Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

214 results about "Regasification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

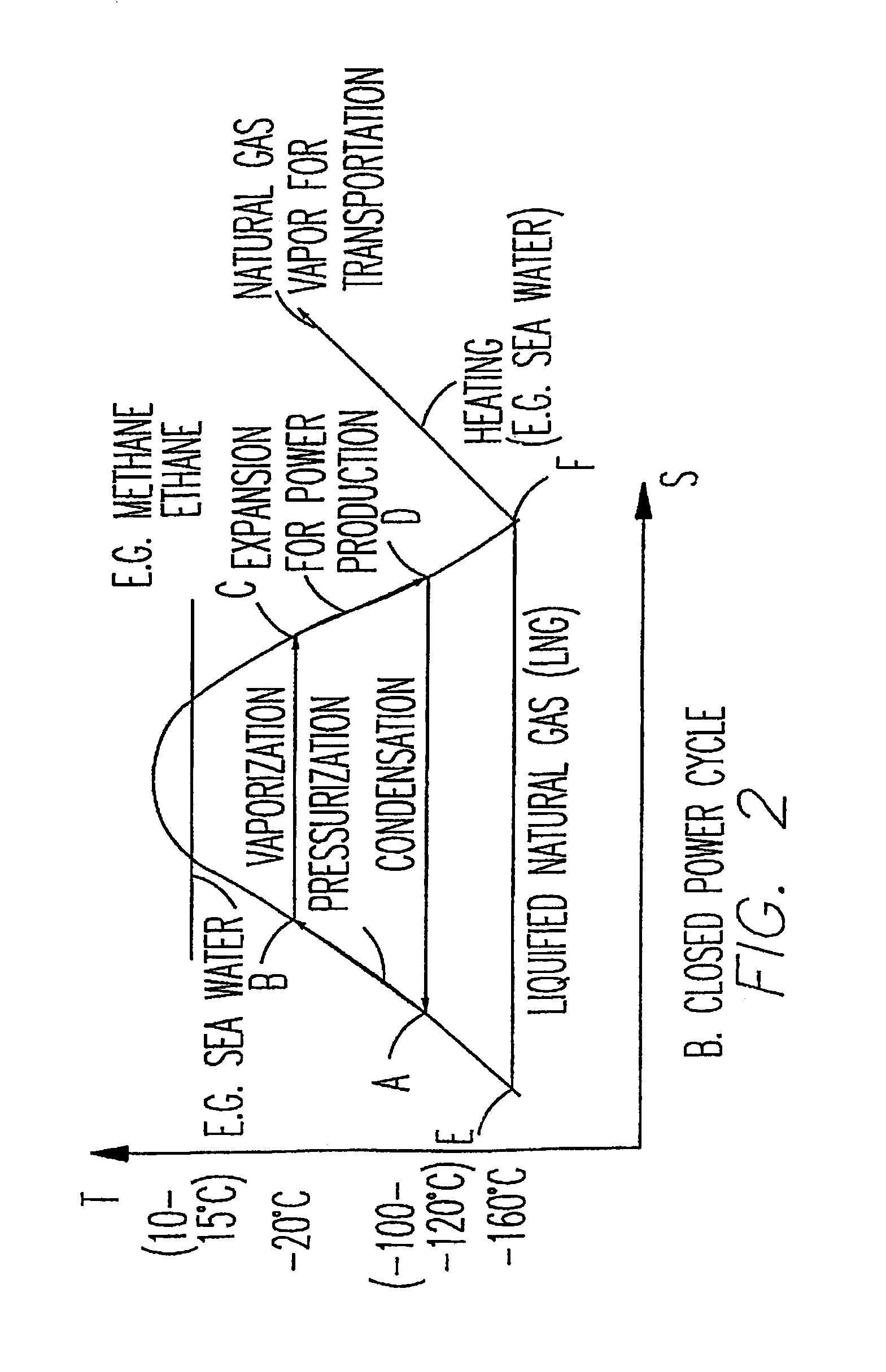

Regasification is a process of converting liquefied natural gas (LNG) at −162 °C (−260 °F) temperature back to natural gas at atmospheric temperature. LNG gasification plants can be located on land as well as on floating barges. Floating barge mounted plants have the advantage that they can be towed to new offshore locations for better usage in response to changes in the business environment. In a conventional regasification plantᴿᵁ, LNG is heated by sea water to convert it to natural gas / methane gas.

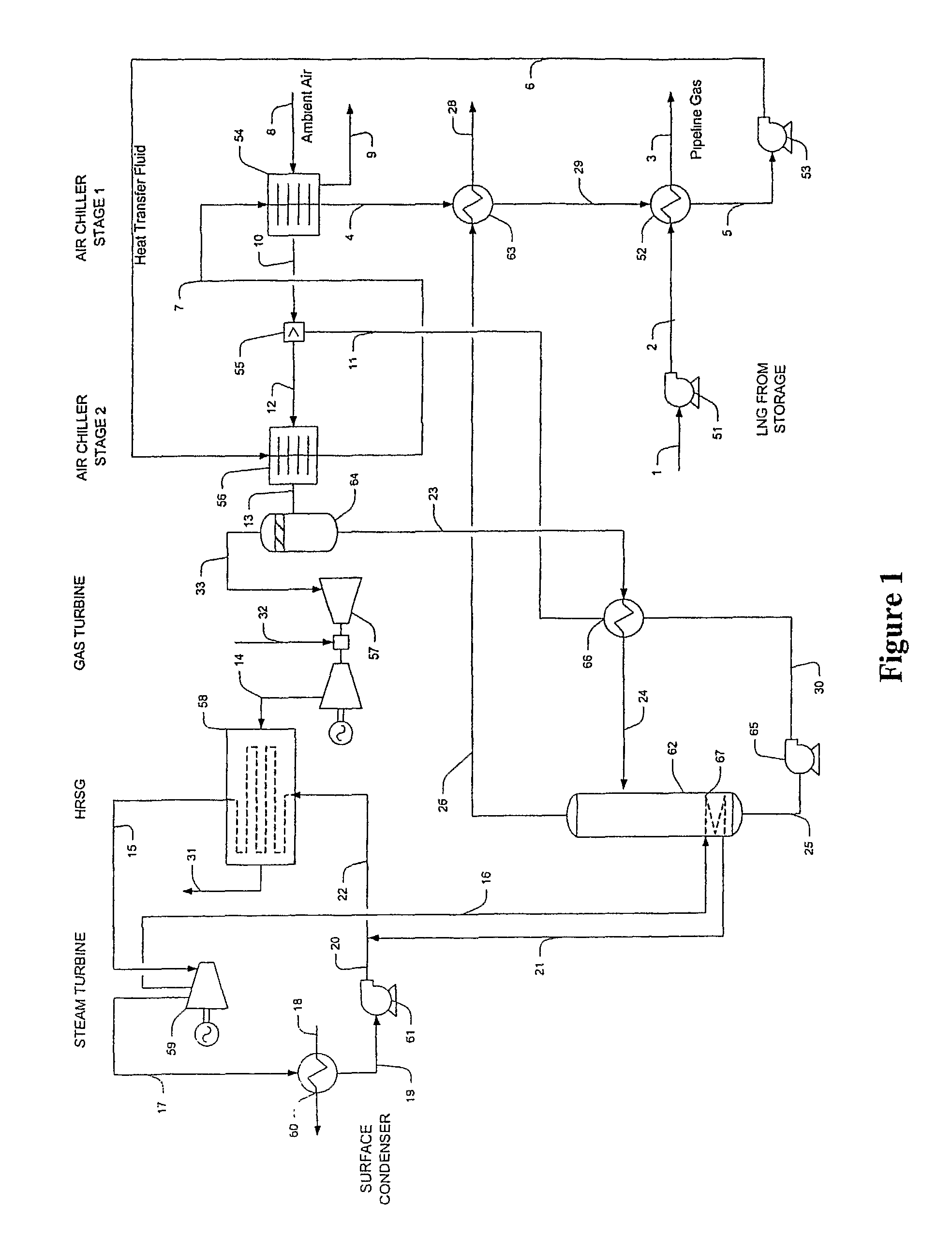

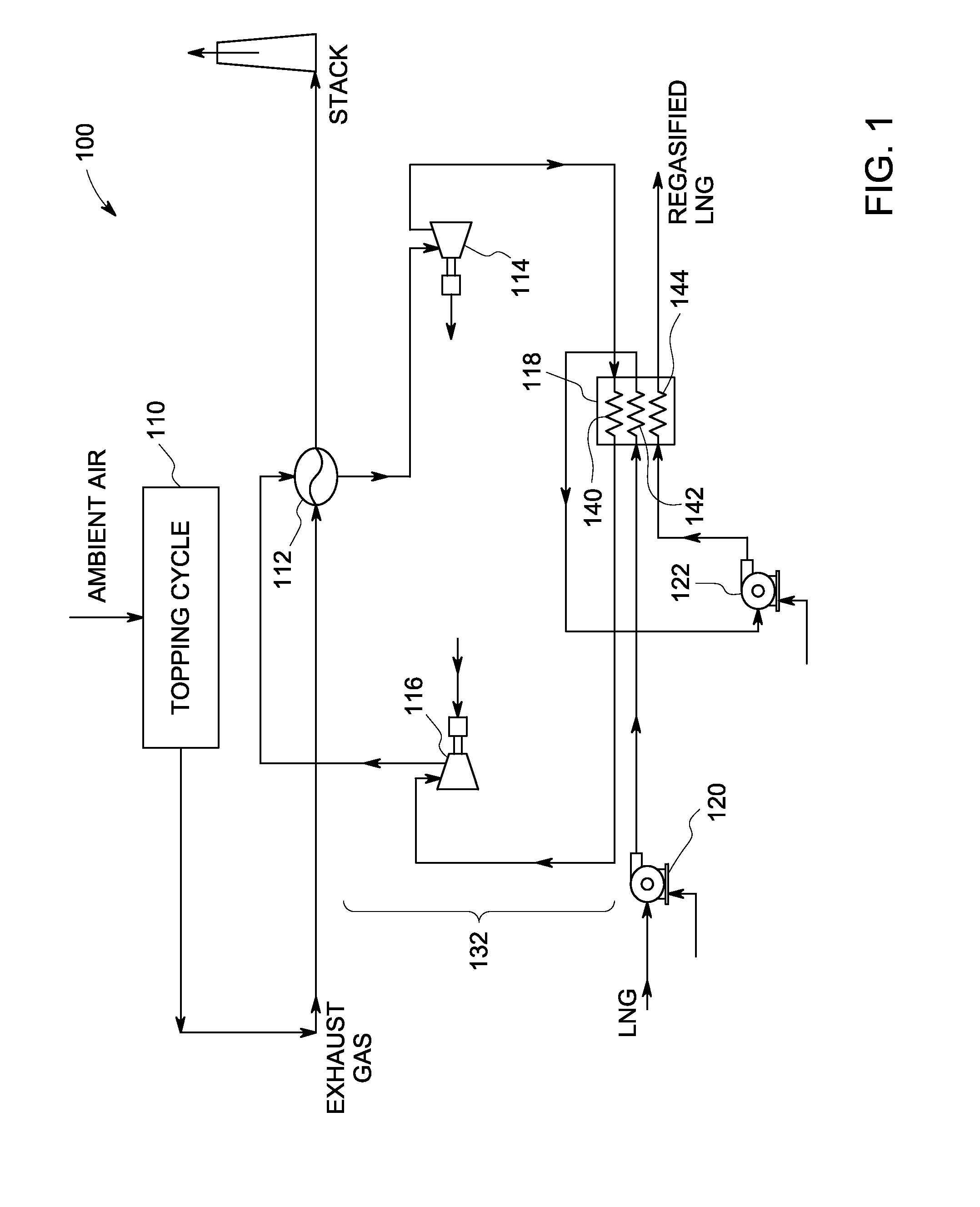

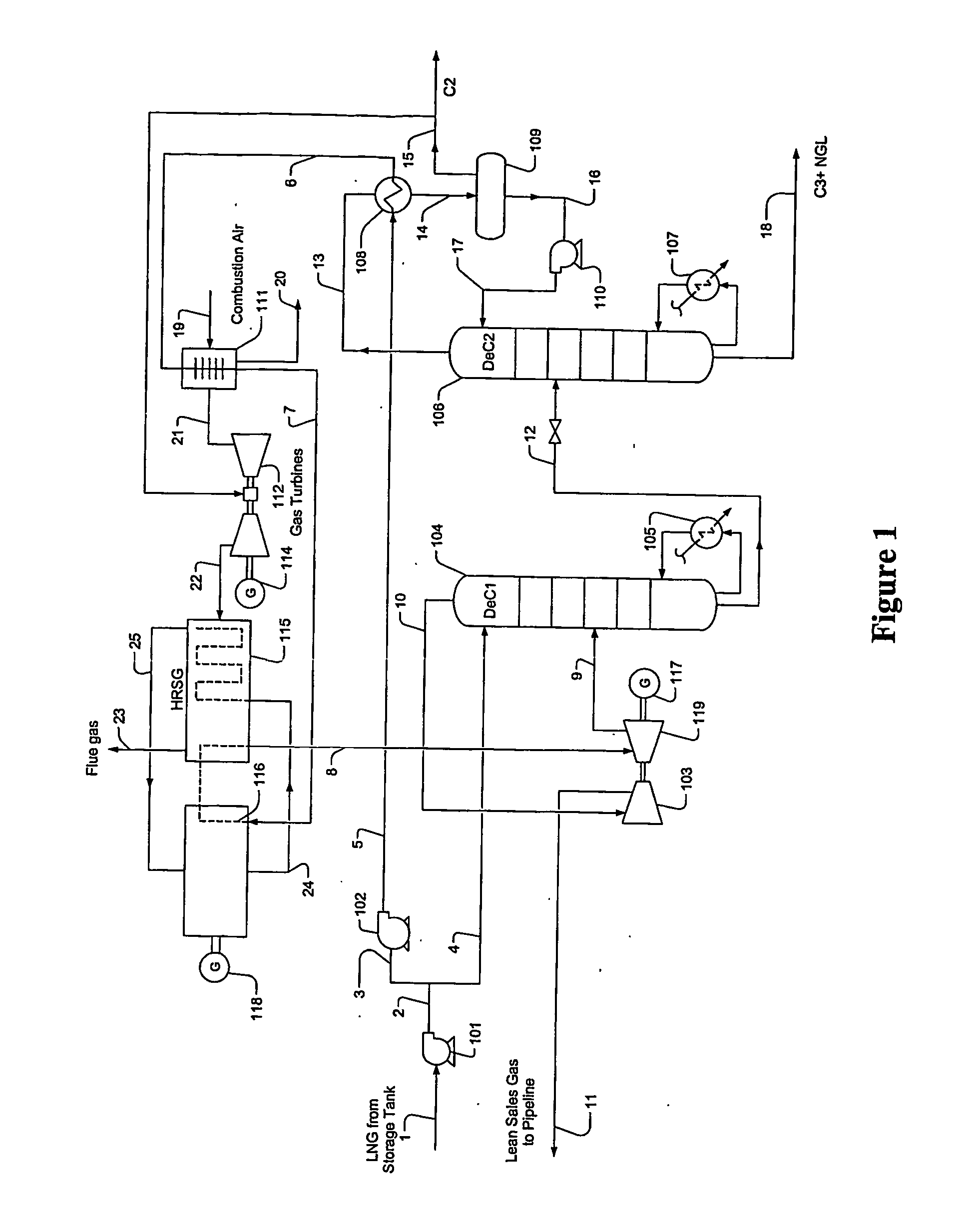

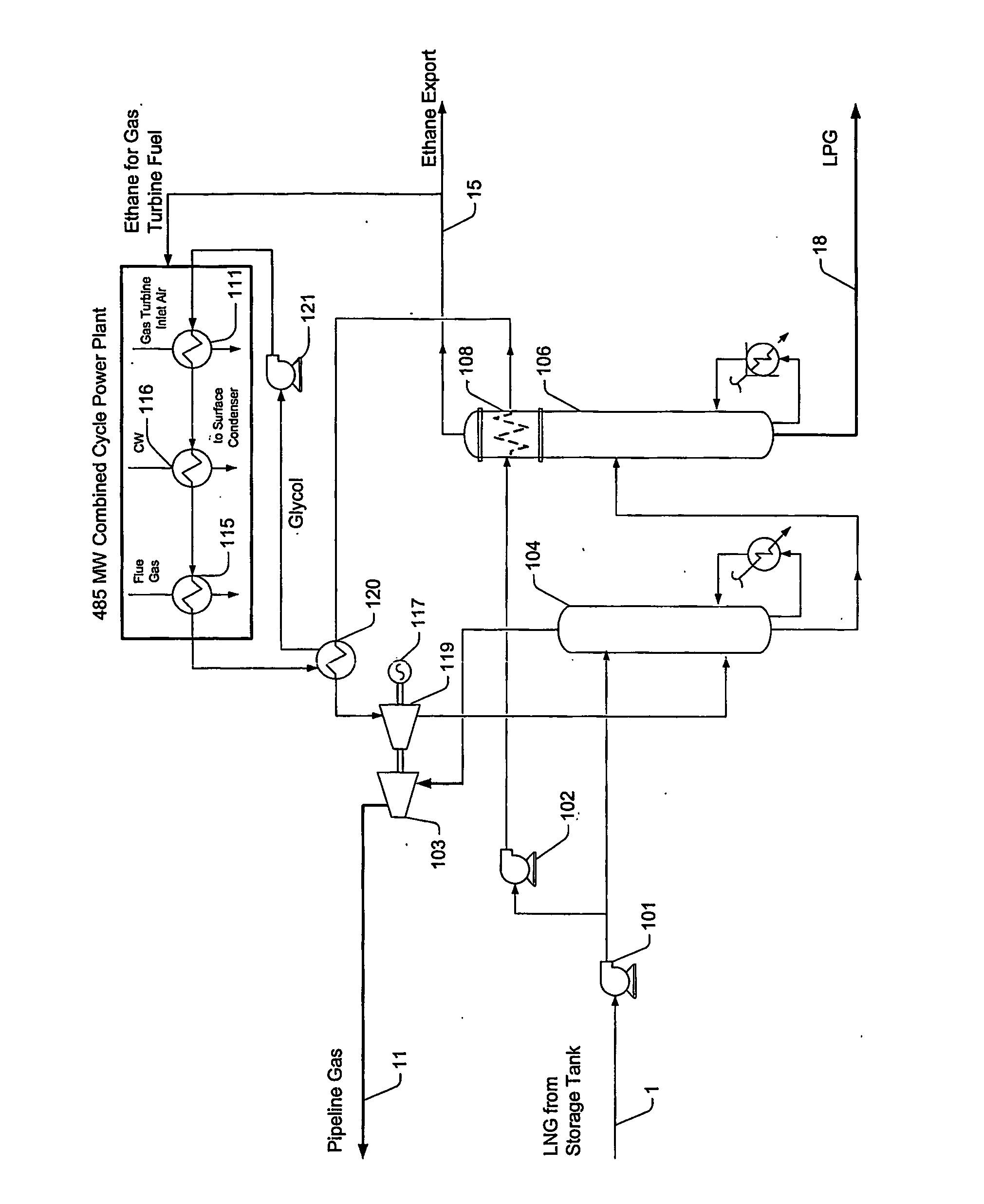

Configurations and methods for power generation with integrated LNG regasification

Owner:FLUOR TECH CORP

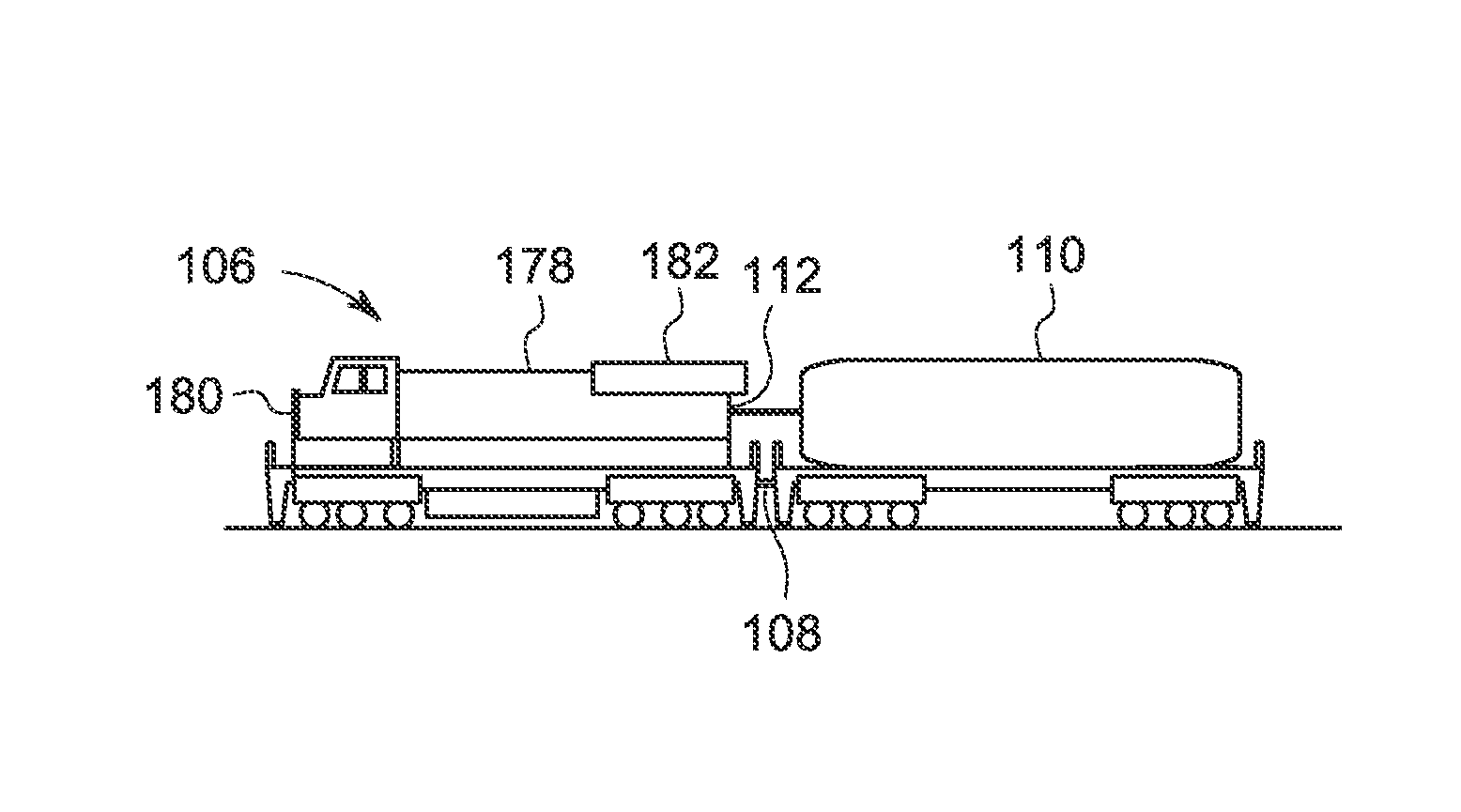

Vehicle system and method

ActiveUS9550501B2Brakes for specific applicationsIC engine locomotivesElectricityCompressed natural gas

Owner:GE GLOBAL SOURCING LLC

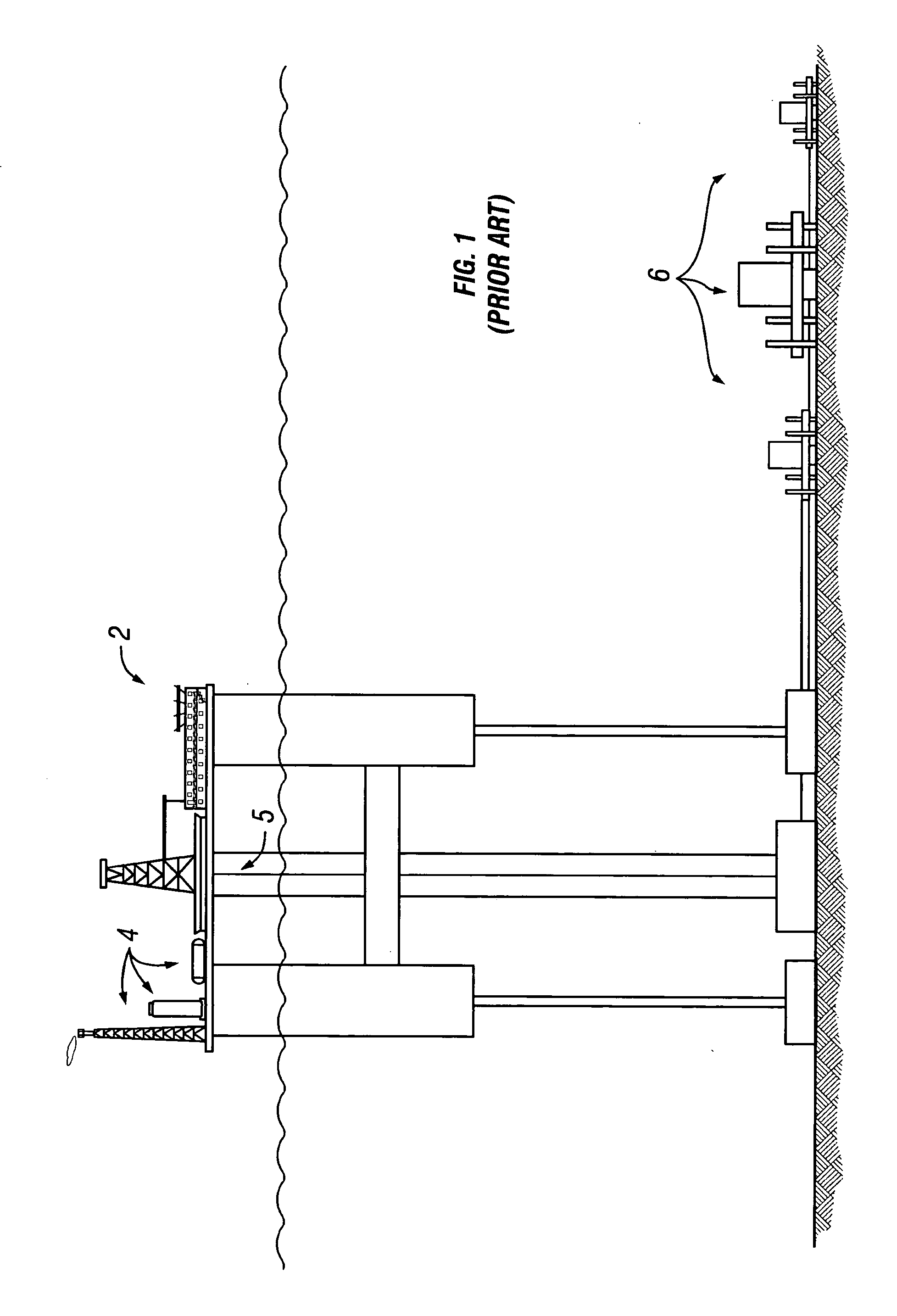

Liquefied natural gas floating storage regasification unit

InactiveUS20060156744A1Reduce the amount requiredProvide protectionGas handling applicationsGas handling/storage effectsMooring systemMarine engineering

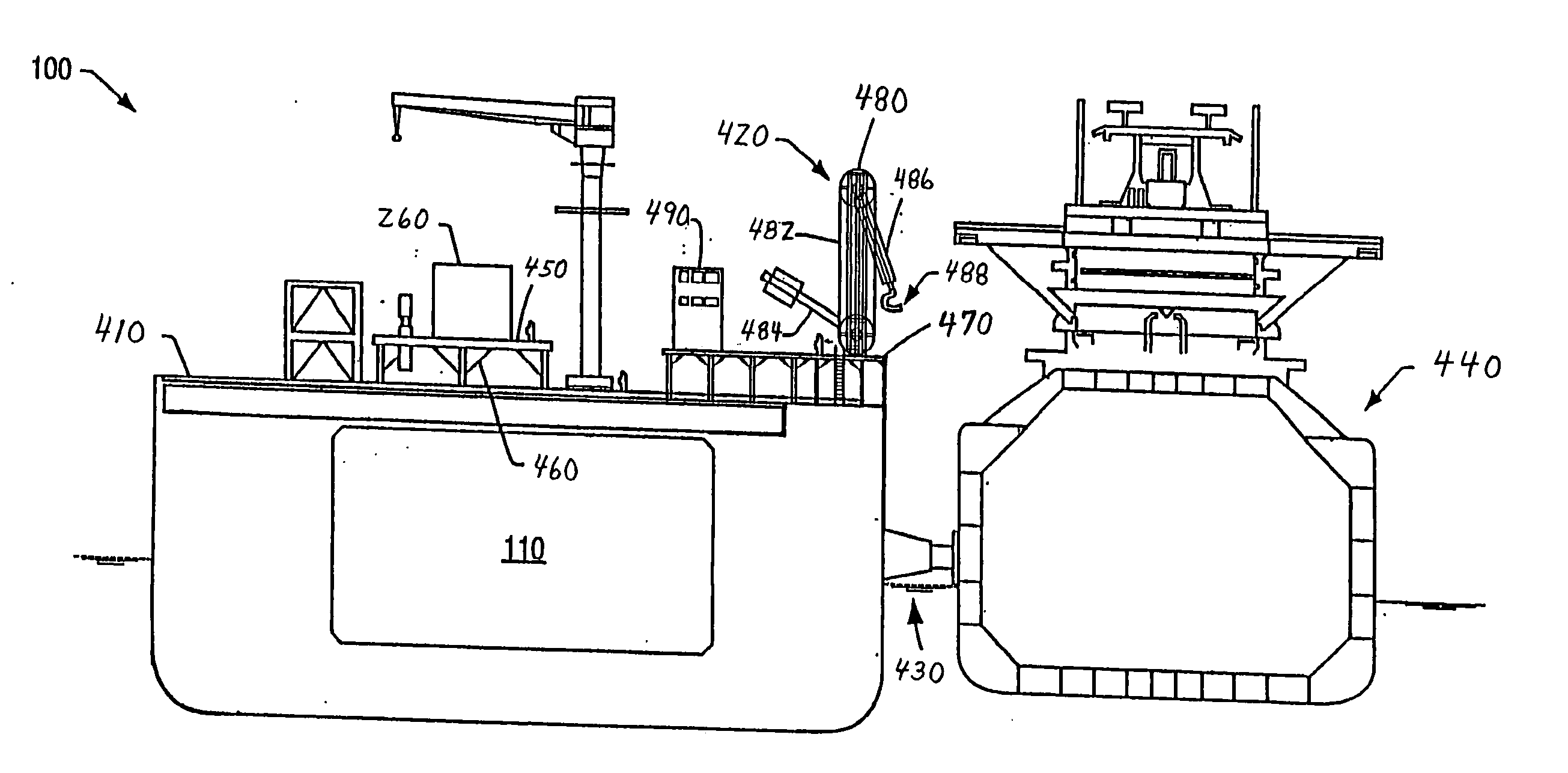

An offshore liquefied natural gas floating storage regasification unit that may receive, store, and process liquefied natural gas from carriers. A floating storage regasification unit may include transfer equipment to offload liquefied natural gas from a carrier, a first mooring system to provide for mooring of a floating storage regasification unit at a location in a body of water, a second mooring system to provide for mooring a carrier to the floating storage regasification unit, and combinations thereof. A portion of the floating storage regasification unit may be composed of a double-hull containment structure.

Owner:SHELL OIL CO

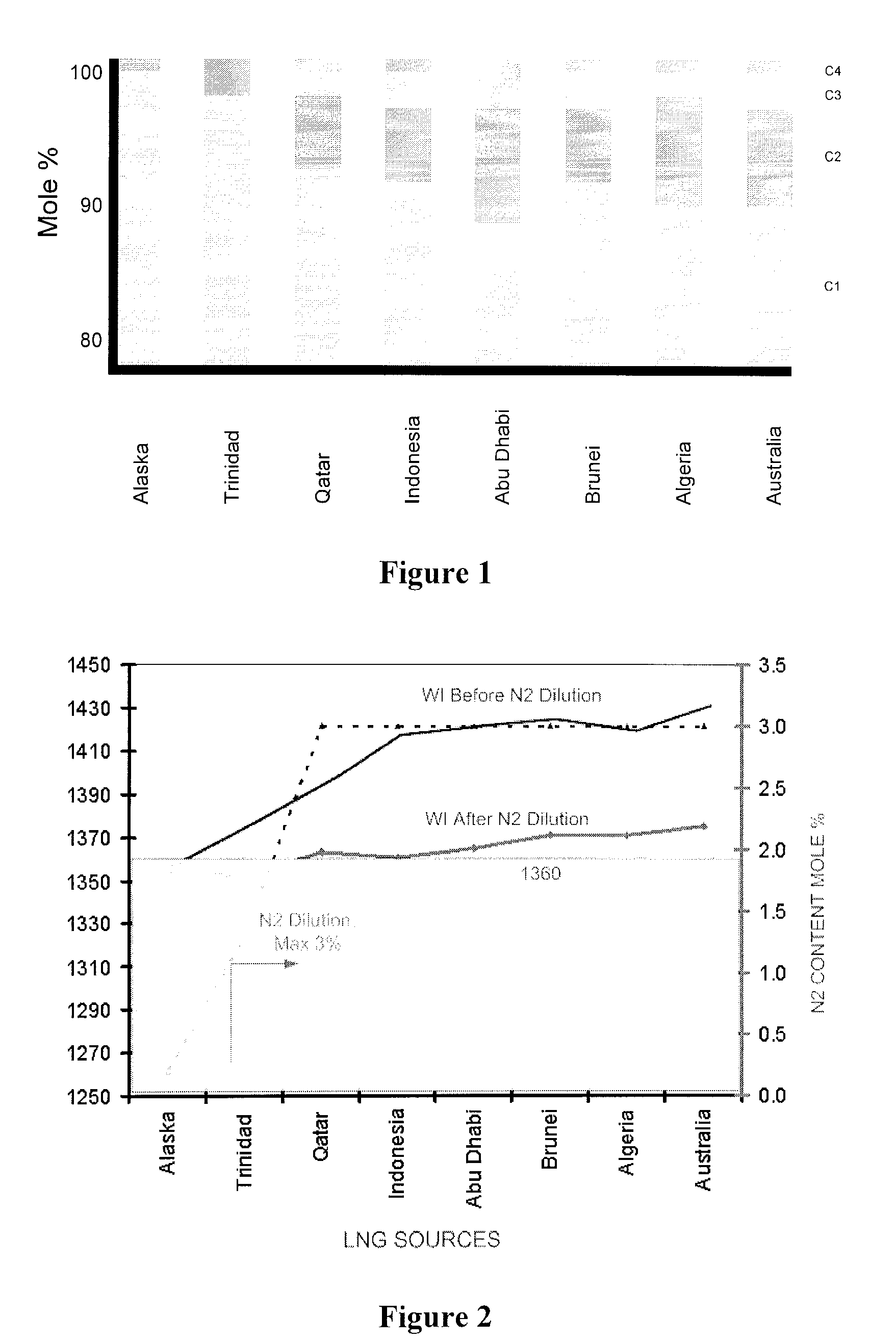

Methods and Configurations of Boil-off Gas Handling in LNG Regasification Terminals

InactiveUS20110056238A1Stable storage tank pressure controlStable controlSolidificationLiquefactionProcess engineeringWobbe index

A LNG storage and regasification plant includes a reliquefaction unit in which boil-off vapors from the storage tanks are re liquefied and recycled back to the LNG storage tanks for tank pressure and Wobbe index control. Preferably, LNG cold is used for reliquefaction and operational flexibility is achieved by feeding a portion of the pressurized boil-off gas to a fuel gas header and / or to be recondensed by the sendout LNG.

Owner:FLUOR TECH CORP

Integration of LNG regasification with refinery and power generation

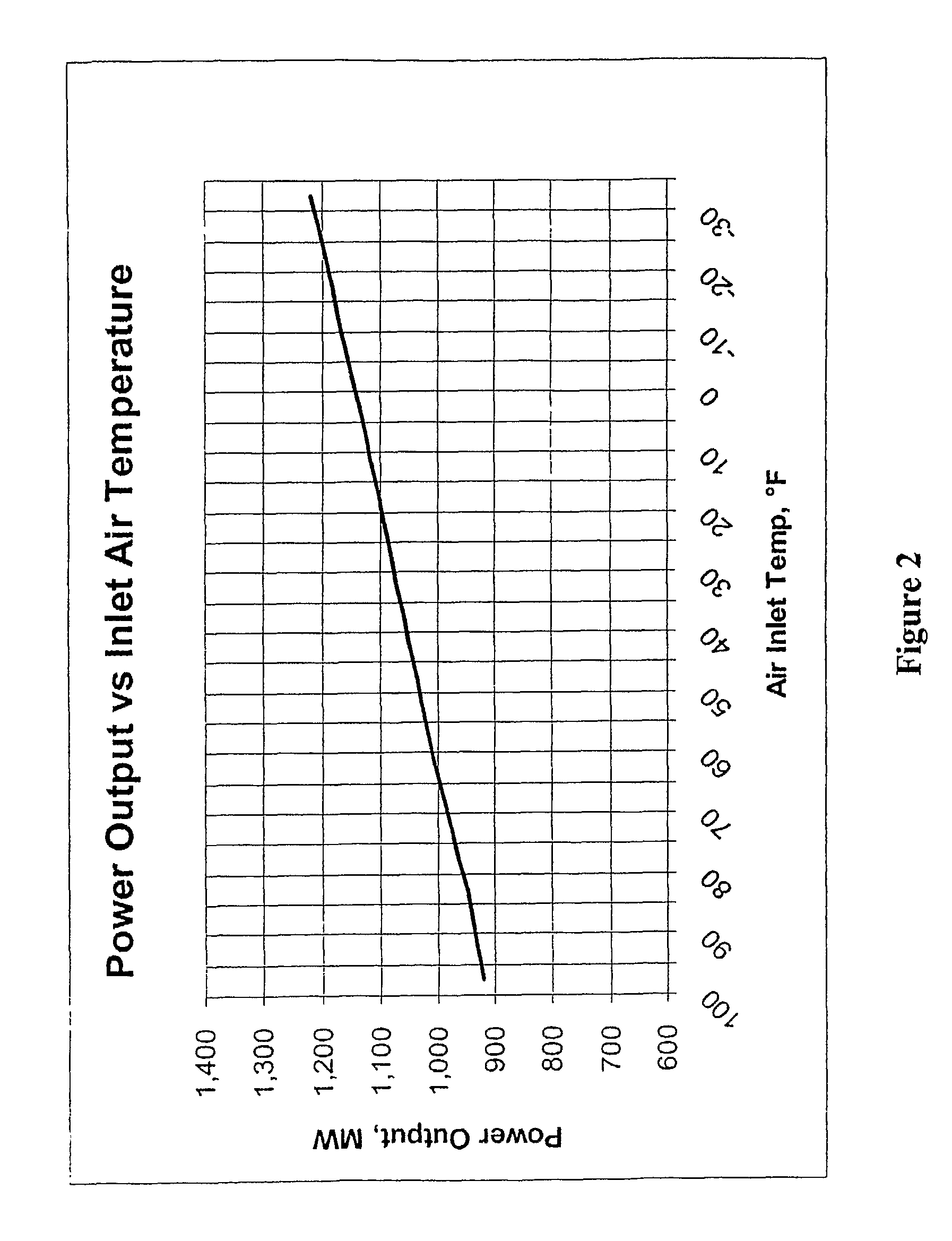

Contemplated plants thermally integrate operation of a refinery component, and most preferably of a hydrocarbon splitter with LNG regasification to provide refrigeration duty and with a power cycle to provide the reboiler duty of the component. It should be noted that such configurations advantageously allow operation of the splitter at a reduced temperature and at reduced pressure, thereby increasing separation efficiency, while the power output is boosted using air intake chilling. Most notably, such process advantages are achieved by satisfying the heating duty of LNG regasification.

Owner:FLUOR TECH CORP

Configurations and methods for thermal integration of LNG regasification and power plants

Owner:FLUOR TECH CORP

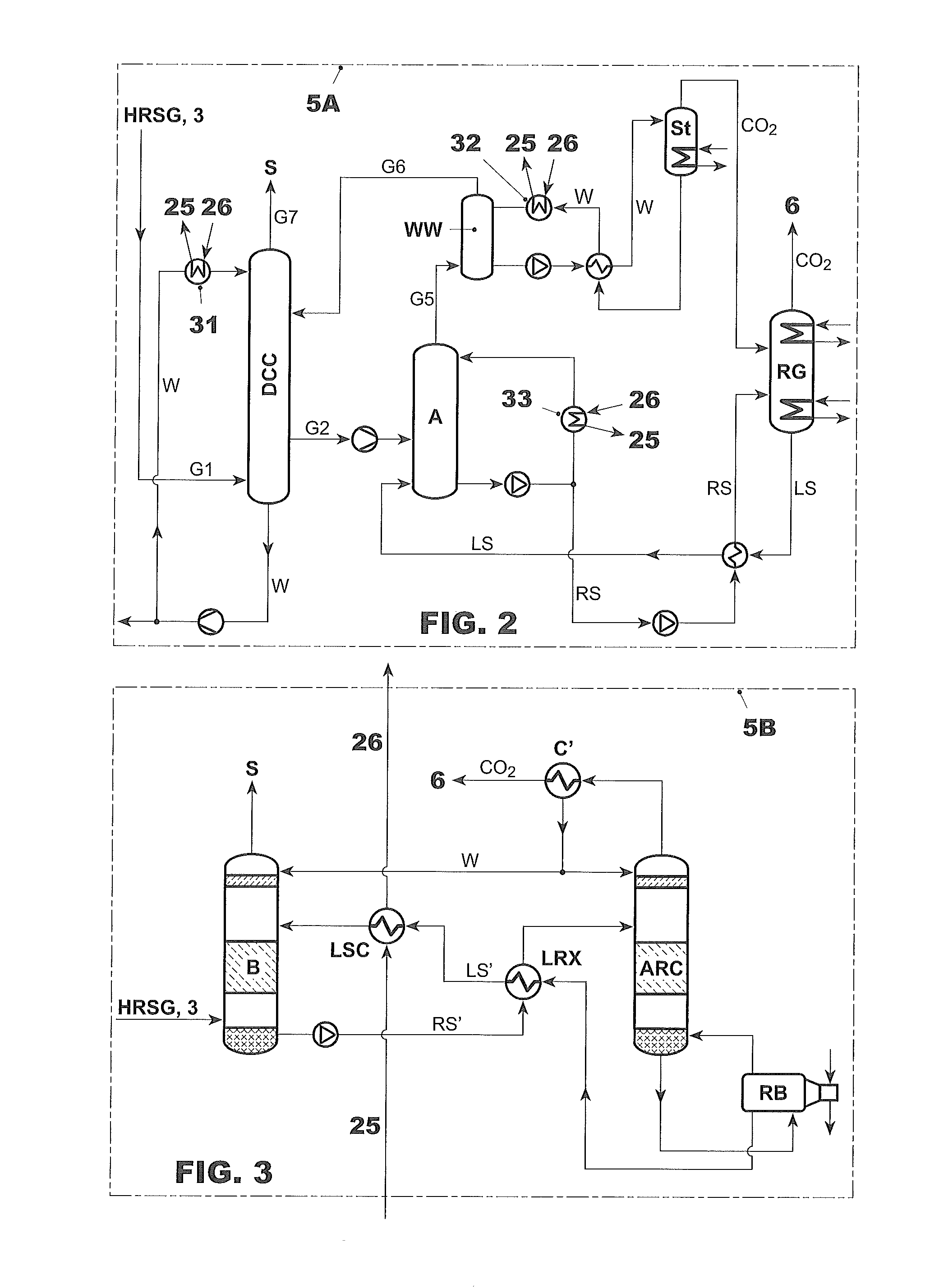

Integrated LNG gasification and power production cycle

ActiveUS20130104525A1Improve efficiencyLow costSolidificationLiquefactionCombustorProcess engineering

The present disclosure provides an integrated power generating system and method and liquefied natural gas (LNG) vaporization system and method. More particularly, heat from a CO2 containing stream from the power generating system and method can be used to heat the LNG for re-gasification as gaseous CO2 from CO2 containing stream is liquefied. The liquefied CO2 can be captured and / or recycled back to a combustor in the power generating system and method.

Owner:8 RIVERS CAPTTAL LLC

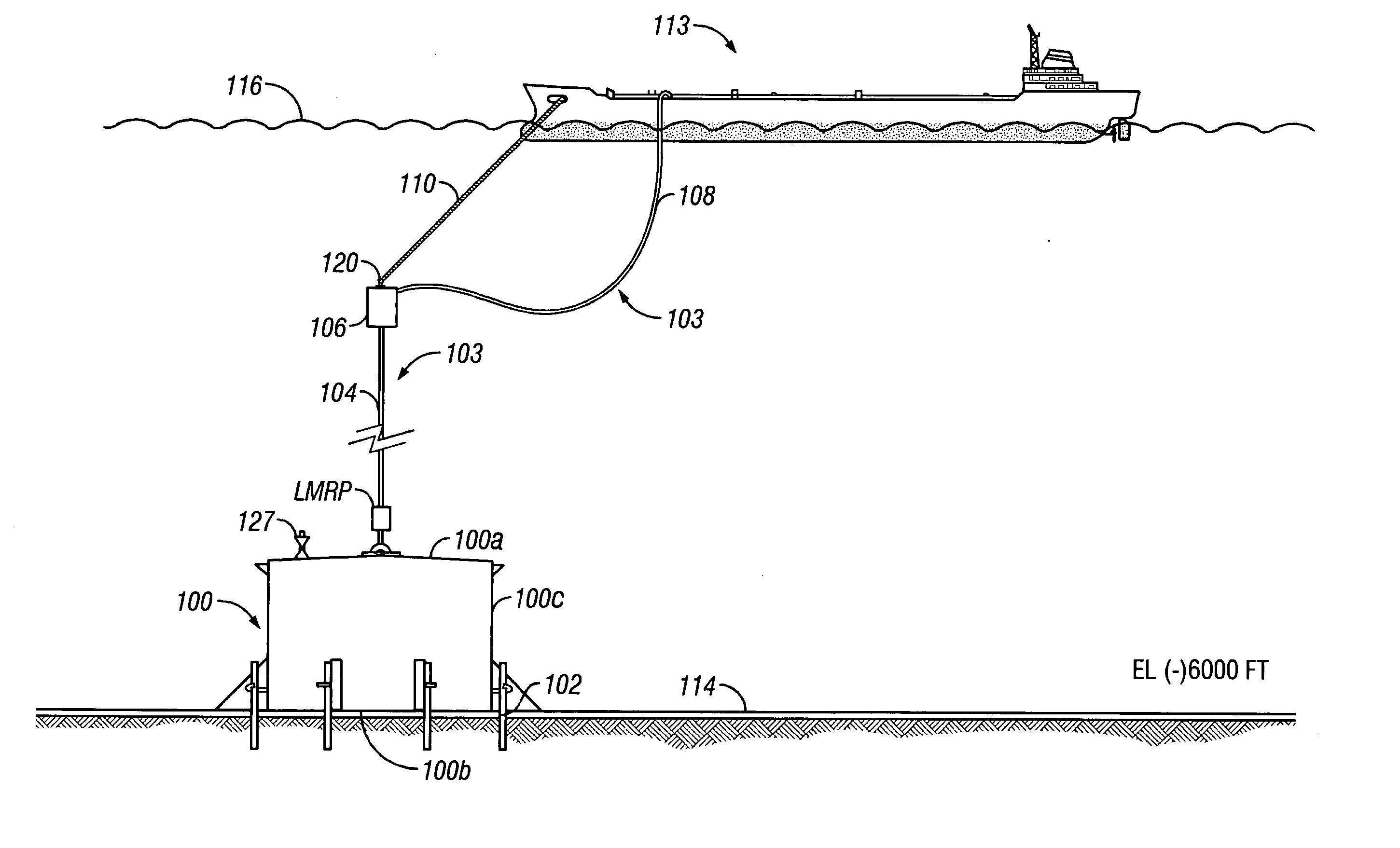

Infrastructure-independent deepwater oil field development concept

A method for developing a sub-sea hydrocarbons field includes sub-sea wells, sub-sea oil / gas separation, storing the degassed oil in a storage tank located or the seabed, liquefying natural gas aboard a vessel using liquid nitrogen aboard the vessel to obtain liquefied natural gas, transporting the liquefied natural gas to an onshore terminal, re-gasifying the liquefied natural gas, and obtaining a new batch of liquid nitrogen using energy recovered from the re-gasifying the liquefied natural gas.

Owner:CONOCOPHILLIPS CO

Regasification system and method

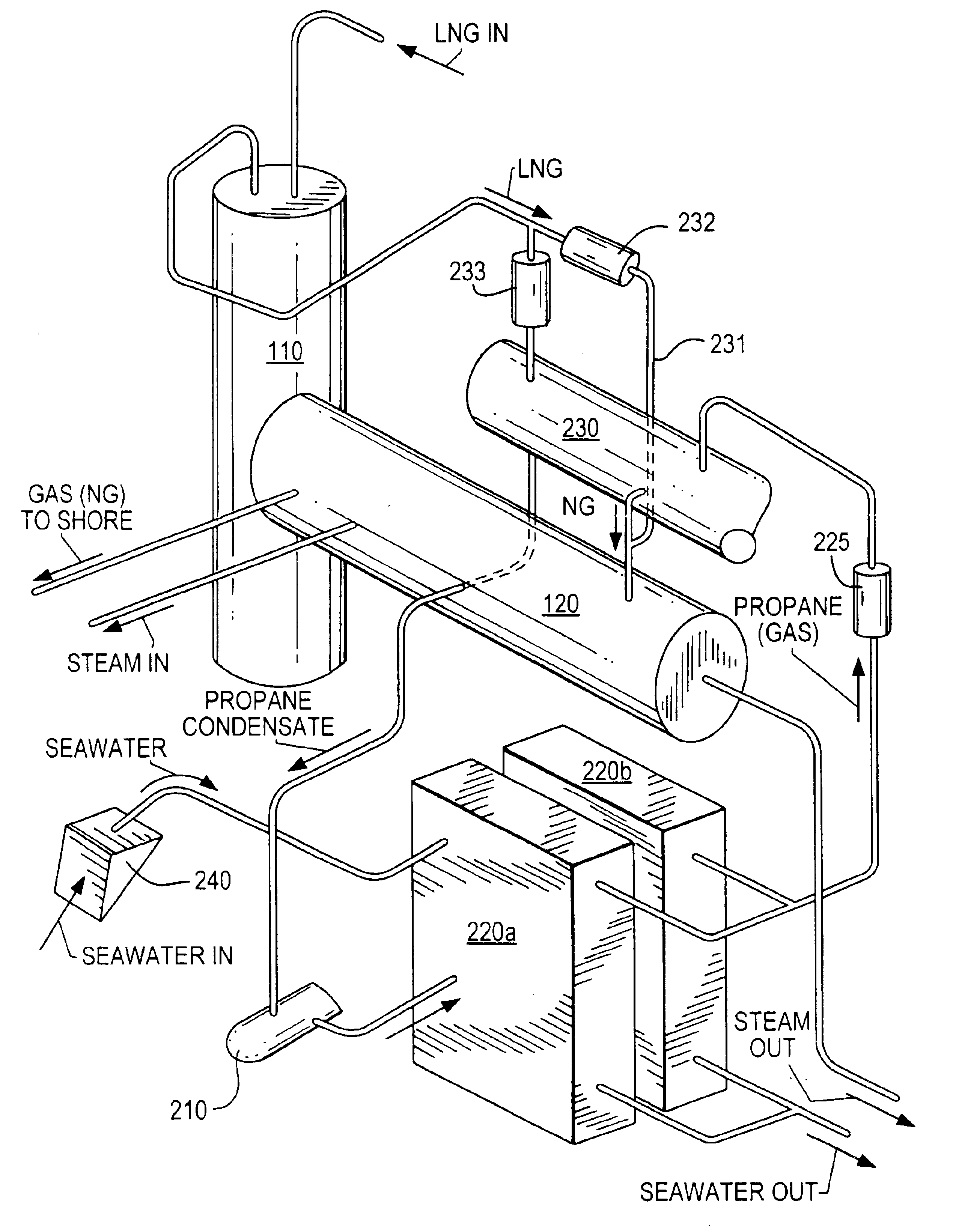

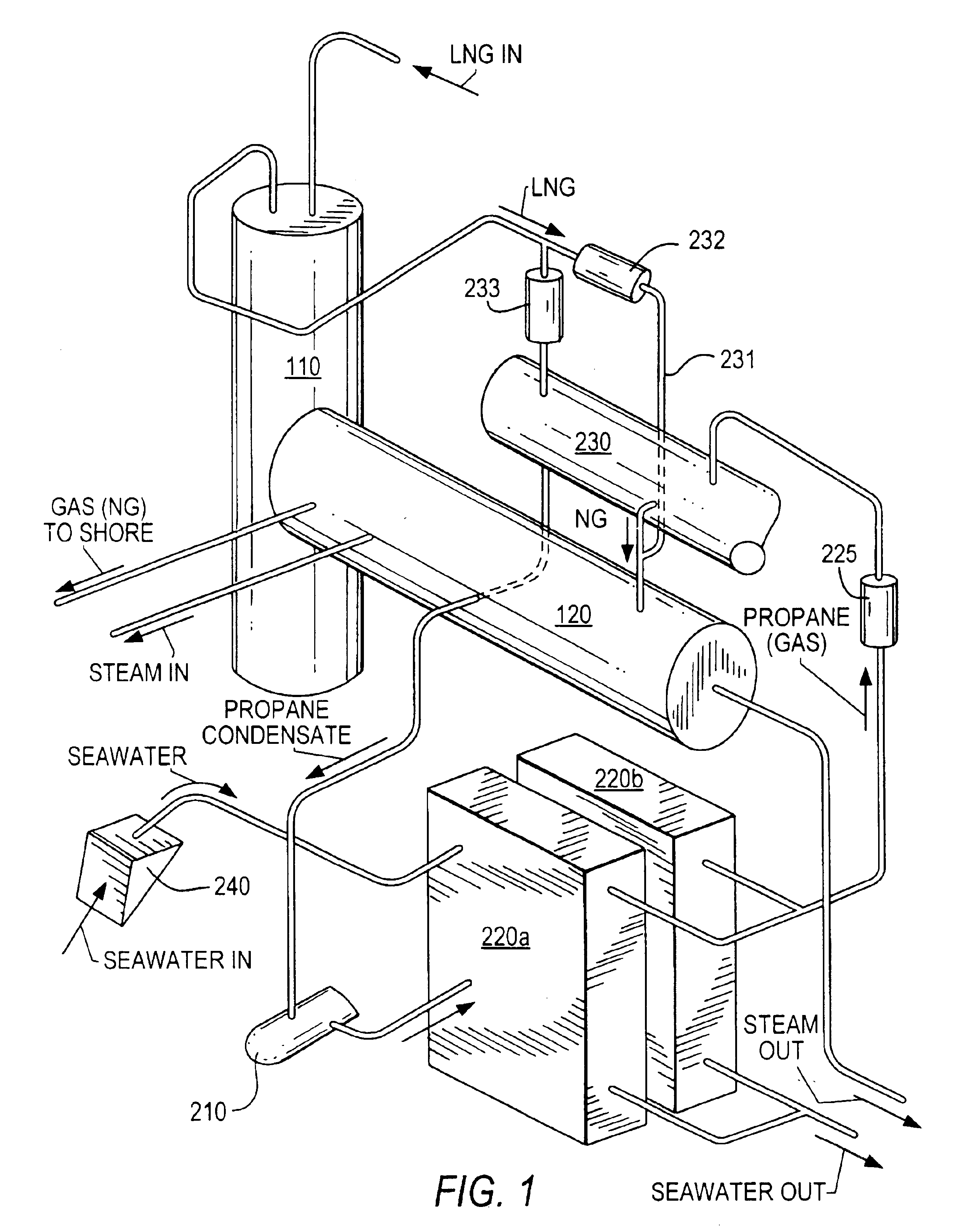

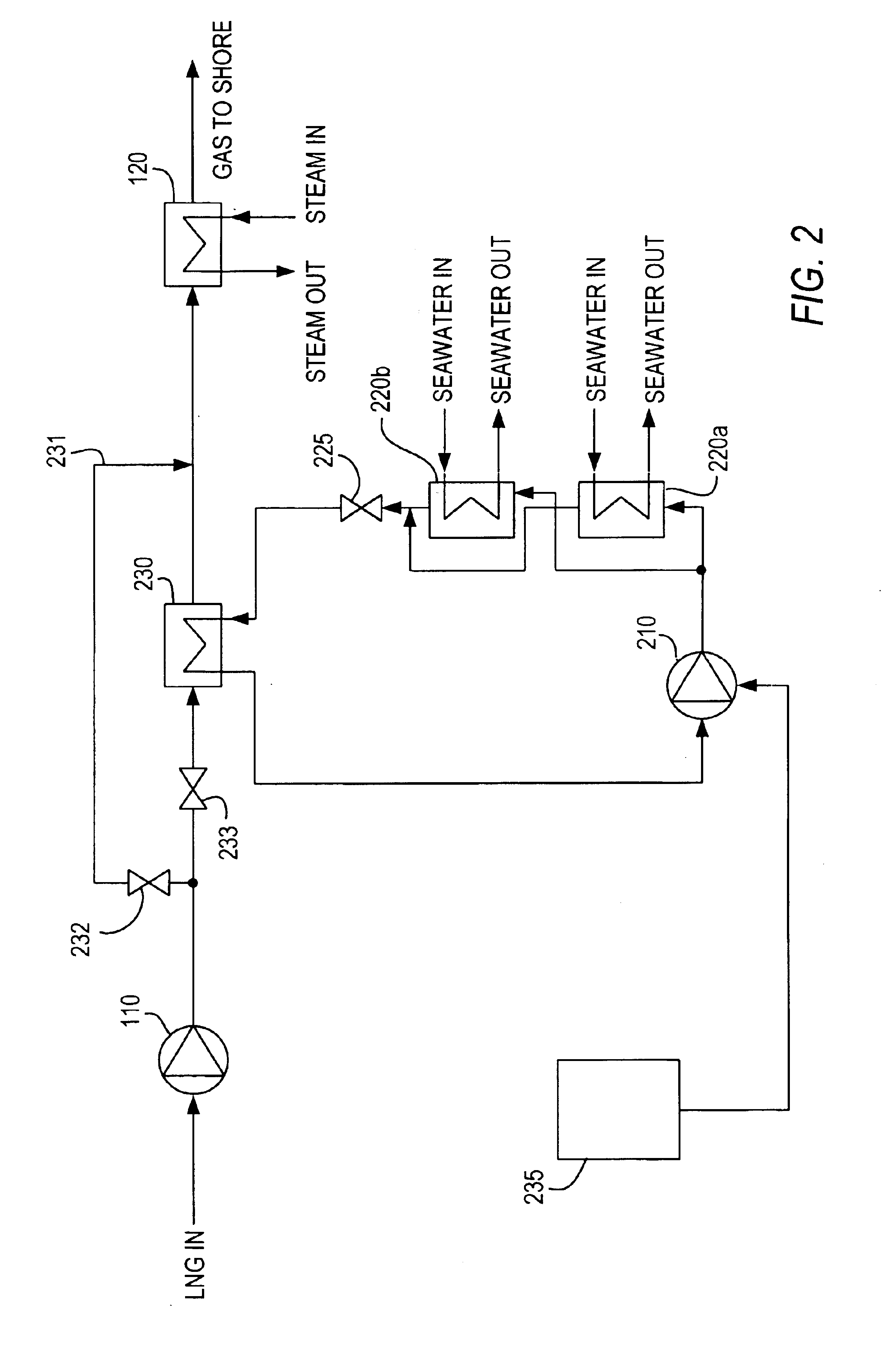

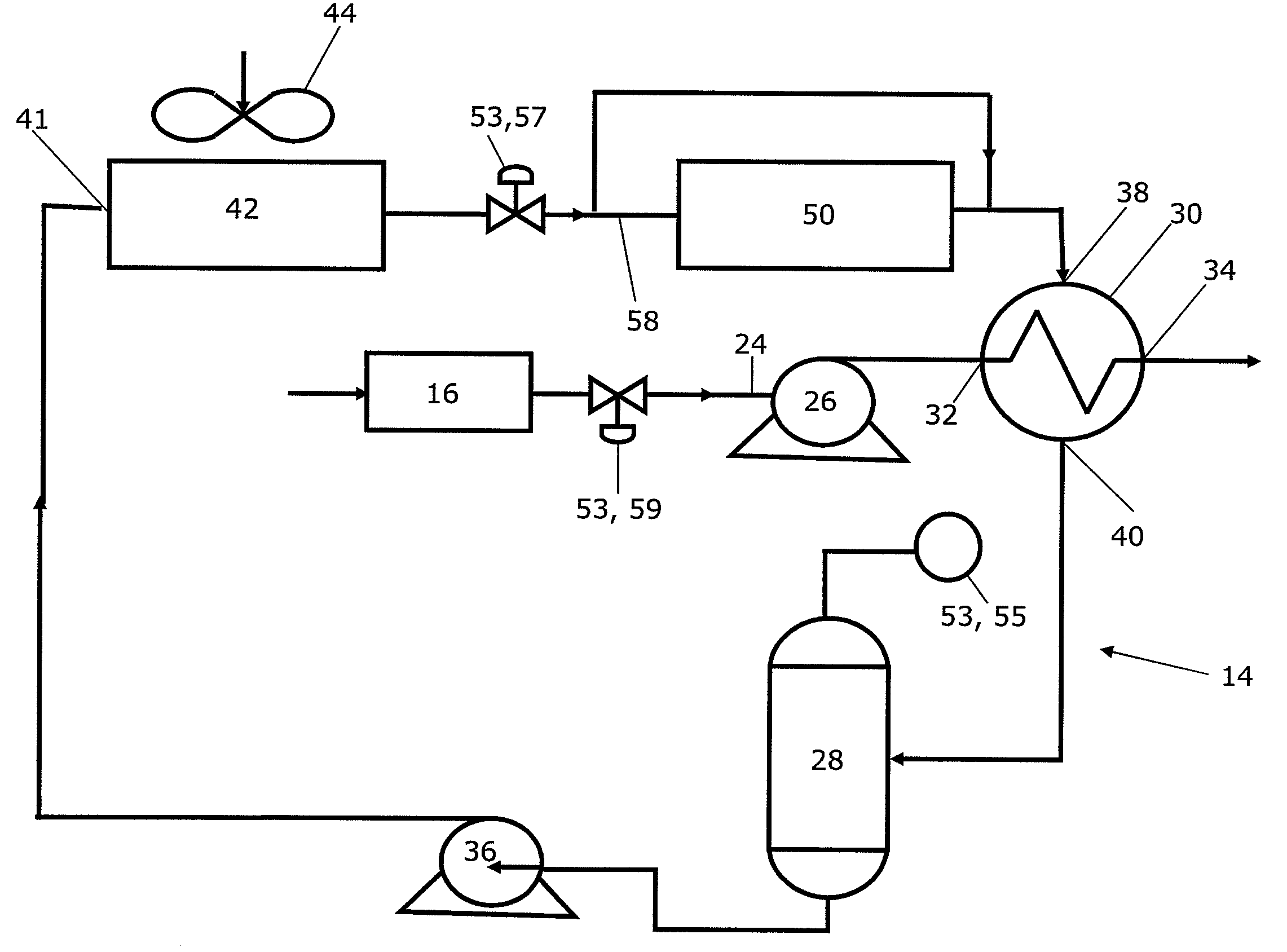

The present invention provides a novel regasification method and system in which the evaporative coolant is forced through an evaporation and condensation cycle, allowing control of the evaporative coolant condensation pressure; thus yielding a more flexible and more compact regasification system than those of the prior art.

Owner:WARTSILA OIL & GAS SYST

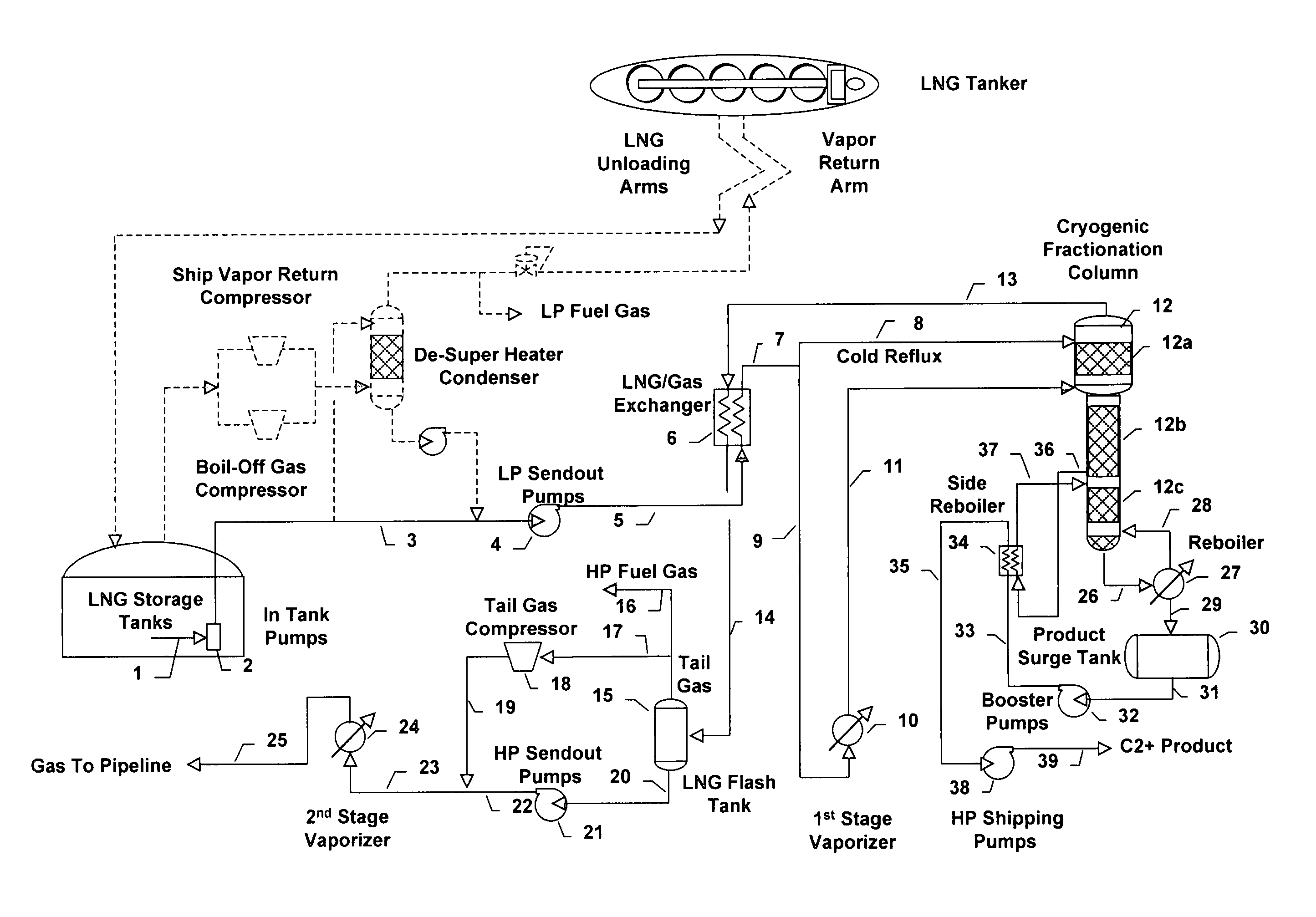

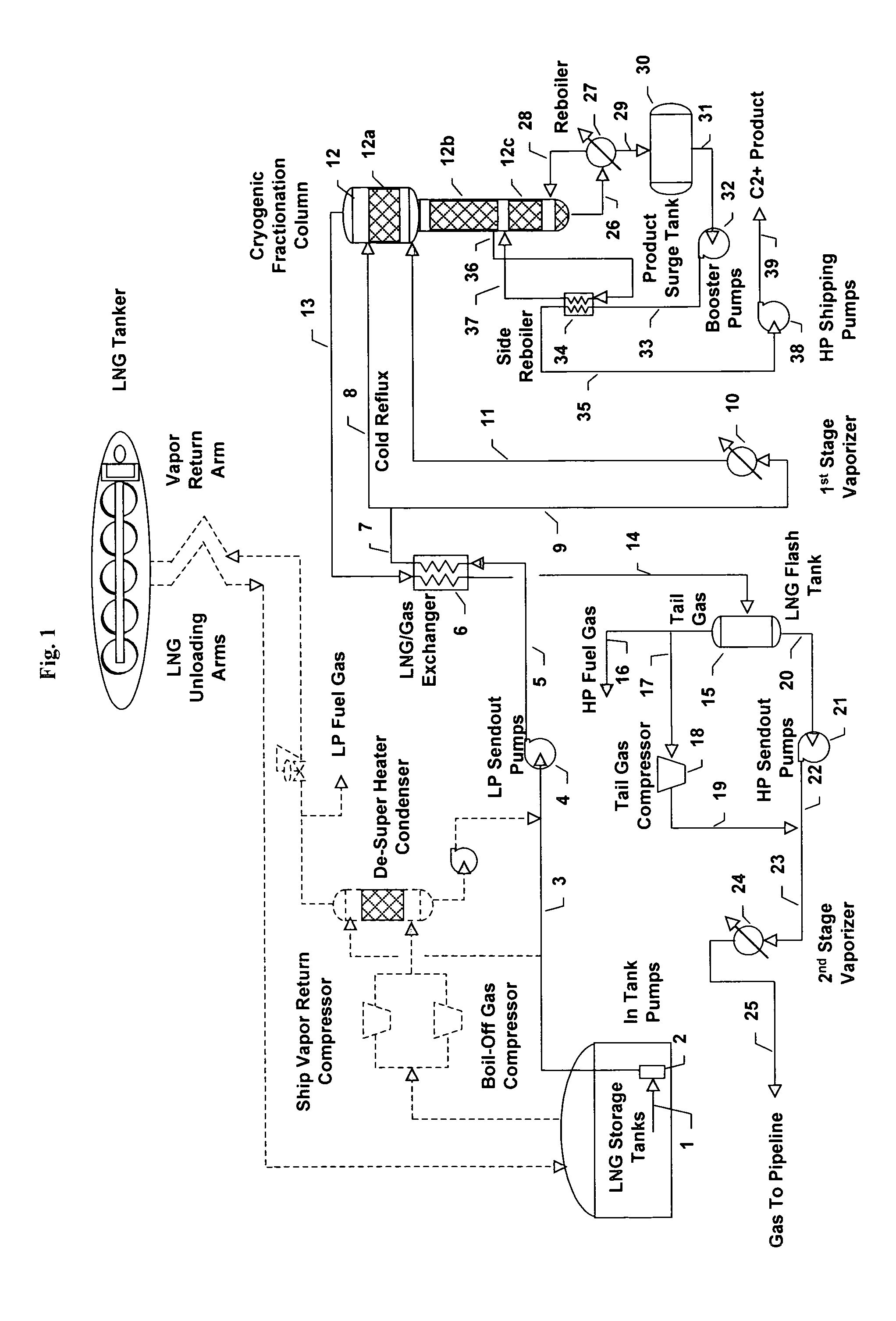

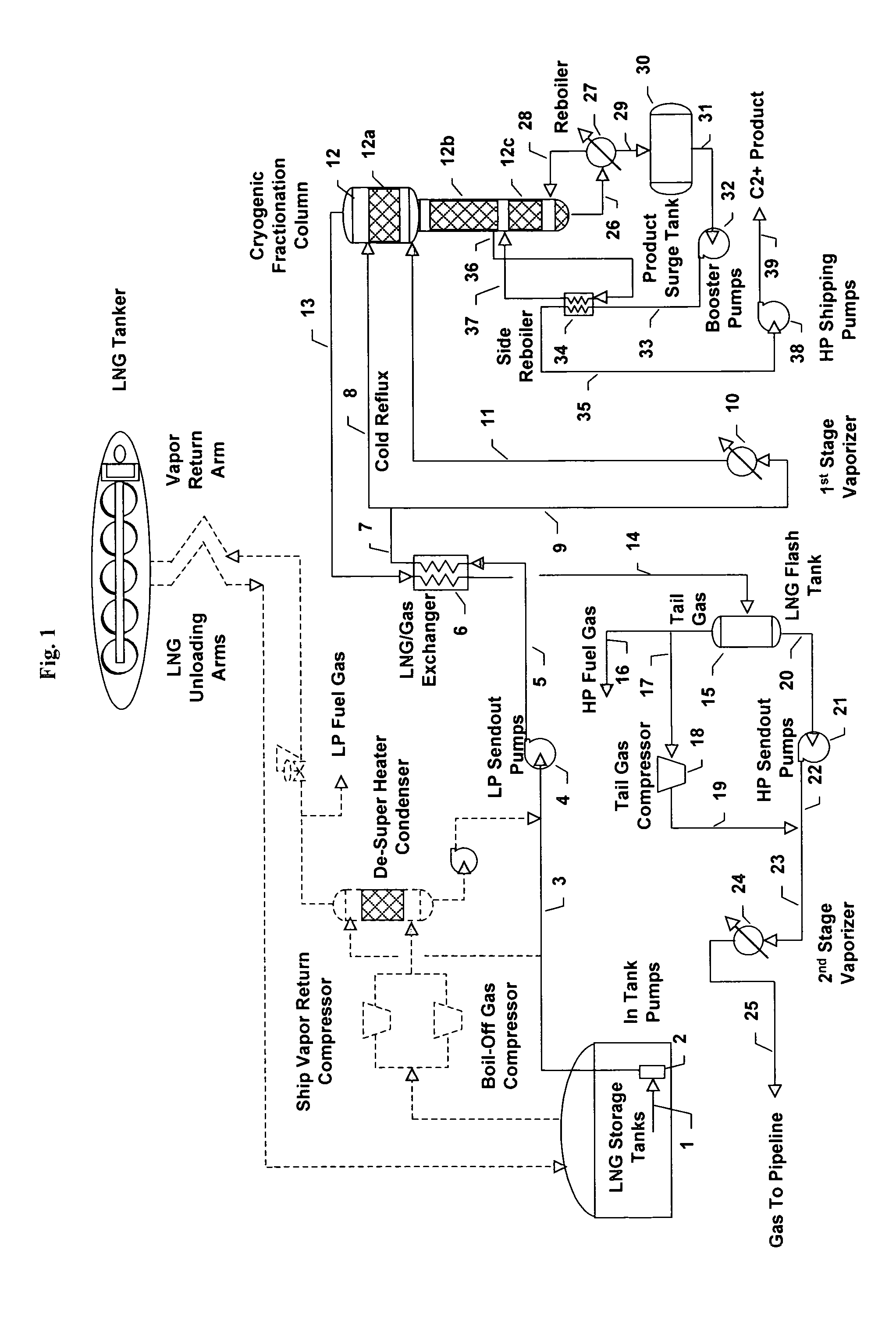

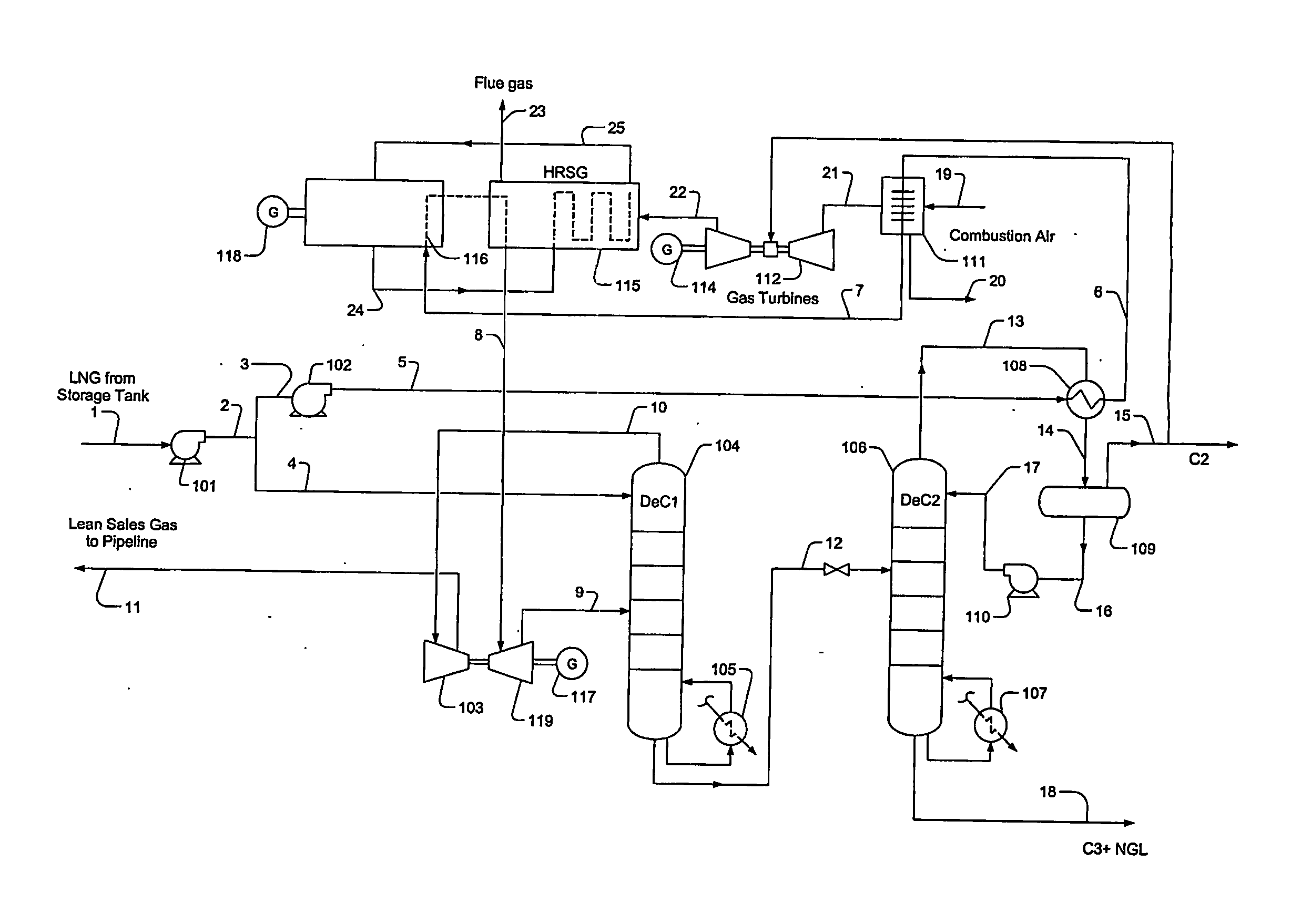

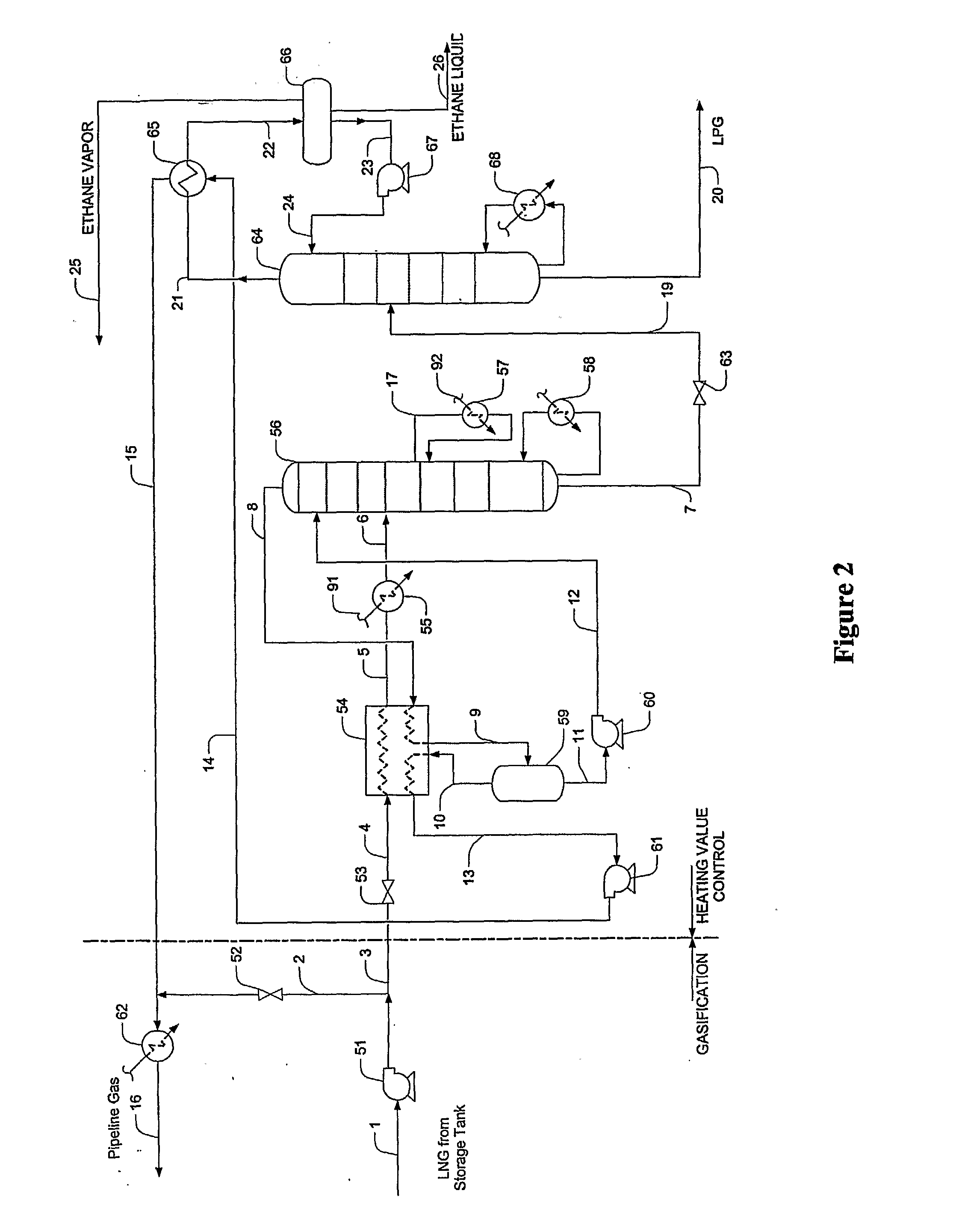

Process for extracting ethane and heavier hydrocarbons from LNG

ActiveUS7165423B2Efficiently extracting NGL productsAdvanced technologySolidificationLiquefactionFuel qualityFractionation

A process for the extraction and recovery of ethane and heavier hydrocarbons (C2+) from LNG. The process covered by this patent maximizes the utilization of the beneficial cryogenic thermal properties of the LNG to extract and recover C2+ form the LNG using a unique arrangement of heat exchange equipment, a cryogenic fractionation column and processing parameters that essentially eliminates (or greatly reduces) the need for gas compression equipment minimizing capital cost, fuel consumption and electrical power requirements.This invention may be used for one or more of the following purposes:to condition LNG so that send-out gas delivered from an LNG receiving and regasification terminal meets commercial natural gas quality specifications;to condition LNG to make Lean LNG that meets fuel quality specifications and standards required by LNG powered vehicles and other LNG fueled equipment;to condition LNG to make Lean LNG so that it can be used to make CNG meeting specifications and standards for commercial CNG fuel;to recover ethane, propane and / or other hydrocarbons heavier then methane from LNG for revenue enhancement, profit or other commercial reasons.

Owner:PI TECH ASSOC INC

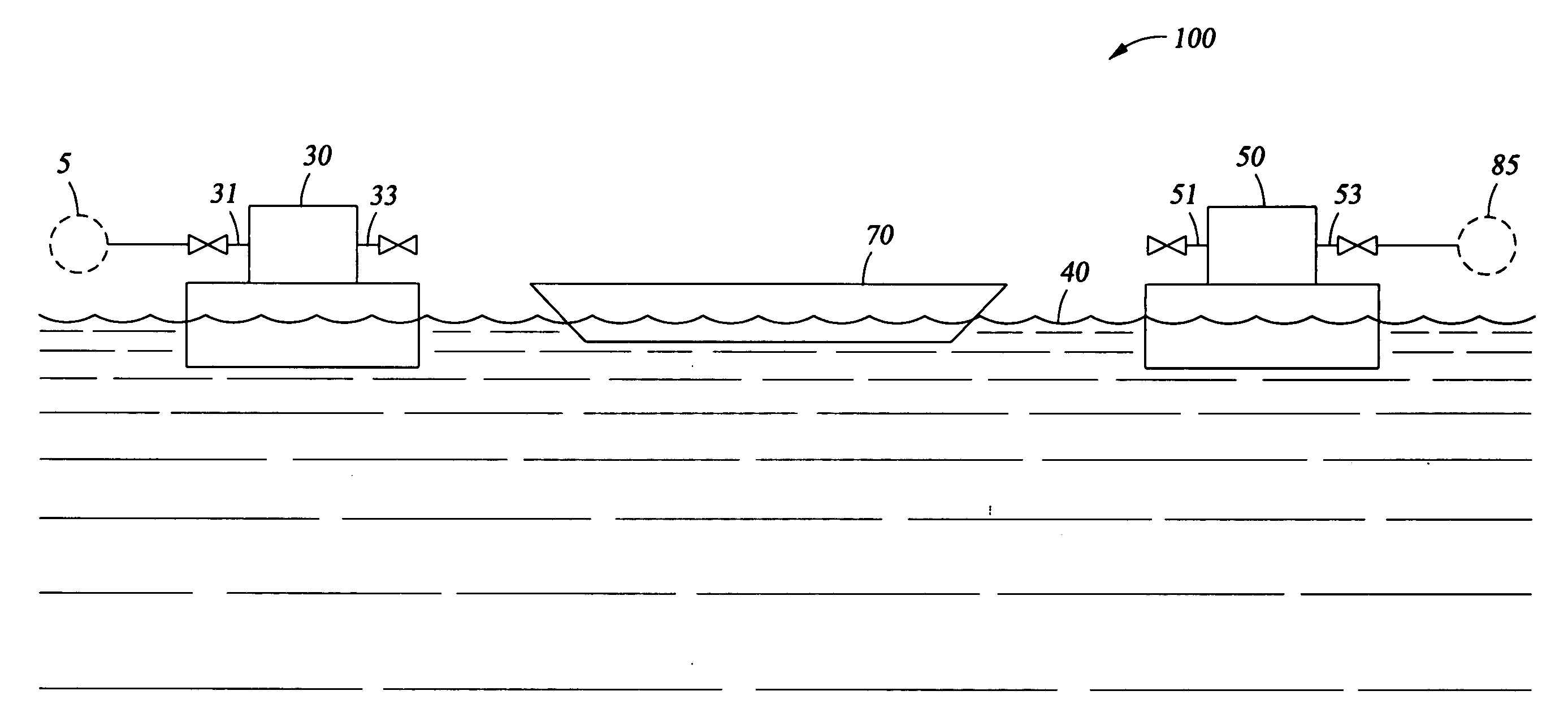

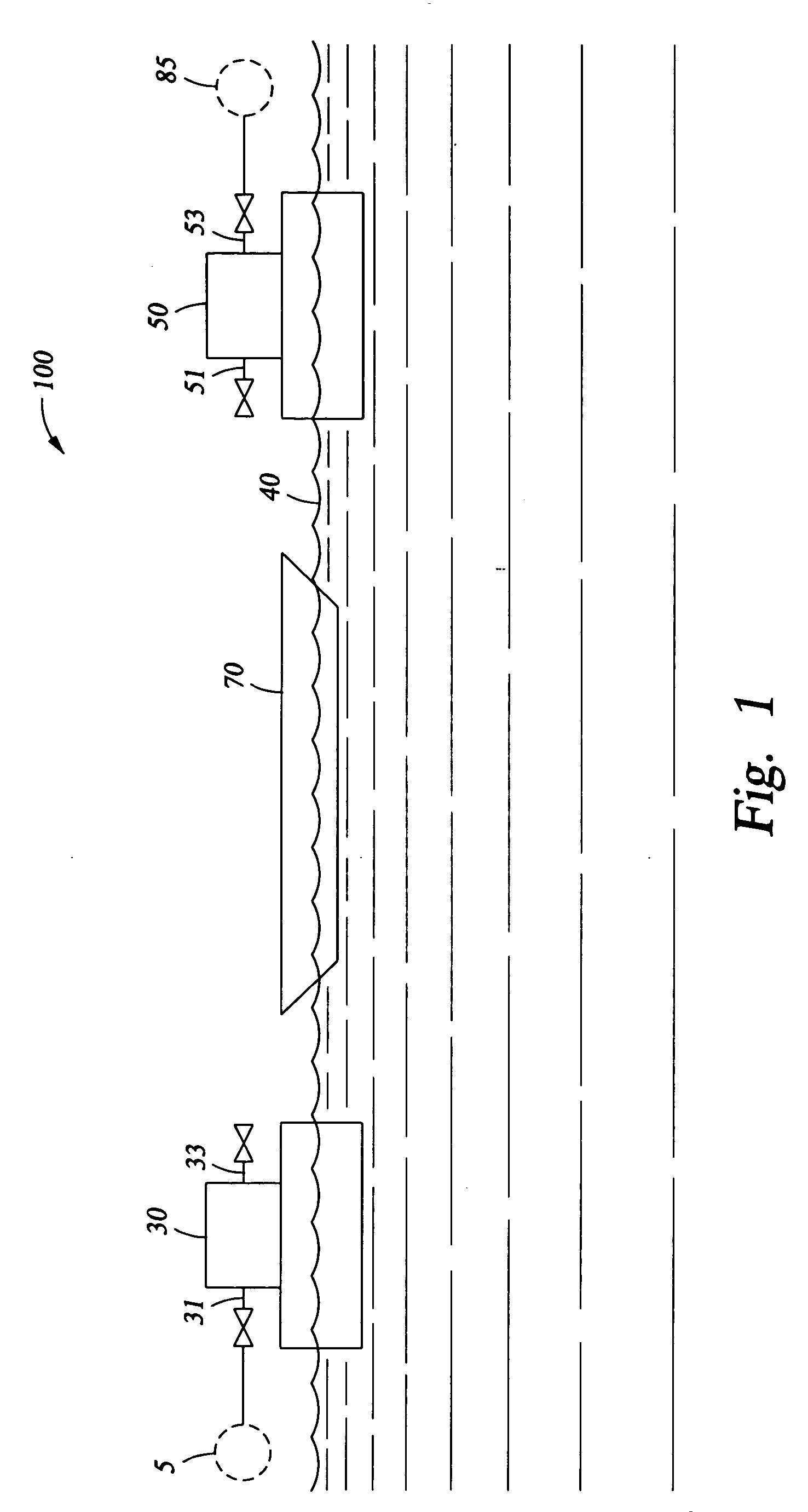

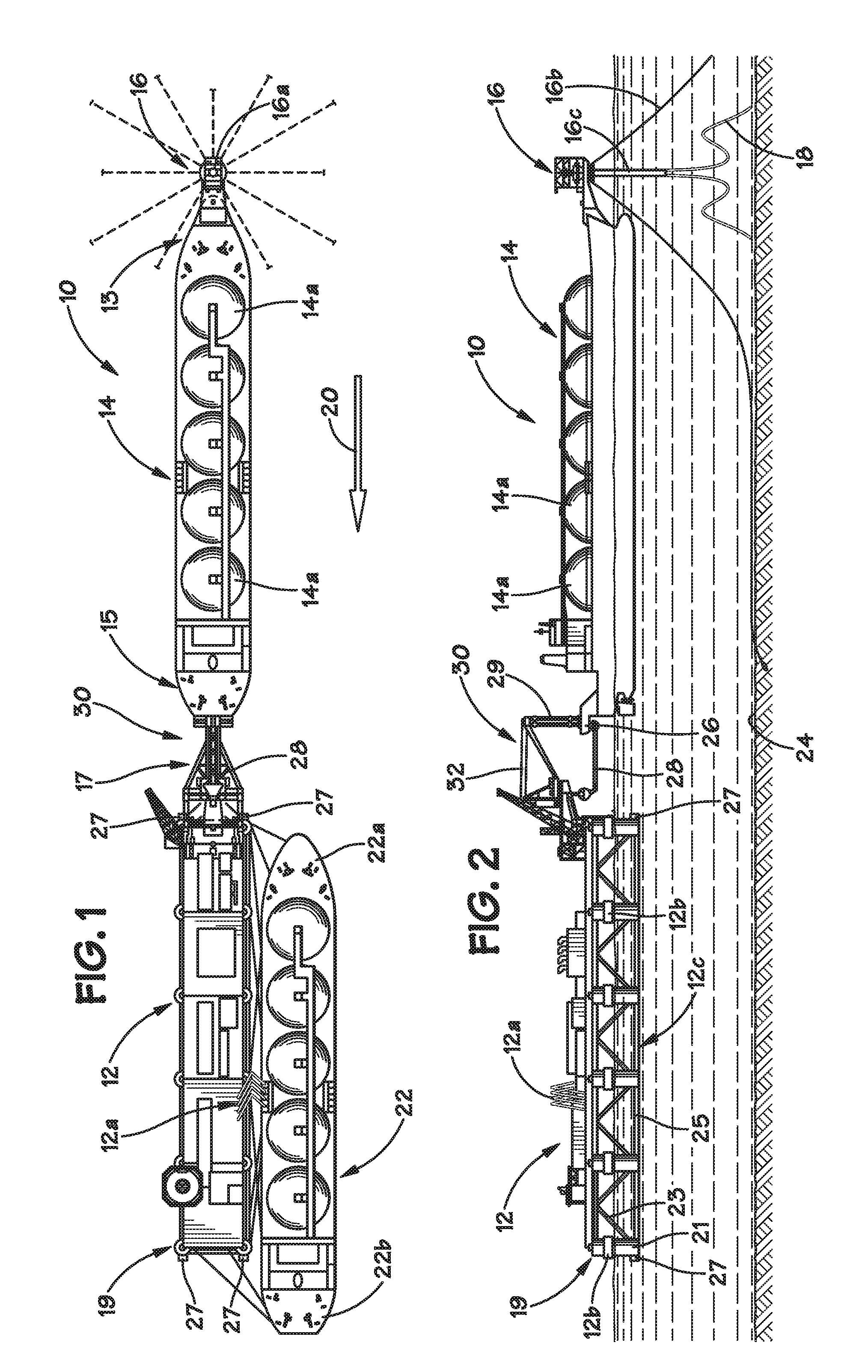

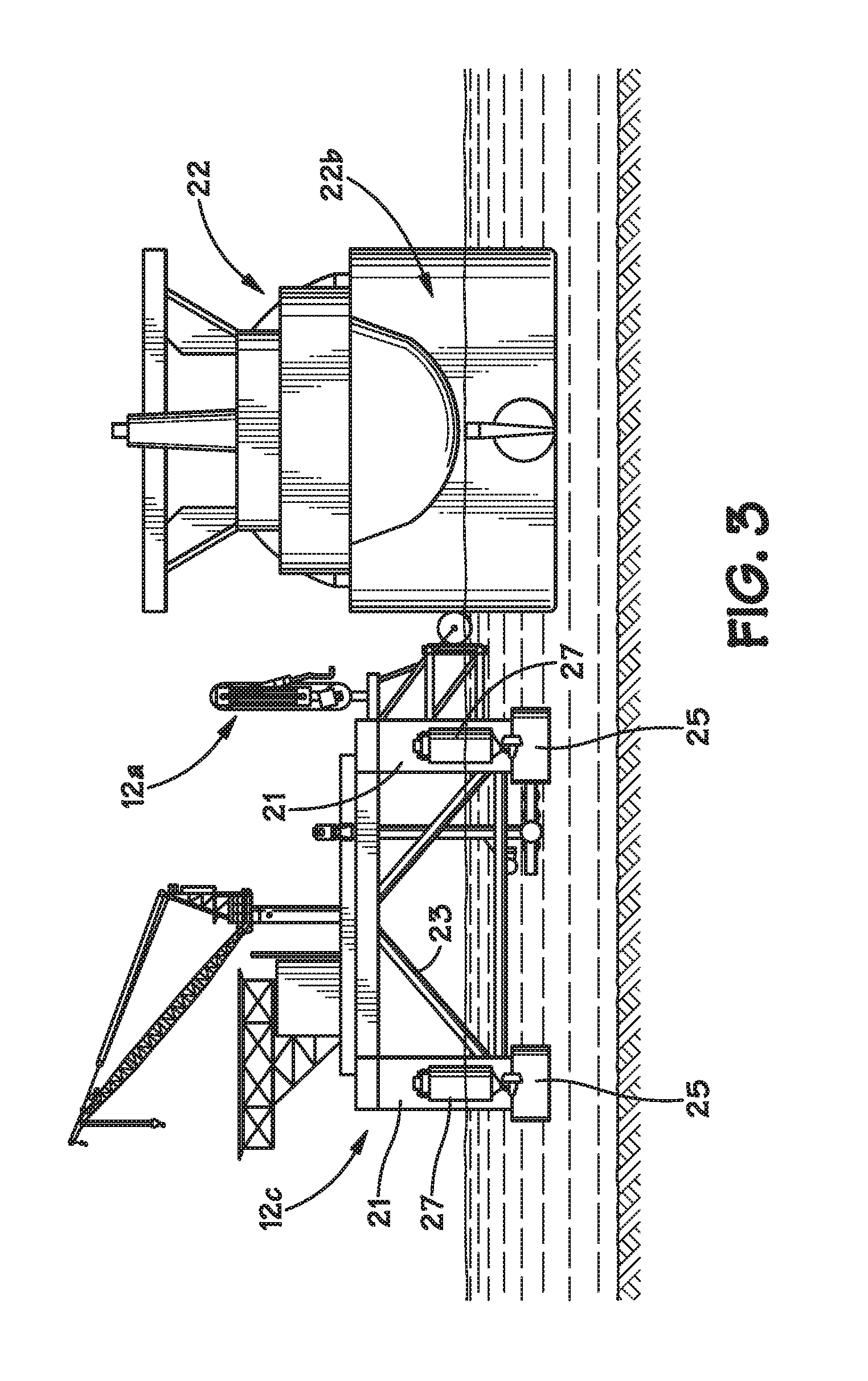

Dockside Ship-To-Ship Transfer of LNG

InactiveUS20100263389A1Gas handling applicationsGas handling/storage effectsMarine engineeringEngineering

Systems and methods for dockside regasification of liquefied natural gas (LNG) are described herein. The methods include providing LNG from a LNG carrier to a regasification vessel. The LNG may be regasified on the regasification vessel. The regasified natural gas may be discharged with a high pressure arm to a dock and delivered onshore. The regasification vessel may be moored to the dock. The LNG carrier may be moored to the regasification vessel or the dock.

Owner:EXCELERATE ENERGY LTD PARNERSHIP

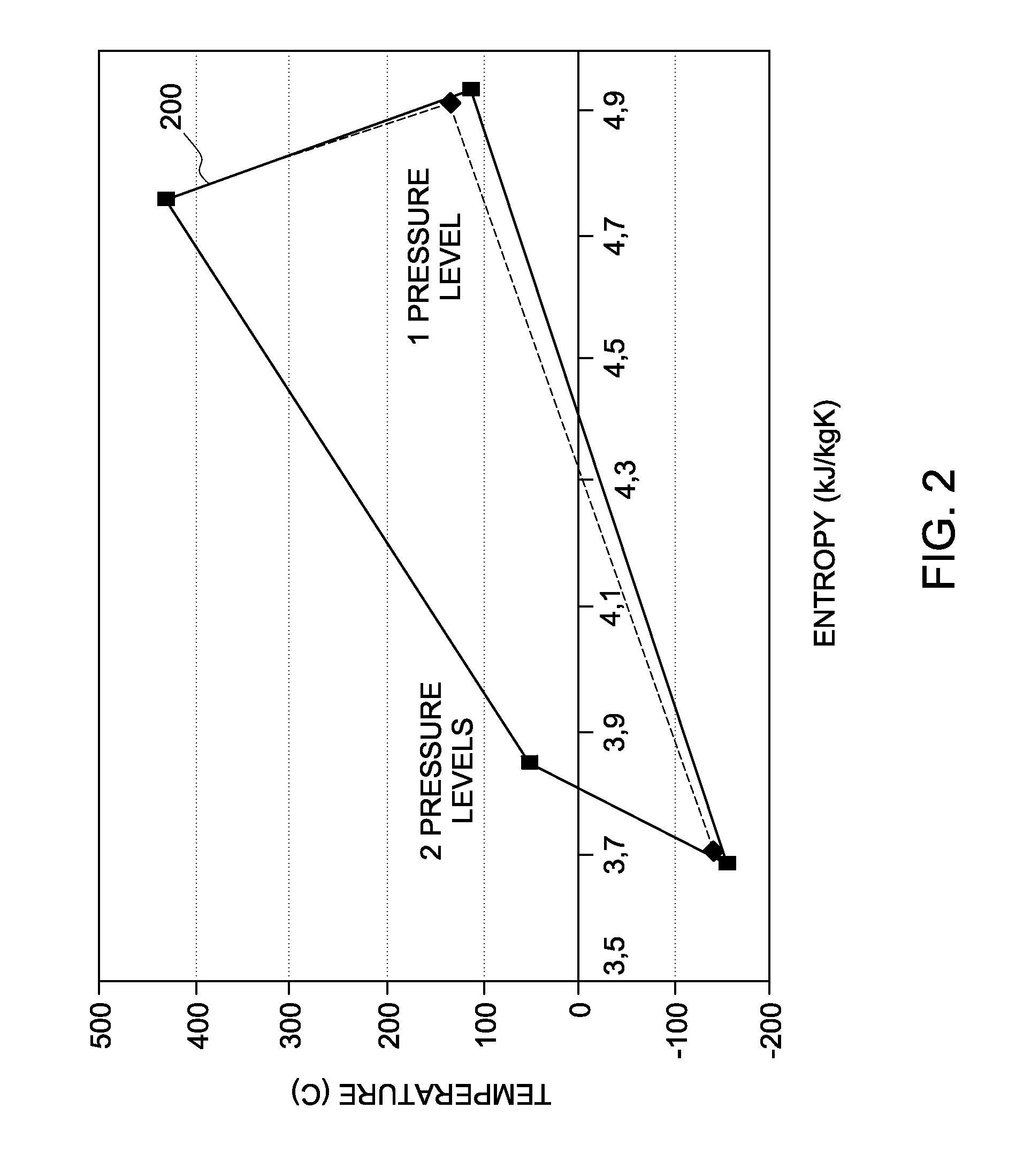

Brayton cycle regasification of liquiefied natural gas

A power plant including an apparatus for regasification of liquefied natural gas (LNG) is provided. The apparatus includes a compressor configured to pressurize a working fluid and a heat recovery system configured to provide heat to a working fluid. A turbine is configured to generate work utilizing the heated working fluid. One or more heat exchangers are configured to transfer heat from the working fluid to a first stage liquefied natural gas at a first pressure and at least one of a second stage liquefied natural gas at a second pressure, and a compressed working fluid.

Owner:GENERAL ELECTRIC CO

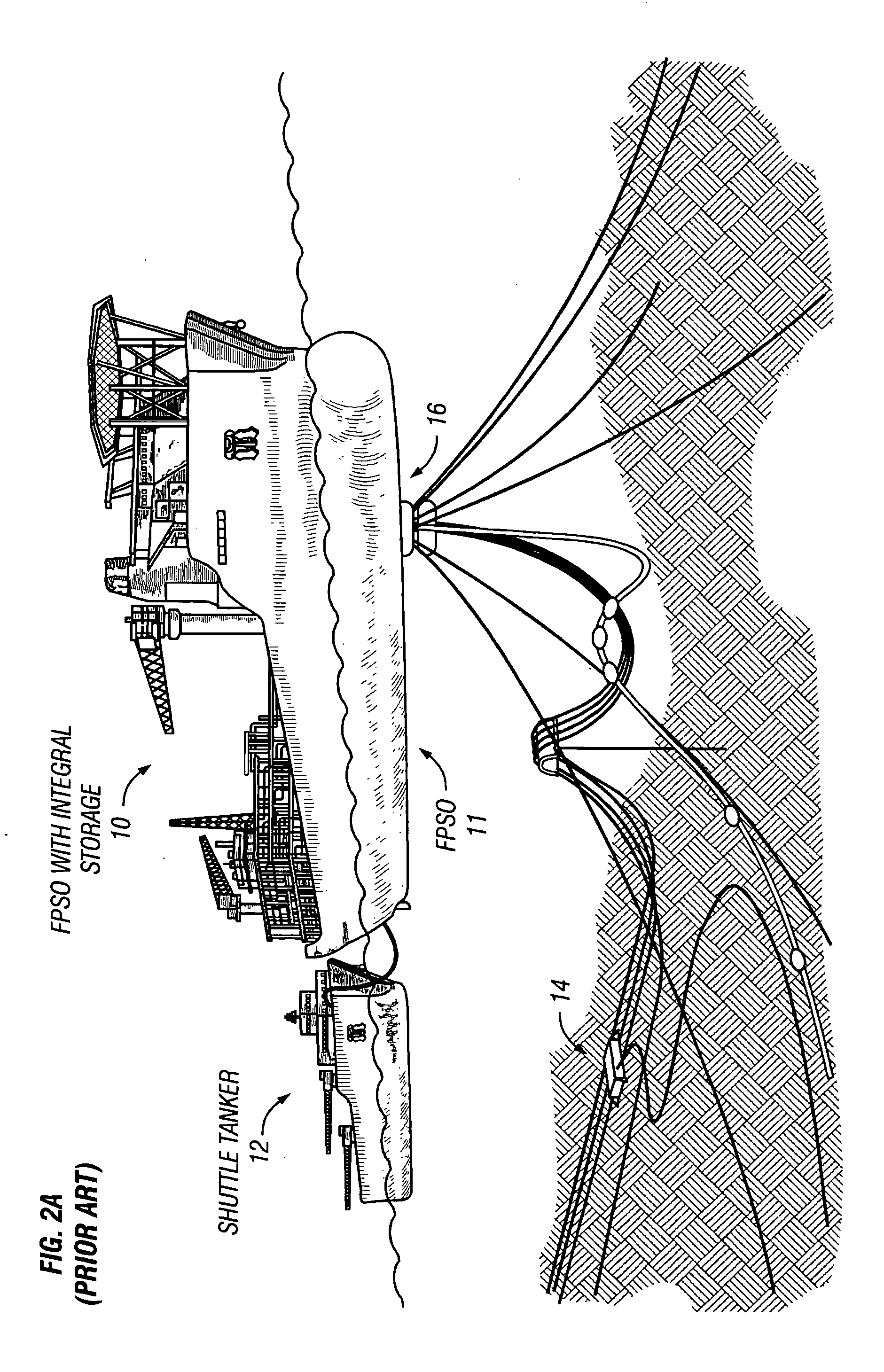

Apparatus for cryogenic fluids having floating liquefaction unit and floating regasification unit connected by shuttle vessel, and cryogenic fluid methods

Methods and systems for transportation of a cryogenic fluid. The system includes a floating liquefaction unit receiving a gas from a source, a shuttle vessel for carrying liquefied gas away from the liquefaction unit, and a floating regasification unit for receiving the liquefied gas from the vessel, regassifying the liquefied gas and providing the gas to a distribution system.

Owner:MUSTANG ENG

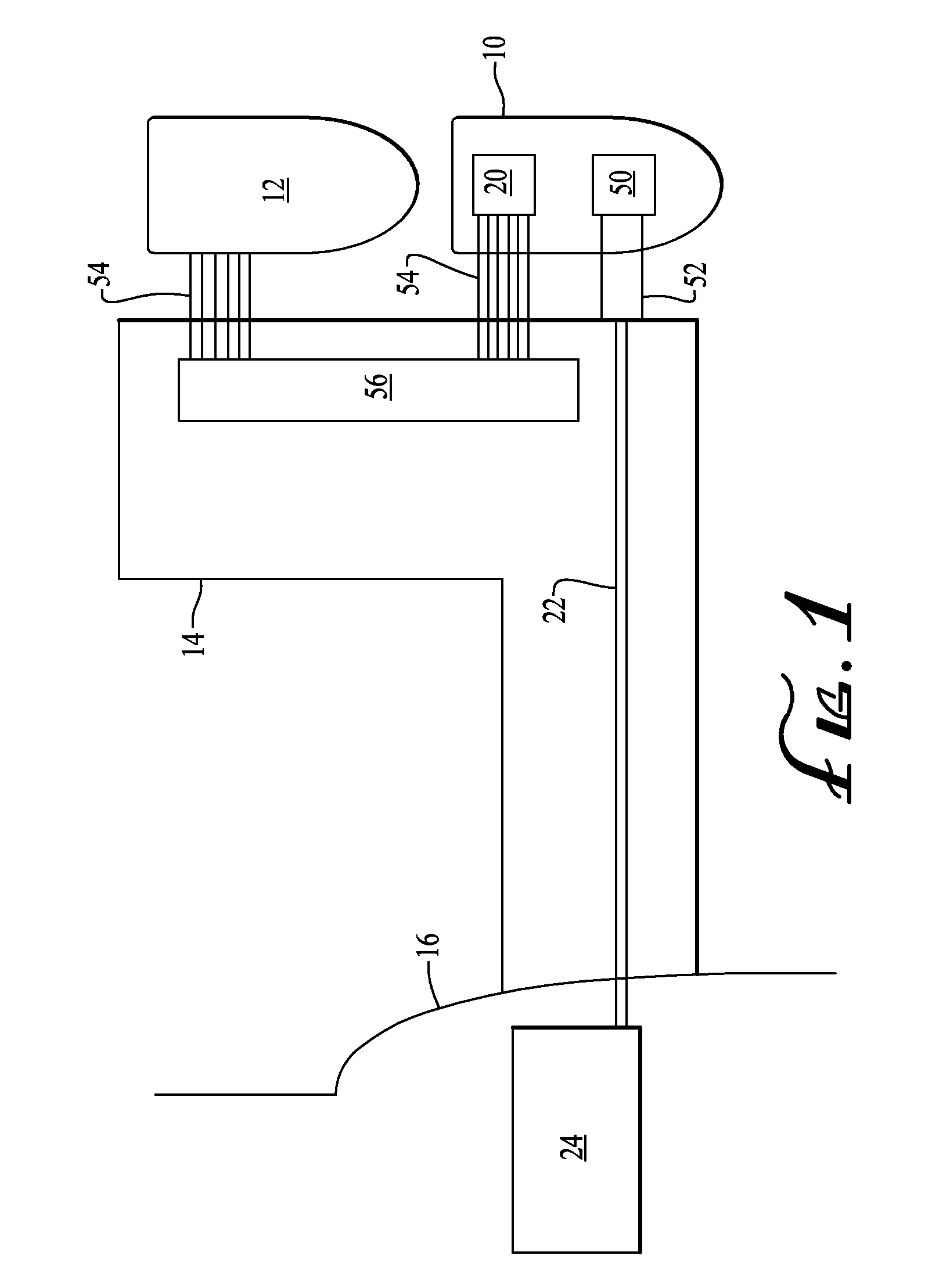

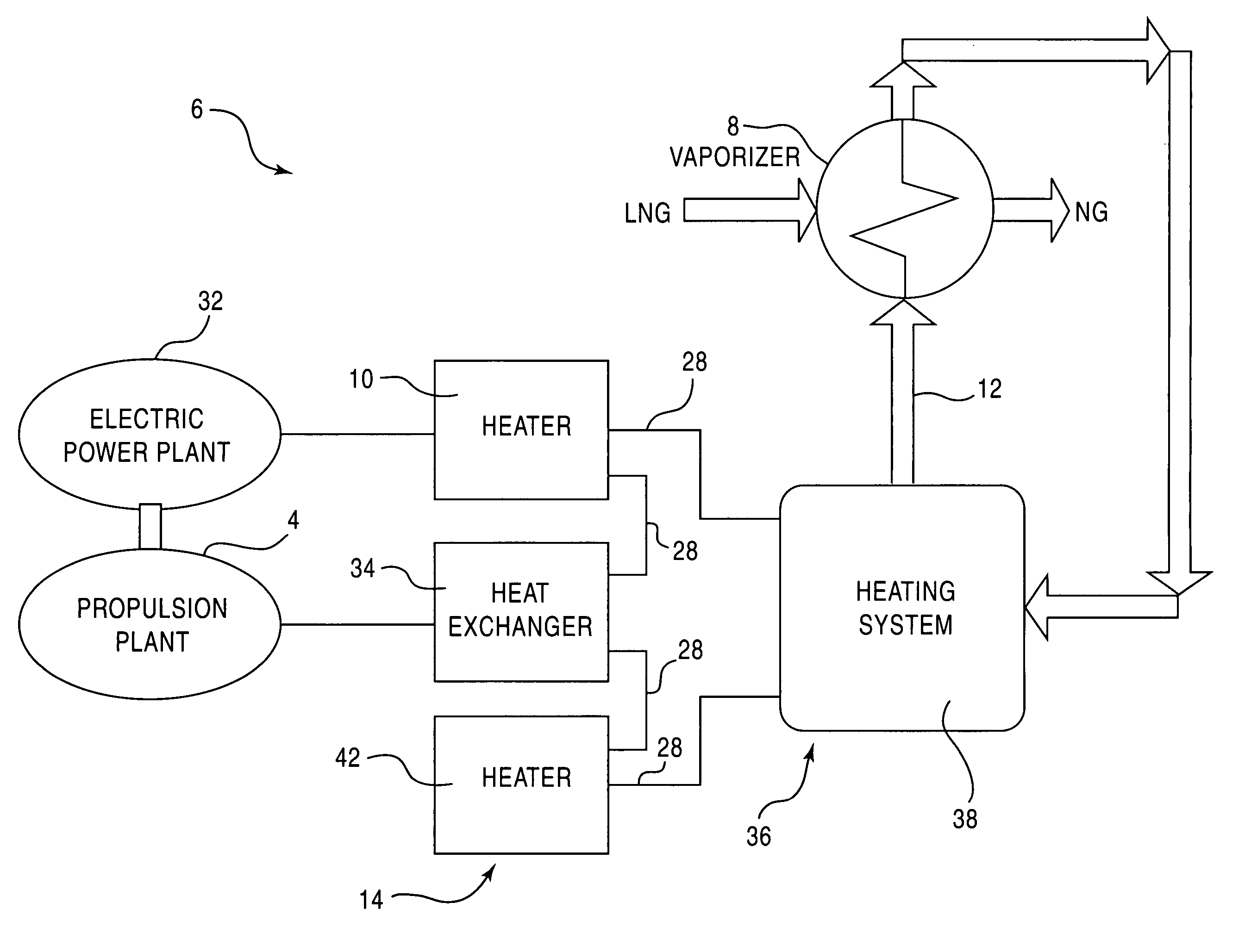

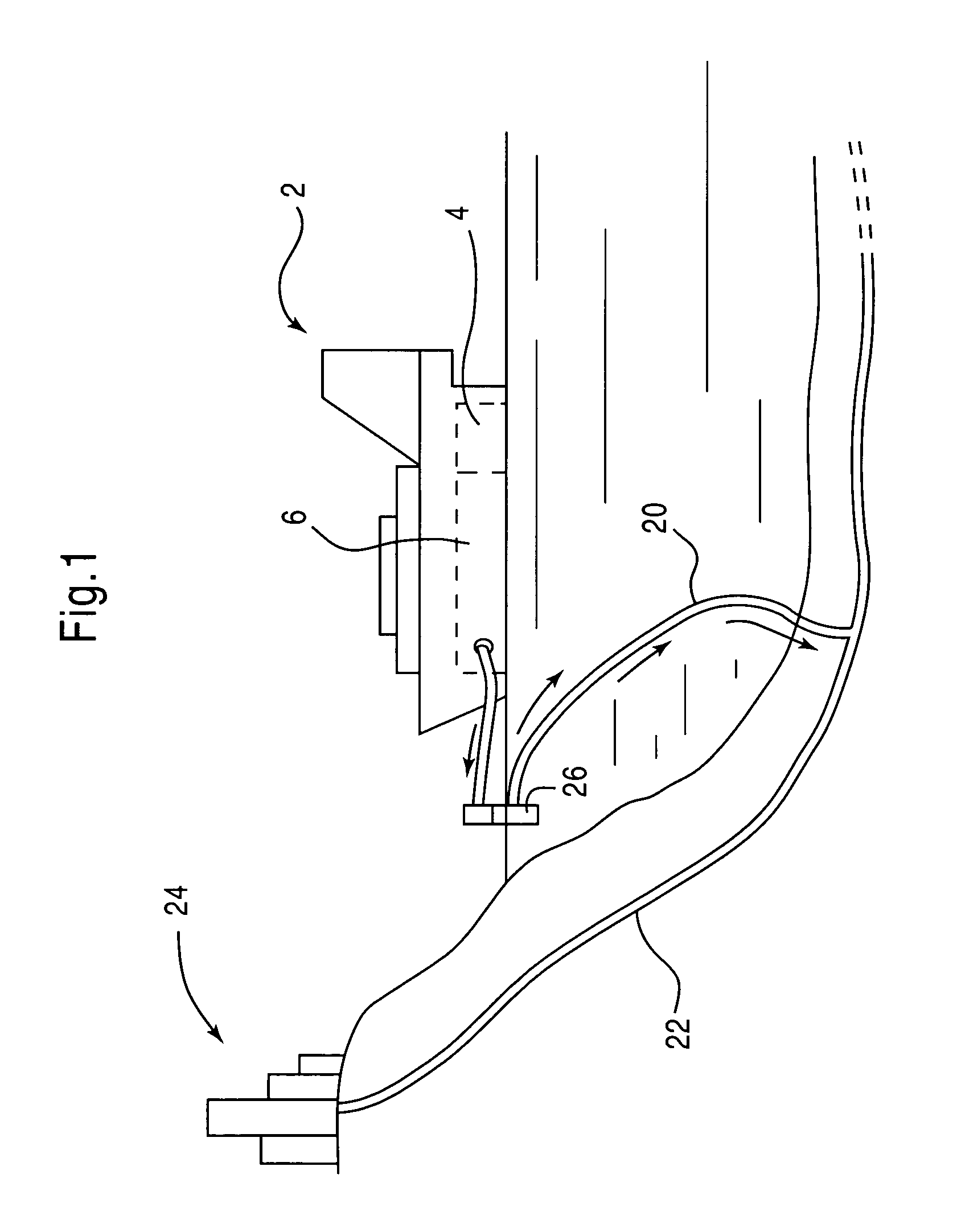

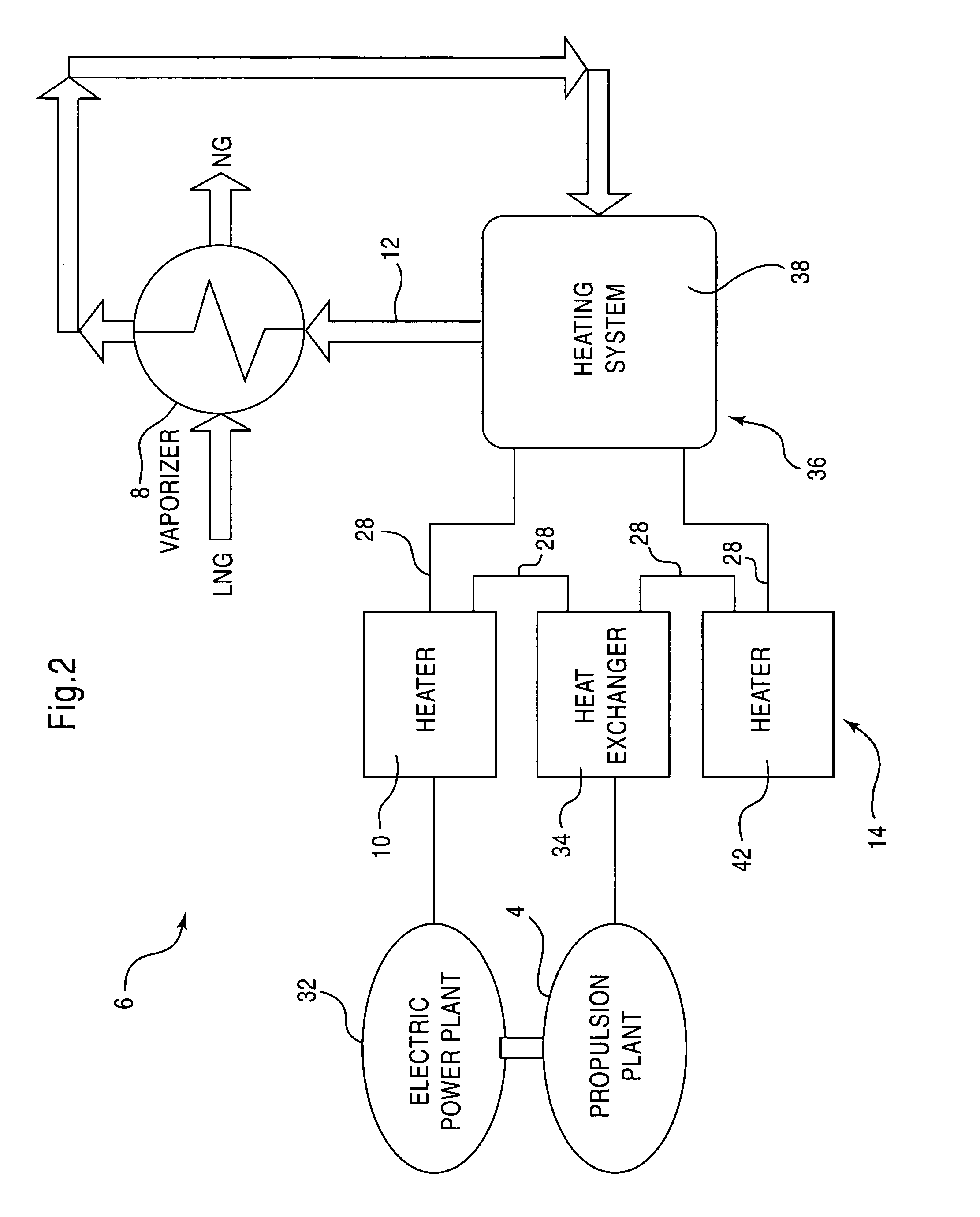

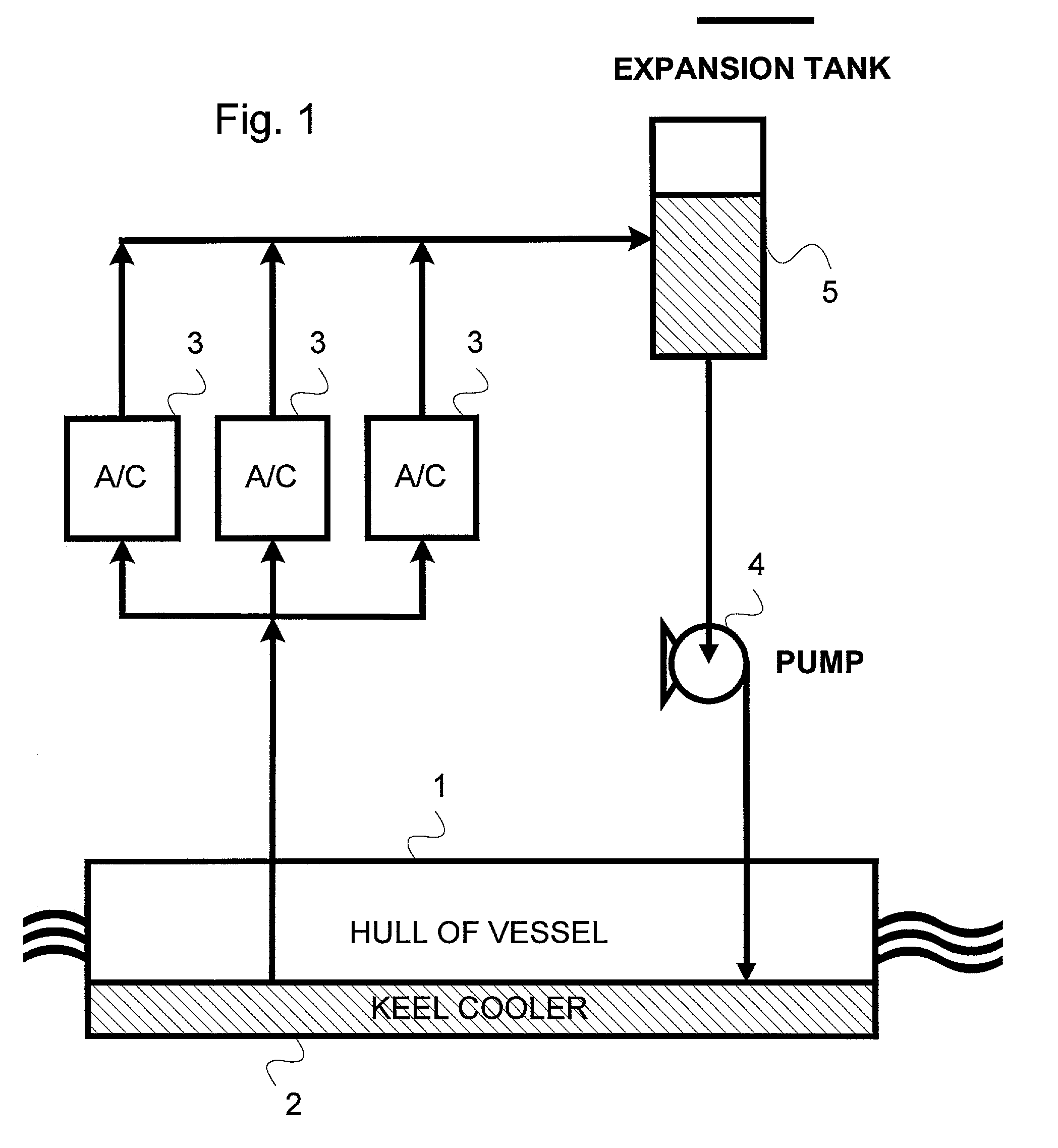

Shipboard regasification for LNG carriers with alternate propulsion plants

A liquefied natural gas carrier uses a diesel engine or gas turbine propulsion plant fitted with a shipboard regasification system. The propulsion plant can provide either a direct mechanical drive of the propeller shaft and propeller, or can be fitted with an integrated electric power plant using an electric motor or motors to drive the propeller shaft and propeller. The regasification system includes a heat input source of exhaust gas heat exchangers, electric water heaters and supplemental heaters to provide an additional heat source to a hot water circulating loop. The liquefied natural gas contacts the hot water or heating medium circulating loop and is regasified. An undersea conduit from the ship transmits the regasified natural gas to an on shore plant.

Owner:EXCELERATE ENERGY LTD PARNERSHIP

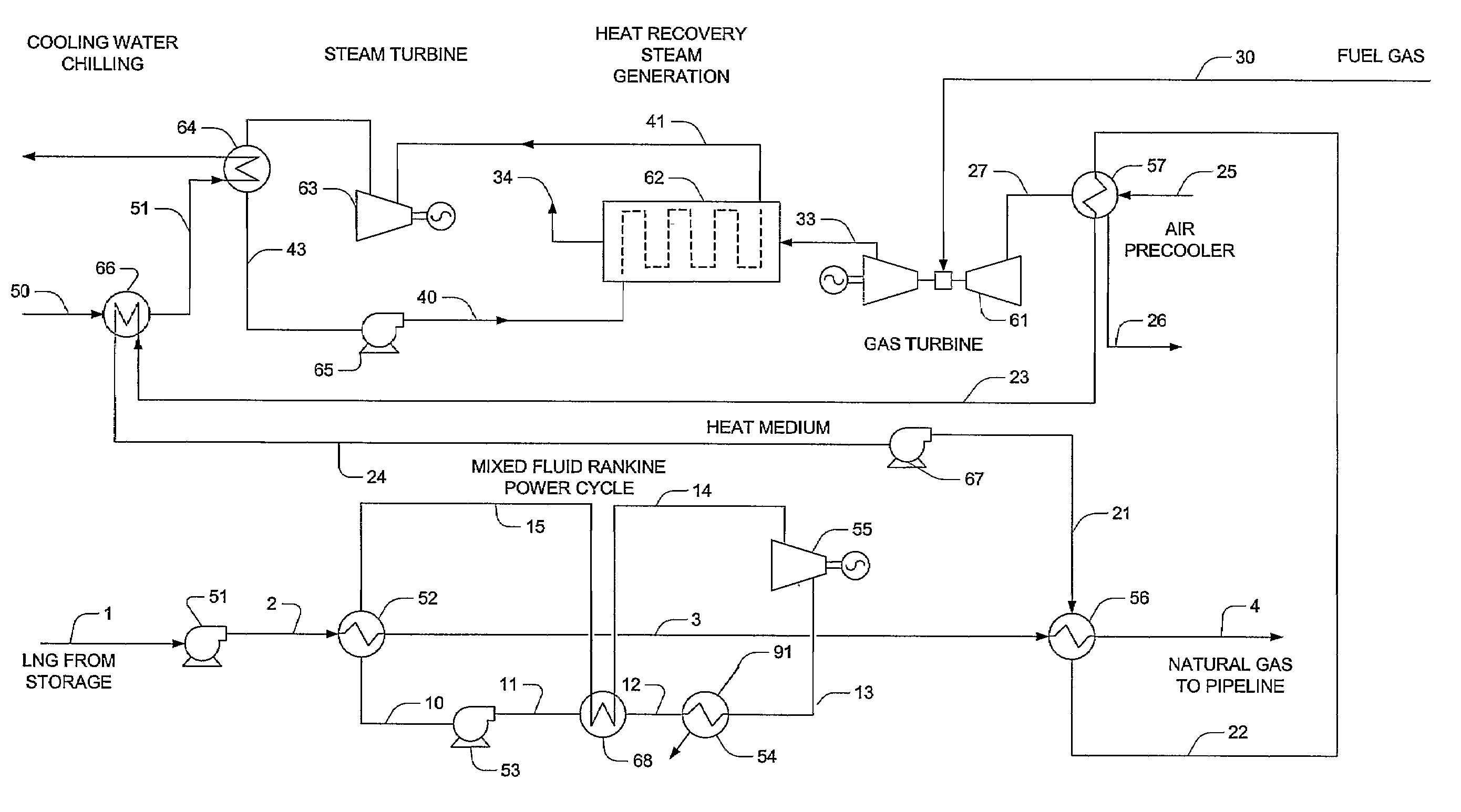

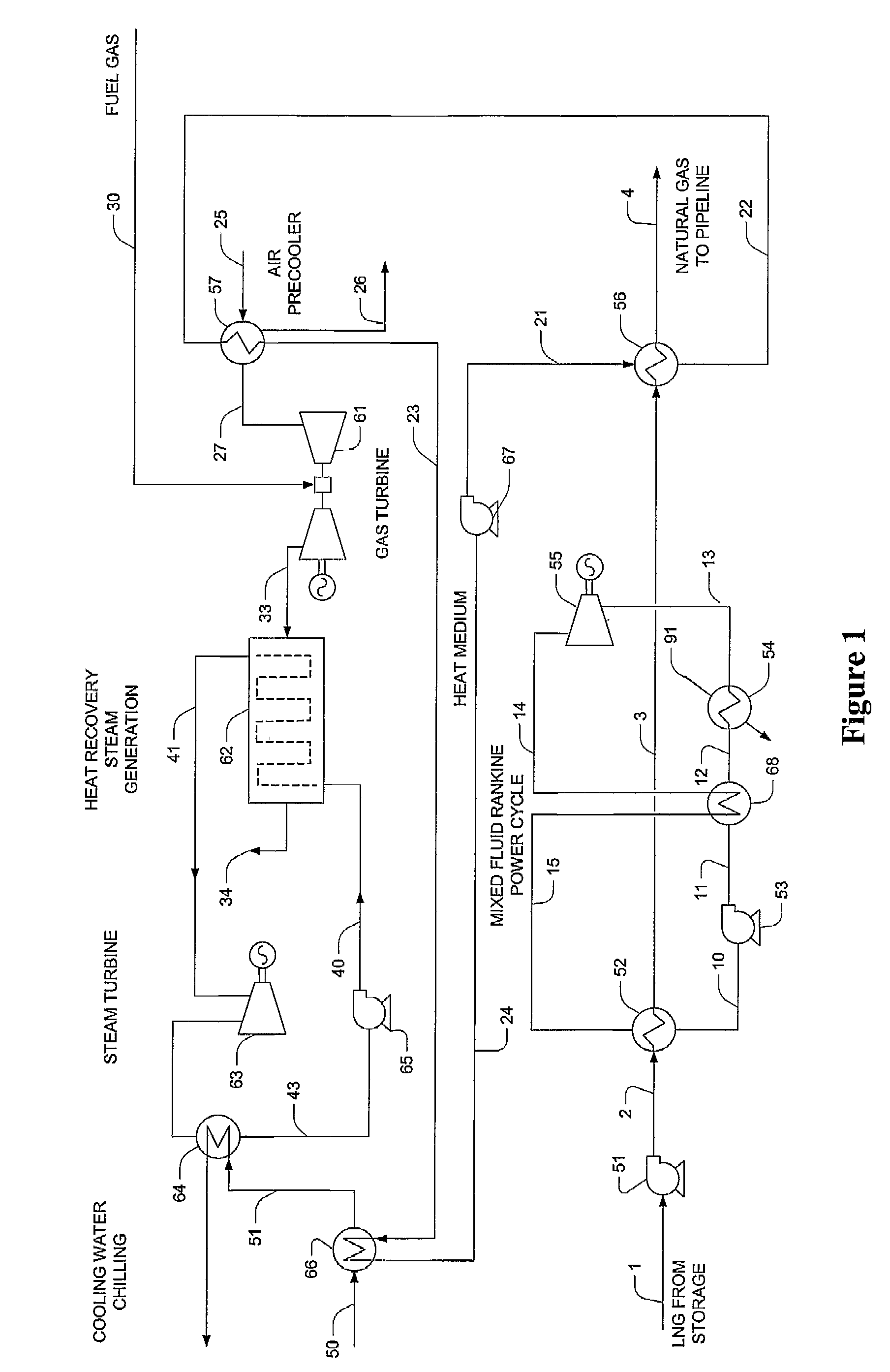

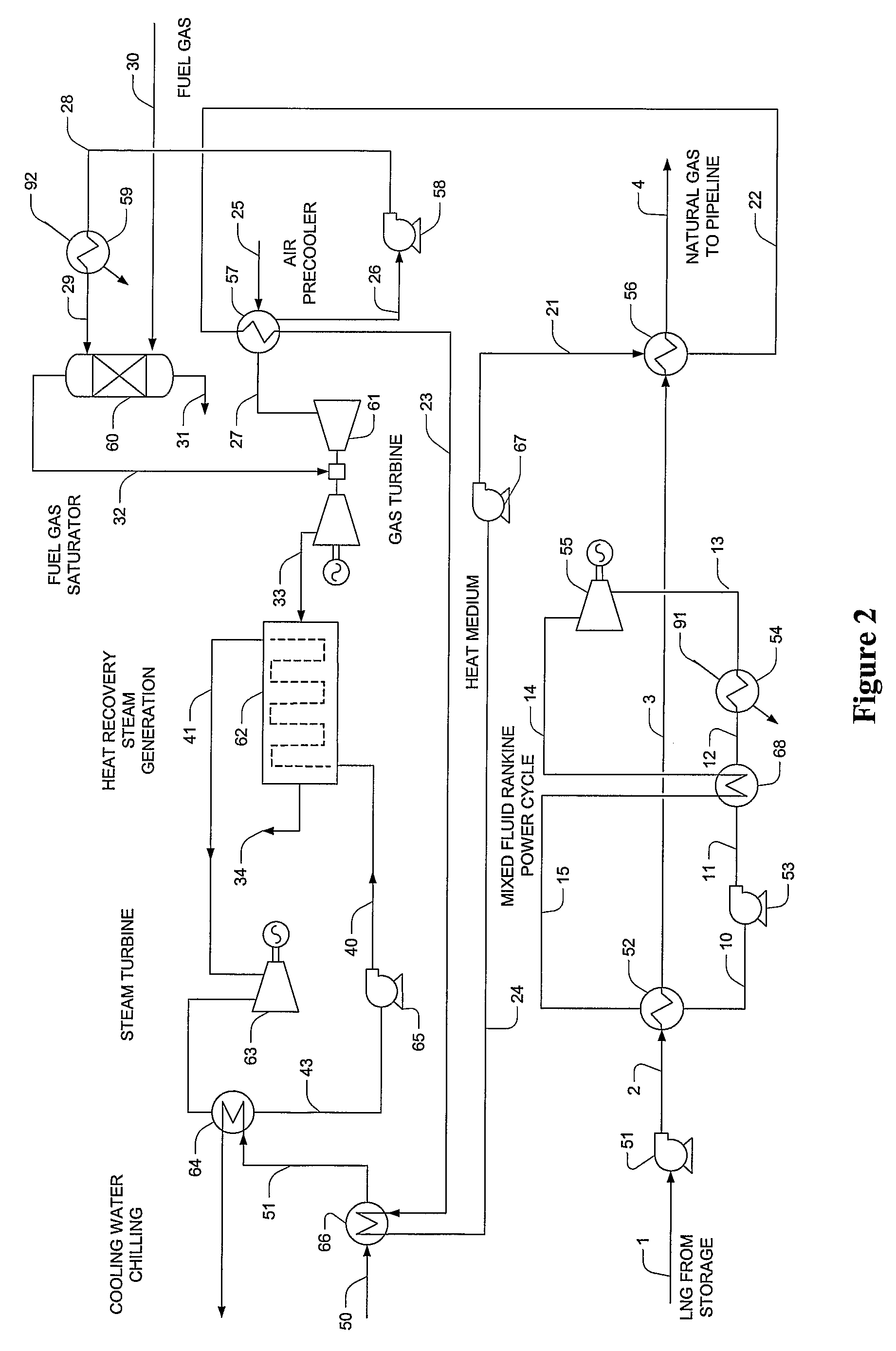

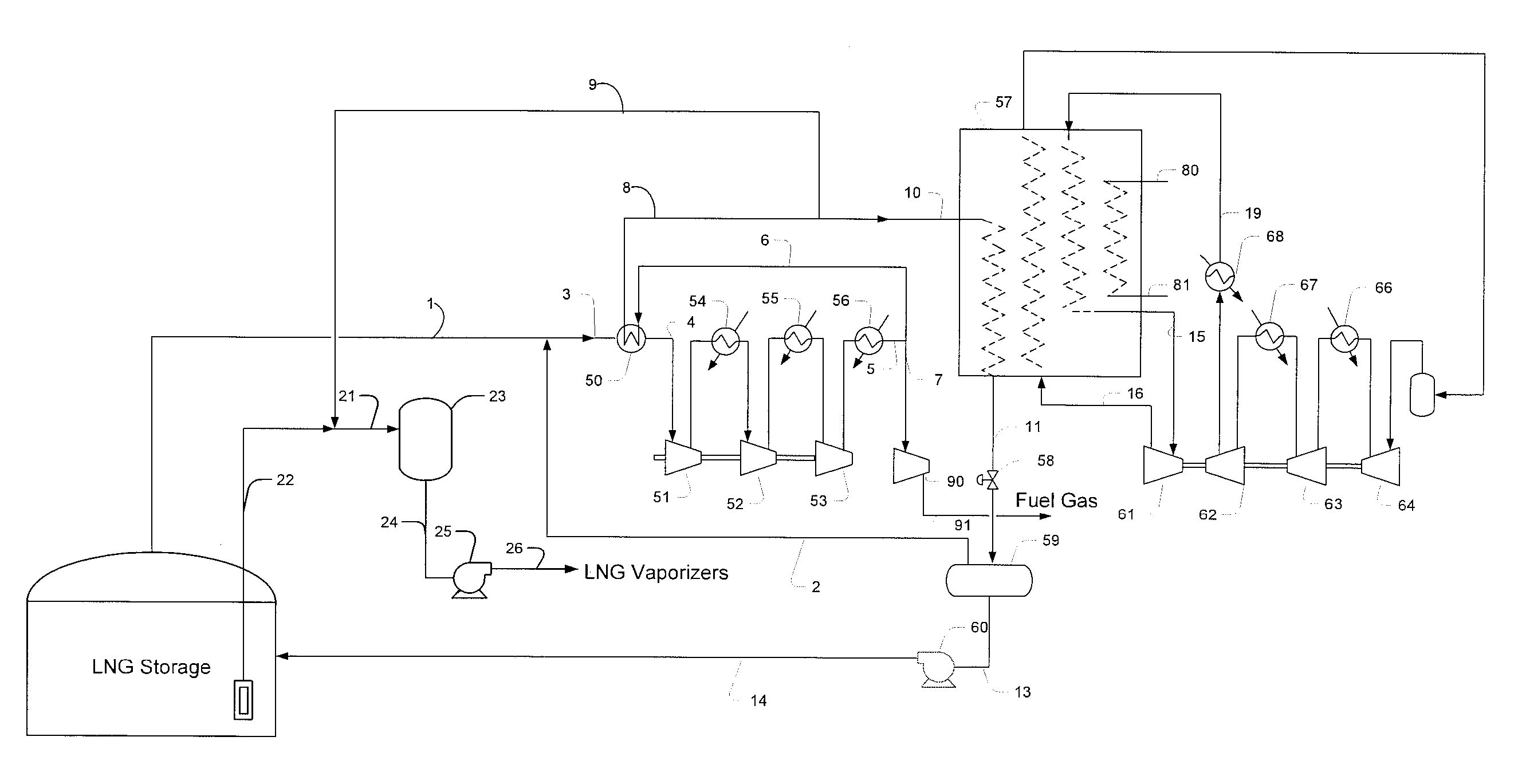

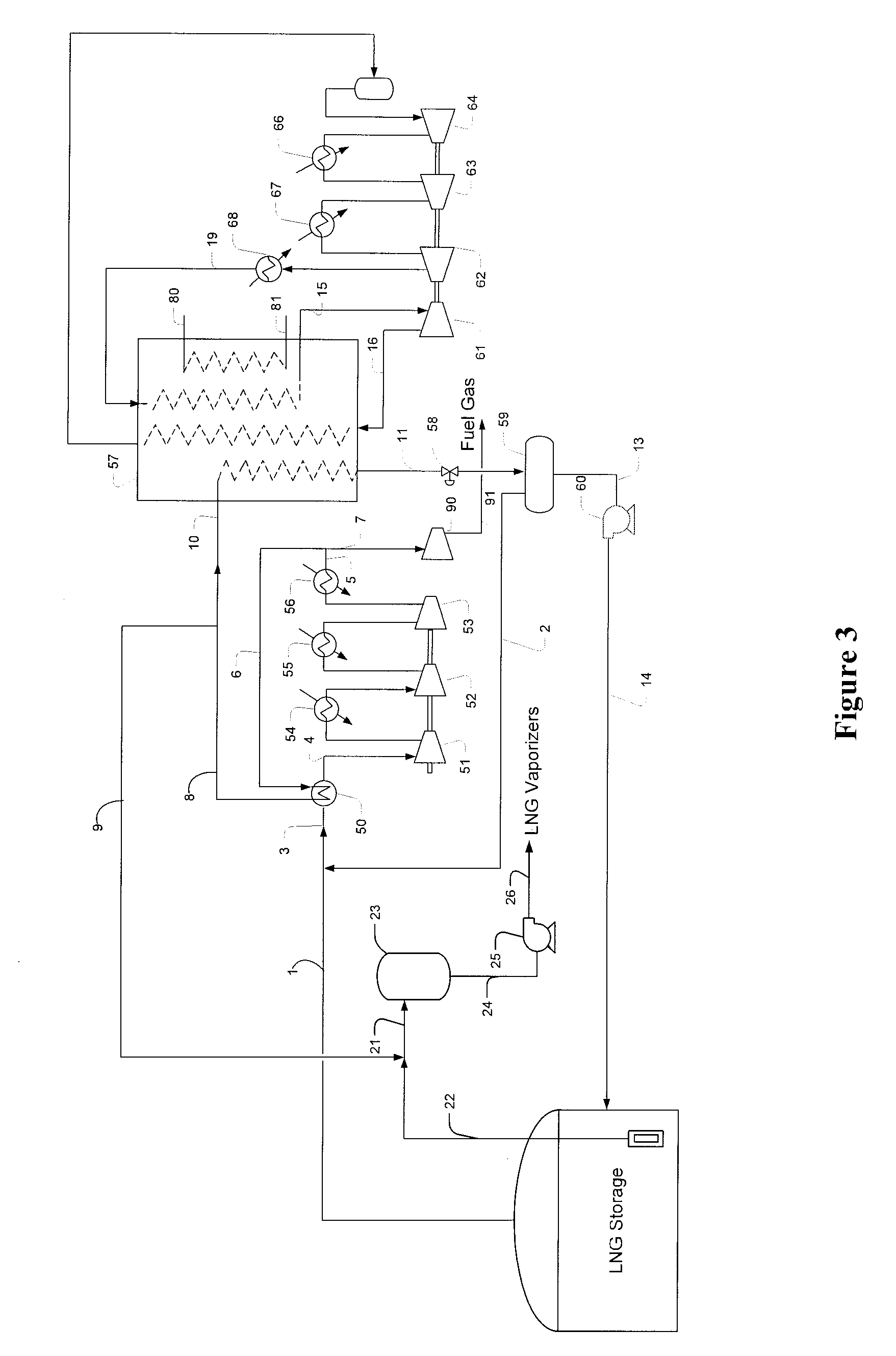

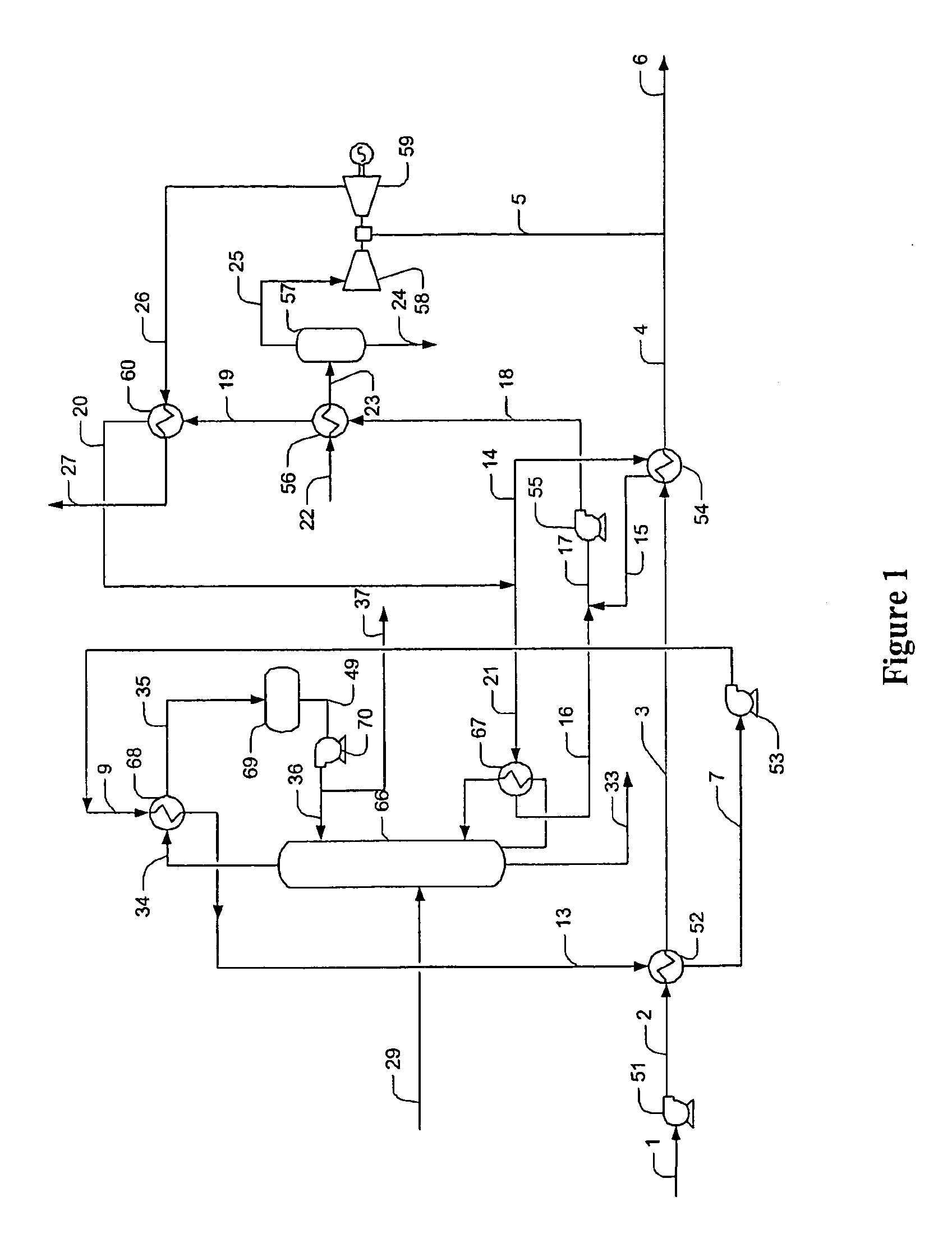

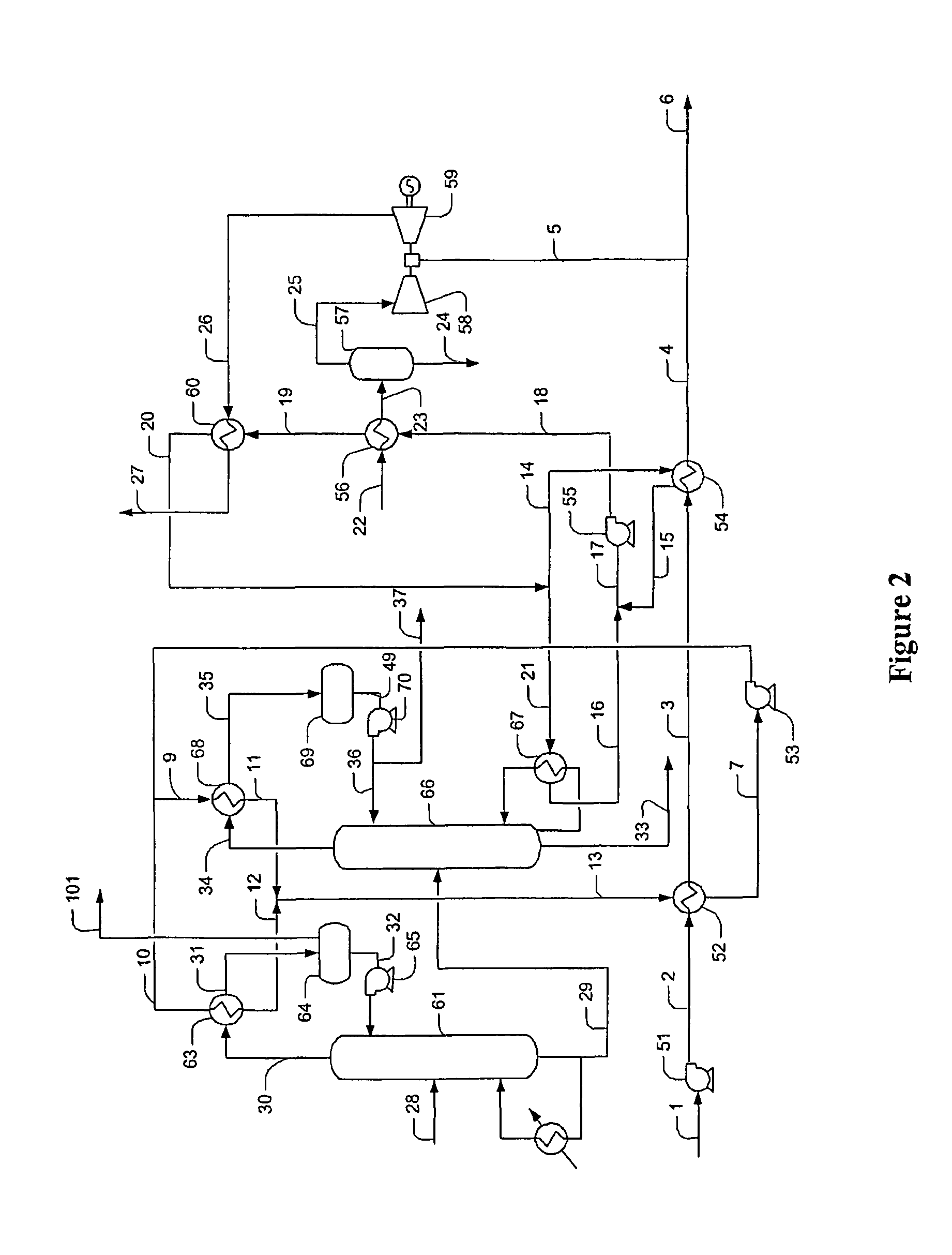

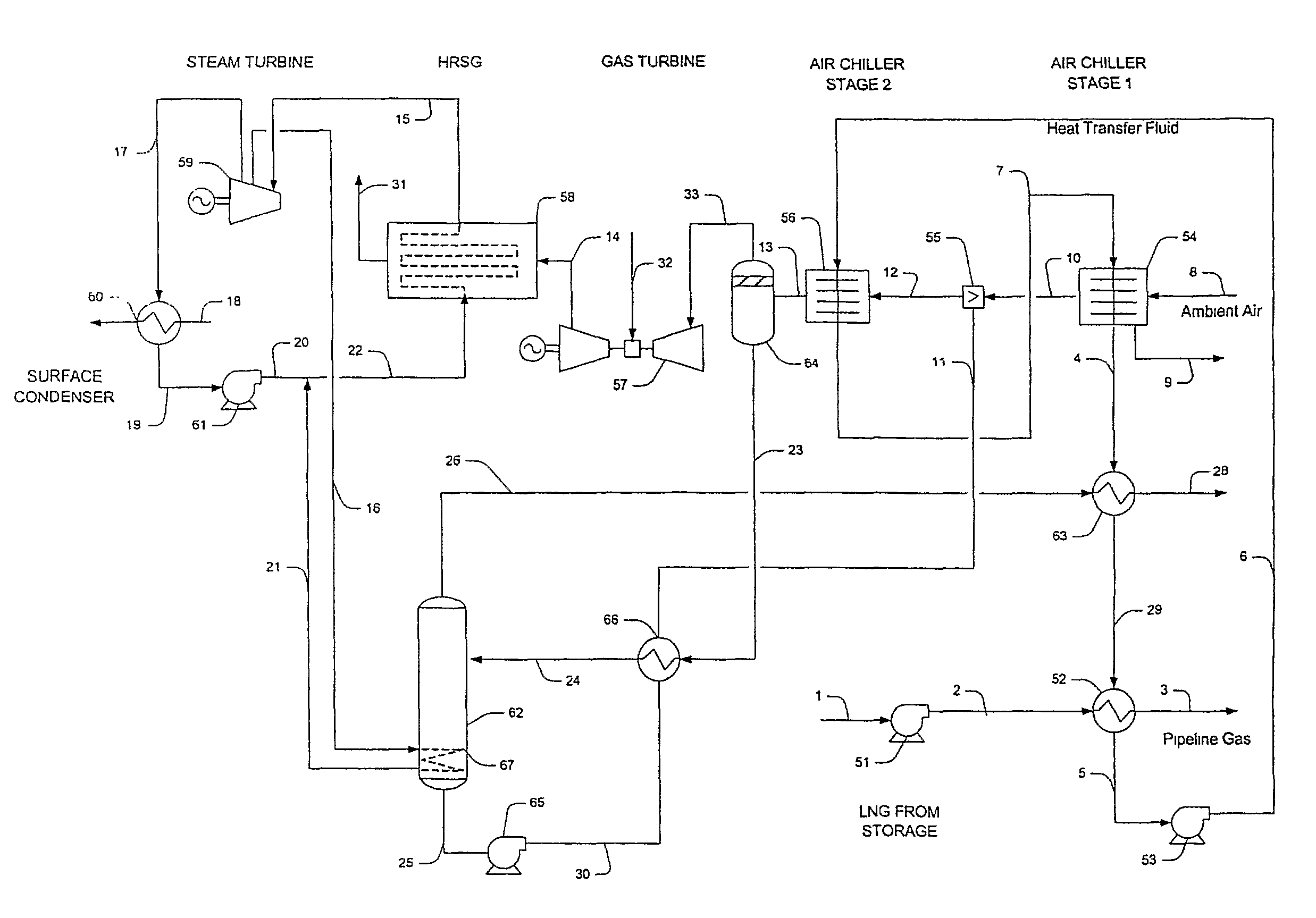

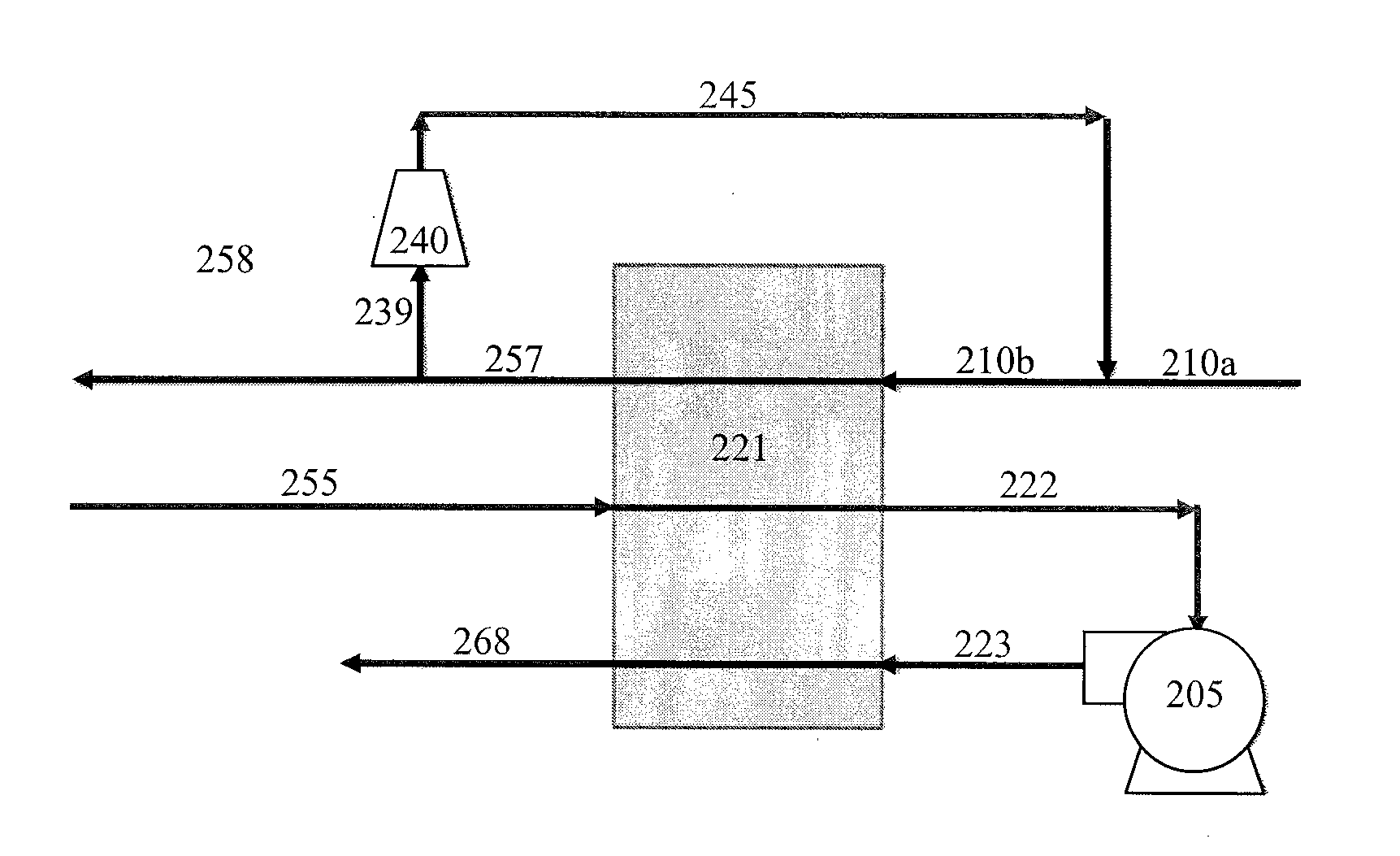

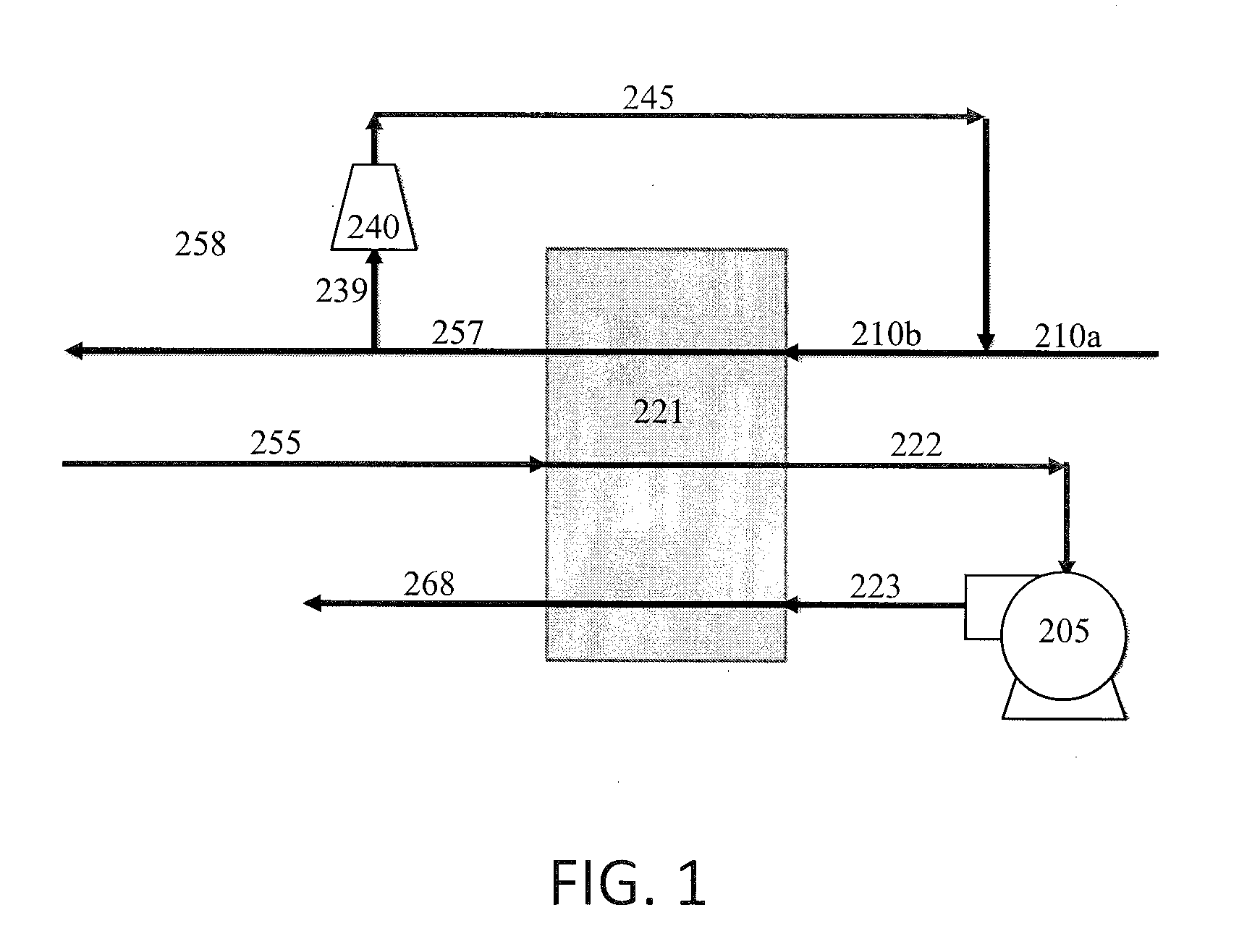

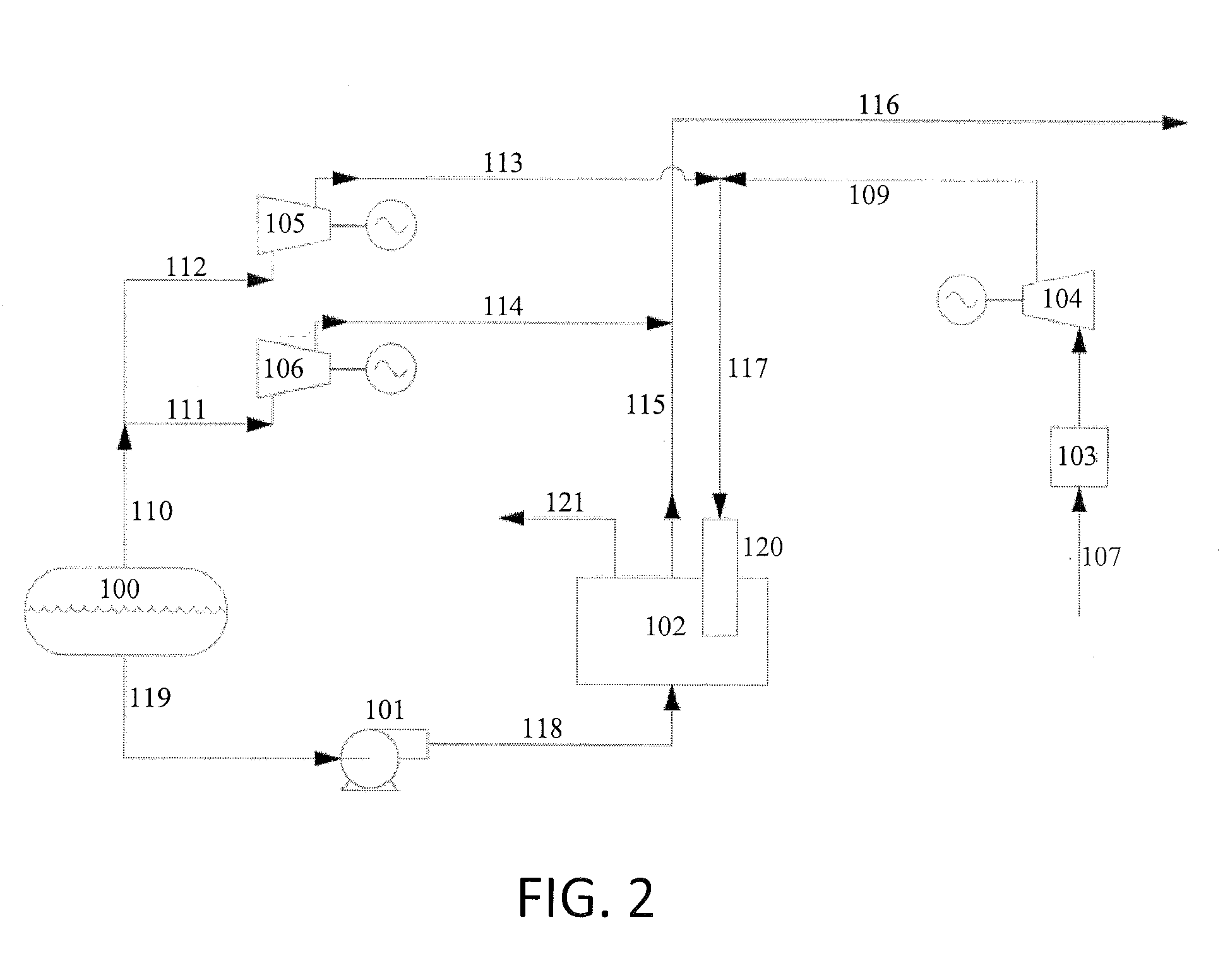

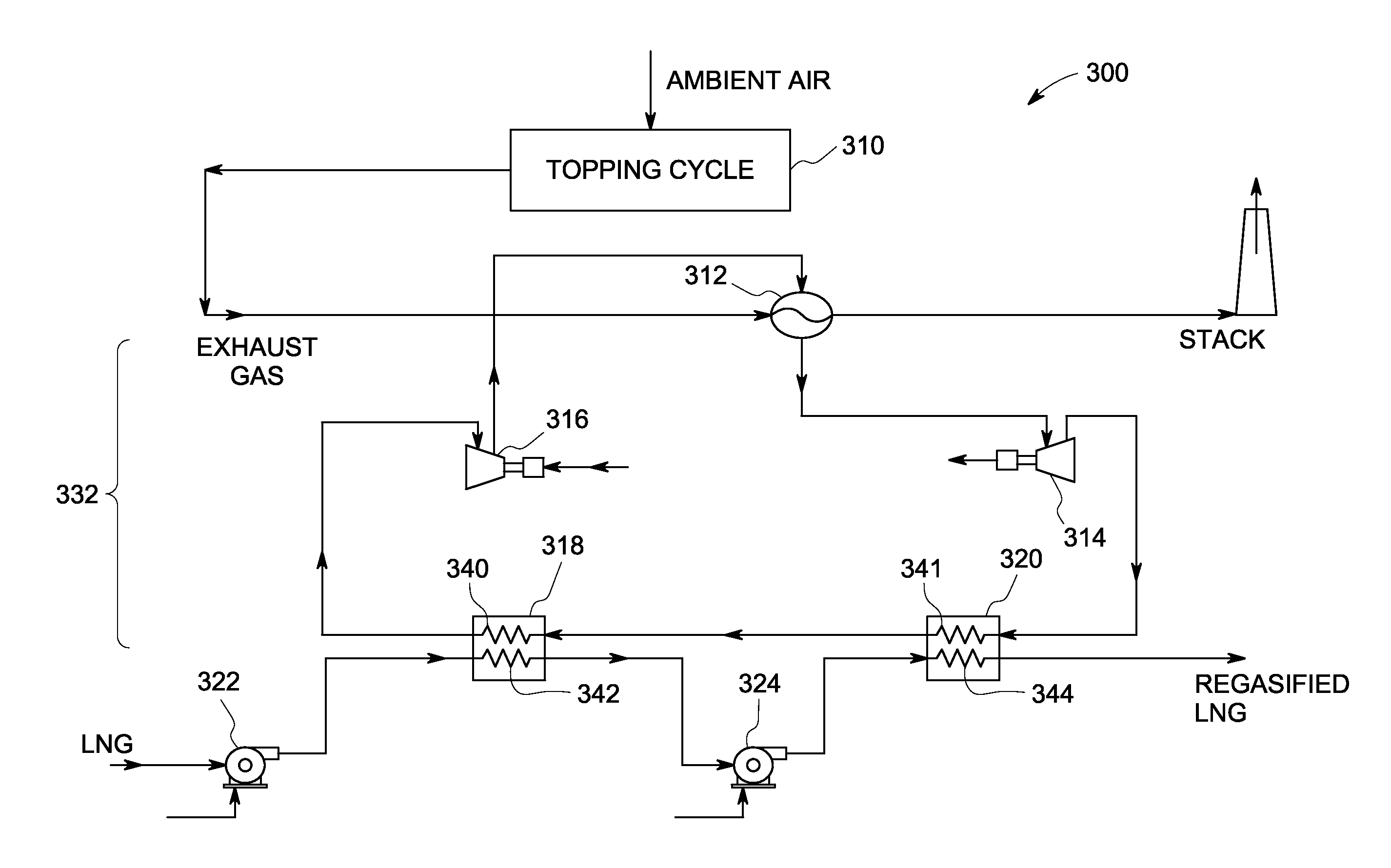

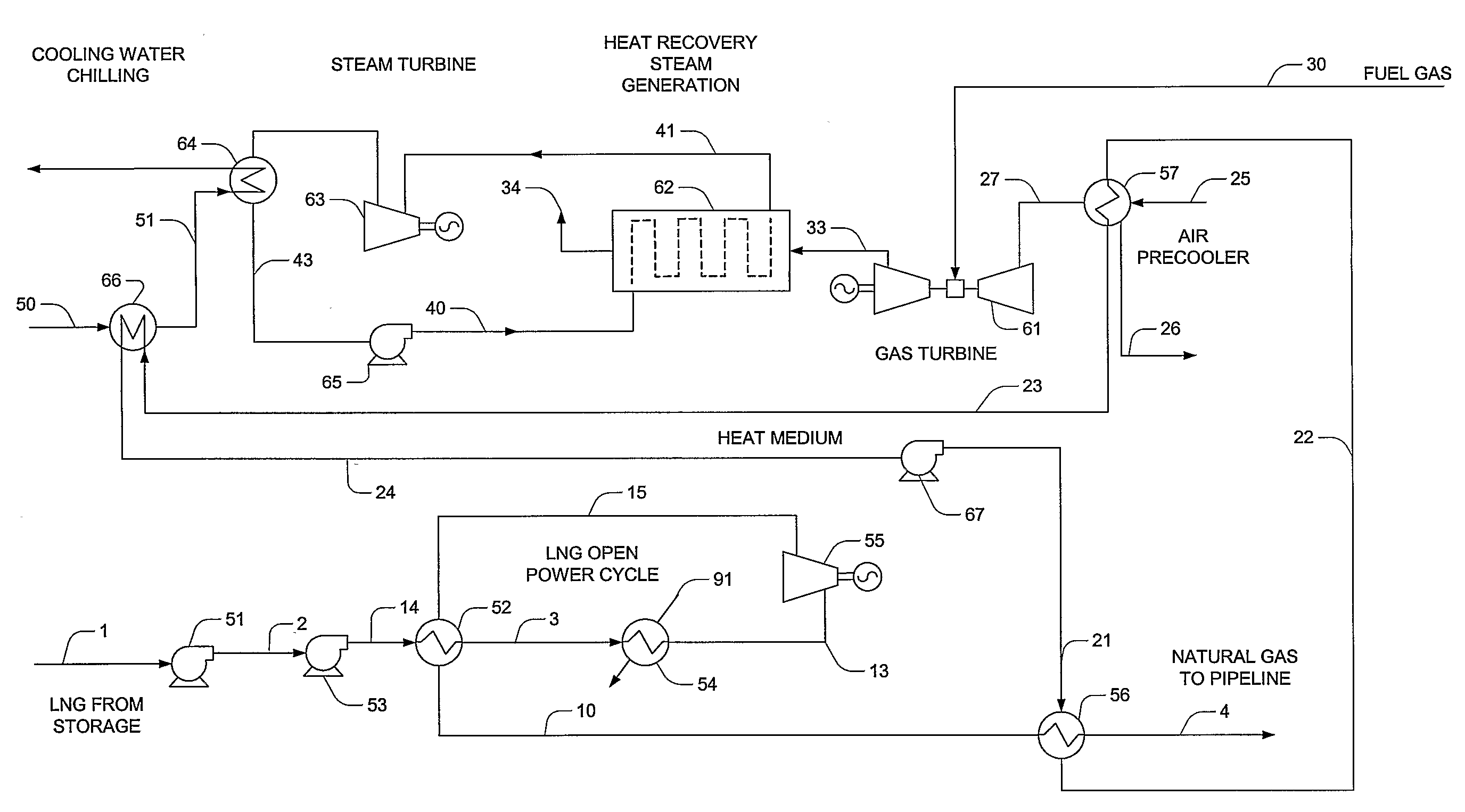

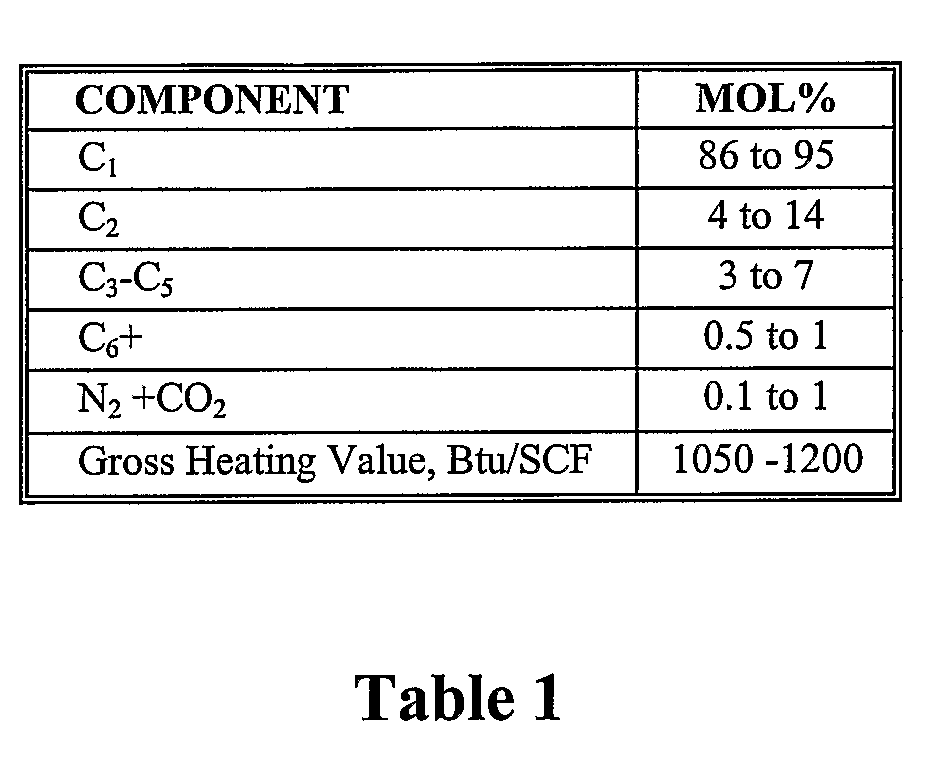

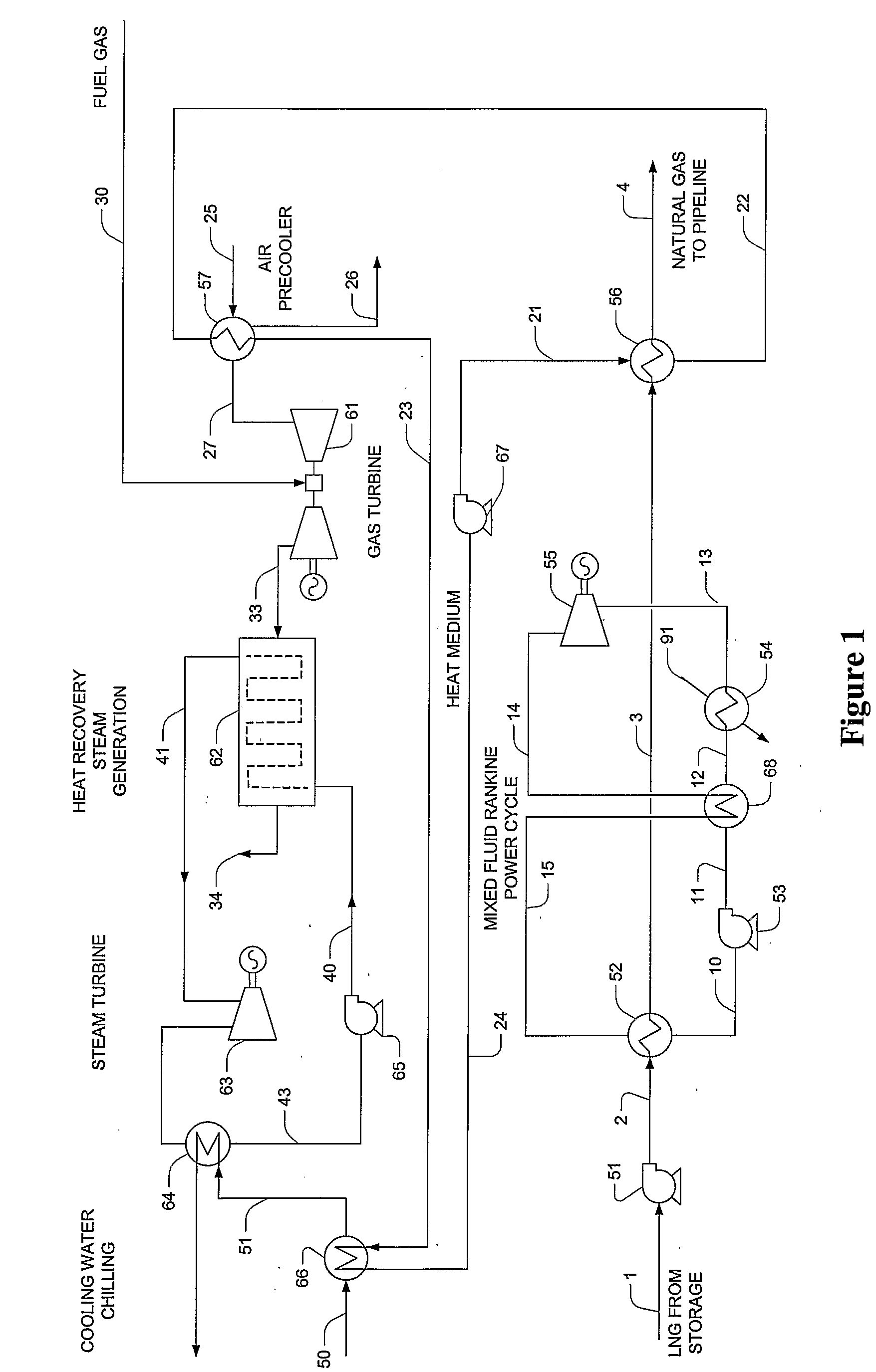

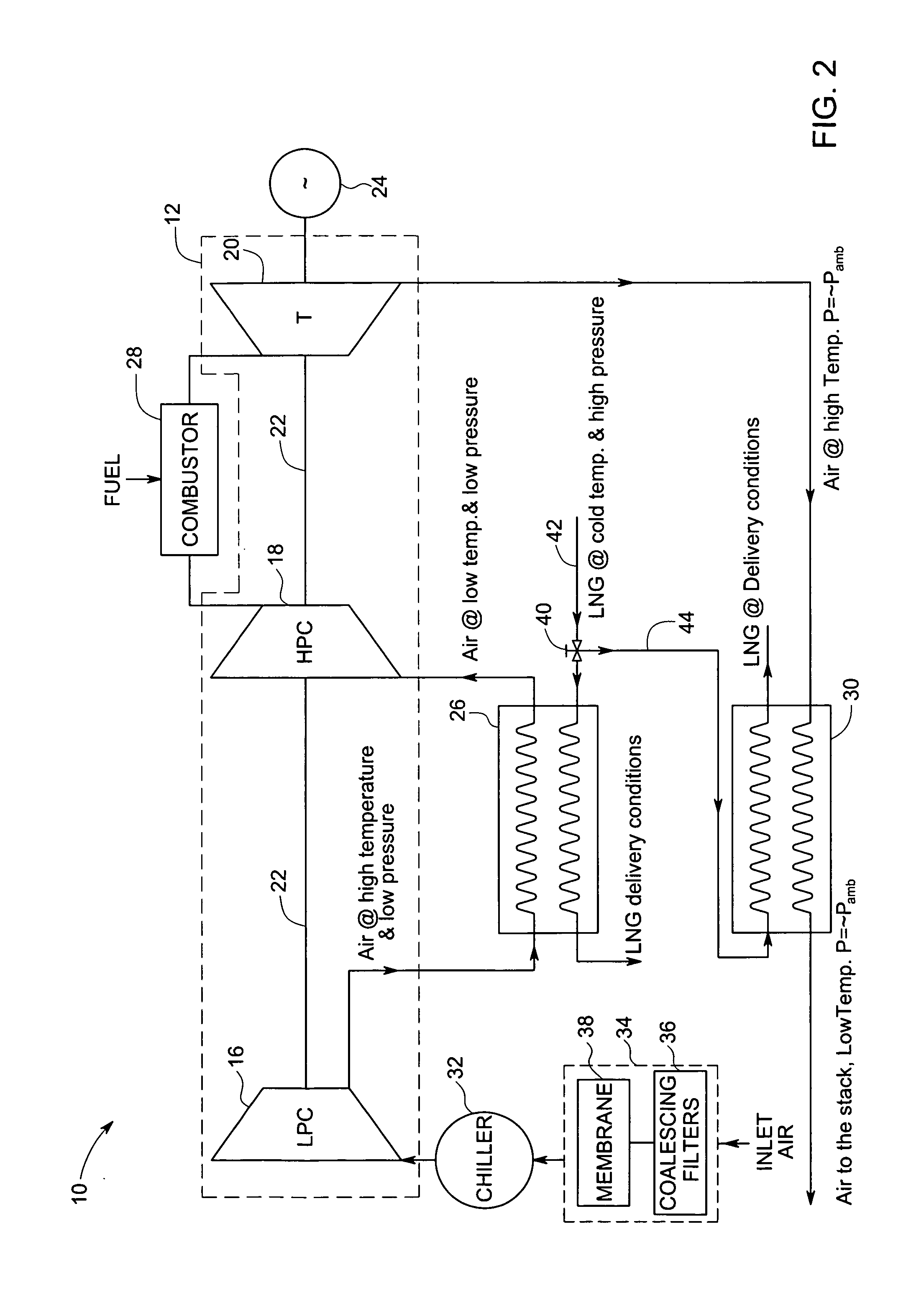

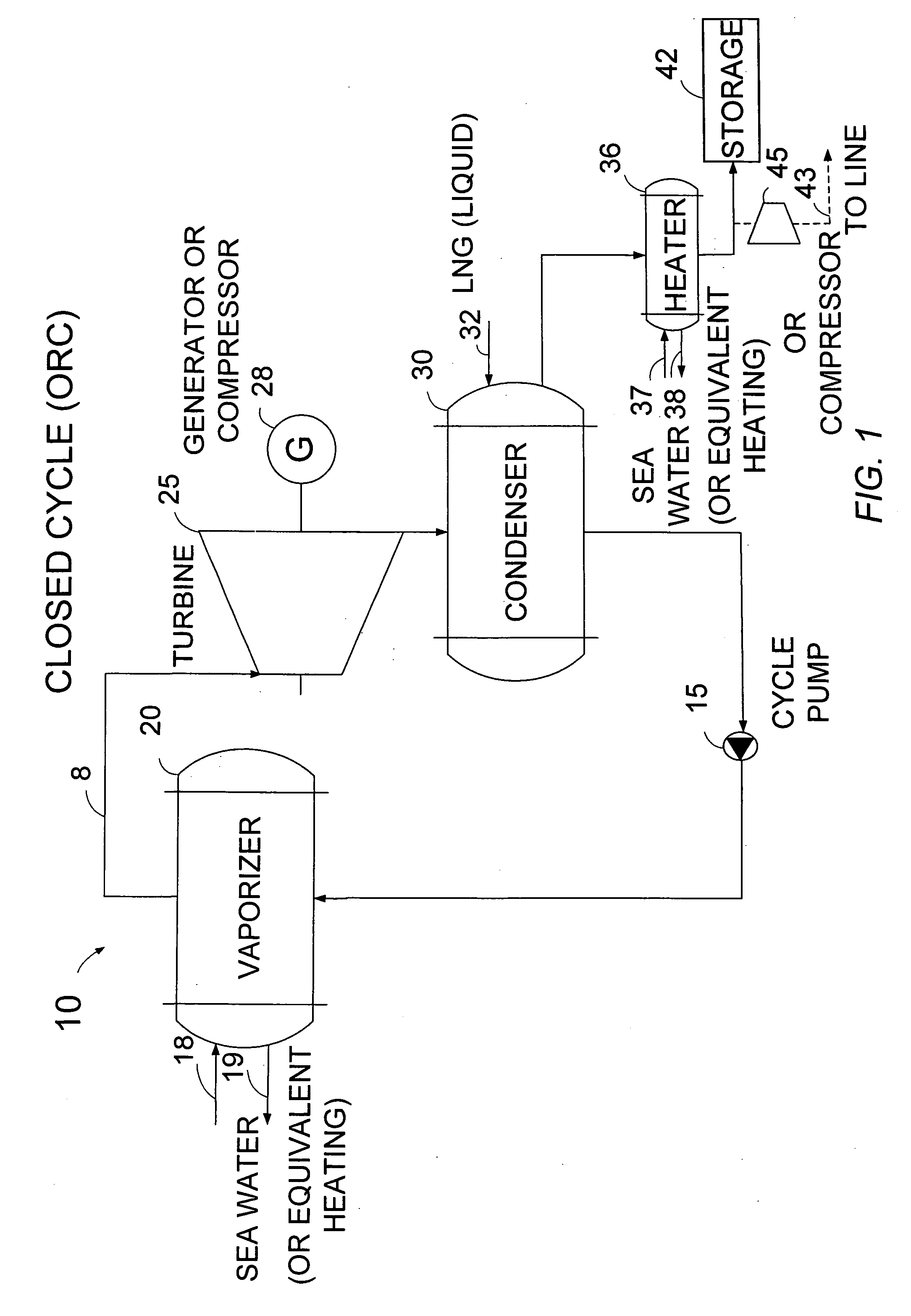

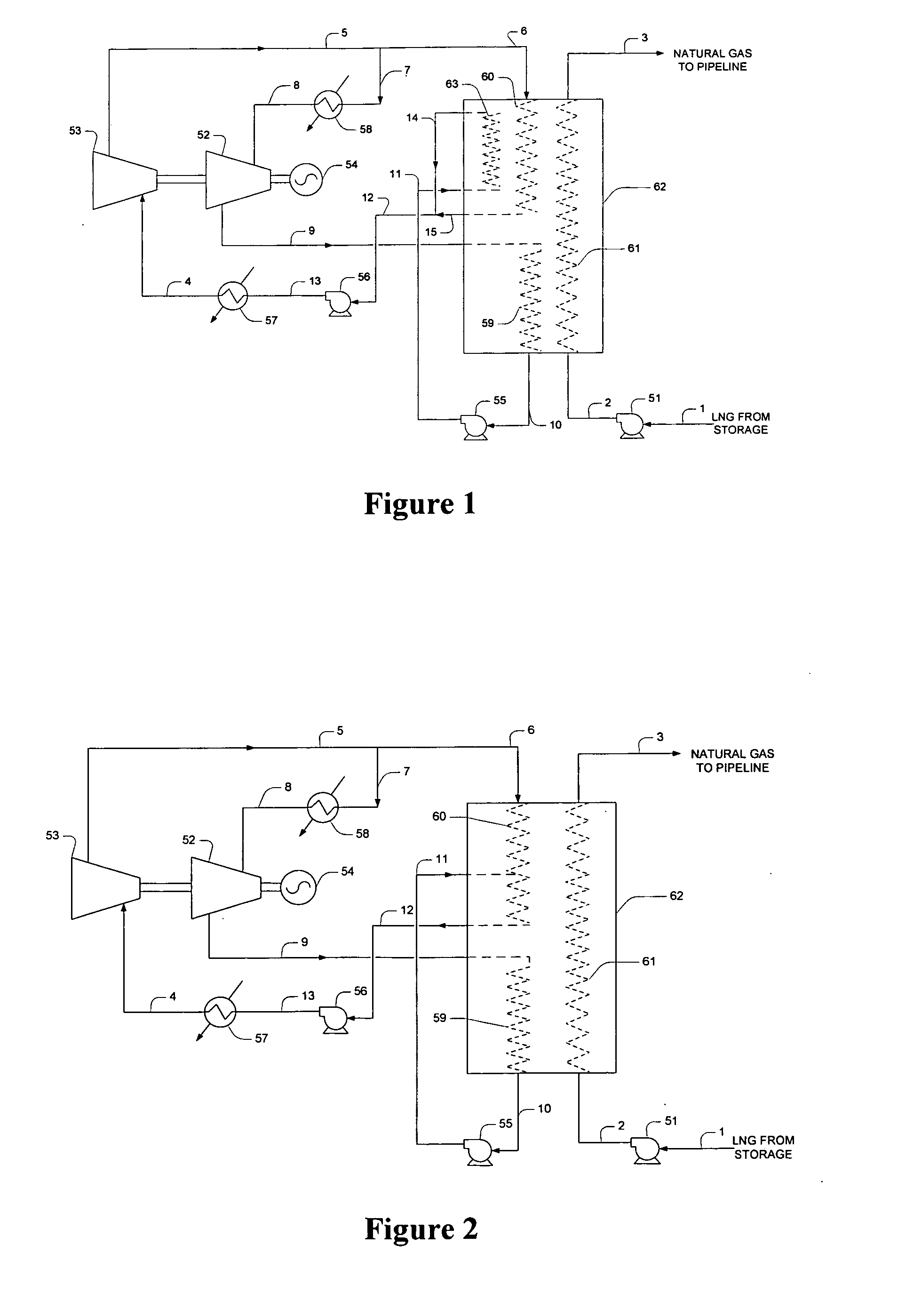

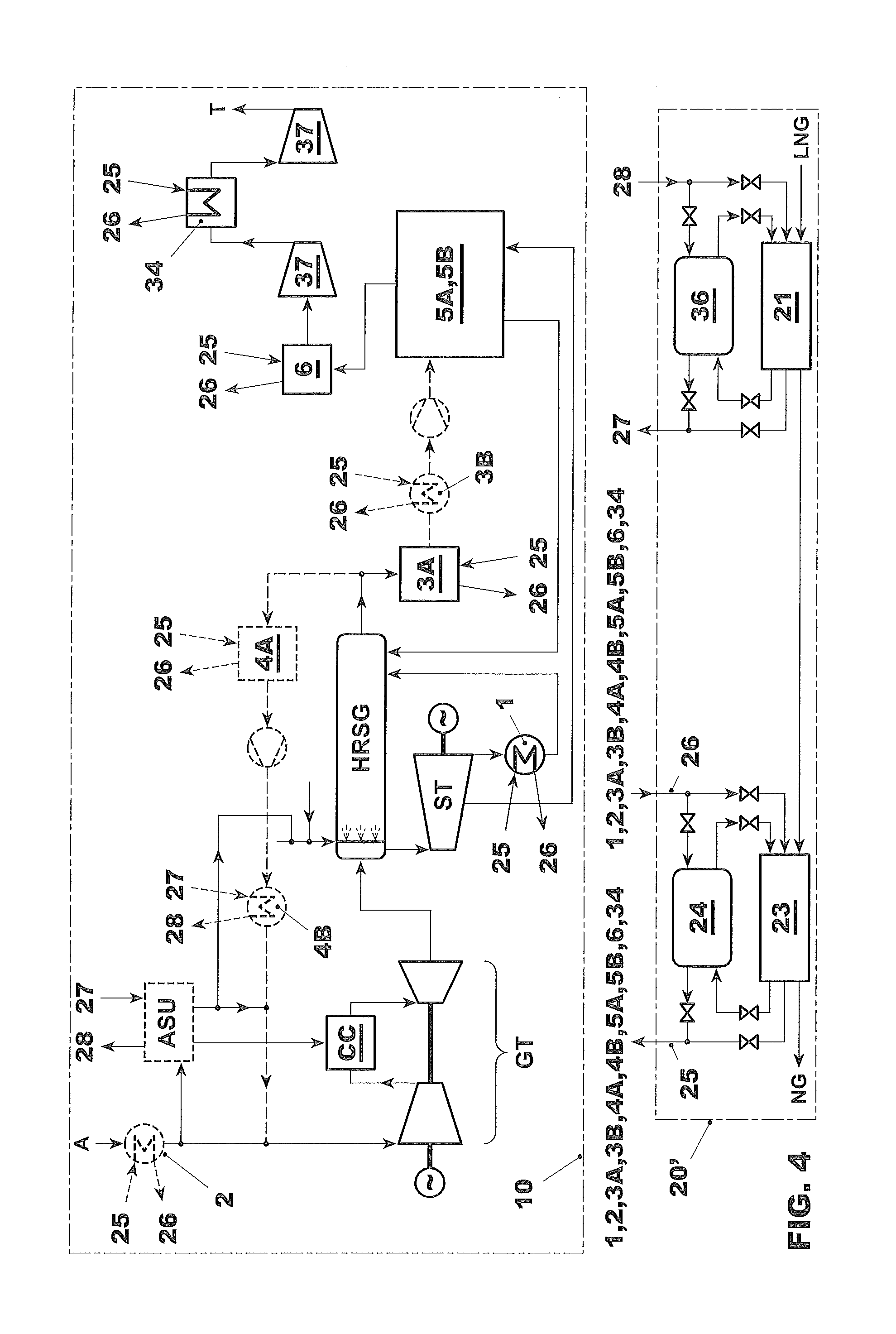

Configurations and Methods for Power Generation with Integrated Lng Regasification

InactiveUS20080190106A1Increase power generationGas handling applicationsGas turbine plantsCombustionPower station

LNG cold is used in a plurality of cycles in a combined power plant to increase power output. Especially preferred plant configurations integrate a combined cycle power plant with a regasification operation in which in a first stage LNG cold provides cooling in an open or closed power cycle. Most preferably, a significant portion of the LNG is vaporized in the first stage. In a second stage LNG cold provides cooling for a heat transfer medium that is used to provide refrigeration for the cooling water to a steam power turbine and for an air intake chiller of a combustion turbine in the power plant.

Owner:FLUOR TECH CORP

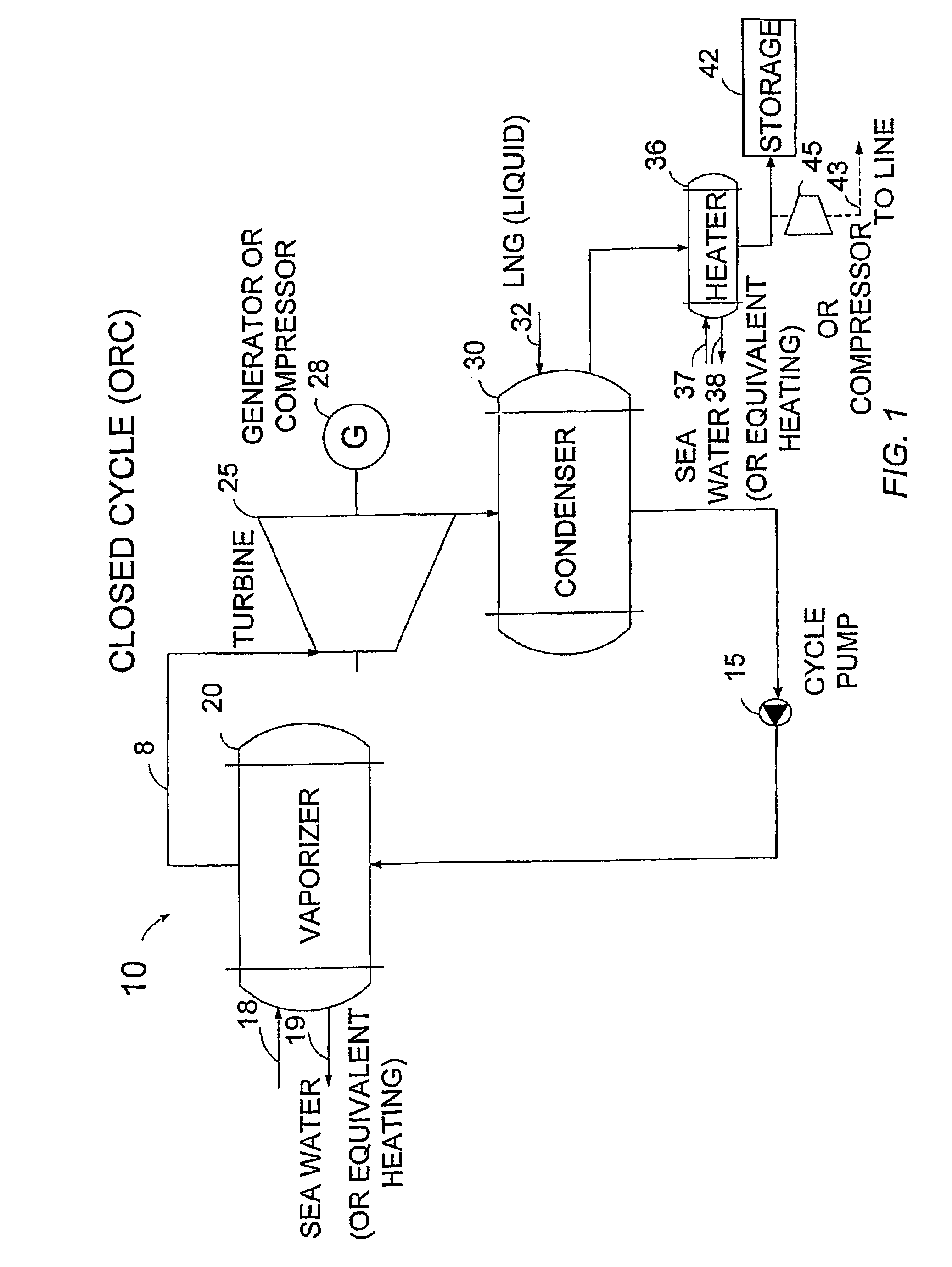

Power and regasification system for LNG

ActiveUS20090100845A1Power generationLarge temperature differenceSteam useGas handling/storage effectsEngineeringTurbine

The present invention provides a power and regasification system based on liquefied natural gas (LNG), comprising a vaporizer by which liquid motive fluid is vaporized, said liquid motive fluid being LNG or a motive fluid liquefied by means of LNG; a turbine for expanding the vaporized motive fluid and producing power; heat exchanger means to which expanded motive fluid vapor is supplied, said heat exchanger means also being supplied with LNG for receiving heat from said expanded fluid vapor, whereby the temperature of the LNG increases as it flows through the heat exchanger means; a conduit through which said motive fluid is circulated from at least the inlet of said vaporizer to the outlet of said heat exchanger means; and a line for transmitting regasified LNG.

Owner:ORMAT TECH INC

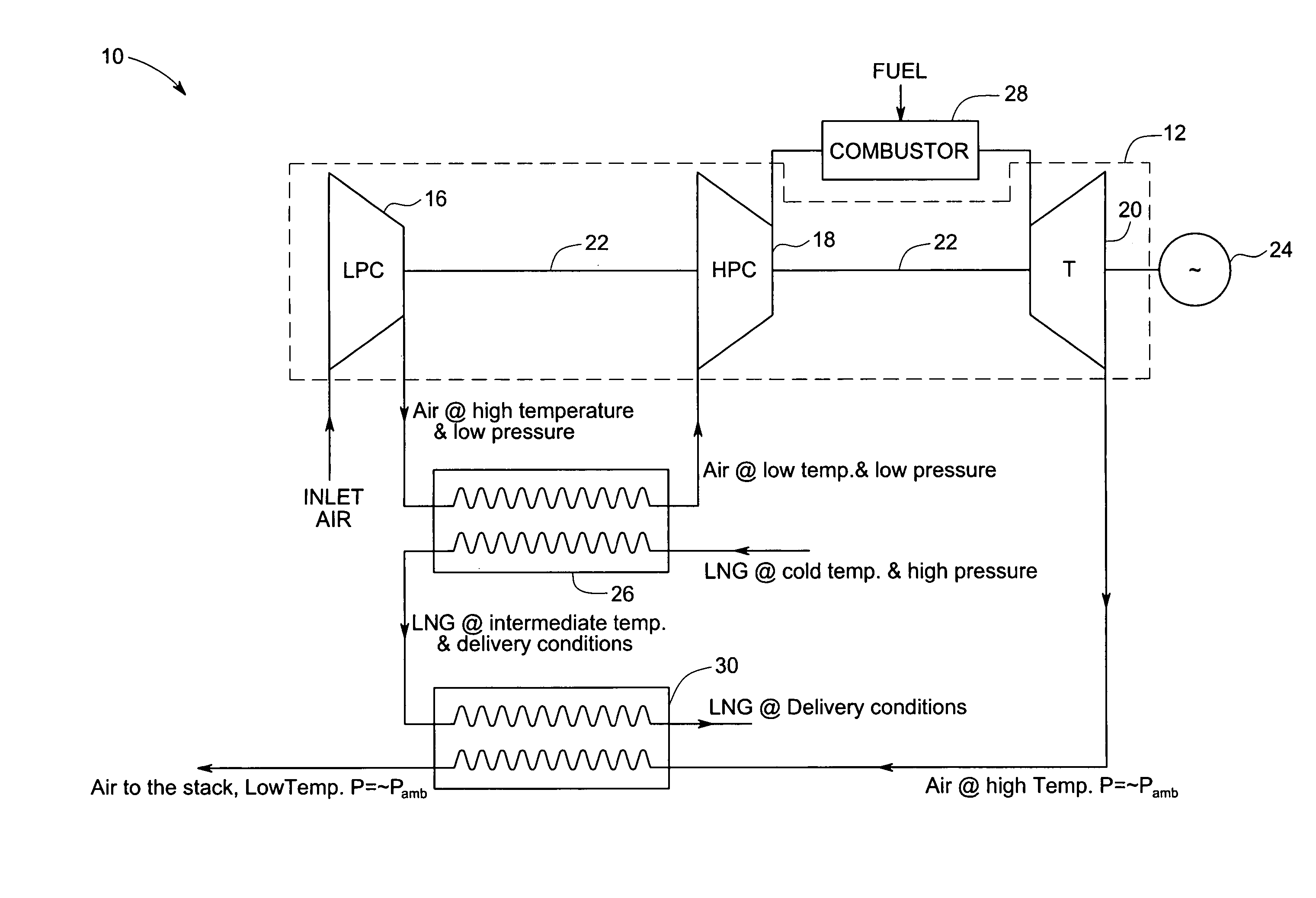

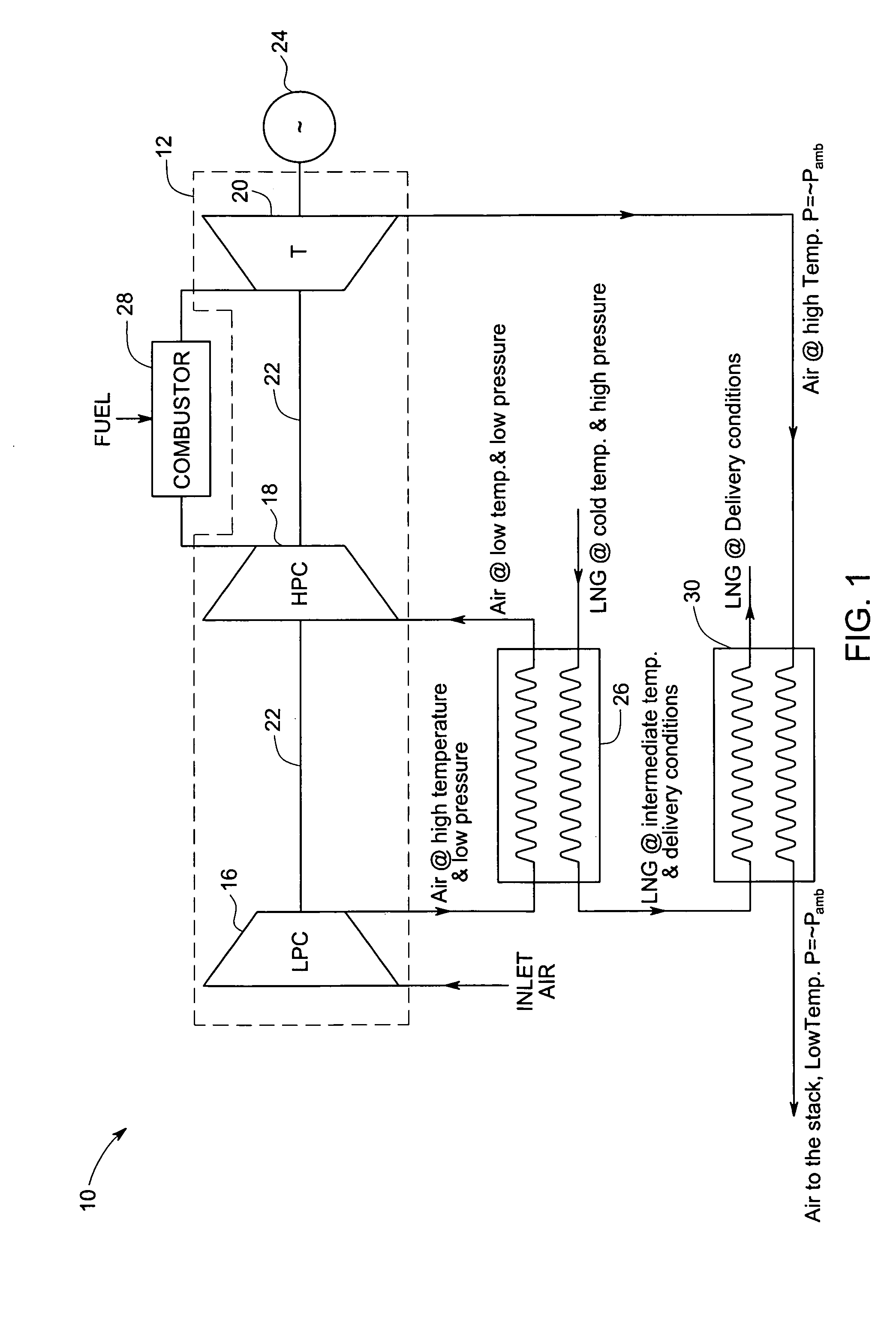

Gas turbine engine system and method of operating the same

InactiveUS20070089423A1Simple systemTurbine/propulsion engine coolingGas turbine plantsCombustion chamberWorking fluid

A gas turbine engine system includes an intercooler coupled between a low-pressure compressor and a high-pressure compressor and configured to cool the compressed air exiting the low-pressure compressor. Liquid natural gas or a cooled intermediate working fluid is used in the intercooler to cool the compressed air exiting the low-pressure compressor. A mixture of fuel and compressed air from the high-pressure are combusted in a combustion chamber of an engine. A turbine is coupled to the engine and configured to expand combustion exhaust gas ejected from the engine to generate power. A heat exchanger is coupled to the turbine and the intercooler and configured to re-gasify the liquid natural gas. The exhaust air exiting the turbine or a heated intermediate working fluid is used to gasify the liquid natural gas in the heat exchanger.

Owner:GENERAL ELECTRIC CO

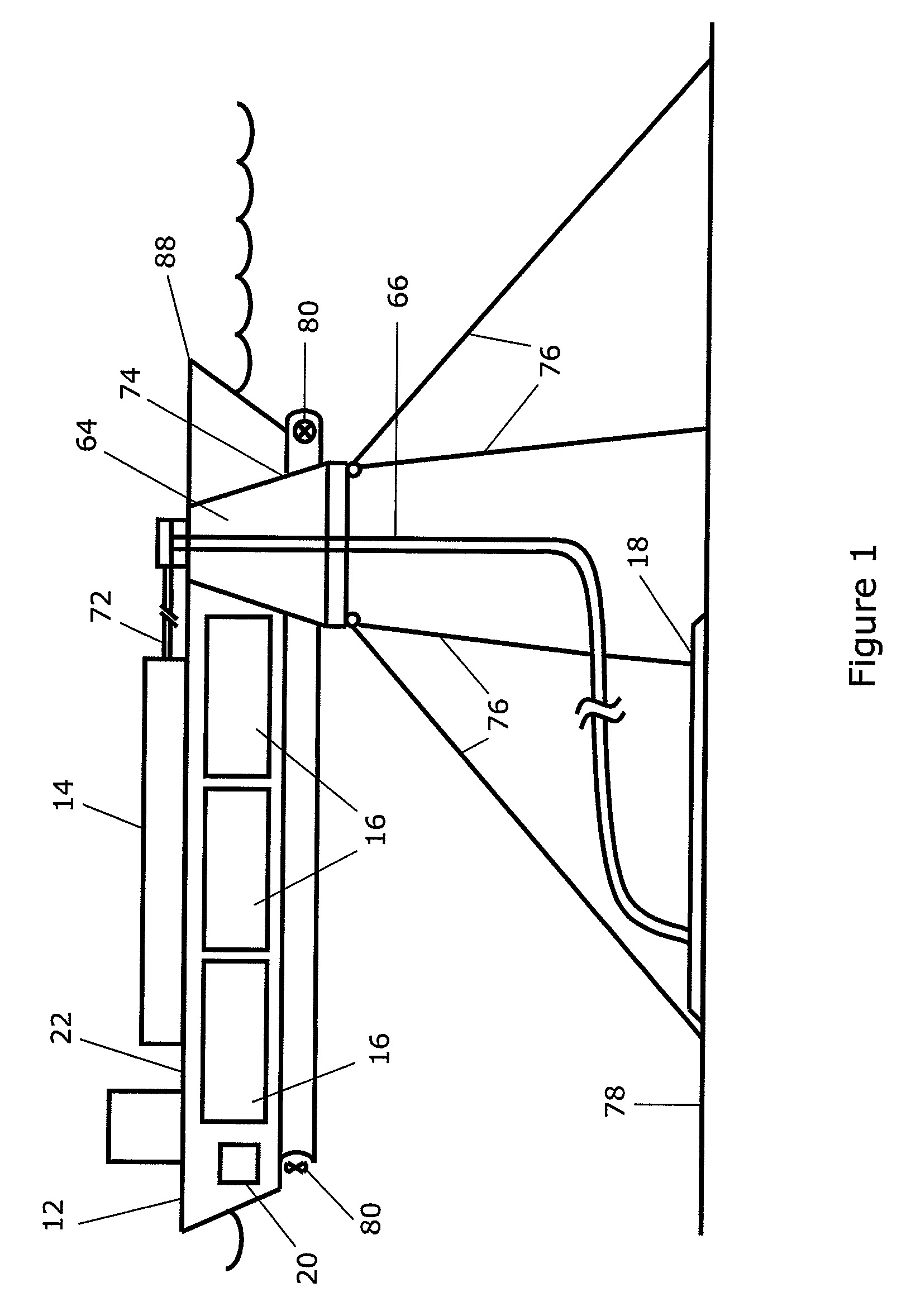

Floating LNG regasification facility with LNG storage vessel

InactiveUS20080295526A1Well formedContainer filling methodsGas handling applicationsMarine engineeringSubmarine pipeline

An LNG terminal is disclosed which includes an offshore mooring turret, an LNG storage vessel operatively coupled to the mooring turret, the LNG storage vessel including at least one LNG storage tank for the storage of liquid natural gas and a regasification vessel operatively coupled to the LNG storage vessel. A method of operating an offshore LNG terminal is also disclosed which includes obtaining liquefied natural gas from at least one LNG storage tank on an LNG storage vessel that is operatively coupled to a mooring turret, regasifying the liquefied natural gas from the LNG storage vessel using a regasification vessel operatively coupled to the LNG storage vessel, and supplying the regasified gas to at least one subsea pipeline via the mooring turret.

Owner:SOFEC

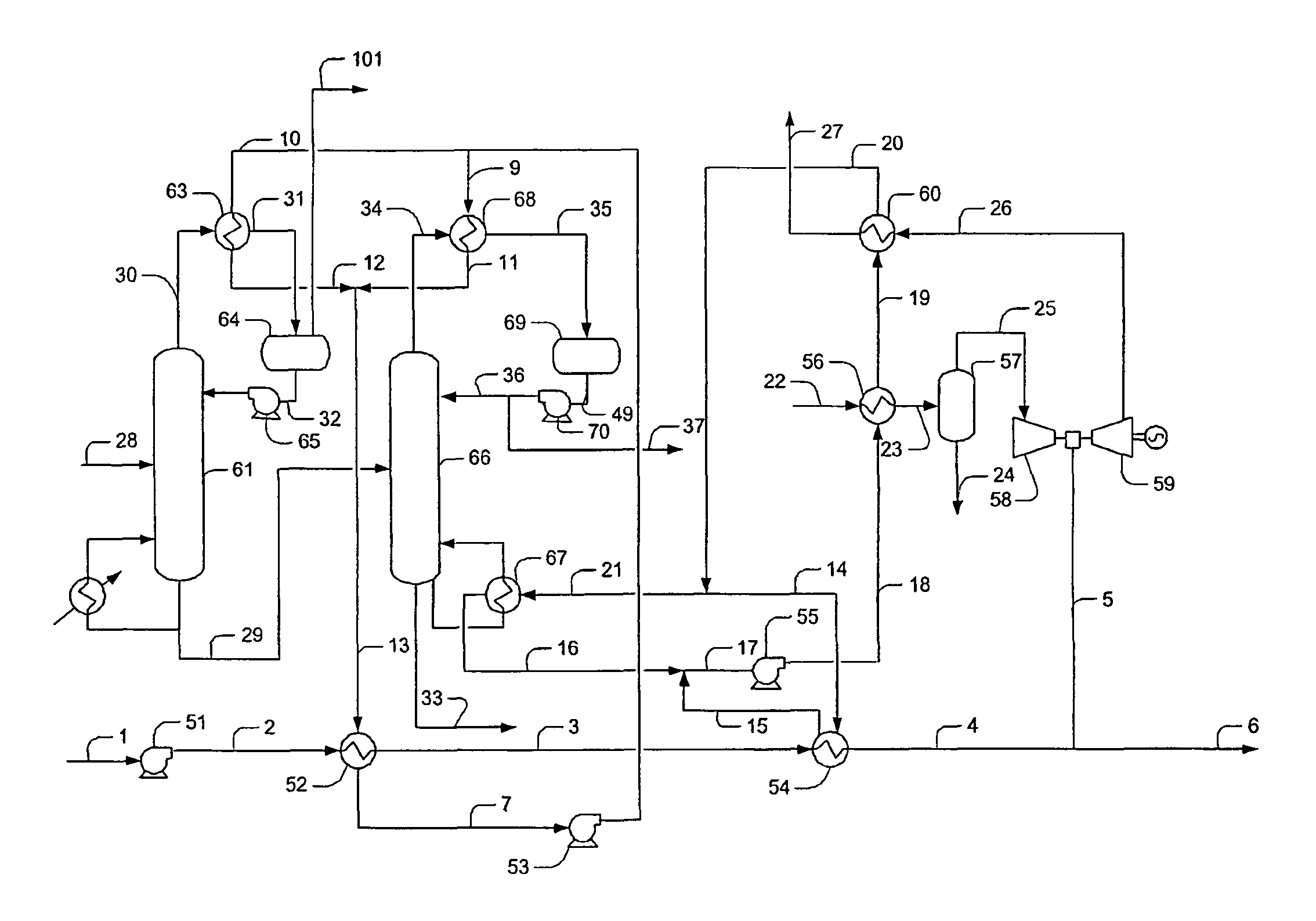

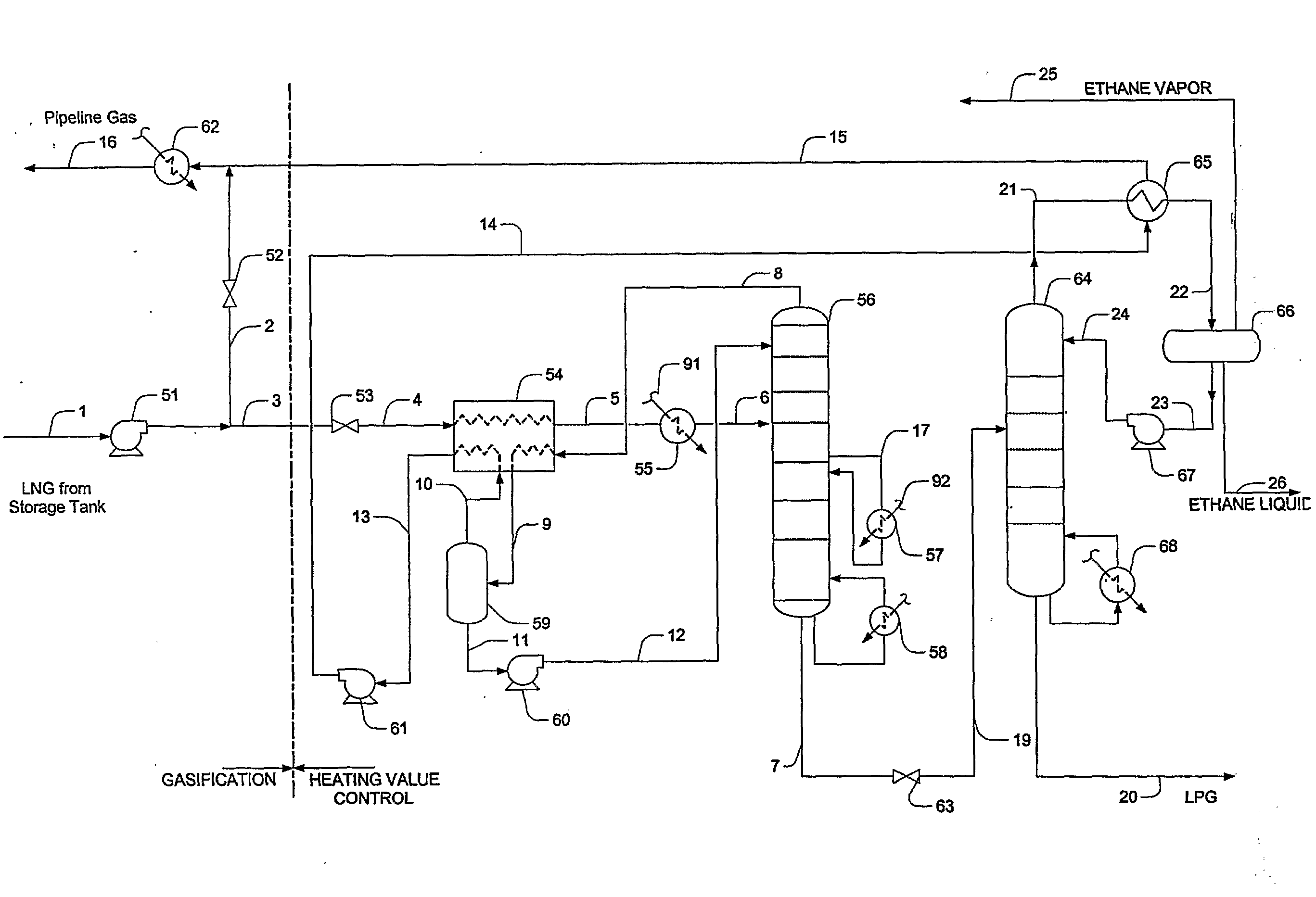

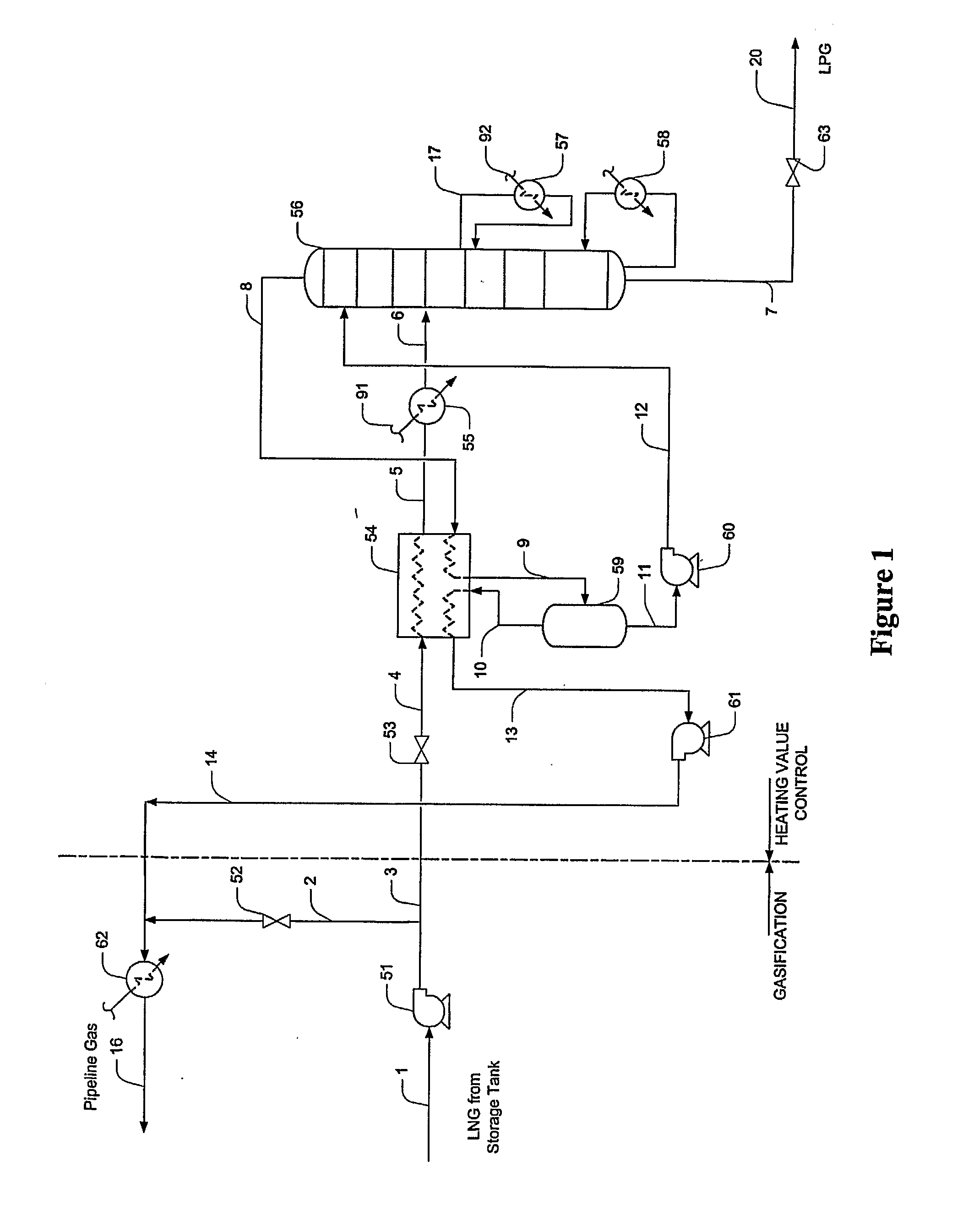

Process for extracting ethane and heavier hydrocarbons from LNG

ActiveUS20060042312A1Advanced technologyEfficiently extracting NGL productsSolidificationLiquefactionFuel qualityFractionation

A process for the extraction and recovery of ethane and heavier hydrocarbons (C2+) from LNG. The process covered by this patent maximizes the utilization of the beneficial cryogenic thermal properties of the LNG to extract and recover C2+ form the LNG using a unique arrangement of heat exchange equipment, a cryogenic fractionation column and processing parameters that essentially eliminates (or greatly reduces) the need for gas compression equipment minimizing capital cost, fuel consumption and electrical power requirements. This invention may be used for one or more of the following purposes: to condition LNG so that send-out gas delivered from an LNG receiving and regasification terminal meets commercial natural gas quality specifications; to condition LNG to make Lean LNG that meets fuel quality specifications and standards required by LNG powered vehicles and other LNG fueled equipment; to condition LNG to make Lean LNG so that it can be used to make CNG meeting specifications and standards for commercial CNG fuel; to recover ethane, propane and / or other hydrocarbons heavier then methane from LNG for revenue enhancement, profit or other commercial reasons.

Owner:PI TECH ASSOC INC

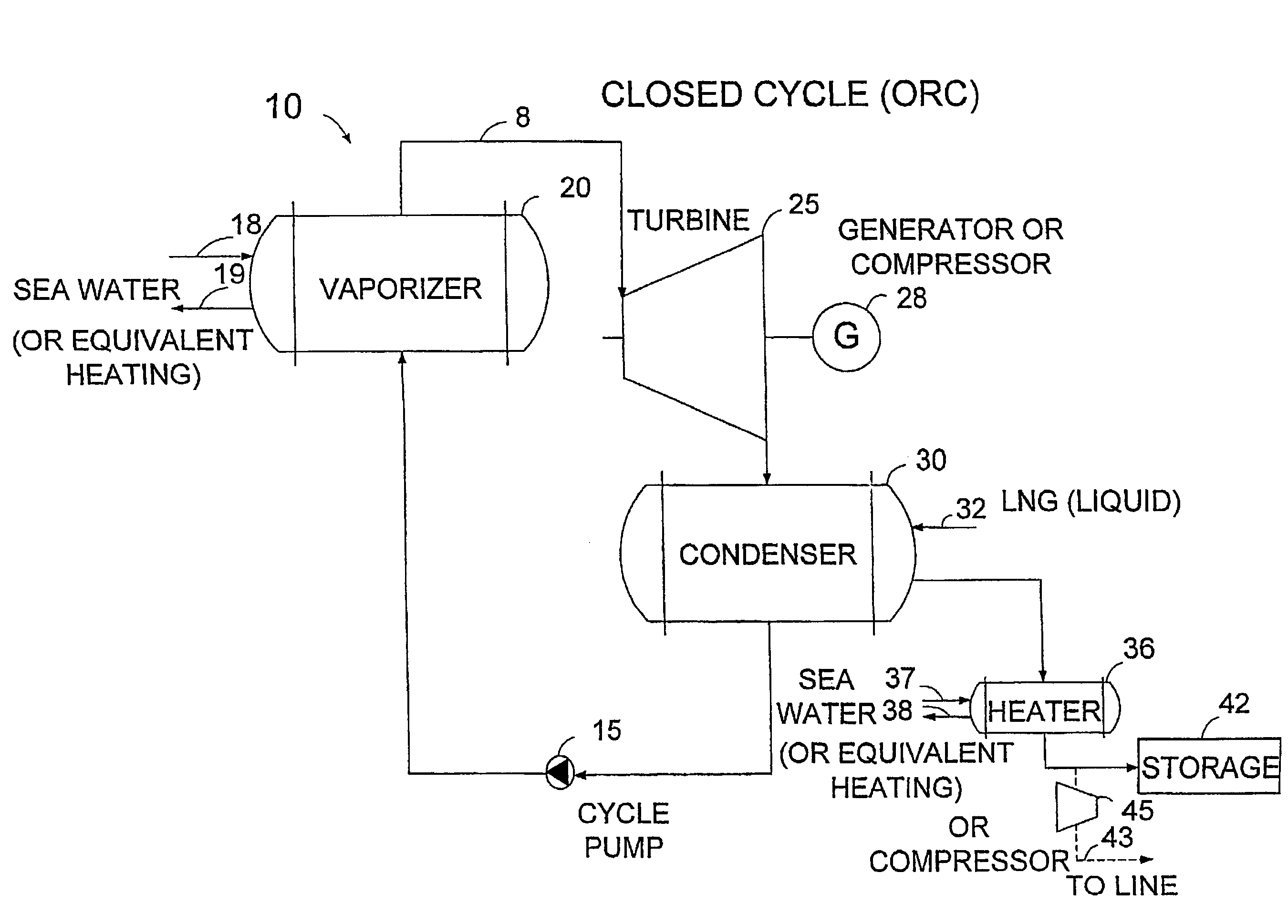

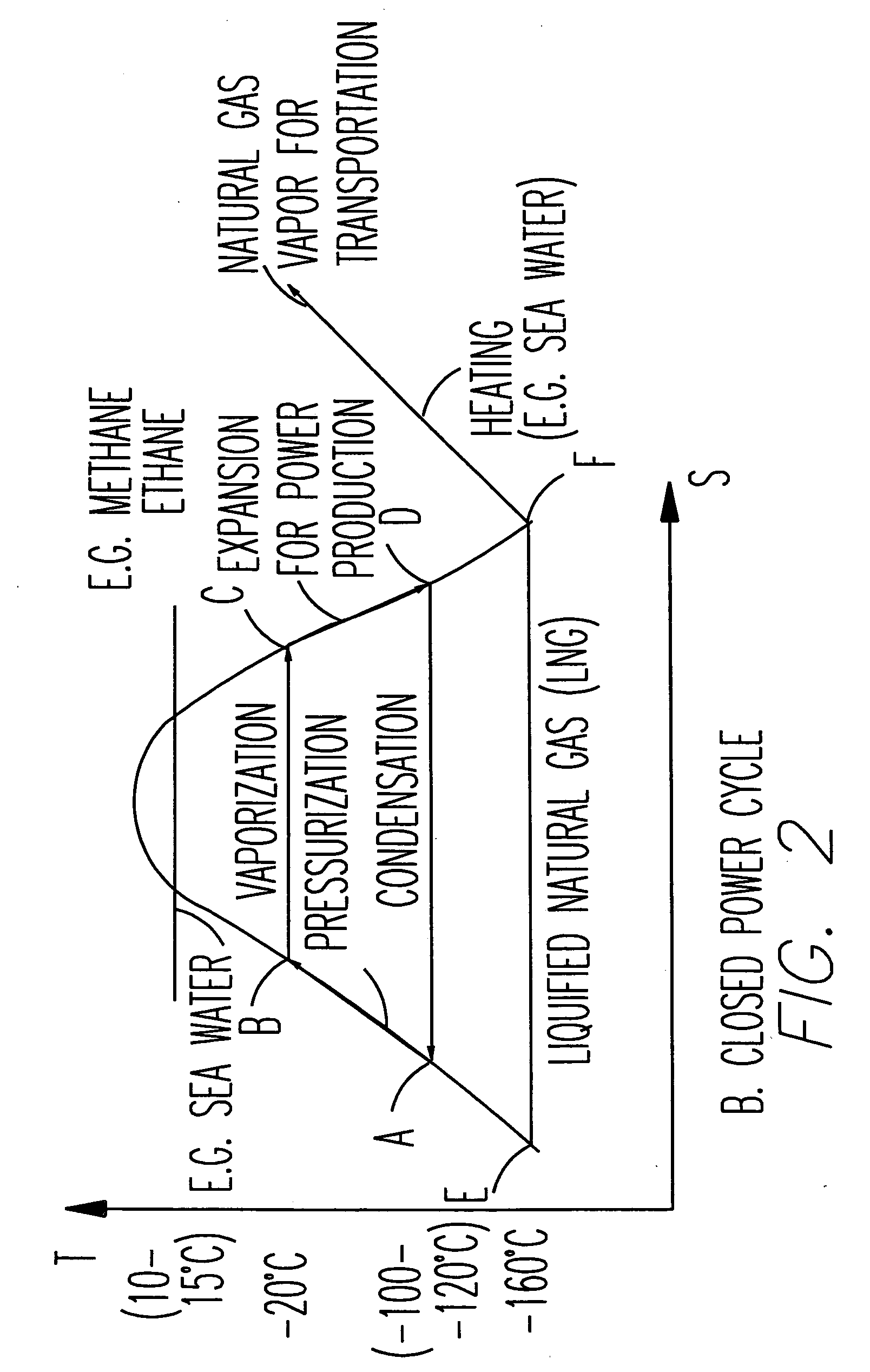

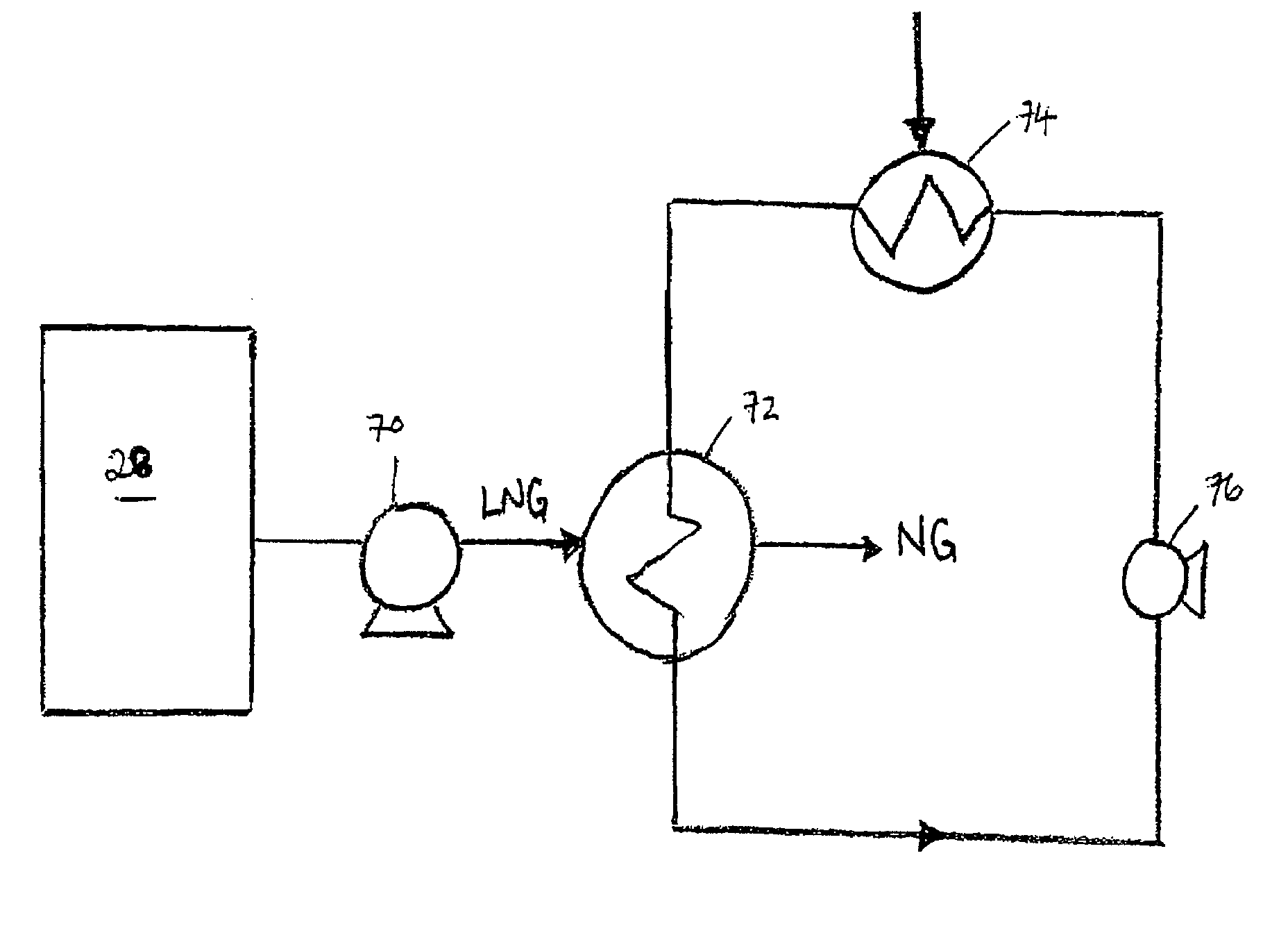

LNG-based power and regasification system

The present invention provides a power and regasification system based on liquefied natural gas (LNG), comprising a vaporizer by which liquid working fluid is vaporized, said liquid working fluid being LNG or a working fluid liquefied by means of LNG; a turbine for expanding the vaporized working fluid and producing power; heat exchanger means to which expanded working fluid vapor is supplied, said heat exchanger means also being supplied with LNG for receiving heat from said expanded fluid vapor, whereby the temperature of the LNG increases as it flows through the heat exchanger means; a conduit through which said working fluid is circulated from at least the inlet of said vaporizer to the outlet of said heat exchanger means; and a line for transmitting regasified LNG.

Owner:ORMAT TECH INC

Liquefied natural gas regasification configuration and method

InactiveUS20070062216A1Reduce security risksImprove power generation efficiencySolidificationLiquefactionPower stationProduct gas

Liquefied natural gas (LNG) is heated in a plant by a heat source and the heated LNG is expanded to produce work. In particularly preferred plants, the heat source is a combined cycle power plant, and the work is used to recompress pipeline gas produced from the heated LNG. Additionally, the refrigeration content in LNG may be utilized to increase the power generation capacity and efficiency of a combined cycle power plant.

Owner:FLUOR TECH CORP

Lng Regasification Configurations and Methods

LNG composition of LNG from a storage tank or other source is modified in a process in which the LNG is pumped to a first pressure and split into two portions. One portion of the pressurized LNG is then reduced in pressure and heavier components are separated from the reduced pressure LNG to thereby form a lean LNG. The lean LNG is then pumped to a higher pressure and combined with the other portion to form a leaner LNG. Preferably, separation is performed using a demethanizer, wherein part of the demethanizer overhead product is condensed to form the lean LNG, while another portion is used for column reflux. In further preferred configurations, ethane recovery is variable and in yet other configurations, propane or ethane can be delivered via a batching pipeline.

Owner:FLUOR TECH CORP

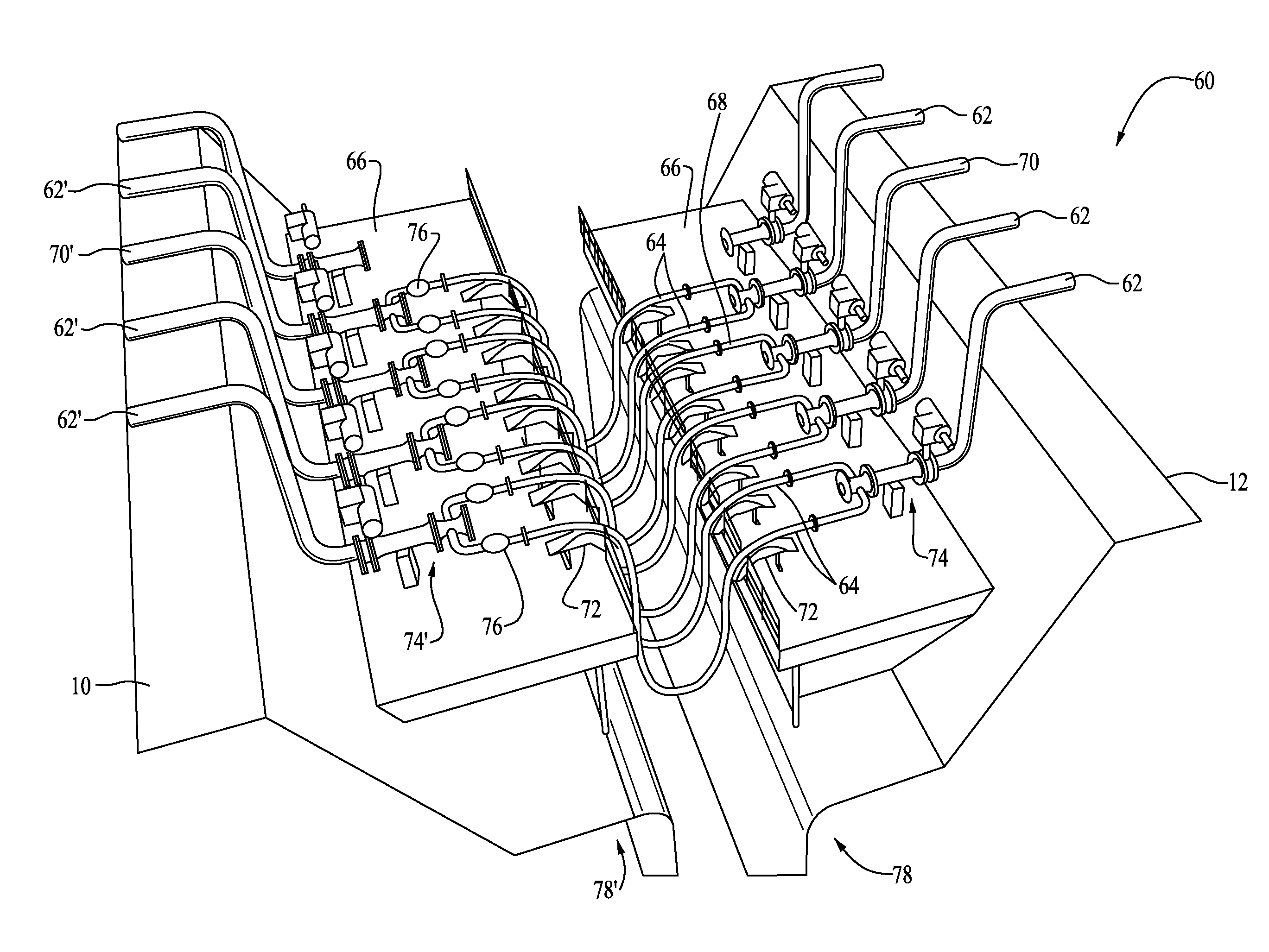

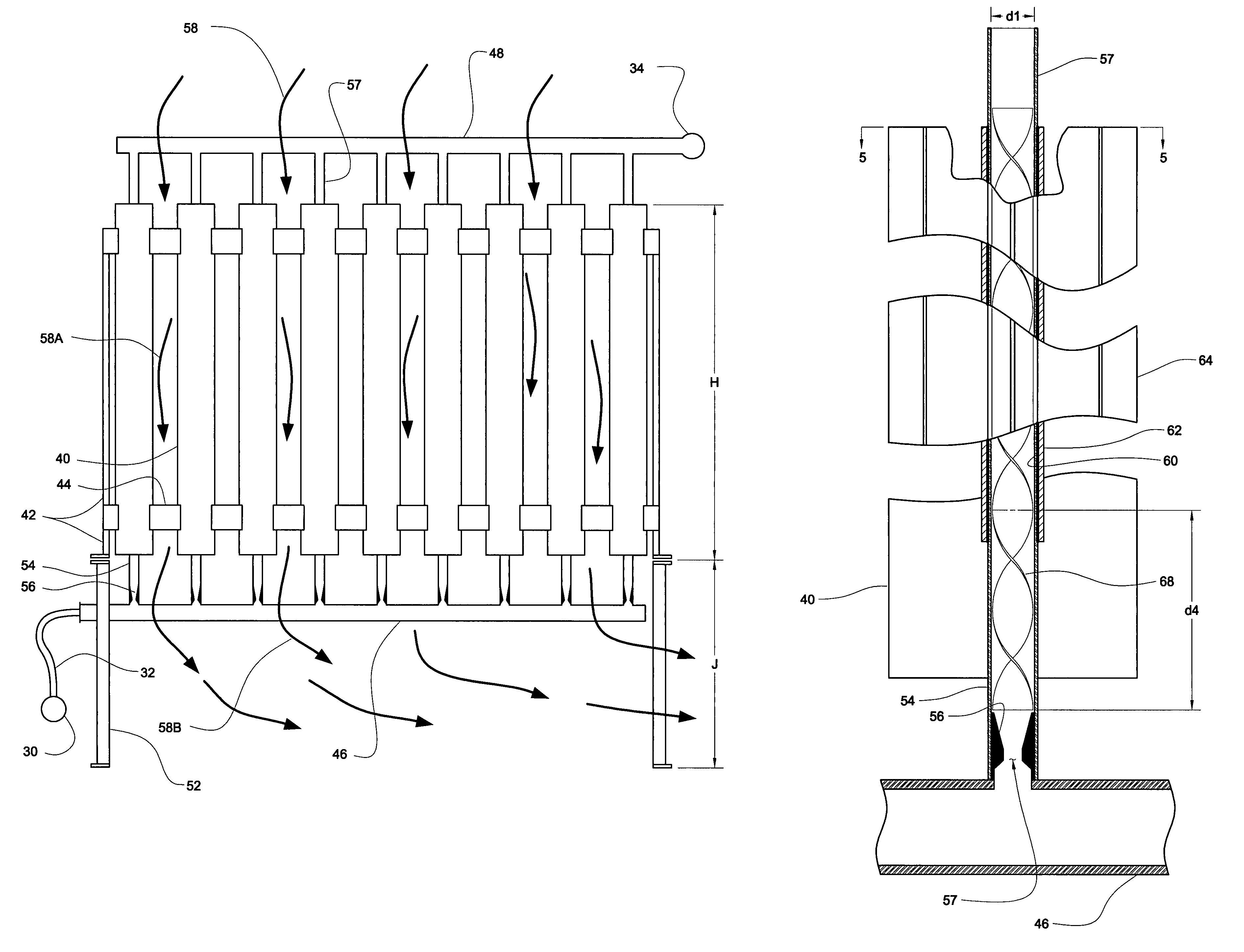

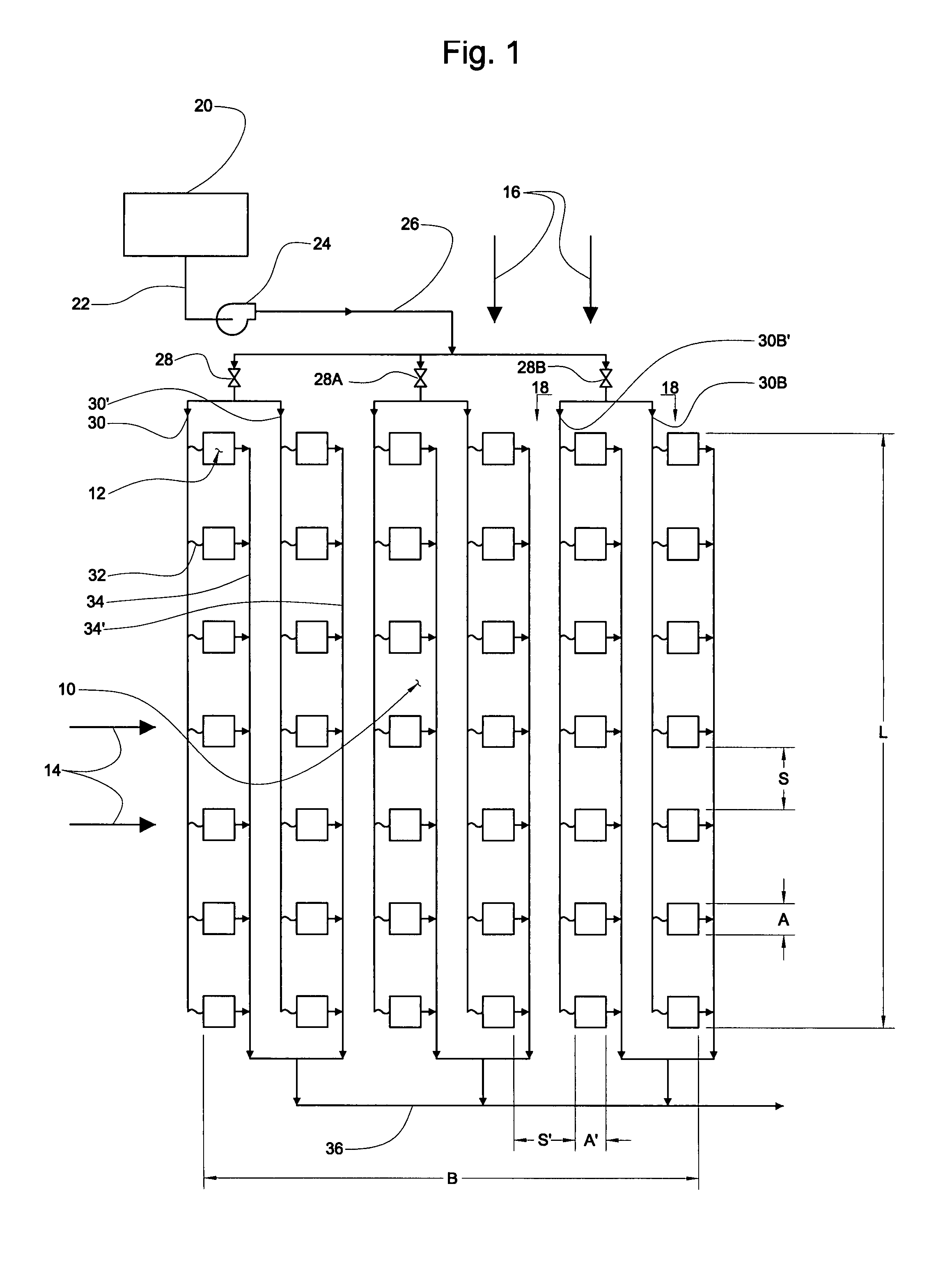

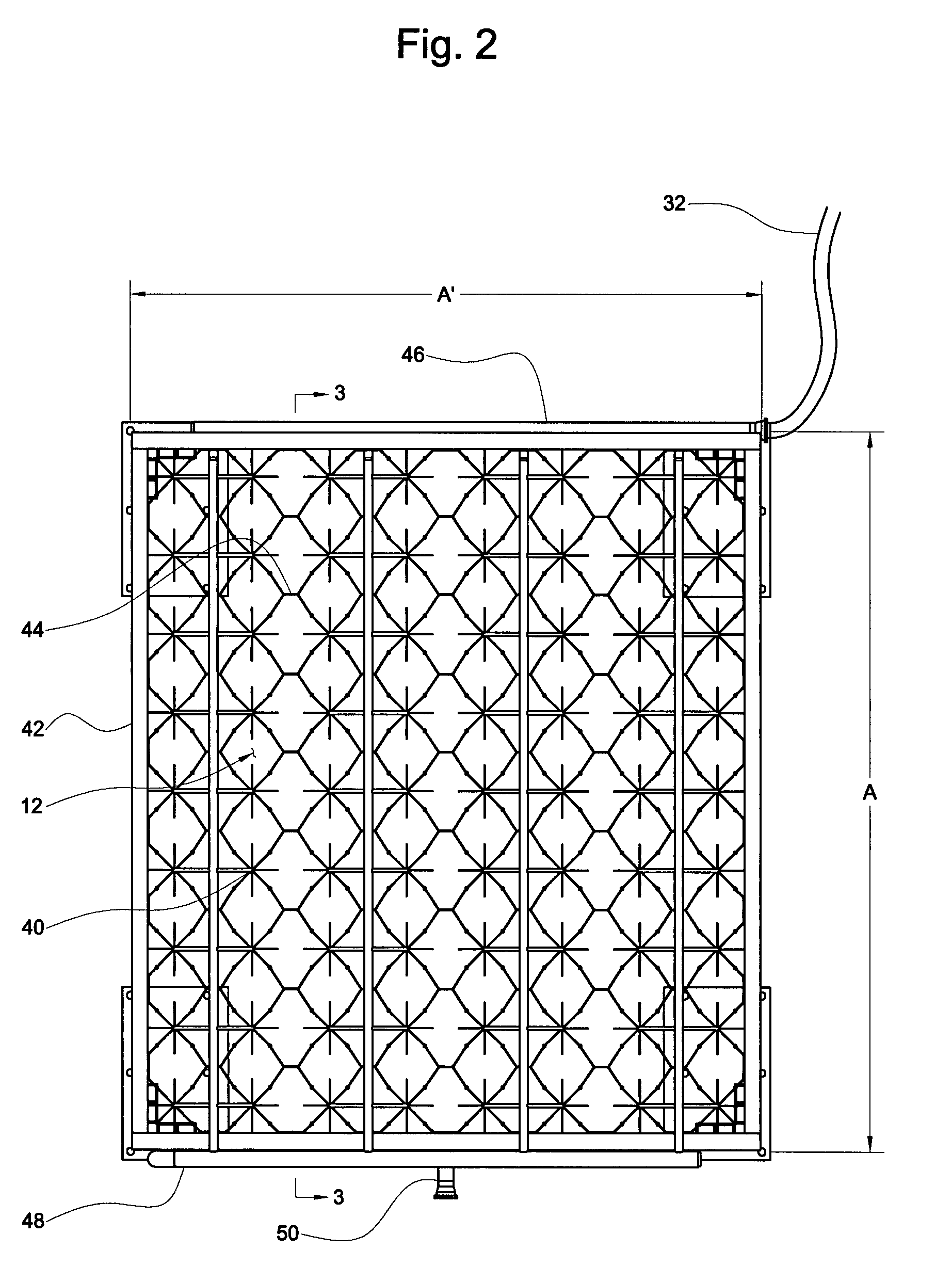

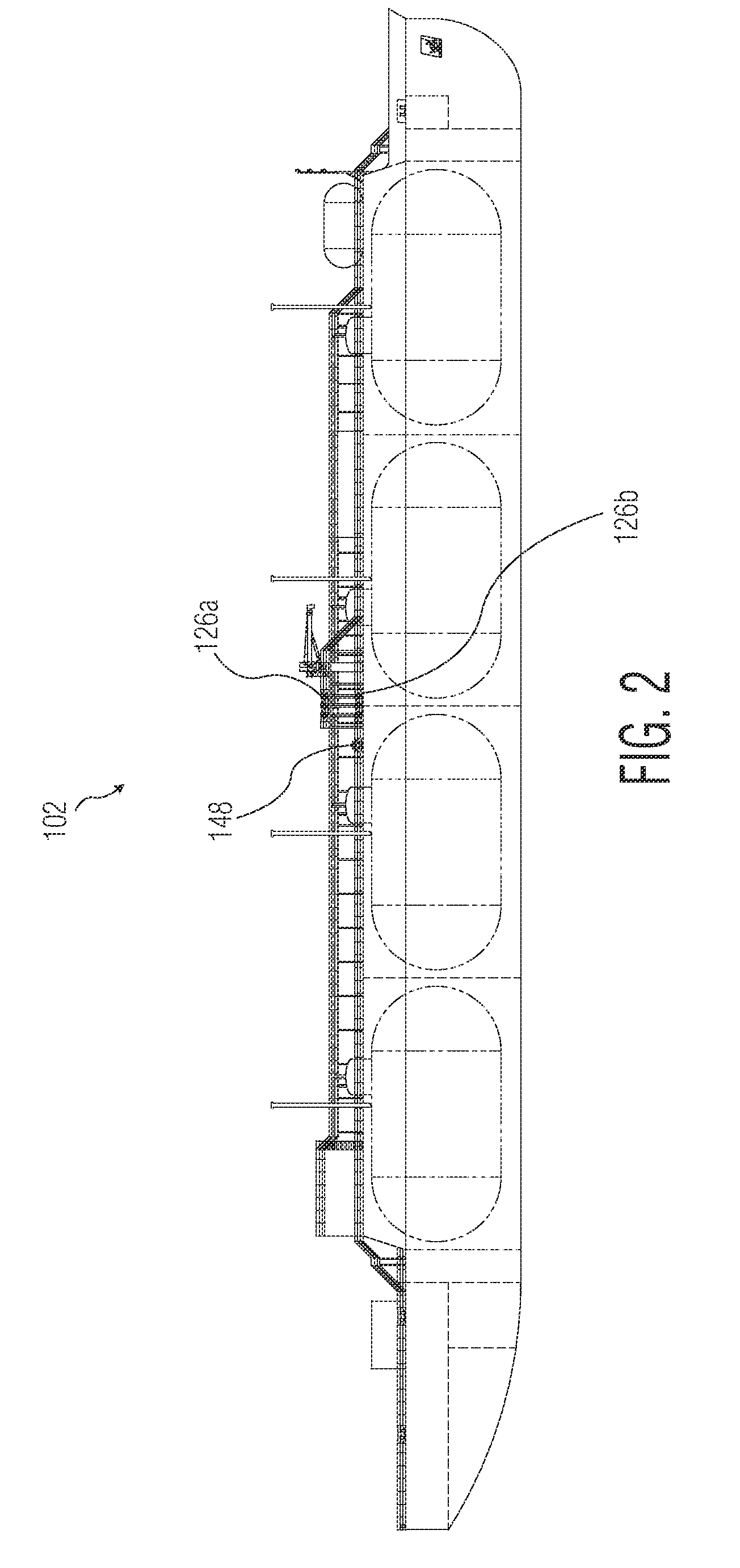

Heat transfer in the liquefied gas regasification process

ActiveUS8069678B1Enhanced internal heat transferIncrease airflowGas handling/storage effectsStationary conduit assembliesAtmospheric airNatural convection

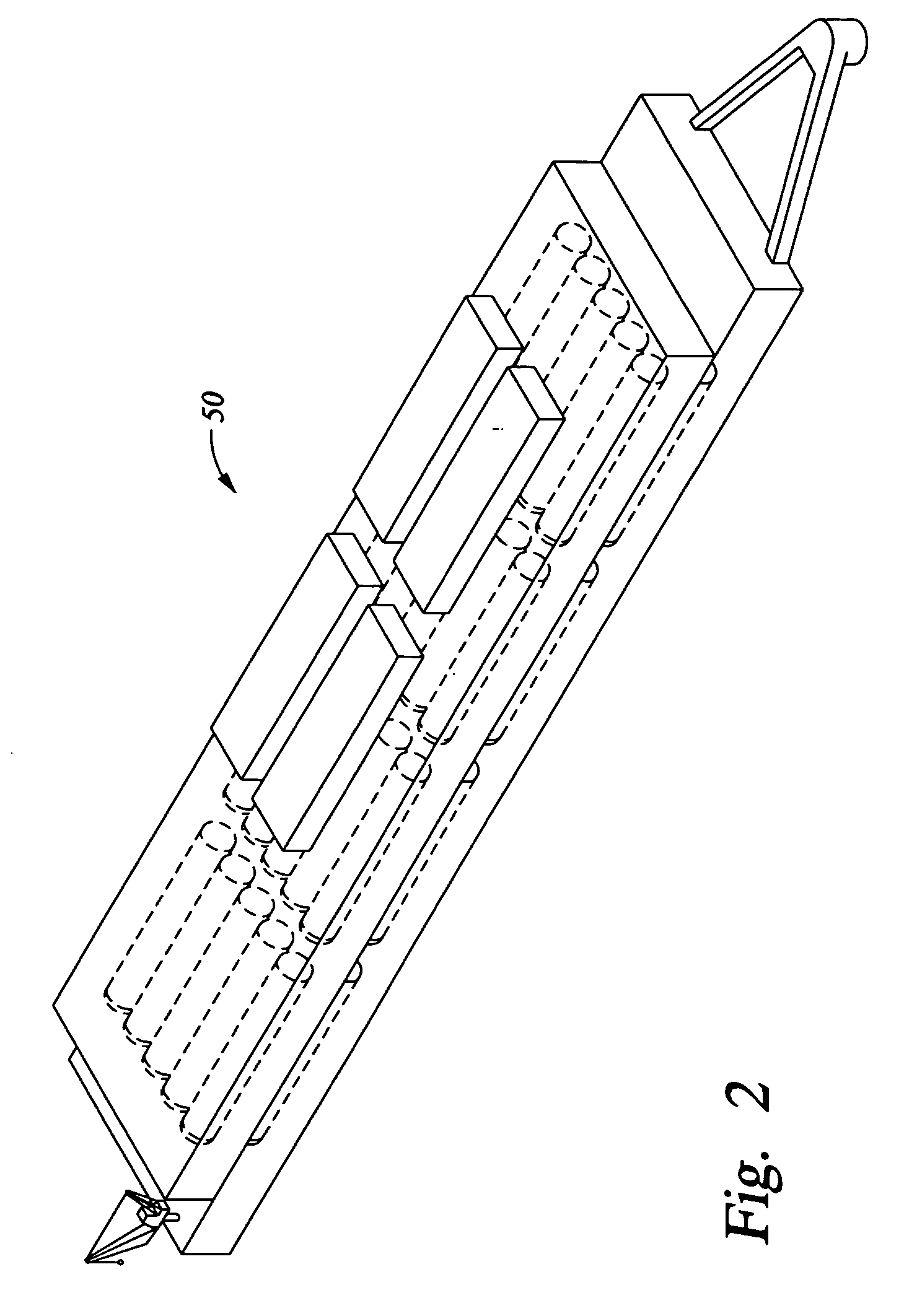

A system and apparatus for regasifying liquefied natural gas (LNG) and other cryogenic liquids on a continuous basis utilizing improved atmospheric air vaporizer heat exchangers of the vertical single pass and parallel connected type. A multiplicity of such heat exchangers is positioned on a defined grid, such as to improve the natural convection of the ambient air heat source. An improved heat exchange system includes heat exchange elements within the heat exchangers comprised of hybrid externally finned elements, smooth interior stainless steel tubes thermally bonded within the externally finned elements, the tubes containing vortex generators. Flow distributors in the form of venturi shaped injectors are positioned at the inlet of each tube of the multiplicity of heat exchangers of the system.

Owner:U S BANK TRUST CO NAT ASSOC ASTHE NOTES COLLATERAL AGENT

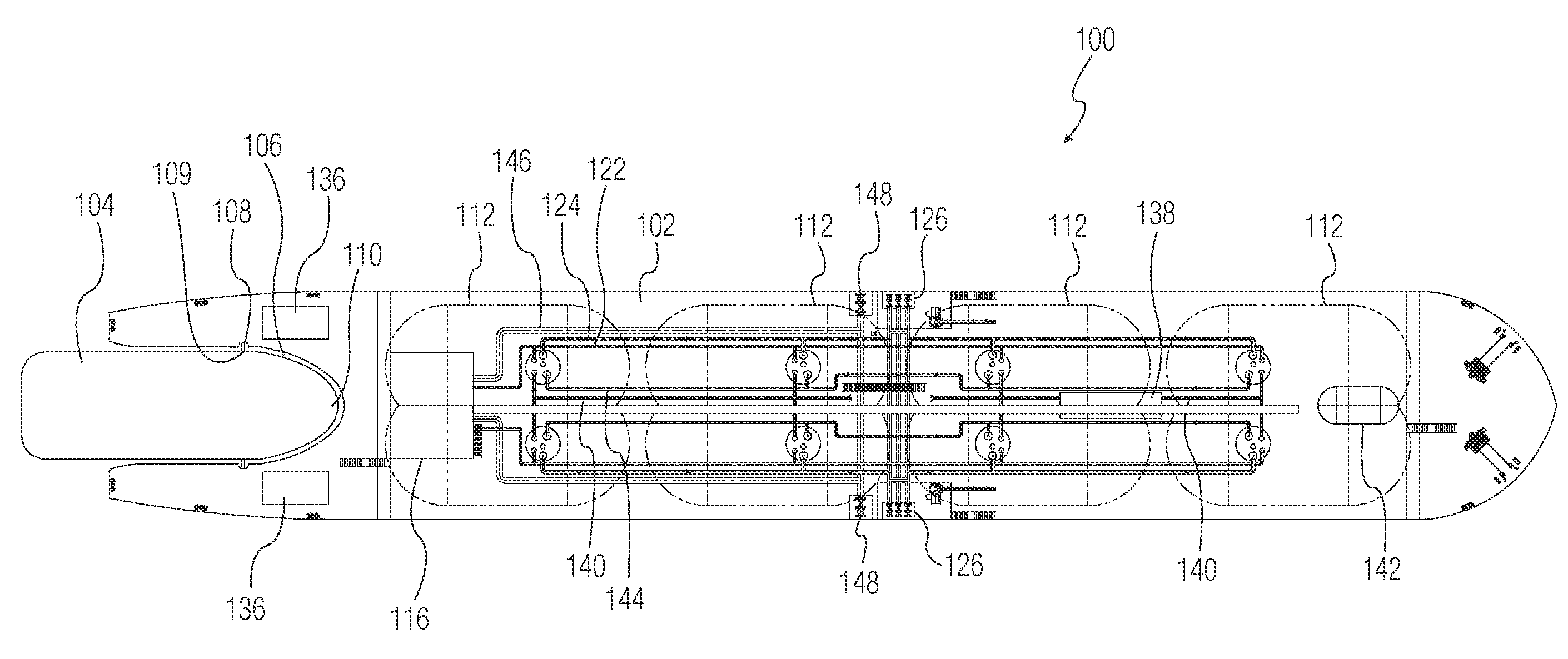

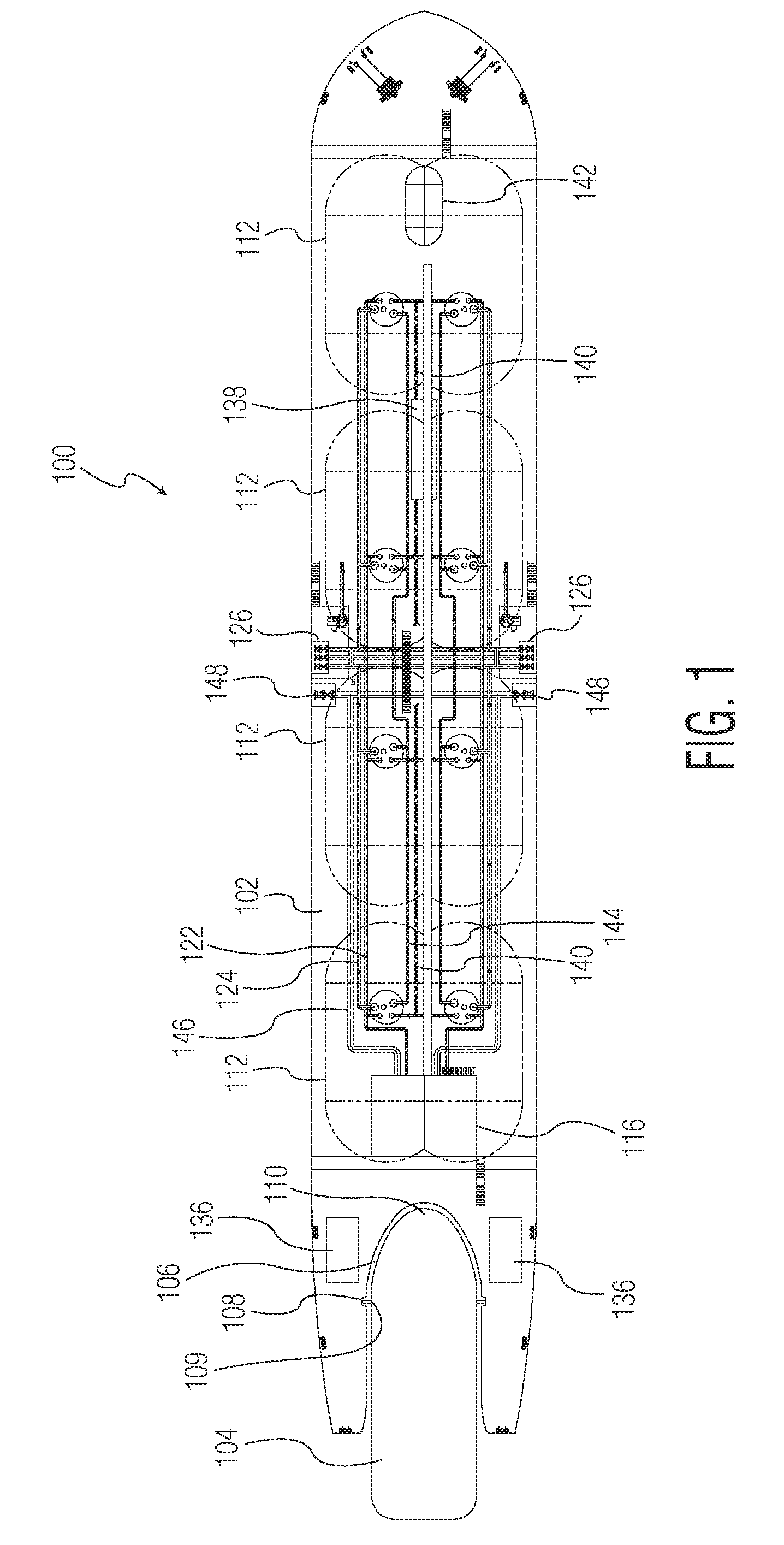

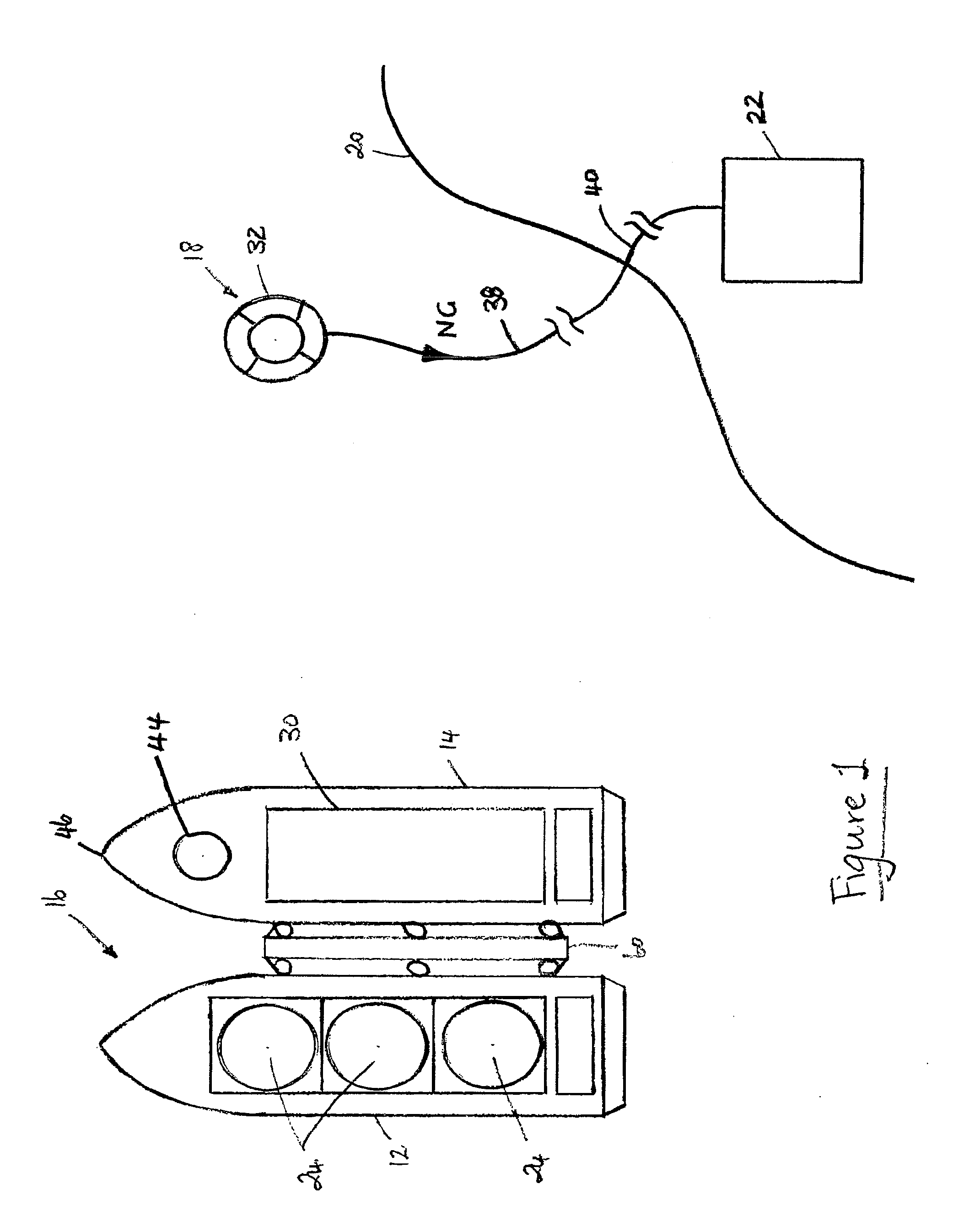

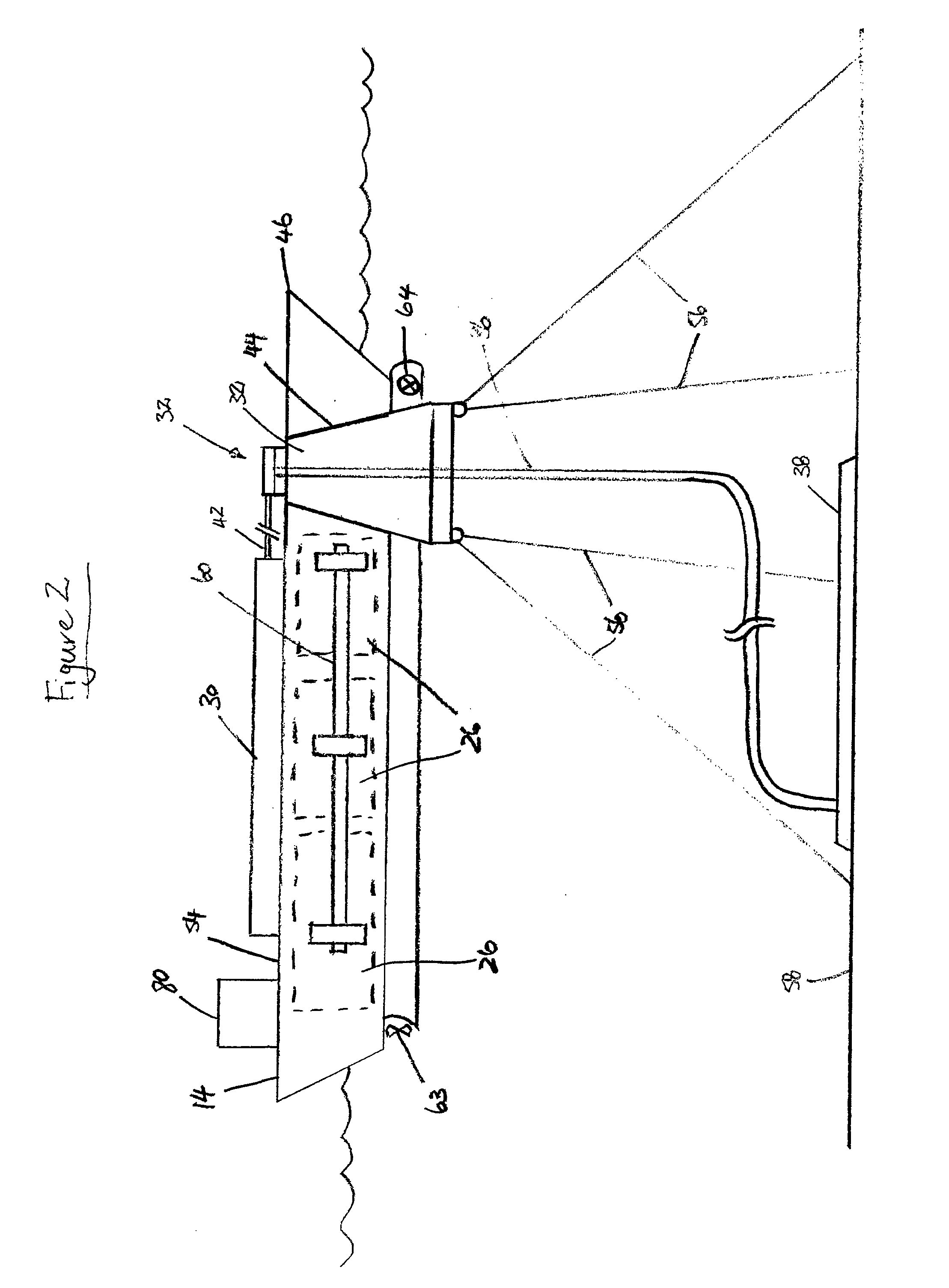

Articulated Tug and Barge Arrangement for LNG Storage, Transportation and Regasification

InactiveUS20120324910A1Easy to operateEliminate needContainer filling methodsGas handling applicationsLighteringSeawater

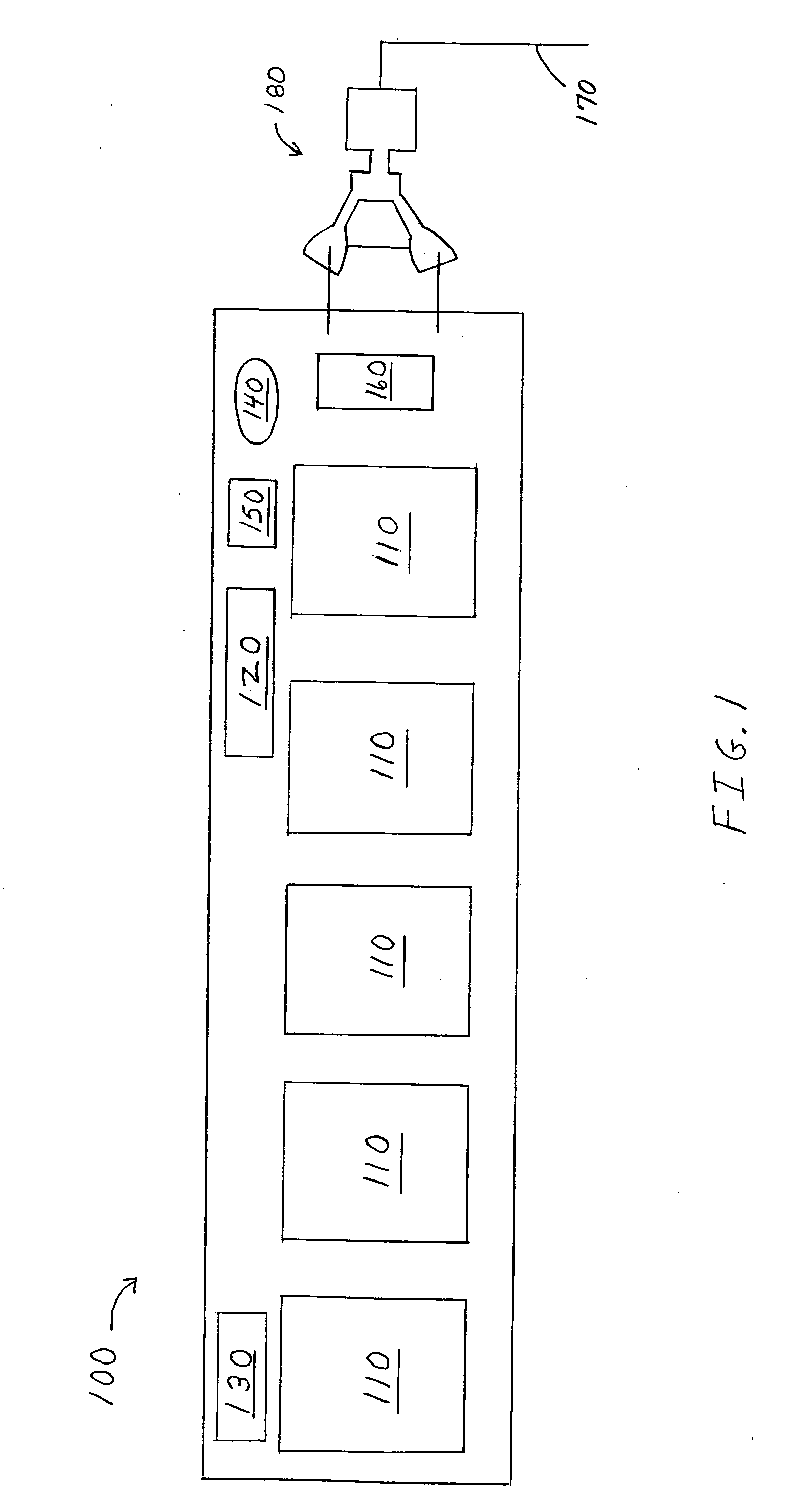

Articulated tug and barge arrangements and methods for transportation, storage and regasification of liquefied natural gas (LNG) aboard barge units and for ballasting the barge units are provided. A barge unit includes a type C tank for the containment of LNG under pressure and a regasification unit fluidly coupled to the type C tank for regasification of LNG aboard the barge unit for offloading natural gas. The barge unit is adapted for loading LNG directly from a liquefaction plant, for transporting LNG by operatively coupling to a tug unit, as well as for storing LNG at a destined off board facility, and for fueling a floating power production facility. The arrangements and methods provide a transport terminal ring. The arrangements and methods provide for the circulation of seawater through the regasification unit and into ballast tanks for ballasting of the barge unit while offloading natural gas.

Owner:WALLER MARINE

Lng Transportation Vessel and Method For Transporting Hydrocarbons

A vessel for transporting liquefied natural gas is provided. The vessel generally includes a gas transfer system for on-loading and off-loading natural gas to and from the vessel at essentially ambient temperature. The vessel further includes a gas processing facility for selectively providing liquefaction and regasification of the natural gas. The vessel also includes a containment structure for containing the liquefied natural gas during transport. The vessel may be a marine vessel or a barge vessel for transporting LNG over water, or a trailer vessel for transporting LNG overthe-road. A method for transporting LNG is also provided, that provides on-loading of natural gas onto a vessel, condensing the natural gas, storing the gas on the vessel in liquefied form, transporting the gas to an import terminal, vaporizing the gas, and off-loading the gas at the terminal.

Owner:BOWEN RONALD R +3

Continuous Regasification of LNG Using Ambient Air

ActiveUS20070214806A1Lighting and heating apparatusGas handling applicationsCelsius DegreeEngineering

Liquefied natural gas is regasified to form natural gas, including circulation of an intermediate fluid between a vaporizer and an ambient air heater, where the intermediate fluid is warmed by exchanging heat with the ambient air as the intermediate fluid passes through the ambient air heater, and the intermediate fluid is cooled by exchanging heat with LNG as the intermediate fluid passes through the vaporizer. The ambient air heater is subjected to a defrosting cycle by intermittently regulating the temperature of the intermediate fluid fed to the ambient air heater to a temperature greater than zero degrees Celsius using a source of supplemental heat.

Owner:WOODSIDE ENERGY

Onboard Regasification of LNG

InactiveUS20070214804A1Protection from damageWaterborne vesselsGas handling applicationsMarine engineeringShore

A method is provided for offshore regasification of liquid natural gas (LNG) for delivery onshore as a gas. The method includes offloading LNG from a first LNG Carrier to a second LNG Carrier at an offloading location, the second LNG Carrier including an onboard regasification facility, transferring the second LNG Carrier from the offloading location to a mooring location closer to shore, regasifying the LNG onboard the second LNG Carrier to form natural gas, and transferring the regasified natural gas to an onshore gas distribution facility for delivery to an end user.

Owner:WOODSIDE ENERGY

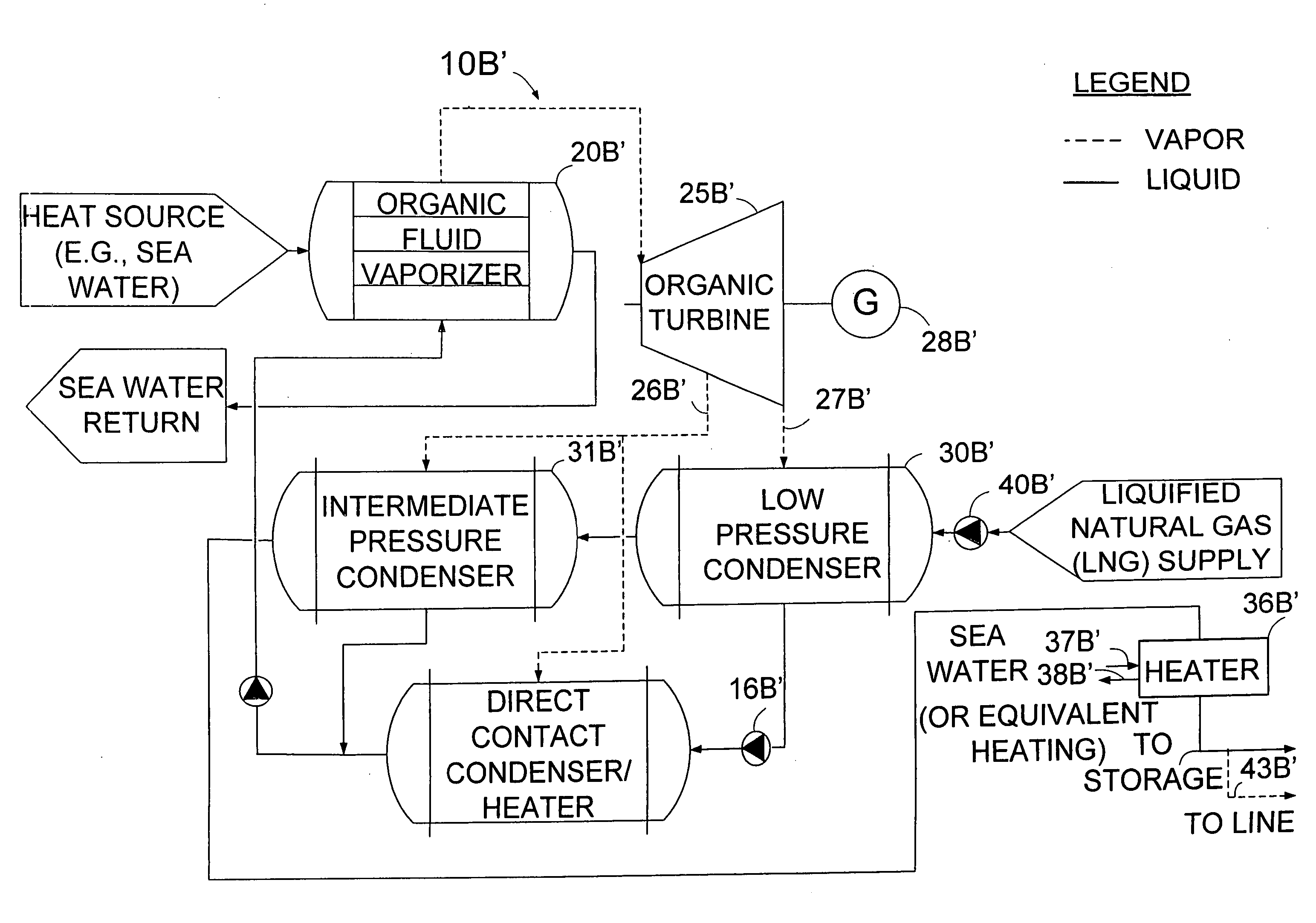

LNG Regasification And Power Generation

LNG is regasified with concurrent power production in systems and methods where the refrigeration content of the LNG condenses a low pressure working fluid vapor and in which the combined refrigeration content of the warmed LNG and low pressure working fluid condensate condenses an intermediate pressure working fluid vapor.

Owner:FLUOR TECH CORP

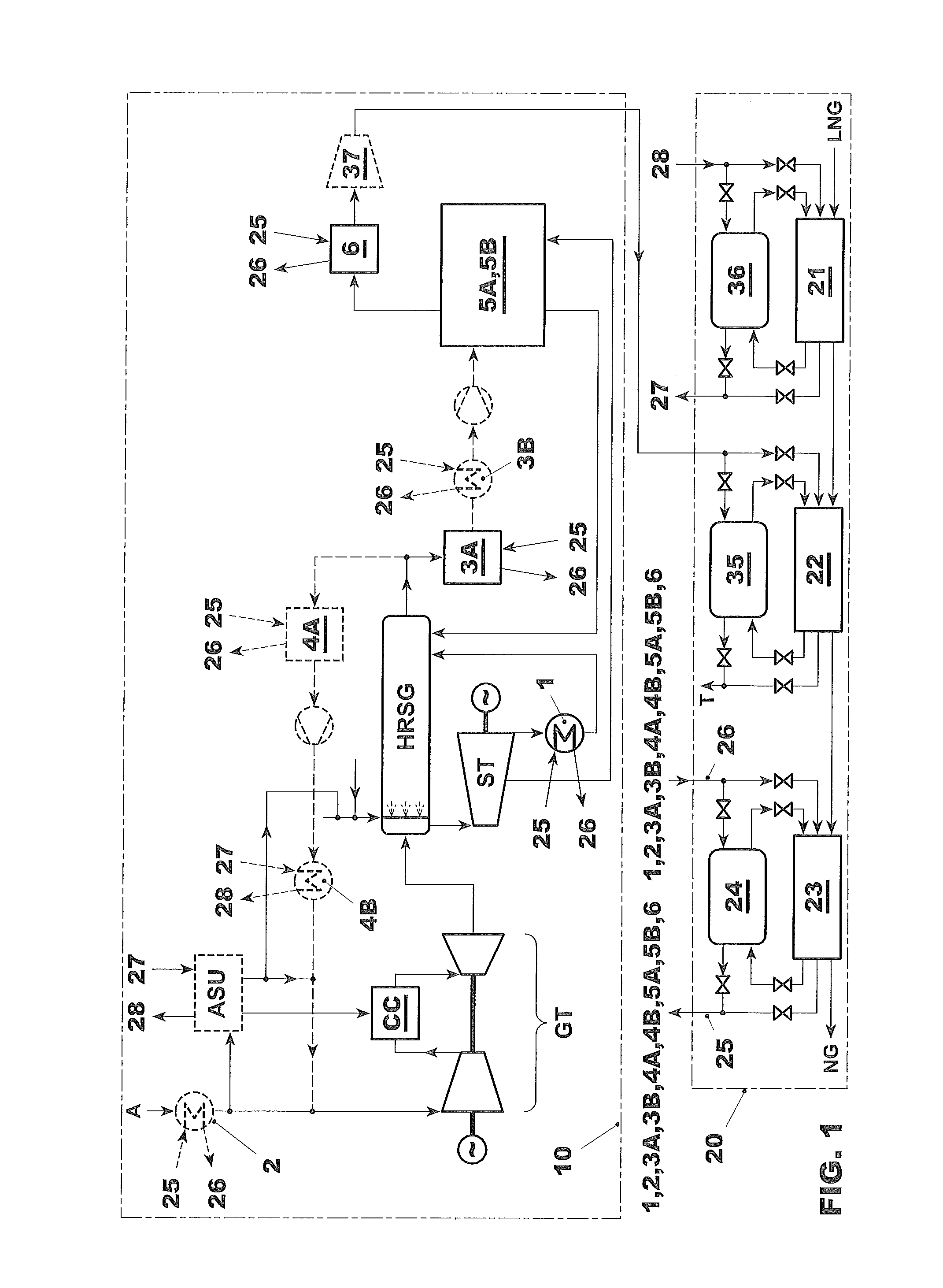

Combined cycle power plant with co2 capture plant

InactiveUS20130312386A1Increased power plant efficiencySolidificationLiquefactionPower stationFlue gas

A combined cycle power plant includes a CO2 capture system operatively integrated with a liquefied natural gas LNG regasification system, where cold energy from the regasification process is used for cooling processes within the CO2 capture system or processes associated with it. These cooling systems include systems for cooling lean or rich absorption solutions for the CO2 capture or the cooling of flue gas. The LNG regasification system is arranged in one or more heat exchange stages having and one or more cold storage units. The power plant with CO2 capture can be operated at improved overall efficiencies.

Owner:ALSTOM TECH LTD

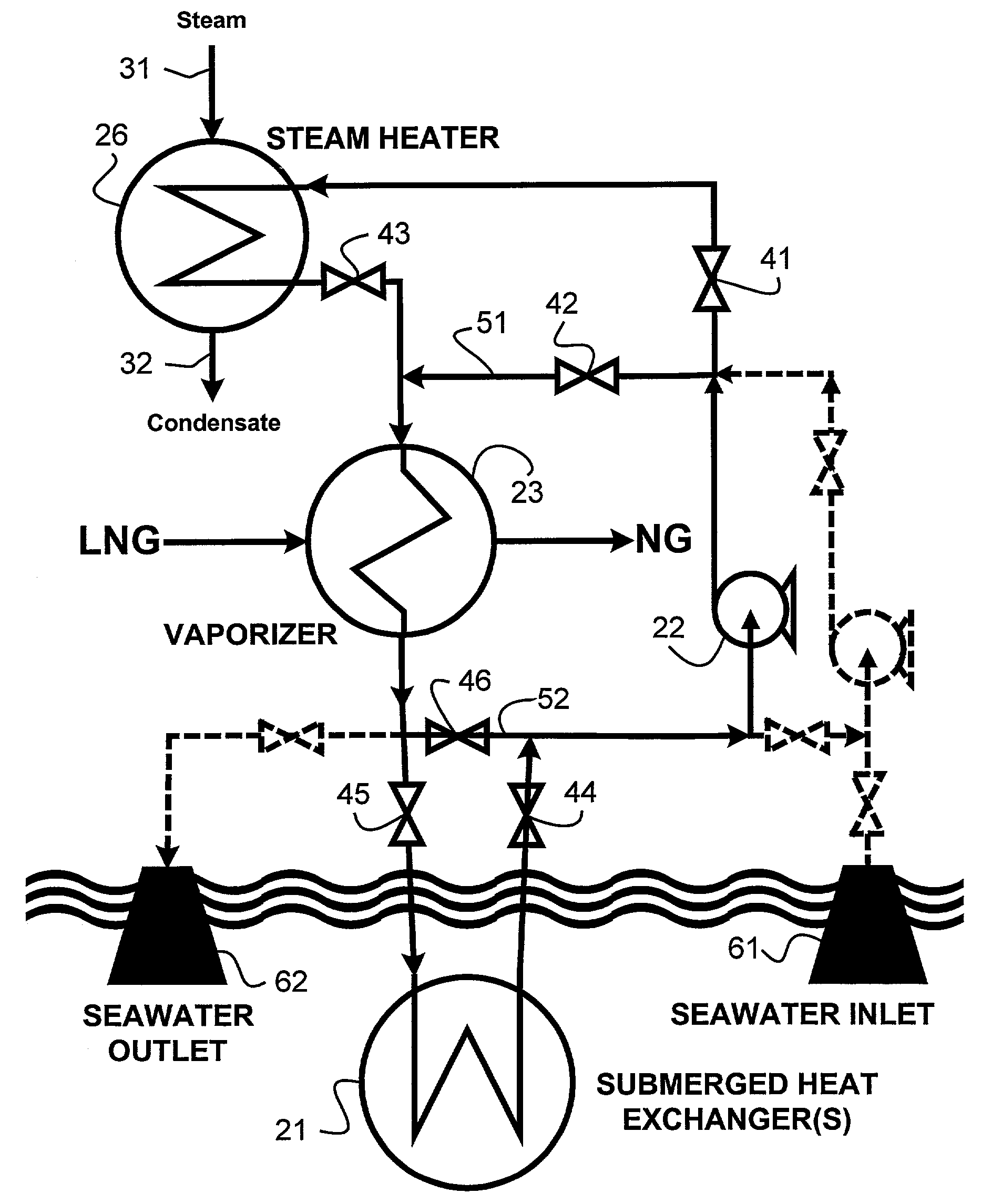

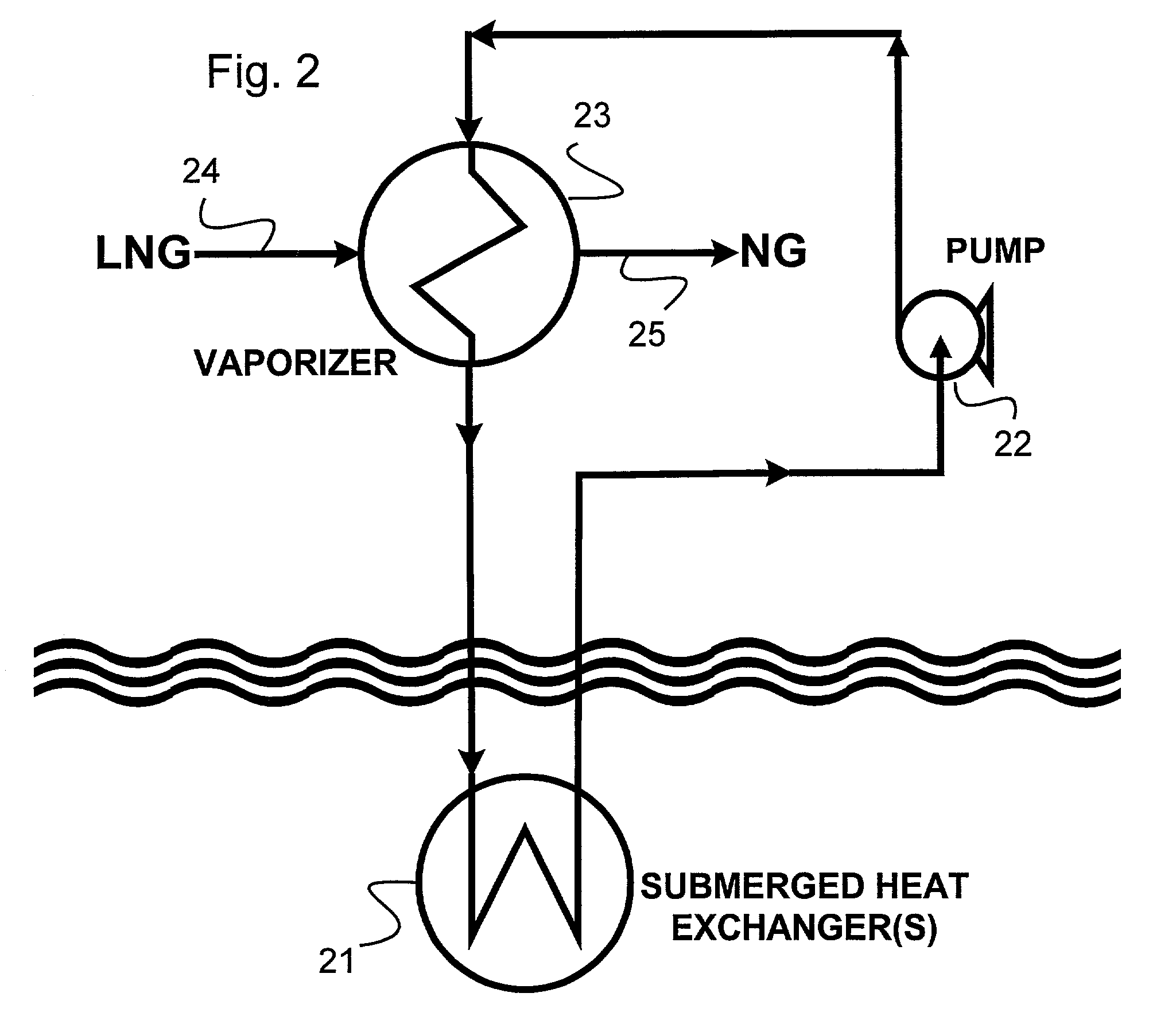

Apparatus for the regasification of LNG onboard a carrier

An LNG carrier for transporting LNG from one location to another that includes a vaporizer on board said LNG carrier for vaporizing the LNG to a gaseous state, one or more heat exchangers at least partially submerged in seawater, an intermediate fluid circulating between said vaporizer and said heat exchanger; and one or more pumps for circulating said intermediate fluid is disclosed.

Owner:EXCELERATE ENERGY LTD PARNERSHIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com