Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

22226 results about "Exhaust fumes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

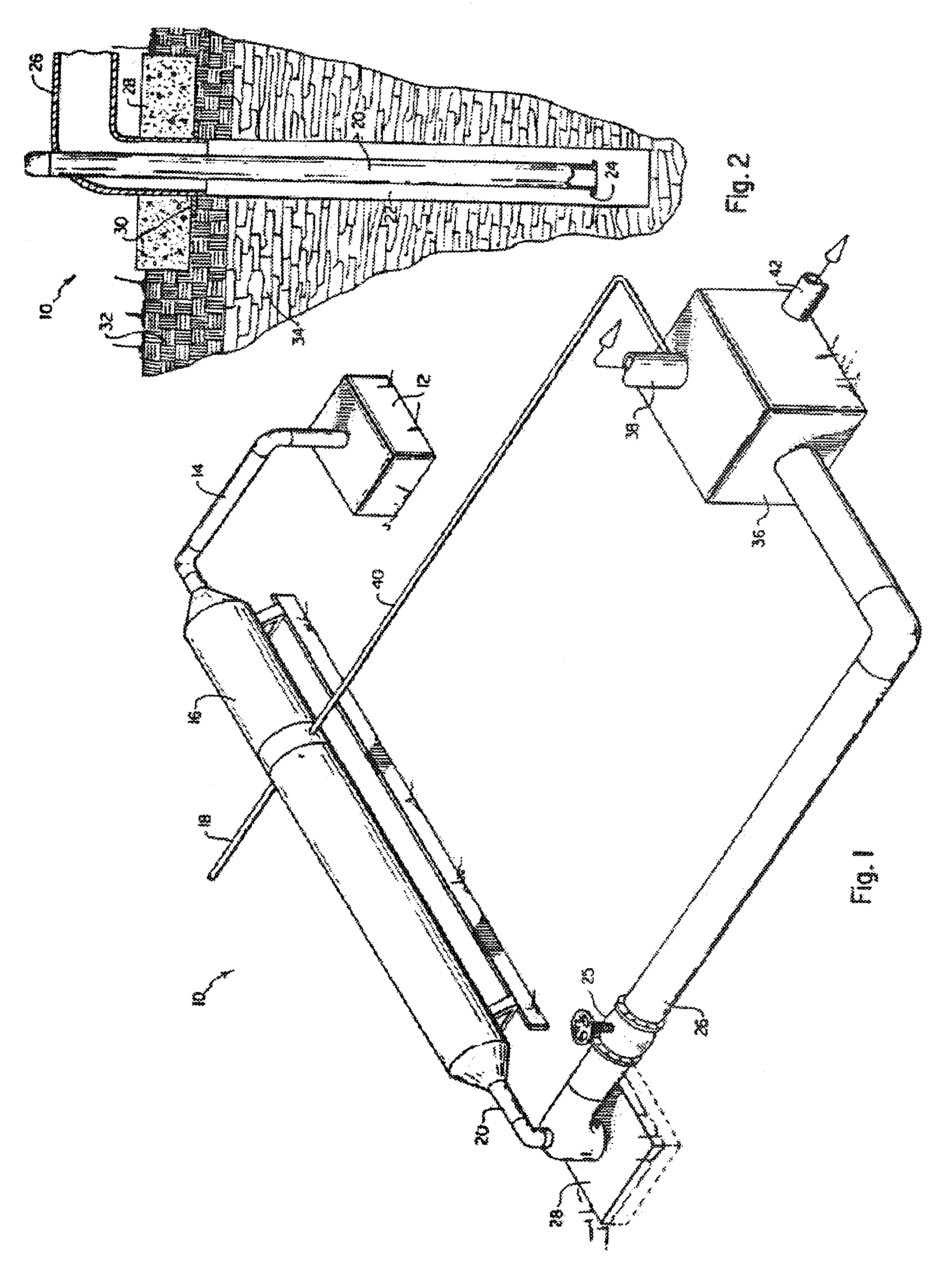

Sorbents and methods for the removal of mercury from combustion gases

InactiveUS6953494B2Improve abilitiesUnified processingGas treatmentOther chemical processesSufficient timeCombustion

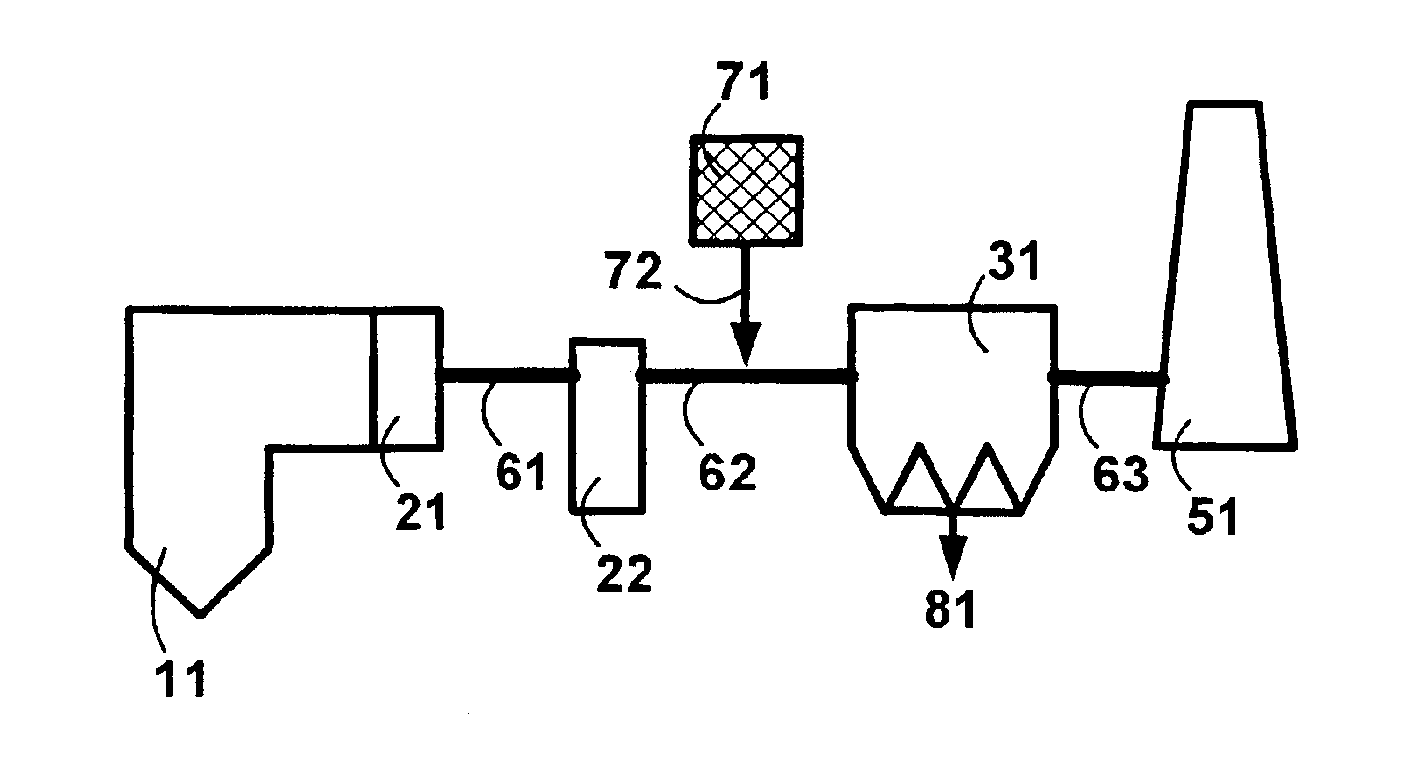

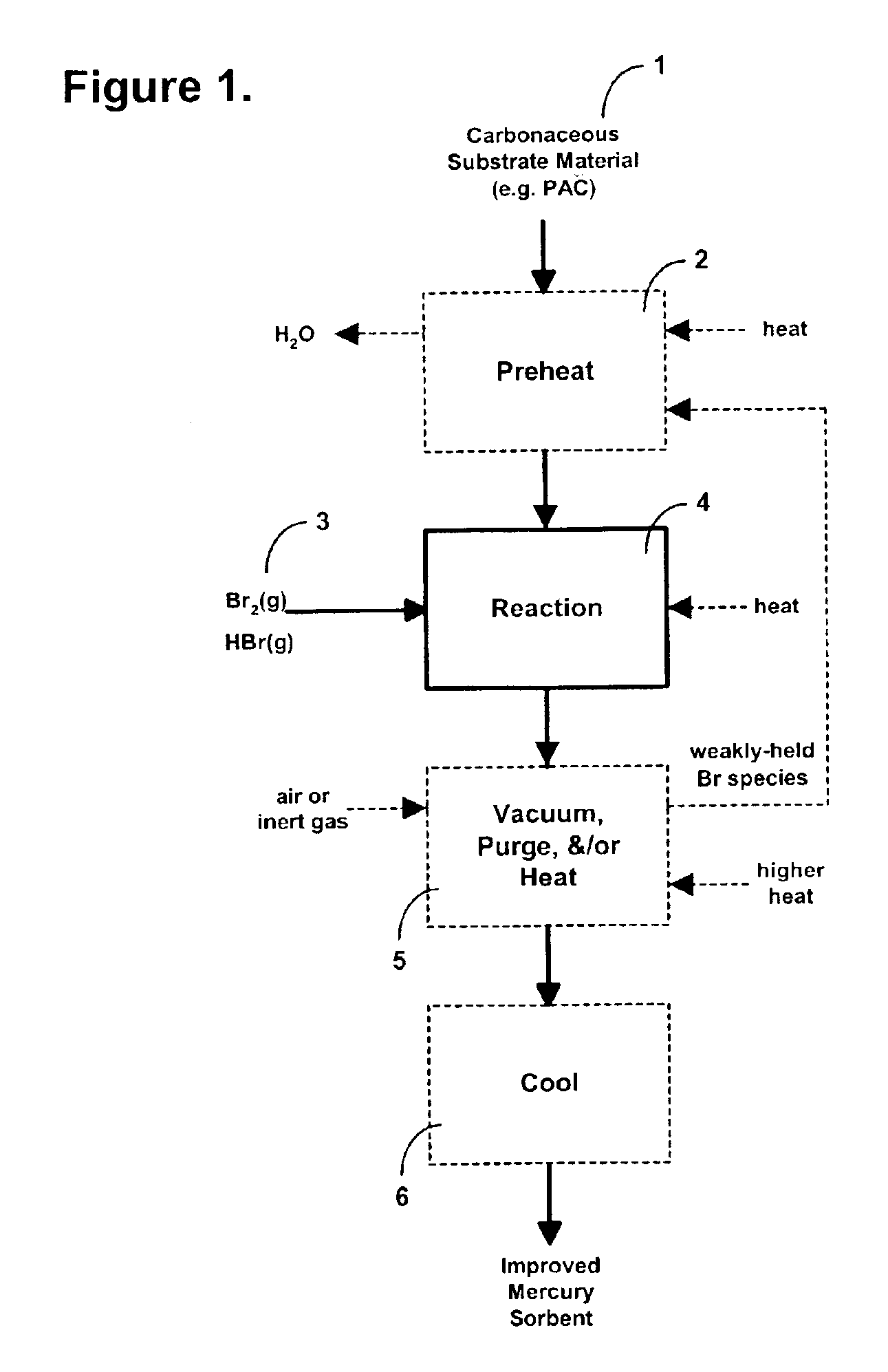

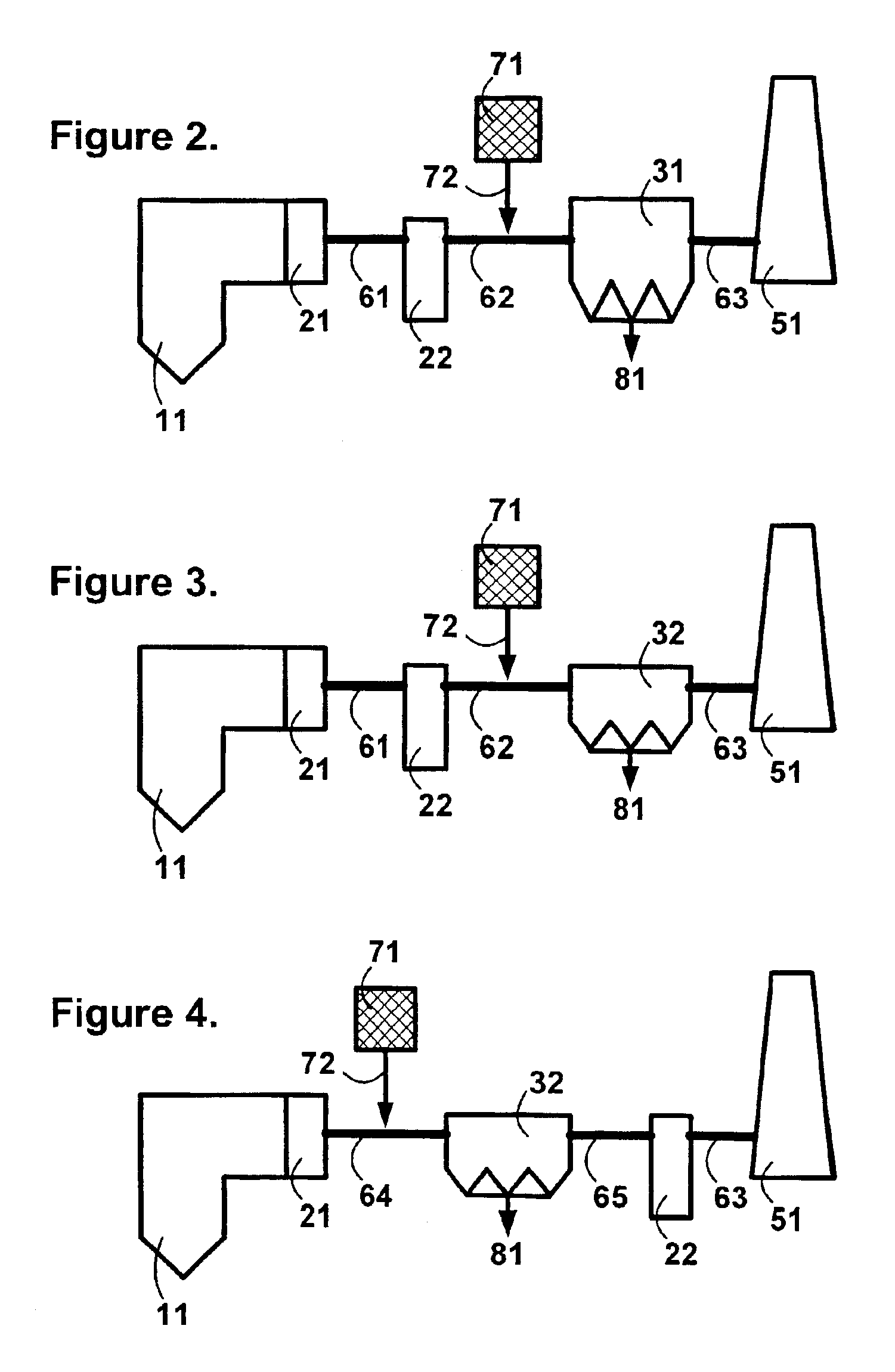

A method for removing mercury and mercury-containing compounds from a combustion gas in an exhaust gas system has the steps of providing a mercury sorbent; injecting the mercury sorbent into a stream of the mercury-containing combustion gas for a sufficient time to allow at least an effective amount of the mercury and mercury-containing compounds in the combustion gas to adsorb onto the mercury sorbent, and collecting and removing the mercury sorbent from the combustion gas stream. The mercury sorbent is prepared by treating a carbonaceous substrate with an effective amount of a bromine-containing gas, especially one containing elemental bromine or hydrogen bromide, for a time sufficient to increase the ability of the carbonaceous substrate to adsorb mercury and mercury-containing compounds. The points of injecting and collecting and removing the mercury sorbent may be varied, depending upon the exact configuration of the exhaust gas system.

Owner:SORBENT TECH +1

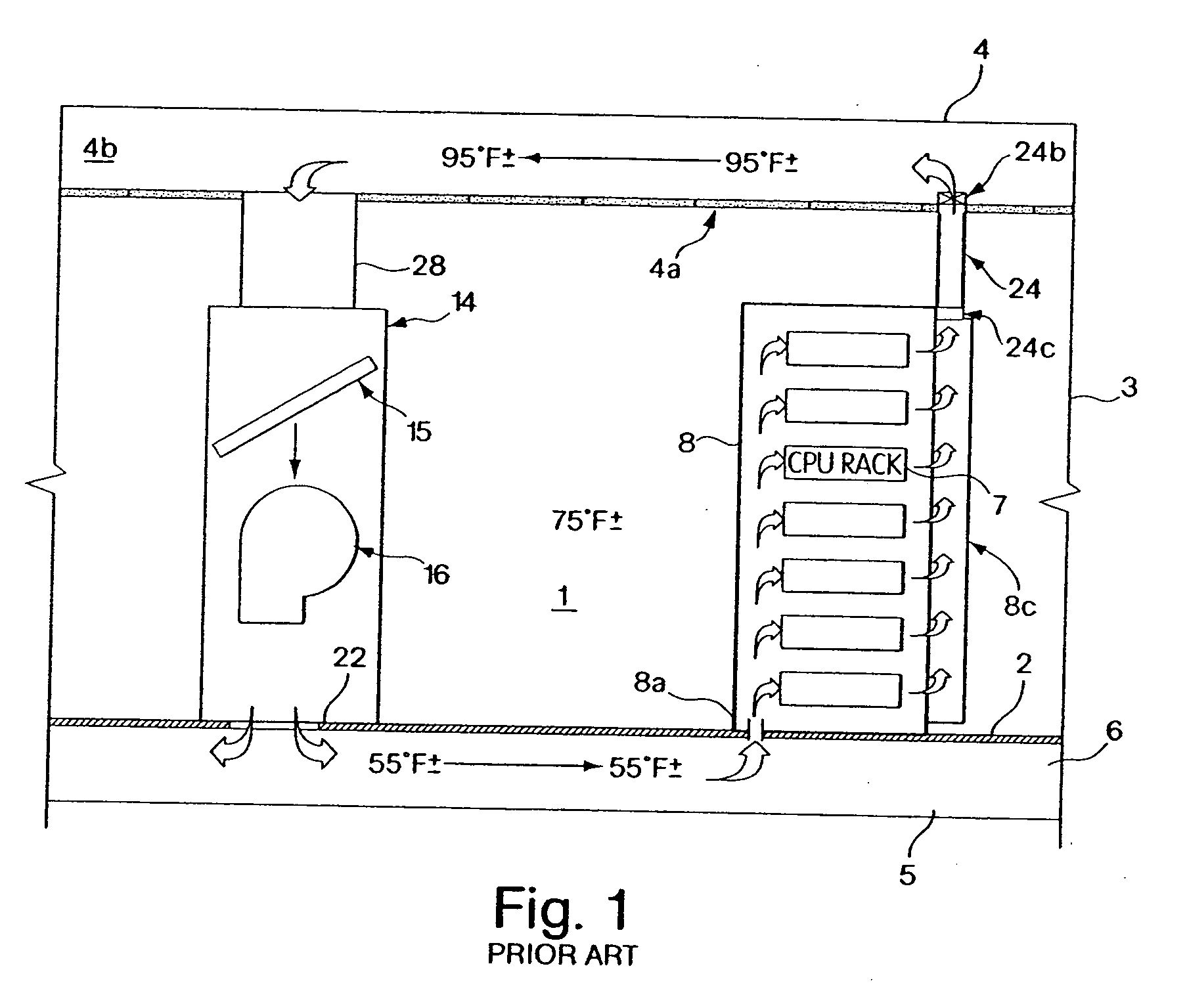

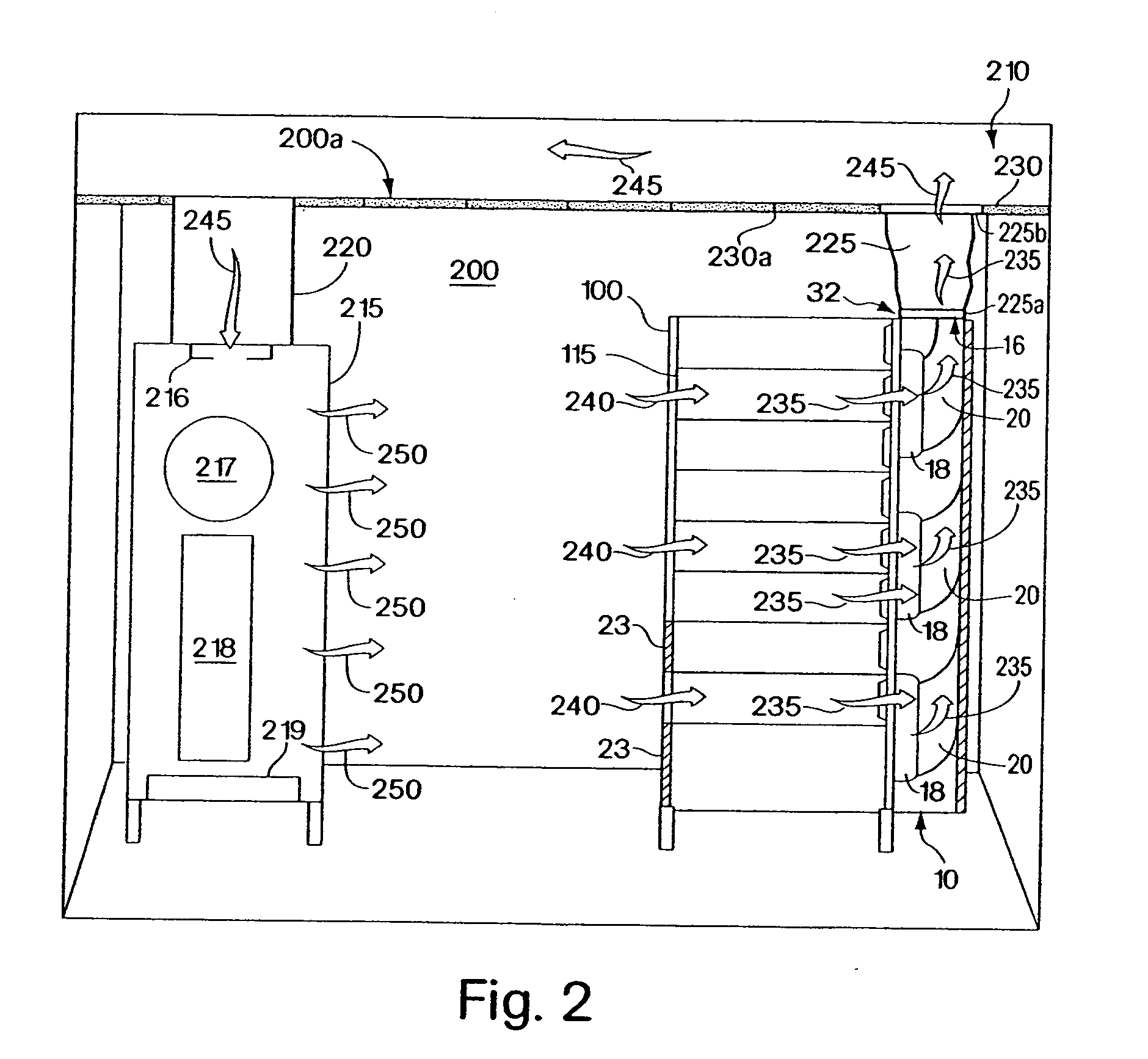

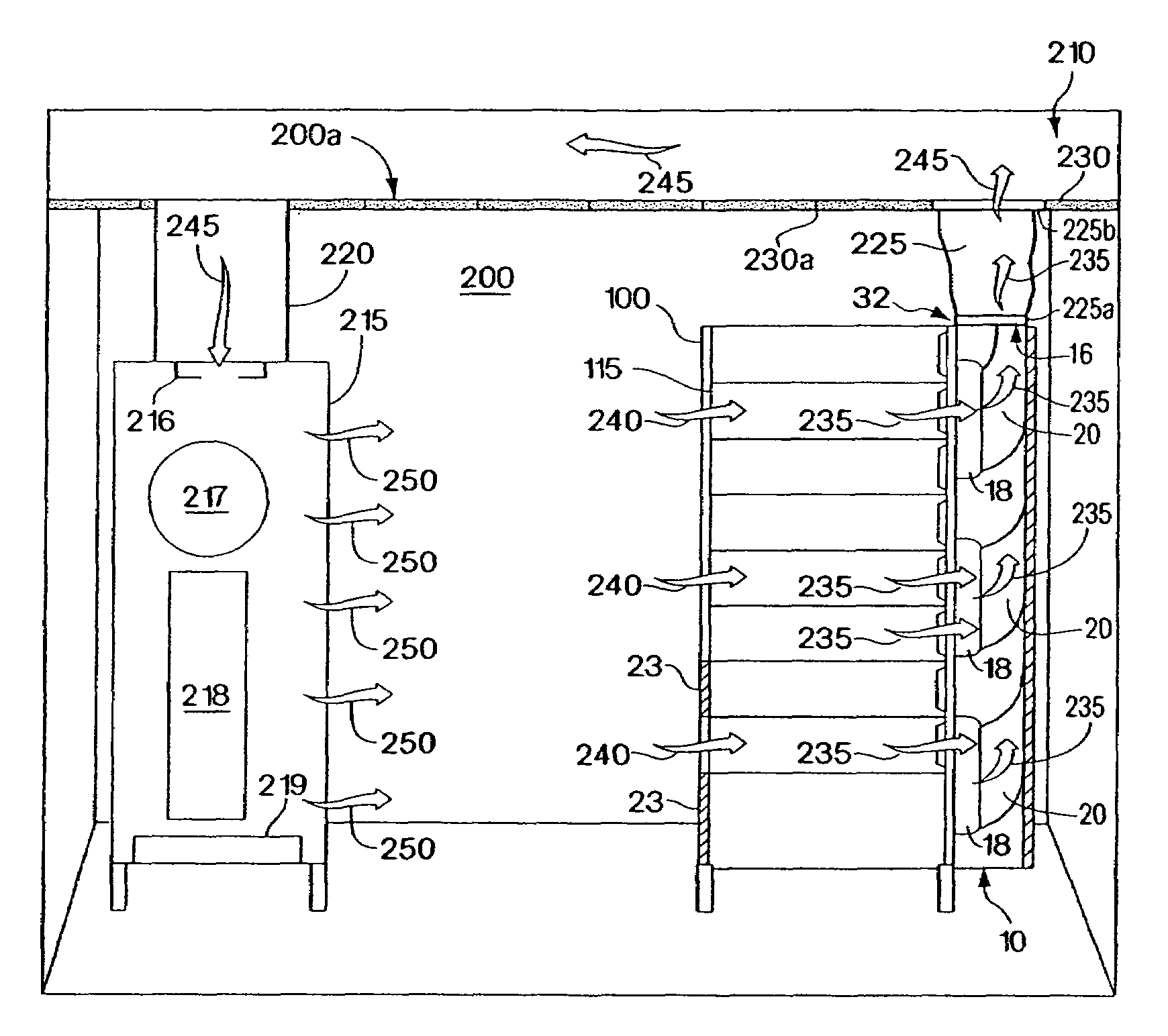

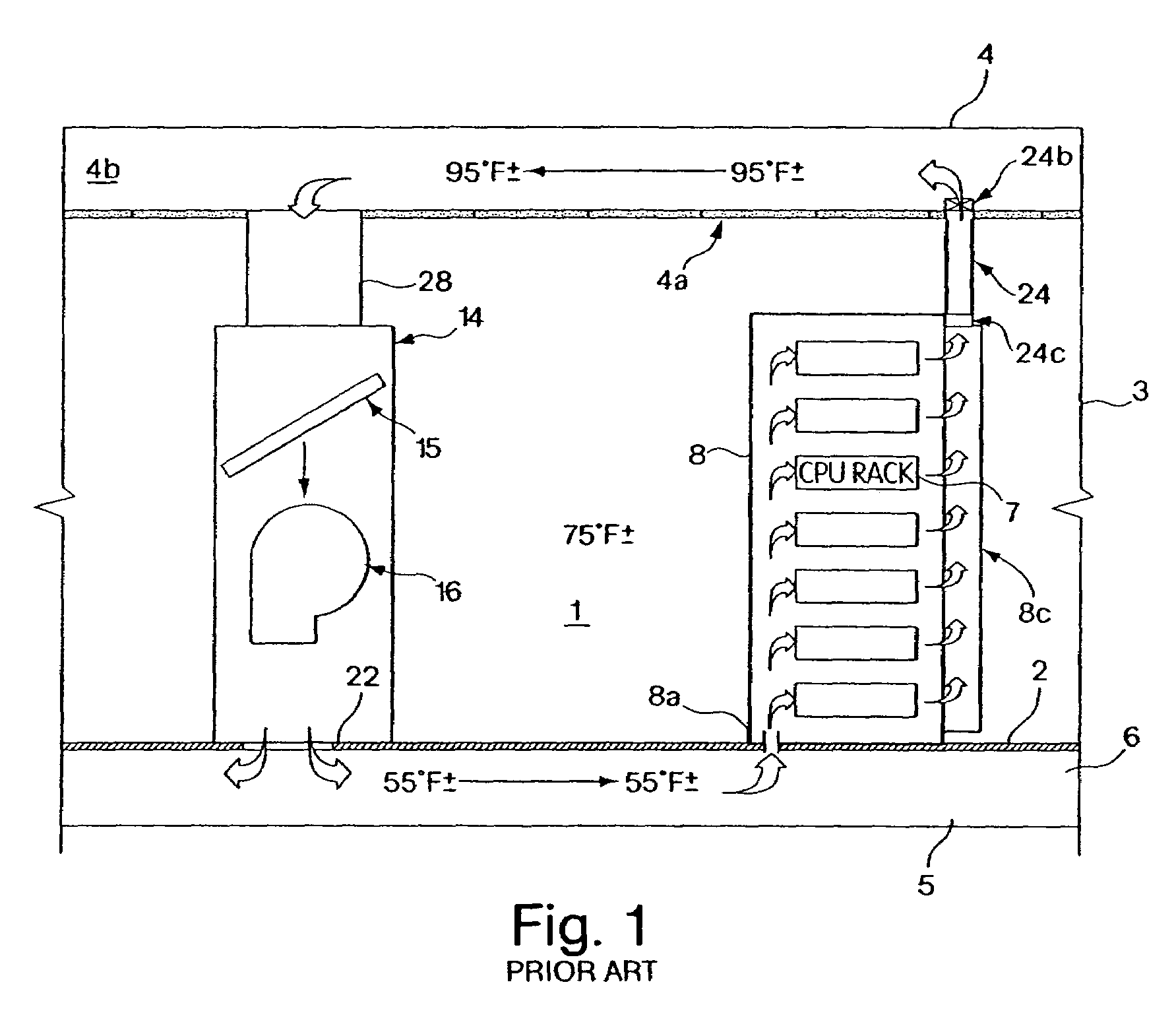

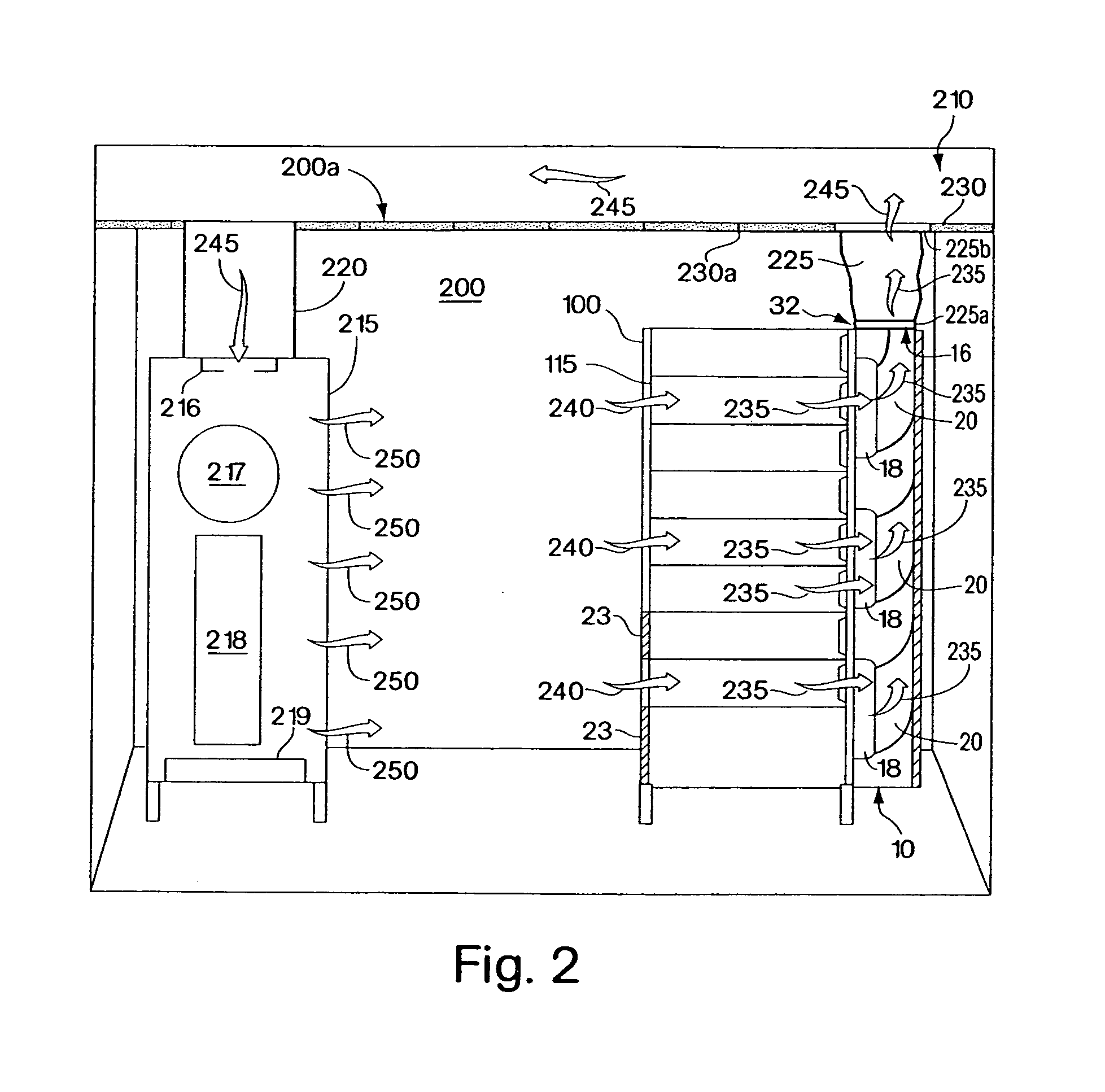

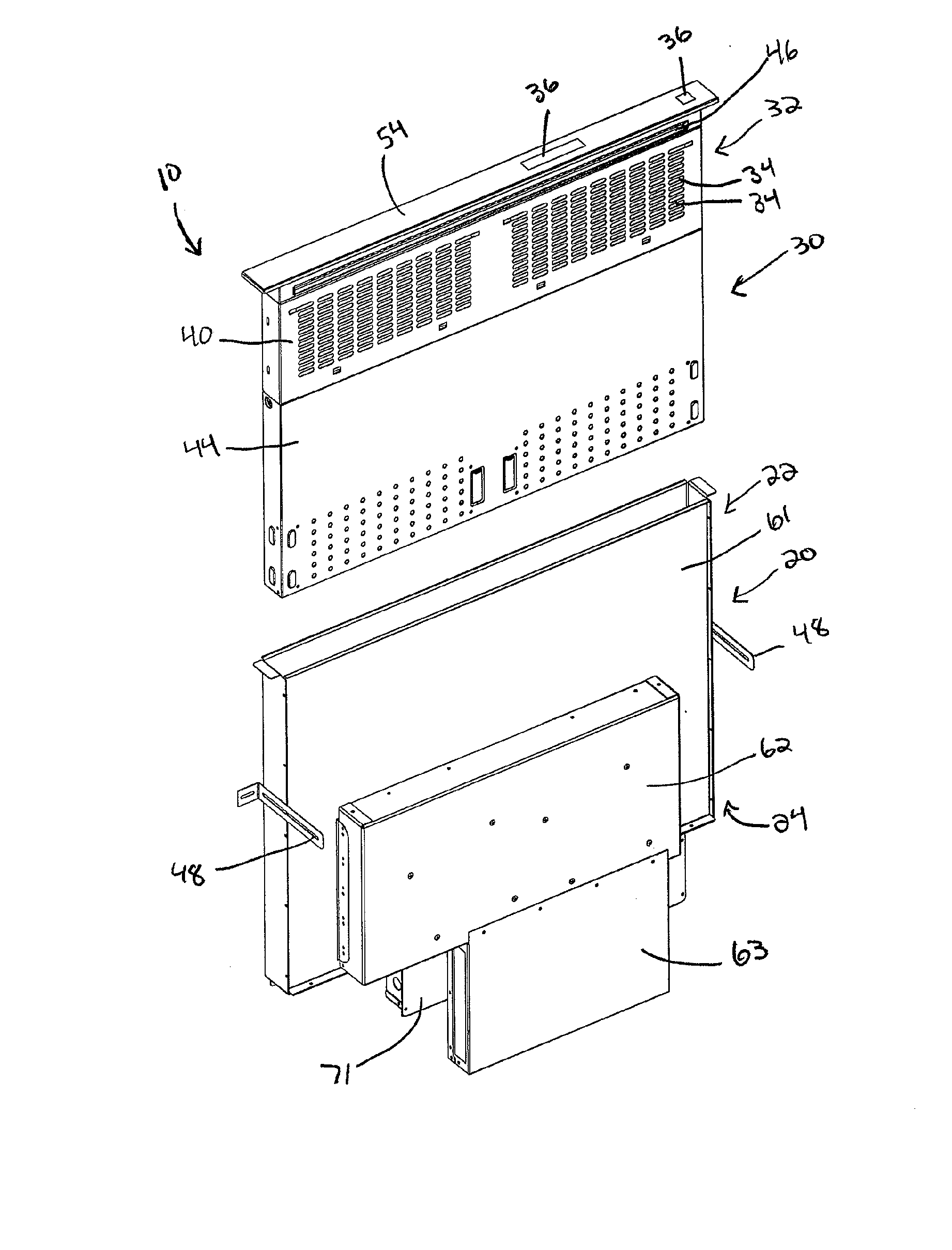

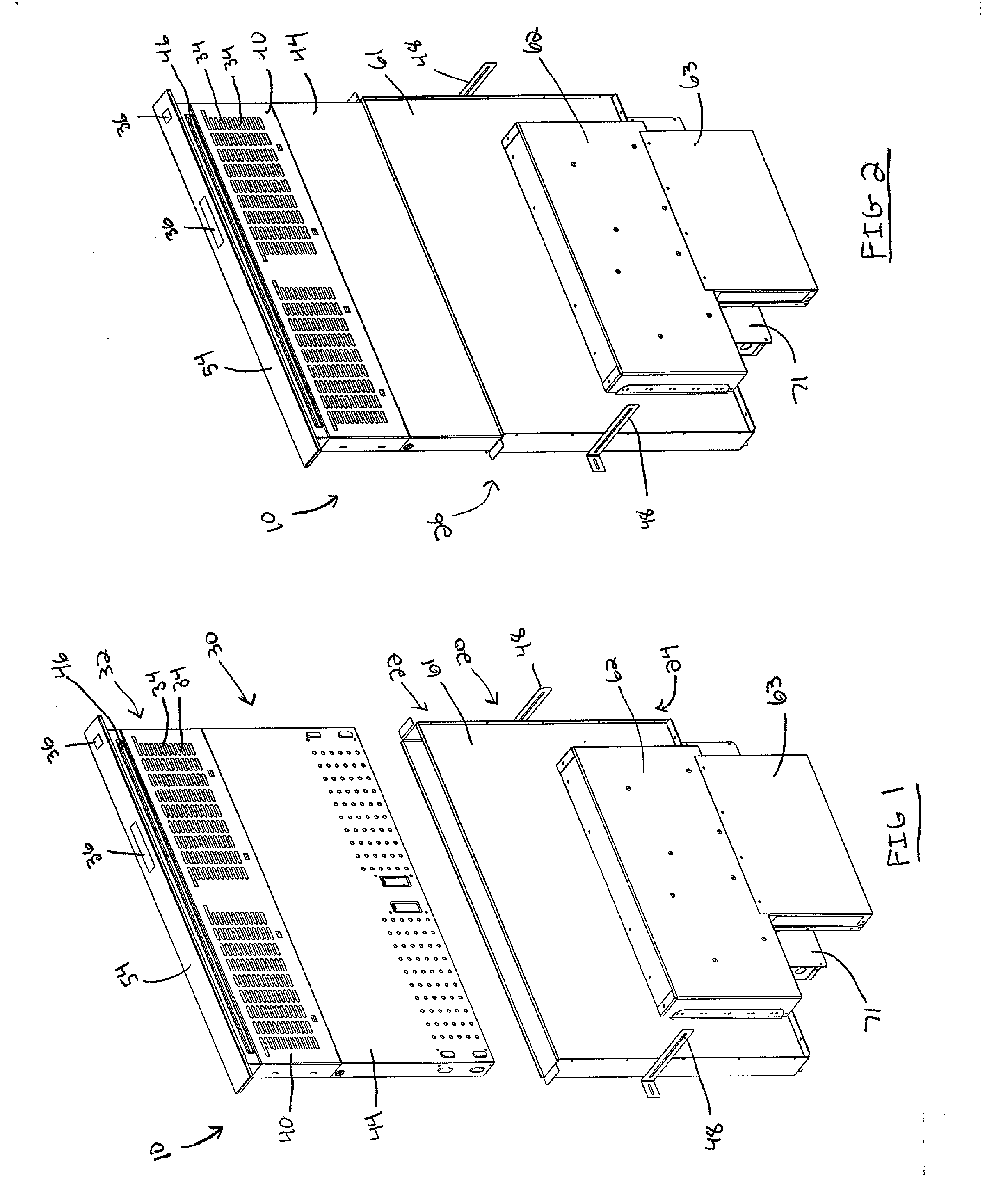

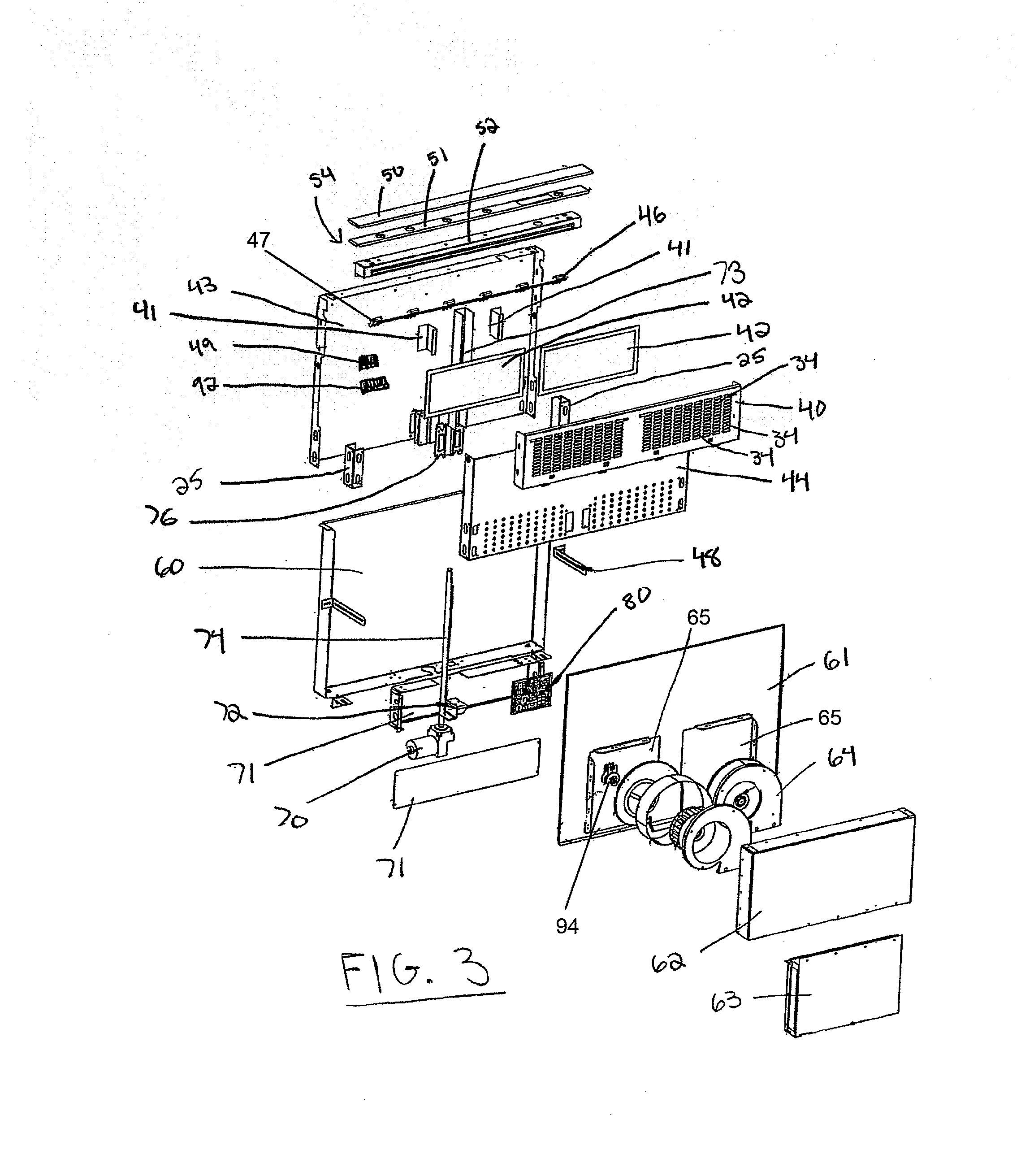

Exhaust air removal system

InactiveUS20050170770A1Mixing with airMeet the requirementsIndirect heat exchangersCooling/ventilation/heating modificationsExhaust fumesBack door

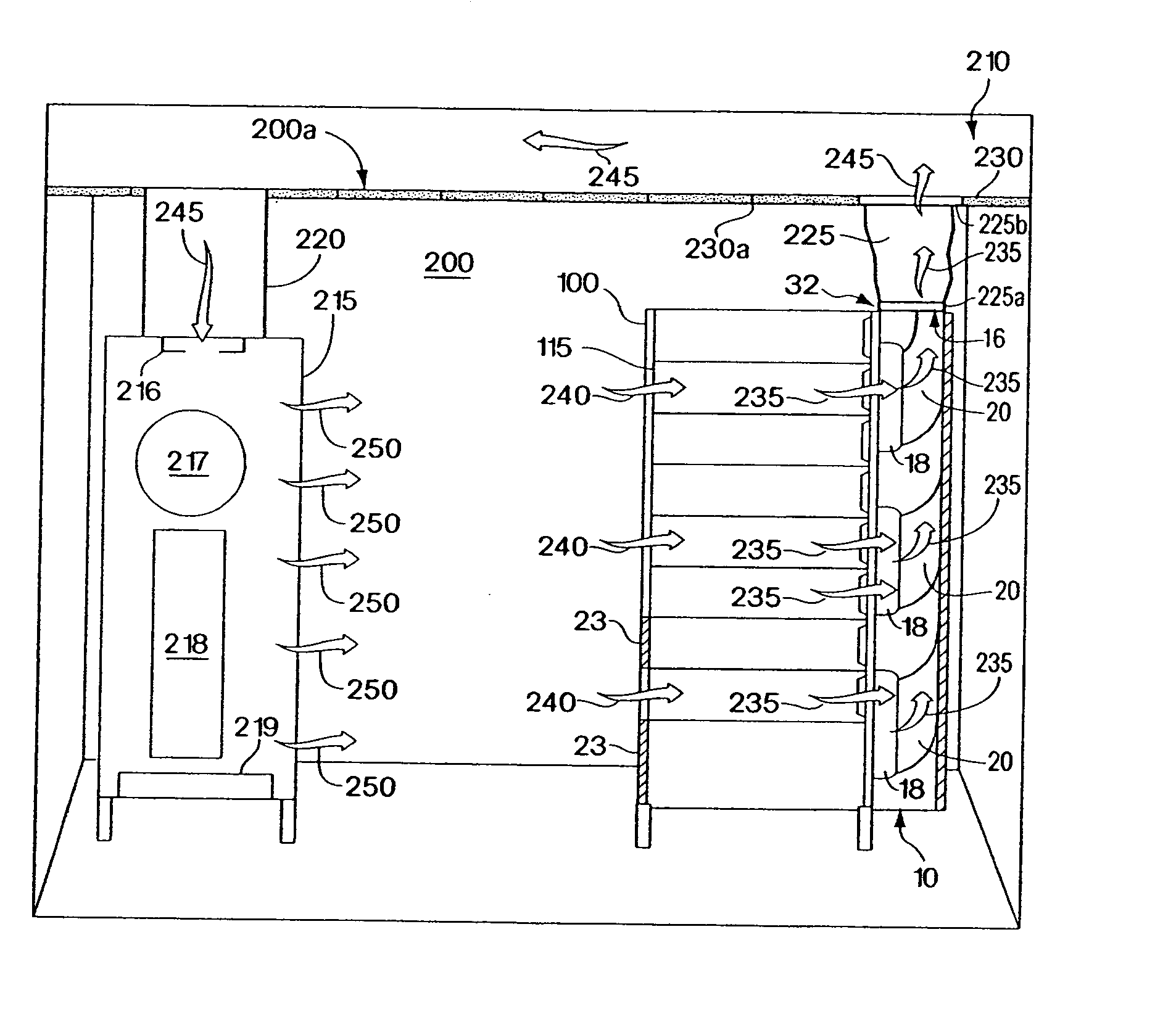

An exhaust air removal system and method for use with a rack or enclosure containing equipment is provided. The system and method are configured for removal of exhaust air vented from equipment during operation to thereby remove heat from the equipment. In one aspect, the system includes a fan unit preferably configured to serve as a back door of an equipment rack or enclosure and configured to provide access to an interior of the rack or enclosure. The fan unit provides multiple fans coupled to internal exhaust ducts that are arranged to draw and to remove exhaust air vented from rack-mounted equipment. The fan unit is further configured to vent exhaust air to an area external to a rack or enclosure, such as an external exhaust duct or plenum. Removal of hot and warm exhaust air vented from rack-mounted equipment enables the equipment to operate effectively, drawing sufficient amounts of cooling air to meet its cooling requirements. The fan unit is constructed for portability and for easy attachment to and removal from a rack or enclosure, providing flexibility in handling equipment exhaust needs.

Owner:SCHNEIDER ELECTRIC IT CORP

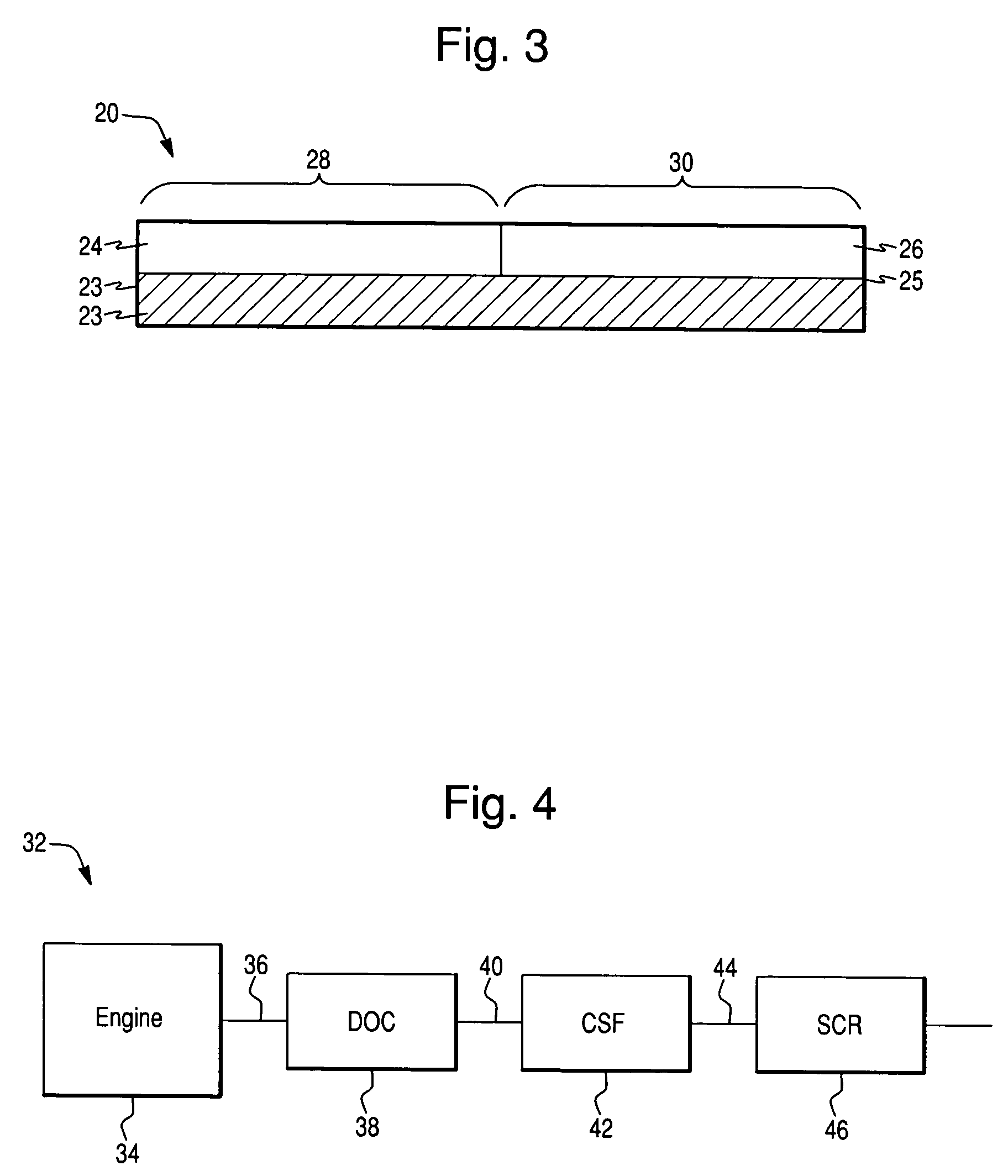

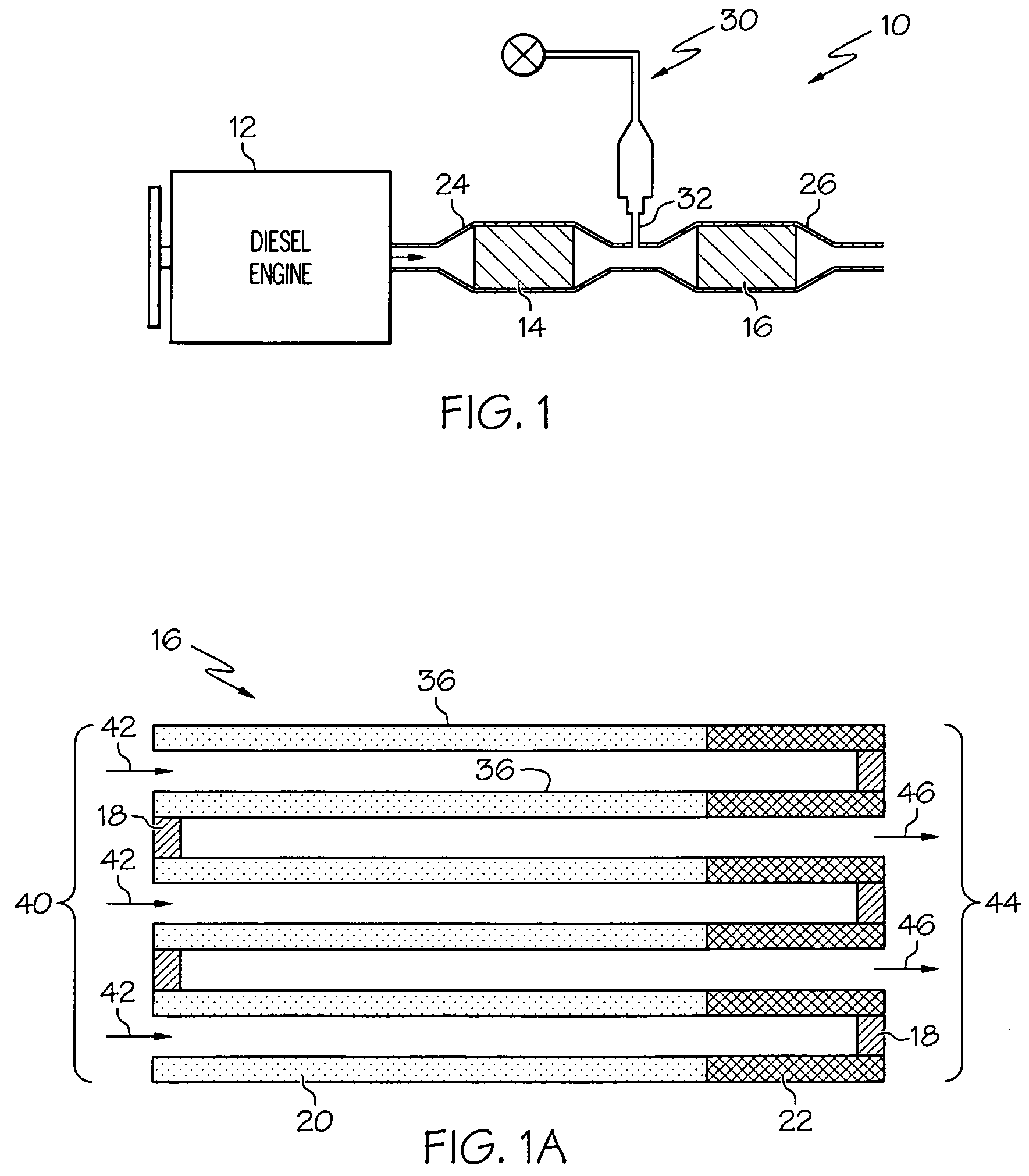

Pt-Pd diesel oxidation catalyst with CO/HC light-off and HC storage function

ActiveUS20080045405A1Nitrous oxide captureMolecular sieve catalystsExhaust gas emissionsNitrogen oxide

The present invention is directed to a diesel oxidation catalyst for the treatment of exhaust gas emissions, such as the oxidation of unburned hydrocarbons (HC), and carbon monoxide (CO) and the reduction of nitrogen oxides (NOx). More particularly, the present invention is directed to a novel washcoat composition comprising two distinct washcoat layers containing two distinctly different ratios of Pt:Pd.

Owner:BASF CATALYSTS LLC

Reactive chemical containment system

A small scale, but effective, reactive chemical containment system includes apparatus and methods for reaction of process gases exhausted from reaction furnaces with a reactant gas in a non-combustible manner to produce and contain particulate or powder byproducts, thereby removing the process gas from the exhaust gas flow. The apparatus provides process gas inlet, treatment reactive gas diffusion, process gas and treatment reactive gas pre-mixing, primary containment, secondary containment, and outlet zones.

Owner:MKS INSTR INC

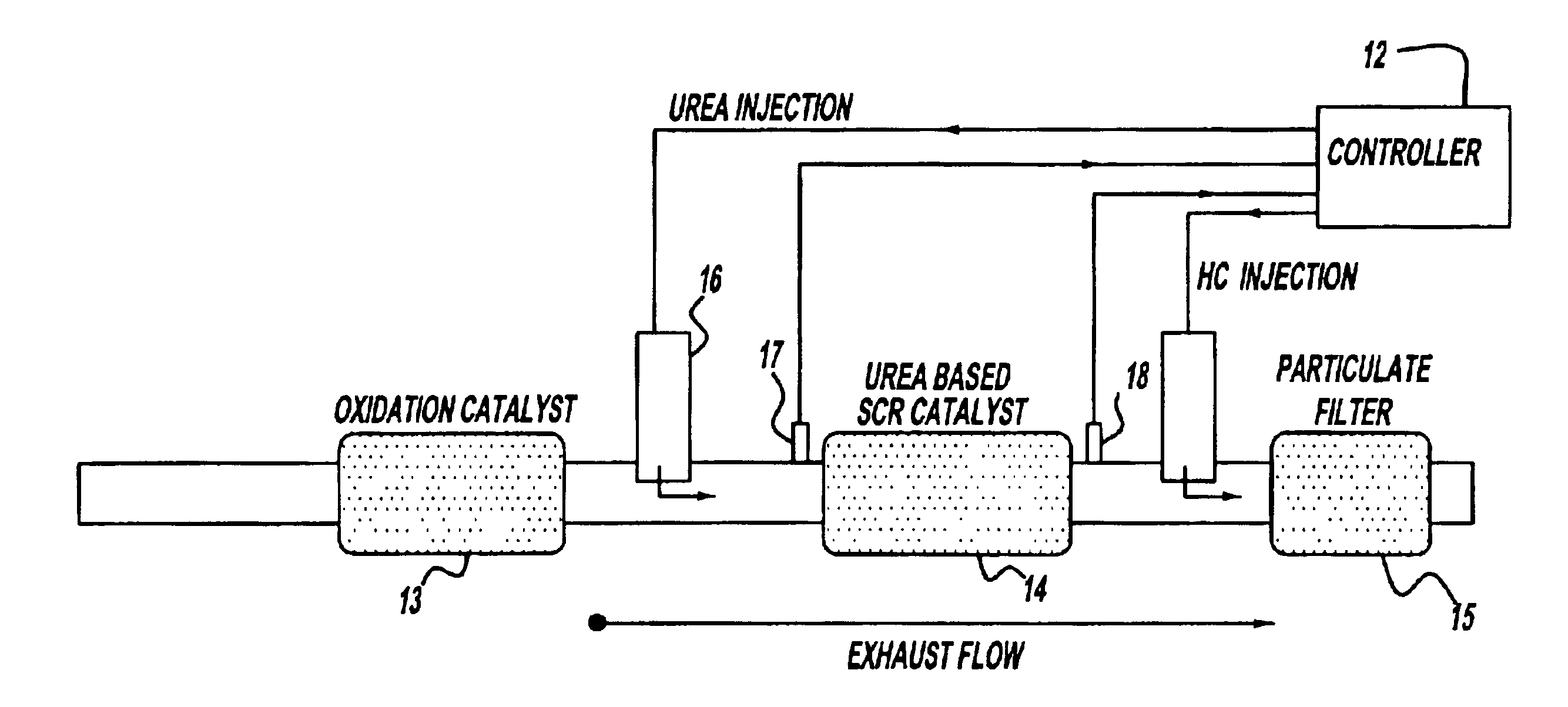

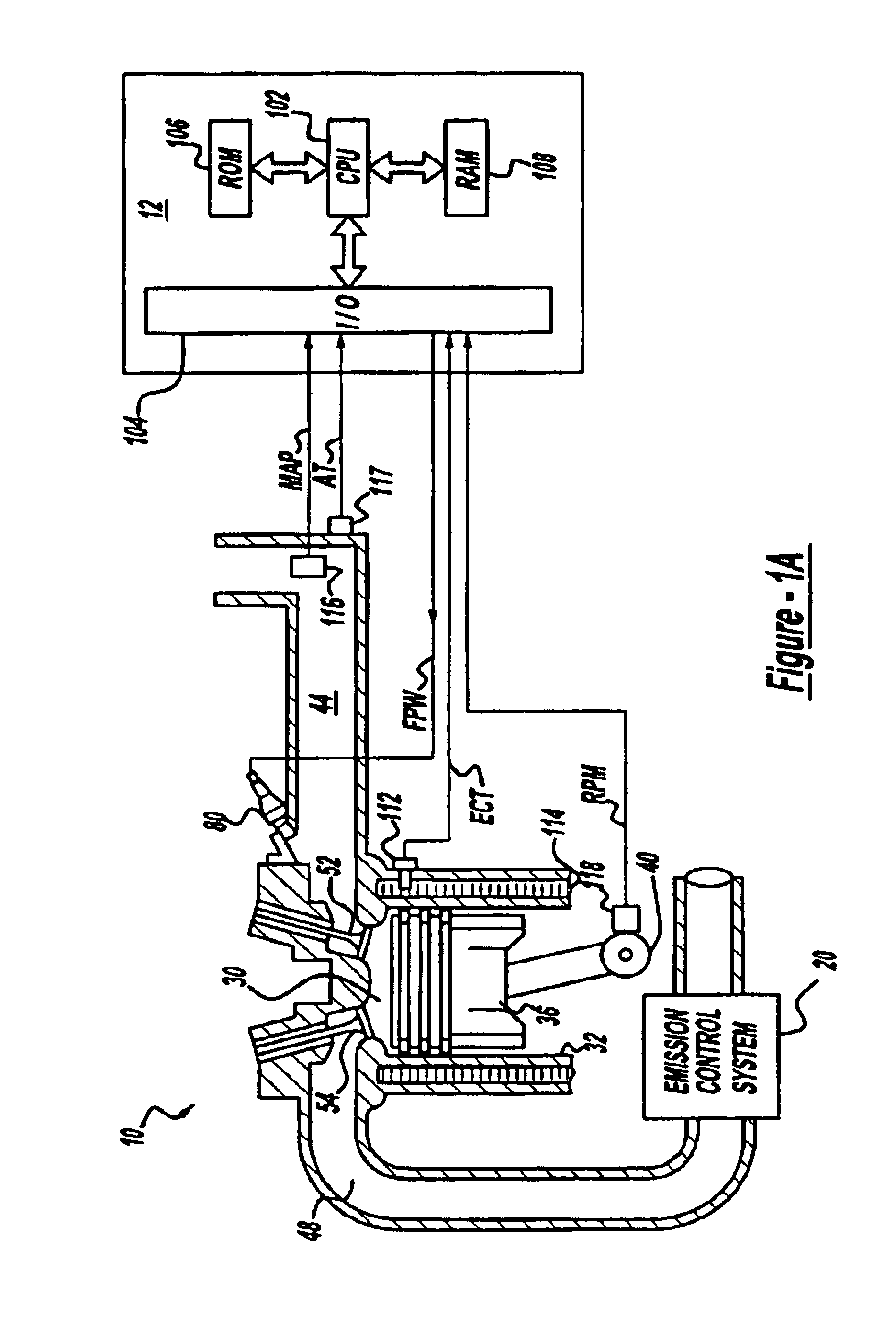

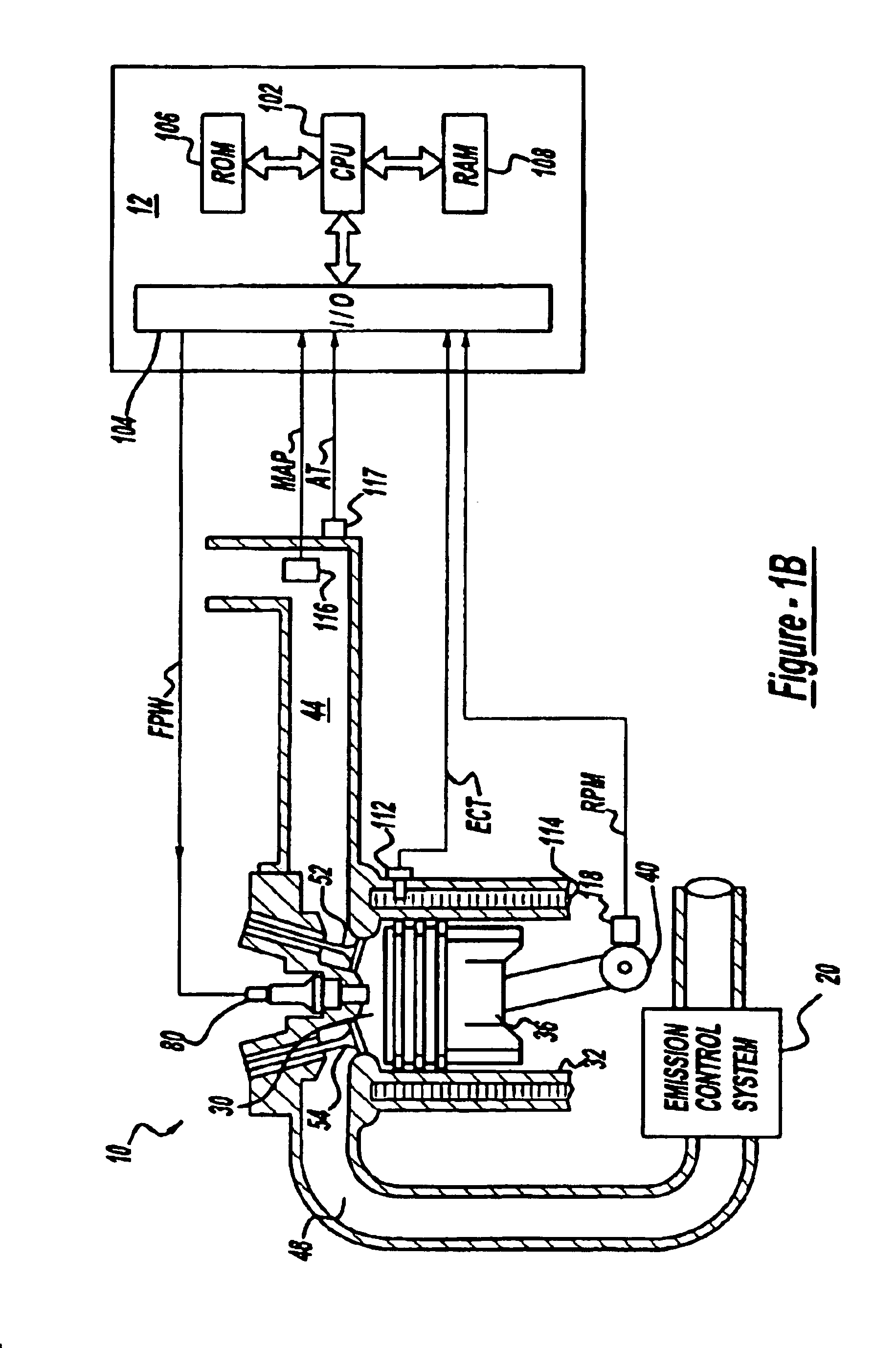

Exhaust gas aftertreatment systems

InactiveUS6928806B2Improve NOx conversion efficiencyHigh operating temperatureElectrical controlInternal combustion piston enginesExhaust fumesSystem configuration

A system for effective NOx and particulate matter control in a diesel or other lean burn internal combustion engine is presented. The system includes a urea-based SCR catalyst having an oxidation catalyst coupled upstream of it and a particulate filter coupled downstream of the SCR catalyst. This system configuration results in improved NOx conversion due to fast SCR catalyst warm-up and higher operating temperatures. Additionally, placing the particulate filter last in this system configuration reduces tailpipe ammonia emissions as well as prevents any thermal damage to the SCR catalyst due to the particulate filter regeneration.

Owner:FORD GLOBAL TECH LLC

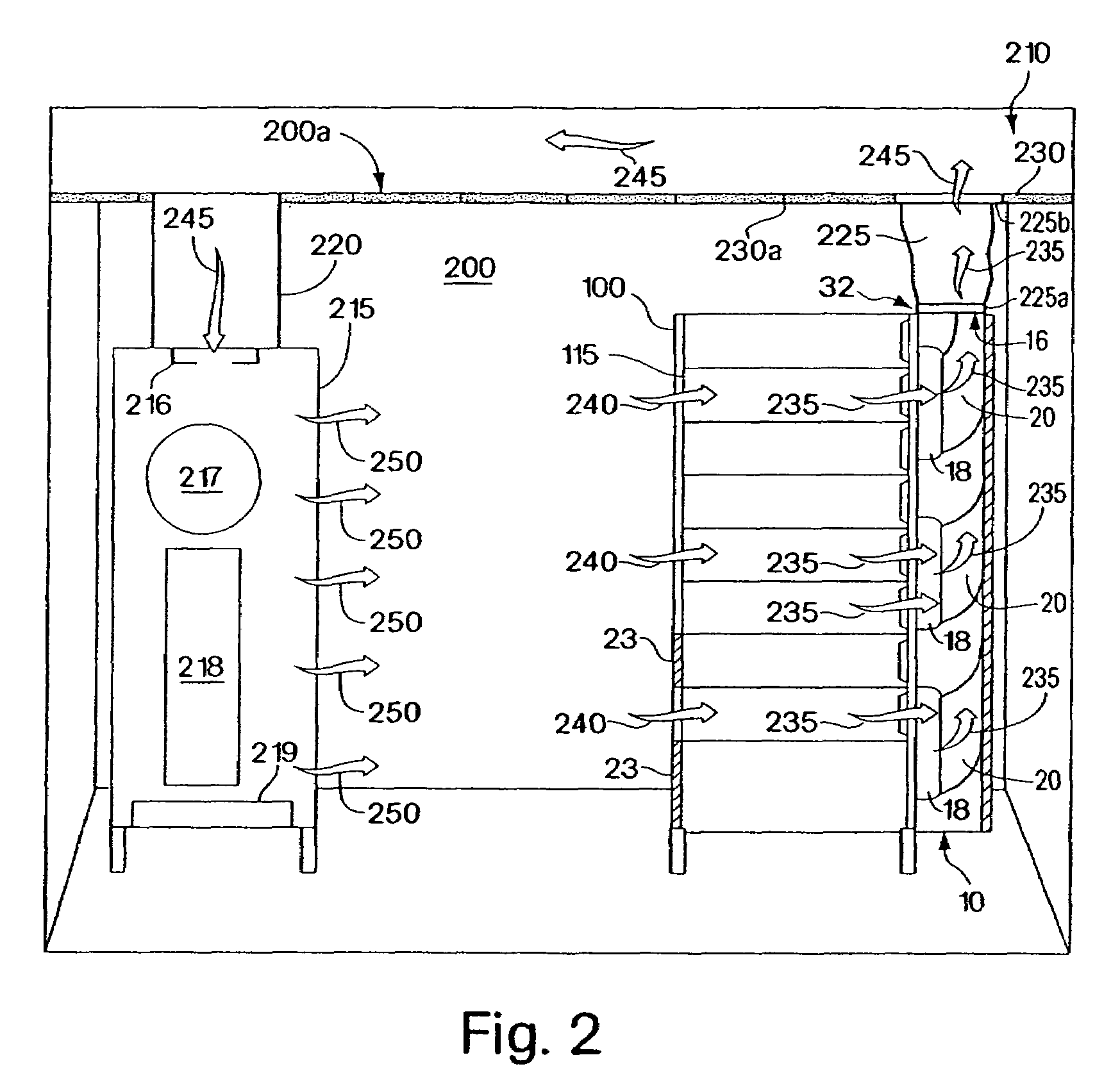

Exhaust air removal system

InactiveUS7500911B2Avoid heat buildupIndirect heat exchangersCooling/ventilation/heating modificationsExhaust fumesBack door

An exhaust air removal system and method for use with a rack or enclosure containing equipment is provided. The system and method are configured for removal of exhaust air vented from equipment during operation to thereby remove heat from the equipment. In one aspect, the system includes a fan unit preferably configured to serve as a back door of an equipment rack or enclosure and configured to provide access to an interior of the rack or enclosure. The fan unit provides multiple fans coupled to internal exhaust ducts that are arranged to draw and to remove exhaust air vented from rack-mounted equipment. The fan unit is further configured to vent exhaust air to an area external to a rack or enclosure, such as an external exhaust duct or plenum. Removal of hot and warm exhaust air vented from rack-mounted equipment enables the equipment to operate effectively, drawing sufficient amounts of cooling air to meet its cooling requirements. The fan unit is constructed for portability and for easy attachment to and removal from a rack or enclosure, providing flexibility in handling equipment exhaust needs.

Owner:SCHNEIDER ELECTRIC IT CORP

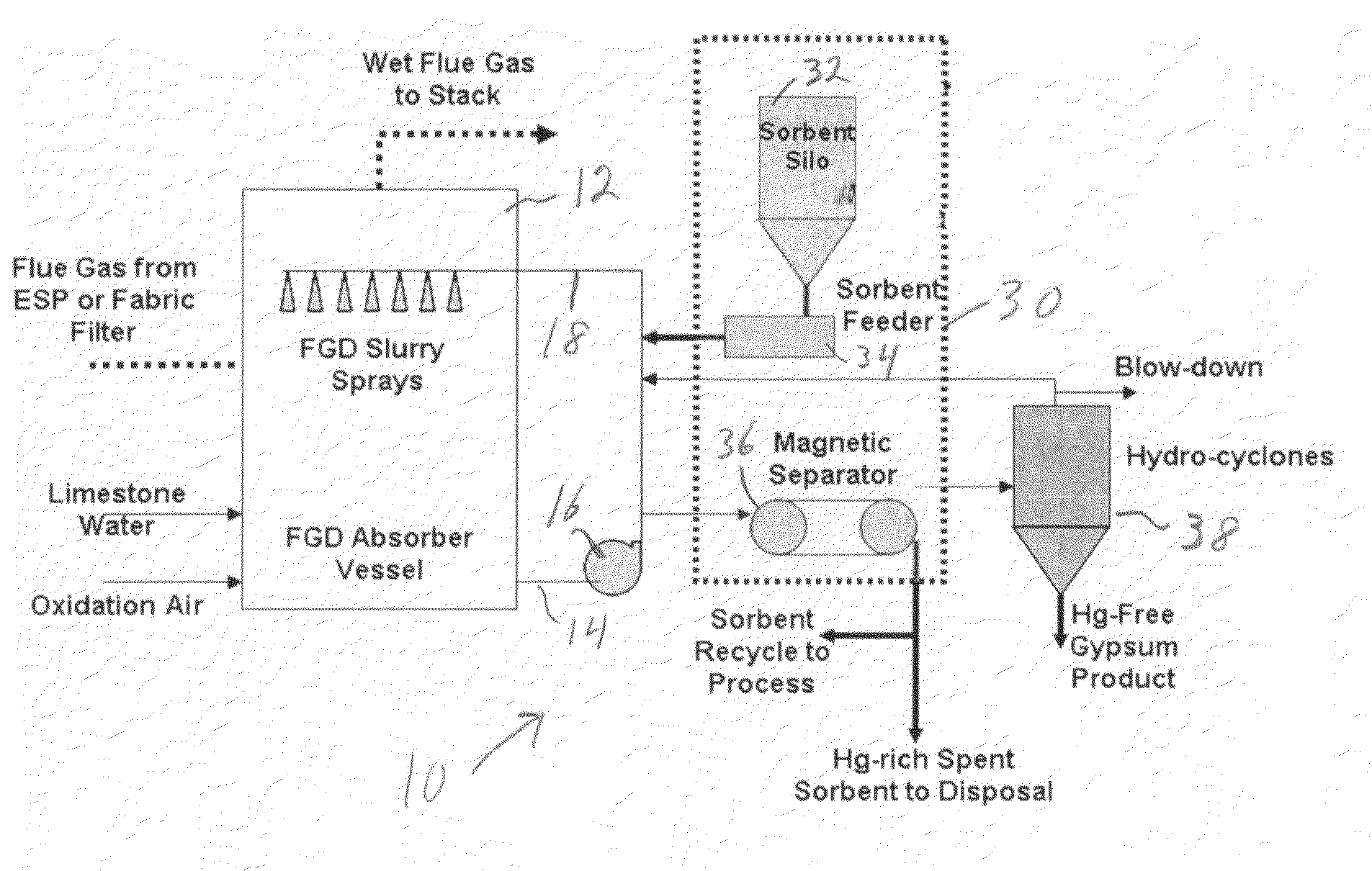

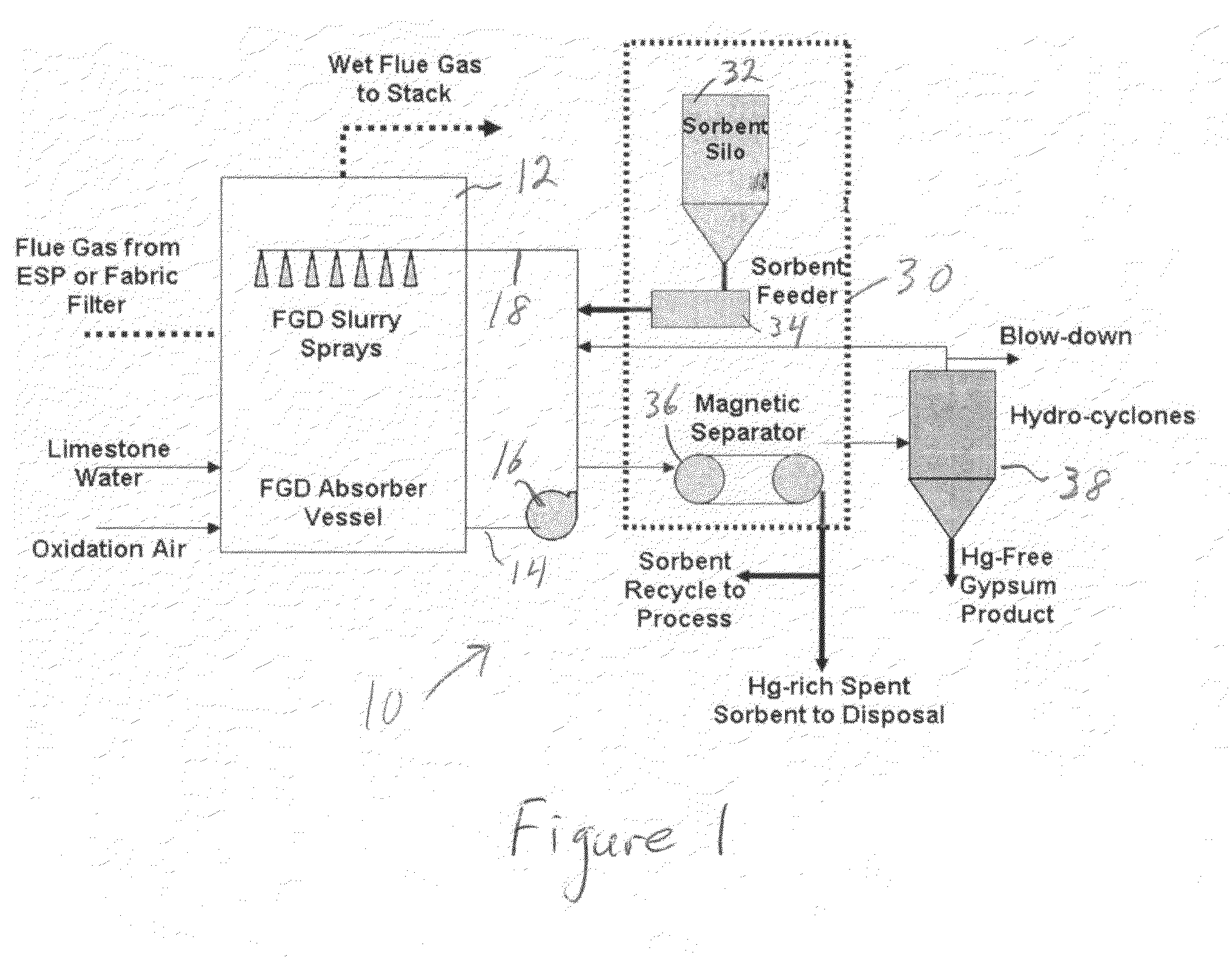

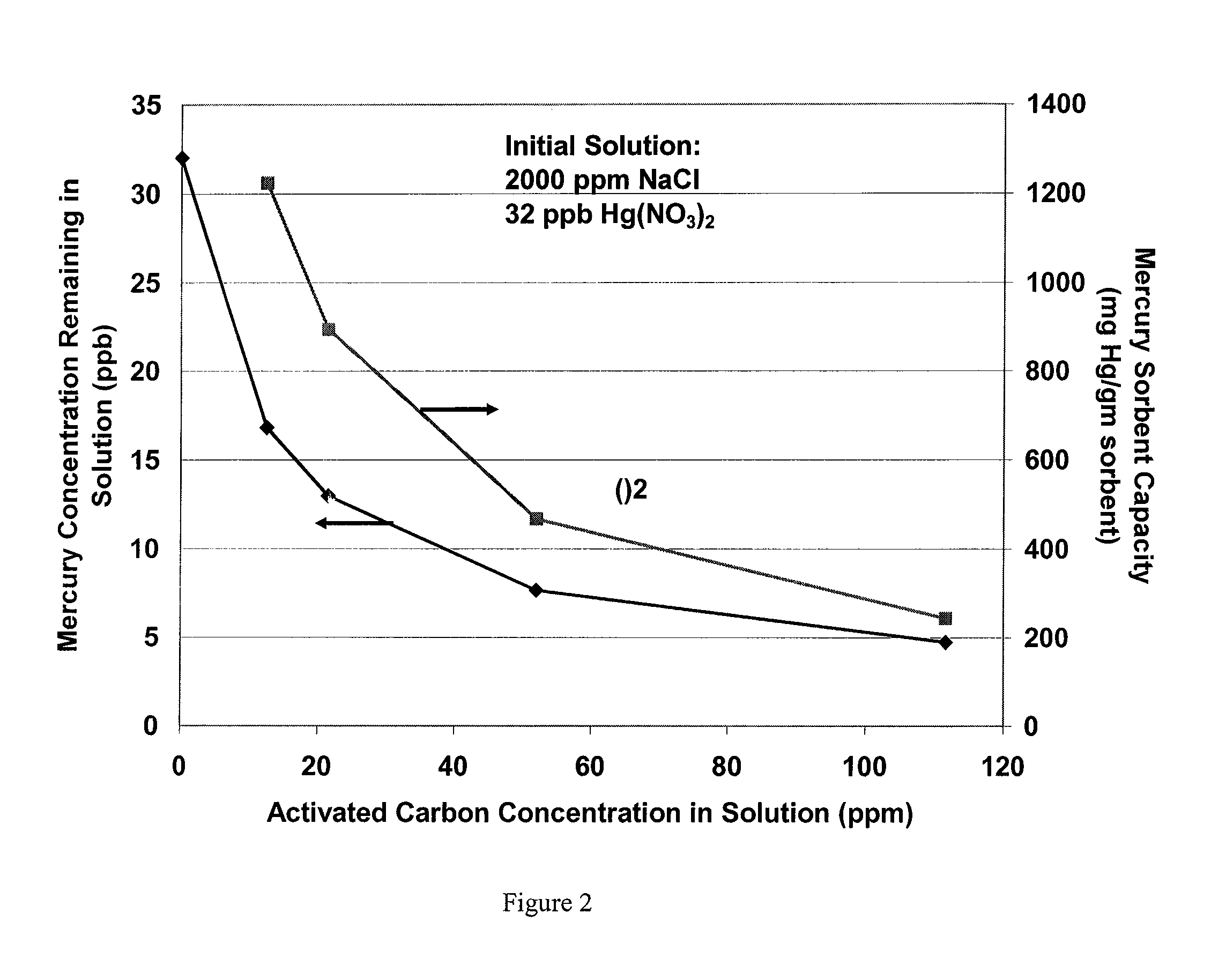

System and method for sequestration and separation of mercury in combustion exhaust gas aqueous scrubber systems

ActiveUS7722843B1Emission reductionMinimize re-emissionCombination devicesExhaust apparatusCombustionSorbent

A process, system and sorbent for removal of mercury from a combustion exhaust gas stream in a combustion exhaust gas purification scheme that includes a combustion exhaust scrubber system that uses an aqueous liquid to remove acid gases from the combustion exhaust gas. A powdered mercury sorbent is used. The sorbent is introduced into the aqueous scrubber liquid in the scrubber system. After introduction of the mercury sorbent into the scrubber liquid, at least some of the mercury sorbent is separated from the scrubber liquid.

Owner:SRINIVASACHAR SRIVATS

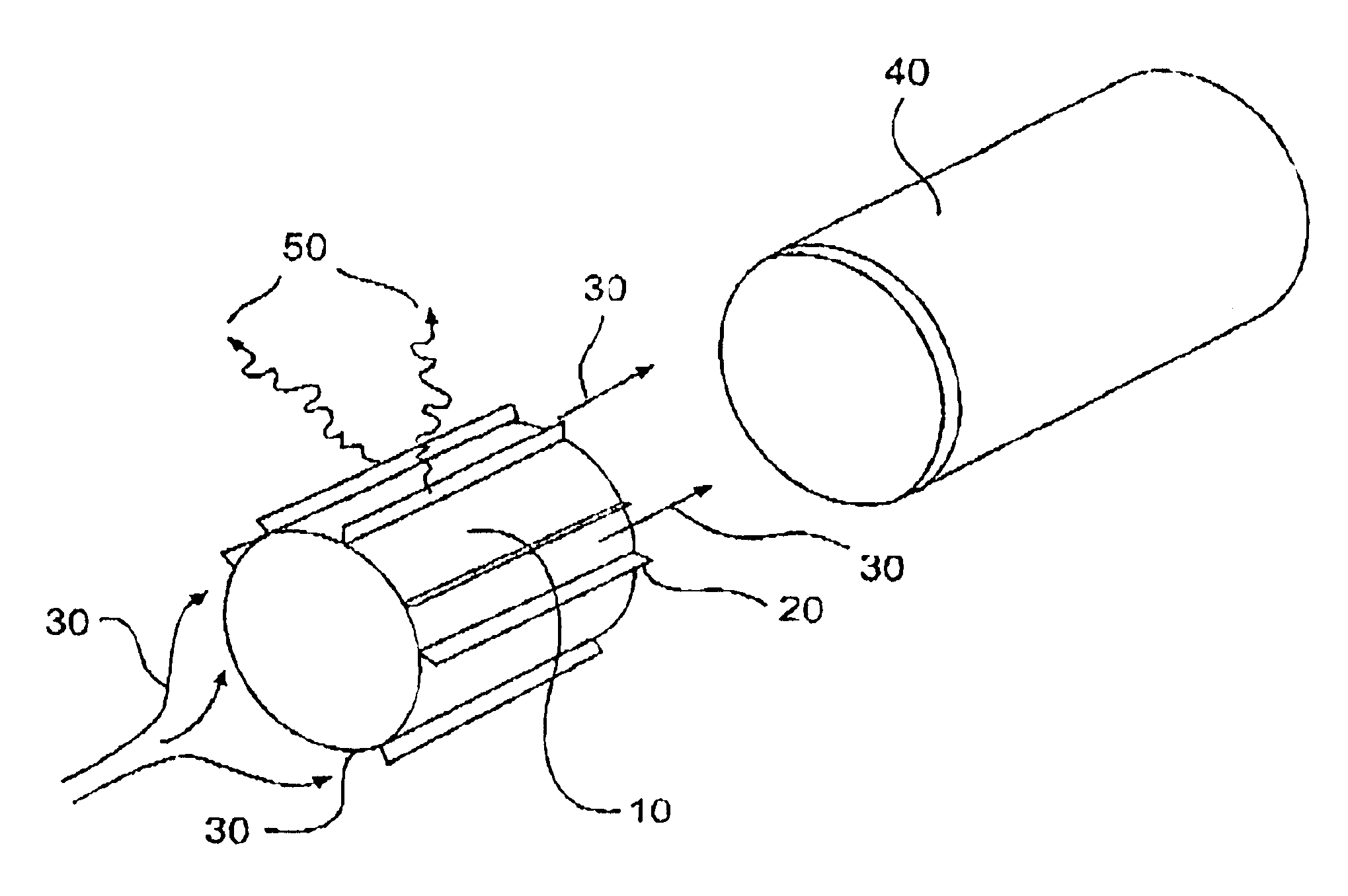

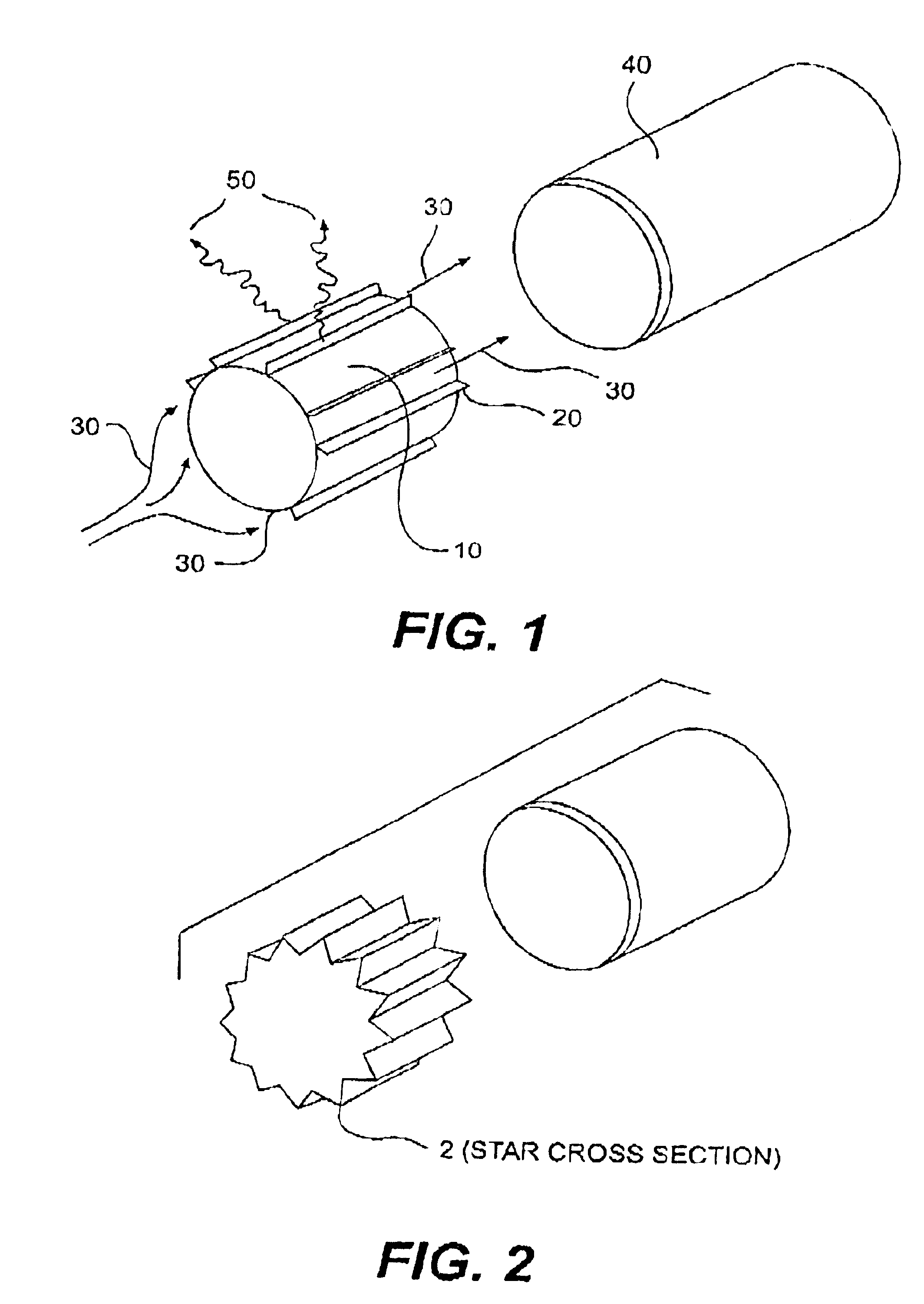

Method and apparatus to increase combustion efficiency and to reduce exhaust gas pollutants from combustion of a fuel

InactiveUS6851413B1Improve combustion efficiencyFacilitate fuel combustionBurnersLiquid fuel feeder/distributionCombustorExhaust fumes

A method and apparatus is disclosed for increasing combustion efficiency in internal combustion engines and external combustors resulting in increased fuel economy and reduced exhaust pollutants. The same principles and apparatus of the invention are used in the exhaust stream to further reduce pollutants.

Owner:RONNELL

Apparatus, method, and system for concentrating adsorbable pollutants and abatement thereof

InactiveUS6105365ALess fuelLow oxygenGas treatmentInternal combustion piston enginesCombustionExhaust fumes

Owner:ENGELHARD CORP

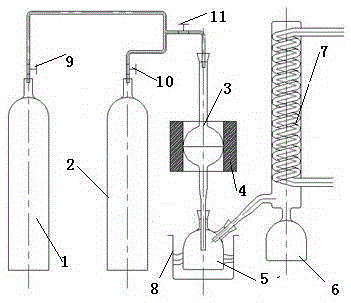

Method for preparing precursor for chemical vapor deposition of metallic rhenium

The invention discloses a method for preparing a precursor for chemical vapor deposition of metallic rhenium and belongs to the technical field of material preparation. According to the method, ReCl5 is made to react in an oxidizing atmosphere, efficient solid-liquid-gas separation is conducted on reactants and products with a sand core filter bulb so that reactants, reaction products and waste gas can be effectively separated, the reaction products ReOCl4 and ReO3Cl are gathered in a collection vessel heated by an oil bath pan at the same time, oxygen introduction is stopped after reaction ends, circulation of inert gases is maintained, a tube furnace is cooled, the oil bath pan is heated at the same time to enable ReO3Cl to volatilize to enter a rectification unit to be collected, ReOCl4 is purified, and then the high-purity precursor ReOCl4 for chemical vapor deposition of metallic rhenium is obtained. By the adoption of the method, reaction efficiency is high, ReOCl4 and ReO3Cl are separated through rectification, and the purity of the product ReOCl4 is improved.

Owner:海朴精密材料(苏州)有限责任公司

Recovery of products from oil shale

InactiveUS7048051B2Maximize recoveryProcedure is time-consume and expensiveFluid removalKerogenThermal energy

A process and system for recovering hydrocarbonaceous products from in situ oil shale formations. A hole is drilled in the oil shale formation and a processing gas inlet conduit is positioned within the hole. A processing gas is pressurized, heated, and introduced through the processing gas inlet conduit and into the hole. The processing gas creates a nonburning thermal energy front within the oil shale formation so as to convert kerogen in the oil shale to hydrocarbonaceous products. The products are withdrawn with the processing gas through an effluent gas conduit positioned around the opening of the hole, and are then transferred to a condenser wherein a liquid fraction of the products is formed and separated from a gaseous fraction.

Owner:GENERAL SYNFUELS INT

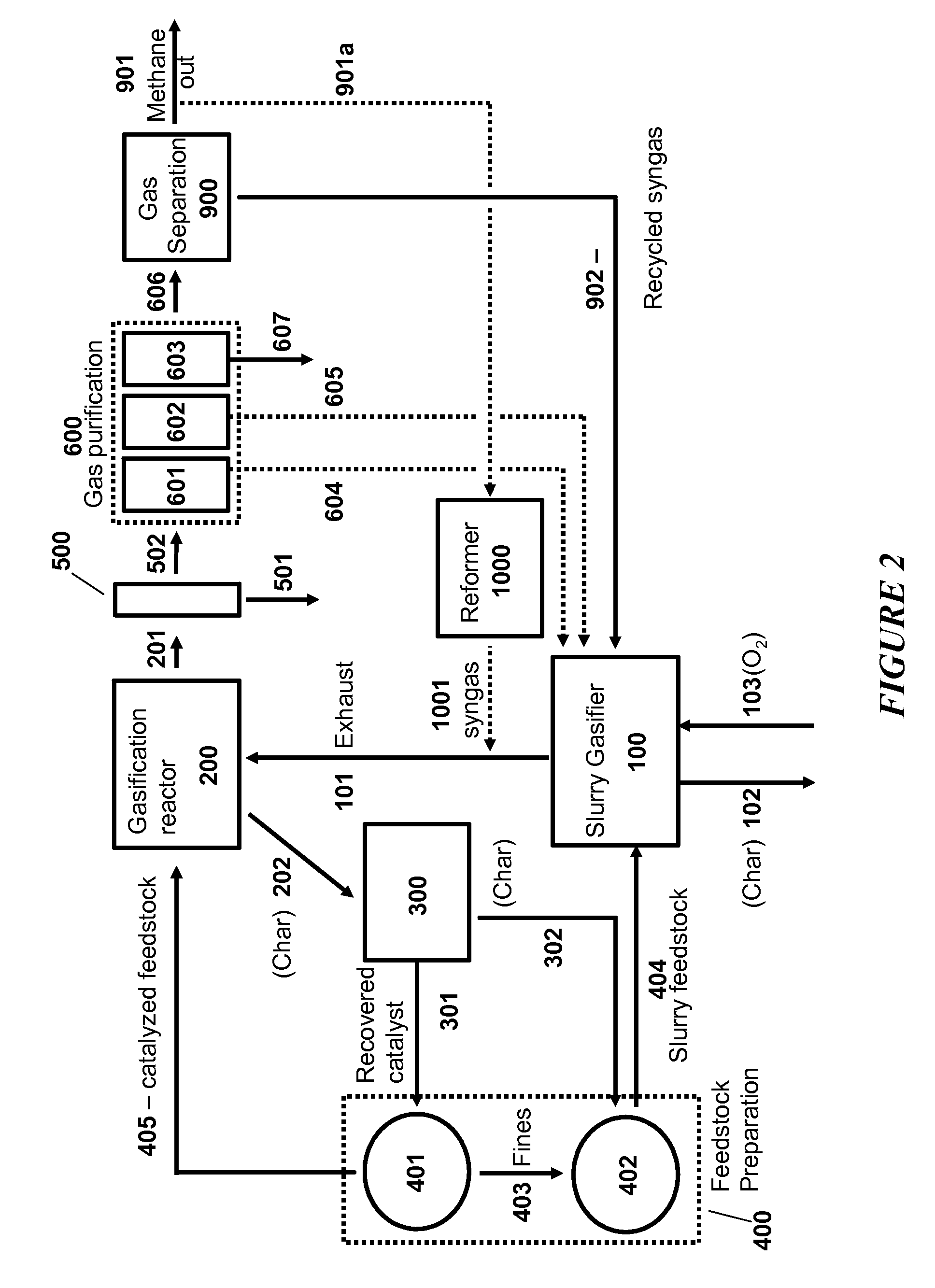

Steam Generating Slurry Gasifier for the Catalytic Gasification of a Carbonaceous Feedstock

Steam generating gasification reactors for providing high-pressure and high-temperature steam for catalytic gasification of a carbonaceous feedstock can be based on oxygen blown gasification reactors adapted for processing a slurry feedstock comprising at least 40% water. The exhaust from the slurry gasifier comprises at least steam, carbon monoxide and hydrogen. The slurry composition and the oxygen to fuel ratio can be varied to control the ratio of carbonaceous gases in the generator exhaust. By directing substantially all of exhaust gases produced from the slurry gasification reactor through the catalytic gasifier and subsequent gas separation and sequestration processes, a greatly higher energy efficiency and decreased carbon footprint can be realized.

Owner:SURE CHAMPION INVESTMENT LTD

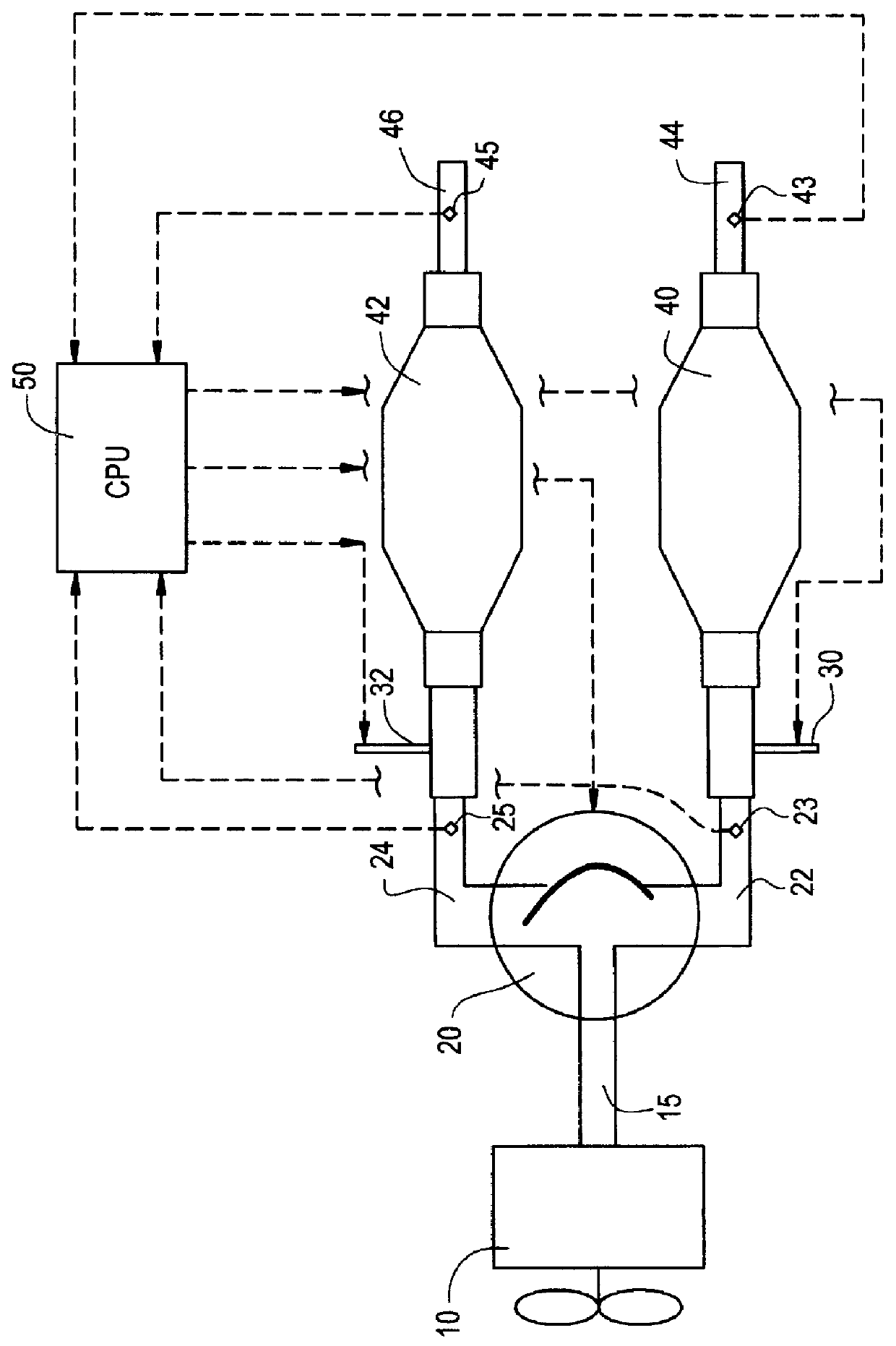

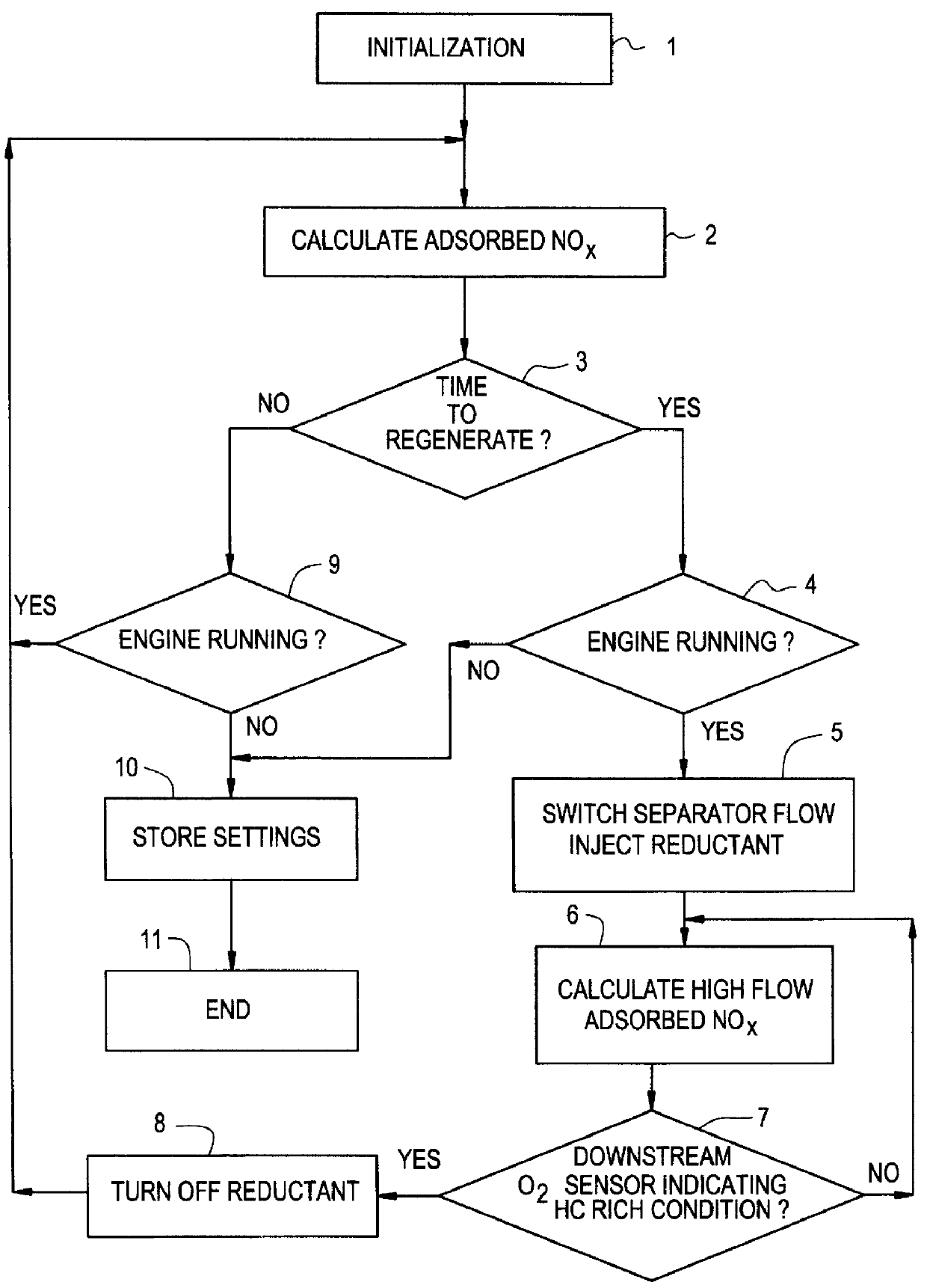

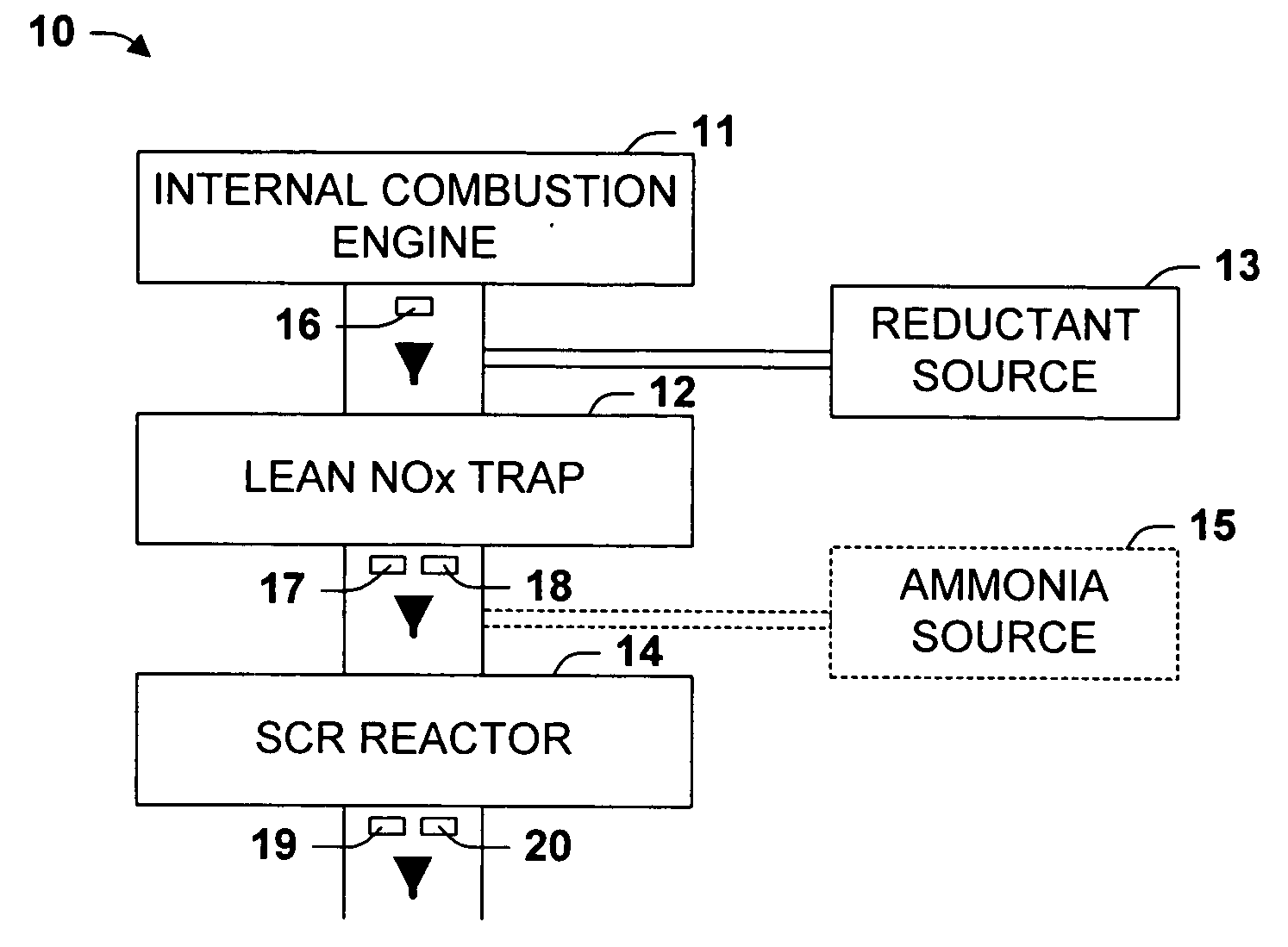

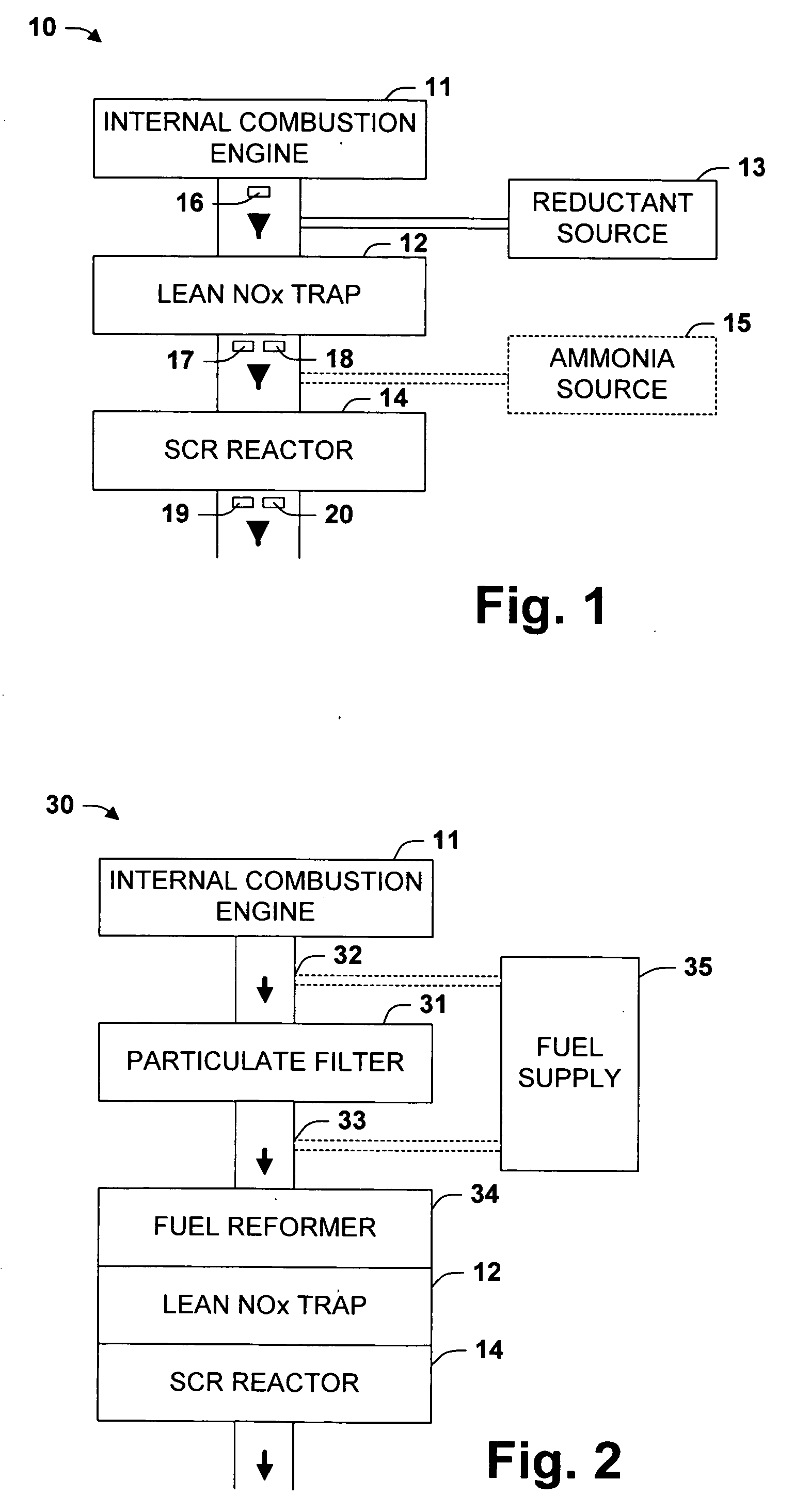

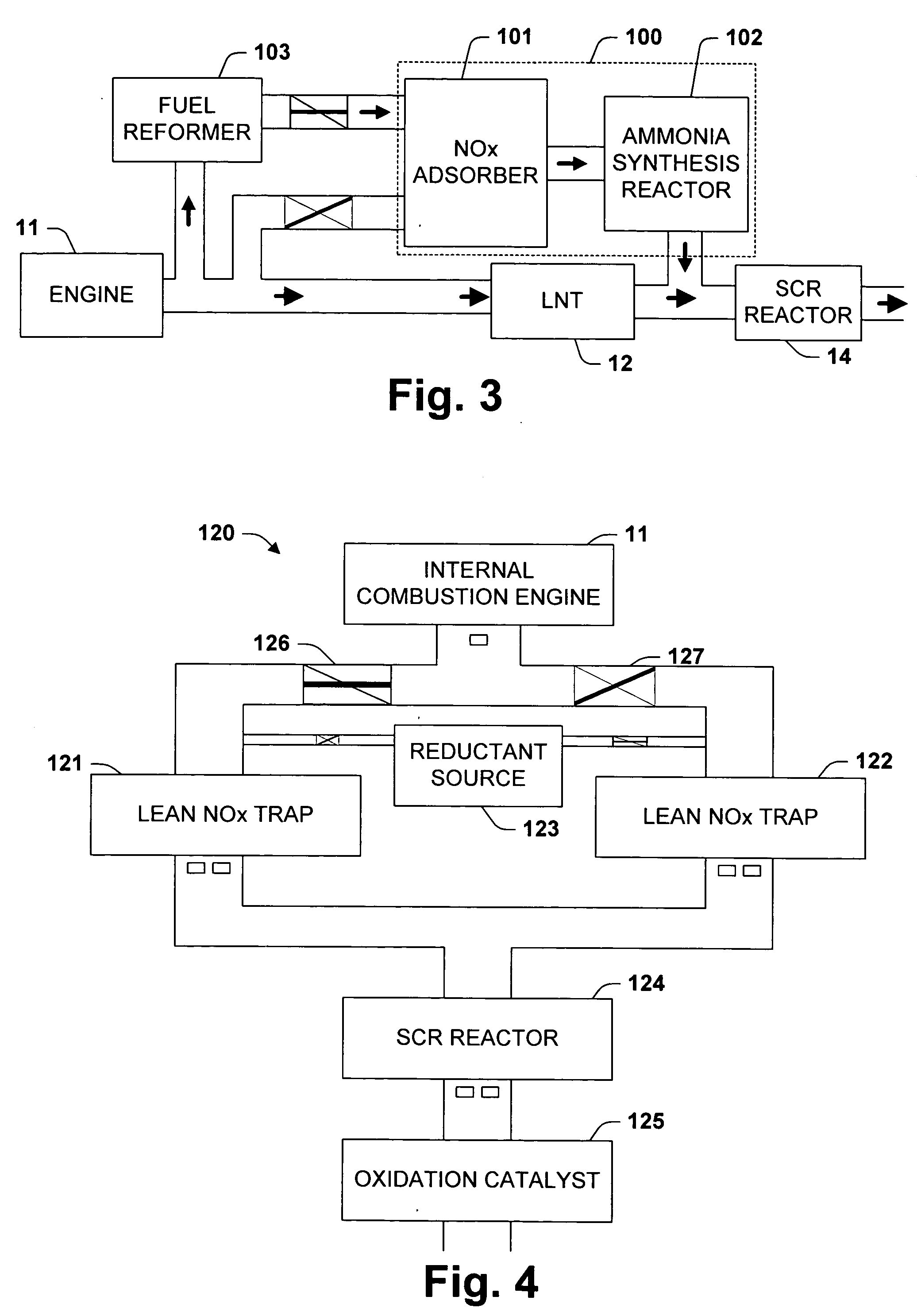

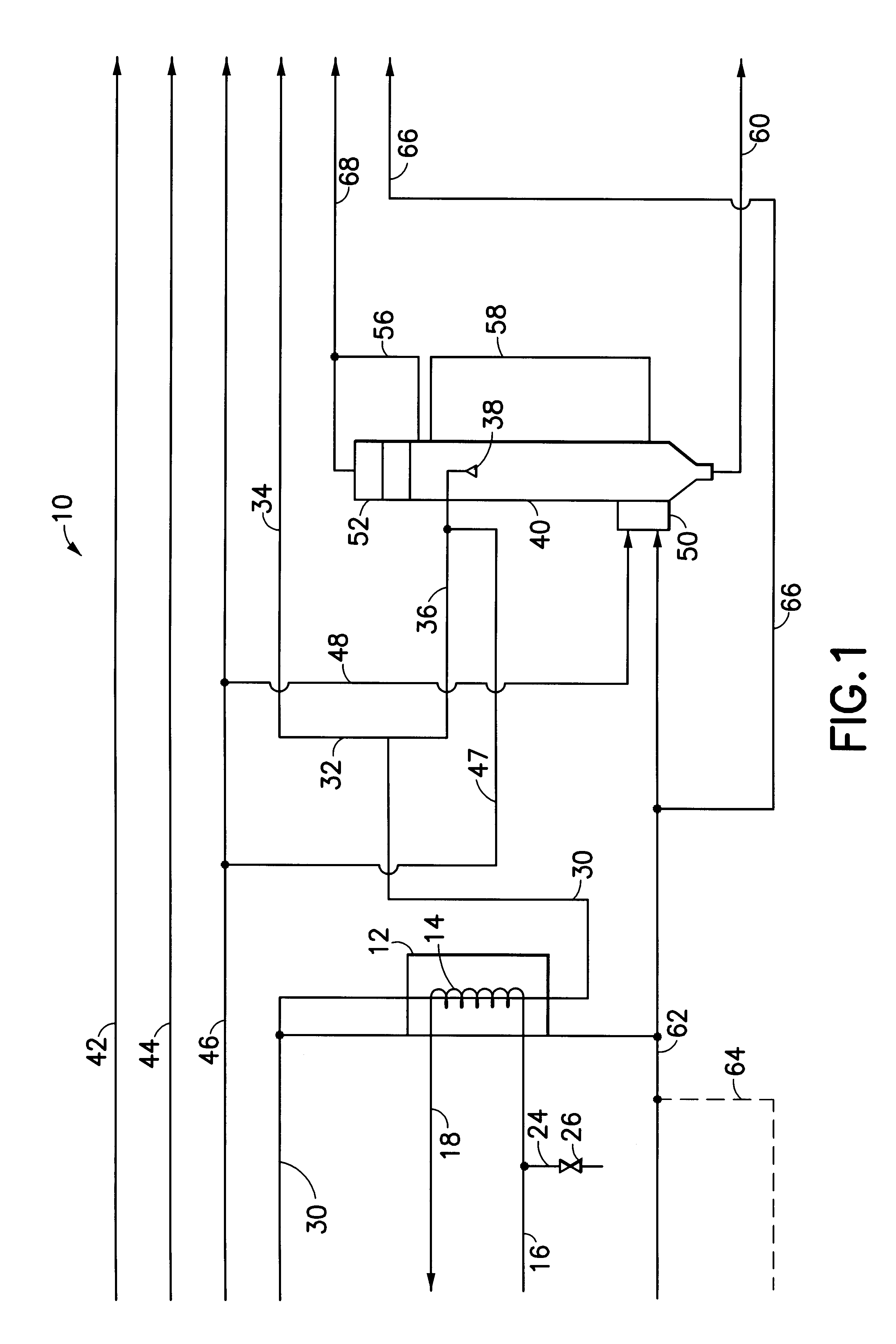

Hybrid catalyst system for exhaust emissions reduction

InactiveUS20060010857A1Improve efficiencySpeed up the conversion processHydrogenGas treatmentExhaust fumesEngineering

One aspect of the invention relates an exhaust treatment system having an SCR reactor following a NOx adsorber. Syn gas is used to regenerate the NOx adsorber. Another aspect relates to an LNT / SCR provided with an ammonia source separate from the LNT. A further aspect relates to a system comprising first and second LNTs and one or more SCRs downstream of the LNTs. A still further aspect relates to a device comprising first and second NOx adsorbers contained in a single housing. Another aspect relates to coating a surface of a moving part in an exhaust system with an oxidation catalyst to mitigate fouling. Additional aspects of the invention relate to strategies for controlling one or more of the time to initiate a regeneration cycle, the time to terminate a regeneration cycle, and the reductant injection rate during regeneration of LNT / SCR exhaust treatment systems.

Owner:INT ENGINE INTPROP CO LLC

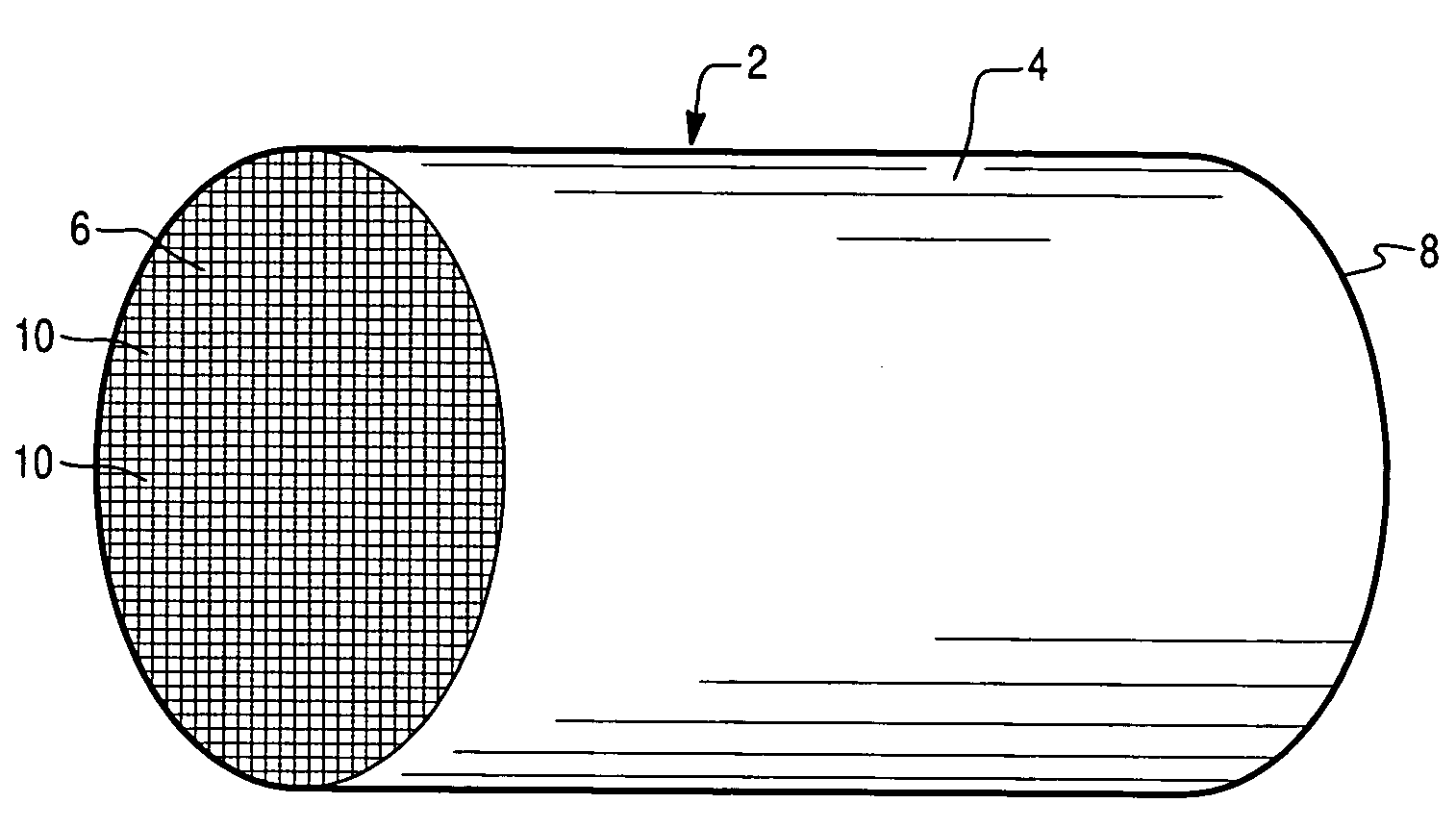

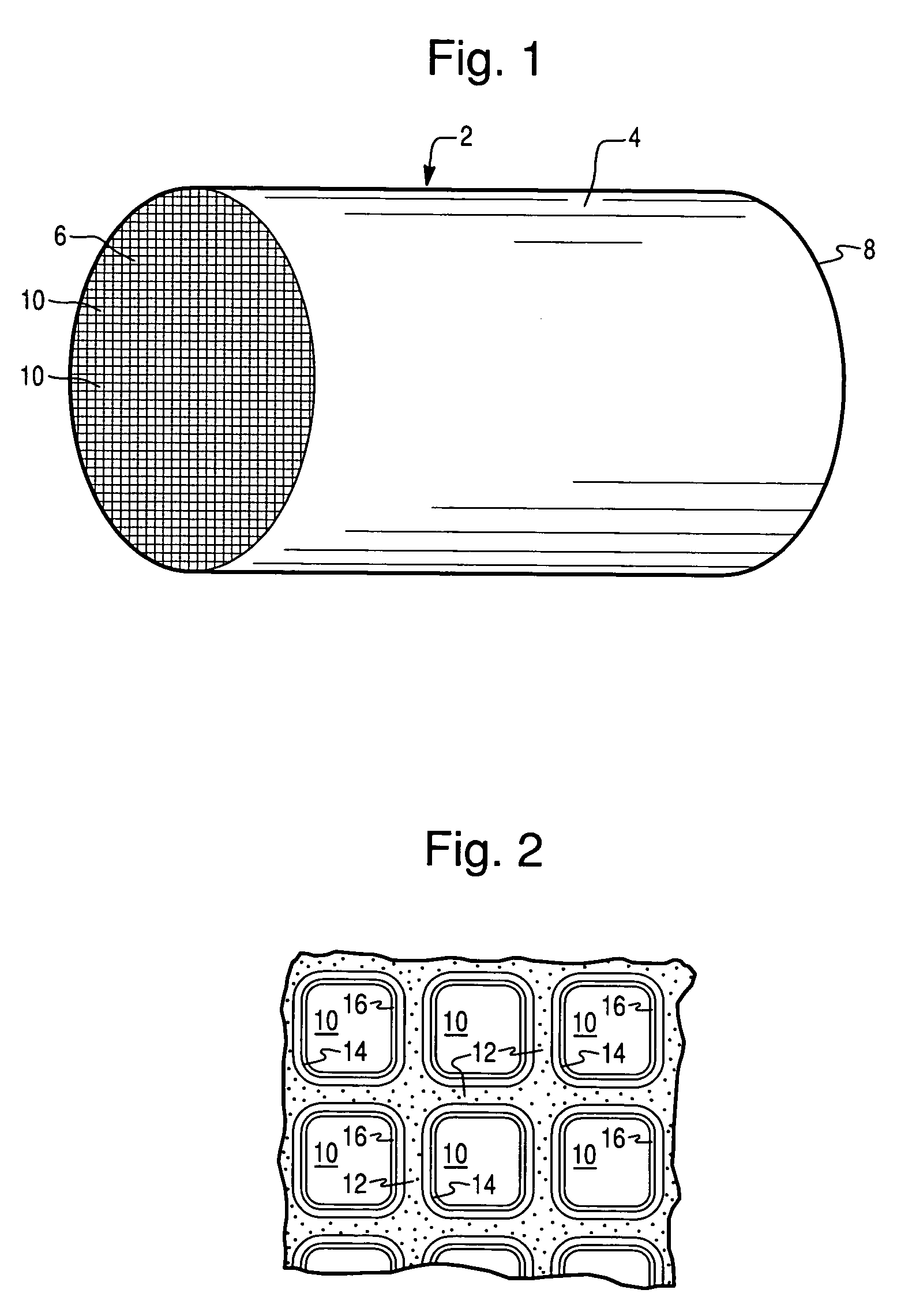

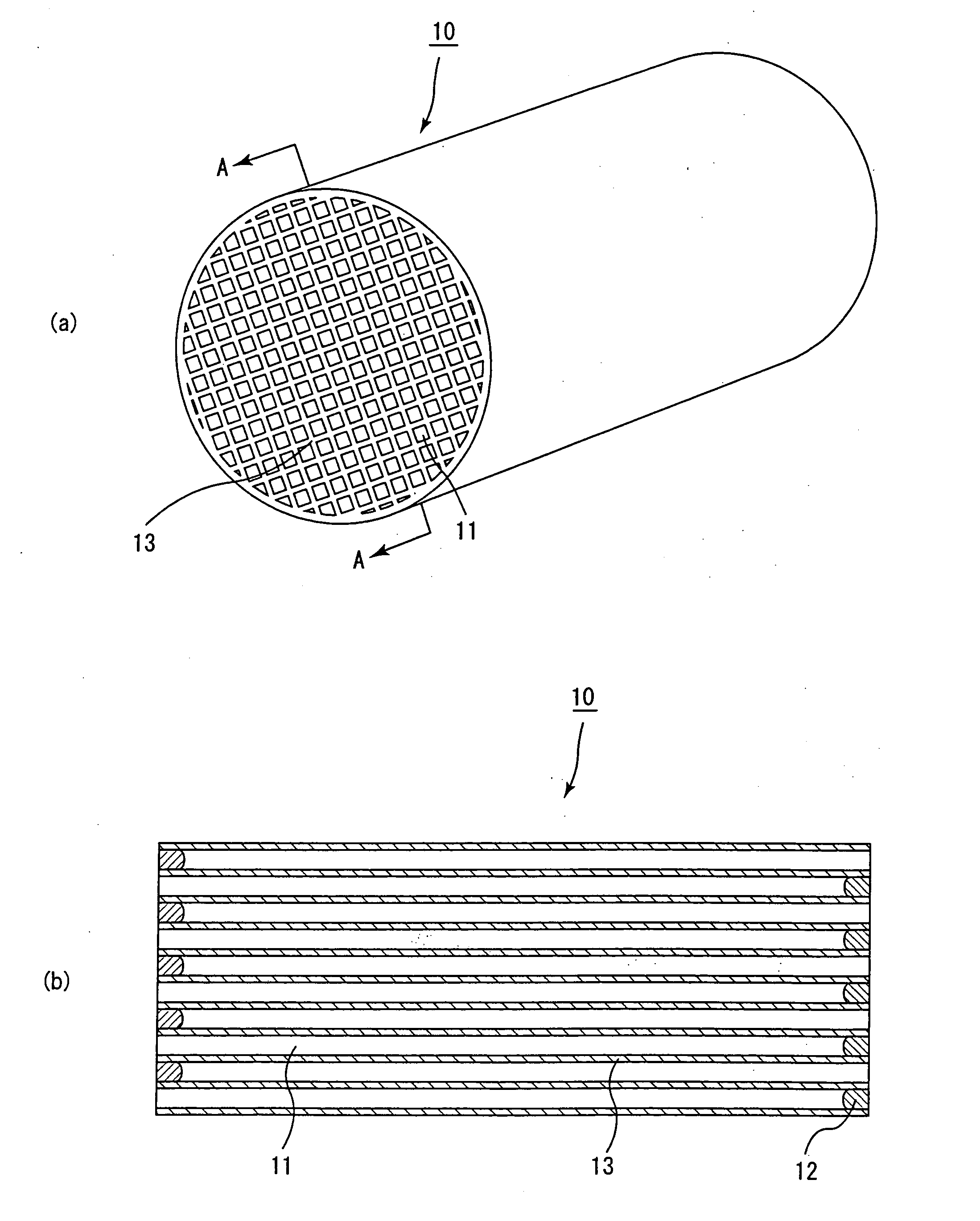

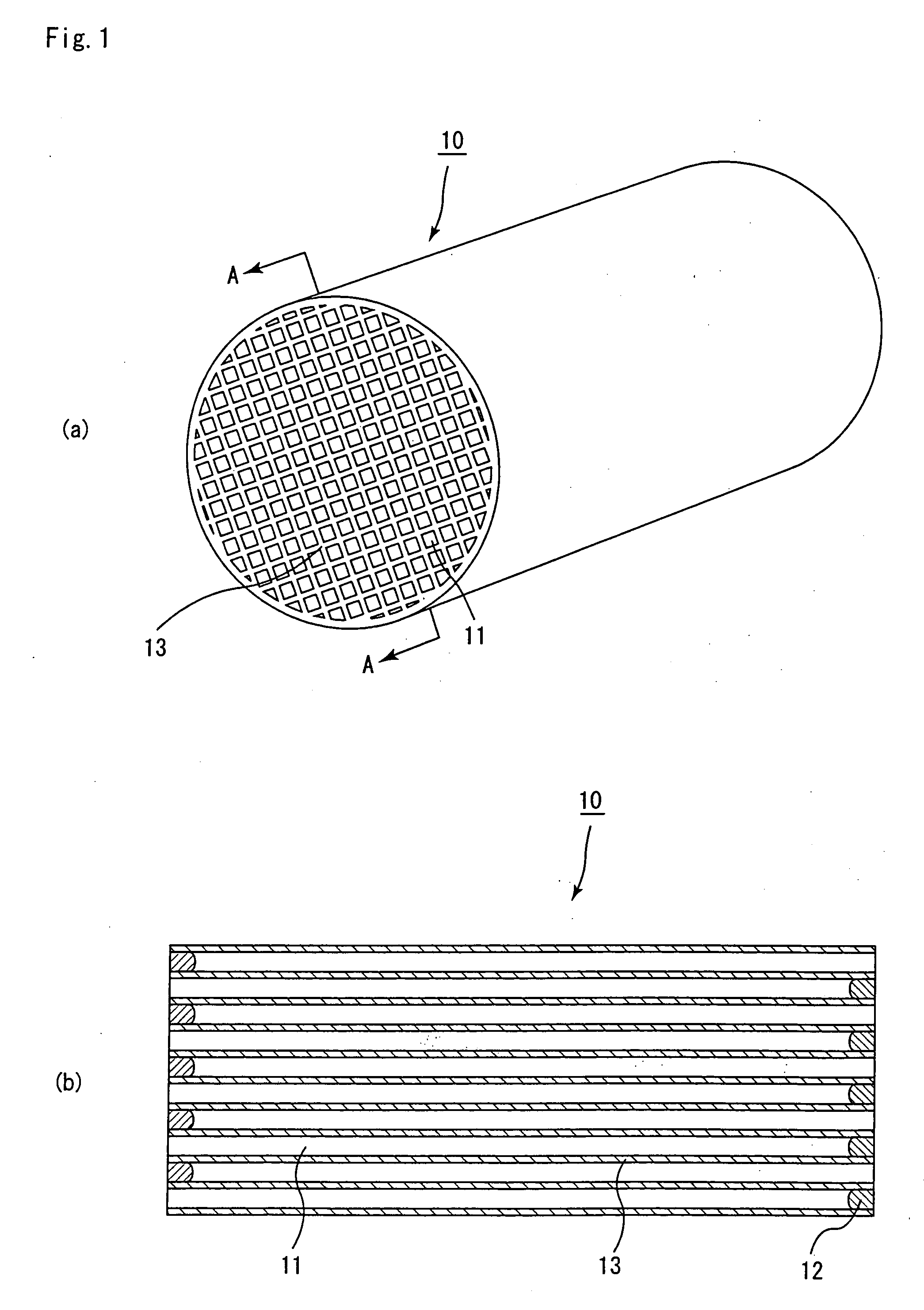

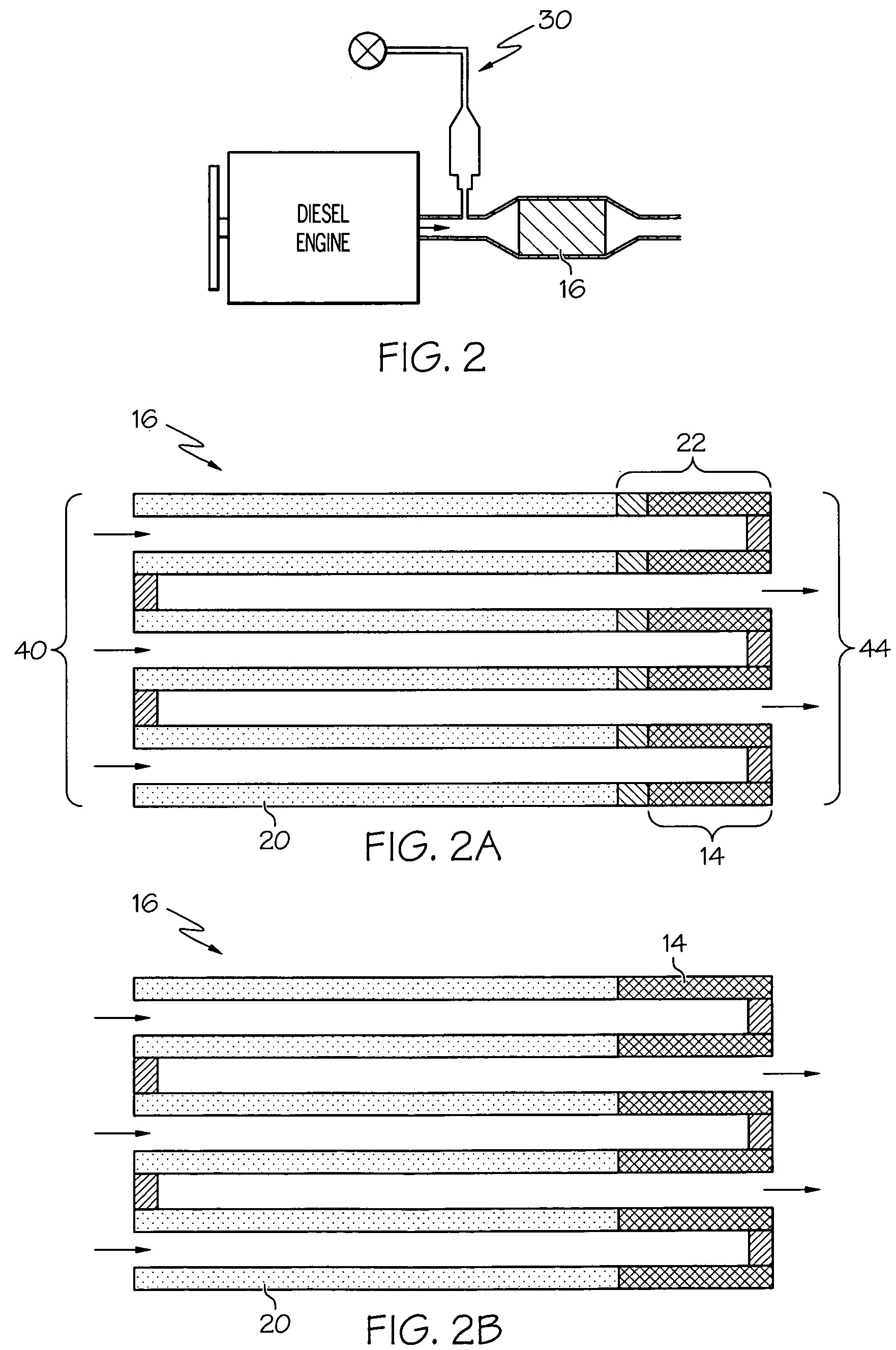

Honeycomb filter for clarifying exhaust gases

InactiveUS20050153099A1Increased durabilityPhysical/chemical process catalystsInternal combustion piston enginesParticulatesHoneycomb

An object of the present invention is to provide a honeycomb filter for purifying exhaust gases that is free from a gap formed between a plug and a partition wall and cracks generated in the plug and a portion of the partition wall contacting the plug, and is superior in durability. The present invention provides a honeycomb filter for purifying exhaust gases which has a structure in which: a columnar body made of porous ceramic comprises a number of through holes, said through holes being placed in parallel with one another in the length direction with a wall portion interposed therebetween; predetermined through holes of said through holes are filled with plugs at one end of said columnar body, while the through holes that have not been filled with said plugs at said one end are filled with plugs at the other end of said columnar body; and a part or all of said wall portion functions as a filter for collecting particulates, wherein the porosity of the columnar body is in a range from 20 to 80%, and the porosity of the plug is 90% or less and is also set to 0.15 to 4.0 times as much as the porosity of the columnar body.

Owner:IBIDEN CO LTD

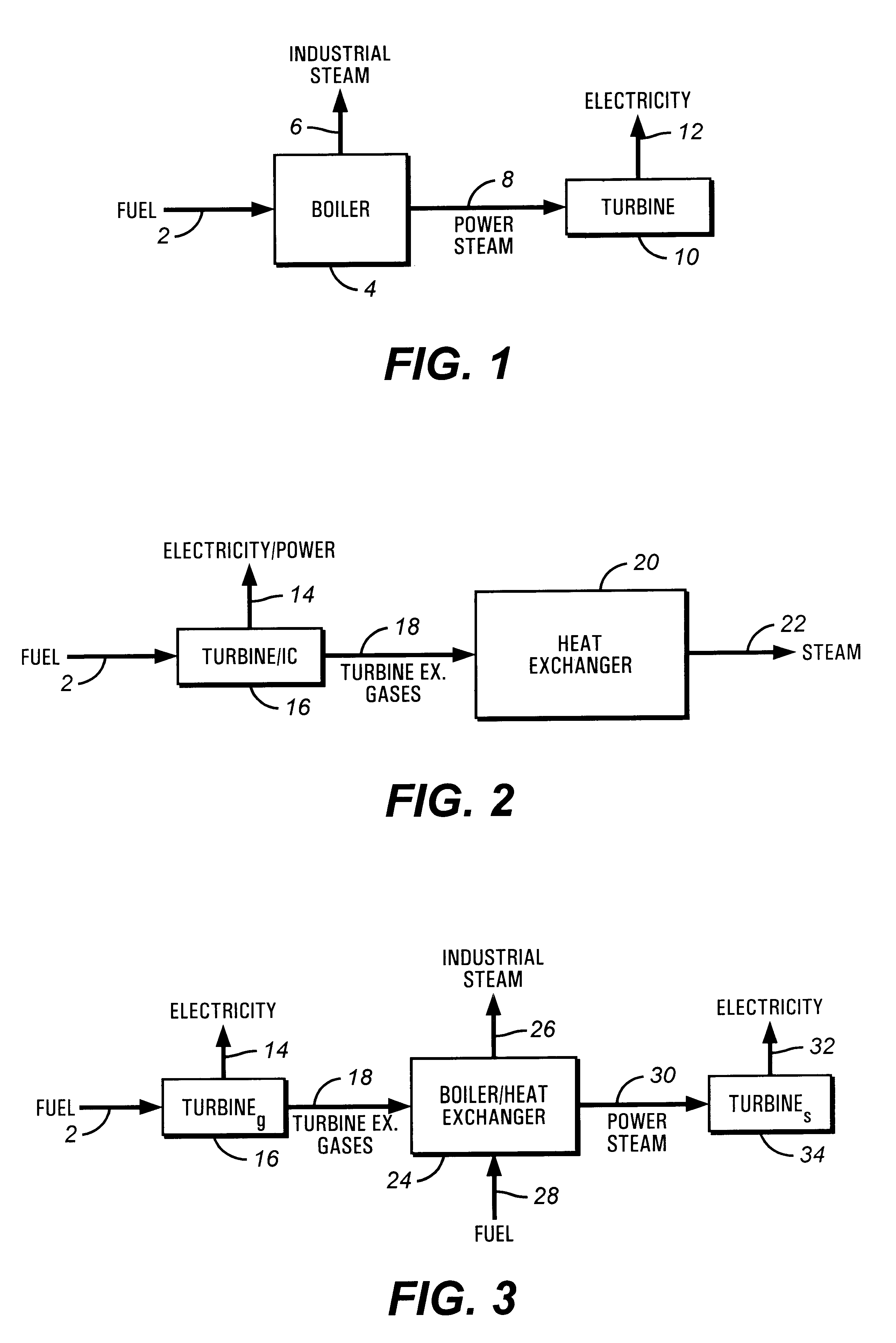

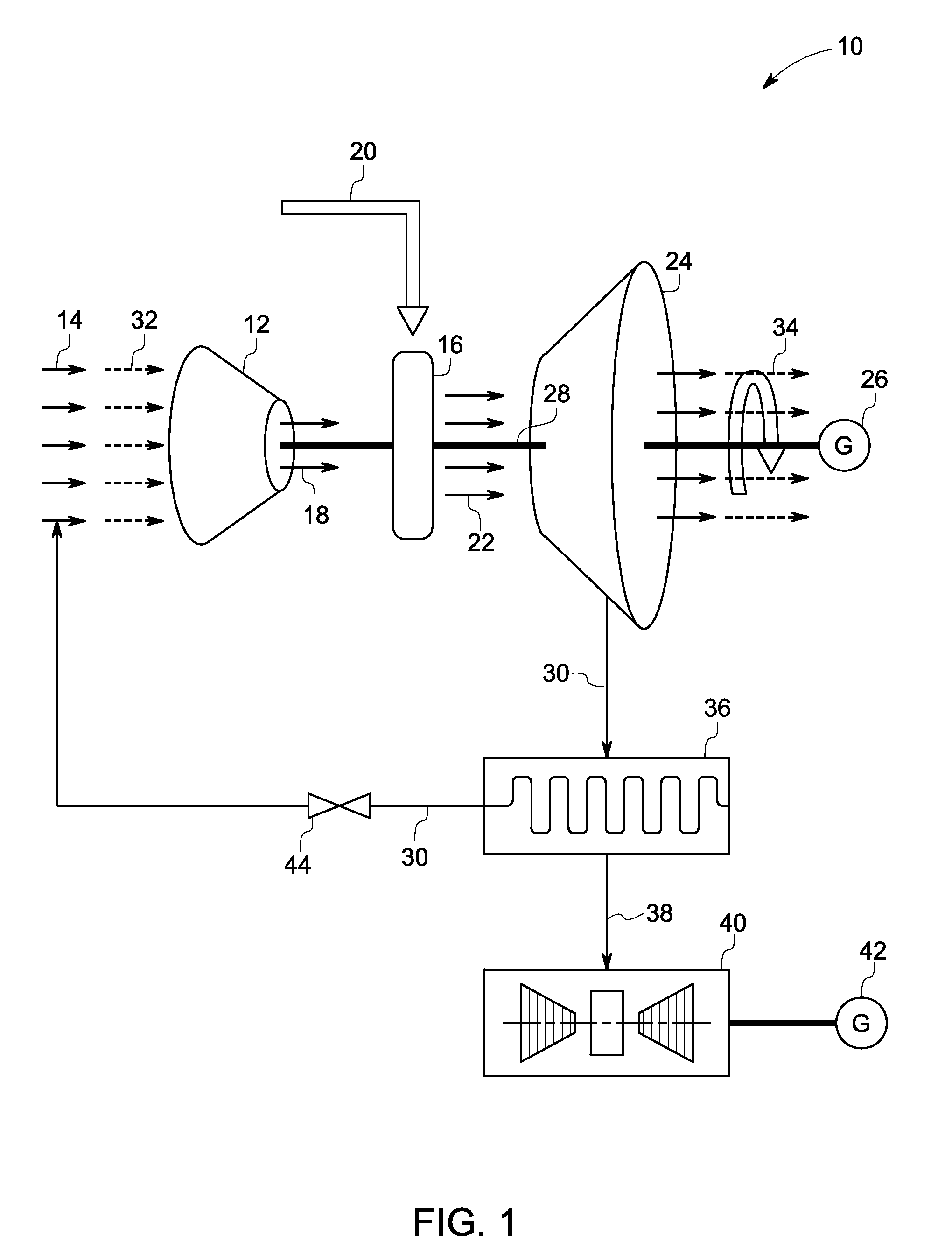

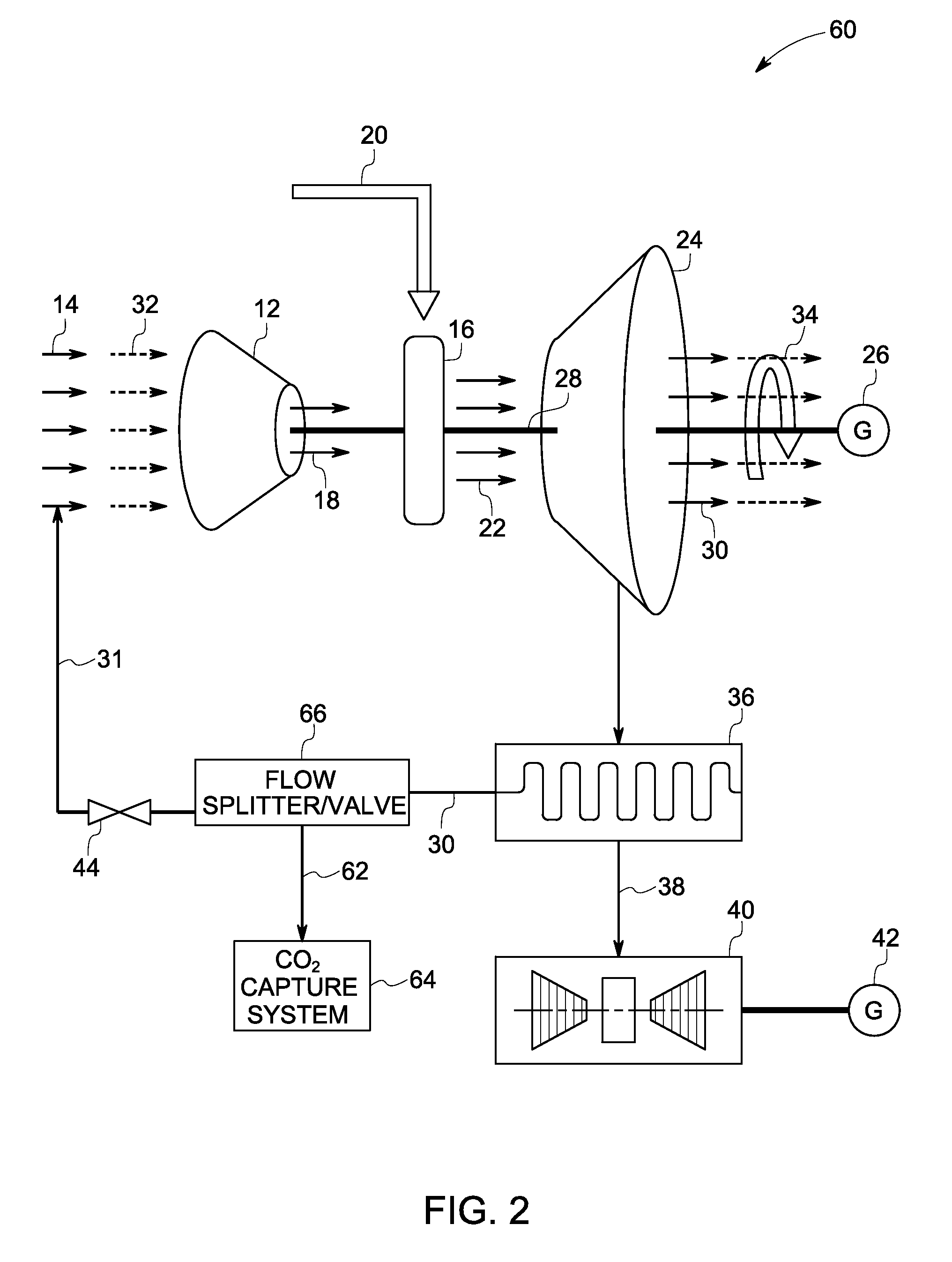

Power cogeneration system and apparatus means for improved high thermal efficiencies and ultra-low emissions

InactiveUS7124589B2Improve thermal efficiencyGas turbine plantsCombined combustion mitigationThermal energyCogeneration

A power cogeneration system employing a partially-open gaseous fluid cycle method and apparatus devices for oxy-fuel combustion conversion of a given hydrocarbon composition fuel's heat-value energy into mechanical or electrical power energy, and transferred useful heat energy, with accompanying large reductions of consumed fuel and undesirable exhaust emissions.

Owner:AES DEV CO

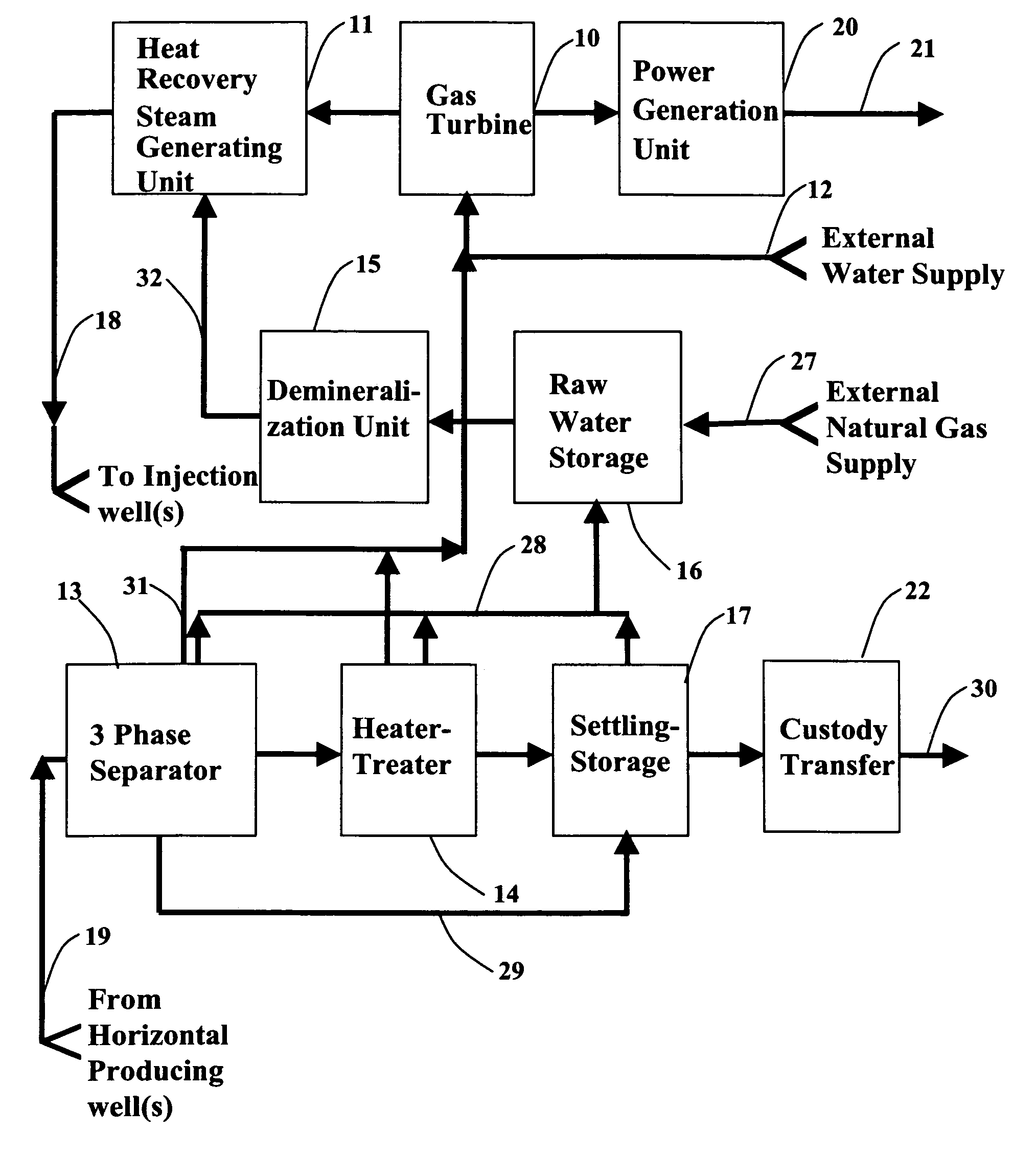

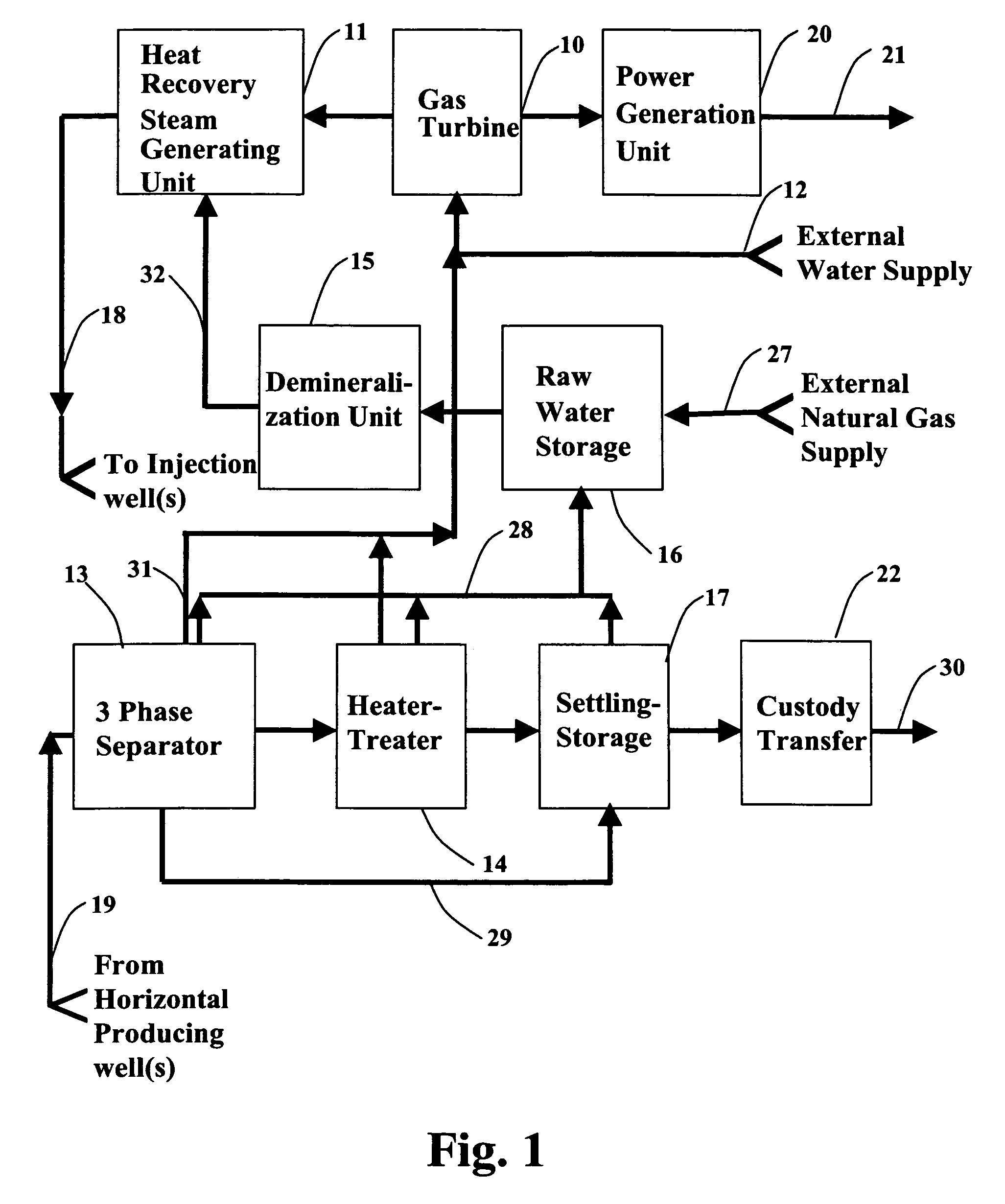

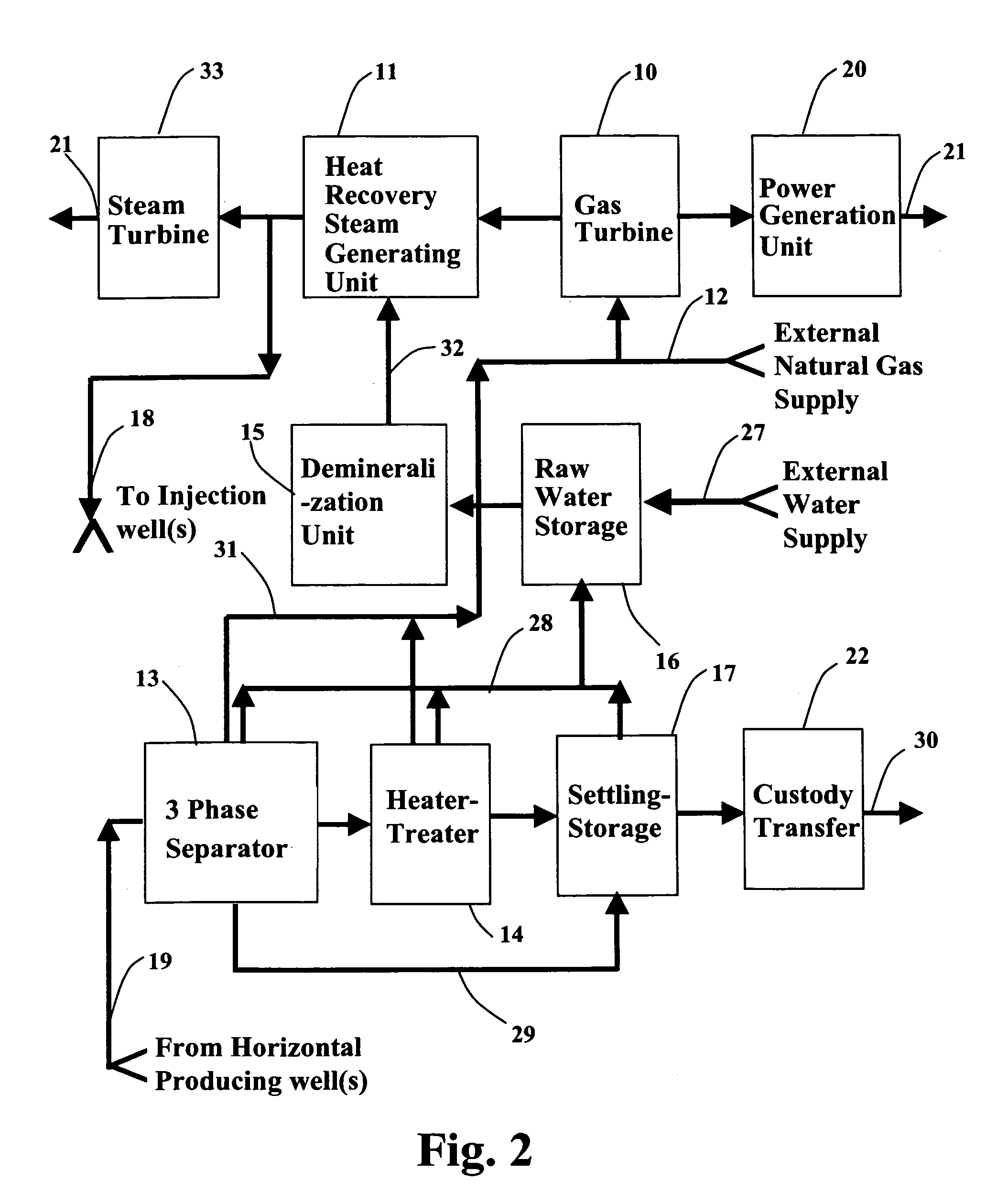

SAGD-plus

A combination of SAGD with cogeneration technology for exploiting shallow heavy oil and bitumen reservoirs under primary, secondary and tertiary thermal recovery. Superheated steam is generated by the heat recovery from the exhaust of an above-ground hydrocarbon powered turbine driven electric generator cogeneration plant and is injected through well bores into the hydrocarbon bearing reservoir that is traversed by at least one horizontal producing well bore and one injection well bore to heat the reservoir formation and to induce gravity drainage of the hydrocarbons and allowing their recovery from the horizontal producing well bore. Electrical power that is generated is sold to the electric grid and can be used to offset the fuel costs for the above ground hydrocarbon turbine-driven elector generators.

Owner:BABCOCK JOHN A

Exhaust air removal system

InactiveUS7752858B2Avoid heat buildupLighting and heating apparatusCooling fluid circulationExhaust fumesBack door

An exhaust air removal system and method for use with a rack or enclosure containing equipment is provided. The system and method are configured for removal of exhaust air vented from equipment during operation to thereby remove heat from the equipment. In one respect, the system includes a fan unit preferably configured to serve as a back door of an equipment rack or enclosure and configured to provide access to an interior of the rack or enclosure. The fan unit provides multiple fans coupled to internal exhaust ducts that are arranged to draw and to remove exhaust air vented from rack-mounted equipment. The fan unit is further configured to vent exhaust air to an area external to a rack or enclosure, such as an external exhaust duct or plenum. Removal of hot and warm exhaust air vented from rack-mounted equipment enables the equipment to operate effectively, drawing sufficient amounts of cooling air to meet its cooling requirements. The fan unit is constructed for portability and for easy attachment to and removal from a rack or enclosure, providing flexibility in handling equipment exhaust needs.

Owner:SCHNEIDER ELECTRIC IT CORP

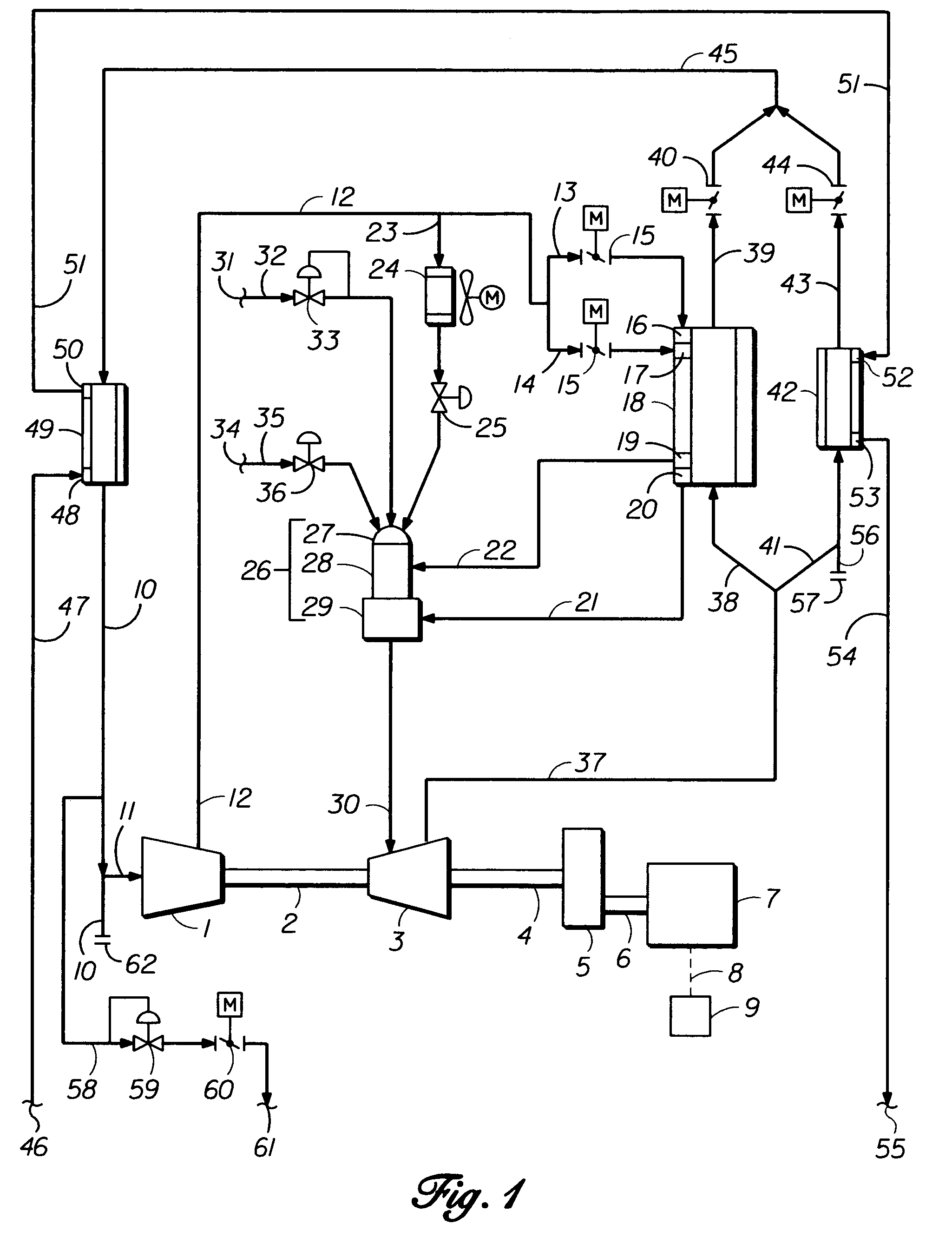

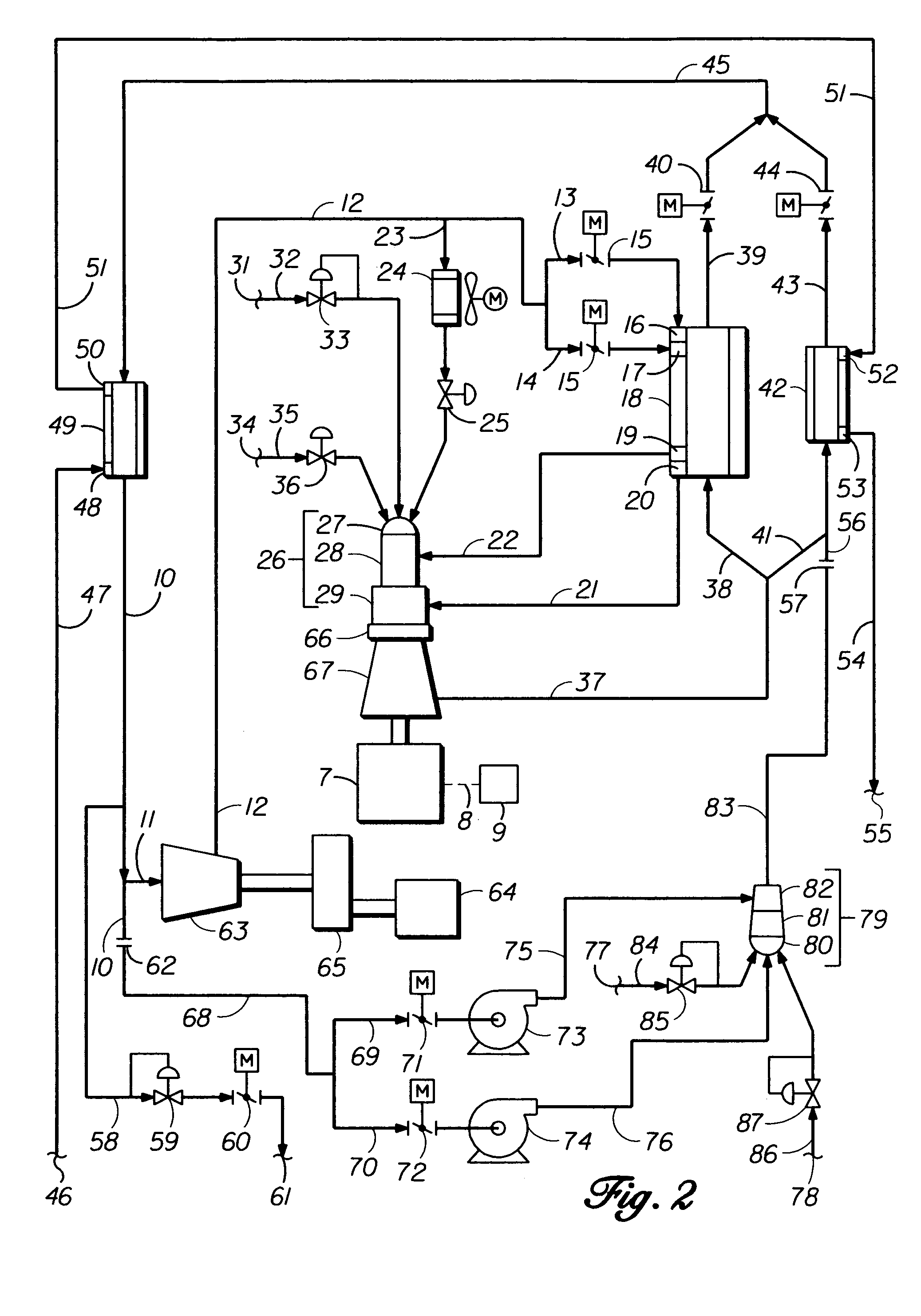

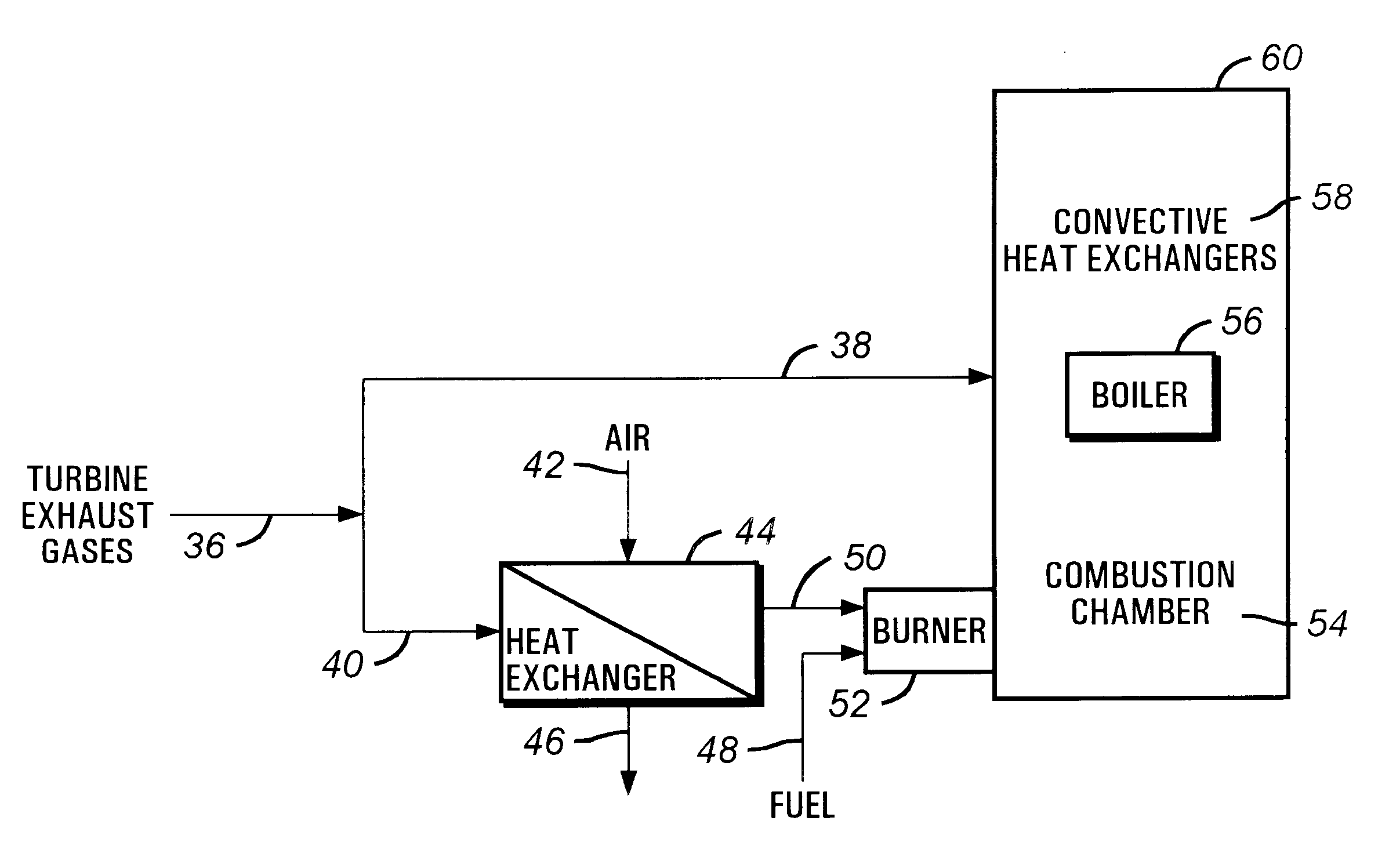

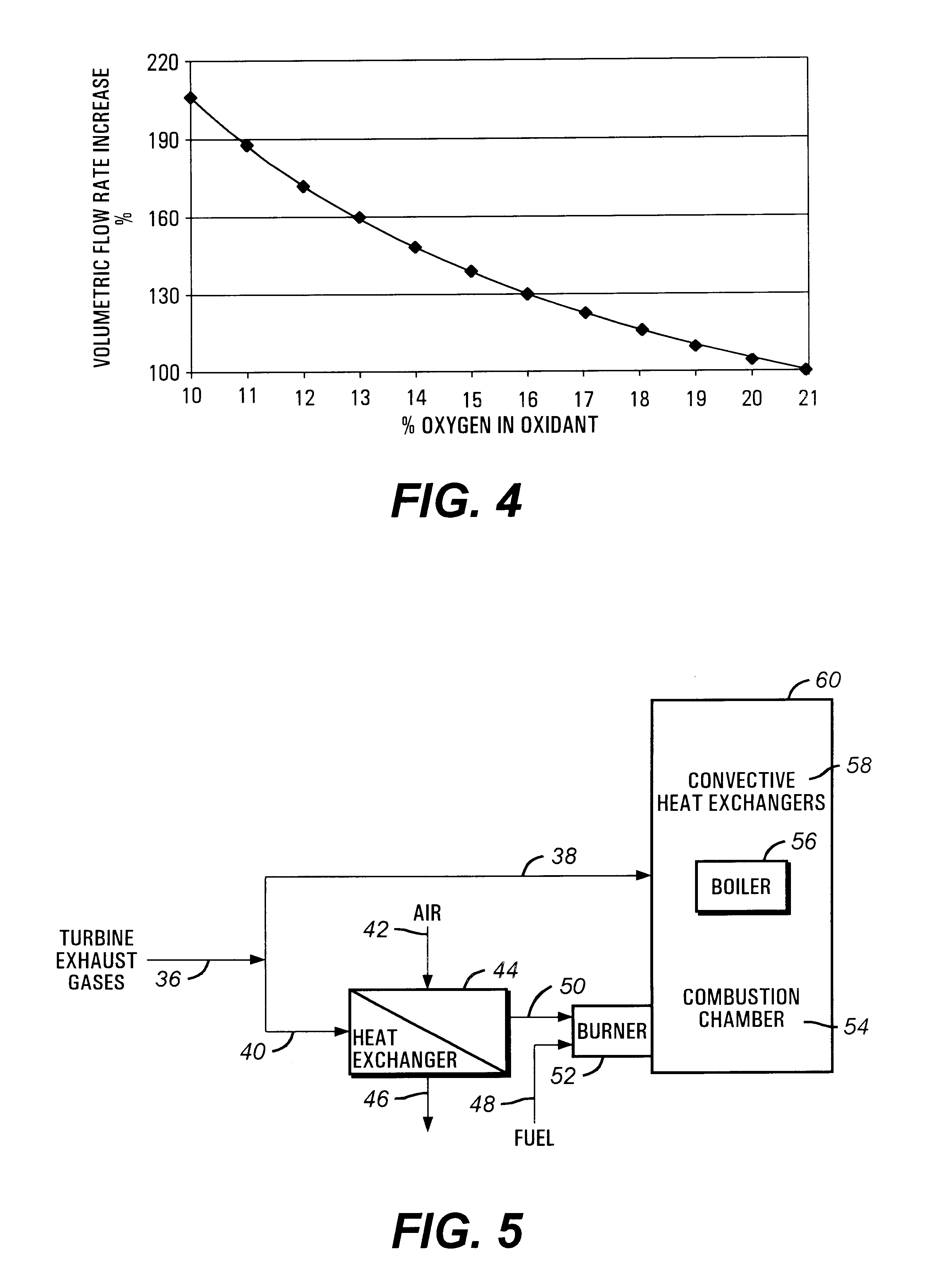

Oxidant control in co-generation installations

InactiveUS6247315B1Steam regenerationIndirect carbon-dioxide mitigationControl system designCogeneration

This invention is related to so-called combined cycle co-generation installations, and it addresses present concerns of the industry. Among these, combustion stability, corrosion (due to large water content in the flue gases), large heat transfer areas, and the like. In some embodiments, an additional heat exchanger is added to heat combustion air with a portion of the exhaust gases resulting from an engine, preferably a gas turbine. As a result, the efficiency of the cycle will improve, the oxidant will be enriched by above 50% oxygen, the combustion process will be enhanced, and the dimensions of the boiler may be reduced. It is considered that the combustion air will require between 10% and 80% of the total flue gas volume, more preferably between 20% and 40%. This is the portion of the flue gases sent through the heat exchanger. A control system designed to optimize the flow of the different streams is also presented. Other inventive embodiments forego heat exchanges in lieu of precise control of two flows of exhaust gas, with preferred addition of additional oxidant to the boiler bumers.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE +1

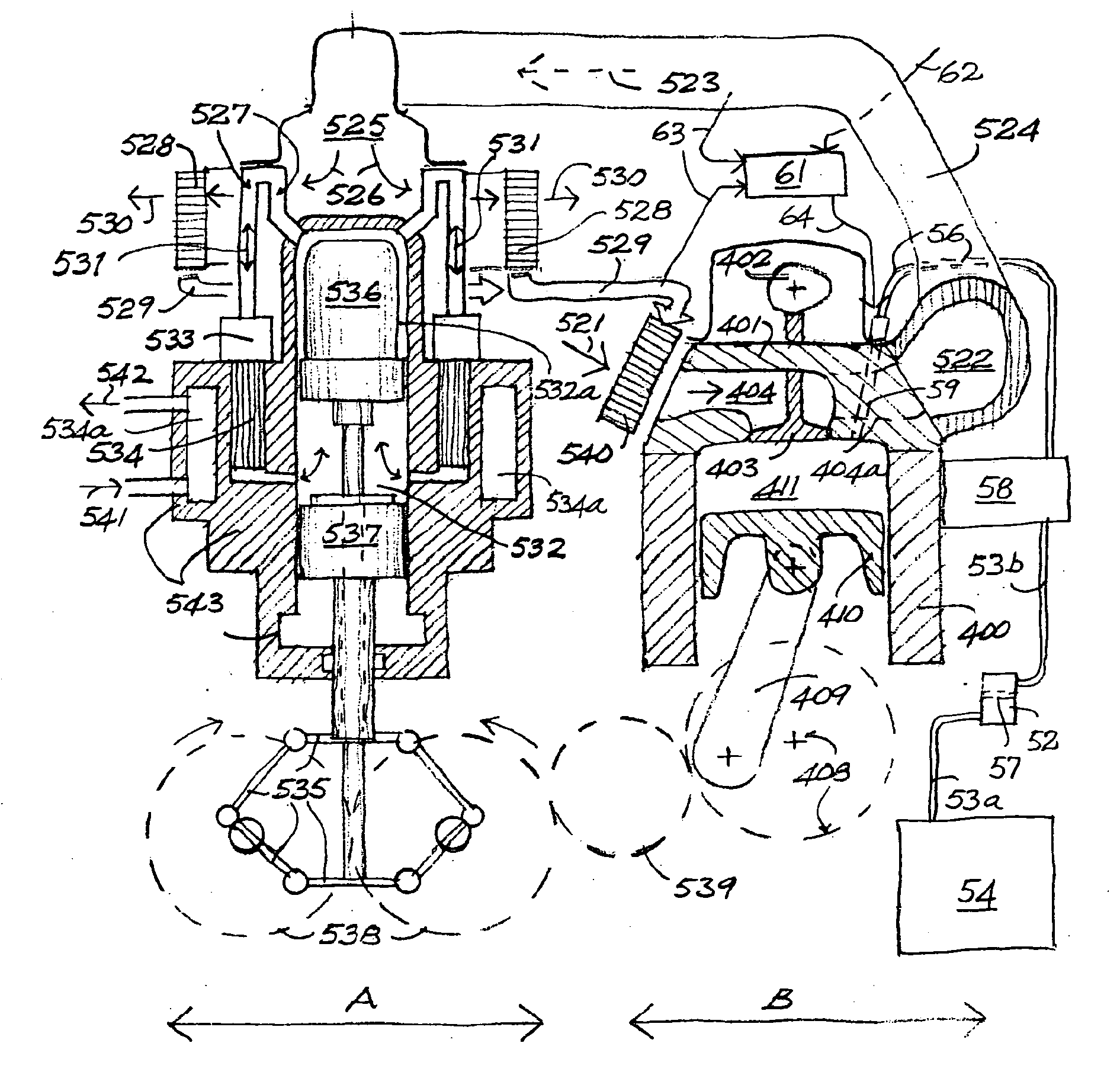

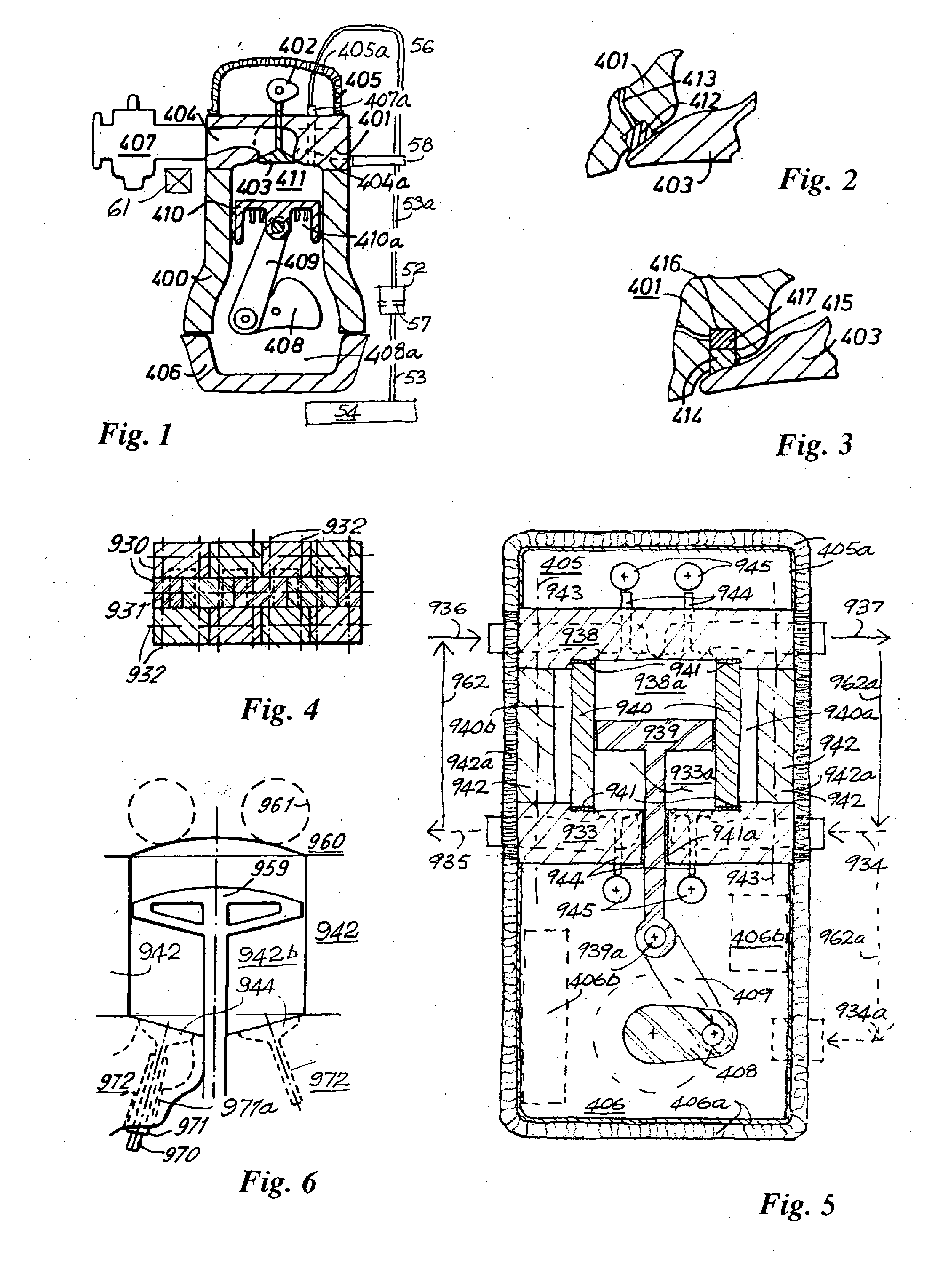

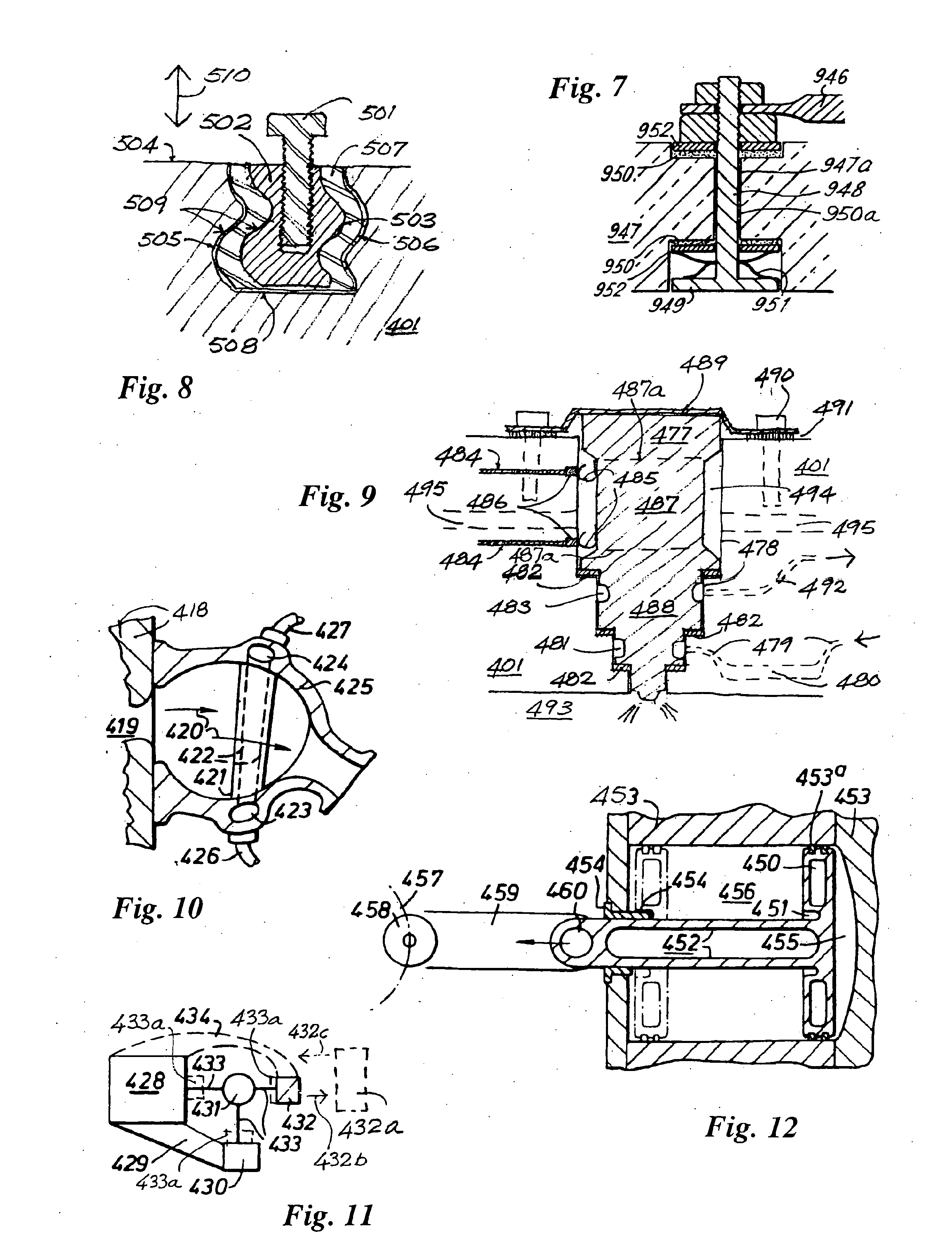

Reciprocating machine & other devices

InactiveUS20120227389A1Improve power densityImprove efficiencyLiquid coolingCasingsCombustionReciprocating motion

The disclosure relates to reciprocating fluid working devices including internal combustion engines, compressors and pumps. A number of arrangements for pistons and cylinders of unconventional configuration are described, mostly intended for use in IC engines operating without cooling. Included are toroidal combustion or working chambers, some with fluid flow through the core of the toroid, a single piston reciprocating between a pair of working chambers, tensile valve actuation, tensile links between piston and crankshaft, energy absorbing piston-crank links, crankshafts supported on gas bearings, cylinders rotating in housings, injectors having components which reciprocate or rotate during fuel delivery. In some embodiments pistons mare rotate while reciprocating. High temperature exhaust emissions systems are described, including those containing filamentary material, as are procedures for reducing emissions during cold start by means of valves at reaction volume exit. Also disclosed are improved vehicles, aircraft, marine craft, transmissions and exhaust emission systems suited to the engines of the invention.

Owner:HINDERKS MITJA VICTOR

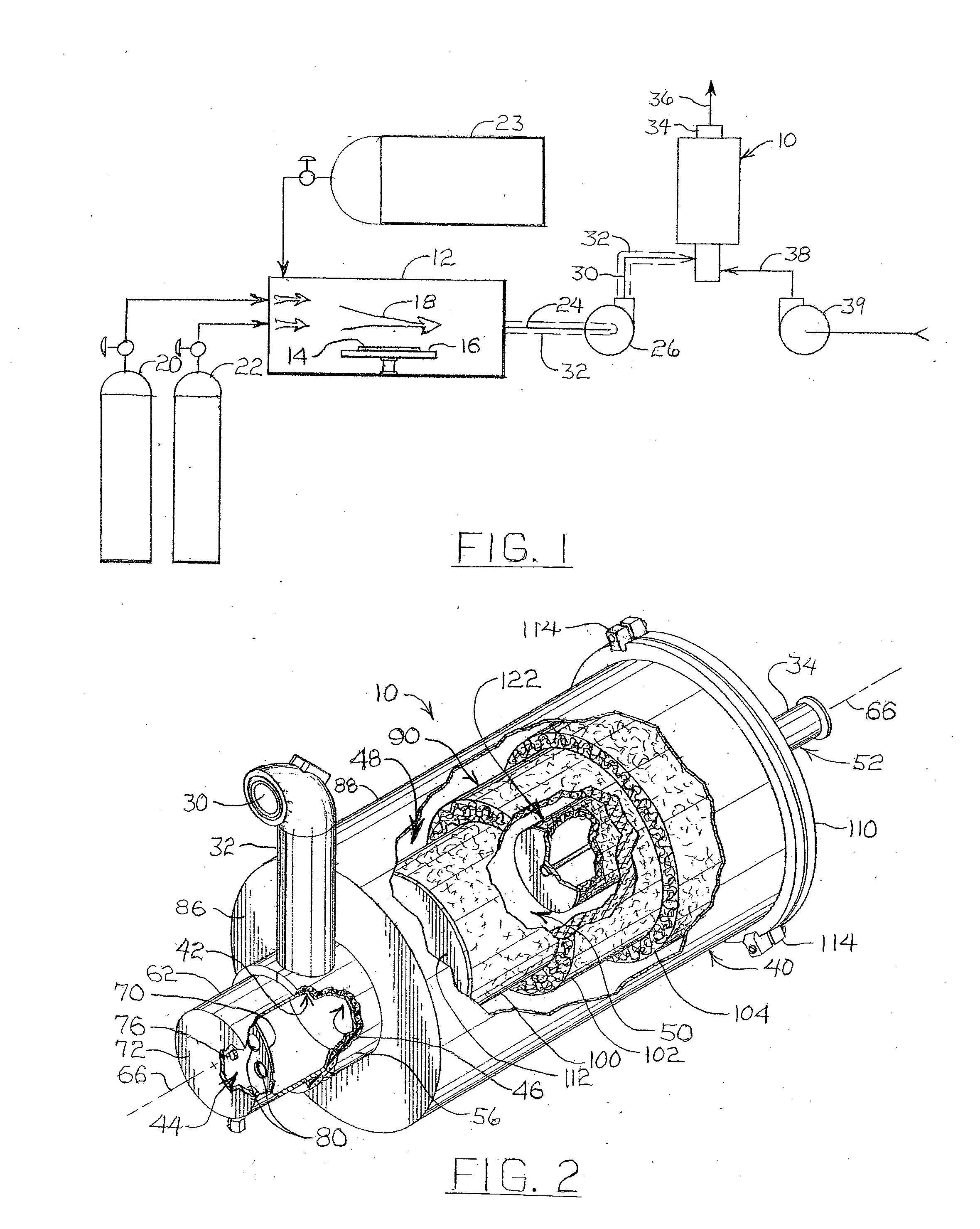

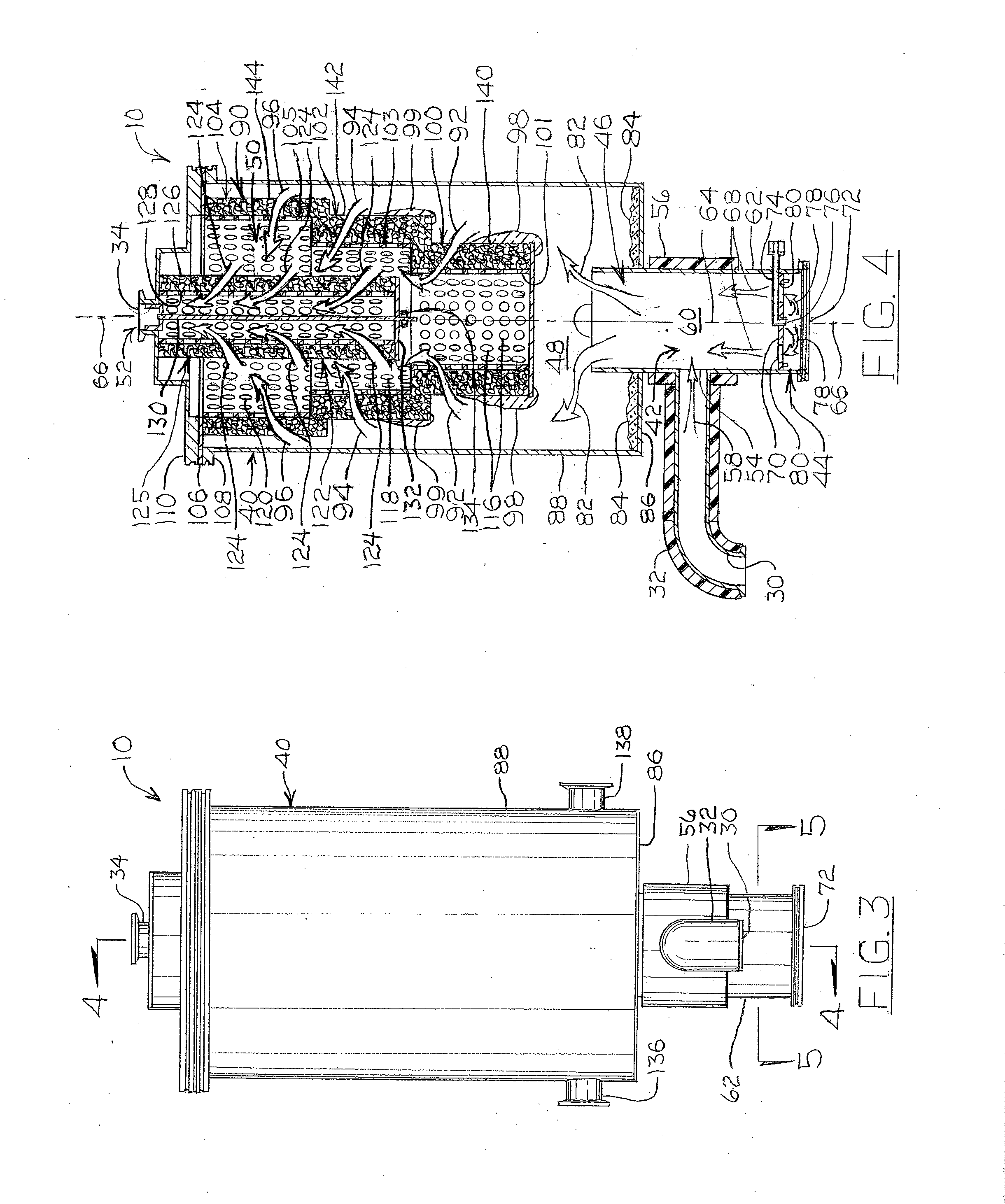

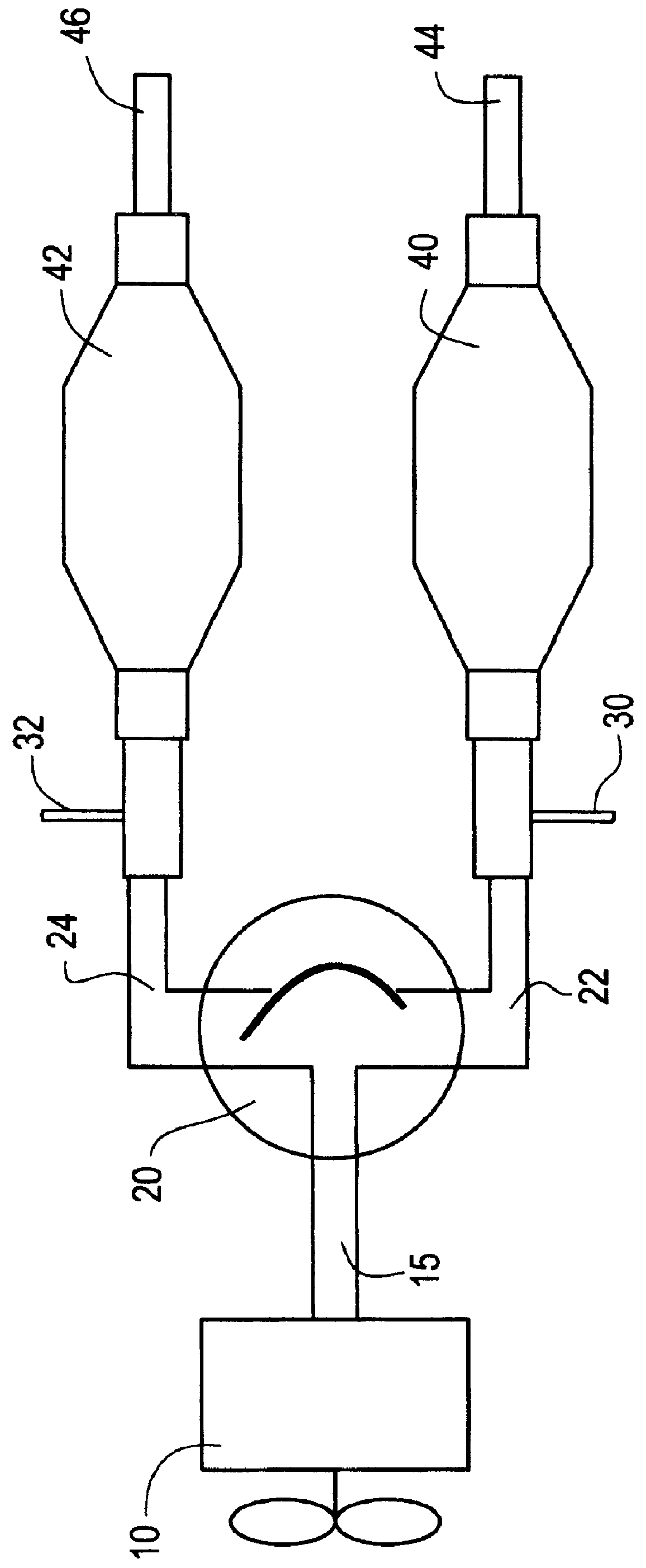

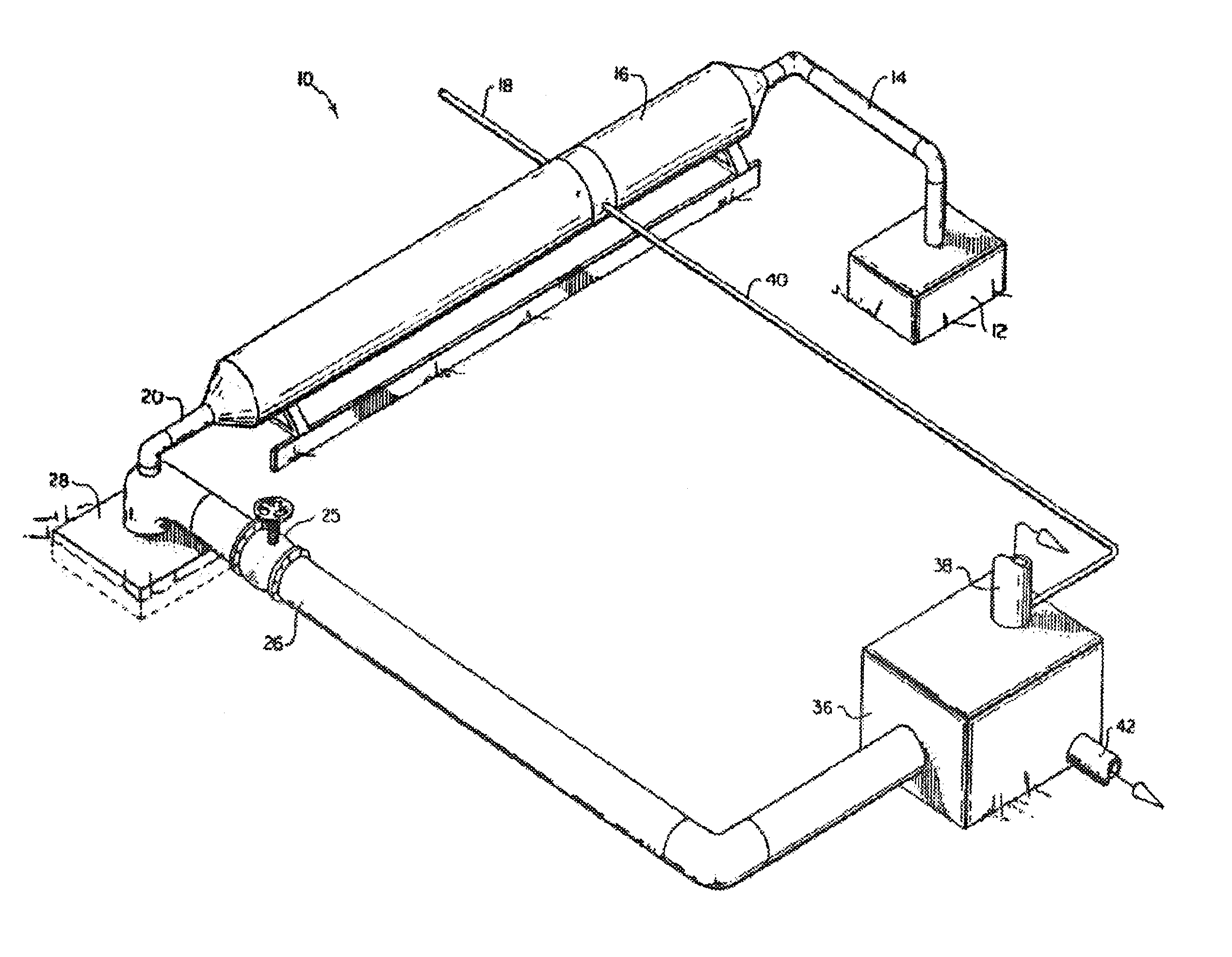

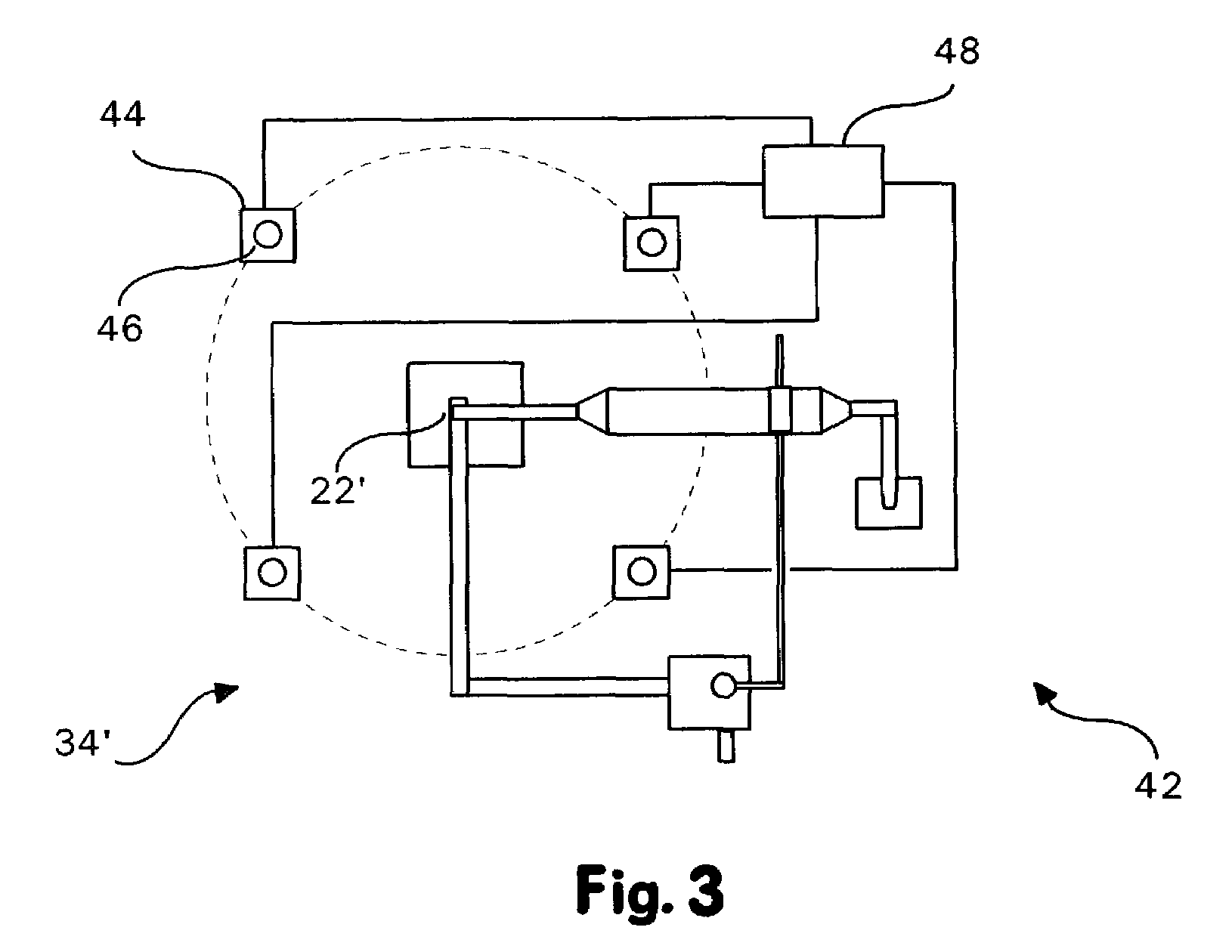

Effluent gas stream treatment system having utility for oxidation treatment of semiconductor manufacturing effluent gases

InactiveUS6322756B1Reduce sensitivityReduces water requiredCombination devicesExhaust apparatusOxygenOxidative treatment

An effluent gas stream treatment system for treatment of gaseous effluents such as waste gases from semiconductor manufacturing operations. The effluent gas stream treatment system comprises an oxidation unit to which an oxygen-containing gas such as ozone may be added, with input of energy (e.g., thermal, radio frequency, electrical, microwave, etc.), to effect oxidation of oxidizable species in the effluent, such as halocompounds (e.g., chlorofluorocarbons, perfluorocarbons), CO, NF3, nitrogen oxides, and sulfur oxides). The effluent gas stream treatment system may include a wet scrubber associated with the oxygen-containing gas source, so that the gas stream is contacted with the oxygen-containing gas during the wet scrubbing operation, to enhance removal of oxidizable species in the gas stream during treatment.

Owner:BHT SERVICES PTE LTD

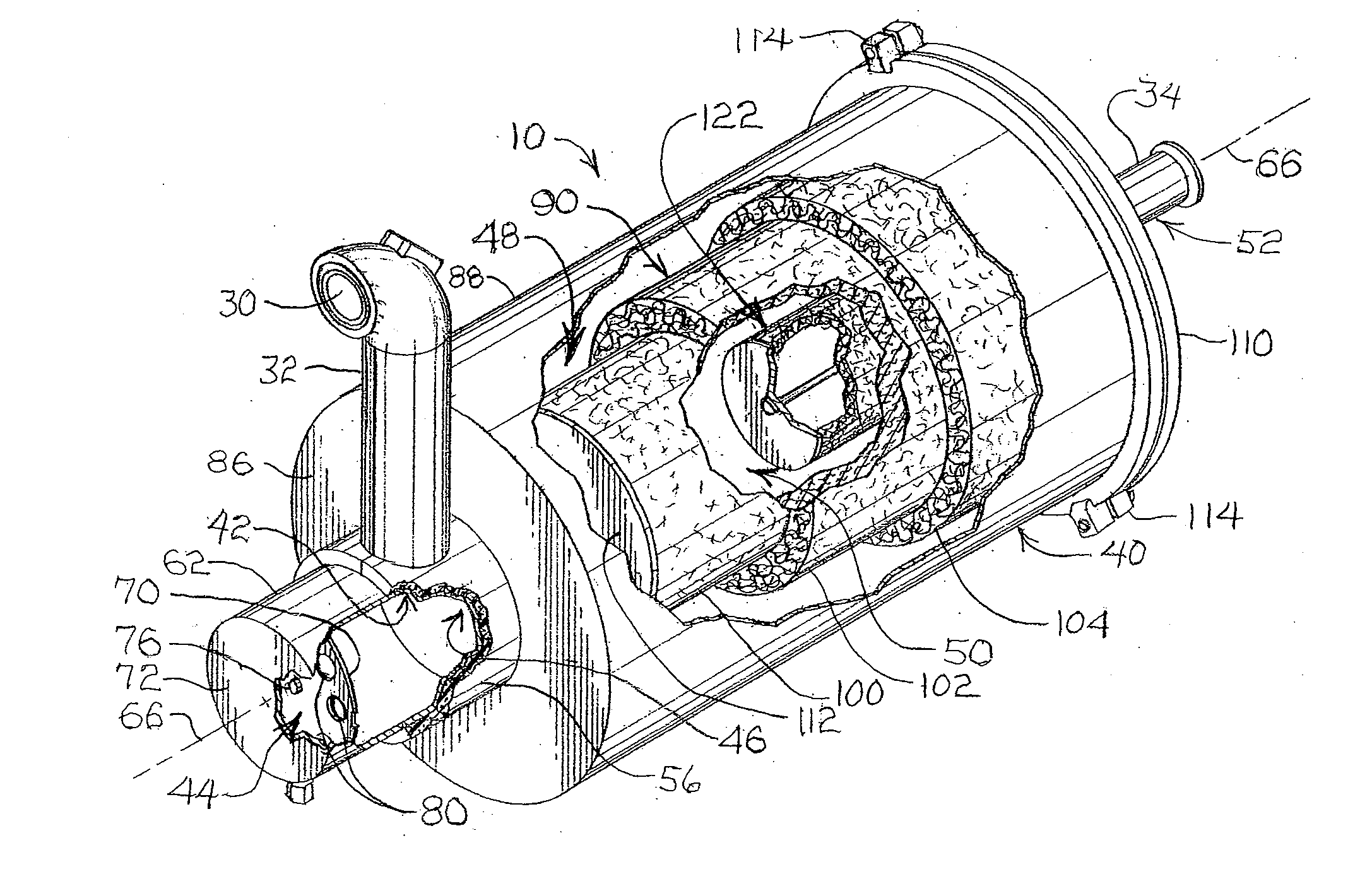

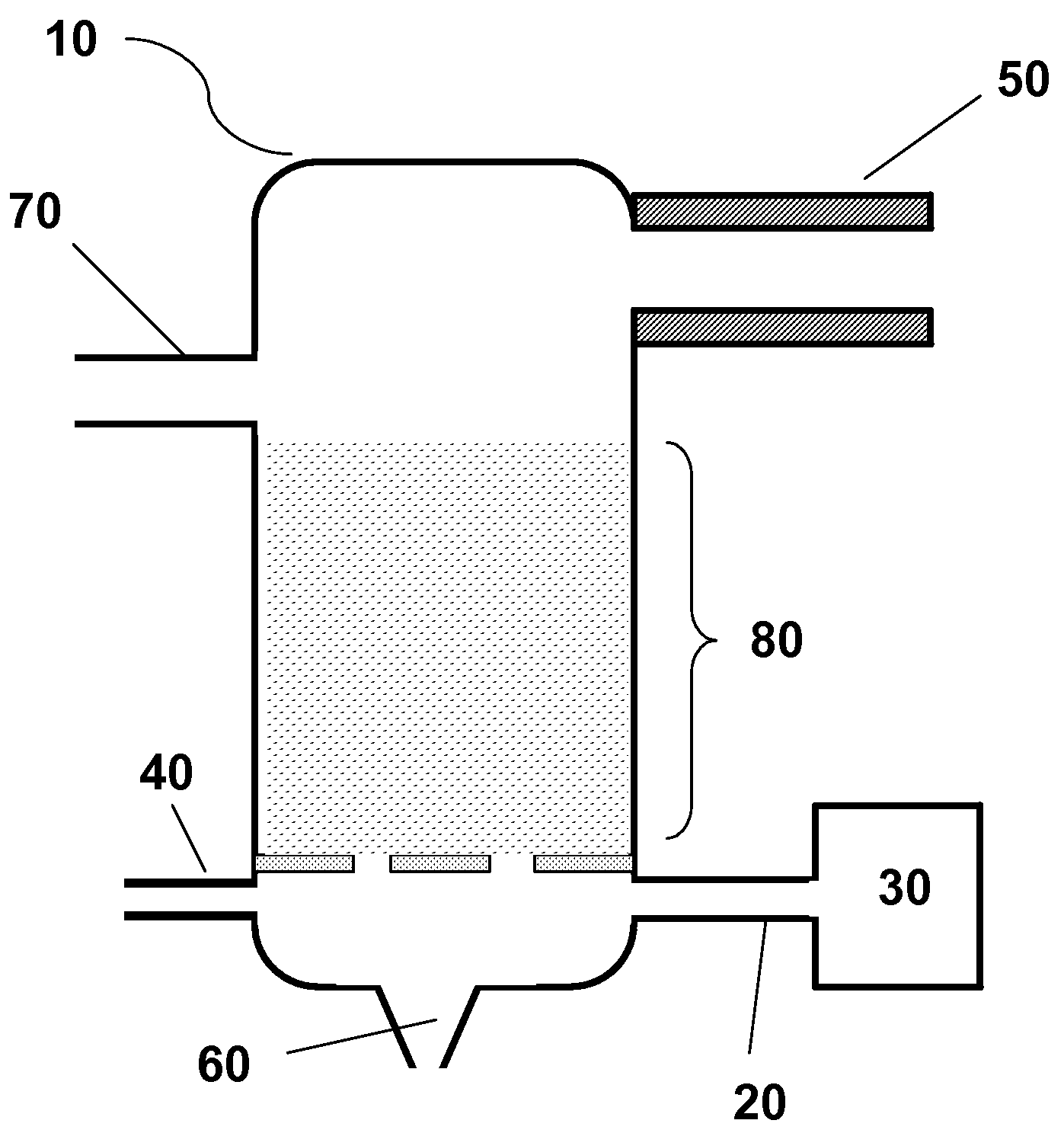

Compact diesel engine exhaust treatment system

ActiveUS20100175372A1Compact efficient in removingMinimal backpressureGas treatmentInternal combustion piston enginesExhaust fumesDiesel particulate filter

A diesel engine exhaust treatment system and method is provided which utilizes a diesel particulate filter positioned in the exhaust gas stream of a vehicle which includes an SCR catalyst, an ammonia oxidation catalyst, and / or a diesel oxidation catalyst. The system is capable of performing multiple functions including converting NOx to N2, converting HC and CO to H2O and CO2, trapping particulates, and minimizing ammonia emissions. The system is more compact and efficient than prior systems utilizing separate catalyst units, and minimizes backpressure while maximizing catalyst performance.

Owner:FORD GLOBAL TECH LLC

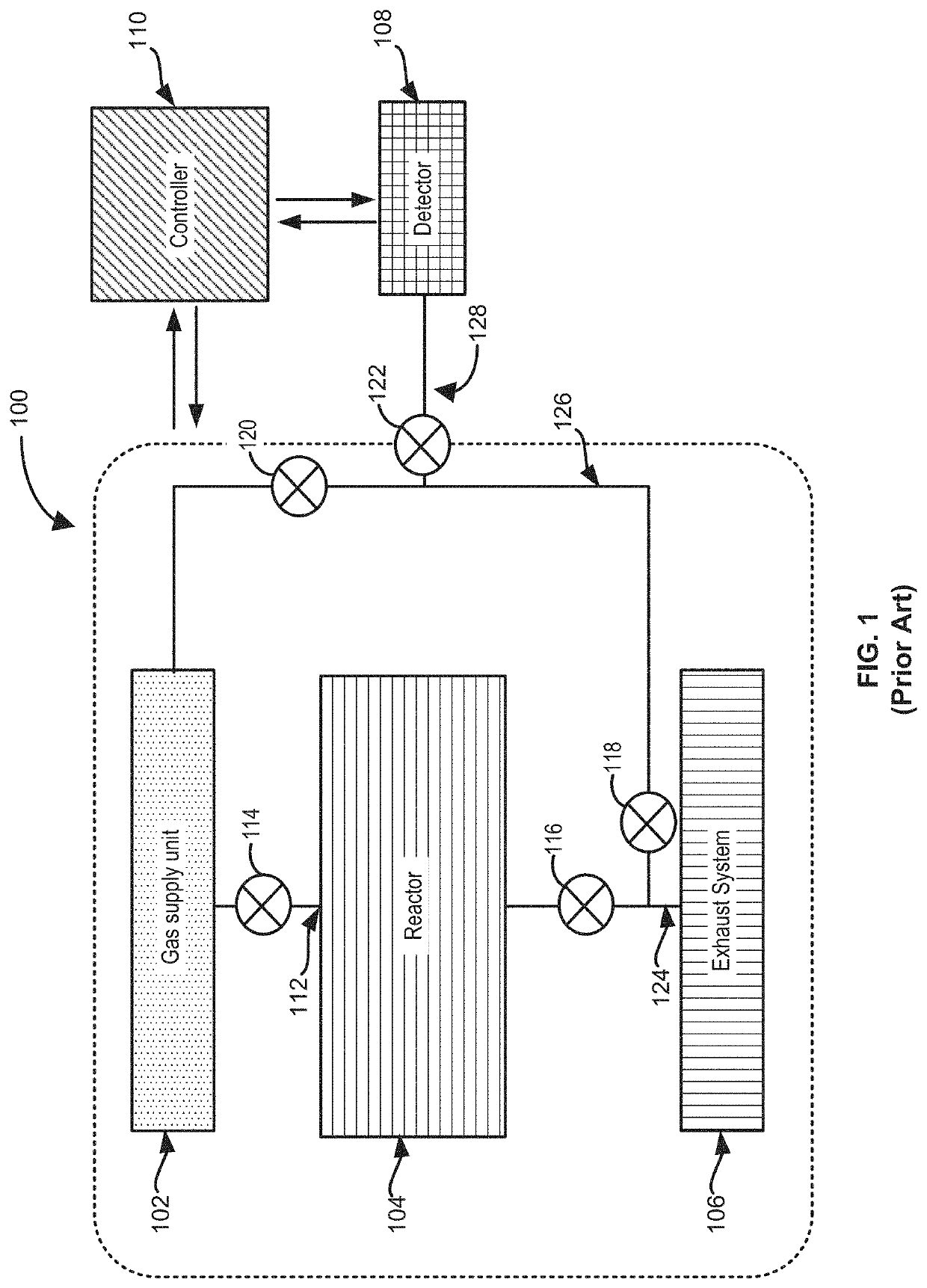

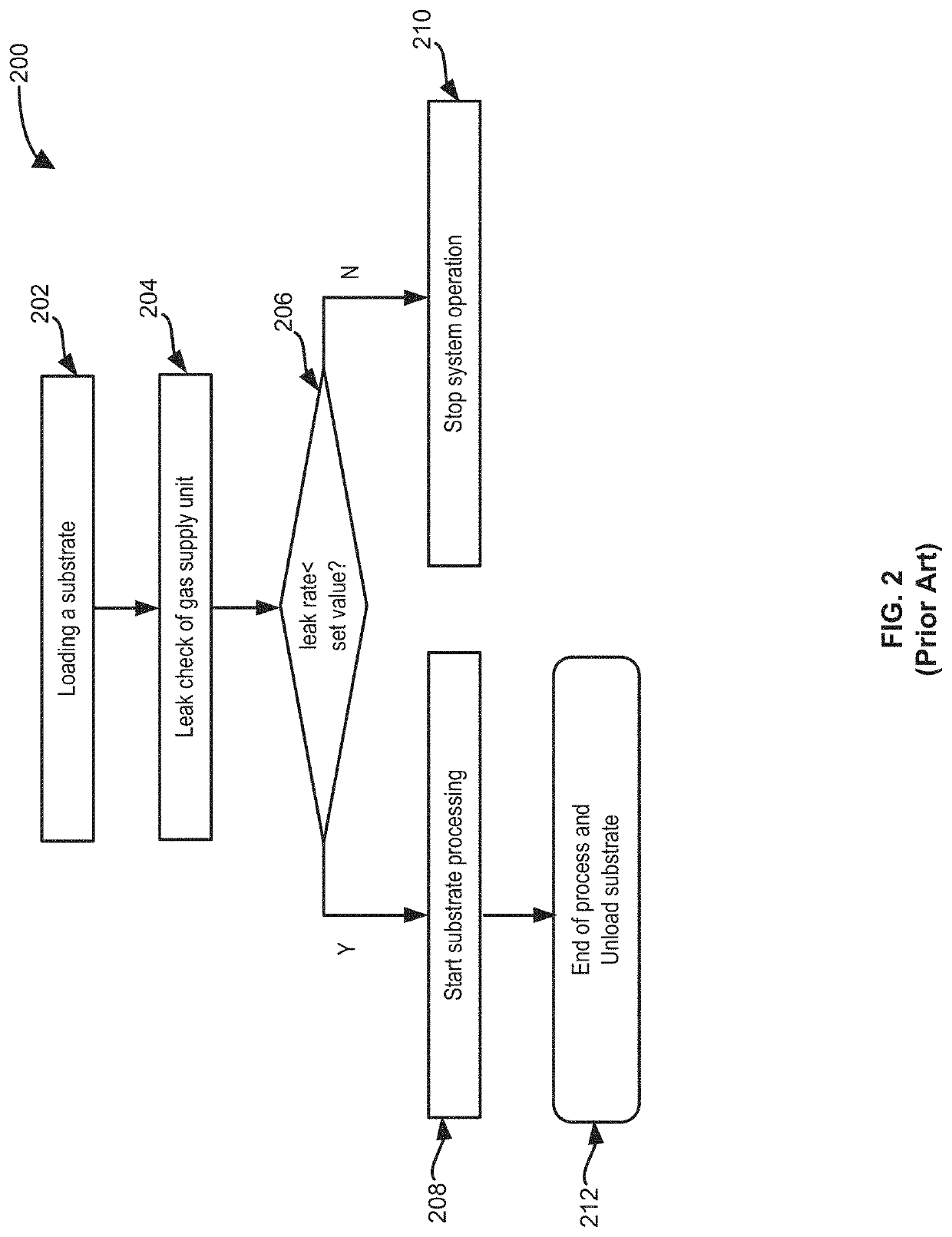

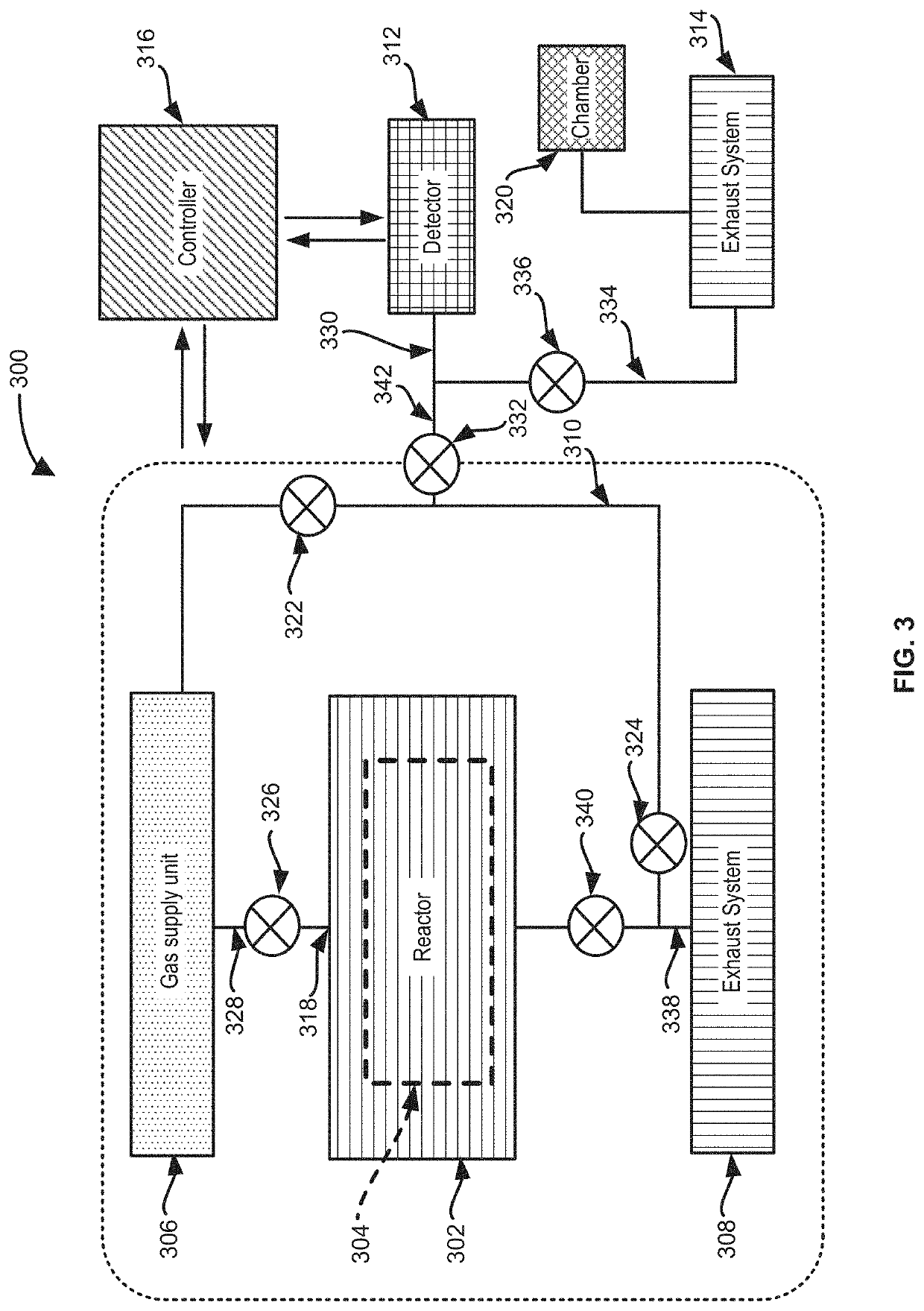

Method of using a gas-phase reactor system including analyzing exhausted gas

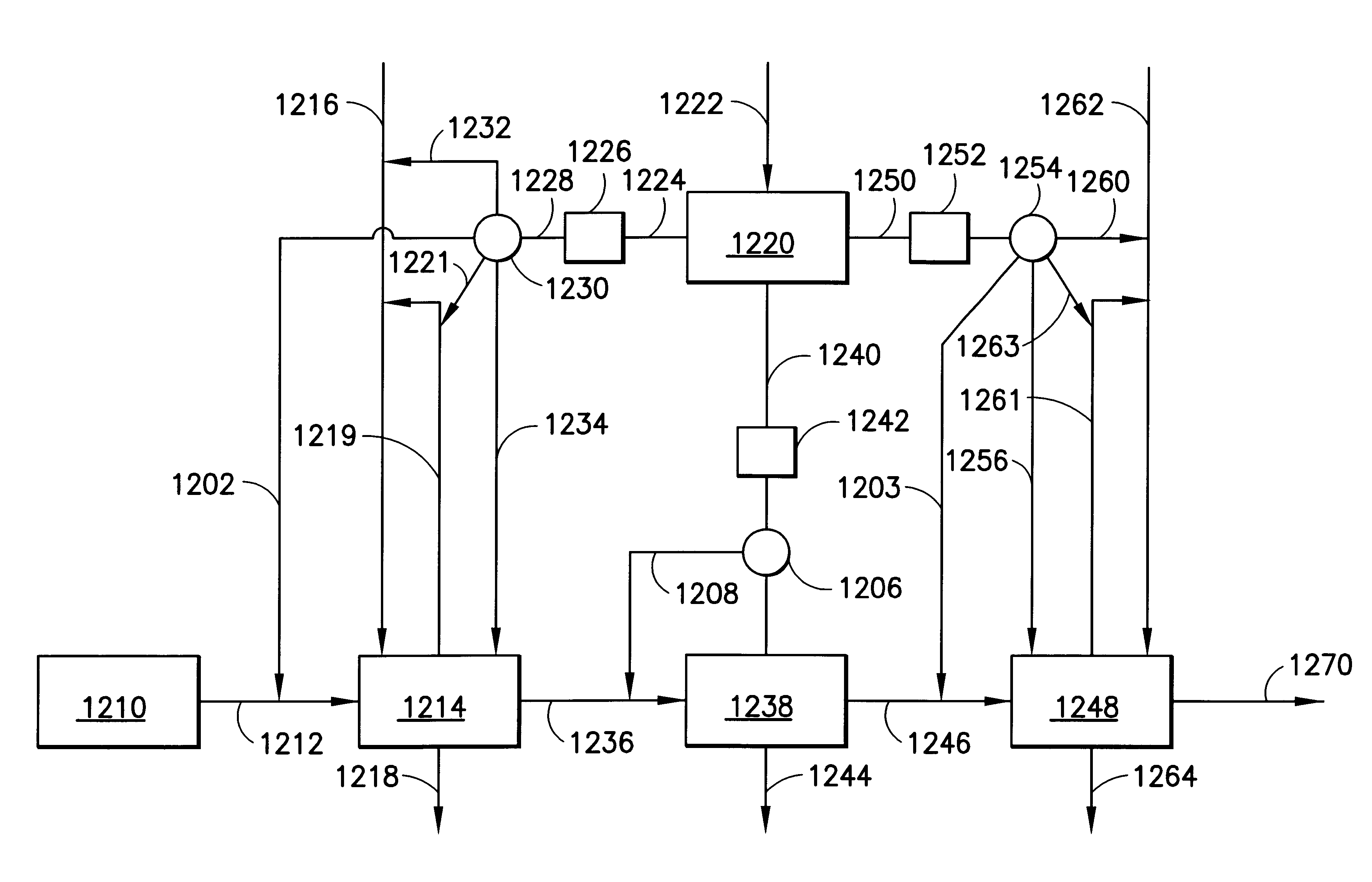

ActiveUS20200385868A1Detection of fluid at leakage pointMeasurement of fluid loss/gain rateThermodynamicsReactor system

Methods of and systems for performing leak checks of gas-phase reactor systems are disclosed. Exemplary systems include a first exhaust system coupled to a reaction chamber via a first exhaust line, a bypass line coupled to a gas supply unit and to the first exhaust system, a gas detector coupled to the bypass line via a connecting line, a connecting line valve coupled to the connecting line, and a second exhaust system coupled to the connecting line. Methods include using the second exhaust system to exhaust the connecting line to thereby remove residual gas in the connecting line that may otherwise affect the accuracy of the gas detector.

Owner:ASM IP HLDG BV

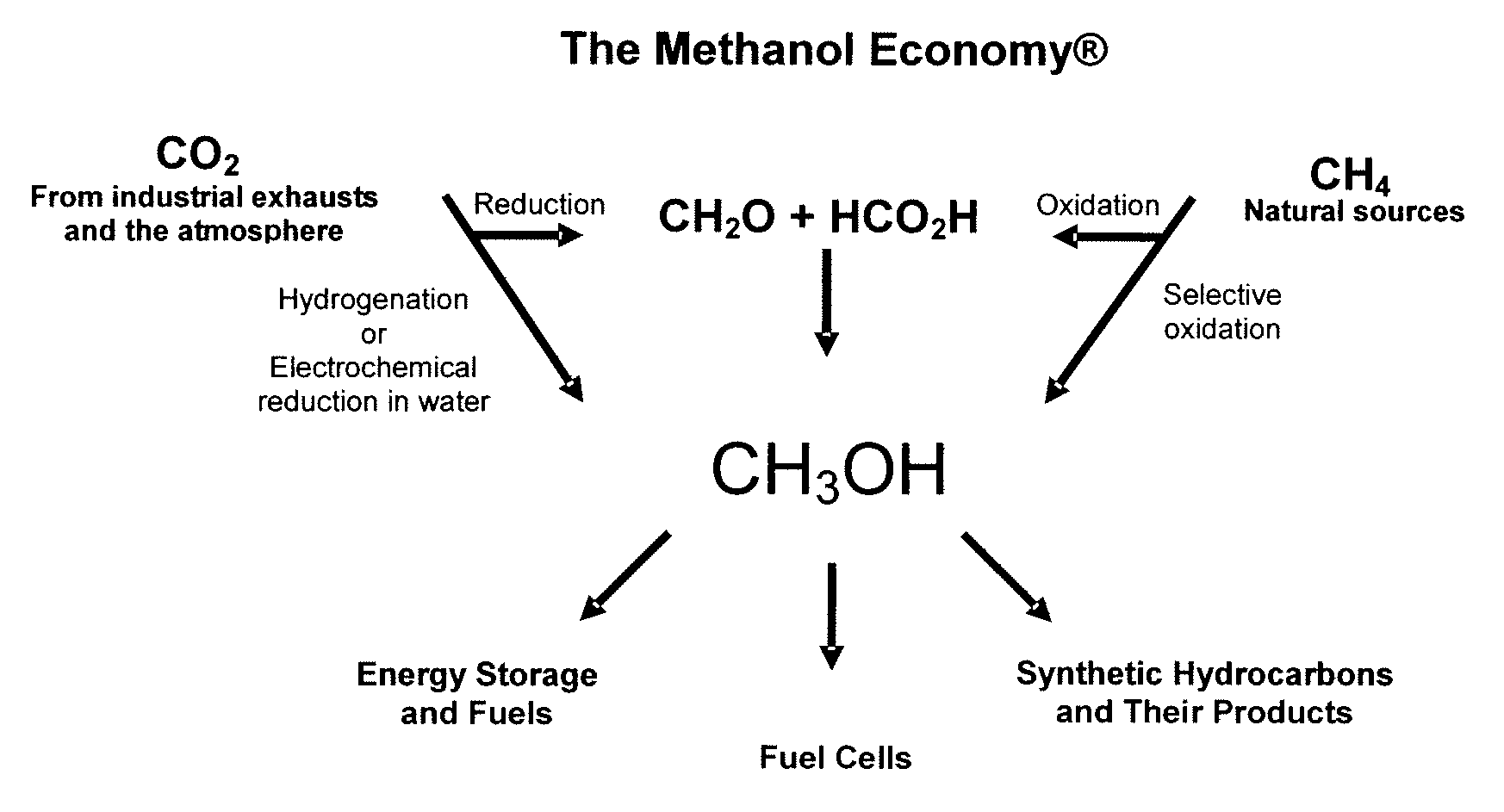

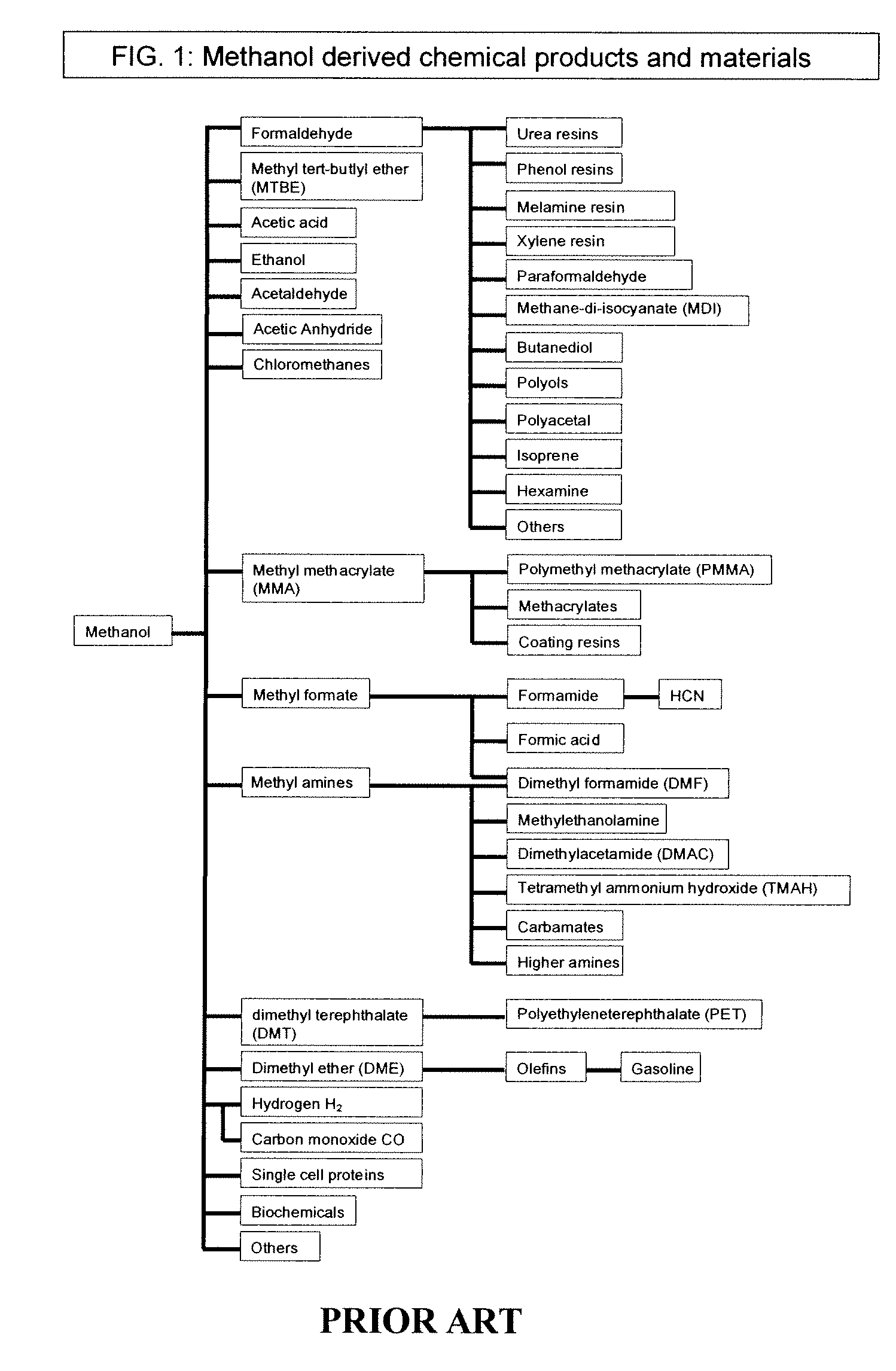

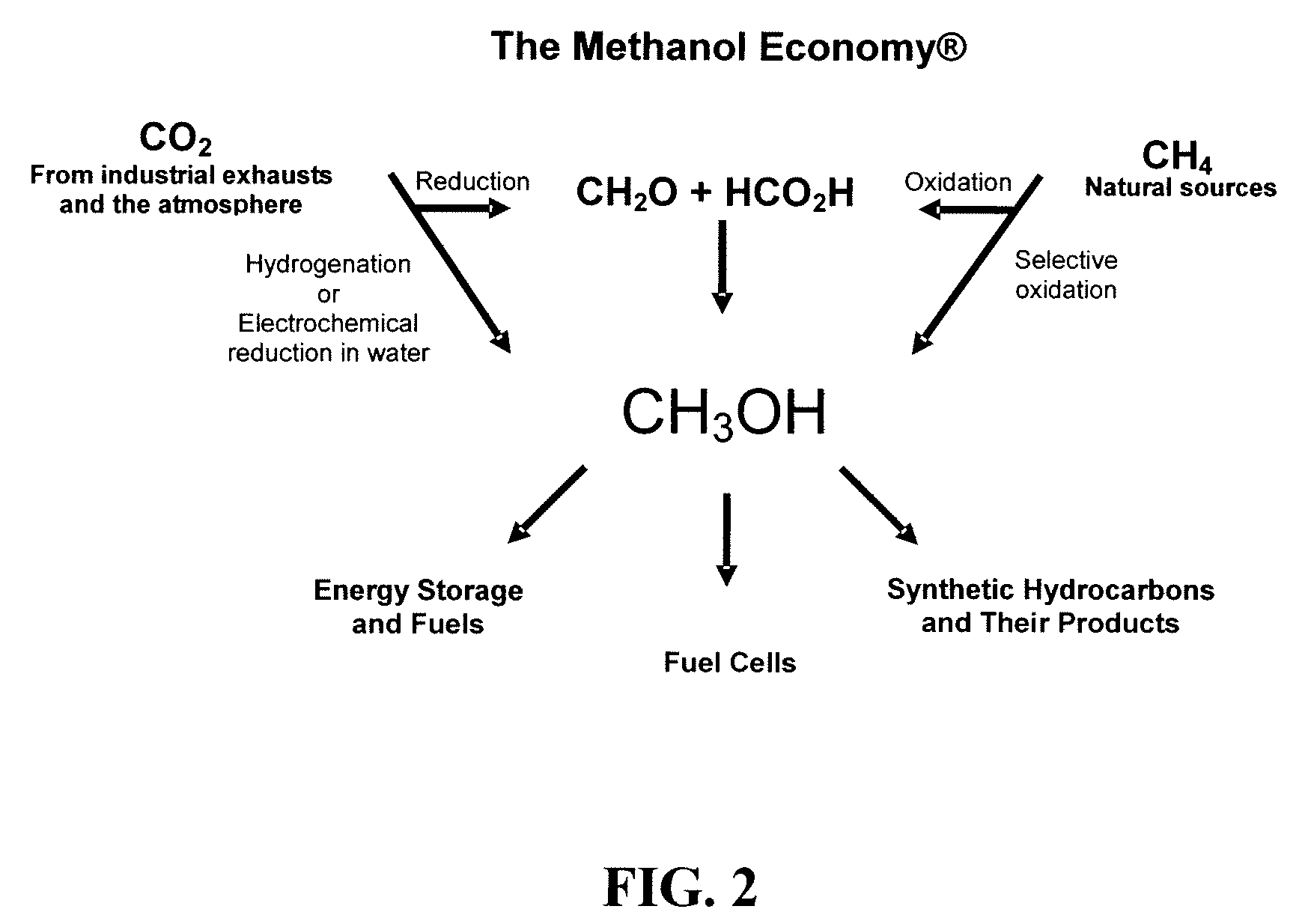

Electrolysis of carbon dioxide in aqueous media to carbon monoxide and hydrogen for production of methanol

An environmentally beneficial method of producing methanol from varied sources of carbon dioxide including flue gases of fossil fuel burning power plants, industrial exhaust gases or the atmosphere itself. Converting carbon dioxide by an electrochemical reduction of carbon dioxide in a divided electrochemical cell that includes an anode in one cell compartment and a metal cathode electrode in another cell compartment that also contains an aqueous solution comprising methanol and an electrolyte of one or more alkyl ammonium halides, alkali carbonates or combinations thereof to produce therein a reaction mixture containing carbon monoxide and hydrogen which can be subsequently used to produce methanol while also producing oxygen in the cell at the anode.

Owner:UNIV OF SOUTHERN CALIFORNIA

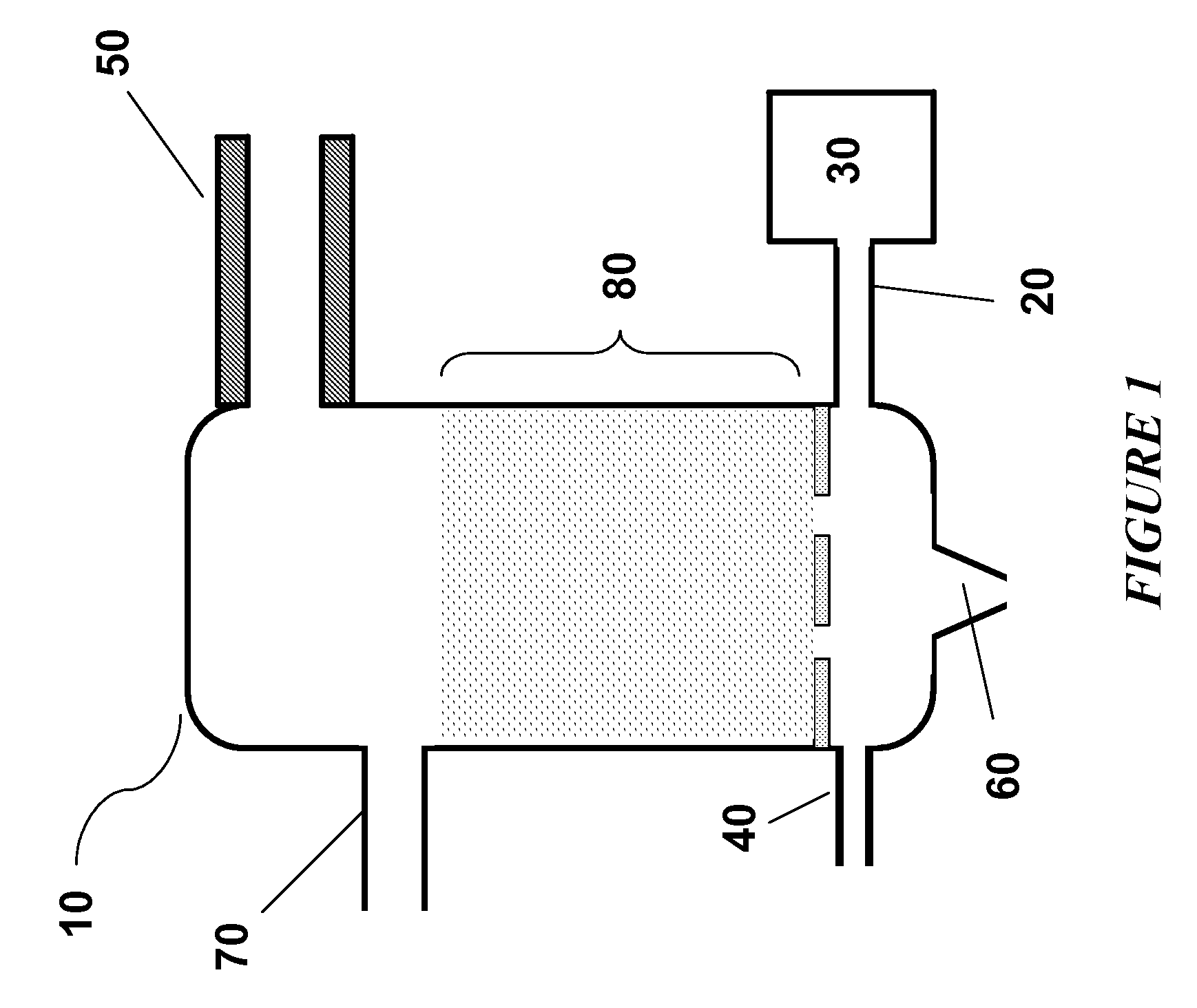

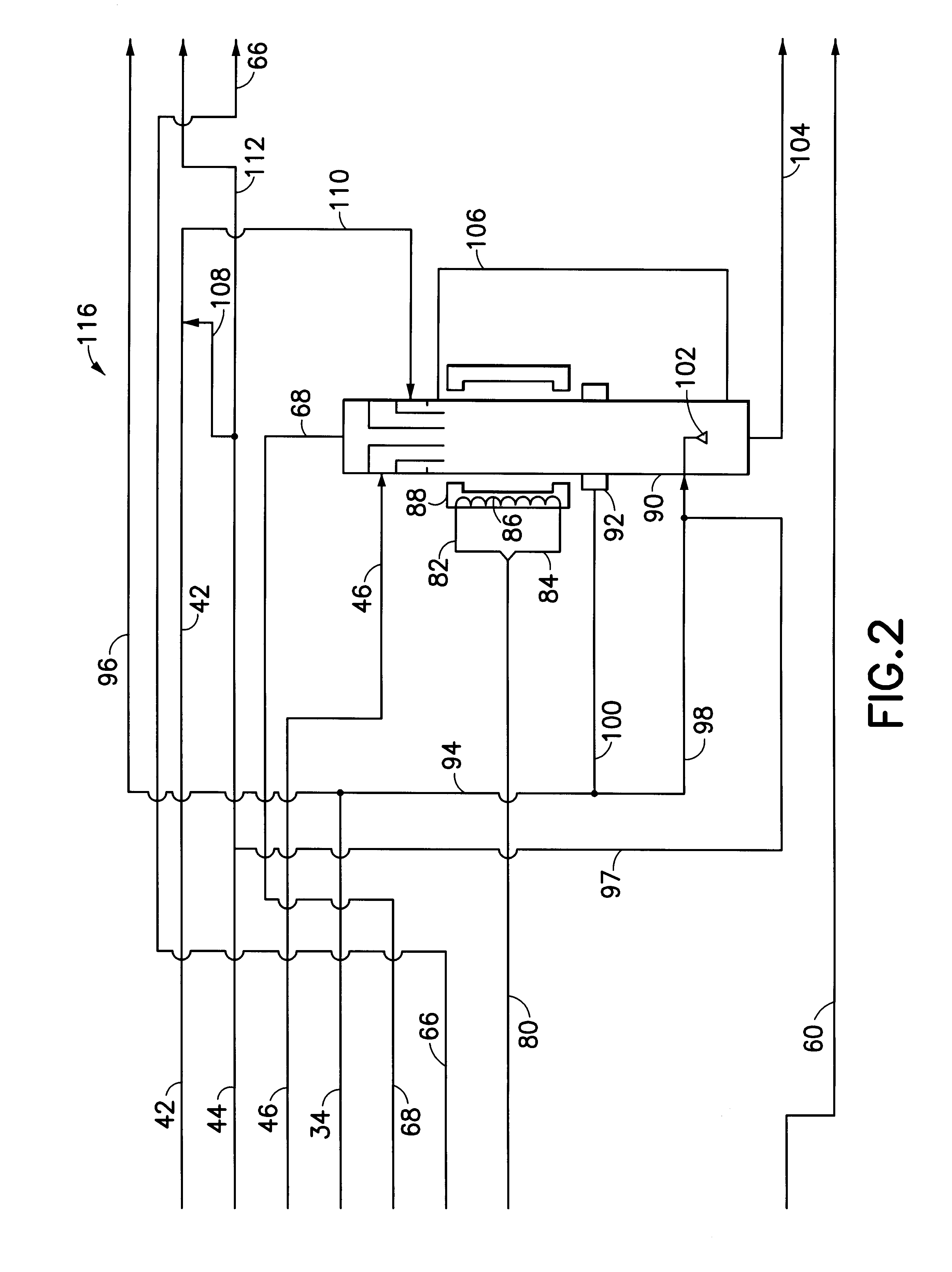

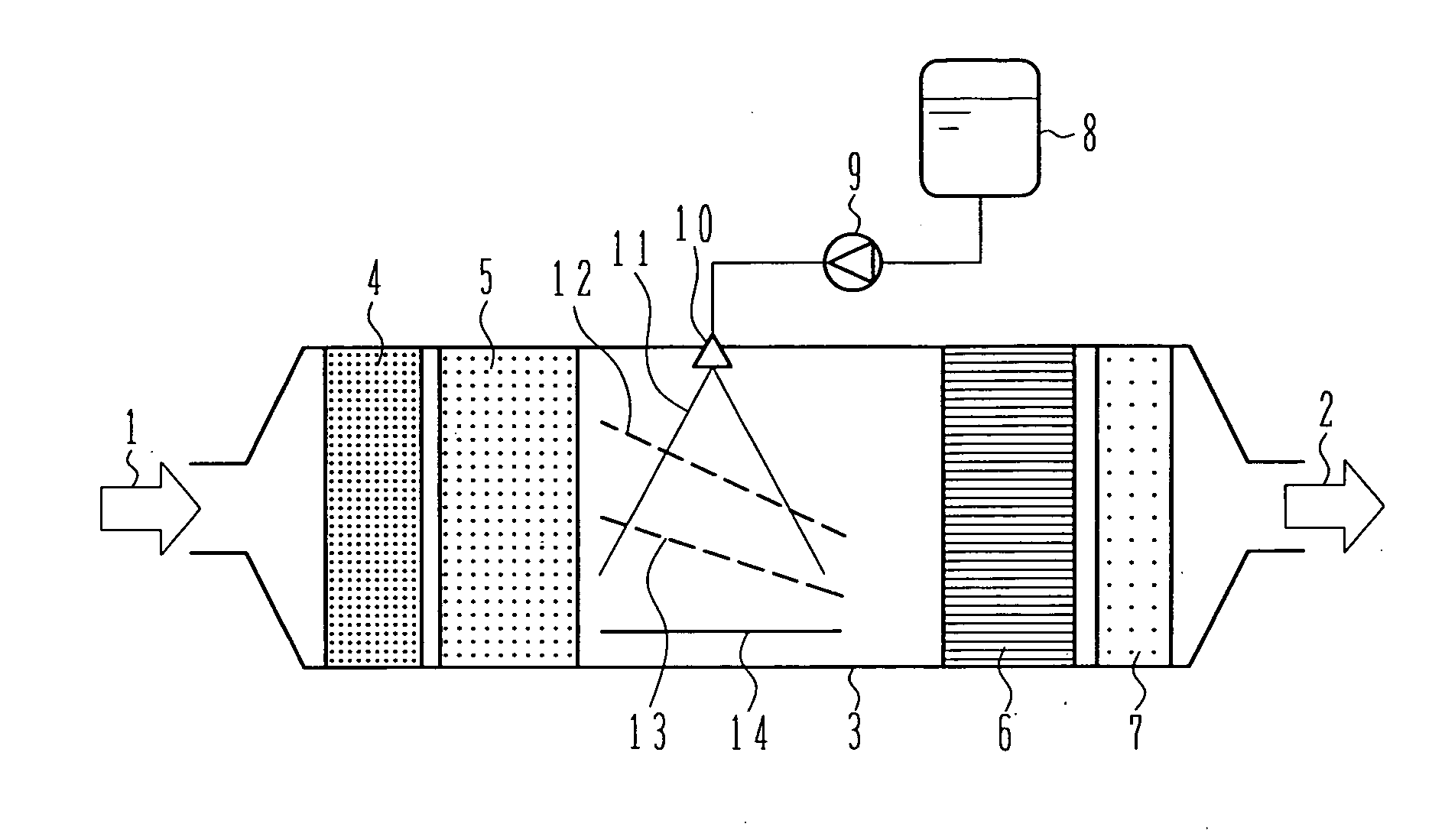

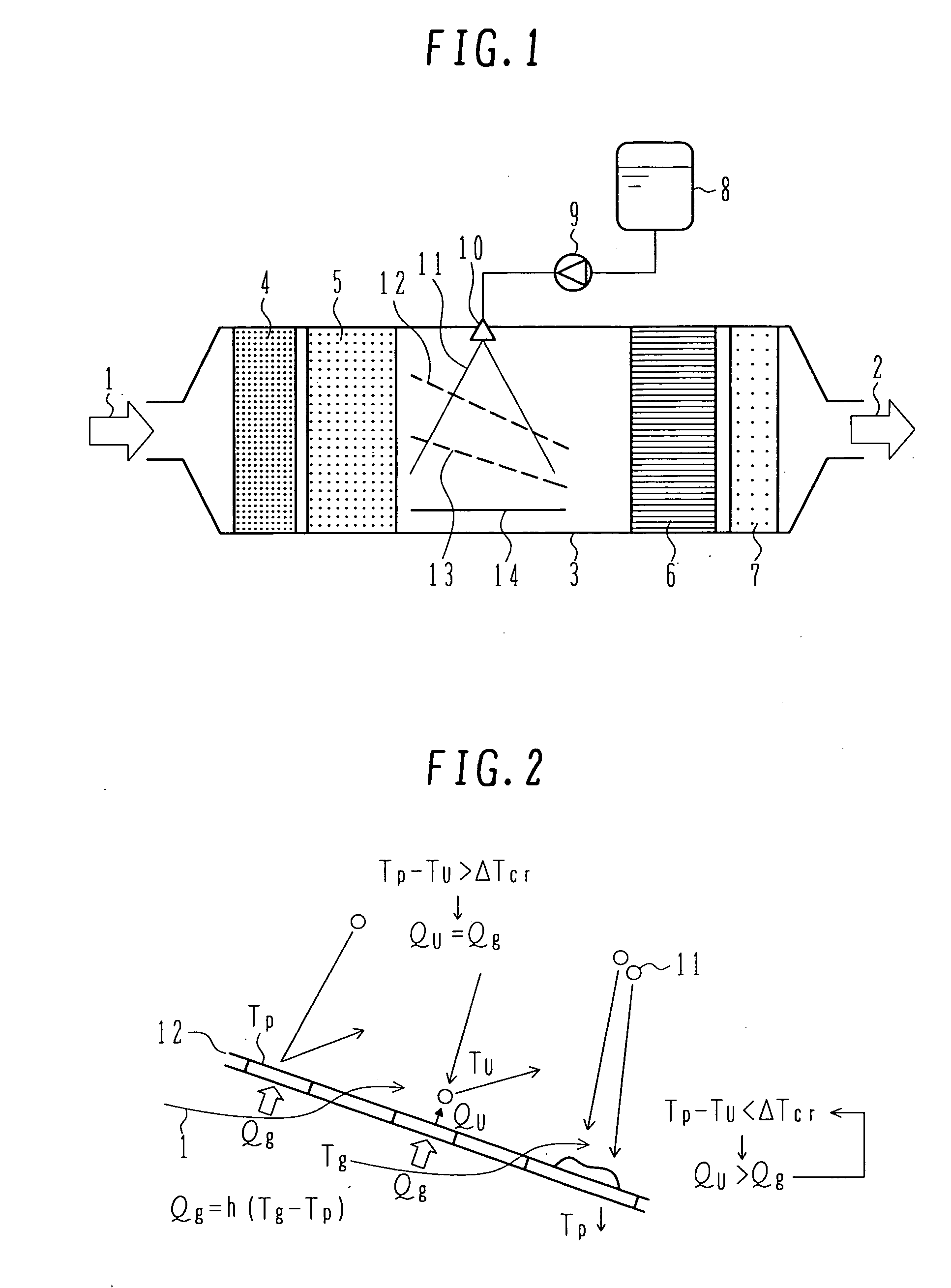

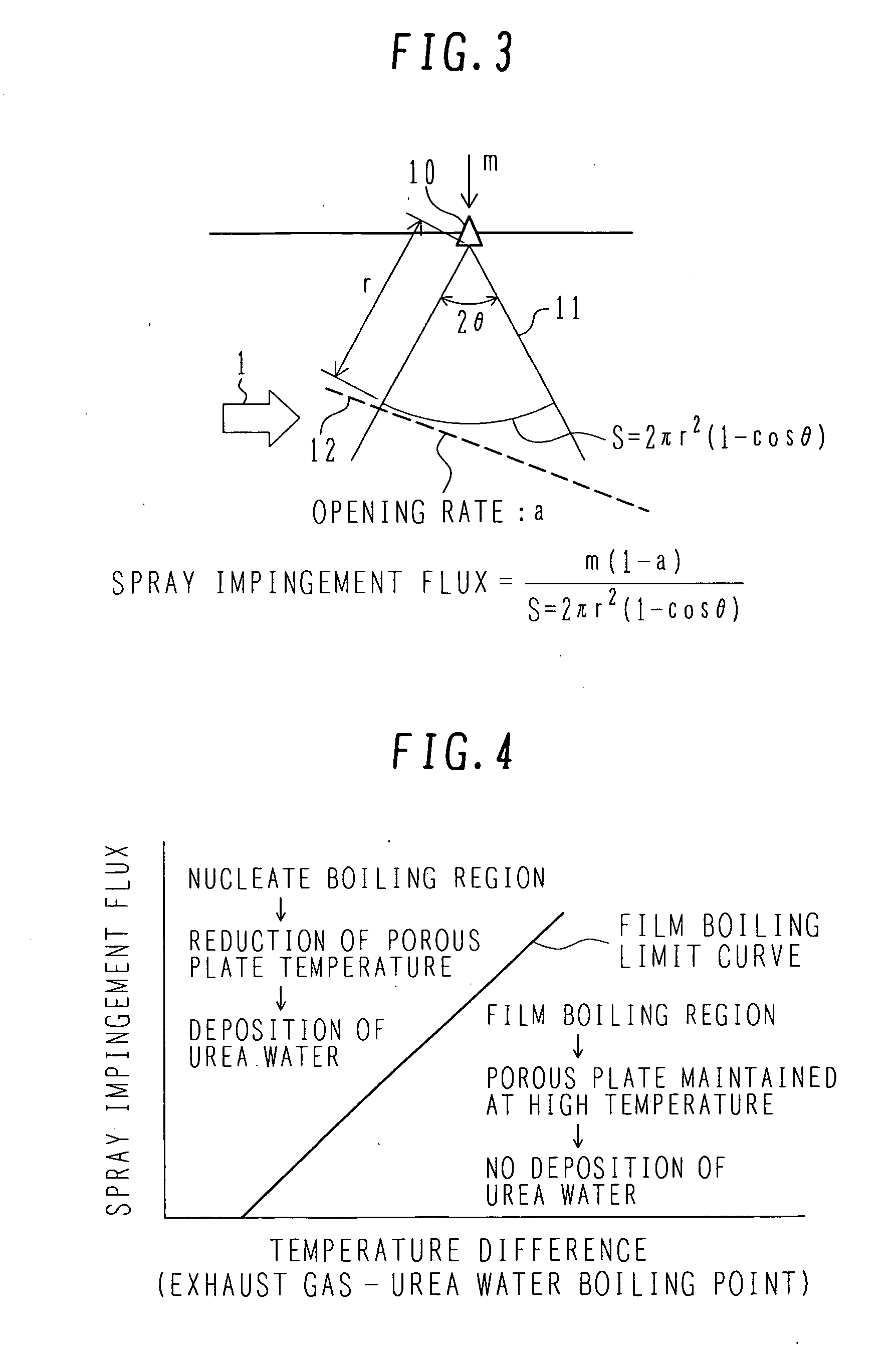

Exhaust aftertreatment system using urea water

InactiveUS20070036694A1Avoid depositionReduced responseCombination devicesInternal combustion piston enginesHandling systemMultiple stages

An exhaust aftertreatment system comprises an injector for injecting urea water into an exhaust duct, and a denitration catalyst disposed downstream of the injector with respect to a flow of exhaust gas. The exhaust aftertreatment system reduces nitrogen oxides in the exhaust gas by the denitration catalyst while using ammonia produced from the urea water injected from the injector. The urea water is injected along a direction of the flow of the exhaust gas within the exhaust duct, and a porous plate is disposed in multiple stages in a space of the exhaust duct such that droplets of the injected urea water impinge against the porous plate before reaching a wall surface of the exhaust duct. A surface of the porous plate subjected to the impingement of the droplets is arranged to face downstream with respect to the flow of the exhaust gas. Deposition of the urea water is prevented by causing film boiling when the droplets impinge against the porous plate, and the urea water reflected by the porous plate is uniformly dispersed into the exhaust gas. Thus, the urea water is uniformly dispersed into the exhaust gas without increasing a pressure loss of the exhaust gas. The urea water is prevented from depositing on the wall surface and producing a precipitate in the form of a solid.

Owner:HITACHI HIGH-TECH CORP +2

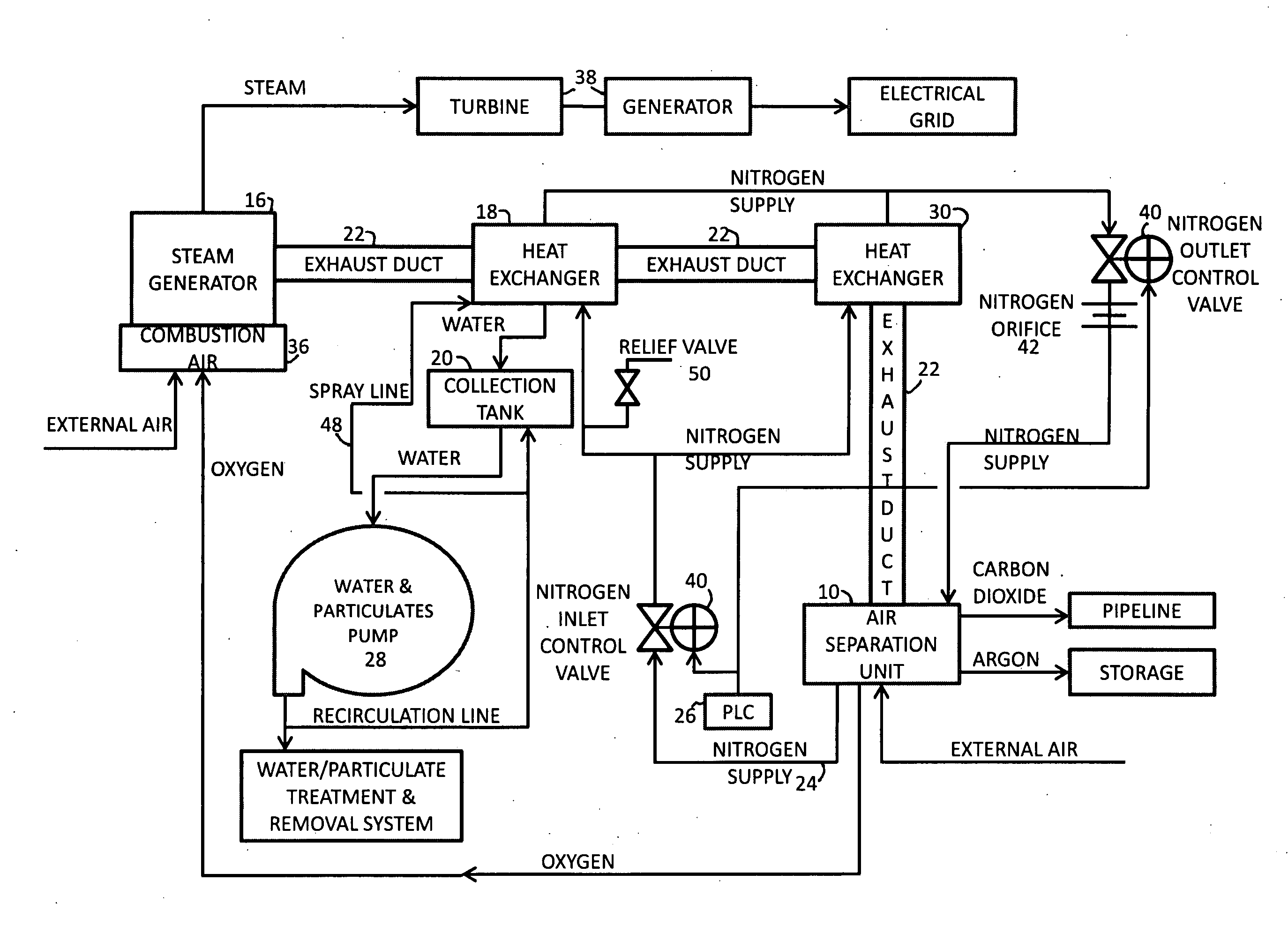

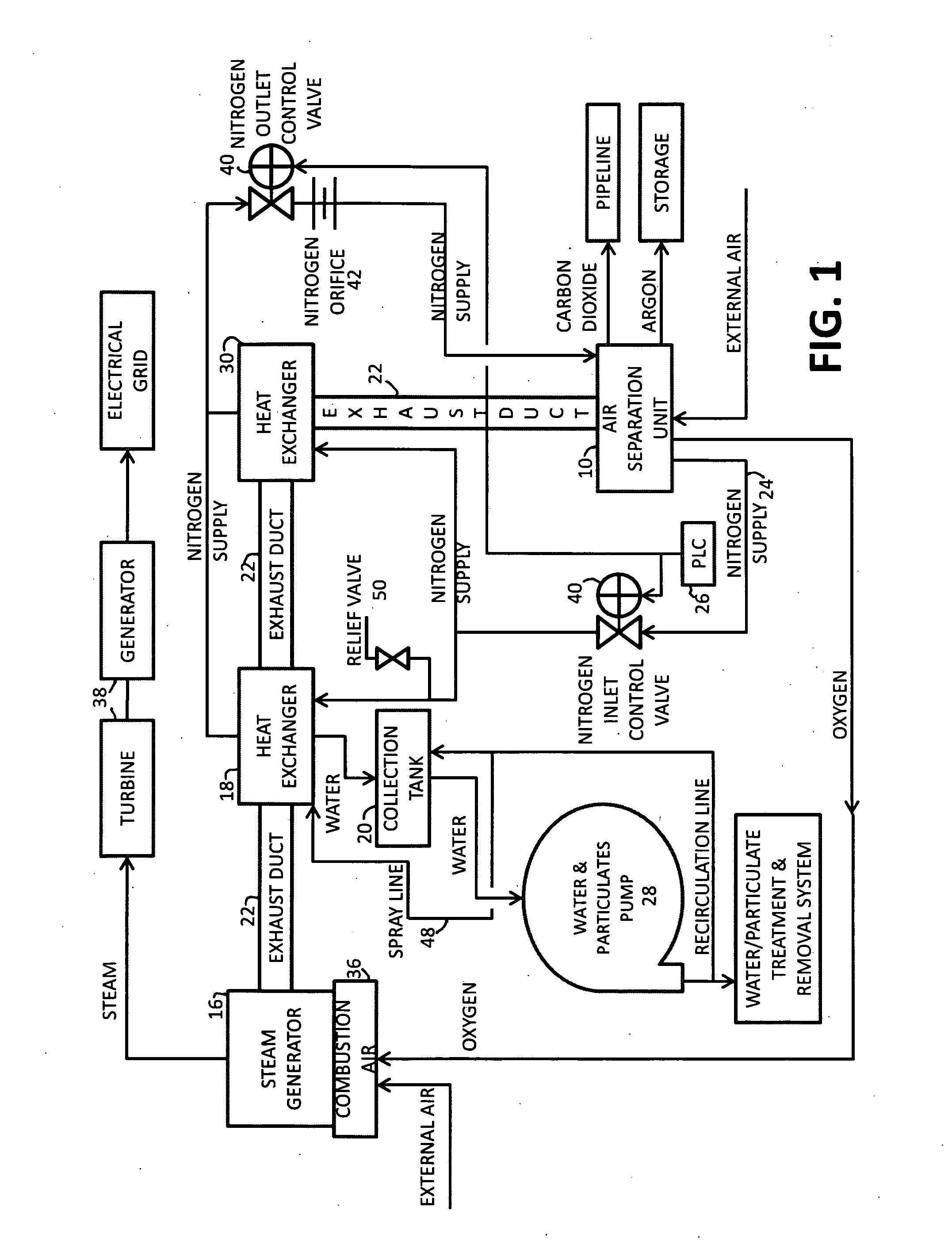

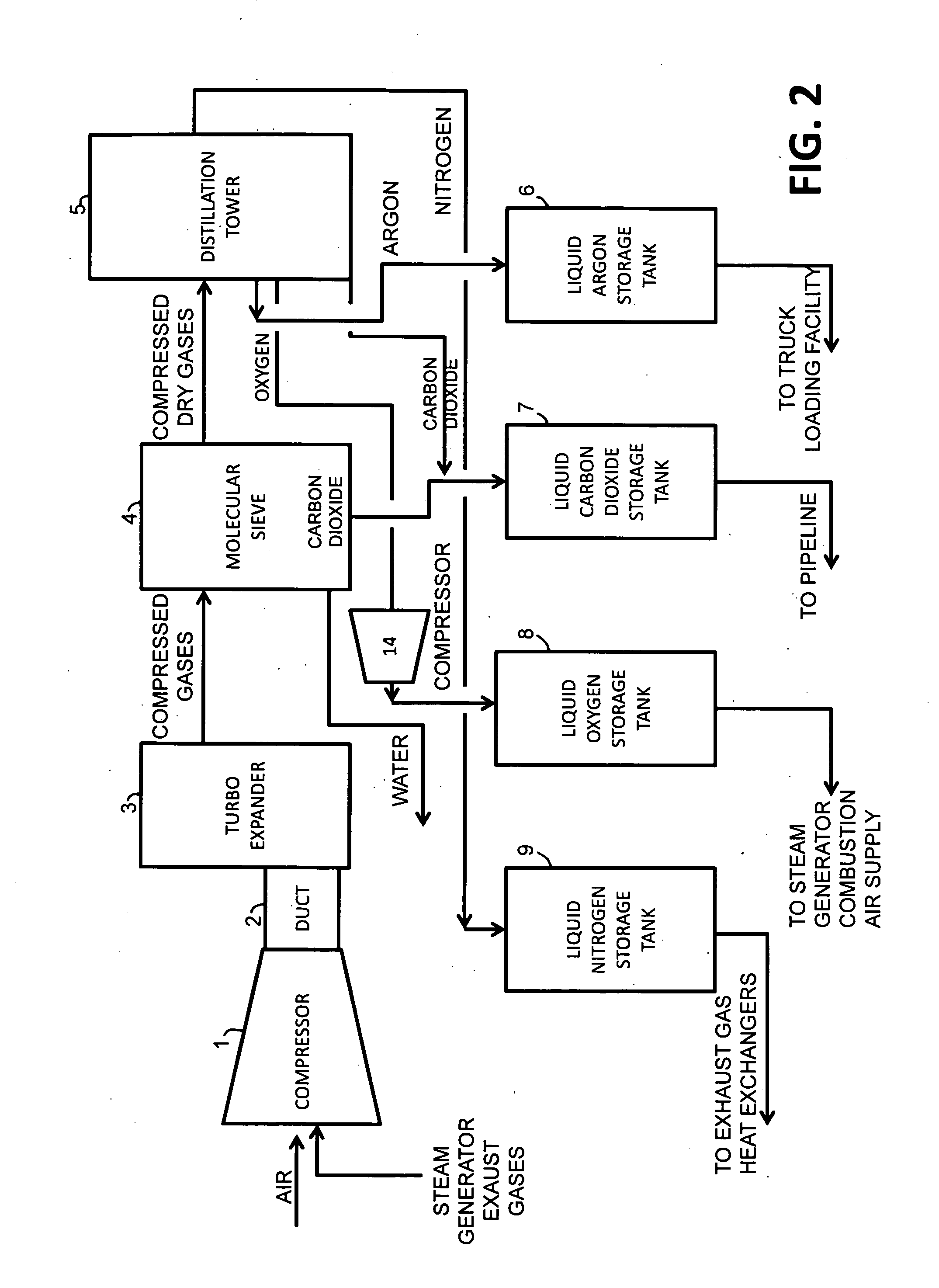

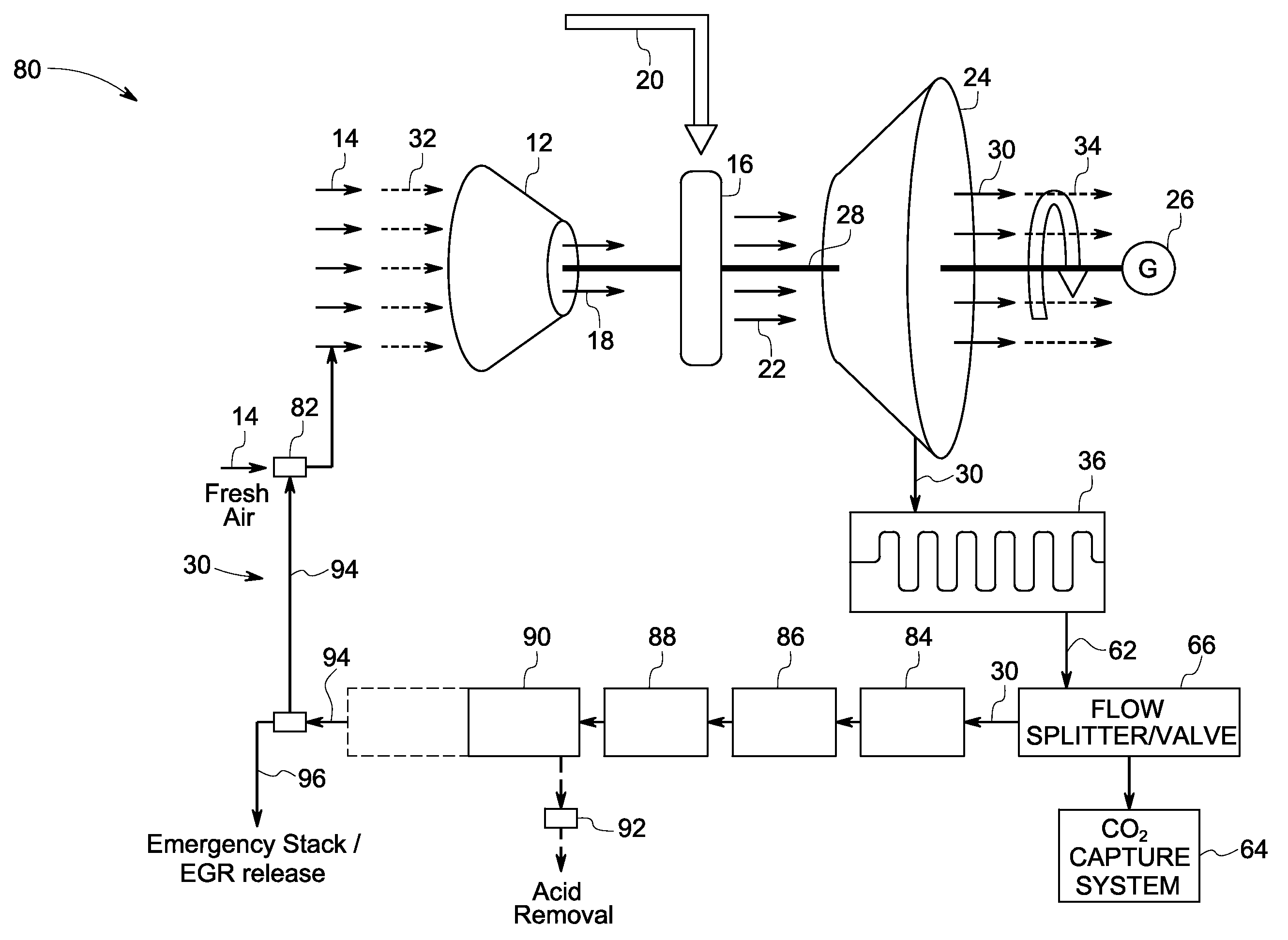

Power plant with emissions recovery

InactiveUS20100018218A1Reduce deliveryEnvironment safetySolidificationLiquefactionParticulatesNitrogen gas

A power plant including an air separation unit (ASU) arranged to separate nitrogen, oxygen, carbon dioxide and argon from air and produce a stream of substantially pure liquid oxygen, nitrogen, carbon dioxide and argon; a steam generator, fired or unfired, arranged to combust a fuel, e.g., natural gas, liquefied natural gas, synthesis gas, coal, petroleum coke, biomass, municipal solid waste or any other gaseous, liquid or solid fuel in the presence of air and a quantity of substantially pure oxygen gas to produce an exhaust gas comprising water, carbon dioxide, carbon monoxide, nitrogen oxides, nitrogen, sulfur oxides and other trace gases, and a steam-turbine-generator to produce electricity, a primary gas heat exchanger unit for particulate / acid gas / moisture removal and a secondary heat exchanger arranged to cool the remainder of the exhaust gases from the steam generator. Exhaust gases are liquefied in the ASU thereby recovering carbon dioxide, nitrogen oxides, nitrogen, sulfur oxides, oxygen, and all other trace gases from the steam generator exhaust gas stream. The cooled gases are liquefied in the ASU and separated for sale or re-use in the power plant. Carbon dioxide liquid is transported from the plant for use in enhanced oil recovery or for other commercial use. Carbon dioxide removal is accomplished in the ASU by cryogenic separation of the gases, after directing the stream of liquid nitrogen from the air separation unit to the exhaust gas heat exchanger units to cool all of the exhaust gases including carbon dioxide, carbon monoxide, nitrogen oxides, nitrogen, oxygen, sulfur oxides, and other trace gases.

Owner:TRIENCON SERVICES

Low Depth Telescoping Downdraft Ventilator

ActiveUS20080029081A1Accuracy in removalEasy to controlCombination devicesLiquid degasificationElectrical resistance and conductanceElectronic controller

A low depth telescoping downdraft ventilator controlled by an electronic controller providing a precisely controlled and efficient way of removing gases and fumes is disclosed. The low depth telescoping downdraft ventilator has the ability to fit behind a built-in oven placed below a cook top unit. The telescoping downdraft ventilator has an almost infinitely selectable range of heights above a cook top with a built in oven. The ventilator collects and draws in exhaust fumes and smoke, filters it and re-circulates or expels it either outdoors or indoors. The inner member of the telescoping ventilator may house the exhaust fans and may move up or down without the use of mechanical switches for elevation detection and stopping. The ventilator may have sensors to detect temperatures, filter change need, fan speeds, telescoping stop points, energy consumption, resistance and voltage, enabling programmable set point operation.

Owner:HAIER US APPLIANCE SOLUTIONS INC D B A GE APPLIANCES

Low emission turbine system and method

InactiveUS20090218821A1Emission reductionGas turbine plantsMechanical energy handlingElectricityCombustor

A turbine system is provided. The turbine system includes a compressor configured to compress ambient air and a combustor configured to receive compressed air from the compressor, and to combust a fuel stream to generate an exhaust gas. The turbine system also includes a turbine for receiving the exhaust gas from the combustor to generate electricity; wherein a first portion of the exhaust gas is mixed with the ambient air to form a low-oxygen air stream, and wherein the low-oxygen air stream is compressed using the compressor, and is directed to the combustor for combusting the fuel stream to generate a low-NOx exhaust gas.

Owner:GENERAL ELECTRIC CO

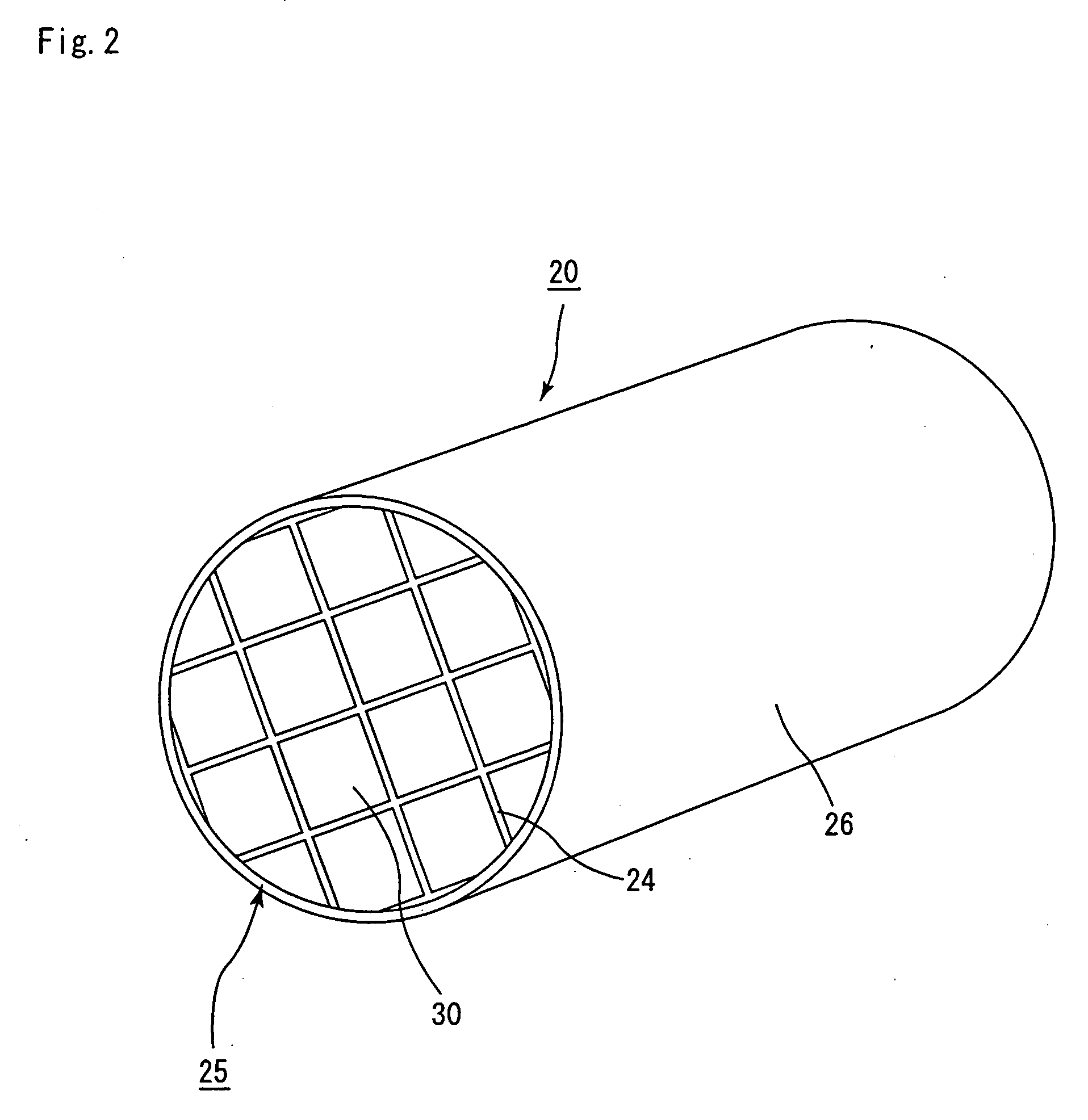

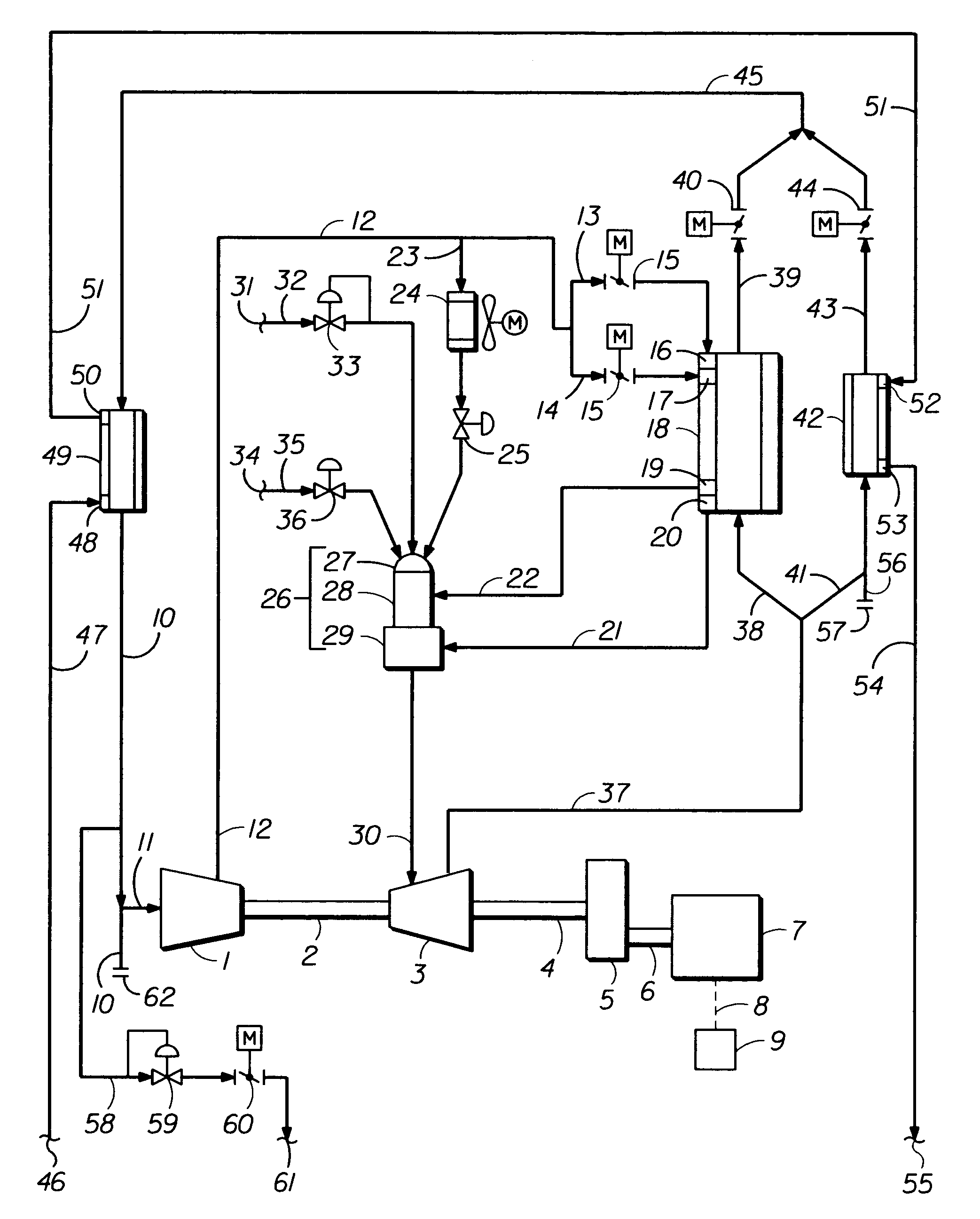

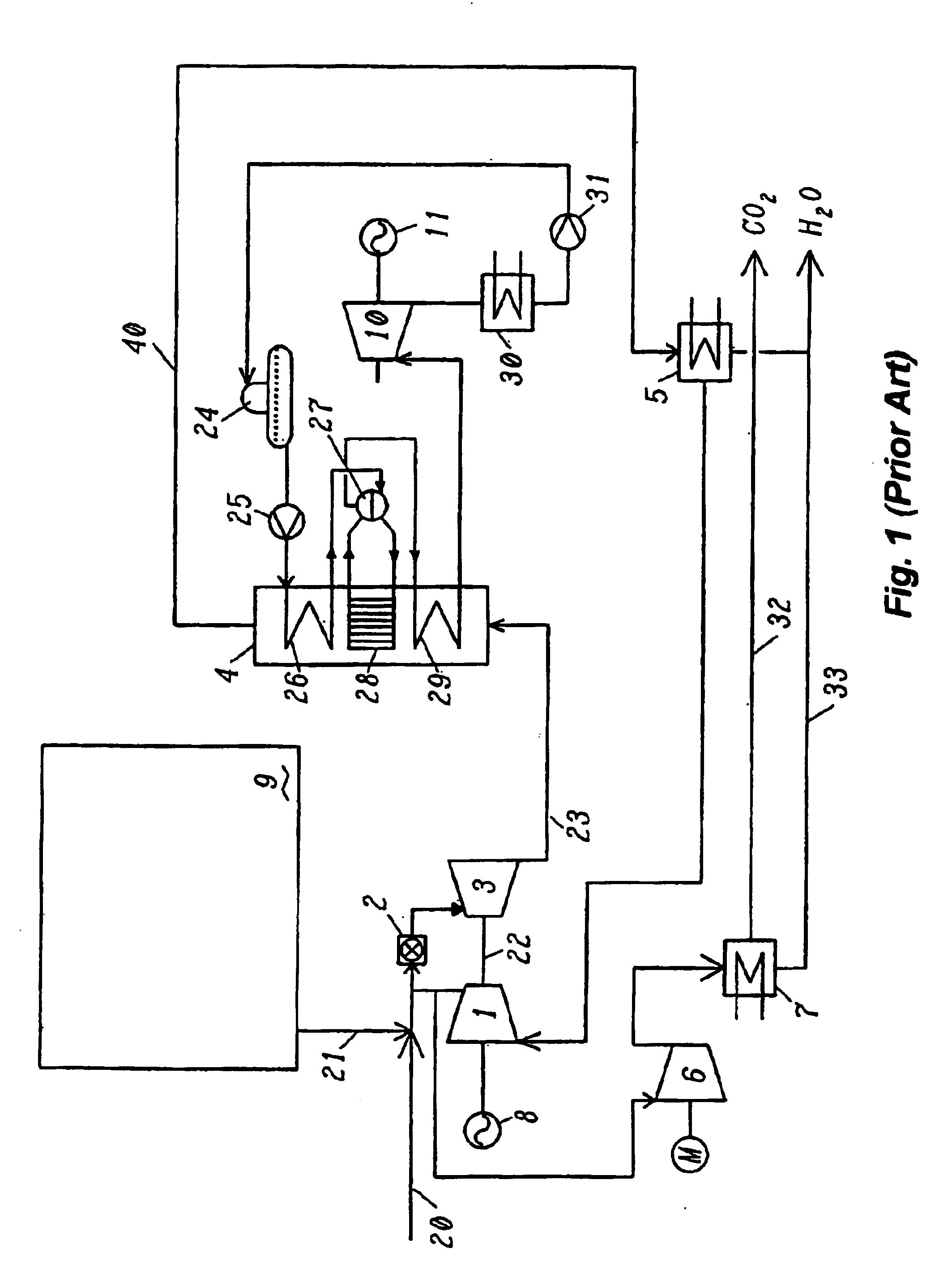

Methods and apparatus for starting up emission-free gas-turbine power stations

InactiveUS6945052B2Large capacityGas turbine plantsIndirect carbon-dioxide mitigationPower stationCombustion chamber

In a power generation plant having at least one gas turbine cycle with heat-recovery boiler (4) and at least one steam turbine cycle operated via the heat-recovery boiler (4), the gas turbine cycle being designed to be semi-closed and essentially free of emissions and essentially comprising a compressor (1), a combustion chamber (2) arranged downstream of the compressor (1), a gas turbine (3) arranged downstream of the combustion chamber (2), a heat-recovery boiler (4) arranged downstream of the gas turbine (3), and at least one generator (8) coupled to the gas turbine (3), modes of operation with the gas turbine cycle stopped and start-up using fresh air are made possible by first means (12) being arranged which alternatively or additionally allow hot gas to be fed into the hot-gas path (23) between gas turbine (3) and heat-recovery boiler (4), and by second means (15) being arranged which alternatively or additionally allow exhaust gas to be expelled from the exhaust-gas path (40) downstream of the heat-recovery boiler (4).

Owner:ANSALDO ENERGIA IP UK LTD

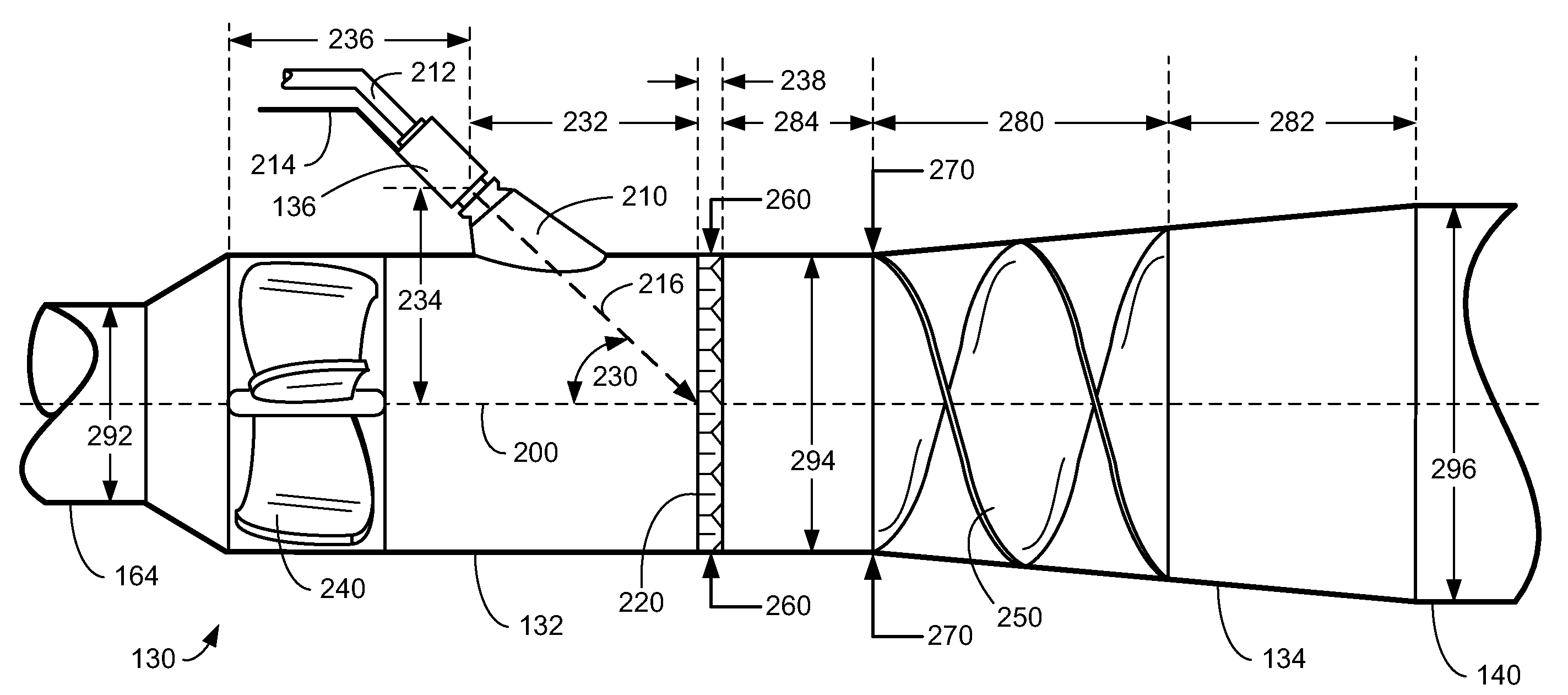

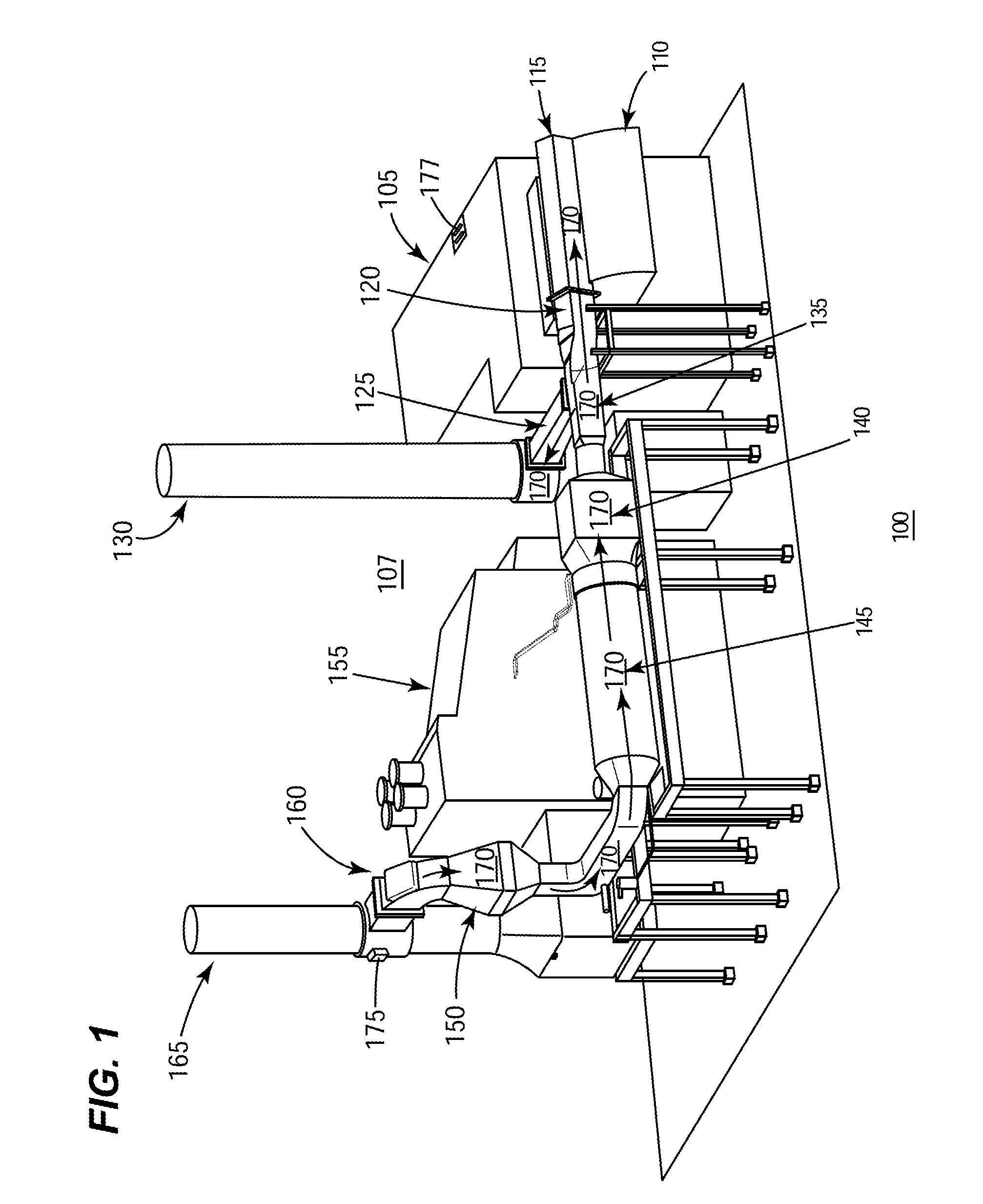

Approach for Delivering a Liquid Reductant into an Exhaust Flow of a Fuel Burning Engine

ActiveUS20090019843A1Extended driving distanceReduction in injector costInternal combustion piston enginesFlow mixersExhaust fumesInternal combustion engine

An exhaust system for an internal combustion engine for a vehicle is provided. The system comprises an exhaust passage for transporting exhaust gases from the engine; an injector coupled to a wall of the exhaust passage, said injector including an injection axis that is angled relative to a longitudinal axis of a mixing region of the exhaust passage; and a first mixing device arranged within the exhaust passage downstream of the injector within the mixing region, said first mixing device including a plurality of flaps, wherein said plurality of flaps are inclined relative to the longitudinal axis; a second mixing device arranged within the exhaust passage downstream of the first mixing device; wherein the injection axis of the injector intersects the first mixing device.

Owner:FORD GLOBAL TECH LLC

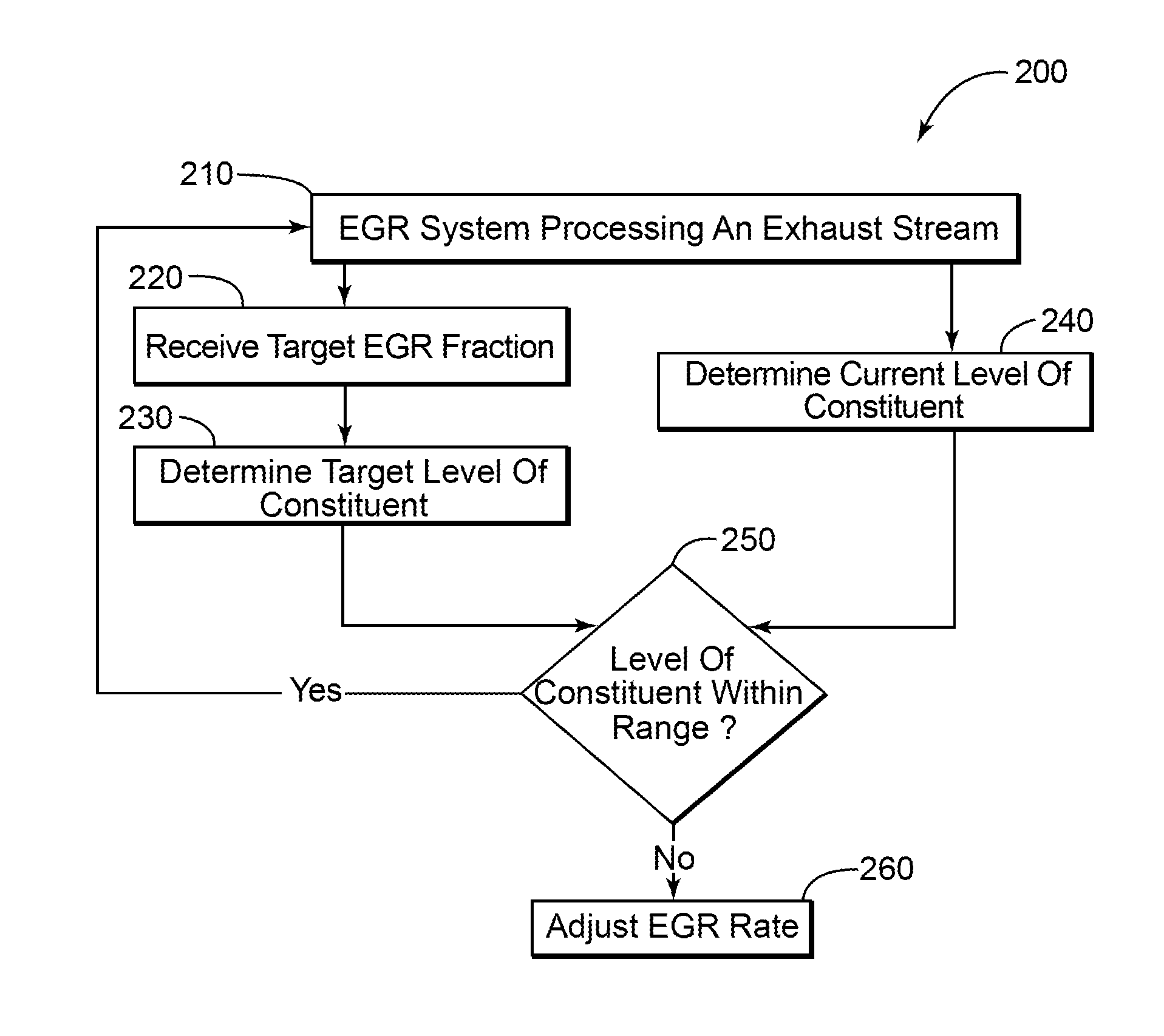

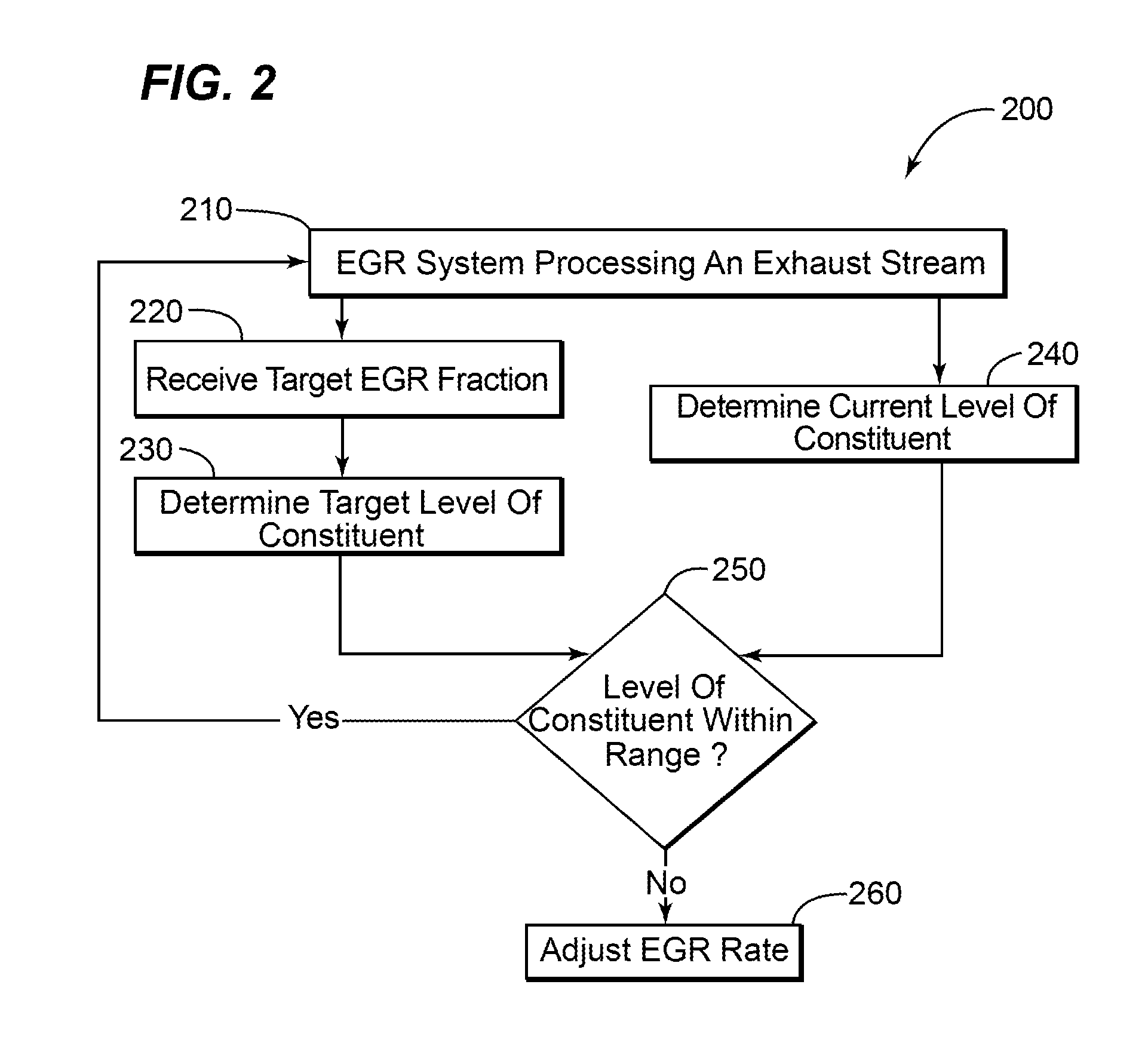

Method and system for controlling a flowrate of a recirculated exhaust gas

ActiveUS7536252B1High trafficAnalogue computers for vehiclesNon-fuel substance addition to fuelStream flowExhaust fumes

A method and system for controlling an exhaust gas recirculation (EGR) system is provided. The EGR system recirculates a portion of an exhaust through an inlet portion of the turbomachine. The EGR system reduces the level of harmful constituents within the exhaust before the recirculation occurs.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com