Wind turbine blade with tripping device and method thereof

A technology of wind turbines and conversion devices, applied to wind engines that are consistent with the wind direction, configurations for installing/supporting wind engines, wind engines, etc., can solve problems affecting lift coefficients, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

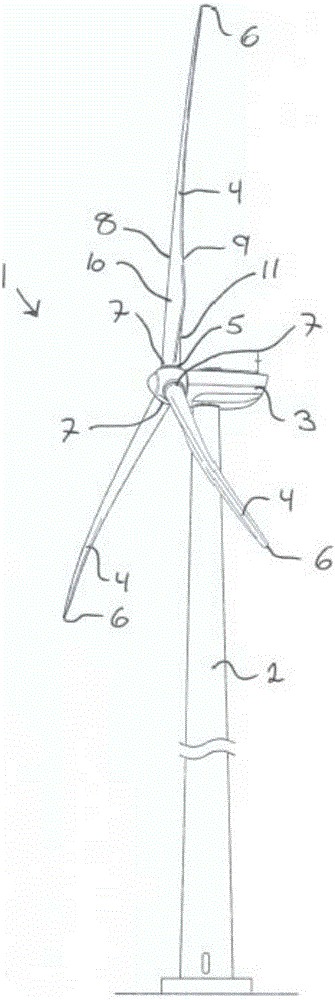

[0111] figure 1 An exemplary embodiment of a wind turbine 1 comprising a wind turbine tower 2 is shown. The nacelle 3 is arranged on top of the wind turbine tower 2 and is connected to the wind turbine tower 2 through a yaw mechanism (not shown). A rotor comprising at least two wind turbine blades 4 , here shown with three blades, is rotatably connected to a drive train arranged inside the nacelle 3 via a shaft. The wind turbine blades 4 are rotatably connected to the hub via a pitch mechanism 5 controlled by a pitch control system.

[0112] Each wind turbine blade 4 has a tip 6 , a root 7 and a body with an aerodynamic shape defining a leading edge 8 and a trailing edge 9 . The side surfaces of the aerodynamically shaped body define a pressure side 10 and a suction side 11 respectively.

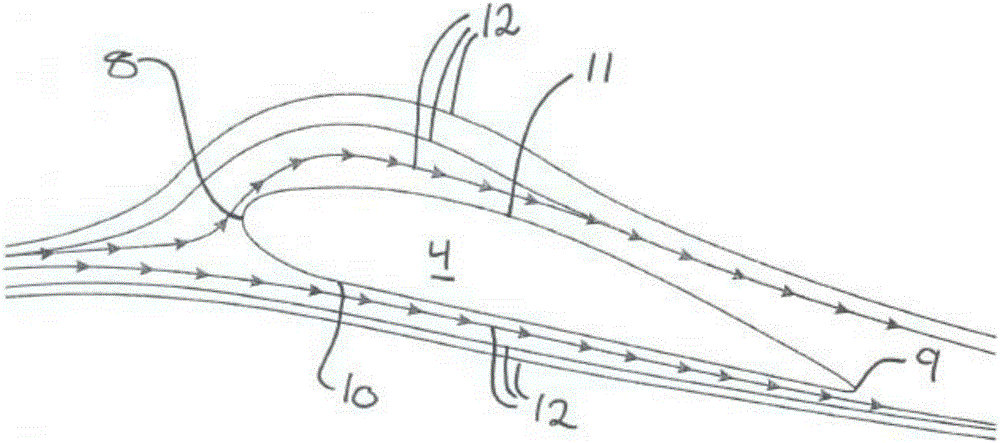

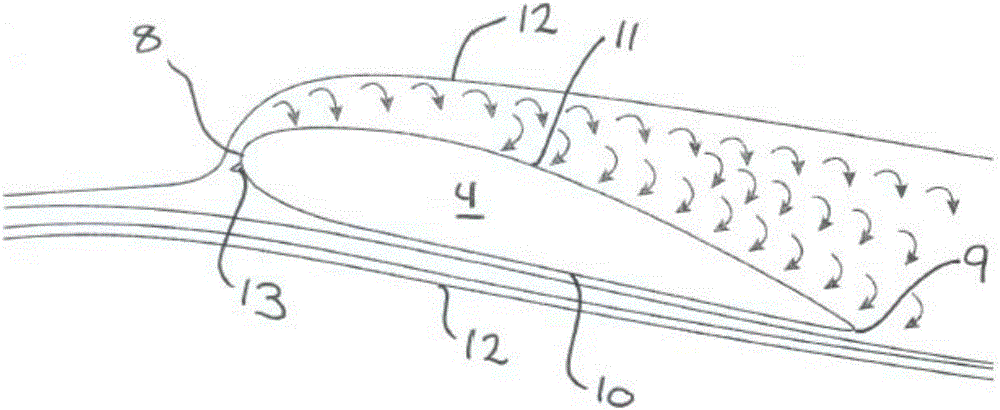

[0113] FIG. 2 shows the air flow around a wind turbine blade 4 that is not equipped with a stall device on the pressure side 10 . The incoming wind strikes the wind turbine blade at an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com