Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

493 results about "Heat recovery steam generator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

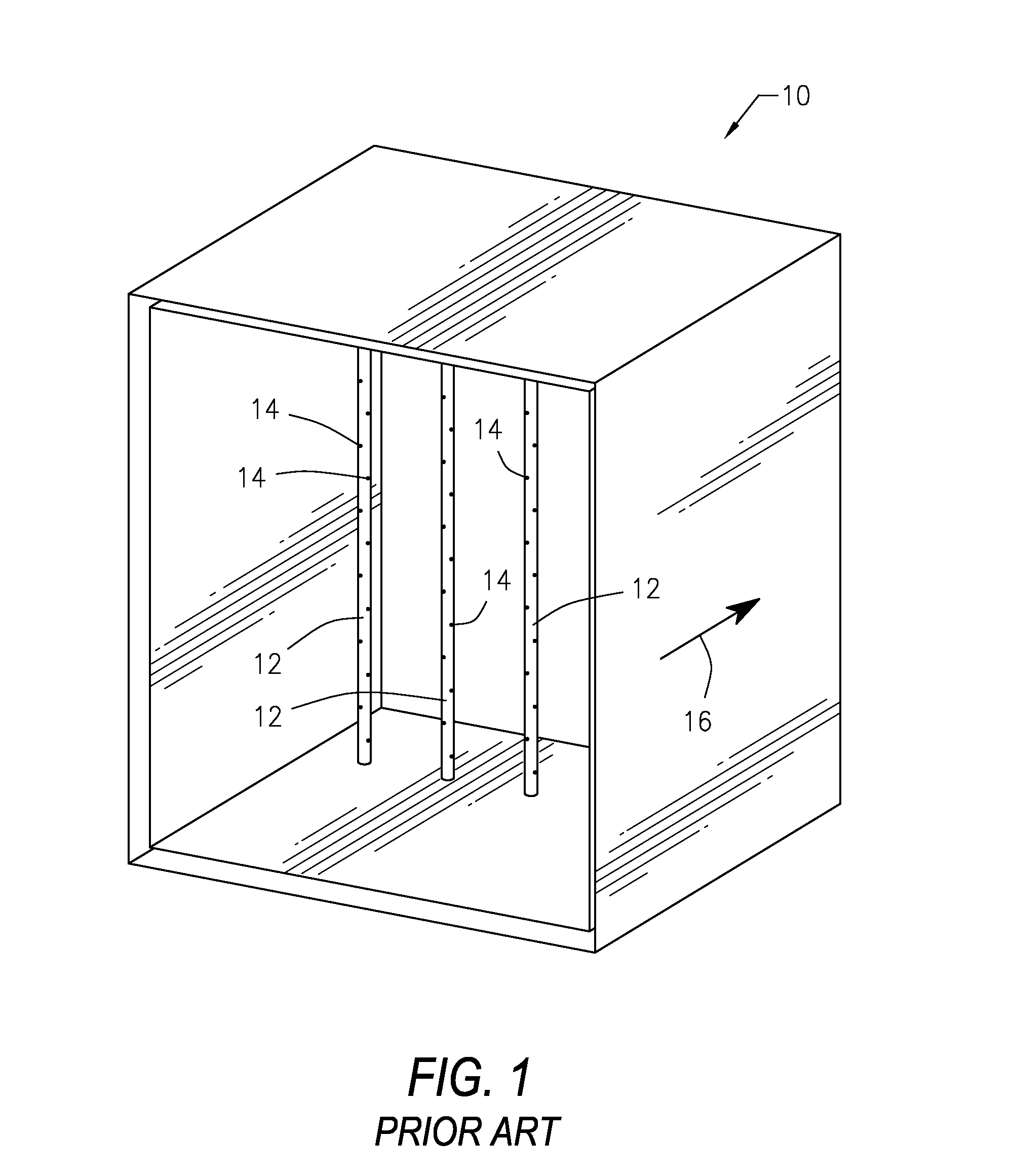

A heat recovery steam generator (HRSG) is an energy recovery heat exchanger that recovers heat from a hot gas stream, such as a combustion turbine or other waste gas stream. It produces steam that can be used in a process (cogeneration) or used to drive a steam turbine (combined cycle).

Dry 3-way catalytic reduction of gas turbine NOx

ActiveUS20090284013A1Reduction in amount of NOxIncrease carbon dioxide concentrationInternal combustion piston enginesExhaust apparatusCombustion chamberGas compressor

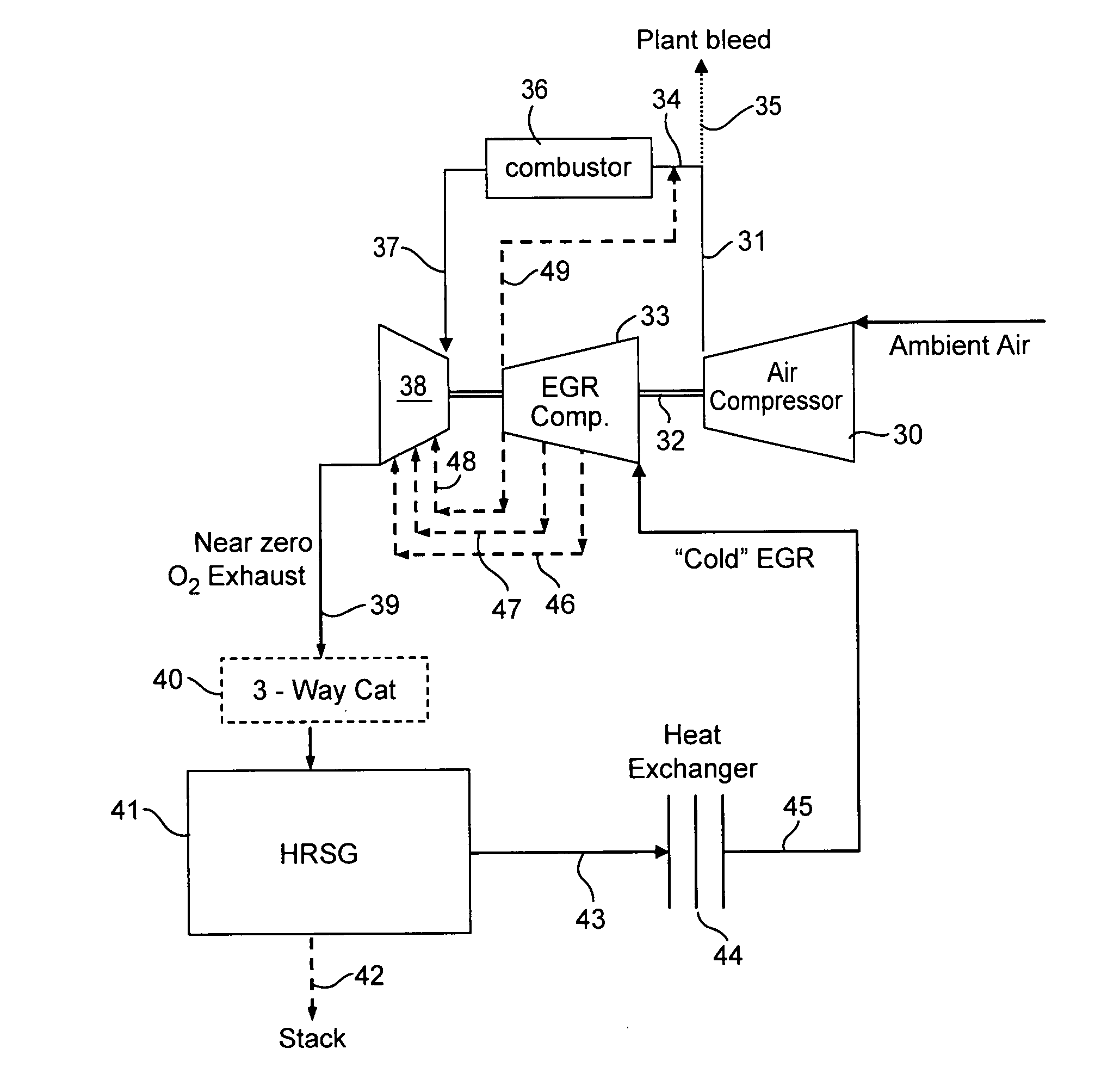

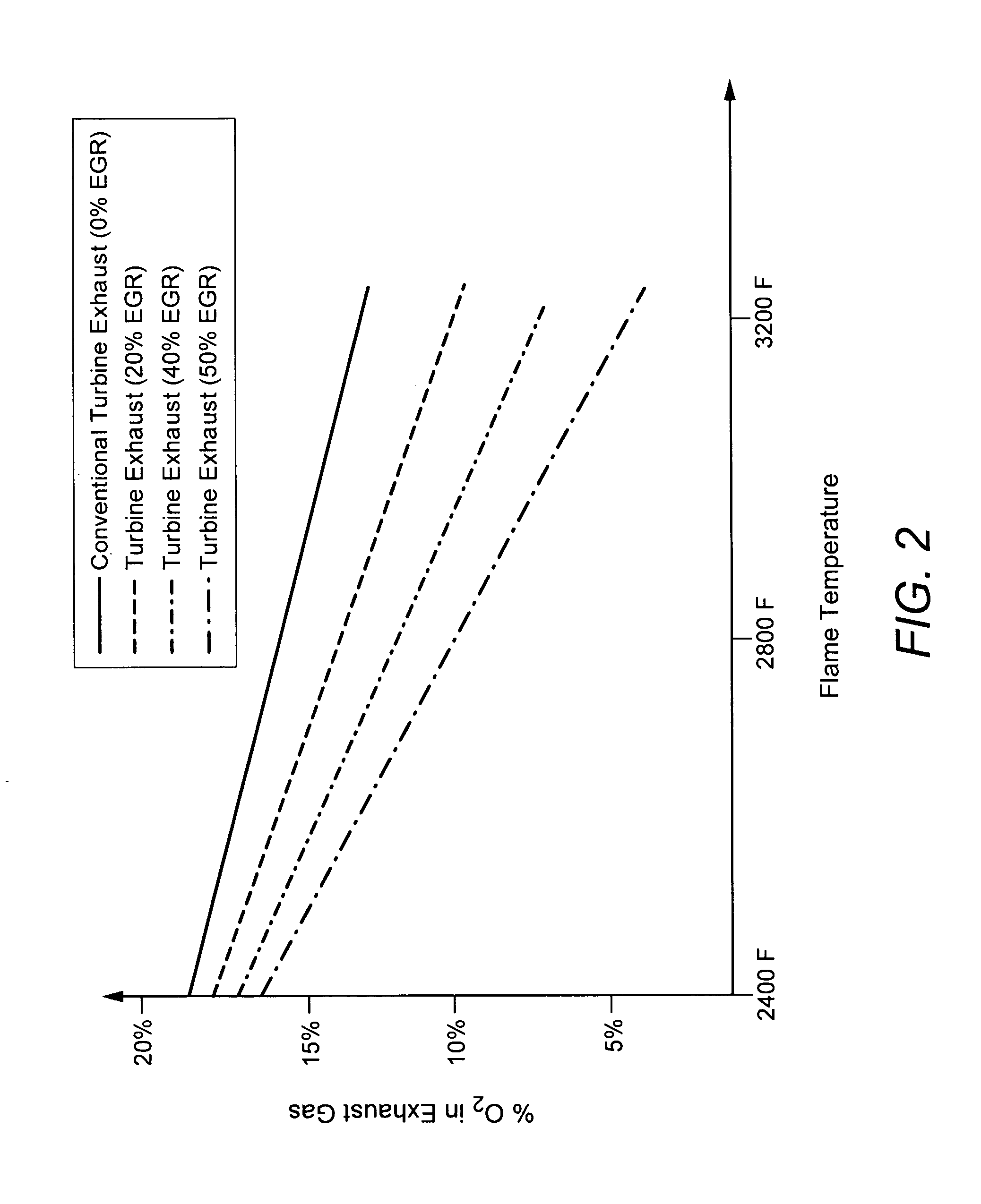

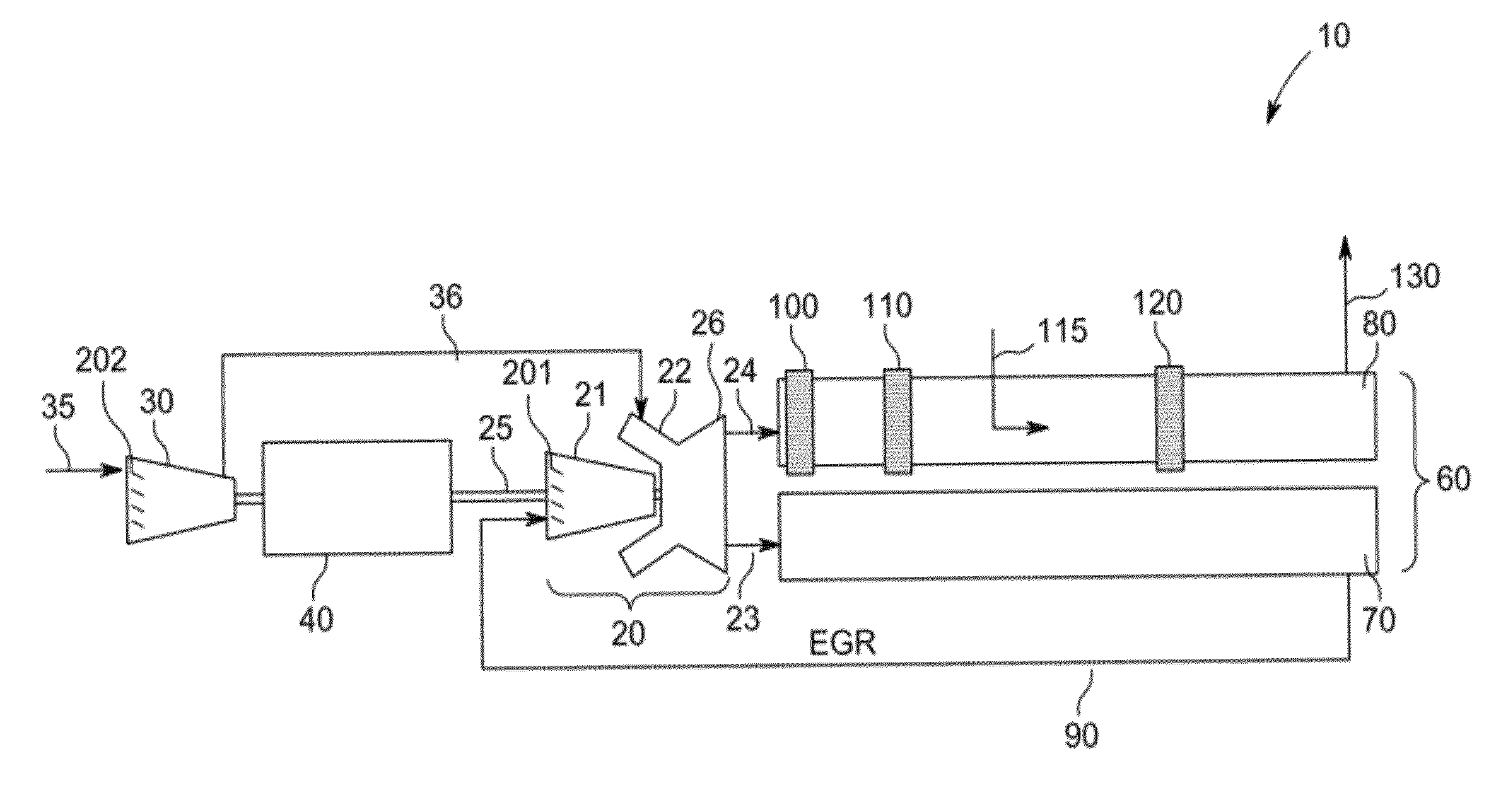

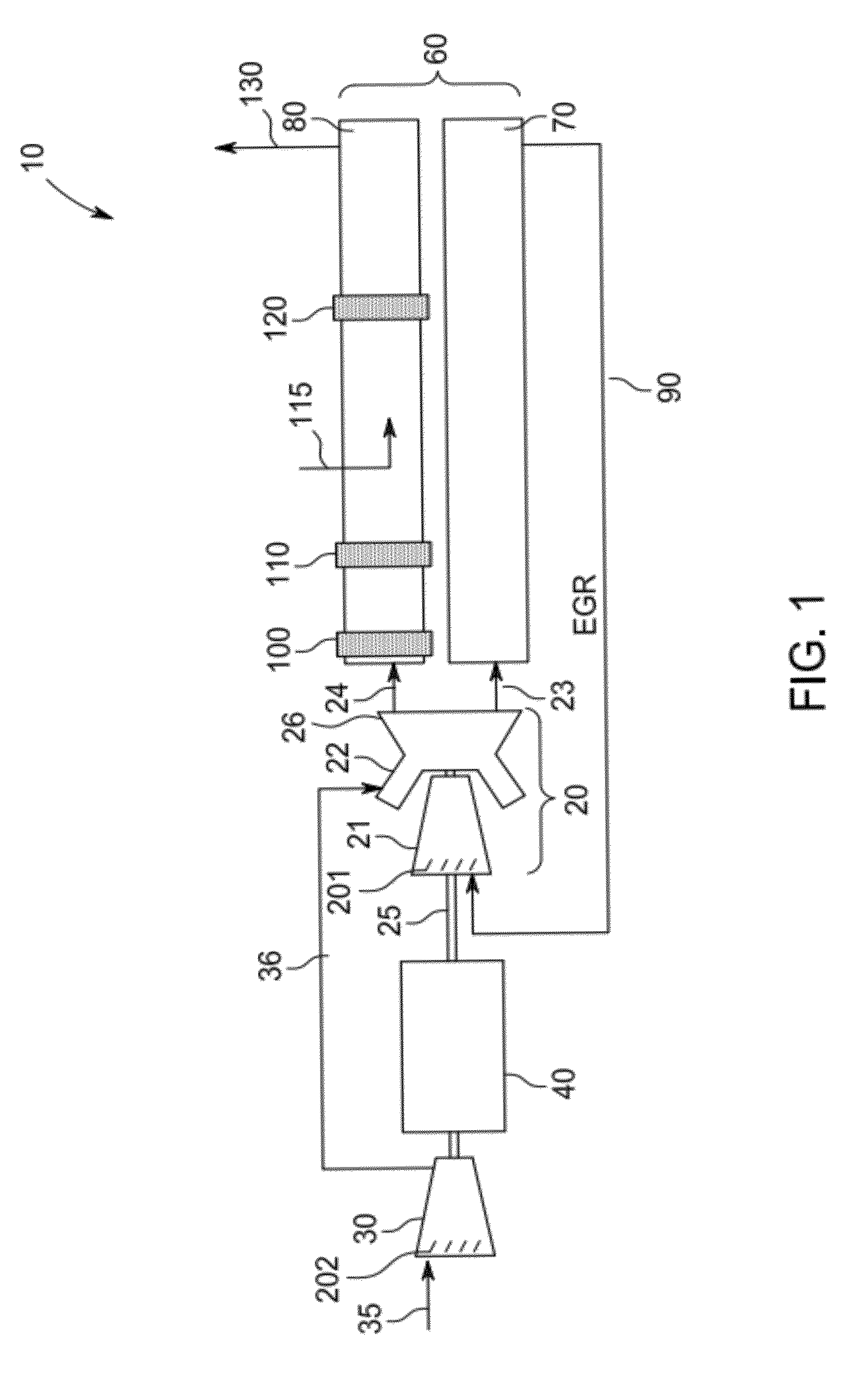

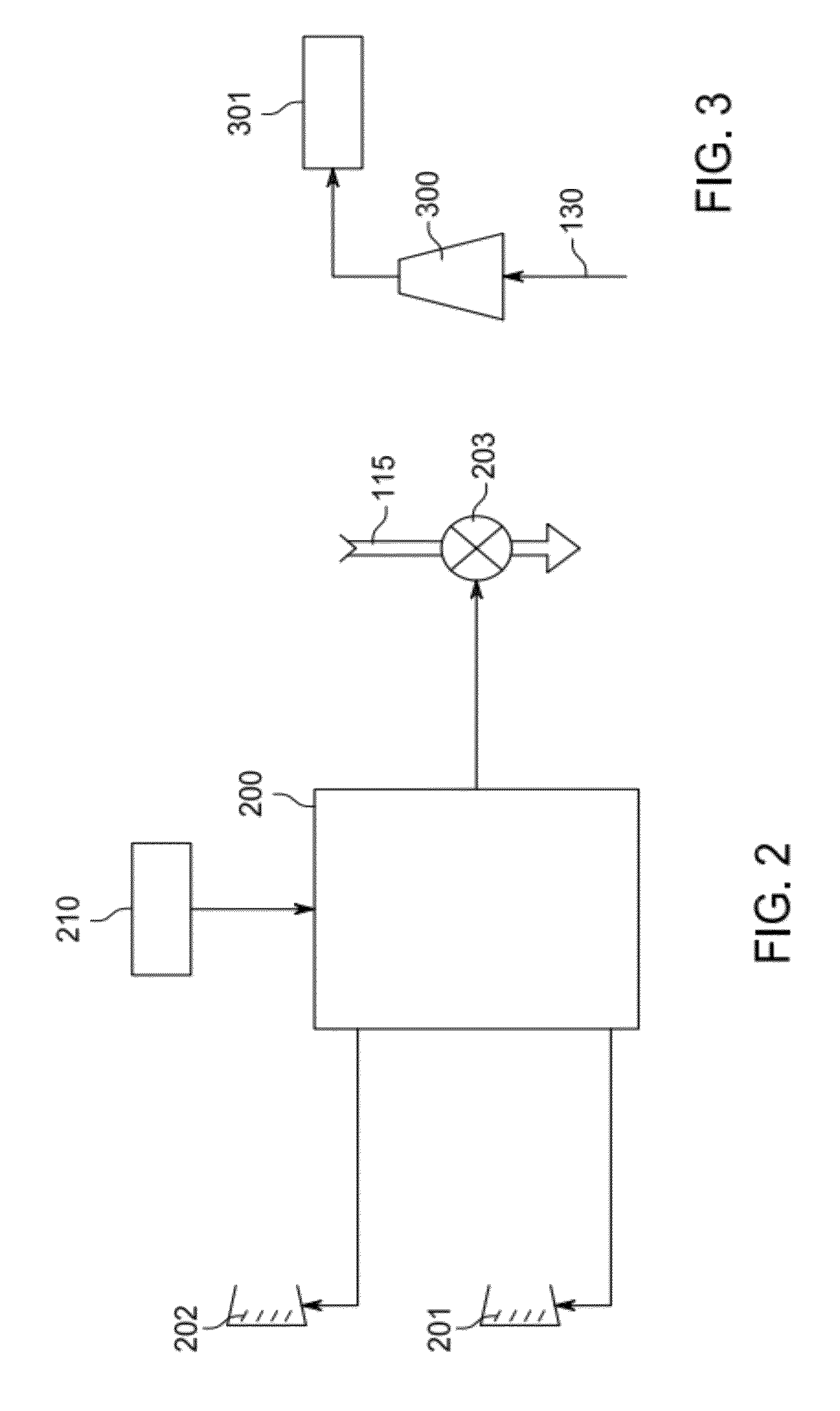

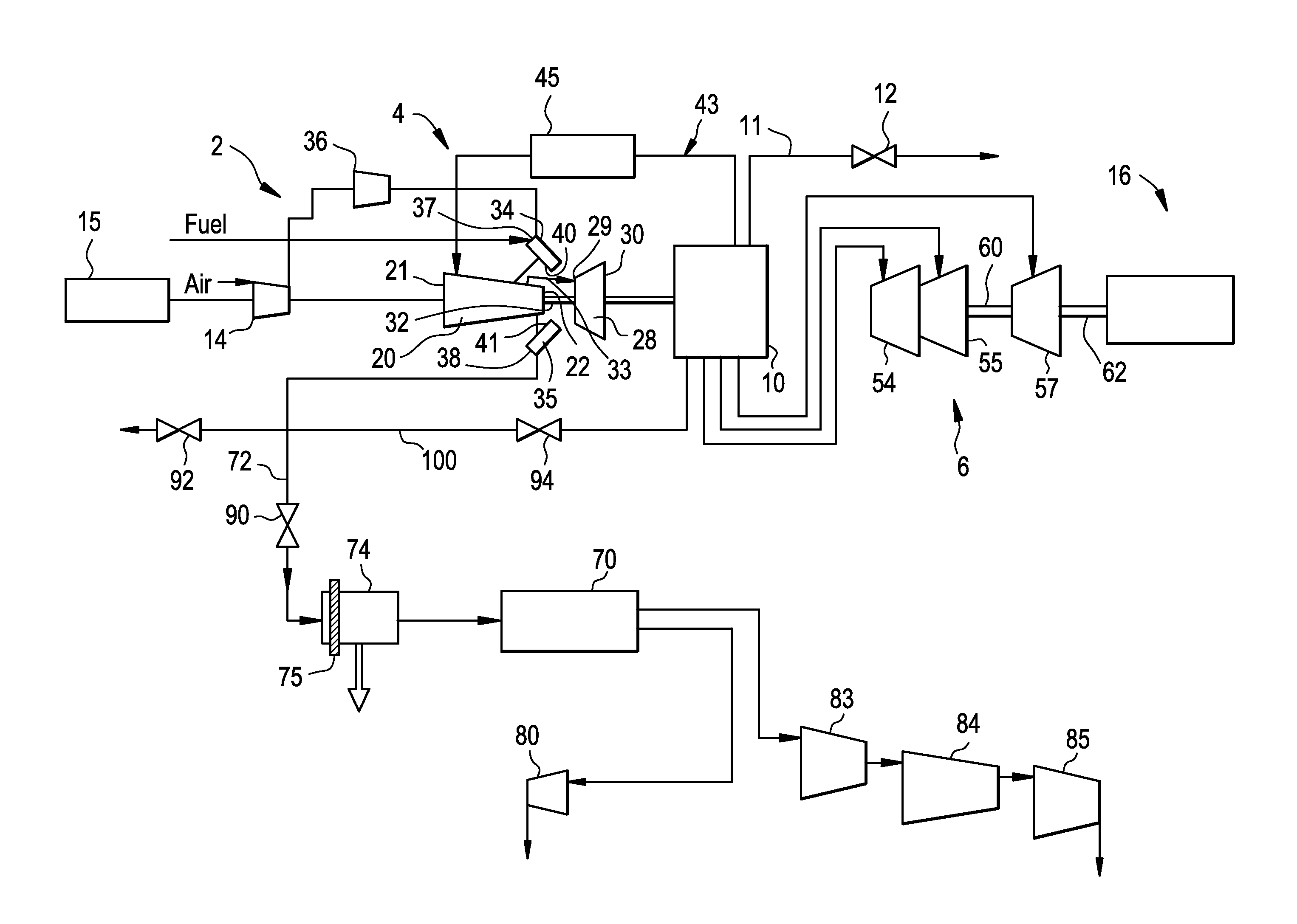

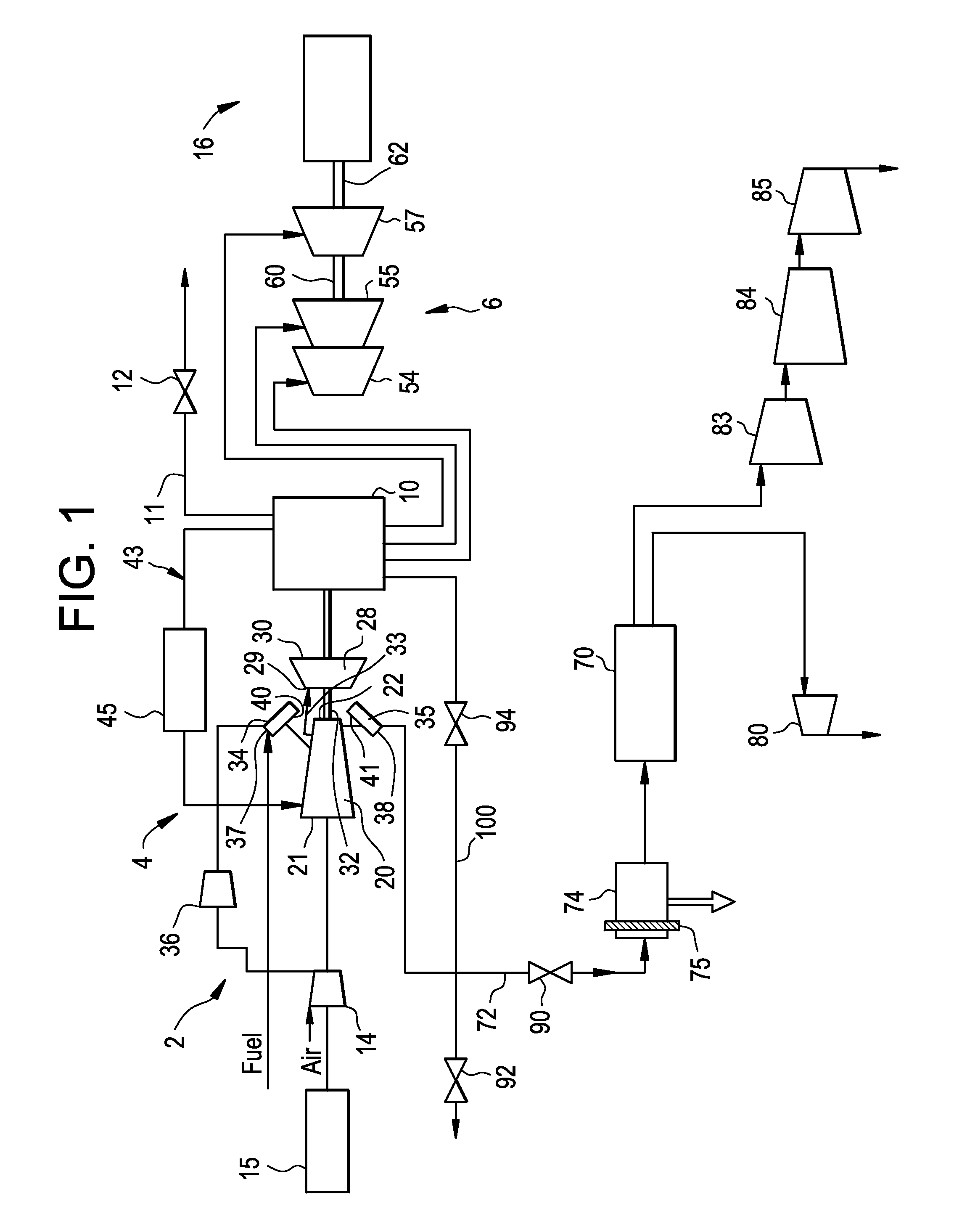

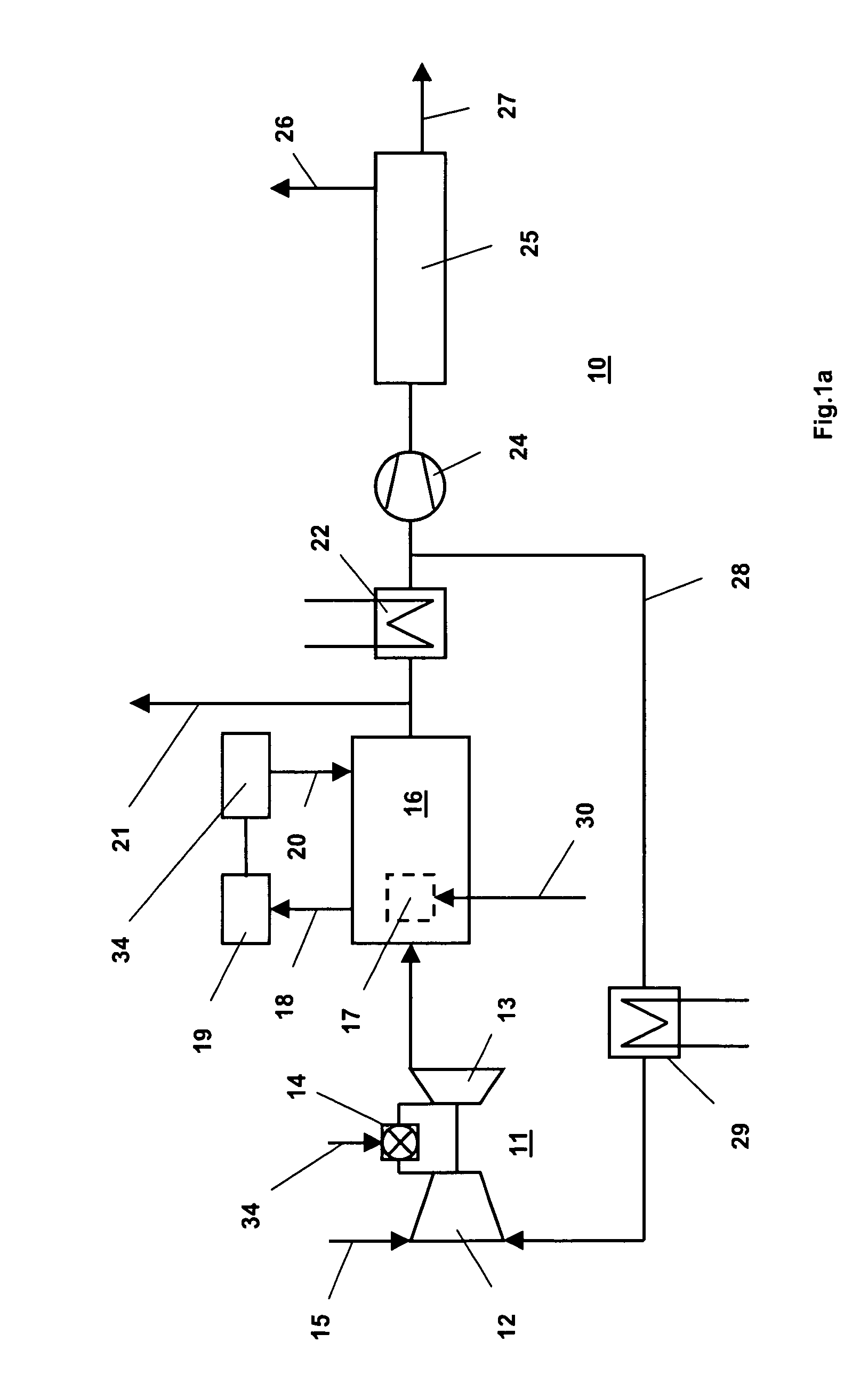

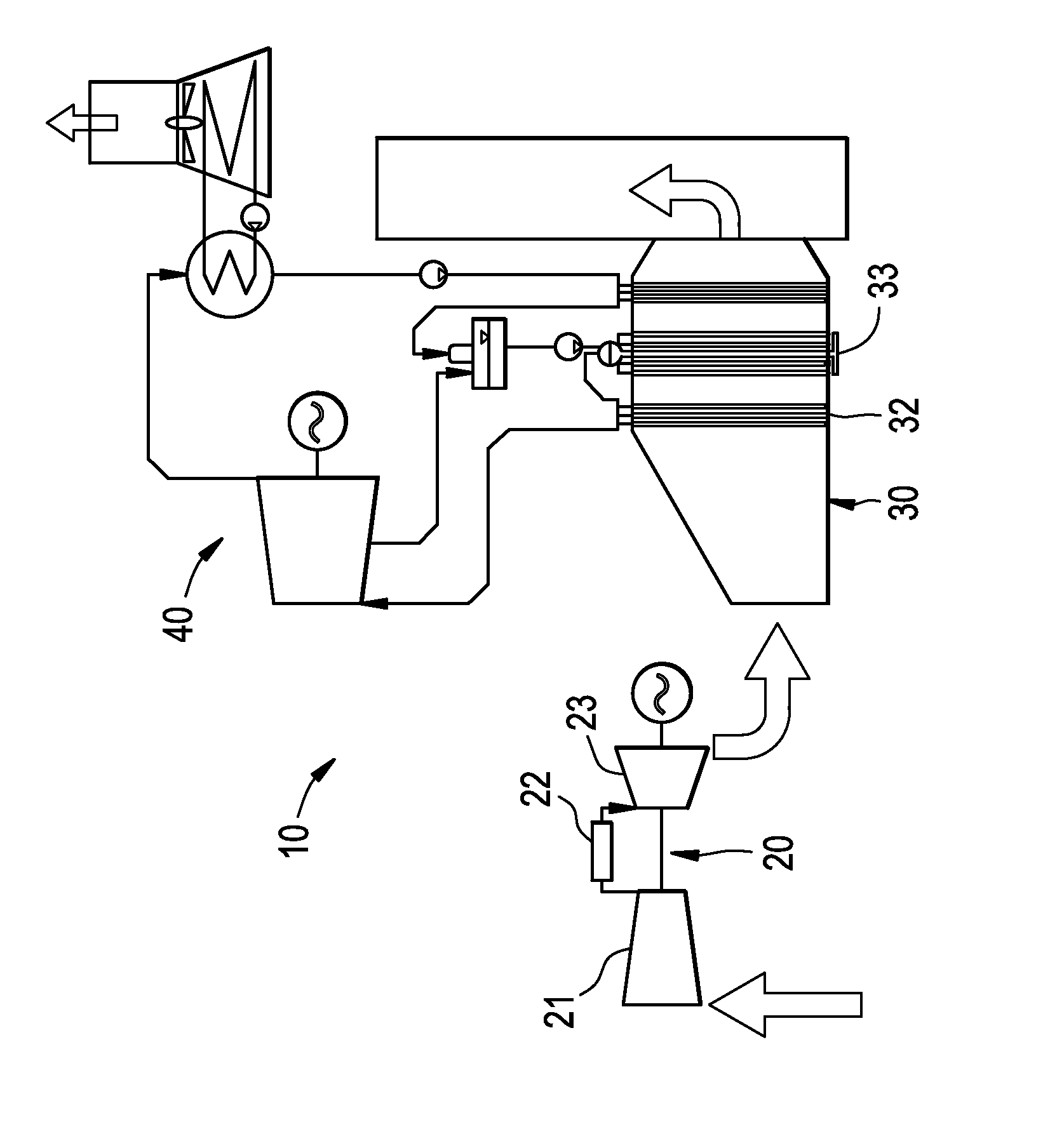

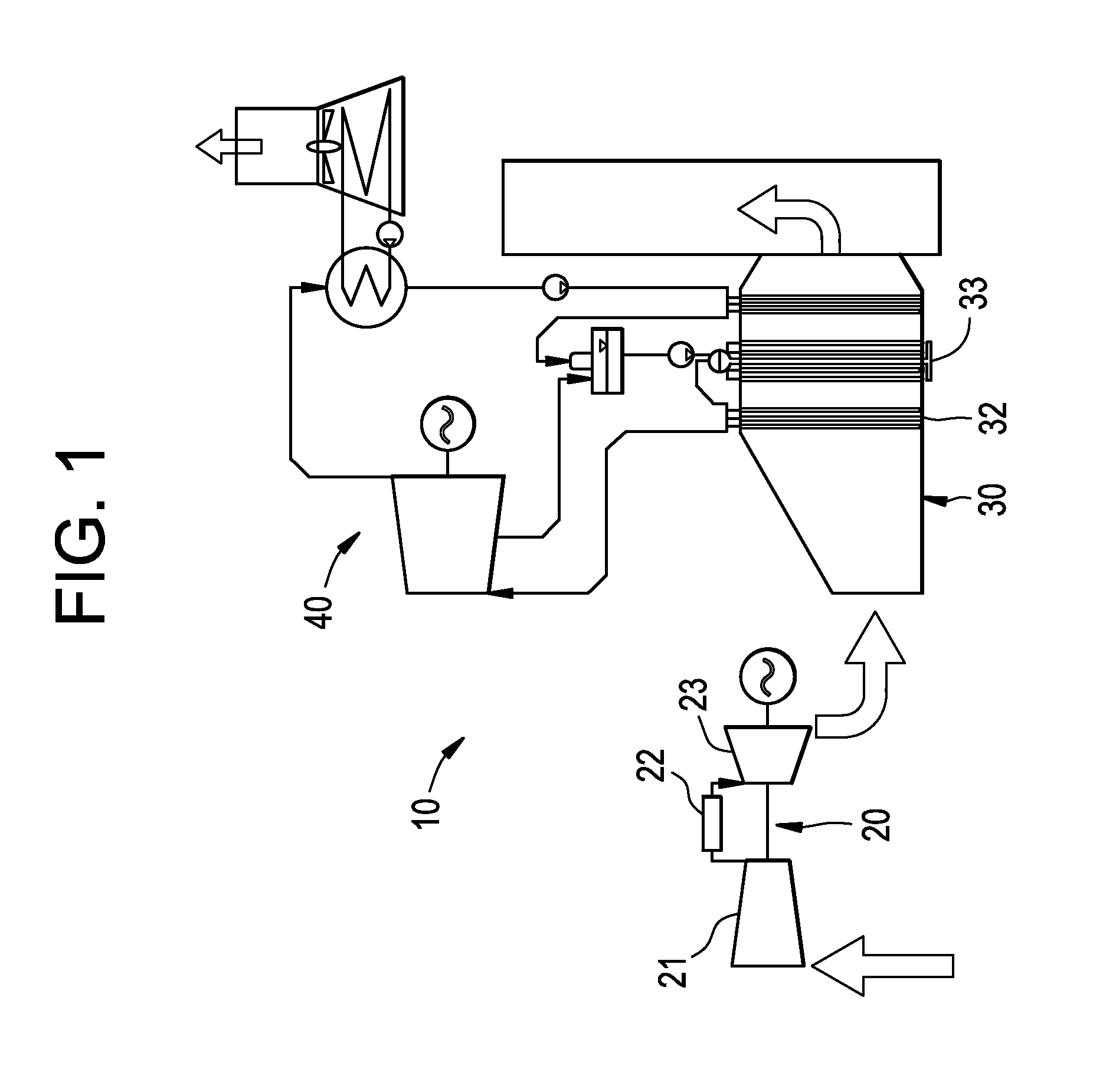

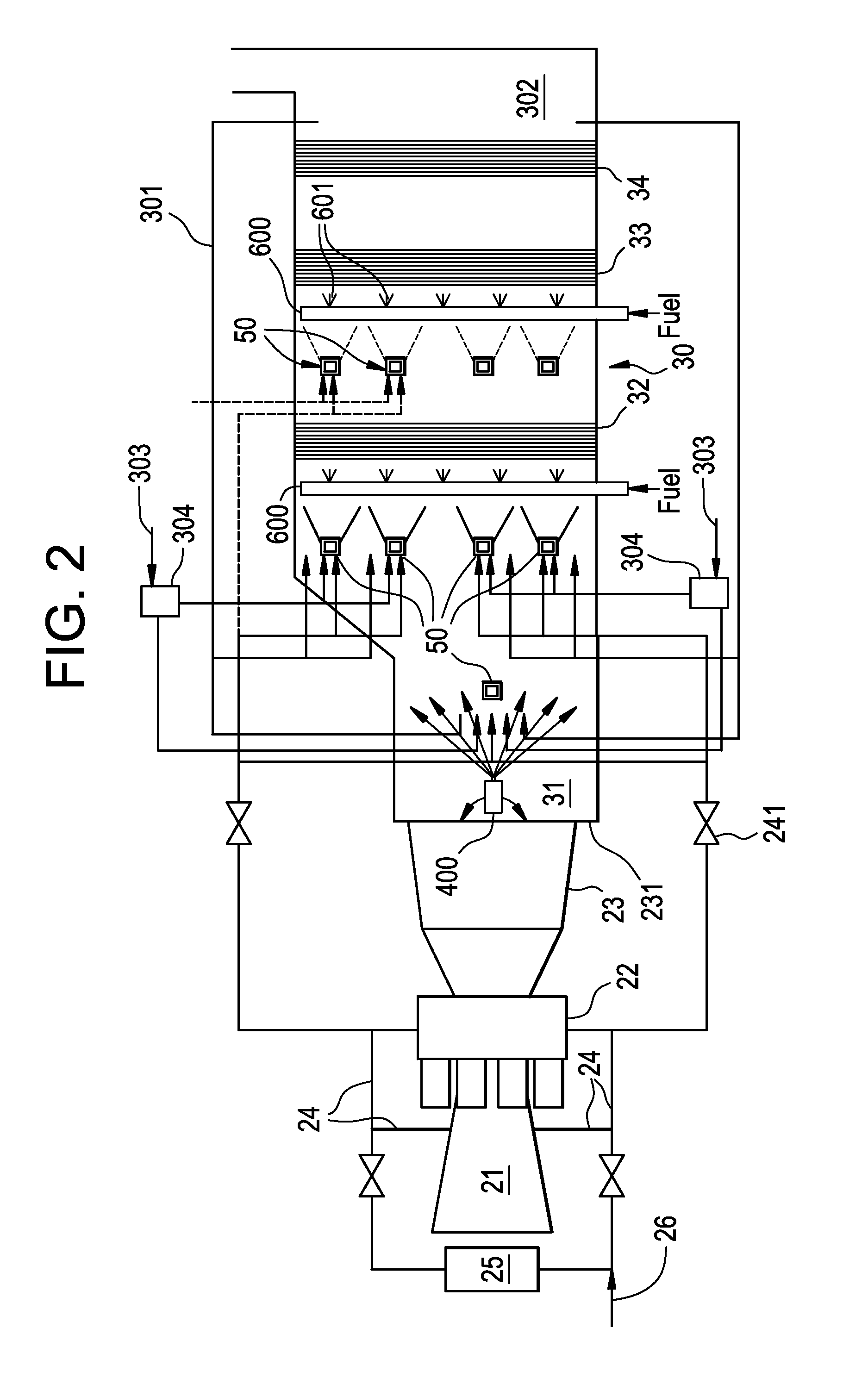

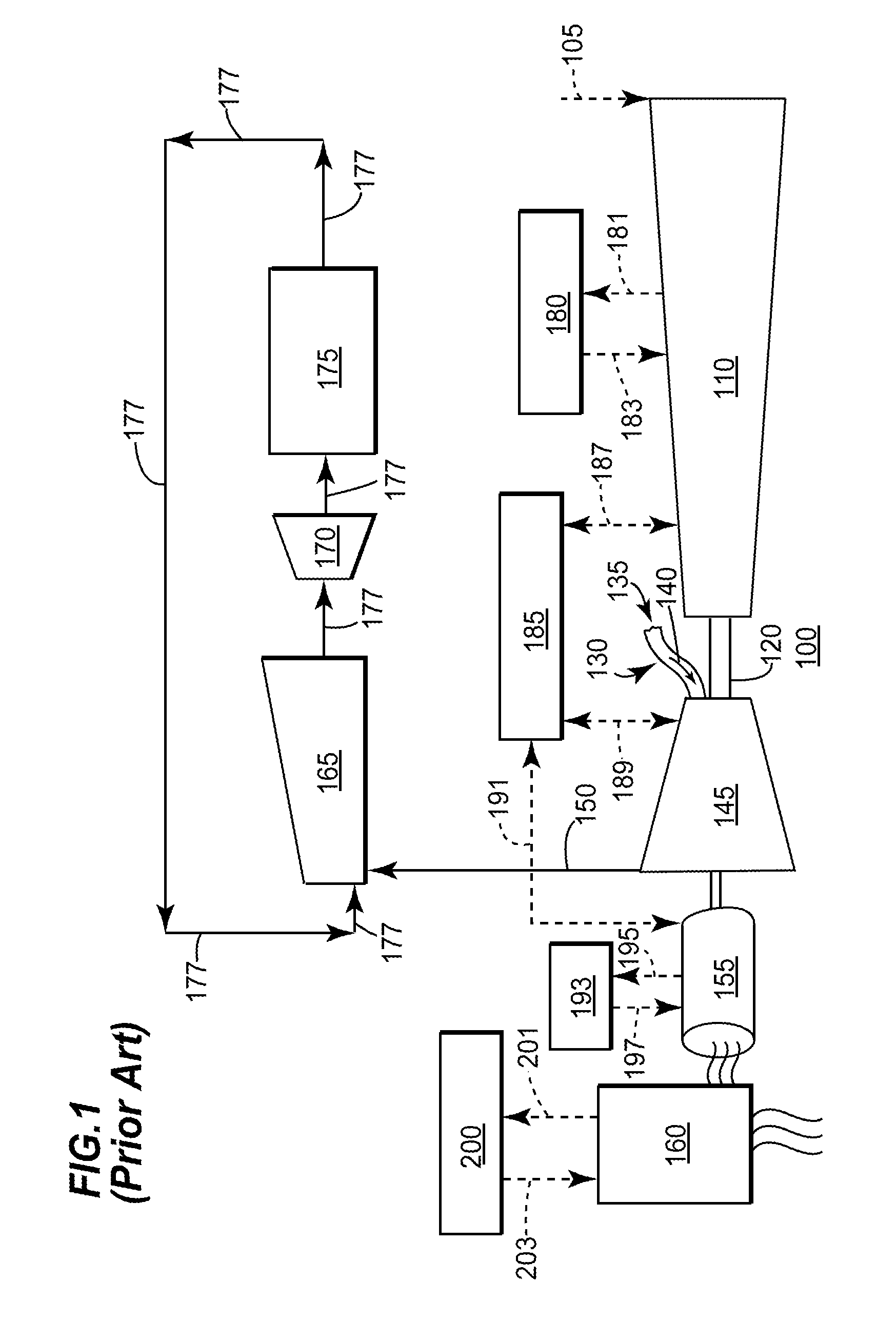

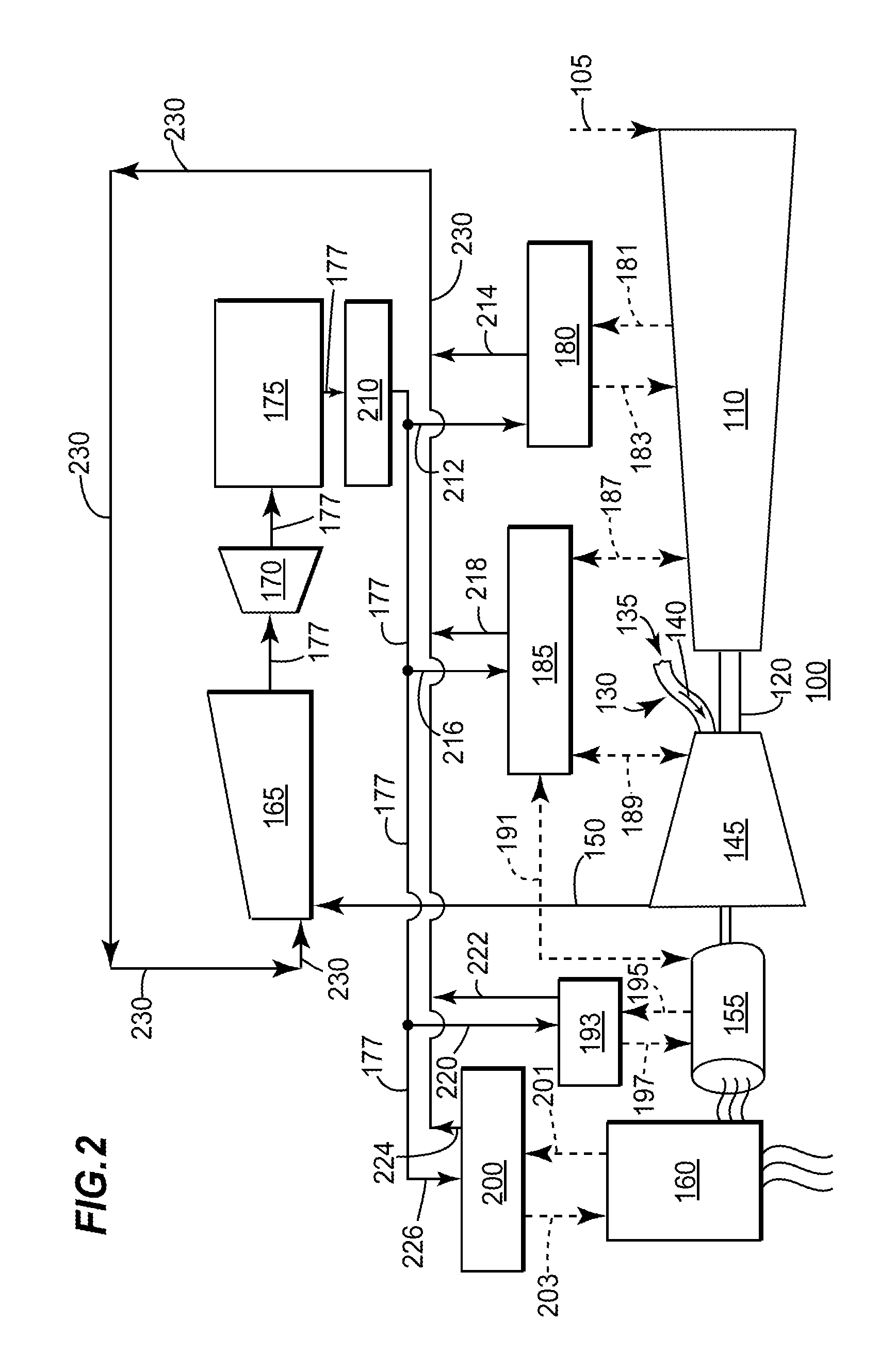

A power generation system capable of eliminating NO, components in the exhaust gas by using a 3-way catalyst, comprising a gas compressor to increase the pressure of ambient air fed to the system; a combustor capable of oxidizing a mixture of fuel and compressed air to generate an expanded, high temperature exhaust gas; a gas turbine engine that uses the force of the high temperature gas; an exhaust gas recycle (EGR) stream back to the combustor; a 3-way catalytic reactor downstream of the gas turbine engine outlet which treats the exhaust gas stream to remove substantially all of the NOx components; a heat recovery steam generator (HRSG); an EGR compressor; and an electrical generator.

Owner:GENERAL ELECTRIC CO

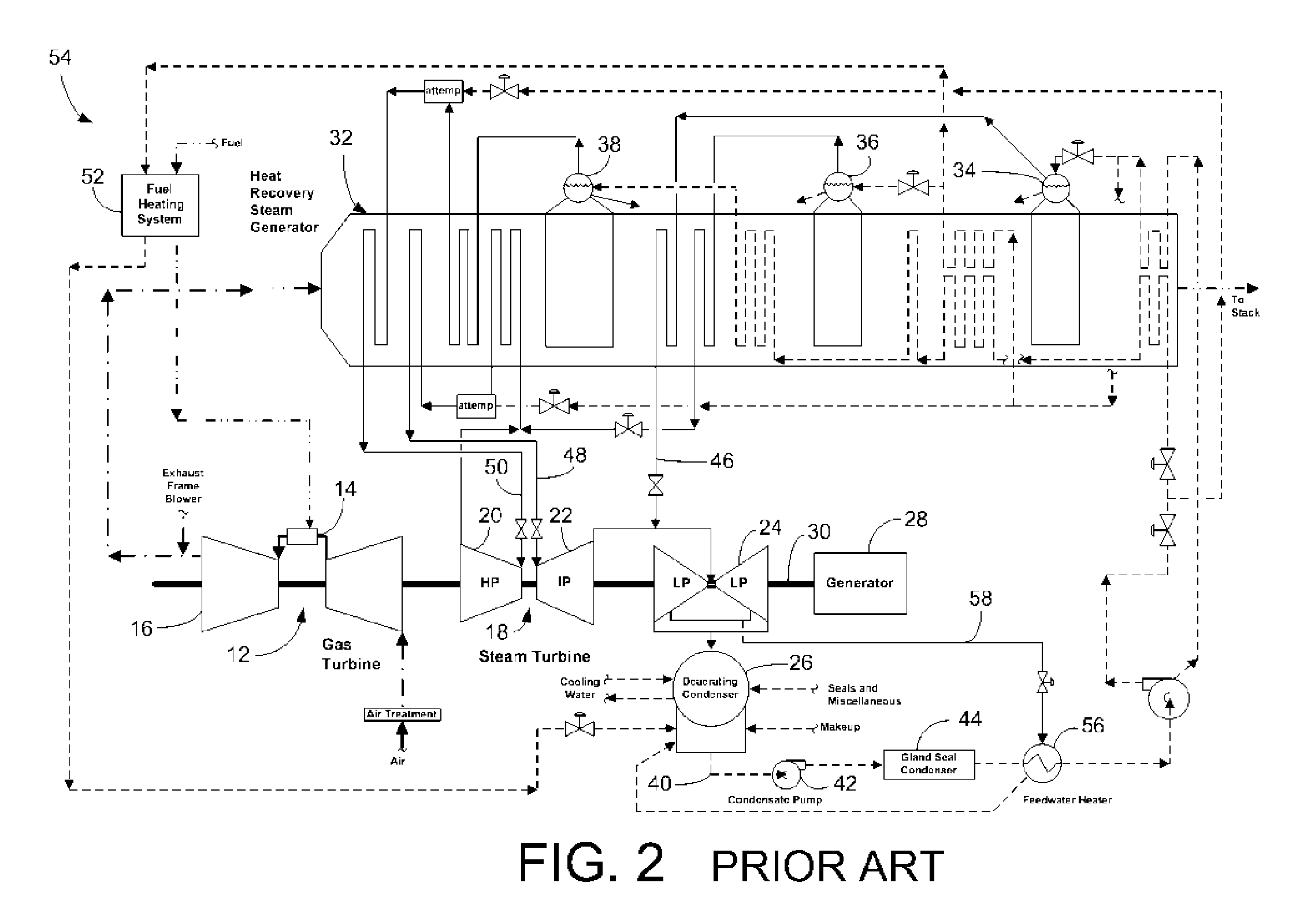

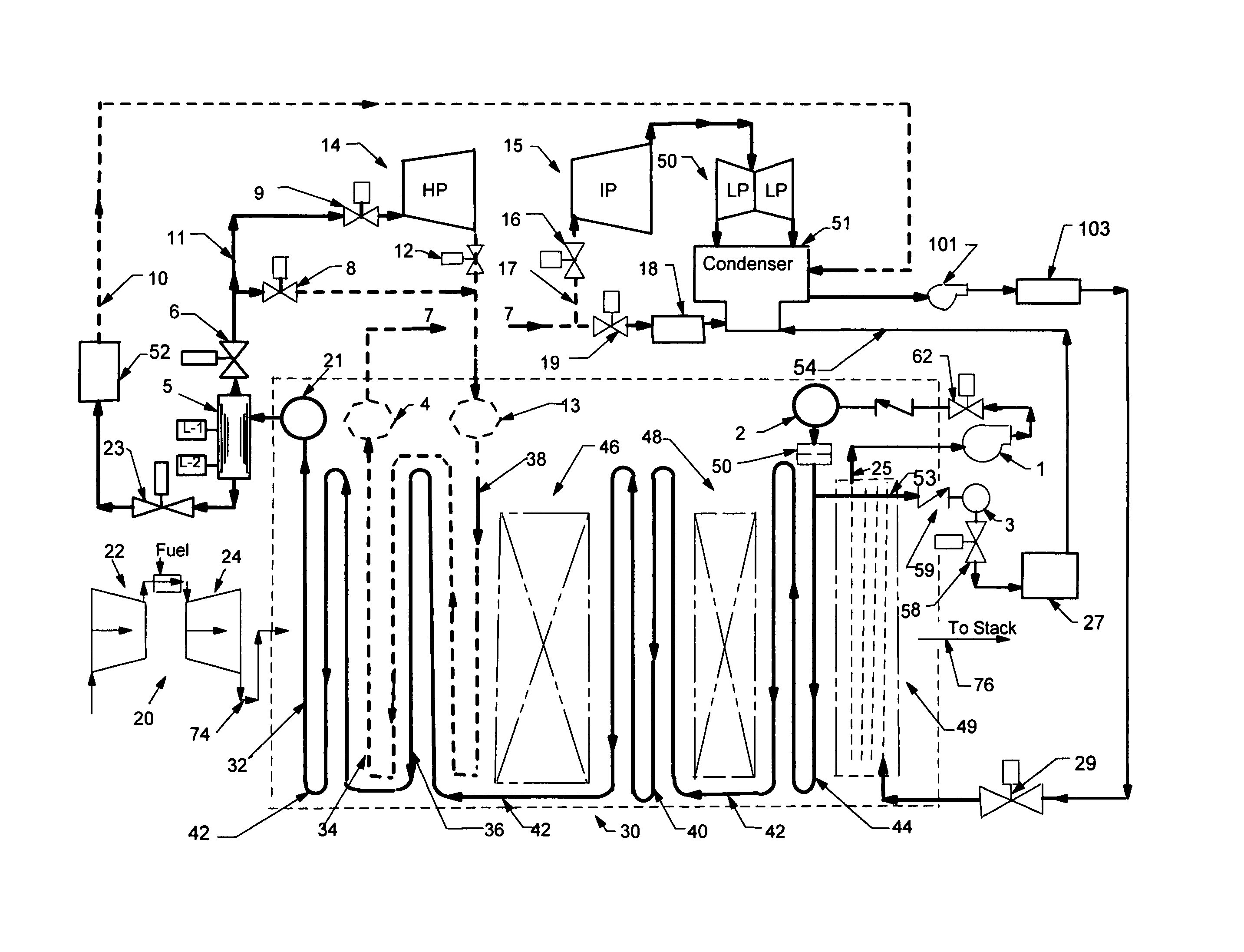

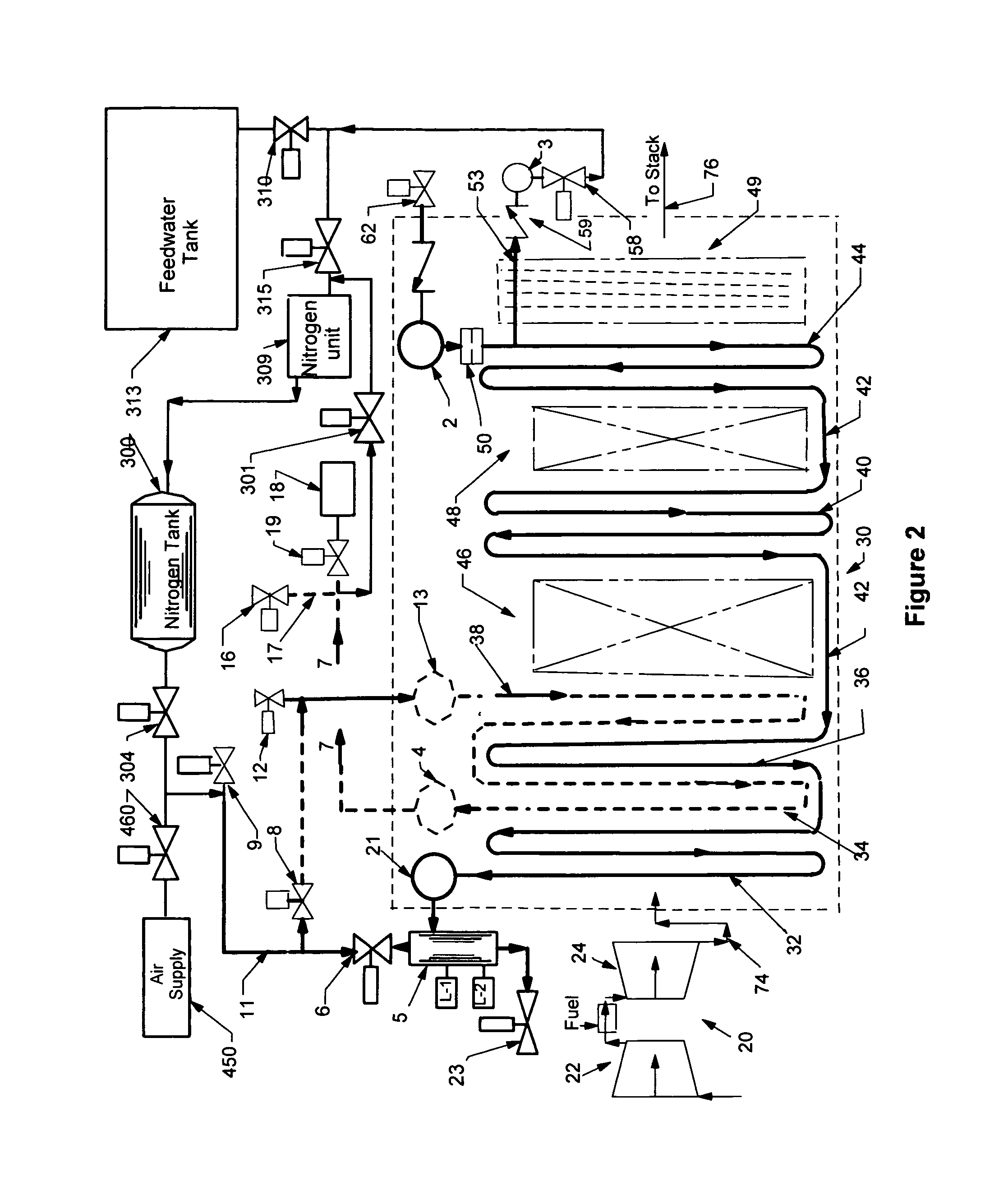

Exhaust heat augmentation in a combined cycle power plant

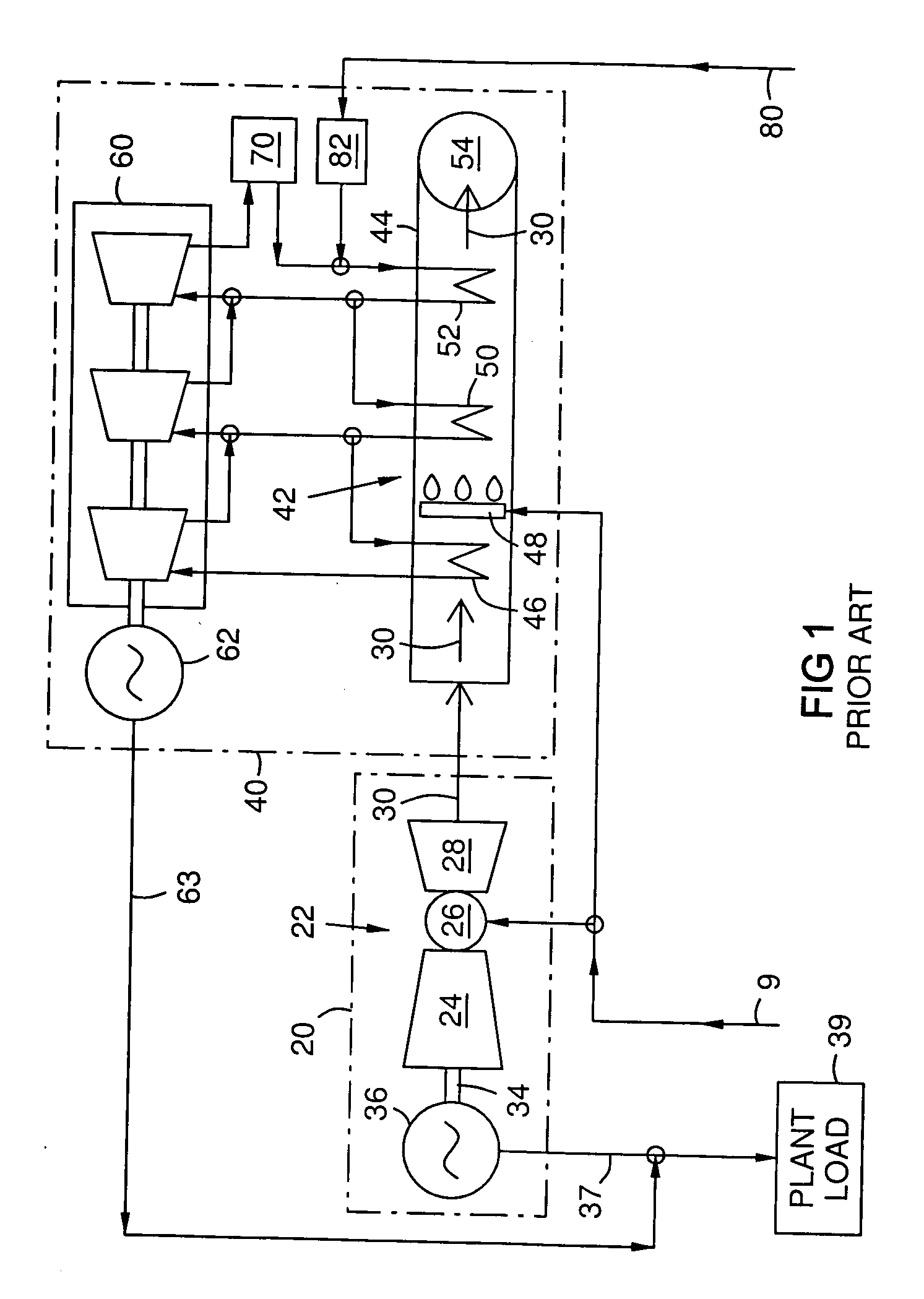

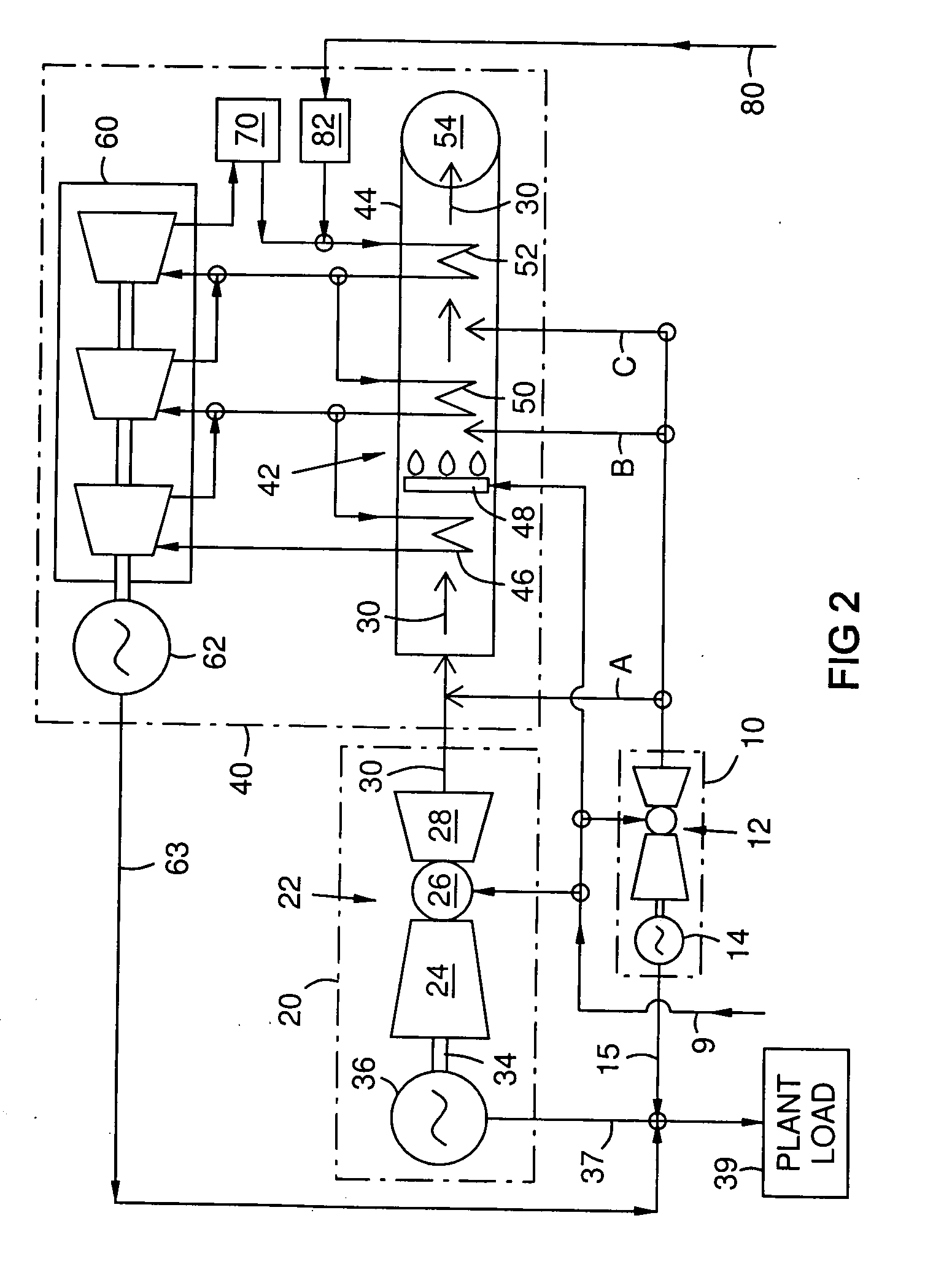

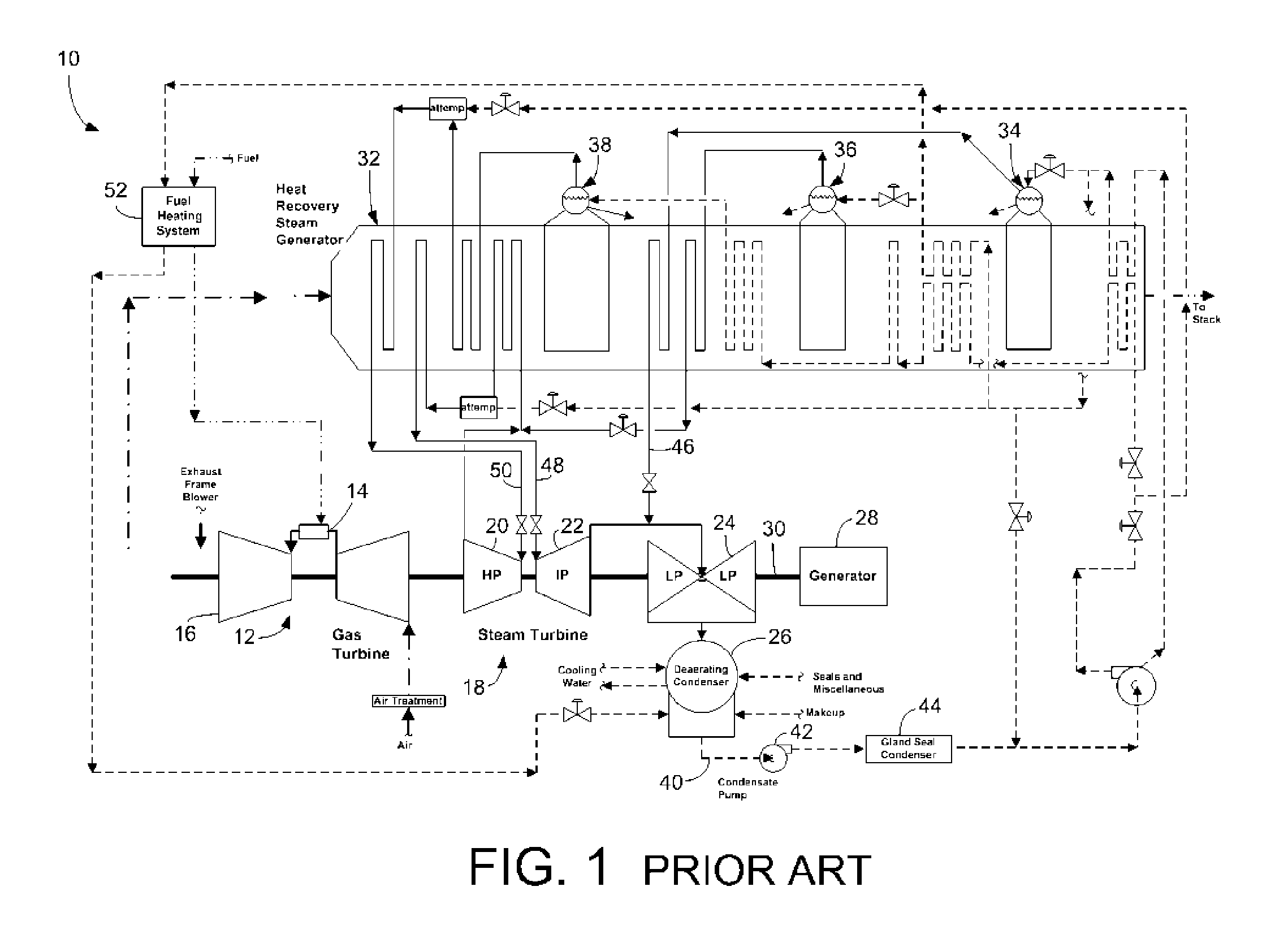

InactiveUS20070130952A1Gas turbine plantsCombined combustion mitigationPower stationElectric generator

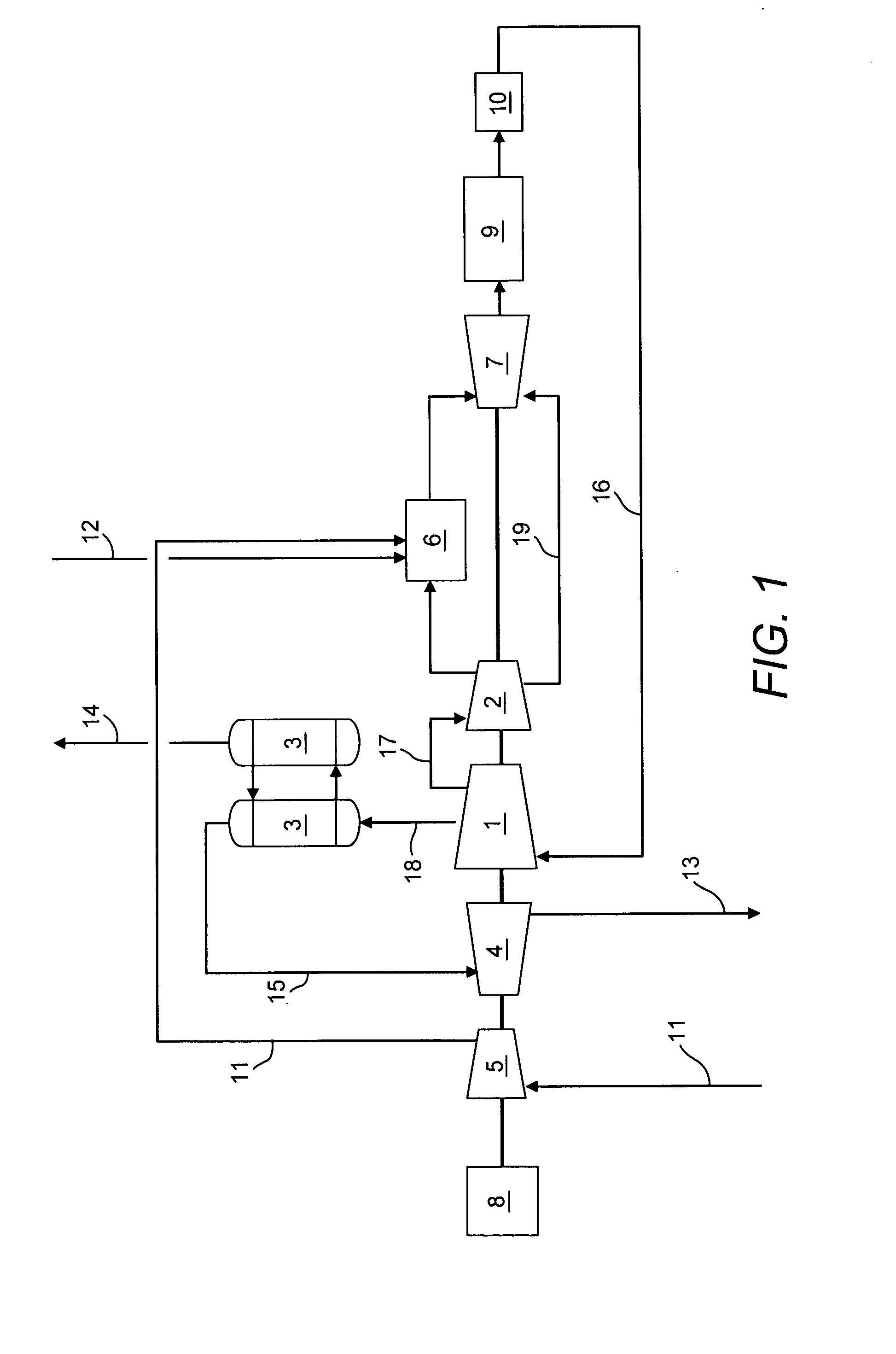

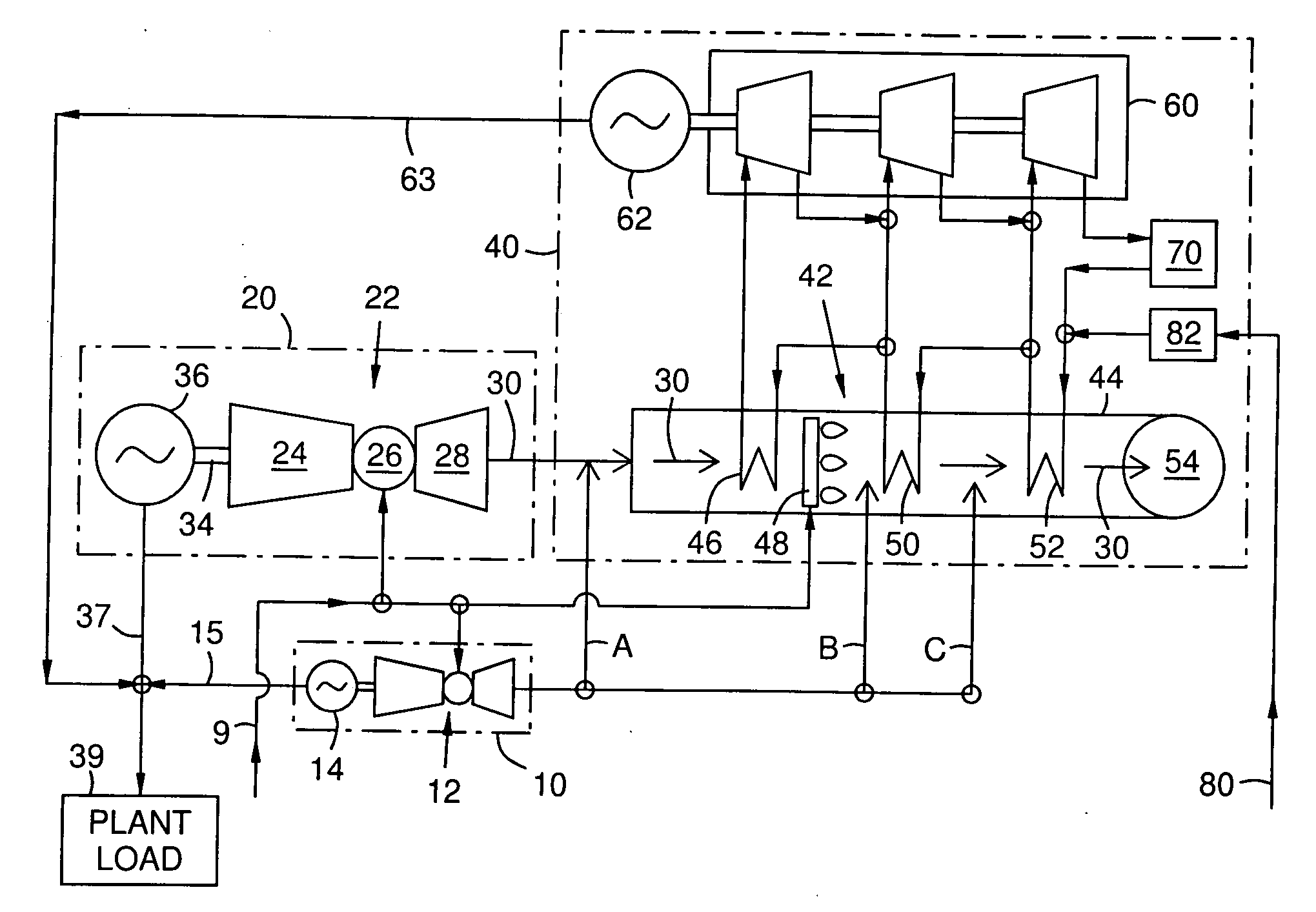

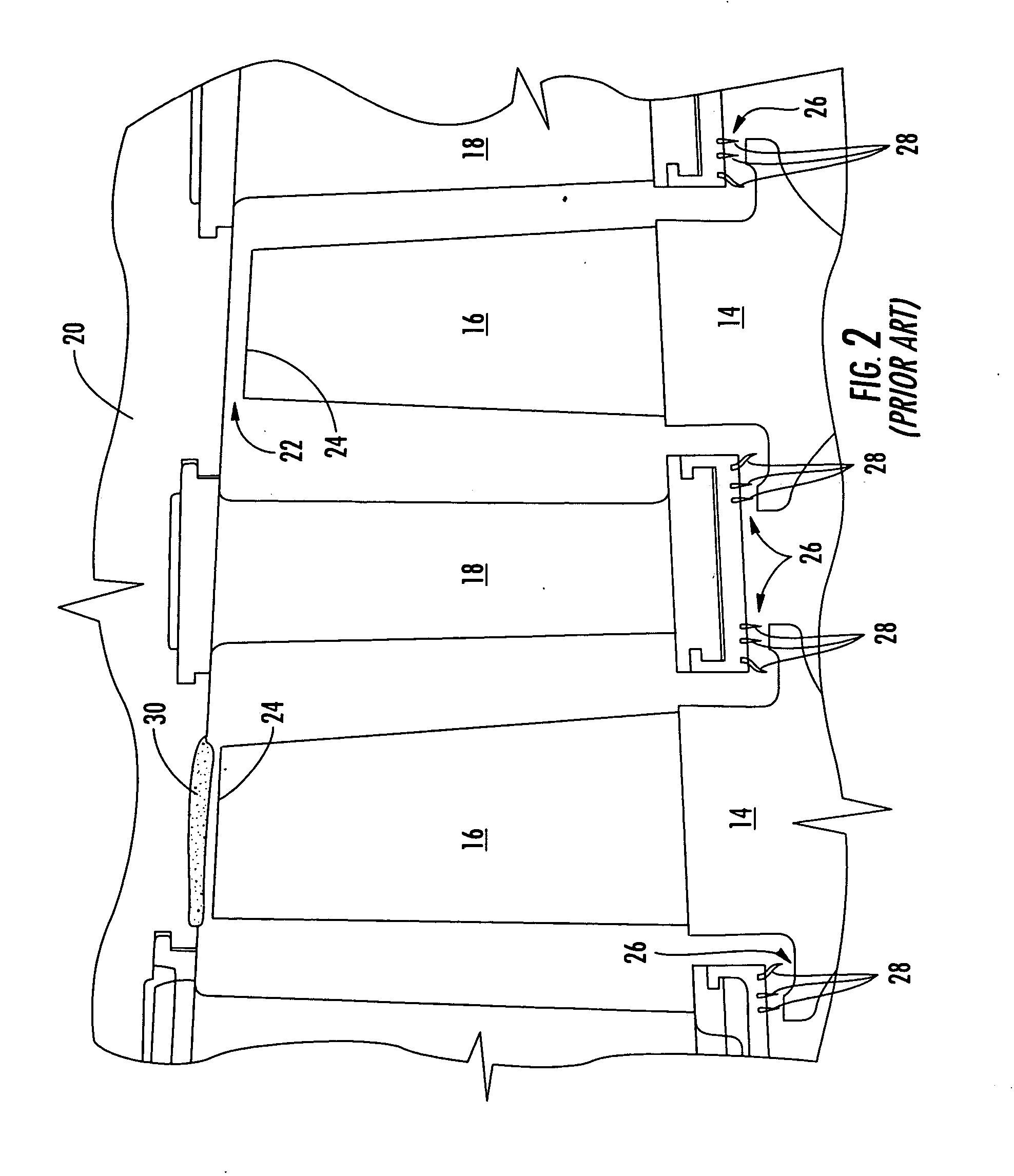

A method and system for augmenting the output of a combined cycle power plant having a base gas turbine (22) driving a generator (36) and a heat recovery steam generator (42) that recovers exhaust heat (30) from the base gas turbine (22) to drive a steam turbine (60). A complementary gas turbine engine (12) is added to the power plant to drive a complementary generator (14). The exhaust (A, B, C) of the complementary gas turbine (12) is merged into the flow path of exhaust gas (30) from the base gas turbine (22) upstream of a selected one or more heat exchangers (46, 50, 52) in the heat recovery steam generator (42). Such a complementary system (10) may be used together with supplemental duct burners (48) in a hybrid augmentation embodiment.

Owner:SIEMENS ENERGY INC

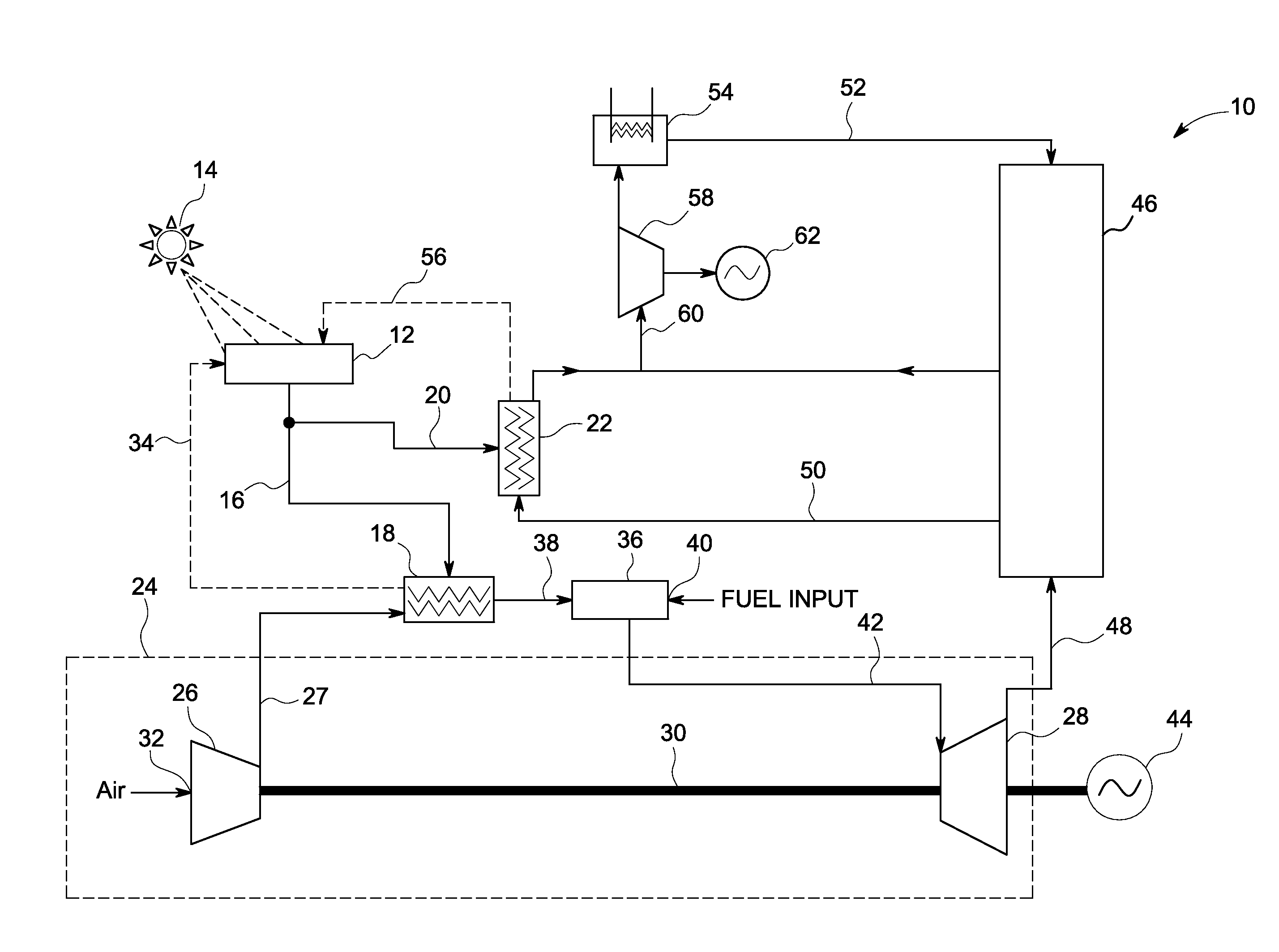

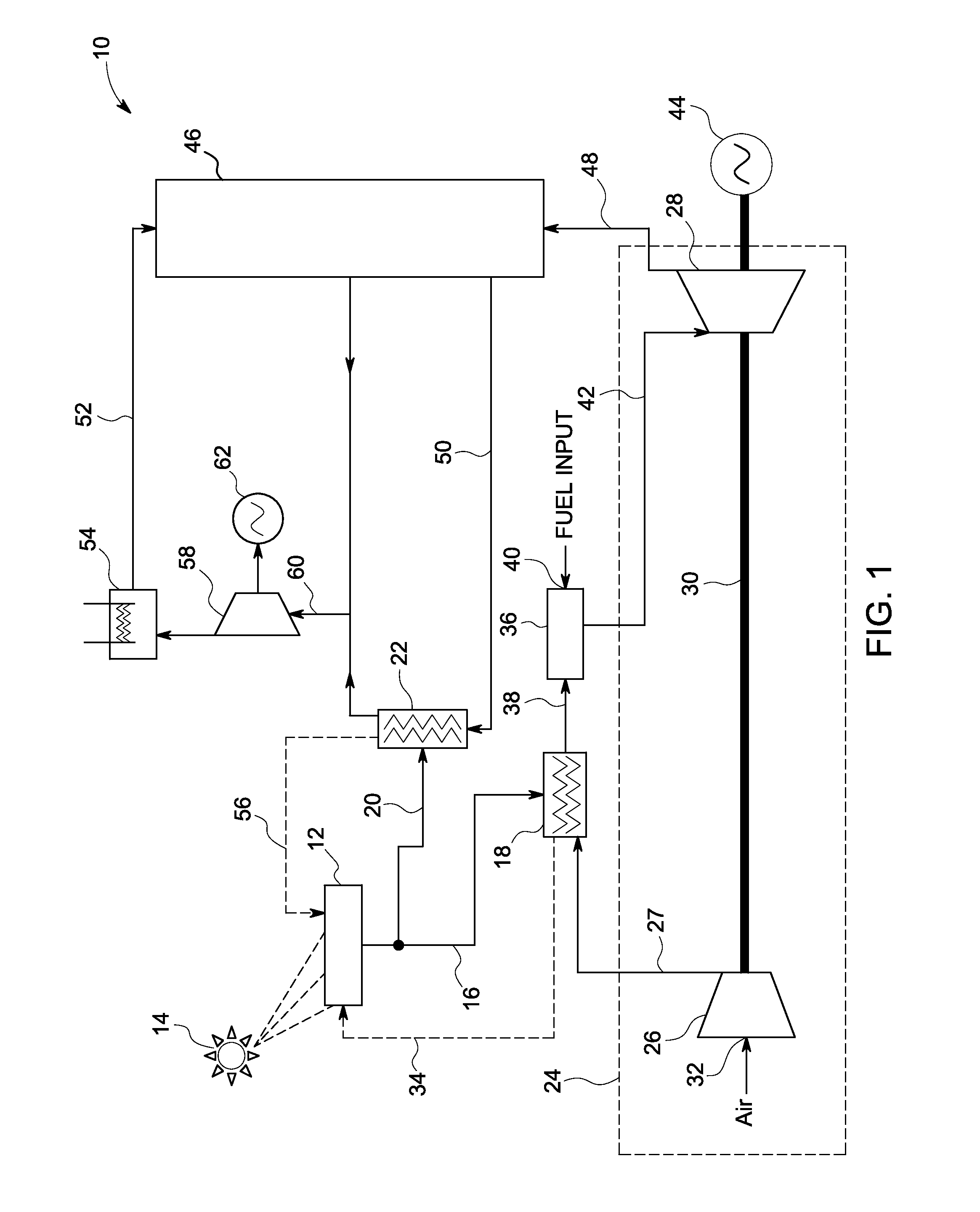

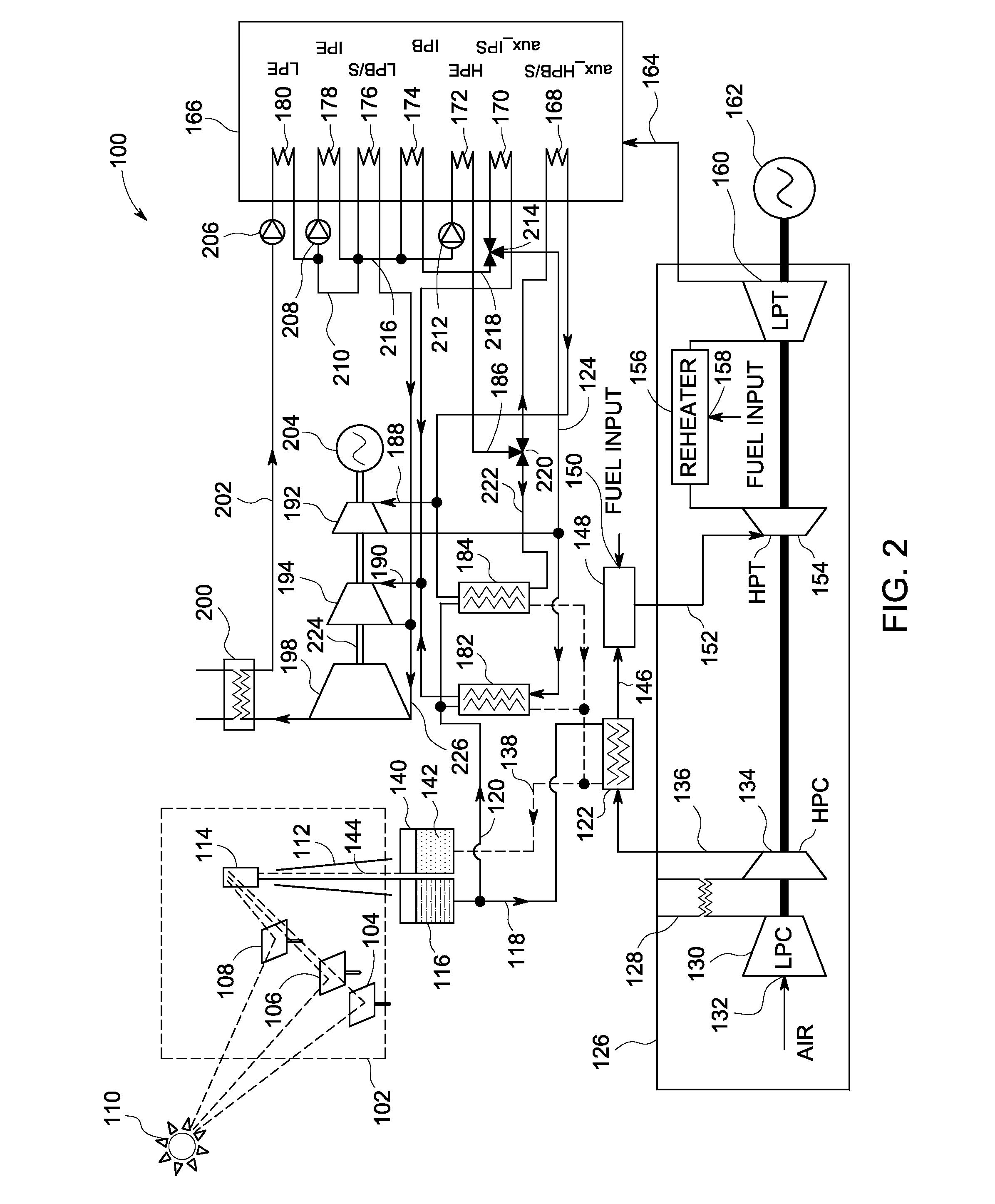

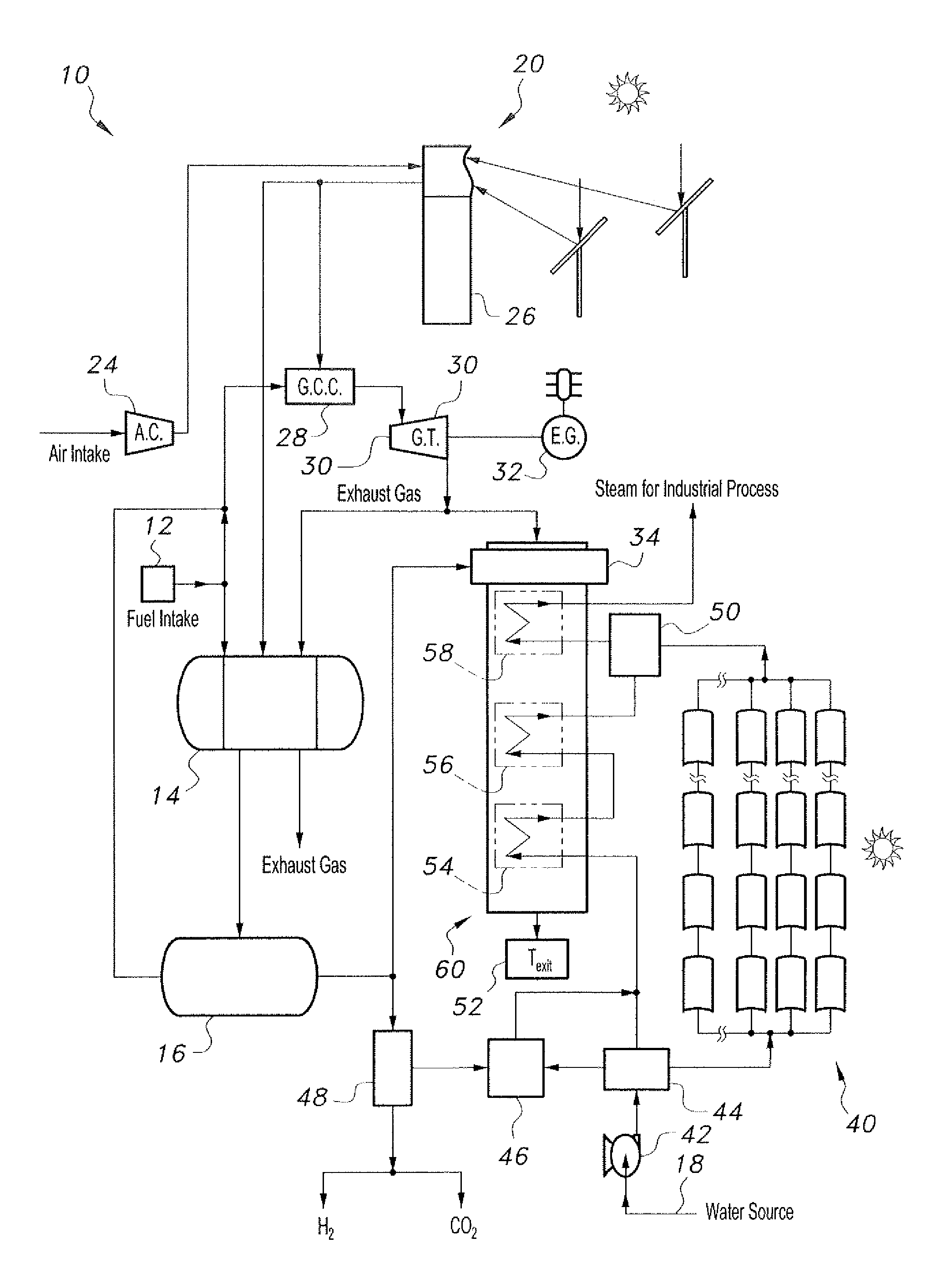

System for generation of power using solar energy

An electricity generation system is presented. The electricity generation system includes a solar preheater for preheating compressed discharge air, a combustor to receive the heated compressed air from the solar preheater, burn a fuel using the heated compressed air to generate hot burned gas, a first turbine to receive the hot burned gas from the combustor, expand the hot burned gas to generate exhaust gas, a heat recovery steam generator to receive the exhaust gas from the first turbine, generate vapor by heating a condensed fluid using the exhaust gas, a solar evaporator / superheater to receive a heated working fluid from the heat recovery steam generator, generate solar vapor by heating the heated working fluid, and a second turbine to drive a second generator using vapor and the solar vapor.

Owner:GENERAL ELECTRIC CO

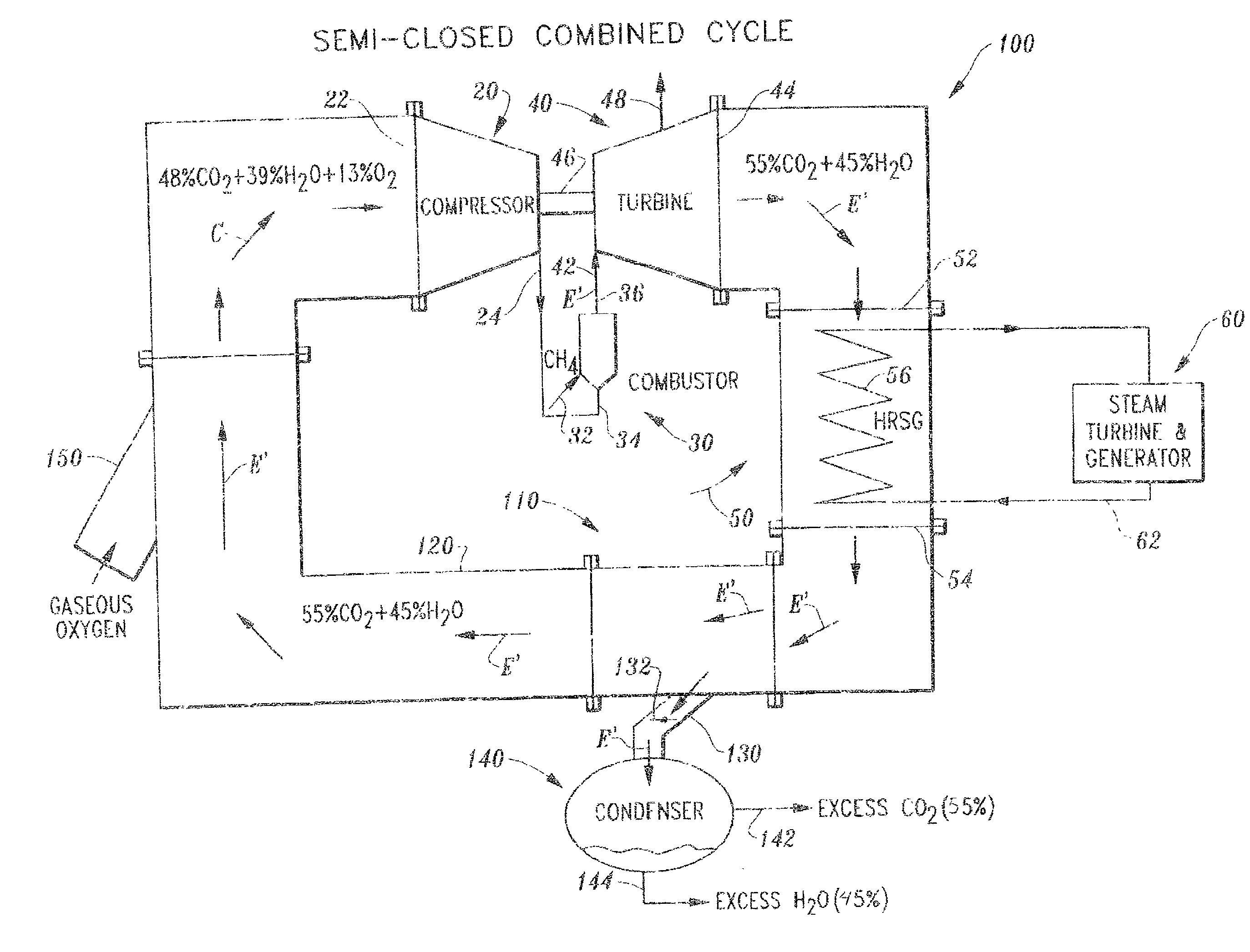

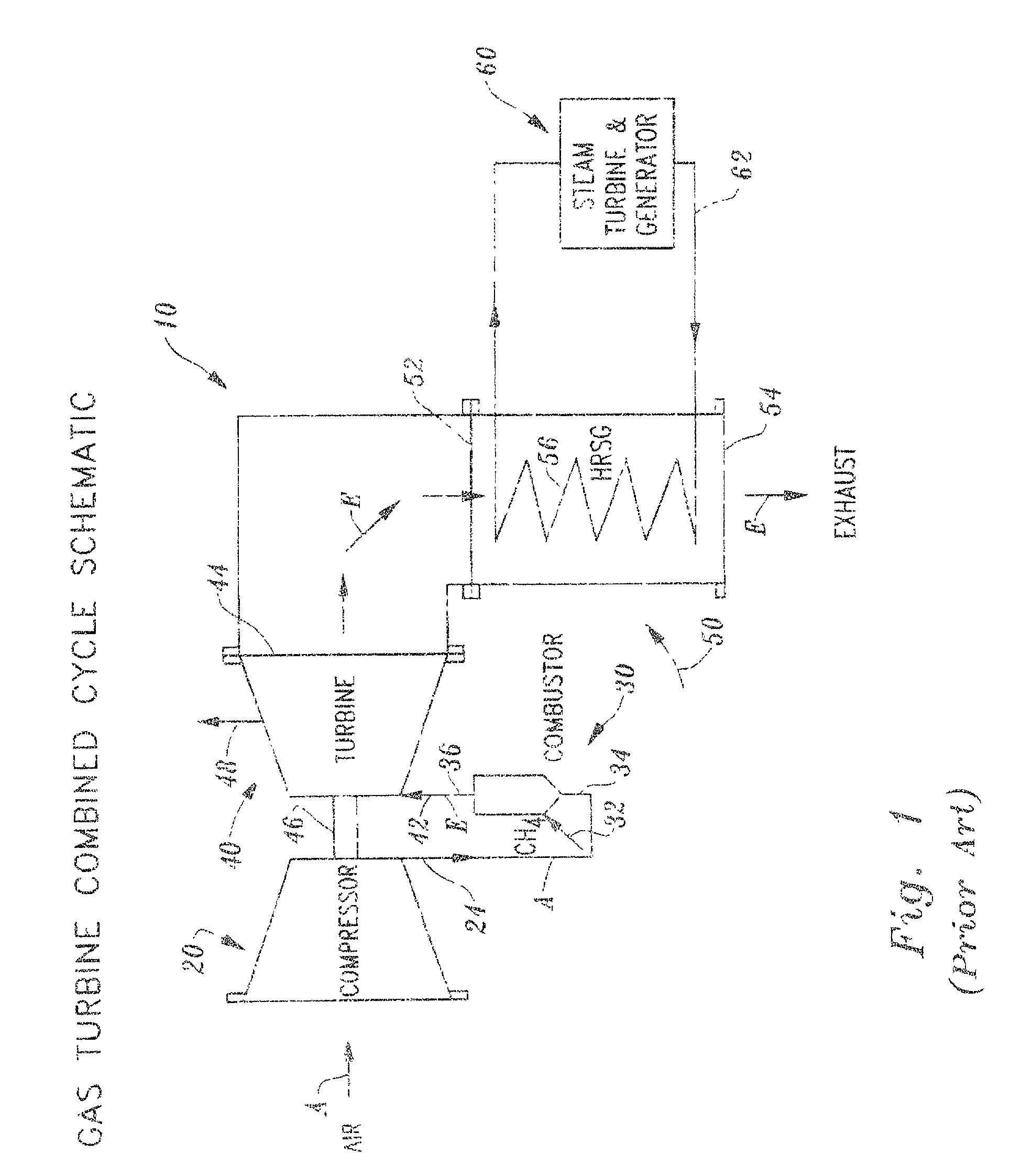

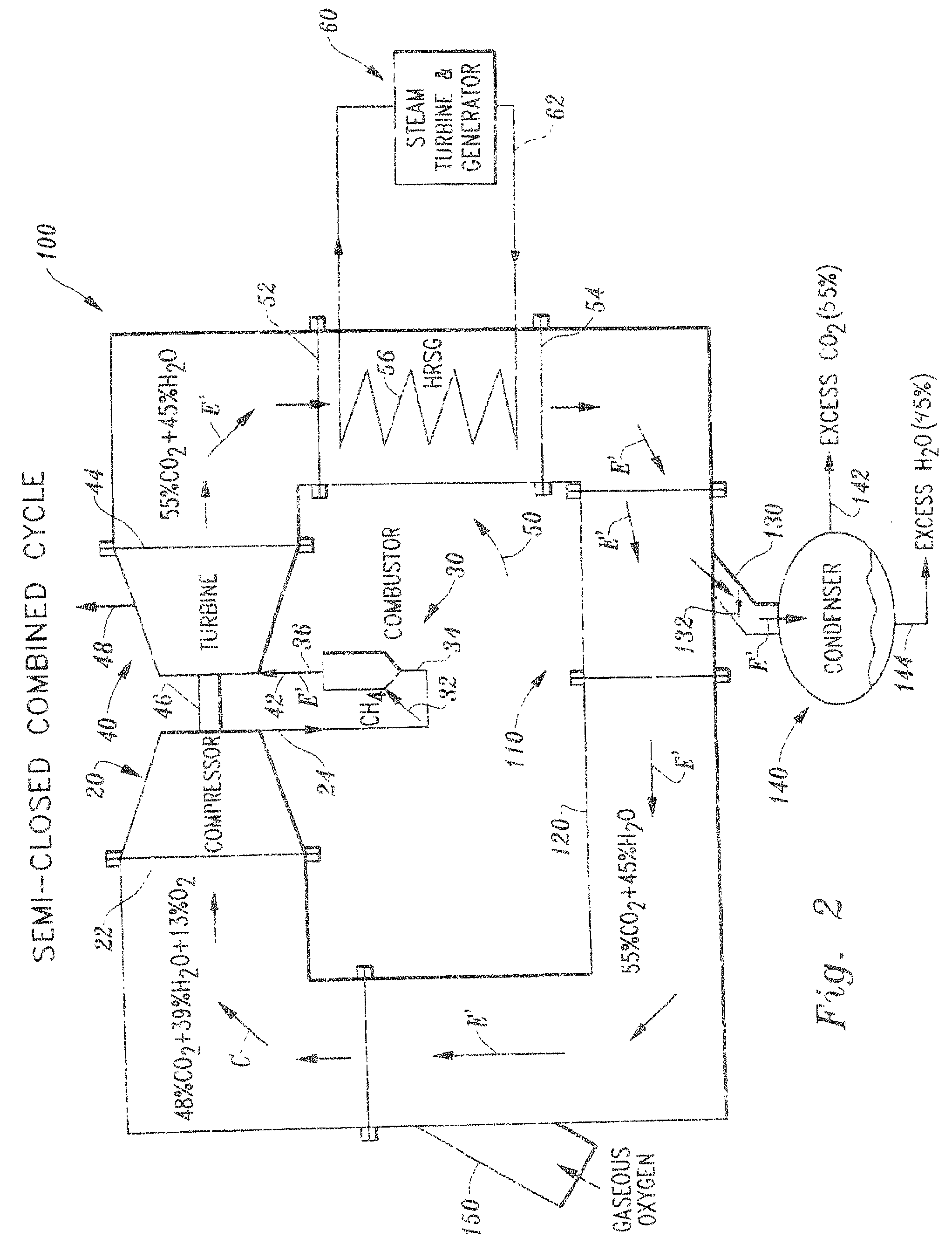

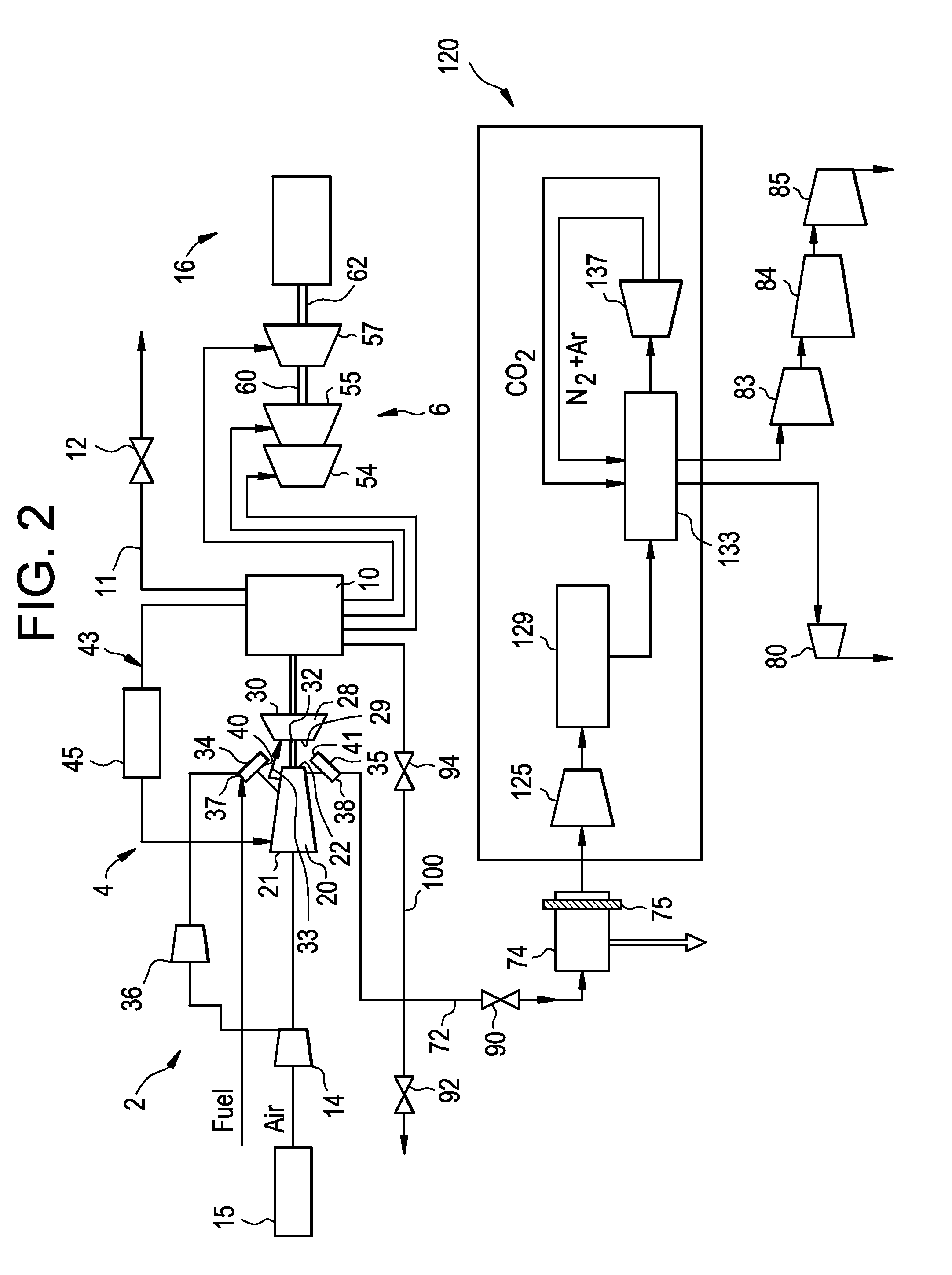

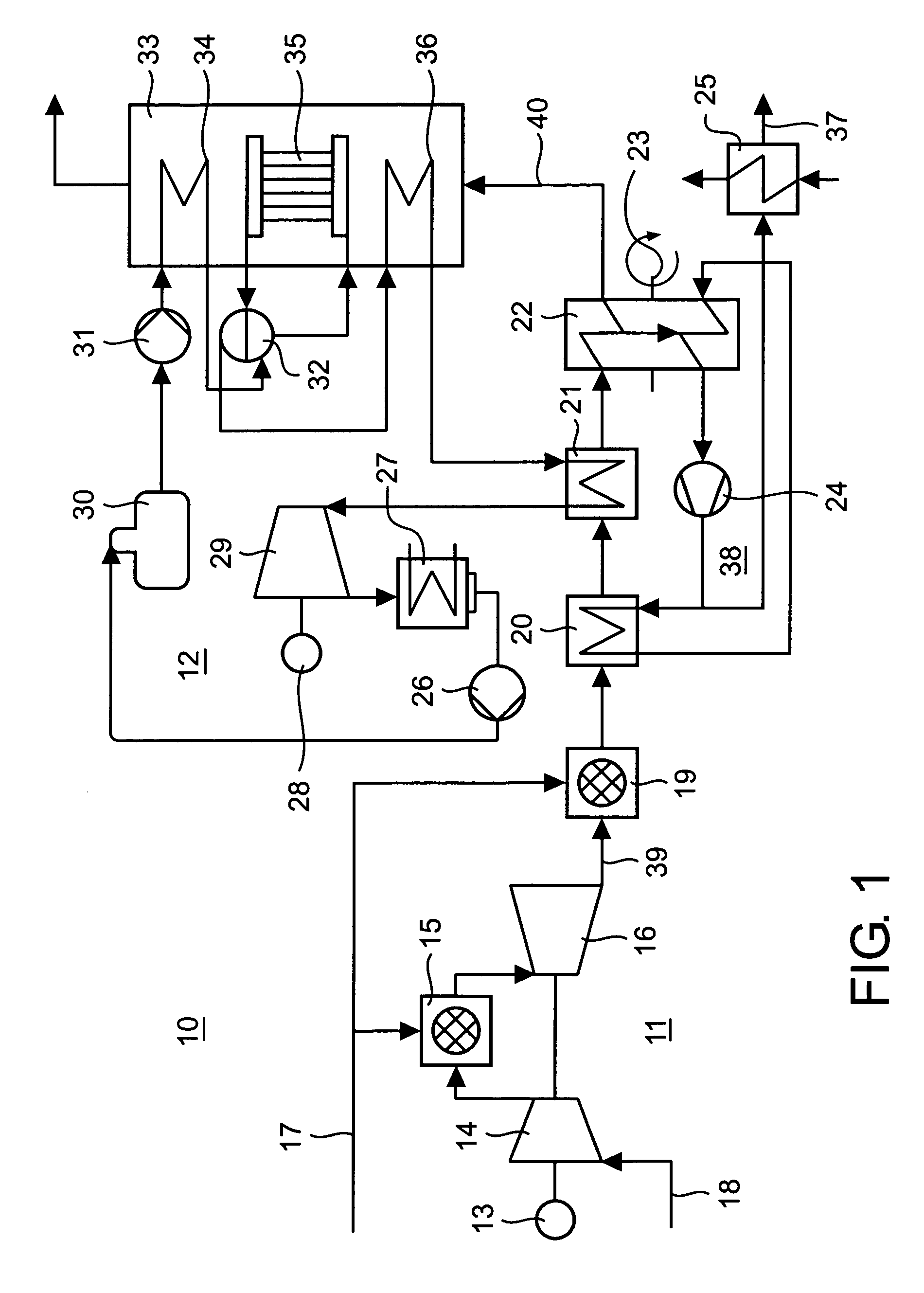

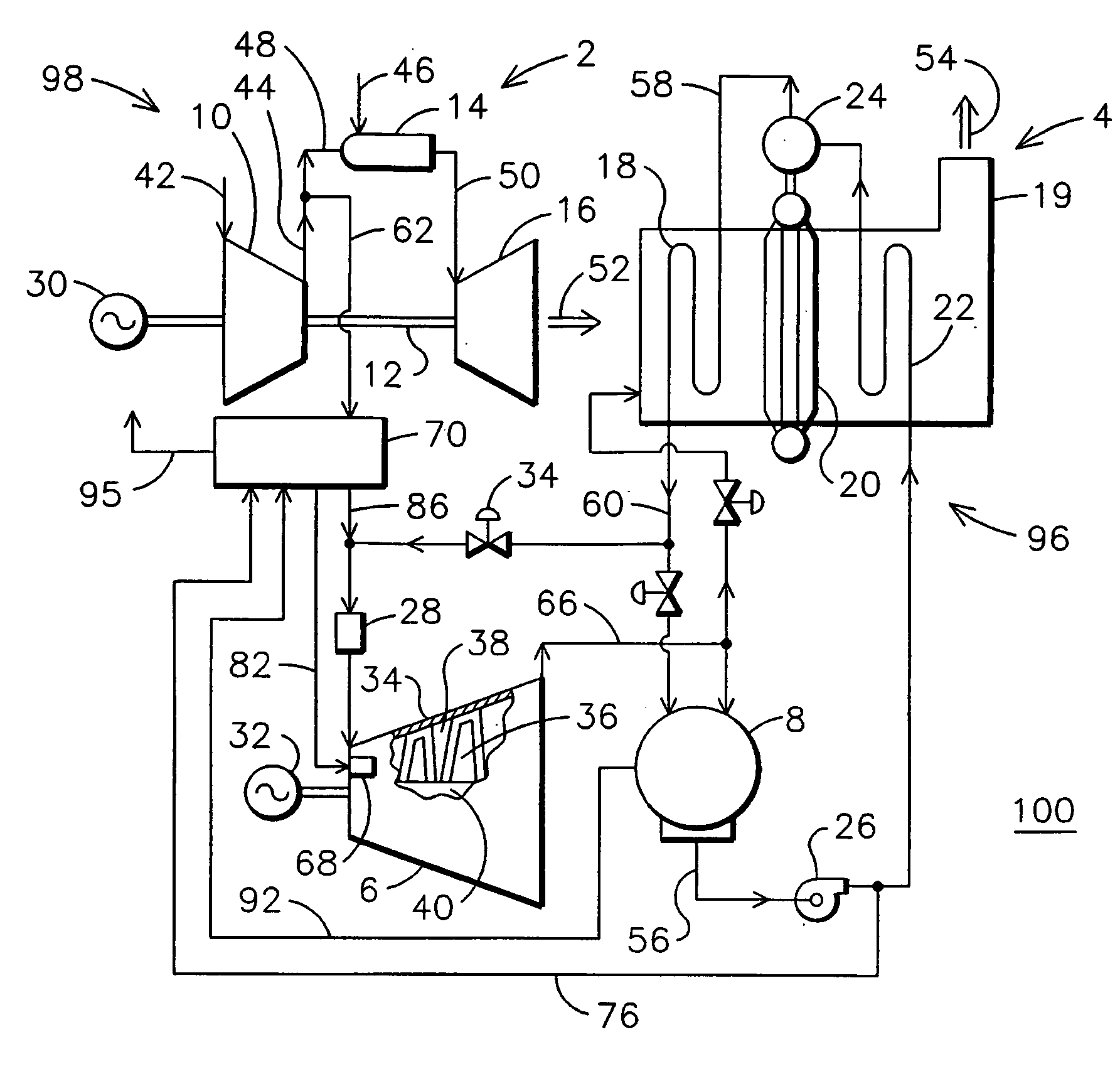

Semi-closed brayton cycle gas turbine power systems

InactiveUS20020023423A1Efficient collectionEliminate emissionsEnergy industryEfficient propulsion technologiesAtmospheric airElectric power system

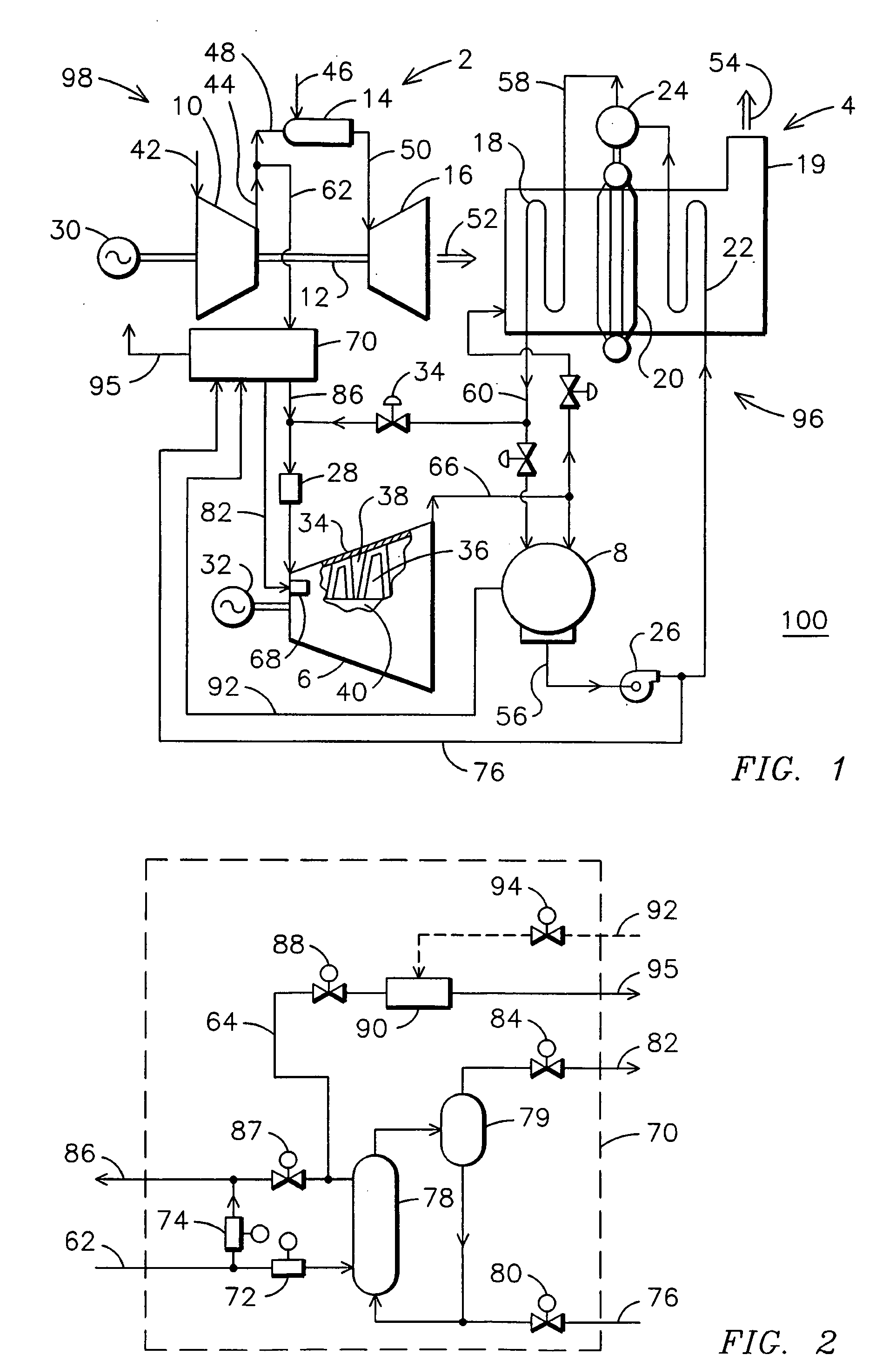

A semi-closed combined cycle power system 100 is provided which can also convert an open combined cycle gas turbine 10 into a non-polluting zero emissions power system. The prior art open combined cycle gas turbine 10 includes a compressor 20 which compresses air A' and combusts the air A' with a fuel, such as natural gas. The products of combustion and the remaining portions of the air form the exhaust E' which is expanded through the turbine 40. The turbine 40 drives the compressor 20 and outputs power. The exhaust E' exits the turbine 40 and then can optionally be routed through a heat recovery steam generator 50 to function as a combined cycle. According to this invention, the exhaust E' is not emitted into the atmosphere, but rather is routed to a divider 110. The divider 110 includes two outlets for the exhaust E' including a return duct 120 and a separation duct 130 which both receive a portion of the exhaust E'. The return duct 120 routes a portion of the exhaust E' back to the compressor 20. Before reaching the compressor 20, an oxygen duct 150 adds additional oxygen to the exhaust E' to form a gas mixture C which includes CO2 and steam from the exhaust E' and oxygen from the oxygen duct 150. This gas mixture C has characteristics which mimic those of air, so that the compressor 20 need not be modified to effectively compress the gas mixture C. The gas mixture C is compressed within the compressor 20 and routed to the combustor 30 where the fuel combusts with the oxygen of the gas mixture C' and produces exhaust E' which is substantially entirely CO2 and steam. This exhaust E' is routed through the turbine 40 and expanded to drive the compressor 20 and output power. The exhaust E' exits the turbine 40 and is routed back to the divider 110, preferably by way of a heat recovery steam generator 50 or other heat removal device, so that the semi-closed cycle operates as a combined cycle power system 100. The divider 110 directs a portion of the exhaust E' to a separation duct 130 which leads to a condenser 140. In the condenser 140 the exhaust E' is separated by condensation of the steam / water portion of the exhaust and removal of the remaining CO2 as gas from the condenser 140. The only exhaust from the semi-closed power system 100 is water and CO2 from the condenser. The CO2 exhaust is substantially pure and ready for appropriate further handling and disposal. Hence, no pollutants are emitted from the semi-closed power system 100. The return duct 120 can

Owner:CLEAN ENERGY SYST

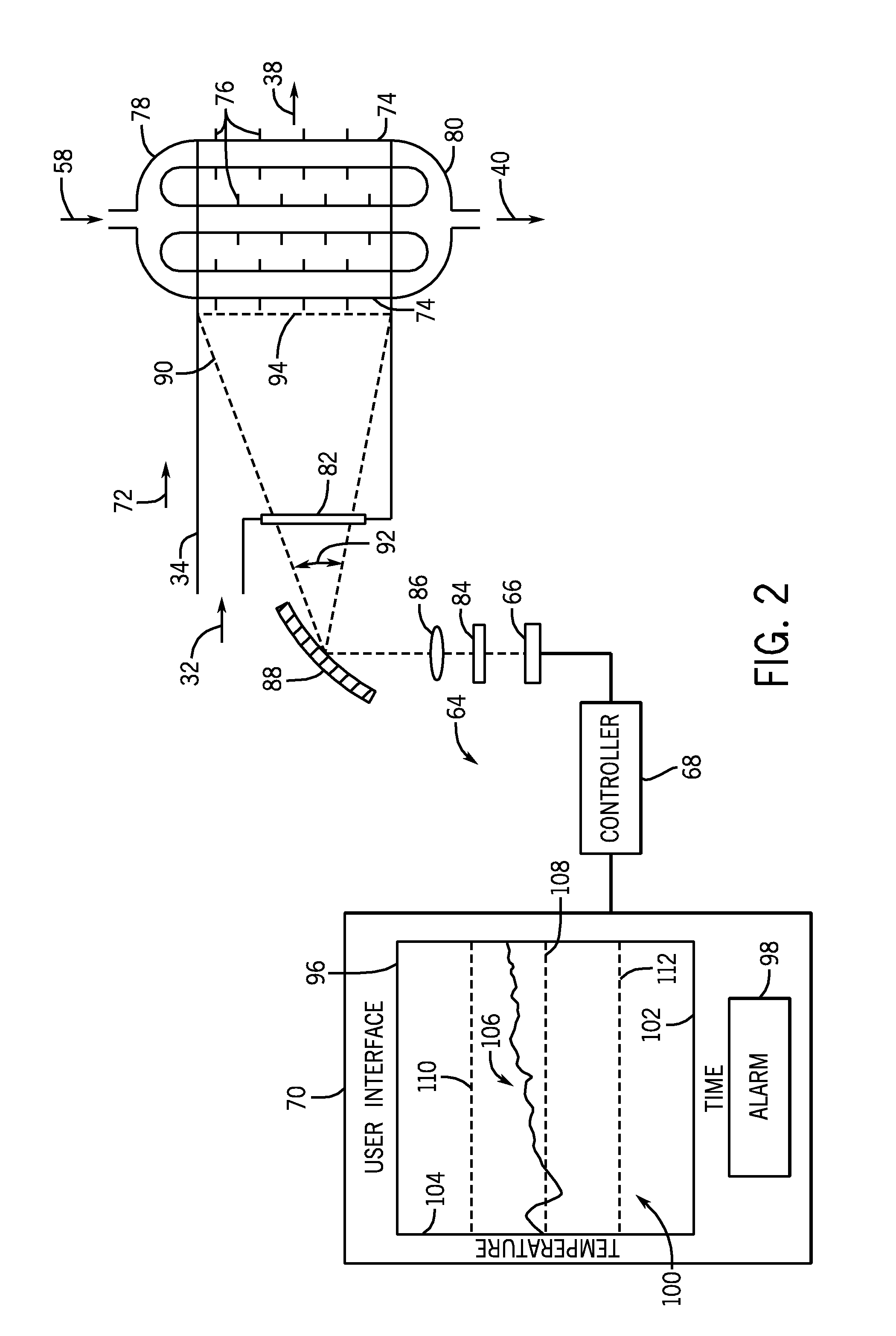

Thermal measurement system for fault detection within a power generation system

InactiveUS20120032810A1Sensing radiation from gases/flamesElectrical testingEngineeringRadiation sensor

A system includes a radiation sensor configured to direct a field of view toward a conduit within a heat recovery steam generator, and to output a signal indicative of a temperature of the conduit. The system also includes a controller communicatively coupled to the radiation sensor. The controller is configured to determine the temperature based on the signal, and to compare the temperature to a threshold value.

Owner:GENERAL ELECTRIC CO

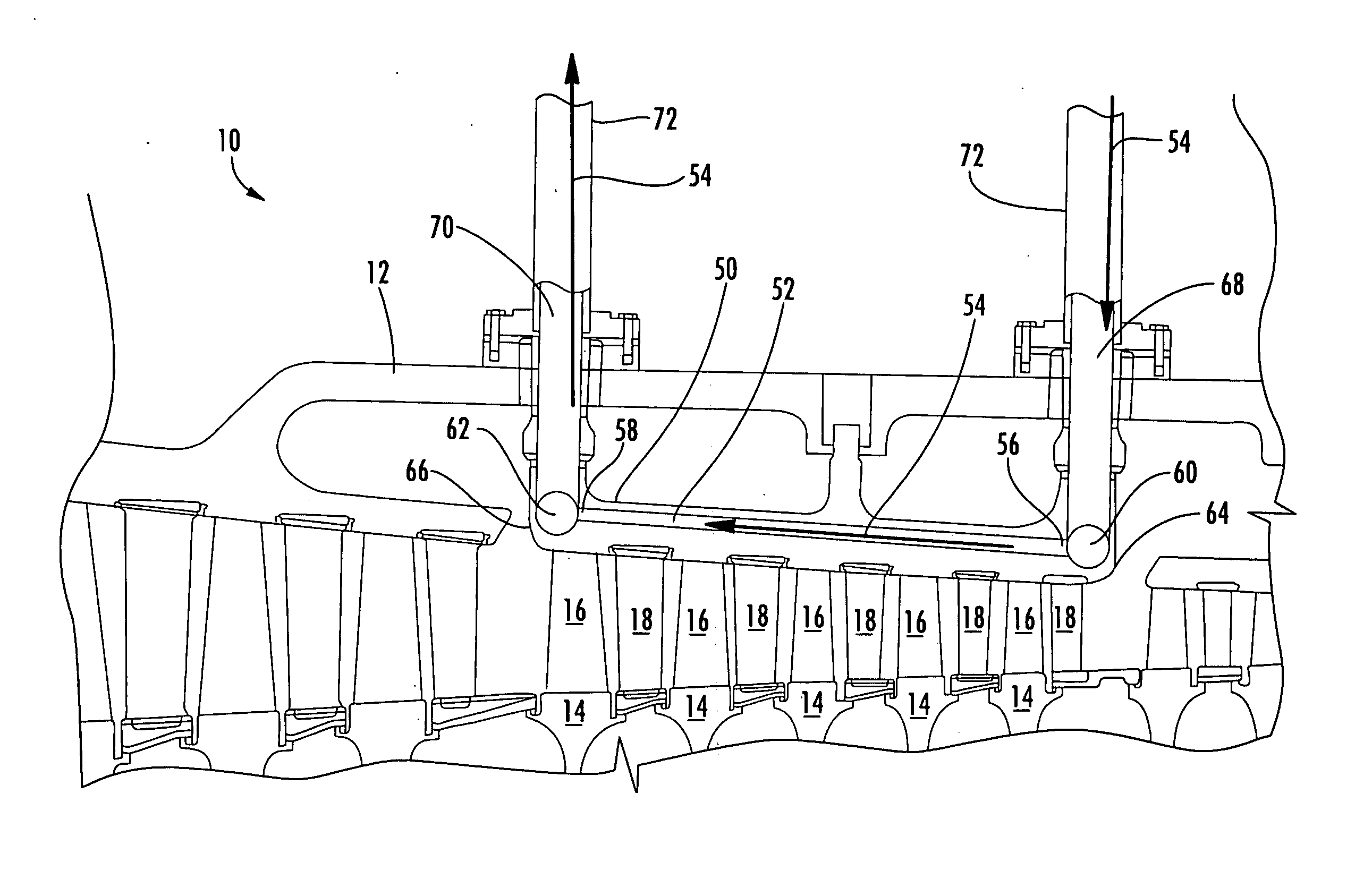

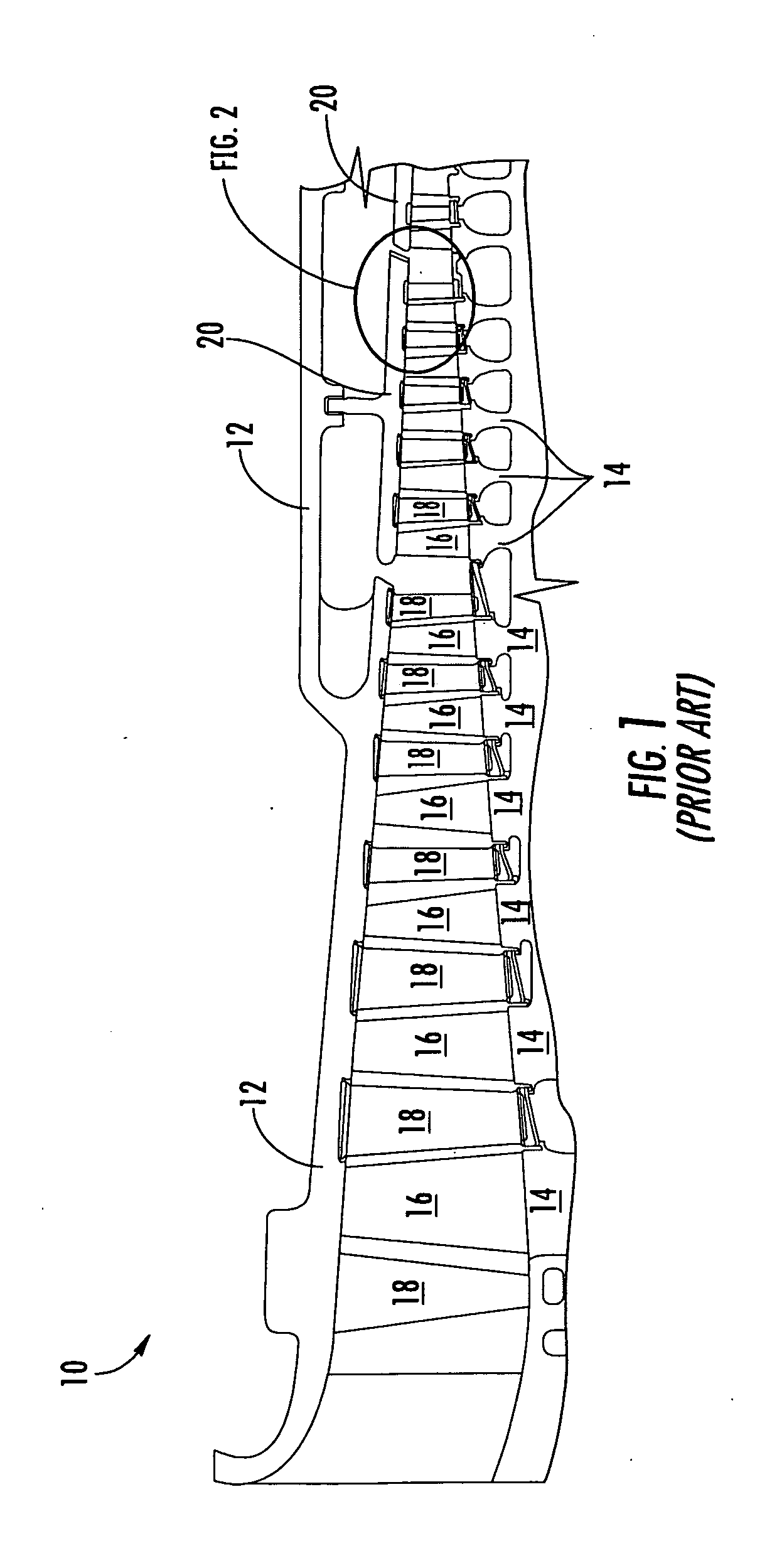

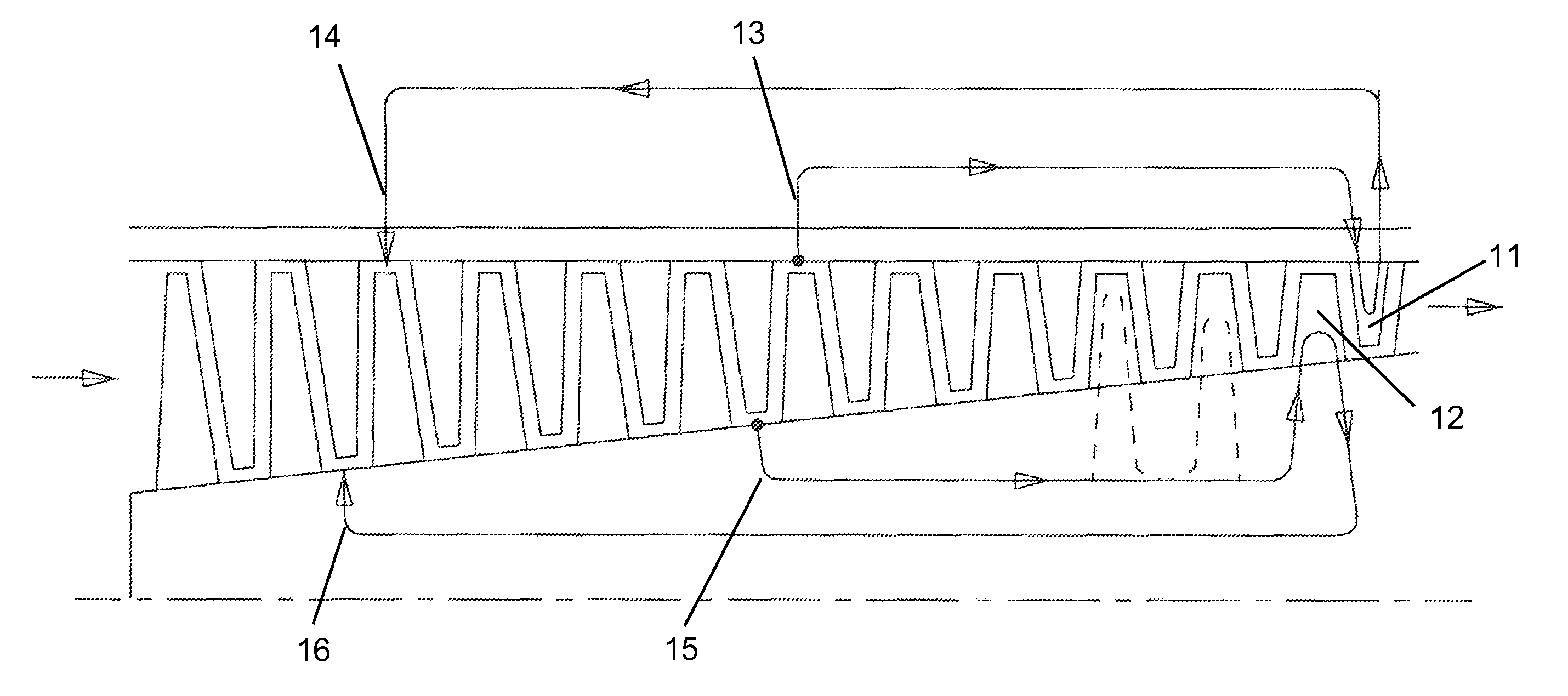

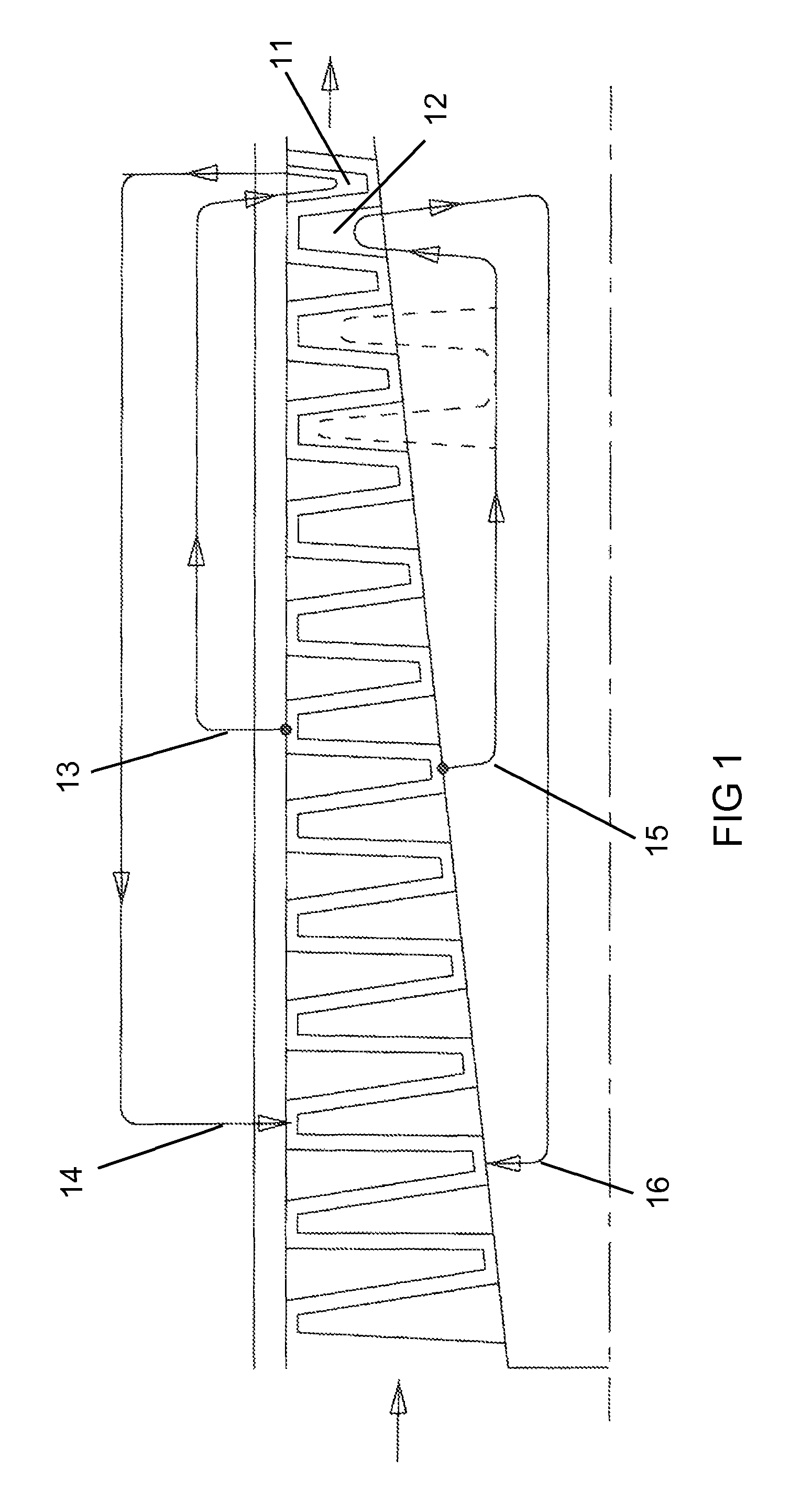

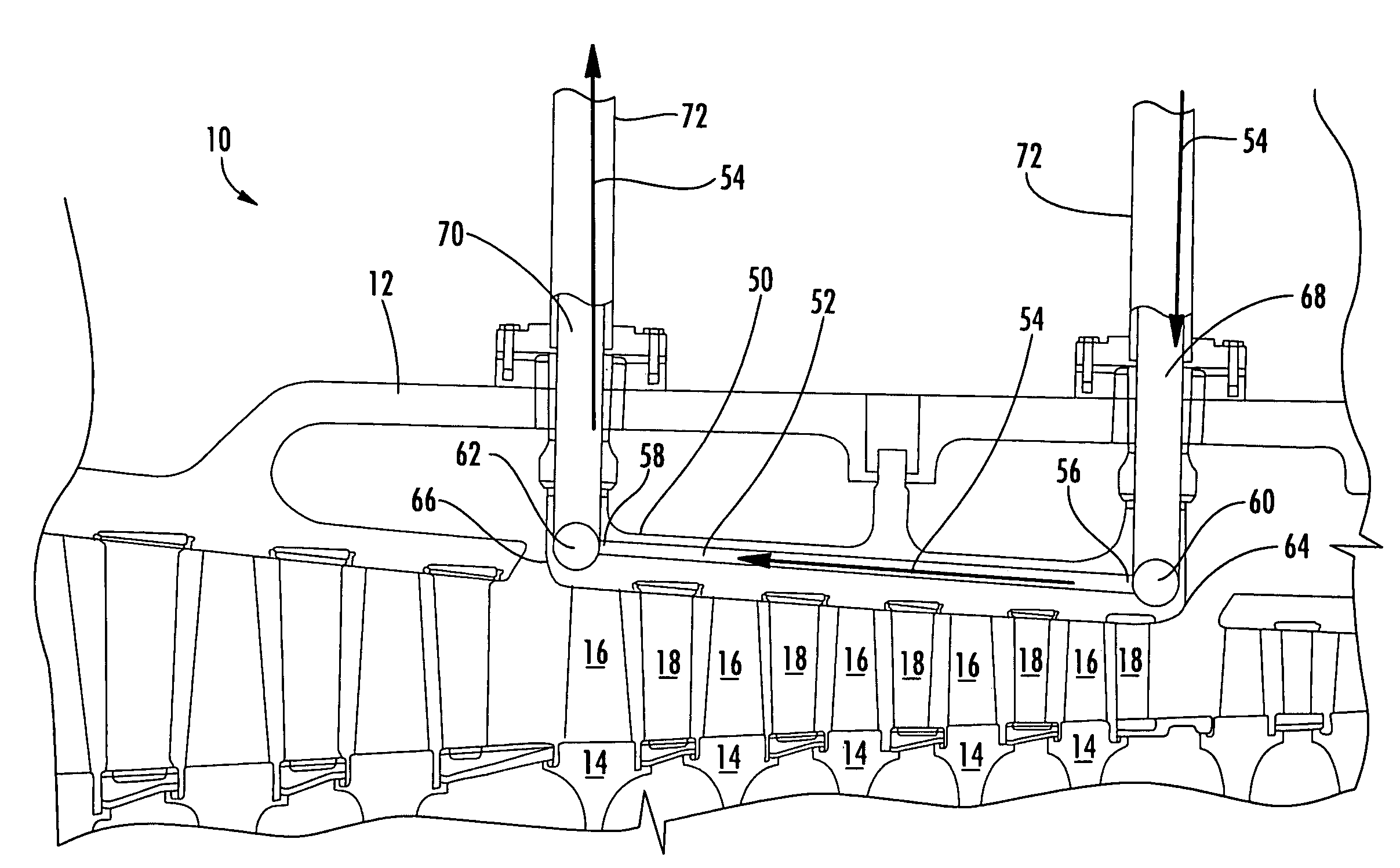

System for actively controlling compressor clearances

InactiveUS20060225430A1Reduce the temperatureMinimize radial expansionPump componentsEngine fuctionsEngineeringBleed air

Aspects of the invention relate to a system and method for actively controlling compressor clearances in a turbine engine by passing a thermal fluid in heat exchanging relation through a compressor vane carrier. During some operational conditions, such as hot restart or spin cool, it may be desirable to heat the vane carrier to enlarge or at least prevent a decrease in compressor clearances. In such cases, a heated thermal fluid can be provided by reclaiming residual exhaust energy from a heat recovery steam generator. At any condition where improved performance is desired, such as at base load operation, the vane carrier can be cooled to minimize compressor clearances. A cooled thermal fluid can be bleed air from an upstream portion of the compressor, water-cooled high pressure bleed air from a downstream portion of the compressor, or feed water from the bottoming cycle in a combined cycle engine.

Owner:SIEMENS ENERGY INC

System and method to generate electricity

InactiveUS8166766B2Emission reductionReduce consumptionGas turbine plantsEngine controlElectricityProcess engineering

A split heat recovery steam generator (HRSG) arrangement including a first HRSG coupled to a turbine and thereby receptive of a portion of the exhaust gases to deliver the portion of the exhaust gases to a compressor, a second HRSG coupled to the turbine and thereby receptive of a remaining portion of the exhaust gases, which includes an NOx catalyst and a CO catalyst sequentially disposed therein to remove NOx and CO from the exhaust gases and an air injection apparatus to inject air into the second HRSG between the NOx catalyst and the CO catalyst to facilitate CO consumption at the CO catalyst.

Owner:GENERAL ELECTRIC CO

Combined cycle power plant including a carbon dioxide collection system

A combined cycle power plant includes a compressor section including a compressor inlet and a compressor outlet, and a turbine section operatively connected to the compressor section. The turbine section includes a turbine inlet and a turbine outlet. A heat recovery steam generator (HRSG) is fluidly connected to the turbine outlet. A combustor includes a head end and a combustor discharge. The head end is fluidly connected to the compressor outlet and the combustor discharge is fluidly connected to the turbine inlet. A carbon dioxide collection system is fluidly connected to one of the compressor outlet and the head end of the combustor. The carbon dioxide collection system is configured and disposed to extract a first fluid comprising carbon dioxide and a second fluid from a substantially oxygen free fluid flow passed from the one of the compressor outlet and the head end of the combustor.

Owner:GENERAL ELECTRIC CO

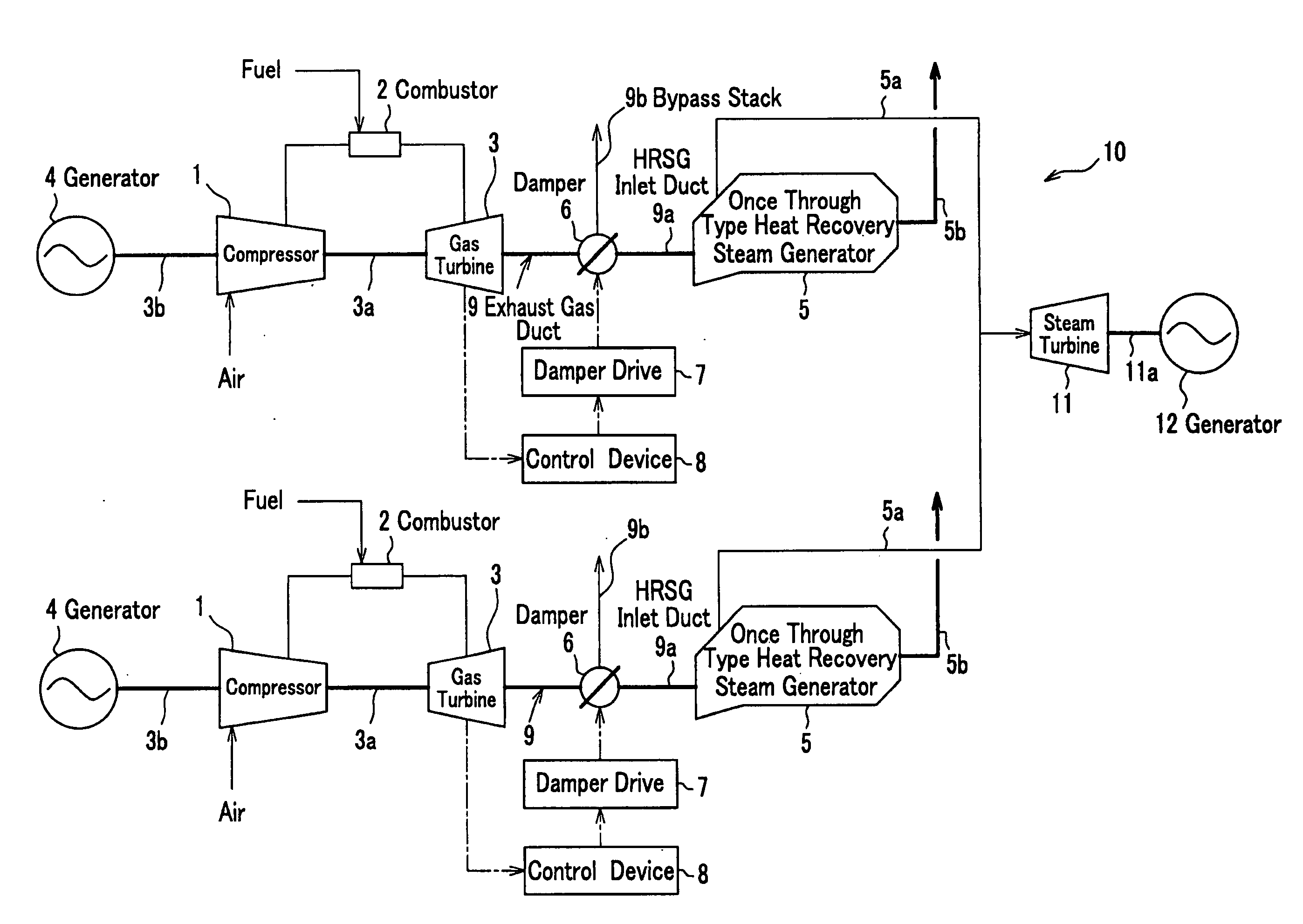

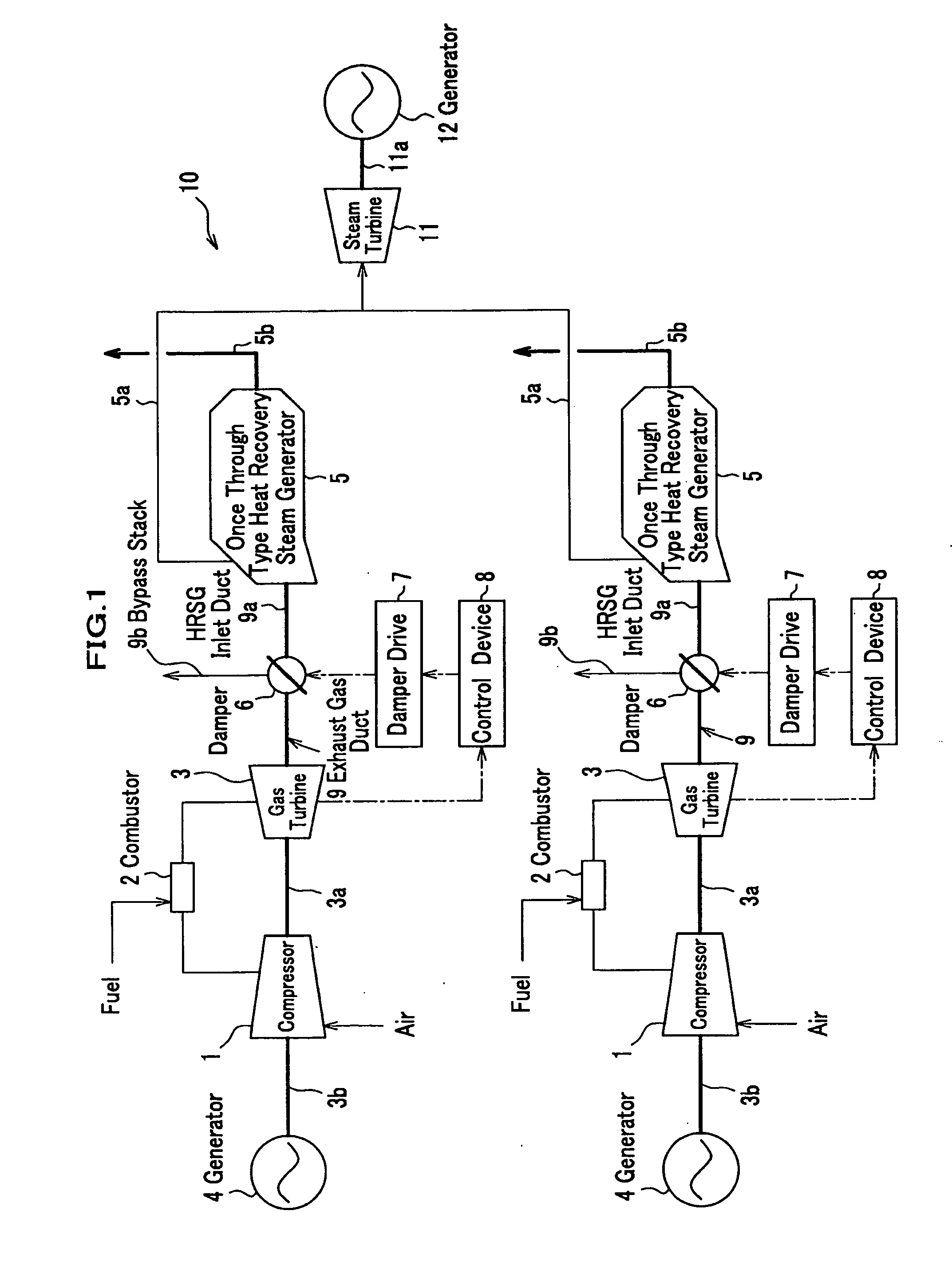

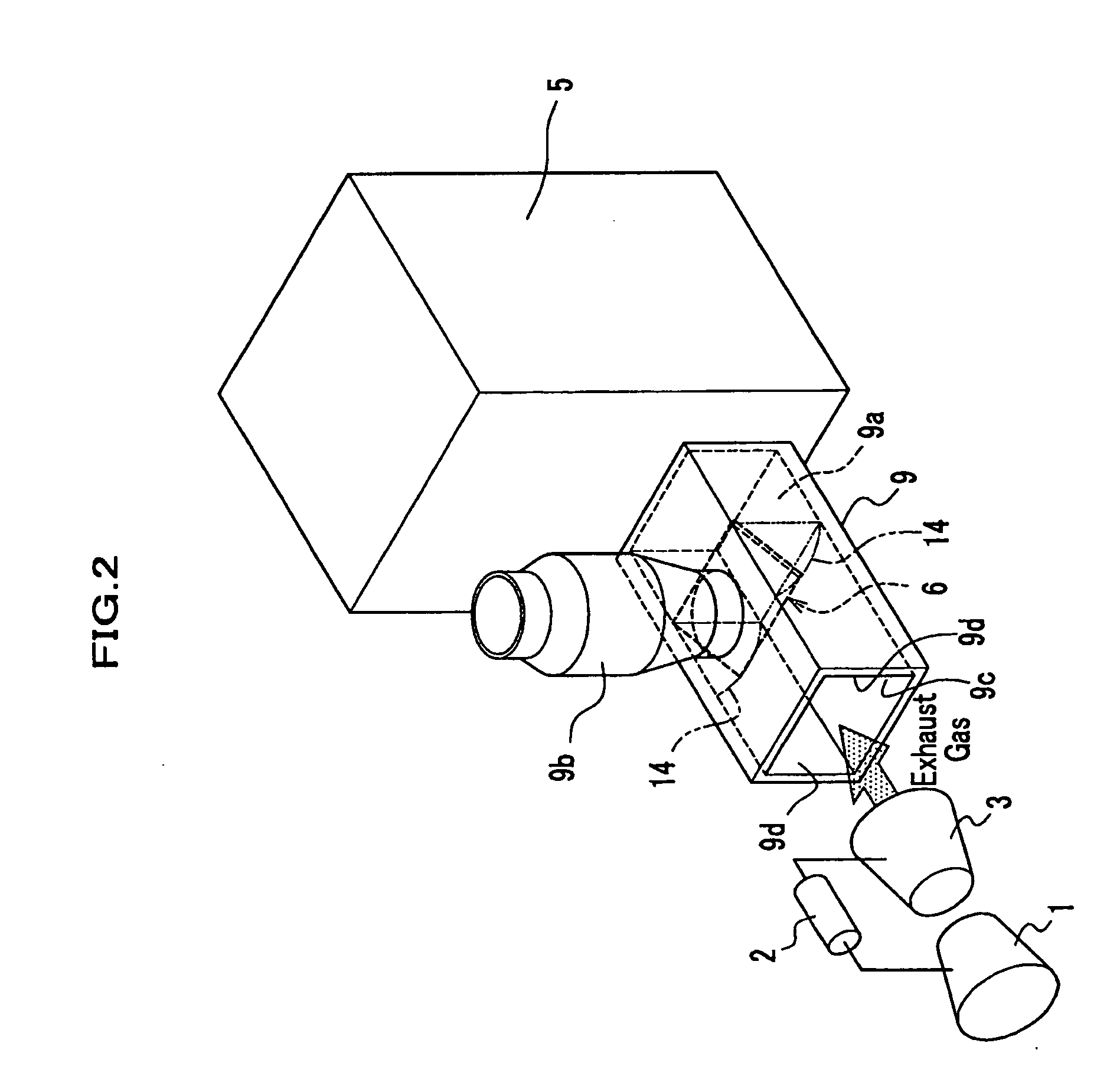

Fast start-up combined cycle power plant

InactiveUS20050268594A1Avoid vibrationReduce the amount requiredEngine fuctionsGas turbine plantsCombustorPower station

A combined cycle power plant of the present invention is configured of a compressor; a combustor for combusting compressed air compressed by the compressor together with supplied fuel; a gas turbine driven by a combustion gas exhausted from the combustor; a heat recovery steam generator for recovering high temperature exhaust heat exhausted from the gas turbine; a steam turbine driven by steam obtained from the heat recovery steam generator; and an exhaust gas duct having an HRSG inlet duct that is provided between the gas turbine and the heat recovery steam generator and introduces an exhaust passage into the heat recovery steam generator, and a bypass stack that leads the exhaust gas outside, wherein the exhaust duct is configured of a damper, a damper drive for changing any of angle and opening of the damper, and a guide mechanism for preventing a vibration of the damper.

Owner:THE TOKYO ELECTRIC POWER CO INC +1

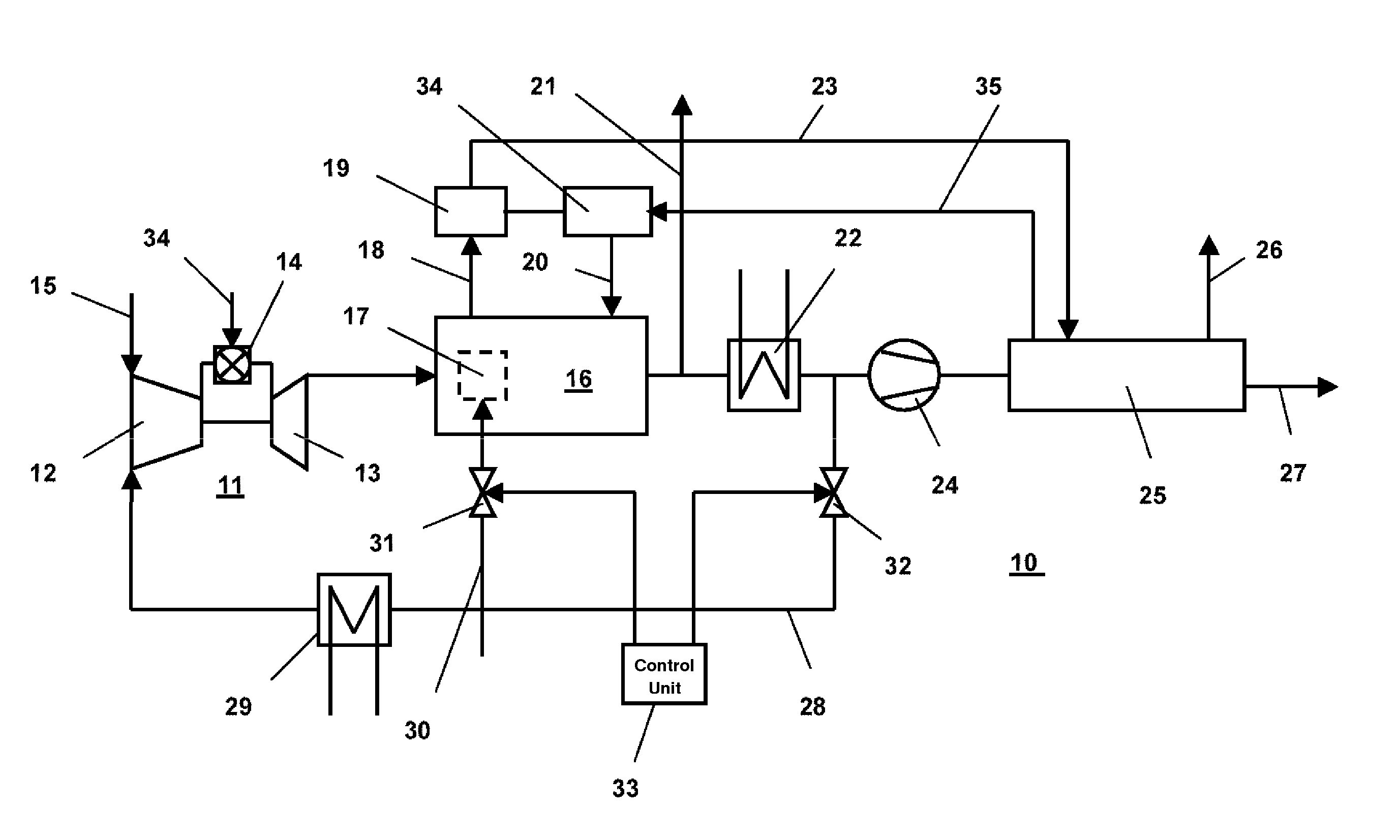

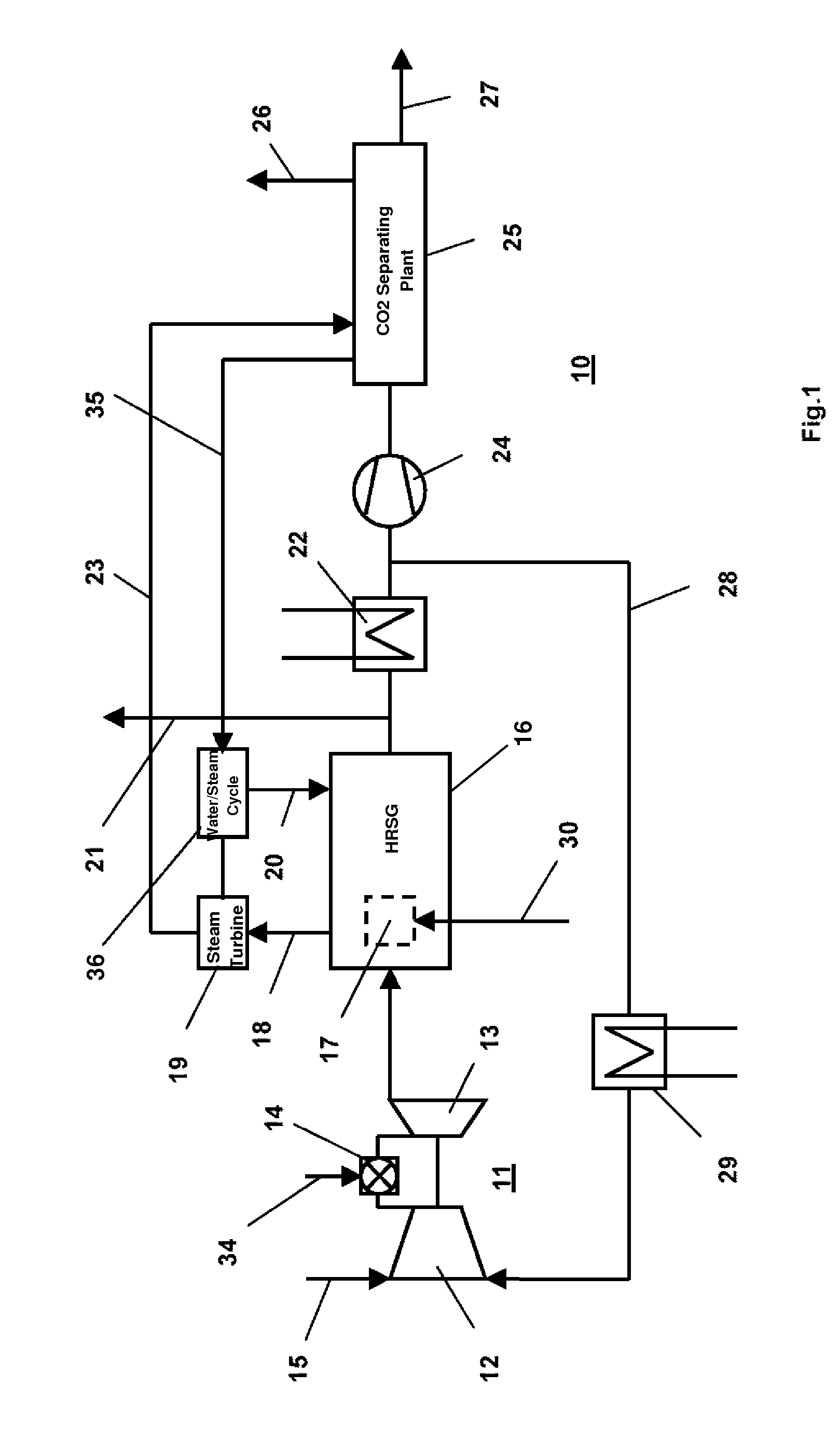

Combined-cycle power plant with exhaust gas recycling and CO2 separation, and method for operating a combined cycle power plant

InactiveUS8424282B2High outputReduce probabilityGas turbine plantsDirect carbon-dioxide mitigationPower stationExhaust fumes

Owner:GENERAL ELECTRIC TECH GMBH

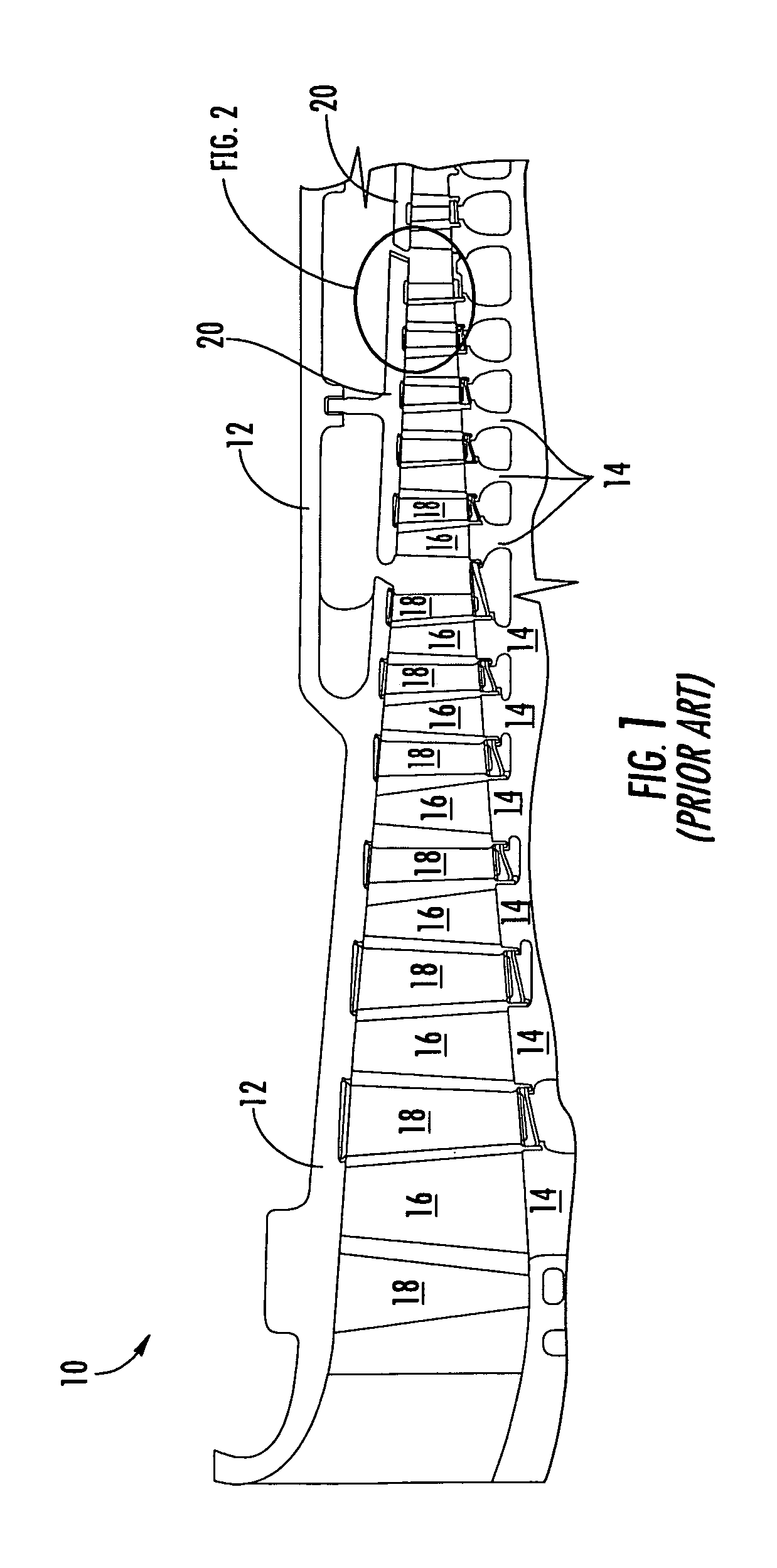

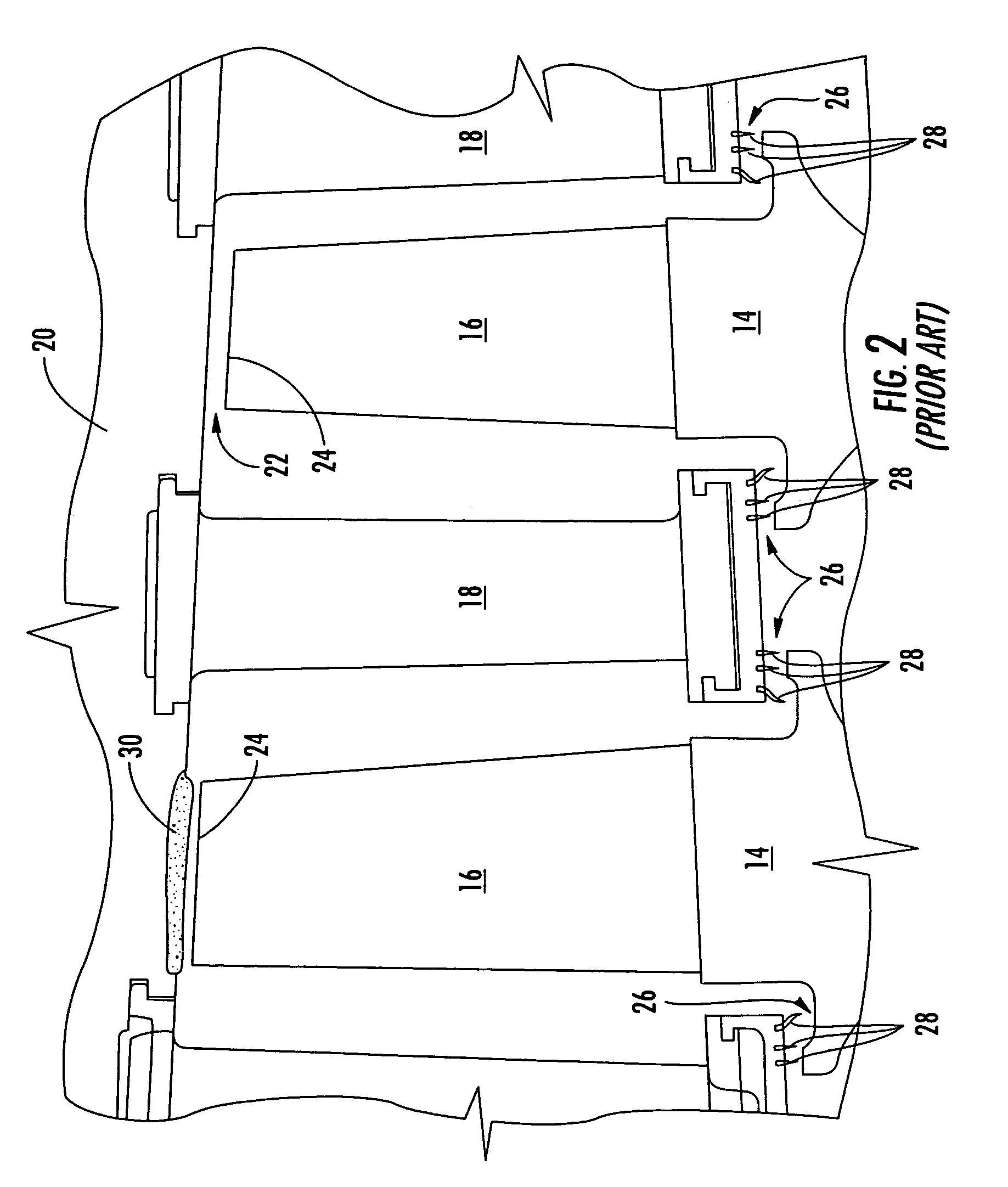

Multiple staged compressor with last stage airfoil cooling

An industrial gas turbine engine in which a compressor includes later stage airfoils that are cooled using a coolant from an external closed loop cooling circuit or from a heat recovery steam generator. Cooling air compressed by a compressor external to the IGT engine can be used for cooling of the main compressor airfoils with a heat exchanger to preheat a fuel used in the combustor. Or, water and steam from a heat recover steam generator can be used to cool the compressor airfoils in which steam can be bled off from the steam generator for cooling and then reintroduced into the HRSG at a downstream stage. Steam is used to cool the rotor blades while water is used to cool the stator vanes.

Owner:FLORIDA TURBINE TECH

Combined Cycle Power Plant

InactiveUS20070017207A1Gas turbine plantsCombined combustion mitigationPower stationProcess engineering

A combined cycle power plant including a gas turbine, a steam turbine, and a heat recovery steam generator. The power plant also includes a feedwater heater positioned downstream of the steam turbine and a fuel moisturization system in communication with the heat recovery steam generator.

Owner:GENERAL ELECTRIC CO

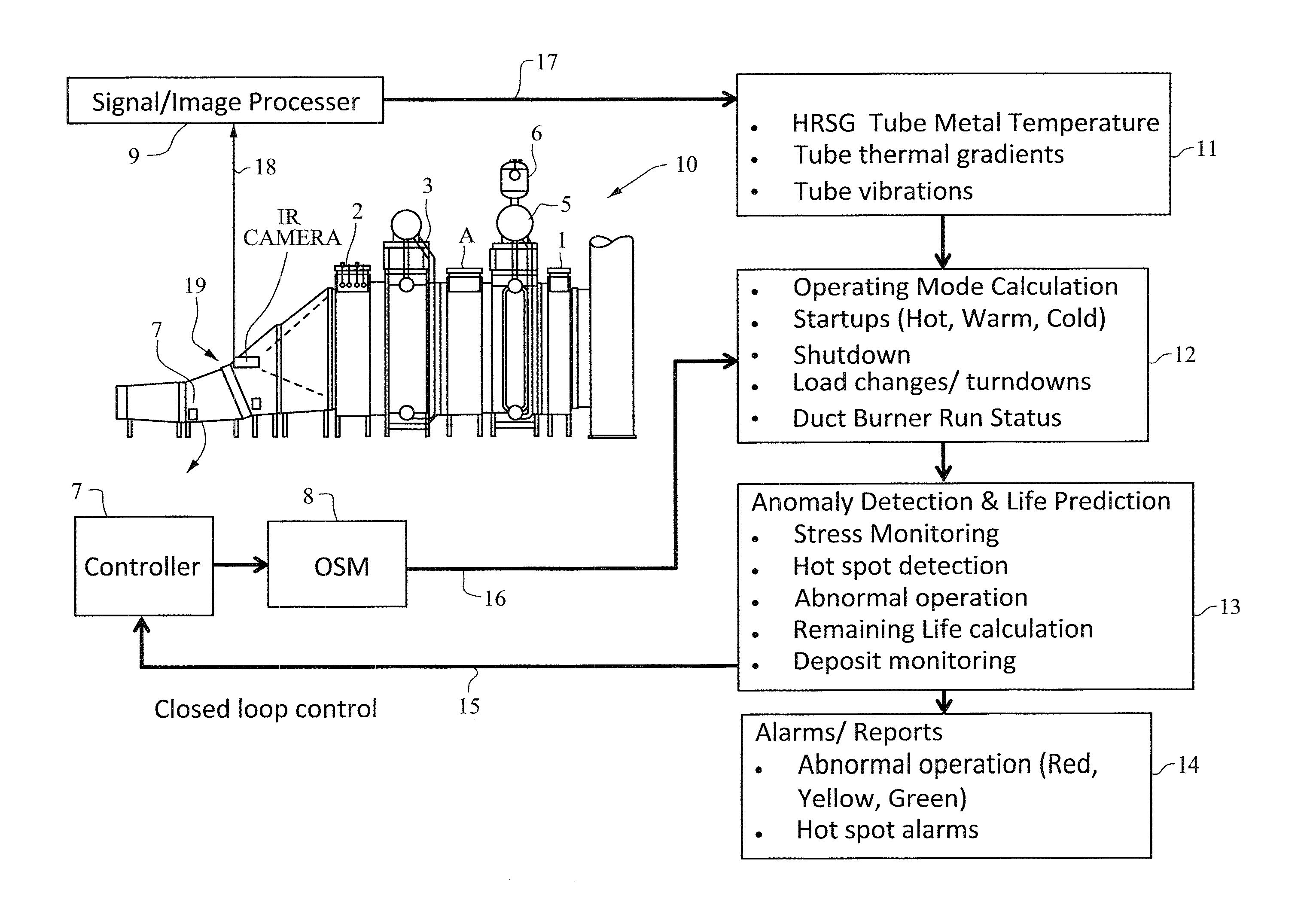

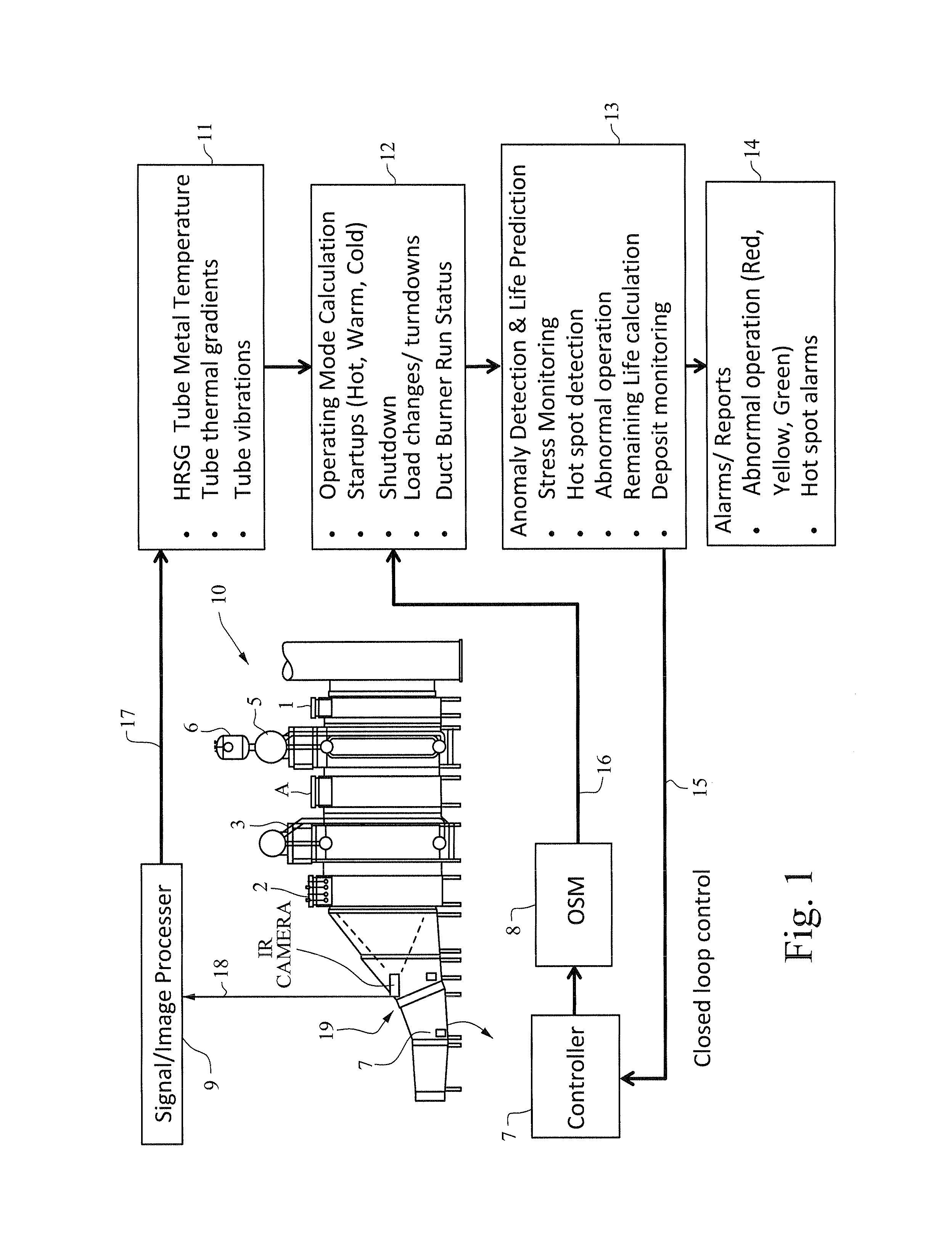

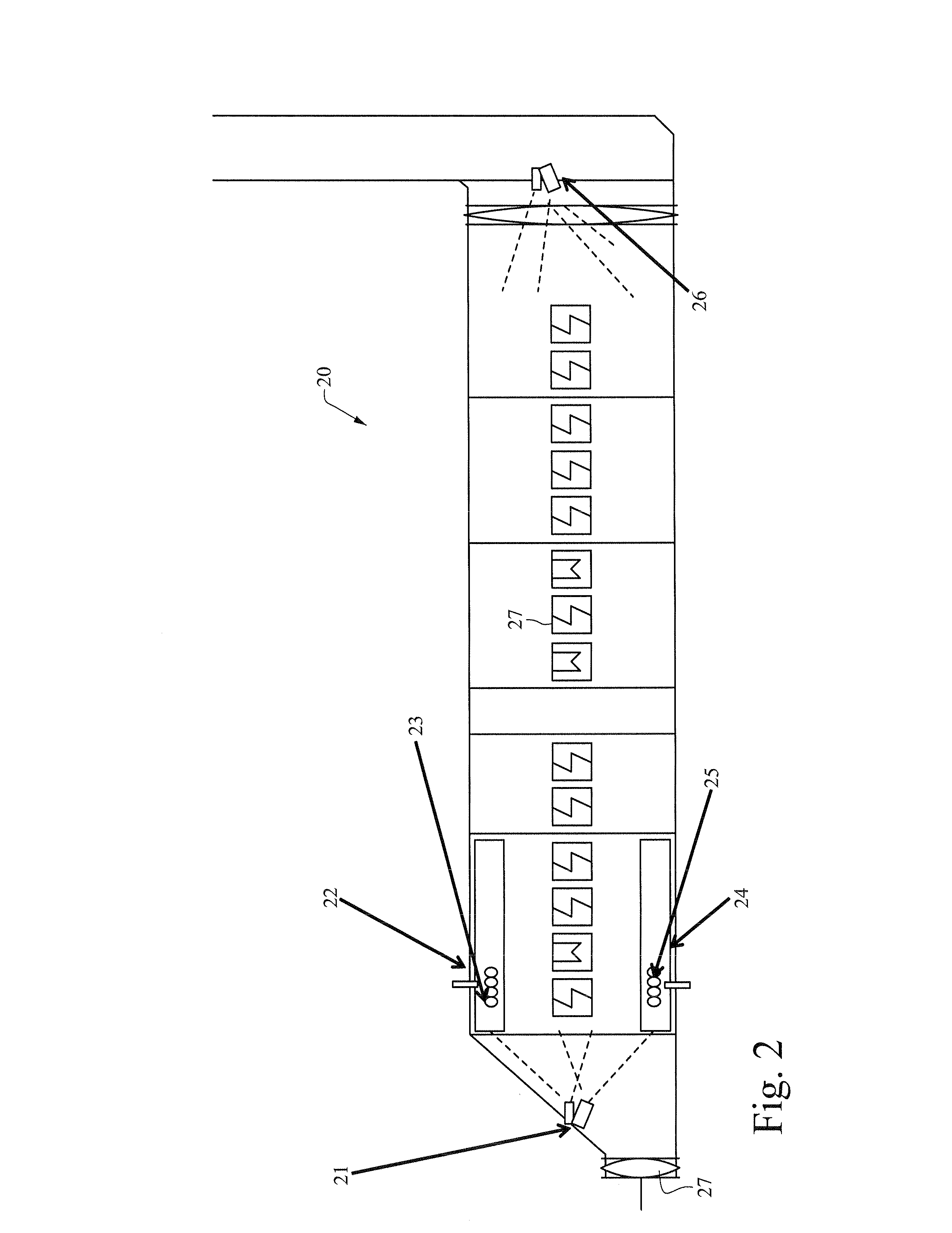

Continuous infrared thermography monitoring and life management system for heat recovery steam generators

ActiveUS20130176418A1Improve reliabilityReduce downtimeTelevision system detailsColor television detailsEngineeringThermography

A method for continuously monitoring the working condition of a heat recovery steam generator (“HRSG”) using infrared thermography, comprising the steps of identifying target locations inside the HRSG, positioning one or more infrared cameras to continuously monitor and record the temperature at each target location, generating continuous thermographic images corresponding to selected components and locations at each target locations, comparing the continuous thermographic images to corresponding, stored base line images and generating a set of comparative data reports in real time for each target location in order to predict the life span or potential failure of HRSG components.

Owner:GENERAL ELECTRIC CO

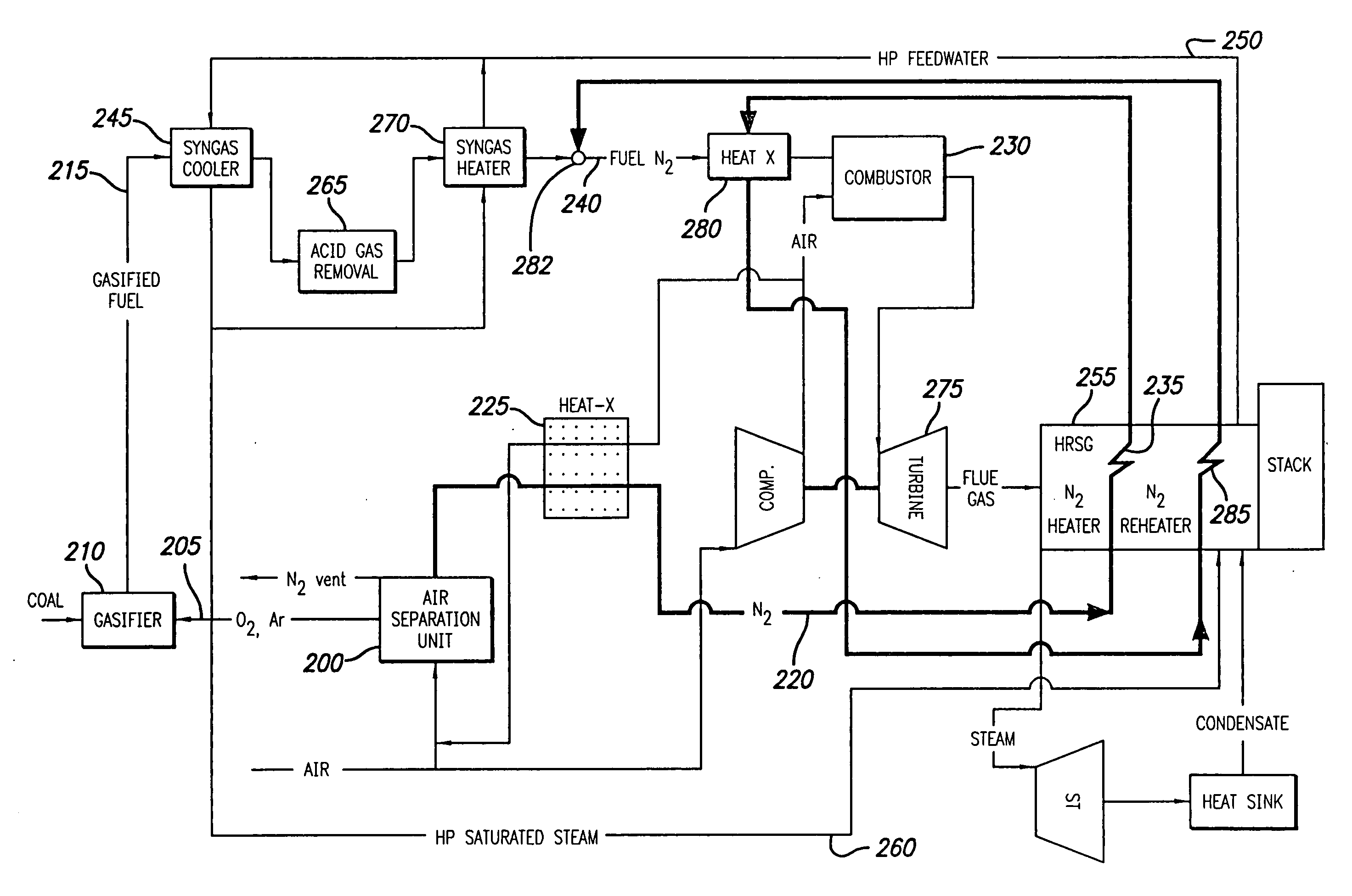

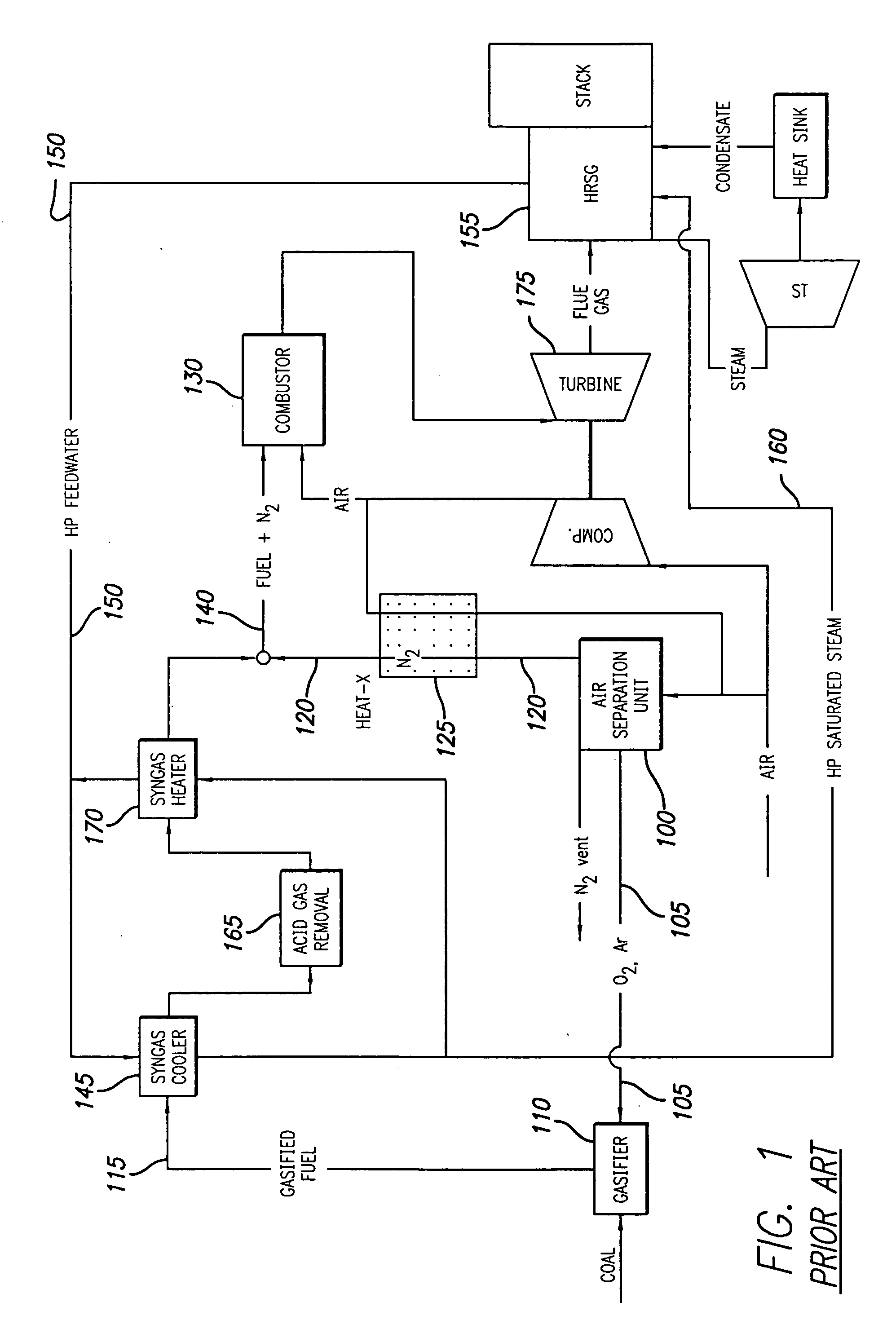

Advanced ASU and HRSG integration for improved integrated gasification combined cycle efficiency

InactiveUS20070180768A1Improve efficiencyIncrease powerSolidificationHydrogenCombustionProcess engineering

A system and method for increasing the efficiency and / or power produced by an integrated gasification combined cycle system by increasing the integration between the air separation unit island, the heat recovery steam generator and the remainder of the system. By integrating heat produced by the heat recovery steam generator in the remainder of the integrated gasification combined cycle system, heat may be utilized that may have otherwise been lost or used further downstream in the system. The integration helps to increase the efficiency of the combustion reaction and / or the gasification reaction used to produce the syngas utilized in the integrated gasification combined cycle system.

Owner:SIEMENS ENERGY INC

Device for removing carbon dioxide from exhaust gas

InactiveUS7022168B2Reduce heat transferLow thermal conductivityCombustion enginesGas turbine plantsProcess engineeringGas turbines

In a method for removing carbon dioxide from the exhaust gas from a gas turbine plant (11), which exhaust gas is subjected to a downstream heat recovery process (12, 33), preferably in the heat recovery steam generator (33) of a water / steam cycle (12), a simplification of the plant engineering is achieved by the fact that the carbon dioxide is removed from the exhaust gas (39) between the gas turbine plant (11) and the heat recovery process (12, 33), and that a rotating, regenerative absorber / desorber (22) is used to remove the carbon dioxide, the absorber side of which absorber / desorber is connected into the exhaust gas stream (39) and the desorber side of which absorber / desorber is connected into a carbon dioxide cycle (38).

Owner:GENERAL ELECTRIC TECH GMBH

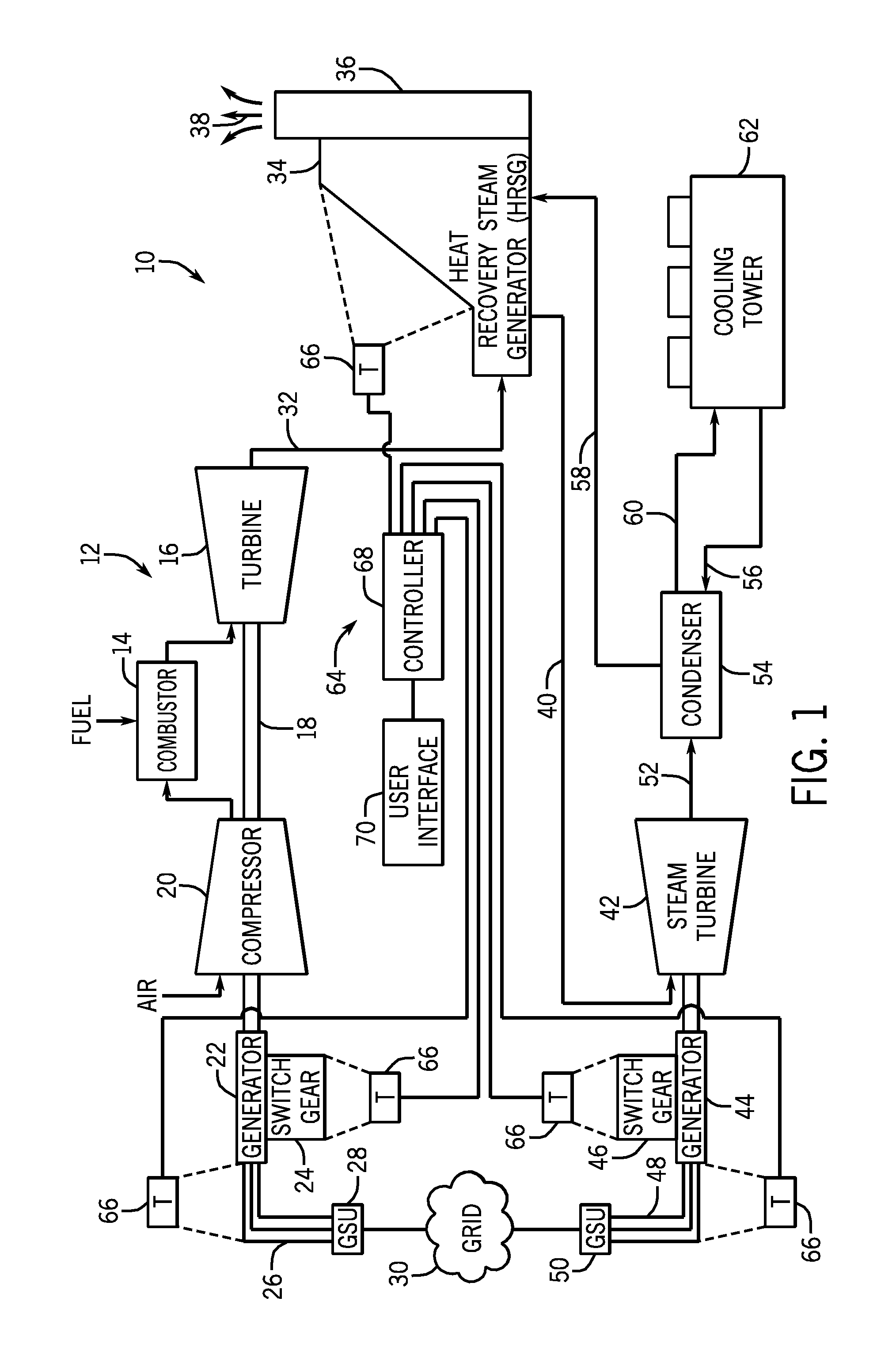

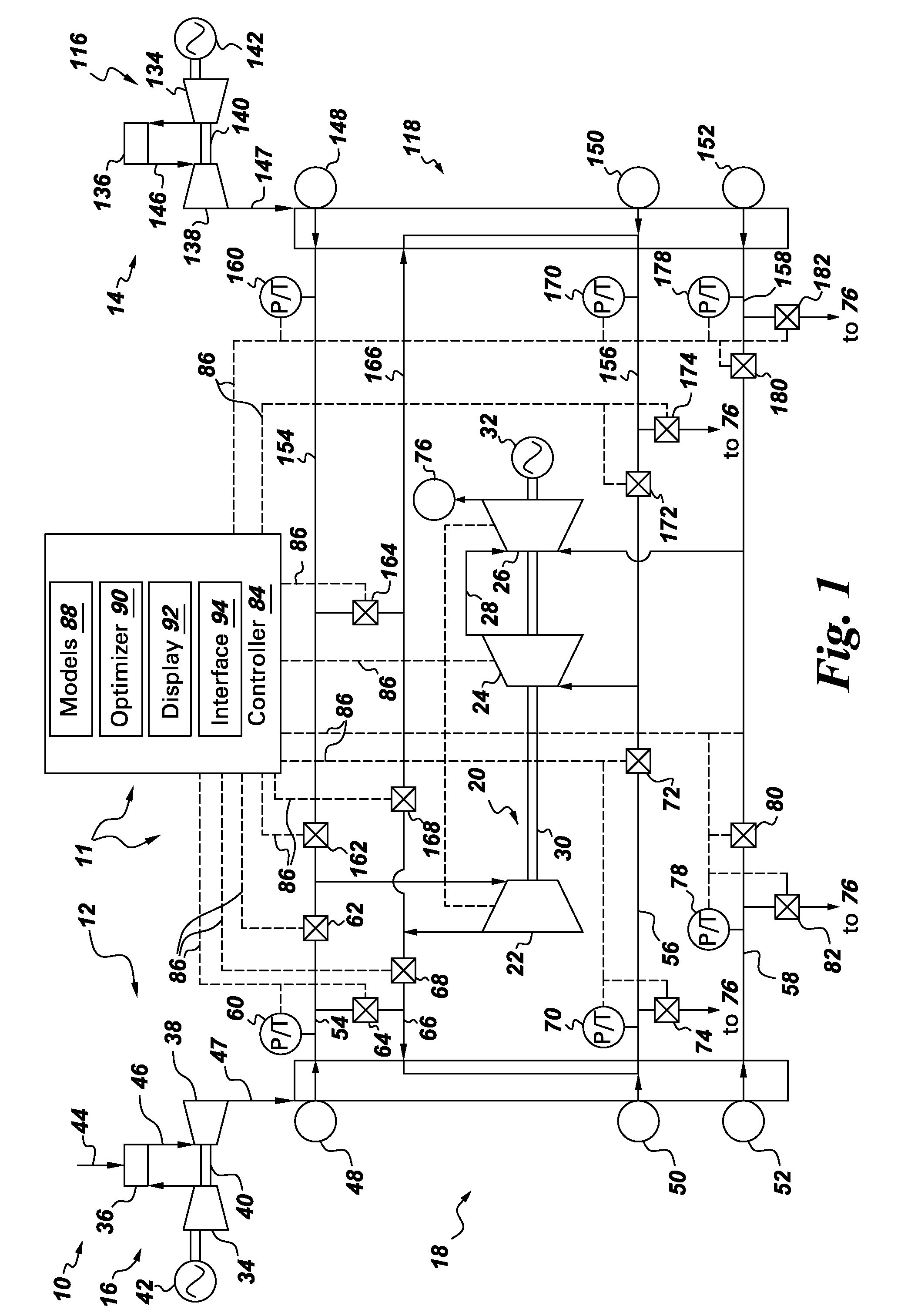

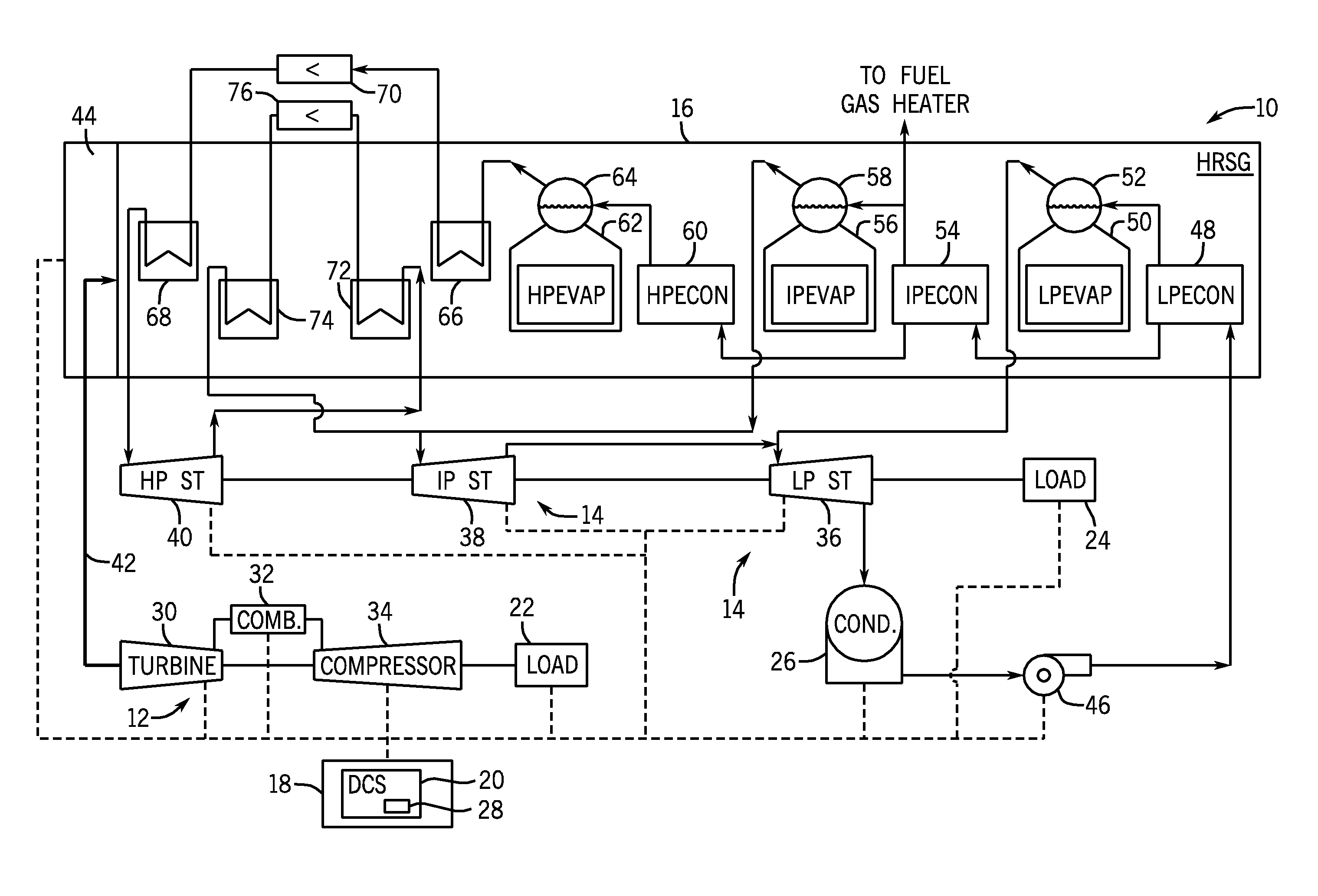

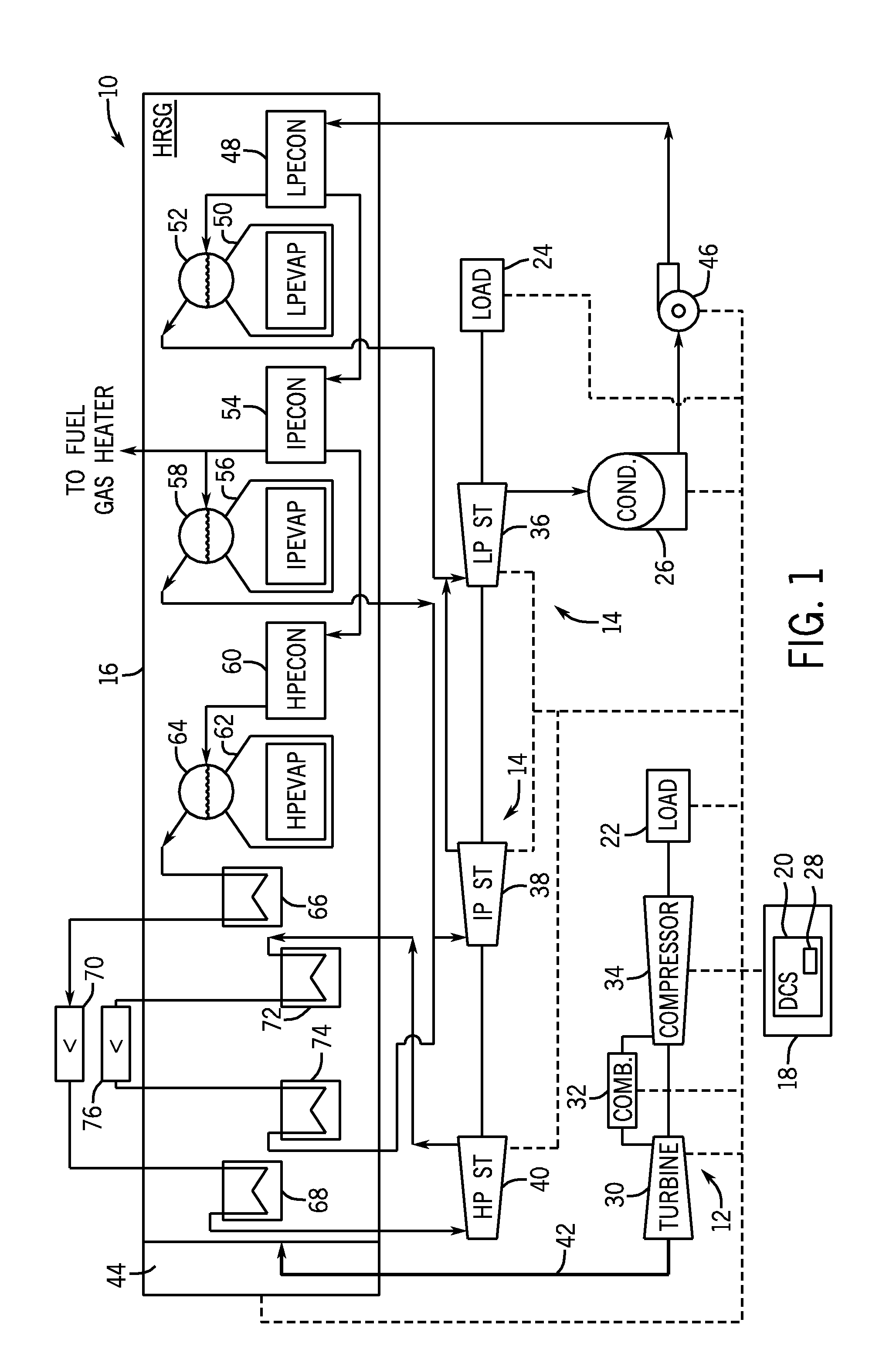

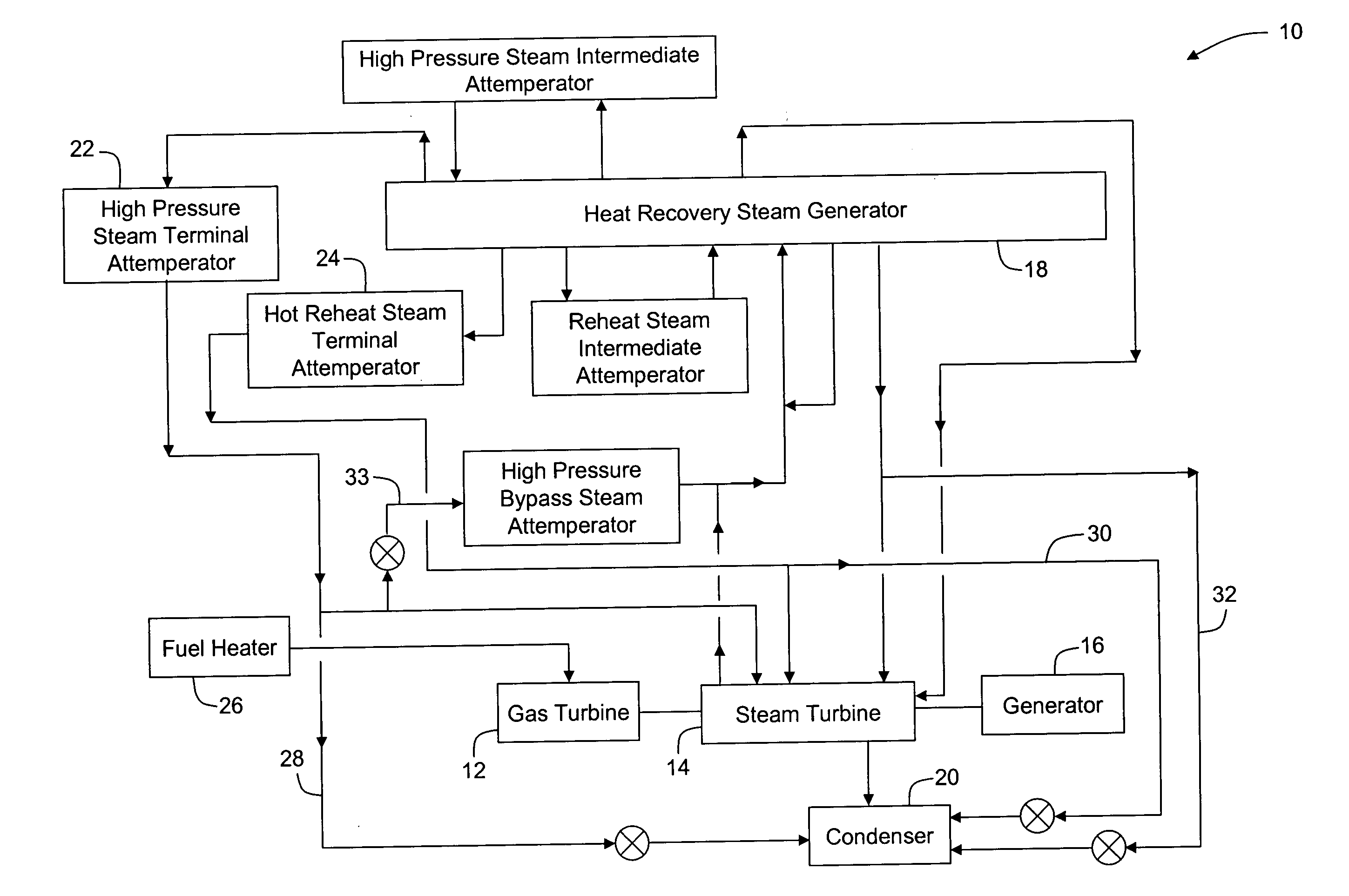

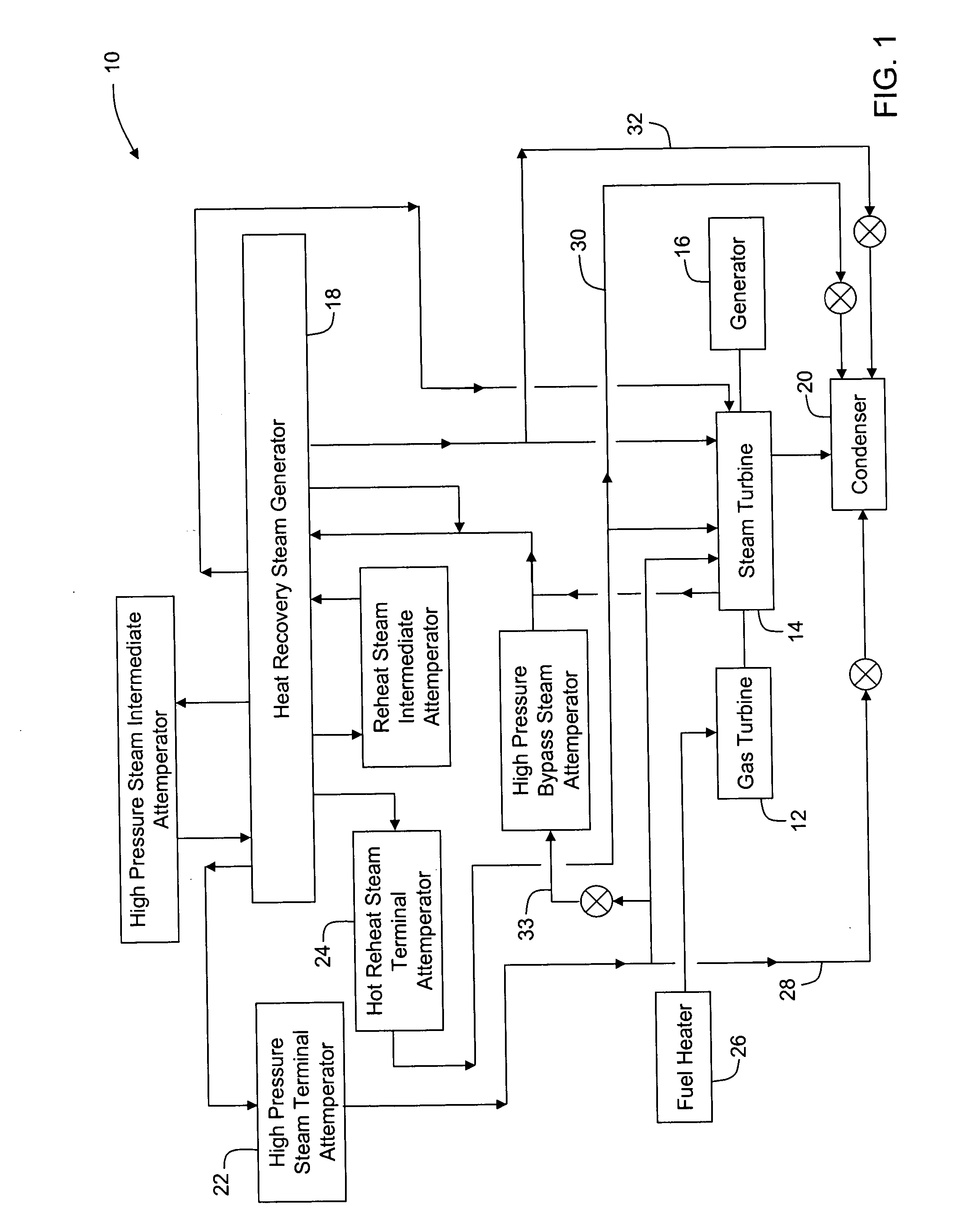

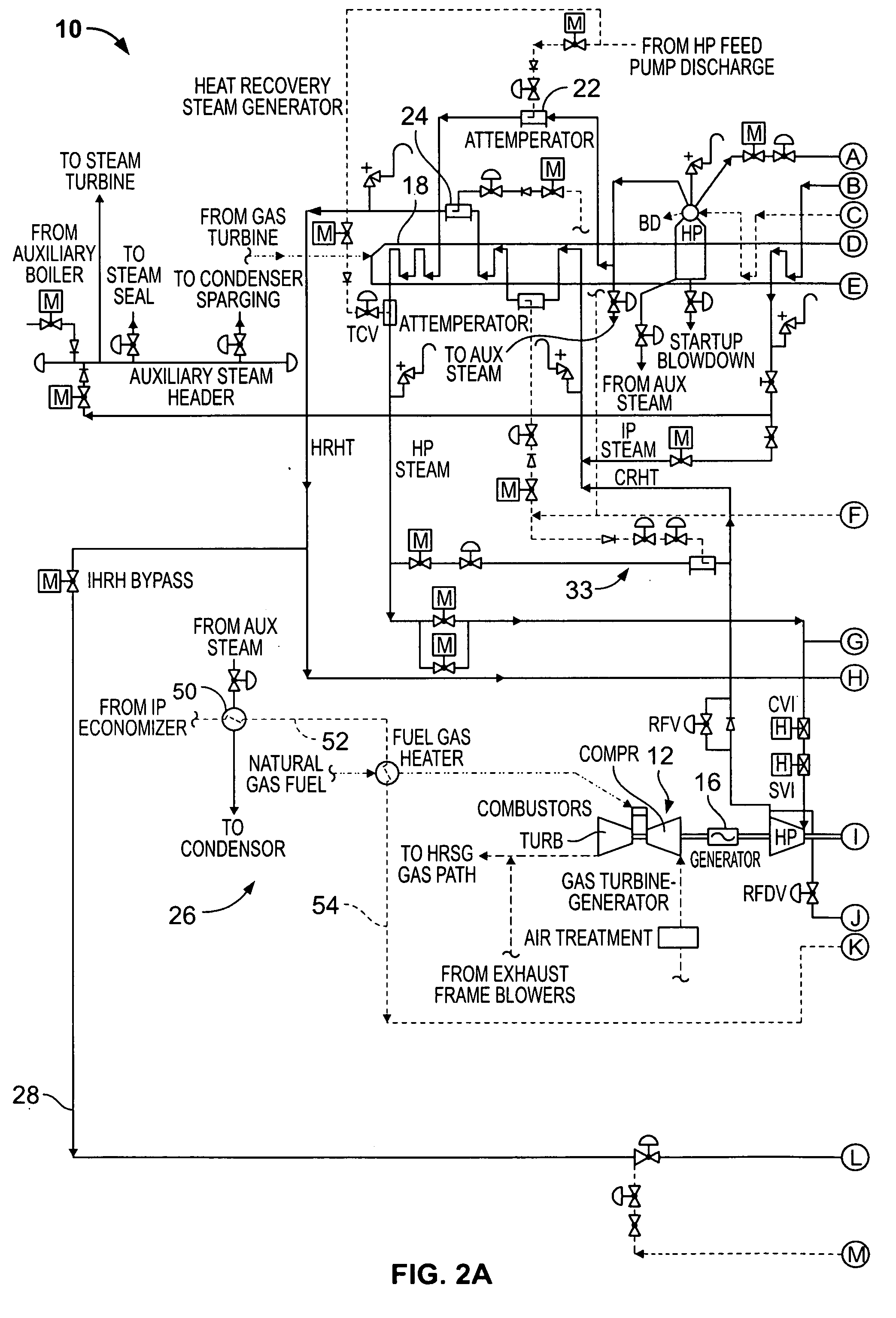

Control of combined cycle power generation system

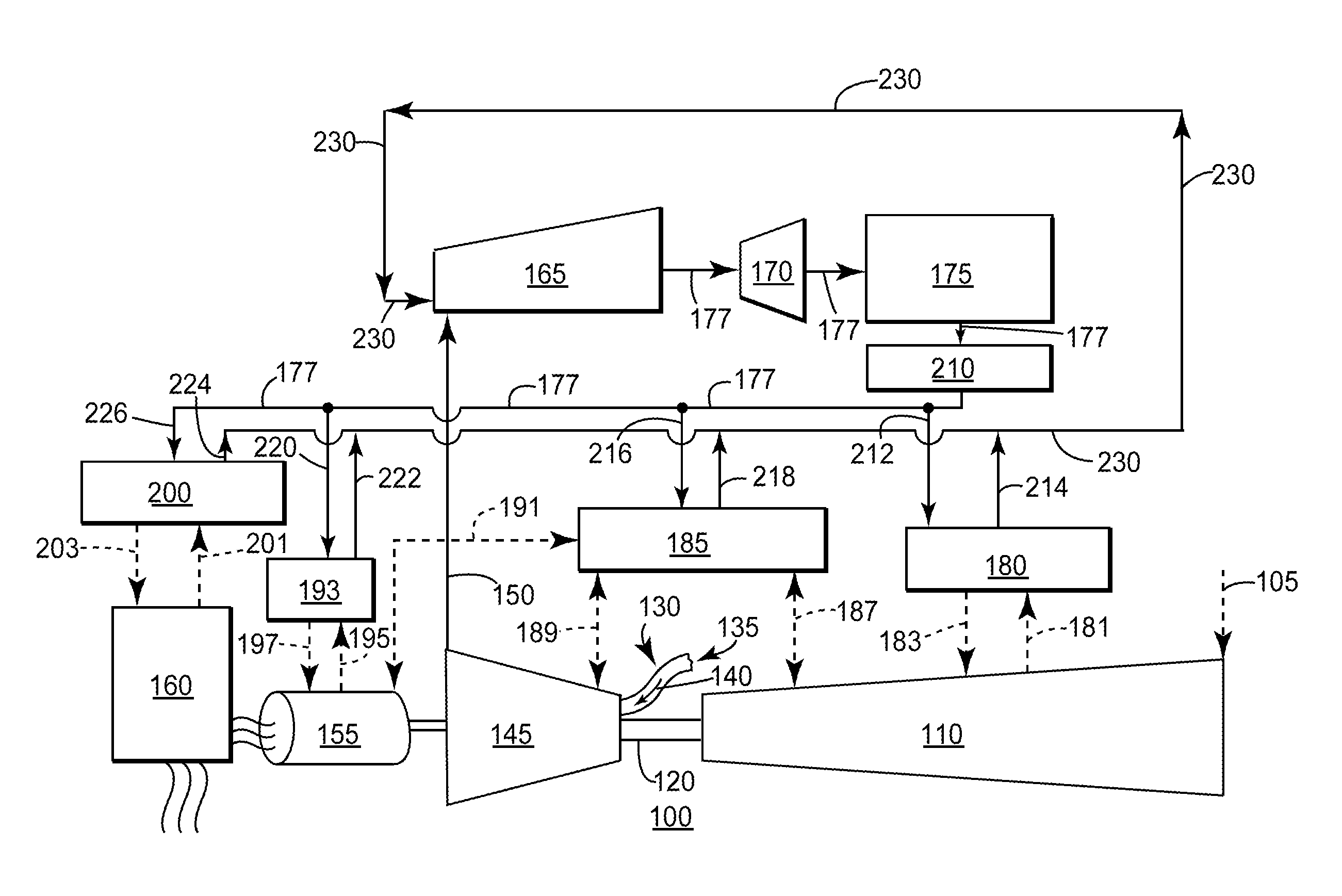

ActiveUS20090292436A1Easy to operateAnalogue computers for vehiclesLevel controlControl systemAlternative control

A control system for a combined cycle power generation system including a gas turbine engine (GT), a heat recovery steam generator (HRSG), and a steam turbine (ST) includes a display wherein an operator may observe information about predicted operating parameters; a user interface wherein an operator may provide additional operating constraints; and a controller configured to generate input profiles of the GT, the HRSG, and the ST that satisfy the nominal constraints and any additional constraints and to generate the information about the predicted operating parameters. The controller may be configured to detect a stage transition of power generation system operation and update the input profiles. The controller may be configured to generate alternative operating scenarios by mapping alternative control actions to an operating constraint of at least one of the system components.

Owner:GENERAL ELECTRIC CO +1

Power Plant

ActiveUS20120260667A1Increase steam productionEngine fuctionsTurbine/propulsion engine coolingHigh energyEngineering

A power plant is provided and includes a gas turbine engine to generate power, a heat recovery steam generator (HRSG) to produce steam from high energy fluids produced from the generation of power in the gas turbine engine, a steam turbine engine to generate additional power from the steam produced in the HRSG and a thermal load reduction system to reduce thermal loading of components of the HRSG and / or the steam turbine engine during at least startup and / or part load operations, which includes an eductor by which a mixture of compressor discharge air and entrained ambient air is injectable into the HRSG and / or an attemperator to cool superheated steam to be transmitted to the steam turbine engine and a detector disposed within the HRSG to facilitate identification of hot spots therein.

Owner:GENERAL ELECTRIC CO

Methods and apparatus for starting up combined cycle power systems

ActiveUS7621133B2Easy loadingIncrease ratingsTurbine/propulsion fuel supply systemsTurbine/propulsion engine ignitionEngineeringStart up

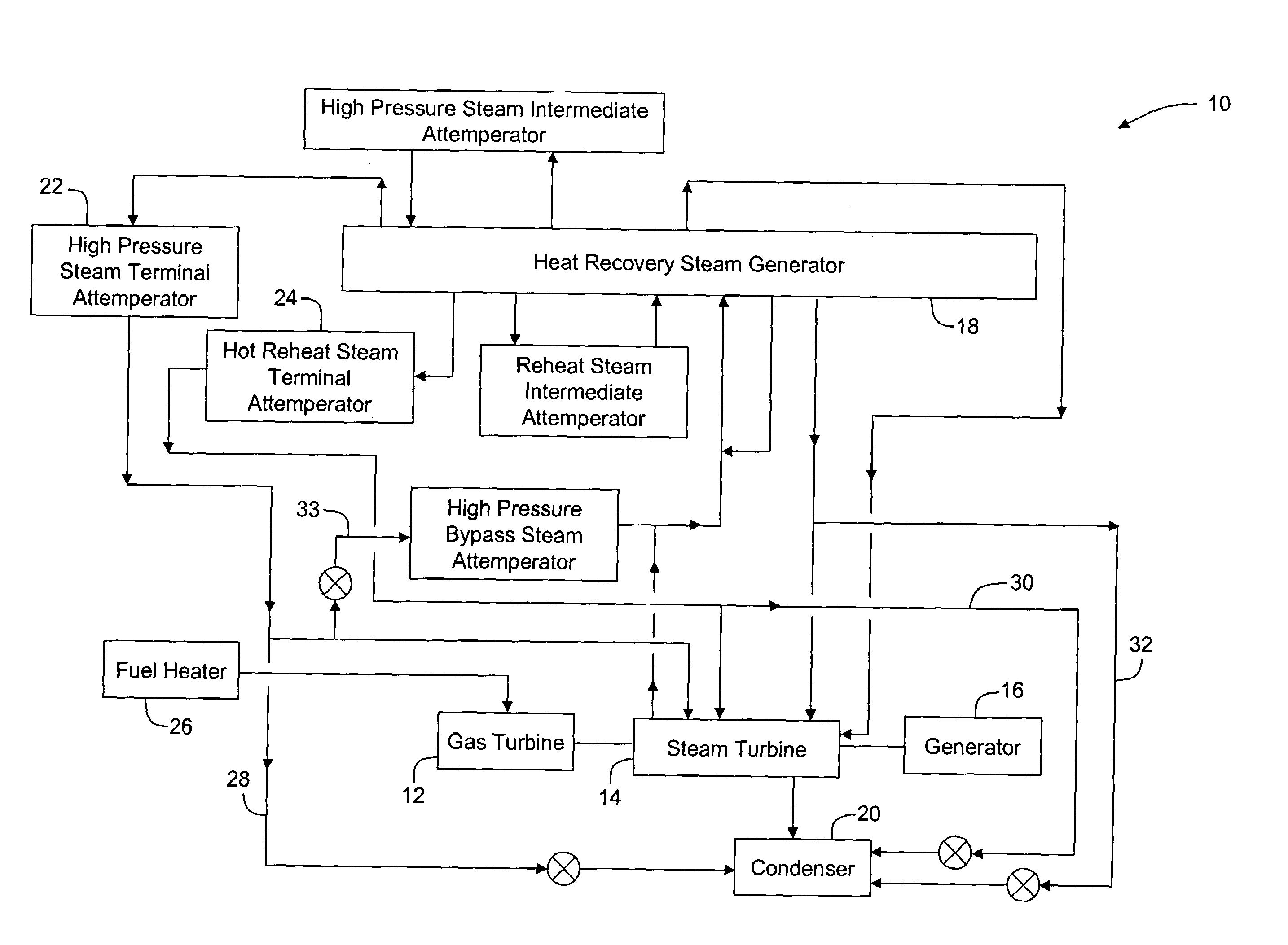

Methods and apparatus for fast starting and loading a combined cycle power system are described. In one example embodiment, the method includes loading the gas turbine at up to it's maximum rate, and loading the steam turbine at its maximum rate with excess steam bypassed to the condenser while maintaining the temperature of steam supplied to the steam turbine at a substantially constant temperature from initial steam admission into the steam turbine until all steam generated by the heat recovery steam generator is being admitted to the steam turbine while the gas turbine operates at up to maximum load.

Owner:GENERAL ELECTRIC CO

Coke plant including exhaust gas sharing

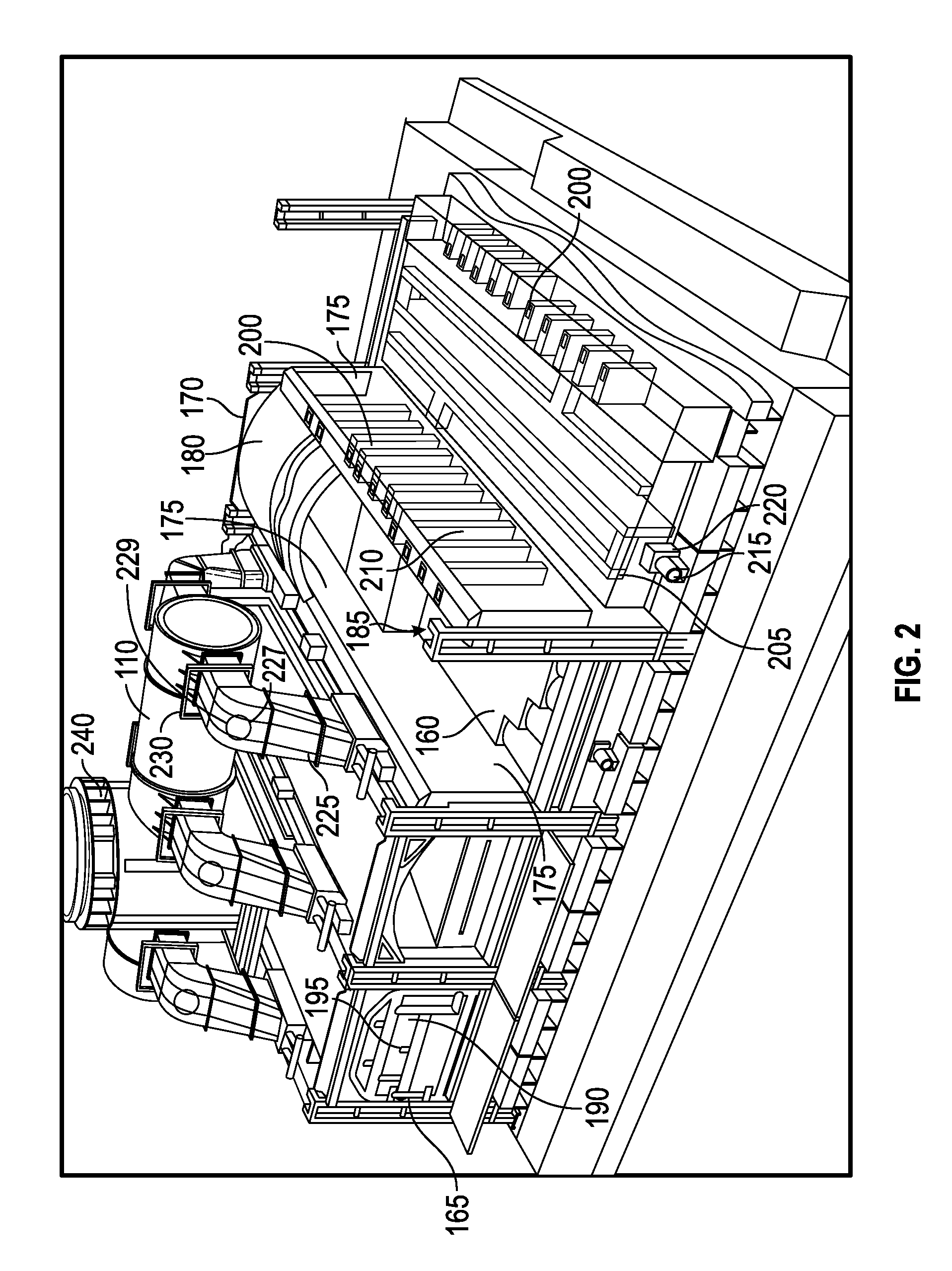

ActiveUS9243186B2Coke oven safety devicesHorizontal chamber coke ovensExhaust fumesProcess engineering

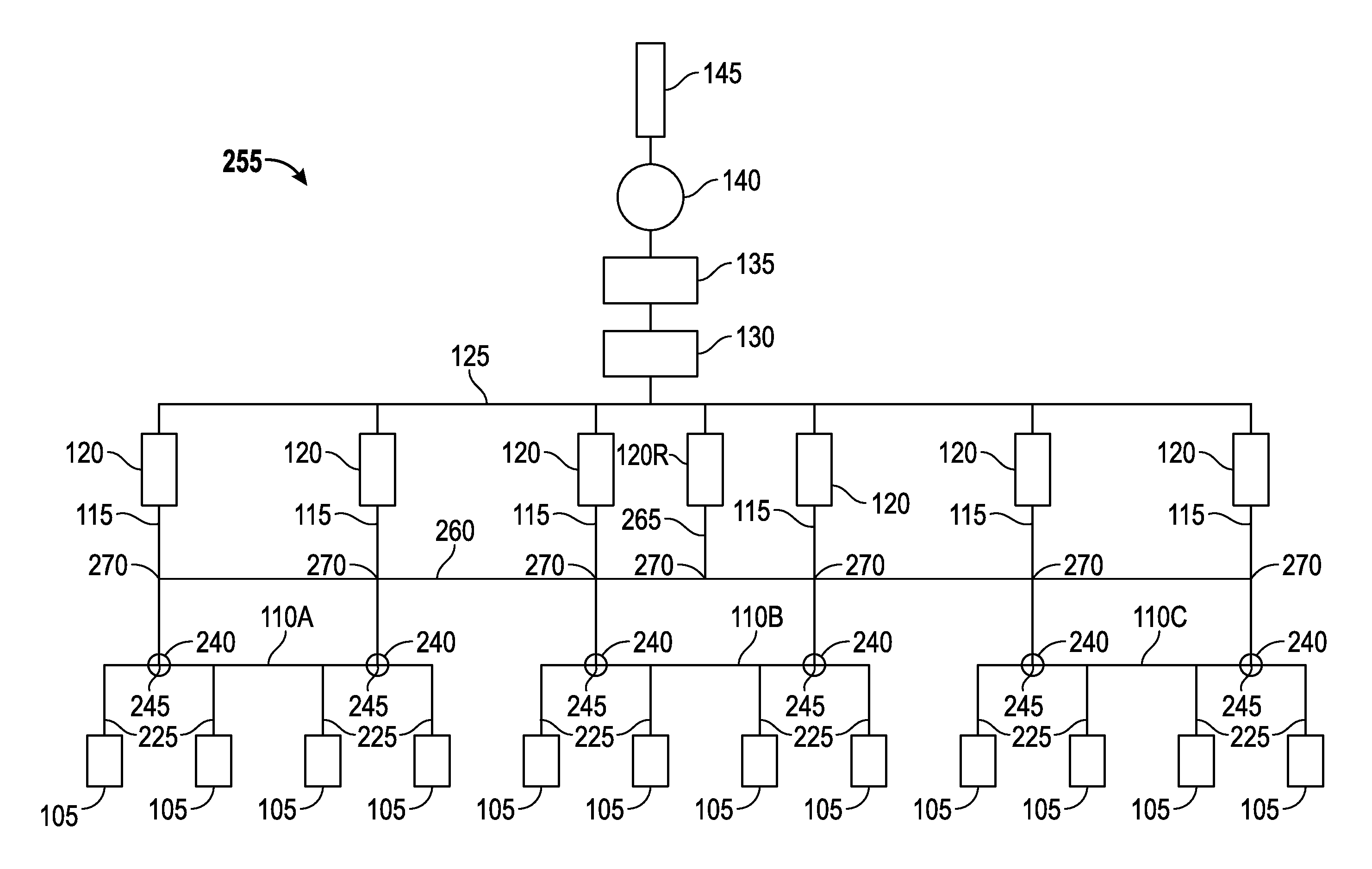

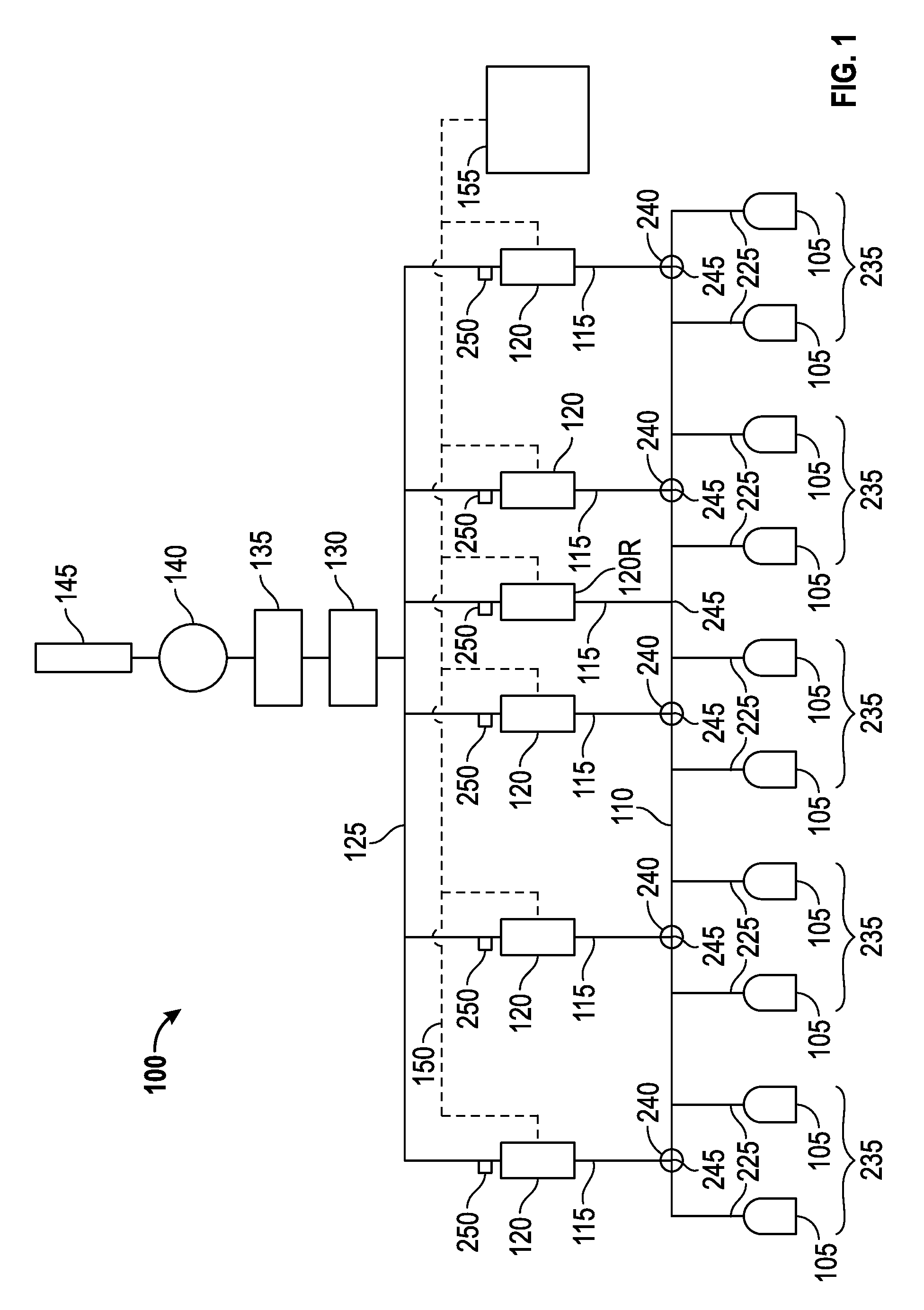

A coke plant includes multiple coke ovens where each coke oven is adapted to produce exhaust gases, a common tunnel fluidly connected to the plurality of coke ovens and configured to receive the exhaust gases from each of the coke ovens, multiple standard heat recovery steam generators fluidly connected to the common tunnel where the ratio of coke ovens to standard heat recovery steam generators is at least 20:1, and a redundant heat recovery steam generator fluidly connected to the common tunnel where any one of the plurality of standard heat recovery steam generators and the redundant heat recovery steam generator is adapted to receive the exhaust gases from the plurality of ovens and extract heat from the exhaust gases and where the standard heat recovery steam generators and the redundant heat recovery steam generator are all connected in parallel with each other.

Owner:SUNCOKE TECH & DEV LLC

Combined cycle power plant using compressor air extraction

A combined cycle power plant (100) utilizing a compressor air bleed (62) as a source of heat for generating steam in a steam generator (78) for supplying the gland seals of the steam turbine (3) and as a motive force for an air ejector (90) for evacuating the condenser (8) during plant start-up. The compressor air bleed avoids delay awaiting the availability of steam from the heat recovery steam generator (4) without the need for an auxiliary boiler.

Owner:SIEMENS ENERGY INC

System for actively controlling compressor clearances

InactiveUS7434402B2Compressor clearances can beReduce gapPump componentsEngine fuctionsEngineeringBleed air

Aspects of the invention relate to a system and method for actively controlling compressor clearances in a turbine engine by passing a thermal fluid in heat exchanging relation through a compressor vane carrier. During some operational conditions, such as hot restart or spin cool, it may be desirable to heat the vane carrier to enlarge or at least prevent a decrease in compressor clearances. In such cases, a heated thermal fluid can be provided by reclaiming residual exhaust energy from a heat recovery steam generator. At any condition where improved performance is desired, such as at base load operation, the vane carrier can be cooled to minimize compressor clearances. A cooled thermal fluid can be bleed air from an upstream portion of the compressor, water-cooled high pressure bleed air from a downstream portion of the compressor, or feed water from the bottoming cycle in a combined cycle engine.

Owner:SIEMENS ENERGY INC

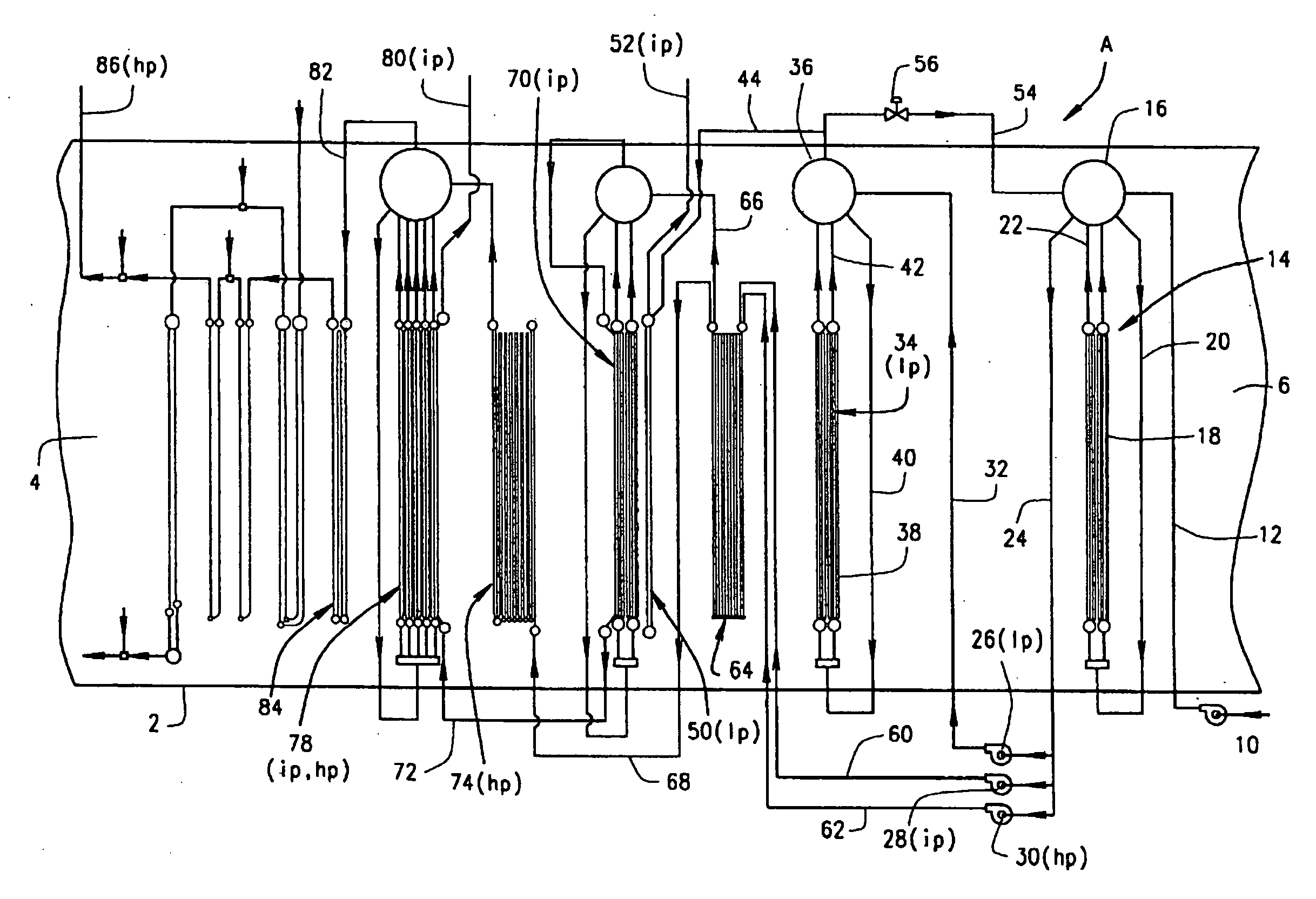

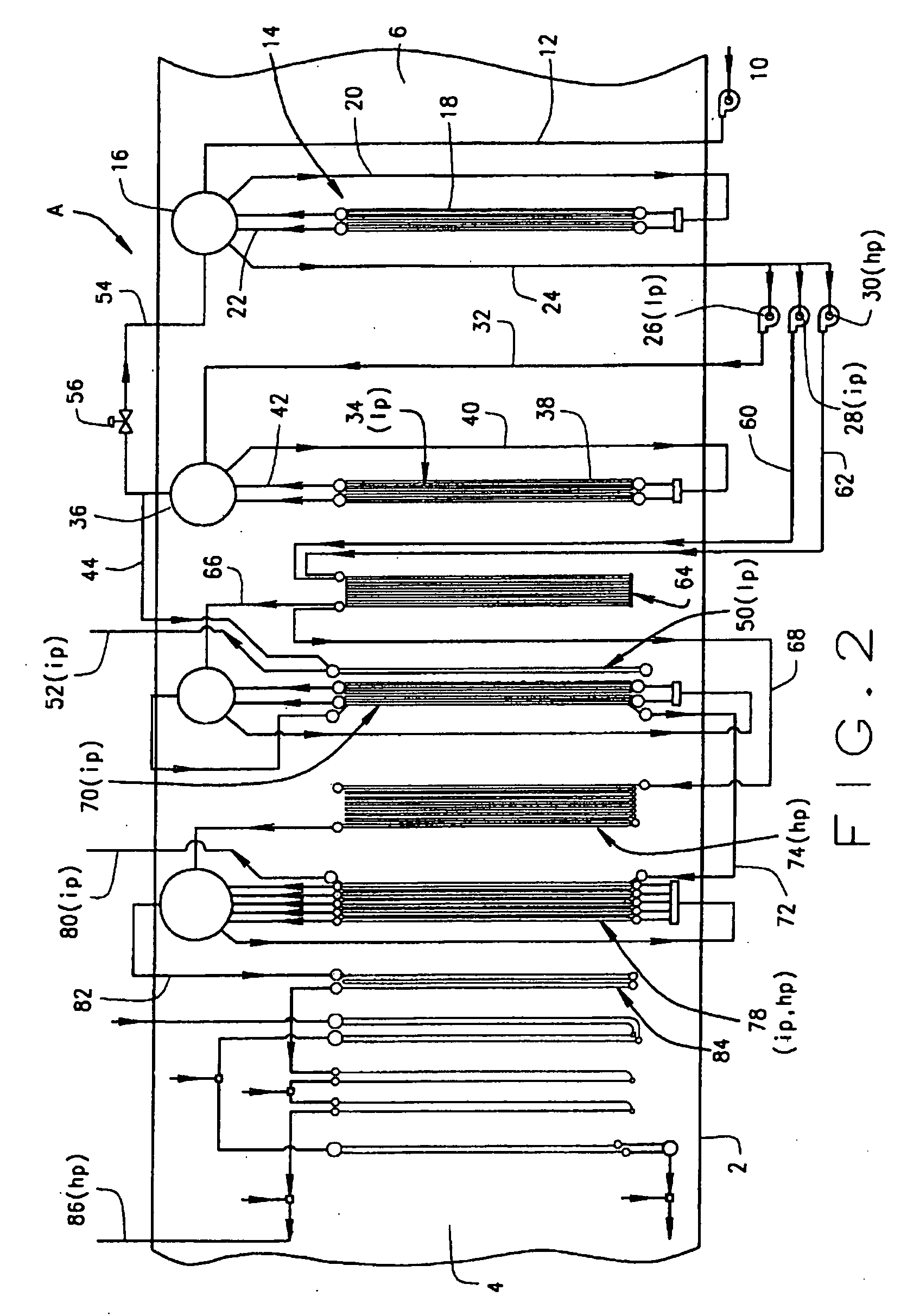

Process and apparatus for heating feedwater in a heat recovery steam generator

InactiveUS20120312019A1Steam generation heating methodsSteam accumulatorsCorrosive acidExhaust fumes

A feedwater heater (14) in a heat recovery steam generator (A,B) lies within a flow of hot exhaust gas. The feedwater heater (14) converts subcooled feedwater into saturated feedwater water, the temperature of which is only lightly above the acid dew point temperature of the exhaust gas so that corrosive acids do not condense on coils (18) of the feedwater heater (14). Yet the temperature of the saturated feedwater lies significantly below the temperature of the exhaust gas at the coils (18), so that the coils (18) operate efficiently and require minimal surface area. Pumps (26, 28, 30) elevate the pressure of the saturated feedwater and direct it into an economizer (64, 90) where, owing to the increase in pressure, the water is again subcooled. The economizer (64, 90) elevates the temperature still further and delivers the higher pressure feedwater to evaporators (34, 70, 78) that convert it into saturated steam that flows on to the superheaters (50, 78, 84). Higher pressure pegging stem admitted to the feedwater heater (14) controls the pressure—and temperature—of saturated steam and water in the feedwater heater (14).

Owner:NOOTER ERIKSEN INC

Heat recovery steam generator and method for fast starting combined cycles

ActiveUS8820078B1Control moisture contentPossible leakageLiquid degasificationSteam generation heating methodsEngineeringSuperheater

A once-through high pressure steam generator and reheater configured to eliminate the majority of components limiting cyclical life of fast start conventional HRSGs. Two remaining problematic components in conventional designs the final superheater and reheater tubes overheat while their headers remain colder in fast starts. In this inventive HRSG the critical components are arranged and started by a method that limits these damaging temperature differentials. At ignition when exhaust gas surges into a wet superheater steam flow starts minutes before conventional systems. This early steam flow cools the tubes while heating the headers, thereby reducing life damaging stresses. Steam temperature is controlled through the start and warms the rest of the plant earlier without attemperators with their problematic thermal stress history. Faster starts than conventional result without damaging fatigue life depletion with this low cost innovation.

Owner:DUFFY THOMAS EDWARD

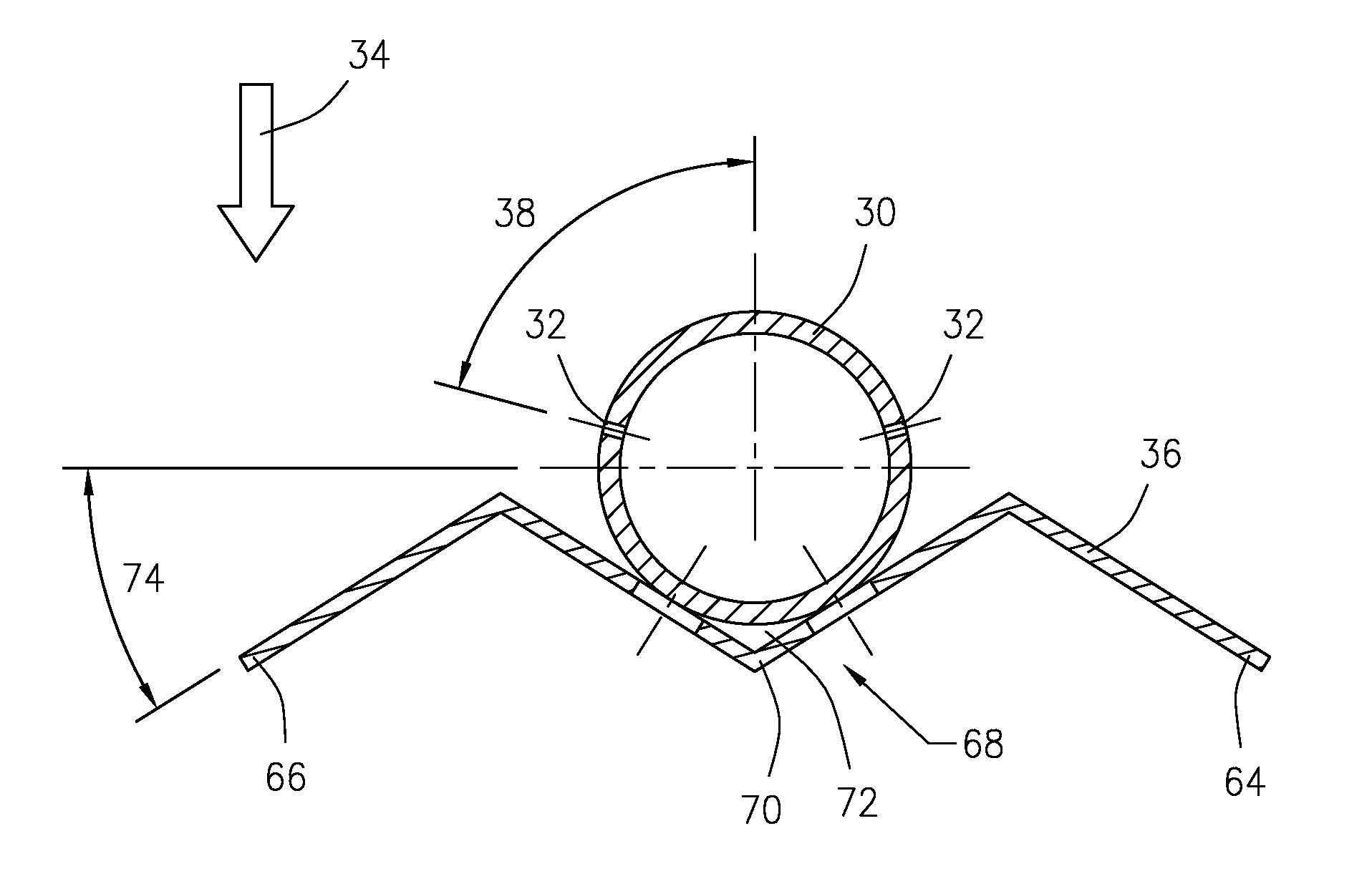

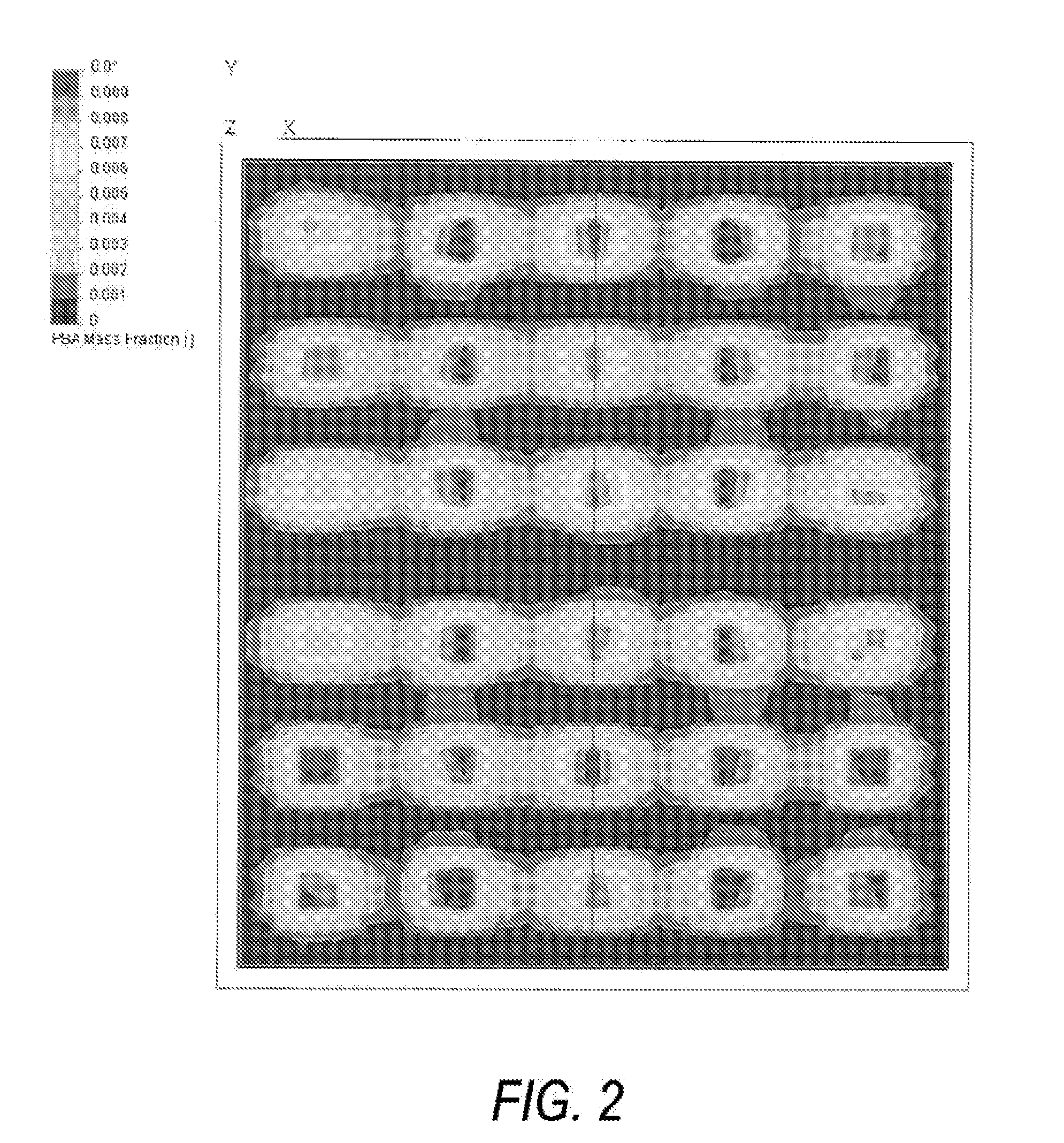

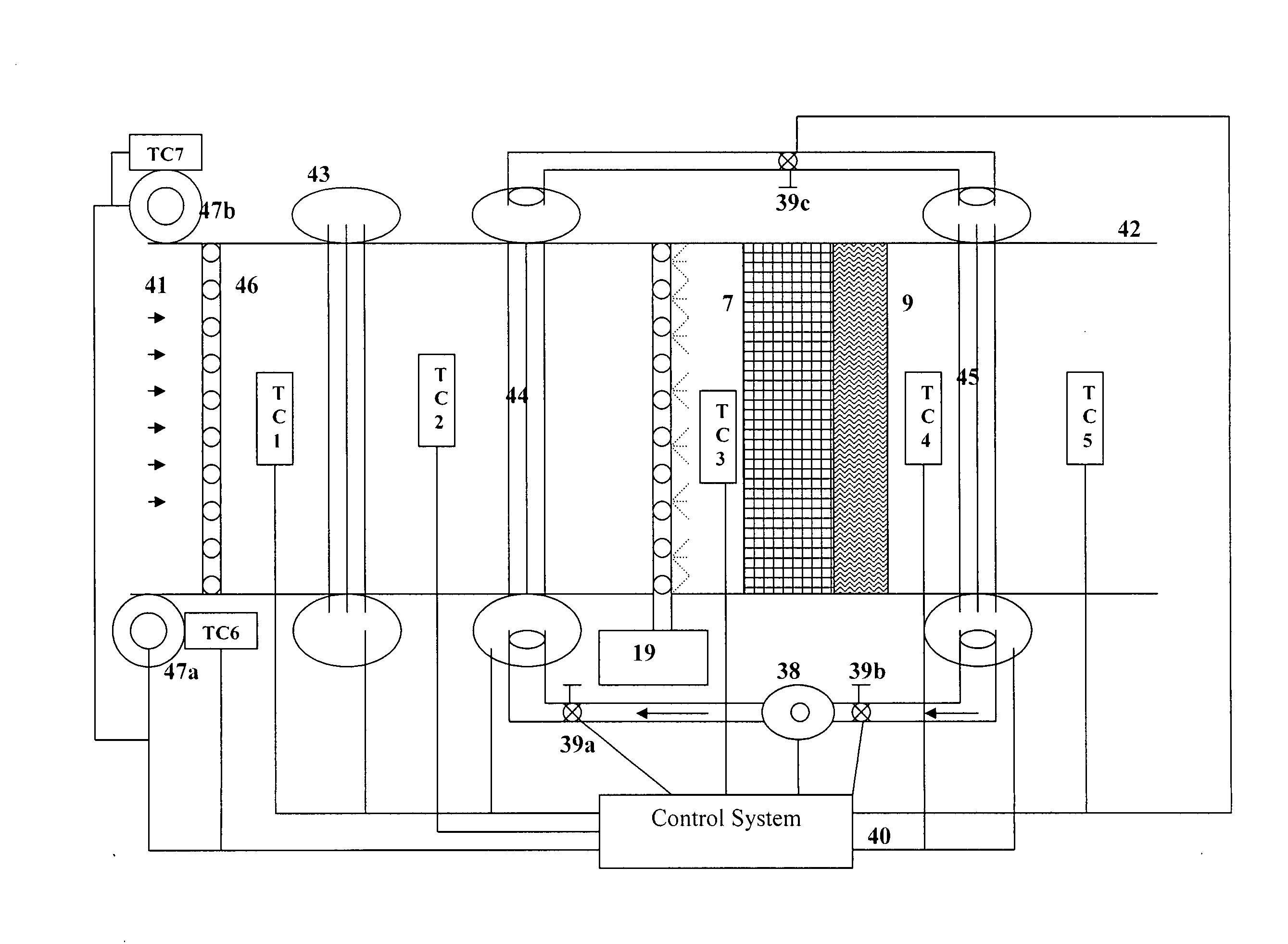

Ammonia injection grid for a selective catalytic reduction system

An ammonia injection grid for a selective catalytic reduction (SCR) system that provides uniform distribution of ammonia to the SCR catalyst in NOx reduction systems for heat recovery steam generation systems, packaged boilers, simple cycle catalyst systems and fired heaters for superior operational efficiency. The ammonia injection grid includes an injection tube having at least one nozzle for injecting ammonia into a flow of flue gas. The ammonia injection grid also includes a corrugated turbulence enhancer associated with the injection tube to generate turbulent wake to enhance turbulent mixing.

Owner:CALLIDUS TECH

System for recovering the waste heat generated by an auxiliary system of a turbomachine

InactiveUS20090301078A1Improve efficiencyWork lessEnergy industryGas pressure propulsion mountingProcess engineeringEconomizer

A system increasing the efficiency of a powerplant by recovering the waste generated by an auxiliary cooling system is provided. The system may include a condensate loop and a heat recovery loop. These loops may integrate the auxiliary cooling systems of a gas turbine with the heat recovery steam generator of the powerplant. The integration may allow a smaller economizer section, which may increase the efficiency of the powerplant.

Owner:GENERAL ELECTRIC CO

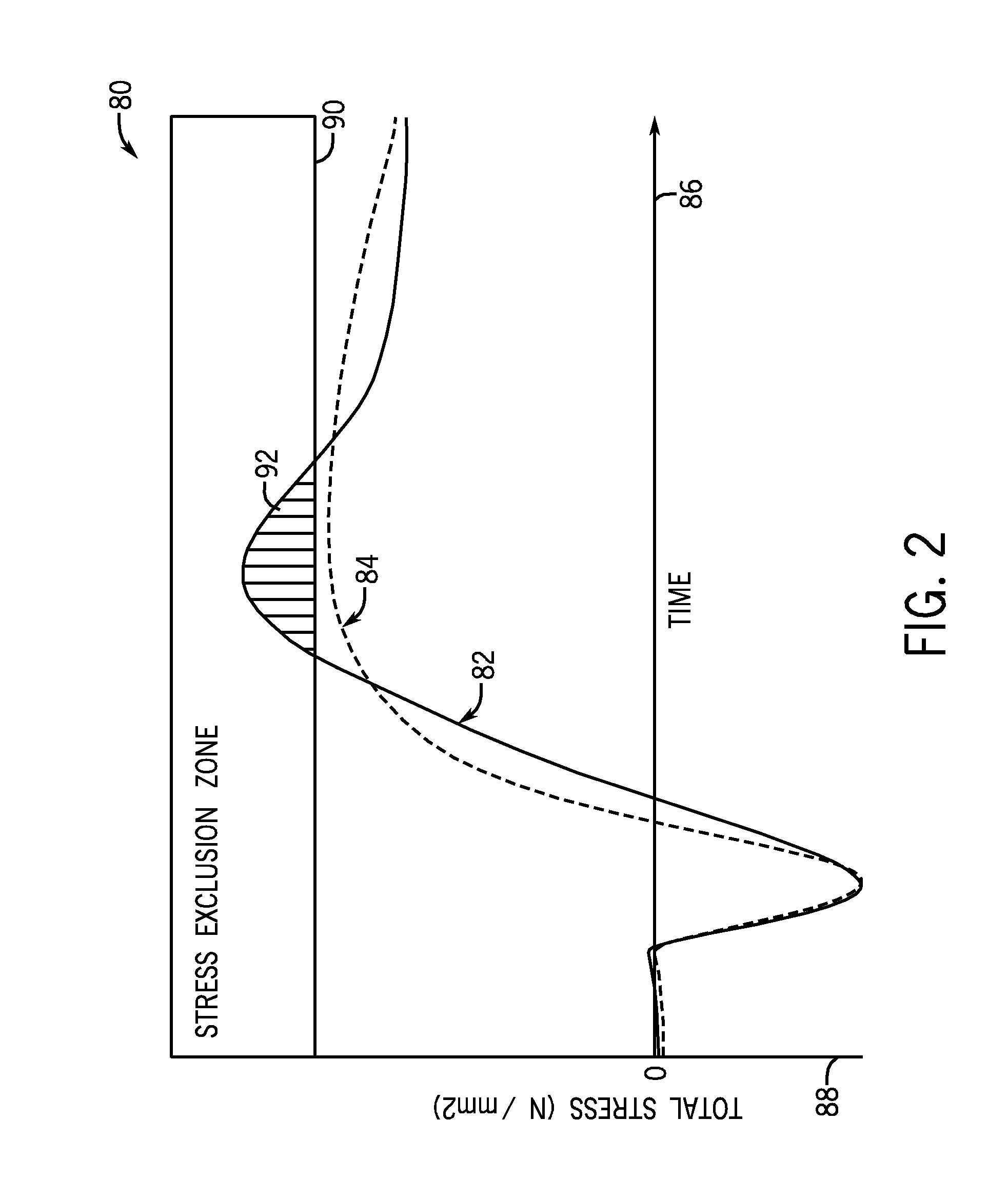

Systems and methods for heat recovery steam generation optimization

The embodiments described herein include a system and a method. In a first embodiment, a system includes a controller configured to control power plant operations. The system further includes a heat recovery steam generator (HRSG) monitor communicatively coupled to the controller and configured to receive inputs corresponding to the power plant operations. The system additionally includes an HRSG life prediction model configured to predict an operating life for an HRSG component. The HRSG monitor uses the HRSG life prediction model and the inputs to communicate a control action to the controller.

Owner:GENERAL ELECTRIC CO

Methods and apparatus for starting up combined cycle power systems

ActiveUS20070113562A1Easy loadingIncrease ratingsTurbine/propulsion fuel supply systemsTurbine/propulsion engine ignitionElectric power systemEngineering

Methods and apparatus for fast starting and loading a combined cycle power system are described. In one example embodiment, the method includes loading the gas turbine at up to it's maximum rate, and loading the steam turbine at its maximum rate with excess steam bypassed to the condenser while maintaining the temperature of steam supplied to the steam turbine at a substantially constant temperature from initial steam admission into the steam turbine until all steam generated by the heat recovery steam generator is being admitted to the steam turbine while the gas turbine operates at up to maximum load.

Owner:GENERAL ELECTRIC CO

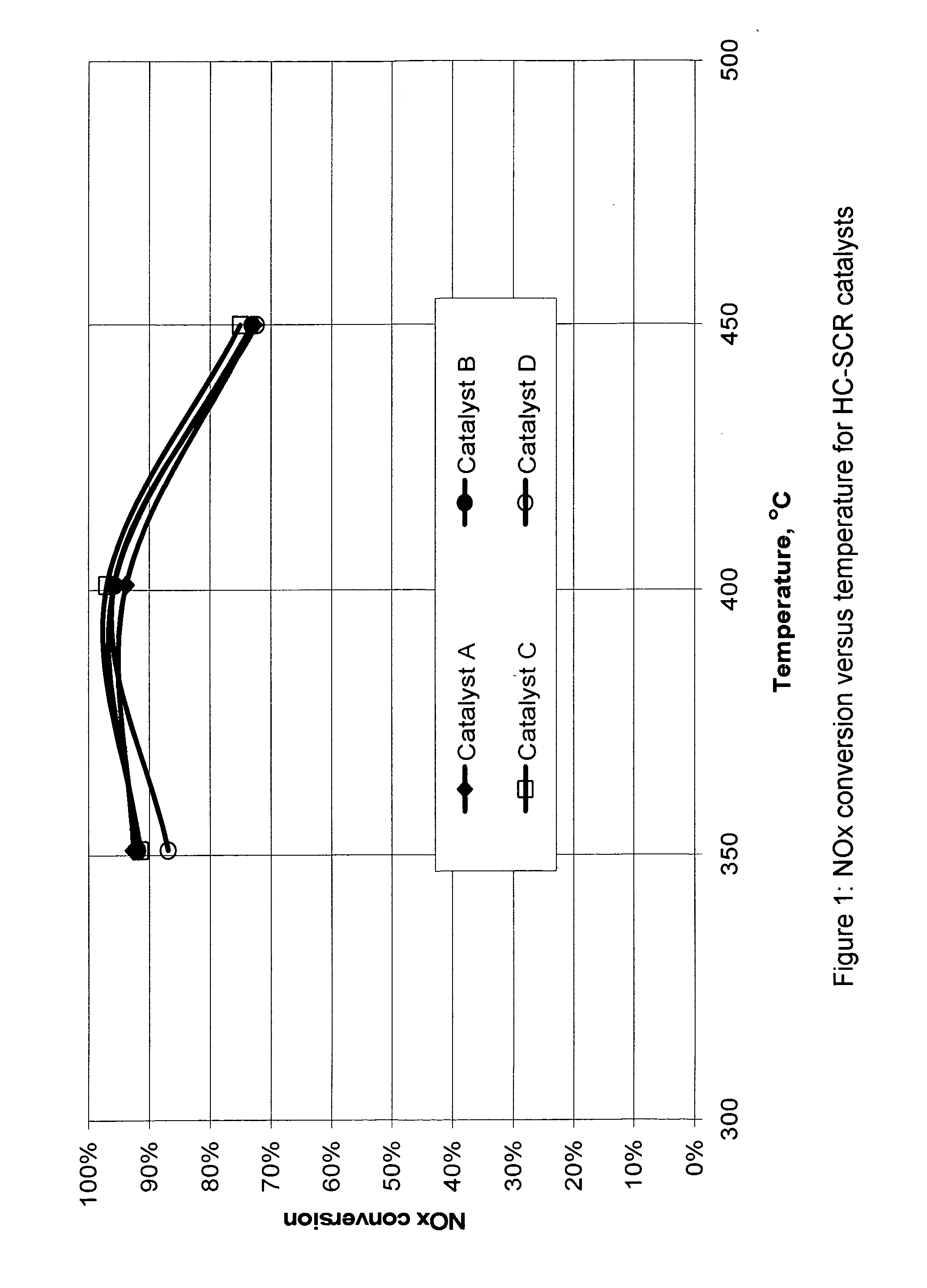

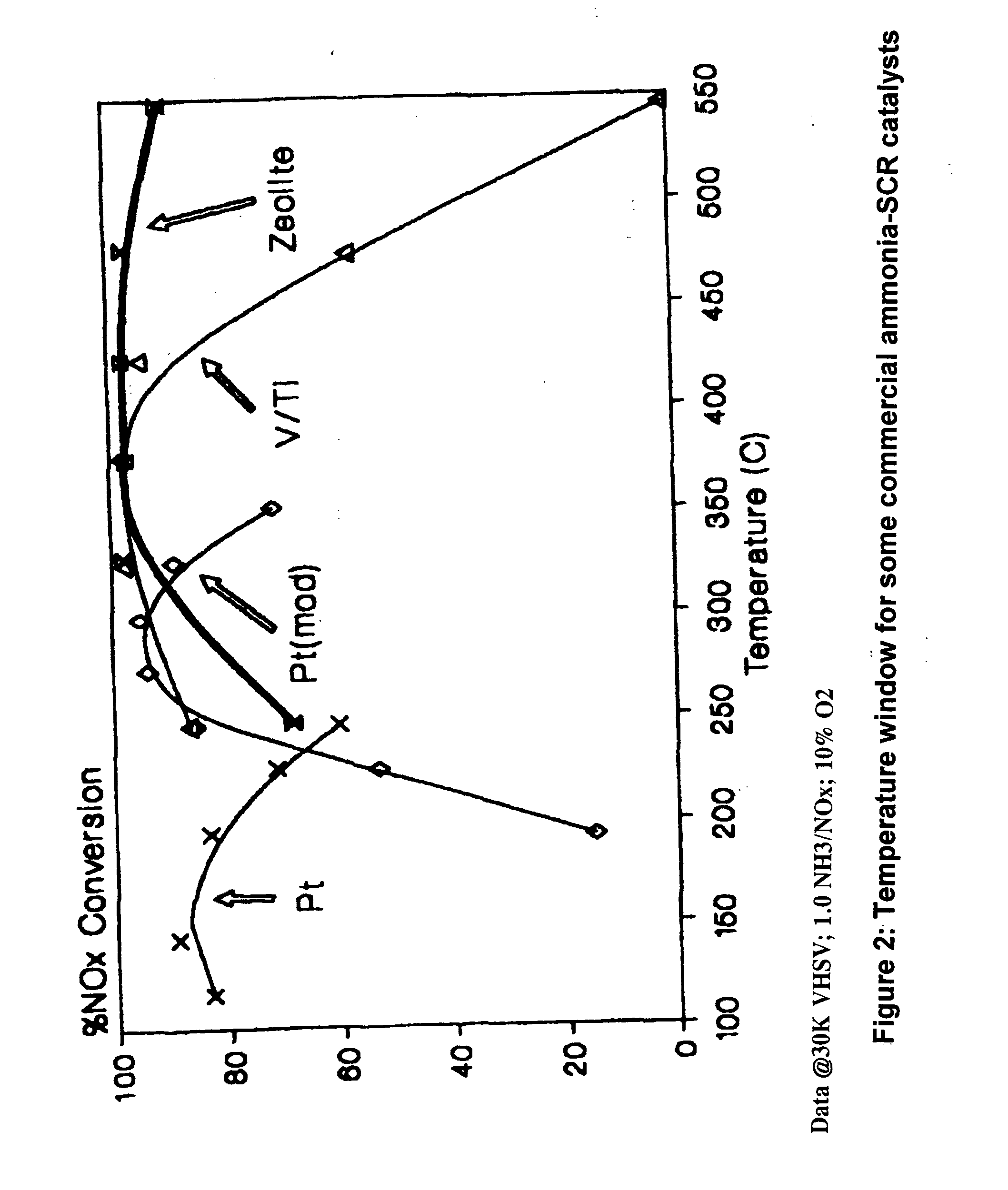

Emission reduction system for use with a heat recovery steam generation system

InactiveUS20090282803A1Quantity minimizationSmall sizeSteam generation heating methodsExhaust apparatusCombustorExhaust fumes

A system and method of maintaining an optimal temperature range for a catalyst section in a HRSG comprising placing a portion of the exhaust stream in a heat exchanger and superheater, diverting a second portion around the heat exchanger and superheater, combining the two portions and contacting the two portions with a catalyst section. Alternatively, a system of heat exchangers are employed to address the fluctuating exhaust temperature caused by the intermittent use of the duct burners.

Owner:JOHNSON MATTHEY INC

Integrated solar-gas turbine cogeneration plant

The integrated solar-gas turbine cogeneration plant includes a fuel reformer, a plurality of solar collectors, and a gas turbine. The fuel reformer produces syngas to be used as fuel for the gas turbine. One solar collector is operatively connected to both the fuel reformer and the turbine to provide heat for the reforming reaction and to preheat air for a combustion chamber. Exhaust gas from the turbine is directed to the fuel reformer and to a heat recovery steam generator, the former as an additional heat source and the latter to heat the generator. Another solar collector is connected to the generator and heats a portion of the water being fed into the generator in order to help produce steam. The syngas is stored in a to fuel storage unit to provide fuel to the gas turbine continuously and to a supplemental heater on the steam generator during low insolation periods.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

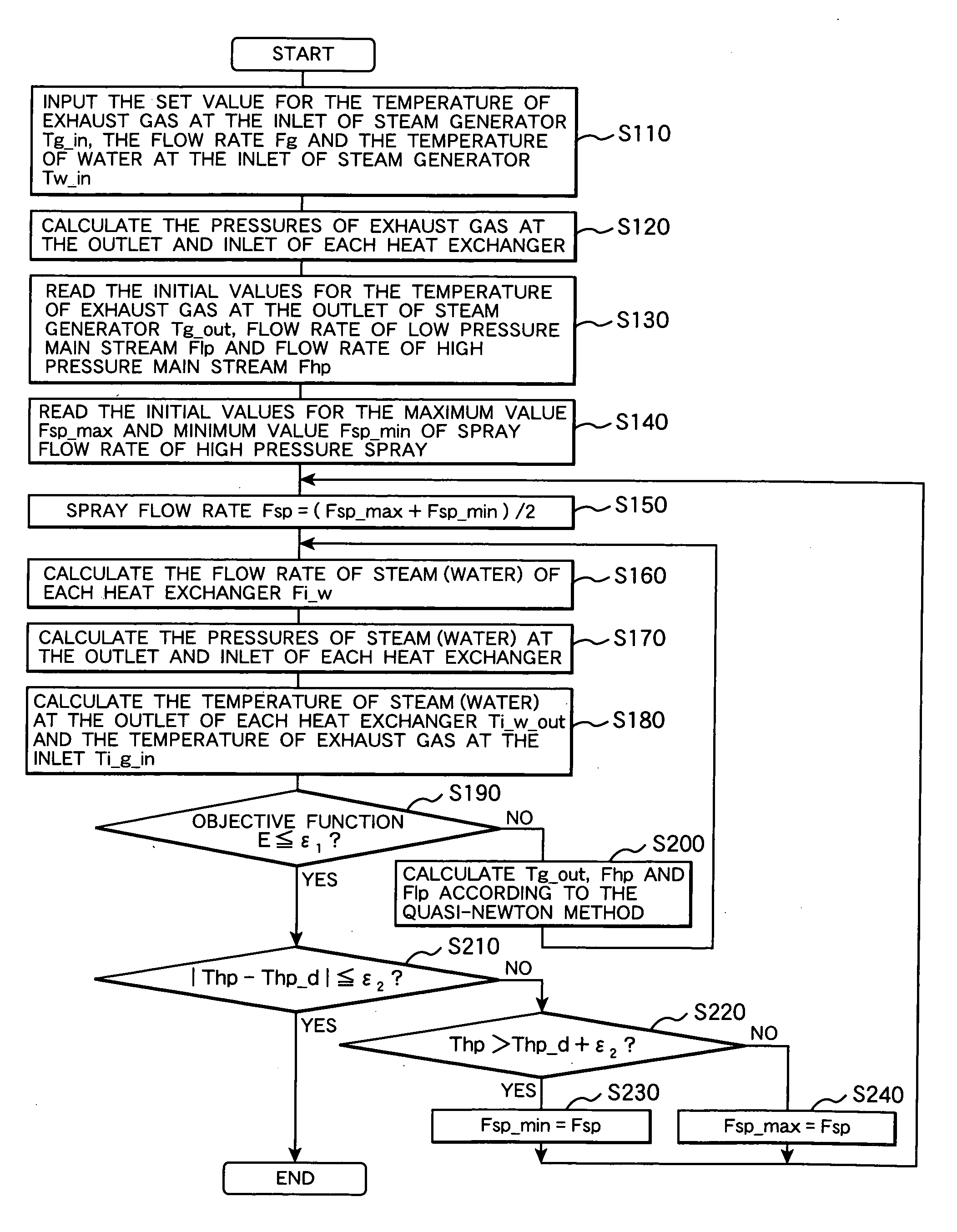

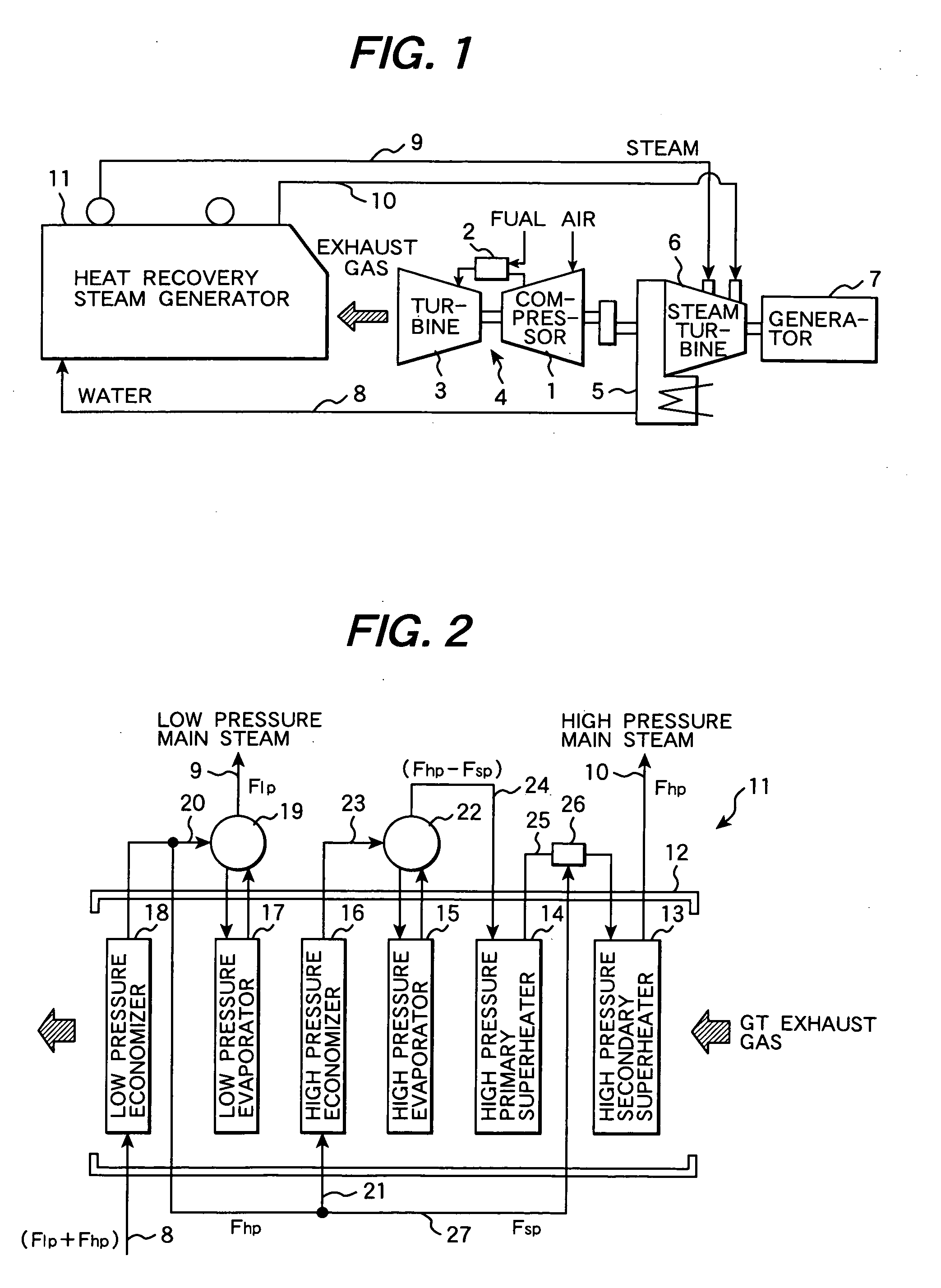

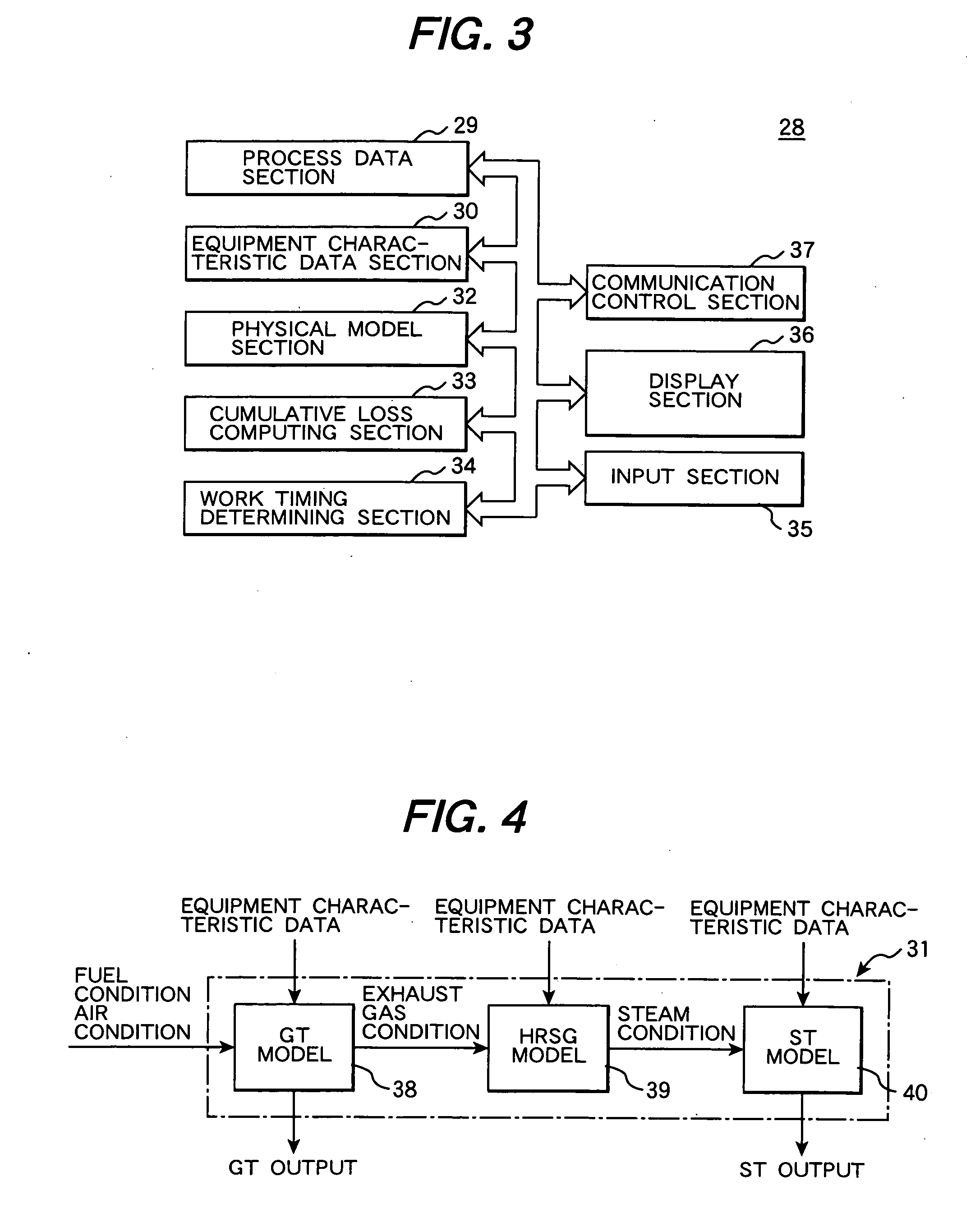

Generated steam estimation method and device for heat recovery steam generator, and maintenance planning support method and system for power generation facility

InactiveUS20060200325A1Level controlComputation using non-denominational number representationMaintenance planningEstimation methods

A method for configuring the physical model of a heat recovery steam generator that can estimate the state quantity of generated steam from the state quantity of the exhaust gas to be introduced, and capable of establishing the physical model of a combined cycle power generation facility thereby. The optimum values for the flow rates Flp and Fhp, pressures and temperatures Tlp and Thp of the low pressure main steam and high pressure main steam are computed in such a way as to ensure that an objective function E stored in advance will come close to zero.

Owner:MITSUBISHI POWER LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com