Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

587 results about "Hydrogen bromide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogen bromide is the diatomic molecule with the formula HBr. It is a colorless compound and a hydrogen halide. Hydrobromic acid is a solution of HBr in water. Both the anhydrous and aqueous solutions of HBr are common reagents in the preparation of bromide compounds.

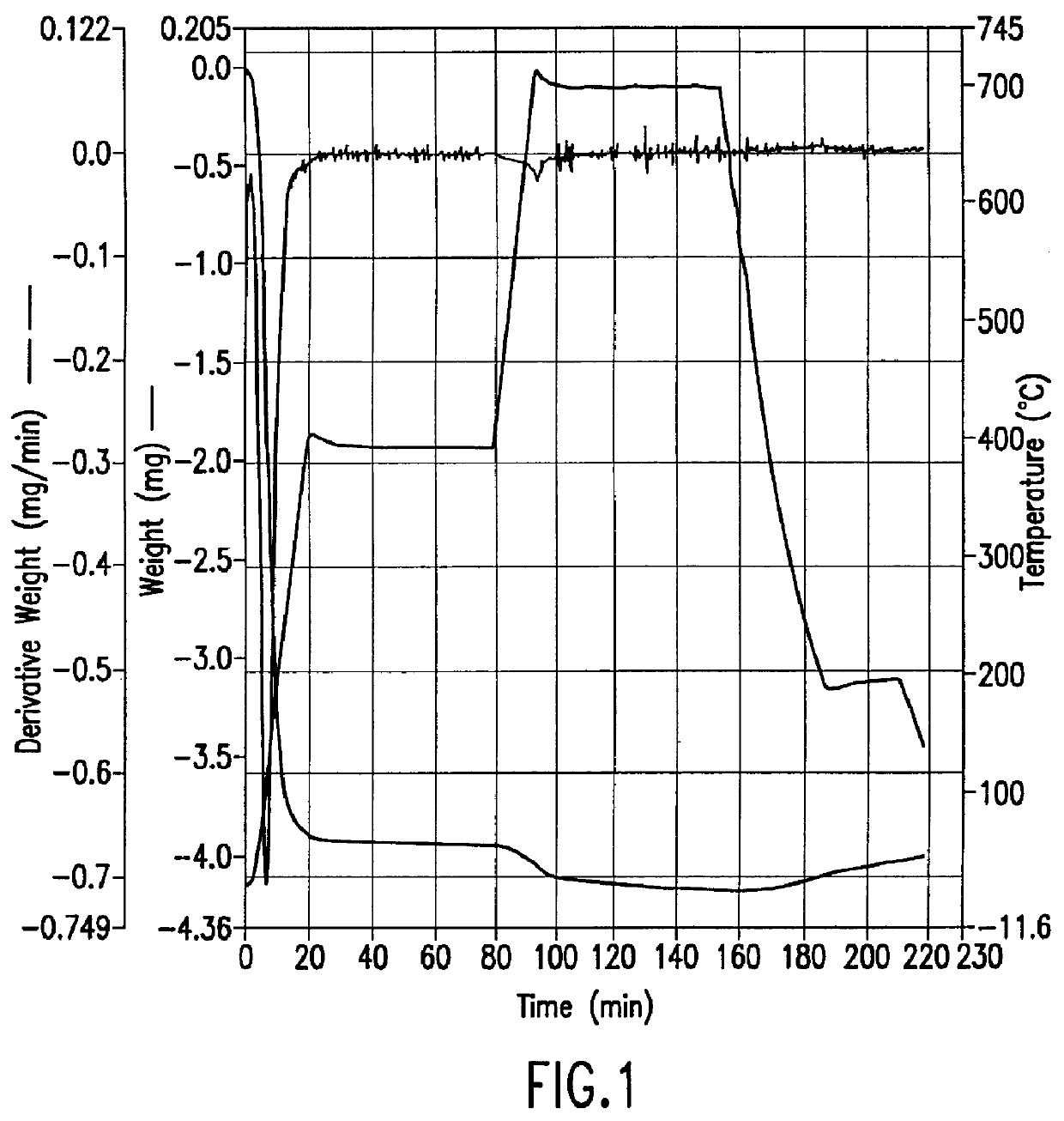

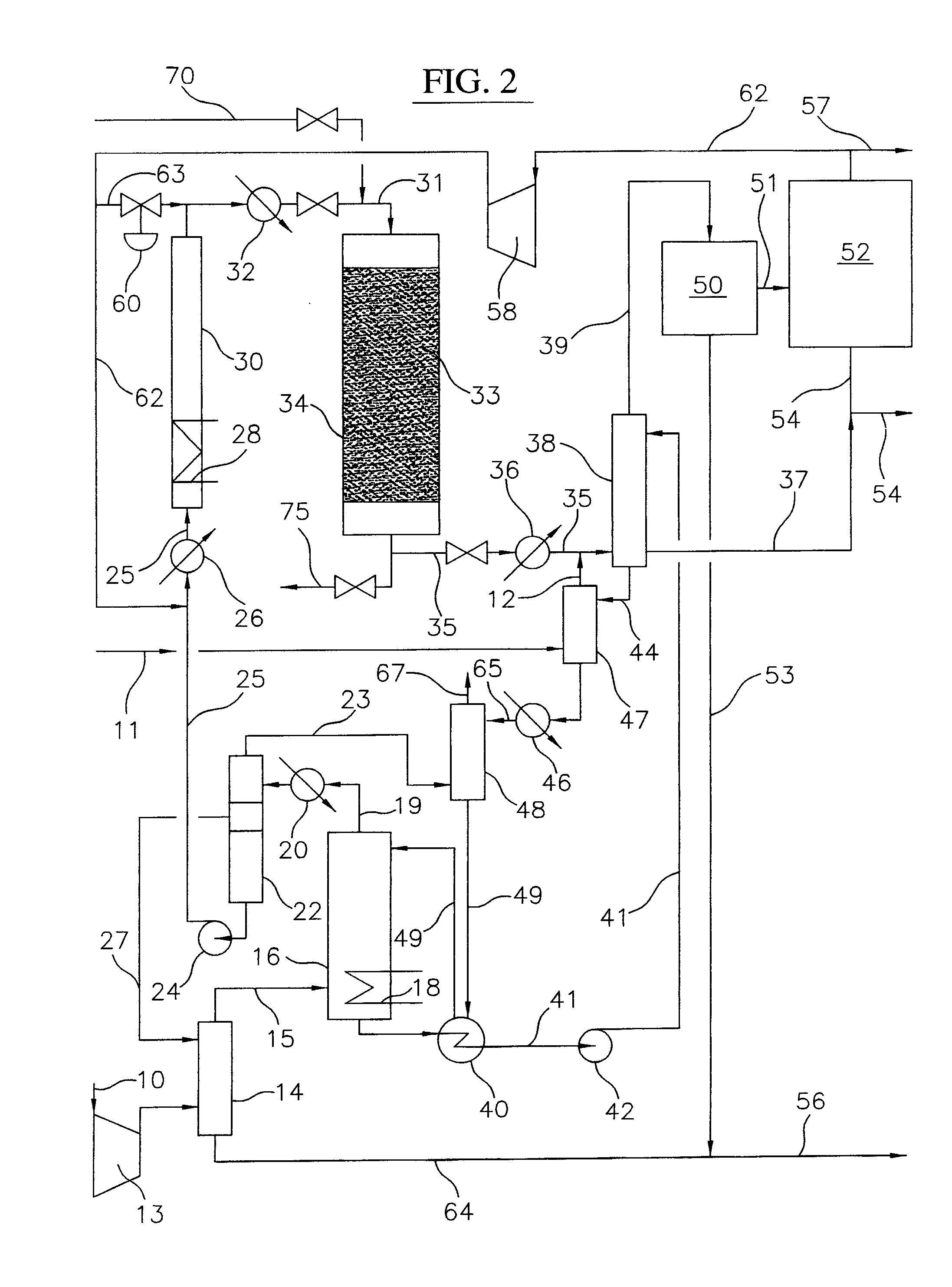

Sorbents and methods for the removal of mercury from combustion gases

InactiveUS6953494B2Improve abilitiesUnified processingGas treatmentOther chemical processesSufficient timeCombustion

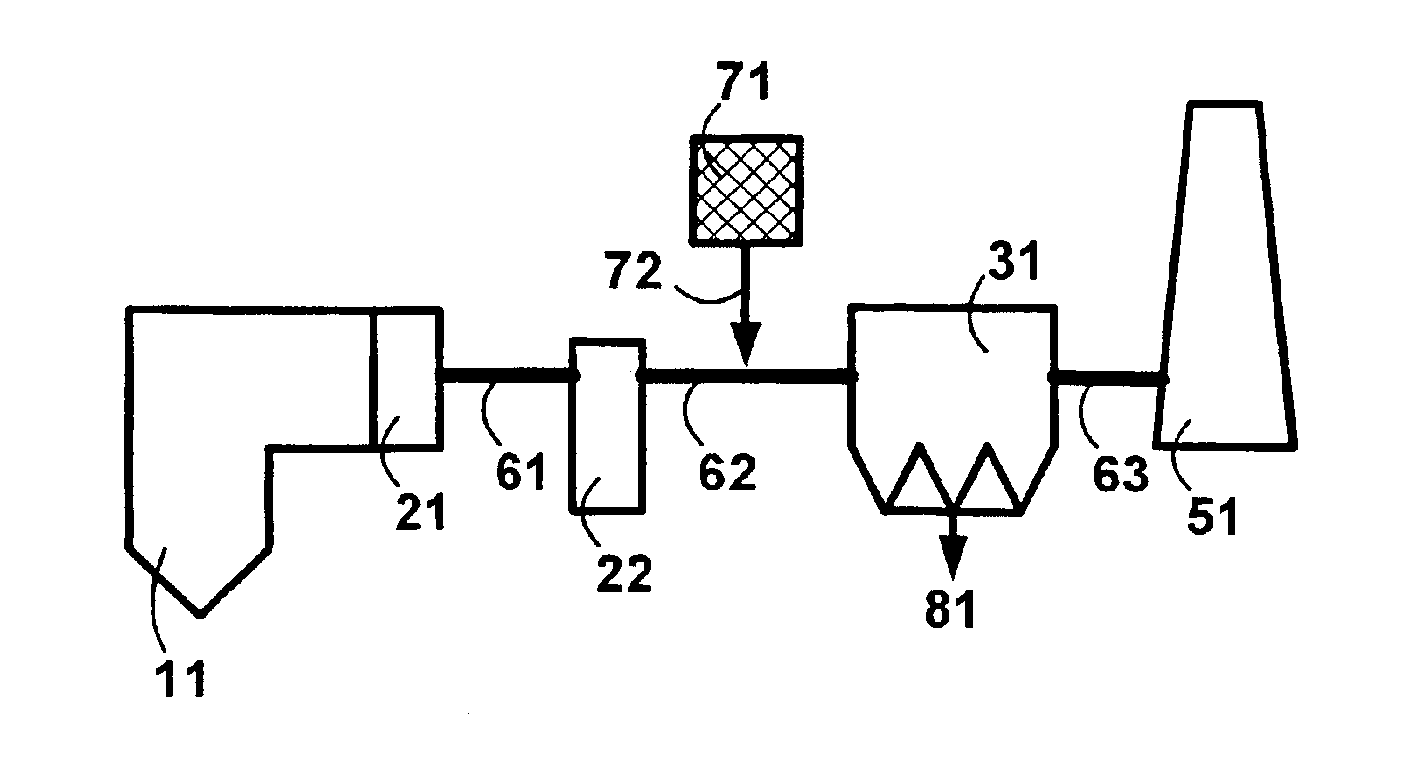

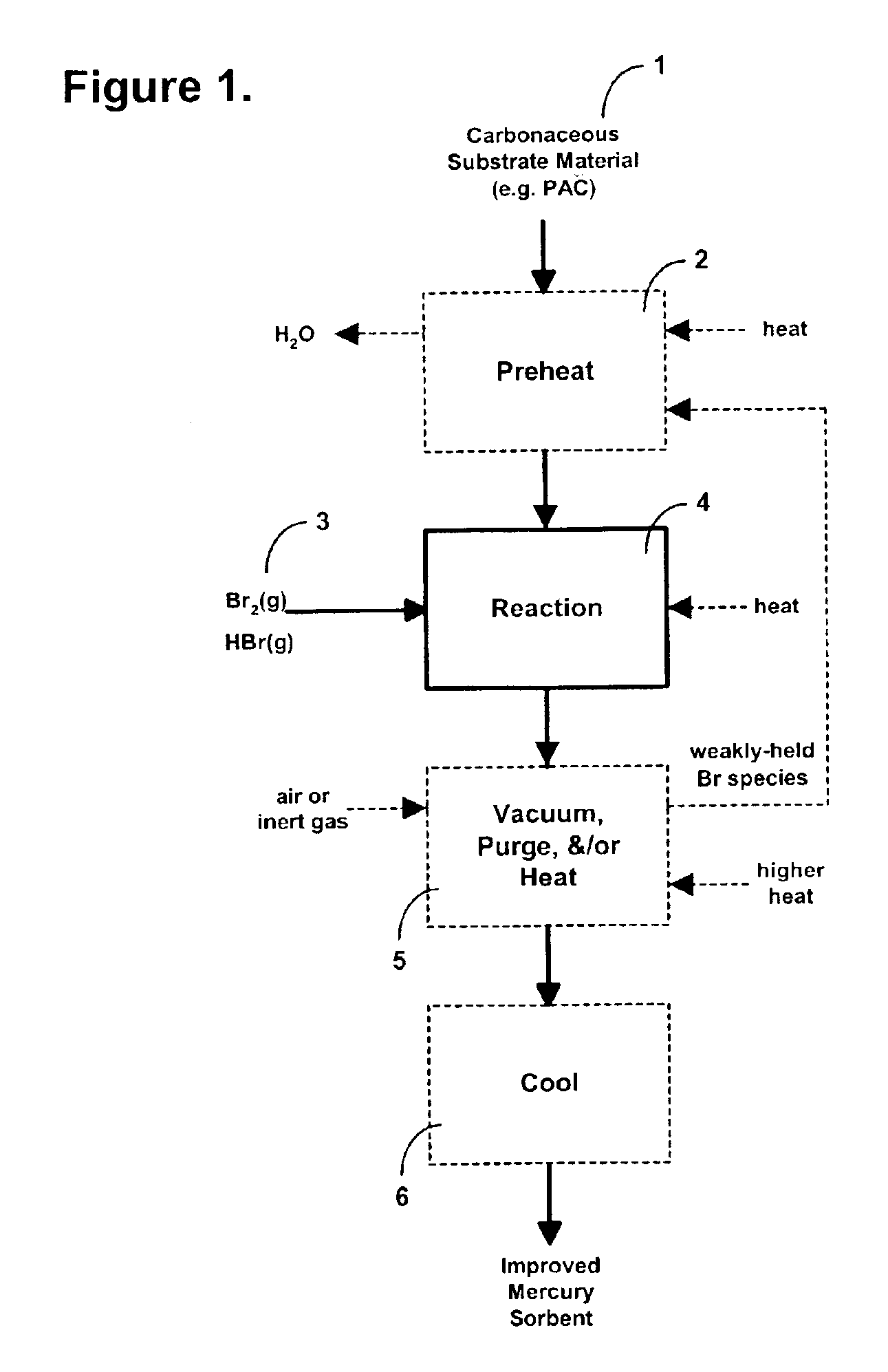

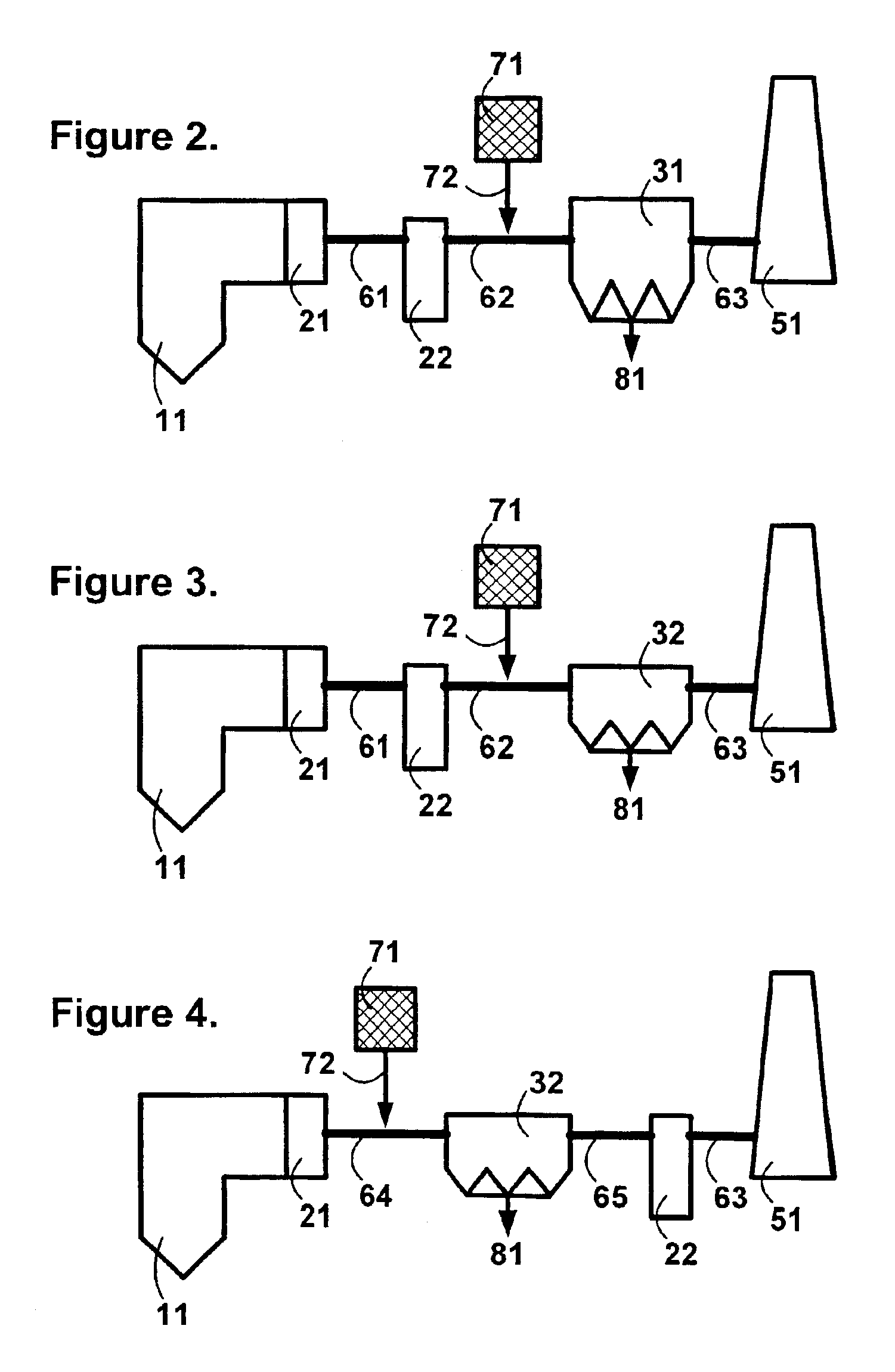

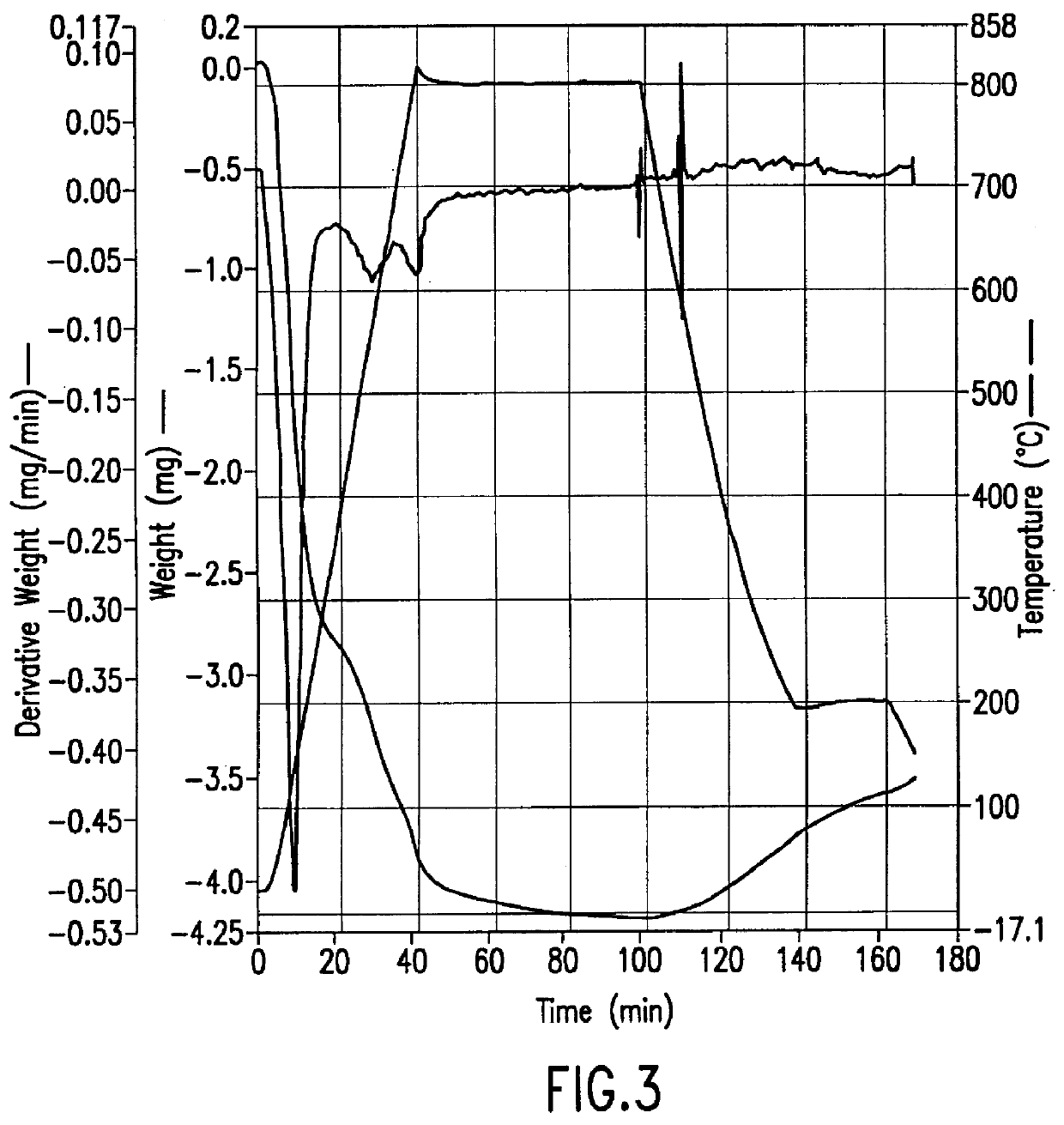

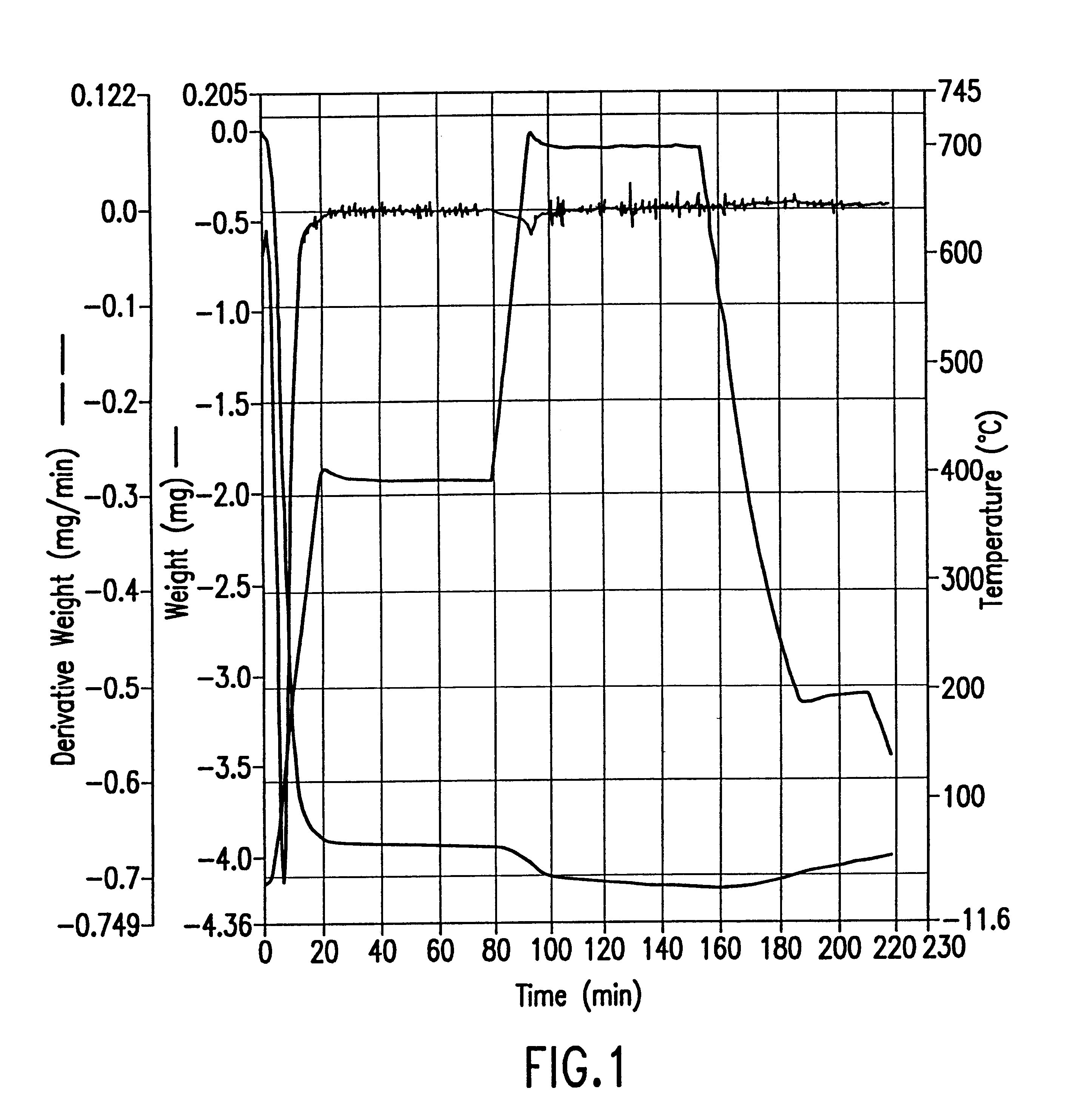

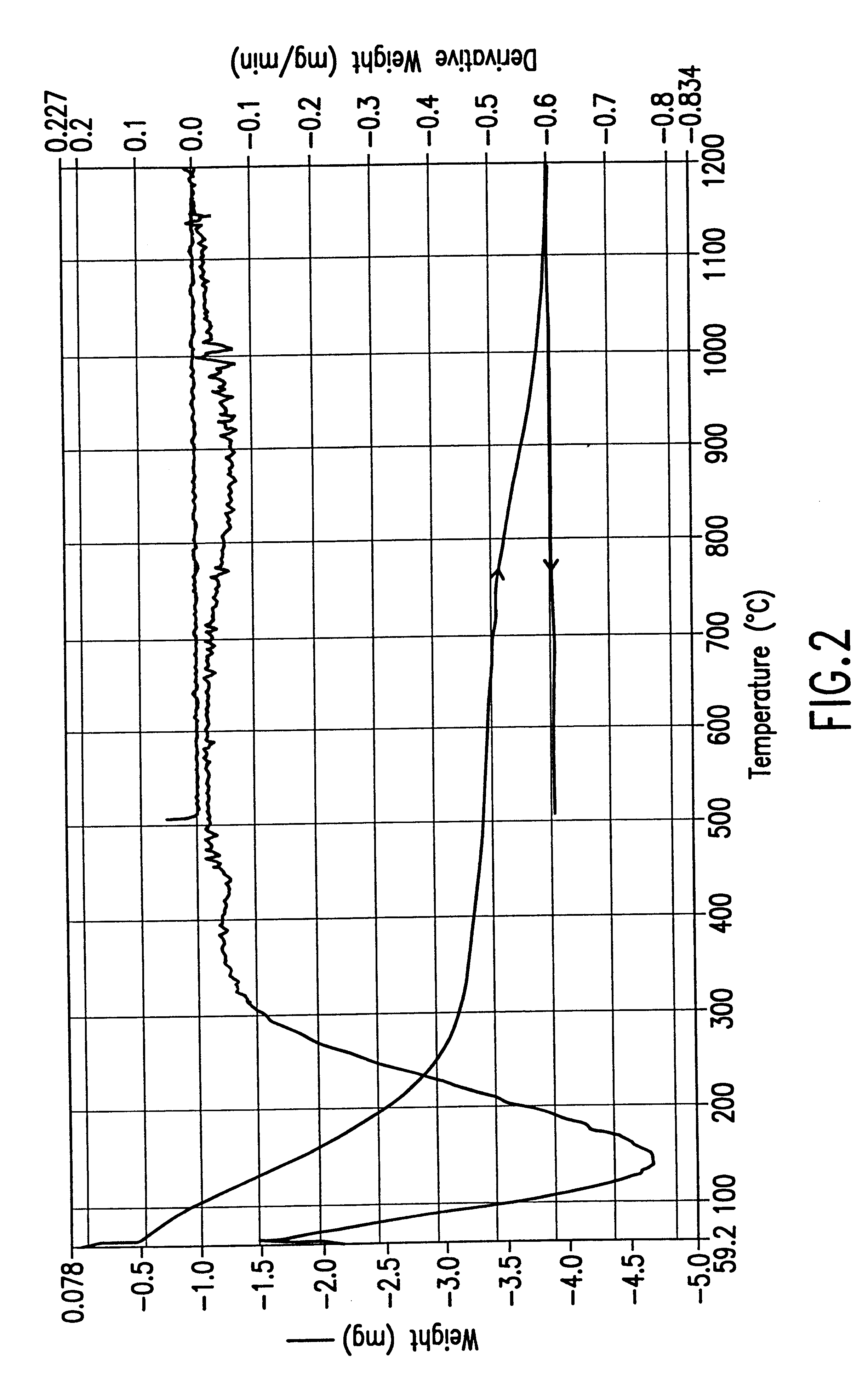

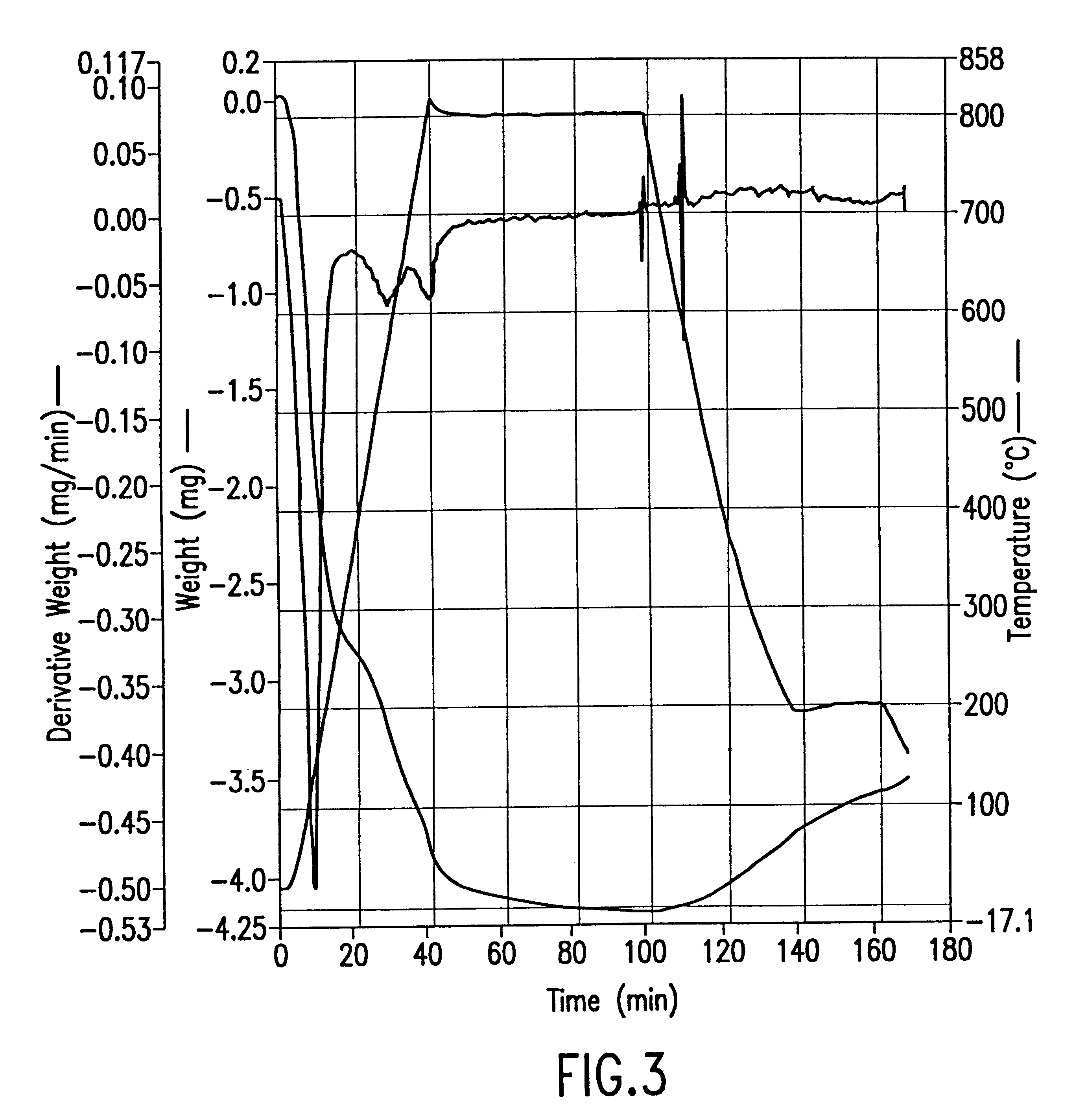

A method for removing mercury and mercury-containing compounds from a combustion gas in an exhaust gas system has the steps of providing a mercury sorbent; injecting the mercury sorbent into a stream of the mercury-containing combustion gas for a sufficient time to allow at least an effective amount of the mercury and mercury-containing compounds in the combustion gas to adsorb onto the mercury sorbent, and collecting and removing the mercury sorbent from the combustion gas stream. The mercury sorbent is prepared by treating a carbonaceous substrate with an effective amount of a bromine-containing gas, especially one containing elemental bromine or hydrogen bromide, for a time sufficient to increase the ability of the carbonaceous substrate to adsorb mercury and mercury-containing compounds. The points of injecting and collecting and removing the mercury sorbent may be varied, depending upon the exact configuration of the exhaust gas system.

Owner:SORBENT TECH +1

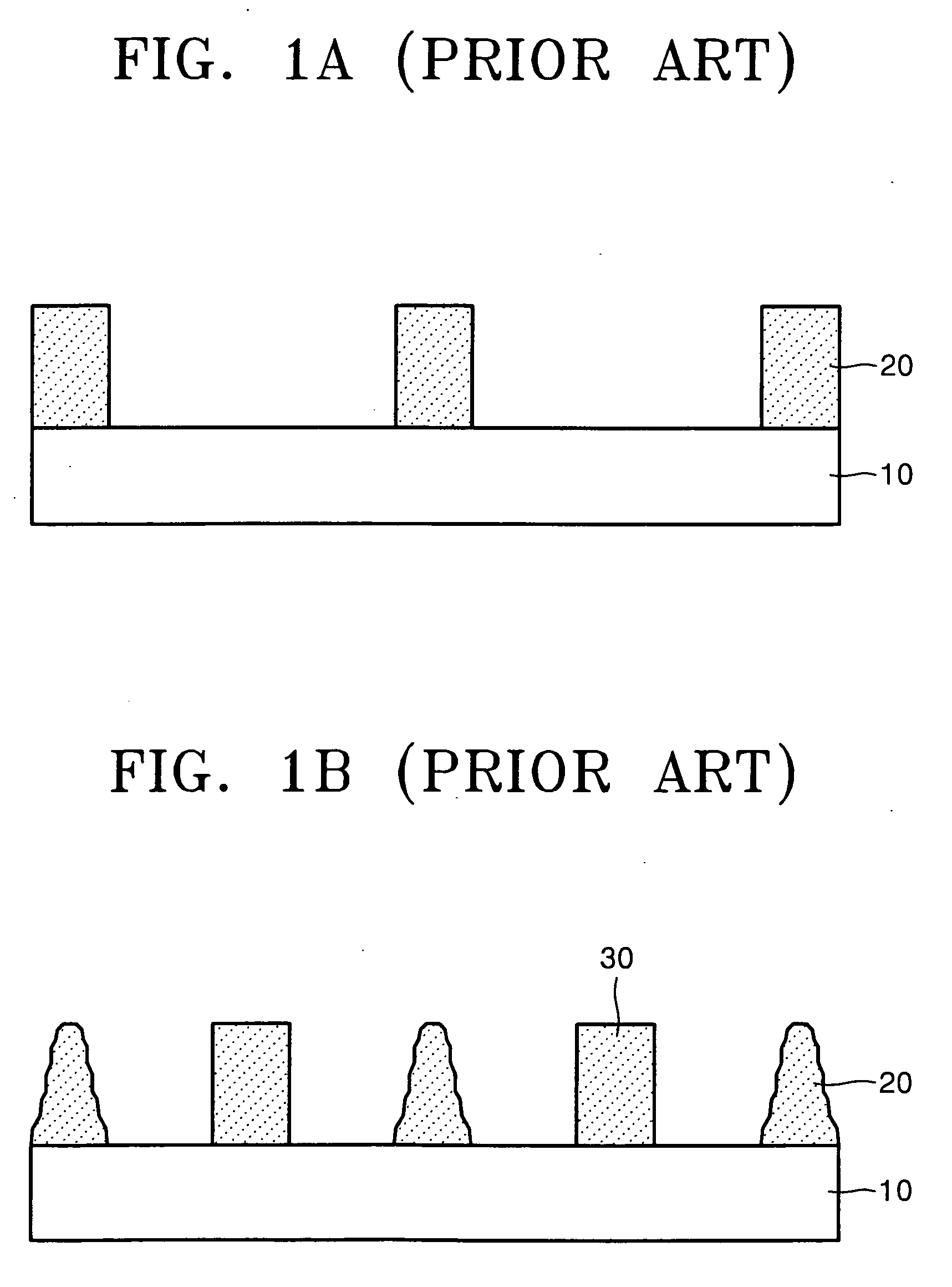

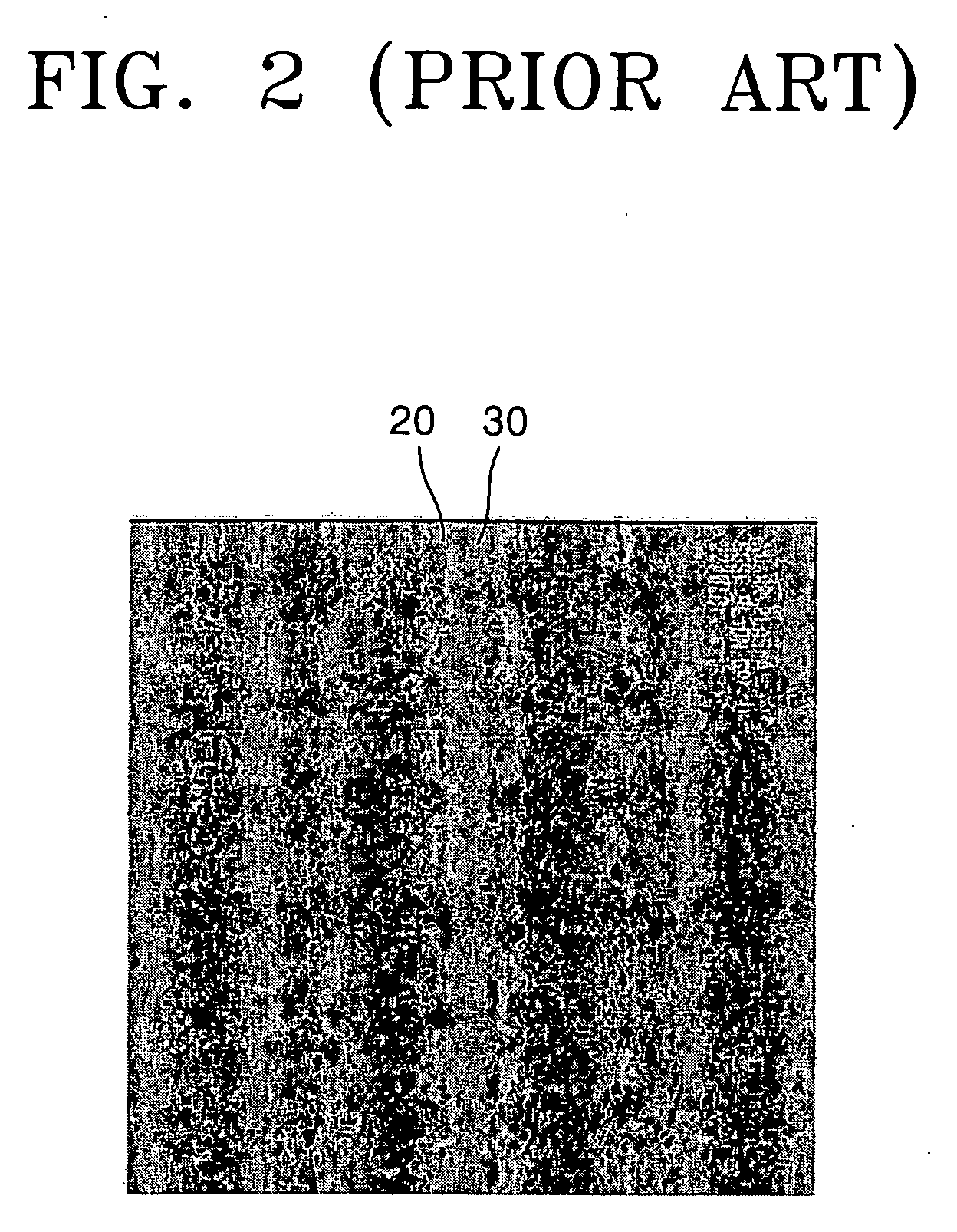

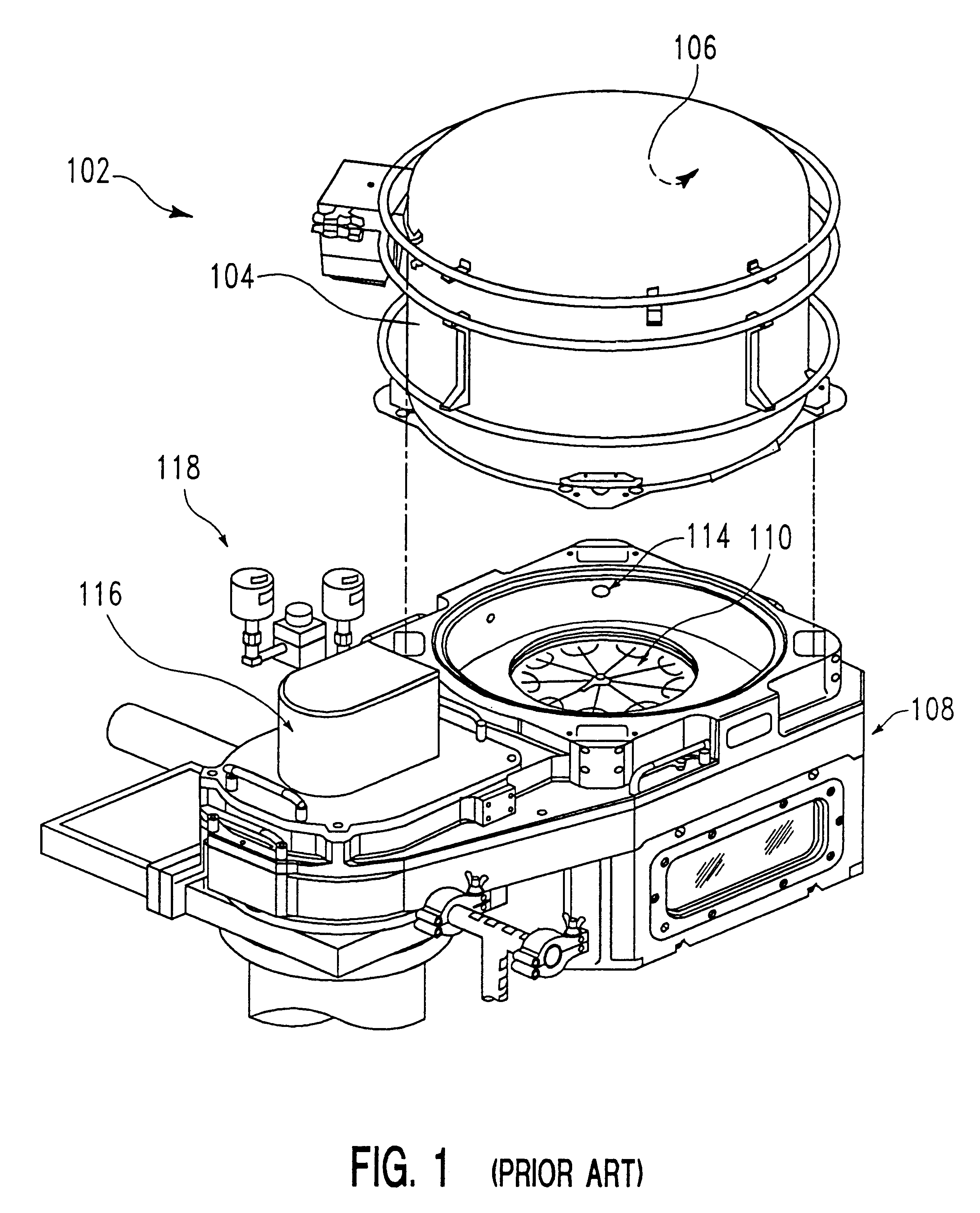

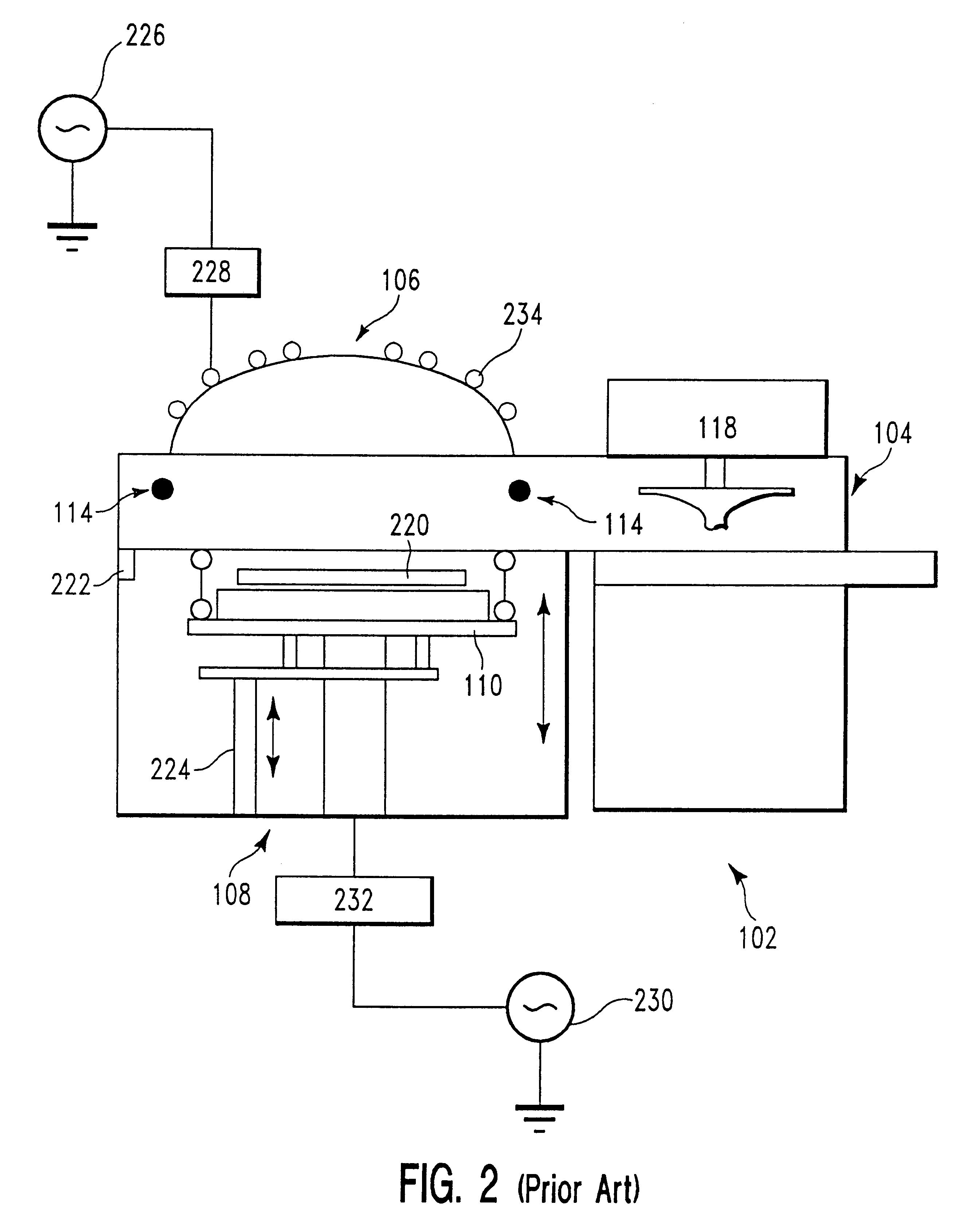

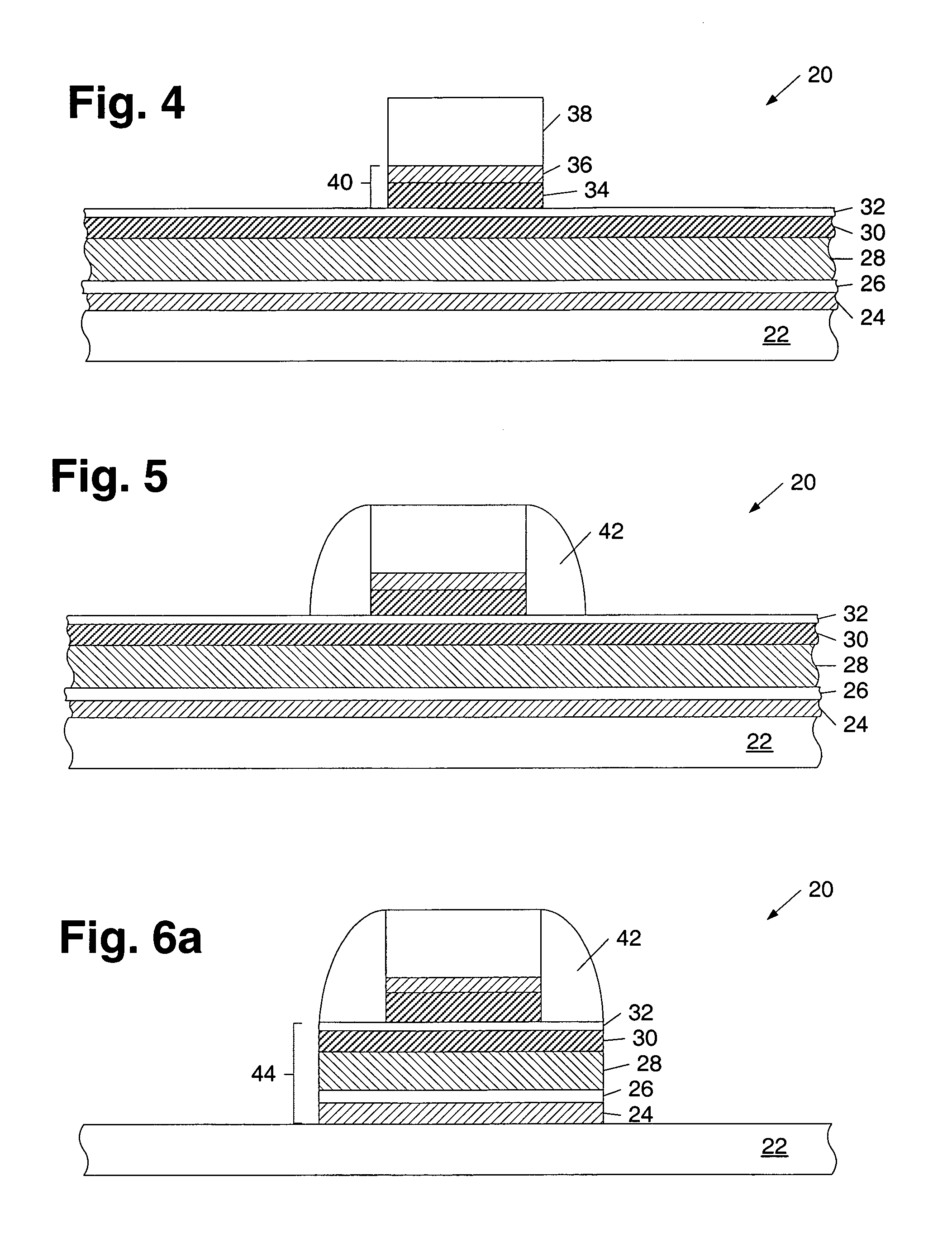

Method of forming fine pitch photoresist patterns using double patterning technique

InactiveUS20060228895A1Electric circuit arrangementsLighting heating/cooling arrangementsHydrogen bromidePhotoresist

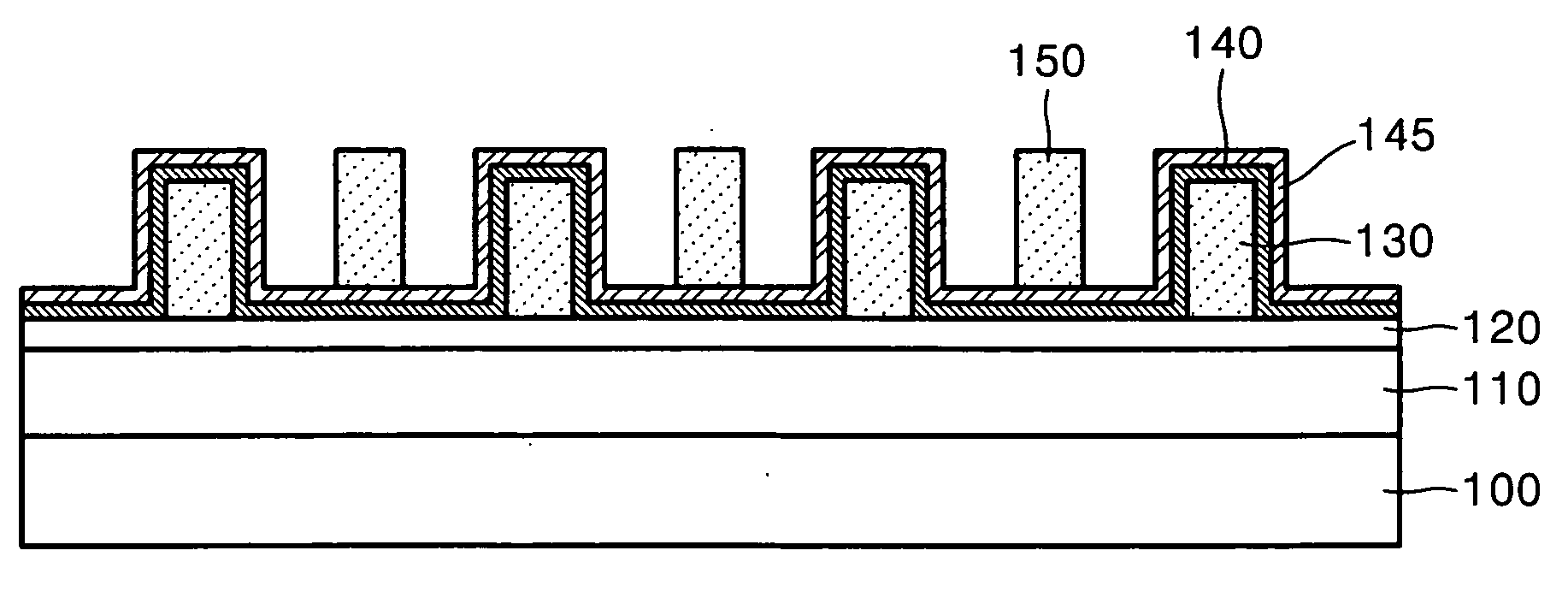

A method of forming a photoresist pattern comprises providing a semiconductor substrate on which a layer to be etched is formed. The method further comprises forming a first photoresist pattern on the layer to be etched, processing the first photoresist pattern with hydrogen bromide (HBr) plasma, and forming a second photoresist pattern on the semiconductor substrate between the first photoresist patterns

Owner:SAMSUNG ELECTRONICS CO LTD

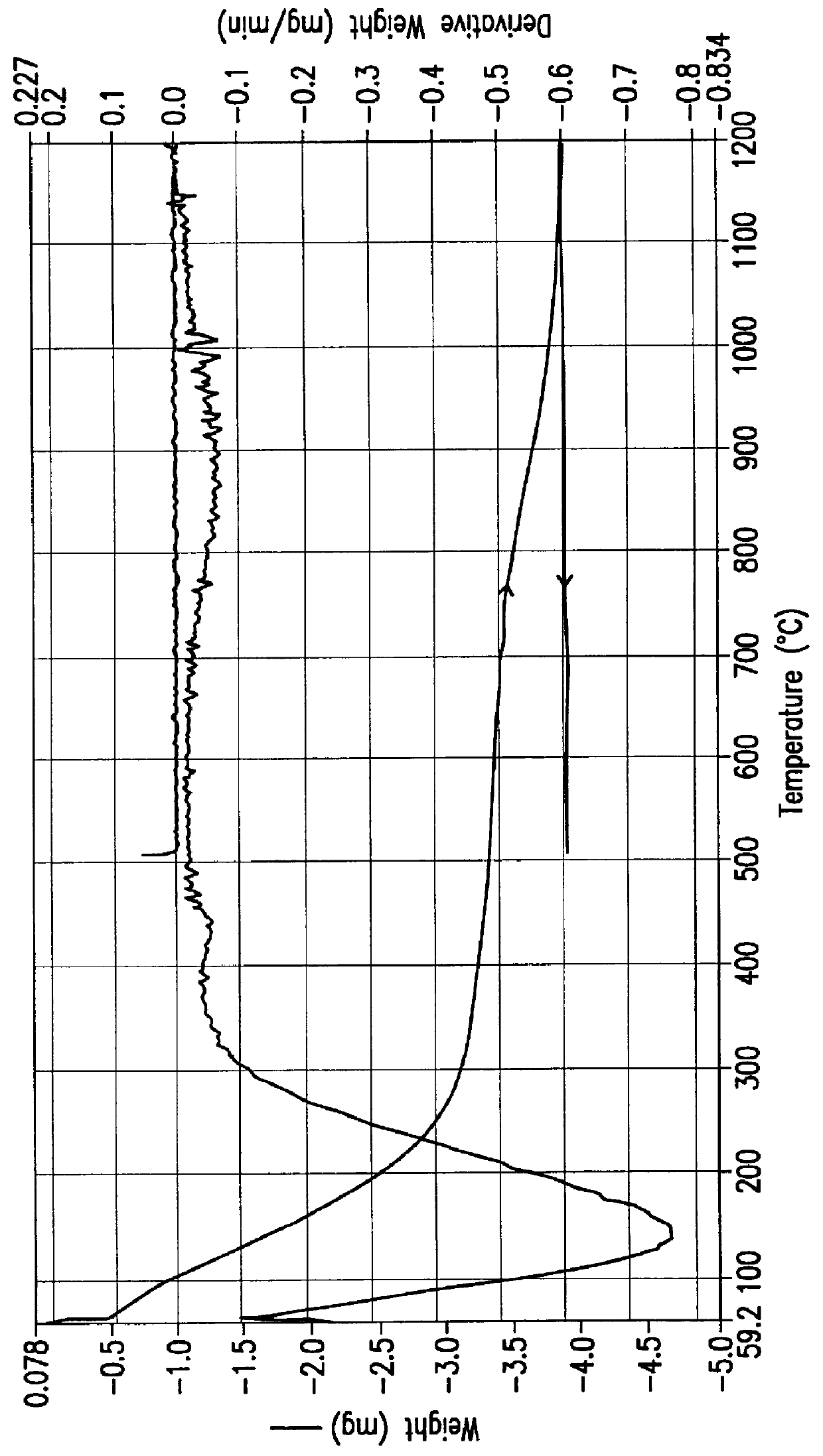

Methods for removal of water from gases using superheated zeolites

InactiveUS6110258AHigh silica-to-alumina ratioReduce metal contentGas treatmentMolecular sieve catalystsBoiling pointSilicon dioxide

A method for removing trace moisture from a gas is disclosed. The method involves heating a zeolite having a high silica-to-alumina ratio to about 400 DEG C. to remove physically absorbed water from the zeolite, followed by heating the zeolite to a temperature in excess of 650 DEG C., to form a superheated zeolite. Heating to temperatures of 650 DEG C. or above is believed to cause dehydroxylation of the zeolite. A method for the preparation of a dehydroxylated zeolite is also disclosed. The superheated zeolite is contacted with the gas, thereby adsorbing water from the gas. A dehydroxylated zeolite for removing trace moisture from a gas wherein the zeolite has a high silica-to-alumina ratio and a low level of metallic impurities is also disclosed. The zeolite and methods of the invention are particularly useful for removing trace water from acid gases such as hydrogen chloride and hydrogen bromide.

Owner:MATHESON TRI GAS INC

Methods for removal of impurity metals from gases using low metal zeolites

InactiveUS6395070B1High silica-to-alumina ratioReduce metal contentGas treatmentMolecular sieve catalystsBoiling pointTrace metal

A method for removing trace moisture from a gas is disclosed. The method involves heating a zeolite having a high silica-to-alumina ratio to about 400° C. to remove physically adsorbed water from the zeolite, followed by heating the zeolite to a temperature in excess of 650° C., to form a superheated zeolite. The superheated zeolite is contacted with the gas, thereby adsorbing water from the gas. A dehydroxylated zeolite for removing trace moisture from a gas wherein the zeolite has a high silica-to-alumina ratio and a low level of metallic impurities is also disclosed. A method for removing metallic impurities from a gas using the low metals zeolite is also disclosed. The zeolites and methods of the invention are particularly useful for removing trace water and trace metal impurities from acid gases such as hydrogen chloride and hydrogen bromide.

Owner:MATHESON TRI GAS INC

Method for manufacturing semiconductor device

InactiveUS20060205129A1Avoid changeAvoid low process precisionSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialInductively coupled plasma

In a gas containing a fluorine atom in the molecule, etching of a SiN film is performed isotropically; therefore, the width of a sidewall gets smaller and it is difficult to widen the width of an LDD region. A silicon nitride film is formed over a gate electrode, a hydrogen bromide is mainly used as an etching gas, the silicon nitride film only over the gate electrode and the surface of a substrate are removed by an etching method such as ICP (Inductively Coupled Plasma), and the silicon nitride film is simultaneously left only on the side surface part of the gate electrode.

Owner:SEMICON ENERGY LAB CO LTD

Metal mask etching of silicon

The present disclosure provides a method for etching trenches, contact vias, or similar features to a depth of 100 mum and greater while permitting control of the etch profile (the shape of the sidewalls surrounding the etched opening). The method requires the use of a metal-comprising masking material in combination with a fluorine-comprising plasma etchant. The byproduct produced by a combination of the metal with reactive fluorine species must be essentially non-volatile under etch process conditions, and sufficiently non-corrosive to features on the substrate being etched, that the substrate remains unharmed by the etch process. Although aluminum is a preferred metal for the metal-comprising mask, other metals can be used for the masking material, so long as they produce an essentially non-volatile, non-corrosive etch byproduct under etch process conditions. By way of example, and not by way of limitation, metallic materials recommended for the mask include aluminum, cadmium, copper, chromium, gallium, indium, iron, magnesium, manganese, nickel, and combinations thereof. In particular, aluminum in combination with copper or magnesium is particularly useful, where the copper or magnesium content is less than about 8% by weight, and other constituents total less than about 2% by weight. The plasma feed gas includes at least one fluorine-containing compound such as nitrogen trifluoride (NF3), carbon tetrafluoride (CF4), and sulfur hexafluoride (SF6), by way of example and not by way of limitation. Oxygen (O2), or an oxygen-comprising compound, or hydrogen bromide (HBr), or a combination thereof may be added to the plasma feed gases to help provide a protective layer over etched sidewalls, assisting in profile control of the etched feature.

Owner:APPLIED MATERIALS INC

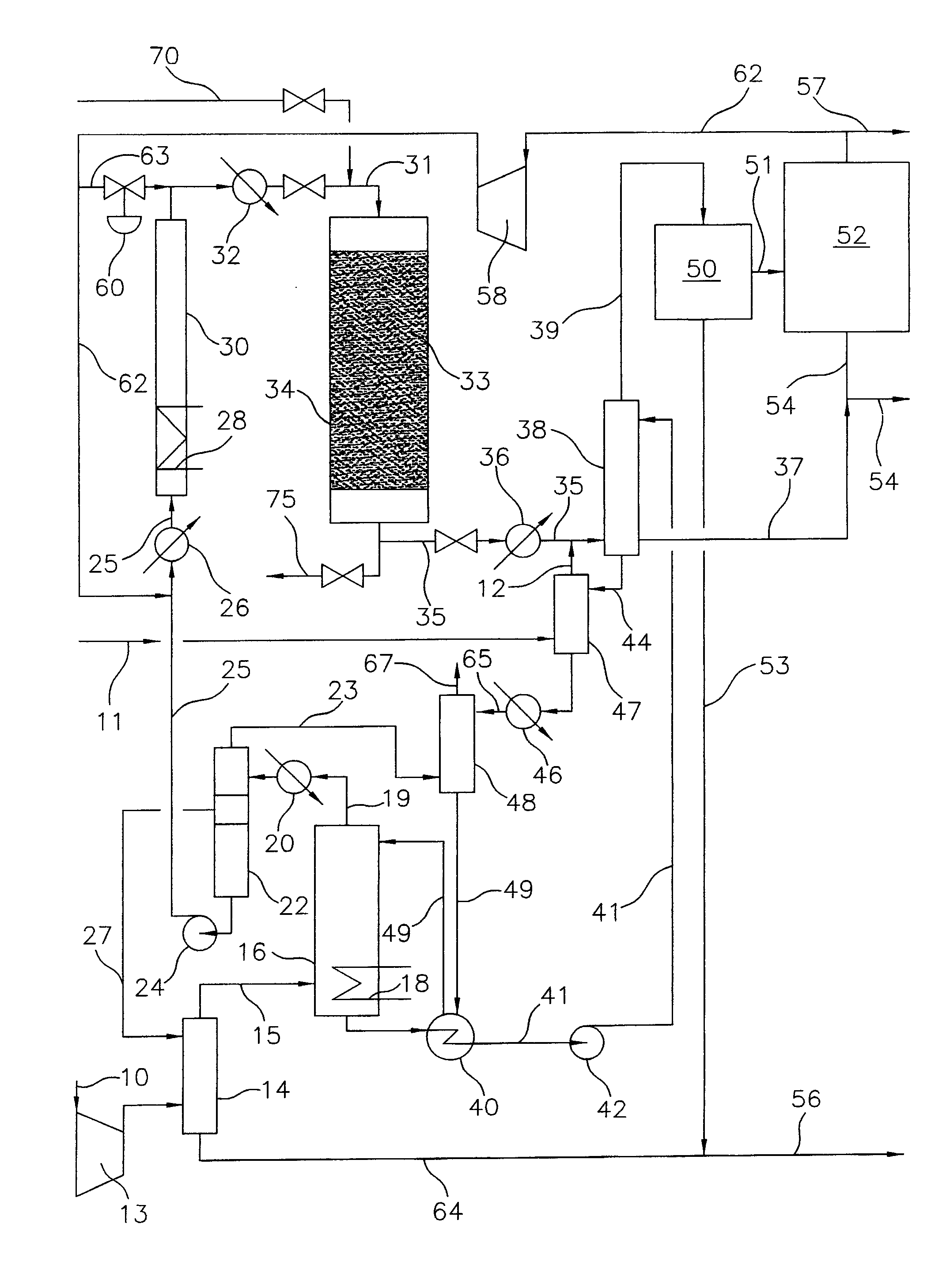

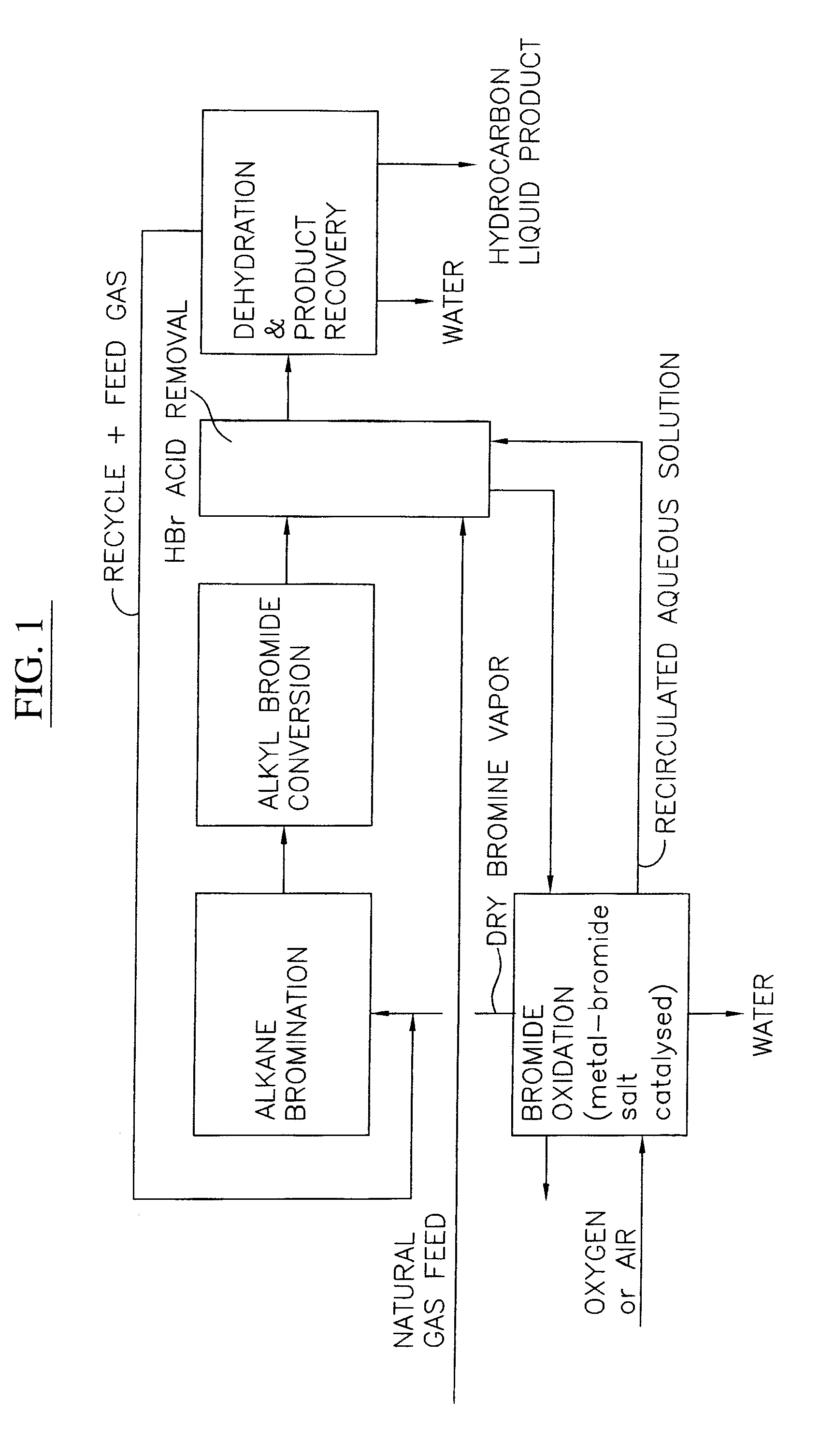

Processes for converting gaseous alkanes to liquid hydrocarbons

A process for converting gaseous alkanes to olefins, higher molecular weight hydrocarbons or mixtures thereof wherein a gaseous feed containing alkanes is thermally reacted with a dry bromine vapor to form alkyl bromides and hydrogen bromide. Poly-brominated alkanes present in the alkyl bromides are further reacted with methane over a suitable catalyst to form mono-brominated species. The mixture of alkyl bromides and hydrogen bromide is then reacted over a suitable catalyst at a temperature sufficient to form olefins, higher molecular weight hydrocarbons or mixtures thereof and hydrogen bromide. Various methods are disclosed to remove the hydrogen bromide from the higher molecular weight hydrocarbons, to generate bromine from the hydrogen bromide for use in the process, and to selectively form mono-brominated alkanes in the bromination step.

Owner:SULZER MANAGEMENT AG

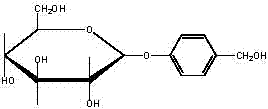

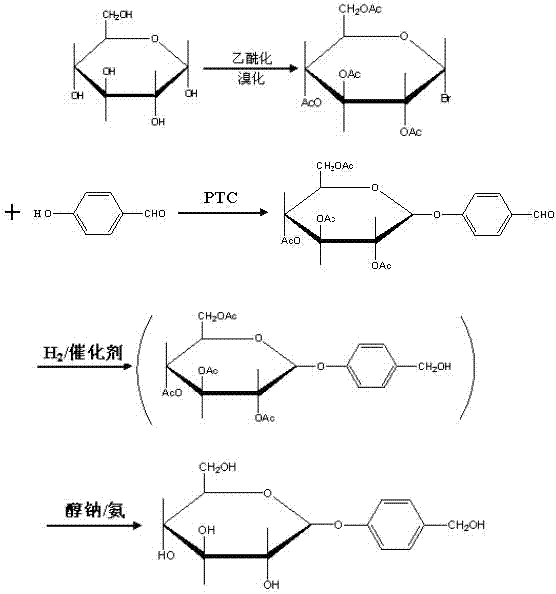

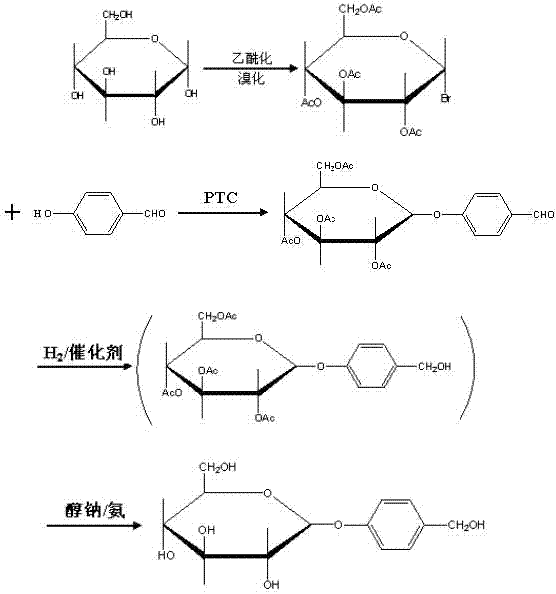

Gastrodin synthesizing method

InactiveCN102516329AReduce pollutionSuitable for industrial productionSugar derivativesSugar derivatives preparationKetone solventsPressure reduction

The invention relates to a gastrodin synthesizing method, which can effectively solve the preparation problem of gastrodin to meet the requirements of the gastrodin in pharmaceuticals. The method comprises the steps of adding catalyst perchloric acid, acetylating anhydrous dextrose by using acetic anhydride to produce per-acetyl dextrose, feeding hydrogen bromide to bromizing hemiacetal hydroxyl of the per-acetyl dextrose to produce bromo-tetraacethyl glucose, further and dropwise adding a bromo-tetraacethyl glucose solution into chloroform and tetrabutyl ammonium bromide, carbonate and para hydroxybenzene in water to obtain 4-formyl benzene-2', 3', 4', 6'- tetraacetyl-beta-D-glucopyranose, performing re-crystallization with ethanol, adding raney nickel or palladium and carbon, feeding hydrogen and pressurizing to hydrogenate, performing filtering, adding sodium alcoholate or ammonia in to filtrate to perform protecting group removal until the reaction is finished completely, performing pressure reduction and concentration to obtain crude gastrodin, and re-crystallizing the crude gastrodin by using alcohol or an alcohol and ester solvent or an alcohol and ketone solvent to obtain the gastrodin. The gastrodin synthesizing method is abundant and cheap in raw materials, simple in process, recycled in solvent, small in pollution and high in quality.

Owner:SHANGHAI MODERN HASEN SHANGQIU PHARMA

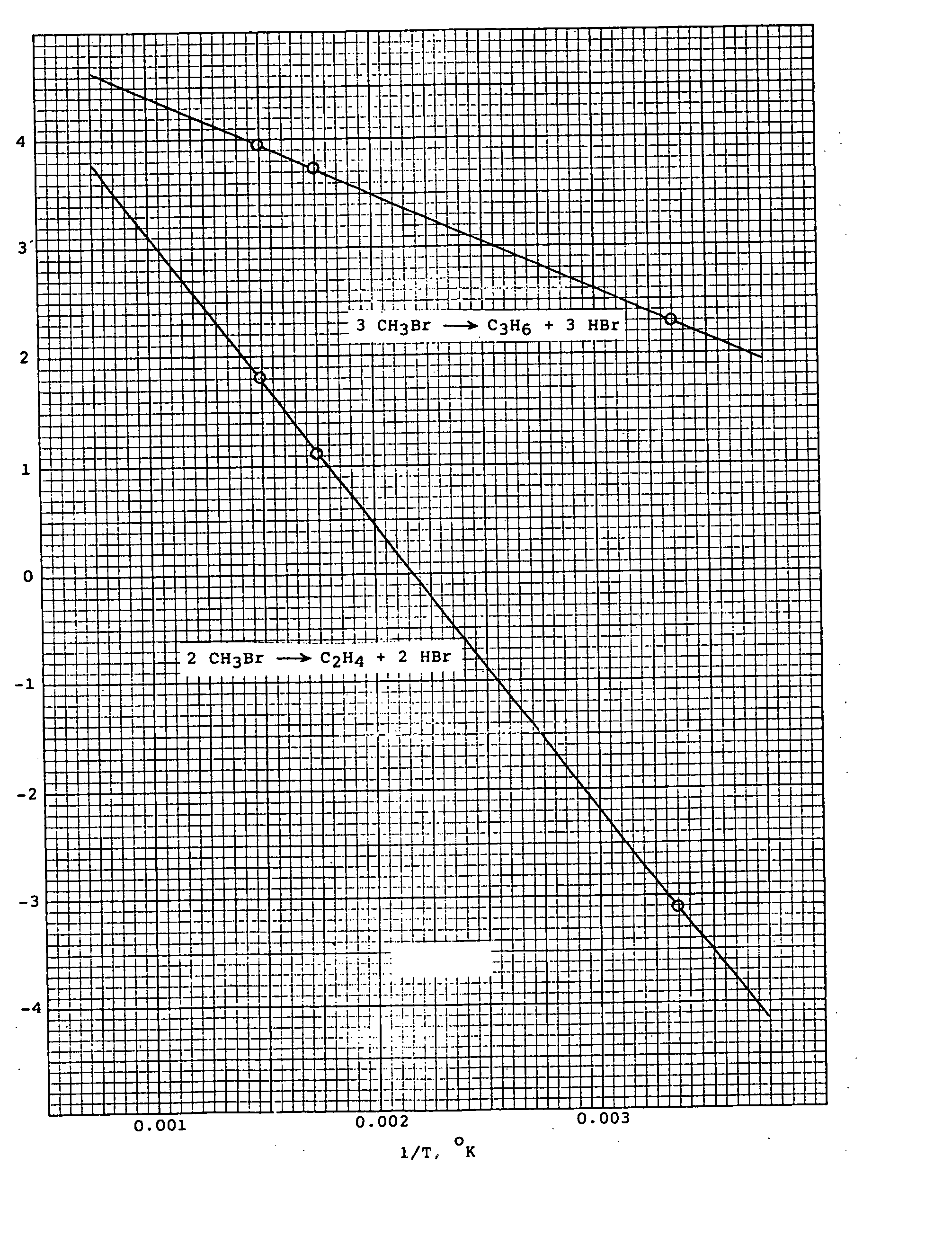

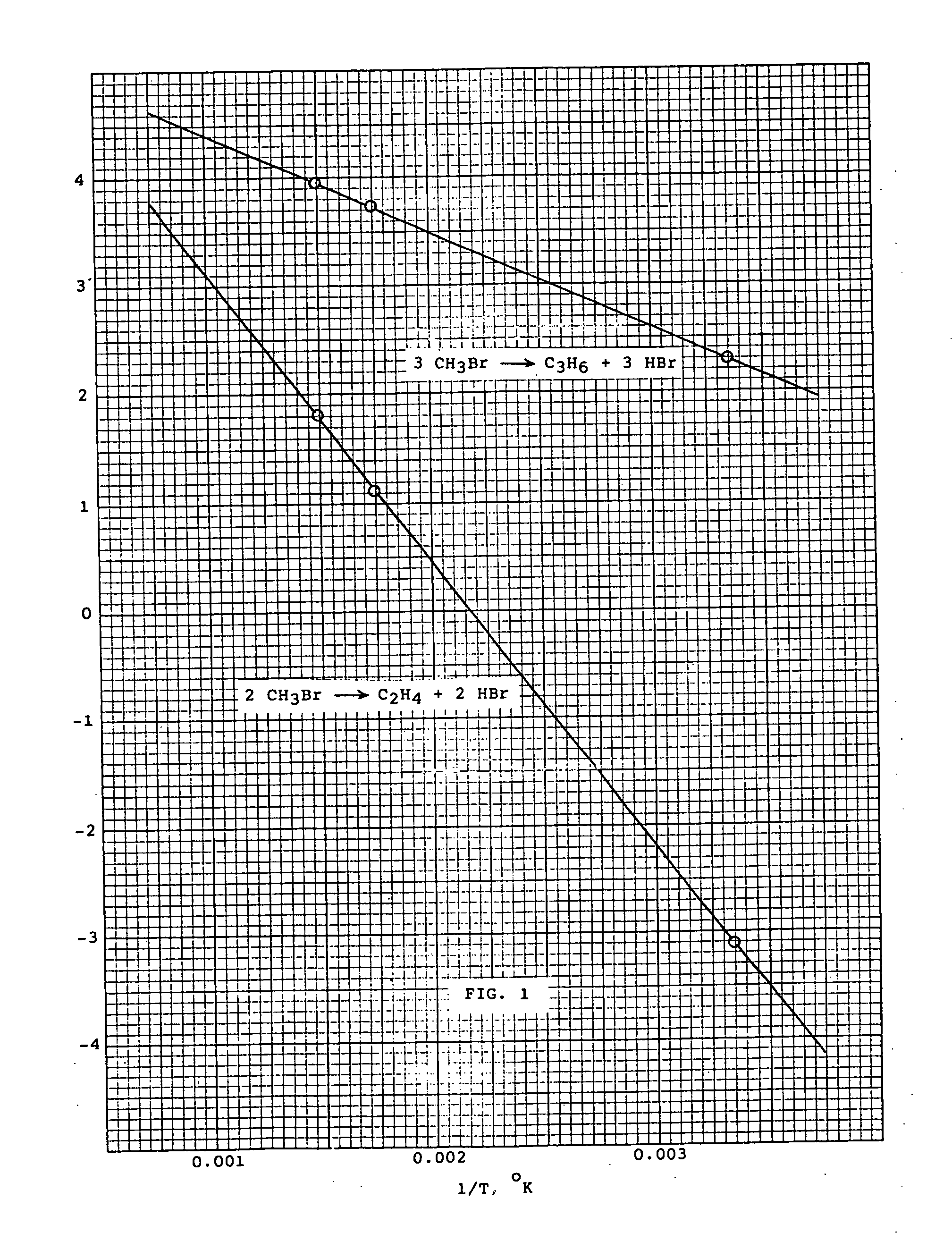

Methyl bromide to olefins

The specification discloses a process for the production of olefins including ethylene, propylene and butenes from methyl bromide. In a chemical reaction methyl bromide is dehydrobrominated to the olefin and hydrogen bromide. The reaction is carried out at elevated temperatures, preferably in the range of 300° C. to 500° C. A catalyst comprising a zeolite may be used.

Owner:JES TECH LLC

Novel flow chart for preparing acetic acid, methanol and dimethyl ether from methane by non synthetic gas process

ActiveCN1640864APreparation by oxidation reactionsOrganic compound preparationAcetic acidGas composition

The new process of synthesizing acetic acid with methane consists of two reaction steps, including the first step of reacting methane, oxygen and hydrogen bromide or hydrobromic acid on catalyst to produce CH3Br, CO and H2O; and the second step of reacting CH3Br, CO and H2O on catalyst to prepare acetic acid. During the reaction of synthesizing methanol and dimethyl ether, the first step of oxybromizing reaction may have the reacting gas composition regulated and different catalyst adopted to reach the aim of creating CH3Br and H2O in high selectivity; and methanol and dimethyl ether may be then produced through hydrolysis on one other kind of catalyst. In the process of preparing acetic acid or methanol and dimethyl ether, HBr as the circular reaction medium is regenerated and returned to the reactor for reuse.

Owner:MICROVAST POWER SYST CO LTD

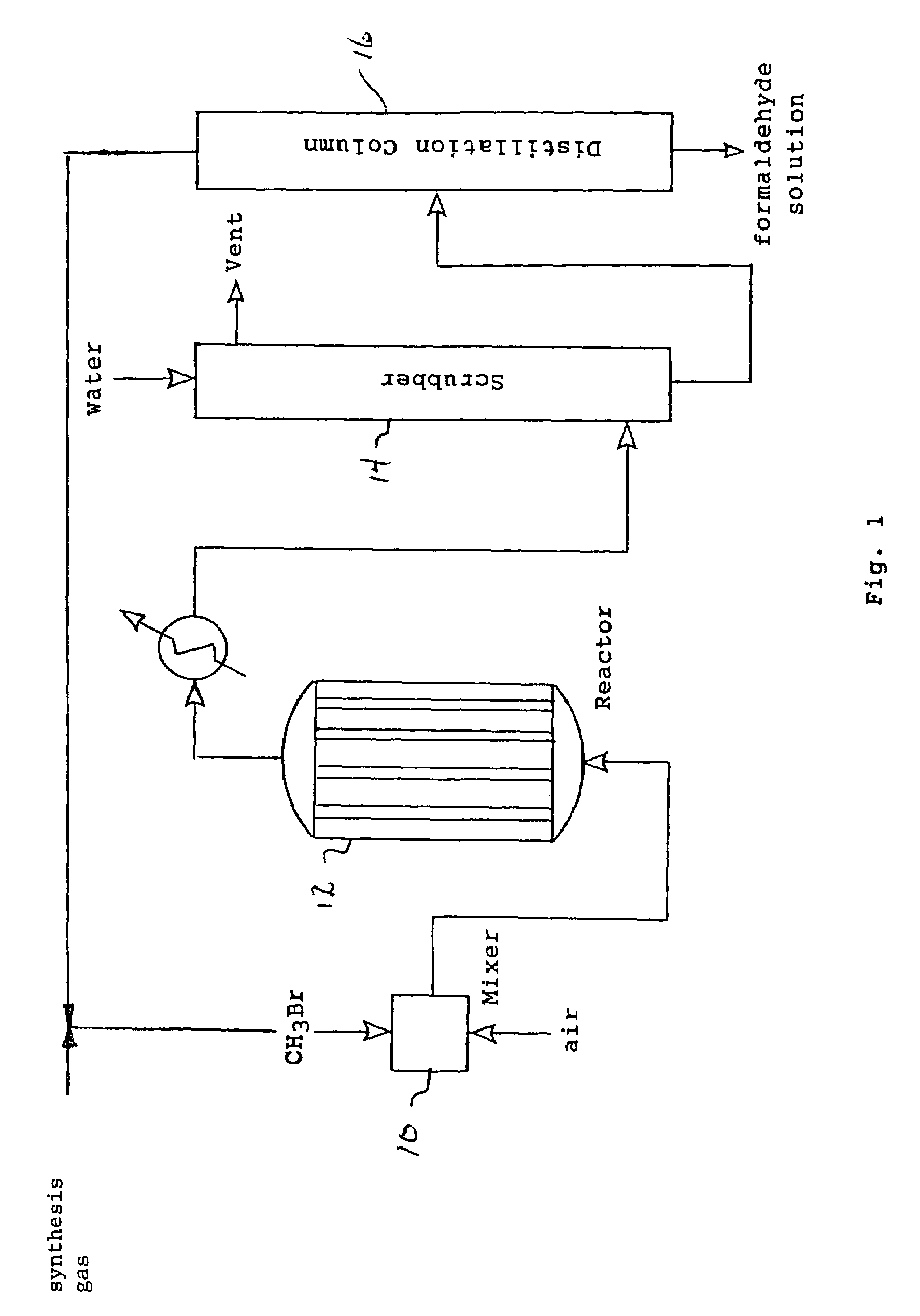

Manufacture of formaldehyde from methyl bromide

A process is provided for the manufacture of formaldehyde from methyl bromide. In the process, methyl bromide is oxidized with air over a catalyst to give formaldehyde and hydrogen bromide. In a preferred embodiment of the invention, a mixture of two different catalysts are employed, one to promote hydrolysis of methyl bromide to methyl alcohol and the other to promote the oxidation of methyl alcohol to formaldehyde.

Owner:JES TECH LLC

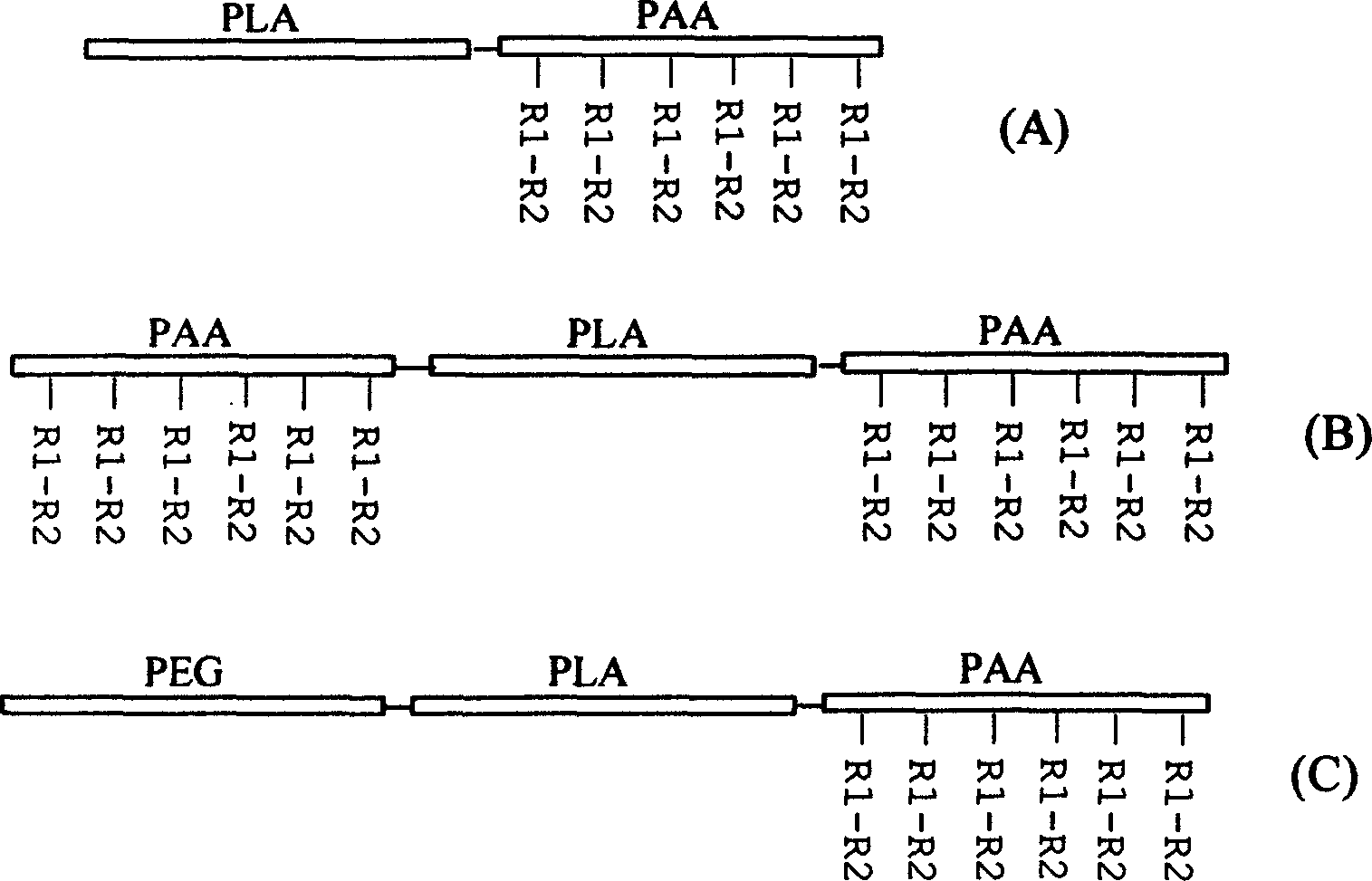

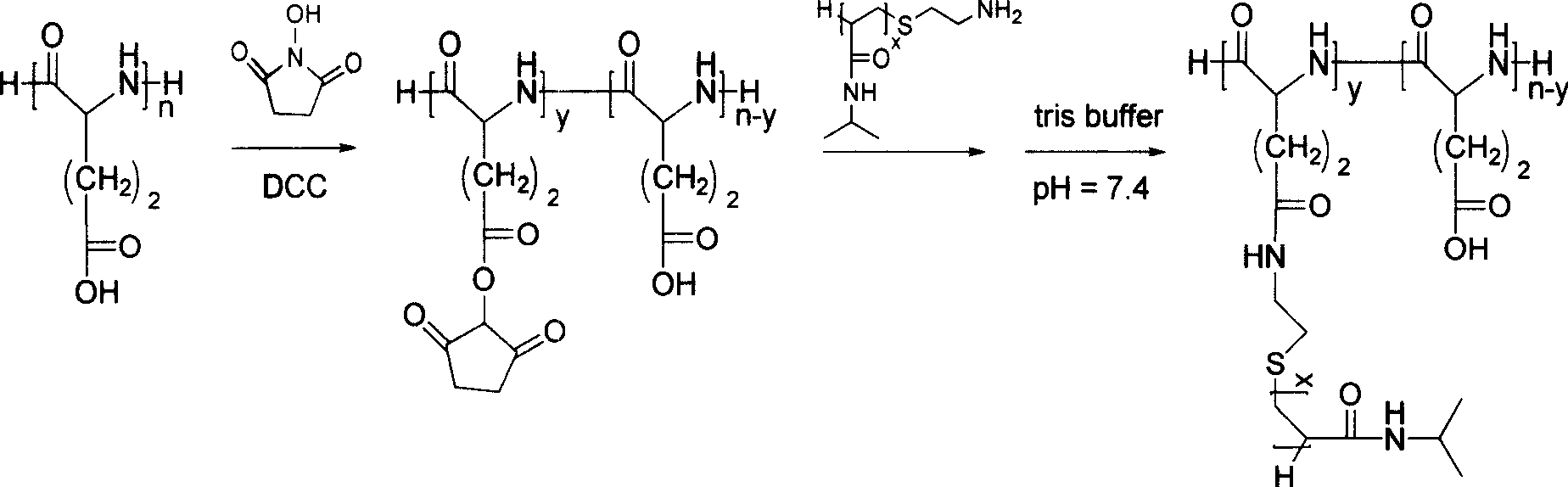

Aliphatic polyester-polyamino acids copolymer with biological function and its synthesis method

InactiveCN1800238AImprove hydrophilicityGood biocompatibilityOrganic active ingredientsPharmaceutical non-active ingredientsPolyesterSynthesis methods

The invention relates to a fatty group polyester-polyamino acid copolymer with biology function and its synthesis method in the field of macromole biological medicine material technique. The block copolymer comprises: the two block copolymer (A) of fatty group polyester -polyamino acid with biology function and three block copolymer (B), and polyoxyethylene-fatty group polyester-polyamino acid three block copolymer (C). The synthesis method comprises: synthesizing the block copolymer of the carboxylic which is protected by benzyl, doing catalytic reduction to the palladium wood coal or hydrolyzing hydrogen bromide to generate the corresponding polymer with free carboxyl, then using NHS (N- hydroxyl succinimide-sauba) to active the flank carboxyl of the polyamino acid section, reacting it with short peptide, sugar or drug with RGD to obtain the fatty group polyester-polyamino acid copolymer with biology function.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

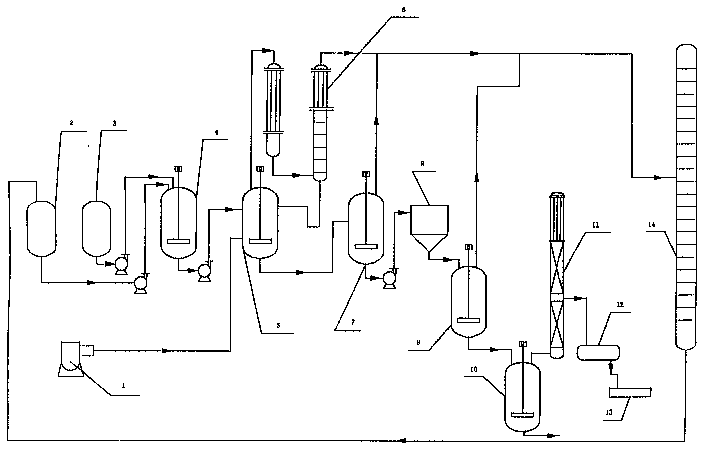

Method for producing butadiene rubber bromide

The invention discloses a process for preparing brominated butadiene rubber, which is characterized in that the process for preparation comprises first, dissolving butadiene rubber solution in dissolvent to form glue solution, second, stirring bromine and the glue solution to transfer with medium to become homogeneous solution, and then having a brominated reaction, third, entering nitrogen or air to remove hydrogen bromide in the glue solution after brominated reaction in a degassing tower, fourth, neutralizing the glue solution with dilute lye in a neutralizing reactor, and repeatedly washing with deionized water, leading the pH value of the glue solution to be 6.5-8.0, fifth, adding dispersing agent and heat-resisting agent to conciliate, sixth, flashing and recovering the dissolvent in the glue solution in a condensation pot to get brominated butadiene rubber gel particle, and getting the end products through squeezing, dewatering, expanding and drying. Compared with the prior art, the invention has the advantages that the invention can be continuously produced, the qualities of the products are stable, and the reaction process is easy to control (expand).

Owner:陈苏

Metal etch process selective to metallic insulating materials

InactiveUS6972265B1Relieve pressureReduce exposureSemiconductor/solid-state device manufacturingGalvano-magnetic device manufacture/treatmentResistOxygen plasma

A method is provided which includes patterning one or more metal layers arranged above a metal insulating layer and terminating the patterning process upon exposure of the metal insulating layer. In particular, the method may be adapted to be more selective to the metal insulating layer than the one or more metal layers. In general, such an adaptation may include exposing the semiconductor topography to an etch chemistry comprising hydrogen bromide. In some cases, the etch chemistry may further include a fluorinated hydrocarbon. In yet other embodiments, the method may further or alternatively include using a reactive ion etch process, etching at a relatively low temperature, using a resist mask, and / or using an etch chemistry substantially absent of an oxygen plasma. In this manner, the method may, in some embodiments, include patterning the one or more metal layers using a reactive ion etch process substantially absent of an oxygen plasma.

Owner:MONTEREY RES LLC

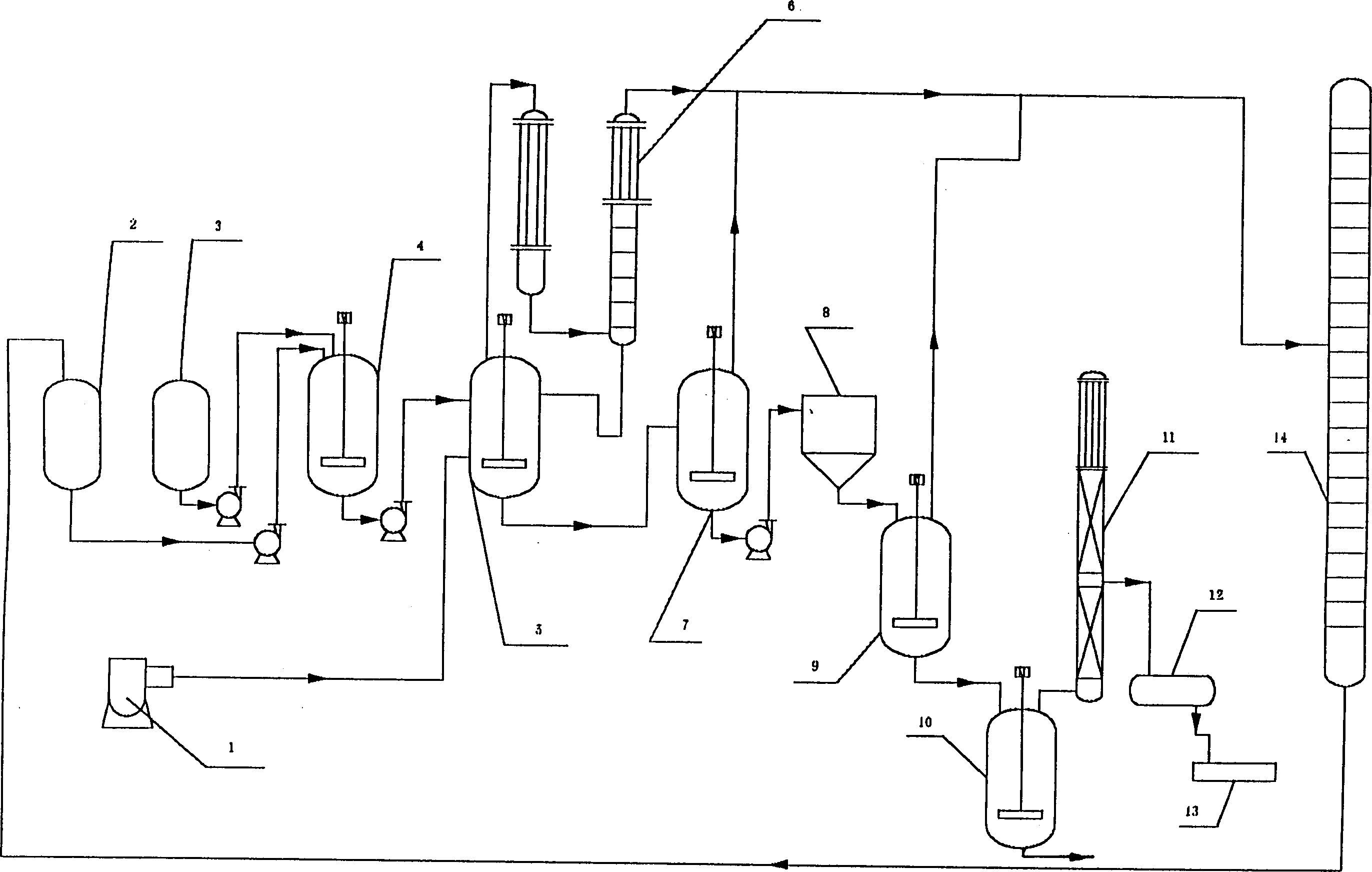

Process for production of trimellitic anhydride by continuous oxidizing process

A process for preparing trimellitic anhydride from metatritoluene, acetic acid as solvent, and catalyst (cobalt acetate, manganess acetate, tetrebromoethane, or hydrogen bromide) by continuous oxidization method includes continuous oxidizing reaction, anhydridization, refining, slicing or granulating and recovering solvent. Its advantages are high yield (up to 120%), high safety, high quality of product, and long service life of equipment.

Owner:JIANGSU ZHENGDAN CHEM IND CO LTD

Method for synthesizing hexafluoro-1,3-butadiene

ActiveCN104844411ASave raw materialsConvenient sourceChemical recyclingHalogenated hydrocarbon preparationChemical synthesisHydrogen fluoride

The invention relates to a method for synthesizing hexafluoro-1,3-butadiene, and belongs to the field of organic chemistry synthesis. The method for synthesizing hexafluoro-1,3-butadiene comprises the following steps: removing hydrogen fluoride from tetrafluoro ethane (HFC-134a) under the action of a catalyst to generate trifluoroethylene; rapidly reacting trifluoroethylene with liquid bromine to generate 1,2-dibromo-1,1,2-trifluoroethane, and removing hydrogen bromide under alkaline conditions to obtain trifluorobromoethylene; and reacting trifluorobromoethylene with activated zinc powder and N,N-dimethyl formamide to generate trifluorovinylzinc, and carrying out a coupling reaction on trifluorovinylzinc under the action of Fe<3+> to generate hexafluoro-1,3-butadiene. A solvent can be recovered after above reactions. The method has the advantages of low price and convenient source of raw materials, good stability and long service of the catalyst, simple separation and purification of the above product, and easy industrial production.

Owner:泉州宇极新材料科技有限公司

Method for preparing 11-aminoundecanoic acid by utilizing 10-undecenoic acid

ActiveCN103804209AIncrease profitSolve the problem that the reaction temperature is difficult to controlOrganic compound preparationAmino-carboxyl compound preparationBenzeneColneleic acid

The invention relates to a process for producing nylon 11 resin by utilizing castor oil, in particular to a method for preparing 11-aminoundecanoic acid by utilizing 10-undecenoic acid. The method comprises the following steps: proportioning 10-undecenoic acid, methylbenzene and benzene to prepare a raw material solution, and generating 11-bromoundecanoic acid by virtue of the additive reaction of the raw material solution with hydrogen bromide in a double-kettle reaction device in the presence of catalyst; ammonolyzing the 11-bromoundecanoic acid by virtue of three different processing ways without the crystallization; adding a phase-transfer catalyst in the ammonolysis reaction to accelerate the ammonolysis reaction; carrying out vacuum filtering after the ammonolysis reaction is completed, wherein a filter cake is a 11-aminoundecanoic acid crude product; adding the crude product into the deionized water, dissolving the crude product by heating the crude product, cooling and crystallizing the crude product, and filtering the crude product to obtain the refined 11-aminoundecanoic acid product.

Owner:江苏东鼎化学科技有限公司

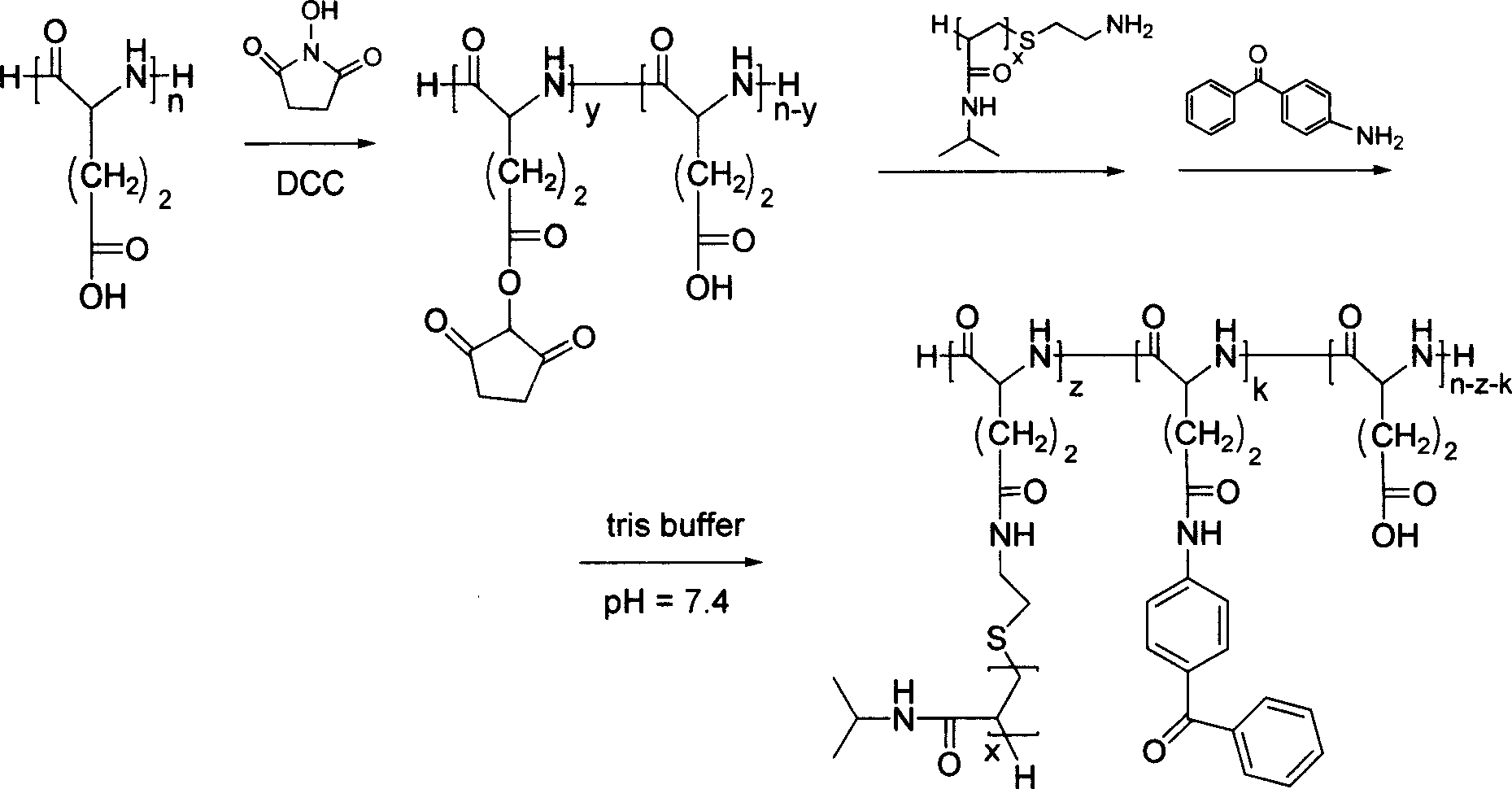

Aliphatic polyester-polyamino acid Y-type three-arm block copolymers and synthetic method thereof

The invention relates to a Y-shaped three-arm segmented copolymer of aliphatic polyester namely polyamino acid and a process for synthesis, which belongs to the high-polymer biological medicine material field. And the process for synthesis comprises protecting amidogens of 2-amidocyanogen-1 and 3-propylene glycol with benzyl chloroformate, ringopening and polymerizing 2-amidocyanogen-1 and 3-propylene glycol with aliphatic cyclic esters monomer in benzene or toluene dissolvent under the condition of warming up and stirring and without water and oxygen through utilizing stannous octoate as catalyst, utilizing amidogens to be macromolecule initiating agent after de-protecting, triggering alpha- amino acid-N-carboxylic acid anhydrides to ring-open and polymerize, getting Y-shaped segmented copolymer of carboxy group which is protected by benzyl group, forming relative polymer with free carboxy group through dewatering hydrogen bromide or catalyzing hydrogenating and deacidizing palladium-charcoal, and then getting the Y-shaped segmented copolymer which can be biodegraded and can have biology functionalization. The invention can be widely applied in the filed such as internal fixation of bone fracture, medicinal carrier, tissue engineering scaffold and the like.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

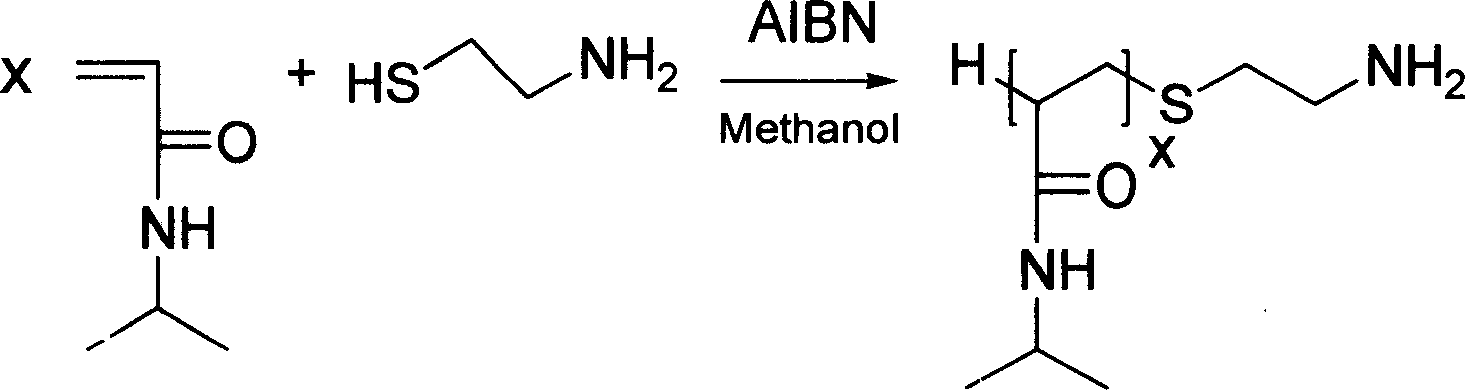

Poly L-glutamic acid-poly N-isopropylacrylamide graft copolymer and preparation method thereof

InactiveCN101058641AGood biocompatibilityControl releasePoly(N-isopropylacrylamide)N isopropyl acrylamide

The invention discloses a two-block copolymer of poly-N-isopropyl acrylamide-polyamino acid and making method, which is characterized by the following: the number average molecular weight of poly-N-isopropyl acrylamide-polyamino acid is 1000-10000; the polyamino acid is poly-L-glutamic acid or poly-L-aspartic acid with number average molecular weight at 1000-30000; the molar percentage of amino acid carbobenzoxy is 0-90%; the invention uses hydrogen bromide or reducing method to strip benzyl through catalyzing and hydrogenating to obtain the product, which possesses double response for temperature and pH value in the solution; the copolymer can be biological decomposed to be discharged out of body through kidney directly, which can be carrier of target drug release and injectable intellectual response aquagel.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Control of patterned etching in semiconductor features

InactiveUS6534416B1Decorative surface effectsSemiconductor/solid-state device manufacturingHydrogenEtching

Copper can be pattern etched in a manner which provides the desired feature dimension and integrity, at acceptable rates, and with selectivity over adjacent materials. To provide for feature integrity, the portion of the copper feature surface which has been etched to the desired dimensions and shape must be protected during the etching of adjacent feature surfaces. To avoid the trapping of reactive species interior of the etched copper surface, hydrogen is applied to that surface. Hydrogen is adsorbed on the copper exterior surface and may be absorbed into the exterior surface of the copper, so that it is available to react with species which would otherwise penetrate that exterior surface and react with the copper interior to that surface. Sufficient hydrogen must be applied to the exterior surface of the etched portion of the copper feature to prevent incident reactive species present due to etching of adjacent feature surfaces from penetrating the previously etched feature exterior surface. The most preferred embodiment of the invention provides for the use of hydrogen chloride (HCl) and / or hydrogen bromide (HBr) as the sole or principal source of the reactive species used in etching copper. Dissociation of the HCl and / or HBr provides the large amounts of hydrogen necessary to protect the copper feature etched surfaces from penetration by reactive species adjacent the etched surface. Additional hydrogen gas may be added to the plasma feed gas which comprises the HCl and / or HBr when the reactive species density in the etch process chamber is particularly high. Although the HCl or HBr may be used as an additive in combination with other plasma feed gases, preferably HCl or HBr or a combination thereof accounts for at least 40%, and more preferably at least 50%, of the reactive species generated by the plasma. Most preferably, HCl or HBr should account for at least 80% of the reactive species generated by the plasma.

Owner:APPLIED MATERIALS INC

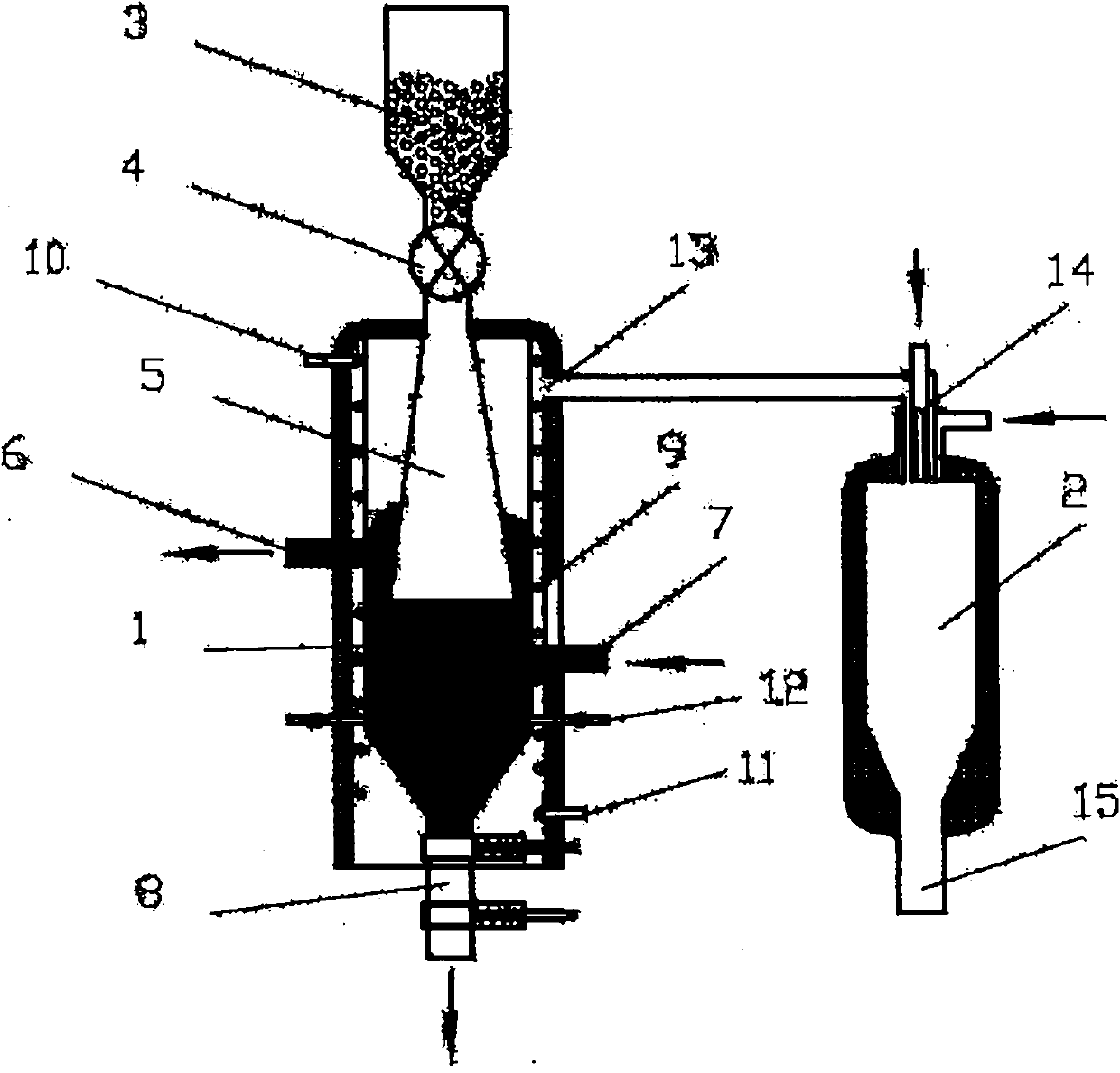

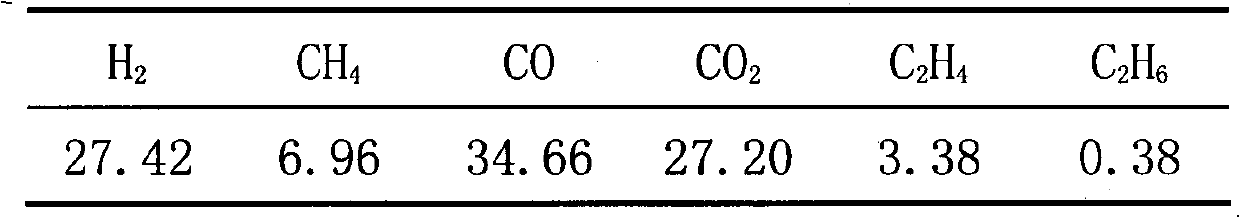

Method and device for comprehensively recycling waste printed circuit boards

ActiveCN101905234AAvoid secondary pollutionStrong process adaptabilitySolid waste disposalElectronic waste recyclingEngineeringPrinted circuit board

The invention discloses a method for comprehensively recycling waste printed circuit boards, which comprises the following: a step of waste printed circuit board gasification, which is to crush the waste printed circuit boards, feed the crushed waste printed circuit boards into a molten salt reacting furnace, perform gasification at the temperature of between 700 and 900 DEG C to obtain gasified residues and a gas product which contains a large amount of tar, allow the gasified residues to layer in molten salt, discharge the layered products from different positions of the molten salt reacting furnace and recycle the products respectively; a step of bromine-containing pollutant removal, which is to release bromine (Br) from the waste printed circuit boards in a form of hydrogen bromide (HBr) when the waste printed circuit boards are gasified, wherein the released acid HBr is instantly absorbed by alkali molten salt and a small amount of bromine-containing organic materials generated at the same time are cracked and absorbed by the molten salt under the catalysis of the molten salt; and a step of gas product reforming, which is to introduce the mixture of the gas product containing a large amount of tar, oxygen-enriched air and vapor according to a ratio of 1: (0.4-0.7): (1-5) into an airflow bed, reform at the temperature of between 1,200 and 1,500 DEG C, regulate the ratio of hydrogen (H2) to carbon monoxide (CO) in the gas to 0.8 to 2 and convert the tar in the gas product at a high temperature in the airflow bed.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

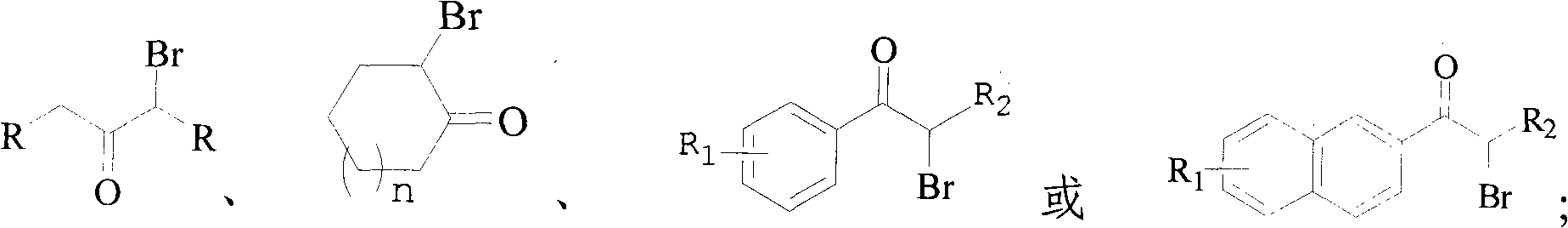

Green synthesizing method of aryl bromide

ActiveCN101857518AReduce usageImprove economyCarboxylic acid nitrile preparationOrganic compound preparationArylHalogen

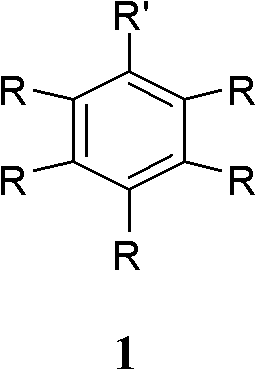

The invention discloses a green synthesizing method of aryl bromide. The synthesizing method comprises the step of carrying out bromination on an aromatic compound of which the structure is shown as a formula (1) to prepare the aryl bromide by using hydrogen bromide as a brominating agent, using copper nitrate as a catalyst and using molecular oxygen as an oxidant, wherein in the formula (I), R is hydrogen; substituent groups R1, R2, R3, R4 and R5 are respectively independently selected from hydrogen, hydroxy, amino, C1 to C8 alkoxy, single C1 to C8 alkyl amino, double C1 to C8 alkyl amino, C1 to C12 alkyl, C6 to C12 aryl, C1 to C8 acyloxy, C1 to C8 acylamino, halogen, nitryl, cyan, carboxyl and C1 to C8 acyl or C1 to C8 carbalkoxyl group; and at least one substituent group of R1, R2, R3,R4 and R5 is hydroxy, amino, C1 to C8 alkoxy, single C1 to C8 alkyl amino, double C1 to C8 alkyl amino, C1 to C8 acyloxy, C1 to C8 acylamino or C1 to C12 alkyl. The synthesizing method of the invention has the advantages of wide application range and high atom utilization, avoids using an organic solvent and has the characteristics of economy and environment protection.

Owner:ZHEJIANG UNIV OF TECH

Process for the preparation glatiramer acetate (copolymer-1)

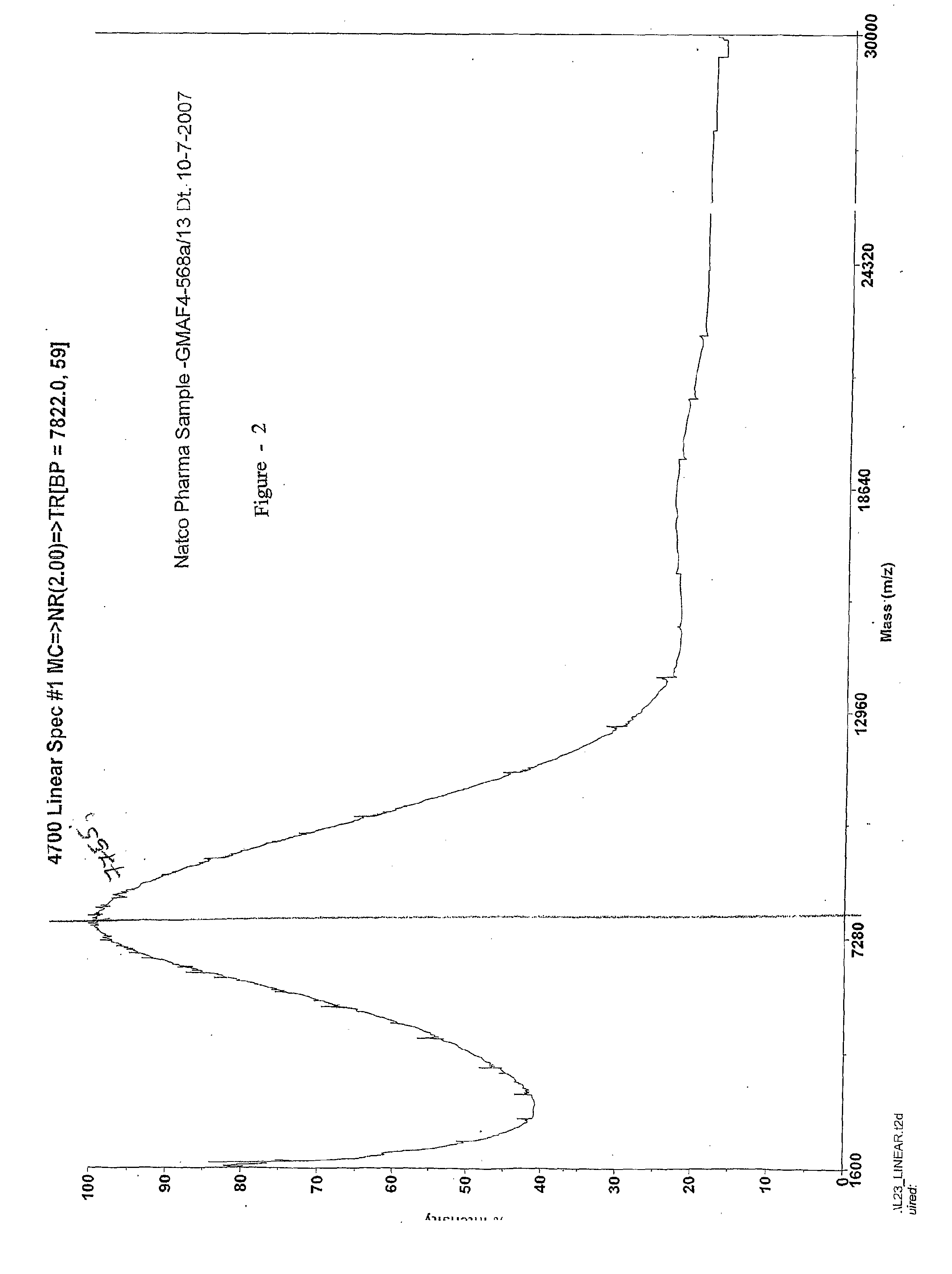

InactiveUS20100324265A1Easy to optimizeShort reaction timePeptide-nucleic acidsNervous disorderBenzoyl bromideTyrosine

This invention relates to a convenient and improved process for preparation of glatiramer acetate (copolymer-1) of pharmaceutical grade. The process involves polymerizing N-carboxyanhydrides of tyrosine, alanine, y-benzyl glutamate and &egr;-N-trifluoroacetyllysine in dioxane with diethylamine as initiator to afford protected copolymer-1. Treatment with hydrogen bromide in acetic acid at 35° C. for 3-5 h cleaves benzyl group to produce trifluoroacetyl copolymer-1. The trifluoroacetyl copolymer-1 is washed with an organic solvent to remove reactive benzyl bromide generated during debenzylation. Deprotection with aqueous piperidine, followed by dialysis offers glatiramer acetate (copolymer-1) of Molecular weight 5000-9000 daltons.

Owner:NATCO PHARMA LTD

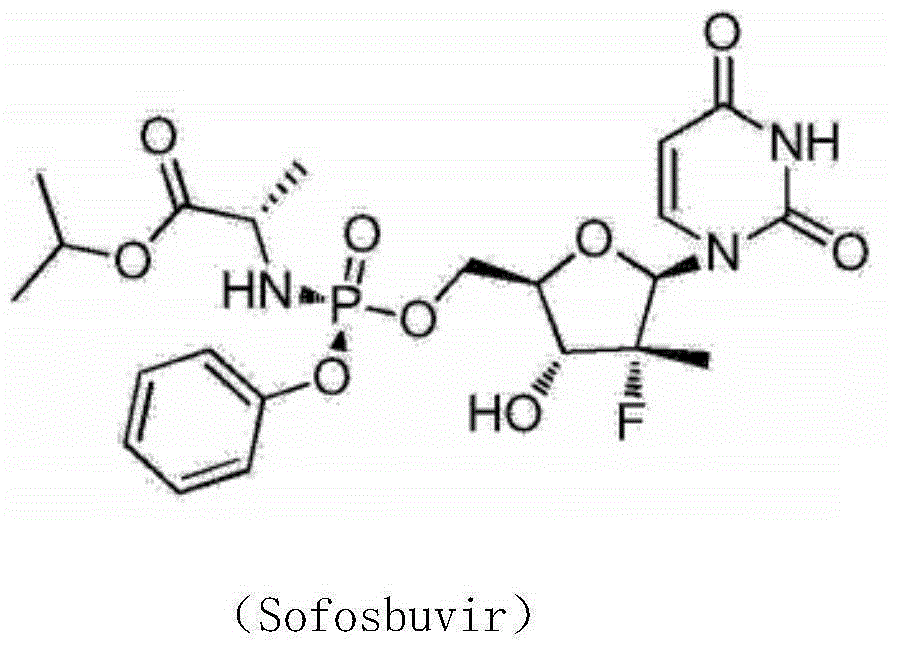

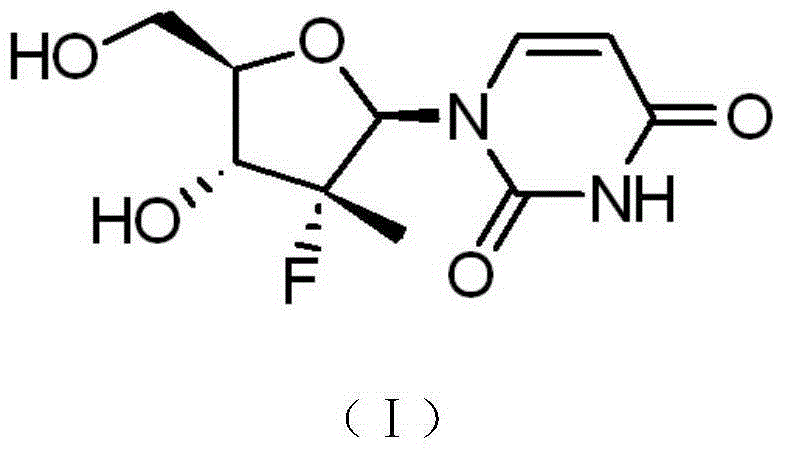

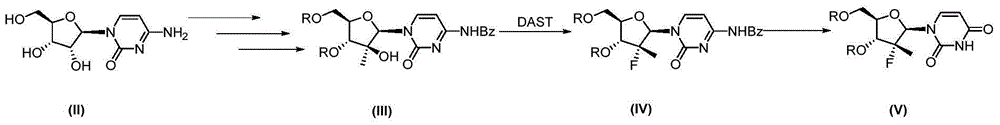

Synthesis method of intermediate compound of sofosbuvir

InactiveCN104987355AHigh yieldMild reaction conditionsSugar derivativesSugar derivatives preparationSodium methoxideSynthesis methods

The invention provides a synthesis method of an intermediate compound of sofosbuvir as shown in formula (I) (see specification). The synthesis method of the intermediate compound of sofosbuvir, a synthetic route of which is as follows: (see specification) the synthesis method comprises the following steps: taking (3R, 4R, 5R)-3-fluoro-dihydro-4-hydroxl3-methyl furan-2(3H)-ketone as an initial raw material to react with pivaloyl chloride to generate an intermediate product (XII); reducing the intermediate product to obtain an intermediate product (XIII); enabling the intermediate product (XIII) to react with pivaloyl chloride to generate an intermediate product (XIV); generating an intermediate product (XV) by virtue of the reaction of the intermediate product (XIV) and a hydrogen bromide; performing silyl-hilbert-johnson reaction for the intermediate product (XV) and uracil to generate an intermediate product (XVI); enabling the intermediate product (XVI) to react with sodium methoxide to obtain a target product. The synthesis method of the intermediate compound (I) is moderate in reaction condition, simple in procedure, low in cost, environment-friendly and favorable for the industrialized production.

Owner:SHANGHAI TWISUN BIO PHARM

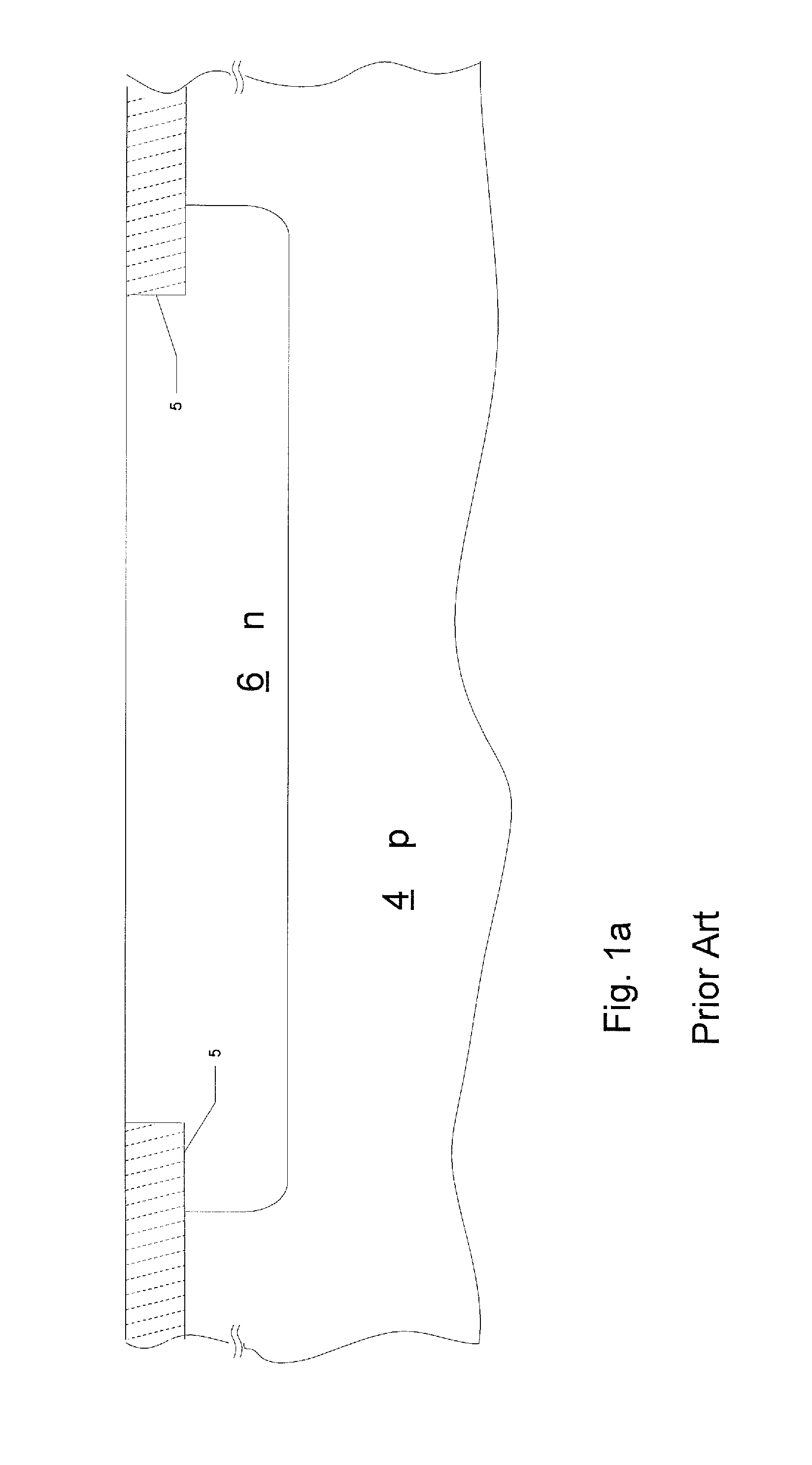

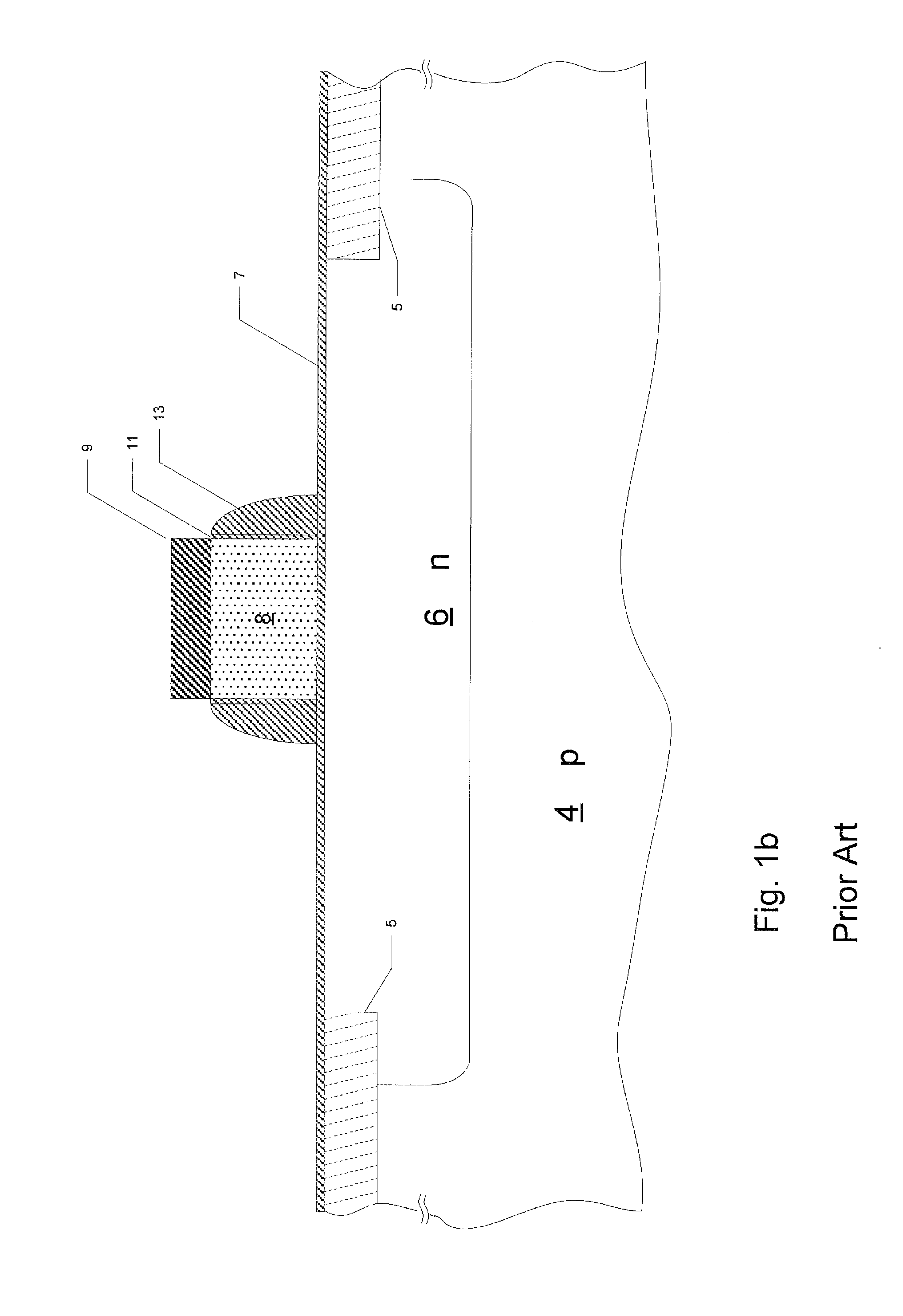

Lateral Uniformity in Silicon Recess Etch

ActiveUS20120064686A1Uniform performanceReduced structureSemiconductor/solid-state device manufacturingSemiconductor devicesSilicon alloyDiluent

A method of etching recesses into silicon prior to formation of embedded silicon alloy source / drain regions. The recess etch includes a plasma etch component, using an etch chemistry of a primary fluorine-based or chlorine-based etchant, in combination with a similar concentration of hydrogen bromide. The concentration of both the primary etchant and the hydrogen bromide is relatively low; a diluent of an inert gas or oxygen is added to the reactive species. Loading effects on the undercut of the recess etch are greatly reduced, resulting in reduced transistor performance variation.

Owner:TEXAS INSTR INC

Preparation method of 1-bromo-1-chloro-2,2-difluoroethylene

ActiveCN105152852AEnable recyclingLow costPreparation by hydrogen halide split-offOperabilityEthyl Chloride

The invention discloses a method for preparing 1-bromo-1-chloro-2,2-difluoroethylene from waste difluorotrichloroethane (R122) generated in a trifluorodichloroethane production process, which comprises the following step: carrying out reduction dechlorination reaction, bromine addition reaction and hydrogen bromide removal reaction. By using the R123 production waste difluorotrichloroethane to produce the high-added-value fluorine-containing intermediate R111211, the raw material cost is low. Meanwhile, the method implements recovery and reutilization on the solvent and catalyst, and reduces the environmental pollution. The method has the advantages of high operability, mild reaction, high reaction speed, high yield, high selectivity, environment friendliness and the like, and can be used for industrial production.

Owner:HUNAN CITY UNIV

Method for synthesizing alpha-brominated aromatic ketones compound

ActiveCN102503751AAvoid pollutionAvoid harmOrganic compound preparationOrganic halogenationOrganic solventHazardous substance

The invention discloses a method for synthesizing an alpha-brominated aromatic ketones compound. The method comprises the following steps: taking an aromatic ketones compound as a substrate, hydrogen bromide as a brominating agent, copper nitrate as a catalyst, oxygen or air as an oxidizing agent and water as a solvent; performing brominating reaction at 25-100 DEG C; and after finishing the reaction, post-processing the reaction solution, thereby obtaining the alpha-brominated aromatic ketones compound. According to the method, water is taken as the solvent, so that the pollution and harm to the environment during a producing, recycling or discharging process caused by an organic solvent are avoided; the method is an environment-friendly green synthesizing technology; the hydrogen bromide is taken as the brominating agent, so that the operation is conveniently and easily controlled, the final reaction products are only alpha-bromoketone and water, no other harmful matter is generated and the defects of the prior art are eliminated; the oxygen or air is taken as the oxidizing agent, so that the price is low and the oxidizing agent is easily obtained; and the method provided by the invention is characterized by convenience in operation, safety, environmental protection, low cost, high economic benefit, and the like, and belongs to a green chemical technology.

Owner:ZHEJIANG UNIV OF TECH

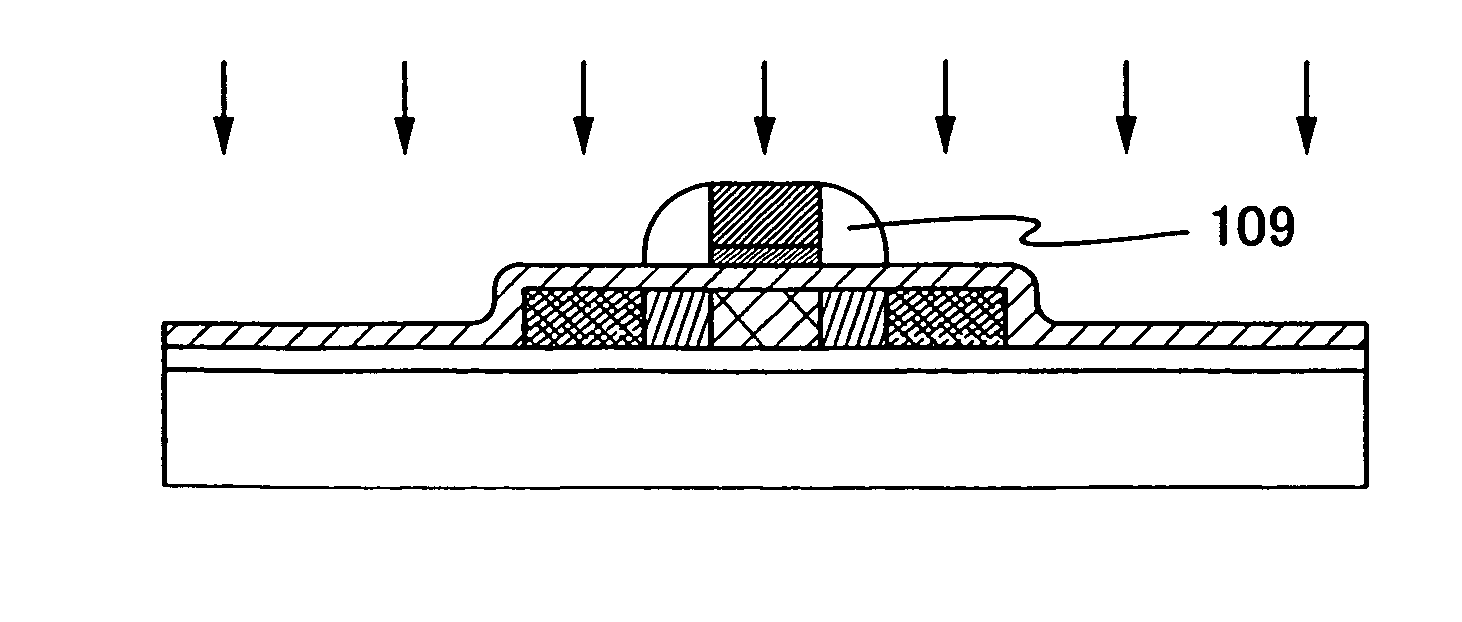

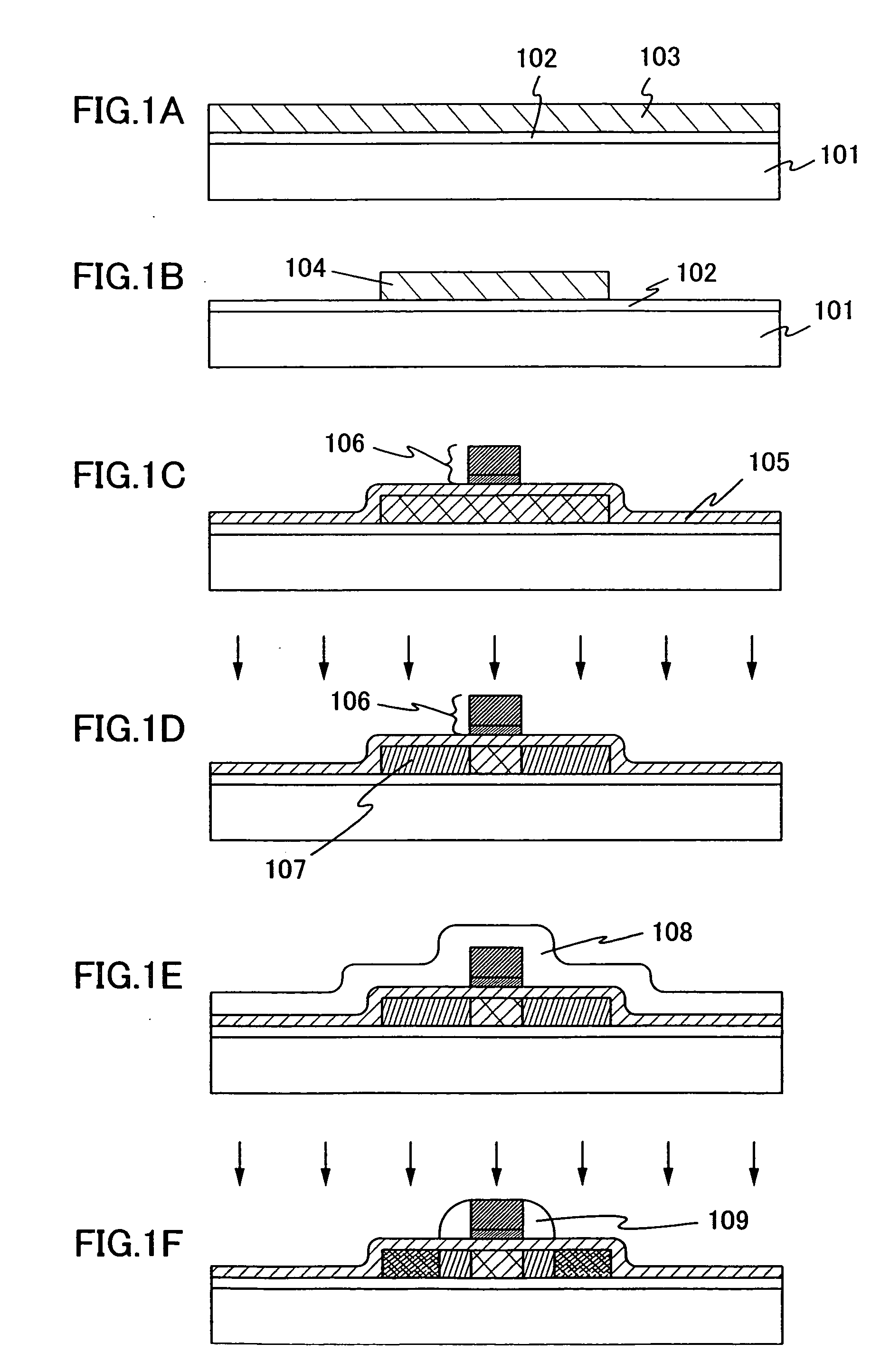

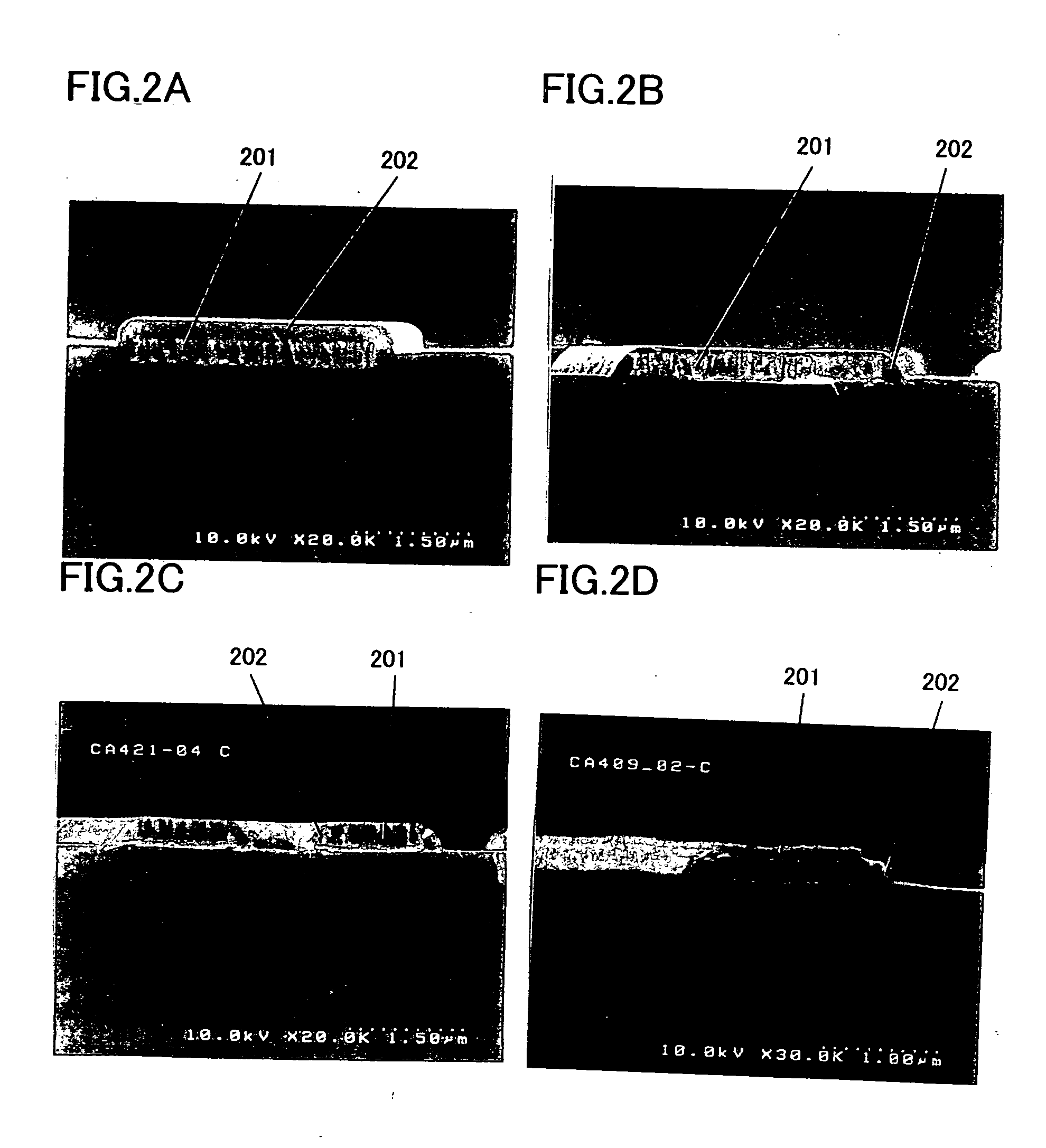

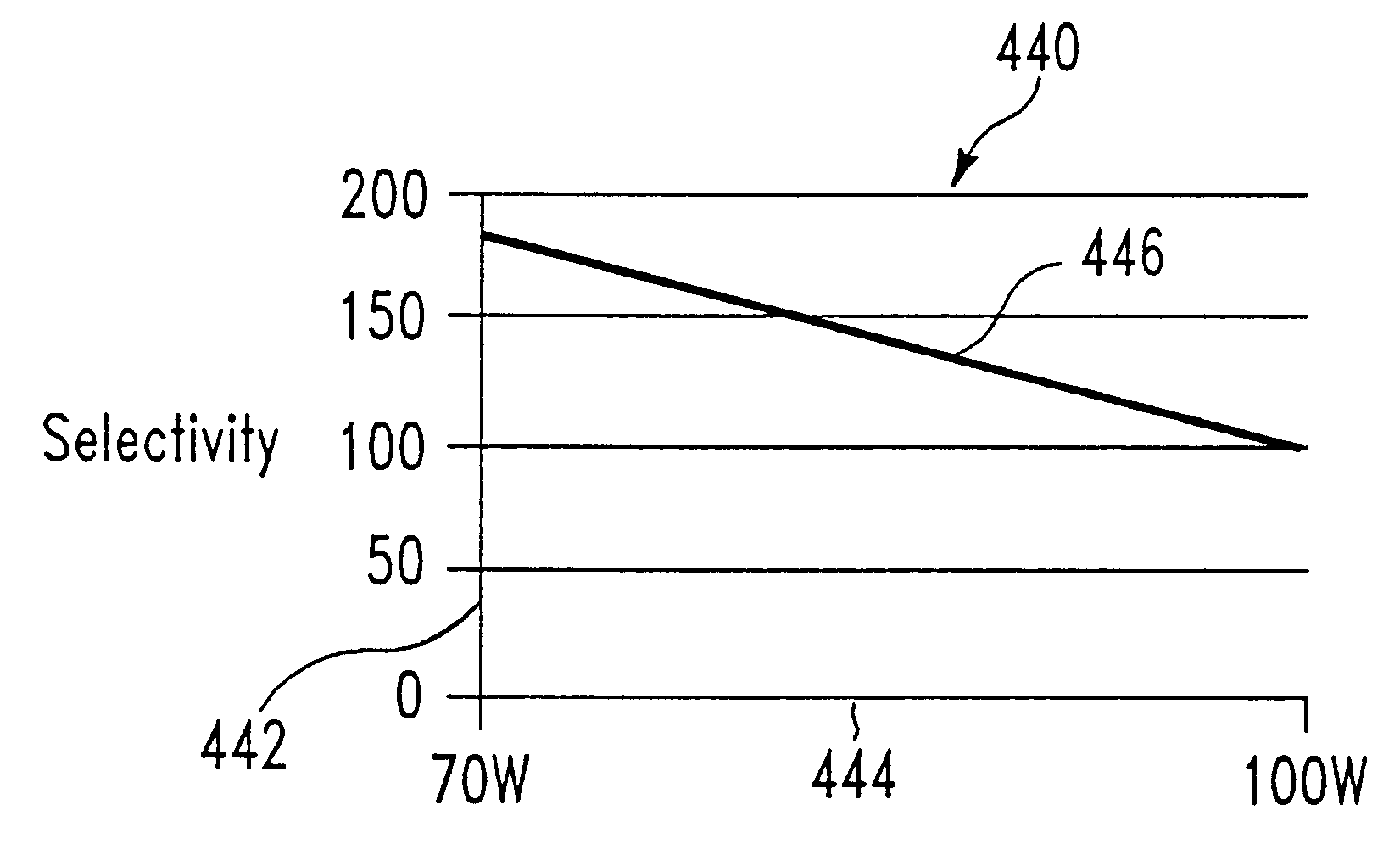

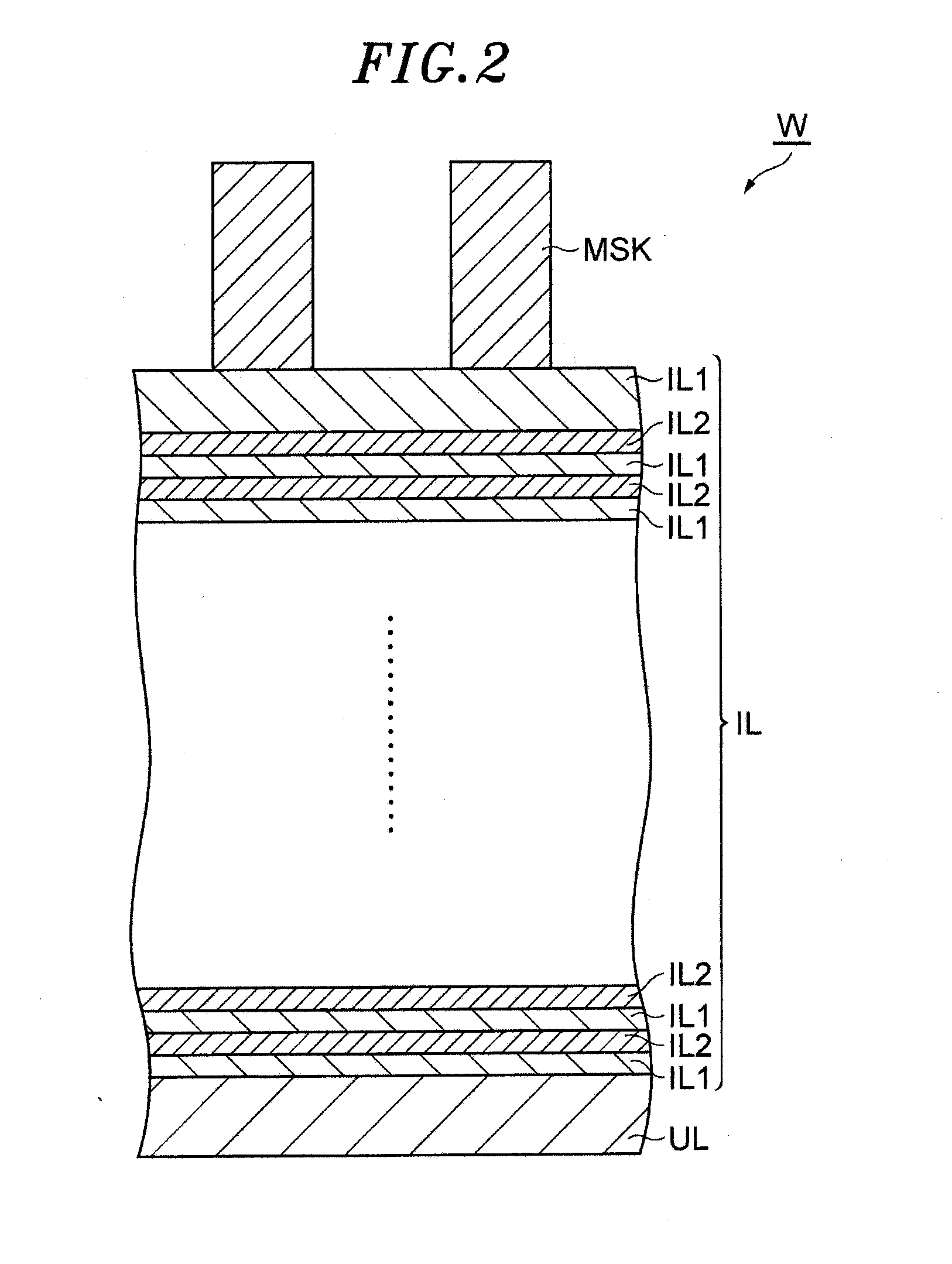

Semiconductor device manufacturing method

ActiveUS20150037982A1Increase widthSmall widthElectric discharge tubesSemiconductor/solid-state device manufacturingSilicon oxideSemiconductor device fabrication

In a semiconductor device manufacturing method, a target object including a multilayer film and a mask formed on the multilayer film is prepared in a processing chamber of a plasma processing apparatus. The multilayer film is formed by alternately stacking a silicon oxide film and a silicon nitride film. The multilayer film is etched by supplying a processing gas containing hydrogen gas, hydrogen bromide gas, nitrogen trifluoride gas and at least one of hydrocarbon gas, fluorohydrocarbon gas and fluorocarbon gas into the processing chamber of the plasma processing apparatus and generating a plasma of the processing gas in the processing chamber.

Owner:TOKYO ELECTRON LTD

Method of synthesizing alpha-brominated ketone compound by hydrogen peroxide oxidizing and brominating method

InactiveCN101928208AAvoid pollutionAvoid harmOrganic compound preparationCarbonyl compound preparationKetoneSolvent

The invention discloses a new process for synthesizing alpha-brominated ketone compound by a hydrogen peroxide oxidizing and brominating method and the process comprises a hydrogen bromide-hydrogen peroxide oxidizing and brominating method and a bromine-hydrogen peroxide oxidizing and brominating method. The process comprises the following specific steps of: when hydrogen bromide (solution of hydrobromic acid) is used as a bromination agent, mixing the ketone compound and the hydrobromic acid and directly dripping hydrogen peroxide into the mixture to oxidize the hydrogen bromide into bromine, and then performing a bromination reaction to generate alpha-brominated ketone; when the bromine is used as the bromination agent, brominating the ketone compound by using bromine liquid to generatethe alpha-brominated ketone compound and the hydrogen bromide; and after the bromine is completely reacted, oxidizing the hydrogen bromide generated in the reaction into the bromine by using the hydrogen peroxide, continuing to perform the bromination reaction on the bromine and the ketone until the ketone compound is completely reacted to generate the alpha-brominated ketone. In the invention, water is used as a solvent, the utilization rate of the bromine is nearly 100 percent, the final products of the reaction are only the alpha-brominated ketone and water; especially, when the hydrobromic acid is used as the bromination agent, the hydrobromic acid is nontoxic, tasteless and free of high corrosion of the bromine liquid without generating any harmful substance; and the process has the advantages of more convenient operation, high efficiency, energy conservation and environmental protection.

Owner:HEBEI UNIVERSITY

Bromol production method

ActiveCN101219935ASimple processMild reaction temperatureOrganic chemistryOrganic compound preparationSodium bicarbonateFiltration

The invention discloses a method for preparing a tribromophenol, which is characterized in that bromine is generated by the hydrogen peroxide reaction between a hydrogen bromide and an oxidant, and then the bromine continues to react with a phenol to synthesize a tribromophenol, and the method can be finished with no middle steps. A crude product passes through water, a sodium bicarbonate liquor and a sodium bisulfite liquor, then after the simple treatments of water washing, impurity removal and filtration, the product can be got. The method has the advantages of simple and convenient process, easy operation, high reaction safety, less pollution and simple post processing. The yield ratio can reach to more than 96 percent. The product has a high purity, is easy to realize industrial production and has a strong practicality.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com