Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2575results about "Wind motor assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

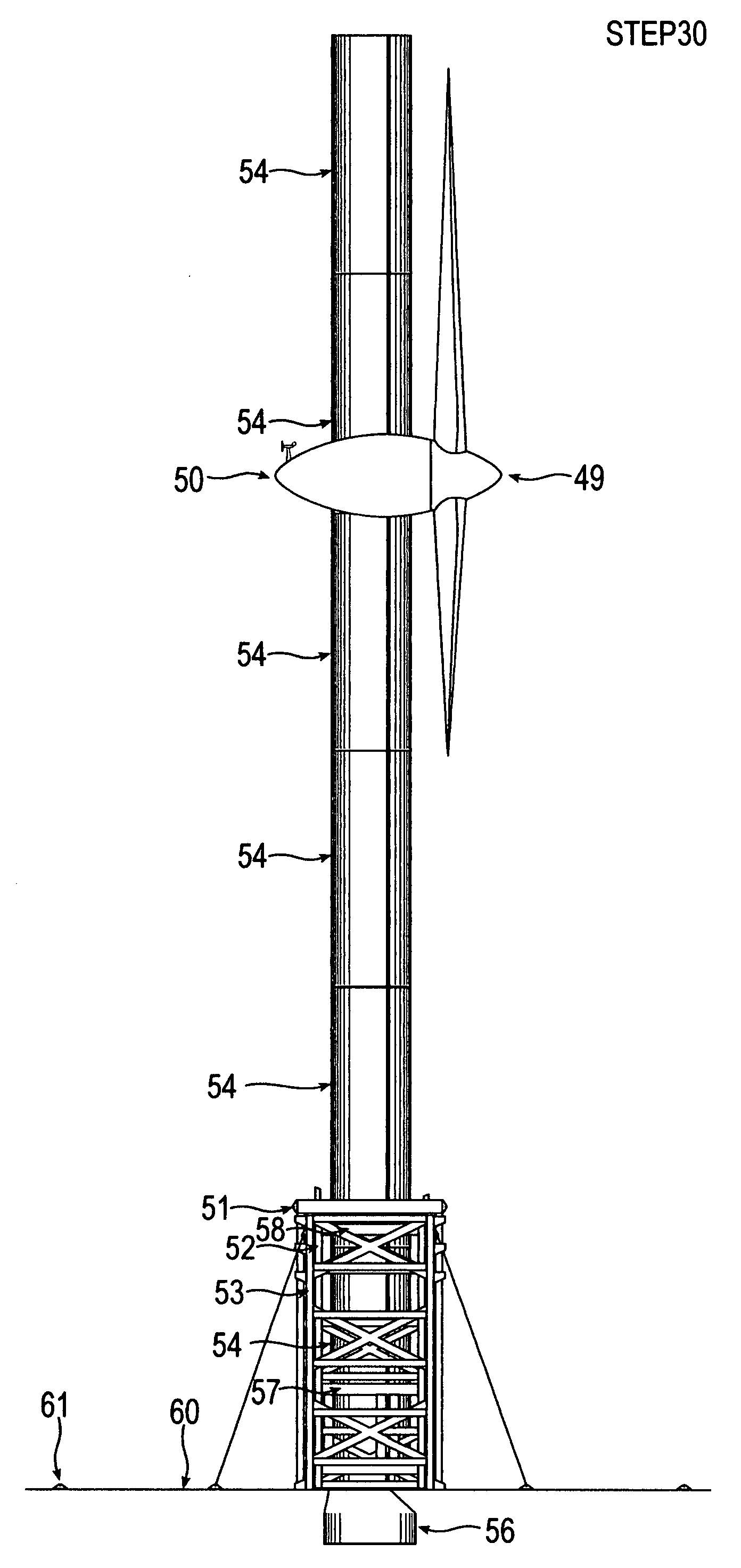

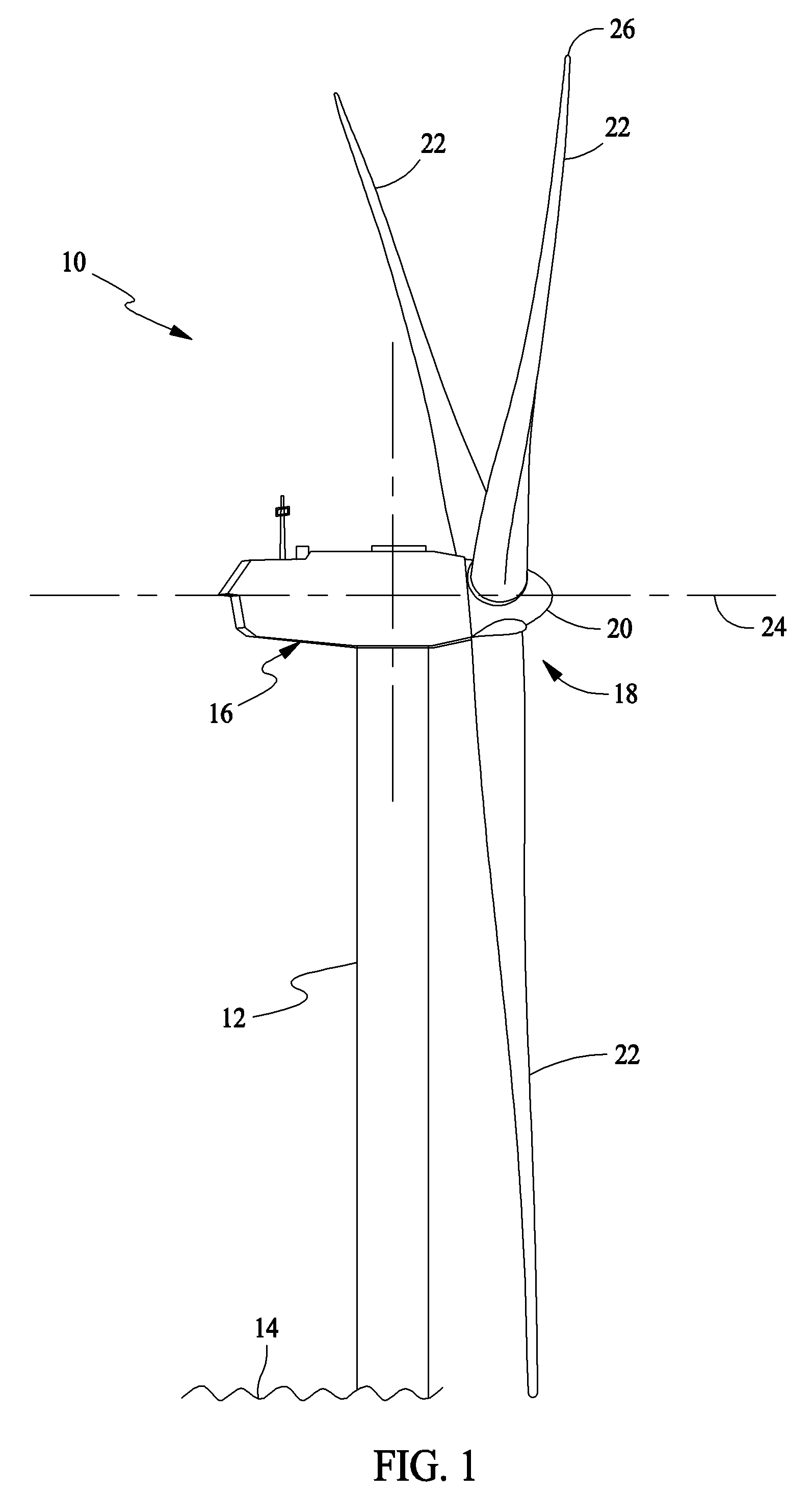

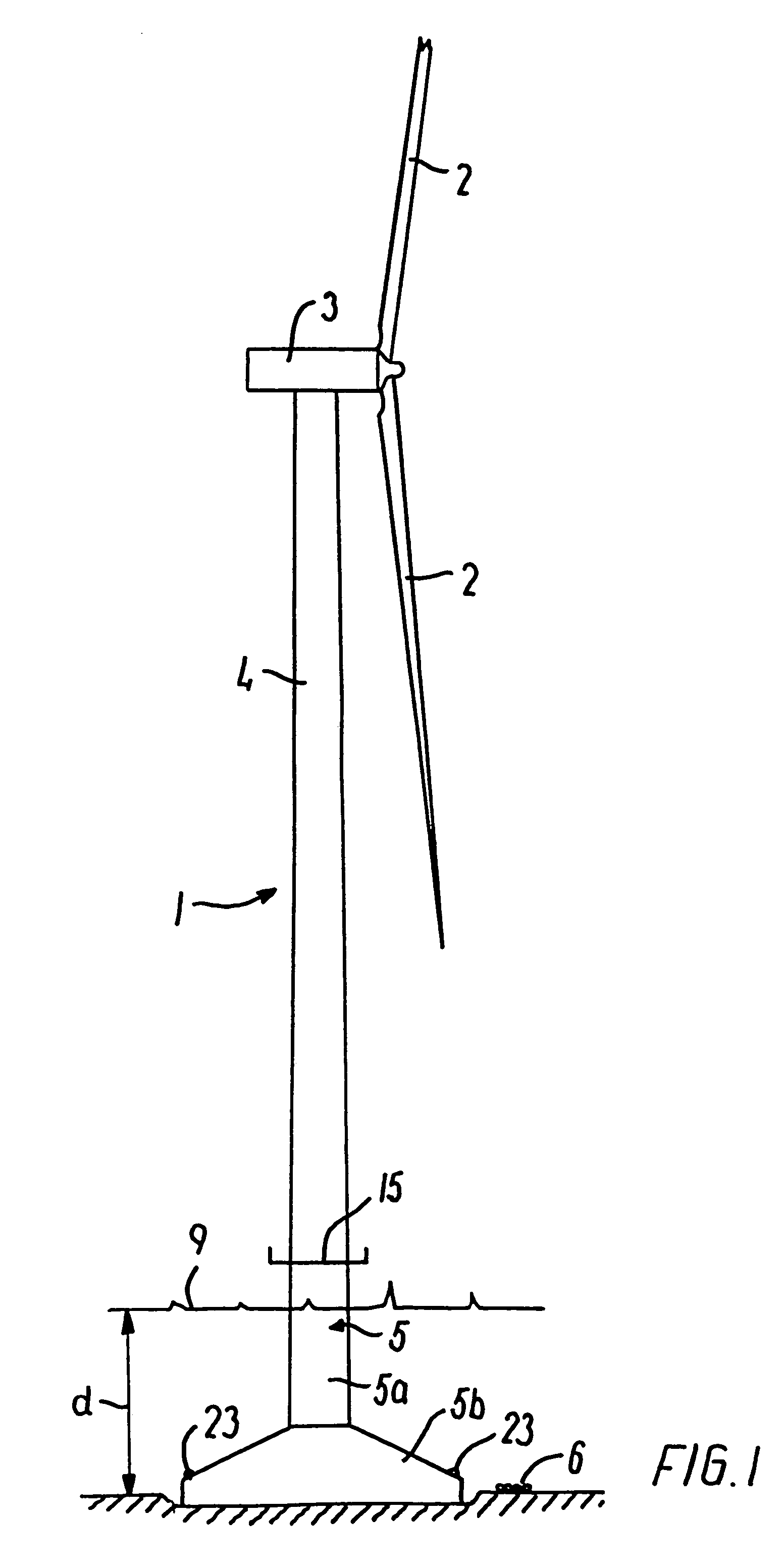

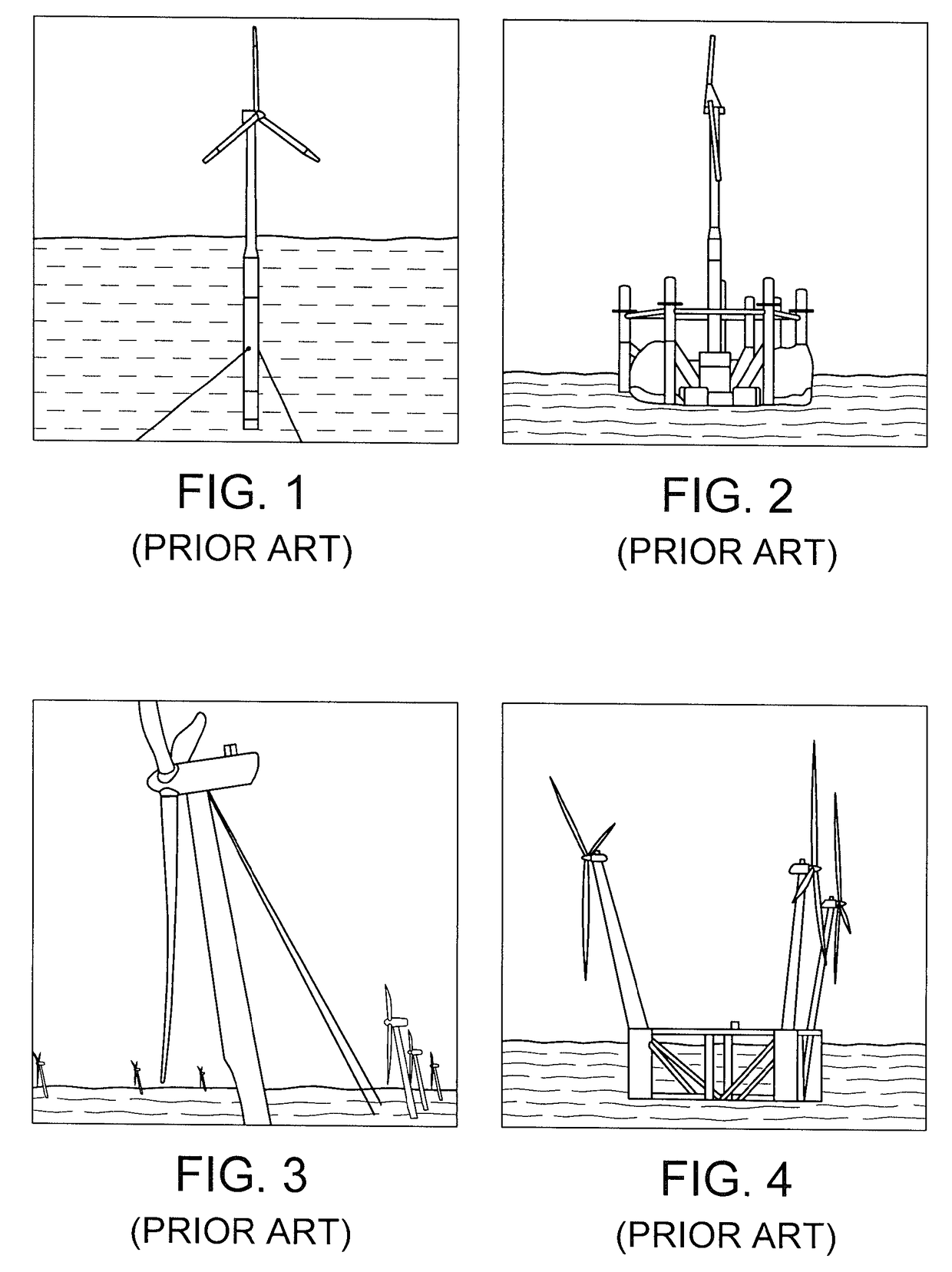

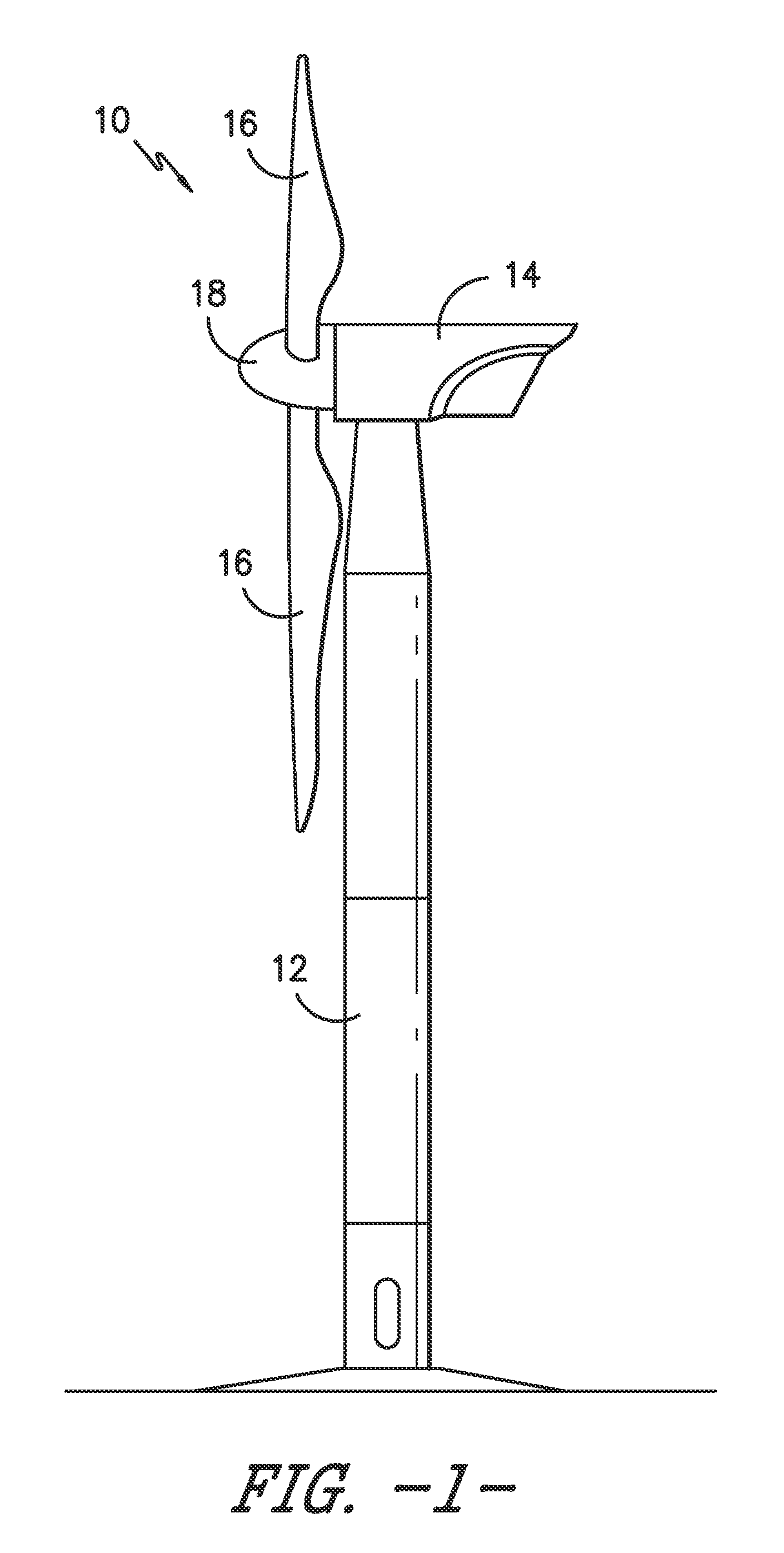

Offshore wind turbine and method for making same

InactiveUS20040169376A1Reduce usageEasy to transportEngine manufactureFinal product manufactureElectricityEngineering

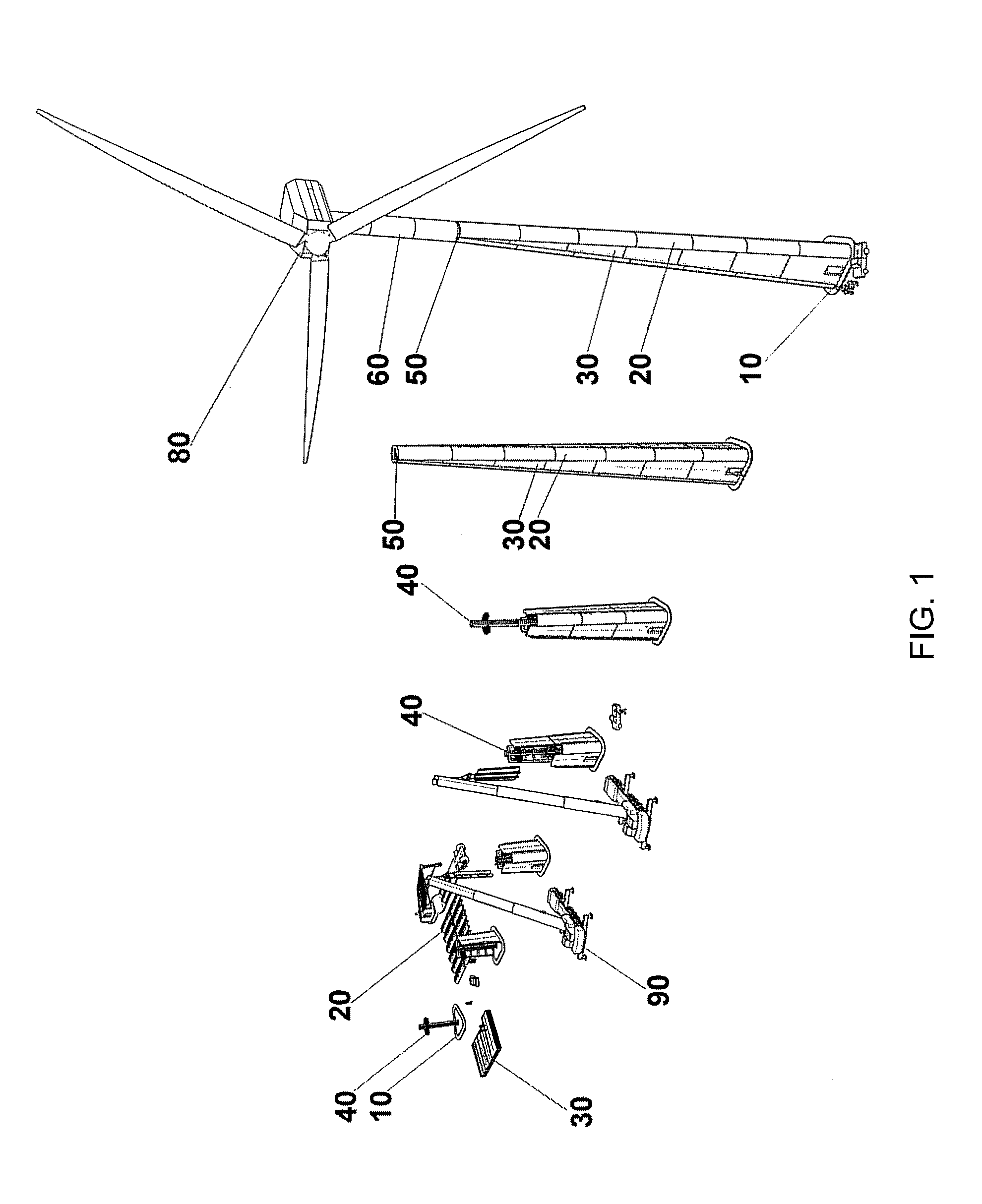

The present invention relates to wind generators installed off-shore, in particular at sea, to support structures forming a part of such wind generators, and to methods of making and installing such wind generators. The technical field of the invention is that of making, transporting, and installing wind generators for producing electricity, more particularly off-shore, and in large numbers, so as to form wind "farms". The wind generator of the invention comprises a wind turbine and a deployable telescopic pylon or support supporting the turbine, and a gravity base supporting the pylon or support.

Owner:SAIPEM SA

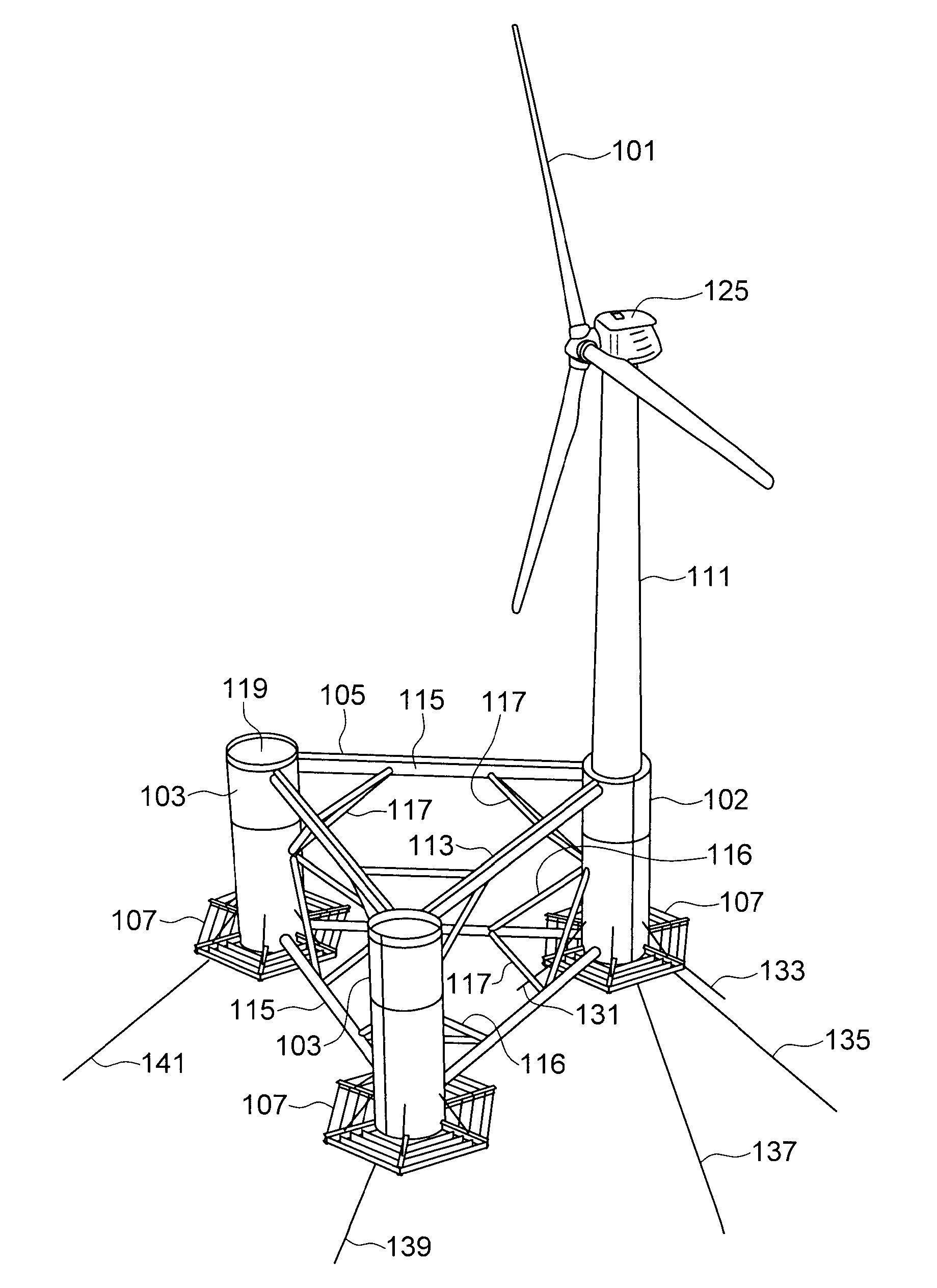

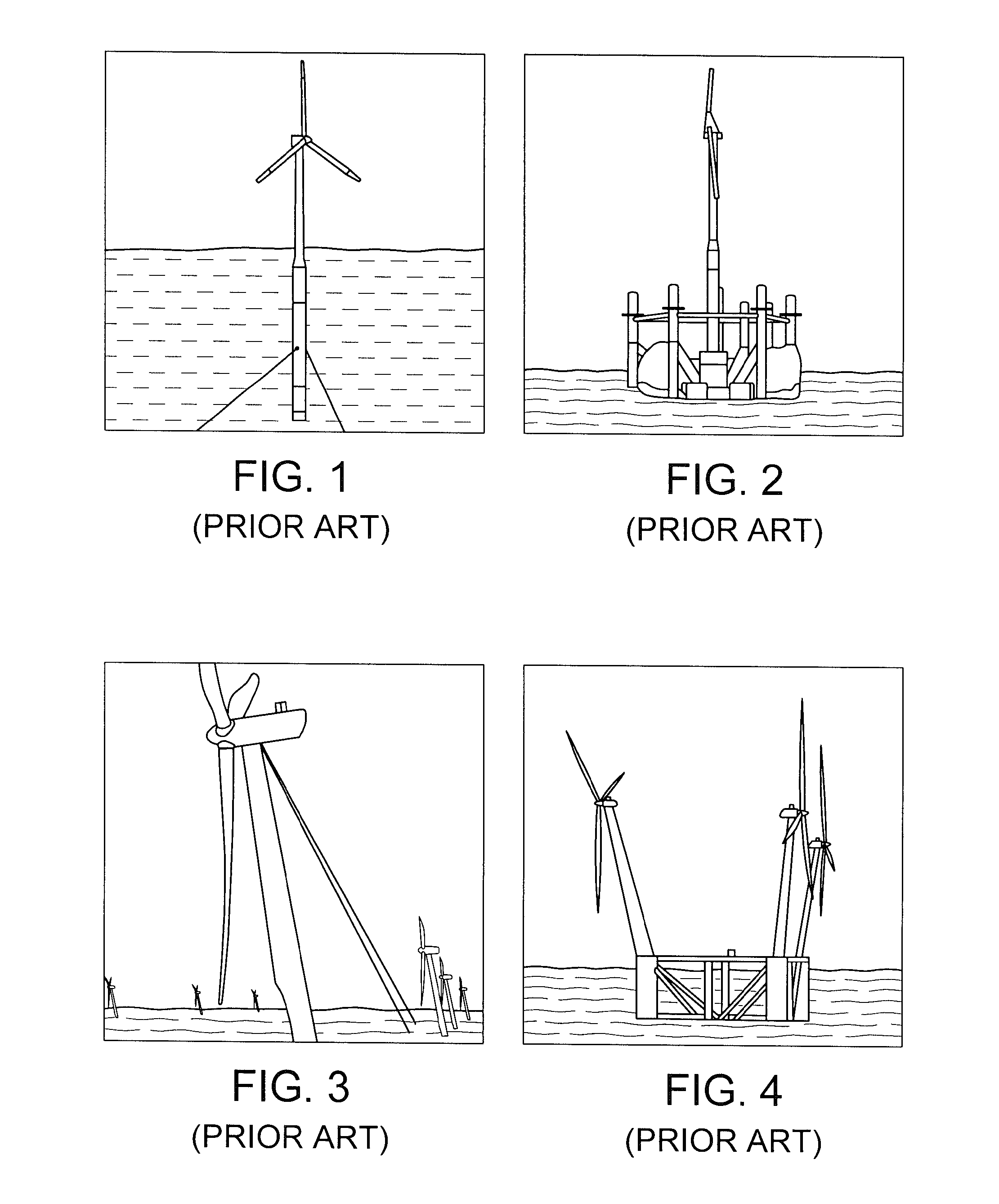

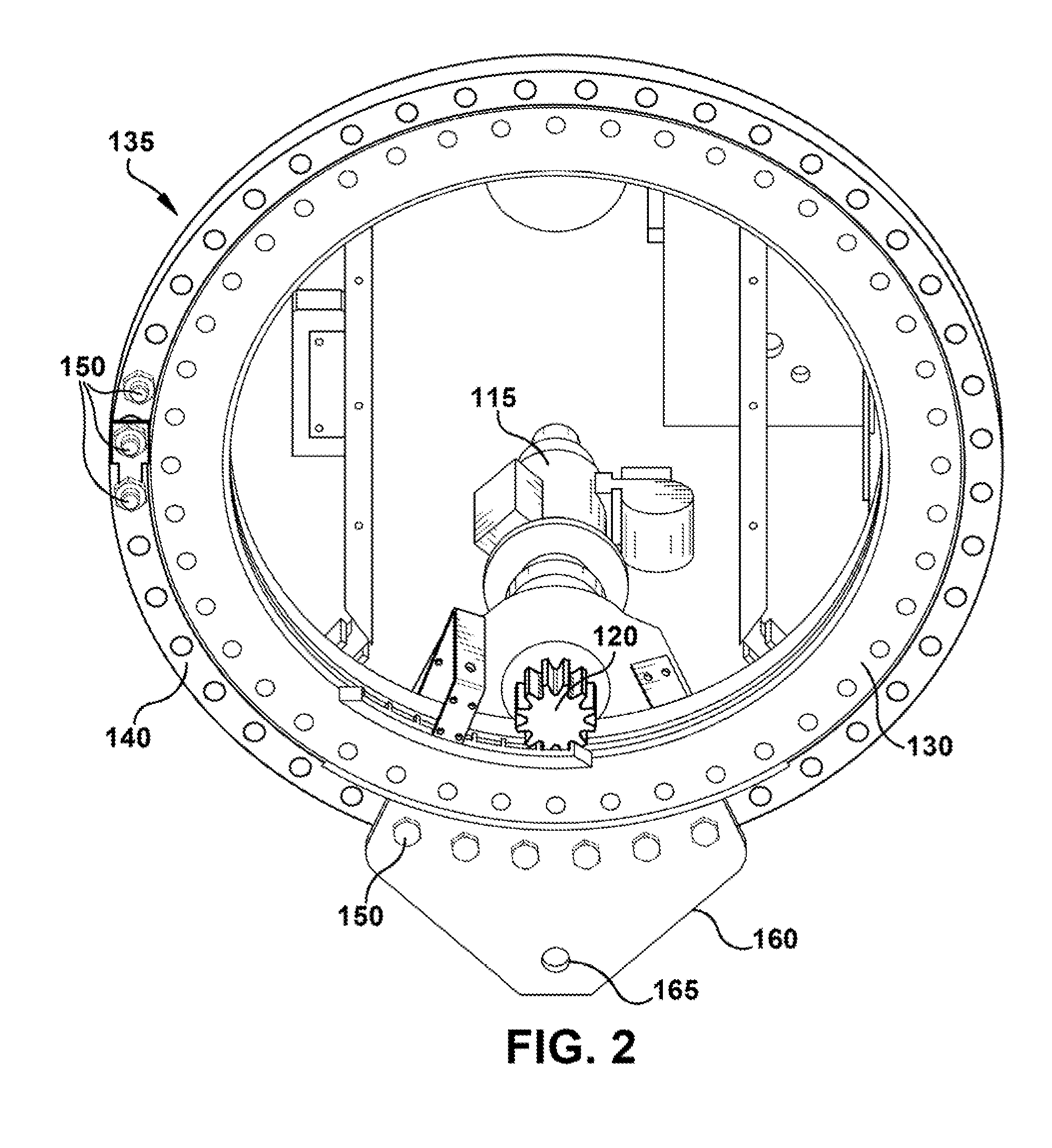

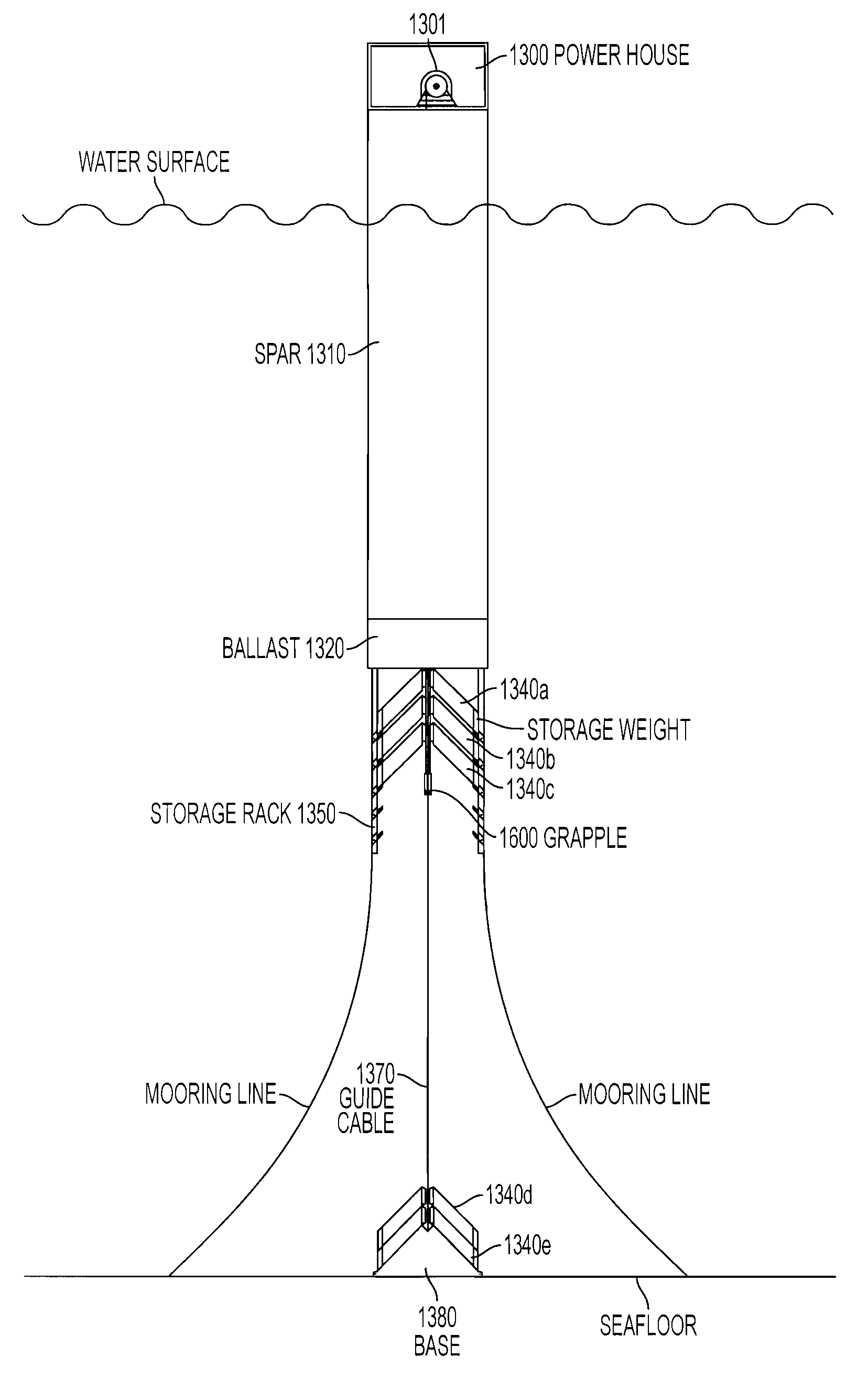

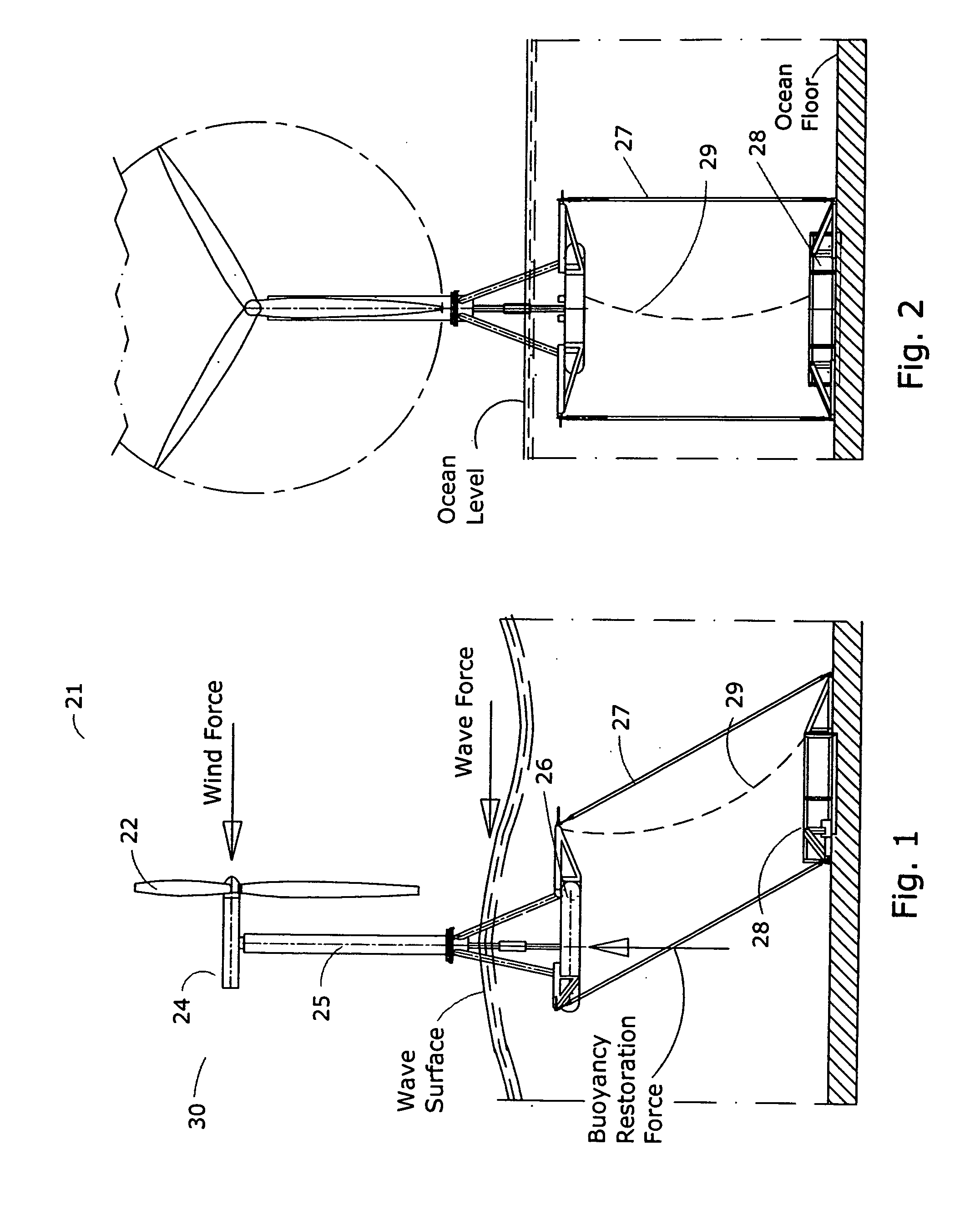

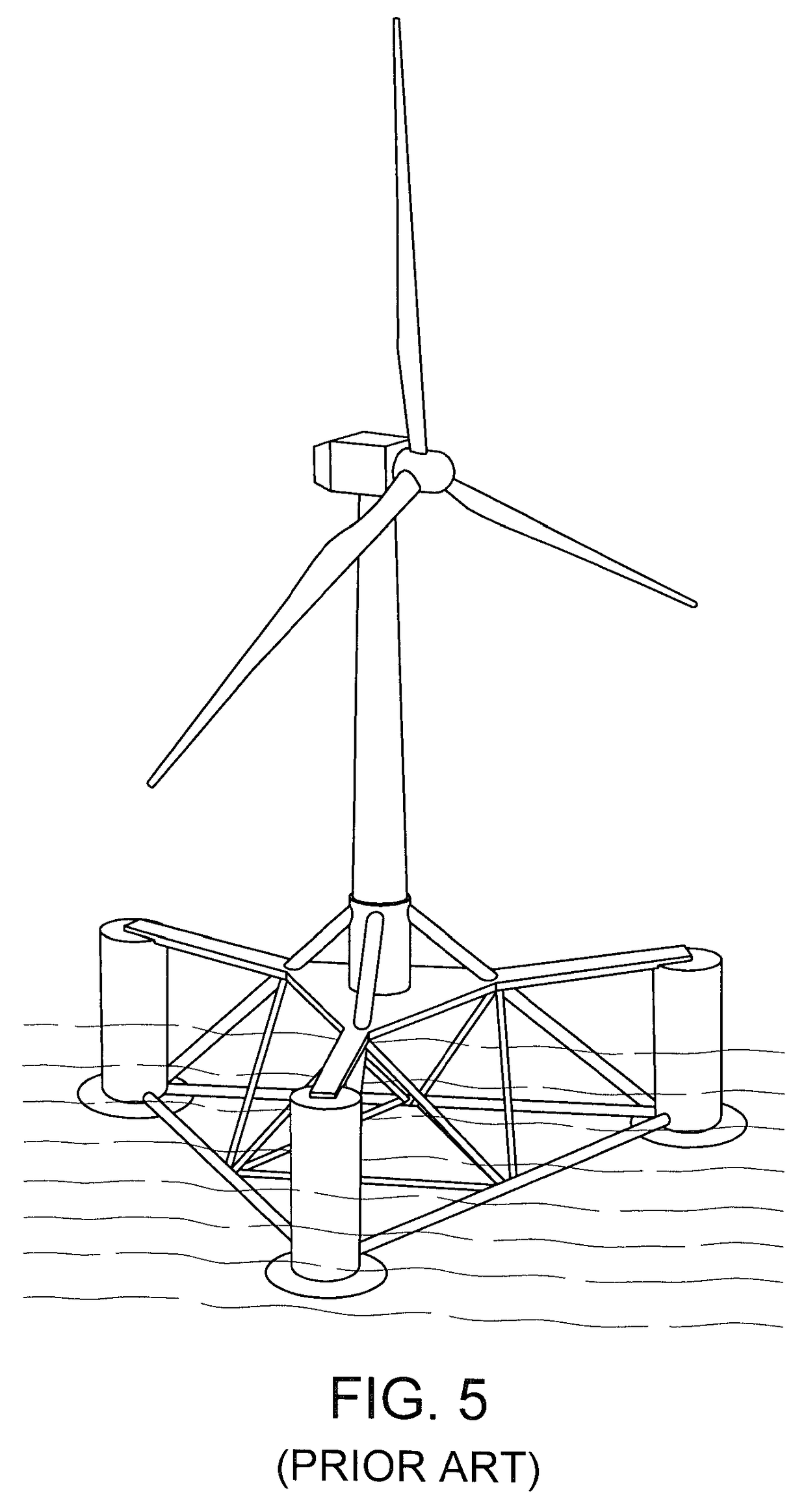

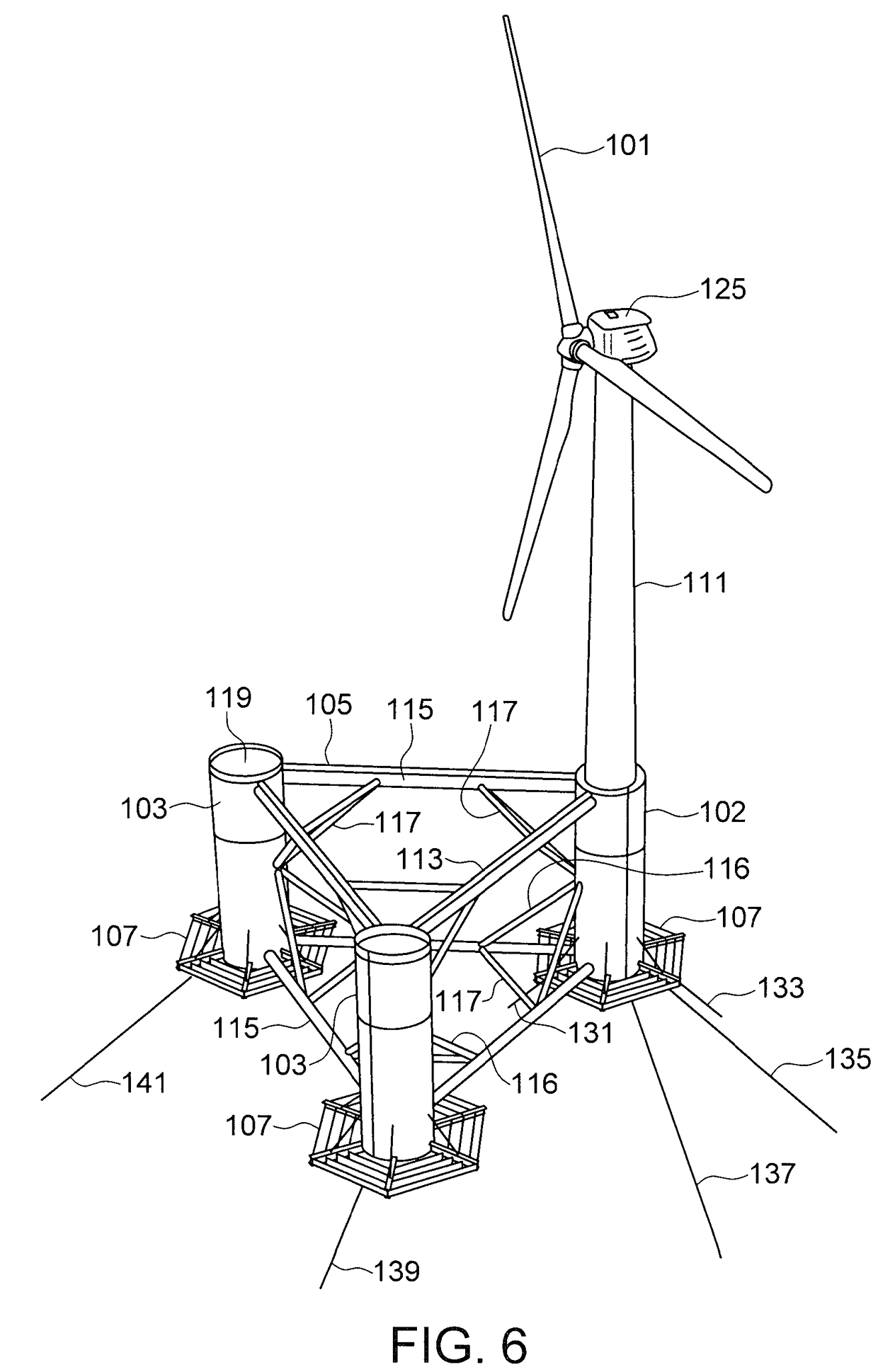

Column-stabilized offshore platform with water-entrapment plates and asymmetric mooring system for support of offshore wind turbines

ActiveUS20110037264A1Improve performanceEasy to produceWind motor controlWind motor assemblyNacelleMooring system

A floating wind turbine platform includes a floatation frame (105) that includes three columns (102, 103) that are coupled to each other with horizontal main beams (115). A wind turbine tower (111) is mounted above a tower support column (102) to simplify the system construction and improve the structural strength. The turbine blades (101) are coupled to a nacelle (125) that rotates on top of the tower (111). The turbine's gearbox generator and other electrical gear can be mounted either traditionally in the nacelle, or lower in the tower (111) or in the top of the tower-supporting column (102). The floatation frame (105) includes a water ballasting system that pumps water between the columns (102, 103) to keep the tower (111) in a 10 vertical alignment regardless of the wind speed. Water-entrapment plates (107) are mounted to the bottoms of the columns (102, 103) to minimize the rotational movement of the floatation frame (105) due to waves.

Owner:PRINCIPLE POWER

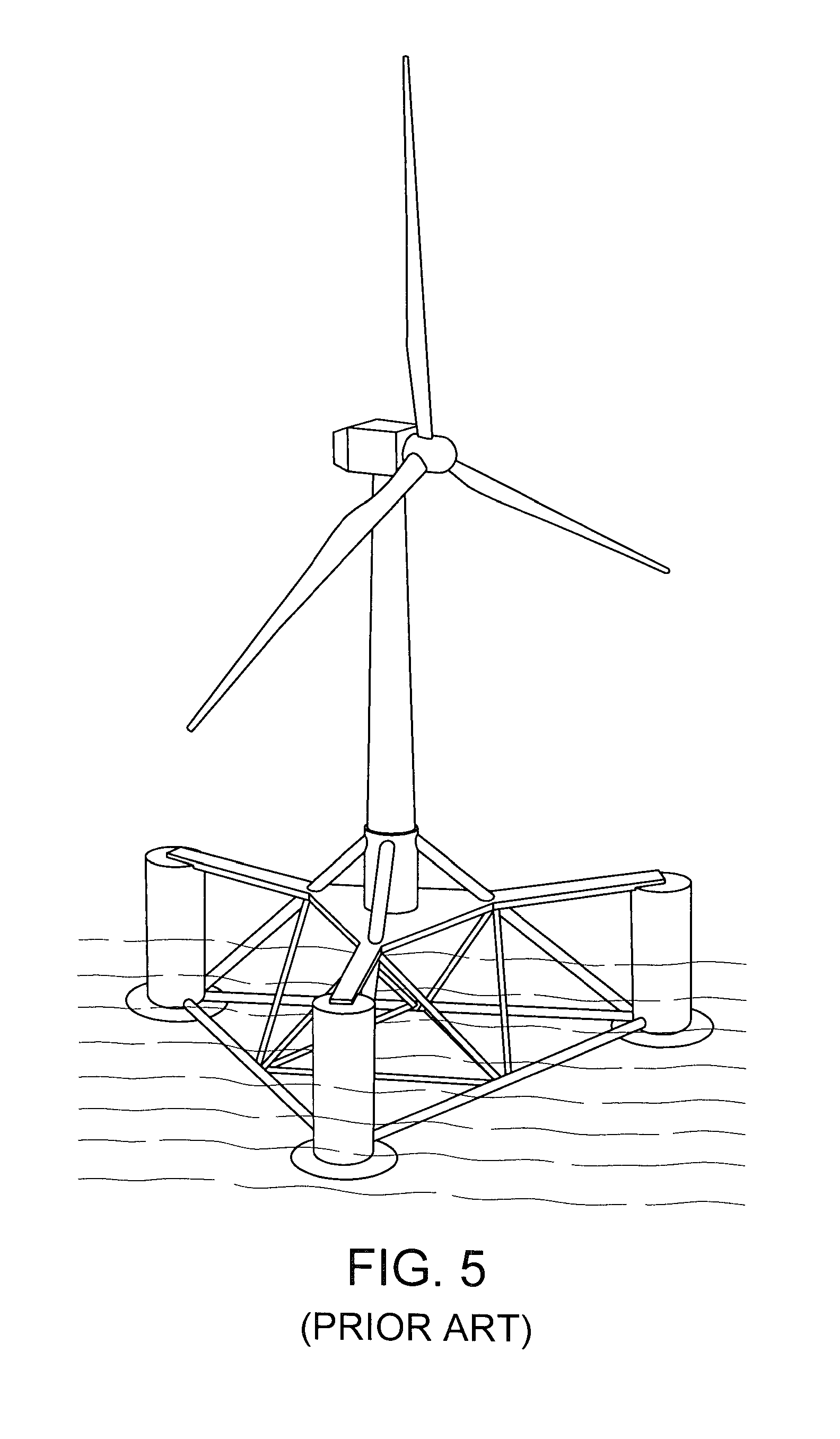

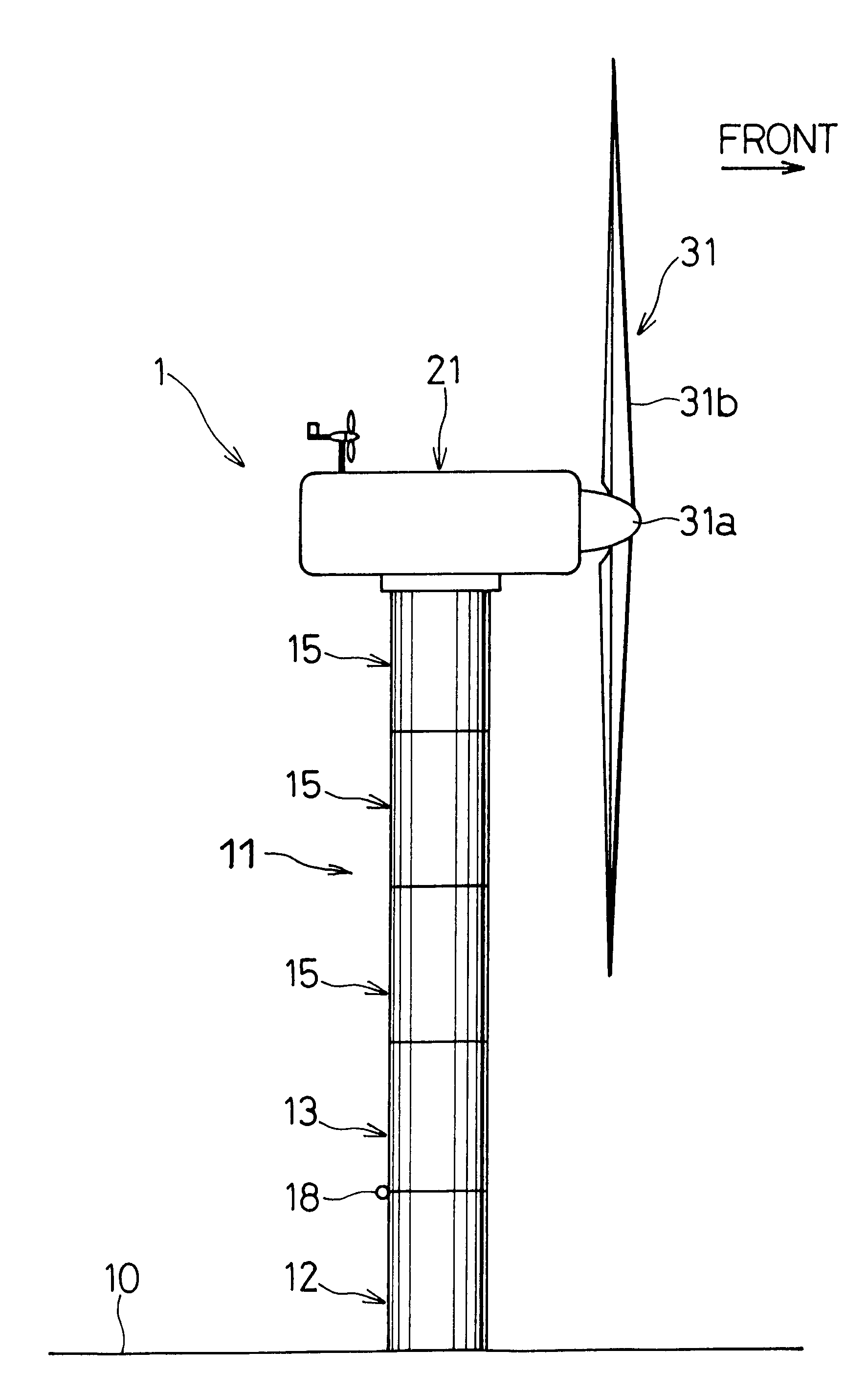

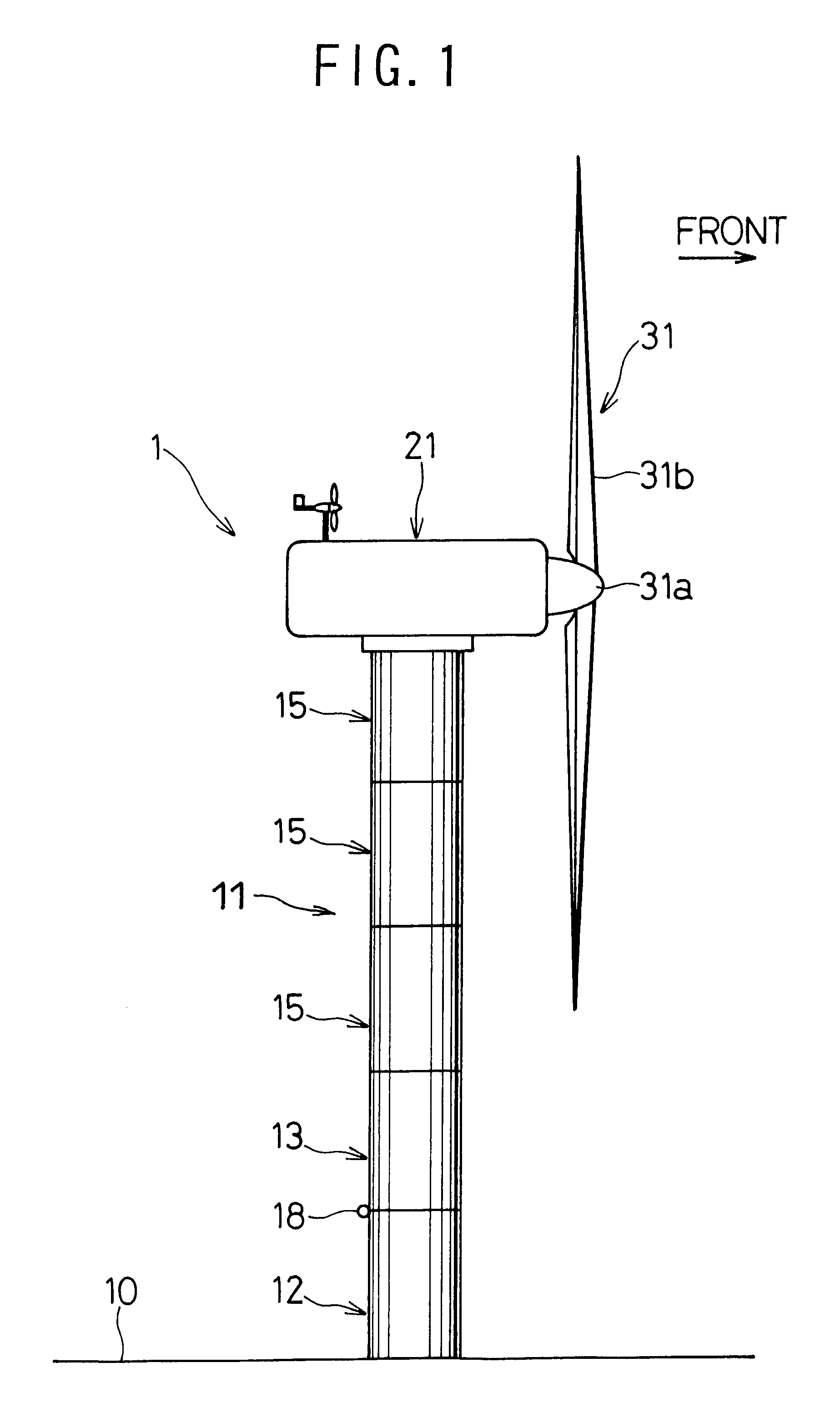

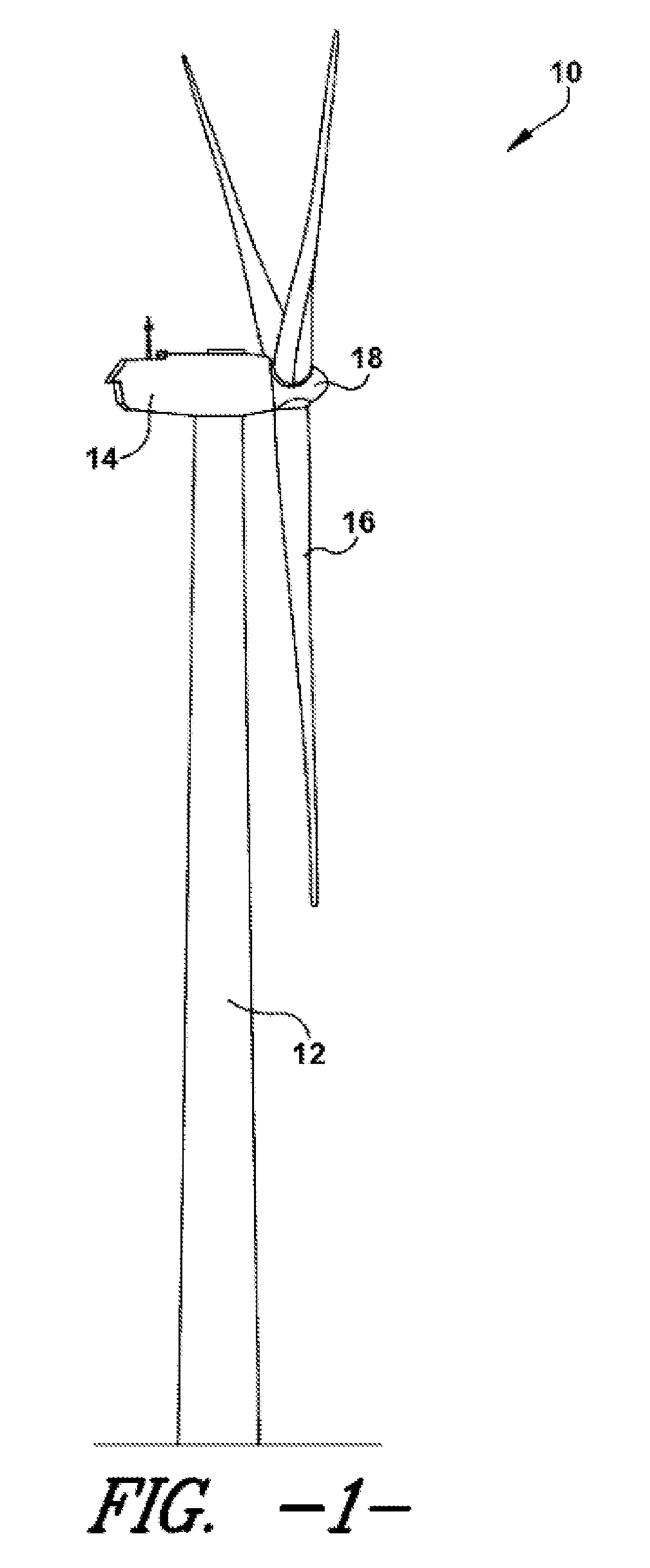

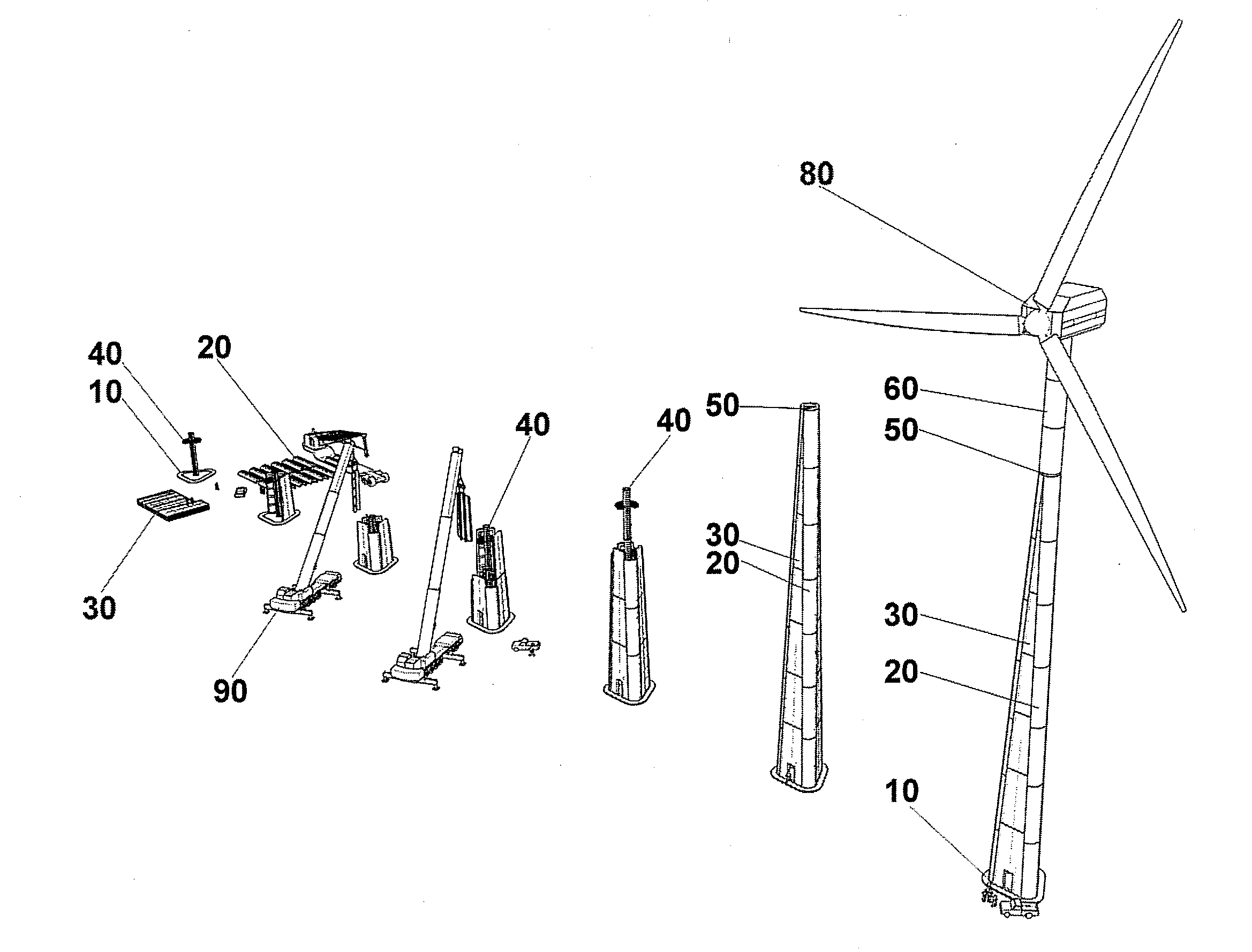

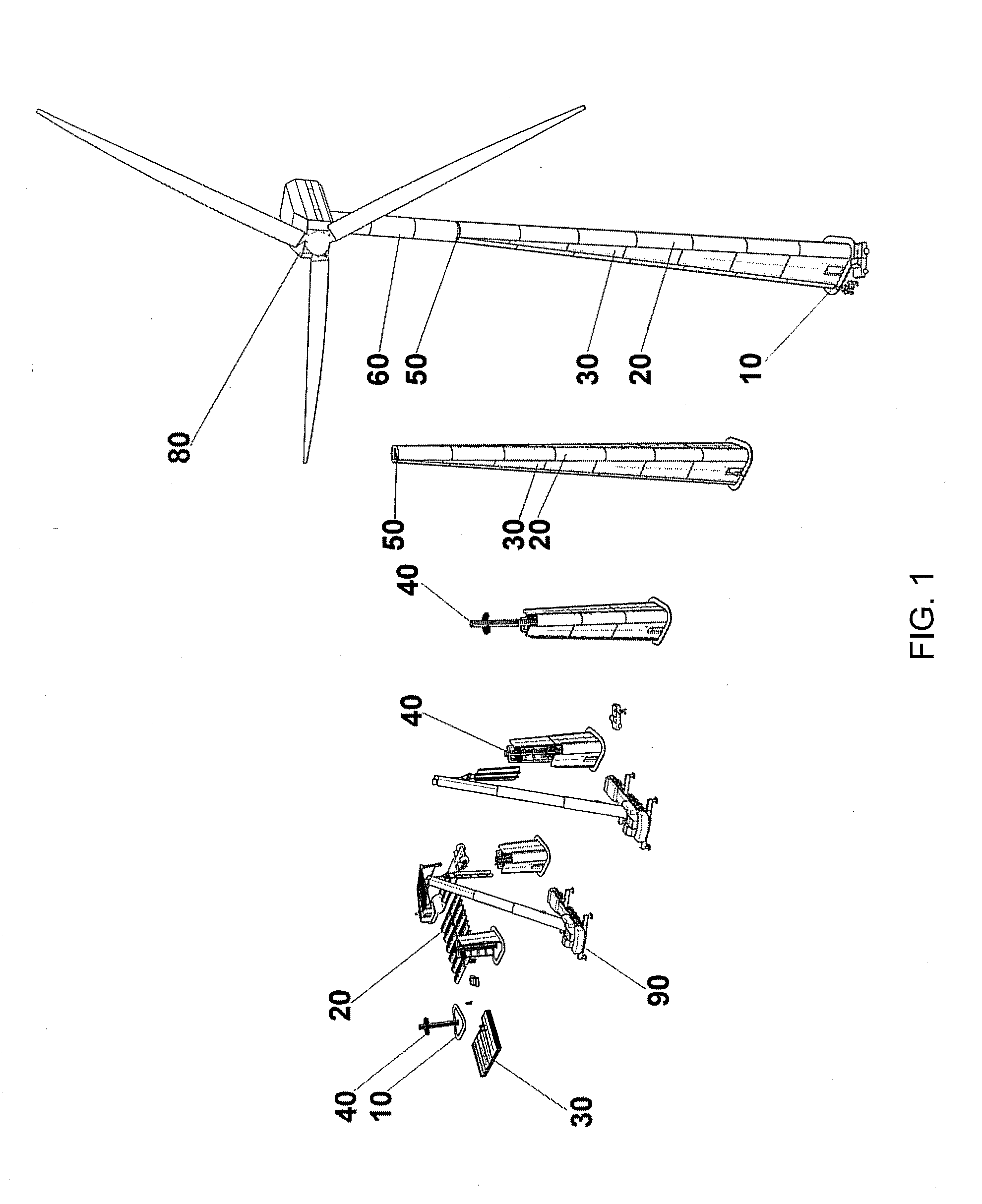

Horizontal axis type wind turbine and method of construction thereof

InactiveUS6408575B1Reduce construction costsEngine manufactureFinal product manufactureNacelleStanding Positions

A tower comprises a base tower member fixed on a base in the ground, a lower tower member hingedly connected at a lower end thereof with an upper end of the base tower member through a hinge and swinging between a lying position and a standing position, a first stage connecting tower member connected at a lower end thereof with an upper end of the lower tower member, a second stage connecting tower member connected at a lower end thereof with an upper end of the first stage connecting tower member, and a third stage connecting tower member connected at a lower end thereof with an upper end of the second stage connecting tower member. Thus formed tower is raised swingingly around the hinge from the lying position to the standing position. A nacelle includes a tower penetrating hole through which the tower vertically penetrates and is formed by a plurality of nacelle sections divisible around the tower penetrating hole. After the tower is built, a plurality of nacelle sections are collected around the tower and are connected with each other while the nacelle is penetrated by the tower. Then, the nacelle is lifted up along the tower in that state and fixed to the top end of the tower.

Owner:SUBARU CORP

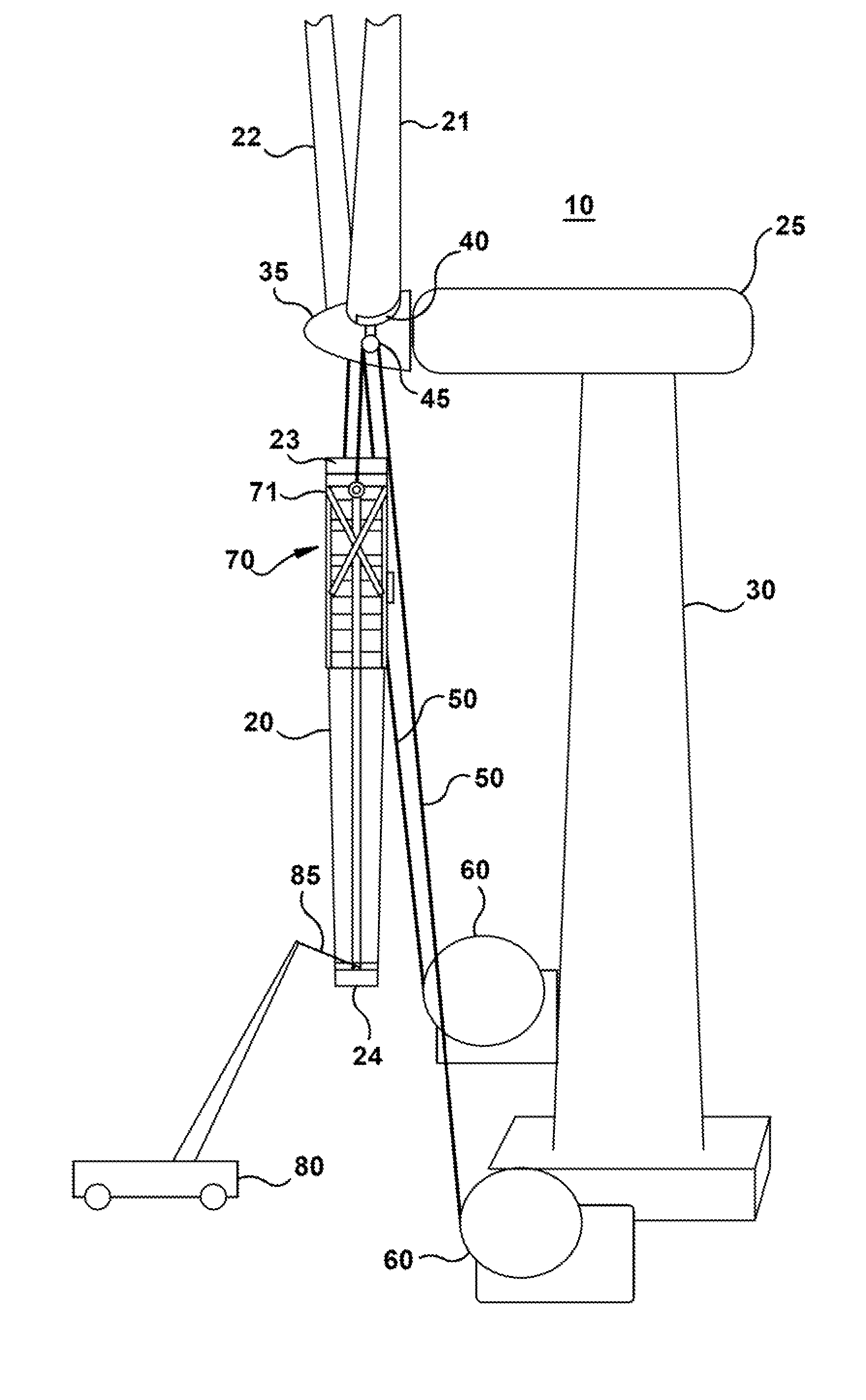

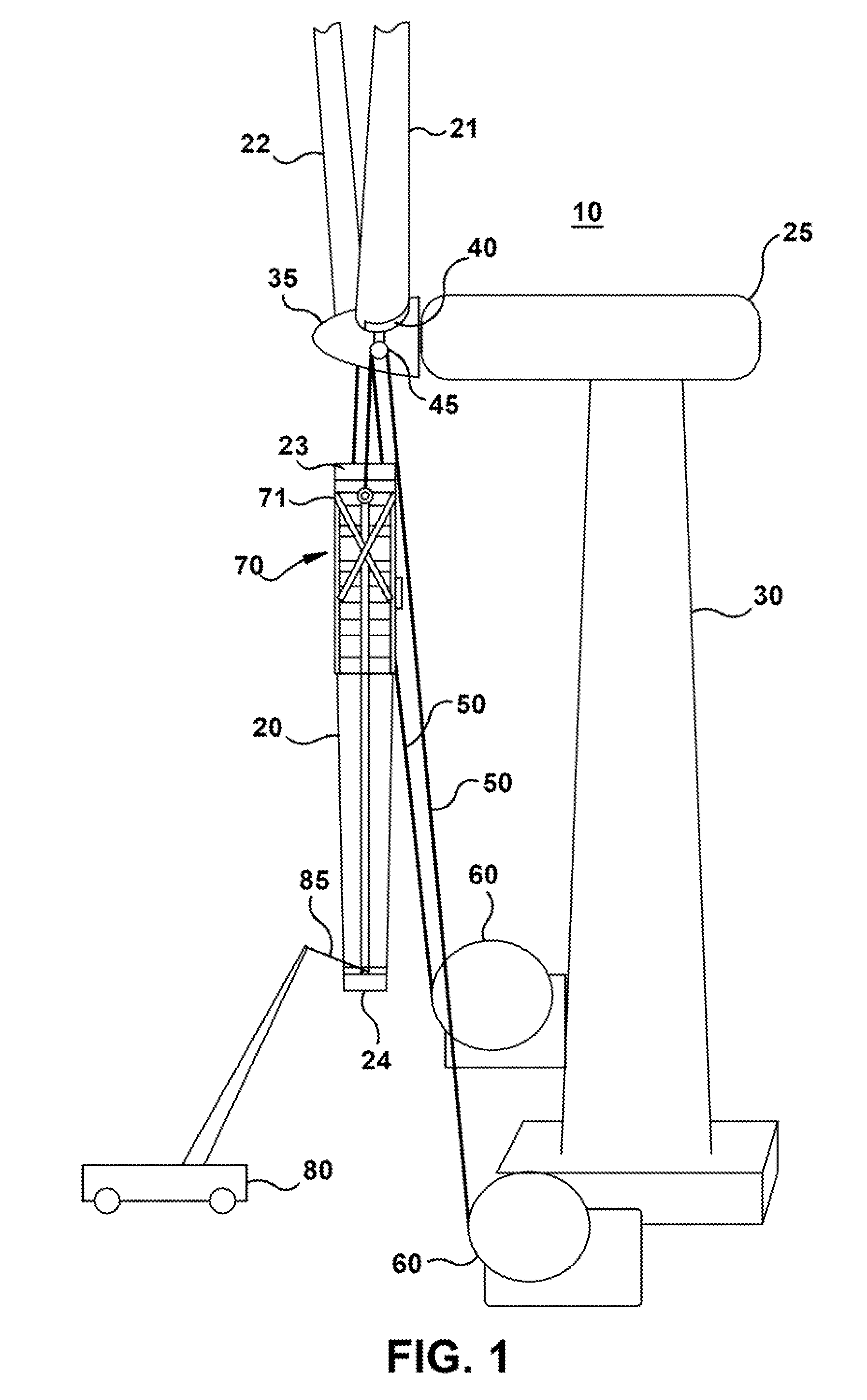

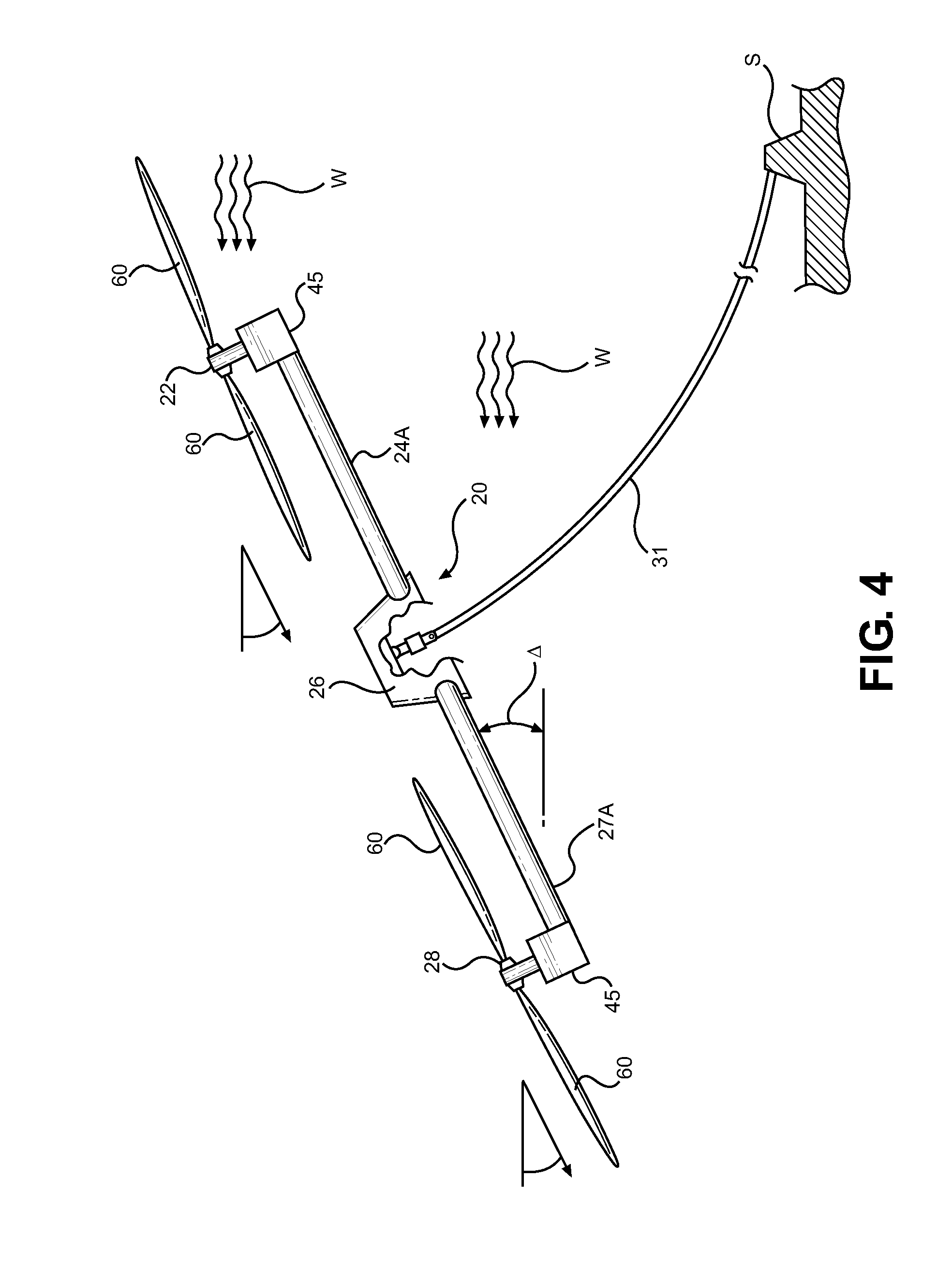

Lowering and raising a single wind turbine rotor blade from six-o'clock position

InactiveUS20100139062A1Prevent insufficient load capacityMetal-working apparatusWind motor assemblyLift lineWinch

A method and lifting arrangement for lowering and raising a single rotor blade of a wind turbine from a six-o'clock position is provided. Lifting fixtures are symmetrically installed on a hub surface about the rotor blade being replaced. Lifting lines from coordinated ground winches pass over the lifting fixtures to support the blade and attach to a blade harness. The blade harness attaches over a substantial length of the rotor blade, distributing the blade weight broadly. A tail pick crane facilitates transfer of the rotor blade between a vertical and a horizontal position stored position.

Owner:GENERAL ELECTRIC CO

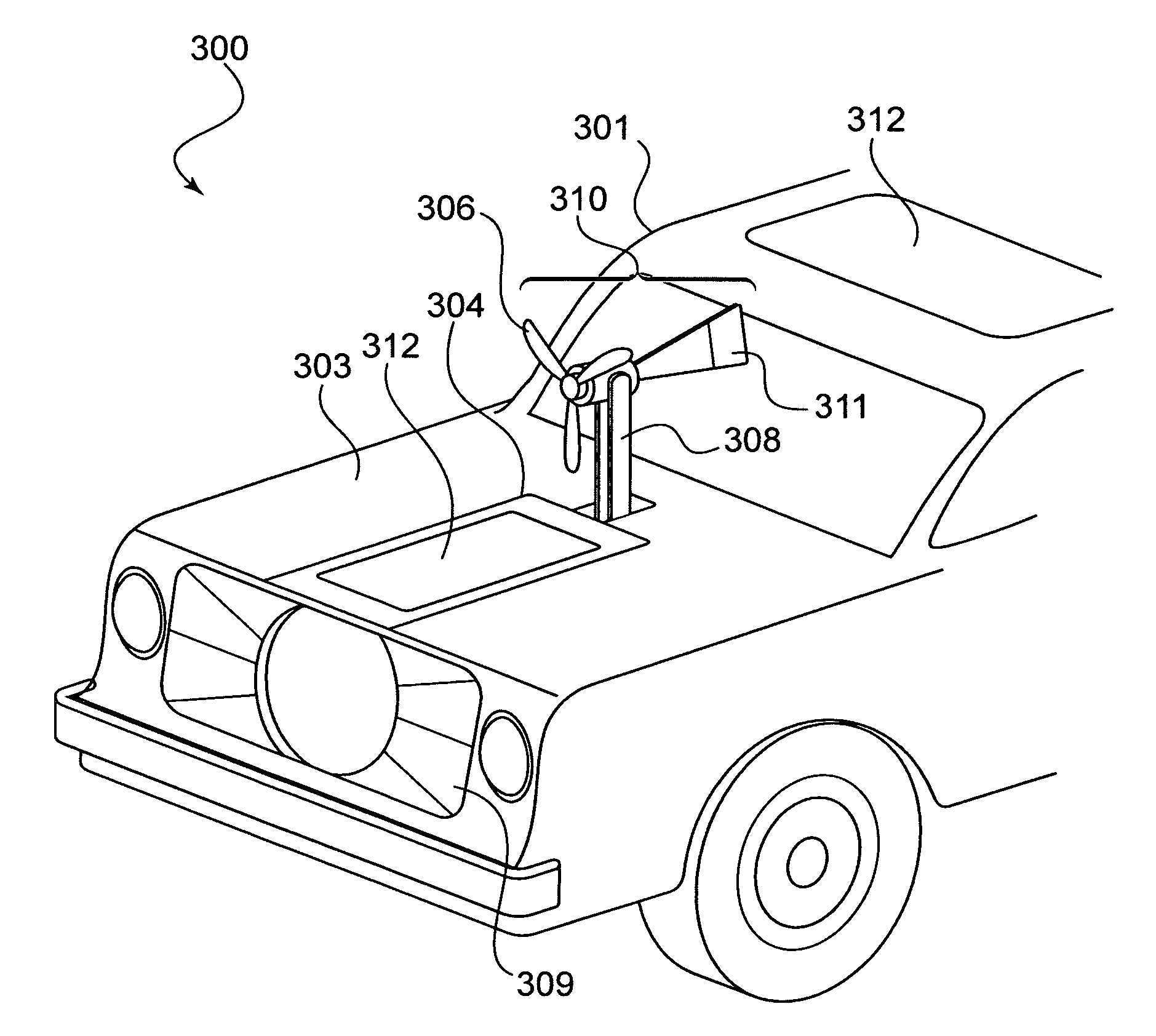

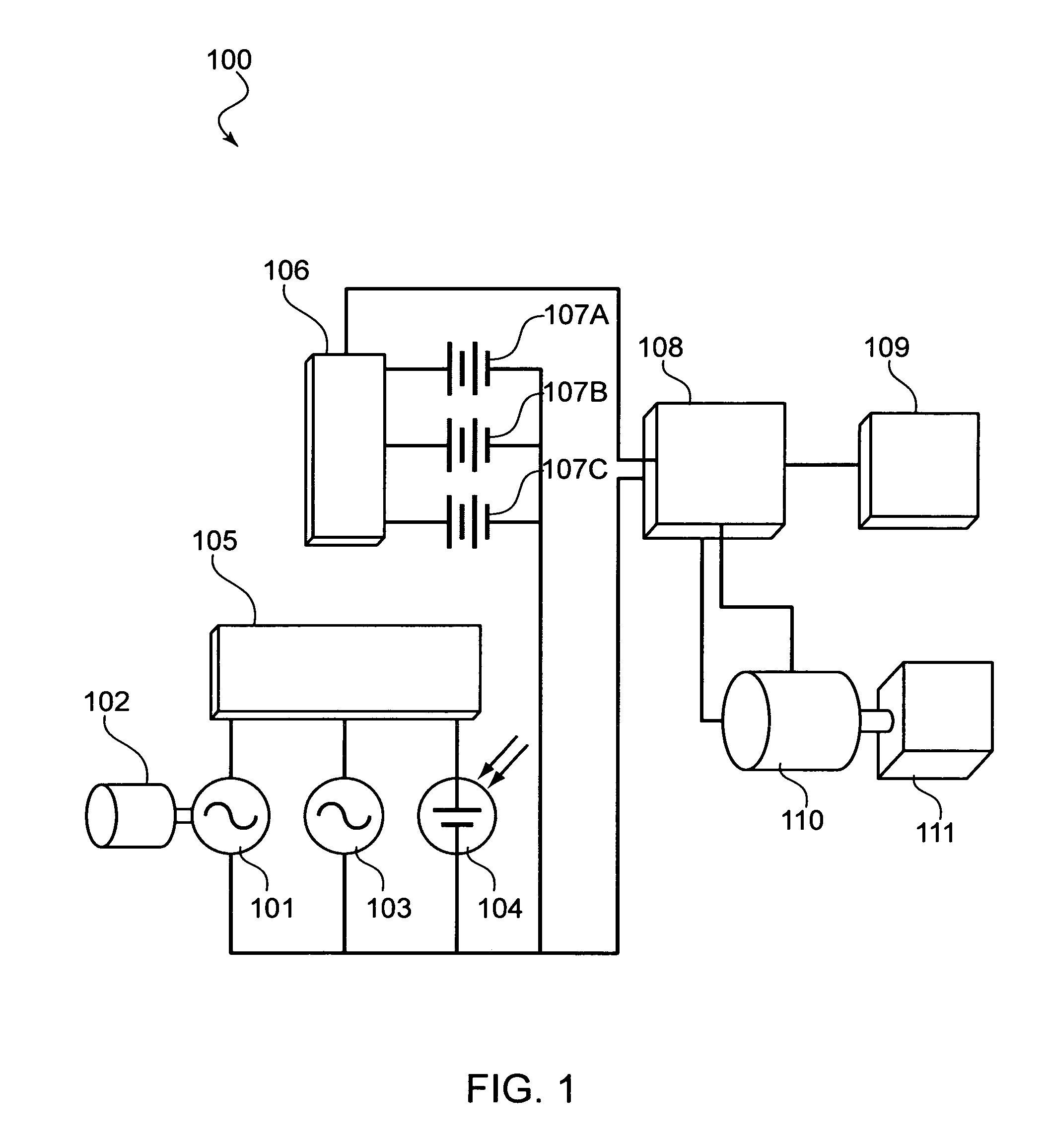

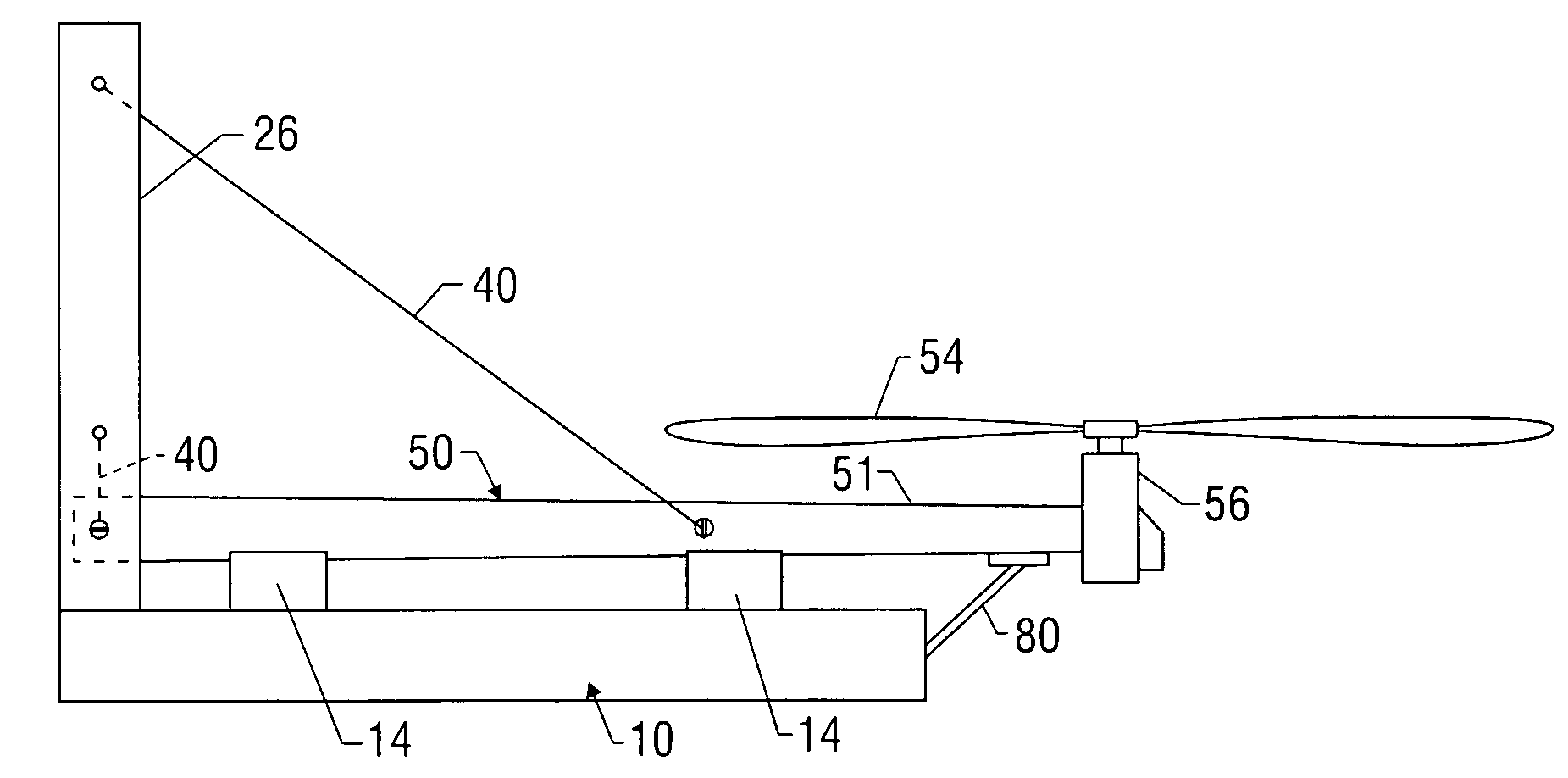

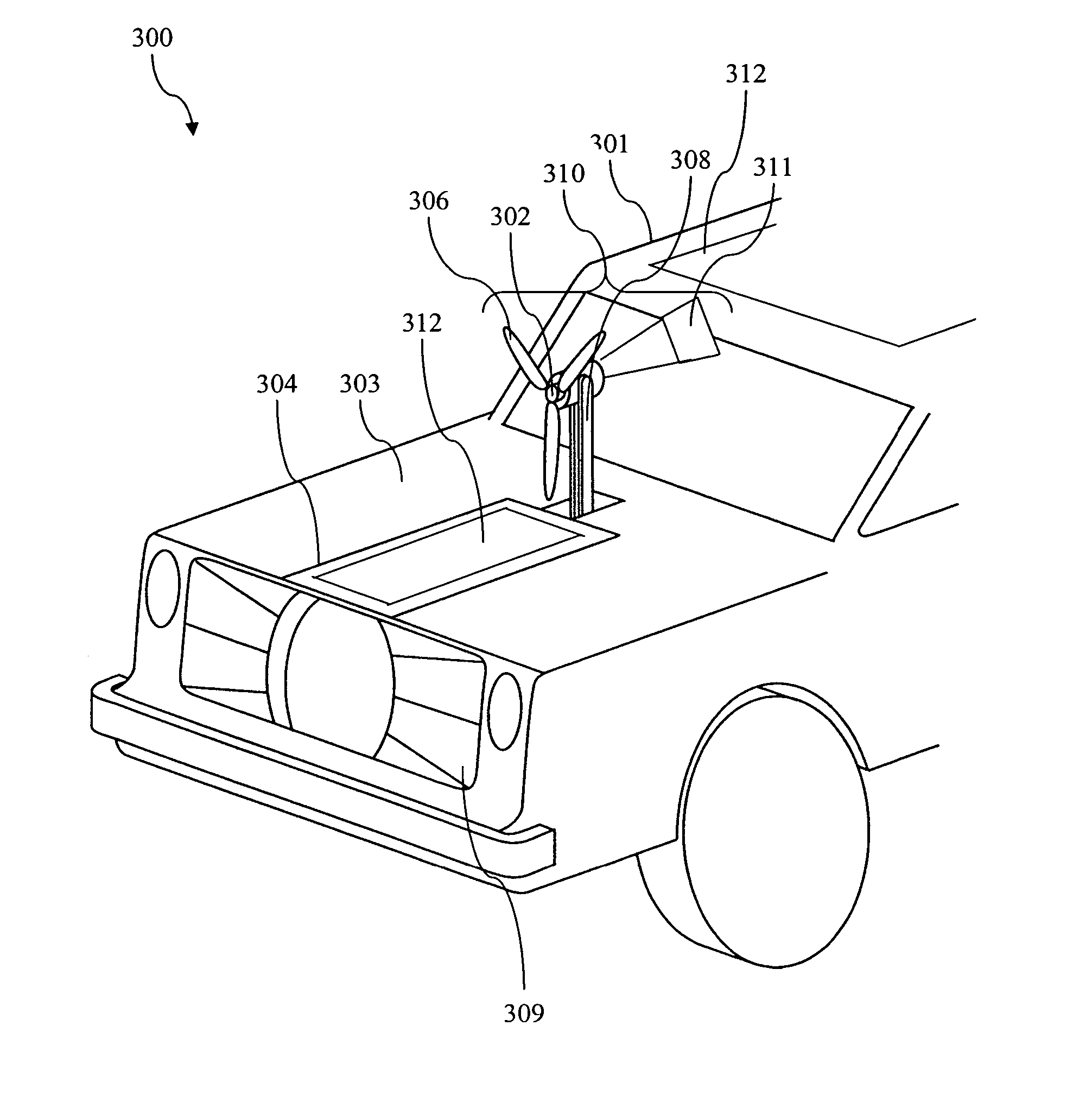

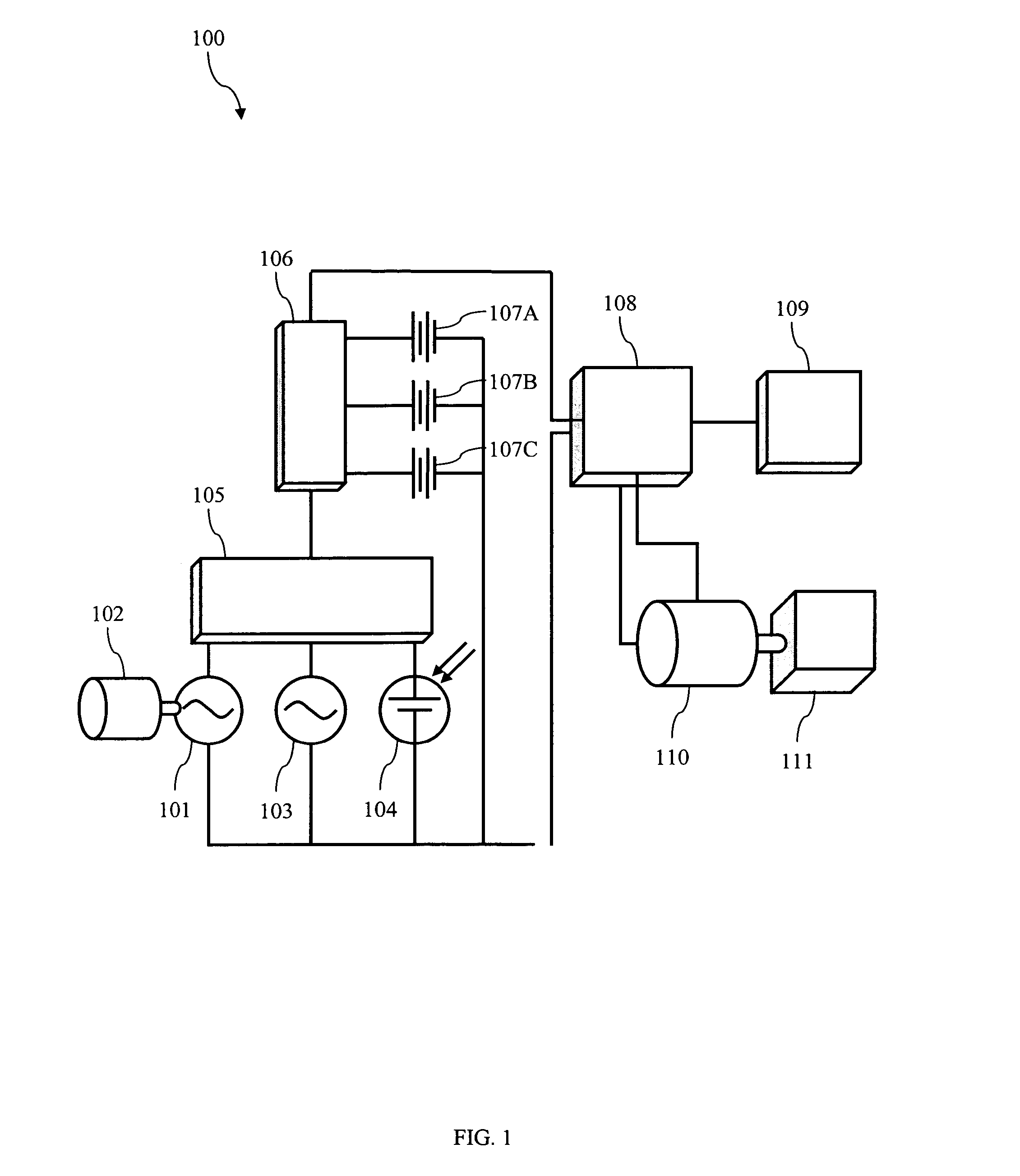

Power system for electric and hybrid vehicles

A power system for an electric vehicle, the power system comprising at least one power generating device selected from a group consisting of a solar panel, a wind turbine capable of producing electrical power, an auxiliary generator driven by an internal combustion engine, and a generator for producing electrical power mechanically connected to, and driven by the rotational force of an axle of a vehicle. The power system being further comprised of a charging device, a battery control device, at least one battery, a motor control device, an electric drive motor electrically connected to the motor control device, and a driver interface connected to the motor control device. The electric drive motor may be used to generate power through regenerative braking. The wind turbine may be raised outside the body of a vehicle while the vehicle is not in motion. The solar panel may be disposed outside the vehicle while remaining electrically connected to the charging device.

Owner:SUTHERLAND DANILO R

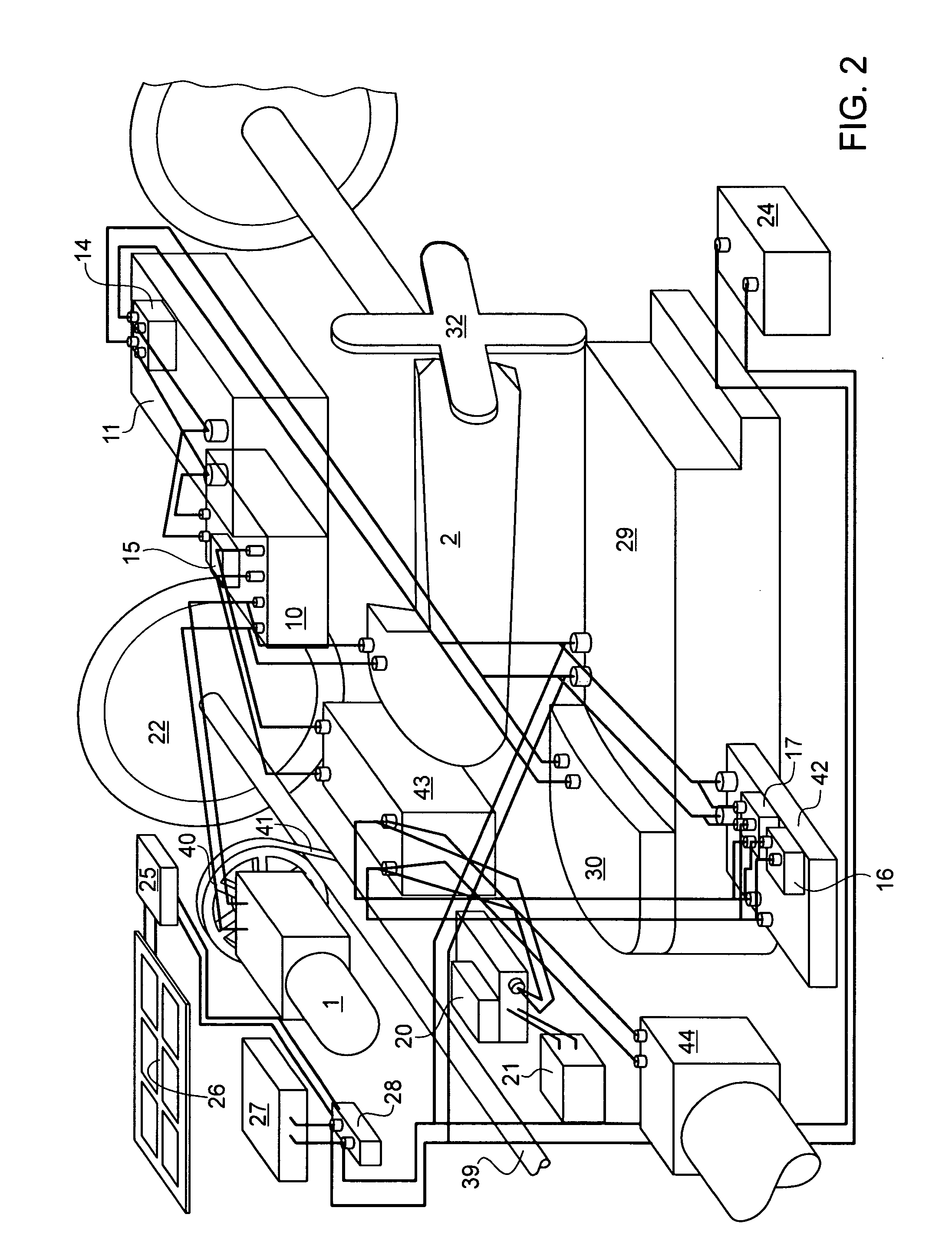

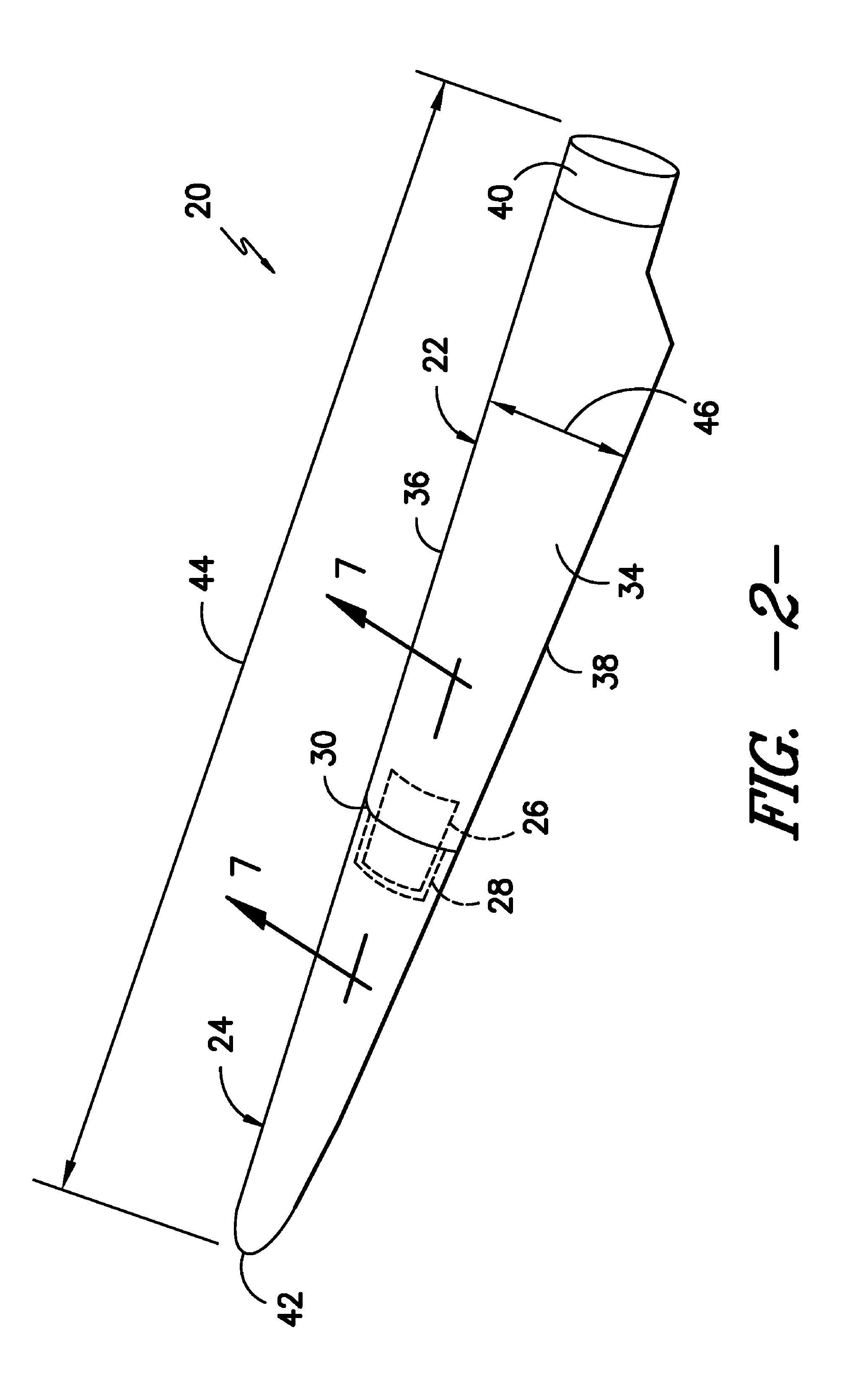

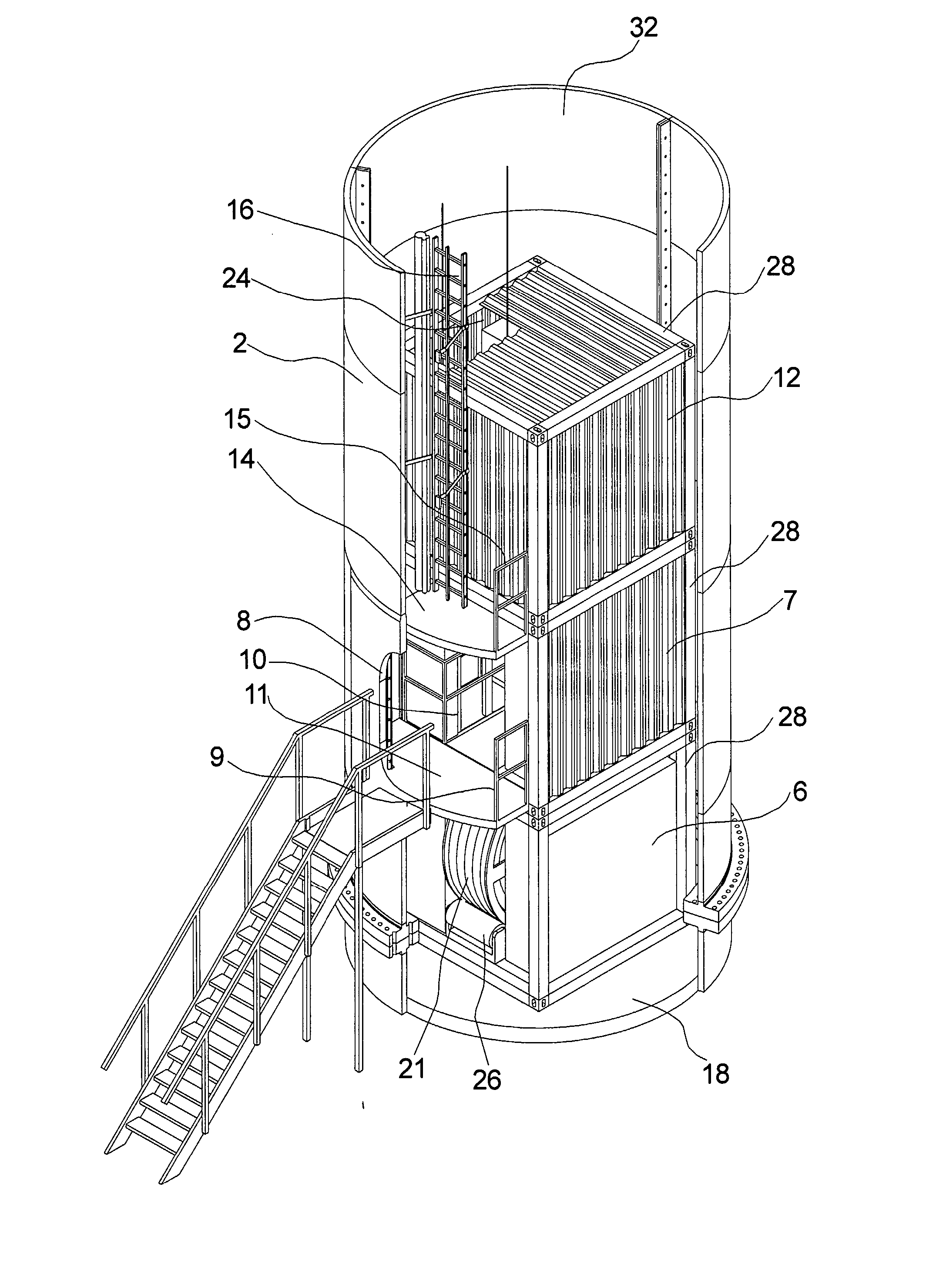

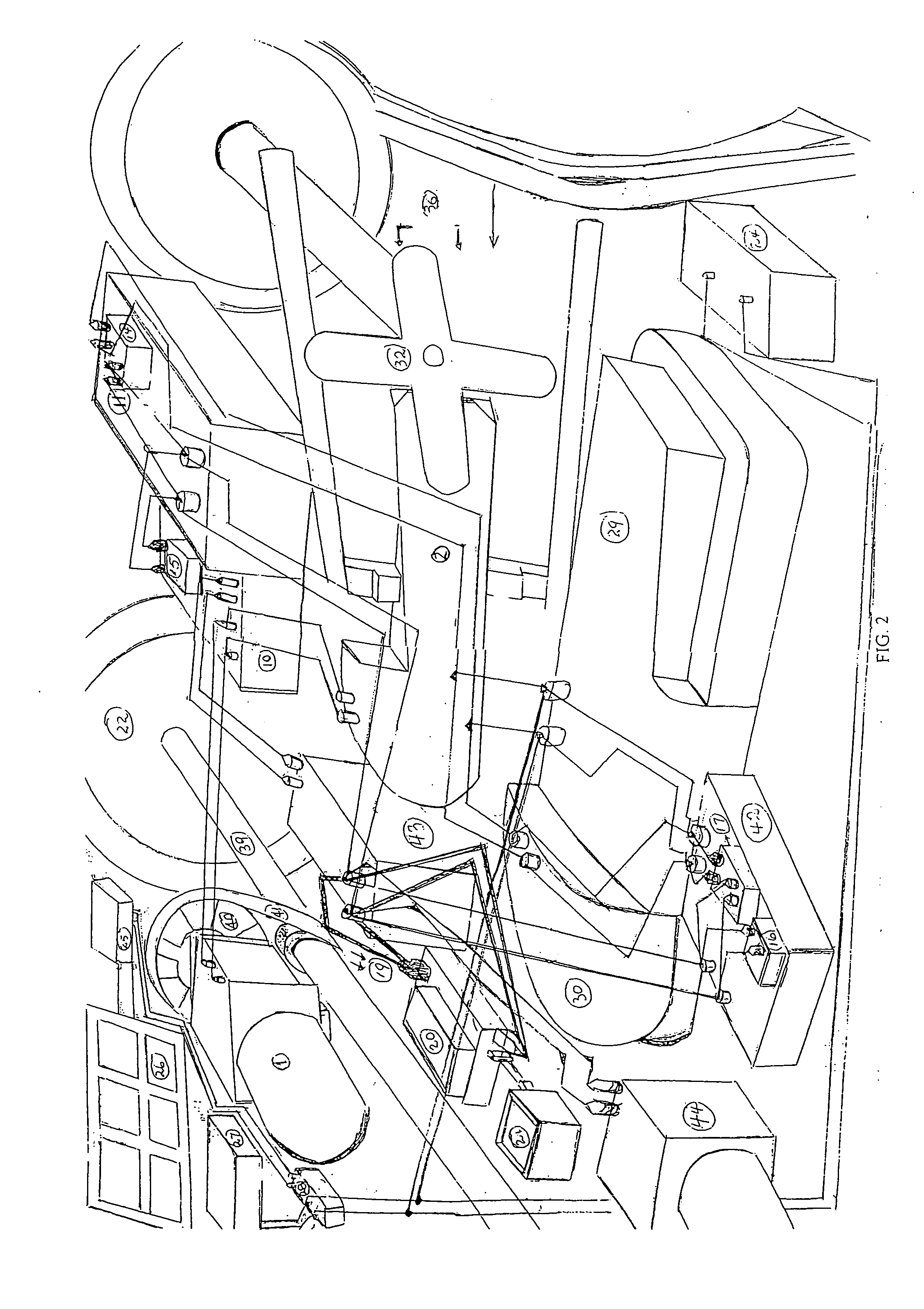

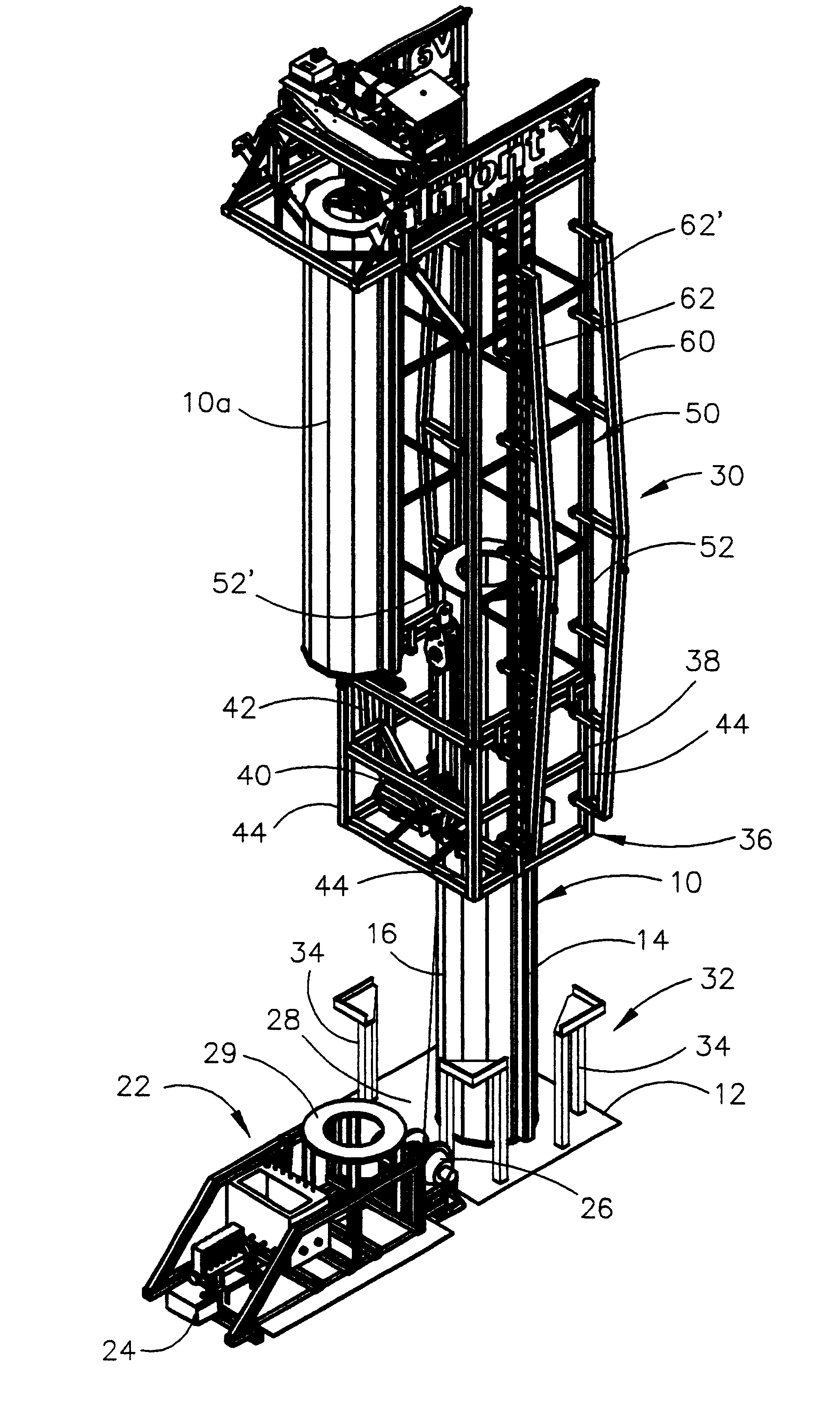

Vertically Adjustable Horizontal Axis Type Wind Turbine And Method Of Construction Thereof

The invention relates to methods of constructing and operating a wind turbine, said methods comprising the steps of lifting a wind turbine nacelle and tower sections with the use of an external lifting system, and using a lifting system to propel said nacelle vertically up and down said tower sections. The external lifting mechanism comprises a guide rail and guide car onto which tower sections are loaded for horizontal movement, a foundation structure joined to a tower section hoist mechanism containing clamps, and a nacelle holding mechanism. A nacelle includes a tower penetrating hole through which said tower vertically penetrates. Tower sections are provided with a plethora of guide rails positioned around said tower extending from the lower end to the upper end of said tower sections, said guide rails contain removable toothed racks meshing with said lifting system to propel said nacelle vertically up and down said tower sections.

Owner:WYBORN GAVIN RAYMOND

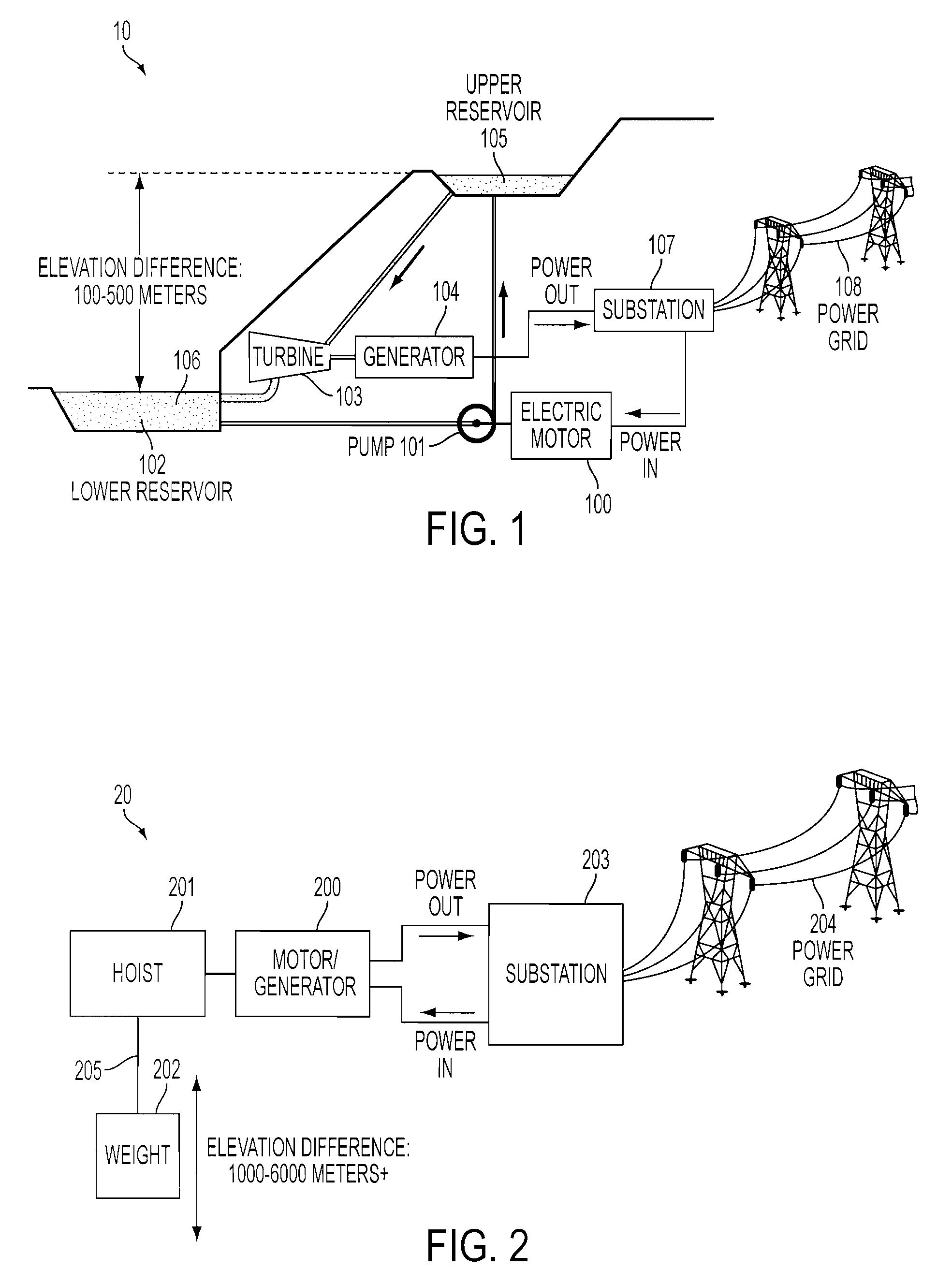

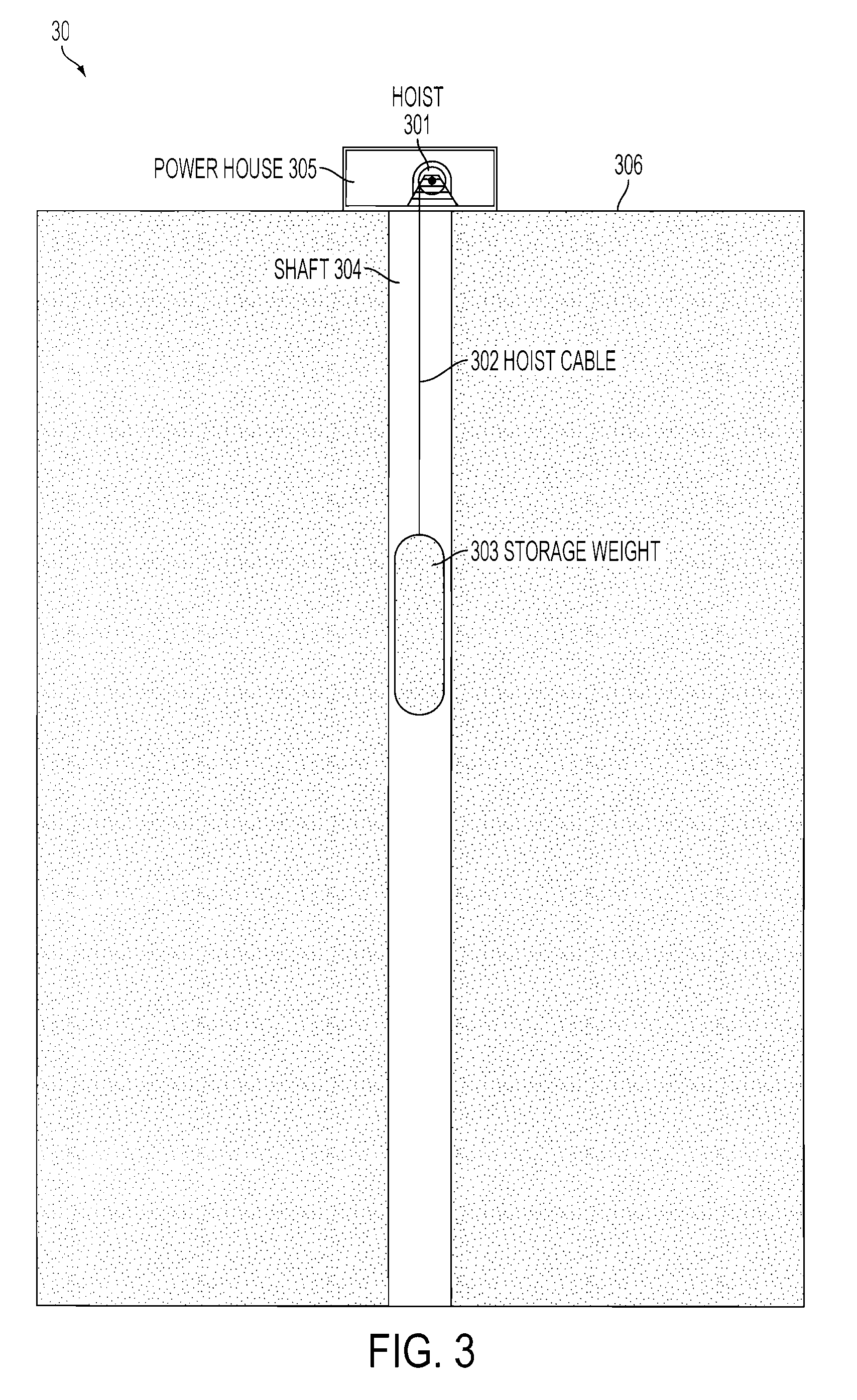

System and method for storing energy

ActiveUS20090193808A1Increase gravitational potential energyIncrease rangeEngine fuctionsWind motor assemblyElectricityEngineering

A system includes at least one body, a link for suspending the body for movement with gravity from a first elevation position to a second elevation position, and an electrical energy generator coupled with the body through the link to drive the generator to generate electricity upon movement of the body with gravity from the first to the second elevation position. The at least one body has a mass of at least approximately 100 tonnes; the first and the second elevation positions define a distance therebetween of at least approximately 200 meters; and / or the system further includes an operator configured to operate the link to controllably move the at least one body against gravity from the second to the first elevation position to increase a gravitational potential energy of the at least one body, and to maintain the gravitational potential energy of the at least one body.

Owner:LAUNCHPOINT TECH

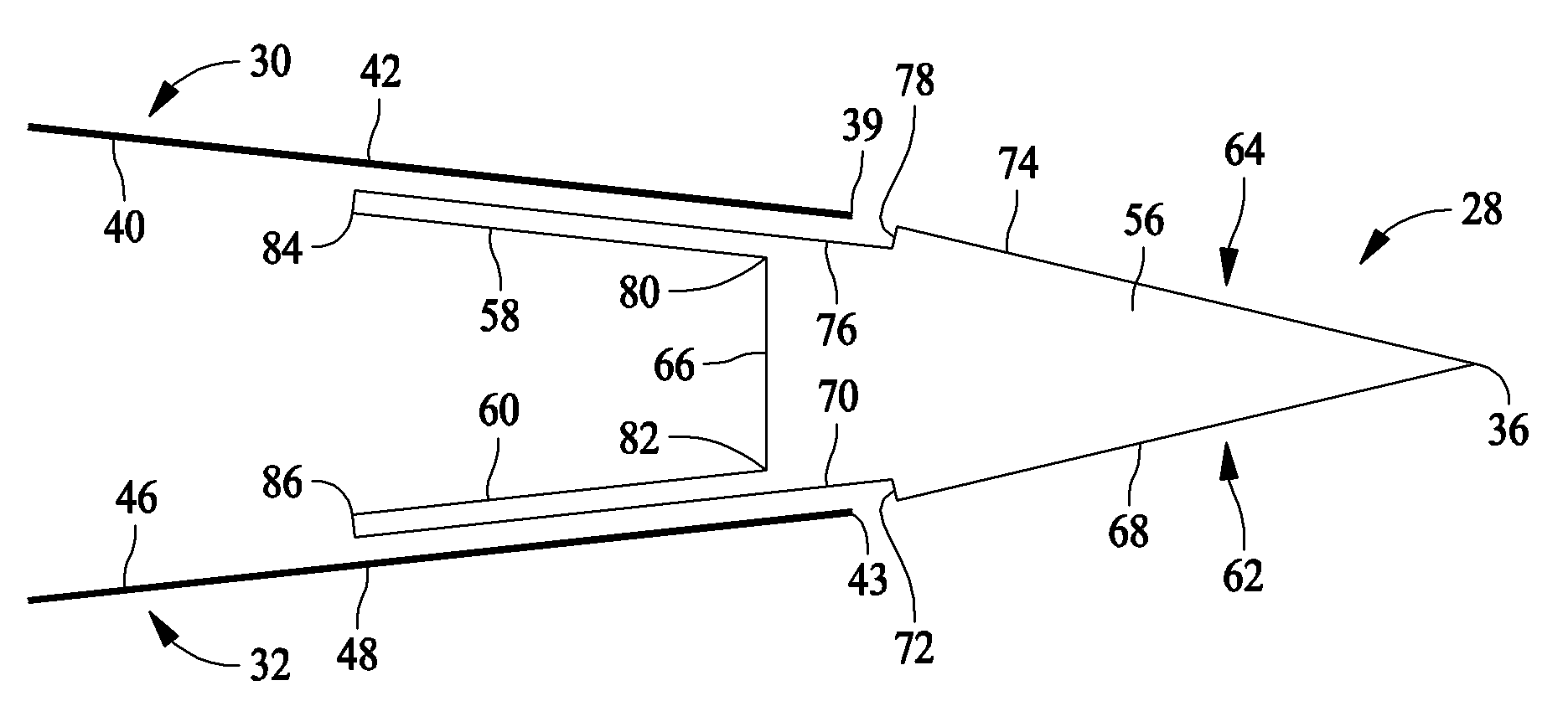

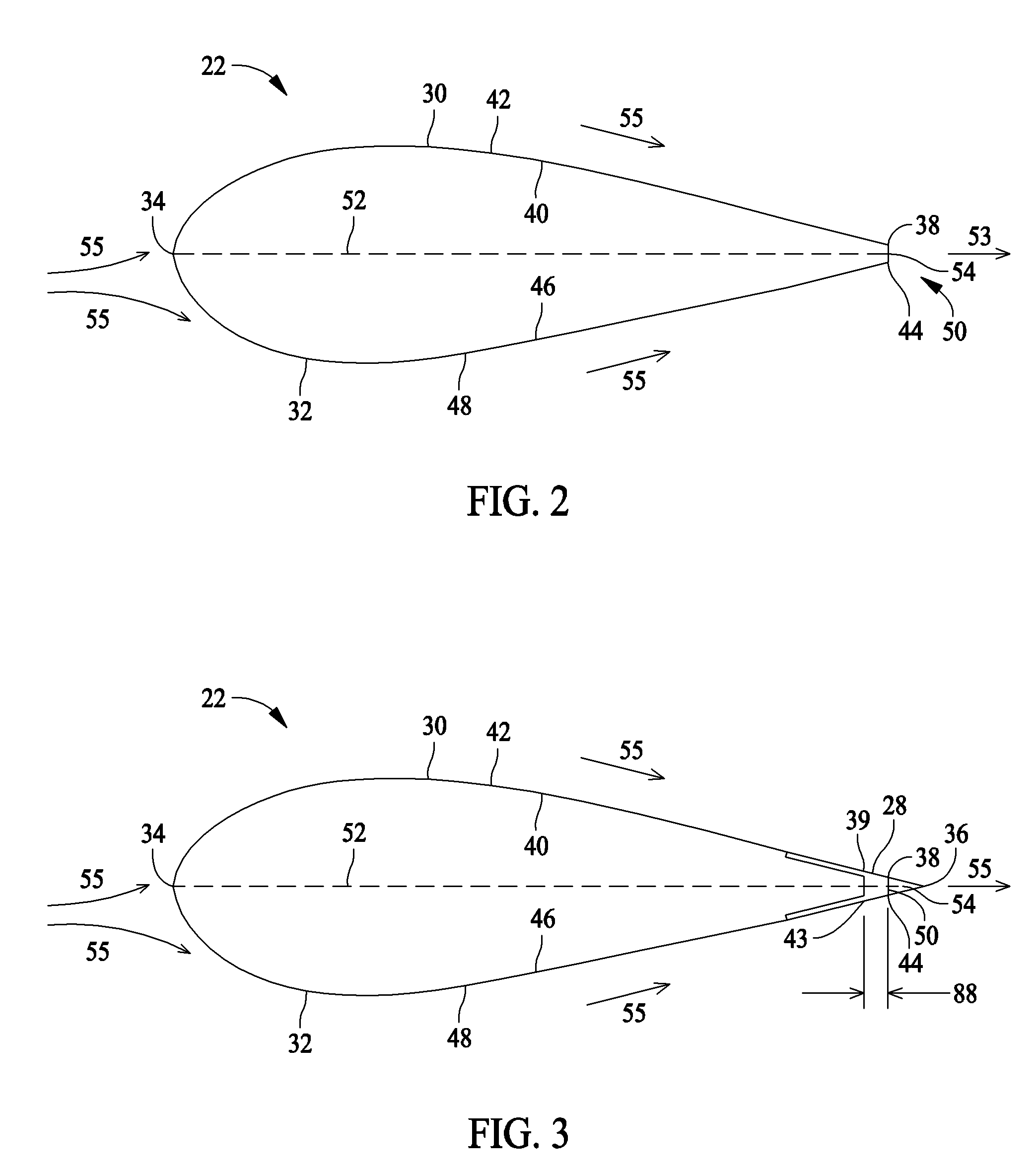

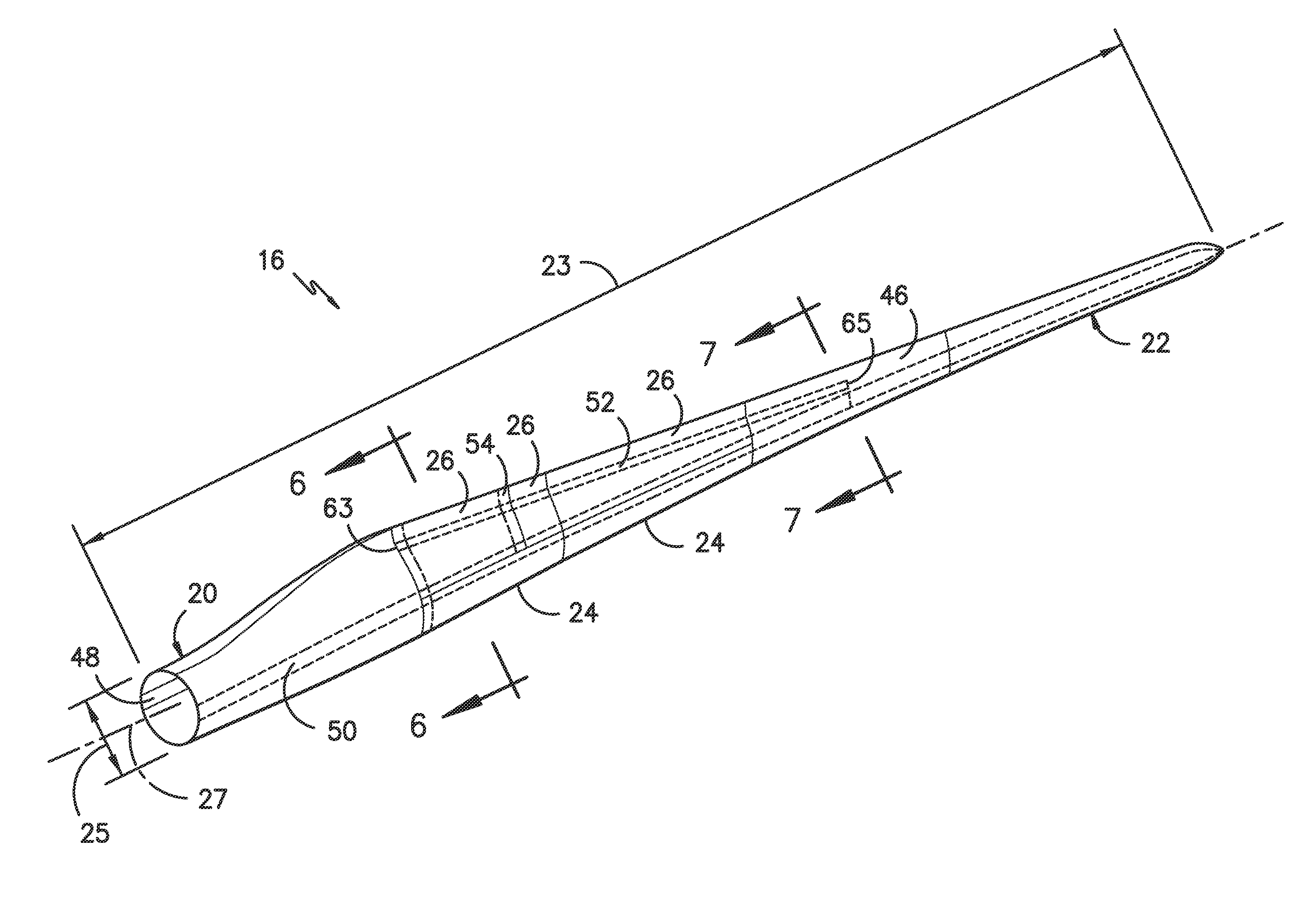

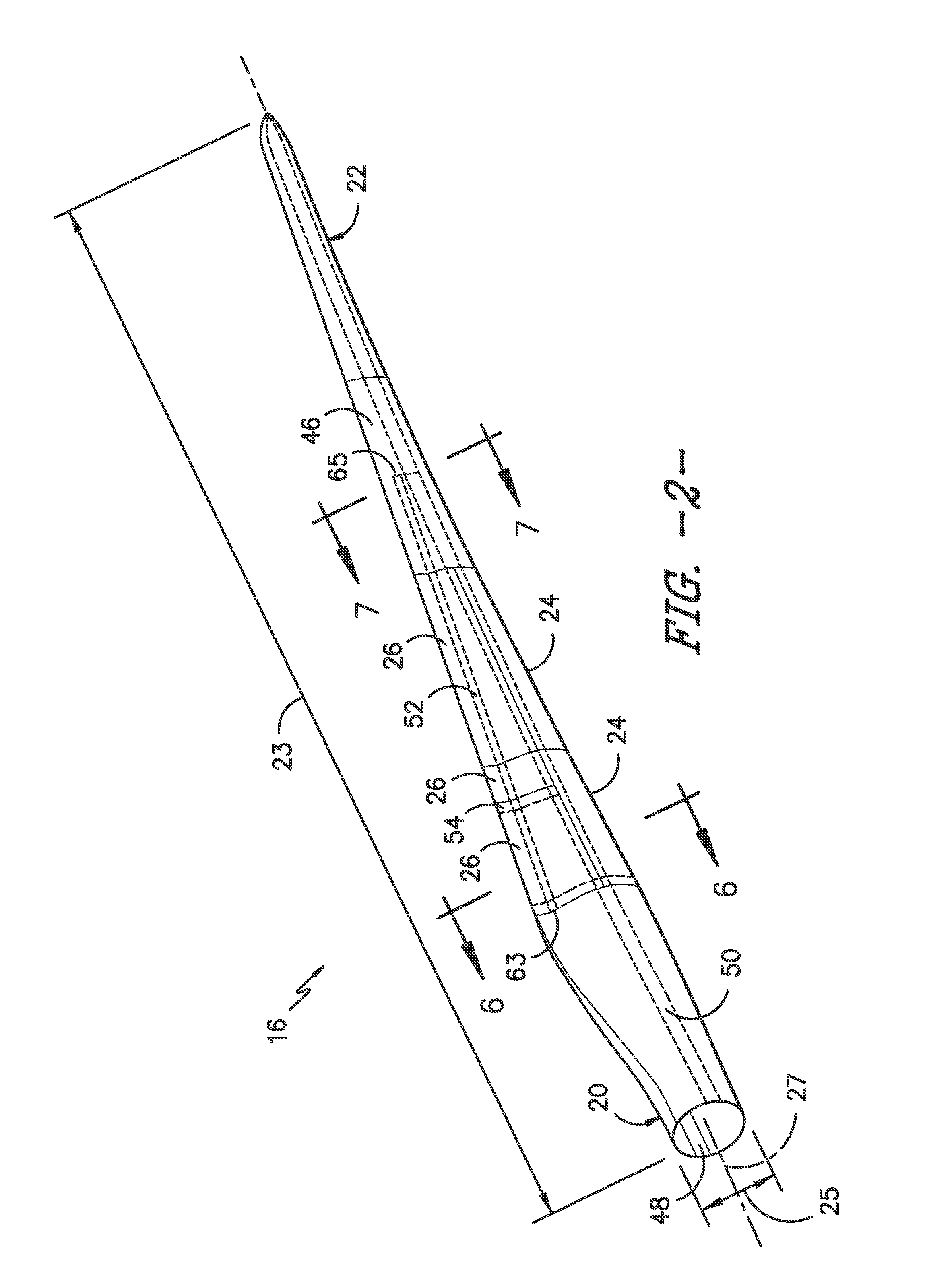

Rotor blade trailing edge assembly and method of use

A method of assembling a rotor blade for a turbine is provided that includes forming a rotor blade trailing edge by coupling a suction side terminus to a pressure side terminus and positioning a trailing edge assembly between the suction side terminus and the pressure side terminus, the trailing edge assembly having a varying cross-section.

Owner:GENERAL ELECTRIC CO

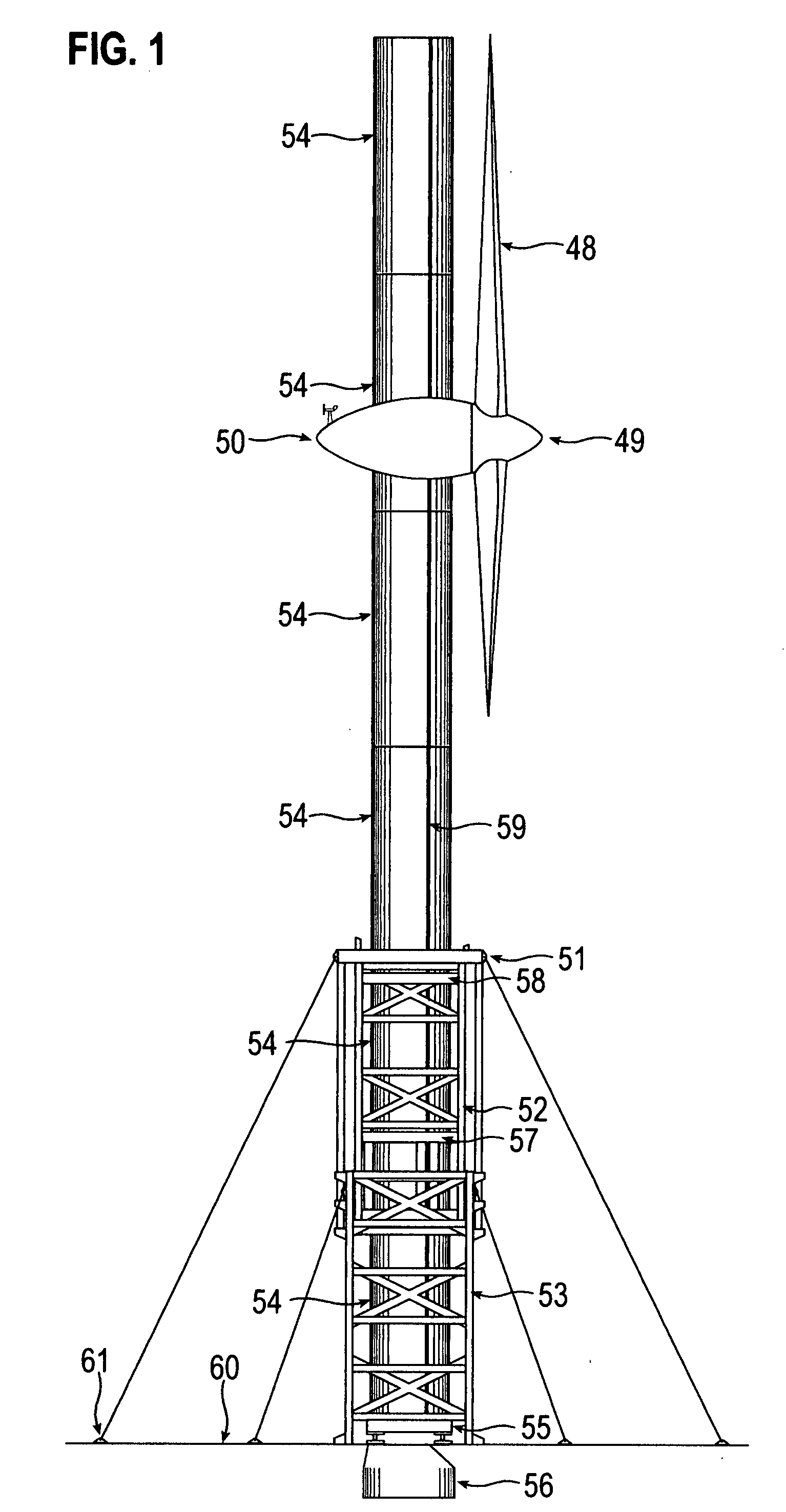

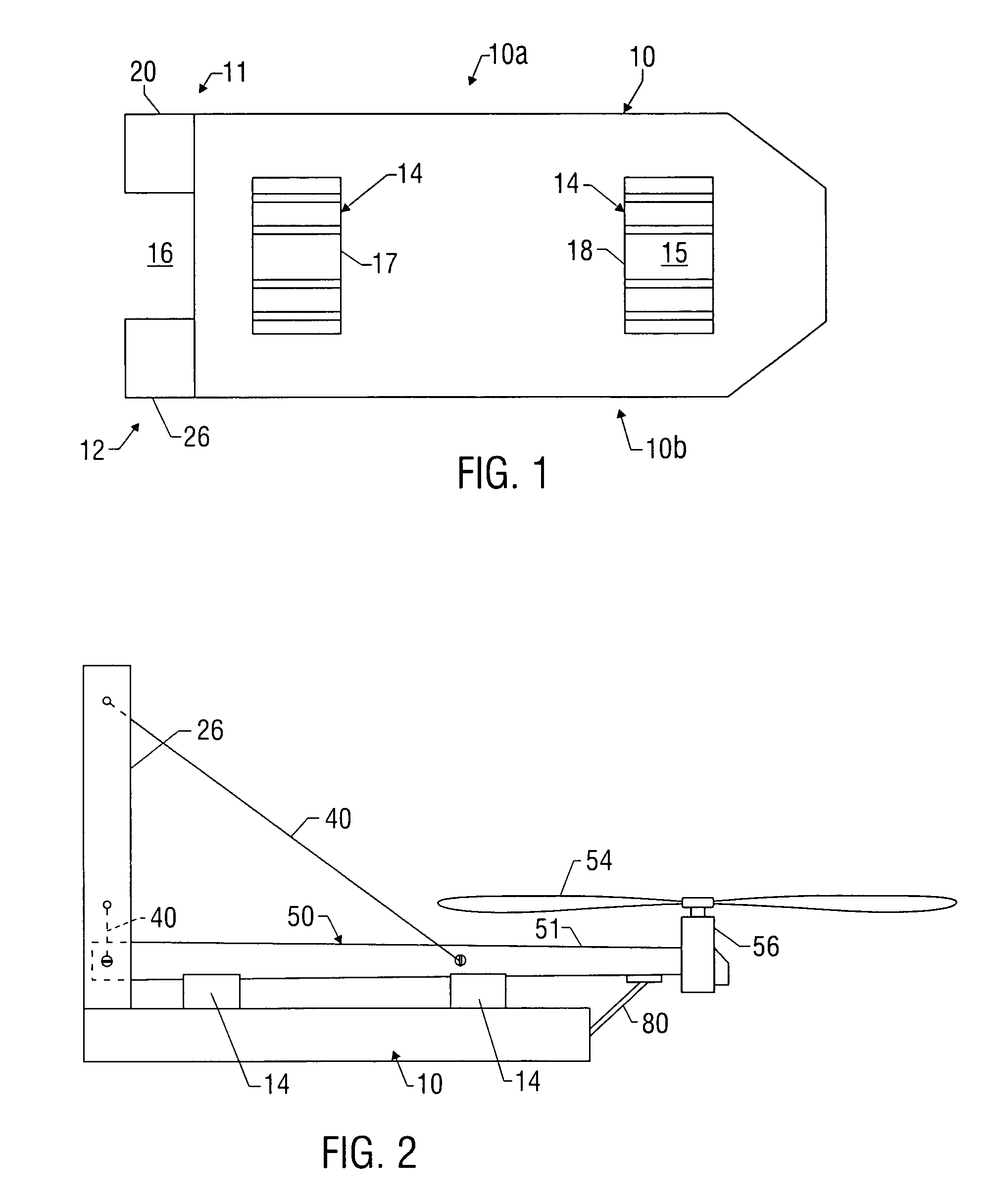

Apparatus, systems and methods for erecting an offshore wind turbine assembly

An embodiment of an apparatus useful for up-righting a wind turbine pillar at an offshore installation location includes a barge having first and second towers and an open area therebetween and which extends downwardly to the offshore installation location. At least two pulling lines extend from the towers to the pillar and are useful to assist in moving the pillar into a generally up-right orientation between the towers and lowering the pillar downwardly through the open area to the offshore installation location.

Owner:GEIGER WILLIAM CLYDE

Joint design for rotor blade segments of a wind turbine

A blade segment of a rotor blade assembly formed from two or more blade segments is disclosed. The blade segment may generally include a body shell and a shear web extending longitudinally within the body shell. The shear web may be disposed between opposed spar caps. The blade segment may also include an attachment member and a spar member. The attachment member may be at least partially disposed within the body shell. The spar member may generally extend outwardly from the spar caps along an inner surface of the body shell and may be configured to support the attachment member within the body shell.

Owner:GENERAL ELECTRIC CO

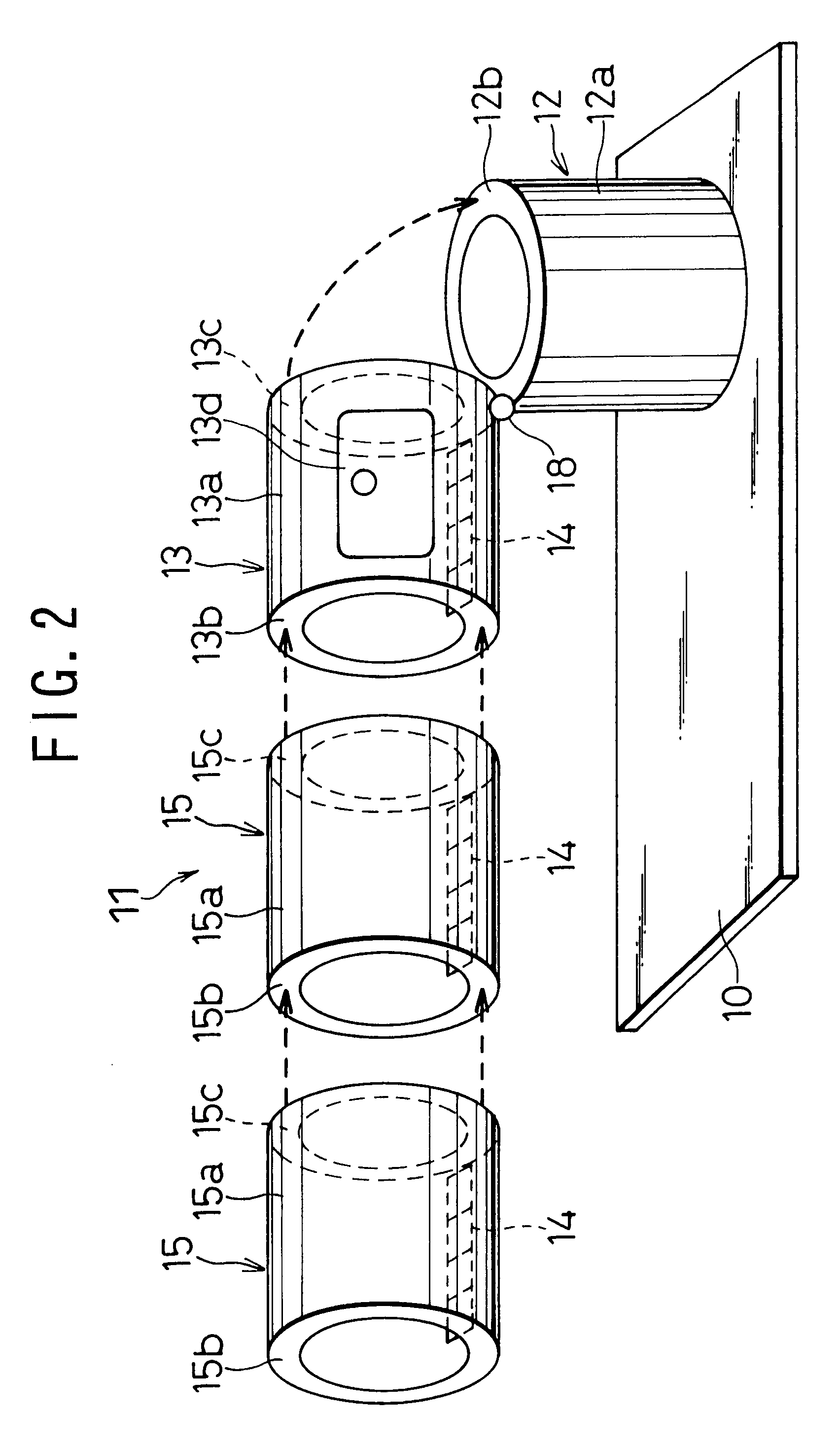

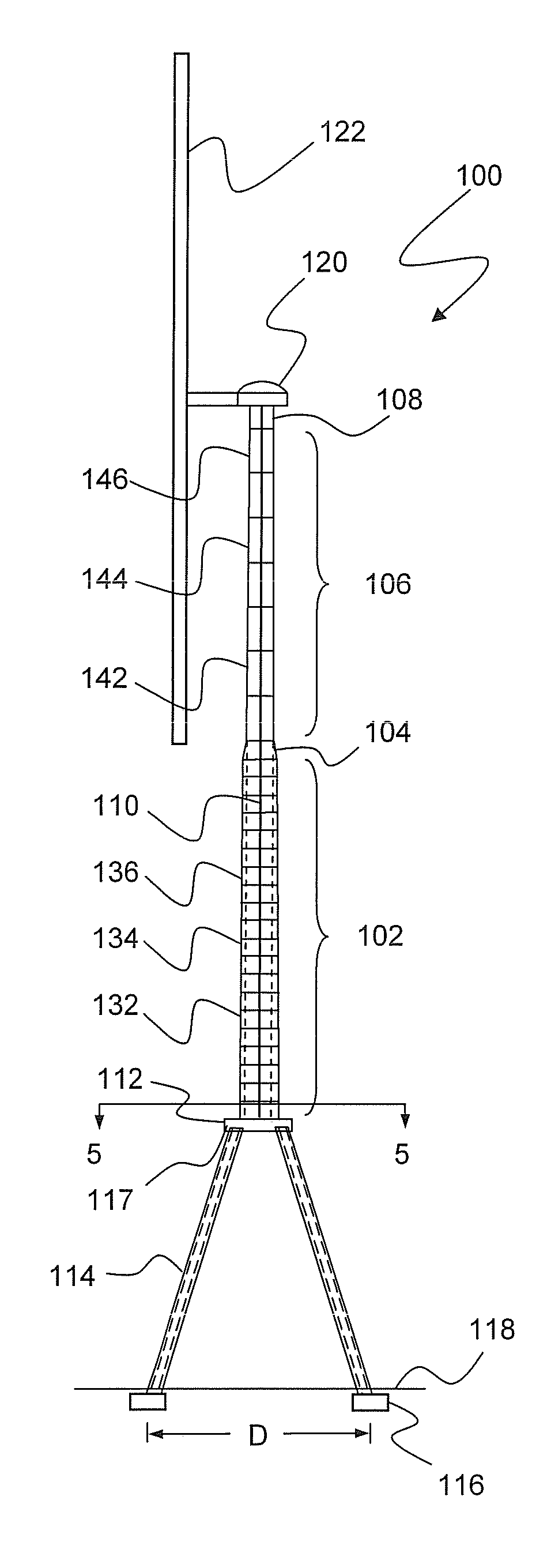

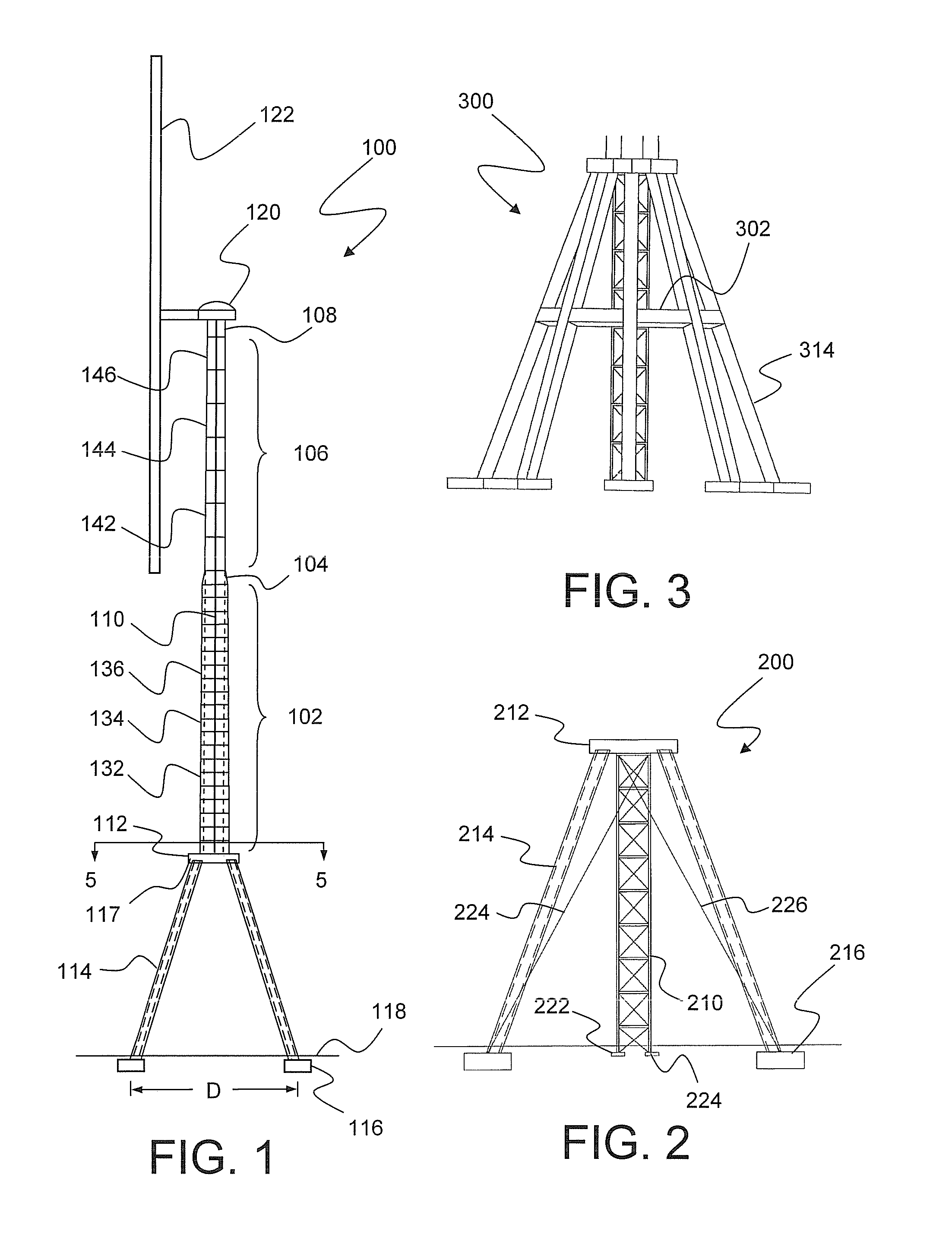

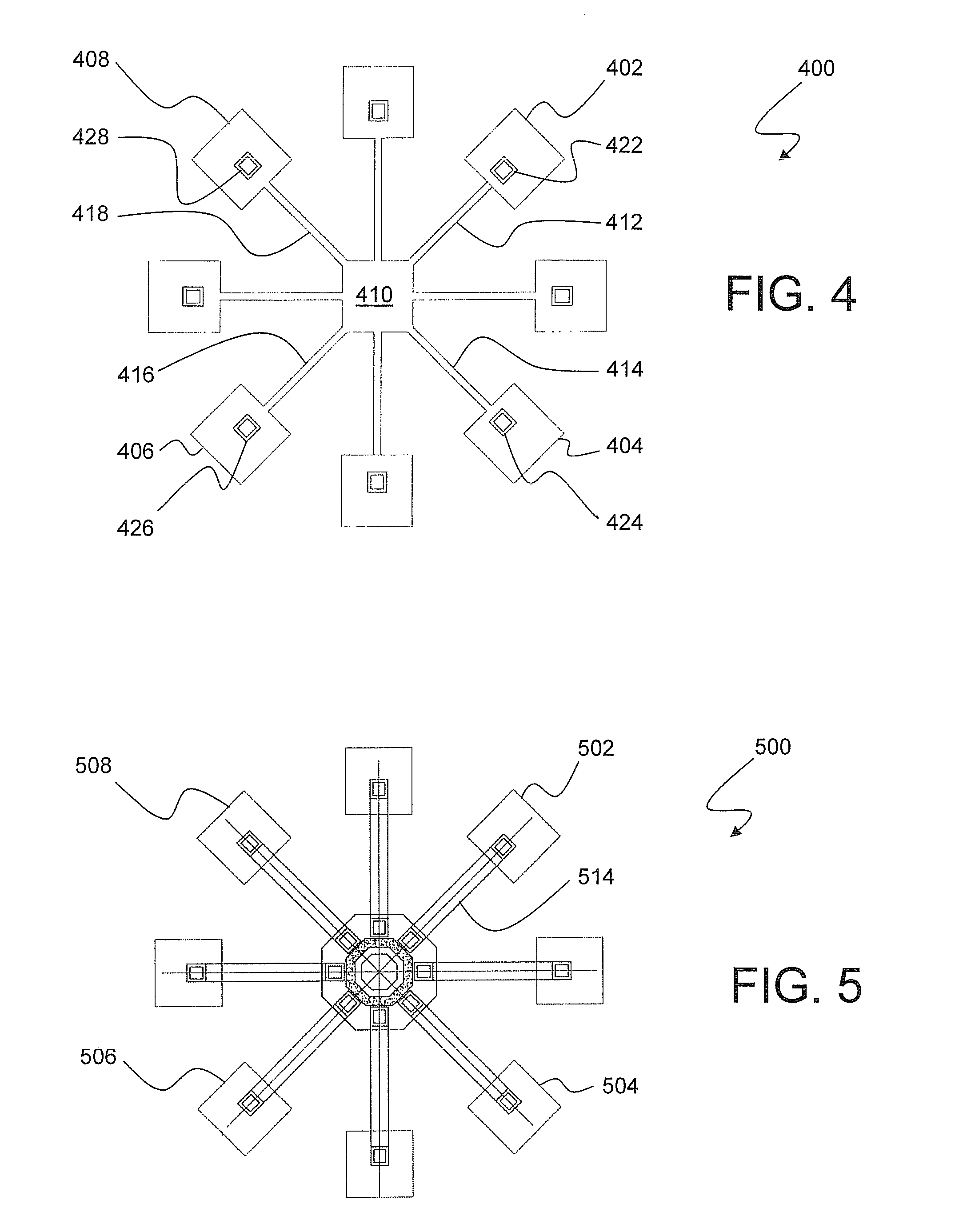

Base support for wind-driven power generators

Disclosed are apparatus and corresponding methodology for providing a base support, such as including concrete, and used such as for a wind-driven generator. Precast concrete cylinders are stacked in place upon a platform that may be partially precast and partially cast in place during assembly and supported, in certain embodiments, by plural concrete legs, the other ends of which are supported on a unitary or subdivided concrete foundation. In other embodiments, the platform may be supported by ribbed concrete panels. The concrete cylinders are glued together using an epoxy and then secured by an internal vertical post tension system extending from the platform to the upper most cylinder. Different types of concrete are used between upper and lower sections of the stacked cylinders. The lower section uses reinforced concrete while the upper section used ultra high performance fiber reinforced concrete.

Owner:TINDALL CORP

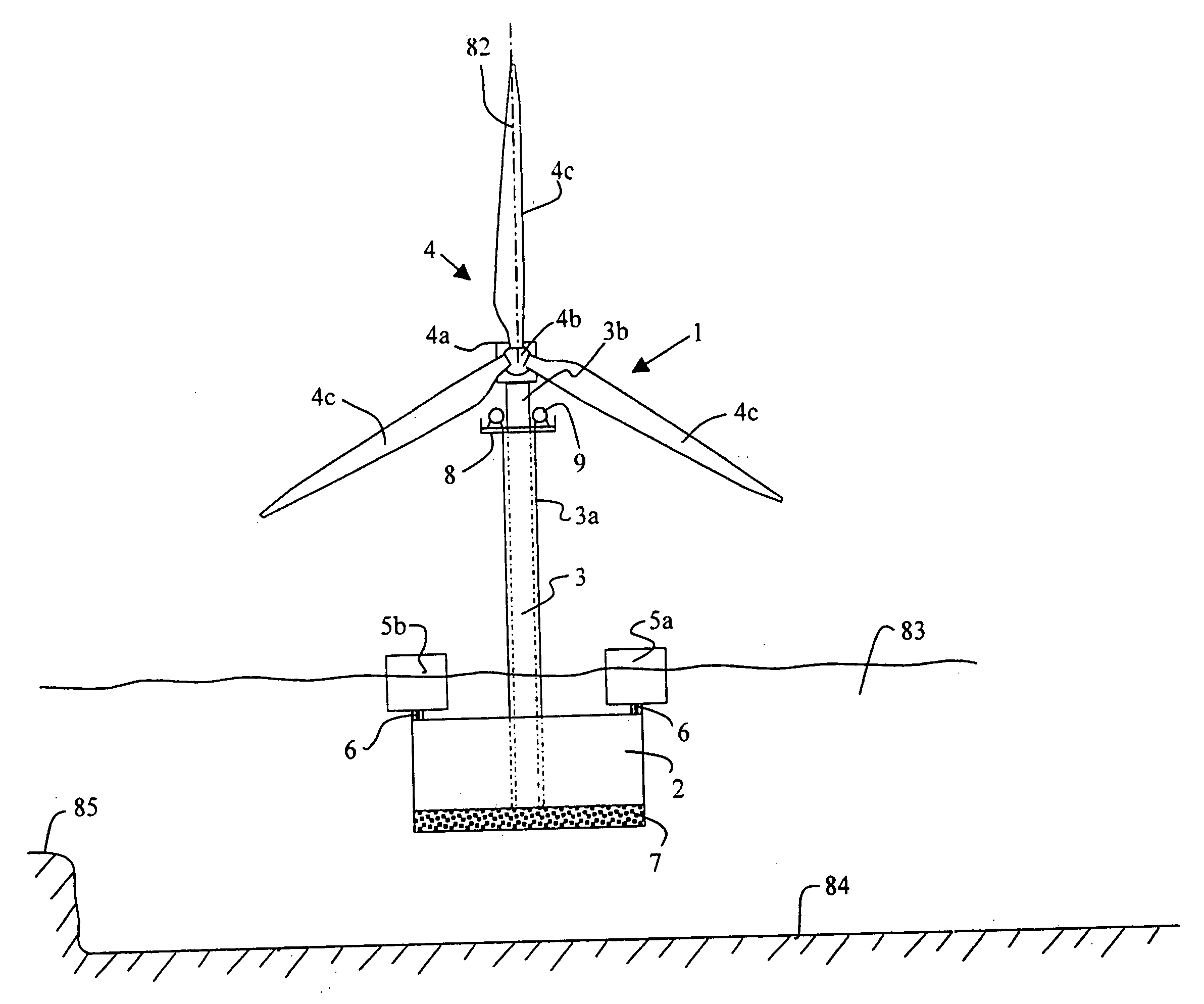

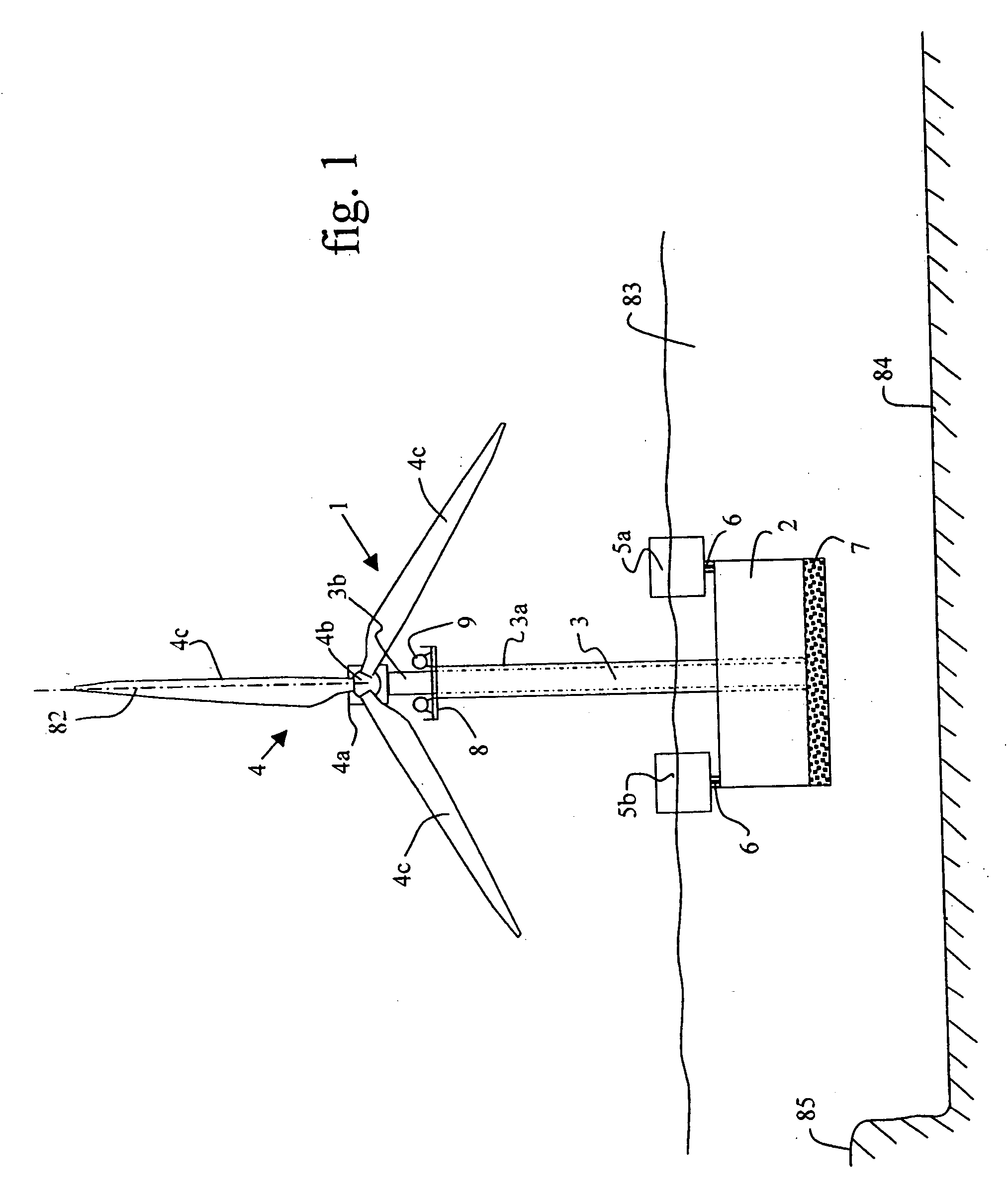

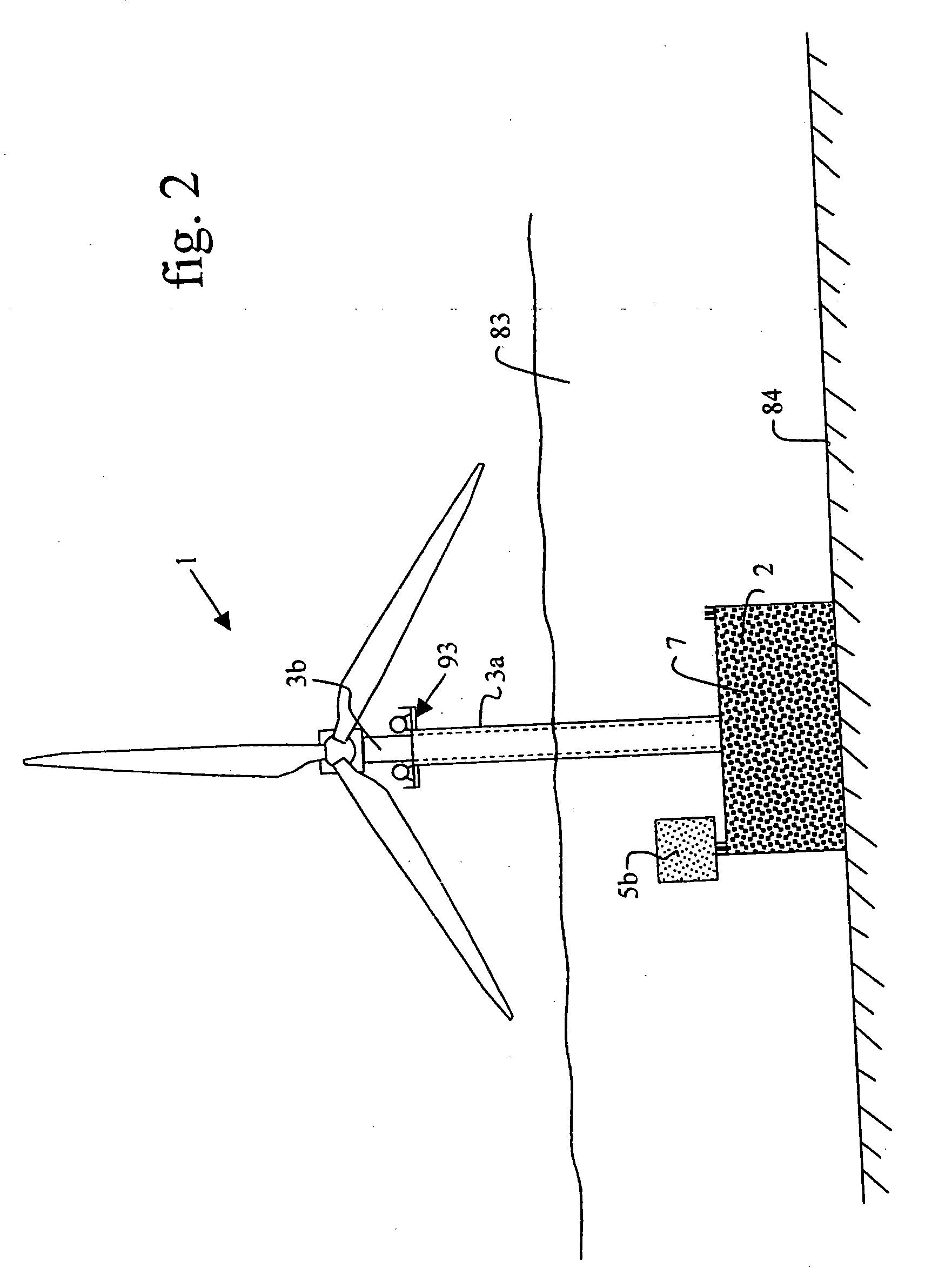

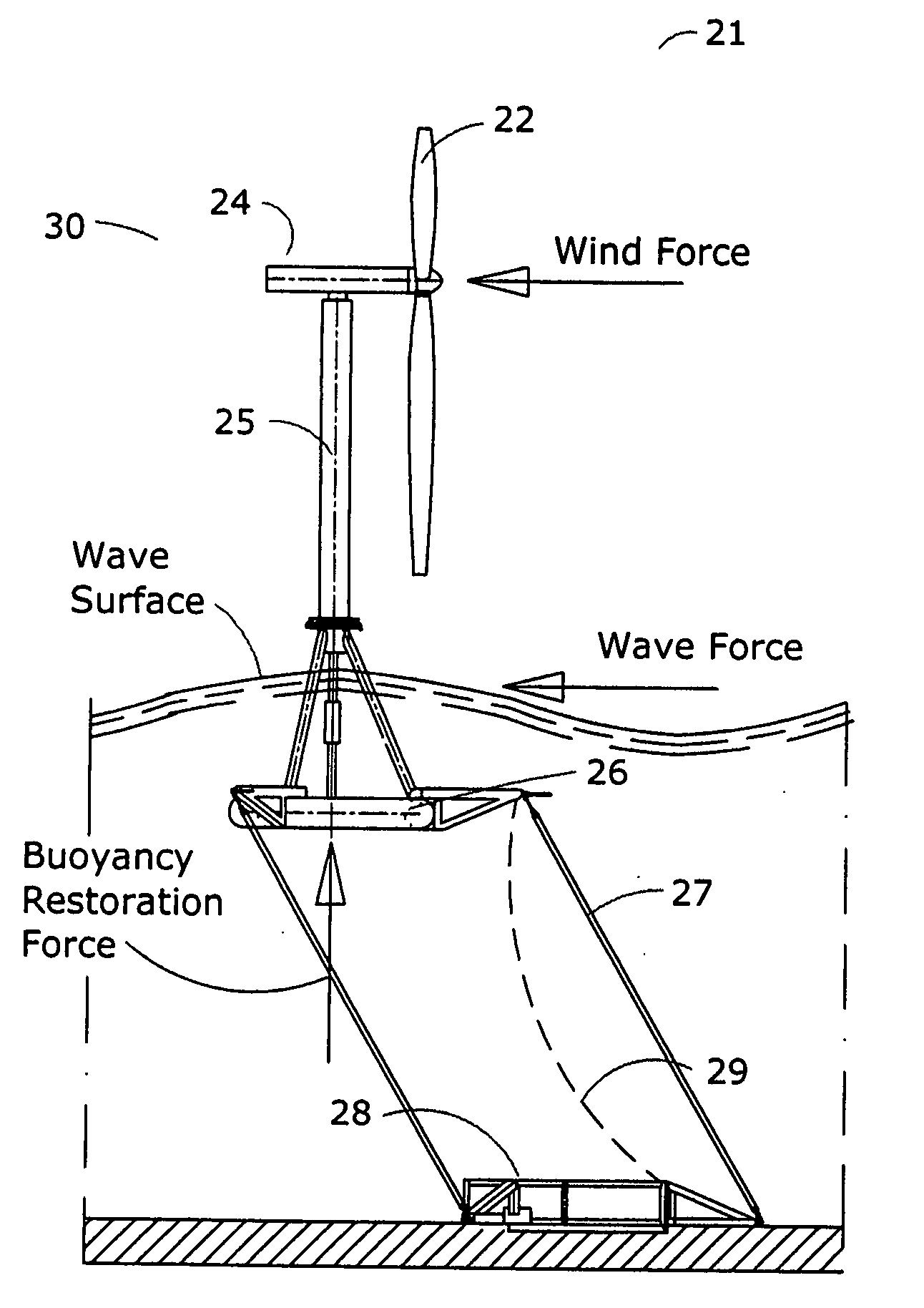

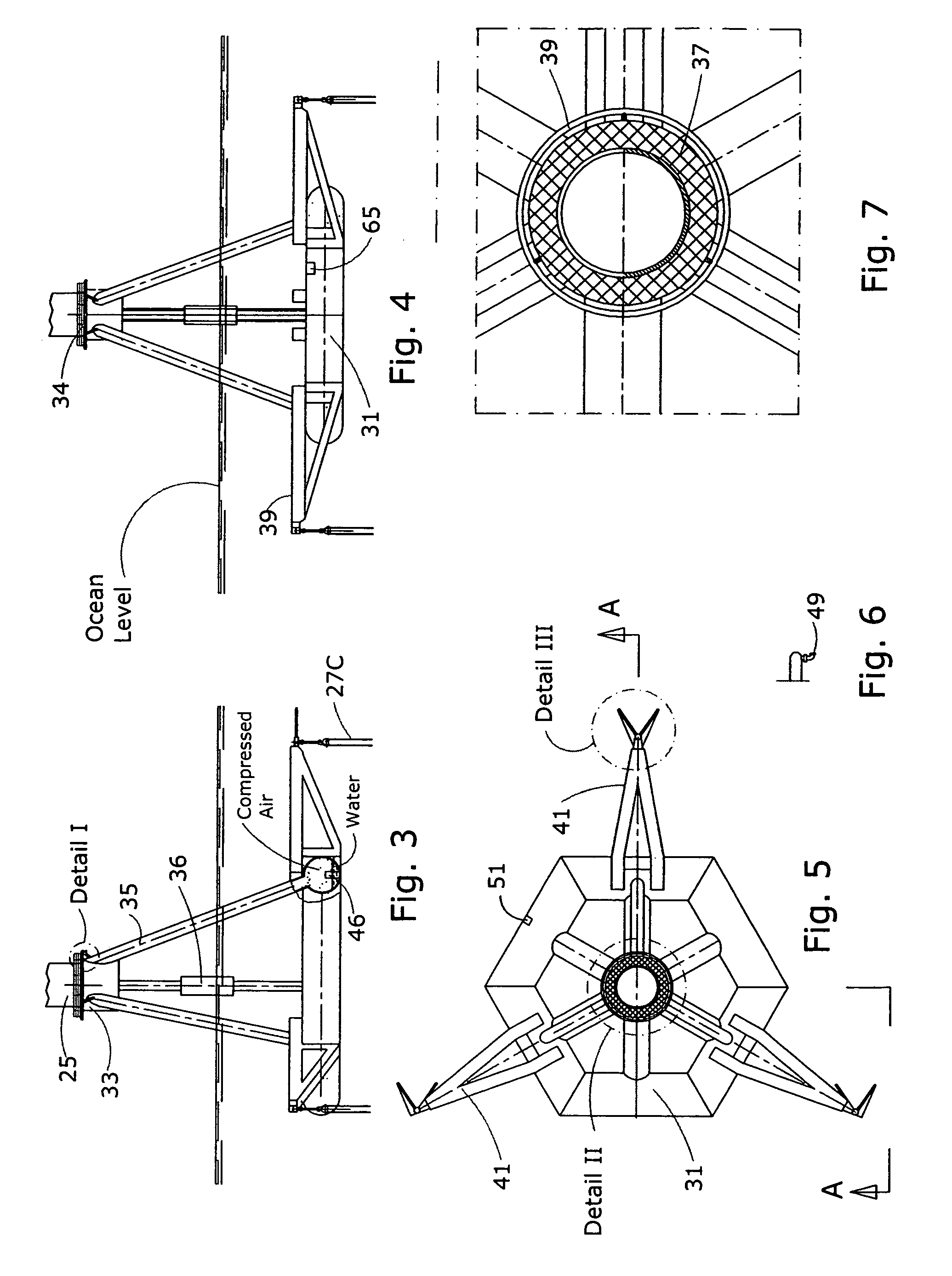

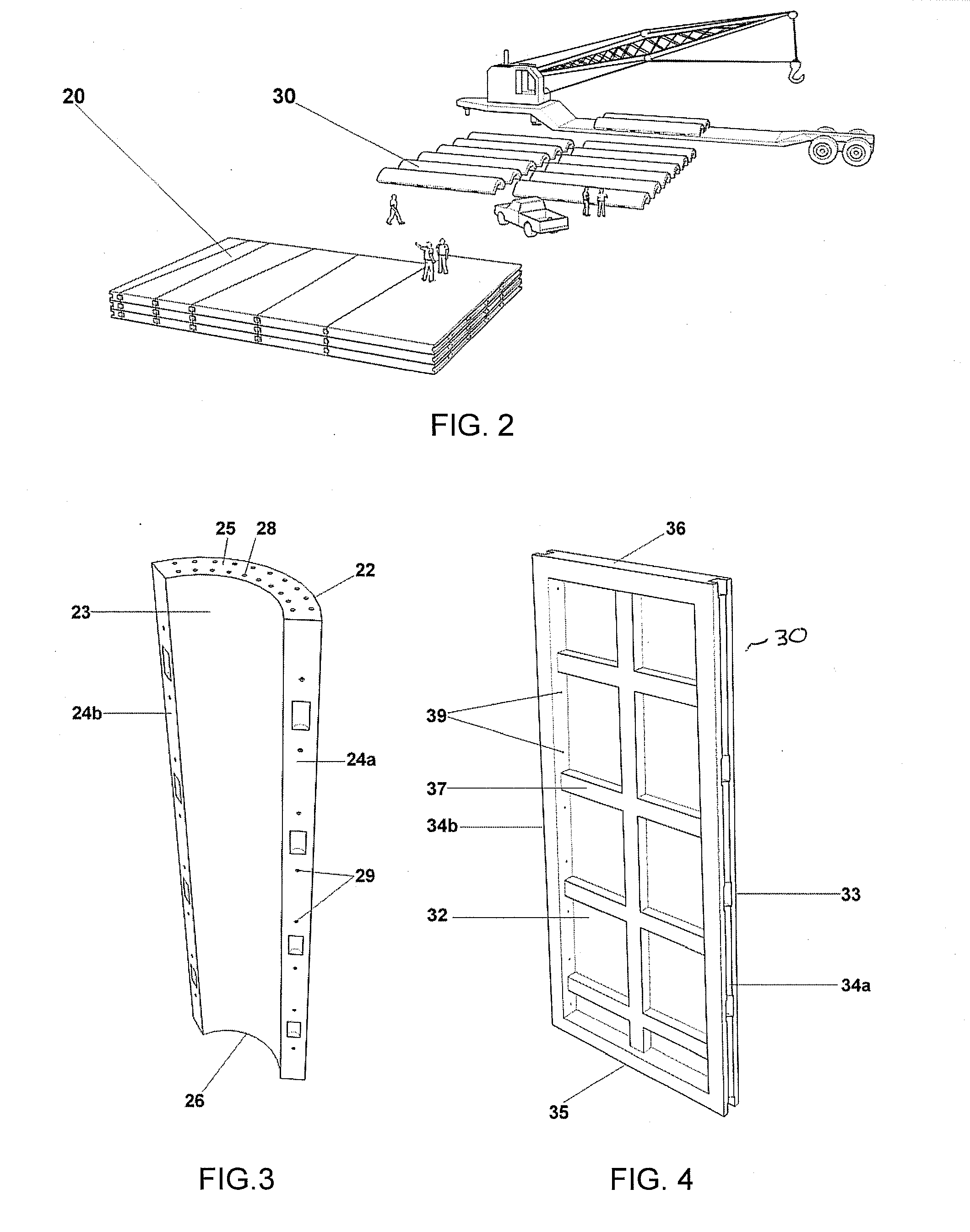

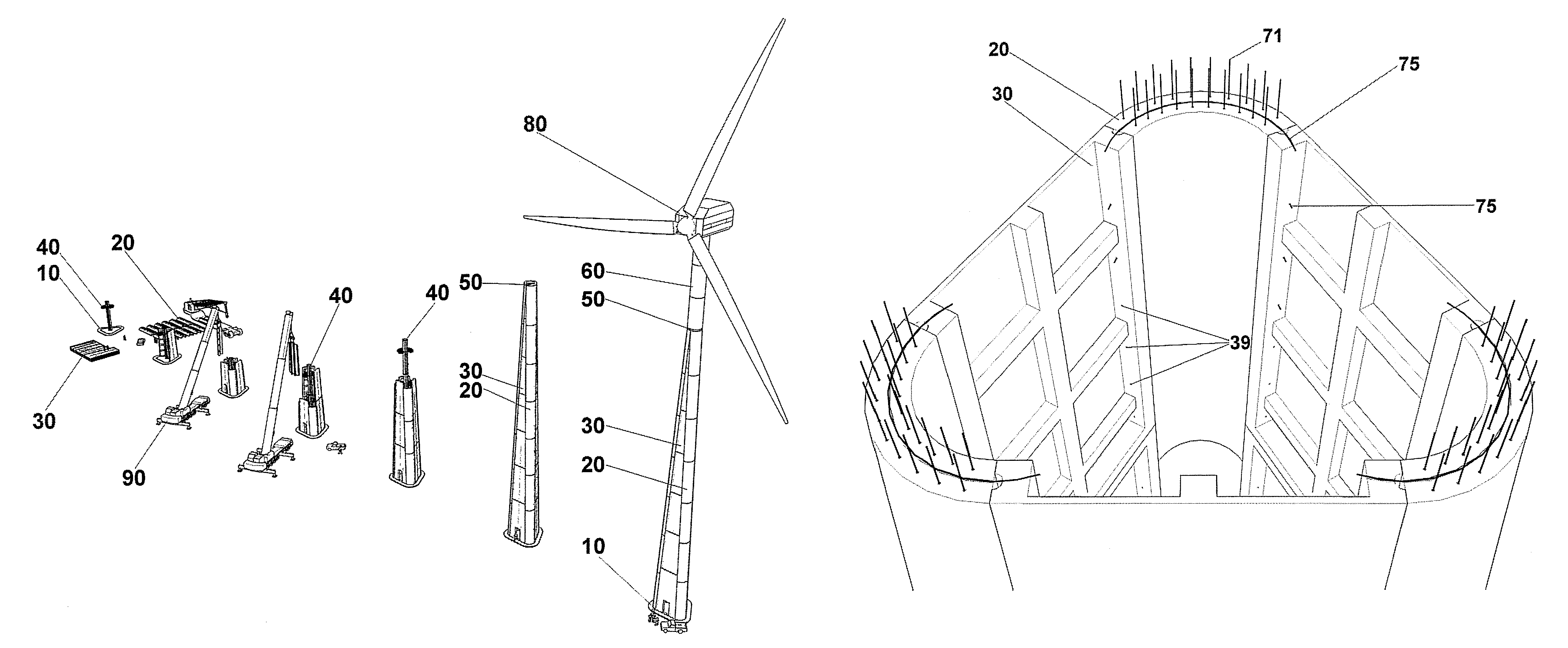

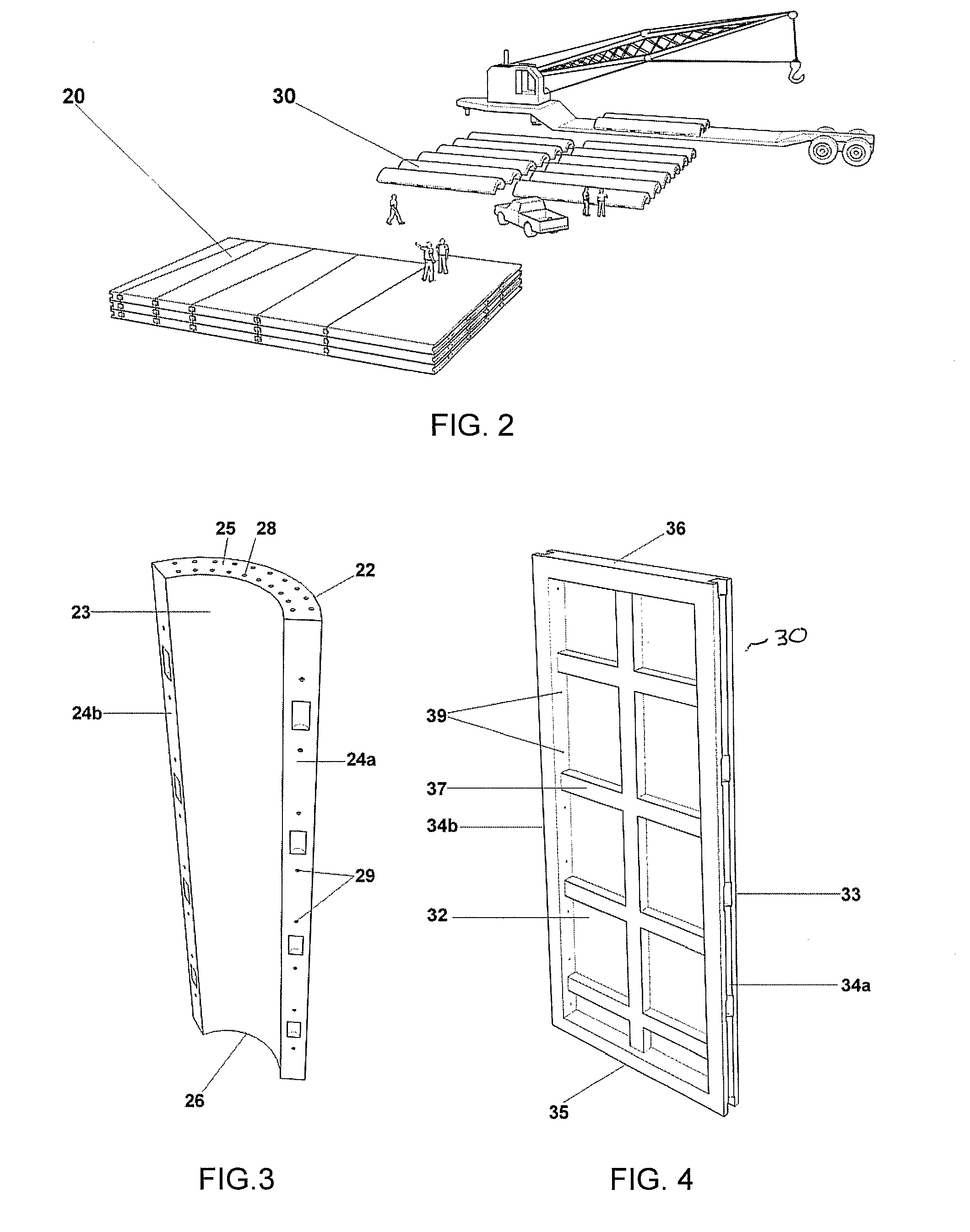

Assembly, transportation and installation of deepwater windpower plant

InactiveUS20080240864A1Reduce installationShorten assembly timeWind motor assemblyWind motor supports/mountsOcean bottomBuoy

A deepwater windpower plant (DWP) has a tension leg-type floating platform with an evacuable base for adjusting its buoyancy for installation at ocean depths ranging from 40 meters up to 1.5 kilometers and more. The DWP has a typical offshore wind turbine assembled close to shore which is then towed to a desired installation site on the ocean, and held in place by a gravity anchoring base (GAB), to which an evacuable portion or space of the DWP platform is anchored. The GAB has upwardly extending mooring tethers and a power cable which are brought to the ocean surface by attached buoys. The GAB is sunk to the ocean floor at the installation site under controlled conditions so that the GAB lands flat on the ocean floor. As the GAB sinks to the ocean floor, the mooring tethers and power cable are pulled to the surface by their respective buoys. The GAB is loaded with heavy ballast material that can be dropped from barges on the ocean surface into the upwardly open GAB below the barges.

Owner:DEEPWATER WIND

Pre-stressed concrete tower for wind power generators

InactiveUS20090031639A1Simplifying erectionSimplifying fabricationFinal product manufactureWind motor assemblyPre stressPre stressing

A pre-stressed segmented concrete tower for wind power generators is described, and a method for its fabrication, wherein in a pyramidal structure is formed by prefabricated segments, the structure comprising three rounded walls formed with circular segments, and three flat walls, formed with flat segments between the circular walls. One standard curved mold is used for the circular walls, and the flat walls are fabricated horizontally, over templates.

Owner:CORTINA INNOVATIONS DE C V

Pre-stressed concrete tower for wind power generators

InactiveUS7739843B2Simplifying erectionSimplifying fabricationFinal product manufactureWind motor assemblyPre stressPre stressing

A pre-stressed segmented concrete tower for wind power generators is described, and a method for its fabrication, wherein in a pyramidal structure is formed by prefabricated segments, the structure comprising three rounded walls formed with semi-circular segments, and three flat walls, formed with flat segments between the semi-circular walls. One standard curved mold is used for the semi-circular walls, and the flat walls are fabricated horizontally, over templates.

Owner:CORTINA INNOVATIONS DE C V

Wind turbine

InactiveUS7323792B2Maximize efficiencyMinimize the air drag affecting the wind turbineWind motor controlEngine fuctionsTurbineWind force

Owner:SOHN CHESTER

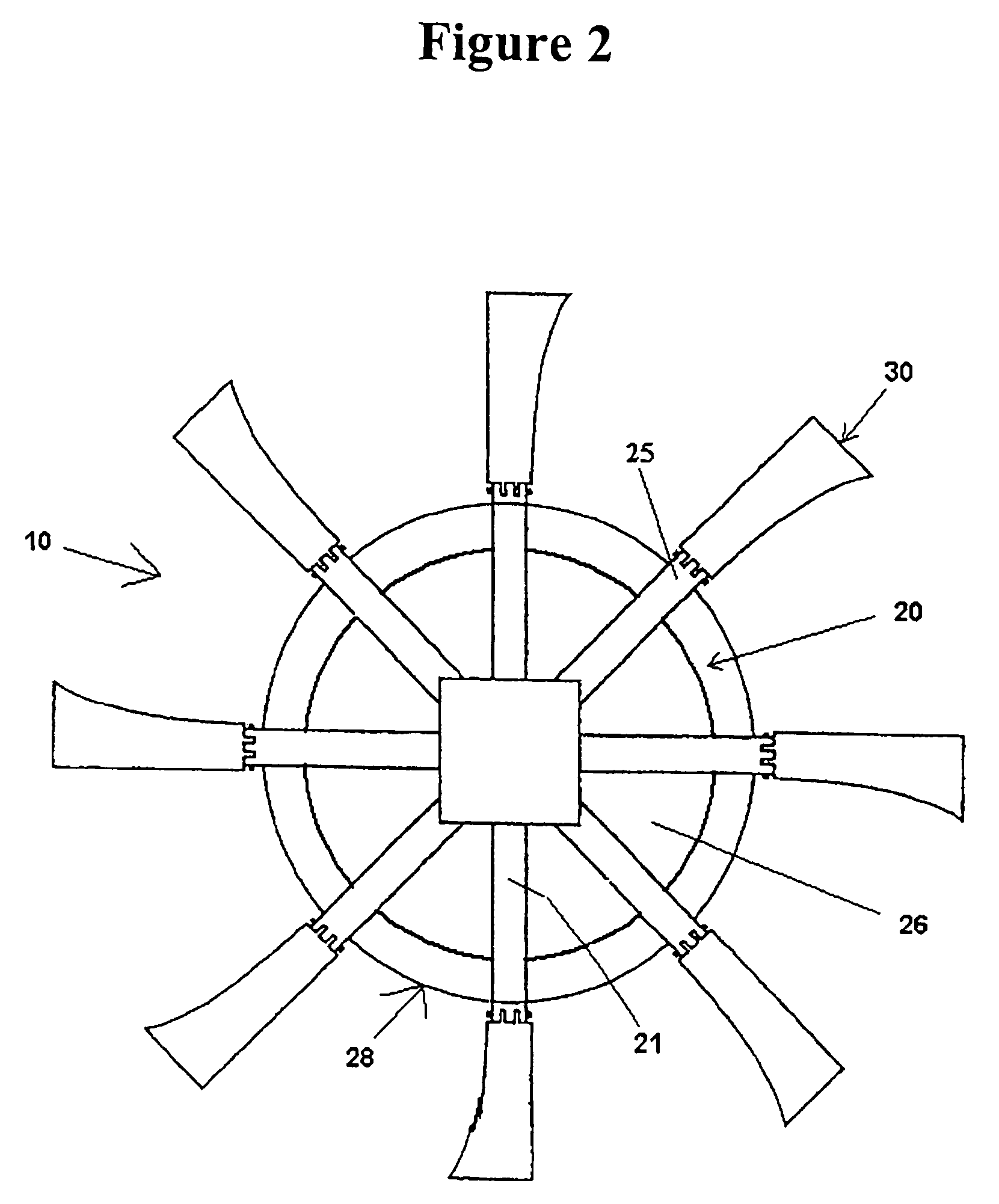

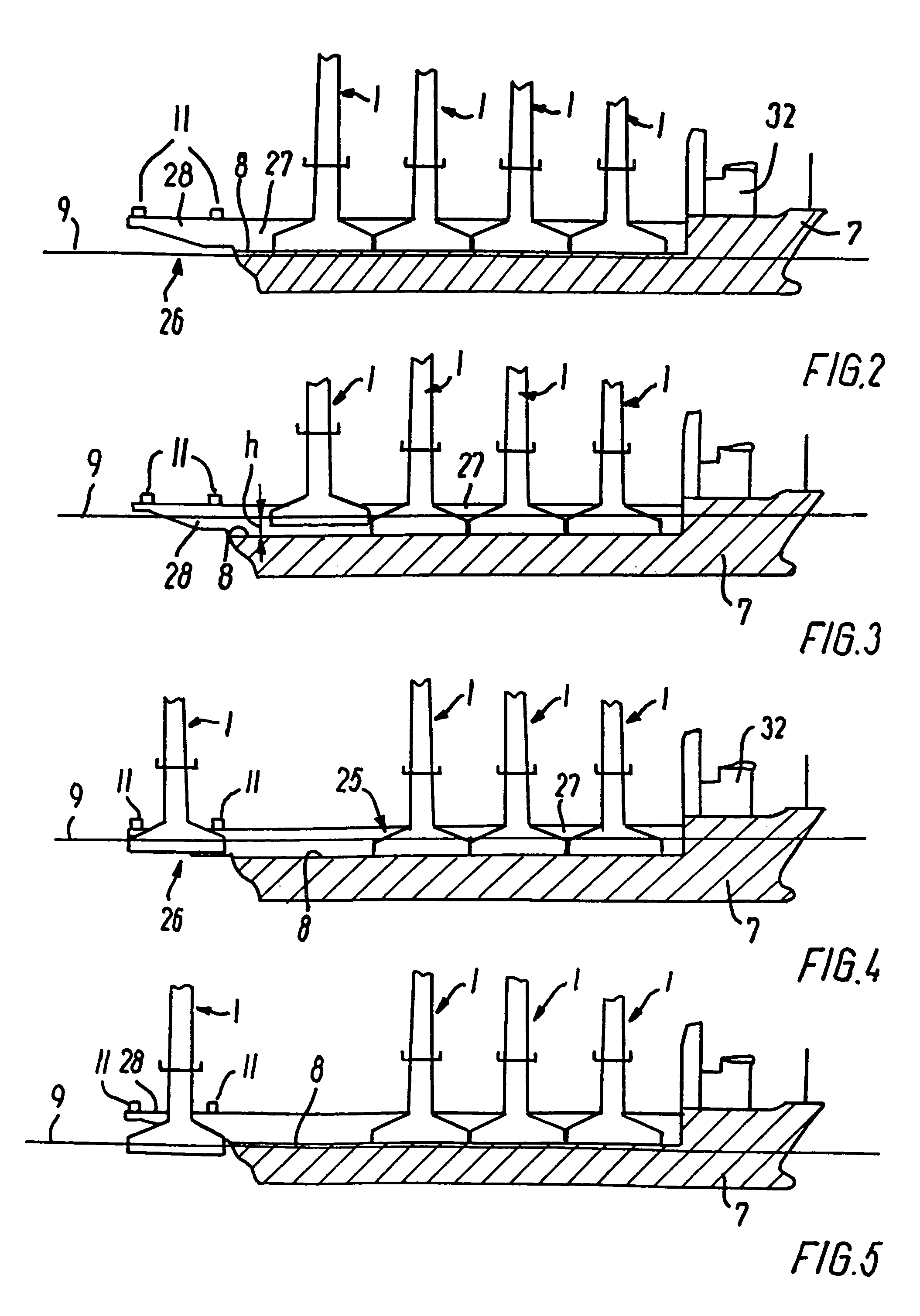

Vessel for transporting wind turbines, methods of moving a wind turbine, and a wind turbine for an off-shore wind farm

A wind turbine (1) has a base (5) divided into at least three ballast tanks (12). A vessel (7) has means for displacing the wind turbine between a loading space (25) and an unloading position (26). At its unloading position the vessel has winches (11) with at least three flexible lines (10) that can be connected with horizontally distanced lifting points (23) on the wind turbine base.

Owner:LOGIMA VSVEND ERIK HANSEN

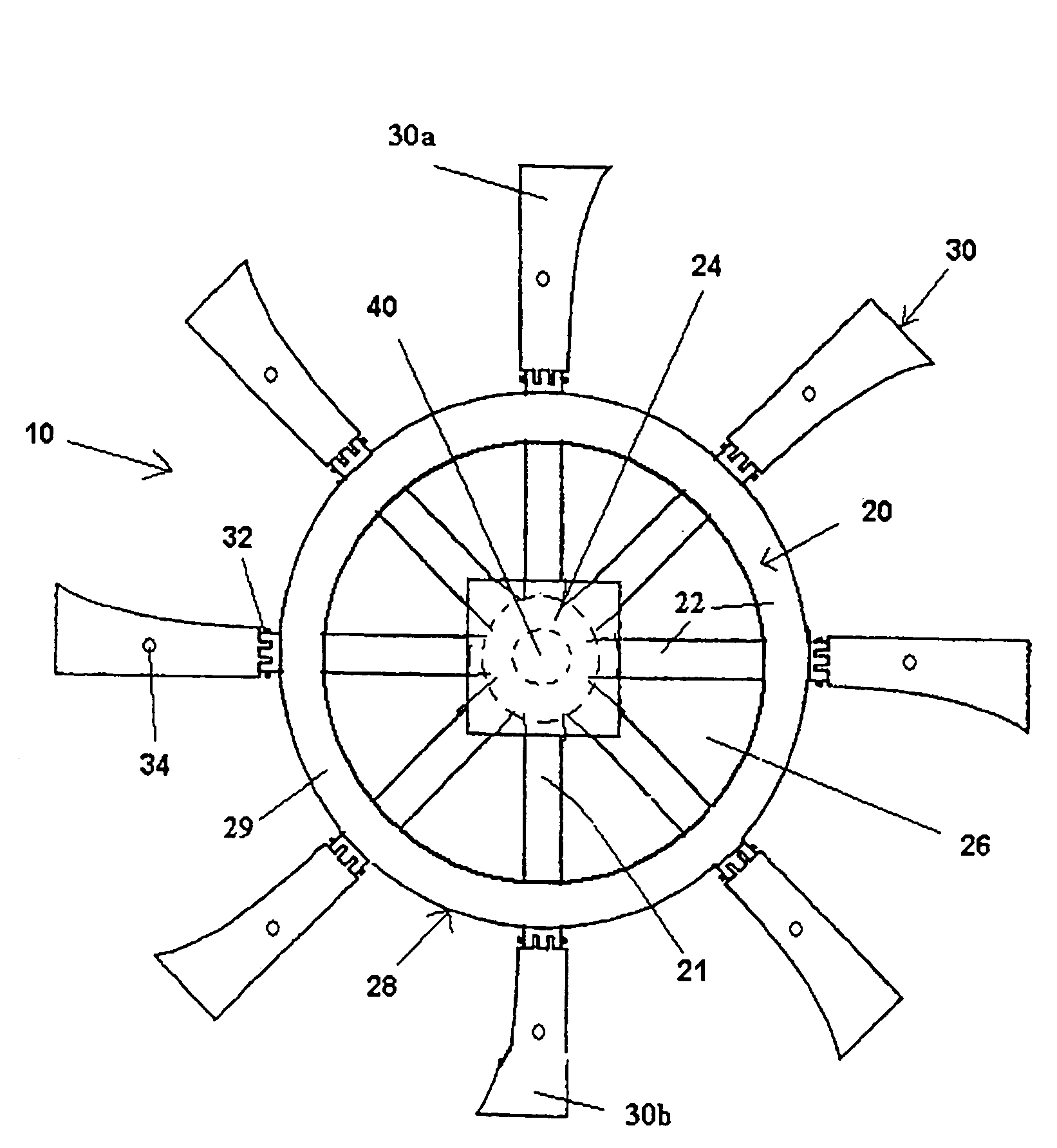

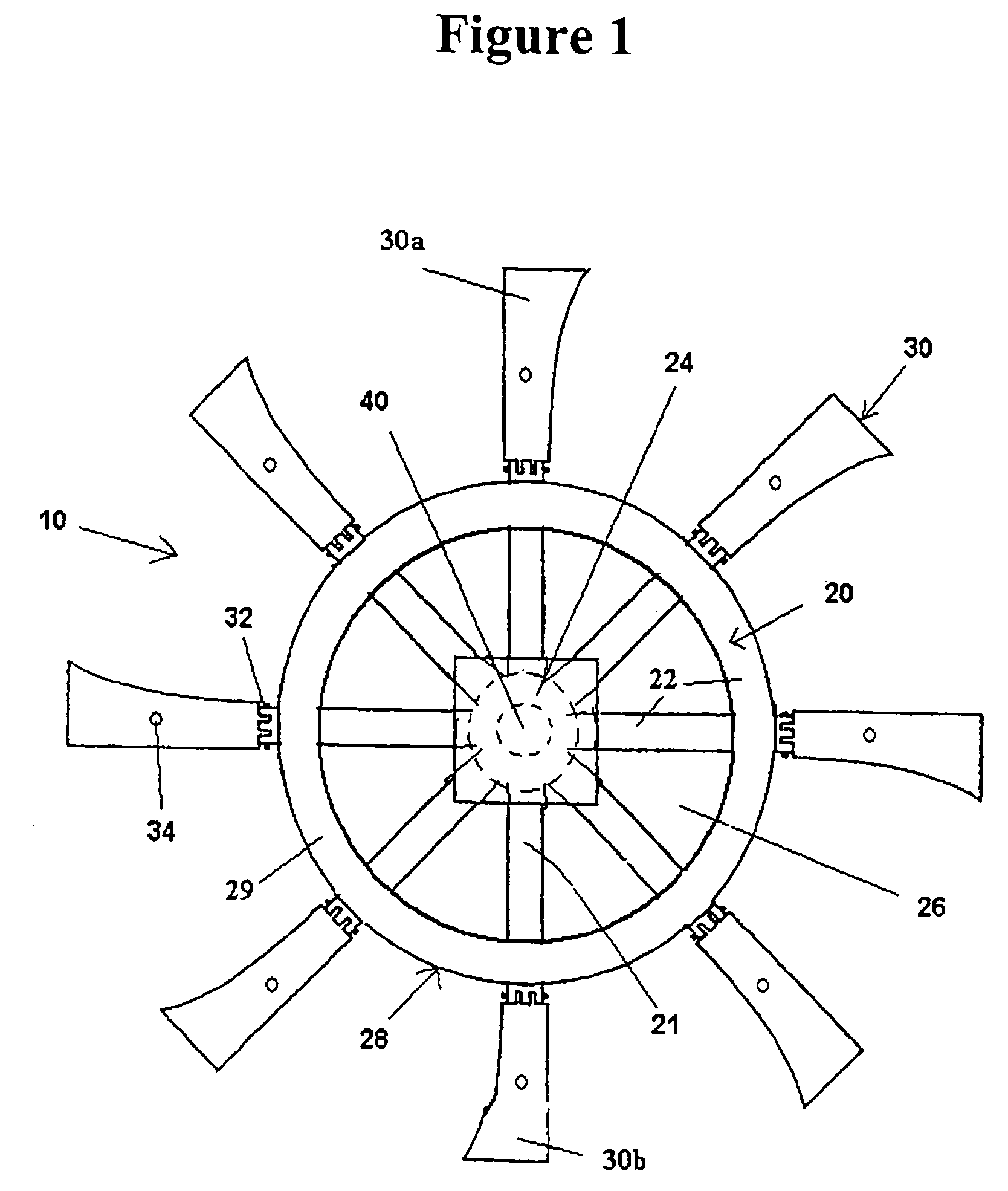

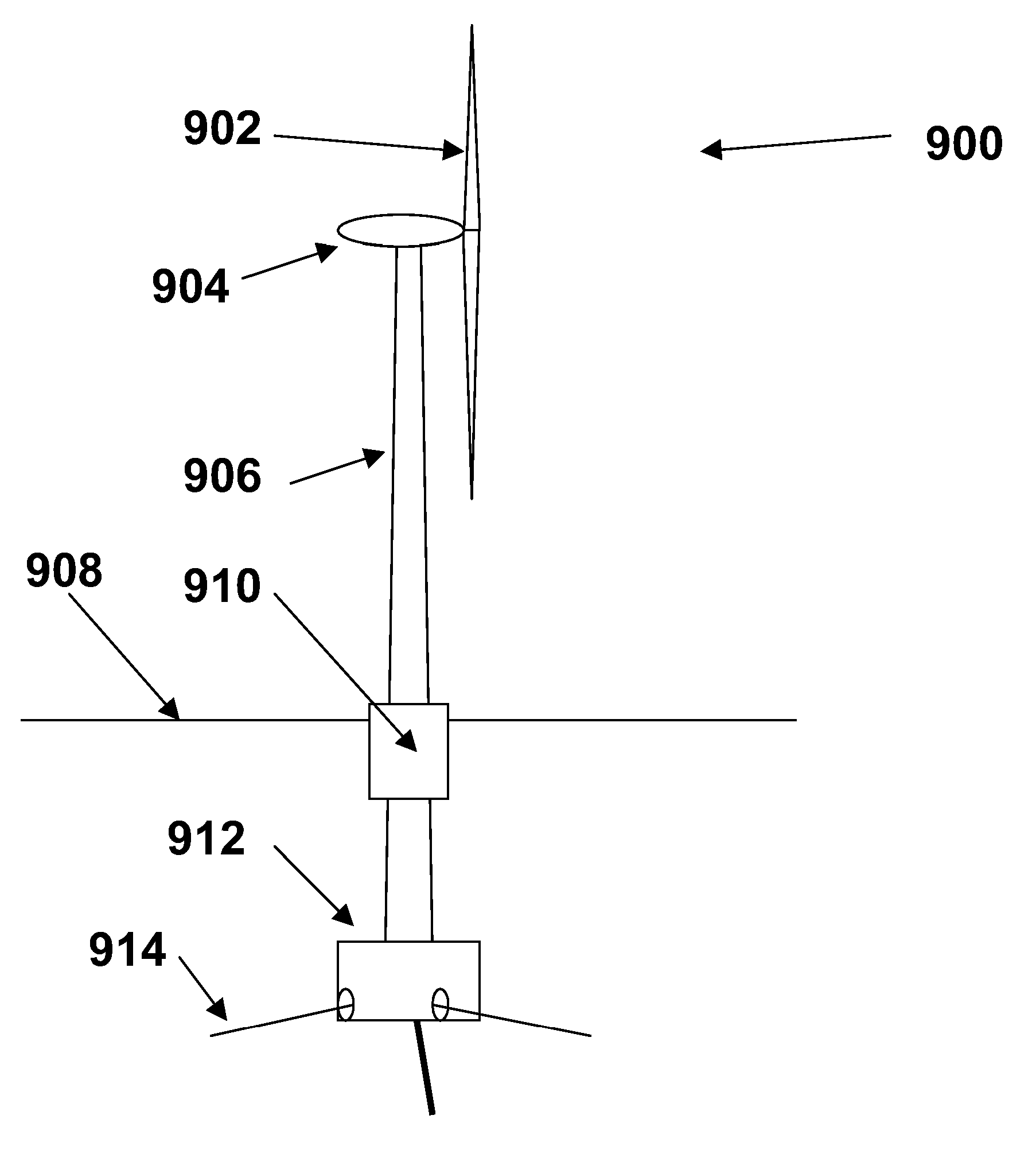

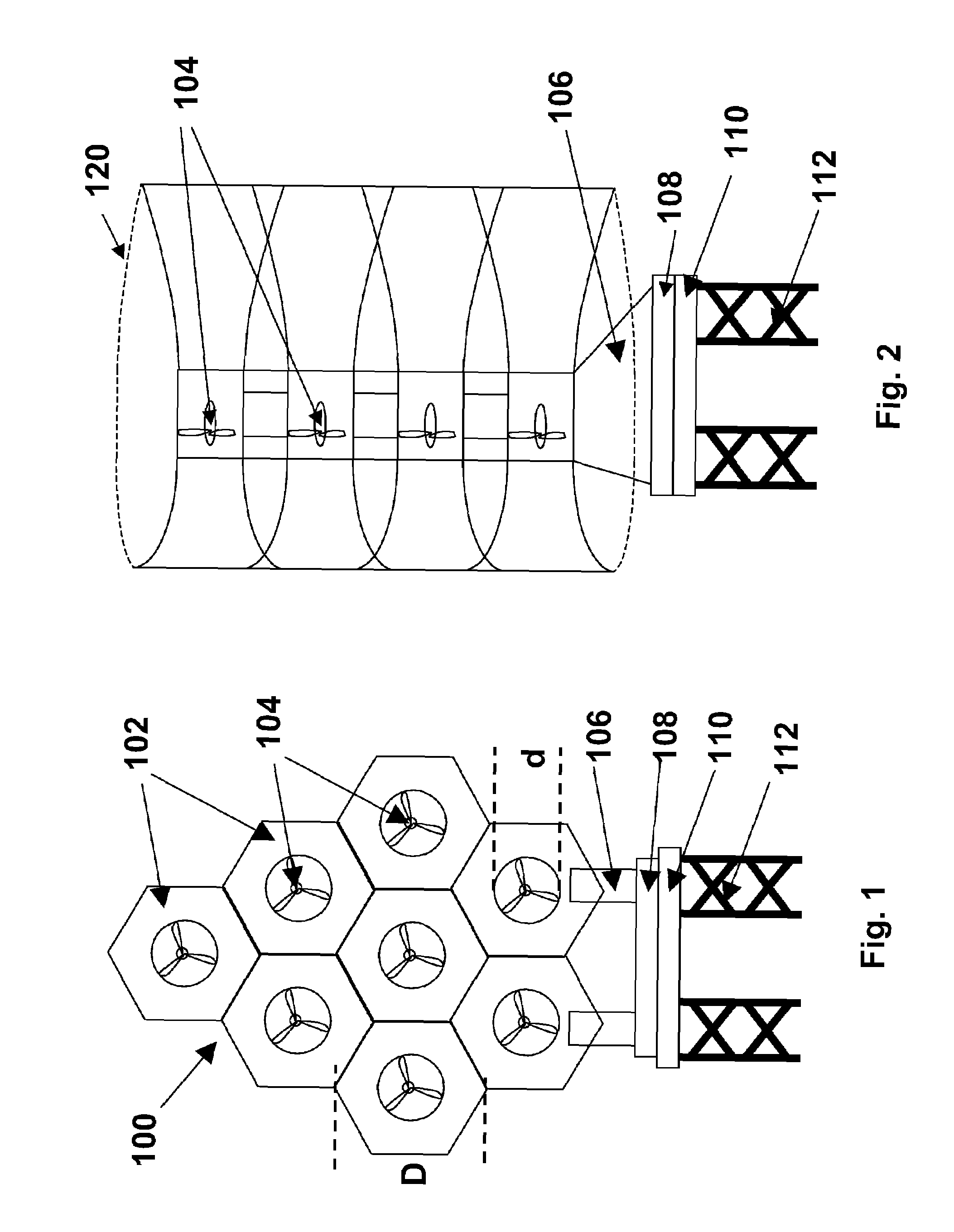

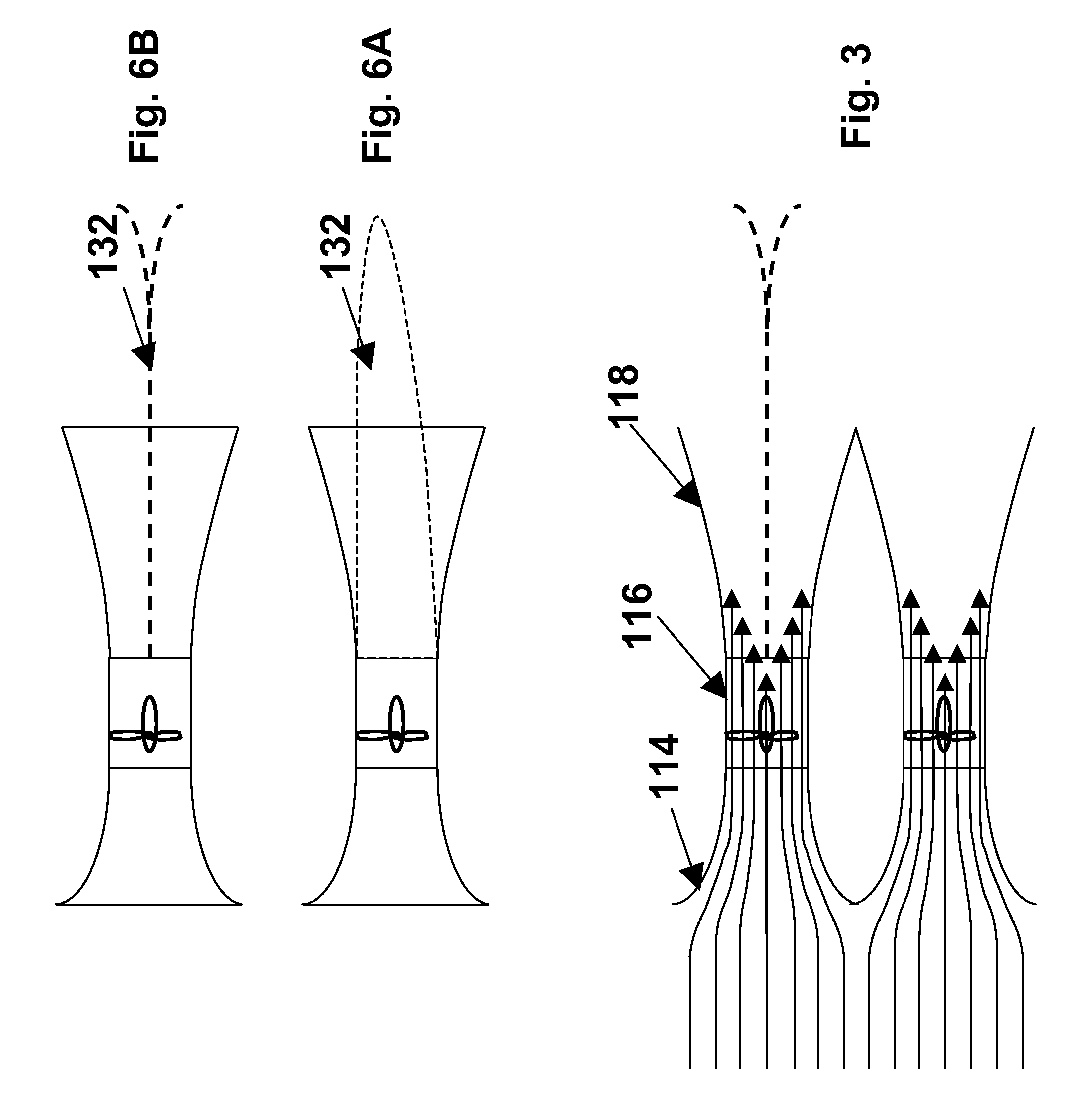

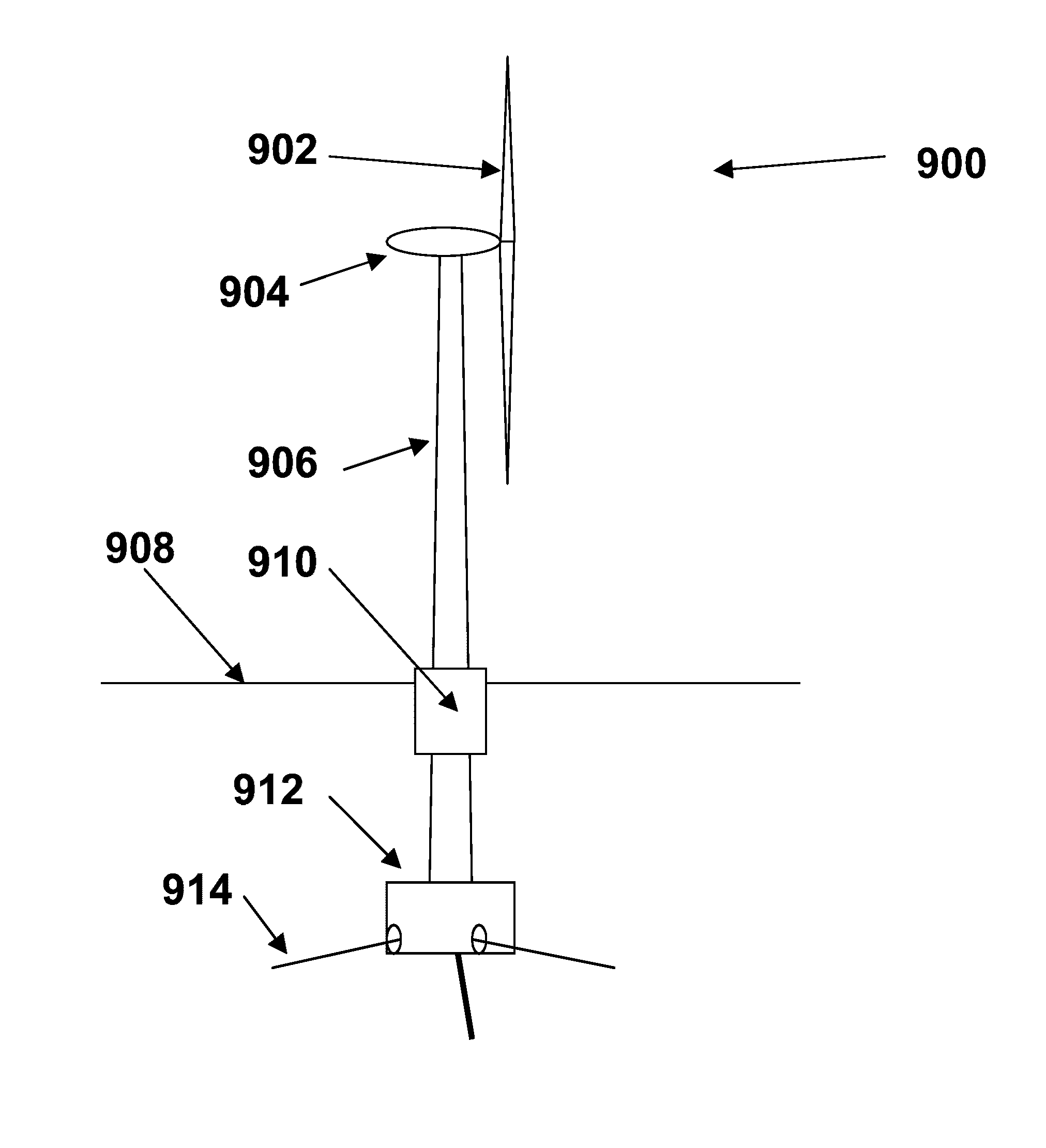

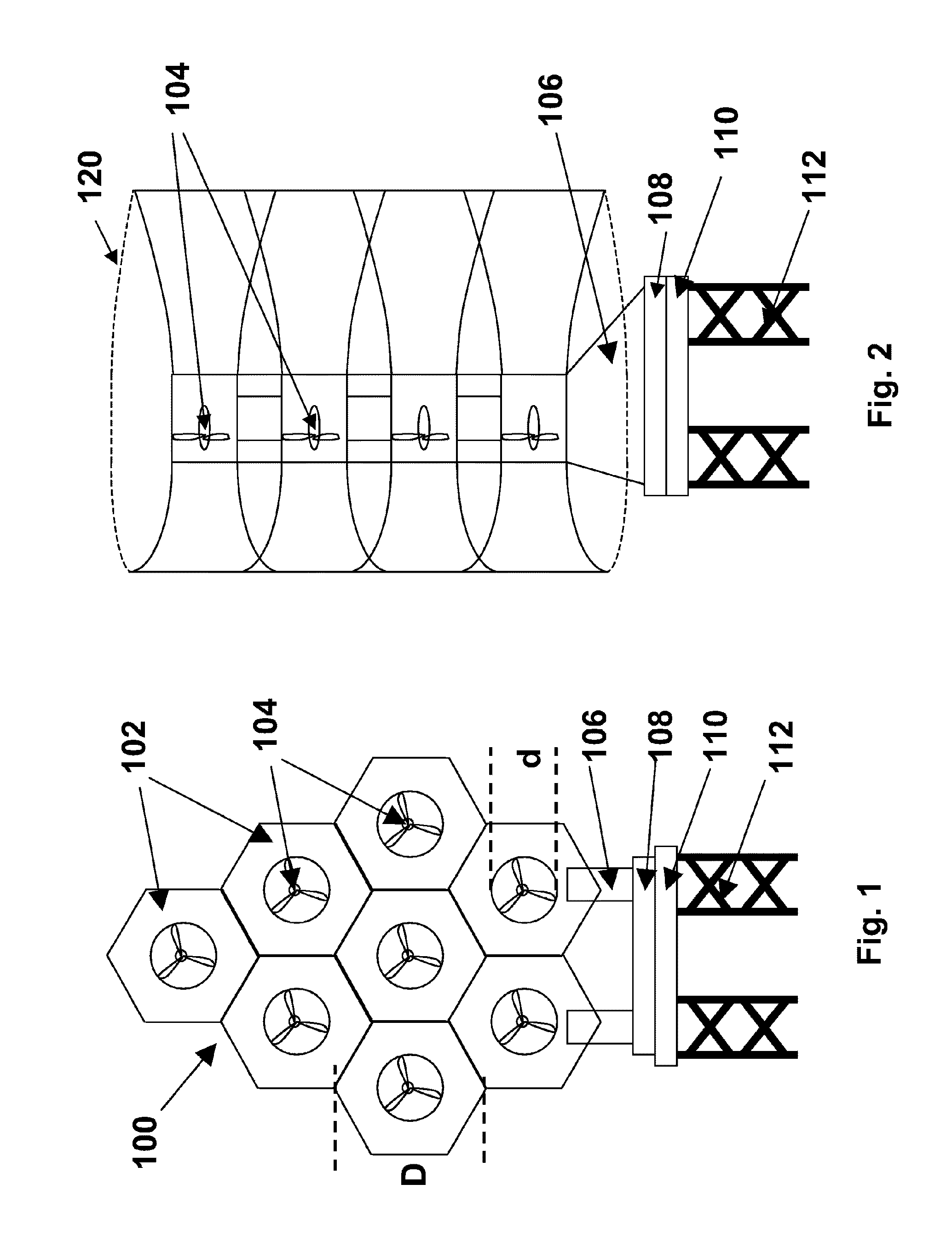

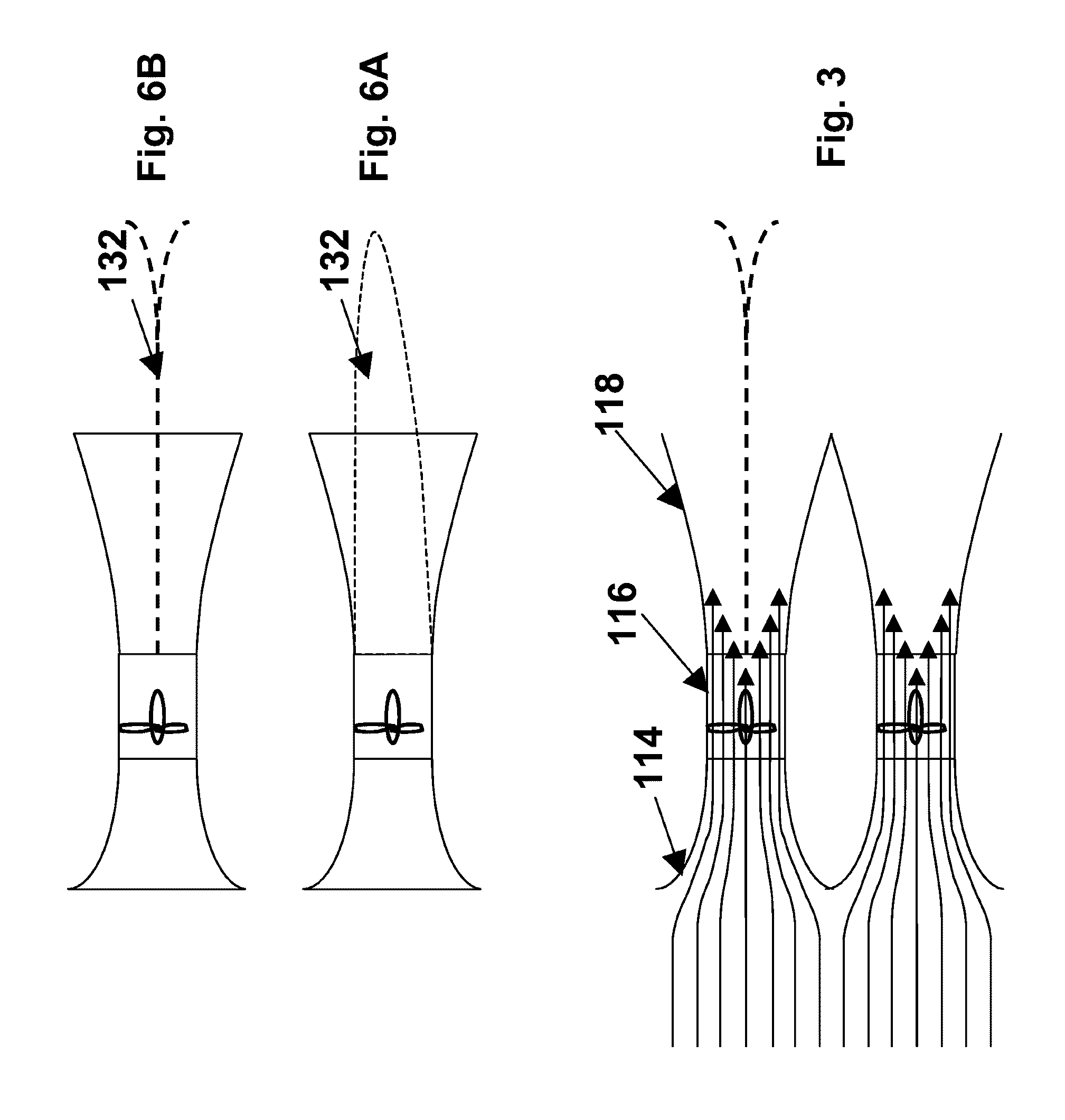

Power generation assemblies, and apparatus for use therewith

ActiveUS7293960B2Increase hydrodynamic massExtended maintenance periodPropellersWind motor controlIsoetes triquetraMarine engineering

A floating power generation assembly comprises at least three floating units (900) floating on a body of water, and at least three anchors (916) secured to a solid surface beneath the body of water, each of the floating units (900) being provided with a power generator, the floating units (900) being arranged substantially at the vertices of at least one equilateral triangle. Ship borne apparatus for deploying the floating units of such a power generation assembly and a novel multiple wind turbine assembly are also described.

Owner:OCEAN WIND TECH

Power generation assemblies and apparatus

InactiveUS20100219645A1Increase hydrodynamic massExtended maintenance periodWind motor assemblyWind motor supports/mountsQuadrilateralTension-leg platform

A floating power generation assembly has at least three floating units (3400) provided with power generation means (3402, 3404) and floating in a body of water. At least one of the three floating units (3400) is a tension leg platform. The assembly also comprises first anchors secured to a surface beneath the water, and first cables (3414, 3416) connecting the buoyant body (3400) to the first anchors. Second anchors are secured to the underwater surface and connected by second cables (3412) to the floating units (3400). The floating units (3400) are arranged substantially at the vertices of at least one triangle or quadrilateral.

Owner:YAMAMOTO SHIGEYUKI +1

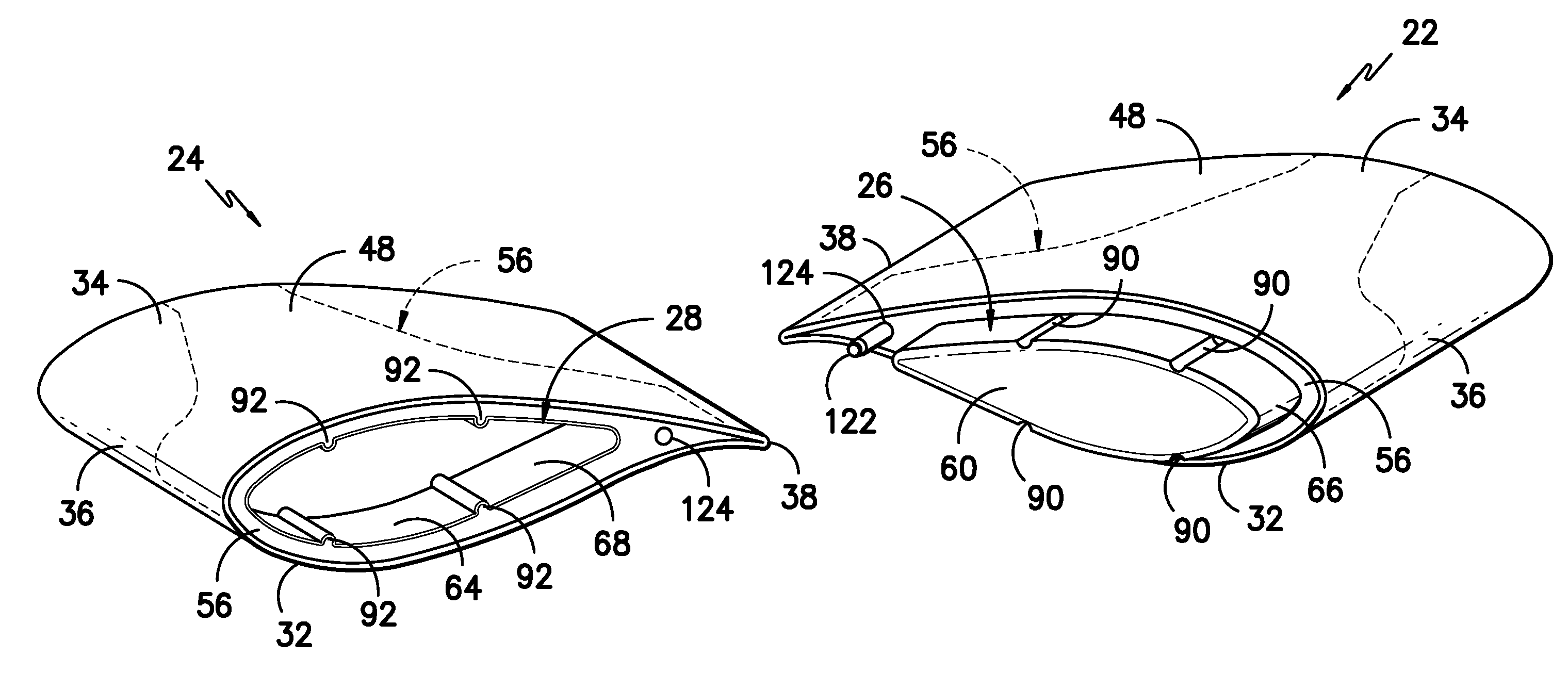

Methods of handling wind turbine blades and mounting said blades on a wind turbine, system and gripping unit for handling a wind turbine blade

The invention relates to methods of handling wind turbine blades and mounting said blades on a wind turbine, said method comprising the steps of lifting a wind turbine hub to the nacelle of wind turbine with a lifting system and mounting the hub on the nacelle. Further, the method comprises the steps of gripping at least one wind turbine blade with a lifting system including at least one gripping unit for handling wind turbine blades, lifting said at least one wind turbine blade into close proximity to said hub, and mounting said at least one wind turbine blade on said hub. The invention also relates to a gripping unit for handling a wind turbine blade during transport.

Owner:VESTAS WIND SYST AS

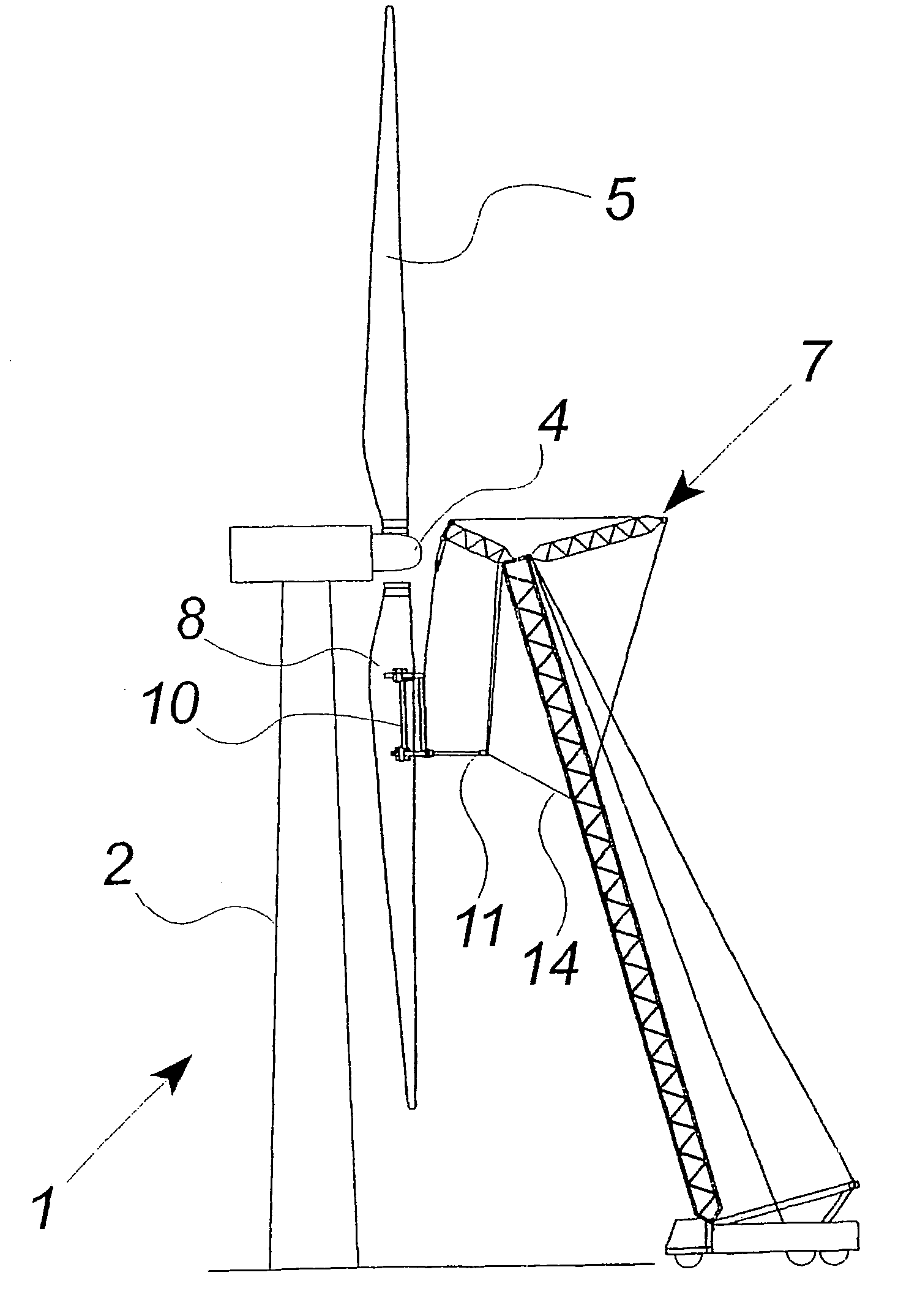

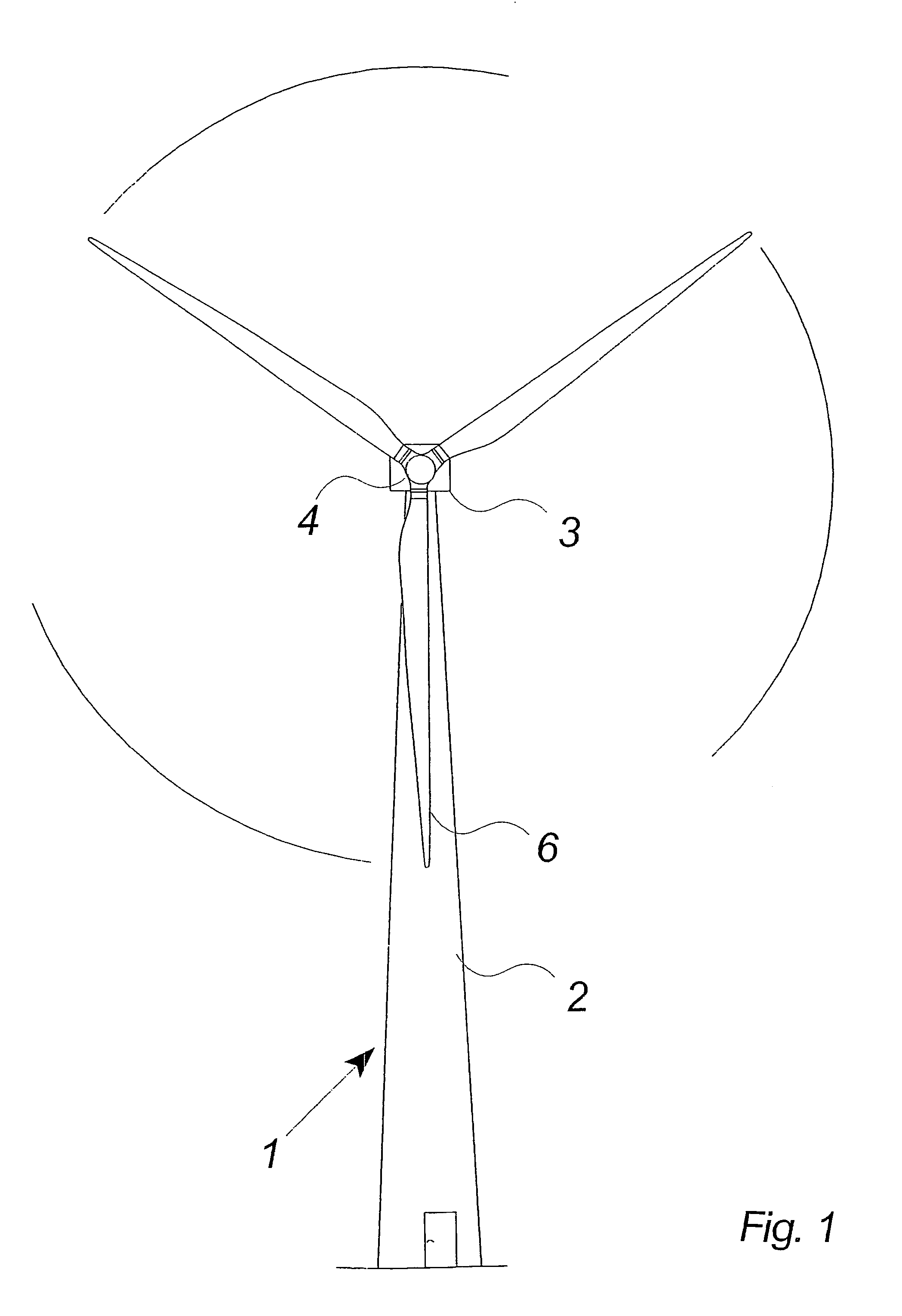

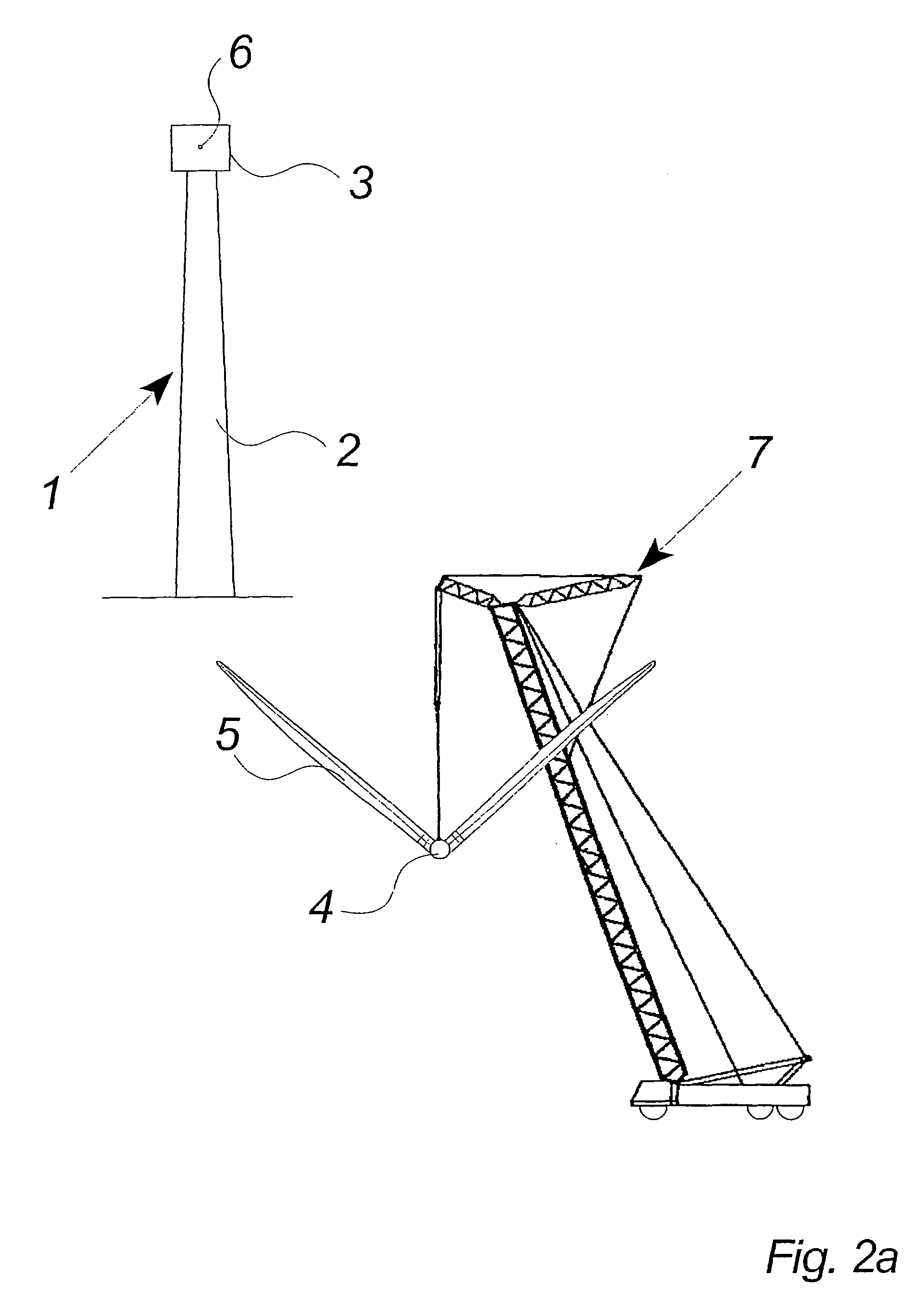

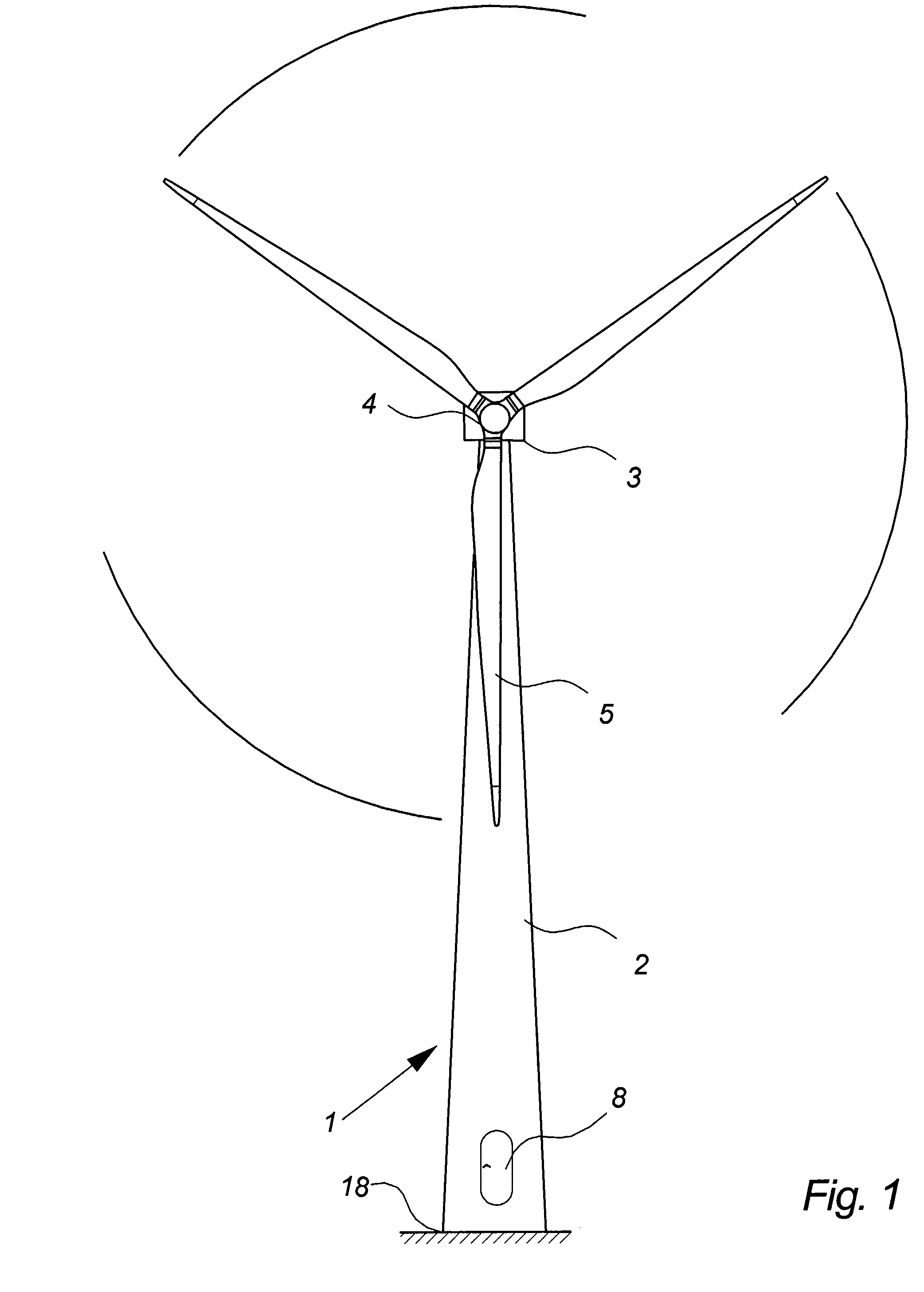

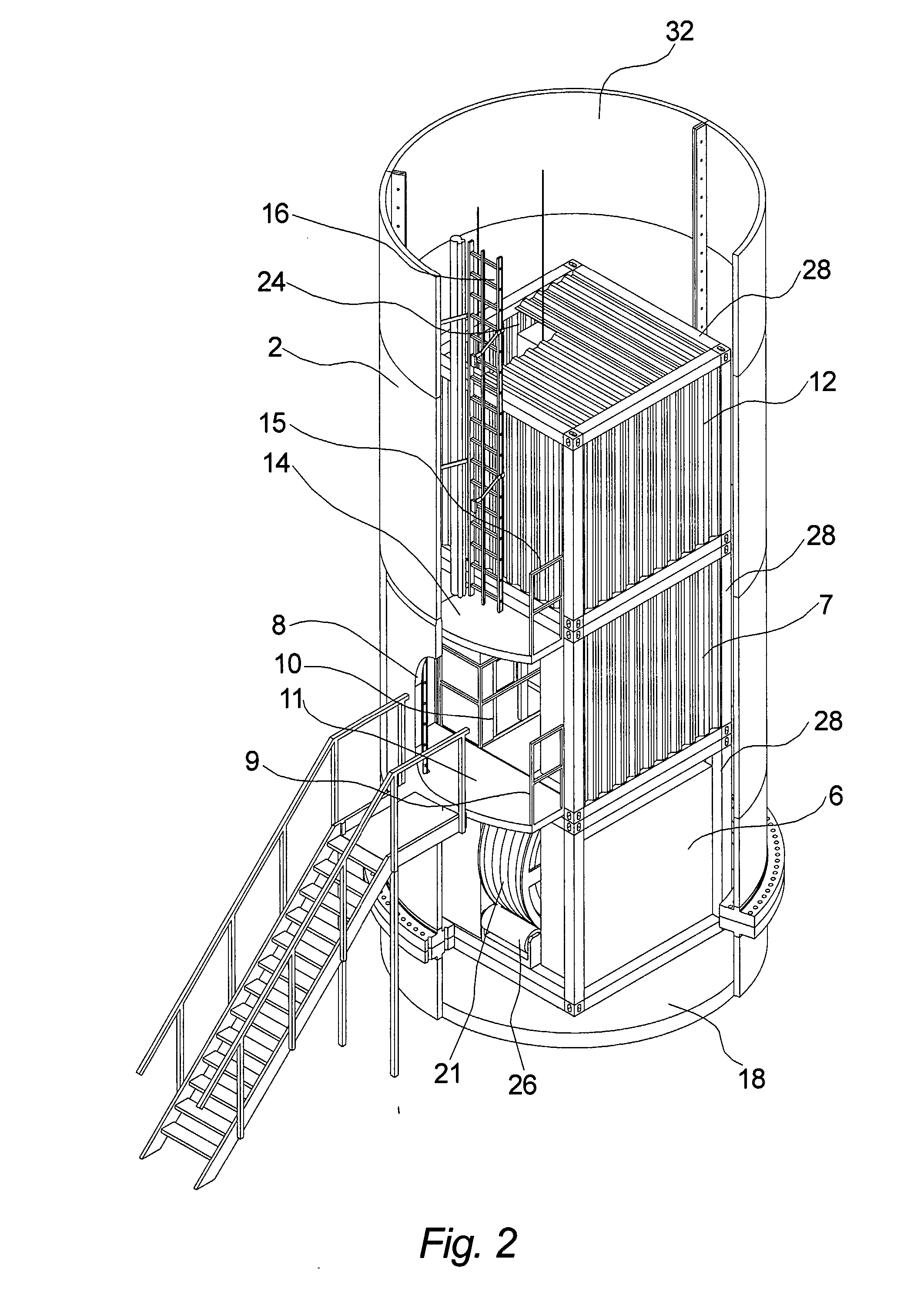

Wind Turbine, a Method for Assembling and Handling the Wind Turbine and Uses Hereof

InactiveUS20070296220A1Avoid reducing tower fatigue limitEngine manufactureFinal product manufactureTowerTurbine

The invention relates to a wind turbine including a foundation and a tower positioned on the foundation where the tower includes more than one modules, where the modules each include a separate strengthening structure defining the outer edges of the module and wind turbine equipment, and where the more than one module are positioned substantially vertically on top of each other in an upright position within the tower. The modules are connected directly and / or indirectly through the strengthening structure, to the foundation (18). The invention further relates to a method for assembling a wind turbine at a wind turbine site and a method for handling more than one wind turbine modules.

Owner:VESTAS WIND SYST AS

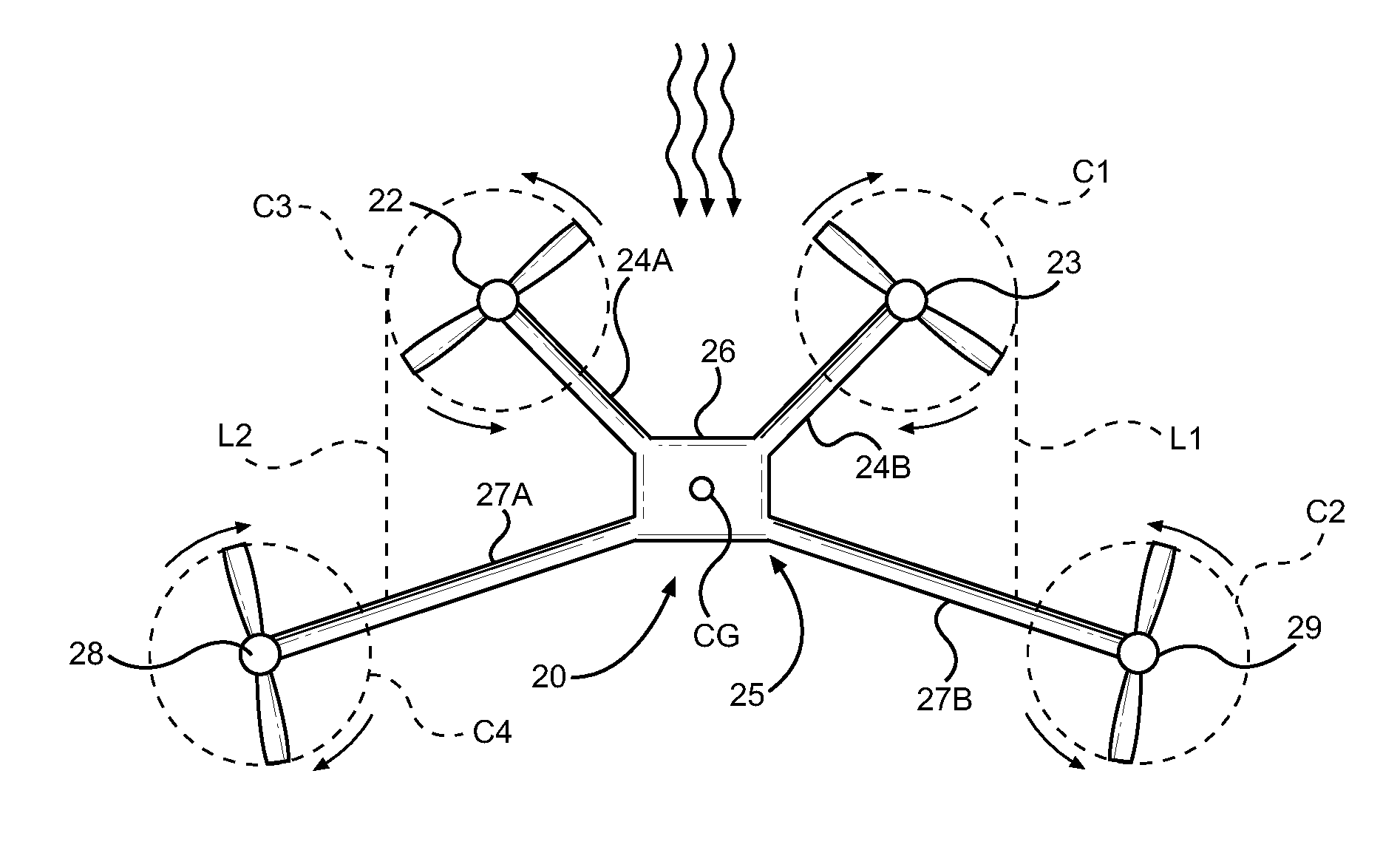

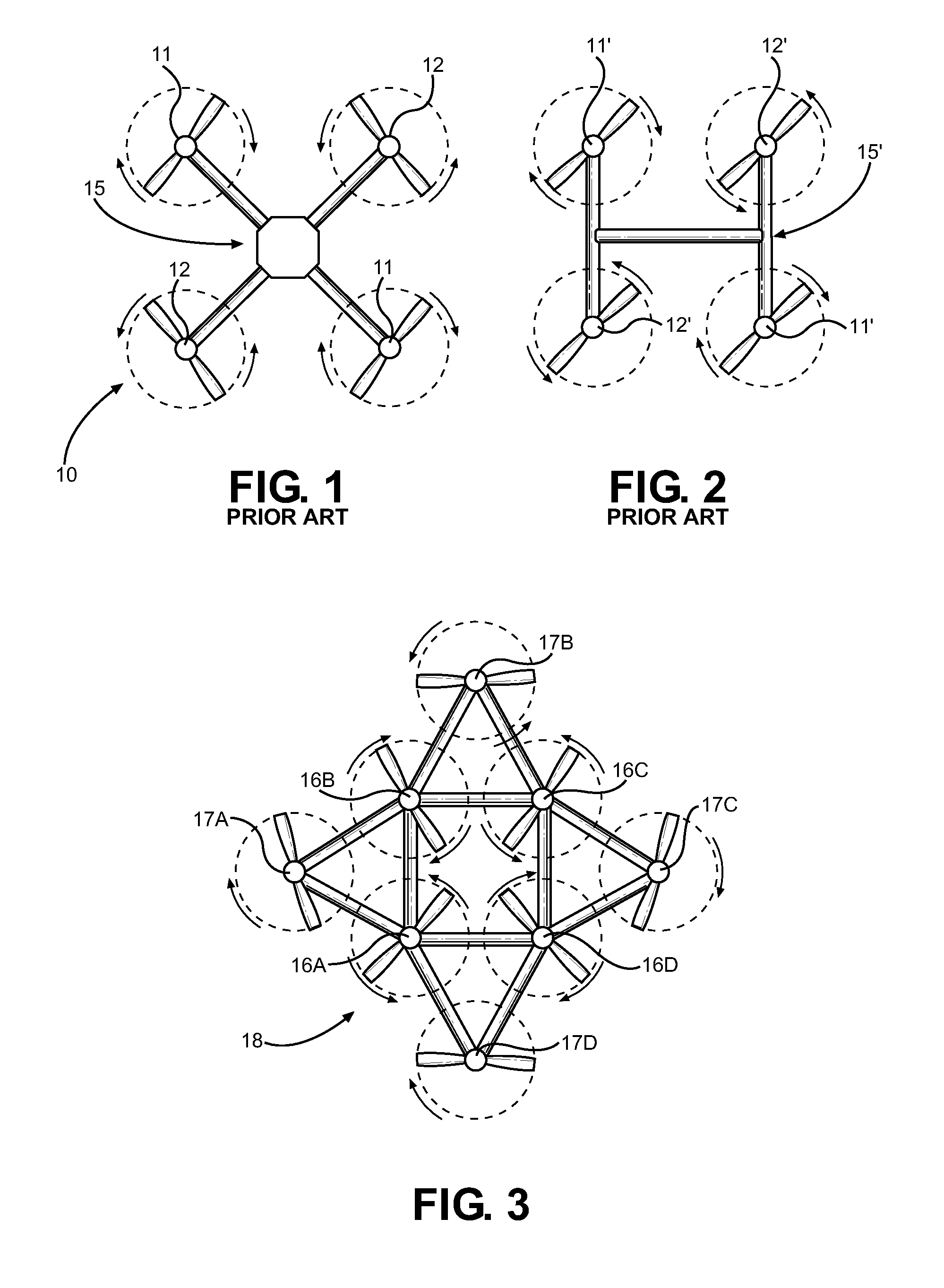

Flying electric generators with clean air rotors

ActiveUS20120298793A1Smooth transitionWind motor controlWind motor assemblyJet aeroplaneFlight vehicle

Flying electric generator aircraft that include groupings of four rotors mounted to booms extending fore and aft of a fuselage structure wherein the rotors are placed so that when the aircraft is facing the wind, each rotor has a direct path to an undisturbed flow of air, regardless of pitch angle and during all flight maneuvers of the aircraft. The rotors are placed in counter-rotating pairs with the booms preferably angled so that the rotors in the front of the aircraft are spaced at a distance from one another that is different than a spacing of the rotors at the rear of the aircraft.

Owner:SKY WINDPOWER CORP

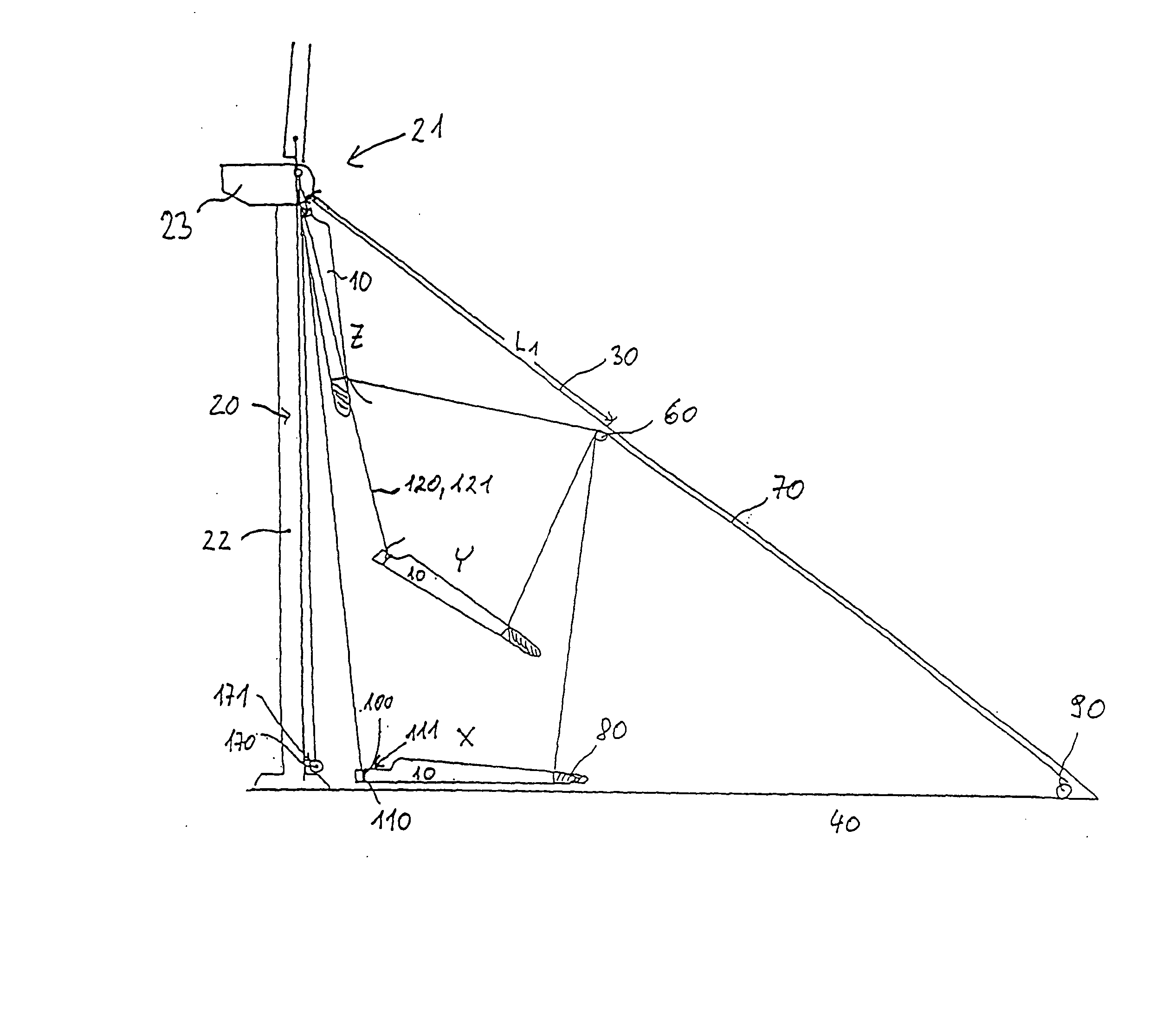

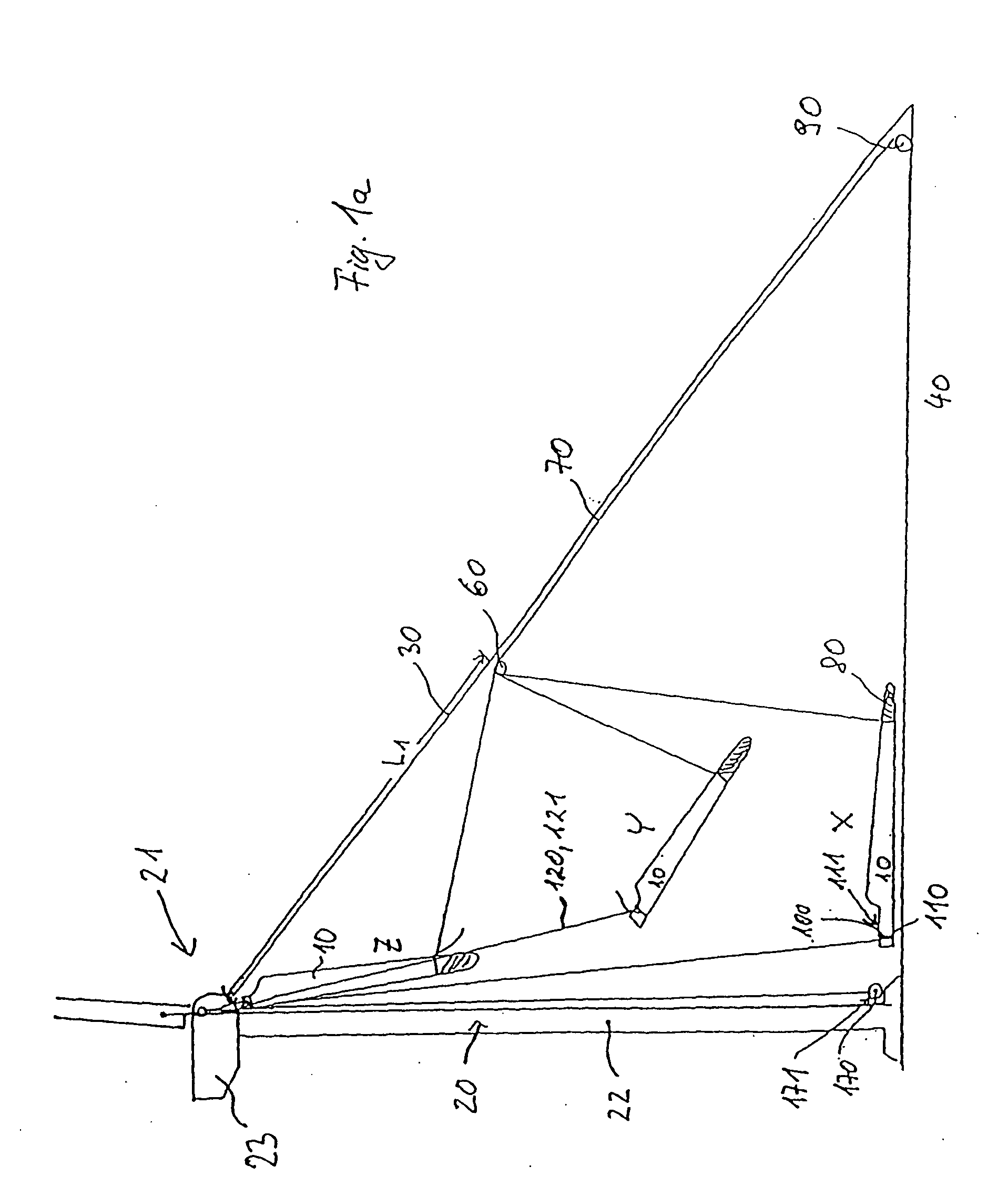

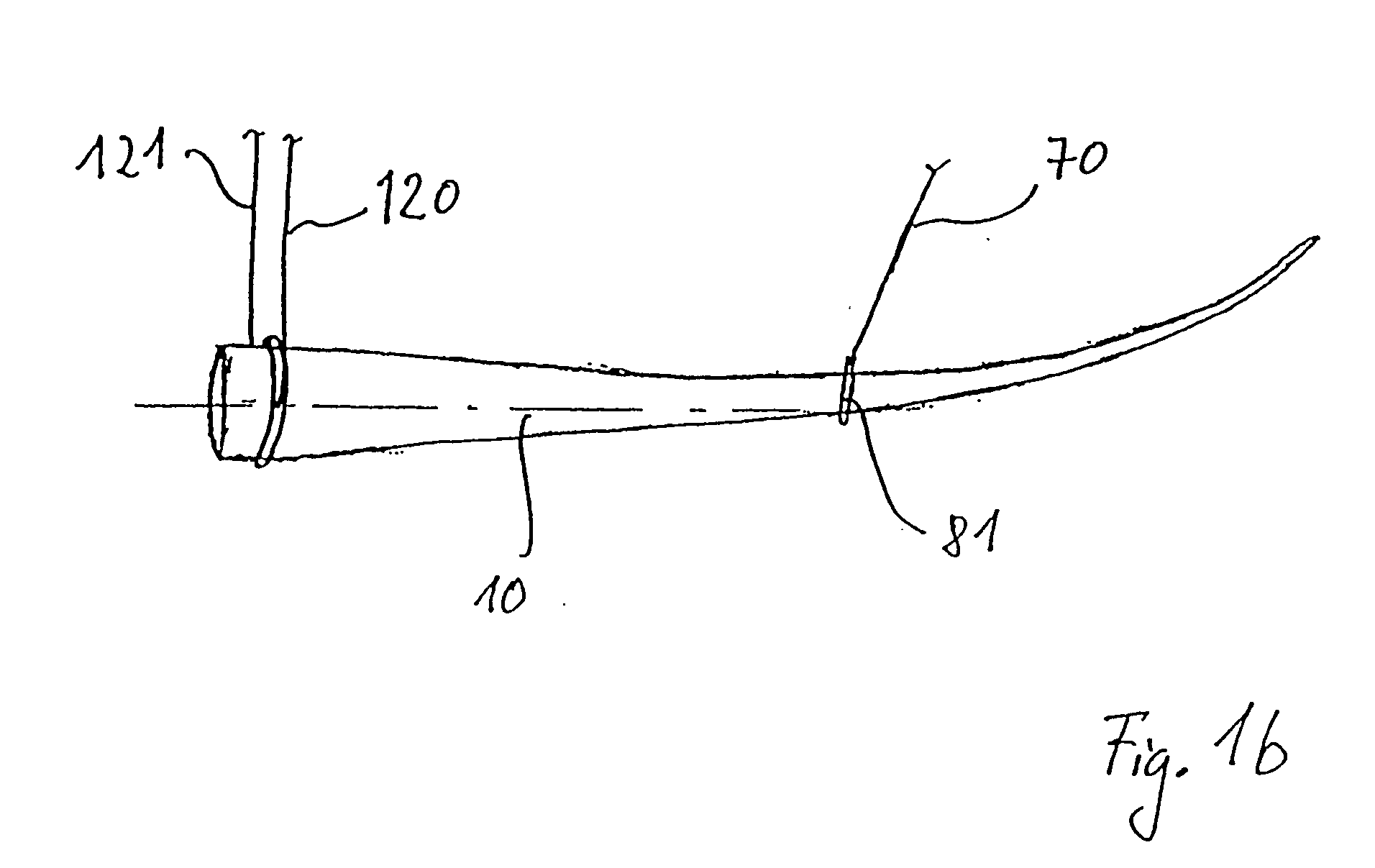

Device and Method for Mounting and Dismantling a Component of a Wind Turbine

The invention relates to a device for mounting and / or dismantling a component (10), in particular a rotor blade of a wind turbine (20) comprising a tower head (21). Said device comprises at least one guide element (30) that stretches between the tower head (21) and the ground (40) and has at least one supporting device (60) that is essentially fixed in the air, supporting at least a partial load of the weight of the component (10) during the transport of the latter (10) between the ground (40) and the wind turbine (20). At least one guy (70) leads from the supporting device (60) to the component (10), whereby the length of said guy between the supporting device (60) and the component (10) can be modified.

Owner:SIEMENS GAMESA RENEWABLE ENERGY SERVICE GMBH

Power system for electric and hybrid vehicles

A power system for an electric vehicle, the power system comprising at least one power generating device selected from a group consisting of a solar panel, a wind turbine capable of producing electrical power, an auxiliary generator driven by an internal combustion engine, and a generator for producing electrical power mechanically connected to, and driven by the rotational force of an axle of a vehicle. The power system being further comprised of a charging device, a battery control device, at least one battery, a motor control device, an electric drive motor electrically connected to the motor control device, and a driver interface connected to the motor control device. The electric drive motor may be used to generate power through regenerative braking. The wind turbine may be raised outside the body of a vehicle while the vehicle is not in motion. The solar panel may be disposed outside the vehicle while remaining electrically connected to the charging device.

Owner:SUTHERLAND DANILO R

Column-stabilized offshore platform with water-entrapment plates and asymmetric mooring system for support of offshore wind turbines

ActiveUS8471396B2Improve performanceEasy to produceWind motor controlWind motor assemblyNacelleMooring system

A floating wind turbine platform includes a floatation frame that includes at least three columns that are coupled to each other with horizontal main beams. A wind turbine tower is mounted above a tower support column to simplify the system construction and improve the structural strength. The turbine blades are coupled to a nacelle that rotates on top of the tower. The turbine's gearbox generator and other electrical gear can be mounted either traditionally in the nacelle, or lower in the tower or in the top of the tower-supporting column. The floatation frame includes a water ballasting system that pumps water between the columns to keep the tower in a vertical alignment regardless of the wind speed. Water-entrapment plates are mounted to the bottoms of the columns to minimize the rotational movement of the floatation frame due to waves.

Owner:PRINCIPLE POWER

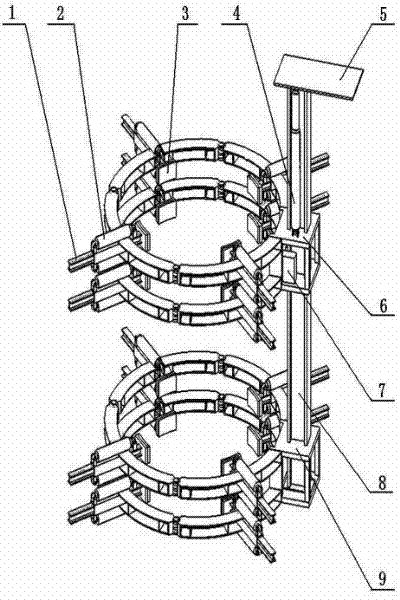

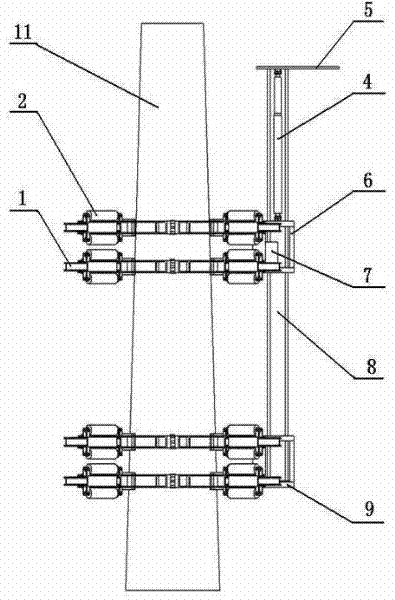

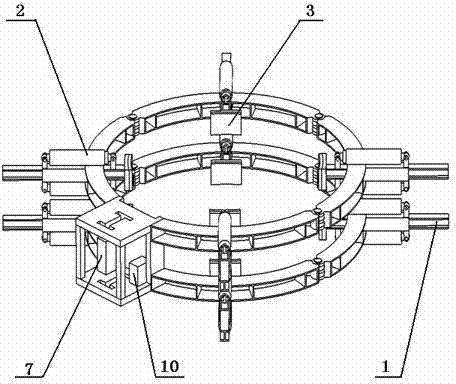

Multifunctional automatic climbing device

InactiveCN102407004AEasy to detectEasy maintenanceWind motor assemblyClimbingHydraulic cylinderRemote control

The invention relates to a multifunctional automatic climbing device, particularly to an automatic climbing device which is suitable for a variable diameter fan tower barrel and can carry various working equipment. The multifunctional automatic climbing device is composed of a guide rail, an upper clamp, a lower clamp, a connecting platform and a power hydraulic cylinder. The lower clamp is fixedly connected to the bottom of the guide rail; the upper clamp is slidingly mounted on the upper part of the guide rail and can be vertically moved along the guide rail by effect of the power hydraulic cylinder; the connecting platform for connecting other working equipment is mounted on the top of the guide rail; the upper and lower clamps have two-layer structures; each layer is equipped with four fingers; and the upper clamp is installed with a control box and a hydraulic box. The multifunctional automatic climbing device can be connected with other working equipment to realize repairing and detection of a wind power generator, for example, the multifunctional automatic climbing device is connected with a lifting device to finish lifting and repairing of parts in a cabin and is connected with an annular platform to realize repairing and maintenance of outer surfaces of the tower barrel and blades. The multifunctional automatic climbing device has the characteristics of no height and region limitation, high automation level, ground remote control, and the like.

Owner:SHENYANG JIANZHU UNIVERSITY

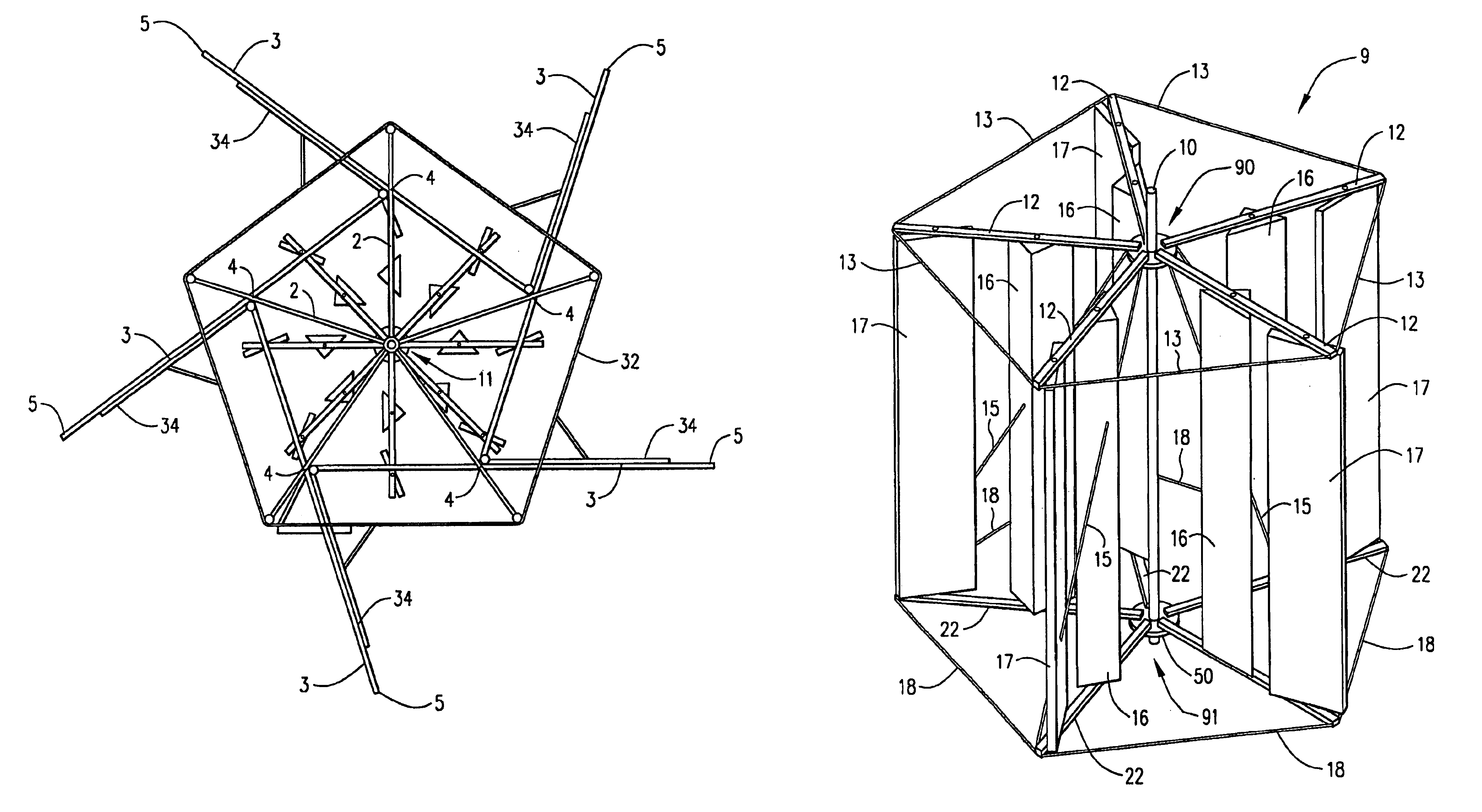

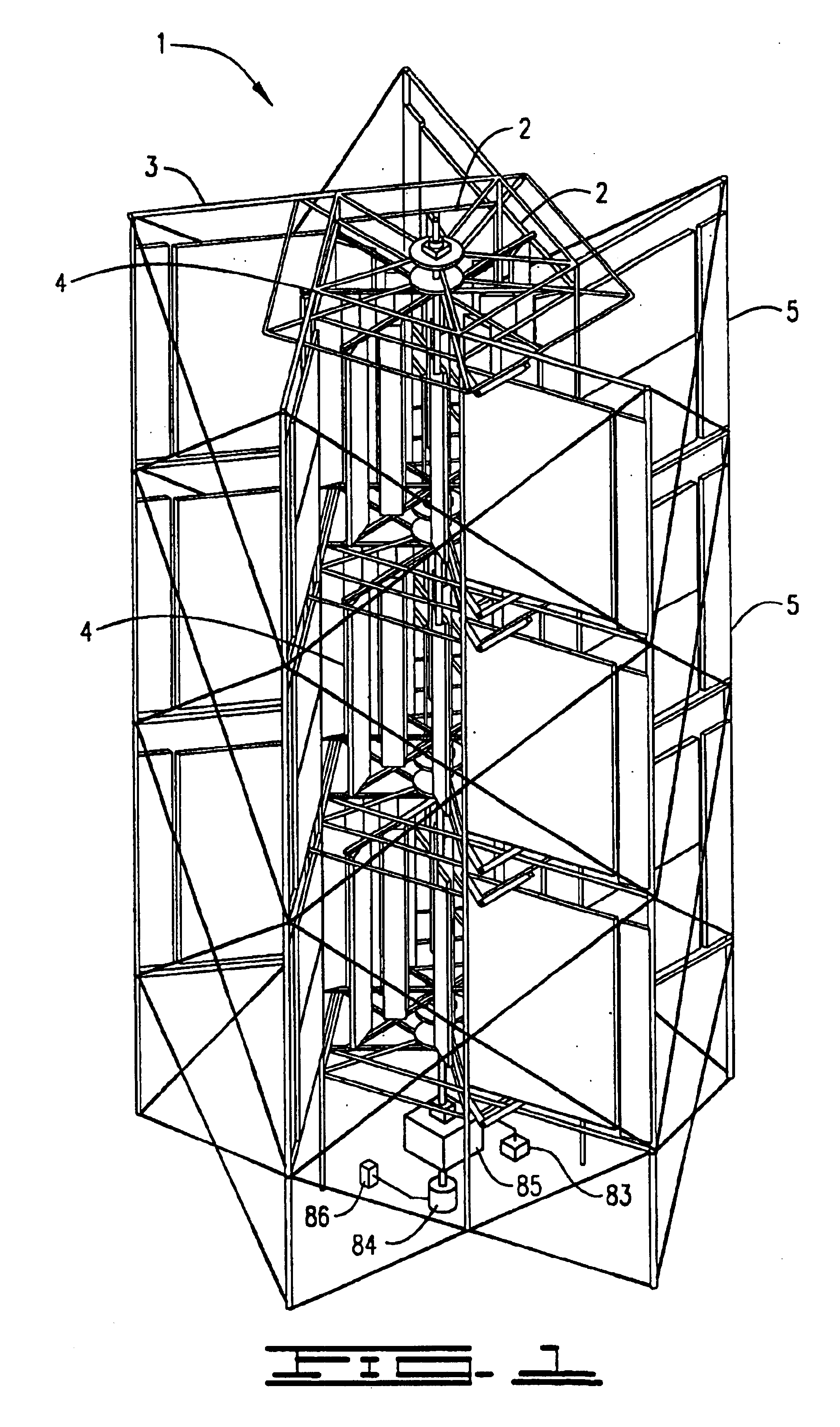

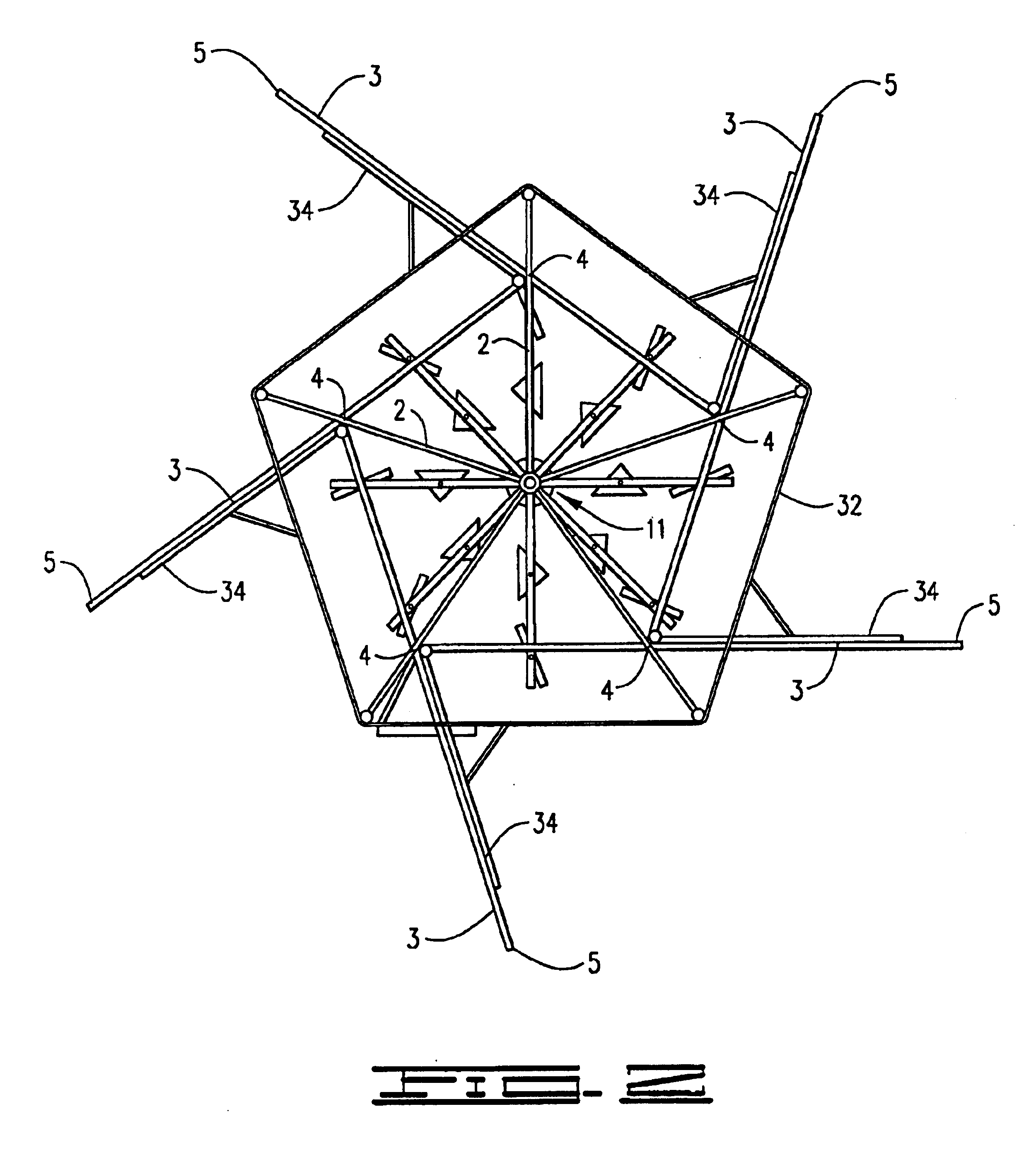

Stackable vertical axis windmill

A stackable, vertical axis windmill comprised of a braced external frame that enables stacking of multiple windmill assemblies. Couplings are located on both ends of the vertical rotor shaft to enable stacking and the transmission of power, an internal wind flow cavity, and controlled wind guides is described. The external frame includes structural bracing that allows for two or more windmill to be stacked one upon another to optimize the use of land or rooftop space for the generation of electricity from wind power. The computer controlled wind guides automatically close partially in high wind conditions in order to prevent damage to the windmill. The internal wind flow cavity allows wind to transfer power to both the windward and leeward rotors blades. The rotor axis is constructed so that all bearings can be replaced without dismantling the structure.

Owner:MILLER LEWIS H

Structural component for a modular rotor blade

The present disclosure is directed to a pre-formed, continuous structural component for use in assembling a modular rotor blade for a wind turbine. Further, the structural component provides support to the modular rotor blade during operation. The pre-formed structural component includes a root portion and a body portion. The root portion is configured for mounting the structural component to a blade root section of the rotor blade. The body portion is configured to extend in a generally span-wise direction. Further, the body portion defines a predetermined cross-section having a flatback portion with a first end and a second end. In addition, the first and second ends each have a flange extending perpendicularly therefrom. Thus, each flange defines a mounting surface for one or more blade segments.

Owner:GENERAL ELECTRIC CO

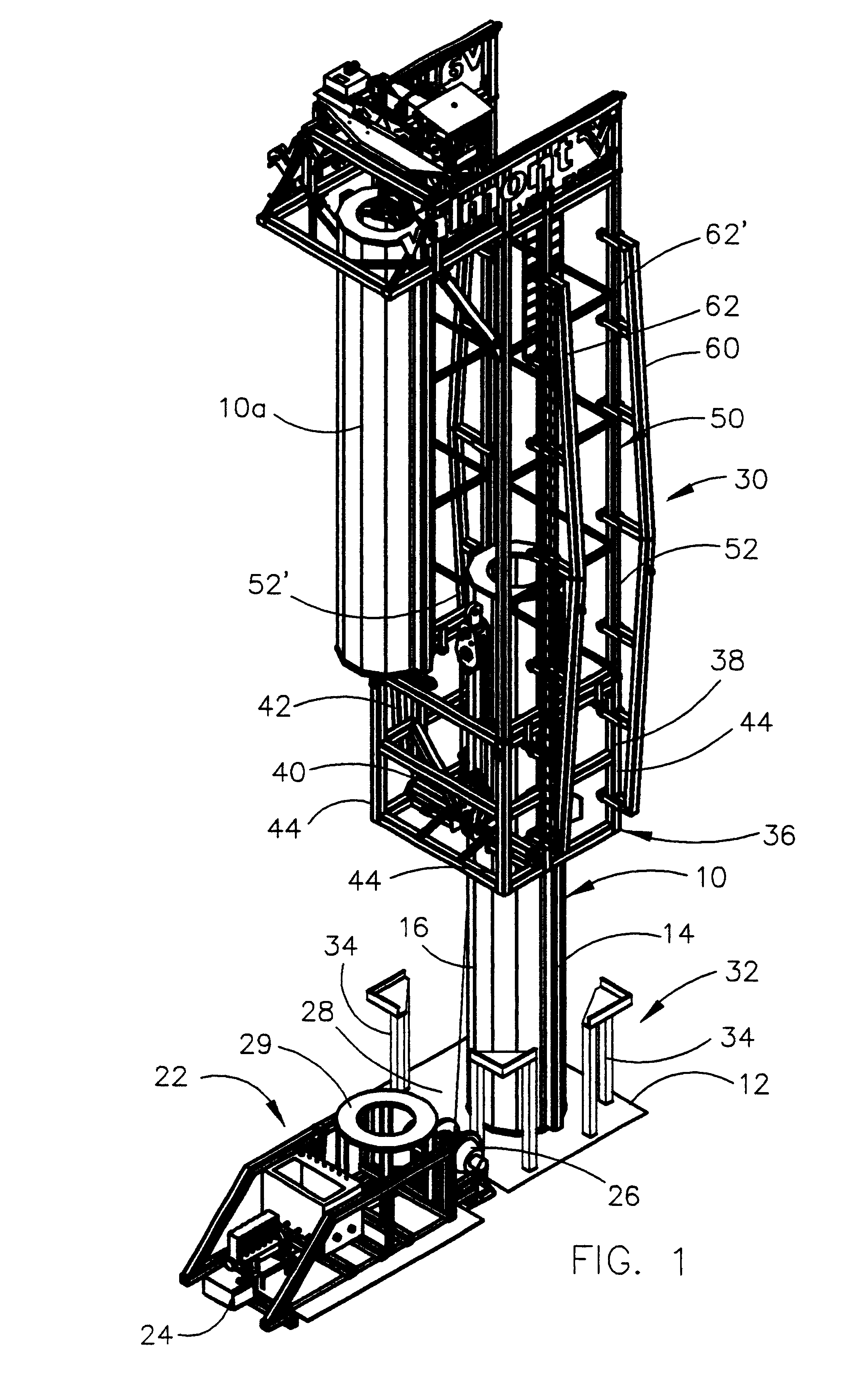

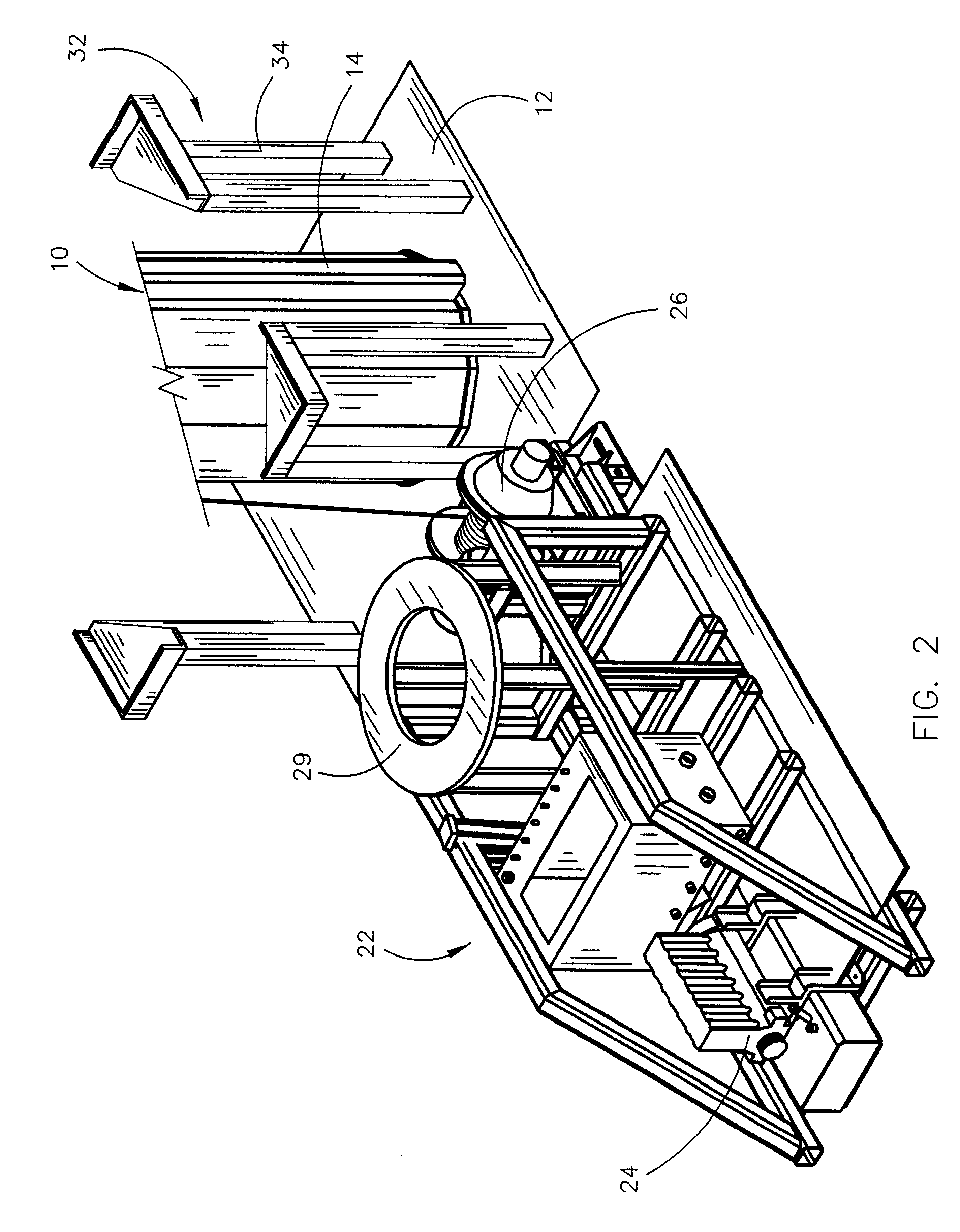

Method and means for erecting a wind energy tower

A wind energy tower erection device is disclosed together with the method of assembling the same and the method of utilizing the device to erect a wind energy tower. The tower erection device successively places tower sections one upon the other until the tower is erected.

Owner:VALMONT INDUSTIES INC

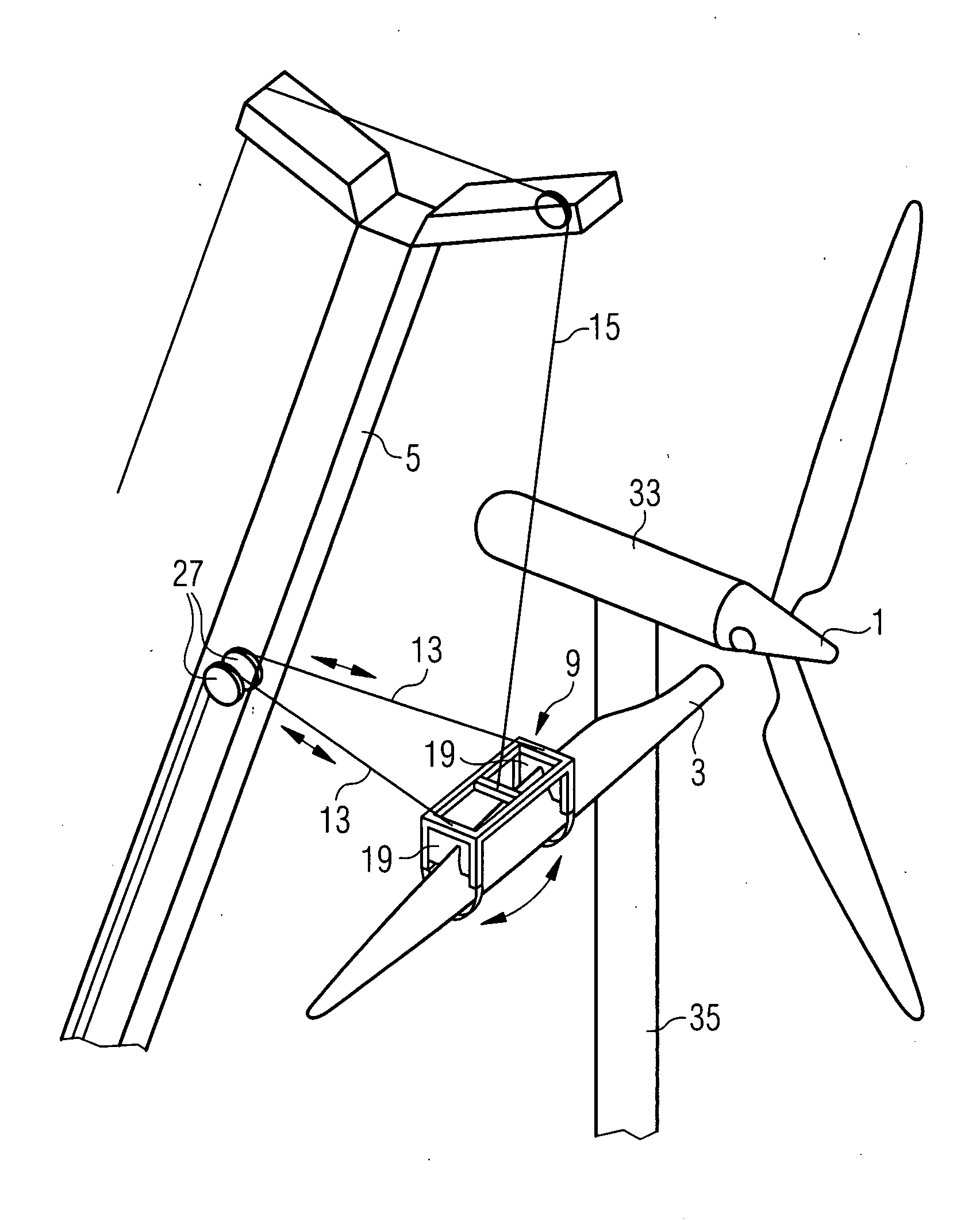

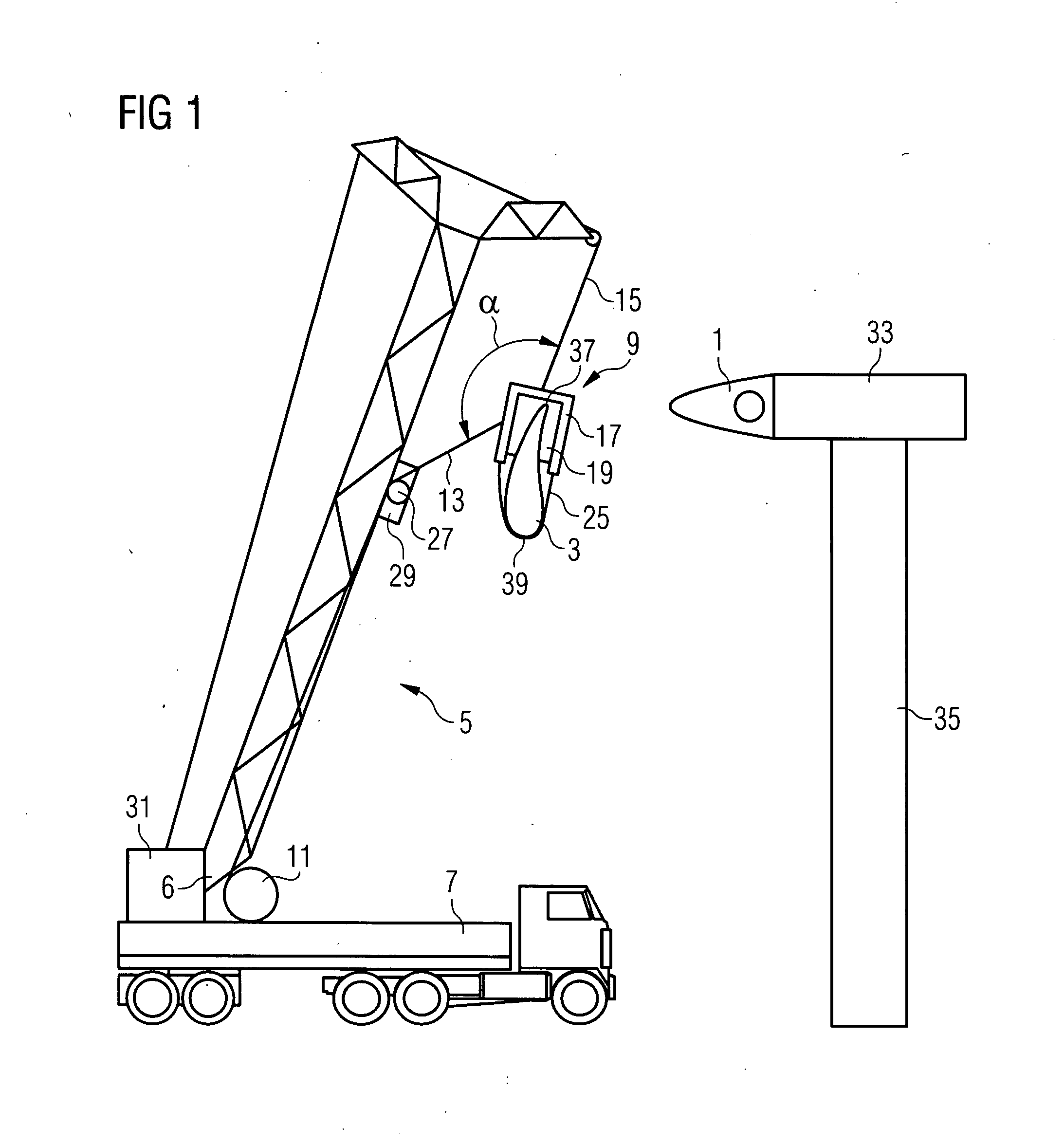

Method and device for mounting of wind turbine blades

A method for mounting a wind turbine blade to a wind turbine hub by use of a crane boom is provided. The orientation of the blade is kept substantially horizontal when the blade is lifted off the ground and mounted to the rotor hub. Control wires which connect the blade via the crane boom to a winch arrangement are used for keeping the blade orientation substantially horizontal in addition to at least one bearing wire for bearing the blade weight.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

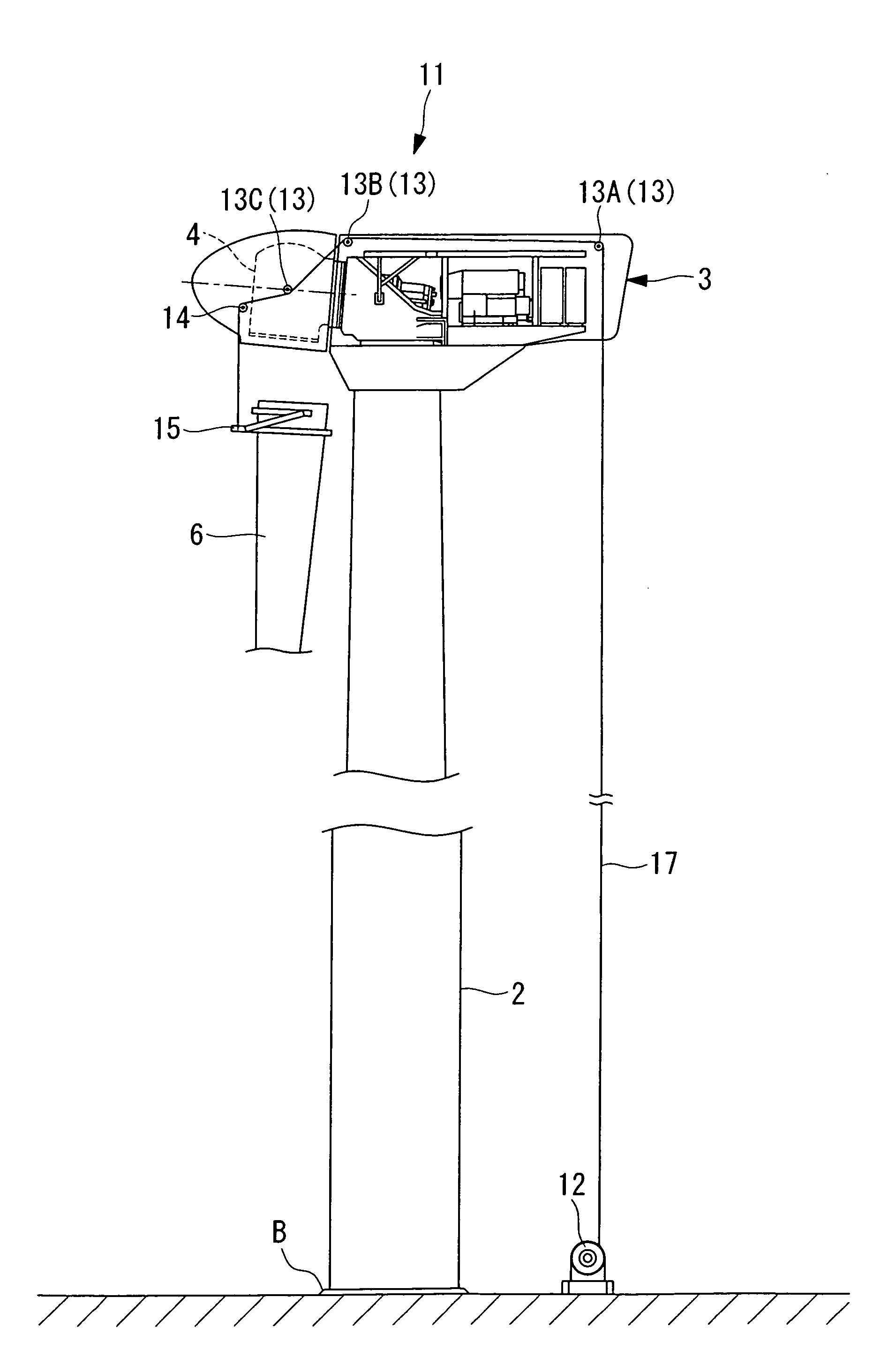

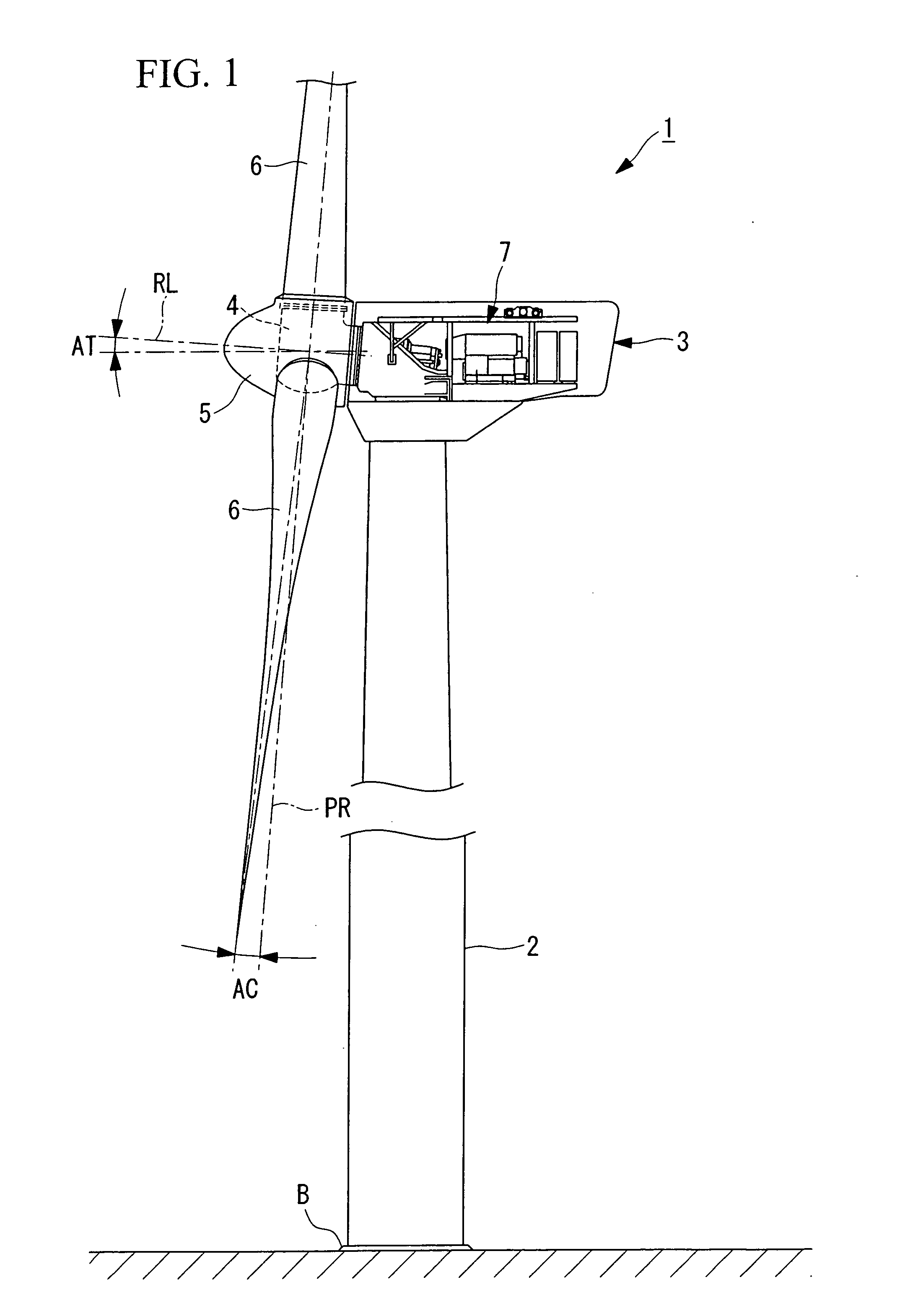

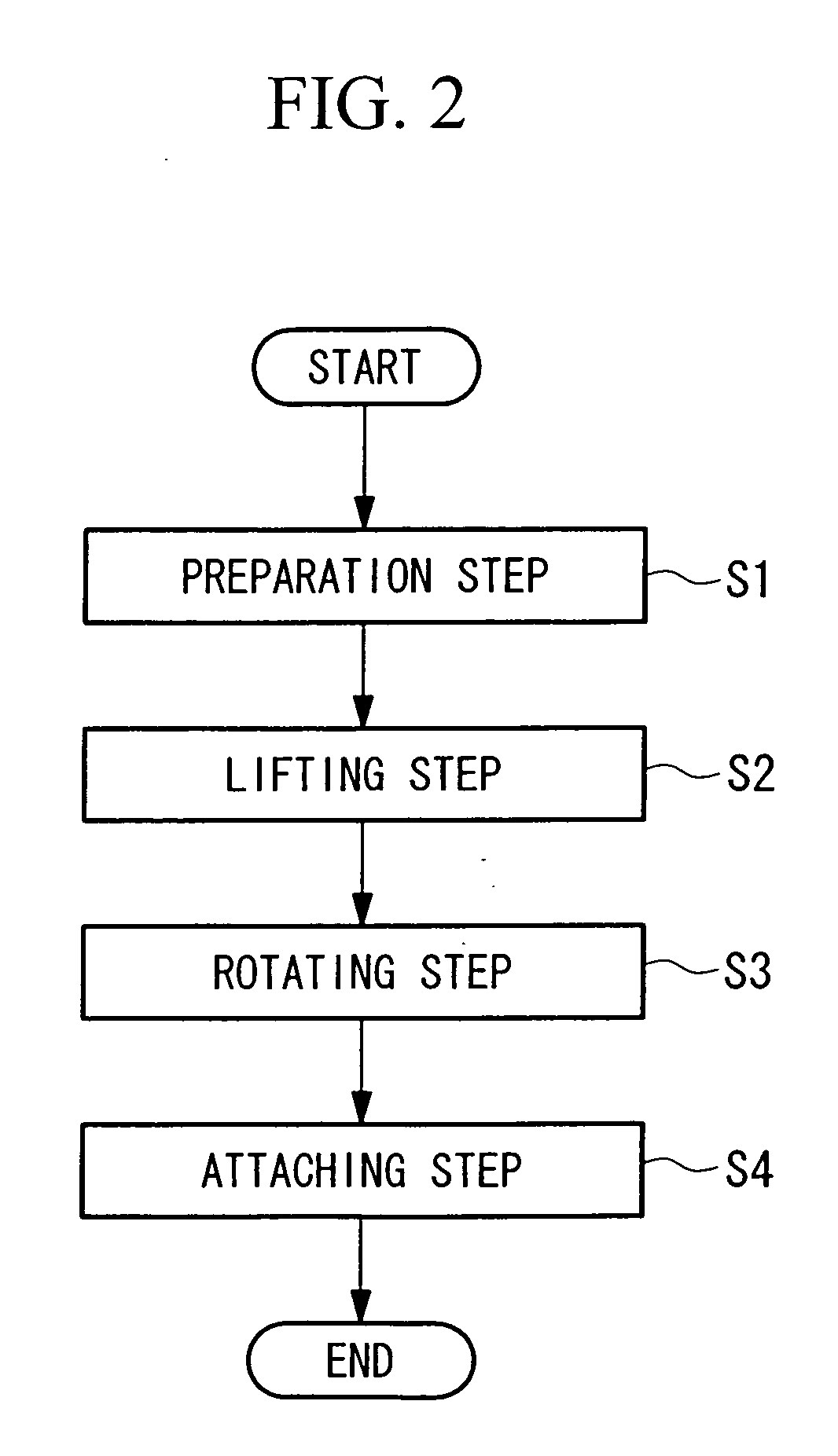

Wind-turbine rotor-blade hoisting apparatus, method for attaching wind-turbine rotor blade, and method for constructing wind power generator

The present invention provides a wind-turbine rotor-blade hoisting apparatus that enables attachment and removal of wind-turbine rotor blades without using a plurality of heavy machines and that enables attachment and removal of wind-turbine rotor blades on a site having a complex land shape with little flat land, a method for attaching a wind-turbine rotor blade, and a method for constructing a wind power generator. The present invention is characterized in that it includes a sheave (14) that guides a hoisting wire (17) from a rotor head (4), to which a wind-turbine rotor blade (6) is to be attached, toward the wind-turbine rotor blade (6) and that is arranged so as to be movable in a direction along the rotation axis of the rotor head (4); a retaining portion (15) that retains an attaching end of the wind-turbine rotor blade (6) such that a line connecting the center of gravity of the wind-turbine rotor blade (6) and a connecting portion, to which the hoisting wire (17) is connected, crosses the longitudinal axis of the wind-turbine rotor blade (6); and a winch (12) that is disposed on the ground and that draws the hoisting wire (17) to wind up or let out the retaining portion (15).

Owner:MITSUBISHI HEAVY IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com