Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

374 results about "Tripping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tripping pipe (or "Making a round trip" or simply "Making a trip") is the physical act of pulling the drill string out of the wellbore and then running it back in. This is done by physically breaking out or disconnecting (when pulling out of the hole) every other 2 or 3 joints of drill pipe at a time (called a stand) and racking them vertically in the derrick. When feasible the driller will start each successive trip on a different "break" so that after several trips fresh pipe dope will have been applied (when running back in the hole) to every segment of the drill string.

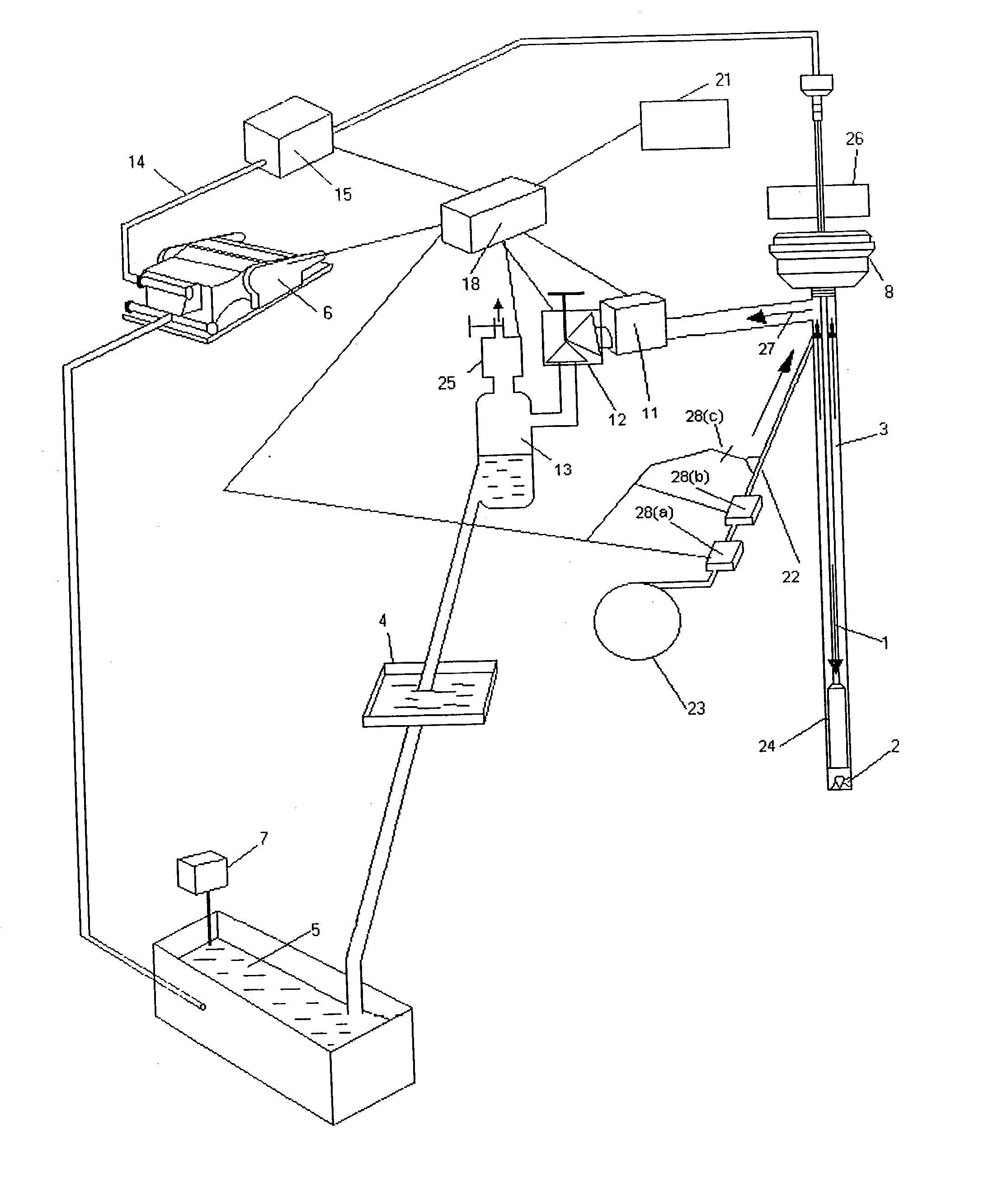

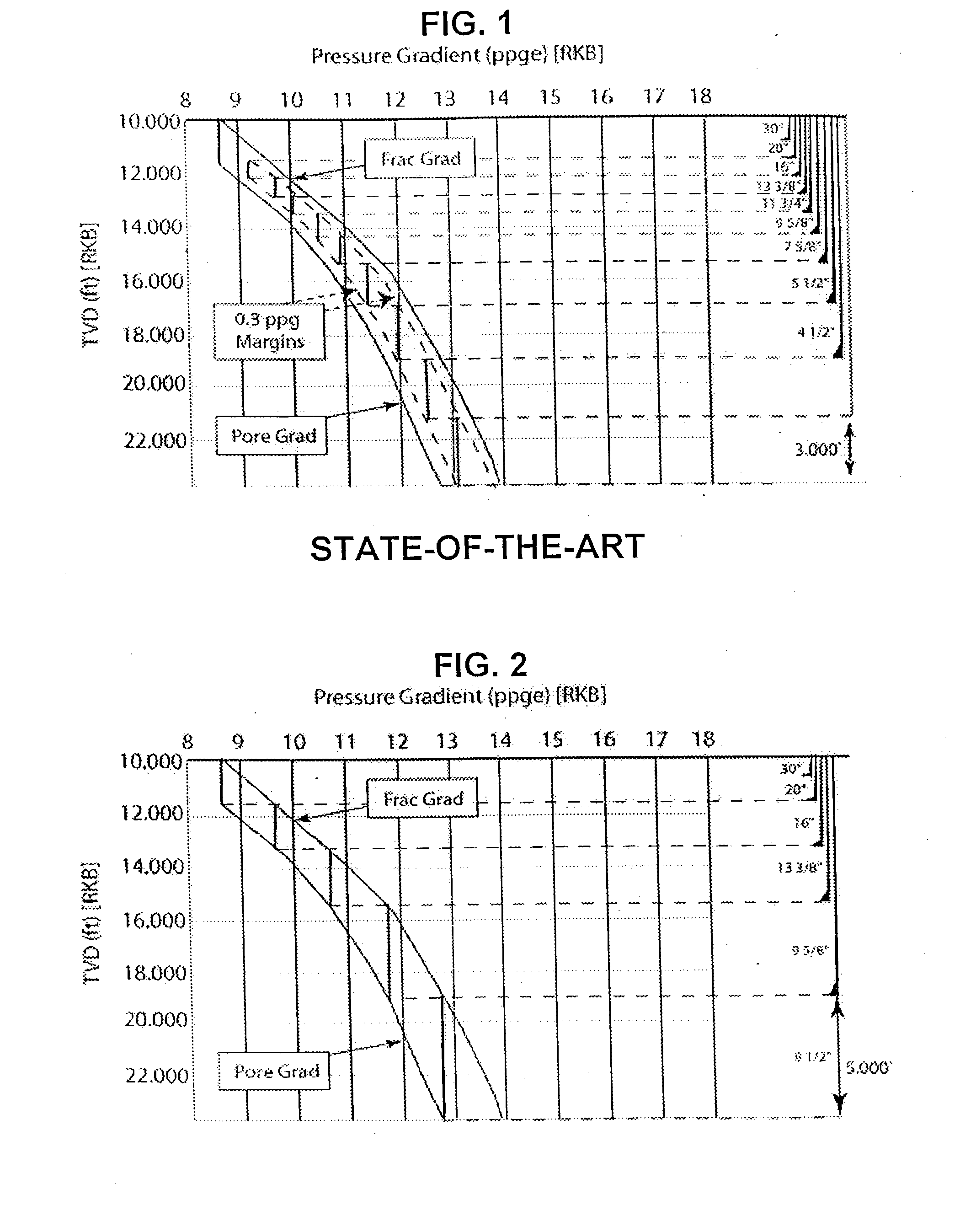

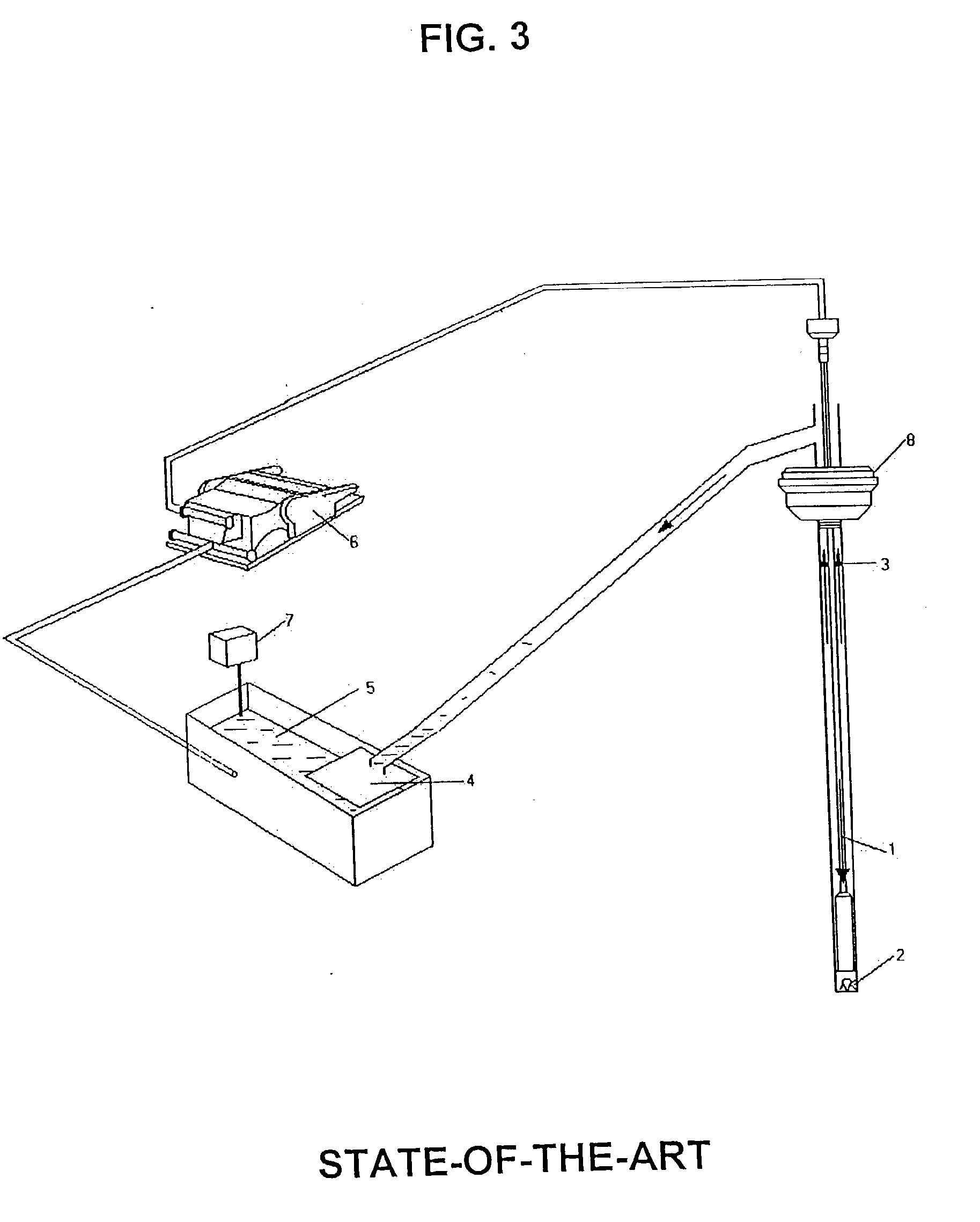

Drilling system and method

InactiveUS20030079912A1Accurate calculationImprove securityConstructionsFlushingWell drillingEngineering

A closed-loop circulating system for drilling wells has control of the flow rates in and out of the wellbore. Kicks and fluid losses are quickly controlled by adjusting the backpressure. Kick tolerance and tripping margins are eliminated by real-time determination of pore and fracture pressure. The system can incorporate a rotating BOP and can be used with underbalanced drilling.

Owner:SECURE DRILLING INT

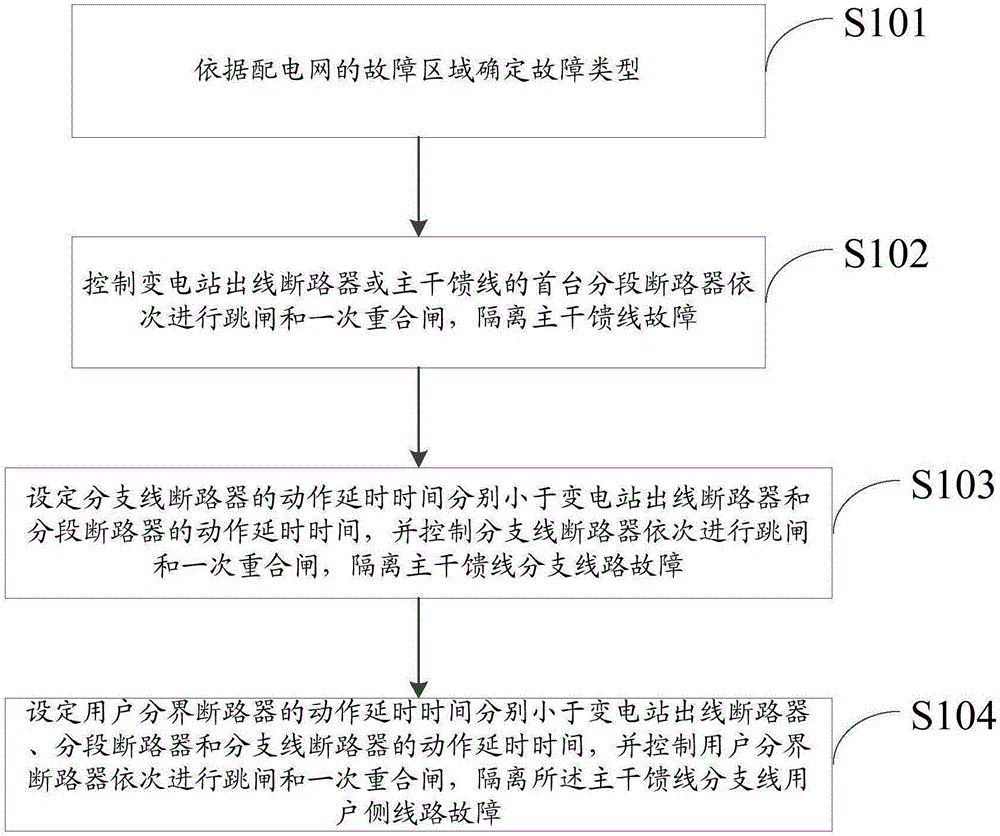

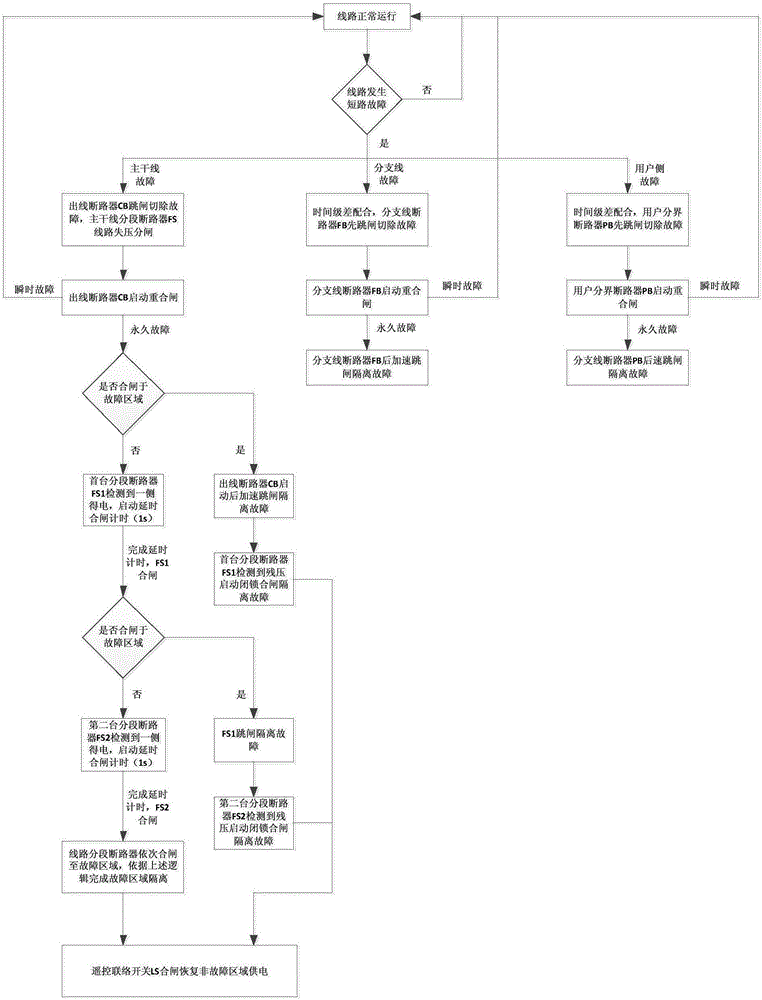

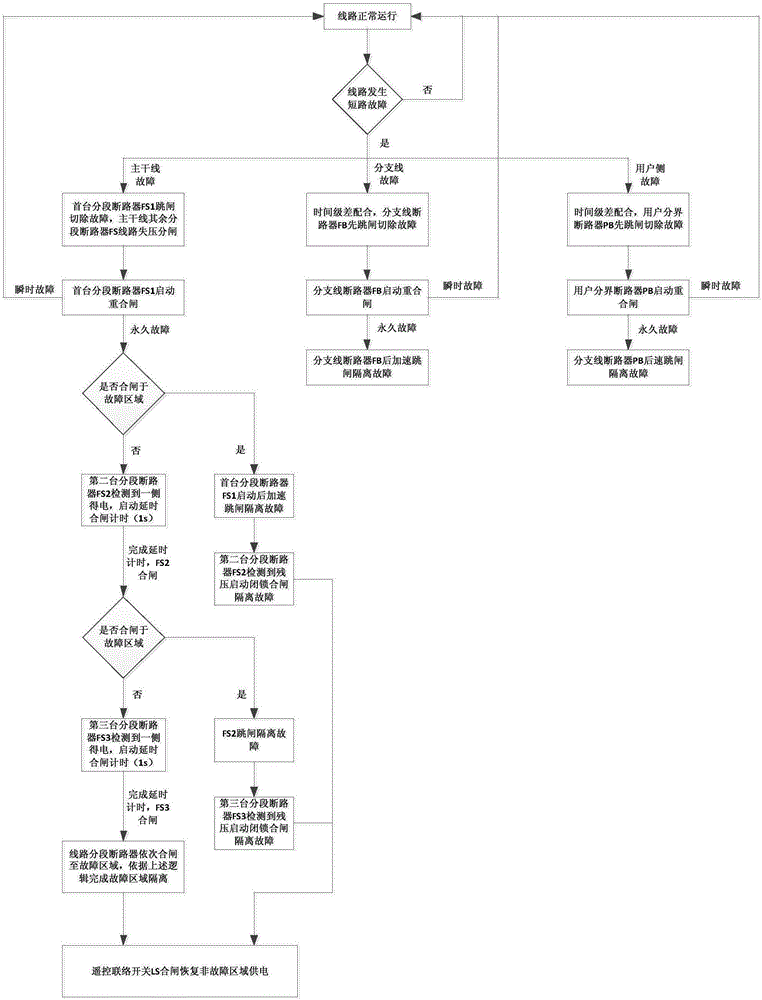

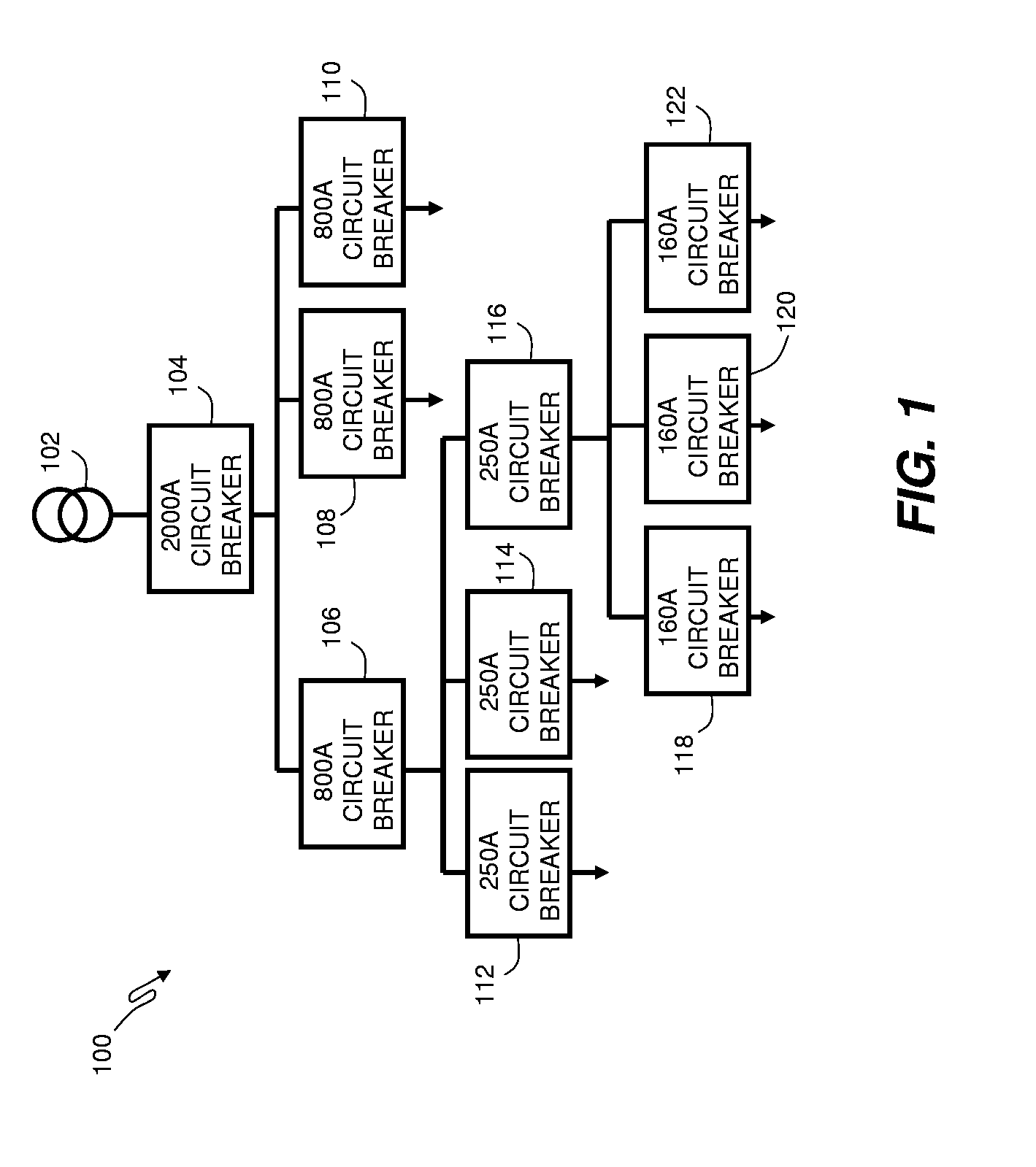

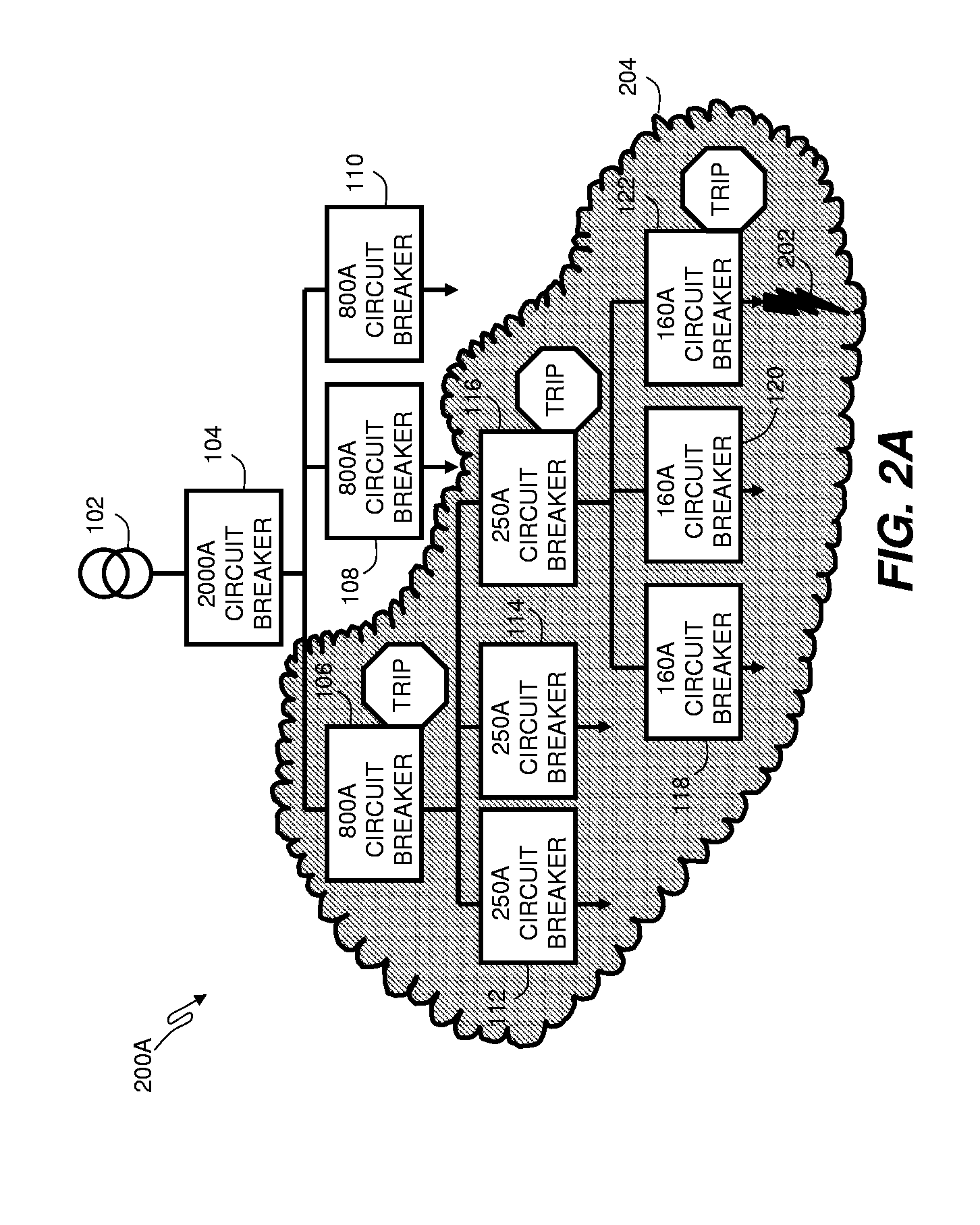

On-site coinciding type fault isolation method and system

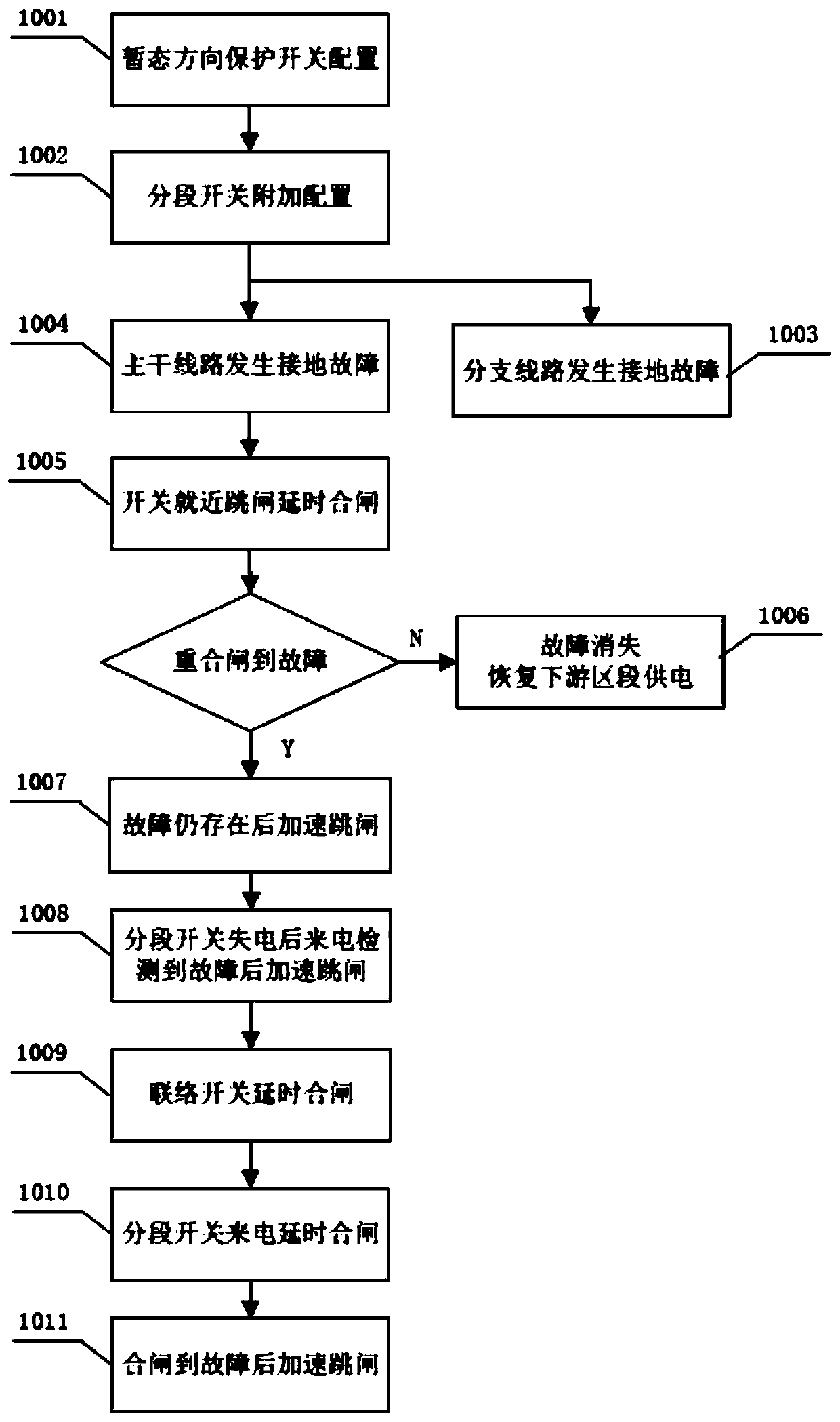

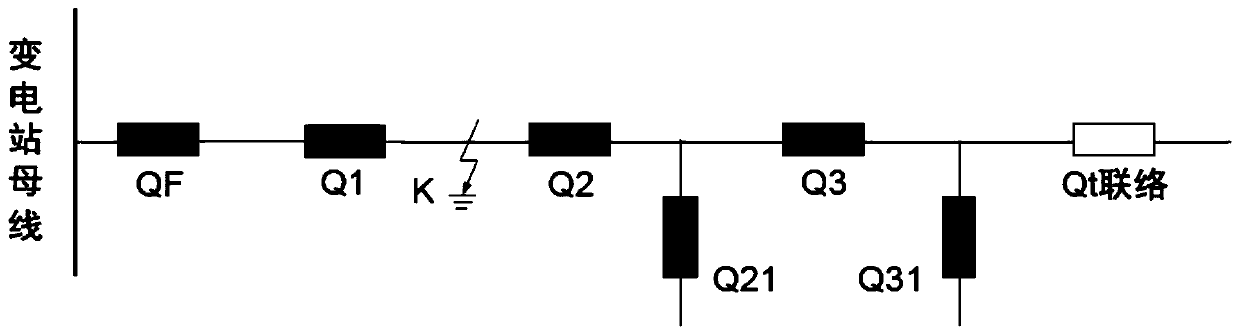

ActiveCN106786425AReduce the number of tripsReduce power restoration timeEmergency protective arrangements for automatic disconnectionDividing circuitsTransformer

The invention provides an on-site coinciding type fault isolation method and system. The method comprises the steps of controlling a transformer substation outgoing breaker or a first section breaker of a main feeder for sequentially forming tripping and single shot reclosing, and isolating a main feeder fault; setting the action delay time of a branch circuit breaker to be shorter than the action delay time of the transformer substation outgoing breaker and the section breaker, and controlling the branch circuit breaker to sequentially perform tripping and single shot reclosing to isolate a main feeder branch circuit fault; setting the action delay time of a user dividing circuit breaker to be shorter than the action delay time of the transformer substation outgoing breaker, the section breaker and the branch circuit breaker, and performing controlling. Compared with the prior art, the on-site coinciding type fault isolation method and system can reduce the tripping frequency of the transformer substation outgoing breaker and further shorten the fault isolation time and the power supply recovery time of a non-fault region.

Owner:CHINA ELECTRIC POWER RES INST +2

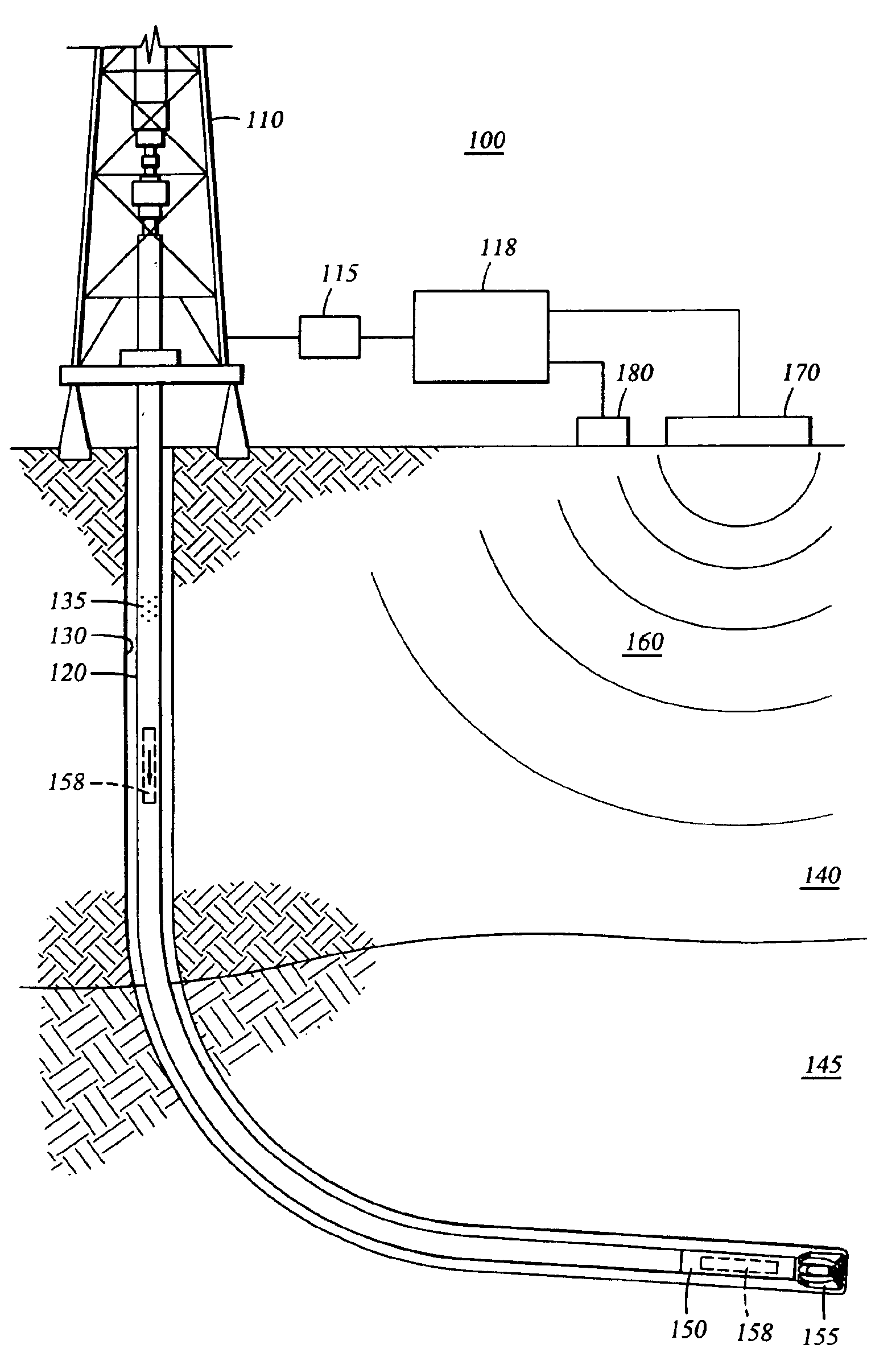

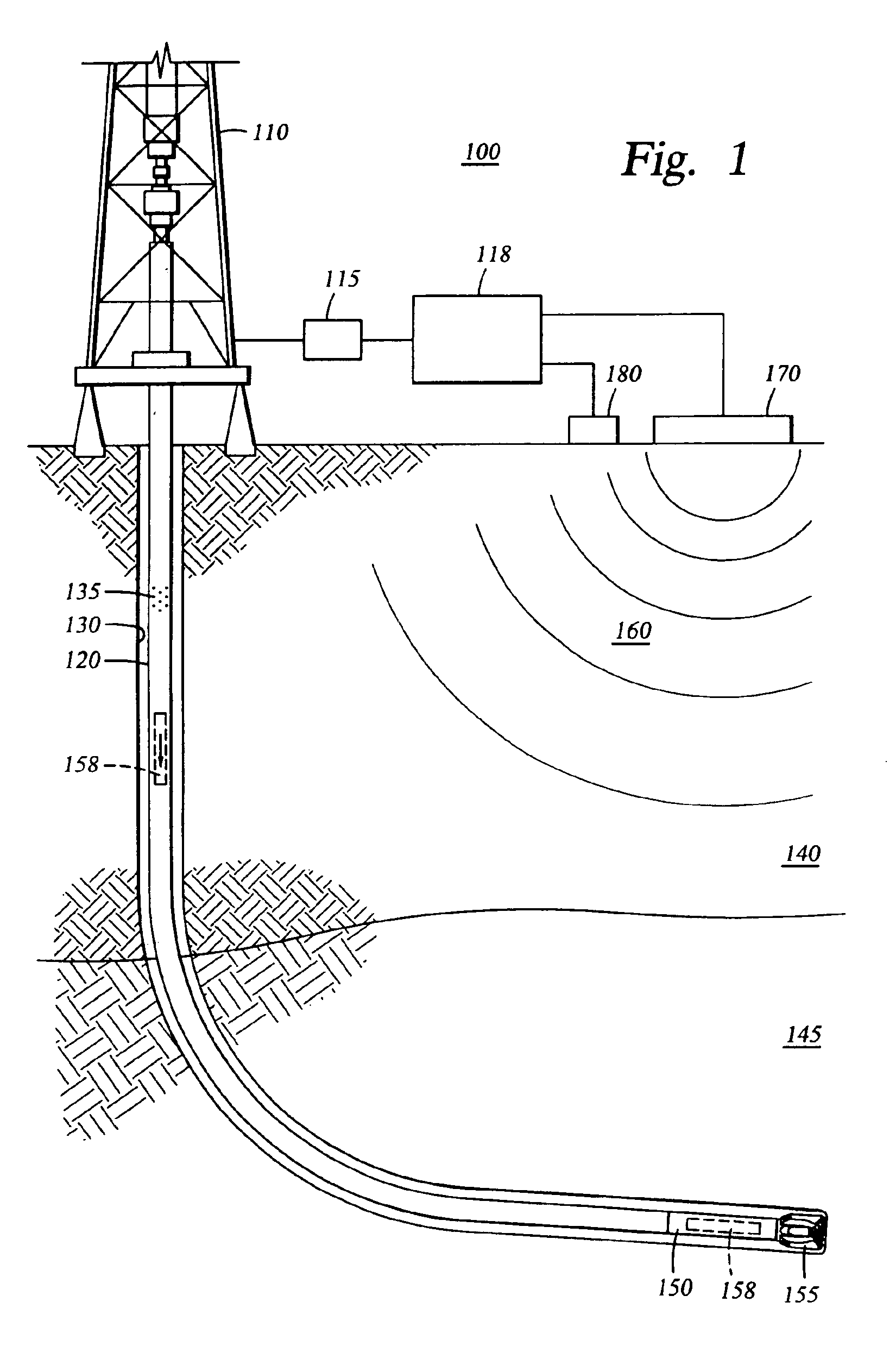

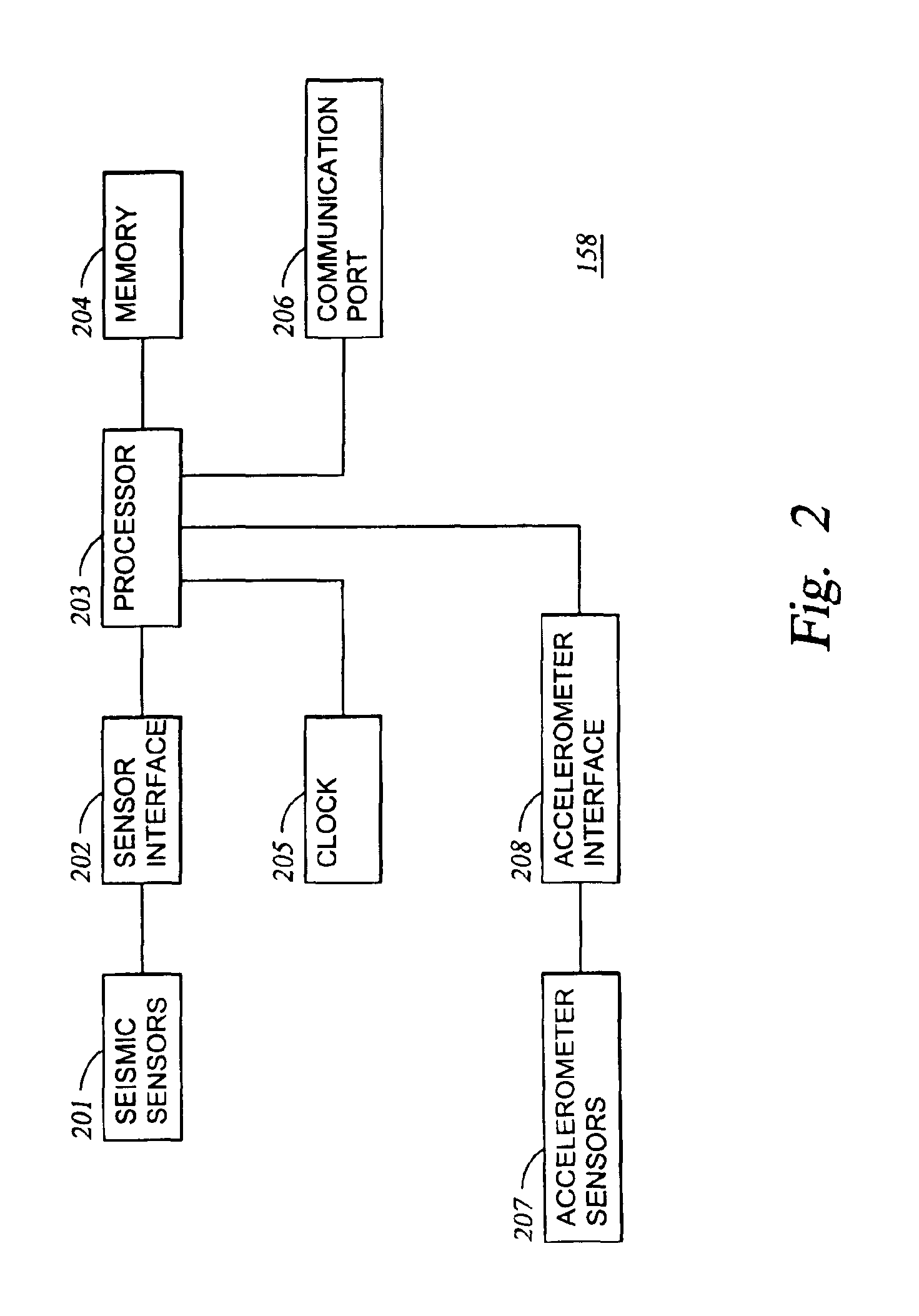

Methods for acquiring seismic data while tripping

Owner:BAKER HUGHES INC

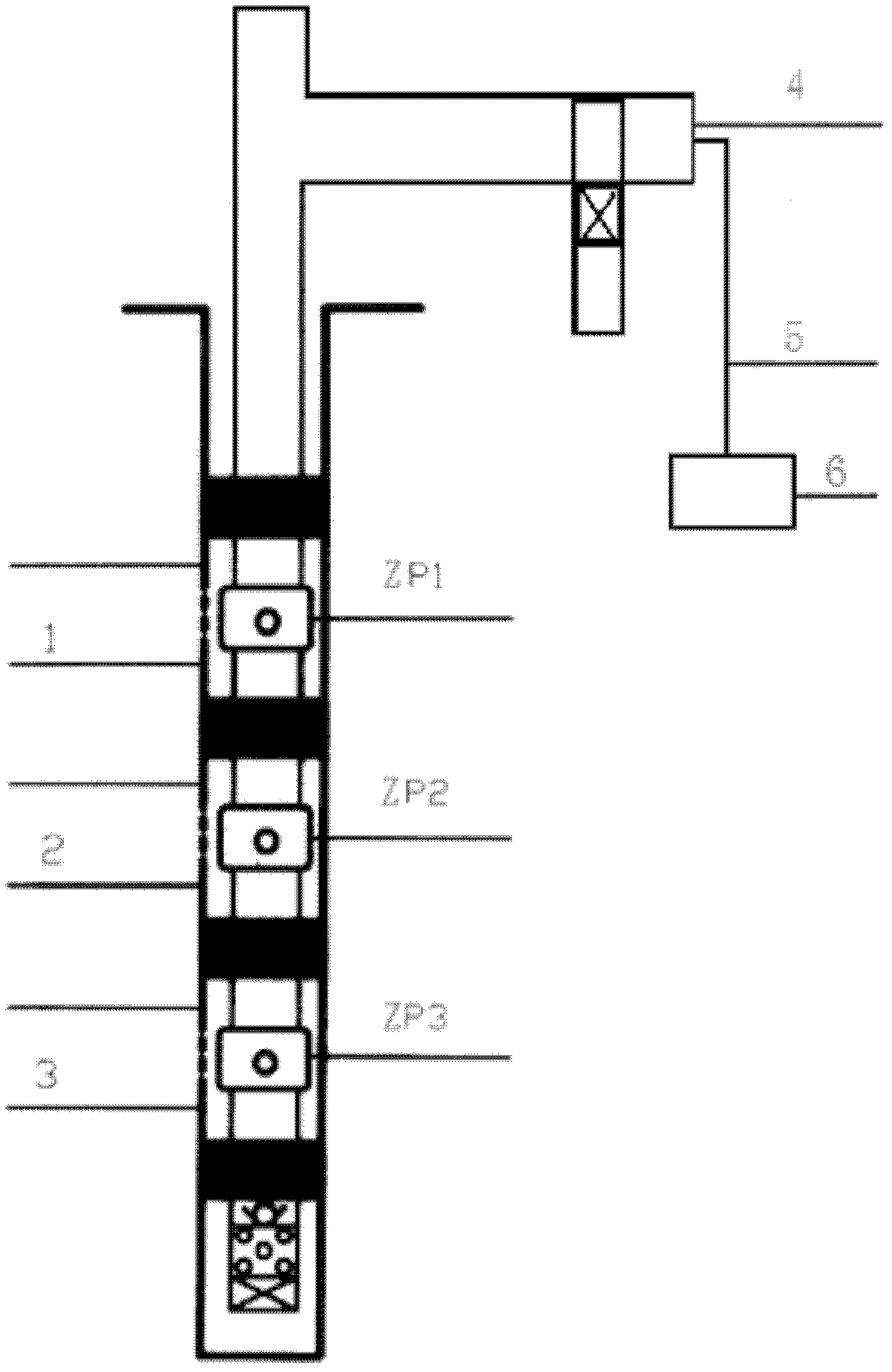

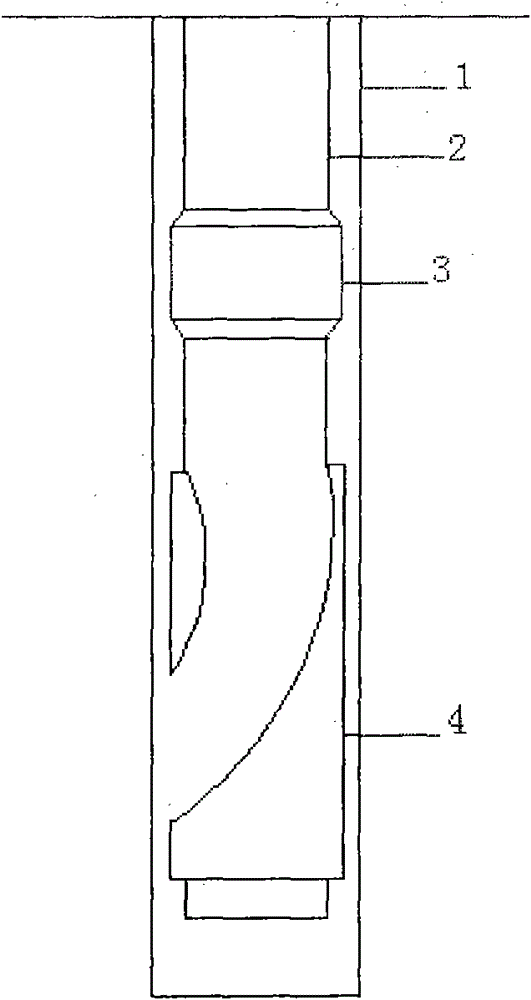

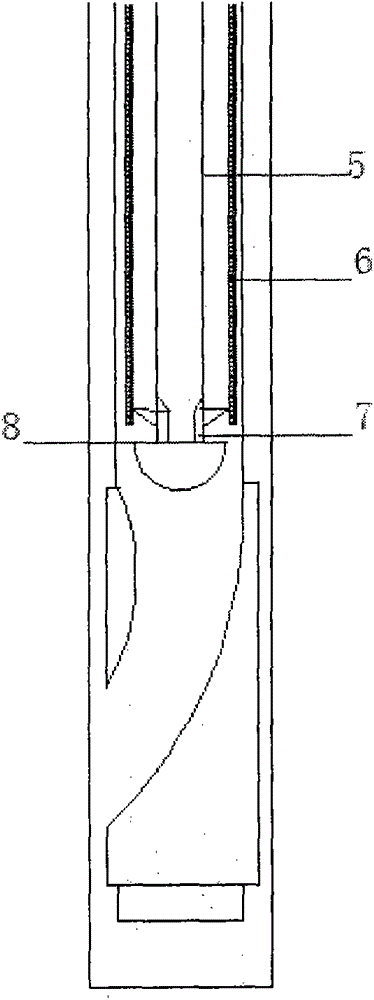

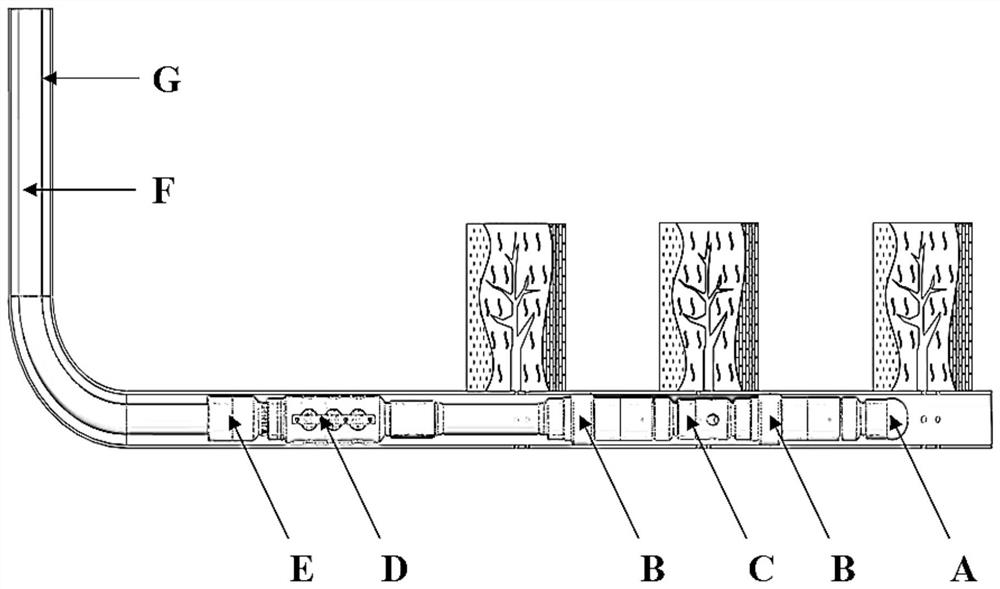

Method for achieving separated layer water distribution by pressure pulse

ActiveCN102839954ASave time and costSave construction costFluid removalDistribution methodHigh pressure water

The invention provides a method for achieving separated layer water distribution by pressure pulse, and belongs to the field of oil and gas. According to the invention, separated layer water distribution is achieved by a wellhead pressure pulse program-controlled generator and a separated layer water injection string which is equipped with an intelligent water distributor. Through the adoption of the method provided by the invention, a separated layer water distribution task can be wirelessly finished in a remotely controlled way without traditional tripping and blending, so that working time and construction cost are saved; and the method provided by the invention is an efficient and advanced separated layer water distribution method with high success rate. Meanwhile, as the wellhead pressure pulse program-controlled generator is used for generating negative pressure pulse, the method provided by the invention has the advantage that separated layer water distribution effects of three layers can be finished within half an hour without stopping a pump, being assisted by other construction operation equipment and using high pressure water as a pressure source; furthermore, the efficiency and the success rate in the prior art are further increased, and the construction cost in the prior art is further reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

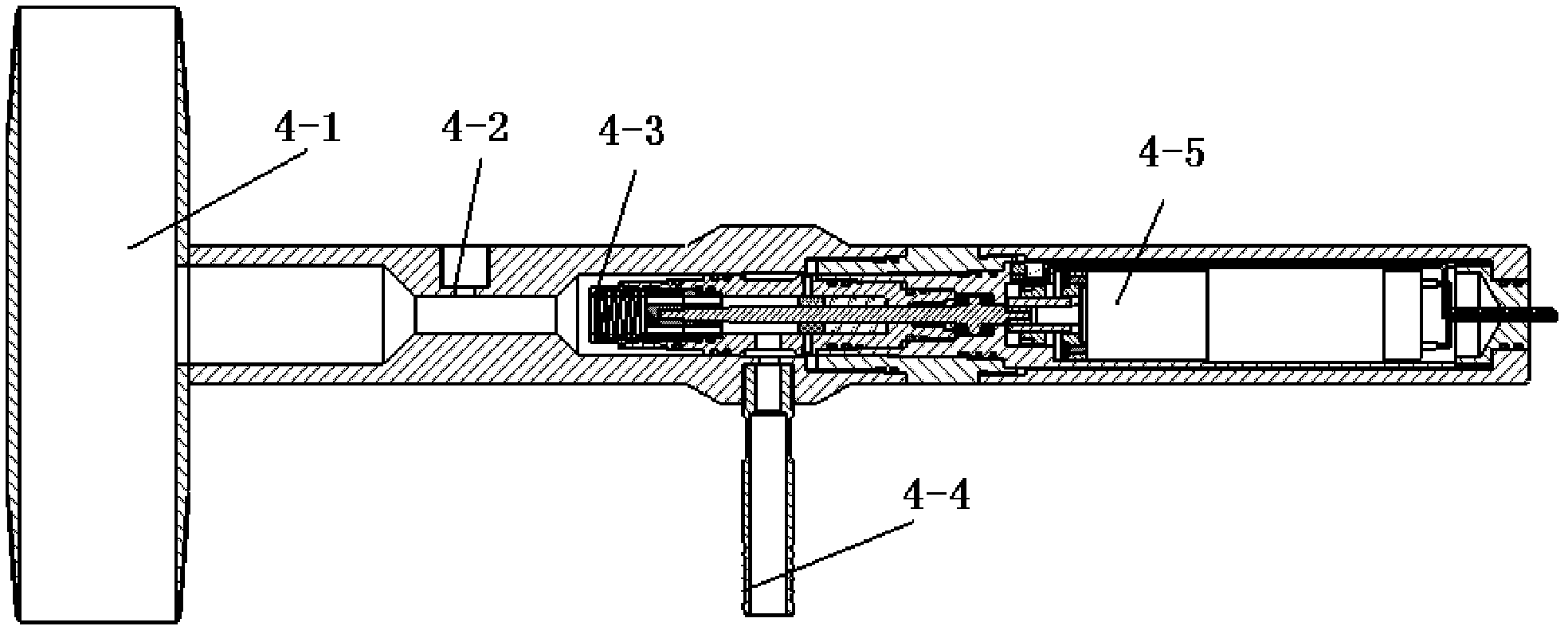

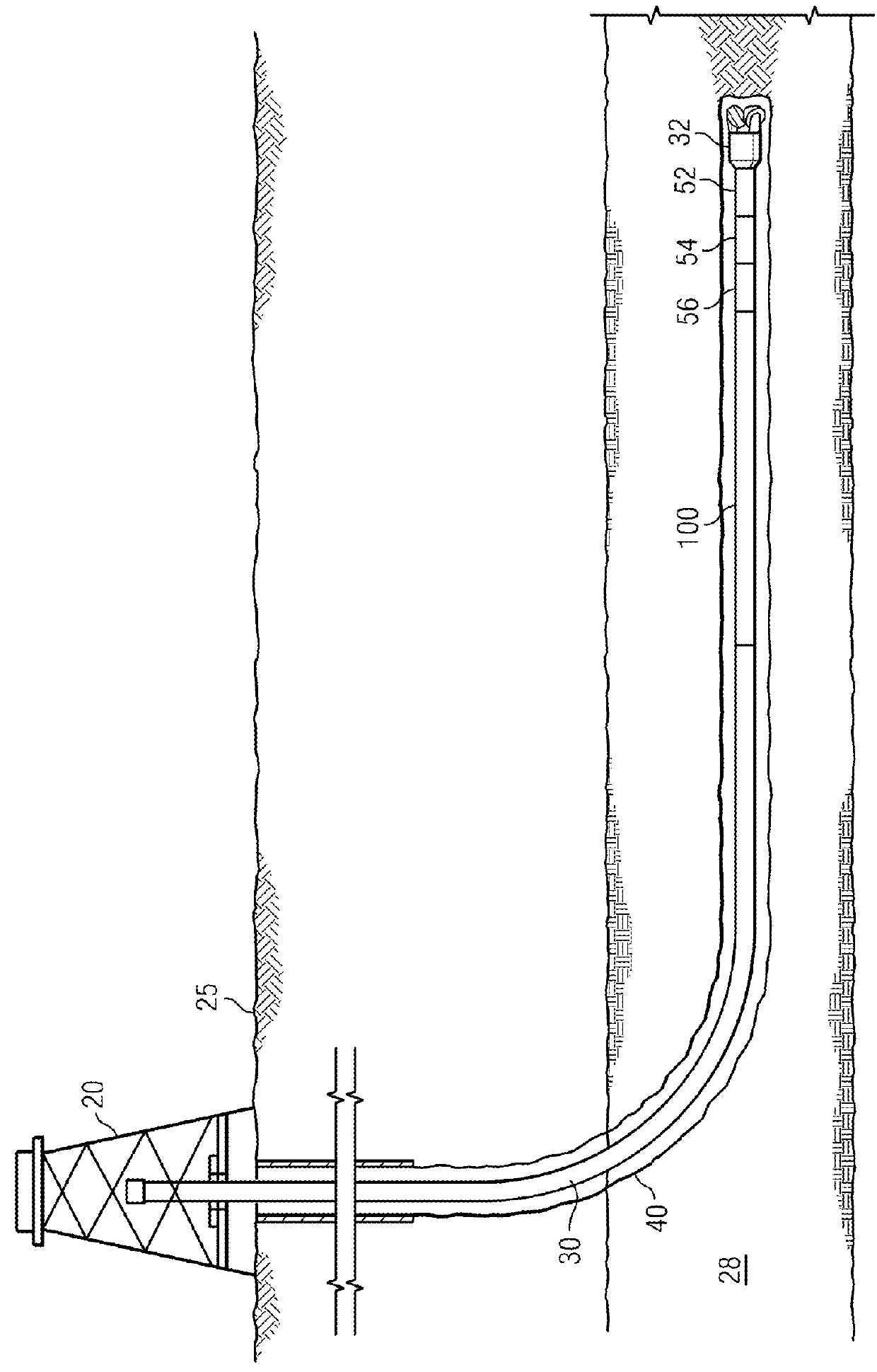

Hydraulic fracturing while drilling and/or tripping

InactiveUS20160053597A1Low costSignificant time savingSurveyDrilling rodsHydraulic fracturingGeophysics

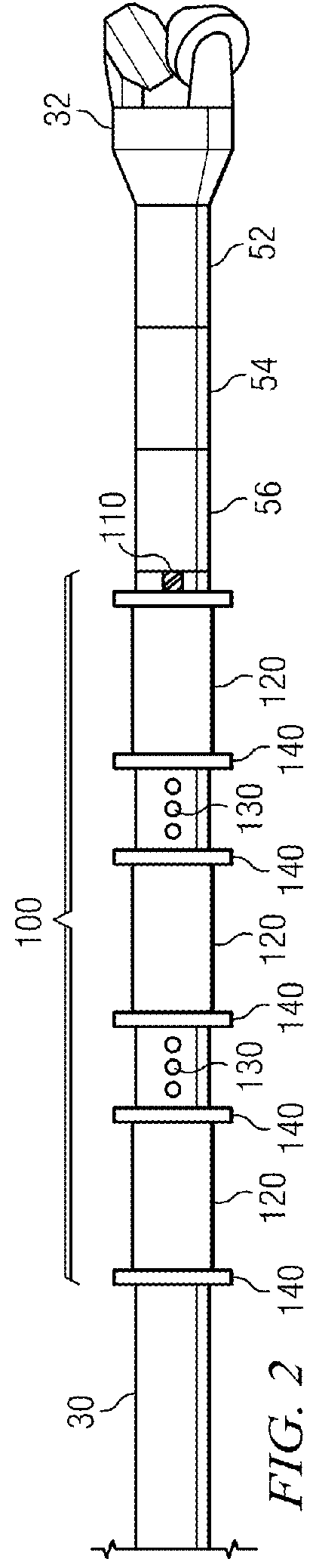

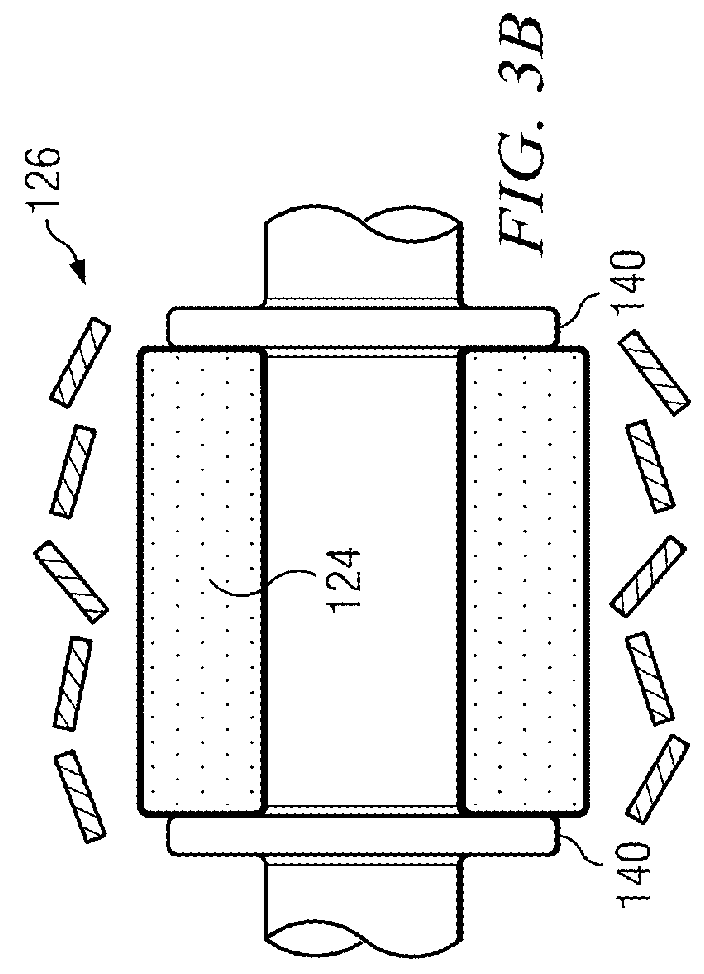

Methods and apparatuses for hydraulically fracturing a subterranean wellbore while drilling and / or tripping are disclosed. A method for hydraulically fracturing a subterranean formation may include rotating a drill string to drill the wellbore and hydraulically fracturing the subterranean formation at a plurality of axially spaced locations along the wellbore while tripping the drill string out of the wellbore. The drill string may include a hydraulic fracturing assembly. The hydraulic fracturing operation may include translating the drill string in an uphole direction so that a set of frac ports in the hydraulic fracturing assembly is adjacent a region of the formation selected for fracturing, expanding at least one pair of packers to seal an annular region of the wellbore exterior to the frac ports, and pumping fracturing fluid downhole through the frac ports to hydraulically fracture the subterranean formation.

Owner:SMITH INT INC

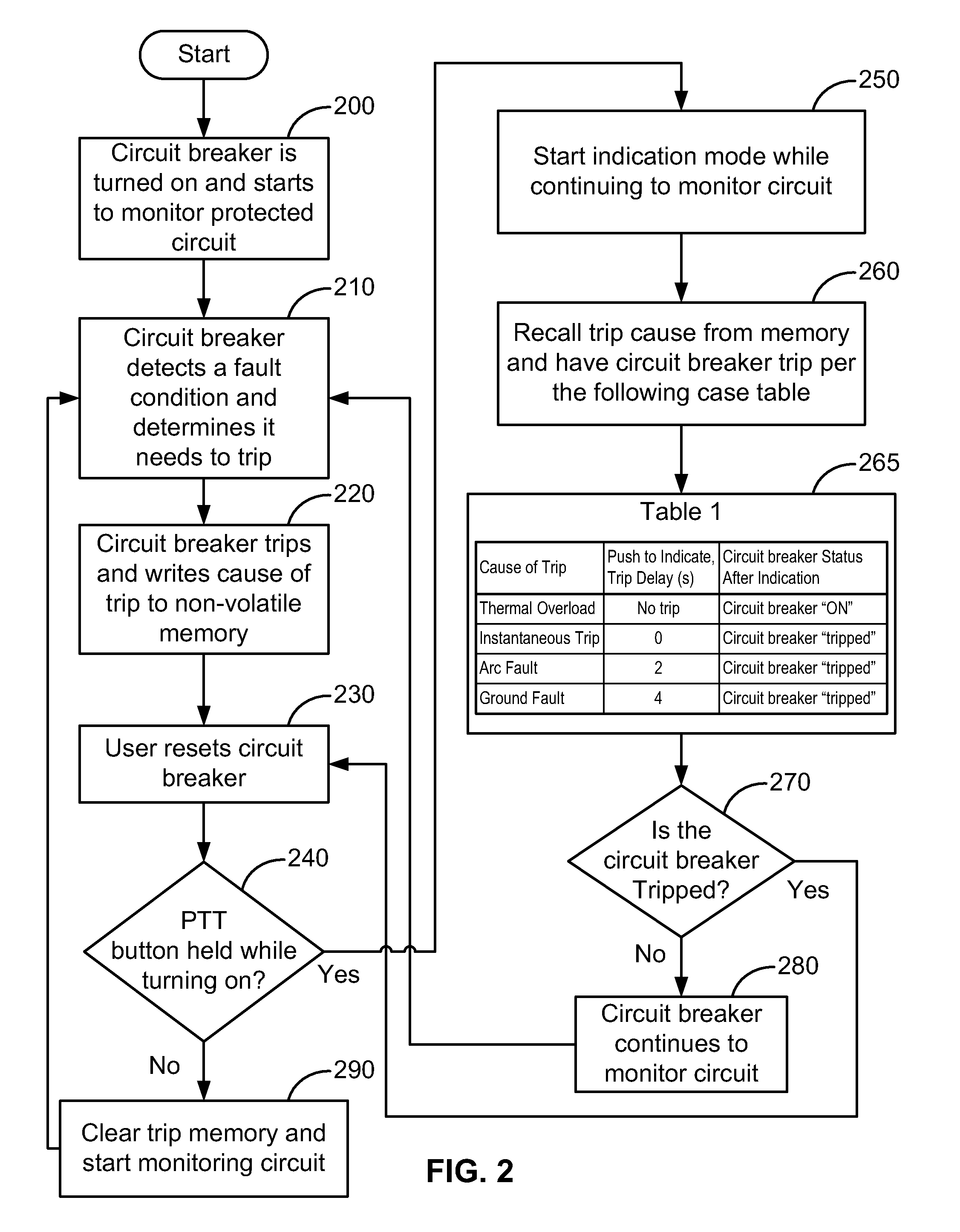

Electronic miniature circuit breaker with trip indication using the breaker tripping function as the feedback mechanism

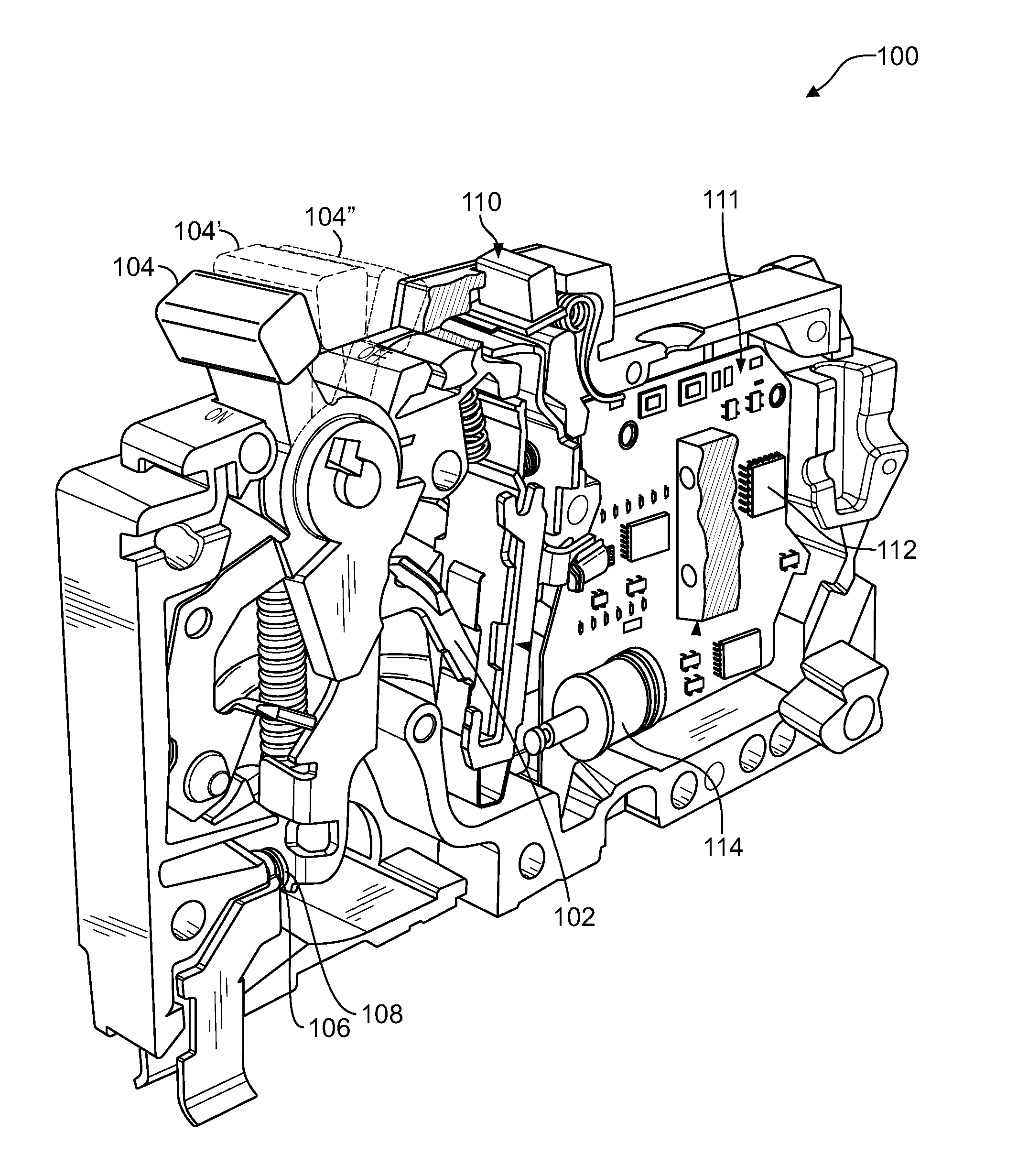

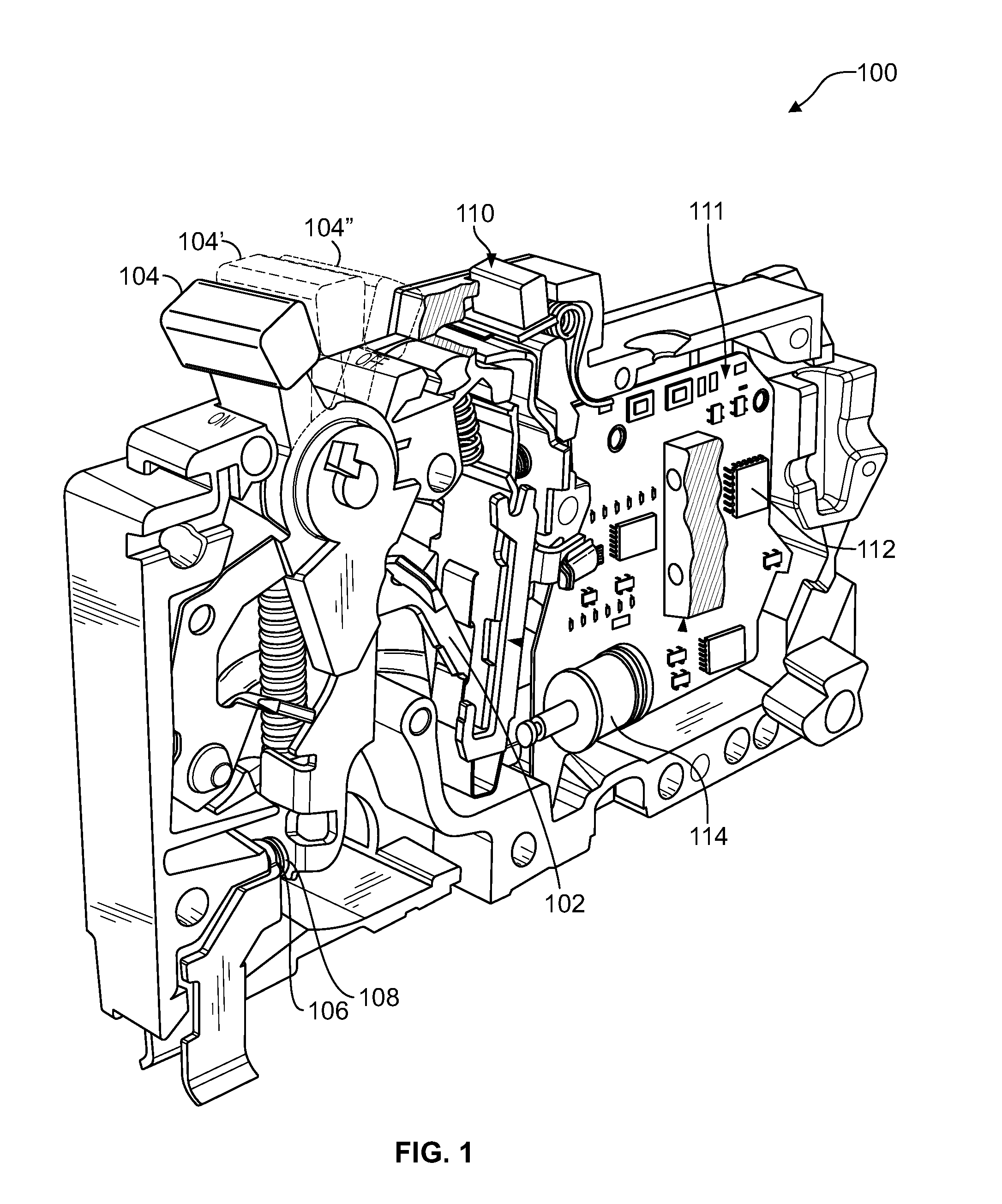

ActiveUS8243411B2Circuit-breaking switches for excess currentsElectric switchesControl signalHemt circuits

A method for identifying a type of fault condition in a circuit breaker includes monitoring a branch circuit for a fault condition. In response to detecting the fault condition, interrupting current flow through the branch circuit. The type of fault condition is stored in a memory device from which it is retrieved in response to receiving a control signal. The type of fault condition is indicated based on the mechanical position of a circuit breaker handle as a function of time.

Owner:SCHNEIDER ELECTRIC USA INC

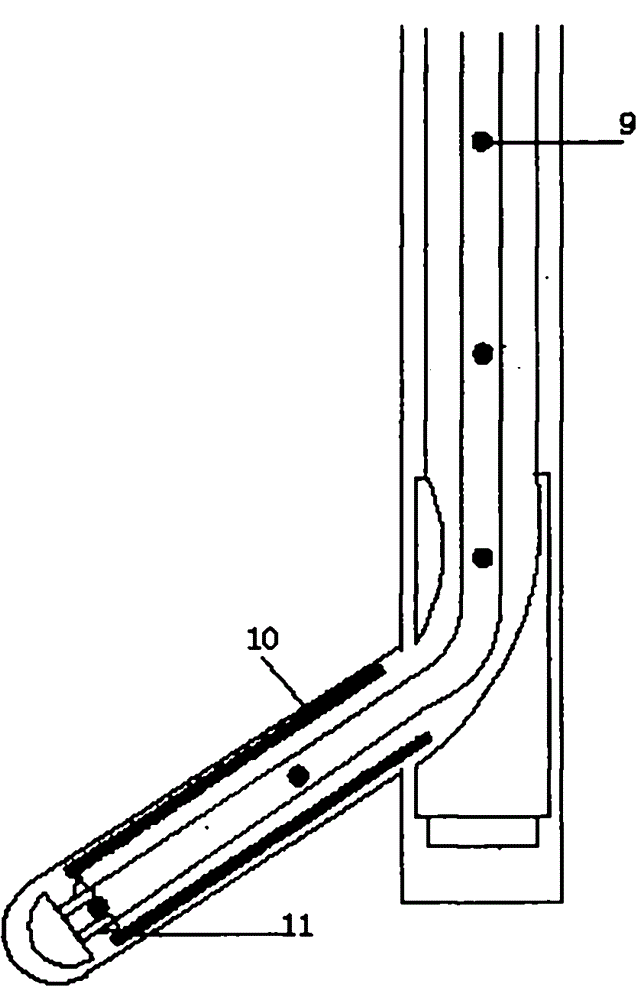

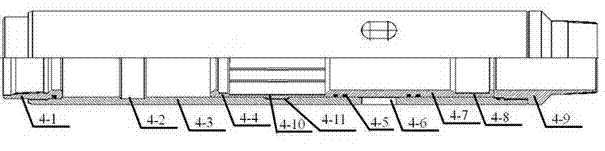

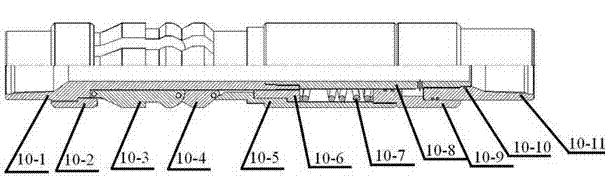

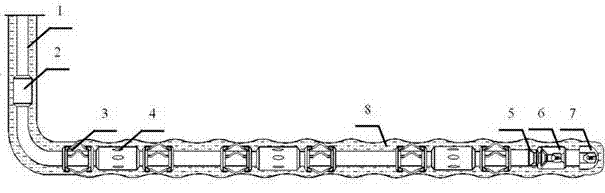

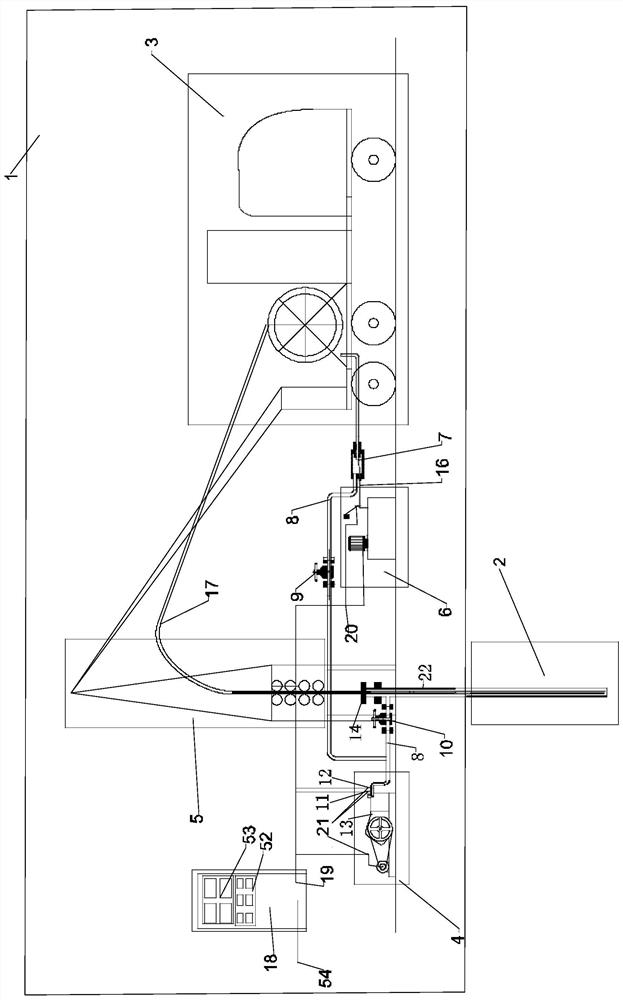

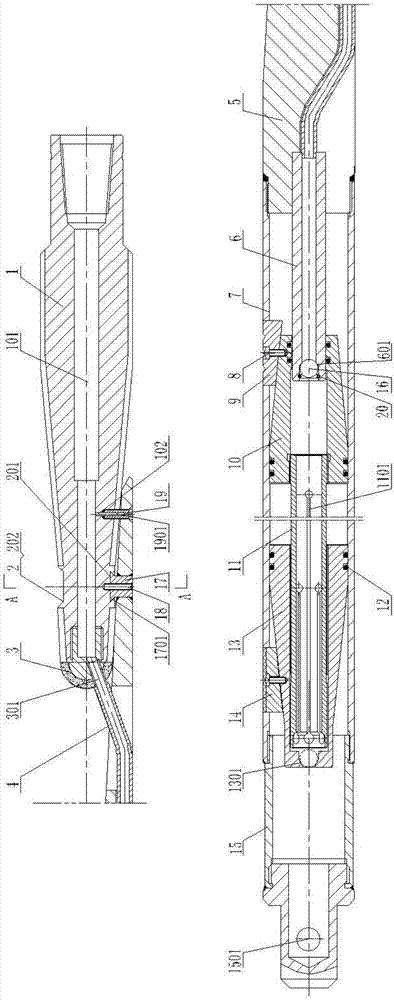

Drilling and completion integration device and method using coiled tubing carrying sieve tubes for sidetracking

The invention provides a pinnate branch well sidetracking and completion integration device and method using a coiled tubing carrying sieve tubes. The technical scheme relates to such devices as a tubing anchor, a diverter, the coiled tubing, a sieve tube separating device and a jet bit. The method comprises the steps of tripping in a tubing provided with the anchor and the diverter after the casing cementing of a main horizontal well section; tripping in the coiled tubing carrying the sieve tubes from the inside of the tubing after setting the direction and anchoring the tubular column; using abrasive jet flow to perform window sidetracking; when the sidetracking reaches the designed well depth of branch well holes, separating the sieve tubes from the separating device and leaving the sieve tubes in the branch well holes through ball throwing and pressure building in the coiled tubing; taking the coiled tubing from the well hole at the same time; performing the window sidetracking and ball throwing separation after adjusting the well depth and the direction of the tubing again. Thus, the drilling and completion integration process using the coiled tubing carrying the sieve tube for sidetracking is completed.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Controlled-valve placed well-cementing staged-fracturing well-completion string and hydraulically-controlled switch string

ActiveCN102410009AIncrease the lengthLarge displacementFluid removalWell/borehole valve arrangementsHorizontal wellsWell cementing

The invention discloses a controlled-valve placed well-cementing staged-fracturing well-completion string and a hydraulically-controlled switch string, which are suitable to be applied to a well-completion process for horizontal wells and vertical wells, and through tripping in the hydraulically-controlled switch string to start and close the controlled-valve placed well-cementing staged-fracturing well-completion string, multi-layer-and-section fracturing well-completion construction is realized, thereby meeting the needs of development on low-permeability oil reservoirs and unconventional oil / gas resources. The controlled-valve placed well-cementing staged-fracturing well-completion string, from top to bottom, is sequentially connected with a hydraulically-controlled switch tool detention cylinder, a switchable control valve and hydraulic casing centralizers connected with the two ends of the switchable control valve, a pressed settling valve and a bottom circulating valve by using a casing; and at least a set of switchable control valve and hydraulic casing centralizers connected with the two ends of the switchable control valve are equipped in the string. The hydraulically-controlled switch string comprises hydraulically-controlled switch tools and a continuous oil pipe, and a set of hydraulically-controlled switch tool is connected to the bottom of the continuous oil pipe. The switchable control valves are same in inner drift diameter (same in size), and can carry out well completion on stratums through the sand fracturing of the casing, thereby satisfying the needs of large-displacement and large-scale fracturing reformation.

Owner:CHINA PETROLEUM & CHEM CORP +1

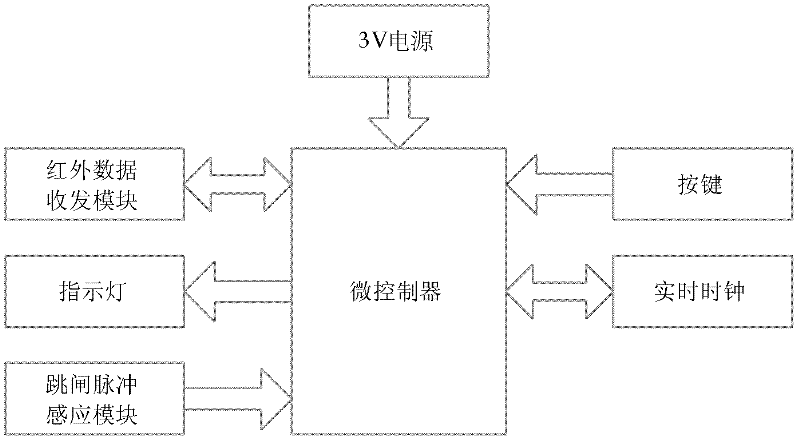

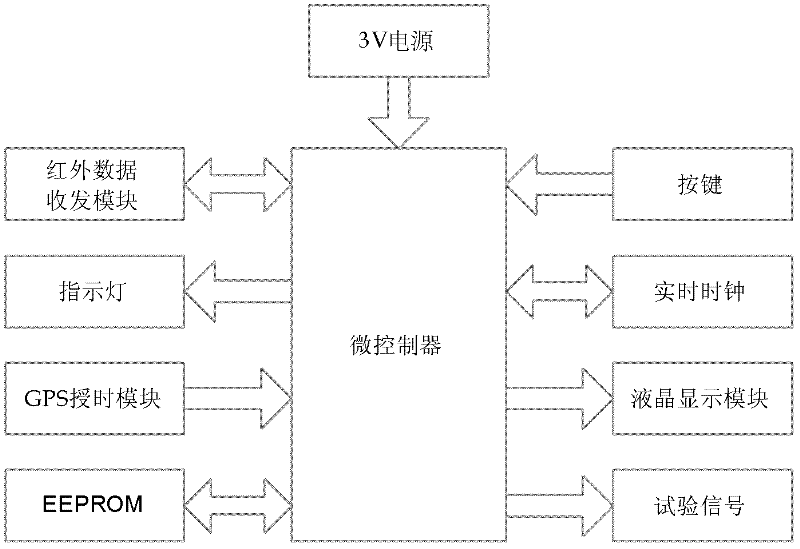

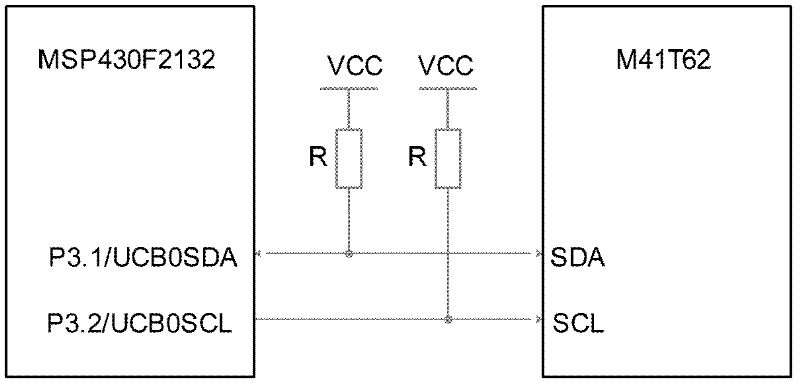

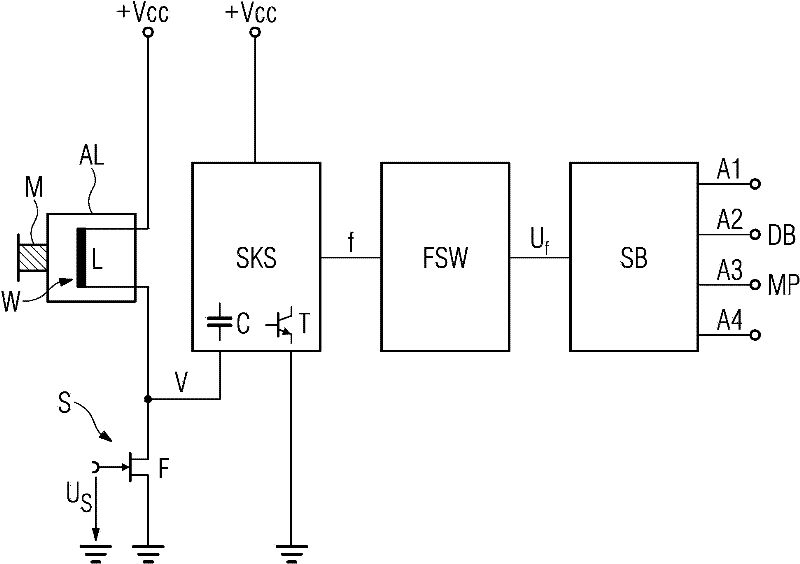

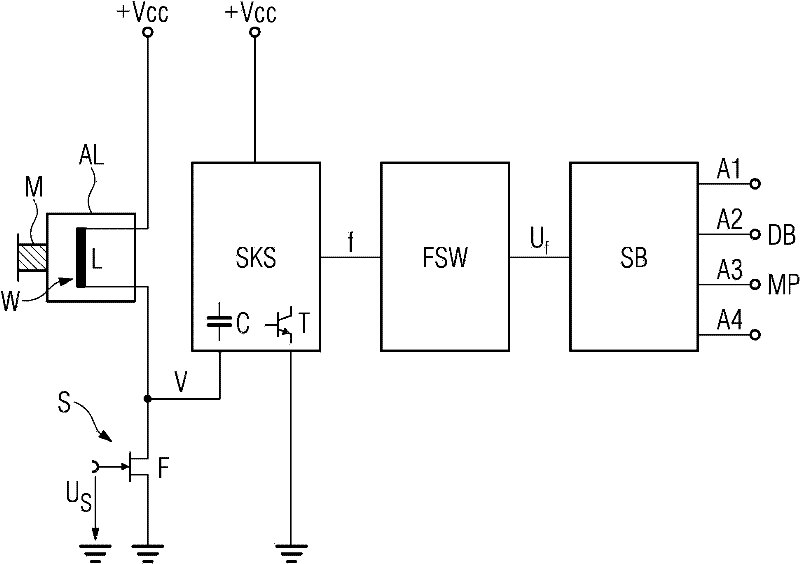

Monitoring system of tripping pulse of breaker

ActiveCN102393506ASmall form factorReduce power consumptionTransmission systemsPulse characteristics measurementsMonitoring siteMonitoring system

The invention discloses a monitoring system of a tripping pulse of a breaker. The system comprises a tripping pulse monitor and a tripping signal reader. The tripping signal reader reads monitored tripping generation time and a monitored tripping pulse width from the tripping pulse monitor as well as converts the read tripping generation time and the read tripping pulse width into GPS time service time to carry out displaying; in order to solve a breaker's non-fault trip accident without a protection action signal, it can be rapidly discriminated that whether the breaker's tripping action is caused by a secondary circuit fault or by itself reason, so that a tripping reason can be determined; and thus, a corresponded measure is taken to enable the breaker to work normally again. The monitoring system has characteristics of small and exquisite appearance, low power dissipation, and maintenance-free property; besides, the monitoring system can be installed without need of power failure; and monitoring points can be arranged reasonably and a fault searching range can be rapidly and effectively reduced. Moreover, the tripping signal reader is utilized to read data related to tripping from the tripping pulse monitor in a wireless communication mode to conveniently carry out an analysis and comparison, so that the fault can be eliminated rapidly and safe operation of the system can be guaranteed.

Owner:SUZHOU POWER SUPPLY OF JIANGSU ELECTRIC POWER +3

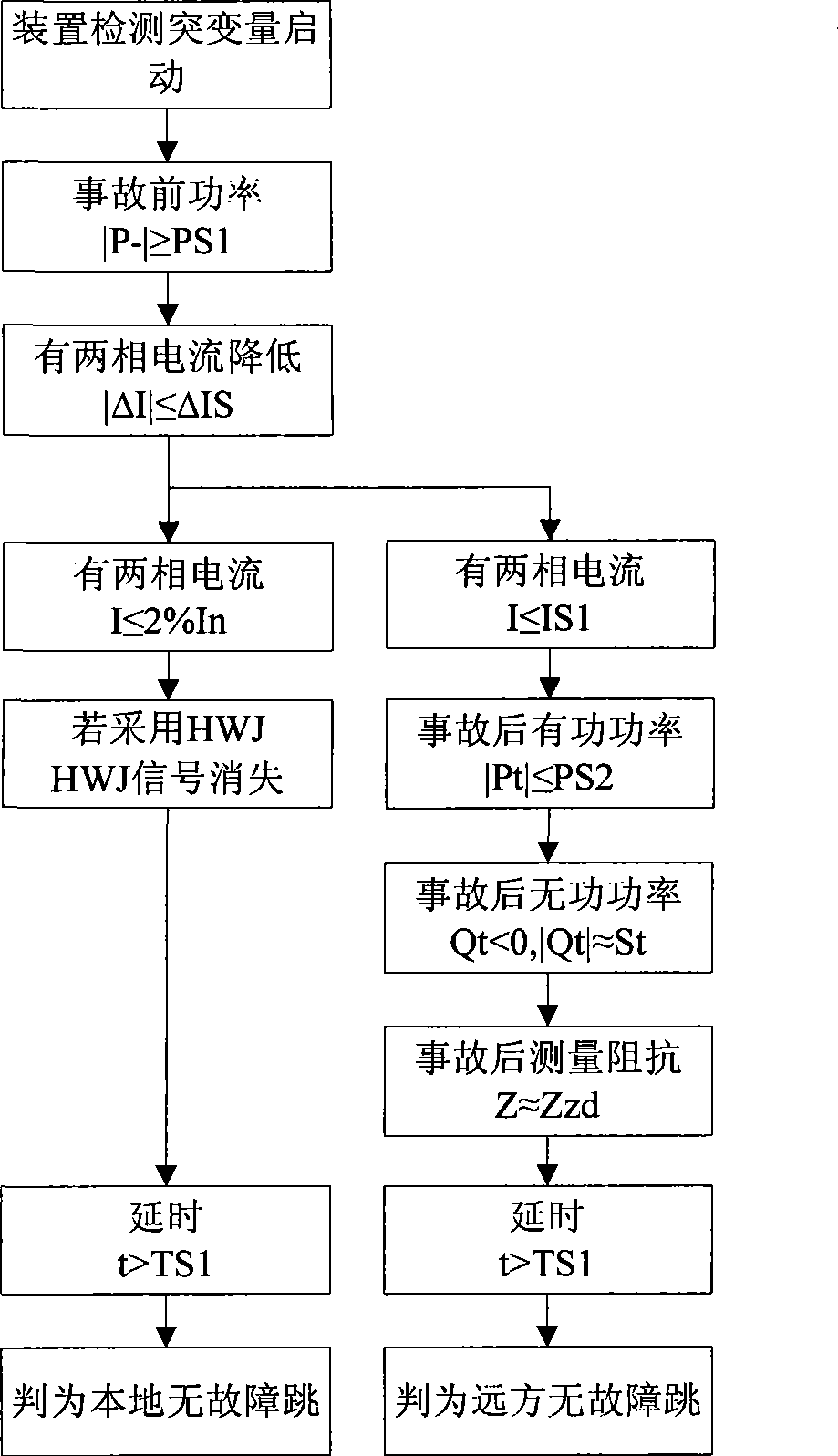

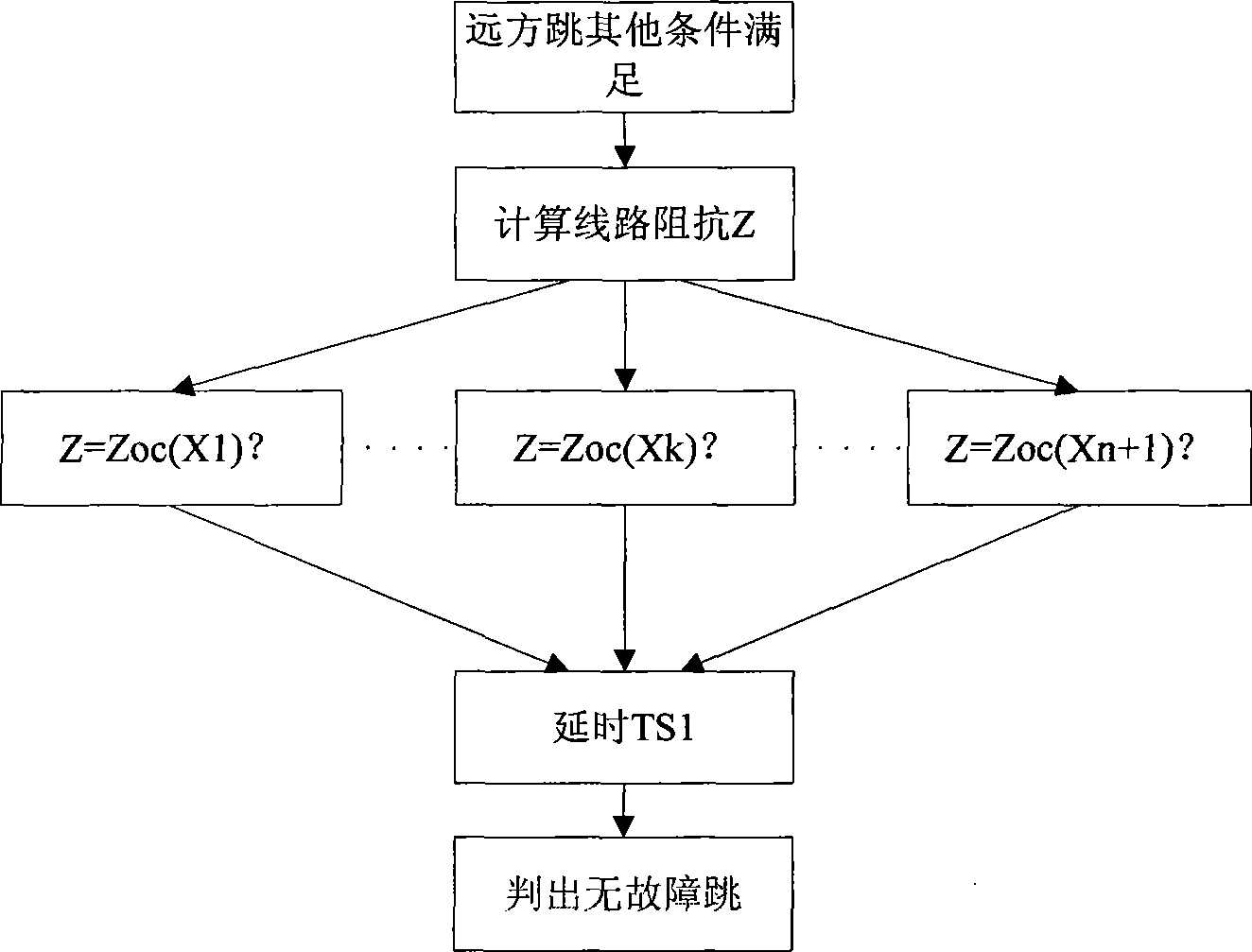

Non-failure valve tripping criteria recognizing breaking point based on local measurement

InactiveCN101388543AAccurate judgmentImprove applicabilityEmergency protective arrangements for automatic disconnectionBreaking pointJumping

The invention discloses a fault-free tripping operation criterion based on local measurement to identify the distance between an opening point and a breakpoint. The fault-free tripping operation criterion comprises the following steps: firstly, detecting the starting of break variable, recording the starting time, conserving current, power and switch position signal information before starting, detecting the power of 200ms before starting, judging whether current has the rapid drop process or not in the process of disturbing, if switch position signals are detected to disappear in the process of starting, and current is detected to near zero, and judging local fault-free tripping operation after delaying, if current is not near zero, and detecting current, active power, reactive power and positive sequence impedance by a device after starting, if current is stabilized on a lower value, line power flow is totally capacitive reactive power, measured impedance is equal to open-circuit impedance which is set in advance, and judging remote fault-free tripping operation criterion after delaying. The fault-free tripping operation criterion can effectively distinguish the processes of local jumping, remote jumping and, which has excellent adaptability in segmented circuits.

Owner:STATE GRID ELECTRIC POWER RES INST +1

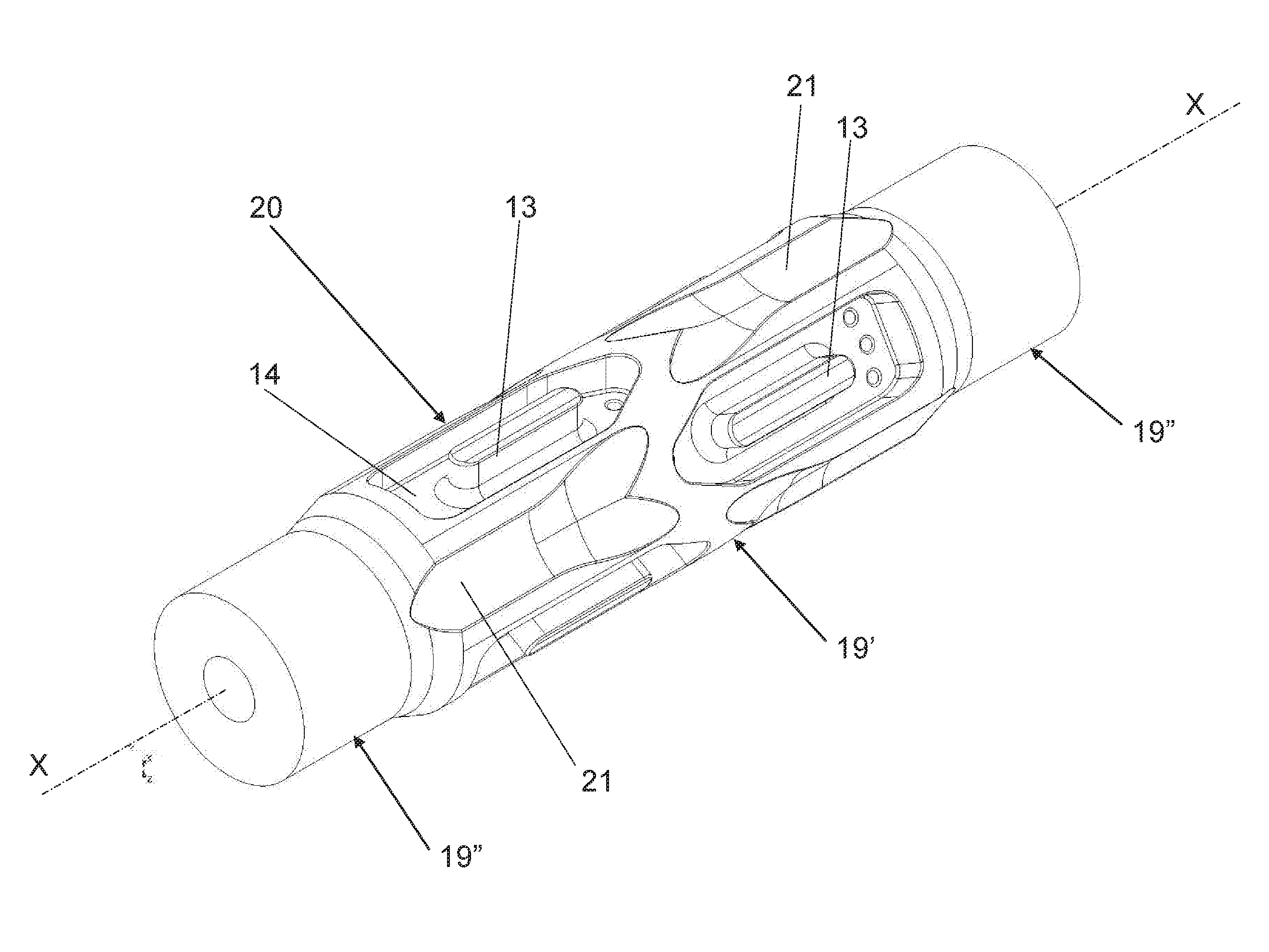

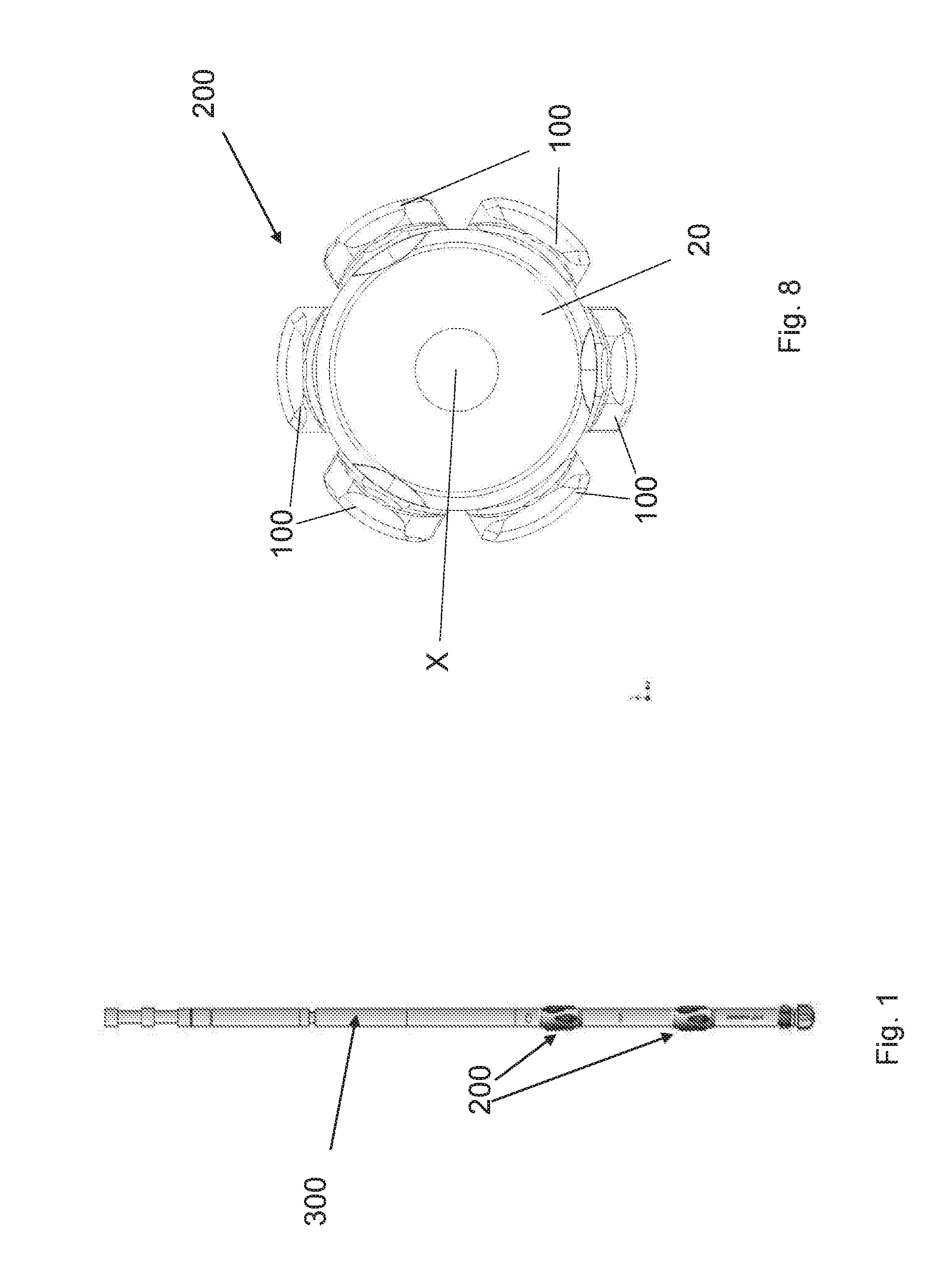

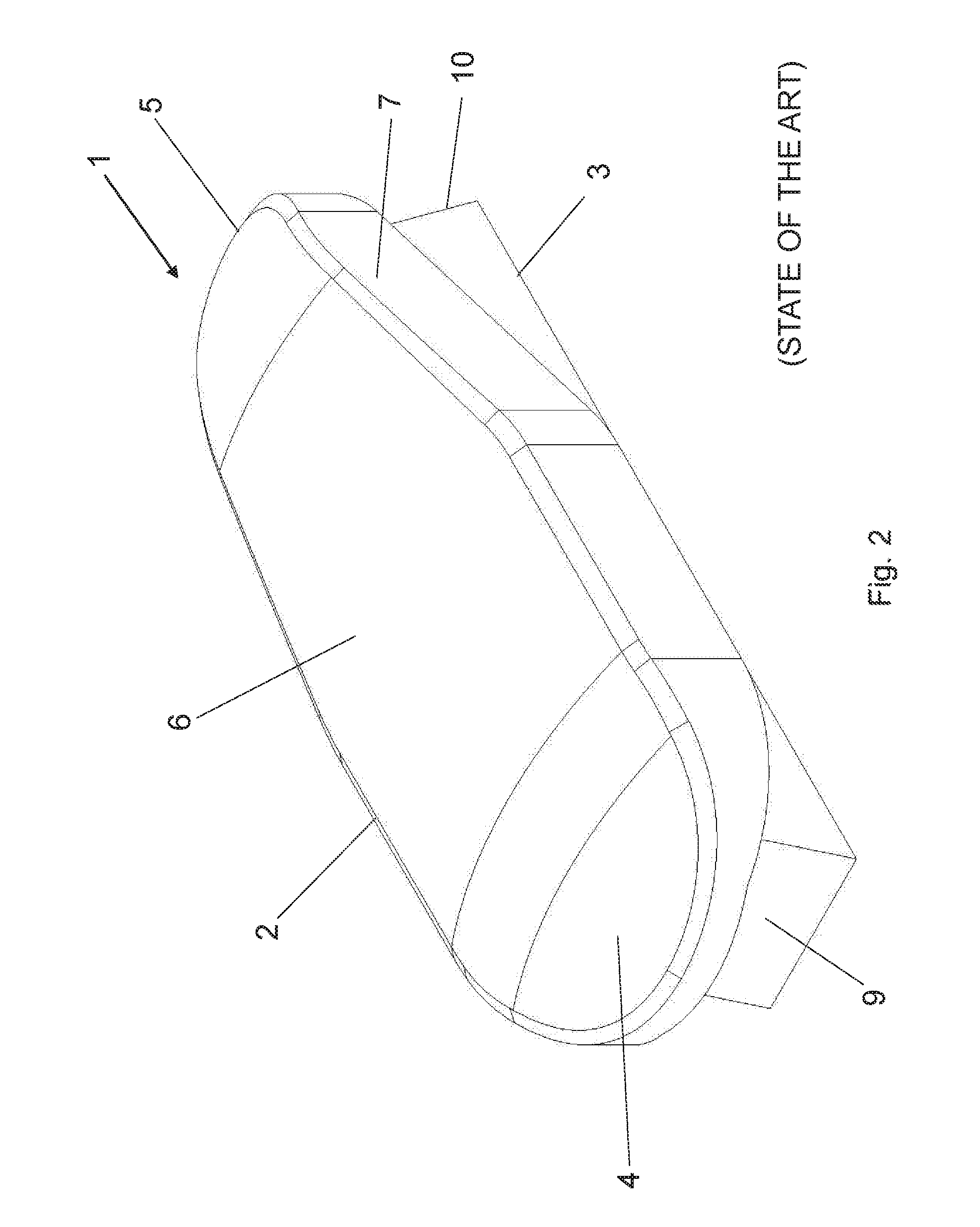

Blade stabiliser tool for drill string

ActiveUS20160265287A1For quick replacementQuick changeDrilling rodsDrilling casingsClassical mechanicsStructural engineering

A drilling string stabiliser tool comprises a cylindrical body and a plurality of stabiliser blades mounted on the outer surface of the cylindrical body. The stabiliser blades have an elongated shape and a monolithic structure with an upper stabilizing part and a lower mounting part. Between each two adjacent blades there can optionally be a hydrodynamic flute for improving the flow of liquid and cuttings during drilling and tripping.

Owner:EURON DRILLING PROJECTS BV

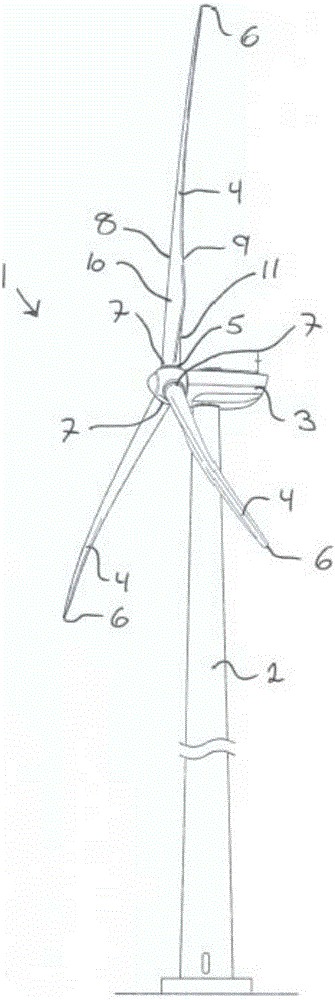

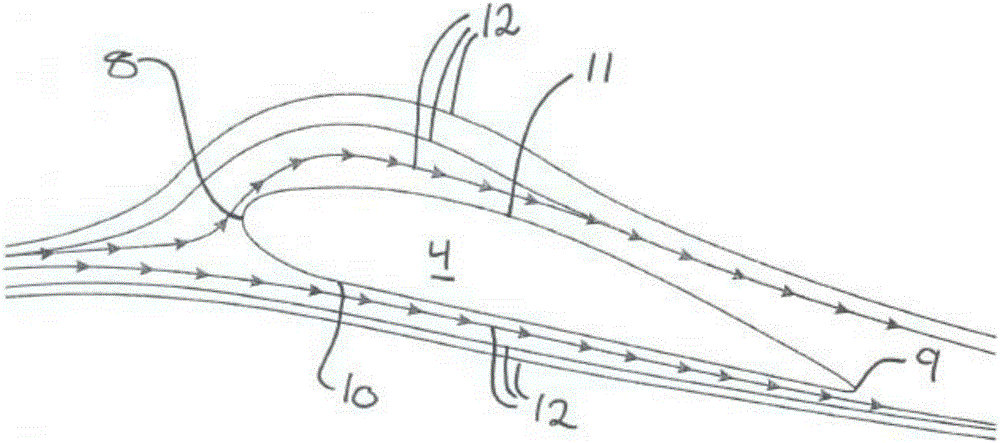

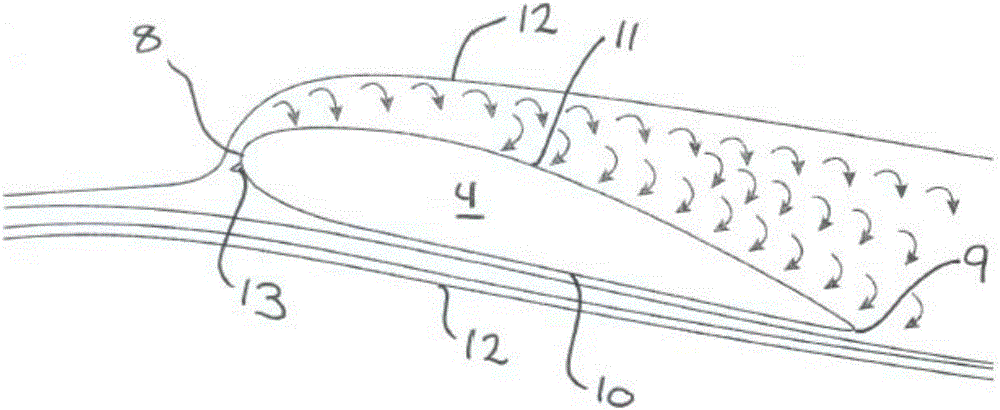

Wind turbine blade with tripping device and method thereof

ActiveCN106468241AEasy to removeEasy to replaceEngine fuctionsWind motor assemblyTurbine bladeEngineering

The present invention relates to a wind turbine and a method of reducing extreme loads and fatigue loads by using a passively activated tripping device arranged on the pressure side of the wind turbine blade. The tripping device is configured to interrupt the passing airflow, when activated, and transform the airflow into a turbulent airflow. The tripping device is positioned close to the leading edge, wherein its dimensions are optimised so that it reduces the maximum lift coefficient as well as increases the minimum lift coefficient which in turn reduces the range of the lift coefficient. The tripping device is activated at both negative and positive angle-of-attacks outside the normal operating range.

Owner:YUANJIAN WIND POWER JIANGYINENVISION ENERGY CO LTD

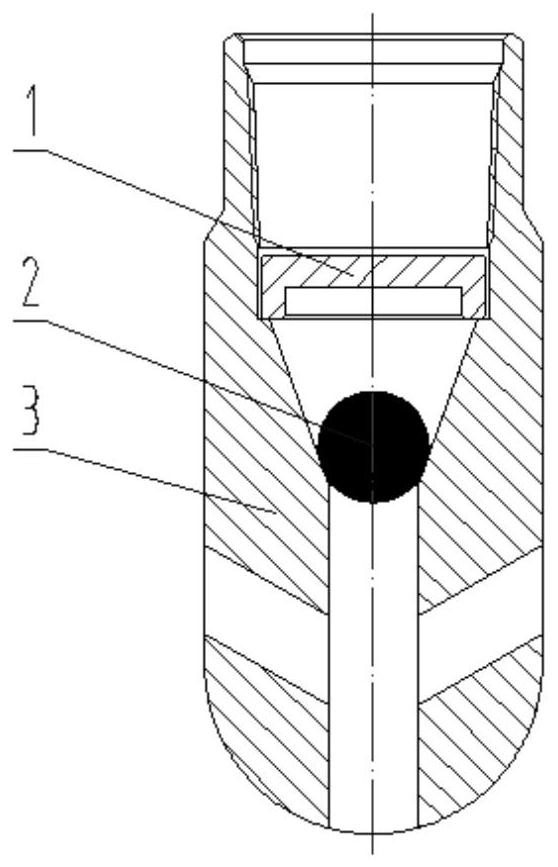

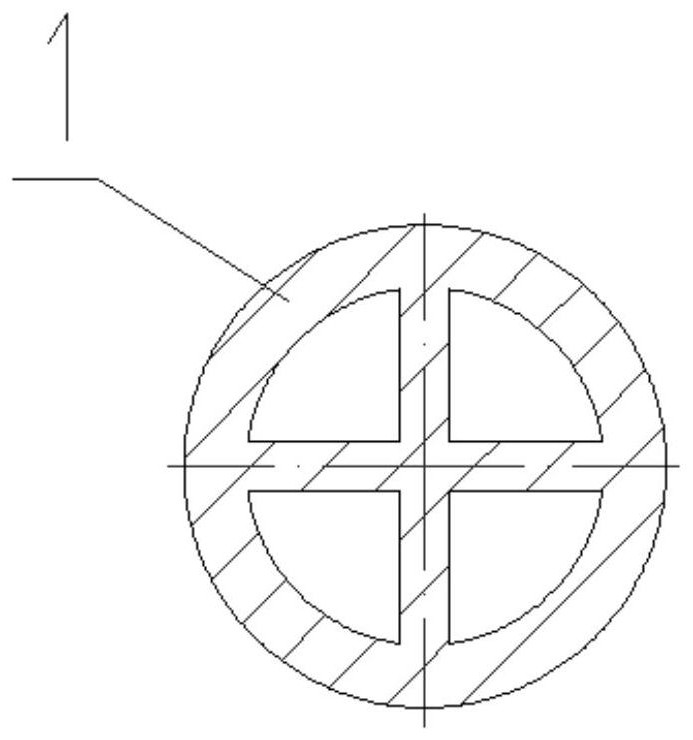

Seated sealing tool for preventing seated sealing in advance, and hanging technology for protecting open holes of packer

InactiveCN111535780AEasy to useVerify closureFlushingWell/borehole valve arrangementsOil fieldSteel ball

The invention provides a seated sealing tool for preventing seated sealing in advance, and a hanging technology for protecting open holes of a packer, and relates to the technical field of oilfield completion. The seated sealing tool for preventing seated sealing in advance comprises a seated sealing assembly and a double release assembly which are sequentially connected, wherein a seated sealingpreventing member which can shear pins is arranged on the seated sealing assembly, and is connected with a pressure ring of the packer; and a locking pawl which can shear pins is arranged on the double release assembly, and is connected with the locking pawl. The hanging technology for protecting open holes of a packer comprises the following steps of tripping in a sand control string and a service string loading the seated sealing tool for preventing seated sealing in advance to a preset position; putting into a steel ball on the packer for performing seated sealing and performing seal inspection on the packer; performing positive rotation or annular space pressurizing on the service string, so that the seated sealing assembly and the packer are released; lifting the service string, performing pressurizing on the service string, shearing the ball seat, establishing a new positive cycle passage, and realizing large-displacement well flushing; continuing lifting the service string, closing a sliding bush, and verifying the sliding bush closing situation; and pulling out the service string. The technical effect of reducing the possibility that the seated sealing tool is subjected toseated sealing in advance is achieved.

Owner:东营市瑞丰石油技术发展有限责任公司

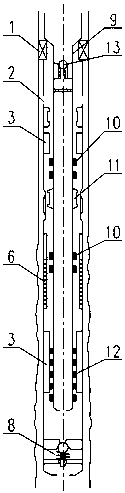

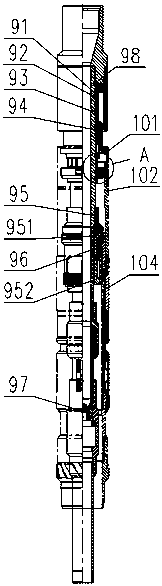

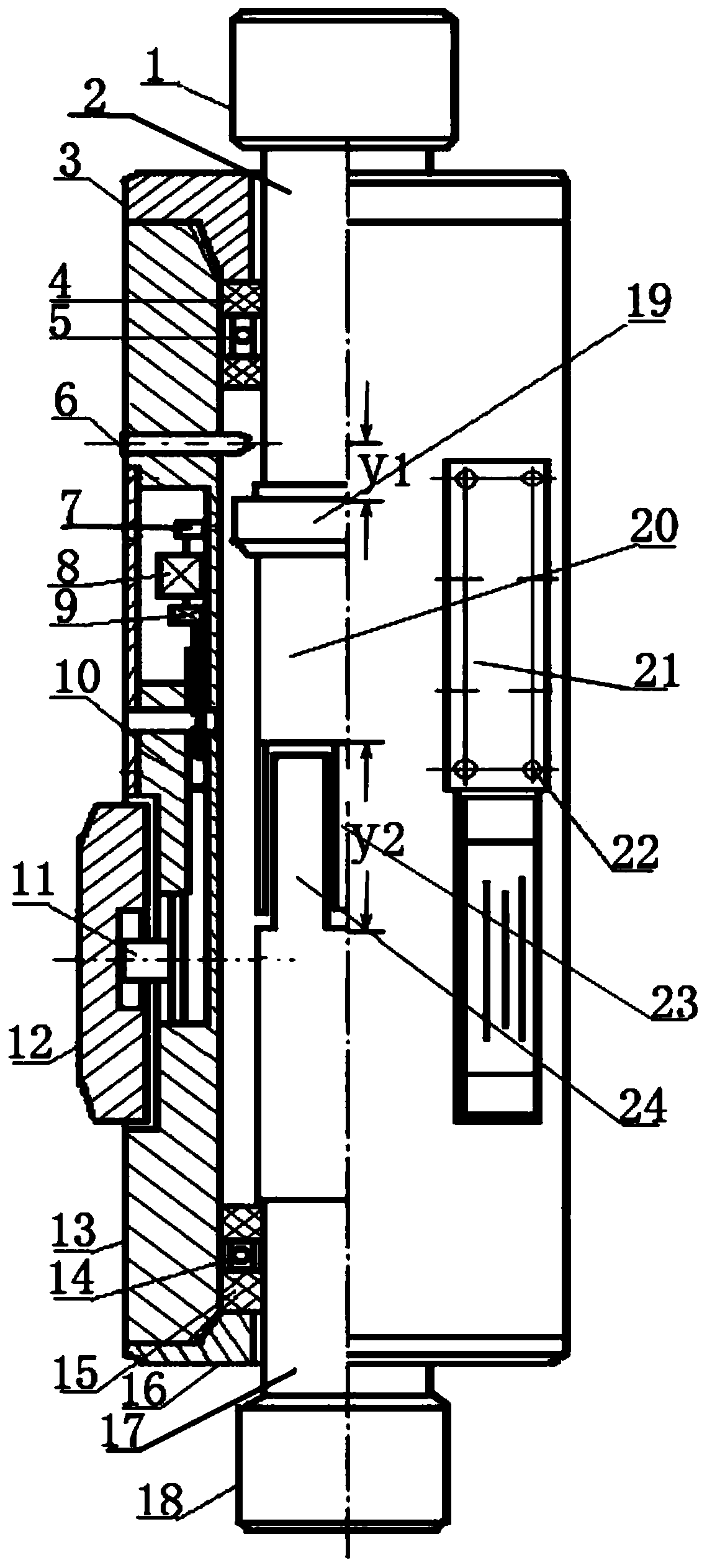

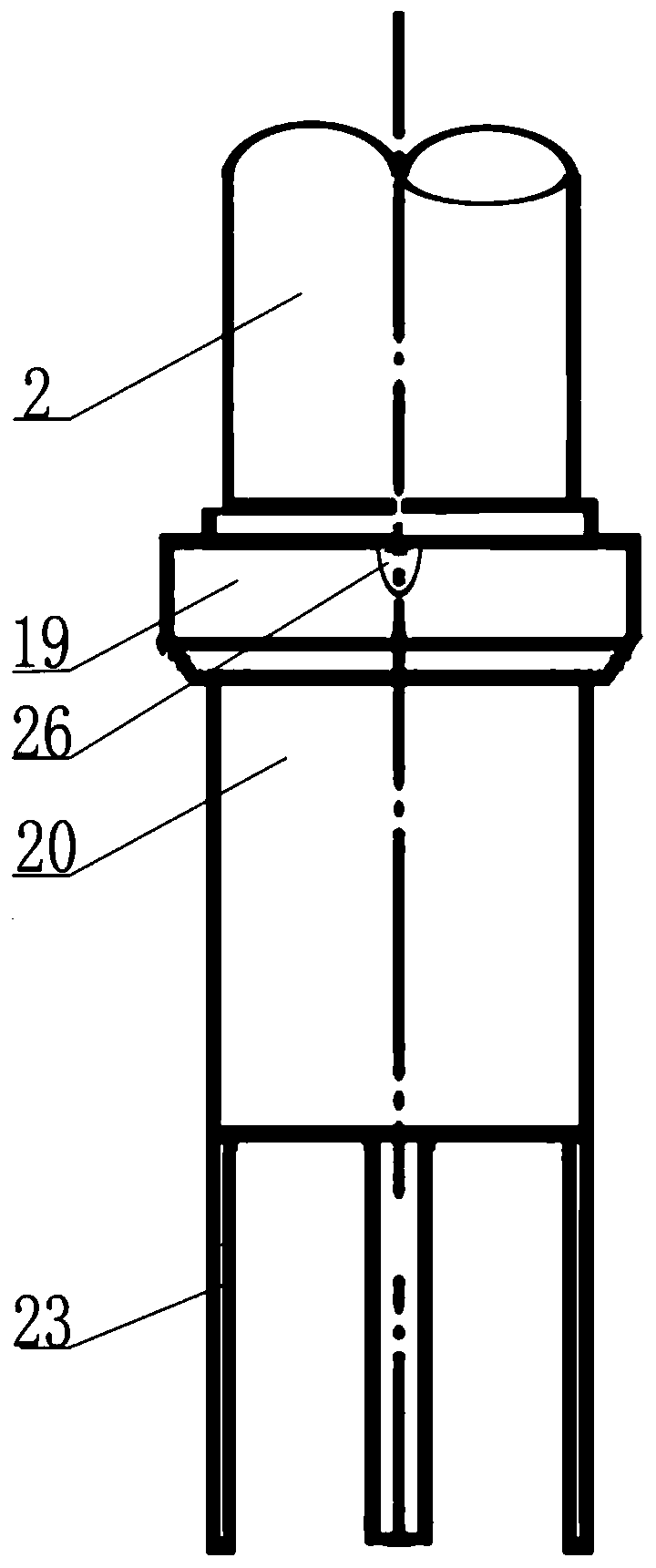

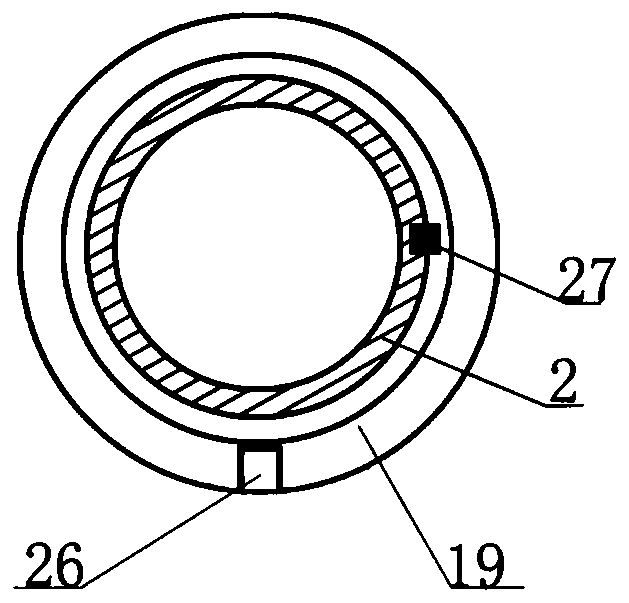

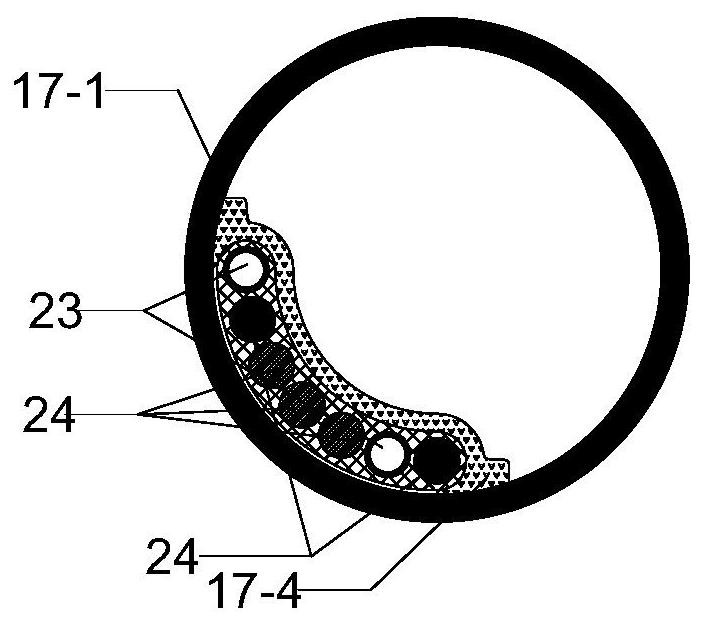

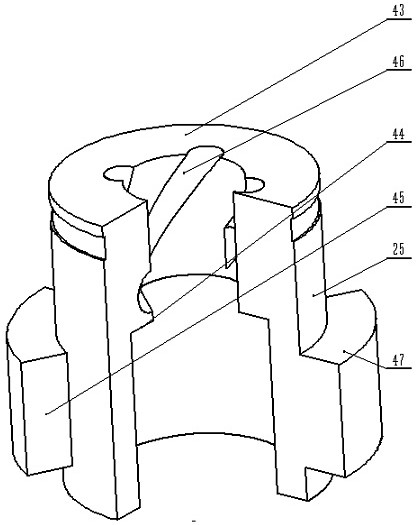

Rotary steering tool for well drilling

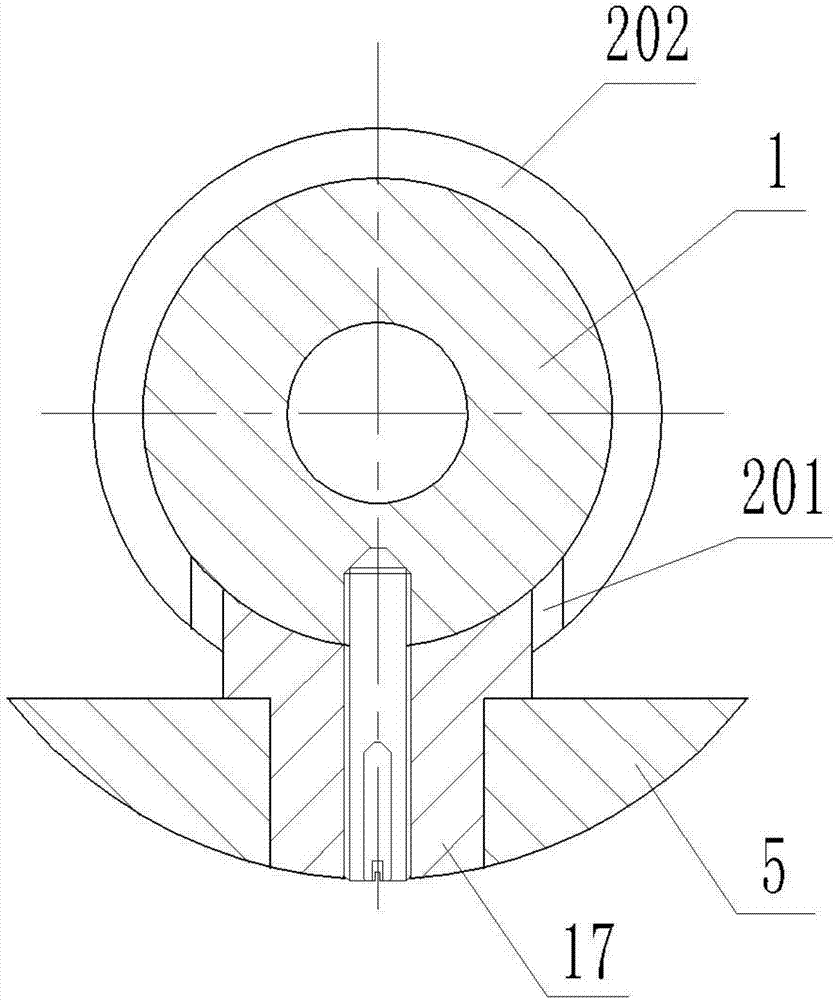

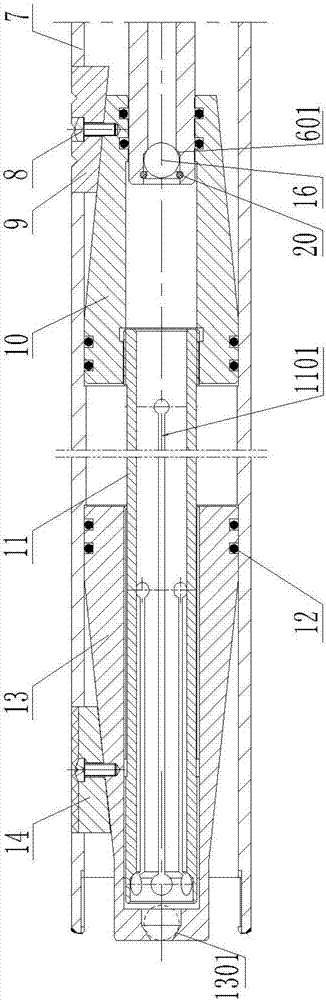

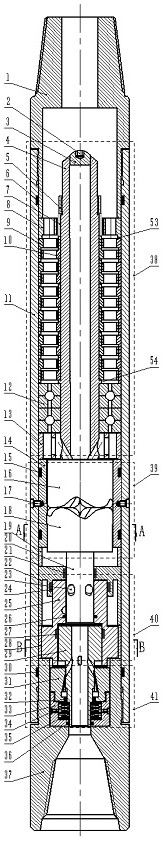

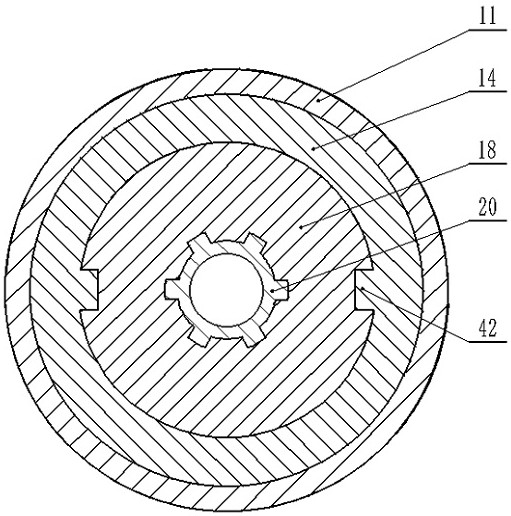

PendingCN111287657AHave the ability to guideIngenious ideaDirectional drillingAutomatic control for drillingHydraulic cylinderLight pipe

The invention discloses a rotary steering tool for well drilling. The rotary steering tool for well drilling comprises a pair of hollow joints arranged up and down and in butt joint, wherein each hollow joint is provided with a threaded head section and a light pipe section which are of an integral structure, the threaded head sections of the upper hollow joint and the lower hollow joint are oppositely arranged, the light pipe sections of the upper hollow joint and the lower hollow joint are each provided with a rolling bearing, an outer sleeve is arranged on the periphery of each rolling bearing, and the outer sleeves are supported on the rolling bearings; three hollow windows arranged in the circumferential direction are formed in each outer sleeve, wherein each hollow window is providedwith a supporting block, each supporting block is provided with a hydraulic cylinder, and the hydraulic cylinders drive the supporting blocks to stretch out along the hollow windows and abut againstthe well wall with mud pressure difference between the interior and the exterior of a drill column as power; when no pressure difference exists between the inner mud and the outer mud of the drill column, reset springs of the hydraulic cylinders enable the supporting block to retract; and a mud channel is formed in the connecting portion of the upper hollow joint and the lower hollow joint, so that mud in the tool enters the hydraulic cylinder, and pistons can be driven to push the supporting blocks to stretch out; one hydraulic cylinder of one supporting block is further provided with a reversing valve which is used for enabling the hydraulic cylinder of the supporting block to communicate with the mud in the drill column or the mud outside the drill column. According to the rotary steering tool for well drilling, a stable inclined drilling working mode, a rotary steering working mode, a full-closed tripping working mode and a tripping working mode can be selectively realized.

Owner:四川海斯特能源技术有限责任公司

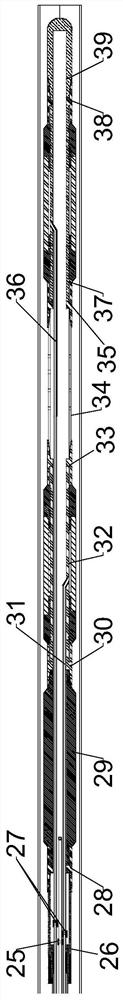

Composite coiled tubing with cable oil-water well casing leakage detection system and method

PendingCN111878069AResolve failureAvoid usage feesSurveyCable installations in surface ductsInjection pressureCoiled tubing

The invention discloses a composite coiled tubing with cable oil-water well casing leakage detection system and a method. The system and the method are characterized in that any section of an oil wellcasing can be separated and sealed through an upper hydraulic packer assembly and a lower hydraulic packer assembly, so that the problems that according to an existing leakage detection method, due to the fact that a packer cannot be subjected to setting, testing cannot be conducted; and packer failure is caused by frequent tubular column tripping operations are solved; and the pressure and temperature in a shaft are tested through an underground temperature and pressure sensor, water injection operation is conducted in the position, at the closed part of the upper hydraulic packer assembly and the lower hydraulic packer assembly, of the oil well casing through a water injection system, and the leakage detection work of the oil-water well casing is completed by recording injection pressure and flow. According to the system and the method, the problems that a common casing water exploration packer is large in setting position error, the packer is continuously and repeatedly subjected to setting, and unsetting and setting effect verifying are difficult are solved; the problems that testing cannot be conducted due to the fact that the packer cannot be subjected to setting, and the packer failure is caused by frequent tubular column tripping operations are solved; and the technical difficulty is small, a large amount of software using cost is avoided, and the oil-water well repairing cost is reduced.

Owner:华信唐山石油装备有限公司

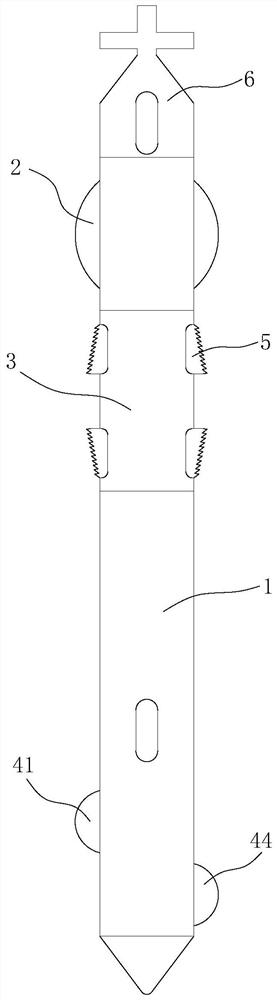

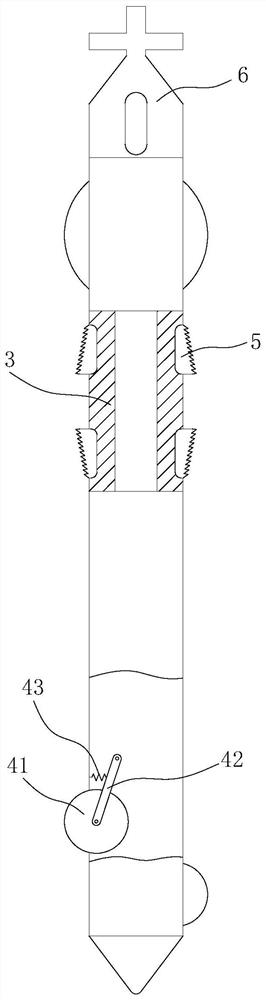

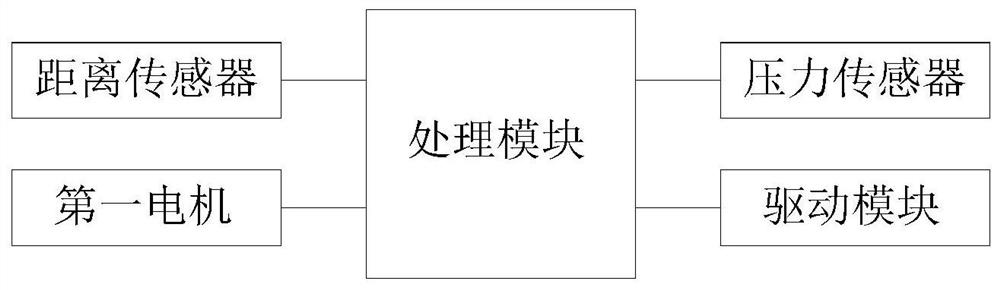

Self-driven induction type oil pipe inner blanking plug

PendingCN113790038AReduce the risk of human errorImprove the success rate of settingSurveyConstructionsDrive wheelHorizontal wells

The invention belongs to the technical field of oil and gas field development engineering, and discloses a self-driven induction type oil pipe inner blanking plug. The self-driven induction type oil pipe inner blanking plug comprises a blanking plug body, wherein a pressure sensor, a driving wheel set, a driven wheel set and a sealing rubber cylinder are arranged on the blanking plug body, and a processing module, a first motor and a driving module are arranged in the blanking plug body; and the first motor, the driving module and the pressure sensor are electrically connected with the processing module, and the processing module is used for enabling the driving module to be started and closed according to a pressure pulse signal received by the pressure sensor. According to the self-driven induction type oil pipe inner blanking plug, the tripping-in depth can be designed through the processing module, the driving module is started by using the pressure pulse signal to enable the sealing rubber cylinder and slips to expand, one-time setting is achieved, the risk of manual operation errors is reduced, and the setting success rate is improved. The driving wheel set rotates to drive the oil pipe inner blanking plug to automatically reach a horizontal well section for setting, and the self-driven induction type oil pipe inner blanking plug is suitable for highly-deviated wells and horizontal wells.

Owner:SICHUAN SHENGNUO OIL & GAS ENG TECH SERVICE CO LTD

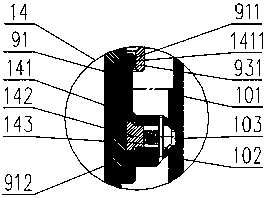

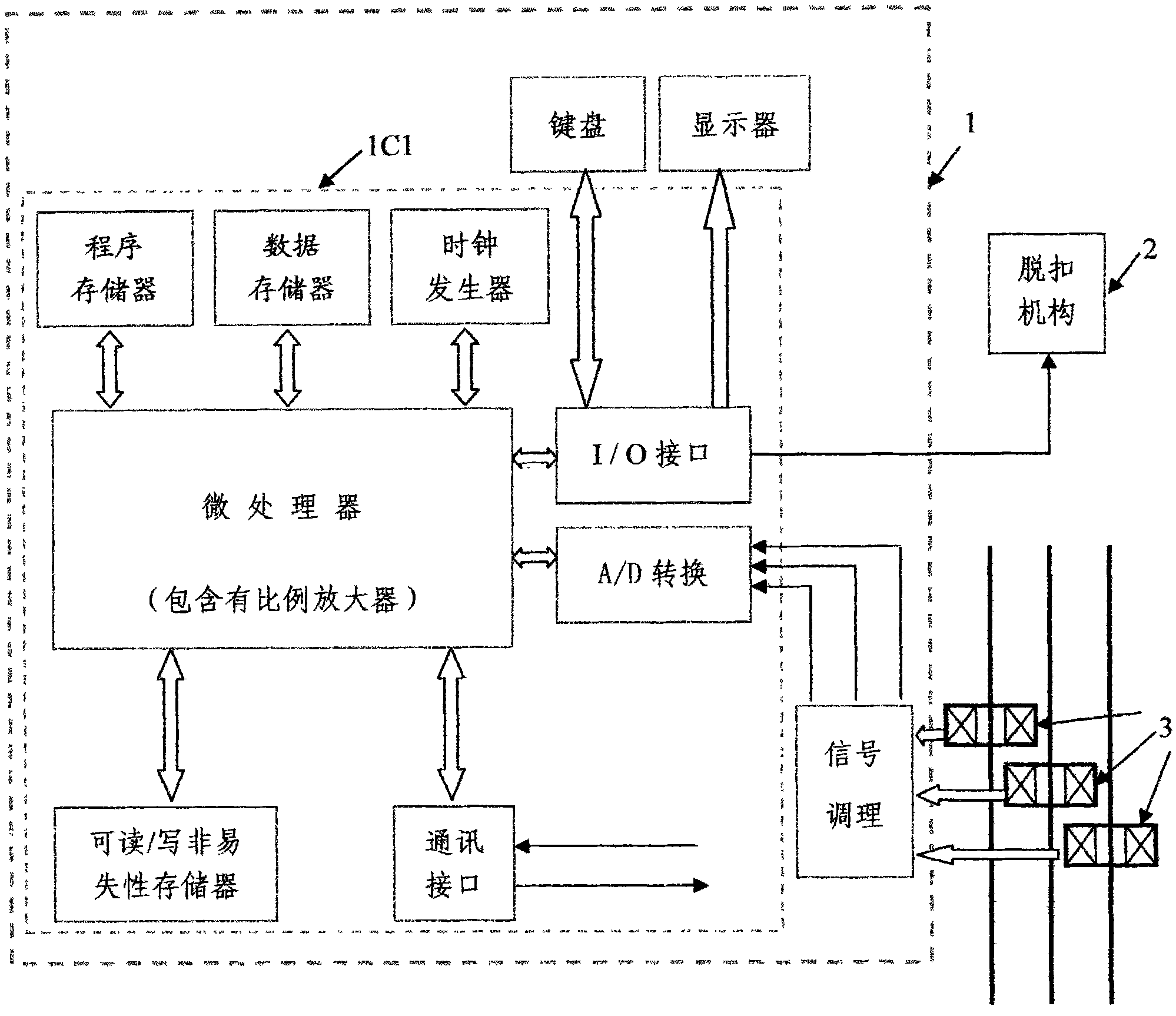

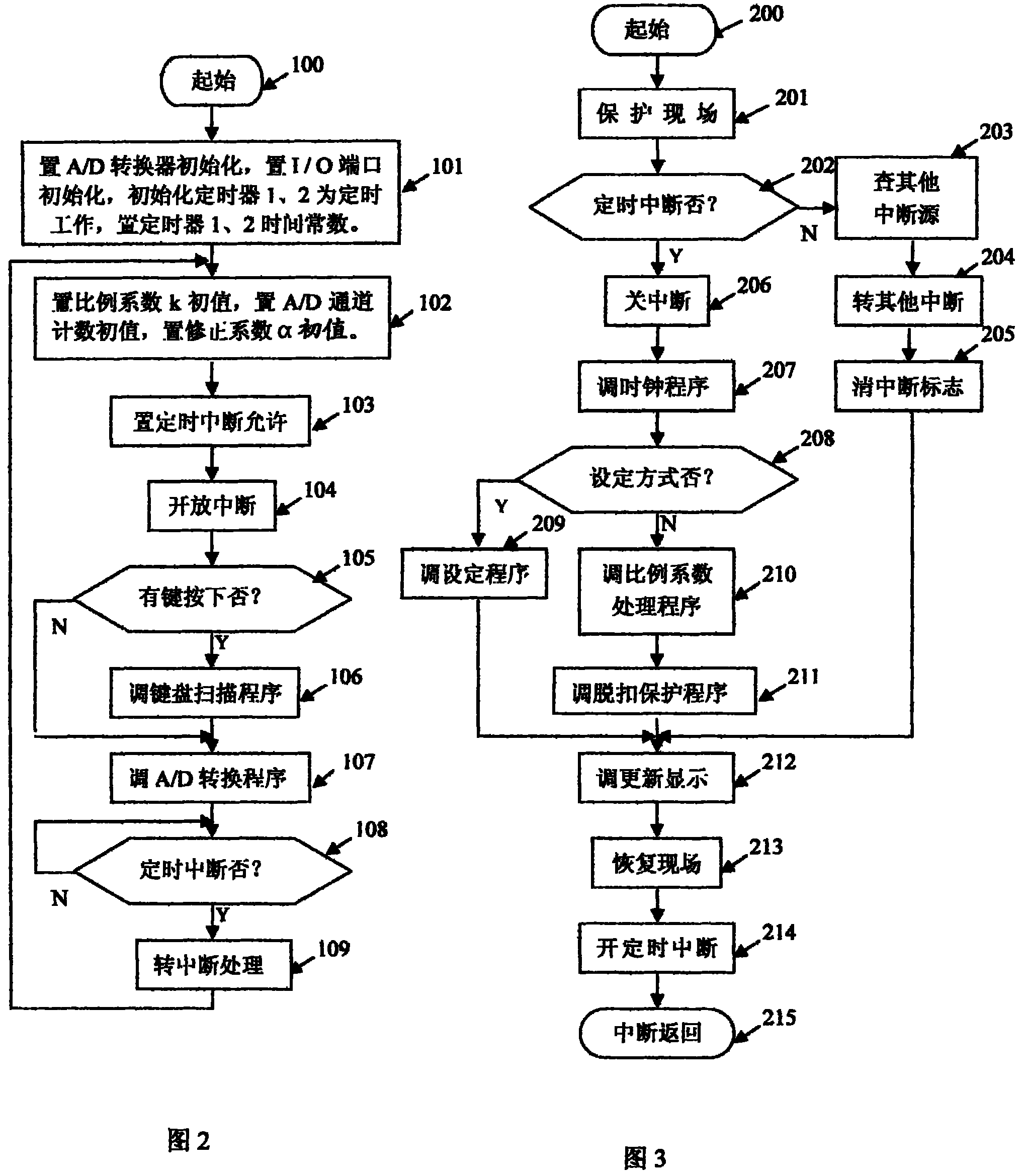

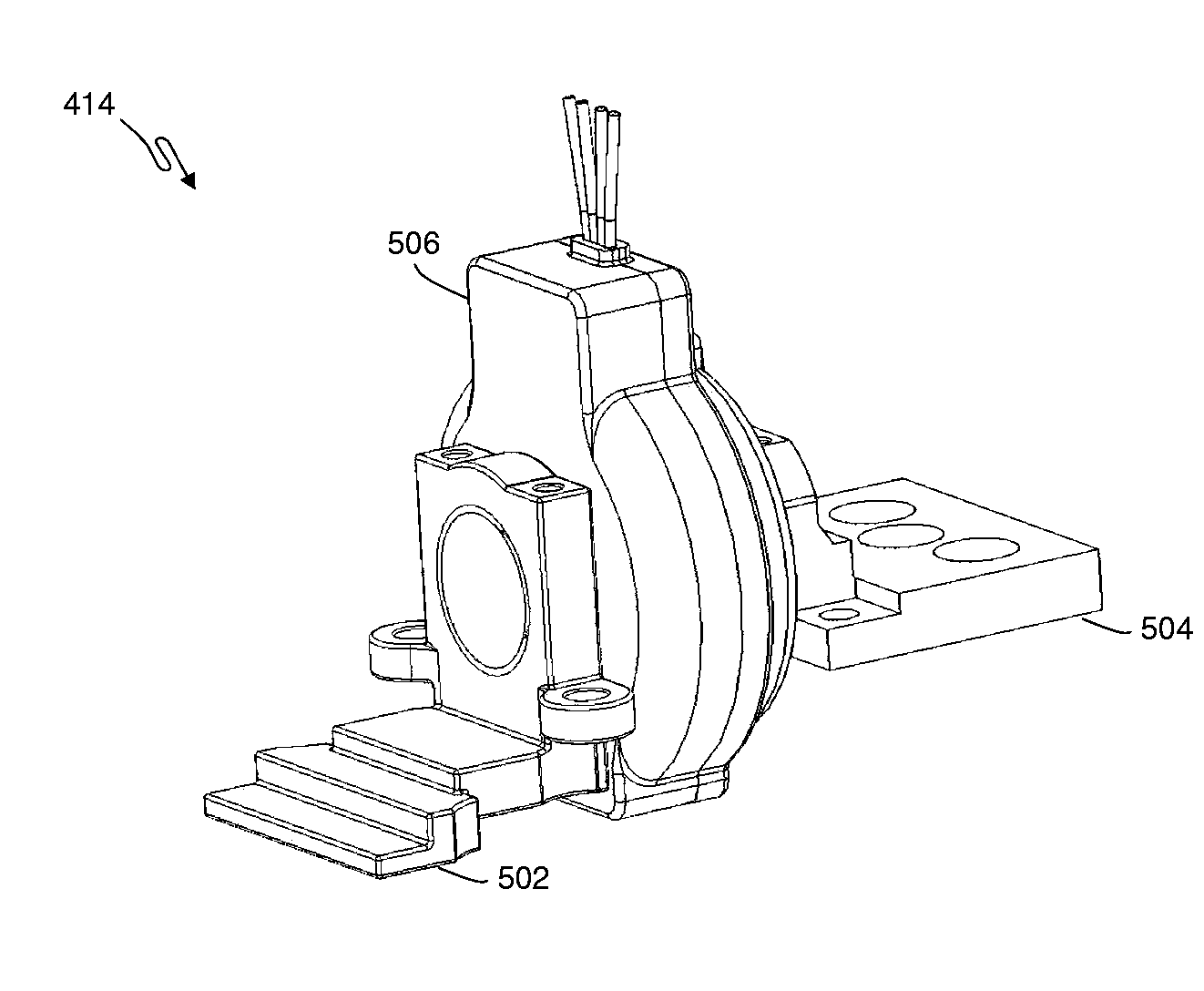

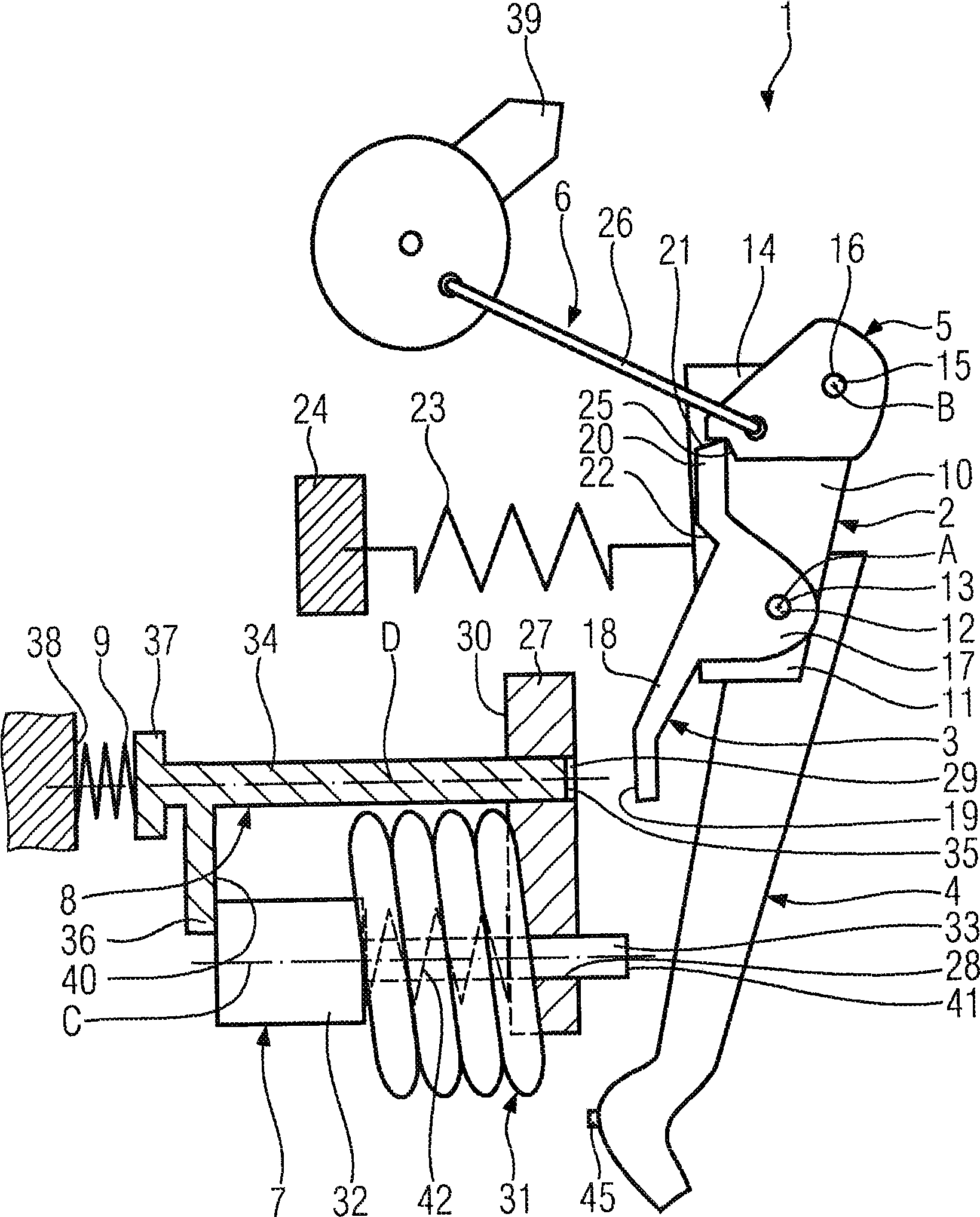

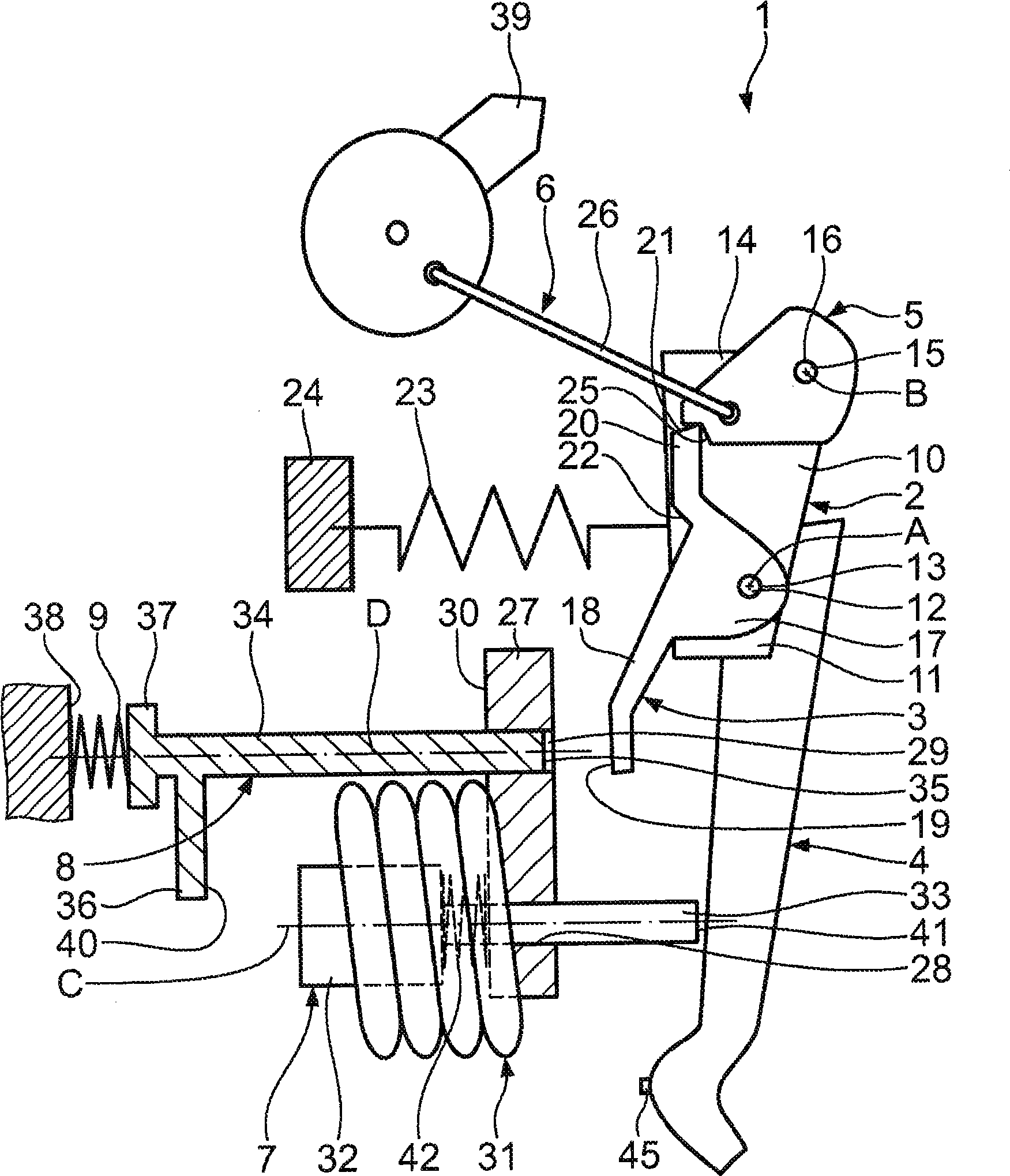

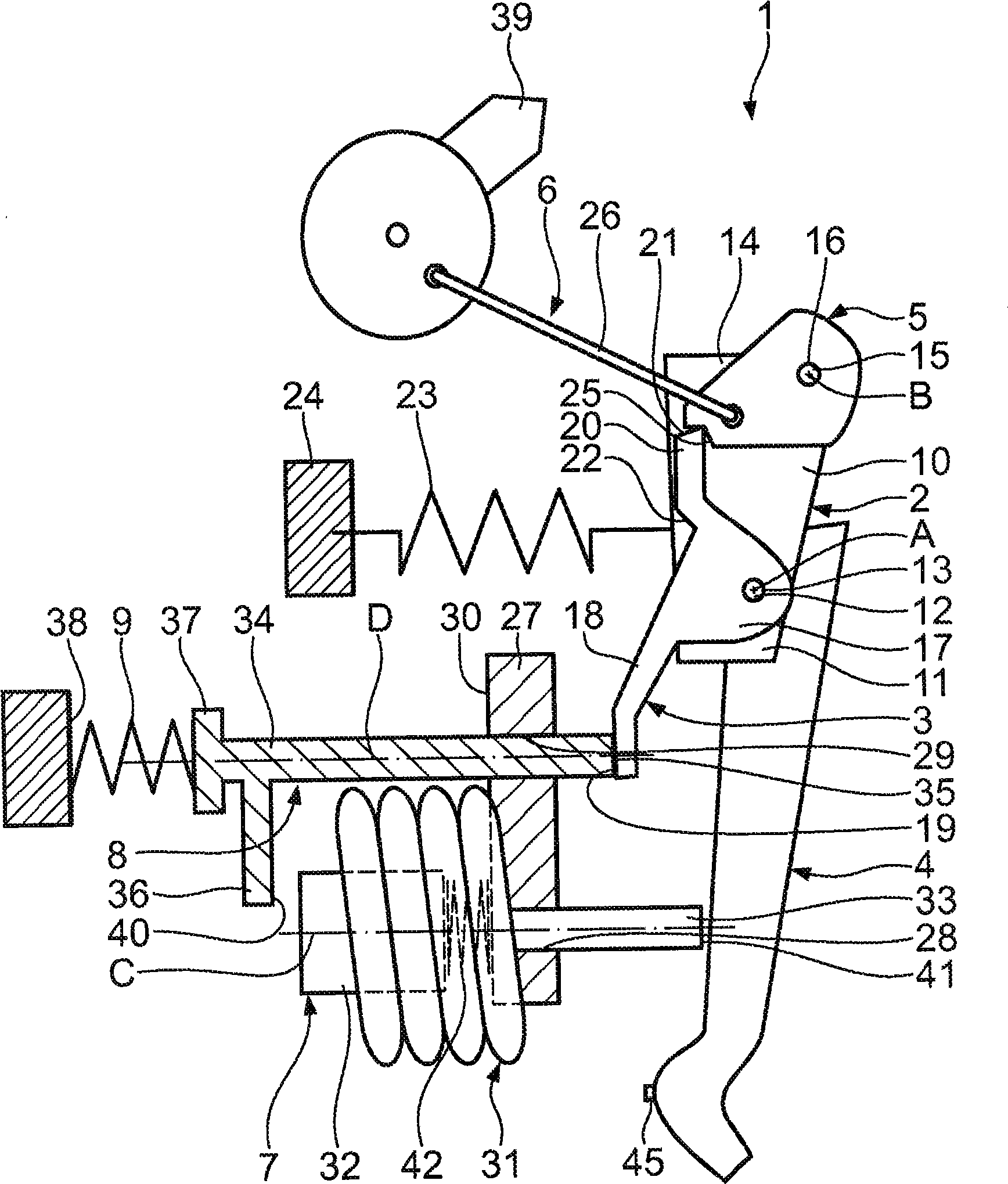

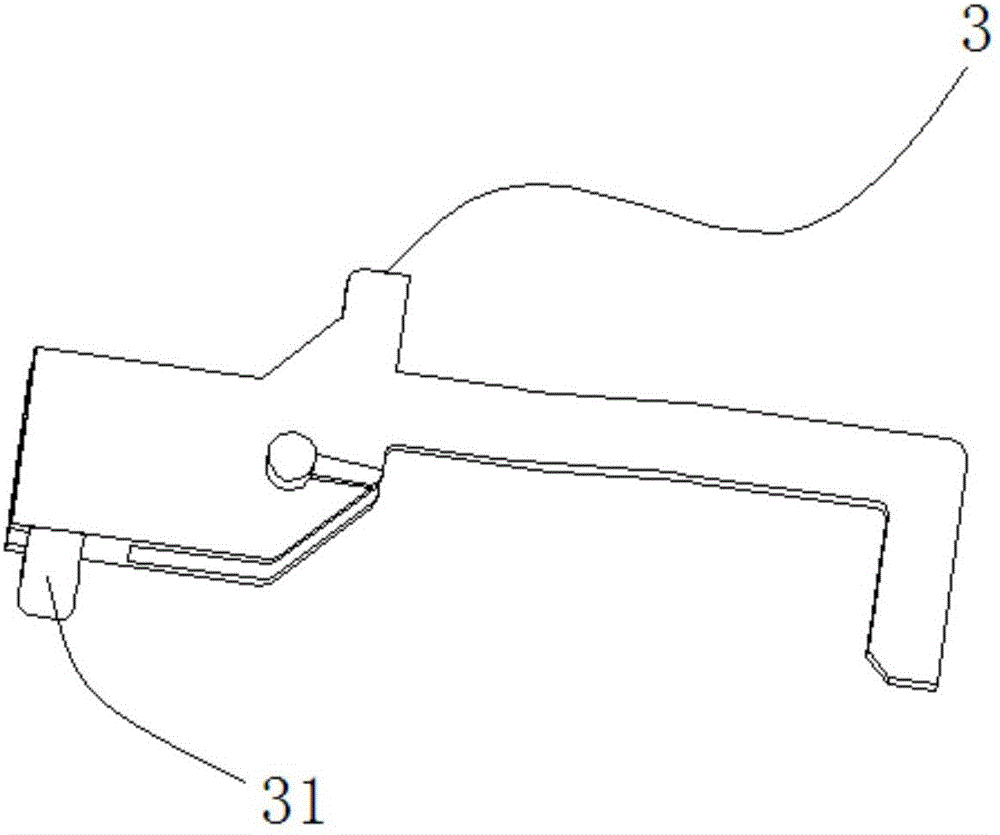

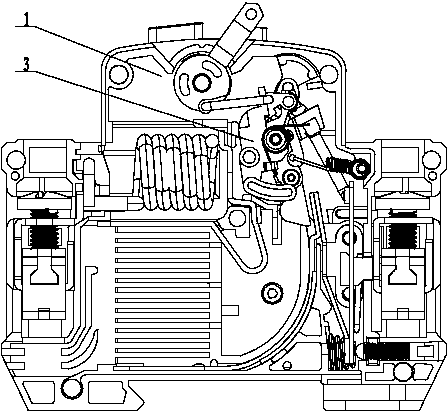

Precision tripping device

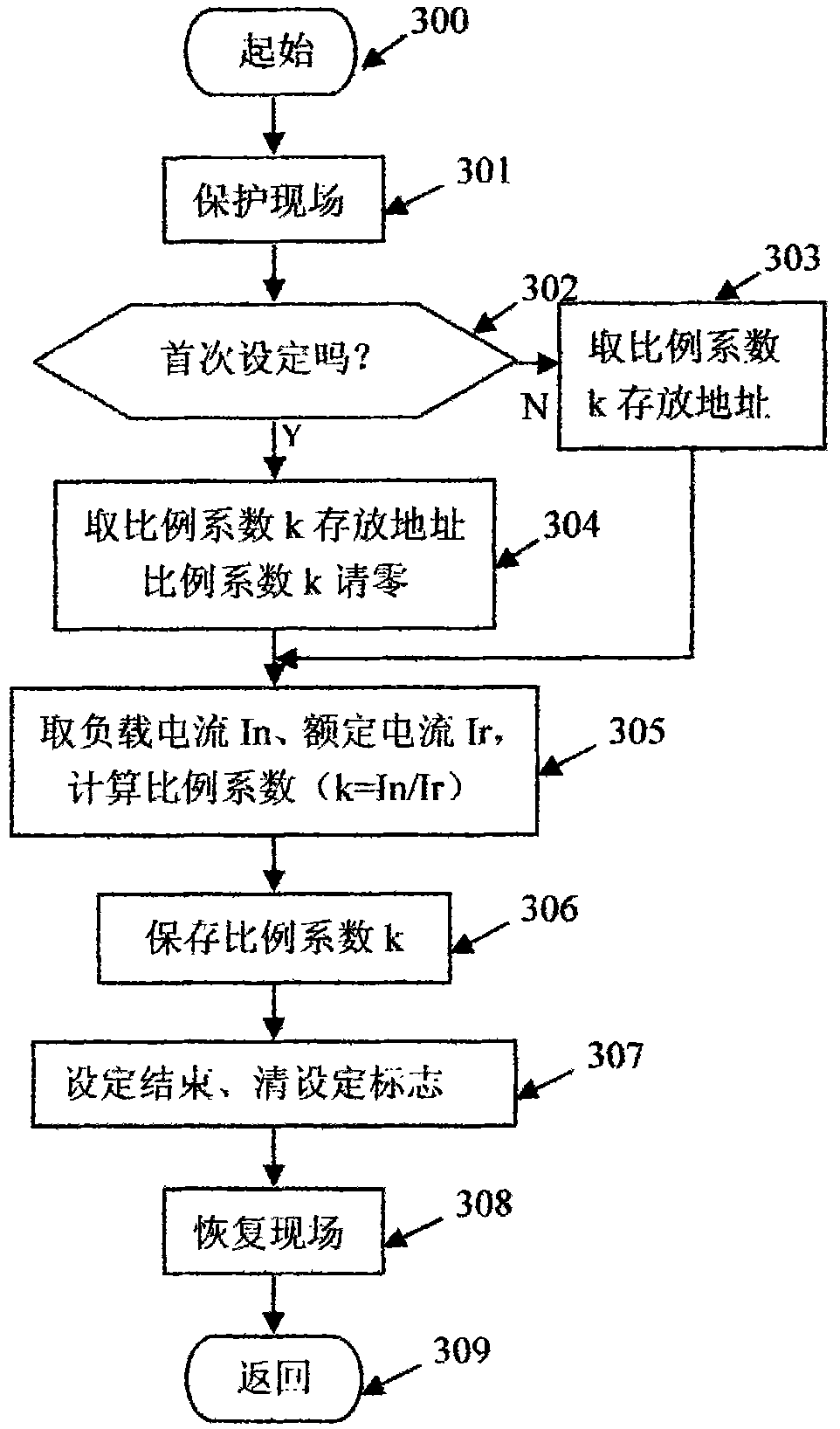

ActiveCN102044381AHigh sensitivityHigh precisionProtective switch detailsEmergency protection data processing meansLow voltageCurrent sensor

The invention belongs to the technical field of high-voltage and low-voltage electric appliances and relates to a precision tripping device which mainly comprises an electronic control system 1, a tripping mechanism 2 and a current sensor 3. The functions of precision tripping protection and control are fulfilled, and in a set mode, the comparison operation are carried out on a collected load current and a rated current, a ratio coefficient of an operation result is memorized and stored, and the collected load current which is smaller than the rated value is enlarged to be equal to or approach the rated current value in a running mode, thereby acquiring the precision safety protection characteristics of high sensitivity and high accuracy, ensuring safe running of electric equipment and anelectric line and putting an end to occurrence of personal and equipment accidents and fires. The invention is mainly used for precision tripping protection and precision control of various circuit breakers, is suitable for precision control of a contactor, a relay, an electromagnet and an electromagnetic valve and is additionally suitable for other control devices adopting a proportion amplification method to enhance the sensitivity and the accuracy.

Owner:张 世兴

Oil pipe dragging fracturing pipe column with packer as bottom seal and fracturing method

InactiveCN112523734APrevent pre-settingImprove securityFluid removalSealing/packingHorizontal wellsTripping

The invention discloses an oil pipe dragging fracturing pipe column with a packer as a bottom seal and a fracturing method. The oil pipe dragging fracturing pipe column comprises a flow guide ball seat, a sand prevention hydraulic anchor, a throttling-free self-service unsetting packer, a hydraulic ejector and a hydraulic safety connector connected to the upper part of the hydraulic ejector through an oil pipe, wherein the flow guide ball seat, the sand prevention hydraulic anchor, the throttling-free self-service unsetting packer and the hydraulic ejector are sequentially connected from bottom to top. The flow guide ball seat comprises a cylindrical body, a valve ball and a baffle ring, wherein the valve ball and the baffle ring are arranged in the cylindrical body from bottom to top; andthe packer comprises a pipe body structure, a sealing mechanism and a power mechanism, wherein the sealing mechanism and the power mechanism sleeve the pipe body from bottom to top, and a compressionspring is arranged in the power mechanism and can move upwards under the hydraulic action to compress the sealing mechanism to form setting. According to the oil pipe dragging fracturing pipe columnwith the packer as the bottom seal and the fracturing method, the tripping-in safety of the fracturing tubular column can be improved, setting and unsetting are achieved through pressure changes in the fracturing tubular column, throttling is not needed, the tripping-in and tripping-out processes of the tubular column are convenient to operate, the fracturing operation efficiency is high, the costis low, the risk is small, and the oil pipe dragging fracturing pipe column can be applied and popularized on vertical wells and horizontal wells.

Owner:CNPC BOHAI DRILLING ENG +1

Methods and apparatus for an improved magnetic armature selective tripping device of a circuit breaker

InactiveUS20150035630A1Increase volumeActivation point of the selectivity deviceProtective switch detailsSwitches with electromagnetic openingMagnetic tension forceElectrical conductor

Methods, apparatus, and systems are provided for a selectivity device for a circuit breaker. The invention includes a modular assembly adapted to be coupled to a load conductor assembly. The modular assembly includes a tripping plunger including a cam surface adapted to interact with a breaker tripping mechanism; an armature coupled to the tripping plunger; a yoke adapted to generate a magnetic field in response to an electric current in the load conductor assembly and disposed to apply a magnetic force proportionate to the electric current on the armature; and a spring assembly adapted to counter-balance the magnetic force up to a predefined tripping current in the load conductor assembly. Numerous additional aspects are disclosed.

Owner:SIEMENS AG

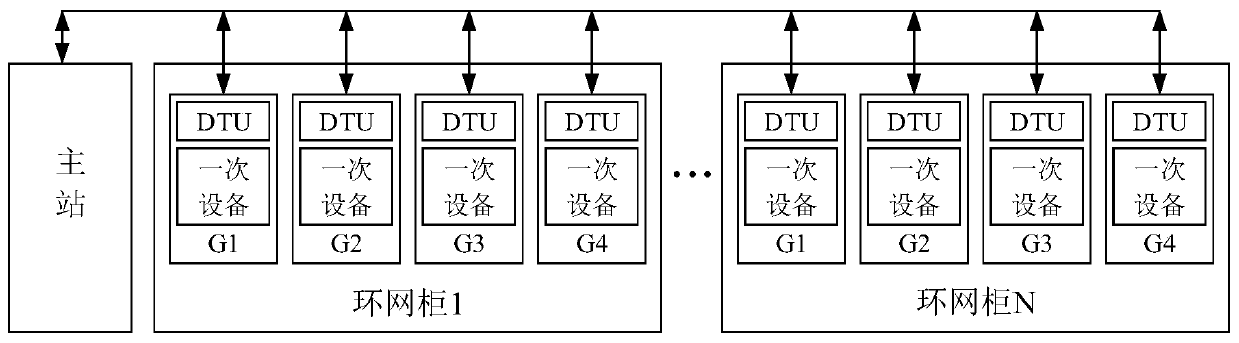

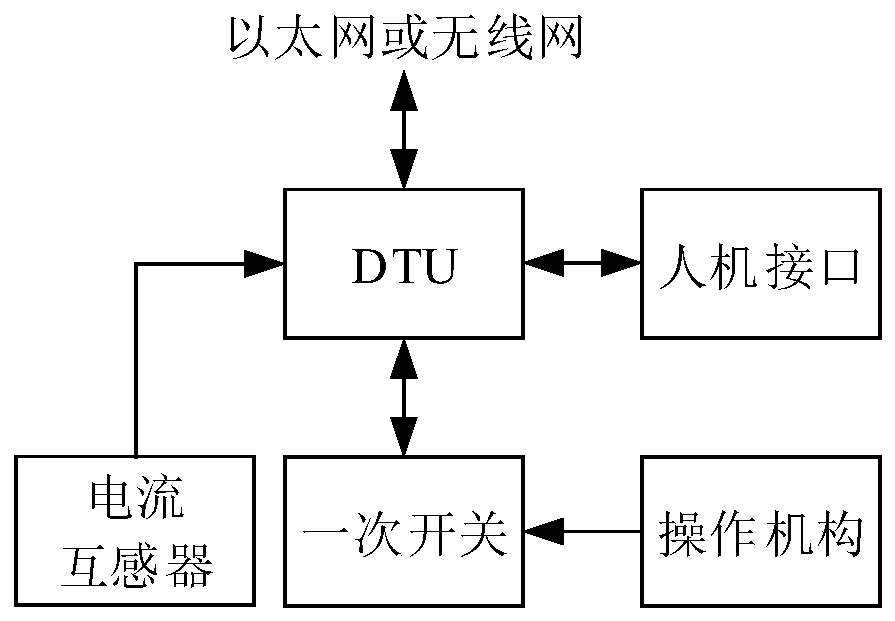

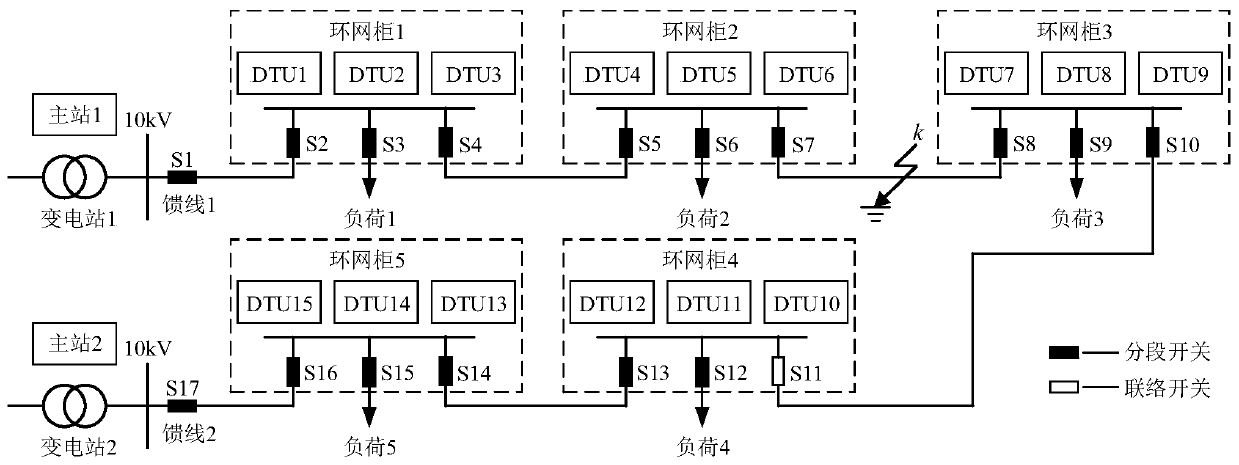

Integrated intelligent ring main unit system, intelligent power distribution network and fault positioning method

PendingCN111431057AFast fault locationFast failoverSubstation/switching arrangement detailsEmergency protective circuit arrangementsFeeder lineRecloser

The invention provides an integrated intelligent ring main unit system, an intelligent power distribution network and a fault positioning method. The intelligent power distribution network comprises the intelligent ring main unit system. Each interval unit of the system is provided with an independent DTU. Primary equipment and secondary equipment are integrally mounted; the DTUs can perform information interaction with the adjacent DTUs and a power distribution main station. The feeder line section where fault current is detected and the fault current is not detected at the downstream is a fault section; and rapid fault isolation is realized through tripping of a circuit breaker, fault recovery at the upstream of the fault section is realized through reclosing of the circuit breaker, andfault recovery at the downstream of the fault section is realized through closing of an interconnection switch. The method is suitable for quick fault positioning, fault isolation and fault recovery of the intelligent power distribution network with a high power supply capacity grid frame, realizes a quick self-healing function of the intelligent power distribution network, and improves the powersupply quality and the power supply reliability.

Owner:江苏恒新源电气有限公司

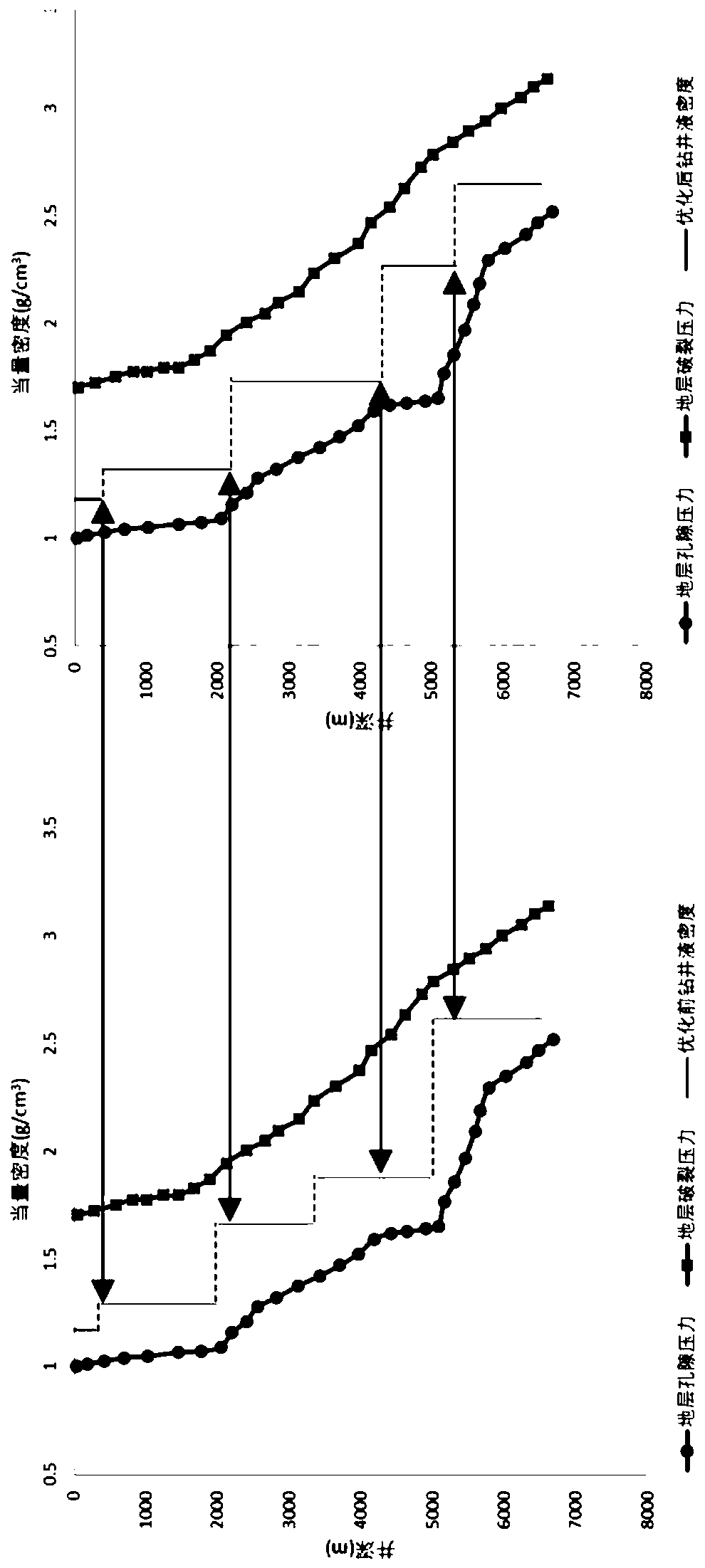

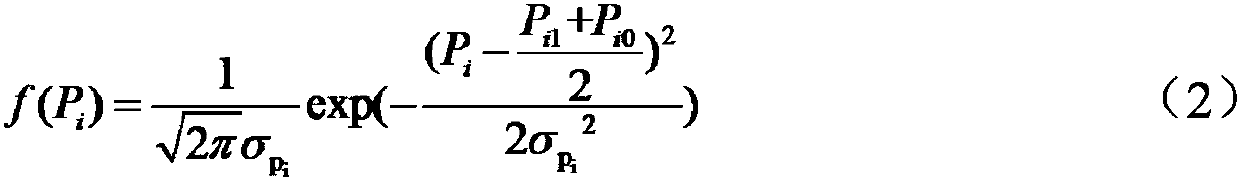

Design method of deep complex stratum well bore structure based on risk assessment

The invention relates to a design method of a deep complex stratum well bore structure based on risk assessment. The design method comprises the following steps: 1) preliminarily determining a casinglayer and a depth; 2) calculating to obtain a risk coefficient of each layer of sleeve; 3) analyzing and coordinating the risk of each layer of sleeve according to the principle that the shallow layerof sleeve shares more risks and the deep layer of sleeve shares less risks: judging whether the risk coefficient of each sleeve is greater than a safety threshold value K or not; checking the tripping-in depth: if the safety factor RNi of the casing pipe at the ith layer is greater than K, selecting the casing pipe layer with the minimum safety factor from the upper casing pipe layers, and deepening the tripping-in depth h of the casing pipe layer; and 4) repeating the steps 2)-3) until the risk coefficient of each layer of sleeve is smaller than the safety threshold K. According to the method, the risk of the deep well bore structure is properly moved upwards, more design space is provided for the layer and the depth of the sleeve of the deep stratum, the comprehensive risk of the wholewell bore structure is reduced to the maximum extent, and a guarantee is provided for safe and efficient drilling.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

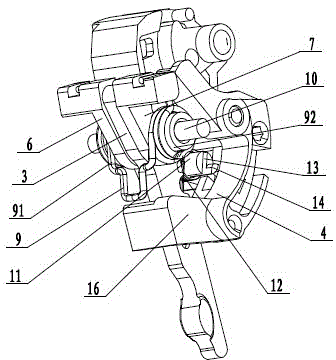

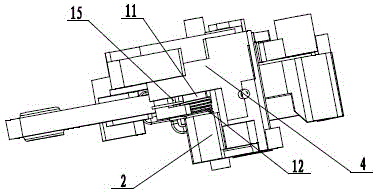

Switching unit

InactiveCN101501806AAchieve releaseProtective switch operating/release mechanismsTime delaysElectrical and Electronics engineering

The invention relates to the switching unit for the selective switching off of at least one consumer, having at least one contact point with a moveably mounted contact lever (4), an actuable hammer armature (7) for opening of the contact point by moving of the contact lever (4) and a switching lock (6) with a moveably mounted latch (5) and a moveably mounted tripping lever (3) being assigned to the latch (5). The tripping lever (3) is moveable between a latch-release-position and a latch-locking-position. The release of the latch (5) by the tripping lever (3) is time-delayed compared to the actuation of the contact lever (4) by the hammer armature (7).

Owner:SIEMENS AG

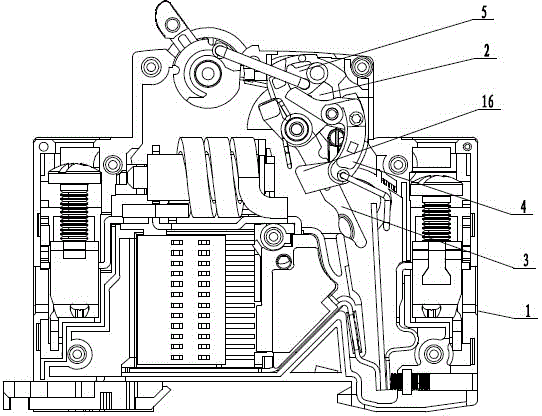

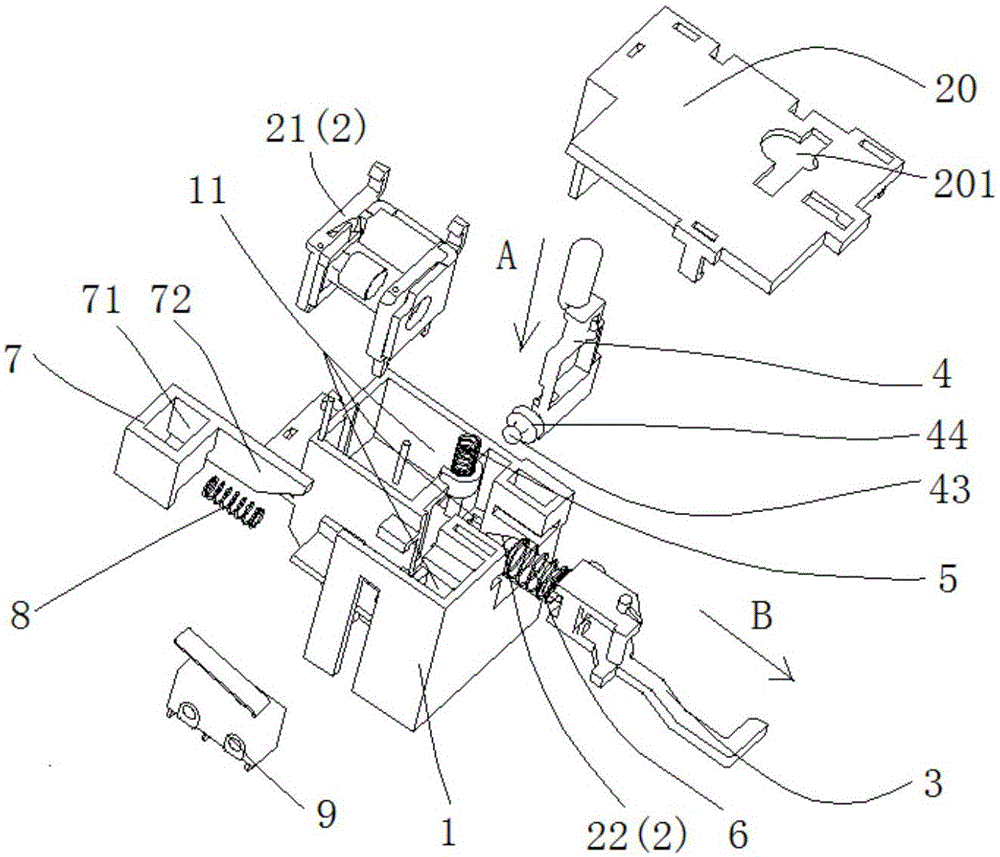

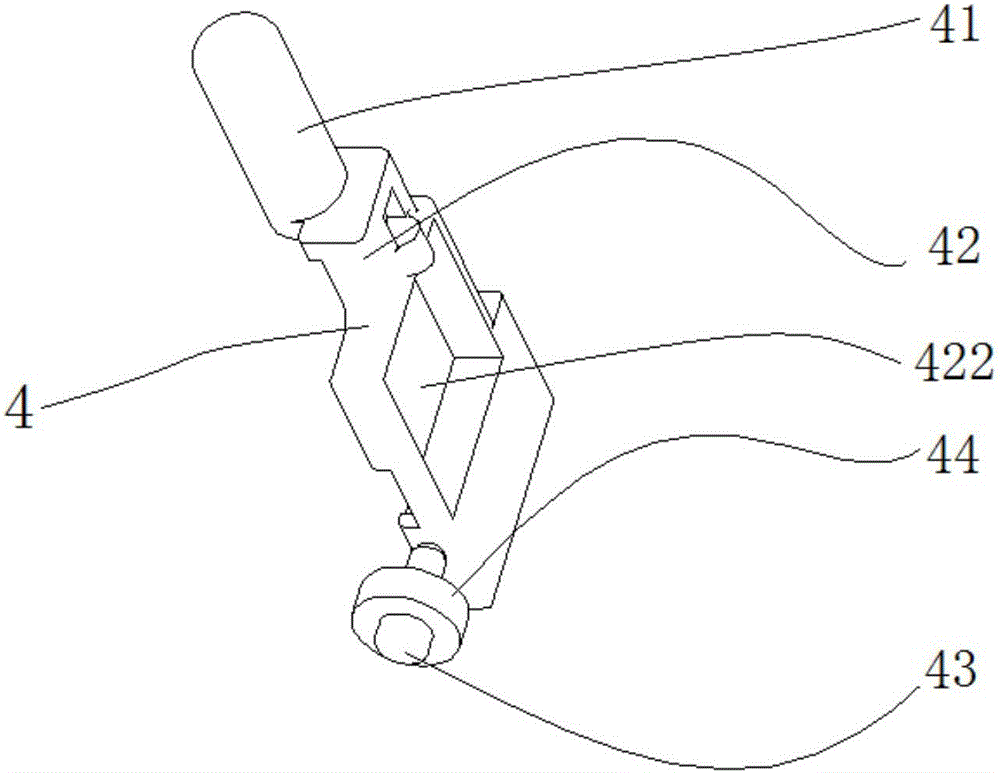

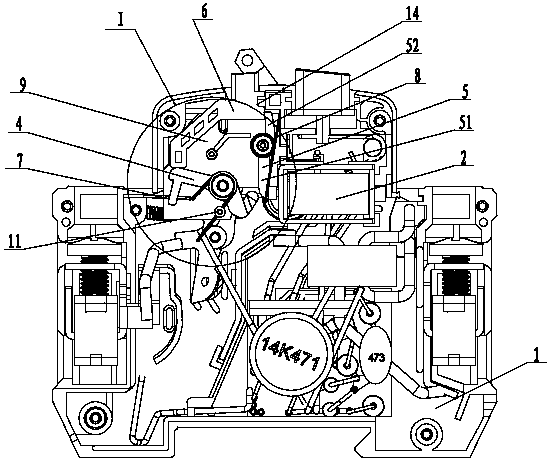

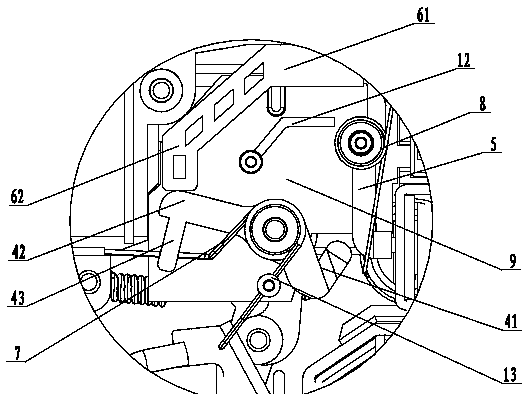

Miniature circuit breaker

ActiveCN104167333APrecise positioningImprove stabilityEmergency protective device manufactureProtective switch operating/release mechanismsStructural engineeringTripping

The invention relates to a miniature circuit breaker. The technical problems that an operating mechanism of an existing miniature circuit breaker is poor in precision, low in stability and poor in using performance when used are mainly solved. The miniature circuit breaker comprises an outer shell, a contact support, a moving contact, a lock catch and a tripping buckle. The lock catch is matched with the tripping buckle, a first locating plate and a second locating plate which are spaced by a certain gap are arranged on the contact support, protruding rings are arranged on the outer side of the first locating plate and the outer side of the second locating plate, double torsional springs are arranged on the contact support and comprise a first torsional spring and a second torsional spring, the first torsional spring and the second torsional spring are symmetrically distributed on the two sides of the moving contact, the protruding rings of the locating plates are sleeved with the first torsional spring and the second torsional spring respectively, one end of the first torsional spring and one end of the torsional spring are respectively in clamping fit with the contact support, the other end of the first torsional spring and the other end of the second torsional spring are connected and are respectively in clamping fit with the moving contact, the first locating plate, the second locating plate and the protruding rings are provided with a fixed shaft, and the moving contact is arranged in a clearance and is hinged to the fixed shaft. Due to the fact that the miniature circuit breaker is reasonable in structural design, locating is accurate, high stability and good use performance are achieved, and in addition, the miniature circuit breaker has the advantages of being simple in structure, low in cost, convenient to mount and the like.

Owner:GACIA ELECTRICAL APPLIANCE

Electric leakage tripping device and leakage circuit breaker containing the tripping device

ActiveCN106328456AReduce in quantitySimple structureProtective switch operating/release mechanismsState variationCircuit breaker

Owner:DELIXI ELECTRIC

Method for testing the functionality of the electromagnetic tripping of a switch, in particular of a circuitbreaker for low voltages

ActiveCN102419419ADecreased electronic propertiesCircuit interrupters testingRelaysLow voltageEngineering

A method is disclosed for testing the functionality of the electromagnetic tripping of a switch, in particular of a circuit breaker for low voltages, which has switching contacts which are opened with the aid of a tripping shaft, which is held prestressed by a switching mechanism and is unlatched by a tripping magnet which for this purpose has a winding through which a current is sent for tripping. In order to test the functionality with relatively little effort, it is proposed in at least one embodiment that the winding is connected as an inductance in a resonant circuit, the resonant frequency of the resonant circuit is detected, and the functionality of the tripping magnet is assessed on the basis of the detected resonant frequency.

Owner:SIEMENS AG

Integrated window sidetrack drilling tool

ActiveCN106930712AWon't enterAvoid missettingBorehole/well accessoriesDrilling machines and methodsAdhesive beltControl engineering

The invention discloses an integrated window sidetrack drilling tool which comprises a hollow cone mill bit, wedge deflection tool tapered iron and a setting and anchorage device which are sequentially connected. A liquid guide pipe is arranged in the wedge deflection tool tapered iron. The lower end of the liquid guide pipe is connected with a jet pipe in the setting and anchorage device. A setting ball is arranged at the lower end of an inner hole of the jet pipe. The upper portion of the setting ball is clamped to the annular upper clamping edge of the jet pipe. A limiting structure or limiting adhesive tape is arranged at the lower end inside the jet pipe. The setting ball is clamped to the upper clamping edge during downward drilling. An annular lower clamping edge is arranged at the lower end of an inner hole of a lower cone body of the setting and anchorage device. During setting operation, the setting ball breaks through the limiting structure or the limiting adhesive tape under pushing of a high-pressure drilling fluid and falls off to be clamped to the lower clamping edge to achieve setting. By adoption of the integrated window sidetrack drilling tool, the situation that the drilling fluid in a drill stem in the downward drilling process generates excited pressure, and halfway error setting is caused can be avoided, the situation that tripping-out is too fast, pumping is generated, and halfway error setting is caused can also be avoided, operation is reliable, the operating efficiency can be improved, and the operating cost is lowered.

Owner:JINZHOU QINGHUA MACHINERY

Efficient rock breaking oscillation device with disc spring-sealing cavity buffering function

ActiveCN112177529AReduce the maximum loadWon't failBorehole drivesVibration devicesUpper jointSteel ball

The invention relates to an efficient rock breaking oscillation device with a disc spring-sealing cavity buffering function. The device comprises an upper joint, a shell, a turbine driving assembly, asine shaft impact assembly, a spiral torsional impact assembly, a disc spring-sealing cavity buffer assembly and a lower joint, and is characterized in that the turbine driving assembly is positionedat the upper part of a tool and provides power required by the operation of the tool; and the sine shaft impact assembly adopts a sine surface structure to generate axial reciprocating impact, the spiral torsional impact assembly adopts a spiral slide way, a steel ball and a linear short slide way structure to generate torsional impact, and the disc spring-sealing cavity buffer assembly positioned at the lower part of the tool adopts a disc spring and forms a closed sealing cavity structure, so that excessively strong torsional impact can be buffered. The efficient rock breaking oscillation device can play a role in buffering excessively-strong torsion impact so as to reduce part loading, prolong the service life of the torsion impact tool, improve the rock breaking efficiency and the drilling speed of a drill bit, reduce tripping and reduce the drilling cost.

Owner:SOUTHWEST PETROLEUM UNIV

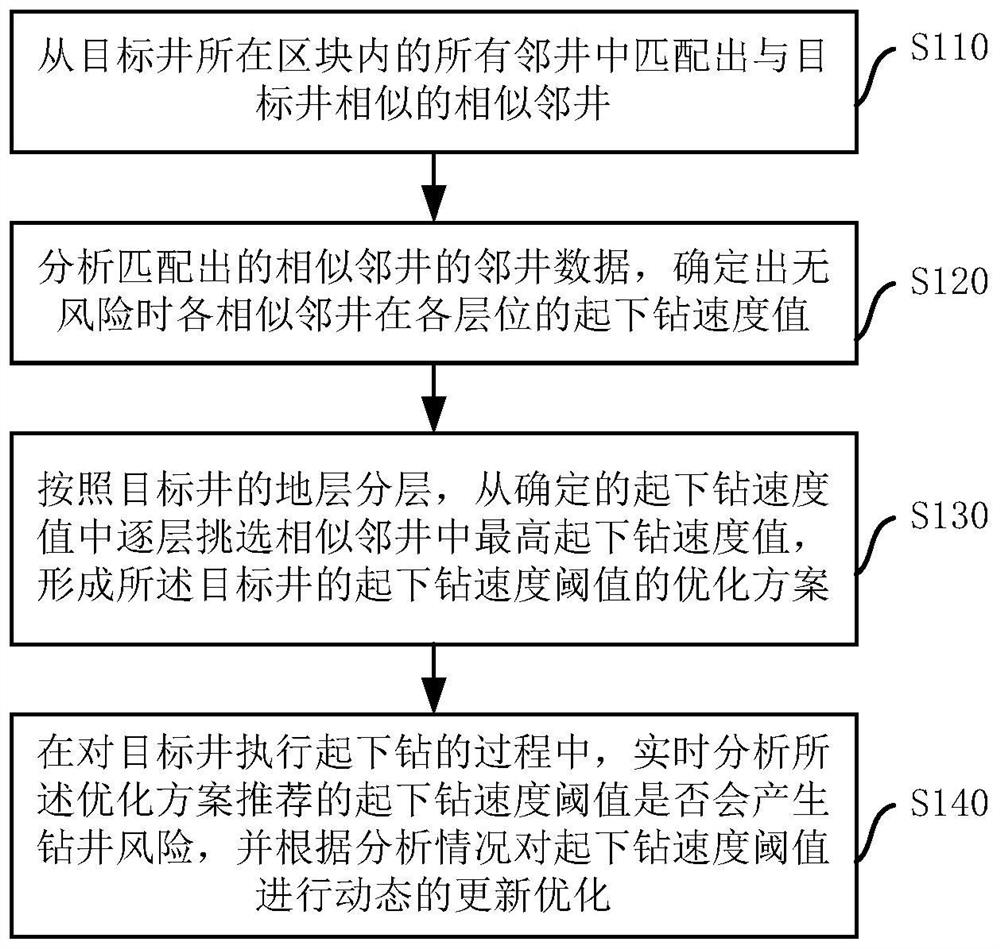

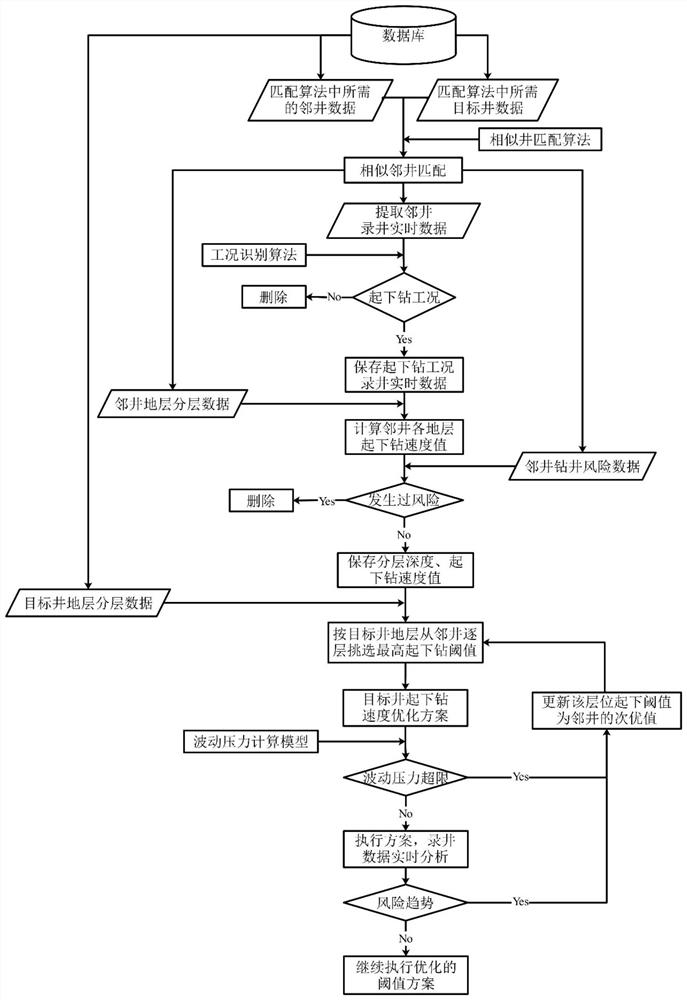

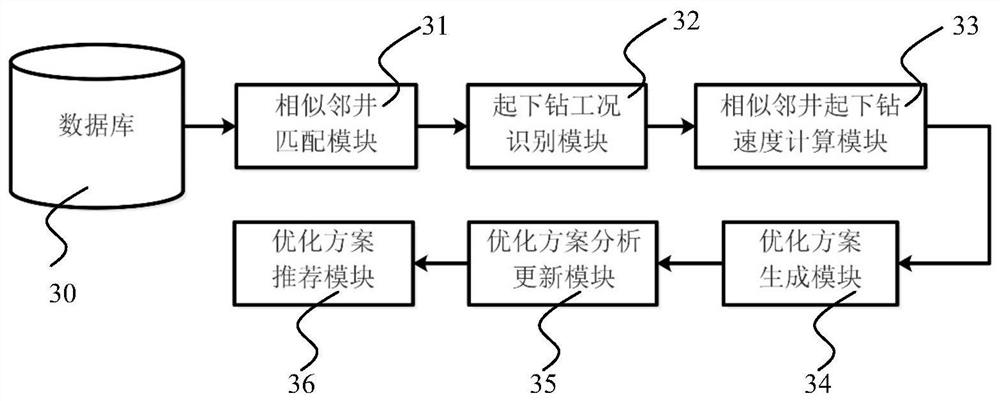

Method and system for optimizing tripping speed threshold value of drilling well

PendingCN113378344AAvoid reducing ergonomicsDesign optimisation/simulationReal time analysisWell drilling

The invention discloses a method and a system for optimizing a tripping speed threshold value of a drilling well. The method comprises the following steps: matching a similar adjacent well similar to a target well from all adjacent wells in a block where the target well is located; determining adjacent well data of the matched similar adjacent wells are obtained and analyzed, and tripping speed values of all the similar adjacent wells at all the layers when no risk exists; according to the stratum layering of the target well, the highest tripping speed value in the similar adjacent wells is selected from the determined tripping speed values layer by layer, and an optimization scheme of the tripping speed threshold value of the target well is formed; and in the process of executing tripping on the target well, whether the tripping speed threshold value recommended by the optimization scheme can generate a drilling risk or not is analyzed in real time, and the tripping speed threshold value is dynamically updated and optimized according to the analysis condition. On the premise of safe operation, high-speed tripping operation is achieved, tripping operation time is shortened, drilling operation efficiency is improved, and cost is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Electric-leakage circuit breaker

ActiveCN104183430AEasy to useSimple structureSwitching device condition indicationControl theoryTripping

The invention relates to an electric-leakage circuit breaker which mainly solves a problem that the prior electric-leakage circuit breakers do not have electric-leakage indication at electric leakage tripping so that a user is incapable of judging whether breaking is caused by a leakage fault according to a concrete condition and thus specific effects are caused on use. The electric-leakage circuit breaker includes an electric-leakage indication mechanism which includes a tumbler, a lever and an indication button. The indication button includes a first position of extending out of a casing and a second position of burial in the casing. The tumbler is hinged below the indication button. One end of the tumbler contacts the indication button. The lever is hinged in the casing. One side of the lower end of the lever is corresponding to an electric-leakage release, and the other side is in jacking-pressing fit with the tumbler. The upper end of the lever is in clamping fit with the indication button. The electric-leakage release pushes upwards the indication button to spring out through the lever and the tumbler so that the first position is formed and when the indication button is pressed to slide downwards to clamp with the lever so that the second position is formed. The tumbler cooperates with a lock catch. Because an electric-leakage indication function is arranged in an electric-leakage part of the electric-leakage circuit breaker, when tripping and opening happen in the circuit breaker, whether tripping is caused by the leakage fault can be clearly displayed through the indication function so that follow-up operations of the user are facilitated and convenience is brought to use.

Owner:ZHEJIANG TENGEN ELECTRIC

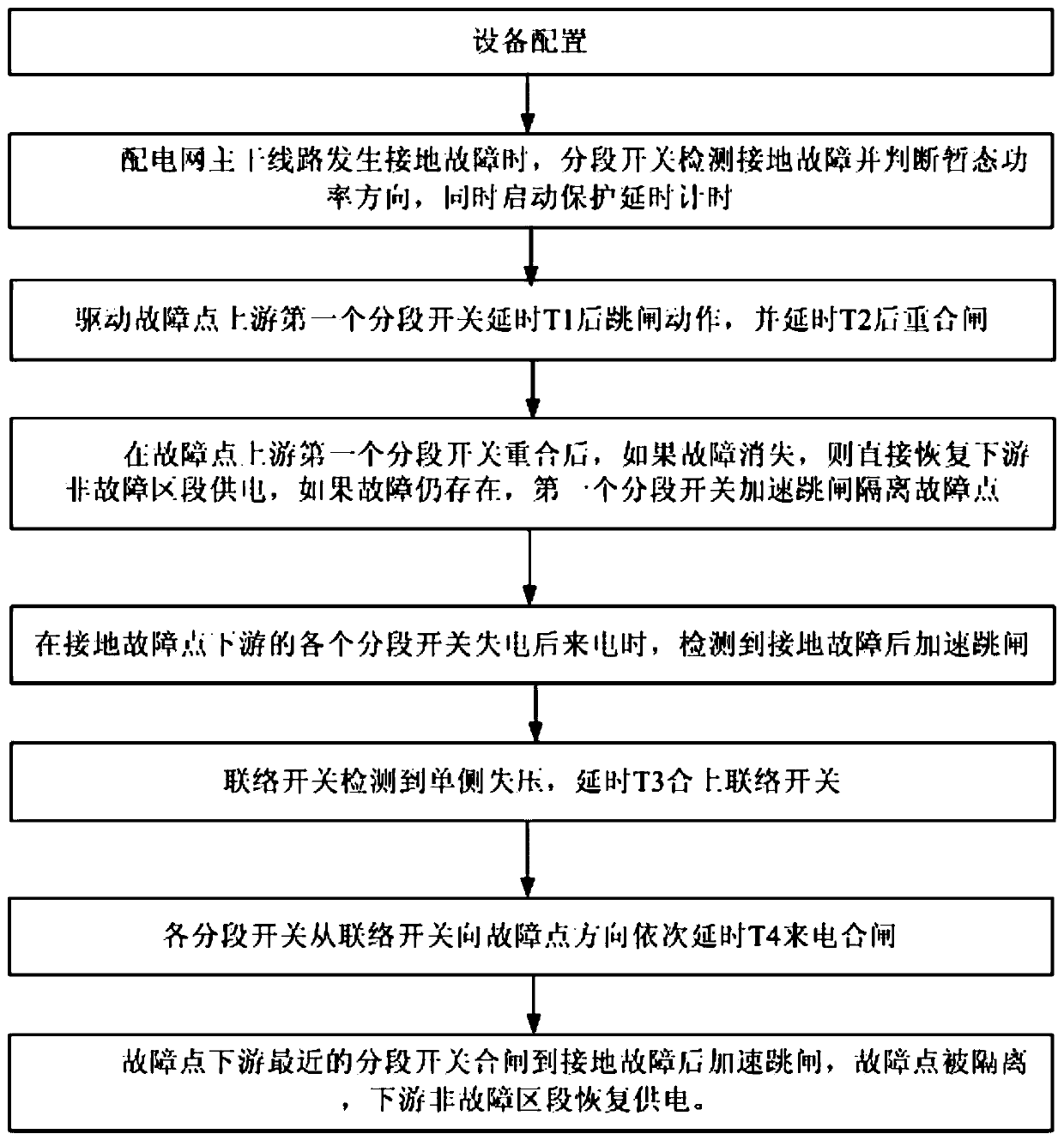

Method and equipment for recovering power supply of non-fault section at downstream of grounding fault

ActiveCN111525525AAdd acceleration trip functionImprove power supply reliabilityEmergency protective circuit arrangementsInformation technology support systemTransient stateRecloser

The invention discloses a method and equipment for recovering power supply of a non-fault section at the downstream of a grounding fault. The method comprises the following steps of: configuring equipment; when a grounding fault occurs in a main line of a power distribution network, detecting the grounding fault through section switches, and judging a transient power direction while starting protection delay timing; driving the first section switch at the upstream of the fault point to delay T1 and then tripping, and delaying T2 and then reclosing; after the first section switch is coincided,if the fault disappears, directly recovering the power supply of a downstream non-fault section, otherwise, accelerating tripping to isolate the fault point; when each section switch at the downstreamof the grounding fault point loses power and then is powered on, accelerating tripping after a grounding fault is detected; when an interconnection switch detects single-side voltage loss, delaying T3, and turning on the interconnection switch; making each section switch sequentially delay T4 from the interconnection switch to the fault point direction so as to be switched on; and after the nearest section switch at the downstream of the fault point is switched on to the grounding fault, accelerating tripping, so that the fault point is isolated, and the downstream non-fault section recoverspower supply.

Owner:国网山东省电力公司营销服务中心(计量中心) +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com