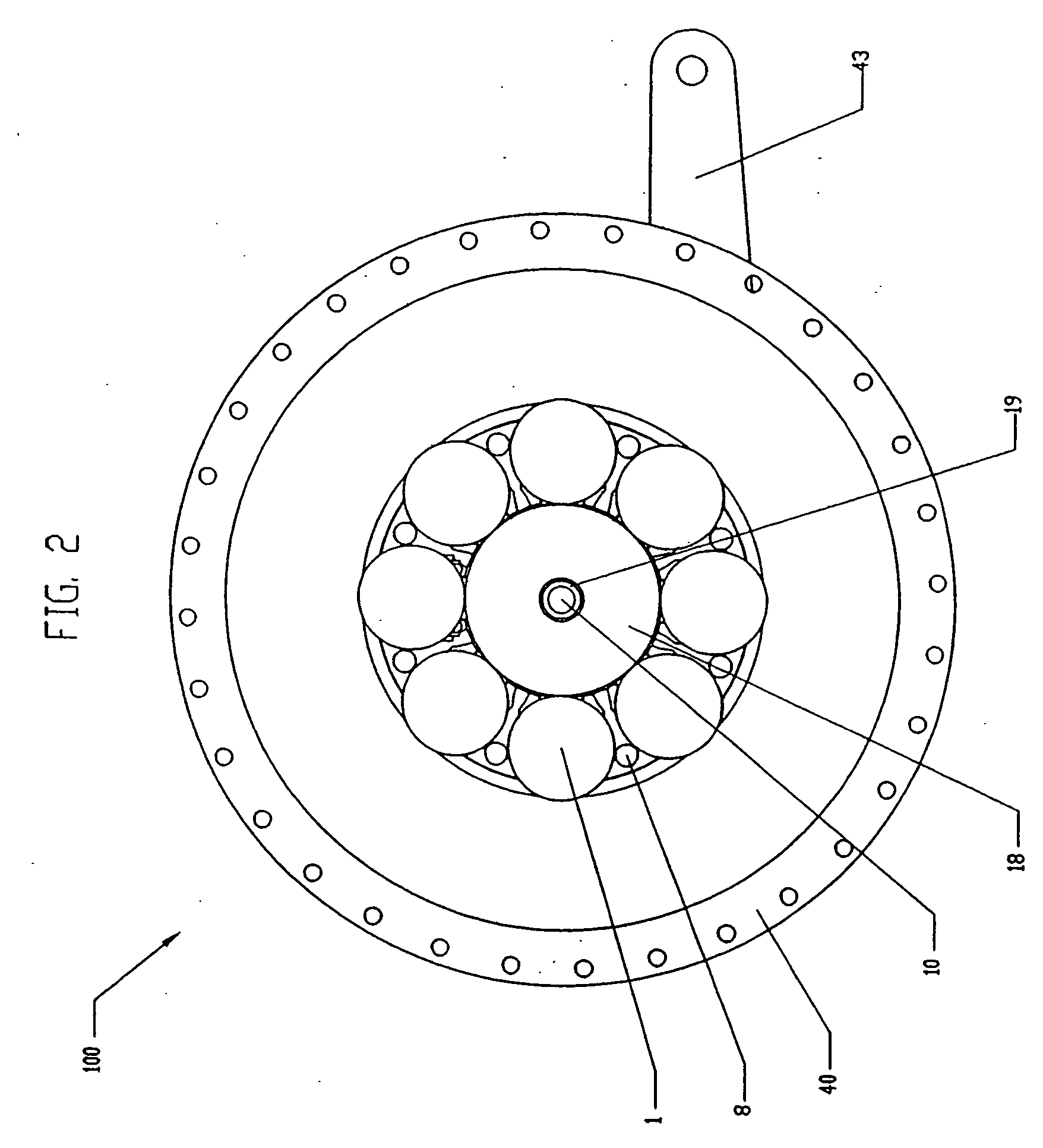

Continuously variable planetary gear set

A continuously variable planetary gear set is described having a generally tubular idler, a plurality of balls distributed radially about the idler, each ball having a tiltable axis about which it rotates, a rotatable input disc positioned adjacent to the balls and in contact with each of the balls, a rotatable output disc positioned adjacent to the balls opposite the input disc and in contact with each of the balls such that each of the balls makes three-point contact with the input disc, the output disc and the idler, and a rotatable cage adapted to maintain the axial and radial position of each of the balls, wherein the axes of the balls are oriented by the axial position of the idler.

Owner:FALLBROOK INTPROP COMPANY

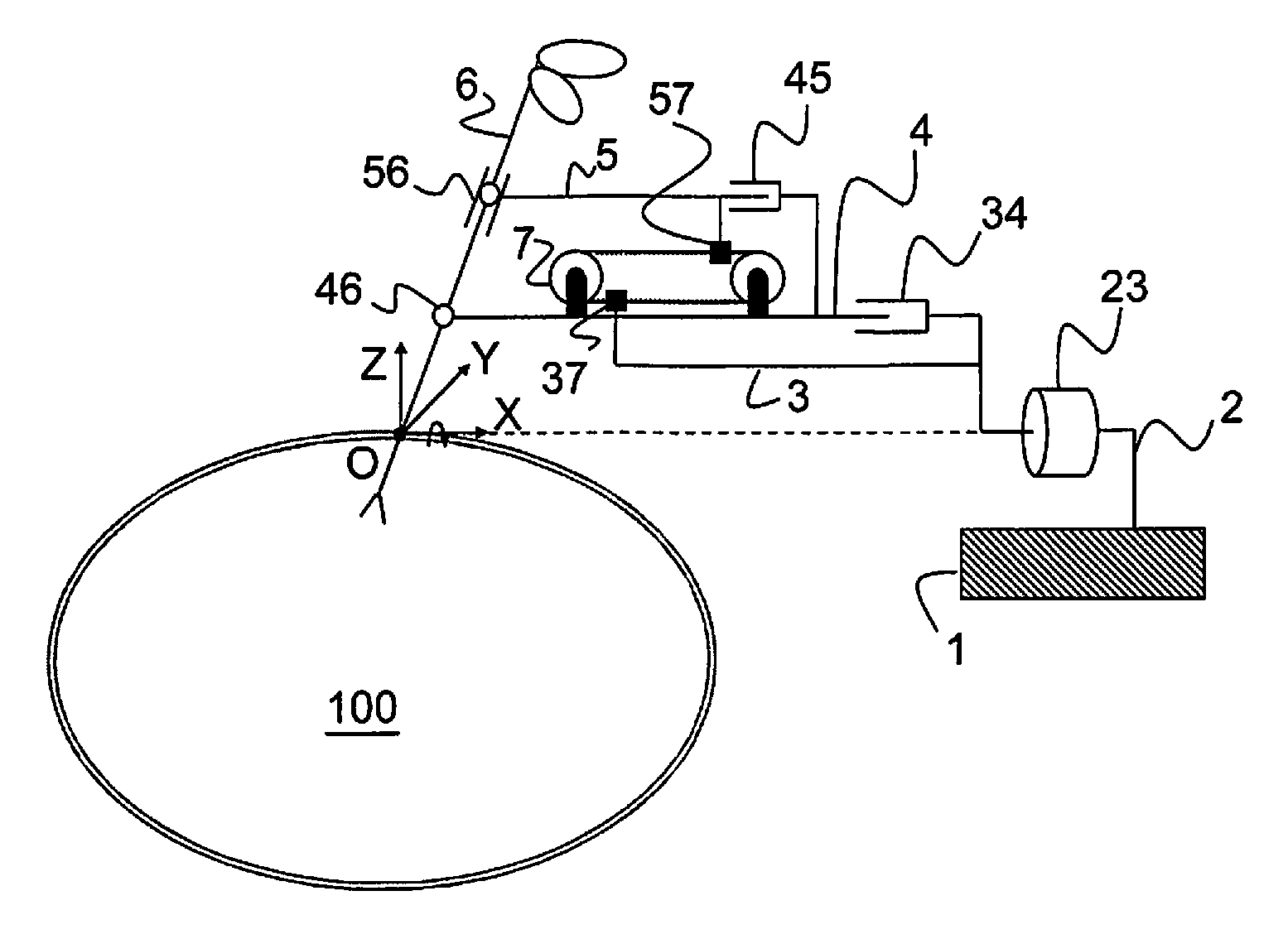

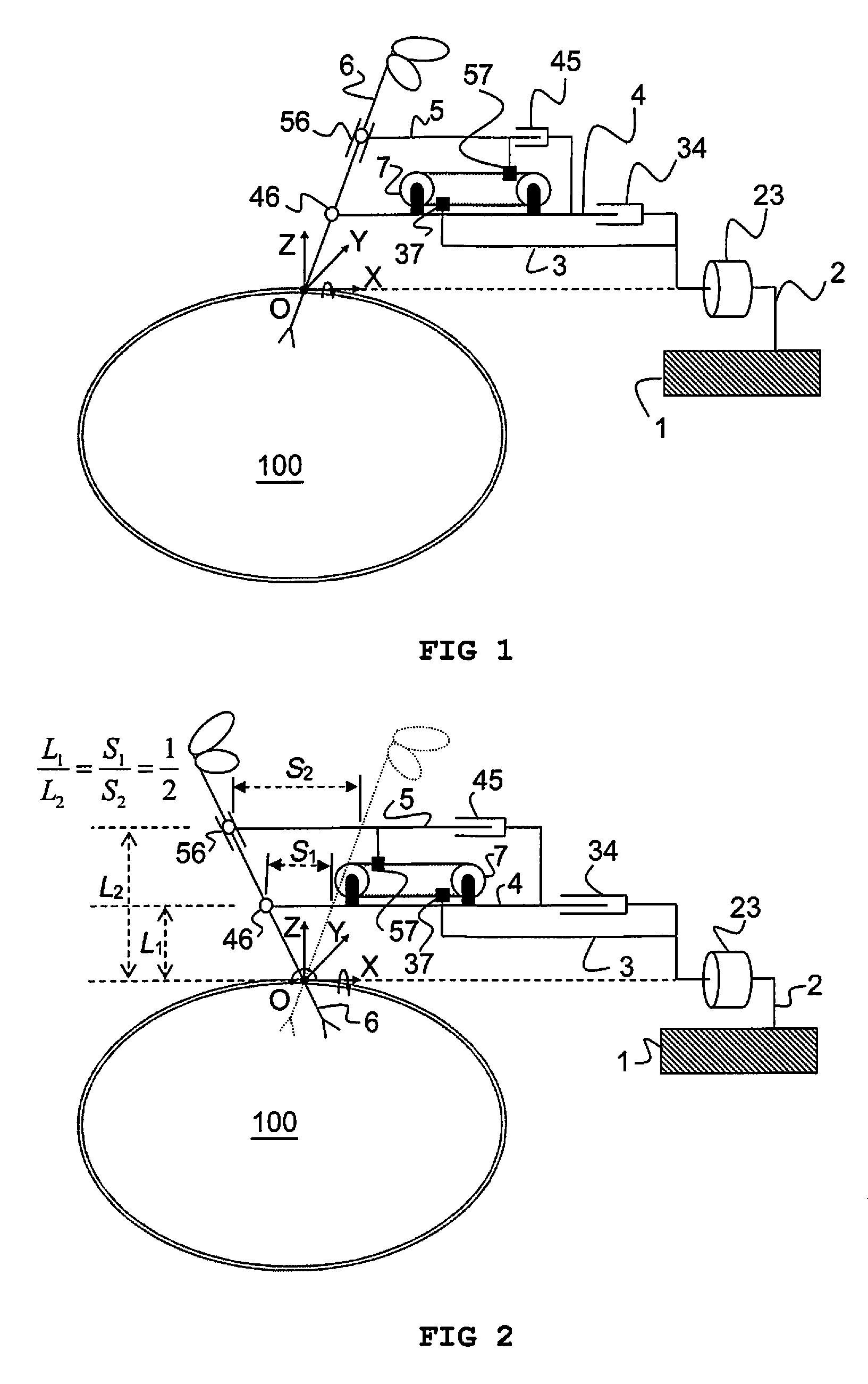

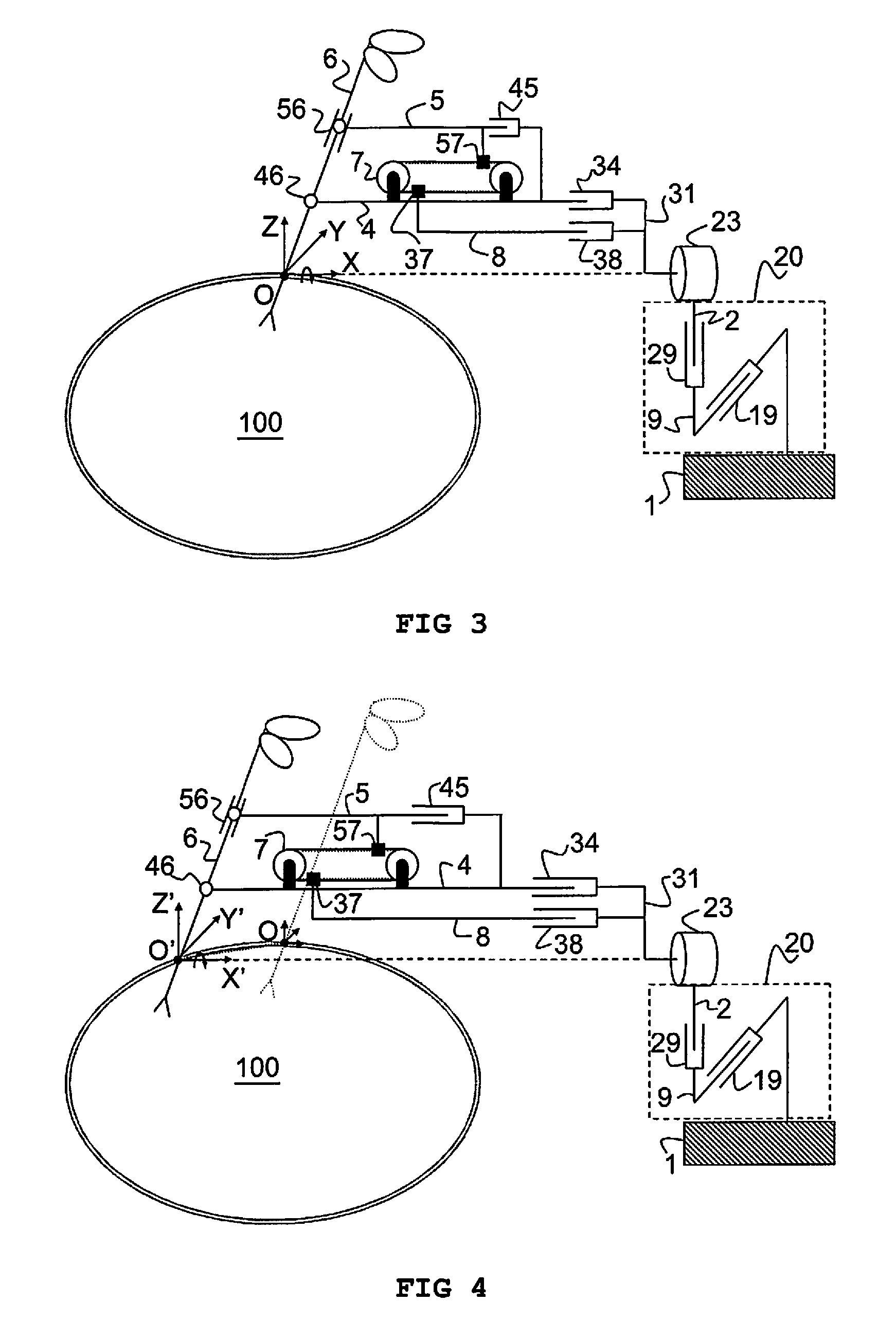

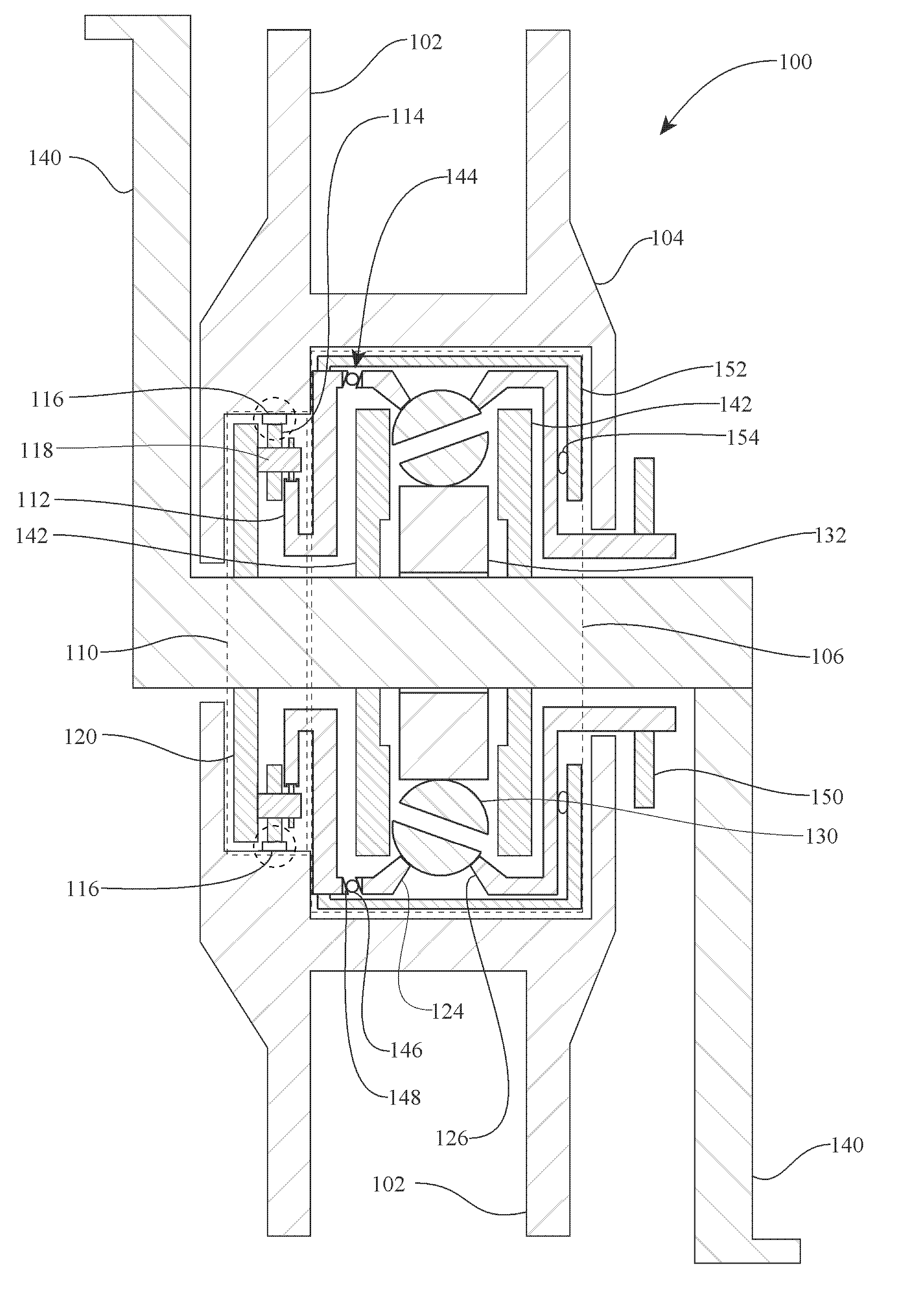

Remote centre of motion positioner

An apparatus having a member that revolves about a remote center of motion (RCM) and a base link coupled to a mounting fixture. A first and second link are pivotably coupled to the member at respective distances from the RCM and are translatable relative to the base link along a first direction, at a fixed ratio of displacement. The ratio of respective distances equals a fixed ratio of displacement. The apparatus has a translational motion generator for a first and second element along parallel opposing directions. The translational motion generator is disposed on the first link and enables motion parallel to the first direction. The base link is fixed in position, the first element is fixed to the base link and the second element is fixed to the second link, such that the first and second link may translate relative to the base link with fixed ratio of displacement.

Owner:KATHOLIEKE UNIV LEUVEN

Continuously variable transmission

InactiveUS20070155567A1Easy to adjustImprove translationWheel based transmissionChain/belt transmissionEngineeringMechanical engineering

Traction planets and traction rings can be operationally coupled to a planetary gearset to provide a continuously variable transmission (CVT). The CVT can be used in a bicycle. In one embodiment, the CVT is mounted on the frame of the bicycle at a location forward of the rear wheel hub of the bicycle. In one embodiment, the CVT is mounted on and supported by members of the bicycle frame such that the CVT is coaxial with the crankshaft of the bicycle. The crankshaft is configured to drive elements of the planetary gearset, which are configured to operationally drive the traction rings and the traction planets. Inventive component and subassemblies for such a CVT are disclosed. A shifting mechanism includes a plurality of pivot arms arranged to pivot about the centers of the traction planets as a shift pin hub moves axially.

Owner:FALLBROOK INTPROP COMPANY

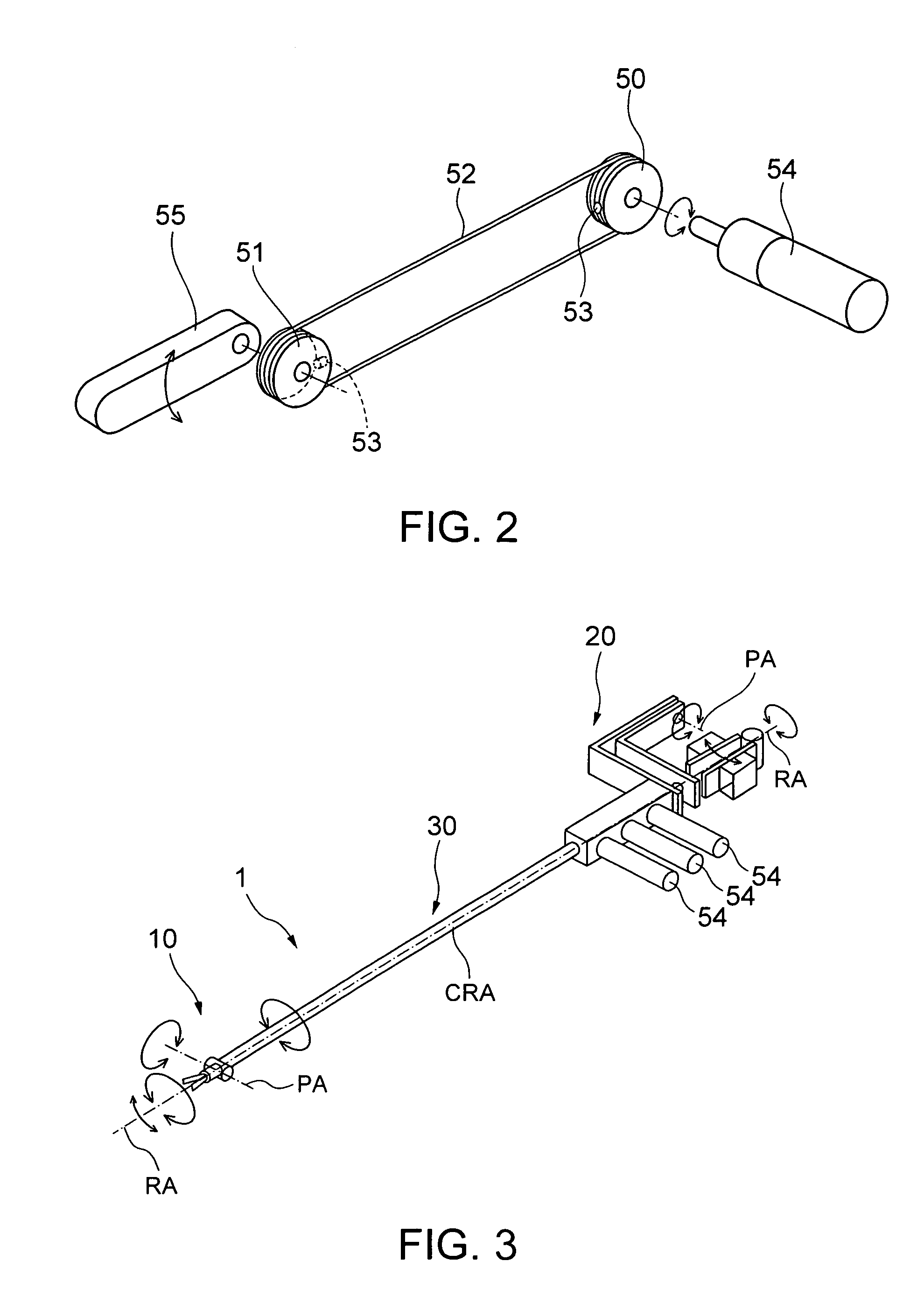

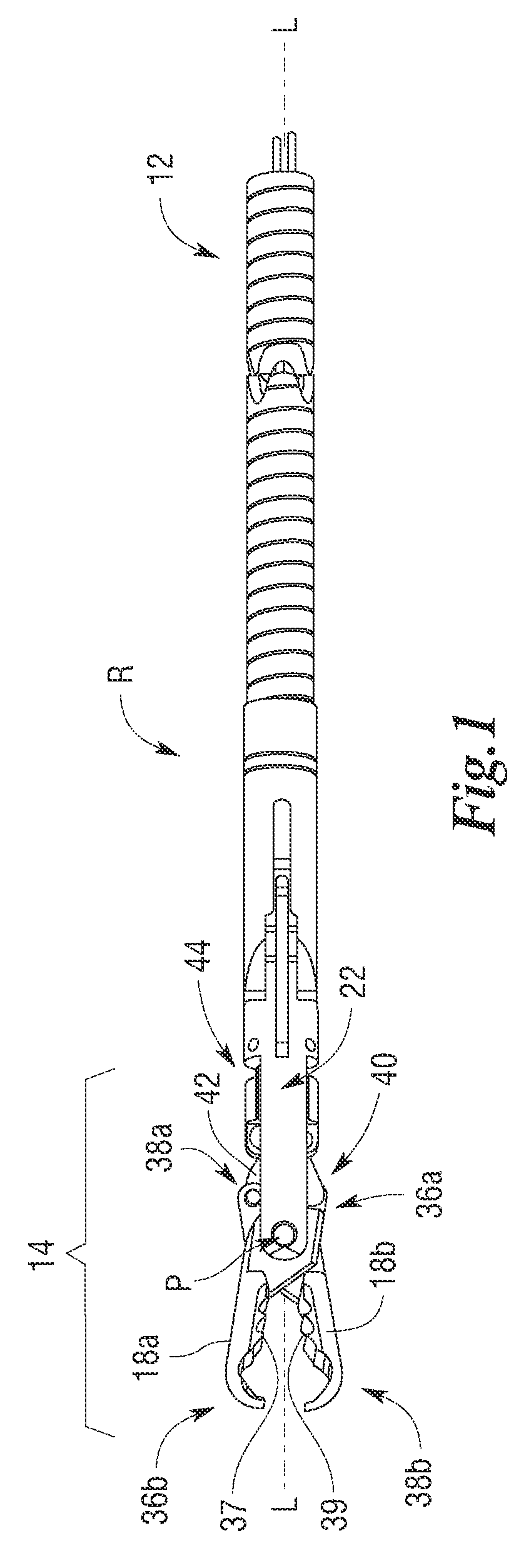

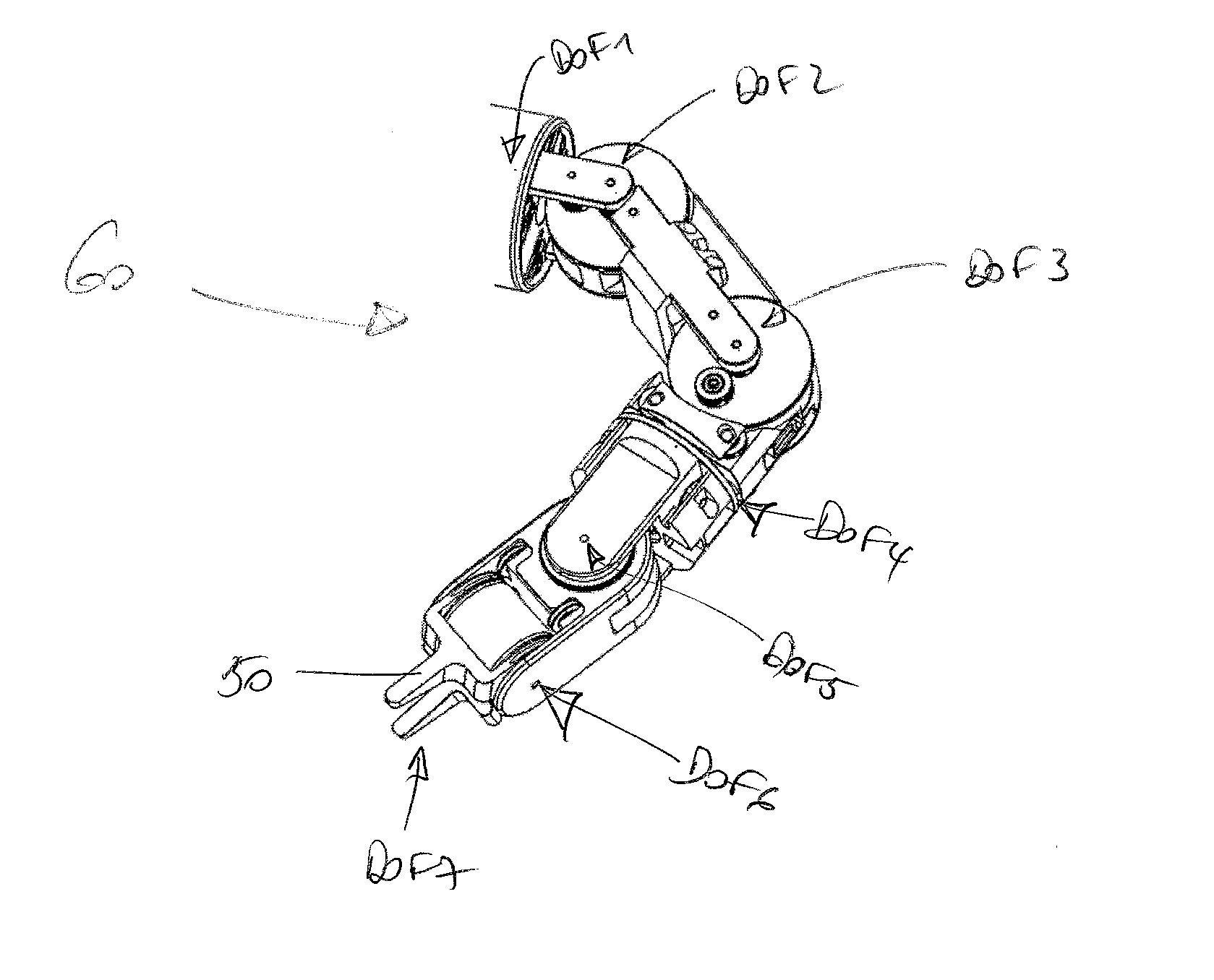

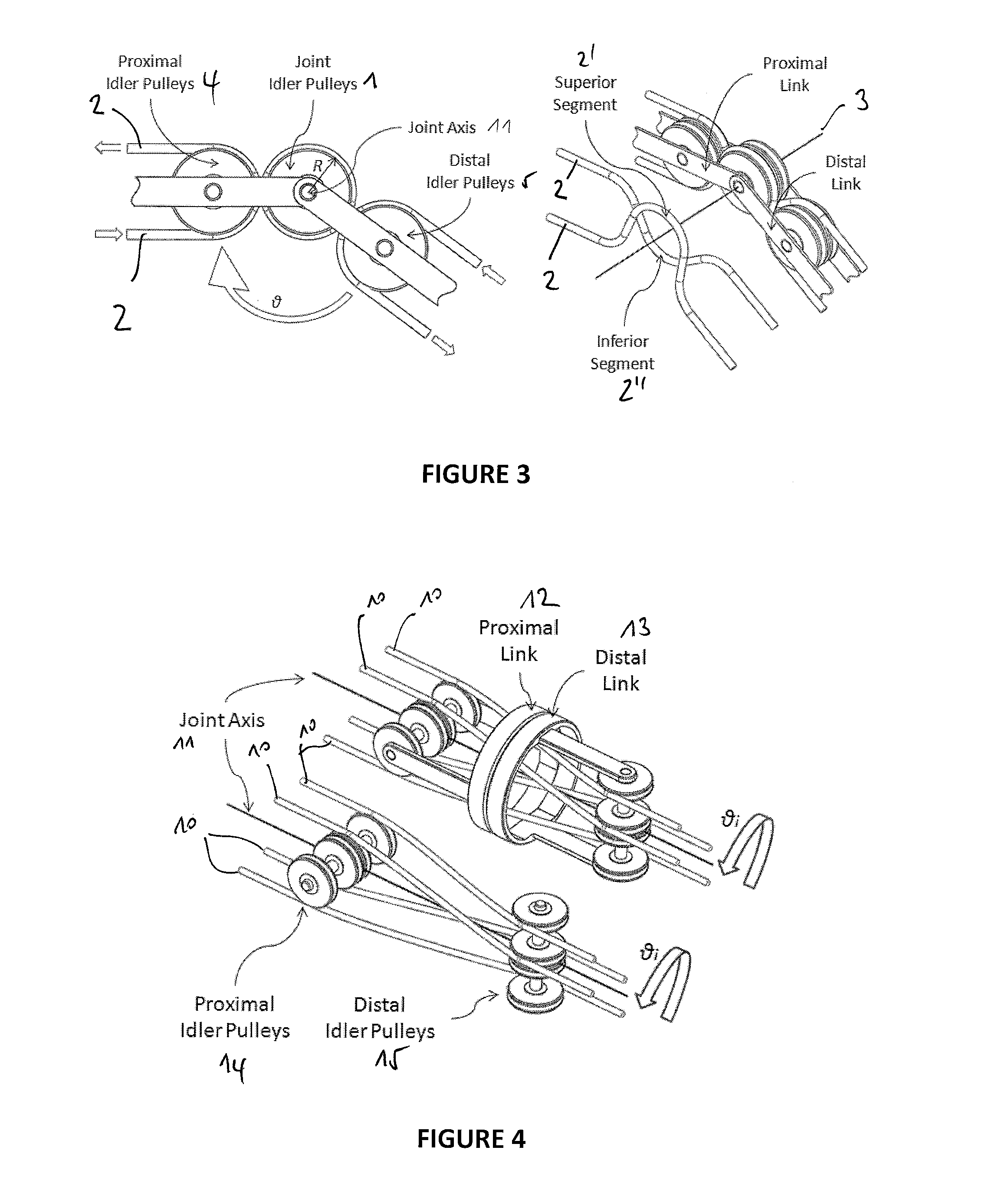

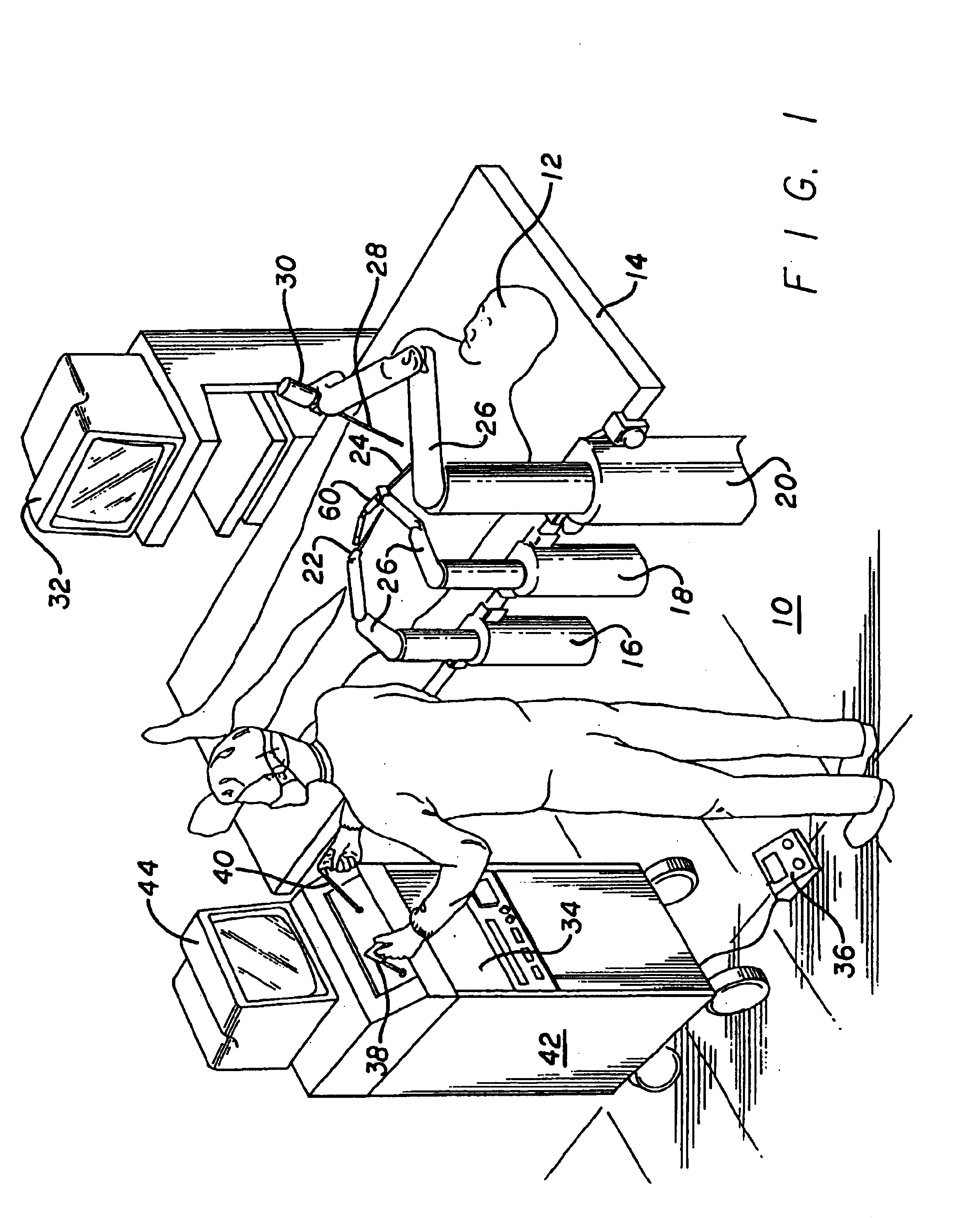

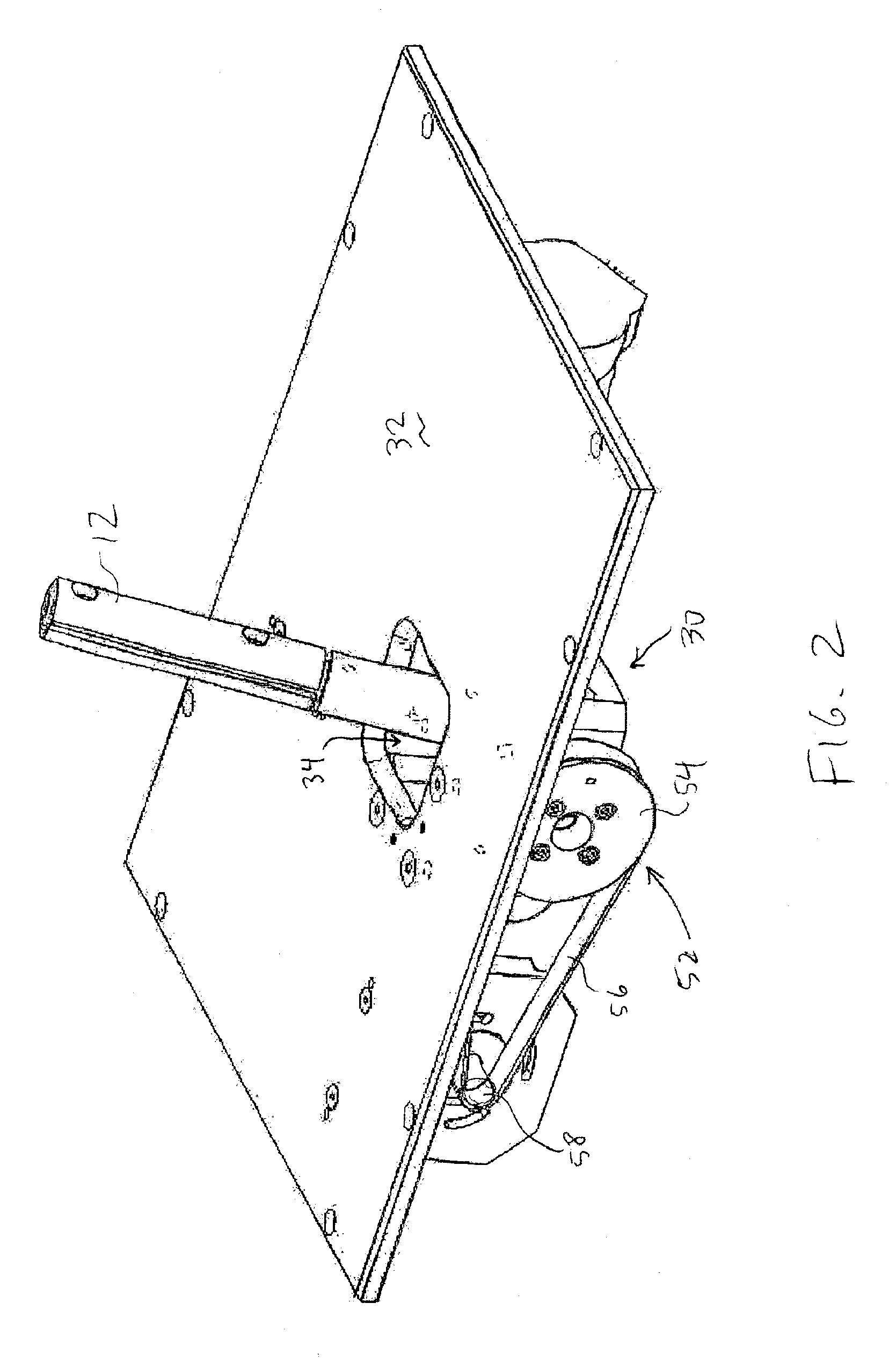

Mechanical manipulator for surgical instruments

ActiveUS20130304084A1Solve the lack of stiffnessSolve the lack of precisionDiagnosticsSurgical manipulatorsConventional laparoscopyEngineering

A novel mechanical system, based on a new cable driven mechanical transmission, able to provide sufficient dexterity, stiffness, speed, precision and payload capacity to actuate multi-DOF micro-manipulators. Besides the possibility of being used in several articulated surgical instruments and robotic systems for surgery or other applications involving remote manipulation, it enables the design of a novel fully mechanical surgical instrument, which offer the advantages of conventional laparoscopy (low cost, tactile feedback, high payload capacity) combined with the advantages of single port surgery (single incision, scarless surgery, navigation through several quadrants of the abdominal cavity) and robotic surgery (greater degrees of freedom, short learning curve, high stiffness, high precision, increased intuition). The unique design of the proposed system provides an intuitive user interface to achieve such enhanced manoeuvrability, allowing each joint of a teleoperated slave system to be driven by controlling the position of a mechanically connected master unit.

Owner:ECOLE POLYTECHNIQUE FEDERALE DE LAUSANNE (EPFL)

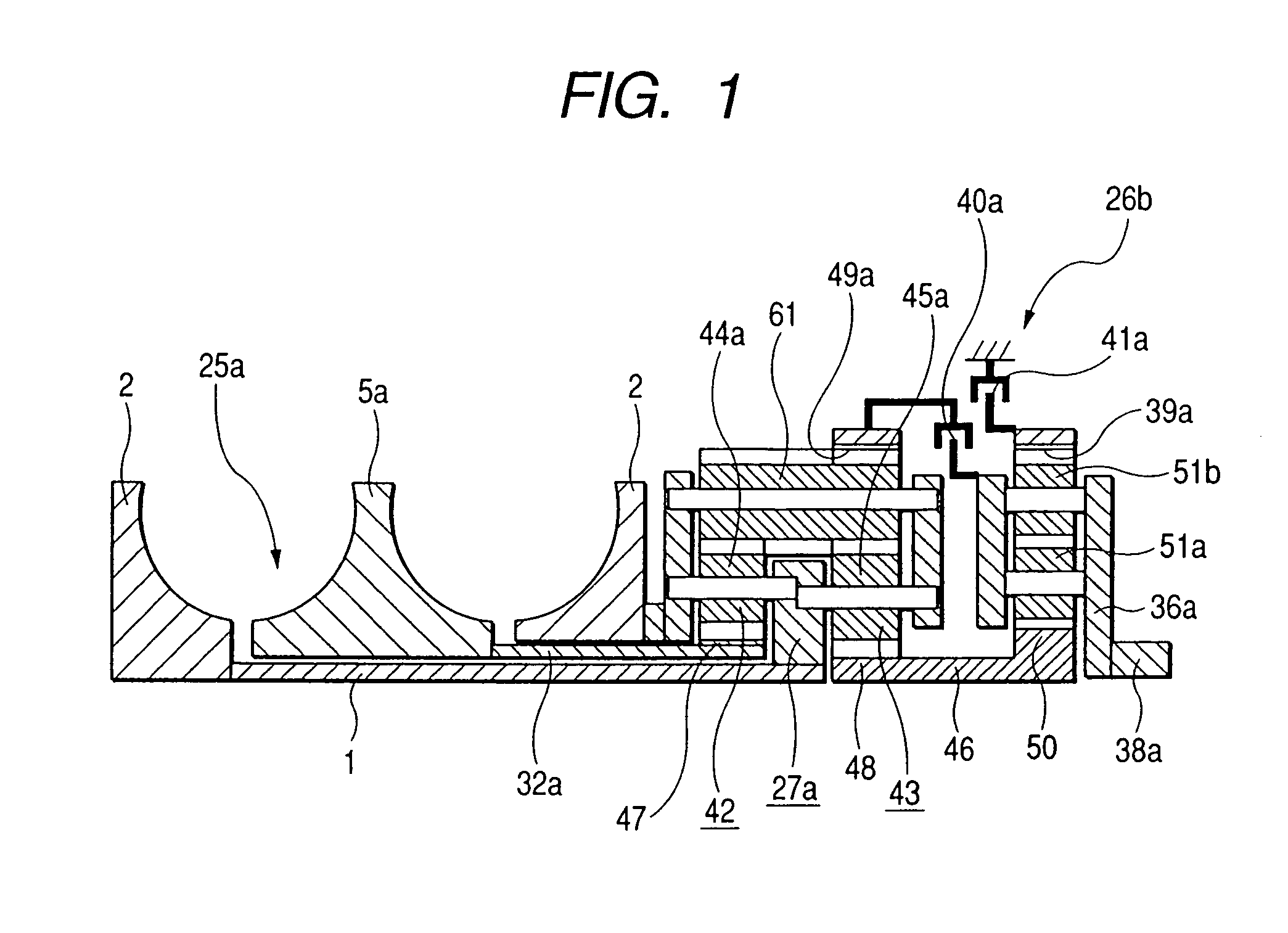

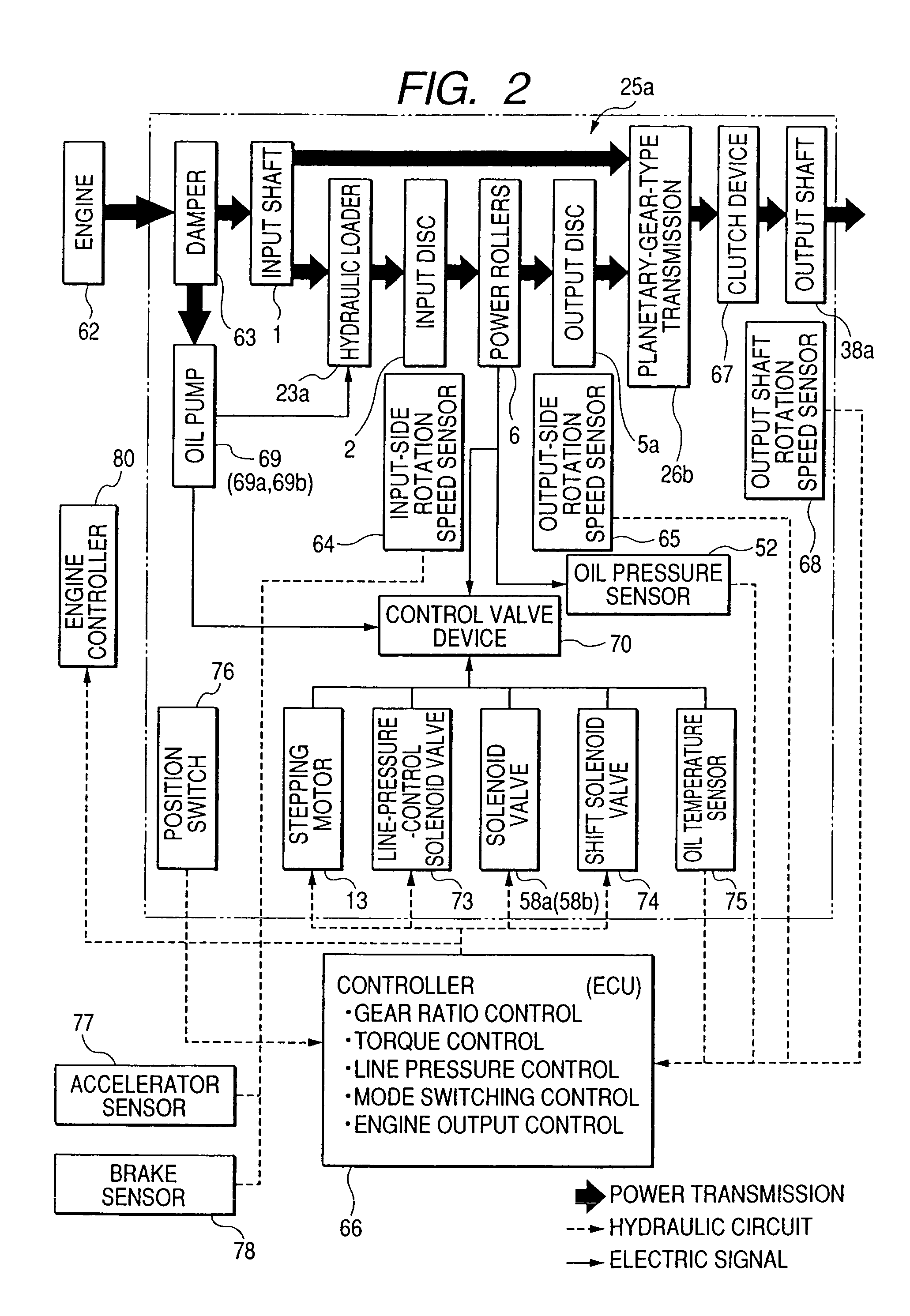

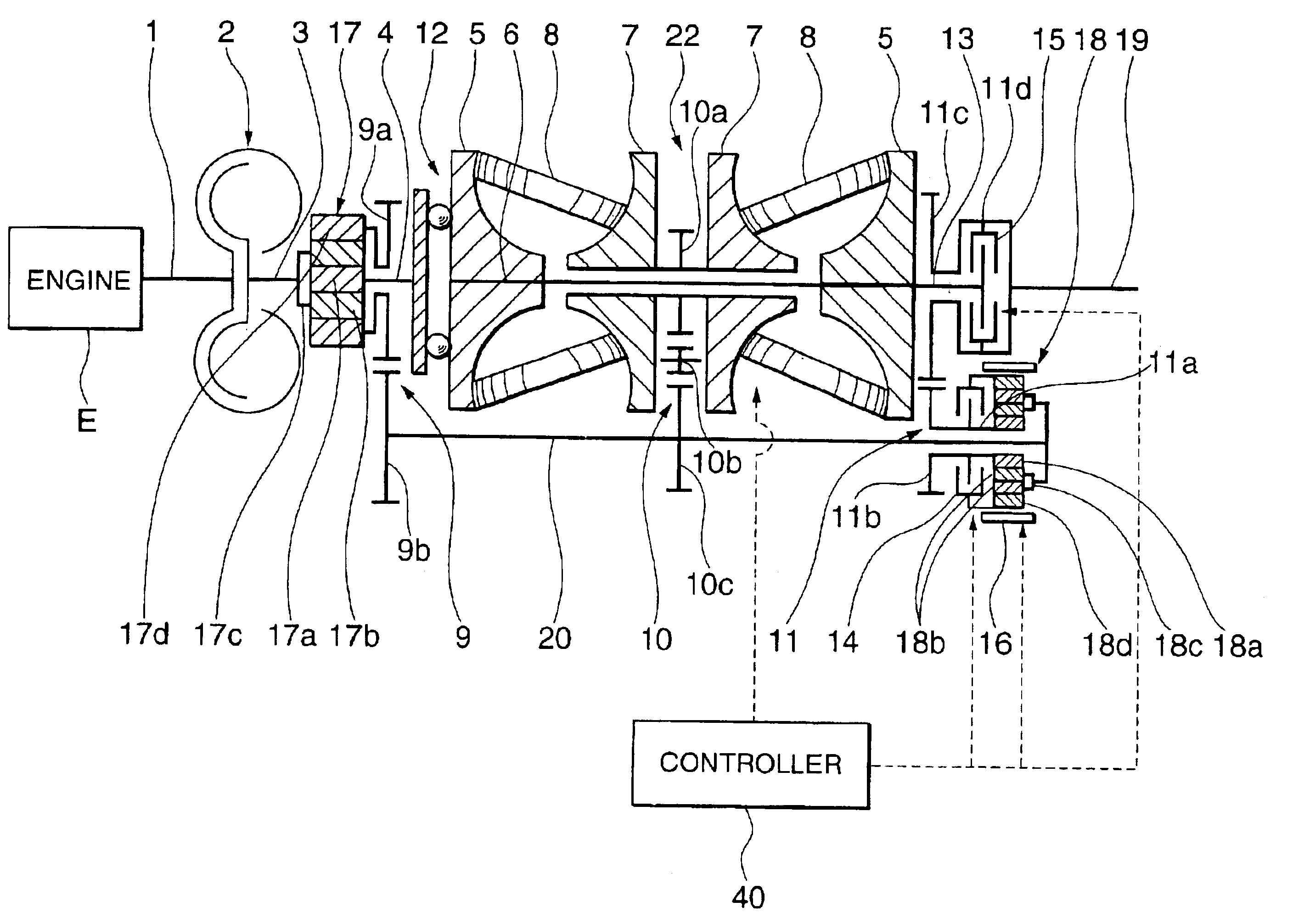

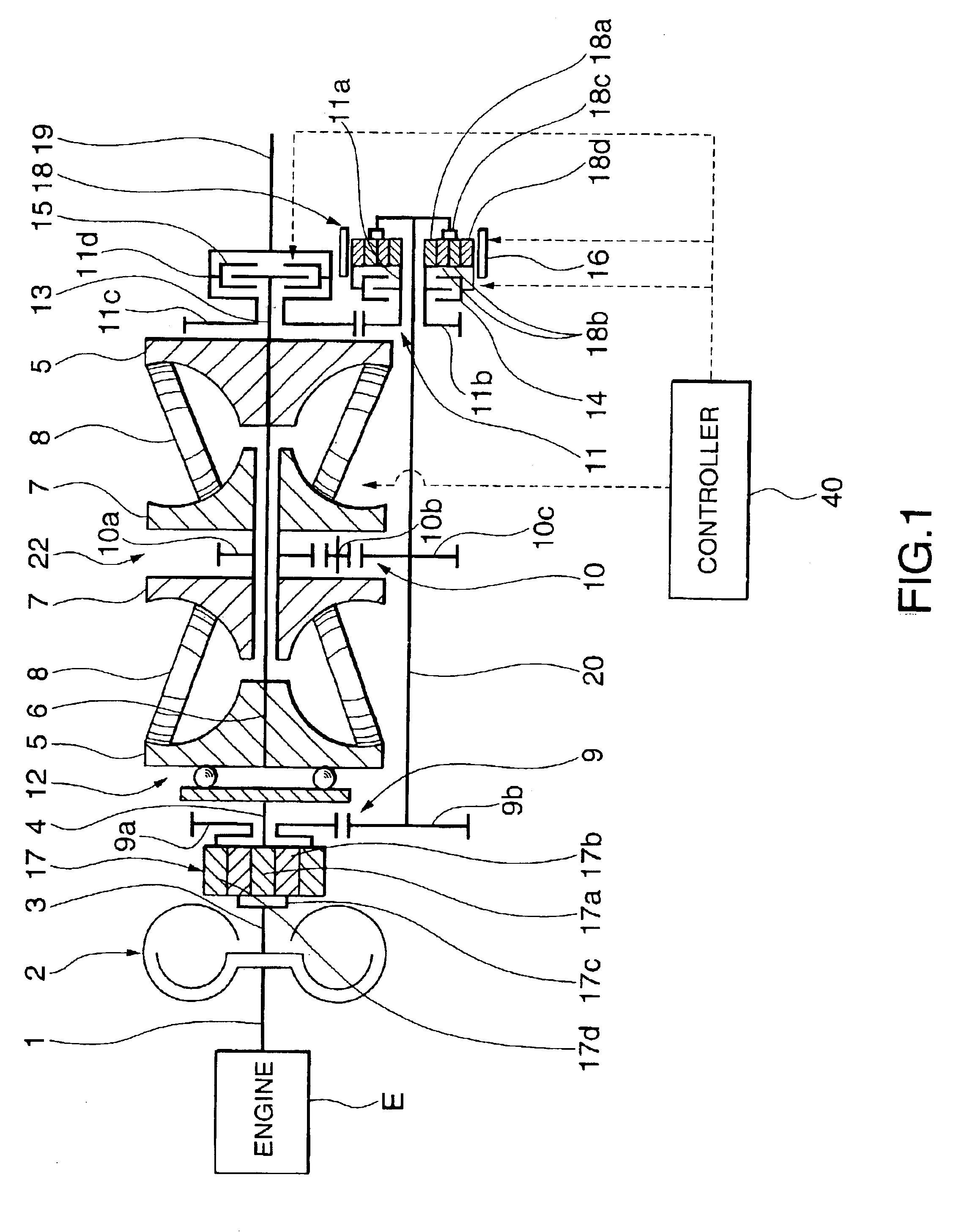

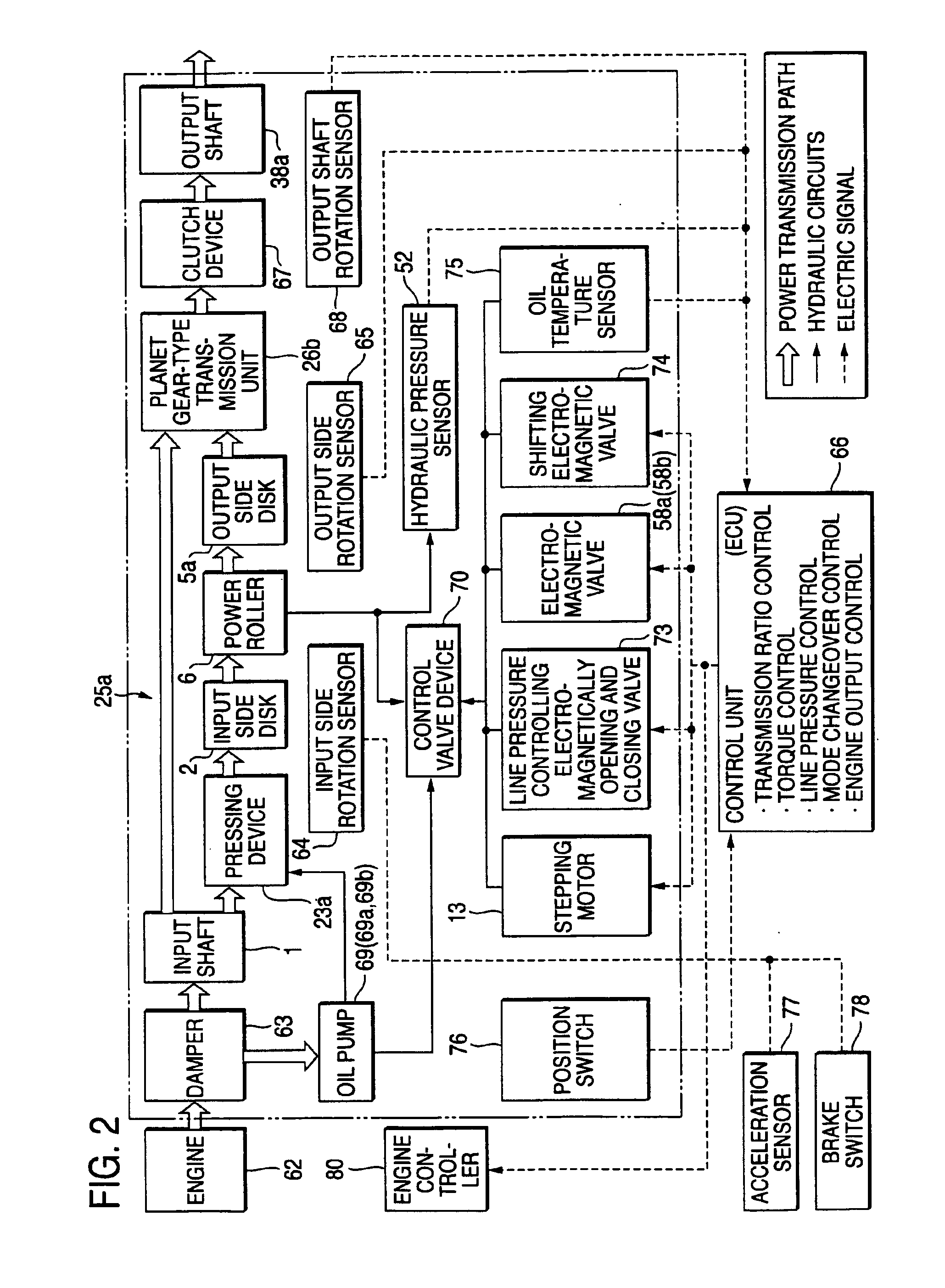

Continuously variable transmission apparatus

InactiveUS7160220B2Avoid feeling uncomfortableGearing controlEngine controllersControl theoryContinuously variable transmission

A continuously variable transmission apparatus includes: an input shaft, an output shaft, a toroidal continuously variable transmission, a gear-type differential unit including a plurality of gears, and a controller. The controller calculates a torque actually passing through the toroidal continuously variable transmission to obtain a deviation of the torque from a target value and adjusts a transmission ratio of the toroidal continuously variable transmission to eliminate the deviation. The controller stops the adjustment of the transmission ratio when the torque is not stable.

Owner:NSK LTD

Continuously variable power-split transmission

The second platenary gear mechanism 18 is a so-called double pinion type planetary gear comprising a sun gear 18a, paired pinions 18b, a carrier 18c which supports the pinions, and a ring gear 18d. The pinions 18b of eeach pair meshes with each other in a state where one of the paired pinions 18b meshes with the sun gear 18a while the other one of the paired pinions 18b meshes with the ring gear 18d. The carrier 18c is coupled to the countershaft 20 and the sun gear 18a is connected to a shaft 11a which is coupled to a gear 11b of a third gear unit 11.

Owner:JATCO LTD

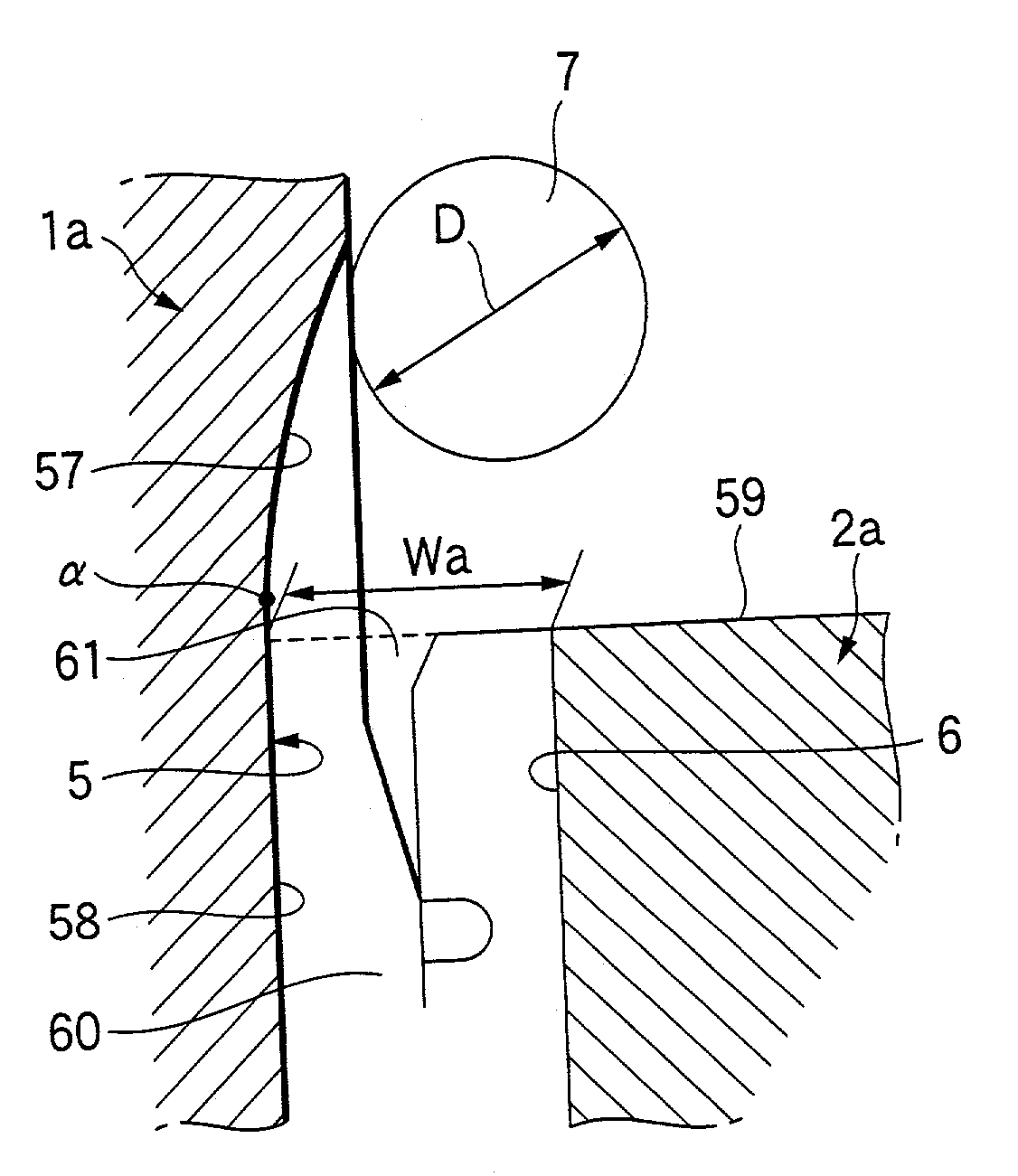

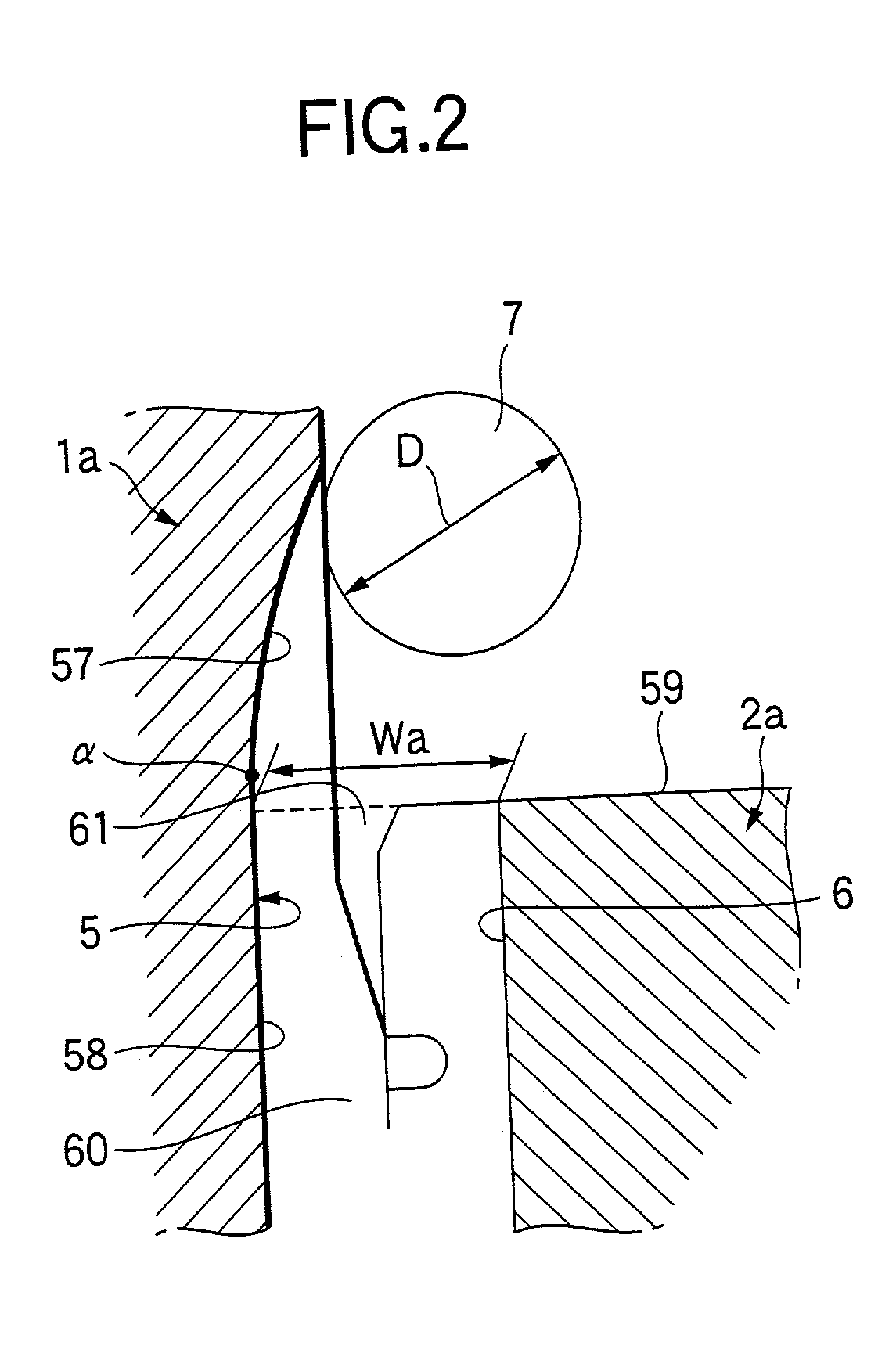

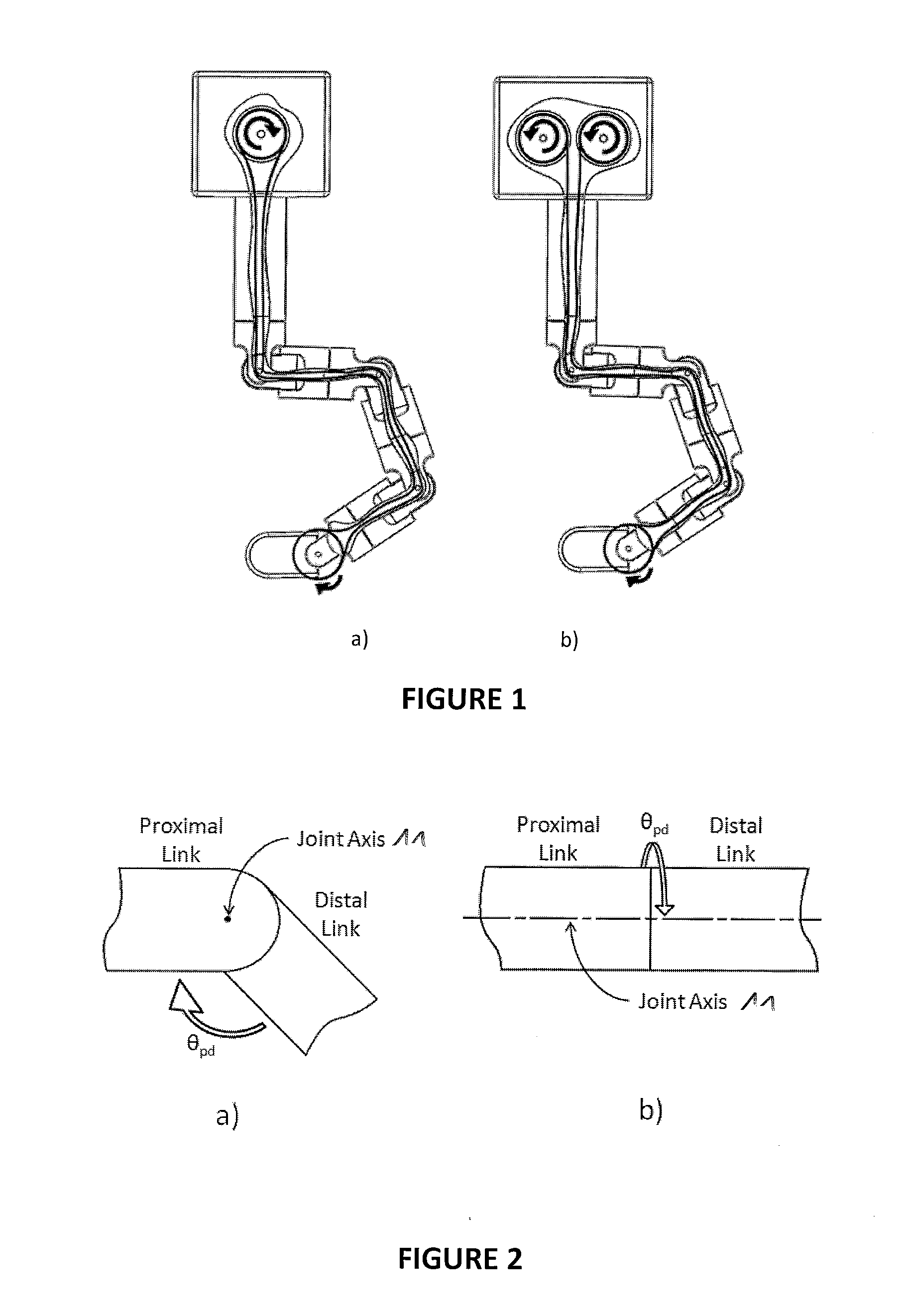

Drive roller control for toric-drive transmission

ActiveUS7217220B2Improve energy efficiencyReduce the amount requiredGearing controlFriction gearingsDegrees of freedomRotational degrees of freedom

A toric-drive transmission comprising a drive disk for receiving a power input. A driven disk transmits a power output. A roller device has a roller displaceably mounted between the drive disk and the driven disk. The roller has three rotational degrees of freedom. A first degree of freedom transmits motion from the drive disk to the driven disk to convert the power input to the power output. A second degree of freedom varies a ratio of the power output to the power input as a function of an orientation of the roller along the second degree of freedom. A third degree of freedom initiates a rotation of the roller about the second degree of freedom. A controller system is operatively connected to the roller device for changing the orientation of the roller in the second degree of freedom by actuating a displacement of the roller in the third degree of freedom.

Owner:S O E TECH

Continuously variable planetary gear set

A continuously variable planetary gear set is described having a generally tubular idler, a plurality of balls distributed radially about the idler, each ball having a tiltable axis about which it rotates, a rotatable input disc positioned adjacent to the balls and in contact with each of the balls, a rotatable output disc positioned adjacent to the balls opposite the input disc and in contact with each of the balls such that each of the balls makes three-point contact with the input disc, the output disc and the idler, and a rotatable cage adapted to maintain the axial and radial position of each of the balls, wherein the axes of the balls are oriented by the axial position of the idler.

Owner:FALLBROOK INTPROP COMPANY

Heart stabilizer

A heart stabilizer that may include a wrist which couples an end effector to a first linkage. The end effector and wrist may be inserted through an incision in the chest of a patient to assist in performing a minimally invasive coronary procedure. The wrist provides dexterity so that the end effector can be placed on the heart to stabilize the same.

Owner:INTUITIVE SURGICAL OPERATIONS INC

Continuously variable transmission mechanism and transmission using the same

InactiveUS20110319222A1Increase rotation speedRotational radiusFriction gearingsRotation velocityControl theory

A continuously variable transmission adapted to set a speed change ratio in accordance with a tilt angle of a rolling member mediating a torque being transmitted, and to transmit a torque among three elements. The transmission mechanism is provided with a rolling member having a smooth outer face and capable of tilting a rotational center axis thereof, and a rotary member arranged to be contacted with a predetermined portion of the outer face of the rolling member in a torque transmittable manner. Specifically, the continuously variable transmission mechanism is configured to vary a rotational speed of the rotary member by changing a rotation radius of a contact point between the rolling member and the rotary member by tilting the rotational center axis of the rolling member.

Owner:TOYOTA JIDOSHA KK

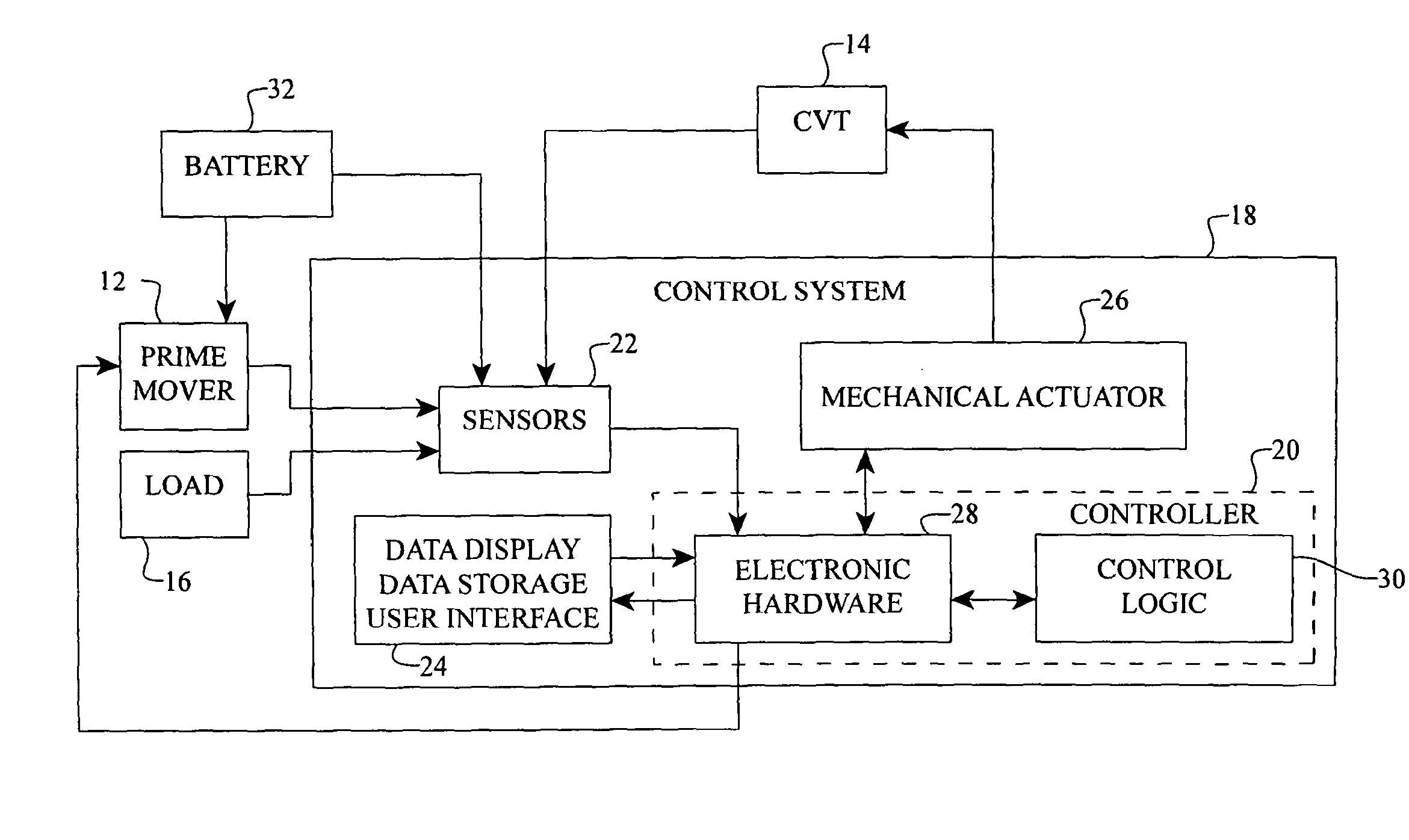

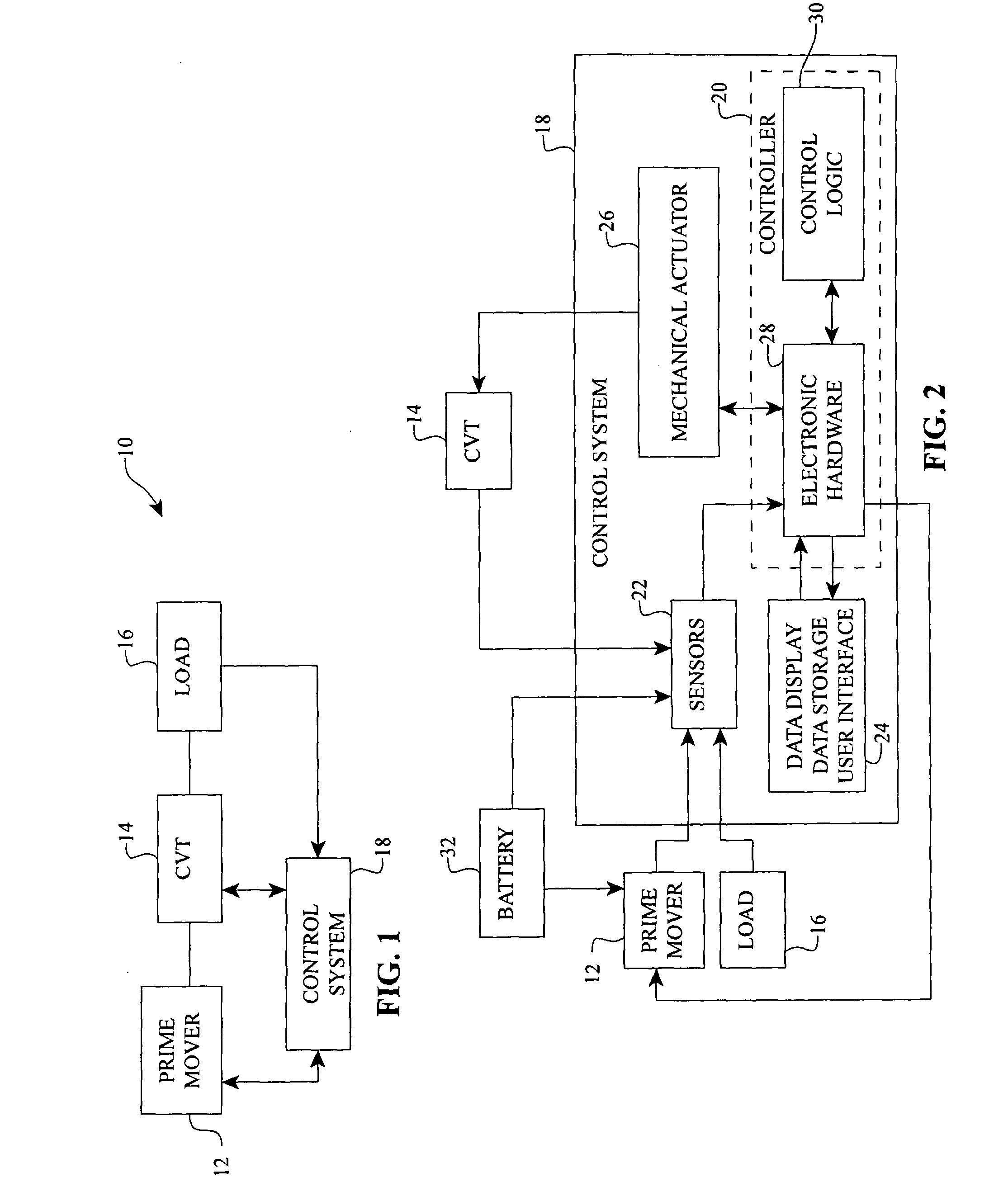

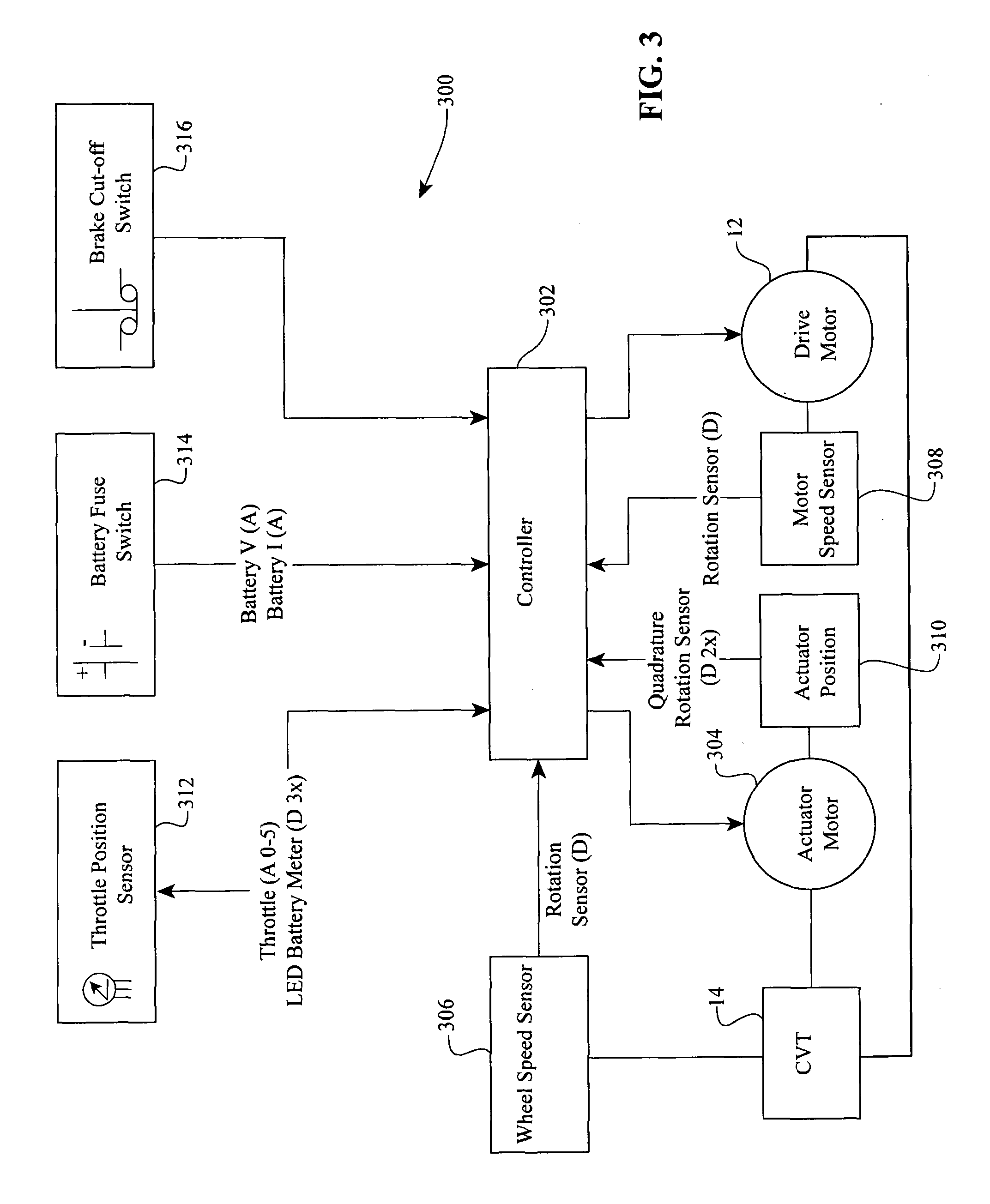

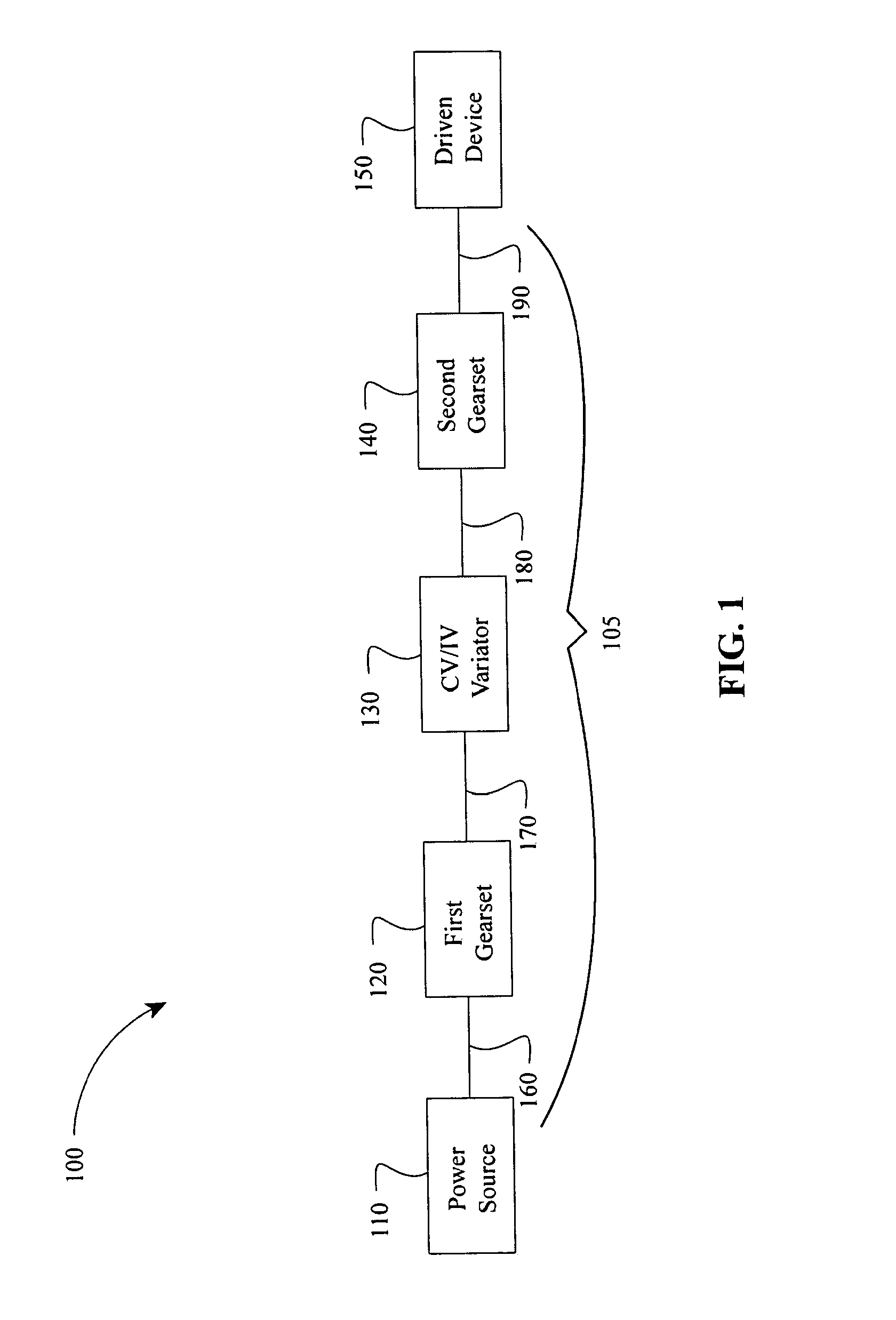

Systems and methods for control of transmission and/or prime mover

Disclosed here are inventive systems and methods for a powertrain of an electric vehicle (EV). In some embodiments, said powertrain includes a continuously variable transmission (CVT) coupled to an electric drive motor, wherein a control system is configured to control the CVT and / or the drive motor to optimize various efficiencies associated with the EV and / or its subsystems. In one specific embodiment, the control system is configured to operate the EV in an economy mode. Operating in said mode, the control system simultaneously manages the CVT and the drive motor to optimize the range of the EV. The control system can be configured to manage the current provided to the drive motor, as well as adjust a transmission speed ratio of the CVT. Other modes of operation are also disclosed. The control system can be configured to manage the power to the drive motor and adjust the transmission speed ratio of the CVT taking into account battery voltage, throttle position, and transmission speed ratio, for example.

Owner:FALLBROOK INTPROP COMPANY

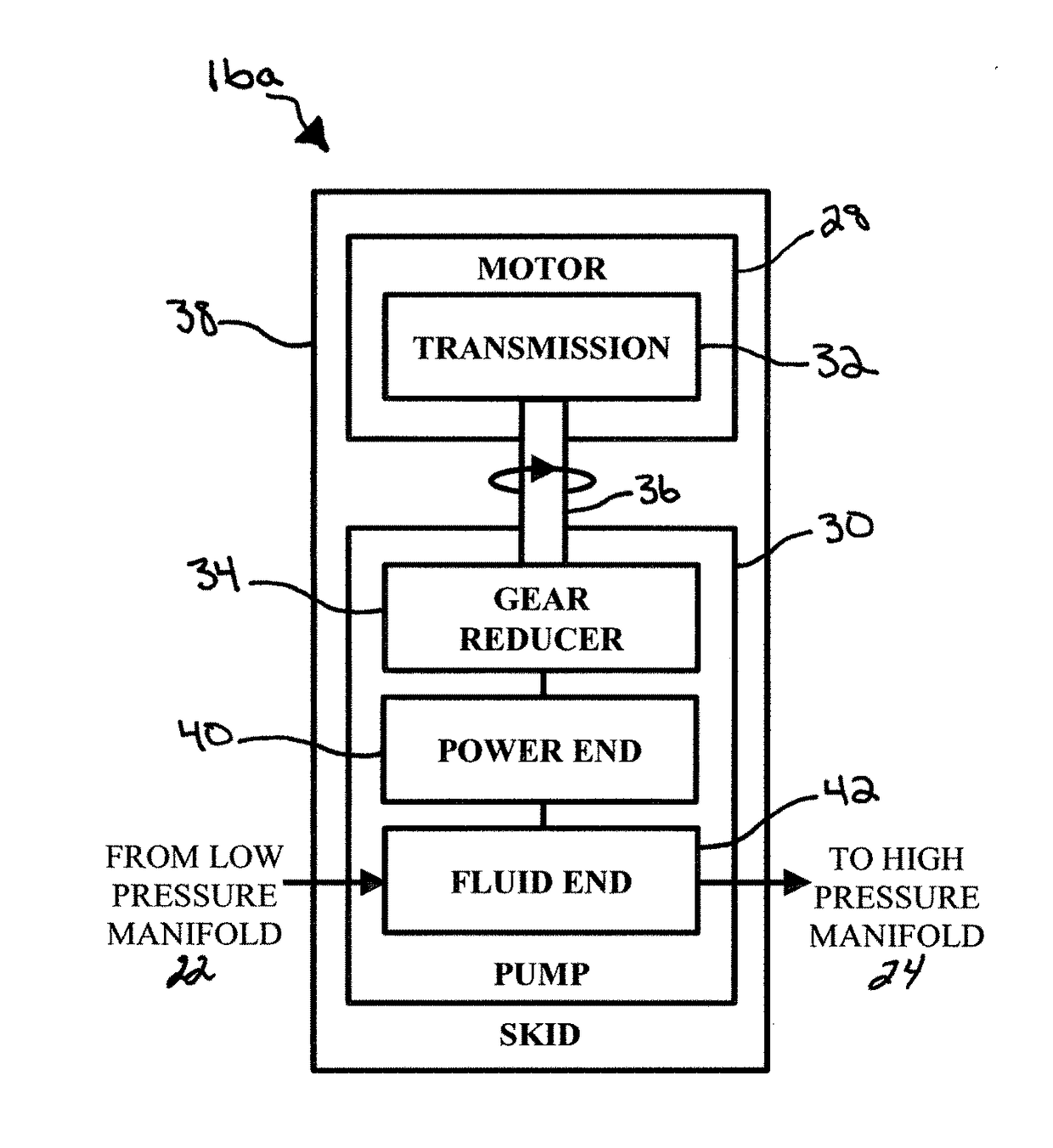

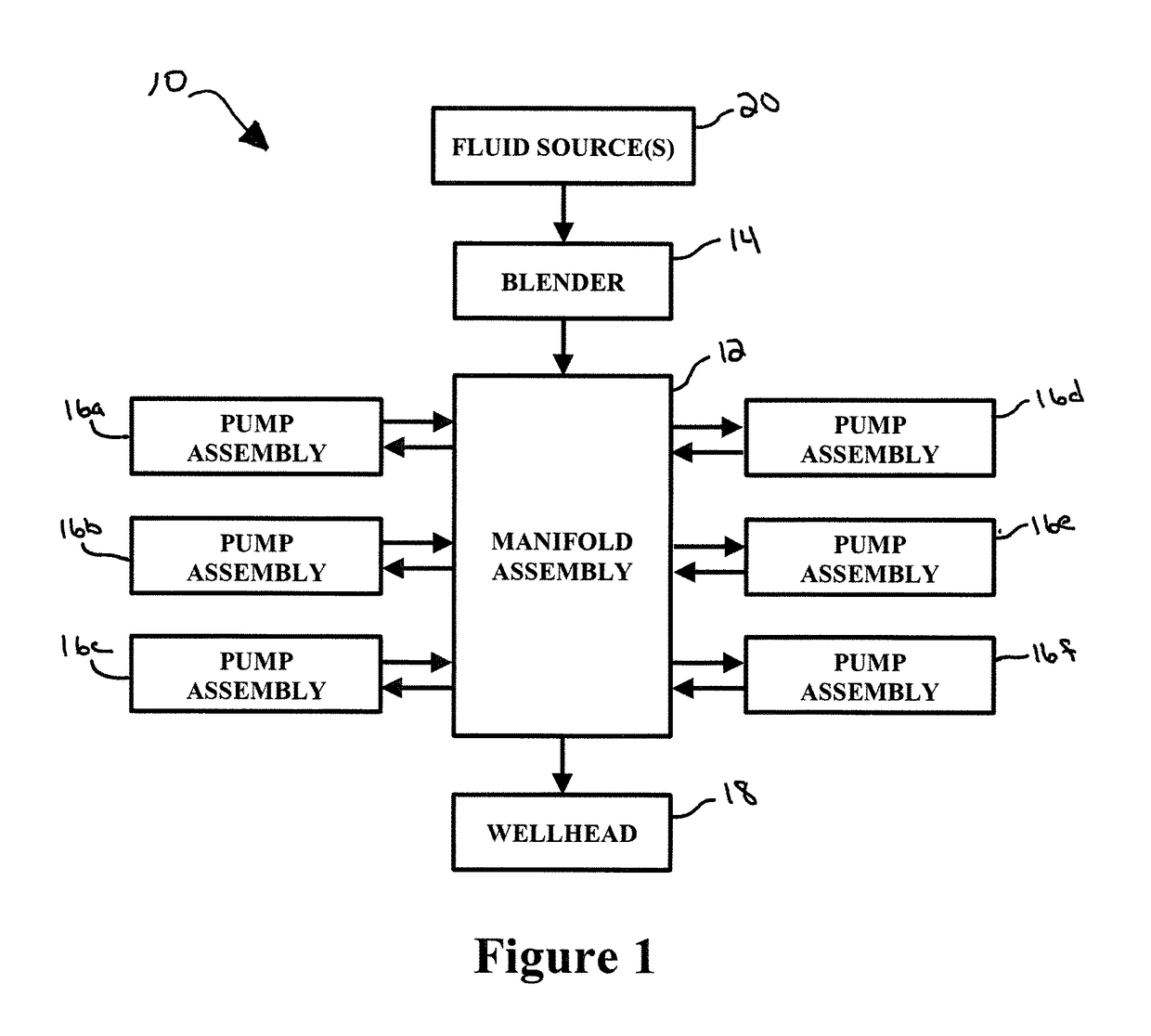

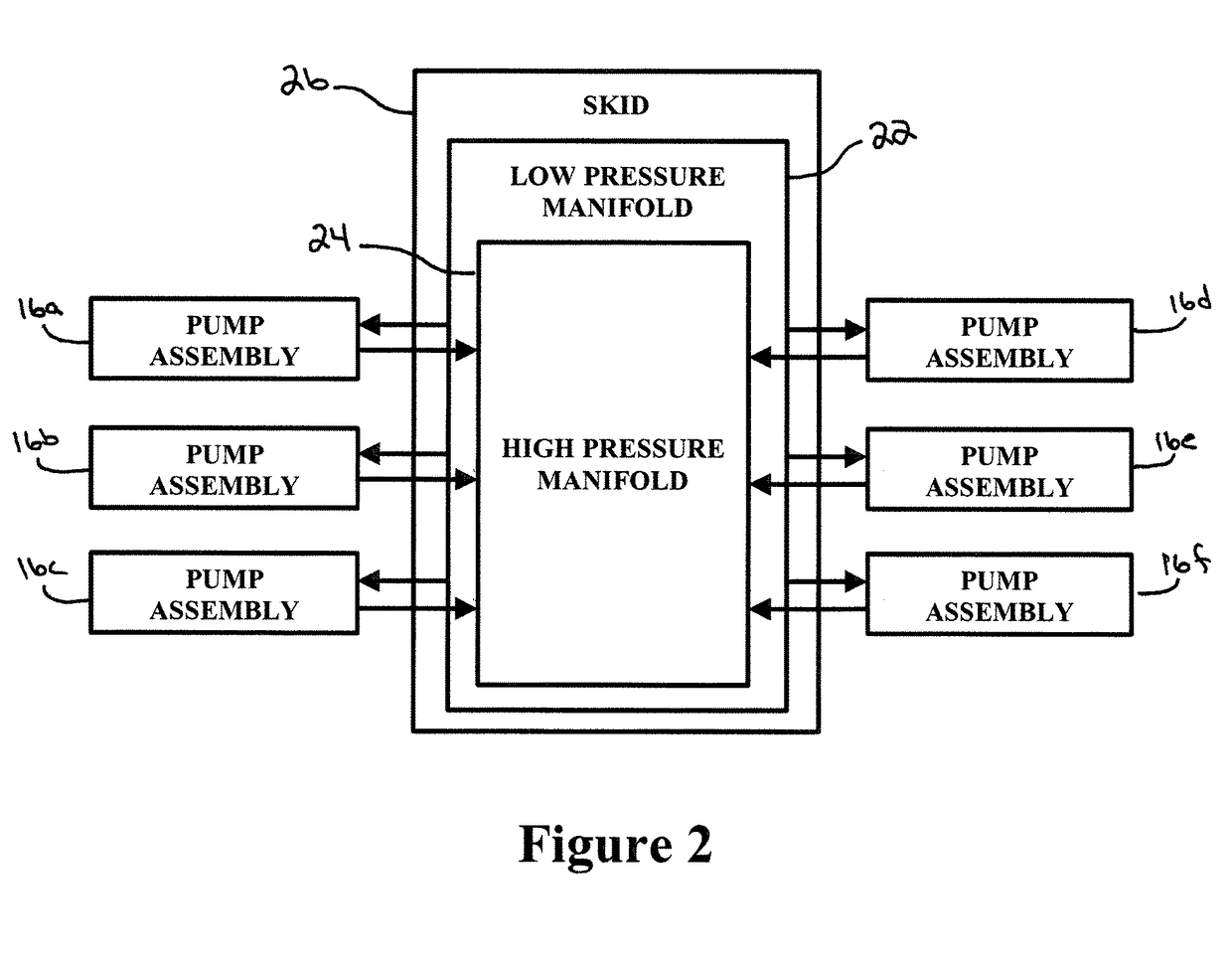

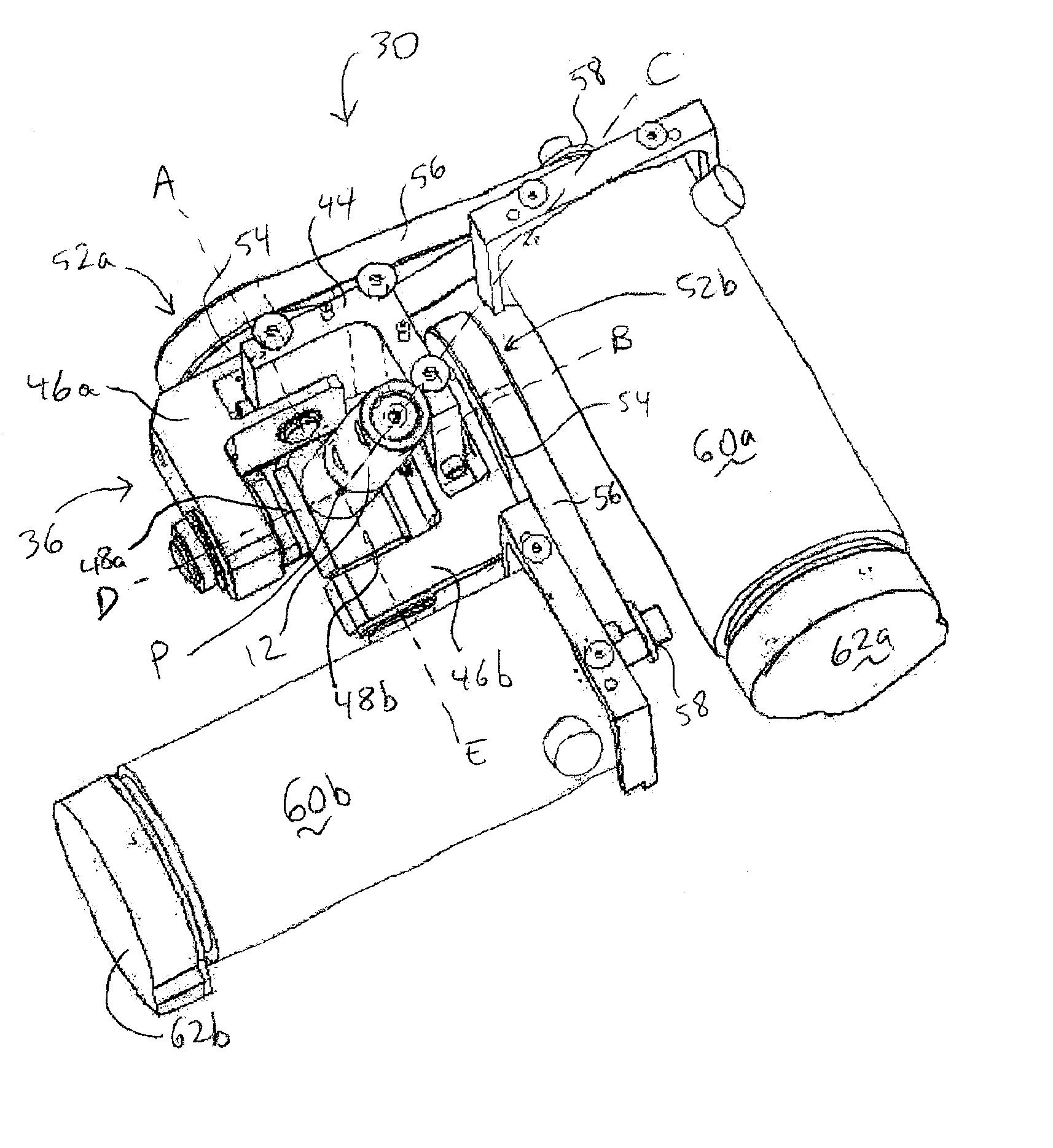

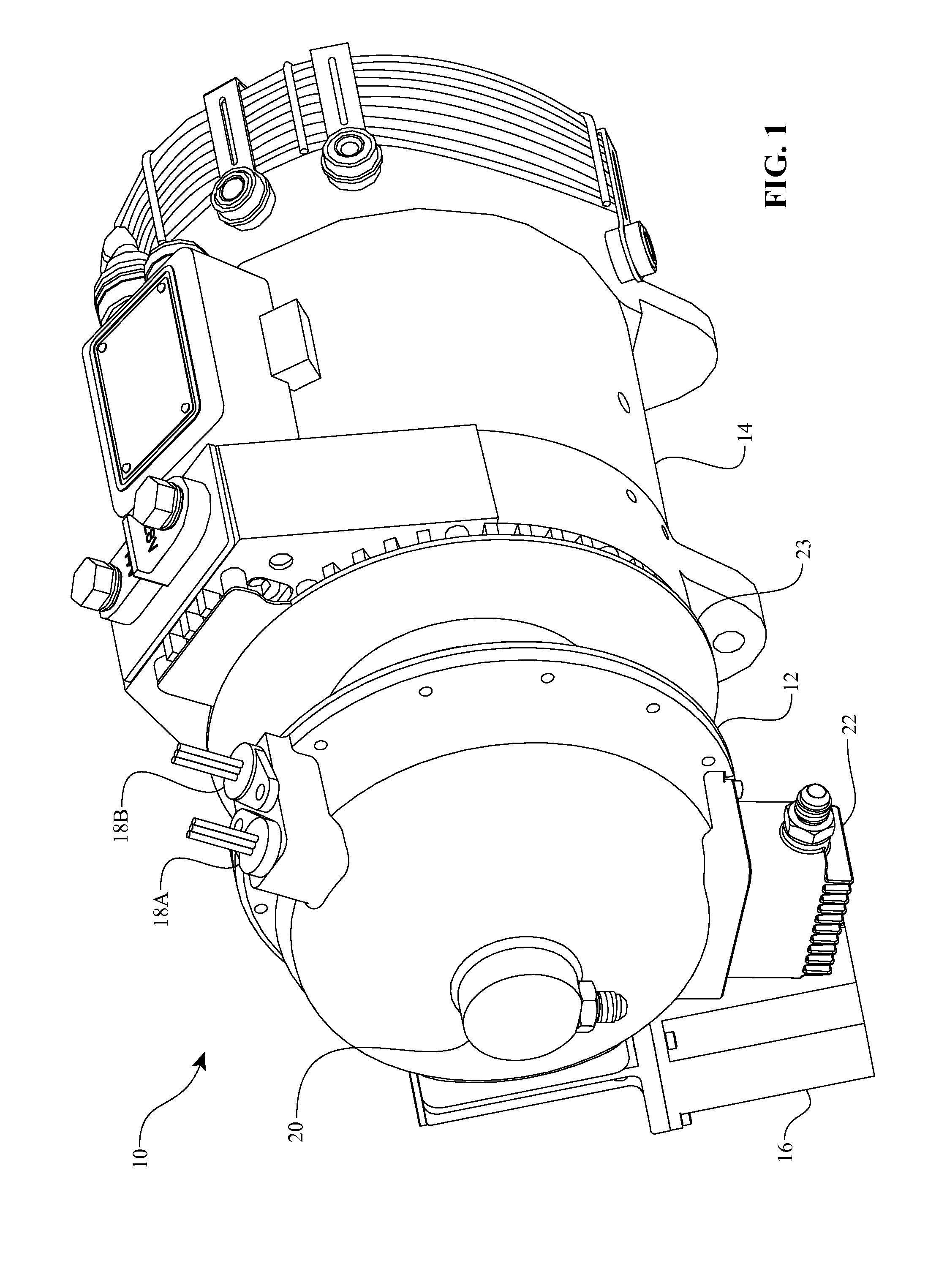

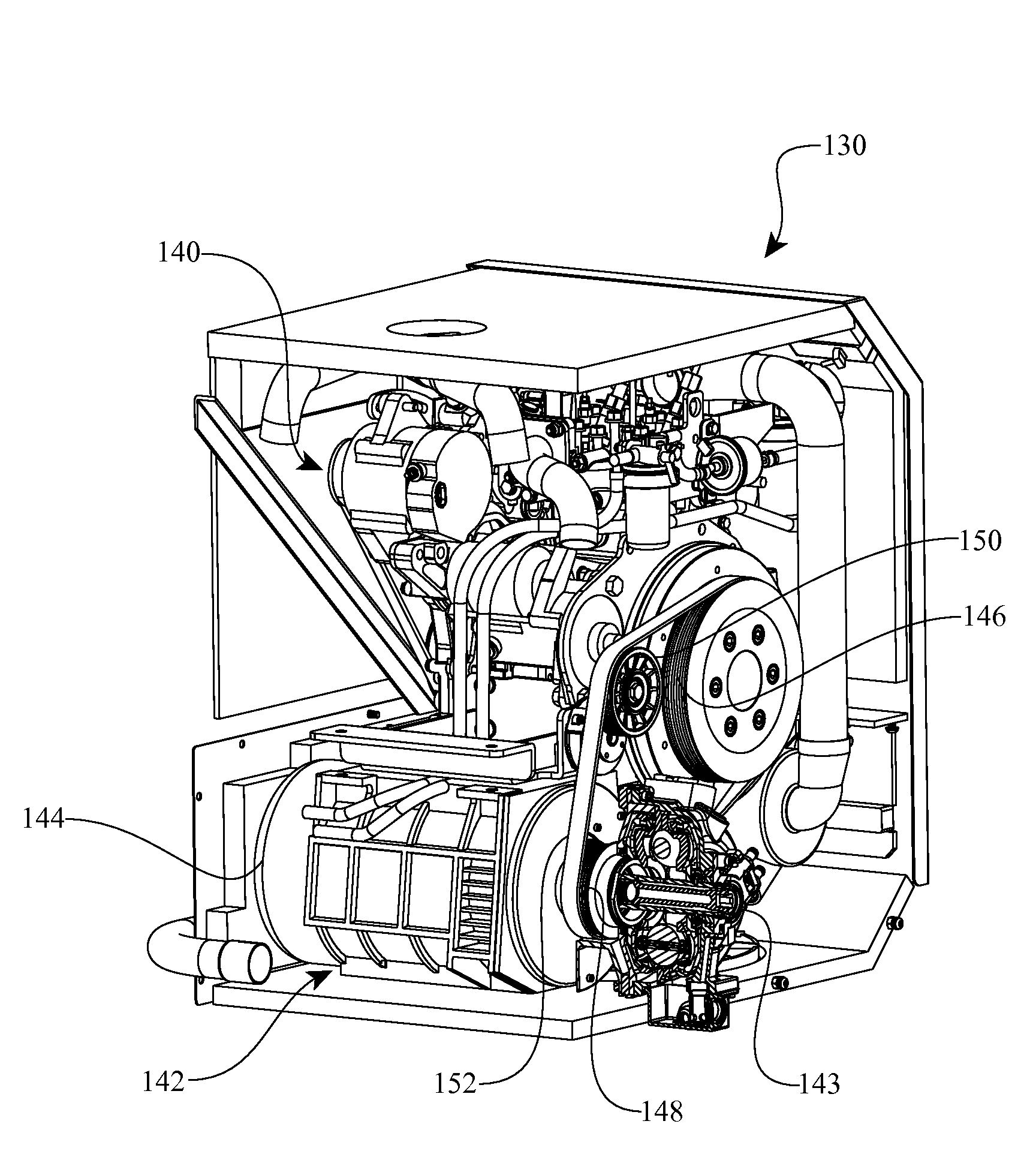

Transmission for pump such as hydraulic fracturing pump

InactiveUS20170234308A1Positive displacement pump componentsFlexible member pumpsAngular velocityFracturing fluid

An apparatus and method according to which a fluid, such as a fracturing fluid, is pressurized. The apparatus includes a motor that produces a first rotational output including a first angular velocity, a pump operably coupled to the motor, the pump comprising a fluid end and a power end operably coupled to the fluid end, and a transmission operably coupled between the motor and the pump. The transmission receives the first rotational output as a first rotational input, the first rotational input including the first angular velocity, and converts the first rotational input into a second rotational output, the second rotational output including a second angular velocity. The power end receives the second rotational output as a second rotational input, the second rotational input including the second angular velocity. In some embodiments, the transmission is directly connected to, or part of, the pump and the motor.

Owner:S P M FLOW CONTROL

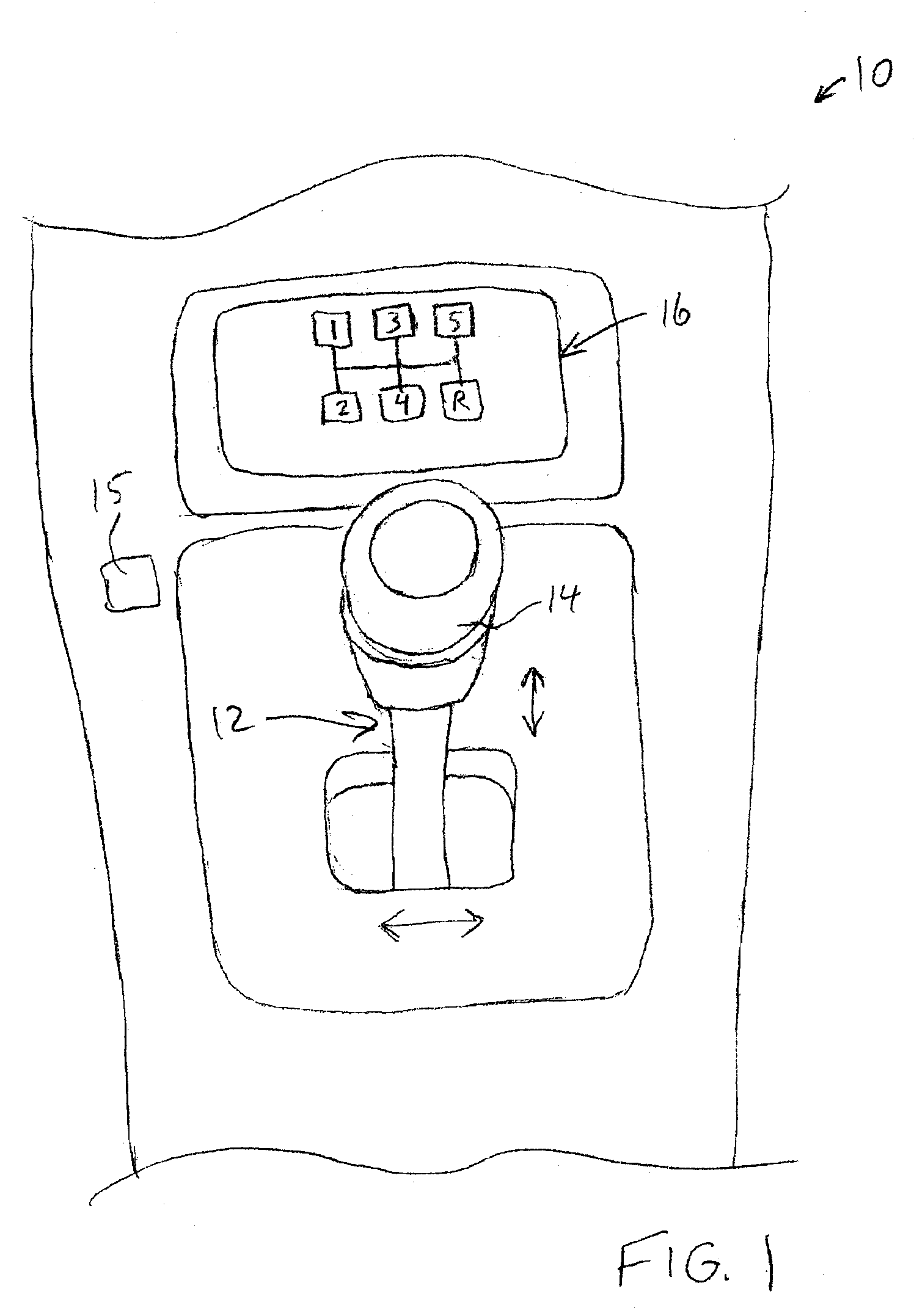

Haptic shifting devices

InactiveUS6904823B2Control operationsControl selectionManual control with multiple controlled membersGearing controlIn vehicleEngineering

A haptic shift device for use in shift-by-wire systems in vehicles. The haptic shift device includes a shift lever manipulatable by a user. At least one sensor detects a position of the shift lever, and a transmission gear of the vehicle is caused to be changed based on the position of the shift lever. At least one electrically-controlled actuator outputs a force on the shift lever. In some embodiments, the shift lever is moveable within a pattern and is blocked from areas outside the boundaries of the pattern. The actuator(s) can be active or passive, and / or a variable mechanical gate can be used to implement the pattern. Provided shifting modes can include automatic, manual, and / or sequential modes. Other shifting modes can also be provided.

Owner:IMMERSION CORPORATION

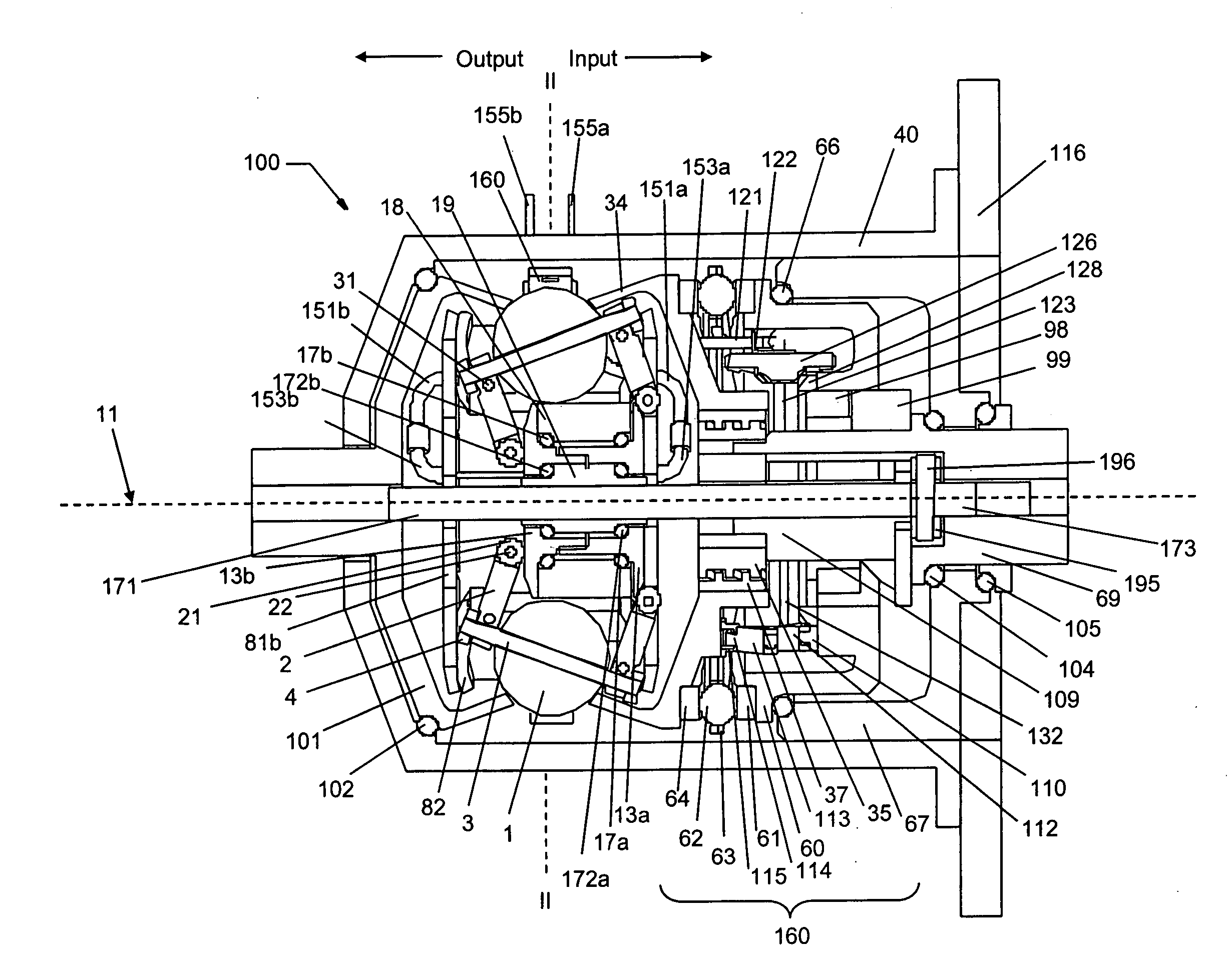

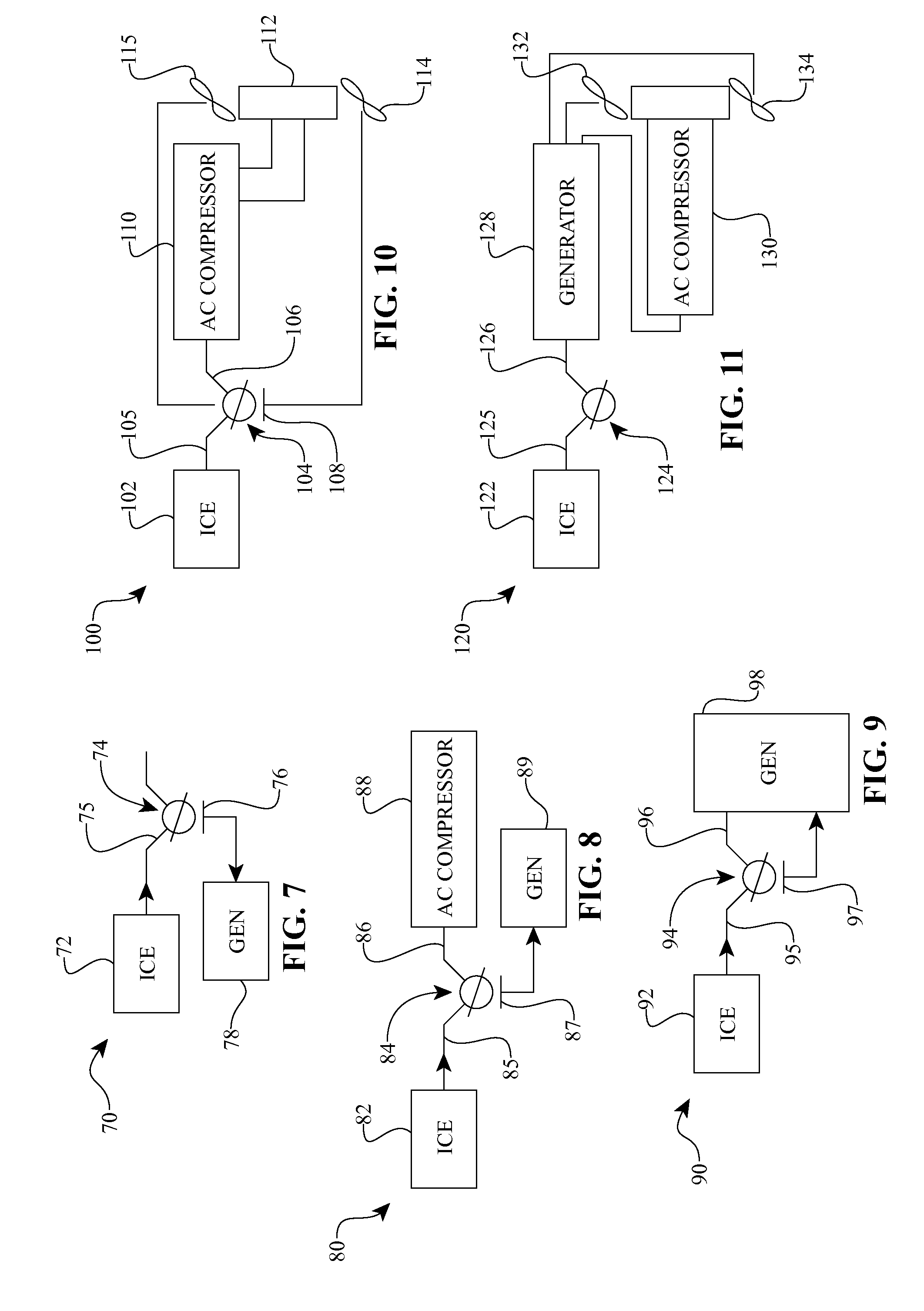

Continuously variable transmission

Inventive embodiments are directed to components, subassemblies, systems, and / or methods for continuously variable accessory drives (CVAD). In one embodiment, a skew-based control system is adapted to facilitate a change in the ratio of a CVAD. In another embodiment, a skew-based control system includes a skew actuator coupled to a carrier member. In some embodiments, the skew actuator is configured to rotate a carrier member of a CVT. Various inventive traction planet assemblies can be used to facilitate shifting the ratio of a CVT. In some embodiments, the traction planet assemblies include legs configured to cooperate with the carrier members. In some embodiments, a traction planet assembly is operably coupled to the carrier members. Embodiments of a shift cam and a traction sun are adapted to cooperate with other components of the CVT to support operation and / or functionality of the CVT. Among other things, shift control interfaces for a CVT are disclosed.

Owner:FALLBROOK INTPROP COMPANY

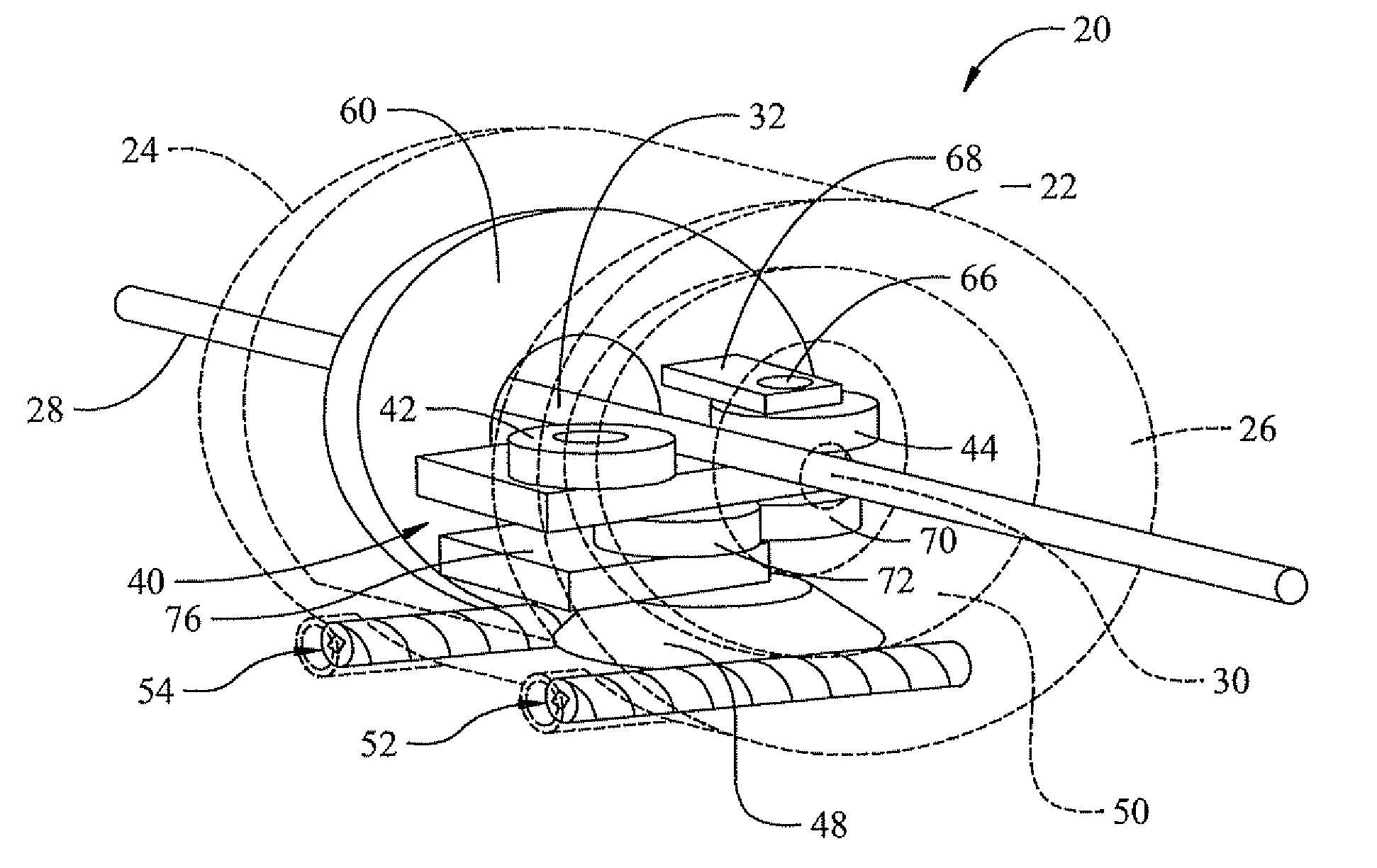

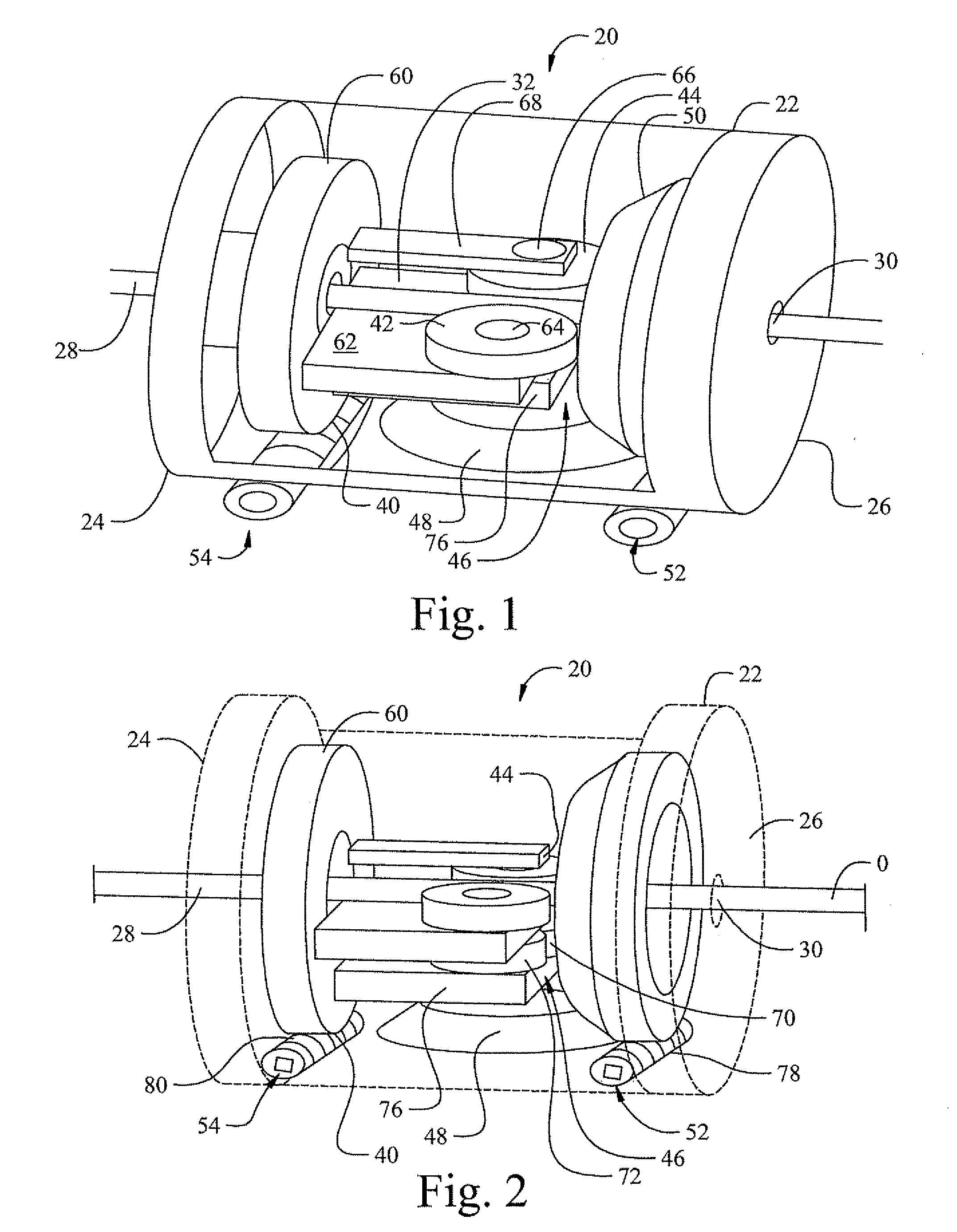

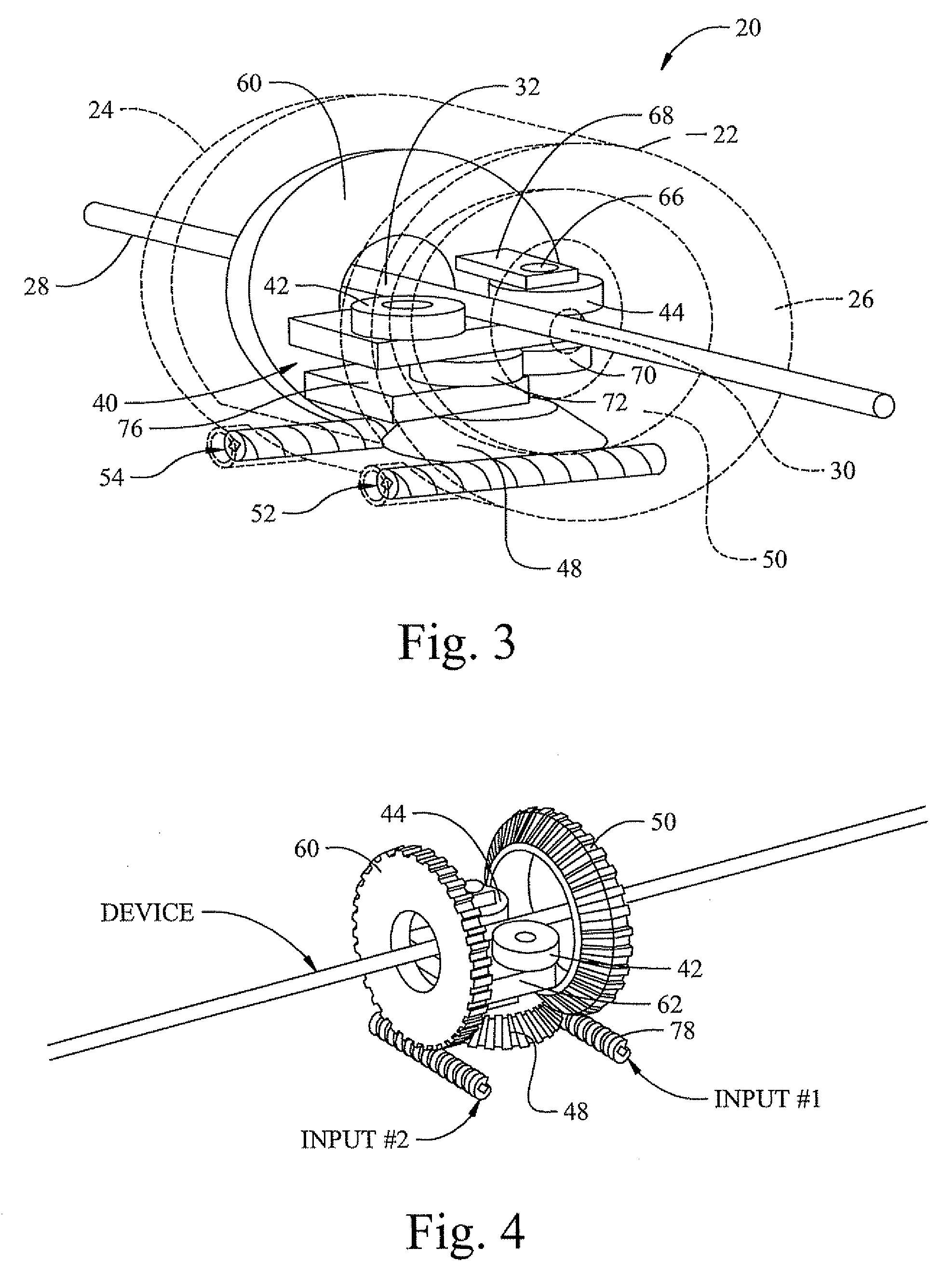

Continuously variable transmission

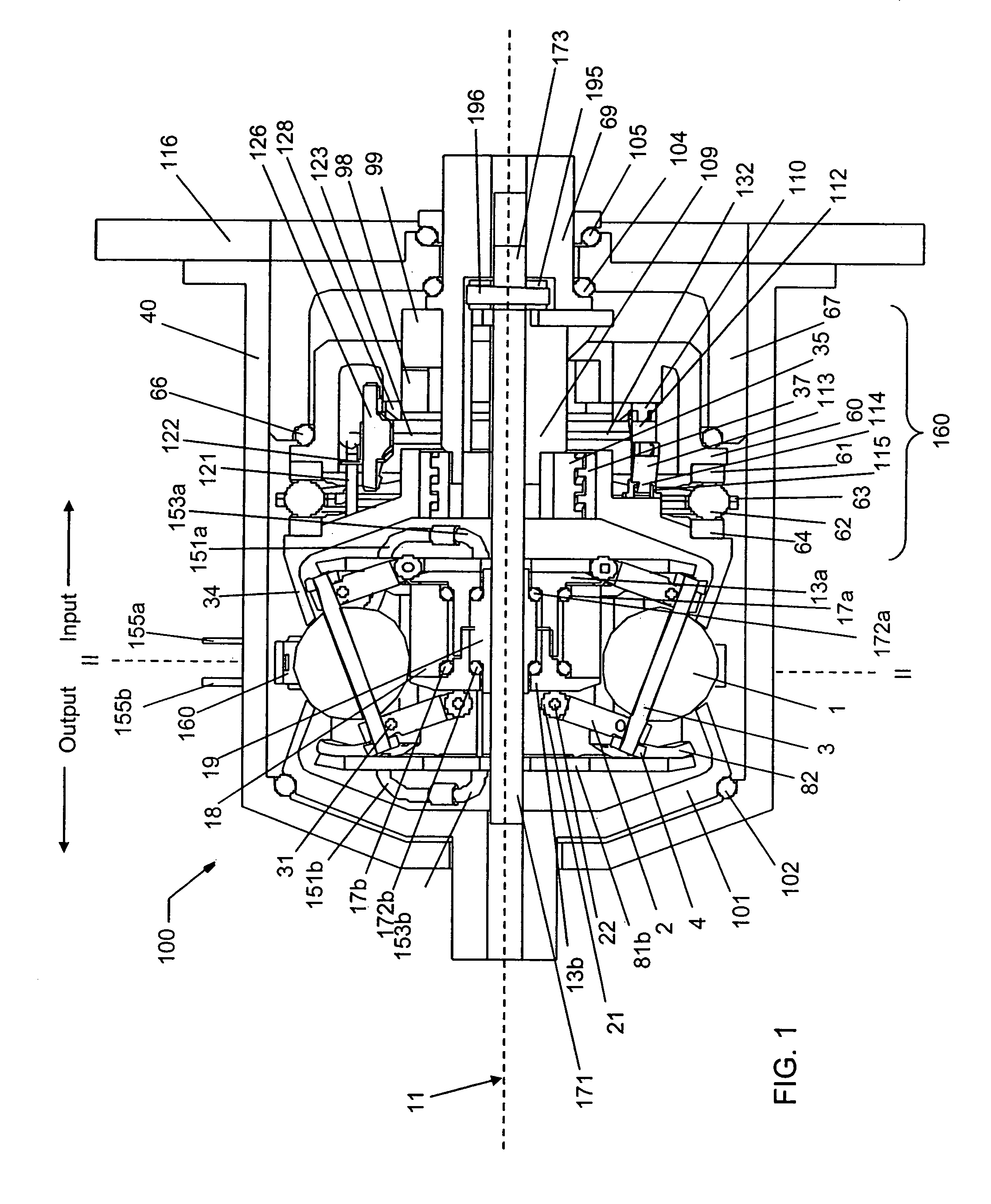

A continuously variable transmission is disclosed for use in rotationally or linearly powered machines and vehicles. The transmission provides a simple manual shifting method for the user. Further, the practical commercialization of traction roller transmissions requires improvements in the reliability, ease of shifting, function and simplicity of the transmission. The present invention includes a continuously variable transmission that may be employed in connection with any type of machine that is in need of a transmission. For example, the transmission may be used in (i) a motorized vehicle such as an automobile, motorcycle, or watercraft, (ii) a non-motorized vehicle such as a bicycle, tricycle, scooter, exercise equipment or (iii) industrial equipment, such as a drill press, power generating equipment, or textile mill.

Owner:FALLBROOK INTPROP COMPANY

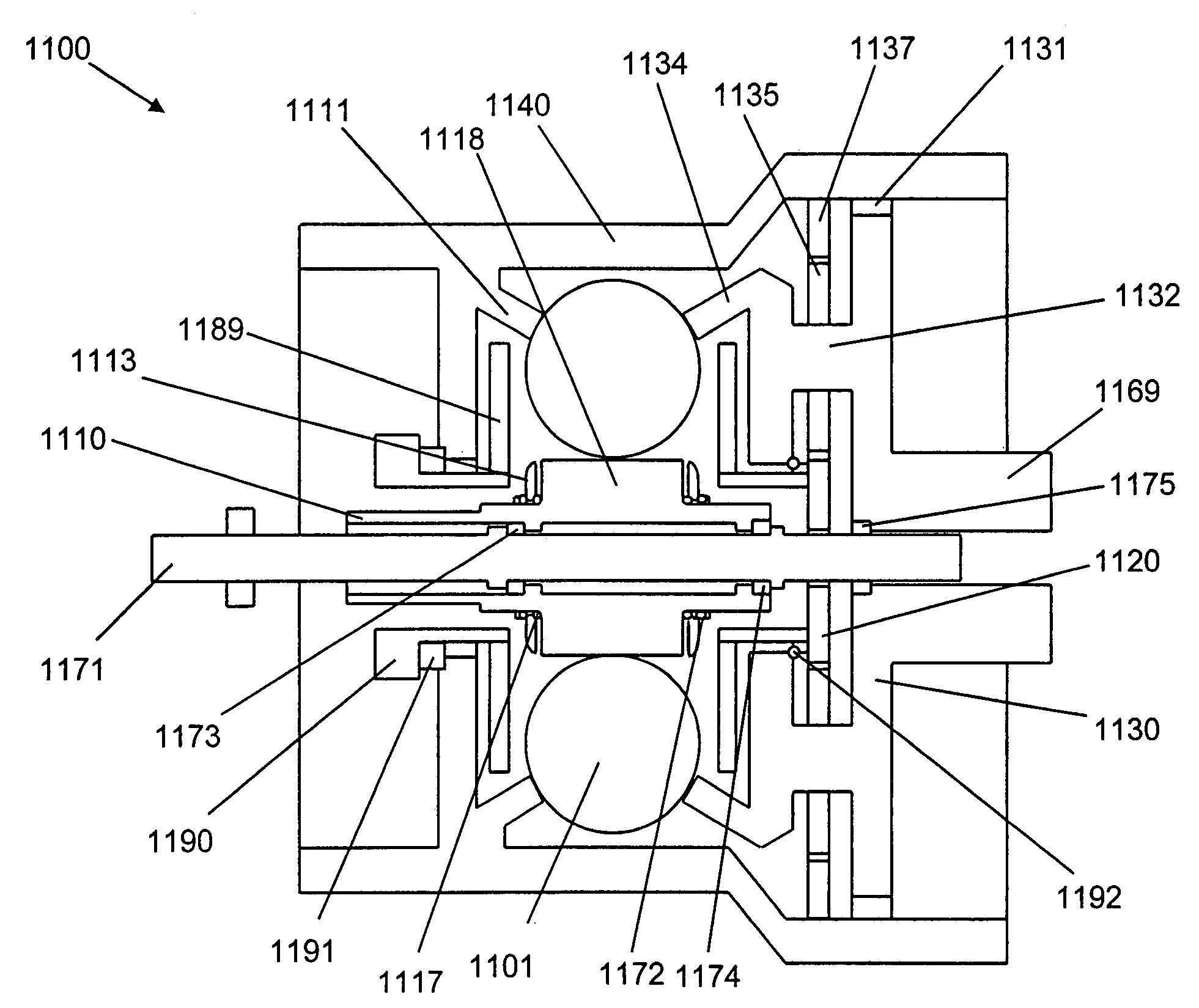

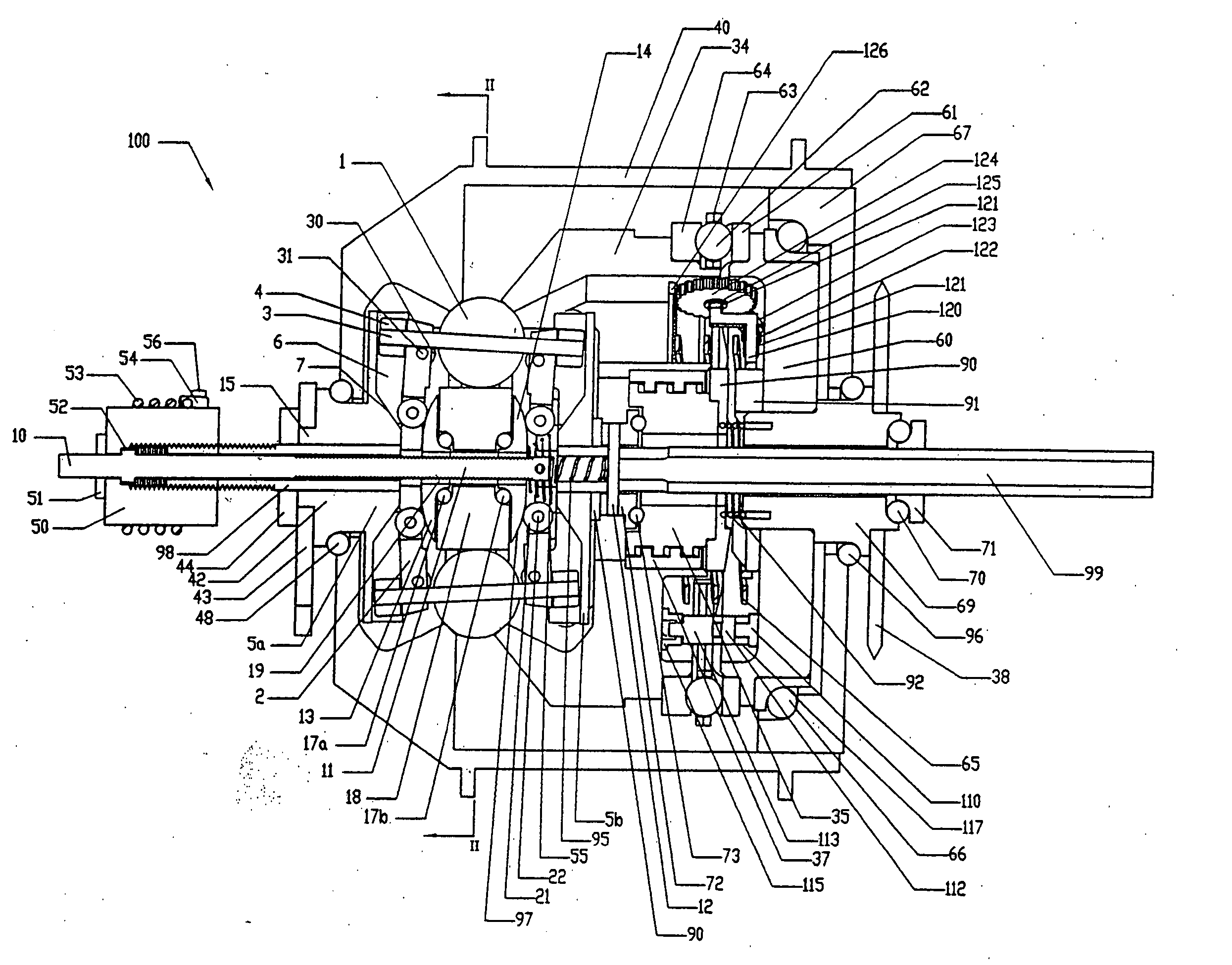

Infinitely variable transmissions, continuously variable transmissions, methods, assemblies, subassemblies, and components therefor

Inventive embodiments are directed to components, subassemblies, systems, and / or methods for infinitely variable transmissions (IVT) having a variator provided with a plurality of tilting spherical planets. In one embodiment, a variator is provided with multiple planet arrays. In another embodiment, a hydraulic system is configured to control the transmission ratio of the IVT. Various inventive idler assemblies and planet-pivot arm assemblies can be used to facilitate adjusting the transmission speed ratio of an IVT. Embodiments of a transmission housing and bell housing are adapted to house components of an IVT and, in some embodiments, to cooperate with other components of the IVT to support operation and / or functionality of the IVT. Various related devices include embodiments of, for example, a control feedback mechanism, axial force generation and management mechanisms, a control valve integral with an input shaft, and a rotatable carrier configured to support planet-pivot arm assemblies.

Owner:FALLBROOK INTPROP COMPANY

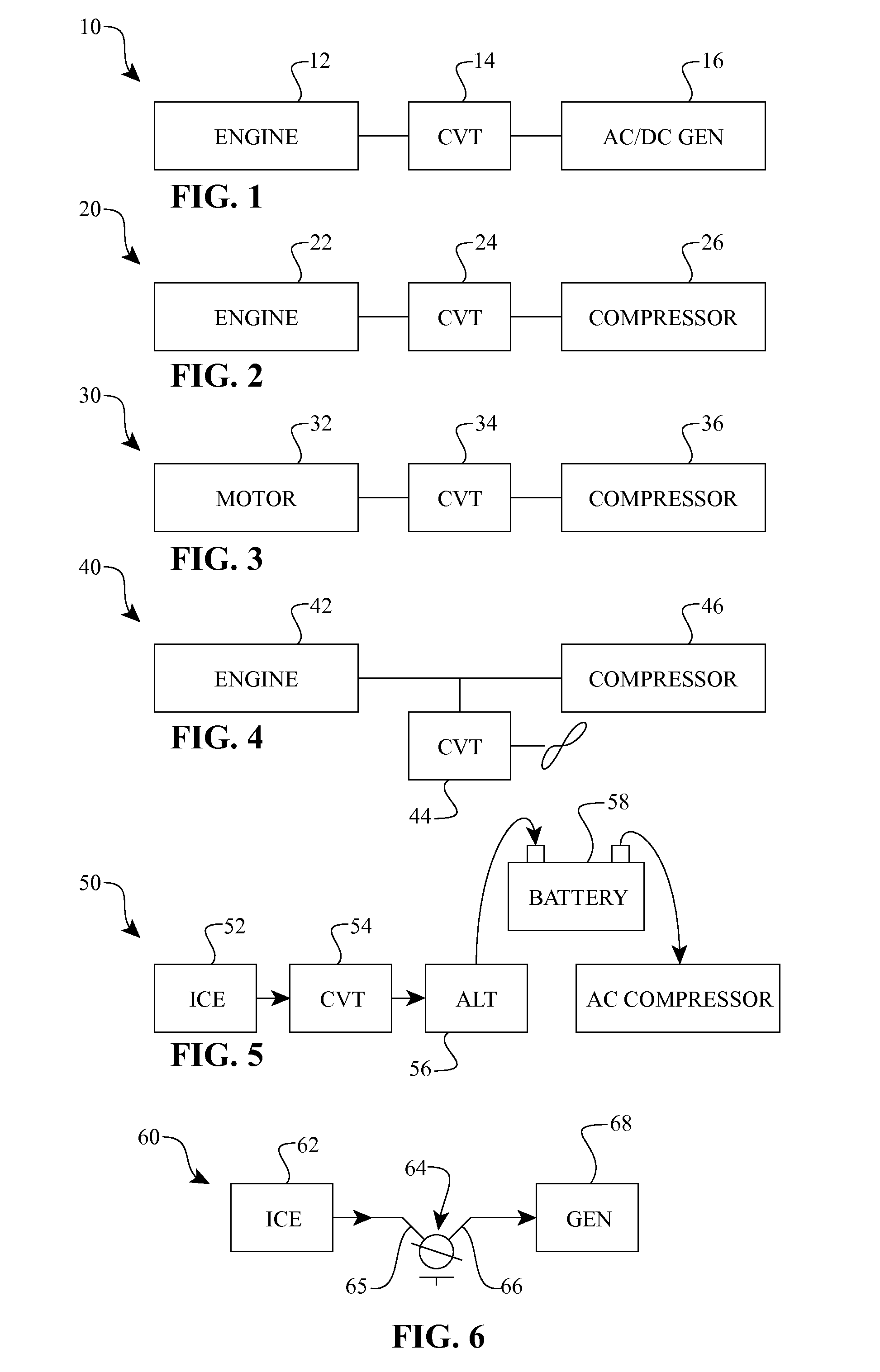

Auxiliary power unit having a continuously variable transmission

InactiveUS20120258839A1Fuel consumption is minimizedIncreased power demandAuxillary drivesVehicle fittingsCombustionControl system

Inventive embodiments are directed to components, subassemblies, systems, and / or methods for auxiliary power units (APU). In one embodiment, the APU includes a source of rotational power such as a combustion engine operably coupled to a continuously variable transmission (CVT). The CVT can be coupled to a load. In some embodiments, the load is provided by a generator. In one embodiment, the APU has a control system configured to control the operation of the engine and the operation of the CVT. The control system can facilitate substantially constant speed operation of the generator in the presence of variable operation of the engine. In another embodiment, the APU includes a continuously variable accessory drive (CVAD) operably coupled to an engine. The CVAD can include a continuously variable transmission operably coupled to a generator. In one embodiment, a skew-based control system is adapted to facilitate a change in the ratio of a CVAD.

Owner:FALLBROOK INTPROP COMPANY

Continuously variable transmission apparatus

A continuously variable transmission apparatus having input and output shafts, a toroidal-type continuously variable transmission unit (CVT unit), a gear-type differential unit with gears, and a control unit, the CVT unit has; input and output side disks, power rollers, input and output side rotation sensors, wherein the differential unit has; a first input portion and a second input portion, and wherein the control unit regulates the transmission ratio of the CVT unit so as to change relative displacement speeds of the gears of the differential unit to thereby convert the rotational state of the output shaft to forward and backward rotations with a stationary state being interposed therebetween, with the input shaft being kept rotating in one direction, and to calculate a rotational speed of the output shaft based on rotational speeds of the input and output side disks and a gear ratio of the differential unit.

Owner:NSK LTD

Electromotive drives

A transmission having a plurality of tilting balls and opposing input and output discs provides an infinite number of speed combinations over its transmission ratio range. The transmission provides multiple powerpaths and can be combined with electrical components to provide motor / generator functionality, which reduces the overall size and complexity of the motor and transmission compared to when they are constructed separately. In one embodiment, rotatable components of a continuously variable transmission are coupled separately to an electrical rotor and to an electrical stator so that the rotor and stator rotate simultaneously in opposite directions relative to one another. In other embodiments, an electrical rotor is configured to transfer torque to or from a disc that is in contact with a plurality of speed adjusters, while an electrical stator is configured to transfer torque to a shaft that is operationally coupled to the speed adjusters via an idler.

Owner:FALLBROOK INTPROP COMPANY

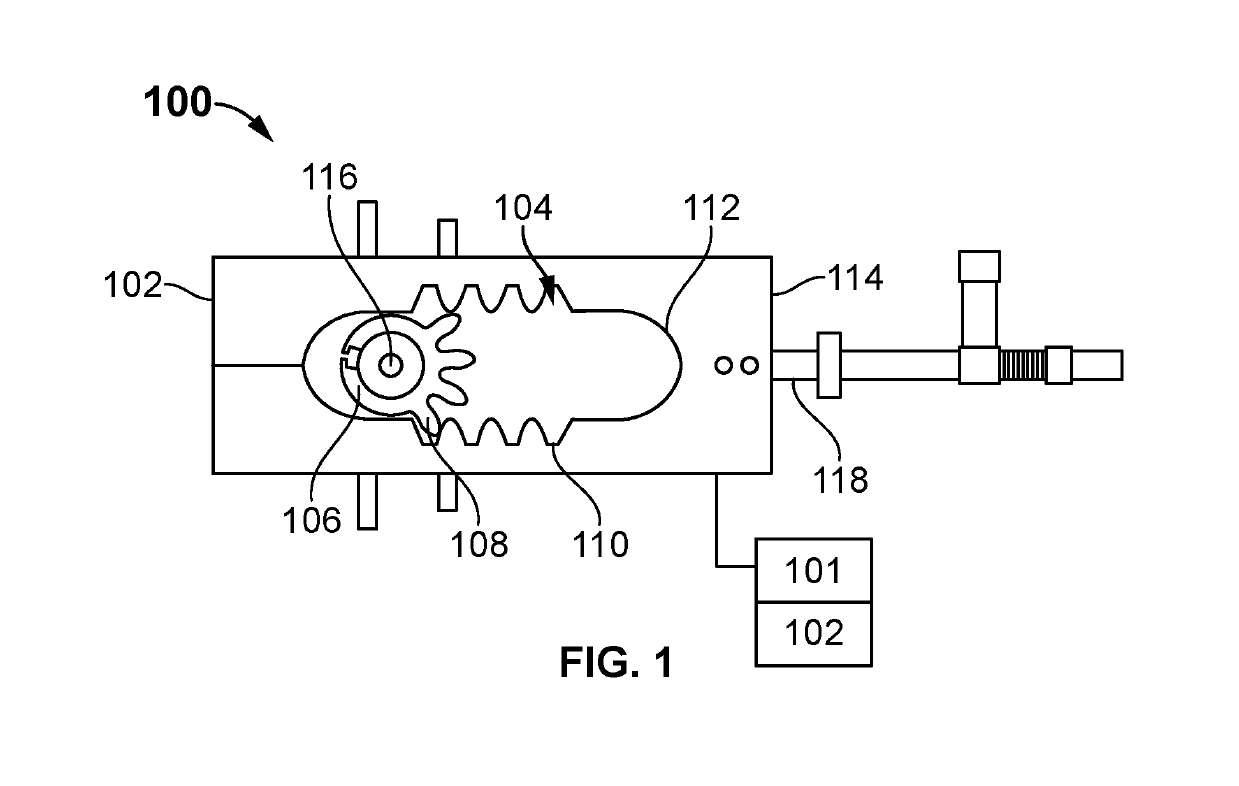

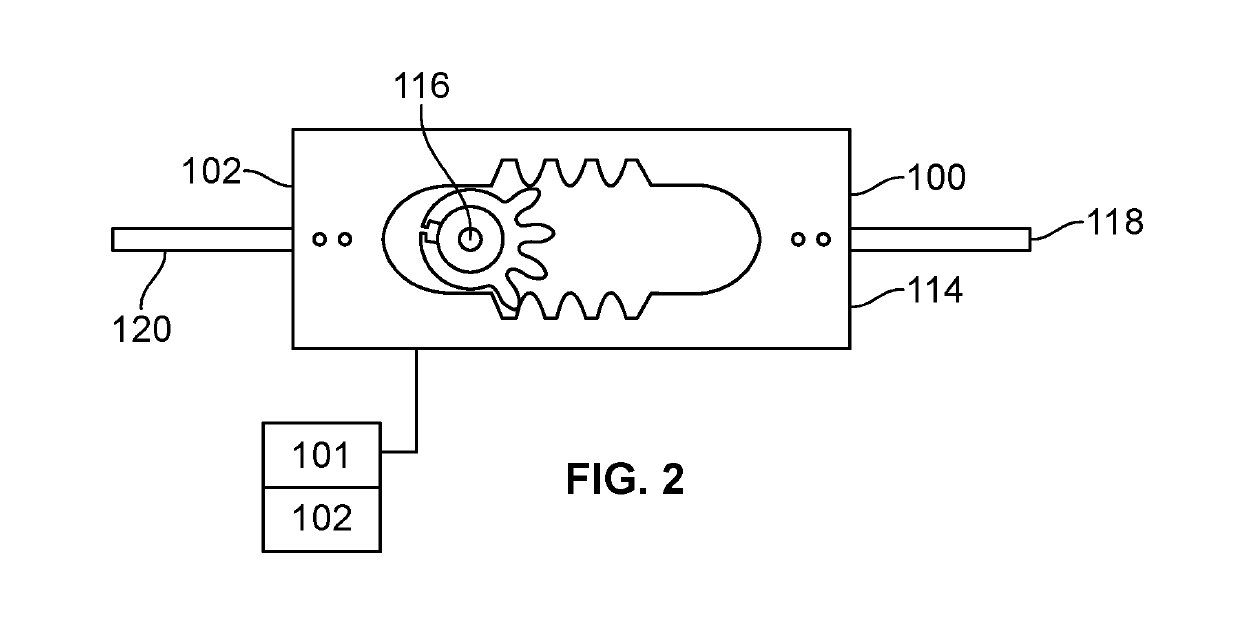

System and Method for a Reciprocating Injection Pump

A reciprocating injection pump is disclosed including but not limited to a reciprocating block driven by a rotating gear, the gear having a substantially circular shape with four gear teeth formed on the rotating gear along approximately one fourth of the substantially circular shape, the rotating gear is attached to a rotating motor, the rotating motor having a right-angle motor shaft.

Owner:PREDOMINANT PUMPS & AUTOMATION SOLUTIONS LLC

Continuously variable transmission

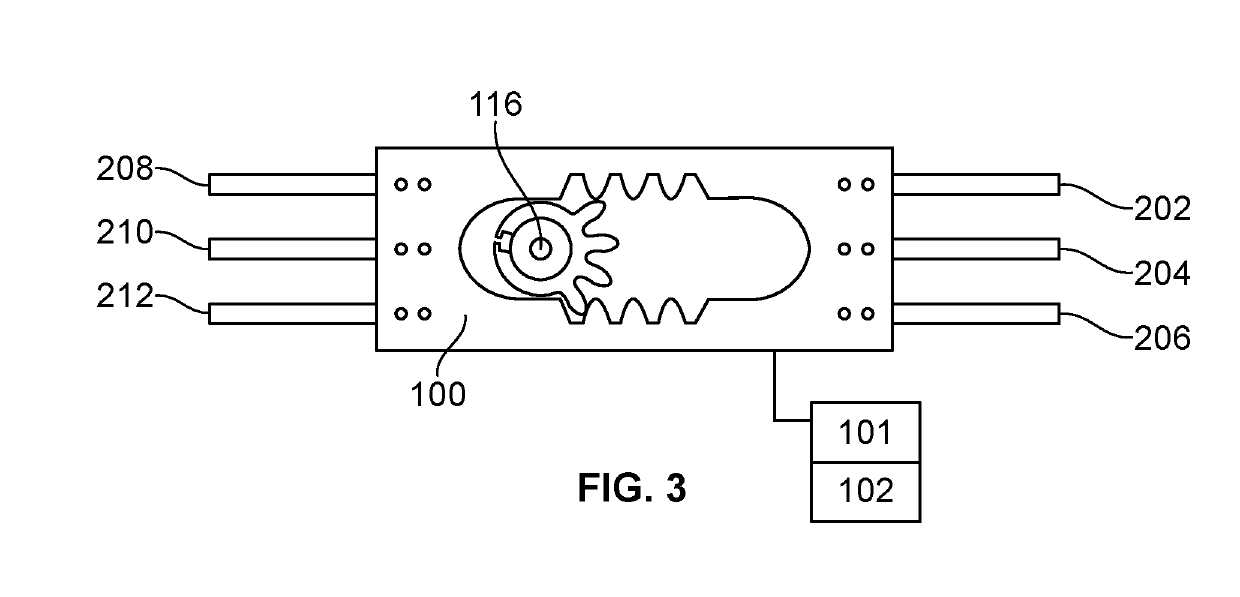

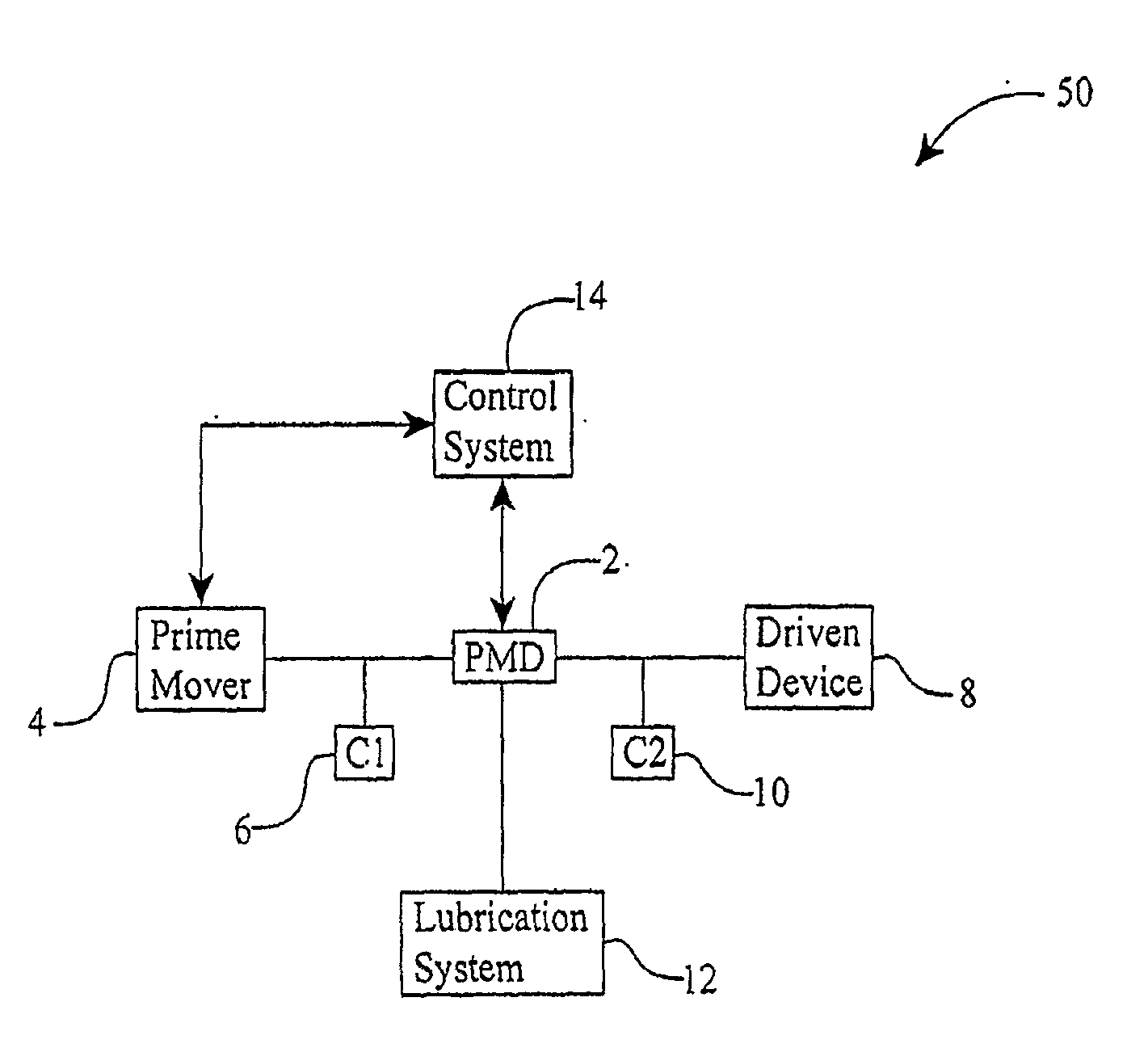

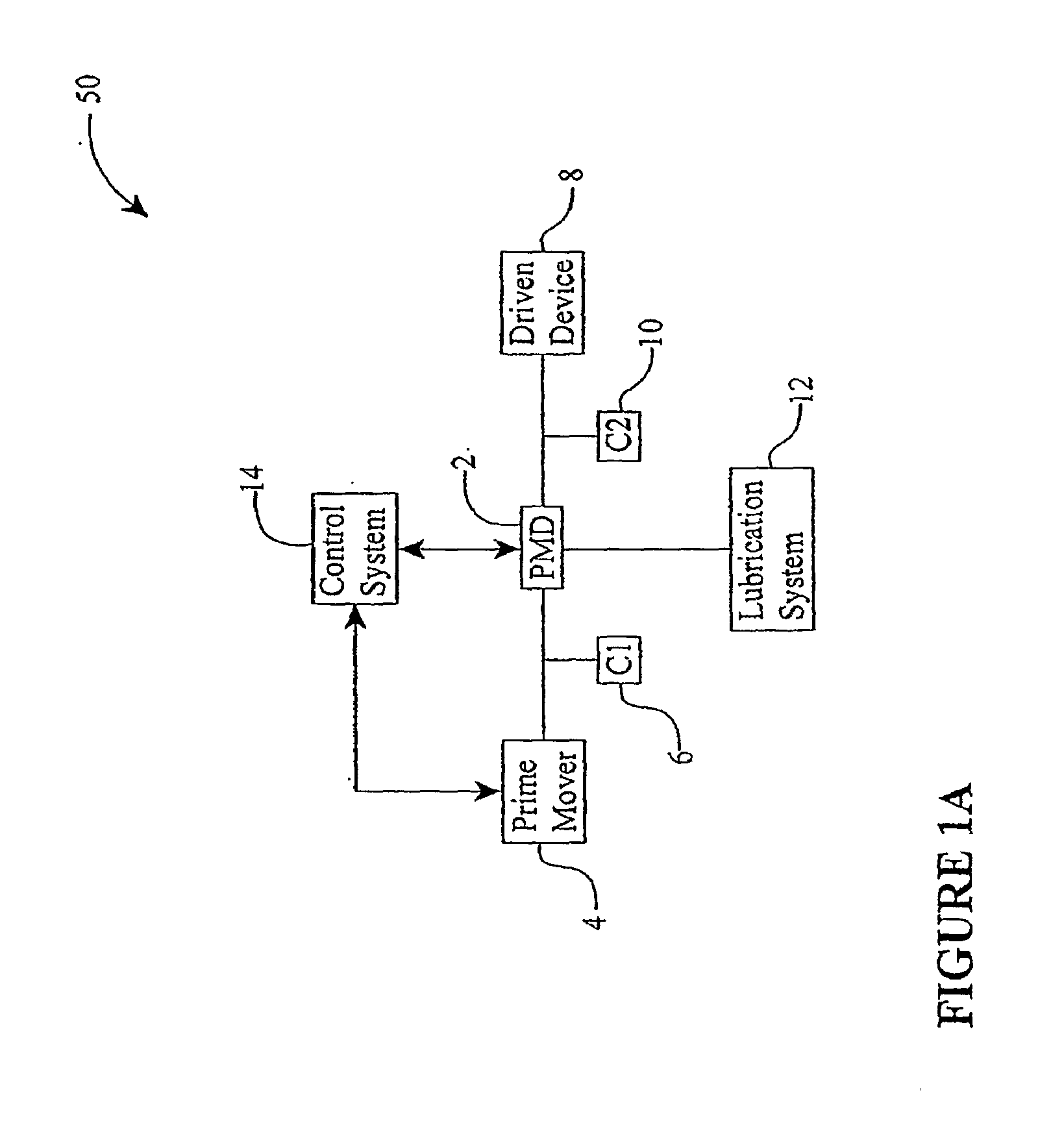

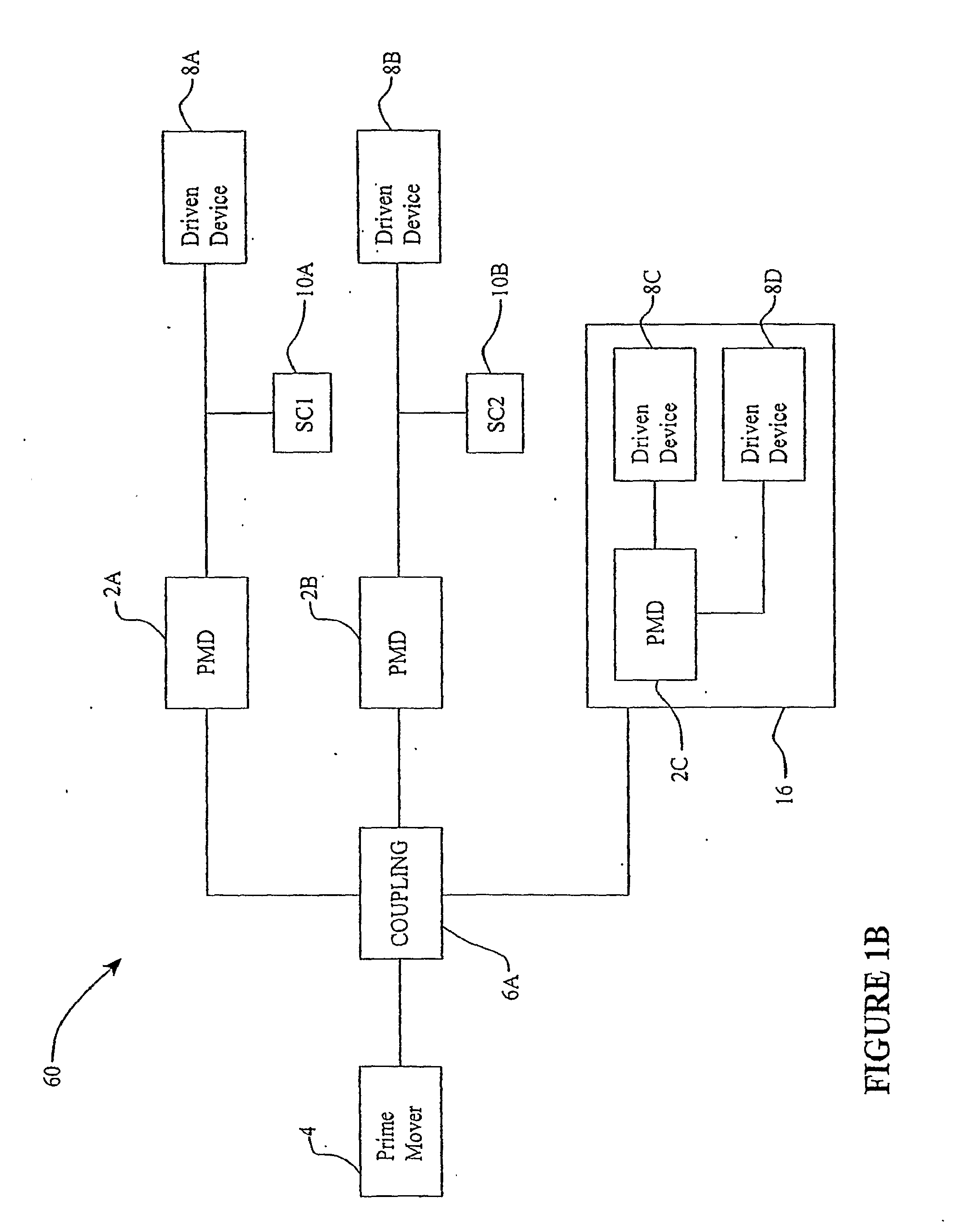

Embodiments are directed to a front end accessory drive (FEAD), subassemblies, and components therefor. Embodiments disclosed cover power modulating devices (PMD) which can be used in a FEAD. In one embodiment, a continuously variable transmission (CVT) is coupled directly to a crankshaft of a prime mover, and the CVT is used to regulate the speed and / or torque delivered to an accessory. A compound drive device includes a motor / generator subassembly cooperating with a CVT subassembly to provide a motor functionality with torque multiplication or division, or alternatively, a generator functionality with torque multiplication or division. In some embodiments, a FEAD includes a PMD having a sun shaft configured to couple to a sun of the PMD and to an electric motor component, such as an electrical armature or an electrical field. In one embodiment, the electrical armature the electrical field are placed concentrically and coaxially and configured to rotate relative to one another in opposite directions.

Owner:FALLBROOK INTPROP COMPANY

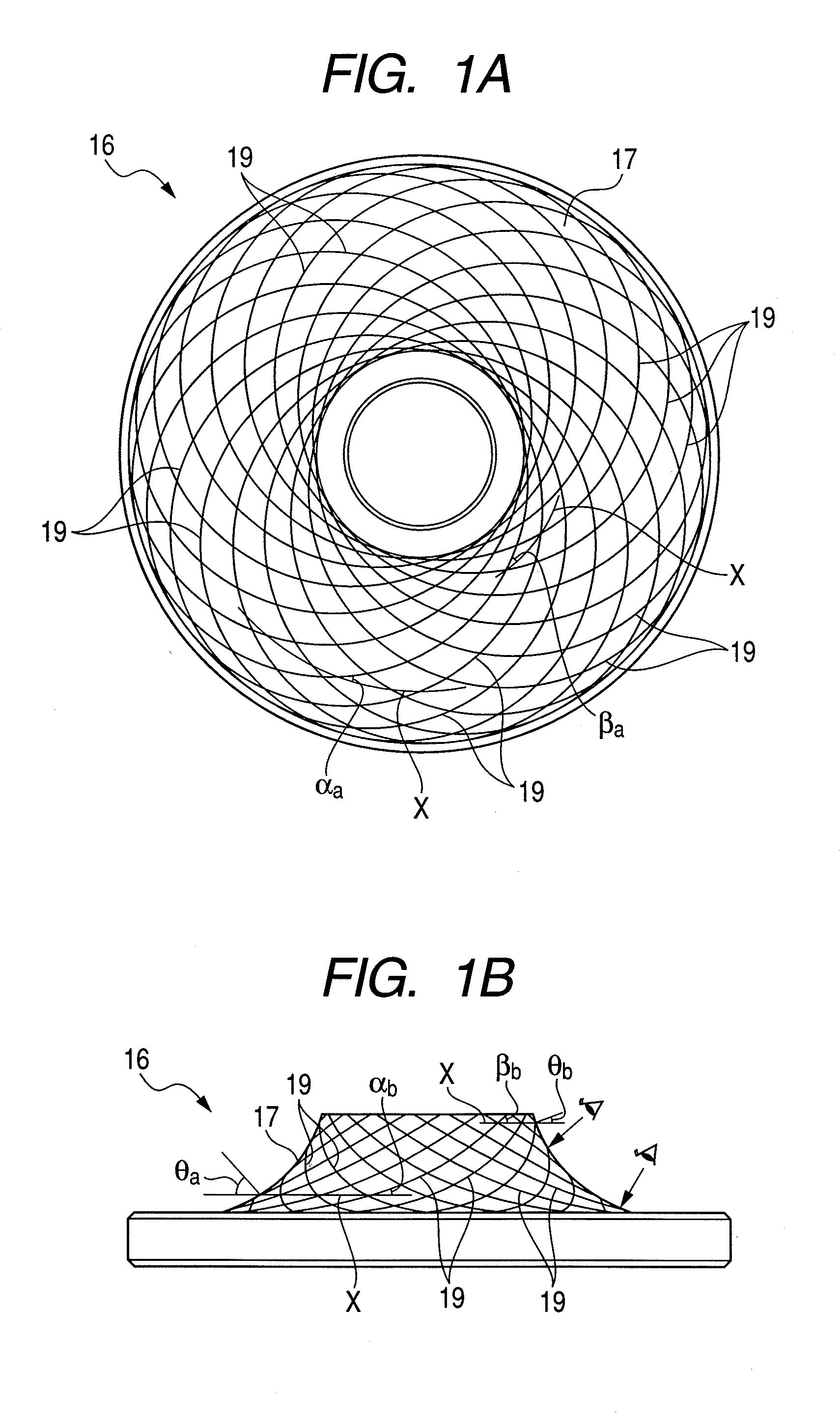

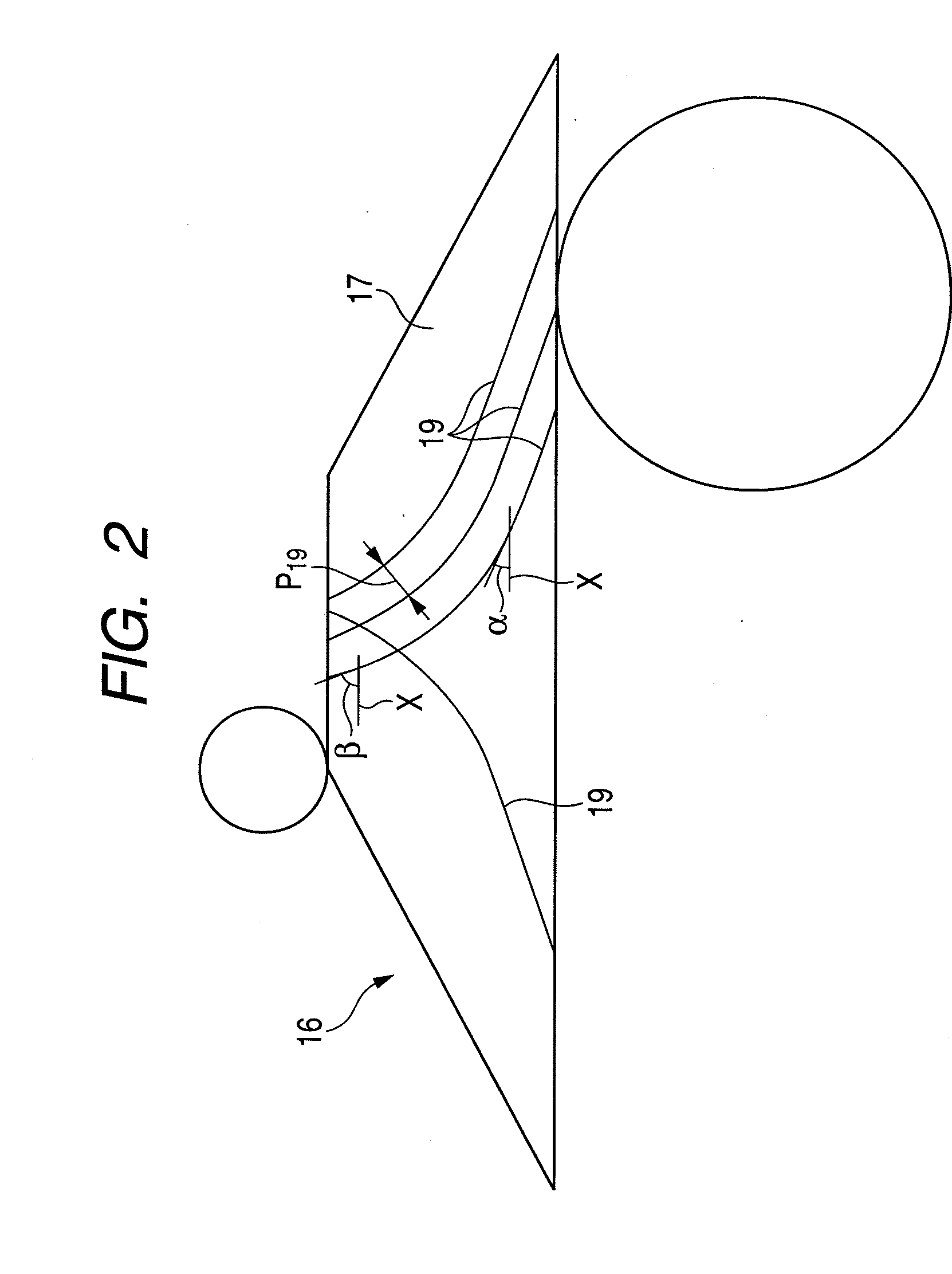

Toroidal continuously variable transmission

ActiveUS20080305920A1Low costReduce processing costsMetal-working apparatusGear wheelsEngineeringGear ratio

Power roller-side concave grooves are opposed to disk-side concave grooves 19, 19 so as to have angles therebetween in a rolling contact area between a peripheral surface of the power roller and a one-side surface 17 of a disk 16 in an axial direction regardless of a transmission gear ratio of a toroidal continuously variable transmission. Accordingly, the disk-side concave grooves 19, 19 are formed so as to have angles with respect to a circumferential direction of the disk 16 when viewed from a normal direction relative to the one-side surface 17 in the axial direction. Meanwhile, the power roller-side concave grooves are formed into a concentric shape (or a spiral shape) about a central shaft of the power roller. As a result, it is possible to prevent a decrease of a contact area in the rolling contact area regardless of the transmission gear ratio.

Owner:NSK LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com