Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

298 results about "Accessory drive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The accessory drive is a gearbox that forms part of a gas turbine engine. Although not part of the engine's core, it drives the accessories, fuel pumps etc., that are otherwise essential for the operation of the engine or the aircraft on which it is mounted. Accessory drives on large engines handle between 400–500 hp.

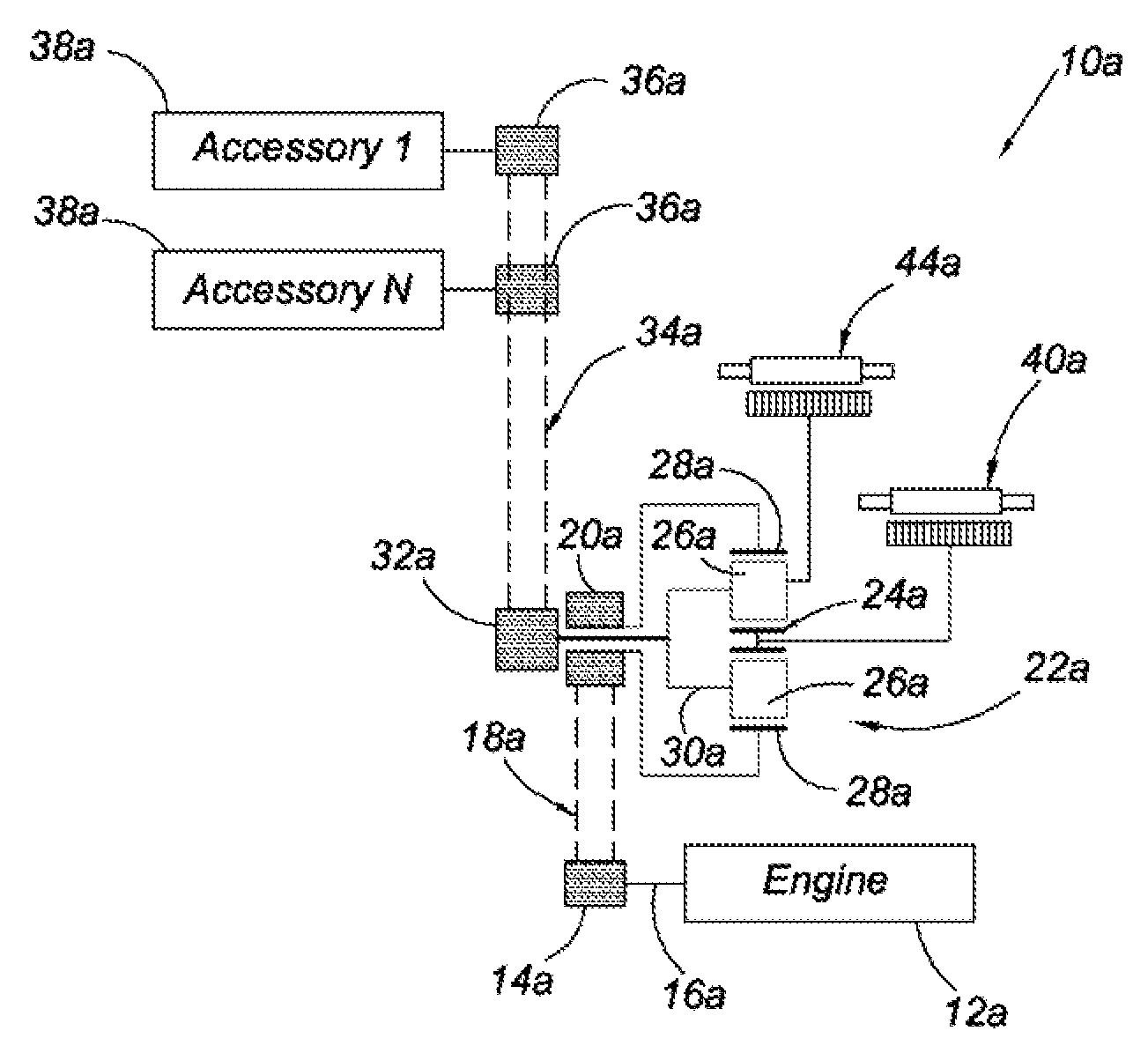

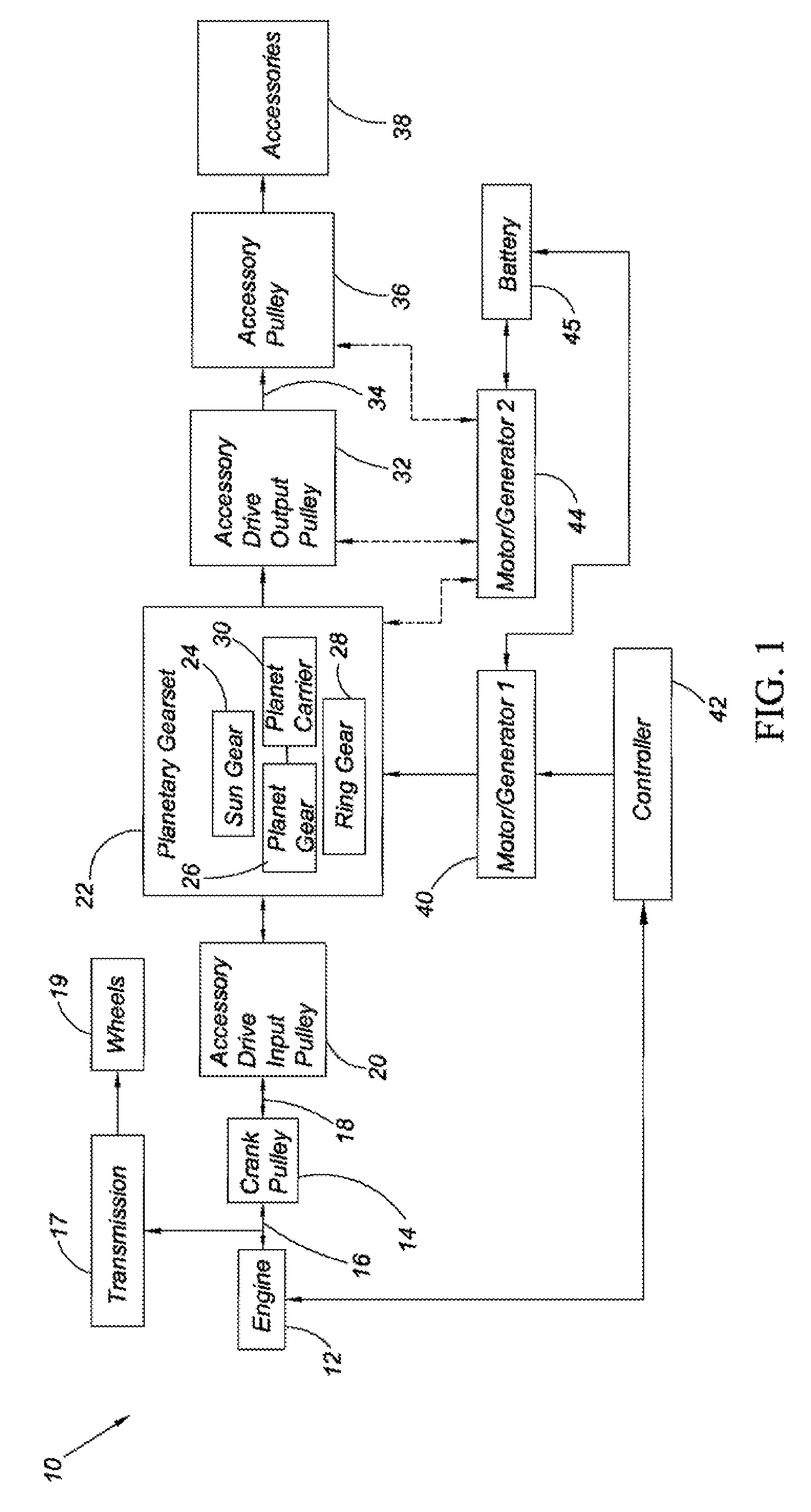

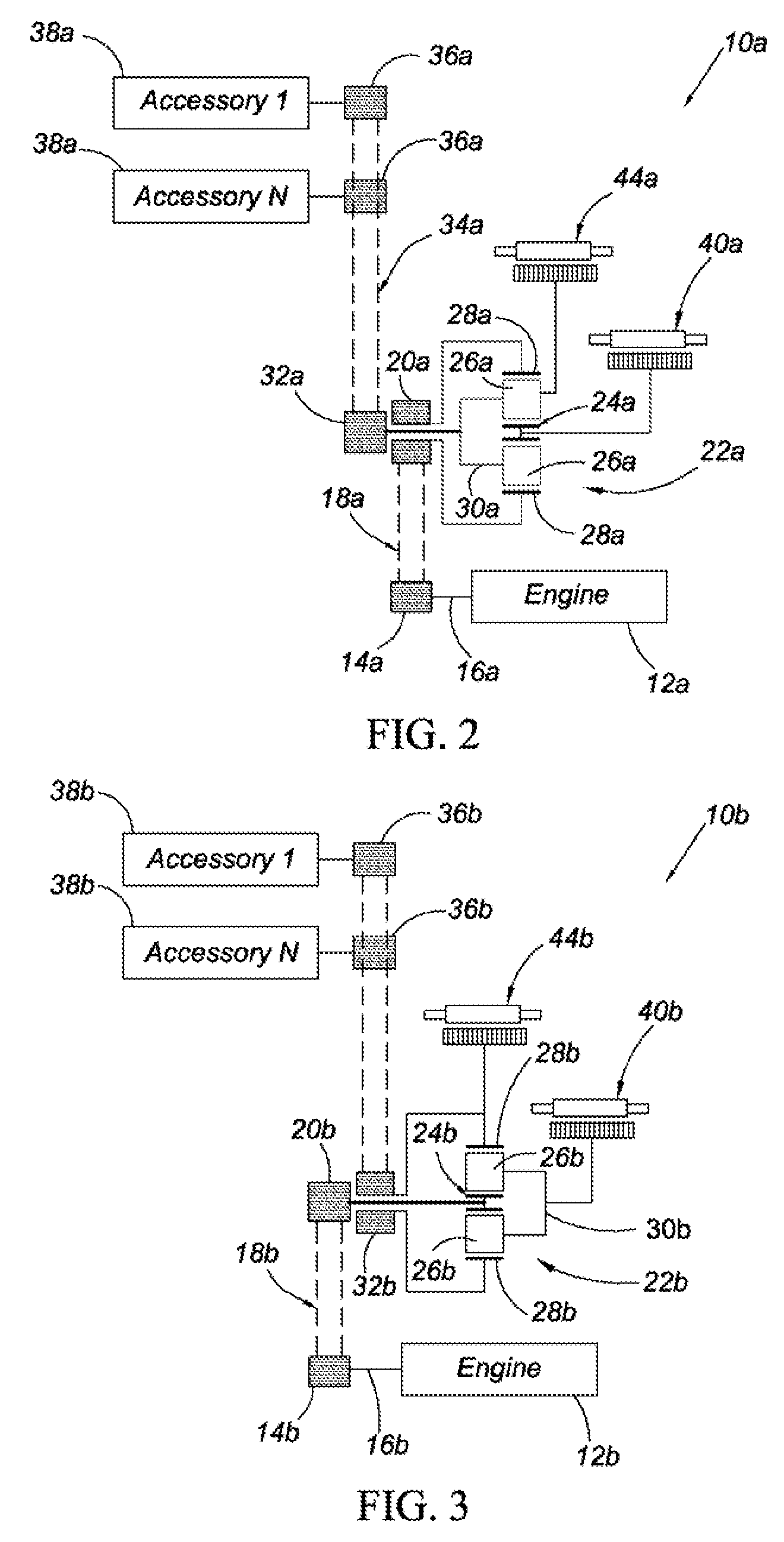

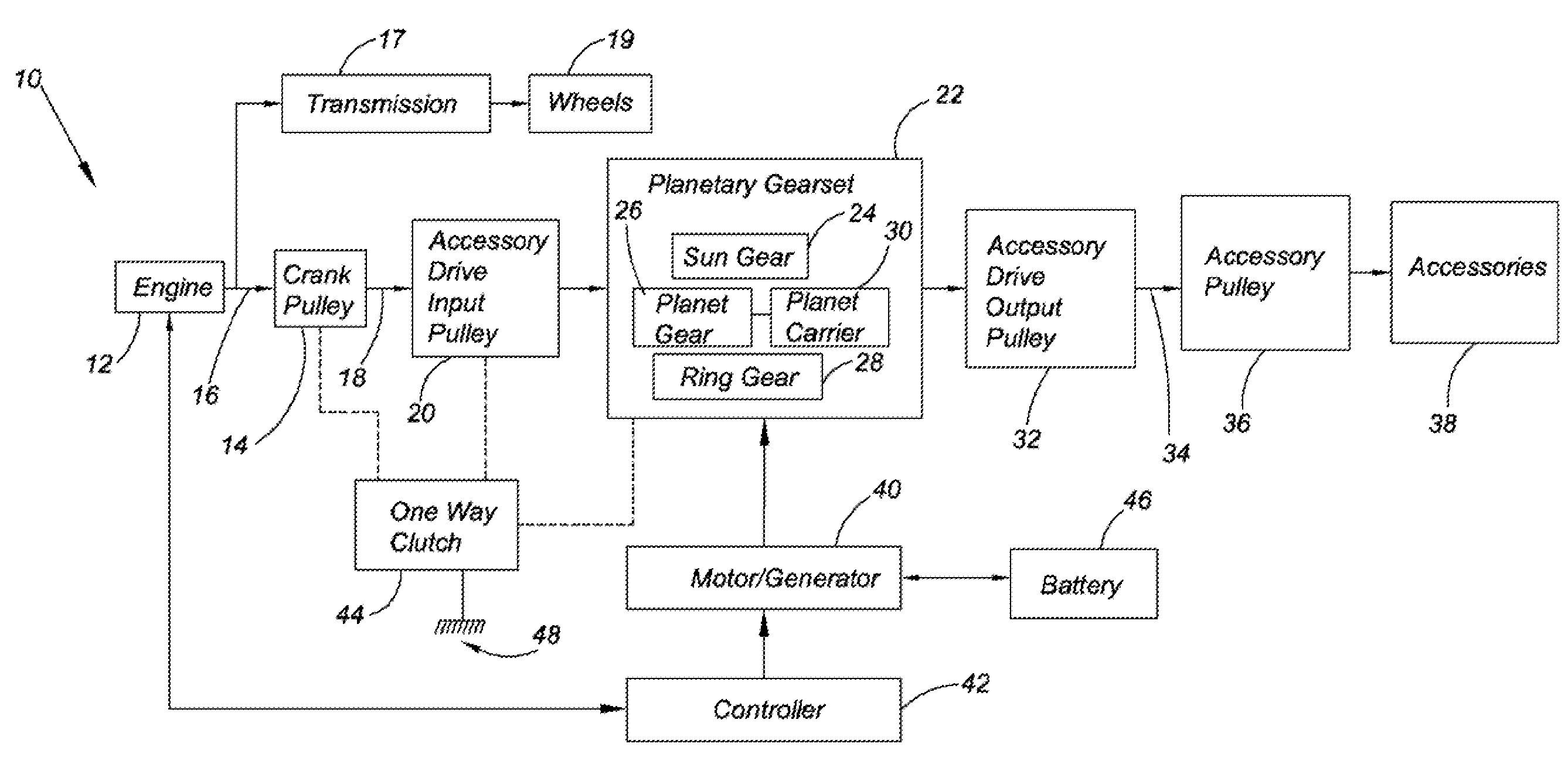

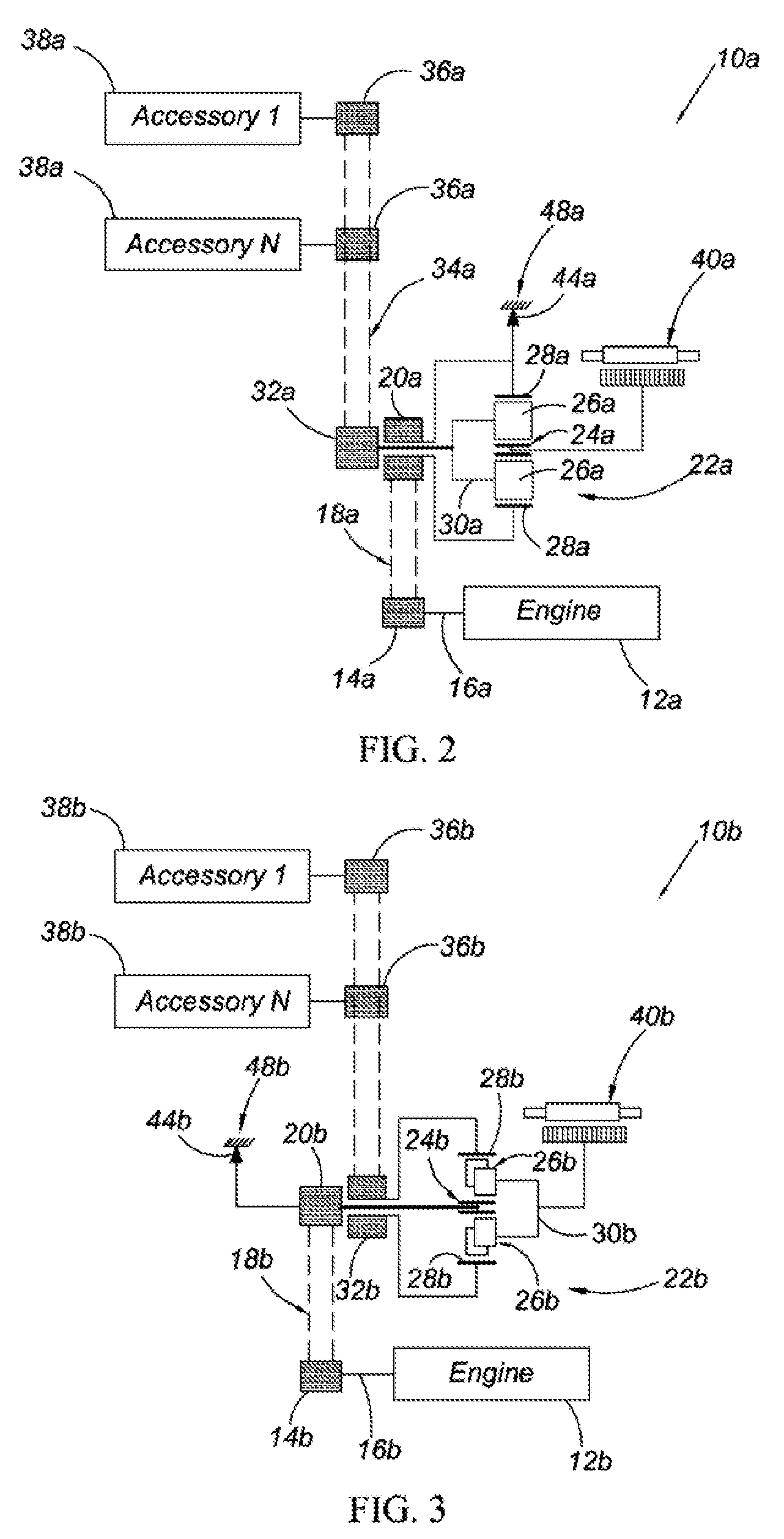

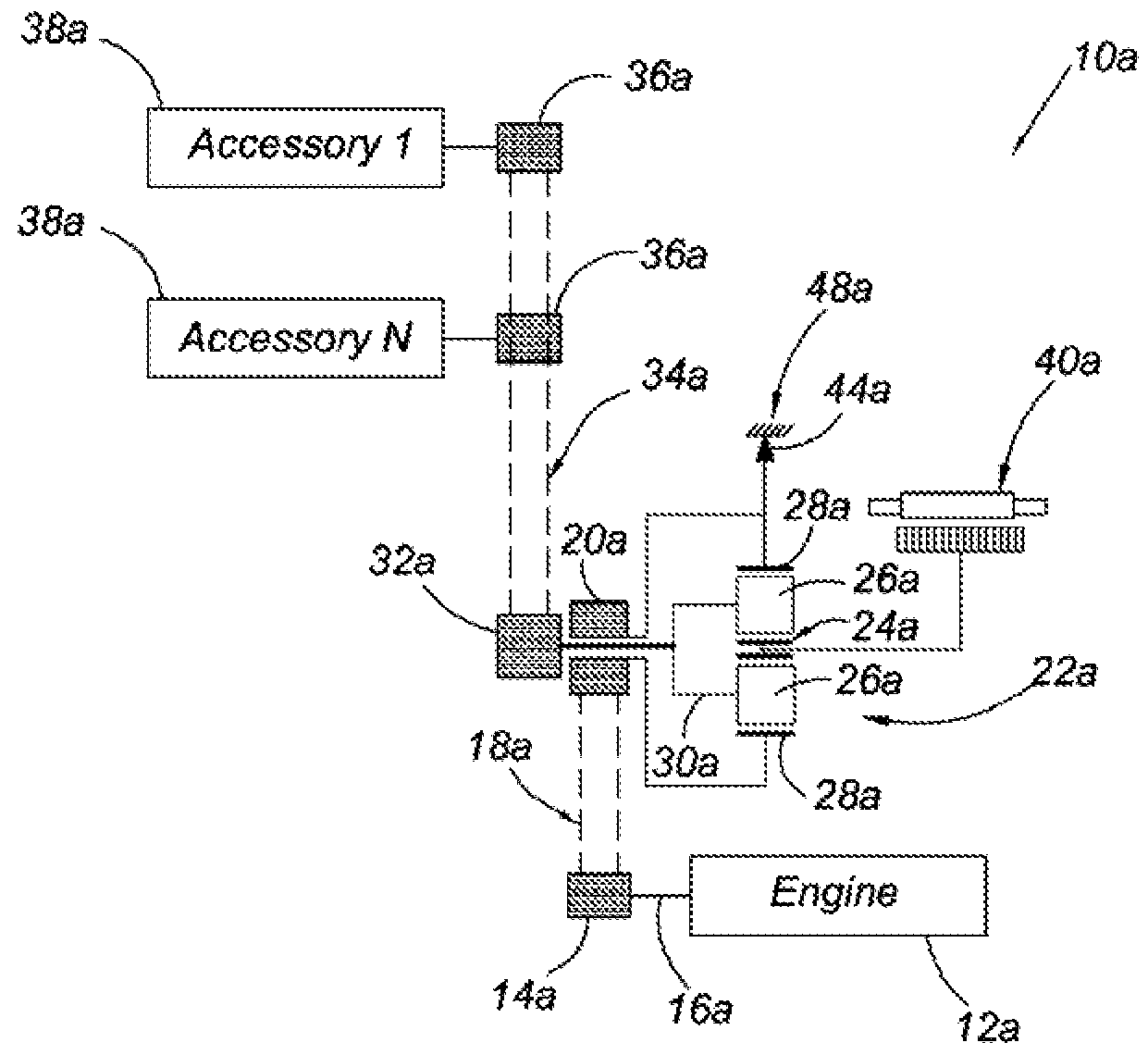

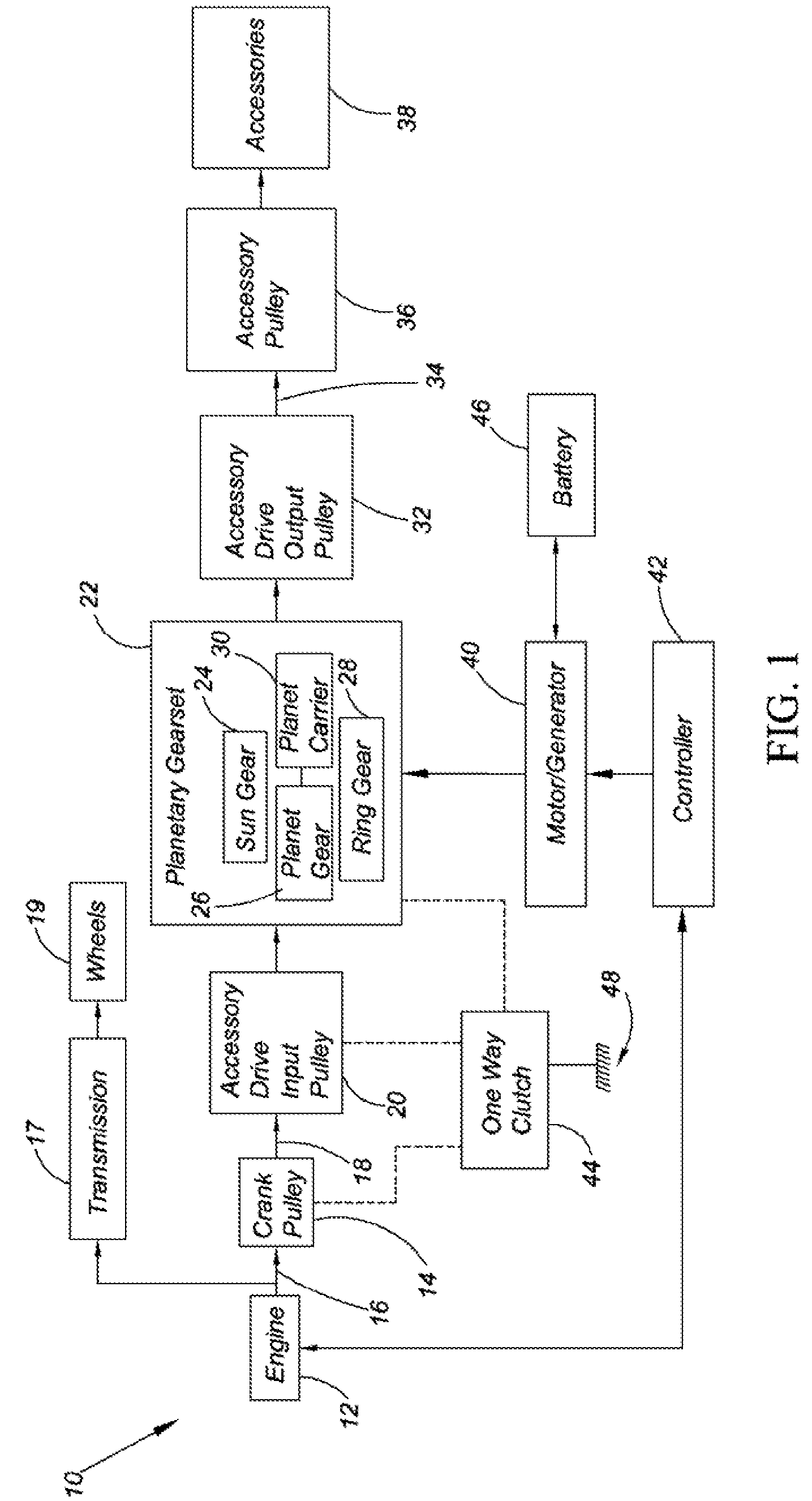

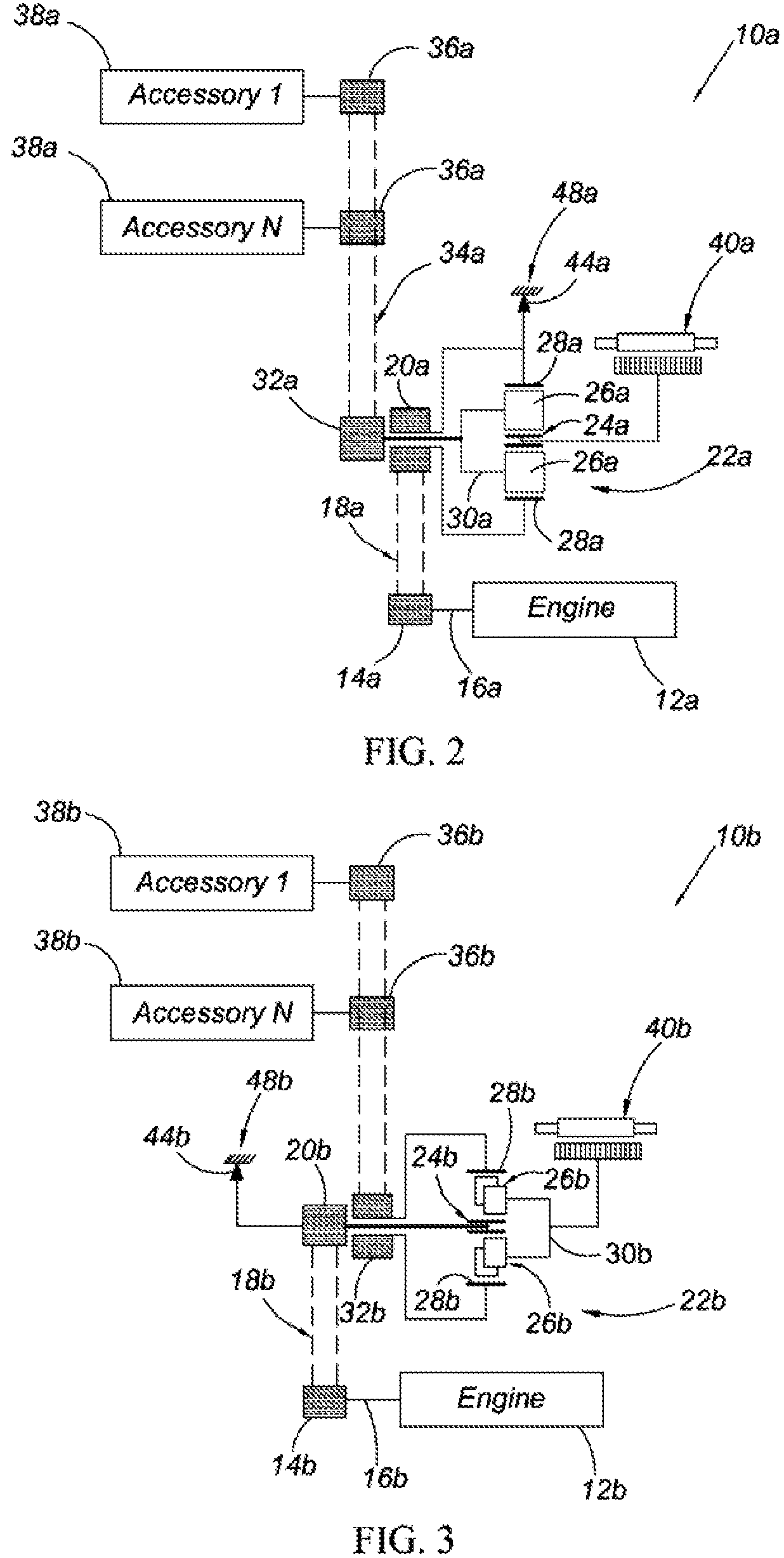

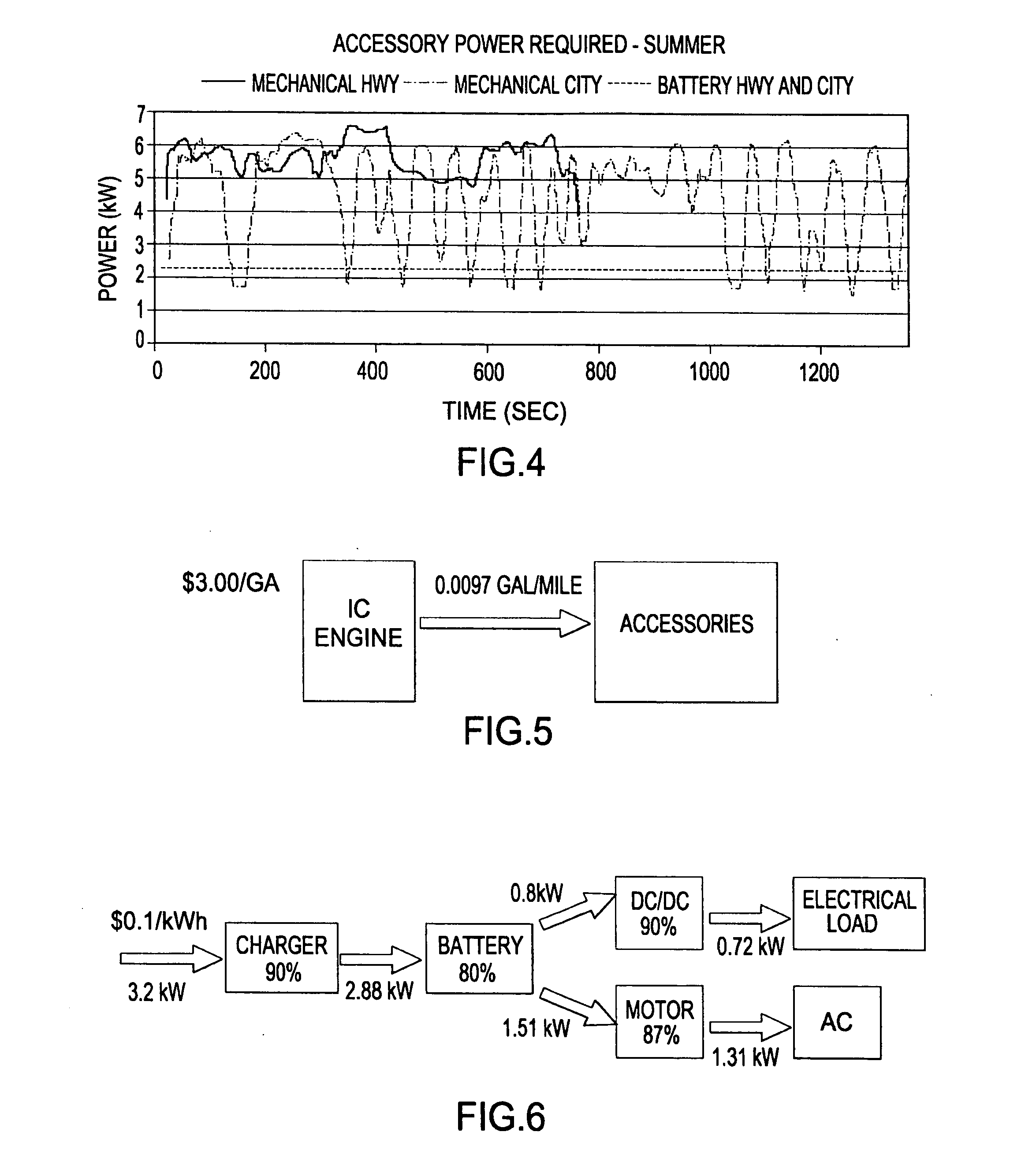

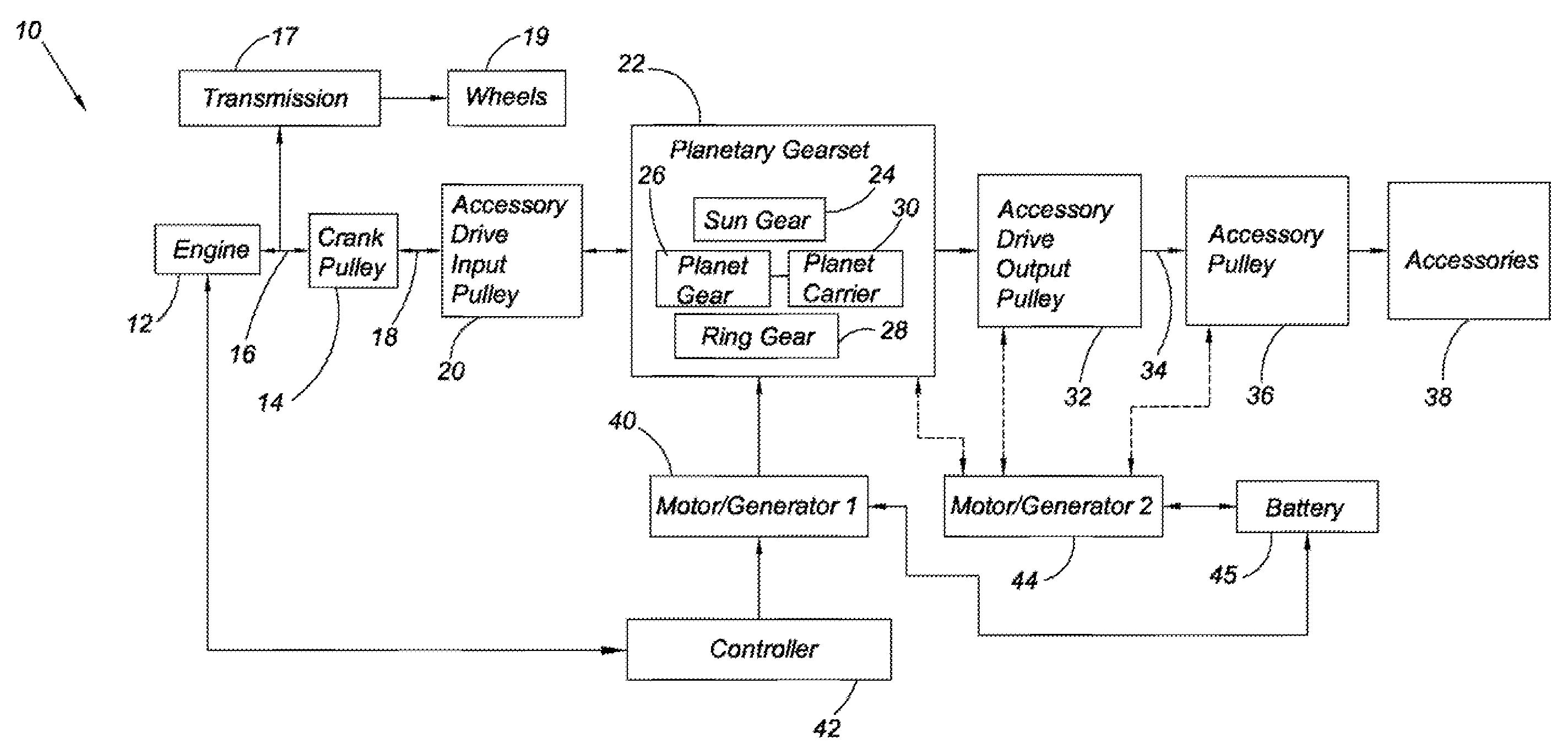

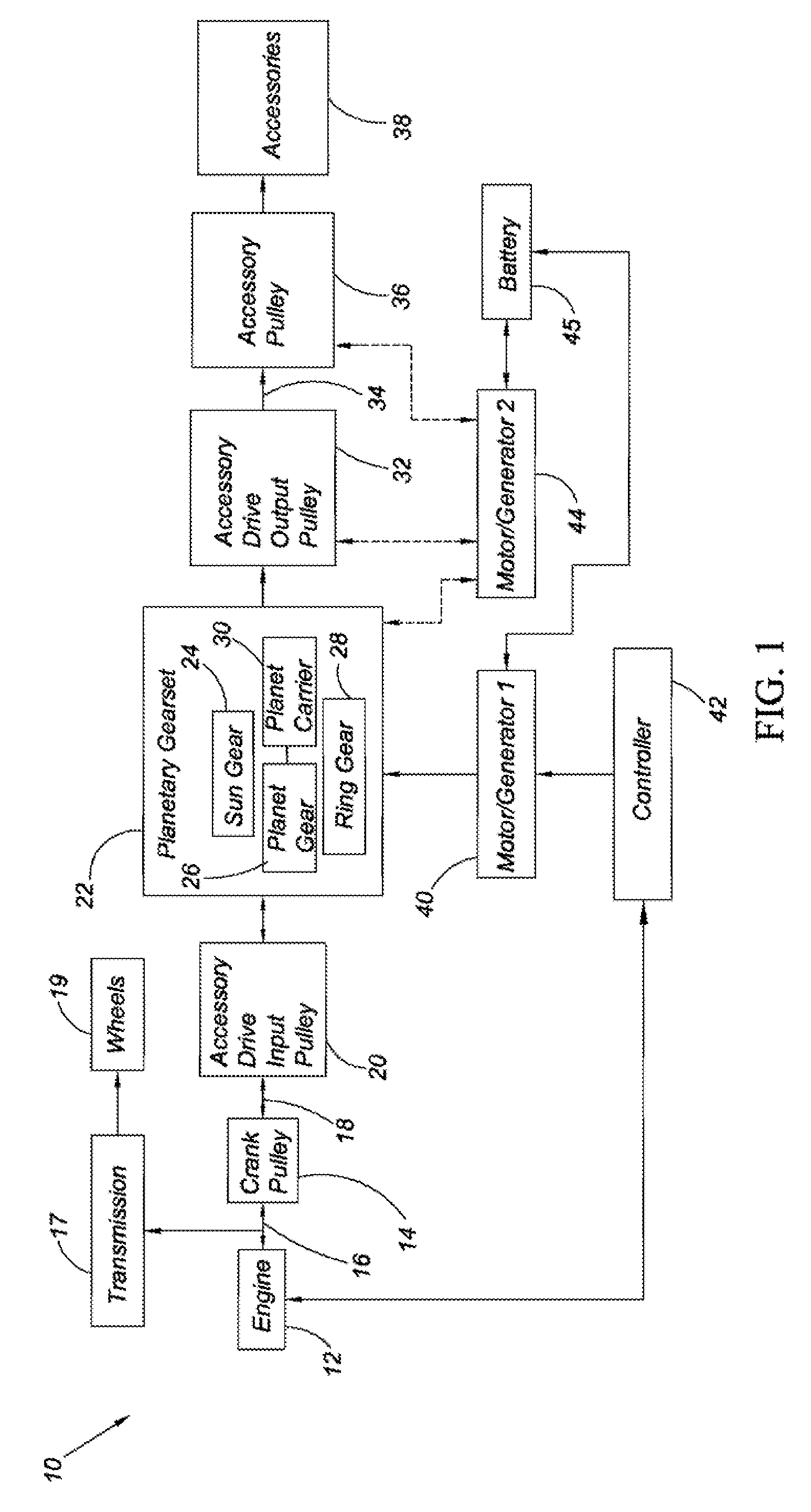

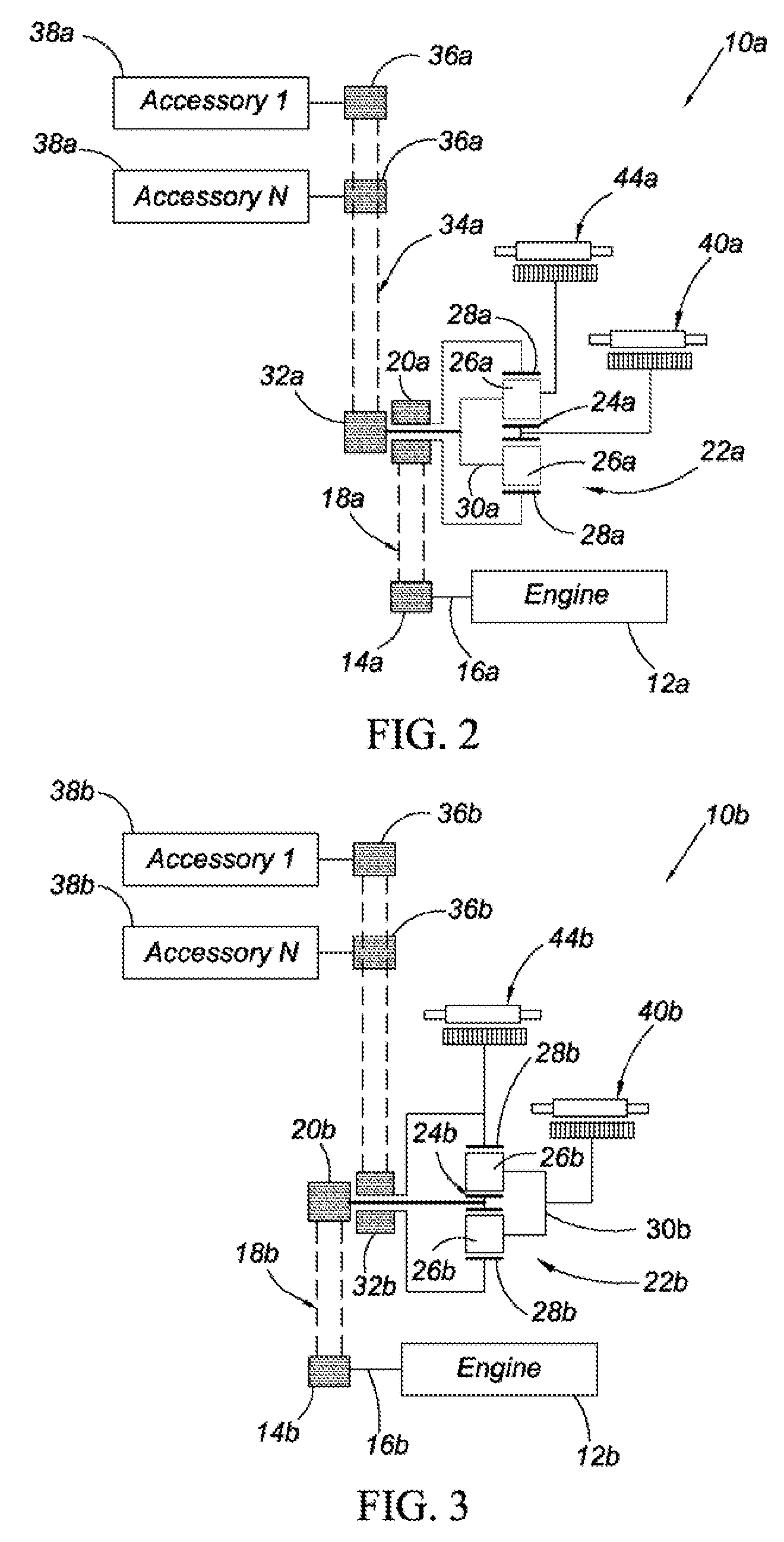

Starter alternator accessory drive system for a hybrid vehicle

The present invention provides an alternator starter accessory drive system for a hybrid vehicle. The starter alternator accessory drive system includes a planetary gear set having a first, second, and third planetary member. An engine is operatively connected to the first planetary member, and a first motor / generator is operatively connected to the second planetary member. A torque transfer device operatively connects a plurality of accessories to the third planetary member. A second motor / generator is operatively connected to either the third planetary member or the torque transfer device. Engine output is transferable through the planetary gear set to drive the accessories at a selectable rate, and the first and second motor / generators are controllable to run the accessories while the engine is off and to re-start the engine.

Owner:GM GLOBAL TECH OPERATIONS LLC

Continuously variable transmission

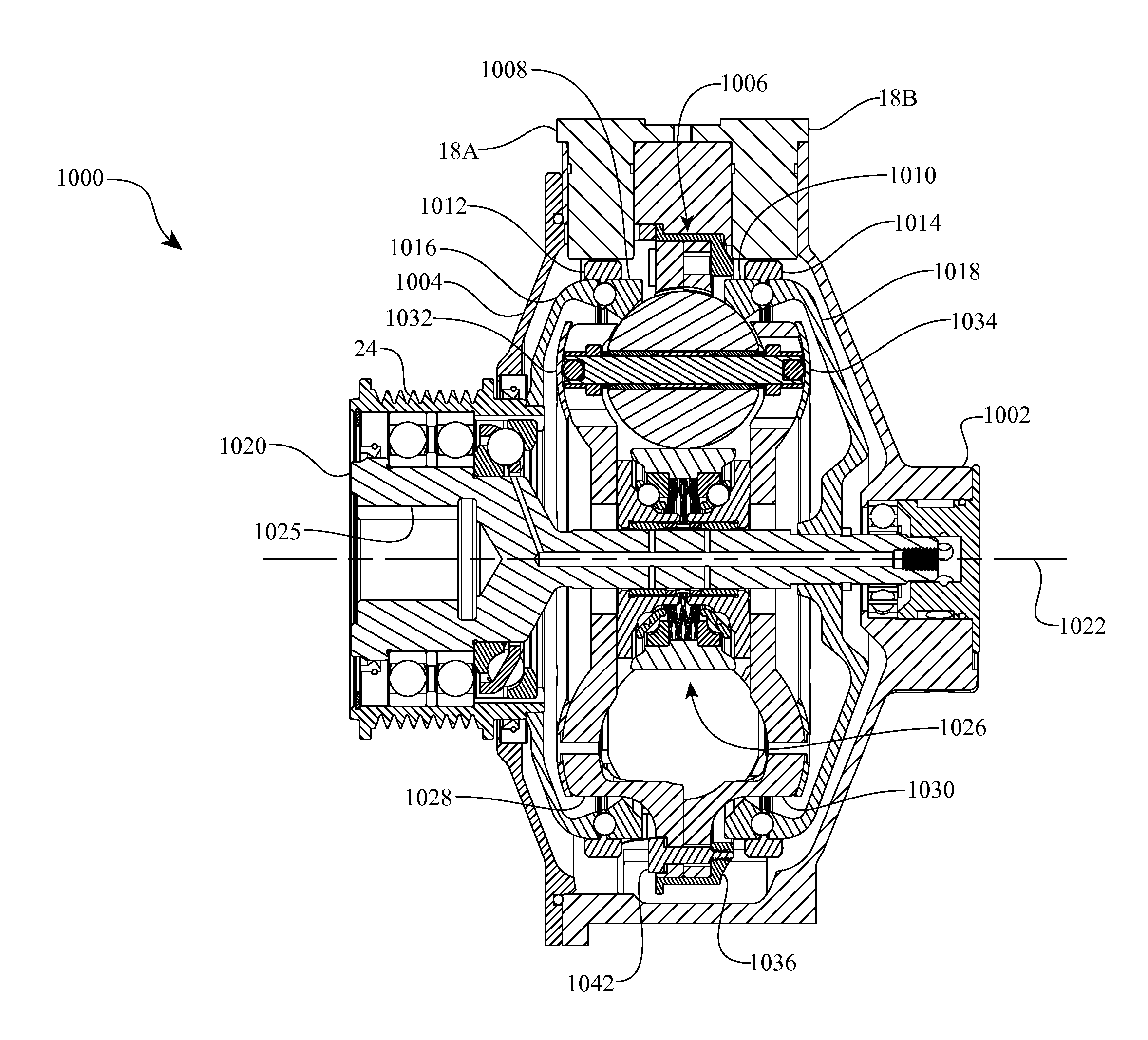

Inventive embodiments are directed to components, subassemblies, systems, and / or methods for continuously variable accessory drives (CVAD). In one embodiment, a skew-based control system is adapted to facilitate a change in the ratio of a CVAD. In another embodiment, a skew-based control system includes a skew actuator coupled to a carrier member. In some embodiments, the skew actuator is configured to rotate a carrier member of a CVT. Various inventive traction planet assemblies can be used to facilitate shifting the ratio of a CVT. In some embodiments, the traction planet assemblies include legs configured to cooperate with the carrier members. In some embodiments, a traction planet assembly is operably coupled to the carrier members. Embodiments of a shift cam and a traction sun are adapted to cooperate with other components of the CVT to support operation and / or functionality of the CVT. Among other things, shift control interfaces for a CVT are disclosed.

Owner:FALLBROOK INTPROP COMPANY

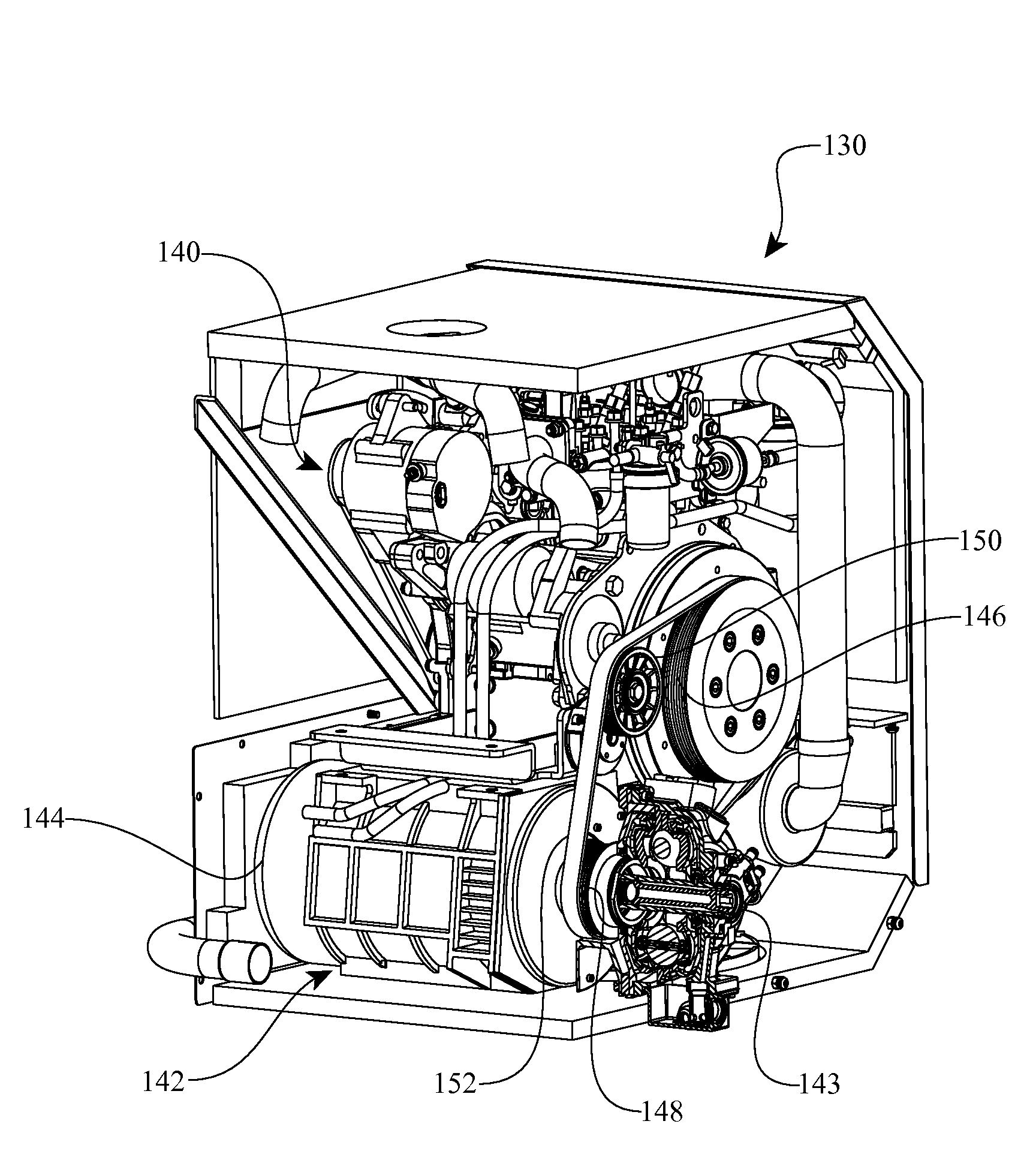

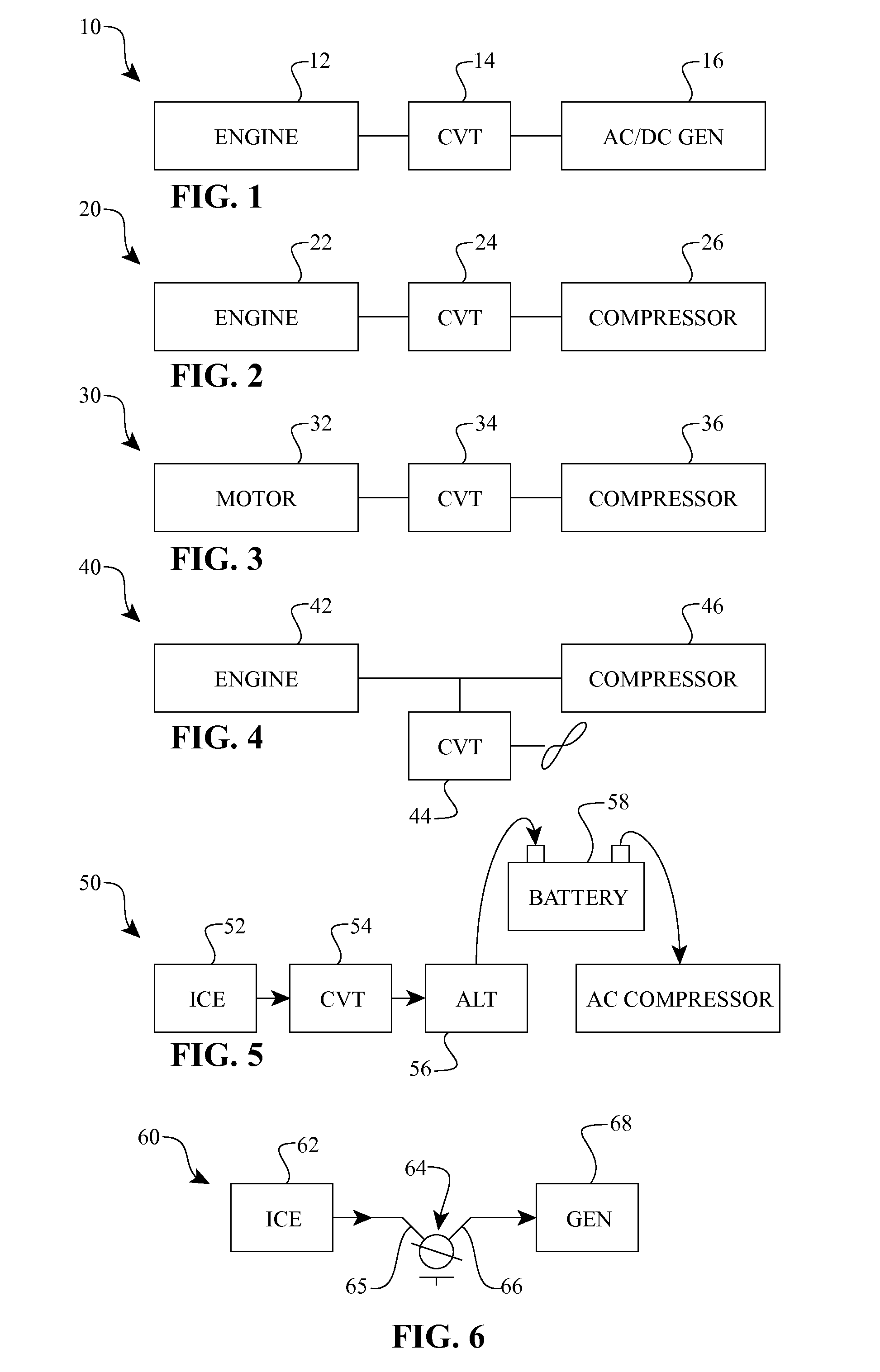

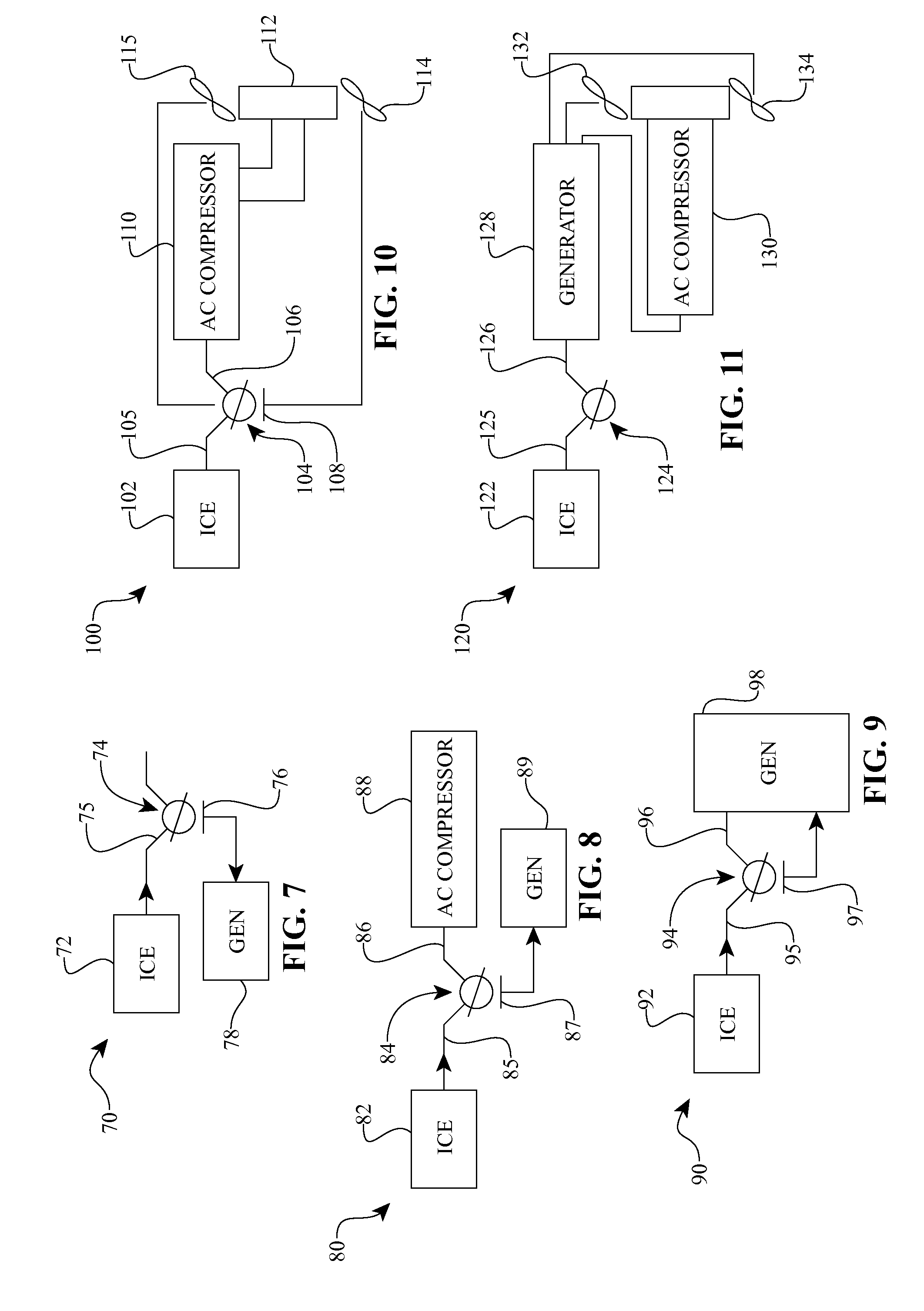

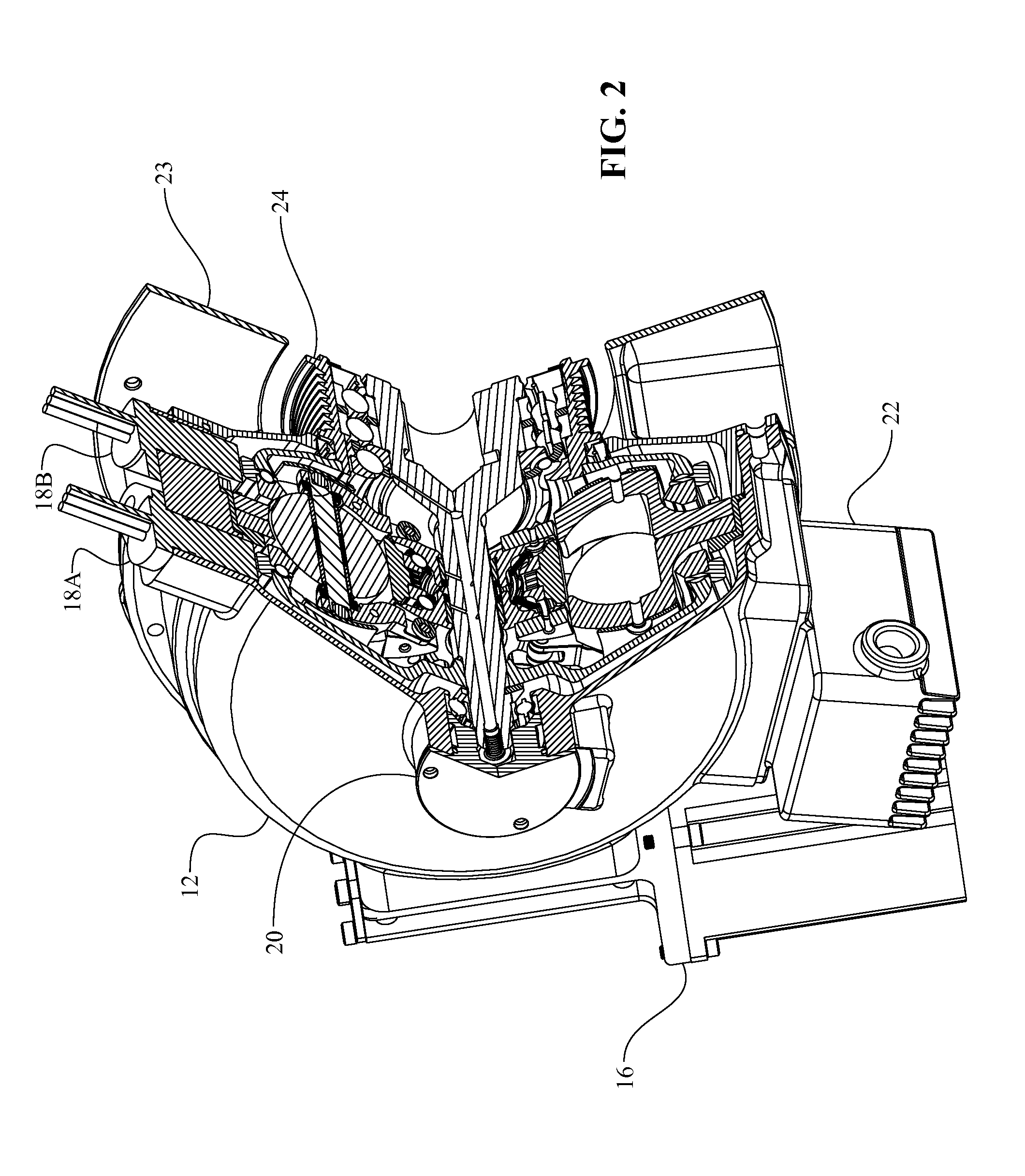

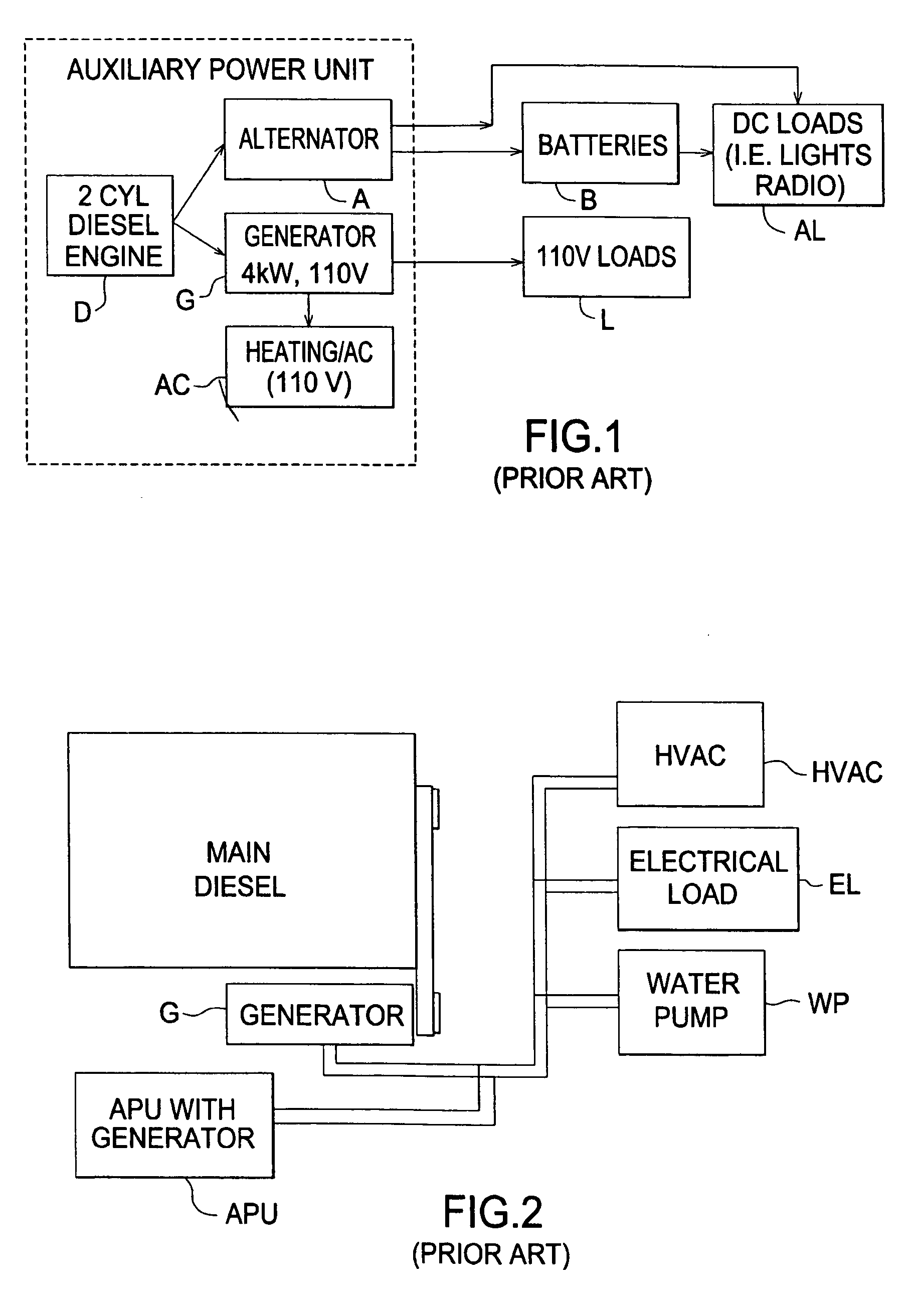

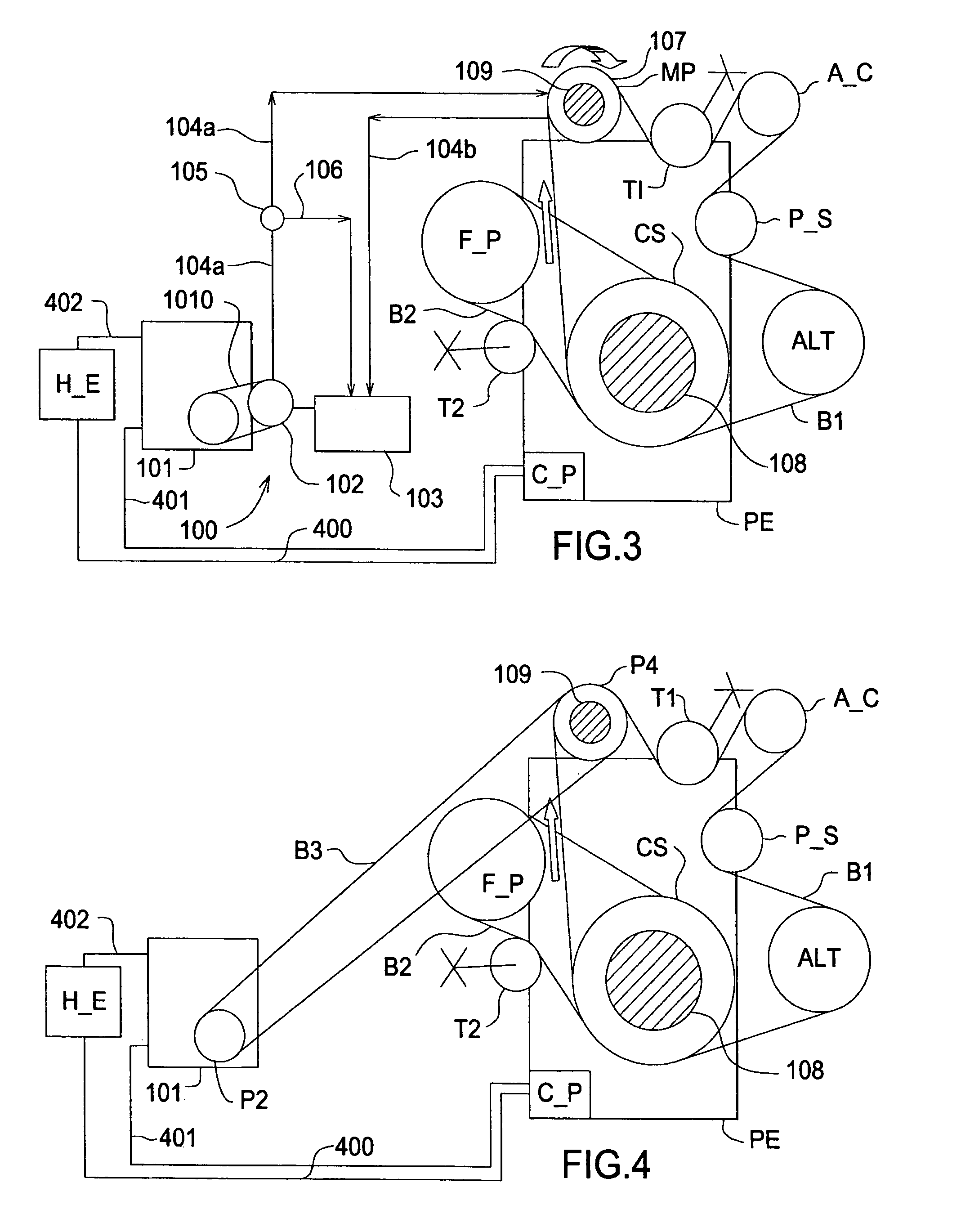

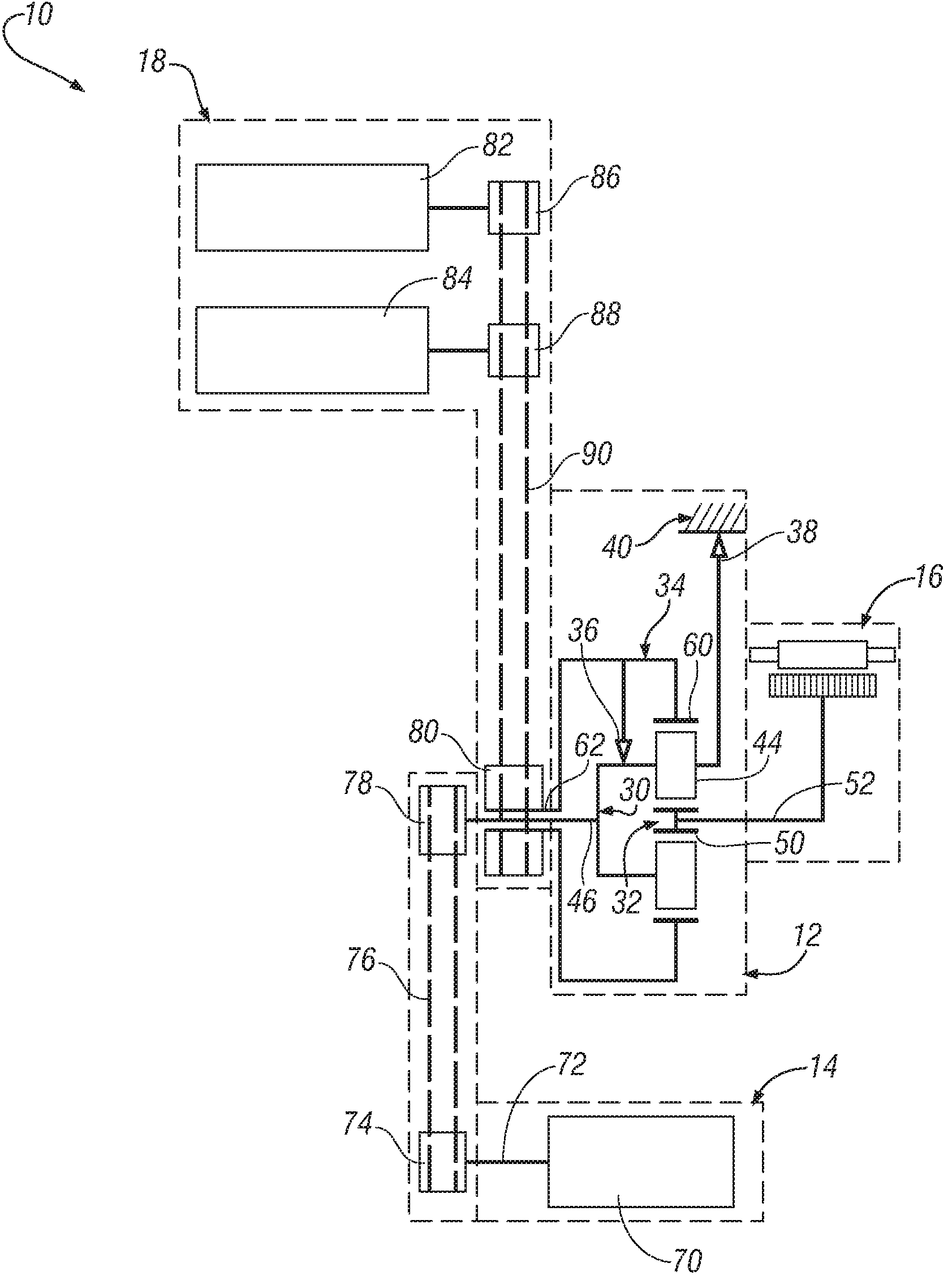

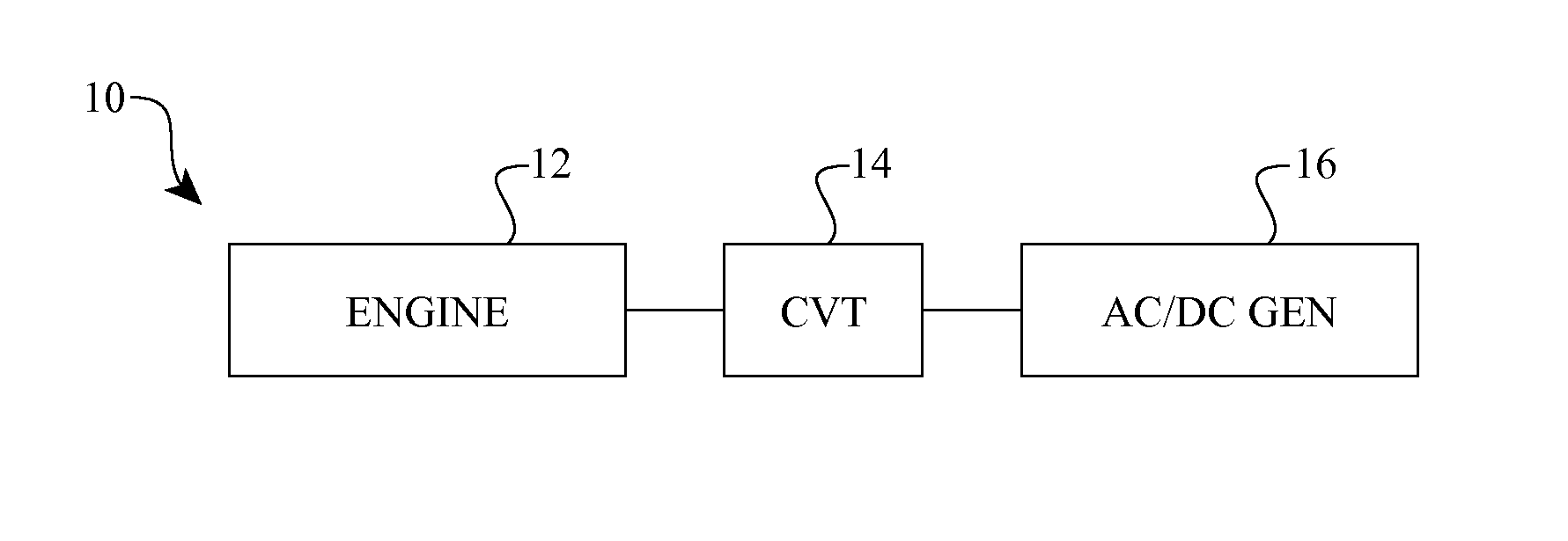

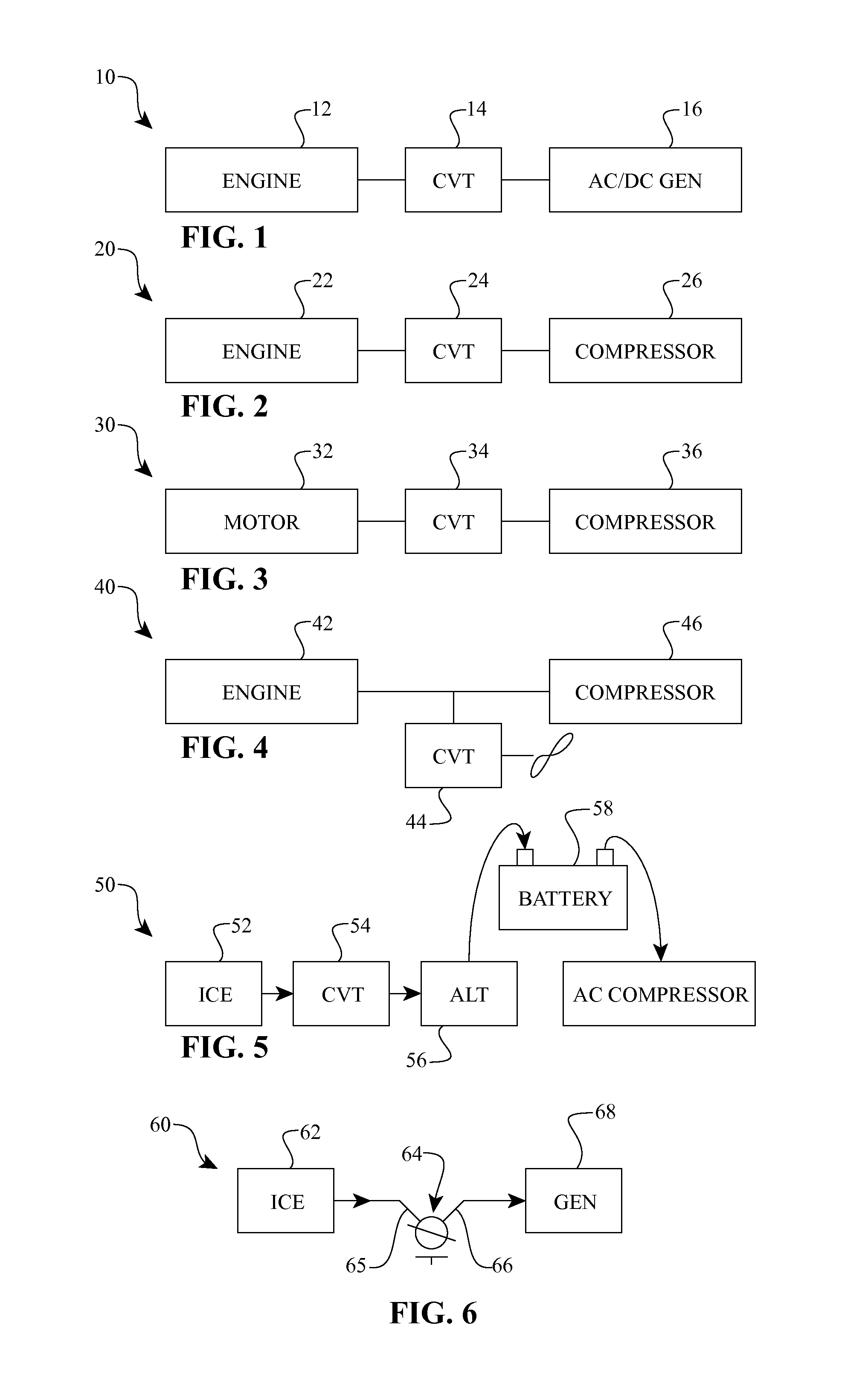

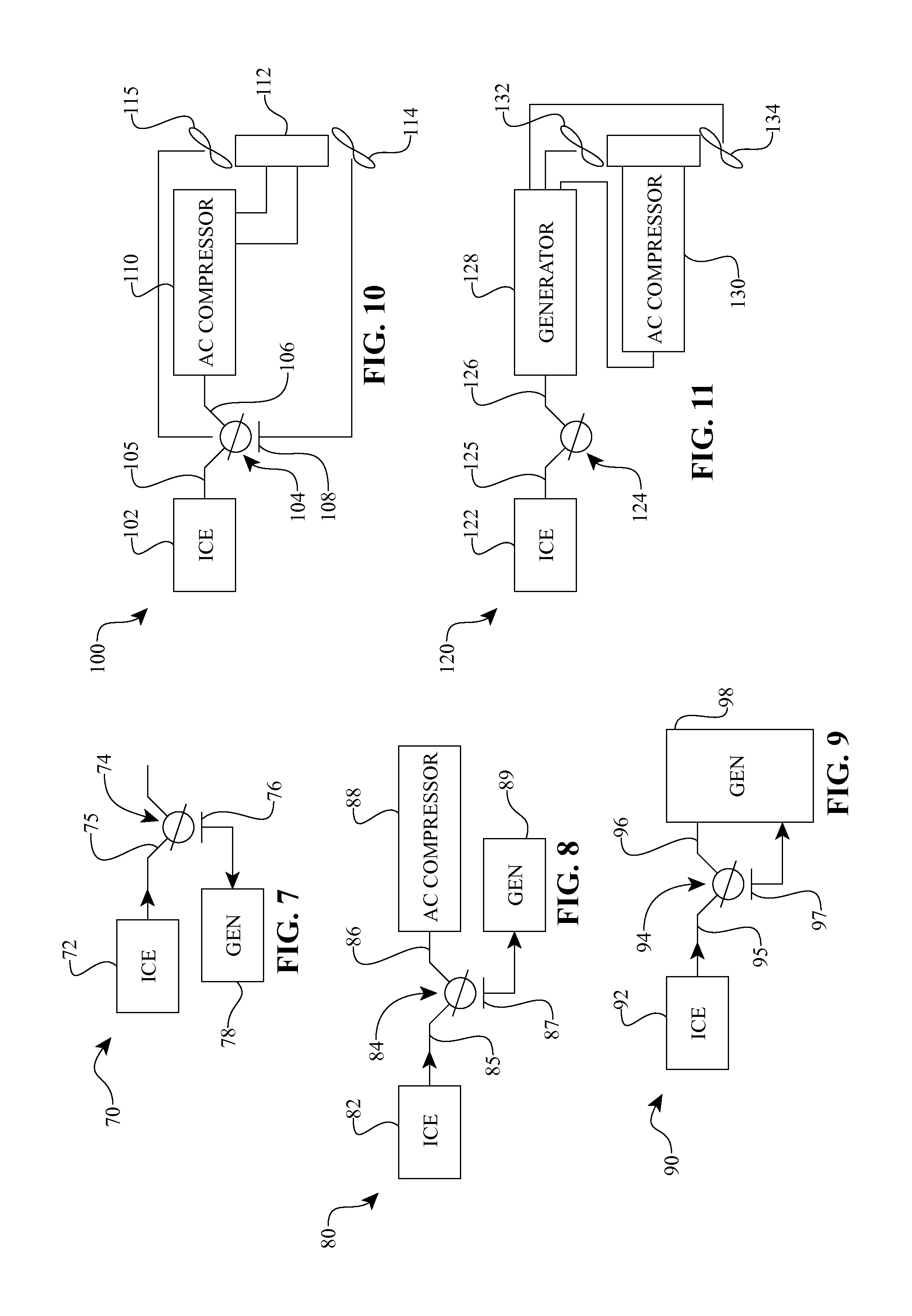

Auxiliary power unit having a continuously variable transmission

InactiveUS20120258839A1Fuel consumption is minimizedIncreased power demandAuxillary drivesVehicle fittingsCombustionControl system

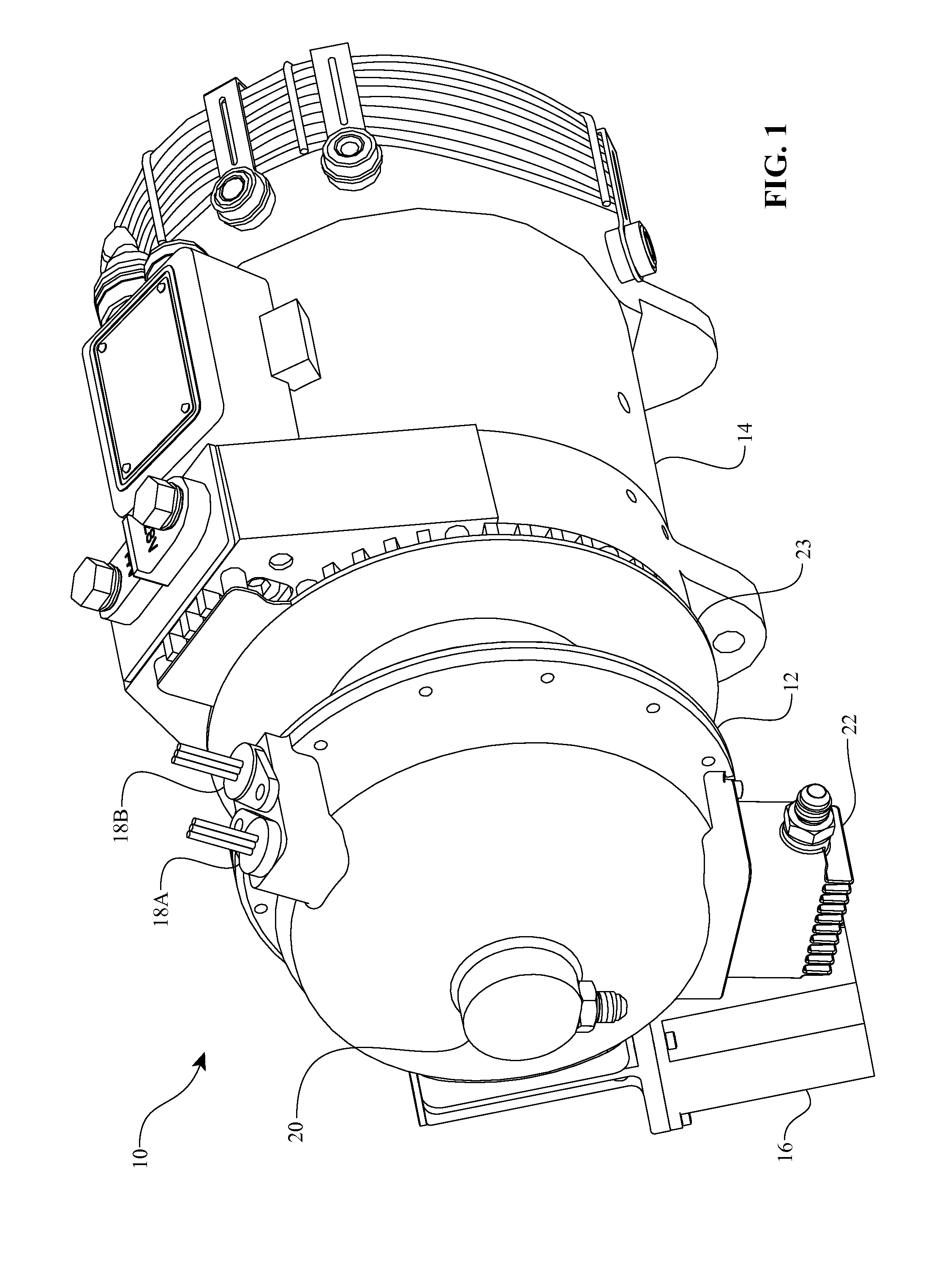

Inventive embodiments are directed to components, subassemblies, systems, and / or methods for auxiliary power units (APU). In one embodiment, the APU includes a source of rotational power such as a combustion engine operably coupled to a continuously variable transmission (CVT). The CVT can be coupled to a load. In some embodiments, the load is provided by a generator. In one embodiment, the APU has a control system configured to control the operation of the engine and the operation of the CVT. The control system can facilitate substantially constant speed operation of the generator in the presence of variable operation of the engine. In another embodiment, the APU includes a continuously variable accessory drive (CVAD) operably coupled to an engine. The CVAD can include a continuously variable transmission operably coupled to a generator. In one embodiment, a skew-based control system is adapted to facilitate a change in the ratio of a CVAD.

Owner:FALLBROOK INTPROP COMPANY

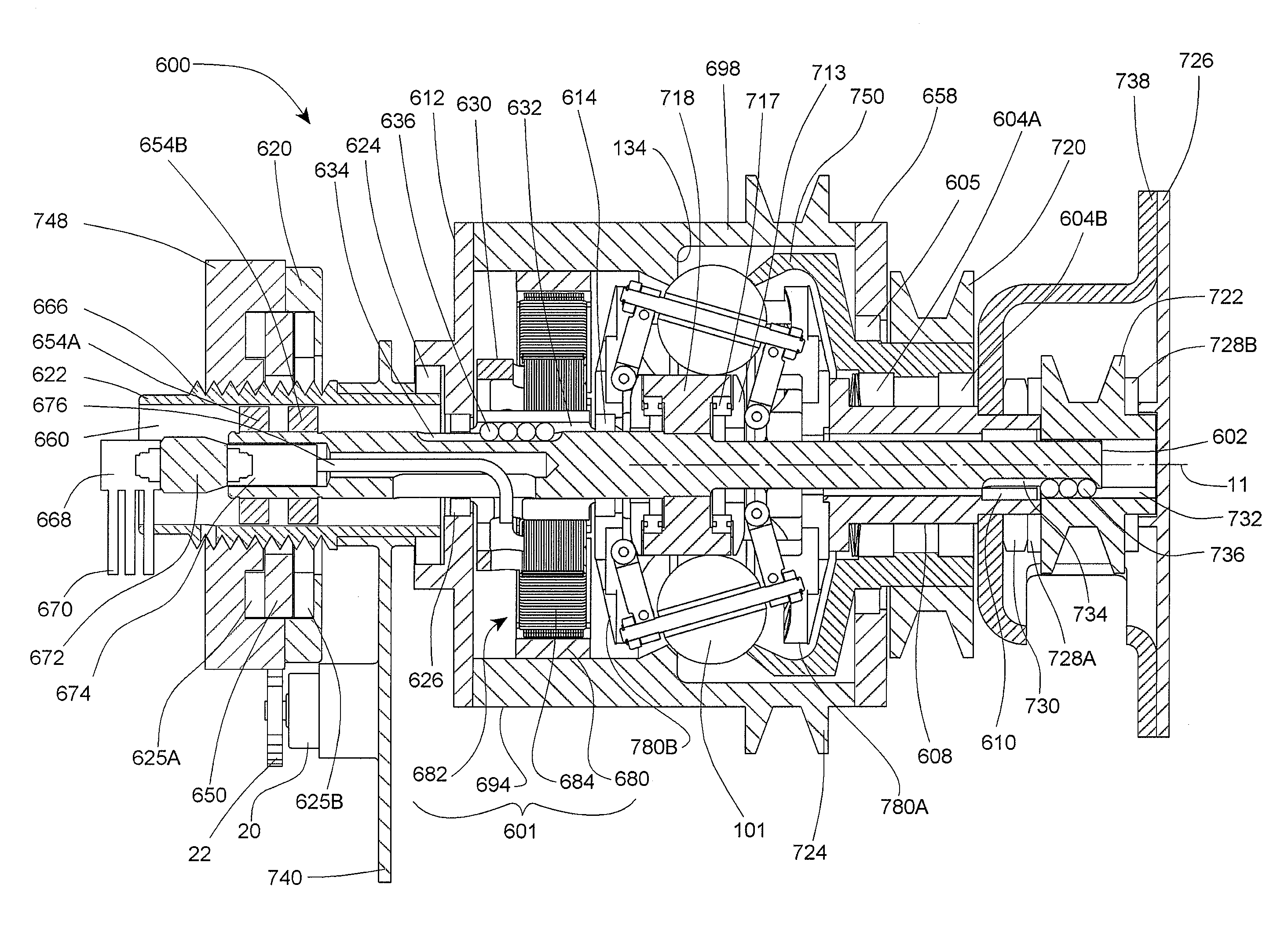

Continuously variable transmission

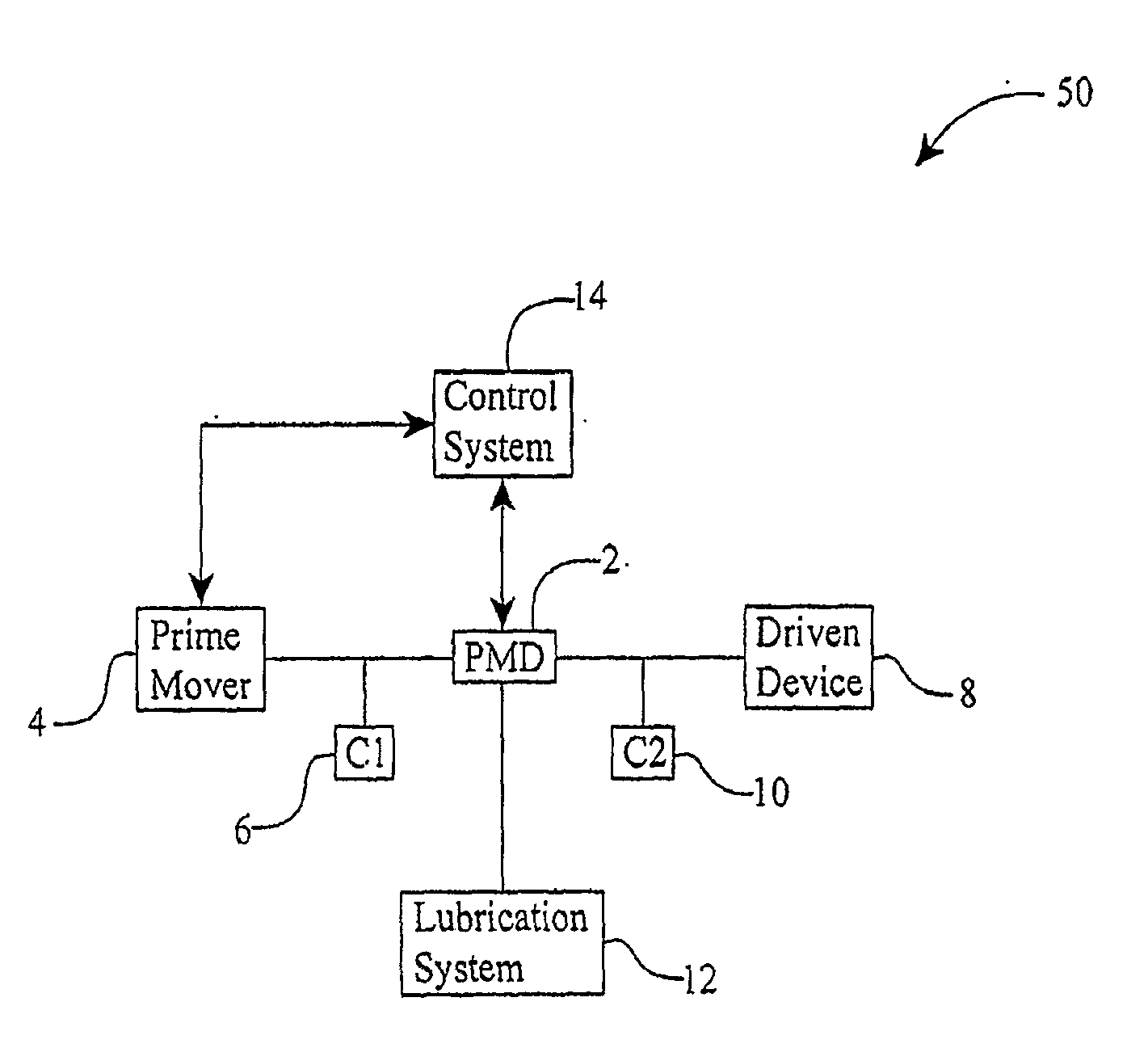

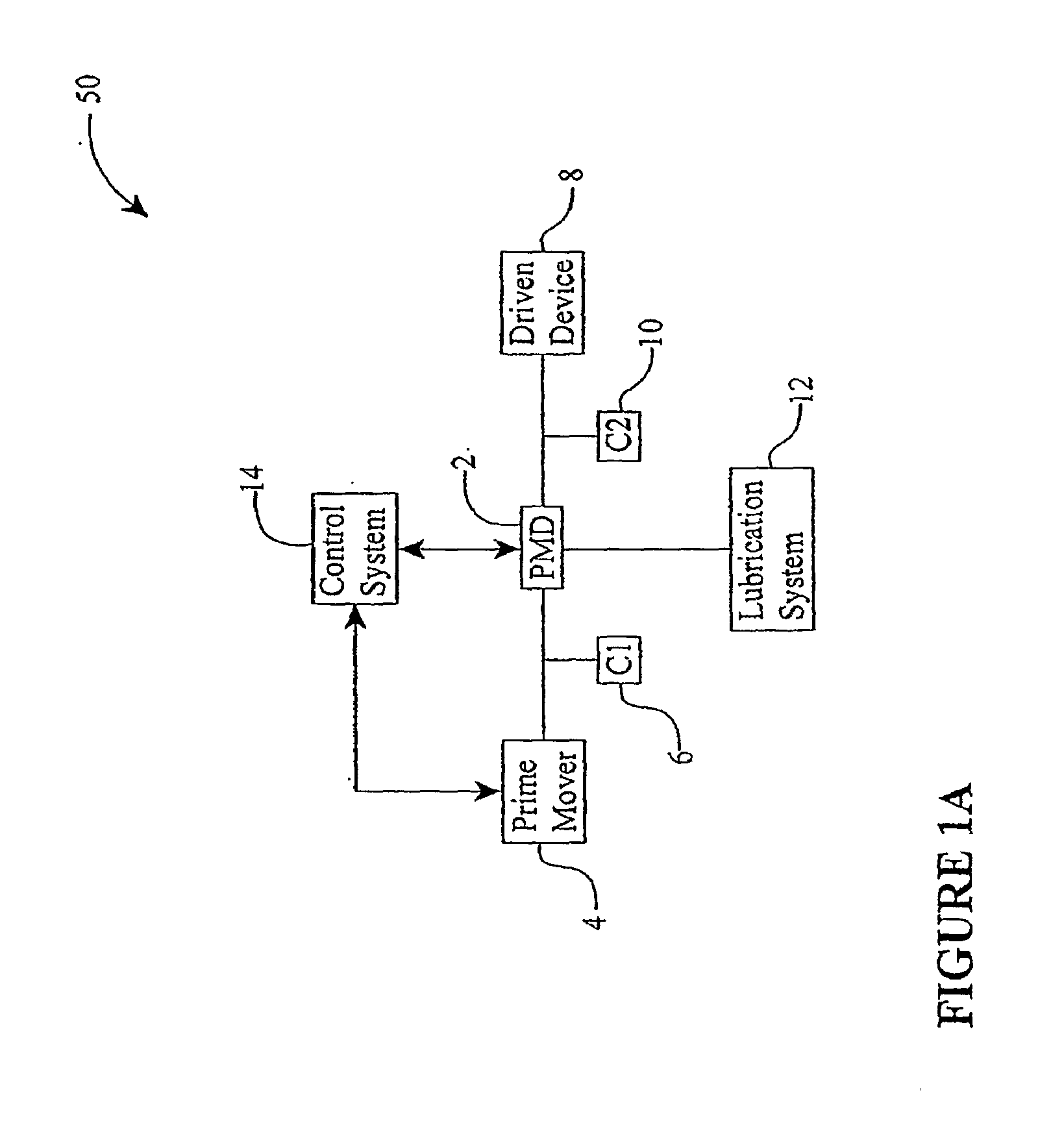

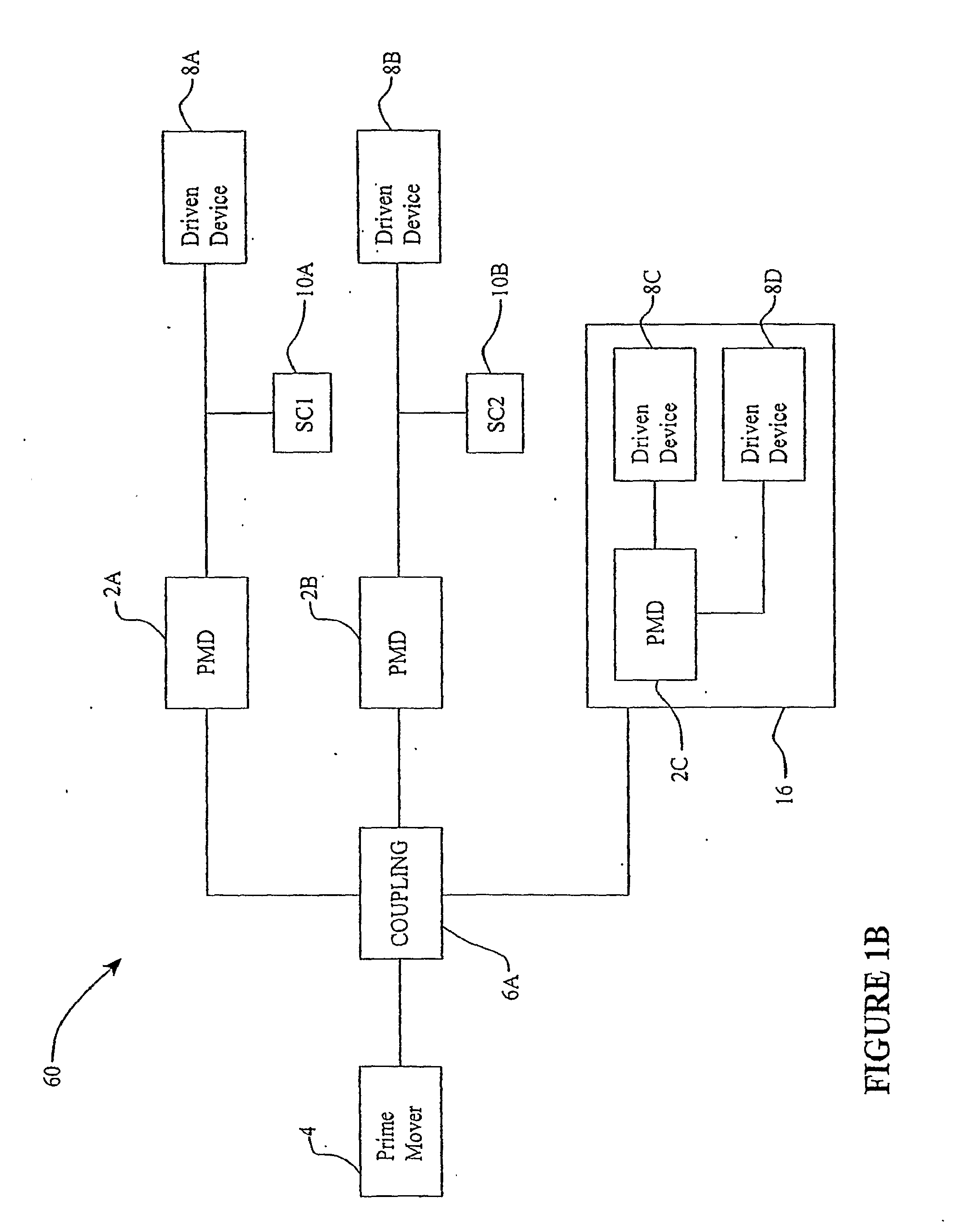

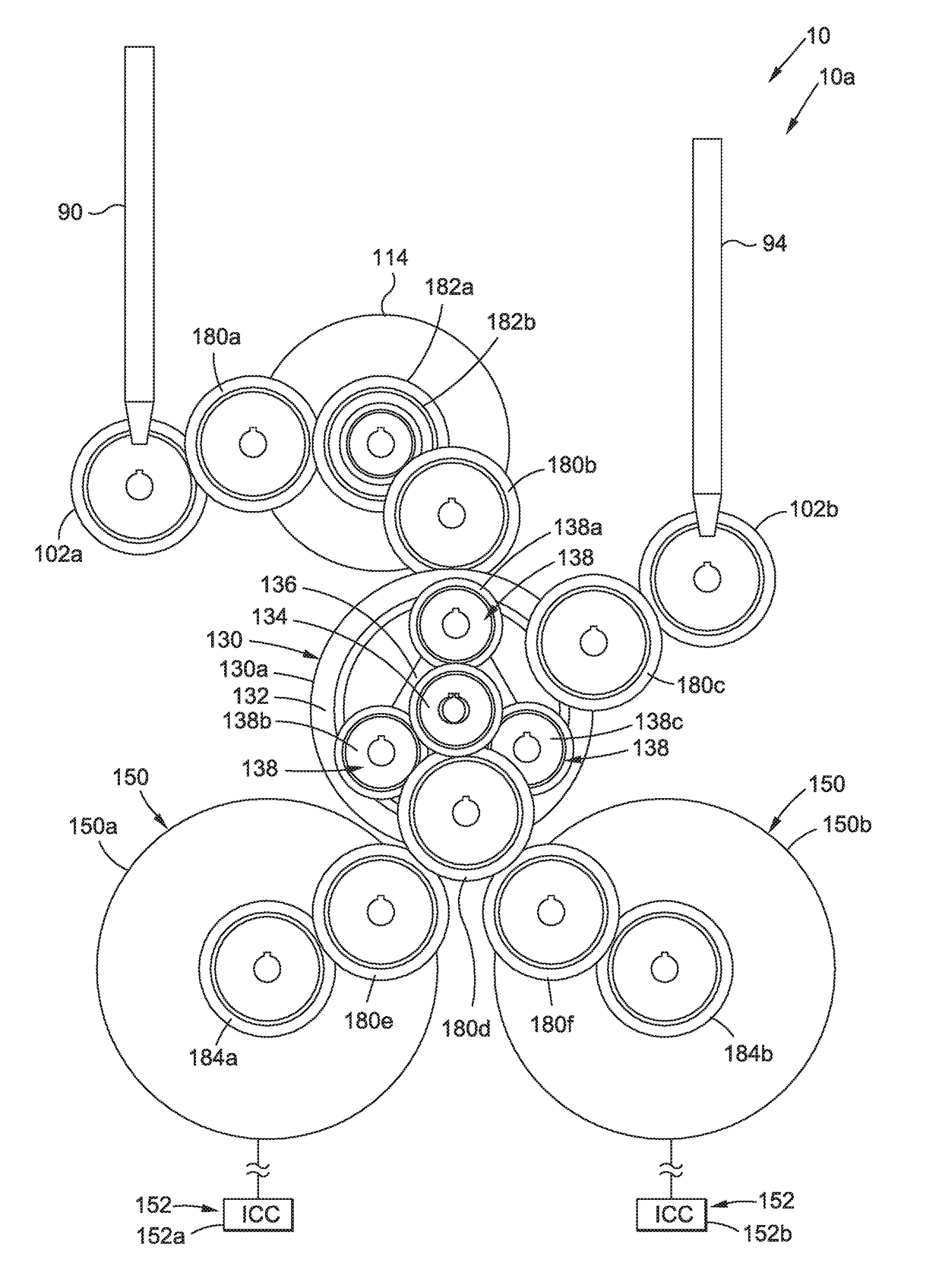

Embodiments are directed to a front end accessory drive (FEAD), subassemblies, and components therefor. Embodiments disclosed cover power modulating devices (PMD) which can be used in a FEAD. In one embodiment, a continuously variable transmission (CVT) is coupled directly to a crankshaft of a prime mover, and the CVT is used to regulate the speed and / or torque delivered to an accessory. A compound drive device includes a motor / generator subassembly cooperating with a CVT subassembly to provide a motor functionality with torque multiplication or division, or alternatively, a generator functionality with torque multiplication or division. In some embodiments, a FEAD includes a PMD having a sun shaft configured to couple to a sun of the PMD and to an electric motor component, such as an electrical armature or an electrical field. In one embodiment, the electrical armature the electrical field are placed concentrically and coaxially and configured to rotate relative to one another in opposite directions.

Owner:FALLBROOK INTPROP COMPANY

Continuously variable transmission

Inventive embodiments are directed to components, subassemblies, systems, and / or methods for continuously variable accessory drives (CVAD). In one embodiment, a skew-based control system is adapted to facilitate a change in the ratio of a CVAD. In another embodiment, a skew-based control system includes a skew actuator coupled to a carrier member. In some embodiments, the skew actuator is configured to rotate a carrier member of a CVT. Various inventive traction planet assemblies can be used to facilitate shifting the ratio of a CVT. In some embodiments, the traction planet assemblies include legs configured to cooperate with the carrier members. In some embodiments, a traction planet assembly is operably coupled to the carrier members. Embodiments of a shift cam and a traction sun are adapted to cooperate with other components of the CVT to support operation and / or functionality of the CVT. Among other things, shift control interfaces for a CVT are disclosed.

Owner:FALLBROOK INTPROP COMPANY

Continuously variable transmission

Embodiments are directed to a front end accessory drive (FEAD), subassemblies, and components therefor. Embodiments disclosed cover power modulating devices (PMD) which can be used in a FEAD. In one embodiment, a continuously variable transmission (CVT) is coupled directly to a crankshaft of a prime mover, and the CVT is used to regulate the speed and / or torque delivered to an accessory. A compound drive device includes a motor / generator subassembly cooperating with a CVT subassembly to provide a motor functionality with torque multiplication or division, or alternatively, a generator functionality with torque multiplication or division. In some embodiments, a FEAD includes a PMD having a sun shaft configured to couple to a sun of the PMD and to an electric motor component, such as an electrical armature or an electrical field. In one embodiment, the electrical armature the electrical field are placed concentrically and coaxially and configured to rotate relative to one another in opposite directions.

Owner:FALLBROOK INTPROP COMPANY

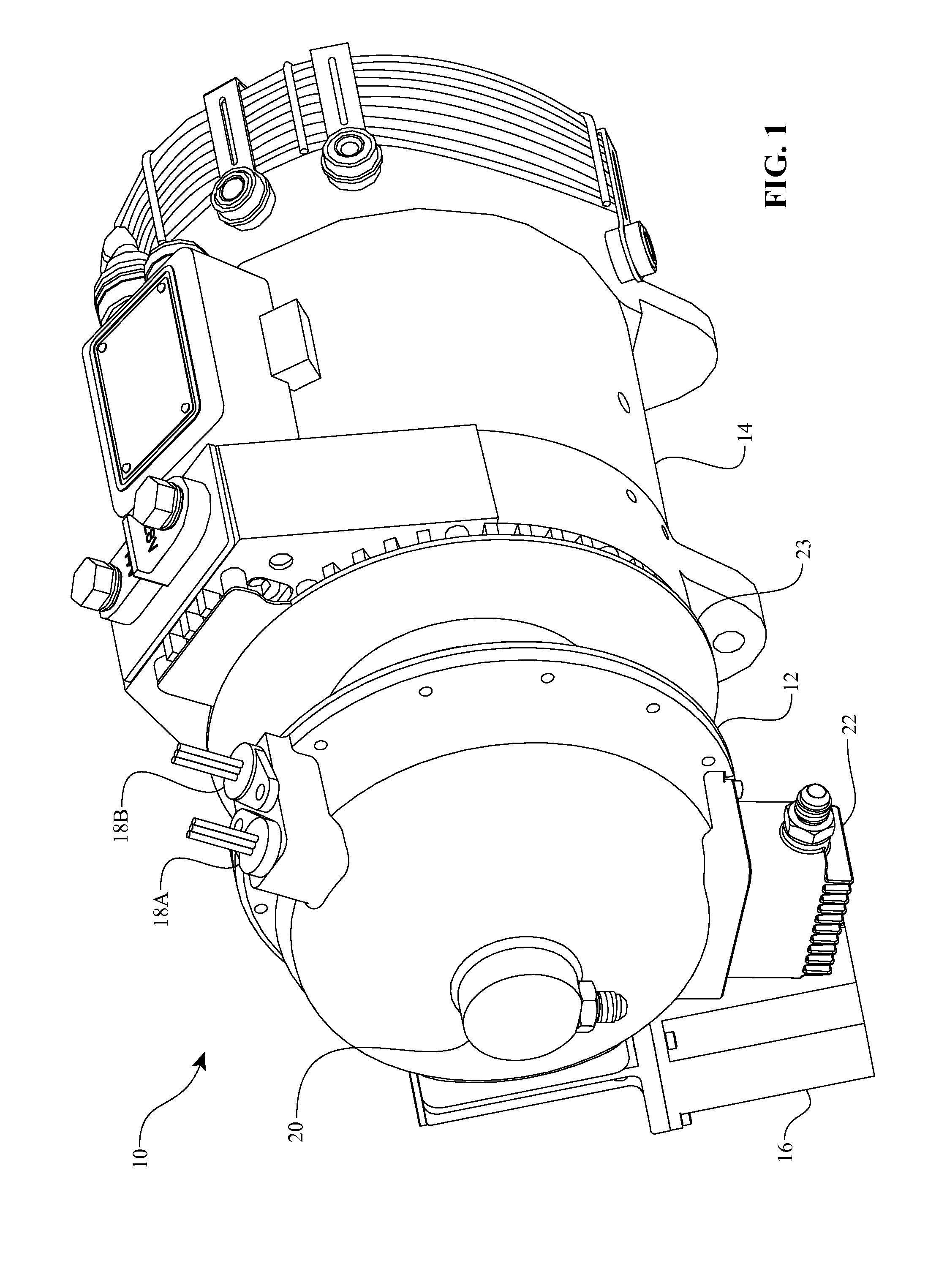

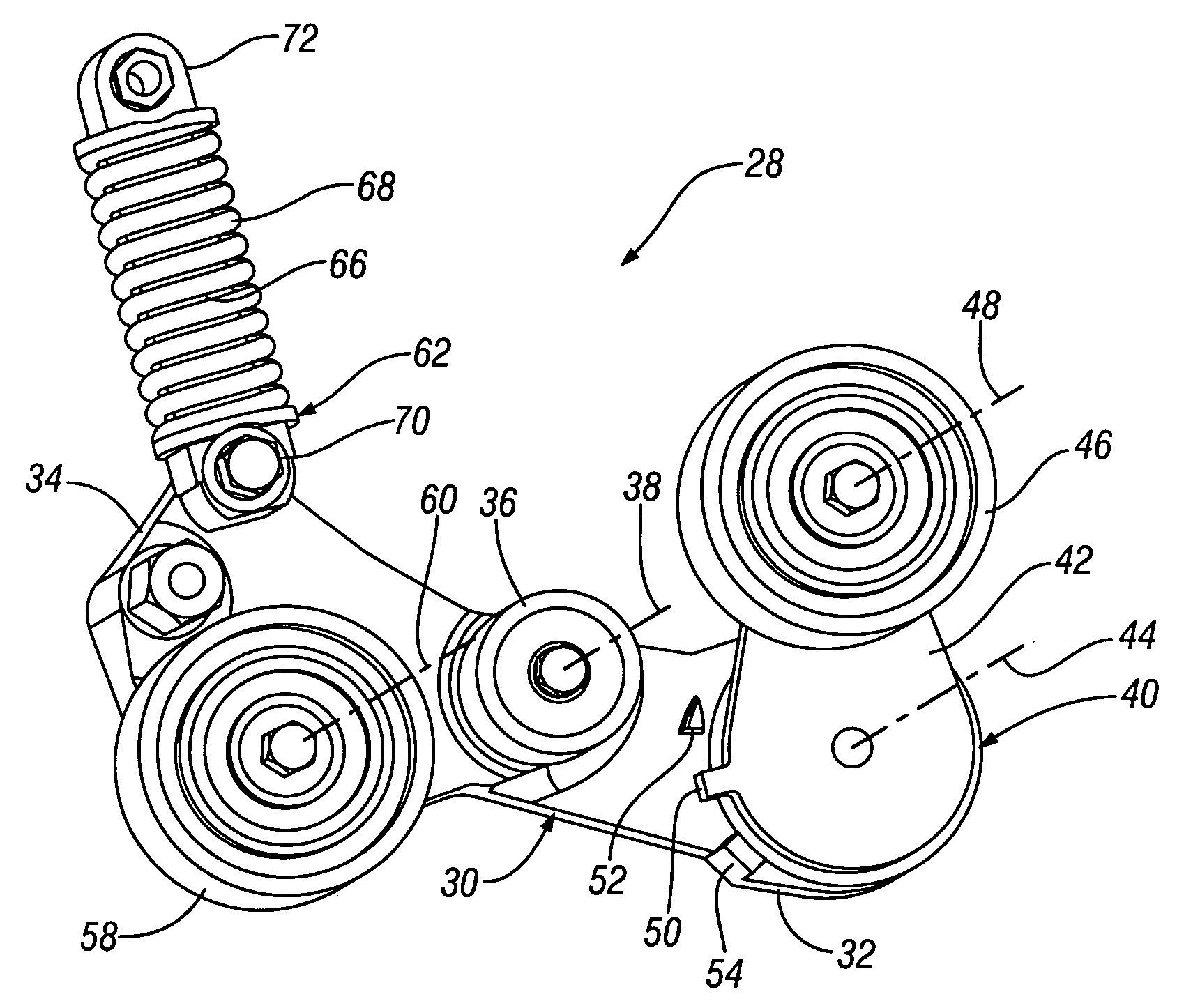

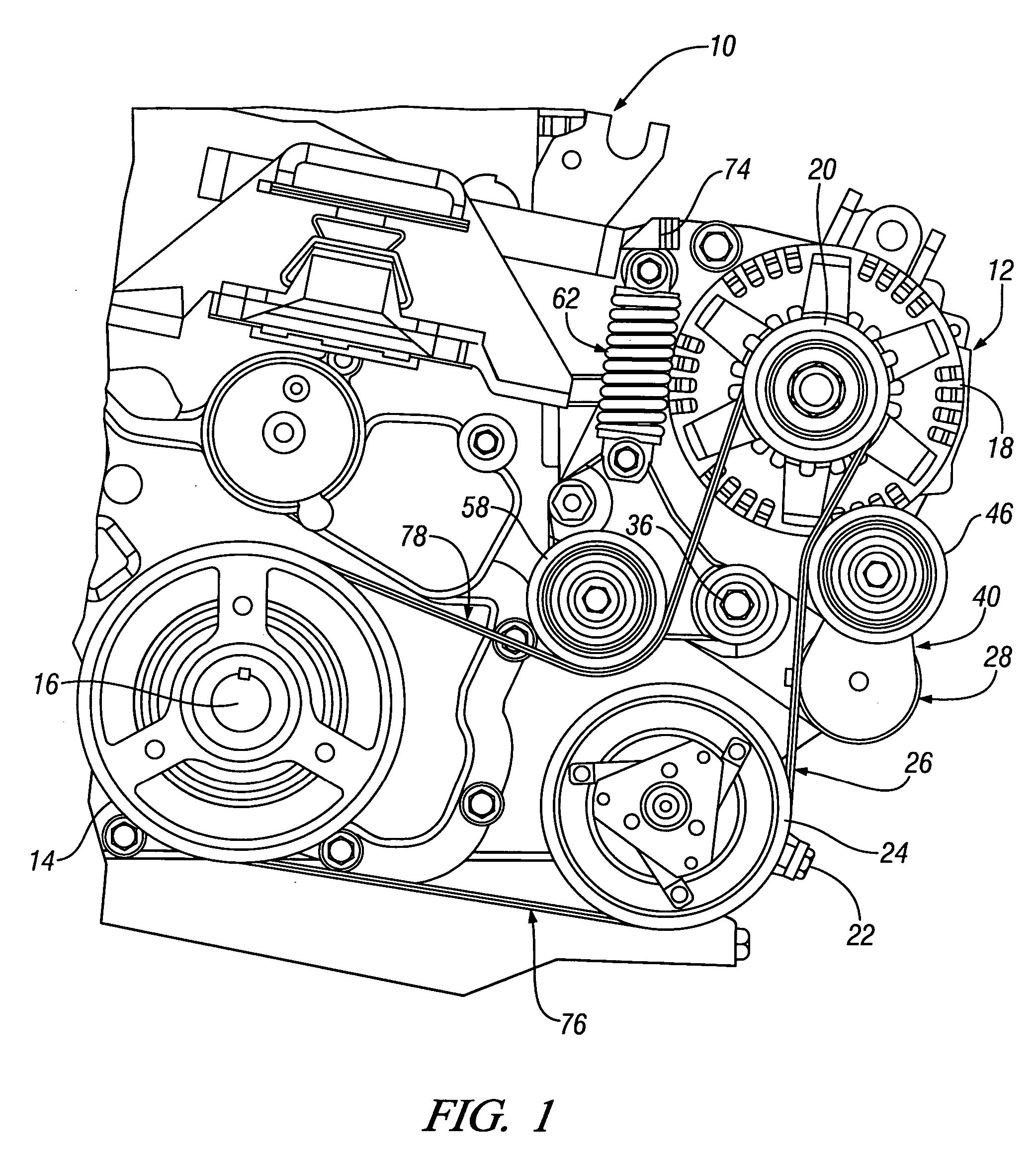

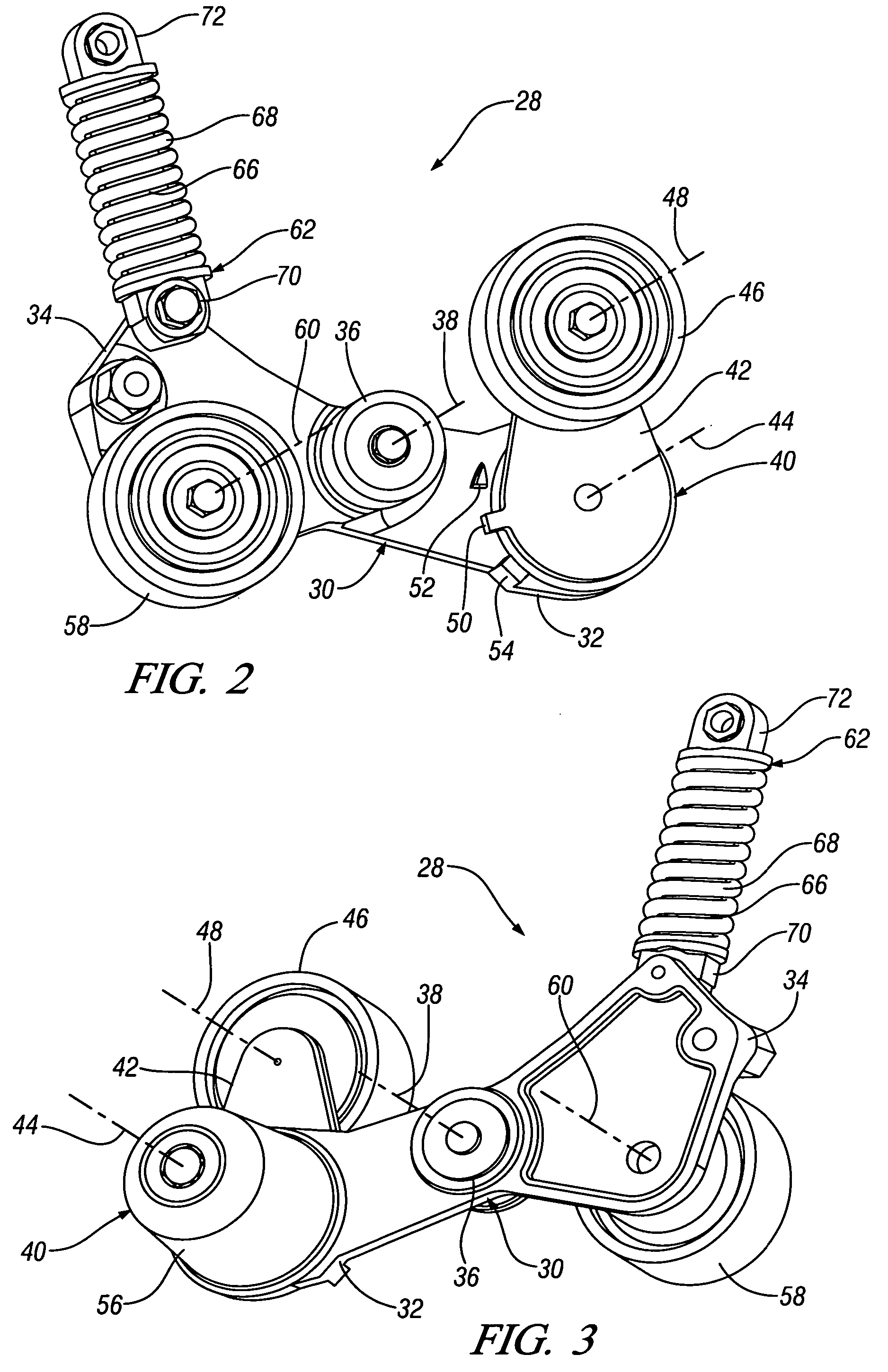

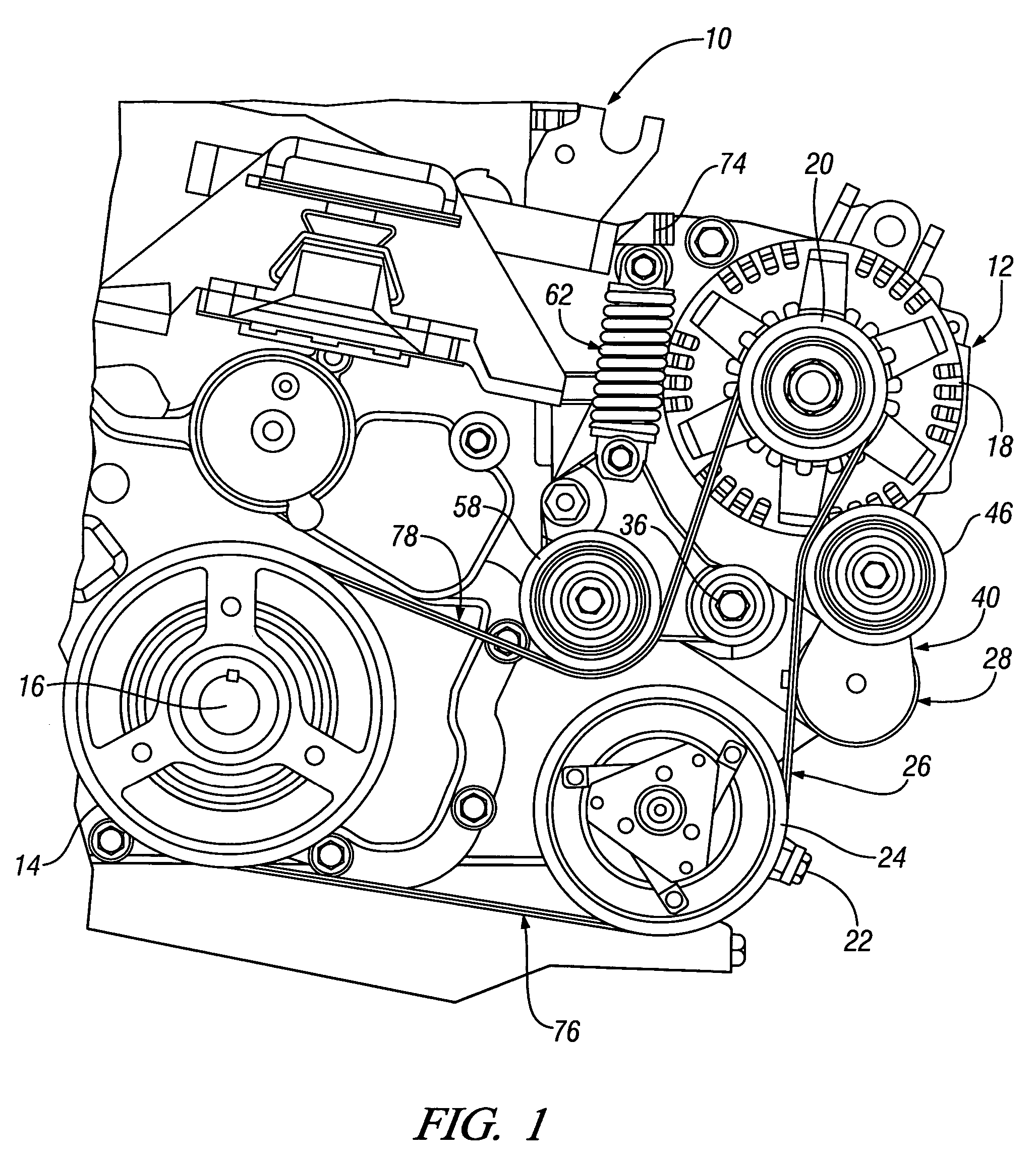

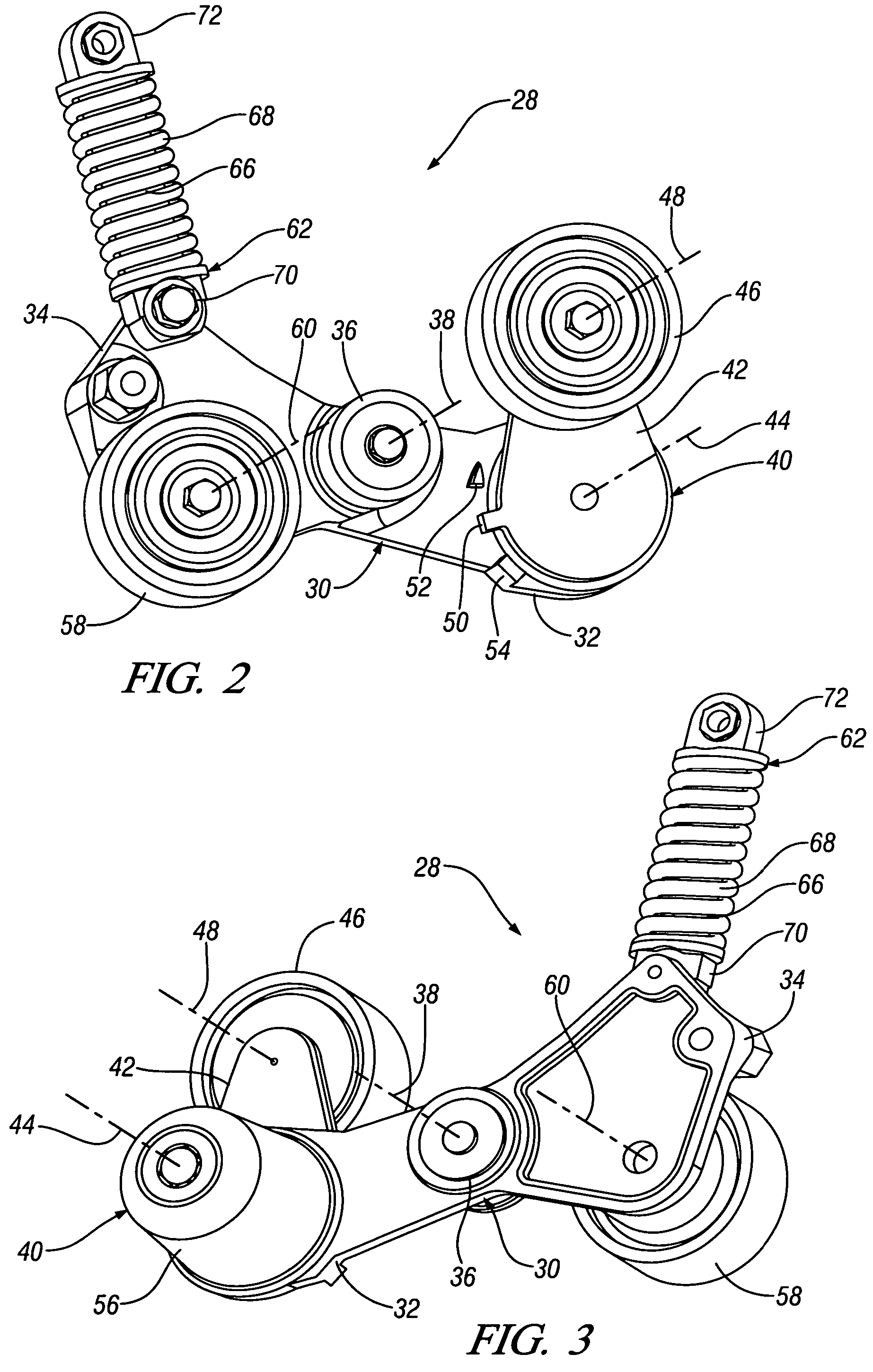

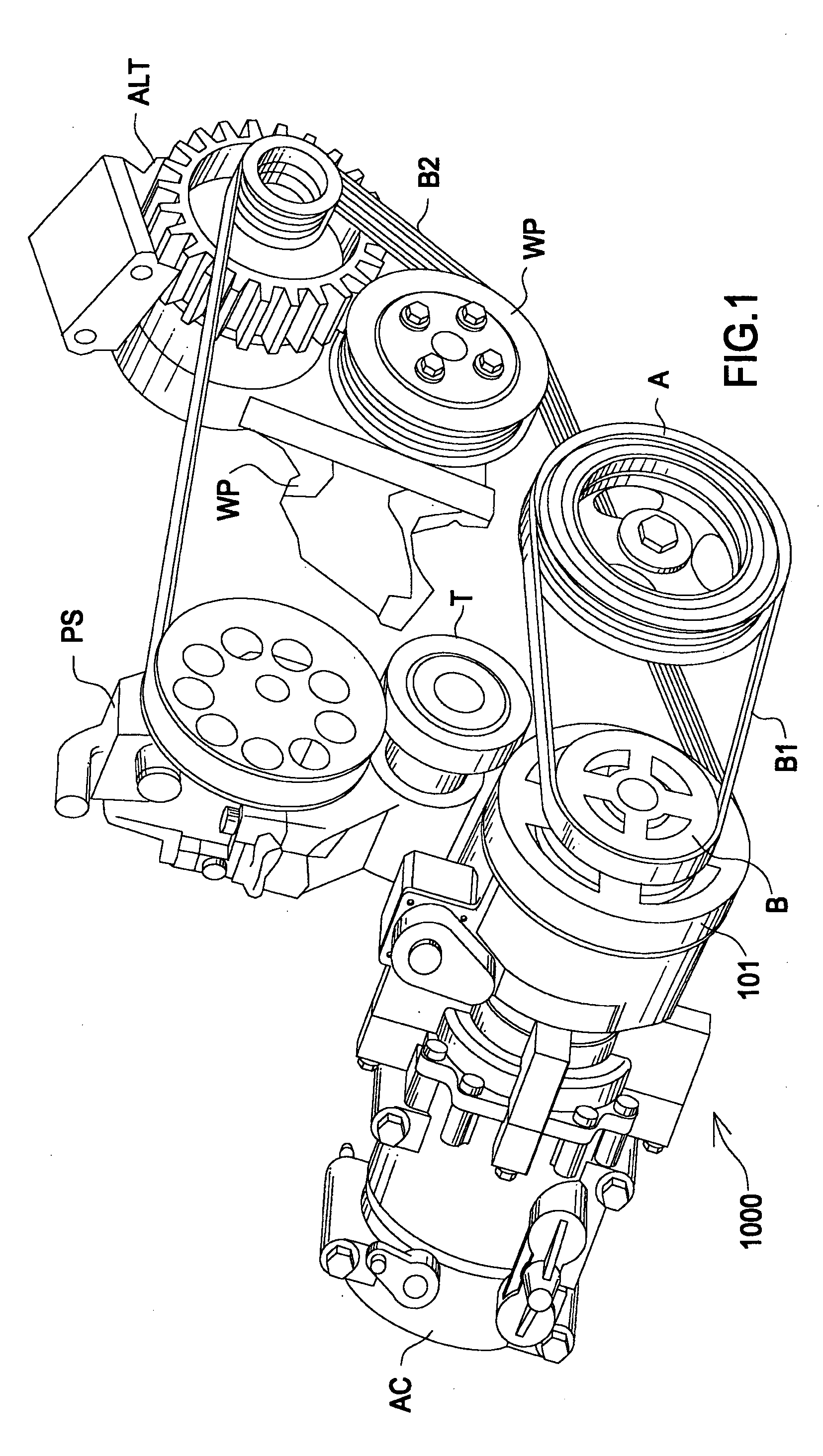

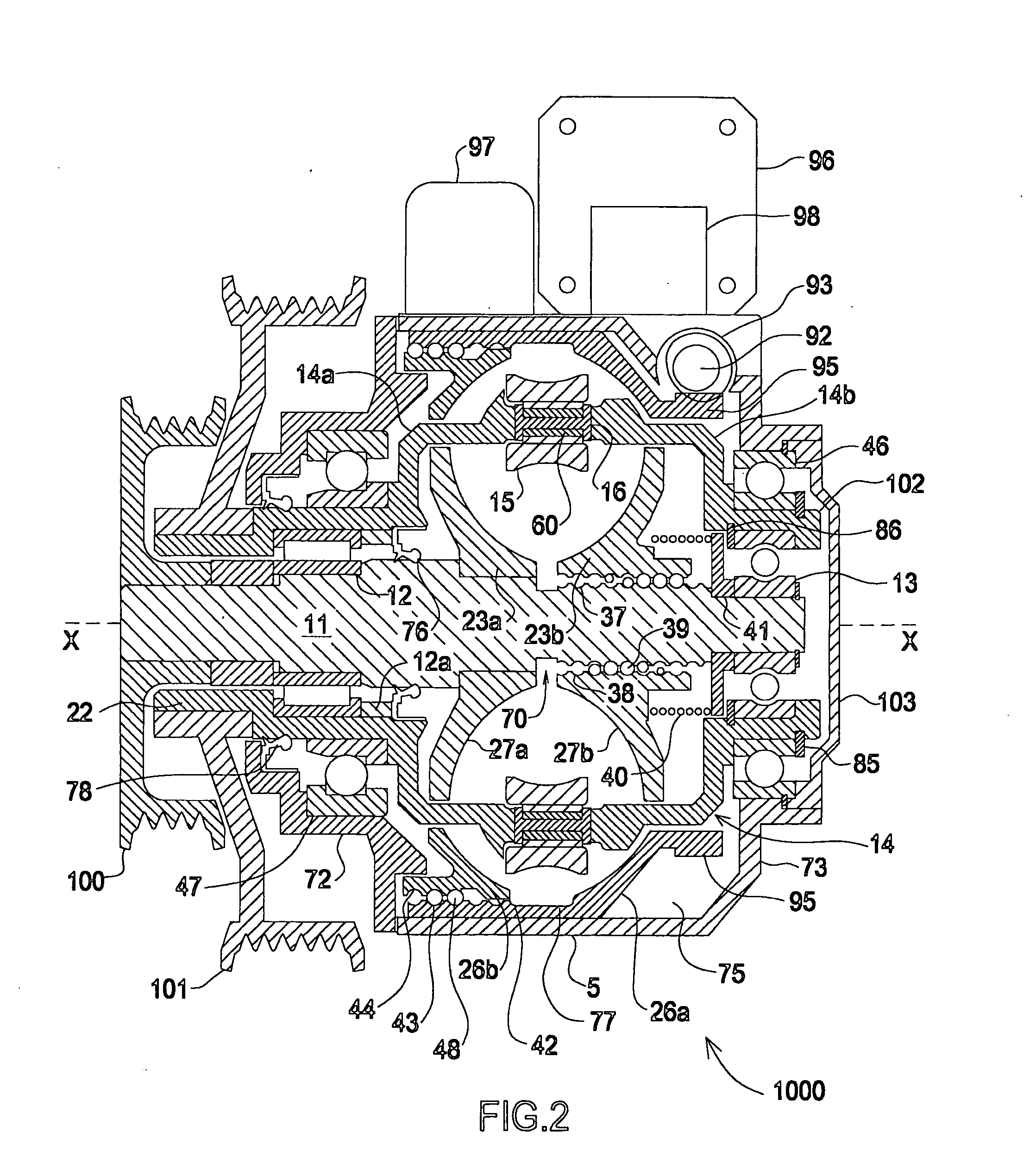

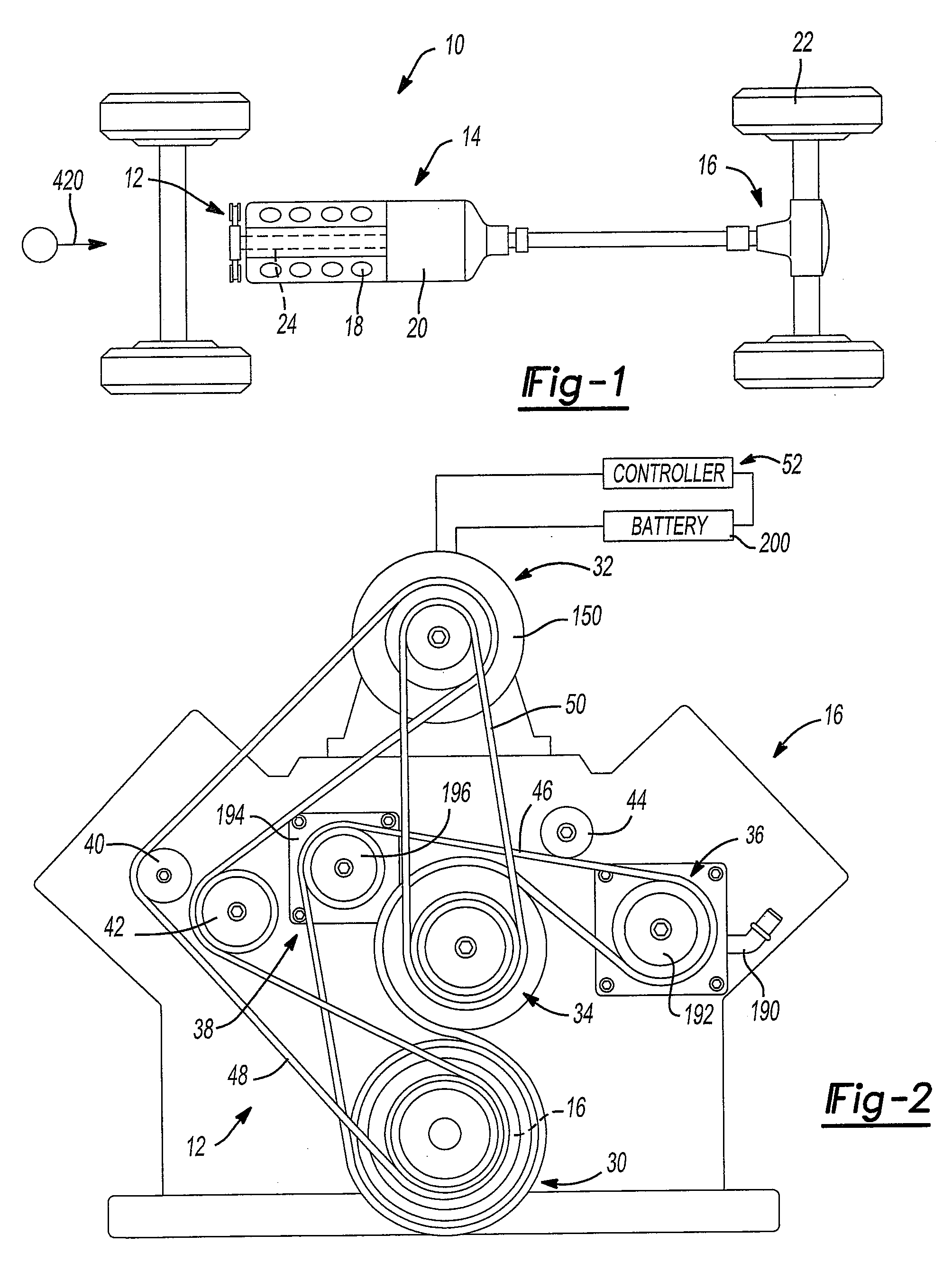

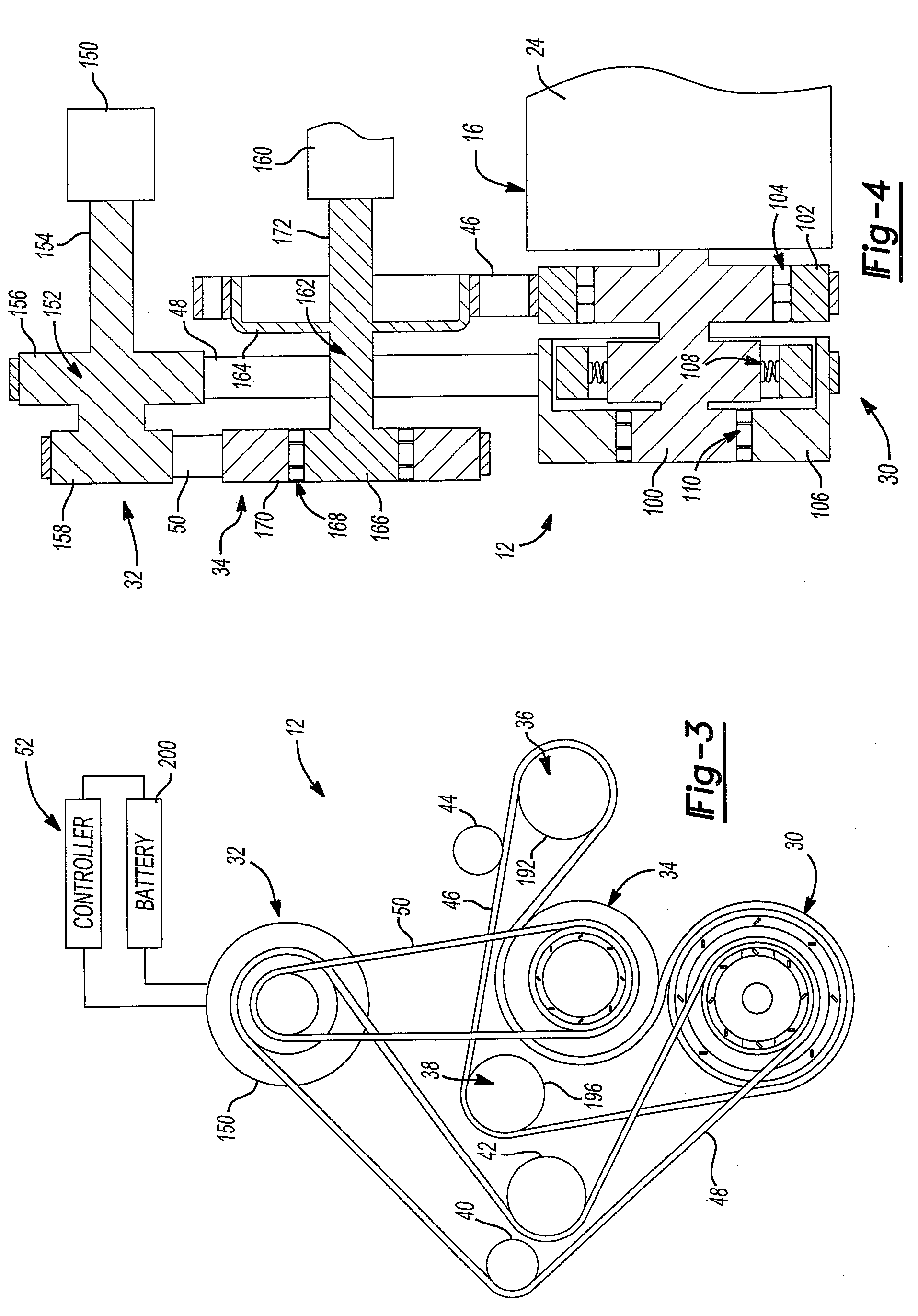

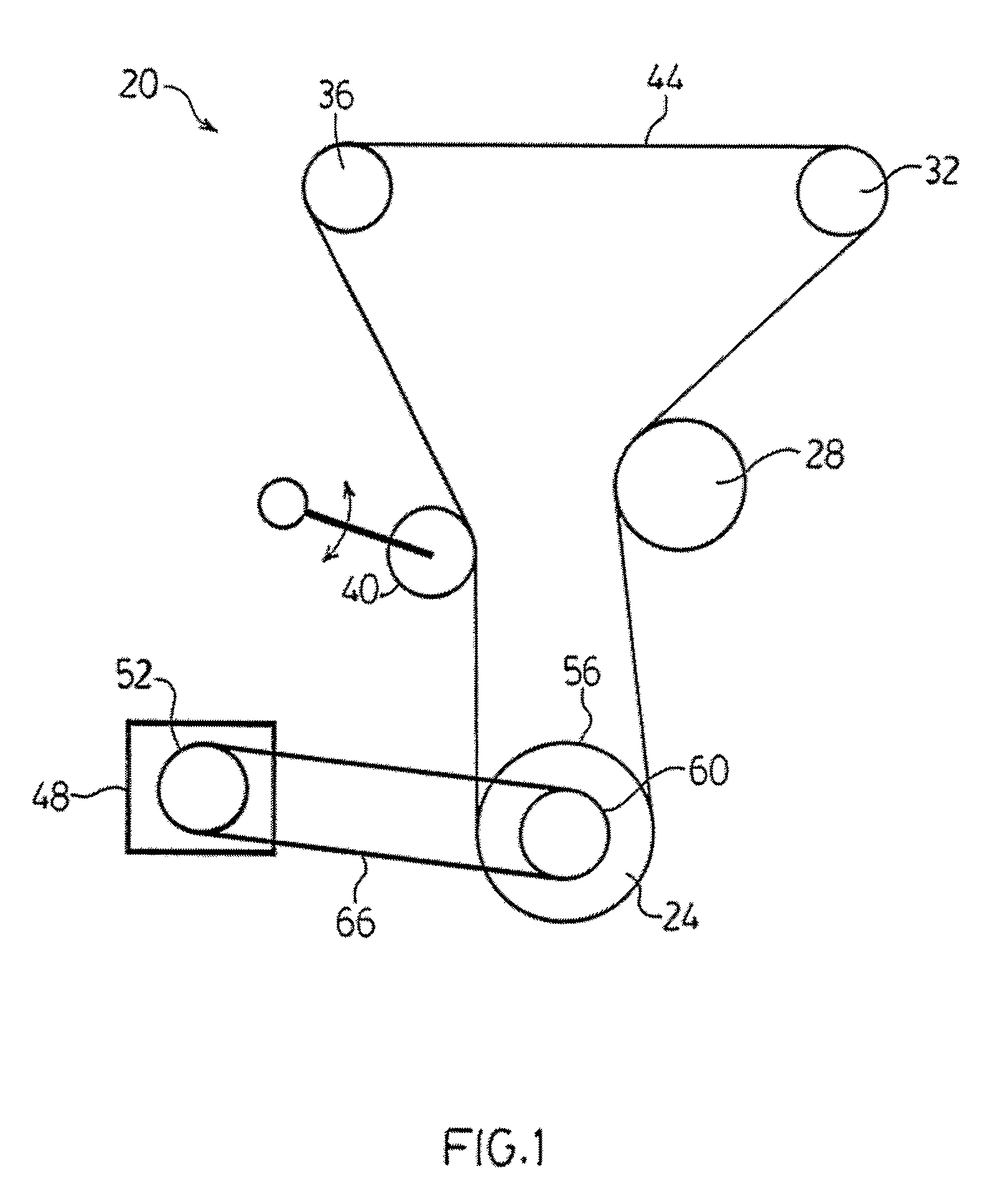

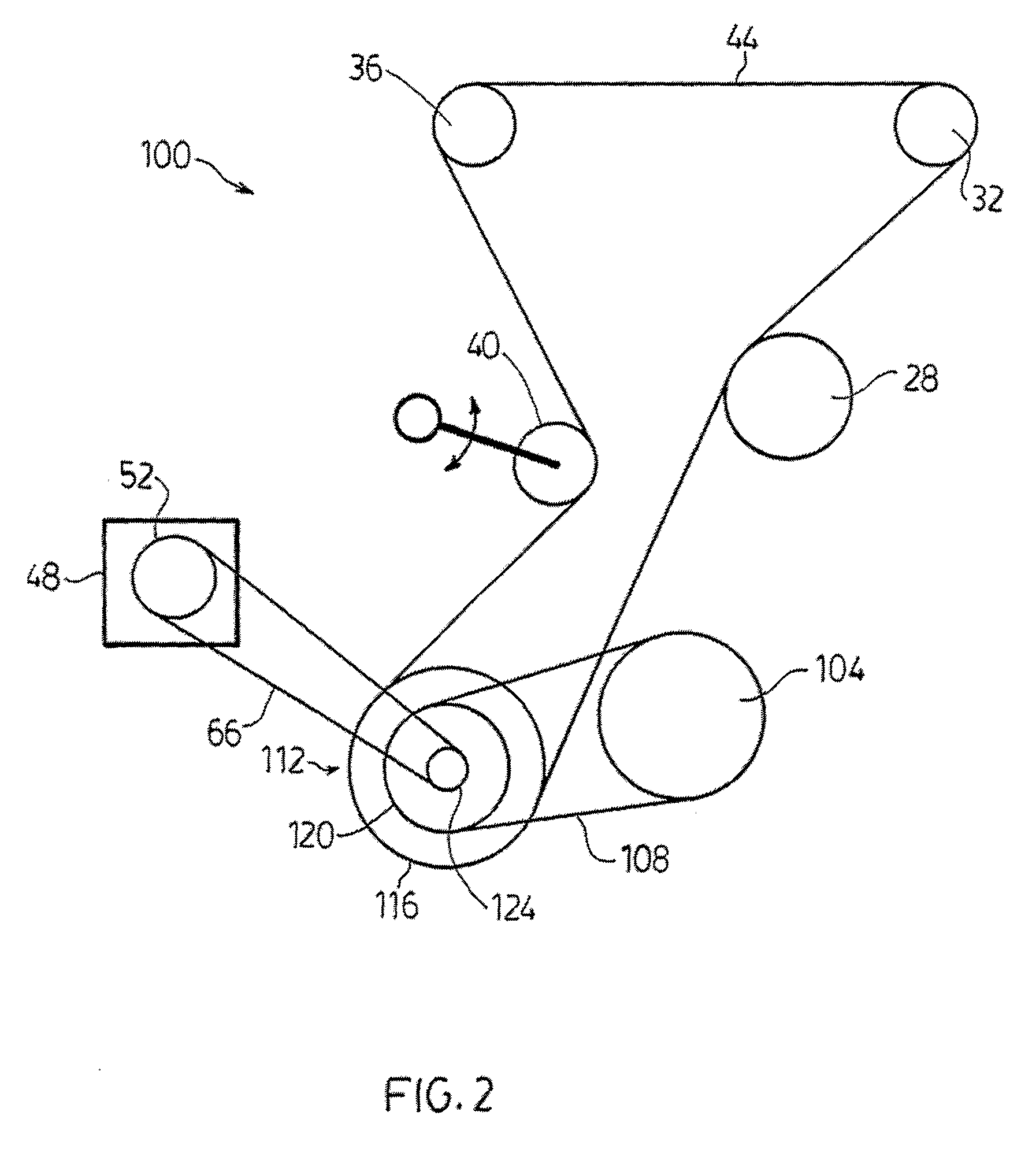

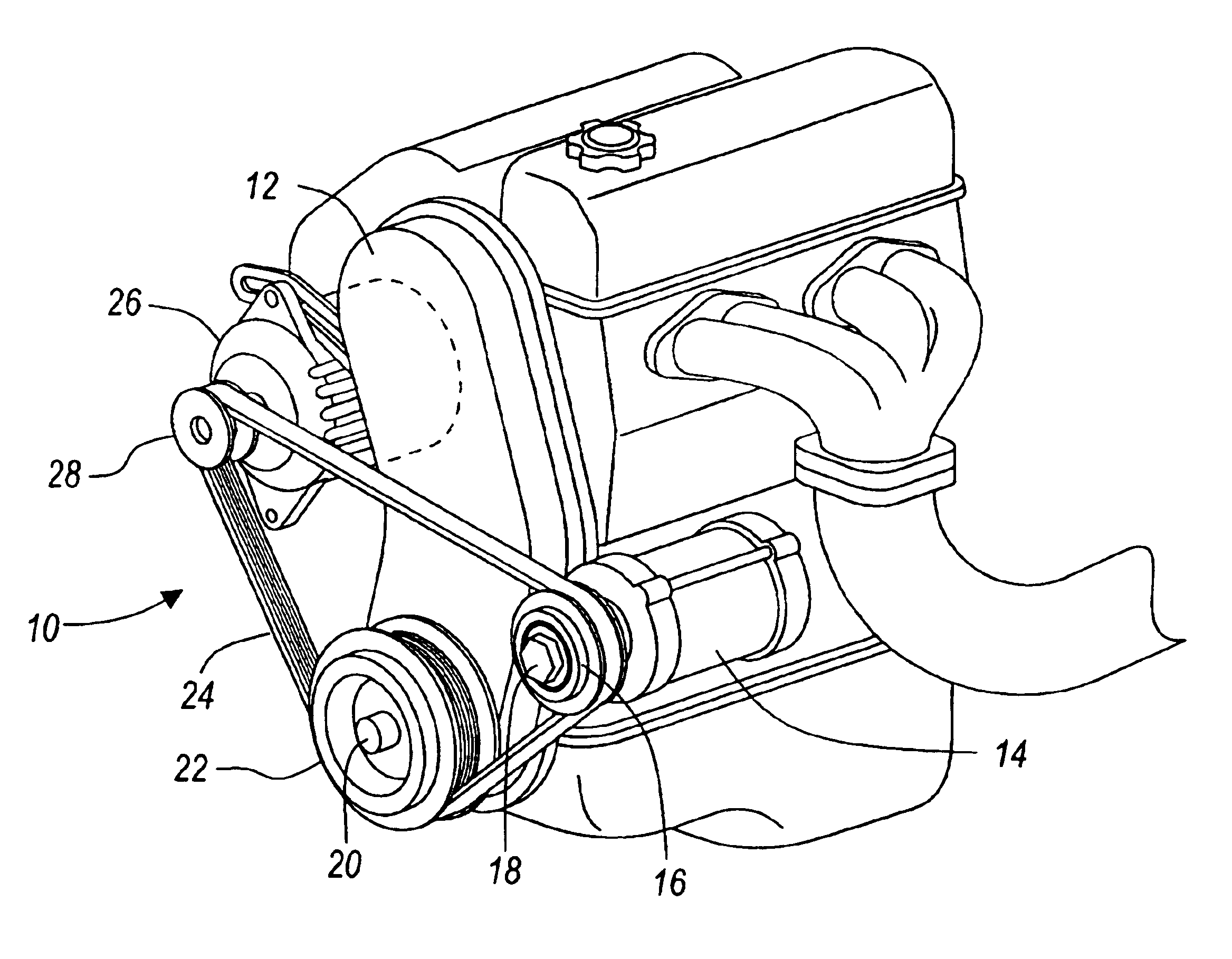

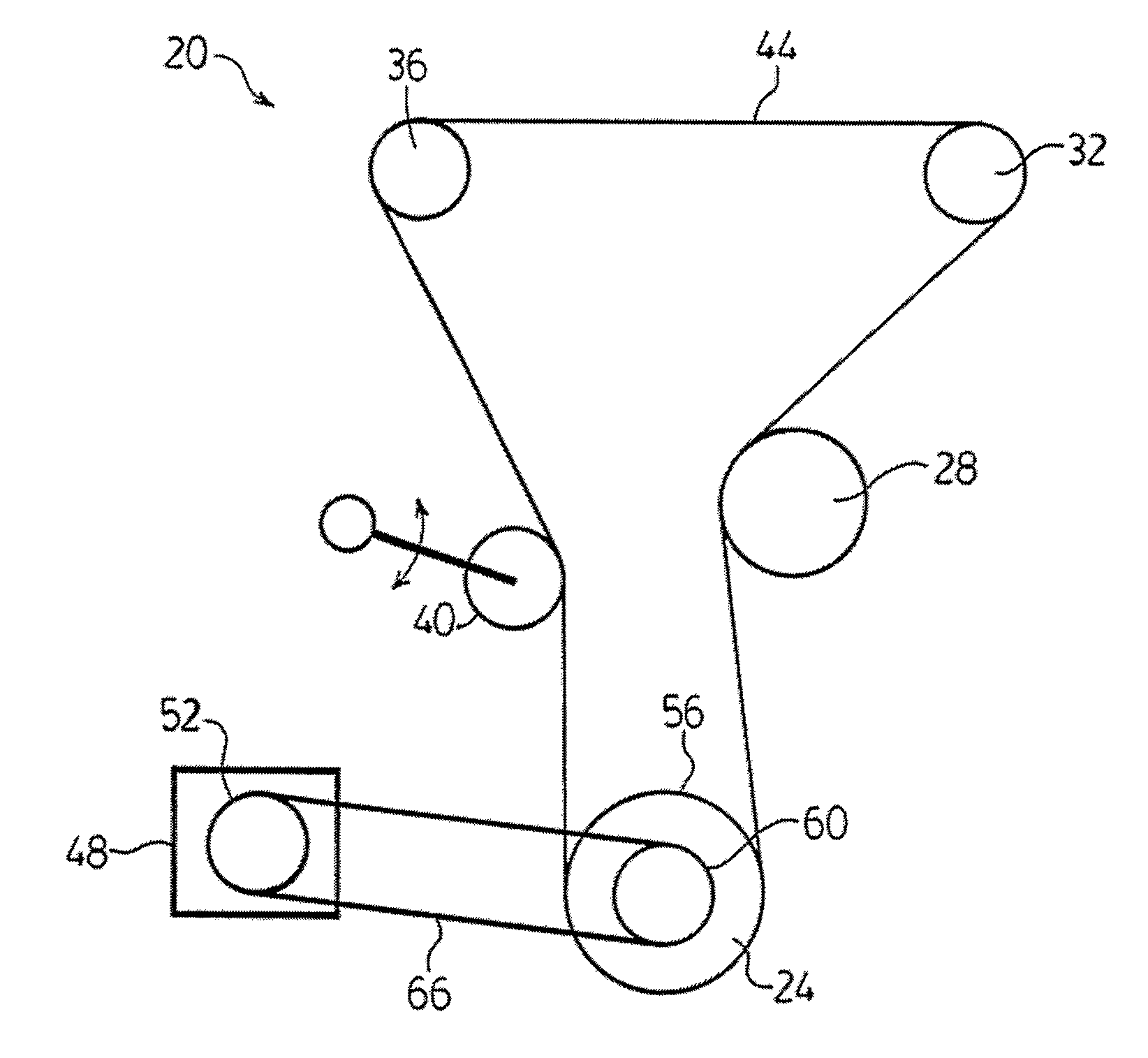

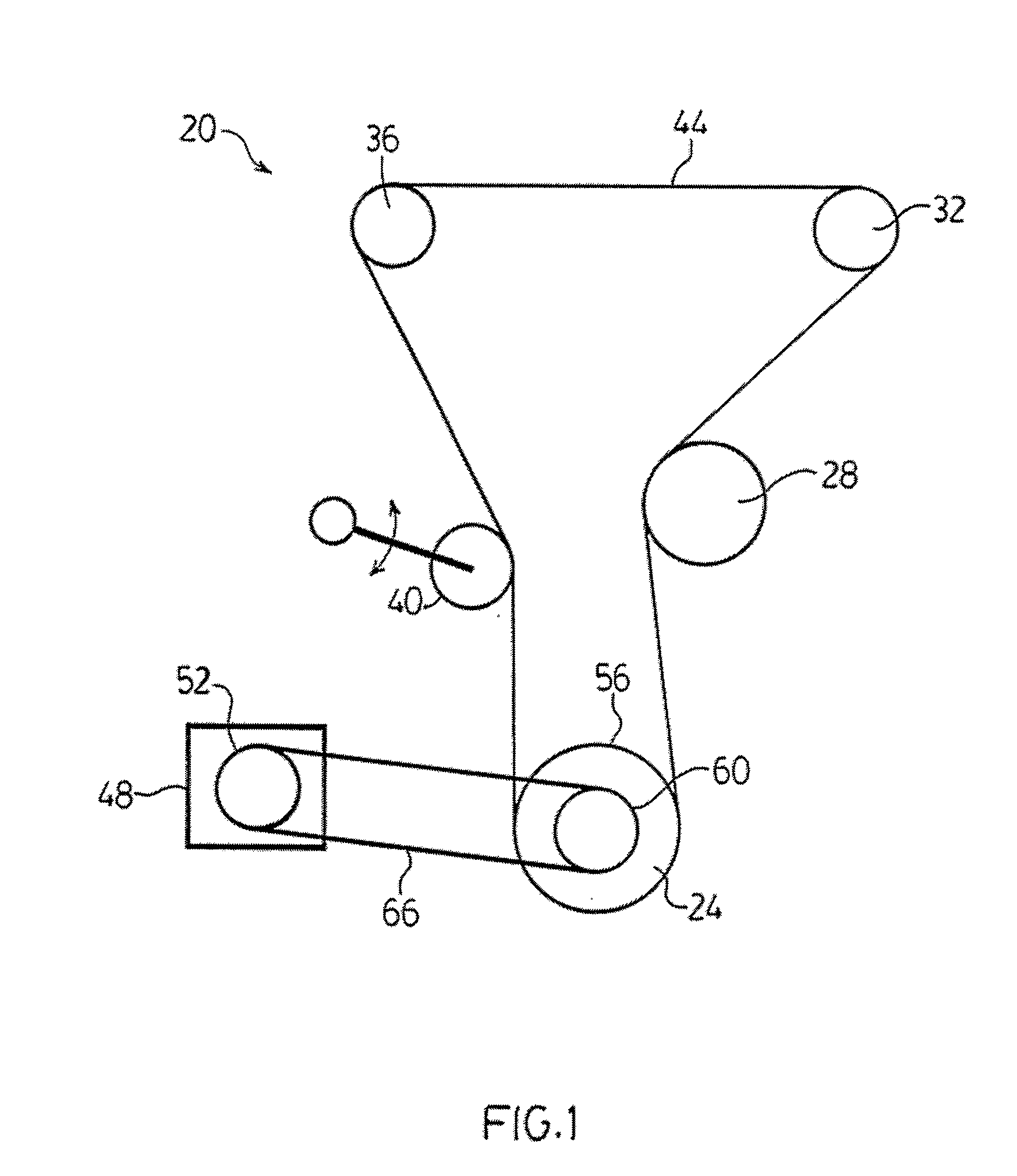

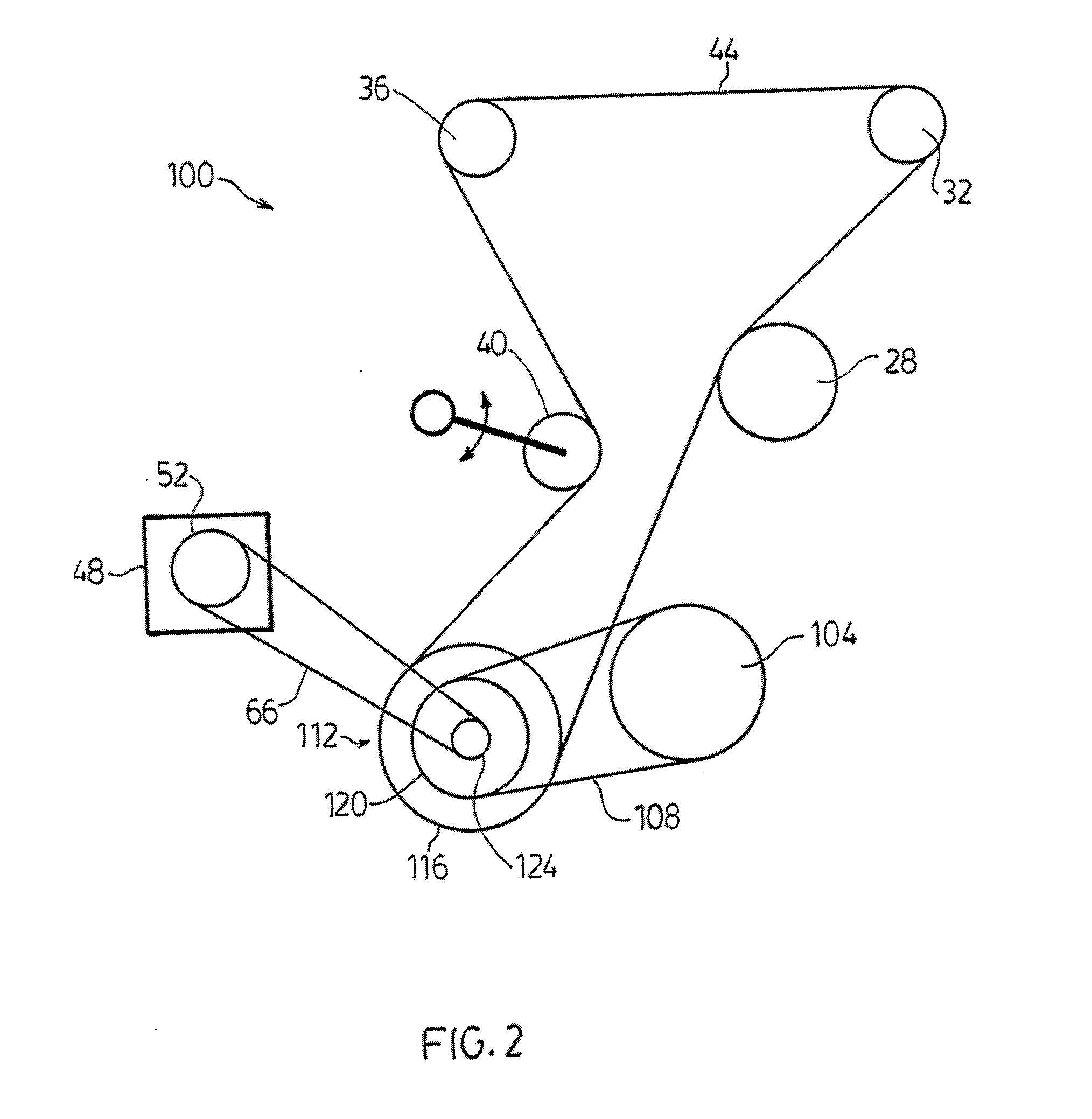

Belt alternator starter accessory drive with dual tensioner

An accessory drive for an engine has a belt driven starter generator adapted for driving and being driven by the engine. In an exemplary embodiment, the drive includes a first engine drive pulley and a second starter drive pulley. A drive belt engages the drive pulleys for driving either pulley from the other. A dual belt tensioner made as a preassembled unit has a carrier with a central pivot mounted to the engine and first and second carrier arms extending radially from the central pivot. A first tensioner mounted on the first arm carries a first tensioner pulley biased against a first belt run adjacent the second drive pulley that is slack during engine starting. A second tensioner pulley carried on the second arm is biased against a second belt run adjacent the second drive pulley that is taut during engine starting A hydraulic strut connected to the second arm, and preferably included in the preassembled unit, provides moderate biasing for the second tensioner pulley during normal engine operation and velocity sensitive resistance, to increased belt forces, that limits reactive movement of the second tensioner pulley during engine starting and transient engine operation.

Owner:GM GLOBAL TECH OPERATIONS LLC

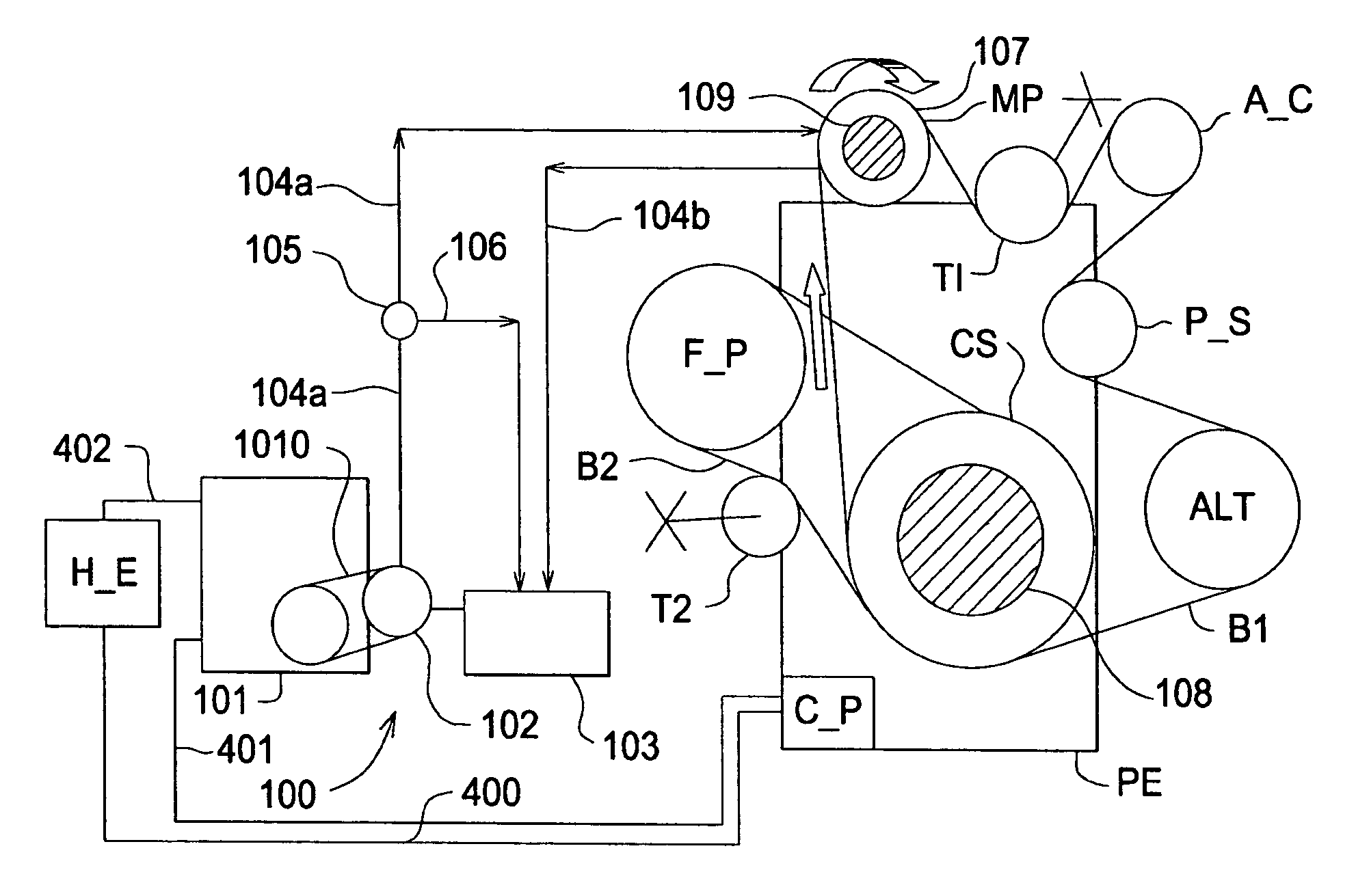

Auxiliary power system for a motor vehicle

An auxiliary power system for a motor vehicle primary engine used to drive primary engine accessories when the primary engine is not operating. The system comprises a secondary engine that drives a hydraulic pump. The hydraulic pump is connected to a hydraulic motor. The hydraulic motor is integrated with an accessory belt drive system on a primary engine. The secondary engine drives the ABDS system through the hydraulic pump and hydraulic motor when the primary engine is not operating, thus allowing various primary engine accessories such as air conditioning to be operated while the primary engine is off. A one-way clutch on the primary engine crankshaft prevents the primary engine crankshaft from being turned when the hydraulic motor is driving the belt. A one-way clutch on the hydraulic motor prevents it from being driven when the primary engine is in operation.

Owner:THE GATES CORP

Belt alternator starter accessory drive with dual tensioner

An accessory drive for an engine has a belt driven starter generator adapted for driving and being driven by the engine. In an exemplary embodiment, the drive includes a first engine drive pulley and a second starter drive pulley. A drive belt engages the drive pulleys for driving either pulley from the other. A dual belt tensioner made as a preassembled unit has a carrier with a central pivot mounted to the engine and first and second carrier arms extending radially from the central pivot. A first tensioner mounted on the first arm carries a first tensioner pulley biased against a first belt run adjacent the second drive pulley that is slack during engine starting. A second tensioner pulley carried on the second arm is biased against a second belt run adjacent the second drive pulley that is taut during engine starting A hydraulic strut connected to the second arm, and preferably included in the preassembled unit, provides moderate biasing for the second tensioner pulley during normal engine operation and velocity sensitive resistance, to increased belt forces, that limits reactive movement of the second tensioner pulley during engine starting and transient engine operation.

Owner:GM GLOBAL TECH OPERATIONS LLC

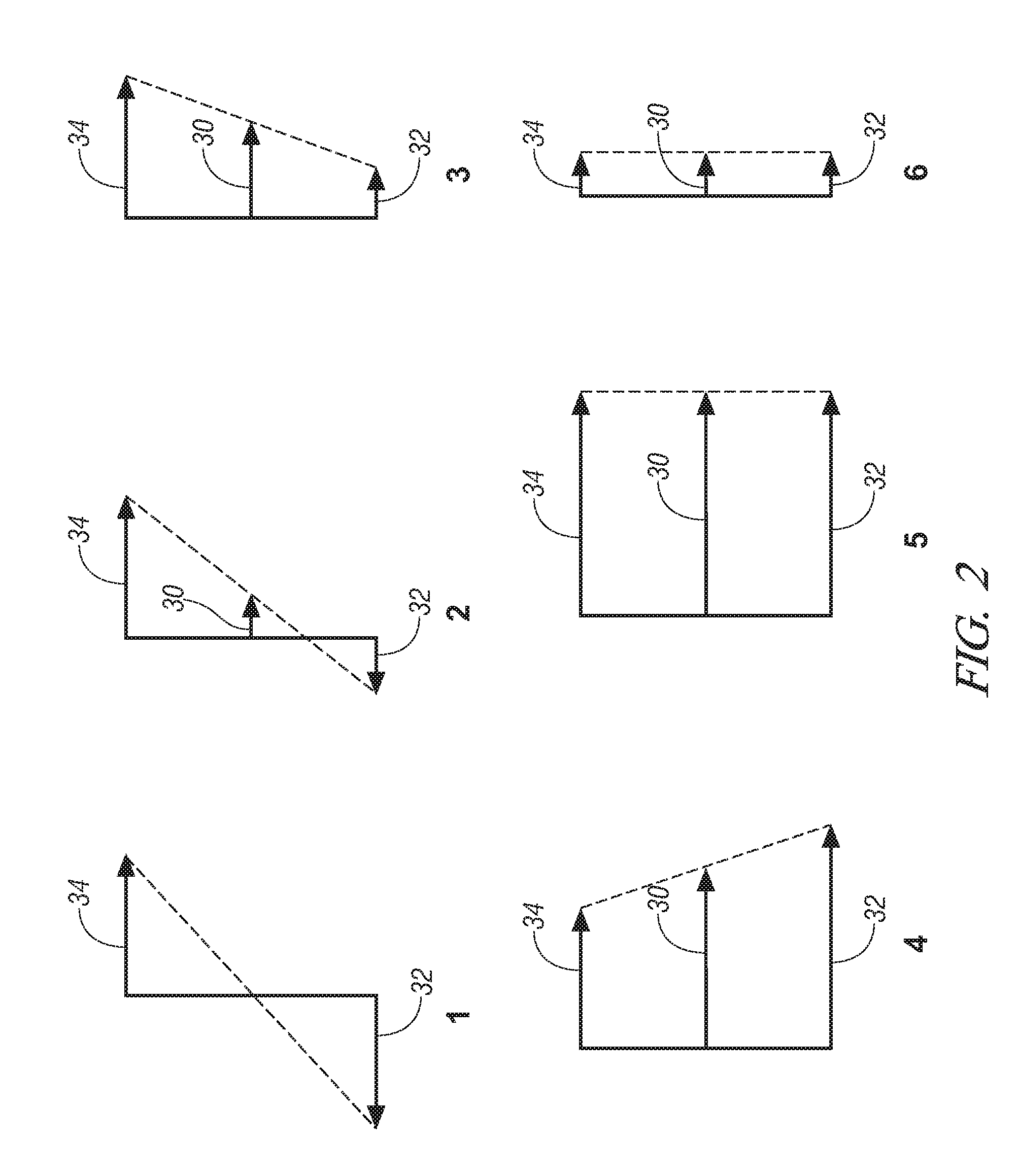

Transmission and constant speed accessory drive

A method of operating a belt drive accessory system comprising the steps of transmitting a torque with a first endless member from a driver member to a planetary ball transmission input, coaxially aligning the planetary ball transmission input with a planetary ball transmission output, transmitting a torque by a second endless member from the planetary ball transmission output to a driven accessory, selecting a speed ratio of the planetary ball transmission according to a driver member rotational speed, thereby operating the driven accessory at a substantially constant speed at a point of substantially maximum efficiency over a drive member rotational speed range, and frictionally locking the speed ratio of the planetary ball transmission when a drive member speed is constant.

Owner:THE GATES CORP

Transmission and constant speed accessory drive

InactiveUS20050181905A1Constant output speedGearing controlFriction clutchesControl systemDirect coupling

An infinitely variable speed ratio planetary ball transmission comprising planetary members in rolling contact with moveable inner and outer races and a constant speed accessory drive system utilizing the transmission. The transmission is infinitely variable between ratios of approximately 0.3 and 1.0. A transmission input shaft is connected to a prime mover such as a vehicle engine crankshaft by a drive belt. The transmission comprises at least one output shaft that is coaxial with the input shaft. An output pulley is attached to the output shaft. A belt is engaged between the output pulley and various engine accessories. A second end of the transmission output shaft may be directly coupled to an engine accessory mounted on the transmission. An included control system senses a crankshaft speed. A processor analyses the crankshaft speed and accordingly adjusts the transmission ratio using a stepper motor connected to a worm drive to maintain a constant output speed regardless of crankshaft speed.

Owner:THE GATES CORP

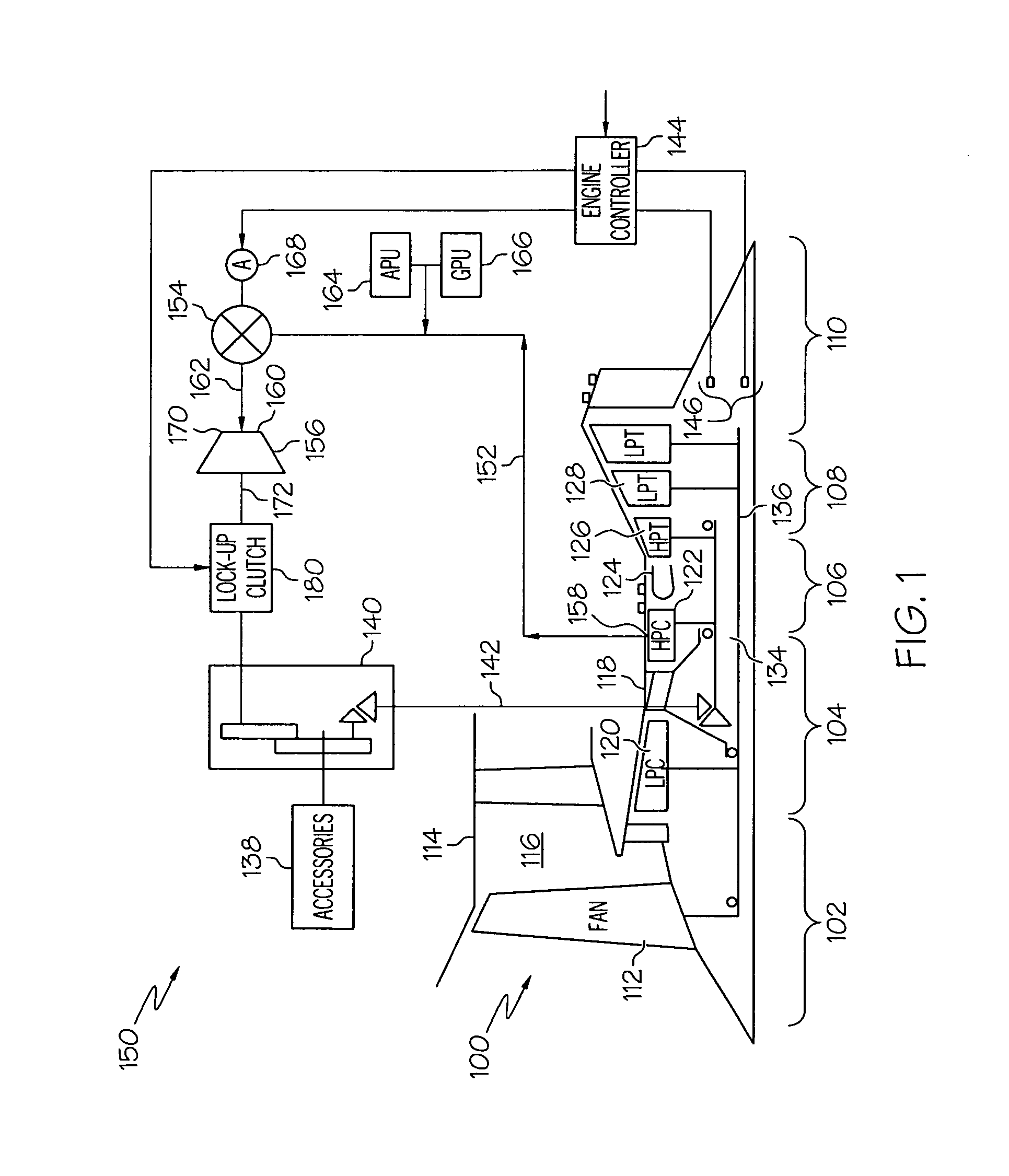

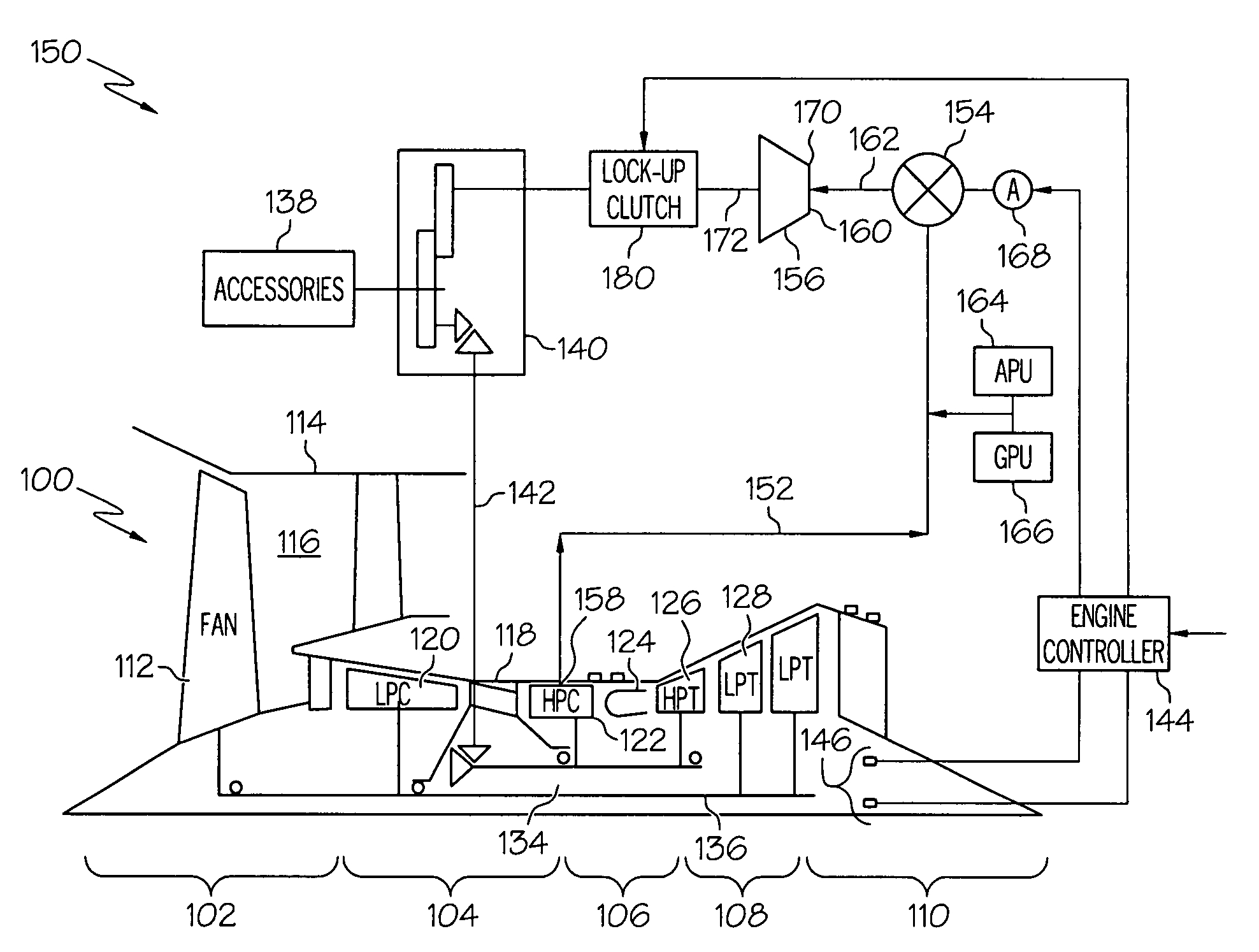

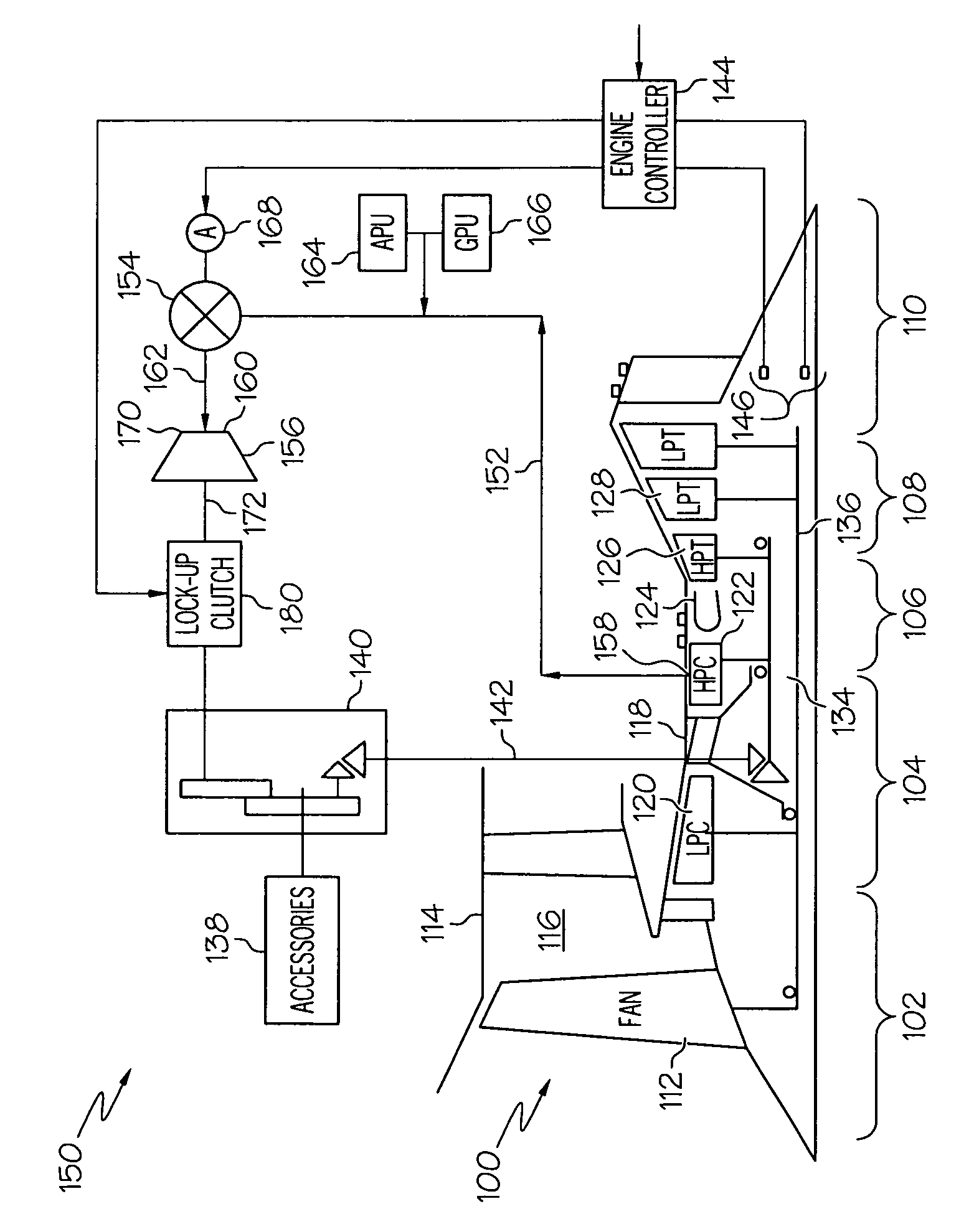

Turbine drive system with lock-up clutch and method

InactiveUS20090288421A1Turbine/propulsion fuel supply systemsTurbine/propulsion engine ignitionLow speedBleed air

A pneumatically driven turbine drive system is coupled to a gas turbine engine that includes low and high pressure compressors, low and high pressure turbines, a lock-up clutch, and at least one engine accessory driven by the high pressure compressor. The pneumatically driven turbine drive system selectively bleeds air discharged from the high pressure compressor and supplies it to an air turbine that is coupled to the at least one engine accessory. Thus, the system selectively reduces the power extracted from the high pressure compressor and is capable of supplying power back to the engine core. This, coupled with the bleed air that is diverted from the high pressure turbine and the low pressure turbine, allows the high pressure spool and the low pressure spool to run at lower speeds when high engine thrust is not needed or desired, but when the at least one engine accessory is still needed.

Owner:HONEYWELL INT INC

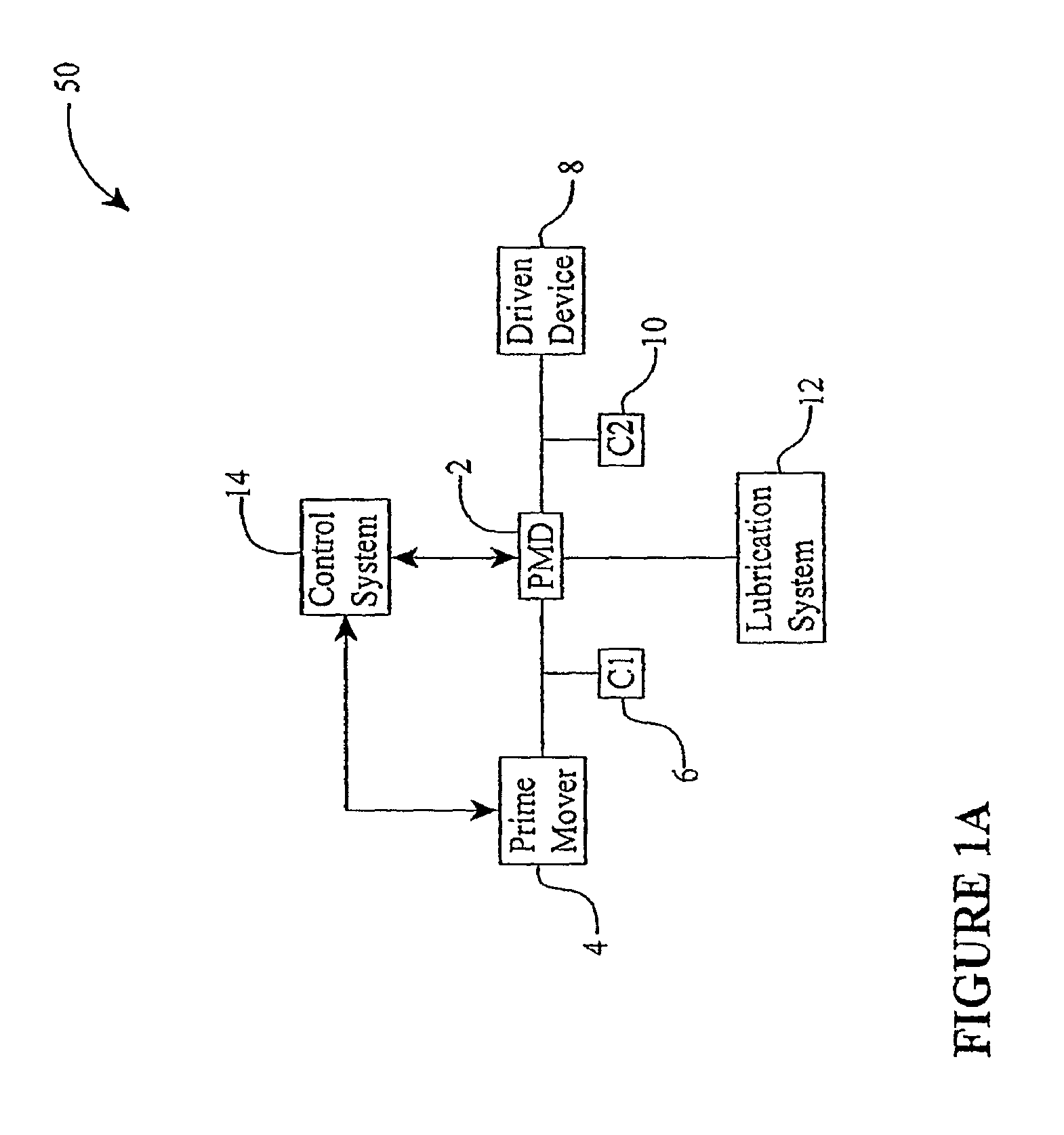

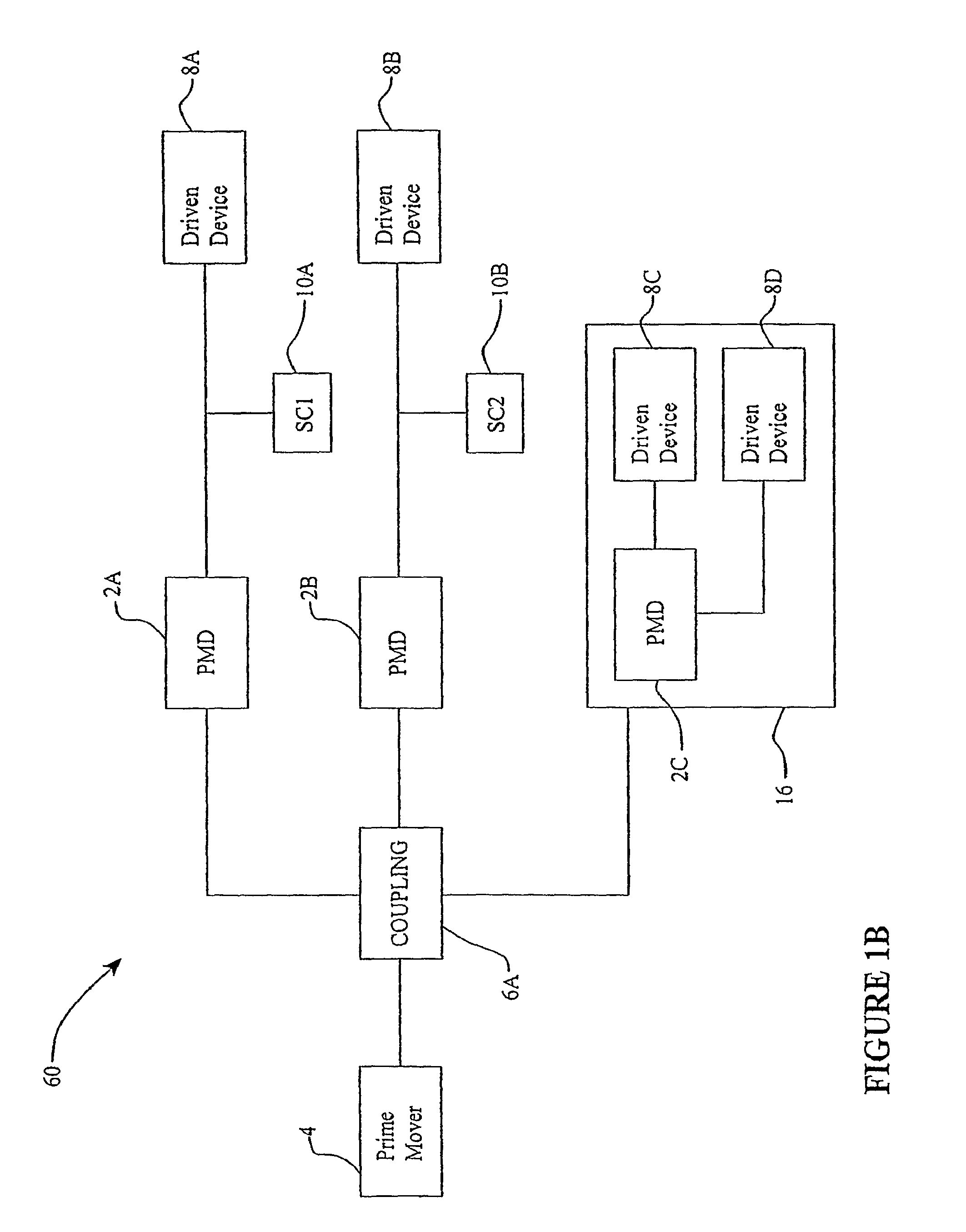

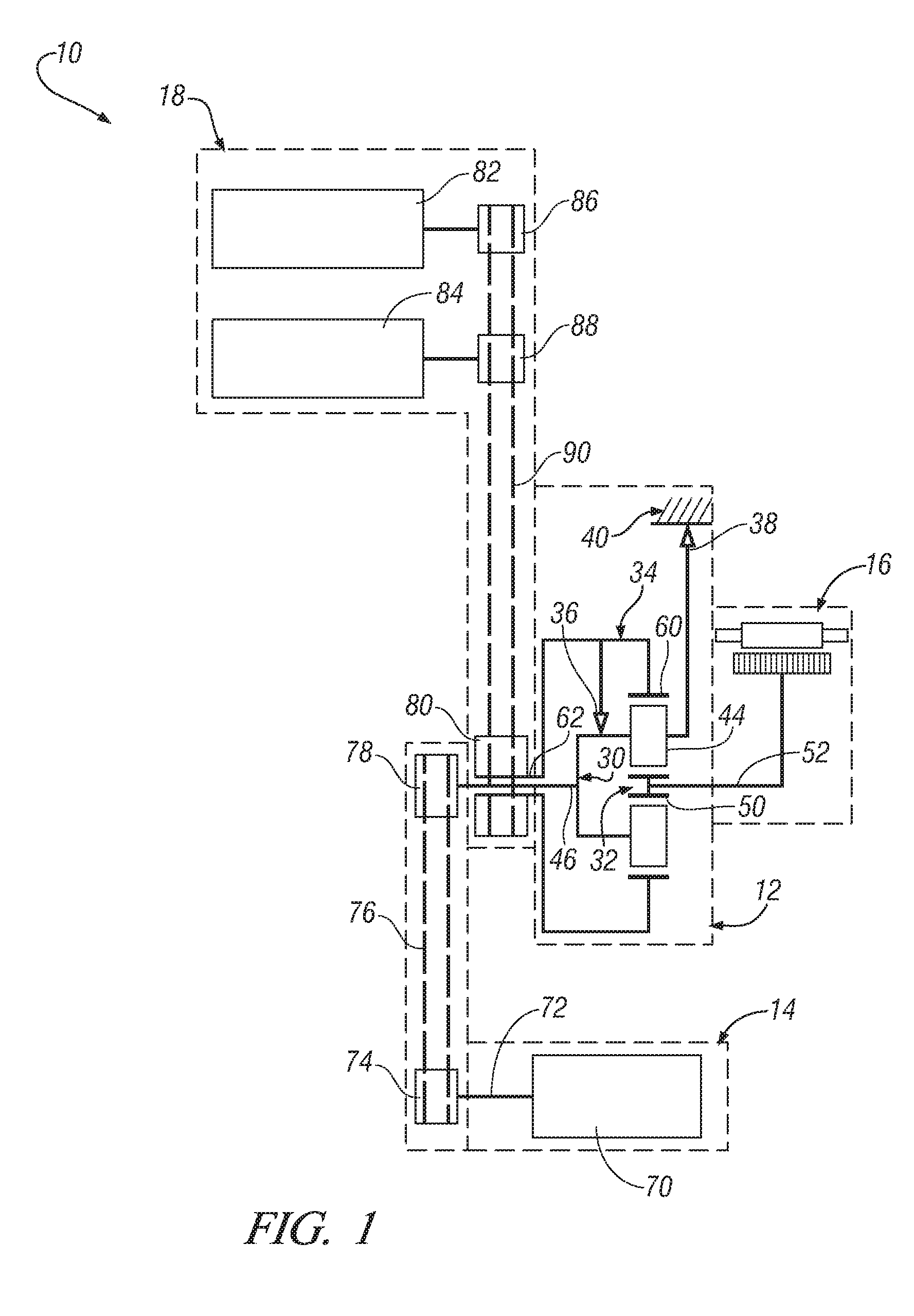

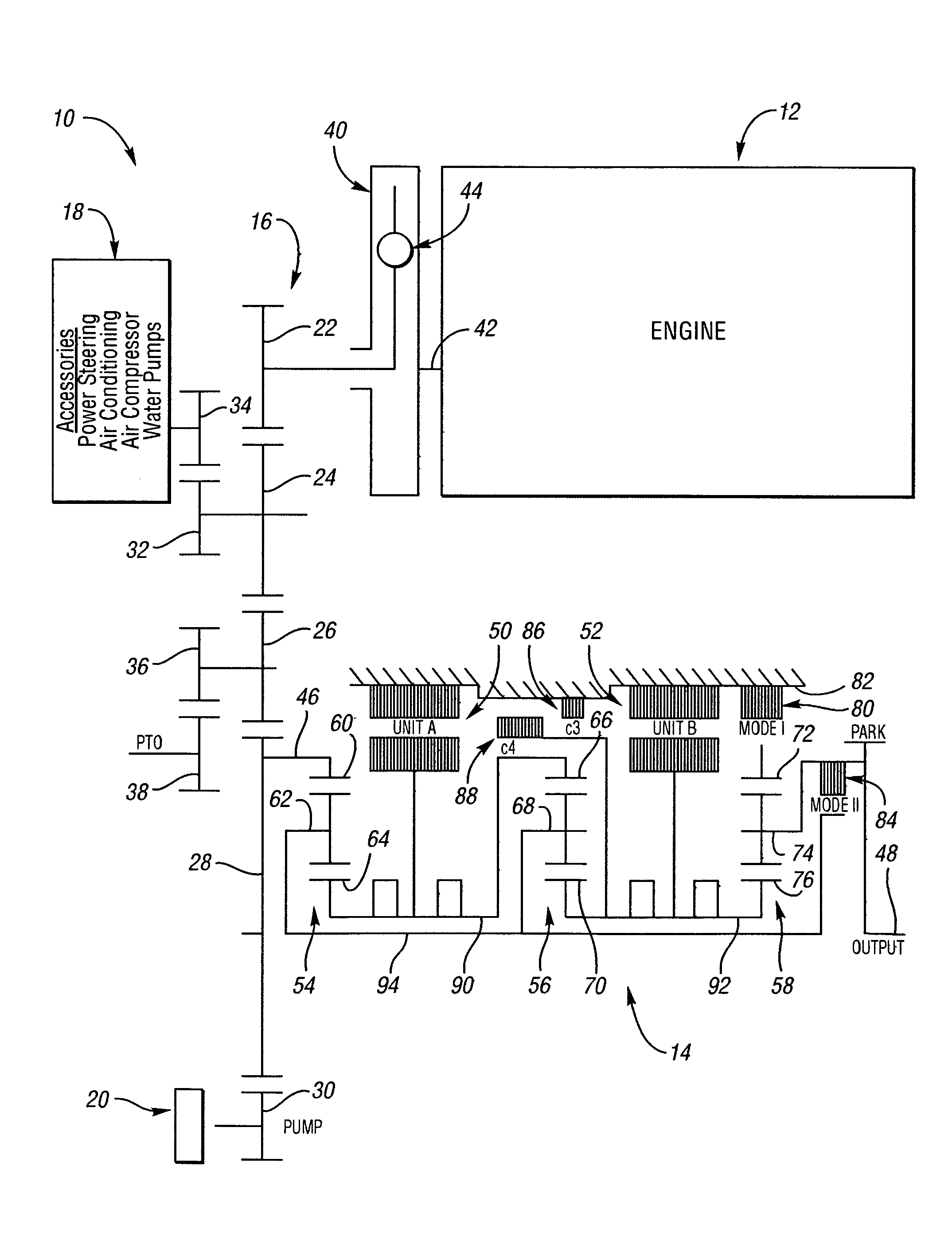

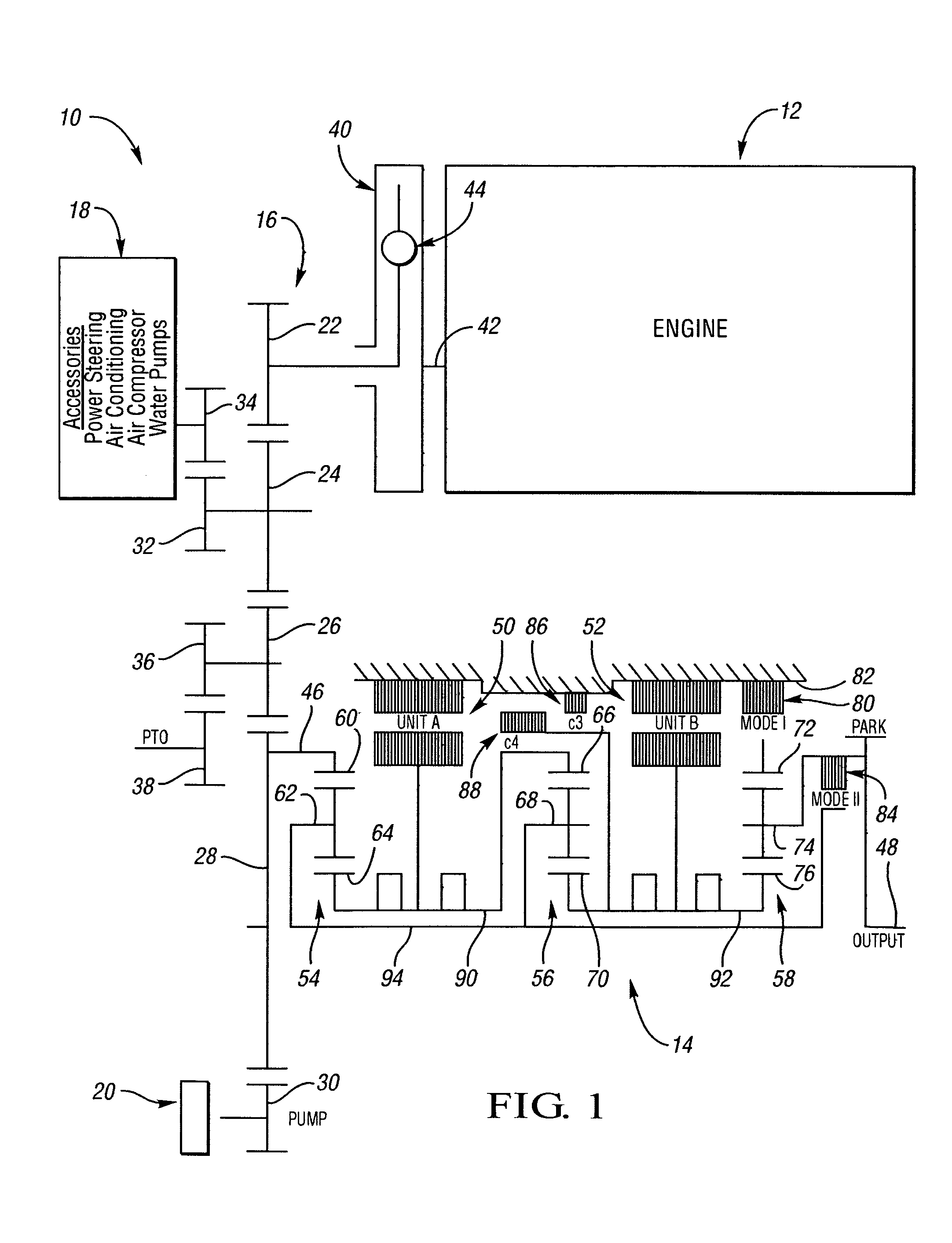

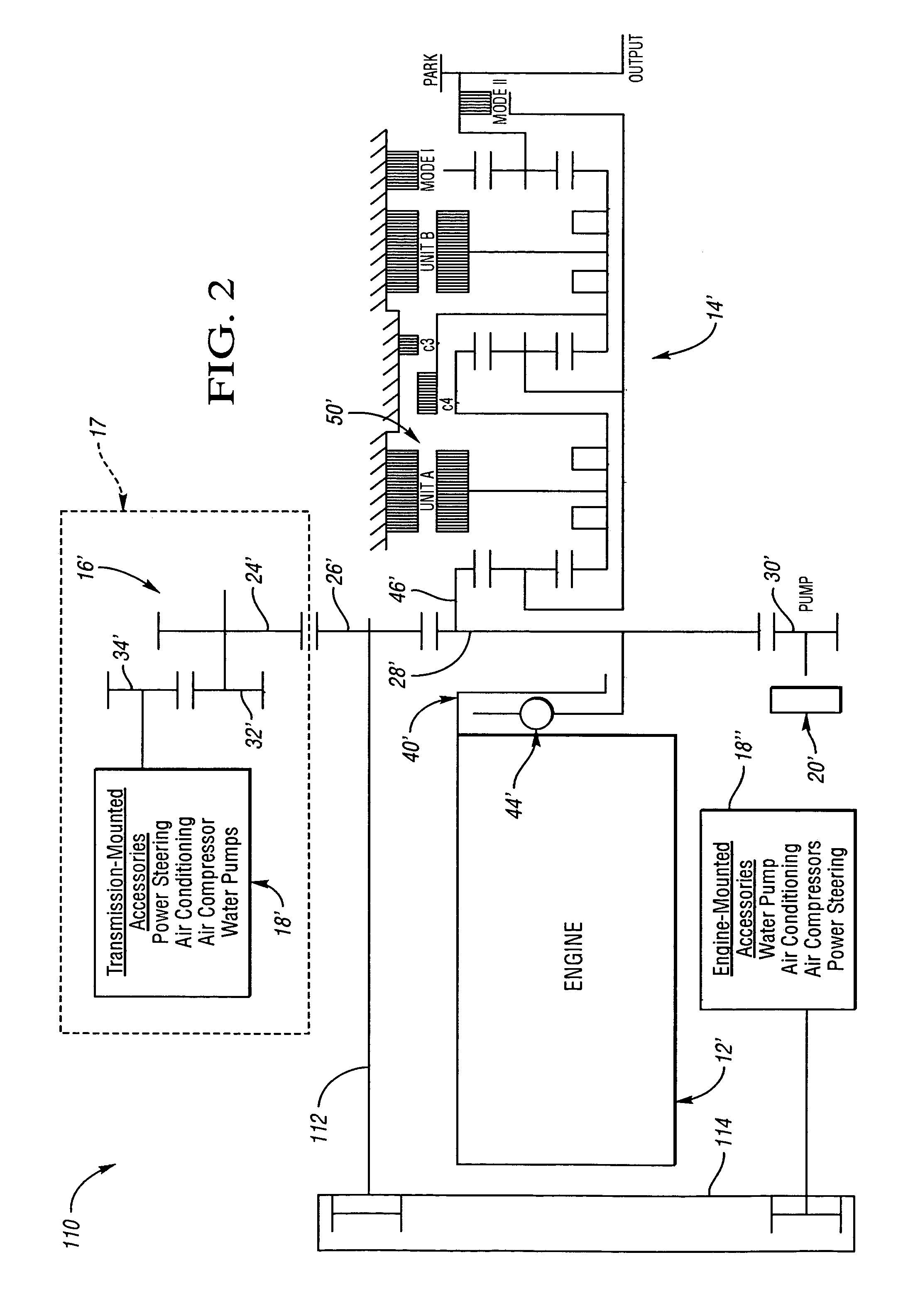

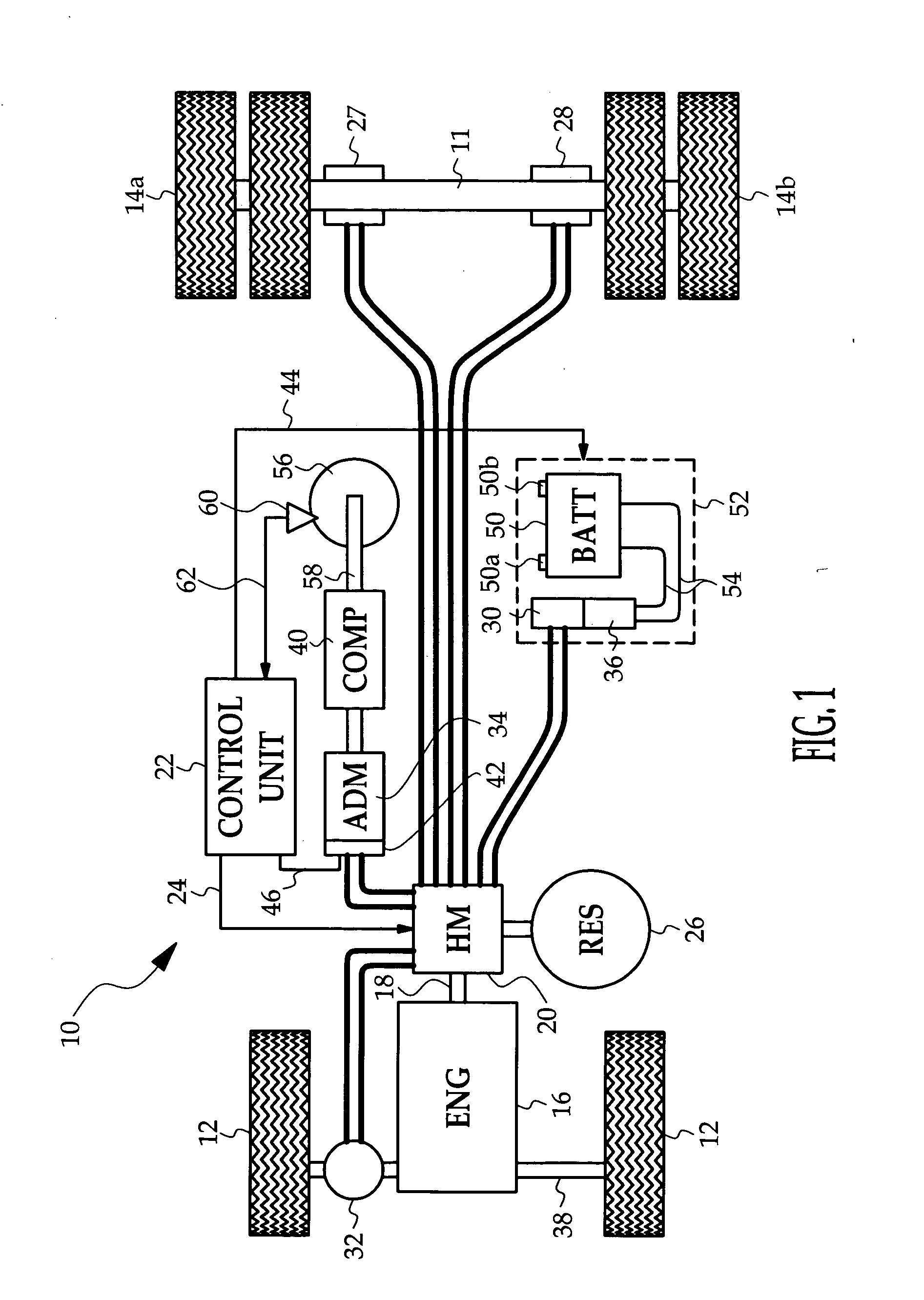

Vehicle drive system, power management device, and method for managing power

InactiveUS7753147B2Auxillary drivesDigital data processing detailsDistribution power systemEngineering

A power distribution system for a hybrid vehicle having an engine is disclosed. The power distribution system includes an electric motor / generator, a vehicle accessory drive system comprising a first accessory, and a power distribution apparatus. The power distribution apparatus includes a first power transfer member comprising a first shaft, the first shaft being configured to transfer power to the engine and from the engine. The power distribution apparatus further includes a second power transfer member comprising a second shaft, the second shaft being configured to transfer power to the motor / generator and from the motor / generator. The power distribution apparatus further includes a third power transfer member comprising a third shaft, the third shaft being configured to transfer power to the accessory drive system to drive the first accessory. The power distribution apparatus further includes a first clutch and a second clutch.

Owner:GM GLOBAL TECH OPERATIONS LLC

Engine powered device having accessory drive and reversing motor for selectively starting engine and powering accessory drive

A device having an engine, a motor / generator and an accessory system having an accessory that is driven by rotary power. The device can be operated in a first mode in which the engine provides rotary power for driving the accessory and the motor / generator. The device can be operated in a second mode for starting the engine and driving the accessory in which rotary power is output from the motor / starter in a first rotational direction. The device can also be operated in a third mode in which the motor / generator outputs rotary power in a second, opposite rotational direction for driving the accessory while the engine is not operating. A method for operating the device is also provided.

Owner:LITENS AUTOMOTIVE INC

Auxiliary power unit having a continuously variable transmission

InactiveUS8845485B2Minimize consumptionMinimum fuel consumption valueAuxillary drivesAir-treating devicesCombustionControl system

Inventive embodiments are directed to components, subassemblies, systems, and / or methods for auxiliary power units (APU). In one embodiment, the APU includes a source of rotational power such as a combustion engine operably coupled to a continuously variable transmission (CVT). The CVT can be coupled to a load. In some embodiments, the load is provided by a generator. In one embodiment, the APU has a control system configured to control the operation of the engine and the operation of the CVT. The control system can facilitate substantially constant speed operation of the generator in the presence of variable operation of the engine. In another embodiment, the APU includes a continuously variable accessory drive (CVAD) operably coupled to an engine. The CVAD can include a continuously variable transmission operably coupled to a generator. In one embodiment, a skew-based control system is adapted to facilitate a change in the ratio of a CVAD.

Owner:FALLBROOK INTPROP COMPANY

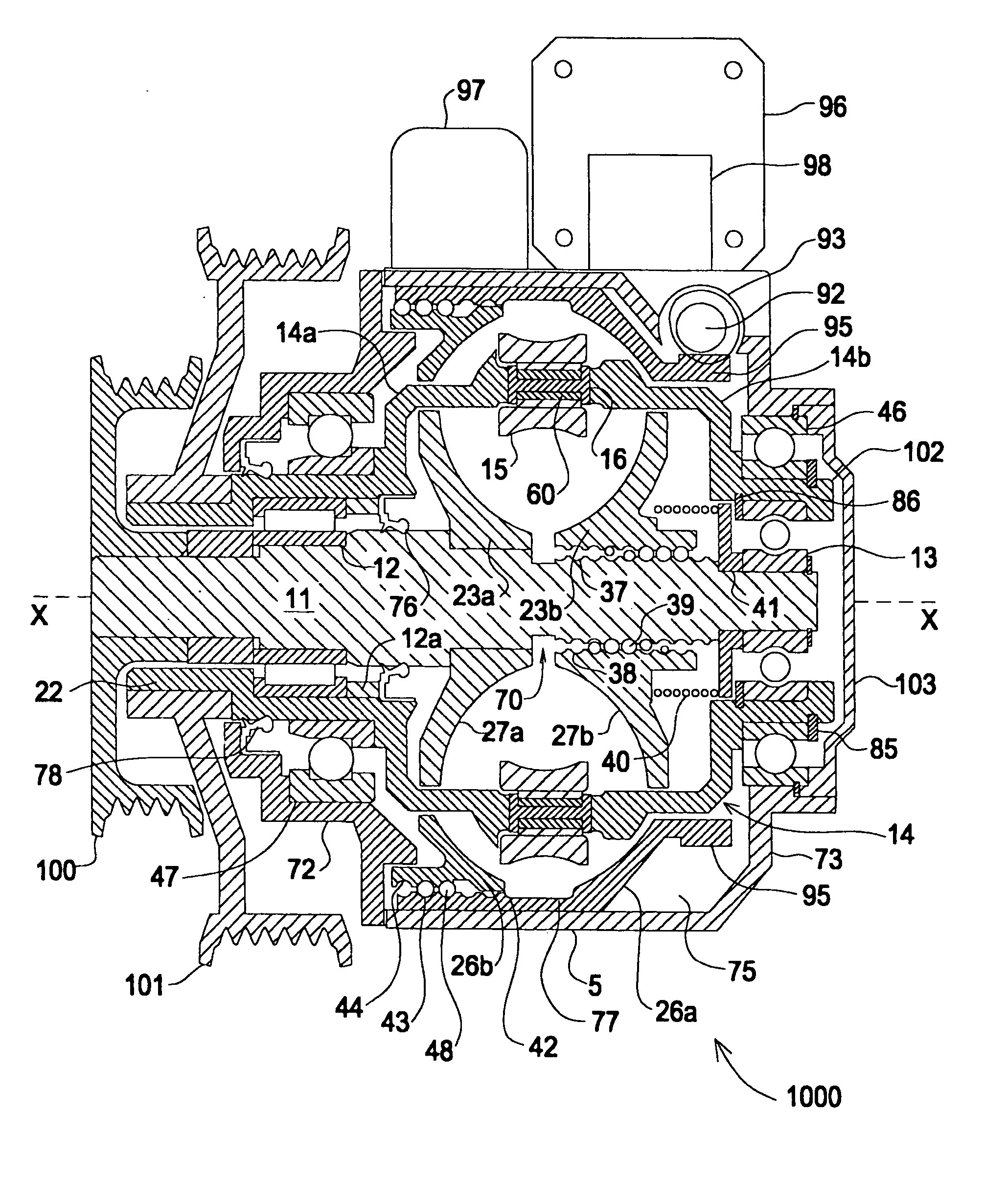

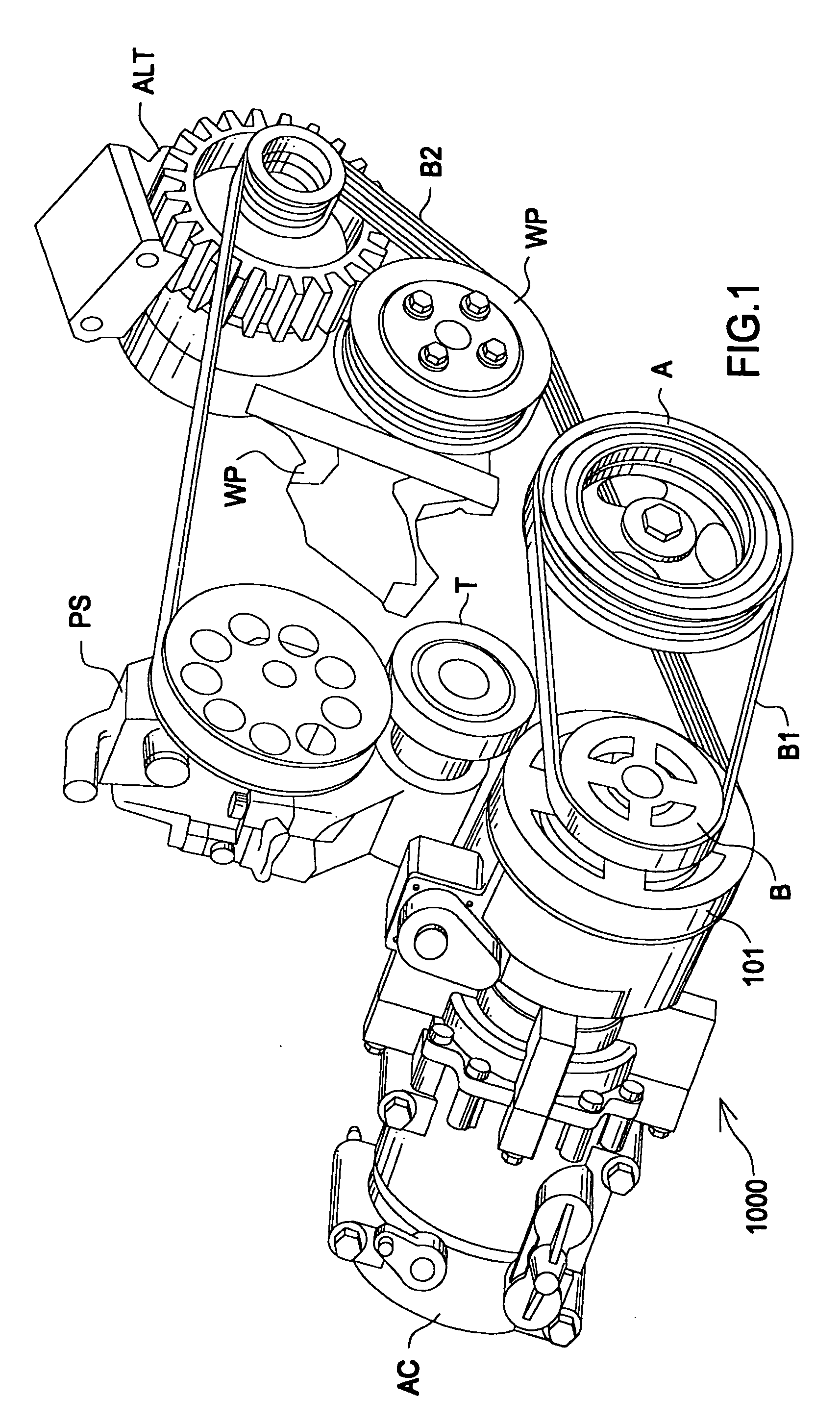

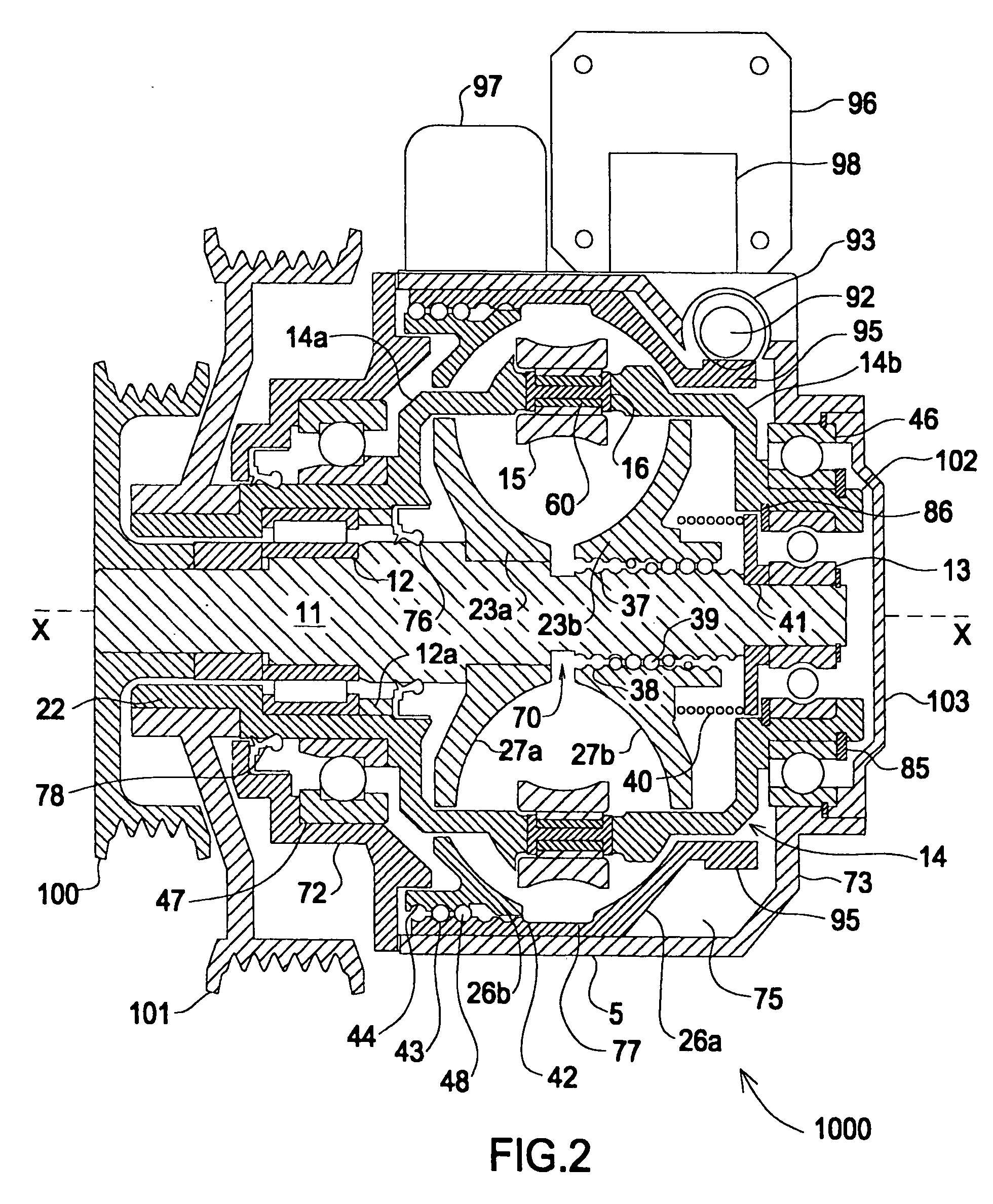

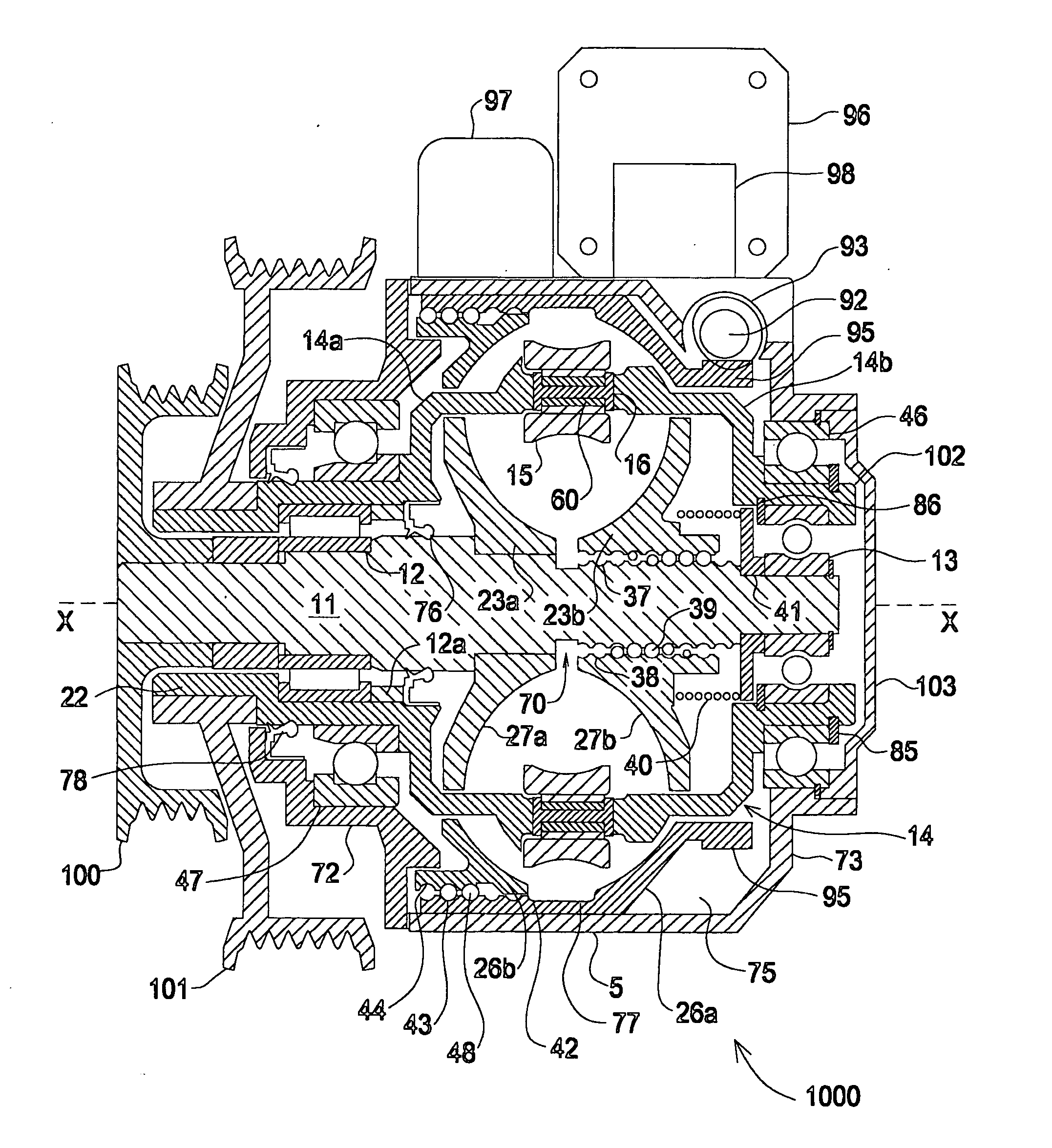

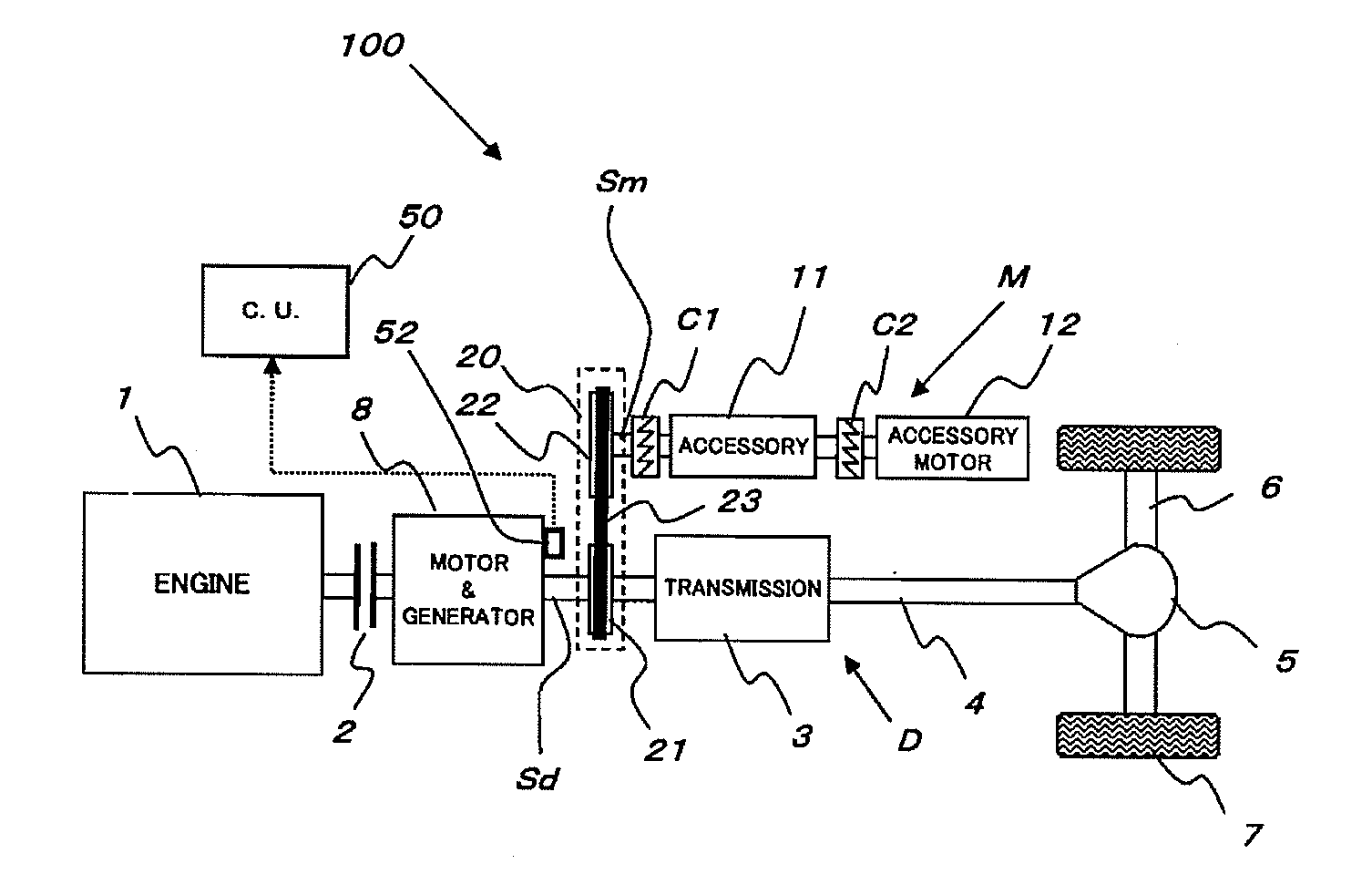

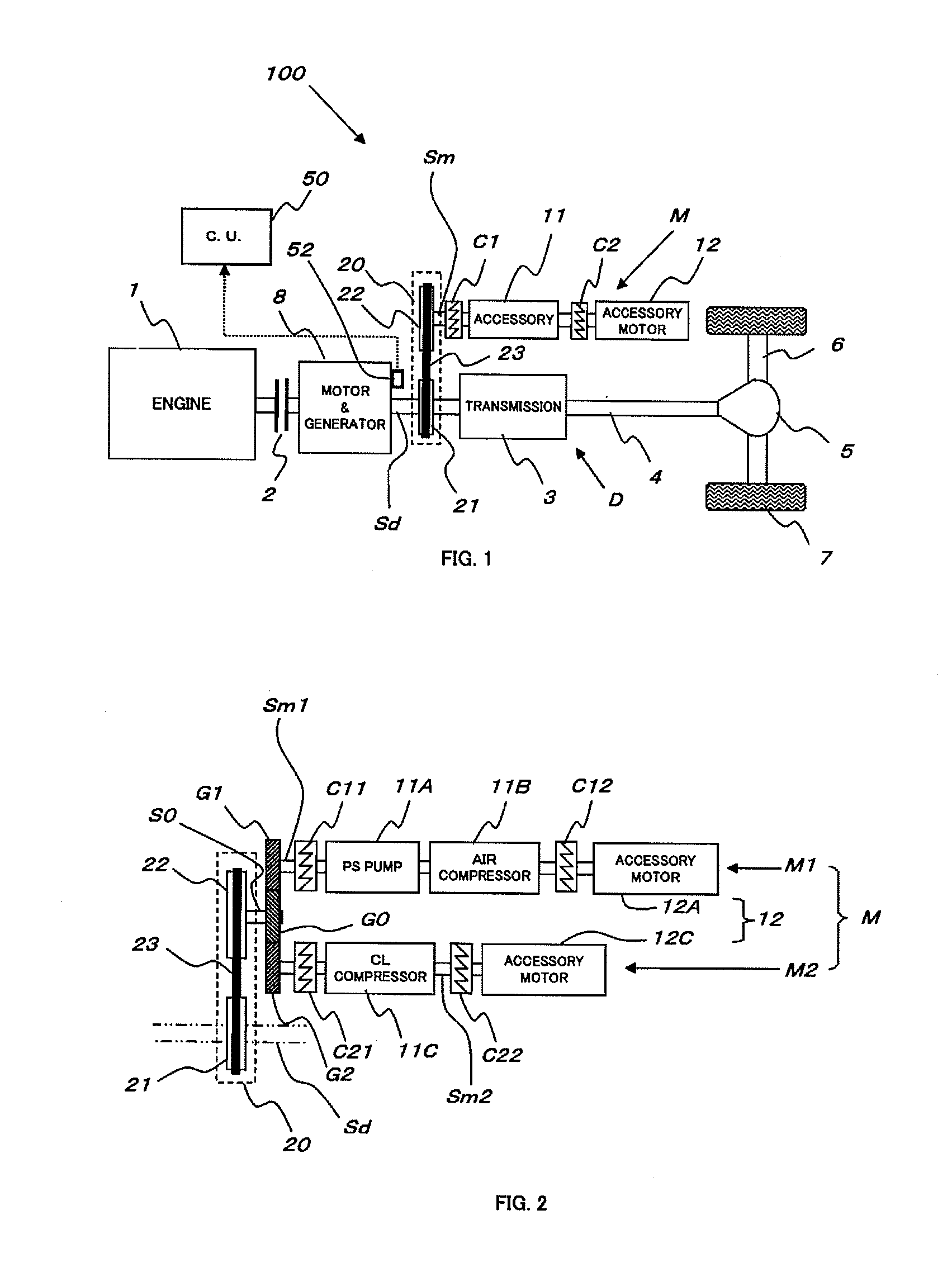

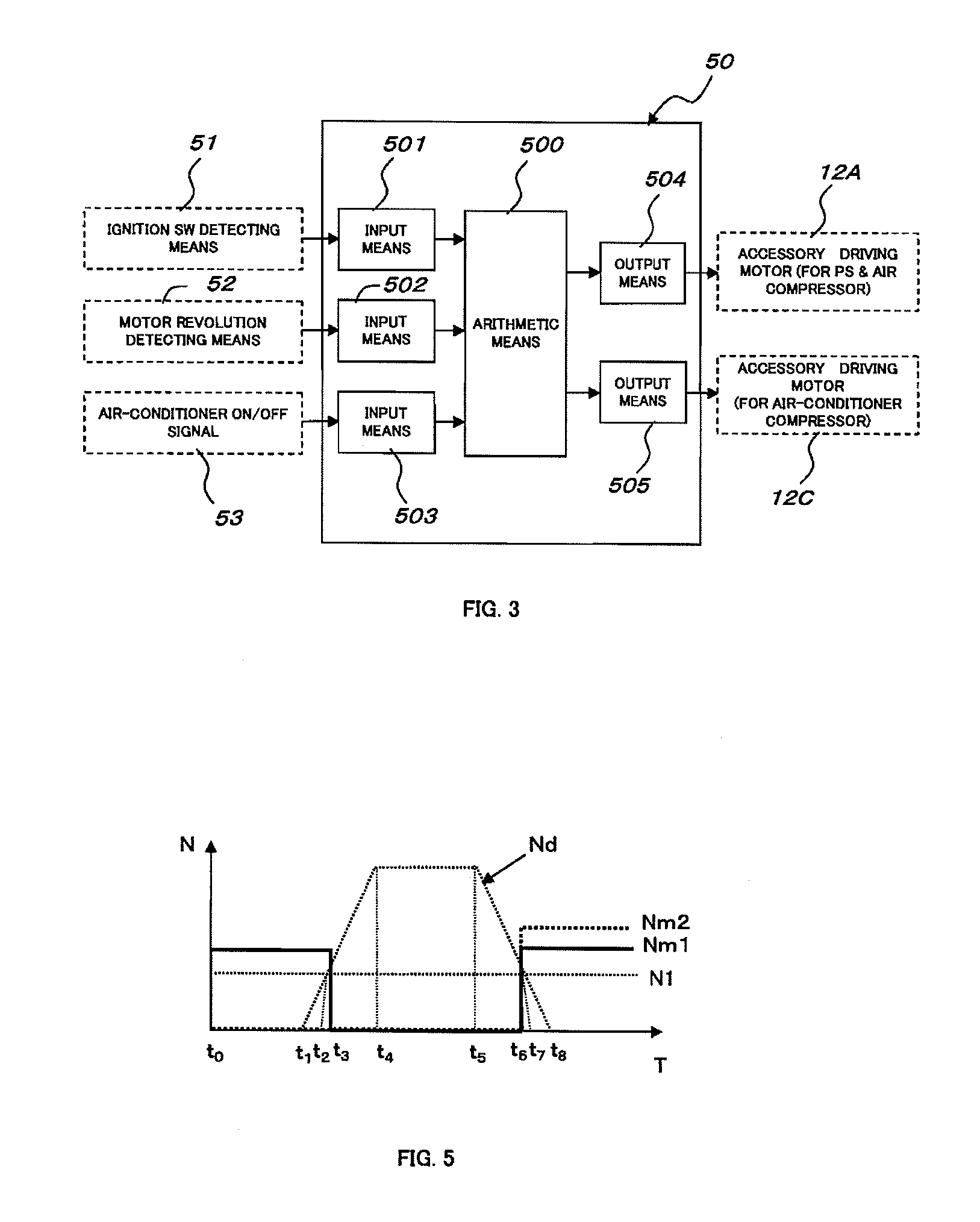

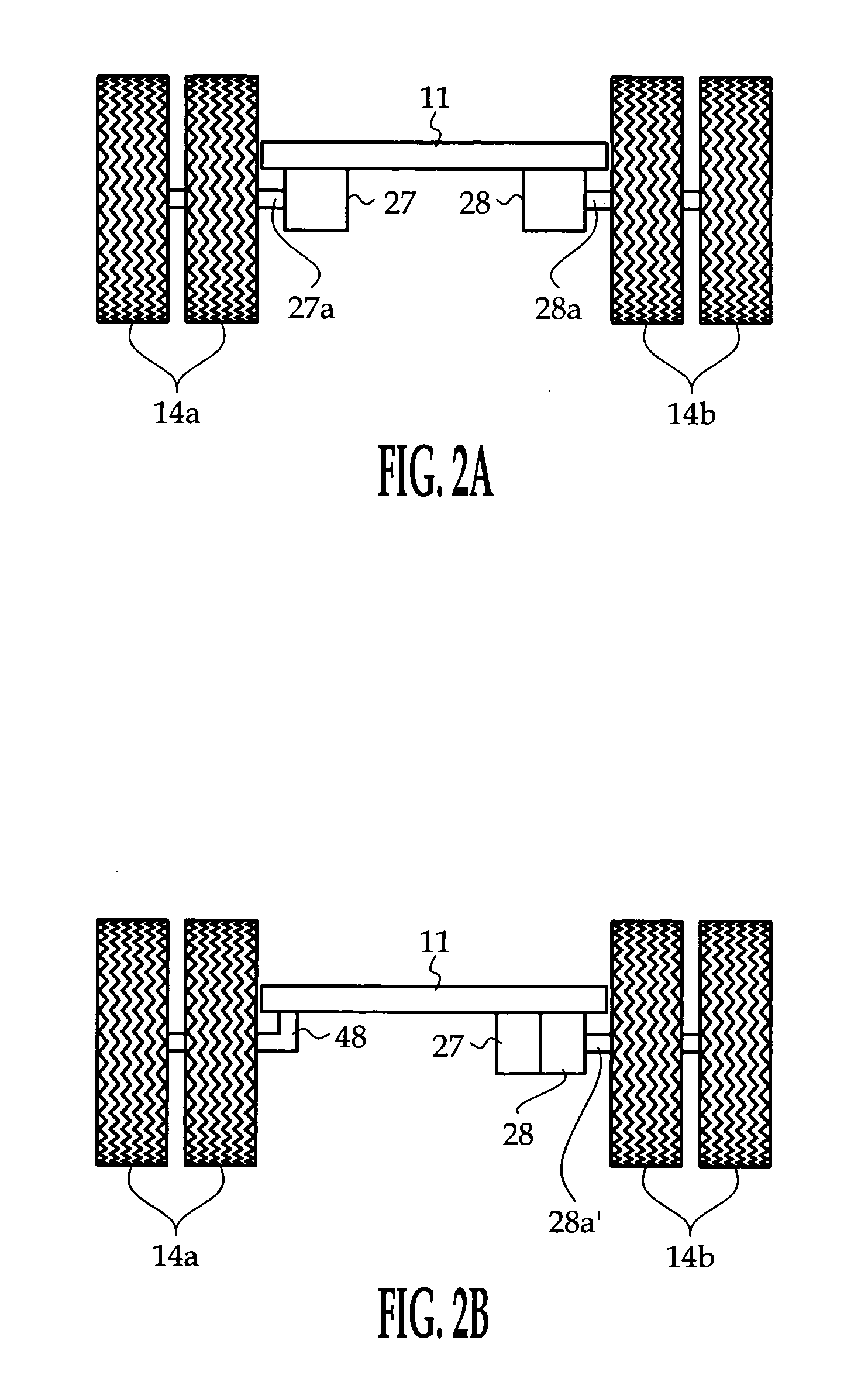

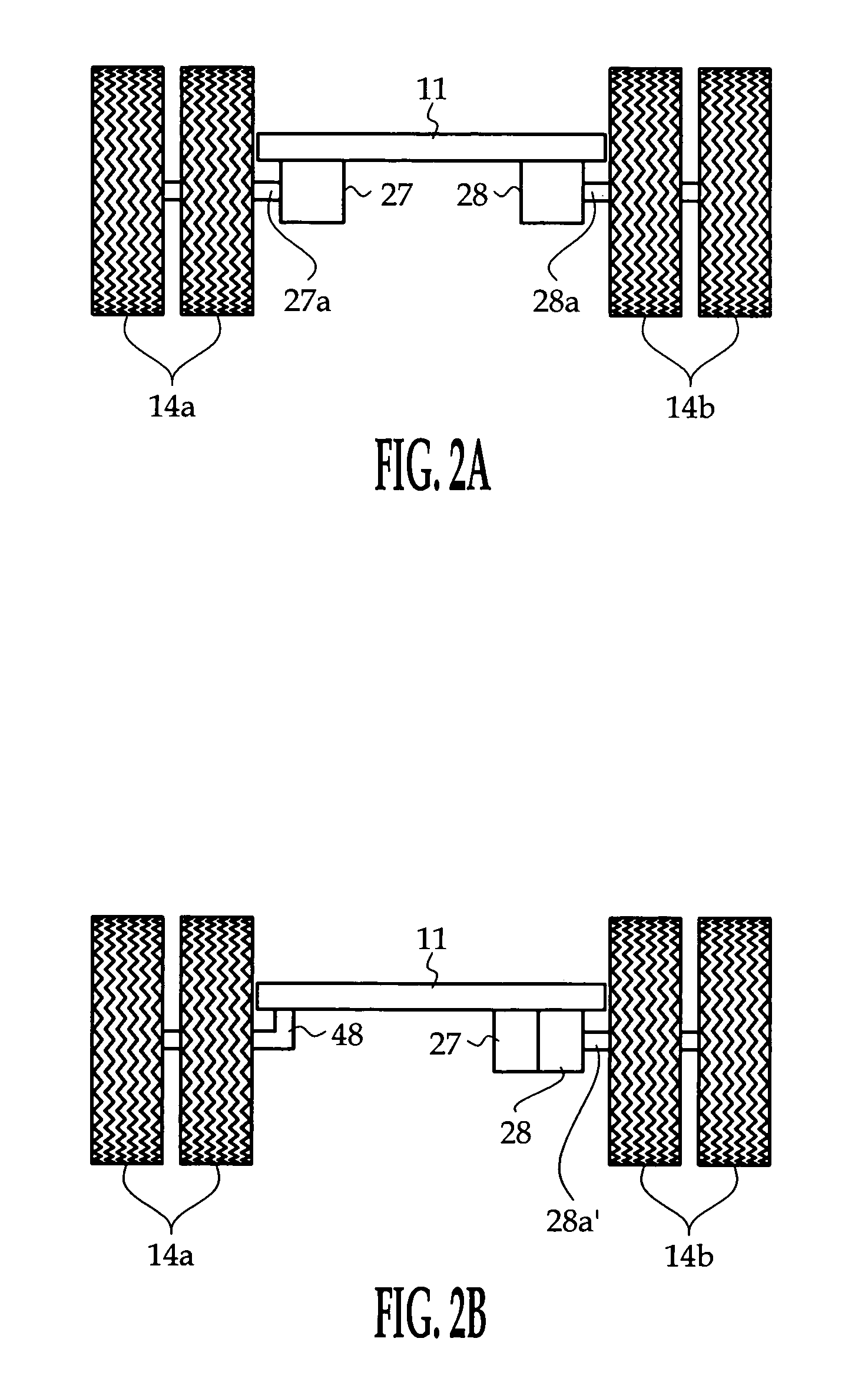

Accessory drive mechanism for hybrid vehicle

ActiveUS20120266701A1Avoid damageImprove reliabilityPropulsion using engine-driven generatorsToothed gearingsEngineeringHybrid vehicle

An accessory drive mechanism for a hybrid vehicle, capable of operating accessories irrespective of the travel state of the vehicle, and also capable of smoothly switching between the power which is transmitted from the traveling motor side and the power which is transmitted from the accessory drive motor side. The accessory drive mechanism is provided with a drive power take-off mechanism (20) for taking out the power from a travel drive system (D). An accessory (11) is connected to the drive power take-off mechanism (20). A first one-way clutch (C1) which can transmit the power only to the accessory (11) side is disposed between the drive power take-off mechanism (20) and the accessory (11). An accessory driving motor (an auxiliary motor (12e)) is connected to the side of the accessory (11) which is on the opposite side from the drive power take-off mechanism (20). A second one-way clutch (C2) which can transmit the power only to the accessory (11) side is disposed between the accessory (11) and the accessory driving motor (12).

Owner:NISSAN DIESEL MOTOR CO

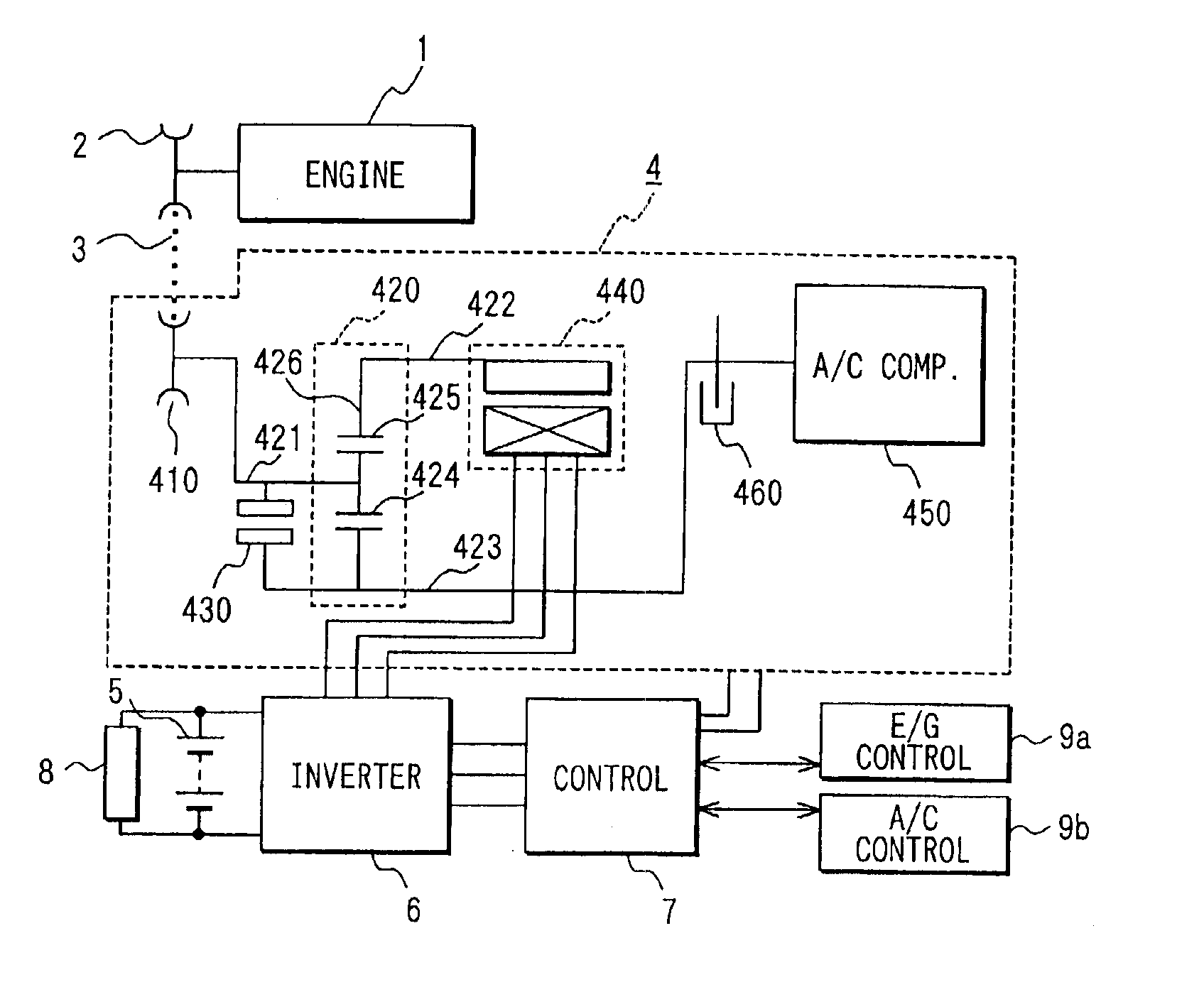

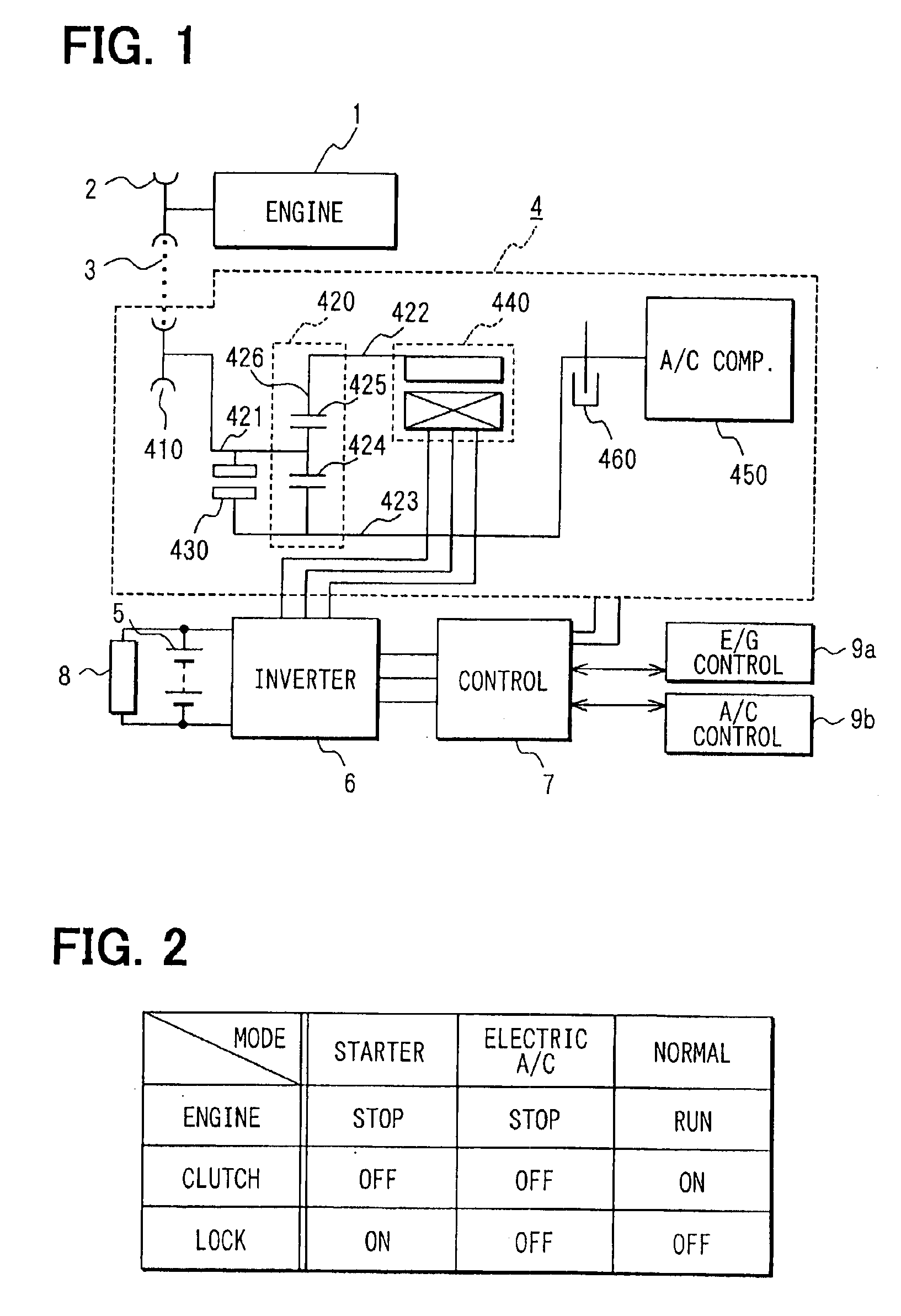

Accessory-driving equipment for an automotive vehicle

InactiveUS6863139B2Low costStable placement effectHybrid vehiclesAuxillary drivesMobile vehicleIdle speed

Accessory-driving equipment connects an engine having an idle stop system, a motor-generator and an accessory including an air-conditioner compressor that is driven even at a time when the idle stop system is operated. The accessory is driven by the engine when the engine is running and driven by the motor-generator when the idle stop system is operated. The accessory-driving equipment includes a first shaft for connecting to the engine, a second shaft for connecting to the motor-generator, a third shaft for connecting to the accessory, a lock device for locking the third shaft and a clutch. The clutch and the lock device are operated so that a torque transmitted from the engine through the first shaft is distributed to the motor-generator and the accessory, or a torque is transmitted from the motor-generator to the engine.

Owner:DENSO CORP

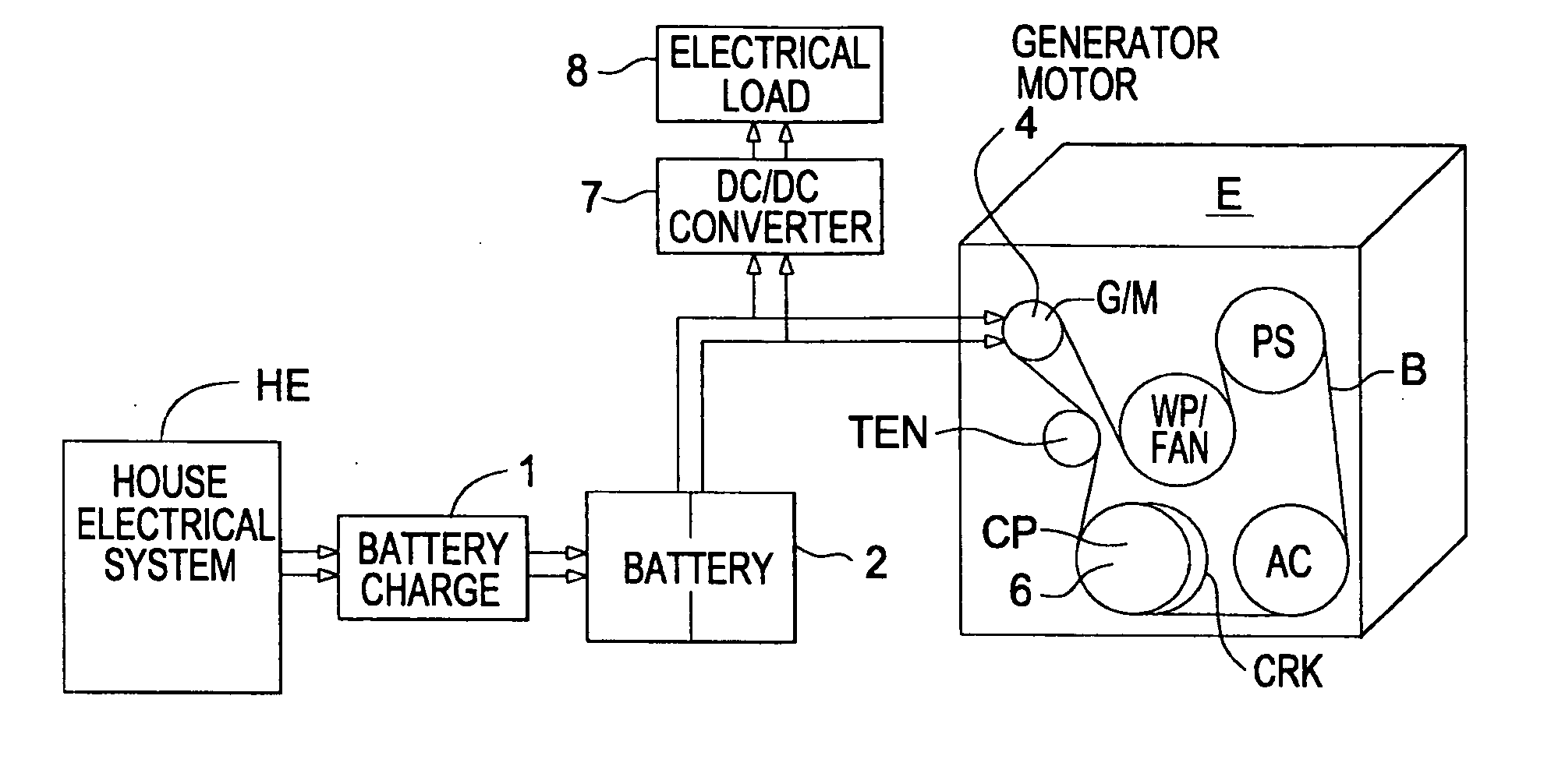

Variable speed accessory drive system for a hybrid vehicle

The present invention provides an accessory drive system for a hybrid vehicle. The accessory drive system includes a planetary gear set having a first, second, and third planetary member. A torque transfer device operatively connects an engine with the first planetary member. A motor / generator is operatively connected to the second planetary member, and a plurality of accessories are operatively connected to the third planetary member. A one-way clutch is preferably operatively connected to either the first planetary member or the torque transfer device such that the accessories can be effectively driven by the motor / generator when the engine is off. Engine output is transferable through the planetary gear set to drive the accessories, and the speed at which the accessories are driven is selectable by controlling the speed of the motor / generator.

Owner:GM GLOBAL TECH OPERATIONS LLC

Powertrain including input disconnect and accessory drive system for an electrically variable transmission

A vehicle powertrain includes an engine connected to an input torque device including a torque isolator. A plurality of intermeshed accessory drive gears are connected to the torque device for driving accessories. A hybrid electromechanical transmission is connected to one of the accessory drive gears. A motor / generator of the hybrid electromechanical transmission is operable to drive the accessory drive gears when the engine is not running.

Owner:GM GLOBAL TECH OPERATIONS LLC

Starter and accessory drive system and method for hybrid drive vehicles

A starter and accessory drive system and method for hybrid drive vehicles is provided. The invention isolates the accessory drive system from the transfer of torque between a starter motor and the crankshaft of the engine. In one embodiment, a dedicated flexible drive member transfers torque from the starter motor to the crankshaft to re-start the engine. In another embodiment, a torque transfer control is employed to selectively apply torque from the starter motor to the accessory drive, to drive the accessories when the engine is stopped, and / or to the engine crankshaft to re-start the engine. In another embodiment of the invention, the accessory drive is isolated from the engine crankshaft and is instead driven by a drive motor on the accessory drive while the engine crankshaft is connected to a starter motor and / or generator which can be energized to re-start the engine.

Owner:LITENS AUTOMOTIVE INC

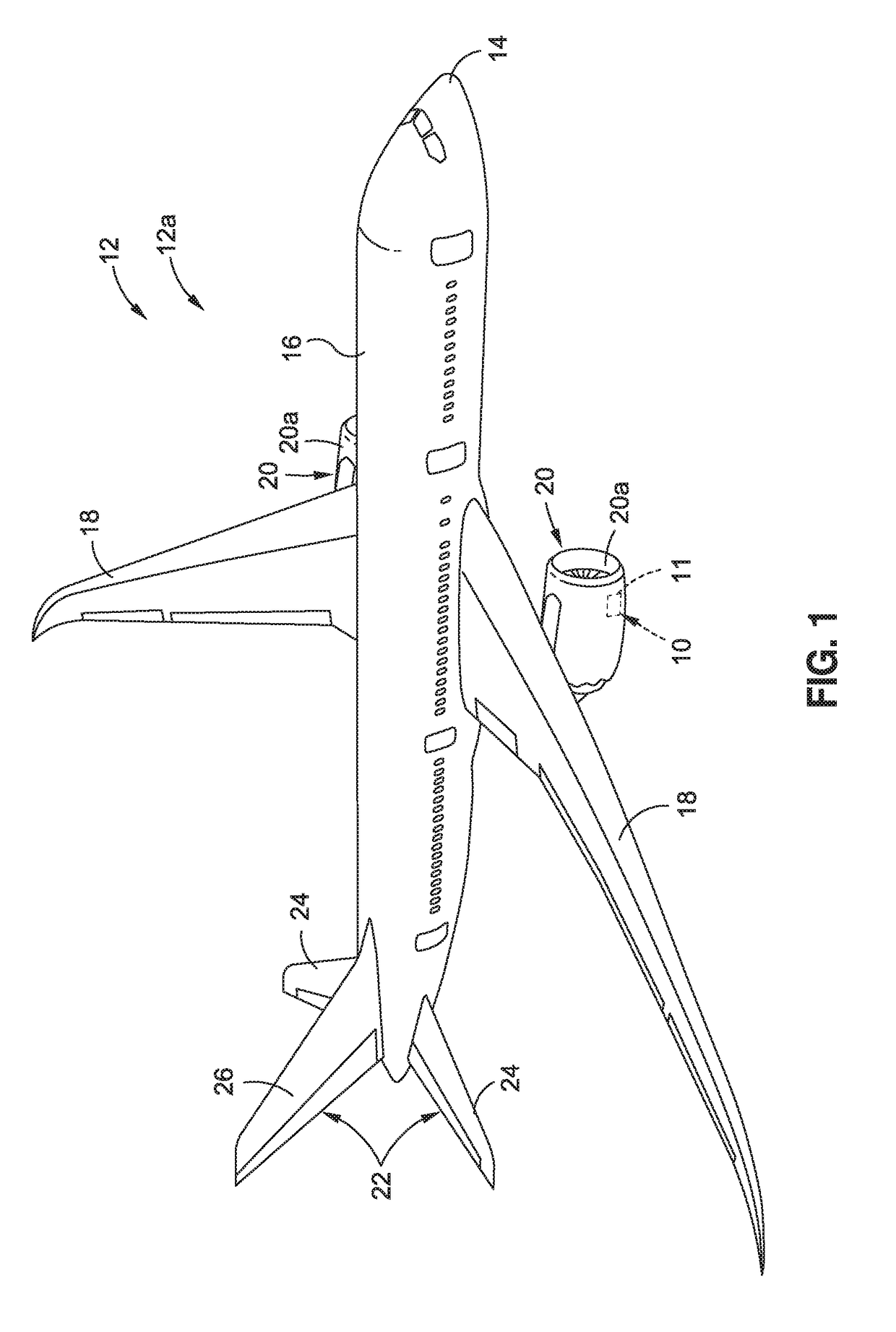

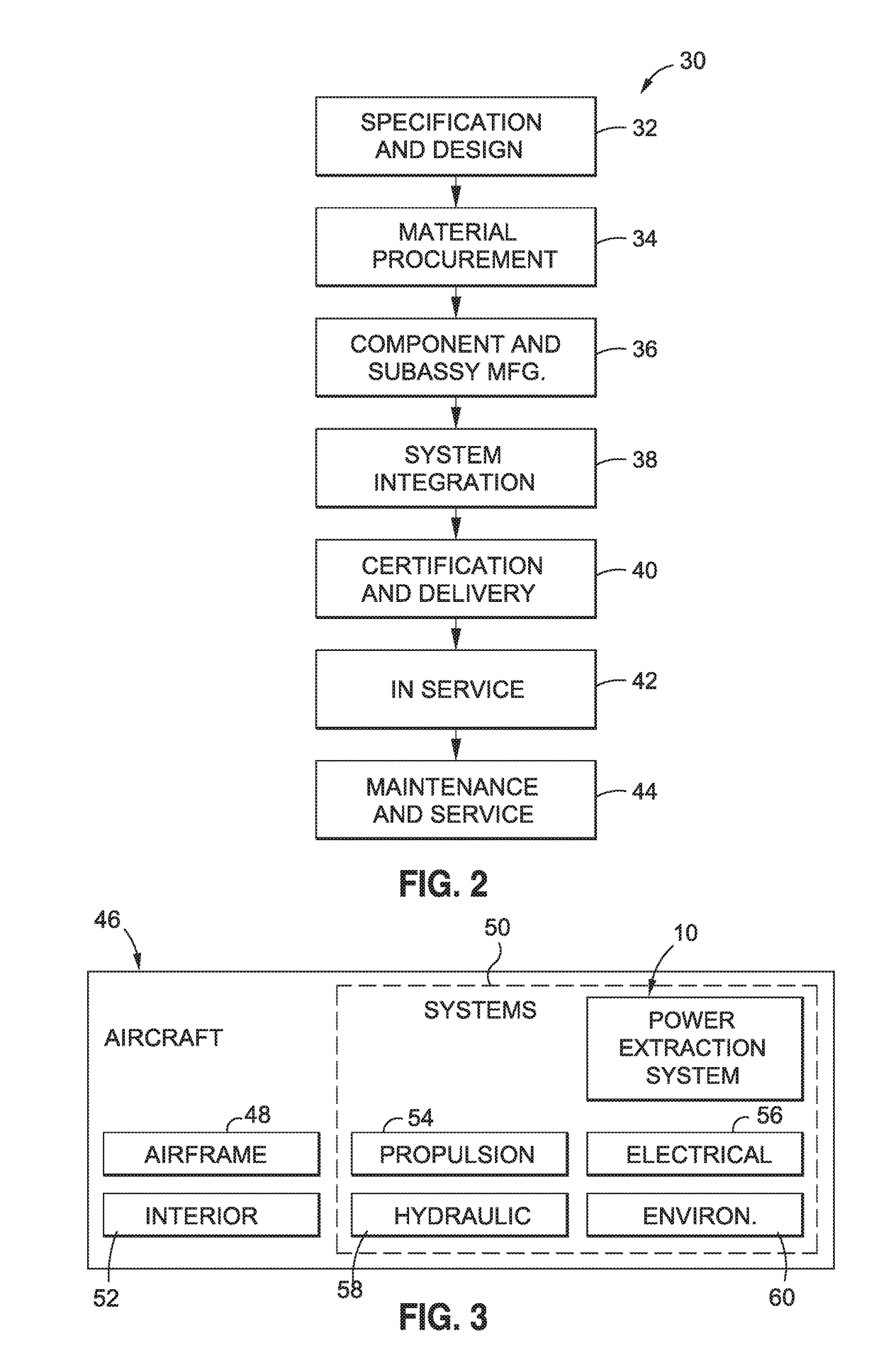

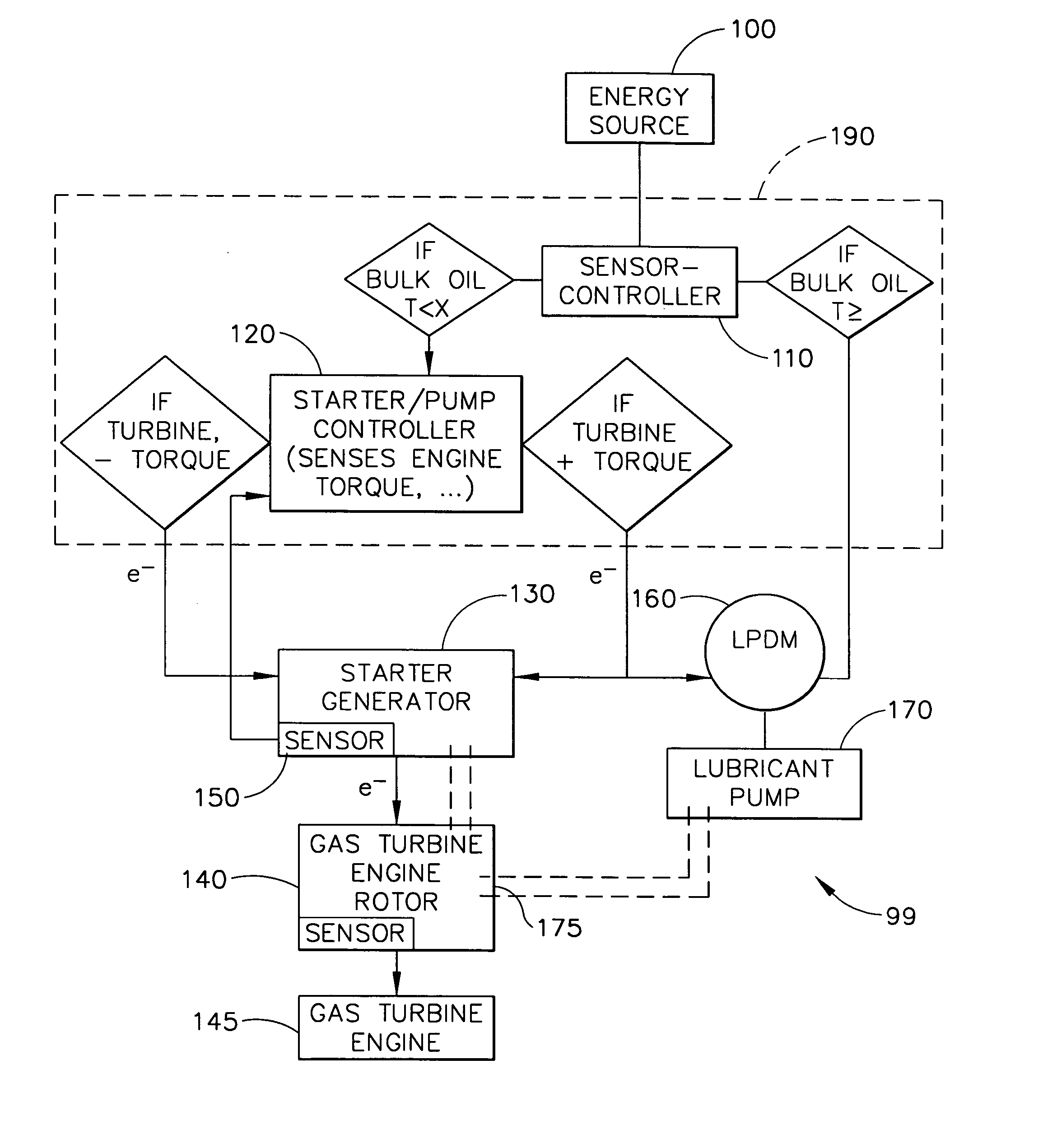

Power extraction system and method for a gas turbine engine of a vehicle

A power extraction system and method for a gas turbine engine of a vehicle are provided. The system has an HP spool tower shaft coupled between an HP spool of the gas turbine engine and an accessory gearbox assembly coupled to the gas turbine engine. The HP spool tower shaft extracts mechanical power from the HP spool. The system has an LP spool tower shaft coupled between an LP spool of the gas turbine engine and the accessory gearbox assembly. The LP spool tower shaft extracts mechanical power from the LP spool. The system further has the accessory gearbox assembly having an accessory drive combining the mechanical power from both the HP spool and LP spool, having a planetary gear train coupled to the accessory drive, and having one or more engine-driven accessories coupled to the planetary gear train and driven by a planetary gear train output to generate power.

Owner:THE BOEING CO

Gas turbine engine cold start mechanization

InactiveUS20070234739A1Engine fuctionsTurbine/propulsion engine ignitionStarter generatorEngineering

An apparatus and method is provided to start gas turbine engines at cold start. A gearbox is not mechanically coupled to any accessory or to the starter-generator. Rather, a controller is used to route power to a starter-generator to rotate the turbine mainshaft to start the gas turbine engine. The controller prevents power to an accessory drive motor, until the starter-generator creates a positive torque. When a positive torque is reached, excess power is routed to the accessory drive motor, typically a brushless direct current motor.

Owner:HONEYWELL INT INC

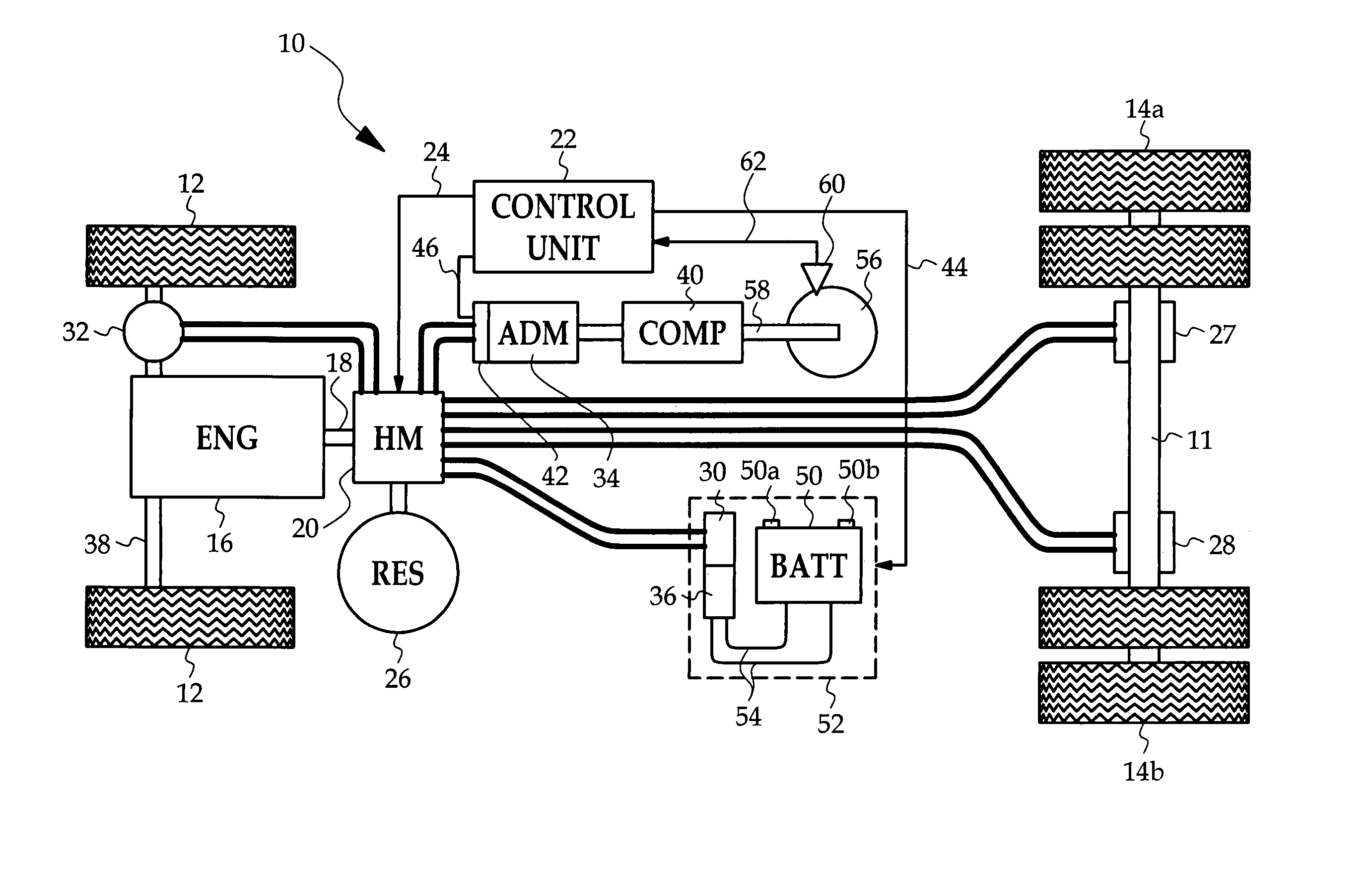

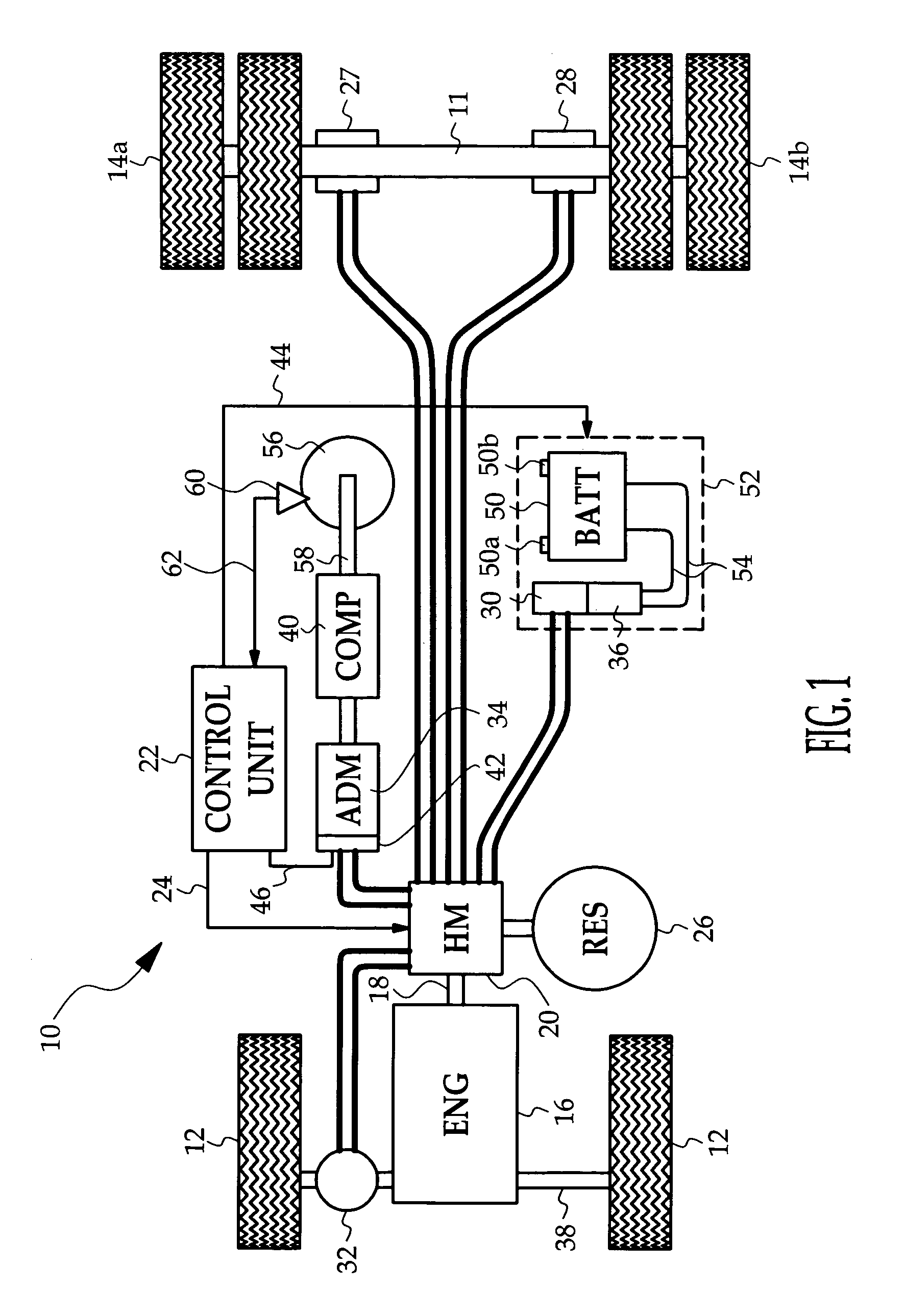

Hydrostatic drive apparatus for a road vehicle

InactiveUS20050167178A1Gas pressure propulsion mountingPlural diverse prime-mover propulsion mountingDrive wheelBattery charge

A road vehicle utilizes hydraulic machines for primary and accessory vehicle drive functions. An internal combustion engine directly drives a first variable capacity hydraulic machine selectively operable as pump or motor, an electric machine electrically coupled to a storage battery is selectively operable as motor or generator and is mechanically coupled to a second hydraulic machine operable as pump or motor, and at least one hydraulic drive motor is coupled to a vehicle drive wheel. A controller regulates the capacity of the first hydraulic machine, and controls the functionality of the first and second hydraulic machines to selectively crank the engine or charge the storage battery. The first hydraulic machine also supplies hydraulic fluid to accessory drive motors including a power steering drive motor, an air compressor drive motor and a supercharger drive motor.

Owner:JOHNSON WELDED PRODS

Hydrostatic drive apparatus for a road vehicle

InactiveUS7111704B2Gas pressure propulsion mountingPlural diverse prime-mover propulsion mountingDrive wheelDrive motor

A road vehicle utilizes hydraulic machines for primary and accessory vehicle drive functions. An internal combustion engine directly drives a first variable capacity hydraulic machine selectively operable as pump or motor, an electric machine electrically coupled to a storage battery is selectively operable as motor or generator and is mechanically coupled to a second hydraulic machine operable as pump or motor, and at least one hydraulic drive motor is coupled to a vehicle drive wheel. A controller regulates the capacity of the first hydraulic machine, and controls the functionality of the first and second hydraulic machines to selectively crank the engine or charge the storage battery. The first hydraulic machine also supplies hydraulic fluid to accessory drive motors including a power steering drive motor, an air compressor drive motor and a supercharger drive motor.

Owner:JOHNSON WELDED PRODS

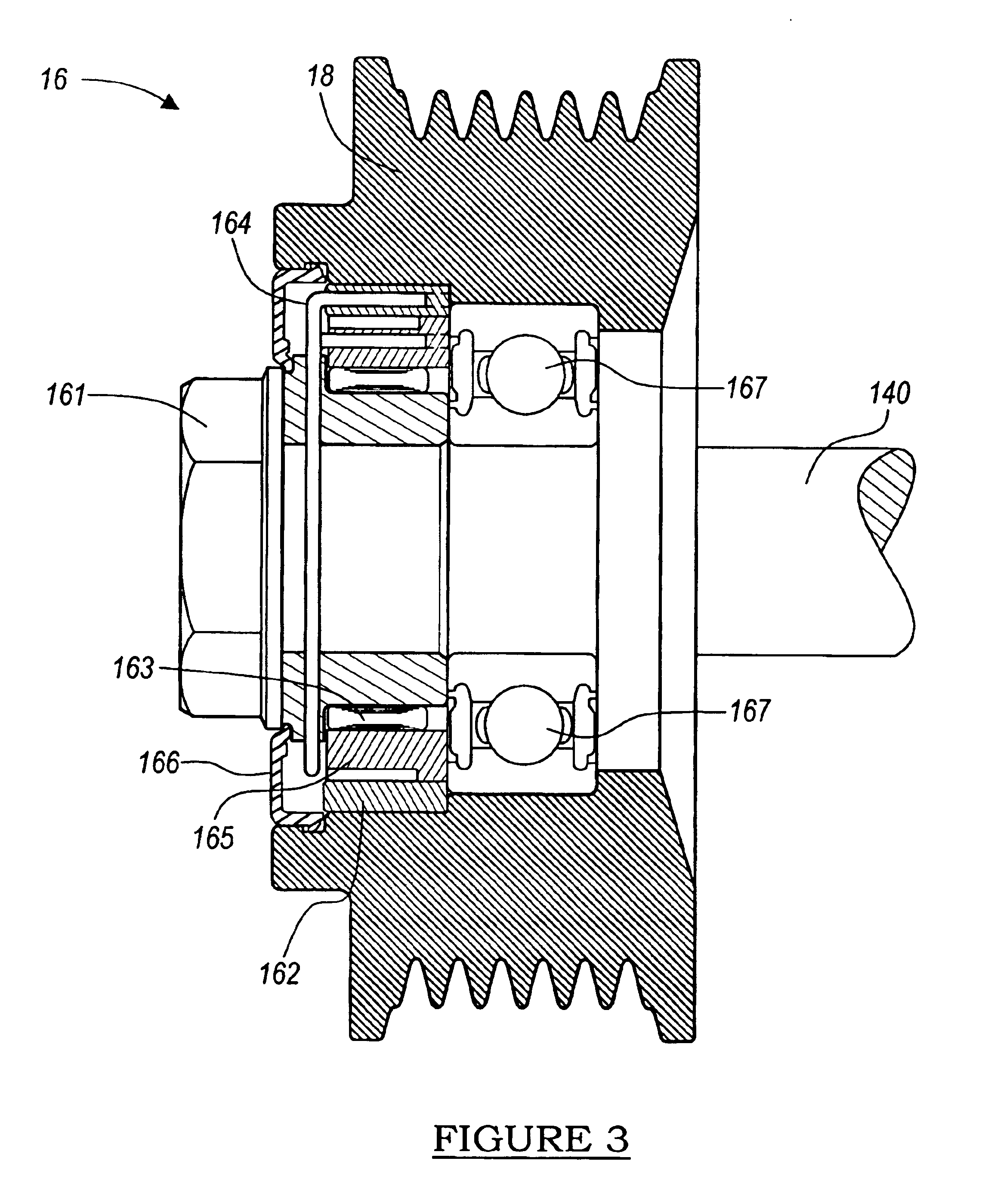

Starter pulley with integral clutch

InactiveUS6848552B2Start fastReduce noisePower operated startersMechanical actuated clutchesExternal combustion engineFuel efficiency

Starter motor systems are described, wherein the systems include a unidirectional clutch system that cooperates with a pulley system to start an internal combustion engine through the front-end accessory drive system. The starter motor systems are especially well suited for new, high fuel efficiency automobiles in which the engine is shut down (e.g., when the automobile stops) and subsequently started (e.g., when the accelerator pedal is depressed).

Owner:NTN CORP

Turbine drive system with lock-up clutch and method

InactiveUS8146370B2Turbine/propulsion fuel supply systemsTurbine/propulsion engine ignitionLow speedBleed air

Owner:HONEYWELL INT INC

Starter and Accessory Drive System And Method For Hybrid Drive Vehicles

A starter and accessory drive system and method for hybrid drive vehicles is provided. The invention isolates the accessory drive system from the transfer of torque between a starter motor and the crankshaft of the engine. In one embodiment, a dedicated flexible drive member transfers torque from the starter motor to the crankshaft to re-start the engine. In another embodiment, a torque transfer control is employed to selectively apply torque from the starter motor to the accessory drive, to drive the accessories when the engine is stopped, and / or to the engine crankshaft to re-start the engine. In another embodiment of the invention, the accessory drive is isolated from the engine crankshaft and is instead driven by a drive motor on the accessory drive while the engine crankshaft is connected to a starter motor and / or generator which can be energized to re-start the engine.

Owner:LITENS AUTOMOTIVE INC

Variable speed accessory drive system for a hybrid vehicle

The present invention provides an accessory drive system for a hybrid vehicle. The accessory drive system includes a planetary gear set having a first, second, and third planetary member. A torque transfer device operatively connects an engine with the first planetary member. A motor / generator is operatively connected to the second planetary member, and a plurality of accessories are operatively connected to the third planetary member. A one-way clutch is preferably operatively connected to either the first planetary member or the torque transfer device such that the accessories can be effectively driven by the motor / generator when the engine is off. Engine output is transferable through the planetary gear set to drive the accessories, and the speed at which the accessories are driven is selectable by controlling the speed of the motor / generator.

Owner:GM GLOBAL TECH OPERATIONS LLC

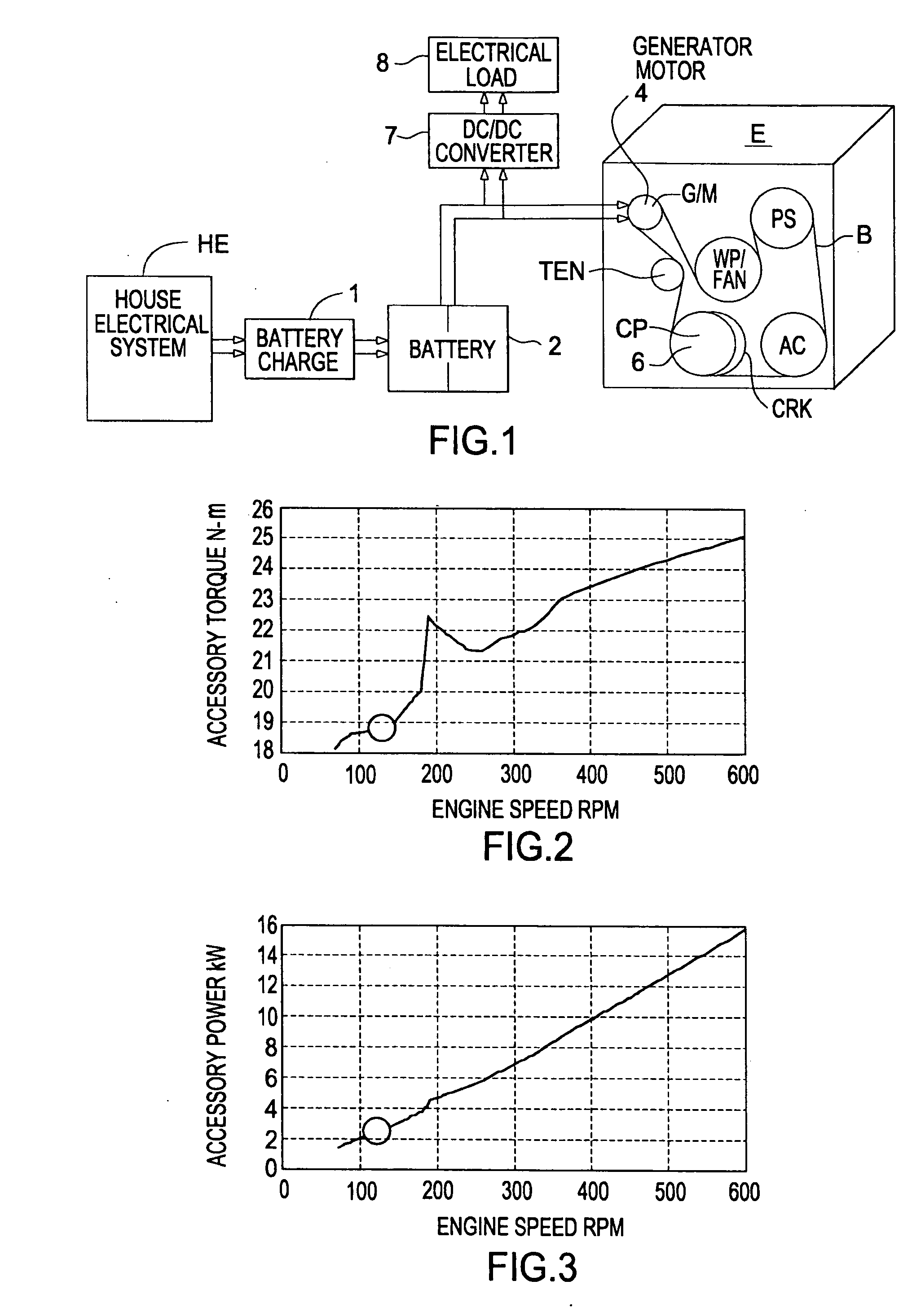

Plug-in hybrid accessory drive system

A plug-in hybrid accessory belt drive system comprising a vehicle engine accessory belt drive, the accessory belt drive comprising engine accessories, a motor / generator engaged with the accessory belt drive, the motor / generator for driving the accessory drive, a rechargeable electrical energy source connected to the motor / generator for driving the motor / generator on demand, the rechargeable electrical energy course connected to a vehicle electrical load, and the rechargeable electrical energy source connectable to a recharging energy source.

Owner:THE GATES CORP

Starter alternator accessory drive system for a hybrid vehicle

The present invention provides an alternator starter accessory drive system for a hybrid vehicle. The starter alternator accessory drive system includes a planetary gear set having a first, second, and third planetary member. An engine is operatively connected to the first planetary member, and a first motor / generator is operatively connected to the second planetary member. A torque transfer device operatively connects a plurality of accessories to the third planetary member. A second motor / generator is operatively connected to either the third planetary member or the torque transfer device. Engine output is transferable through the planetary gear set to drive the accessories at a selectable rate, and the first and second motor / generators are controllable to run the accessories while the engine is off and to re-start the engine.

Owner:GM GLOBAL TECH OPERATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com