Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30828results about "Gas turbine plants" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

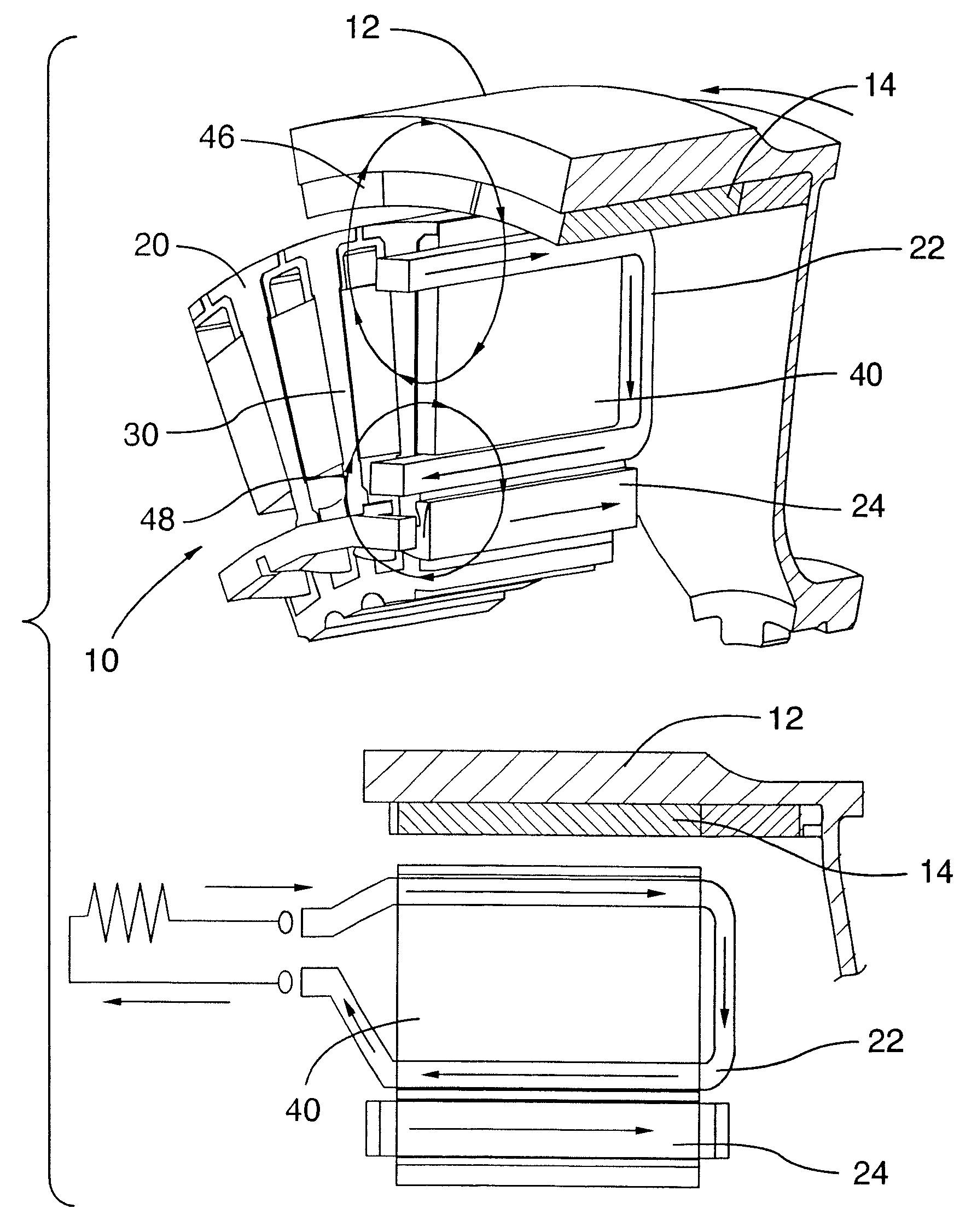

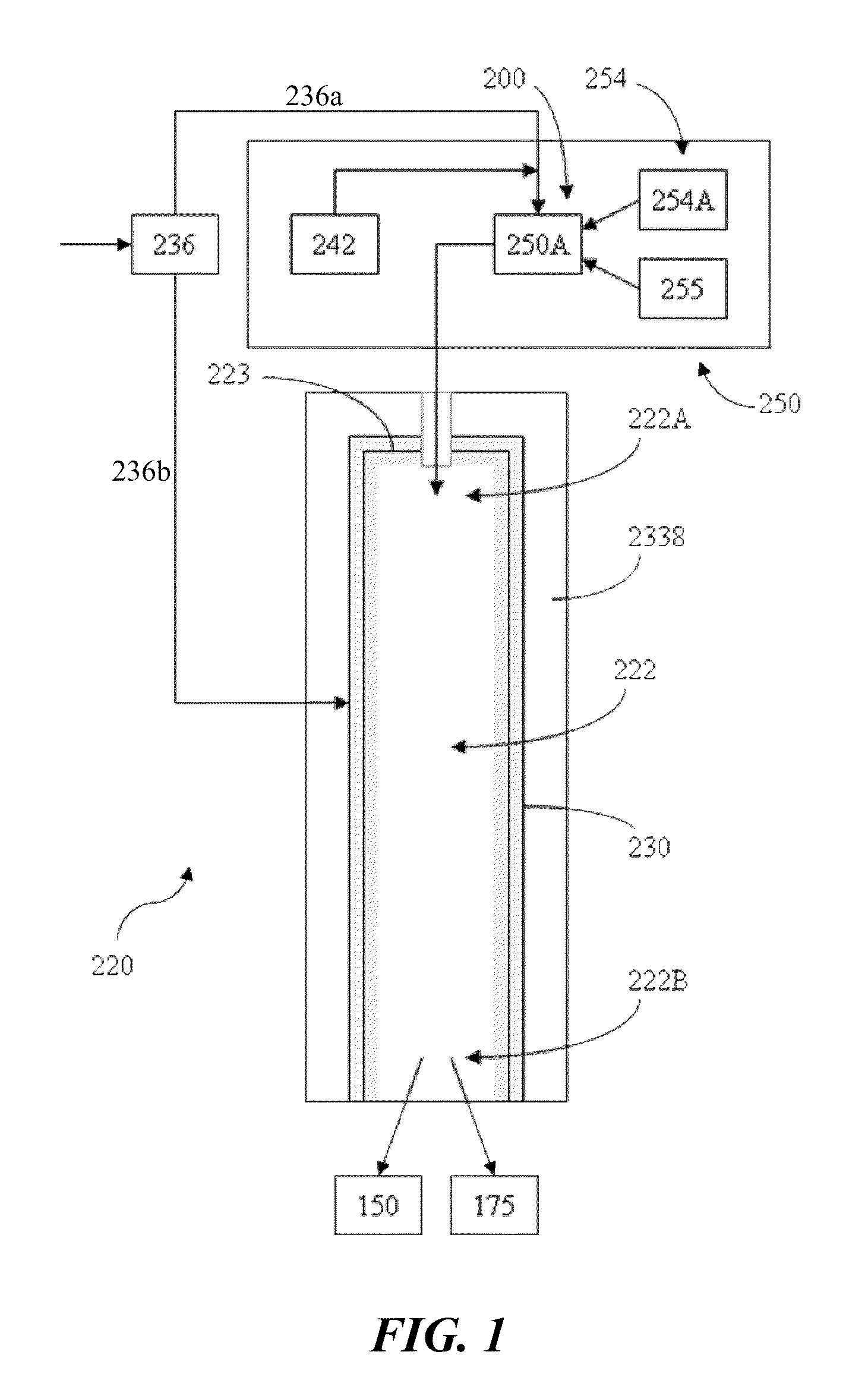

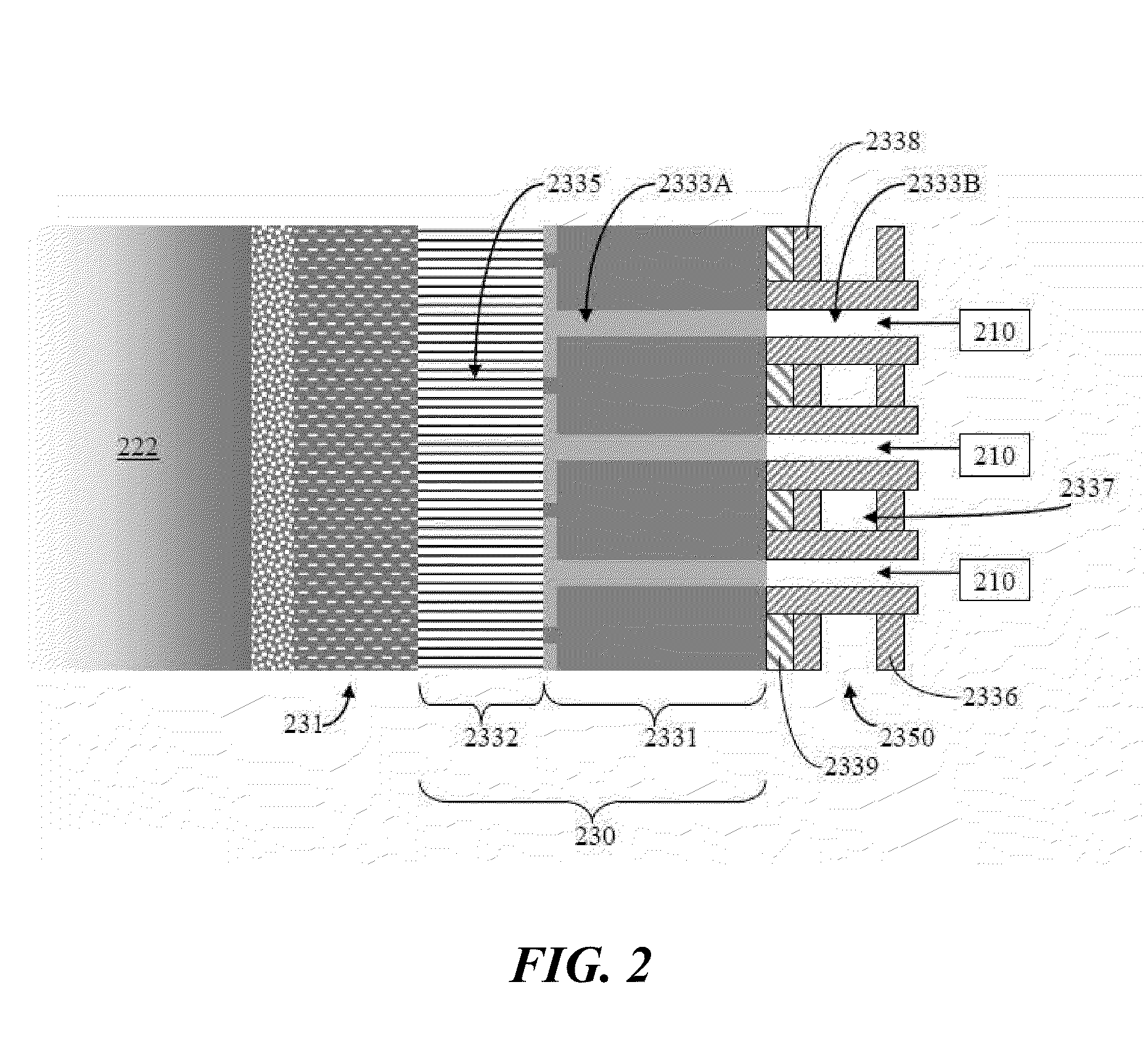

Architecture for electric machine

InactiveUS7583063B2Magnetic circuitEmergency protective circuit arrangementsElectricityElectric machine

The invention includes an electric machine having a rotor, stator and at least one winding in the stator adapted to conduct a current, and a secondary winding, electrically isolated from the first winding and inductively coupled to the first winding, which may be used to control at least one of the output voltage and current of the first winding.

Owner:PRATT & WHITNEY CANADA CORP

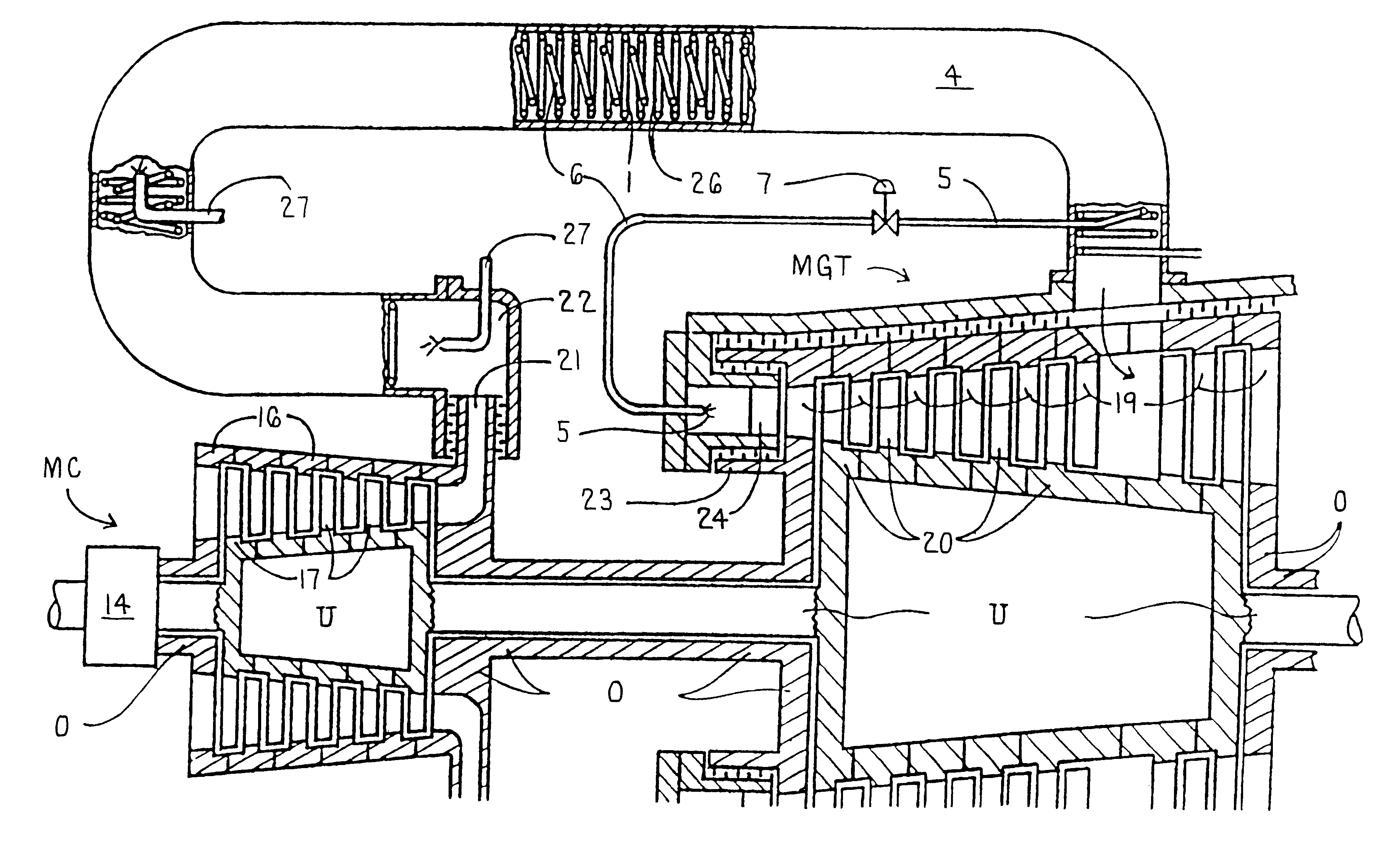

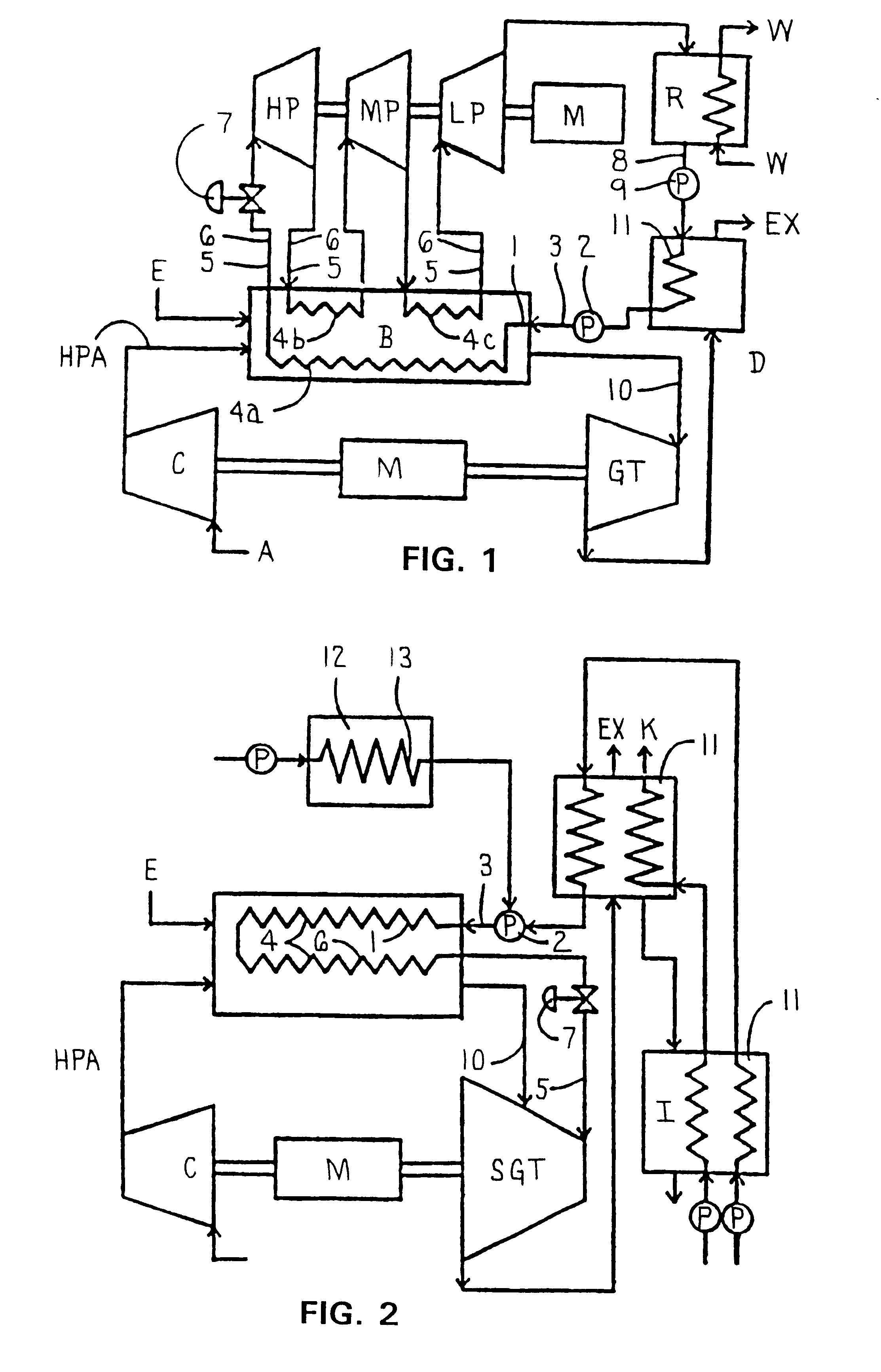

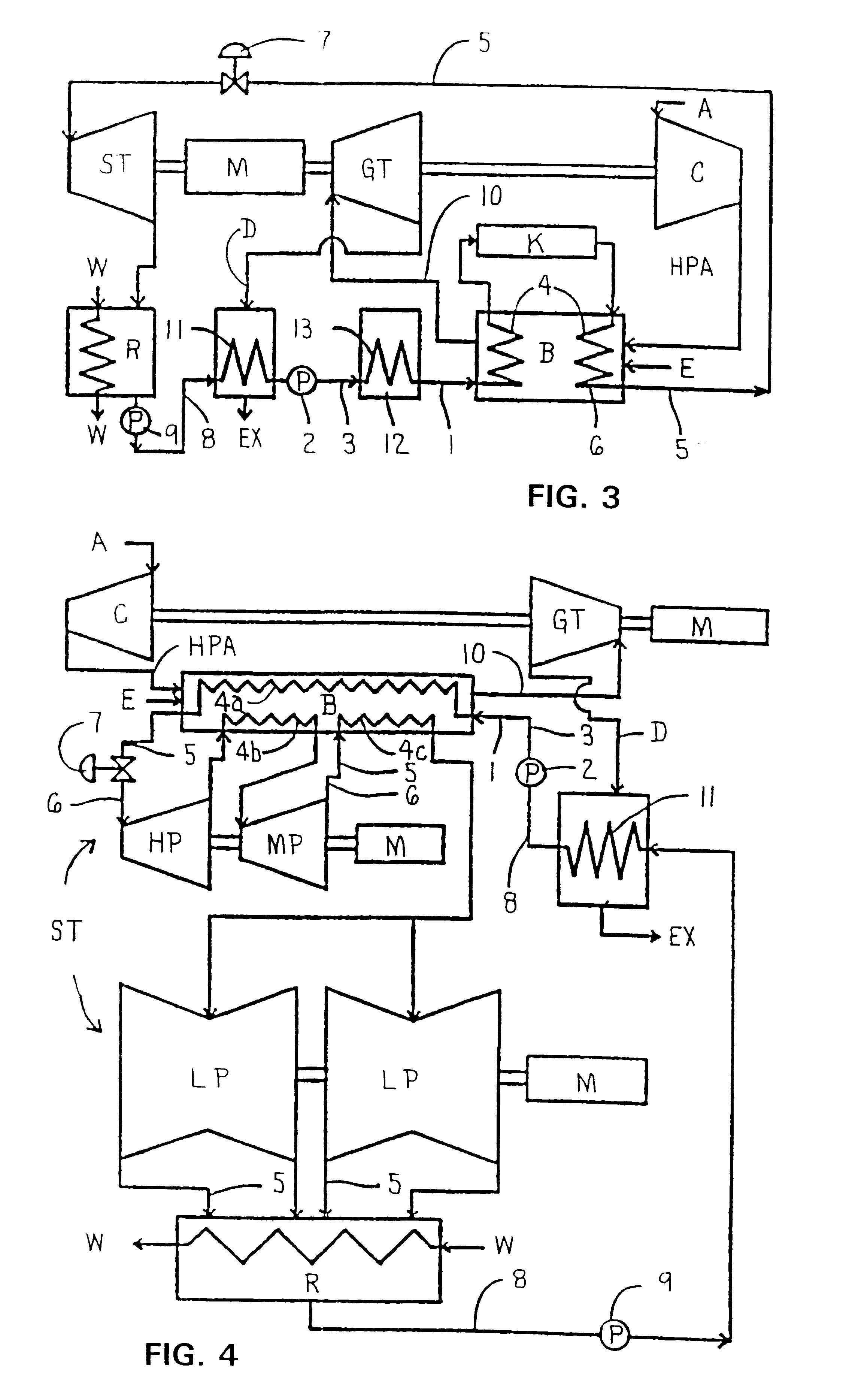

Combined steam and gas turbine engine with magnetic transmission

InactiveUS6263664B1Wide areaImprove system efficiencyContinuous combustion chamberGearingThermal energyCombustion chamber

In a combined steam and gas turbine engine cycle, a combustion chamber is made durable against high pressure and enlarged in length to increase the operation pressure ratio, without exceeding the heat durability temperature of the system while increasing the fuel combustion gas mass flow four times as much as the conventional turbine system and simultaneously for greatly raising the thermal efficiency of the system and specific power of the combined steam and gas turbine engine.Water pipes and steam pipes are arranged inside the combustion chamber so that the combustion chamber can function as a heat exchanger and thereby convert most of the combustion thermal energy into super-critical steam energy for driving a steam turbine and subsequently raising the operation pressure ratio and the thermal efficiencies of the steam turbine cycle and gas turbine cycle. The combustion gas mass flow can be also increased by four times as much as the conventional turbine system (up to the theoretical air to fuel ratio) and the thermal efficiency and the specific power of the gas turbine cycle are considerably increased.Further, the thermal efficiency of the combined system is improved by installing a magnetic friction power transmission system to transmit the power of the system to outer loads.

Owner:TANIGAWA HIROYASU +1

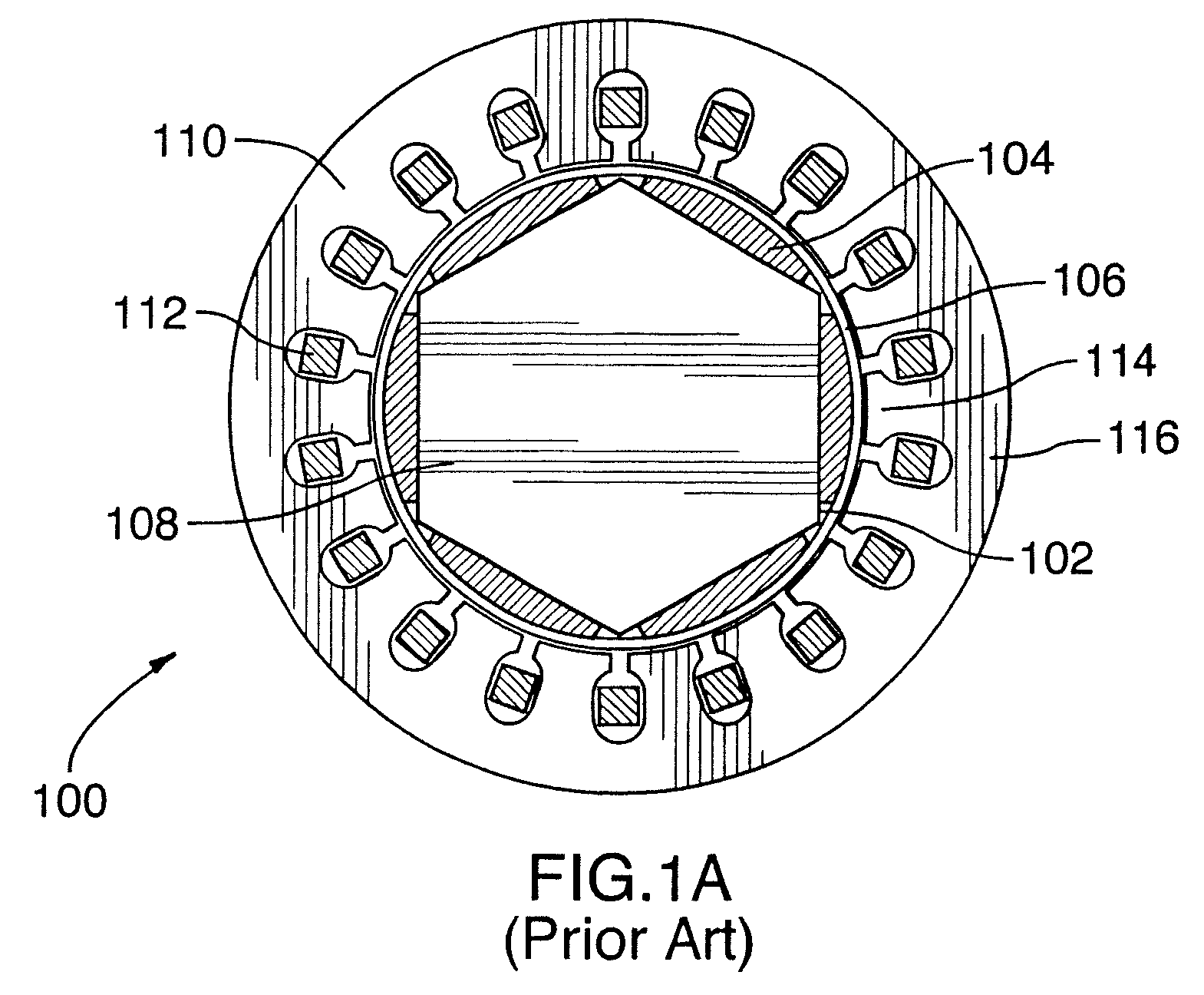

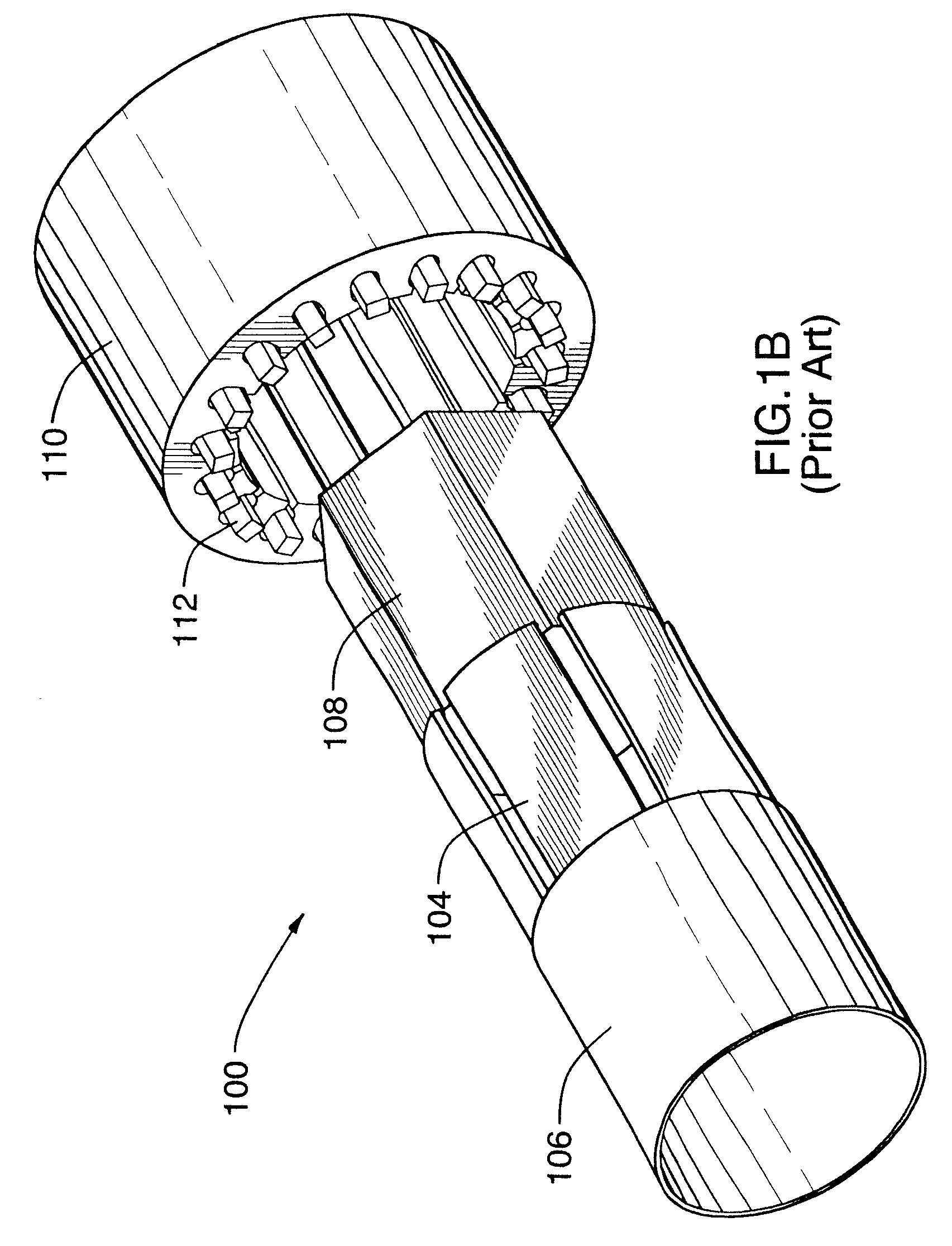

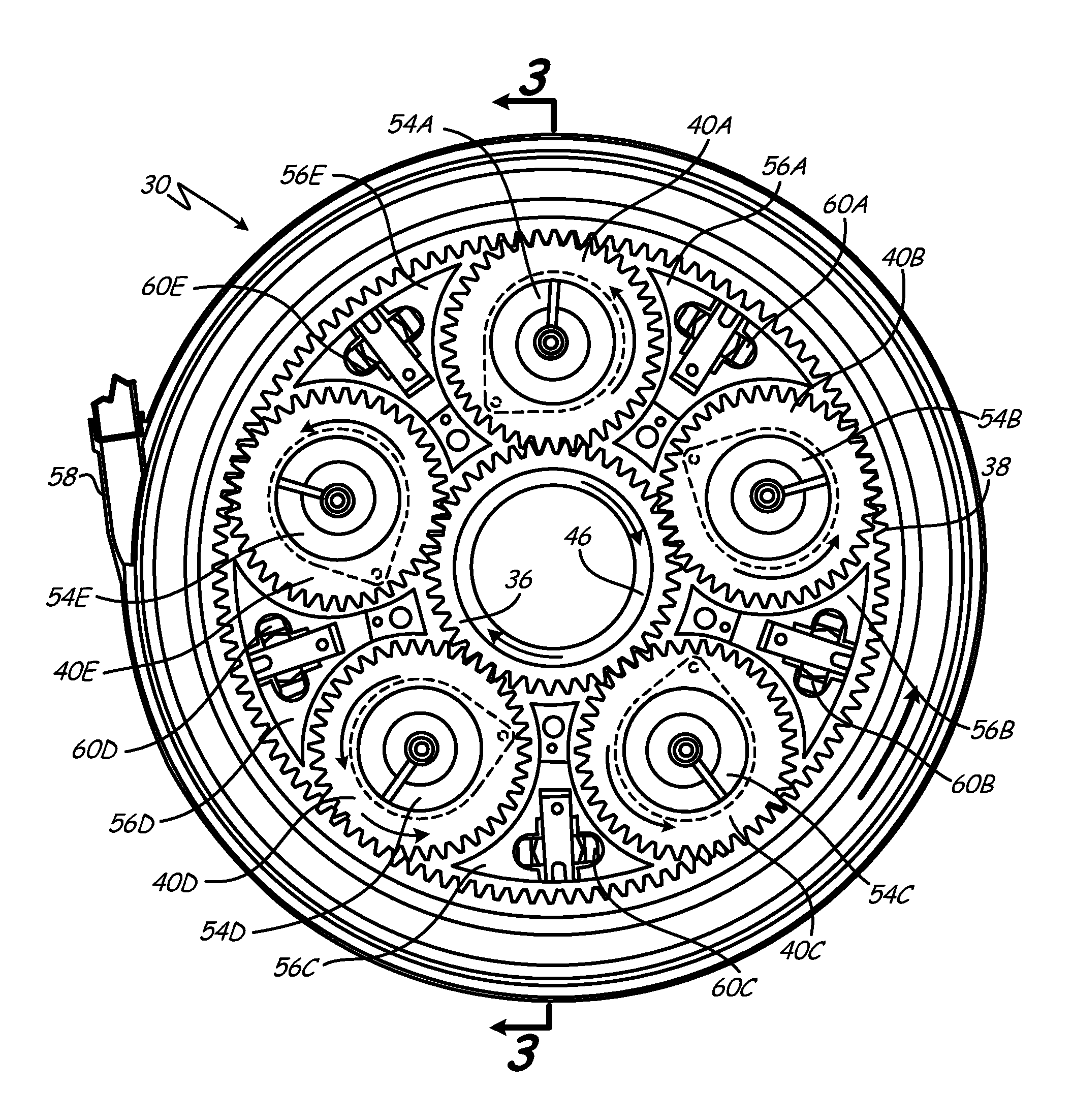

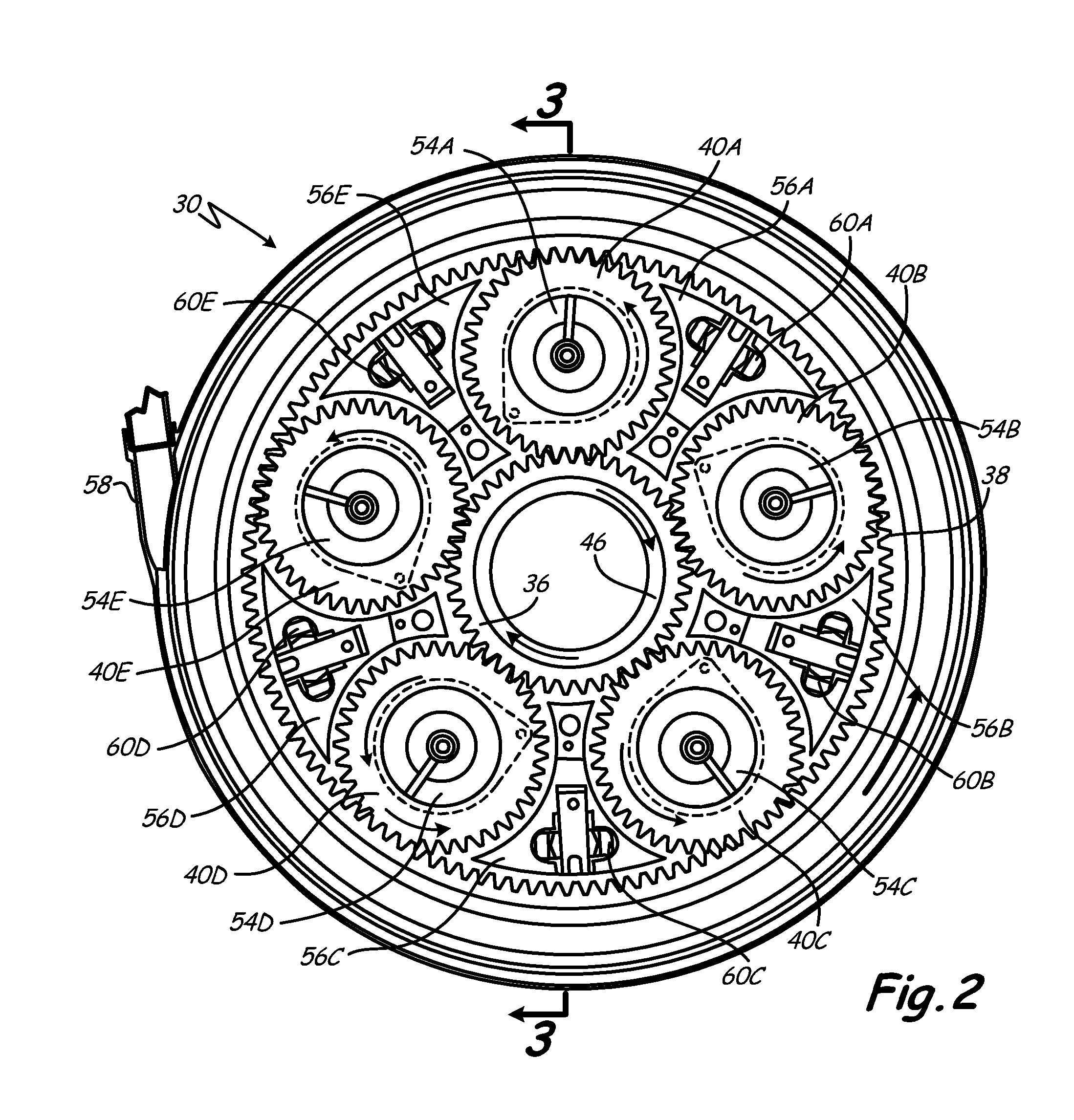

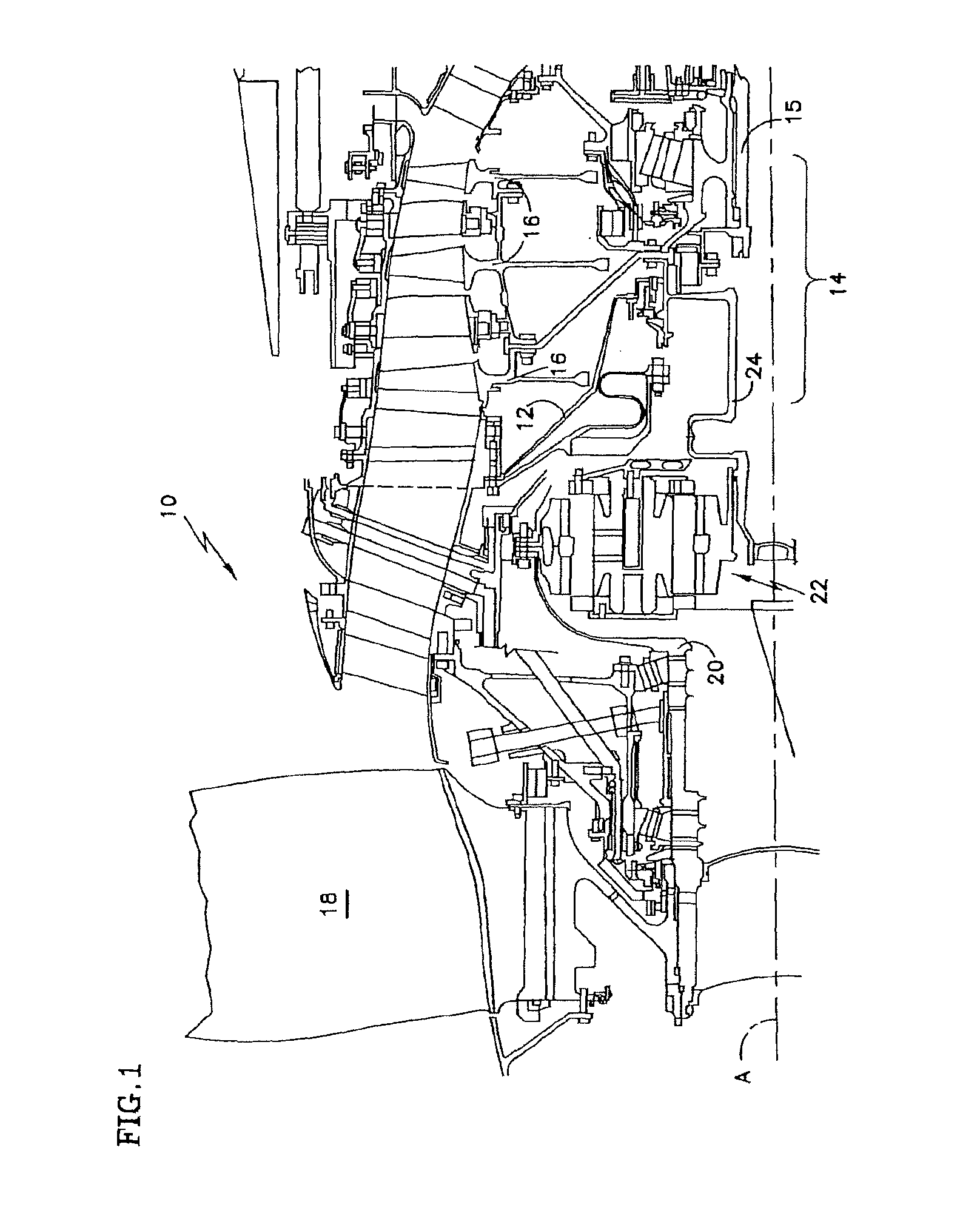

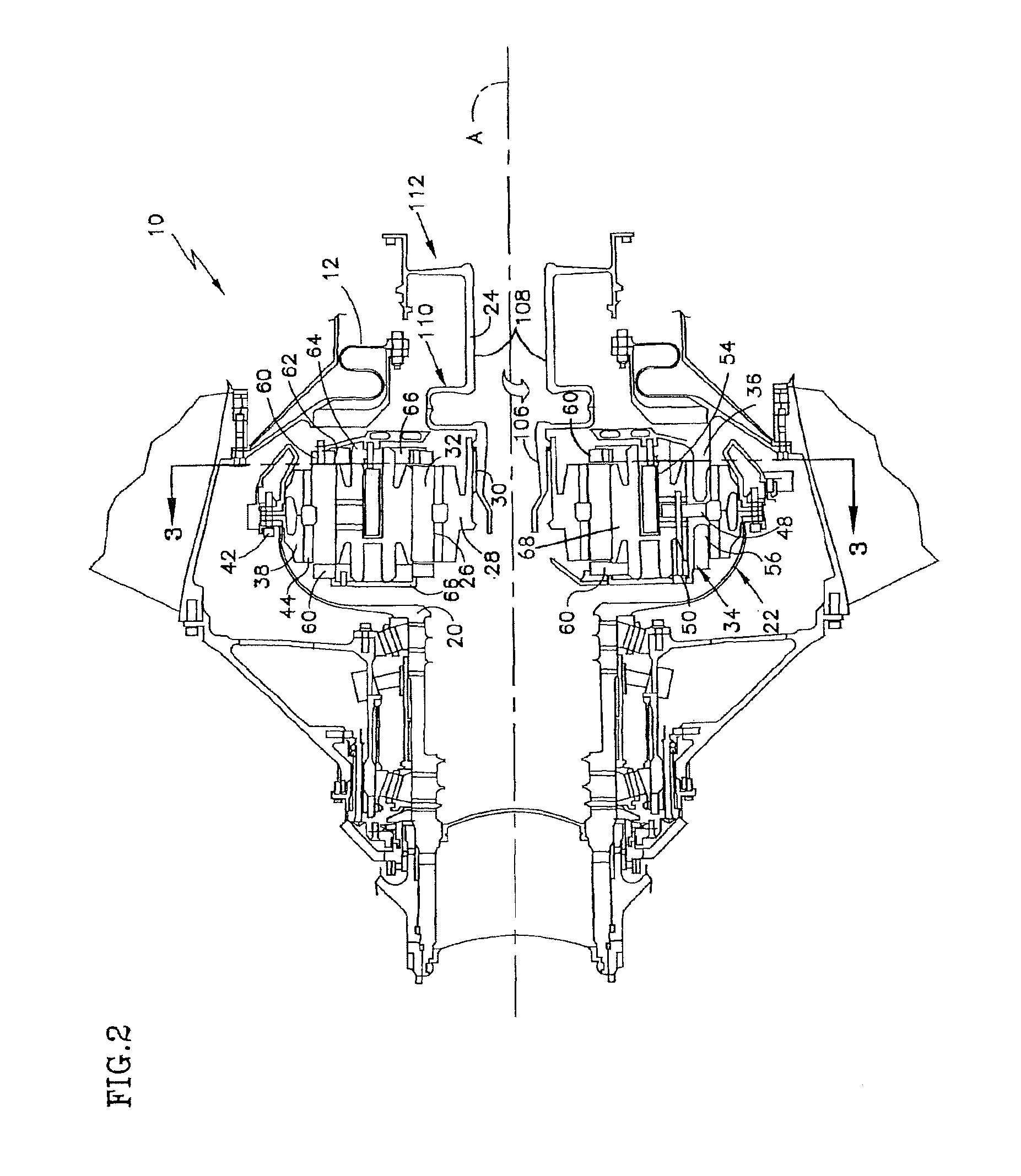

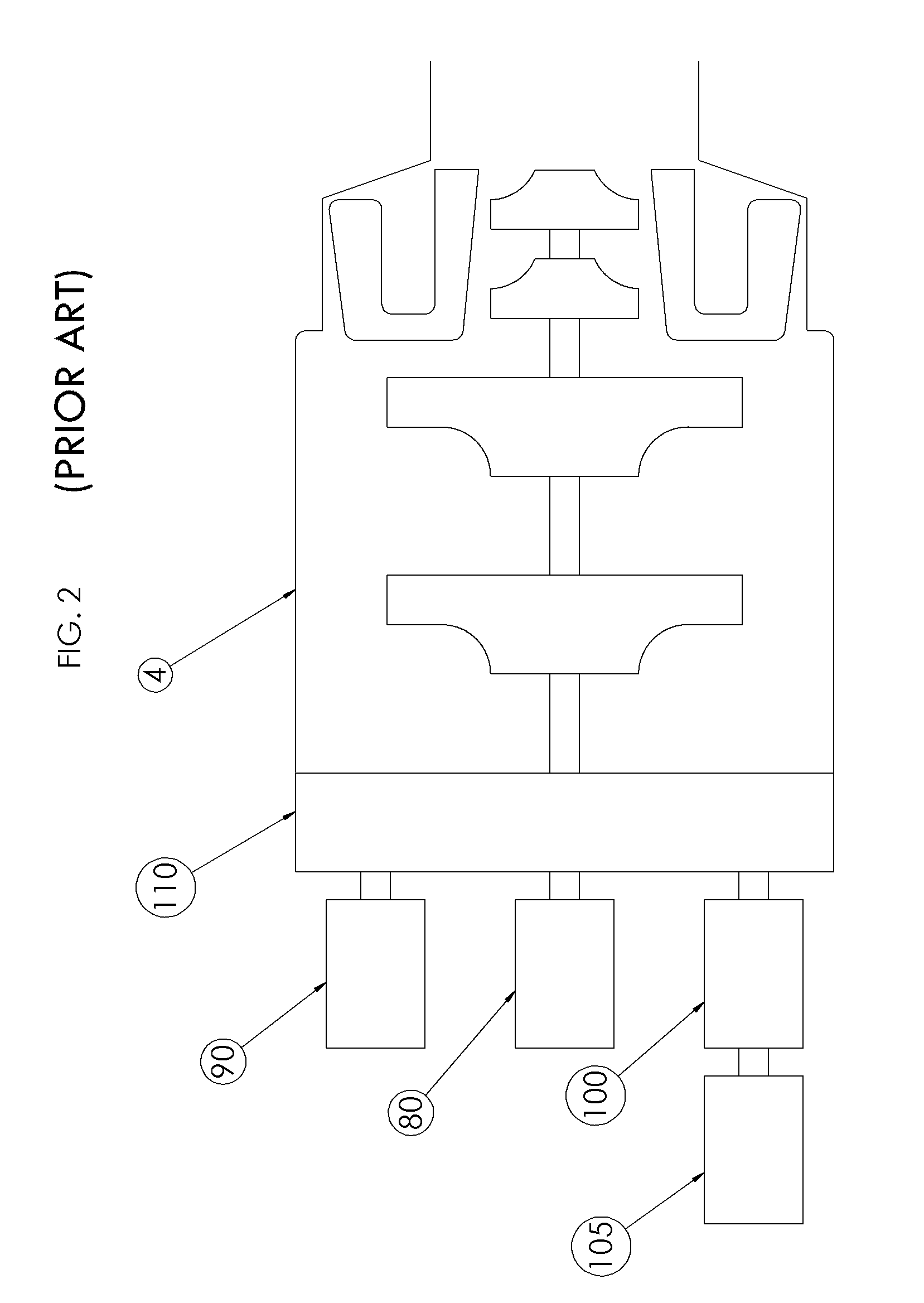

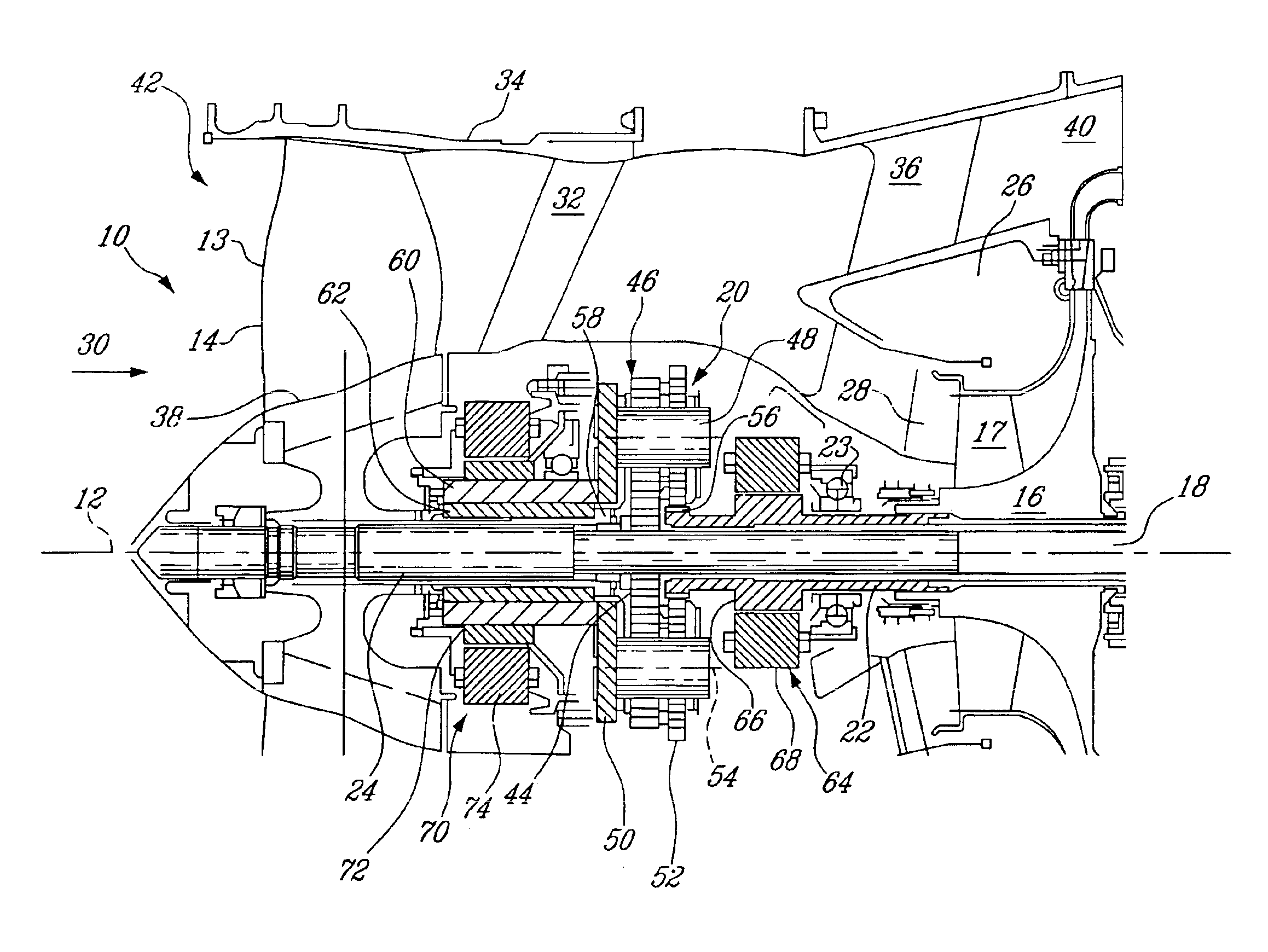

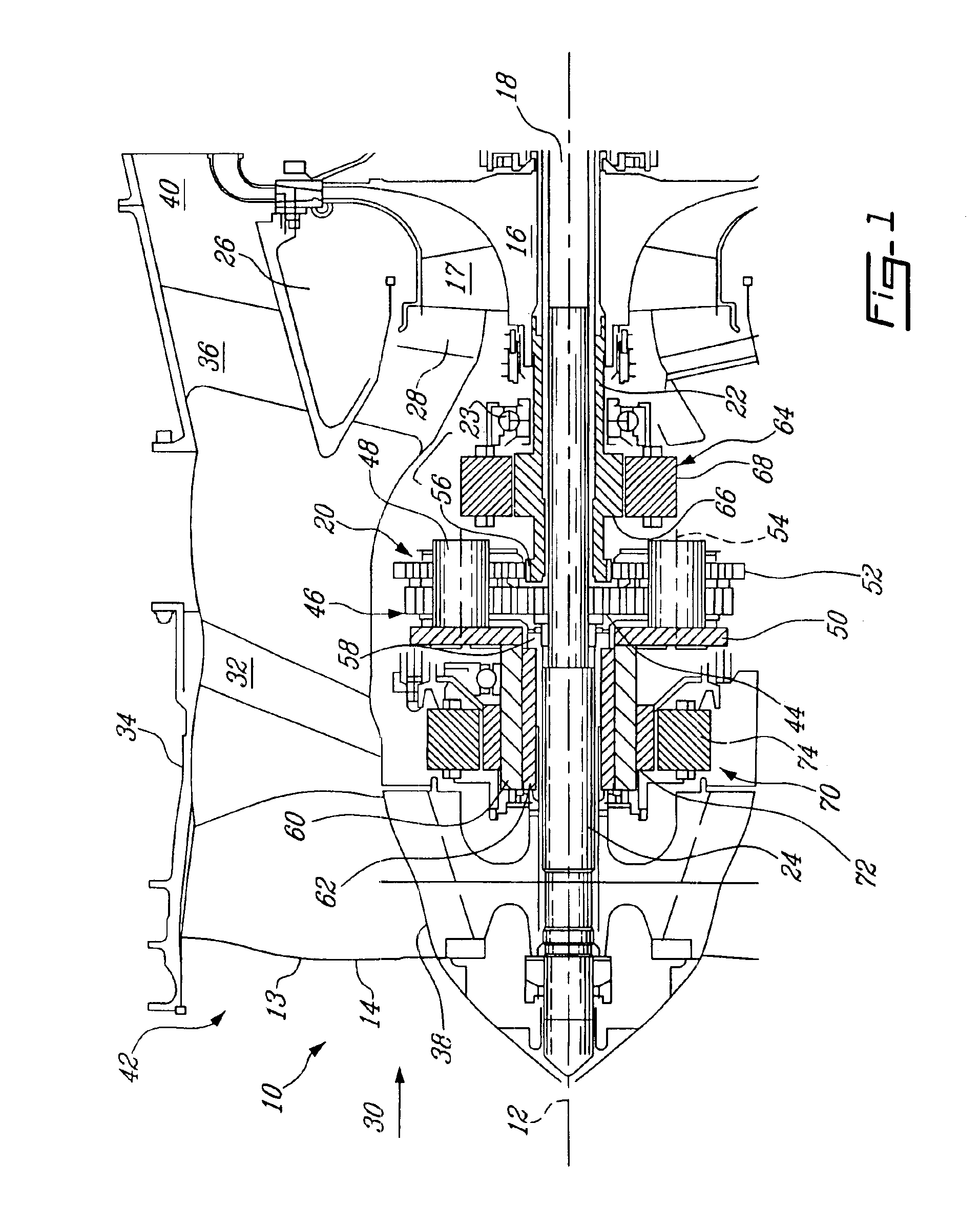

Coupling system for a star gear train in a gas turbine engine

A star gear train for use in a gas turbine engine includes a sun gear, a ring gear, a plurality of star gears and a coupling system. The sun gear is rotatable by a shaft. The ring gear is secured to a ring gear shaft. Each of the plurality of star gears is rotatably mounted in a star carrier and meshes with the sun gear and the ring gear. The coupling system comprises a sun gear flexible coupling, a carrier flexible coupling and a deflection limiter. The sun gear flexible coupling connects the sun gear to the shaft. The carrier flexible coupling connects the carrier to a non-rotating mechanical ground. The deflection limiter is connected to the star carrier to limit excessive radial and circumferential displacement of the star gear train.

Owner:RTX CORP

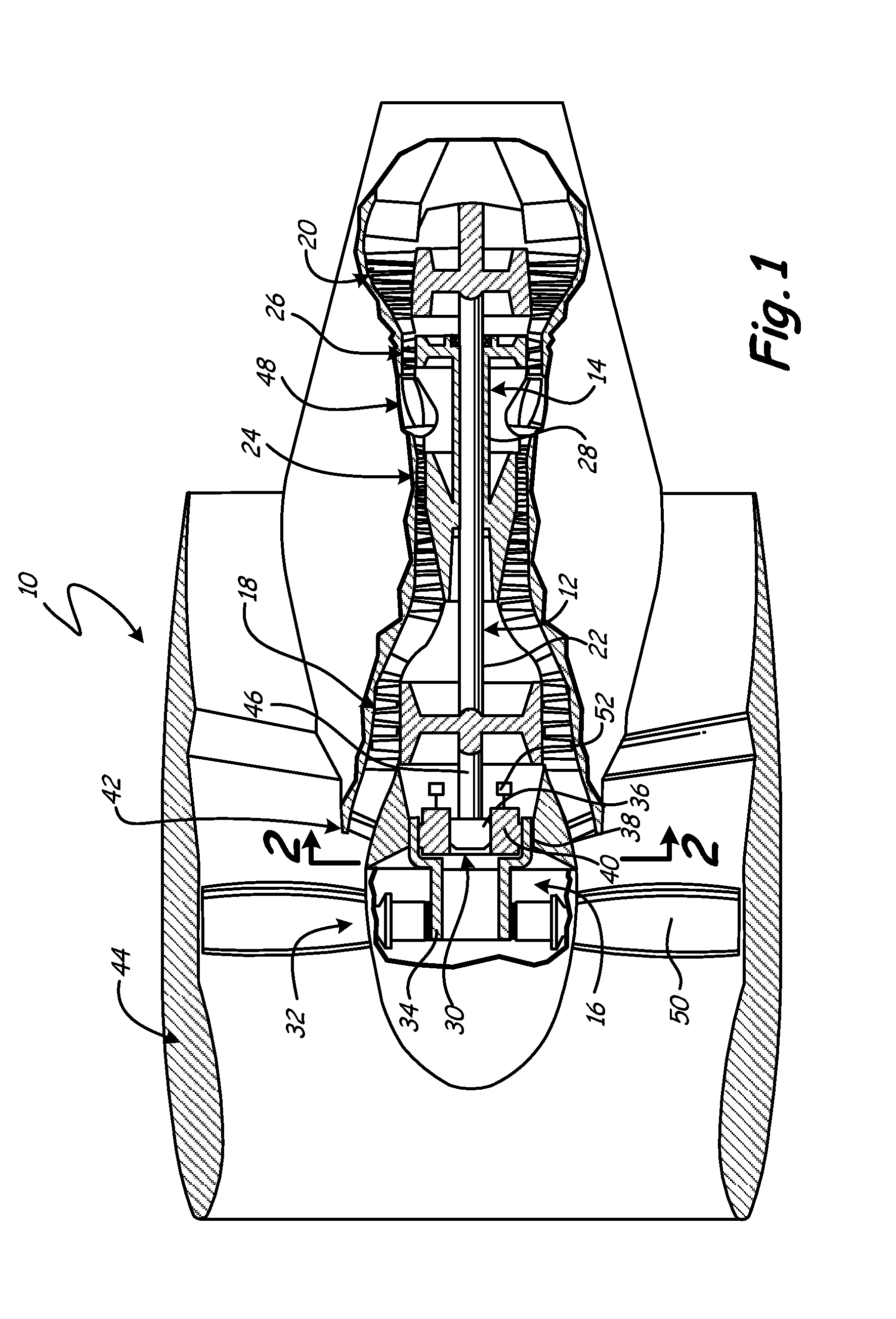

Geartrain coupling for a turbofan engine

Molybdenum disulfide (MoS2) is used as a journal coating for a gearing system. A particular application is the planetary gear system of a geared turbofan engine. Particularly advantageous coatings are deposited via physical vapor deposition (PVD) techniques.

Owner:RAYTHEON TECH CORP

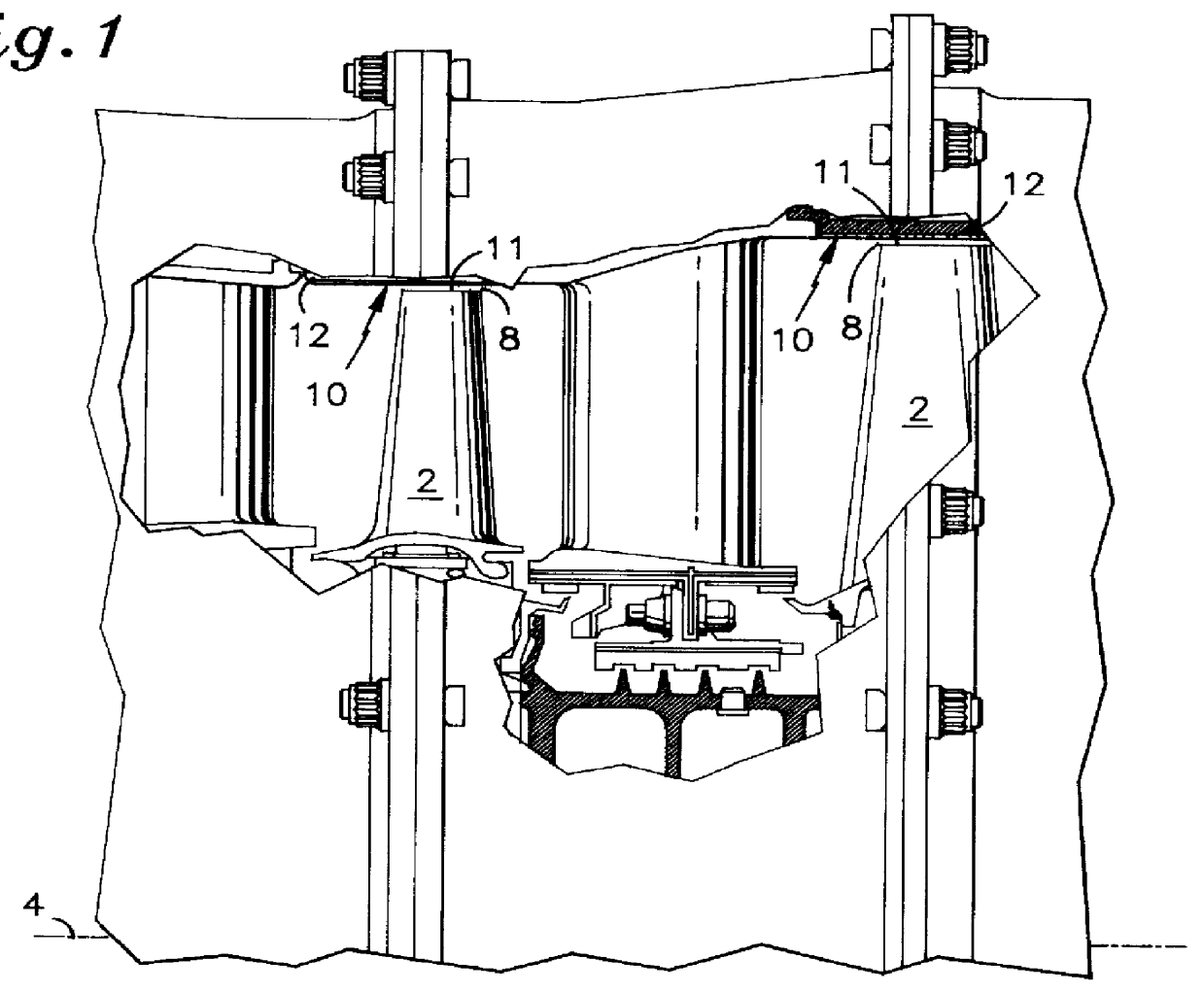

Epicyclic gear train integral sun gear coupling design

A coupling system for connecting a sun gear to a shaft within a planetary gear train, includes a sun gear coupling connecting the sun gear to the shaft. The sun gear coupling has at least one undulant flexible section joined to an inflexible spindle for accommodating misalignment between the sun gear and the shaft. The flexible section comprises a cylindrical ring having a diameter greater than the diameter of the spindle, and joined to the spindle by two longitudinally spaced apart diaphragms. The juncture between the diaphragms, the ring, and the spindle is curved in cross section on an outer side to improve flexibility and minimize stress concentrations, and the inner sides of the diaphragms are straight edges which result in a non-symmetric contour of the diaphragm walls.

Owner:RTX CORP

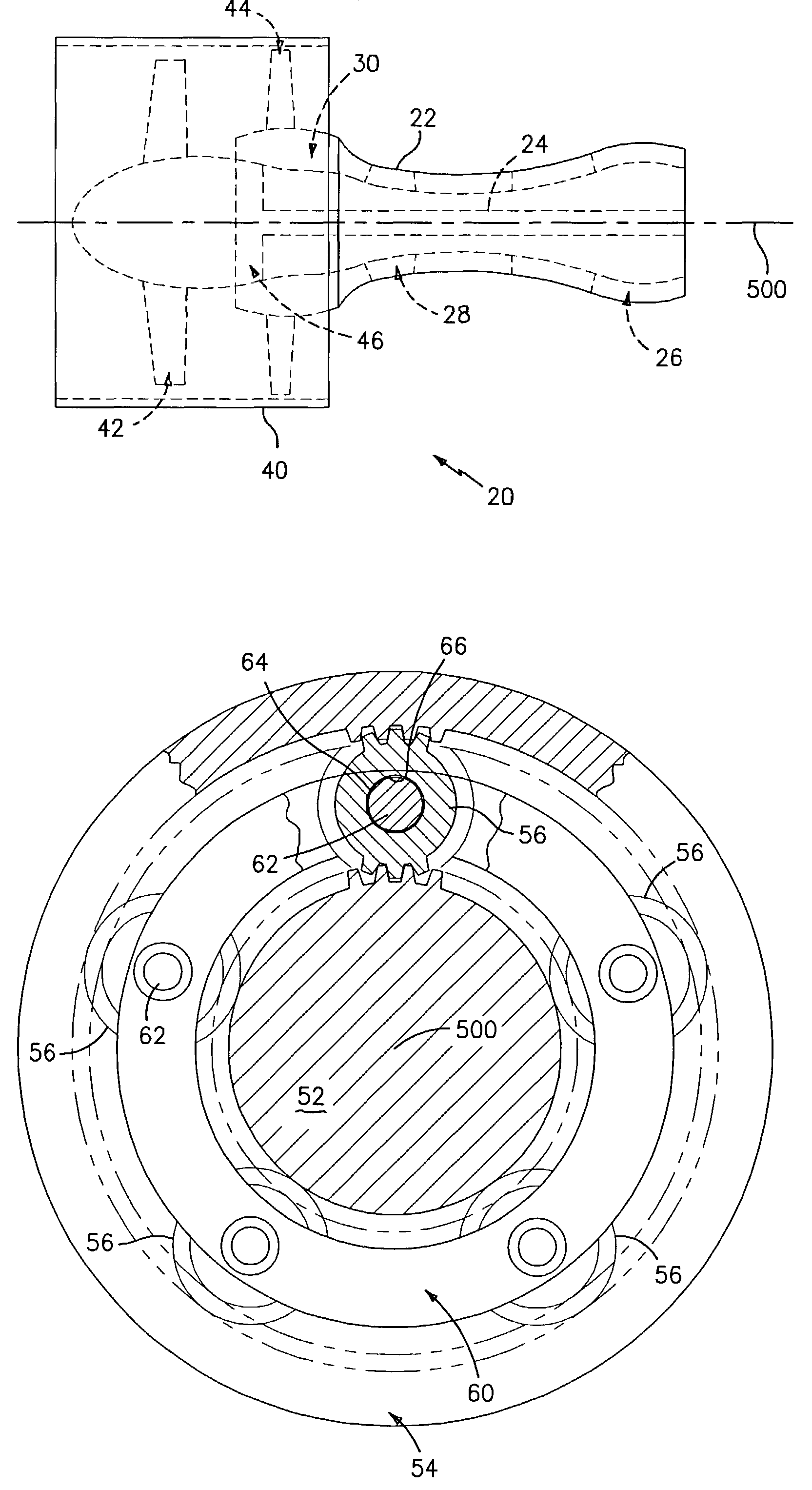

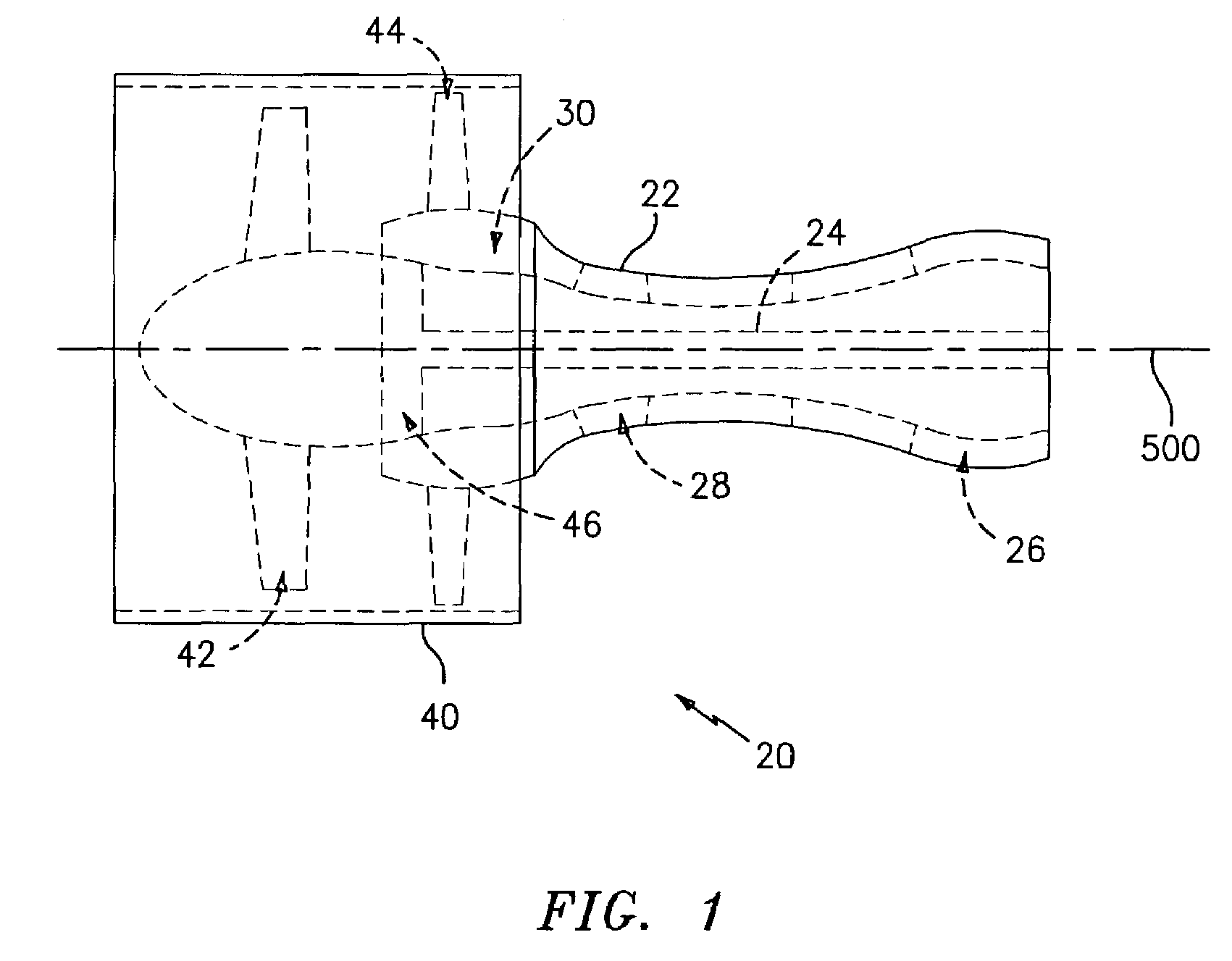

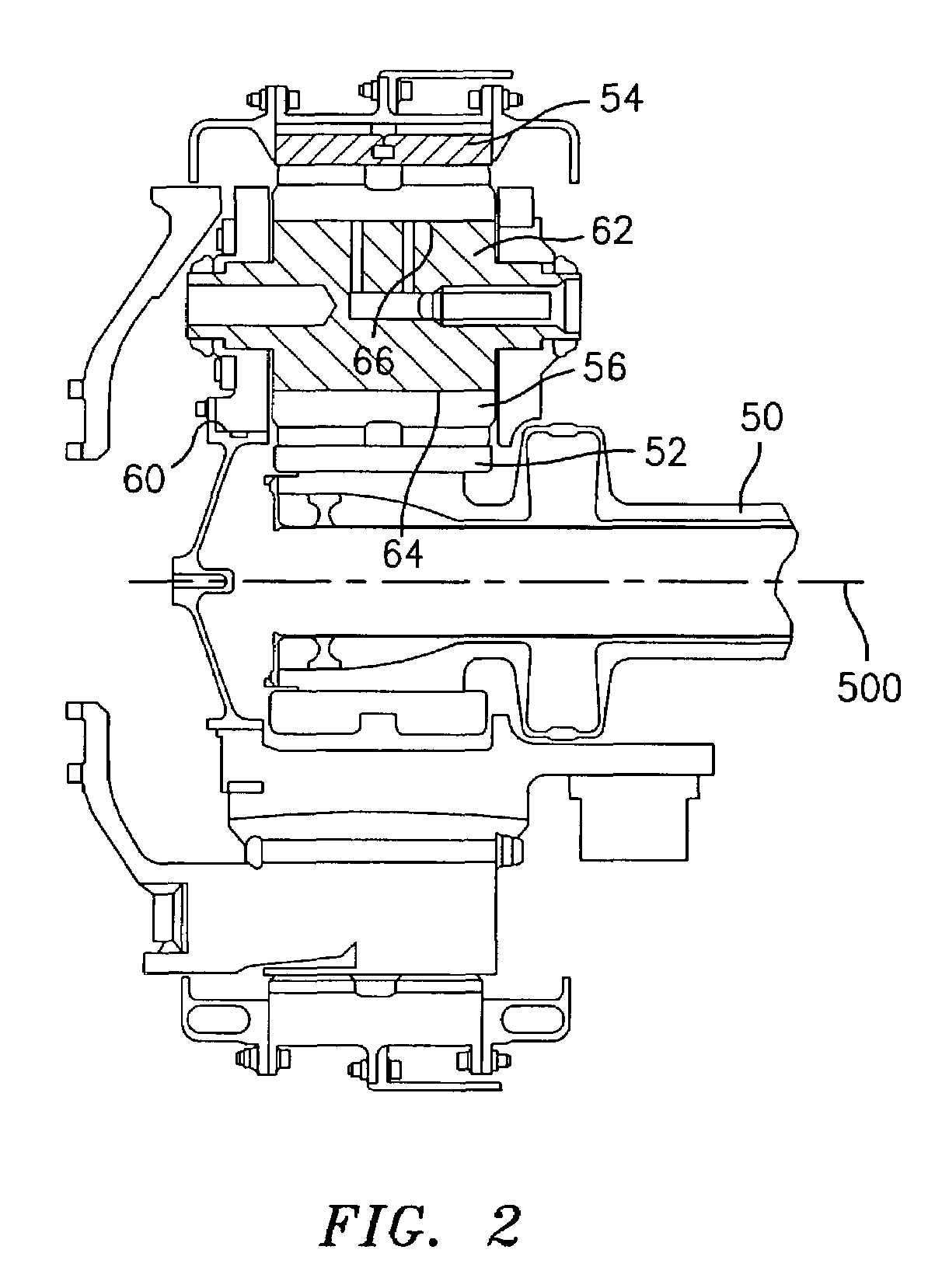

Flexible shaft for gas turbine engine

A shaft for a gas turbine engine is provided that includes a first shaft section, a second shaft section, a first flexible linkage, and a second flexible linkage. The first shaft section extends between a forward axial end and an aft axial end along a first axial centerline. The second shaft section extends between a forward axial end and an aft axial end along a second axial centerline. The first flexible linkage includes a bridge section connected between a first diaphragm and a second diaphragm. The first diaphragm is connected to the aft axial end of the first shaft section. The second diaphragm is connected to the forward axial end of the second shaft section. The second flexible linkage includes a diaphragm and a hub. The second flexible linkage diaphragm cantilevers radially outwardly from an inner radial end to an outer radial end, and is connected to the aft axial end of the second shaft section. The hub is connected to the outer radial end of the second flexible linkage diaphragm, and includes an engine shaft coupling connected to the hub.

Owner:RTX CORP

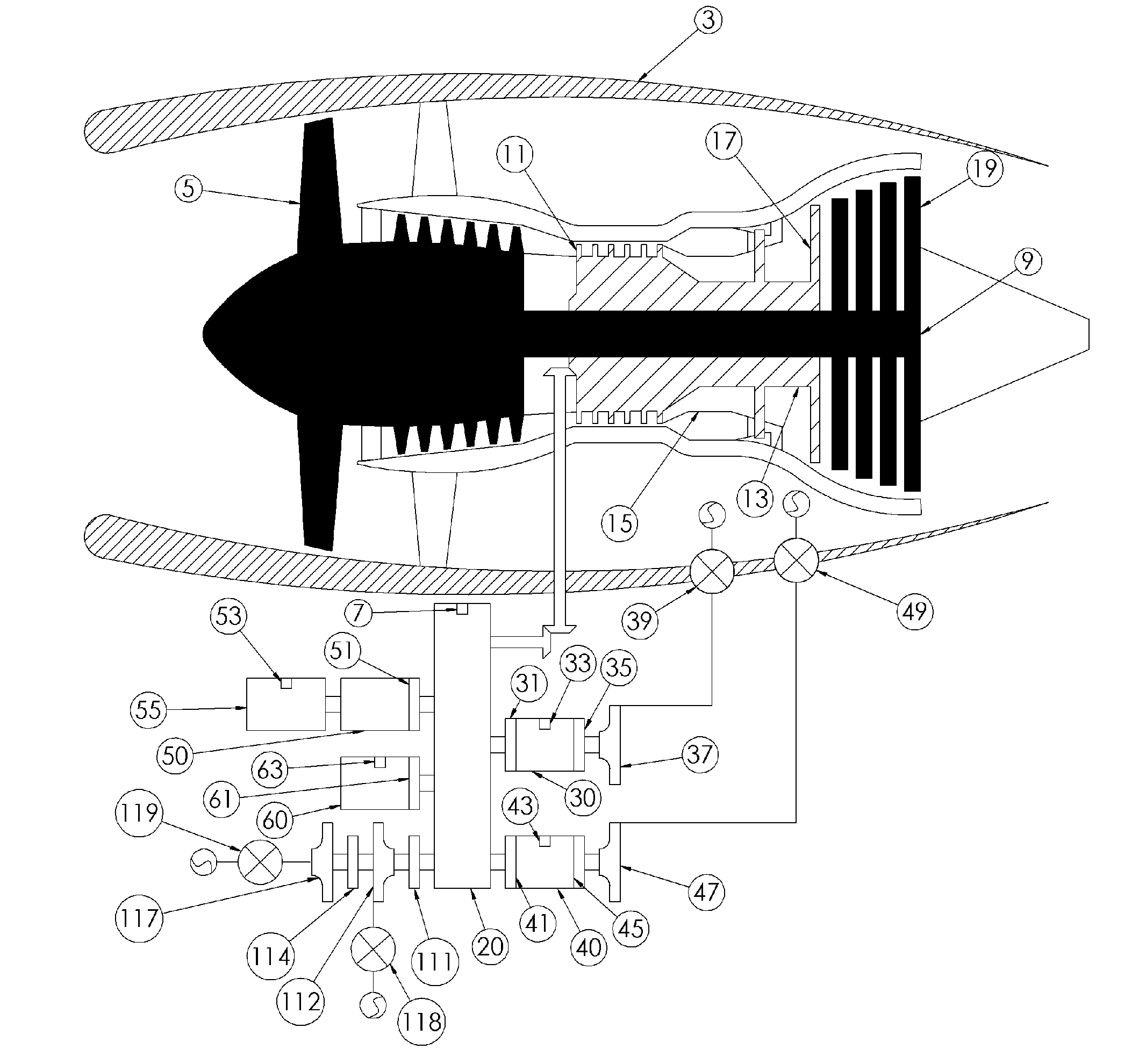

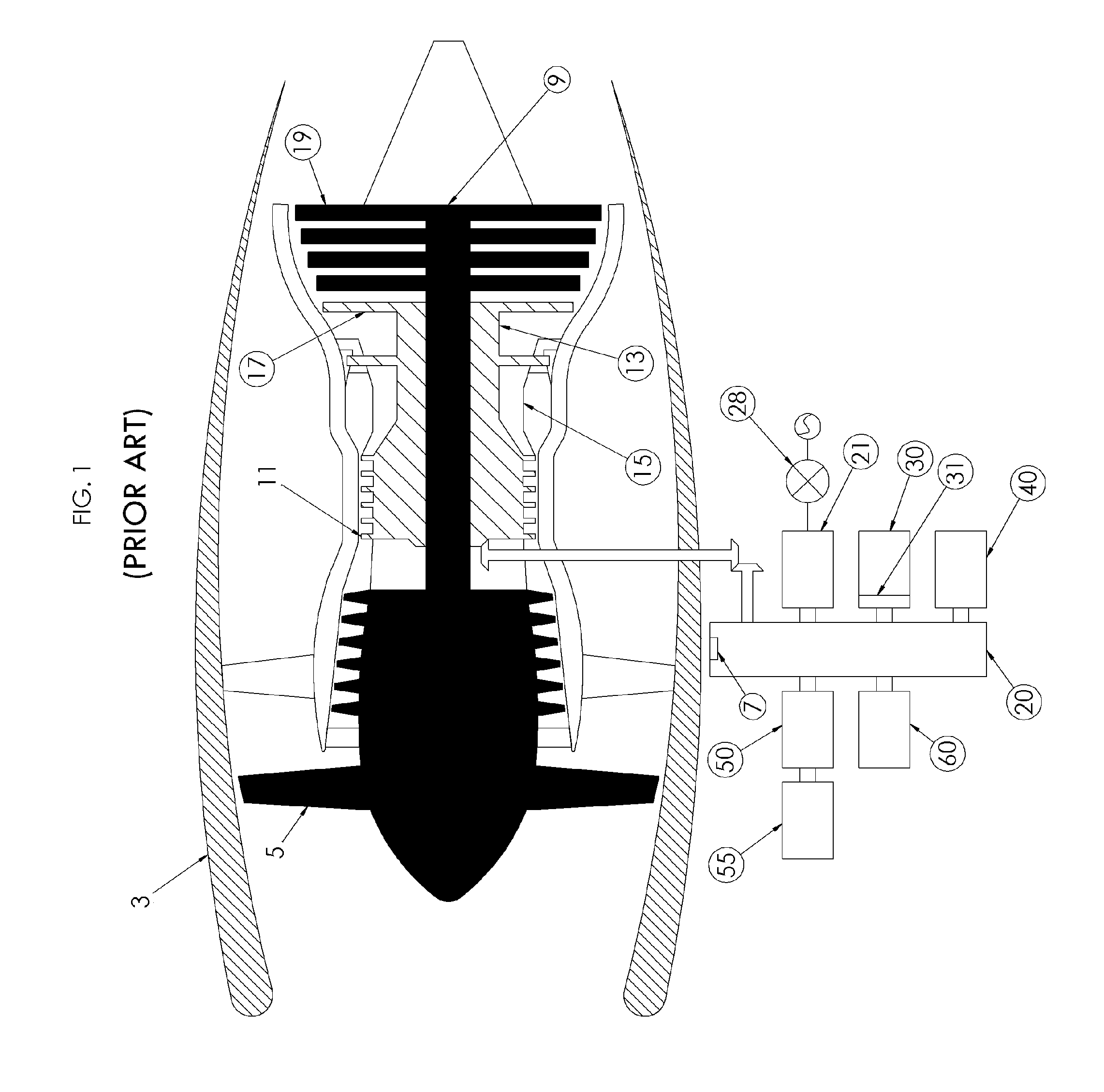

Aircraft with disengageable engine and auxiliary power unit components

InactiveUS20060260323A1Avoid damageSufficient torqueEngine fuctionsGas turbine plantsFlight vehicleGround testing

Several improvements to an aircraft turbine engine and Auxiliary Power Unit (APU) are disclosed, as well as methods of using these improvements in routine and emergency aircraft operations. The improvements comprise the addition of cockpit-controllable clutches that can be used to independently disconnect the engine's integrated drive generator (IDG), engine driven pump (EDP), fuel pump, and oil pump from the engine gearbox. These engine components may then be connected to air turbines by the use of additional clutches and then powered by the turbines. Similar arrangements are provided for the APU components. Cranking pads, attached to various engine and APU components, are disclosed to provide a means for externally powering the components for testing purposes and to assist with engine and APU start. Detailed methods are disclosed to use the new components for routine ground-testing and maintenance and for the enhancement of flight safety, minimization of engine component damage, and extension of engine-out flying range in the case of an emergency in-flight engine shutdown.

Owner:MOULEBHAR DJAMAL

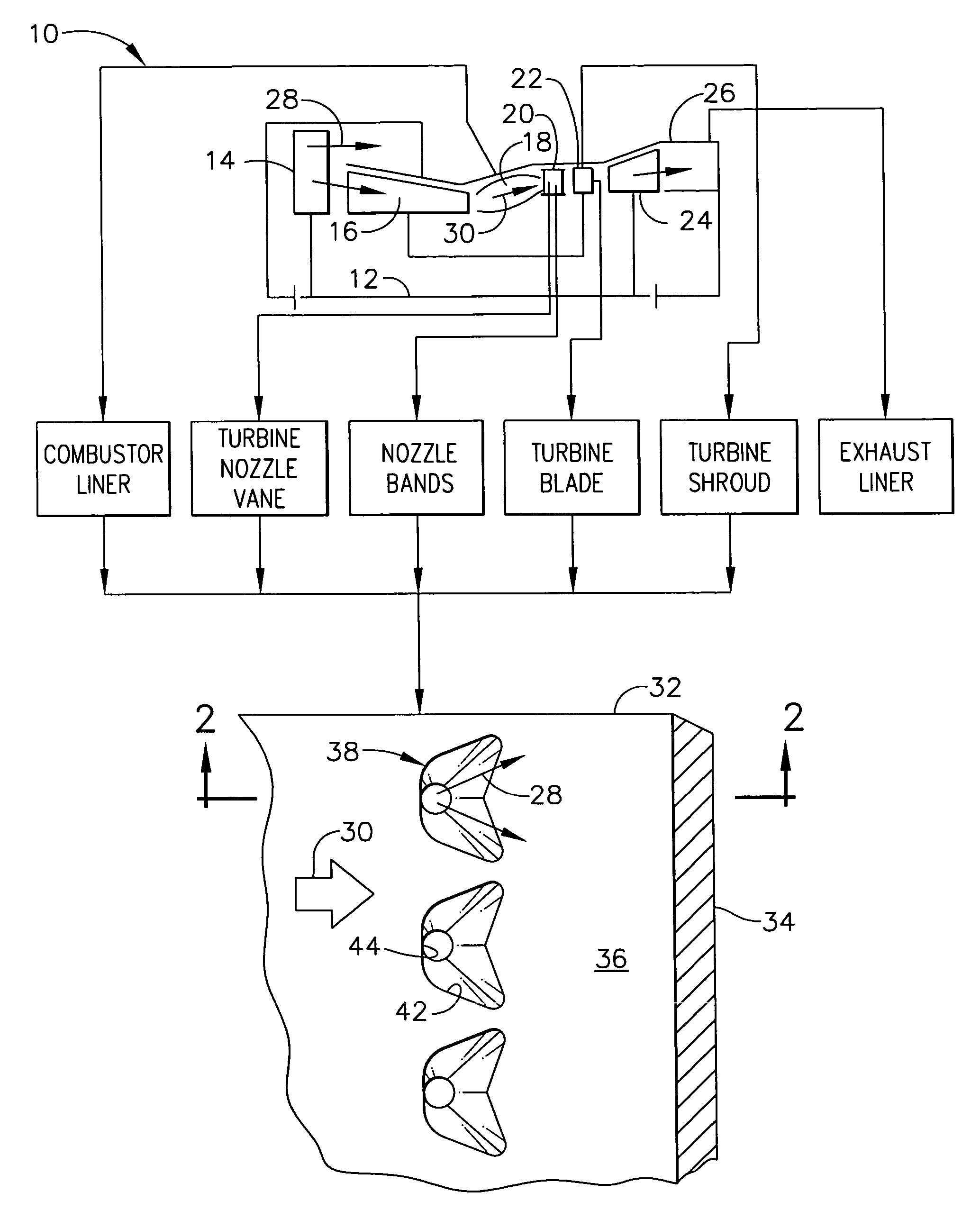

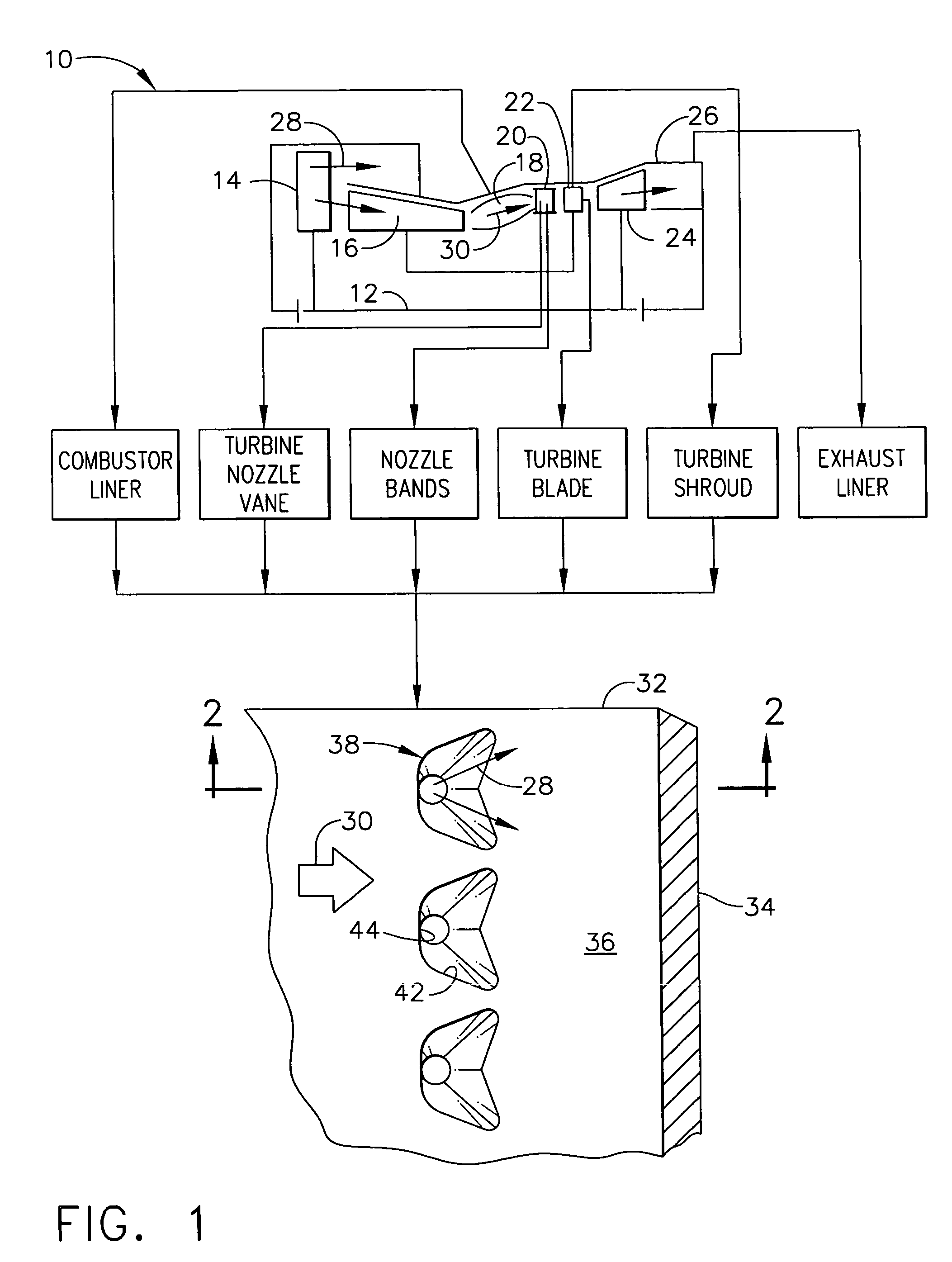

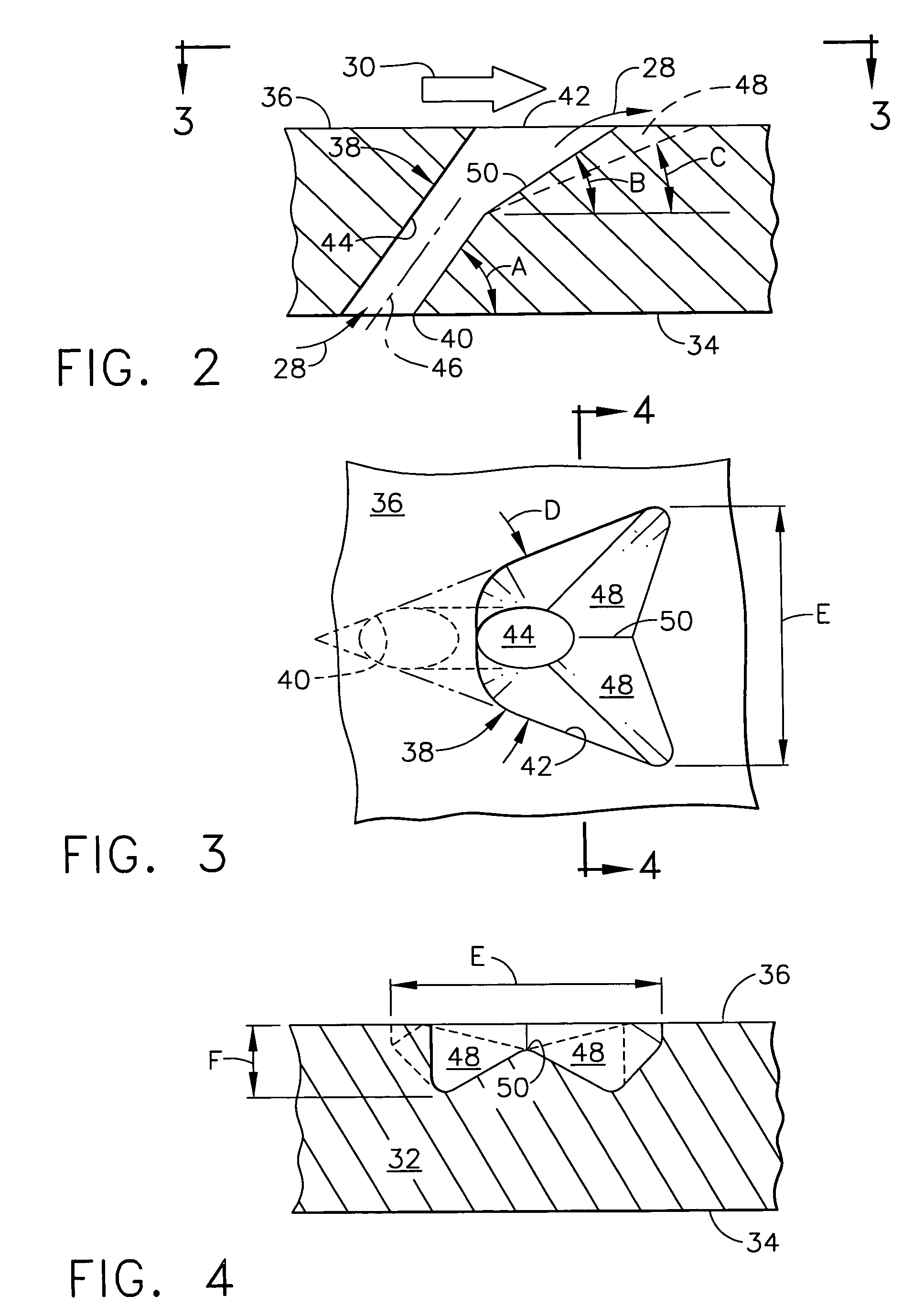

Chevron film cooled wall

A wall in a gas turbine engine includes inner and outer surfaces having a row of compound chevron film cooling holes extending therethrough. The chevron holes diverge both longitudinally and laterally between an inlet at the wall inner surface and a chevron outlet at the wall outer surface.

Owner:GENERAL ELECTRIC CO

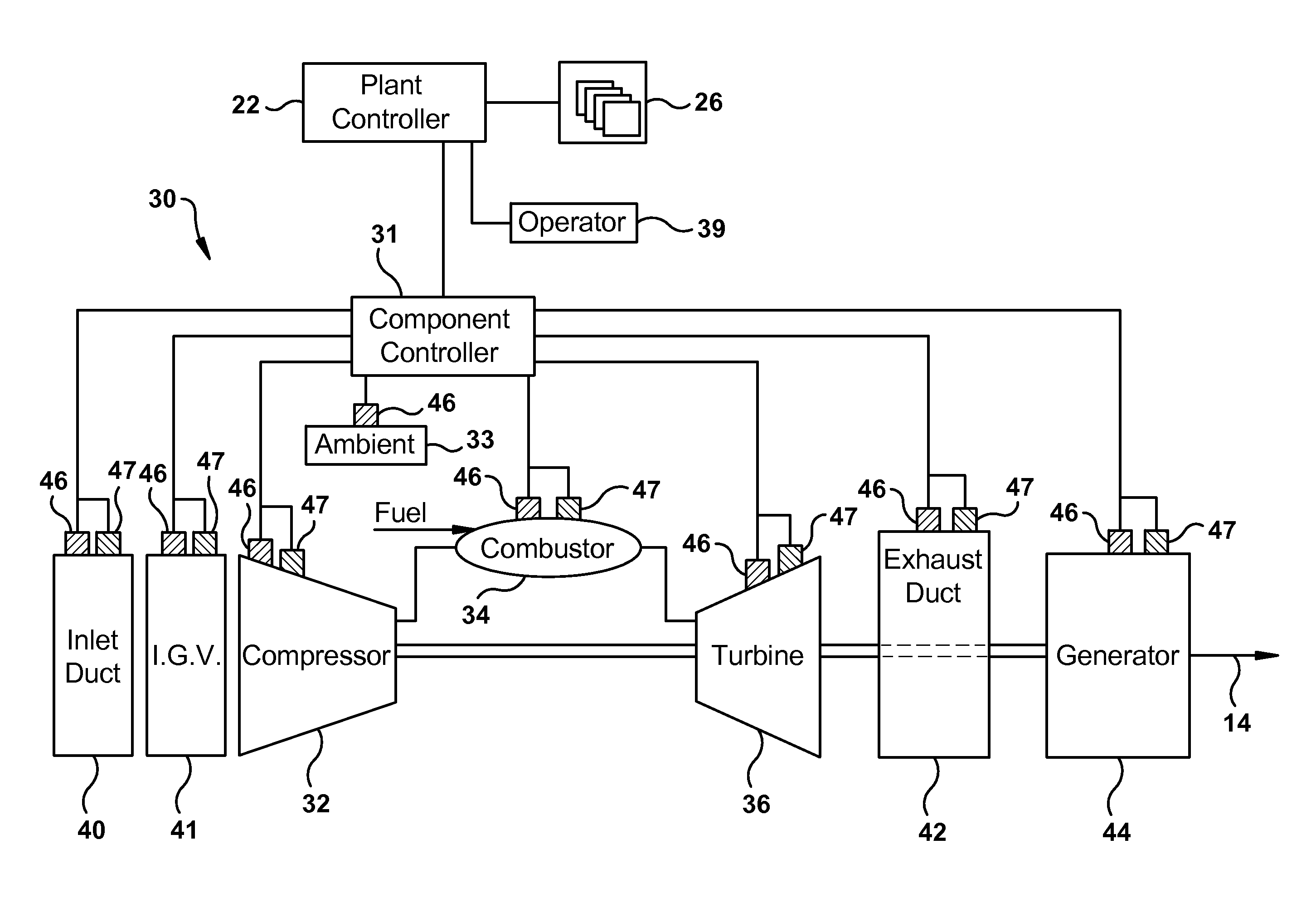

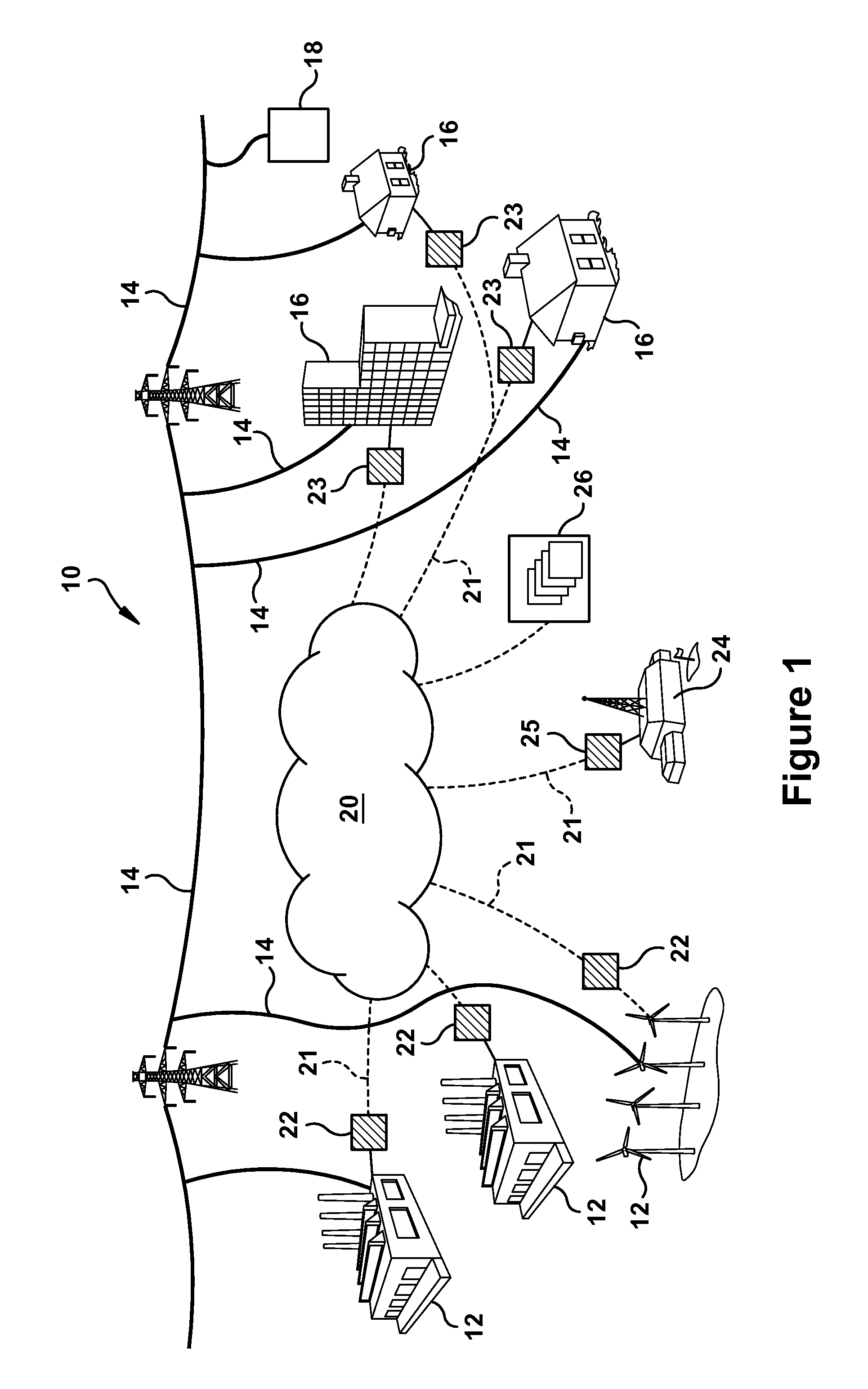

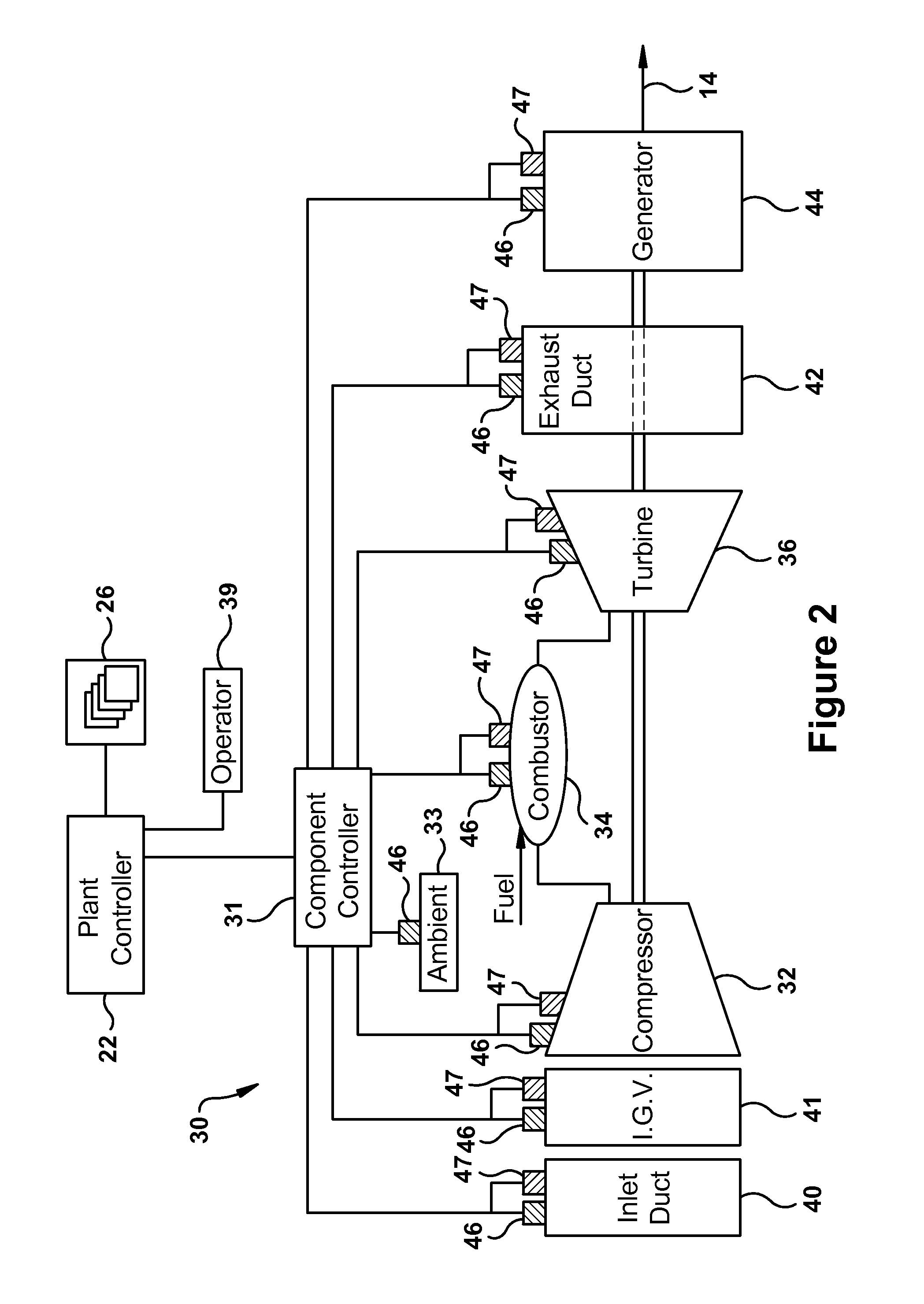

Methods and systems for enhancing control of power plant generating units

A control method for optimizing or enhancing an operation of a power plant that includes thermal generating units for generating electricity. The power plant may include multiple possible operating modes differentiated by characteristics of operating parameters. The method may include tuning a power plant model so to configure a tuned power plant model. The method may further include simulating proposed operating modes of the power plant with the tuned power plant model. The simulating may include a simulation procedure that includes: defining a second operating period; selecting the proposed operating modes from the possible operating modes; with the tuned power plant model, performing a simulation run for each of the proposed operating modes whereby the operation of the power plant during the second operating period is simulated; and obtaining simulation results from each of the simulation runs.

Owner:GENERAL ELECTRIC CO

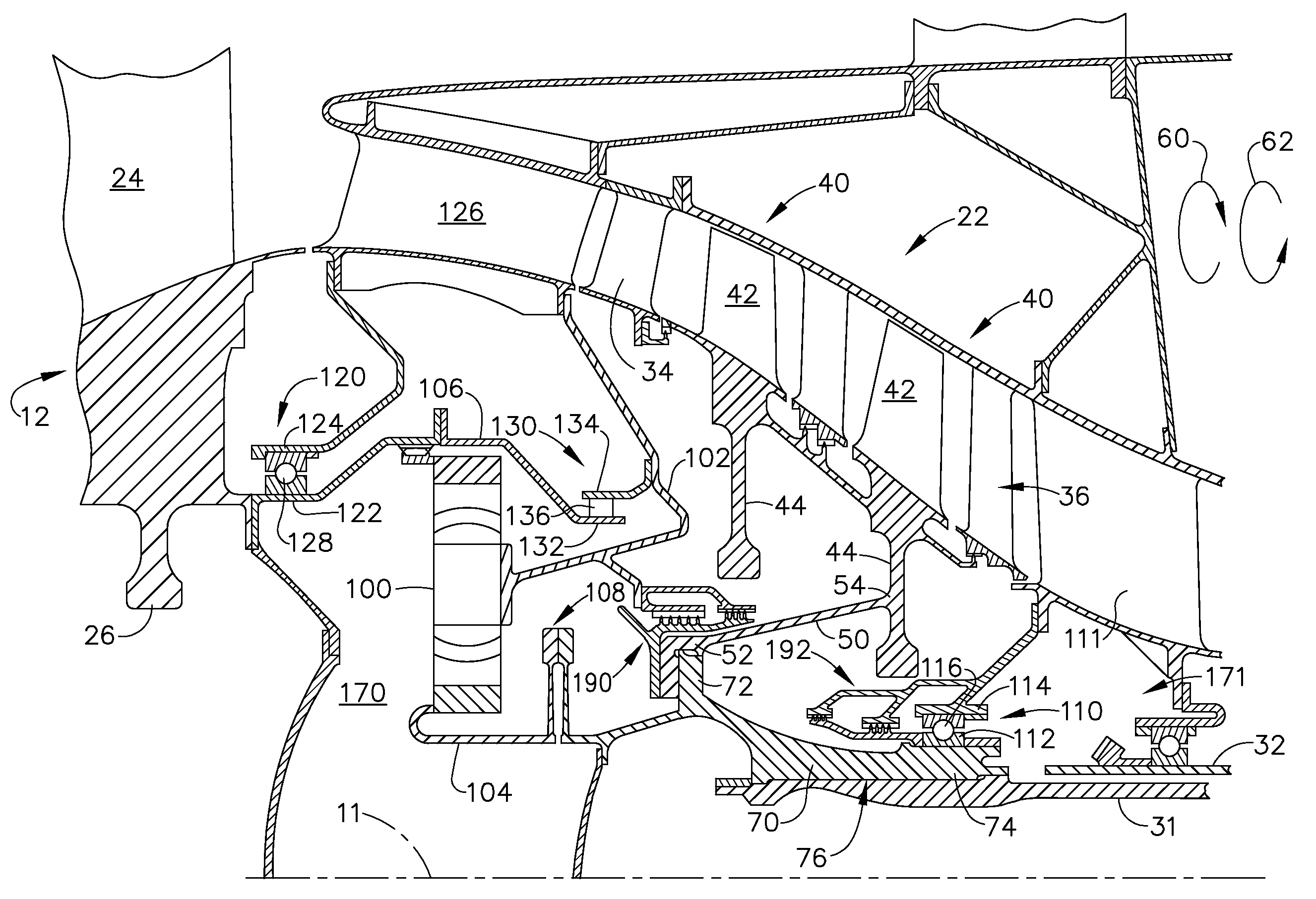

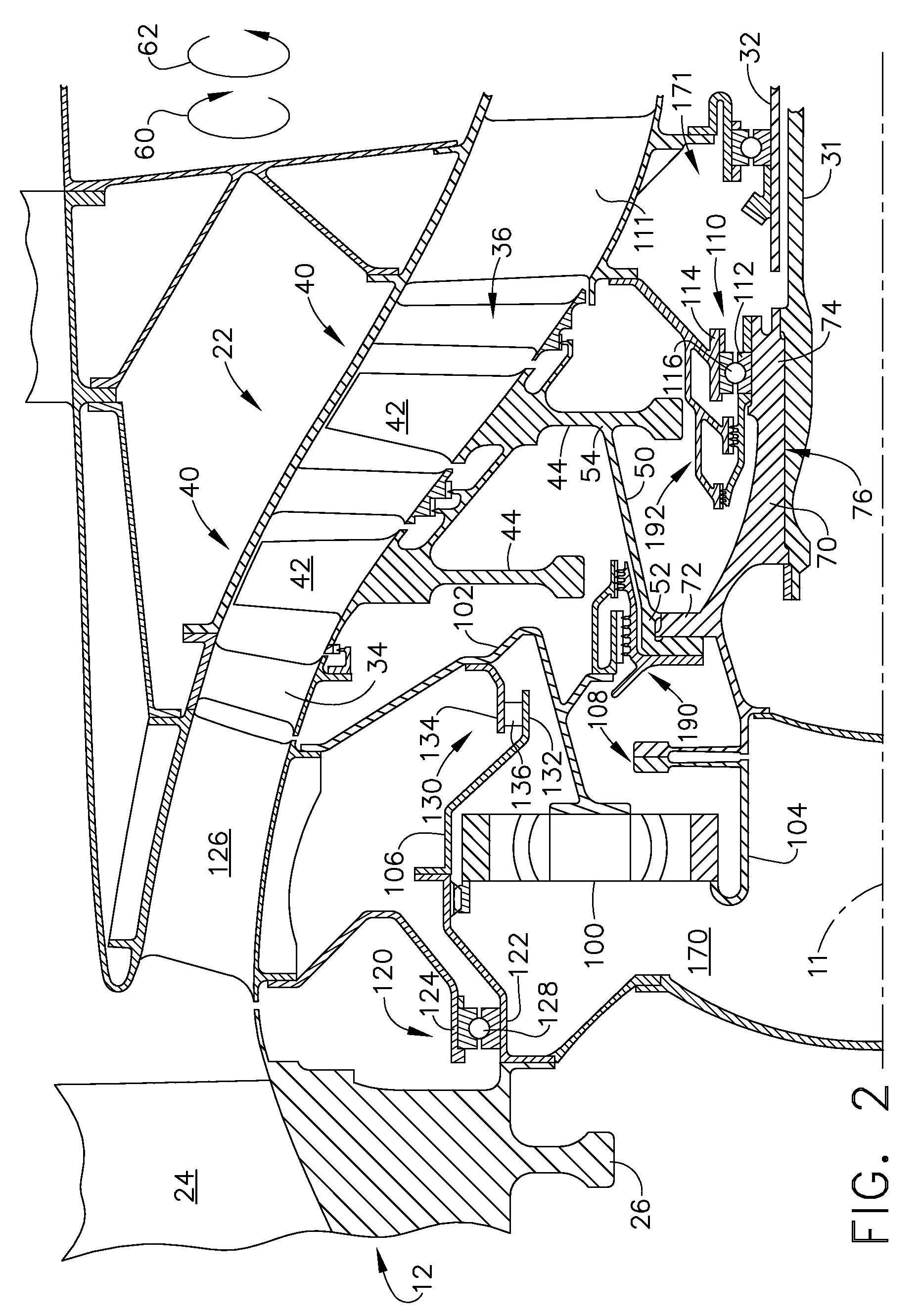

Aircraft engine with inter-turbine engine frame

An aircraft engine turbine frame includes a first structural ring, a second structural ring disposed co-axially with and radially spaced inwardly of the first structural ring about a centerline axis. A plurality of circumferentially spaced apart struts extend between the first and second structural rings. Forward and aft sump members having forward and aft central bores are fixedly joined to forward and aft portions of the turbine frame respectively. A frame connecting means for connecting the engine to an aircraft is disposed on the first structural ring. The frame connecting means may include a U-shaped clevis. The frame may be an inter-turbine frame axially located between first and second turbines of first and second rotors of a gas turbine engine assembly. An axial center of gravity of the second turbine passes though or very near a second turbine frame bearing supported by the aft sump member.

Owner:GENERAL ELECTRIC CO

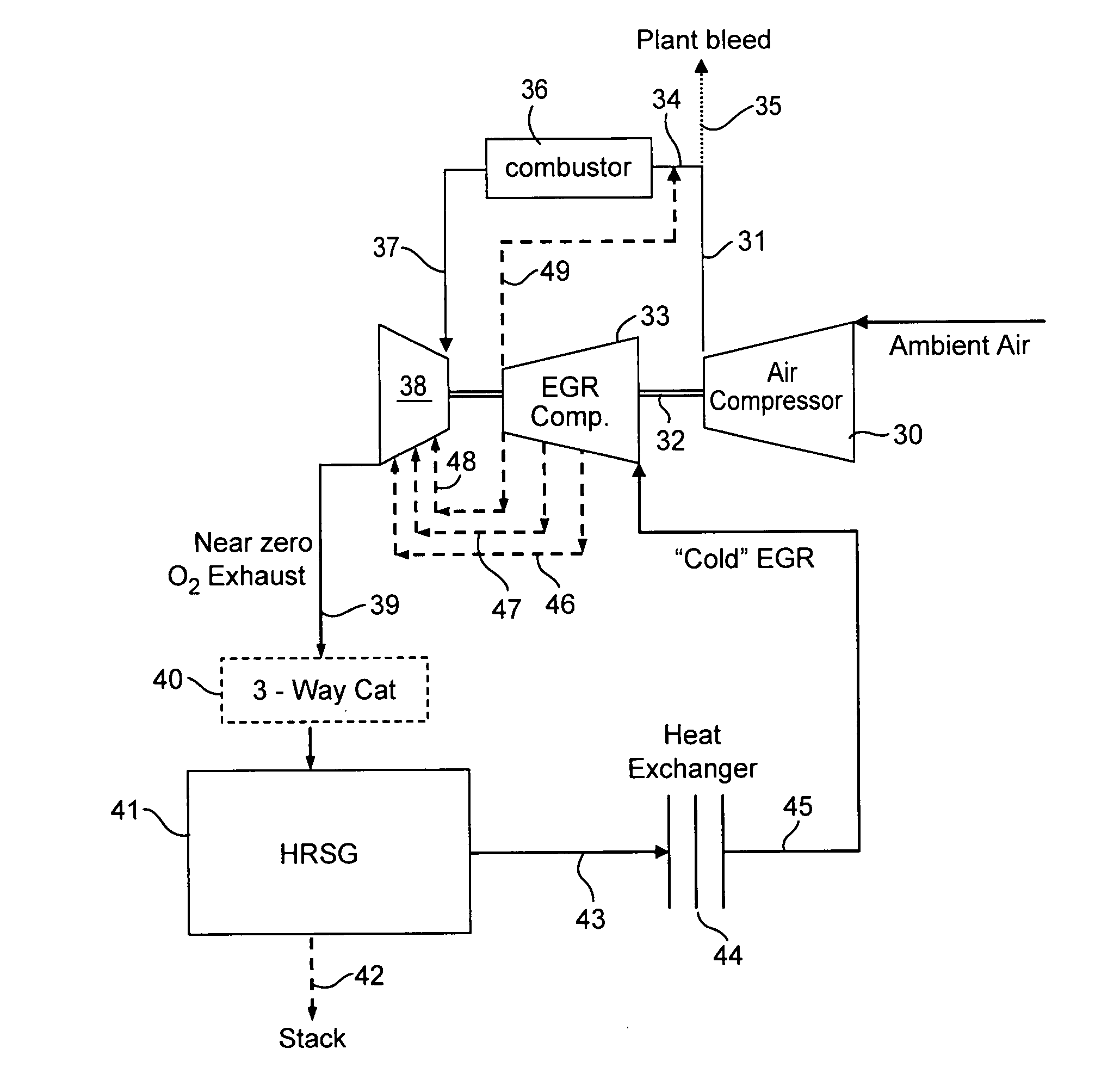

Dry 3-way catalytic reduction of gas turbine NOx

ActiveUS20090284013A1Reduction in amount of NOxIncrease carbon dioxide concentrationInternal combustion piston enginesExhaust apparatusCombustion chamberGas compressor

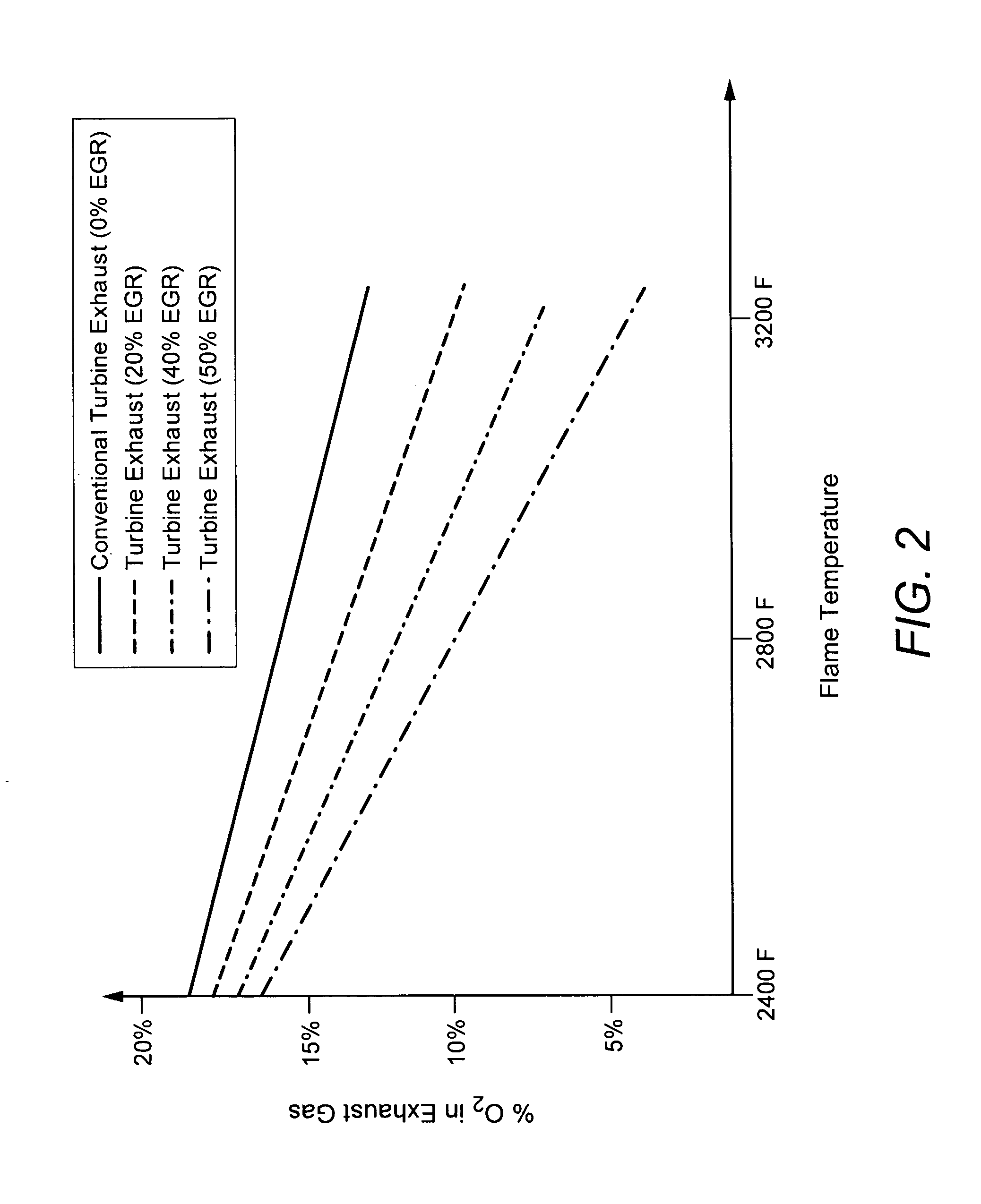

A power generation system capable of eliminating NO, components in the exhaust gas by using a 3-way catalyst, comprising a gas compressor to increase the pressure of ambient air fed to the system; a combustor capable of oxidizing a mixture of fuel and compressed air to generate an expanded, high temperature exhaust gas; a gas turbine engine that uses the force of the high temperature gas; an exhaust gas recycle (EGR) stream back to the combustor; a 3-way catalytic reactor downstream of the gas turbine engine outlet which treats the exhaust gas stream to remove substantially all of the NOx components; a heat recovery steam generator (HRSG); an EGR compressor; and an electrical generator.

Owner:GENERAL ELECTRIC CO

Staged combustion of a low heating value fuel gas for driving a gas turbine

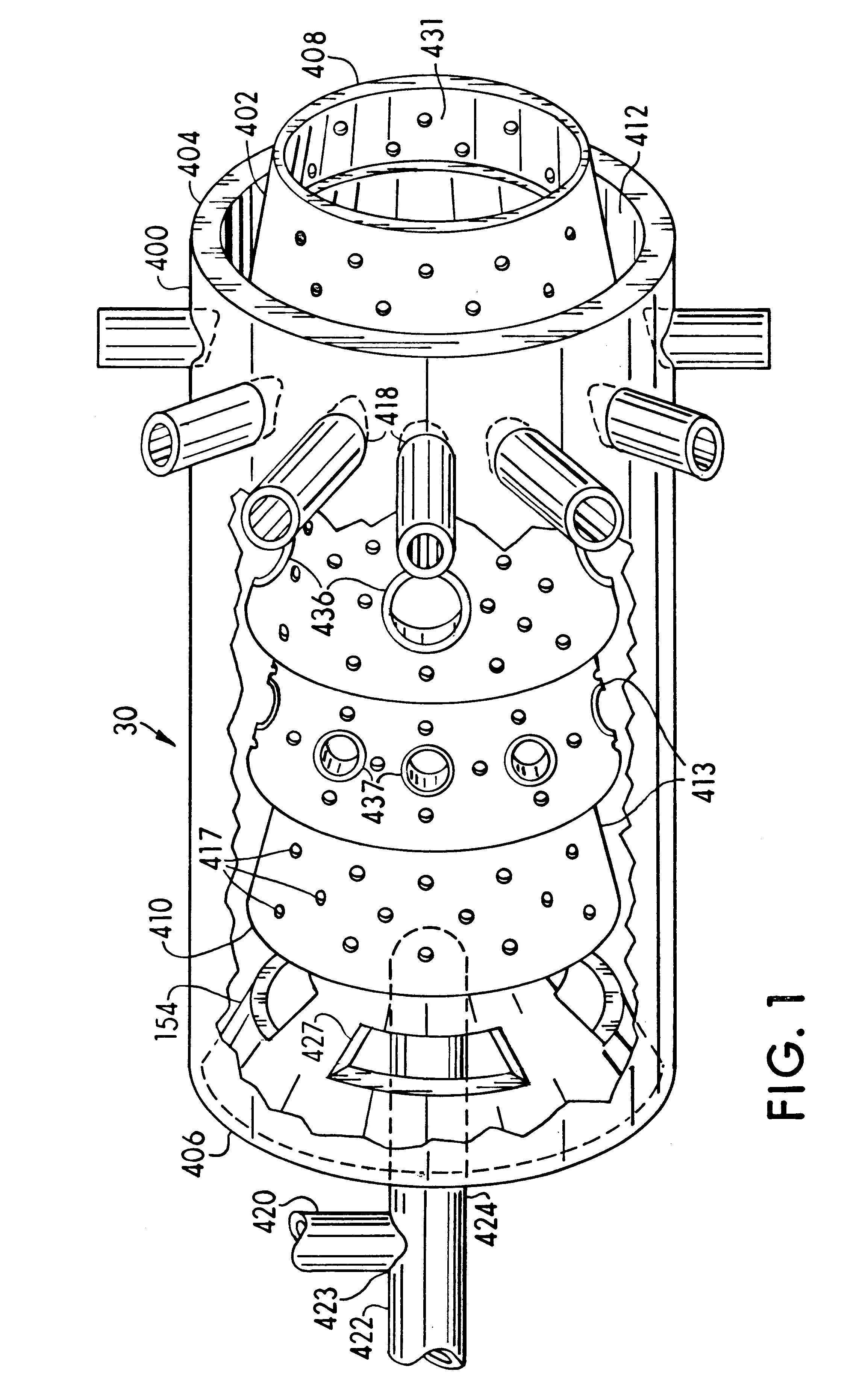

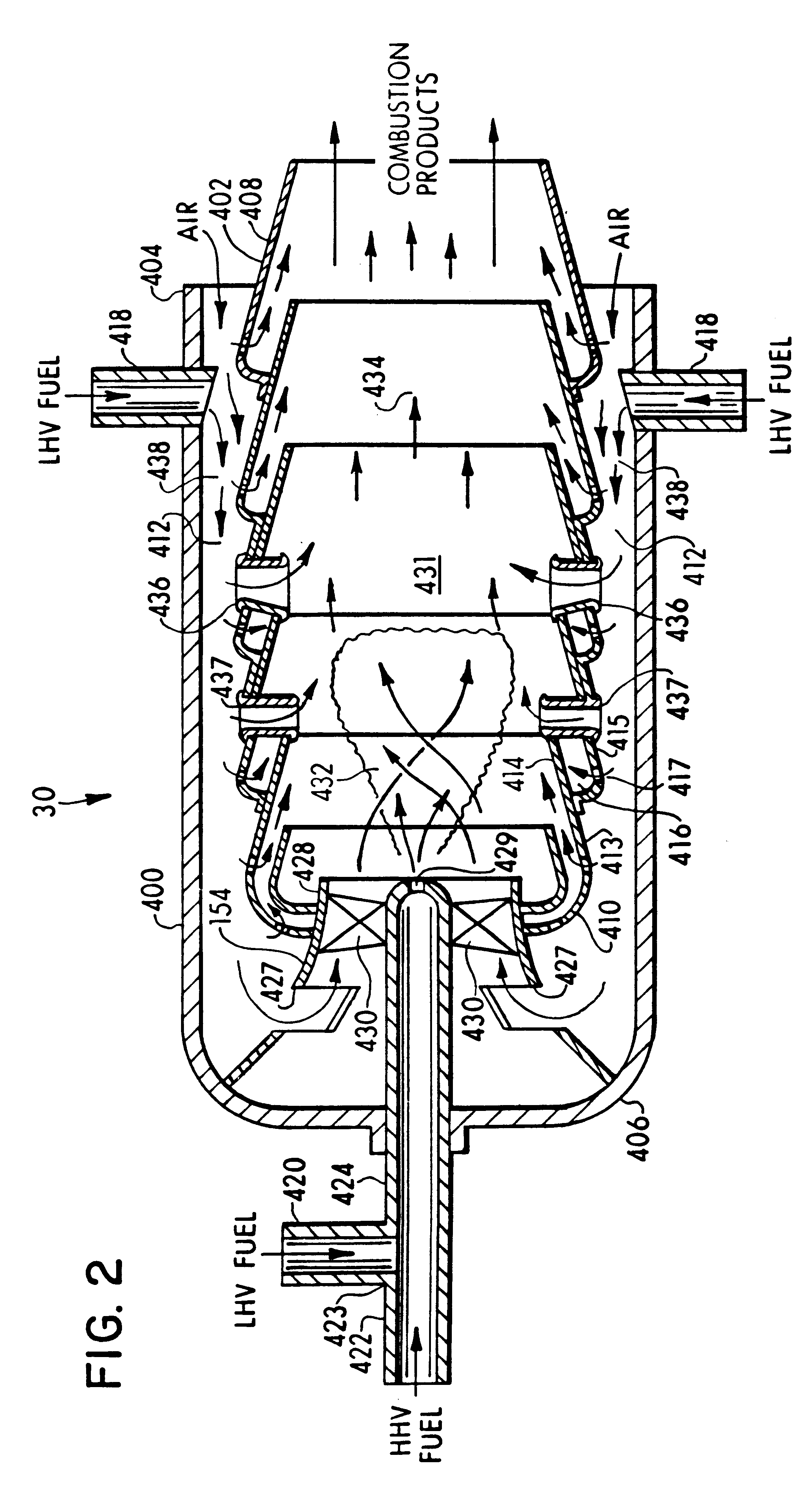

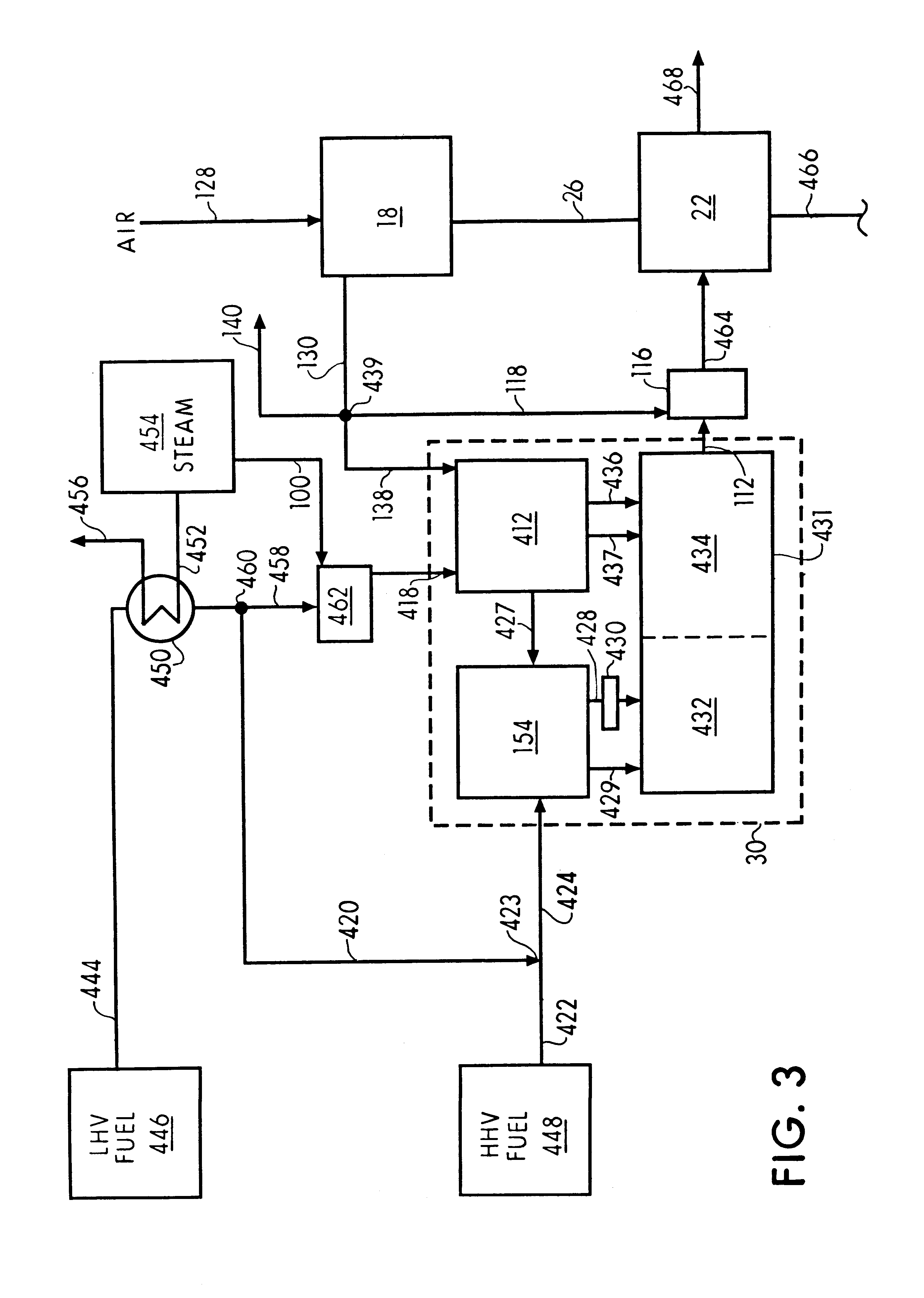

A process is provided for combusting a low heating value fuel gas in a combustor to drive an associated gas turbine. A low heating value fuel gas feed is divided into a burner portion and a combustion chamber portion. The combustion chamber portion and a combustion air are conveyed into a mixing zone of the combustor to form an air / fuel mixture. The burner portion is conveyed into a flame zone of the combustor through a burner nozzle while a first portion of the air / fuel mixture is conveyed into the flame zone through a burner port adjacent to the burner nozzle. The burner portion and first portion of the air / fuel mixture are contacted in the flame zone to combust the portions and produce flame zone products. The flame zone products are conveyed into an oxidation zone of the combustor downstream of the flame zone while a second portion of the air / fuel mixture is also conveyed into the oxidation zone. The second portion is combusted in the oxidation zone in the presence of the flame zone products to produce combustion products. The combustion products are conveyed into the associated gas turbine and drive the gas turbine.

Owner:MARATHON OIL CO +1

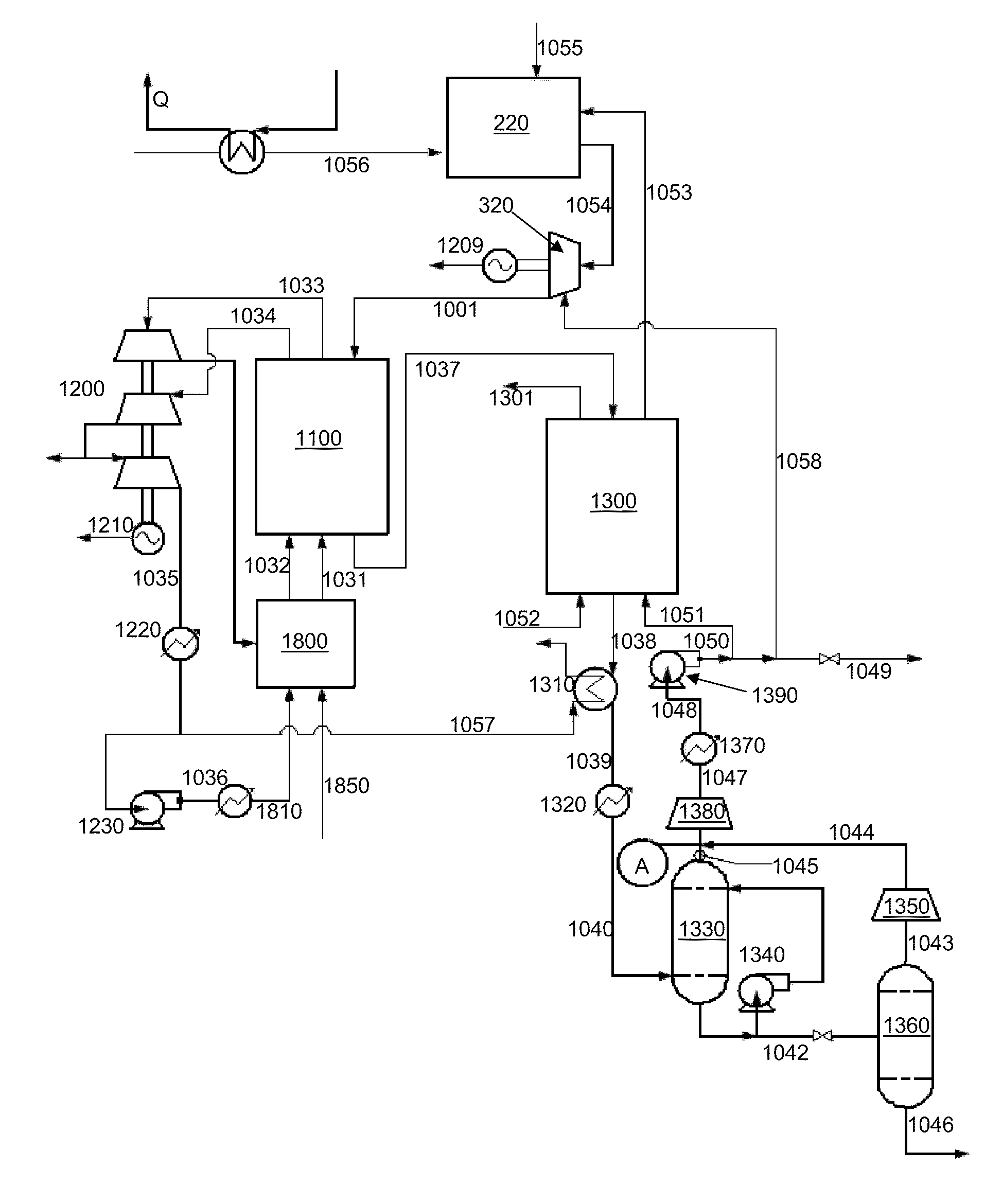

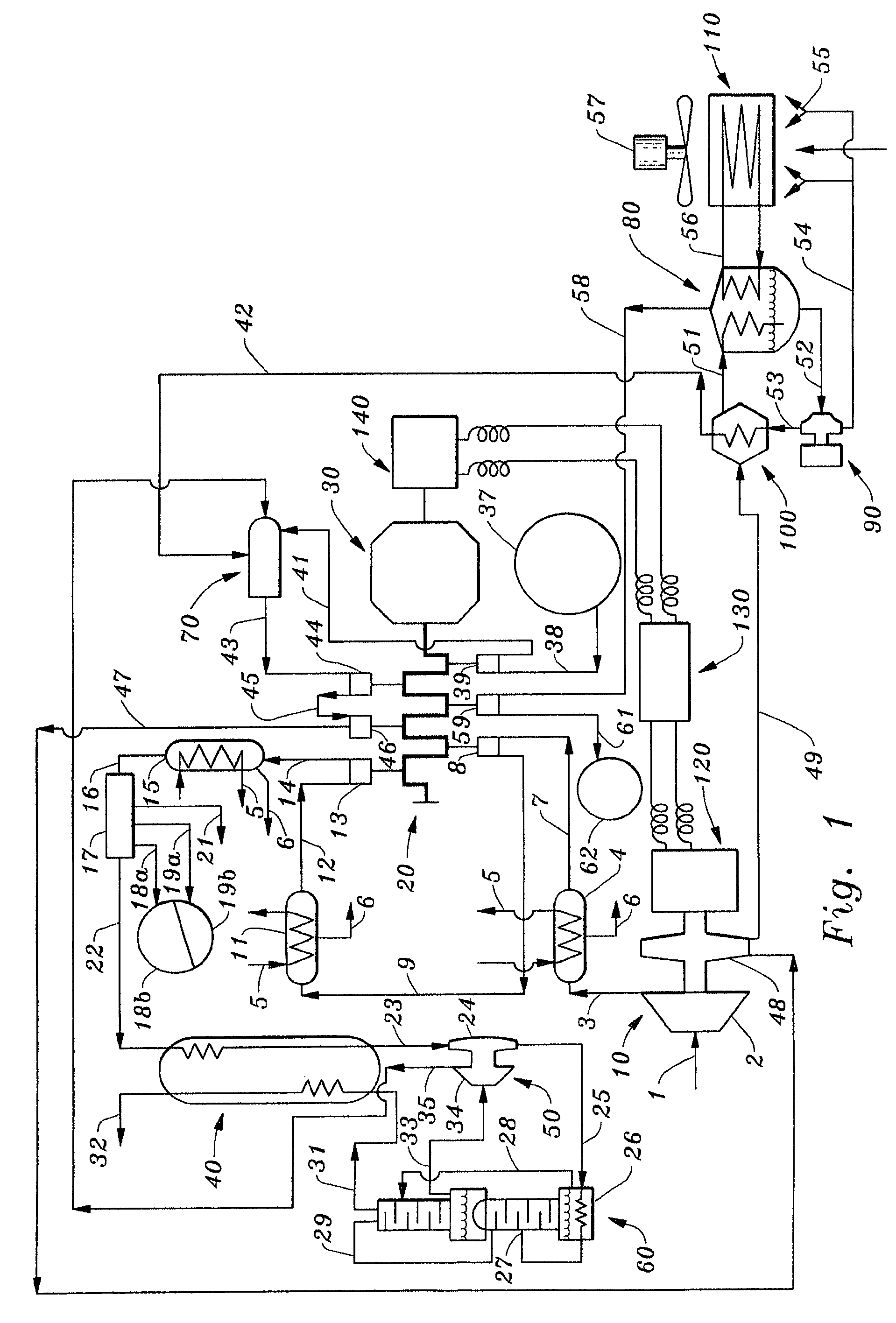

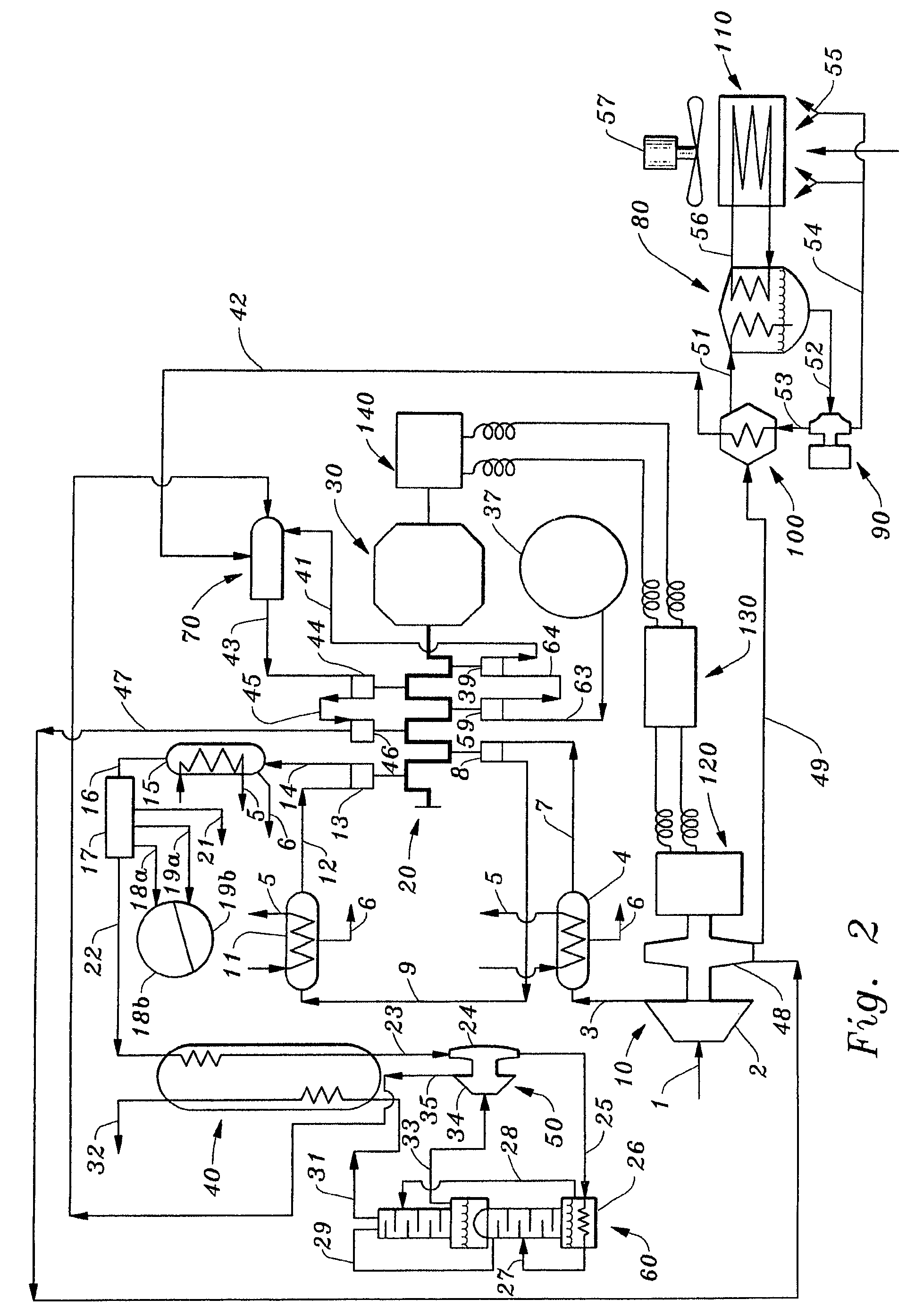

System and method for high efficiency power generation using a carbon dioxide circulating working fluid

ActiveUS20110179799A1Improve efficiencyIncrease pressure ratioSolidificationLiquefactionWorking fluidCombustor

The present invention provides methods and system for power generation using a high efficiency combustor in combination with a CO2 circulating fluid. The methods and systems advantageously can make use of a low pressure ratio power turbine and an economizer heat exchanger in specific embodiments. Additional low grade heat from an external source can be used to provide part of an amount of heat needed for heating the recycle CO2 circulating fluid. Fuel derived CO2 can be captured and delivered at pipeline pressure. Other impurities can be captured.

Owner:8 RIVERS CAPTTAL LLC

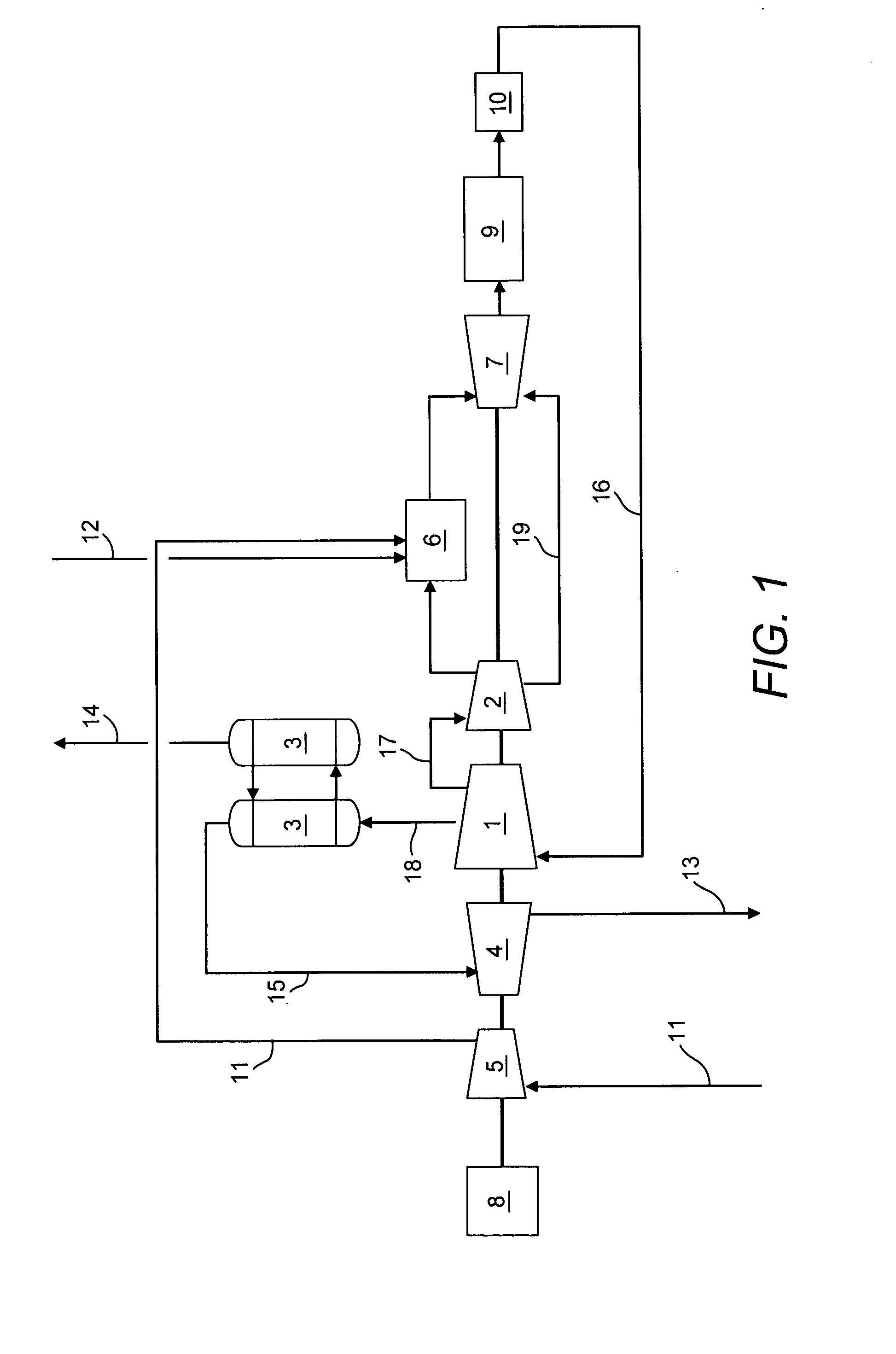

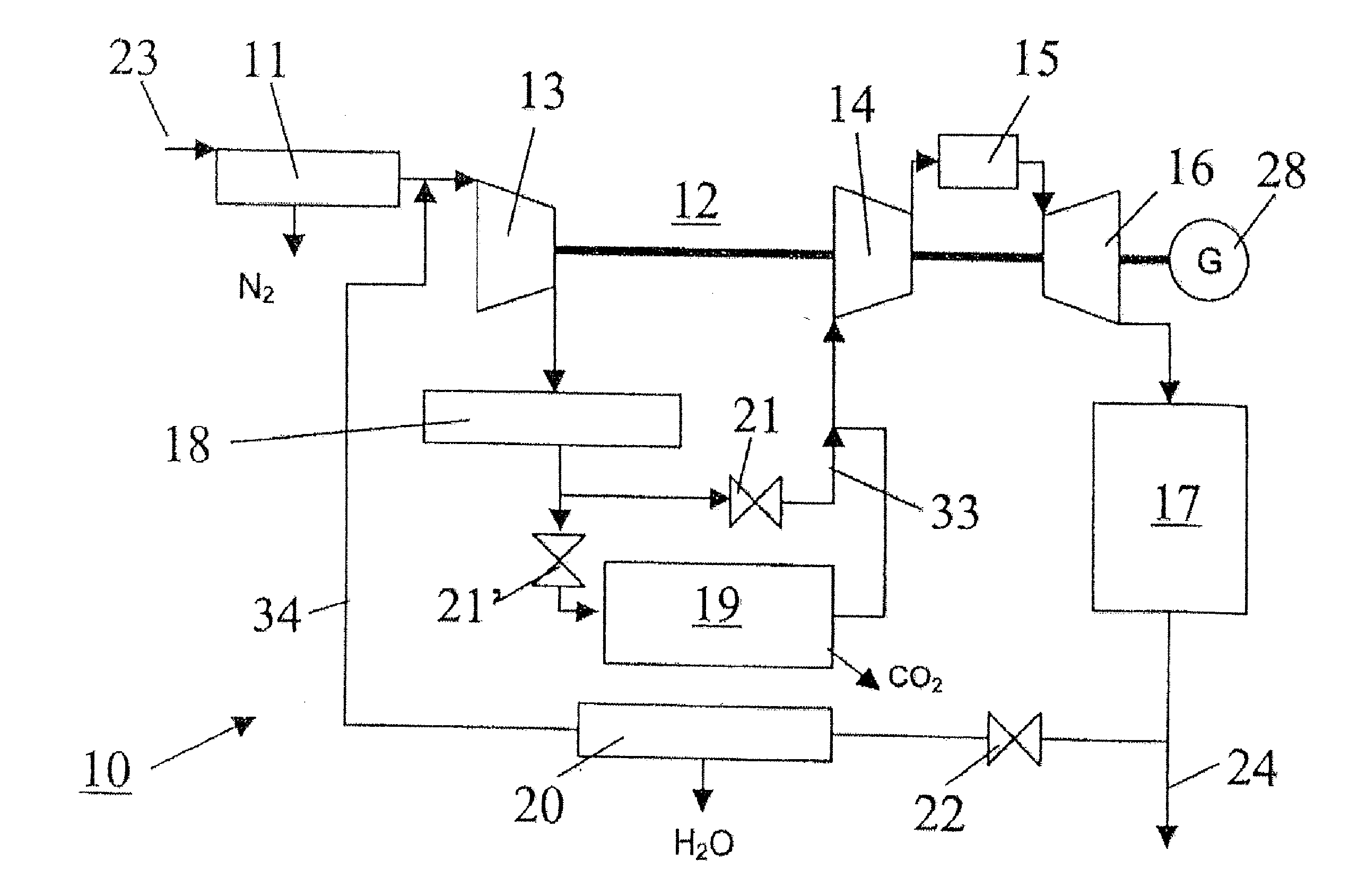

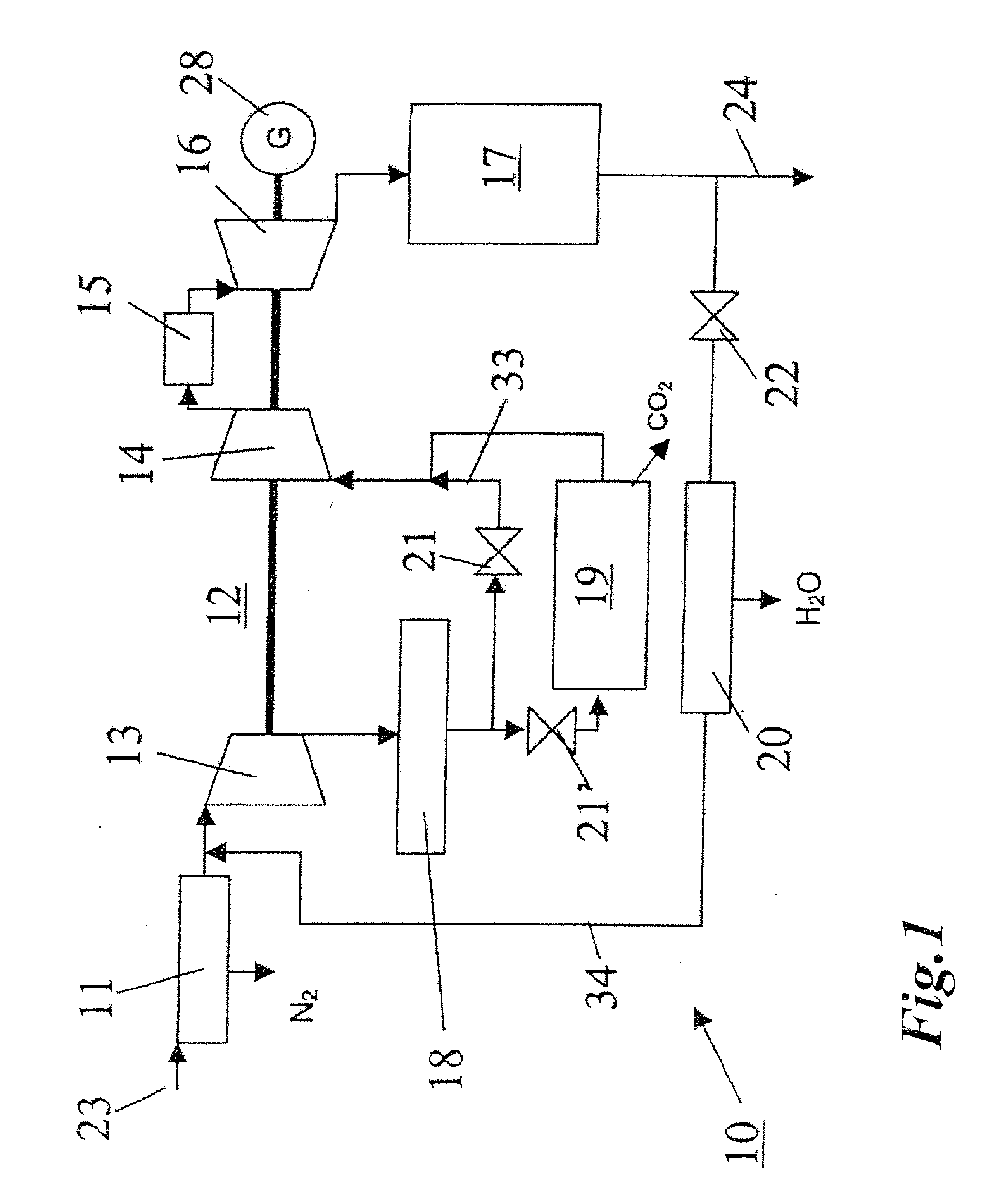

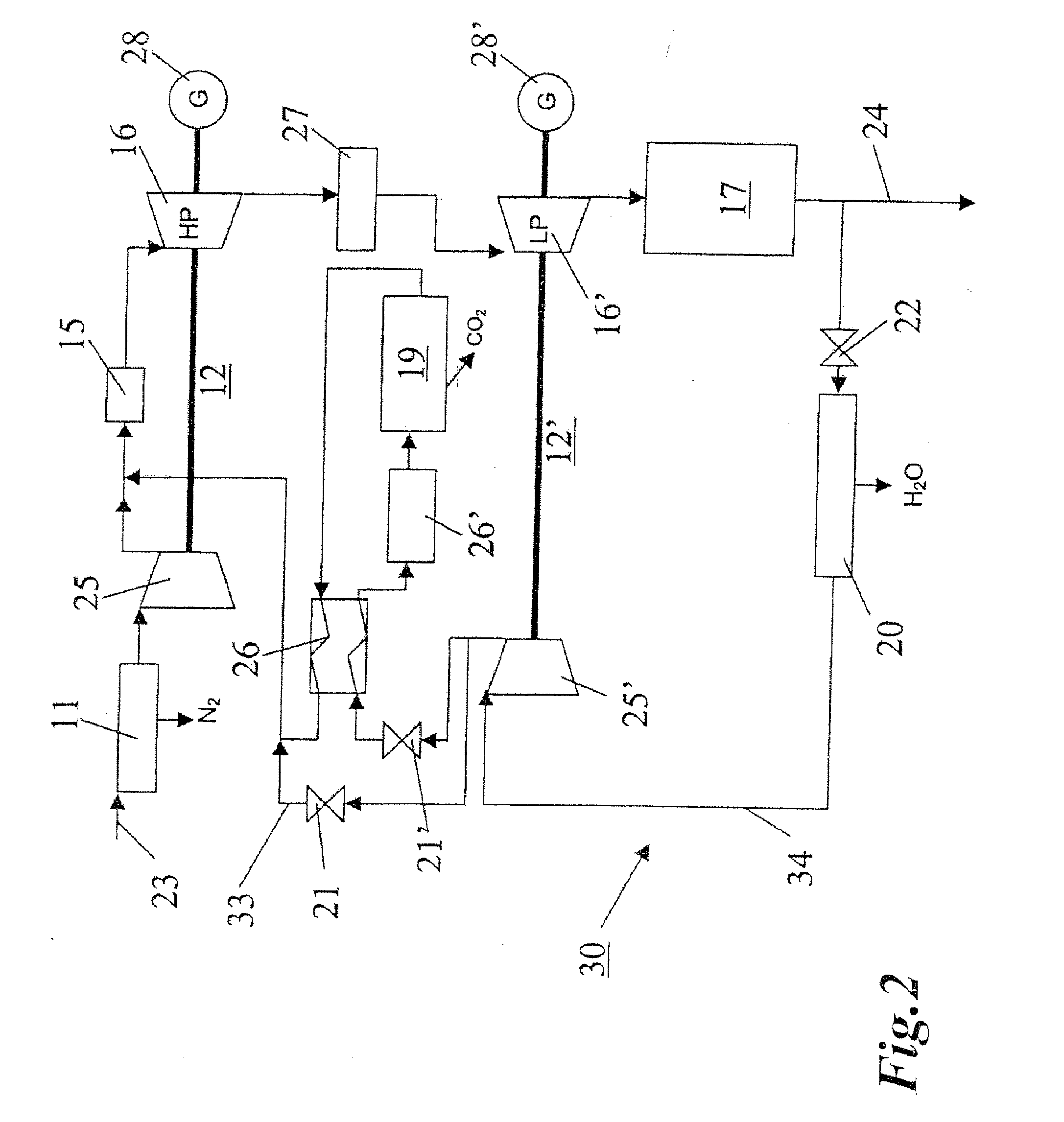

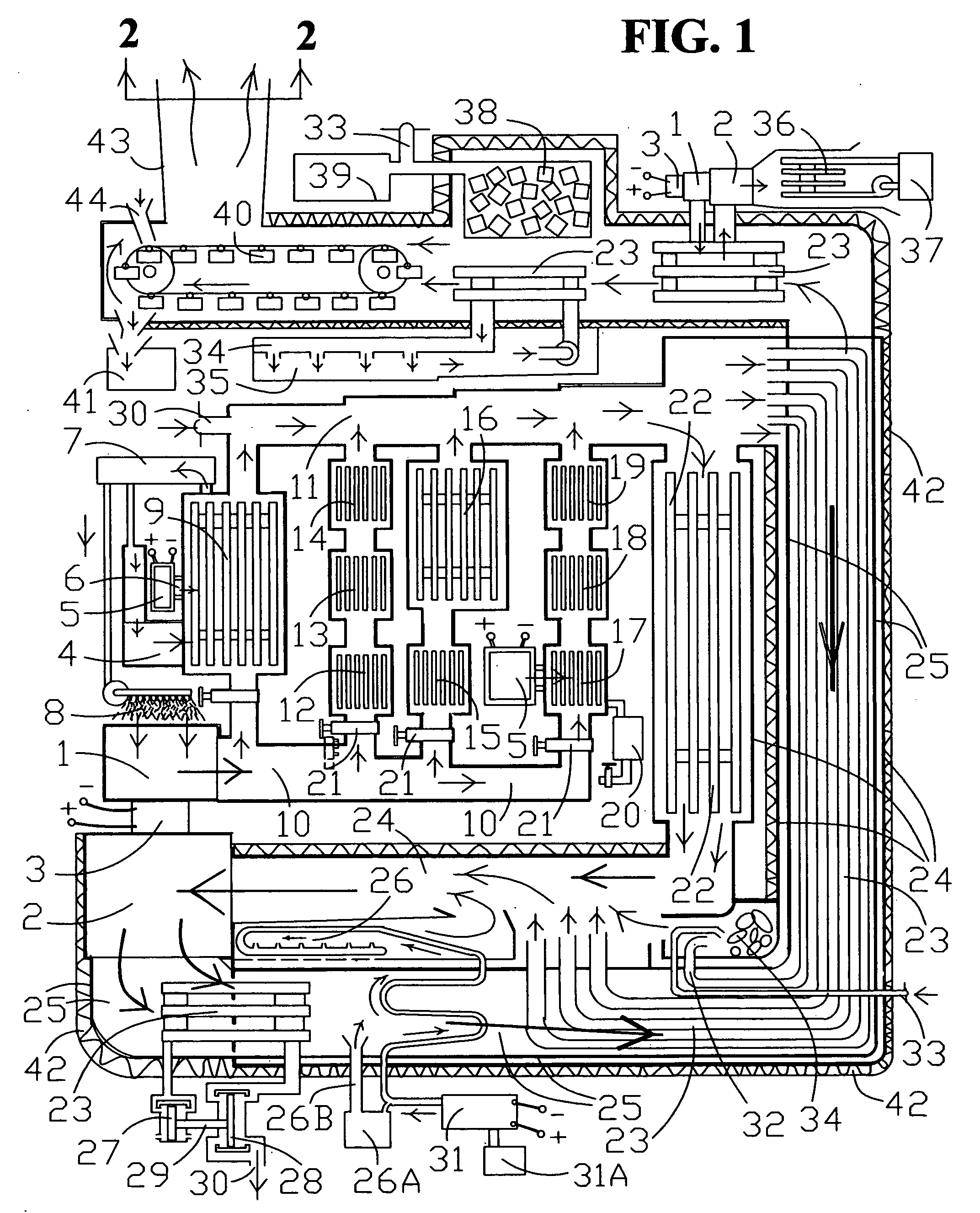

Method for Generating Energy in an Energy Generating Installation Having a Gas Turbine, and Energy Generating Installation Useful for Carrying Out the Method

InactiveUS20080010967A1Efficient removalImprove efficiencyDispersed particle separationGas turbine plantsCyclic processCombustion chamber

In a method for generating energy in an energy generating installation (10) having a gas turbine (12), in a first step, an oxygen-containing gas is compressed in a compressor (13, 14) of the gas turbine (12), in a second step the compressed gas is supplied, with the addition of fuel, for combustion in a combustion chamber (15), in a third step the hot flue gas from the combustion chamber (15) is expanded in a turbine (16) of the gas turbine (12) so as to perform work, and, in a fourth step, a branched-off part stream of the expanded flue gas is recirculated into a part of the gas turbine (12) lying upstream of the combustion chamber (15) and is compressed. A reduction in the CO2 emission, along with minimal losses of efficiency, is achieved in that carbon dioxide (CO2) is separated from the circulating gas in a CO2 separator (19), and in that measures are taken to compensate for the efficiency losses in the gas turbine cyclic process which are associated with the CO2 separation.

Owner:ALSTOM TECH LTD

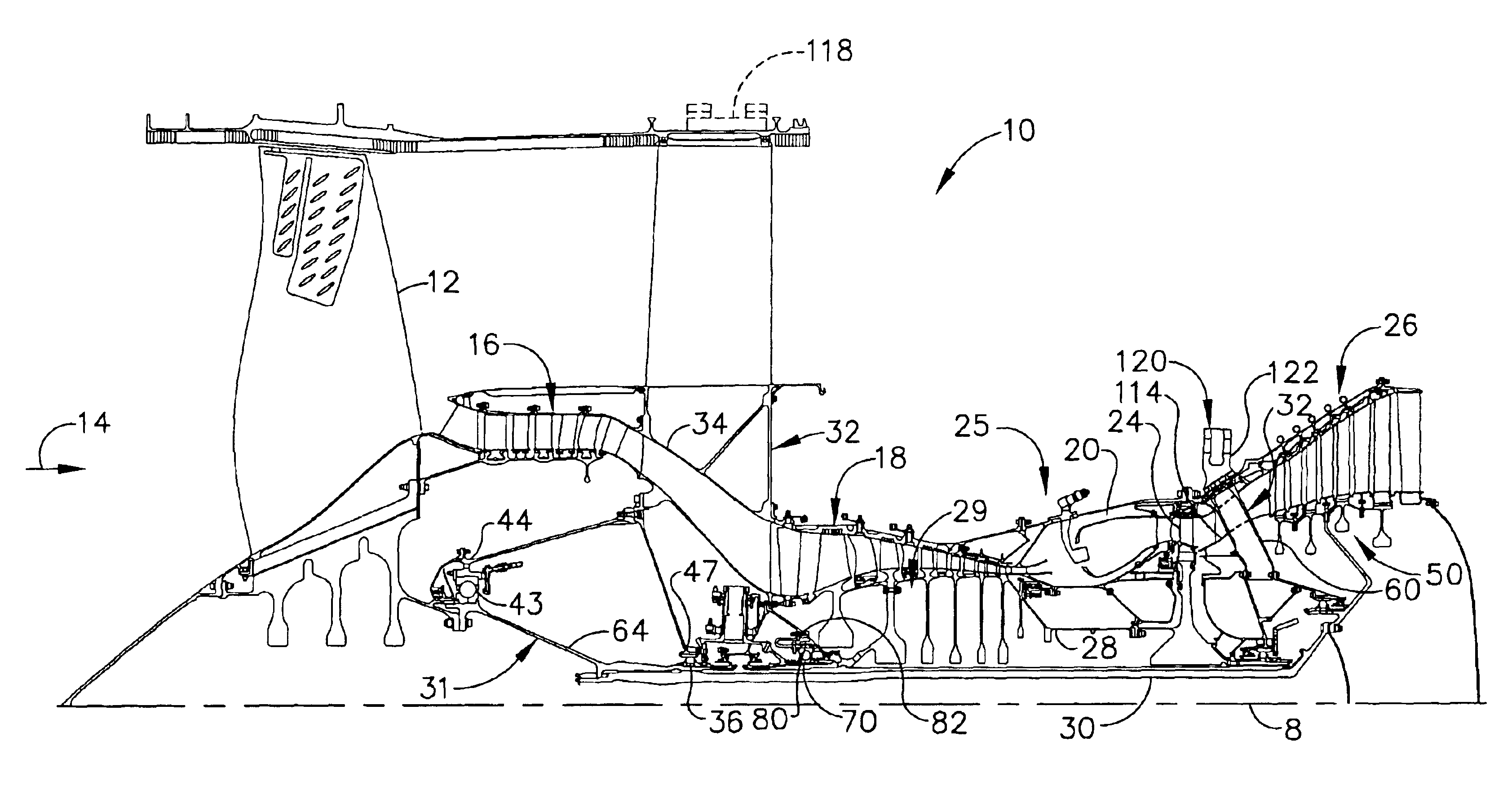

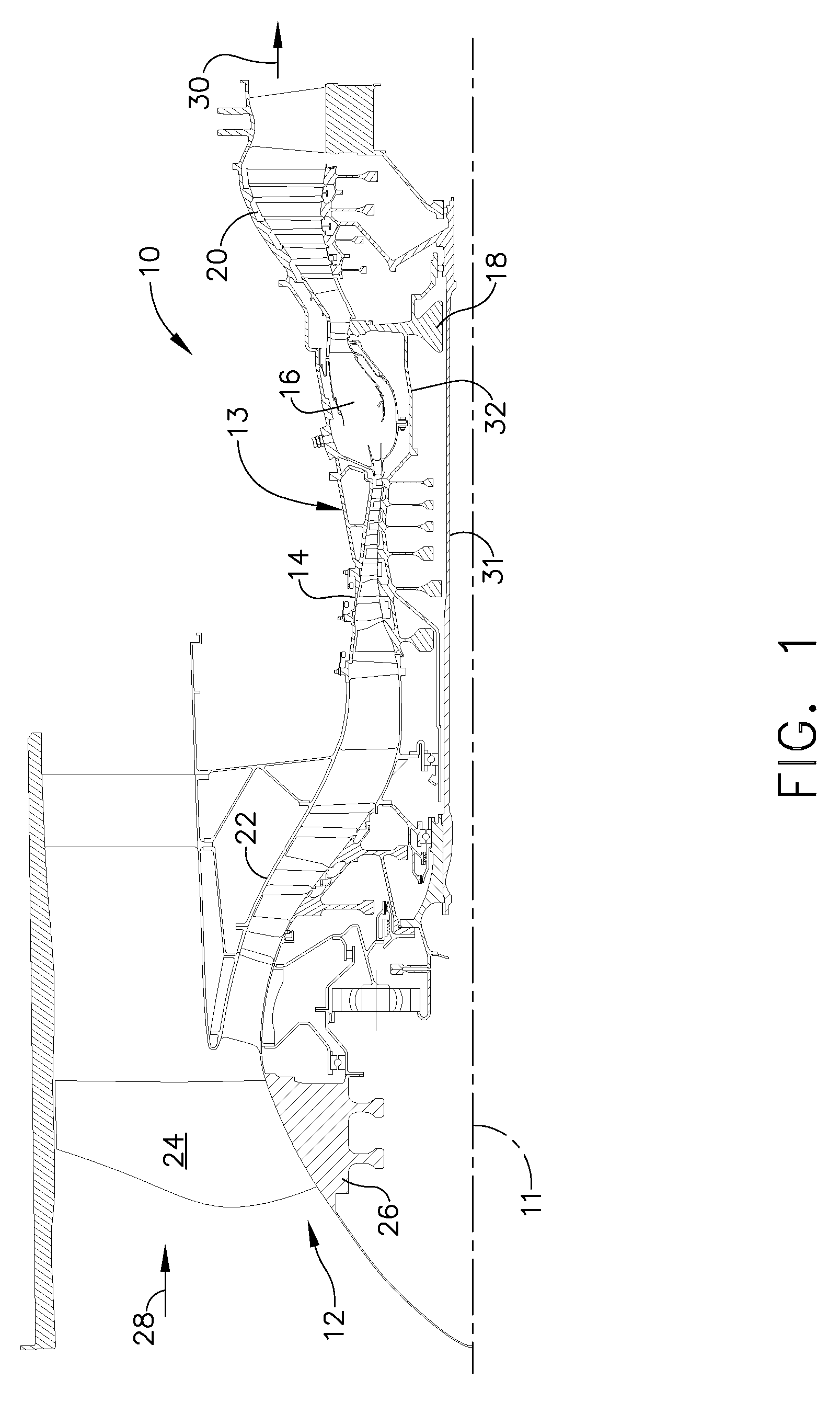

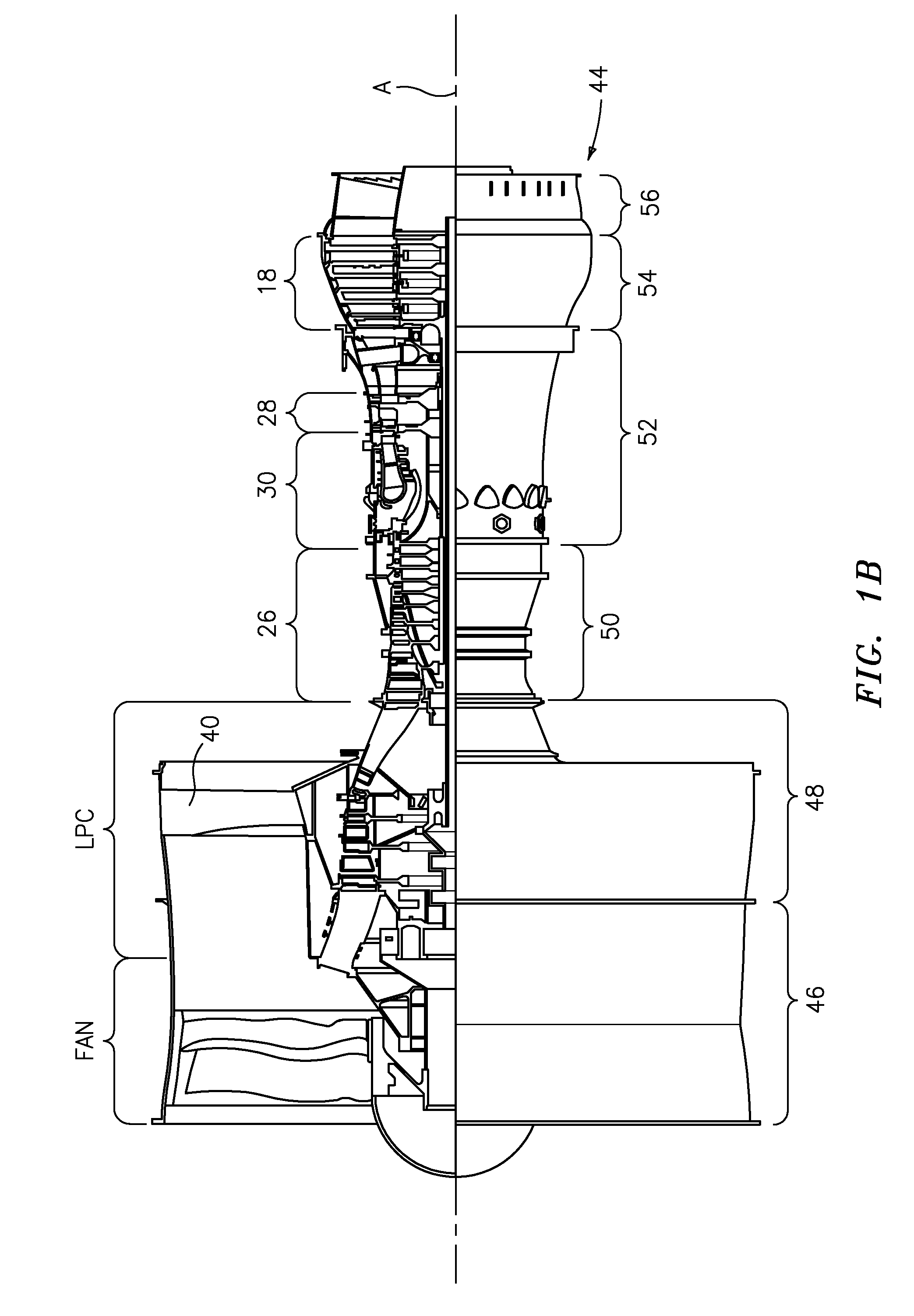

Gas turbine engine assembly and method of assembling same

A method of assembling a gas turbine assembly includes providing a core gas turbine engine including a high-pressure compressor, a combustor, and a turbine, coupling a low-pressure turbine axially aft from the core gas turbine engine, coupling a fan assembly axially forward from the core gas turbine engine, and coupling a booster compressor to the low-pressure turbine such that the booster compressor and the low-pressure turbine rotate at a first rotational speed.

Owner:GENERAL ELECTRIC CO

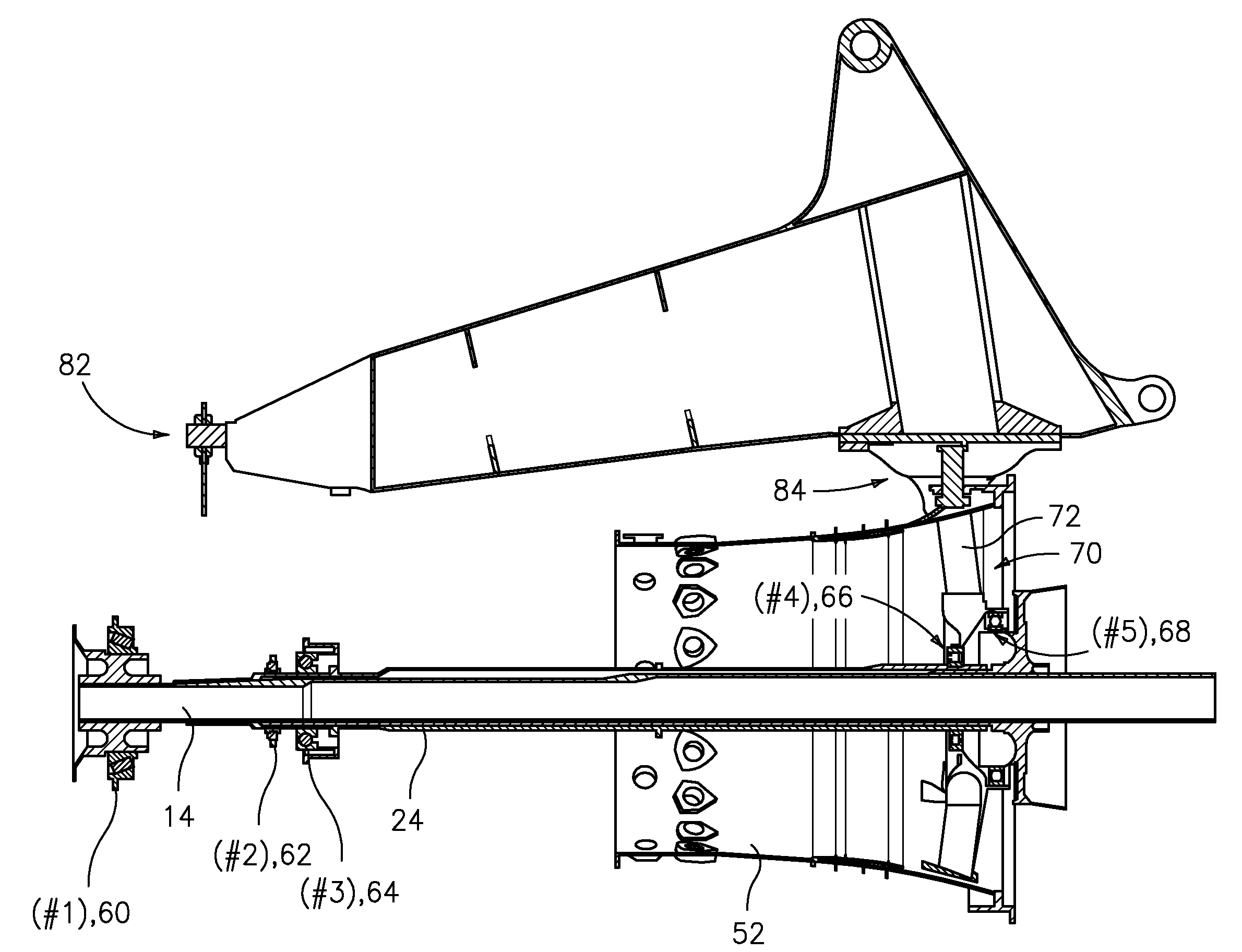

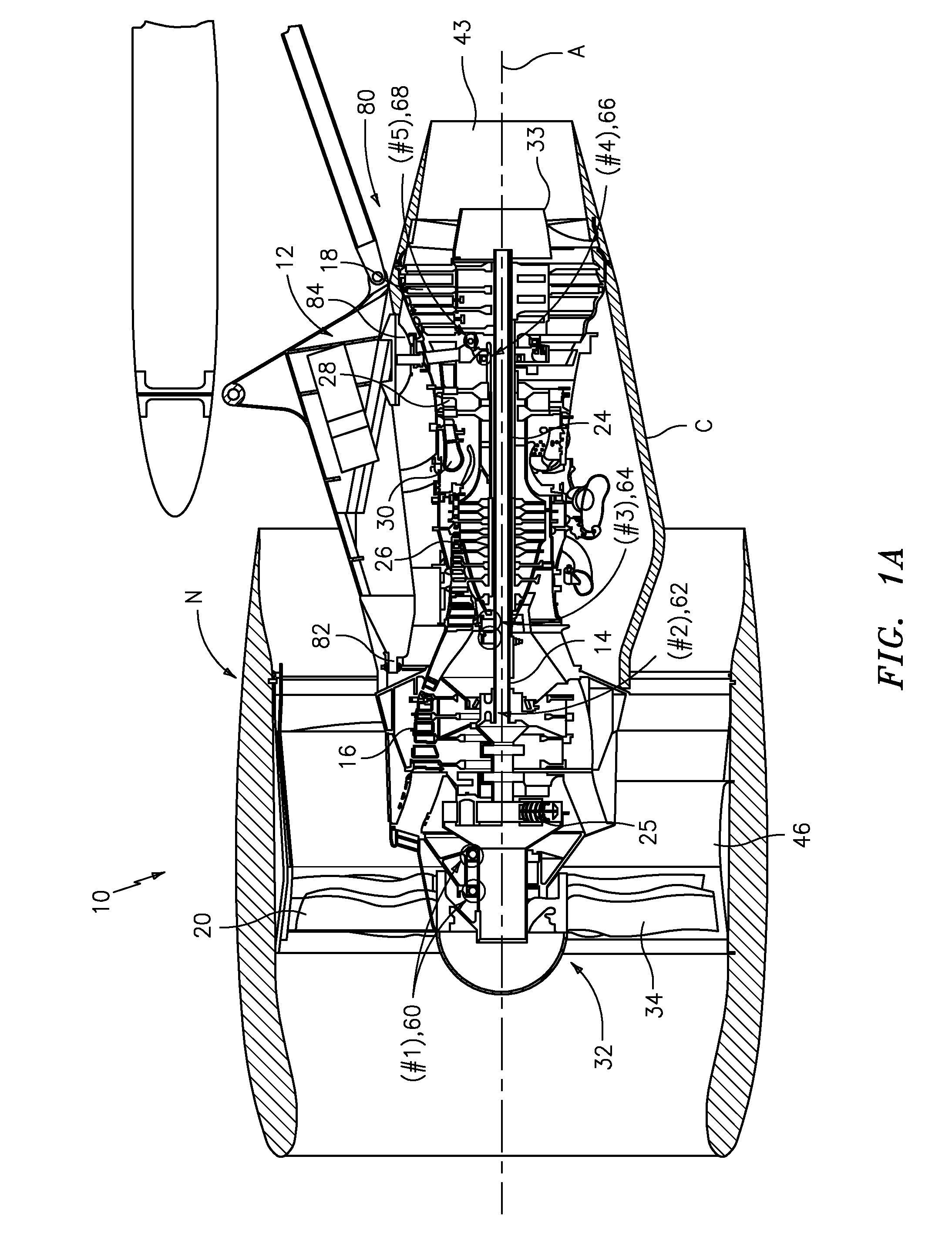

Engine mounting configuration for a turbofan gas turbine engine

ActiveUS20090056343A1Minimizes backbone bendingMinimizes engine case distortionPower plant constructionJet type power plantsNacelleEngine mount

An engine mounting configuration reacts engine thrust at an aft mount. The engine mounting configuration reduces backbone bending of the engine, intermediate case distortion and frees-up space within the core nacelle.

Owner:RAYTHEON TECH CORP

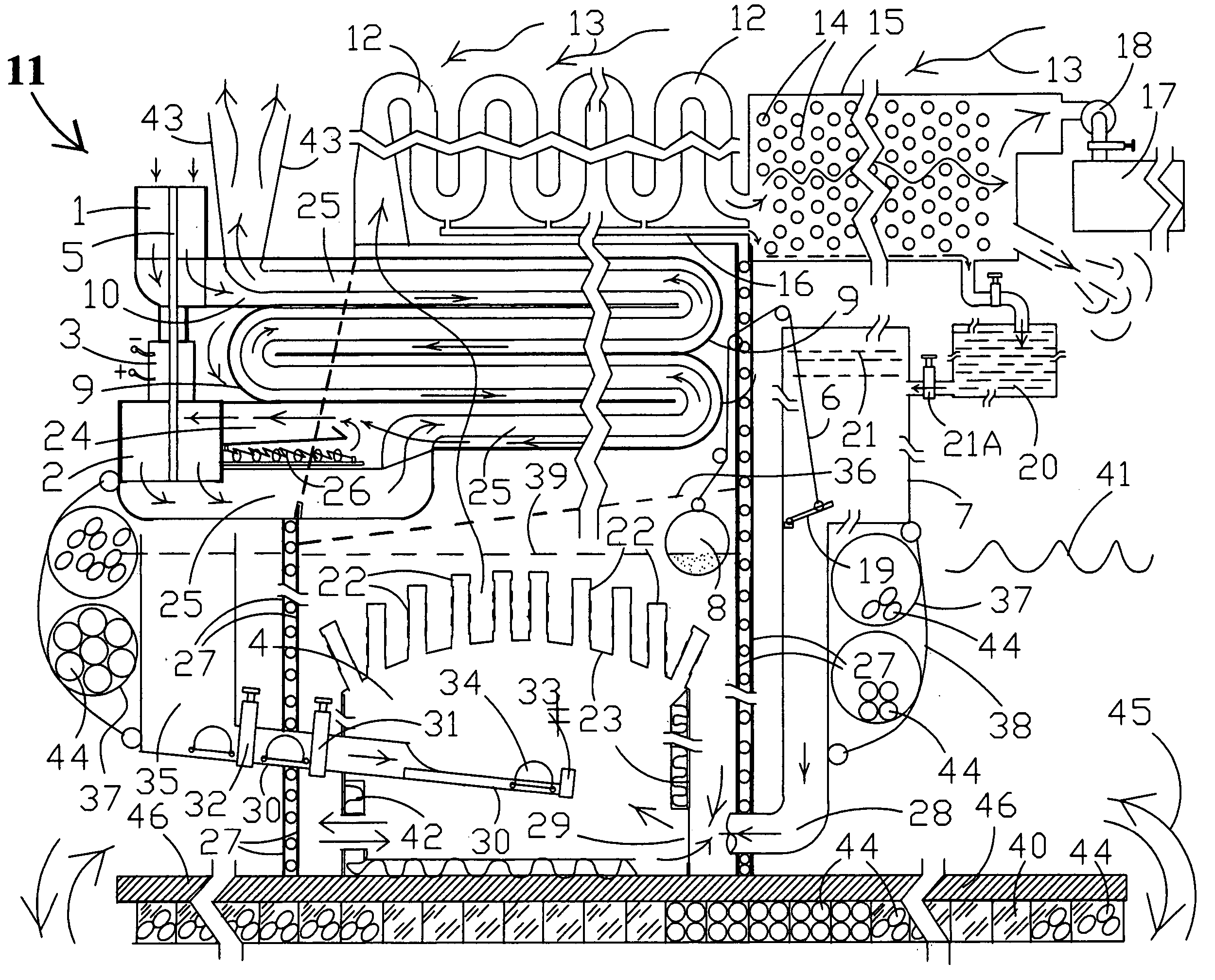

Heat energy recapture and recycle and its new applications

InactiveUS20050120715A1Increase the atmosphereGood sunshineEngine fuctionsEfficient propulsion technologiesThermal energyDistillation

What has been created is a plurality and a variety of processes and a variety of devices correspondingly supportive to each process, wherein, a new partnership between; (1) a heat absorbing radiator compressed air pipes / tubes and (2) a gas turbine engine or a reciprocating piston engine,—is used to recapture and reconvert the, otherwise wasted, heat energies expelled by engines, by factories, by smelting plants, by distillation plants, by chillers / coolers / freezers, by cooking ovens, by lamps / stoves, by trash burners, and the heat energies created by the solar heat on the desert / ocean water,—into electric power and finally into hydrogen-deuterium fuel,—by having the engine's tailpipes submerged in cold compressed air inside the heat absorbing radiator pipes in reverse air flow, to further drive and re-drive the same engine; wherein, in order to capture fusion heat energy the hydrogen bomb is detonated in the deep ocean to catch the flames by the water and the hot water is used to energize the compressed air inside the heat absorbing radiator pipes; wherein, in order to produce fusion energy, an abundant electric arc is passed across liquid deuterium or across gaseous deuterium by the electro-plasma torch and sparkplug in the internal combustion engine, and by detonating a dynamite inside a liquid deuterium; wherein diamond is produced by placing carbon inside the hydrogen bomb; and wherein, deuterium fusion flame is used first in smelting glass to large sizes before running an engine.

Owner:CHRISTIAN SCHOOL OF TECH CHARITABLE FOUND TRUST

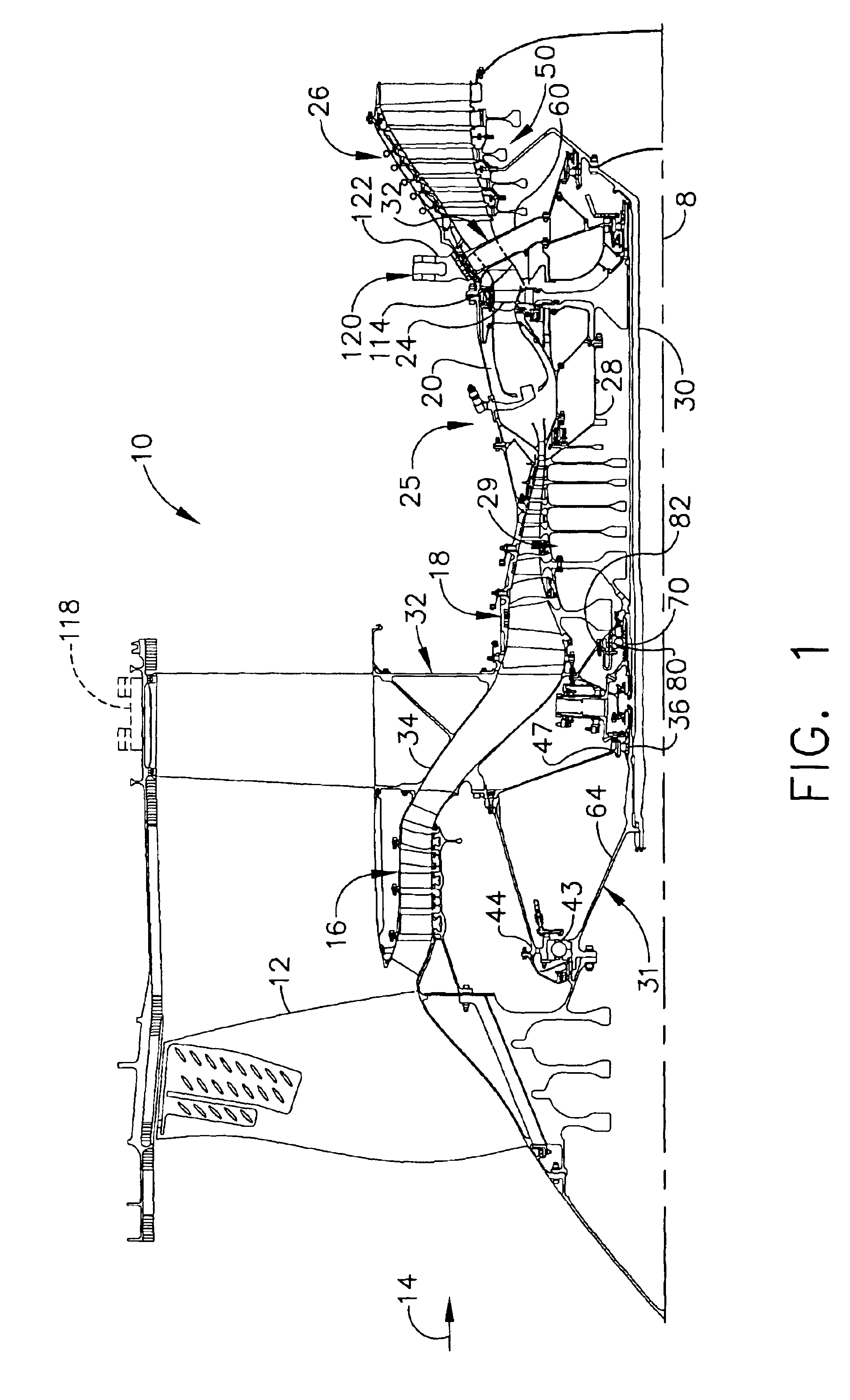

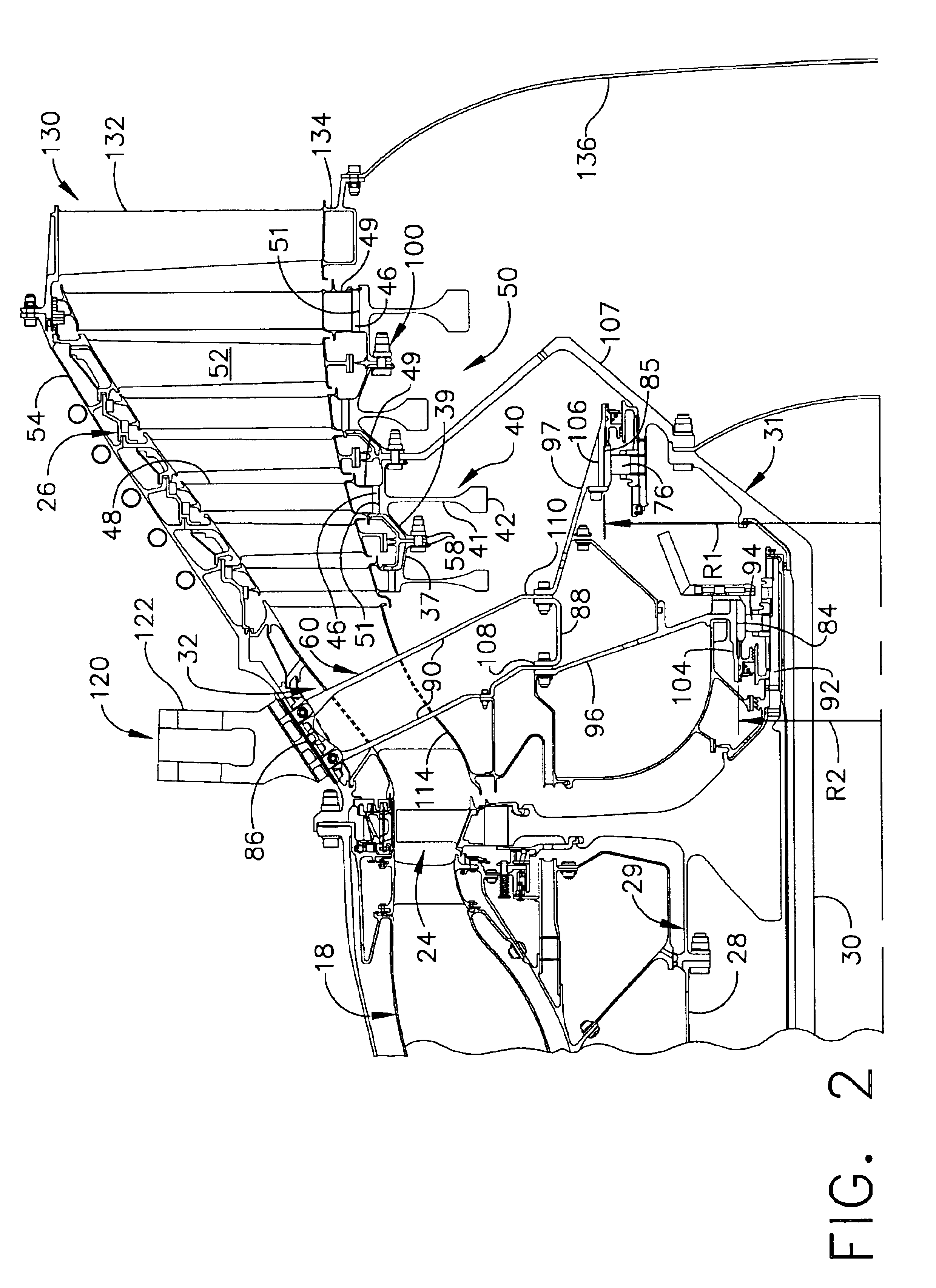

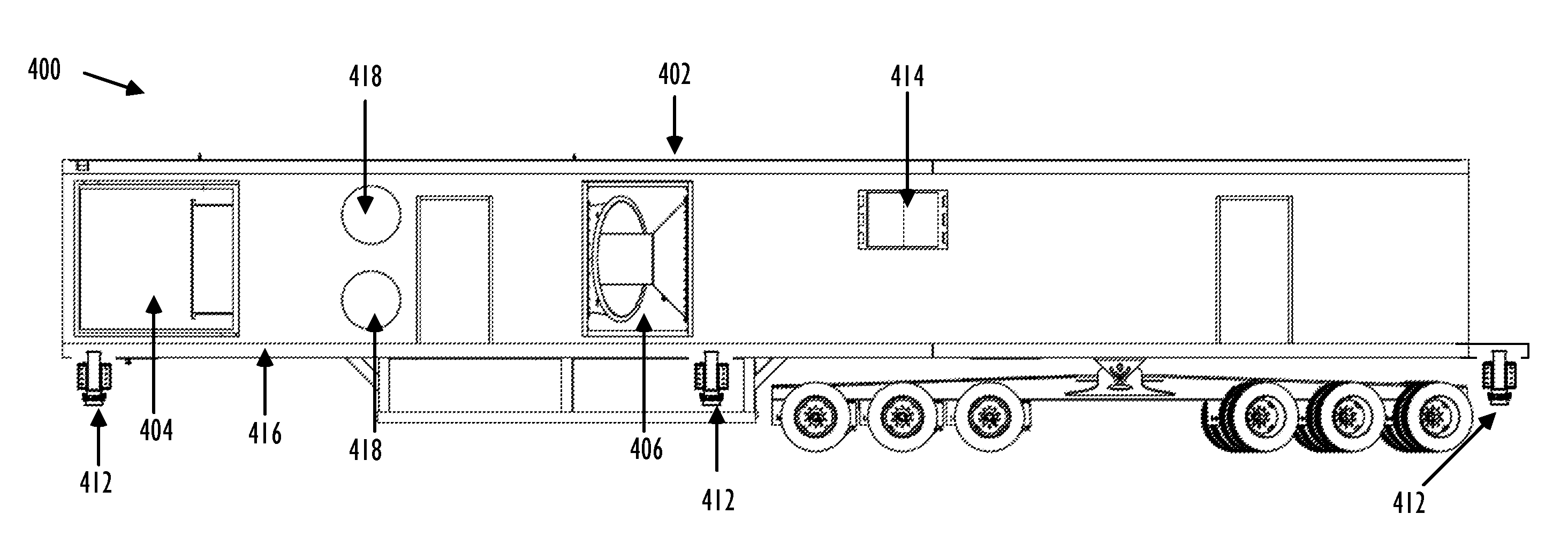

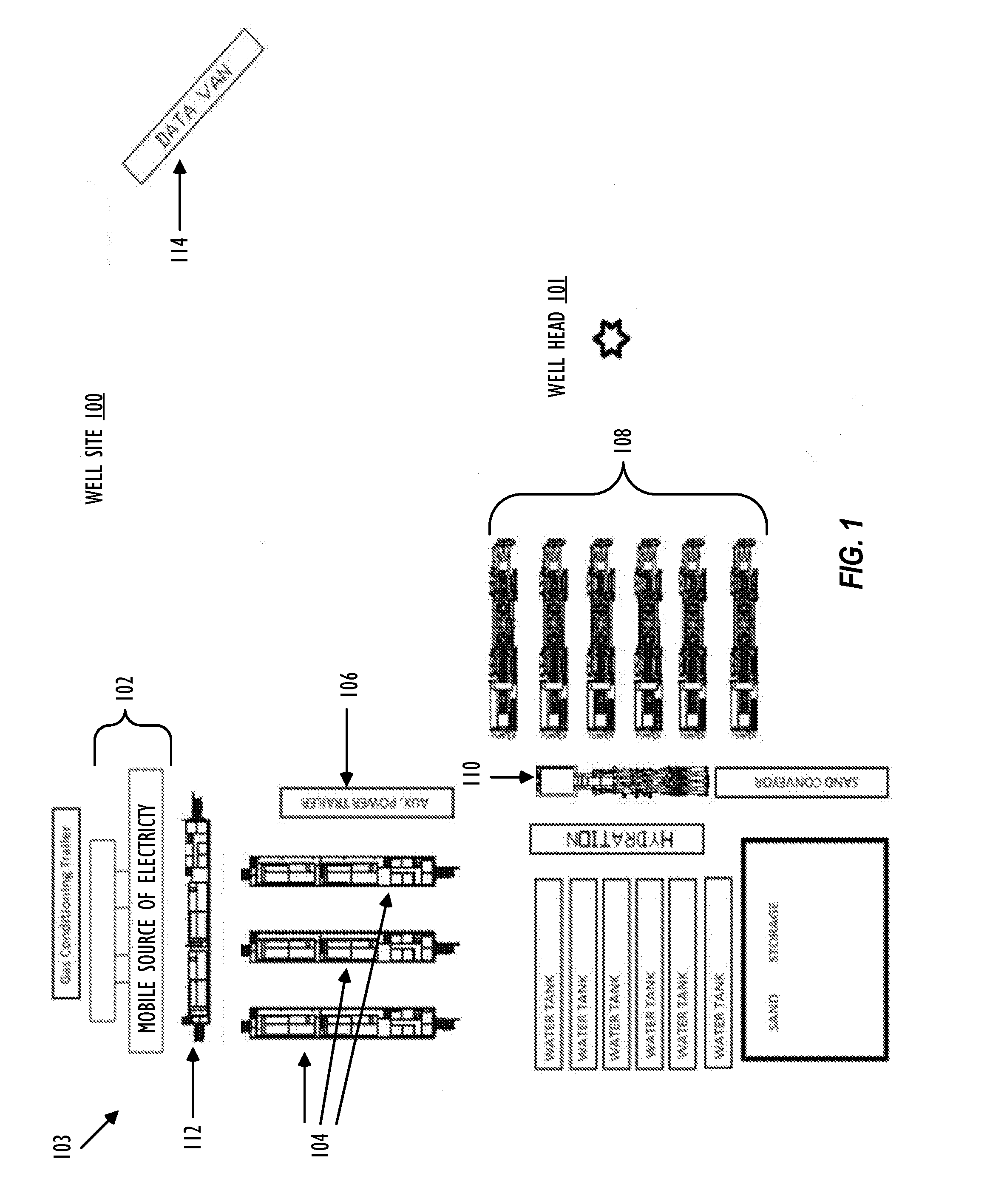

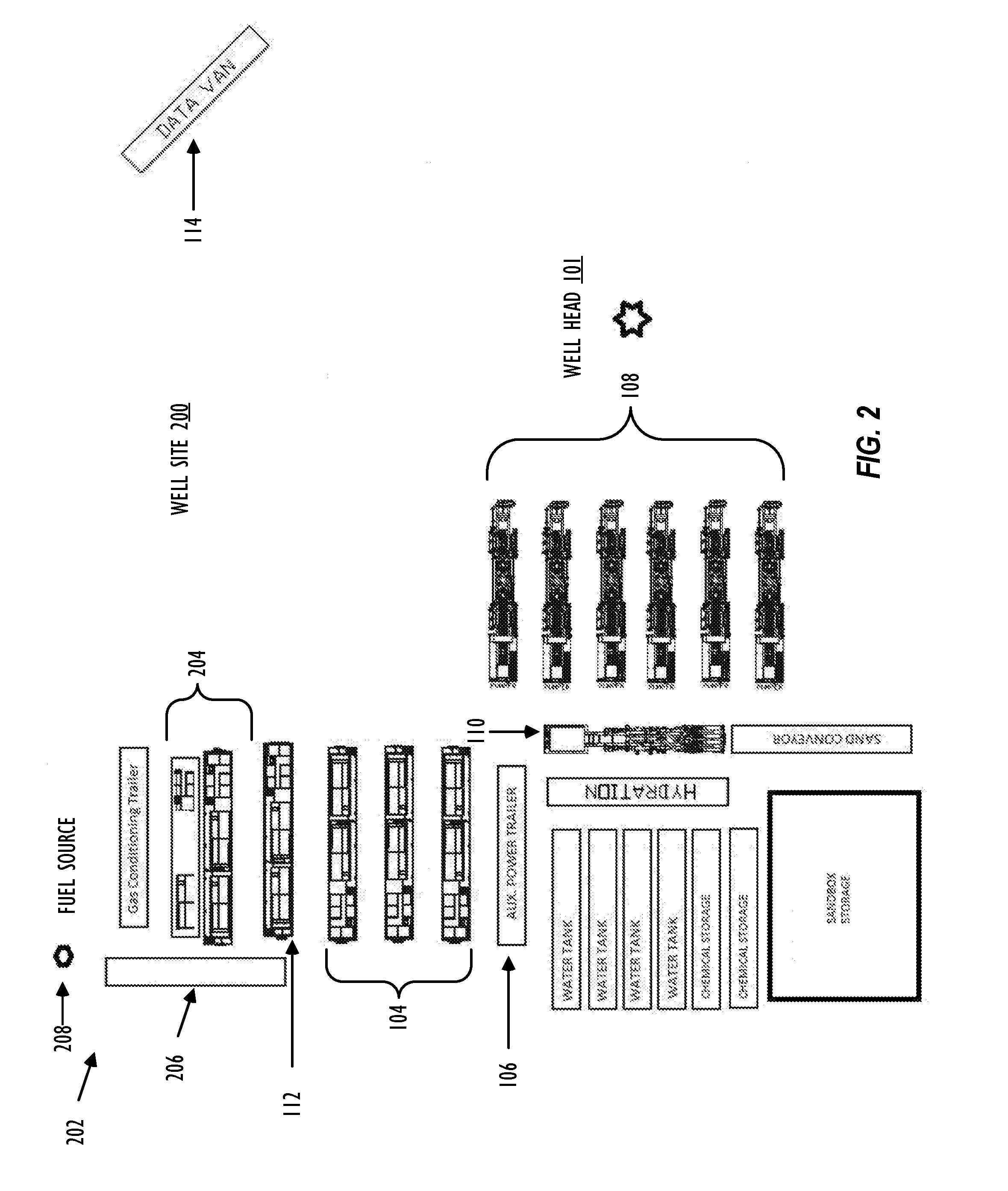

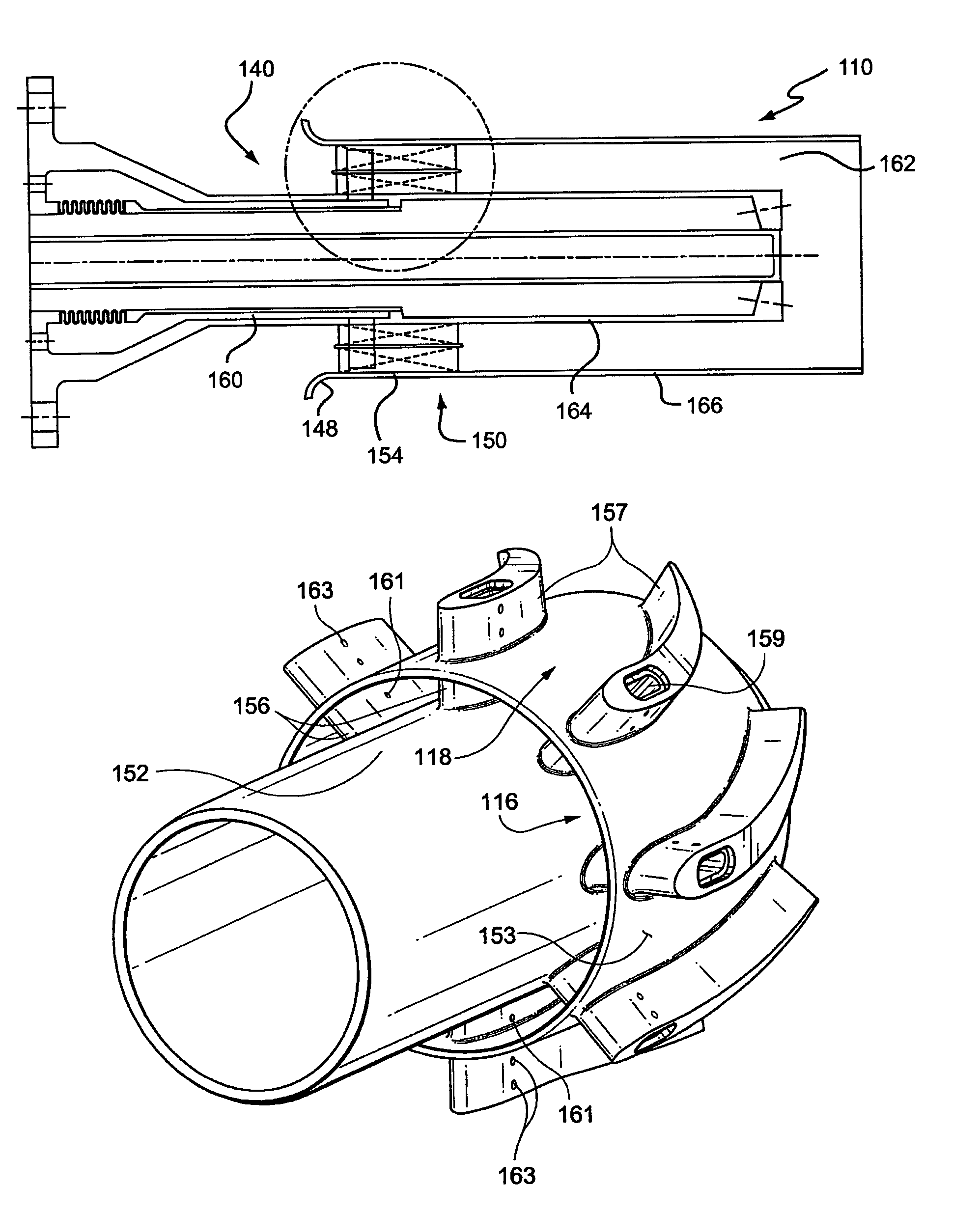

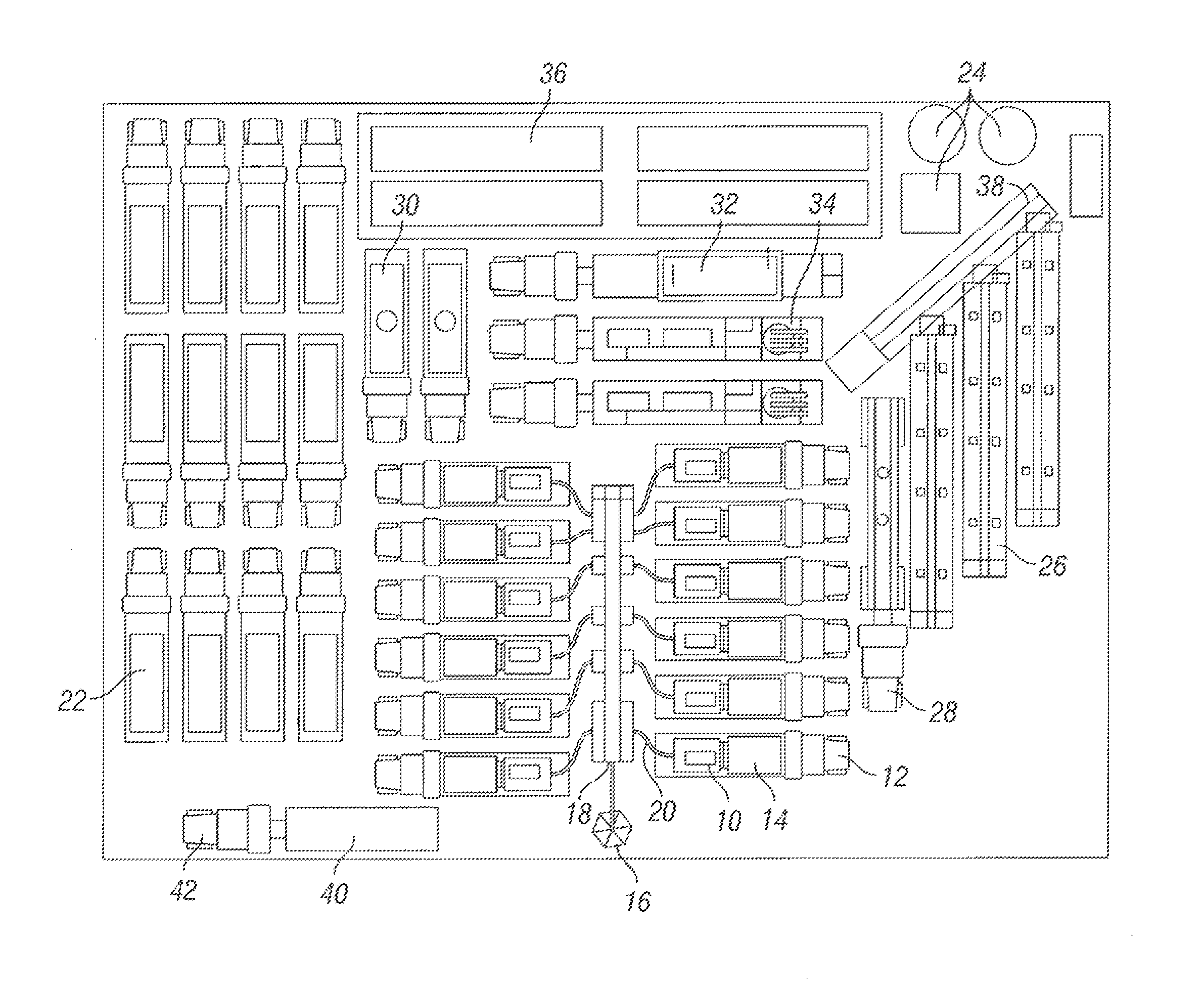

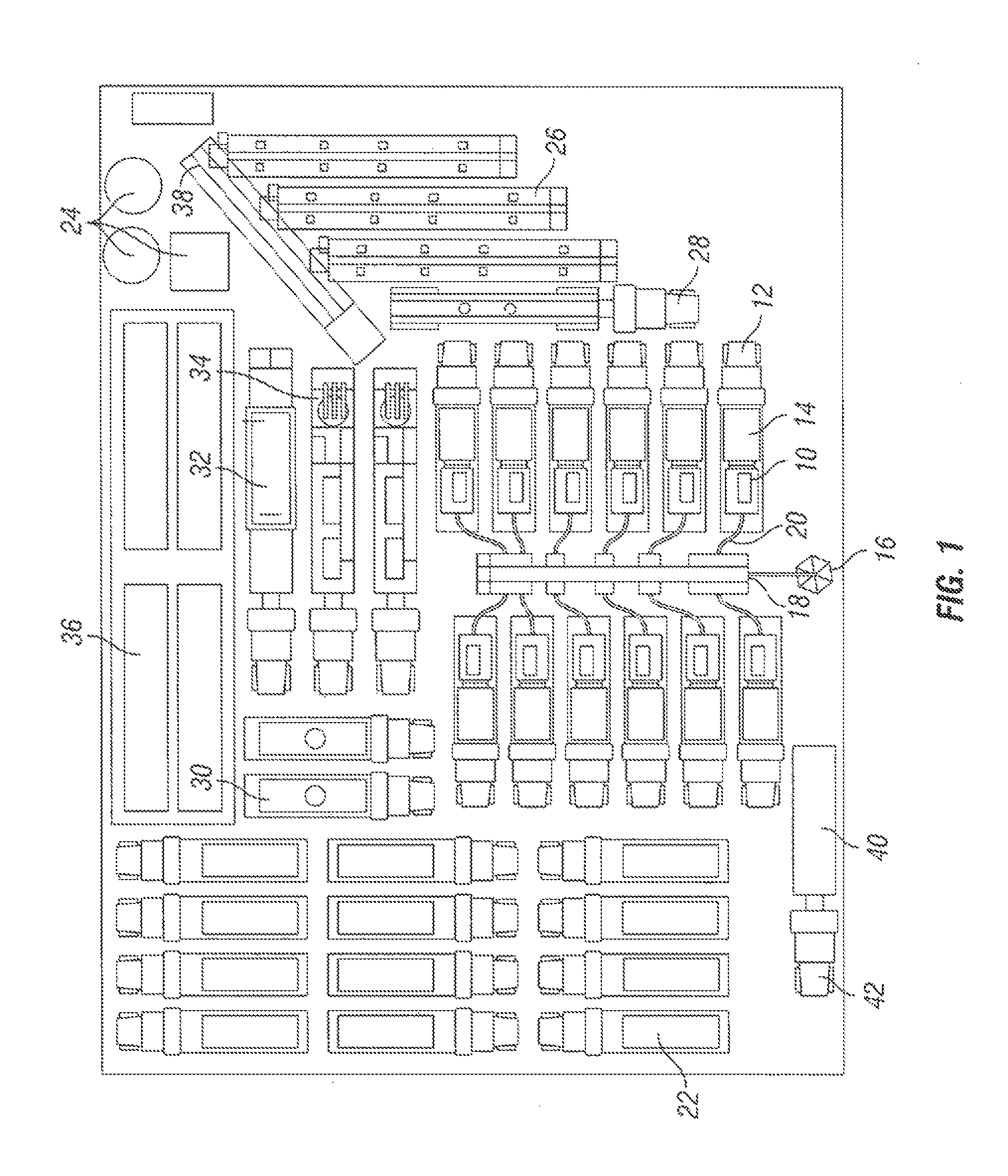

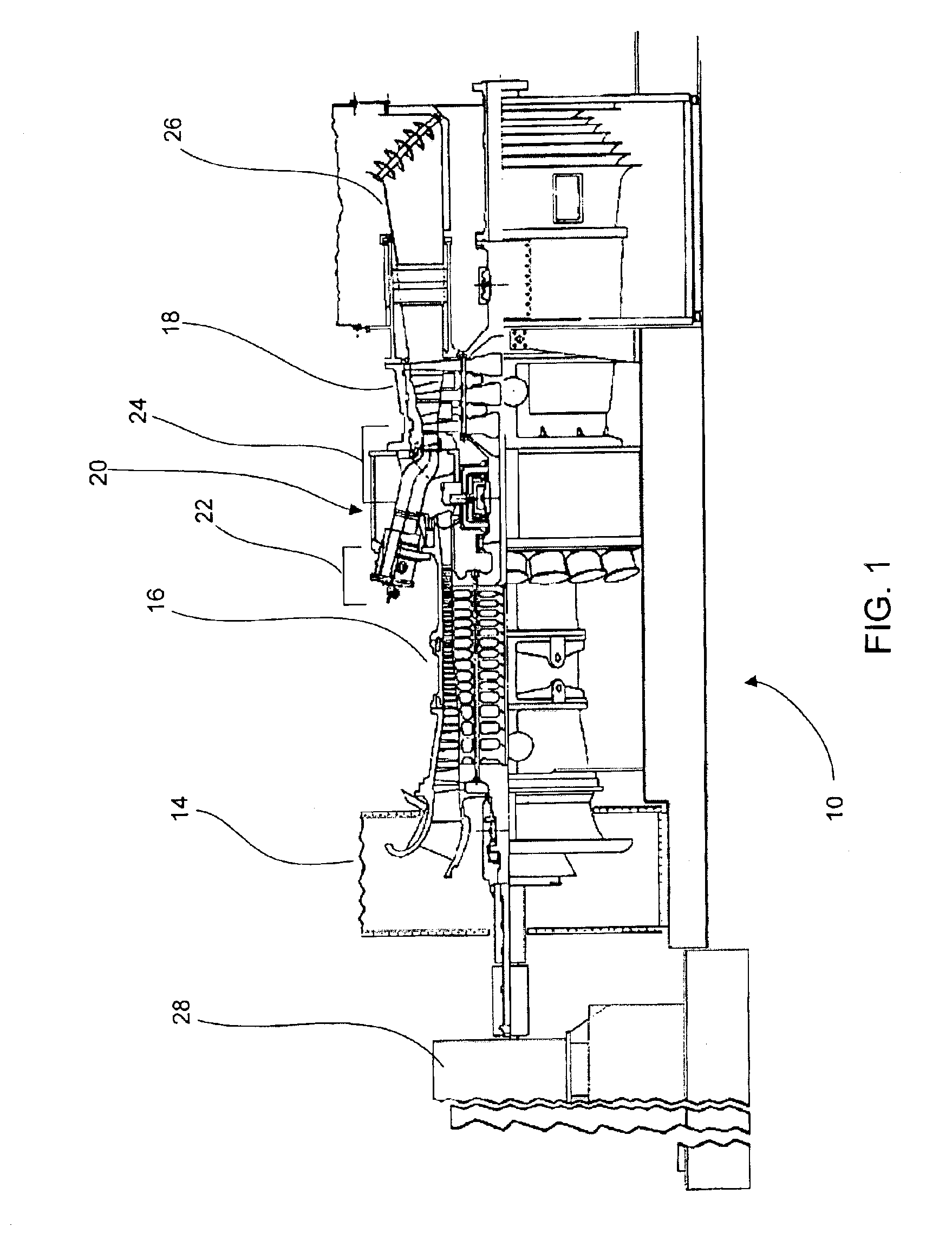

Mobile fracturing pump transport for hydraulic fracturing of subsurface geological formations

ActiveUS20160369609A1Well formedMechanical actuated clutchesGas turbine plantsCouplingFracturing fluid

Providing pressurized fracturing fluid with a fracturing pump transport comprising a first fracturing pump and a second fracturing pump that are coupled on opposite sides of a dual shaft electric motor. A first drive line assembly comprising a first engagement coupling that allows for selective engagement and / or disengagement of the first fracturing pump with the dual shaft electric motor. A second drive line assembly comprising a second engagement coupling that allows for selective engagement and / or disengagement of the second fracturing pump with the dual shaft electric motor. The fracturing pump transport also comprising an engagement panel that allows for selective engagement or disengagement at the first engagement coupling based on receiving a remote command.

Owner:TYPHON TECH SOLUTIONS (U S) LLC

Burner tube and method for mixing air and gas in a gas turbine engine

InactiveUS6993916B2Good mixing propertiesImprove flame stabilityContinuous combustion chamberTurbine/propulsion fuel supply systemsCombustorGas turbines

Owner:GENERAL ELECTRIC CO

System for pumping hydraulic fracturing fluid using electric pumps

A system for hydraulically fracturing an underground formation in an oil or gas well to extract oil or gas from the formation, the oil or gas well having a wellbore that permits passage of fluid from the wellbore into the formation. The system includes a plurality of electric pumps fluidly connected to the well, and configured to pump fluid into the wellbore at high pressure so that the fluid passes from the wellbore into the and fractures the formation. The system can also include a plurality of natural gas powered generators electrically connected to the plurality of electric pumps to provide electrical power to the pumps.

Owner:US WELL SERVICS LLC

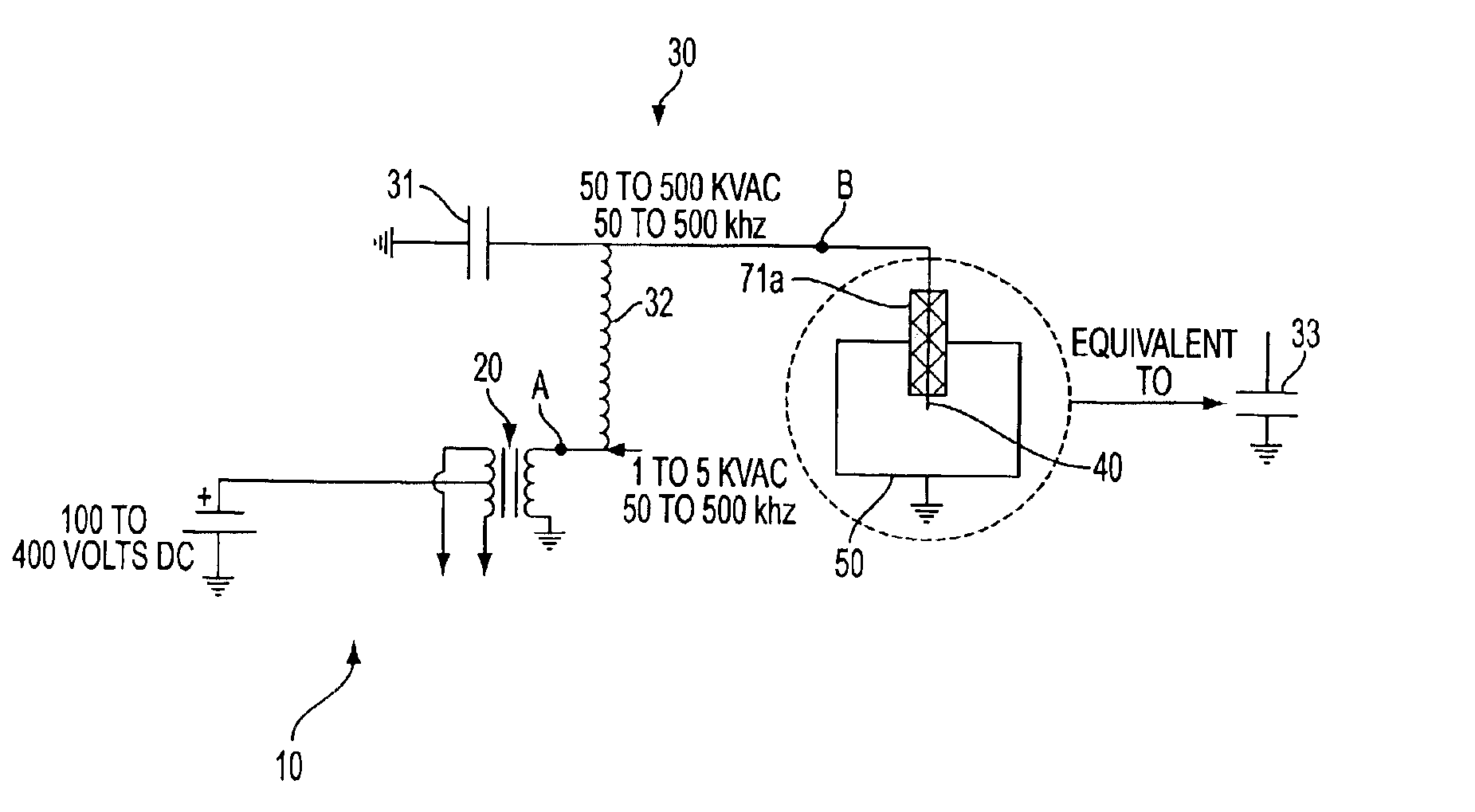

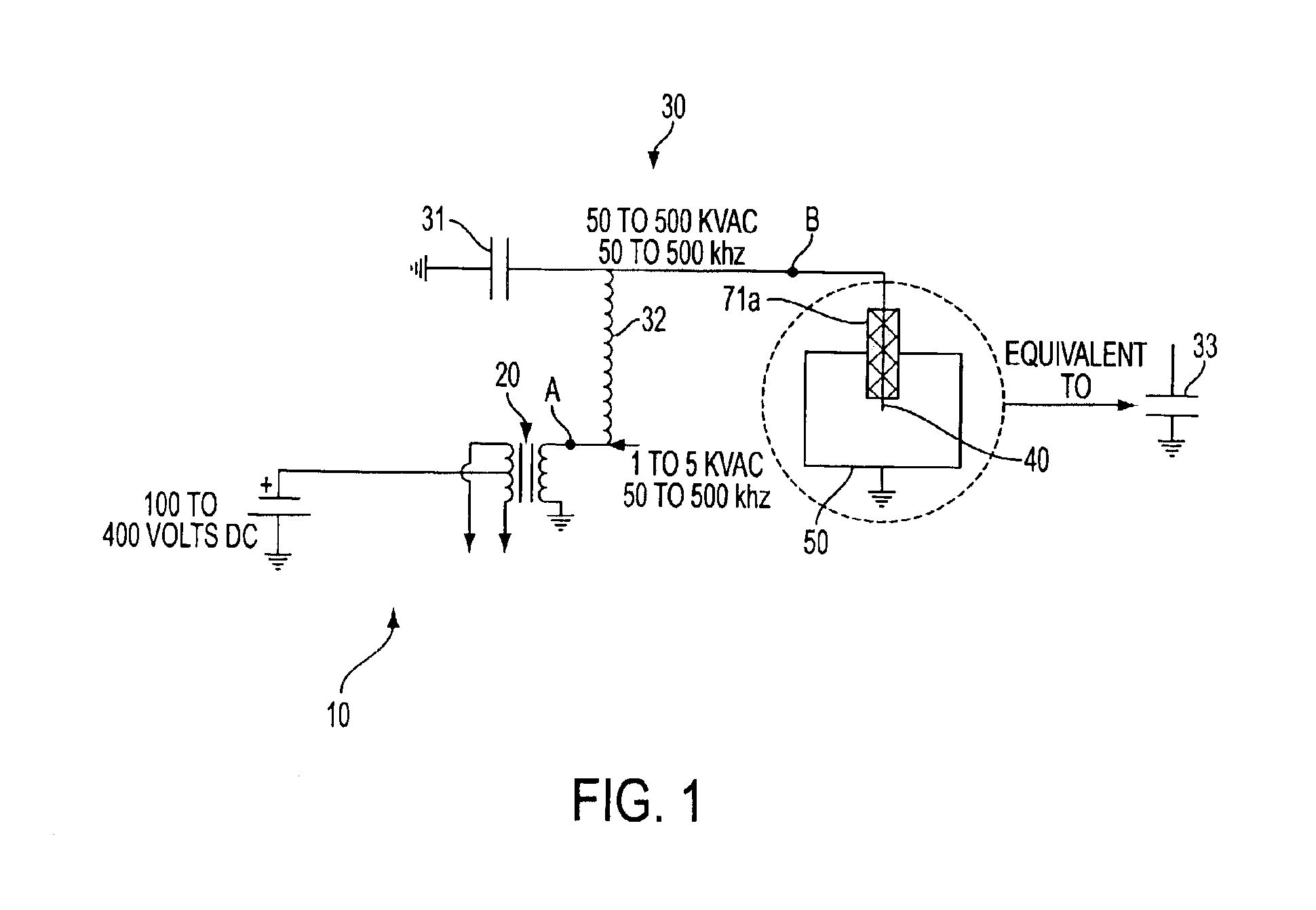

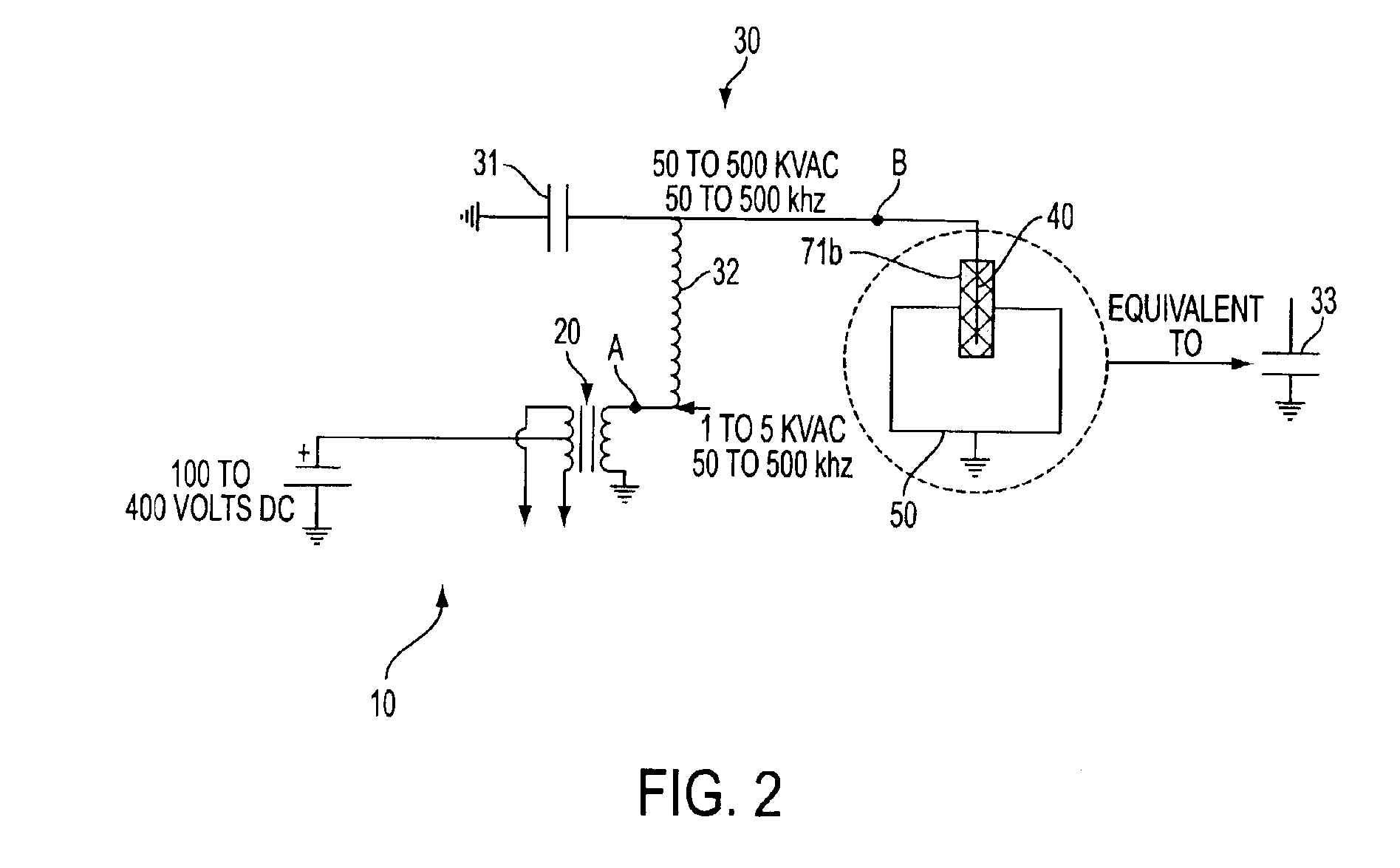

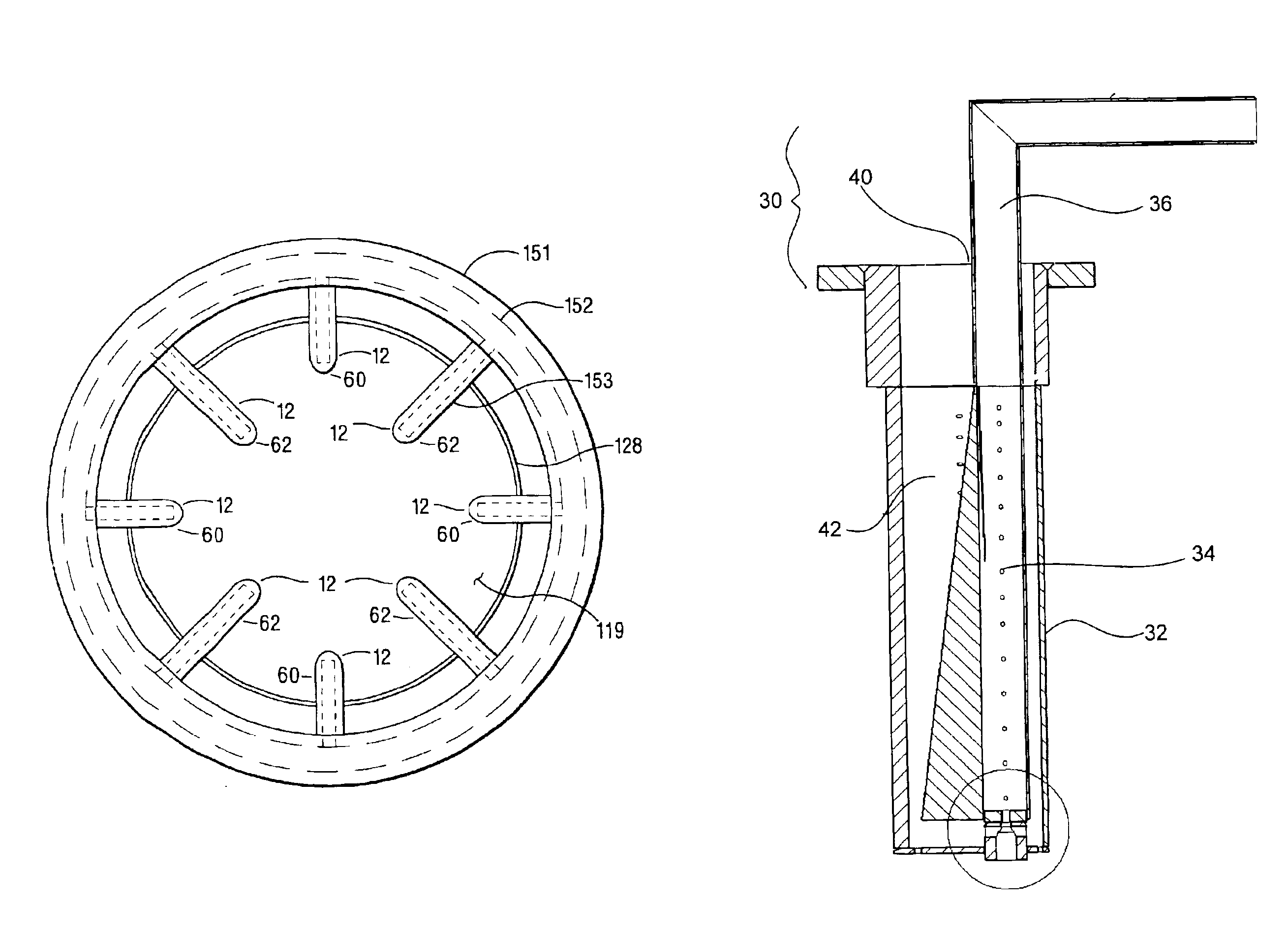

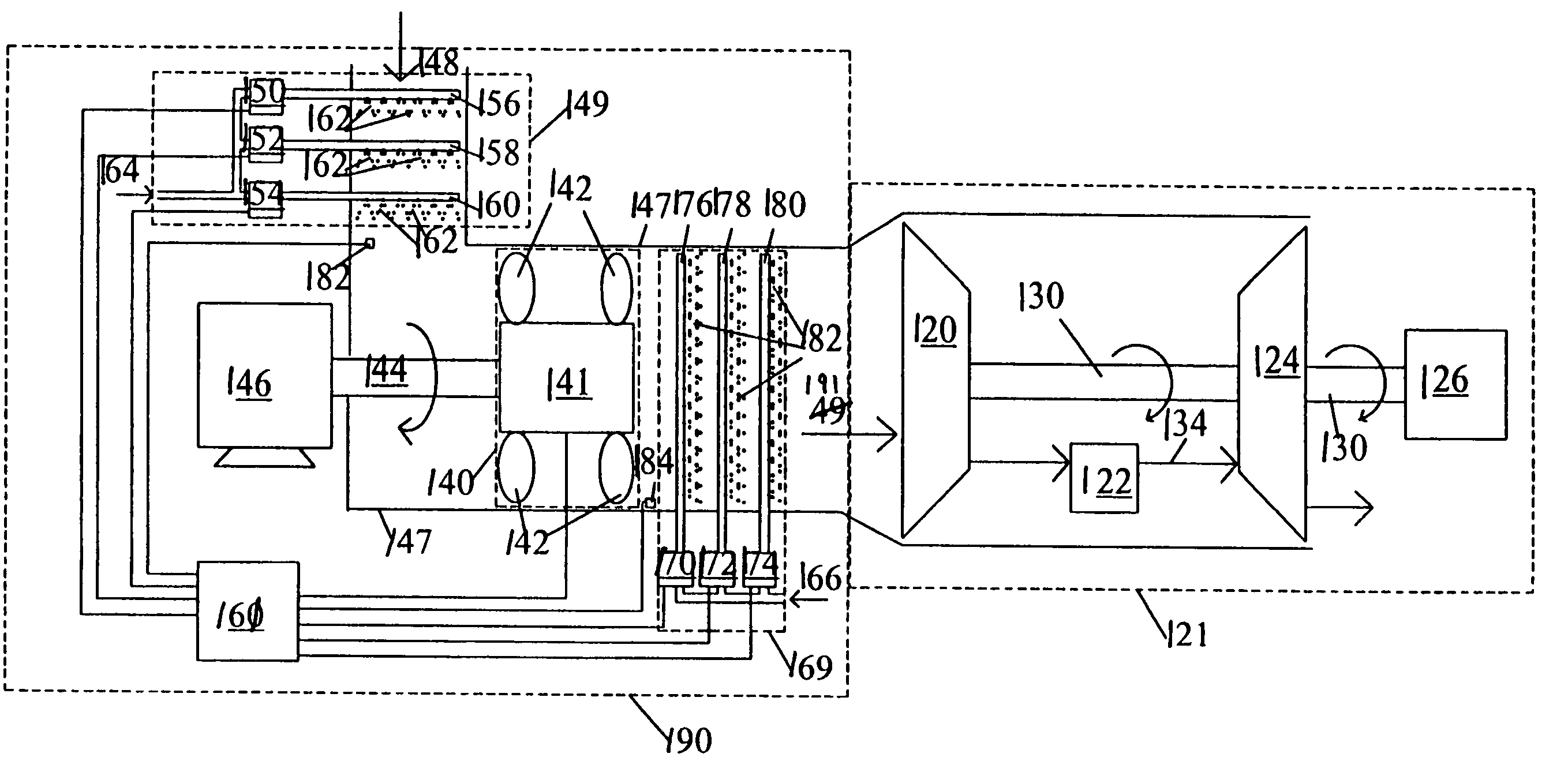

System and method for generating and sustaining a corona electric discharge for igniting a combustible gaseous mixture

InactiveUS6883507B2Sufficient energySparking plugsCombustion enginesCombustion chamberElectric discharge

The invention relates to a system for igniting a fuel-air mixture in a combustion chamber with a corona discharge. The system comprises an electrode inside of the combustion chamber, an electric circuit which provides radio frequency electric power to the electrode, and a ground formed by the combustion chamber walls. A radio frequency voltage differential formed between the electrode and the ground produces a radio frequency electric field therebetween which causes a fuel-air mixture to ionize resulting in combustion of the fuel-air mixture. The system can be utilized in engines such as internal combustion engines or gas turbine engines, for example.

Owner:BORGWARNER INC

Turbine containing system and an injector therefor

A turbine containing system is disclosed. The system includes an intake section, a compressor section downstream from the intake section, a combustor section having a primary combustion system downstream from the intake section, a secondary combustion system downstream from the primary combustion system, a turbine section, an exhaust section and a load. The secondary combustion system includes an injector for transversely injecting a secondary fuel into a stream of combustion products of the primary combustion system. The injector including a coupling, a wall defining an airfoil shape circumscribing a fuel mixture passage, and at least one exit for communication between said fuel mixture passage and said stream of primary combustion products.

Owner:GENERAL ELECTRIC CO

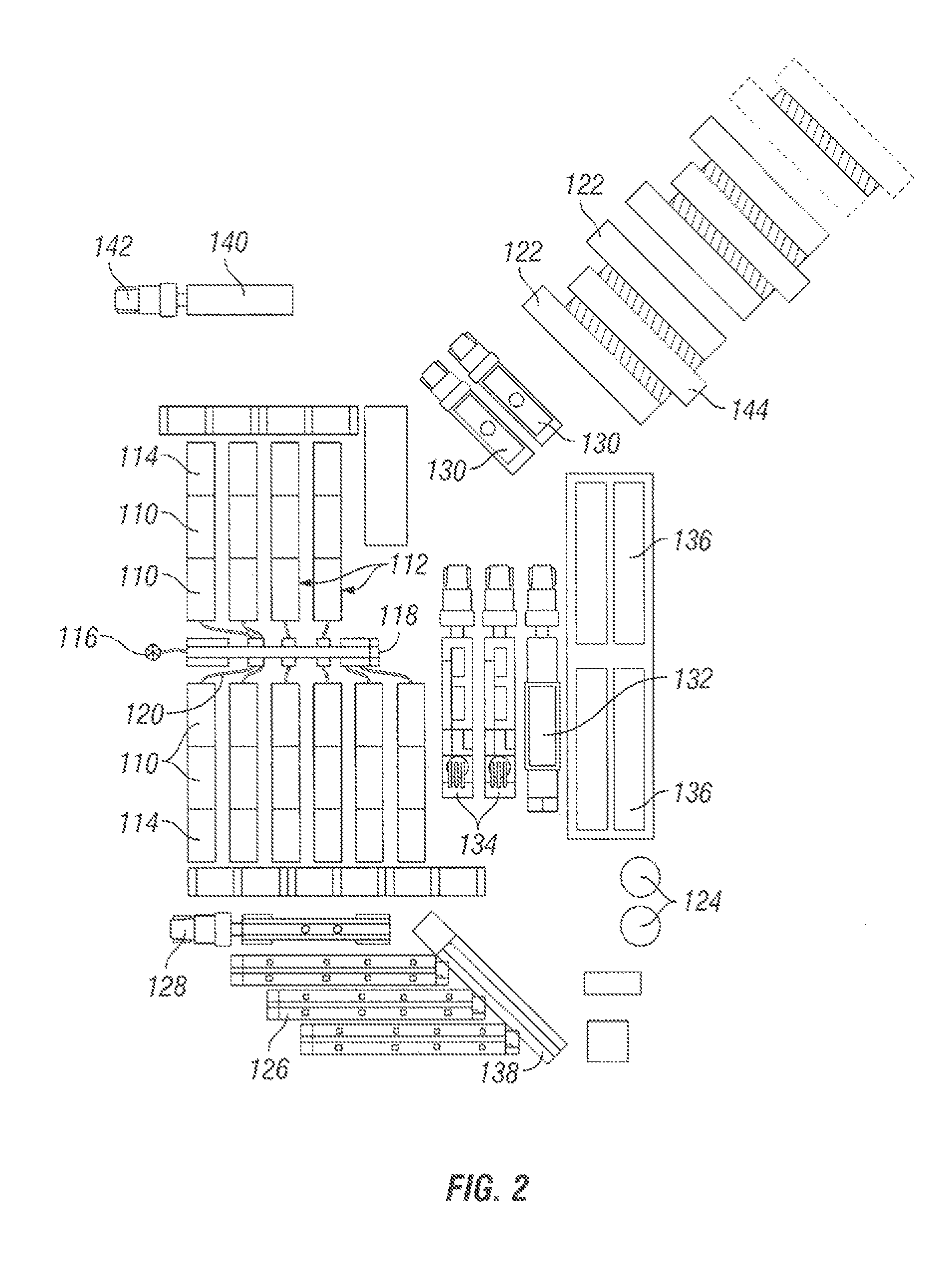

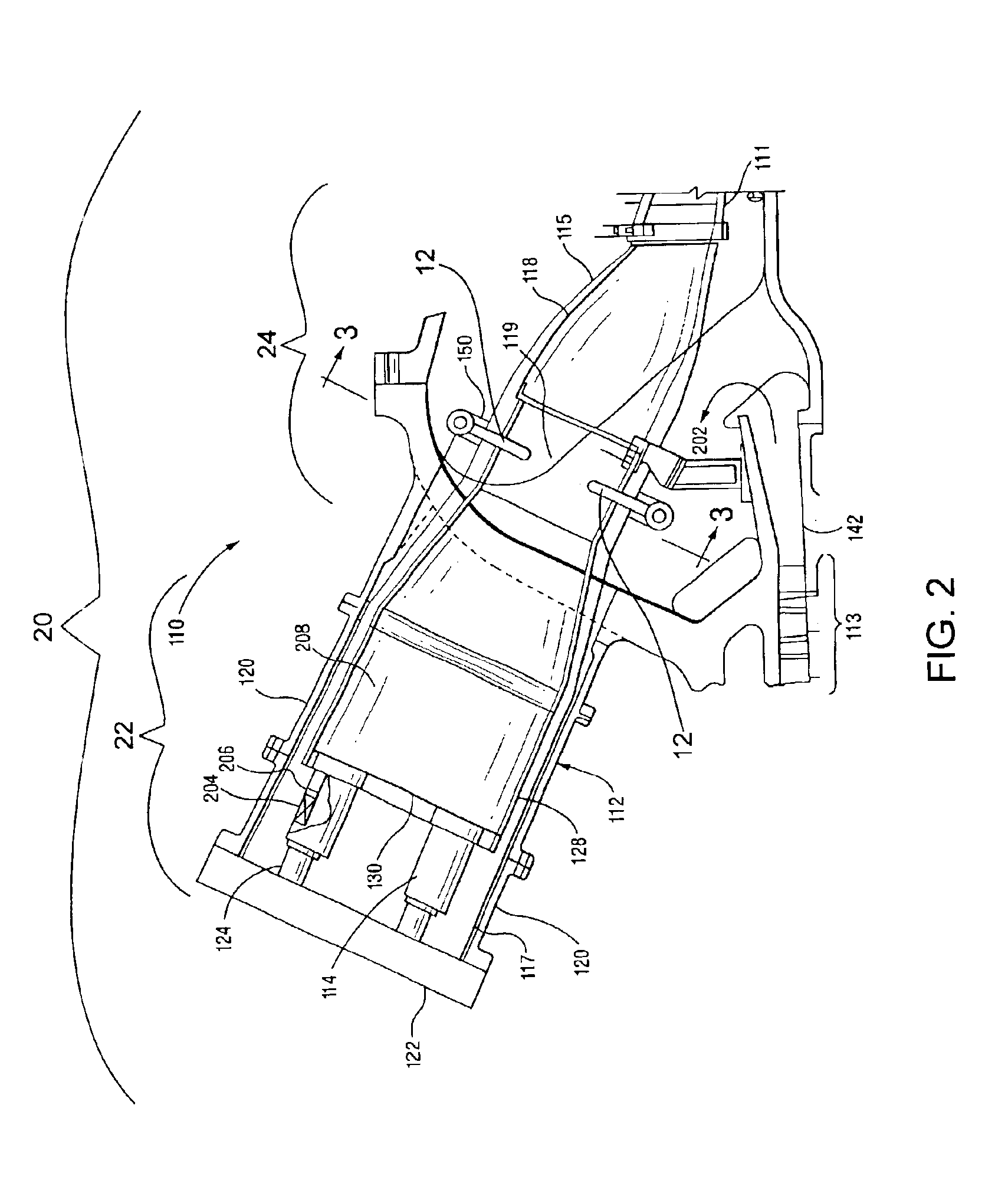

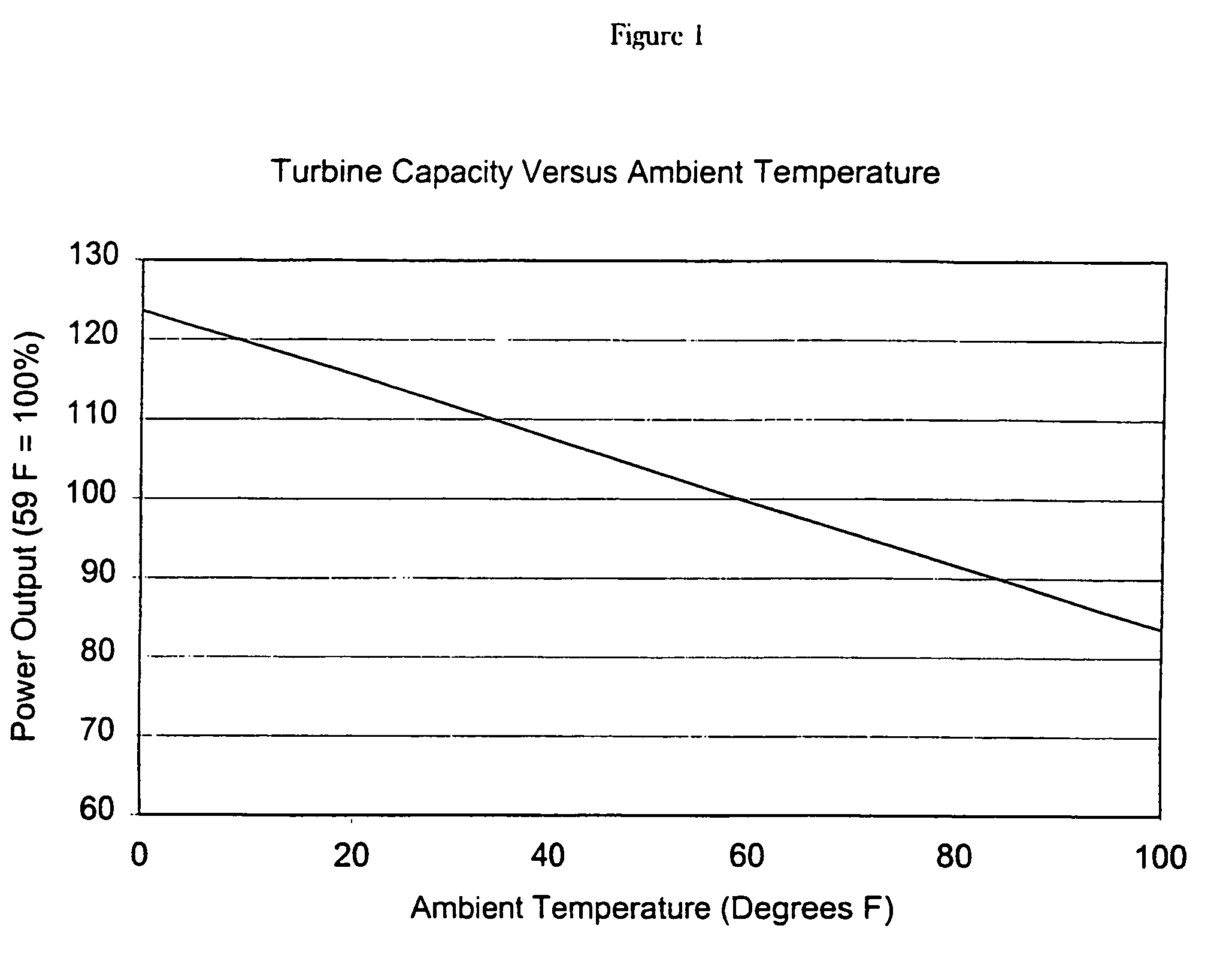

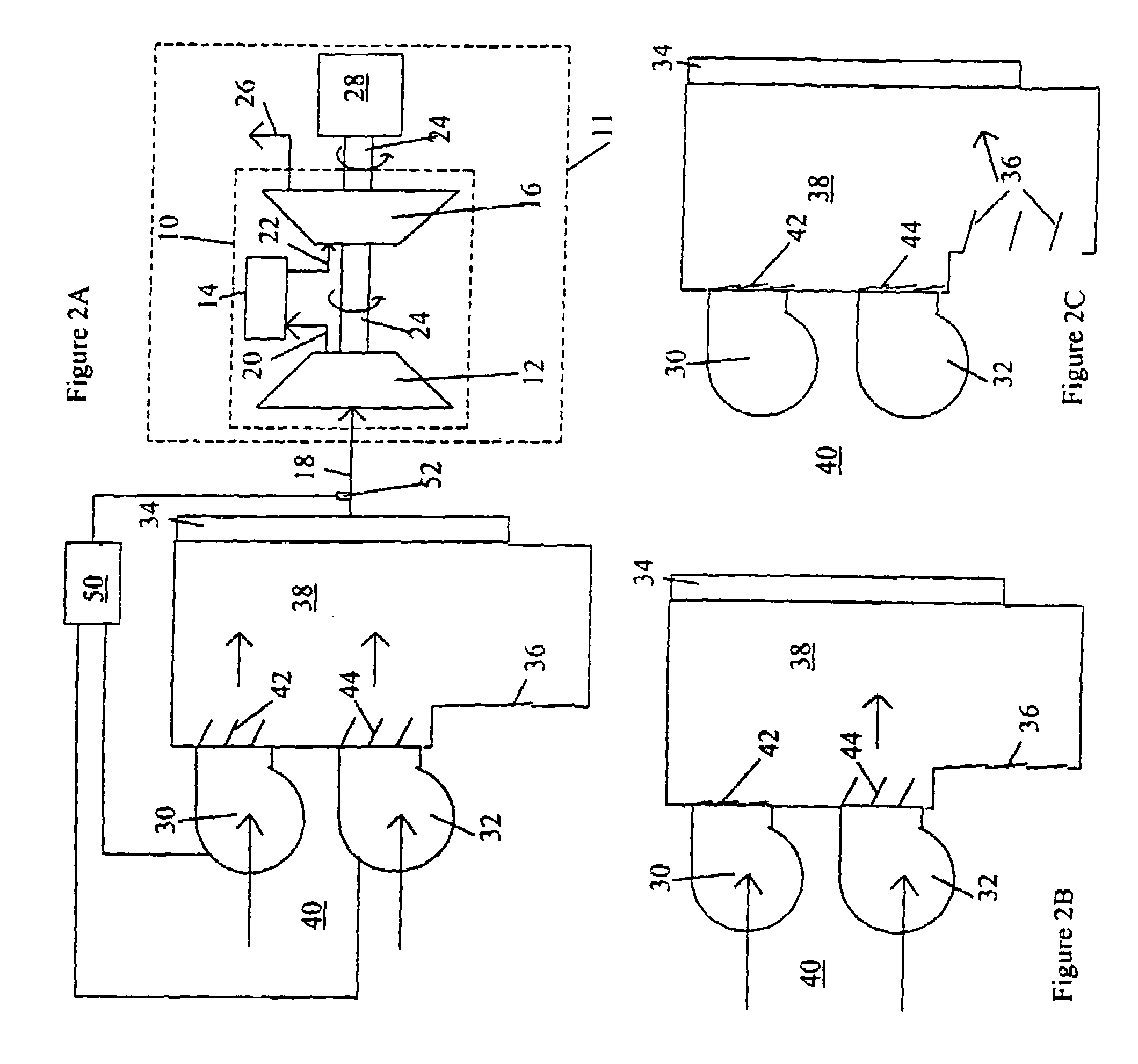

Supercharging system for gas turbines

InactiveUS7065953B1Increase turbine capacityReduce installation costsEfficient propulsion technologiesGas turbine plantsCombustorPower station

A supercharging system for gas turbine power plants (11). The system includes a supercharging fan (30, 32) and controller (50) for limiting turbine power output to prevent overload of the generator (28) at lower ambient temperatures. The controller can limit power output by burner control, inlet temperature control, control of supercharging fan pressure and other options. The system can be retrofit on an existing turbine without replacing the generator and associated parts.

Owner:ENHANCED TURBINE OUTPUT HLDG

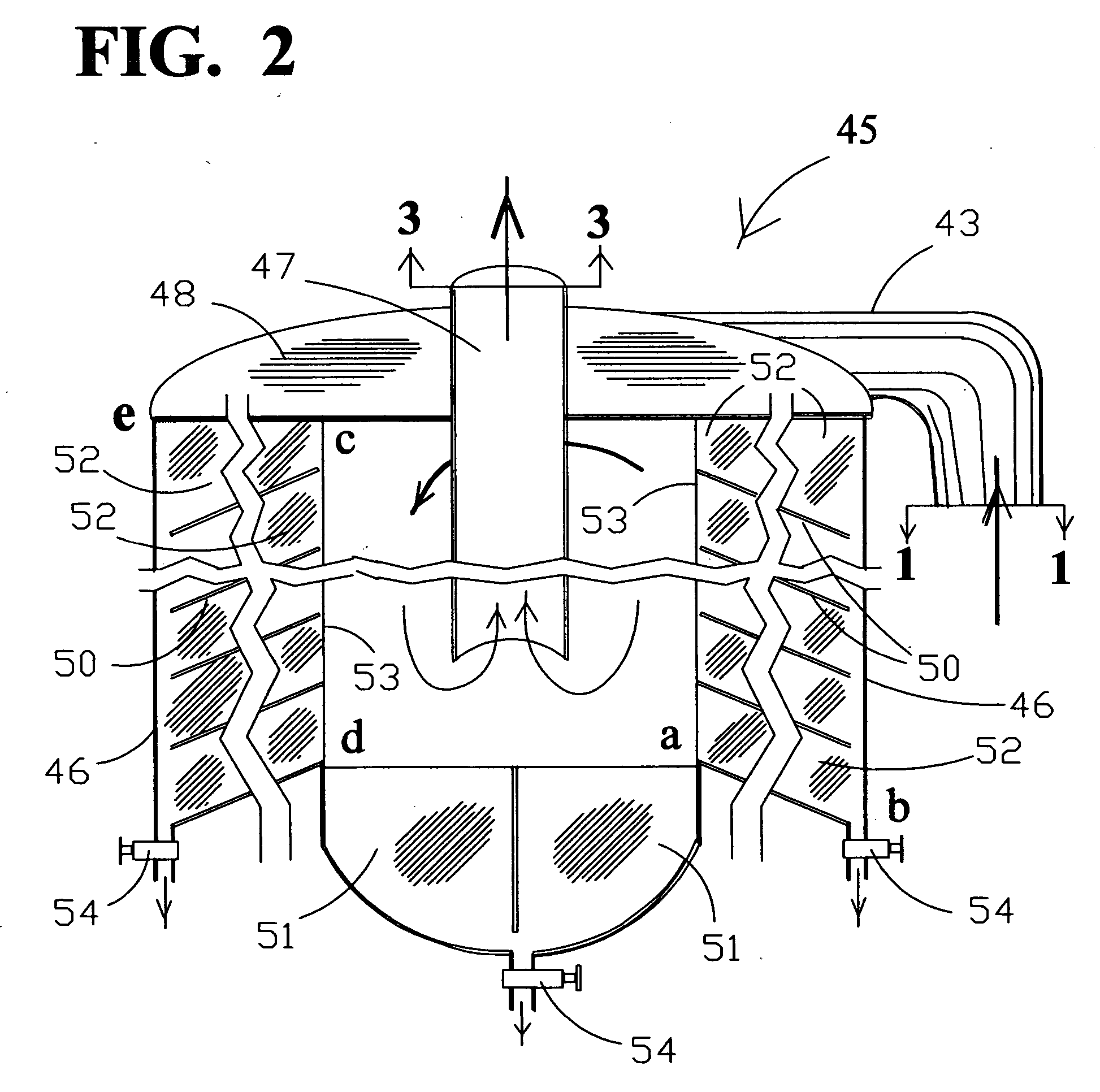

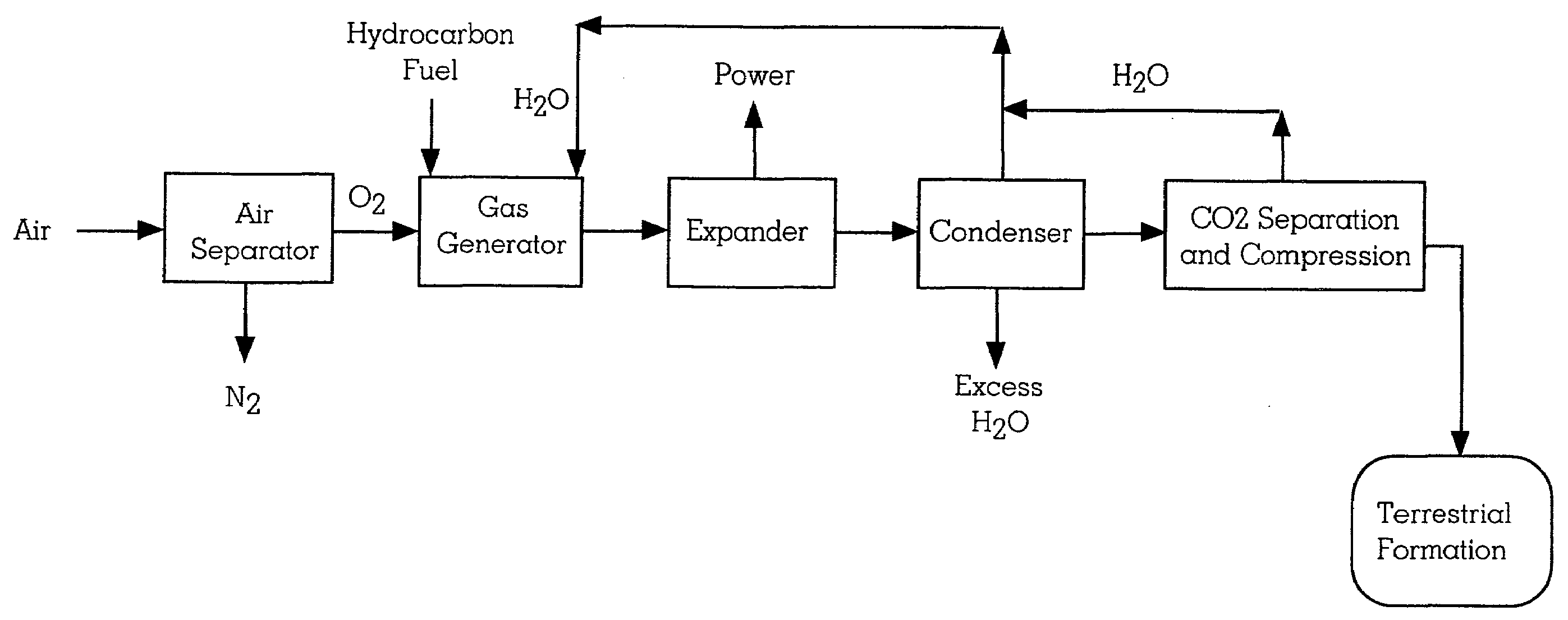

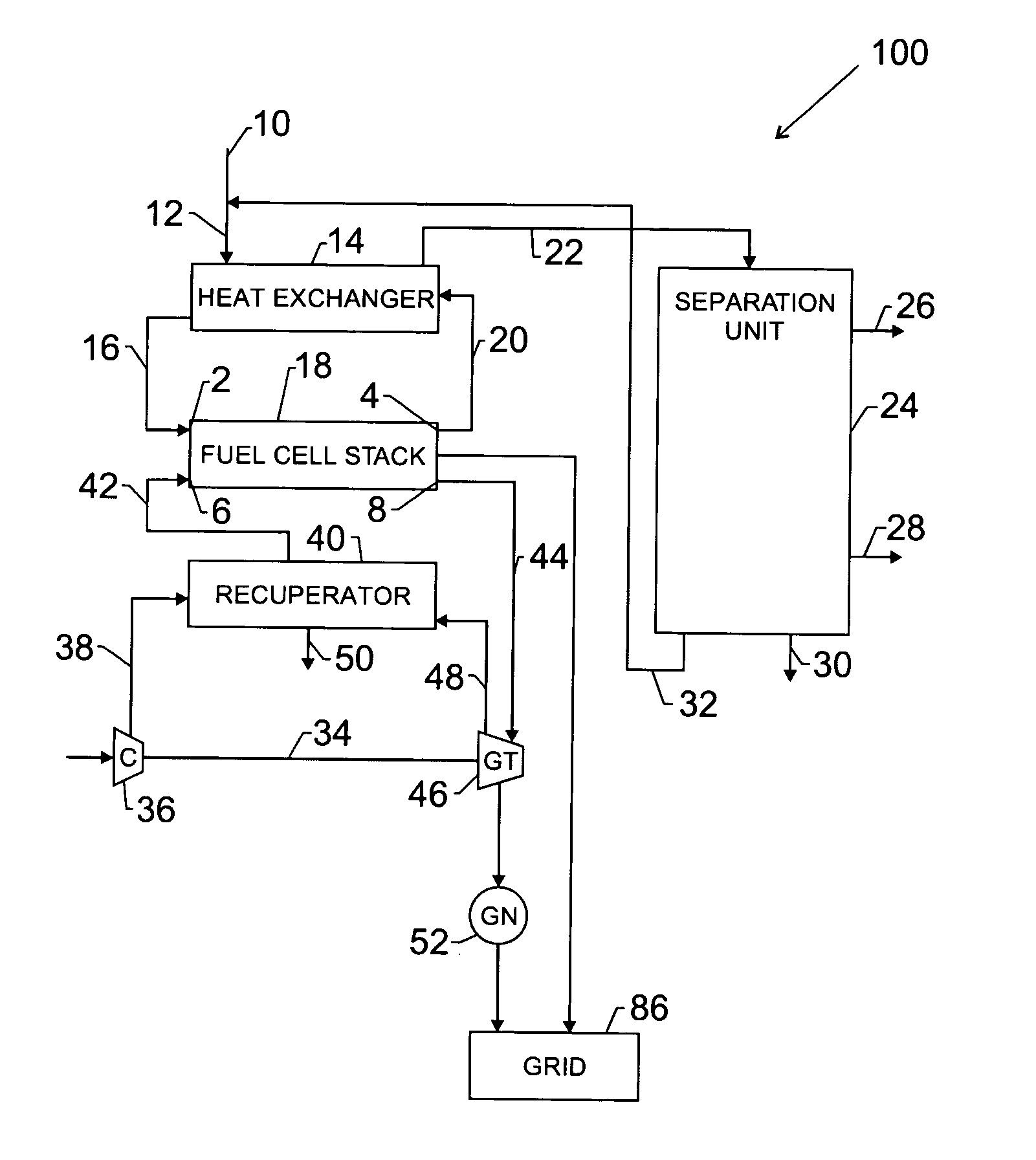

Hydrocarbon combustion power generation system with CO2 sequestration

InactiveUS7043920B2Eliminate needReduce electricity demandReciprocating combination enginesSolidificationAtmospheric airOxygen

A low or no pollution engine is provided for delivering power for vehicles or other power applications. The engine has an air inlet which collects air from a surrounding environment. At least a portion of the nitrogen in the air is removed. The remaining gas is primarily oxygen, which is then routed to a gas generator. The gas generator has inputs for the oxygen and a hydrocarbon fuel. The fuel and oxygen are combusted within the gas generator, forming water and carbon dioxide. The combustion products are then expanded through a power generating device, such as a turbine or piston expander to deliver output power for operation of a vehicle or other power uses. The combustion products are then passed through a condenser where the steam is condensed and the carbon dioxide is collected or discharged. A portion of the water is routed back to the gas generator. The carbon dioxide is compressed and delivered to a terrestrial formation from which return of the CO2 into the atmosphere is inhibited.

Owner:CLEAN ENERGY SYST

Hydrogen production from carbonaceous material

InactiveUS6790430B1Avoid the needCalcium/strontium/barium carbonatesGas turbine plantsCalcinationExothermic reaction

Owner:BOARD OF SUPERVISORS OF LOUISIANA STATE UNIV & AGRI & MECHANICAL COLLEGE +1

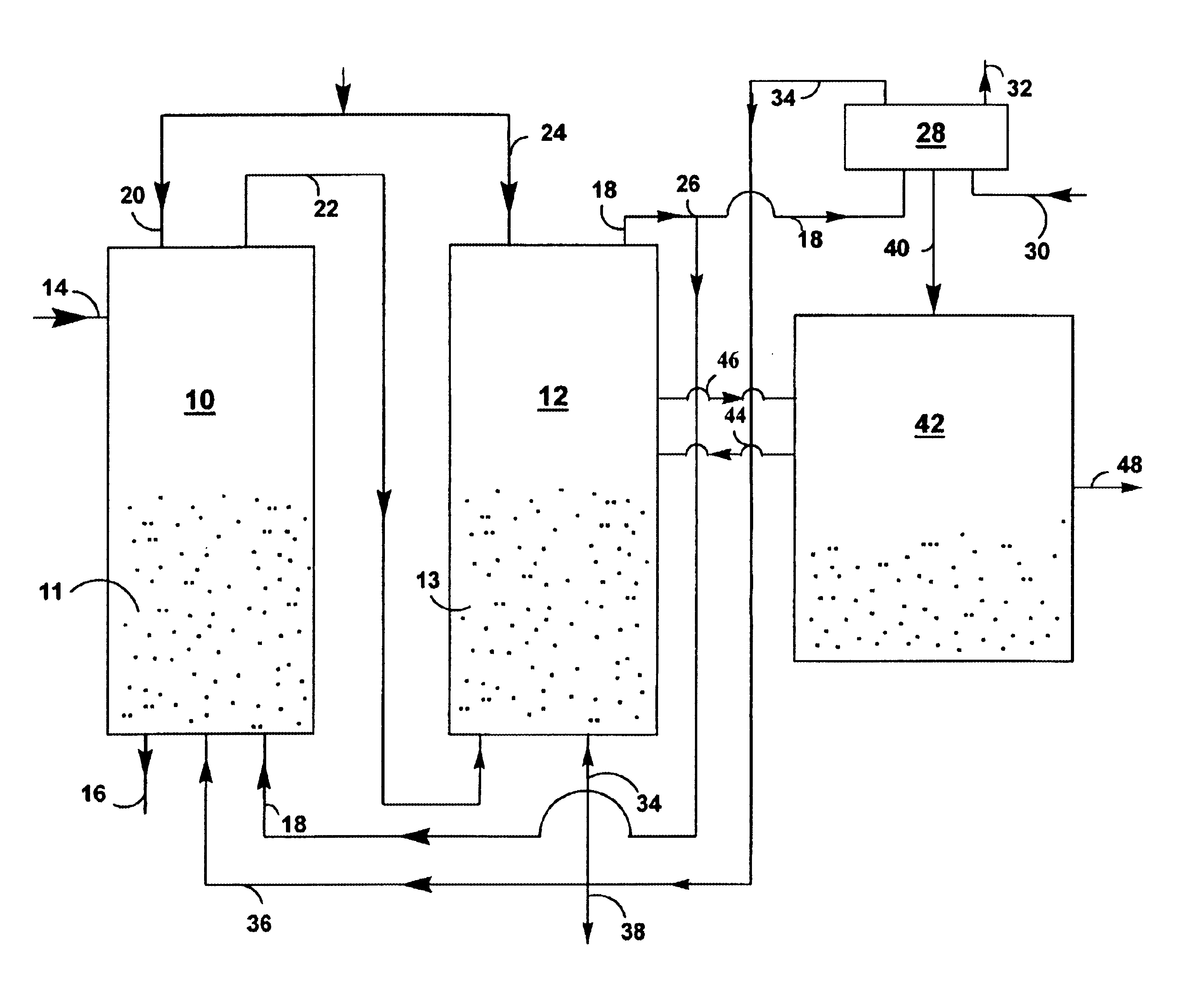

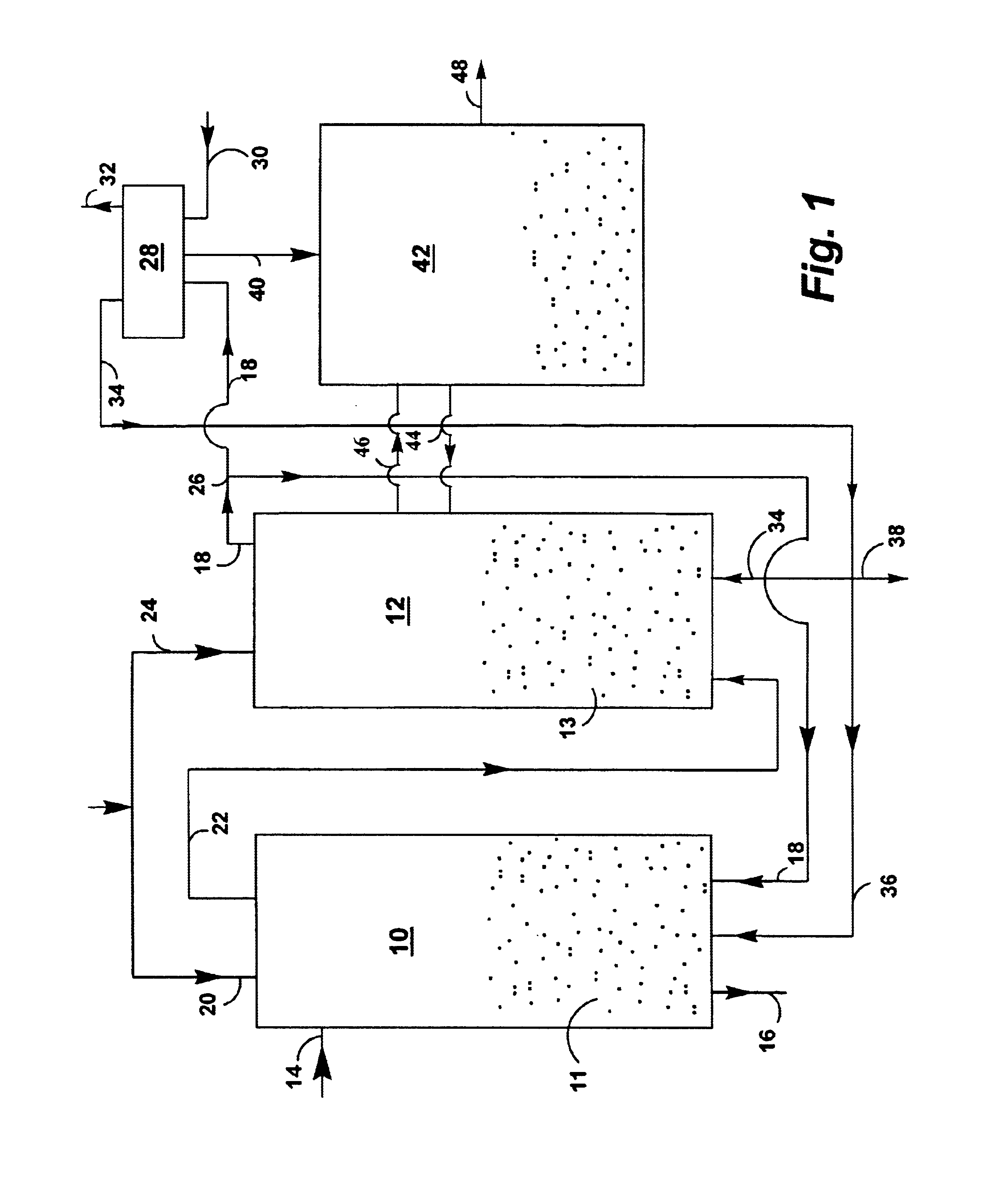

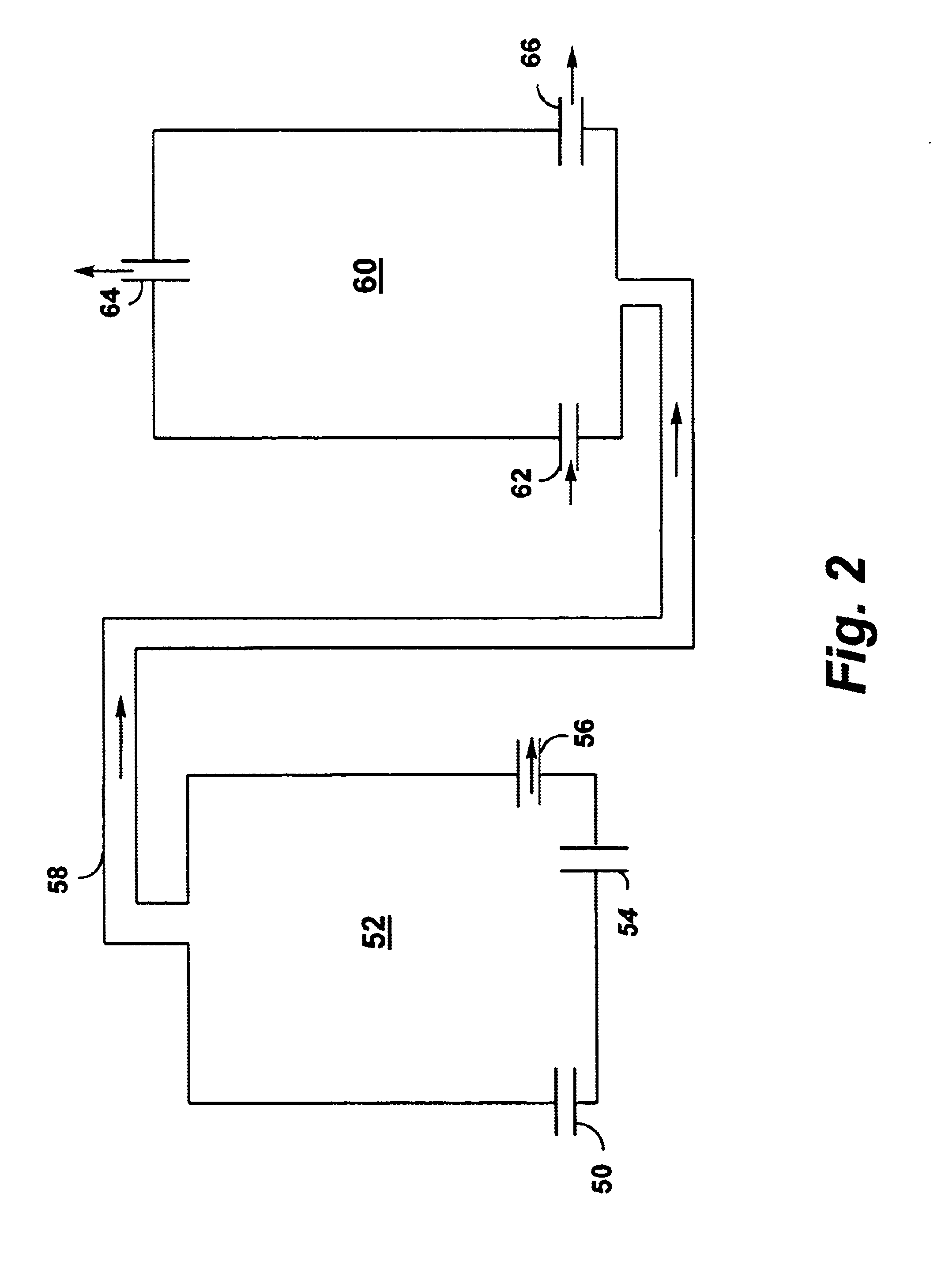

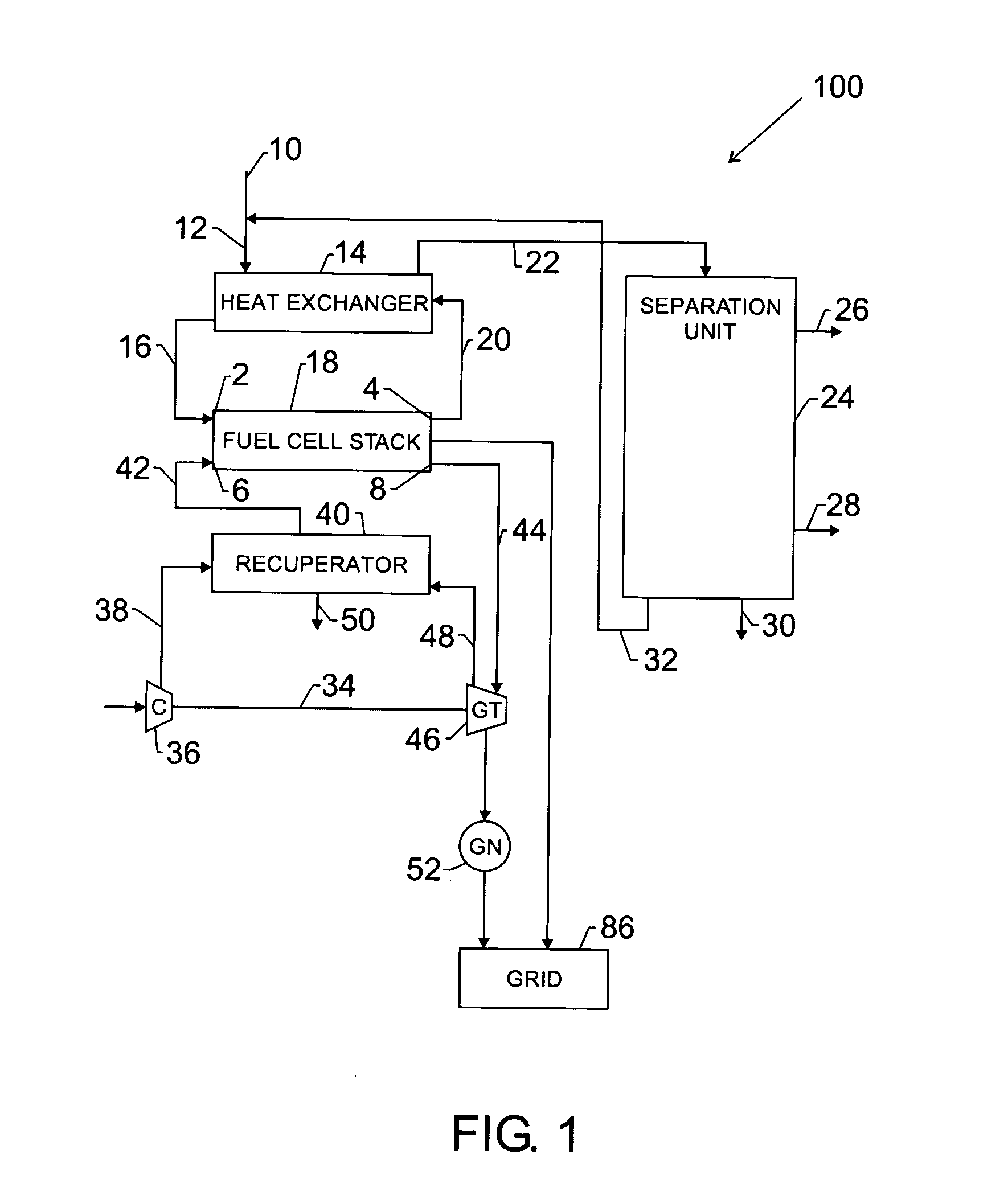

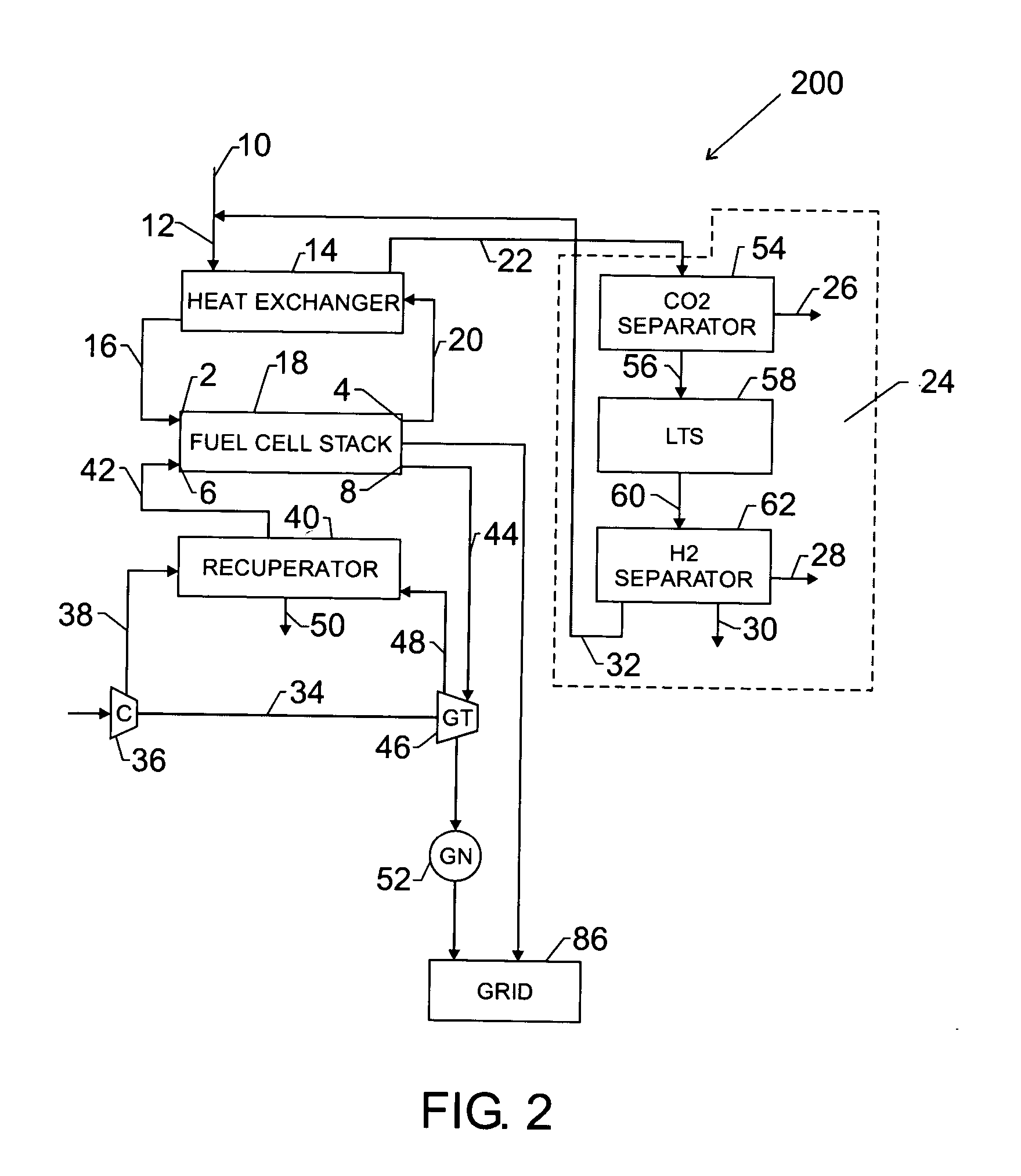

System and method for co-production of hydrogen and electrical energy

InactiveUS20050123810A1Fuel cell combinationsHydrogen separation at low temperatureHydrogenFuel cells

A system and method for co-production of hydrogen and electrical energy. The system comprises a fuel cell assembly comprising a plurality of fuel cells. The fuel cells further comprise a cathode inlet for receiving a compressed oxidant, an anode inlet for receiving a fuel feed stream, an anode outlet in fluid communication with an anode exhaust stream and a cathode outlet in fluid communication with a cathode exhaust stream. At least a portion of the fuel feed stream reacts with the oxidant to produce electrical power. The anode exhaust stream comprises hydrogen. The co-production system further comprises a separation unit in fluid communication with the fuel cell assembly. The separation unit is configured to receive the anode exhaust stream from the fuel cell assembly to separate hydrogen from the anode exhaust stream.

Owner:GENERAL ELECTRIC CO

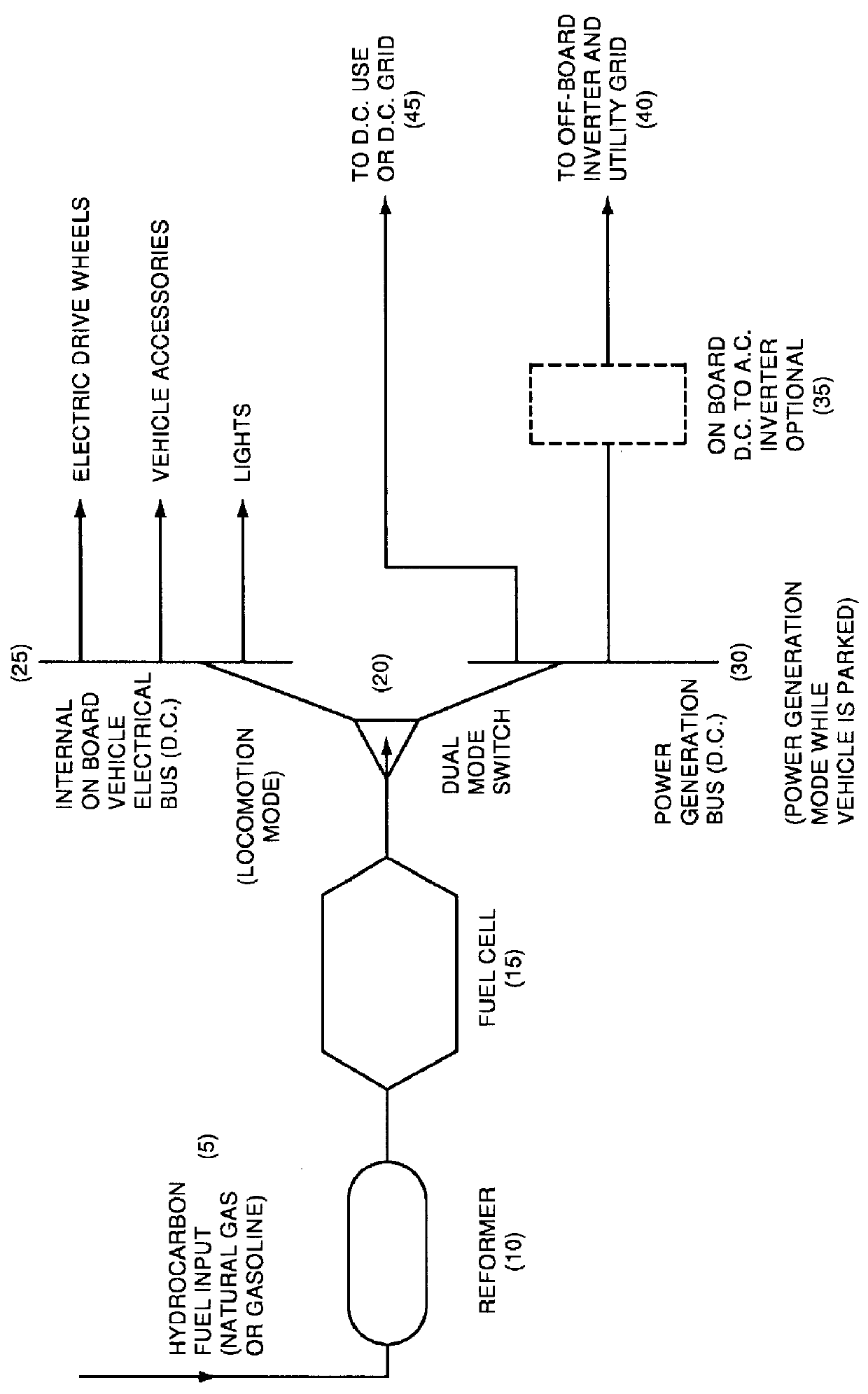

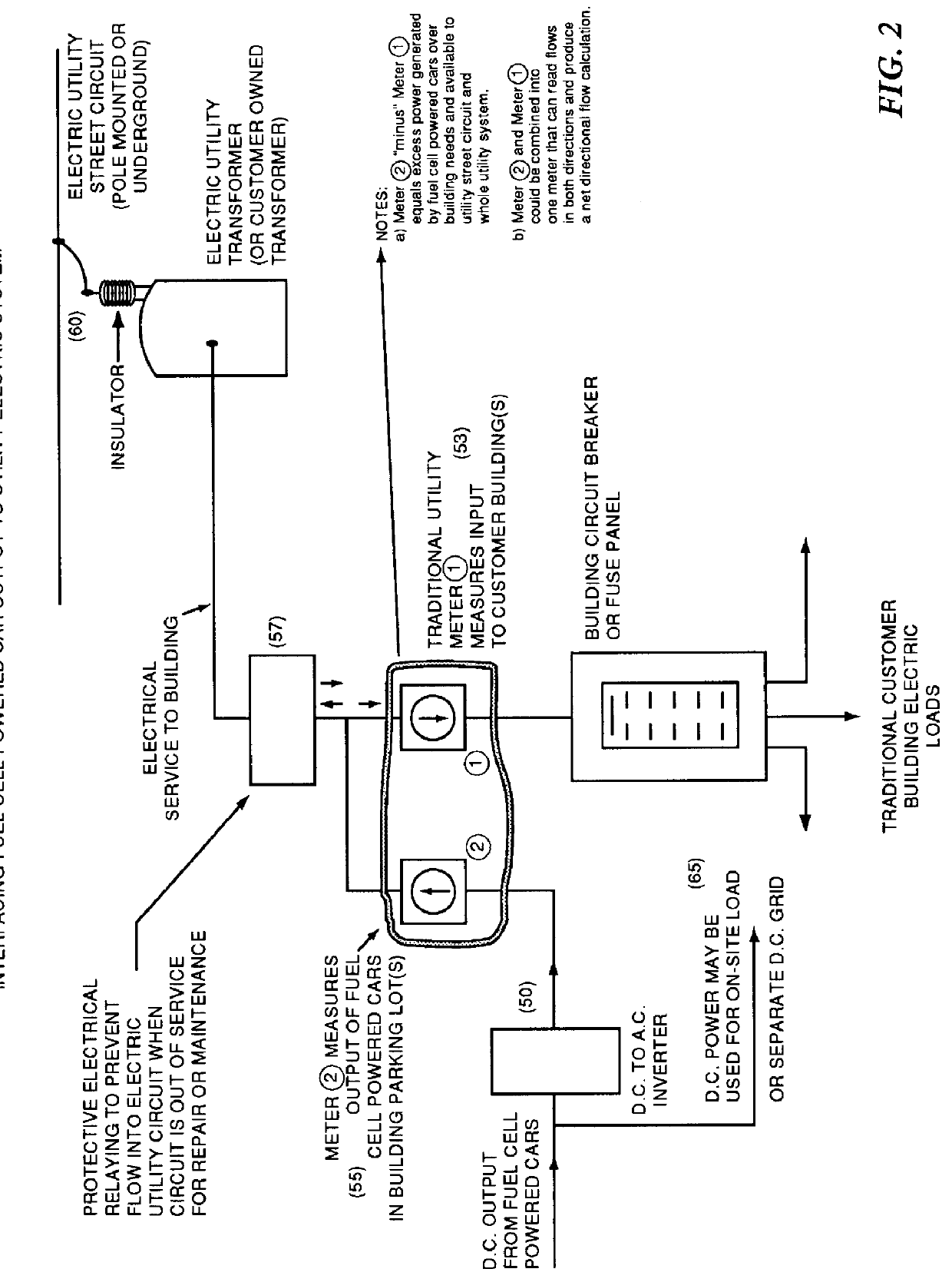

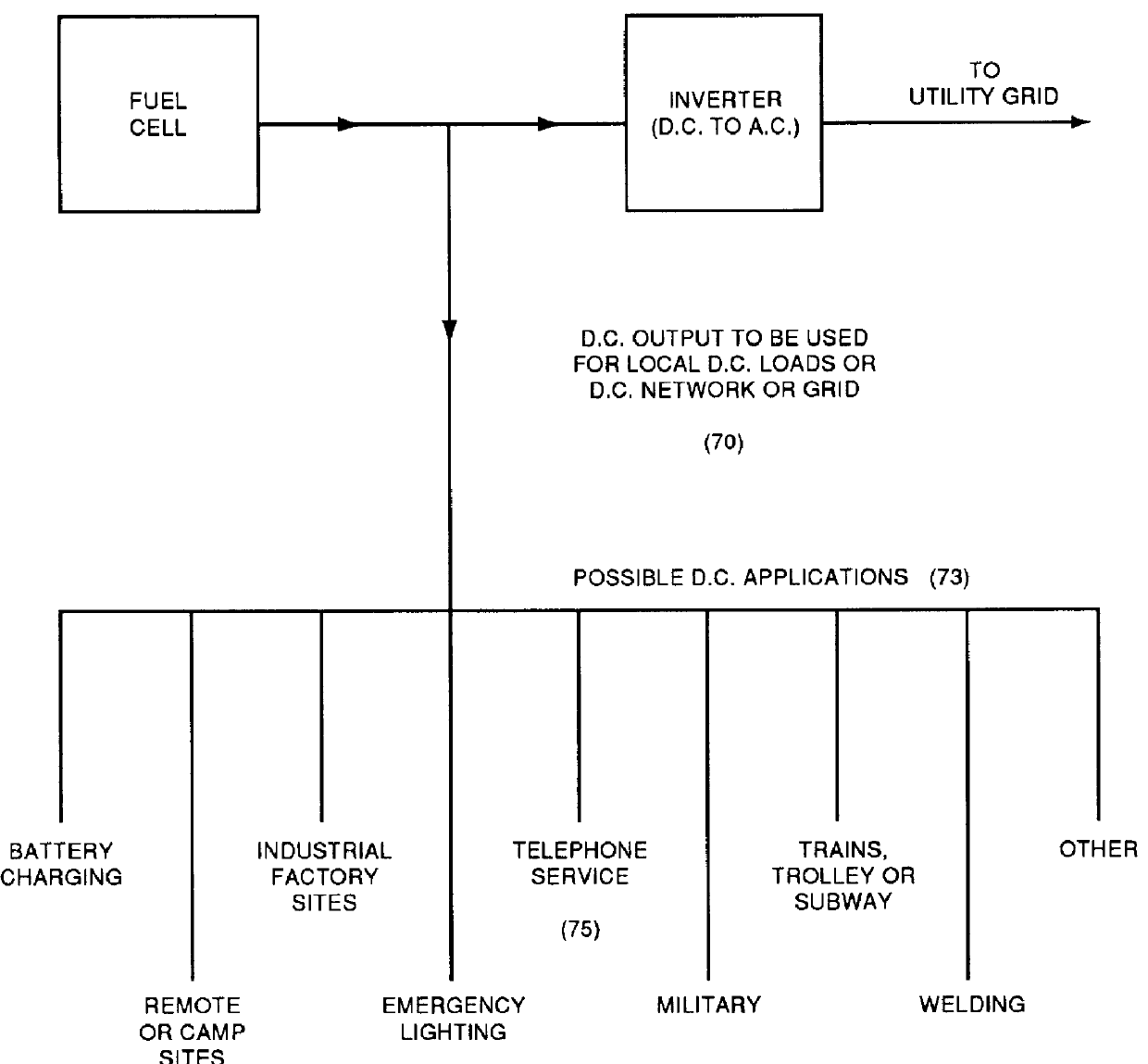

Methods for utilizing the electrical and non electrical outputs of fuel cell powered vehicles

The present invention provides a method and apparatus for generating electrical power from multiple vehicles powered by fuel cells while the vehicles are parked in a parking lot. A plurality of spaced-apart electrical receptacles are provided for receiving an electric cable for connection to a parked vehicle for electrically connecting the fuel cell in each of the parked vehicles to the plurality of electrical receptacles. An electric power grid is electrically connected to the plurality of electrical receptacles for transferring D.C. electrical power from the fuel cells in the parked vehicles to the electric power grid. At least one electric power collection station is electrically connected to the electric power grid for collecting at a common point the D.C. electric power in the electric power grid. In addition, at least one inverter is electrically connected to the electric power collection station for converting the D.C. electric power to A.C. electric power. Apparatus is provided for supplying the A.C. electric power to a load or a utility grid.

Owner:GROW INT

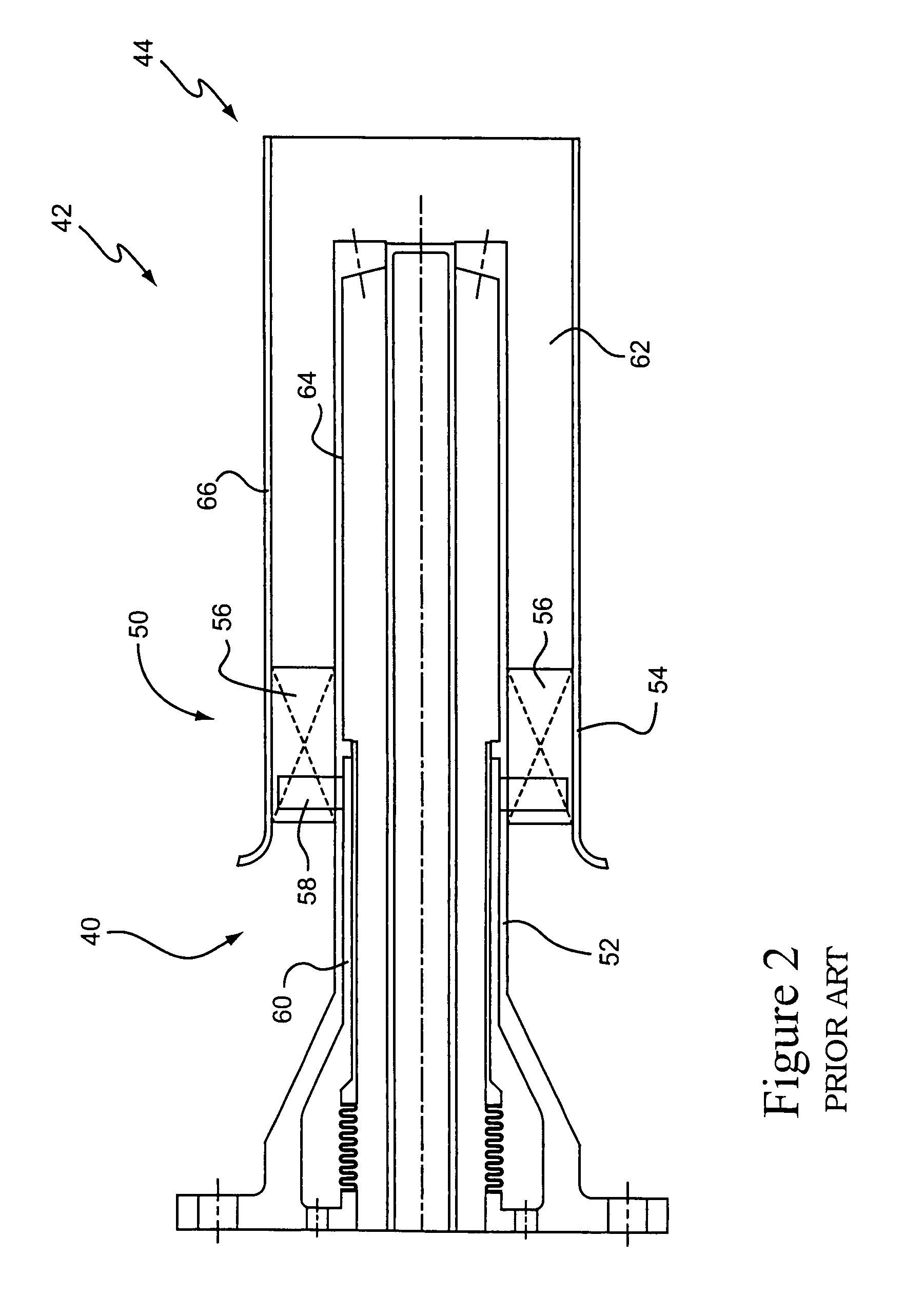

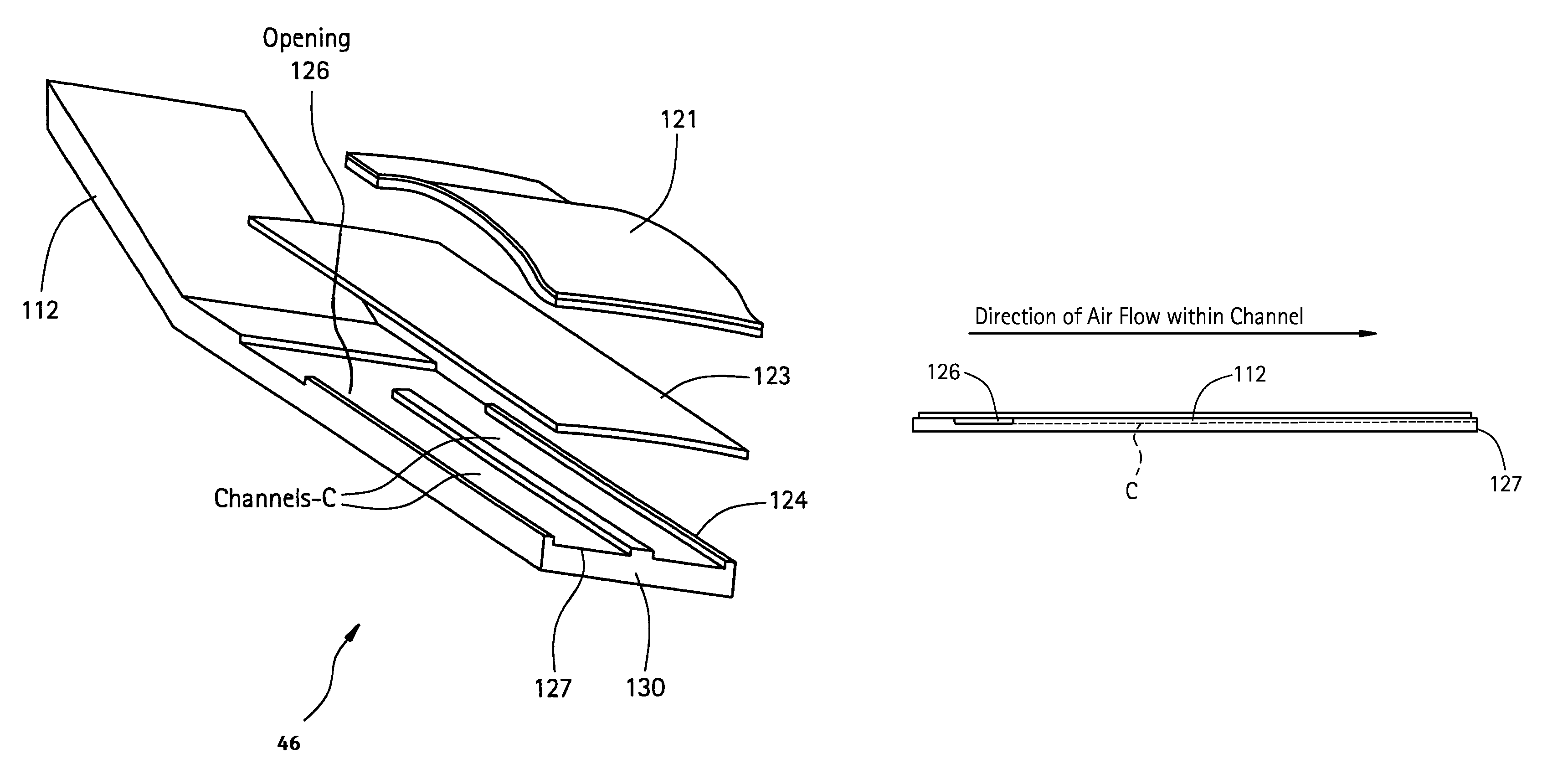

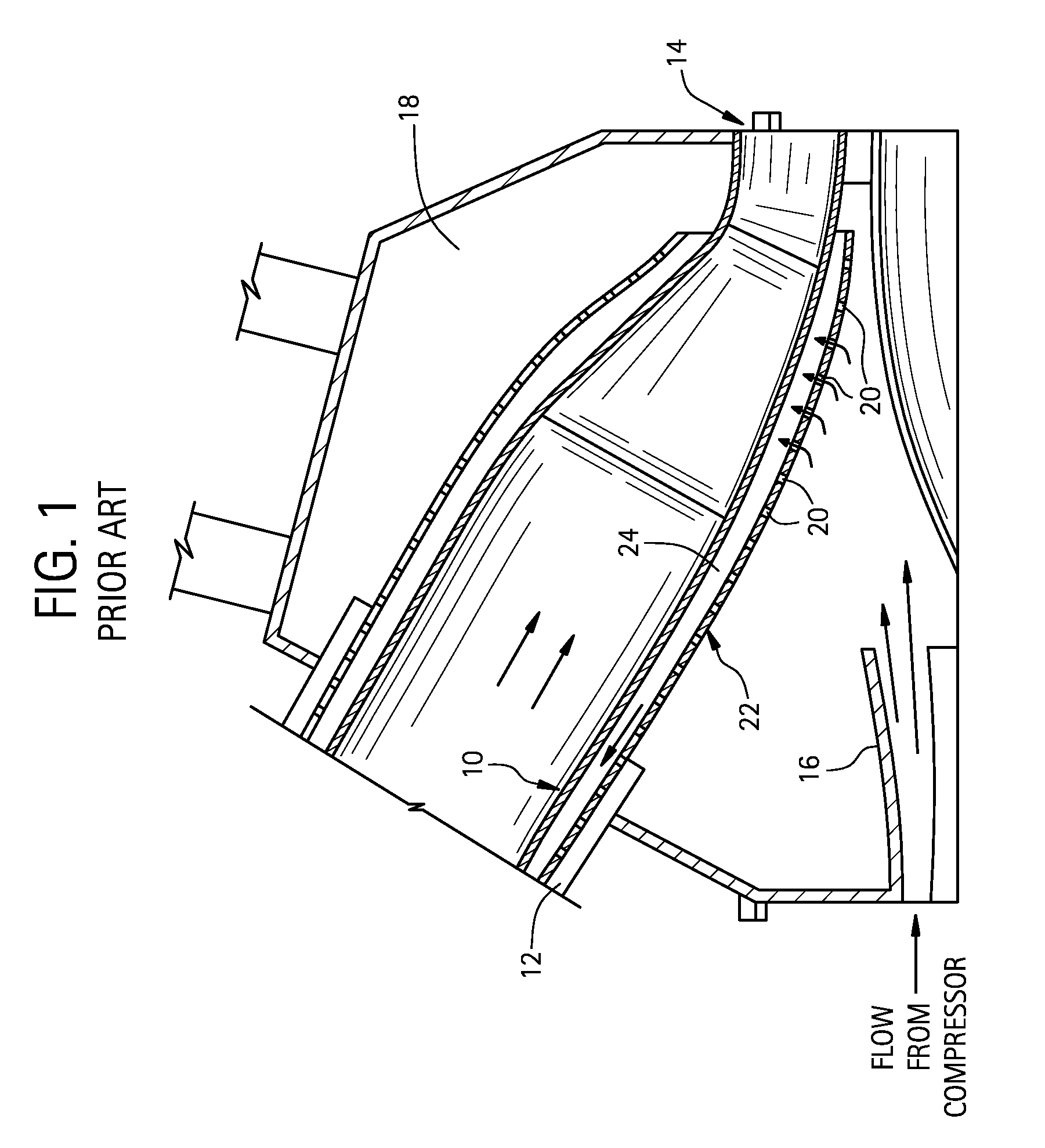

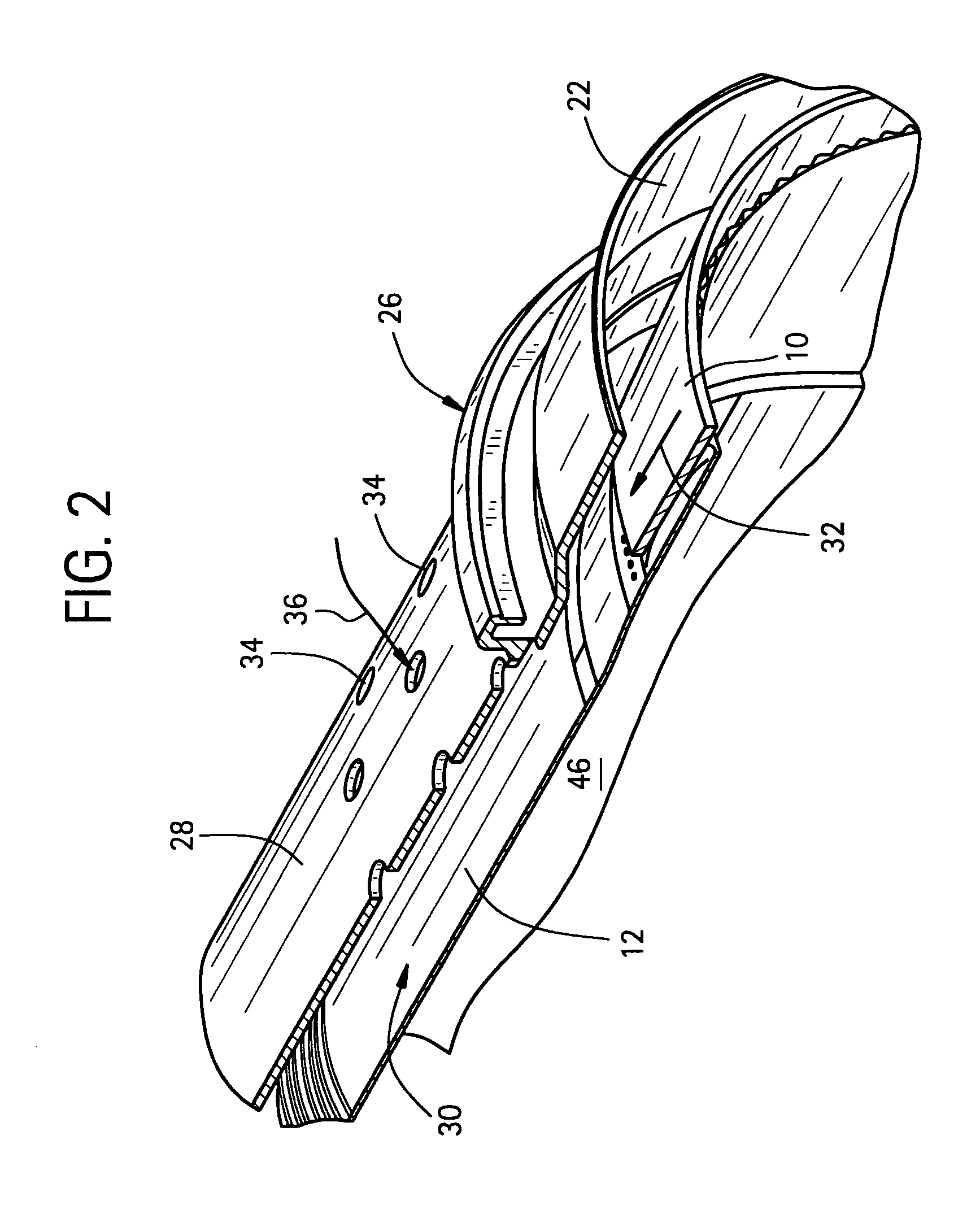

Method and apparatus for cooling combustor liner and transition piece of a gas turbine

ActiveUS7010921B2Easy to installContinuous combustion chamberTurbine/propulsion engine coolingCombustorTurbine

A method and apparatus for cooling a combustor liner and transitions piece of a gas turbine include a combustor liner with a plurality of circular ring turbulators arranged in an array axially along a length defining a length of the combustor liner and located on an outer surface thereof; a first flow sleeve surrounding the combustor liner with a first flow annulus therebetween including a plurality of axial channels (C) extending over a portion of an aft end portion of the liner parallel to each other, the cross-sectional area of each channel either constant or varying along the length of the channel, the first flow sleeve having a plurality of rows of cooling holes formed about a circumference of the first flow sleeve for directing cooling air from the compressor discharge into the first flow annulus; a transition piece connected to the combustor liner and adapted to carry hot combustion gases to a stage of the turbine; a second flow sleeve surrounding the transition piece a second plurality of rows of cooling apertures for directing cooling air into a second flow annulus between the second flow sleeve and the transition piece; wherein the first plurality of cooling holes and second plurality of cooling apertures are each configured with an effective area to distribute less than 50% of compressor discharge air to the first flow sleeve and mix with cooling air from the second flow annulus.

Owner:GENERAL ELECTRIC CO

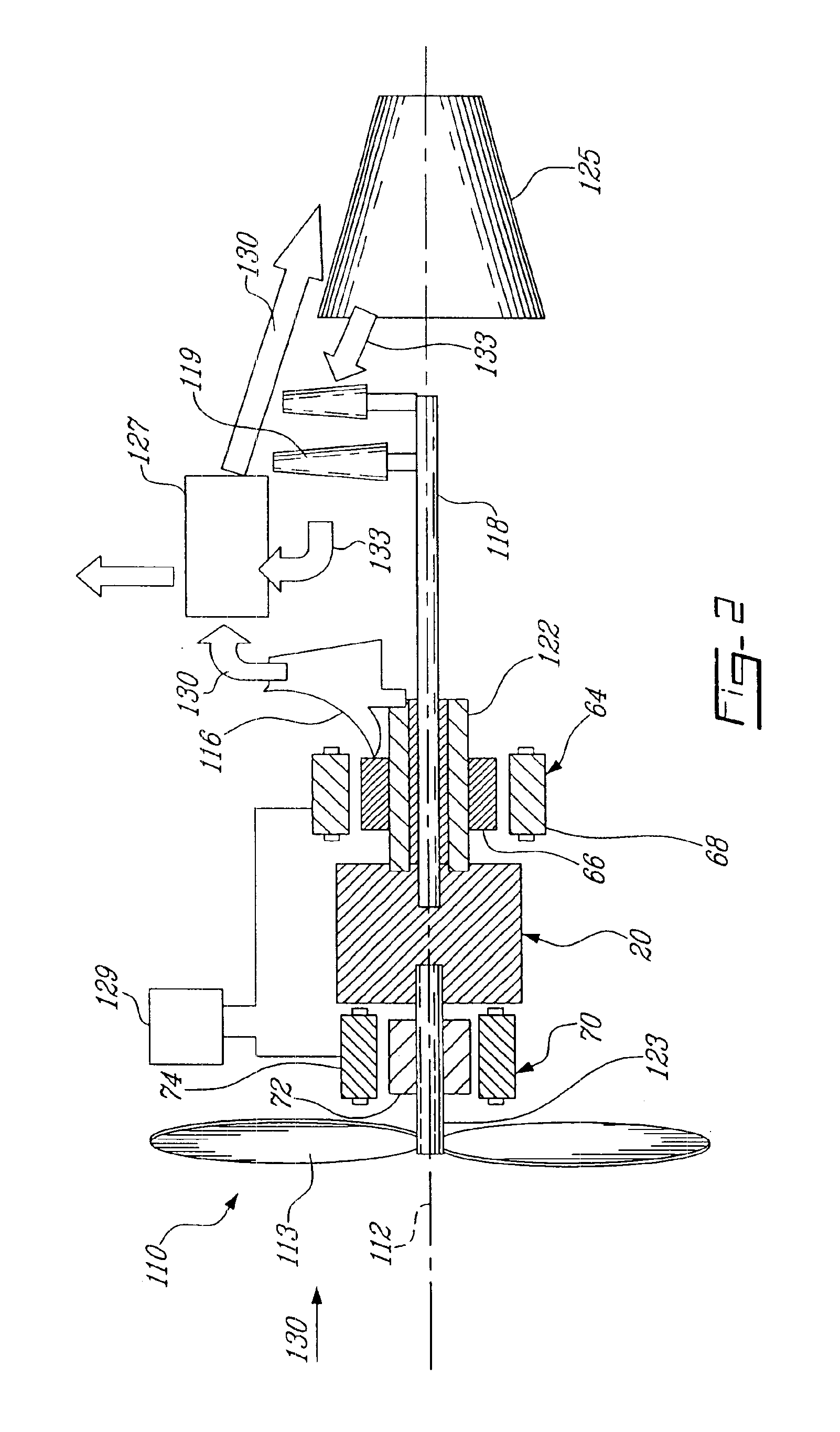

Differential geared turbine engine with torque modulation capability

InactiveUS6895741B2Improve efficiencyMinimal numberEngine fuctionsEfficient propulsion technologiesTorque regulationTurbine

A method and apparatus for controllable distribution of power from a turbine of a gas turbine engine between two rotatable loads of the gas turbine engine, comprises transferring a shaft power of the turbine to the respective rotatable loads using differential gearing operatively coupled with the turbine and the rotatable loads, respectively; and controlling the power transfer using machines operatively coupled with the respective rotatable loads, operable as a generator or a motor for selectively taking power from one of the rotatable loads to drive the other of the rotatable loads, or the reverse.

Owner:PRATT & WHITNEY CANADA CORP

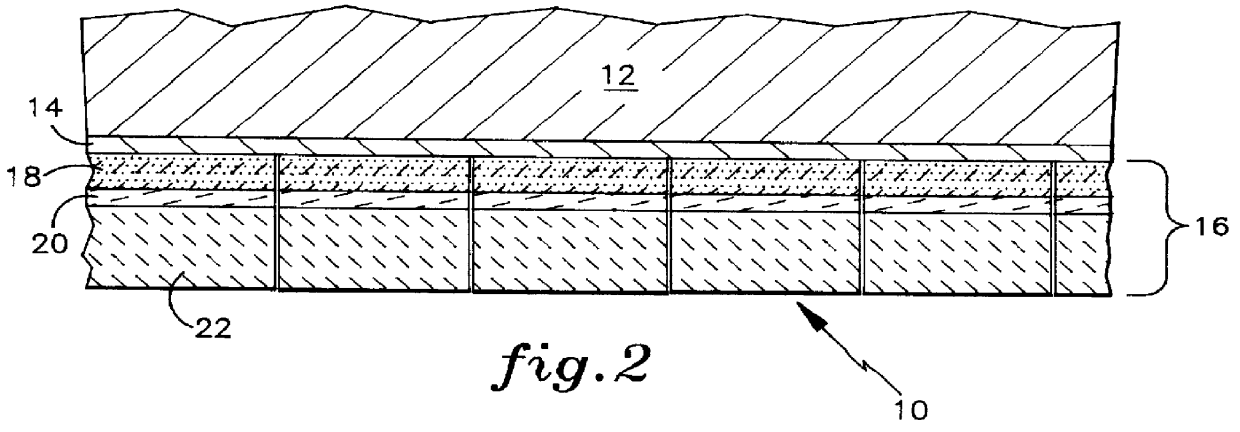

Segmented abradable ceramic coating

InactiveUS6102656AImprove wear resistanceSufficient resistanceMolten spray coatingPump componentsCeramic coatingWear resistance

A segmented abradable ceramic coating system having superior abradability and erosion resistance is disclosed. The system includes a duct segment having a metallic substrate, a MCrAlY bond coat on the substrate and a segmented abradable ceramic coating on the bond coat. The segmented abradable ceramic coating includes a base coat foundation layer, a graded interlayer and an abradable top layer for an overall thickness of preferably about 50 mils (1.270 mm). The coating is characterized by a plurality of vertical microcracks. By precisely controlling the deposition parameters, composition of the layers and layer particle morphology, segmentation is achieved, as well as superior abradability and erosion resistance.

Owner:UNITED TECH CORP

Popular searches

Dynamo-electric converter control Mechanical energy handling Generator control details Synchronous machines with stationary armatures and rotating magnets Windings conductor shape/form/construction Steam engine plants Combined combustion mitigation Jet propulsion plants Hot gas positive displacement engine plants Engine components

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com