Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1427results about "Turbine/propulsion engine ignition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

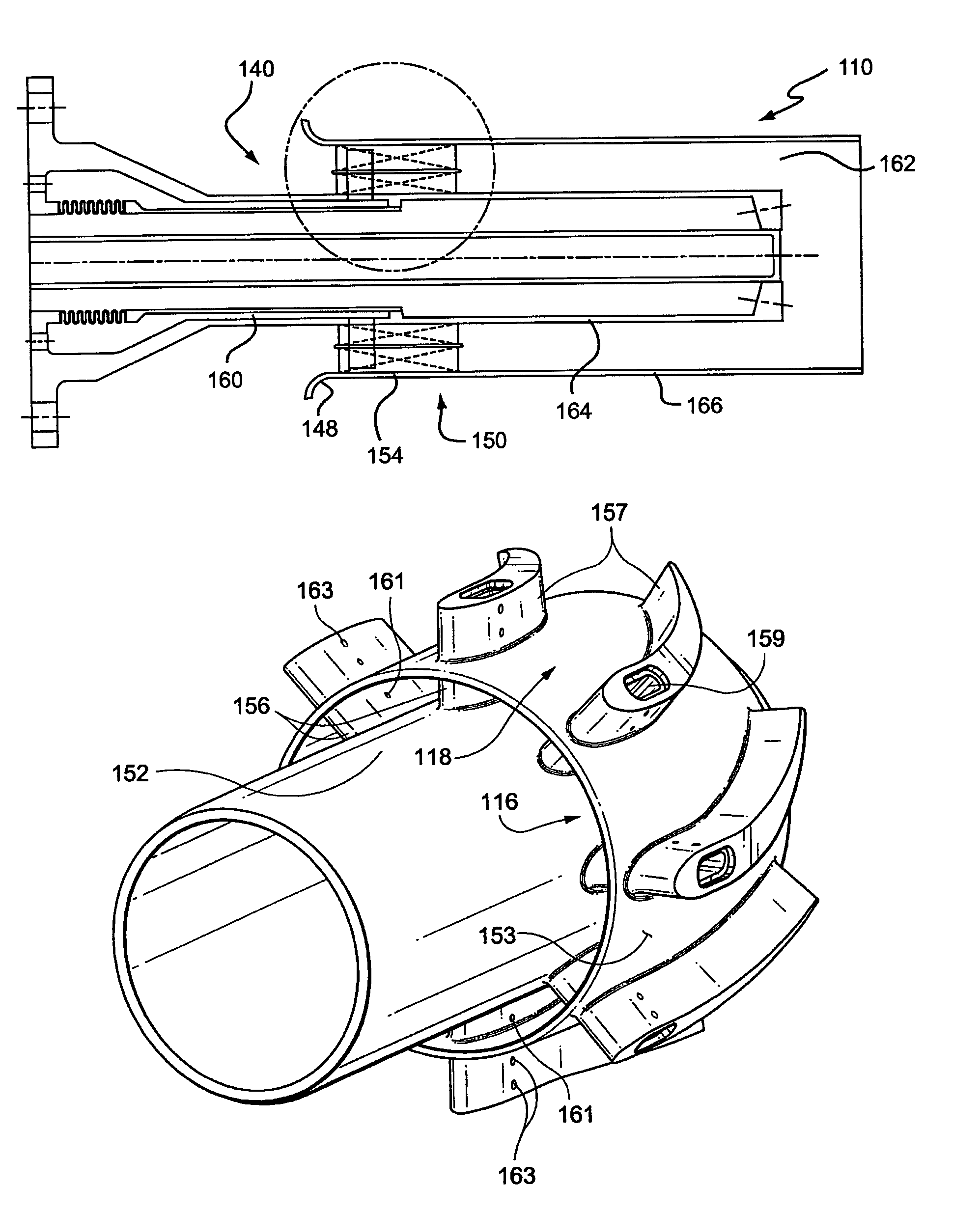

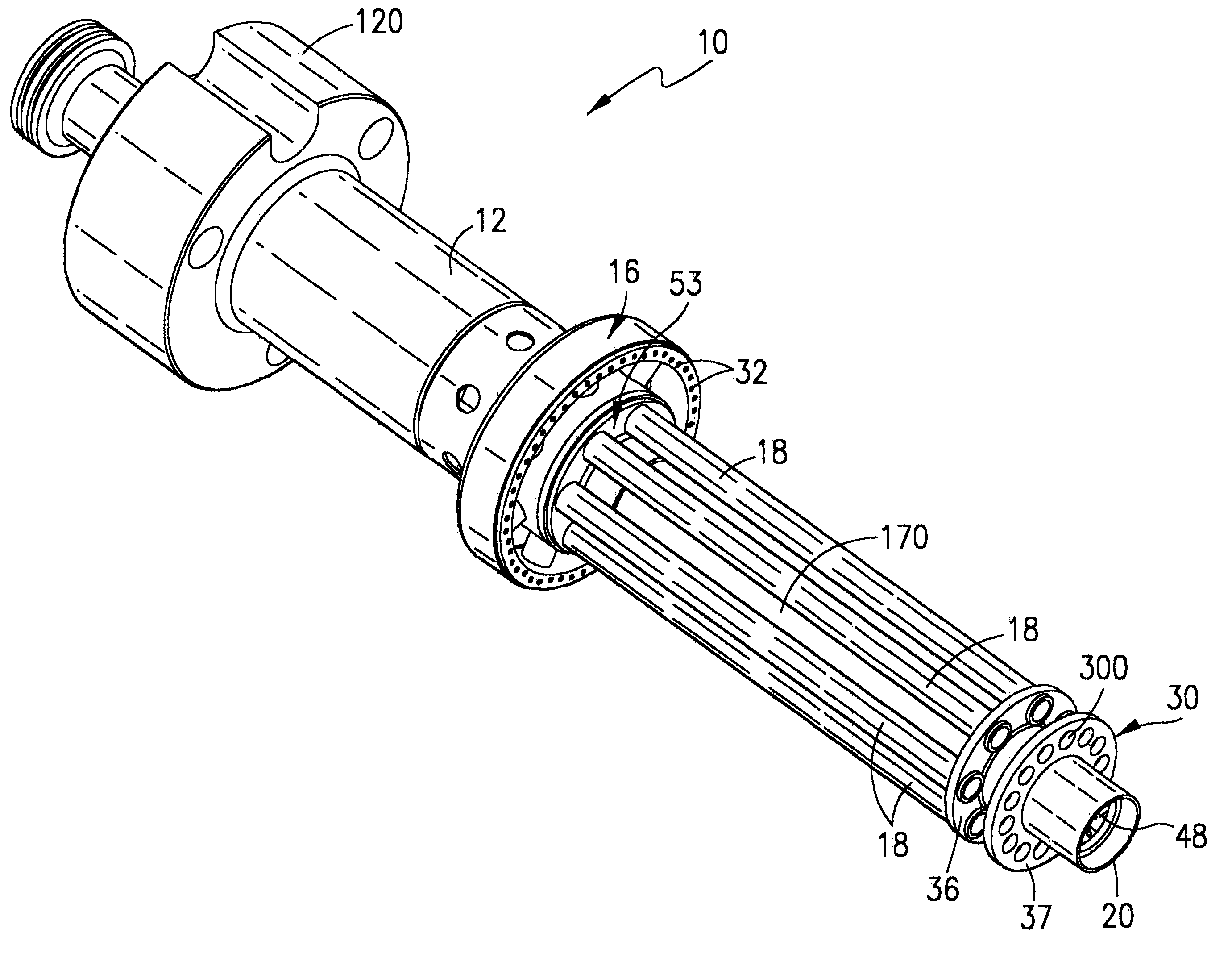

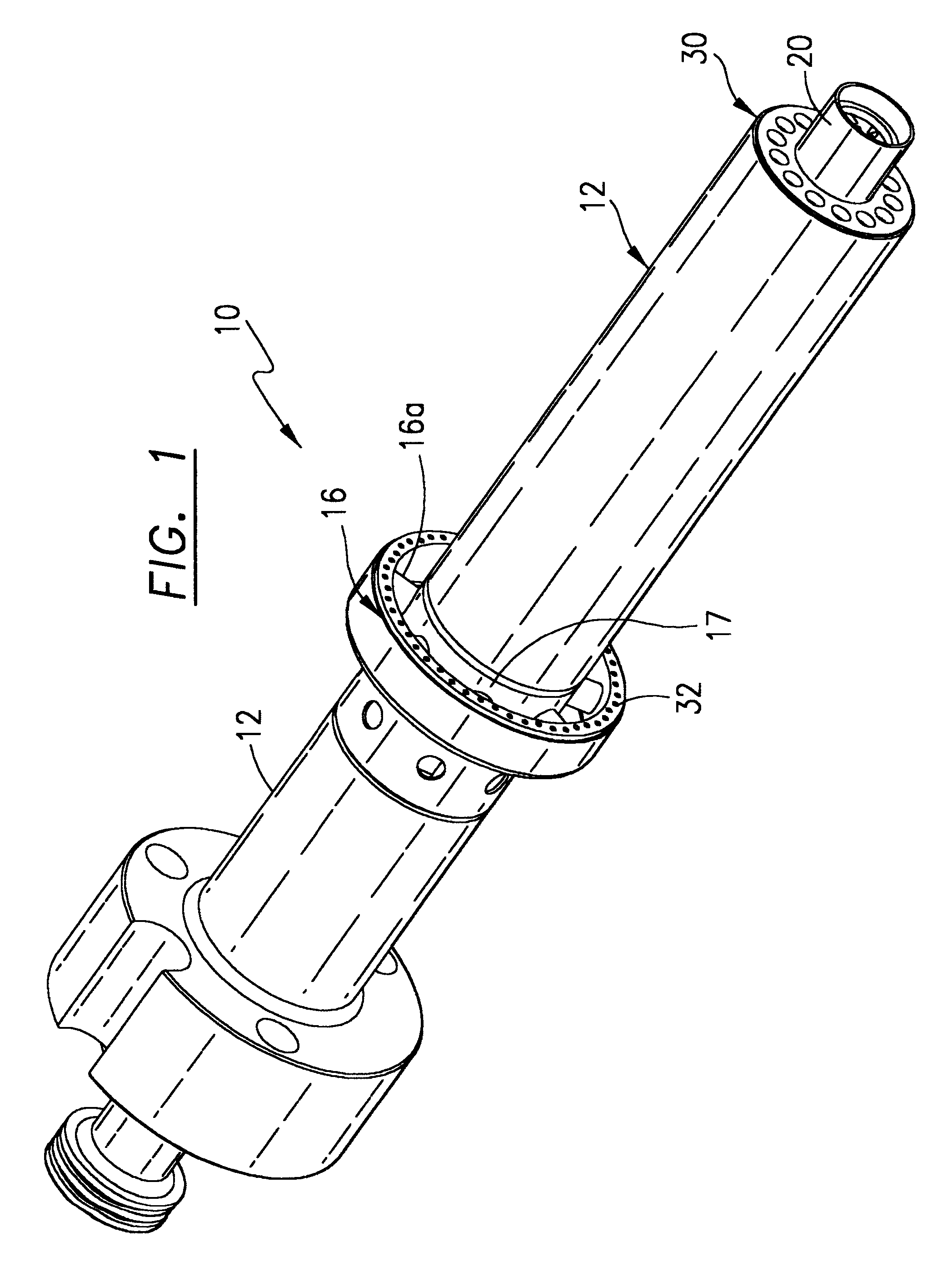

Burner tube and method for mixing air and gas in a gas turbine engine

InactiveUS6993916B2Good mixing propertiesImprove flame stabilityContinuous combustion chamberTurbine/propulsion fuel supply systemsCombustorGas turbines

Owner:GENERAL ELECTRIC CO

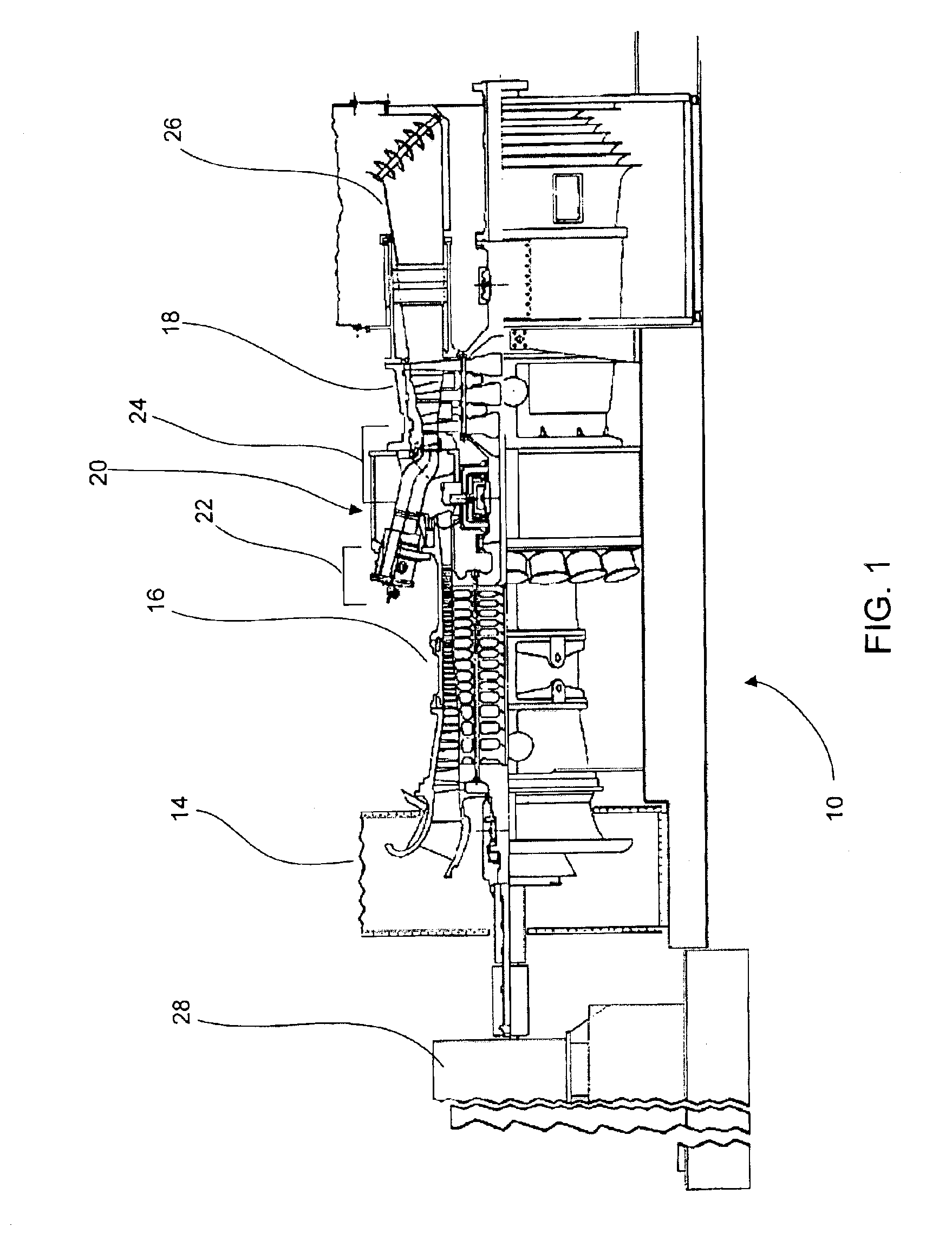

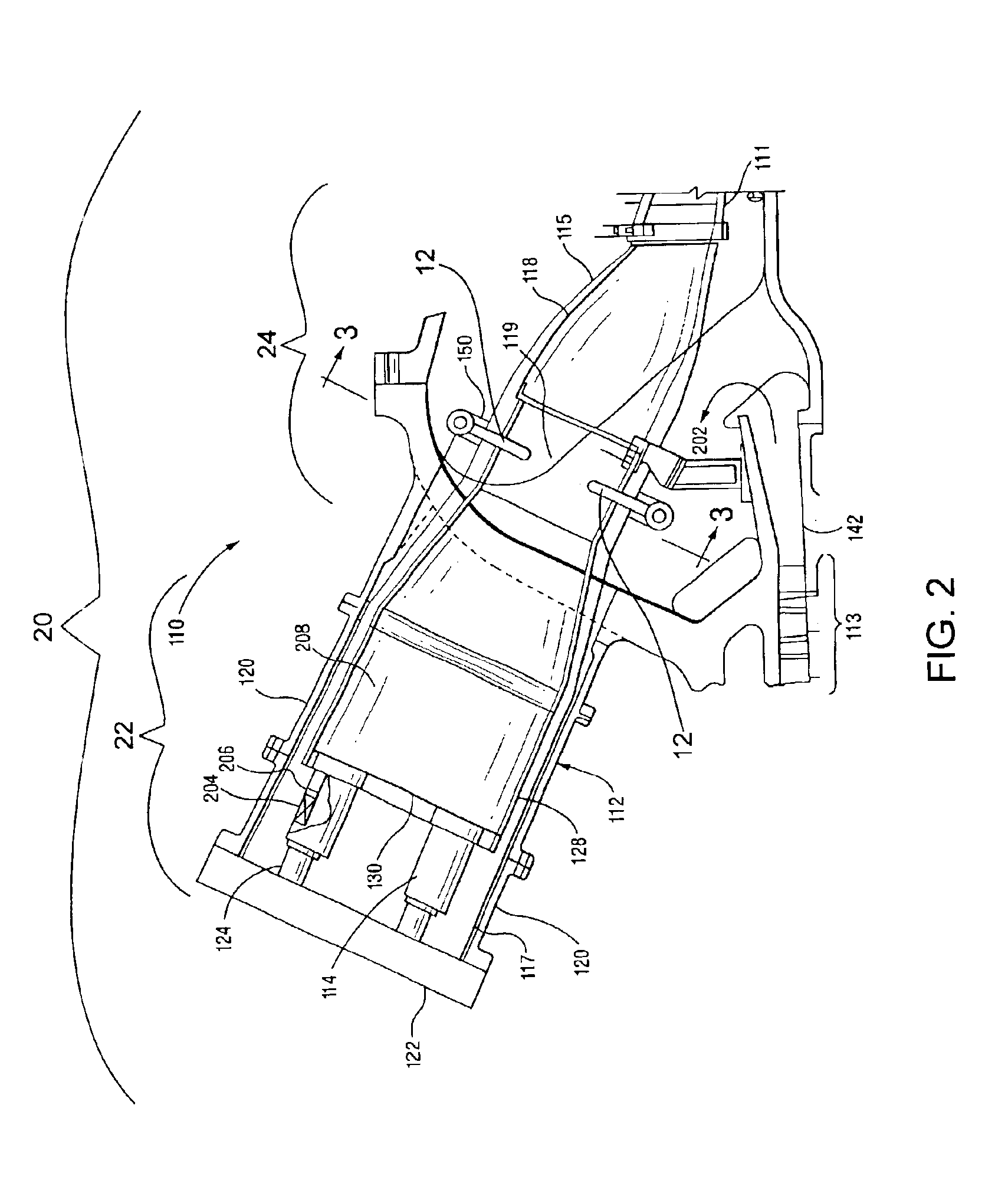

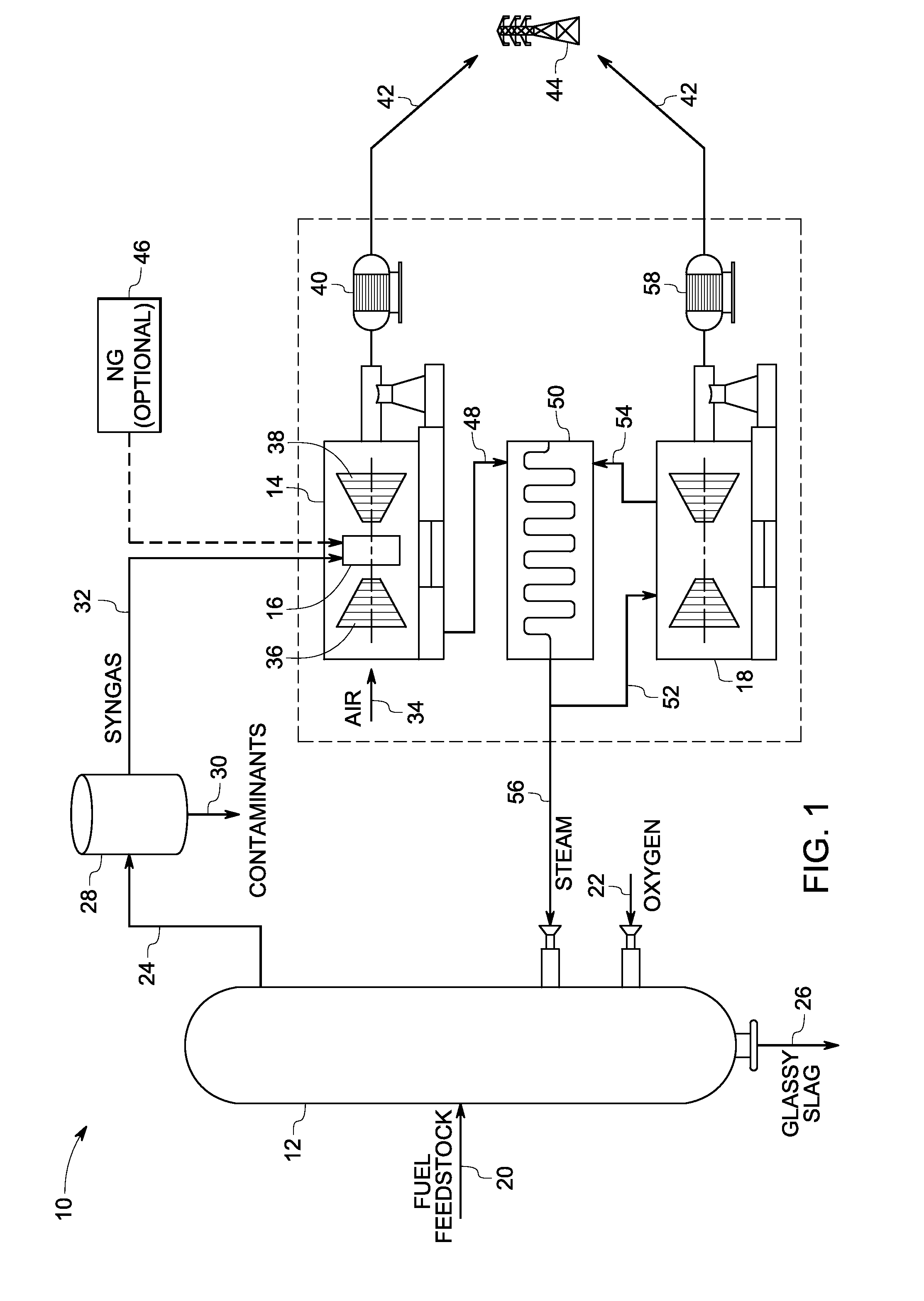

Turbine containing system and an injector therefor

A turbine containing system is disclosed. The system includes an intake section, a compressor section downstream from the intake section, a combustor section having a primary combustion system downstream from the intake section, a secondary combustion system downstream from the primary combustion system, a turbine section, an exhaust section and a load. The secondary combustion system includes an injector for transversely injecting a secondary fuel into a stream of combustion products of the primary combustion system. The injector including a coupling, a wall defining an airfoil shape circumscribing a fuel mixture passage, and at least one exit for communication between said fuel mixture passage and said stream of primary combustion products.

Owner:GENERAL ELECTRIC CO

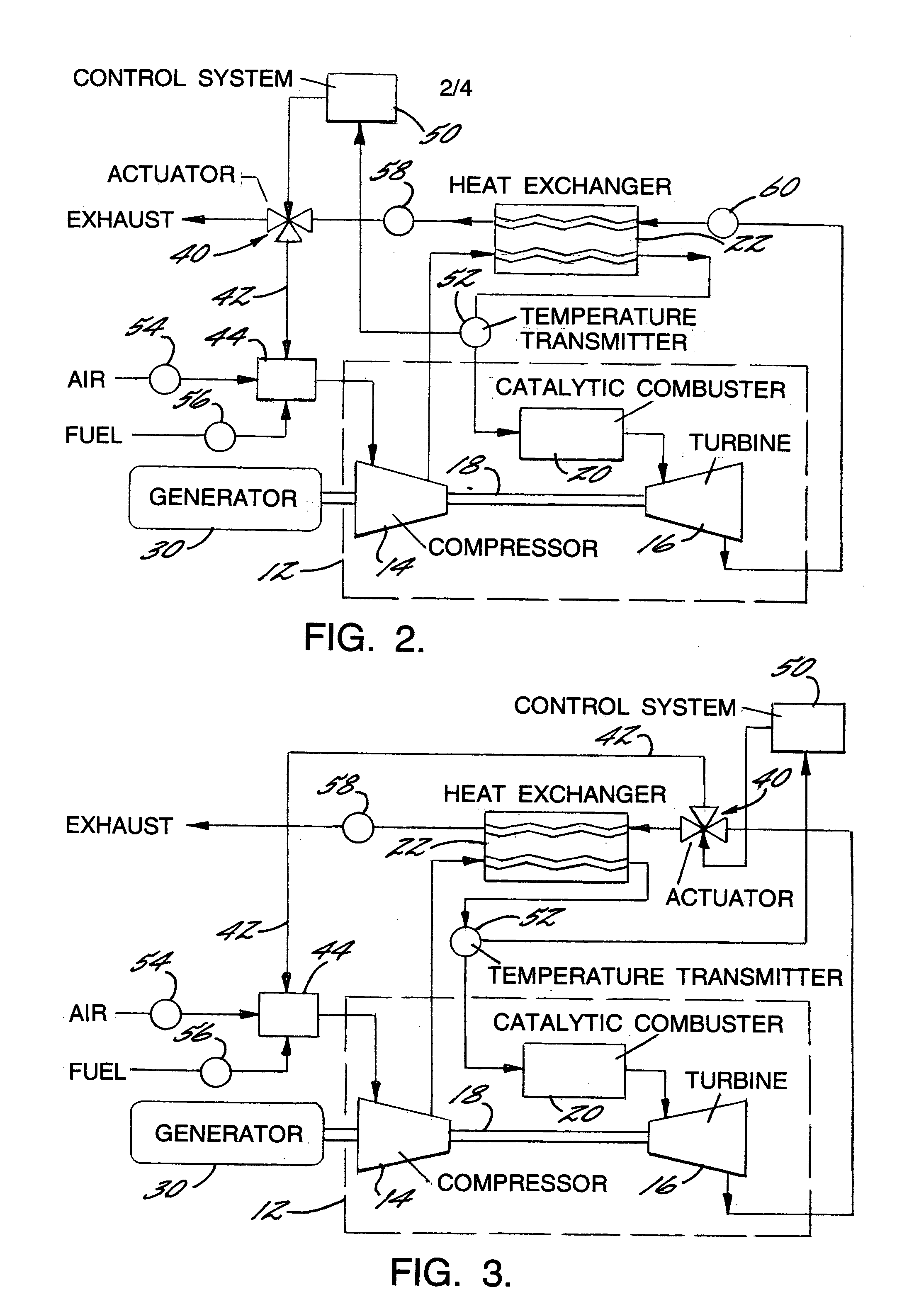

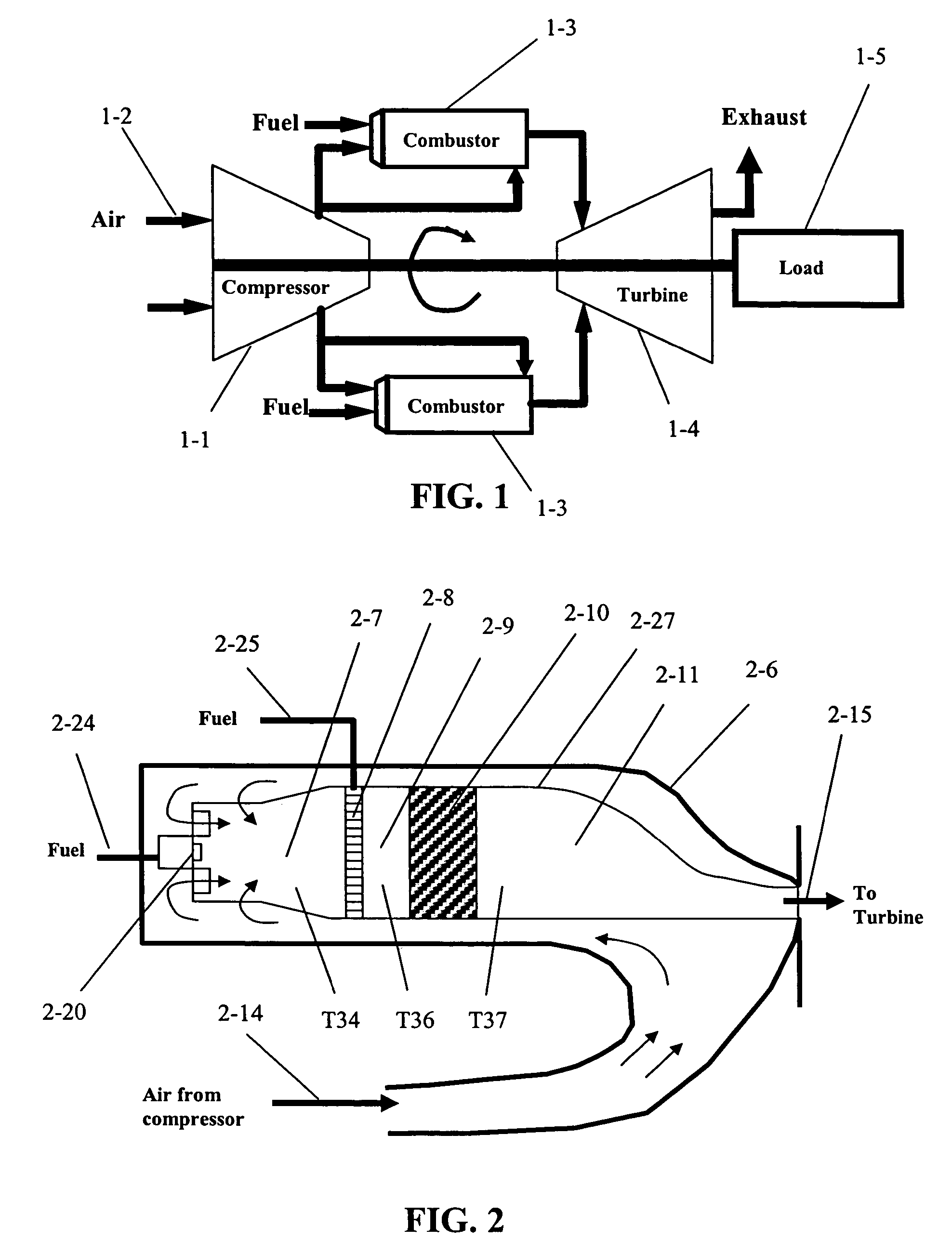

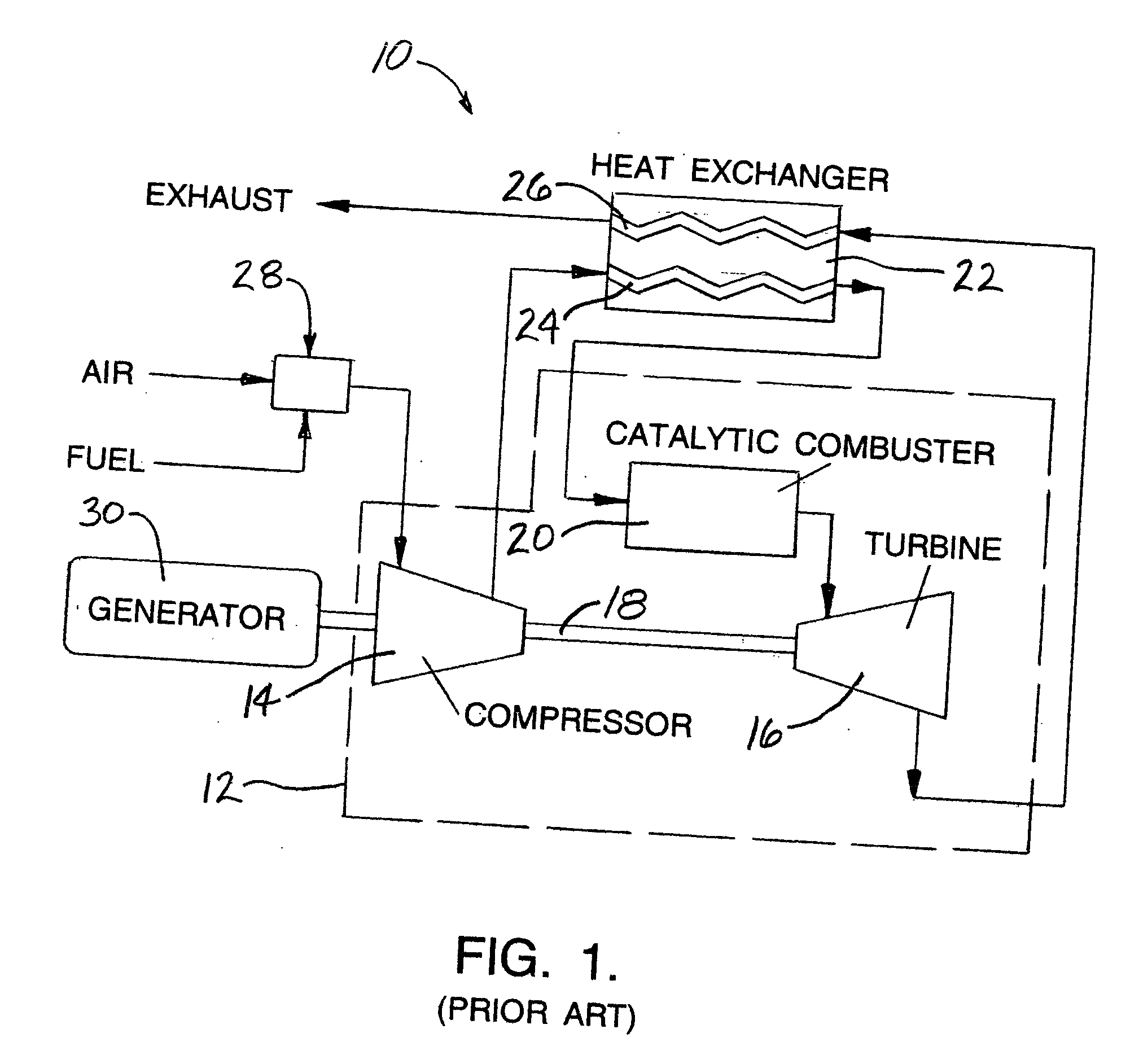

Recuperated gas turbine engine system and method employing catalytic combustion

InactiveUS7007487B2Maximize efficiencyReduce air pollutionTurbine/propulsion fuel supply systemsContinuous combustion chamberCombustorCold weather

A recuperated gas turbine engine system and associated method employing catalytic combustion, wherein the combustor inlet temperature can be controlled to remain above the minimum required catalyst operating temperature at a wide range of operating conditions from full-load to part-load and from hot-day to cold-day conditions. The fuel is passed through the compressor along with the air and a portion of the exhaust gases from the turbine. The recirculated exhaust gas flow rate is controlled to control combustor inlet temperature.

Owner:MES INT INC

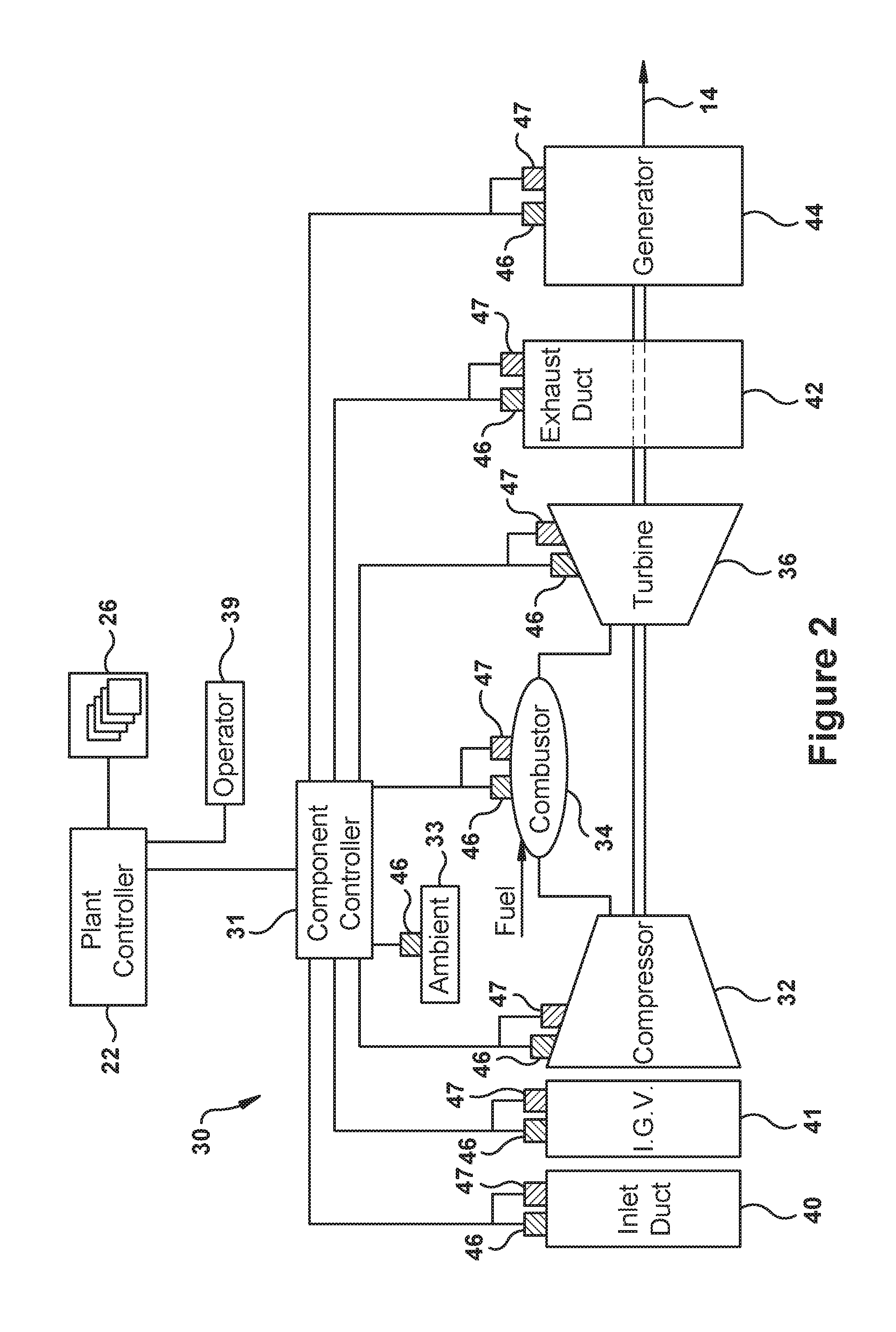

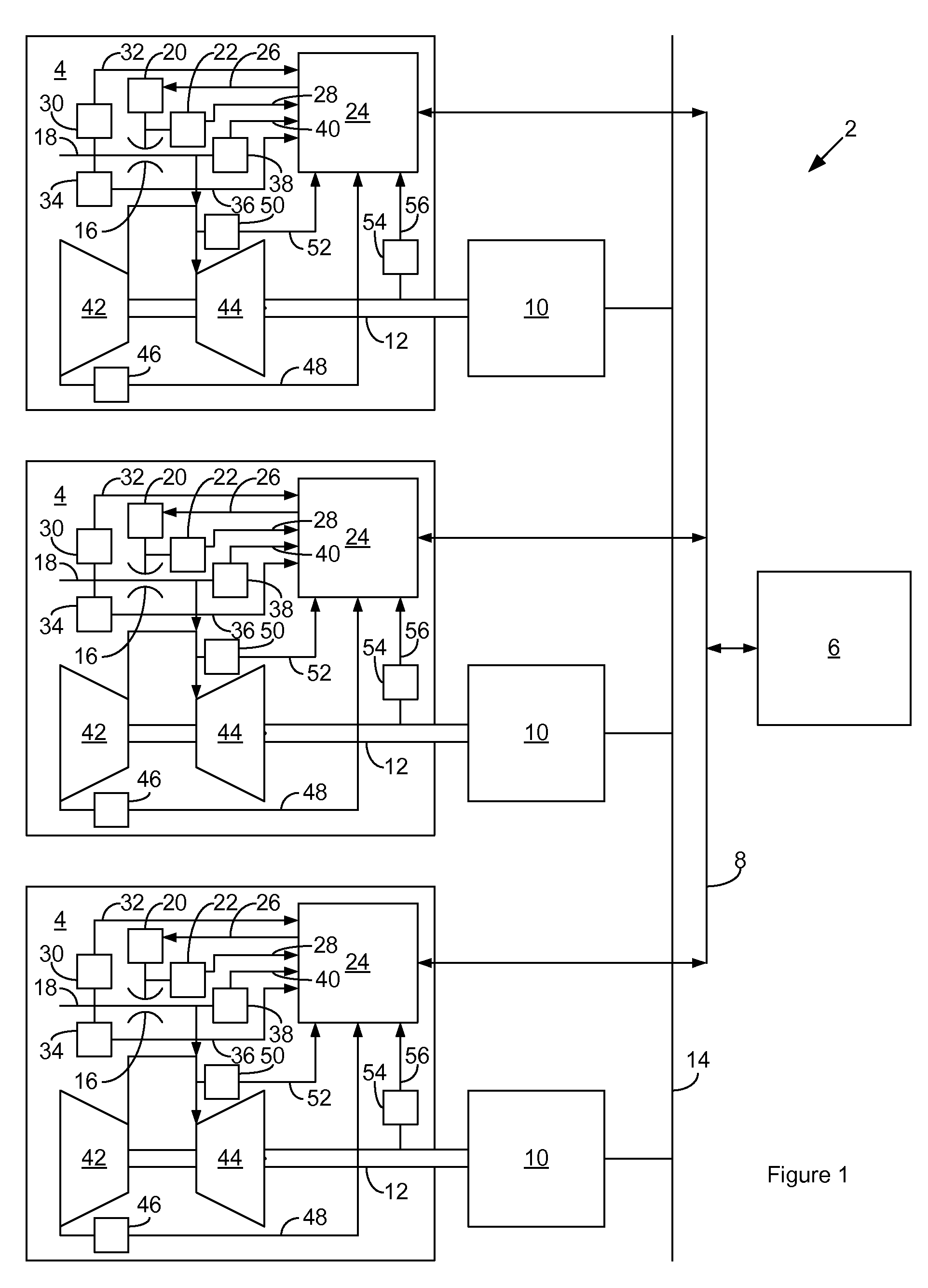

Methods and systems for enhancing operation of power plant generating units and systems

ActiveUS20160281607A1Programme controlTurbine/propulsion engine ignitionPower stationControl engineering

A method for controlling and enhancing a startup operation for a combined cycle power block (block) having at least one gas turbine and at least one steam turbine, wherein operating parameters define performance and operational characteristics for the startup operation, the method comprising: receiving measured operating parameters from a plurality of reference blocks and, for each of the plurality of reference blocks, a plurality of types of the startup operations; given the measured operating parameters, developing one or more reference transfer functions between two of the measured operating parameters; receiving measured operating parameters from the startup operation of a target block; given the measured operating parameters from the target block, developing one or more transfer functions for the target block between two of the operating parameters; selecting one of the reference transfer functions; and normalizing the transfer function of the target block per the selected reference transfer function.

Owner:GENERAL ELECTRIC CO

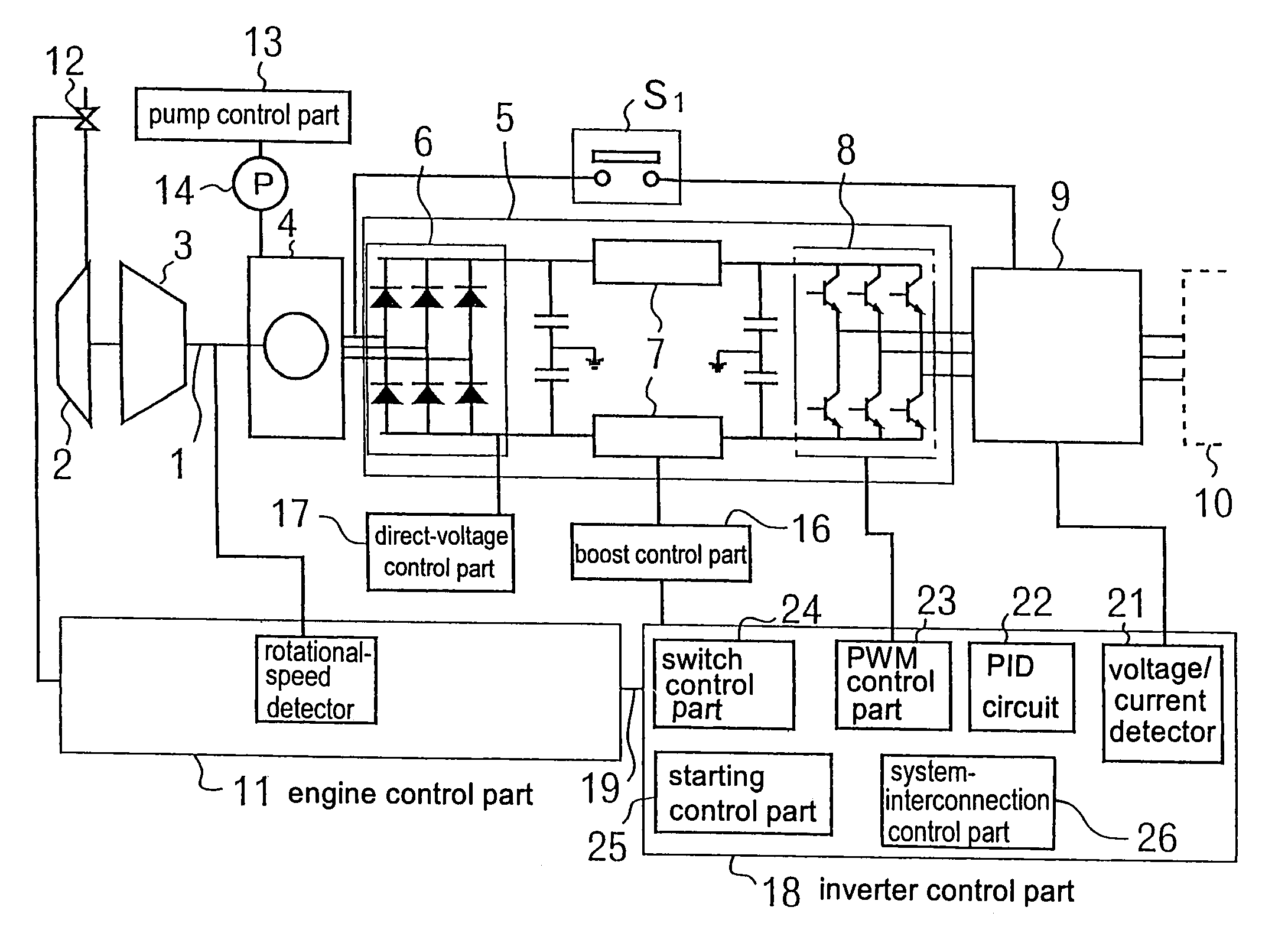

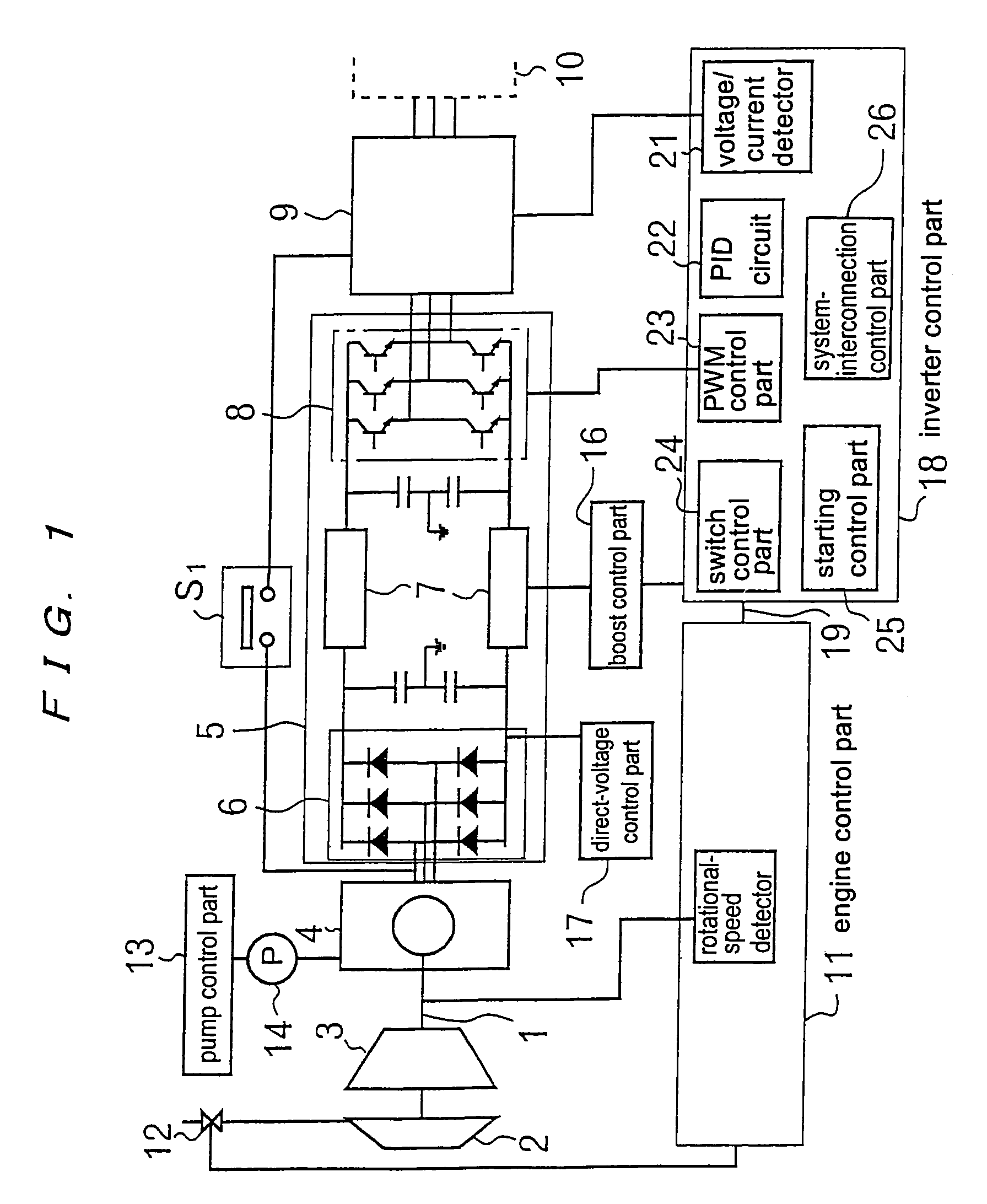

Gas turbine generating apparatus

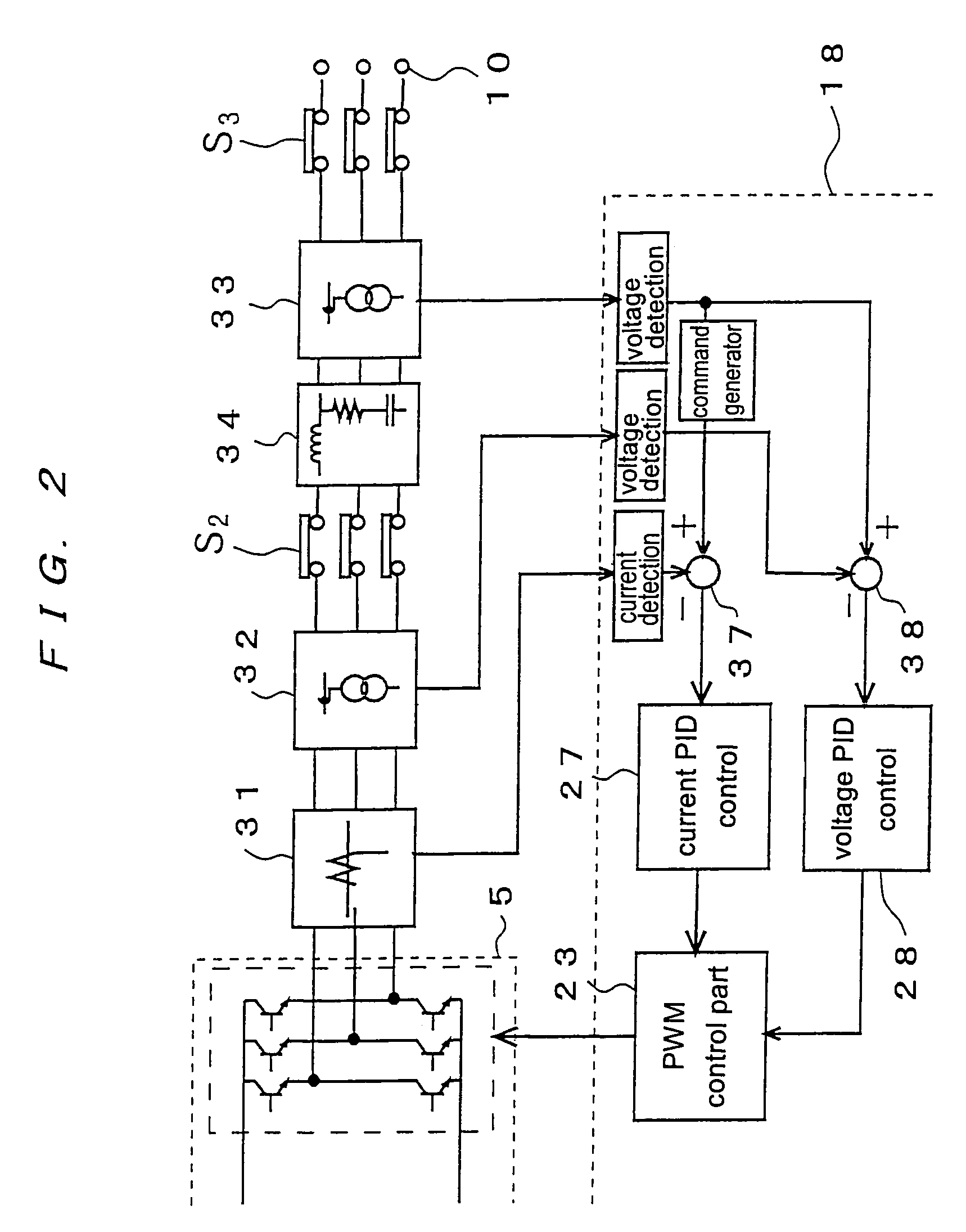

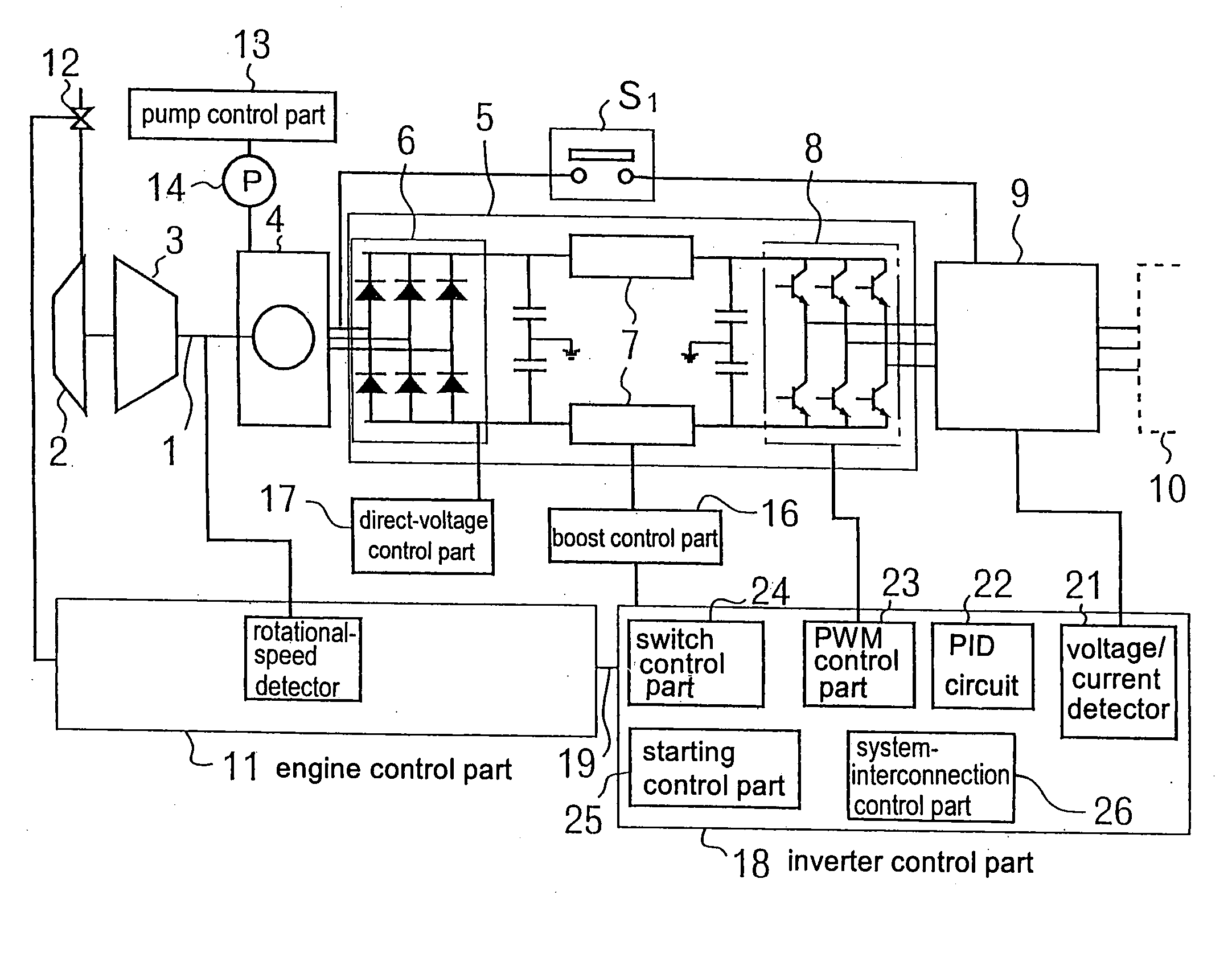

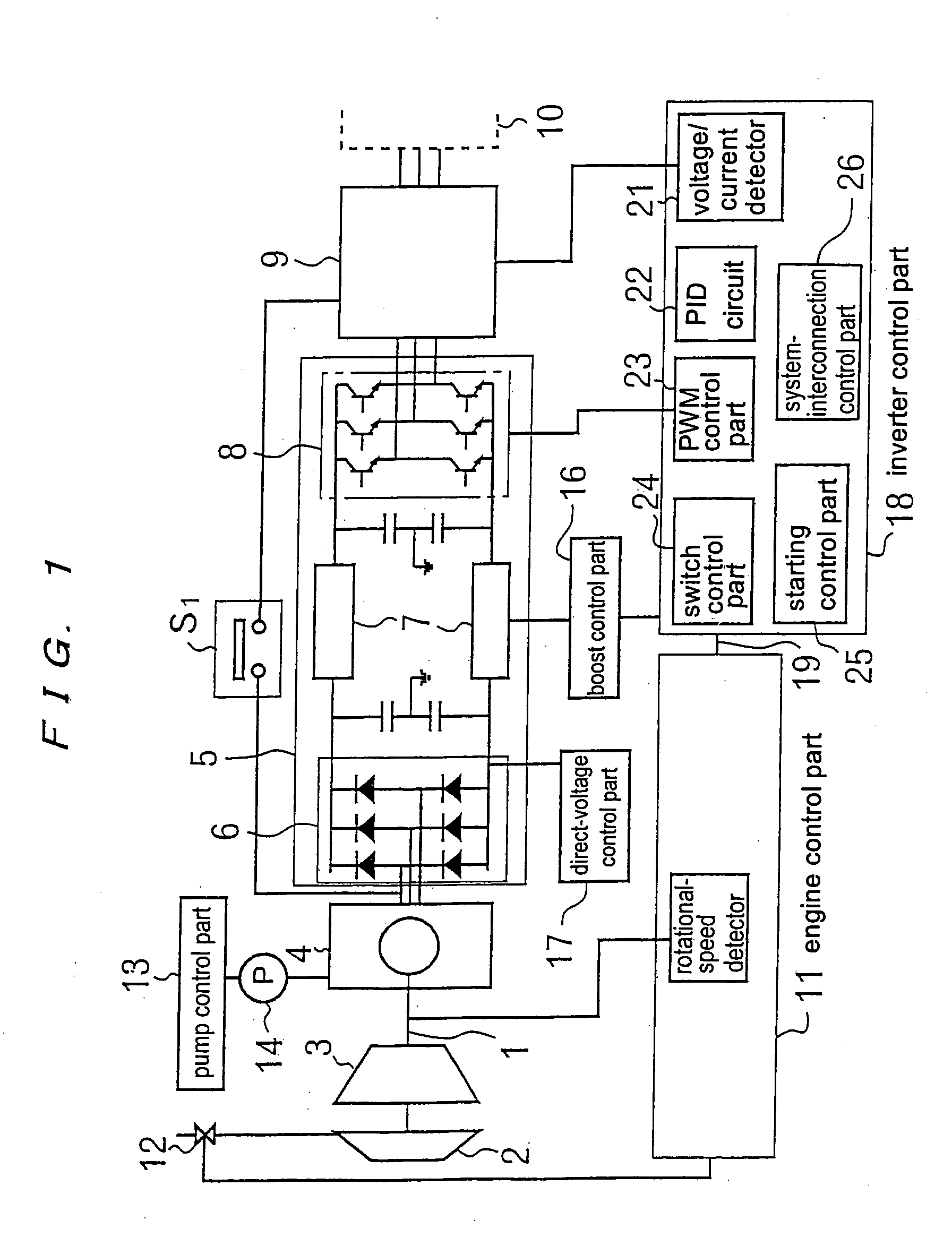

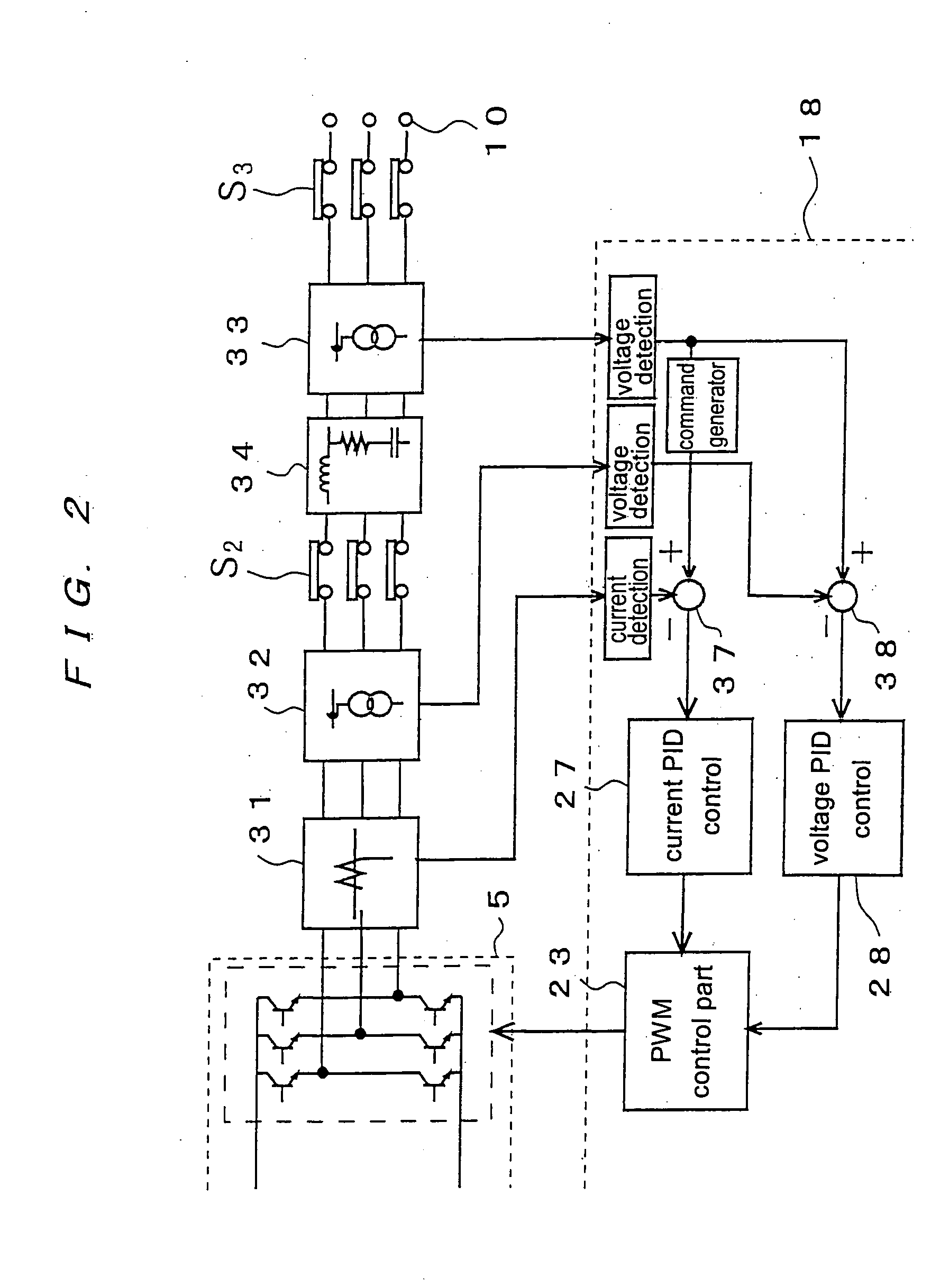

InactiveUS7061211B2Easy interconnectionStarted easily and quicklyMotor/generator/converter stoppersTurbine/propulsion engine ignitionPhase differenceEngineering

A gas turbine generating apparatus according to the present invention comprises a gas turbine capable of a high-speed operation, a permanent-magnet-type generator driven at a high speed by the gas turbine, an inverter device (5) for converting alternating-current power generated by the generator into commercial alternating-current power, and a system-interconnection device (9) for interconnecting output of the inverter device to a commercial AC power supply system (10). The system-interconnection device controls the inverter device based on voltage of the commercial AC power supply system as a criterion such that output current of the inverter device is in phase with the voltage or out of phase with the voltage by a constant phase difference. A control device (18) is provided for operating the permanent-magnet-type generator (4) as a motor at a time of starting the gas turbine, and supplying alternating-current power from a direct-current power supply through the inverter device or another inverter device in addition to the inverter device to the generator for increasing a rotational speed smoothly from zero. The control device detects output current of the inverter device and controls the inverter device to keep the output current constant.

Owner:EBARA CORP +1

Gas turbine generating apparatus

InactiveUS20050179420A1Easy interconnectionStarted easily and quicklyTurbine/propulsion engine ignitionTurbine/propulsion engine startersPhase differenceAc power system

A gas turbine generating apparatus according to the present invention comprises a gas turbine capable of a high-speed operation, a permanent-magnet-type generator driven at a high speed by the gas turbine, an inverter device (5) for converting alternating-current power generated by the generator into commercial alternating-current power, and a system-interconnection device (9) for interconnecting output of the inverter device to a commercial AC power supply system (10). The system-interconnection device controls the inverter device based on voltage of the commercial AC power supply system as a criterion such that output current of the inverter device is in phase with the voltage or out of phase with the voltage by a constant phase difference. A control device (18) is provided for operating the permanent-magnet-type generator (4) as a motor at a time of starting the gas turbine, and supplying alternating-current power from a direct-current power supply through the inverter device or another inverter device in addition to the inverter device to the generator for increasing a rotational speed smoothly from zero. The control device detects output current of the inverter device and controls the inverter device to keep the output current constant.

Owner:EBARA CORP +1

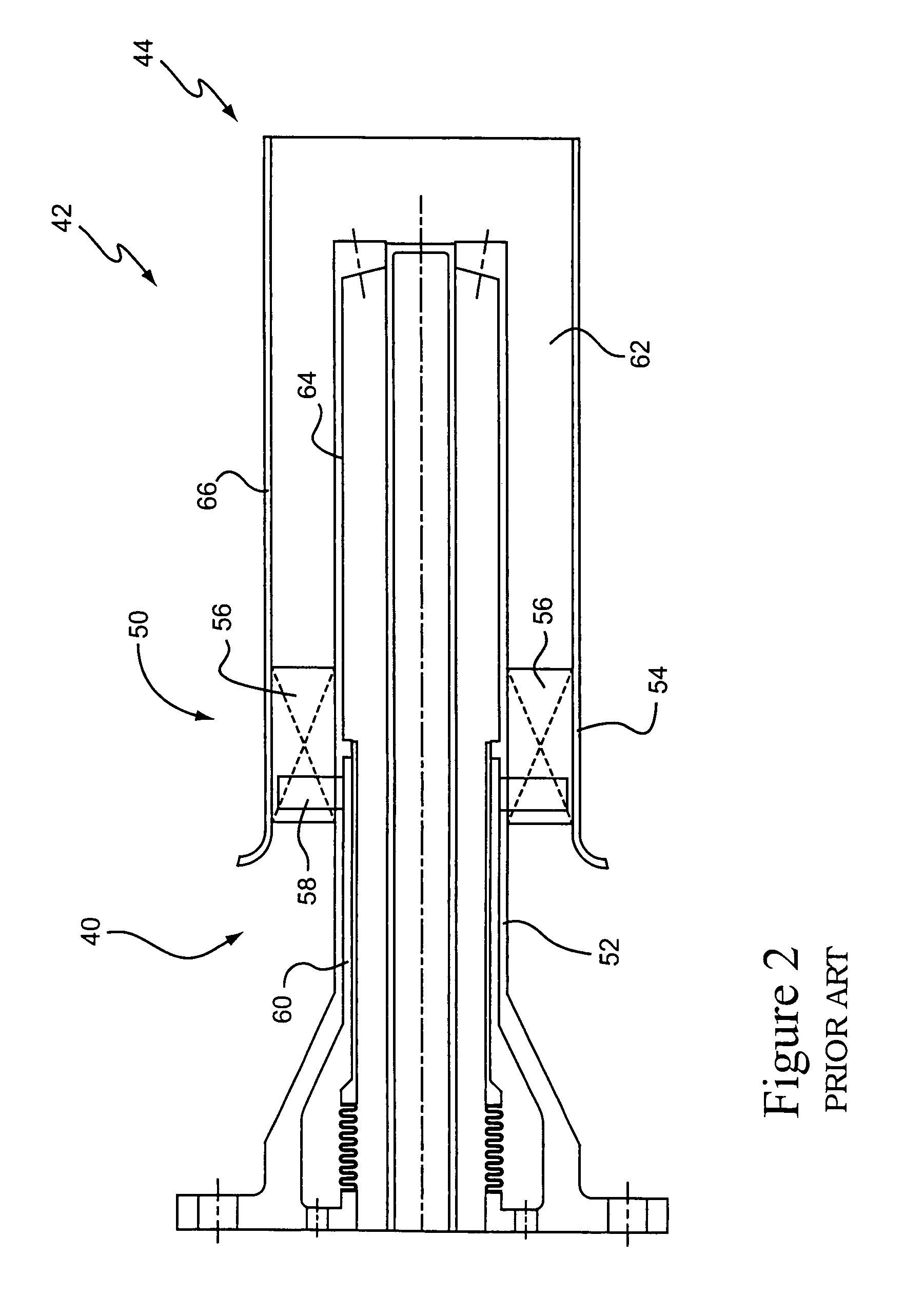

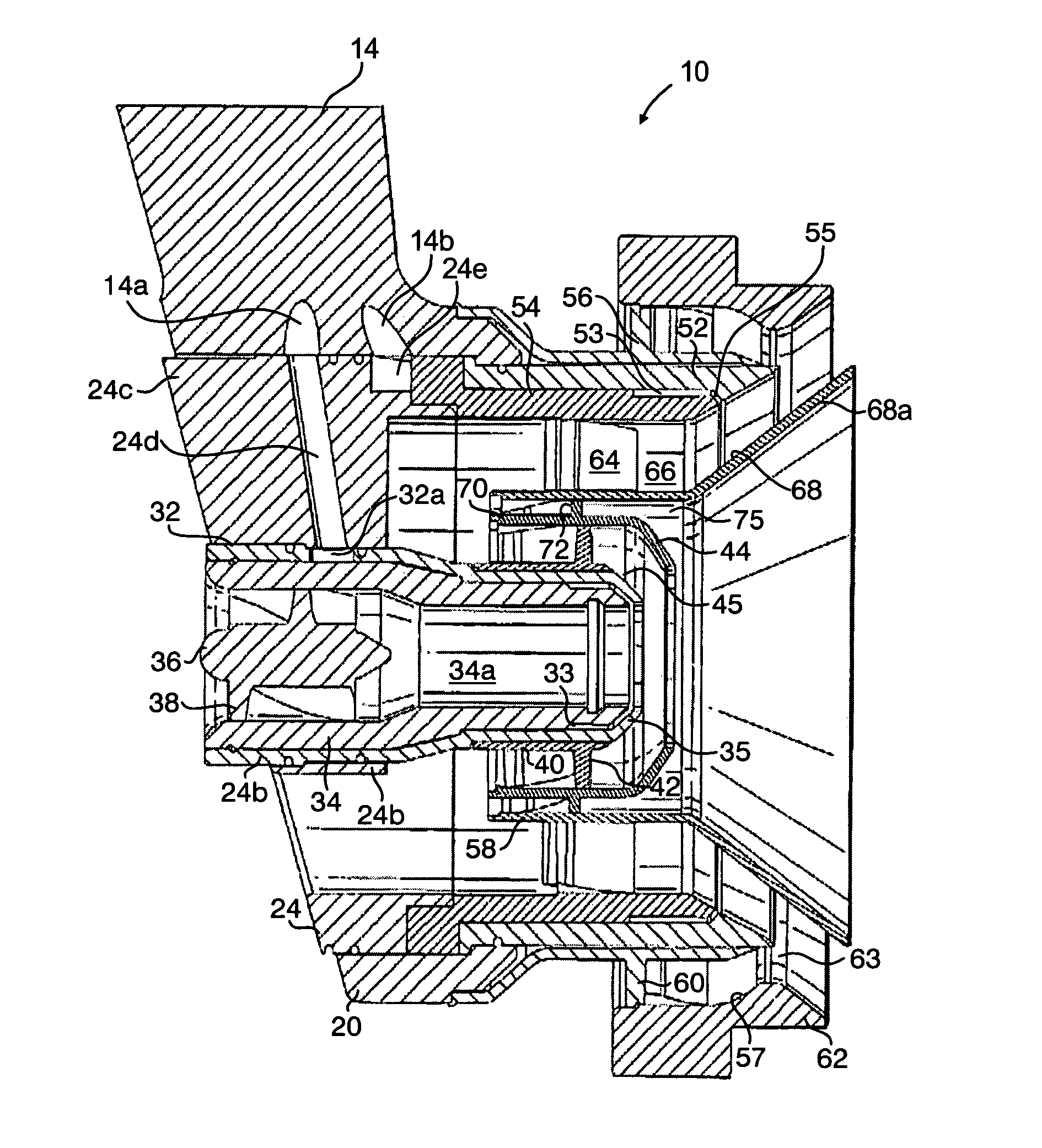

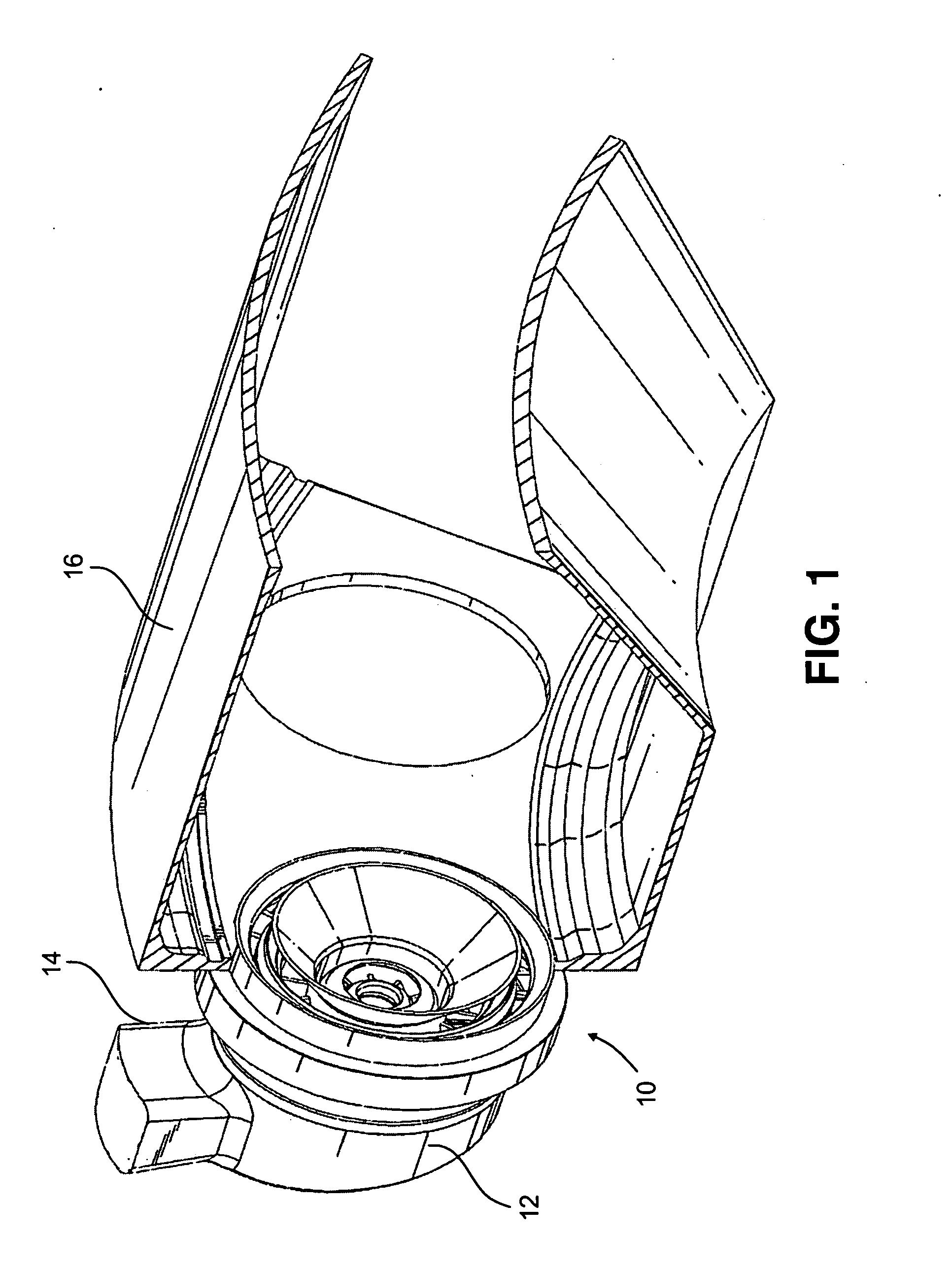

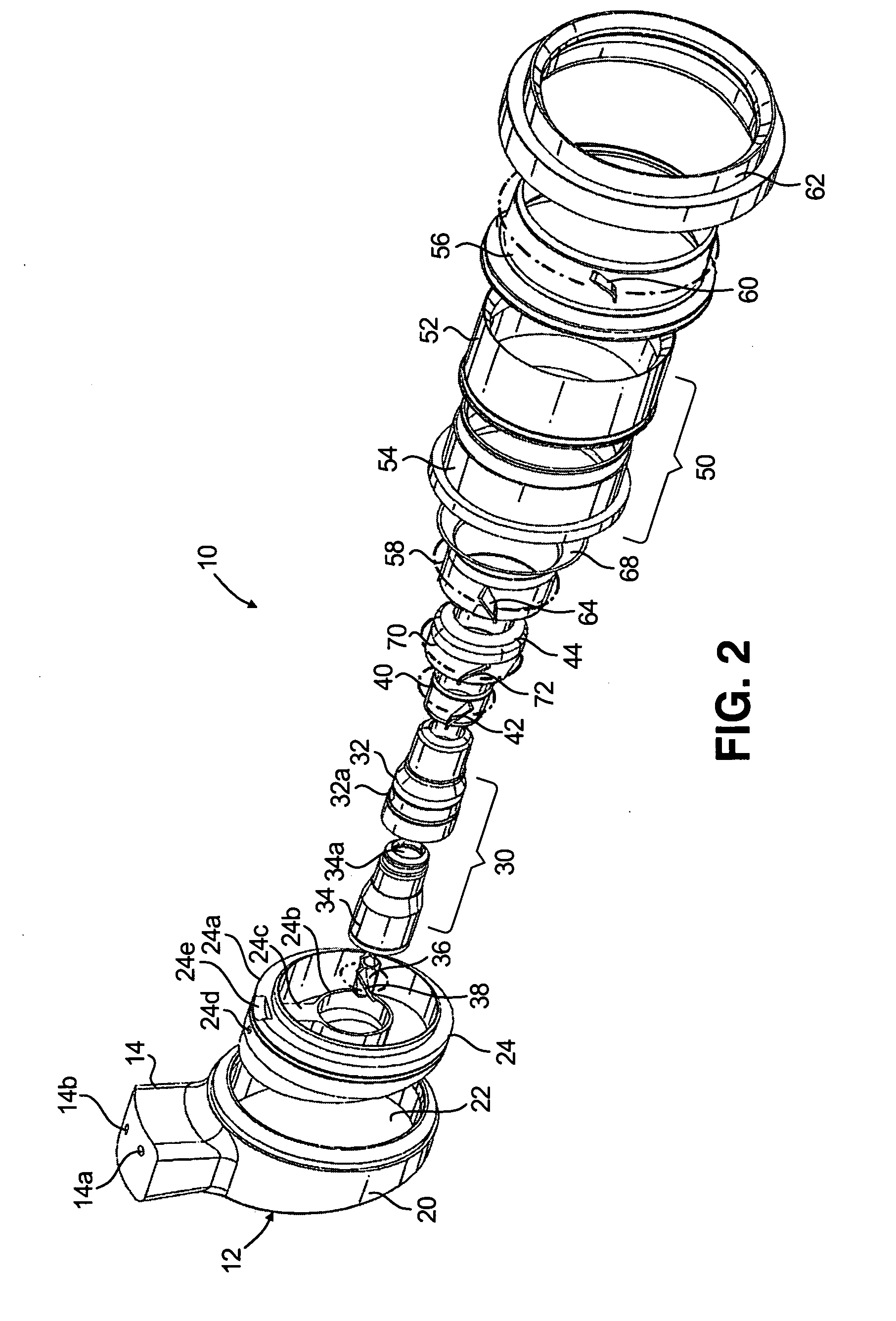

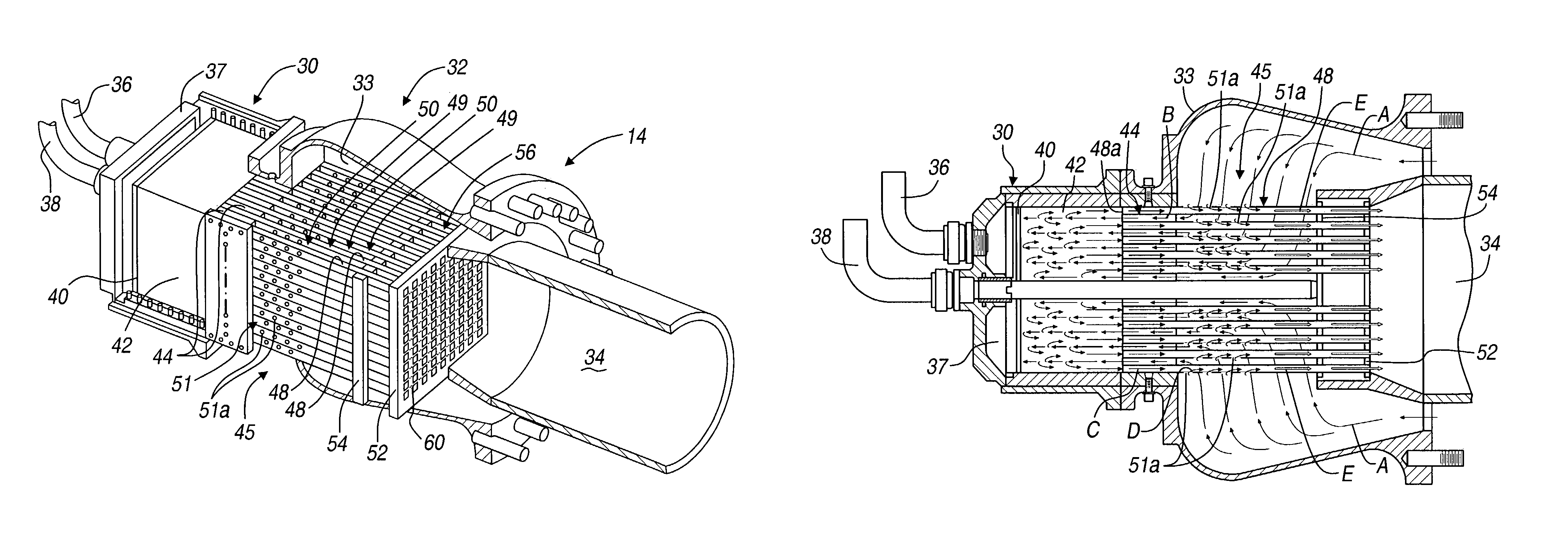

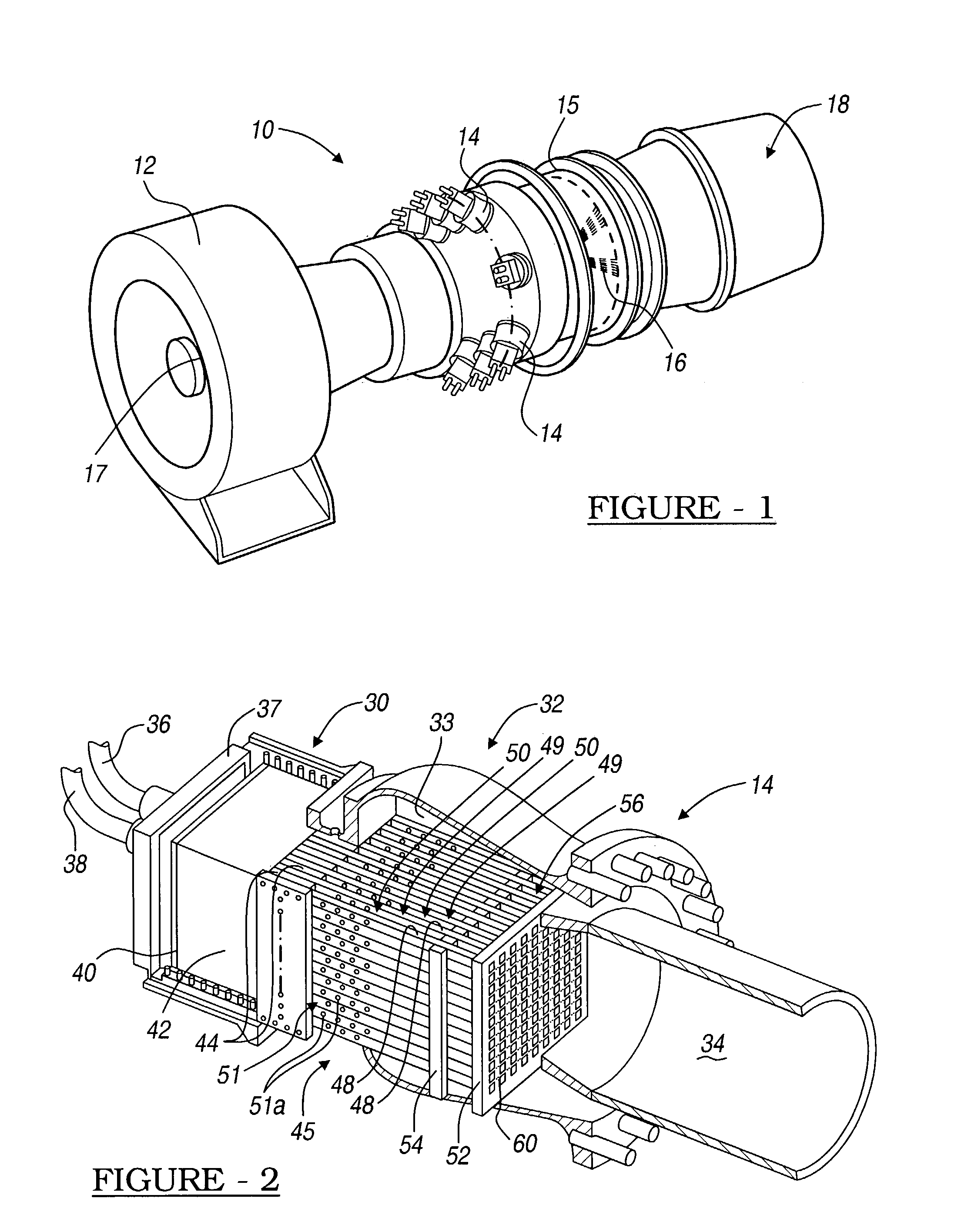

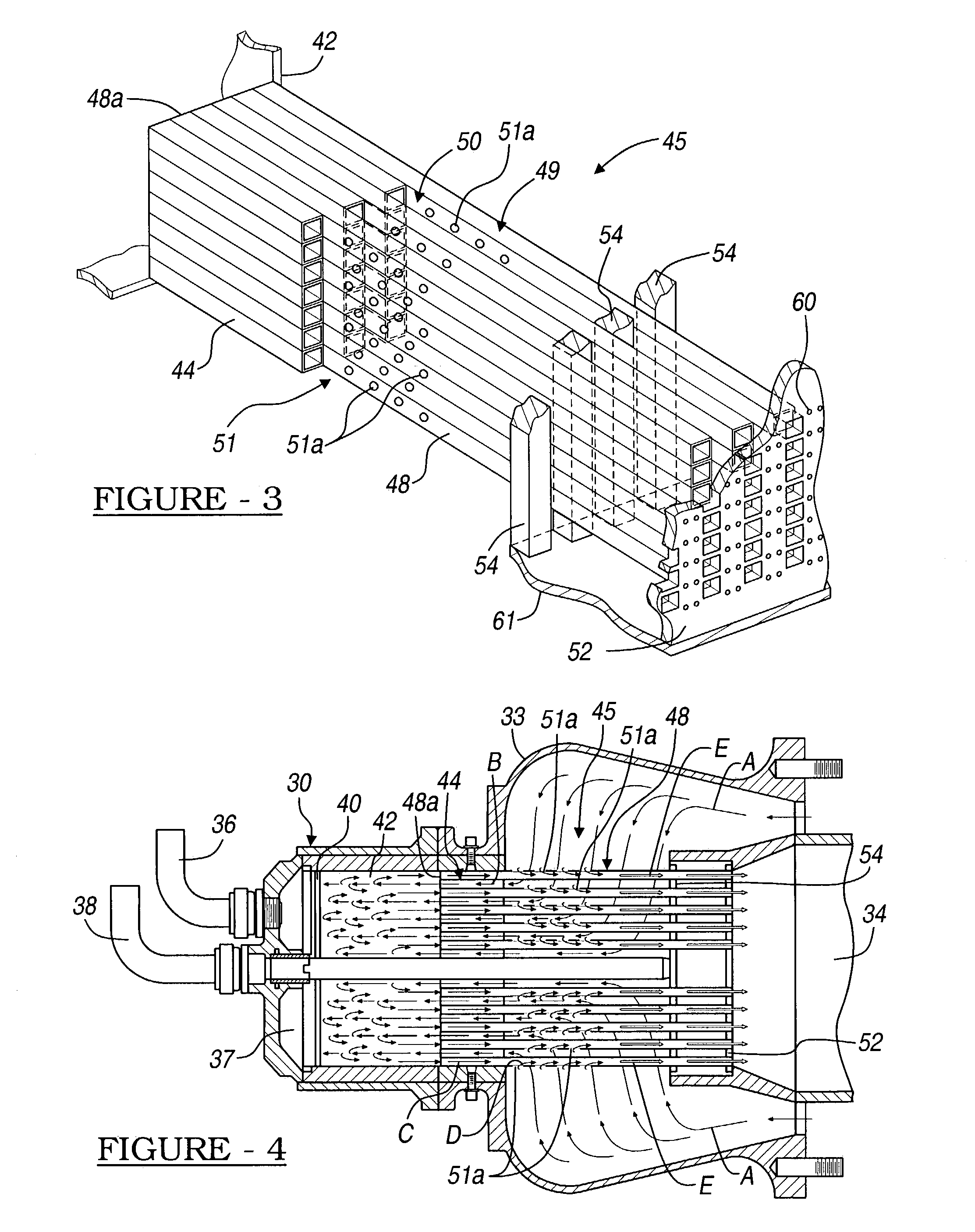

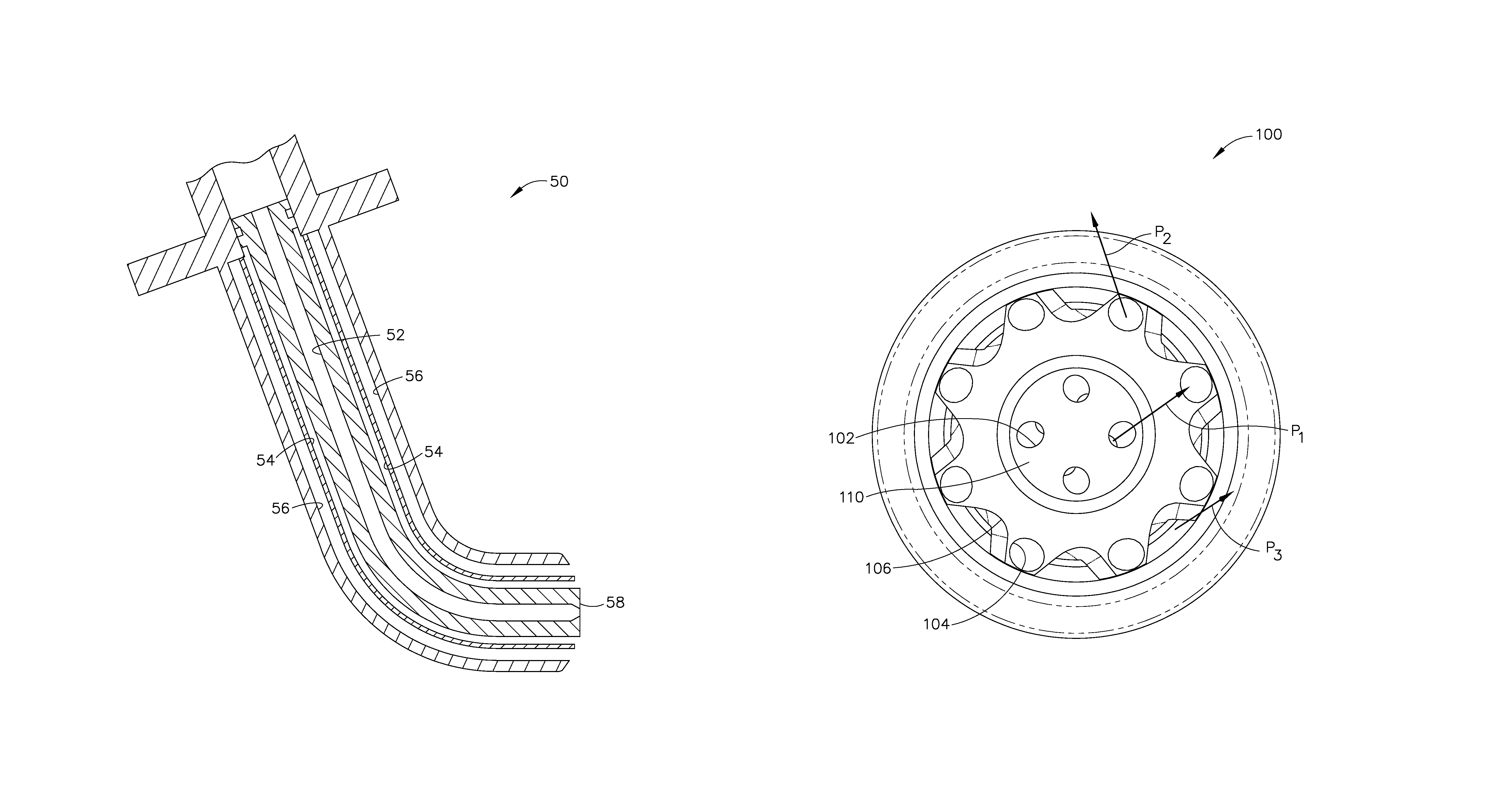

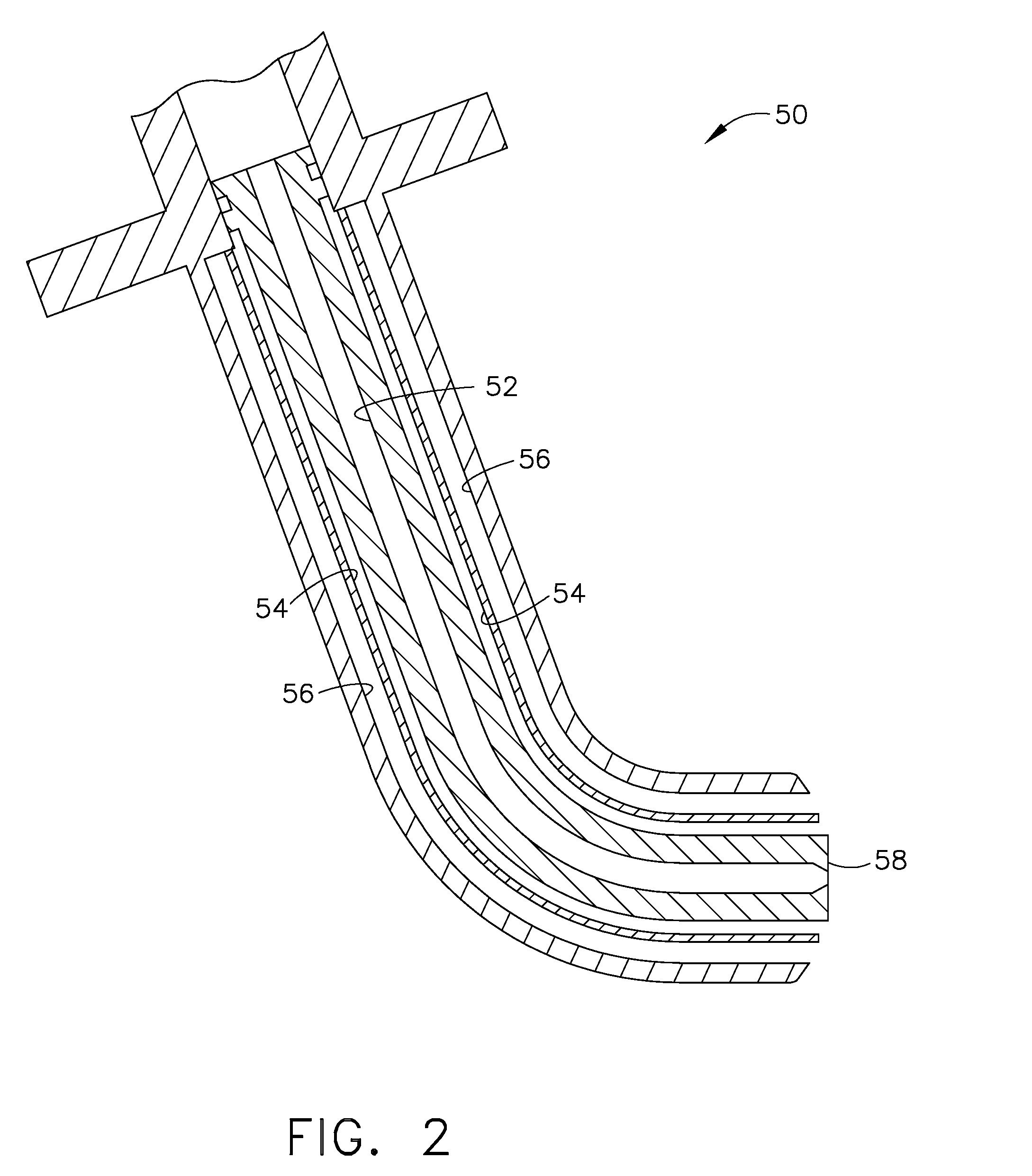

Fuel-air premixing system for a catalytic combustor

InactiveUS7093445B2Continuous combustion chamberTurbine/propulsion fuel supply systemsCombustion systemHybrid system

Disclosed is a unique fuel and air premixing system for a gas turbine catalytic combustion system. The mixer utilizes a multi-channel counter-rotating swirler with aerodynamically shaped fuel pegs located upstream of the swirler. The premixing system provides the downstream catalyst with a fuel-air mixture sufficiently uniform for proper catalyst operation and wide operating limits. Features have been incorporated in the system to make it resistant to flameholding.

Owner:KAWASAKI HEAVY IND LTD

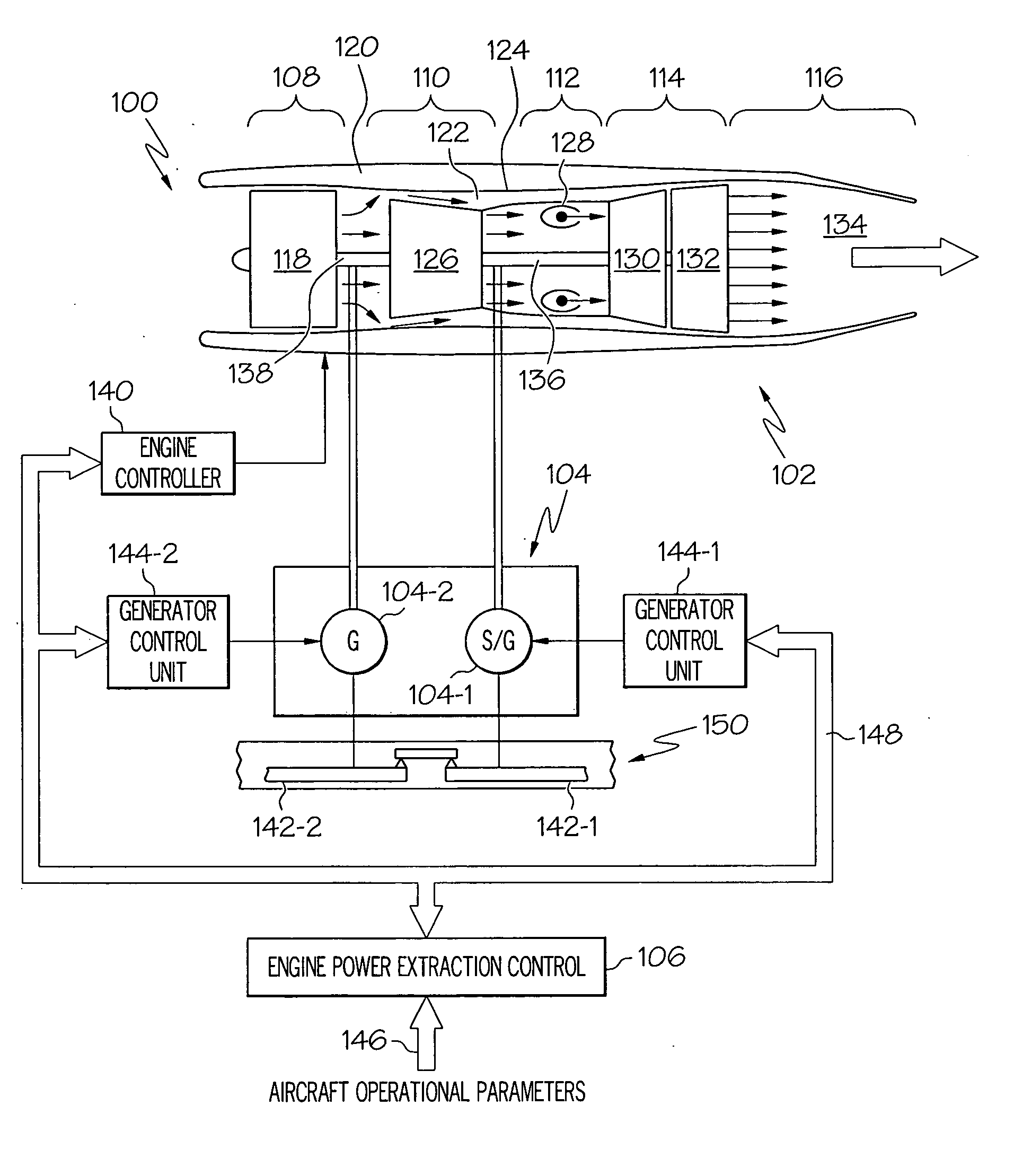

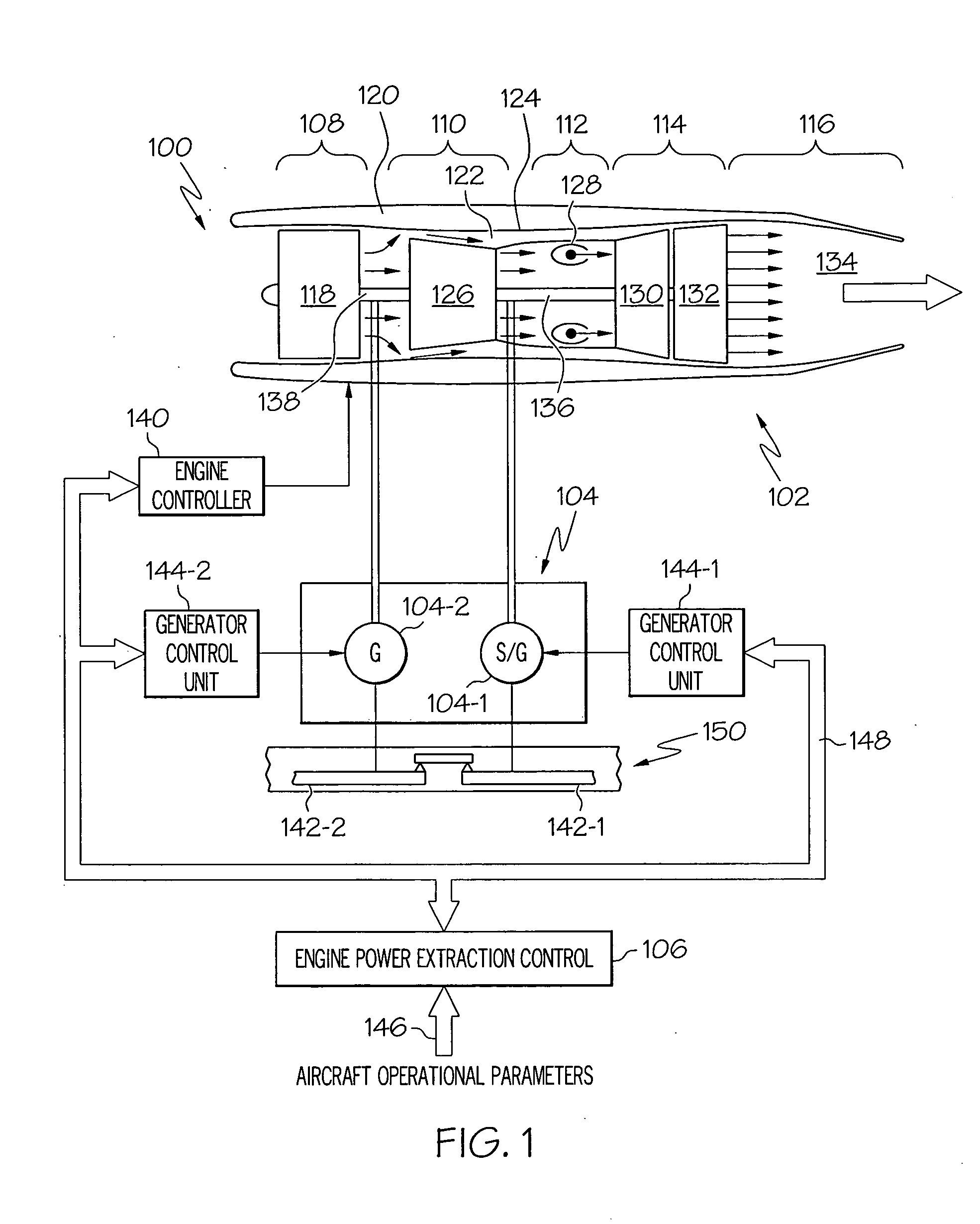

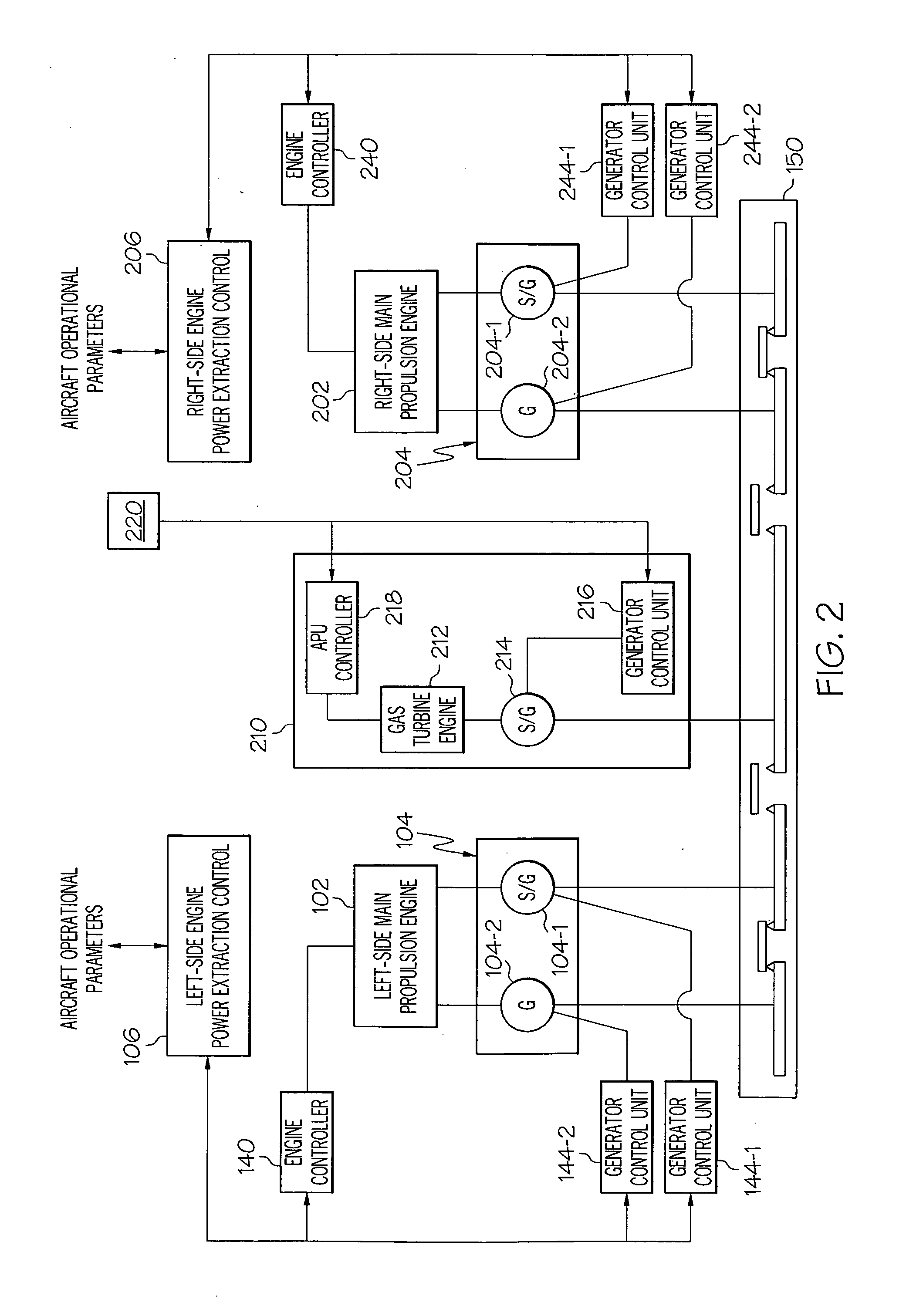

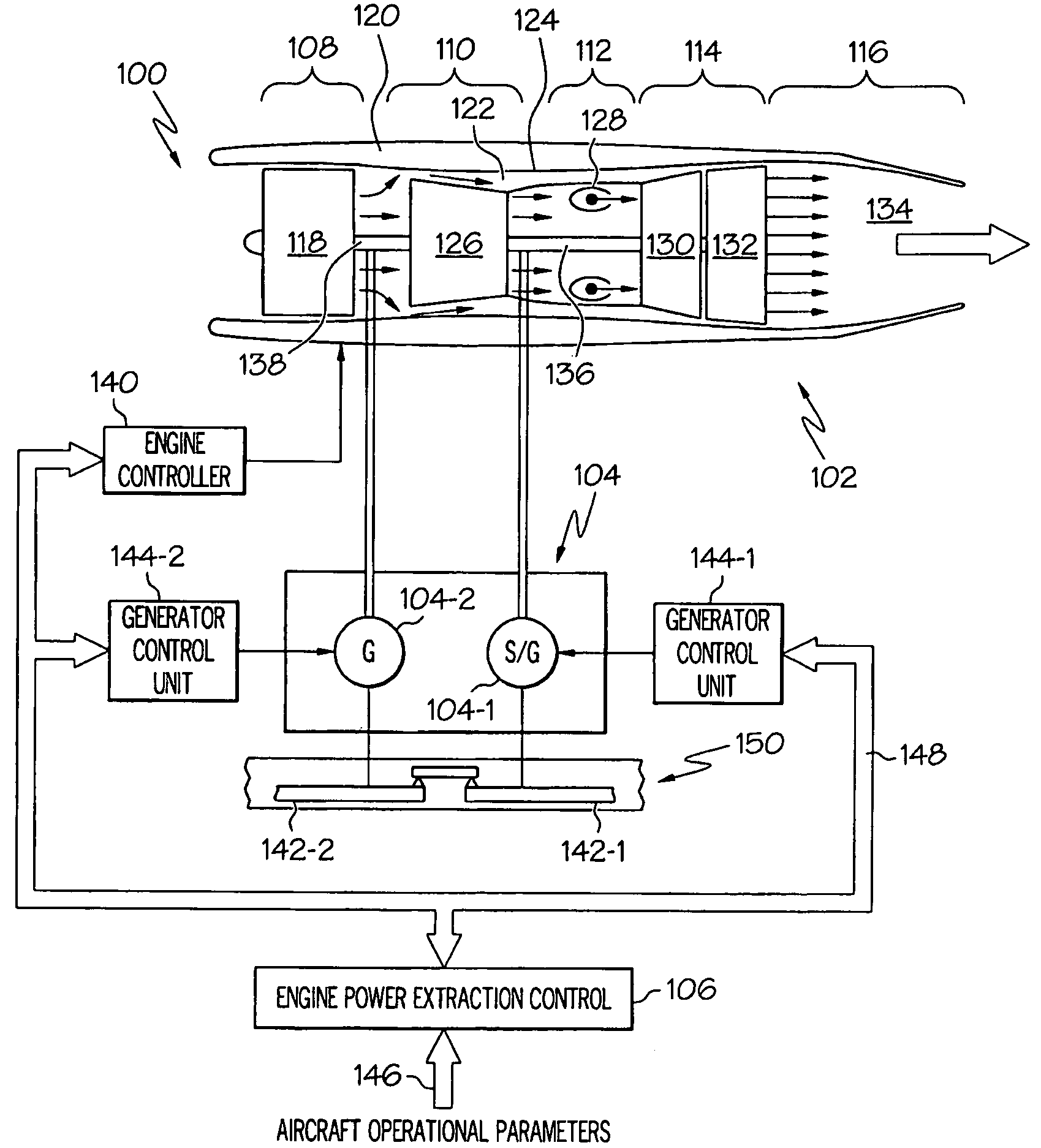

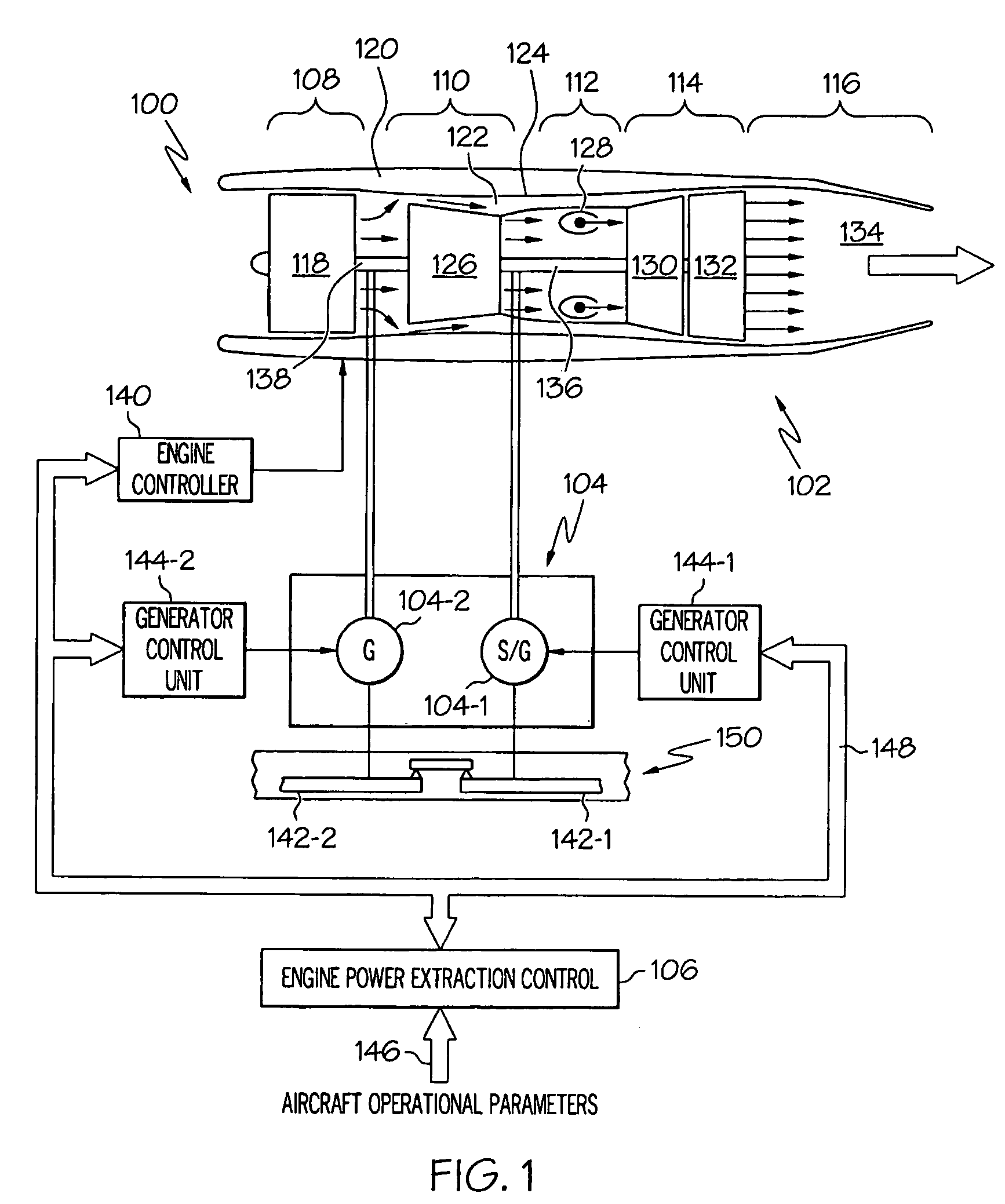

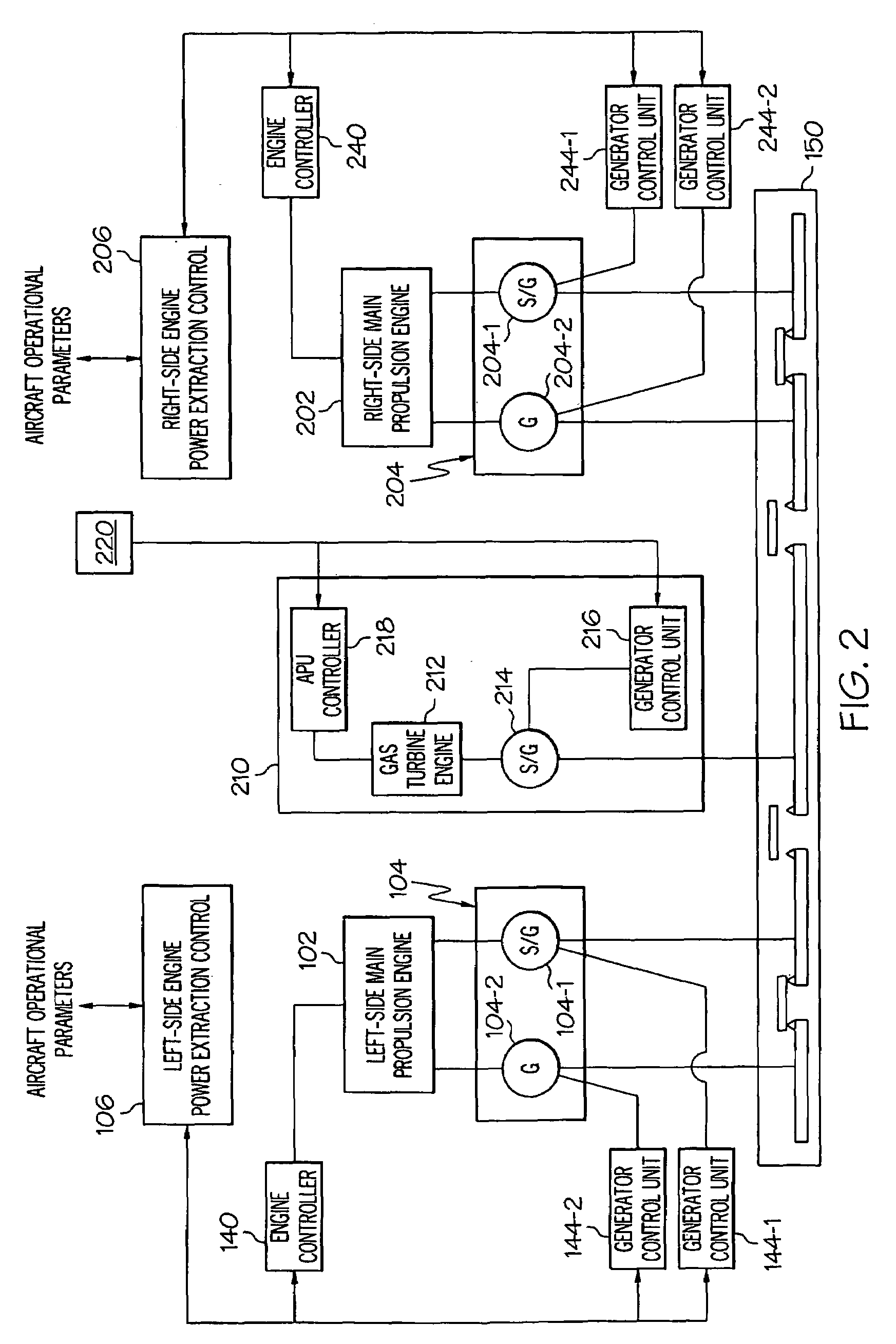

Engine power extraction control system

ActiveUS20060042252A1Increase propulsionEasy to operateReciprocating combination enginesTurbine/propulsion engine ignitionControl systemElectric machine

An engine power extraction control system controls the main propulsion engines and the electrical machines that are coupled thereto to supply an appropriate amount of aircraft thrust and electrical energy to the aircraft. The engines and electrical machines are also controlled so that the propulsion thrust that is generated is split between the various turbines in the main propulsion engines to maintain an adequate surge margin and to minimize residual thrust generation.

Owner:HONEYWELL INT INC

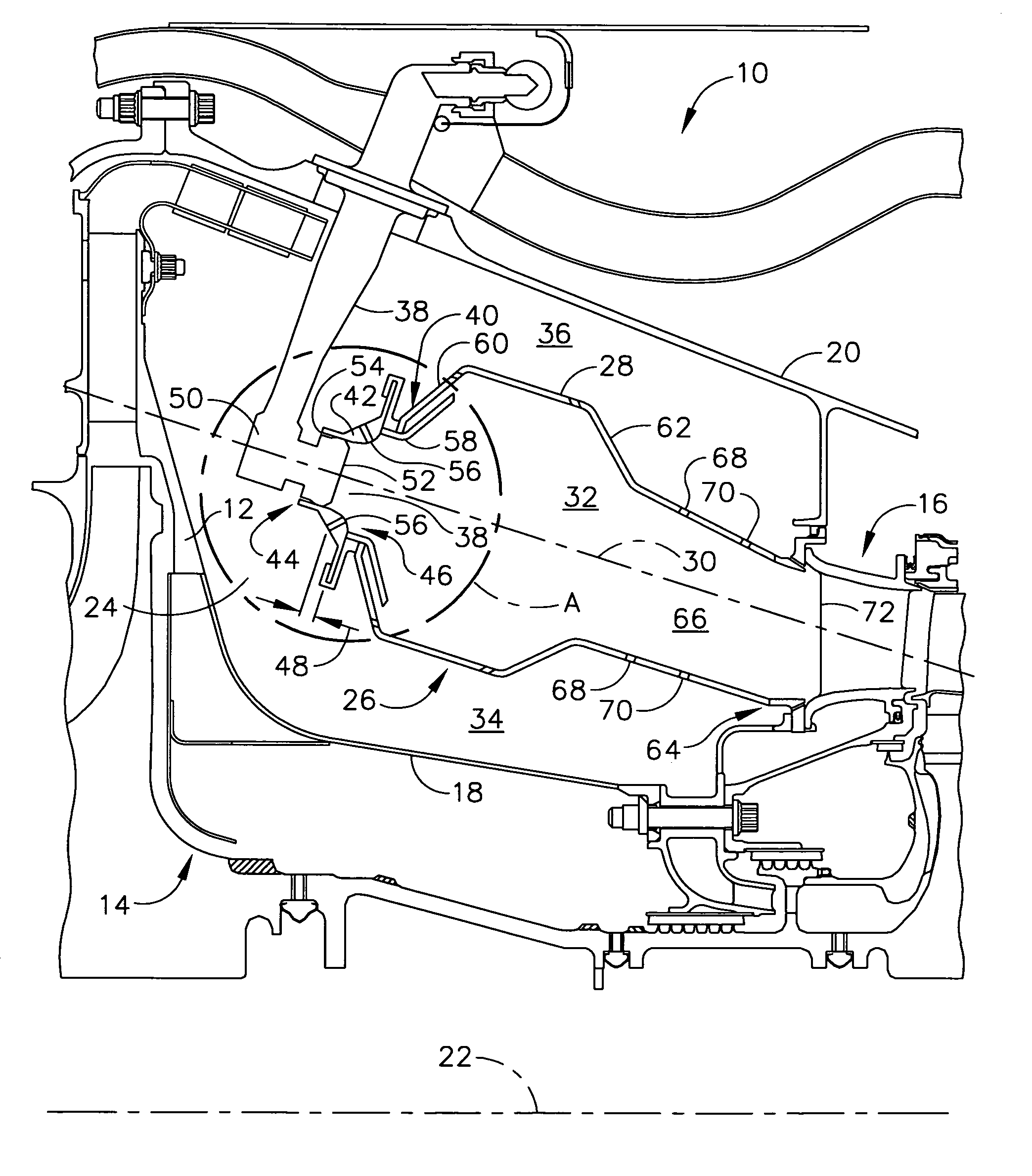

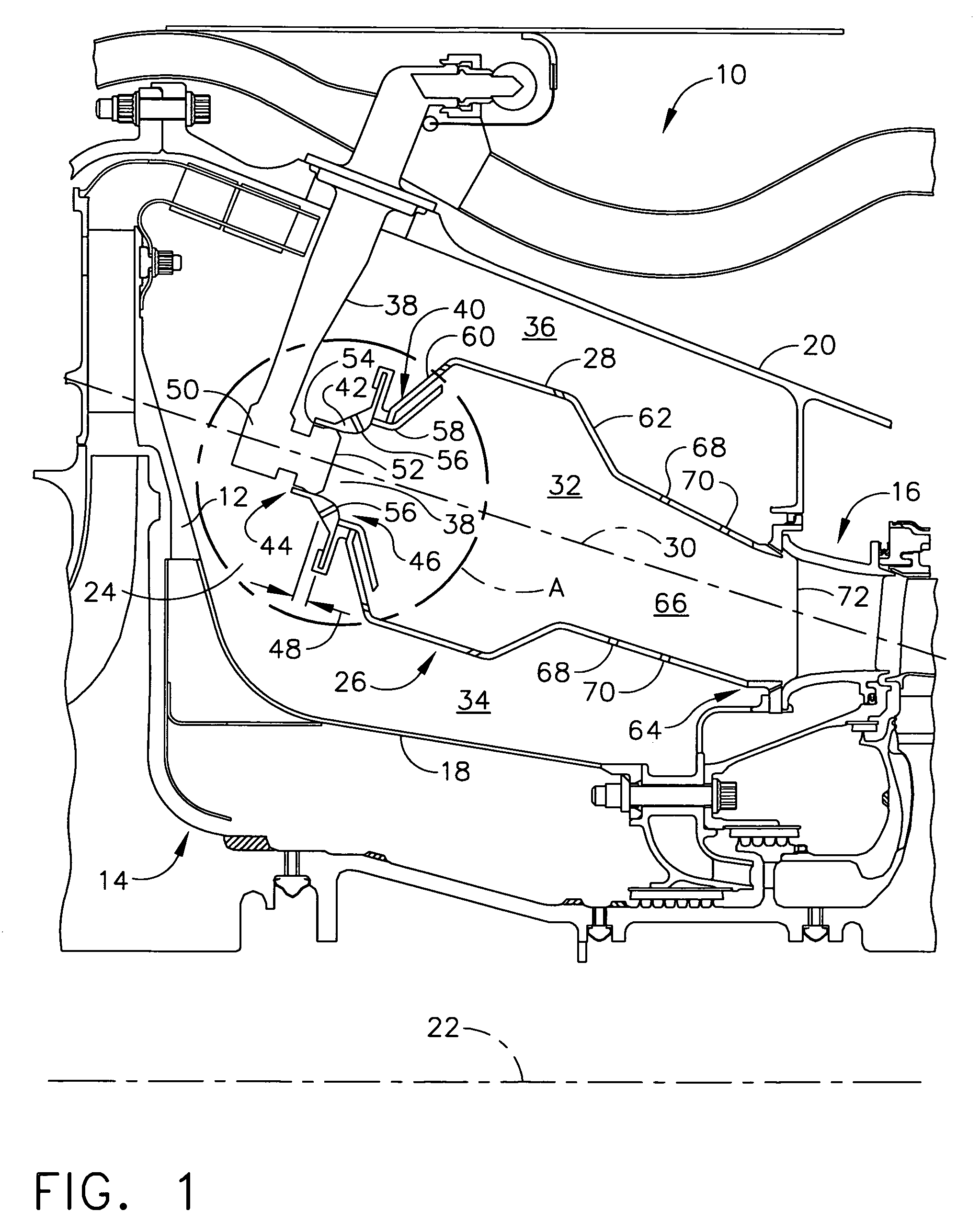

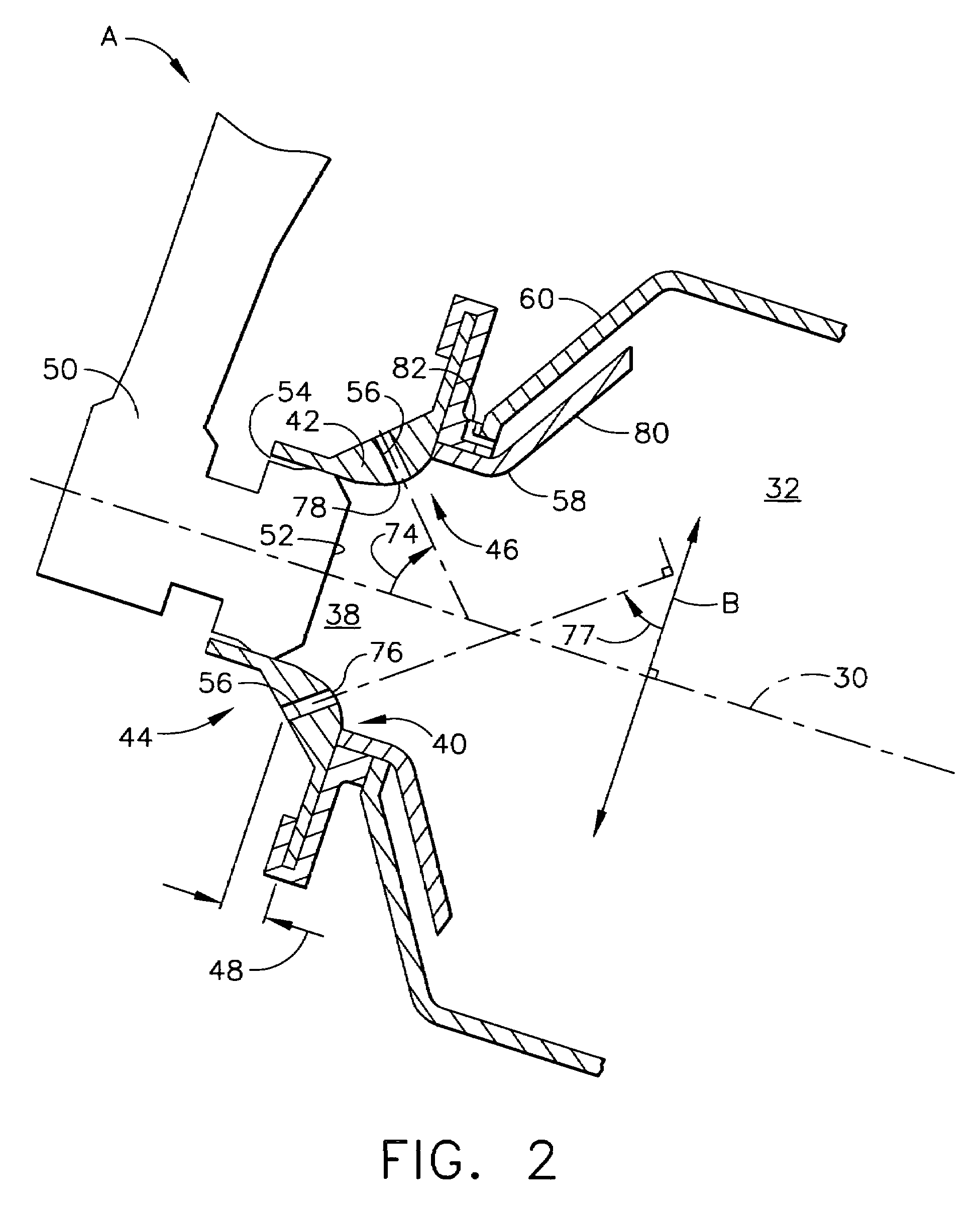

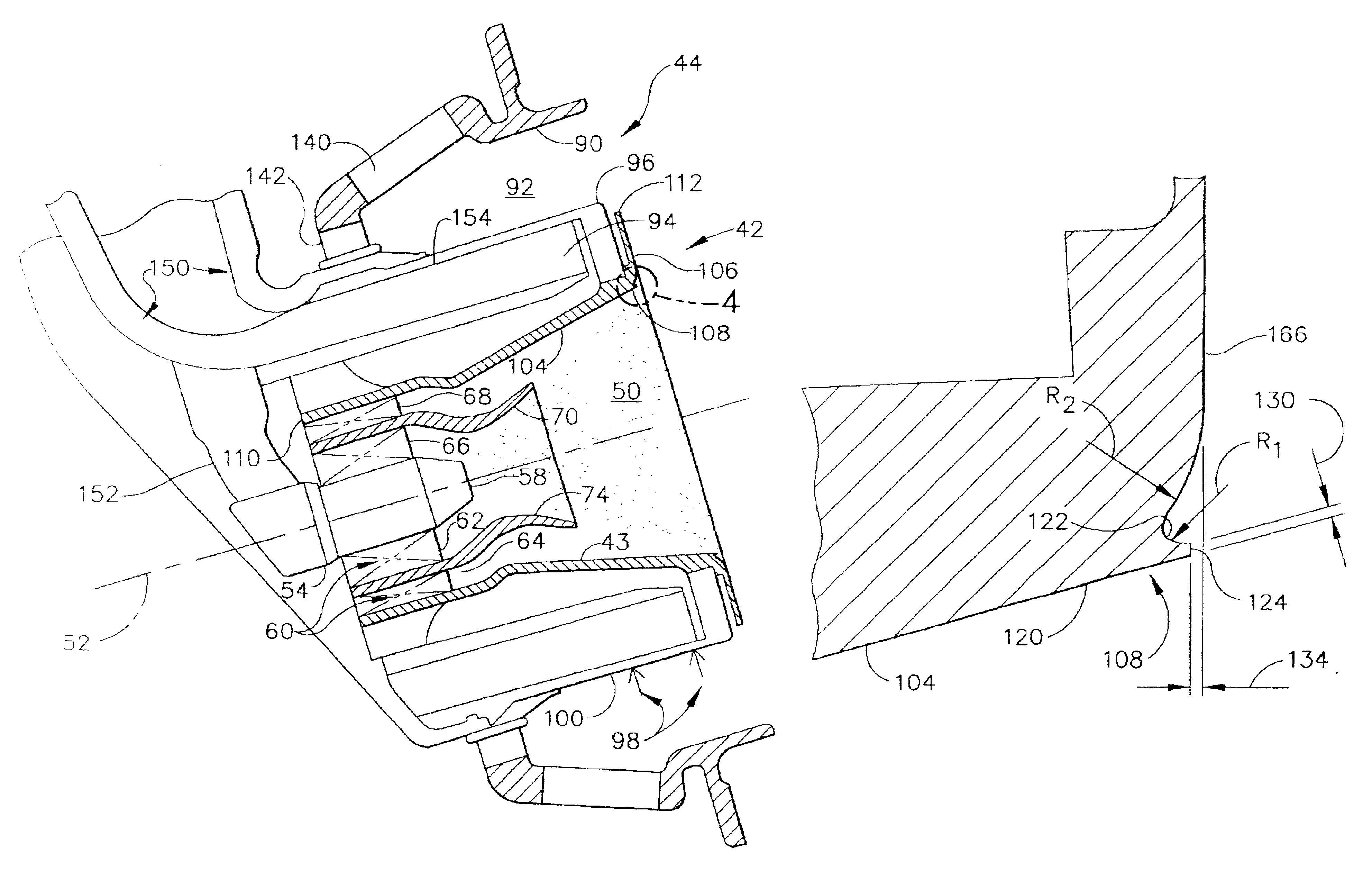

Lean direct injection atomizer for gas turbine engines

ActiveUS20060248898A1Increase pressureBurnersContinuous combustion chamberGas turbinesDelivery system

A lean direct injection fuel nozzle for a gas turbine is disclosed which includes a radially outer main fuel delivery system including a main inner air swirler defined in part by a main inner air passage having a radially inner wall with a diverging downstream surface, an intermediate air swirler radially inward of the main inner air swirler for providing a cooling air flow along the downstream surface of the radially inner wall of the main inner air passage, and a radially inner pilot fuel delivery system radially inward of the intermediate air swirler.

Owner:ROLLS ROYCE PLC

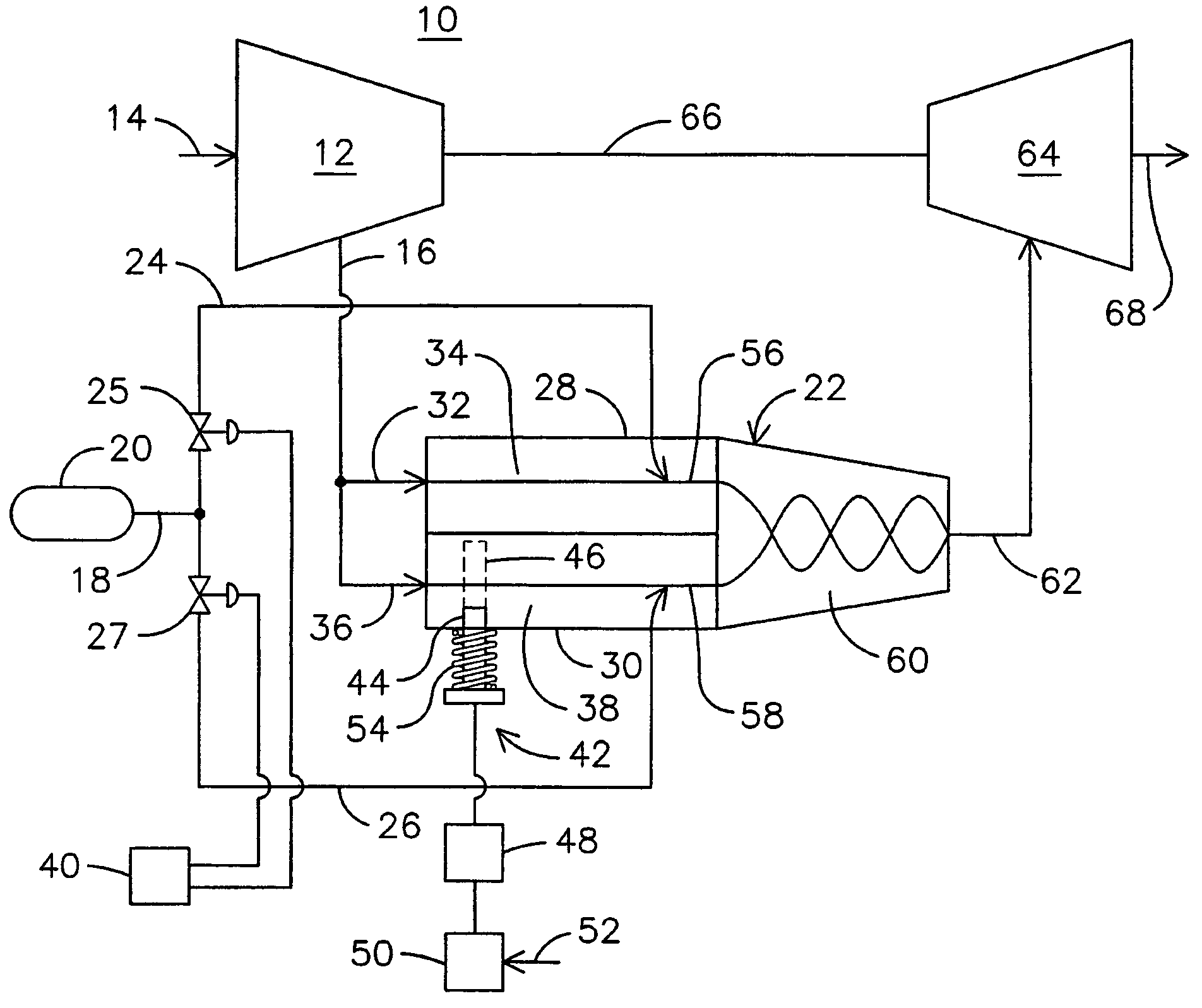

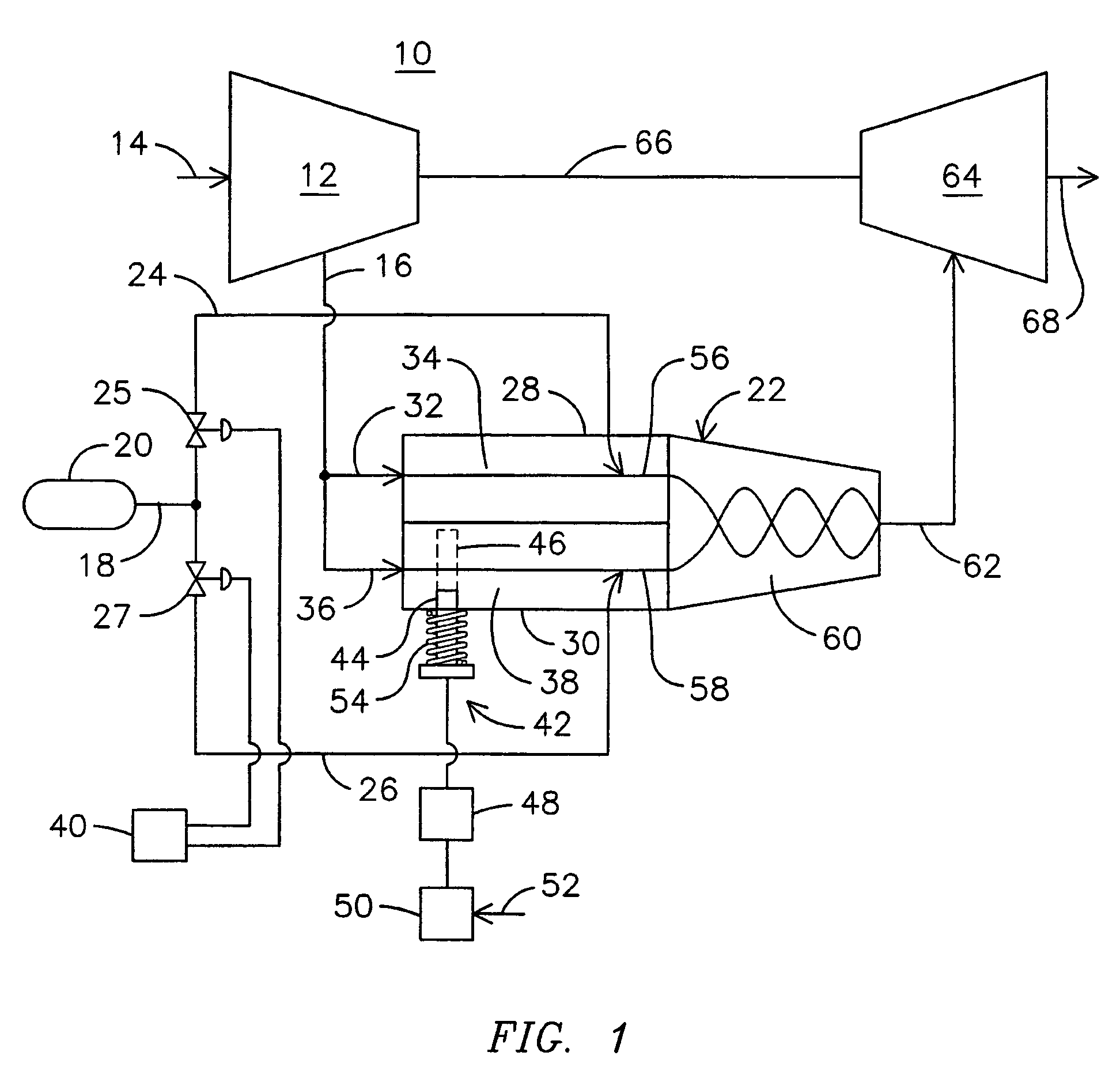

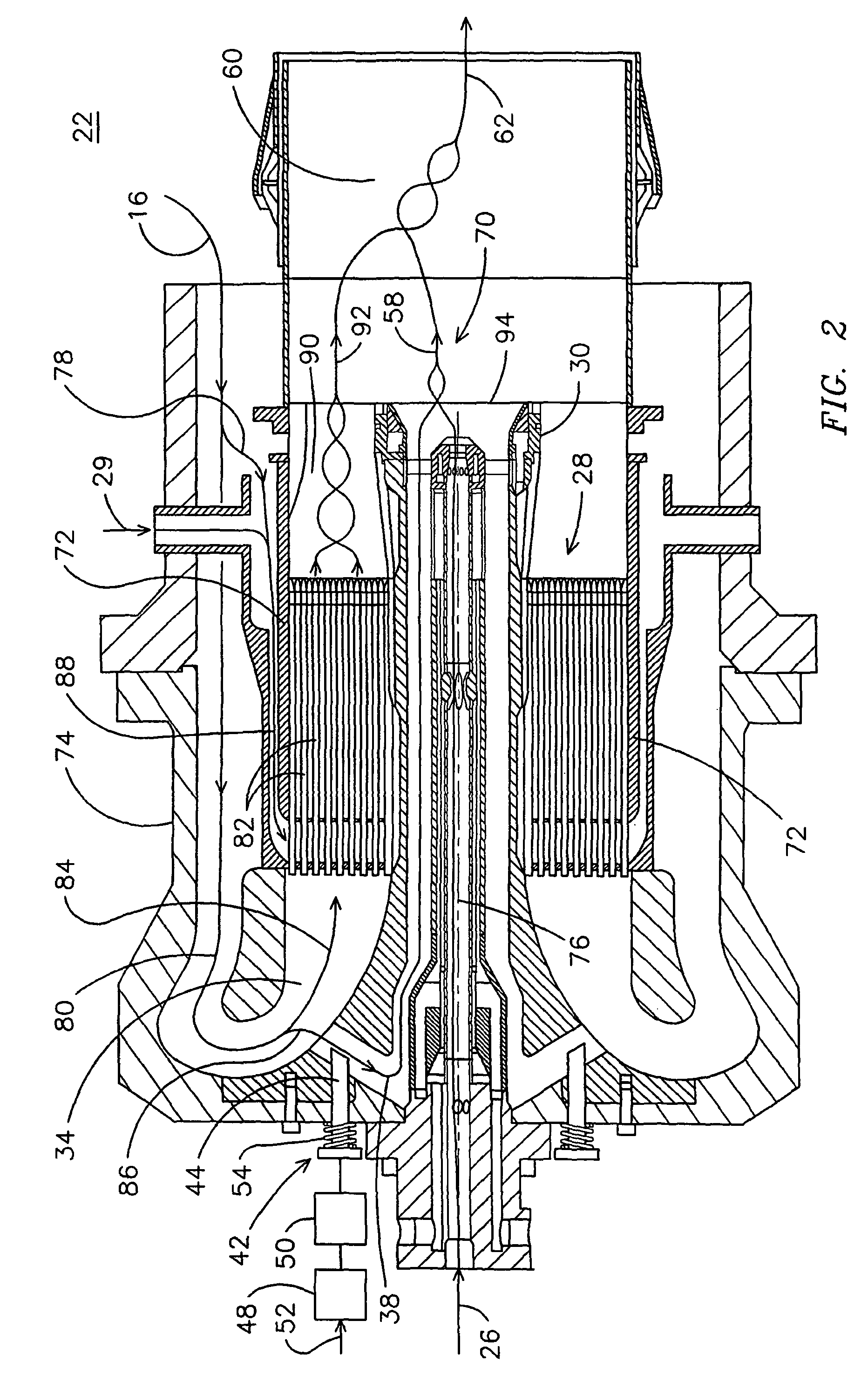

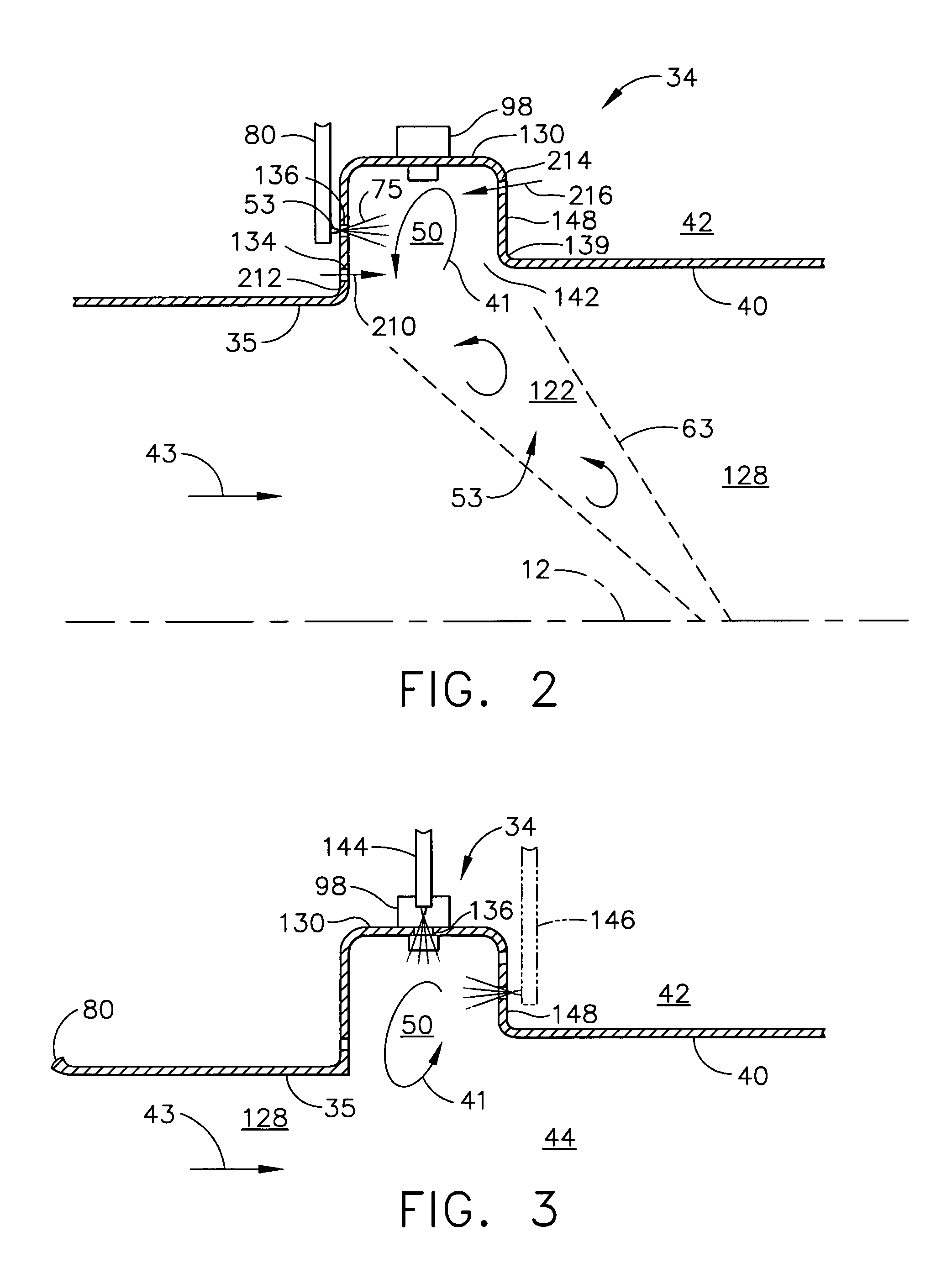

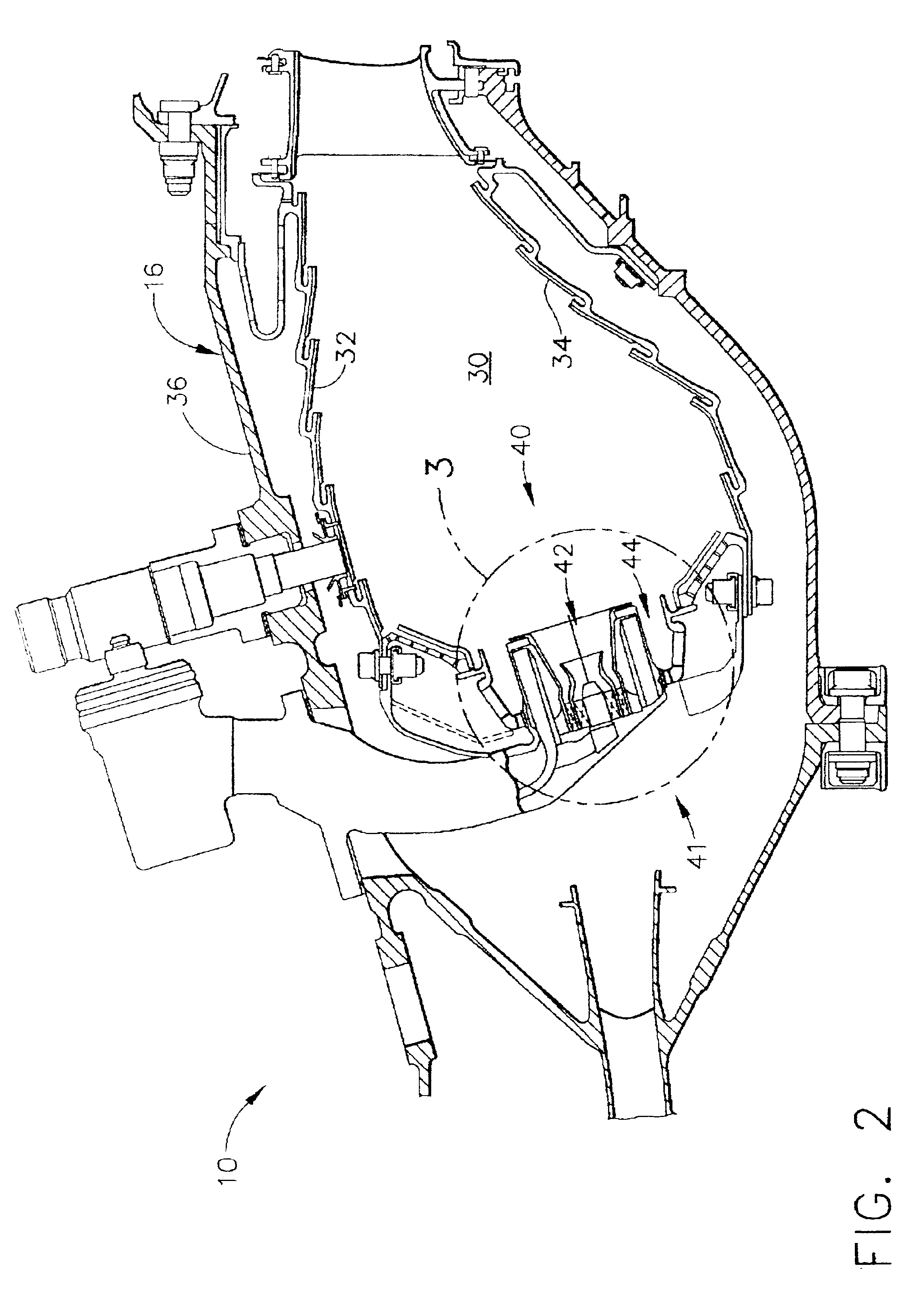

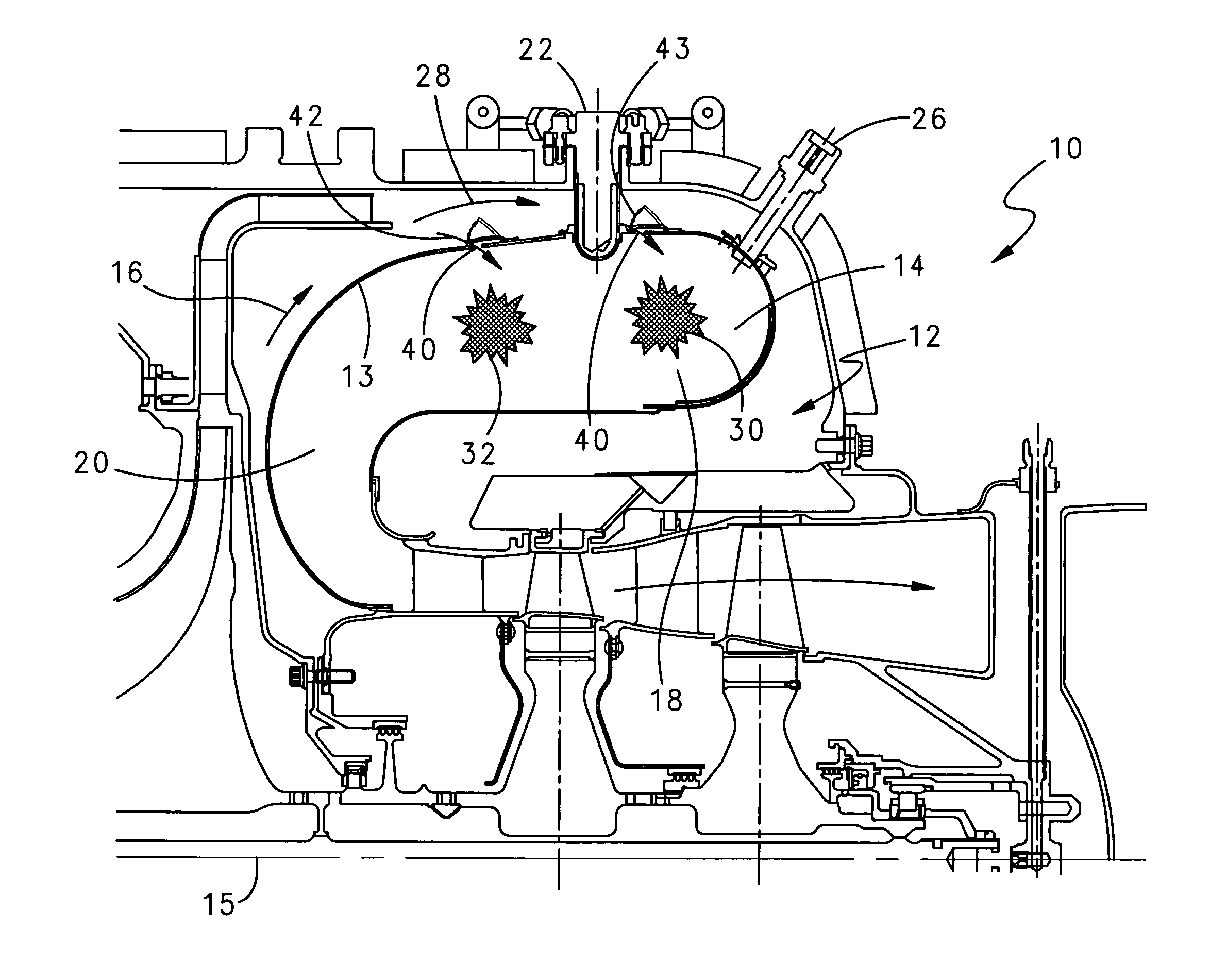

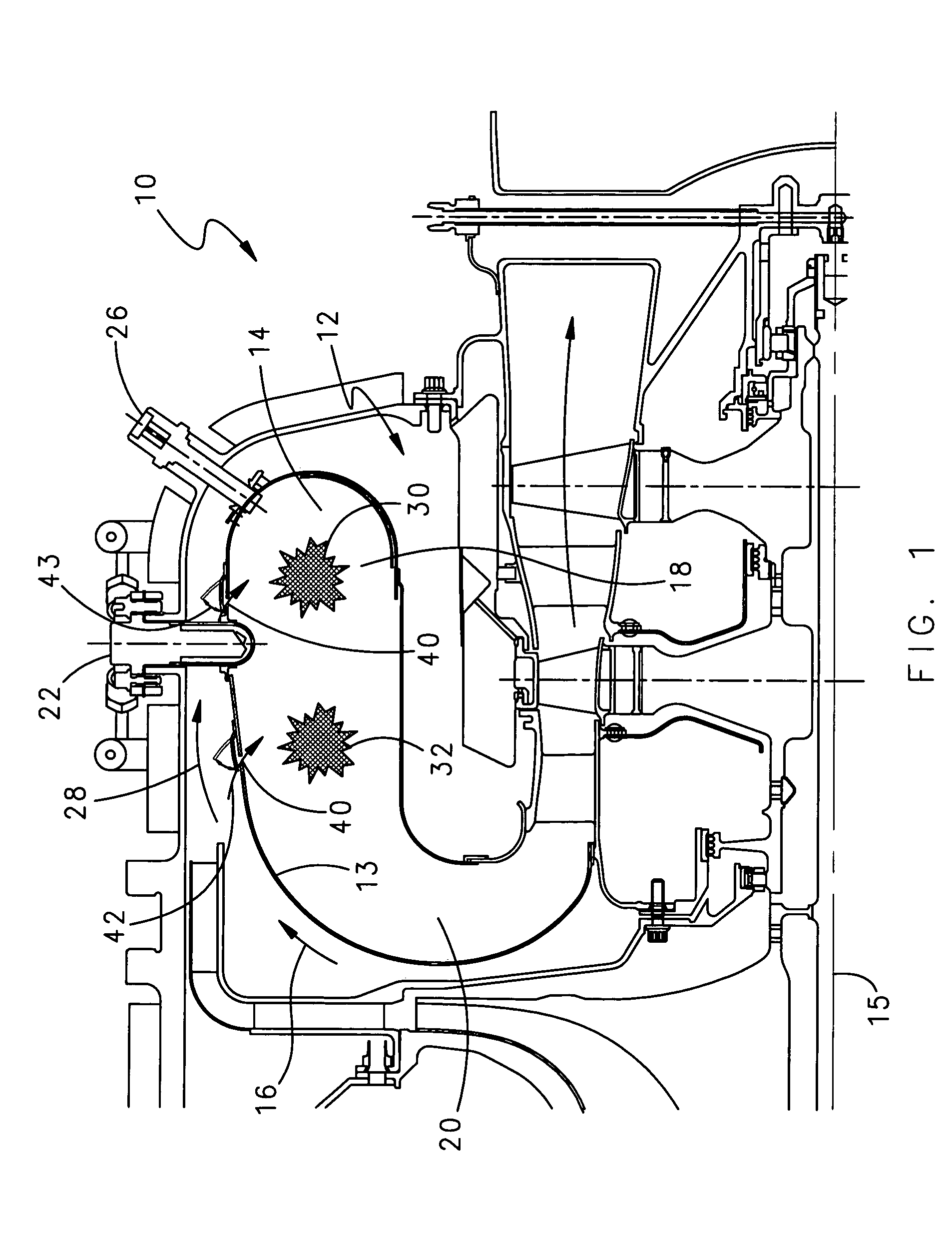

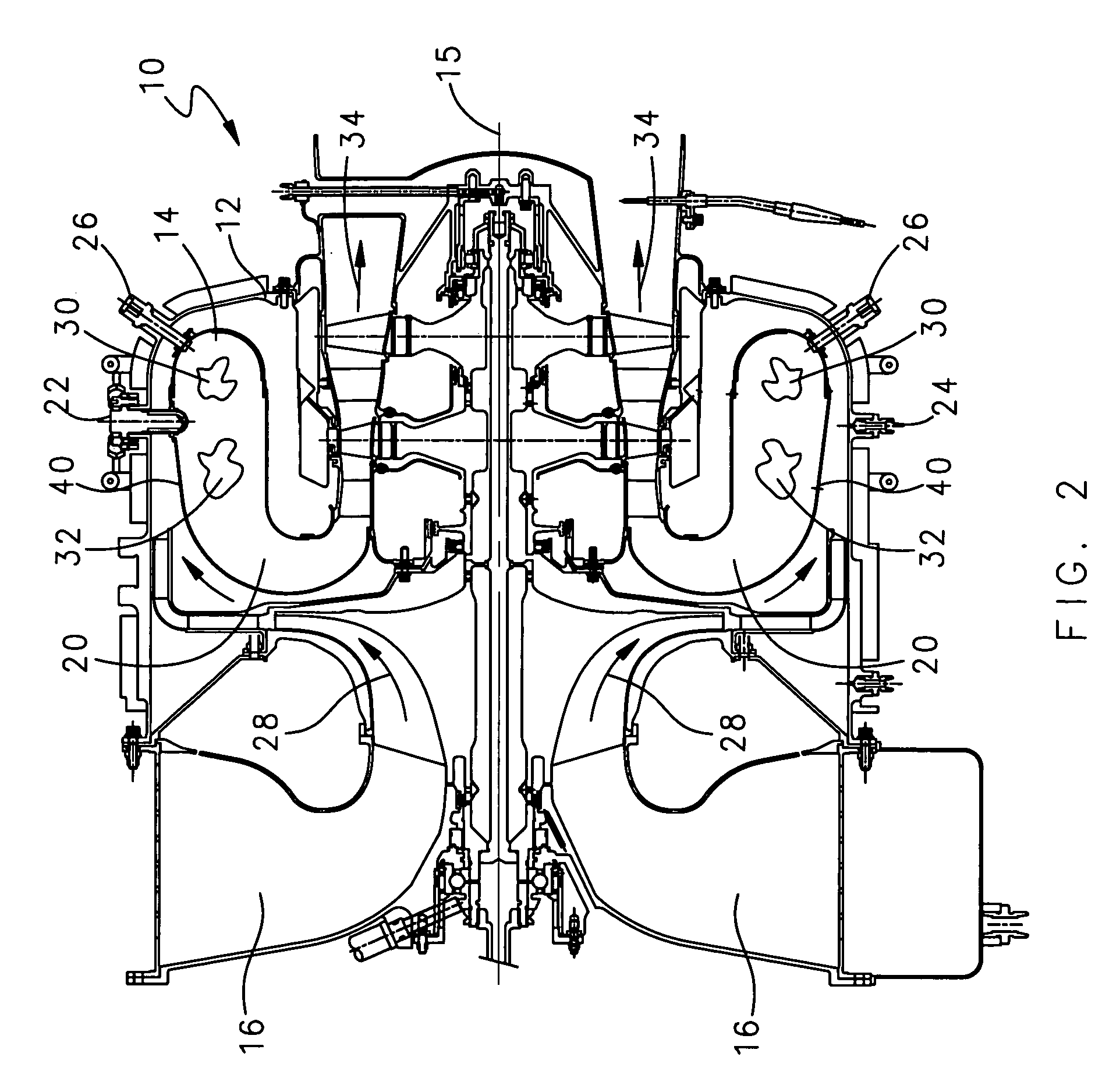

Controlled pilot oxidizer for a gas turbine combustor

InactiveUS7752850B2Turbine/propulsion fuel supply systemsContinuous combustion chamberCombustorCombustion chamber

A combustor (22) for a gas turbine (10) includes a main burner oxidizer flow path (34) delivering a first portion (32) of an oxidizer flow (e.g., 16) to a main burner (28) of the combustor and a pilot oxidizer flow path (38) delivering a second portion (36) of the oxidizer flow to a pilot (30) of the combustor. The combustor also includes a flow controller (42) disposed in the pilot oxidizer flow path for controlling an amount of the second portion delivered to the pilot.

Owner:SIEMENS ENERGY INC

Engine power extraction control system

ActiveUS7285871B2Increase propulsionEasy to operateReciprocating combination enginesTurbine/propulsion engine ignitionControl systemEngine power

An engine power extraction control system controls the main propulsion engines and the electrical machines that are coupled thereto to supply an appropriate amount of aircraft thrust and electrical energy to the aircraft. The engines and electrical machines are also controlled so that the propulsion thrust that is generated is split between the various turbines in the main propulsion engines to maintain an adequate surge margin and to minimize residual thrust generation.

Owner:HONEYWELL INT INC

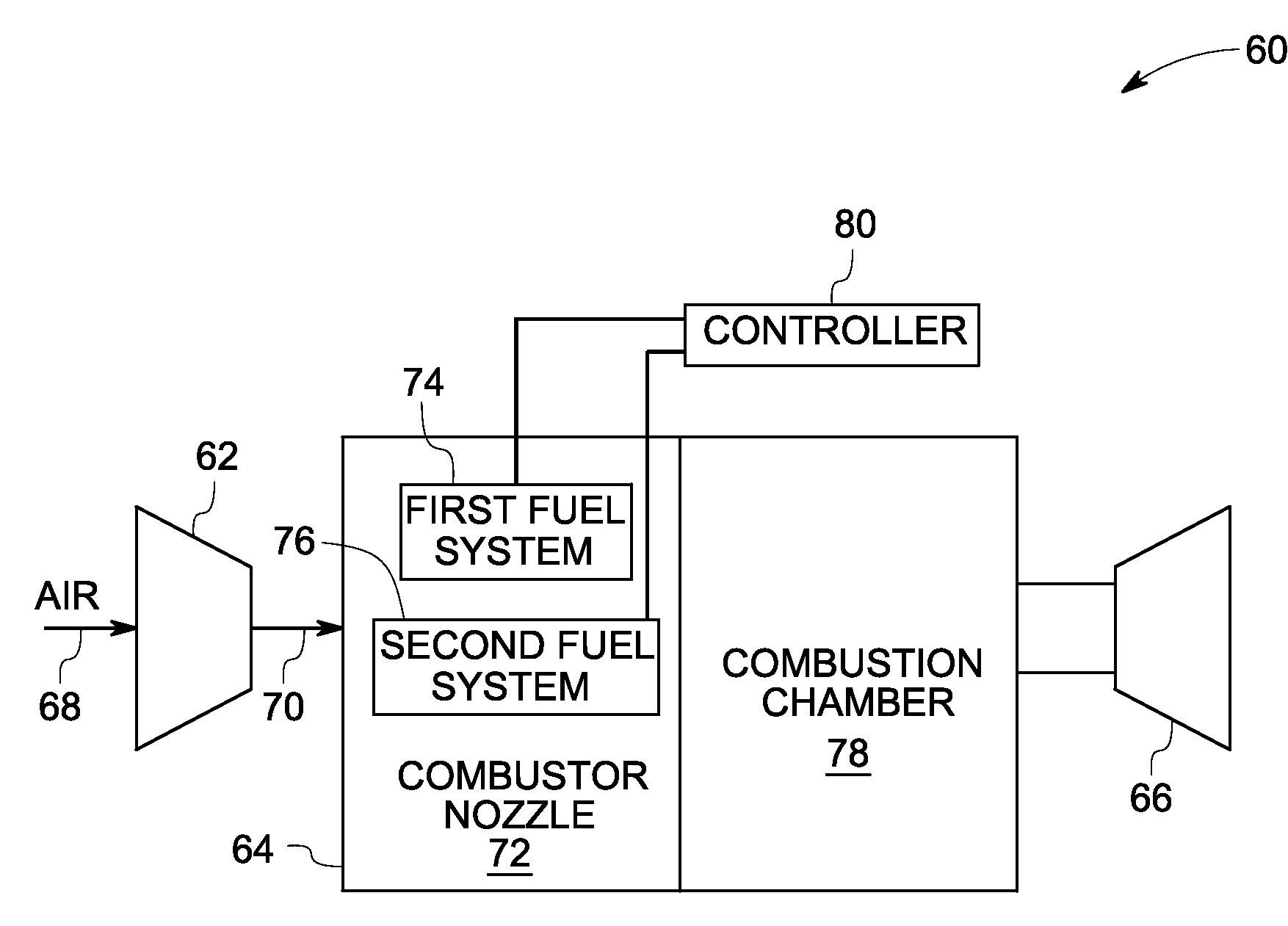

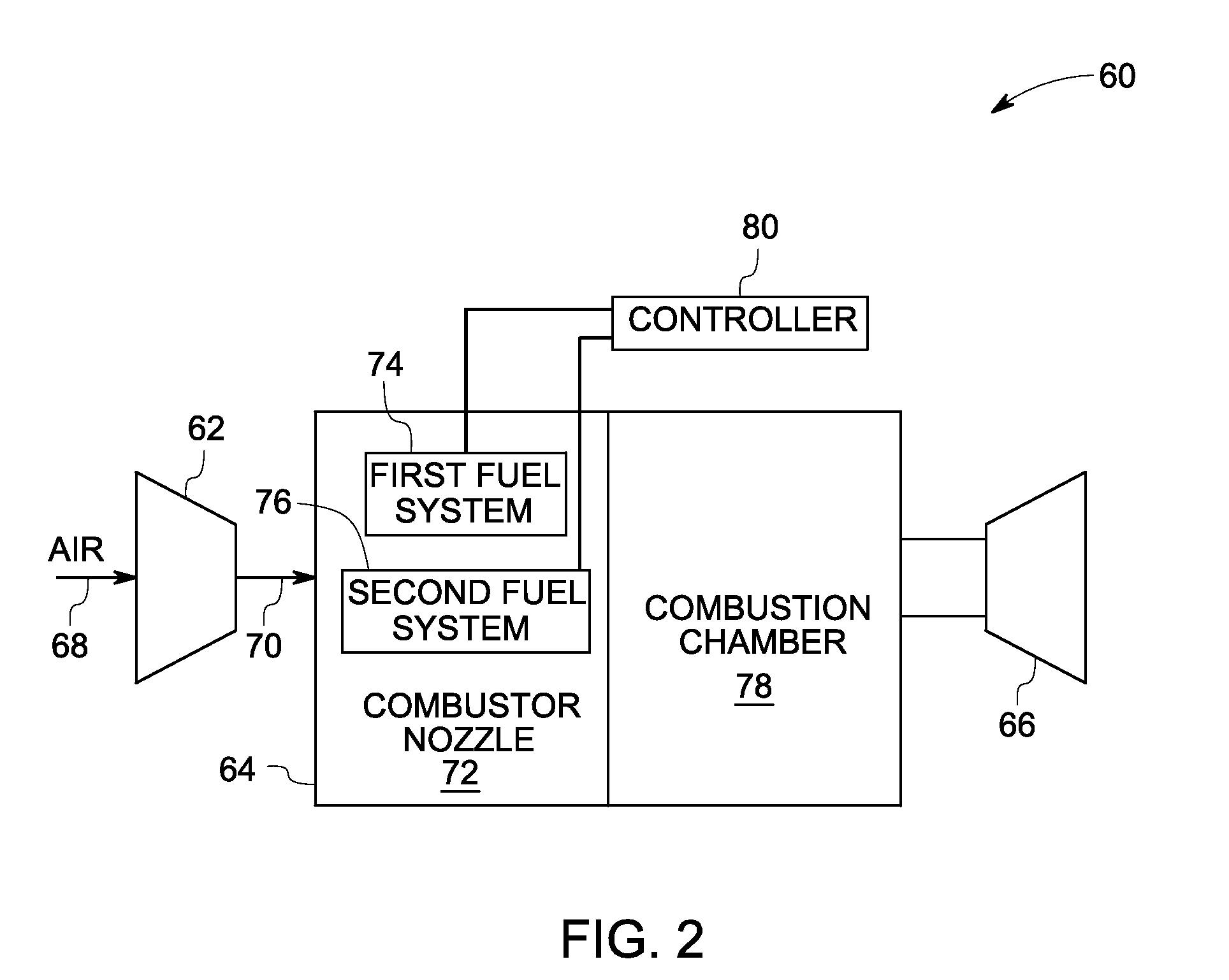

Combustor nozzle for a fuel-flexible combustion system

A combustor nozzle is provided. The combustor nozzle includes a first fuel system configured to introduce a syngas fuel into a combustion chamber to enable lean premixed combustion within the combustion chamber and a second fuel system configured to introduce the syngas fuel, or a hydrocarbon fuel, or diluents, or combinations thereof into the combustion chamber to enable diffusion combustion within the combustion chamber.

Owner:NUOVO PIGNONE TECH SRL

Rich quick mix combustion system

ActiveUS7185497B2Continuous combustion chamberTurbine/propulsion fuel supply systemsCombustion systemEngineering

A premix chamber for a combustor of a gas turbine engine comprises a cylindrical chamber having a premix chamber wall, the cylindrical chamber having a chamber inlet end longitudinally separated from a chamber outlet end along a central axis, a chamber inlet plate in communication with the premix chamber wall at the chamber inlet end, the chamber inlet plate having a fuel nozzle inlet hole disposed through the chamber inlet plate, the chamber inlet plate further comprising a plurality of swirler passages disposed through the chamber inlet plate, and the chamber outlet end being open. A method of producing turbine gas is also disclosed.

Owner:HONEYWELL INT INC

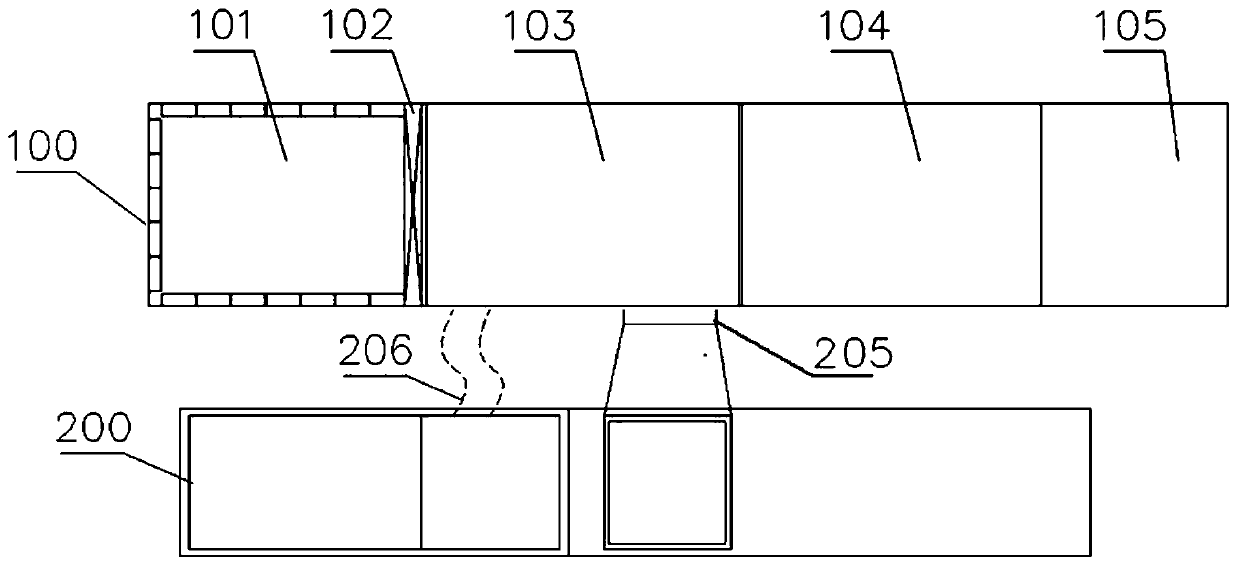

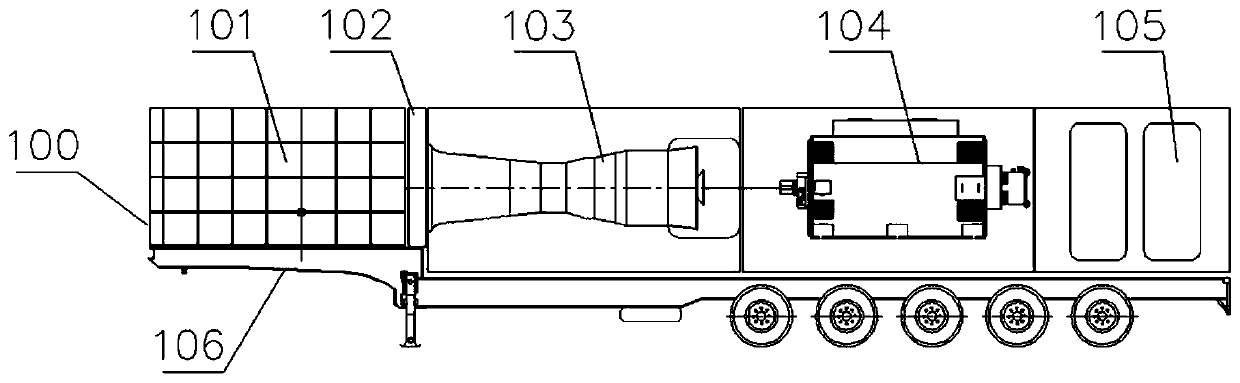

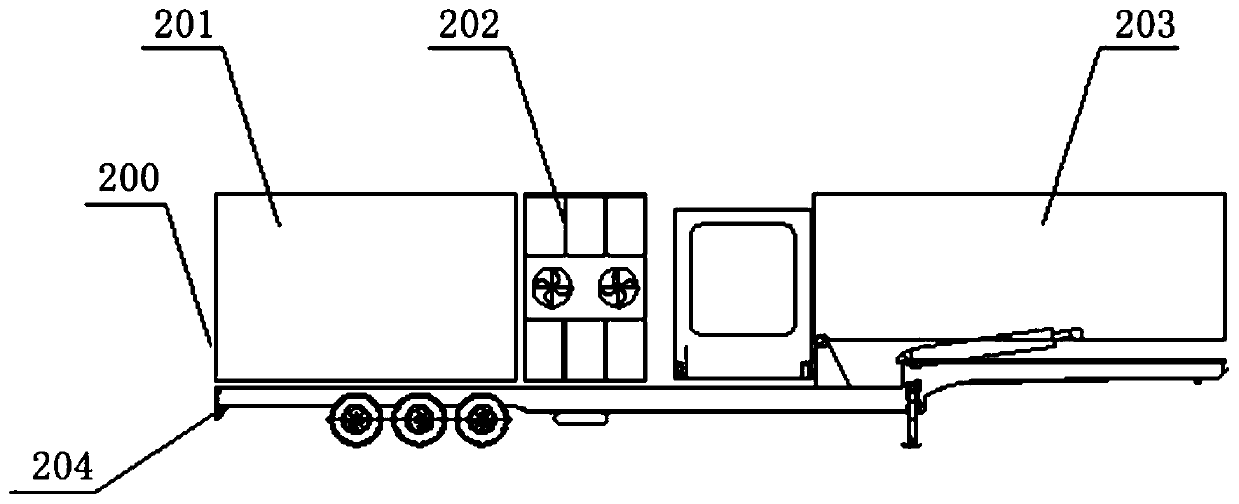

Movable electric power system

PendingCN110374745AAchieve normal startupEfficient integrationEngine fuctionsTurbine/propulsion engine coolingElectric power systemGas turbines

The invention discloses a movable electric power system. The whole movable electric power system is divided into two transport tools, effective integration is achieved, and the number of the transporttools and transport cost are decreased. Through side connection of the two transport tools, fast and convenient connection in the working state is achieved, and the needed installation time is greatly shortened. By arranging a gas turbine starting device on a gas exhaust auxiliary transport unit, a gas turbine can be started when the whole movable electric power system is blacked out.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

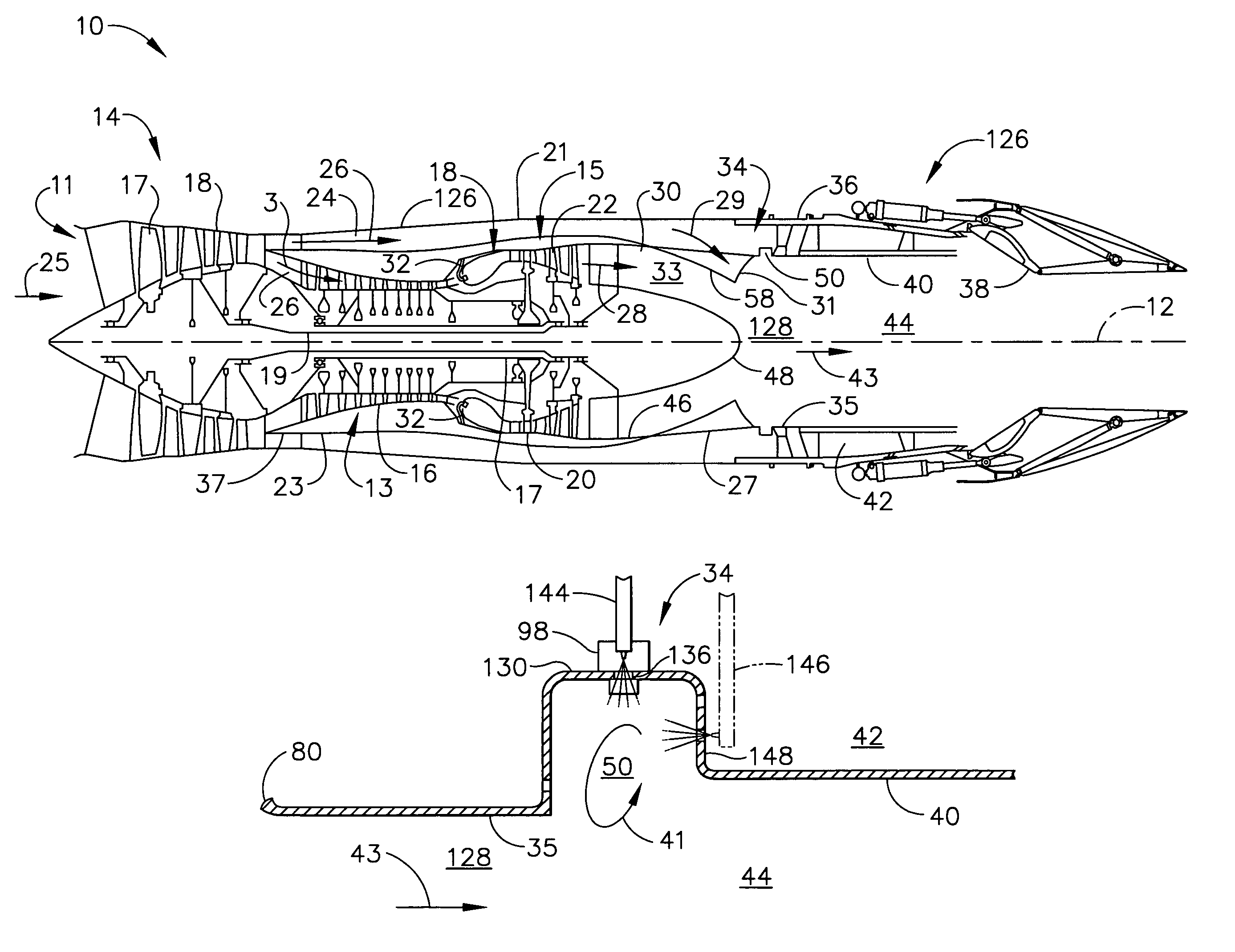

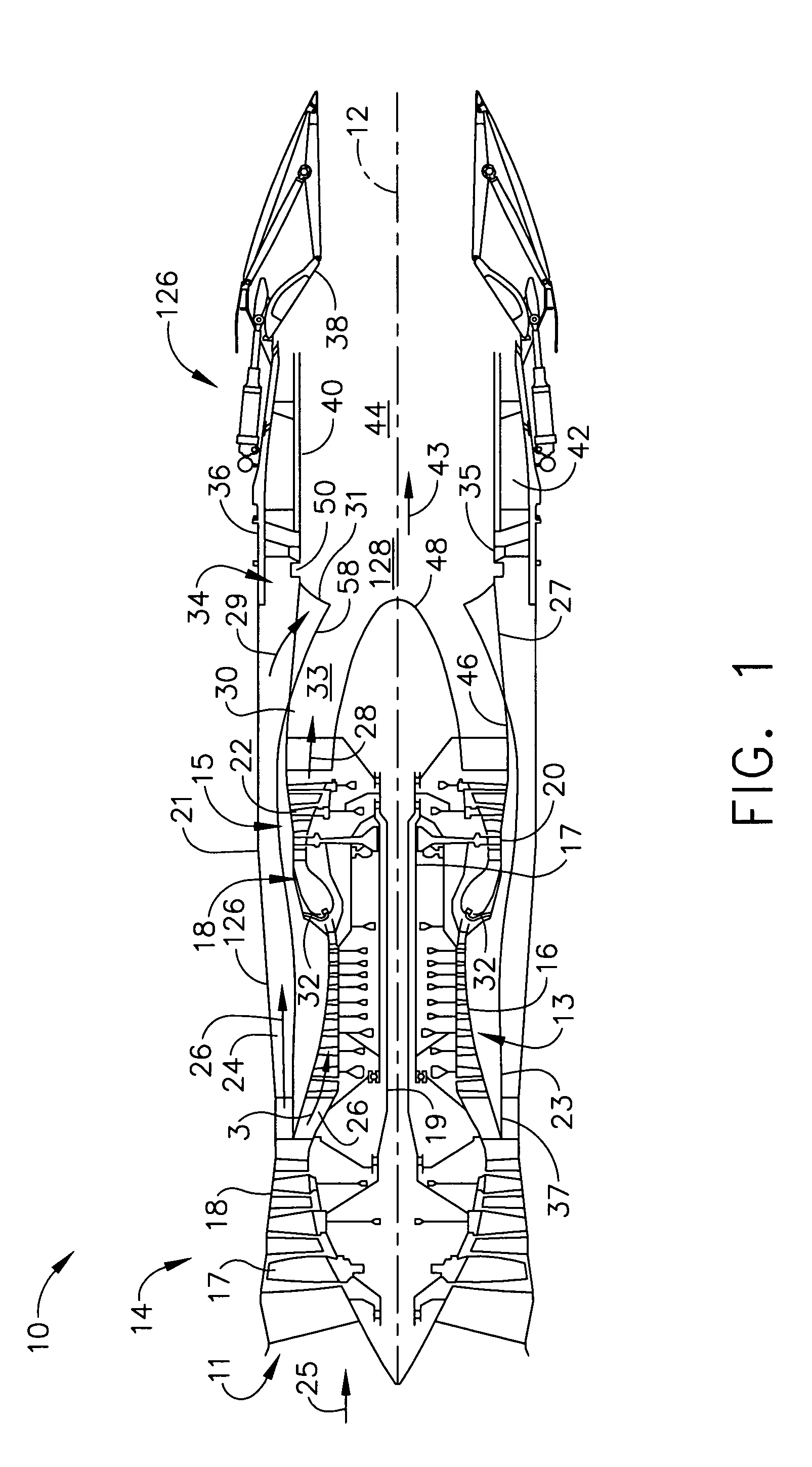

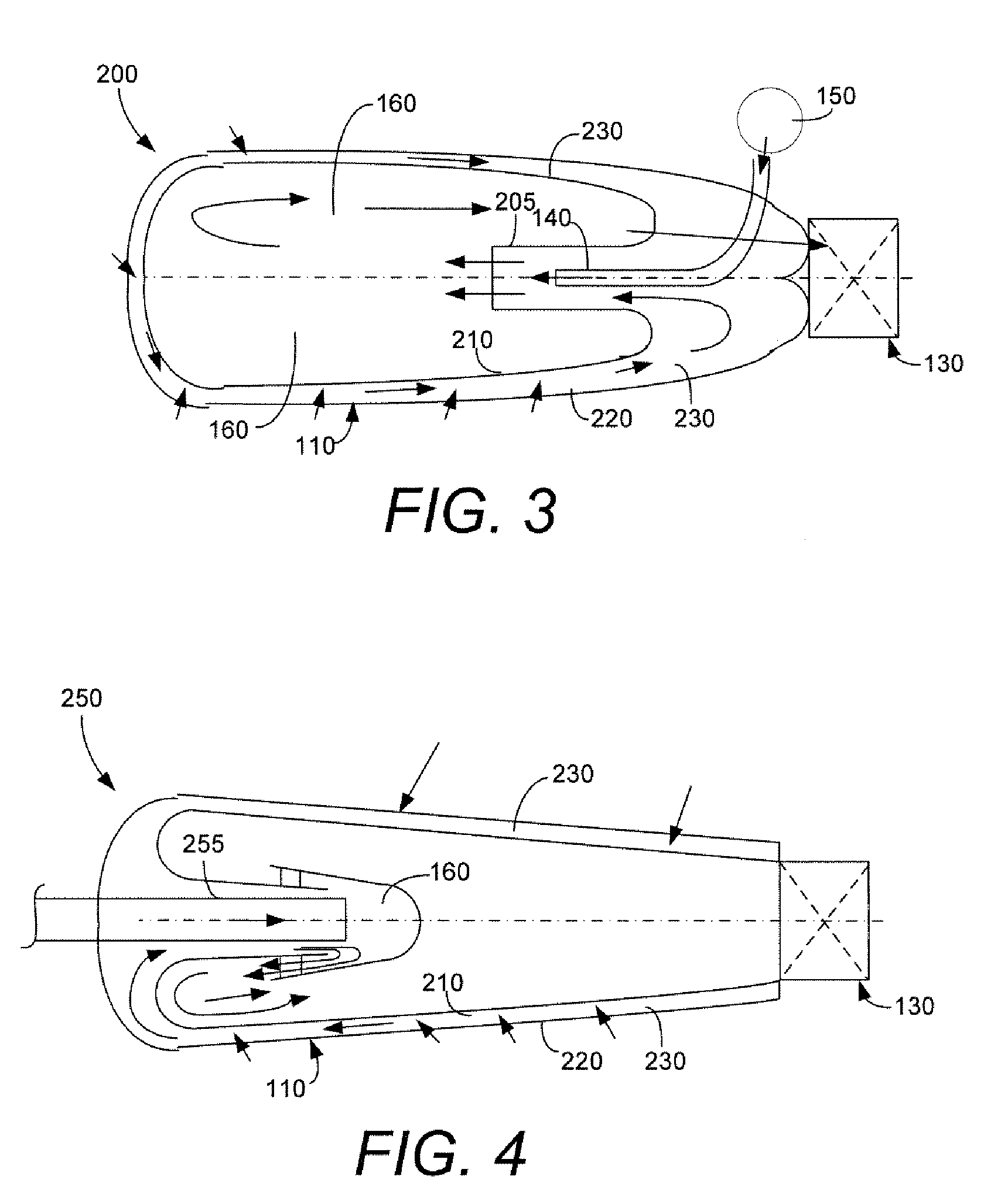

Trapped vortex cavity afterburner

ActiveUS7225623B2Continuous combustion chamberTurbine/propulsion fuel supply systemsTrailing edgeDegree Fahrenheit

A trapped vortex cavity afterburner includes one or more trapped vortex cavity stages for injecting a fuel / air mixture into a combustion zone. The trapped vortex cavity afterburner is operable to provide all thrust augmenting fuel used for engine thrust augmentation. Each stage has at least one annular trapped vortex cavity. The trapped vortex cavity afterburner may be a multi-stage afterburner having two or more trapped vortex cavity stages ganged for simultaneous ignition or operable for sequential ignition. One embodiment of the annular trapped vortex cavity is operable to raise a temperature of an exhaust gas flow through the afterburner about 100 to 200 degrees Fahrenheit. Each of the trapped vortex cavity stages may be operable to produce a single or a different amount of temperature rise of the exhaust gas flow through the afterburner. A chevron shaped trapped vortex cavity and having zig-zag shaped leading and trailing edges may be used.

Owner:GENERAL ELECTRIC CO

Method and apparatus to decrease combustor emissions

A method for operating a gas turbine engine facilitates reducing an amount of emissions from a combustor. The combustor includes a mixer assembly including a pilot mixer, a main mixer, and a centerbody that extends therebetween. The pilot mixer includes a pilot fuel nozzle and a plurality of axial swirlers. The main mixer includes a main swirler and a plurality of fuel injection ports. The method comprises injecting fuel into the combustor through the pilot mixer, such that the fuel is discharged downstream from the pilot mixer axial swirlers, and directing flow exiting the pilot mixer with a lip extending from the centerbody into a pilot flame zone downstream from said pilot mixer.

Owner:GENERAL ELECTRIC CO

Lean-staged pyrospin combustor

ActiveUS7302801B2High power outputIncrease powerBurnersTurbine/propulsion fuel supply systemsCombustorCombustion chamber

Owner:HAMILTON SUNDSTRAND CORP

Apparatus and method for selecting a flow mixture

InactiveUS7007486B2Turbine/propulsion fuel supply systemsContinuous combustion chamberCounter flowChemical species

A counter-flow system for use in a turbine for selecting various mixtures of fluids for use with the system. The system may be used for a combustor for a gas powered turbine which employs a heat exchanger to combust a fuel without the emission of undesired chemical species. A gas powered turbine requires expanding gases to power the turbine blades. Fuel is combusted to produce the required gases. An oxidizer is introduced into the counter-flow system in a first direction before a first portion of fuel is introduced into the oxidizer. The fuel and oxidizer mixture is then flowed through a second pathway wherein the fuel and oxidizer mixture obtains a selected amount of thermal energy. Moreover, in a second pathway an equivalence ratio of the fuel and oxidizer mixture may be altered from the original fuel and oxidizer mixture.

Owner:UNITED TECH CORP +1

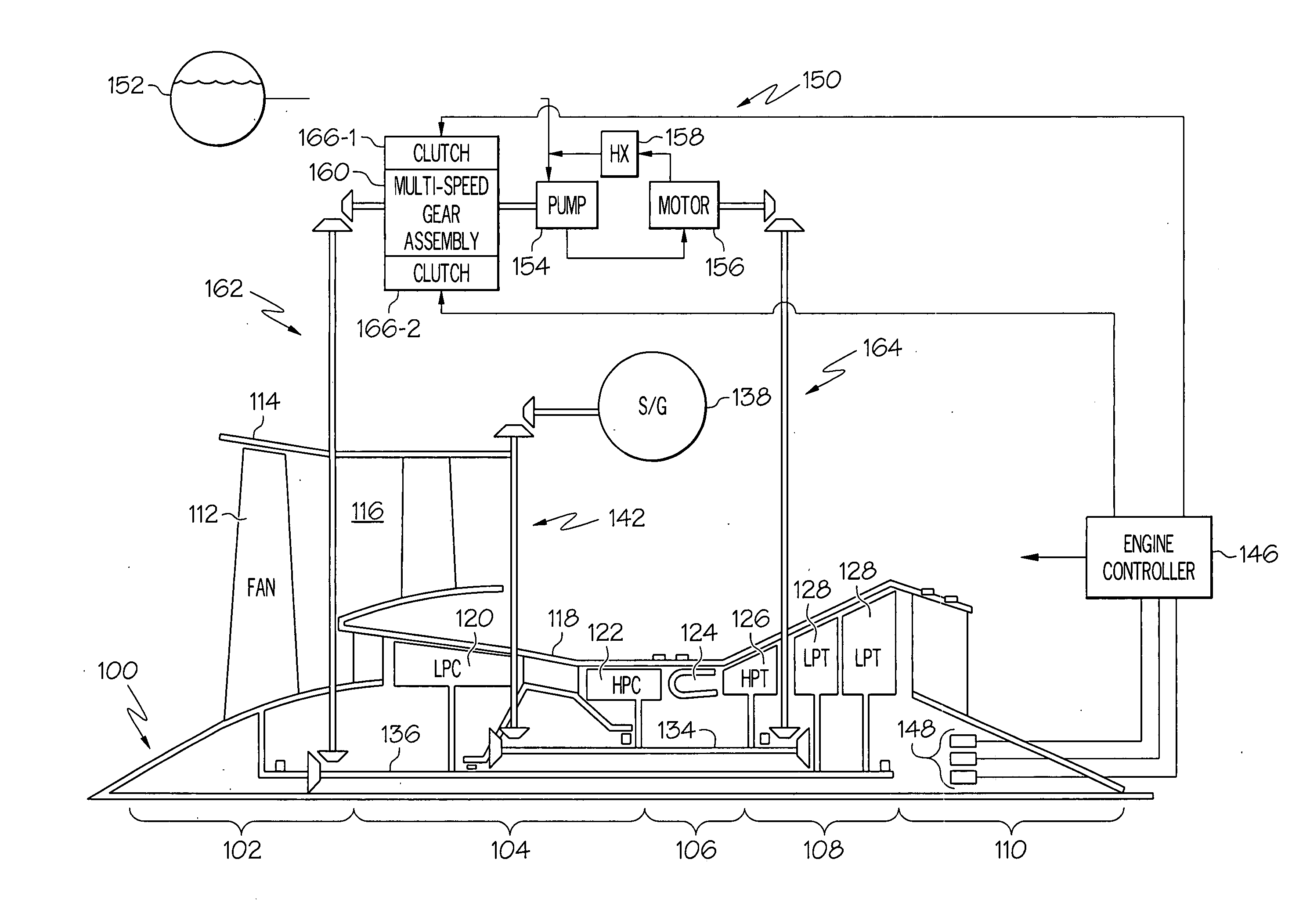

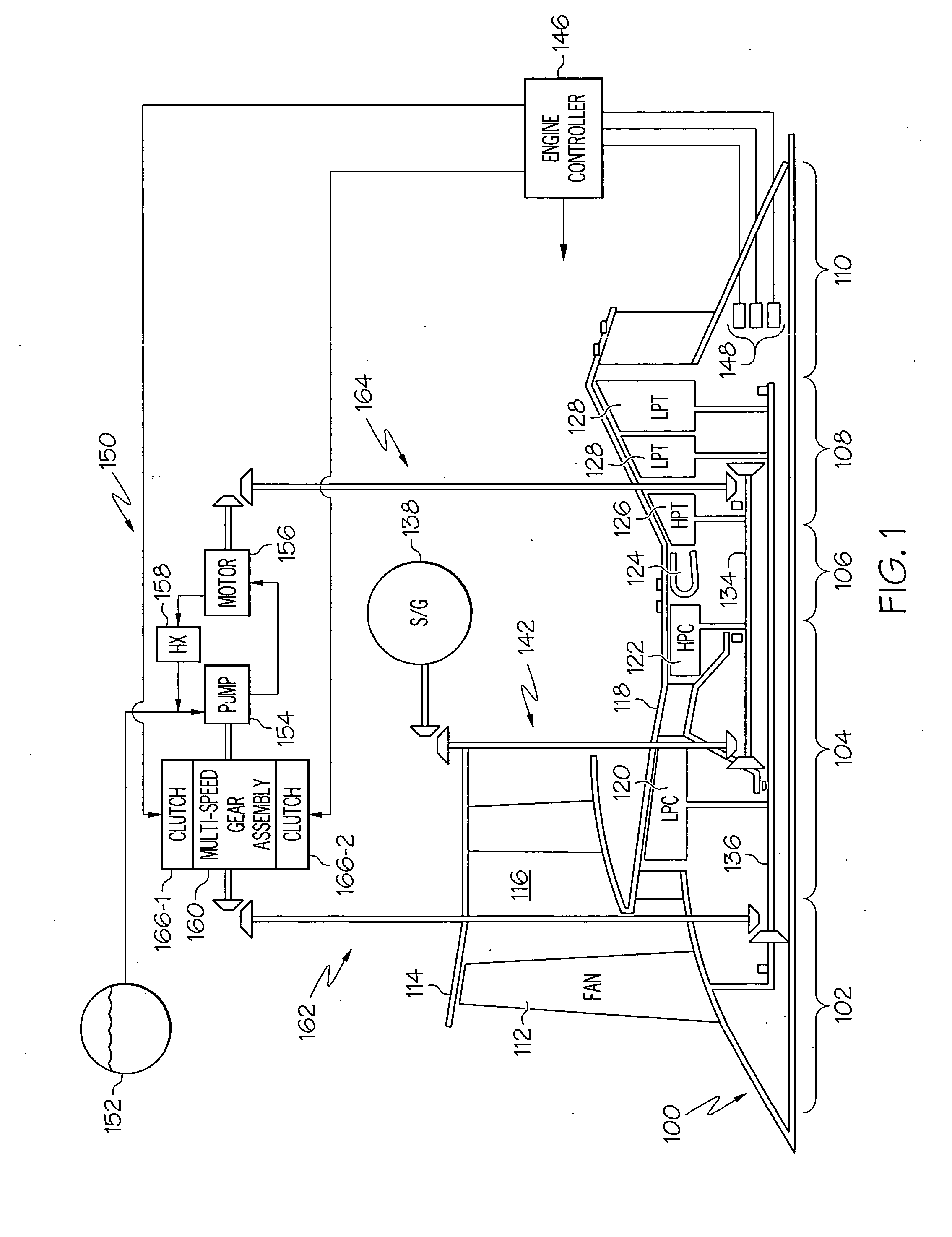

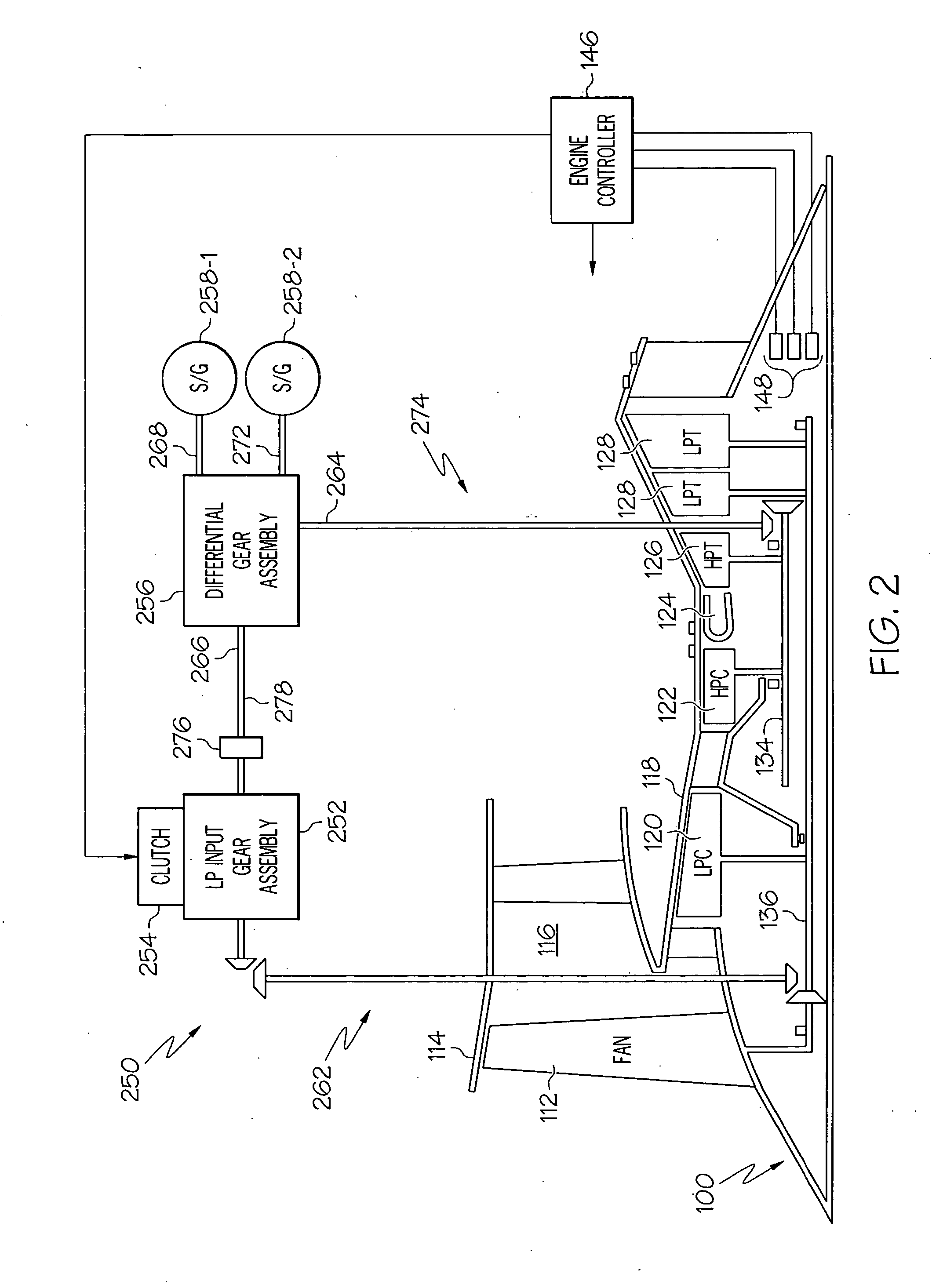

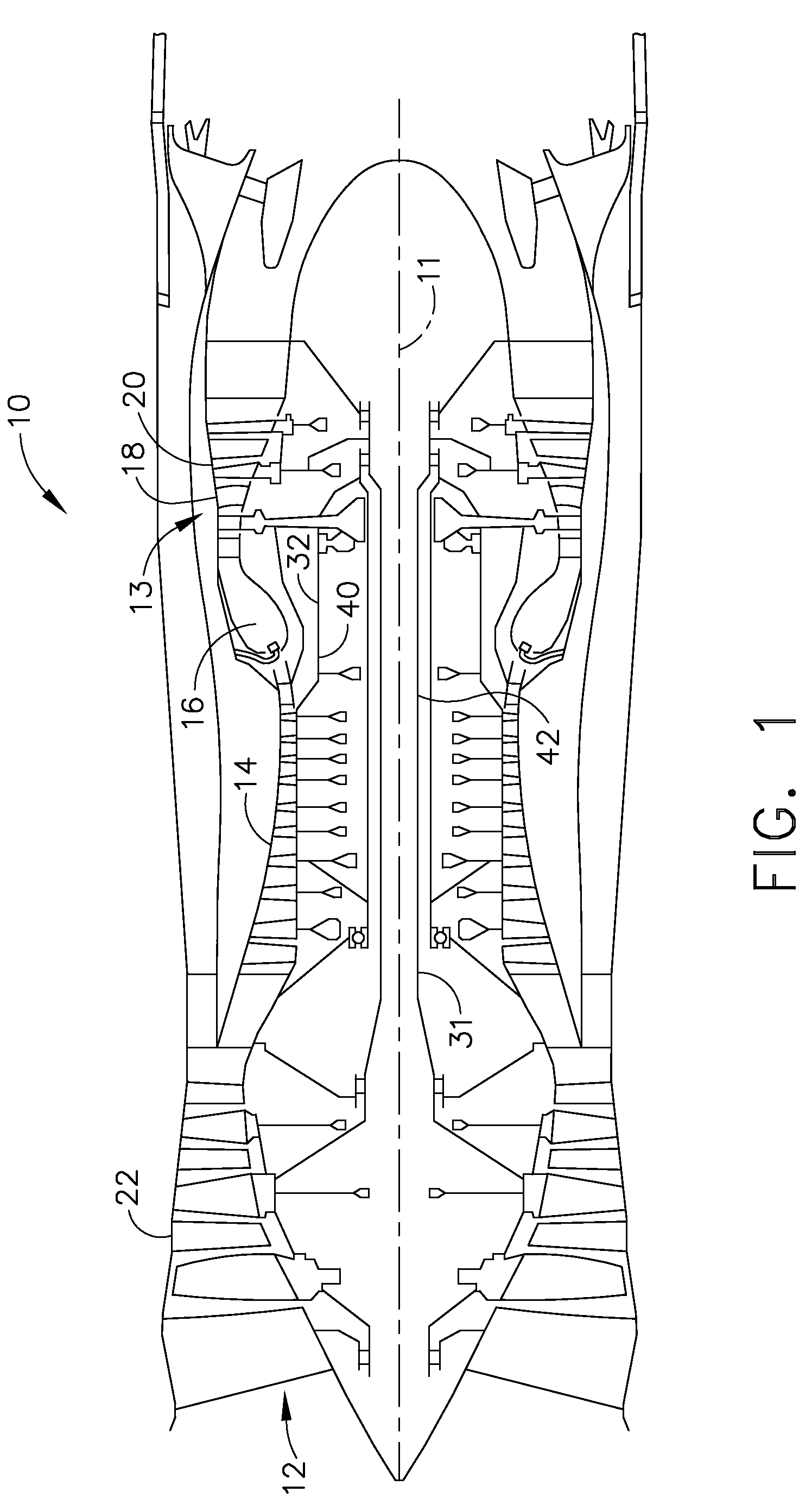

More electric aircraft power transfer systems and methods

InactiveUS20060272313A1Engine fuctionsTurbine/propulsion engine ignitionHydraulic motorElectric aircraft

A turbofan gas turbine propulsion engine includes a system to transfer power from the low pressure turbine to the high pressure turbine and / or extract additional load from the low pressure turbine during certain turbofan engine operational conditions. The systems include a hydrostatic power transfer system that includes a hydraulic pump and a hydraulic motor coupled to the low pressure and high pressure turbine, respectively. The systems additionally include a mechanical and electrical load shifting / loading sharing systems that use clutches and gear assemblies to share and / or shift load between the turbines.

Owner:HONEYWELL INT INC

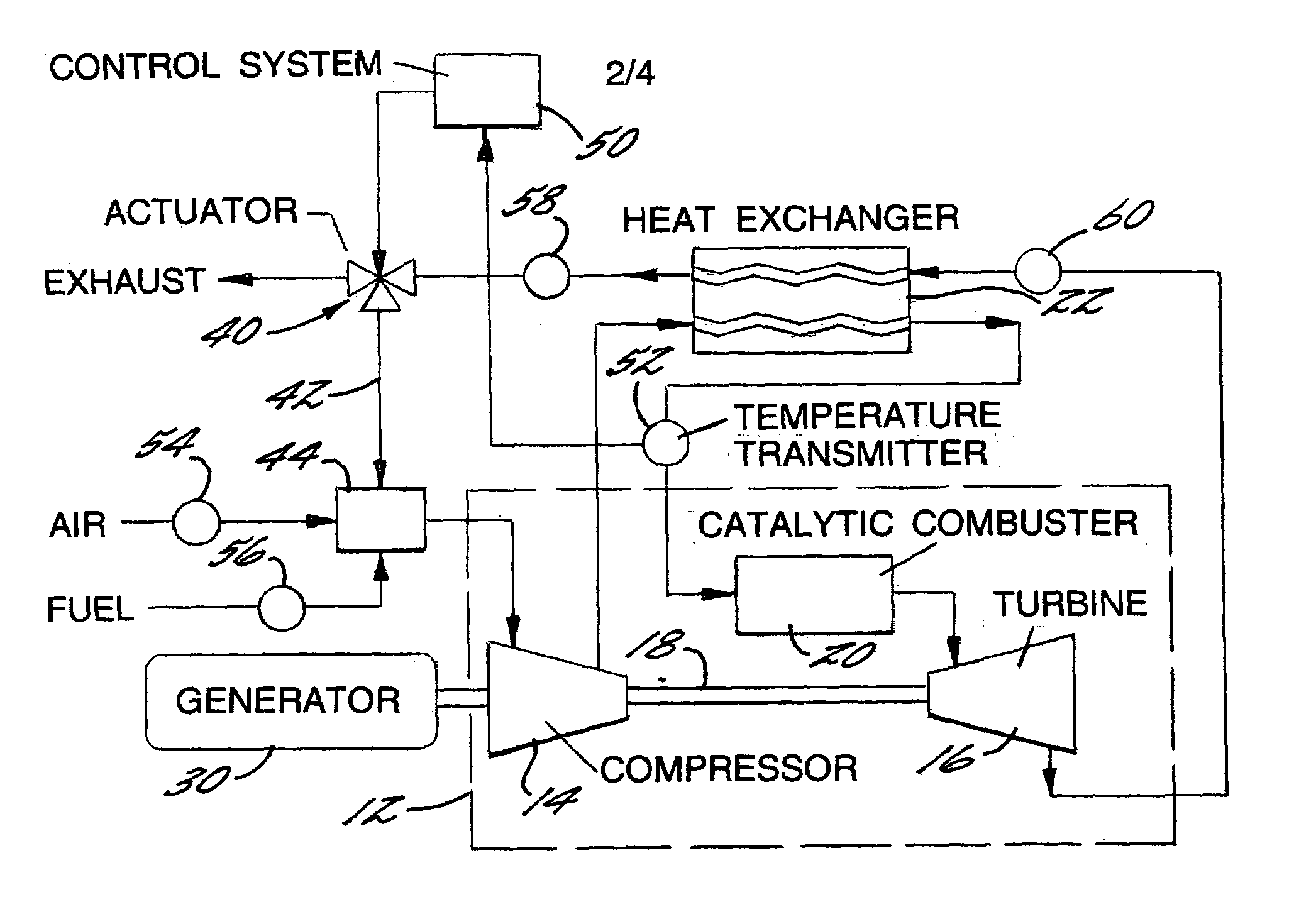

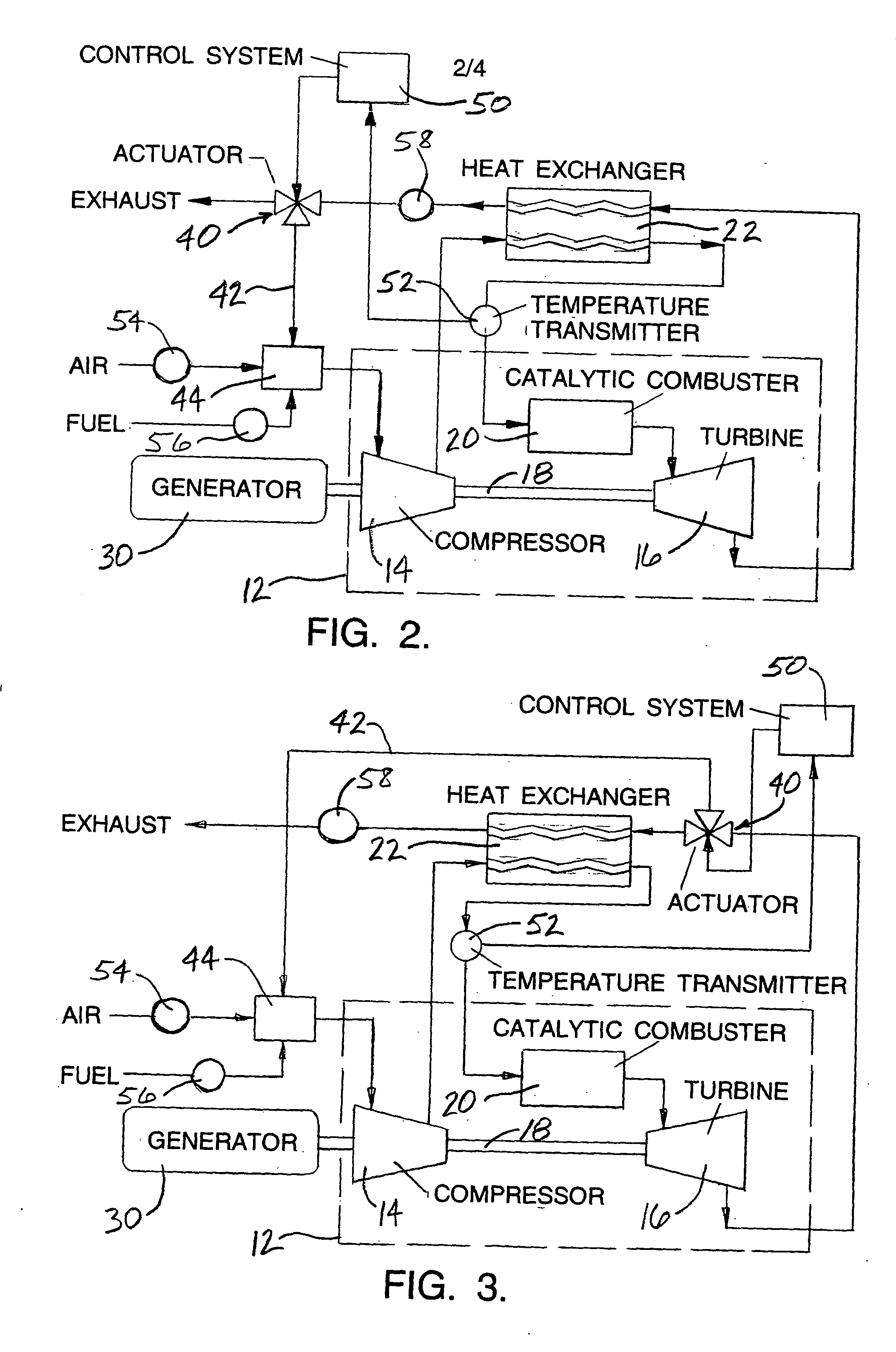

Dynamic control system and method for multi-combustor catalytic gas turbine engine

InactiveUS7152409B2Turbine/propulsion fuel supply systemsContinuous combustion chamberCombustion systemControl system

According to one aspect, a method of controlling a multi-combustor catalytic combustion system is provided for determining a characteristic of a fuel-air mixture downstream of a preburner associated with a catalytic combustor and adjusting the fuel flow to the preburner based on the characteristic. The characteristic may include, for example, a measurement of the preburner or catalyst outlet temperature or a determination of the position of the homogeneous combustion wave in the burnout zone of the combustor.

Owner:KAWASAKI HEAVY IND LTD

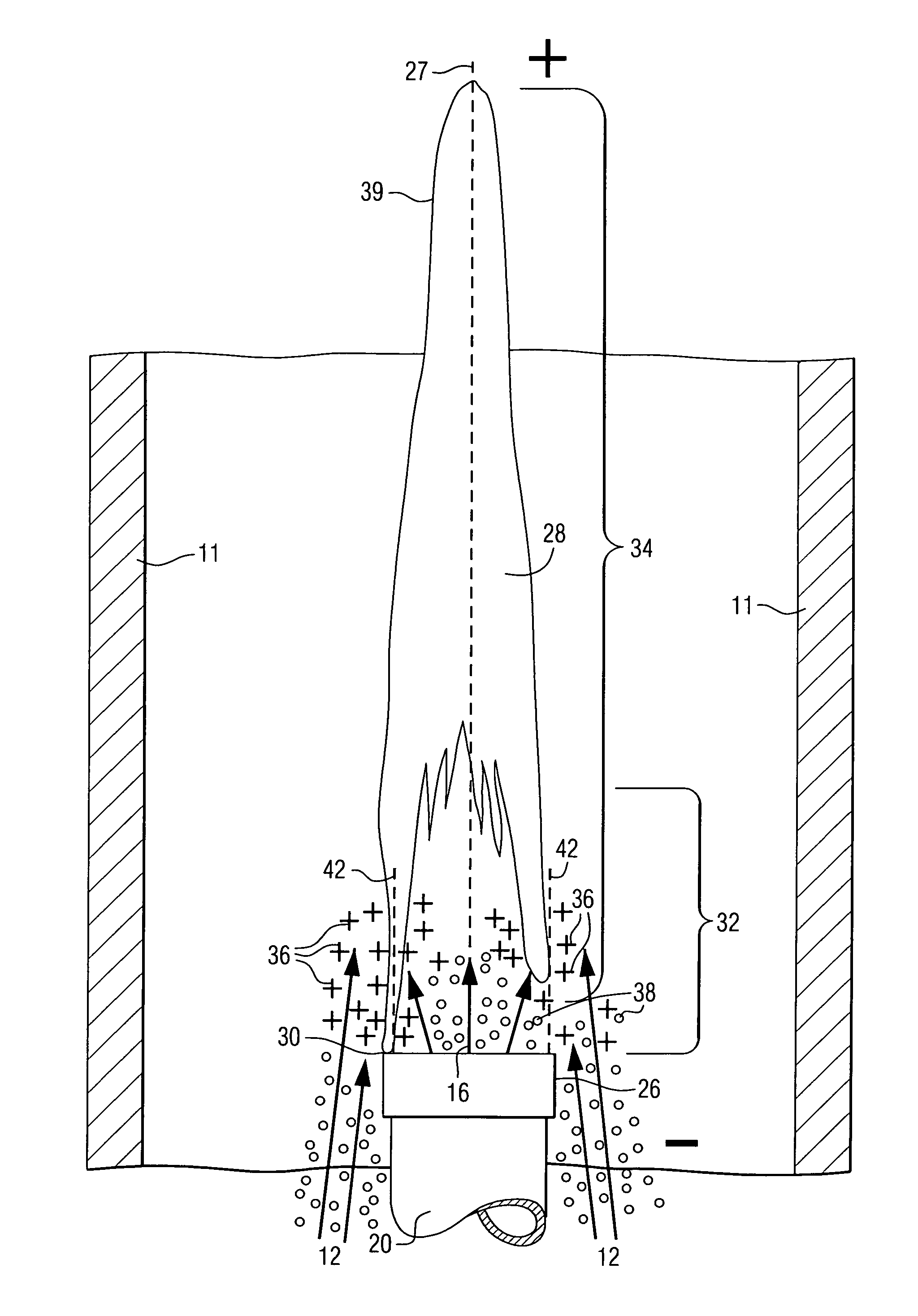

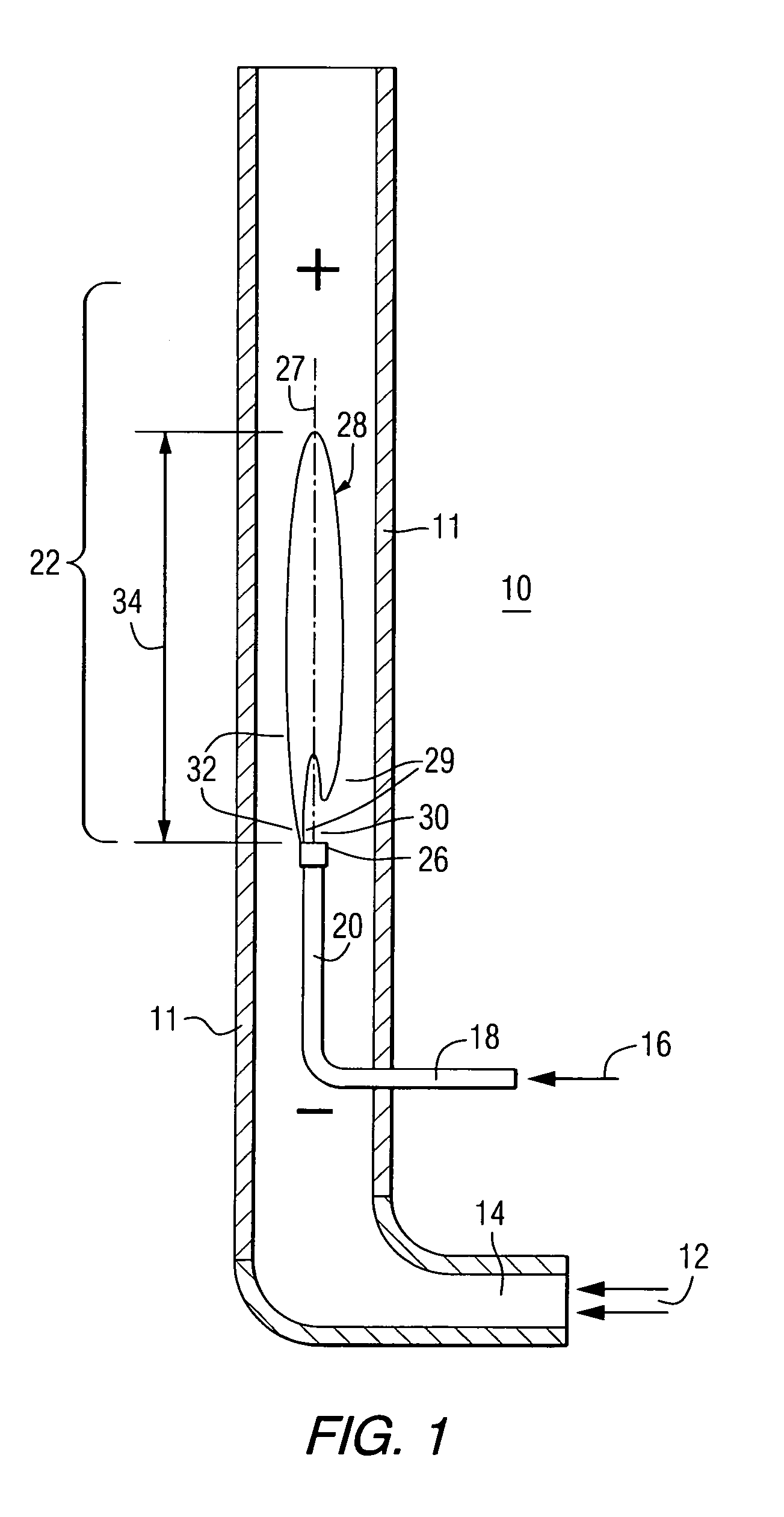

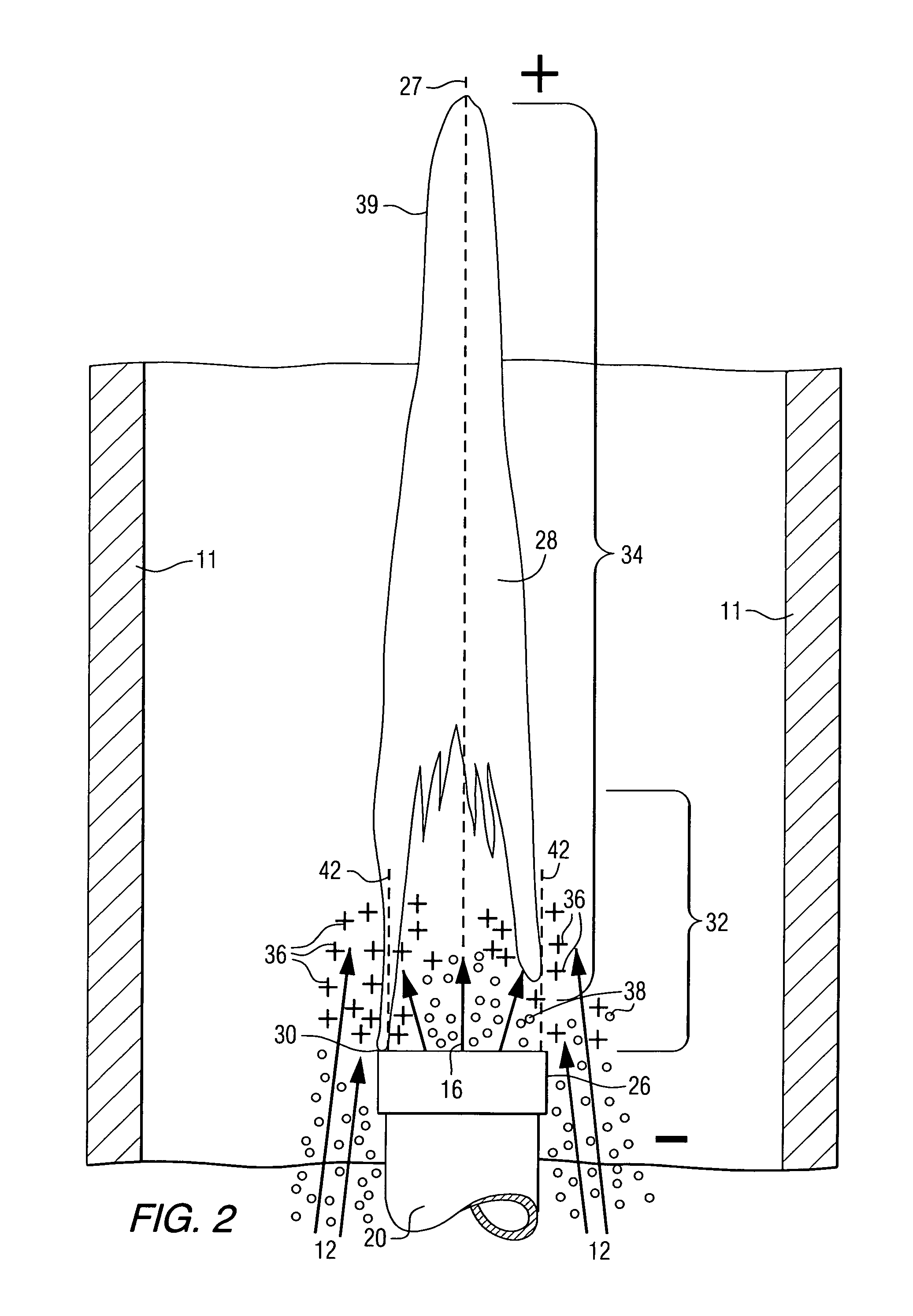

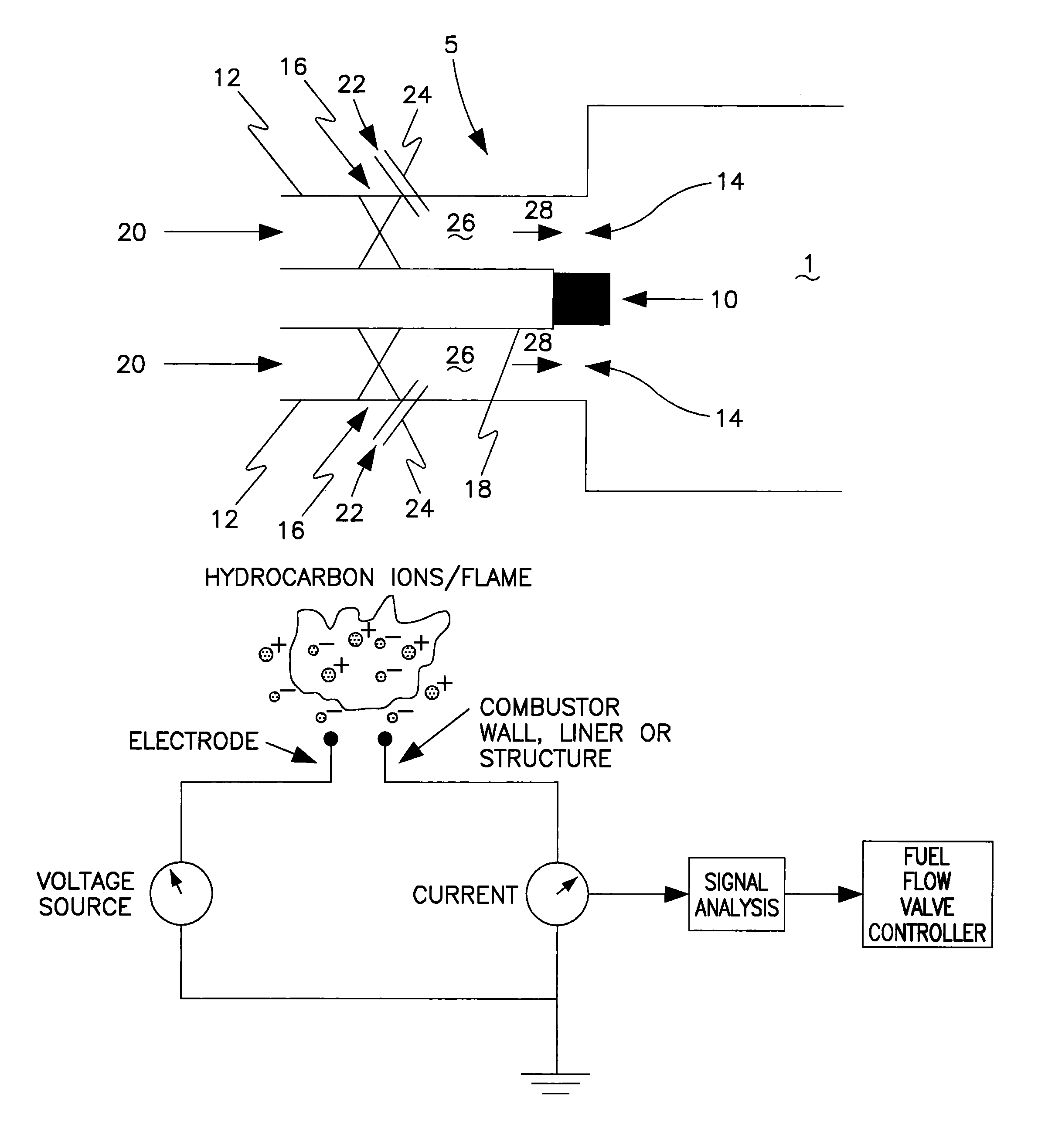

Electric flame control using corona discharge enhancement

InactiveUS7243496B2Increased ionizationPromote combustionTurbine/propulsion fuel supply systemsTurbine/propulsion engine ignitionElectricityCombustor

A method of operating a combustor (10), to provide intimately mixed hot combusted gas (44) for a gas turbine (46), includes feeding gaseous oxidant (12) and gaseous fuel (16) into the combustor (10) near a combustion flame (28) which has a tip end (39) and a root end (29), where corona discharge occurs through adjustment of an electric field (34), and where the corona discharge causes ionized particles (36) to form and also causes intimate turbulent mixing of the gases.

Owner:SIEMENS ENERGY INC

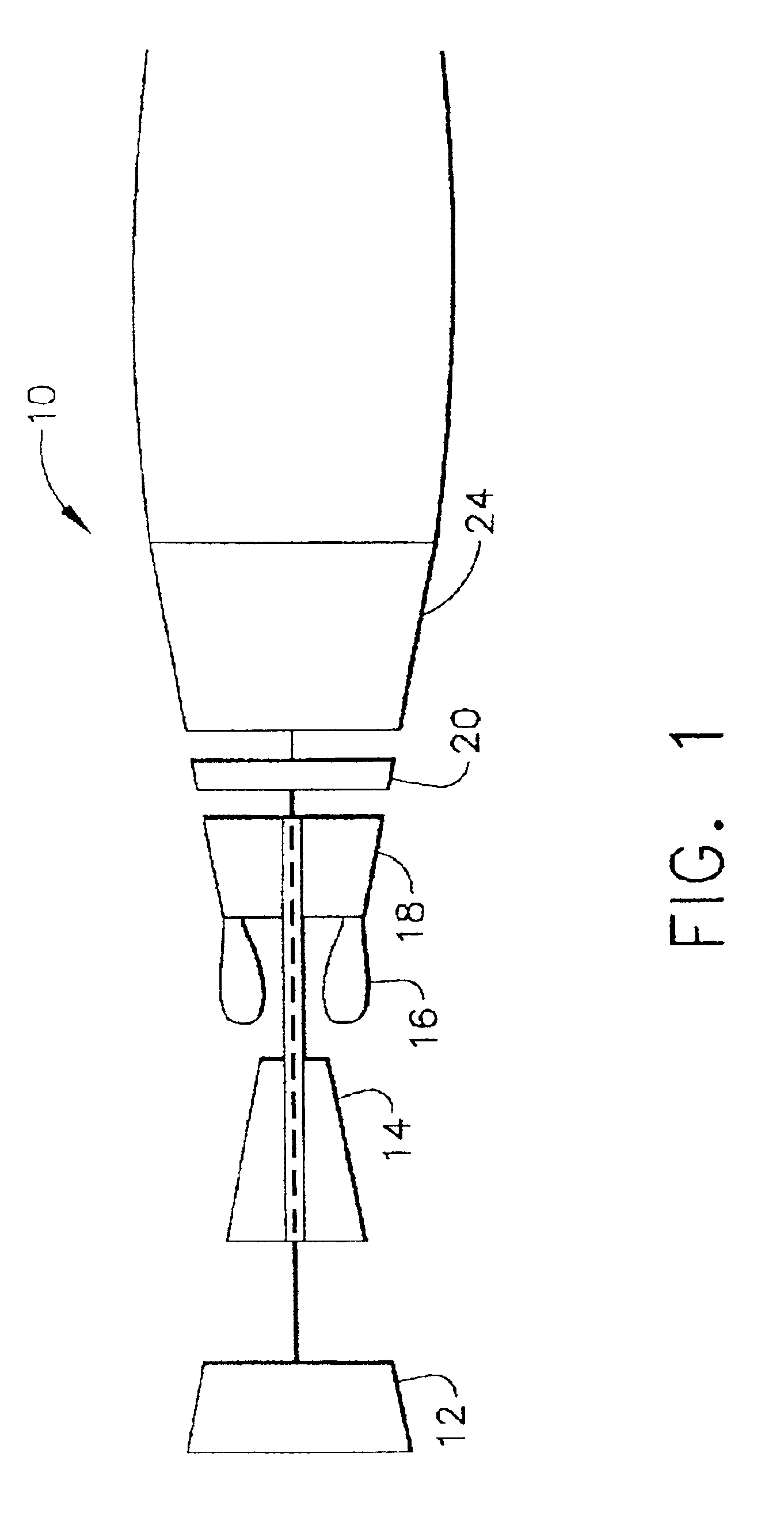

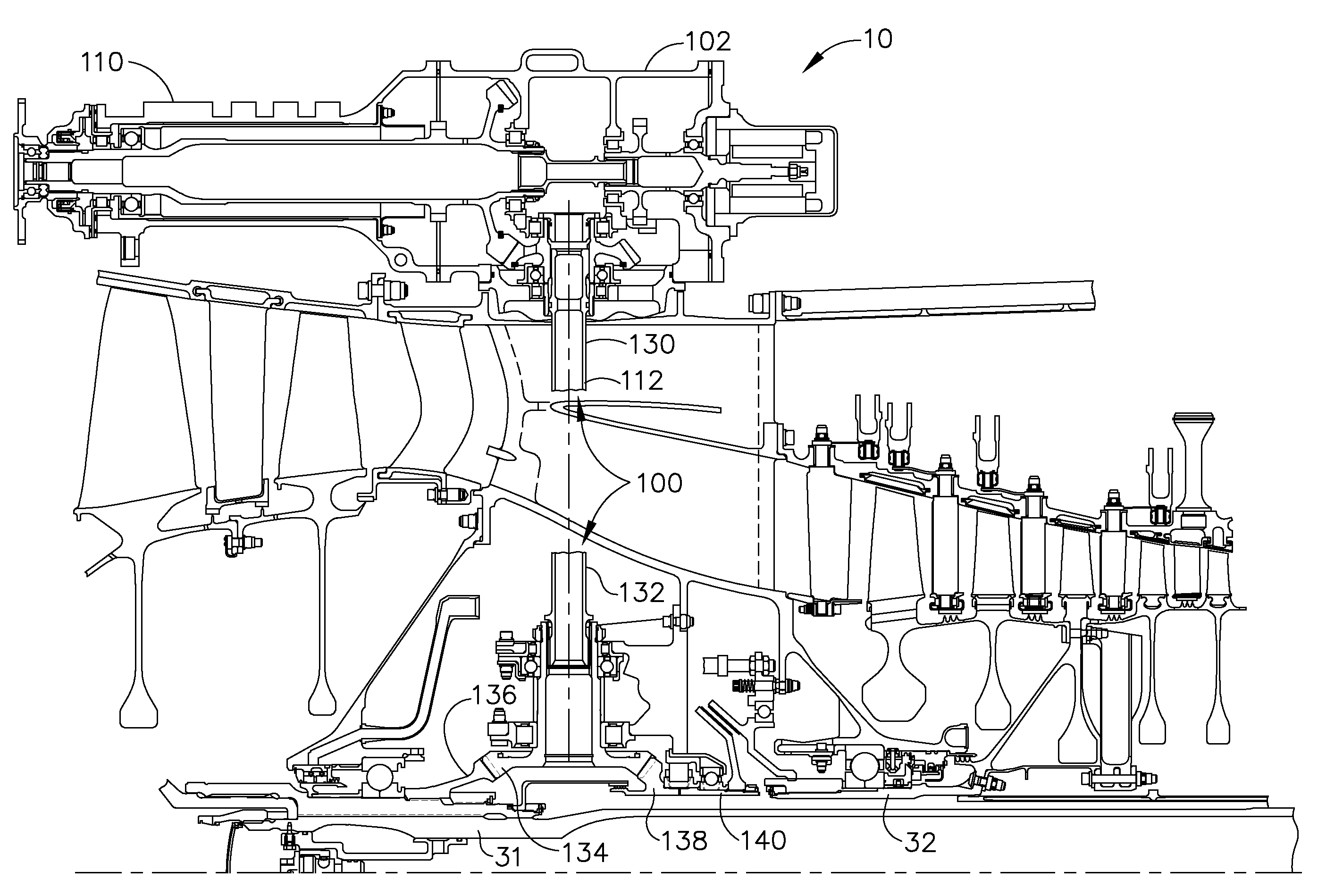

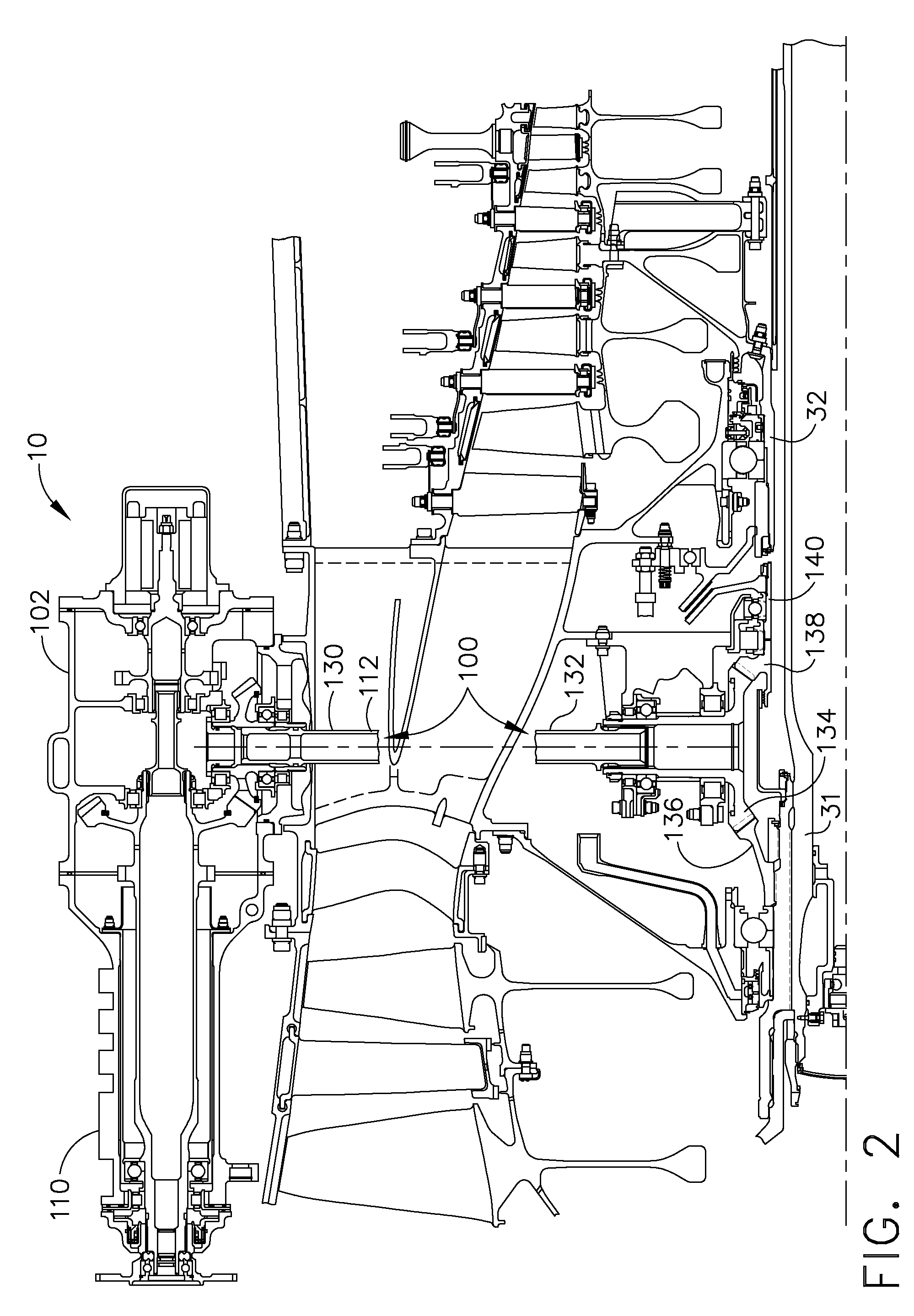

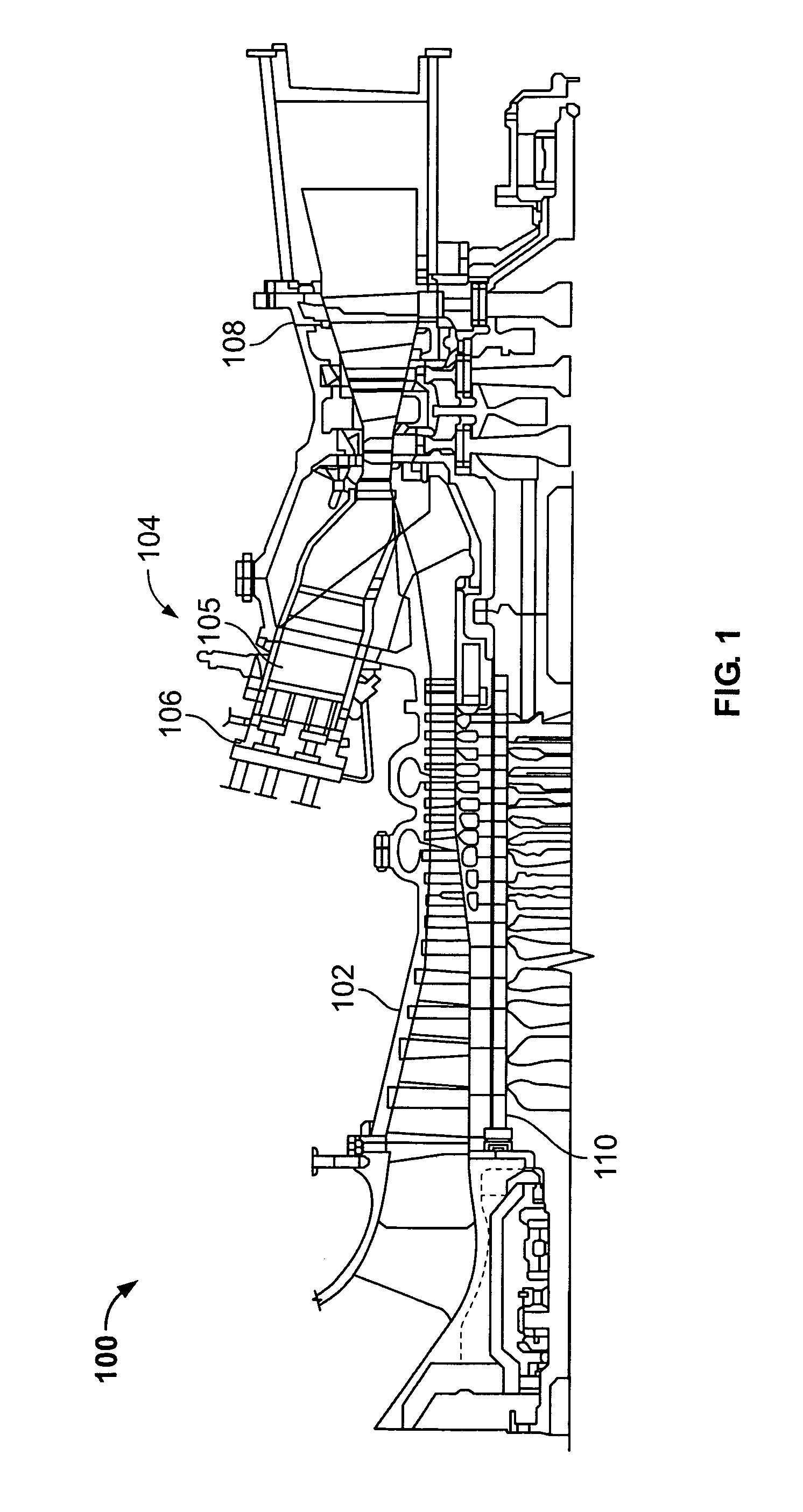

Power take-off system and gas turbine engine assembly including same

ActiveUS8015828B2Turbine/propulsion fuel supply systemsTurbine/propulsion engine ignitionPower take-offGas turbines

A power take-off system for a gas turbine engine includes a starter coupled to a second spool, and a clutch assembly coupled between the starter and a first spool, the clutch assembly configured to couple the first spool to the starter when starting the gas turbine engine assembly. A method of assembling a gas turbine engine assembly that includes the power take-off system, and a gas turbine engine assembly including the power take-off system are also described.

Owner:GENERAL ELECTRIC CO

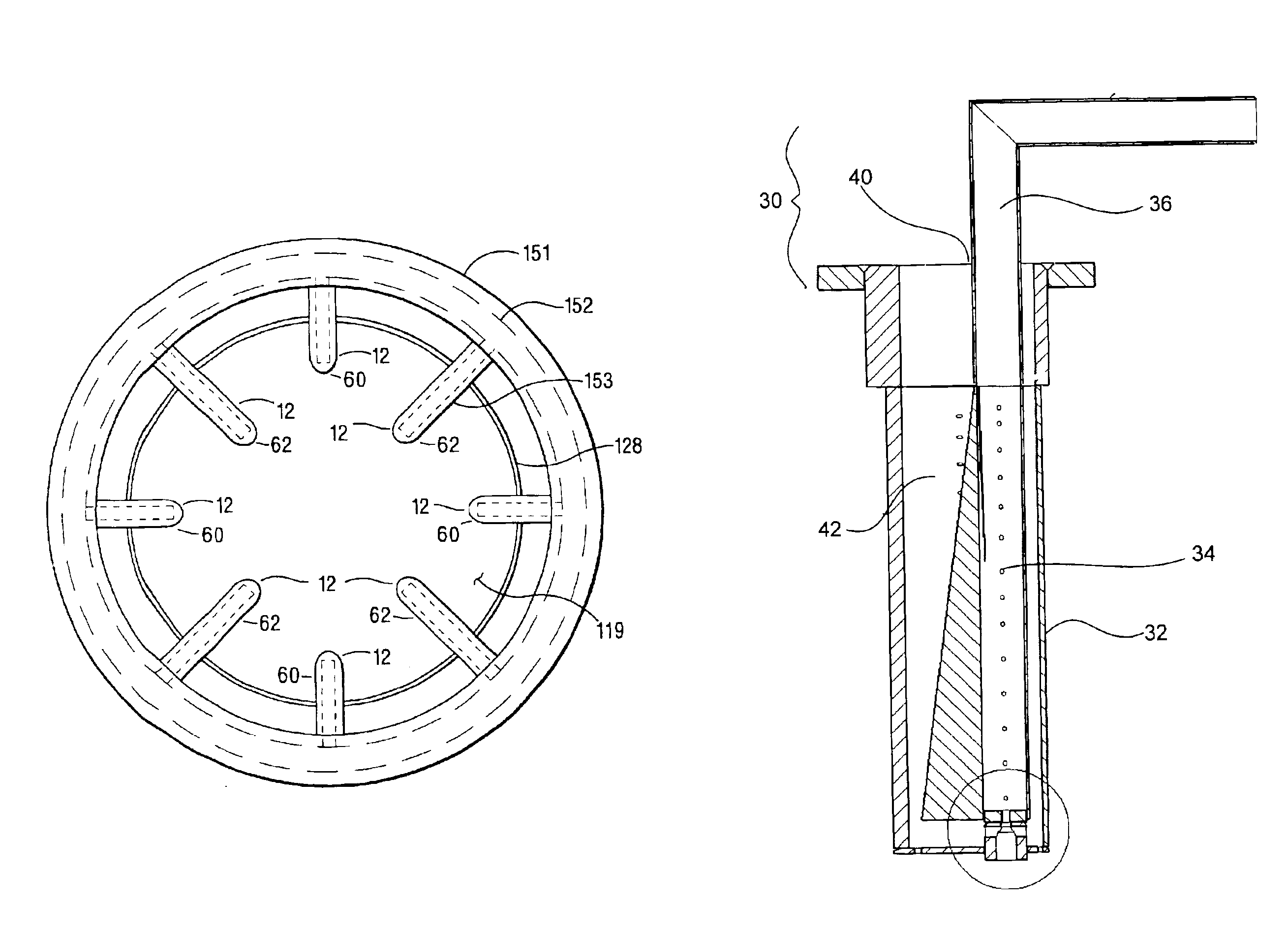

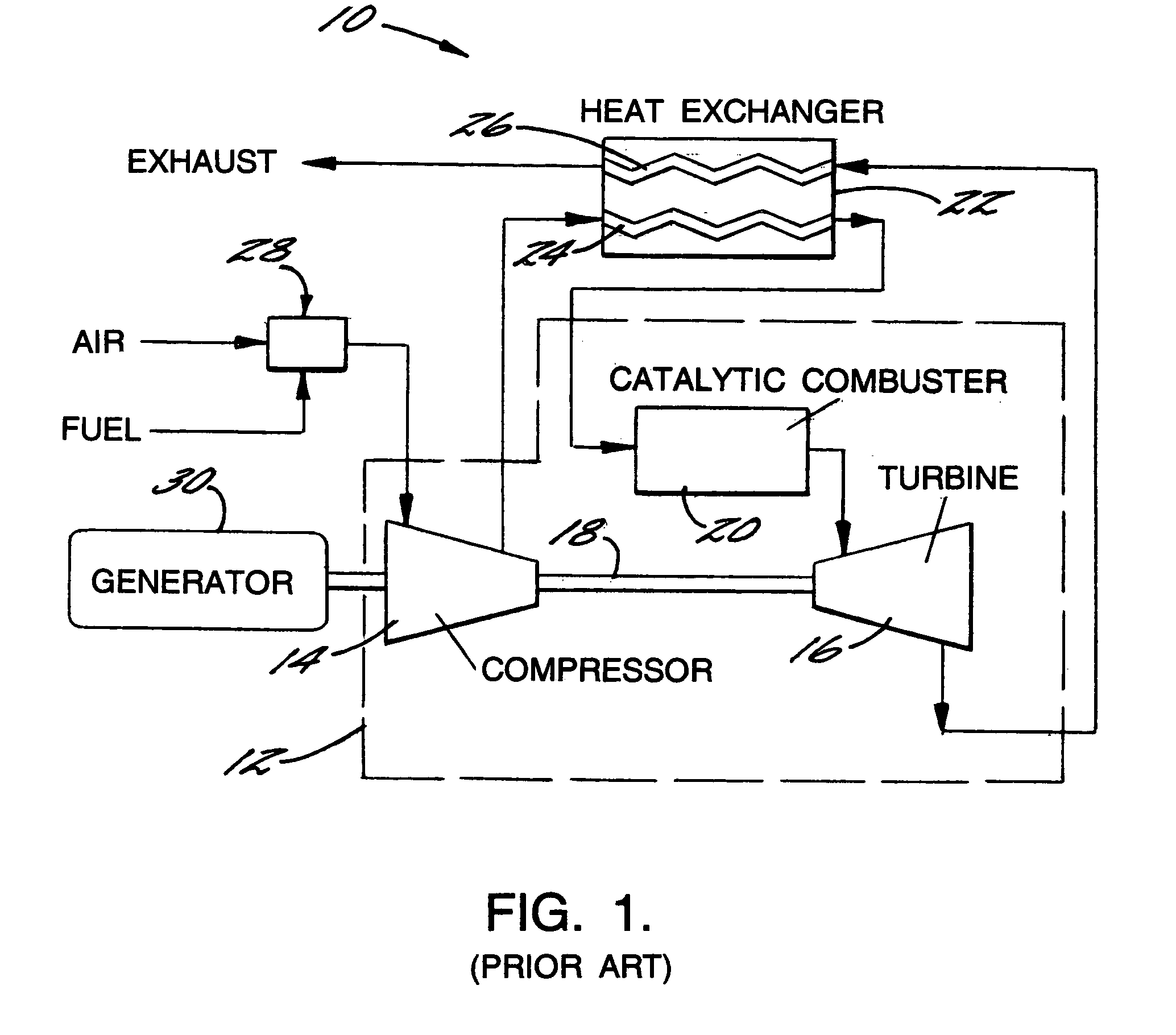

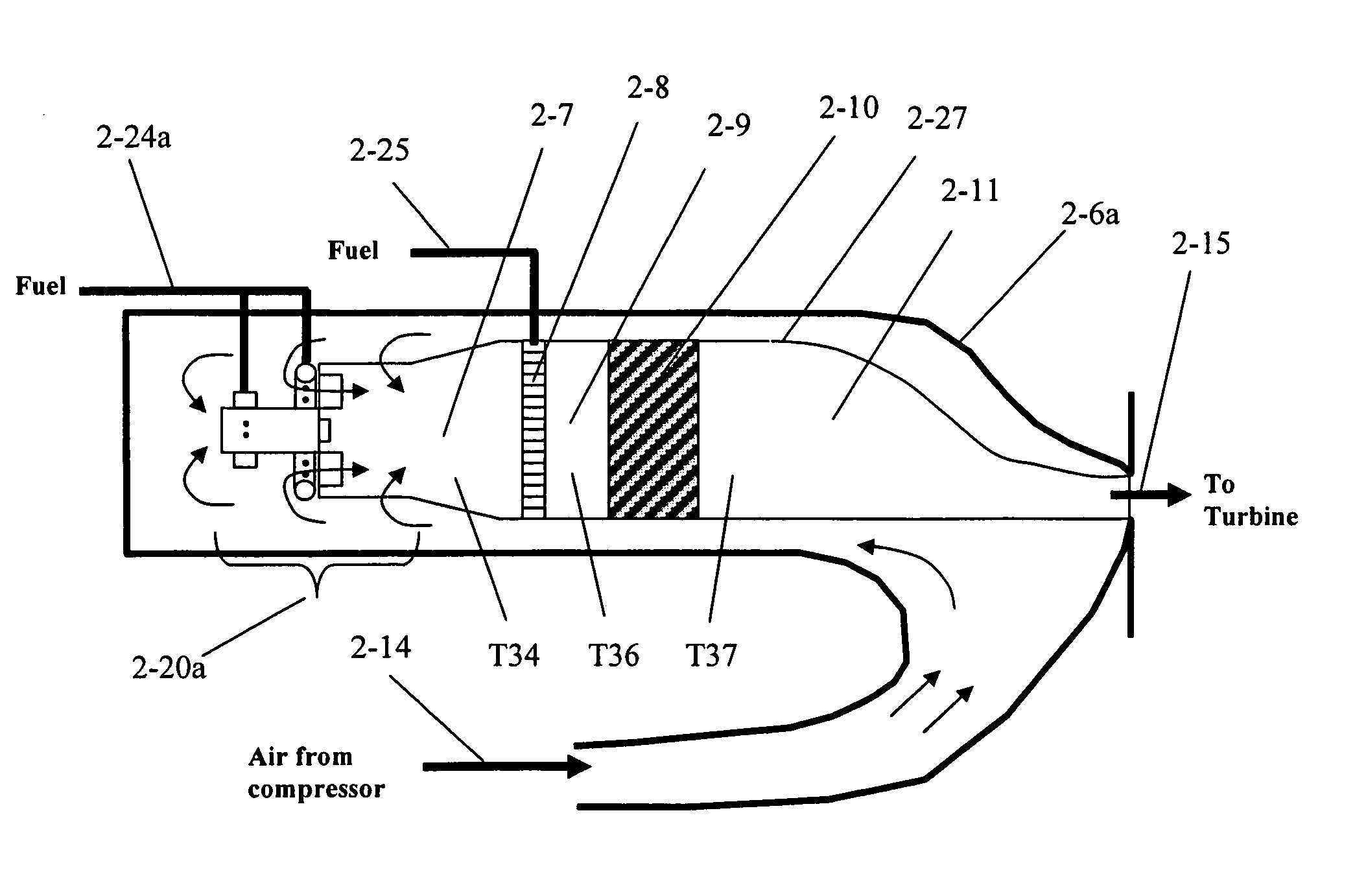

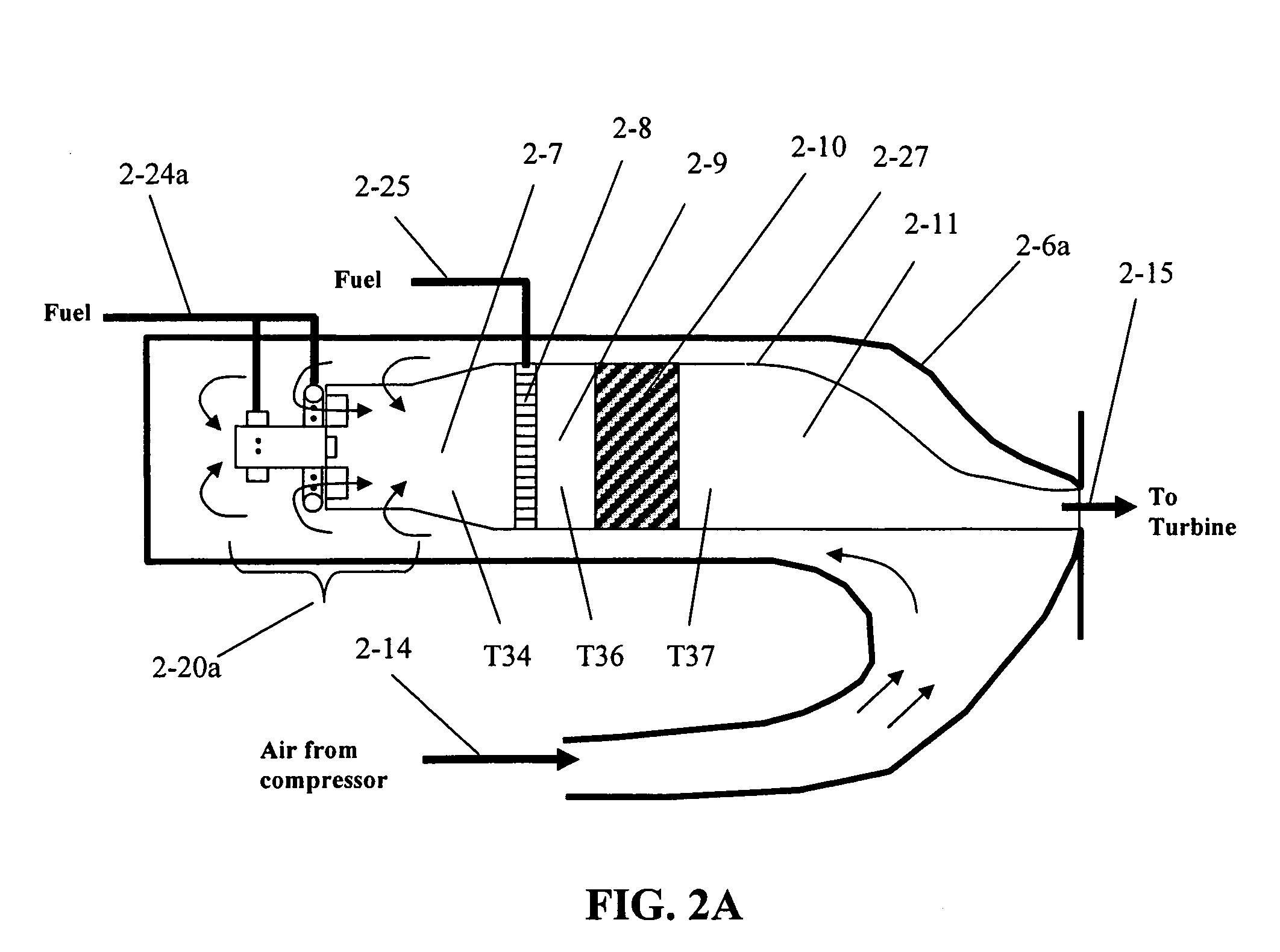

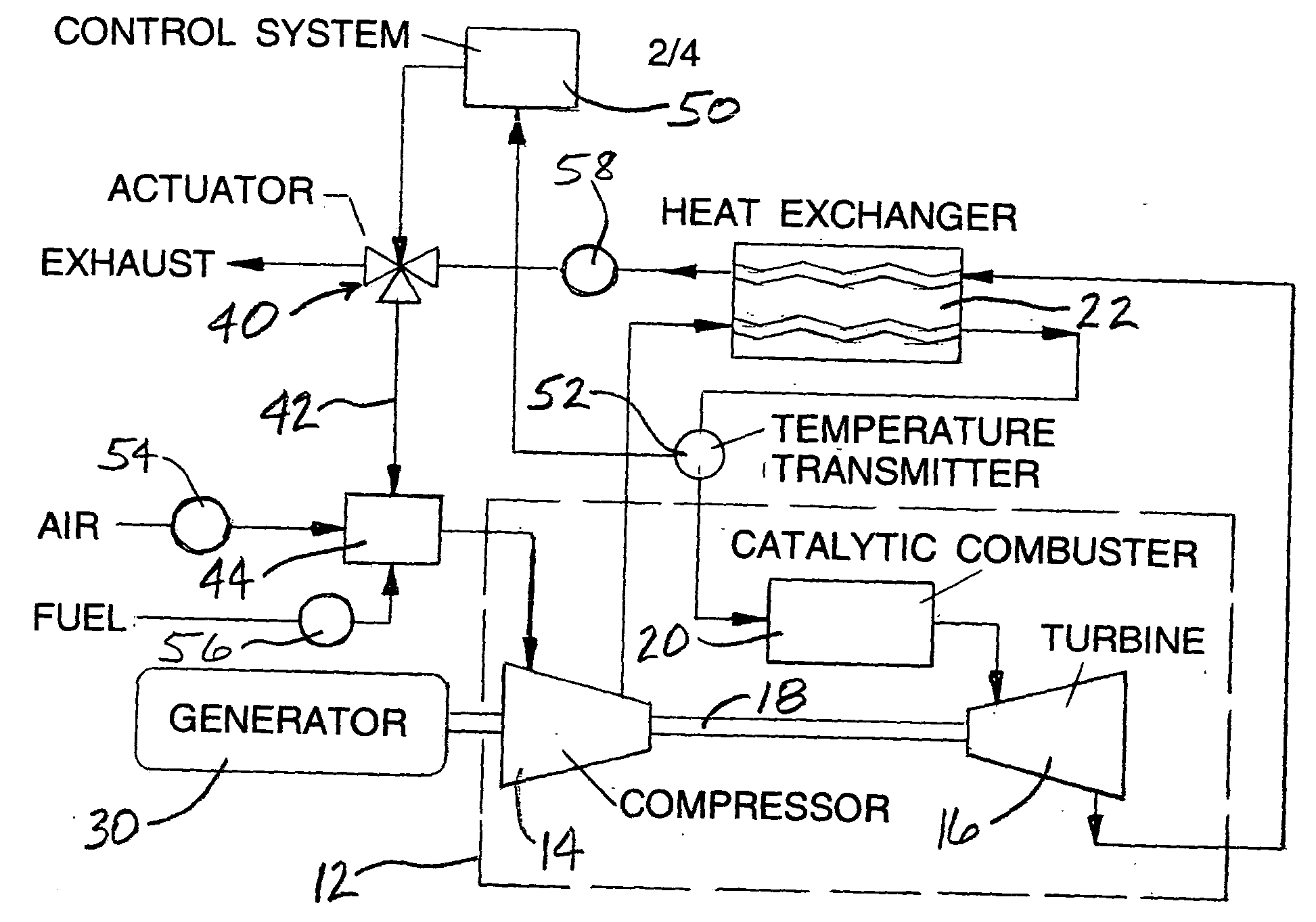

Recuperated gas turbine engine system and method employing catalytic combustion

InactiveUS20050022499A1Increase flow rateReduce the temperatureContinuous combustion chamberTurbine/propulsion fuel supply systemsCombustorCold weather

A recuperated gas turbine engine system and associated method employing catalytic combustion, wherein the combustor inlet temperature can be controlled to remain above the minimum required catalyst operating temperature at a wide range of operating conditions from full-load to part-load and from hot-day to cold-day conditions. The fuel is passed through the compressor along with the air and a portion of the exhaust gases from the turbine. The recirculated exhaust gas flow rate is controlled to control combustor inlet temperature.

Owner:MES INT INC

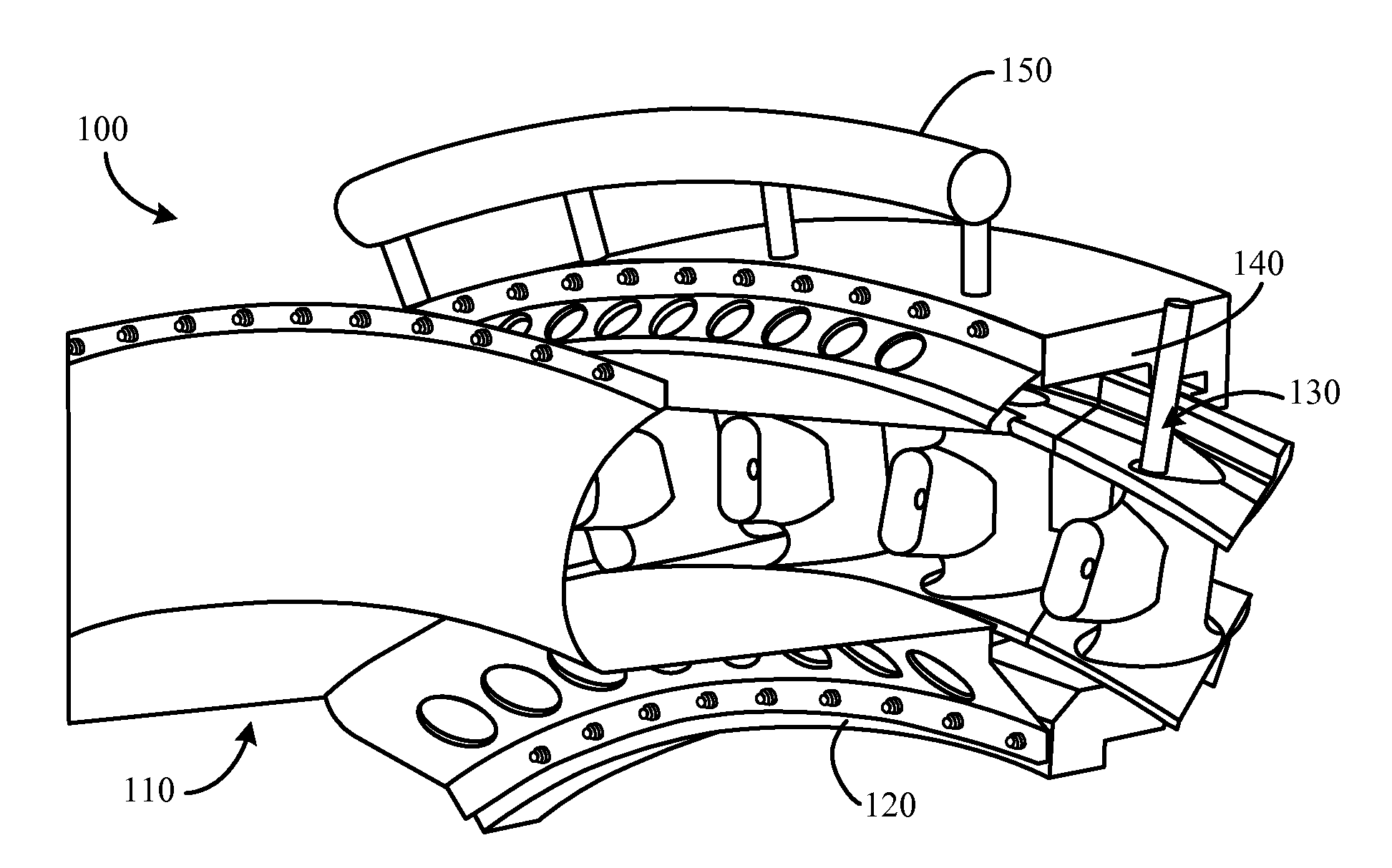

Full ring fuel distribution system for a gas turbine combustor

InactiveUS6282904B1Convenient lightingEnhancing quality and integrityBurnersContinuous combustion chamberCombustion chamberCombustor

A fuel nozzle system for use in a combustor utilized in a combustion turbine for reducing nitrogen oxides and other pollutants including an annular fuel distribution manifold separately mounted away from a diffusion nozzle, said annular manifold having a plurality of fuel emitting passages or holes disposed along the downstream side of the manifold, said manifold being mounted in a position away from the diffuser nozzle body to allow air to stream around the manifold on all sides allowing for a thorough mixture of fuel and air around the annular manifold for better premixing in the combustion chamber.

Owner:ANSALDO ENERGIA SWITZERLAND AG

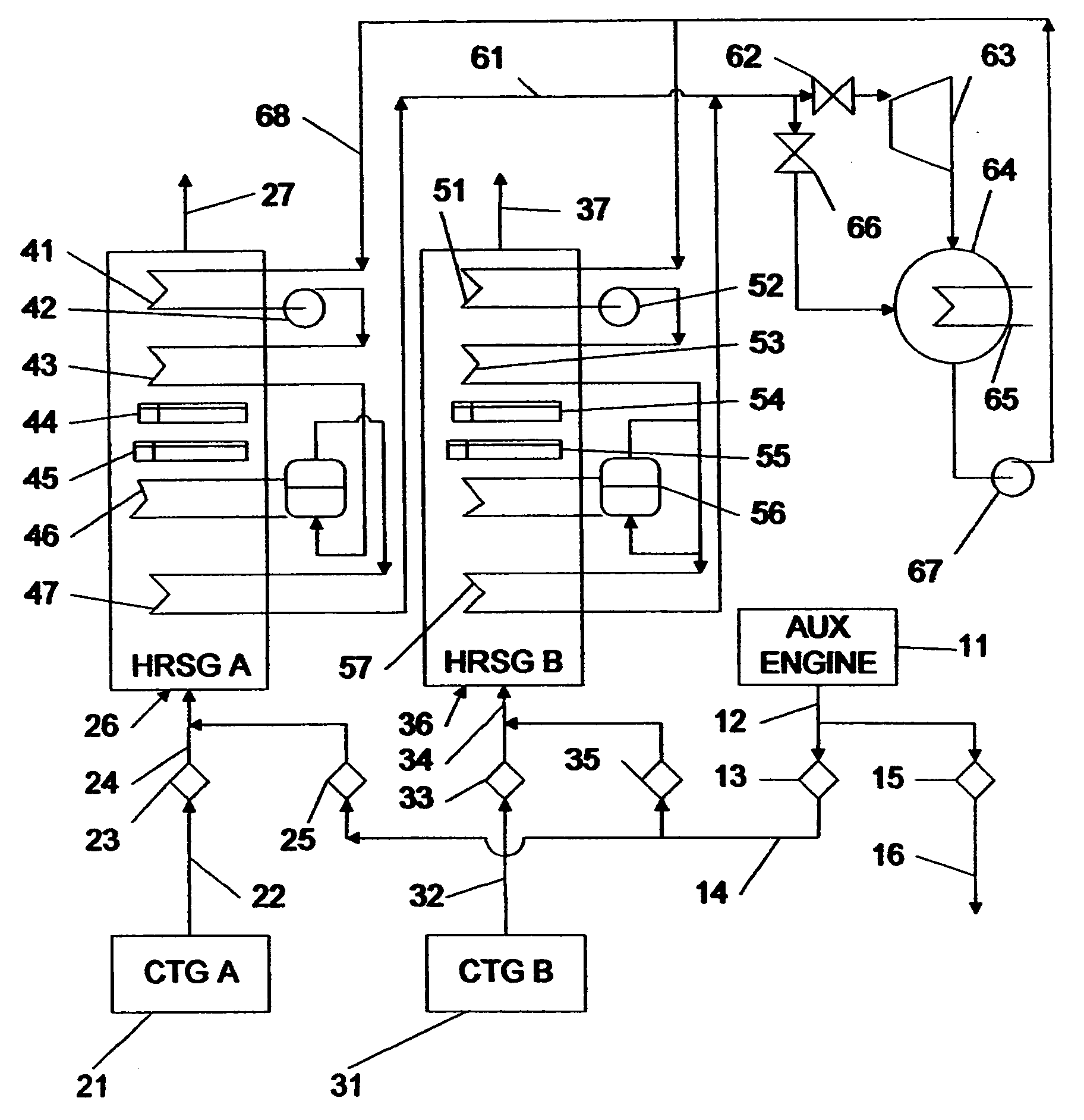

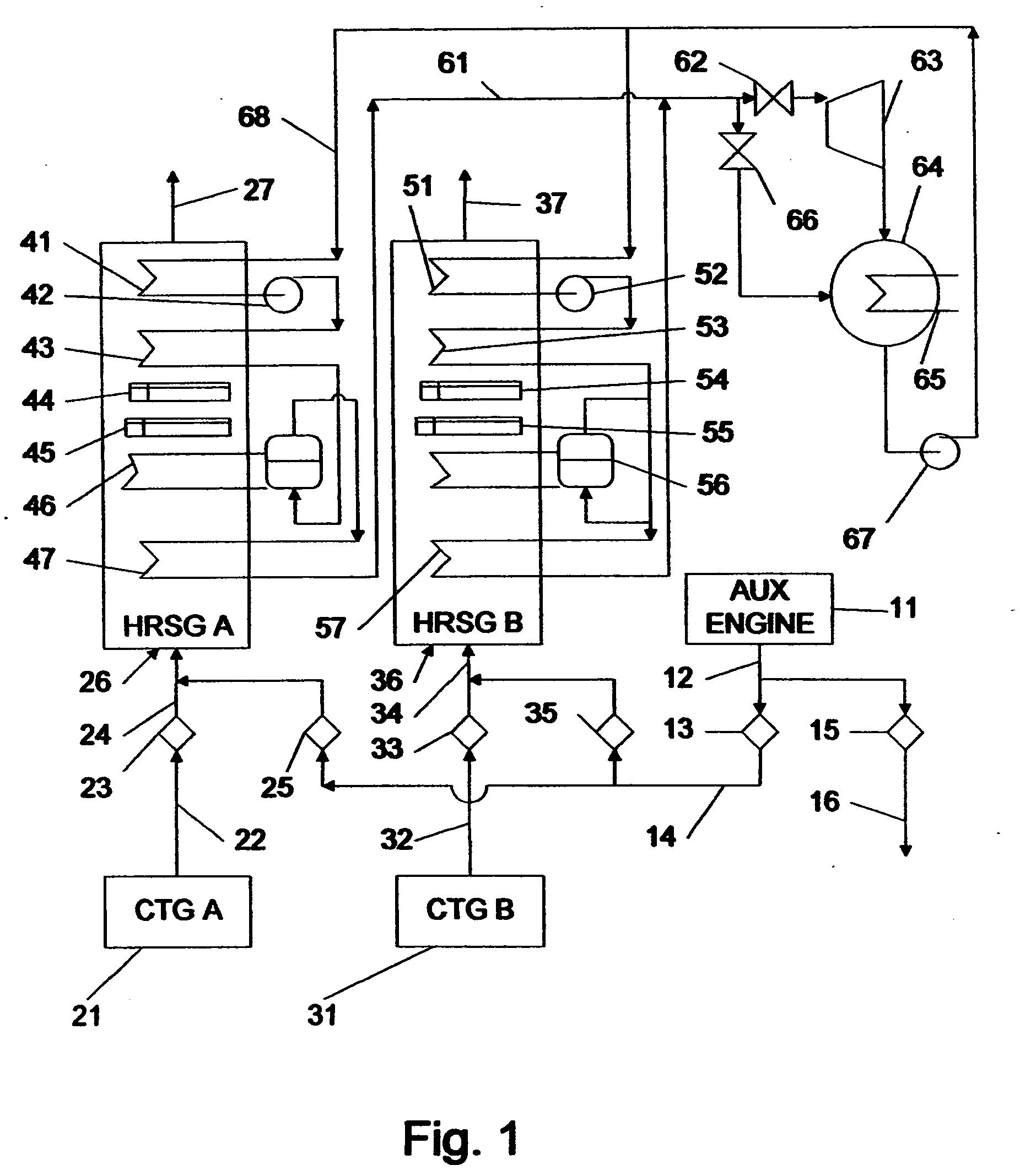

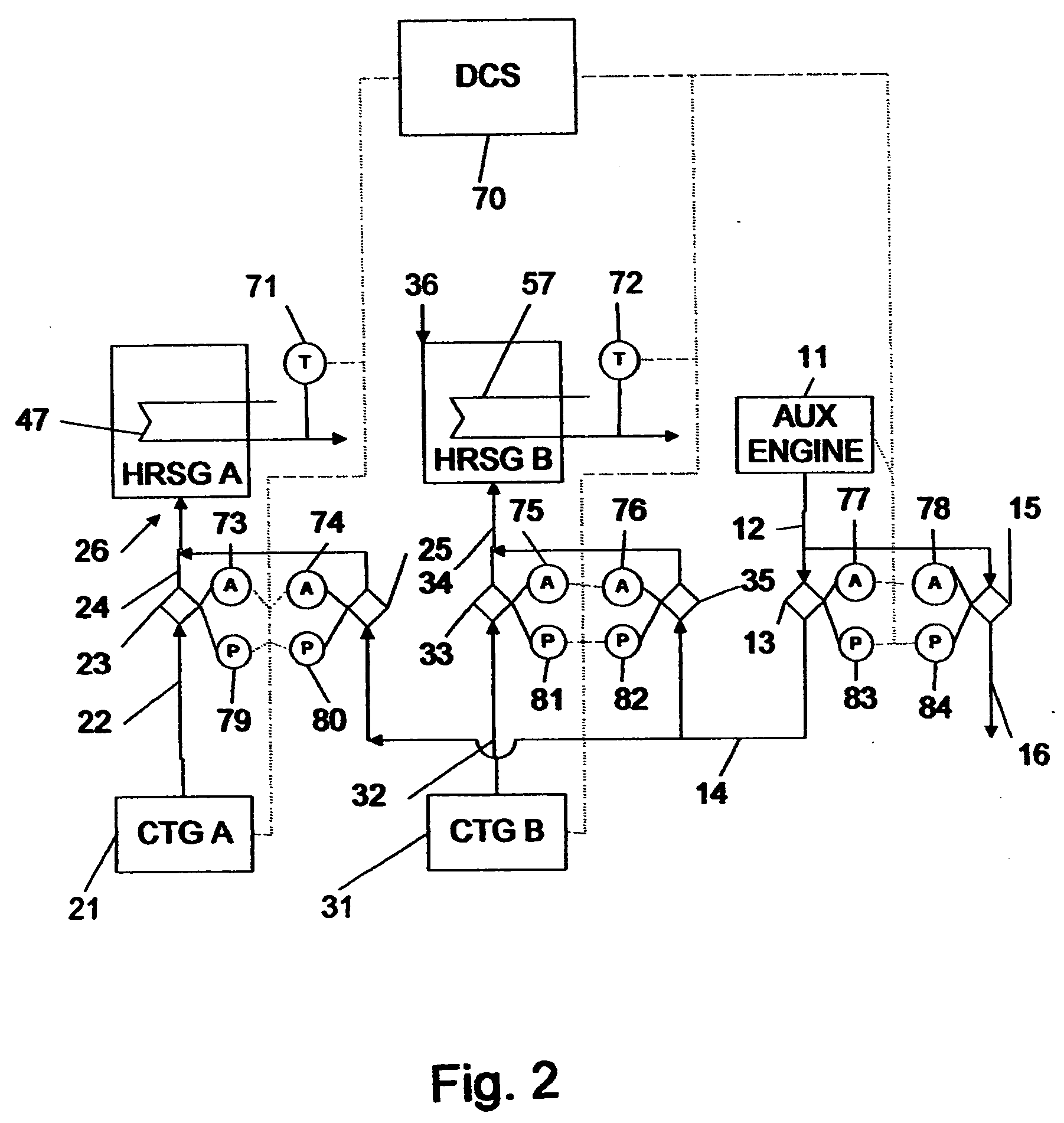

Method and apparatus for combined cycle power plant operation

InactiveUS20050034445A1Stress minimizationEmission reductionTurbine/propulsion fuel supply systemsEngine fuctionsPower stationCombustion

Methods and apparatus are disclosed for starting up a combined cycle plant using a startup duct to connect an auxiliary engine to the inlet of a plurality of HRSGs or other heat recovery systems. Each HRSG is fed by a combustion turbine. Dampers are supplied to isolate each HRSG from the startup duct and its CTG. The auxiliary engine is also ported to a stack allowing simple cycle operation. Dampers are also supplied to isolate the auxiliary engine from the startup duct and from its stack. During startups, the large CTGs will be isolated and the auxiliary engine will be connected to the HRSGs and started, allowing the HRSG to pressurize. As each HRSG pressurizes, it is isolated from the startup duct and connected to its respective CTG. The CTG is then started and loaded. The auxiliary engine is turned off and isolated when the last HRSG pressurizes.

Owner:WASHINGTON GROUP INTERNATIONAL

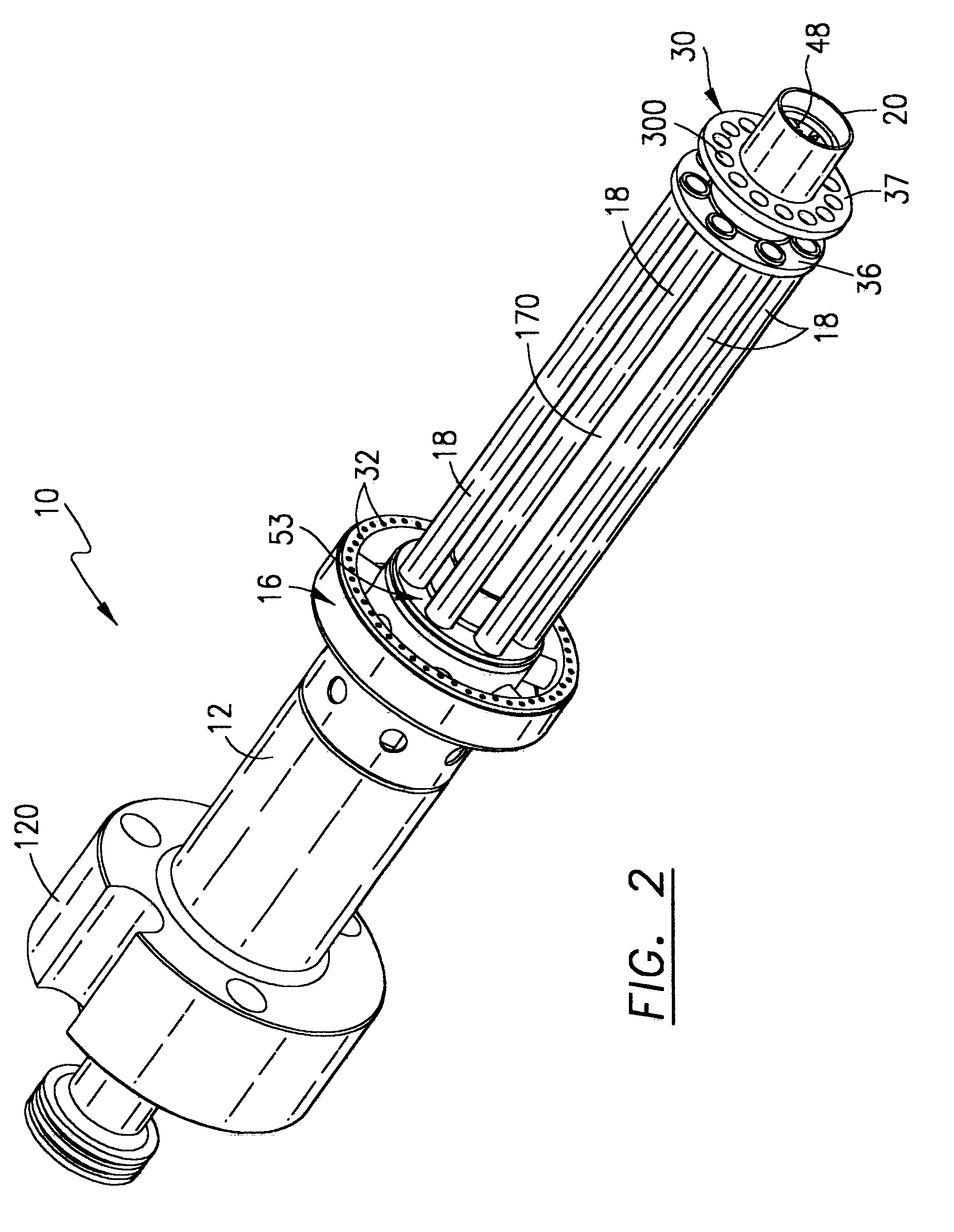

Methods and apparatus for injecting fluids into a turbine engine

ActiveUS7520134B2Well mixedTurbine/propulsion fuel supply systemsContinuous combustion chamberOblique angleTurbine

A method of operating a gas turbine engine is provided. The method includes discharging pilot fuel into a combustion chamber from a nozzle through at least one pilot fuel outlet defined in a tip of the nozzle, discharging steam from the nozzle through a plurality of steam outlets that are spaced circumferentially about the plurality of pilot fuel outlets, and discharging primary fuel from the nozzle through a plurality of primary fuel outlets that are circumferentially aligned with the plurality of steam outlets. To facilitate mixing the primary fuel with the steam, the primary fuel is discharged from the nozzle tip at an oblique angle with respect to a centerline extending through the nozzle tip.

Owner:GENERAL ELECTRIC CO

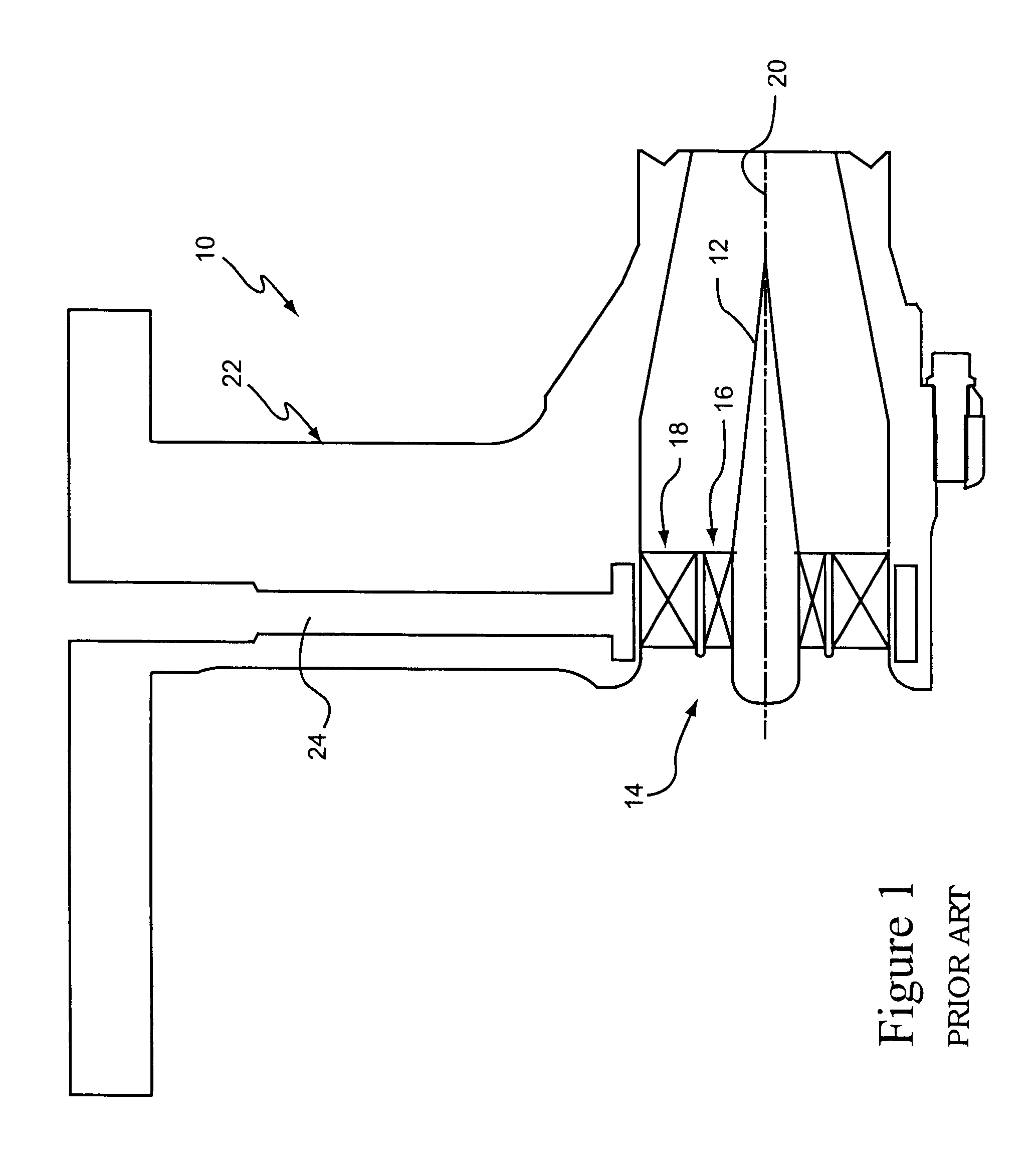

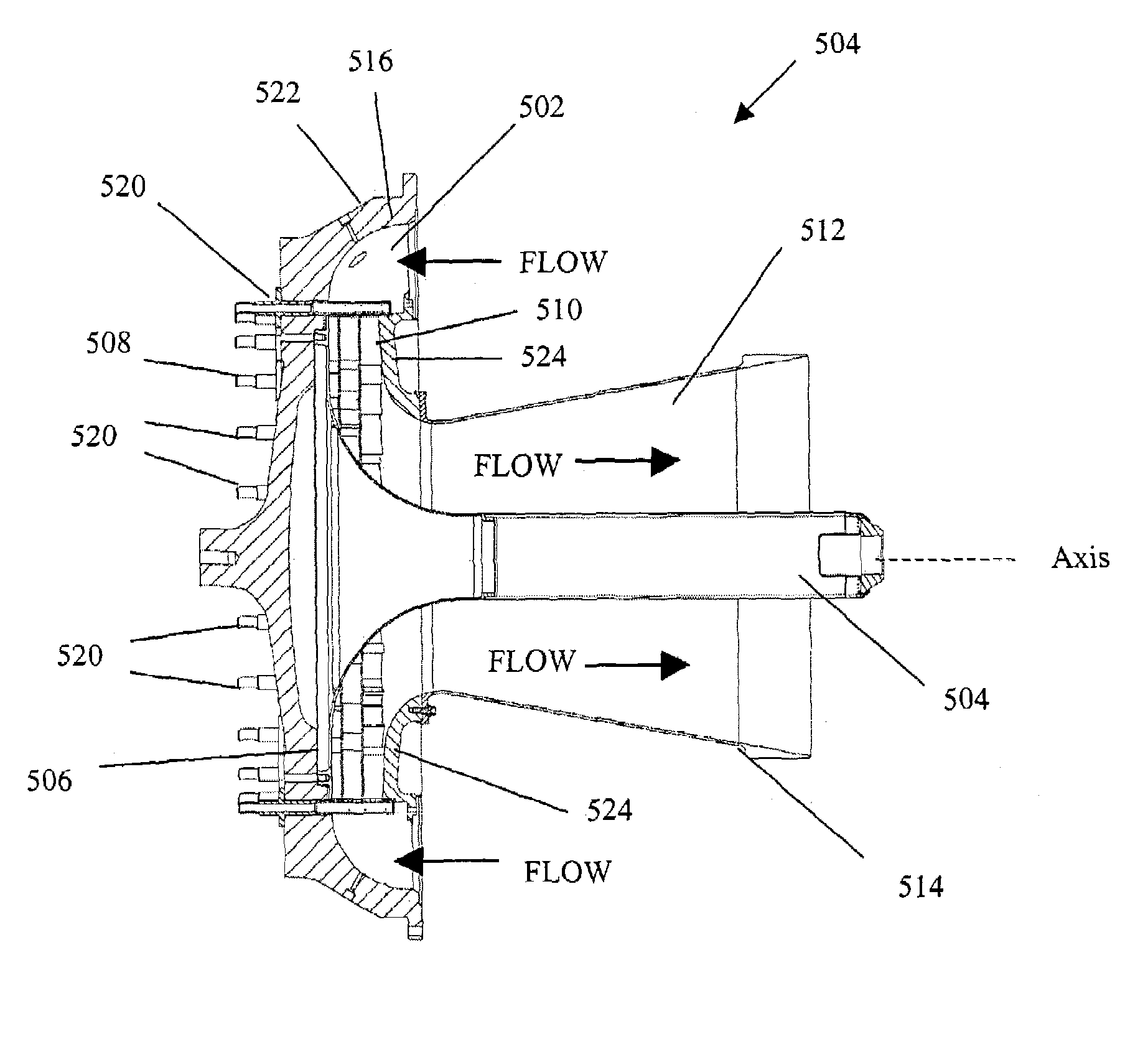

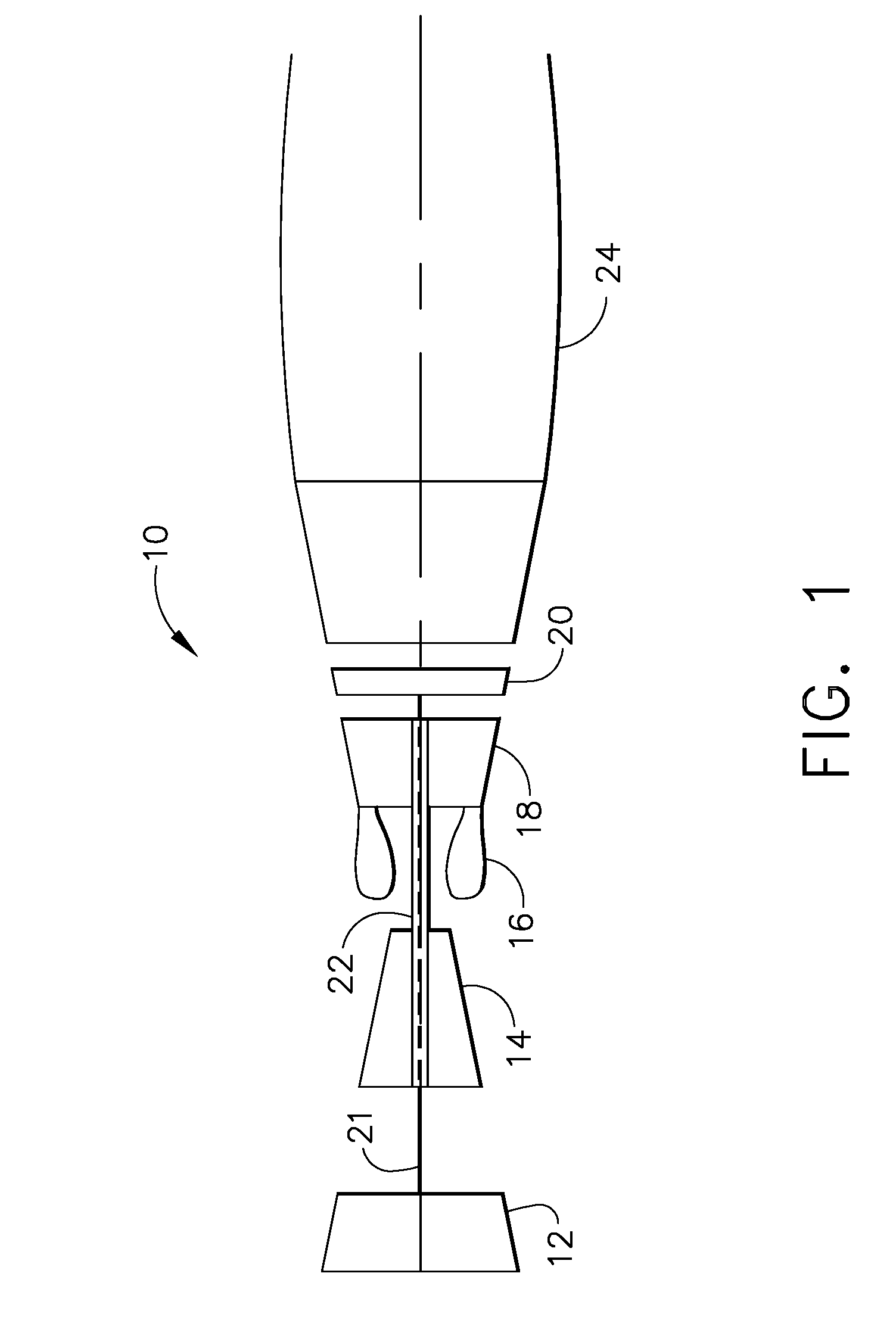

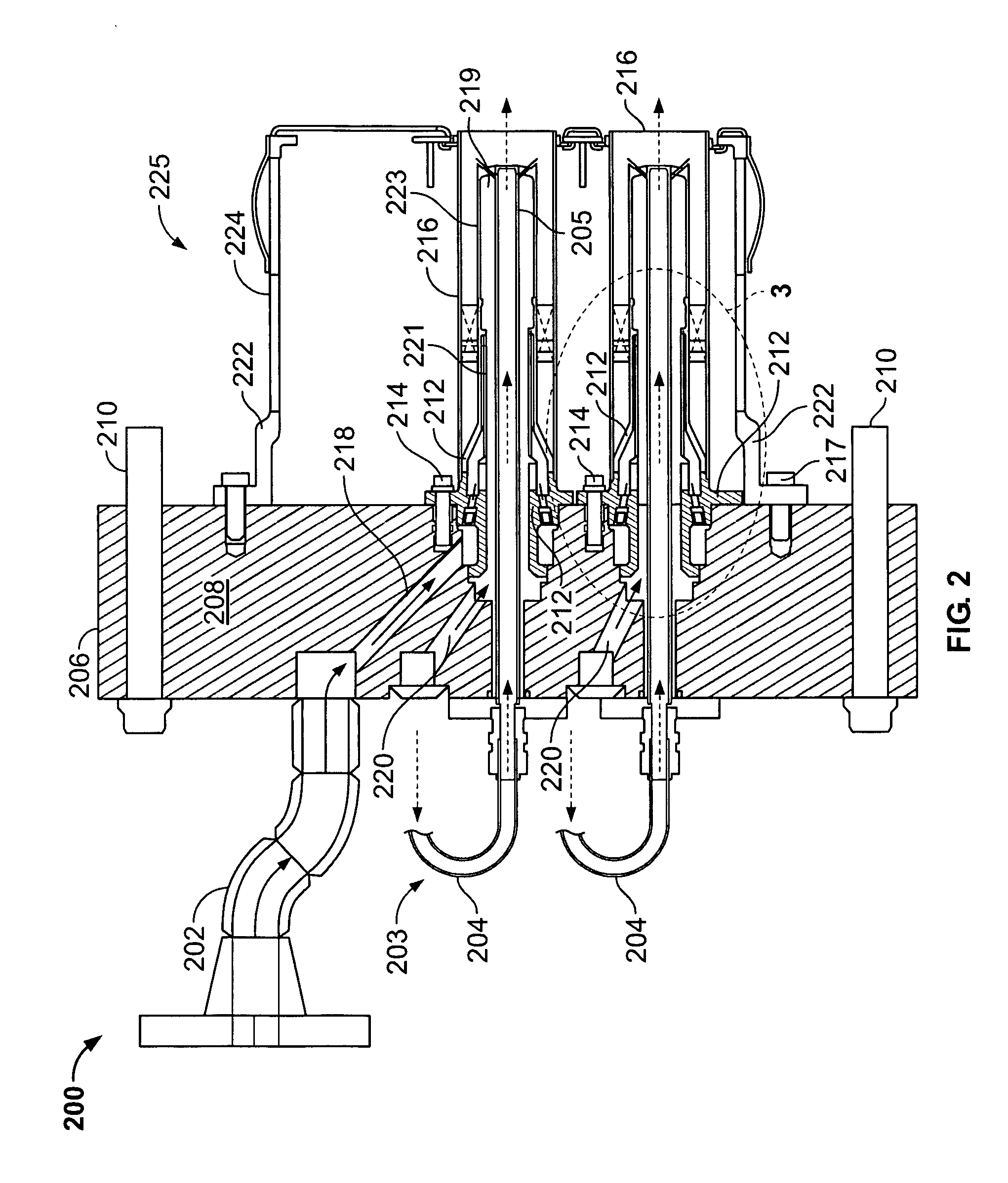

Reverse-flow gas turbine combustion system

InactiveUS7966822B2Turbine/propulsion fuel supply systemsTurbine/propulsion engine ignitionCombustion systemTurbine

A gas turbine combustion system for burning air and fuel into exhaust gases. The gas turbine combustion system may include a combustor, a turbine nozzle integral with the combustor for providing the air to the combustor, and a fuel injector for providing the fuel to the combustor. The turbine nozzle and the fuel injector are positioned within the combustor such that a mixture of the air and the fuel flows in a first direction and the exhaust gases flow in a second direction.

Owner:GENERAL ELECTRIC CO

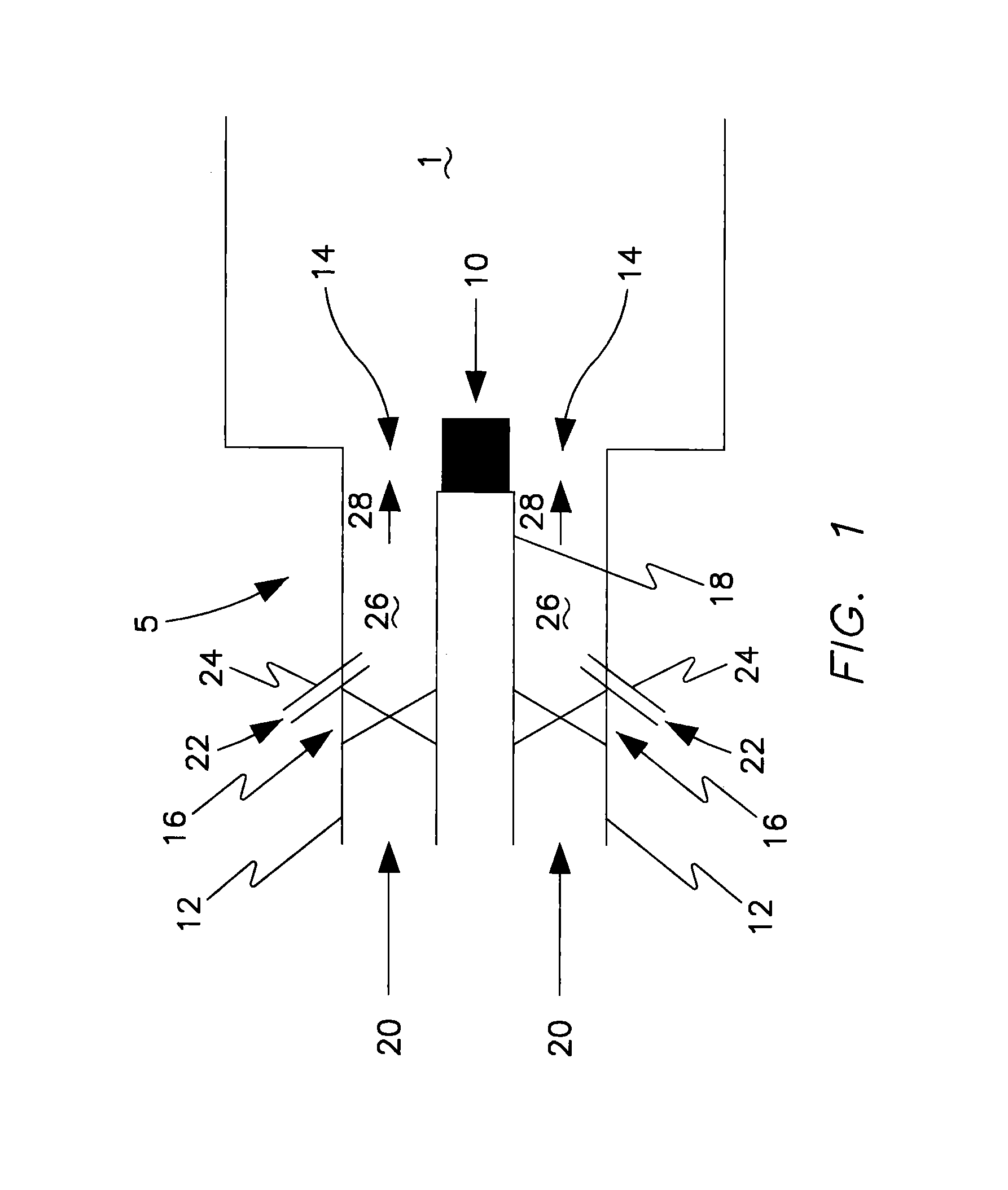

Lean blowoff detection sensor

InactiveUS7197880B2Readily incorporated into burnerMinimal modificationTurbine/propulsion engine ignitionTurbine/propulsion engine startersCombustionEngineering

Apparatus and method for detecting incipient lean blowoff conditions in a lean premixed combustion nozzle of a gas turbine. A sensor near the flame detects the concentration of hydrocarbon ions and / or electrons produced by combustion and the concentration monitored as a function of time are used to indicate incipient lean blowoff conditions.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

Distributed engine control system

A method and apparatus for distributing control of multiple engines amongst the engines in a power generation system that has a central controller, comprises the steps of: receiving aboard each engine from the central controller a control signal representative of a desired fuel flow; metering fuel at a fuel metering point aboard each engine; sensing at least one parameter aboard each engine proximate the fuel metering point that is representative of fuel flow; adjusting the fuel metering aboard each engine to cause the sensed parameter to correlate to the desired fuel flow; and transmitting a monitoring signal from each engine to the central controller that is representative of the adjusted fuel metering.

Owner:PRECISION ENGINE CONTROLS

Combustion turbine engine and methods of assembly

InactiveUS20070151255A1Turbine/propulsion fuel supply systemsContinuous combustion chamberCombustorTurbine

A method of assembling a combustion turbine engine in provided. The method includes coupling at least one fuel nozzle inner atomized air tube to a combustor end cover plate body. The method also includes assembling a fuel nozzle insert sub-assembly by inserting at least one flow control apparatus into a fuel nozzle insert sub-assembly body. The method further includes inserting at least one seal between the combustor end cover plate body and the fuel nozzle insert sub-assembly body as well as inserting at least one seal between the combustor end cover plate body and the fuel nozzle insert sub-assembly body. The method also includes coupling the fuel nozzle insert sub-assembly to the combustor end cover plate body. The method further includes inserting at least one bellows onto a bellows support fitting and inserting the bellows support fitting onto a fuel nozzle insert sub-assembly body support surface. The method also includes assembling a fuel nozzle sub-assembly. The method further includes assembling a fuel nozzle assembly by coupling the fuel nozzle sub-assembly to the combustor end cover plate body.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com