Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

899 results about "Mooring system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

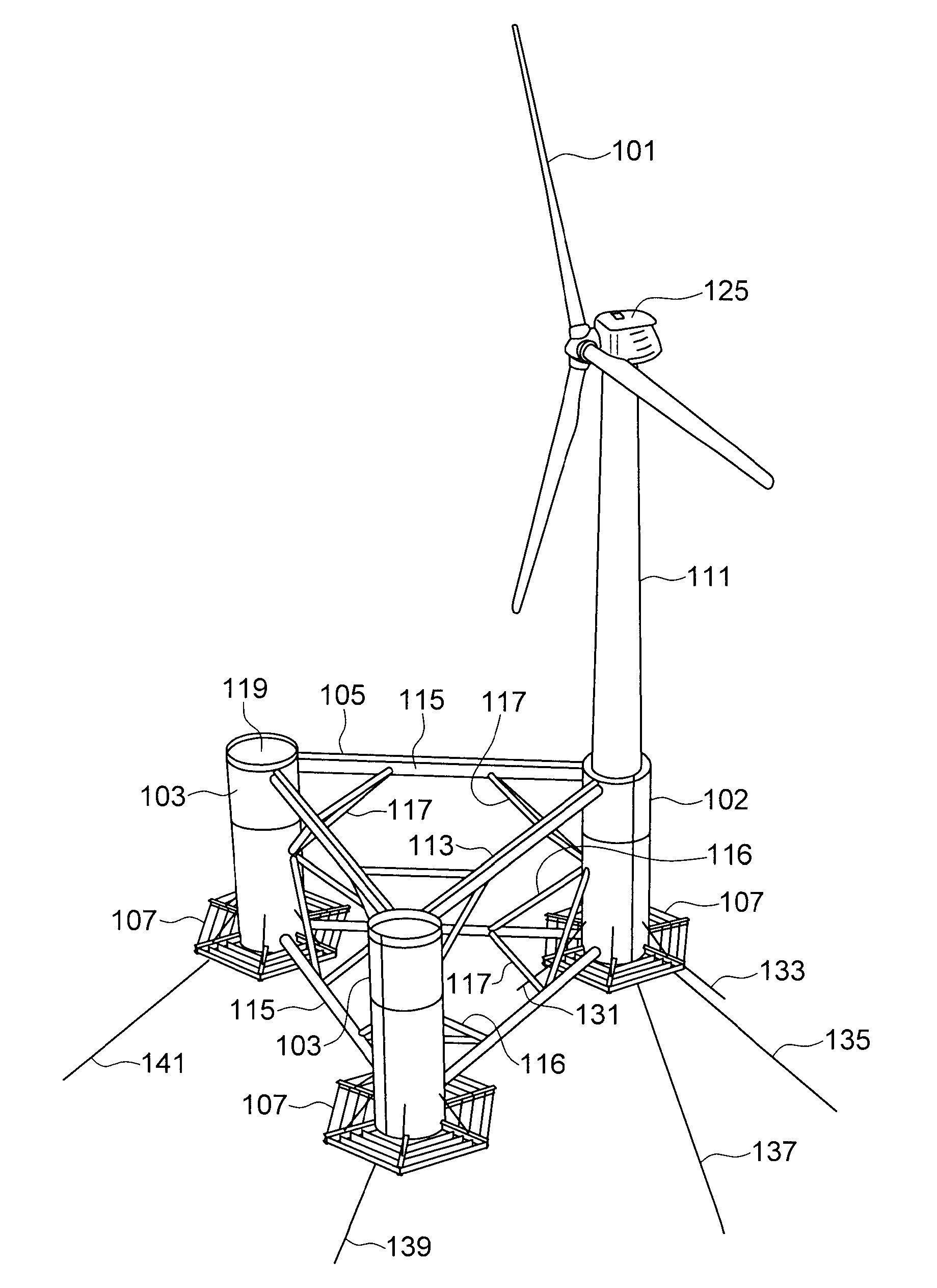

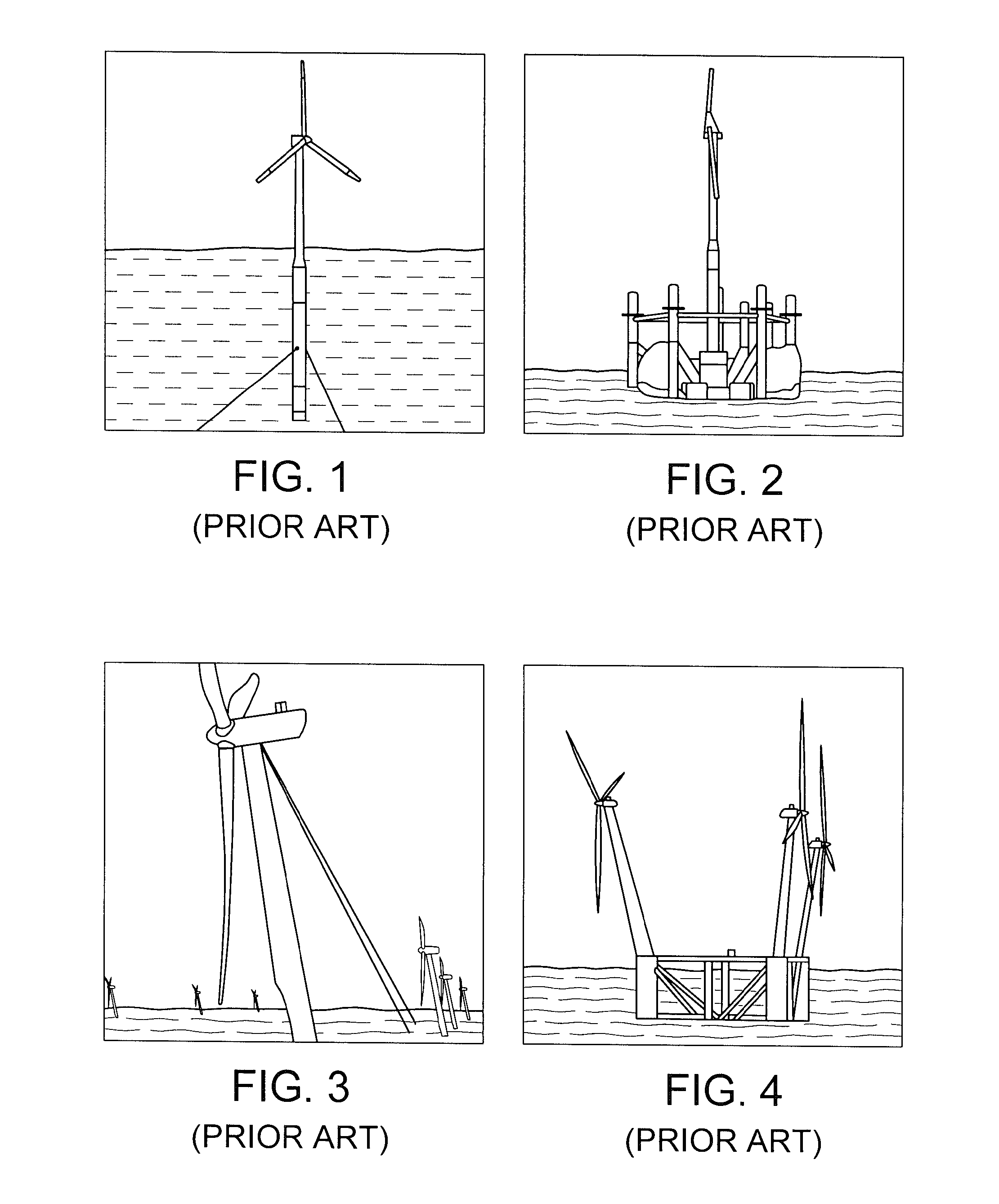

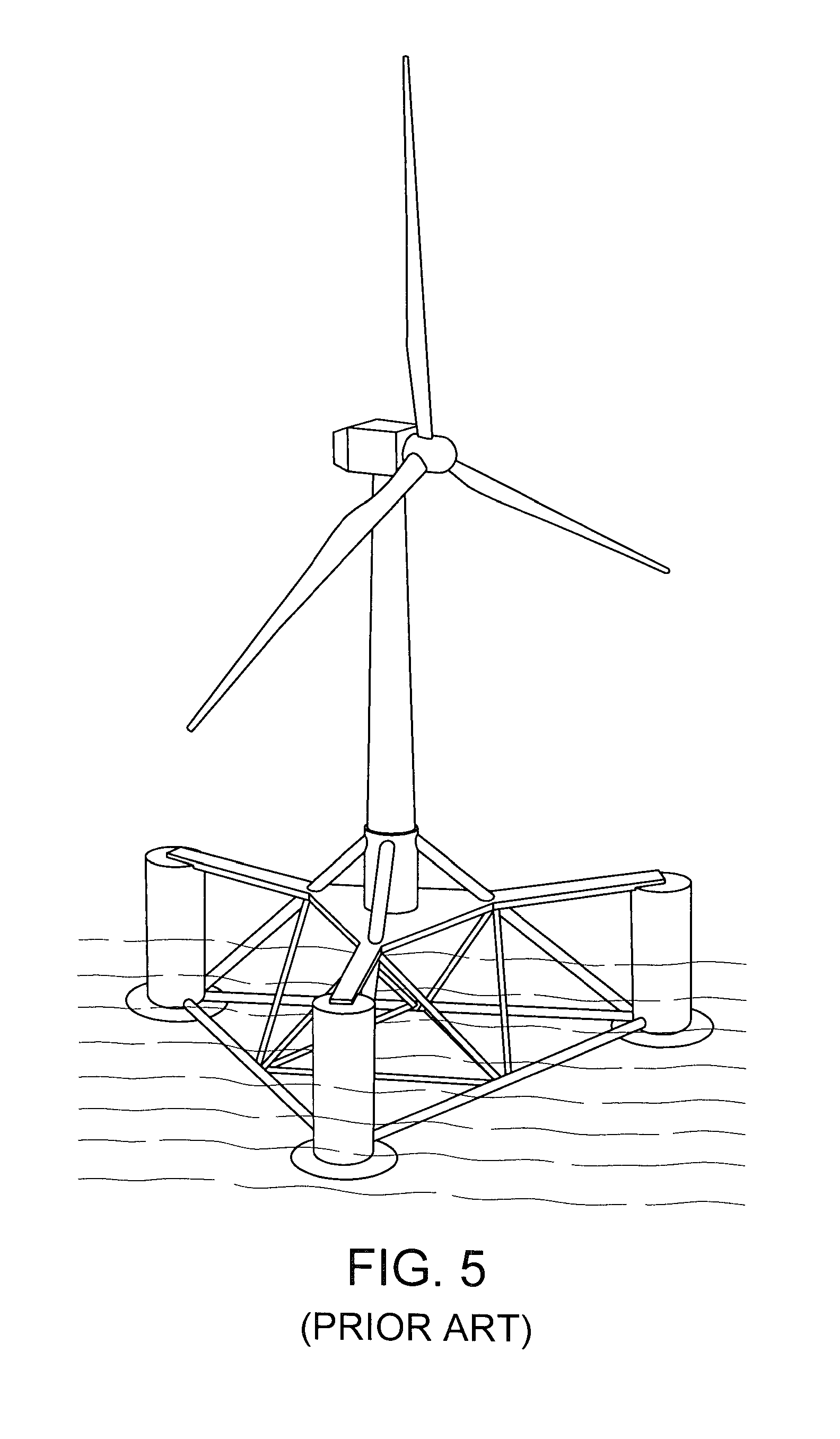

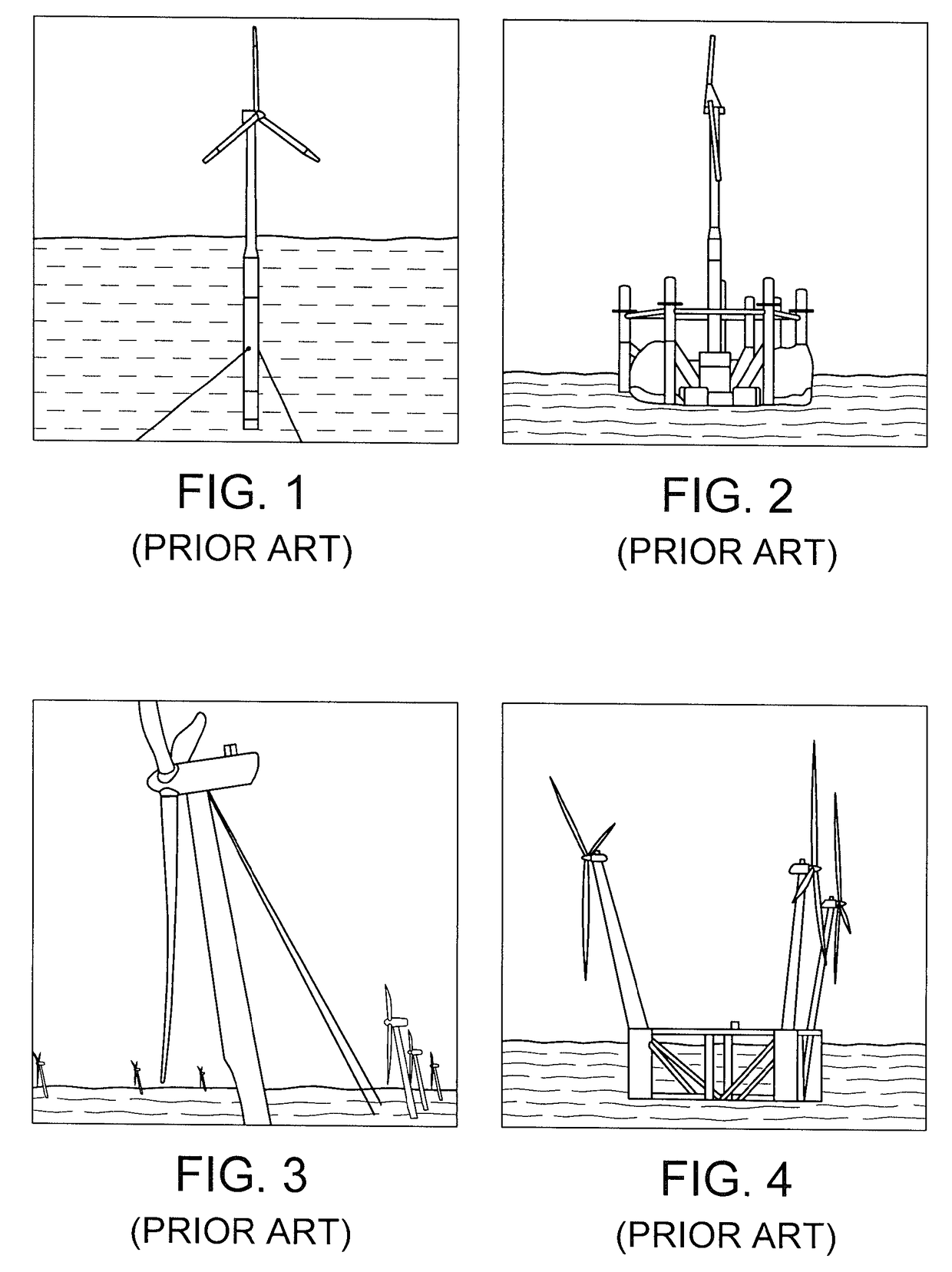

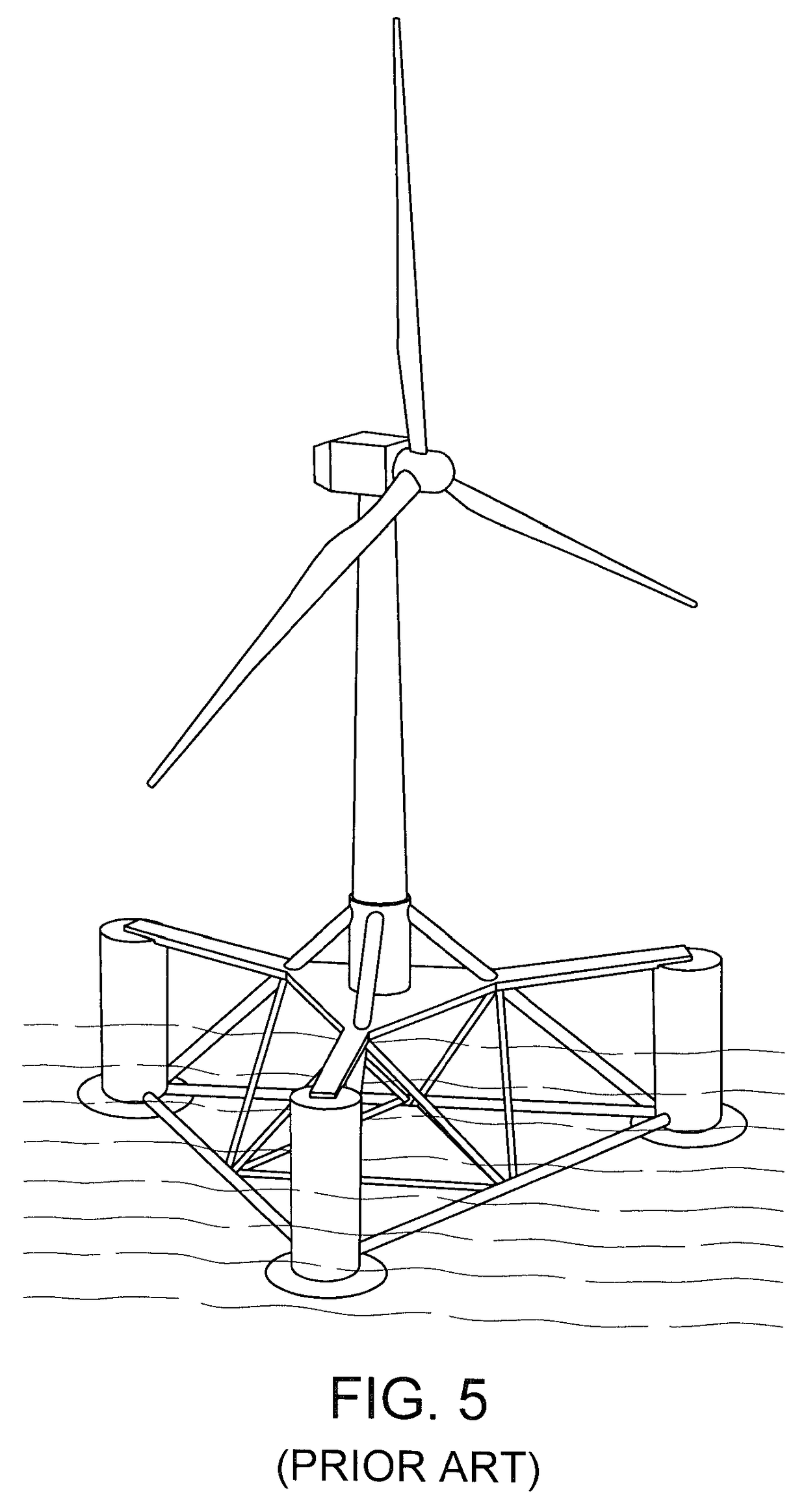

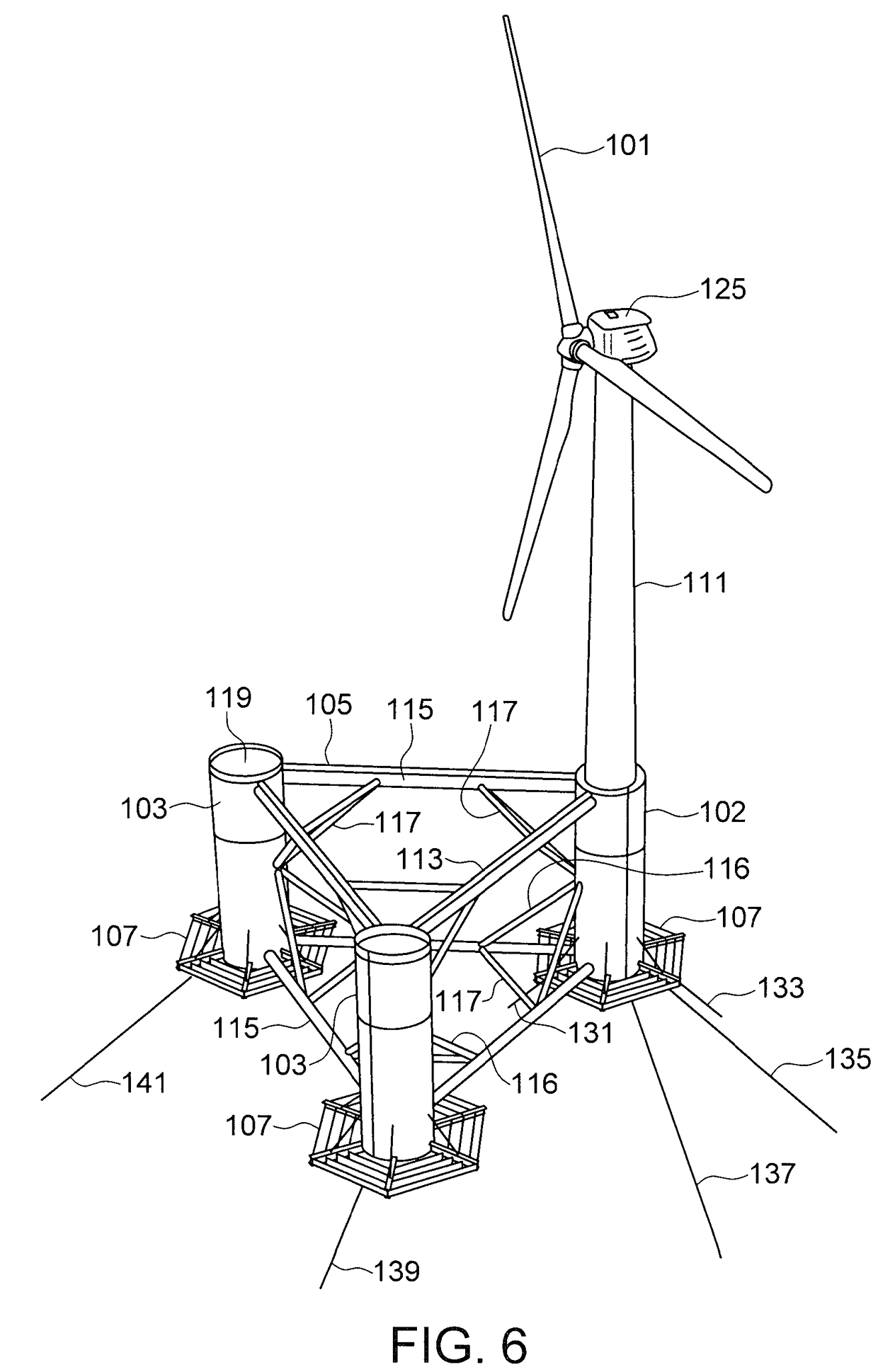

Column-stabilized offshore platform with water-entrapment plates and asymmetric mooring system for support of offshore wind turbines

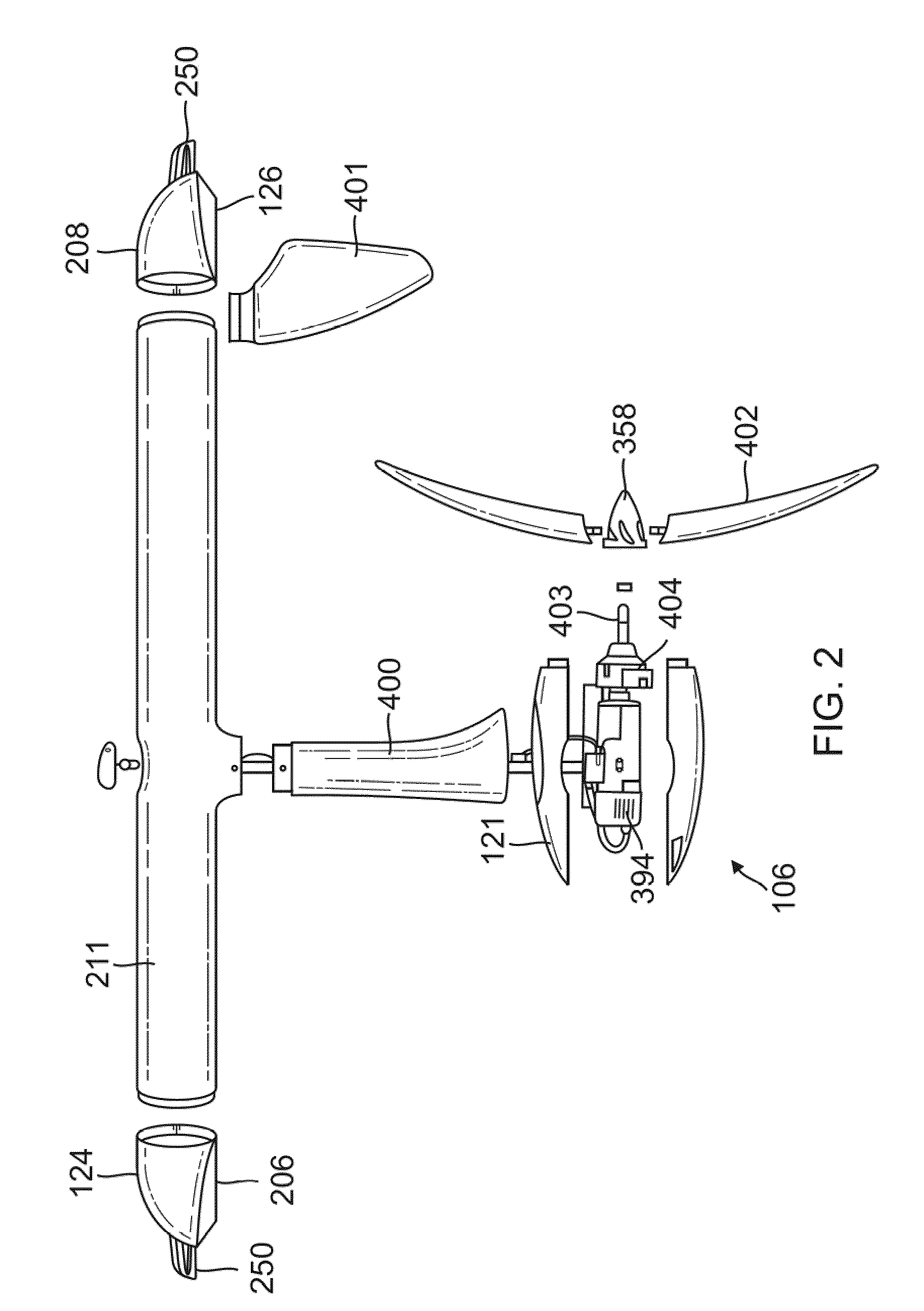

ActiveUS20110037264A1Improve performanceEasy to produceWind motor controlWind motor assemblyNacelleMooring system

A floating wind turbine platform includes a floatation frame (105) that includes three columns (102, 103) that are coupled to each other with horizontal main beams (115). A wind turbine tower (111) is mounted above a tower support column (102) to simplify the system construction and improve the structural strength. The turbine blades (101) are coupled to a nacelle (125) that rotates on top of the tower (111). The turbine's gearbox generator and other electrical gear can be mounted either traditionally in the nacelle, or lower in the tower (111) or in the top of the tower-supporting column (102). The floatation frame (105) includes a water ballasting system that pumps water between the columns (102, 103) to keep the tower (111) in a 10 vertical alignment regardless of the wind speed. Water-entrapment plates (107) are mounted to the bottoms of the columns (102, 103) to minimize the rotational movement of the floatation frame (105) due to waves.

Owner:PRINCIPLE POWER

Liquefied natural gas floating storage regasification unit

InactiveUS20060156744A1Reduce the amount requiredProvide protectionGas handling applicationsGas handling/storage effectsMooring systemMarine engineering

An offshore liquefied natural gas floating storage regasification unit that may receive, store, and process liquefied natural gas from carriers. A floating storage regasification unit may include transfer equipment to offload liquefied natural gas from a carrier, a first mooring system to provide for mooring of a floating storage regasification unit at a location in a body of water, a second mooring system to provide for mooring a carrier to the floating storage regasification unit, and combinations thereof. A portion of the floating storage regasification unit may be composed of a double-hull containment structure.

Owner:SHELL OIL CO

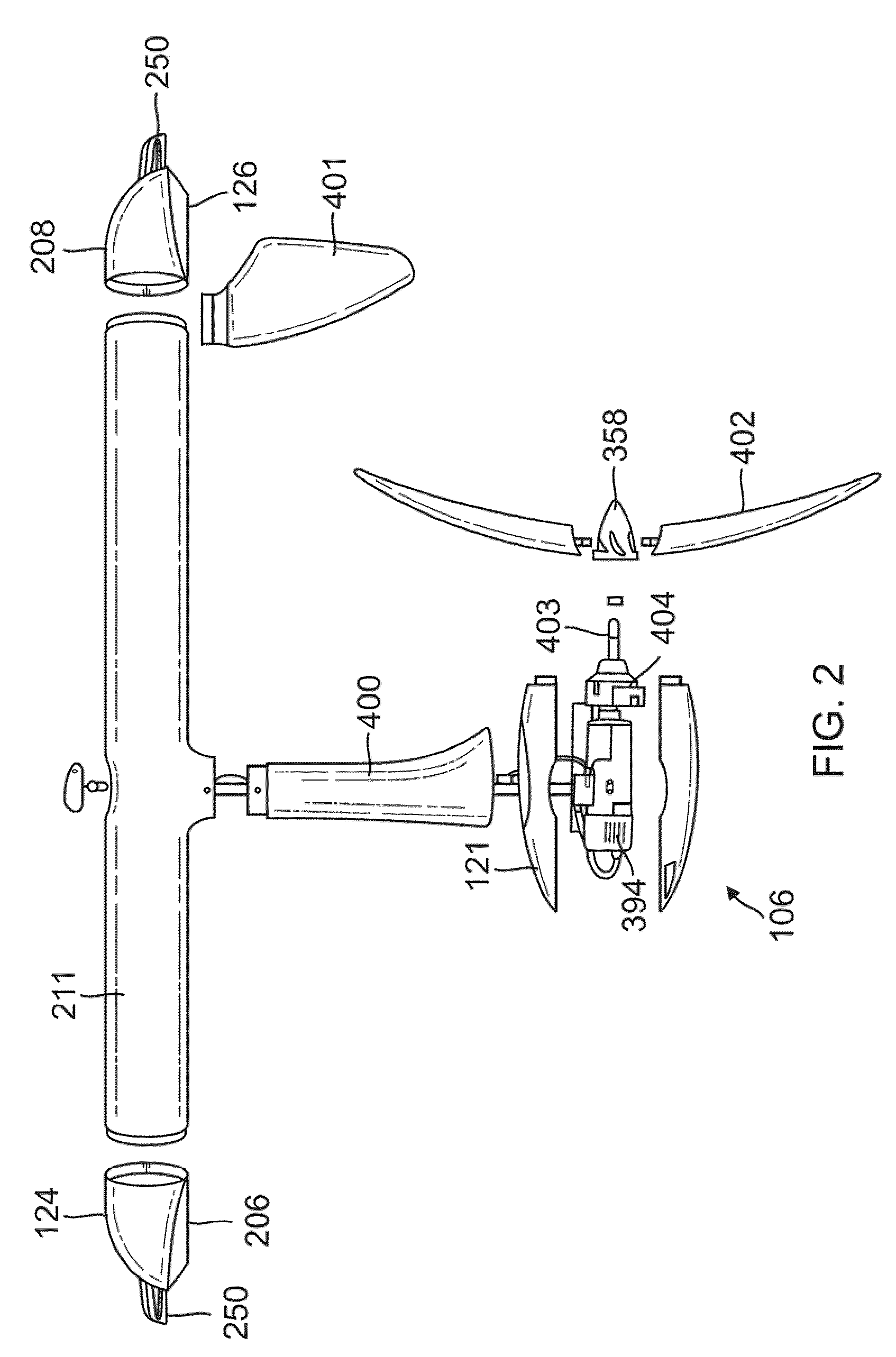

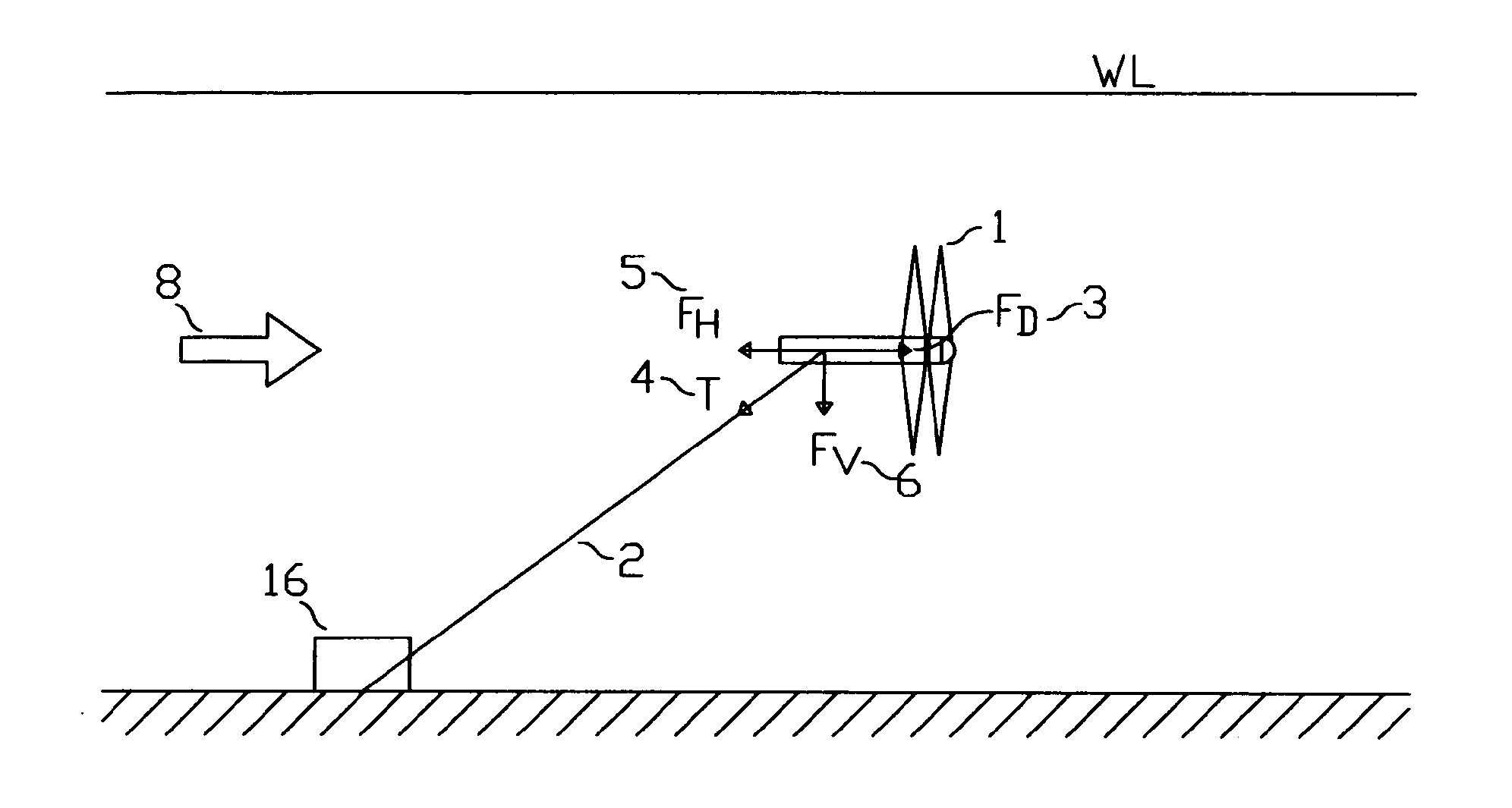

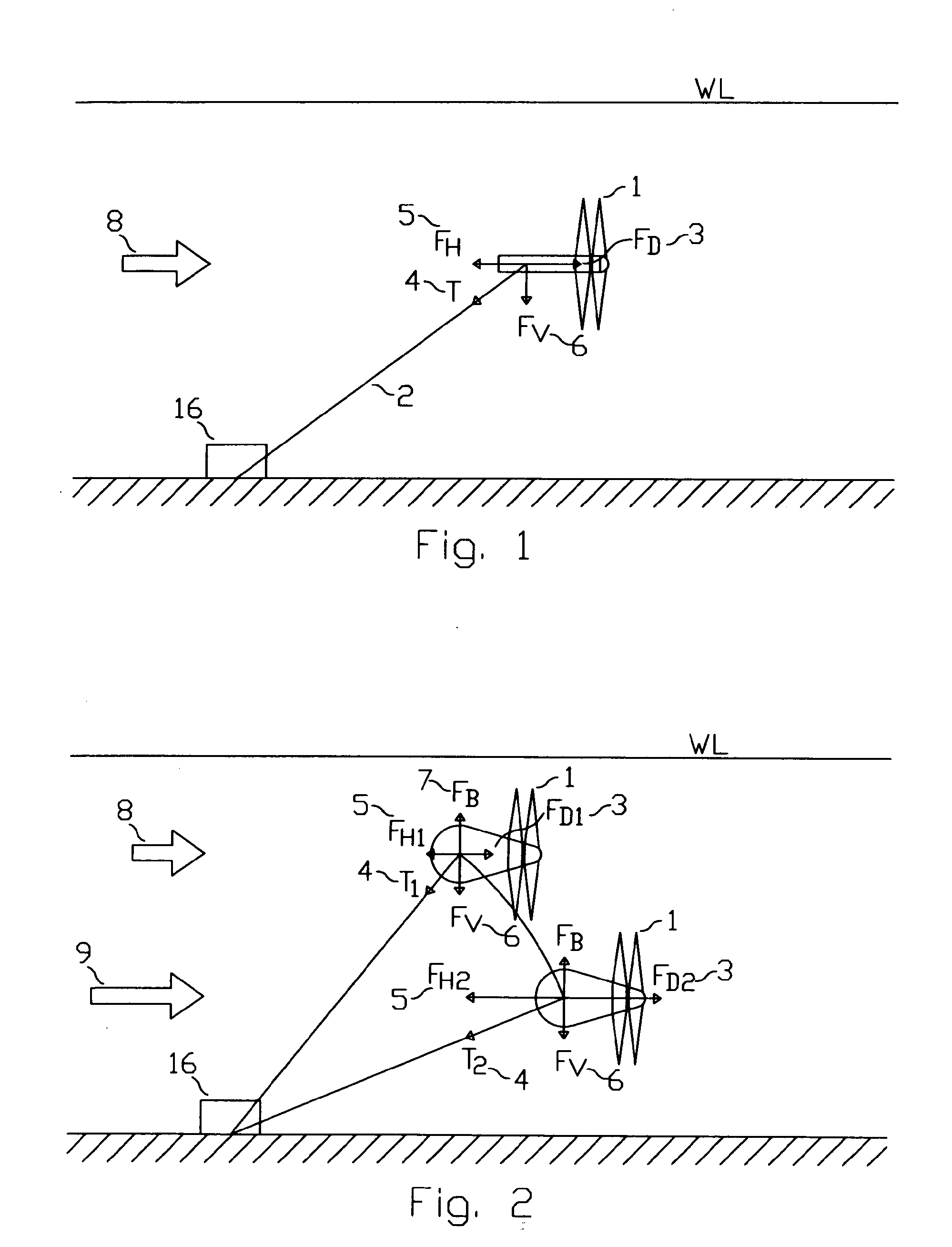

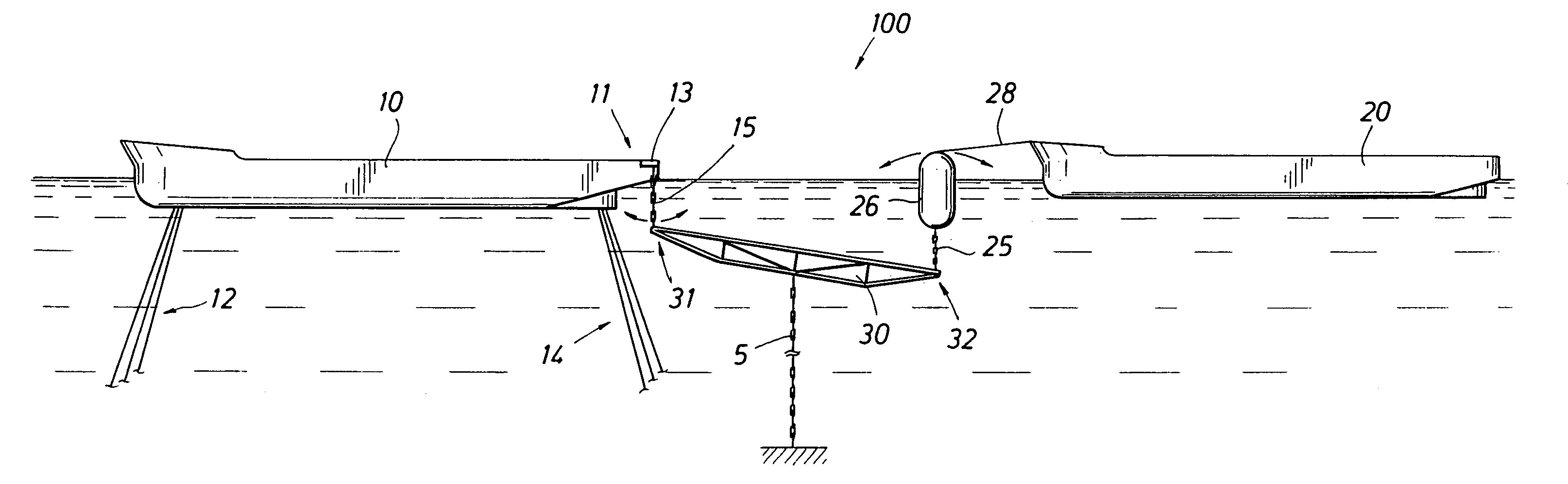

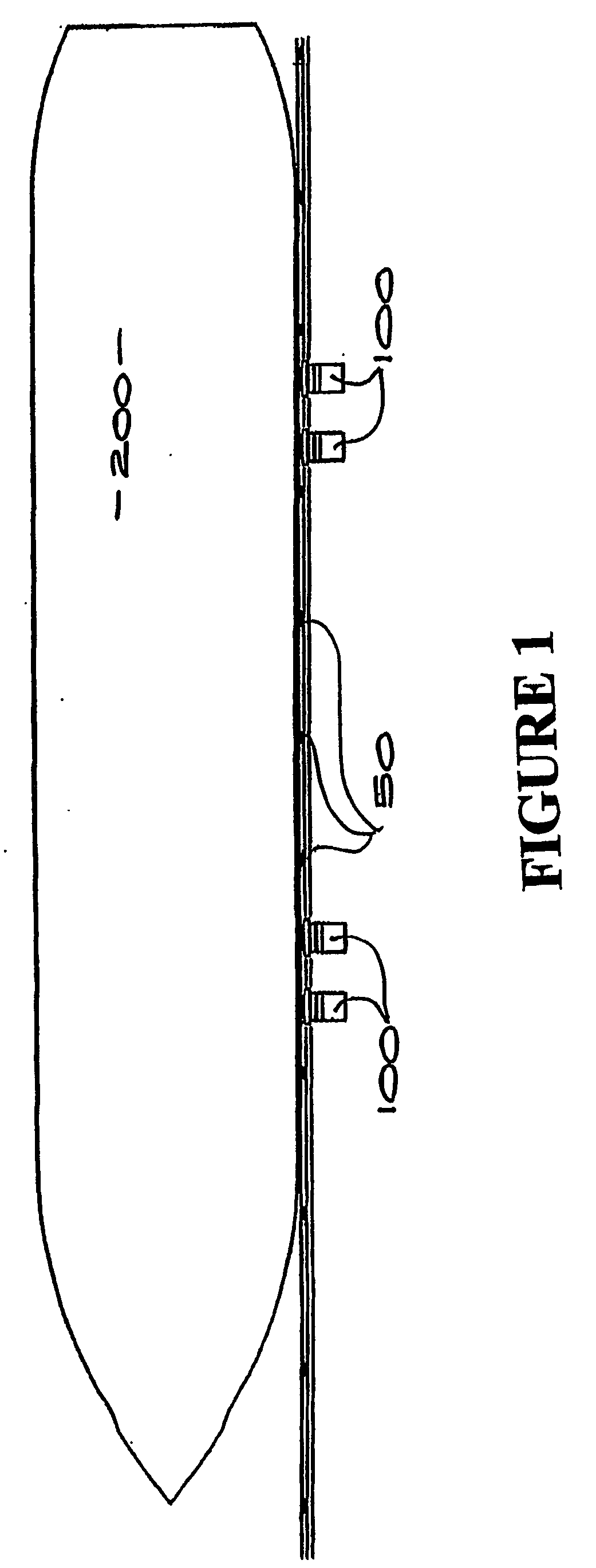

River and tidal power harvester

InactiveUS20090230686A1Reduce buildReduce installationWater resource protectionWaterborne vesselsMooring systemFluvial

An energy module comprising an energy absorber; and a mooring system, comprising a wing-shaped polymer shell attached to the energy absorber, the wing-shaped polymer shell designed to utilize the force of a passing current to create a downward force and thereby reduce any upward motion in the energy module; and a mooring cable housed inside the wing-shaped polymer shell and anchored to maintain the energy module in a fore and aft and a side-to-side position to provide stability, and to negate a rotational force on the energy module.

Owner:CATLIN CHRISTOPHER S

Column-stabilized offshore platform with water-entrapment plates and asymmetric mooring system for support of offshore wind turbines

ActiveUS8471396B2Improve performanceEasy to produceWind motor controlWind motor assemblyNacelleMooring system

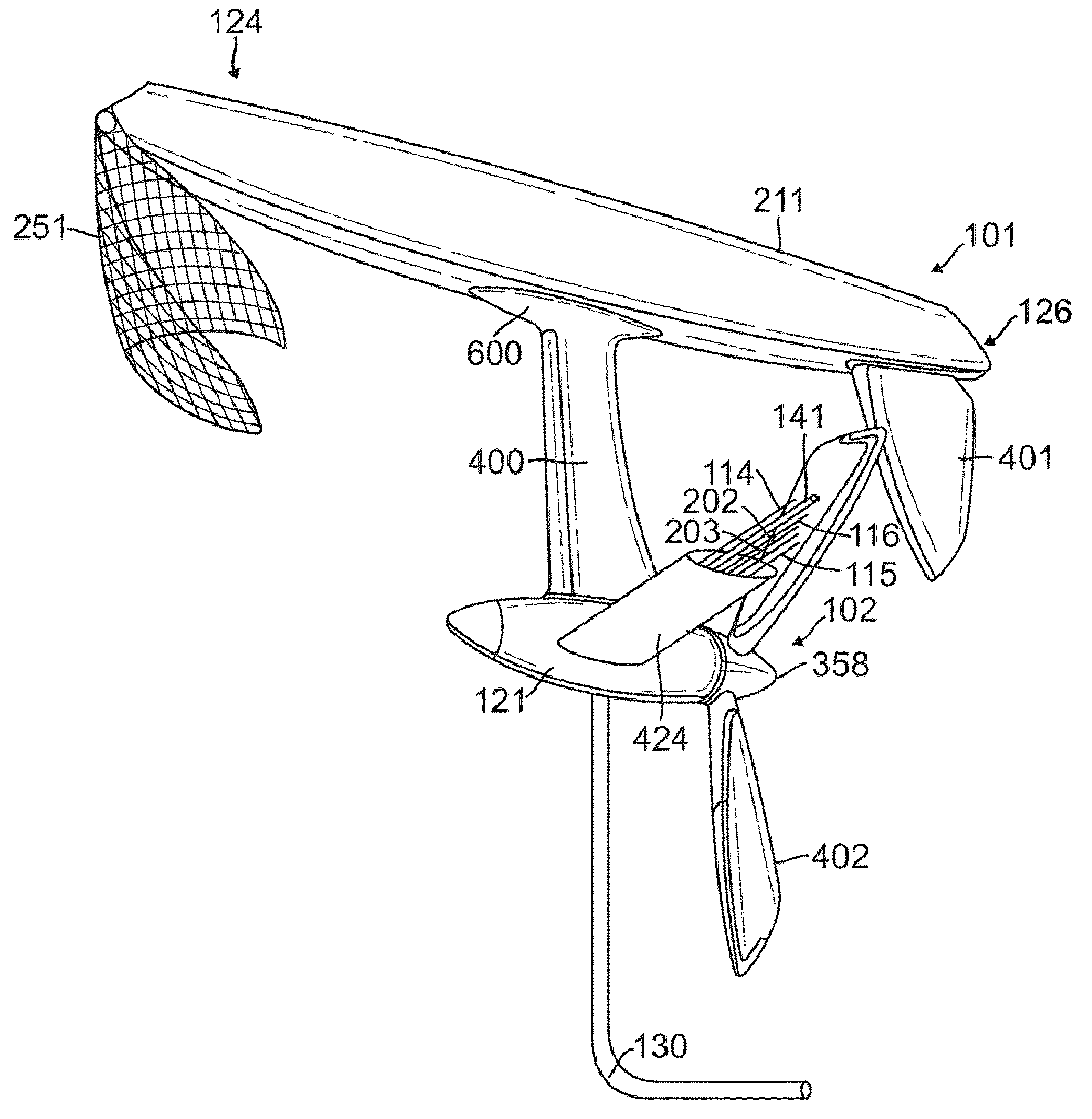

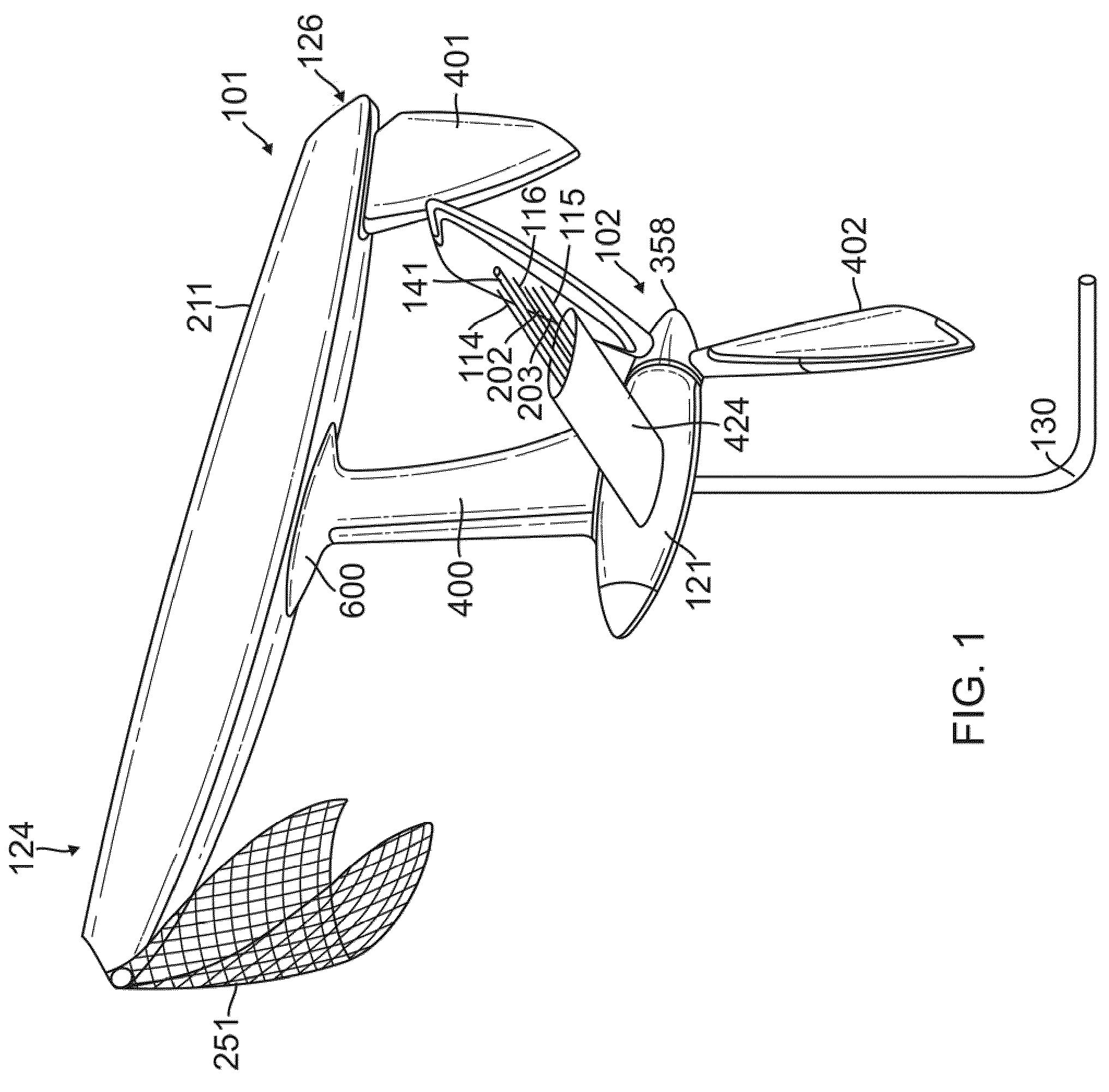

A floating wind turbine platform includes a floatation frame that includes at least three columns that are coupled to each other with horizontal main beams. A wind turbine tower is mounted above a tower support column to simplify the system construction and improve the structural strength. The turbine blades are coupled to a nacelle that rotates on top of the tower. The turbine's gearbox generator and other electrical gear can be mounted either traditionally in the nacelle, or lower in the tower or in the top of the tower-supporting column. The floatation frame includes a water ballasting system that pumps water between the columns to keep the tower in a vertical alignment regardless of the wind speed. Water-entrapment plates are mounted to the bottoms of the columns to minimize the rotational movement of the floatation frame due to waves.

Owner:PRINCIPLE POWER

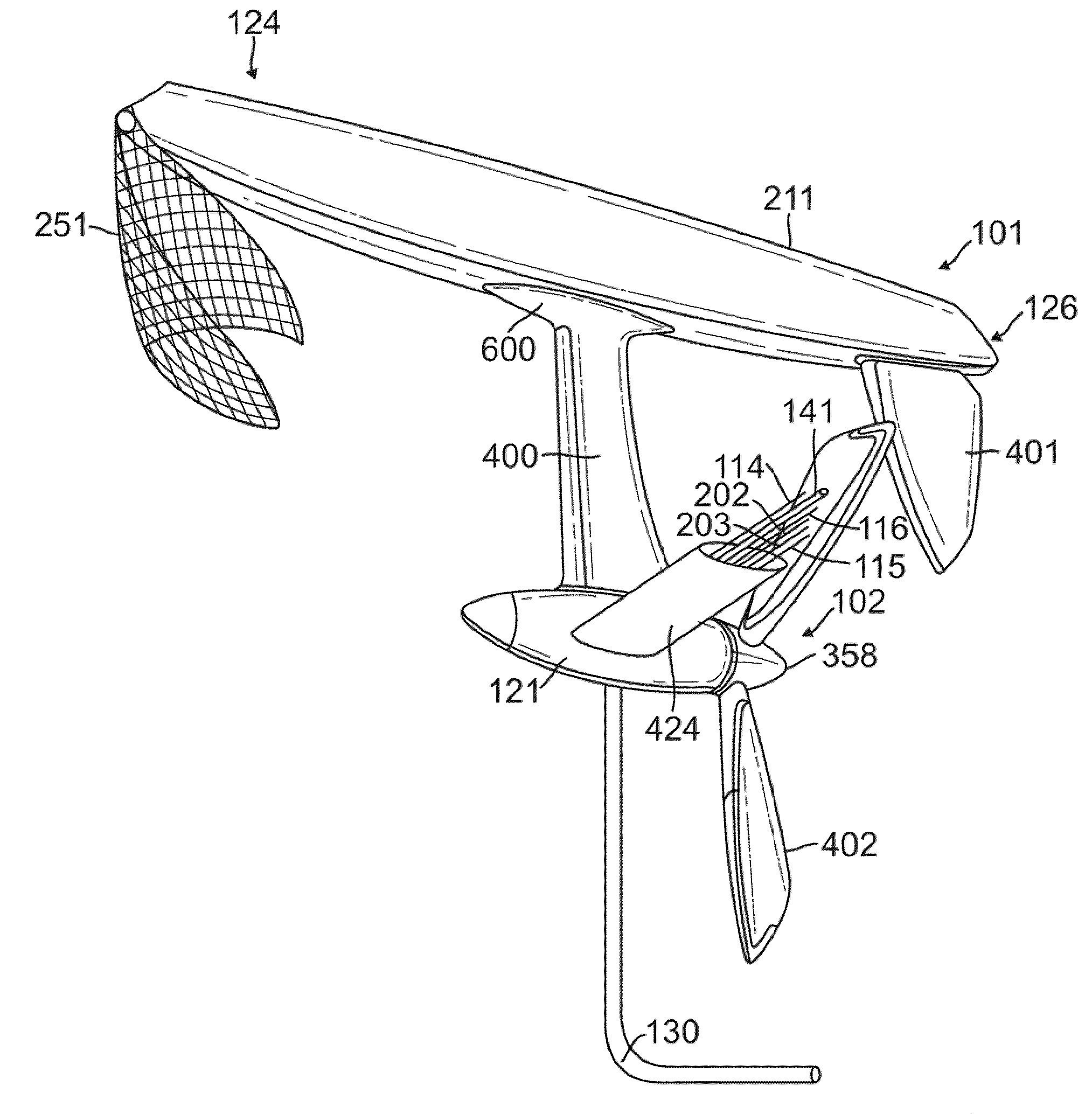

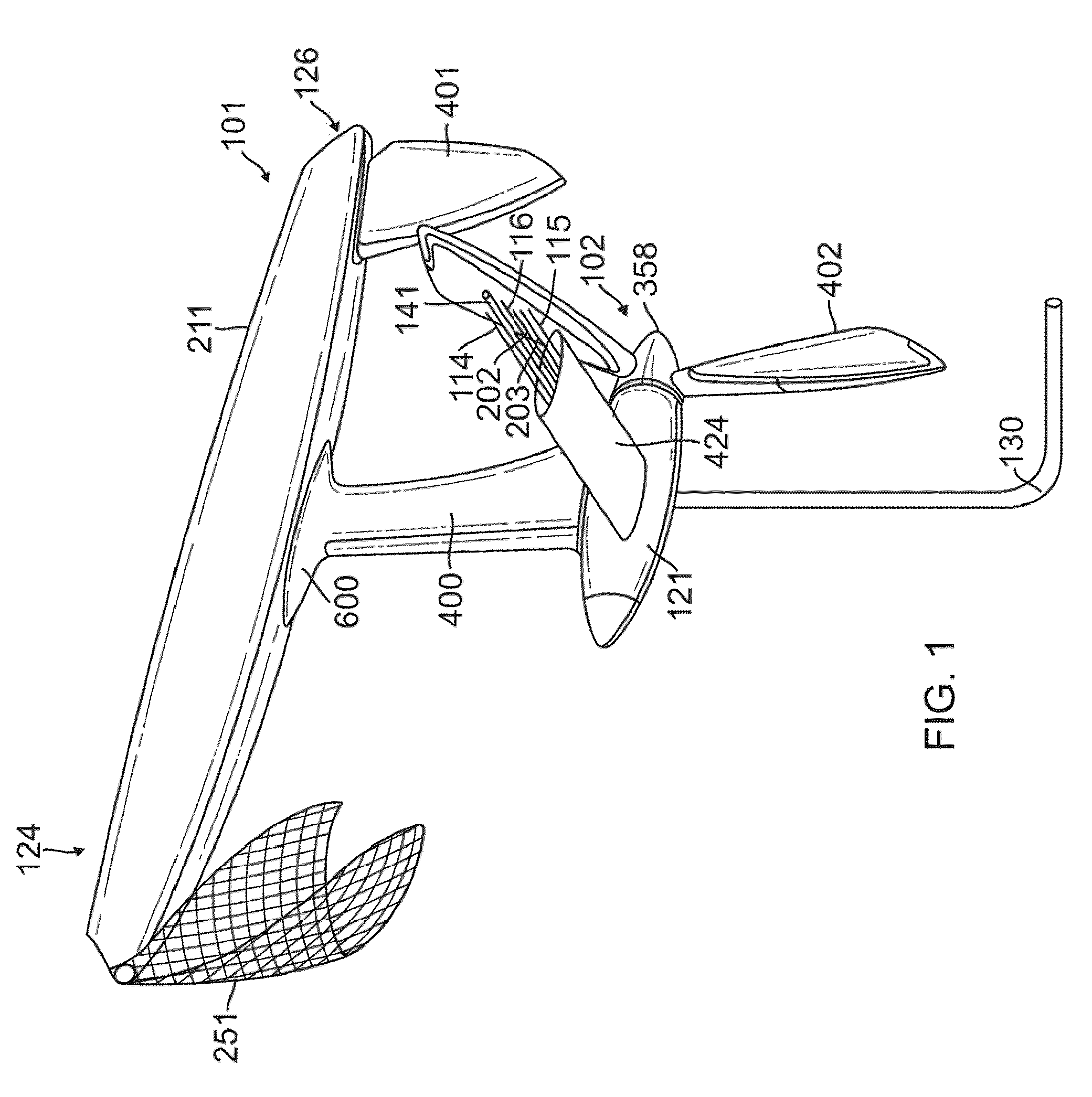

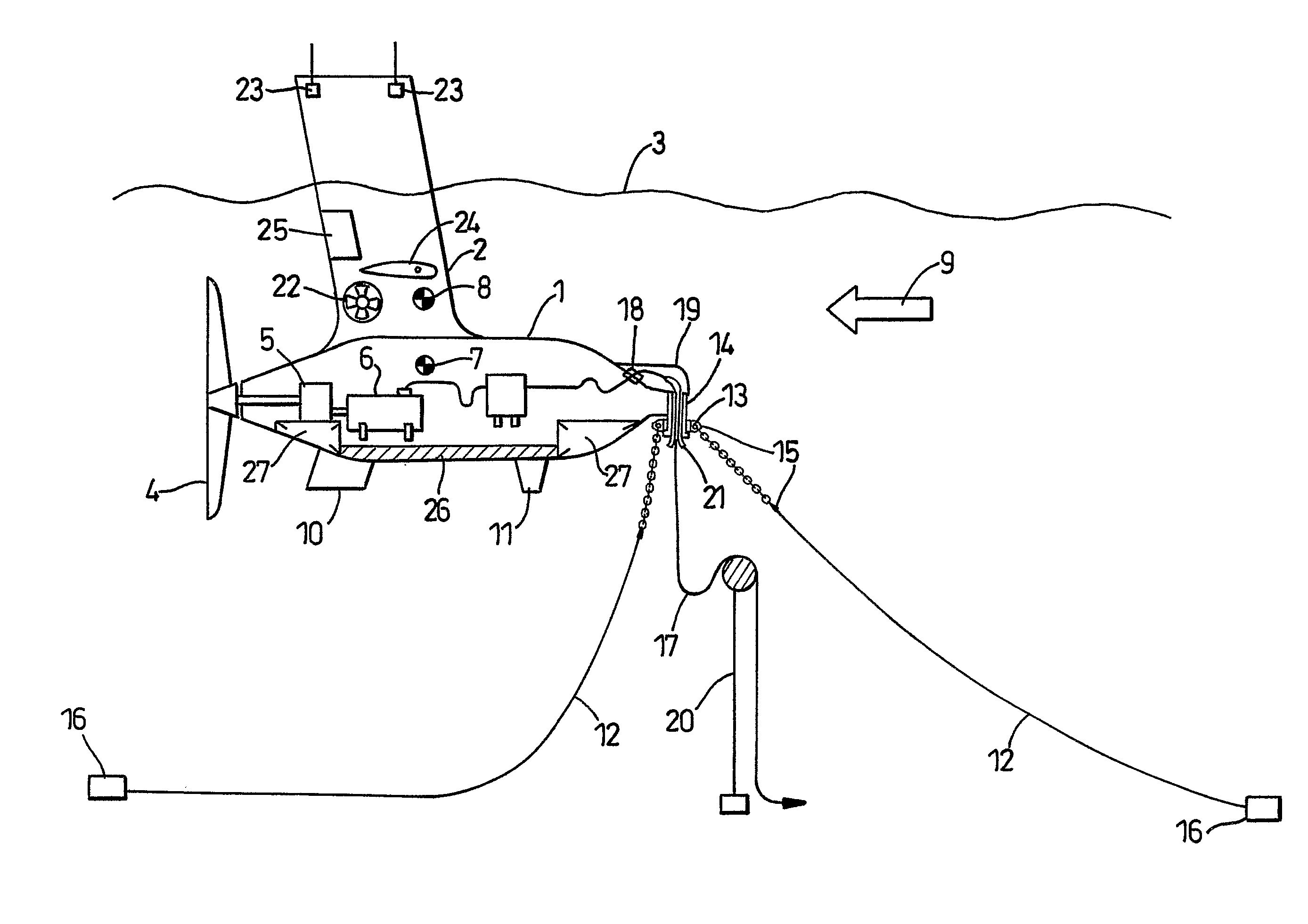

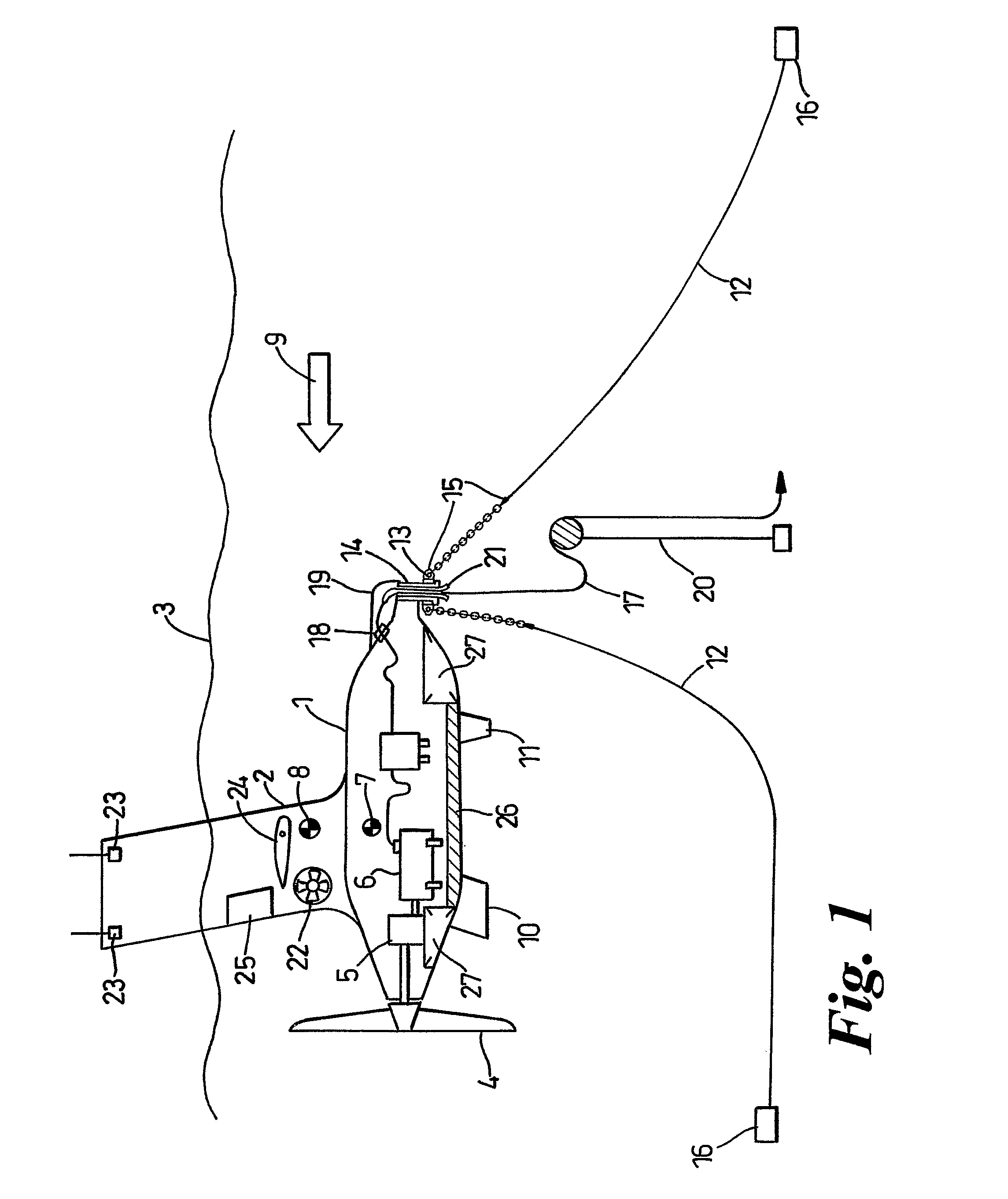

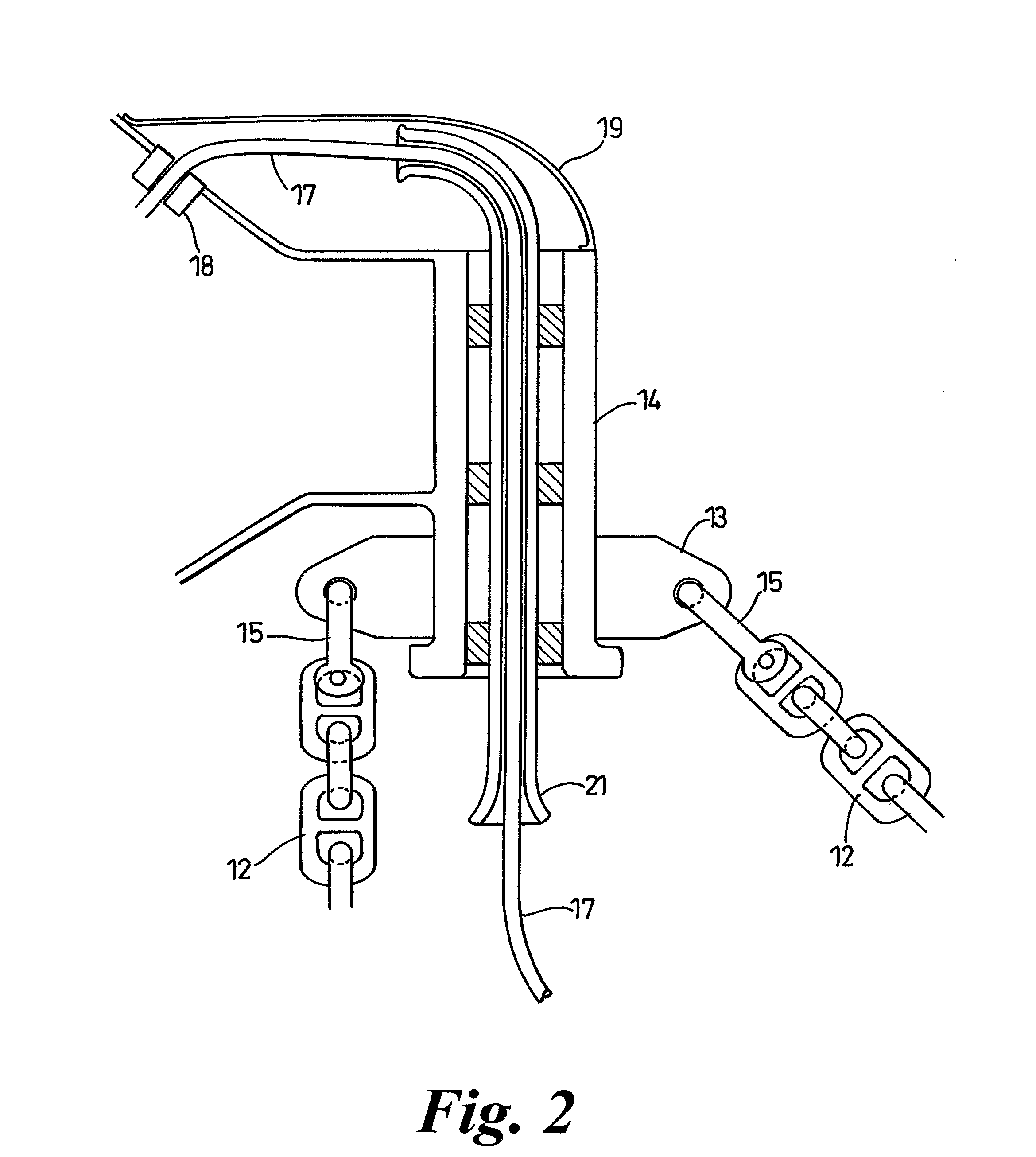

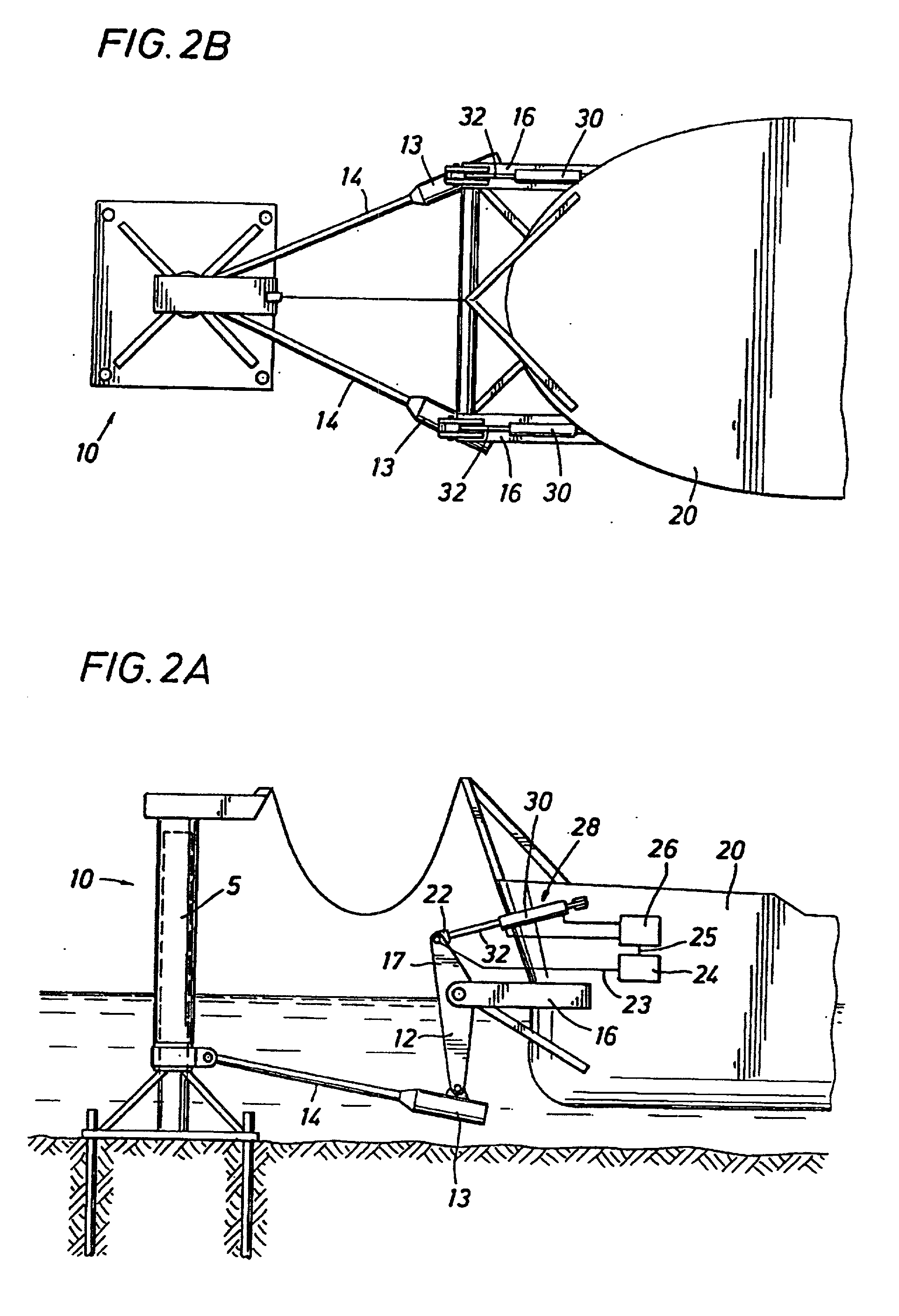

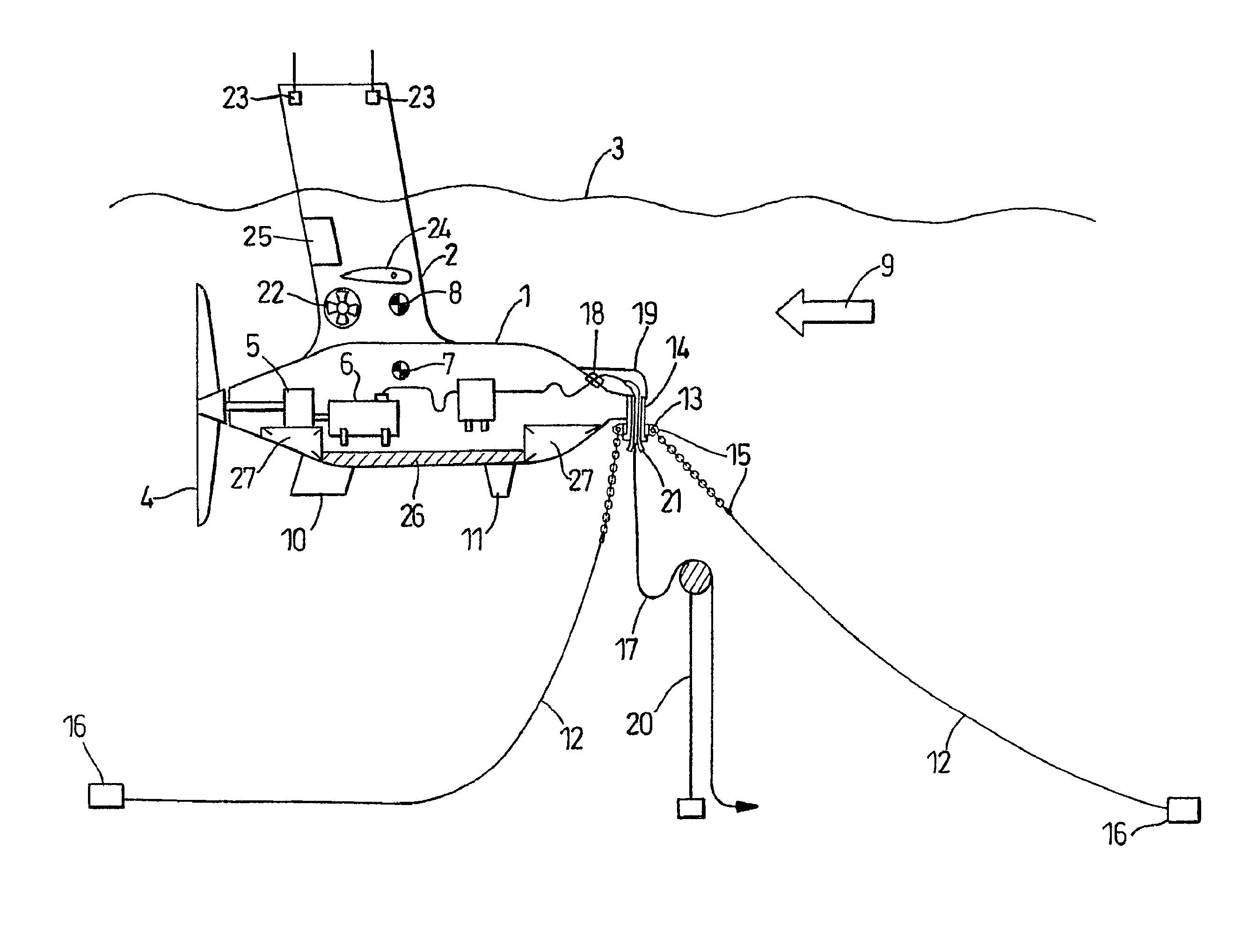

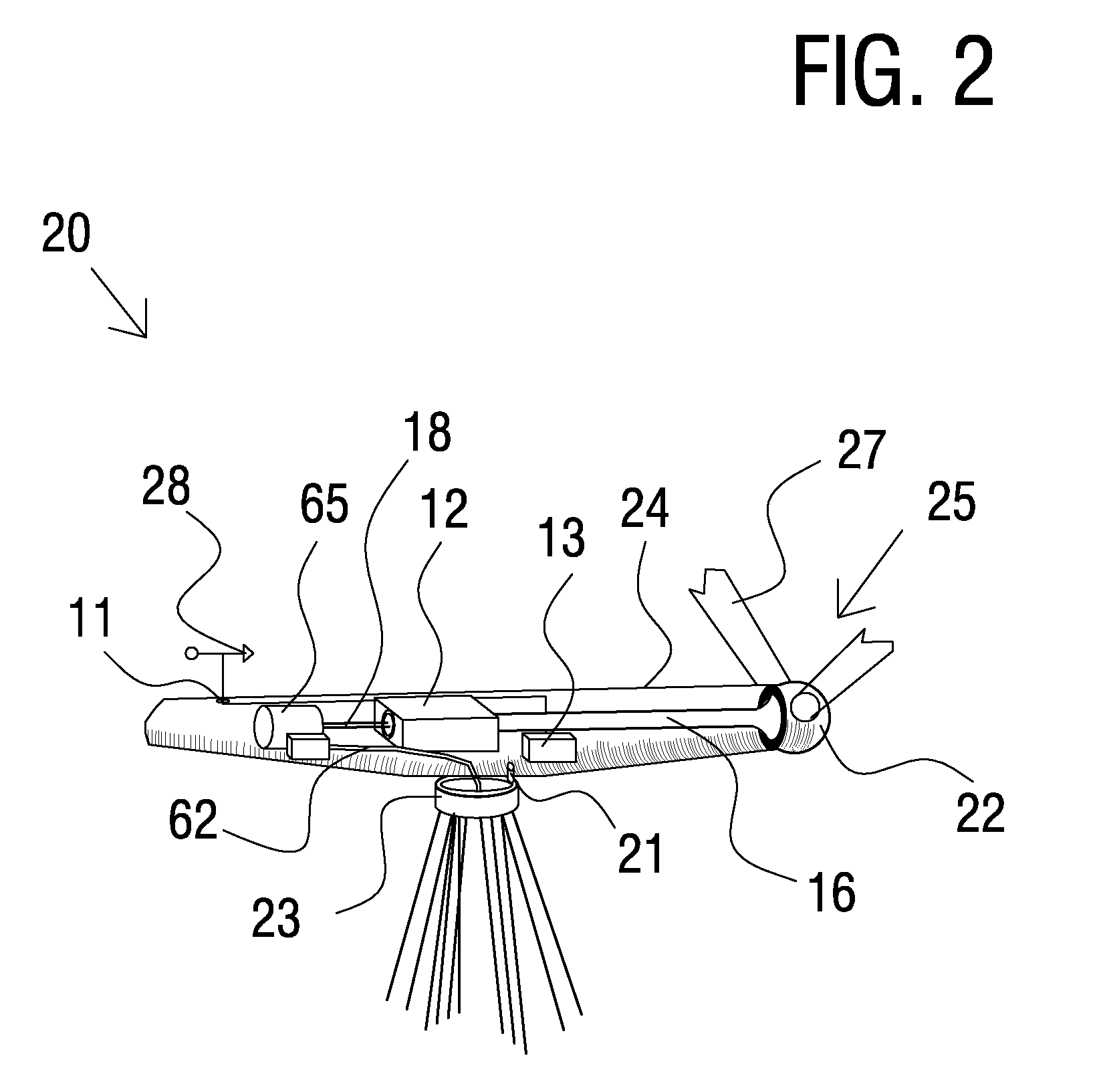

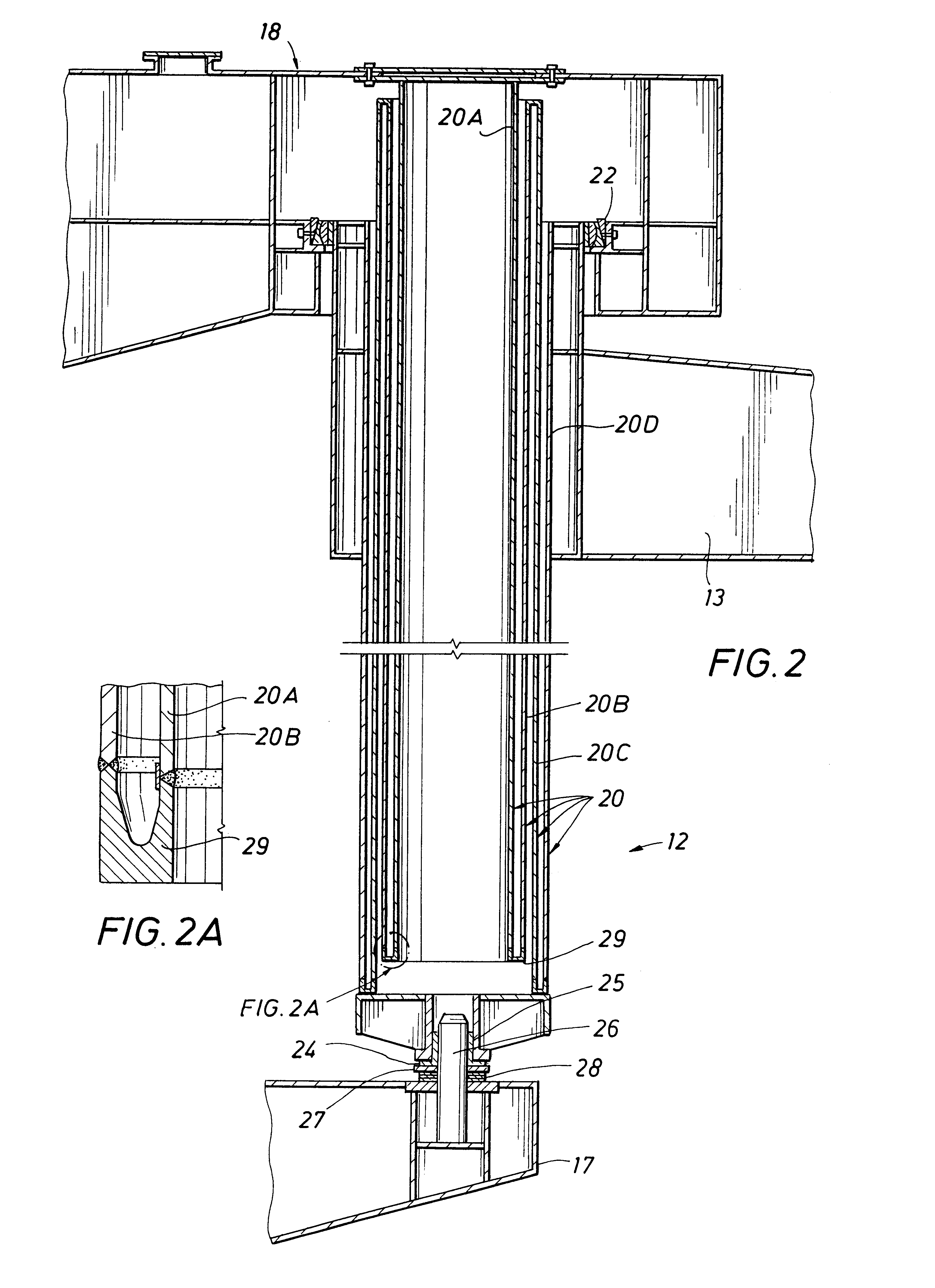

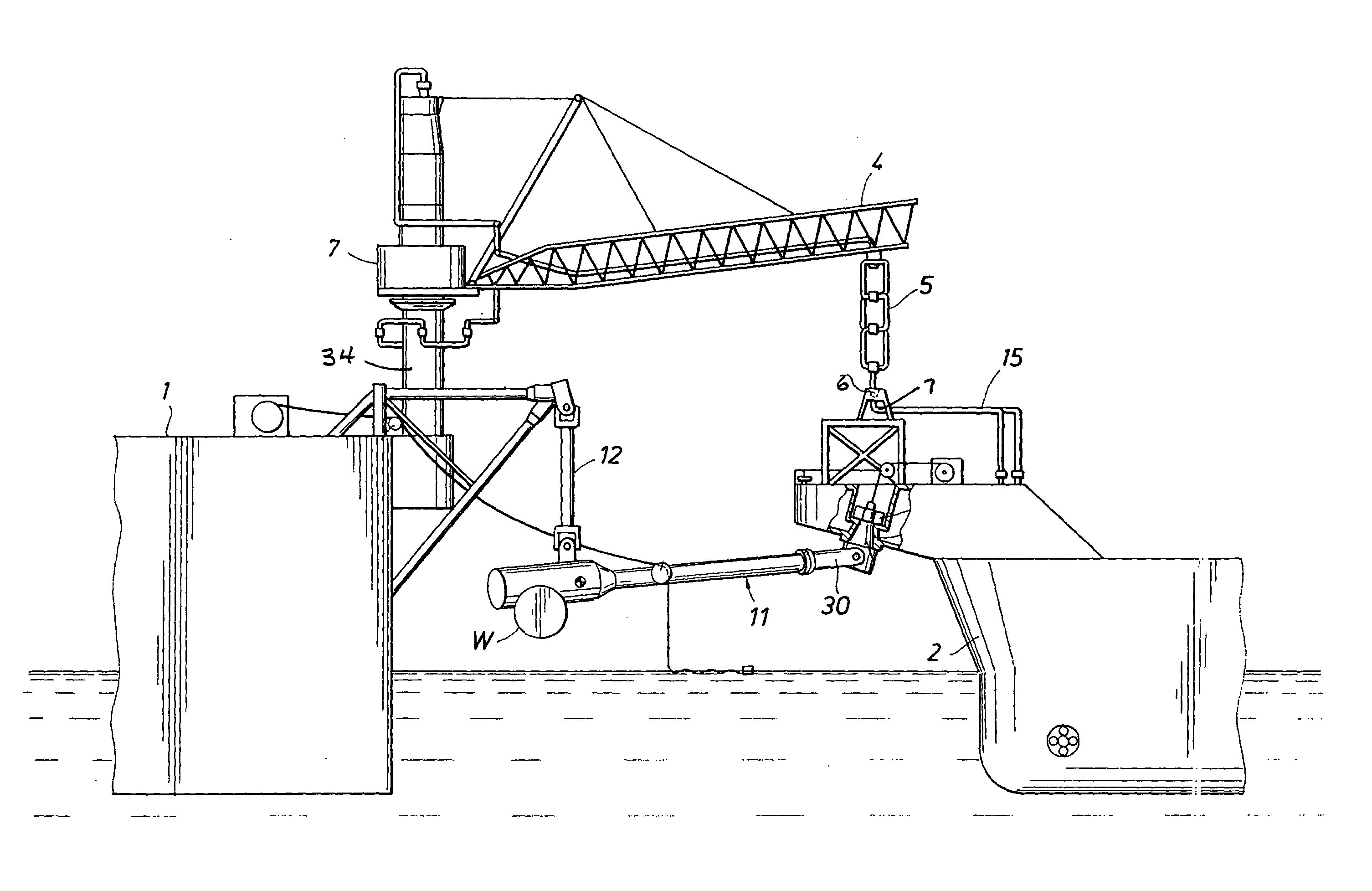

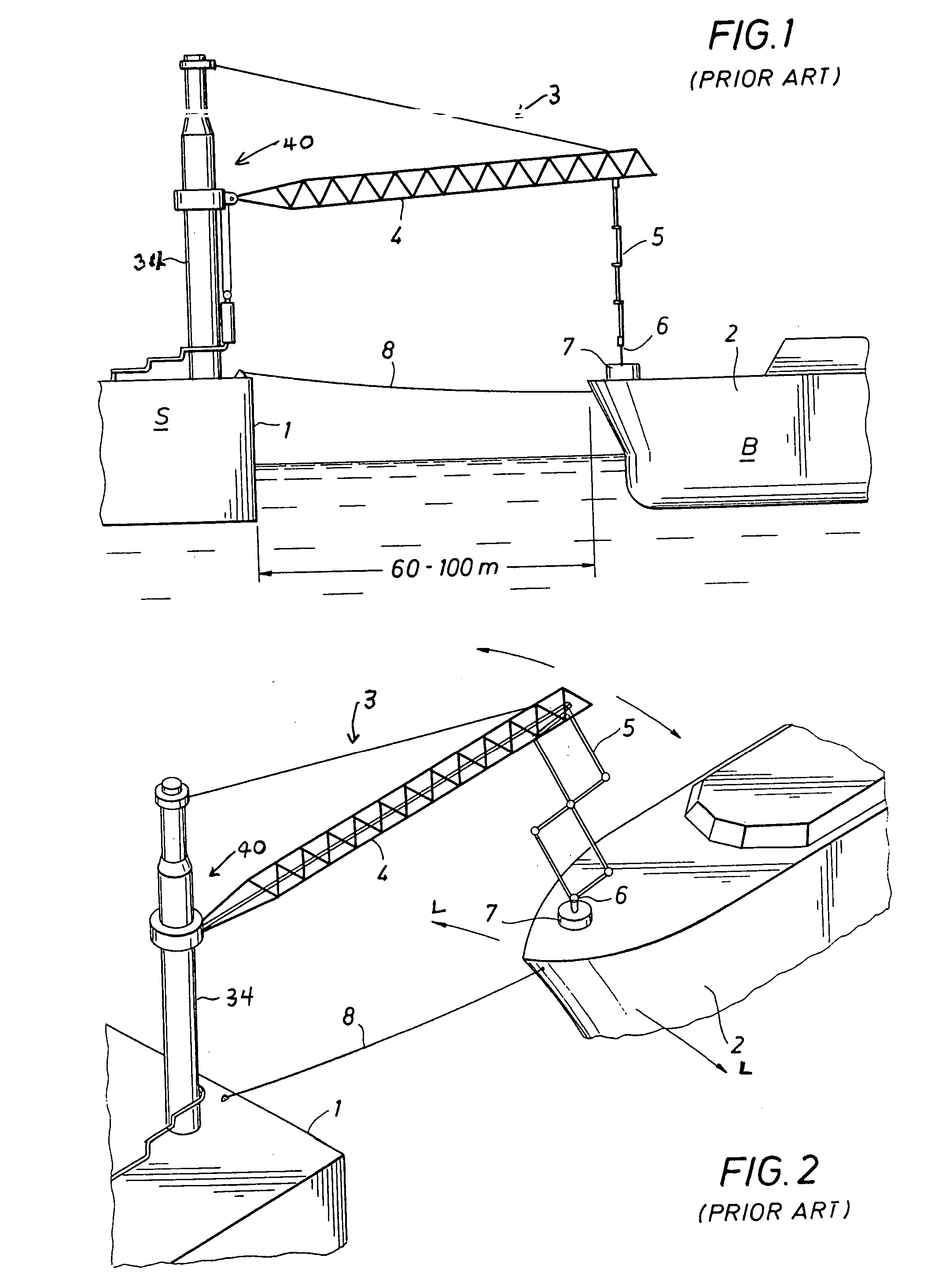

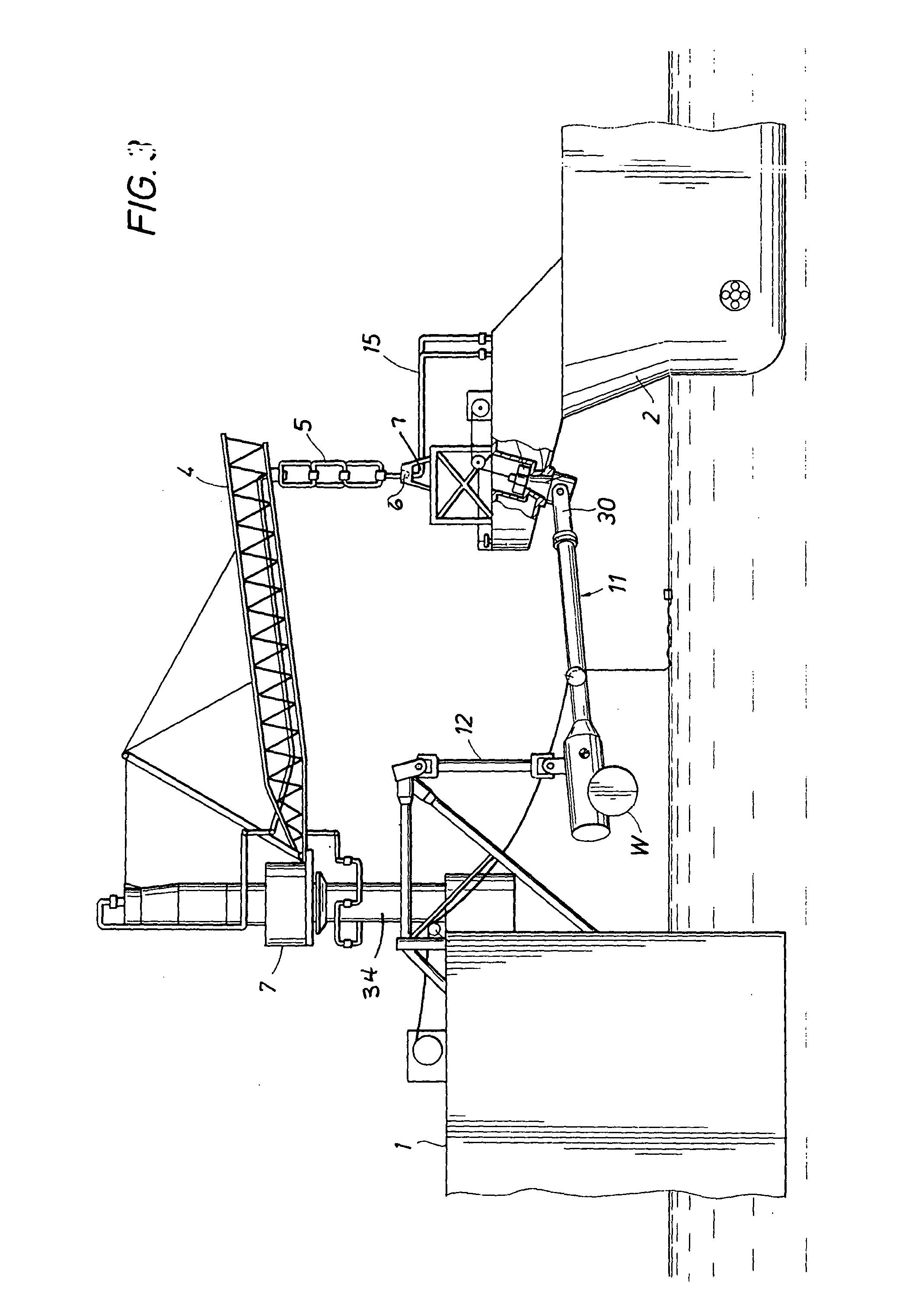

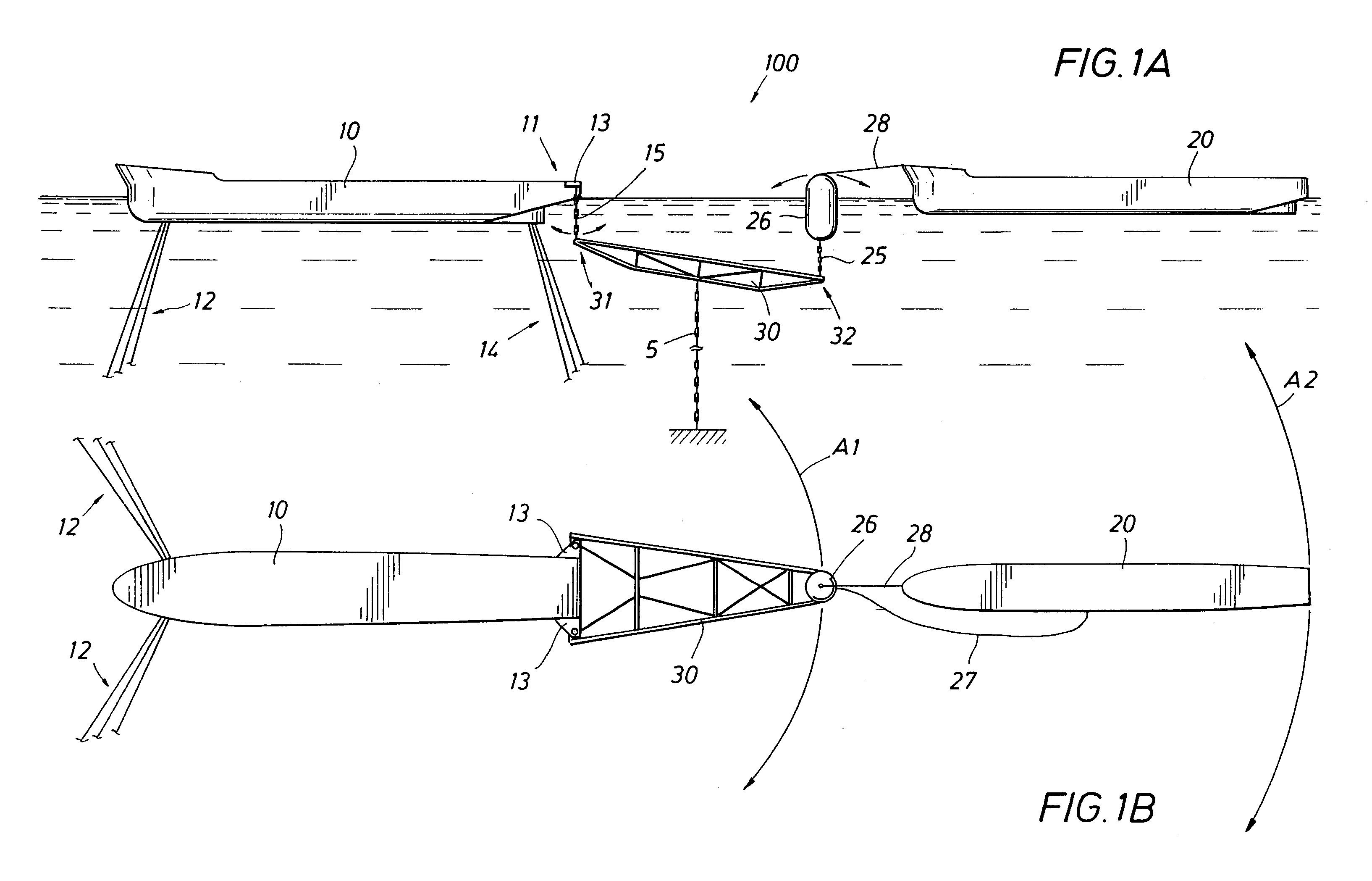

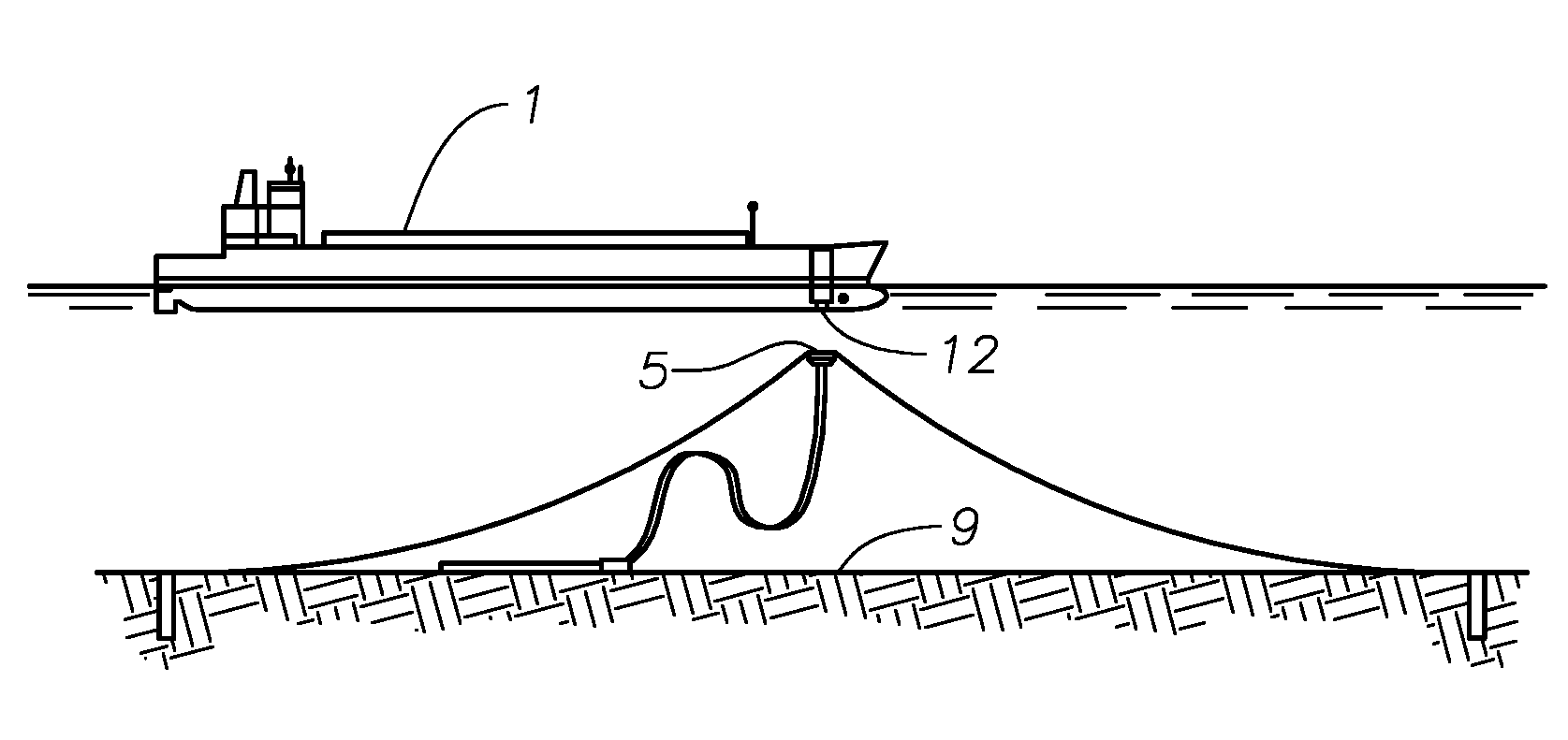

Floating Apparatus for Deploying in Marine Current for Gaining Energy

ActiveUS20080050993A1Effective supportHigh suppression characteristicsArtificial islandsWaterborne vesselsHorizontal axisRudder

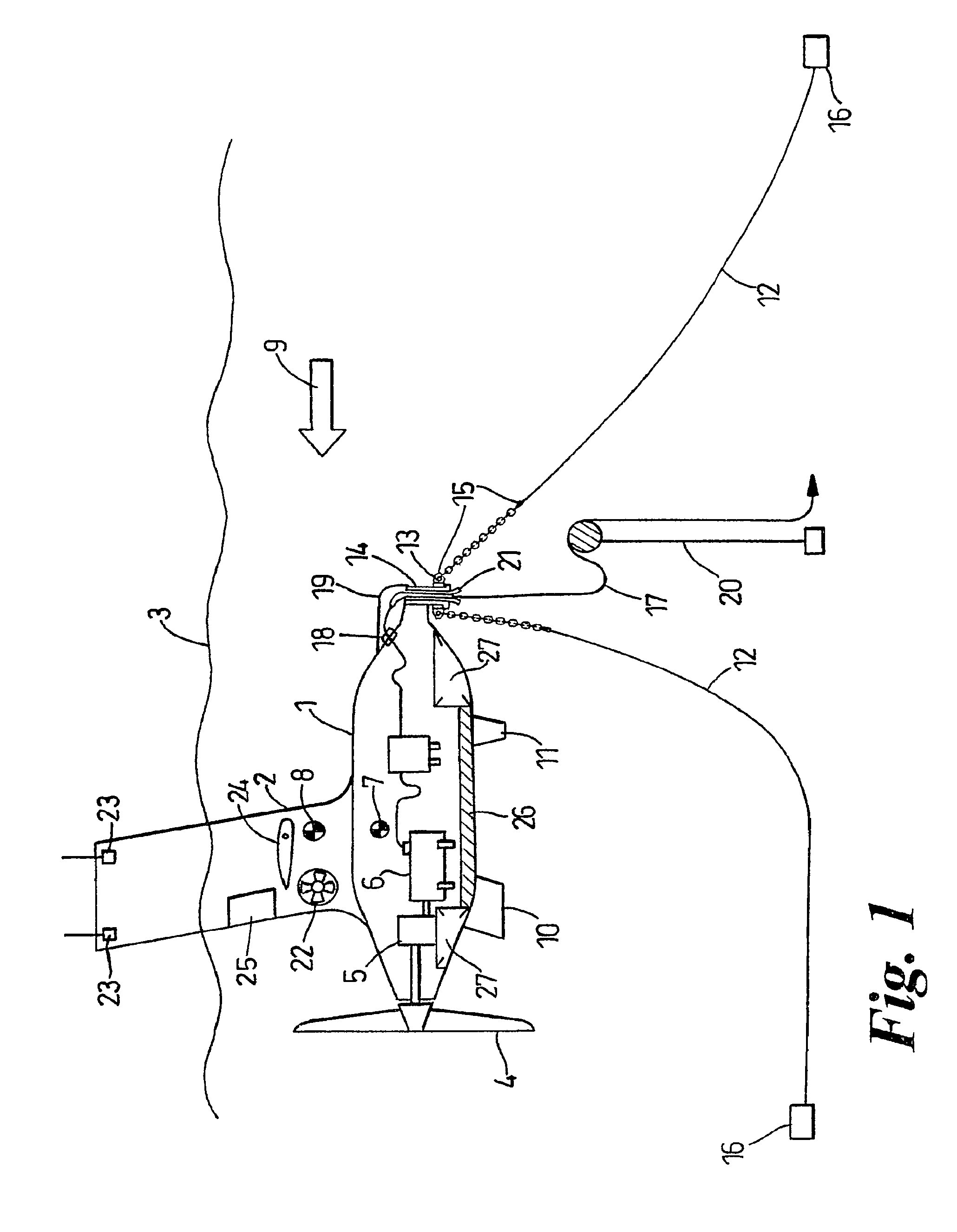

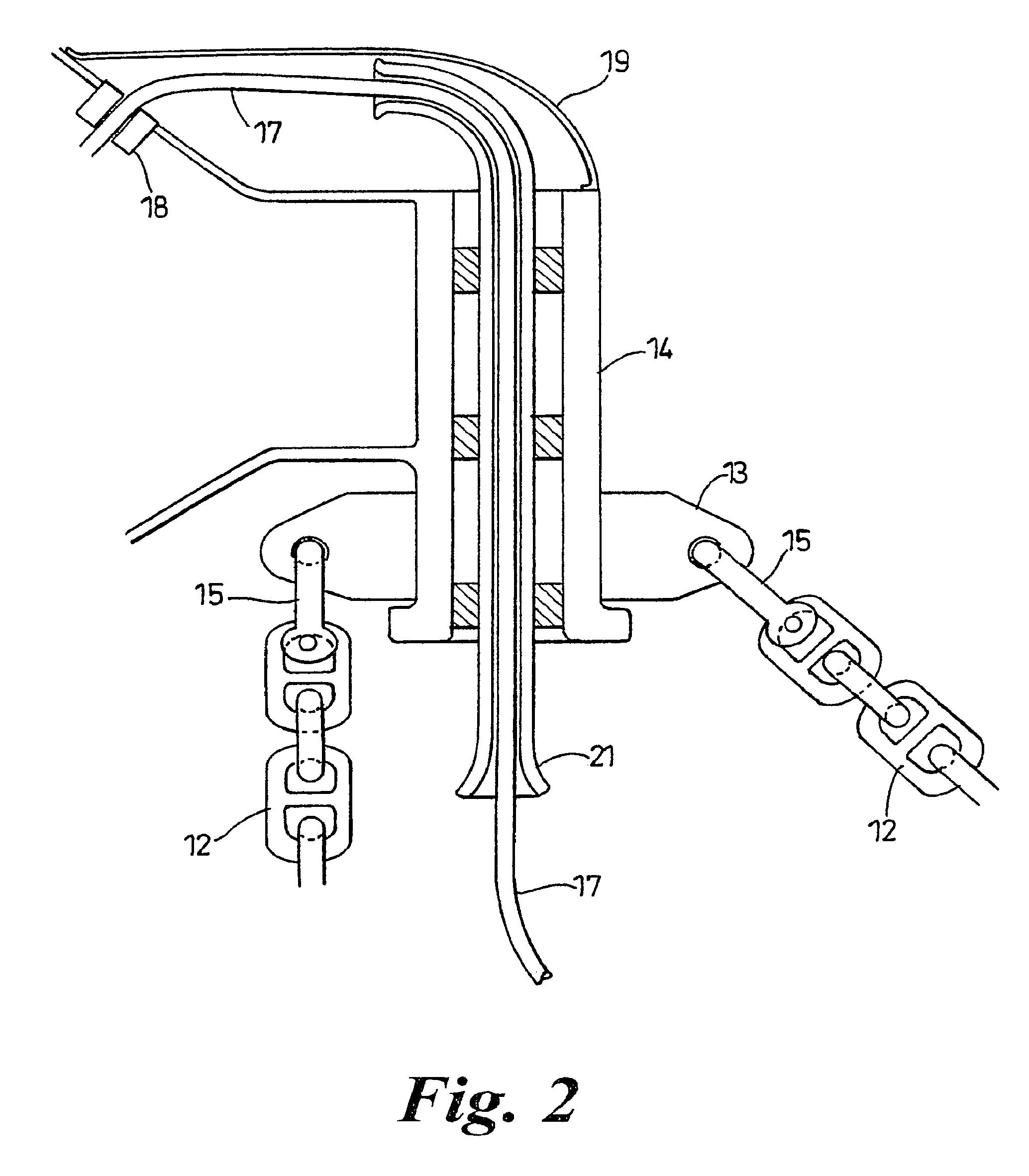

A floating, semi-submerged, tethered device that supports a horizontal axis turbine and power generation equipment for extracting kinetic energy from a tidal stream or ocean current. A submerged body (1) is supported by surface piercing struts (2) of small water plane area (FIG. 6). The device is tethered to the seabed by a spread of mooring lines (12) that are deployed both into and away from the direction of the tidal current. A horizontal axis turbine (4) harnesses energy from the water flow and drives a generator housed within the body. A horizontal strut hydrofoil (24) corrects the trim of the device when subject to varying loads from the mooring system and can also be used to dampen pitch motion. Rudder flaps in the struts (25) can be used to counteract roll motion. Power is exported from the device to the seabed by an umbilical (17). A thrusters (22) can be used to constrain the rotation of the device about its mooring system to prevent excessive twist building up between the mooring lines and the power export umbilical.

Owner:OCEAN FLOW ENERGY

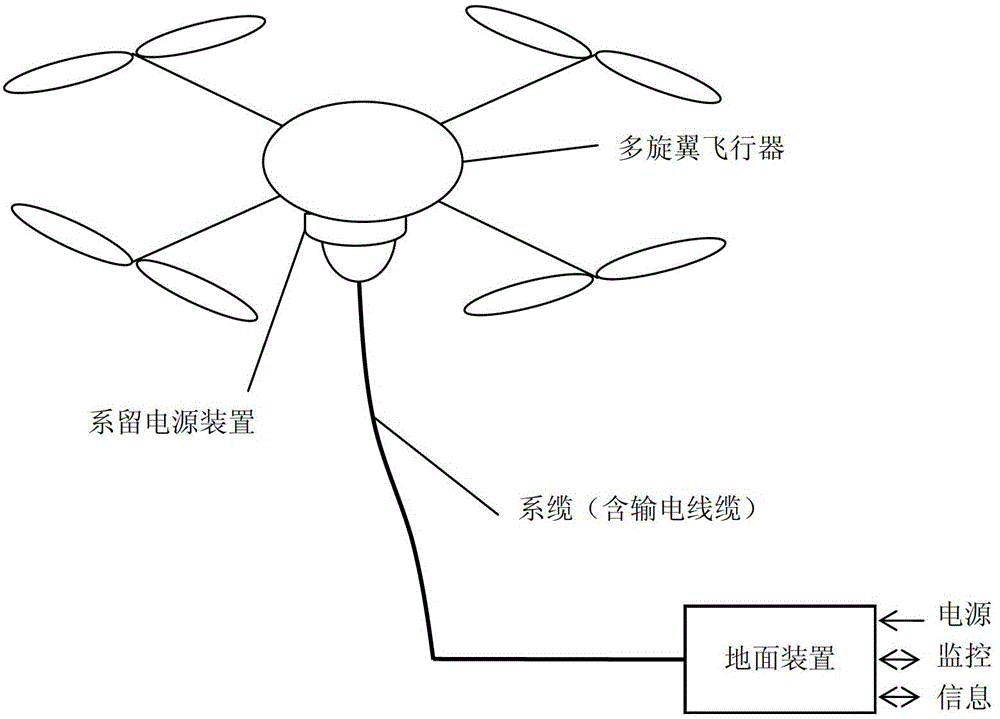

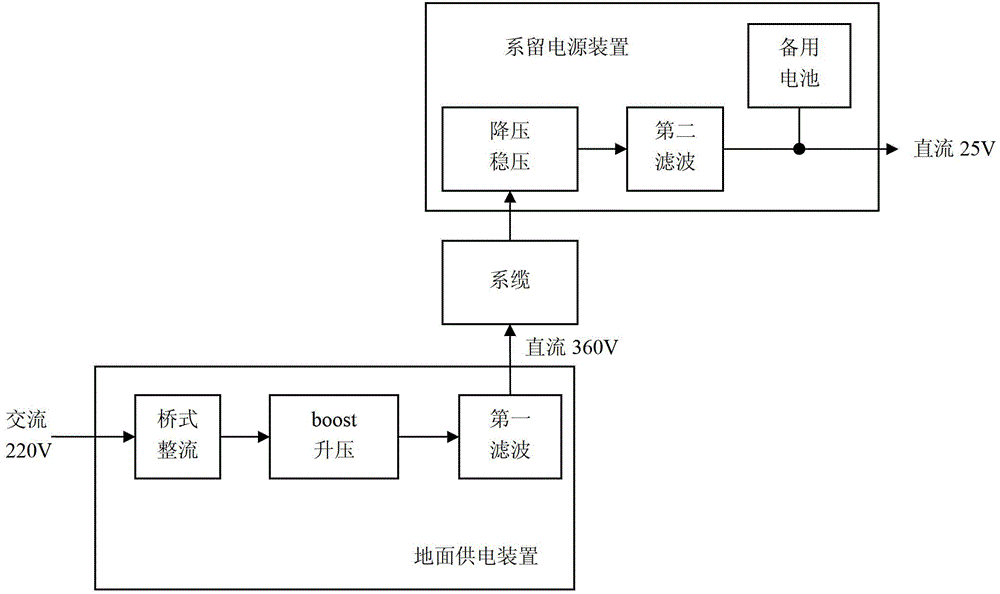

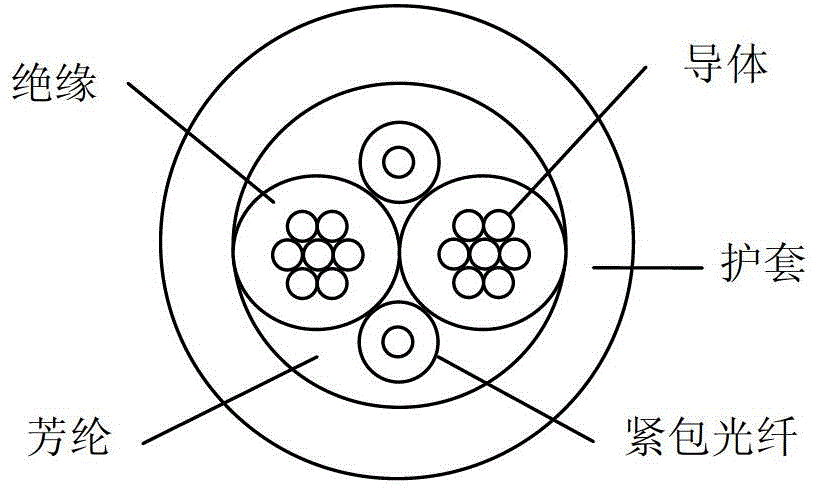

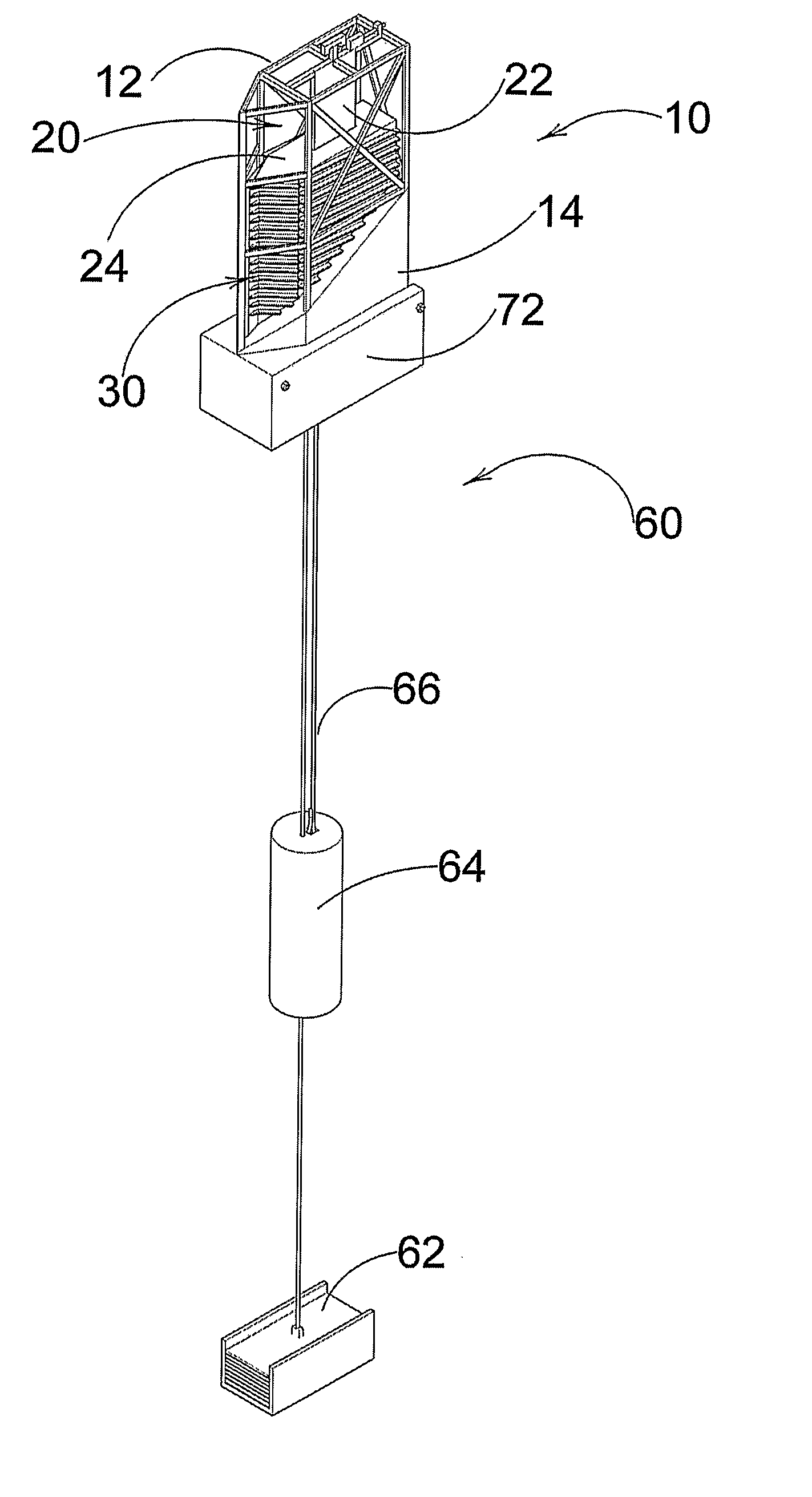

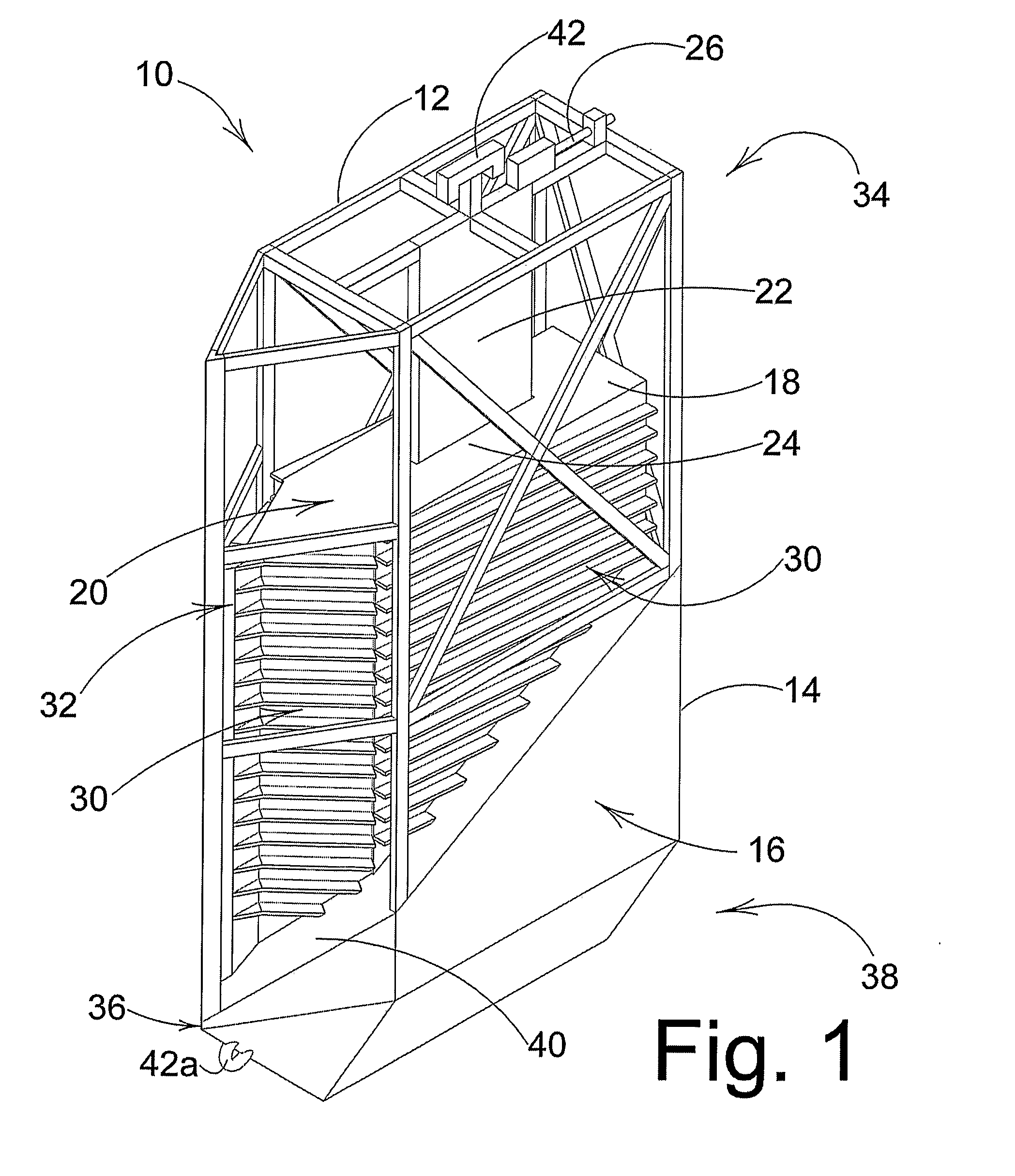

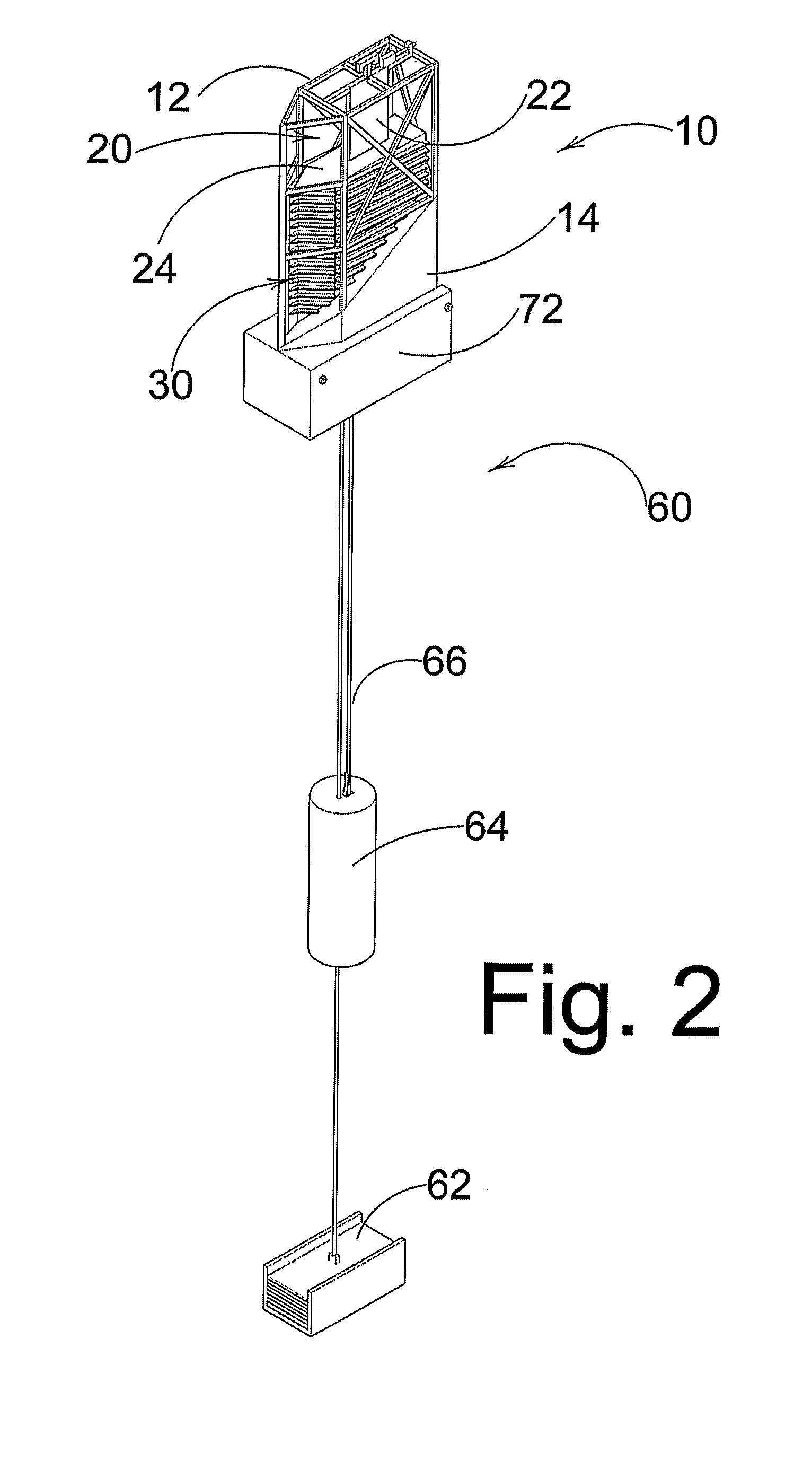

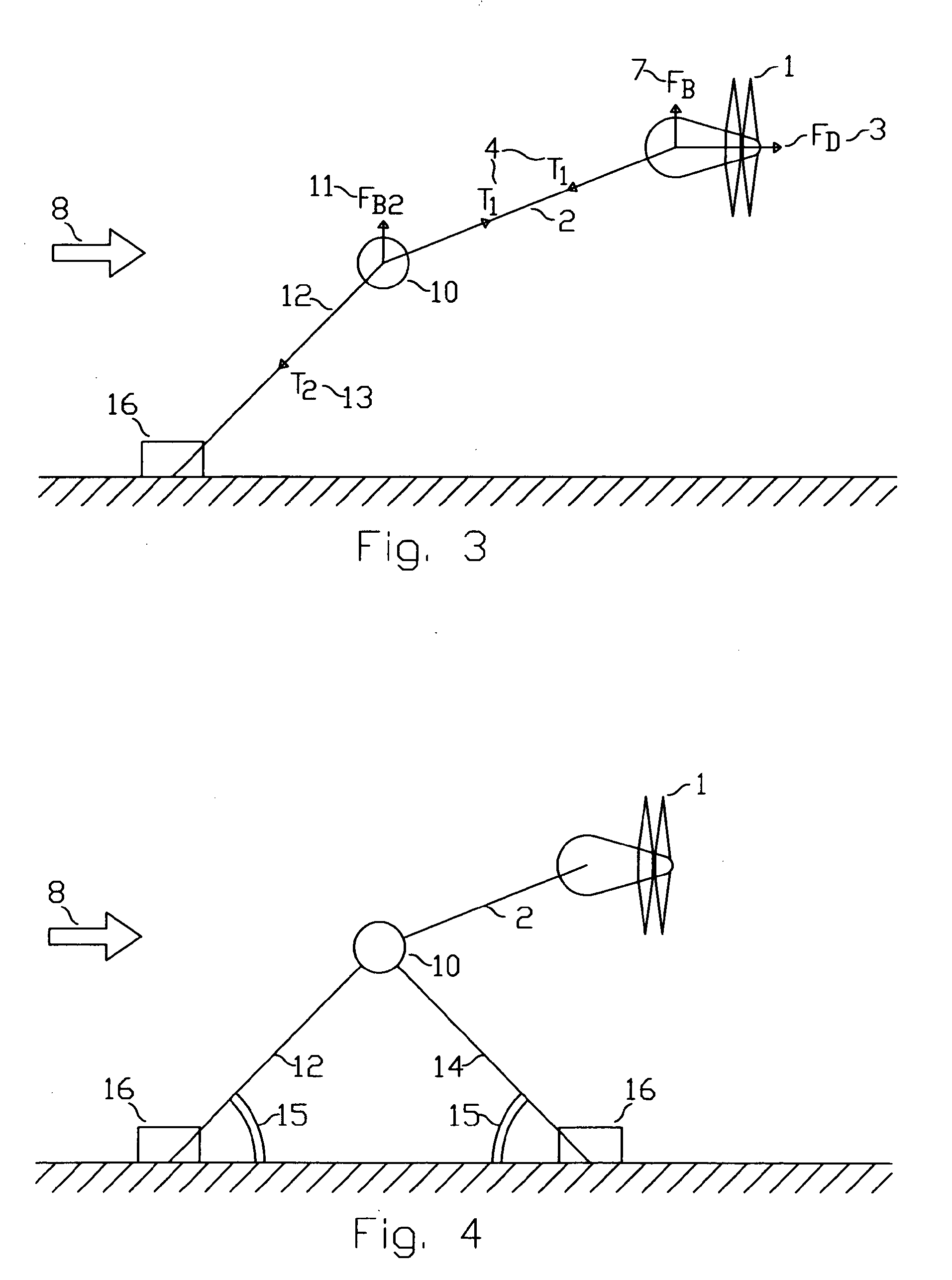

Multi-rotor-wing unmanned aerial vehicle mooring system

ActiveCN103144779ASimple structureImprove reliabilityPower cablesFor captive aircraftsMooring systemFlight vehicle

The invention discloses a multi-rotor-wing unmanned aerial vehicle mooring system, which comprises a multi-rotor-wing unmanned aerial vehicle serving as a mooring platform, a mooring line and a ground device, wherein the mooring line is connected with the multi-rotor-wing unmanned aerial vehicle and the ground device; the multi-rotor-wing unmanned aerial vehicle comprises a mooring supply unit; the mooring line comprises a power transmission cable; the ground device comprises a ground power supply device; and the mooring supply unit is connected with the ground power supply device via the power transmission cable in the mooring line. The multi-rotor-wing unmanned aerial vehicle mooring system disclosed by the invention has the characteristics of simple structure, high reliability, stability in hovering, convenience in use and low cost, the mooring mode is applied to the multi-rotor-wing unmanned aerial vehicle, and the problems of the mooring platform on the aspects of stability, erection convenience, use flexibility and use cost are solved. In addition, through the power transmission cable in the mooring line, a ground power supply can continuously supply power to the mooring platform, and the long-time hovering flight of the aerial vehicle is realized.

Owner:CHINA ELECTRONICS TECH GRP NO 7 RES INST

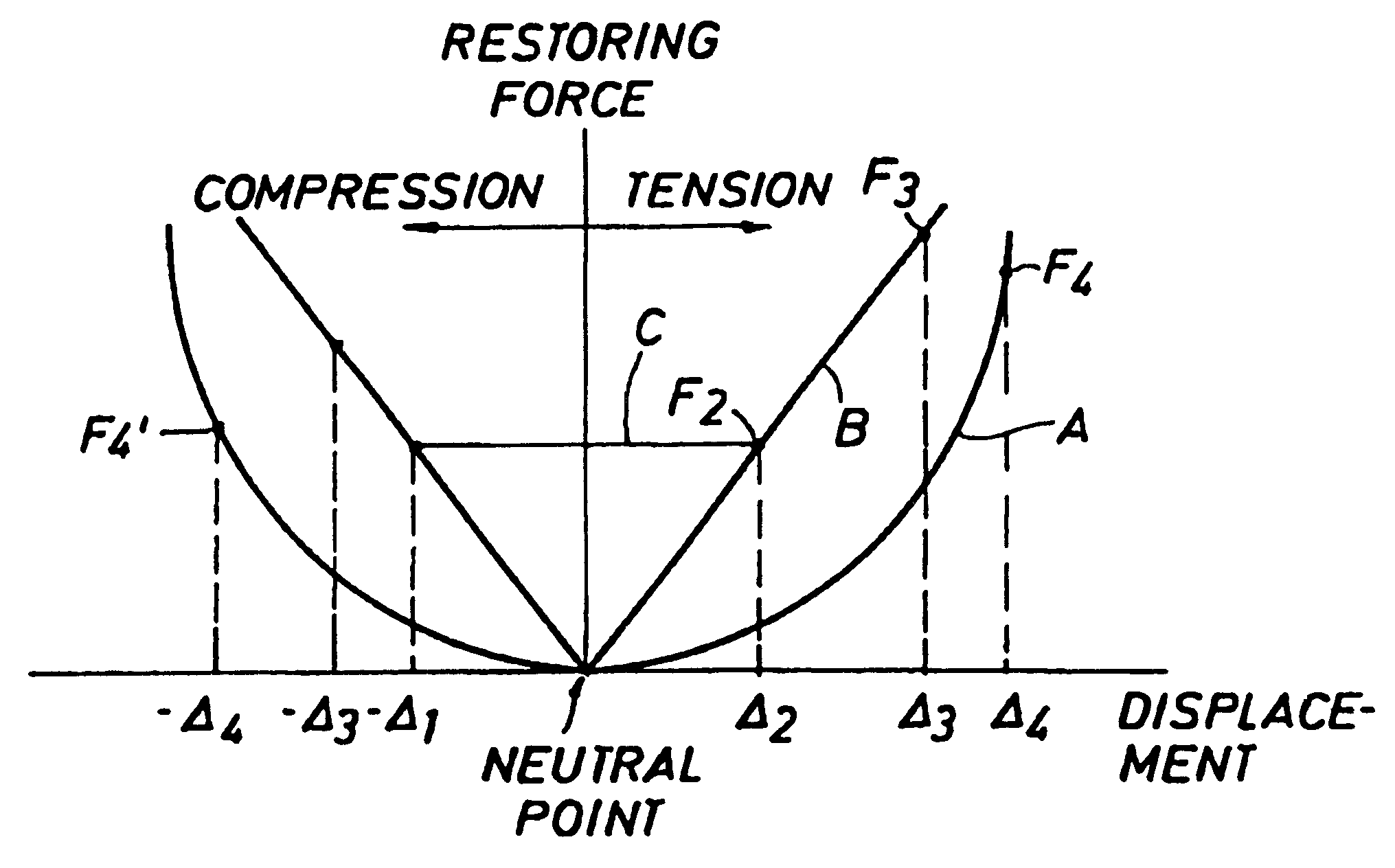

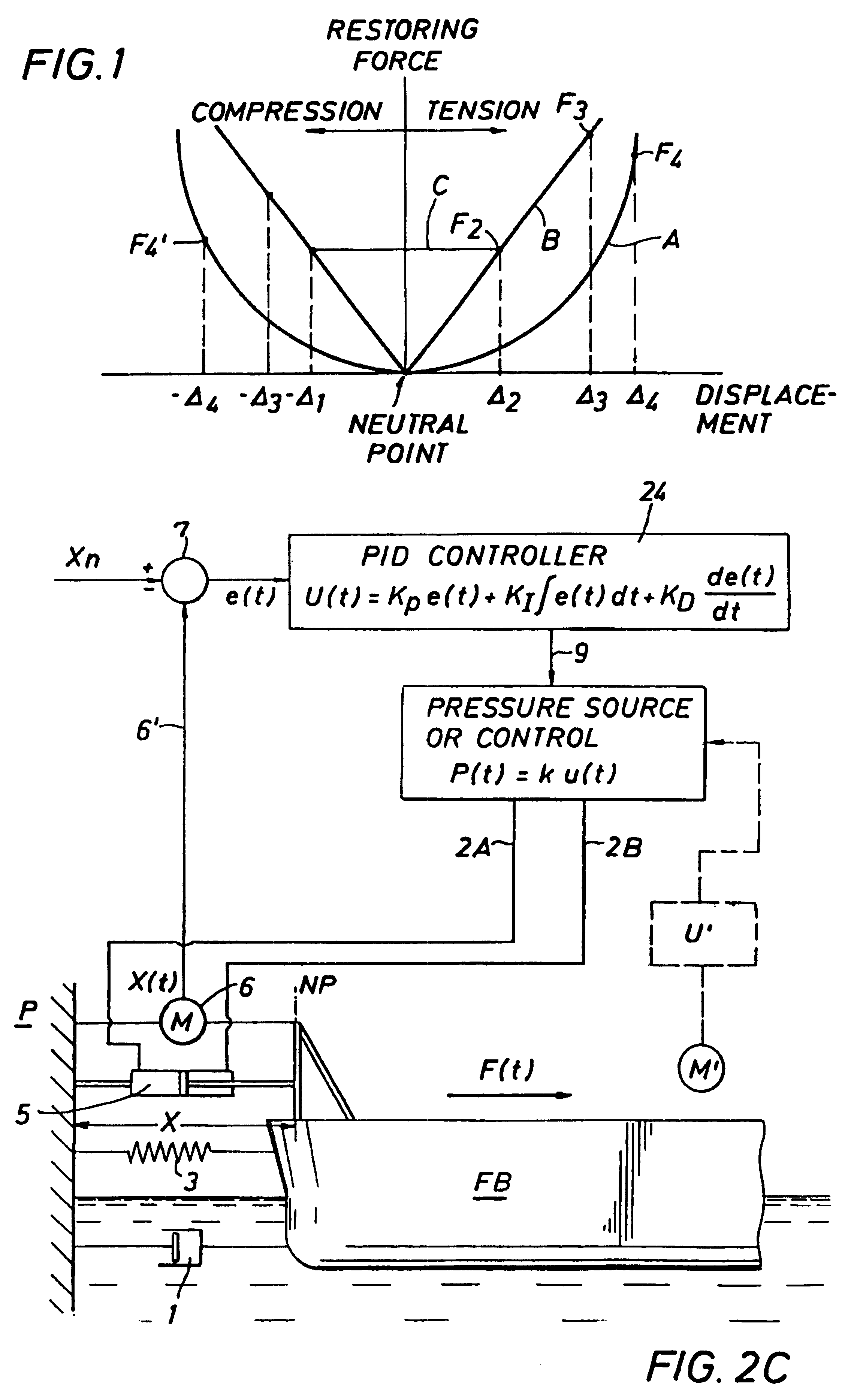

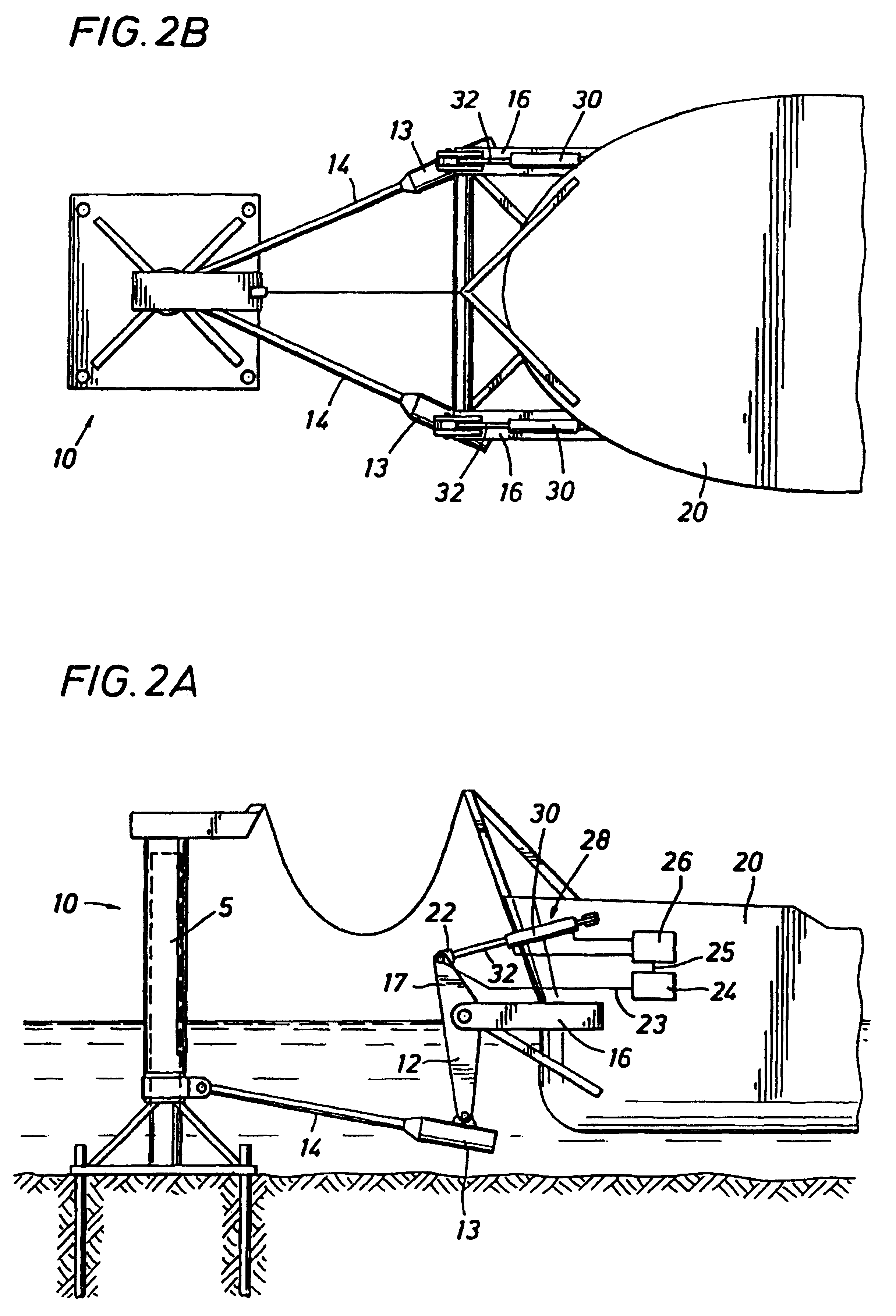

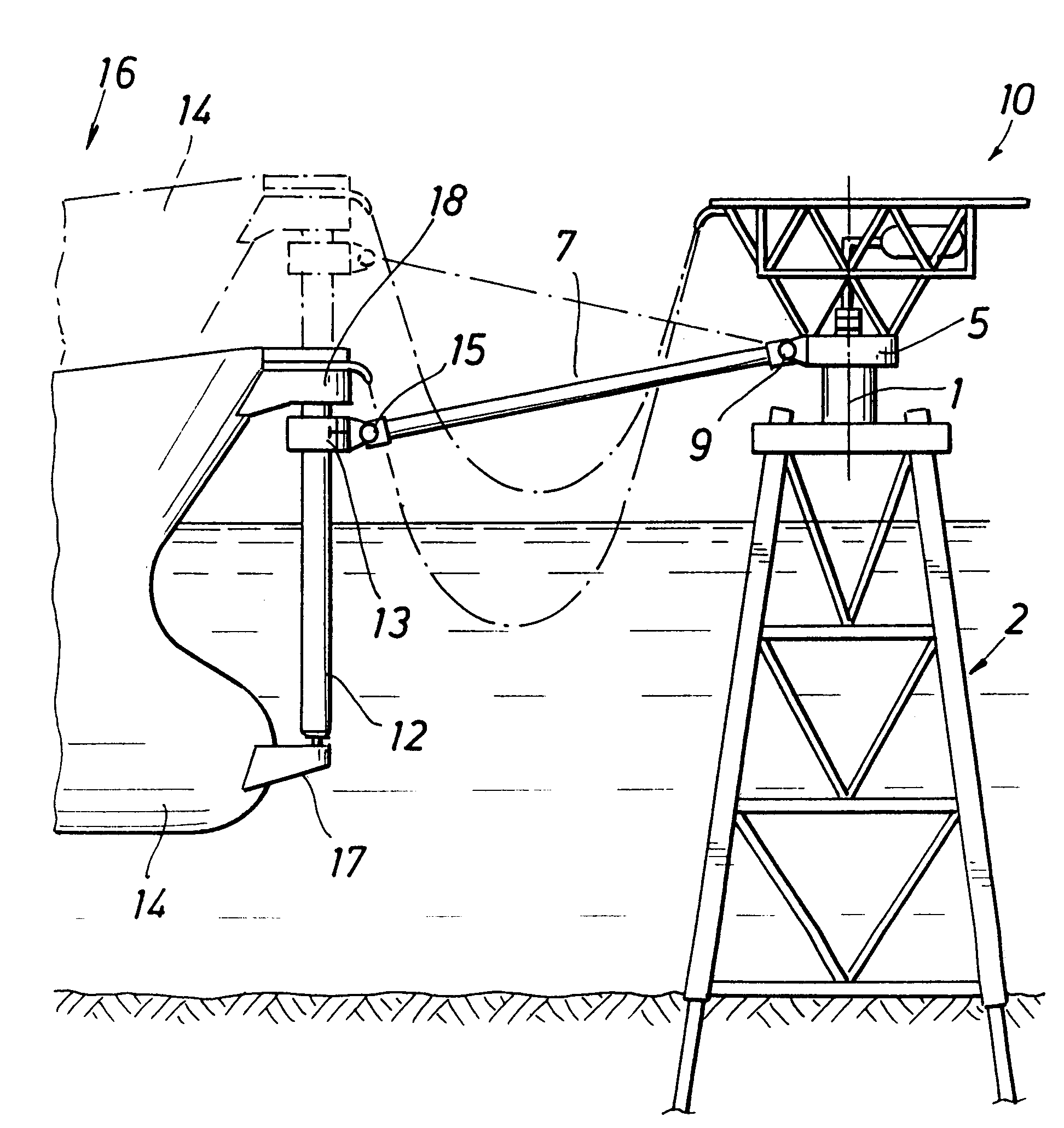

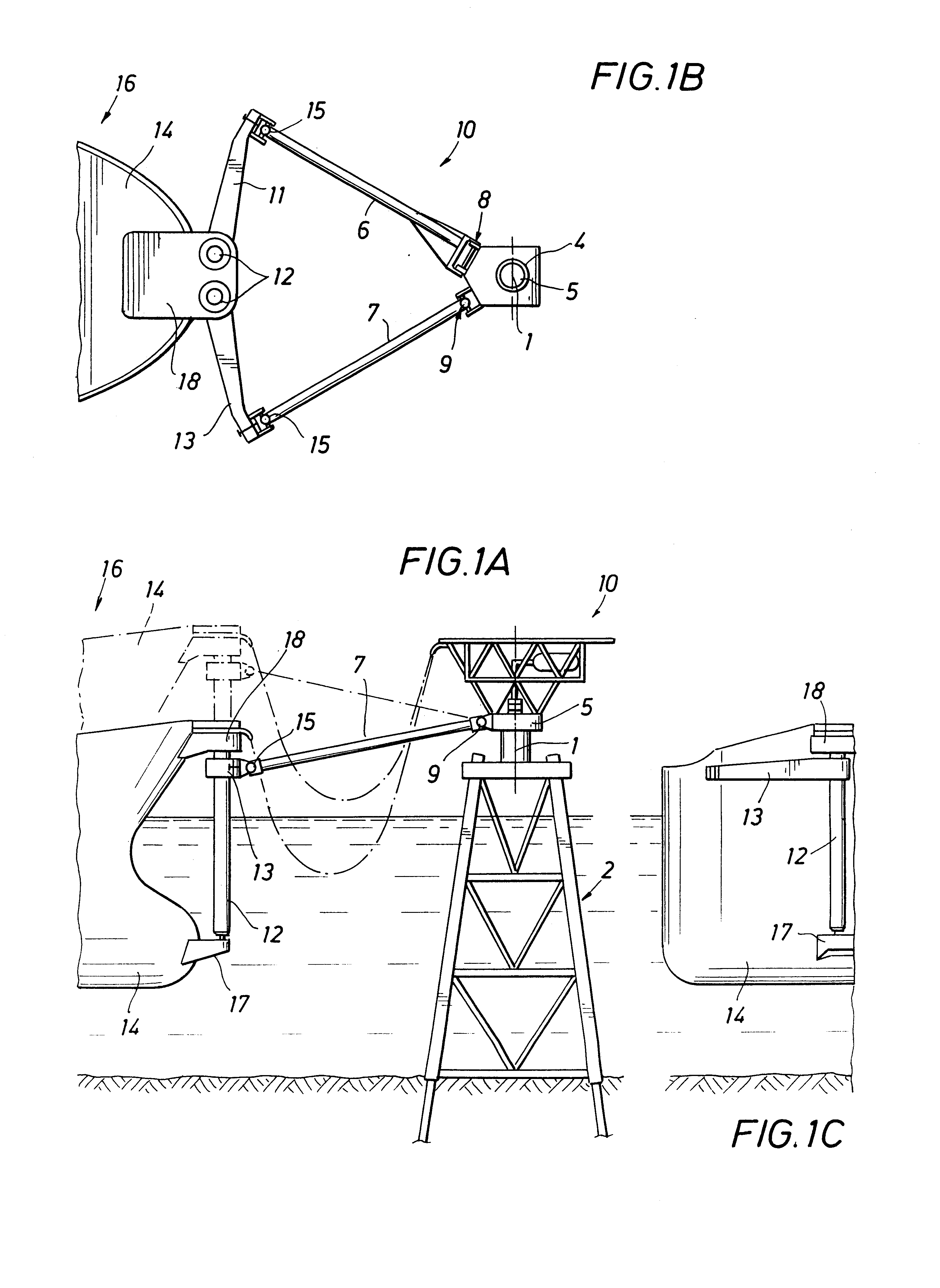

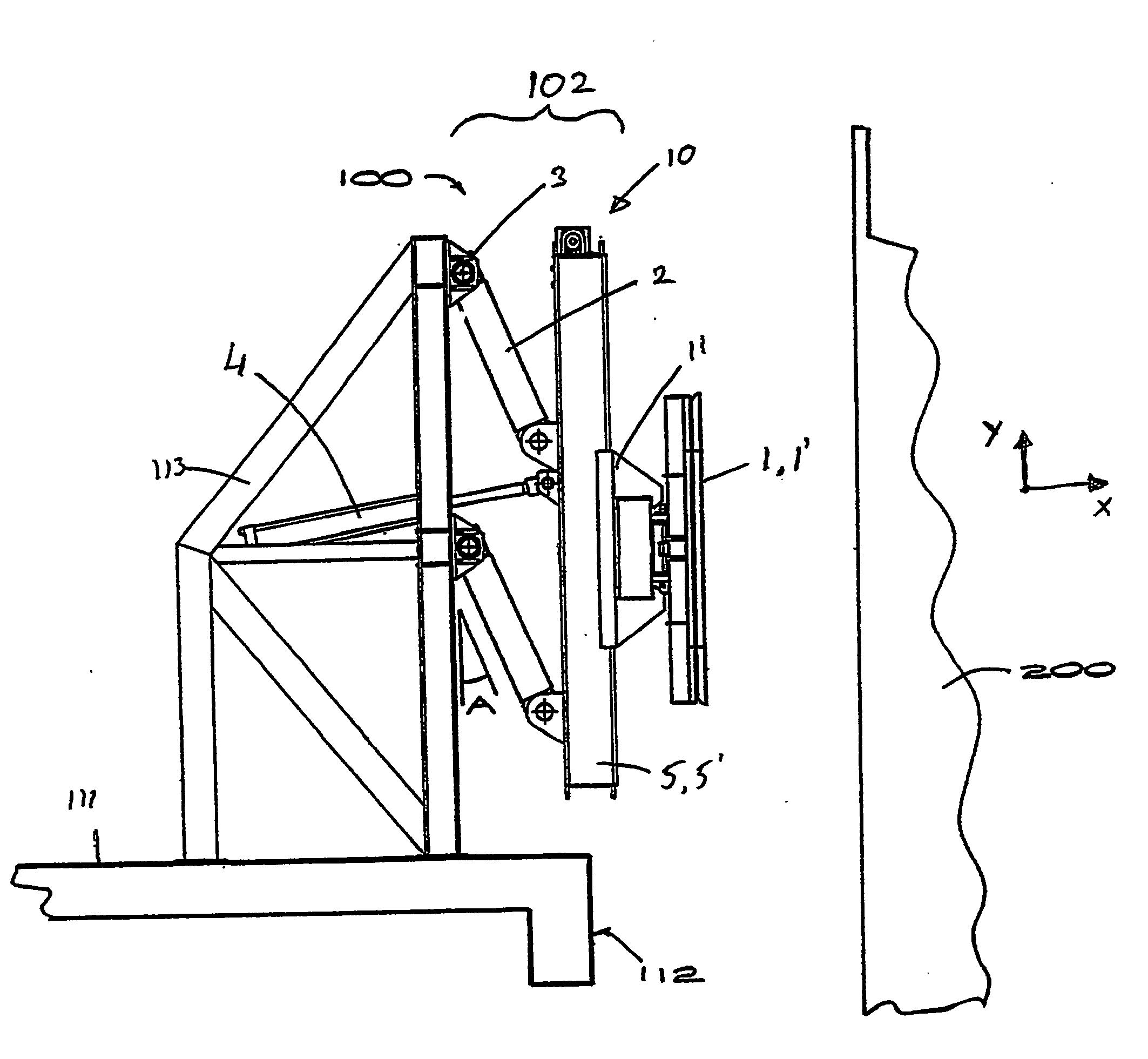

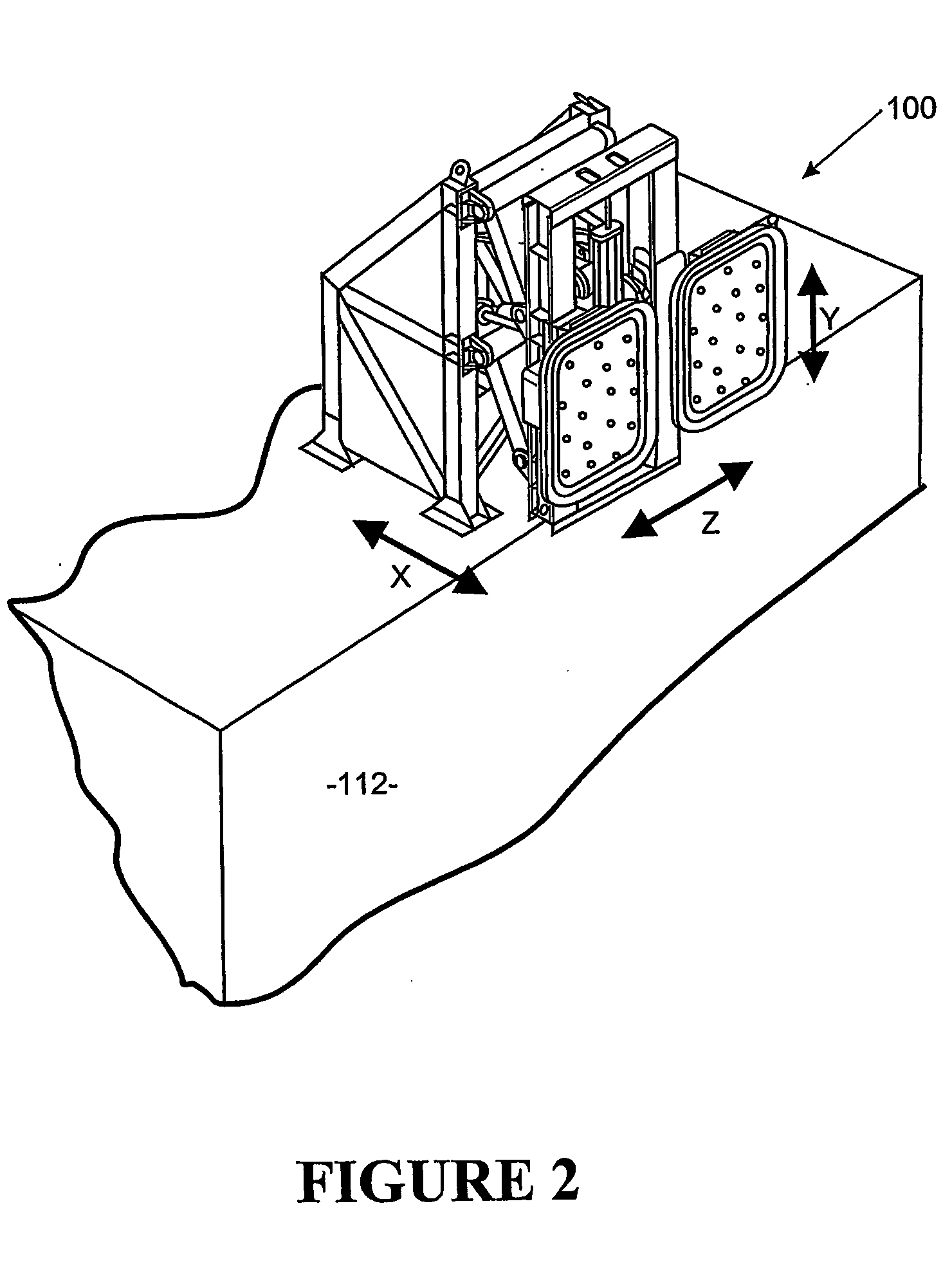

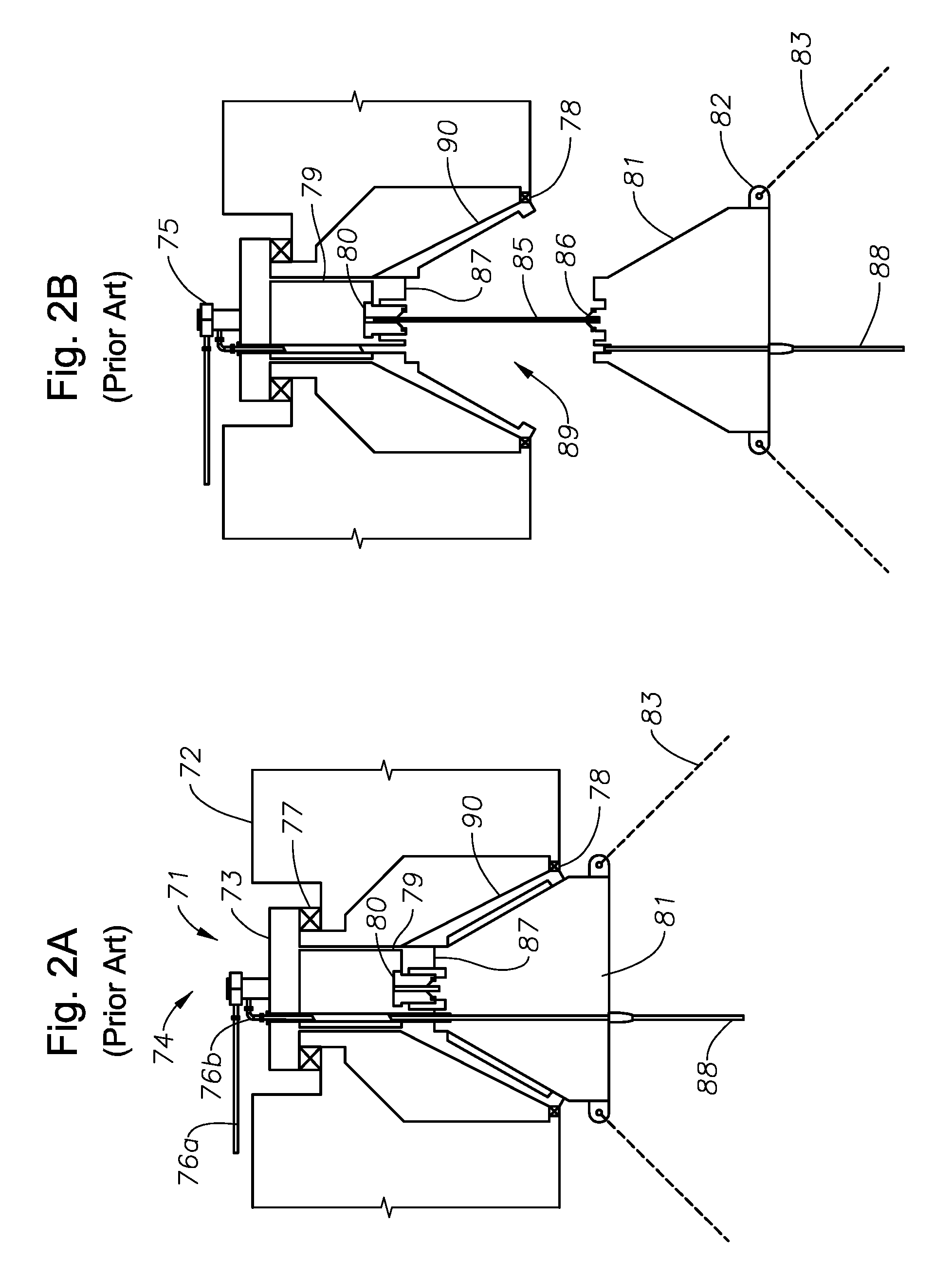

Mooring systems with active force reacting systems and passive damping

A mooring system including a body / arm / vessel arrangement with passive damping and / or an active force restoring system. The active force restoring system includes a sensor for generating a displacement signal representative of the displacement of the vessel from a quiescent position and an active forcing device which responds to the displacement signal to force the arm in a direction to move the vessel toward the quiescent position. The passive damping arrangement includes a device, independent of and in addition to the damping of the water on the vessel or the arm, that damps the oscillation of the vessel in response to environmental conditions which force the vessel from its quiescent position. Hydraulic cylinder arrangements are provided for active forcing and passive damping. Powered winch / cable arrangements are also provided for active force systems. Alternative devices for active and passive damping systems of torque actuators include hydraulic powered cans with internal fins, or cans with internal elastomeric elements or disk brake elements.

Owner:SOFEC

Floating apparatus for deploying in marine current for gaining energy

A floating, semi-submerged, tethered device that supports a horizontal axis turbine and power generation equipment for extracting kinetic energy from a tidal stream or ocean current. A submerged body (1) is supported by surface piercing struts (2) of small water plane area (FIG. 6). The device is tethered to the seabed by a spread of mooring lines (12) that are deployed both into and away from the direction of the tidal current. A horizontal axis turbine (4) harnesses energy from the water flow and drives a generator housed within the body. A horizontal strut hydrofoil (24) corrects the trim of the device when subject to varying loads from the mooring system and can also be used to dampen pitch motion. Rudder flaps in the struts (25) can be used to counteract roll motion. Power is exported from the device to the seabed by an umbilical (17). A thrusters (22) can be used to constrain the rotation of the device about its mooring system to prevent excessive twist building up between the mooring lines and the power export umbilical.

Owner:OCEAN FLOW ENERGY

River and tidal power harvester

InactiveUS8102071B2Reduce buildReduce installationWater resource protectionWaterborne vesselsMooring systemEngineering

An energy module comprising an energy absorber; and a mooring system, comprising a wing-shaped polymer shell attached to the energy absorber, the wing-shaped polymer shell designed to utilize the force of a passing current to create a downward force and thereby reduce any upward motion in the energy module; and a mooring cable housed inside the wing-shaped polymer shell and anchored to maintain the energy module in a fore and aft and a side-to-side position to provide stability, and to negate a rotational force on the energy module.

Owner:CATLIN CHRISTOPHER S

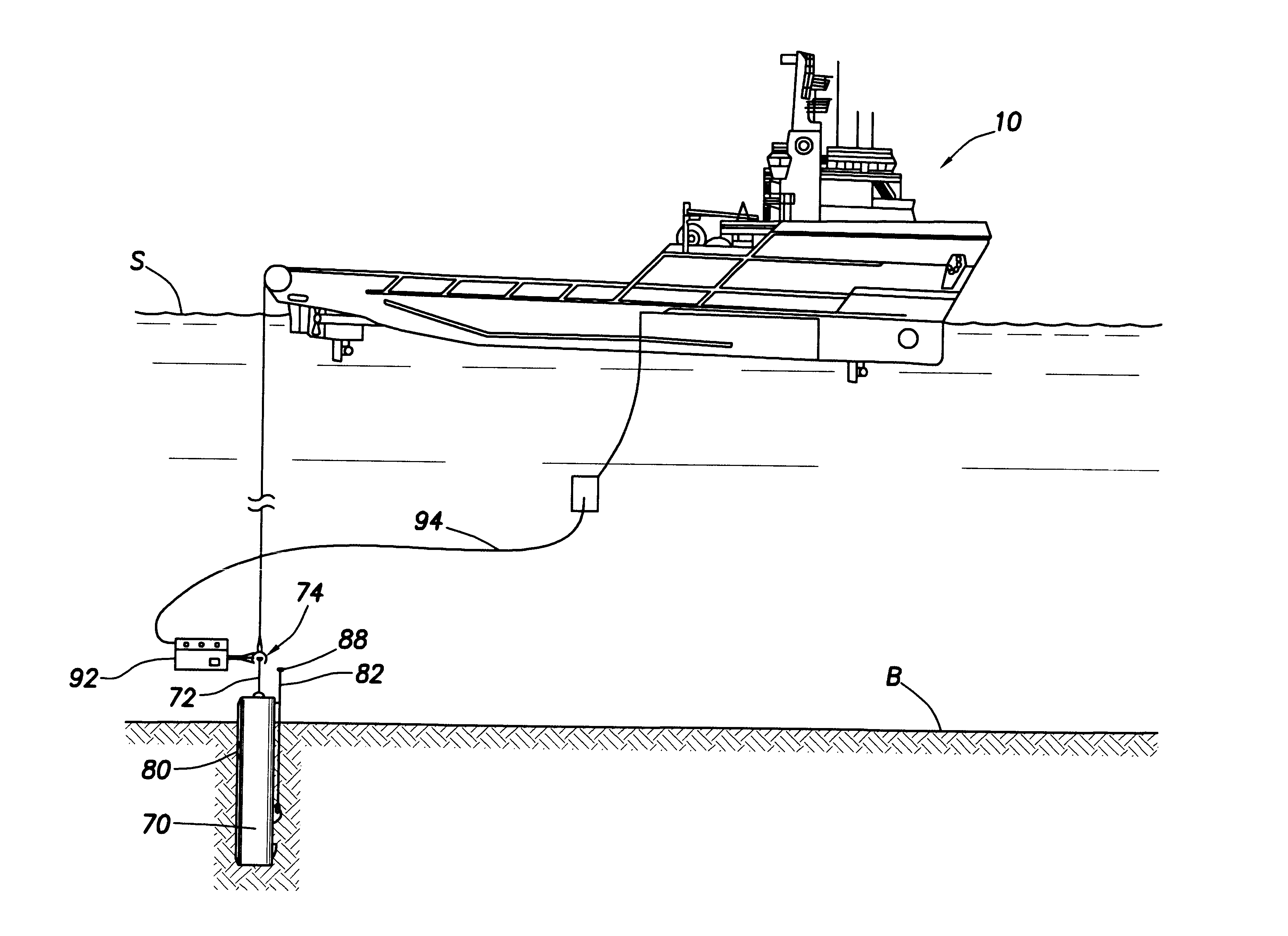

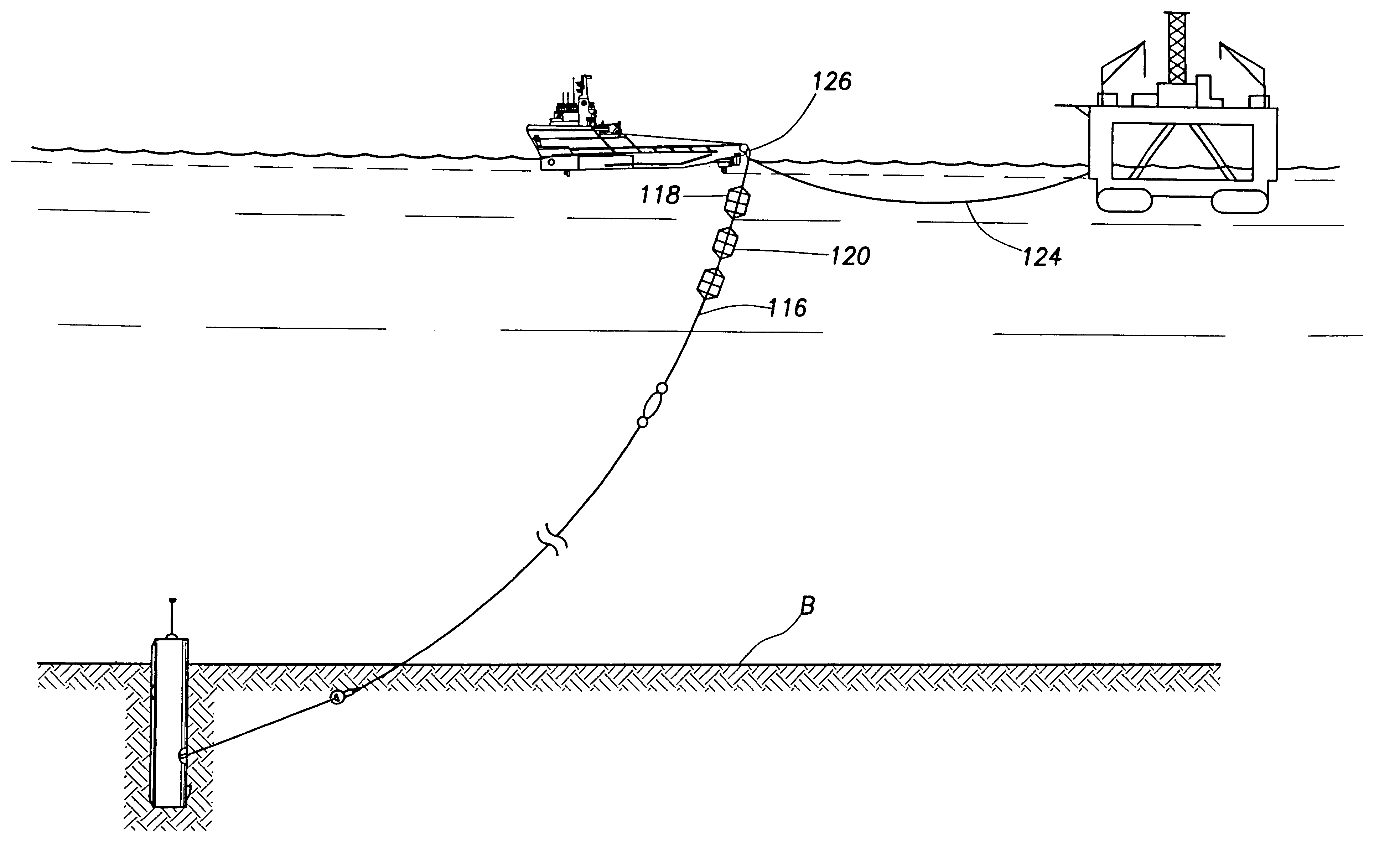

Method and apparatus for suction anchor and mooring deployment and connection

A method and apparatus for deployment of mooring systems for buoyant marine structure such as mobile offshore drilling units (MODU's) and for connecting the same to the mooring lines thereof. An anchor handling vessel carries one or more anchors each having a deployment connection and a mooring connection and individually moves each anchor over its stern roller and deploys it to the sea bottom for installation. A handling line is disconnected by ROV from the deployment connection and is moved from the deployment connection to the mooring connection so as to become the main mooring line. Syntactic buoys are then mounted on the main mooring line for elevating it above the sea bottom for recovery. When MODU stationing is desired the anchor handling vessel then recovers the surface buoy and connects to the rig mooring line using a short section of mooring chain. A J-chaser stopper device is then installed in the mooring string and is connected to the mooring line of the MODU by a short section of chain. The J-chaser lowers the mooring string, completing the mooring connection between the anchor and the MODU. A plurality of mooring strings, typically eight, are deployed in this manner to properly station the MODU. Disconnection of the MODU is accomplished essentially by the reverse of the above deployment procedure.

Owner:DELMAR SYST

Wave energy converter

InactiveUS20090309366A1Positive buoyancyImprove braking effectWaterborne vesselsWorking fluid for enginesMooring systemEngineering

A wave energy converting apparatus 44 and its associated tension mooring system 50 is described. The wave energy converting apparatus 44 comprises an elongate support structure 45 designed to extend above a mean water level in the ocean. The support structure 45 has a submerged member 46 provided in connection therewith below the mean water level. A float member 48 of positive buoyancy is slidably mounted on the support structure 45 so as to be movable in a vertical direction. The apparatus 44 also comprises a linear electric generator 49 having a stator provided in connection with the support structure 45 and a translator integrated into the body of the float member 48. Differential motion of the float member 48 relative to the support structure 45 results in the generation of electrical power by the linear electric generator 49. The tension mooring system 50 comprises a cable 51 extending from a ballast means 52 to a counterbalancing means 53 adapted to be suspended from the submerged member 46 via a pulley mechanism 54. The tension mooring system 50 allows the apparatus 44 to be “tuned” to the prevailing ocean conditions.

Owner:PROTEAN ENERGY AUSTRALIA

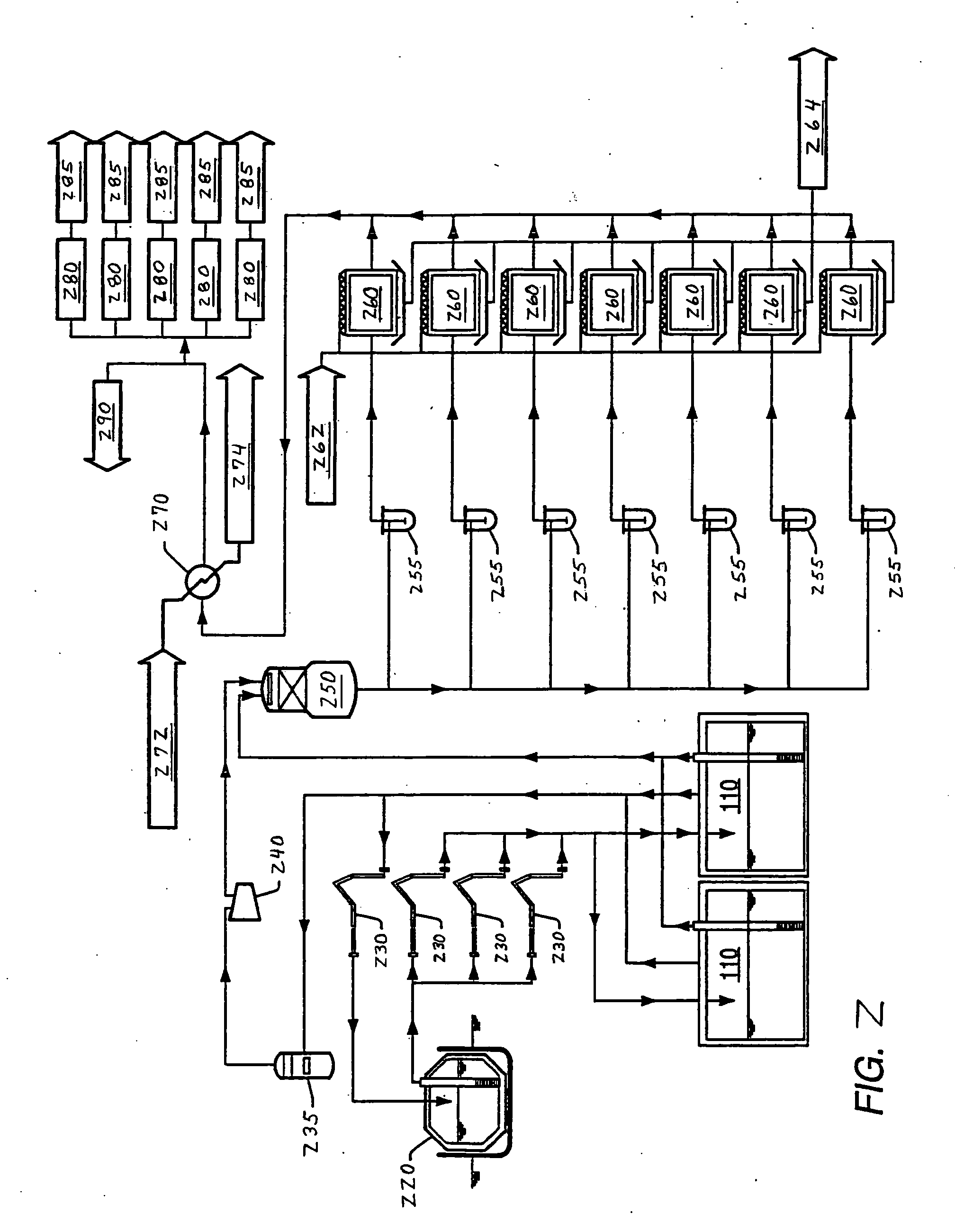

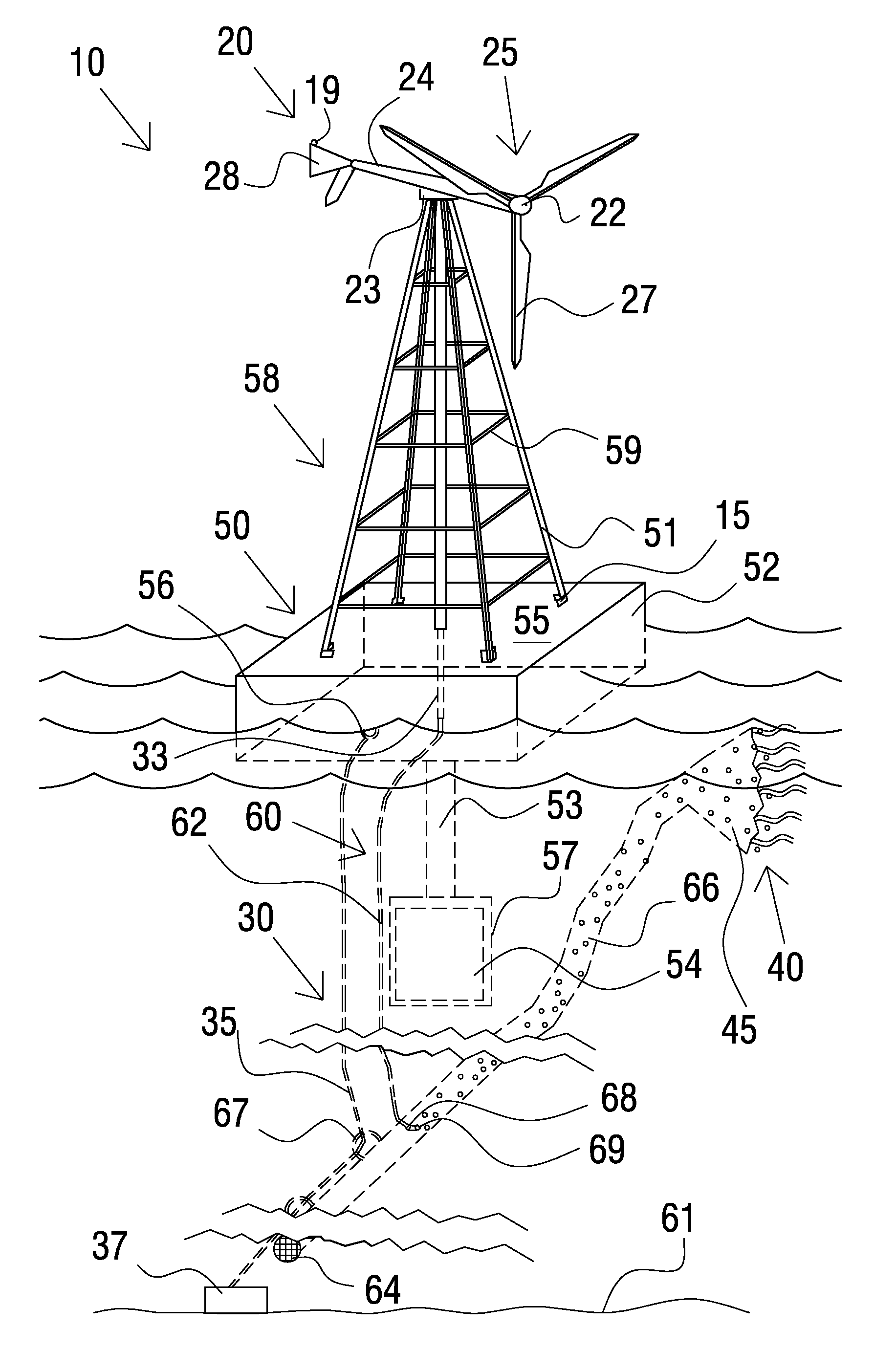

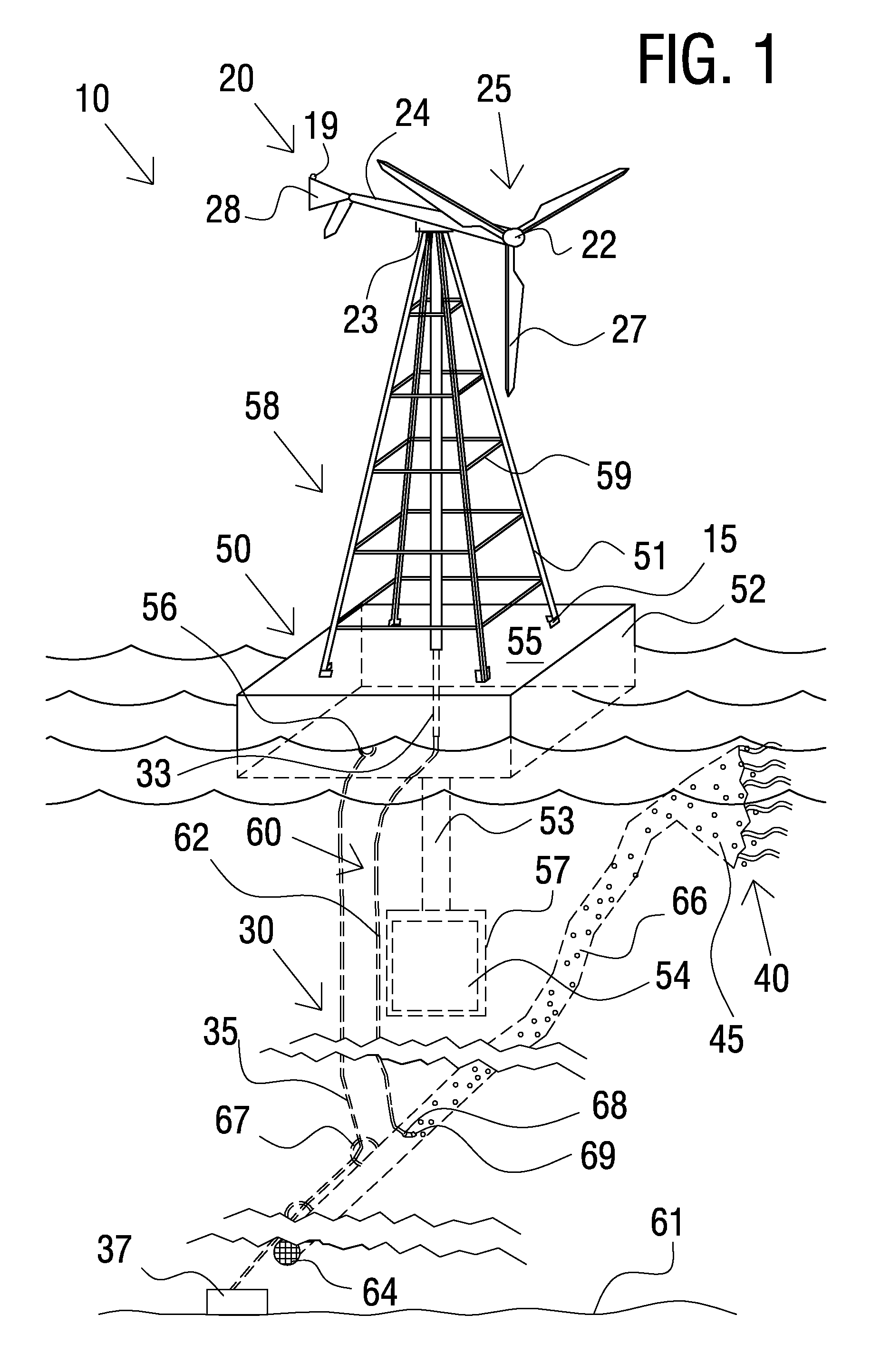

Hurricane prevention system and method

InactiveUS7520237B1Suitable for useDecreases sea surface temperatureSedimentation separationVessel movement reduction by wave dampingWind drivenMooring system

The hurricane prevention system and method for use in ocean water is provided including a buoyant platform on which is disposed a wind-driven power source, a water-moving system, and a water-dispersing system. The wind-driven power source is configured to use wind energy to power the water-moving system, which is configured to transport water from somewhat deeper ocean water levels to, or near, the level of the ocean. The water-dispersing system is preferably configured to disperse the water from the water-moving system to an area at or near the sea surface. The buoyant platform preferably is anchored by a mooring system. The hurricane prevention system and method is designed to bring cooler water from deeper in the ocean to or near the ocean surface and to disperse that cooler water in that area to reduce the sea surface temperature, thereby preventing or inhibiting the formation of hurricanes.

Owner:DIMOV ZHEKOV VLADIMIR

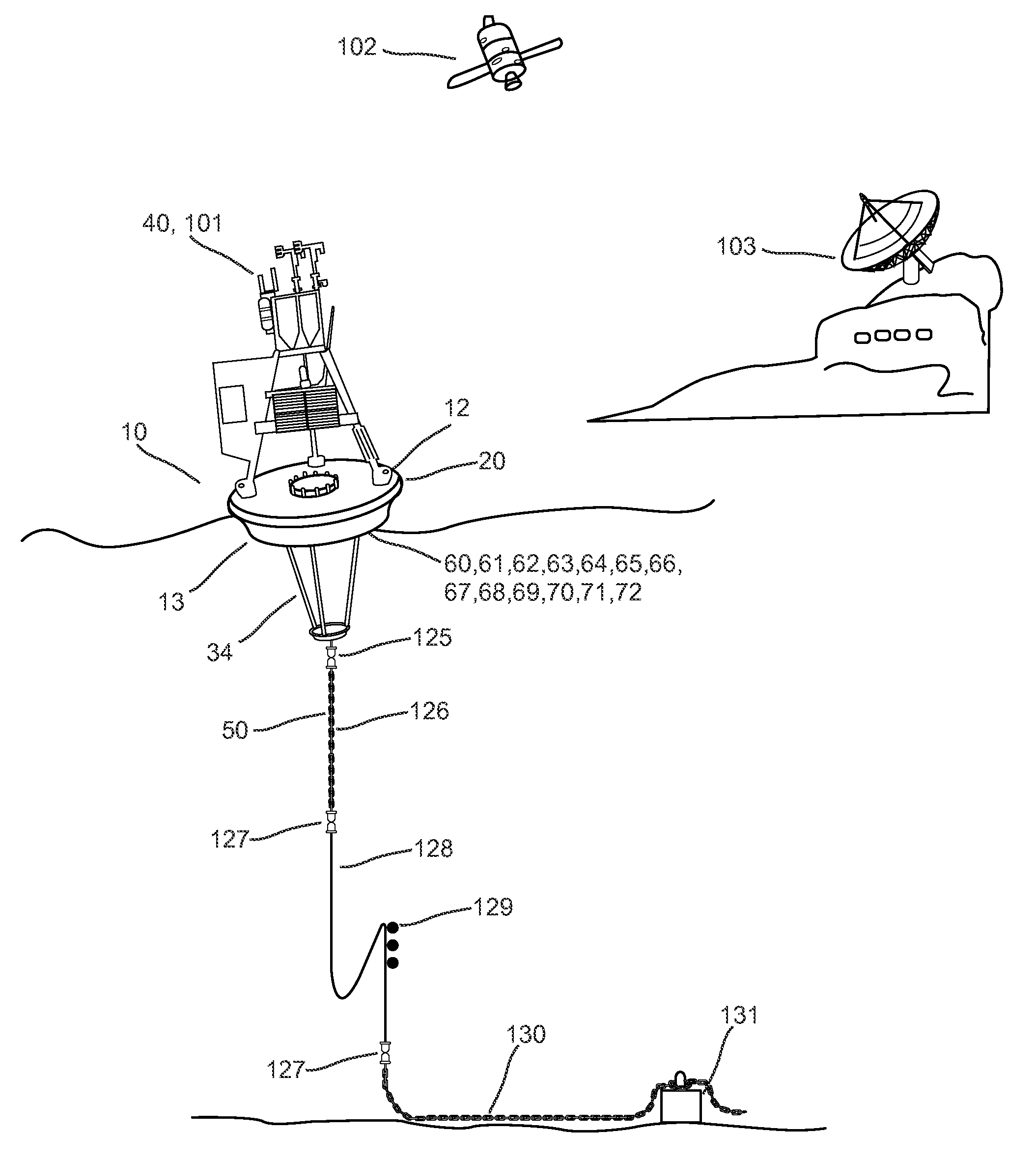

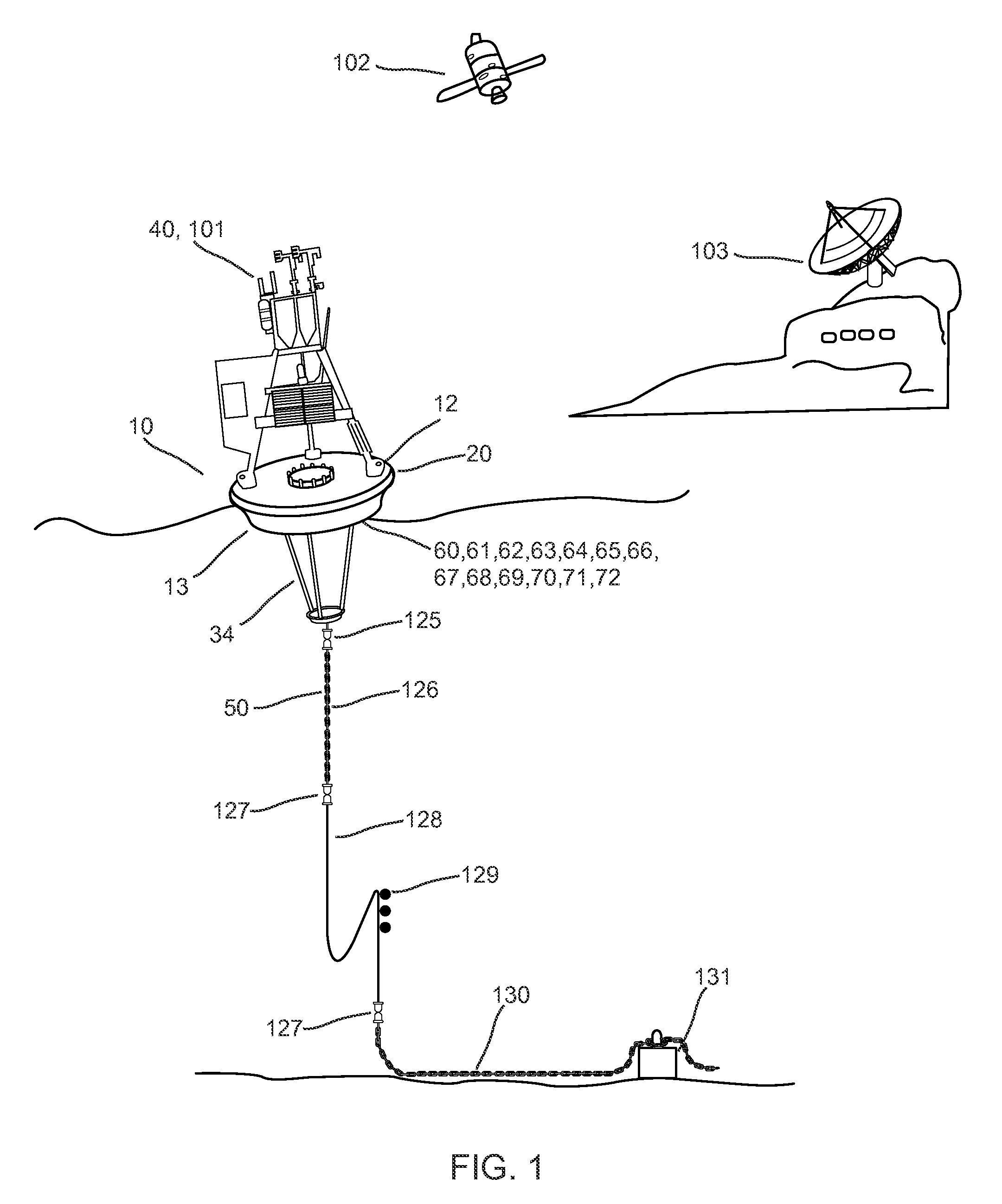

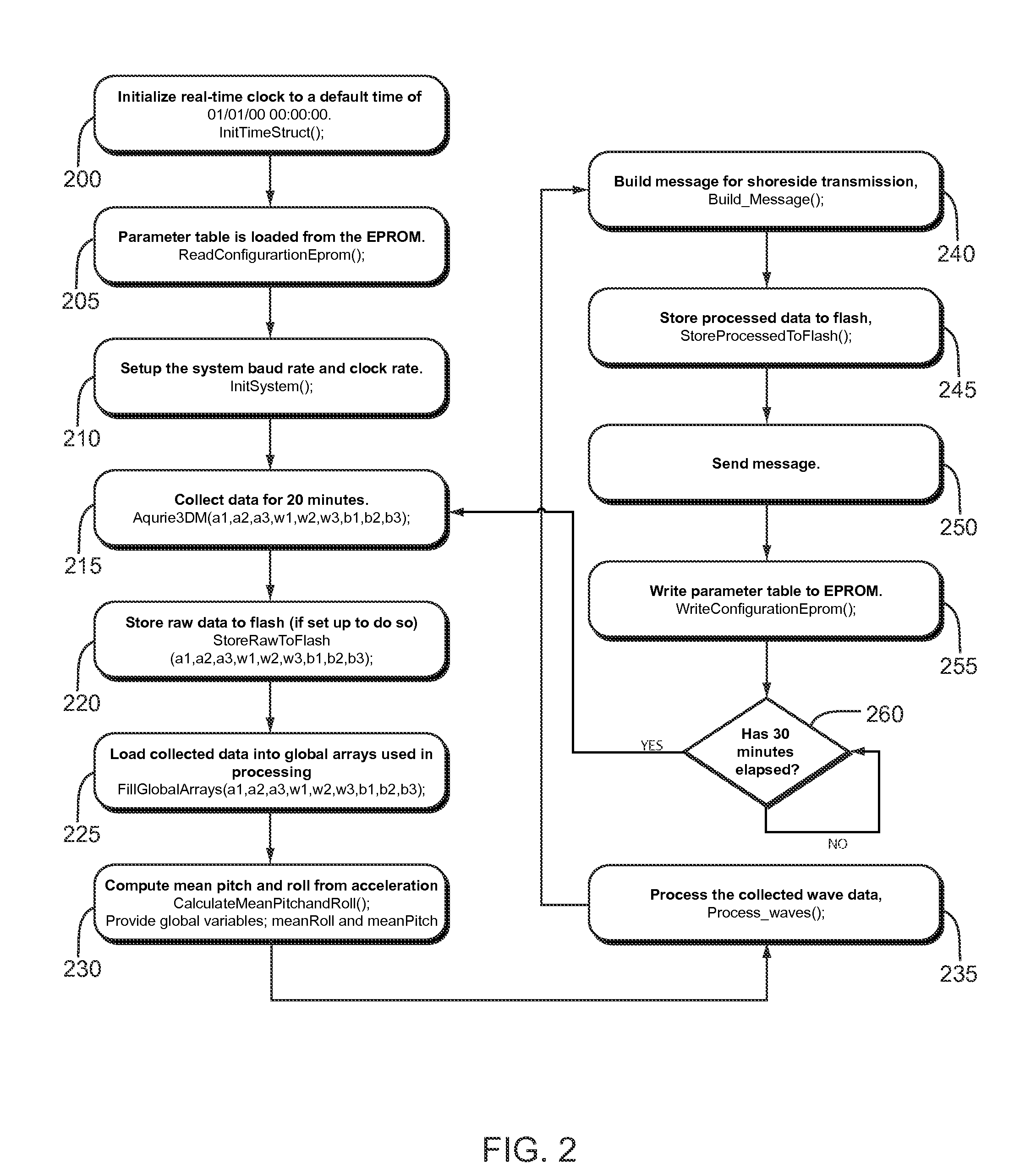

System for monitoring, determining, and reporting directional spectra of ocean surface waves in near real-time from a moored buoy

InactiveUS20110060525A1Accurate and precise determinationReliable and cost-effectiveVolume/mass flow measurementAcceleration measurementOcean bottomWave parameter

A moored buoy floating at the ocean surface and anchored to the seafloor precisely measures acceleration, pitch, roll, and Earth's magnetic flux field of the buoy over a limited sampling period. The system includes: 1) A buoy, 2) A mooring system, 3) An electronic data logger controlling communications between the system and the on-board remote telecommunications system, 4) an embedded computer for data input / output, temporary or permanent data storage, and algorithms to convert the measured time series data into surface ocean wave spectra and quality assurance statistics and encode the results for transfer to the data logger, 5) Sensors include one or three acceleration sensors, three orthogonal angular rate sensors, and three orthogonal magnetometers to measure the Earth's magnetic flux field, 6) A telecommunications system that links the buoy data logger and a shoreside processing system, and 7) A shoreside processing system that decodes the transmitted data, performs, quality control, and computes derived wave parameters.

Owner:UNITED STATES OF AMERICA SEC OF COMMERCE

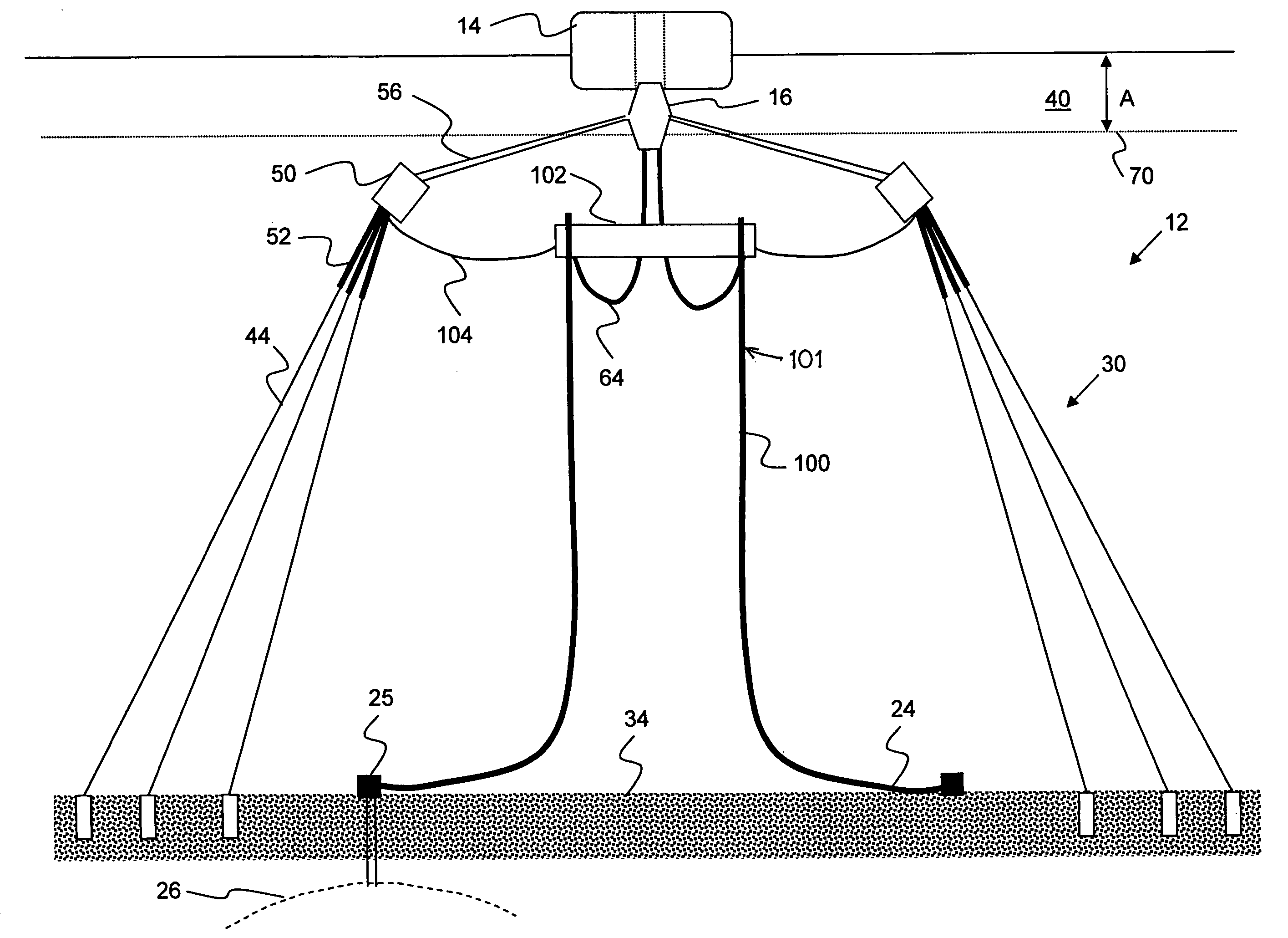

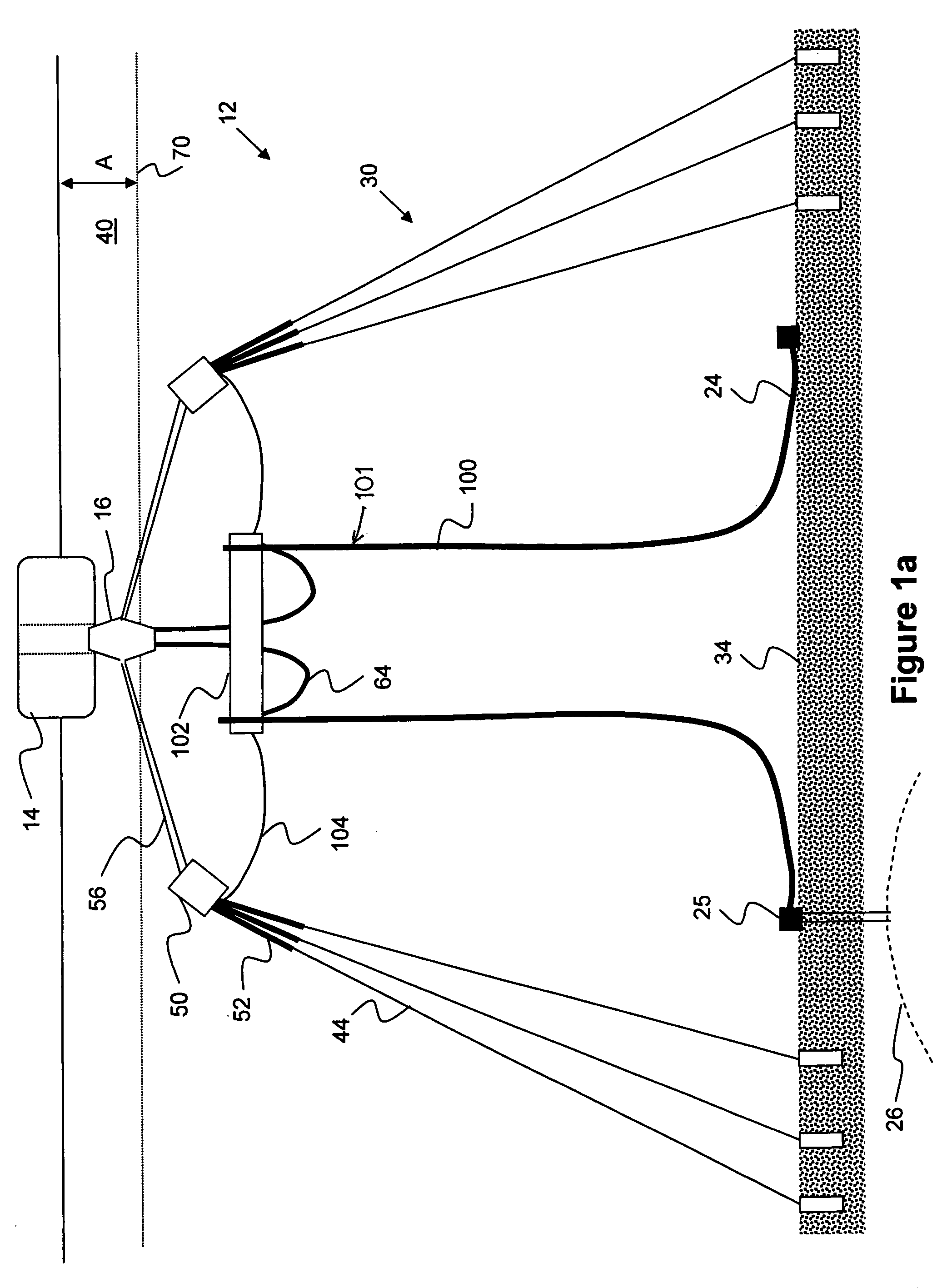

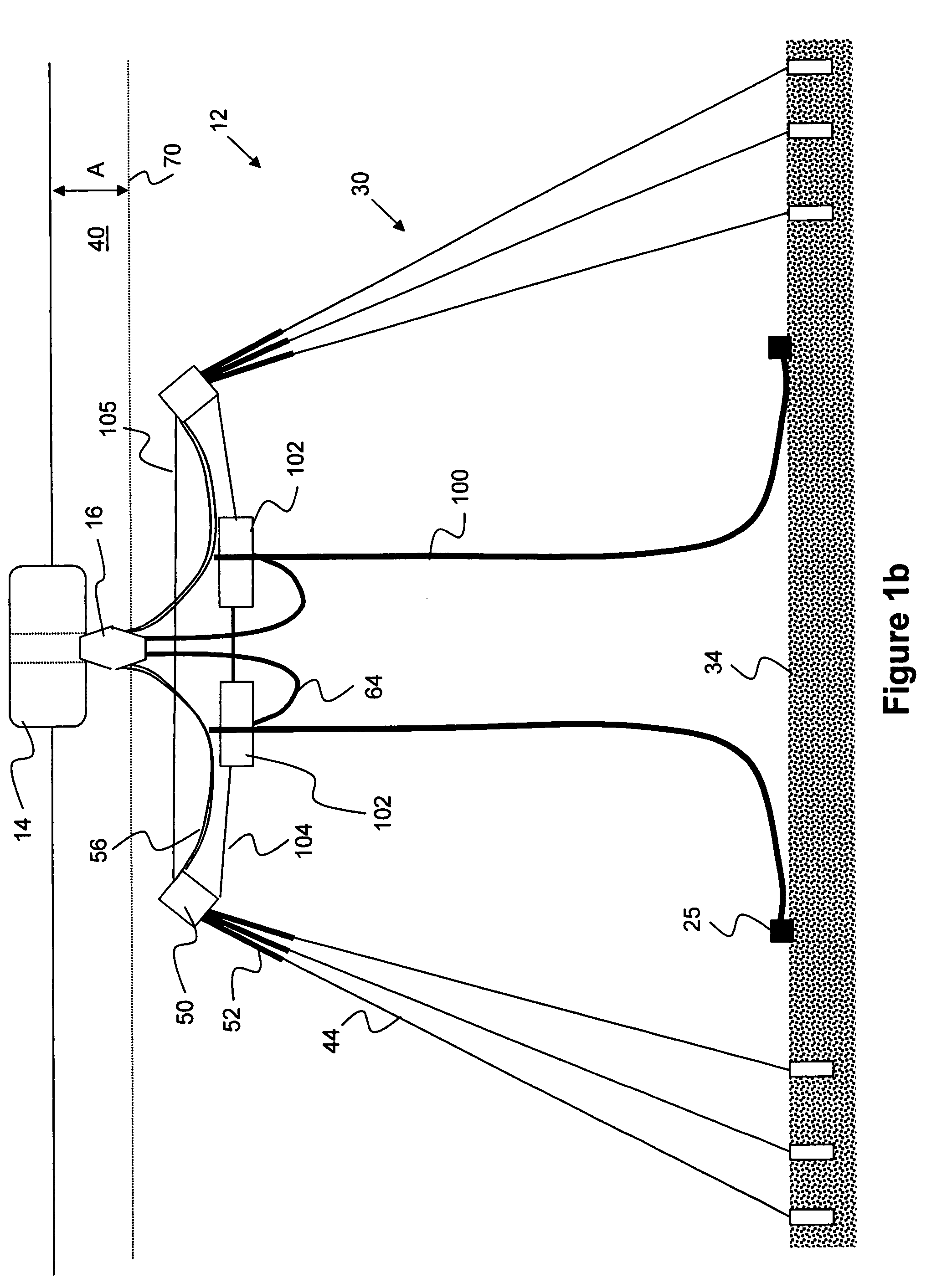

Disconnectable riser-mooring system

A system is described for use at offshore locations of large depth, for mooring a production vessel or floating unit (14) at a location over a hydrocarbon reservoir (26) and for connecting risers (101) that can be carrying hydrocarbons up from the sea floor to a production vessel that stores the hydrocarbons, flowlines for water injection, gas lift, gas export, umbilicals and mooring lines that moor the vessel. Both the mooring lines and the risers are disconnectably connected to the vessel though a connection buoy, or connector (16). The invention concerns a system that allows a connector (16) to be used that is of minimum mass and volume, to ease its handling especially during its connection and disconnection to and from a vessel.

Owner:SINGLE BUOY MOORINGS INC

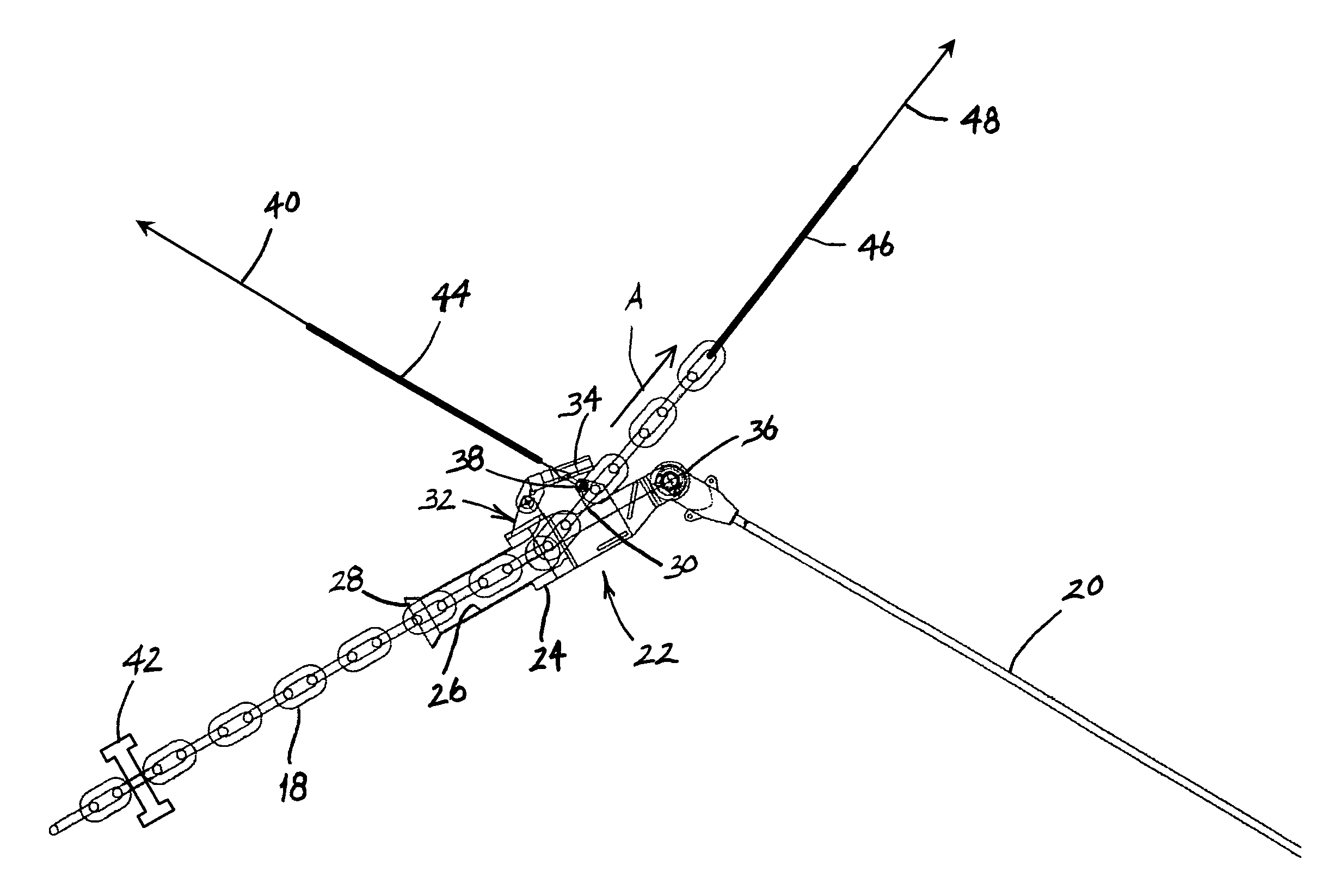

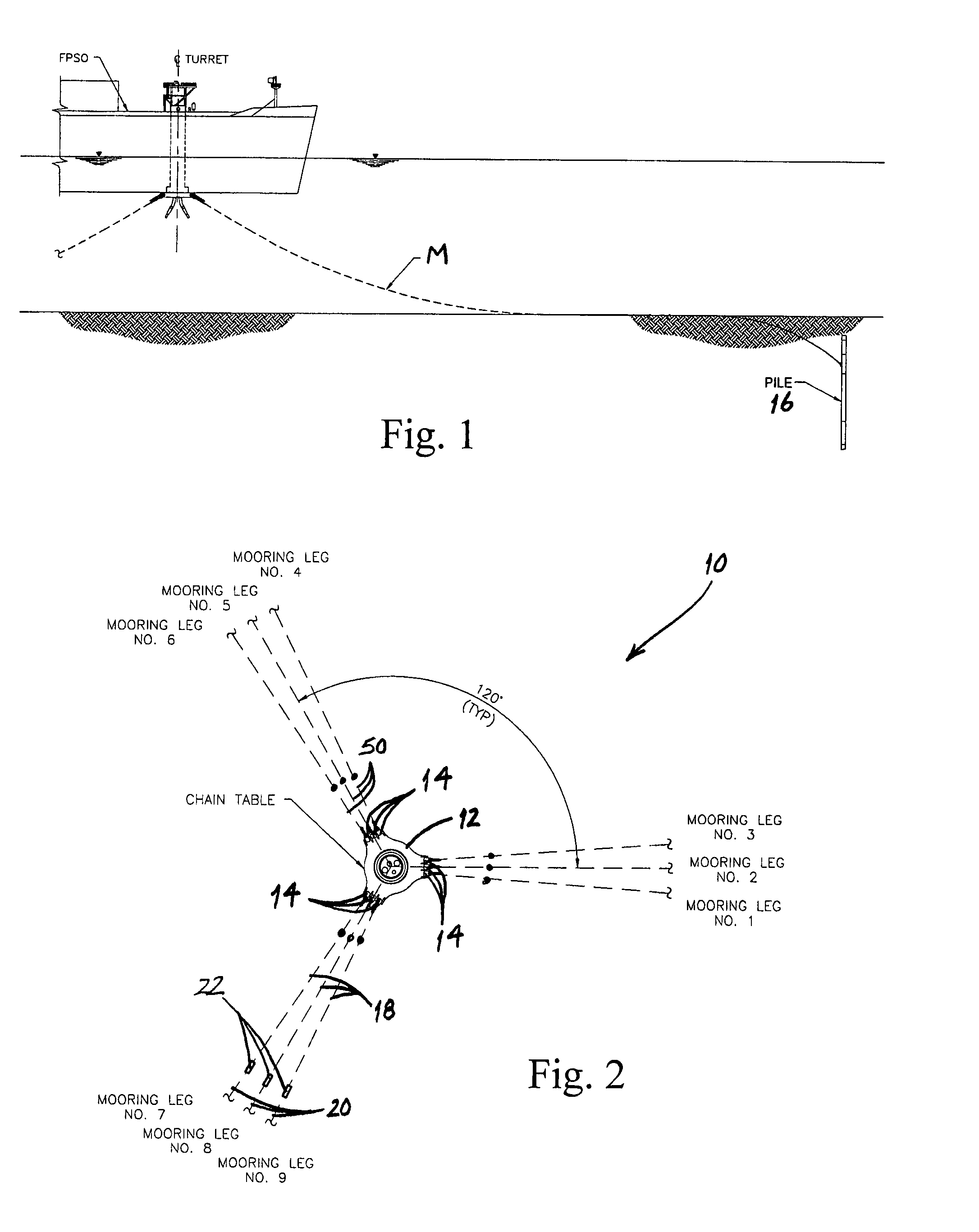

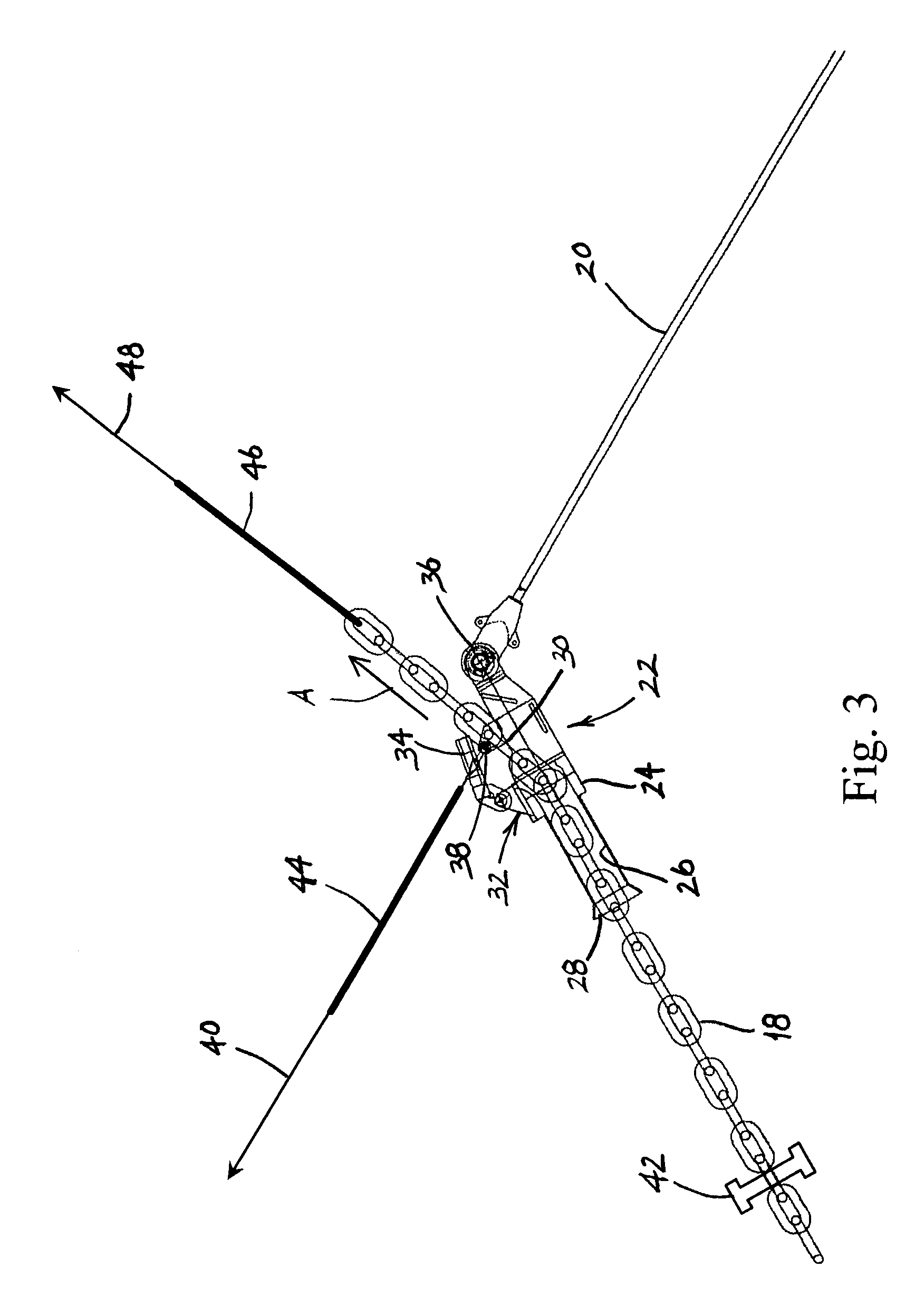

Mooring apparatus and method

ActiveUS7421967B1The process is convenient and fastReduce forceAnchorsMooring equipmentOcean bottomMooring system

A mooring system for securing a floating vessel to the sea floor comprises a plurality of mooring legs, at least one of which includes separate first and second mooring lines. The first mooring line comprises a first end which is connected to the vessel and the second mooring line comprises a first end which is secured to the sea floor. The mooring system also comprises a connection and tensioning device which includes a body, a bore which extends through the body, a chain stopper for adjustably securing the first mooring line to the body, and a connector for connecting a second end of the second mooring line to the body. In use, a second end of the first mooring line is inserted into the bore and the first mooring line is pulled through the bore while the body is subject to an opposing pulling force. Once the first mooring line is pulled through the bore a desired distance, the chain stopper maintains the first mooring line in position relative to the body to thereby secure the vessel to the sea floor.

Owner:SOFEC

Disconnectable mooring system and LNG transfer system and method

InactiveUS20030226487A1Cargo handling apparatusPassenger handling apparatusMooring systemTransfer system

A disconnectable mooring system for connecting an LNG carrier vessel to a permanently moored LNG liquefaction process vessel in combination with an LNG offloading system. One end of a mooring yoke is suspended from a frame at the stern of the LNG process vessel. A male coupler is mounted to an opposite end of the mooring yoke via a universal joint. A female coupler is mounted on the LNG carrier vessel, with pull-in arrangements for pulling the LNG carrier vessel into position and the male coupler into selective coupling with the female coupler.

Owner:SOFEC

Mooring System for Tidal Stream and Ocean Current Turbines

InactiveUS20100230971A1Reduce riskReduce resistanceArtificial islandsMachines/enginesFree rotationMooring system

A tidal stream or ocean current turbine is connected to a submerged buoy that is tethered to the seabed to create a virtual seabed level that is higher than the actual seabed. The buoy is constrained by tensioned tethers or catenary mooring lines such that it is approximately geofixed at a prescribed depth of immersion and orientation. The turbine device is attached to the submerged buoy by a connector strut that allows the device to swivel about the geofixed location. The strut to buoy connection incorporates a bearing system that allows the strut freedom of rotation in the horizontal and vertical planes about the geofixed buoy. The reserve of buoyancy in the submerged buoy acts to resist the vertical component of the mooring force such that the drag force on the turbine device cannot lead the device to submerge excessively or cause the downstream tension tether mooring lines to go slack.

Owner:OCEAN FLOW ENERGY

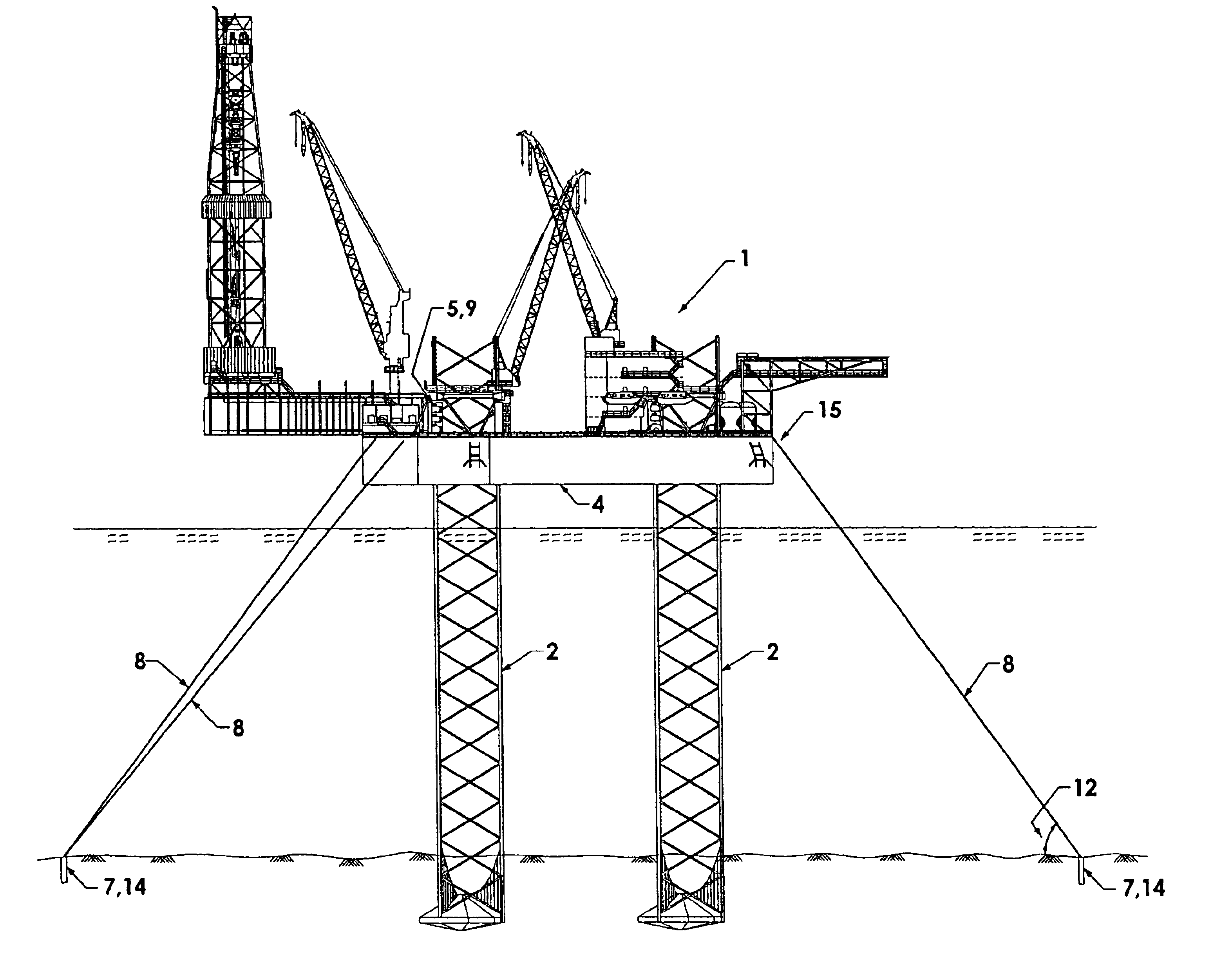

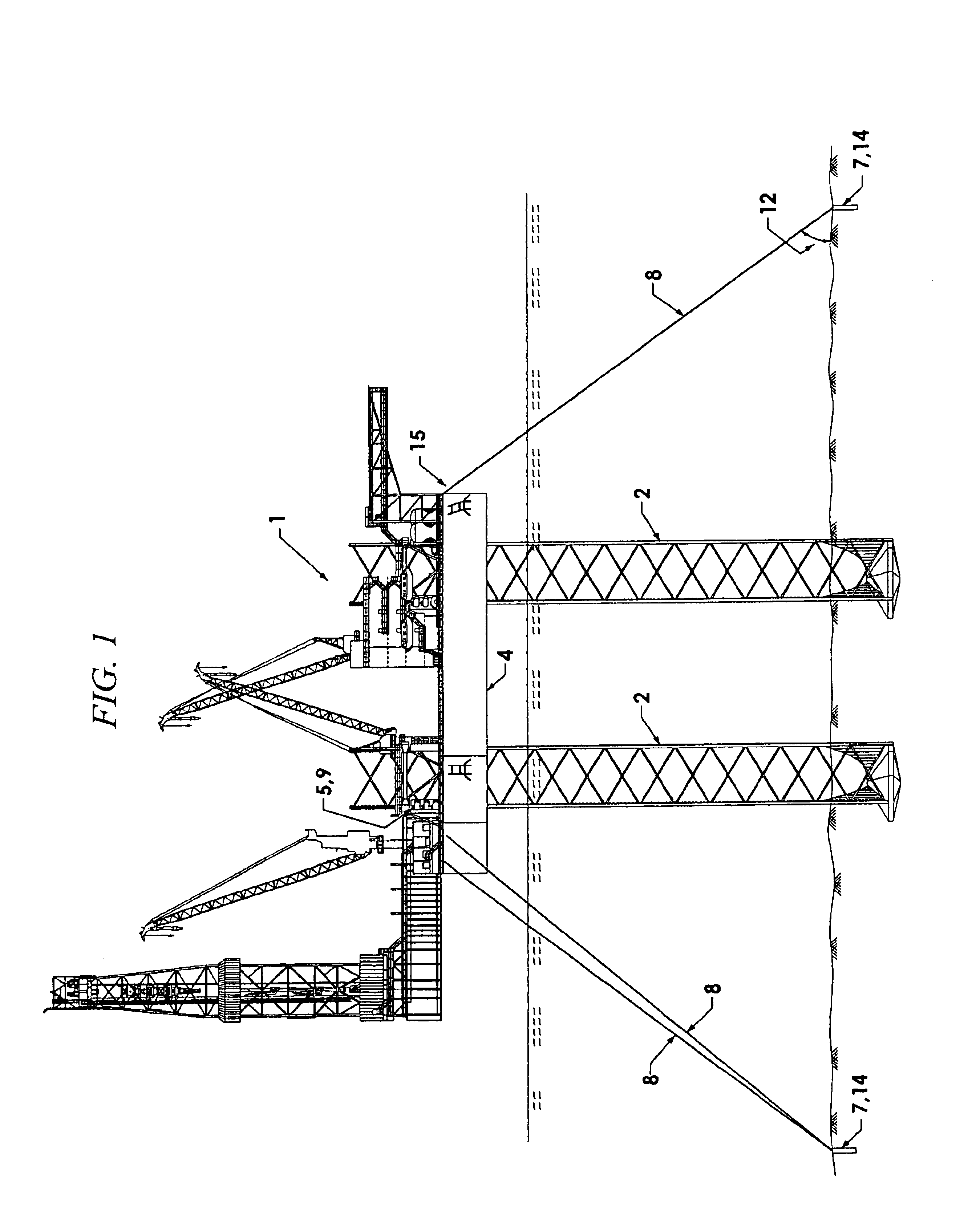

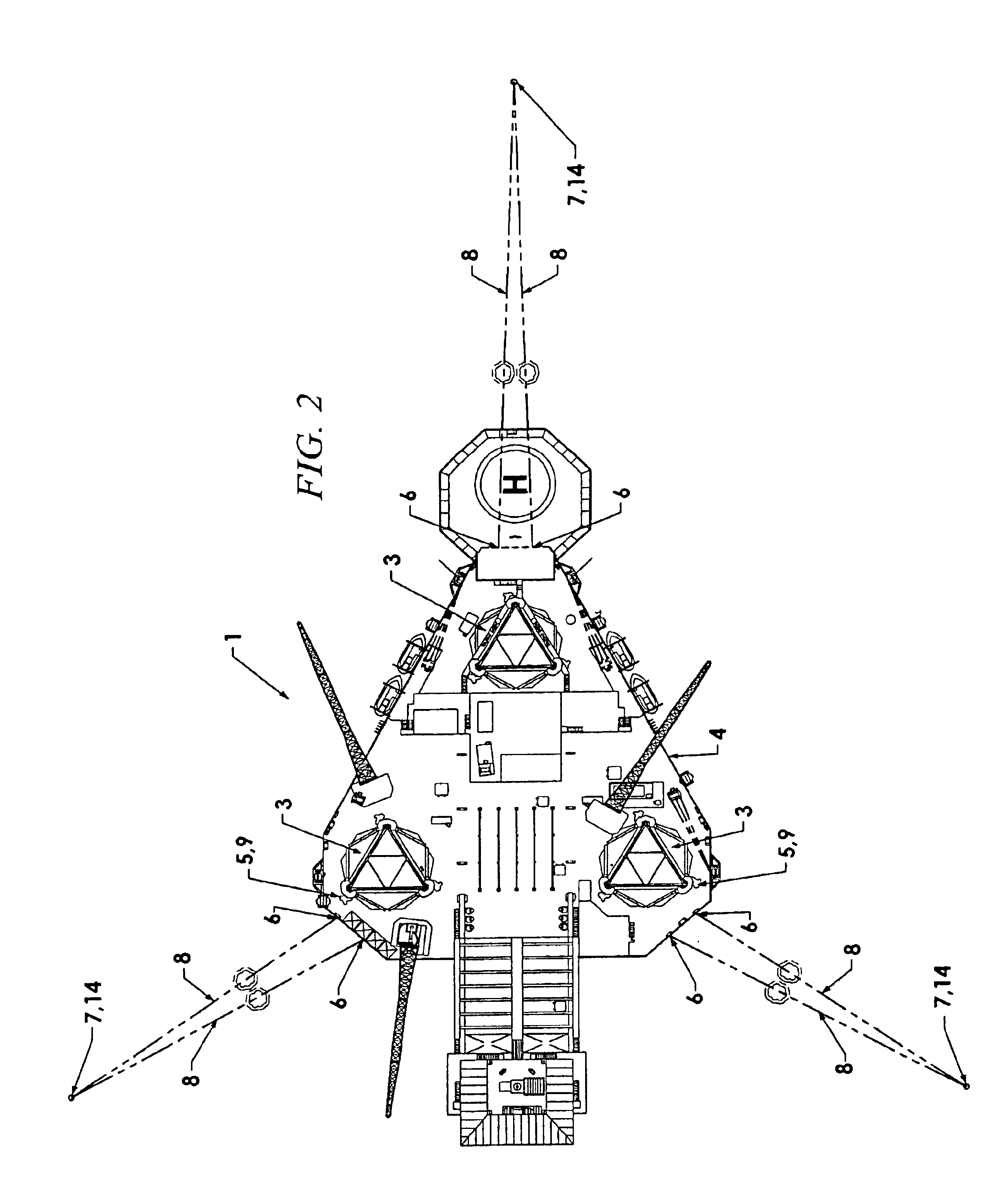

Taut mooring system for jack-up type mobile offshore platforms

InactiveUS6869252B1Reduce natural periodExtended maintenance periodArtificial islandsUnderwater structuresMooring systemMarine engineering

A taut mooring system for use on a mobile offshore jack-up platform while it is in an elevated operating condition. The elevated operating condition is with the hull jacked up a safe distance above the highest anticipated wave crests, on vertically movable legs which extend to the ocean floor. The mooring system consists of: radially spaced mooring line attachment means on the structure of the platform; suction piles that are radially spaced around the platform, consistent with the radial spacing of the mooring line attachment means; and taut mooring lines which radially connect the suction piles to the attachment means. The flexibility of the taut mooring system provides the ability to coact with the platform's free standing storm resistance capabilities, yielding enhanced capabilities that will enable the platform to safely resist storm induced forces that the platform would not normally be capable of withstanding, and to enable the platform to be used with longer legs in deeper water.

Owner:ZENTECH

Mooring systems with active force reacting systems and passive damping

InactiveUS6439147B2Displacement amplitude can be reduced and evenLow costBuoysShipping equipmentHydraulic cylinderMooring system

A mooring system including a body / arm / vessel arrangement with passive damping and / or an active force restoring system. The active force restoring system includes a sensor for generating a displacement signal representative of the displacement of the vessel from a quiescent position and an active forcing device which responds to the displacement signal to force the arm in a direction to move the vessel toward the quiescent position. The passive damping arrangement includes a device, independent of and in addition to the damping of the water on the vessel or the arm, that damps the oscillation of the vessel in response to environmental conditions which force the vessel from its quiescent position. Hydraulic cylinder arrangements are provided for active forcing and passive damping. Powered winch / cable arrangements are also provided for active force systems. Alternative devices for active and passive damping systems of torque actuators include hydraulic powered cans with internal fins, or cans with internal elastomeric elements or disk brake elements.

Owner:SOFEC

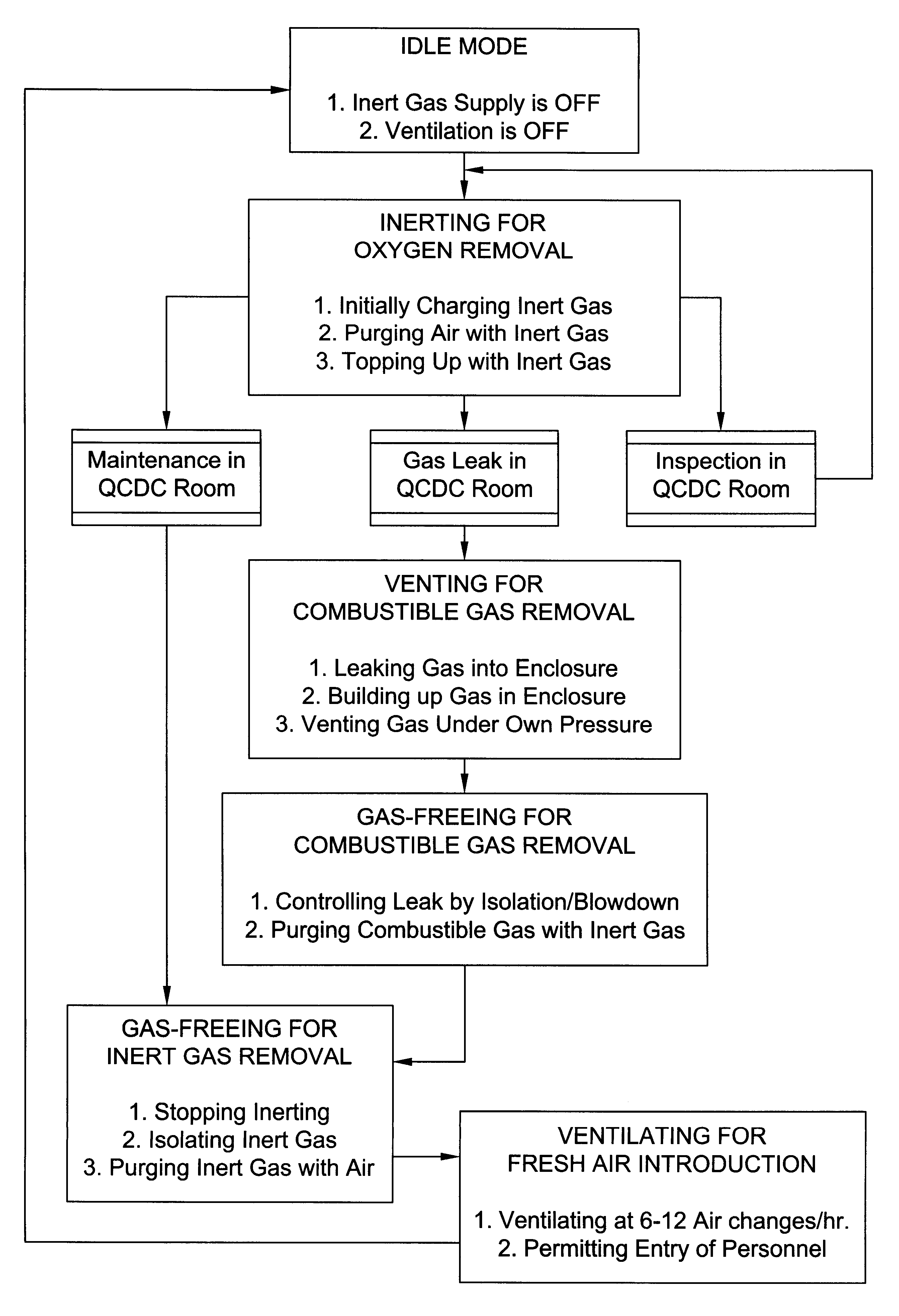

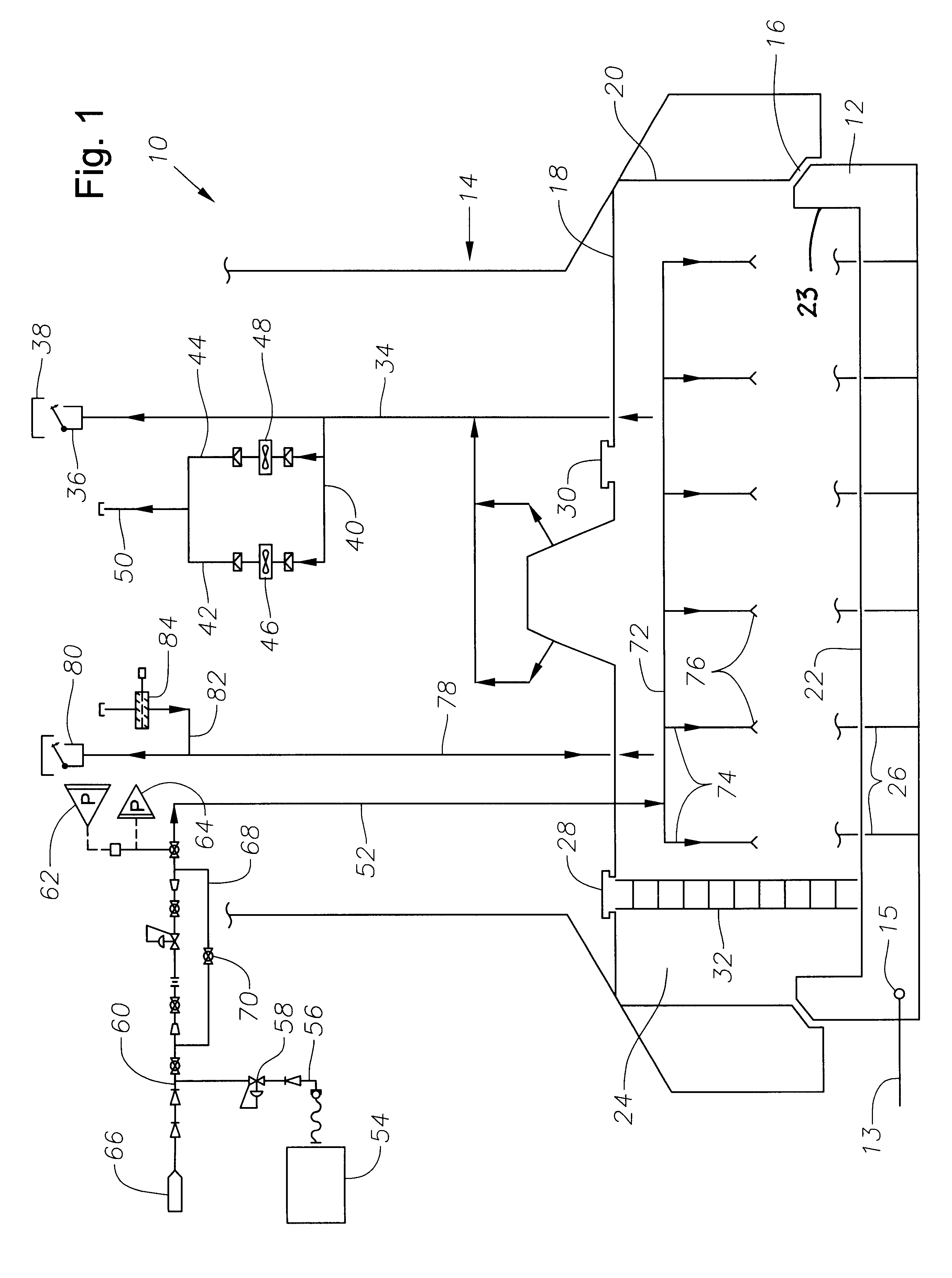

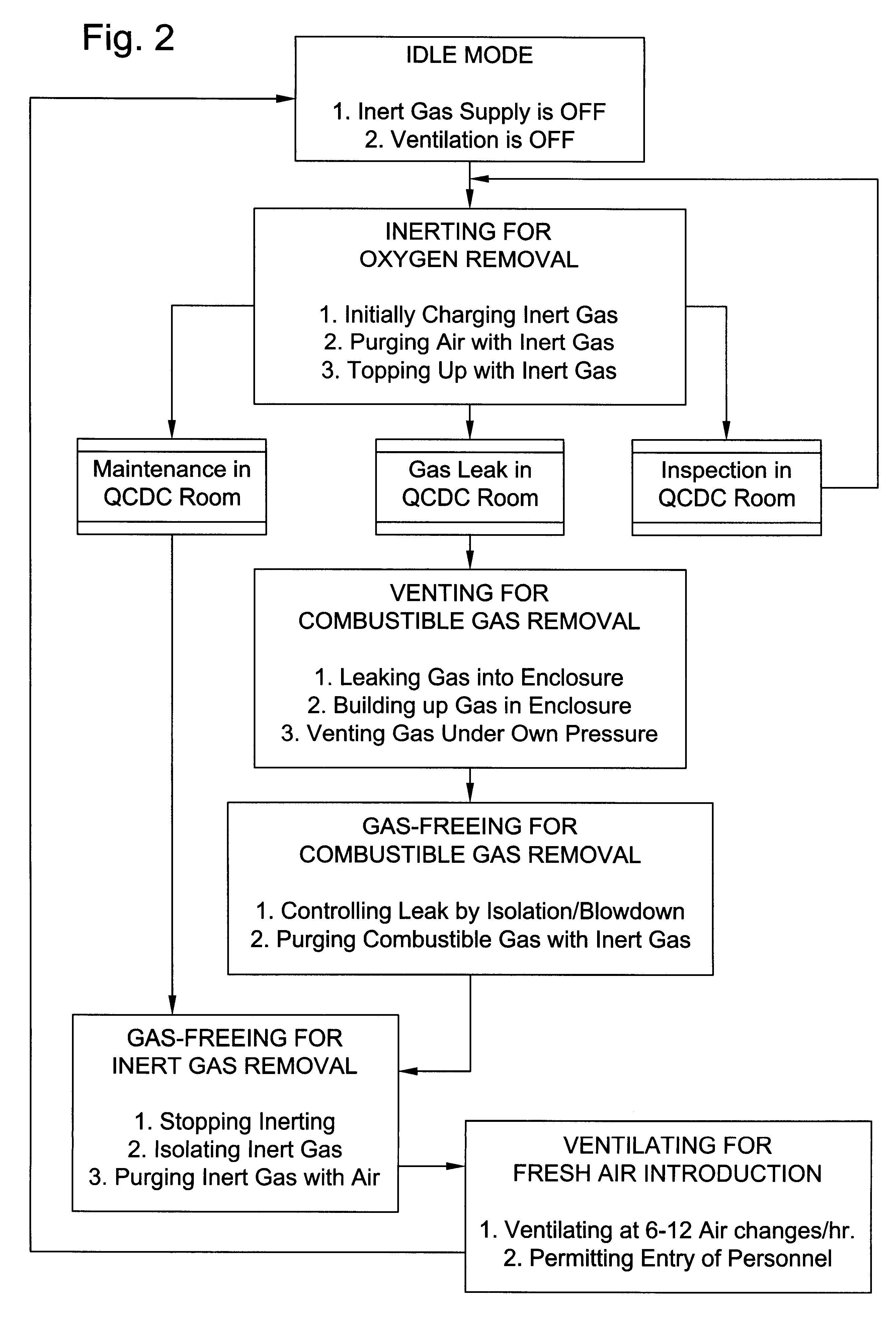

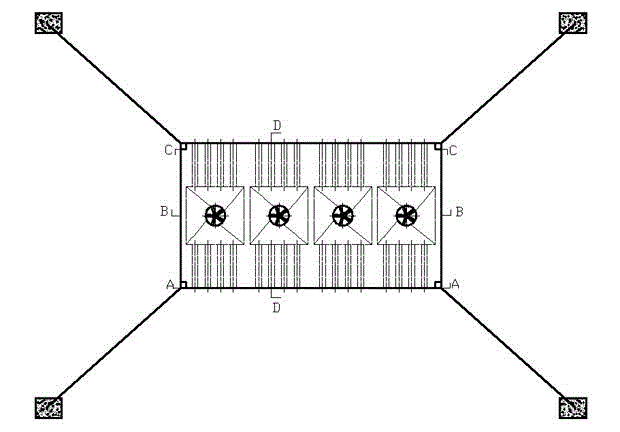

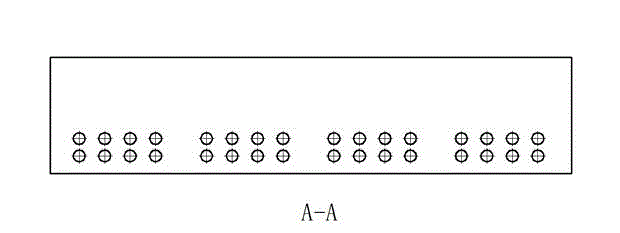

Explosion prevention system for internal turret mooring system

InactiveUS6341572B1Reduce the risk of explosionReduce probabilityFluid removalFire rescueNuclear engineeringOperation mode

A method and apparatus for ensuring against explosion of the gaseous atmosphere of a closed chamber, such as the QDCD room of an internal turret of an offshore production and offloading buoy wherein the closed chamber has production risers and conduit connectors that represent a potential source of flammable gas. The method comprises mixing and diluting the oxidant content of the air by introducing within the closed chamber a sufficient quantity of inert gas to render the mixture of the air and any flammable gas non-combustible regardless of the flammable gas content of the mixture. The method includes removal of the non-combustible mixture of air and any flammable gas from the closed chamber by purging thereof to the natural atmosphere, while introducing inert gas, thereby leaving a substantially inert atmosphere within the closed chamber. The turret system provides for control of the gaseous atmosphere within the closed chamber at all modes of turret operation, including the idle, on-line and ventilation modes and also provides for gas pressure control to accommodate normal operating conditions and conditions of gas leakage into the chamber.

Owner:SOFEC

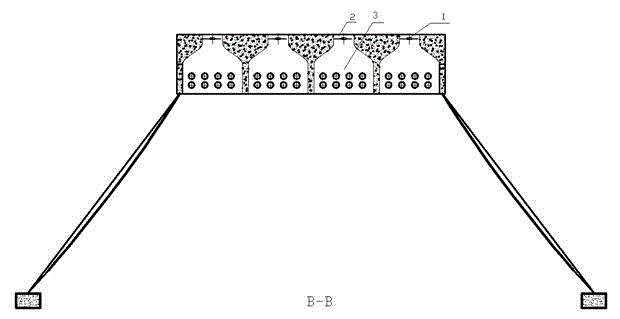

Floating breakwater doubling as wave power generation device

The invention relates to the technical field of breakwater engineering and wave power generation, in particular to a floating breakwater generation device arranged in open sea. The floating breakwater generation device comprises floating members, air turbine generator sets, air chambers, airflow passages, mooring systems and signal transmission devices, and is characterized in that the floating members are respectively connected with concrete anchor blocks at the sea bottom through anchor chains; a plurality of wave dissipating perforations penetrating through a floating body are formed in the head-sea face of each floating member; the air turbine generator sets are respectively arranged in the airflow passages; the floating bodies are driven by waves to vertically move, so that water in the air chambers vibrates and air in the air chambers is pushed to move, and the air turbine generator sets are further driven to generate electricity. The floating breakwater generation device disclosed by the invention has the characteristics of being stable in structure, low in erection cost, high in generation conversion efficiency, convenient to maintain, and the like, and can be applied to sea areas with deep water, high waves and complex terrain; while wave impacts are weakened and a steady water area environment is provided for surrounding water areas, the waves can be converted into electric energy, and the electric power supply problem of harbor district or island residents is effectively solved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method and apparatus for suction anchor and mooring deployment and connection

A method and apparatus for deployment of mooring systems for buoyant marine structures such as mobile offshore drilling units (MODU's) and for connecting the same to the mooring lines thereof. An anchor handling vessel carries one or more anchors each having a deployment connection and a mooring connection and individually moves each anchor over its stem roller and deploys it to the sea bottom for installation. A handling line is disconnected by ROV from the deployment connection and is moved from the deployment connection to the mooring connection so as to become the main mooring line. Syntactic buoys are then mounted on the main mooring line for elevating it above the sea bottom for recovery. When MODU stationing is desired the anchor handling vessel then recovers the surface buoy and connects to the rig mooring line using a short section of mooring chain. A J-chaser stopper device is then installed in the mooring string and is connected to the mooring line of the MODU by a short section of chain. The J-chaser lowers the mooring string, completing the mooring connection between the anchor and the MODU. A plurality of mooring strings, typically eight, are deployed in this manner to properly station the MODU. Disconnection of the MODU is accomplished essentially by the reverse of the above deployment procedure.

Owner:BERGERON BILLY J

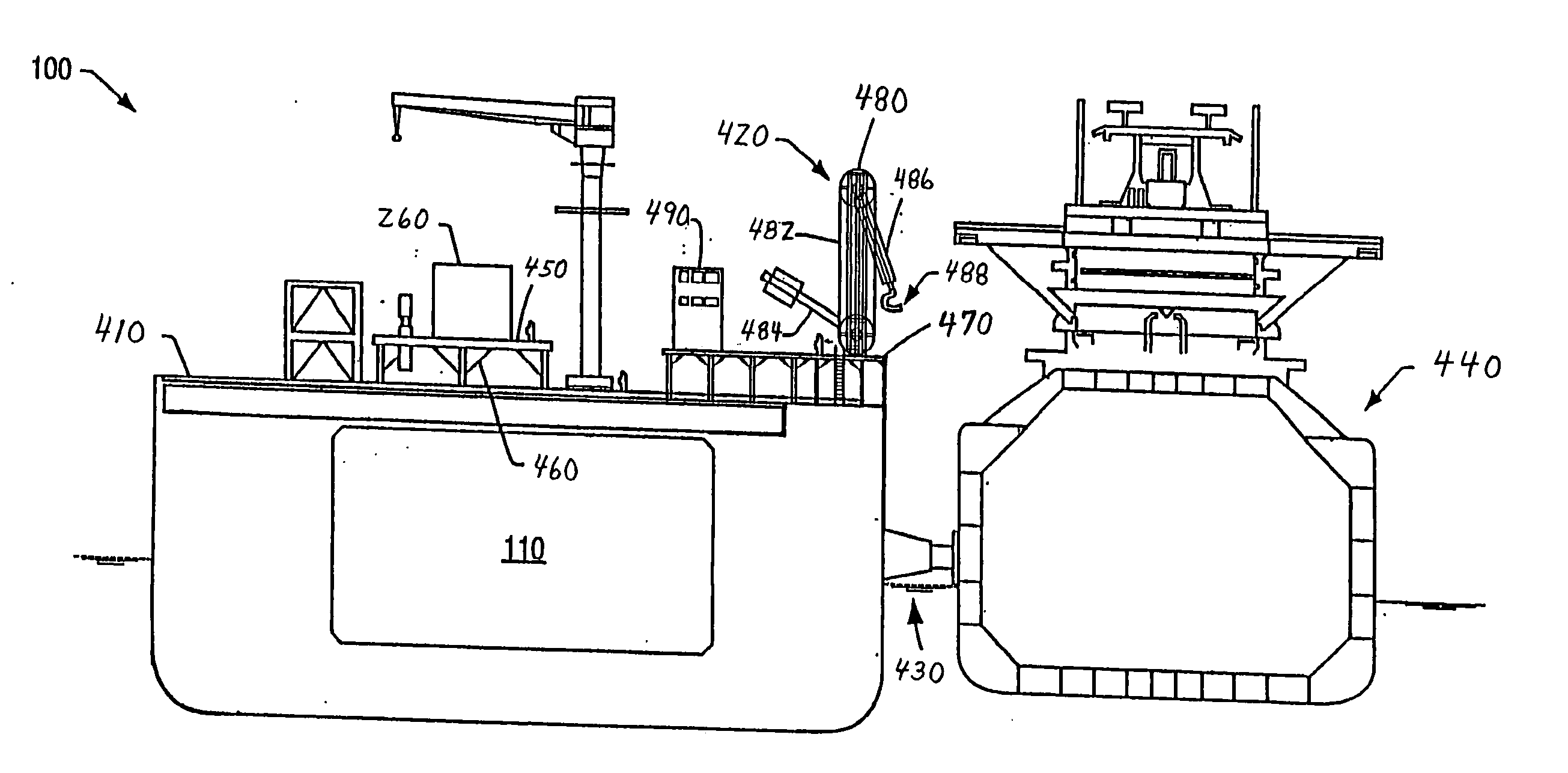

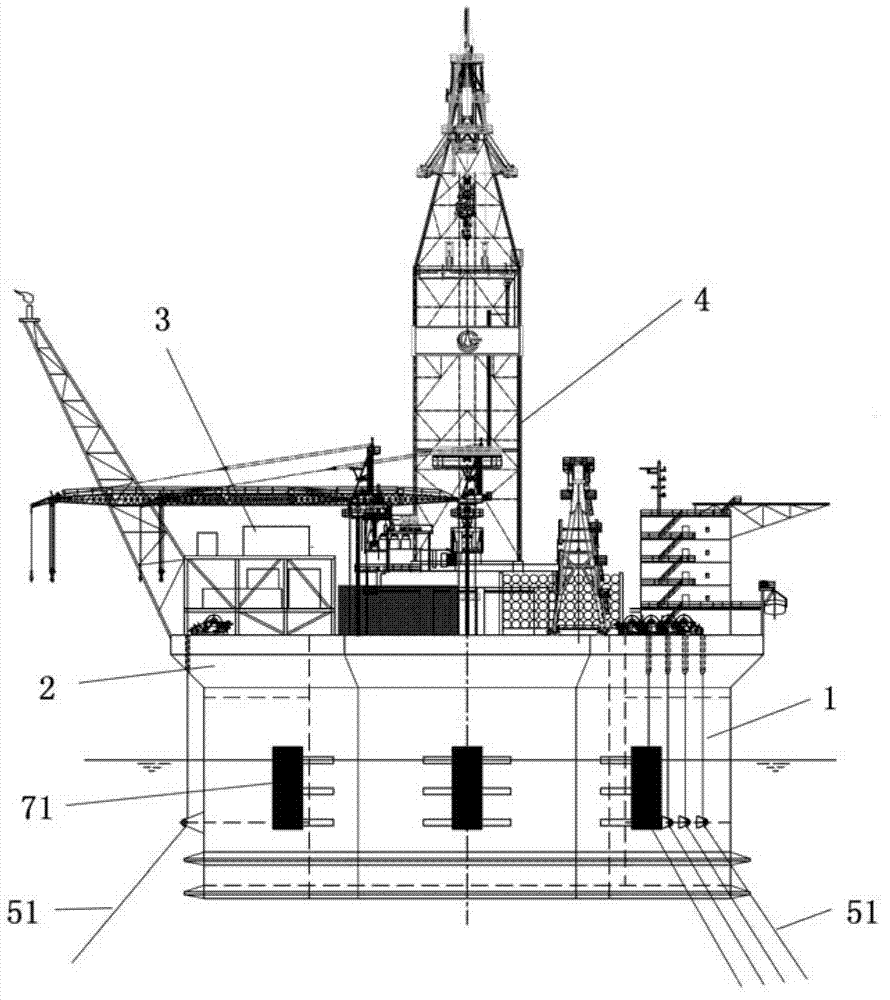

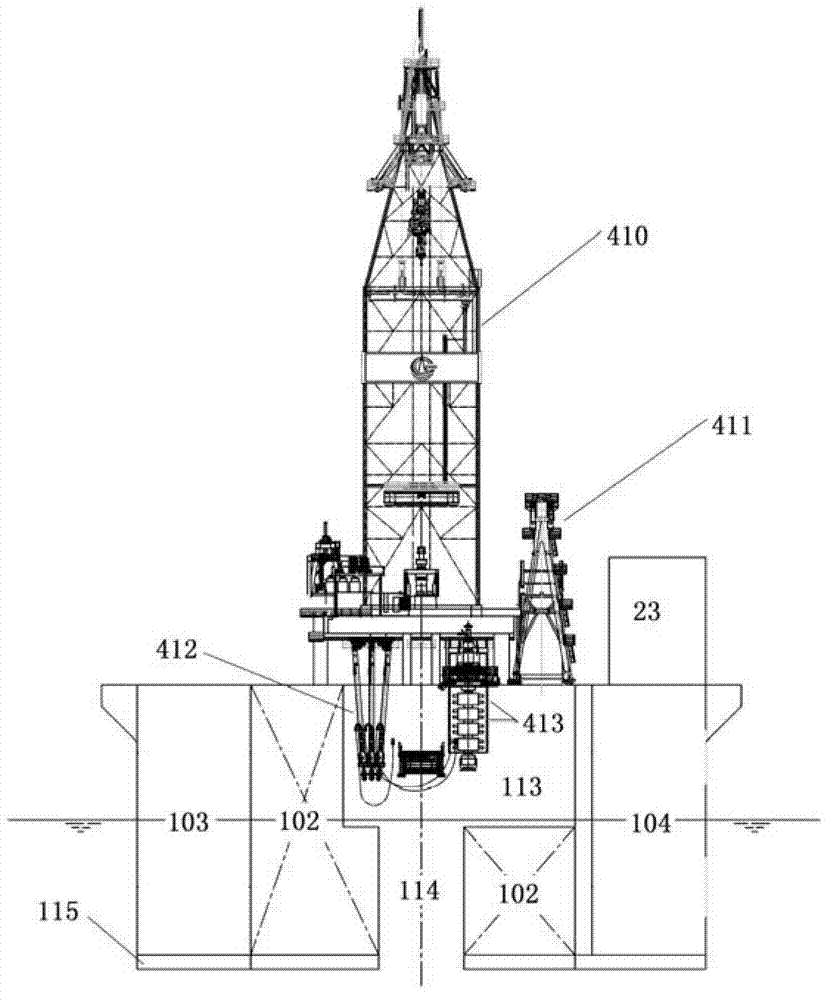

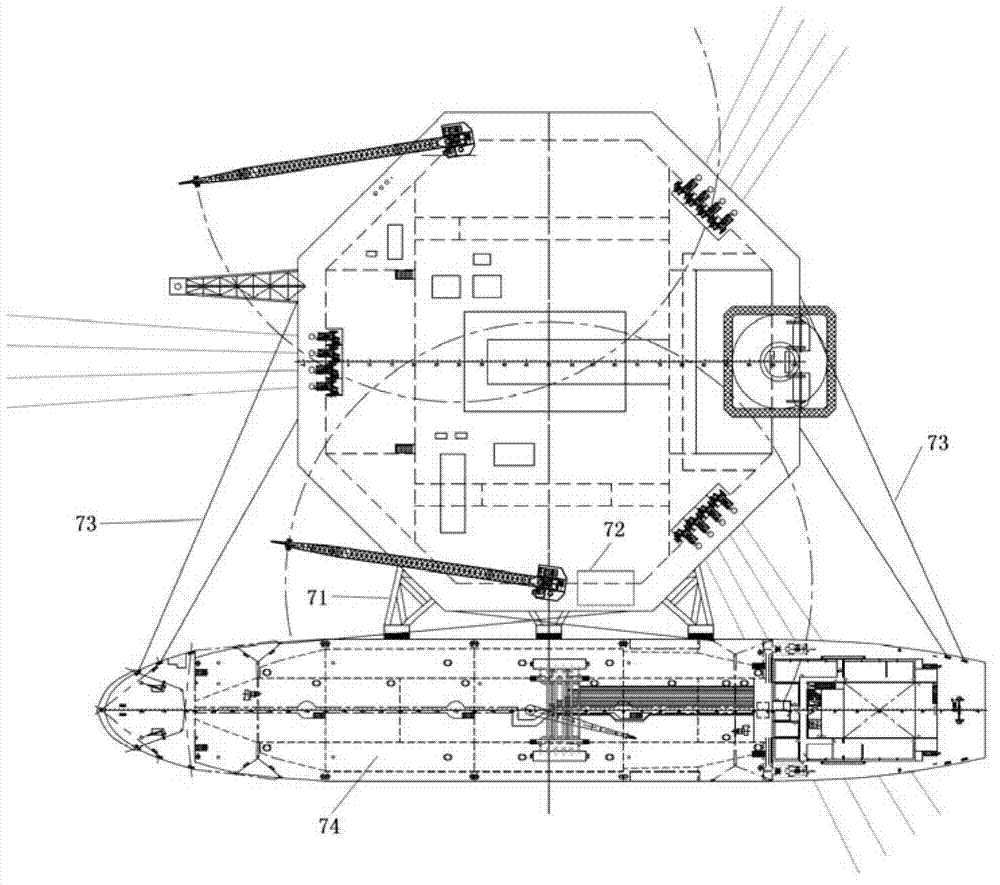

Floating type production platform capable of taking well drilling and oil storage into consideration

ActiveCN102756793AReduce economic riskThe vertical and horizontal scales are the sameFloating buildingsPrismTreatment system

The invention discloses a floating type production platform capable of taking well drilling and oil storage into consideration. The floating type production platform comprises an octagonal-prism floating body with an octagonal horizontal section and a deck, wherein a ballast water tank, an oil storage tank, a production functional cabin, a well-drilling equipment cabin and a pump cabin; the deck is arranged on the floating body; an oil gas treatment system, well-drilling equipment and a positioning mooring system are arranged on the deck; and a moon pool is arranged on the floating type production platform. The floating type production platform has the functions of oil gas production, storage, transportation and well drilling, can be migrated and reused, is flexible and suitable for early trial production and well drilling development of an oil field with the water depth of more than 100 m, and can effectively reduce the economic risk of development of the oil and gas field. The floating type production platform has the same longitudinal and transverse size, has the size less than the longitudinal size of the boat type FDPSO, has basically same environmental force from each direction under the same environment condition and has the environmental force less than that of the boat type FDPSO under the transverse environment, adopts a multi-point mooring system, and can meet the requirements of platform well drilling and oil and gas production operation under the sever marine environment such as the South China Sea and the like.

Owner:CHINA NAT OFFSHORE OIL CORP +1

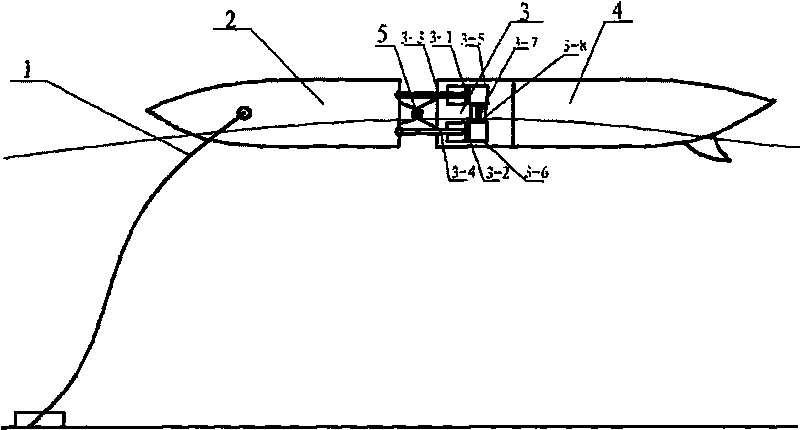

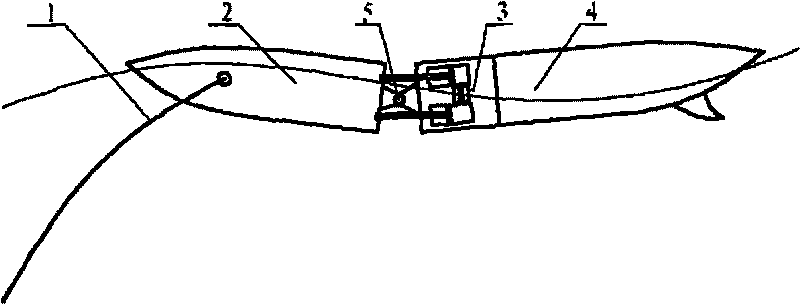

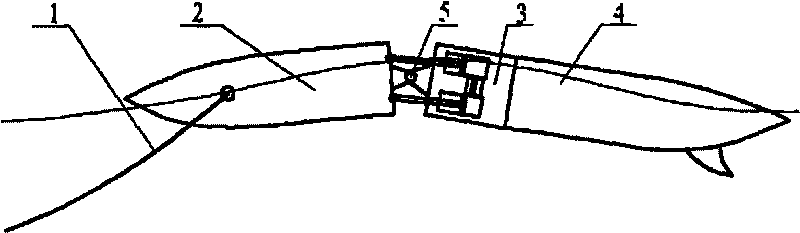

Fishlike raft-type liquid-metal magnetohydrodynamic wave energy direct power generating device

InactiveCN101718247AEfficient use ofOptimize layoutMachines/enginesEngine componentsMooring systemEngineering

The invention relates to a floating, fishlike and raft-type liquid-metal magnetohydrodynamic wave energy direct power generating device which mainly comprises a front float, a rear float, a hinge, a liquid-metal magnetohydrodynamic (LMMHD) generator, a mooring system, and the like. The power generating device has a floating structure and can be arranged at different sea areas according to requirements; an adopted fishlike raft-type wave energy acquisition device can absorb the wave energy better and simultaneously has stronger storm resisting capacity; and the power generating device adopts a liquid-metal magnetohydrodynamic direct power generating technology, has less intermediate conversion links and improves the whole conversion efficiency.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Torsion spring torque arm yoke mooring system

InactiveUS6227135B1Improve performanceCost effectiveWaterborne vesselsShipping equipmentMooring systemTorsion spring

A soft yoke mooring system, with torsional spring devices to provide restoring force to yoke arms coupled to a mooring body. Two torsional spring device types are preferred. A first torsional spring device type includes a plurality of nested tubular shafts, which are coupled end to end to each other in a coaxial array. Torque arms extend from a yoke arm end to one end of the tubular shafts, with the other end of the shafts coupled to a vessel. A second torsional spring device type includes stacks of elastomeric shear unit arrays or blocks of elastomeric material, which are coupled between a torque diaphragm device and a vessel and with the torque diaphragm device coupled by a torque arm to an end of a yoke arm.

Owner:FMC TECH INC

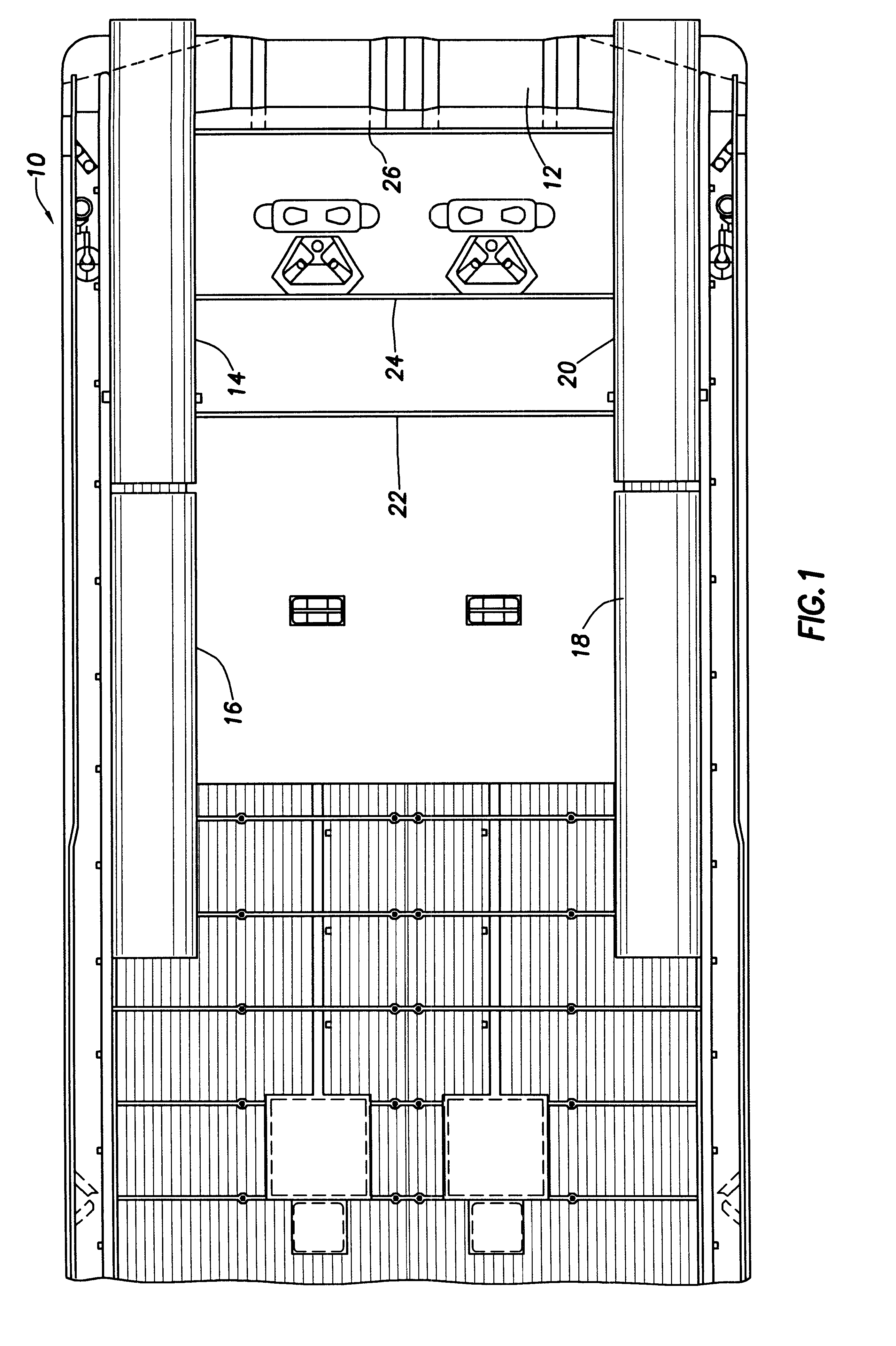

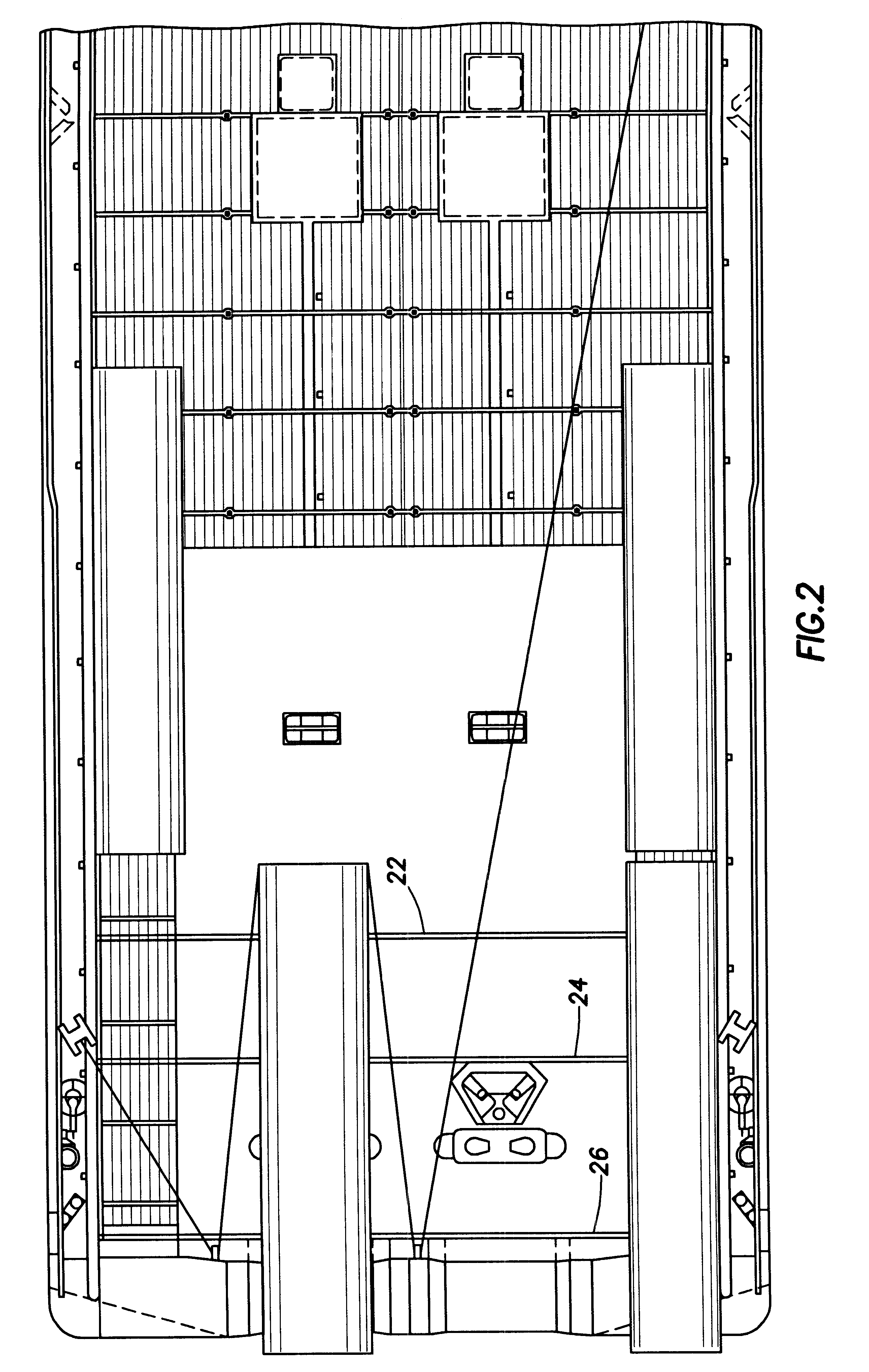

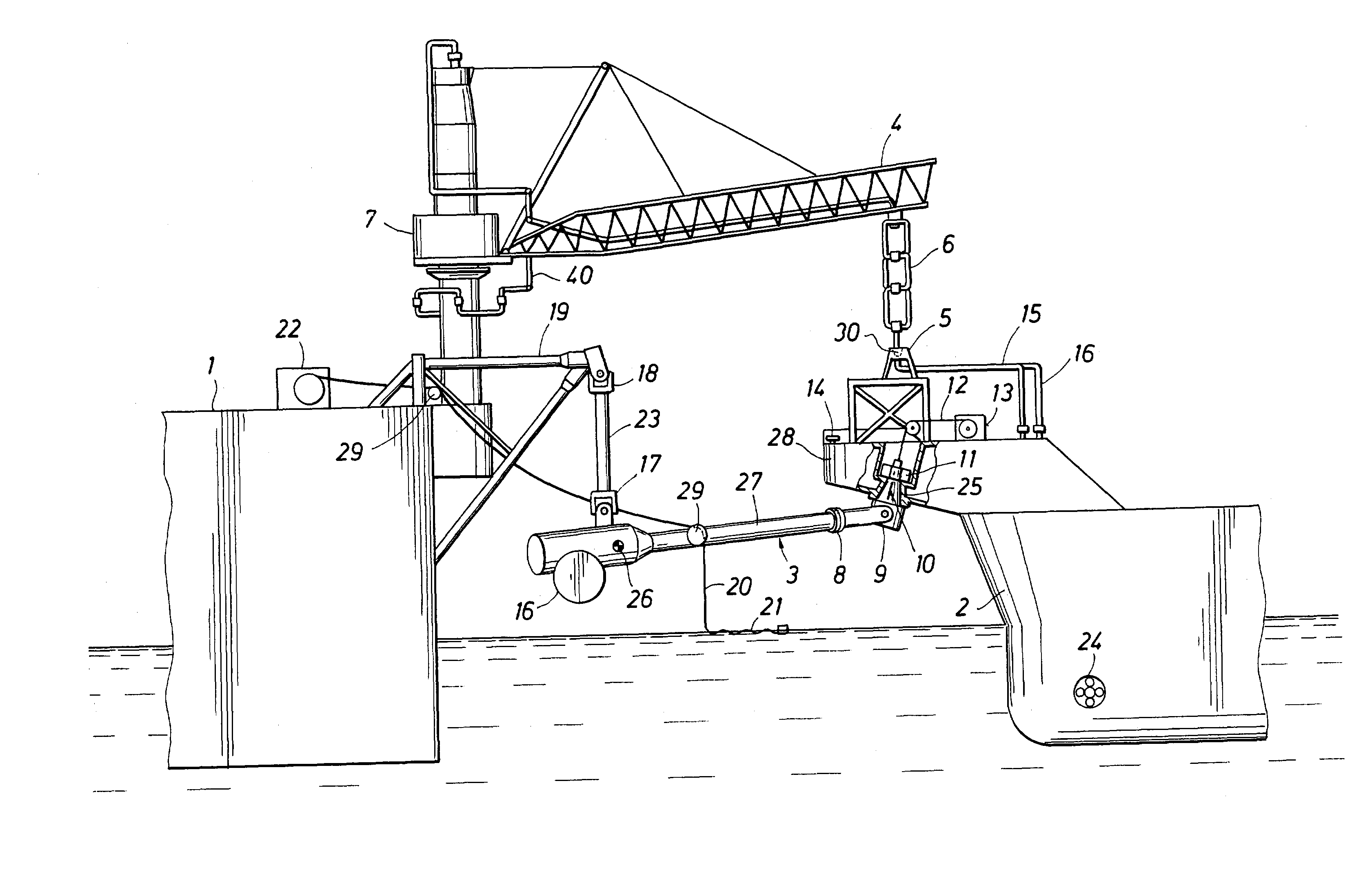

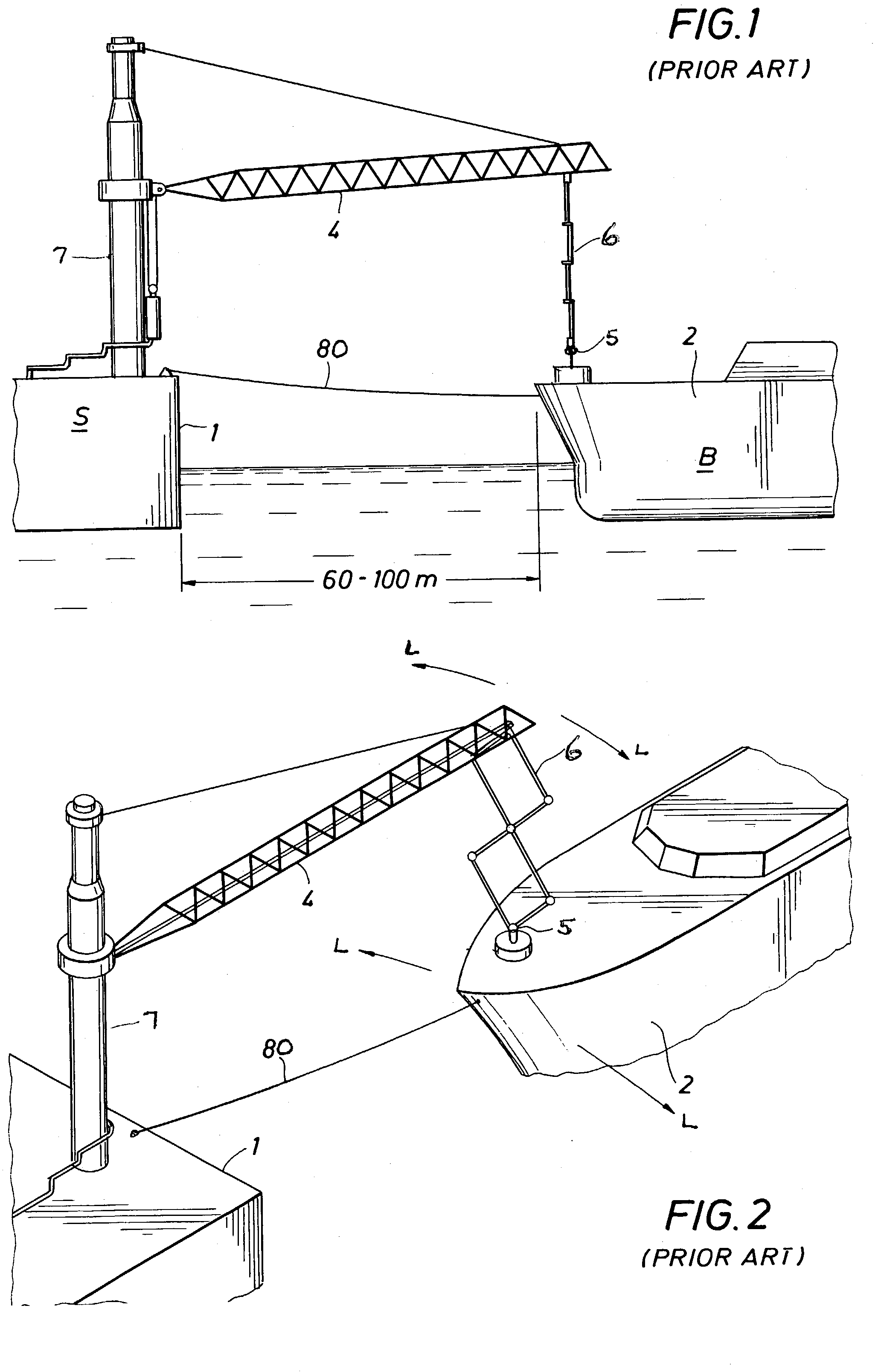

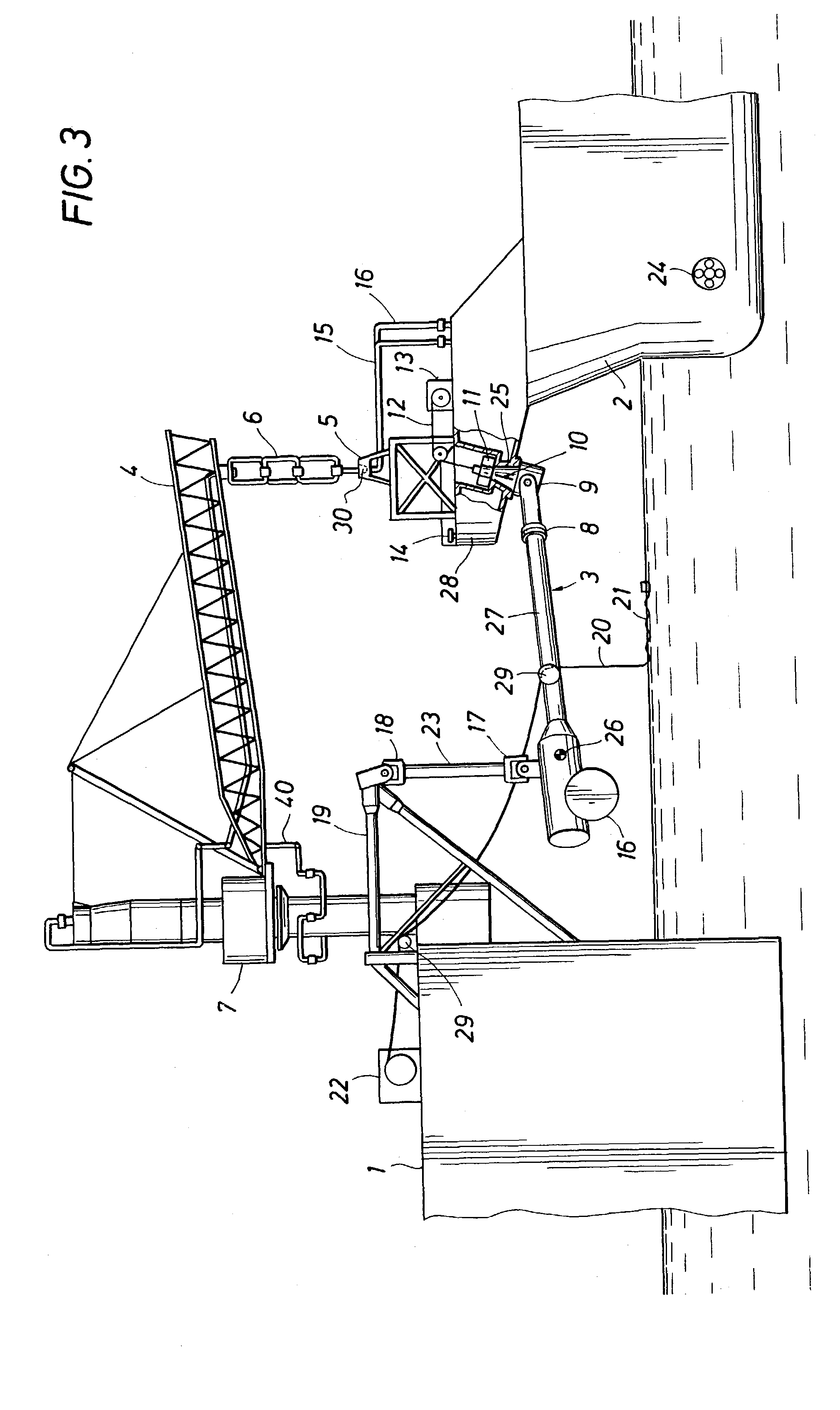

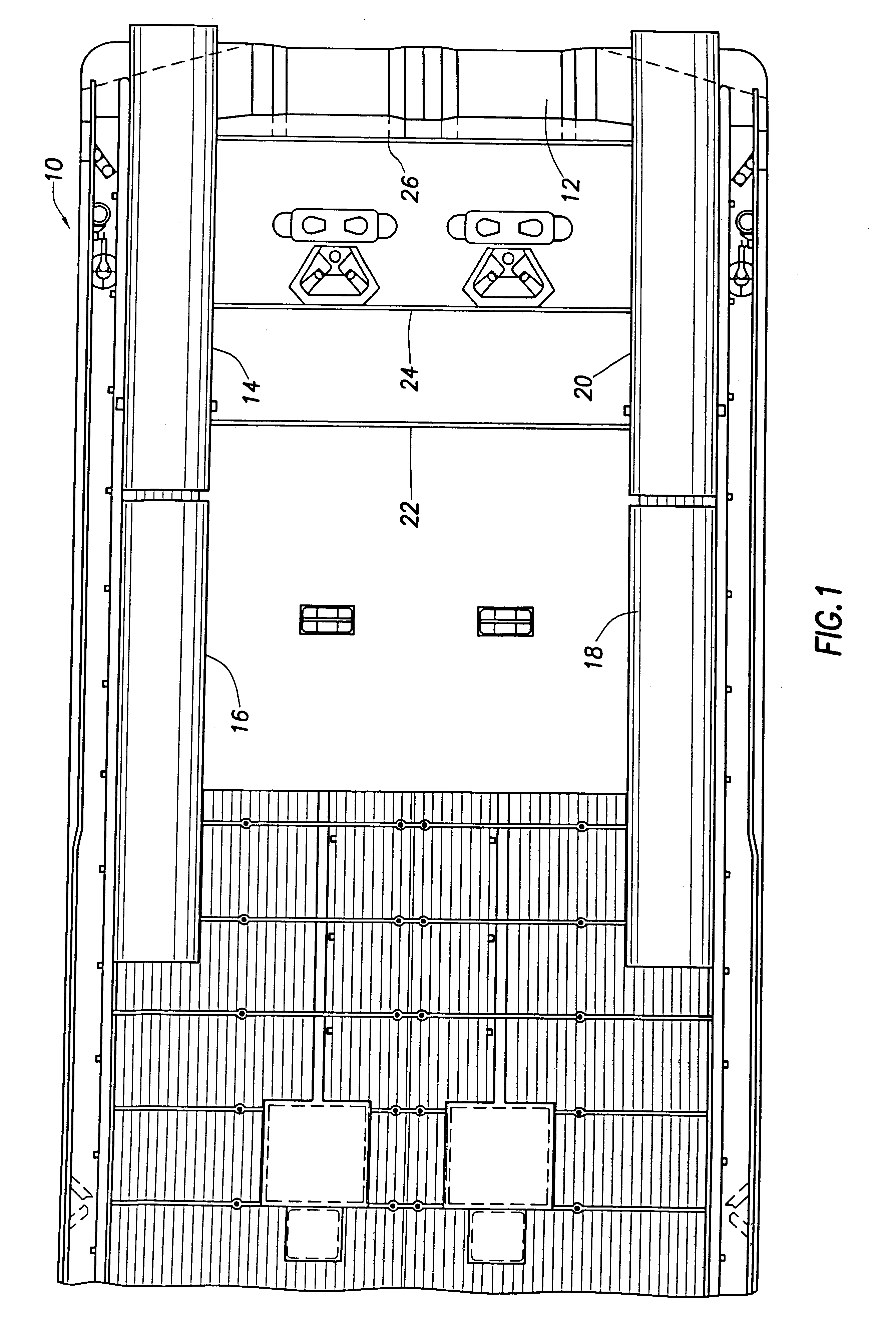

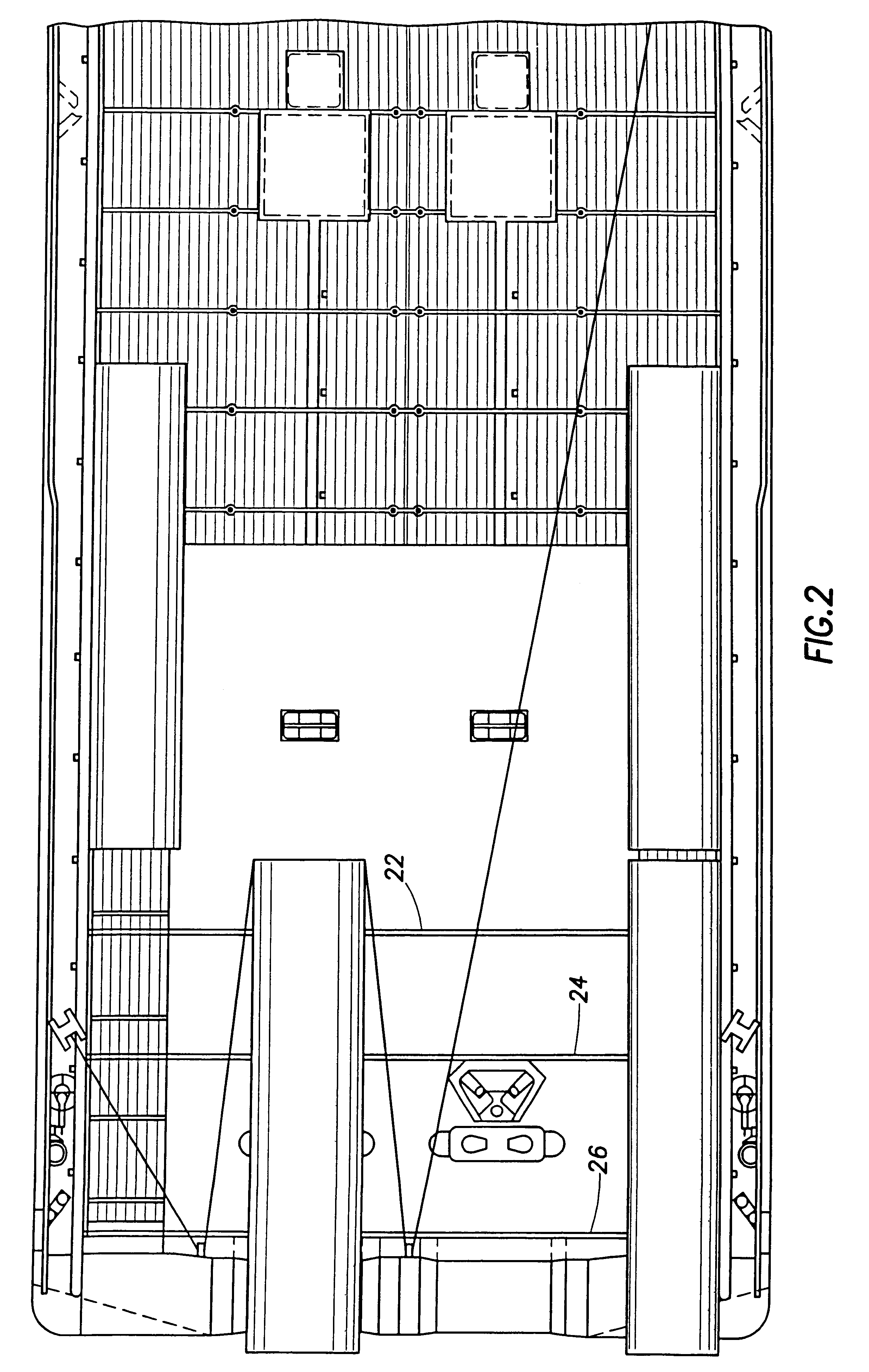

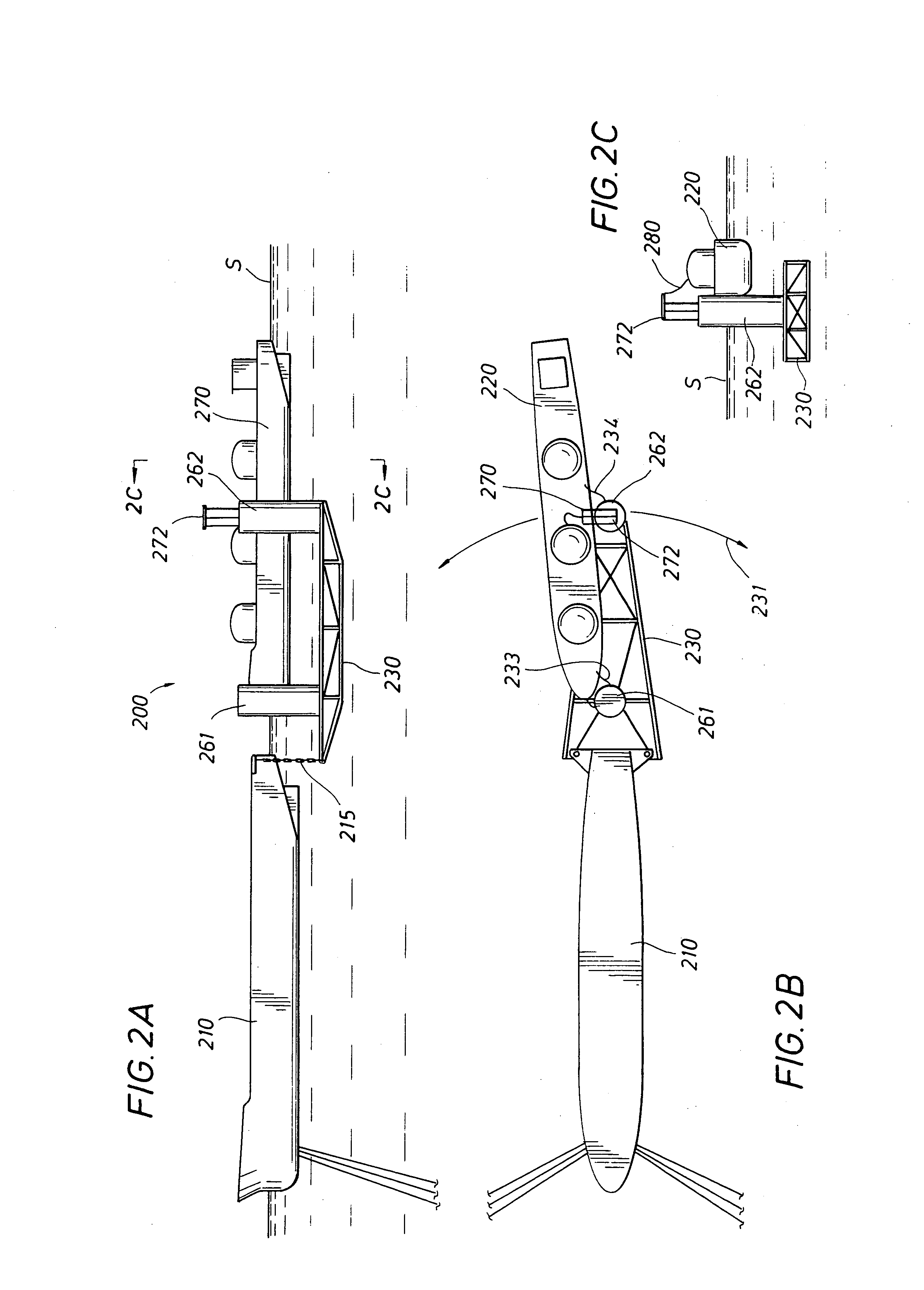

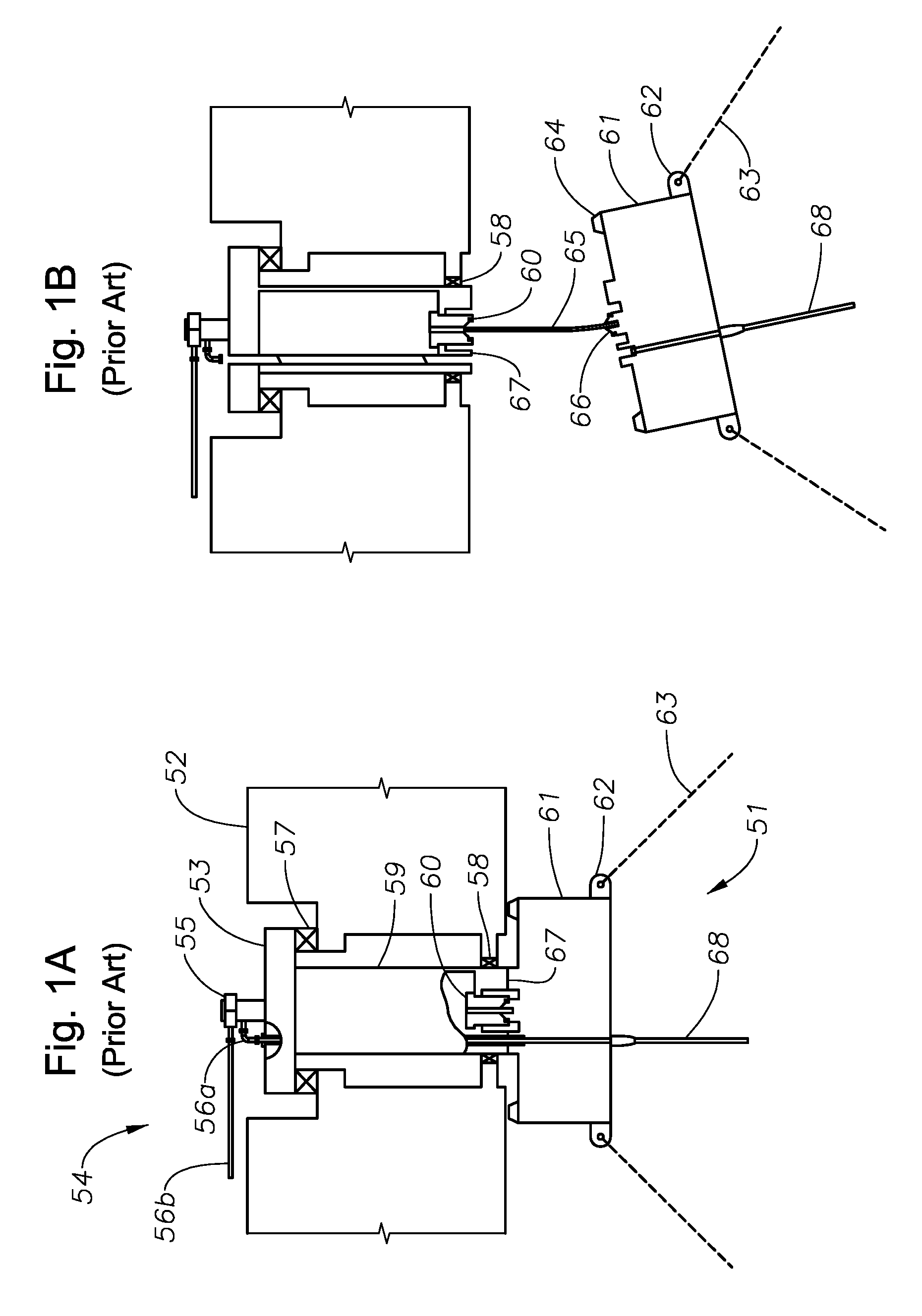

Duplex yoke mooring system

ActiveUS20040025772A1Improve reliabilityImprove securityCargo handling apparatusPassenger handling apparatusElectricityTransverse force

An offshore offloading system for hydrocarbon products from a storage station such as an LNG / FPSO to a shuttle vessel. The system includes a yoke mooring arrangement having a yoke and a connection assembly. One end of the yoke is selectively disconnectable to the shuttle vessel, while the other end of the yoke is rotatably connected to an end of the connection assembly which has its other end rotatably connected to a frame which extends from an end of the storage station. The yoke and connection assembly are arranged such that a transverse force in the lateral or y-direction moves the end of the yoke less than twice the movement of the yoke in response to an x-direction force. The system also includes arrangements for providing a hydrocarbon fluid flow path from the storage station to the shuttle vessel when the shuttle vessel is disconnectably moored to the storage station. A first fluid flow path arrangement includes a crane / boom arrangement mounted on a frame extension of the storage station so that a crane slewing arc radius of the transfer system is not larger than one half the separation distance between the storage station and a forward perpendicular of the shuttle vessel. A second arrangement includes a fixed frame with a piping pantograph mount at its end. A trolley and service platform suspended therefrom move between an operational position away from the pantograph and a service position beneath the pantograph when it is folded into a storage position.

Owner:SOFEC

Offloading arrangements and method for spread moored FPSOs

InactiveUS6983712B2Avoid contactRapid disconnectionCargo handling apparatusPassenger handling apparatusMooring systemDynamic positioning

A mooring arrangement between a floating storage body spread moored in deep water and a shuttle tanker, the arrangement including a single point buoyant member that is adapted for mooring a shuttle tanker in offloading position relative to a floating production, storage and offloading vessel (FPSO) with a link between the floating storage body and the single point buoyant member. One embodiment (100) of the invention employs a submerged yoke (30), having one end (31) rotatably coupled to a FPSO (10) and a second end (32), supported by a buoy. A mooring hawser (28) extends from the buoy to the shuttle tanker and product hoses connect the shuttle tanker with the FPSO and extend along the submerged yoke. In another embodiment, the mooring buoy is stationed by a hold-back mooring system (303–304) and the FPSO or the tanker or both is provide with traction device (308) to move the tanker into loading position with respect to the FPSO. Other embodiments of the invention establish mooring of a shuttle tanker so that it can weathervane 360 degrees during offloading activity. In another embodiment, the mooring buoy (600) is provided with a dynamic positioning system (614) for controlling shuttle tanker positioning with respect to conditions of the environment or for moving the tanker to a desired position during loading.

Owner:SOFEC

Mooring system with active control

InactiveUS20060081166A1Performance maximizationReduce energy consumptionShipping equipmentMooring equipmentMooring systemMarine engineering

A vessel mooring system which includes at least two mooring robots secured to a terminal, each robot includes an attractive force attachment element eg. a vacuum cup and a base structure fixed relative to the terminal. The attachment element is able to be engaged with a vertically extending side vessel surface and to exert an attractive force normal to the vessel surface at where it is to be attached. Each robot can measure the attractive force between the attachment element and the vessel to provide an “attractive force capacity reading”. Also provided is capability to measure the force between the attachment element and the fixed structure of the mooring robot to provide a “normal force reading”. From monitoring of the relationship between the attractive force capacity reading and the normal force a control of the mooring robot can be provided such that if there is a tending to separate the attachment elements from said vessel the attractive force may be increased and / or alarm is sounded.

Owner:CAVOTEC MOORMASTER

Detachable mooring and fluid transfer system

Owner:SOFEC

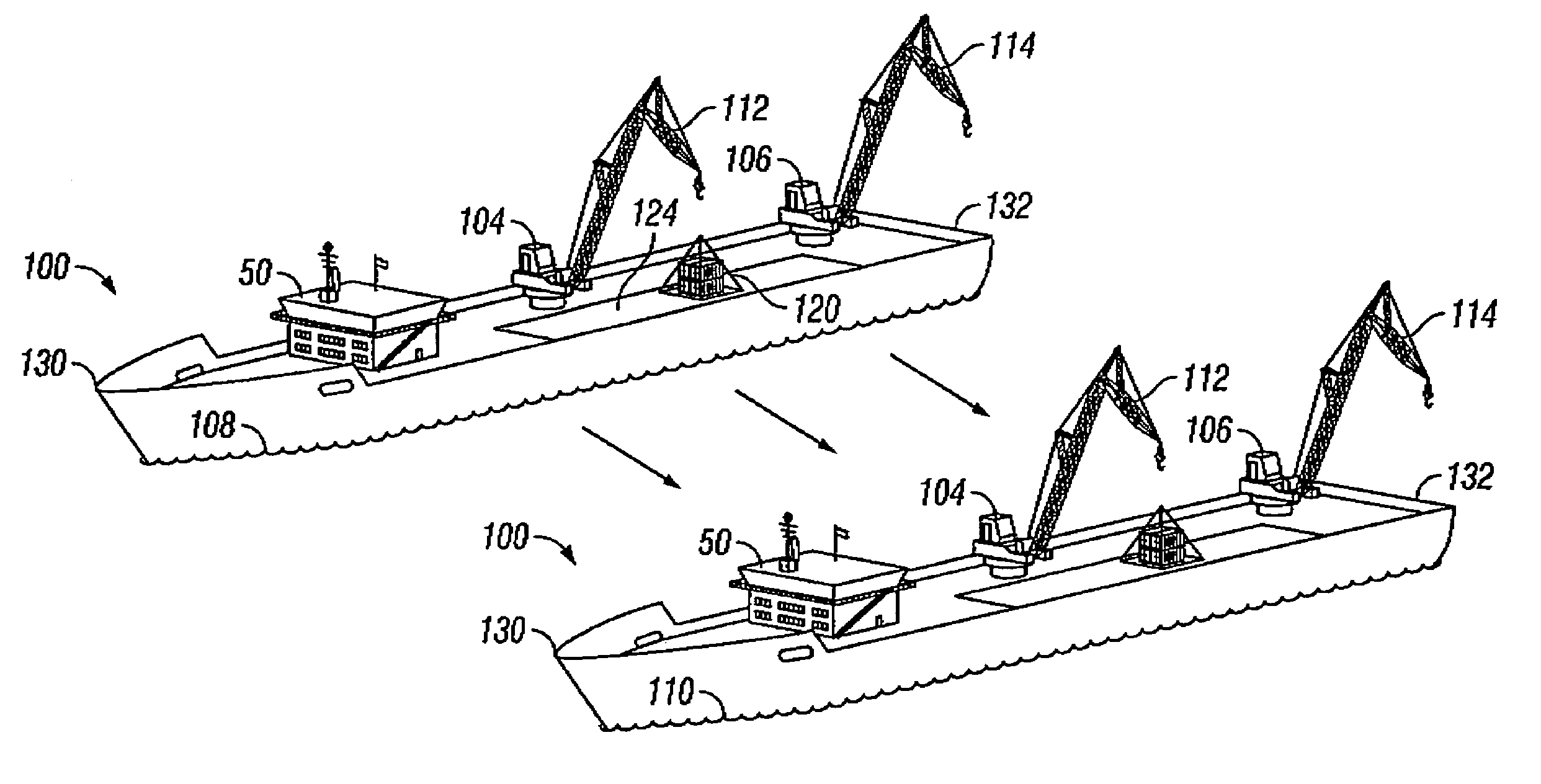

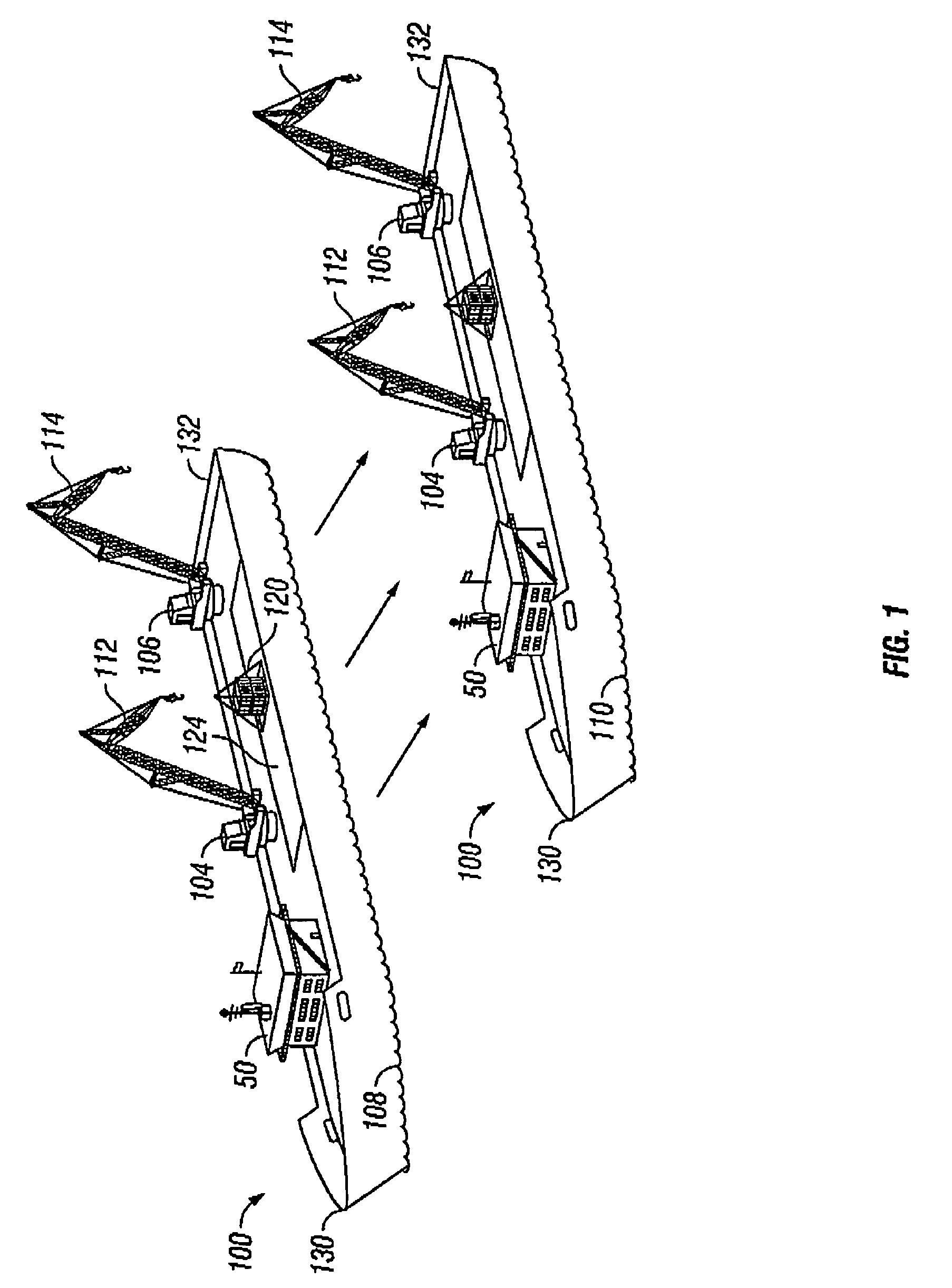

Method for lifting and transporting a heavy load using a fly-jib

InactiveUS6932326B1Increase reachIncrease heightArtificial islandsDry-dockingMooring systemHeavy load

The invention is a method for lifting and transporting a heavy load by using a heavy lift vessel with at least two heavy lift cranes adapted to operate simultaneously; mounting fly-jibs on the heavy lift crane to increase reach and height of the heavy lift crane; picking up a load from a first location using the fly-jib modules simultaneously; shifting the load from the first location to over a second location on the heavy lift vessel; placing the load on the second location; moving the heavy lift vessel to a second position; using a mooring system to maintain the heavy lift vessel at the second position; picking up the load from the second location using the fly-jib modules simultaneously; shifting the load from a second location to over a third location; and placing the load on the third location.

Owner:KRABBENDAM RICHARD L

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com