Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3727results about "Turbine/propulsion fuel control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

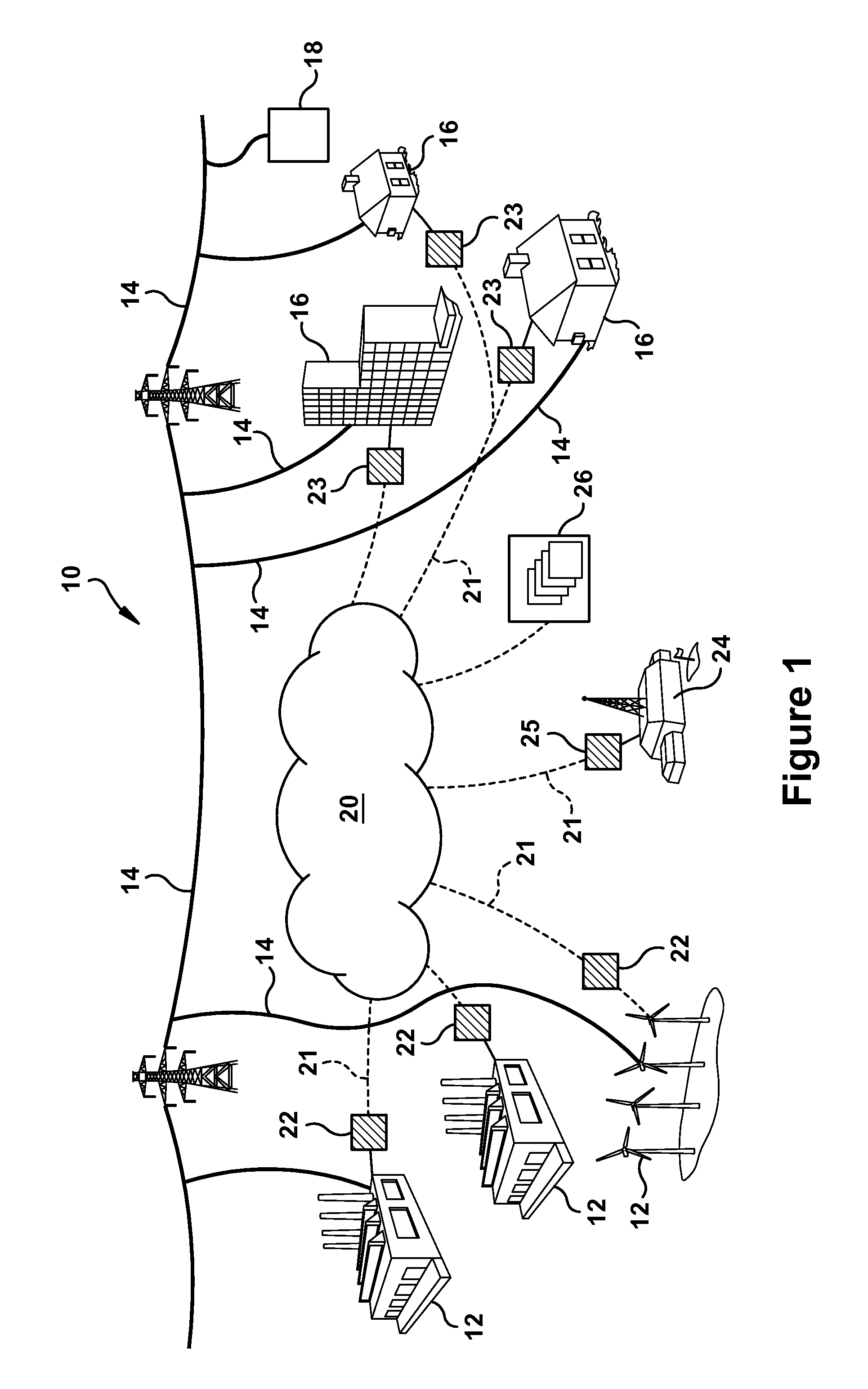

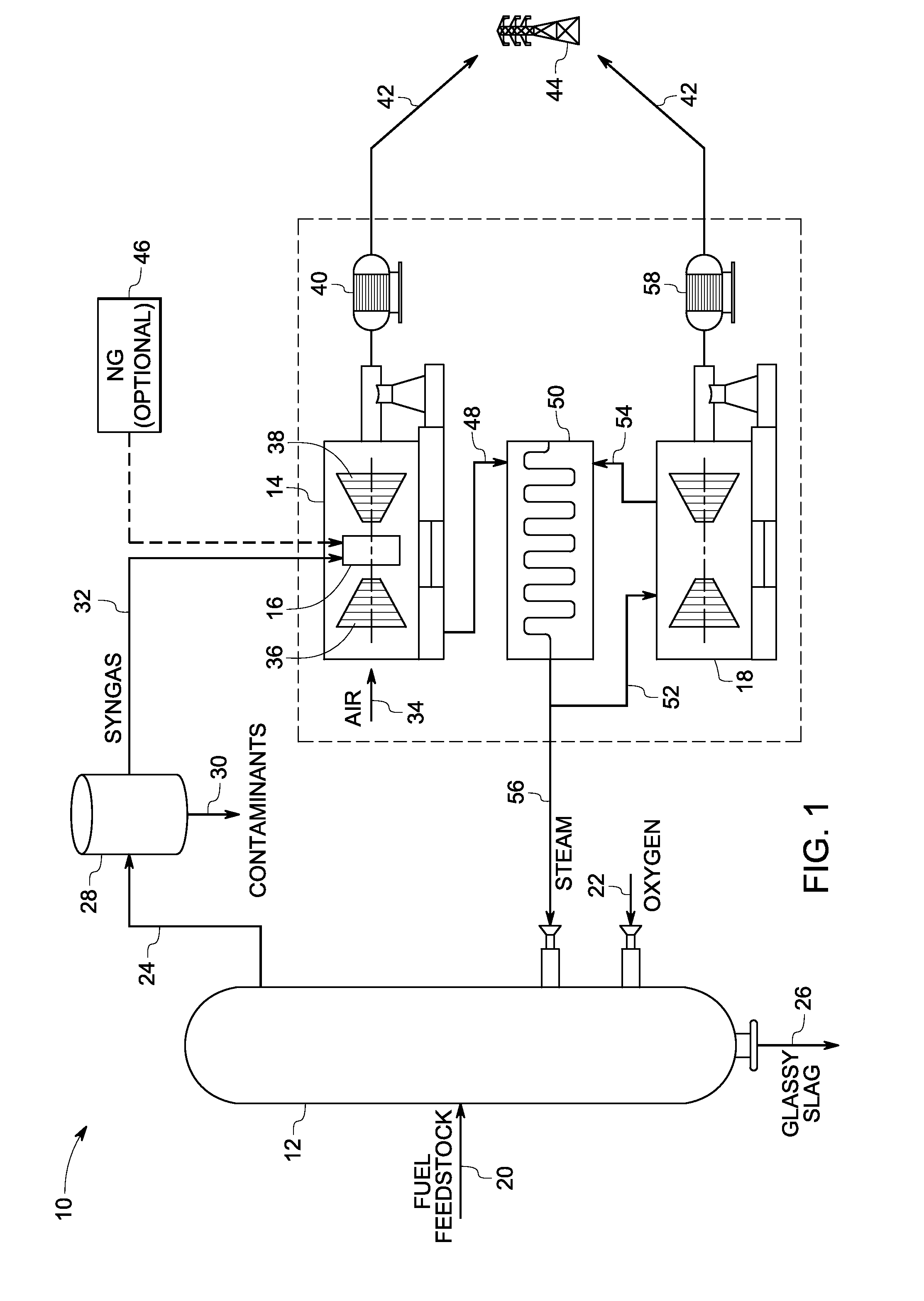

Methods and systems for enhancing control of power plant generating units

A control method for optimizing or enhancing an operation of a power plant that includes thermal generating units for generating electricity. The power plant may include multiple possible operating modes differentiated by characteristics of operating parameters. The method may include tuning a power plant model so to configure a tuned power plant model. The method may further include simulating proposed operating modes of the power plant with the tuned power plant model. The simulating may include a simulation procedure that includes: defining a second operating period; selecting the proposed operating modes from the possible operating modes; with the tuned power plant model, performing a simulation run for each of the proposed operating modes whereby the operation of the power plant during the second operating period is simulated; and obtaining simulation results from each of the simulation runs.

Owner:GENERAL ELECTRIC CO

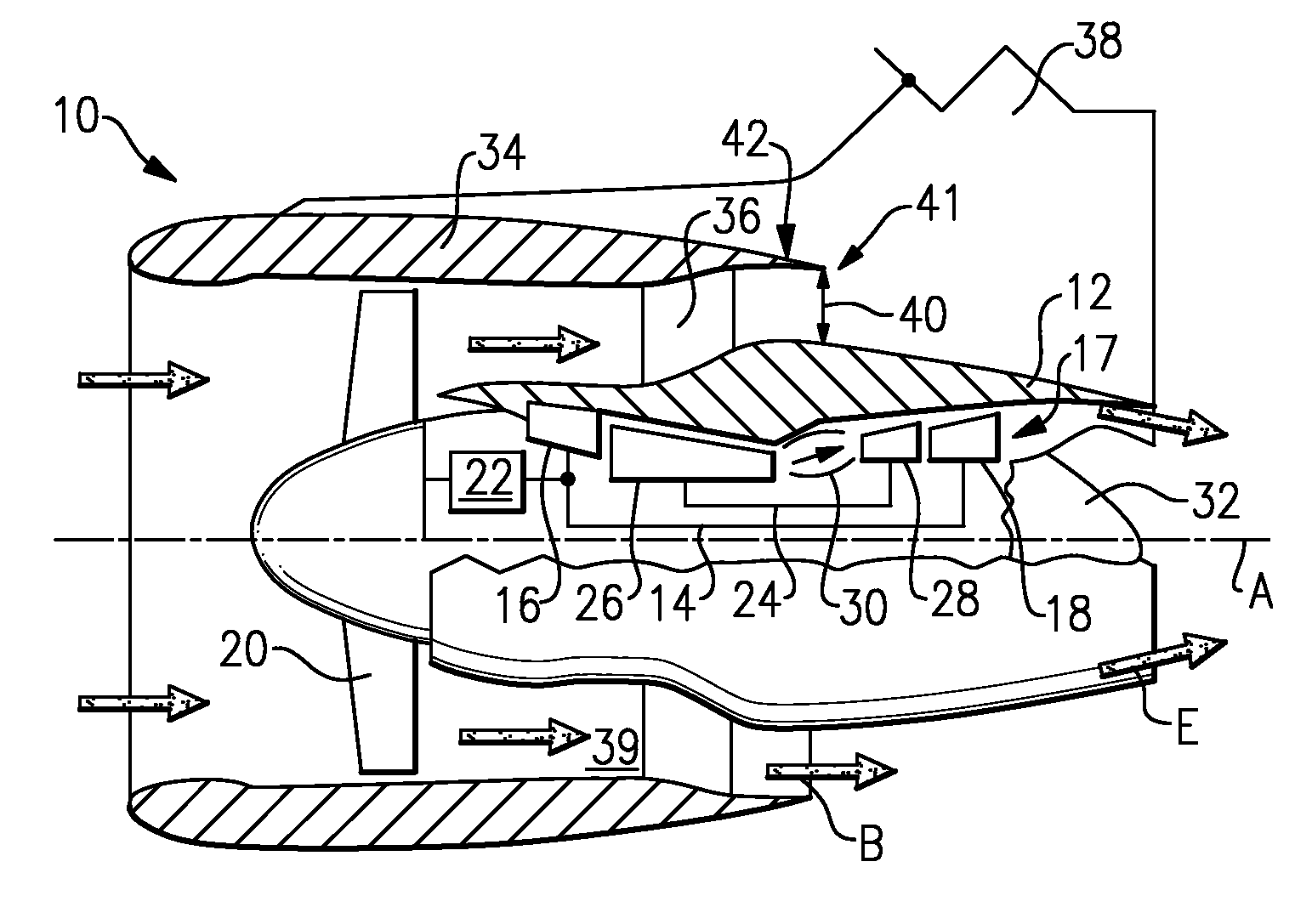

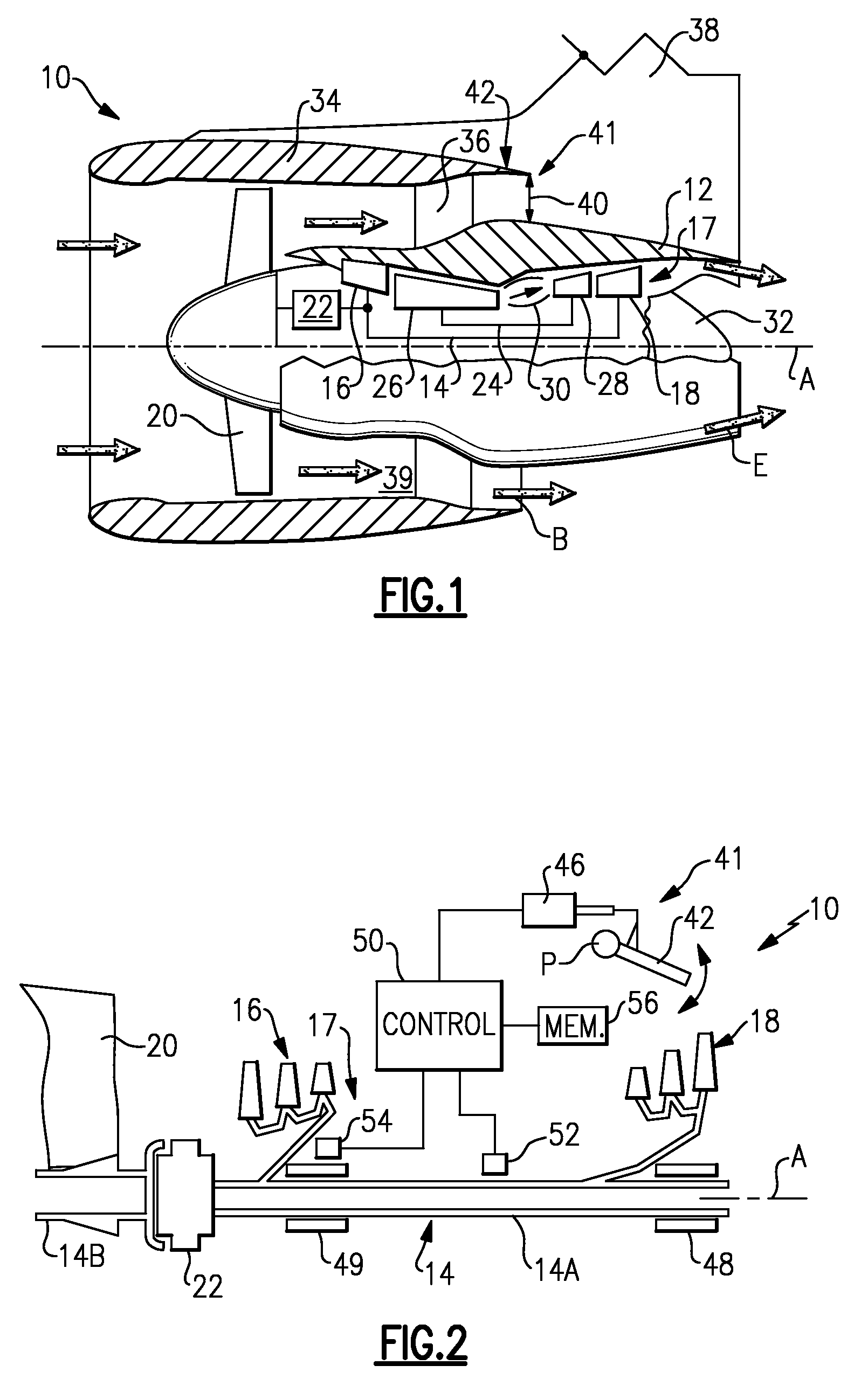

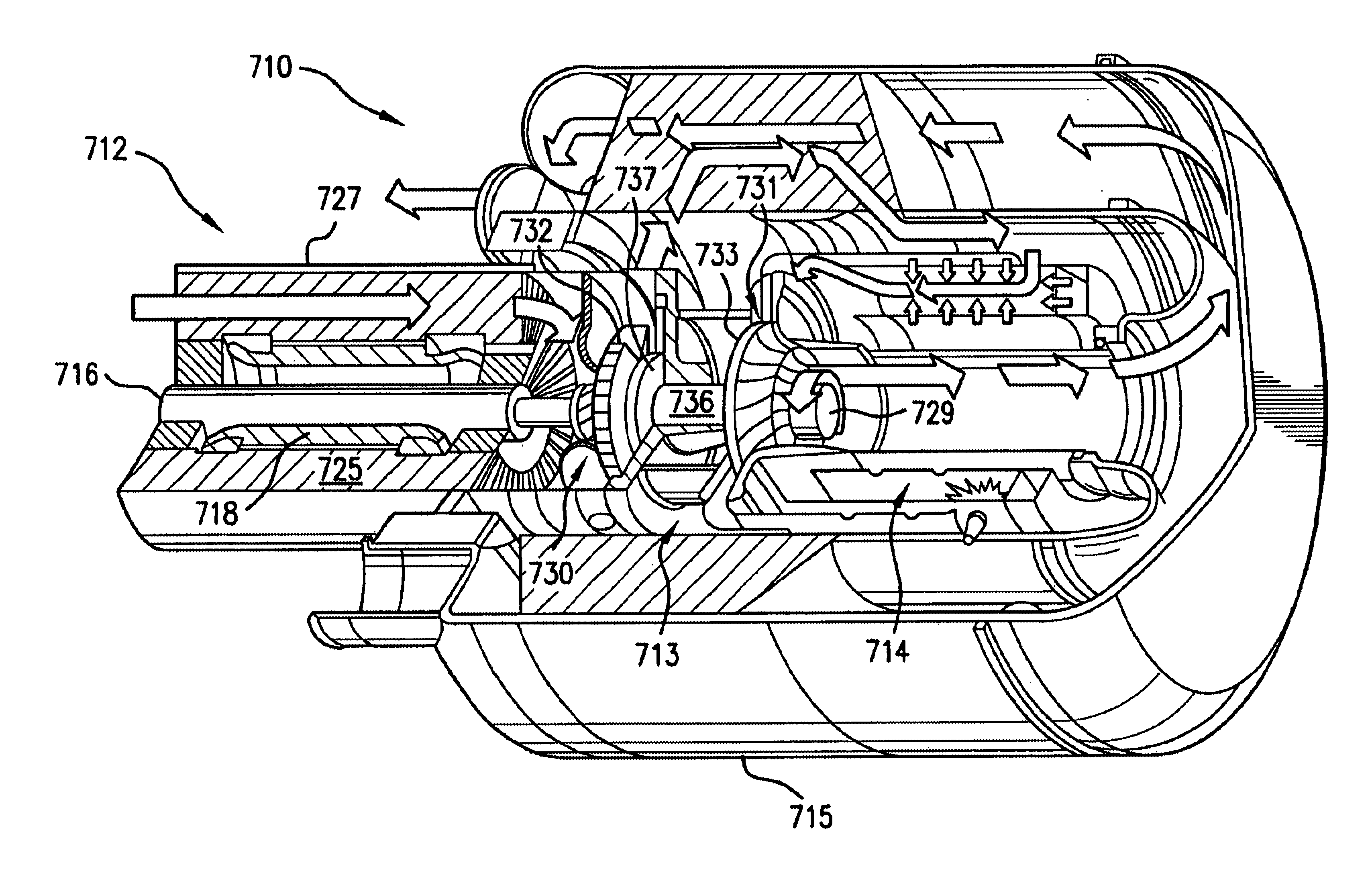

Managing spool bearing load using variable area flow nozzle

A turbine engine provides a spool supporting a turbine. The spool is arranged in a core nacelle and includes a thrust bearing. A fan is arranged upstream from the core nacelle and is coupled to the spool. A fan nacelle surrounds the fan and core nacelle and provides a bypass flow path that includes a fan nozzle exit area. A flow control device is adapted to effectively change the fan nozzle exit area. A controller is programmed to monitor the thrust bearing and command the flow control device in response to an undesired load on the thrust bearing. Effectively changing the fan nozzle exit area with the flow control device actively manages the bearing thrust load to desired levels.

Owner:RTX CORP

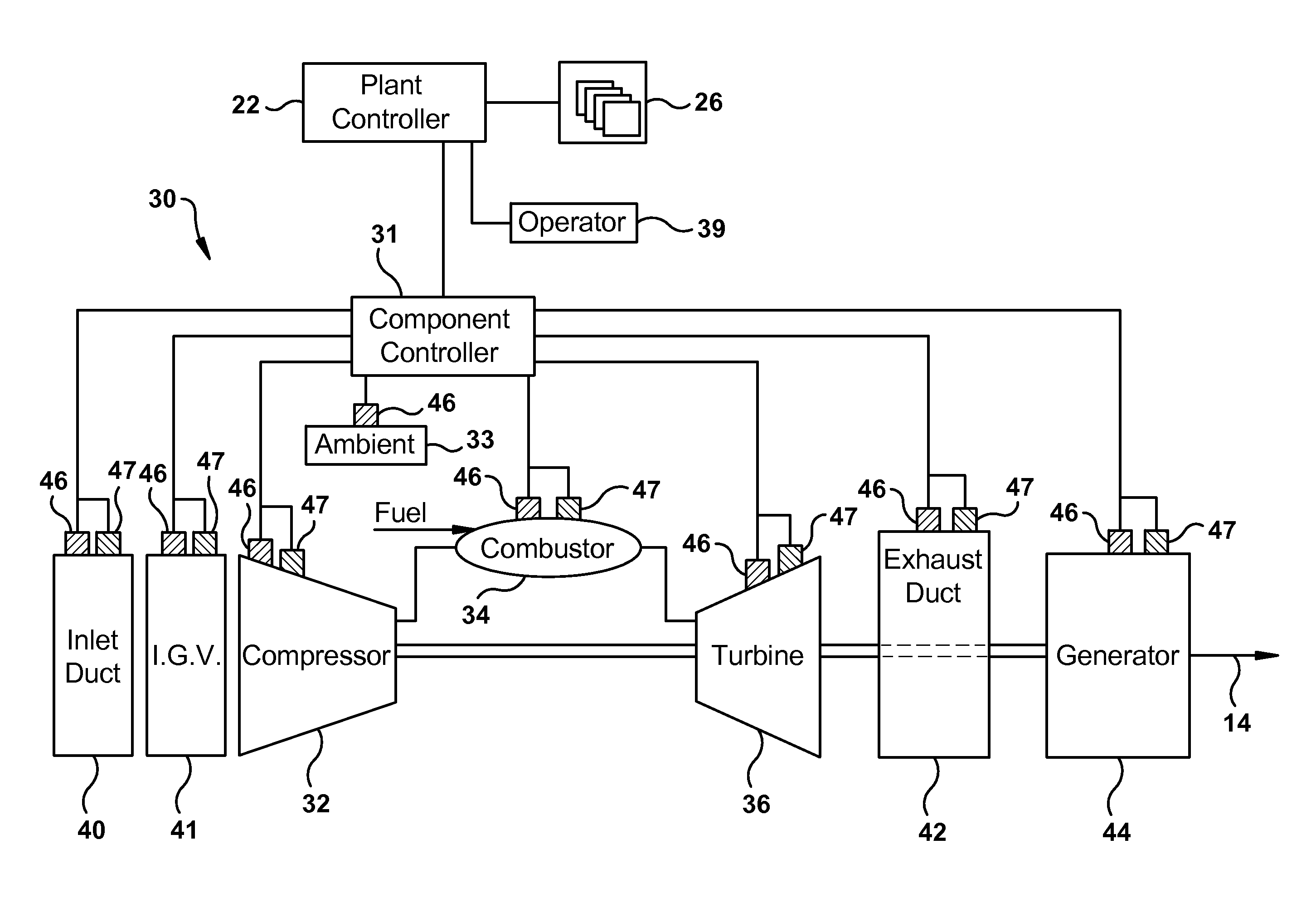

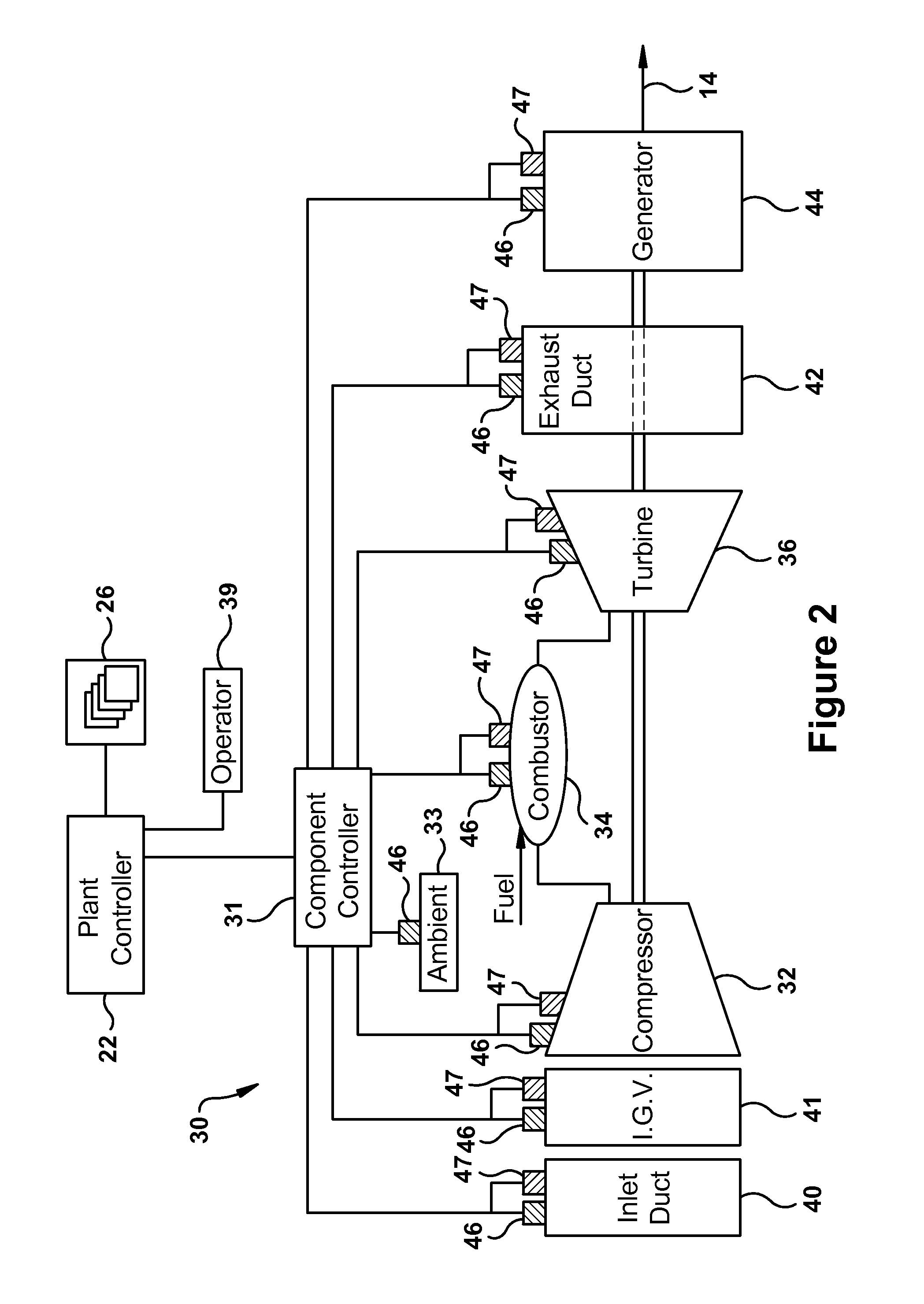

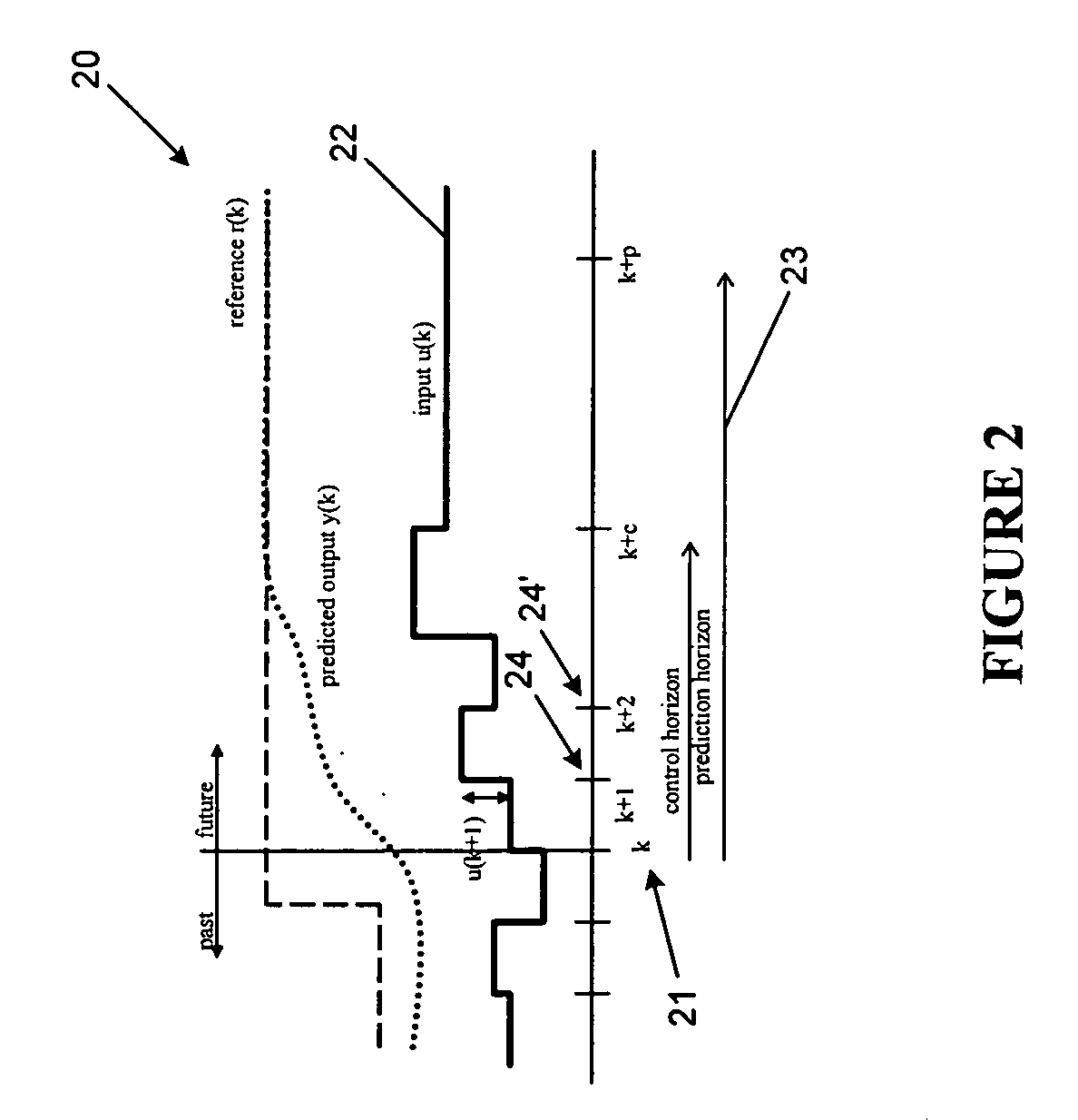

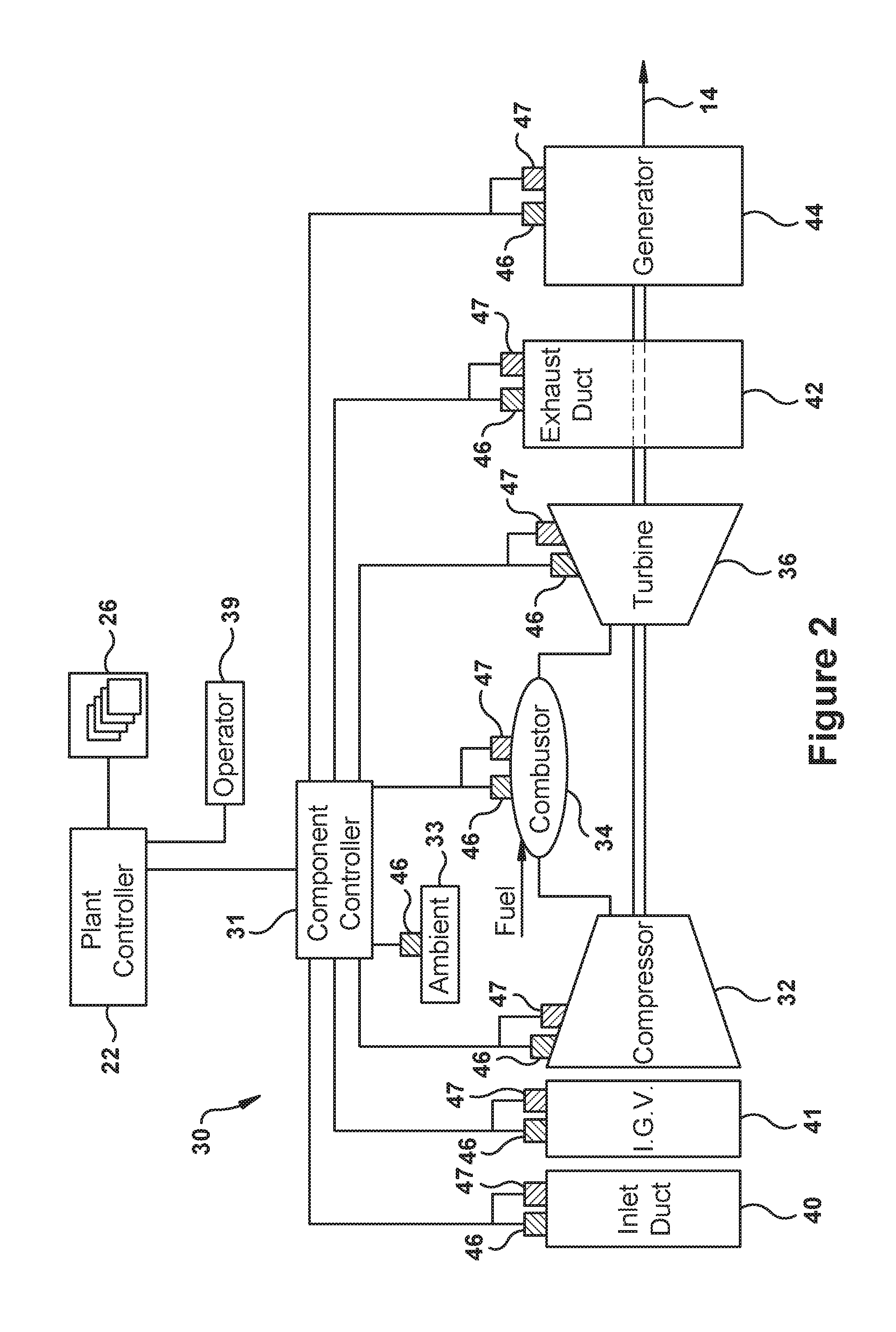

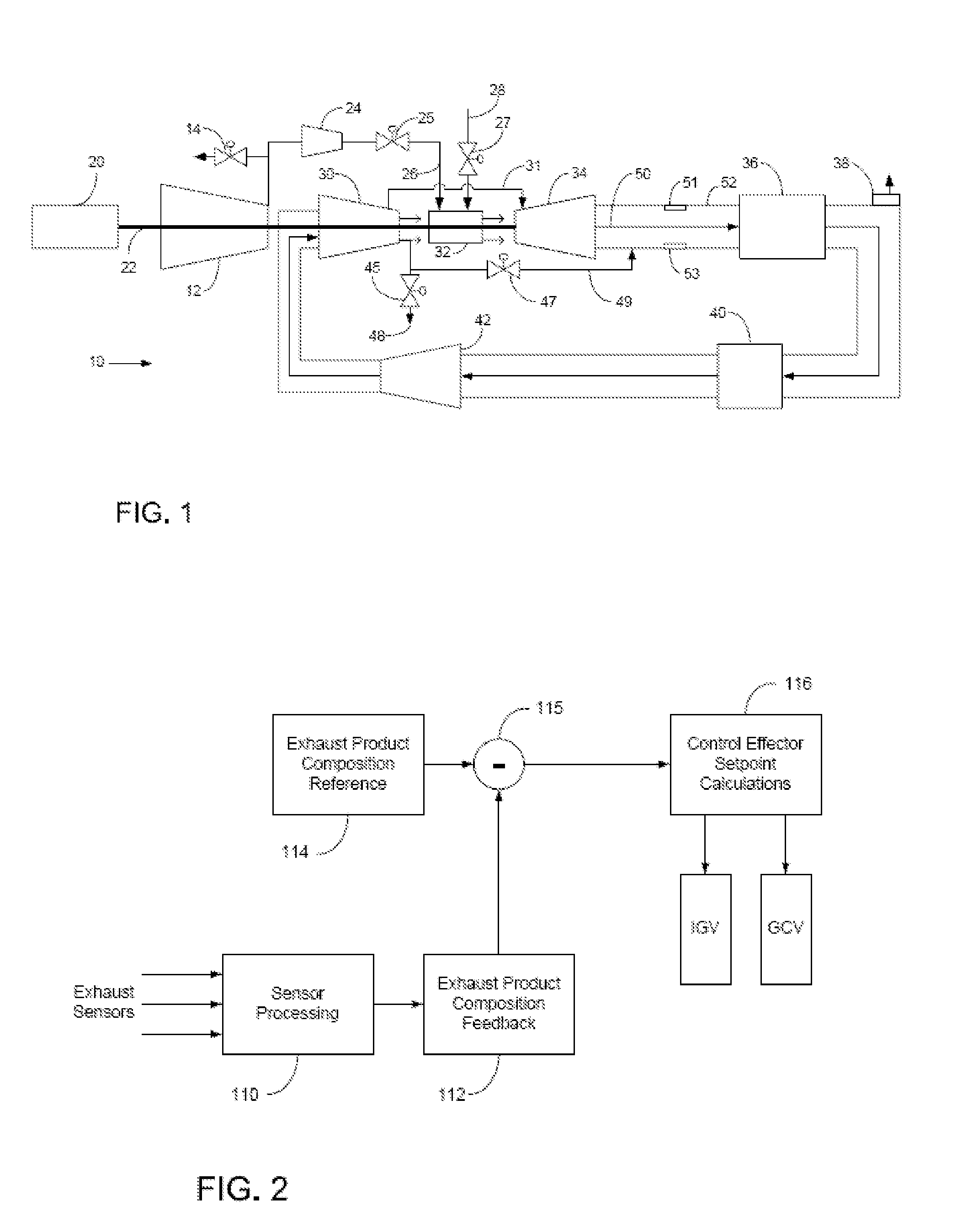

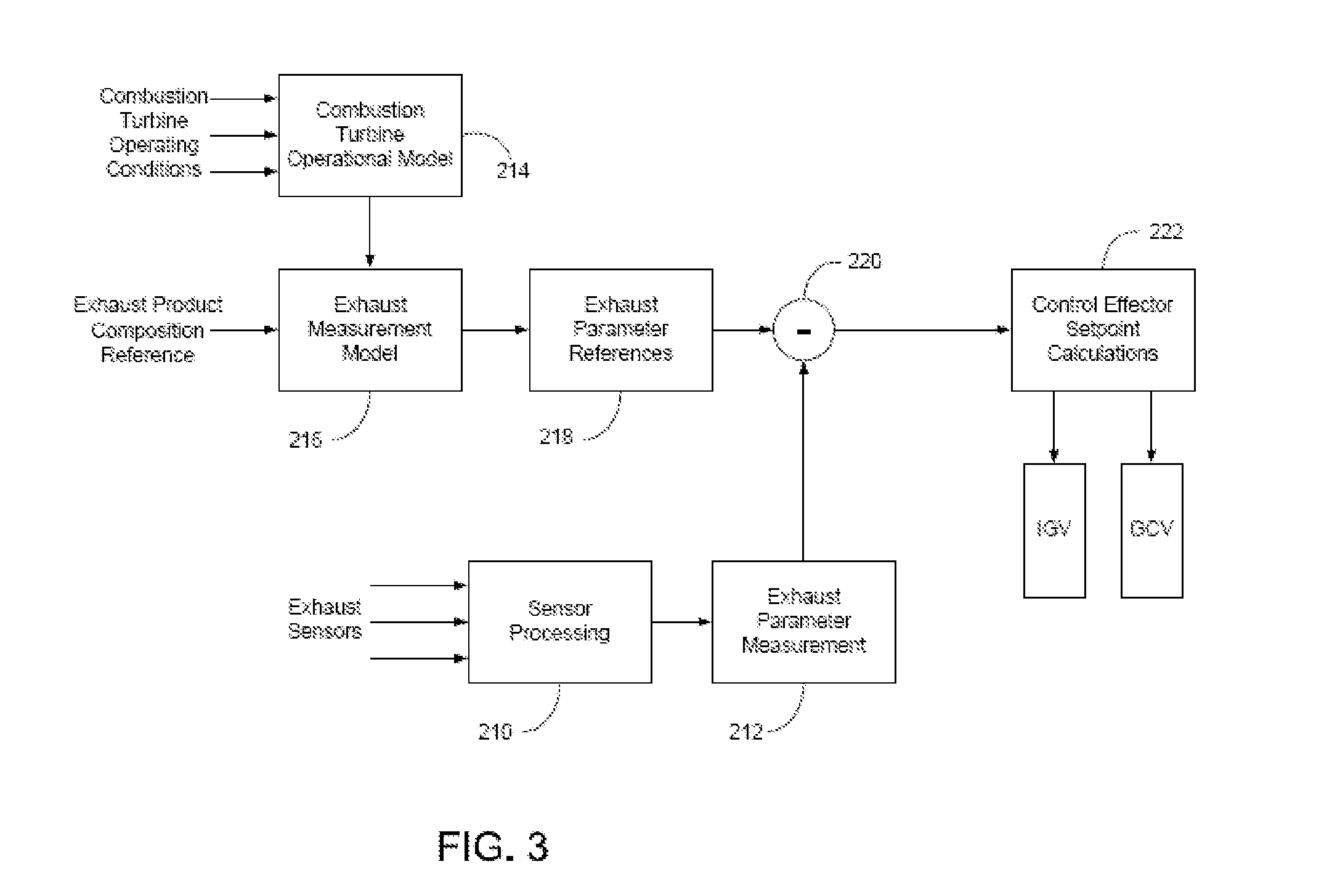

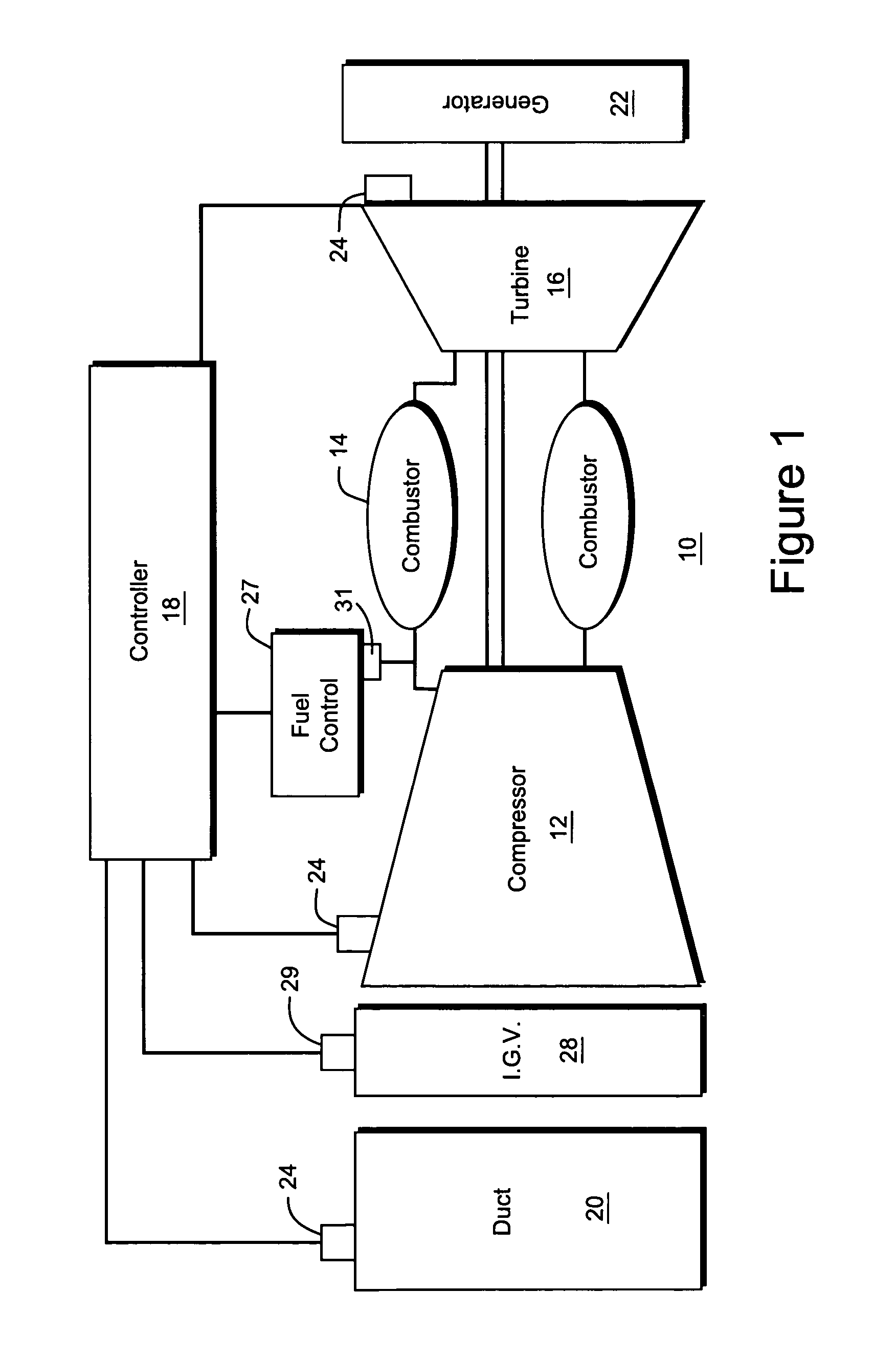

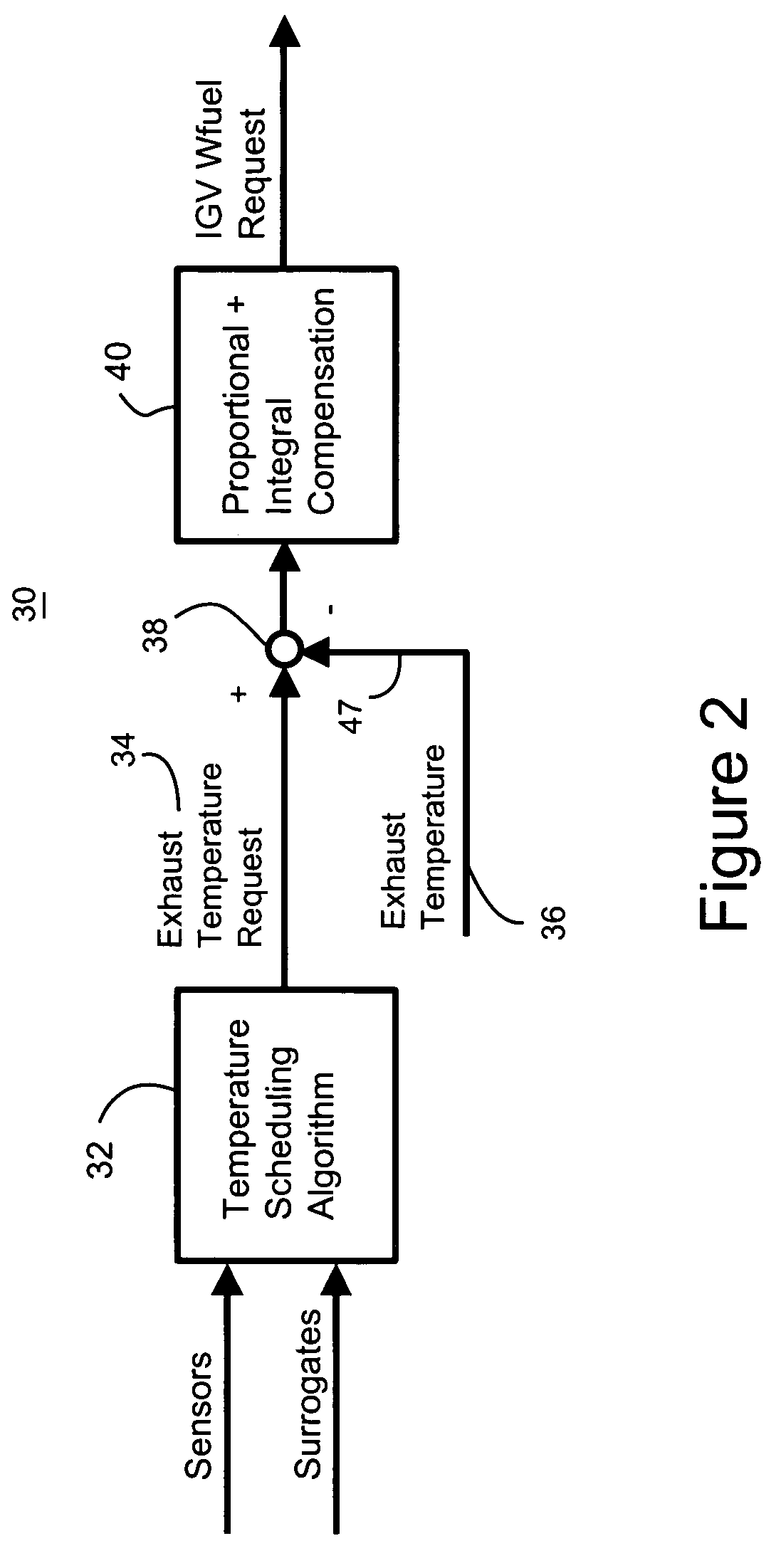

Methods and Systems for Model-Based Control of Gas Turbines

ActiveUS20080243352A1Reduce errorsAnalogue computers for vehiclesGas turbine plantsClosing loopsEngineering

Embodiments of systems and methods for tuning a turbine are provided. In one embodiment, a method may include receiving at least one of a measured operating parameter or a modeled operating parameter of a turbine during operation; and tuning the turbine during operation. The turbine may be tuned during operation by applying the measured operating parameter or modeled operating parameter or parameters to at least one operational boundary model, applying the measured operating parameter or modeled operating parameter or parameters to at least one scheduling algorithm, comparing the output of the operational boundary model or models to the at output of the scheduling algorithm or algorithms to determine at least one error term, and closing loop on the one error term or terms by adjusting at least one turbine control effector during operation of the turbine.

Owner:GENERAL ELECTRIC CO

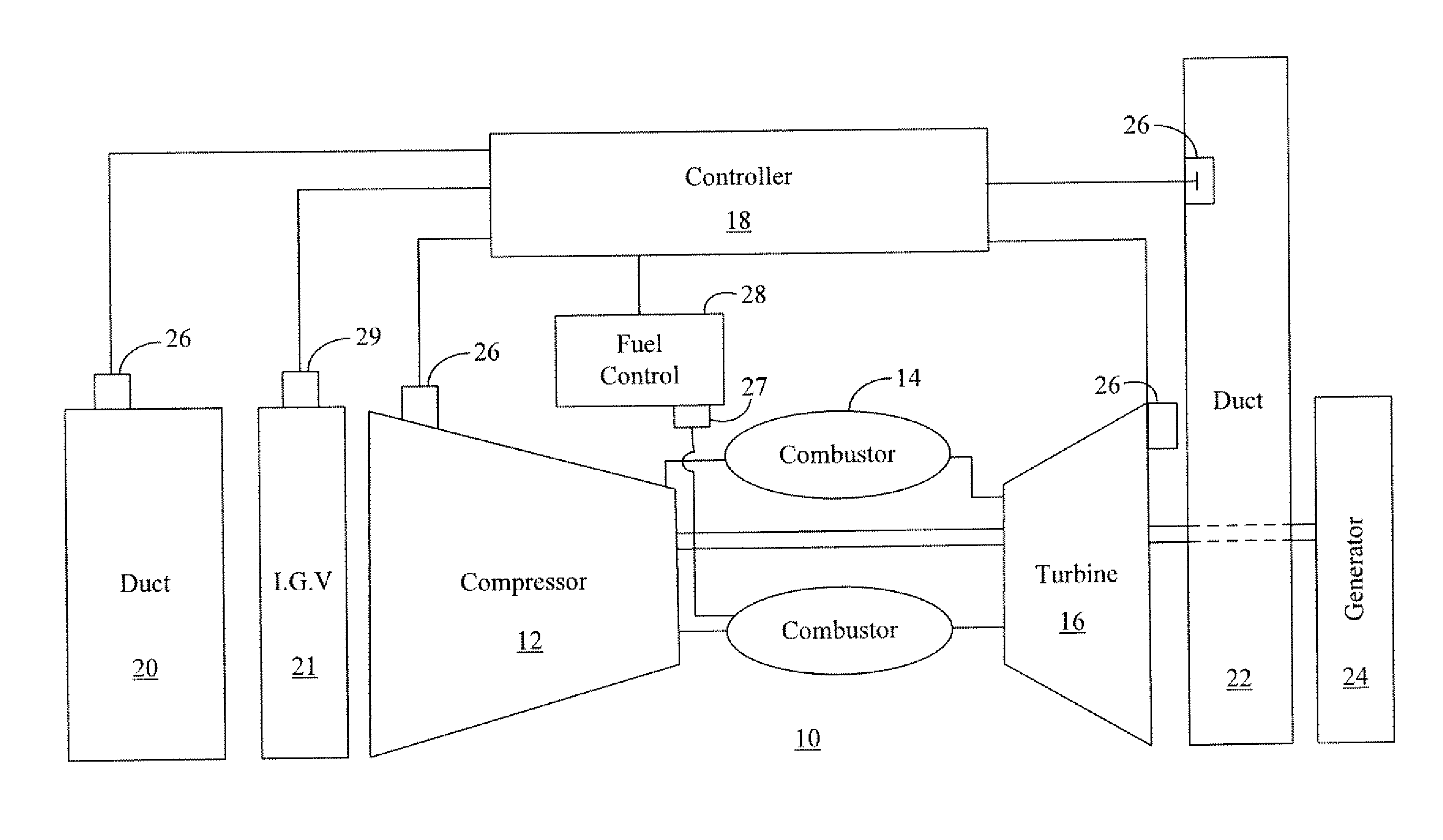

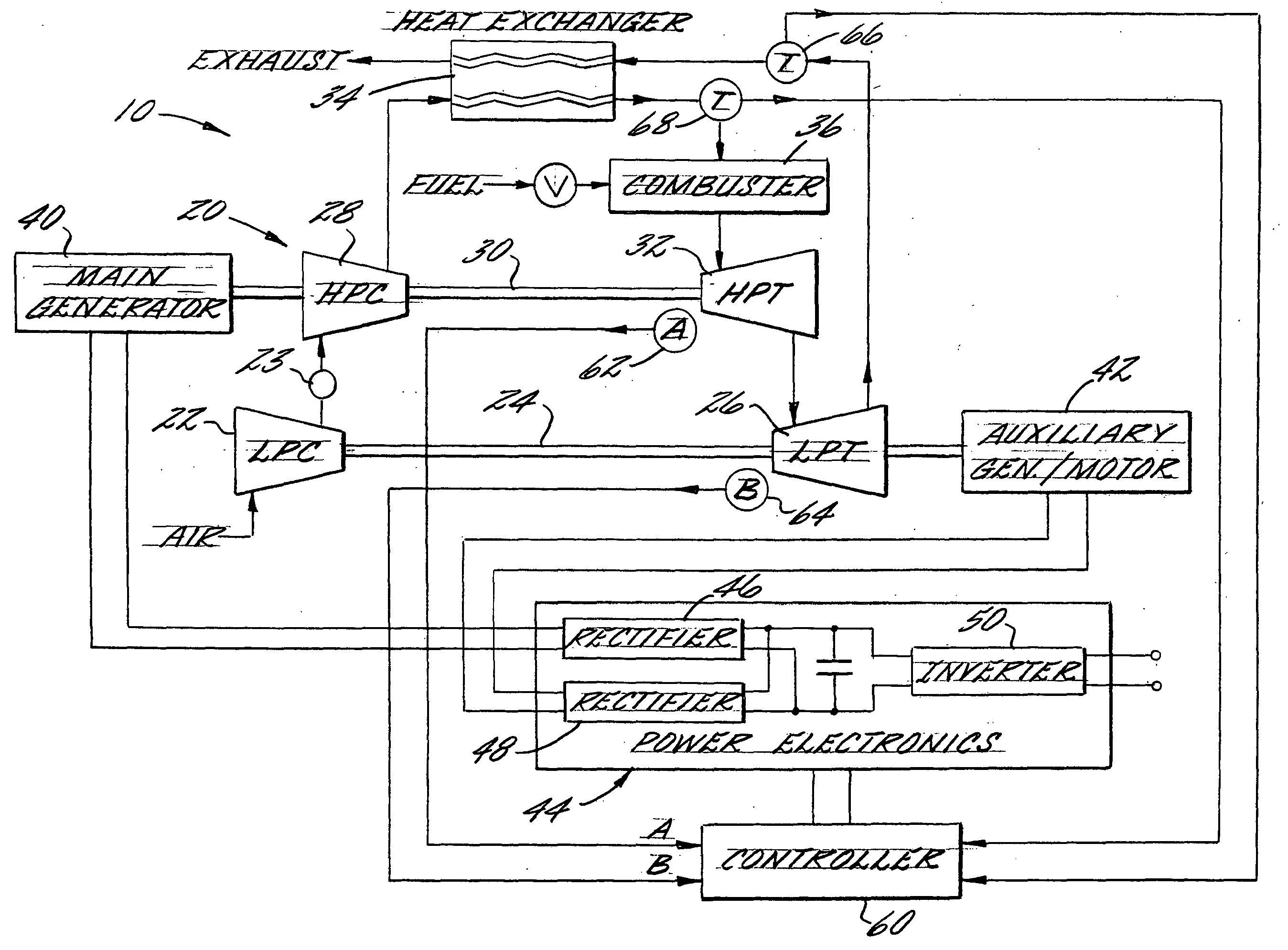

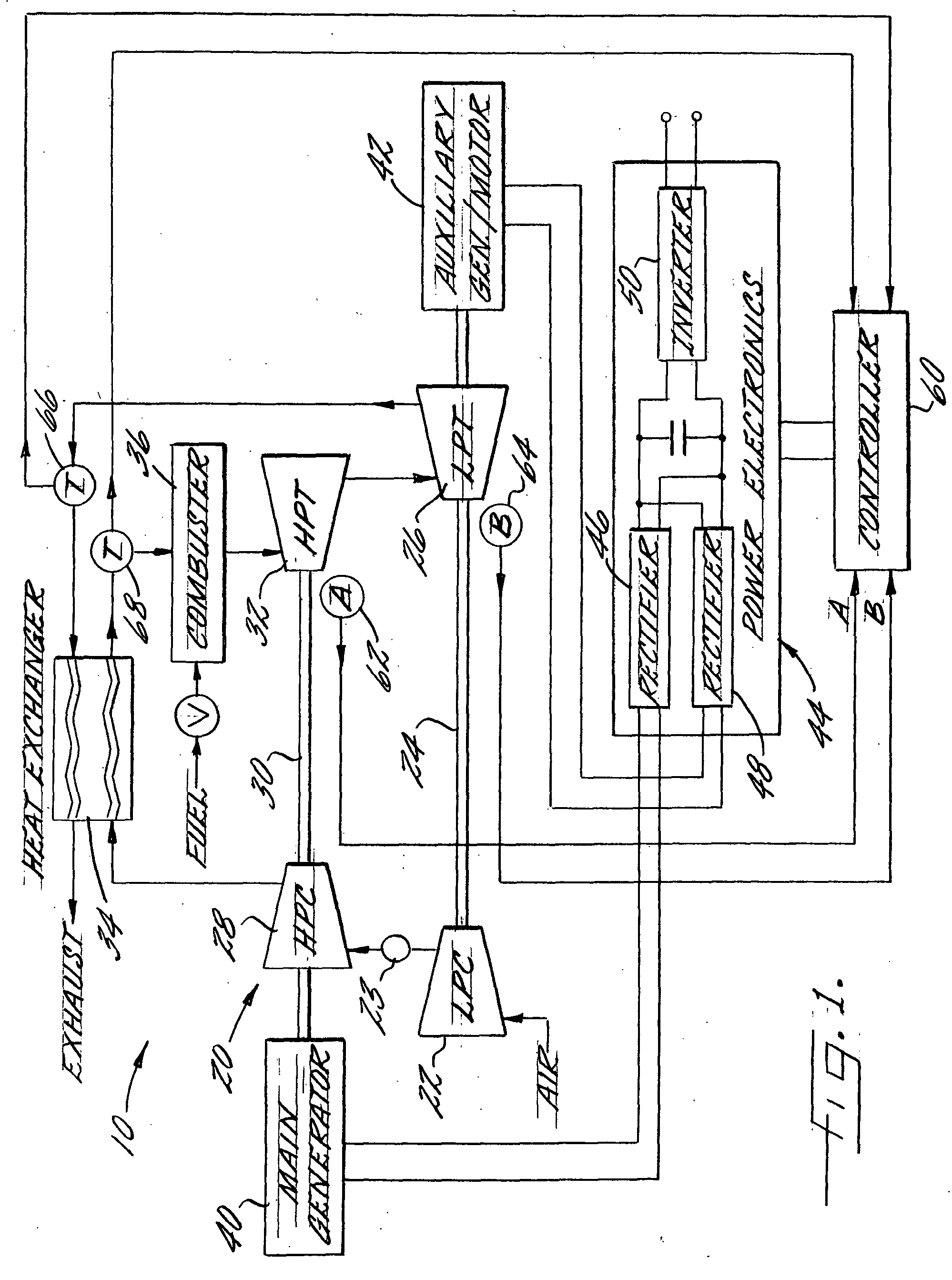

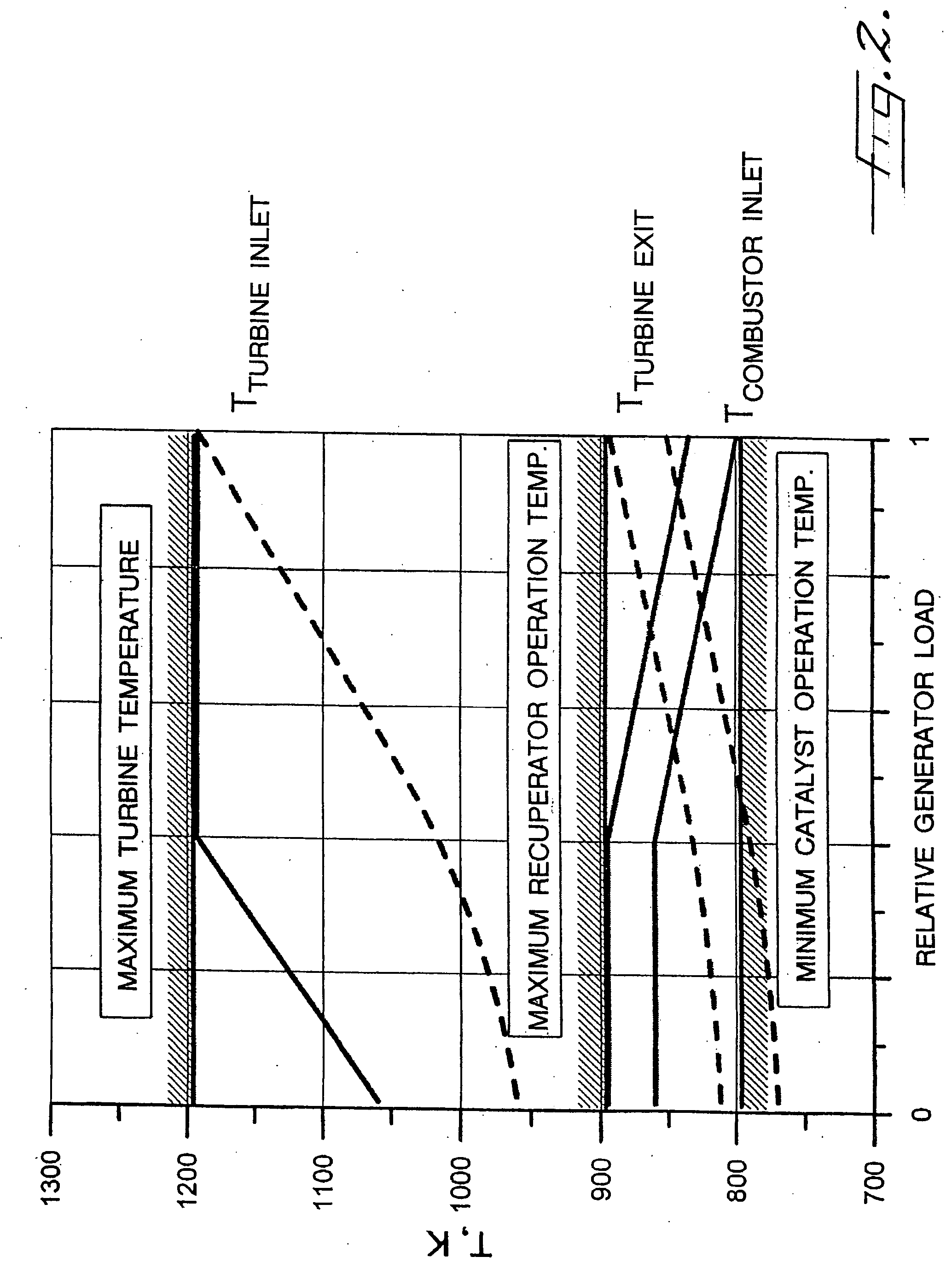

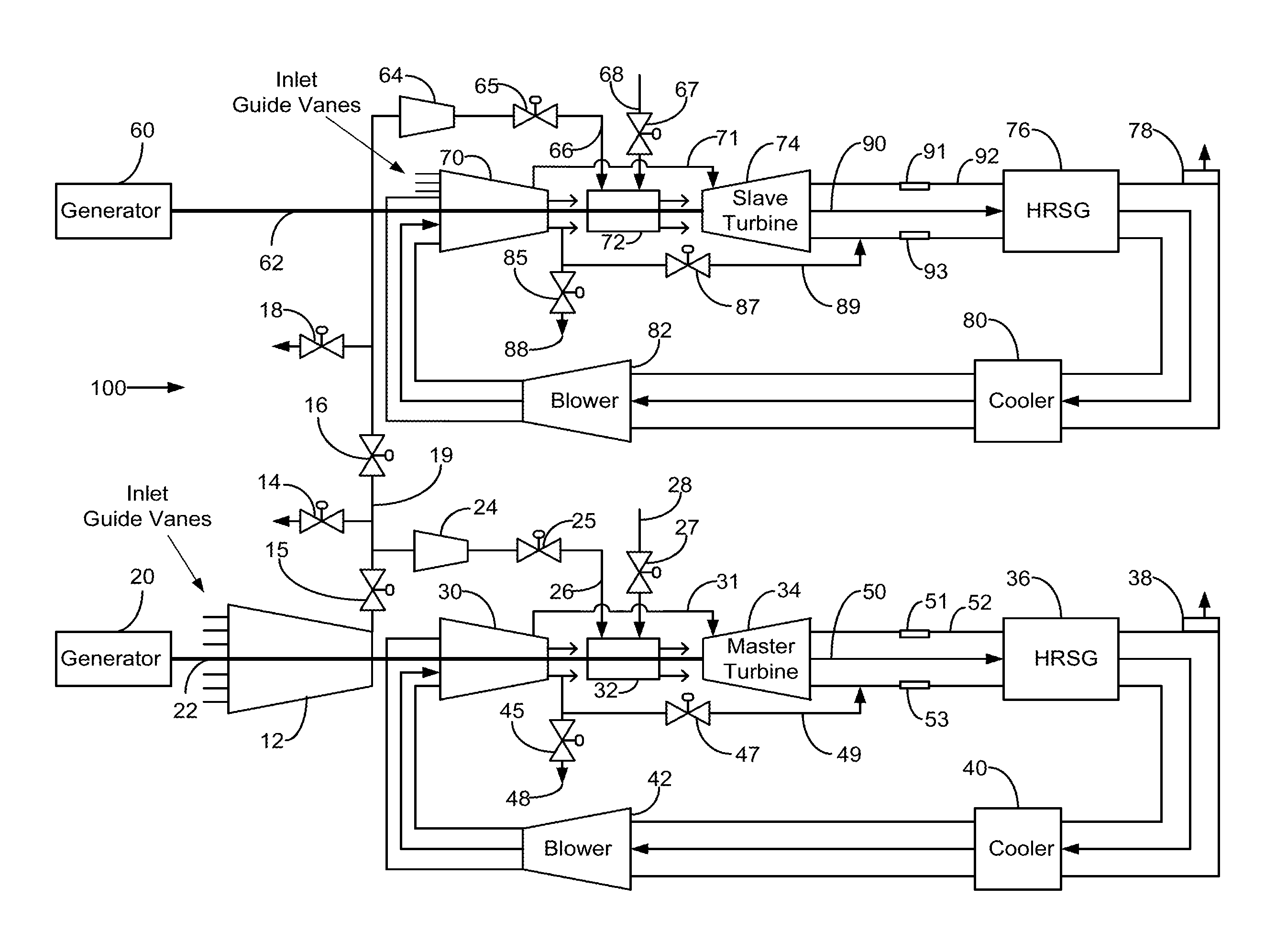

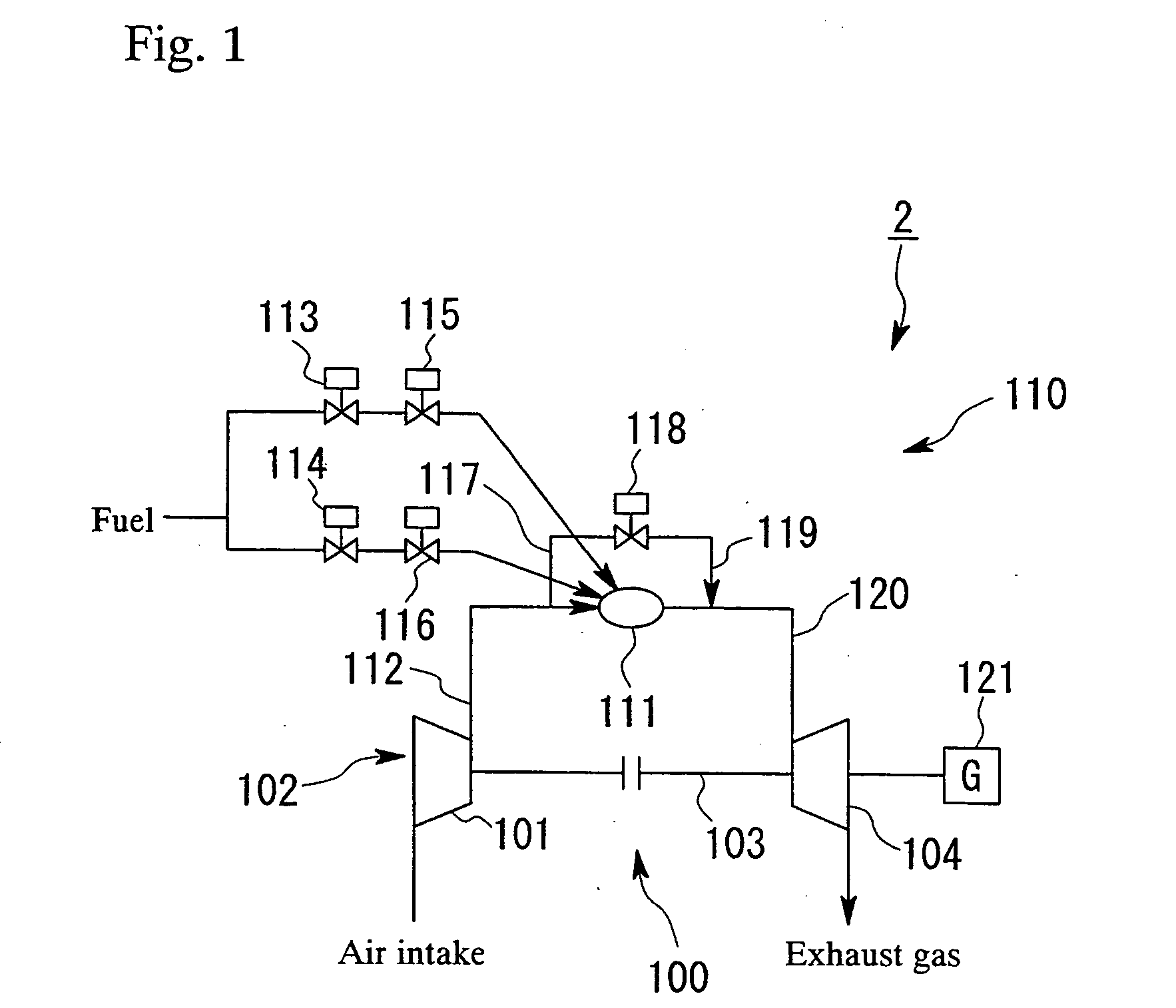

Multi-spool turbogenerator system and control method

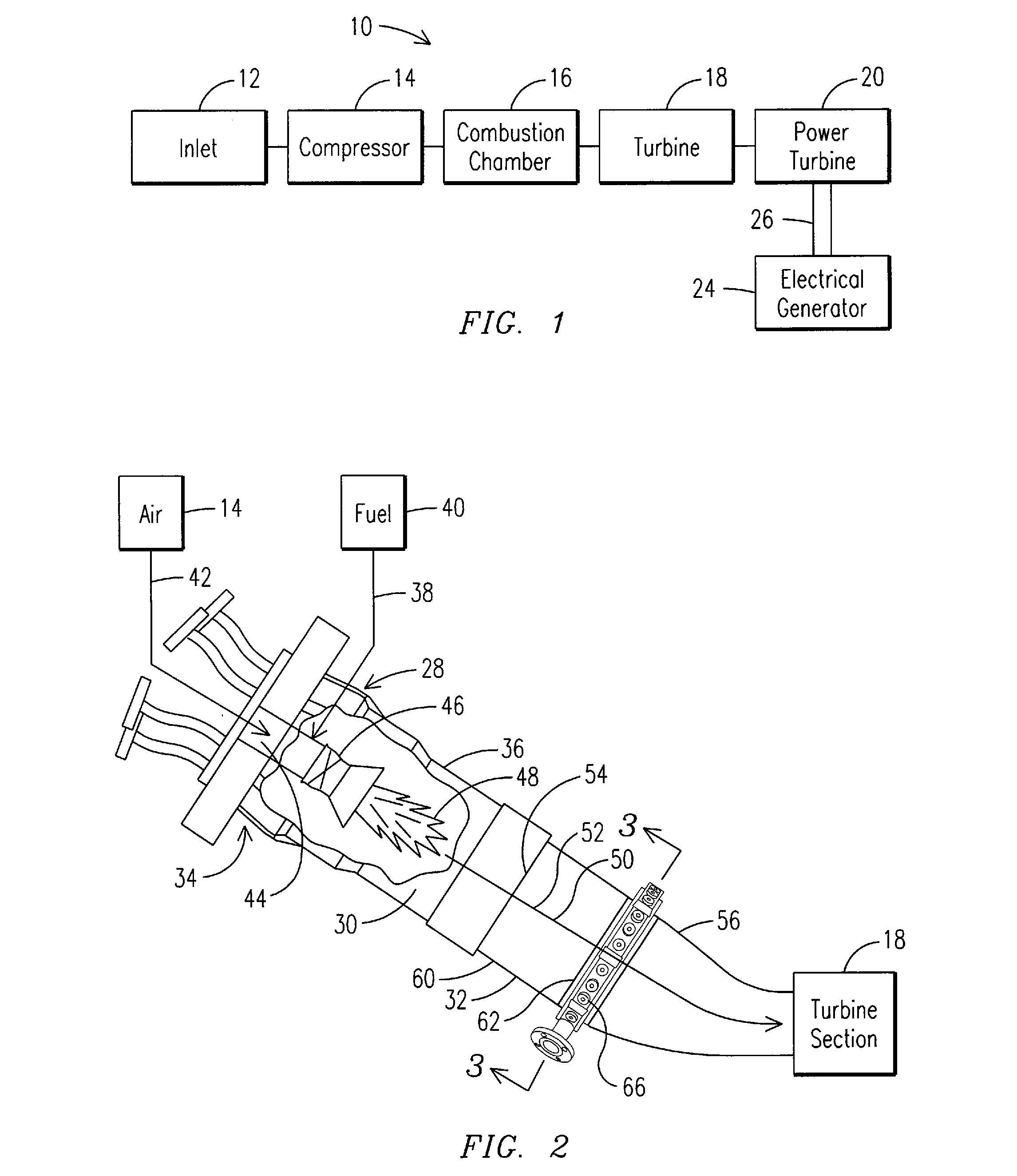

ActiveUS20050056021A1Eliminate needMinimize and eliminate needCombustion enginesGas turbine plantsTurbineGas turbines

An electrical power generating system is driven by a multi-spool gas turbine engine including at least first and second spools. The first spool comprises a turbine and a compressor mounted on a first shaft; the second spool has at least a turbine mounted on a second shaft that is not mechanically coupled to the first shaft. A main generator is coupled with one of the spools, and an auxiliary generator / motor is also coupled with one of the spools. Speed control of each of the generators is employed for controlling operation of the engine. The auxiliary generator / motor can operate in either a generation mode to extract power from its spool or a motor mode to inject power into its spool.

Owner:MES INT INC

Model-based control systems and methods for gas turbine engines

A method and system of controlling a gas turbine engine is disclosed. The engine has sensors to detect one or more parameters and actuators adapted to respond to commands. The method includes receiving data from the sensors of the engine for one or more measured or sensed parameters, estimating a state of the engine by estimating one or more unmeasured or unsensed parameters using the data from the sensors and a predictive model of the engine, generating commands for the actuators based on the state using an optimization algorithm; and transmitting the commands to the engine. The system includes a state estimator adapted to estimate a state of the engine by estimating one or more unmeasured or unsensed parameters using data from the sensors of the engine for one or more measured or sensed parameters. The estimator includes a model of the engine. The system also includes a control module adapted to generate commands for the actuators based on the state. The control module includes an optimization algorithm for determining the commands.

Owner:GENERAL ELECTRIC CO

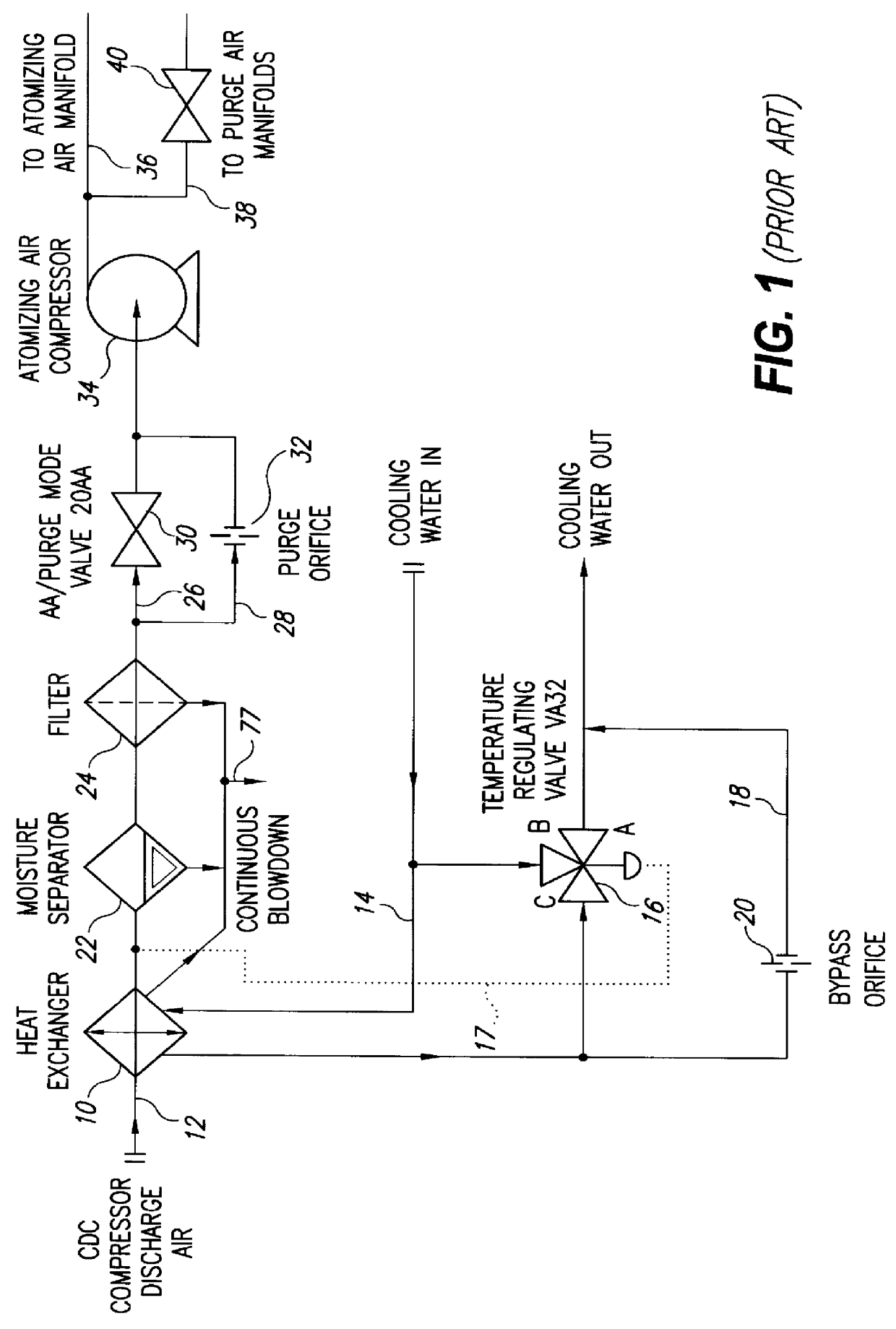

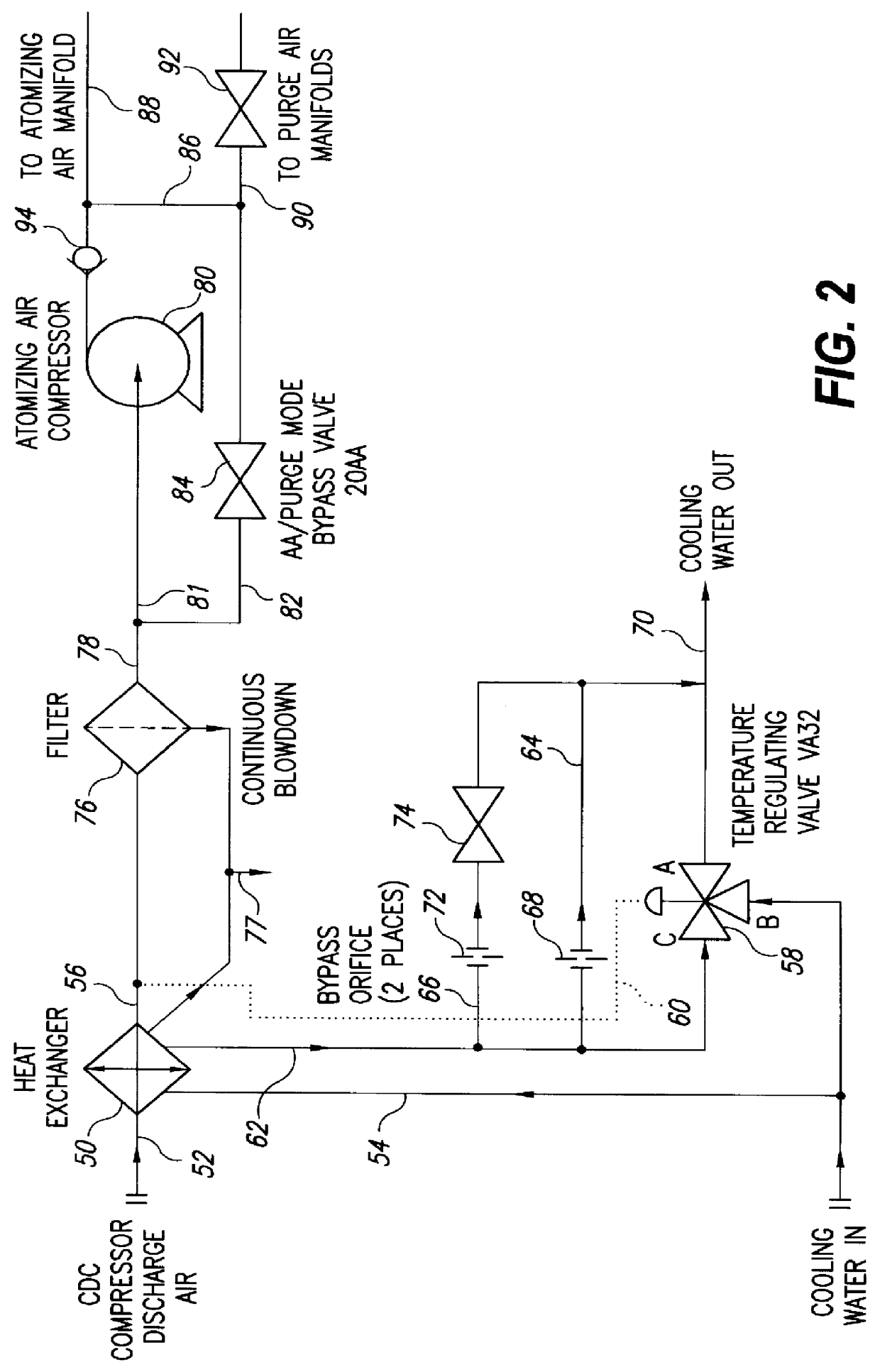

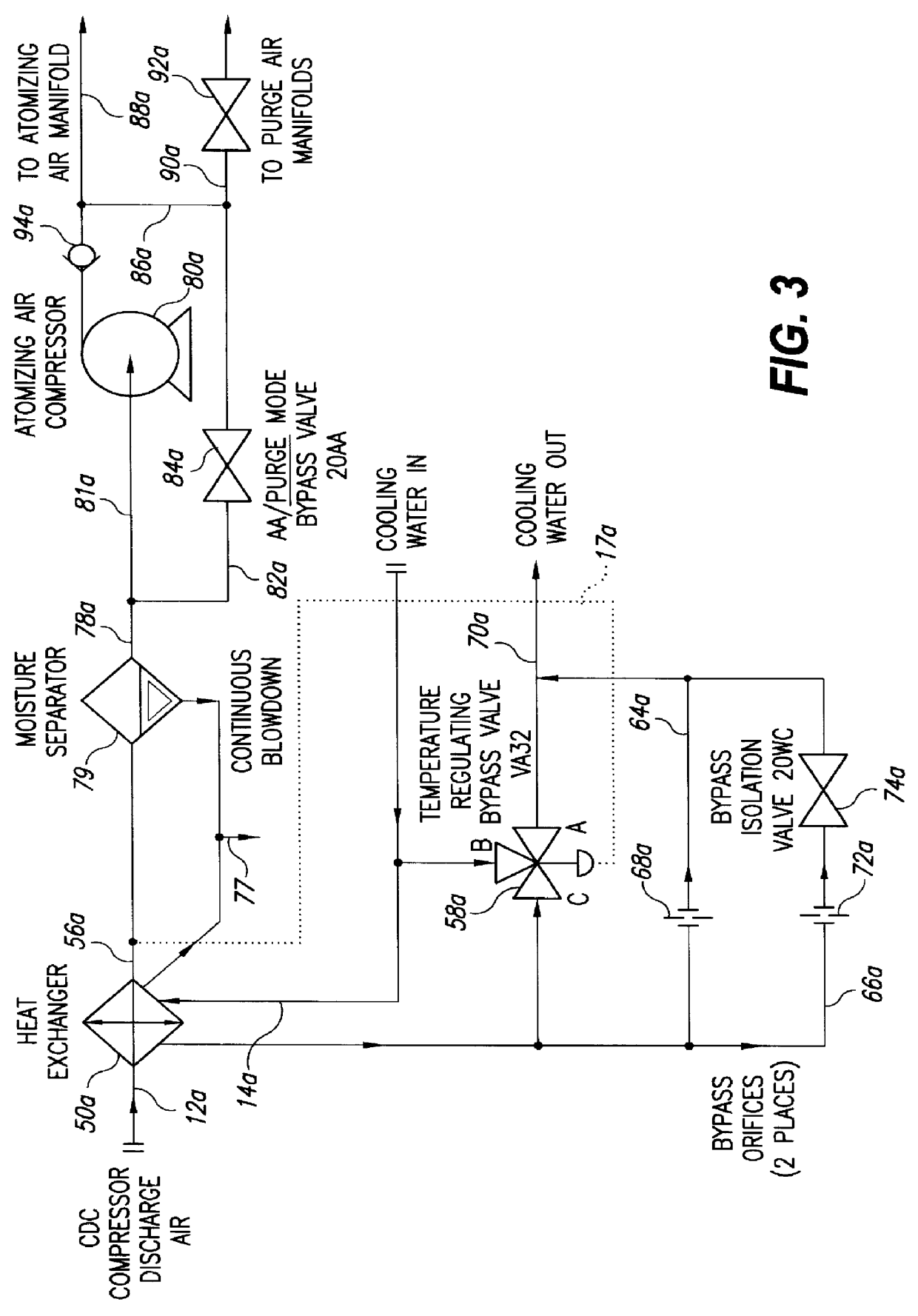

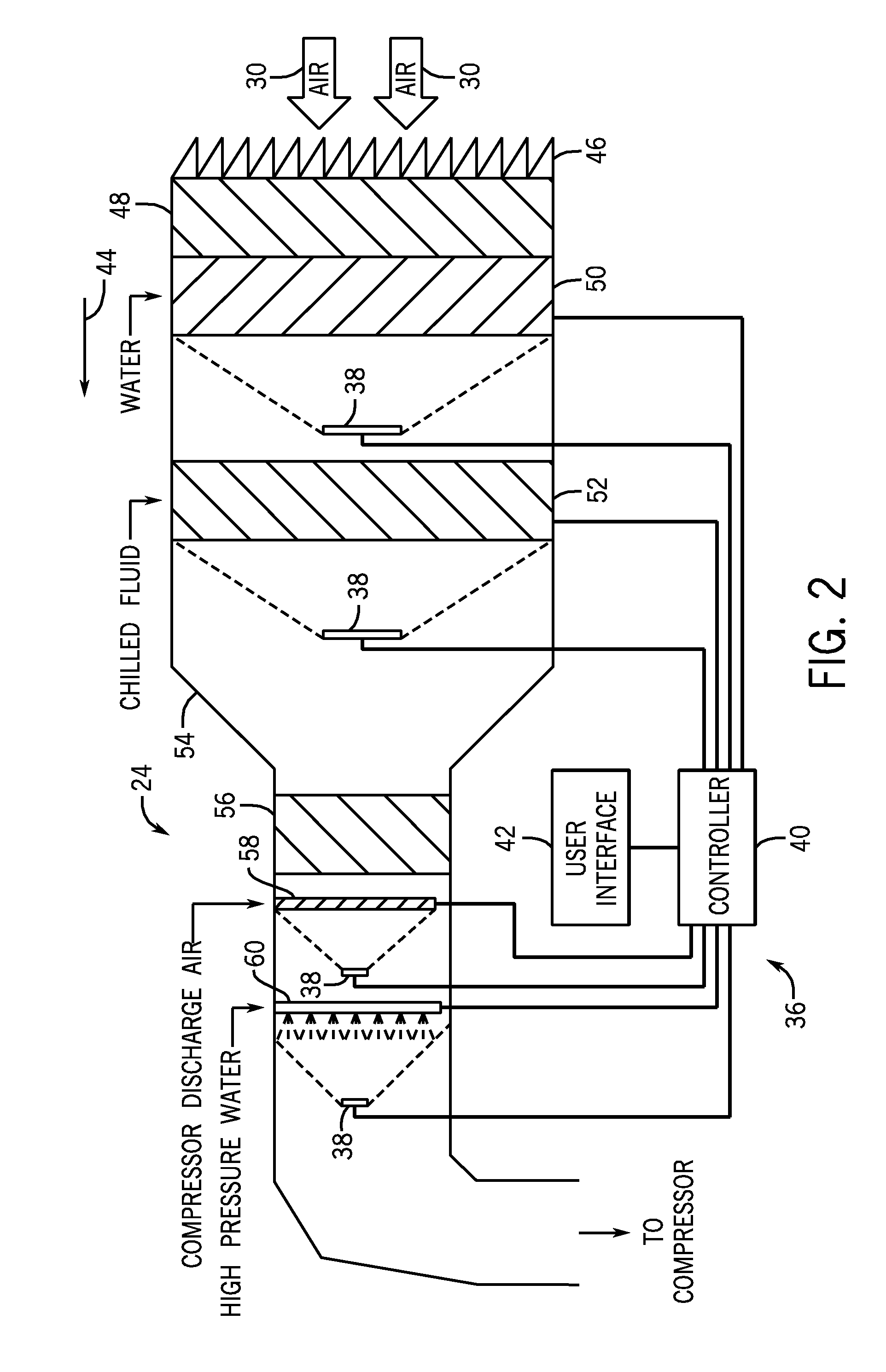

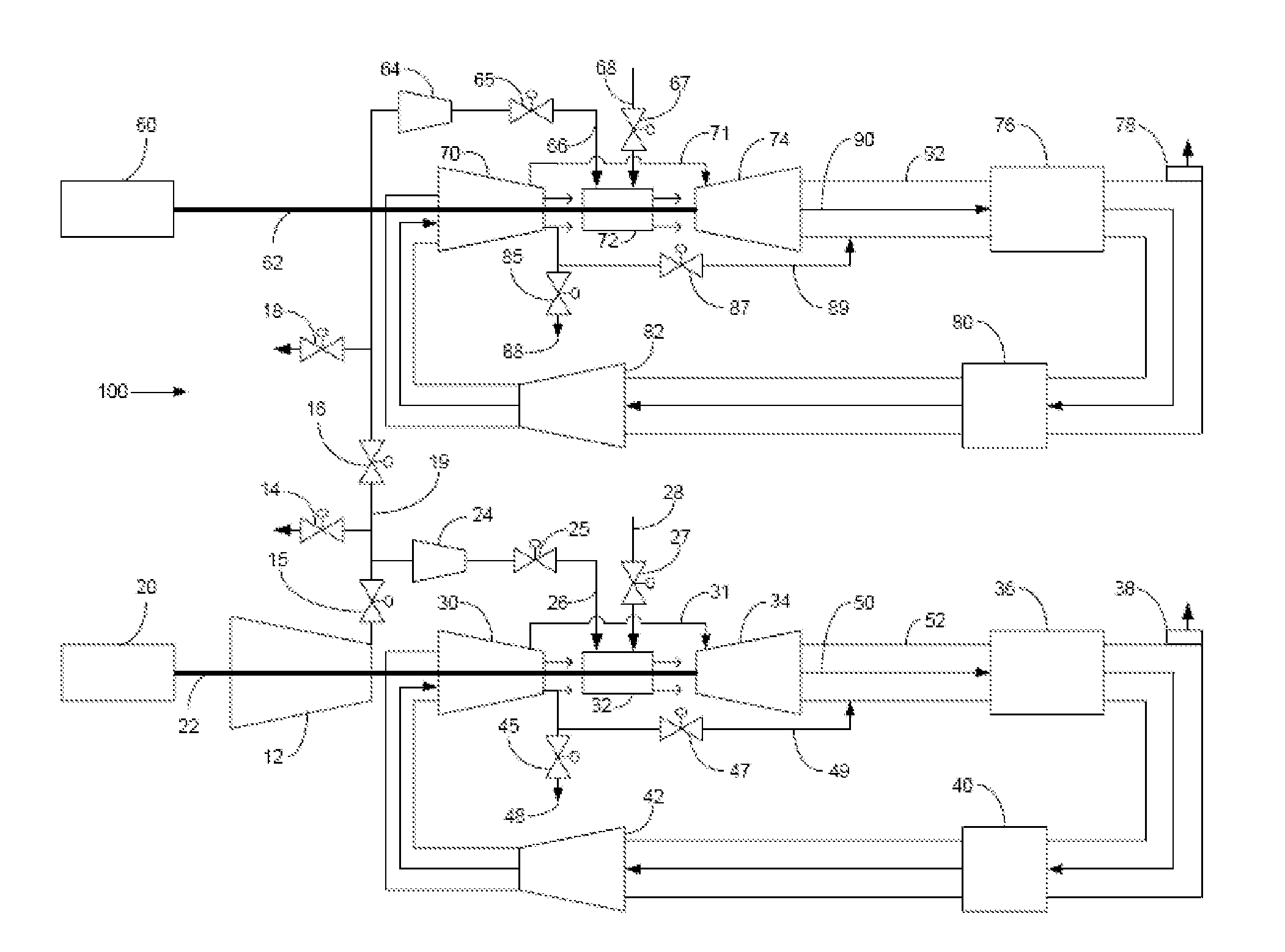

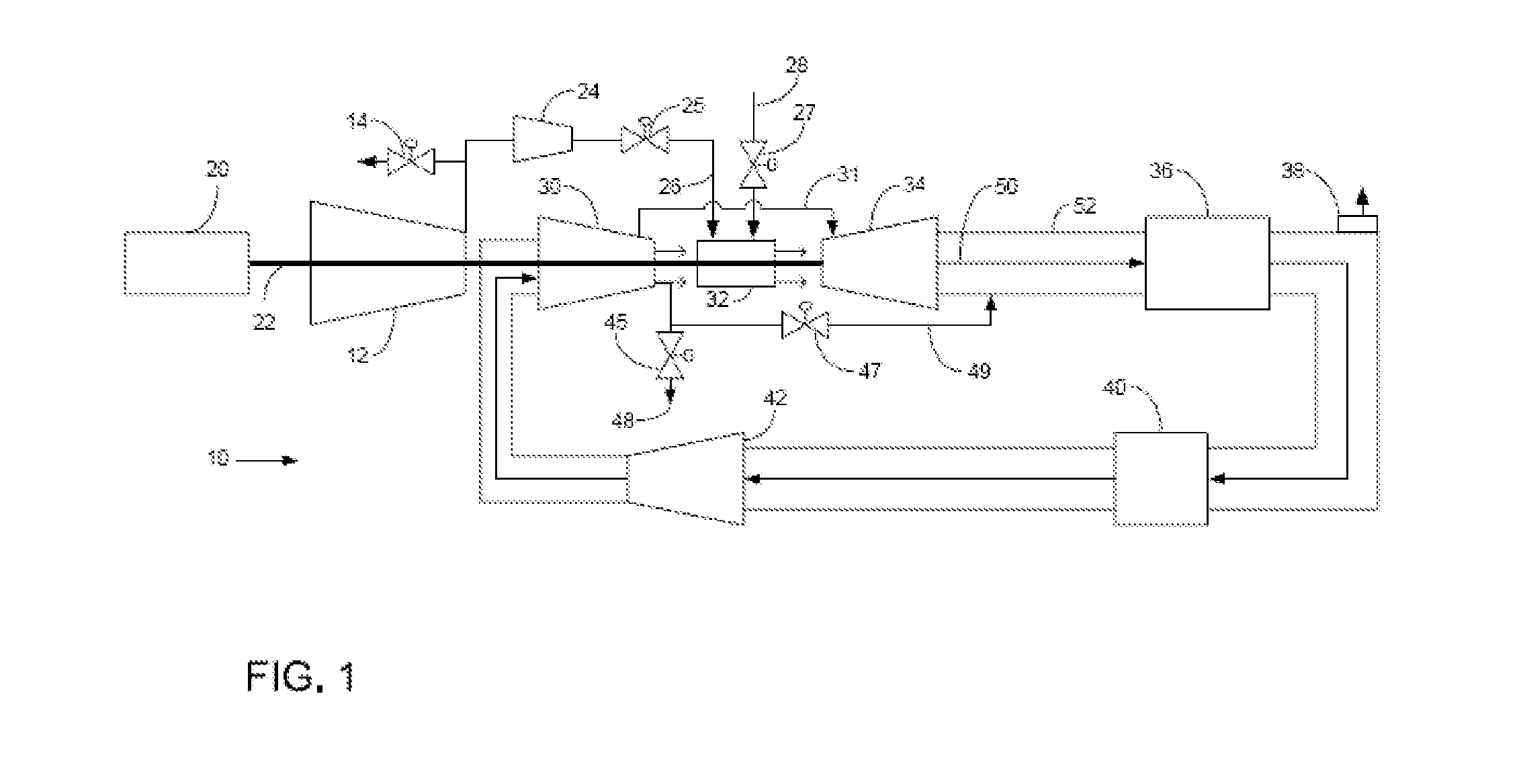

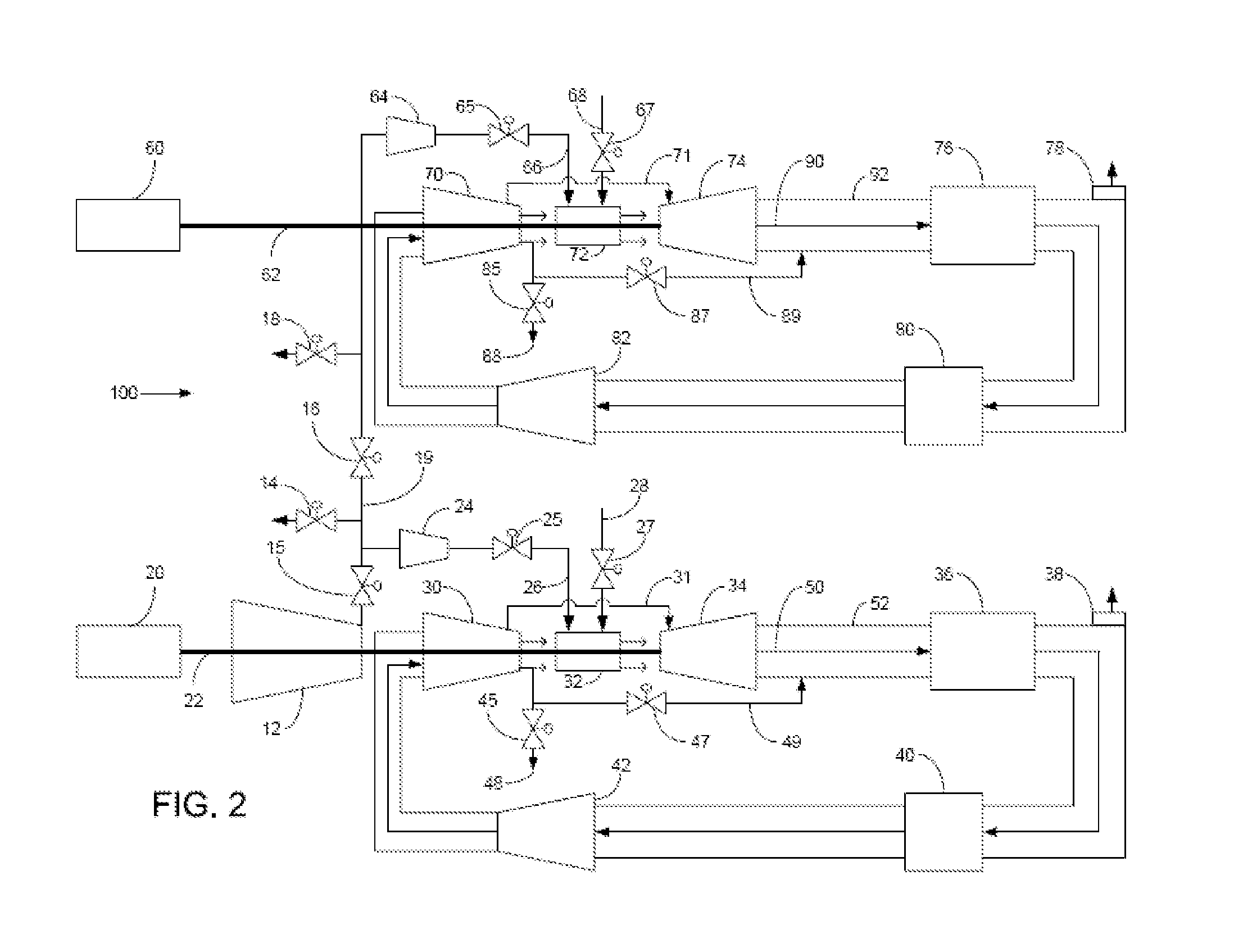

Dual orifice bypass system for dual-fuel gas turbine

InactiveUS6145318AReduce trafficAvoid heat buildupBurner safety arrangementsBurnersCombustorHeat rejection

Compressor discharge air flows through a heat exchanger in heat exchange relation with cooling water and is supplied at reduced temperature in atomizing air and purge modes to combustors in a dual-fuel gas turbine. The heat exchanger has a pair of bypass passages in parallel with a temperature regulating valve controlling flow of water through the heat exchanger in response to the temperature of the compressor discharge air exiting the heat exchanger. Should the flow control valve close in response to low temperature of the compressor discharge air, in the air atomizing mode, the bypass passages with orifices therein provide a minimum protective flow of cooling water to the heat exchanger. In the purge mode where only half the air flow and heat rejection is required in the heat exchanger and the flow control valve closes, a bypass valve in one of the bypass passages closes to enable reduced flow of cooling water through the heat exchanger.

Owner:GENERAL ELECTRIC CO

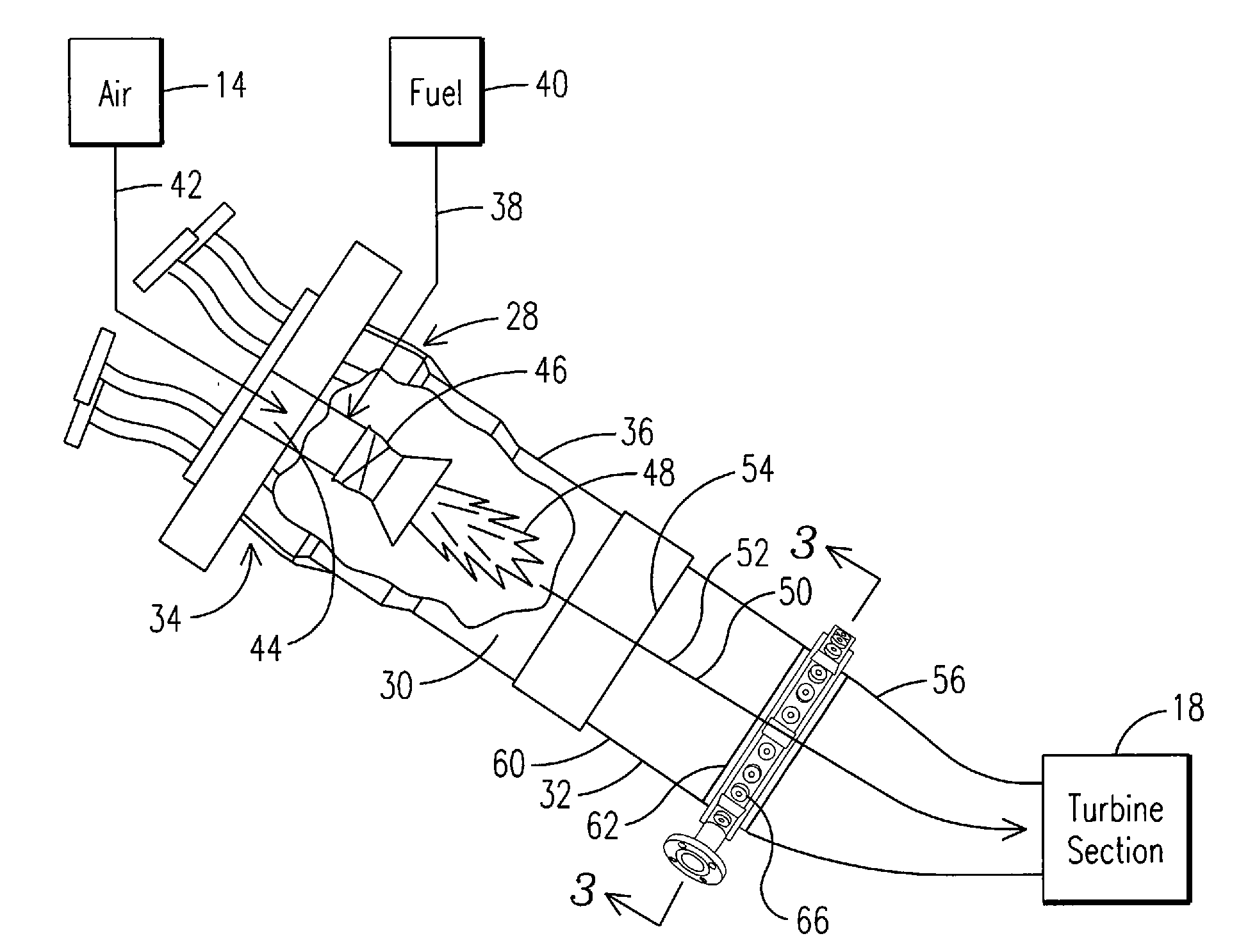

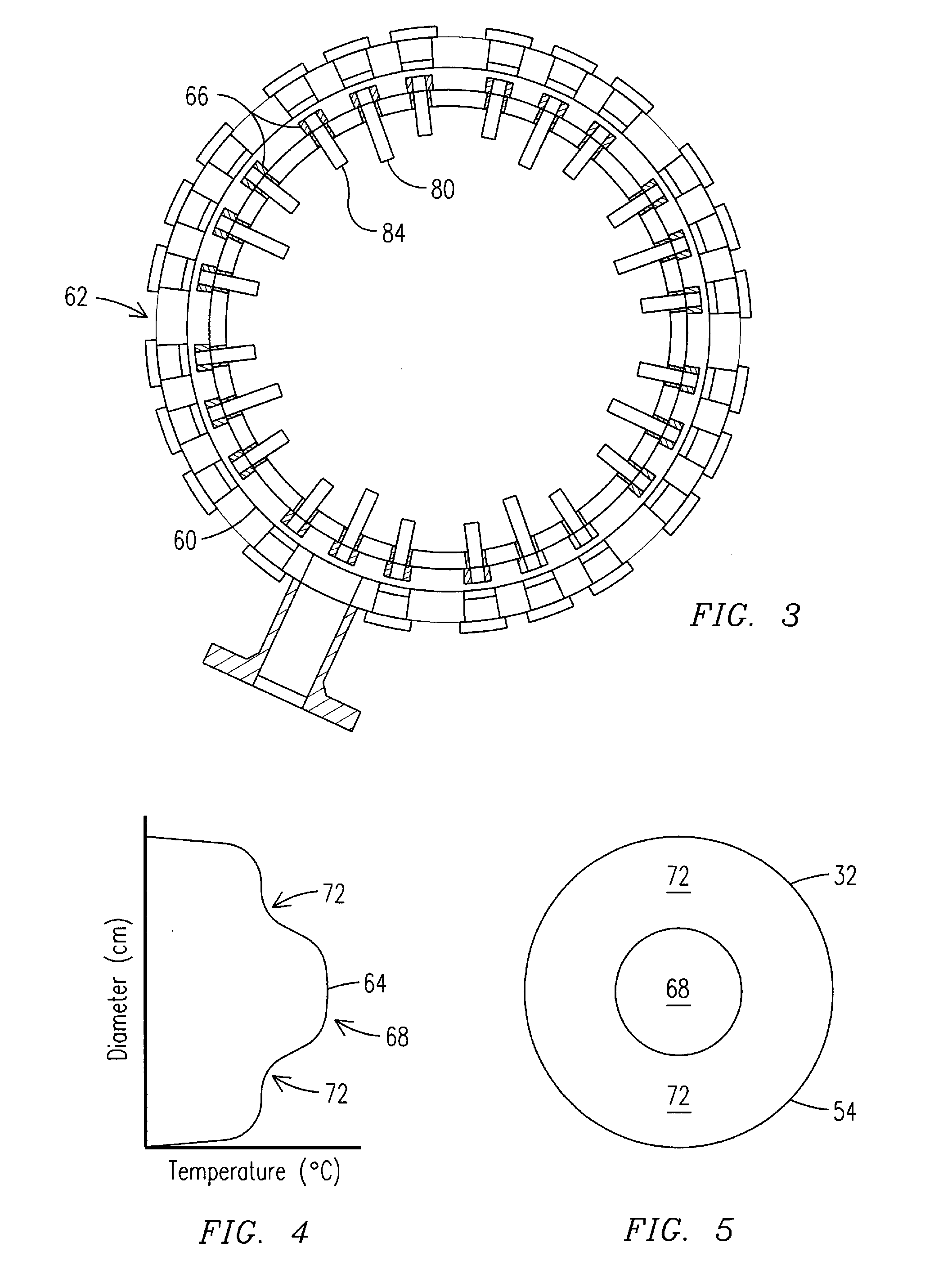

Apparatus and Method for Controlling the Secondary Injection of Fuel

In one embodiment, a combustor (28) for a gas turbine engine is provided comprising a primary combustion chamber (30) for combusting a first fuel to form a combustion flow stream (50) and a transition piece (32) located downstream from the primary combustion chamber (30). The transition piece (32) comprises a plurality of injectors (66) located around a circumference of the transition piece (32) for injecting a second fuel into the combustion flow stream (50). The injectors (66) are effective to create a radial temperature profile (74) at an exit (58) of the transition piece (32) having a reduced coefficient of variation relative to a radial temperature profile (64) at an inlet (54) of the transition piece (32). Methods for controlling the temperature profile of a secondary injection are also provided.

Owner:SIEMENS ENERGY INC

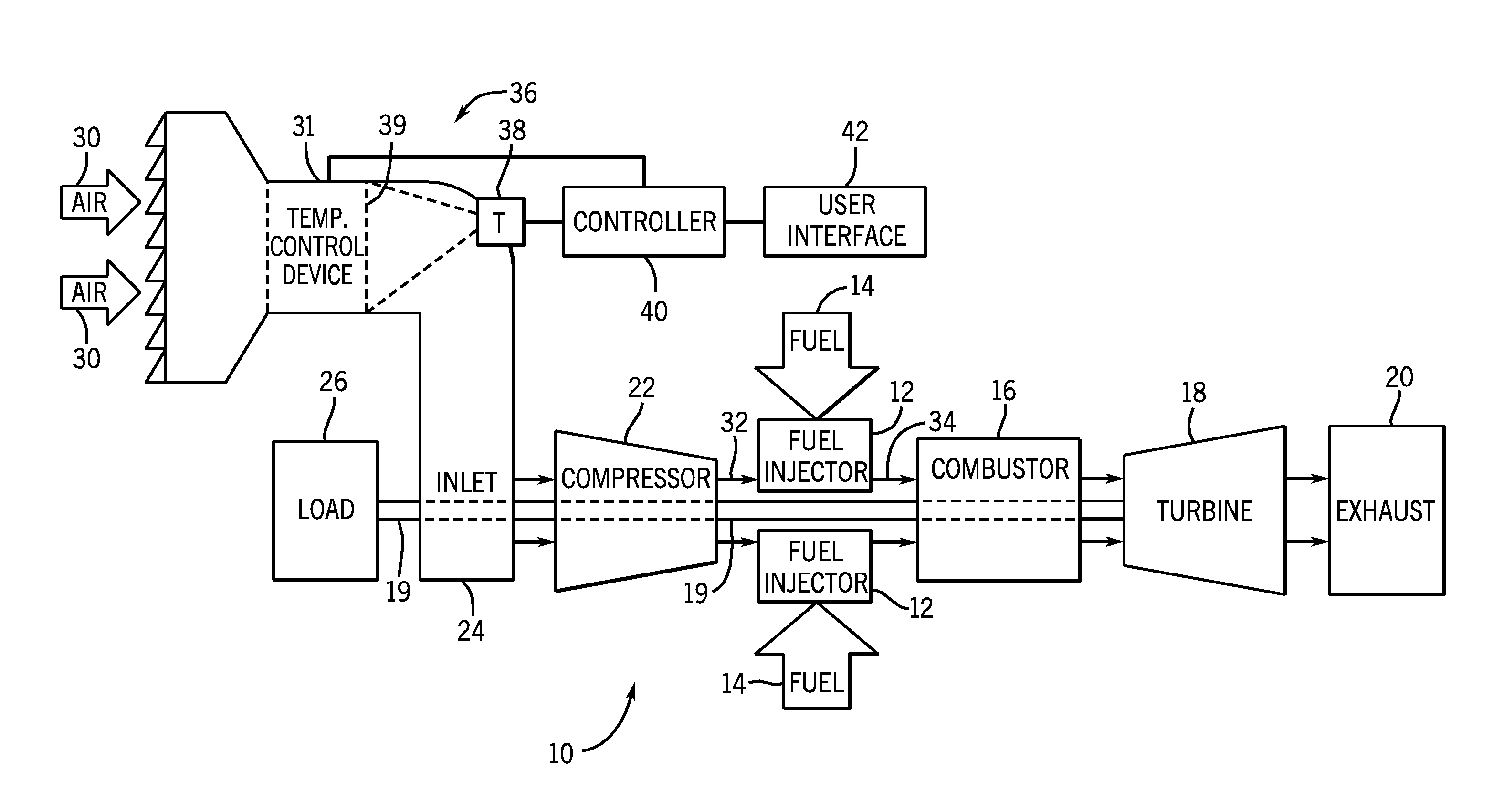

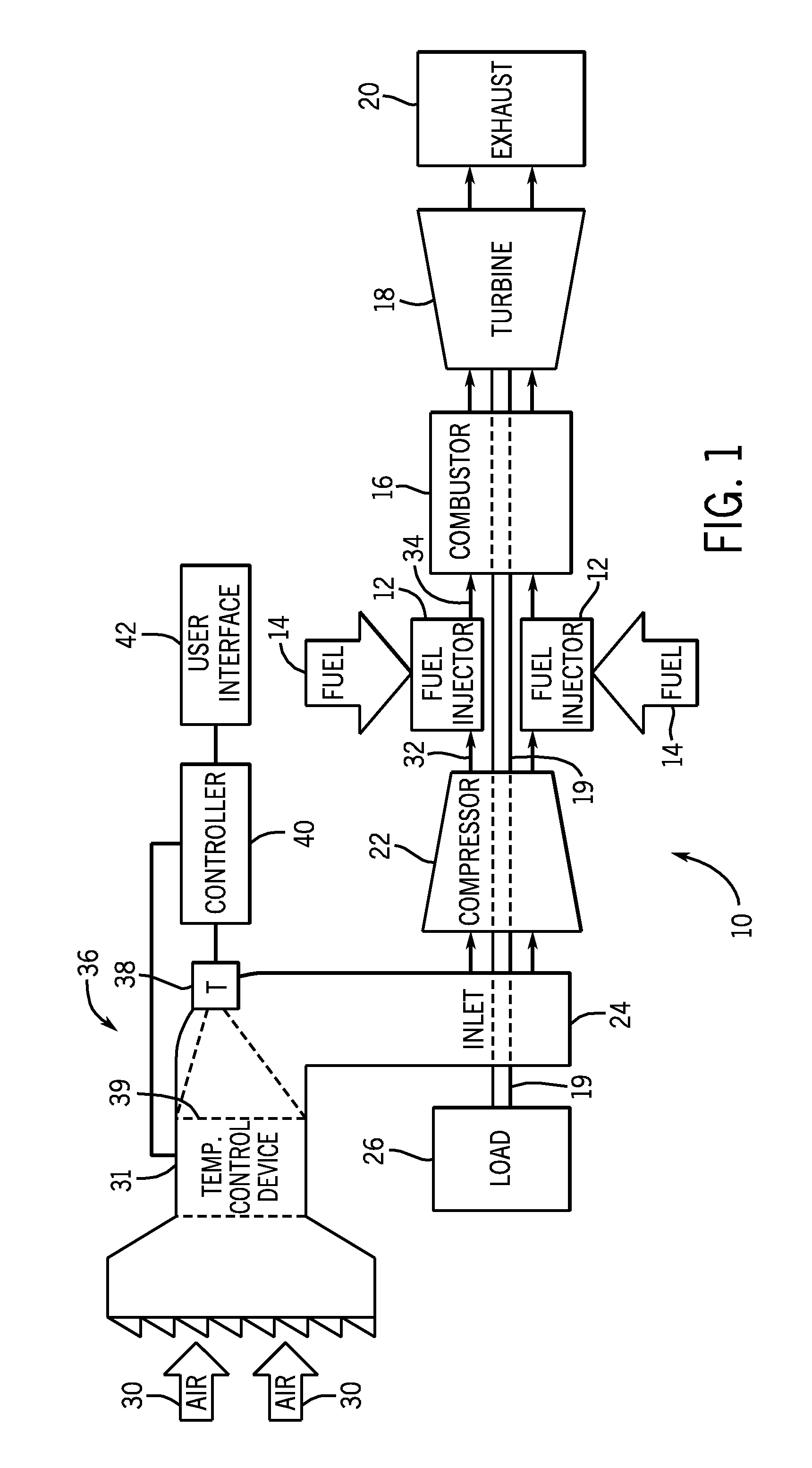

System and method for adjusting compressor inlet fluid temperature

InactiveUS20110265443A1Continuous combustion chamberPump componentsTemperature controlDetector array

A system includes a radiation detector array directed toward a fluid flow into a compressor. The radiation detector array is configured to output a signal indicative of a two-dimensional temperature profile of the fluid flow. The system also includes a controller communicatively coupled to the radiation detector array. The controller is configured to detect a temperature variation across the fluid flow based on the signal, and to adjust a parameter of a temperature control device to compensate for the detected temperature variation.

Owner:BHA ALTAIR

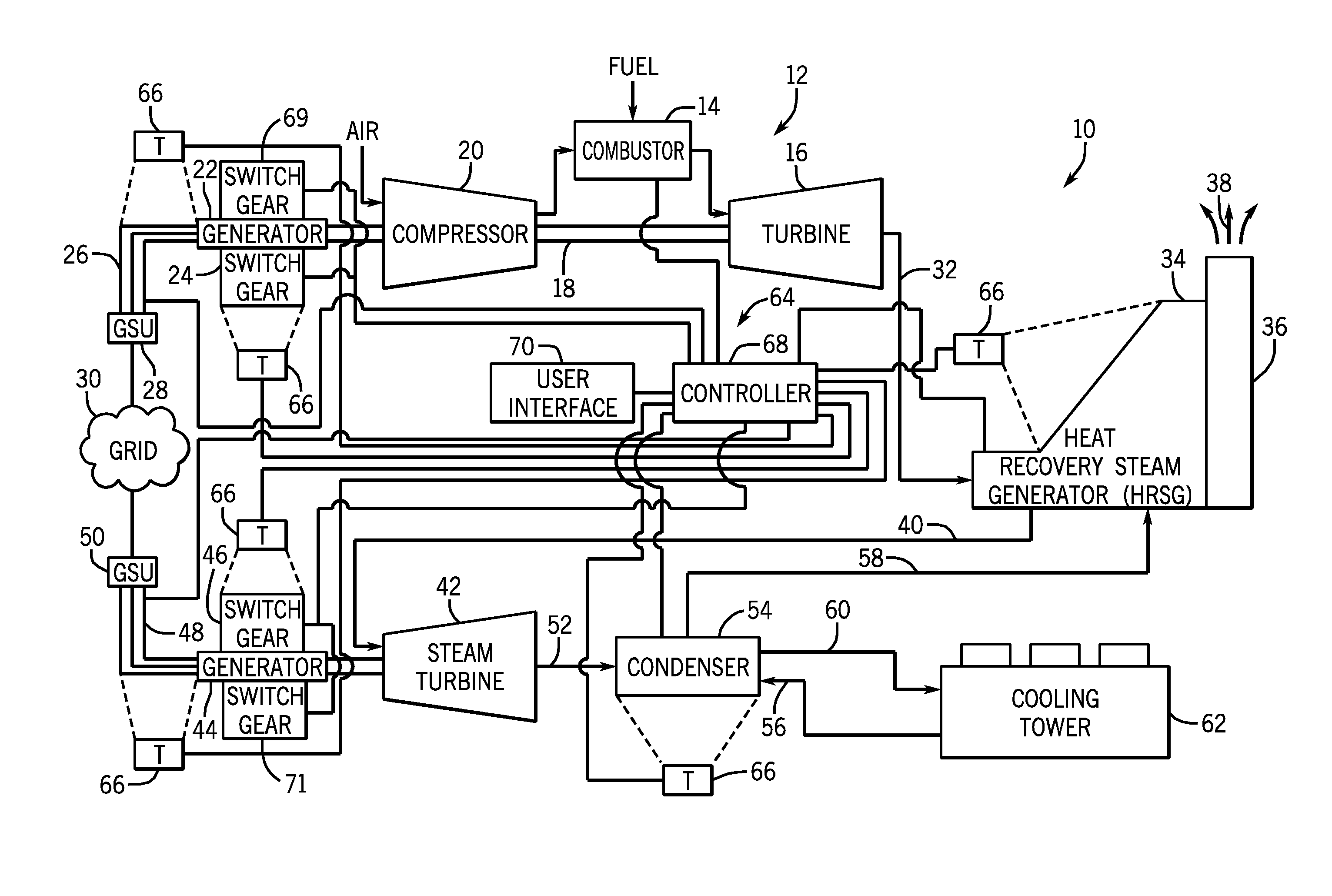

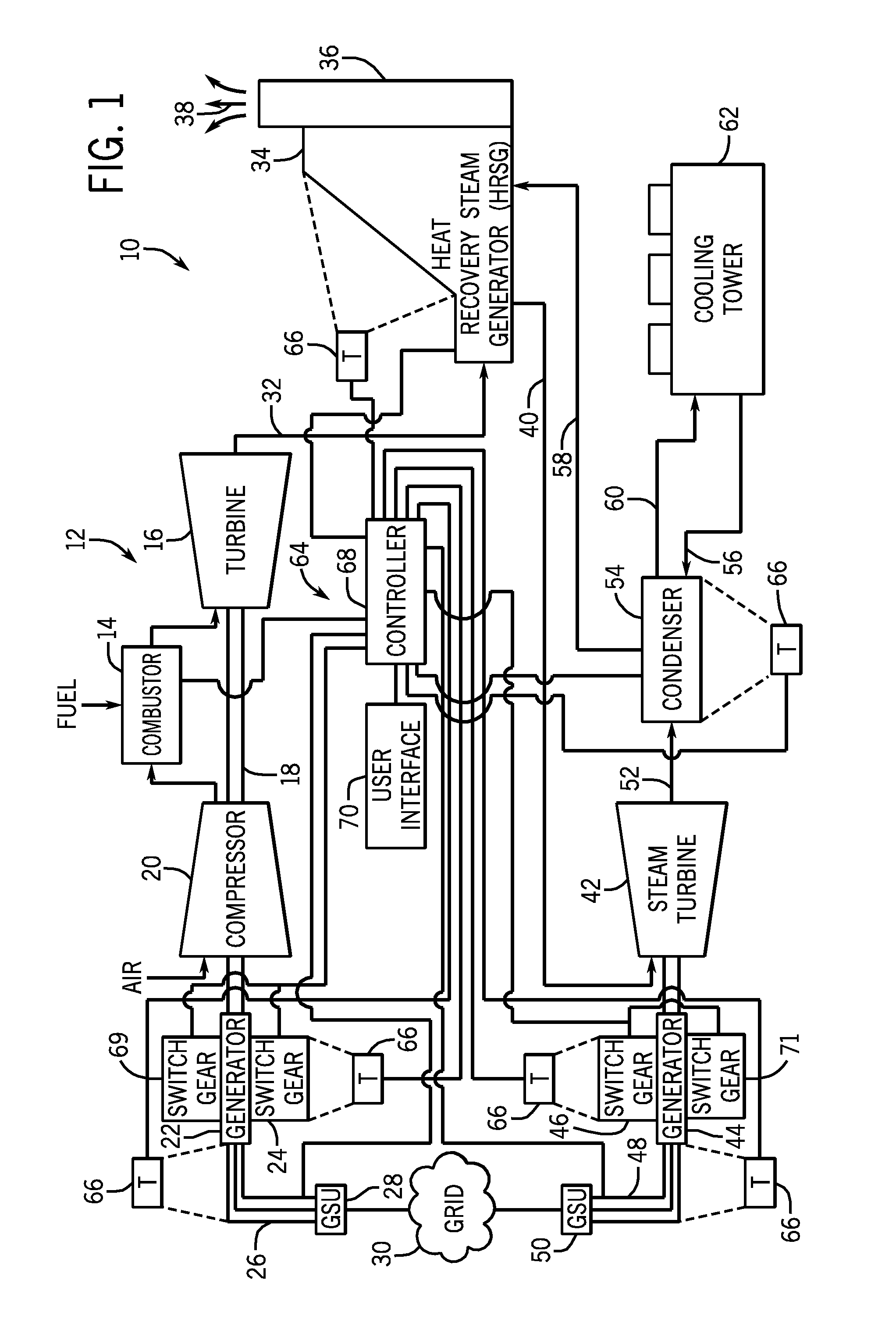

Methods and systems for enhancing operation of power plant generating units and systems

ActiveUS20160281607A1Programme controlTurbine/propulsion engine ignitionPower stationControl engineering

A method for controlling and enhancing a startup operation for a combined cycle power block (block) having at least one gas turbine and at least one steam turbine, wherein operating parameters define performance and operational characteristics for the startup operation, the method comprising: receiving measured operating parameters from a plurality of reference blocks and, for each of the plurality of reference blocks, a plurality of types of the startup operations; given the measured operating parameters, developing one or more reference transfer functions between two of the measured operating parameters; receiving measured operating parameters from the startup operation of a target block; given the measured operating parameters from the target block, developing one or more transfer functions for the target block between two of the operating parameters; selecting one of the reference transfer functions; and normalizing the transfer function of the target block per the selected reference transfer function.

Owner:GENERAL ELECTRIC CO

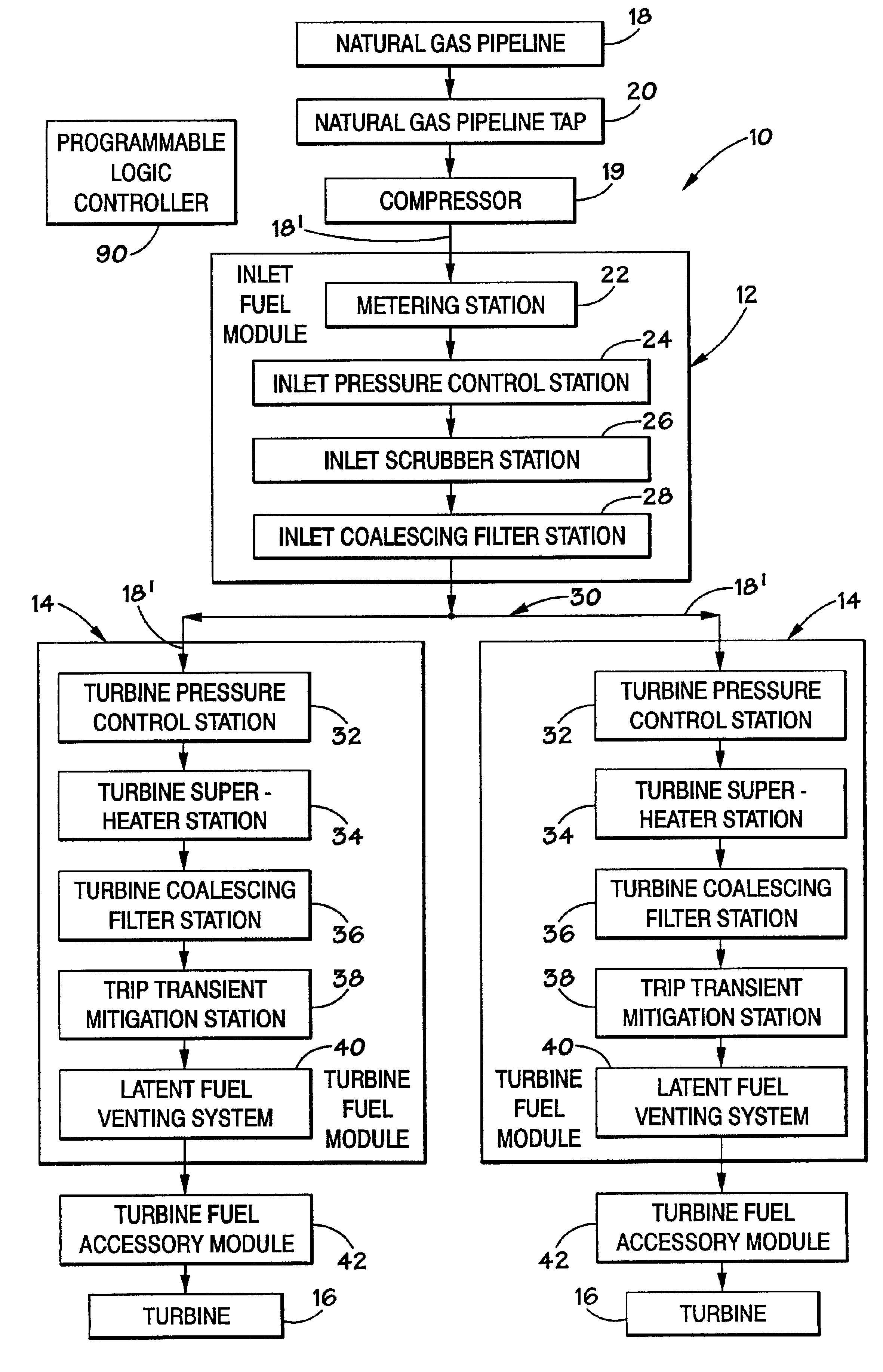

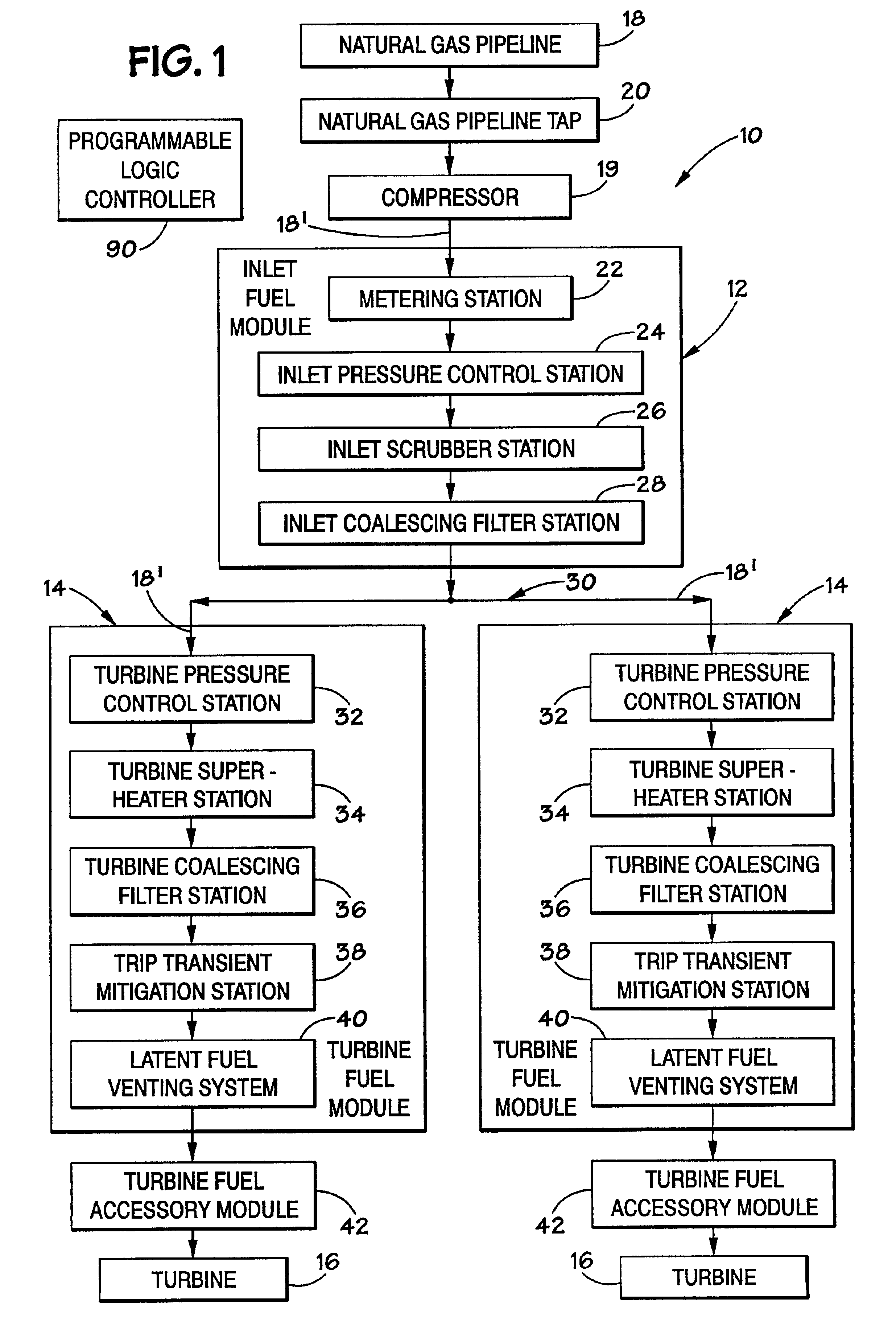

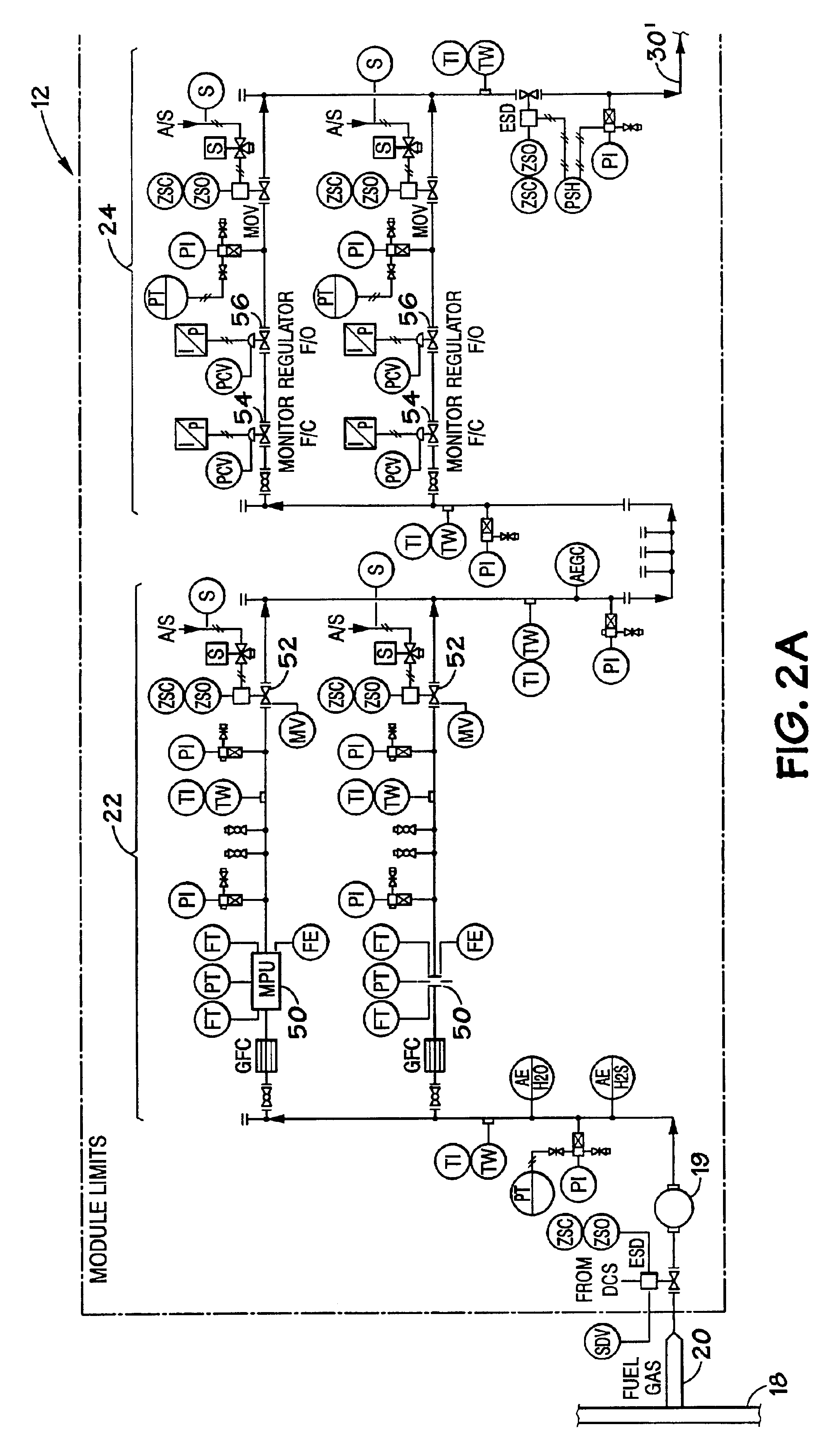

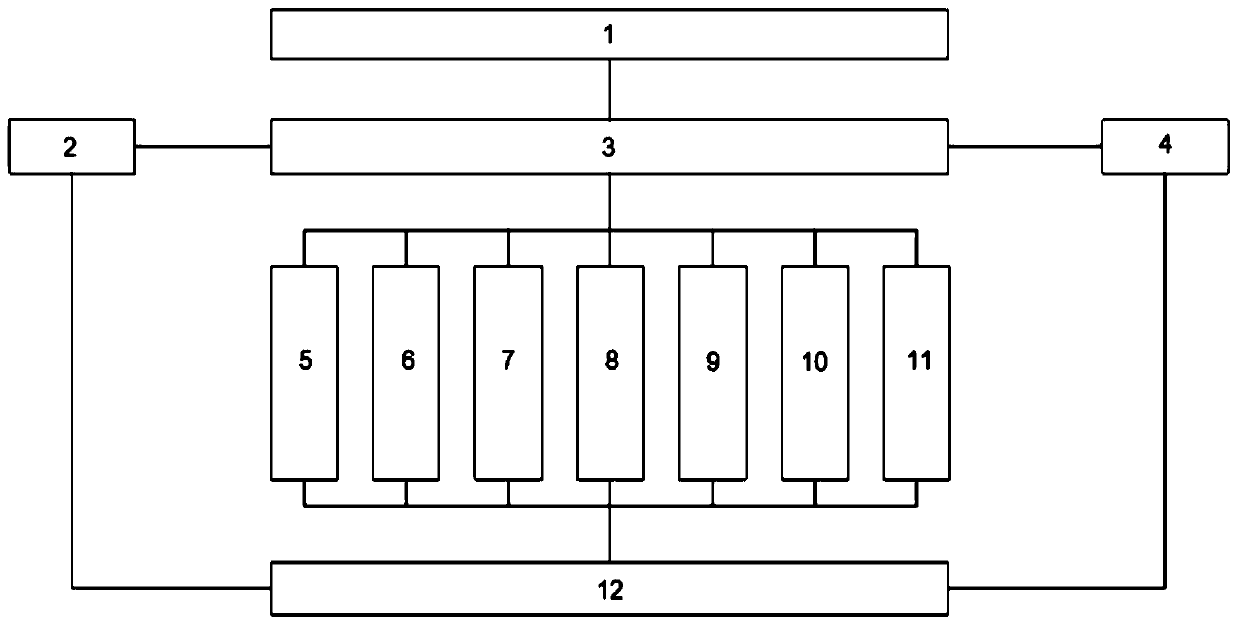

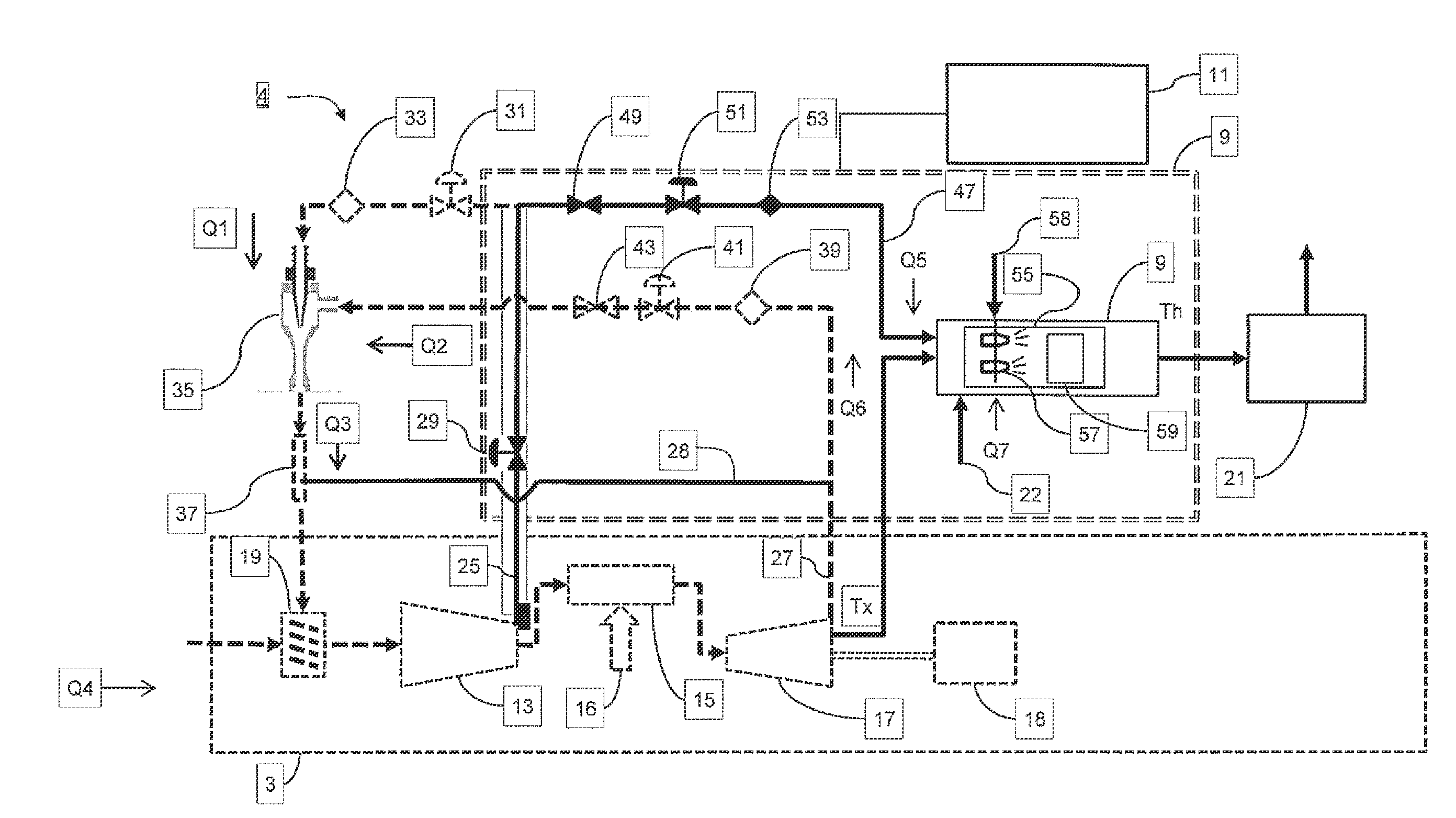

Modular fuel conditioning system

InactiveUS6901735B2Reduce pressureControl moreGas turbine plantsTurbine/propulsion fuel heatingProgrammable logic controllerModularity

A fuel conditioning system for a turbine plant may include an inlet fuel module followed by a turbine fuel module for each turbine, the modules being monitored and controlled by a programmable logic controller. The inlet fuel module may include a metering station, an inlet pressure control station, an inlet scrubber station, and an inlet coalescing filter station. Each turbine fuel module has a turbine pressure control station, a turbine super-heater station, and a turbine coalescing filter station. The fuel conditioning system may also include a trip transient mitigation system and a latent fuel venting system. The programmable logic controller collects data from all of the stations and systems as well as the turbine and then uses self-correcting algorithms to control the stations and systems. The programmable logic controller also stores the data collected and transmits the data to an off-site storage and verification center.

Owner:PIPELINE CONTROLS

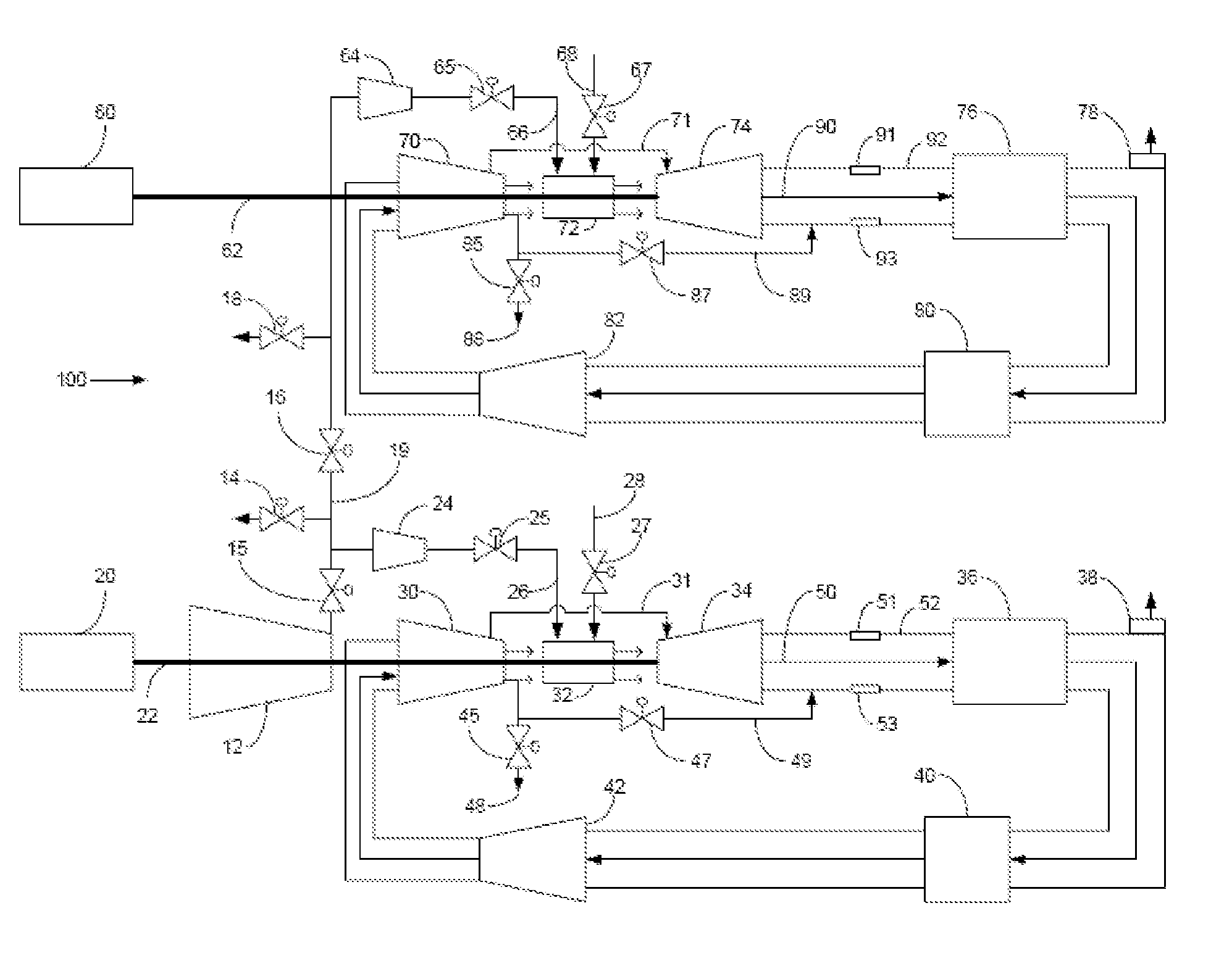

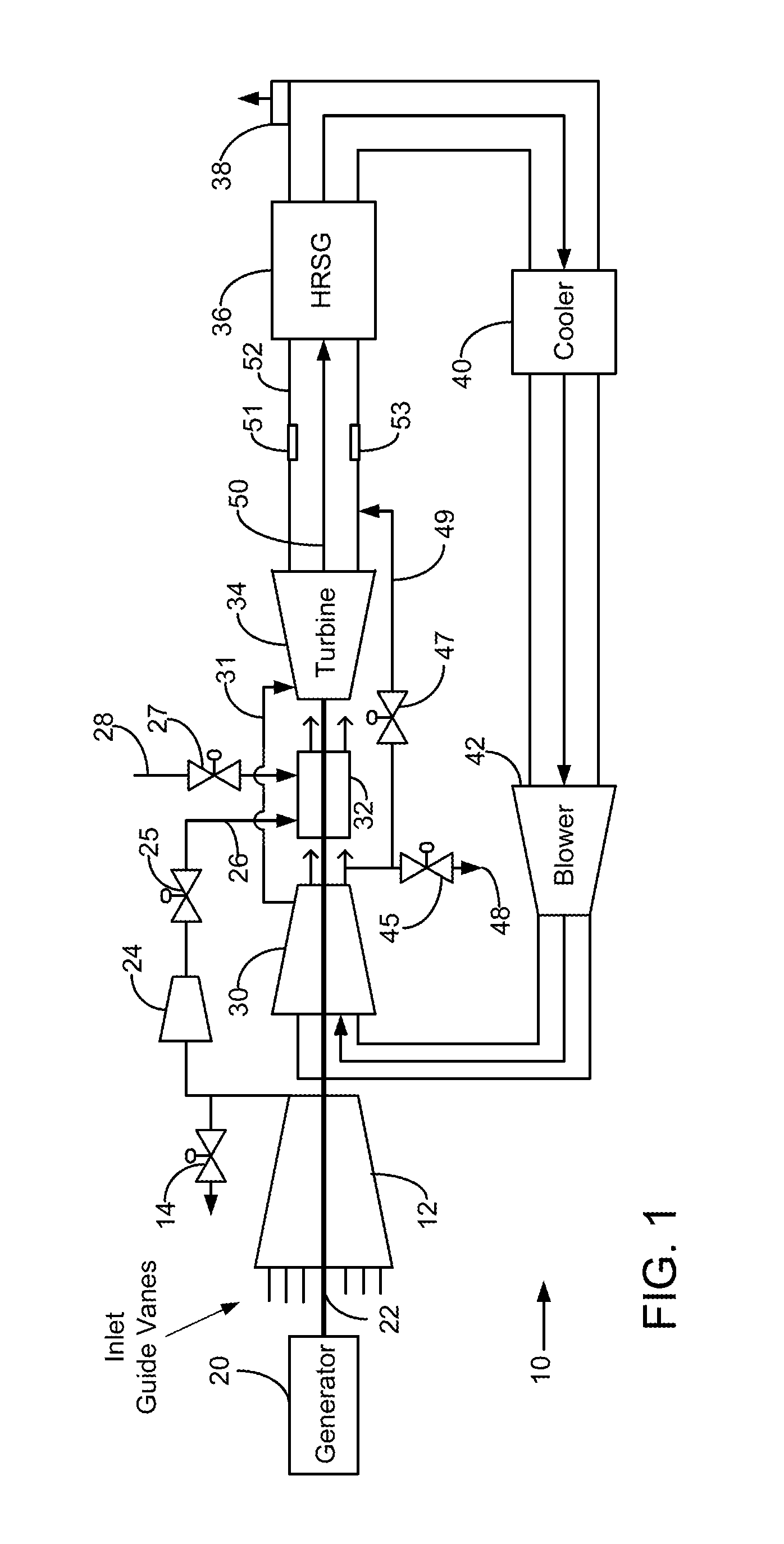

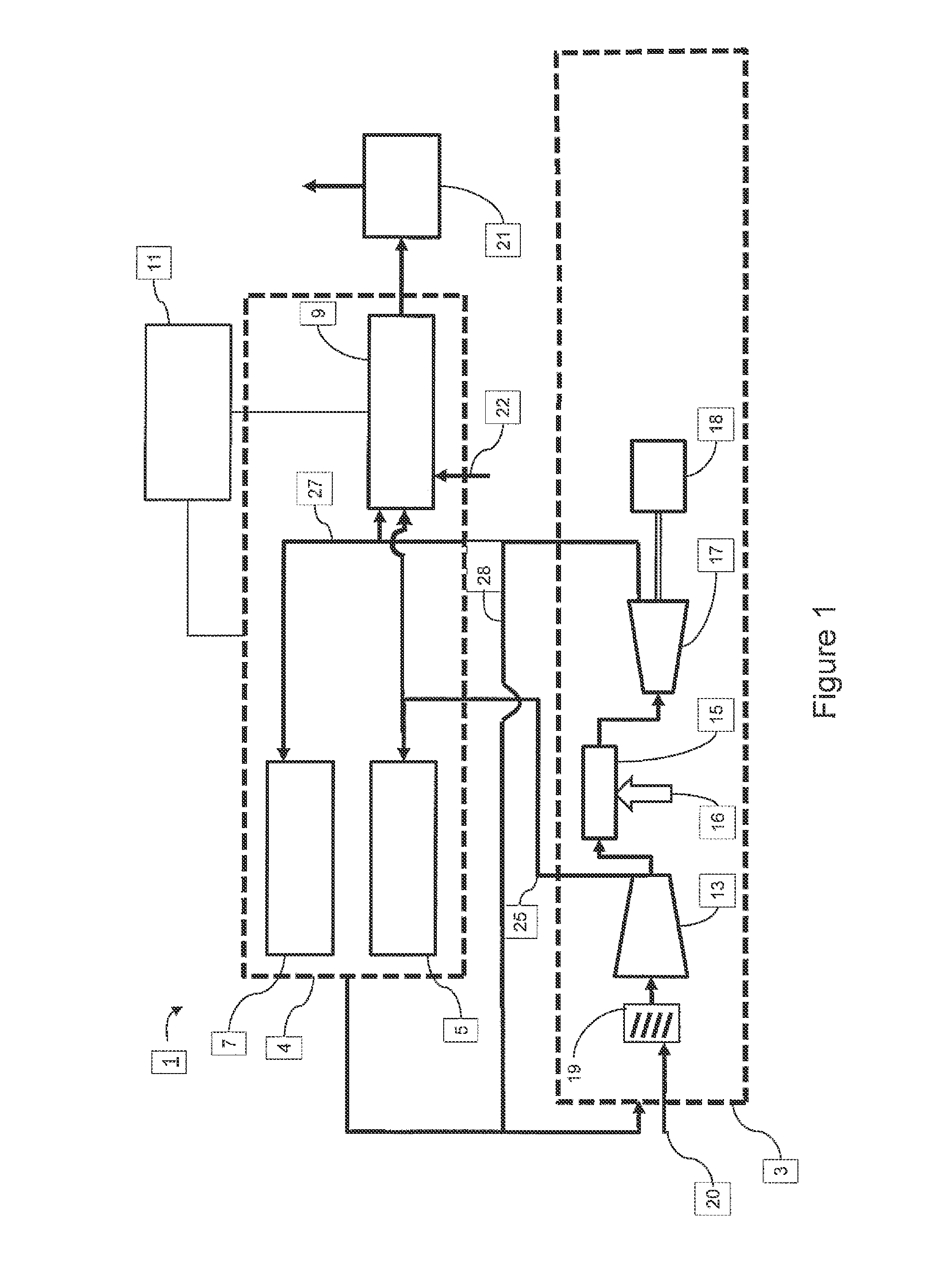

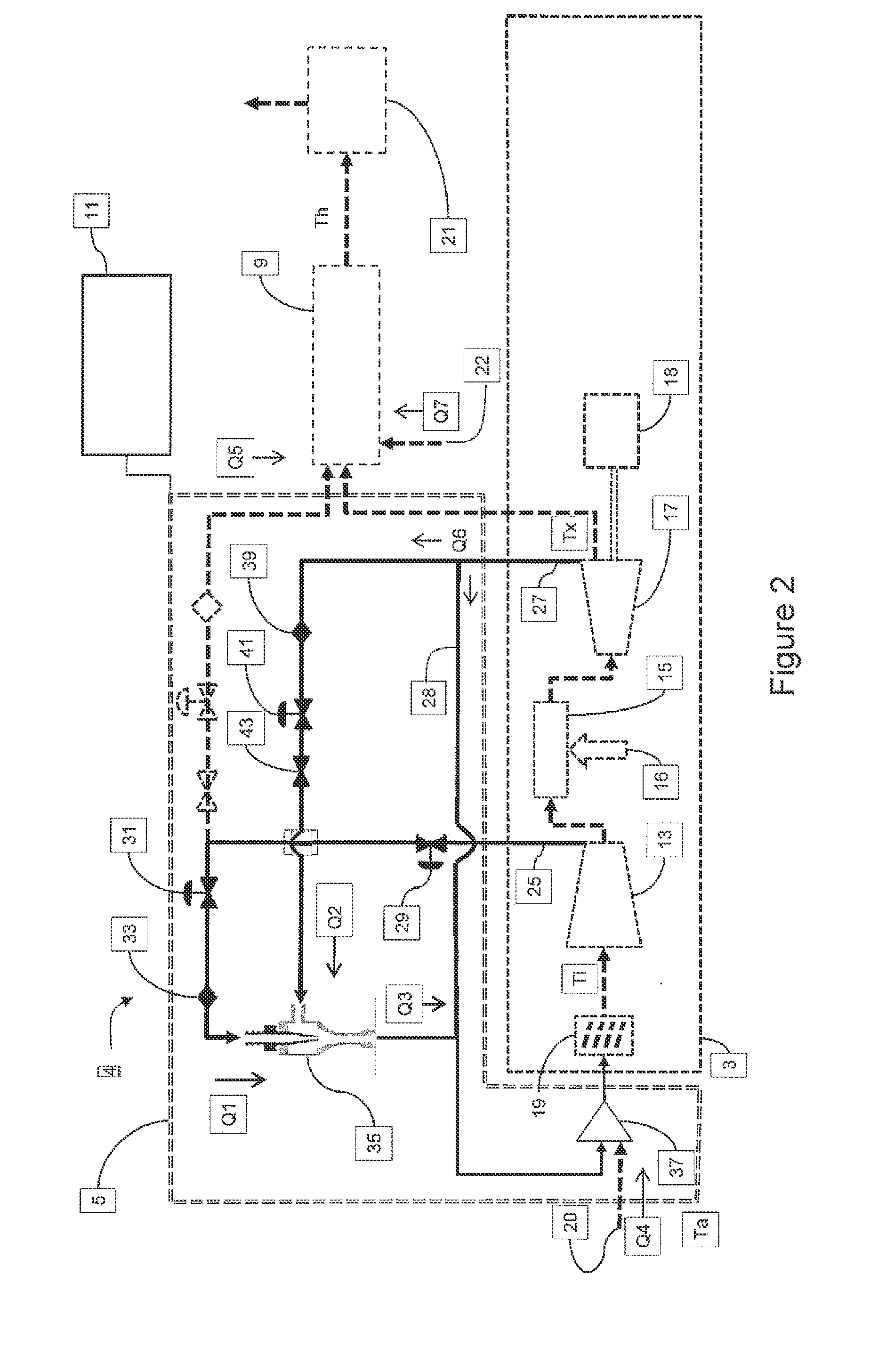

Power plant and control method

Ambient air is compressed into a compressed ambient gas flow with a main air compressor. The compressed ambient gas flow having a compressed ambient gas flow rate is delivered to a turbine combustor and mixed with a fuel stream having a fuel stream flow rate and a portion of a recirculated gas flow to form a combustible mixture. The combustible mixture is burned and forms the recirculated gas flow that drives a turbine. The recirculated gas flow is recirculated from the turbine to the turbine compressor using a recirculation loop. At least one emission level is measured by at least a first emission sensor in the recirculated gas flow and at least a first control signal is generated. The fuel stream flow rate is adjusted based on the at least a first control signal to achieve substantially stoichiometric combustion.

Owner:GENERAL ELECTRIC CO

Multi-compatible digital engine controller

A digital engine controller compatible with multiple variants of gas turbine engine is programmed to receive identification of a variant of gas turbine engine coupled to the digital controller and thereafter to automatically determine and adjust inputs to the engine, according to the received identification of engine variant, to meet user-specified output.

Owner:TURBINE POWERED TECH LLC 51

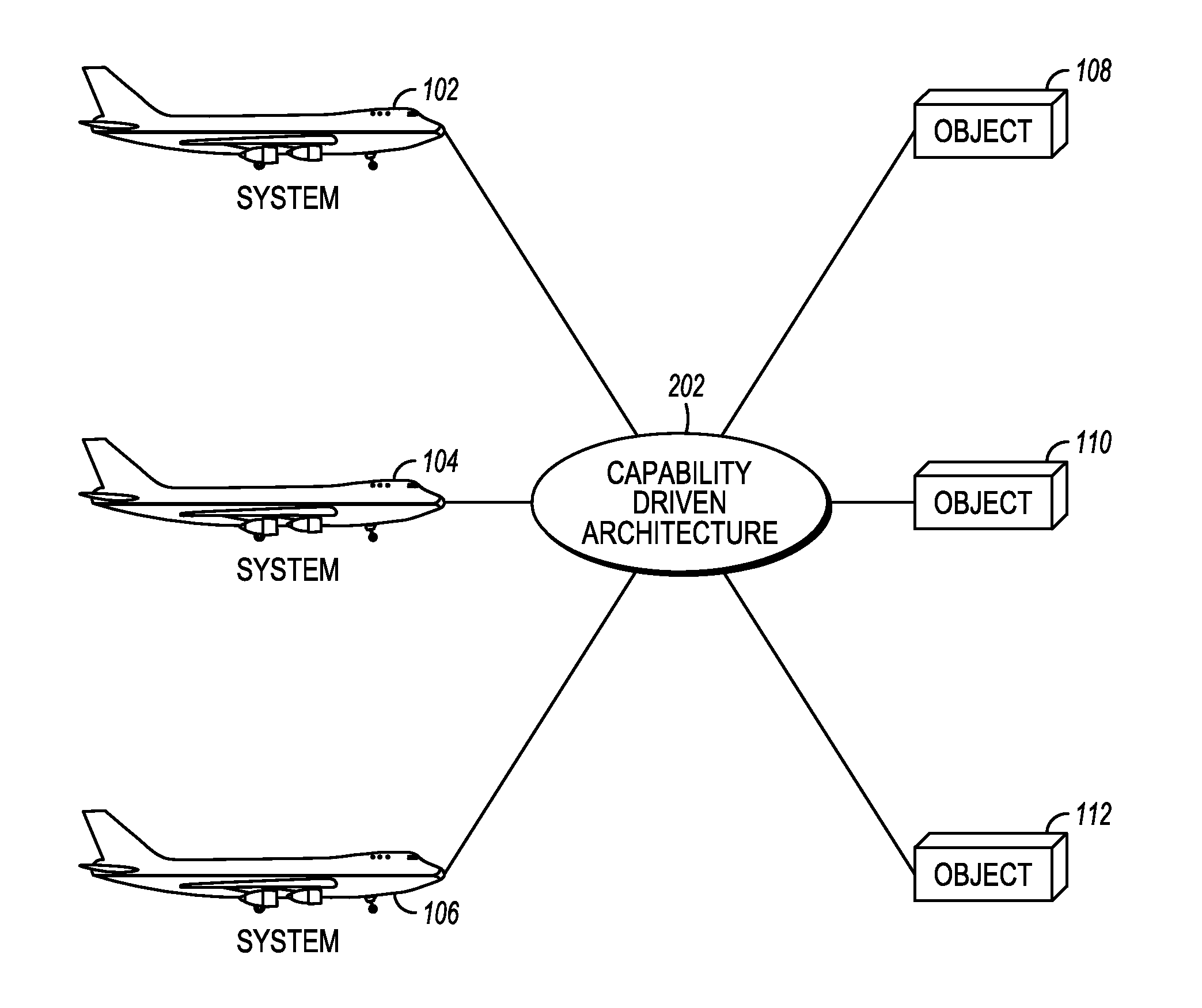

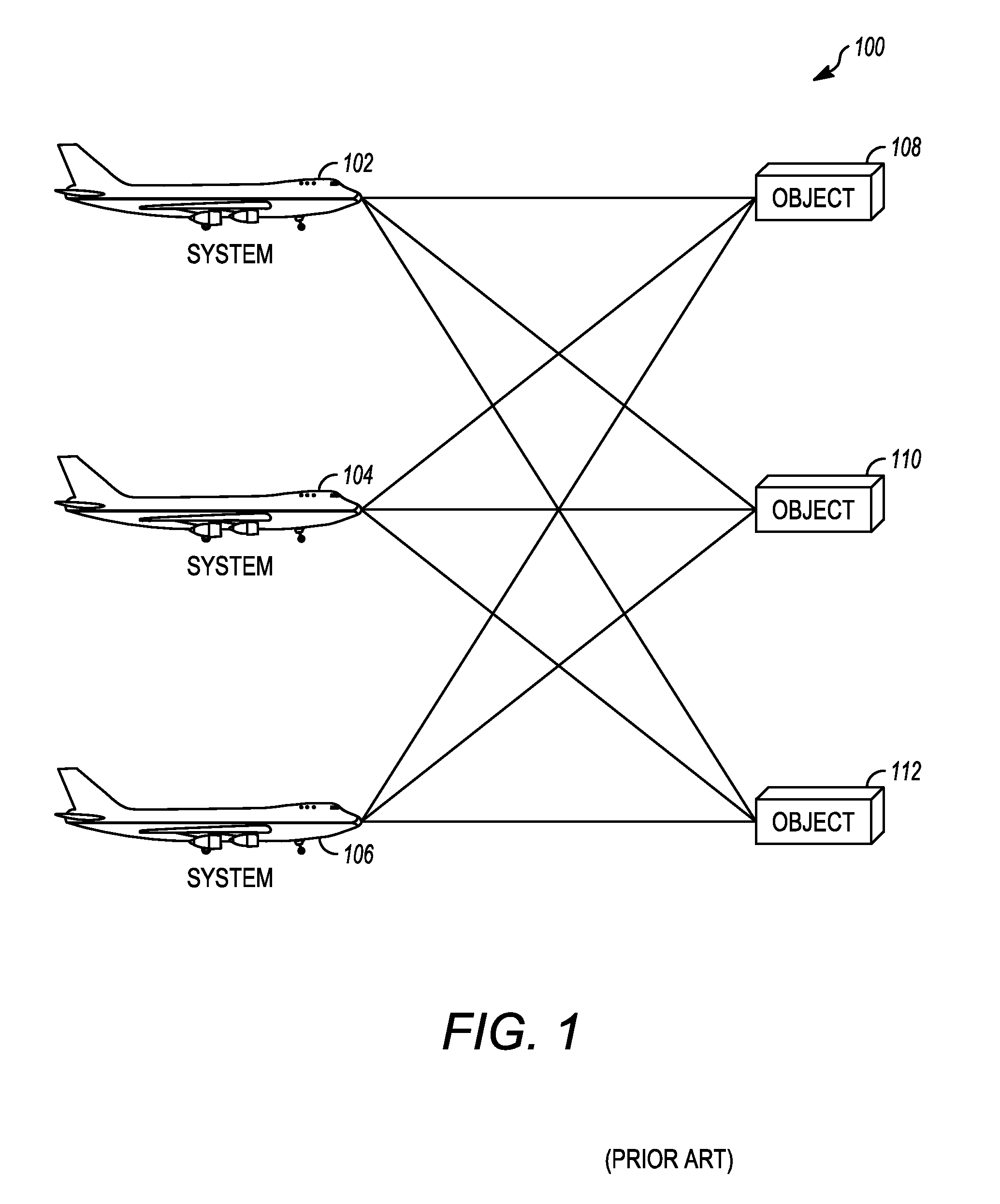

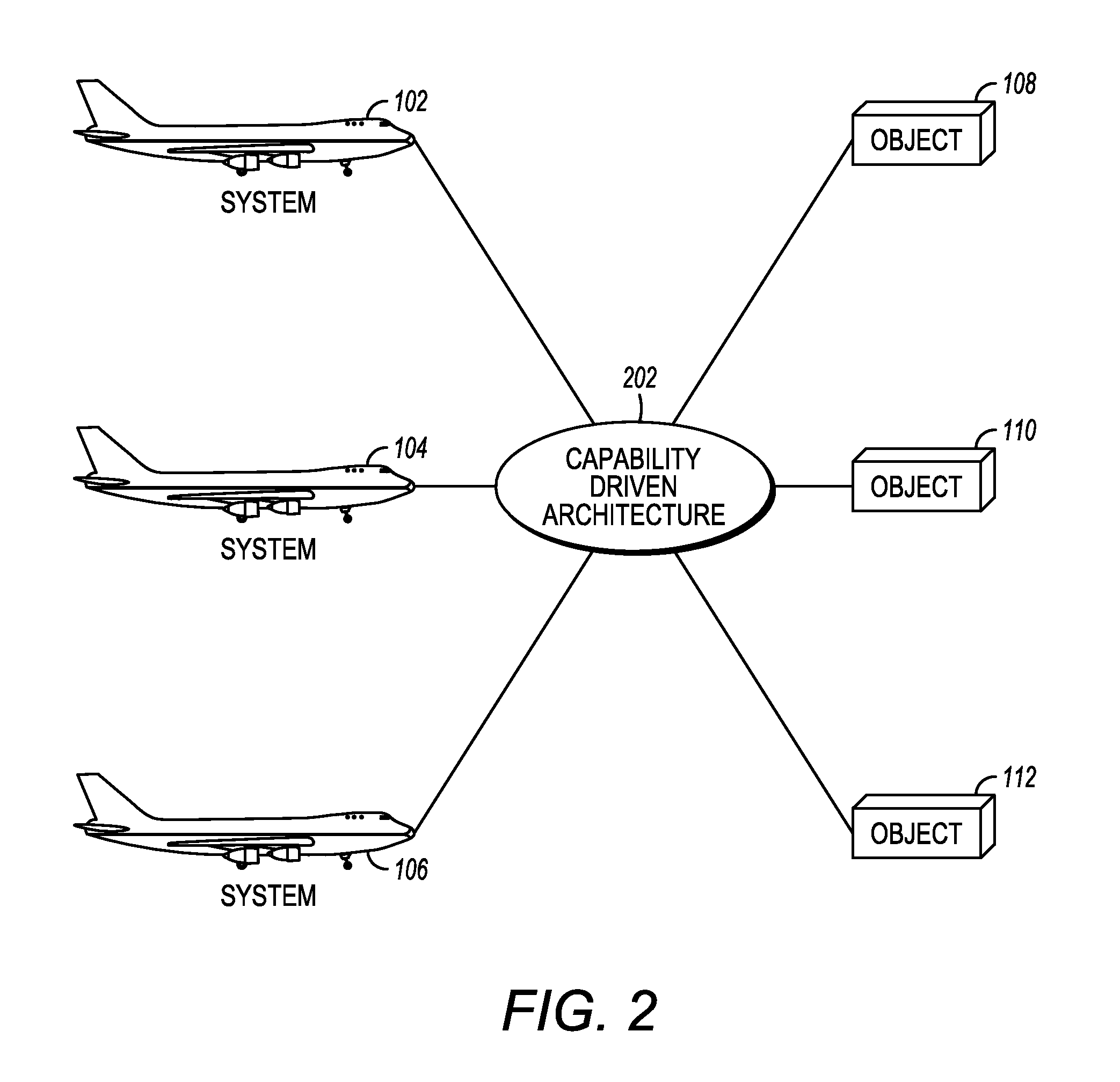

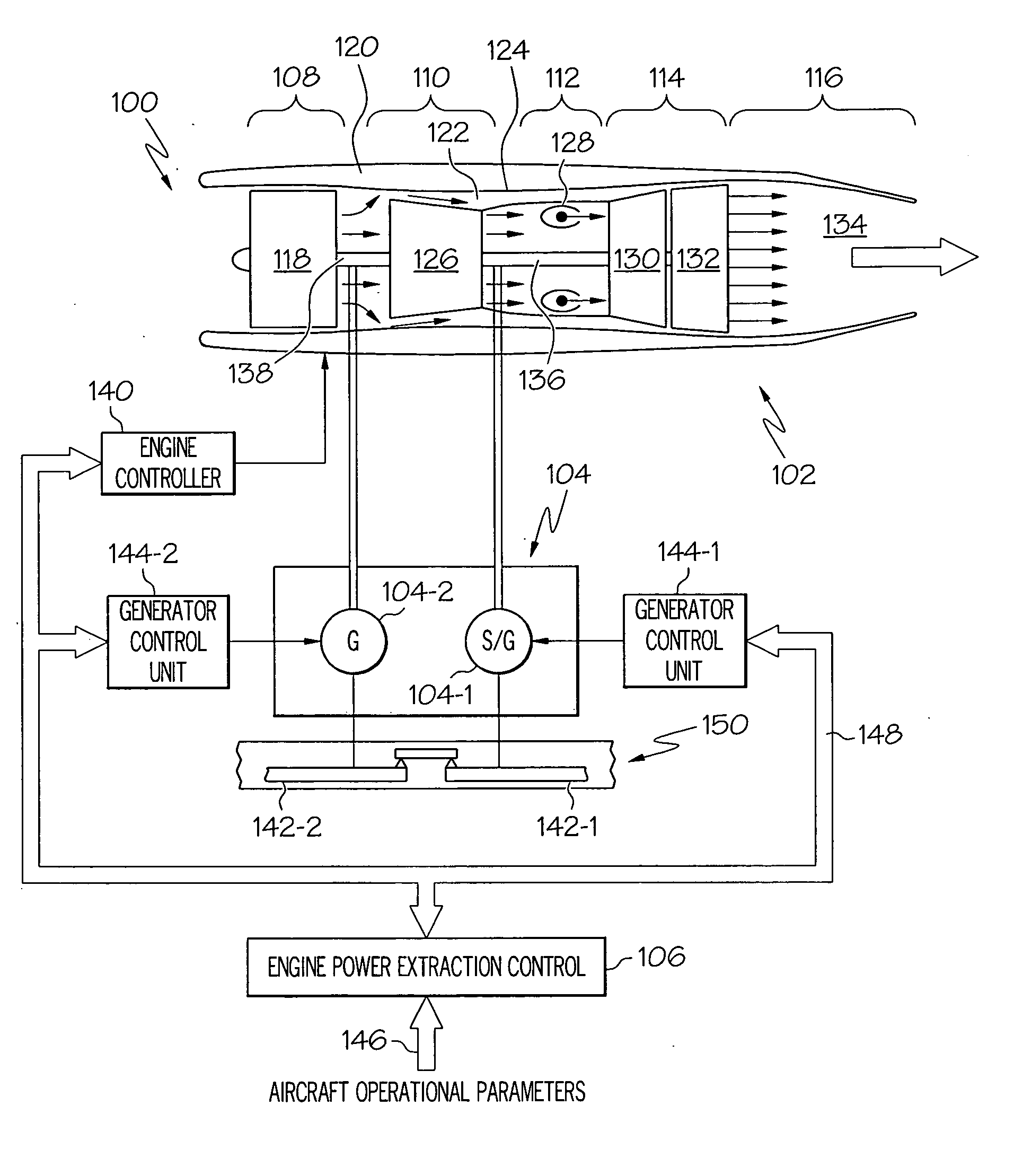

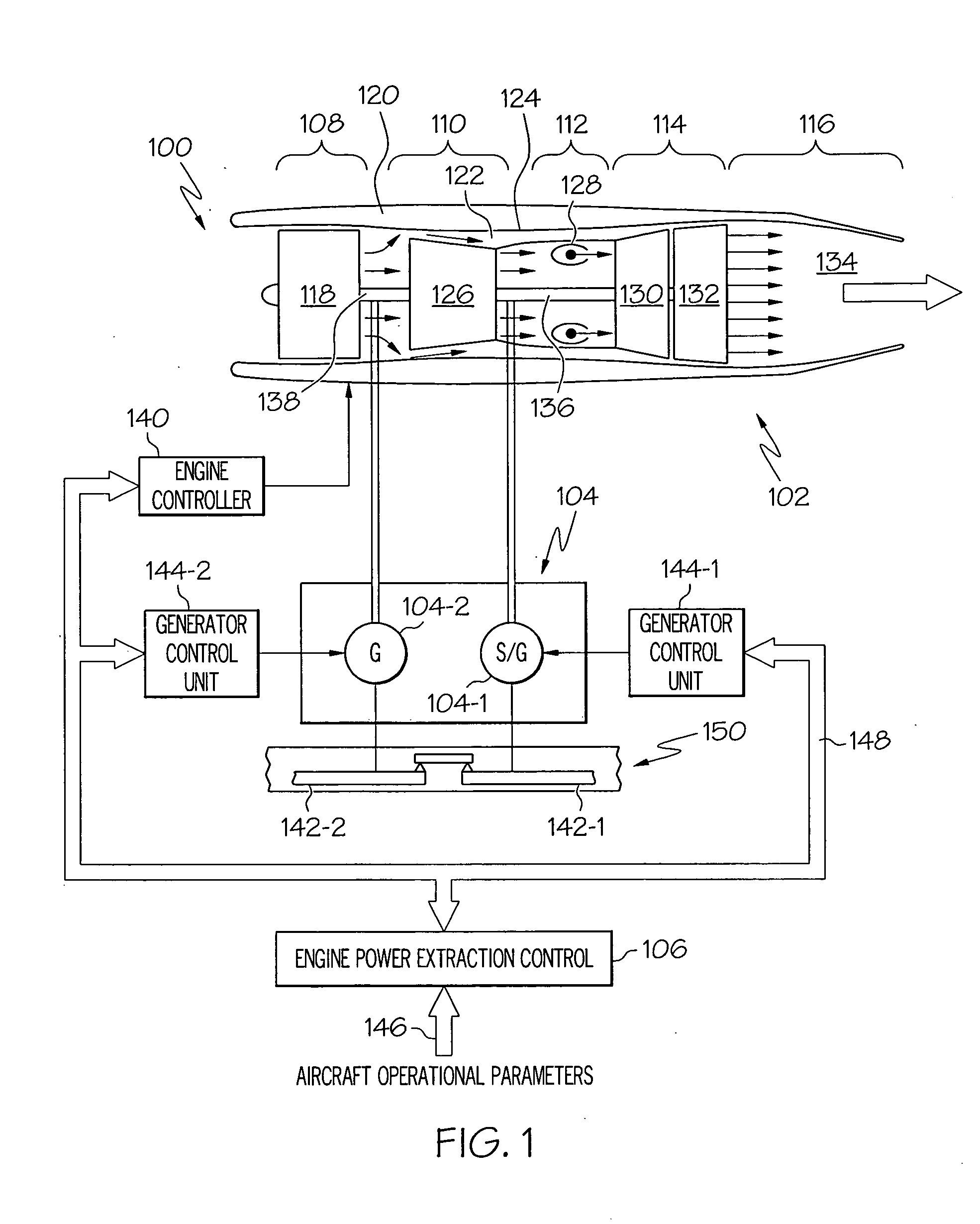

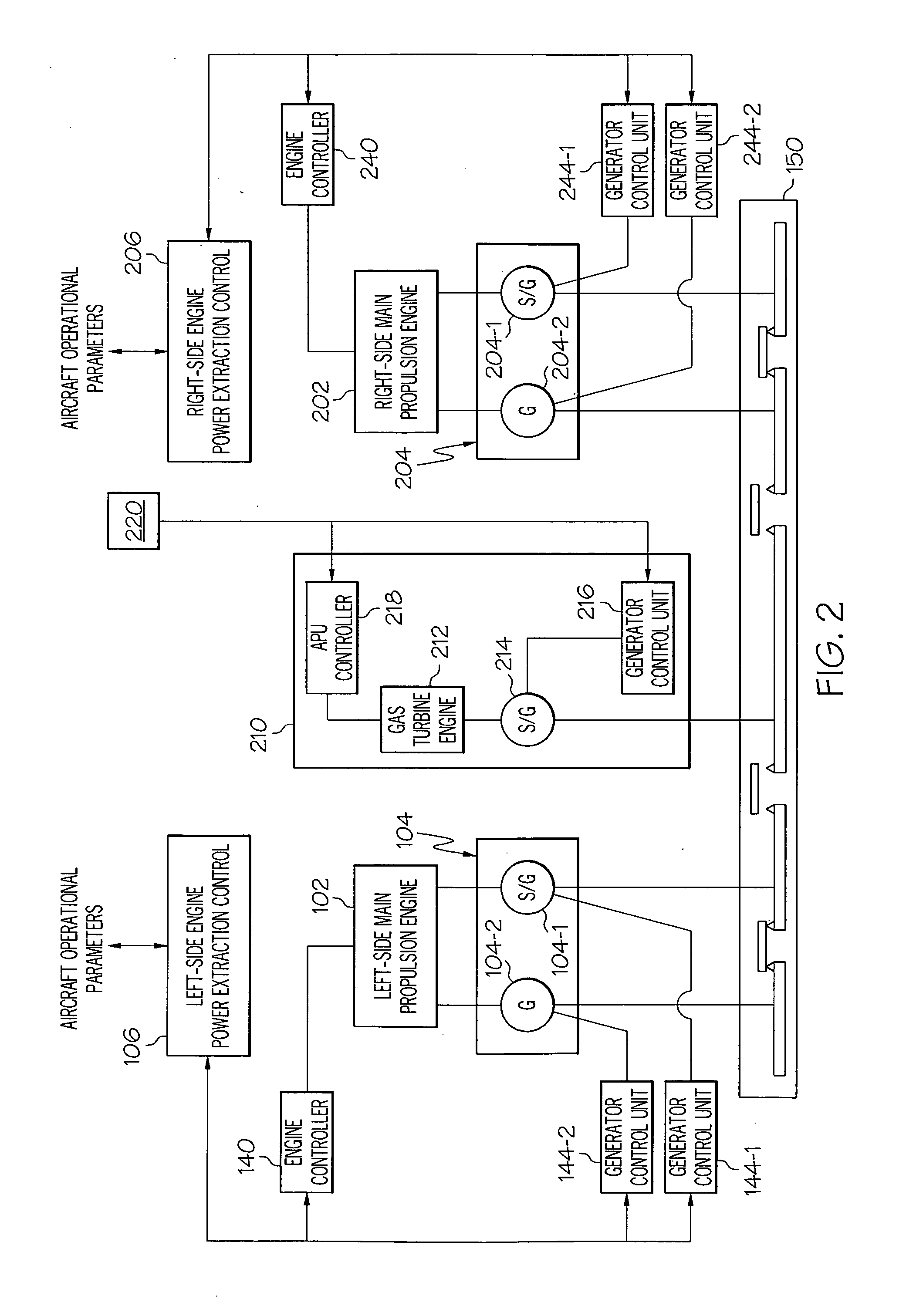

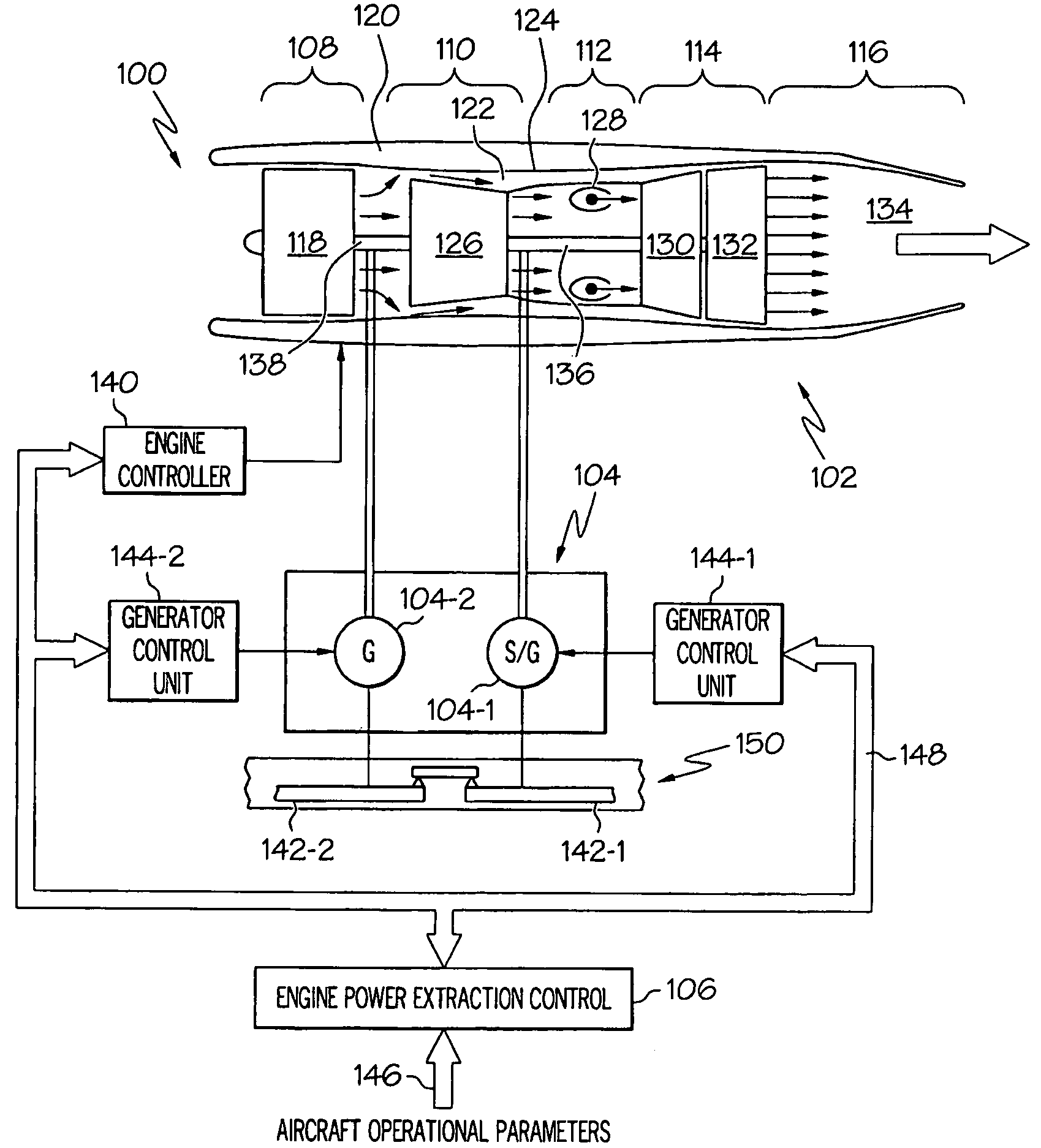

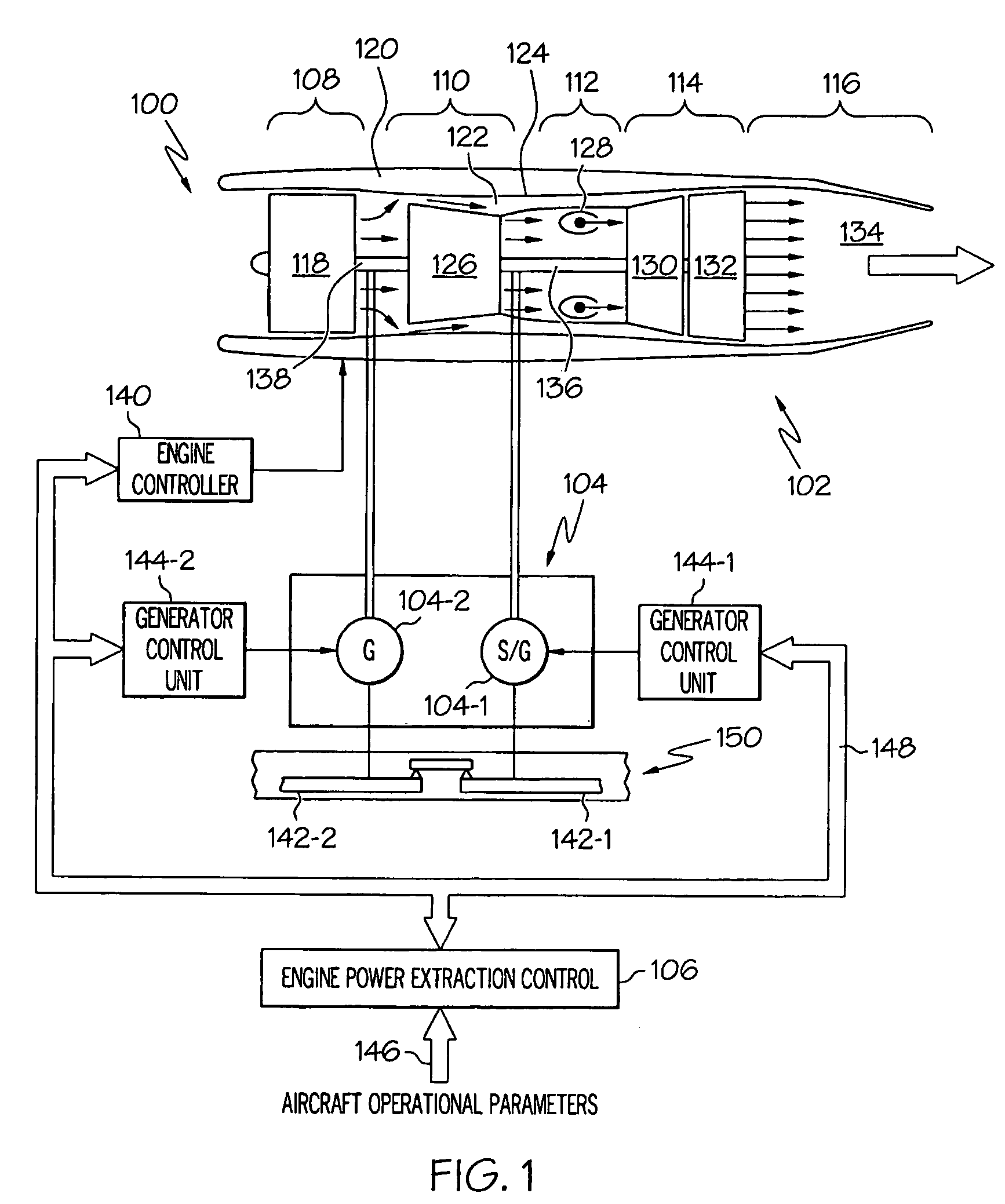

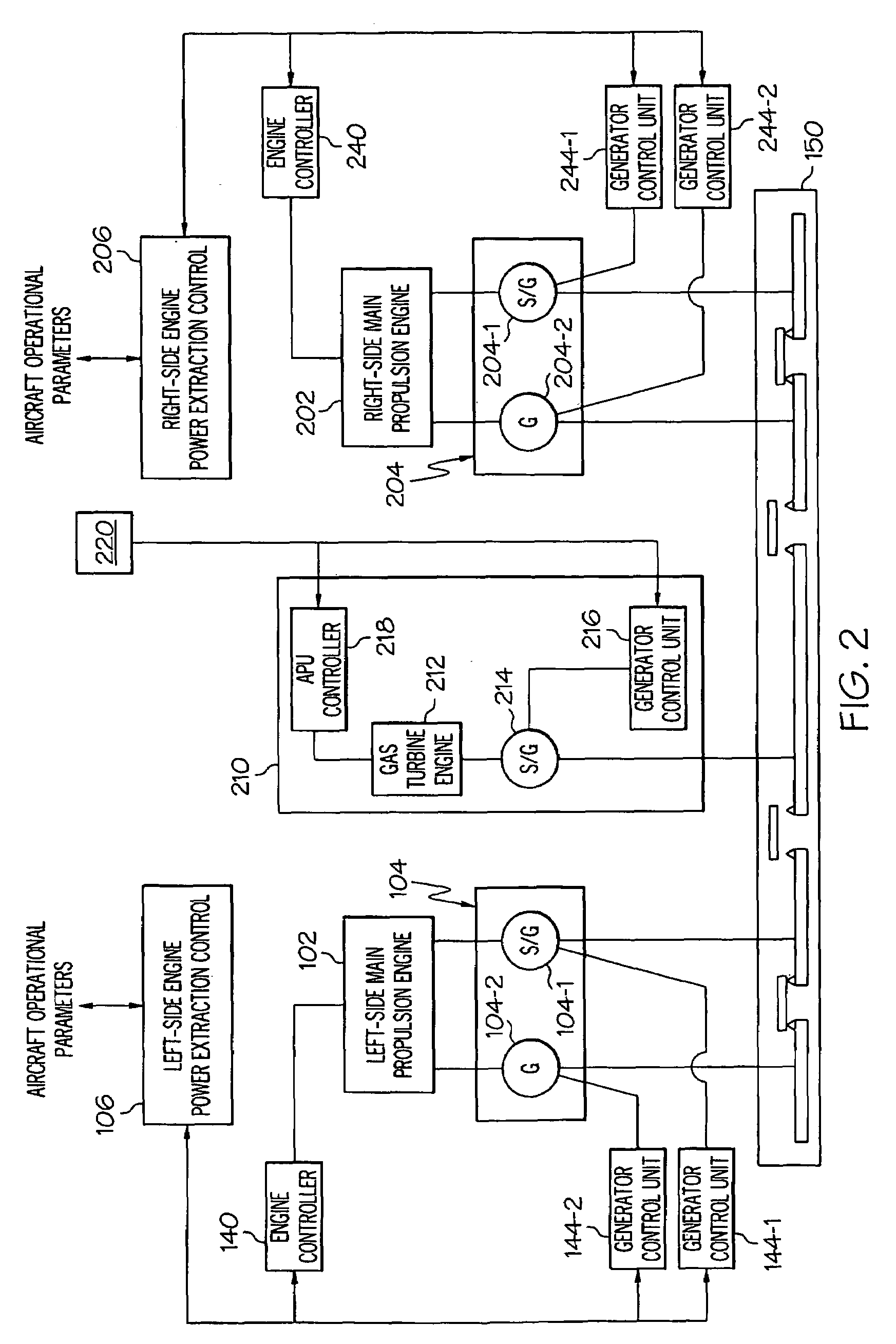

Engine power extraction control system

ActiveUS20060042252A1Increase propulsionEasy to operateReciprocating combination enginesTurbine/propulsion engine ignitionControl systemElectric machine

An engine power extraction control system controls the main propulsion engines and the electrical machines that are coupled thereto to supply an appropriate amount of aircraft thrust and electrical energy to the aircraft. The engines and electrical machines are also controlled so that the propulsion thrust that is generated is split between the various turbines in the main propulsion engines to maintain an adequate surge margin and to minimize residual thrust generation.

Owner:HONEYWELL INT INC

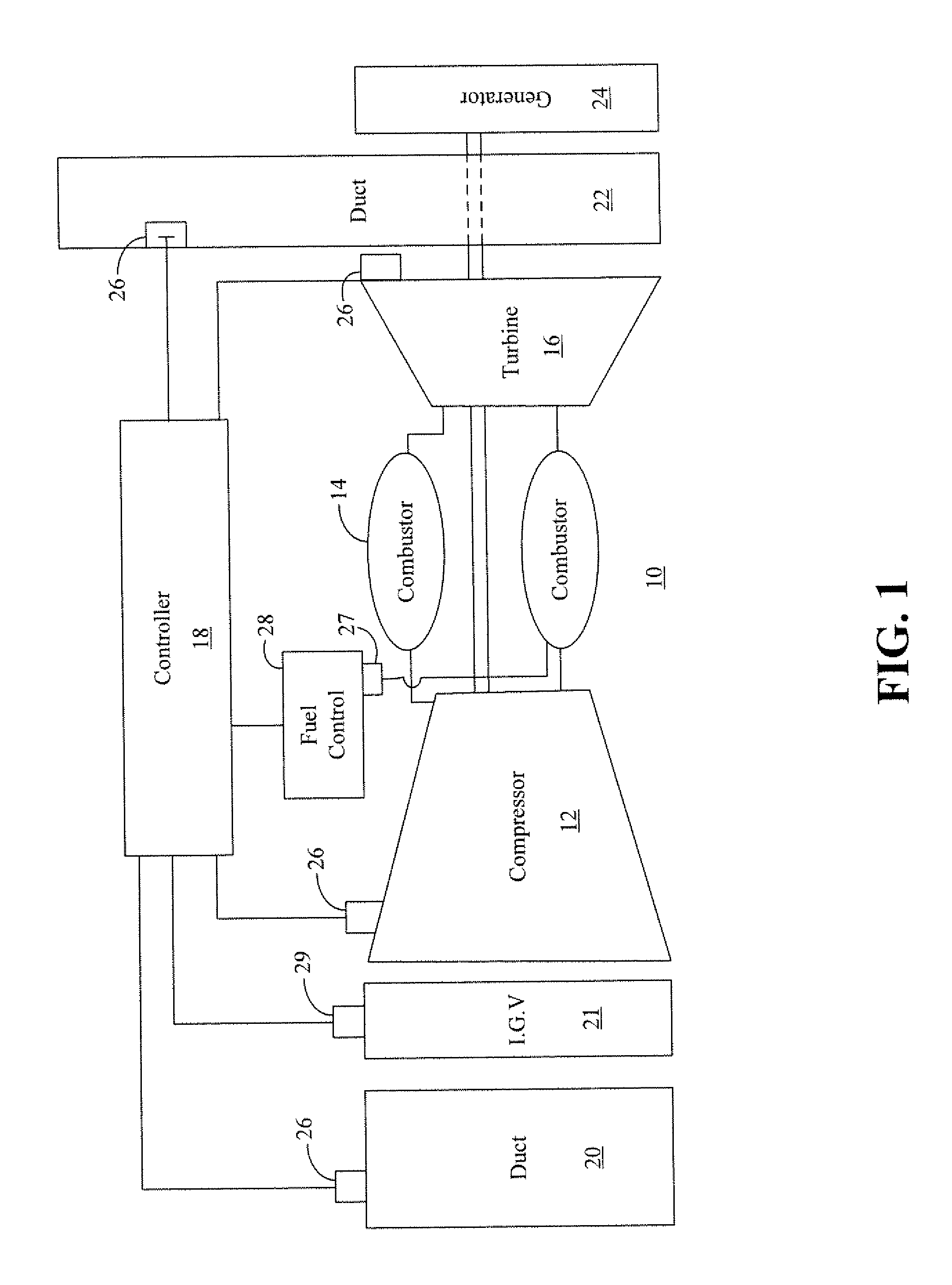

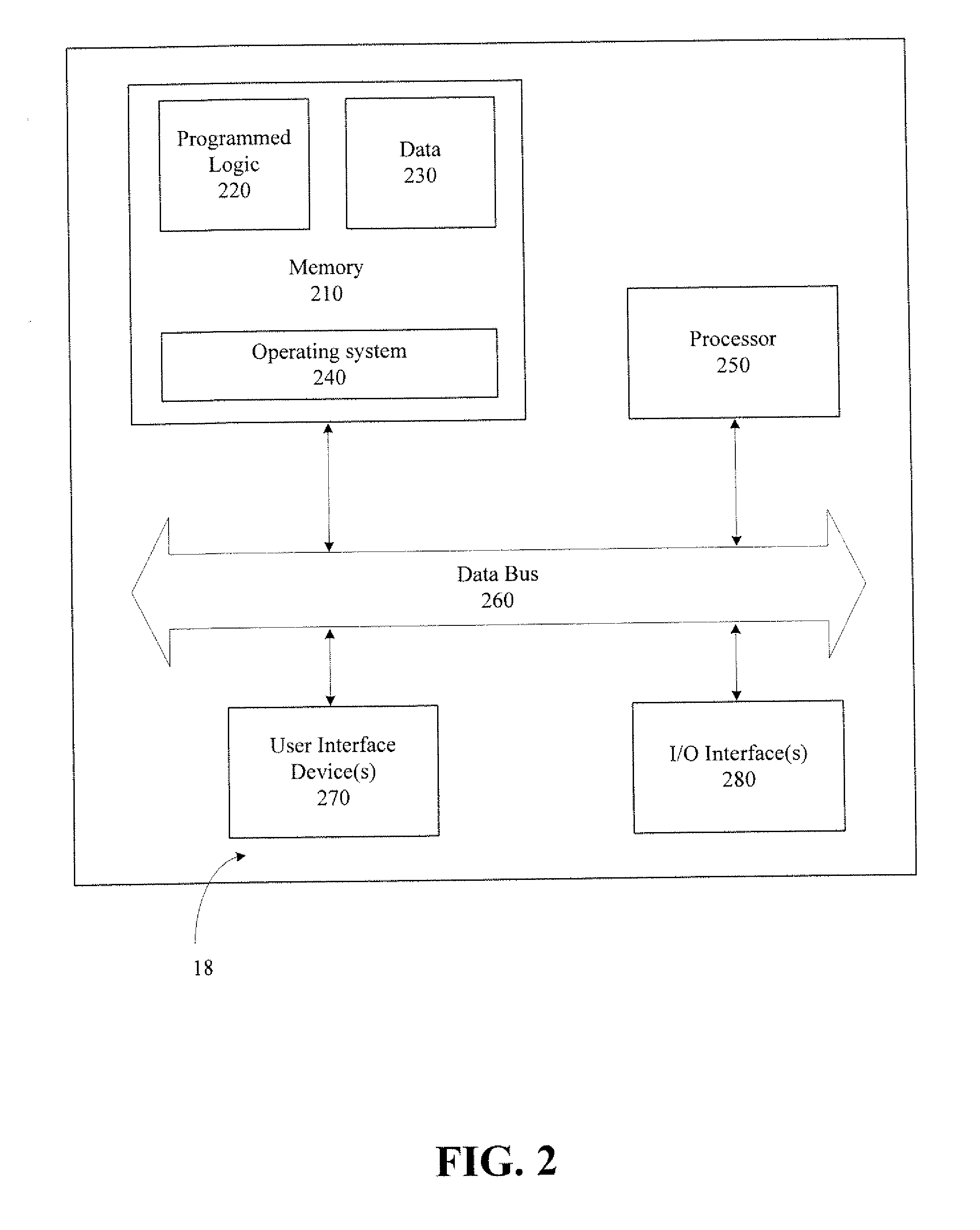

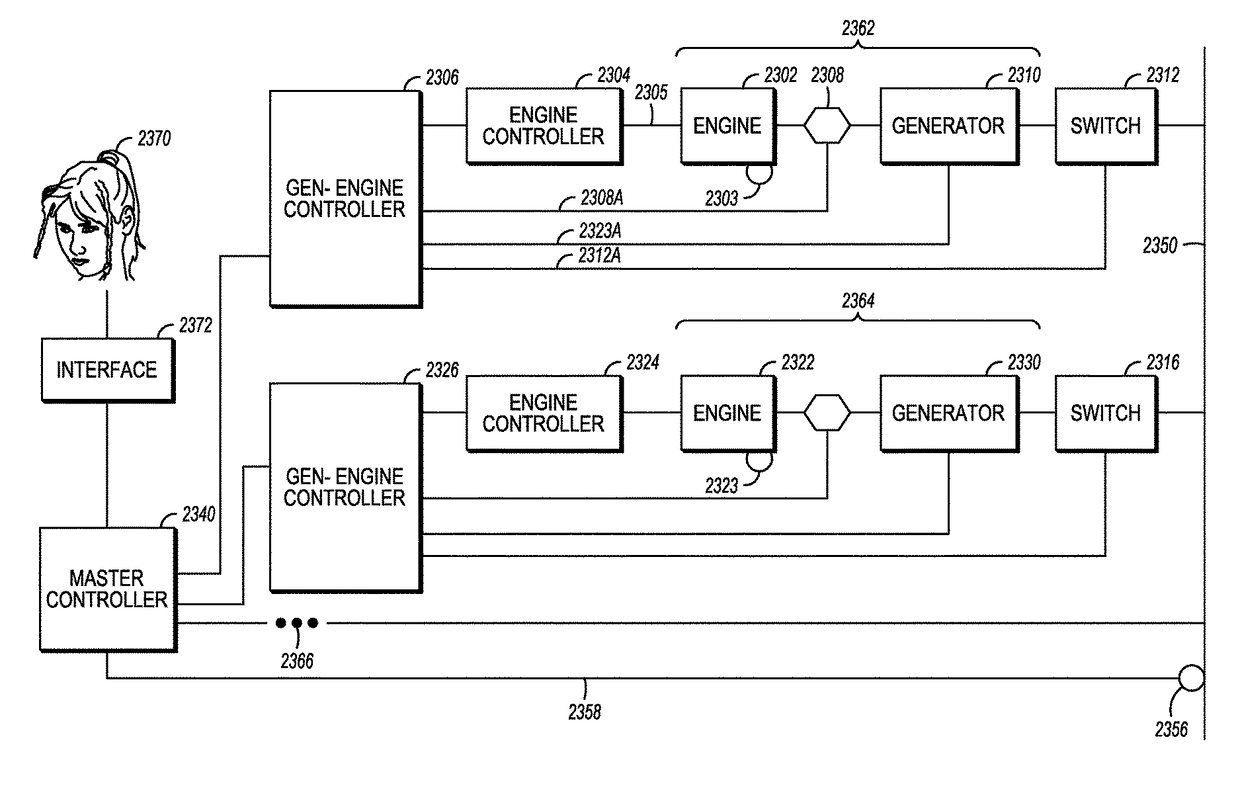

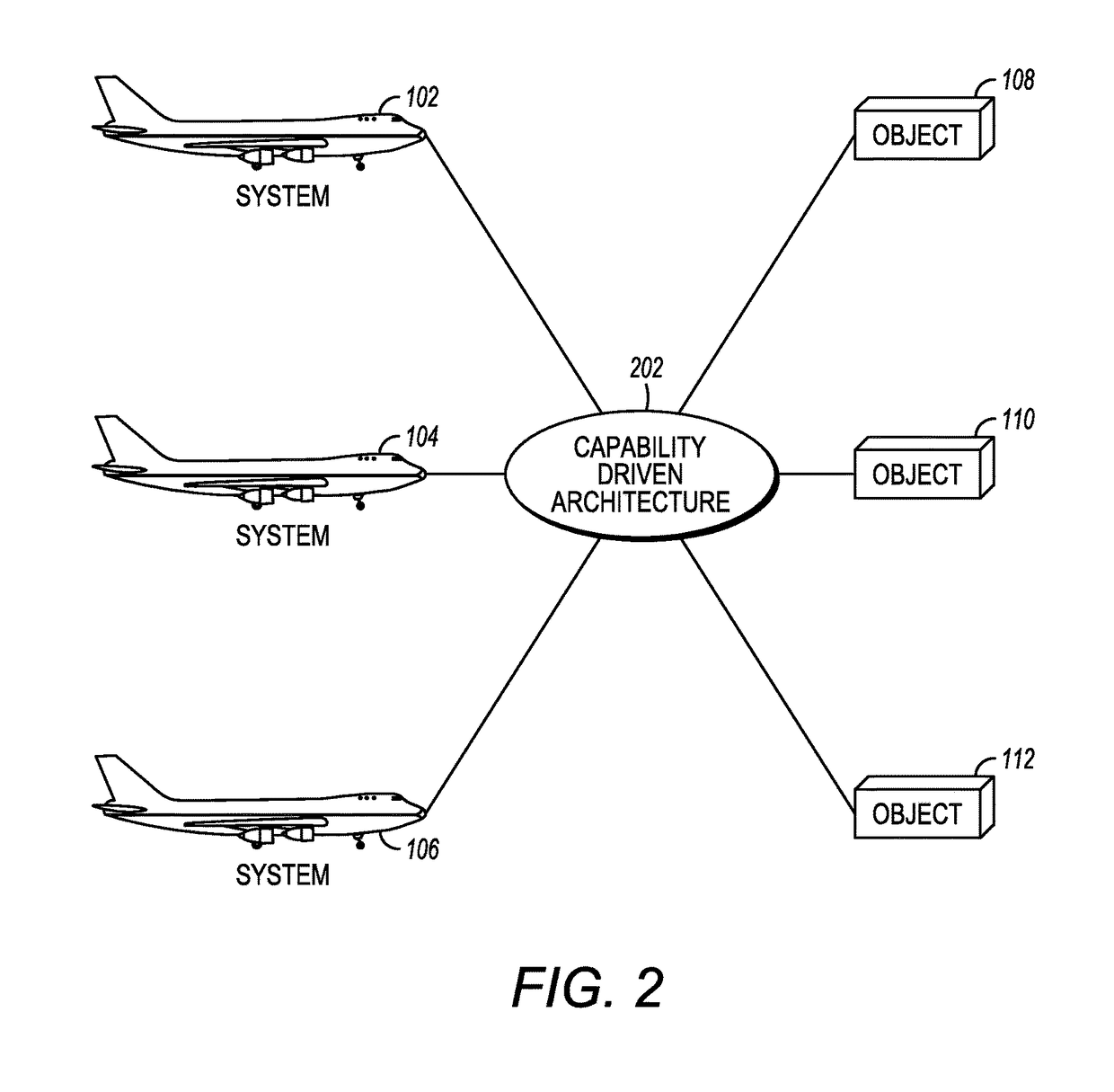

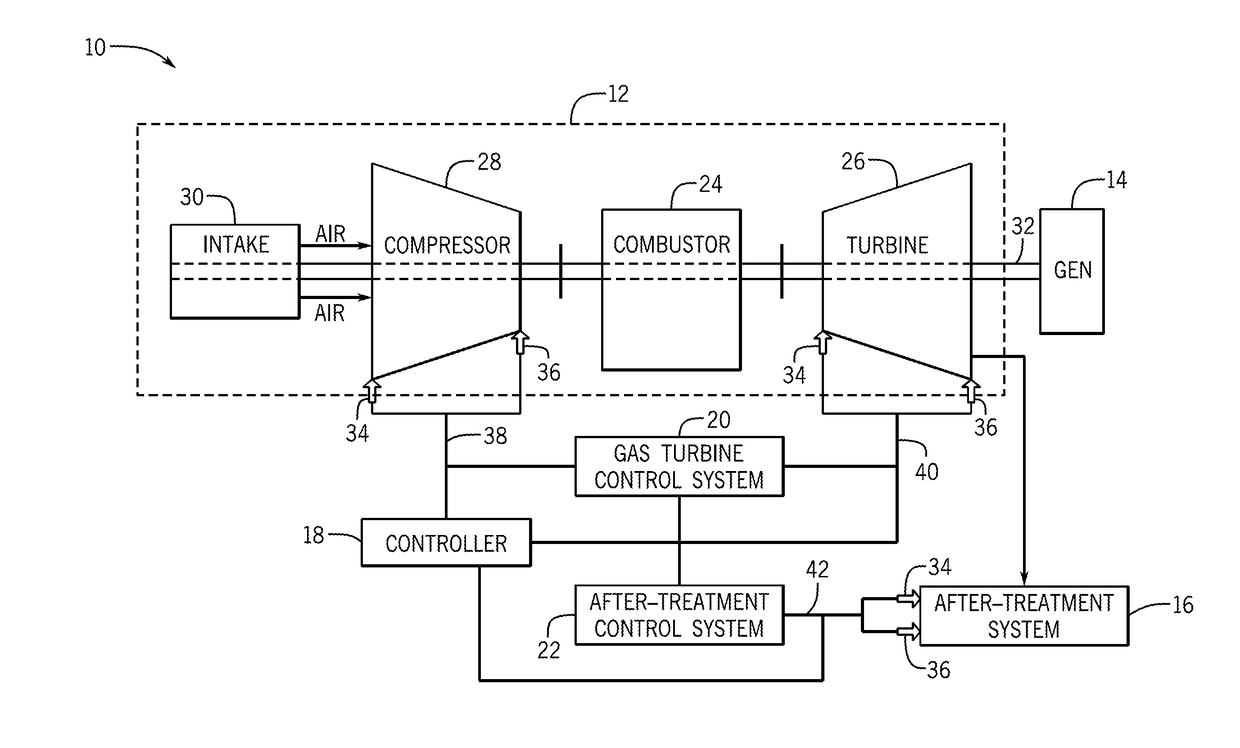

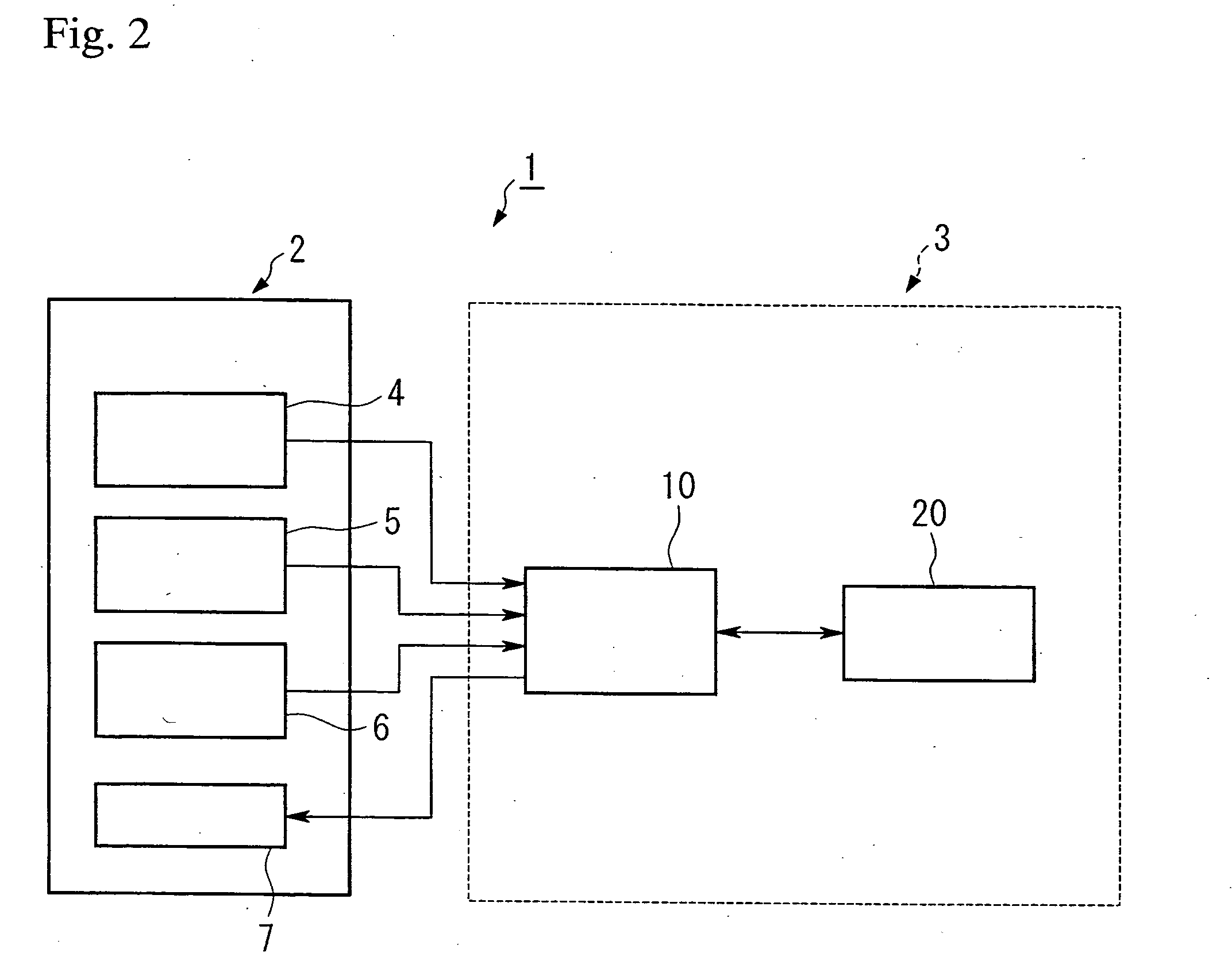

System and method for automatically controlling one or multiple turbogenerators

At least one controller manages a gas turbine engine driving a generator directly or indirectly coupled to the engine. The controller is programmed to automatically determine and adjust inputs to the gas turbine engine in order to cause the generator to produce a user-specified electrical output. Multiple sets of generator, engine, and controller may be used, in which case a master controller individually manages the other controllers to collectively provide the a user-specified electrical output.

Owner:TURBINE POWERED TECH LLC

Power plant and control method

Ambient air is compressed into a compressed ambient gas flow with a main air compressor. The compressed ambient gas flow having a compressed ambient gas flow rate is delivered to a turbine combustor and mixed with a fuel stream having a fuel stream flow rate and a portion of a recirculated gas flow to form a combustible mixture. The combustible mixture is burned and forms the recirculated gas flow that drives a turbine. The recirculated gas flow is recirculated from the turbine to the turbine compressor using a recirculation loop. At least one emission level is measured by at least a first emission sensor in the recirculated gas flow and at least a first control signal is generated. The fuel stream flow rate is adjusted based on the at least a first control signal to achieve substantially stoichiometric combustion.

Owner:GE INFRASTRUCTURE TECH INT LLC

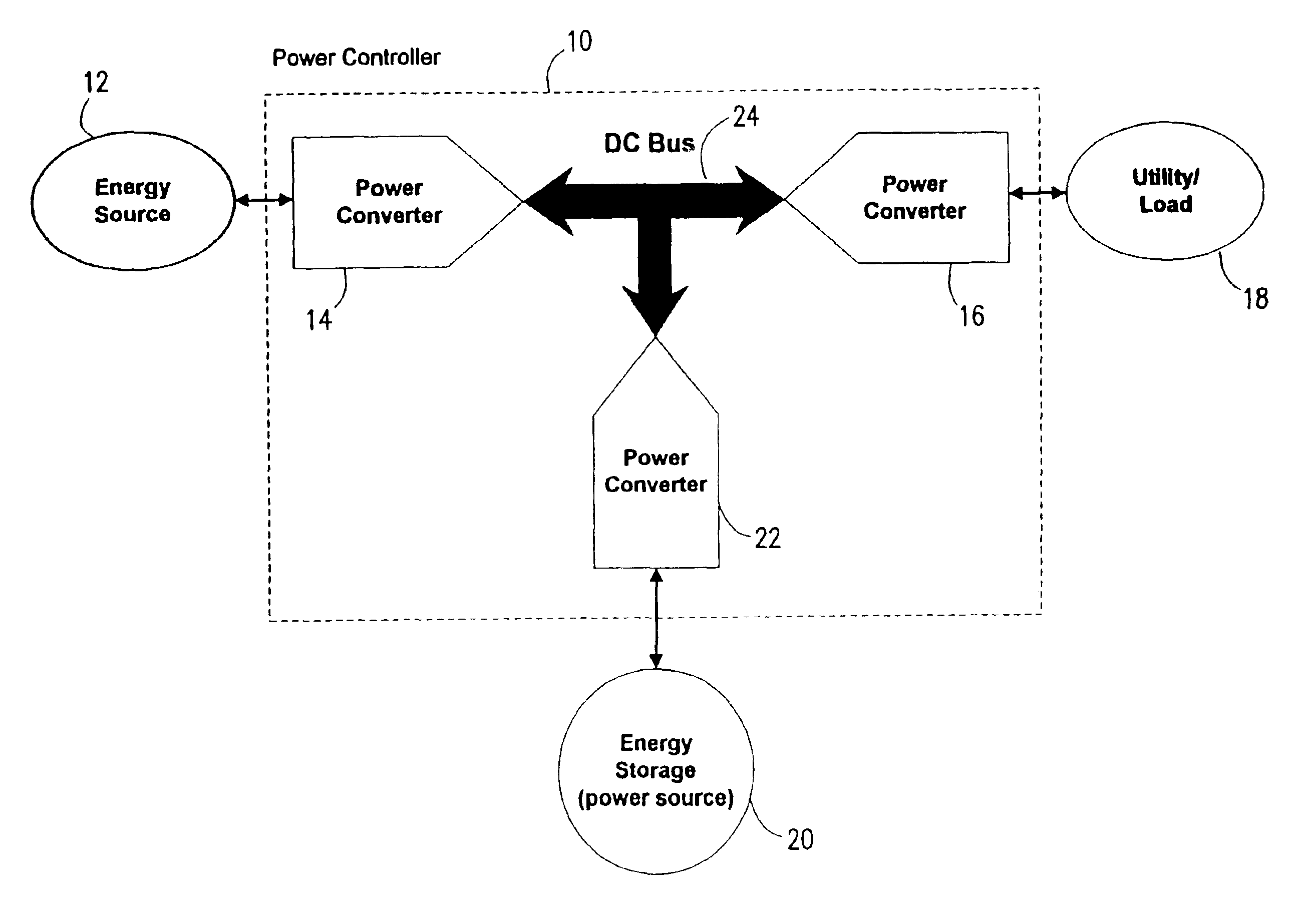

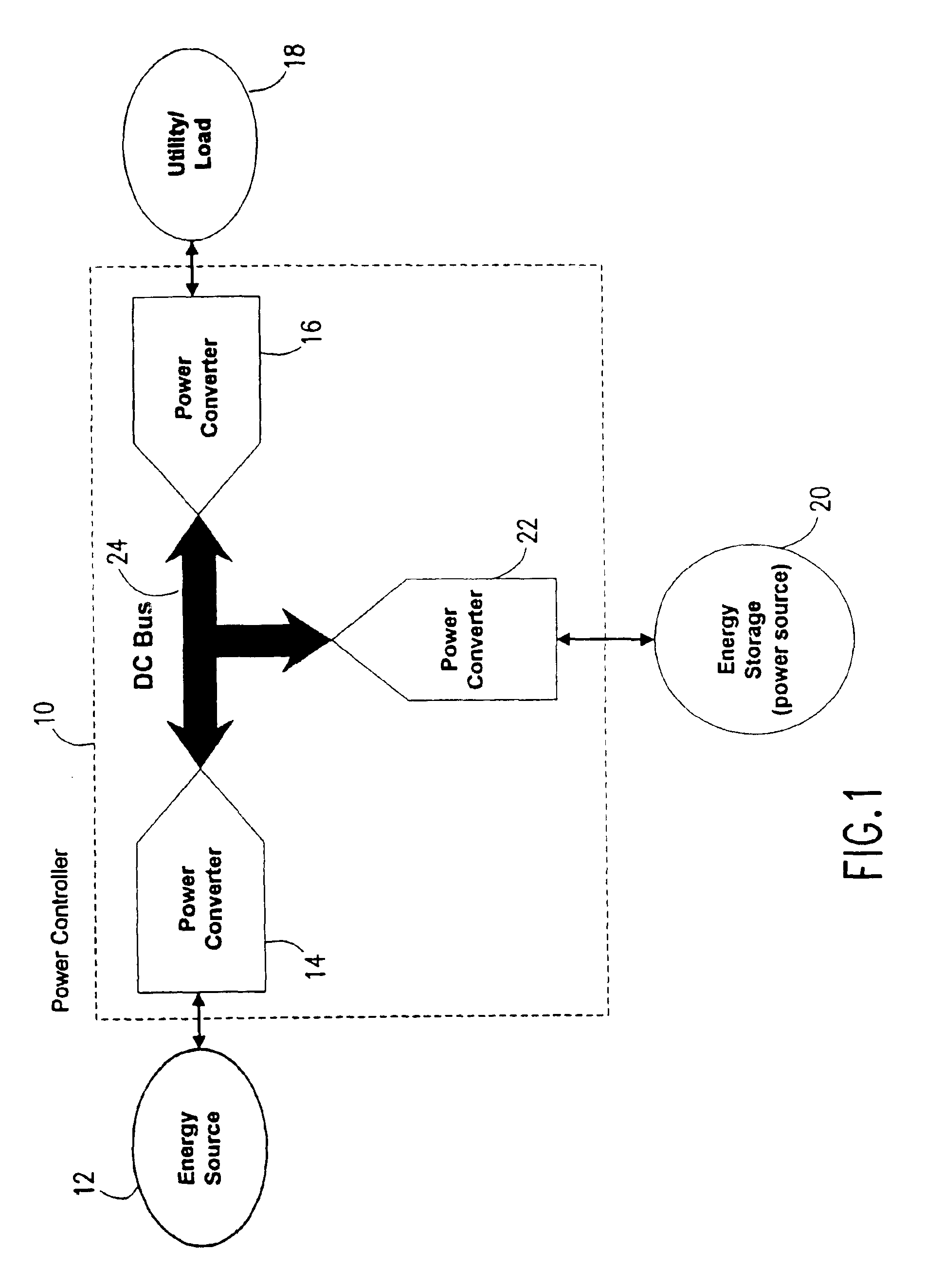

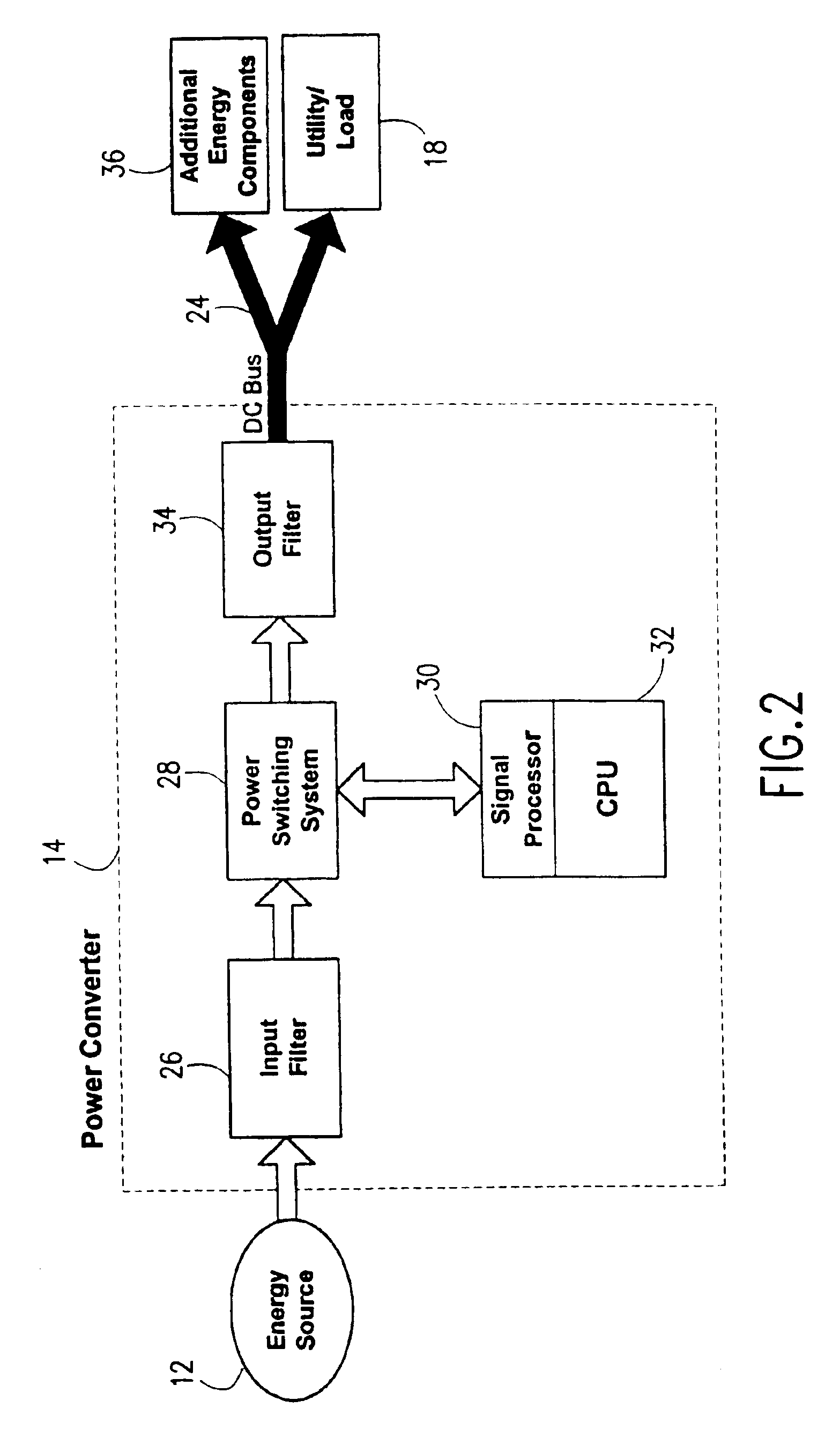

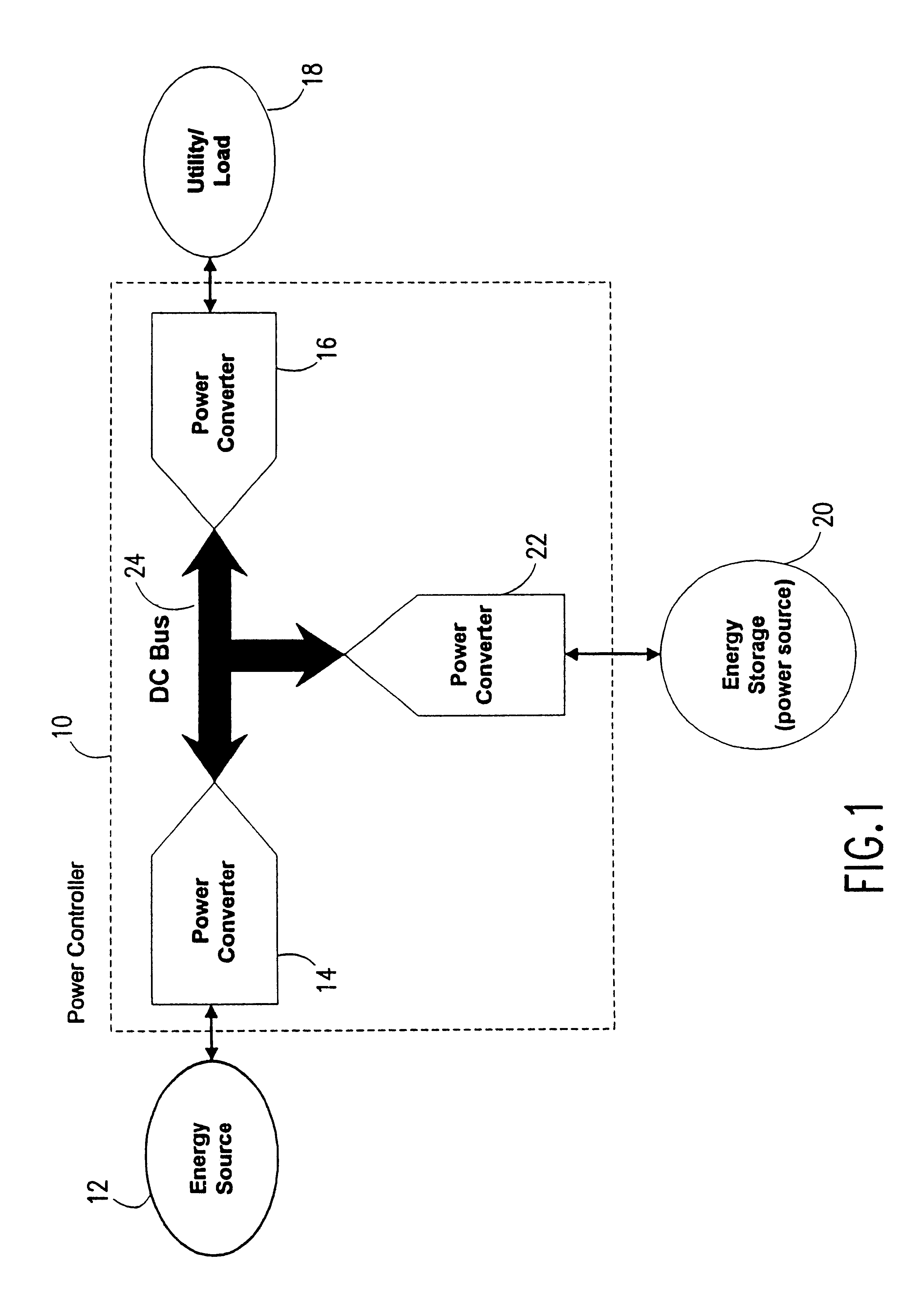

Method and system for control of turbogenerator power and temperature

InactiveUS6958550B2Efficiency of turbine is maximizedIncrease speedLoad balancing in dc networkSteam usePower controllerEngineering

A power controller controls the turbine of a turbine powered generating system regardless of the load on the system to maximize the efficiency of the turbine and maintains the turbine at a substantially constant temperature during a system load change by using an energy storage device to provide power to the load while the turbine is changing speed to meet the new load demand.

Owner:CAPSTONE TURBINE

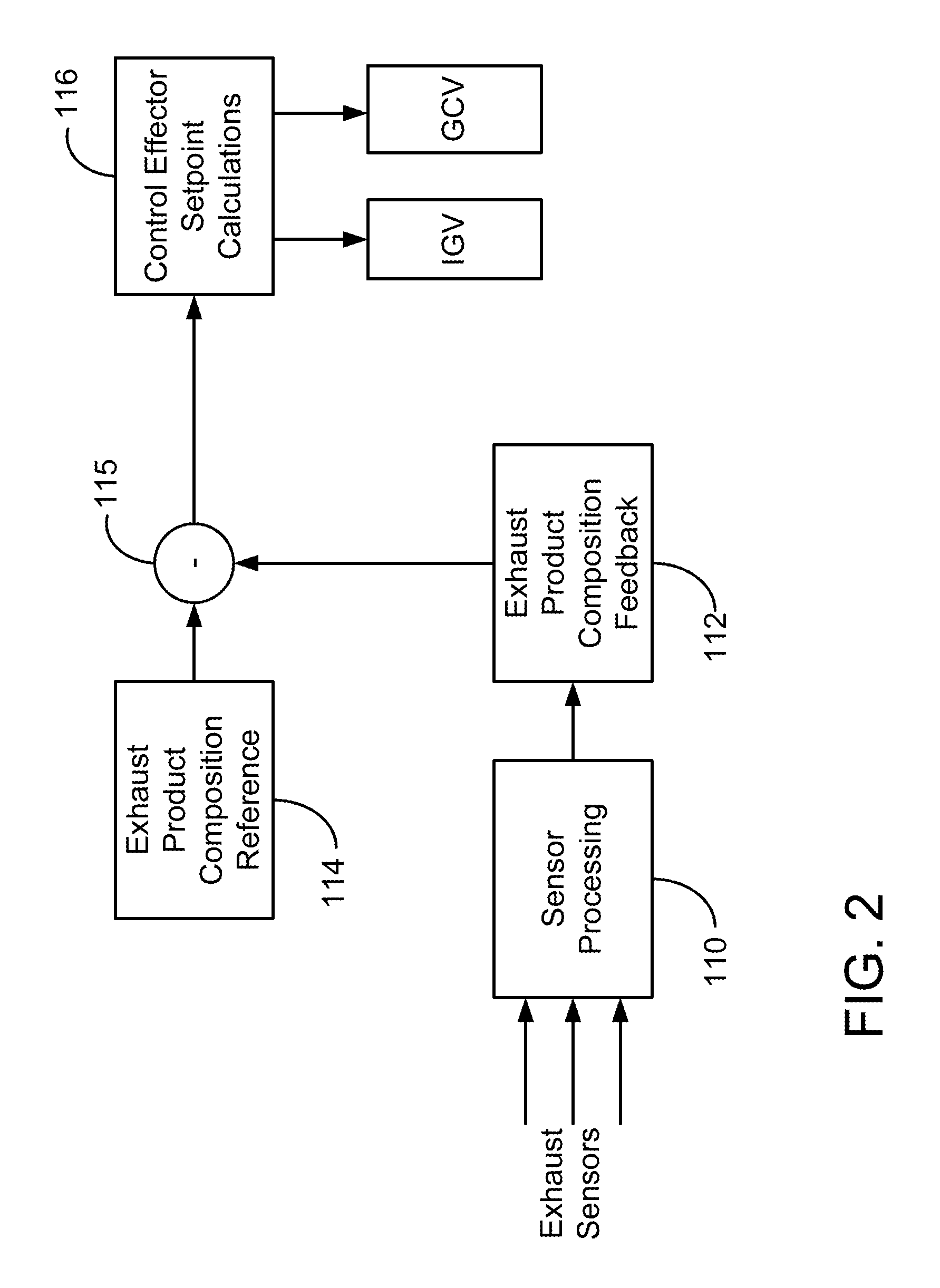

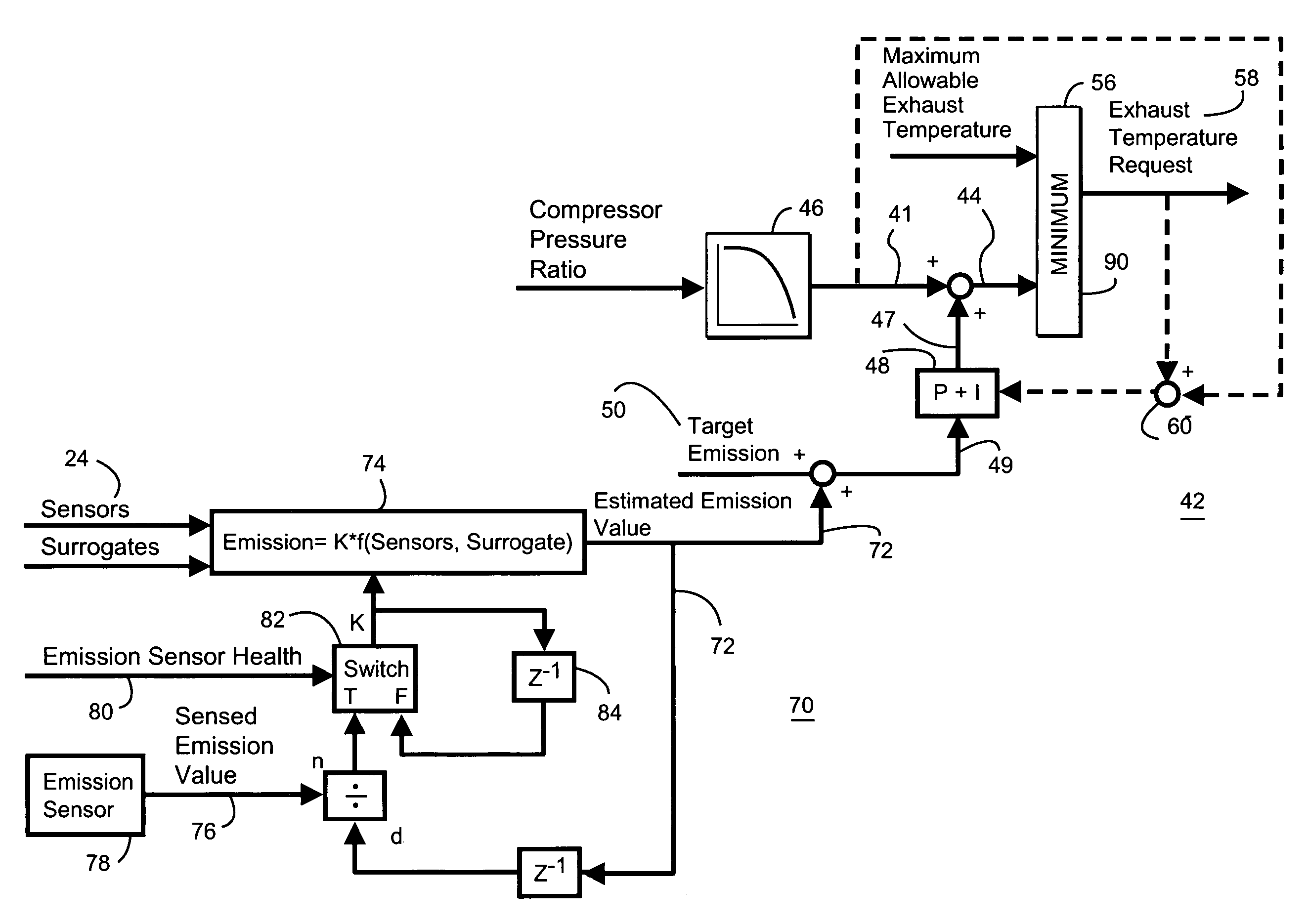

Method and system for incorporating an emission sensor into a gas turbine controller

A method for determining an estimated operating parameter for a gas turbine including the steps of: determining an estimated operating parameter using an algorithm have an input from a sensor, wherein the algorithm includes a trim factor; determining a first trim factor based on a comparison of the first estimated operating parameter and the output of the sensor when a condition of the sensor is in a first mode, and during a subsequent determination of the estimated operating parameter, applying the first trim factor to subsequently determine the estimated operating condition if the condition of second sensor is in a second mode.

Owner:GENERAL ELECTRIC CO

Minitype gas turbine generator wellhead shale gas supply device control system

PendingCN111350595AMeet the requirements of water hydrocarbon dew pointGuaranteed uptimeTurbine/propulsion fuel valvesGas turbine plantsMicro gas turbineHydrocarbon dew point

The invention discloses a minitype gas turbine generator wellhead shale gas supply device control system. A control protection system comprises a particle liquid drop control system, a temperature control system, a pressure control system, a liquid level control system, a water hydrocarbon dew point control system, a fine treatment control system and a system safety protection system which are independently arranged side by side, a working condition parameter signal acquisition system transmits acquired signals to a logic judgment command system, the logic judgment command system is correspondingly connected with a parameter setting system, the control protection system and a data storage remote transmission system, and a micro gas turbine power generation system is correspondingly connected with the parameter setting system, the control protection system and the data storage remote transmission system. The control system has the beneficial effects that stable control over the water hydrocarbon dew point is achieved, and normal and stable operation of the micro gas turbine is guaranteed; the pollution discharge is accurately controlled according to the fluctuation condition of theactual working condition, and the overall operation cost is reduced; and automatic liquid drainage under different working condition fluctuations is achieved, and the risks of tripping and blow-by arereduced.

Owner:JEREH OIL & GAS ENG

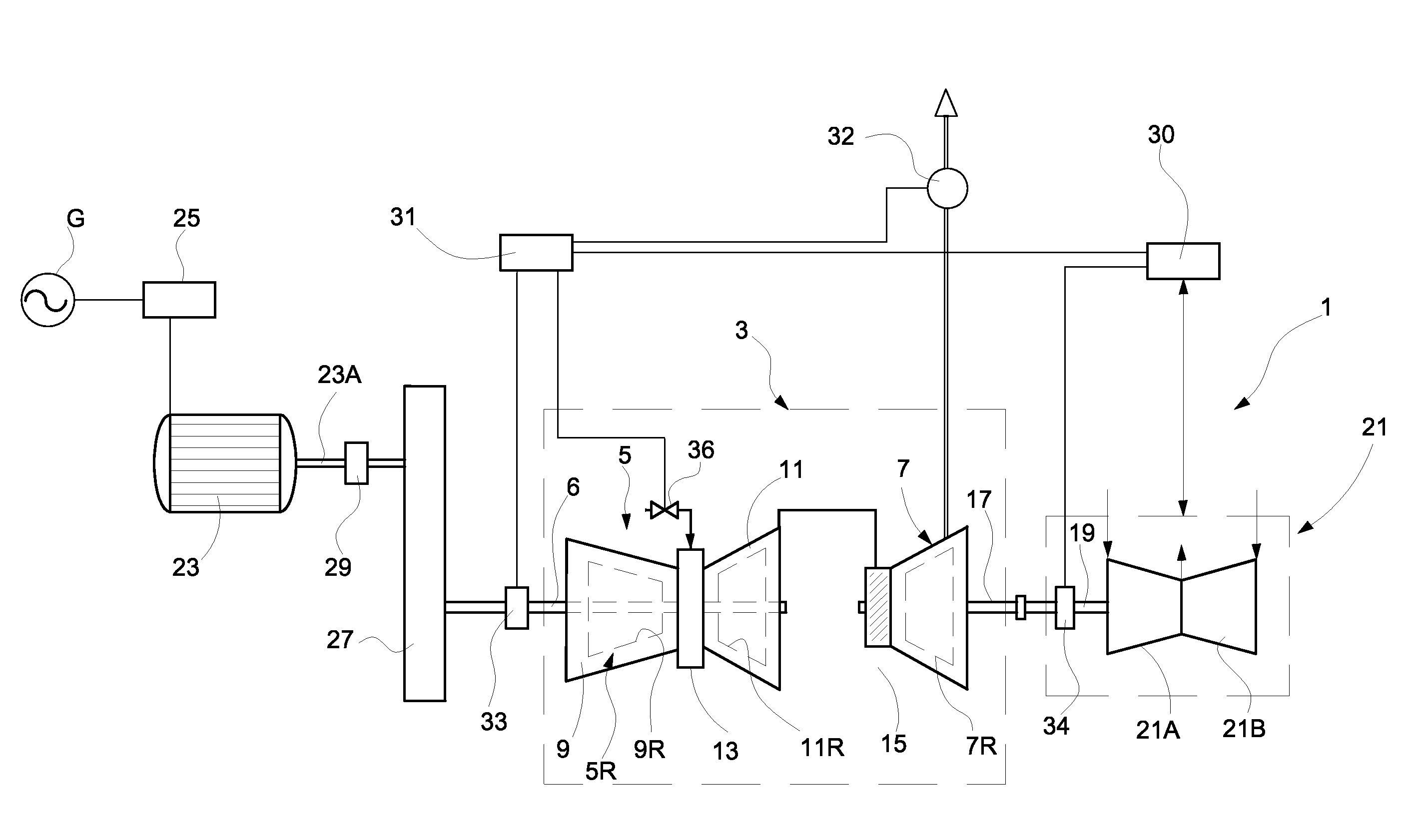

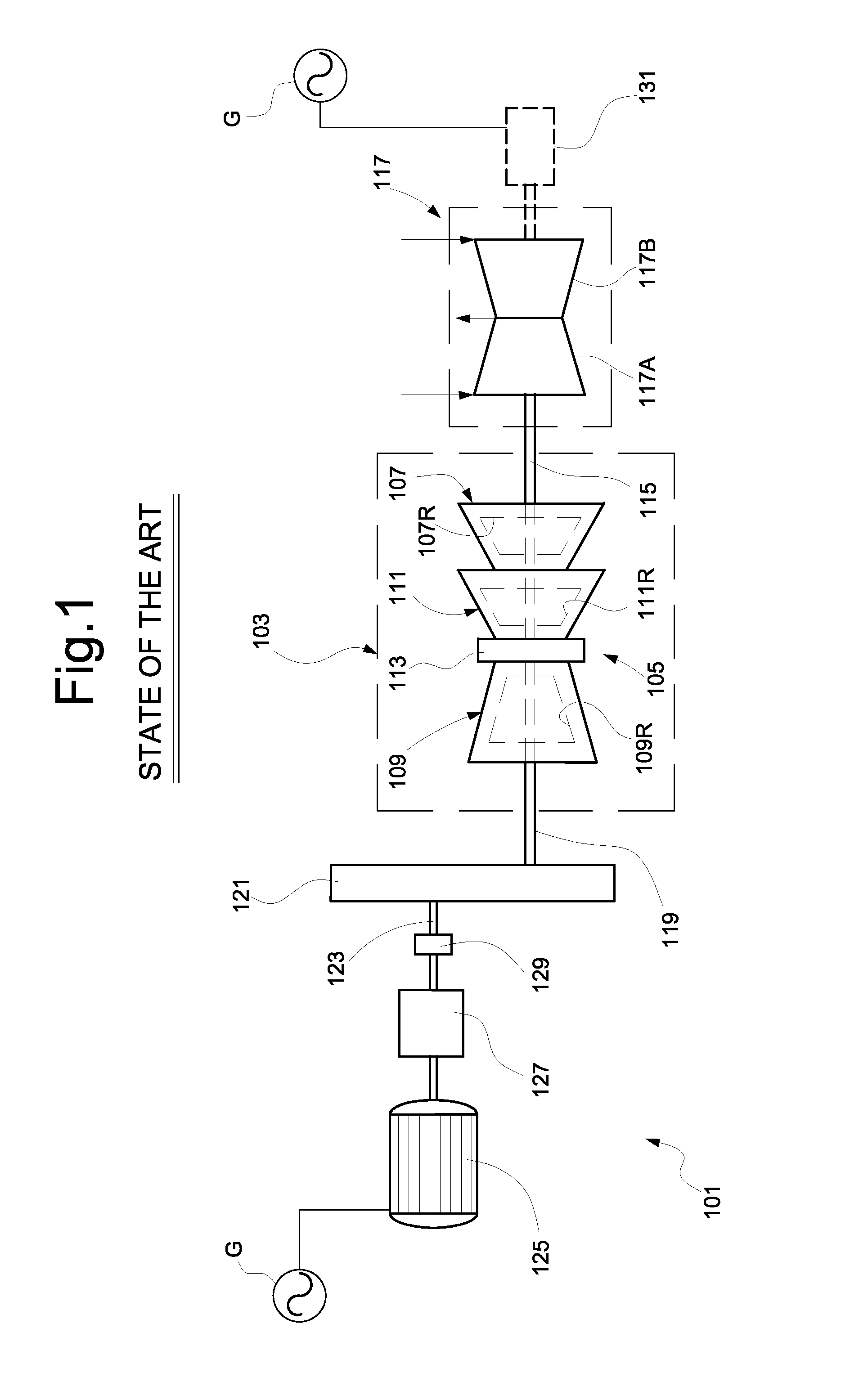

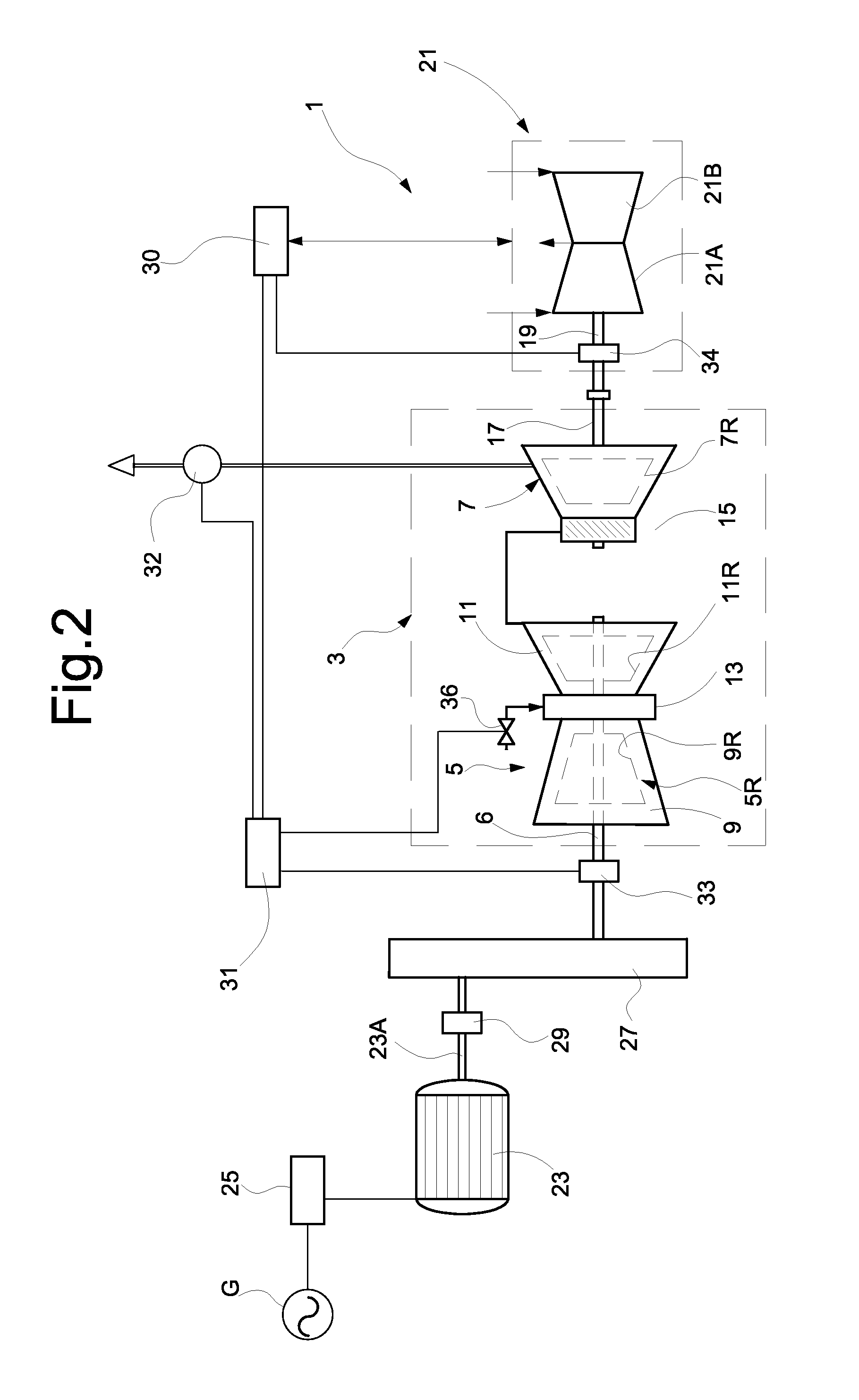

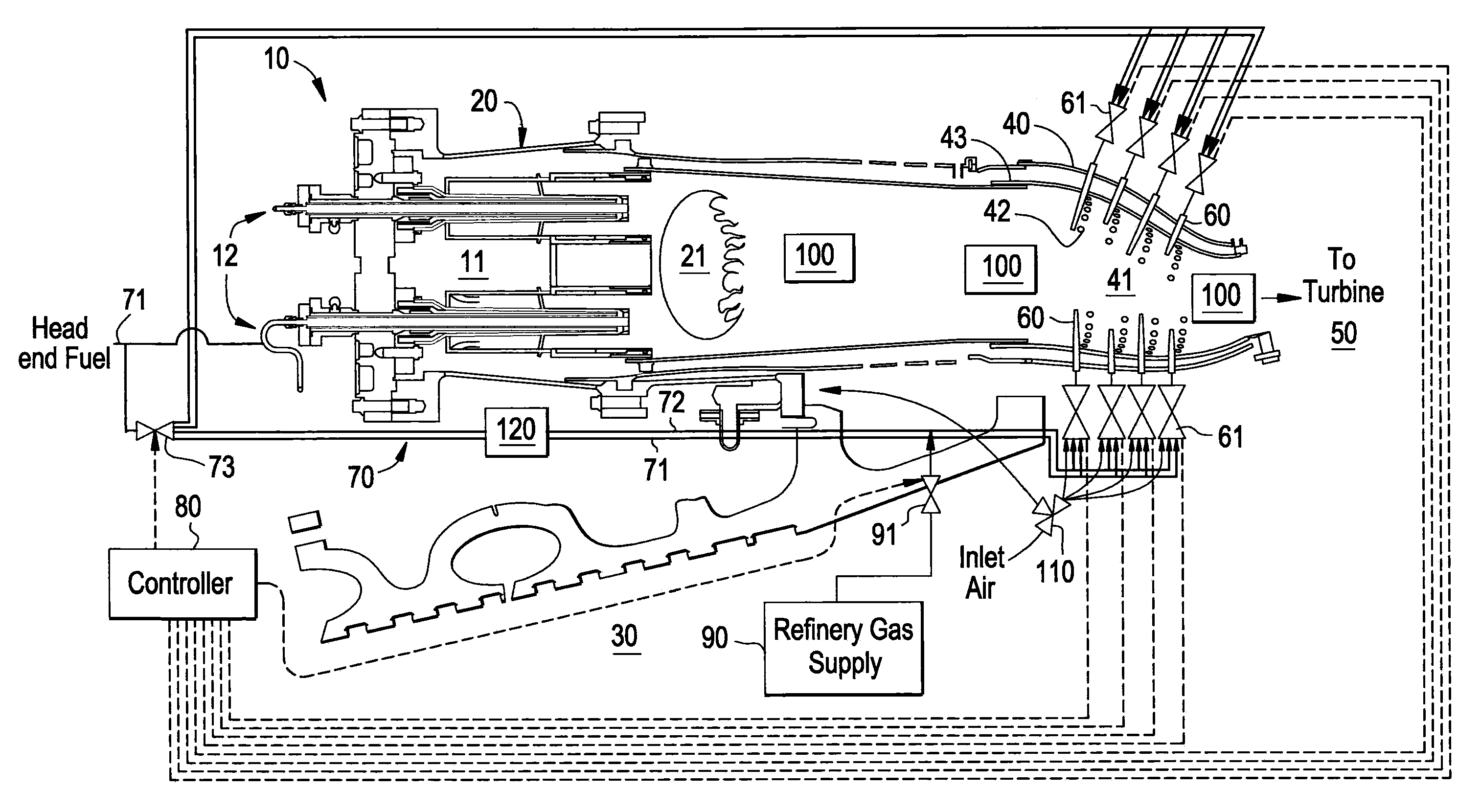

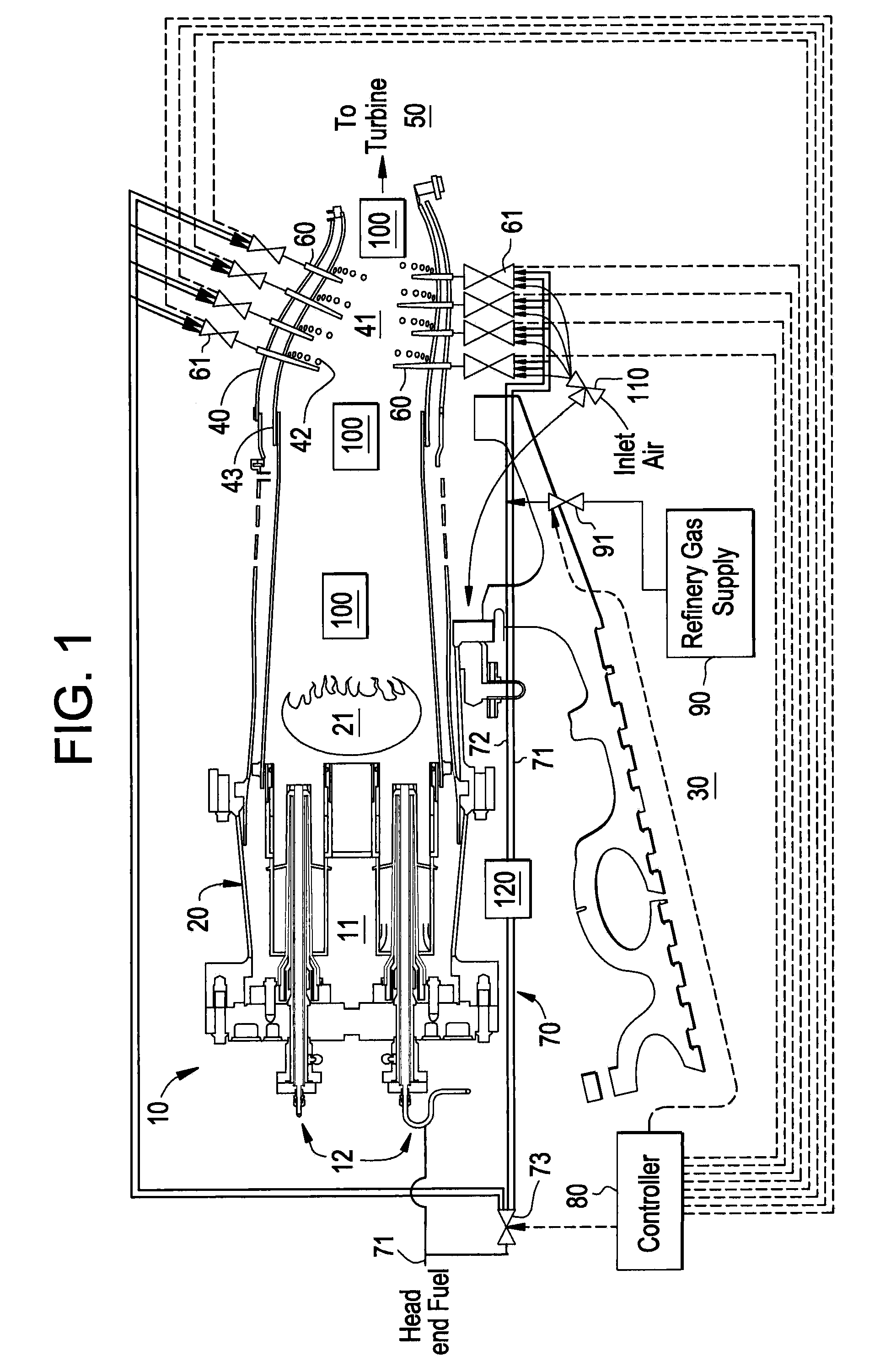

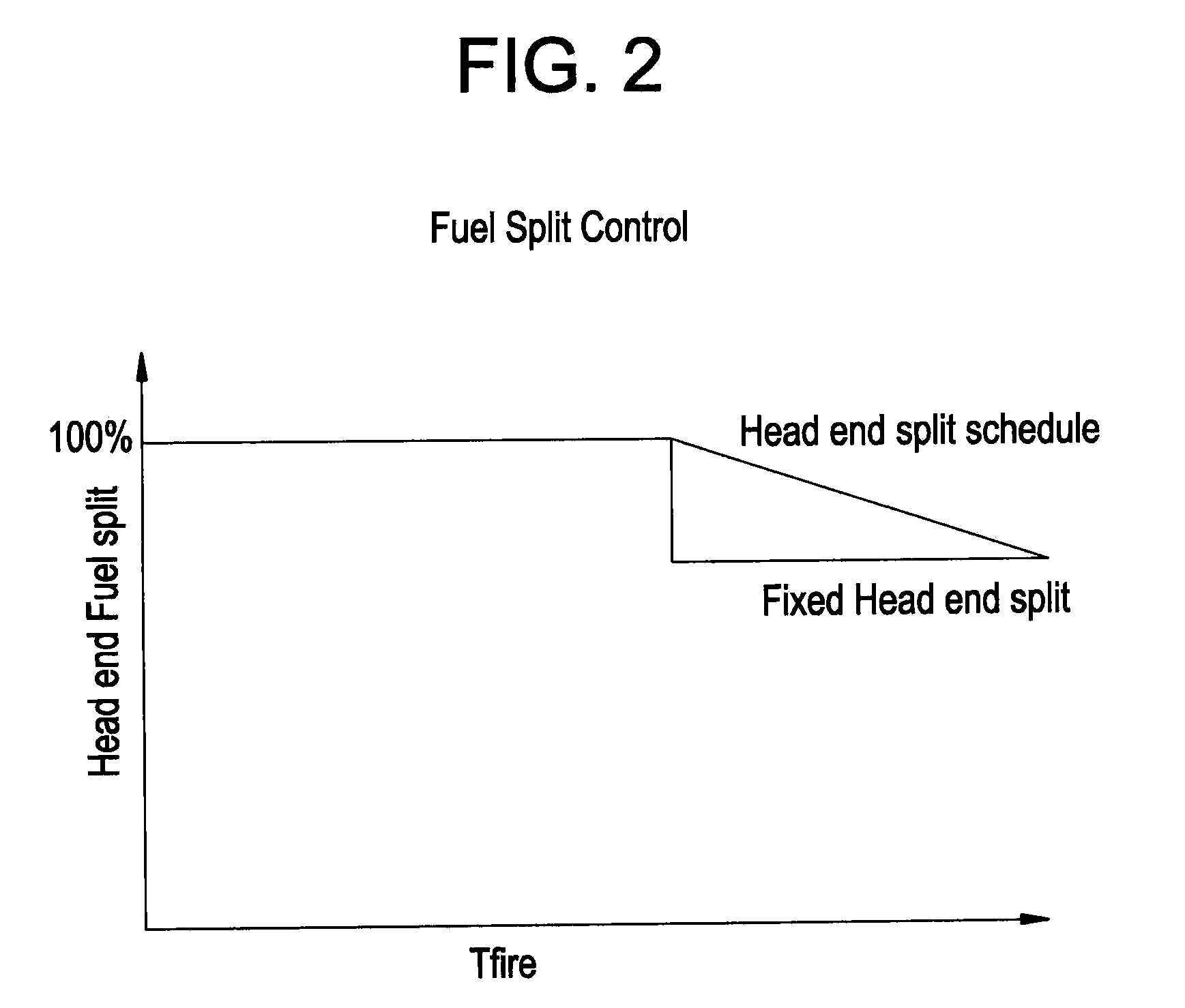

Gas turbines in mechanical drive applications and operating methods

A drive system for driving a load by a gas turbine. The gas turbine comprises a gas generator having a gas-generator rotor and comprising at least one gas-generator compressor and one high-pressure turbine driving the gas-generator compressor. The gas turbine further comprises a power turbine having a power-turbine rotor, which is torsionally independent of the gas-generator rotor. The load is connected to the power-turbine rotor. The system further comprises an electric motor / generator mechanically connected to the gas-generator rotor and electrically connected to an electric power grid. The electric motor / generator is adapted to function alternatively: as a generator for converting mechanical power from the gas turbine into electrical power; and as a motor for supplementing driving power to the load. A set of movable nozzle guide vanes is arranged at the inlet of the power turbine.

Owner:NUOVO PIGNONE SPA

Engine power extraction control system

ActiveUS7285871B2Increase propulsionEasy to operateReciprocating combination enginesTurbine/propulsion engine ignitionControl systemEngine power

An engine power extraction control system controls the main propulsion engines and the electrical machines that are coupled thereto to supply an appropriate amount of aircraft thrust and electrical energy to the aircraft. The engines and electrical machines are also controlled so that the propulsion thrust that is generated is split between the various turbines in the main propulsion engines to maintain an adequate surge margin and to minimize residual thrust generation.

Owner:HONEYWELL INT INC

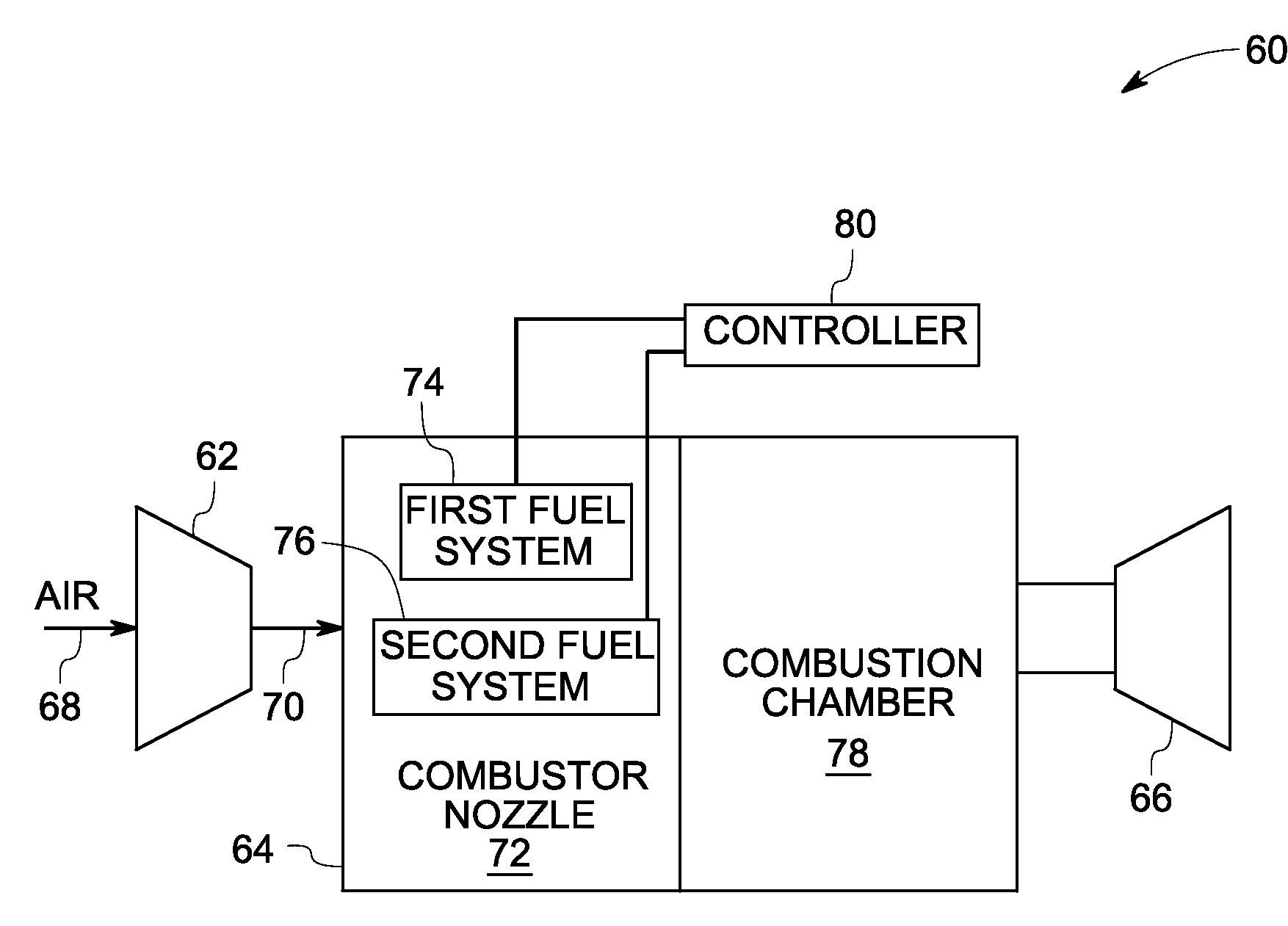

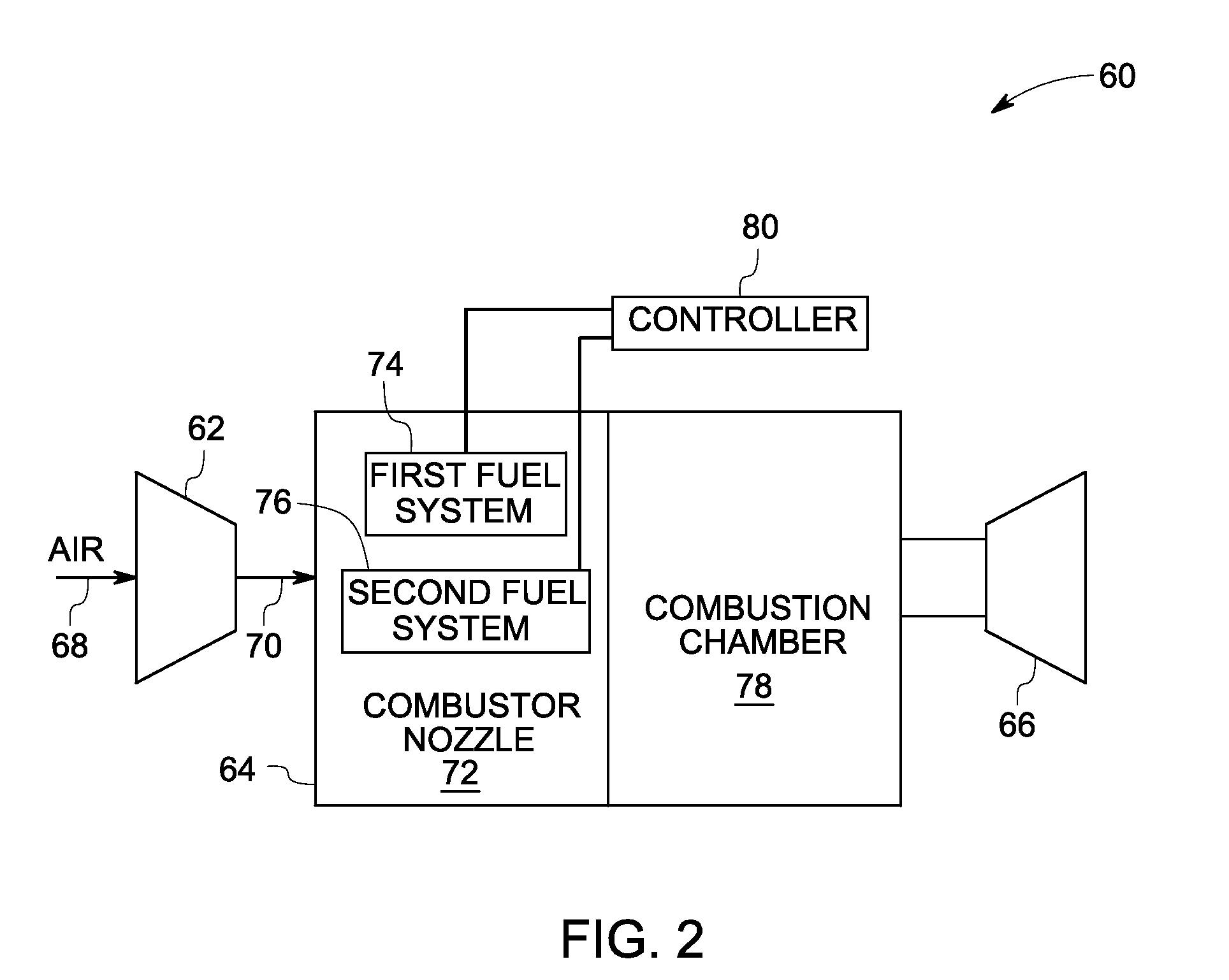

Combustor nozzle for a fuel-flexible combustion system

A combustor nozzle is provided. The combustor nozzle includes a first fuel system configured to introduce a syngas fuel into a combustion chamber to enable lean premixed combustion within the combustion chamber and a second fuel system configured to introduce the syngas fuel, or a hydrocarbon fuel, or diluents, or combinations thereof into the combustion chamber to enable diffusion combustion within the combustion chamber.

Owner:NUOVO PIGNONE TECH SRL

Turbine integrated bleed system and method for a gas turbine engine

InactiveUS20100107594A1Minimizing throttling inefficienciesEfficient extractionEfficient propulsion technologiesGas turbine plantsEngineeringBleed air

A bleed system for a gas turbine engine includes: (a) a bleed air turbine having a turbine inlet adapted to be coupled to a source of compressor bleed air at a first pressure; (b) a bleed air compressor mechanically coupled to the bleed air turbine, and having a compressor inlet adapted to be coupled to a source of fan discharge air at a second pressure substantially lower than the first pressure; and (c) a mixing duct coupled to a turbine exit of the bleed air turbine and to a compressor exit of the bleed air compressor.

Owner:GENERAL ELECTRIC CO

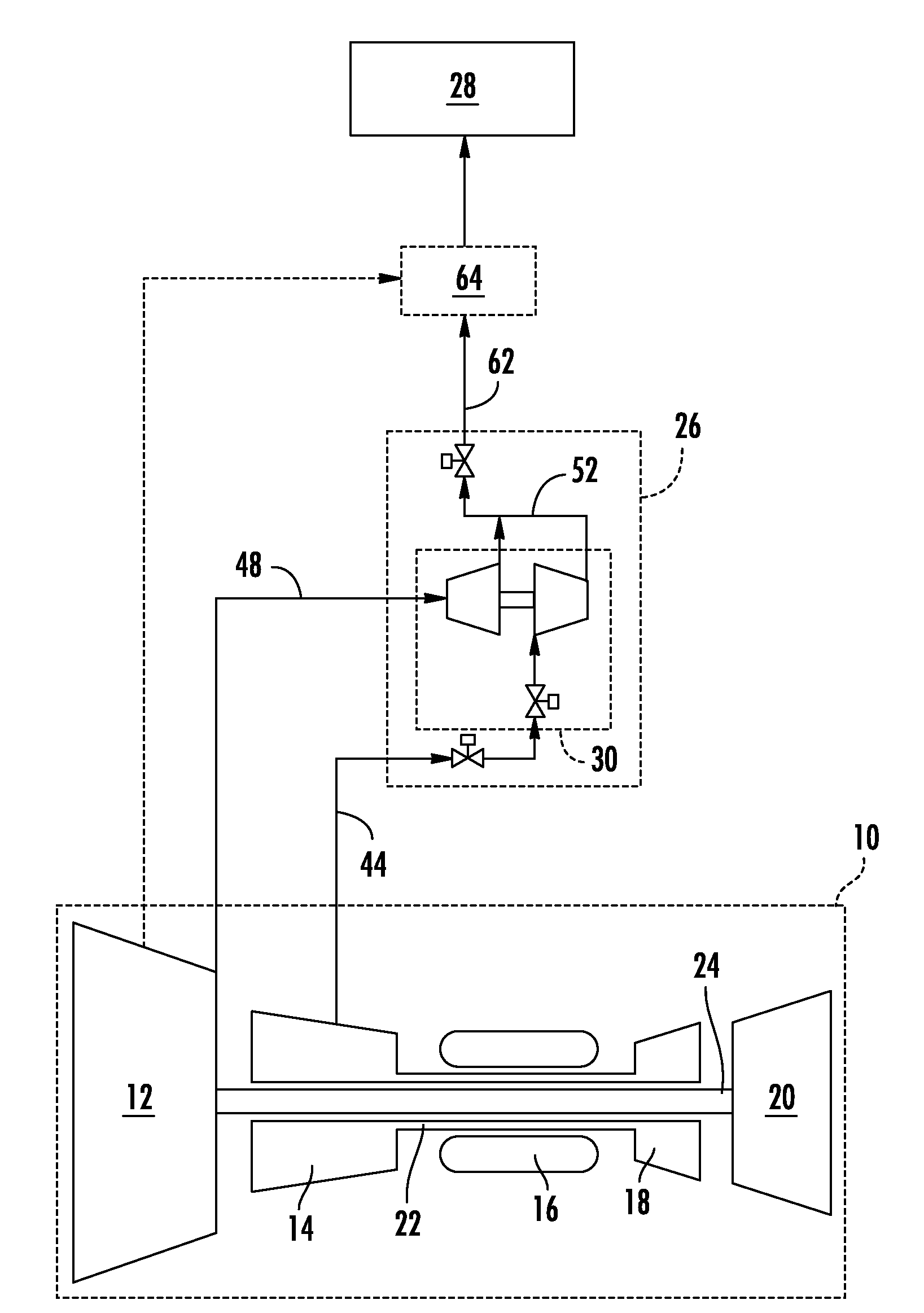

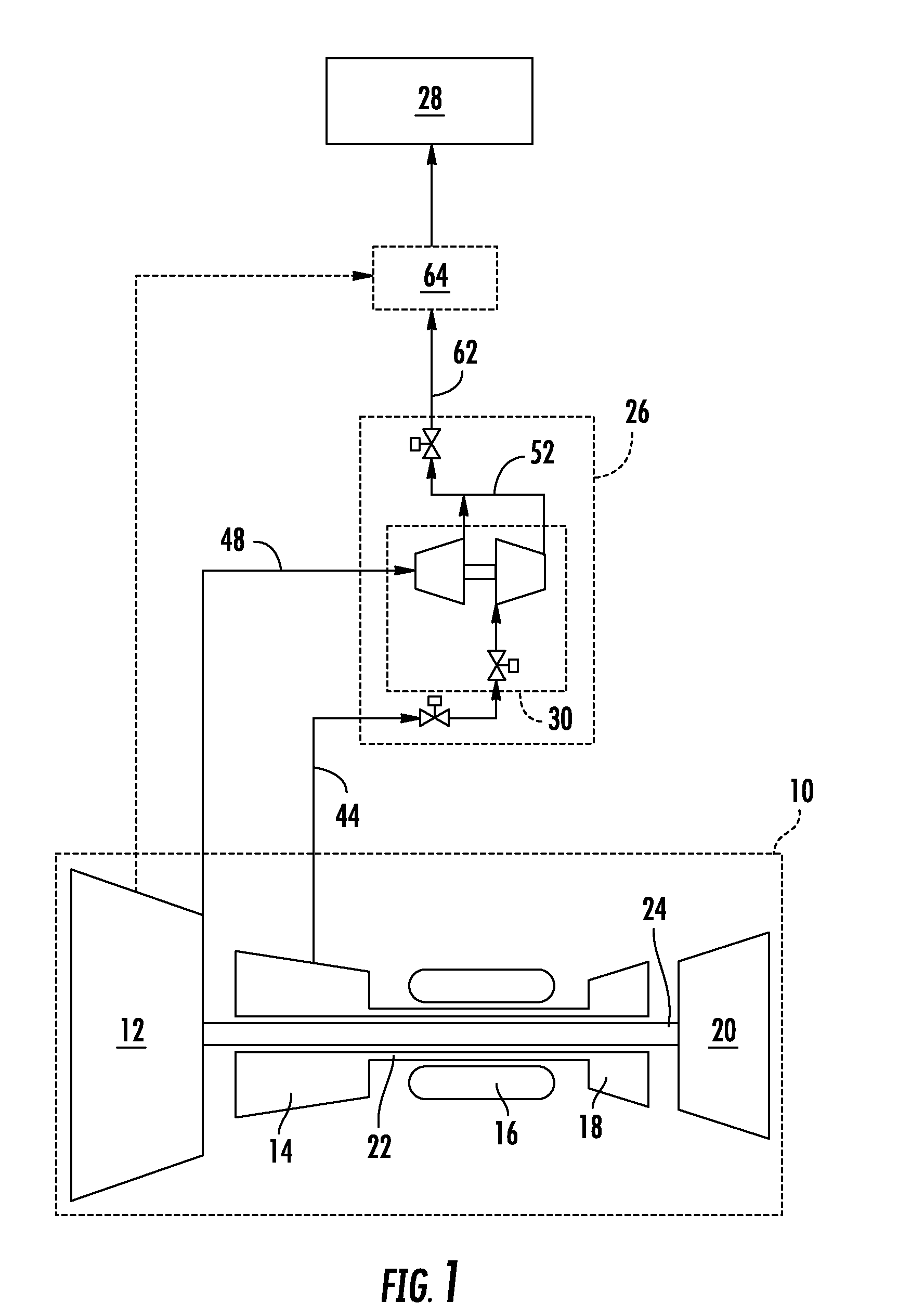

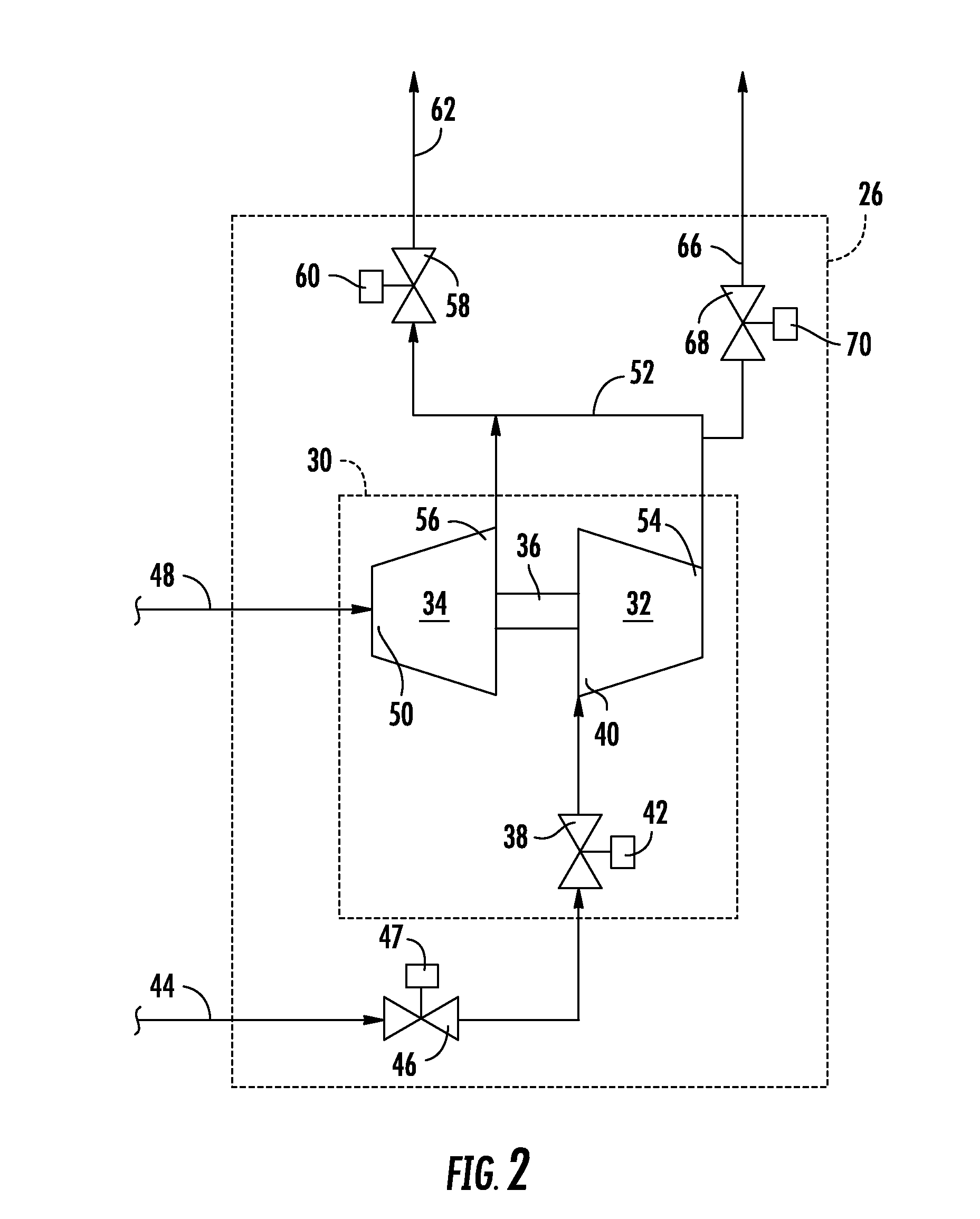

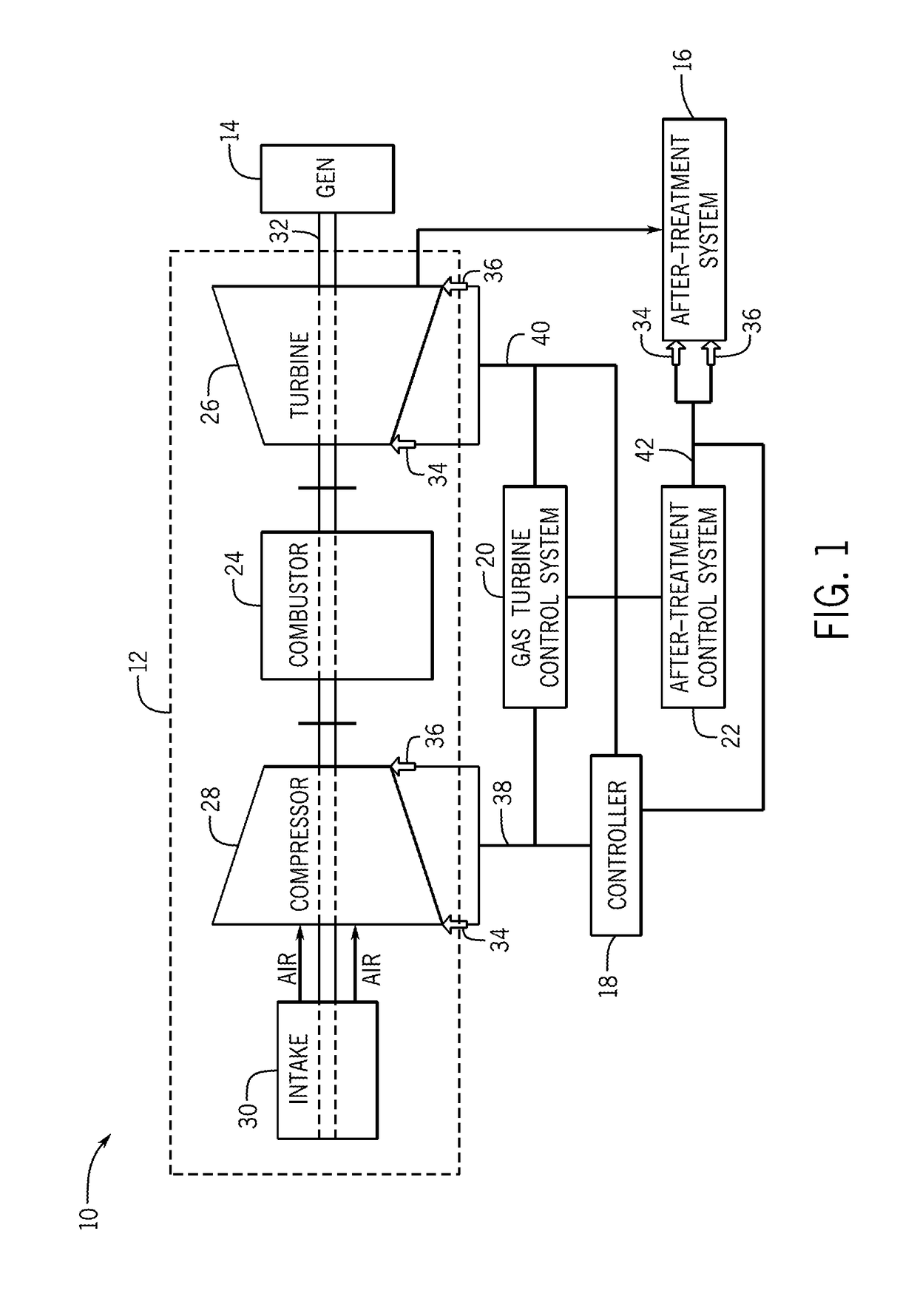

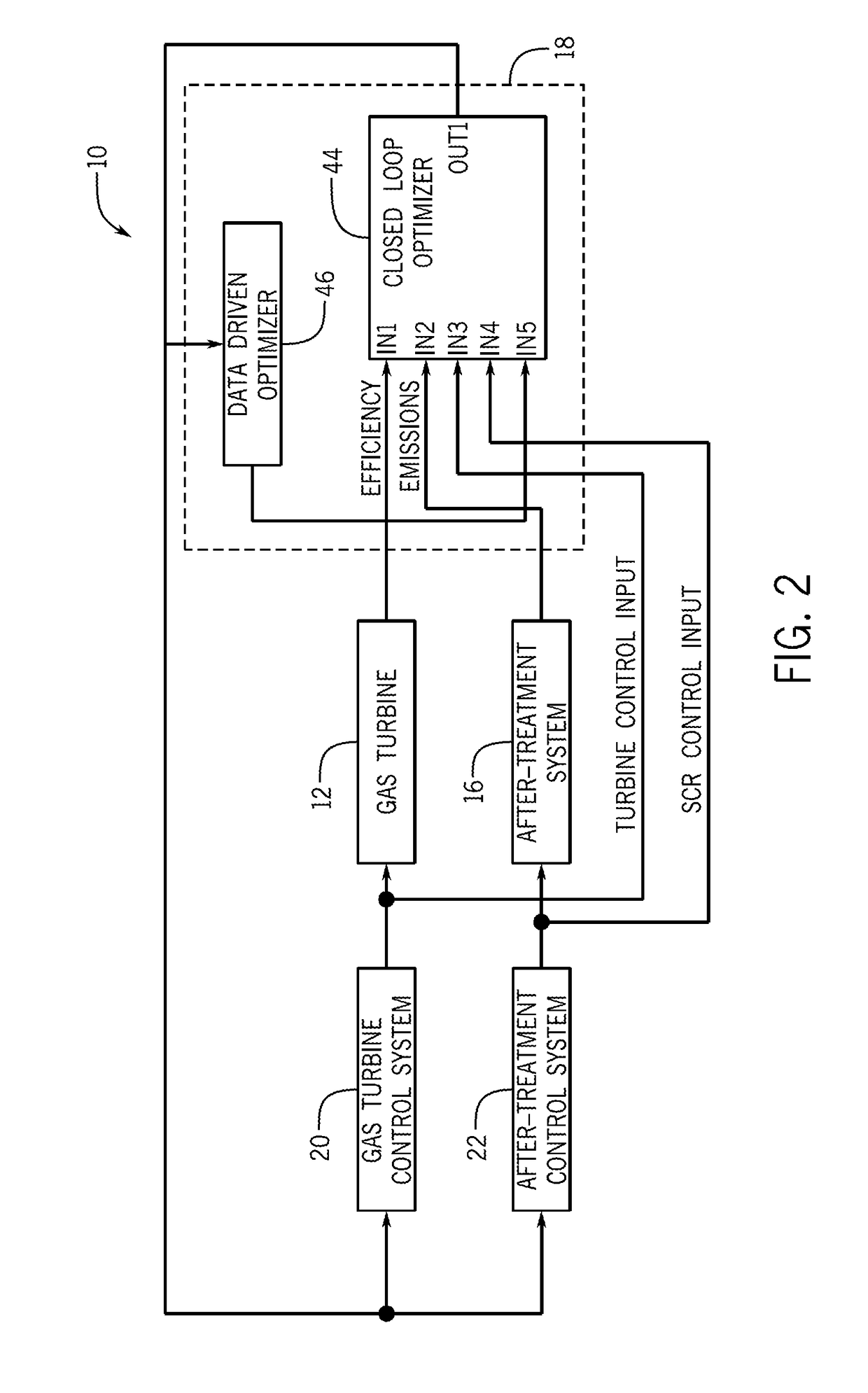

Enhanced performance of a gas turbine

ActiveUS20170175645A1Reduce outputMinimizes outputExhaust apparatusEngine fuctionsAfter treatmentOperational behavior

In one embodiment, a system may include a gas turbine system. the gas turbine system includes a gas turbine, an after-treatment system that may receive exhaust gases from the gas turbine system, and a controller that may receive inputs and model operational behavior of an industrial plant based on the inputs. The industrial plant may include the gas turbine and the after-treatment system. The controller may also determine one or more operational parameter setpoints for the industrial plant, select the one or more operational parameter setpoints that reduce an output of a cost function, and apply the one or more operational parameter setpoints to control the industrial plant.

Owner:GENERAL ELECTRIC CO

Gas turbine engine control using acoustic pyrometry

A method and apparatus for operating a gas turbine engine including determining a temperature of a working gas at a predetermined axial location within the engine. Acoustic signals are transmitted from a plurality of acoustic transmitters and are received at a plurality of acoustic receivers. Each acoustic signal defines a distinct line-of-sound path from one of the acoustic transmitters to an acoustic receiver corresponding to the line-of-sound path. A time-of-flight is determined for each of the signals traveling along the line-of-sound paths, and the time-of-flight for each of the signals is processed to determine a temperature in a region of the predetermined axial location.

Owner:SIEMENS ENERGY INC

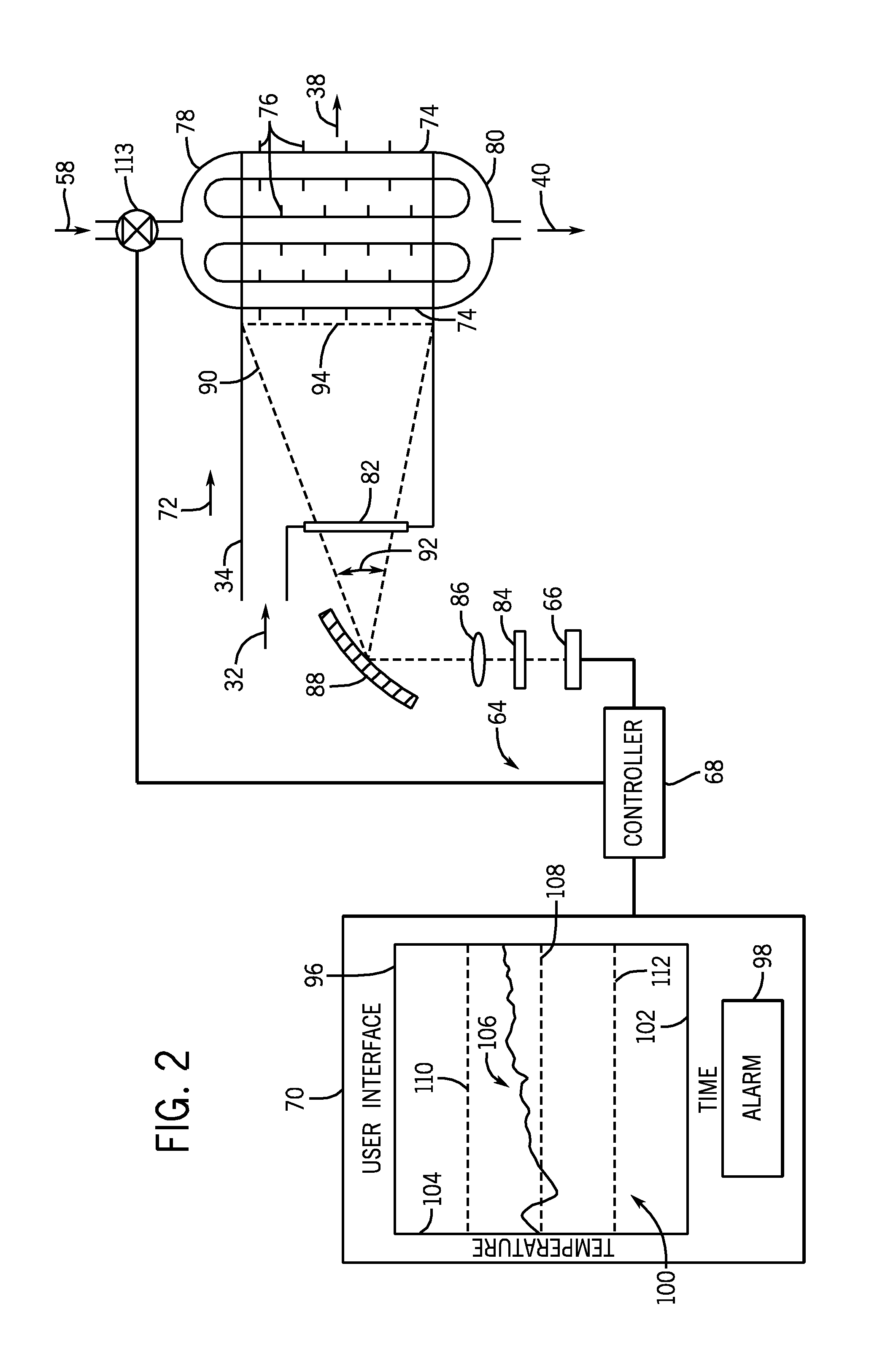

Thermal control system for fault detection and mitigation within a power generation system

InactiveUS20120031581A1Air-treating devicesSensing radiation from gases/flamesRadiation sensorThermal control system

A system includes a radiation sensor configured to direct a field of view toward at least one conduit along a fluid flow path into a heat exchanger. The radiation sensor is configured to output a signal indicative of a temperature of the at least one conduit. The system also includes a controller communicatively coupled to the radiation sensor. The controller is configured to determine the temperature based on the signal, to compare the temperature to a threshold range, and to adjust a fluid flow through the fluid flow path or the at least one conduit if the temperature deviates from the threshold range.

Owner:GENERAL ELECTRIC CO

Late lean injection with adjustable air splits

ActiveUS20100174466A1Raise the ratioAnalogue computers for vehiclesContinuous combustion chamberCombustorControl system

A gas turbine engine is provided and includes a combustor having a first interior in which a first fuel is combustible, a turbine into which products of at least the combustion of the first fuel are receivable, a transition zone, including a second interior in which a second fuel and the products of the combustion of the first fuel are combustible, a plurality of fuel injectors which are configured to supply the second fuel to the second interior in any one of a single axial stage, multiple axial stages, a single axial circumferential stage and multiple axial circumferential stages, a compressor, by which air is supplied to the first and second interiors for the combustion therein, and a control system configured to control relative amounts of the air to the first and second interiors and relative amounts of the first and second fuels supplied to the first and second interiors.

Owner:GENERAL ELECTRIC CO

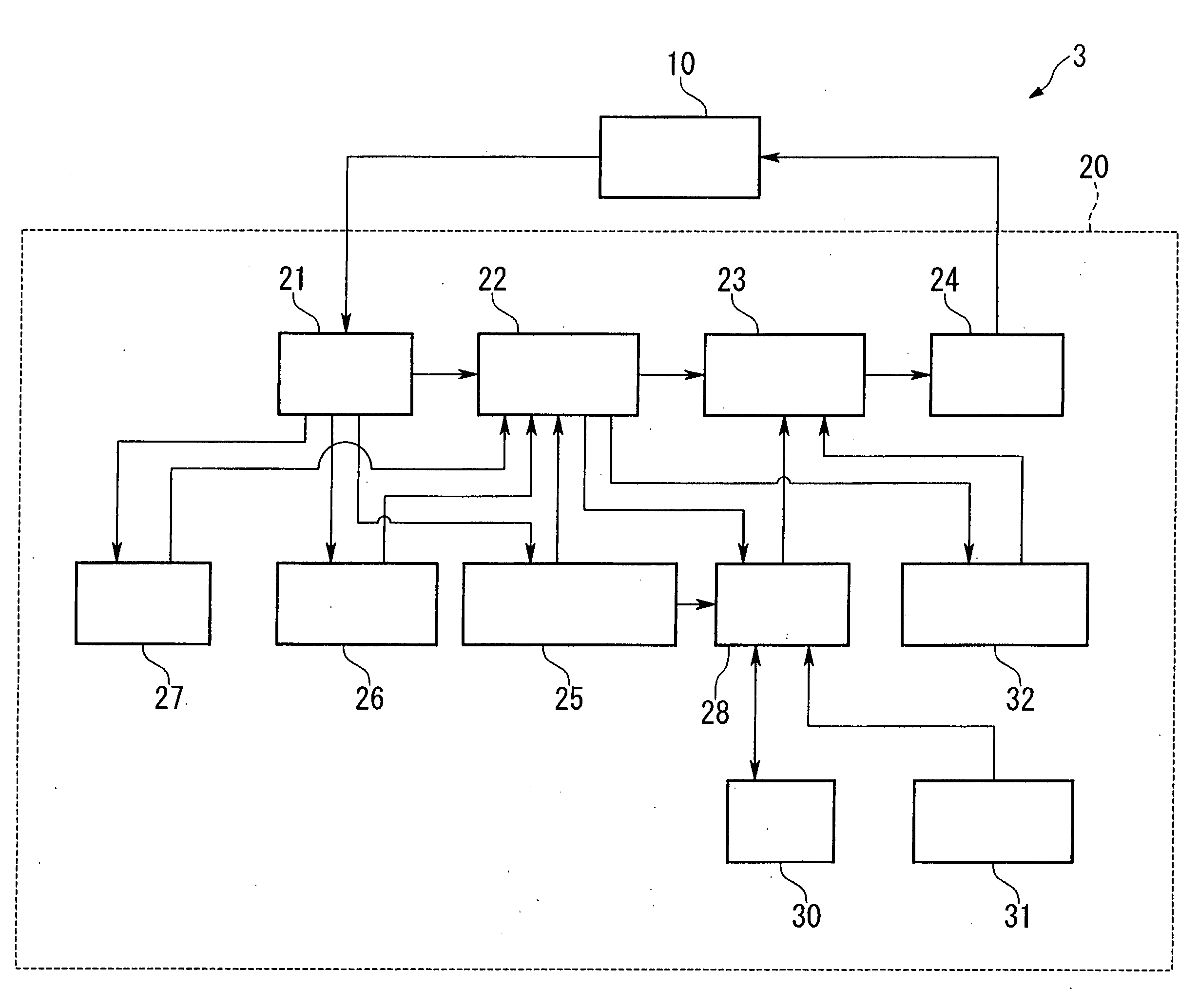

Gas turbine control apparatus, gas turbine system and gas turbine control method

ActiveUS20050107942A1Suppress fluctuationsImprove the state of combustionAnalogue computers for vehiclesDigital data processing detailsCombustionCountermeasure

A gas turbine control apparatus, etc. are provided by which combustion fluctuation, even if arising in plural frequency bands, can be effectively suppressed. If the combustion fluctuation arises in plural frequency bands, corresponding to a predetermined priority order, adjustment is done so that the combustion fluctuation of the frequency band of a high priority order is suppressed. If the gas turbine state changes after the adjustment, this is reflected on a data base 30. If no sufficient data is stored yet in the data base 30 for any the reason, such as immediately after installation of the gas turbine, correction is made using data of countermeasures based on data of another same type gas turbine contained in a basic data base 31 and data of countermeasures based on experiences of skilled adjusting operators contained in a knowledge data base 32. Also, in a stabilized operation, operation condition may be varied so that an optimal operation condition is automatically searched.

Owner:MITSUBISHI POWER LTD

Method and apparatus for optimizing the operation of a turbine system under flexible loads

ActiveUS20130125557A1Expand the adjustment rangeImprove efficiencyContinuous combustion chamberEngine fuctionsCombustorStream flow

A gas turbine system includes a compressor protection subsystem; a hibernation mode subsystem; and a control subsystem that controls the compressor subsystem and the hibernation subsystem. At partial loads on the turbine system, the compressor protection subsystem maintains an air flow through a compressor at an airflow coefficient for the partial load above a minimum flow rate coefficient where aeromechanical stresses occur in the compressor. The air fuel ratio in a combustor is maintained where exhaust gas emission components from the turbine are maintained below a predetermined component emission level while operating at partial loads.

Owner:GENERAL ELECTRIC CO

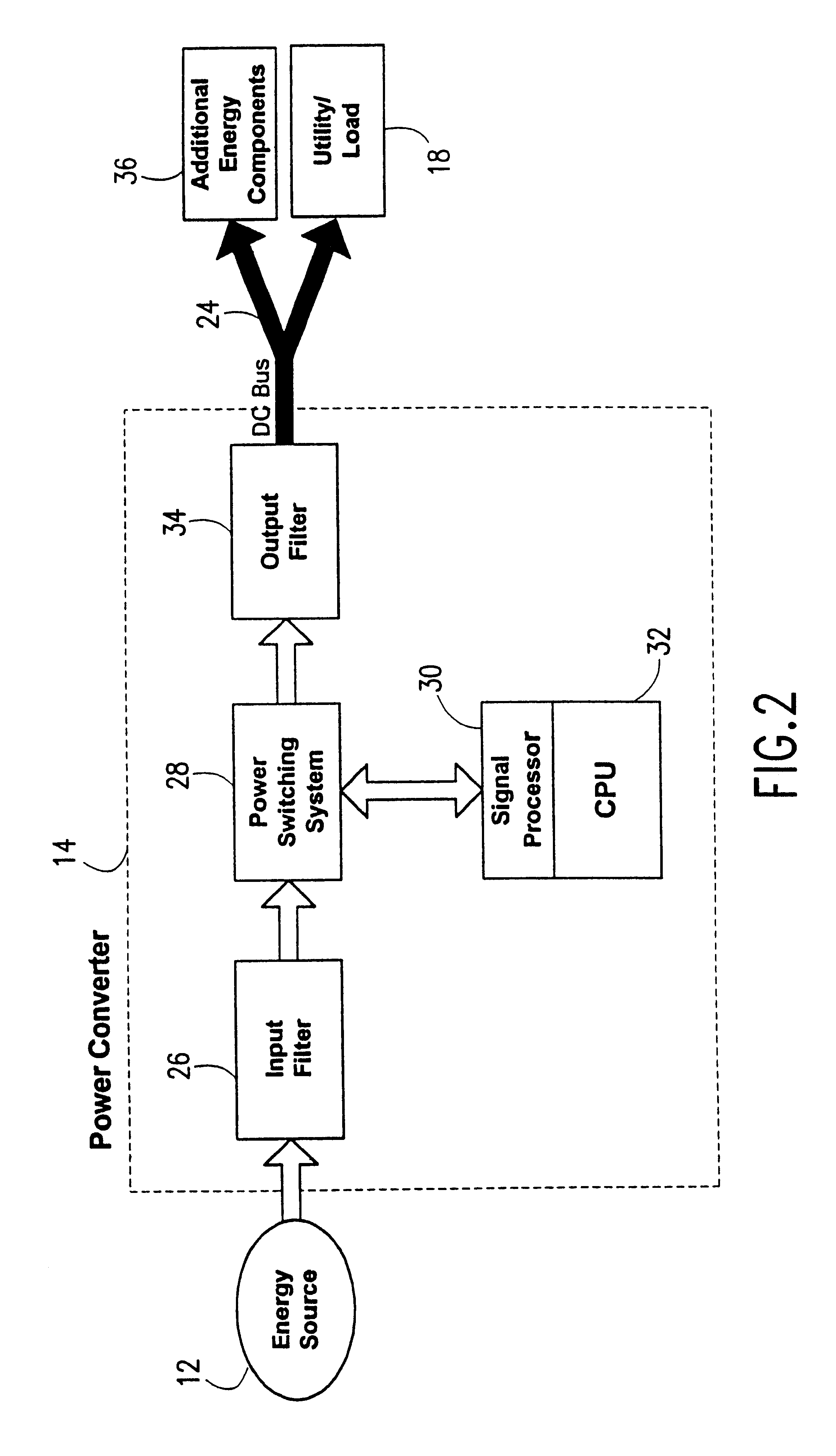

Method and system for control of turbogenerator power and temperature

InactiveUS6870279B2Maximize efficiencyIncrease speedAnalogue computers for vehiclesLoad balancing in dc networkPower controllerTurbine

A power controller controls the turbine of a turbine powered generating system regardless of the load on said system to maximize the efficiency of the turbine and maintains the turbine at a substantially constant temperature during a system load change by using an energy storage device to provide power to the load while the turbine is changing speed to meet the new load demand.

Owner:CAPSTONE TURBINE

Power plant and control method

Ambient air is compressed into a compressed ambient gas flow with a main air compressor. The compressed ambient gas flow having a compressed ambient gas flow rate is delivered to a turbine combustor and mixed with a fuel stream having a fuel stream flow rate and a portion of a recirculated low oxygen content gas flow to form a combustible mixture. The combustible mixture is burned and forms the recirculated low oxygen content gas flow that drives a turbine. A portion of the recirculated low oxygen content gas flow is recirculated from the turbine to the turbine compressor using a recirculation loop. The compressed ambient gas flow rate and the fuel stream flow rate are adjusted to achieve substantially stoichiometric combustion. An excess portion, if any, of the compressed ambient gas flow is vented. A portion of the recirculated low oxygen content gas flow is extracted using an extraction conduit.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com