Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1143results about How to "Small width" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

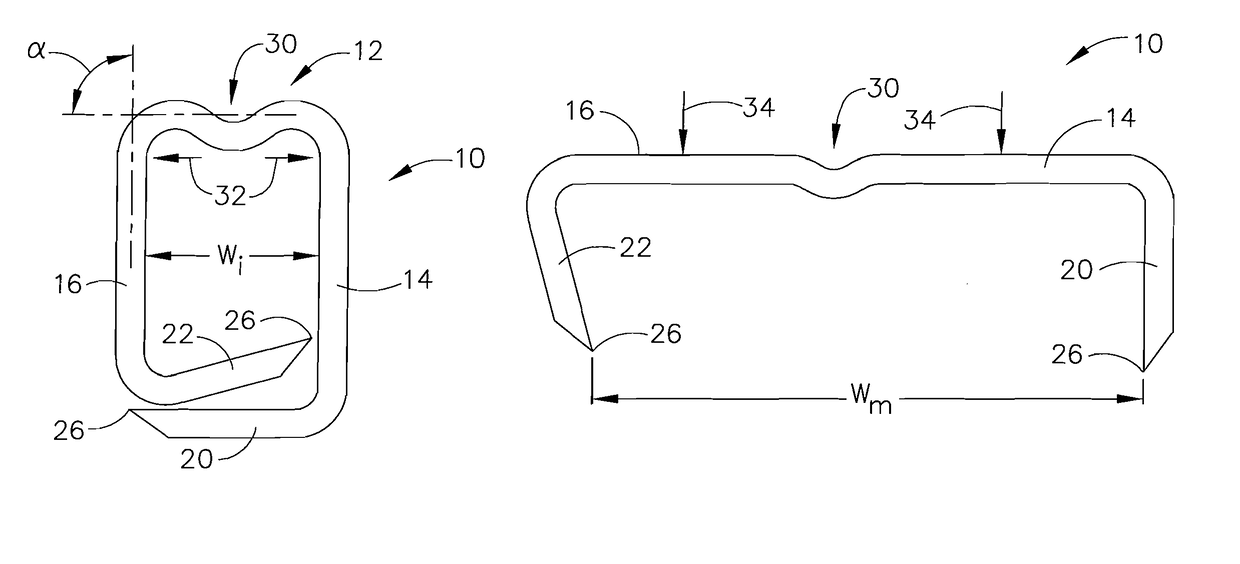

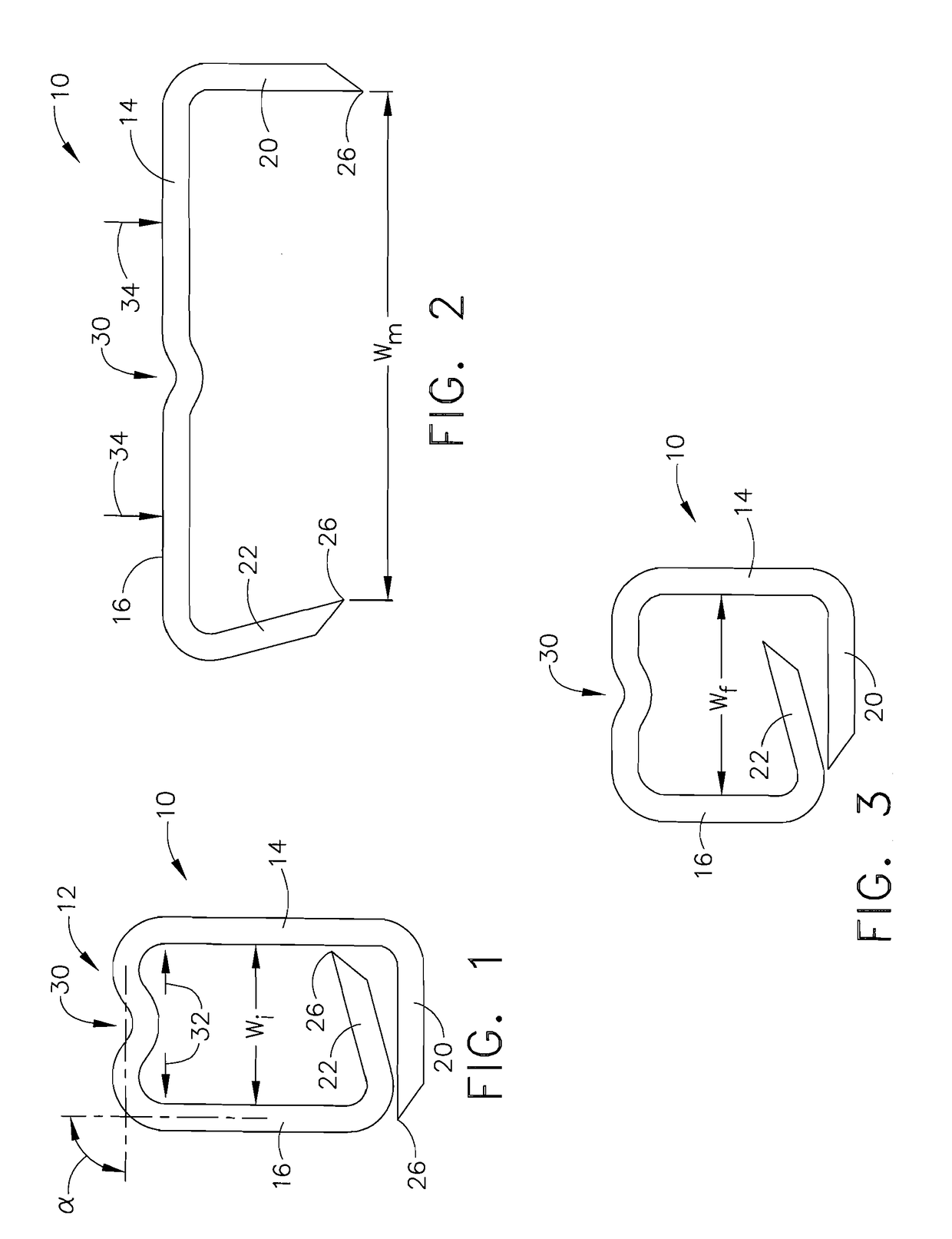

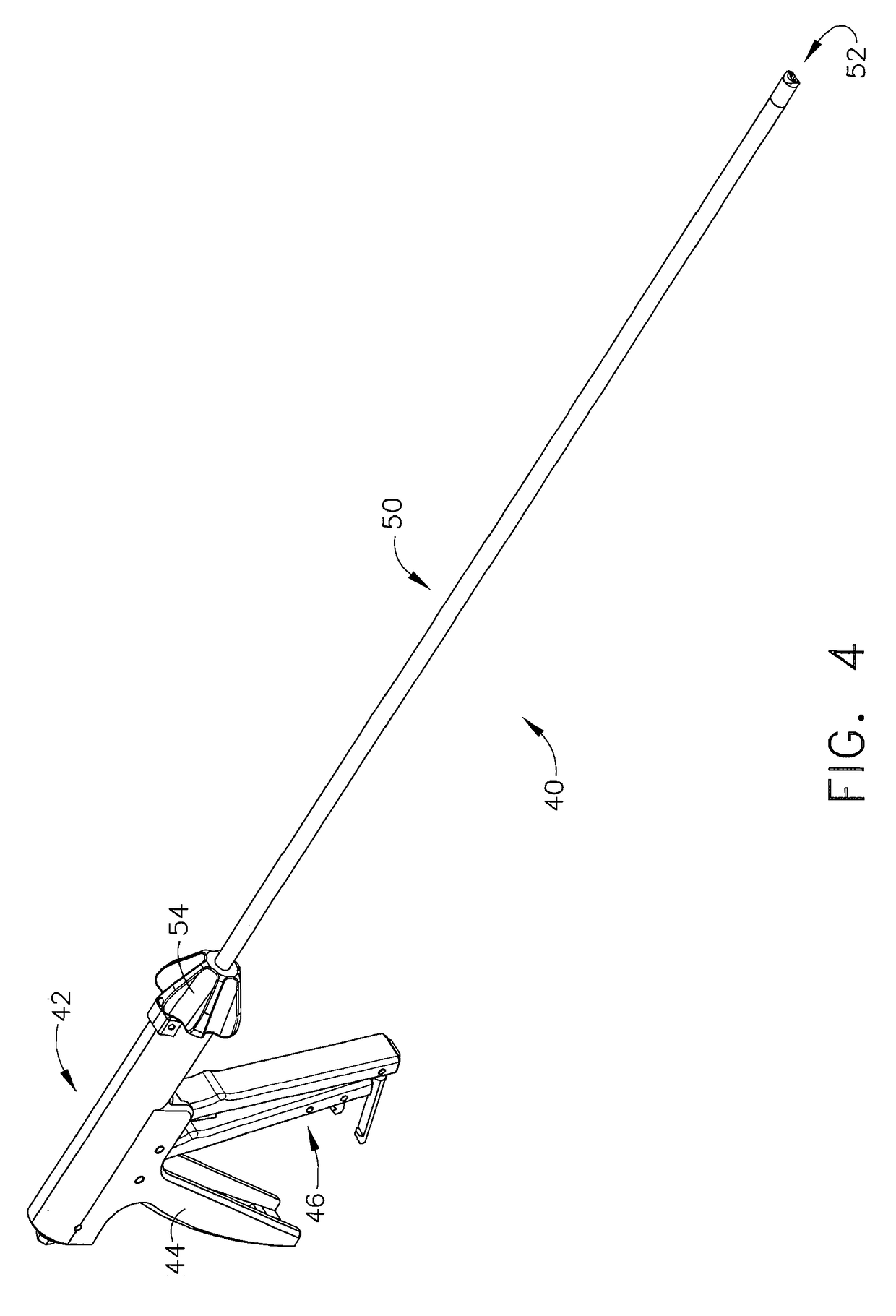

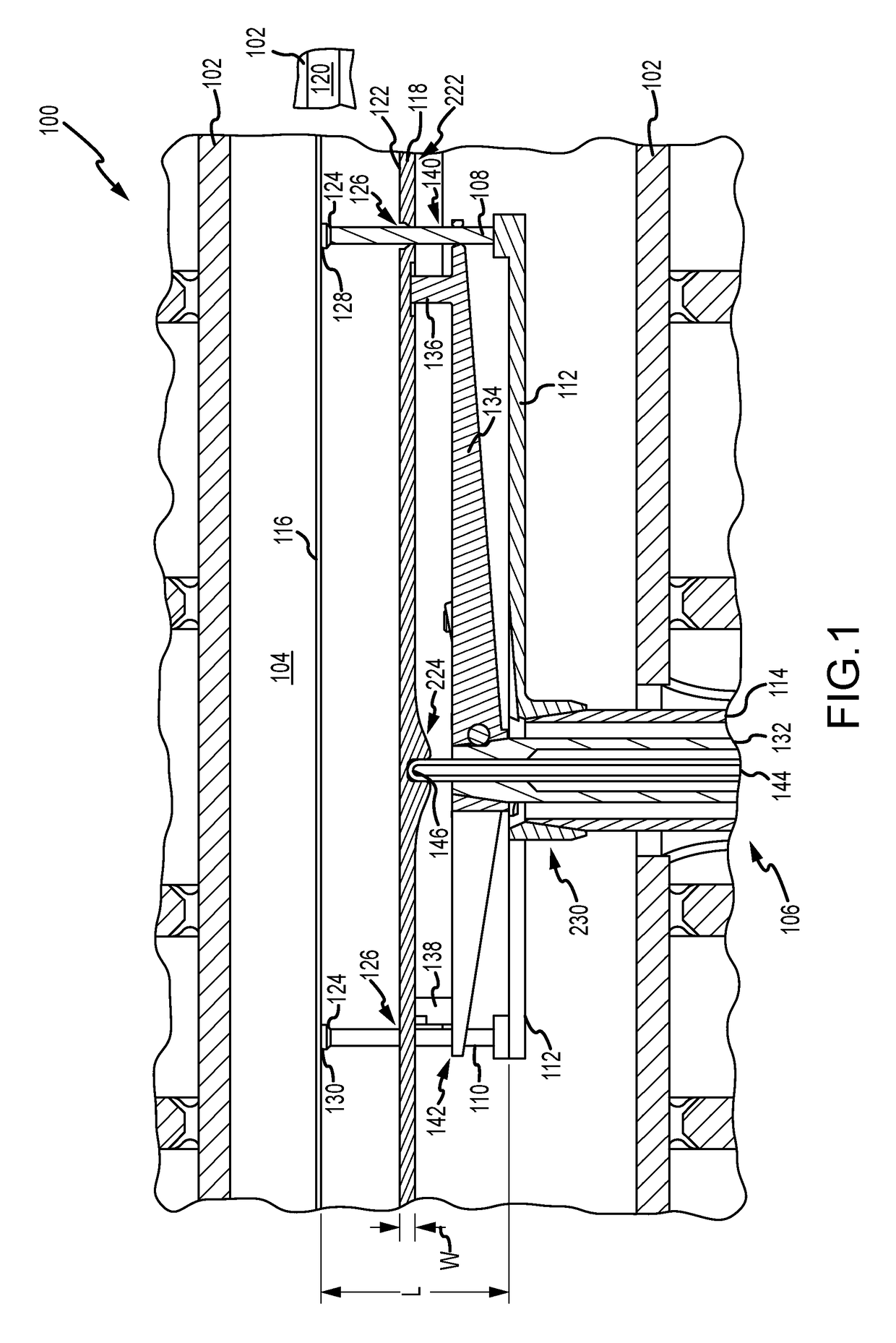

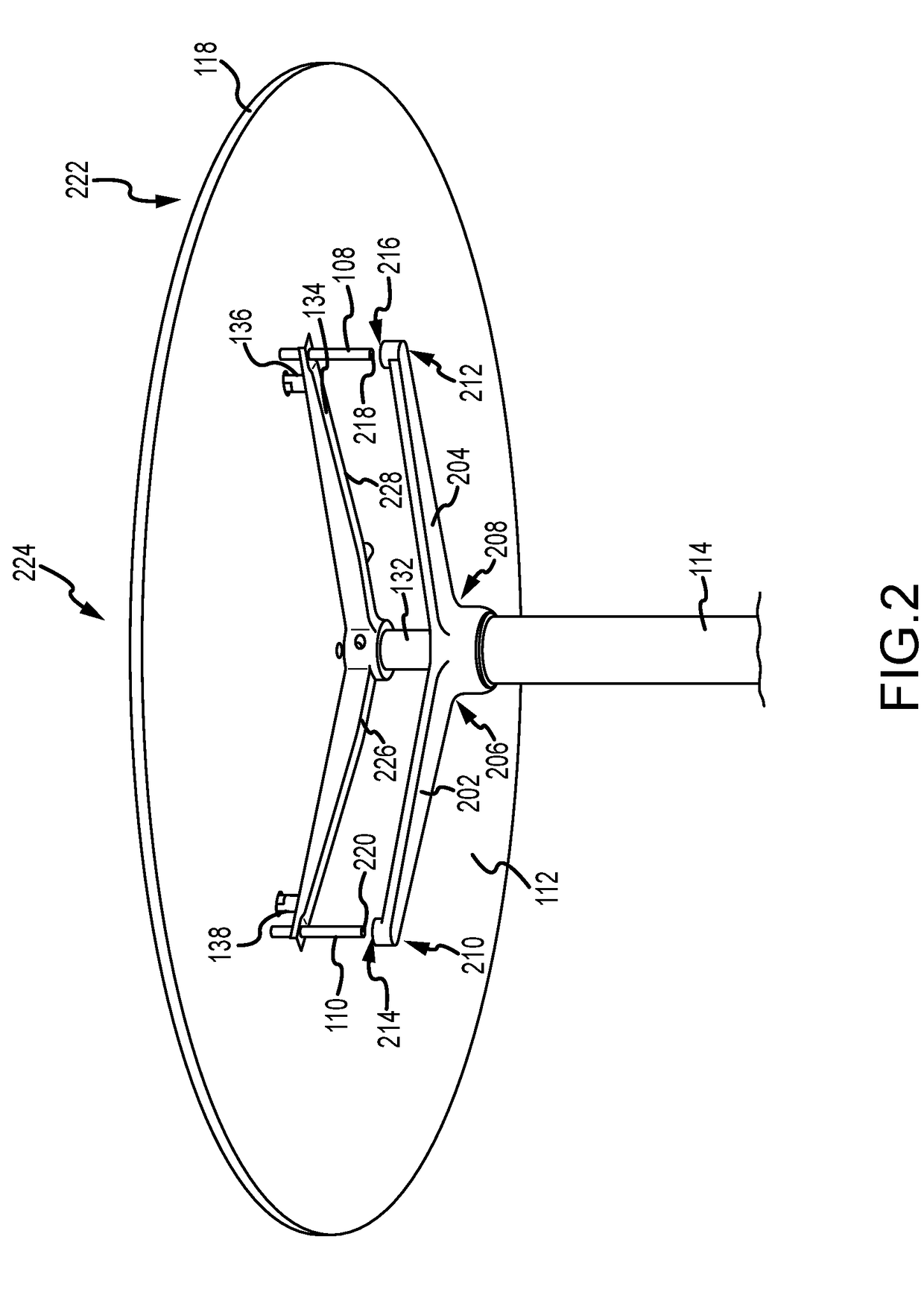

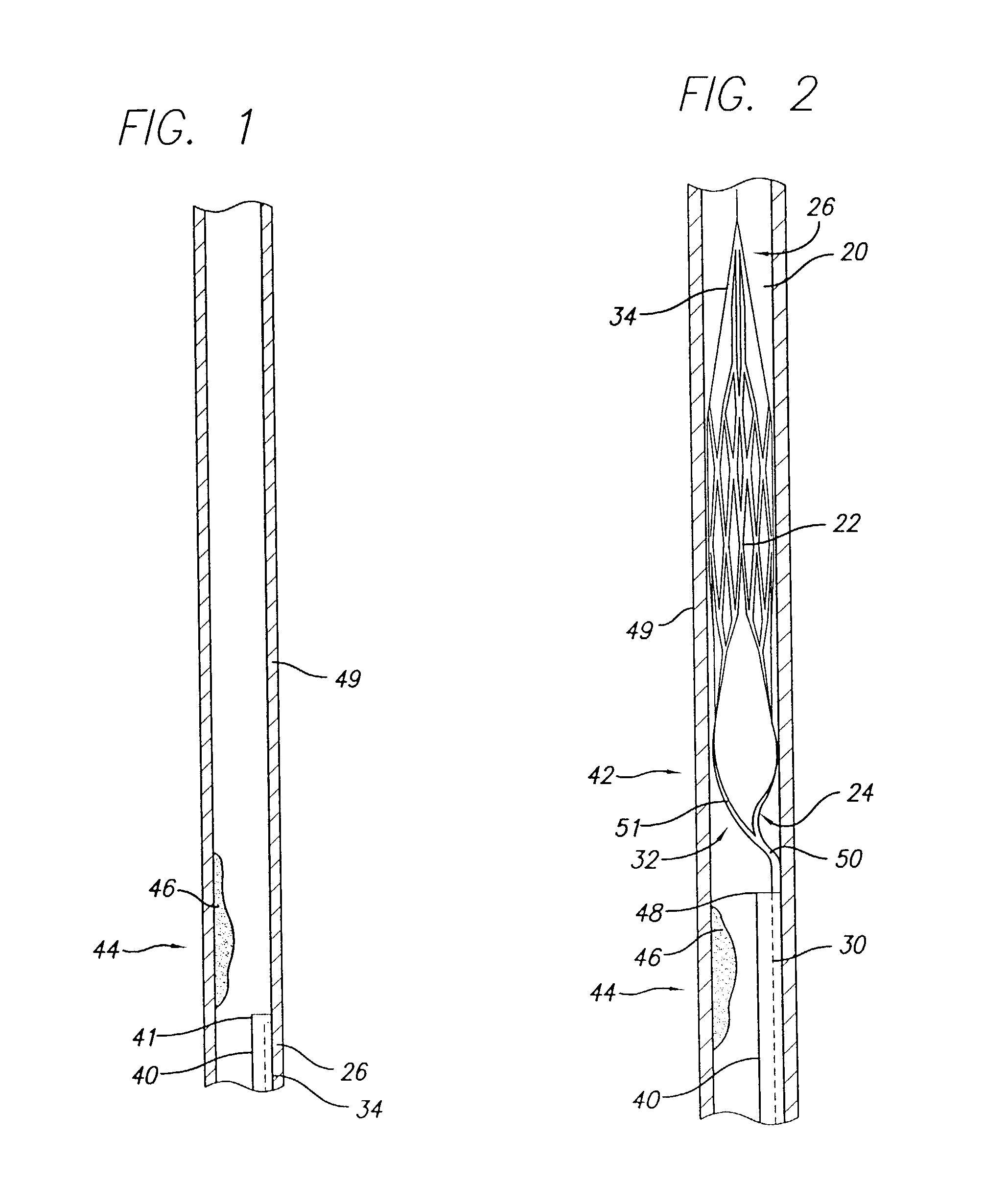

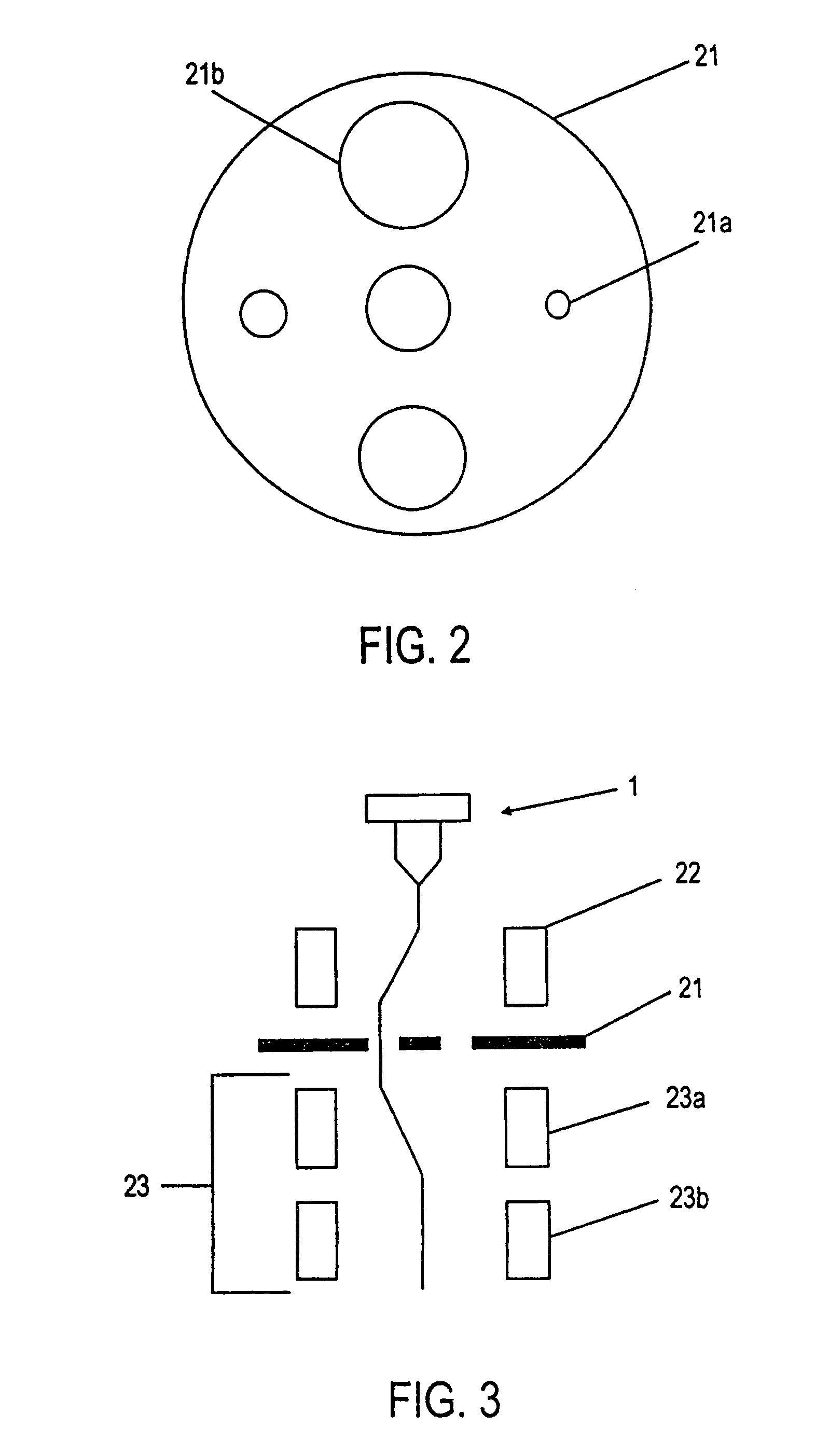

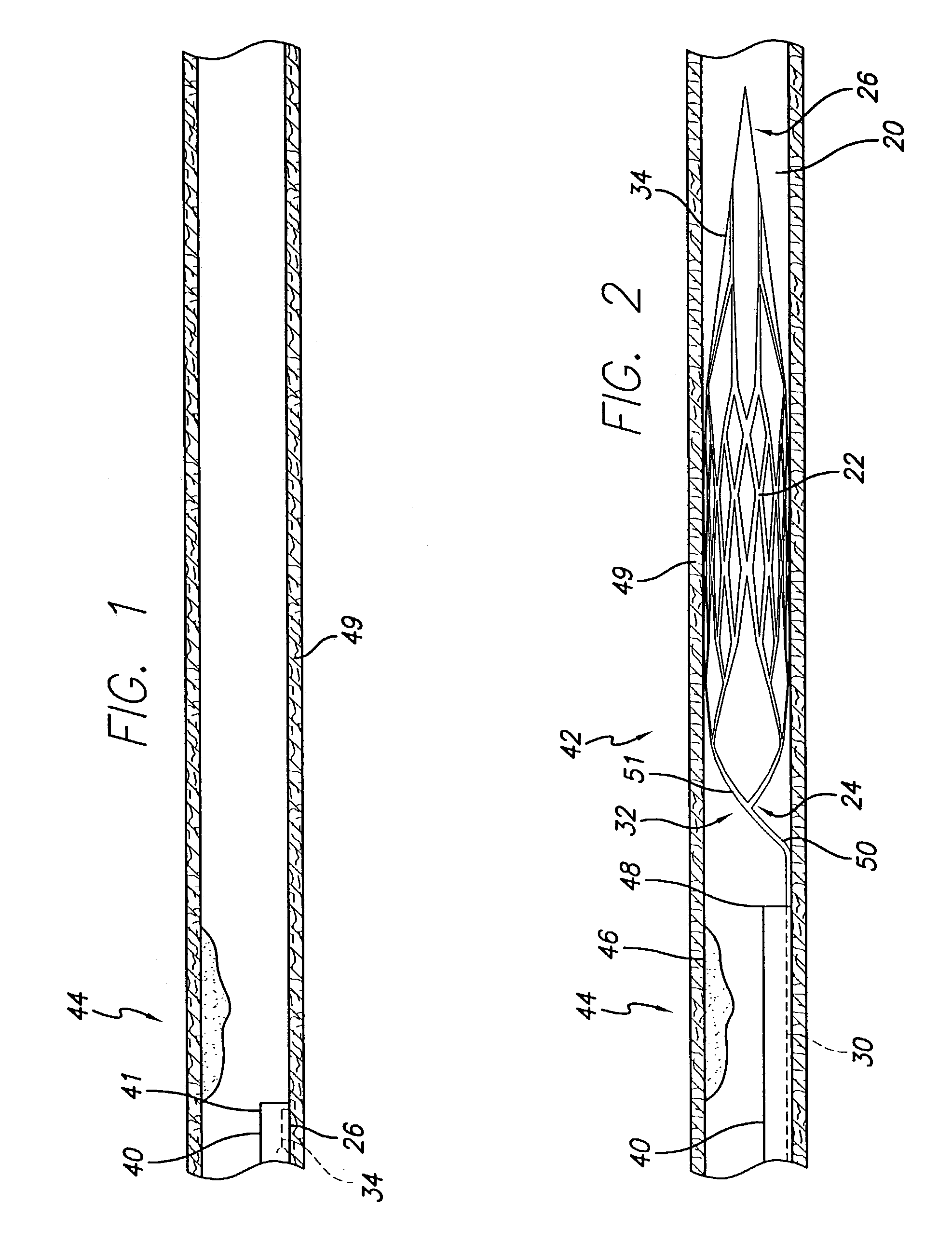

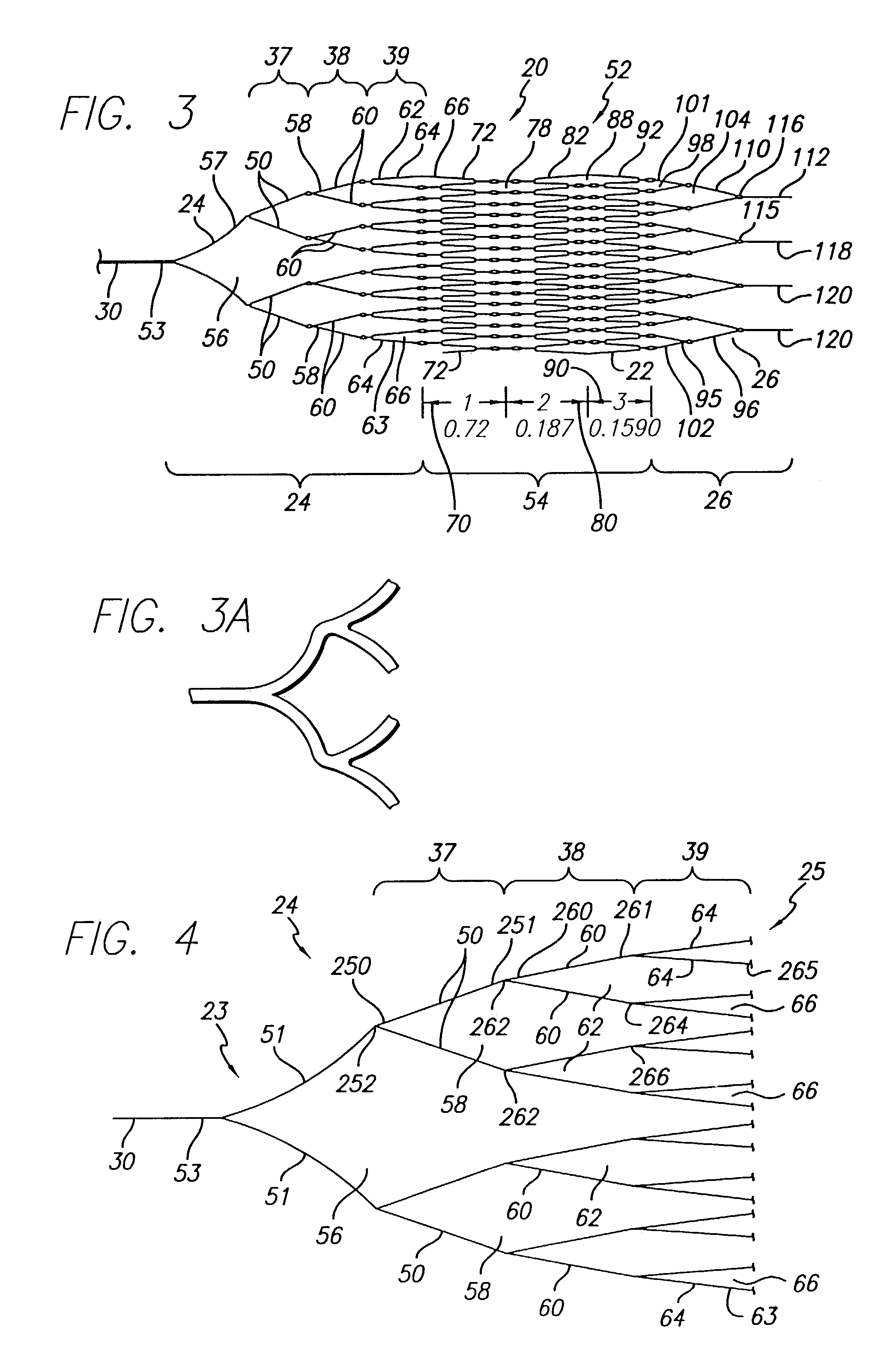

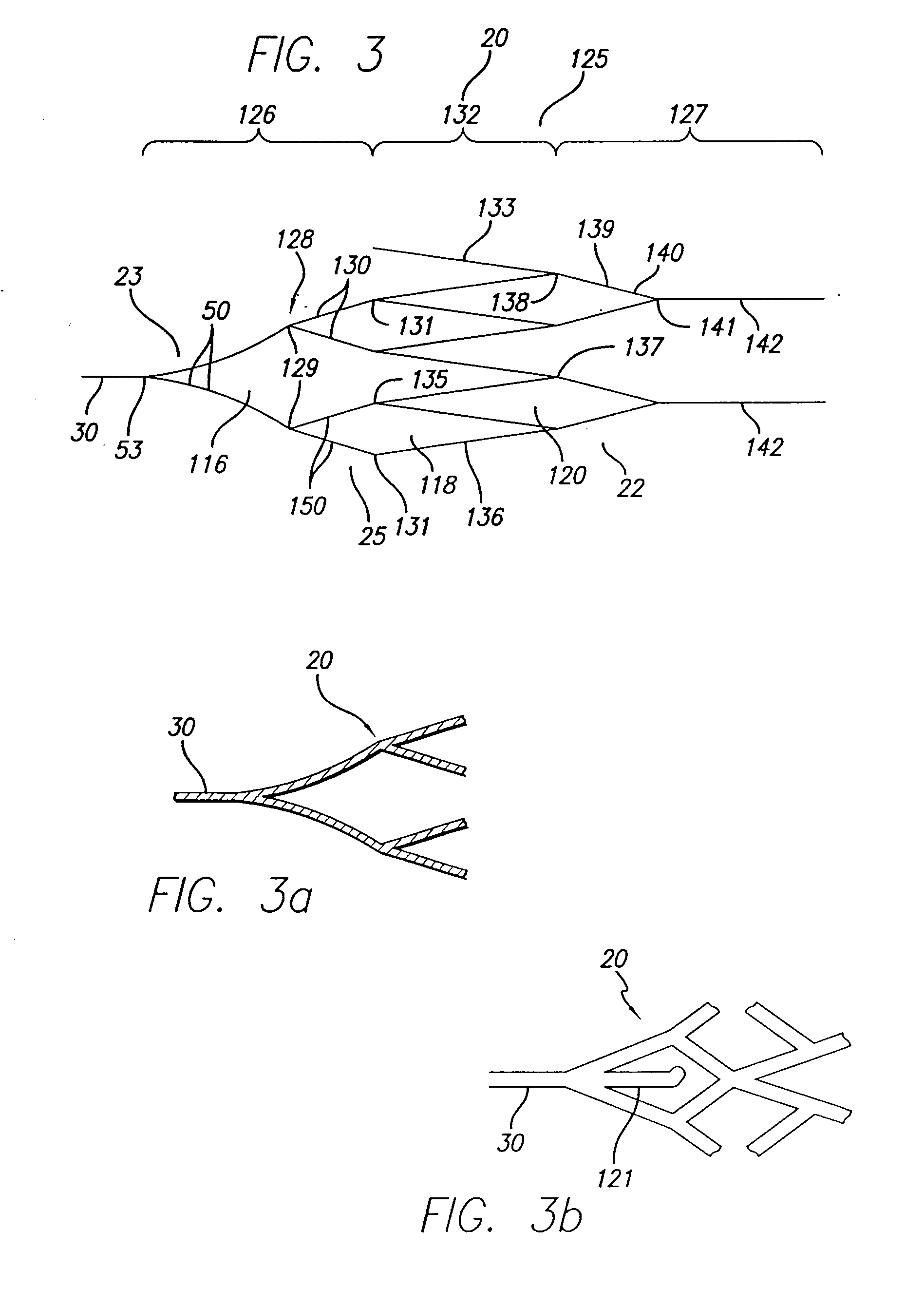

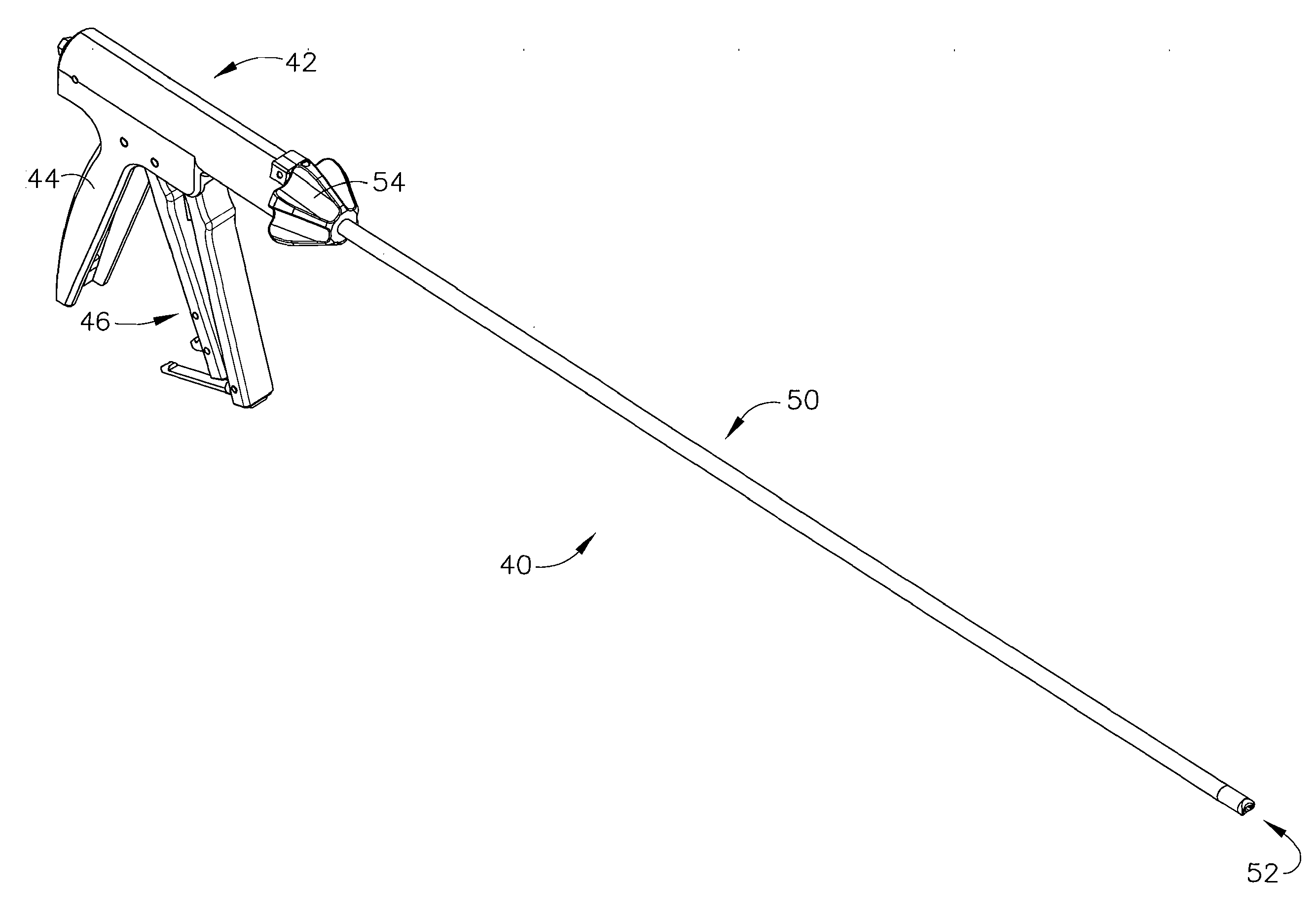

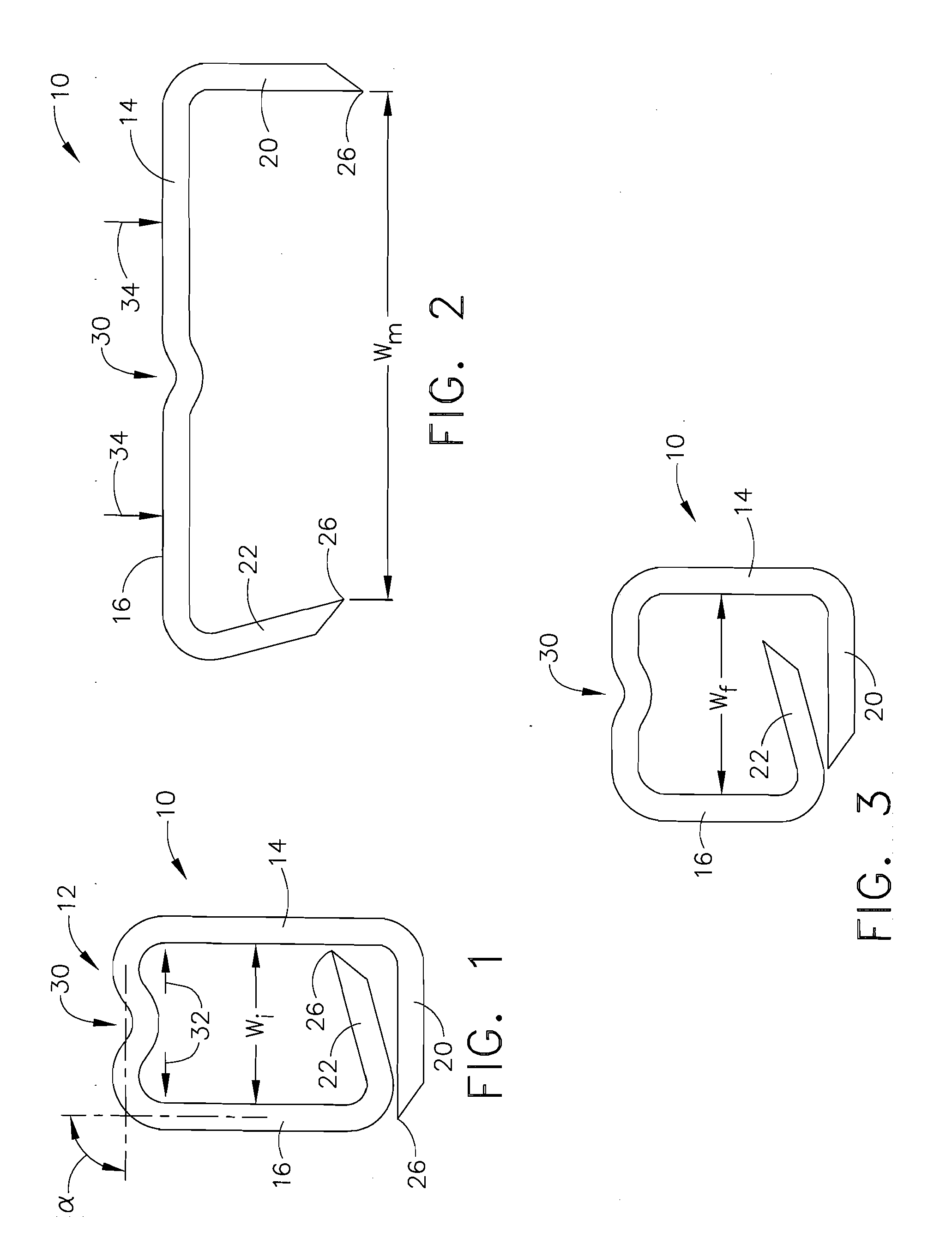

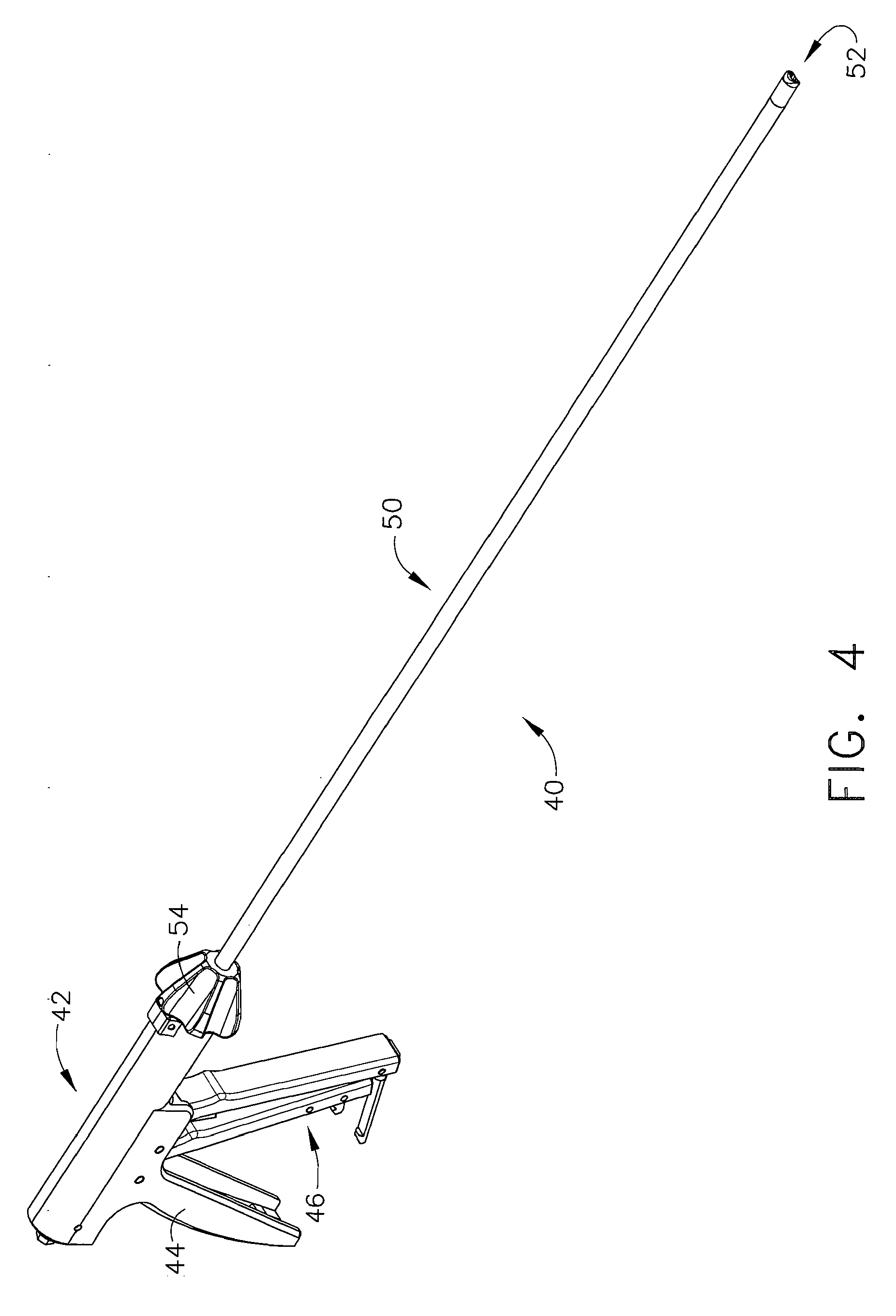

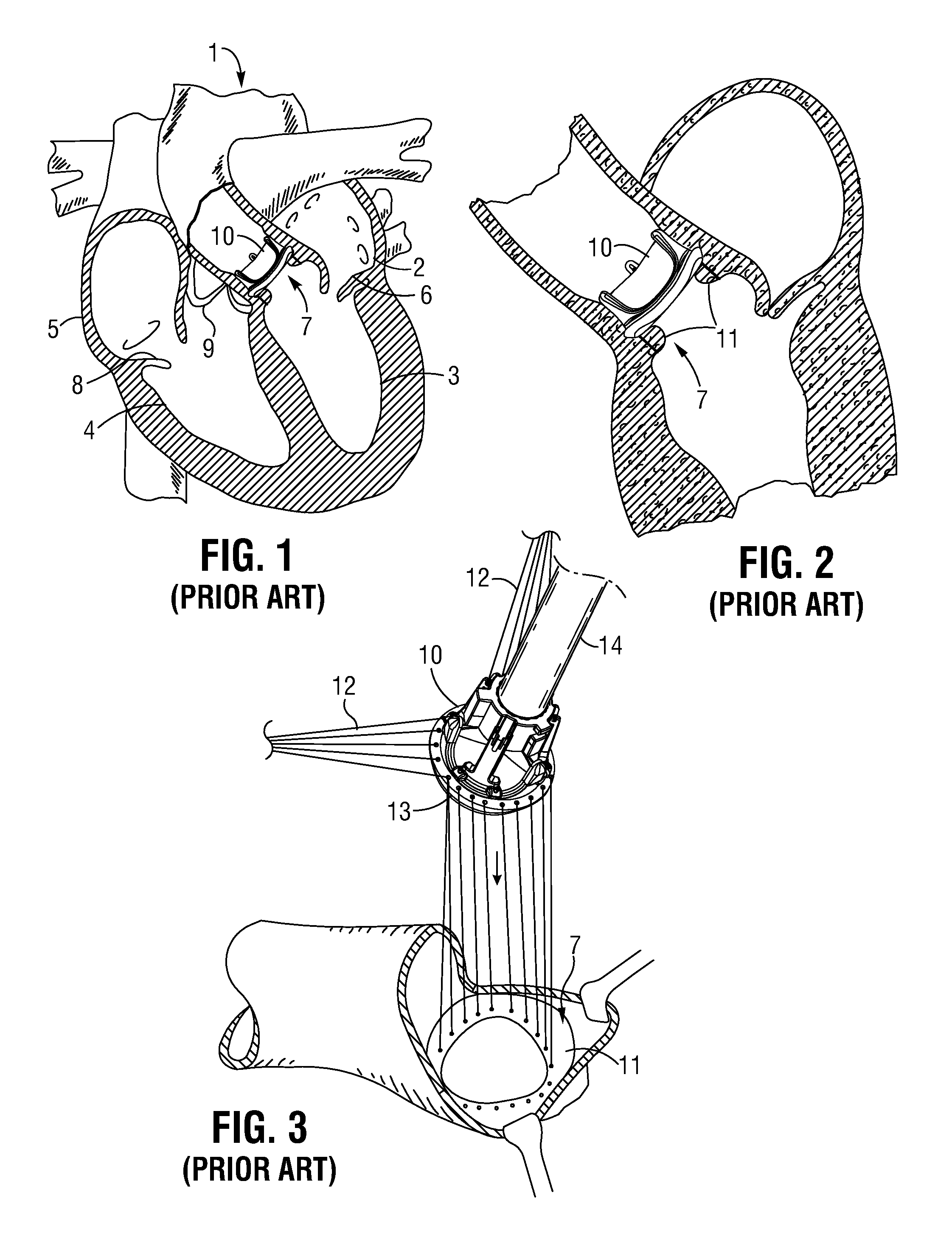

Surgical stapler for applying a large staple through a small delivery port and a method of using the stapler to secure a tissue fold

ActiveUS9713468B2Small shapeHigh strengthSuture equipmentsStapling toolsEngineeringBiomedical engineering

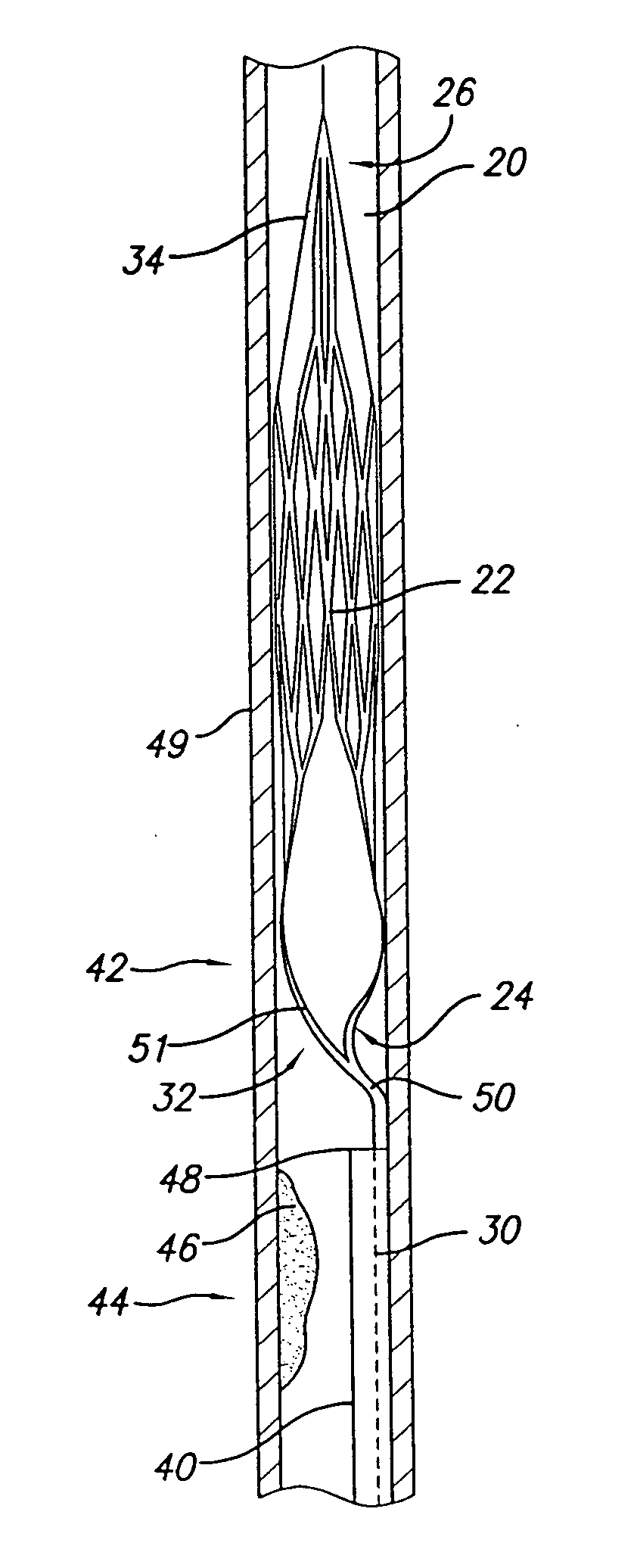

A method of deploying a surgical fastener into a patient by introducing the fastener into a body of a patient while the fastener is in a first shape having a first loop with a back span and an original size and shape. The method then involves moving end segments of the fastener away from each other substantially along an entire length thereof while keeping the back span in substantially its original size and shape. The method then involves forming the fastener into a second loop having a width greater than a width of the first loop.

Owner:ETHICON ENDO SURGERY INC

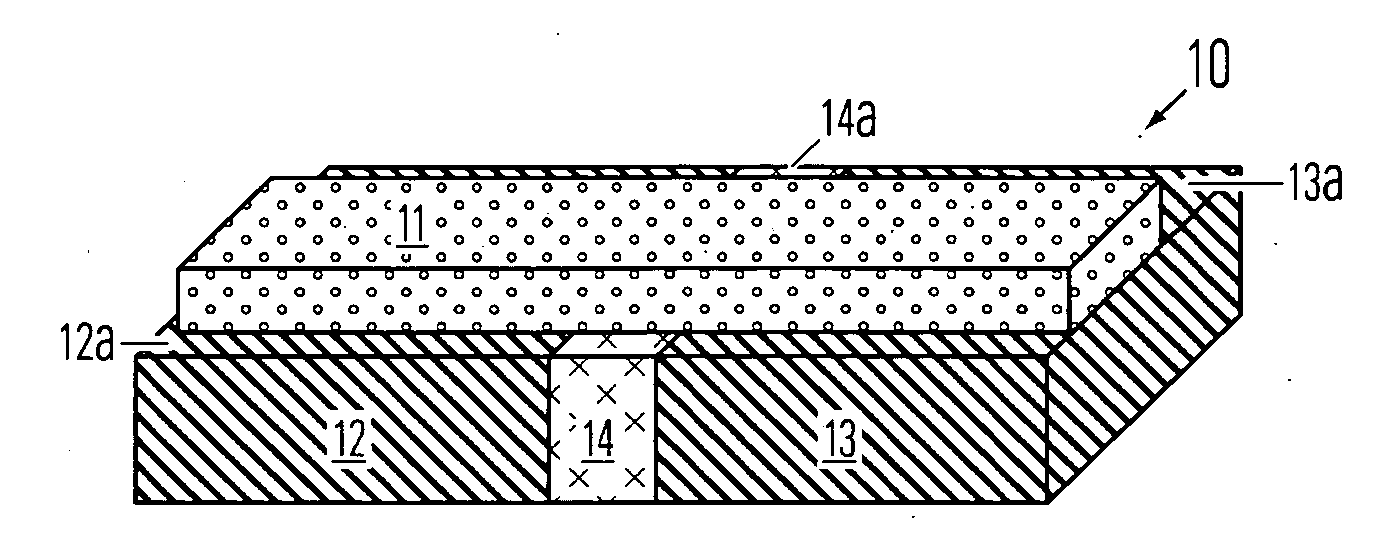

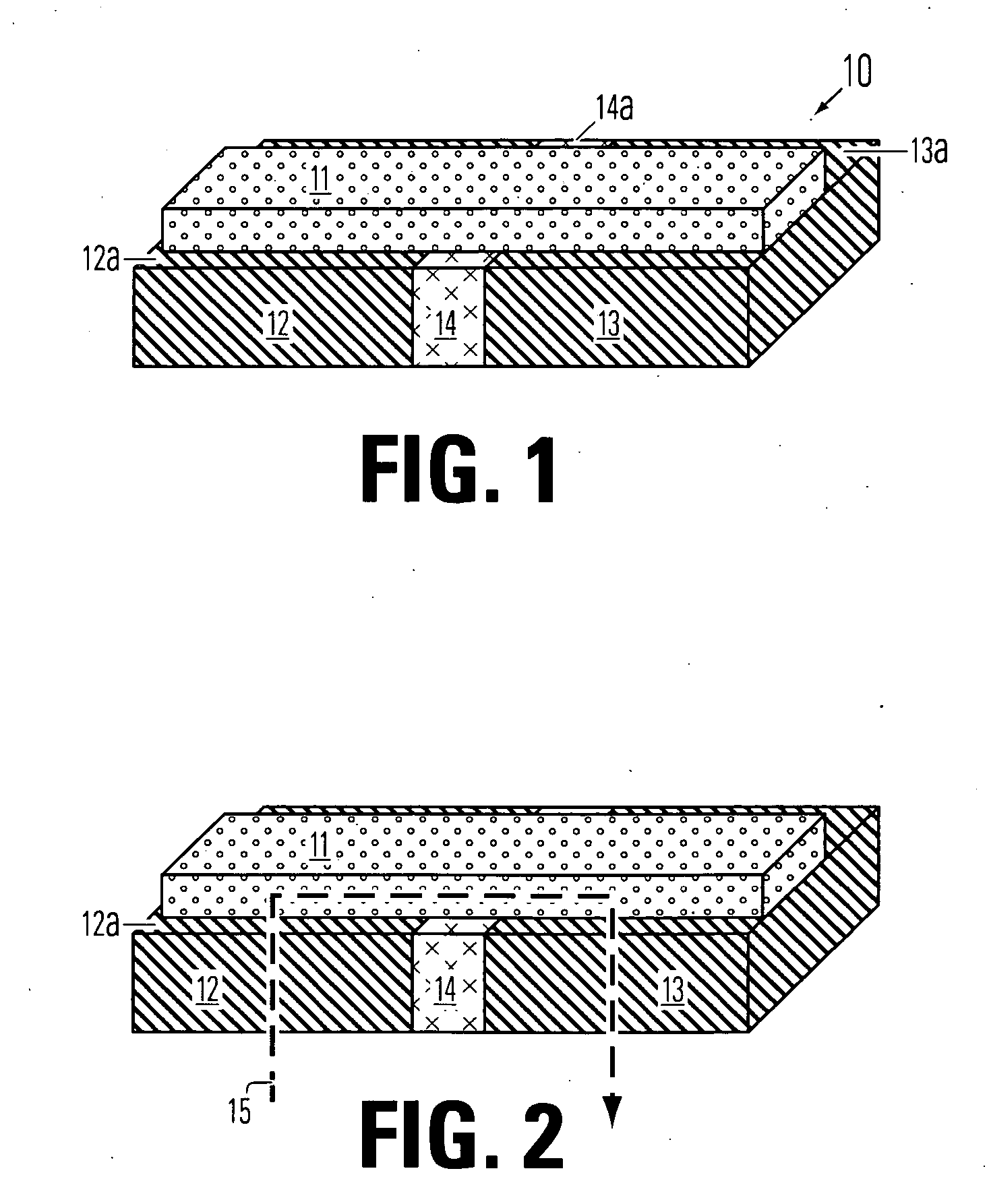

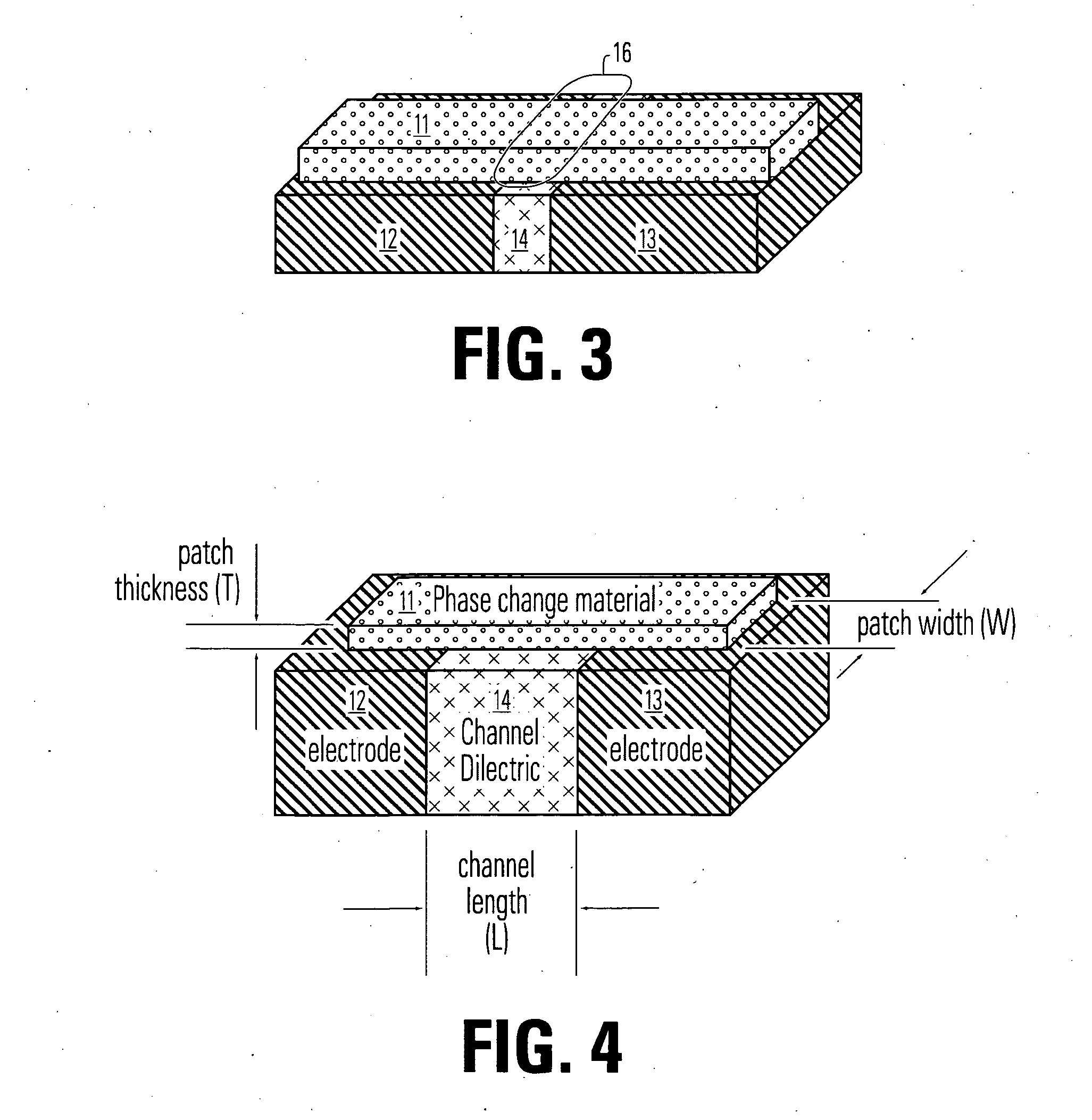

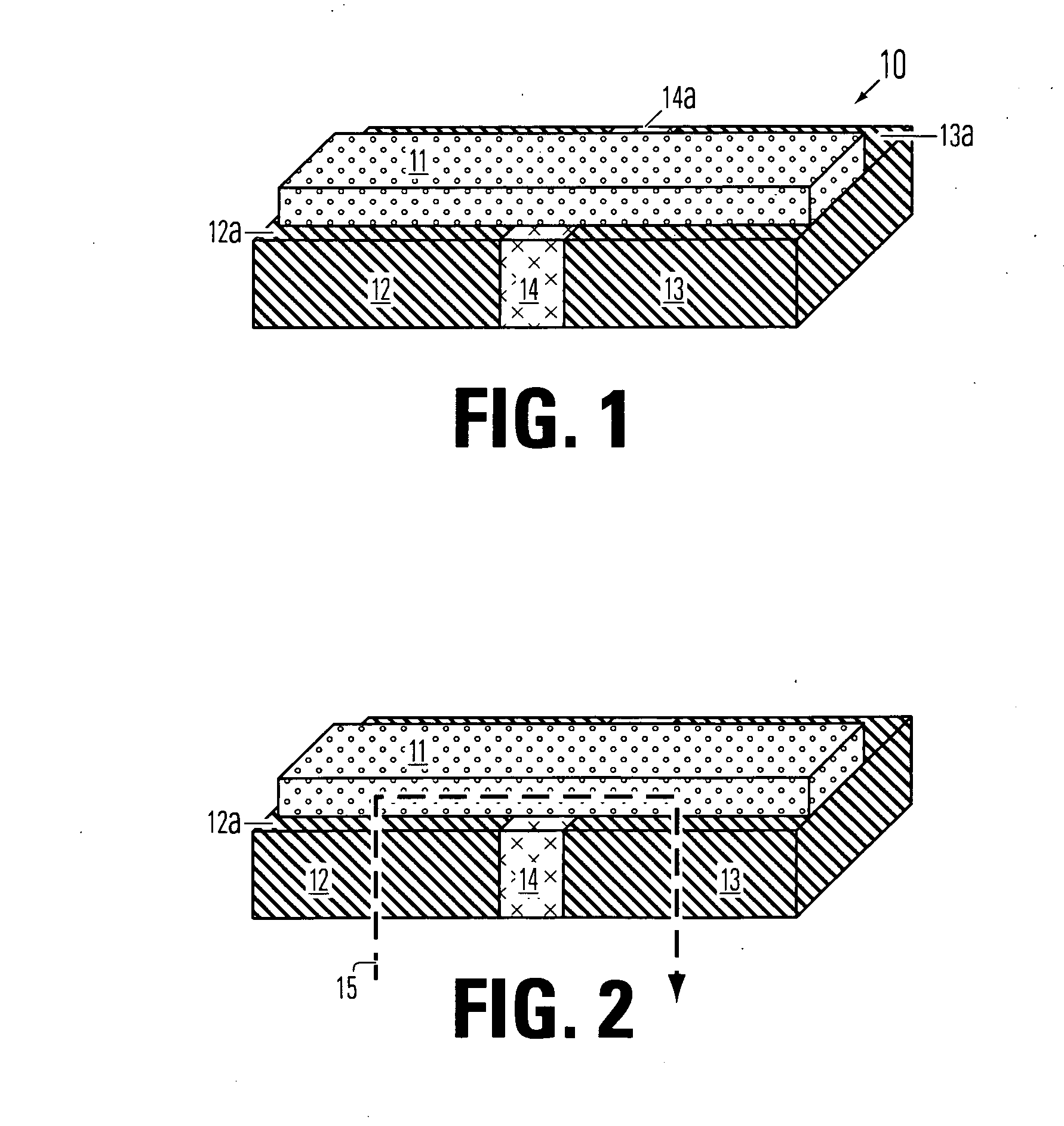

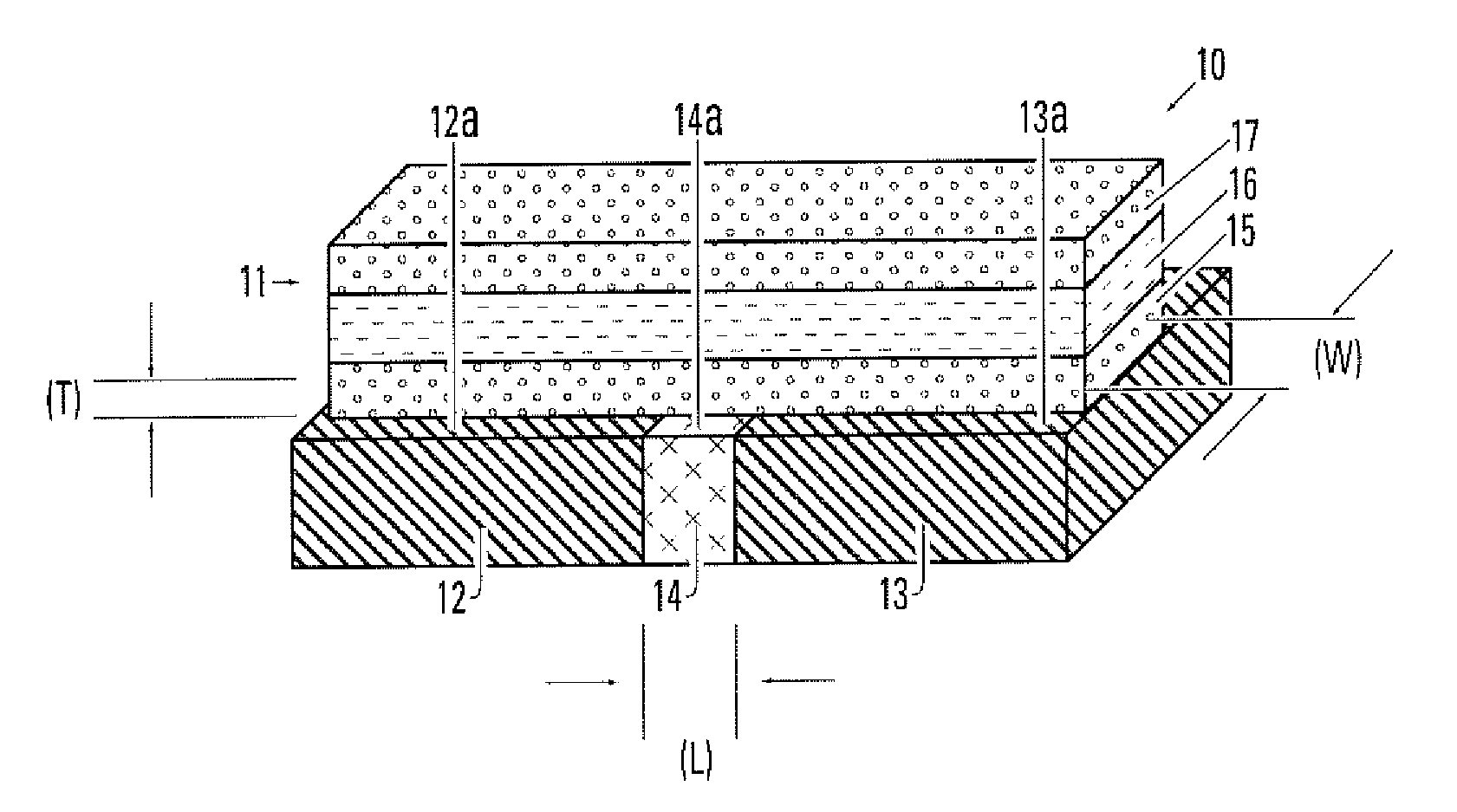

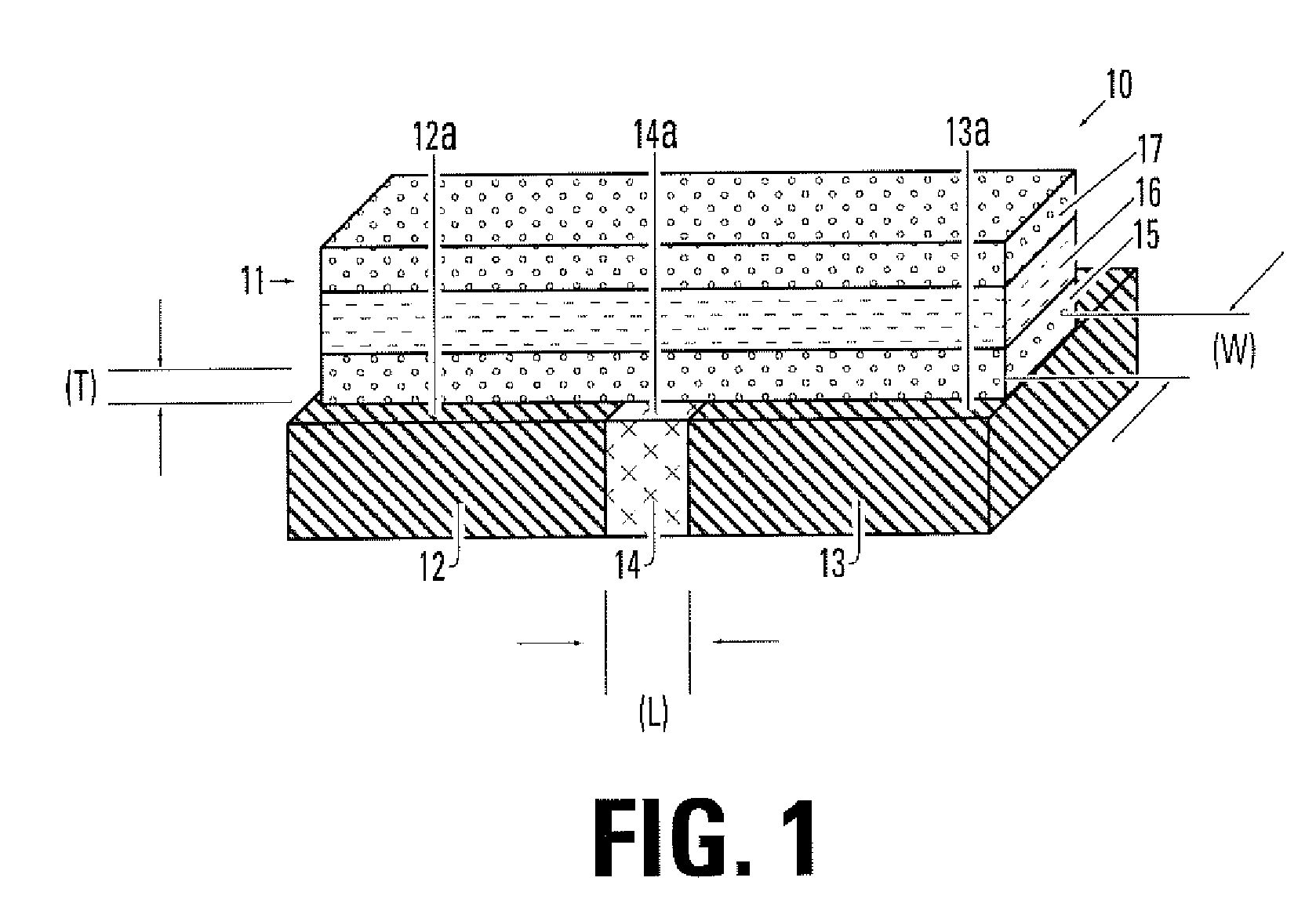

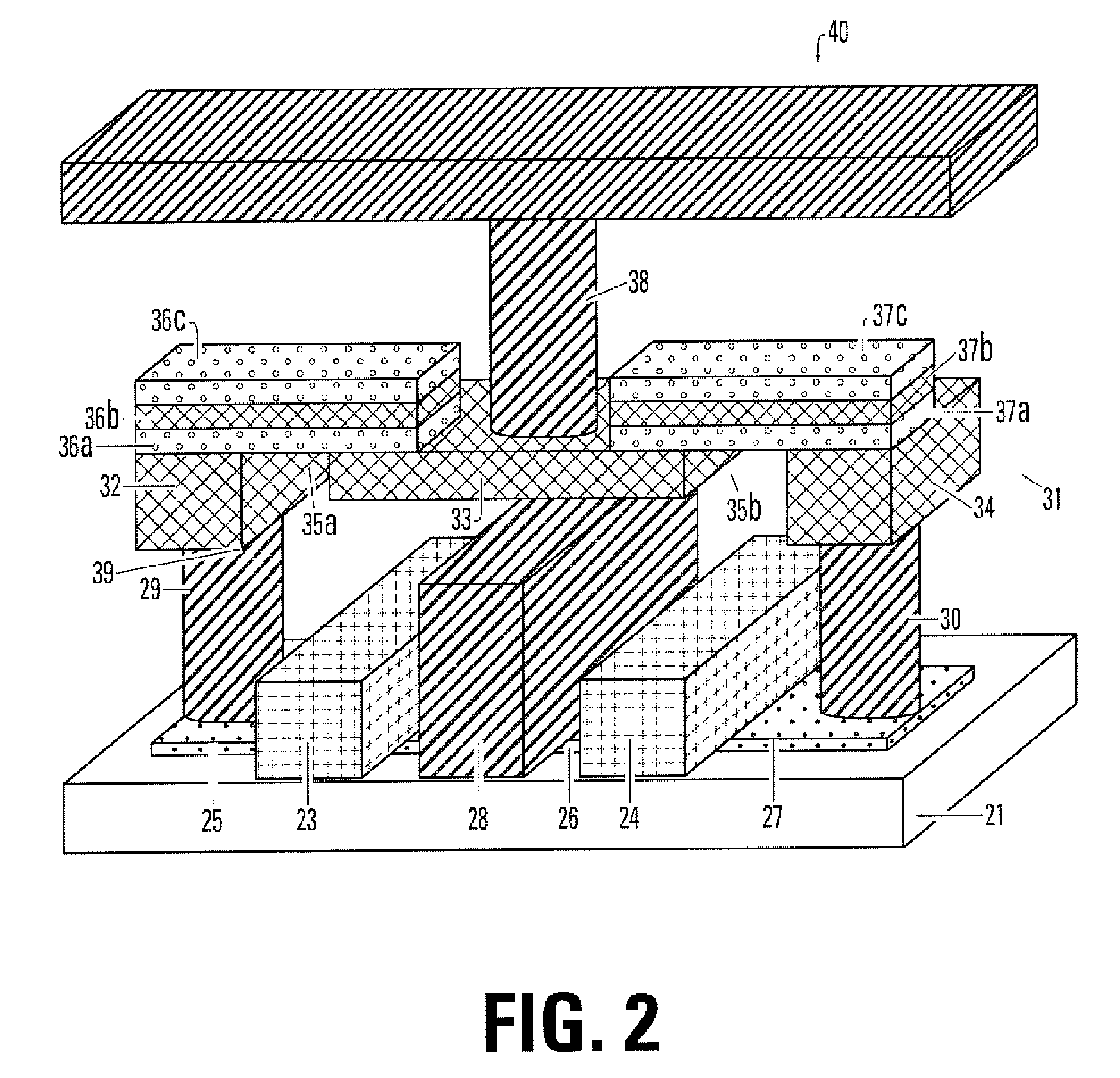

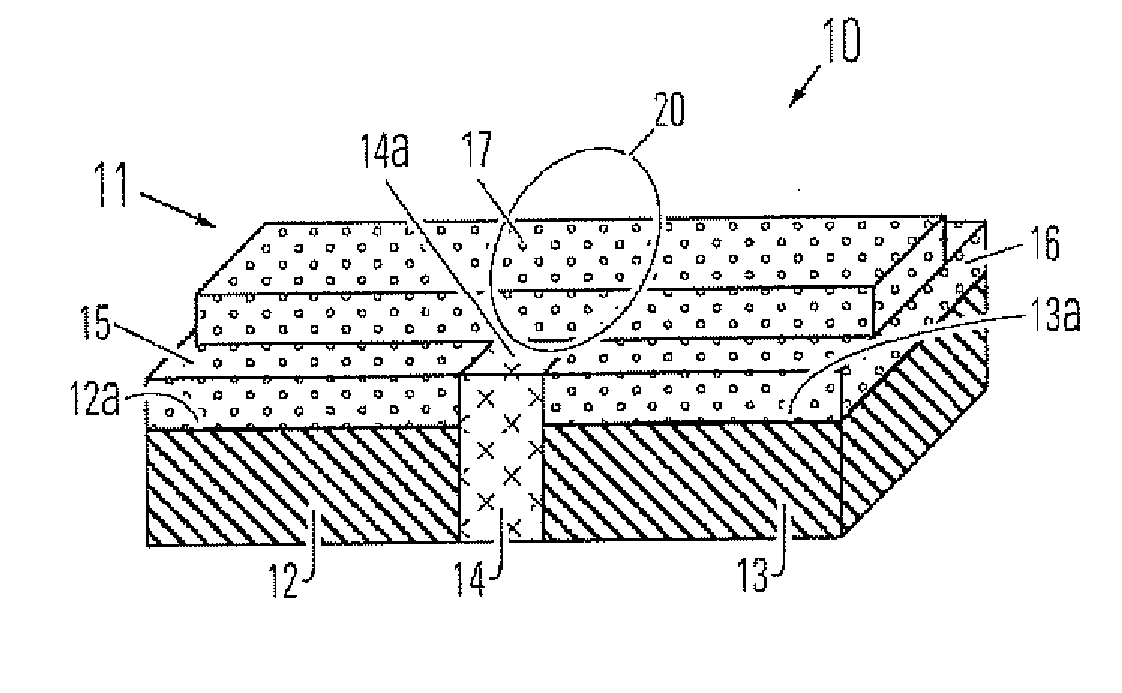

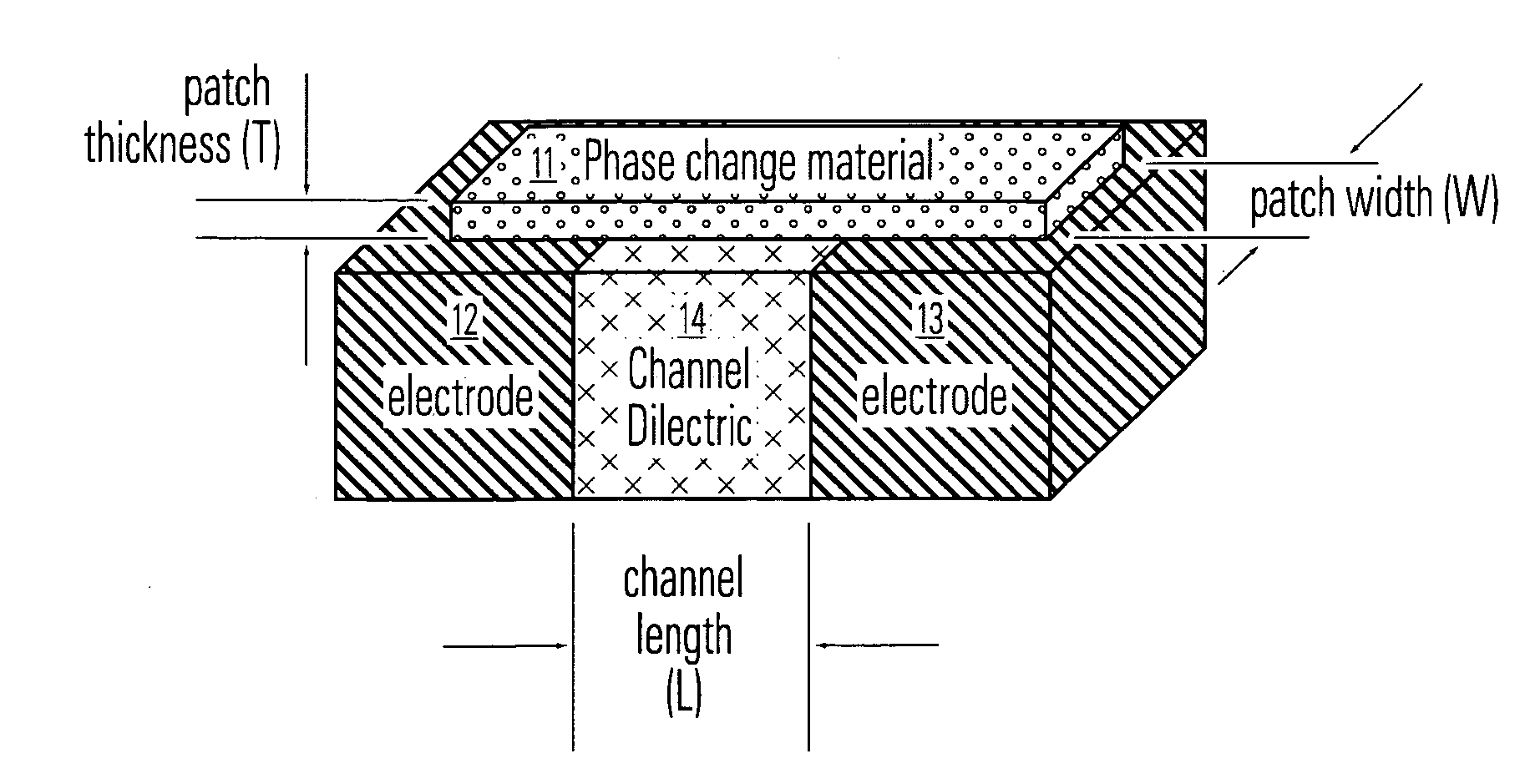

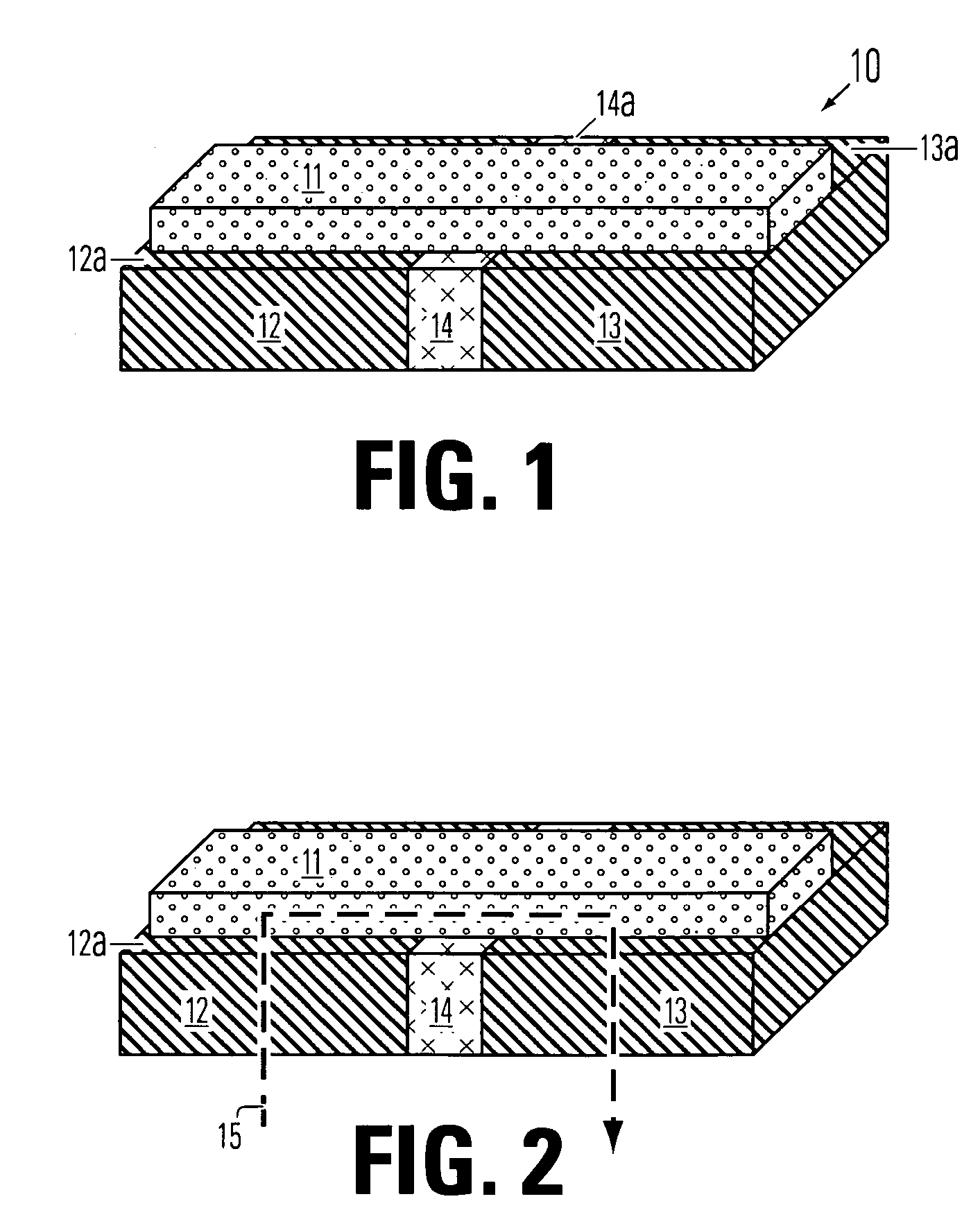

Thin film fuse phase change RAM and manufacturing method

ActiveUS20060284279A1Simple structureReduce power consumptionSolid-state devicesDigital storageEngineeringPhase change

A memory device comprising a first electrode having a top side, a second electrode having a top side and an insulating member between the first electrode and the second electrode. The insulating member has a thickness between the first and second electrodes near the top side of the first electrode and the top side of the second electrode. A bridge of memory material crosses the insulating member, and defines an inter-electrode path between the first and second electrodes across the insulating member. An array of such memory cells is provided. In the array, a plurality of electrode members and insulating members therebetween comprise an electrode layer on an integrated circuit. The bridges of memory material have sub-lithographic dimensions.

Owner:MACRONIX INT CO LTD

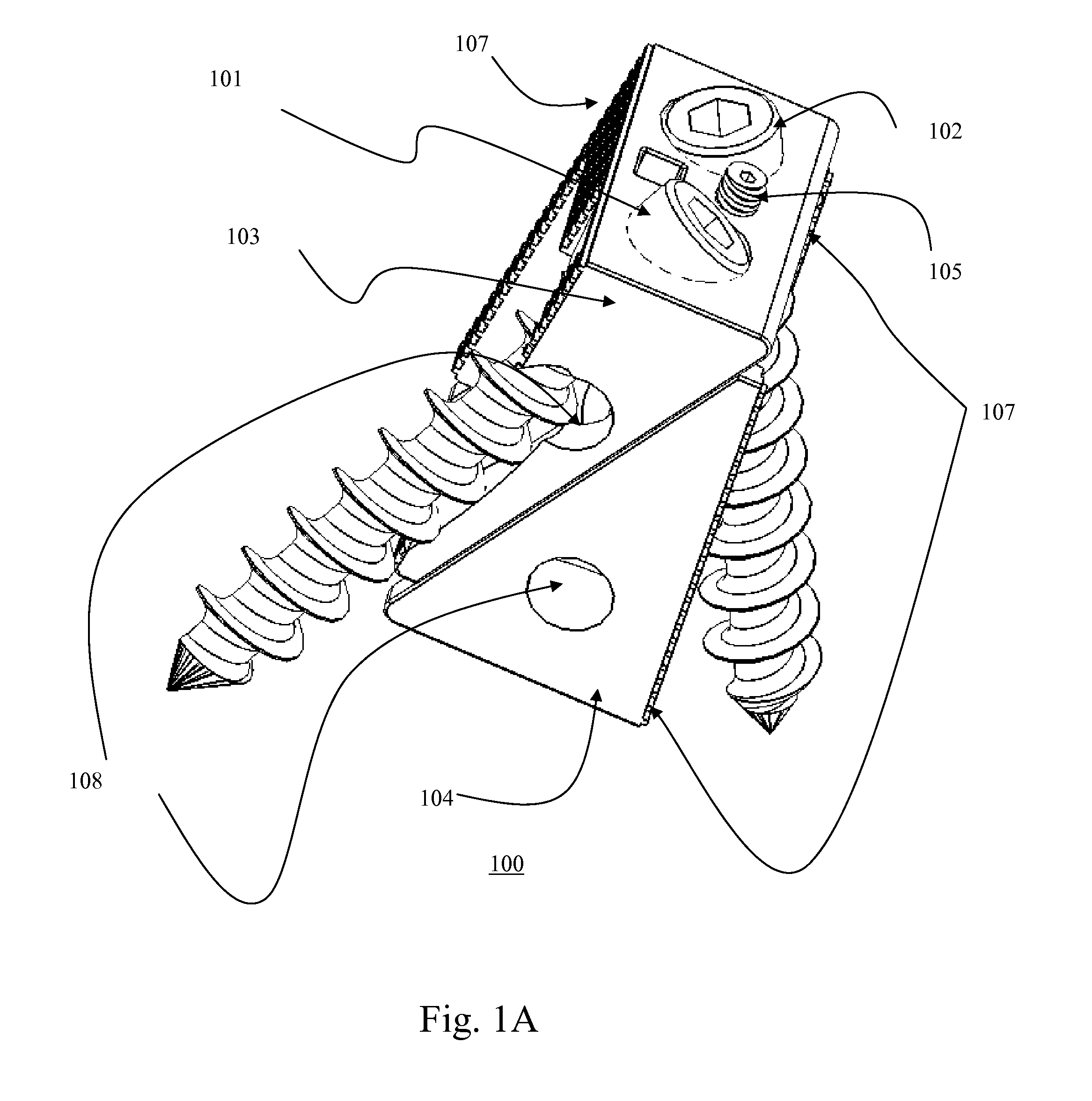

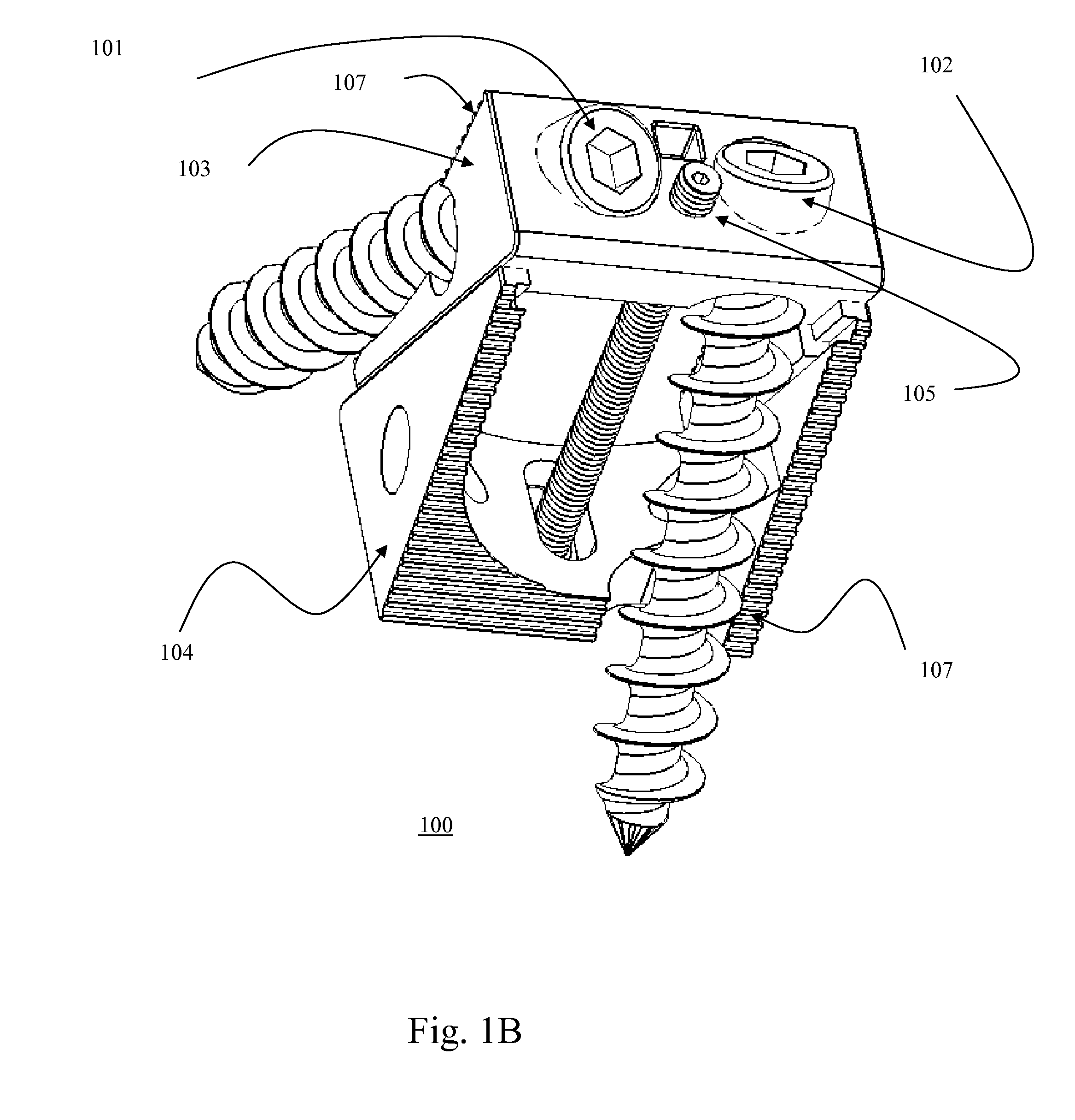

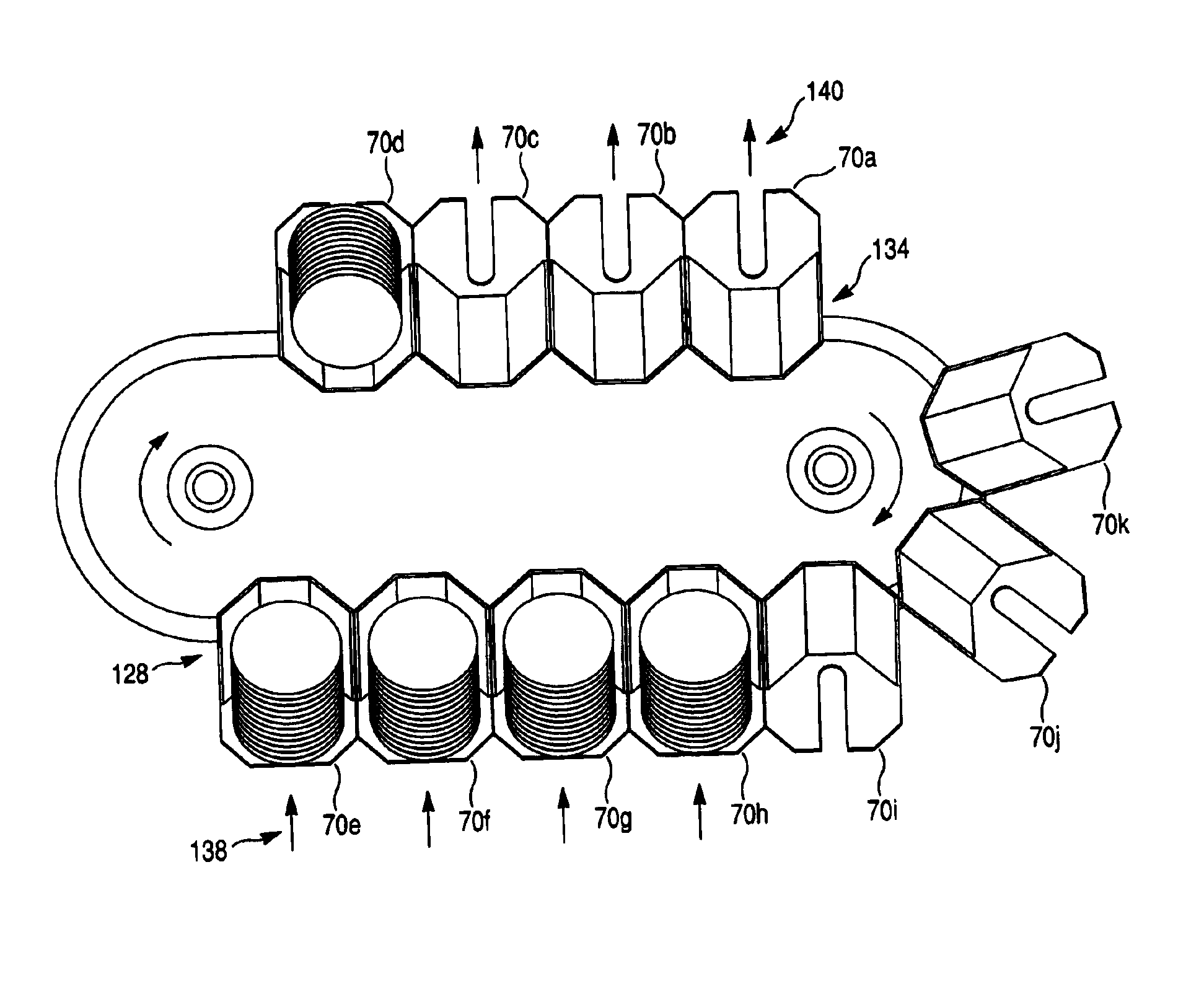

Bi-directional fixating transvertebral body screws and posterior cervical and lumbar interarticulating joint calibrated stapling devices for spinal fusion

ActiveUS20080033440A1Reduce widthAvoid excessive retractionInternal osteosythesisBone implantBones fusionLumbar vertebrae

A self-drilling bone fusion screw apparatus is disclosed which includes at least first and second sliding boxes. A first screw member having a tapered end and a threaded body is disposed within the first sliding box, and a second screw member having a tapered end and a threaded body disposed within the second sliding box. An adjuster adjusts the height of the sliding boxes. The screw members are screwed into vertebral bodies in order to fuse the vertebral bodies together. A plurality of the self-drilling bone fusion screw apparatuses may be attached together and / or integrated via a plate or cage. Also disclosed is a cervical facet staple that includes a curved staple base and at least two prongs attached to the bottom surface of the curved staple base.

Owner:MOSKOWITZ FAMILY LLC

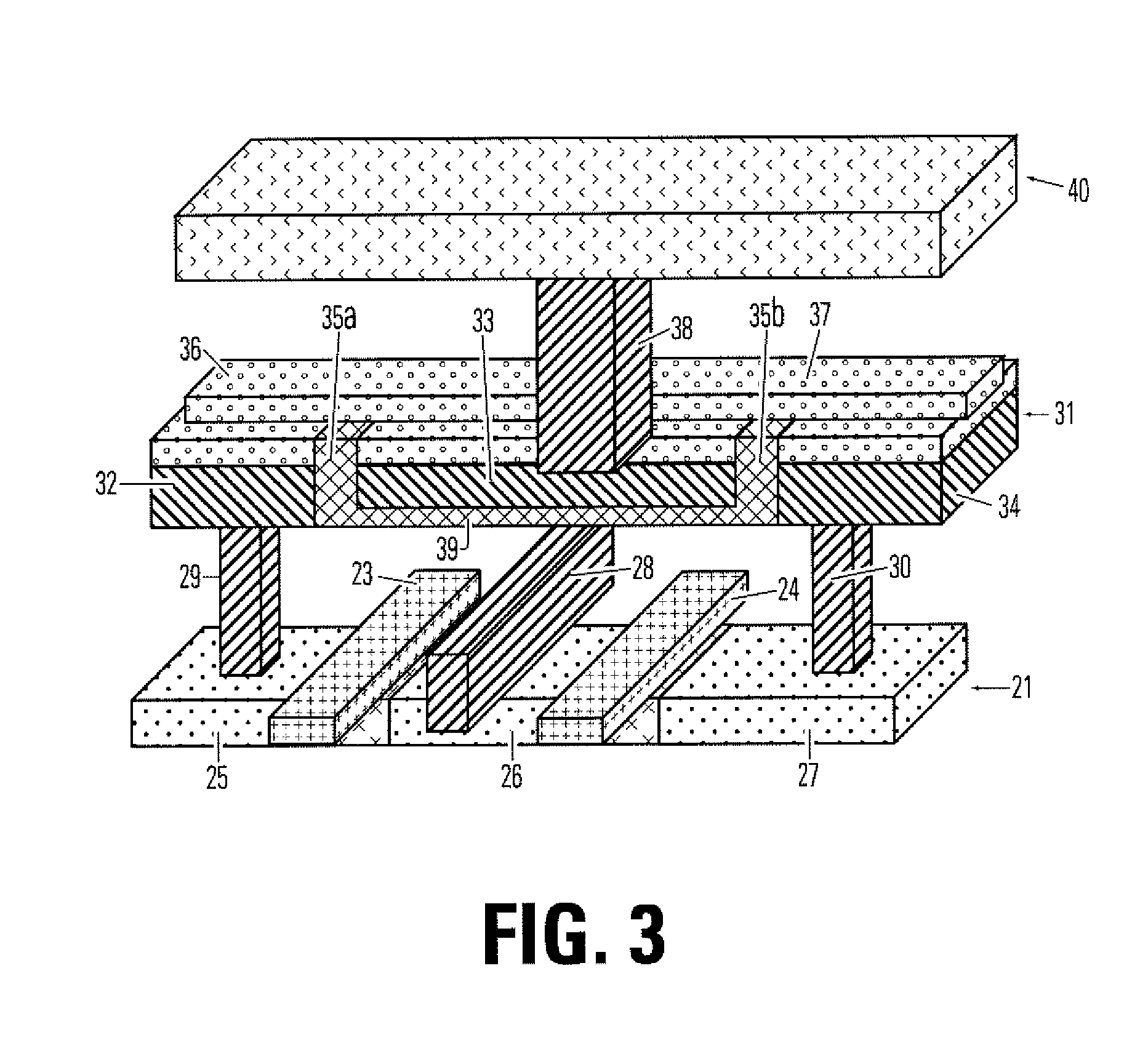

Manufacturing methods for thin film fuse phase change ram

InactiveUS20060286709A1Simple structureReduce power consumptionSolid-state devicesSemiconductor/solid-state device manufacturingPhase-change memoryOptoelectronics

A method for manufacturing a memory device comprises forming an electrode layer on a substrate which comprises circuitry made using front-end-of-line procedures. The electrode layer includes a first electrode and a second electrode, and an insulating member between the first and second electrodes for each phase change memory cell to be formed. A bridge of memory material is formed on the top surface of the electrode layer across the insulating member for each memory cell to be formed. An access structure over the electrode layer is made by forming a patterned conductive layer over said bridge, and forming a contact between said first electrode and said patterned conductive layer.

Owner:MACRONIX INT CO LTD

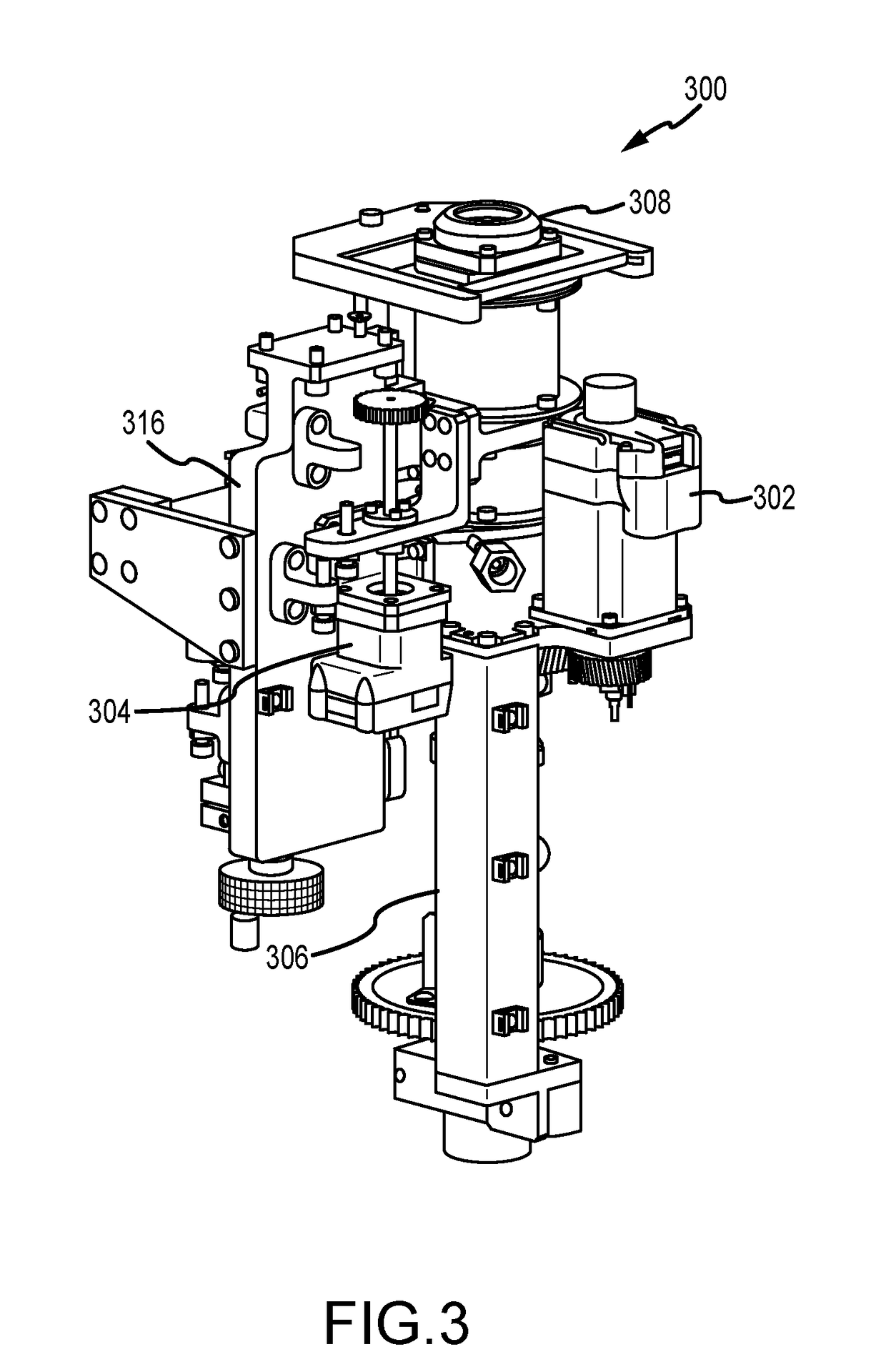

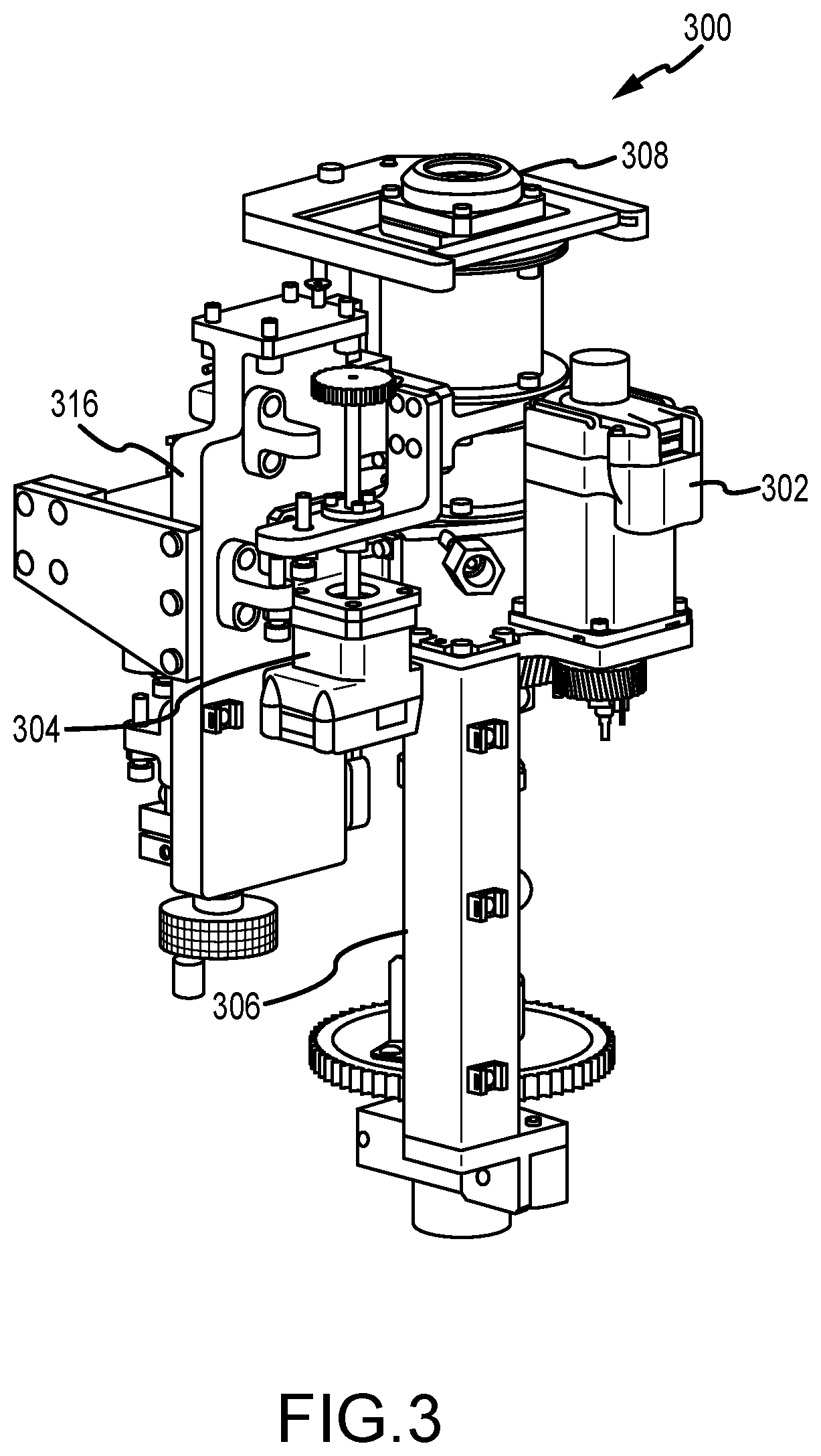

Substrate lift mechanism and reactor including same

ActiveUS20190051555A1Easy to maintain and process substrateReduce amount of timeElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringSusceptor

A substrate support assembly suitable for use in a reactor including a common processing and substrate transfer region is disclosed. The substrate support assembly includes a susceptor and one or more lift pins that can be used to lower a substrate onto a surface of the susceptor and raise the substrate from the surface, to allow transfer of the substrate from the processing region, without raising or lowering the susceptor.

Owner:ASM IP HLDG BV

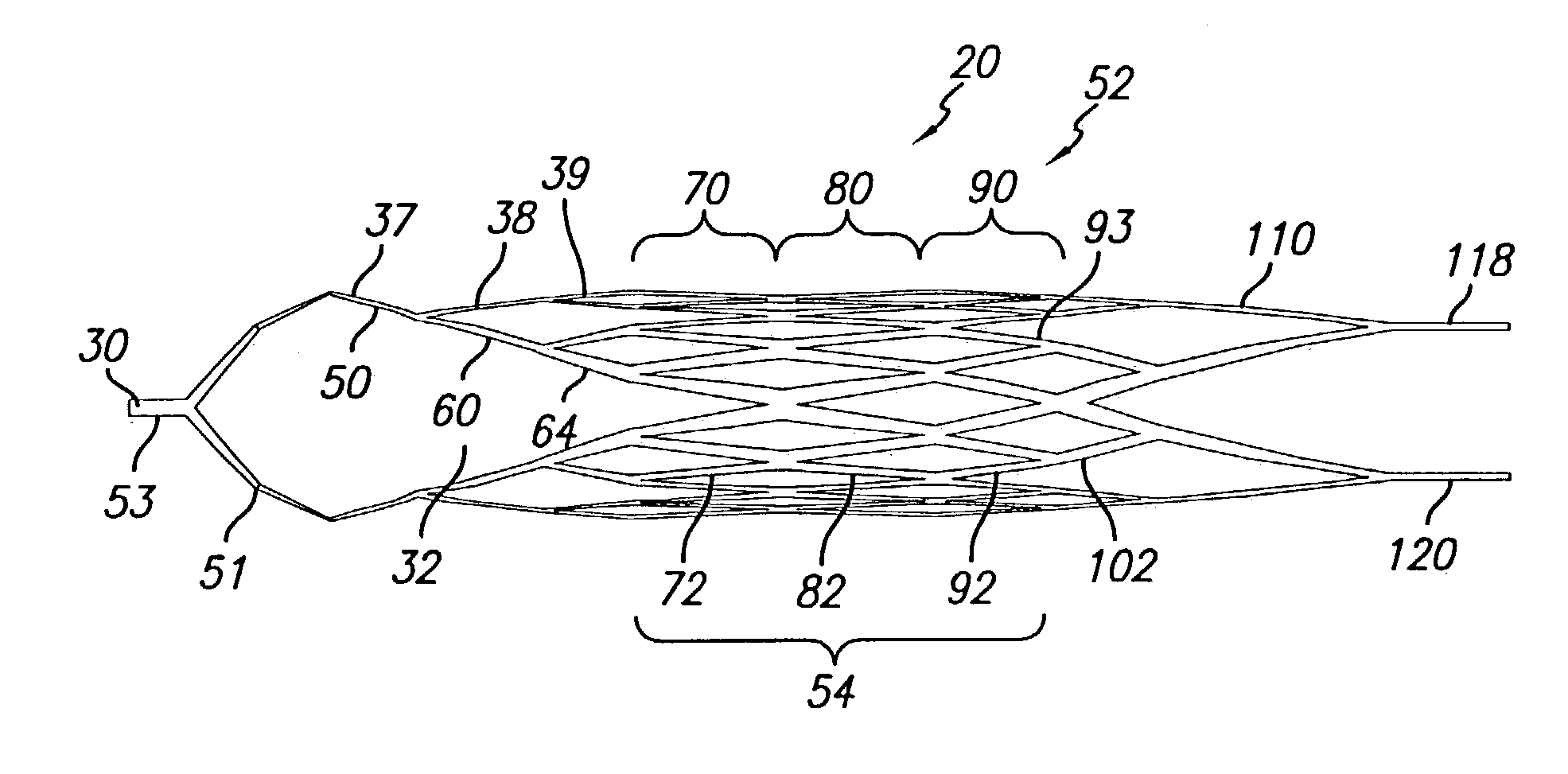

Embolic basket

Owner:ENDOVASCULAR TECH

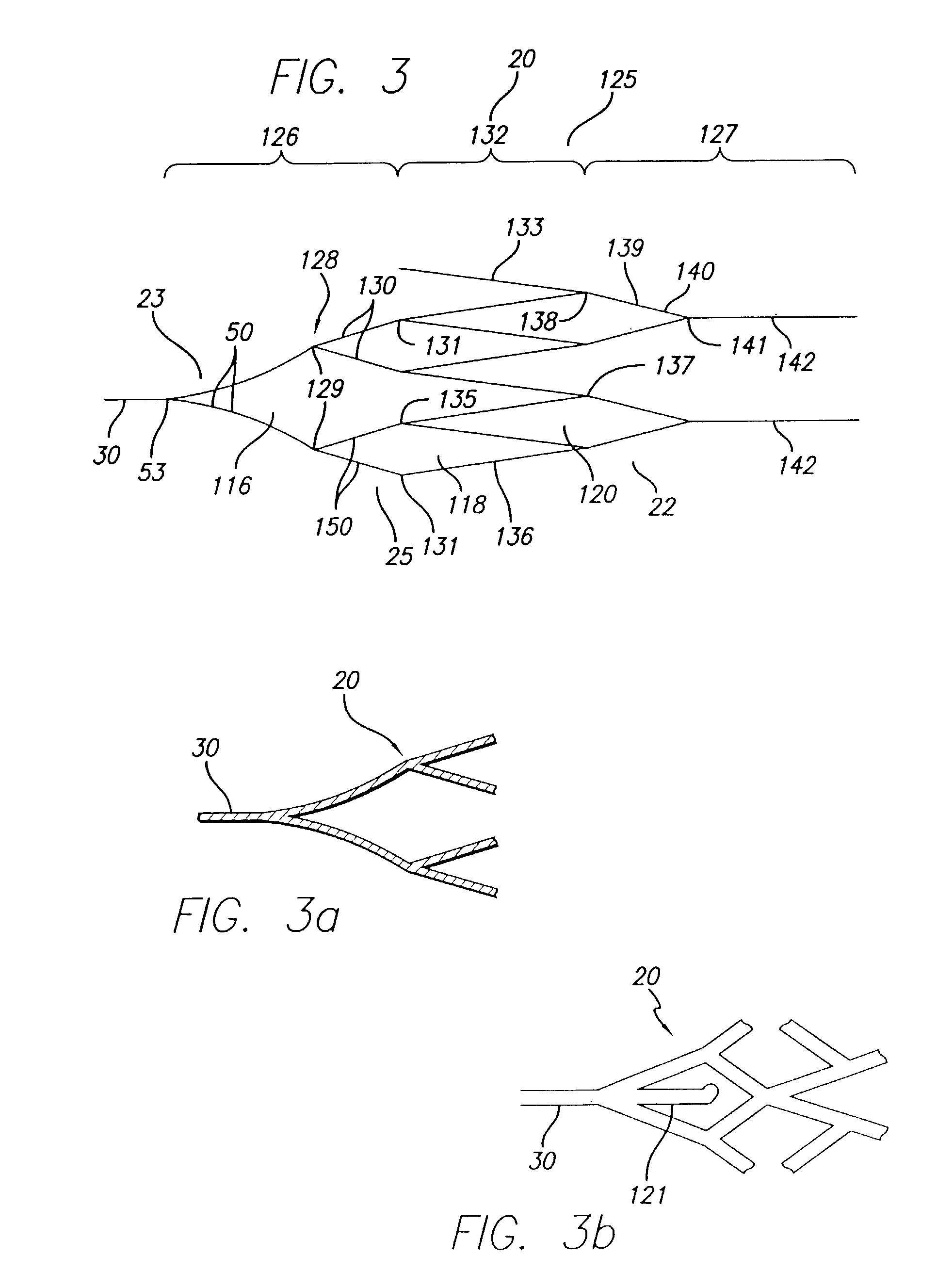

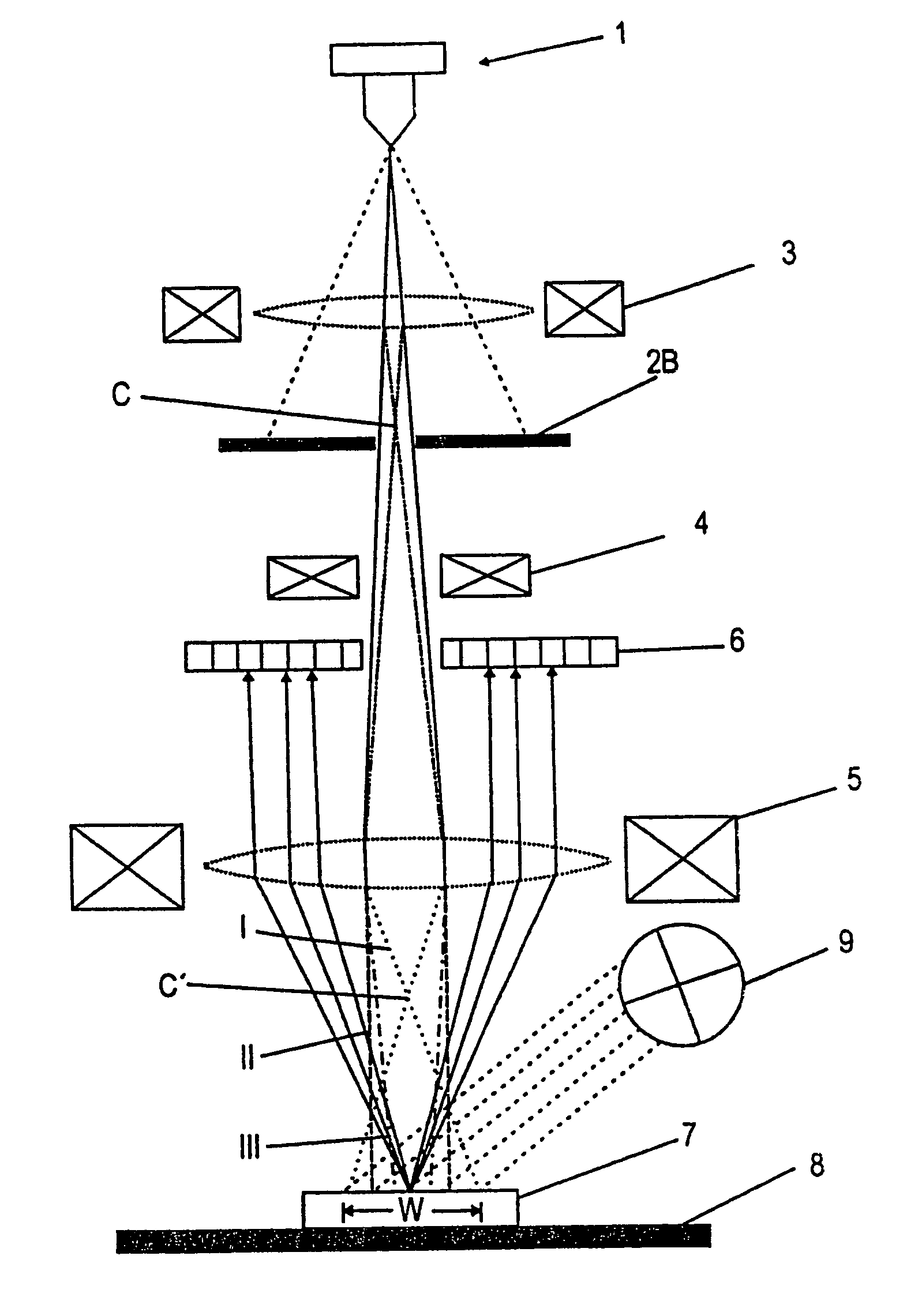

Charged particle beam apparatus and method for operating the same

ActiveUS7045781B2Less spaceLow costMaterial analysis using wave/particle radiationElectric discharge tubesLight beamParallel imaging

A charged particle beam apparatus is provided which comprises a charged particle source for producing a primary beam of charged particles, aperture means for collimating said primary beam of charged particles, wherein said aperture means is adapted to switch between a collimation of said primary beam to a width appropriate for serial imaging of a sample as well as a collimation of said primary beam to a width appropriate for parallel imaging of said sample, a condenser lens for condensing said primary beam of charged particles, scanning means for deflecting said primary beam of charged particles, an objective lens for focusing said condensed primary beam, a sectorized detector for detecting a secondary charged particles. Also, several different operation modes of the beam apparatus are described allowing for serial imaging as well as parallel imaging.

Owner:ICT INTEGRATED CIRCUIT TESTING GESELLSCHAFT FUER HALBLEITERPRUEFTECHNIK GMBH

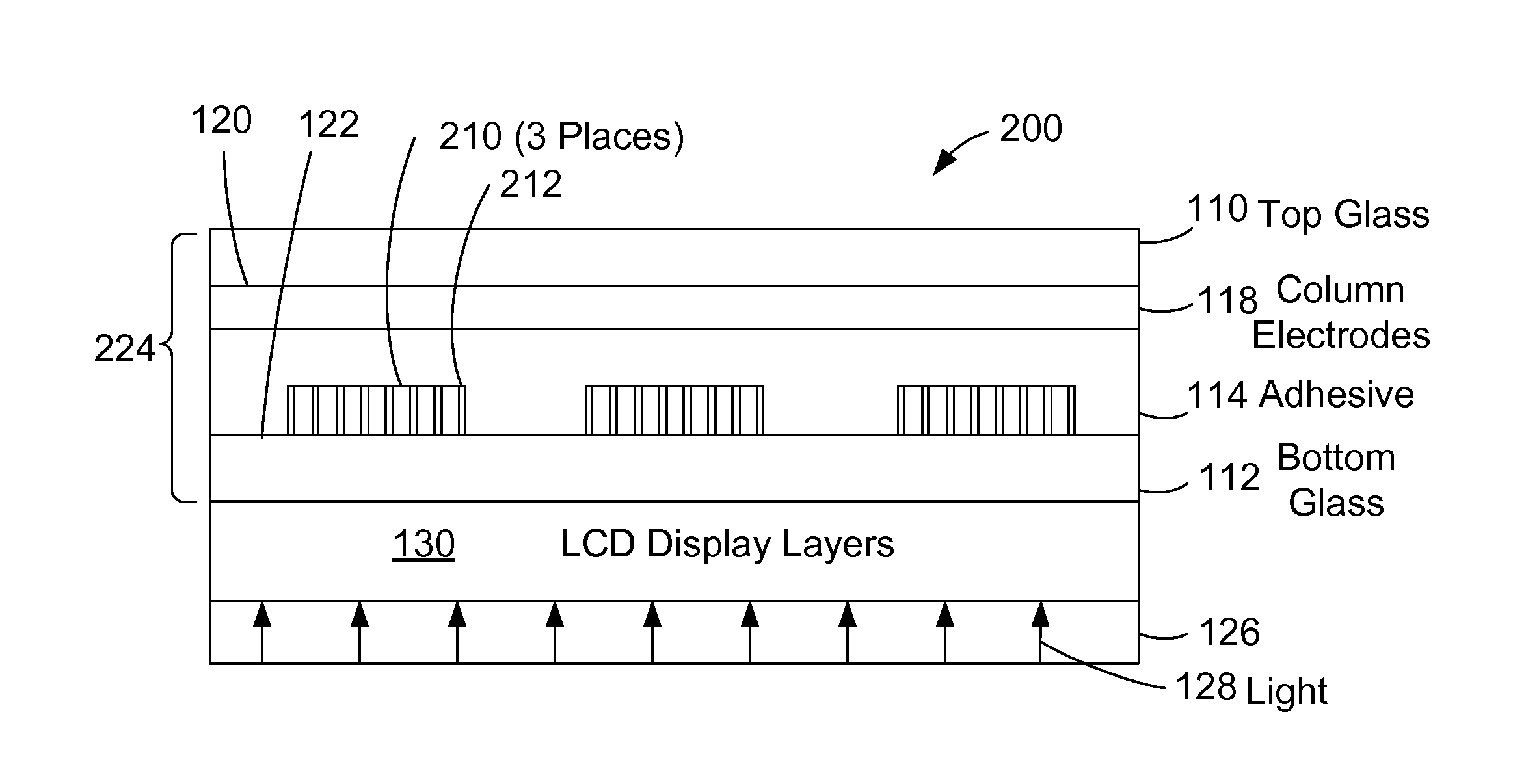

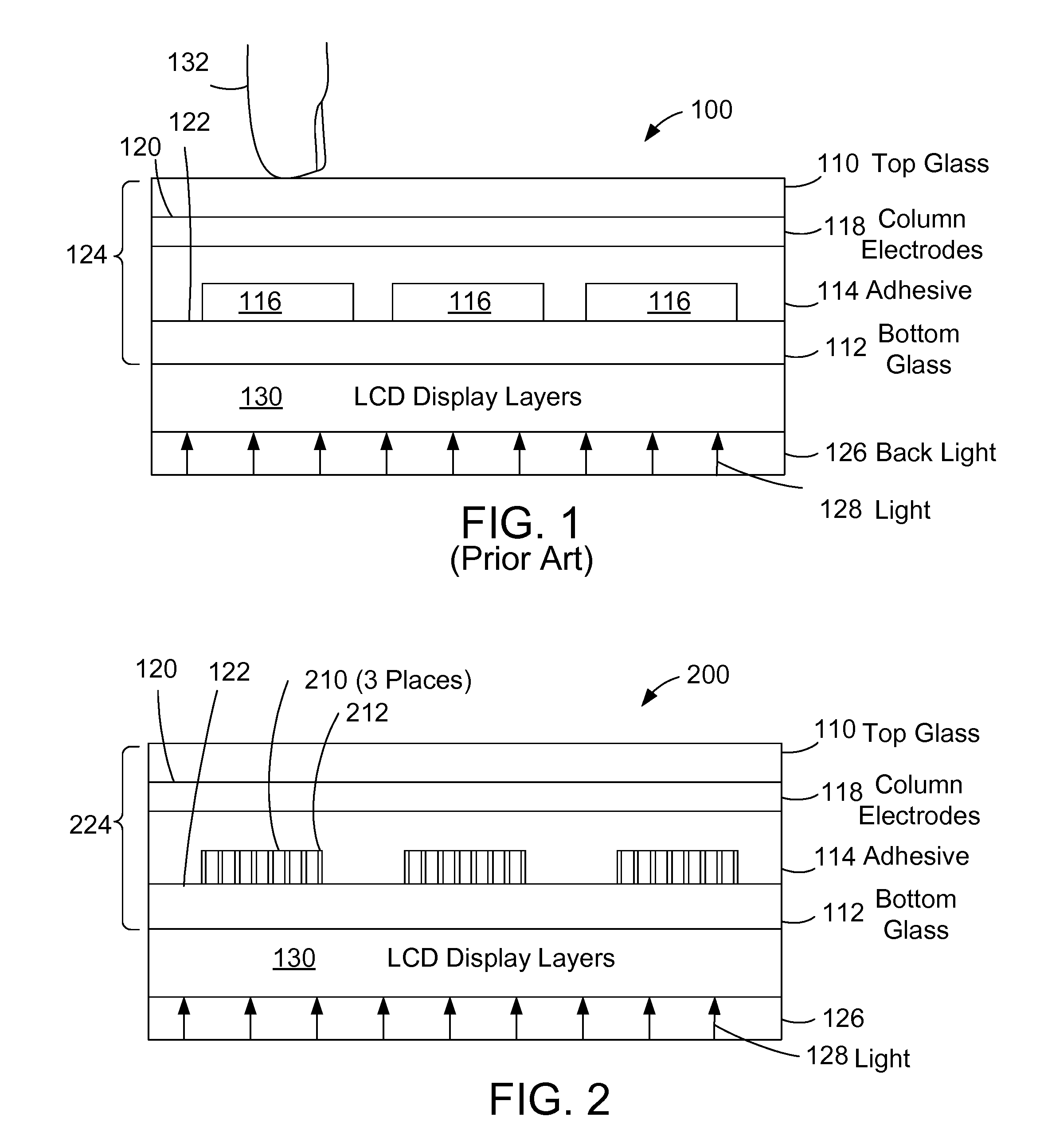

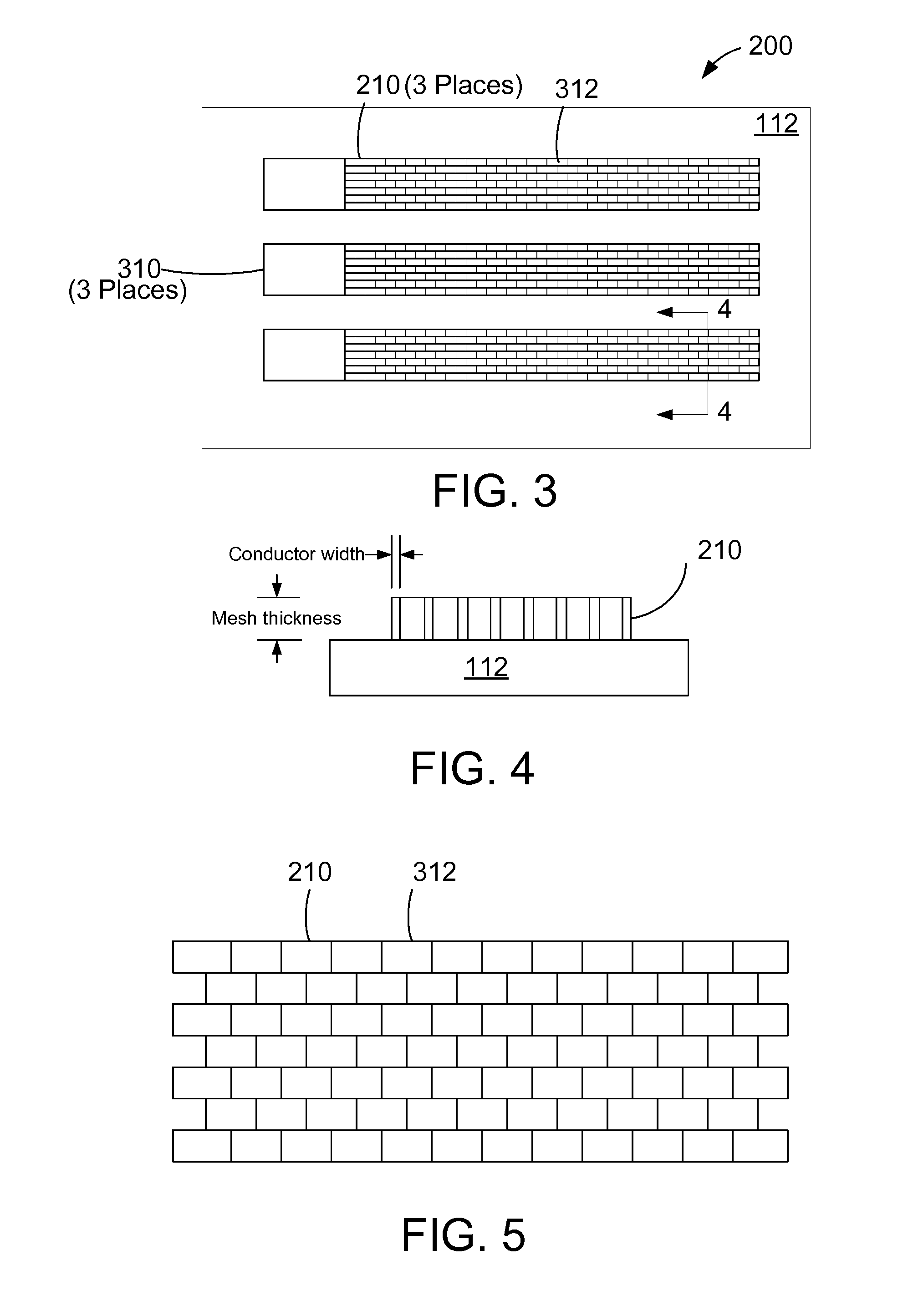

Capacitive touch screen with a mesh electrode

InactiveUS20110007011A1Improve electrical performanceImprove optical qualityInput/output processes for data processingElectrical resistance and conductanceConductive materials

An improved touch screen provides enhanced electrical performance and optical quality. The electrodes on the touch screen are made of a mesh of conductors to reduce the overall electrode resistance thereby increasing the electrical performance without sacrificing optical quality. The mesh electrodes comprise a mesh pattern of conductive material with each conductor comprising the mesh having a very small width such that the conductors are essentially invisible to the user of the touch screen.

Owner:OCULAR LCD

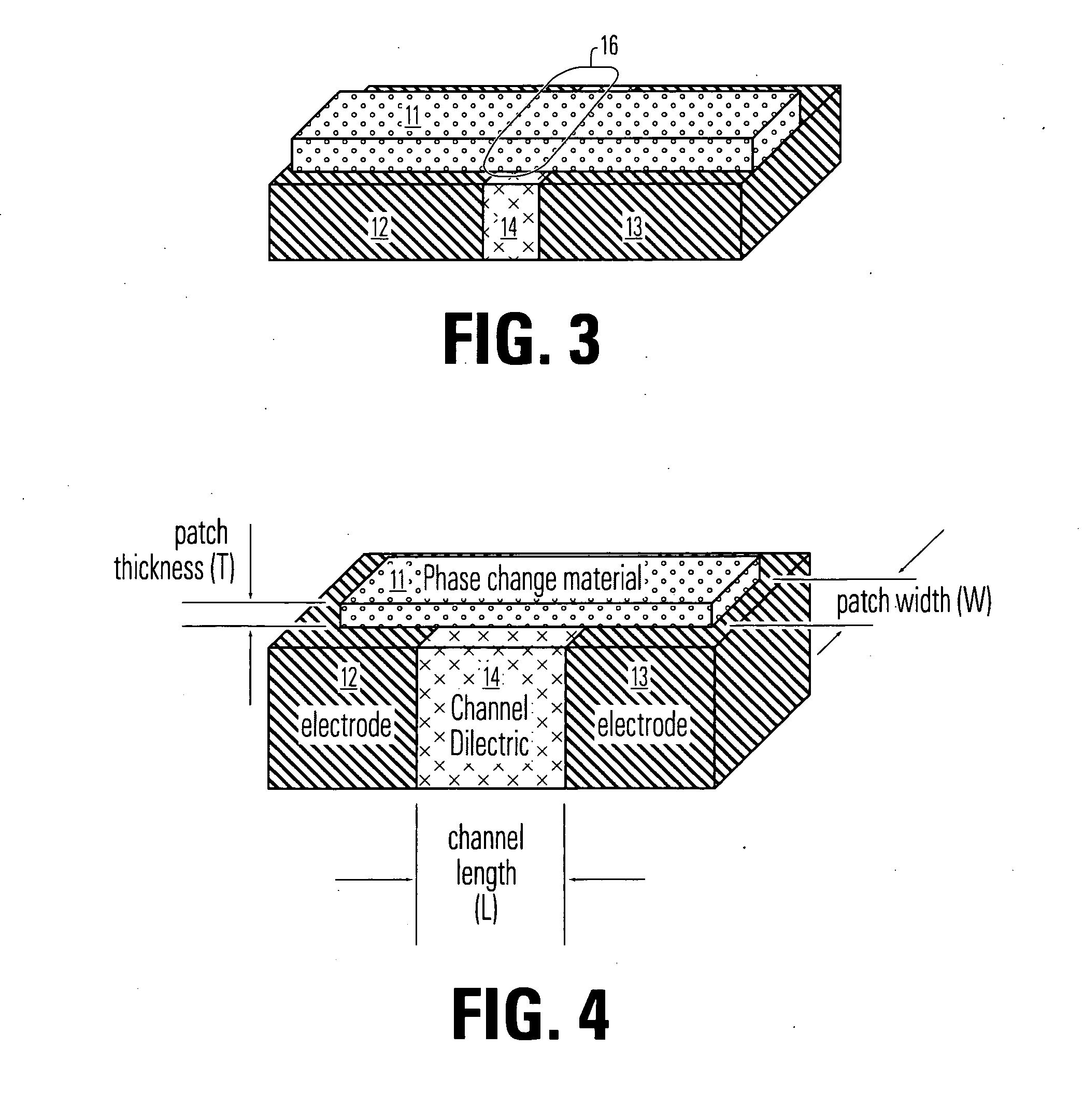

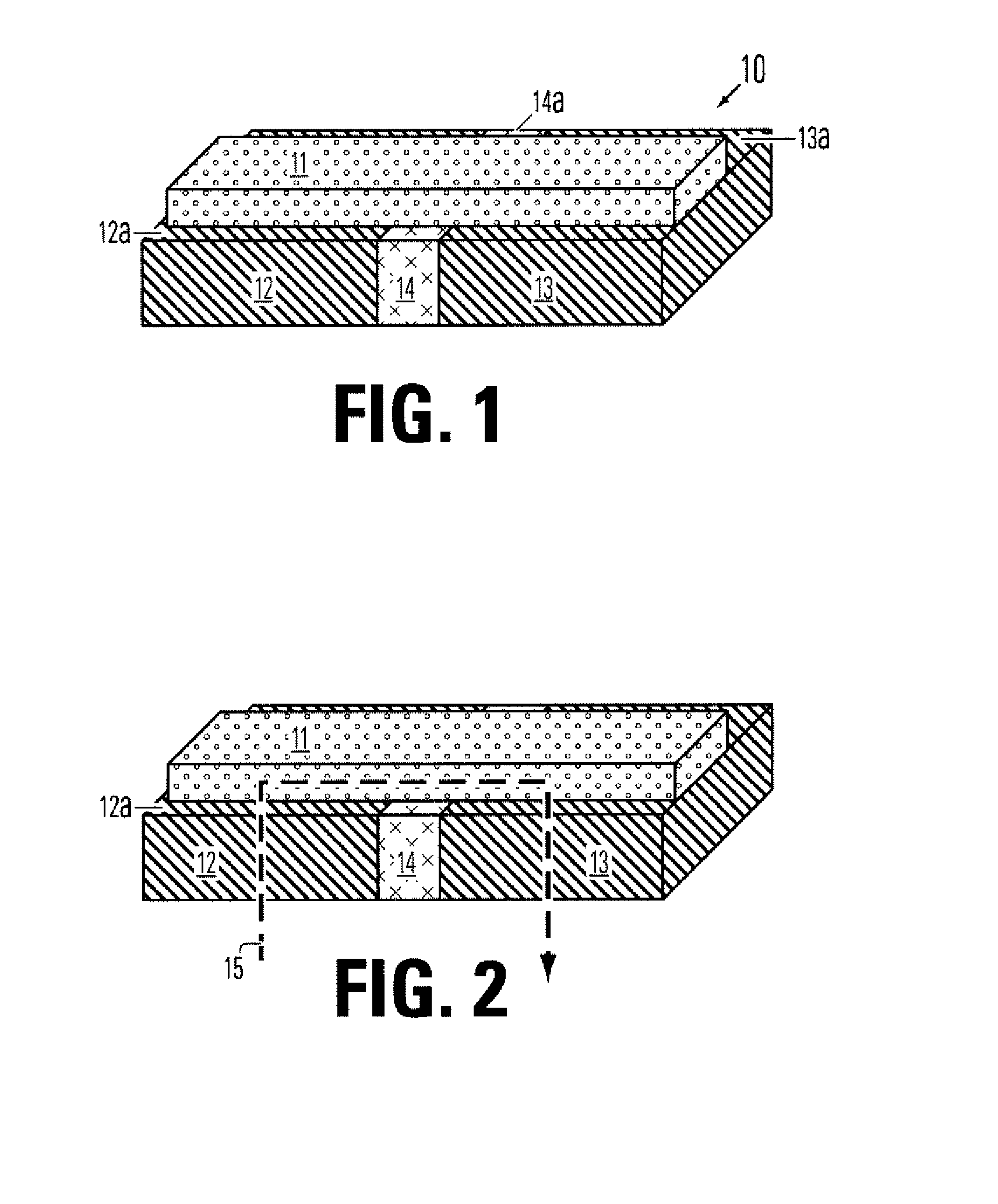

Thin film fuse phase change cell with thermal isolation layer and manufacturing method

ActiveUS20060284214A1Simple structureReduce power consumptionSolid-state devicesDigital storageThermal isolationEngineering

A memory device comprising a first electrode having a top side, a second electrode having a top side and an insulating member between the first electrode and the second electrode. The insulating member has a thickness between the first and second electrodes near the top side of the first electrode and the top side of the second electrode. A bridge of memory material crosses the insulating member, and defines an inter-electrode path between the first and second electrodes across the insulating member. An array of such memory cells is provided. The bridge comprises an active layer of memory material on the first side having at least two solid phases and a blanket of thermal insulating material overlying the memory material having thermal conductivity less than that of an overlying electrically insulating layer.

Owner:MACRONIX INT CO LTD

Thin Film Fuse Phase Change Cell with Thermal Isolation Pad and Manufacturing Method

ActiveUS20070131922A1Simple structureSmall reset currentSolid-state devicesSemiconductor/solid-state device manufacturingThermal isolationEngineering

A memory device comprising a first electrode having a top side, a second electrode having a top side and an insulating member between the first electrode and the second electrode. The insulating member has a thickness between the first and second electrodes near the top side of the first electrode and the top side of the second electrode extends outwardly from the top sides of the first and second electrodes defining a wall of insulating material having top side. A bridge of memory material crosses the insulating member over the top of the wall, and defines an inter-electrode path between the first and second electrodes across the insulating member. An array of such memory cells is provided. The bridge comprises an active layer of memory material on the top side of the wall, having at least two solid phases and a layer of thermal insulating material overlying the memory material having thermal conductivity less than a thermal conductivity of the first and second electrodes.

Owner:MACRONIX INT CO LTD

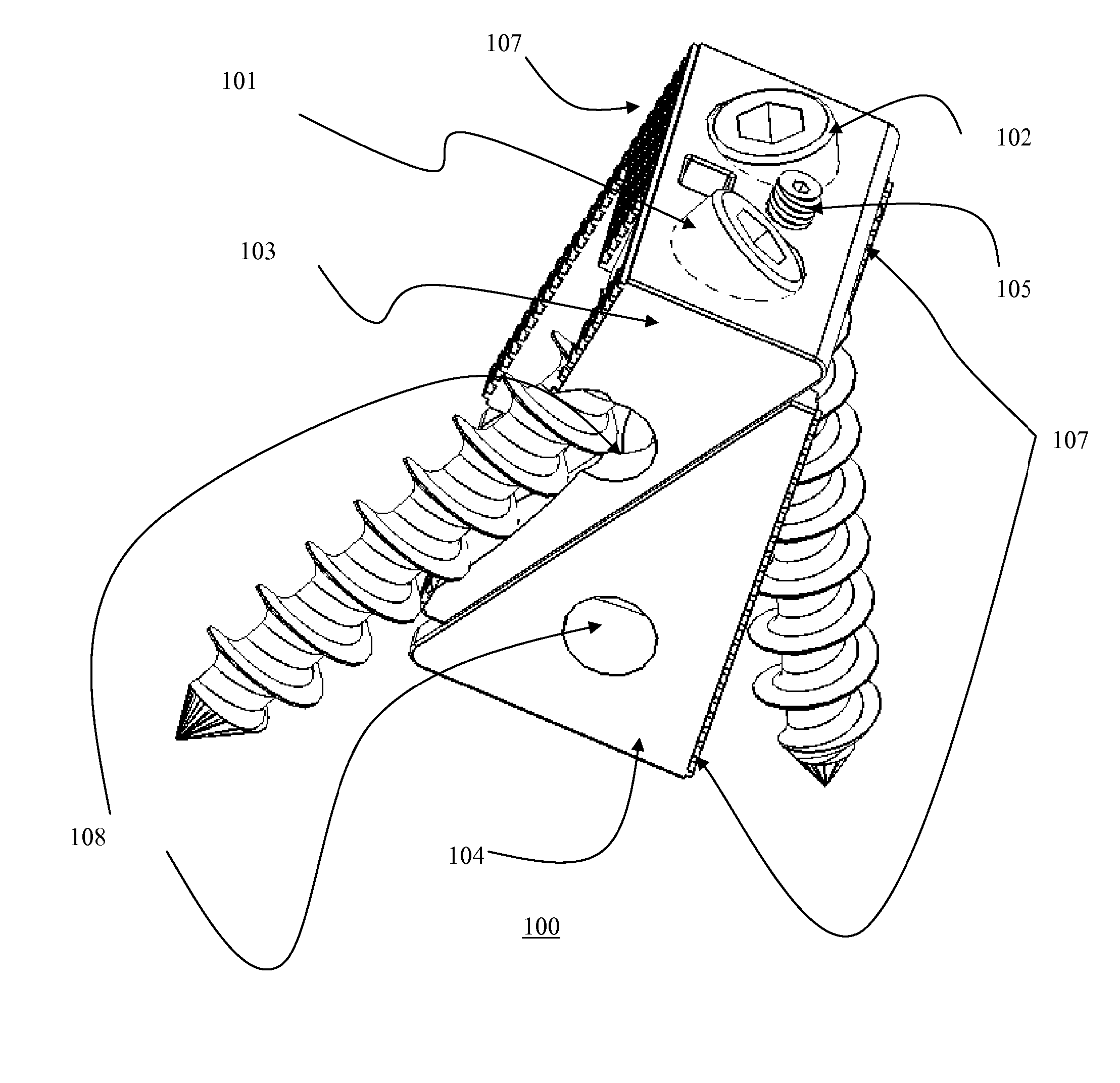

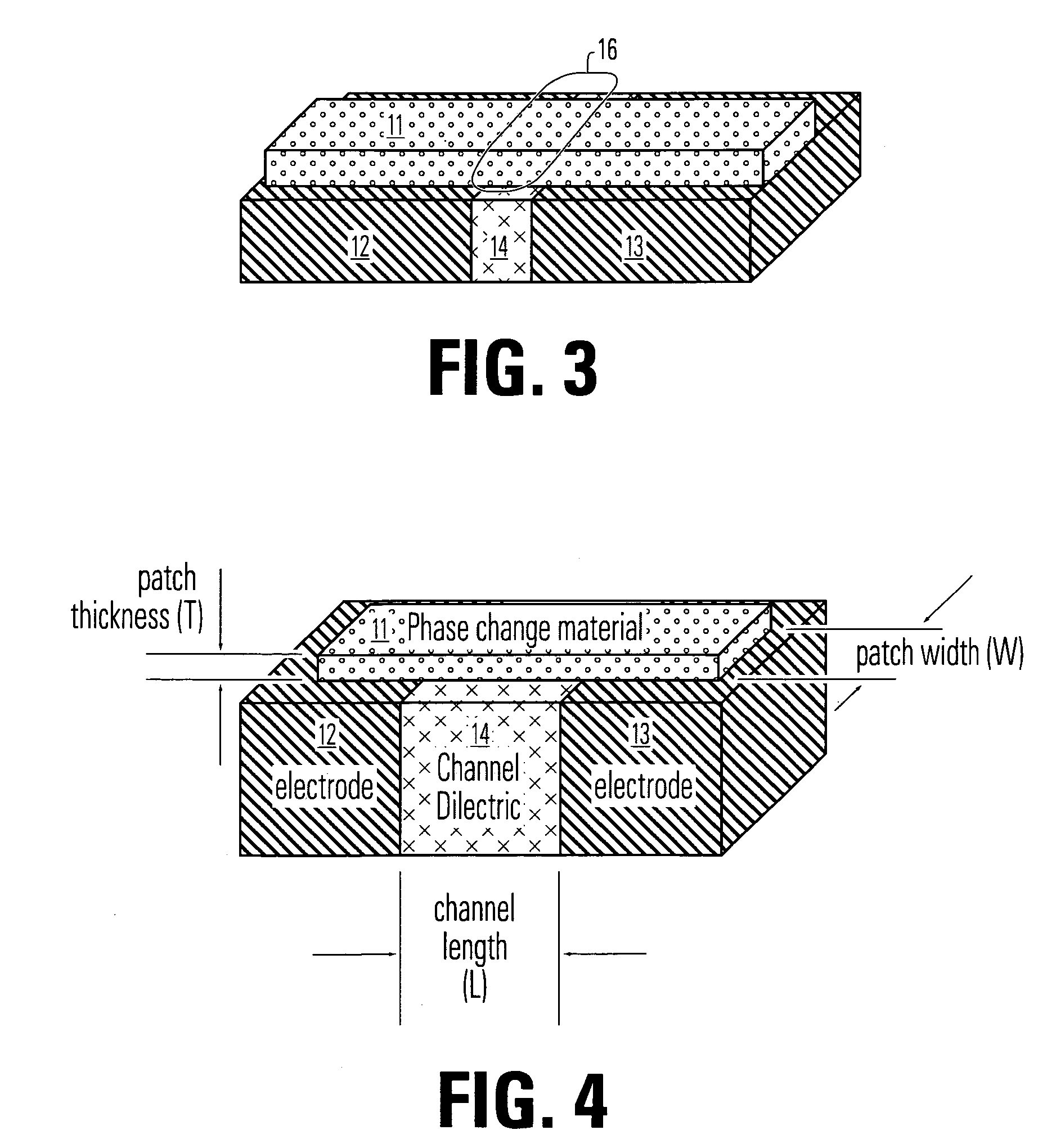

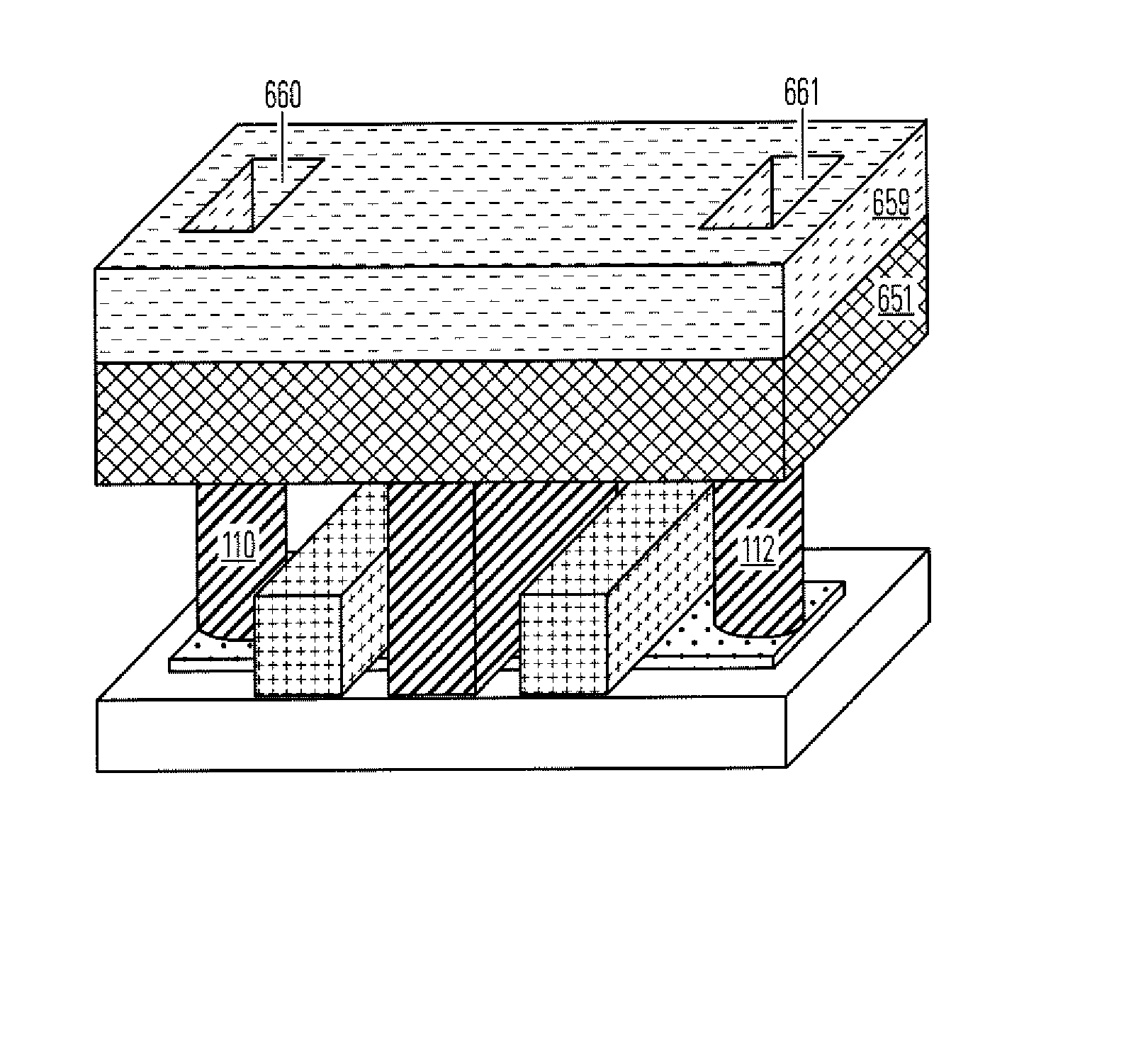

Damascene Phase Change RAM and Manufacturing Method

InactiveUS20070138458A1Damage to surface layerSimple structureSolid-state devicesDigital storageEngineeringElectrical and Electronics engineering

A method for manufacturing a memory device uses a damascene process to define memory elements. The device comprises a first electrode having a top side, a second electrode having a top side and an insulating member between the first electrode and the second electrode. The insulating member has a thickness between the first and second electrodes near the top side of the first electrode and the top side of the second electrode. A damascene patch crosses the insulating member aligned with the first and second electrodes, and defines an inter-electrode path between the first and second electrodes across the insulating member. An array of such memory cells is provided.

Owner:MACRONIX INT CO LTD

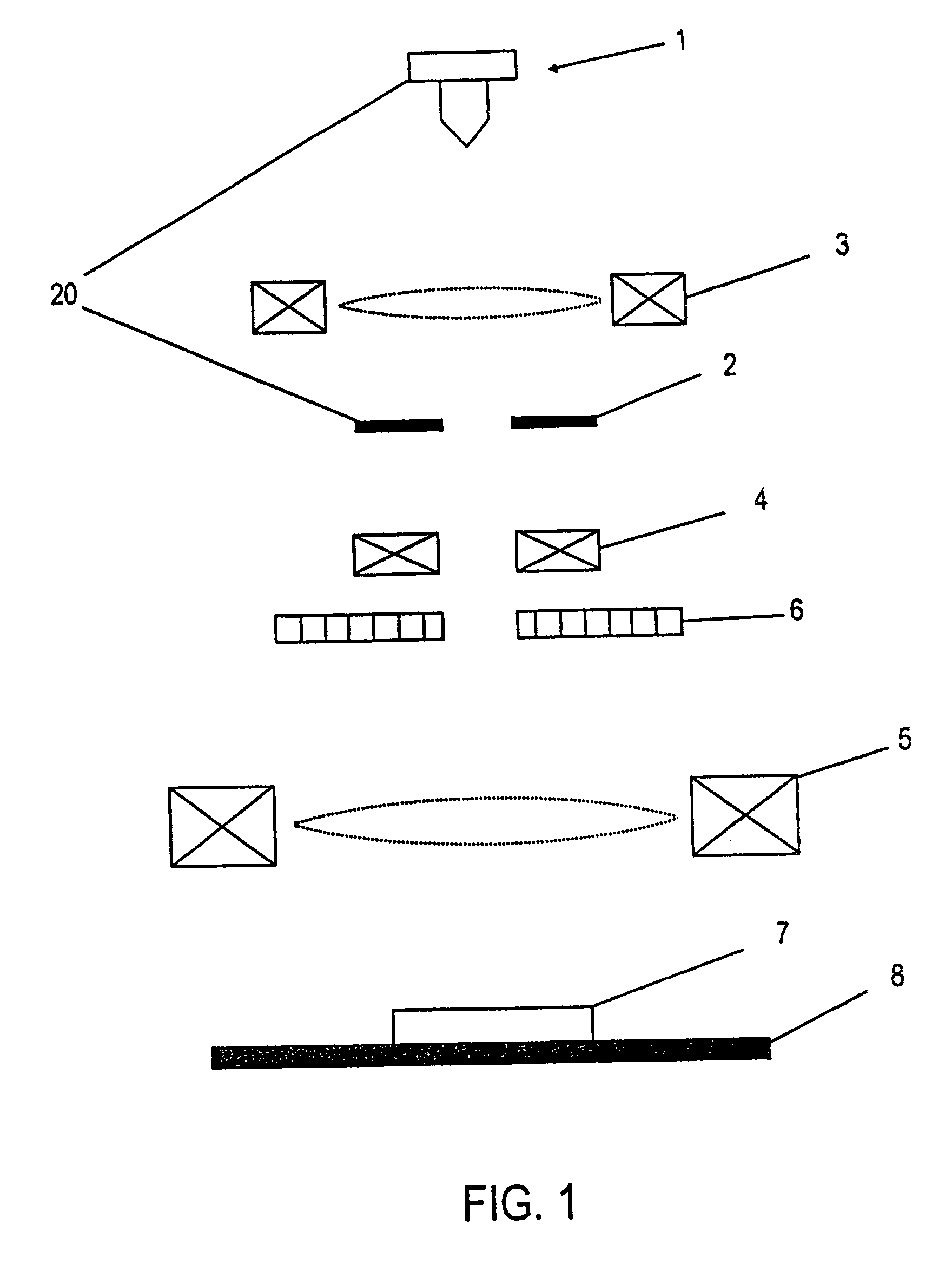

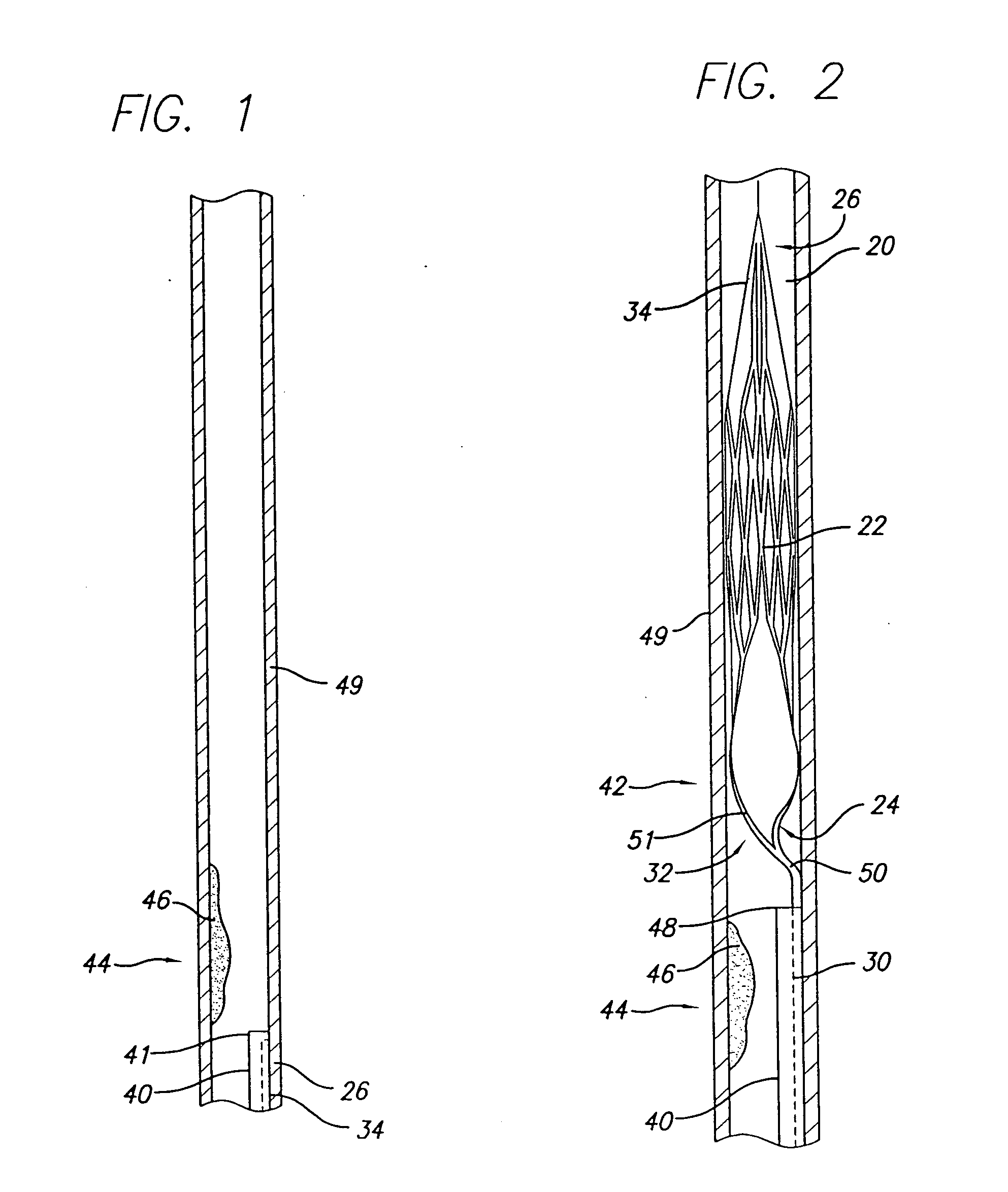

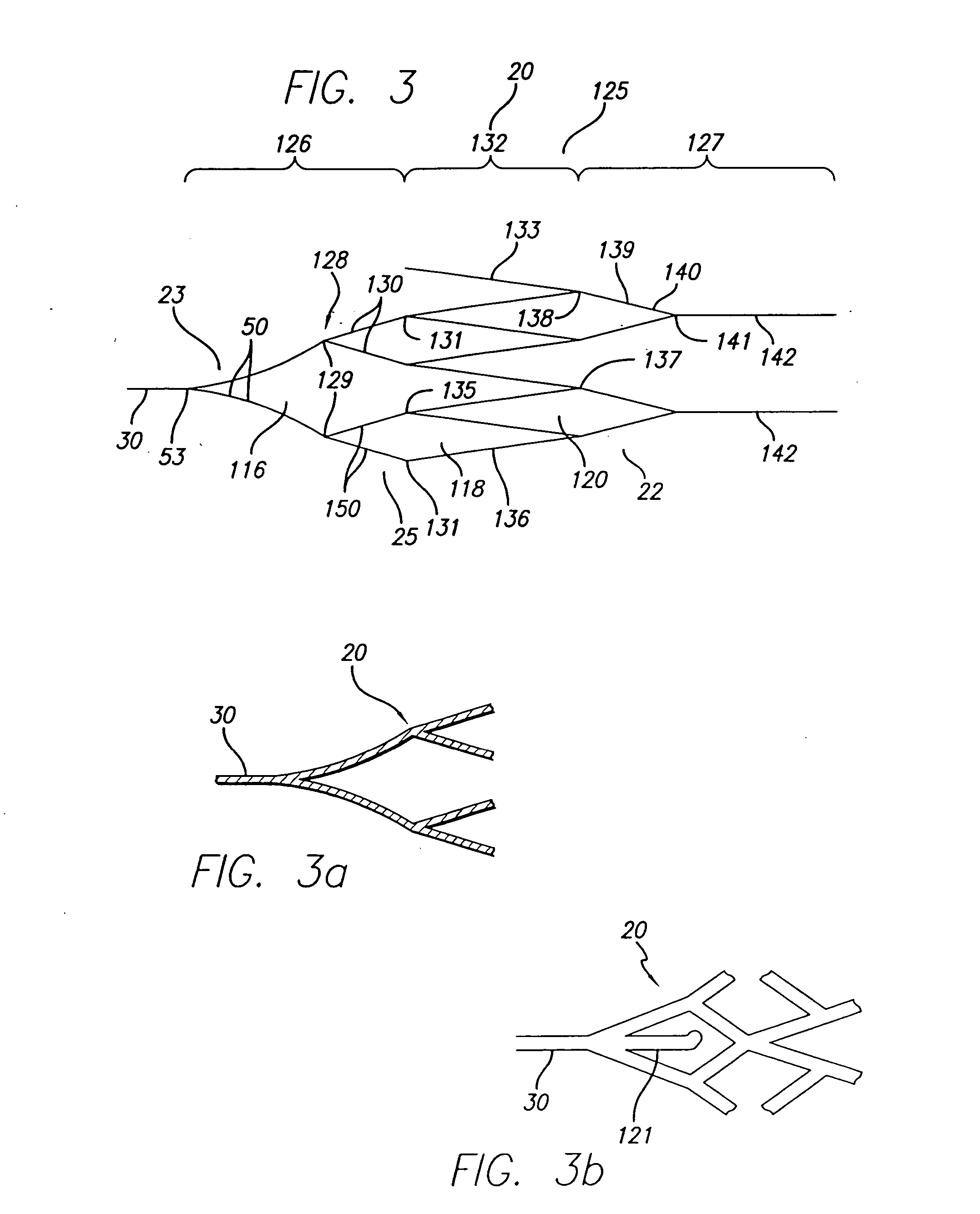

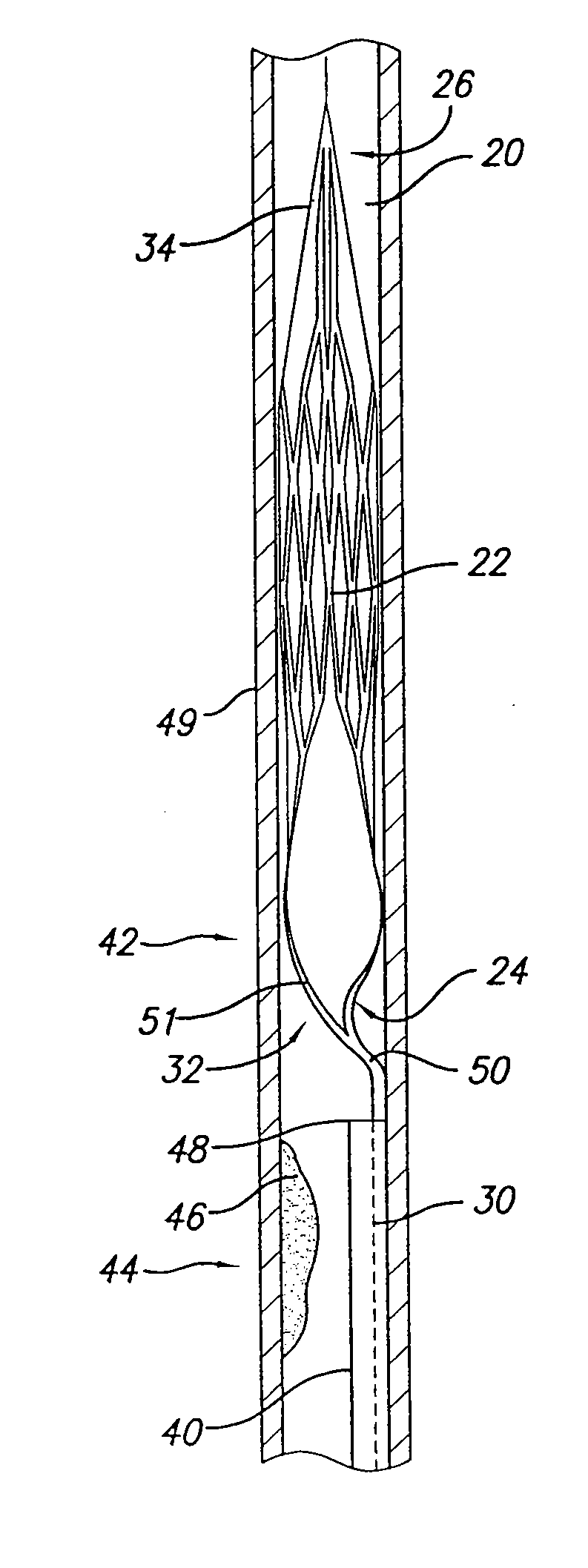

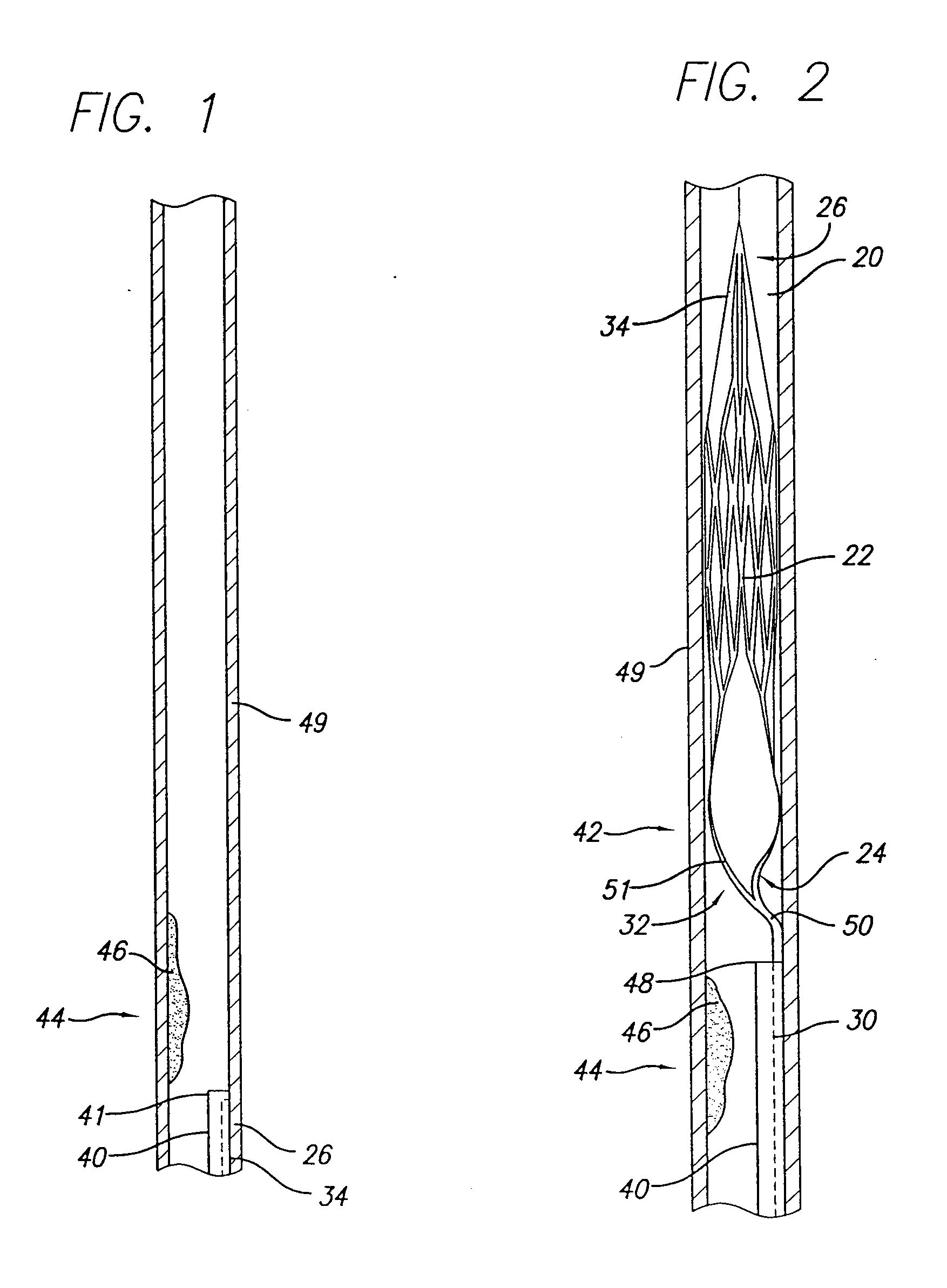

Embolic filter

InactiveUS7004955B2Maintaining and restoring patencyImprove the immunitySurgeryDilatorsEndovascular surgeryBiomedical engineering

An intravascular filter device for use in capturing debris which may occur as a result of an intravascular procedure. The filter device includes a proximal section, a distal section and a mid-section. The mid-section includes three rings configured in a sixteen apices alternating V-pattern. The filter device specifically embodies structure that provides enhanced radial opening and angular resistance to collapse in its expanded state. While, in its compressed state the filter device provides an extremely small compressed profile giving it the desired ability to be delivered into very small vessels of the human vasculature.

Owner:ENDOVASCULAR TECH

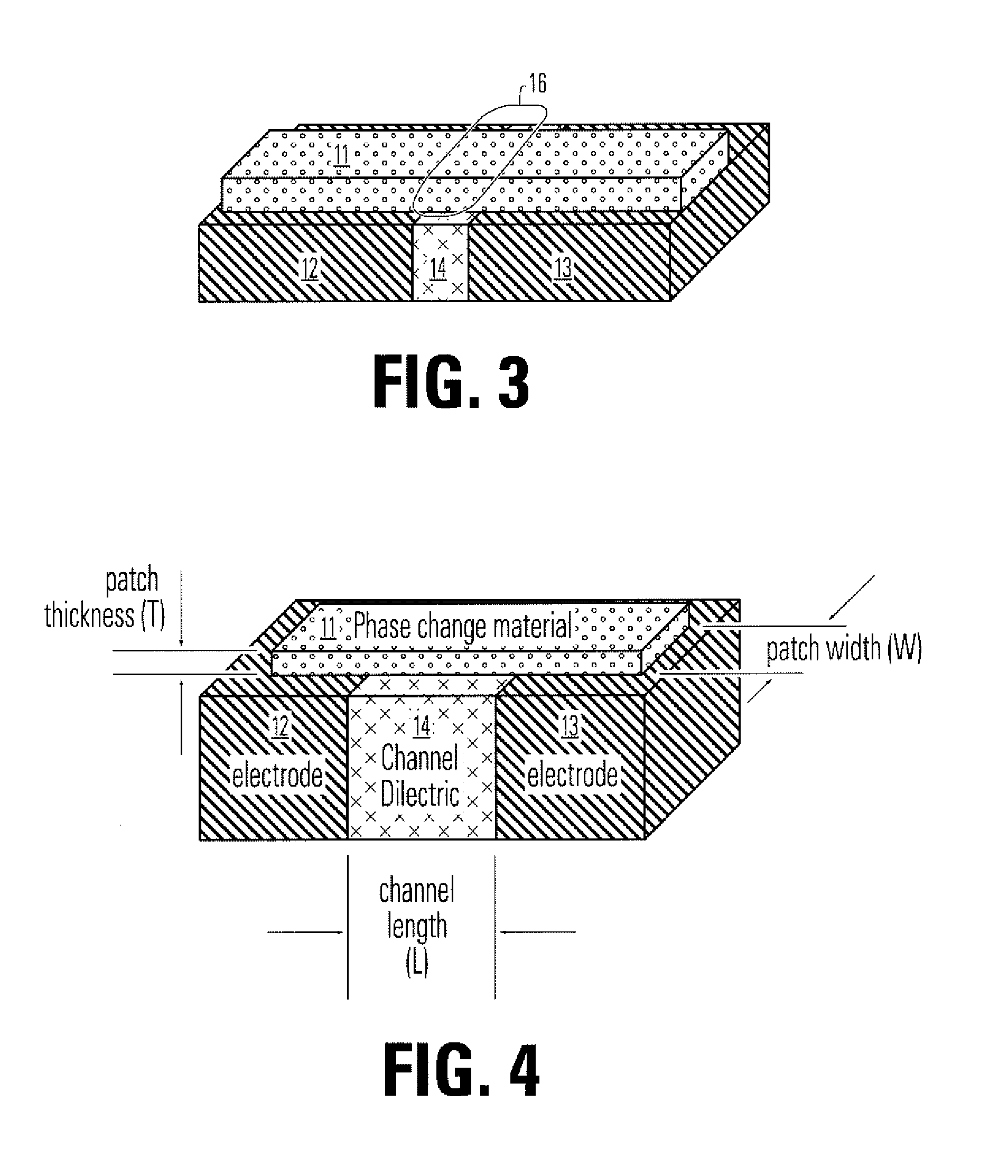

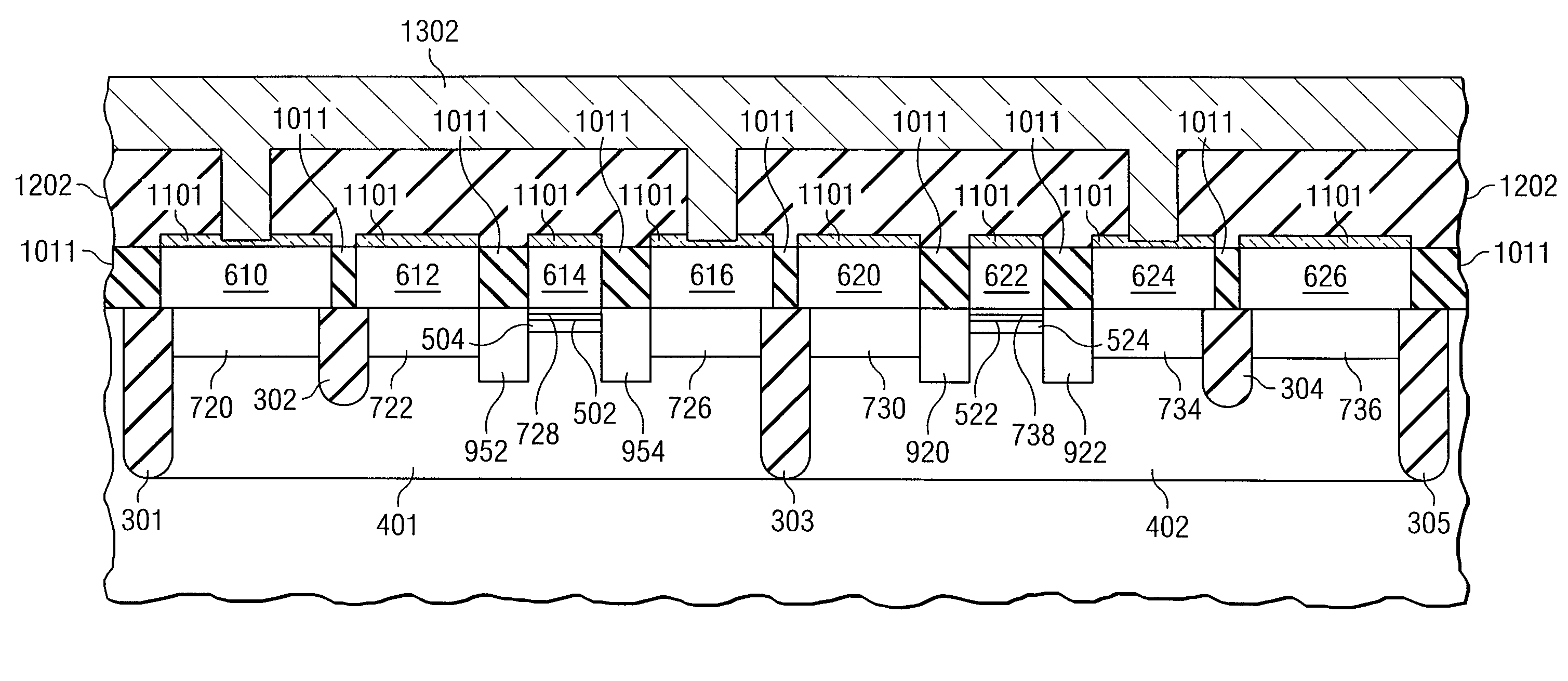

Thin film fuse phase change RAM and manufacturing method

ActiveUS7321130B2Simple structureSmall reset currentSemiconductor/solid-state device detailsSolid-state devicesPhase changeIntegrated circuit

A memory device comprising a first electrode having a top side, a second electrode having a top side and an insulating member between the first electrode and the second electrode. The insulating member has a thickness between the first and second electrodes near the top side of the first electrode and the top side of the second electrode. A bridge of memory material crosses the insulating member, and defines an inter-electrode path between the first and second electrodes across the insulating member. An array of such memory cells is provided. In the array, a plurality of electrode members and insulating members therebetween comprise an electrode layer on an integrated circuit. The bridges of memory material have sub-lithographic dimensions.

Owner:MACRONIX INT CO LTD

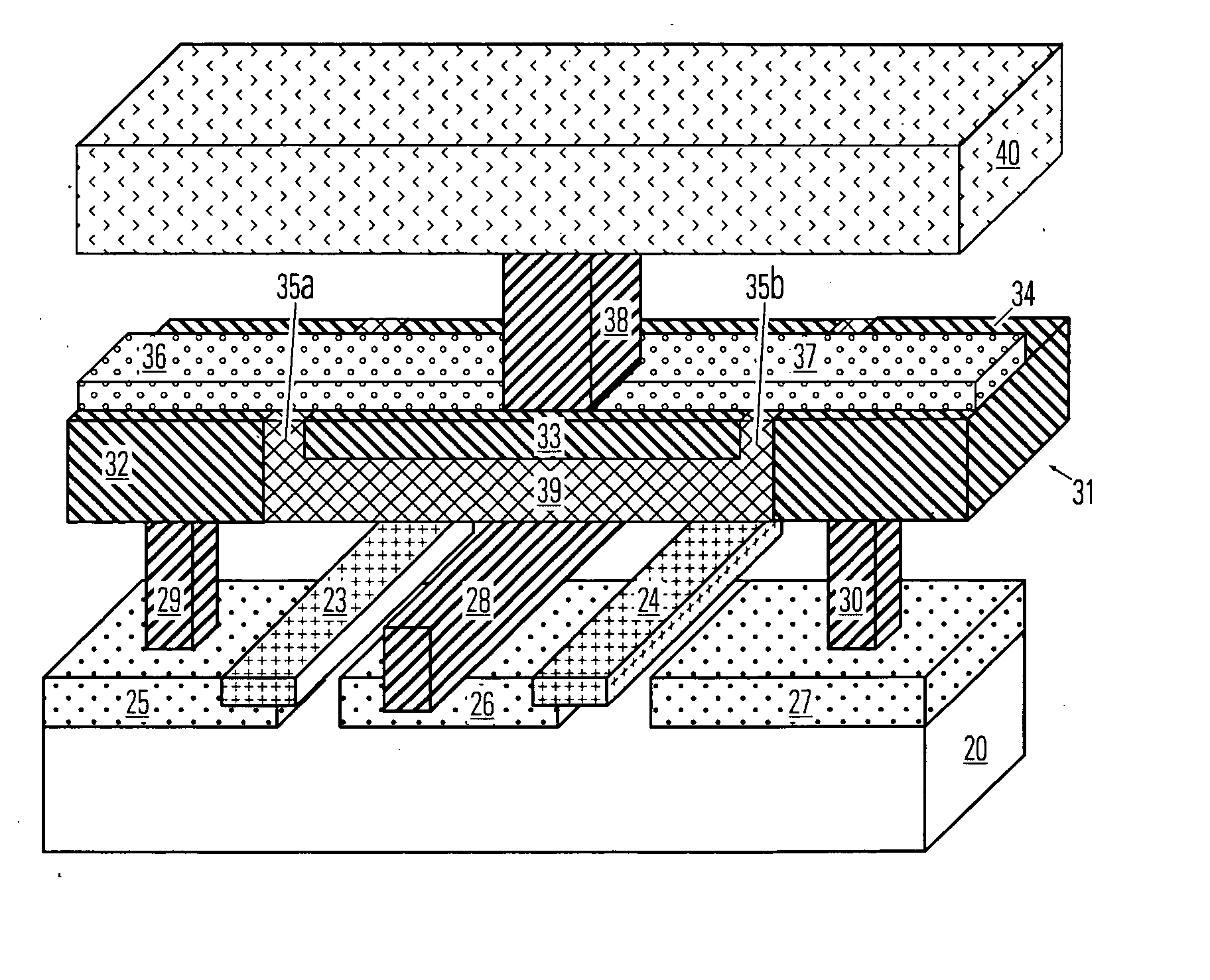

Thin film plate phase change ram circuit and manufacturing method

InactiveUS20070224726A1Simple structureSmall reset currentSolid-state devicesSemiconductor/solid-state device manufacturingBit linePhase-change memory

A memory device comprising a access circuits, an electrode layer over the access circuits, an array of phase change memory bridges over the electrode layer, and a plurality of bit lines over the array of phase change memory bridges. The electrode layer includes electrode pairs. Electrode pairs include a first electrode having a top side, a second electrode having a top side and an insulating member between the first electrode and the second electrode. A bridge of memory material crosses the insulating member, and defines an inter-electrode path between the first and second electrodes across the insulating member.

Owner:MACRONIX INT CO LTD

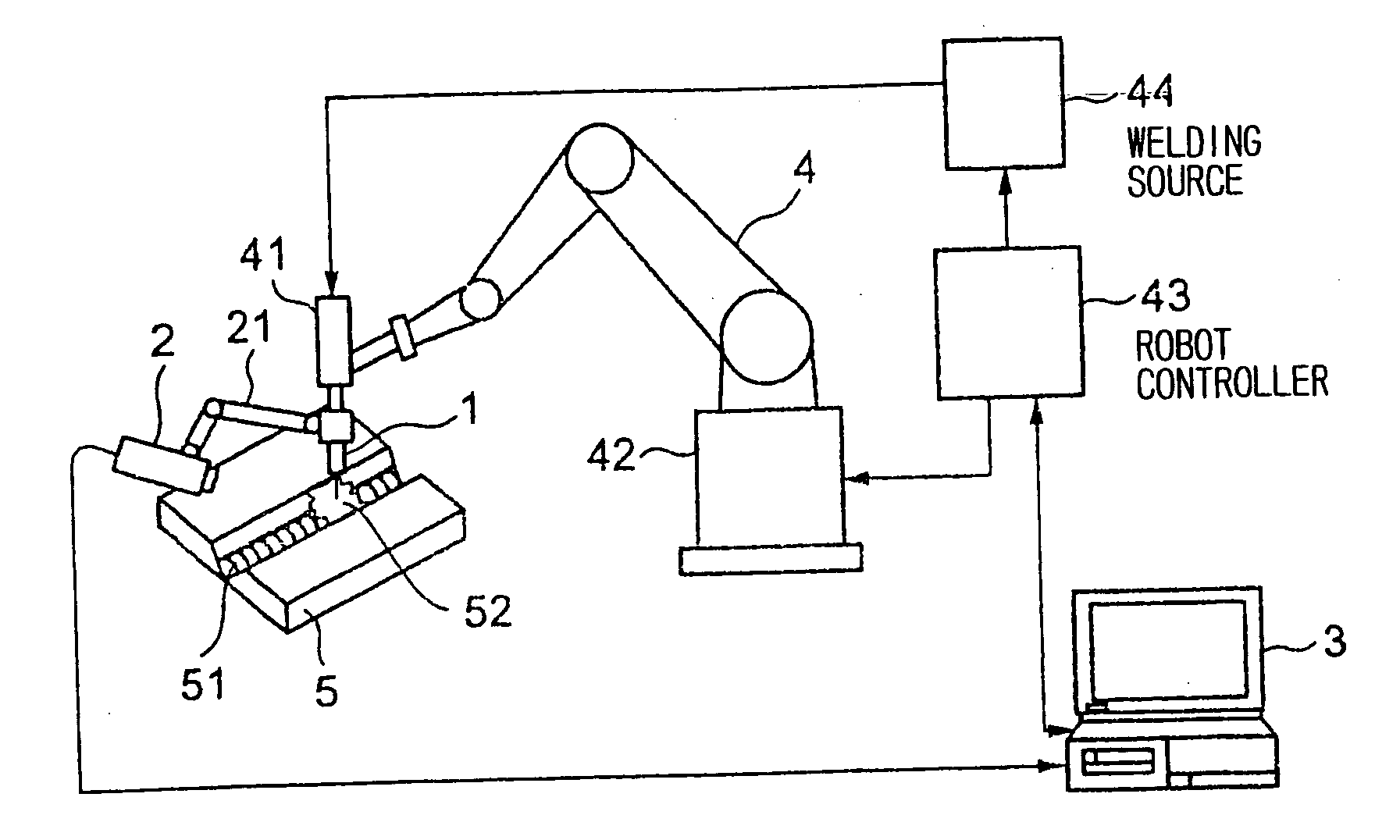

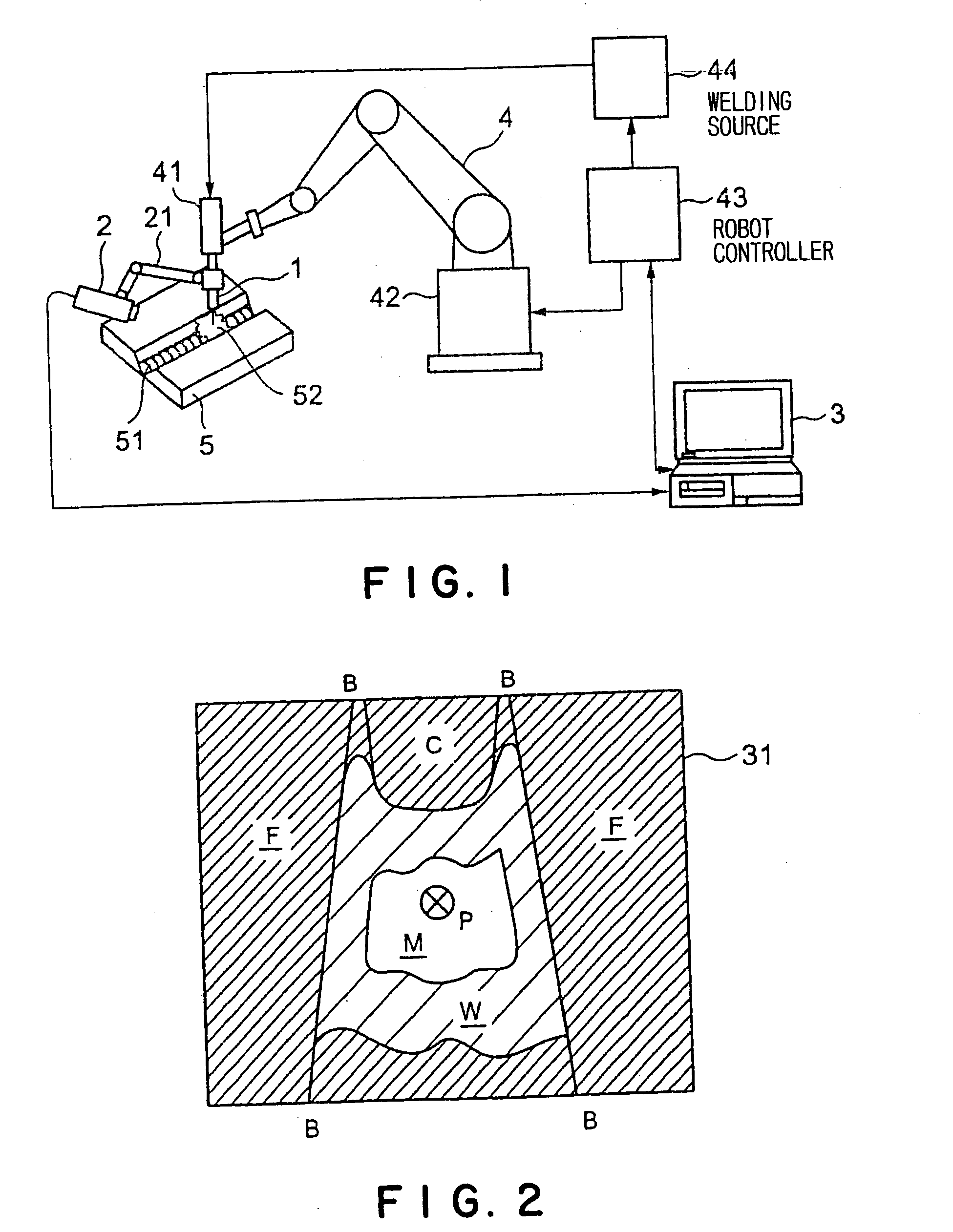

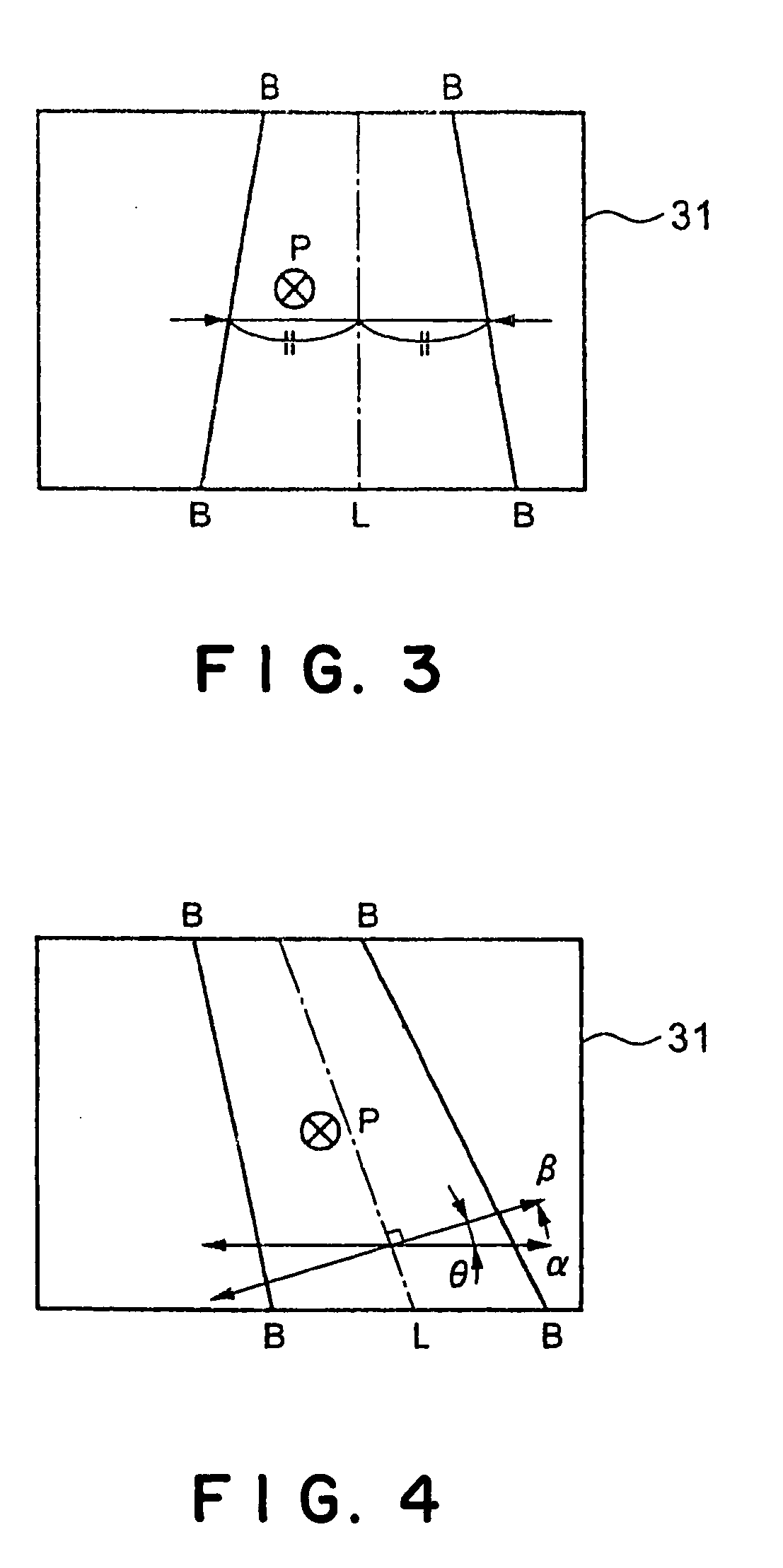

Automatic groove copy welder and welding method

InactiveUS20050103766A1Accurate control operationAccurately carry-outArc welding apparatusEngineeringCcd camera

An automatic groove-tracing welding system is capable of carrying out a welding operation, particularly, a welding operation involving weaving, without requiring monitoring even if conditions of a groove is different from design conditions of the groove. An image processor 3 receives an image signal representing an image of a weld zone 52 including the tip of a welding wire from a camera head 2 provided with a CCD camera, processes the image of the weld zone 52 to determine the position of a groove, calculates the positional relation of the groove with a welding torch 1, and sends a position correction for correcting the position of the welding torch 1 so that the welding path of the tip of the welding torch 1 may coincide with a predetermined middle part in the groove to a robot controller 43 for controlling a welding robot. When the automatic groove-tracing welding system performs a welding operation involving weaving, the image processor 3 receives a weaving phase signal representing phases of weaving from the robot controller 43, calculates the positional relation between the groove and the welding torch on the basis of the phase of weaving, and sends a weaving width correction signal to the robot controller 43.

Owner:KAWASAKI HEAVY IND LTD

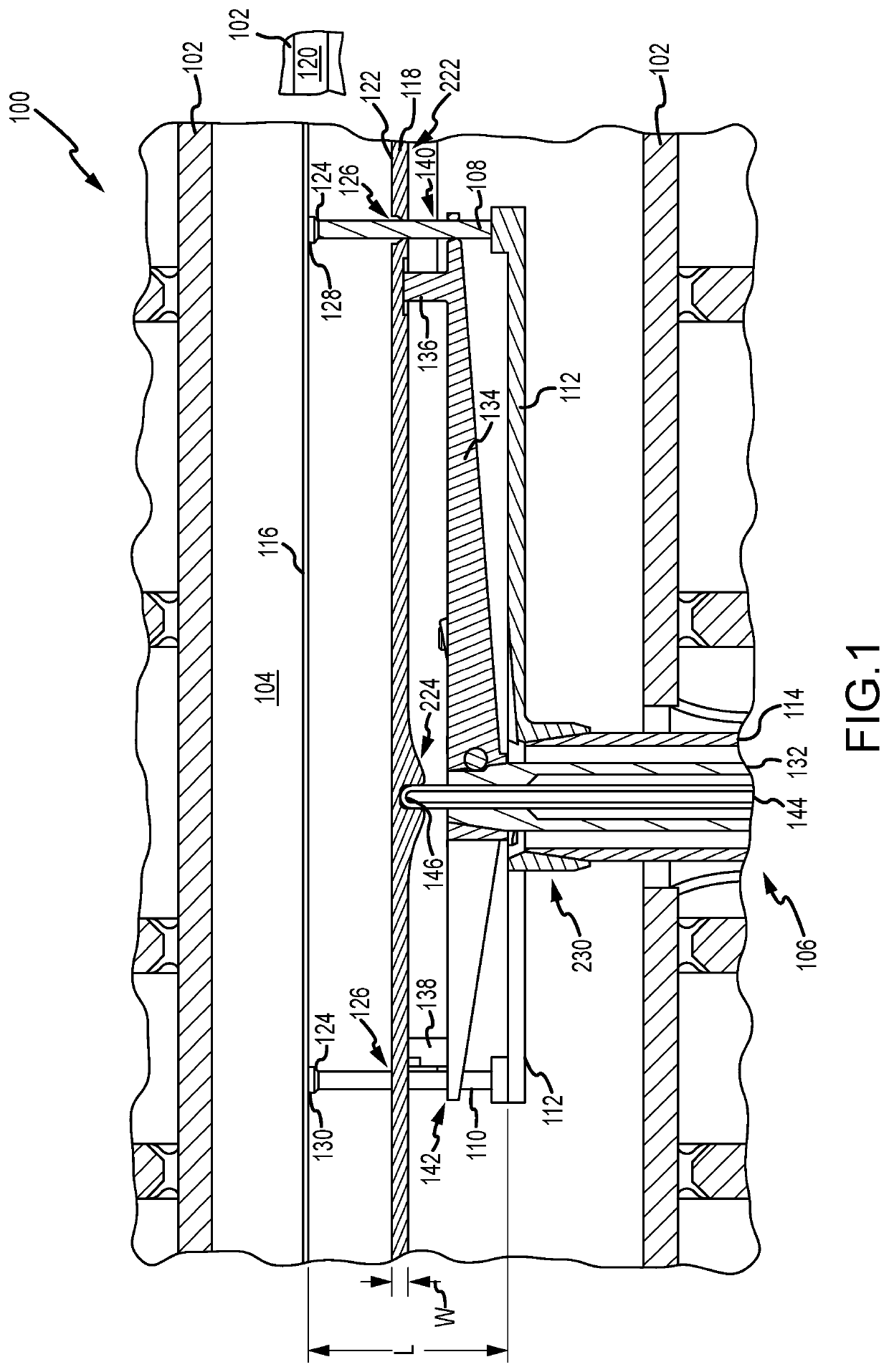

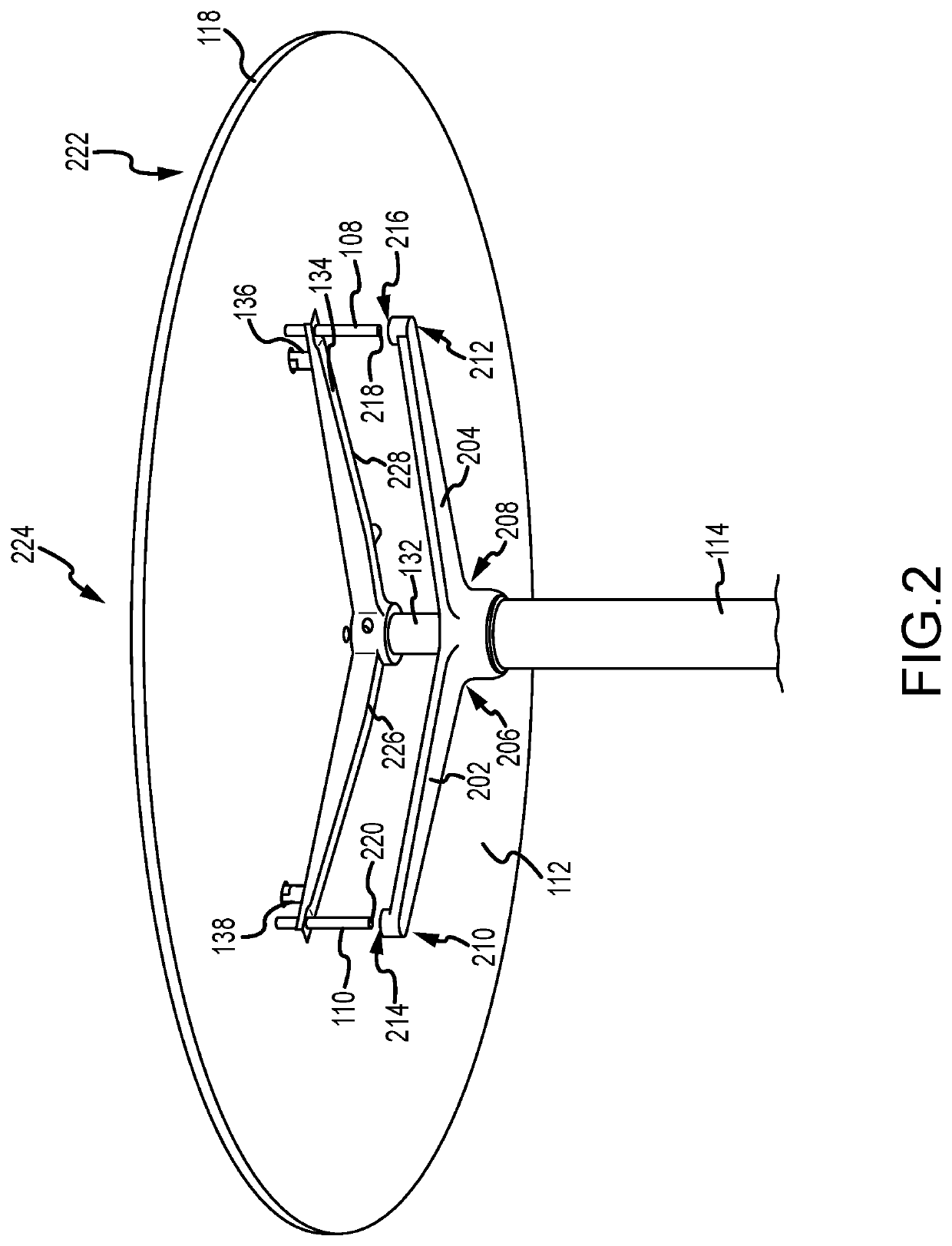

Substrate lift mechanism and reactor including same

ActiveUS10770336B2Small volumeLess complexElectric discharge tubesSemiconductor/solid-state device manufacturingSusceptorEngineering

A substrate support assembly suitable for use in a reactor including a common processing and substrate transfer region is disclosed. The substrate support assembly includes a susceptor and one or more lift pins that can be used to lower a substrate onto a surface of the susceptor and raise the substrate from the surface, to allow transfer of the substrate from the processing region, without raising or lowering the susceptor.

Owner:ASM IP HLDG BV

Thin film plate phase change ram circuit and manufacturing method

ActiveUS7238994B2Simple structureSmall reset currentSolid-state devicesDigital storageBit linePhase-change memory

A memory device comprising a access circuits, an electrode layer over the access circuits, an array of phase change memory bridges over the electrode layer, and a plurality of bit lines over the array of phase change memory bridges. The electrode layer includes electrode pairs. Electrode pairs include a first electrode having a top side, a second electrode having a top side and an insulating member between the first electrode and the second electrode. A bridge of memory material crosses the insulating member, and defines an inter-electrode path between the first and second electrodes across the insulating member.

Owner:MACRONIX INT CO LTD

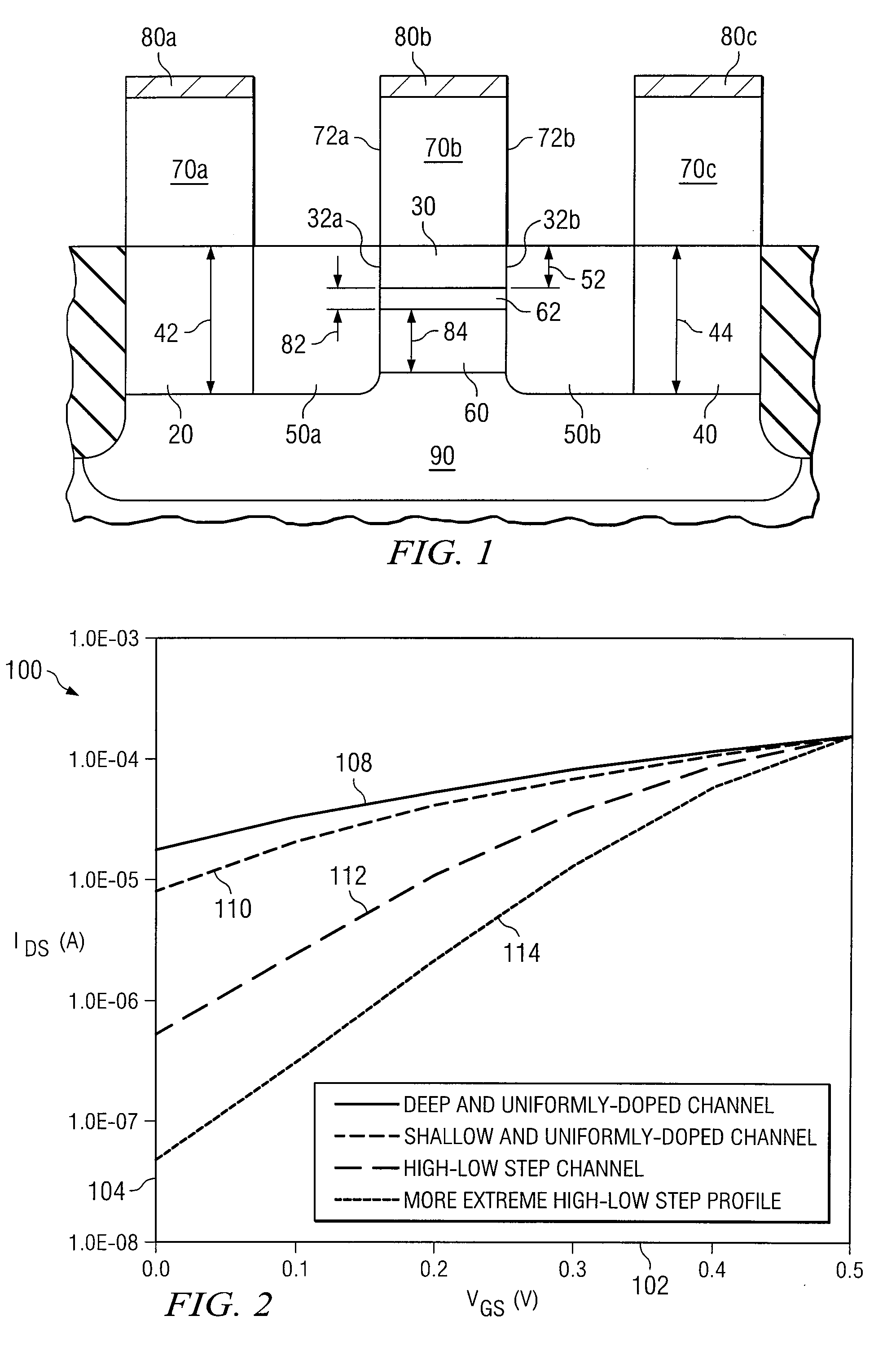

JFET Having a Step Channel Doping Profile and Method of Fabrication

InactiveUS20080272409A1Disadvantages and reduced eliminatedEffect reduced eliminatedTransistorSemiconductor/solid-state device manufacturingHigh concentrationJFET

A junction field effect transistor comprises a semiconductor substrate, a source region formed in the substrate, a drain region formed in the substrate and spaced apart from the source region, and a gate region formed in the substrate. The transistor further comprises a first channel region formed in the substrate and spaced apart from the gate region, and a second channel region formed in the substrate and between the first channel region and the gate region. The second channel region has a higher concentration of doped impurities than the first channel region.

Owner:DSM SOLUTIONS

Embolic basket

InactiveUS20060100663A1Improve the immunityRestoring patency of blood vesselsSurgeryDilatorsThree vesselsEmbolus

Owner:PALMER OLIN +1

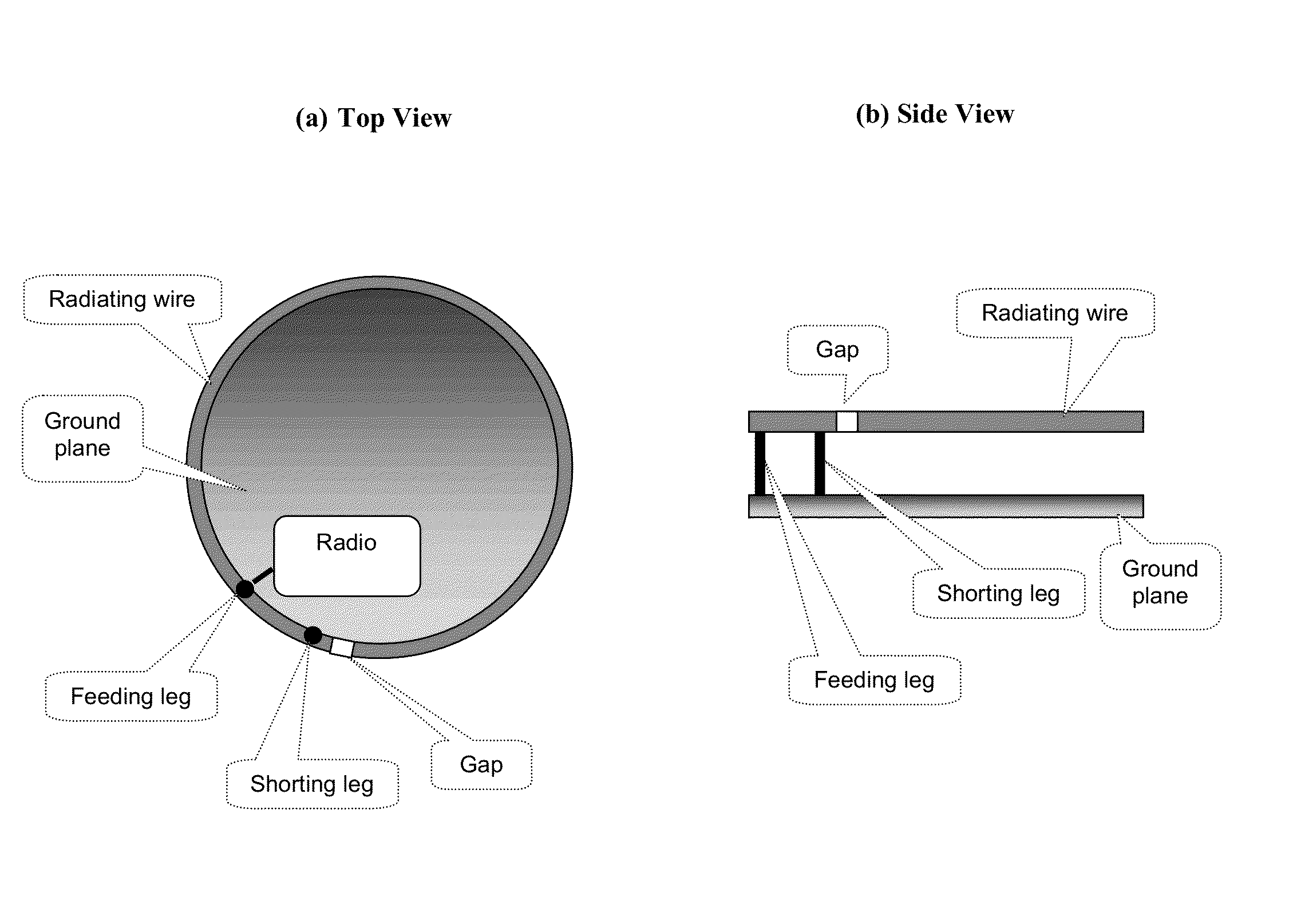

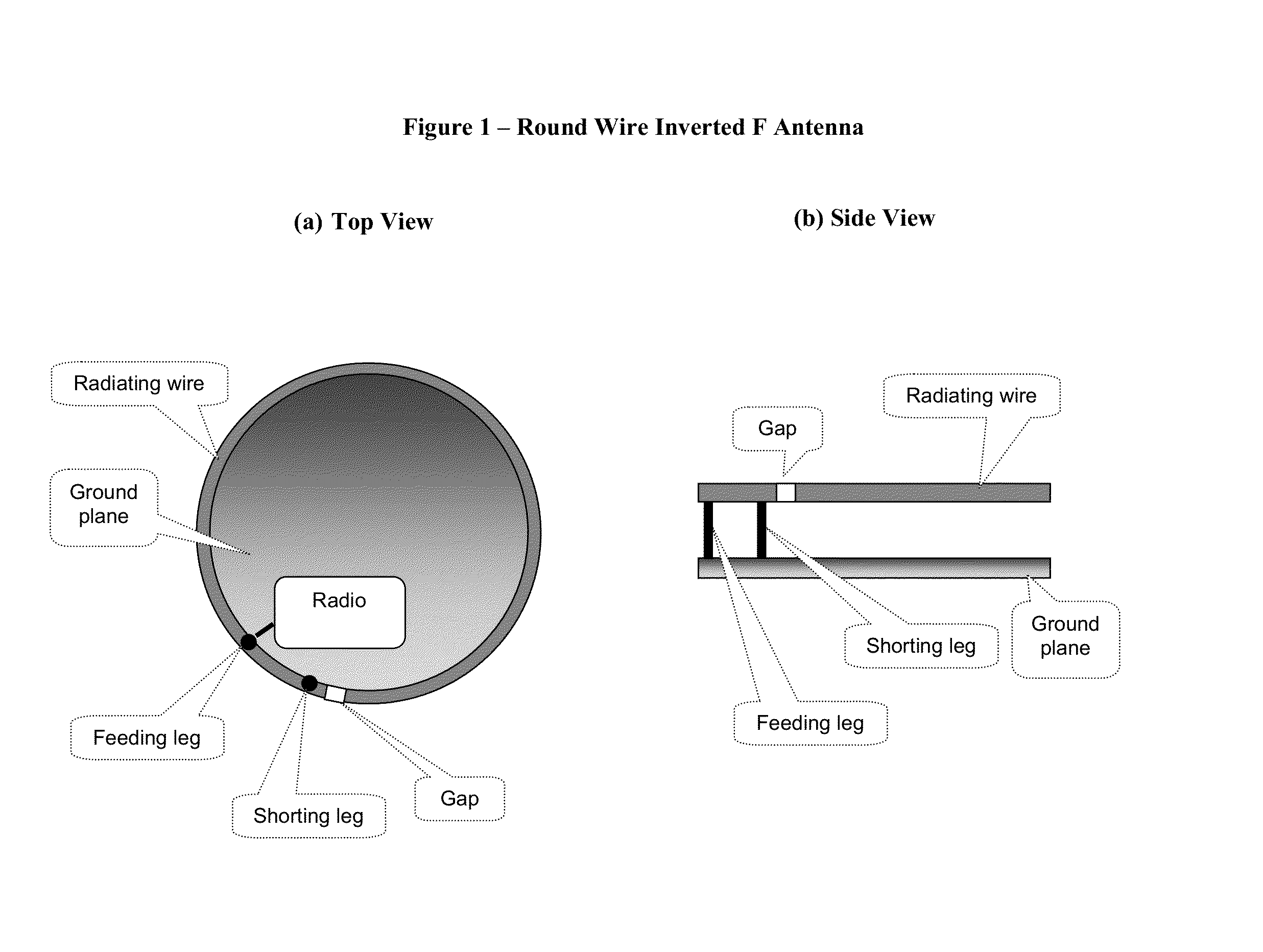

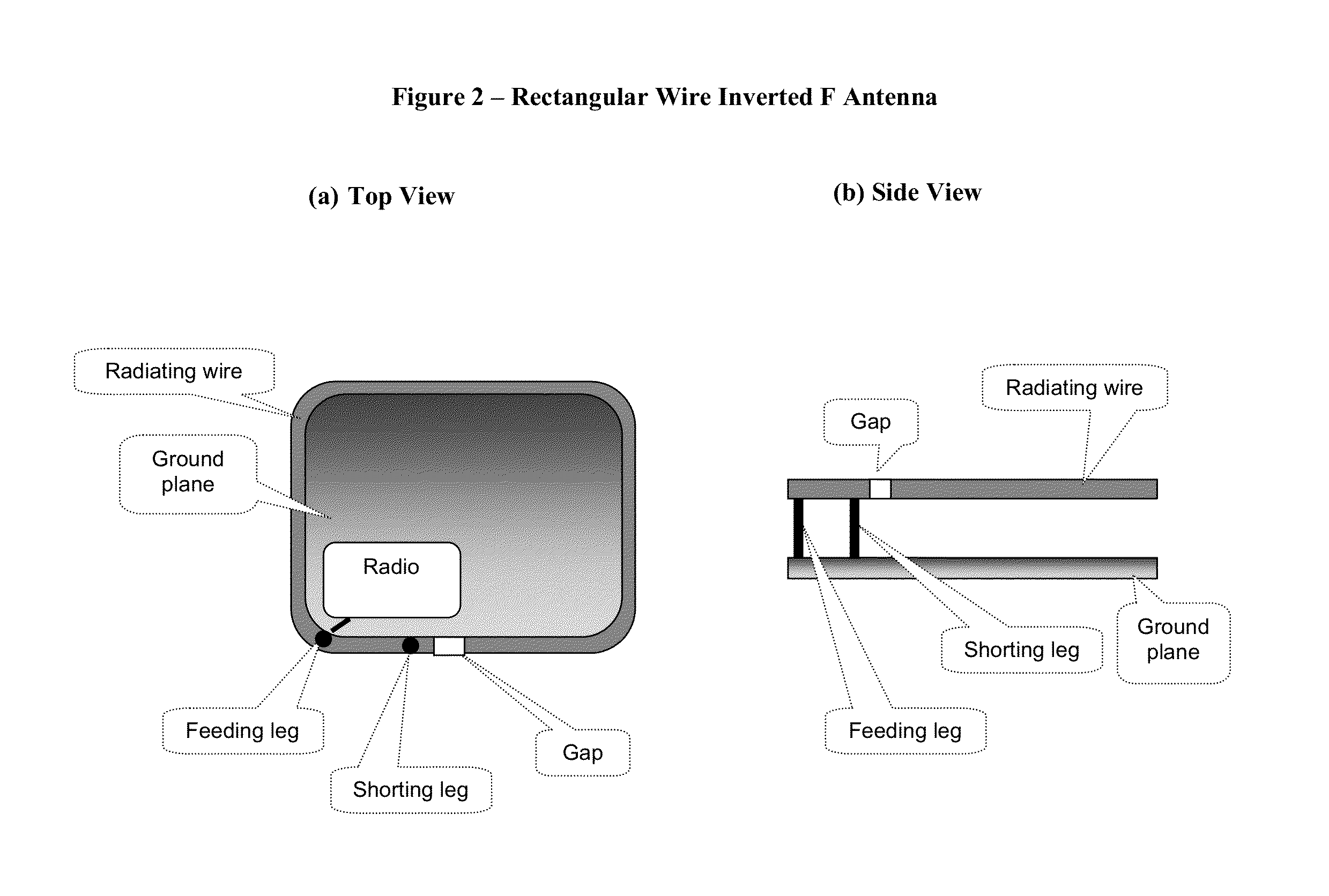

Wrist Worn Device with Inverted F Antenna

InactiveUS20140354494A1Small widthSmall heightAntenna supports/mountingsAntenna adaptation in movable bodiesGps receiverDisplay device

The present invention discloses a wrist worn communication device, possibly integrated with a wrist watch, comprising a radio coupled to a low profile antenna. The antenna, obtaining low and medium angle elevation radiation enabling efficient satellite communications, is configured on the perimeter of the device, giving room for a display on top of this compact device. Preferably, the display is configured to indicate the time, but also possibly other parameters such as position, speed, altitude, temperature, air pressure, heart pace, messages, alarms and so on. According to a preferred embodiment of the present invention, said device is a Personal Locator Beacon (PLB) configured to broadcast distress signals detectable by satellites. According to another embodiment of the present invention, said radio is a GPS receiver.

Owner:KATZ DANIEL A

Embolic basket

InactiveUS20080275498A1Improve the immunityRestoring patency of blood vesselsSurgeryDilatorsThree vesselsEmbolus

Owner:ABBOTT LAB INC

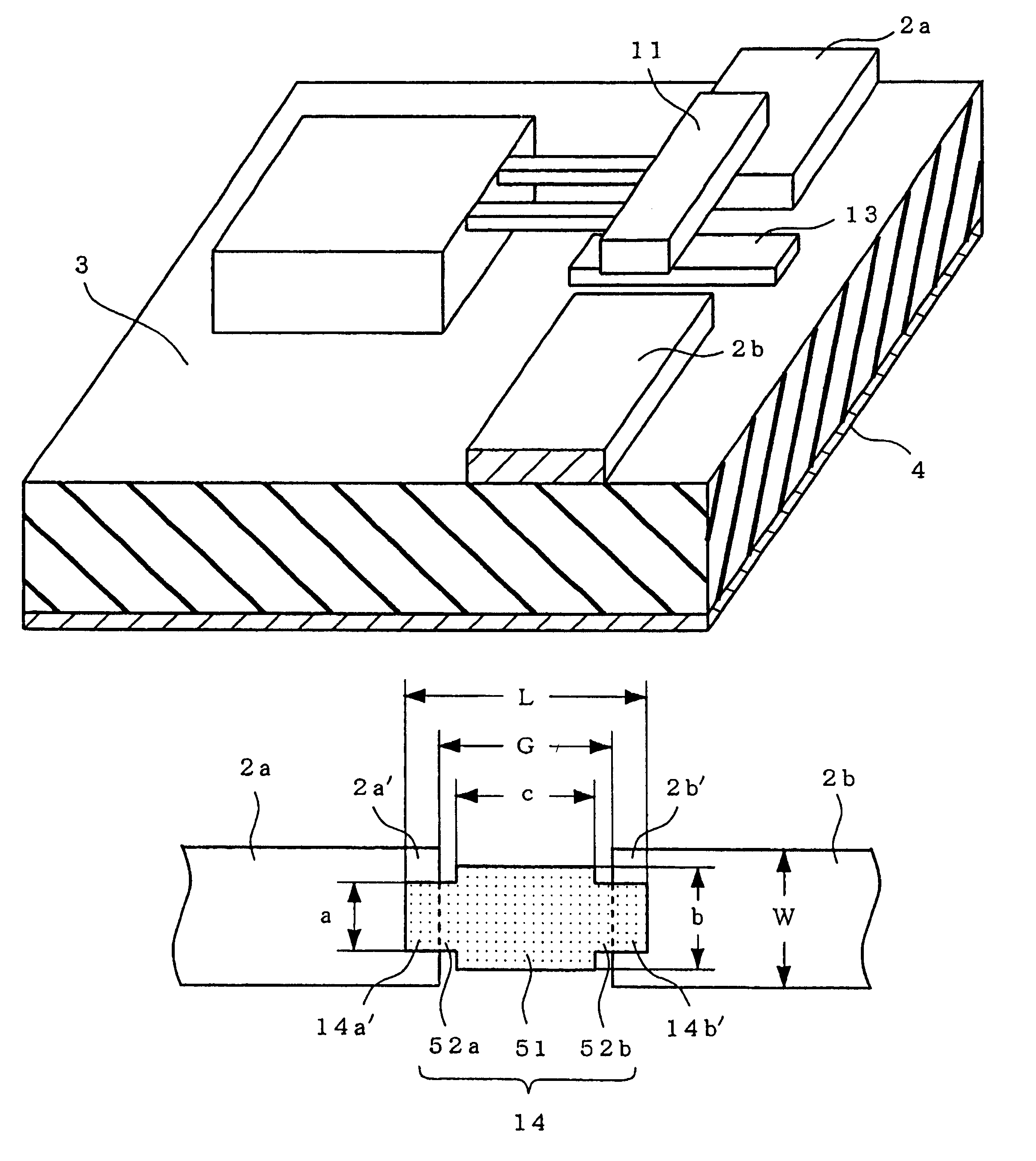

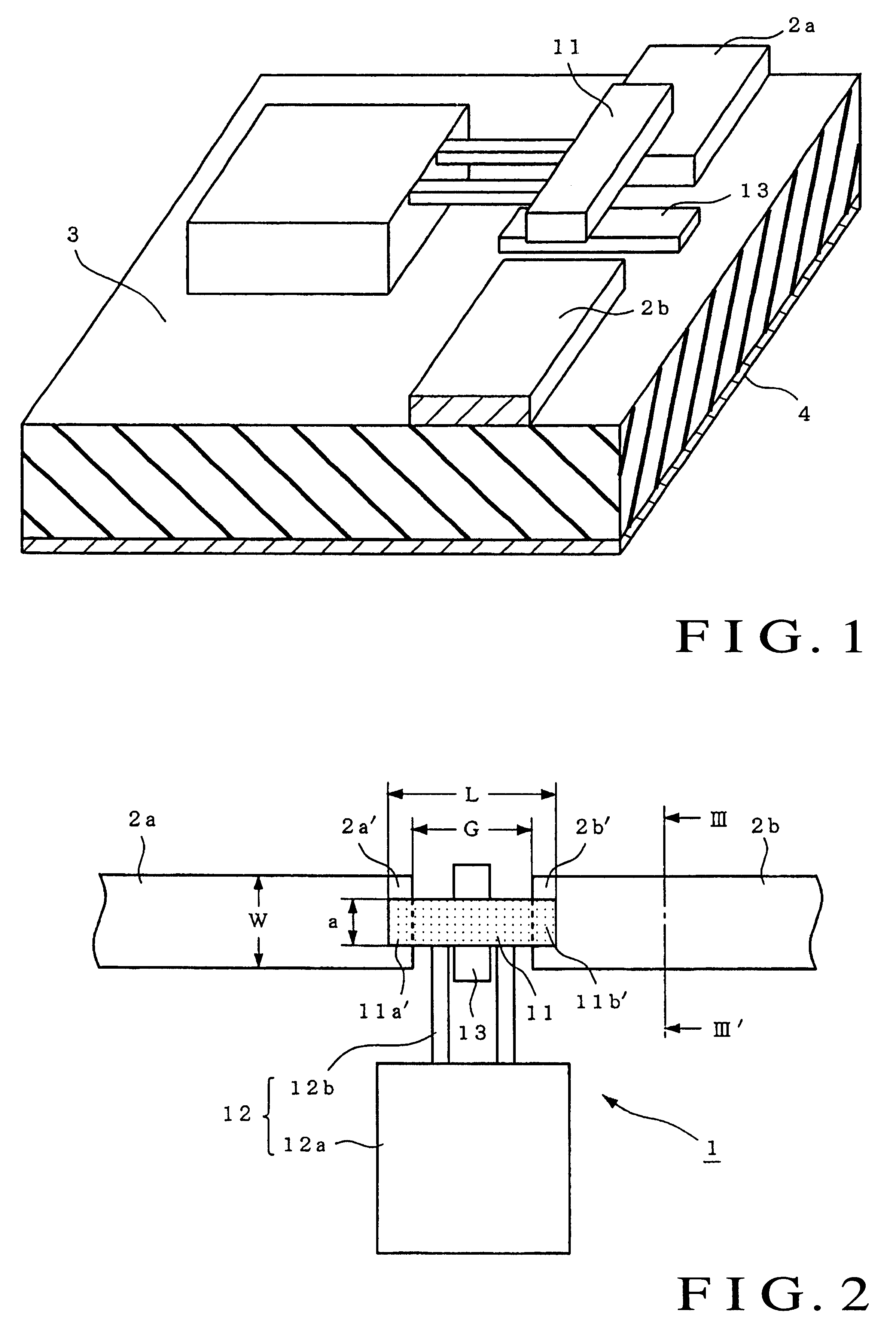

Micromachine MEMS switch

InactiveUS6433657B1Reduce couplingEasy to switchContact surface shape/structureElectrostatic/electro-adhesion relaysEngineeringElectrical and Electronics engineering

A switch includes at least two distributed constant lines (2a, 2b) disposed close to each other, a movable element (11) arranged above the distributed constant lines so as to oppose these distributed constant lines and connecting the distributed constant lines to each other in a high-frequency manner upon contacting the distributed constant lines, and a driving means (13) for displacing the movable element by an electrostatic force to bring the movable element into contact with the distributed constant lines. The movable element has a projection (52a, 52b) formed by notching at least one end of an edge of the movable element which is located on at least one distributed constant line side. In this projection, a width (a) serving as a length in a direction parallel to the widthwise direction of the distributed constant lines is smaller than a width (W) of each of the distributed constant lines.

Owner:NEC CORP

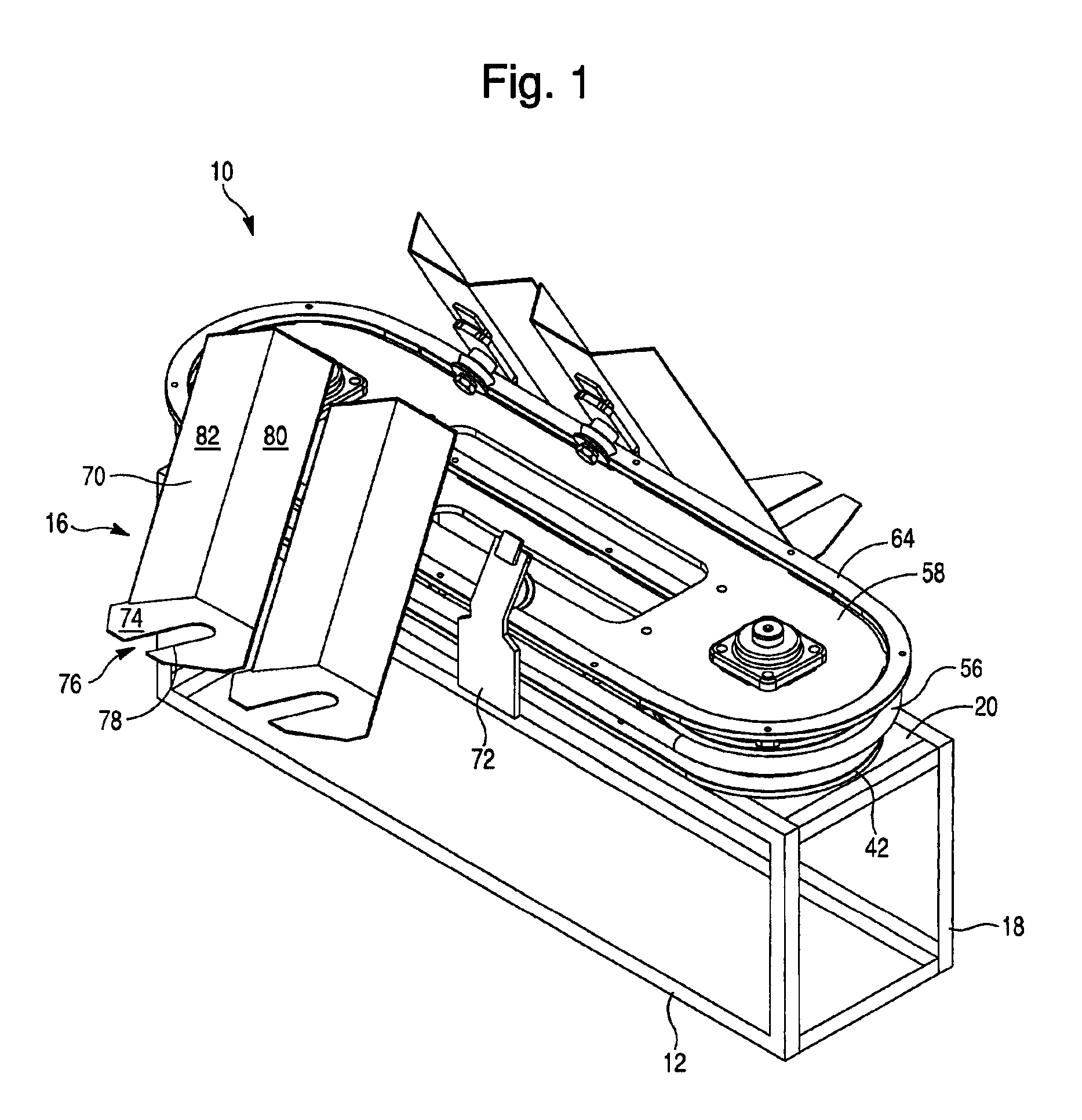

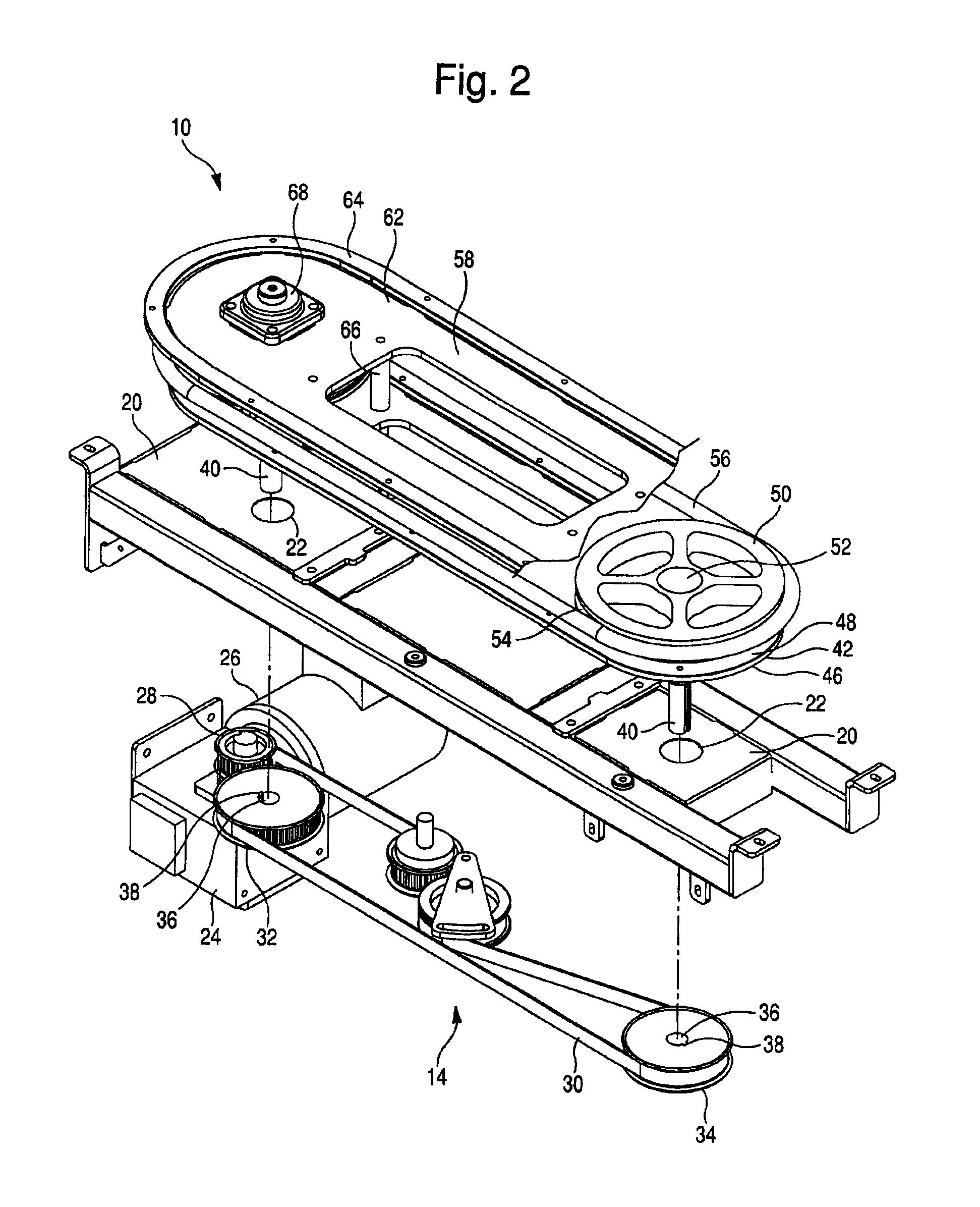

Method and apparatus for buffering a flow of objects

InactiveUS6957941B2Good flexibilityMinimize the numberPackaging meatCharge manipulationEngineeringPackaging machine

A buffer device for buffering a flow of stacks of discrete objects between a stacking machine and a packaging machine is disclosed which buffer includes a plurality of individual trays mounted on carriers which carriers are mounted on a frame and driven about the periphery of the frame by a drive. A first number of stacks of objects is placed on a first number of carriers on a first side of the frame and a second number of stacks are removed from a second number of carriers on a second side of the frame where the first number can be greater than, less than or equal to the first number. The carriers clamp onto a continuously moving drive belt in a manner that allow the drive belt to slip through the carrier clamps when motion of the carriers is obstructed. A method of using the buffer device is also disclosed.

Owner:F R DRAKE

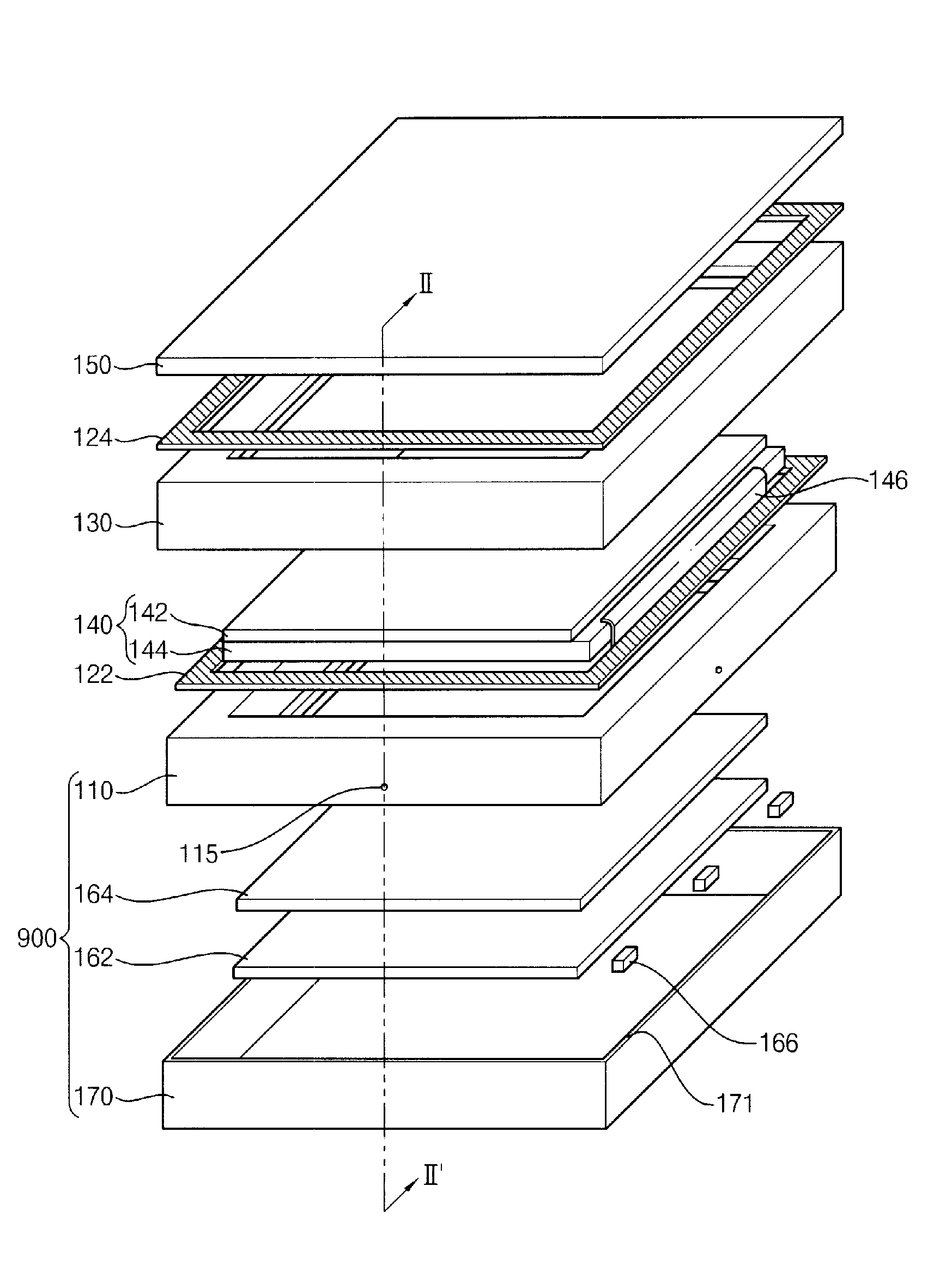

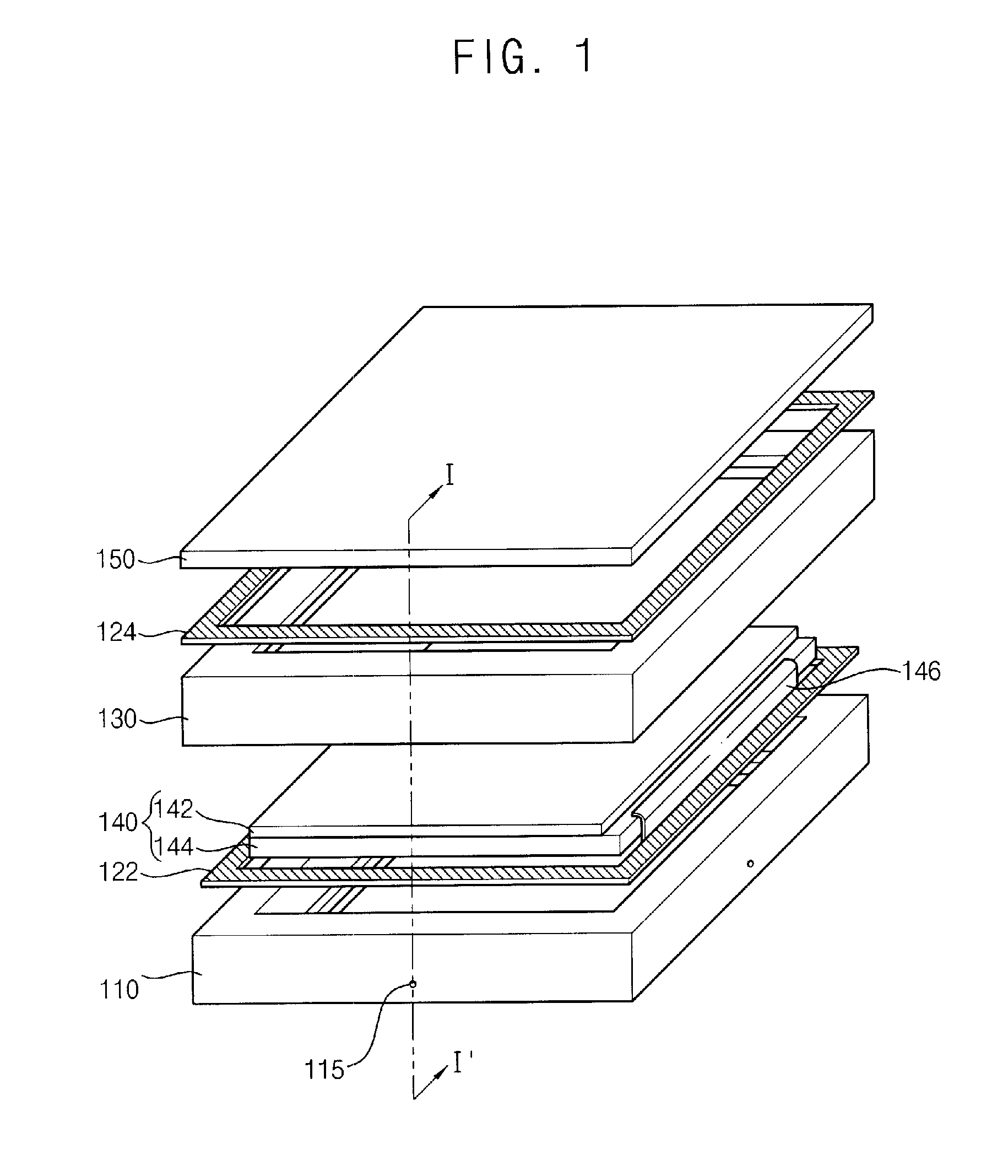

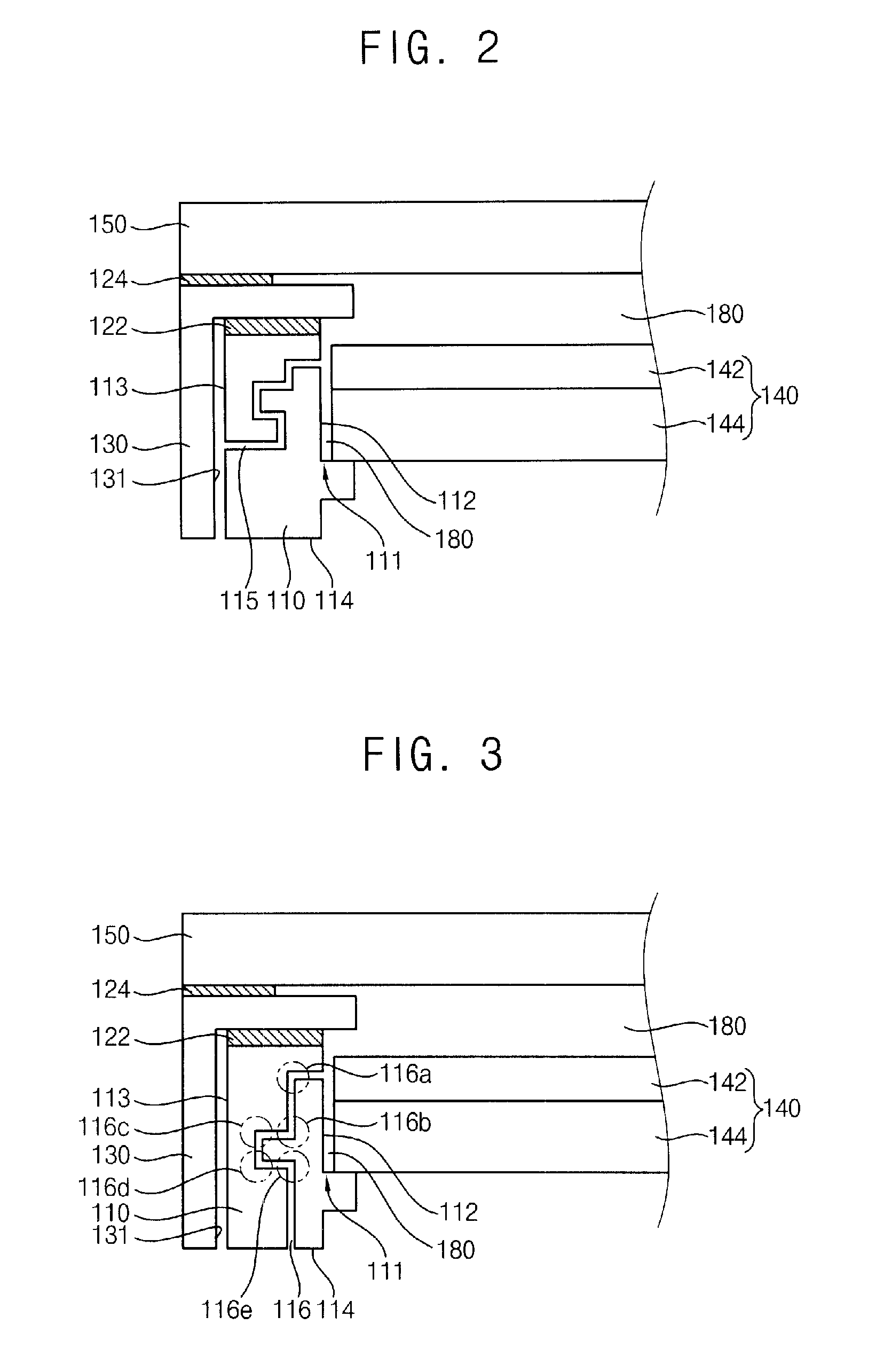

Display device and method of compensating for pressure changes thereof

ActiveUS20080210843A1Eliminating and substantially decreasing defectAvoid spaceSubstation/switching arrangement detailsDigital data processing detailsDisplay devicePressure difference

A display device includes a display panel, a touch screen panel and a receiving container. The display panel displays an image. The touch screen panel is spaced apart from the display panel. The receiving container receives the display panel and has a venting part facing a side surface of the display panel to reduce a pressure difference between a pressure in a space between the display panel and the touch screen panel of the display device and a pressure exterior to the display device.

Owner:SAMSUNG DISPLAY CO LTD

Surgical Stapler For Applying A Large Staple Through A Small Delivery Port And A Method of Using The Stapler To Secure A Tissue Fold

ActiveUS20100191282A1Small shapeHigh strengthSuture equipmentsStapling toolsBiomedical engineeringSurgical Staplers

A method of deploying a surgical fastener into a patient by introducing the fastener into a body of a patient while the fastener is in a first shape having a first loop with a back span and an original size and shape. The method then involves moving end segments of the fastener away from each other substantially along an entire length thereof while keeping the back span in substantially its original size and shape. The method then involves forming the fastener into a second loop having a width greater than a width of the first loop.

Owner:ETHICON ENDO SURGERY INC

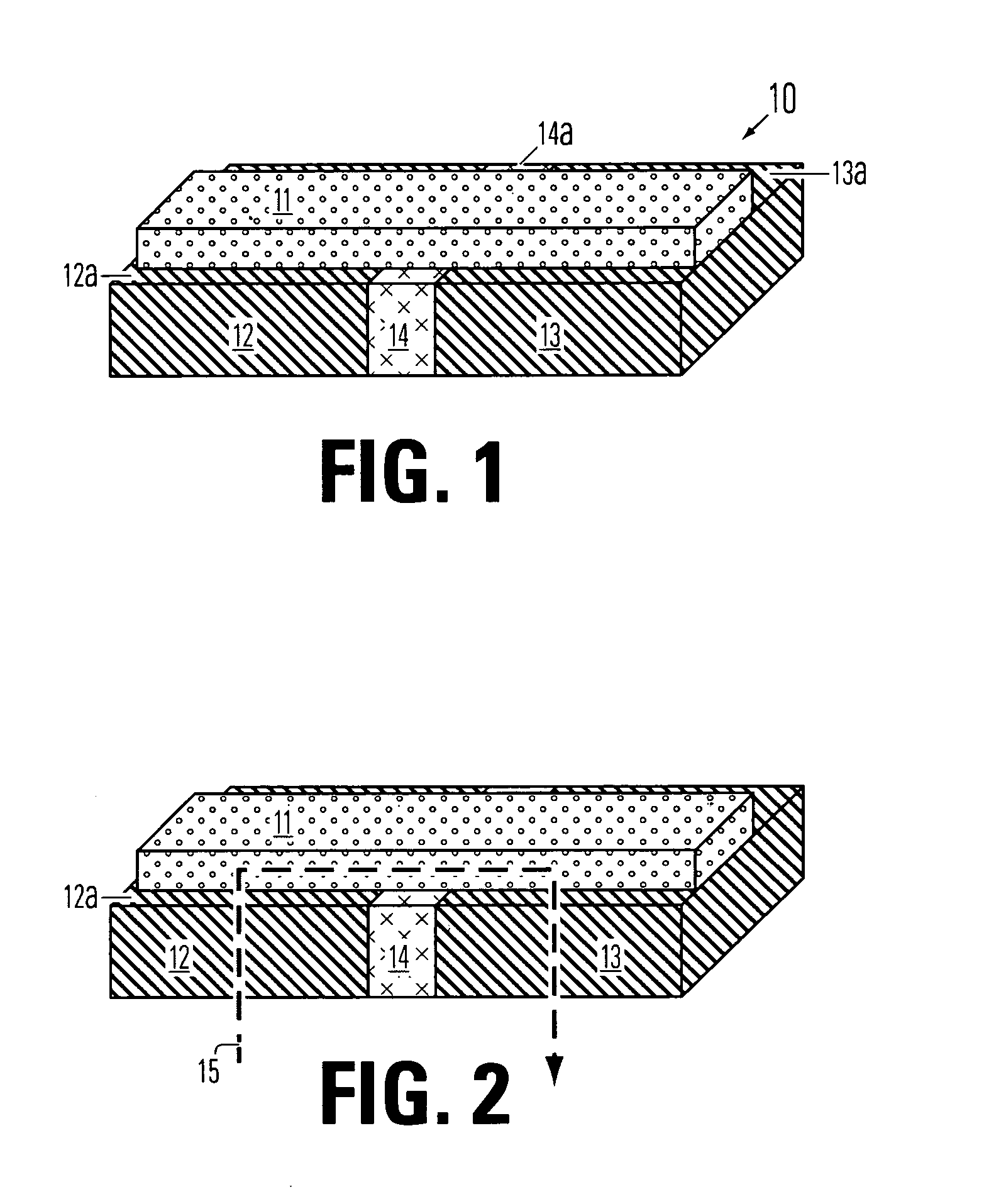

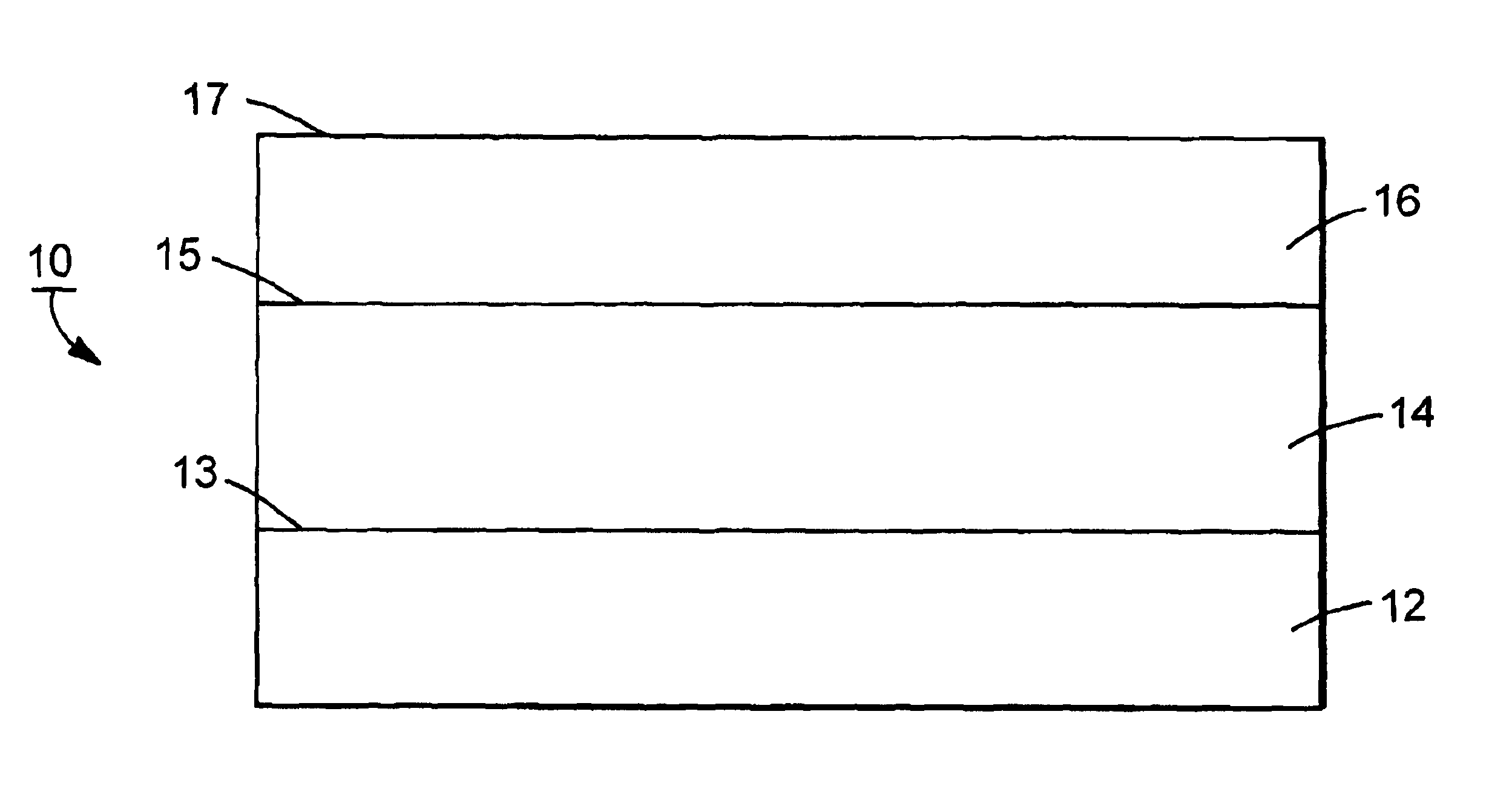

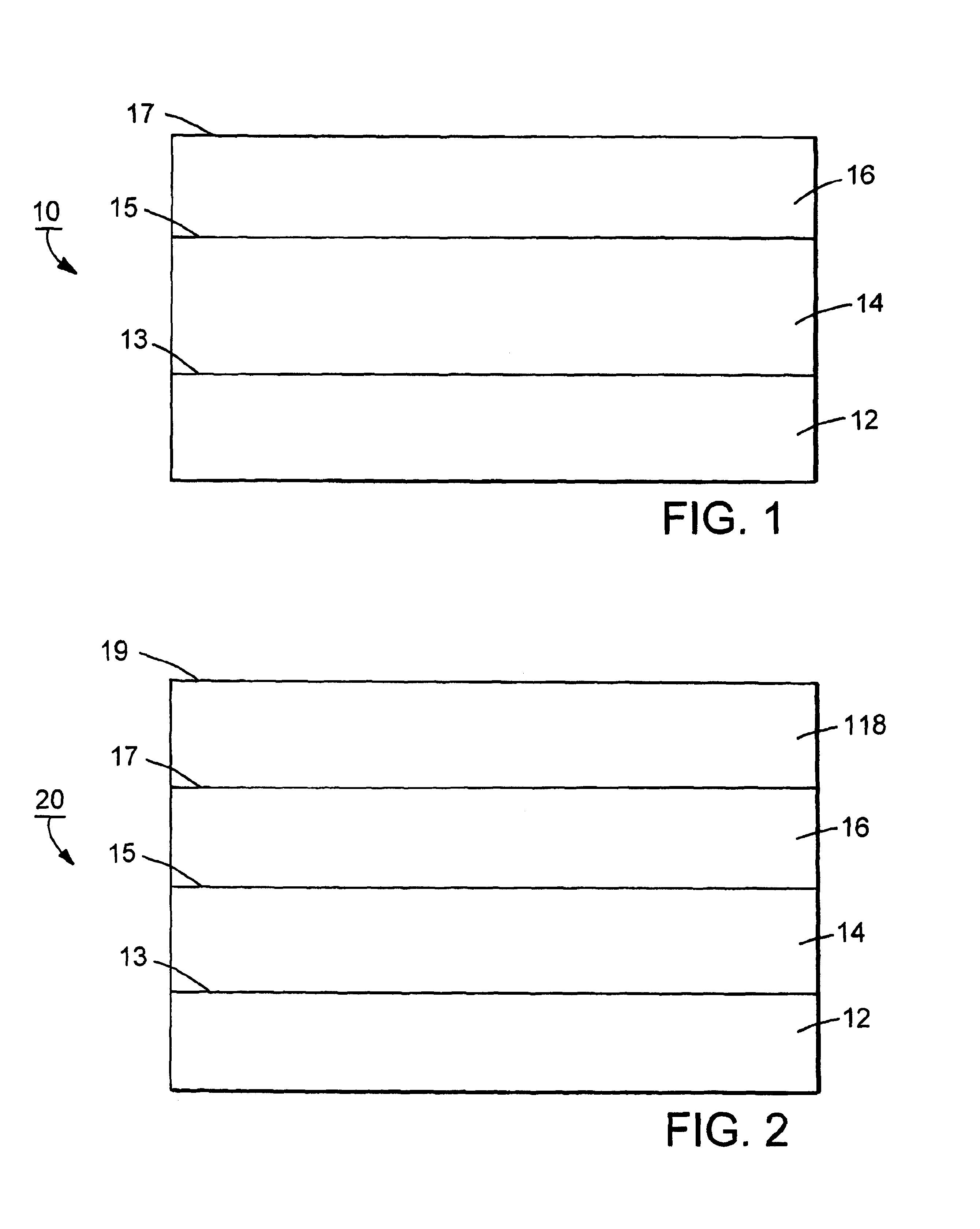

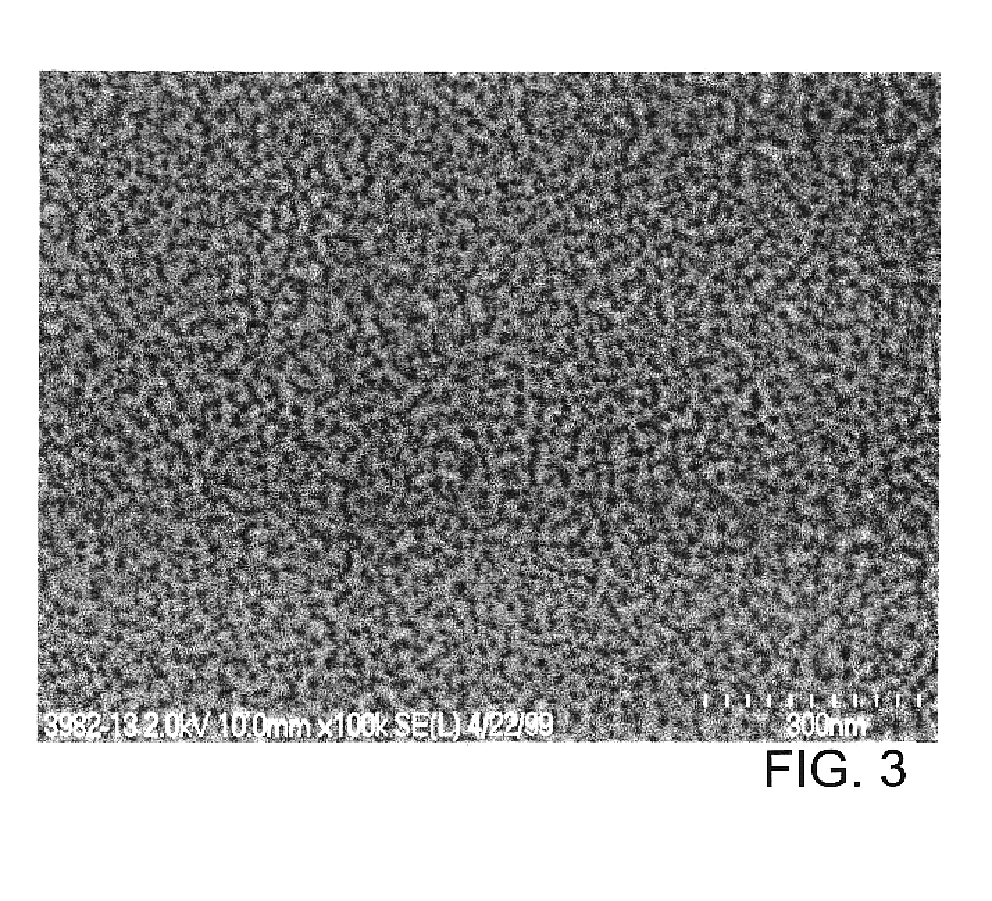

Multi-layer articles and methods of making same

InactiveUS6974501B1High critical current densityHigh densityPolycrystalline material growthFrom normal temperature solutionsPolymer scienceVolumetric Mass Density

The invention relates to multi-layer articles and methods of making such articles. The methods include first conditioning the surface of an underlying layer, such as a buffer layer or a superconductor layer, then disposing a layer of material on the conditioned surface. The conditioned surface can be a high quality surface. Superconductor articles formed by these methods can exhibit relatively high critical current densities.

Owner:AMERICAN SUPERCONDUCTOR

Knotless suture anchoring devices and tools for implants

ActiveUS20130158600A1Improve ease of implantationReduce exposureSuture equipmentsHeart valvesLess invasive surgerySuture anchors

Devices for securing prostheses such as heart valves or annuloplasty rings with sutures and without using knots are disclosed. The devices are particularly well suited for traditional surgery or minimally invasive surgery, and improve the ease of implantation by eliminating surgical knots a clinician would normally tie in the limited space in and around the implant site. The devices have opposed the clamp halves surrounded by a coil spring. Sutures pass between the clamp halves and the coil spring has an inner coil diameter sufficient to compress the sutures between the clamp. A retention member positioned between the clamp halves maintains a minimum space and therebetween to enable the locking device to be slid along the sutures into position, and to adjust the tension of the sutures therethrough. A delivery tool may be used to deliver and deploy the locking devices.

Owner:EDWARDS LIFESCIENCES CORP

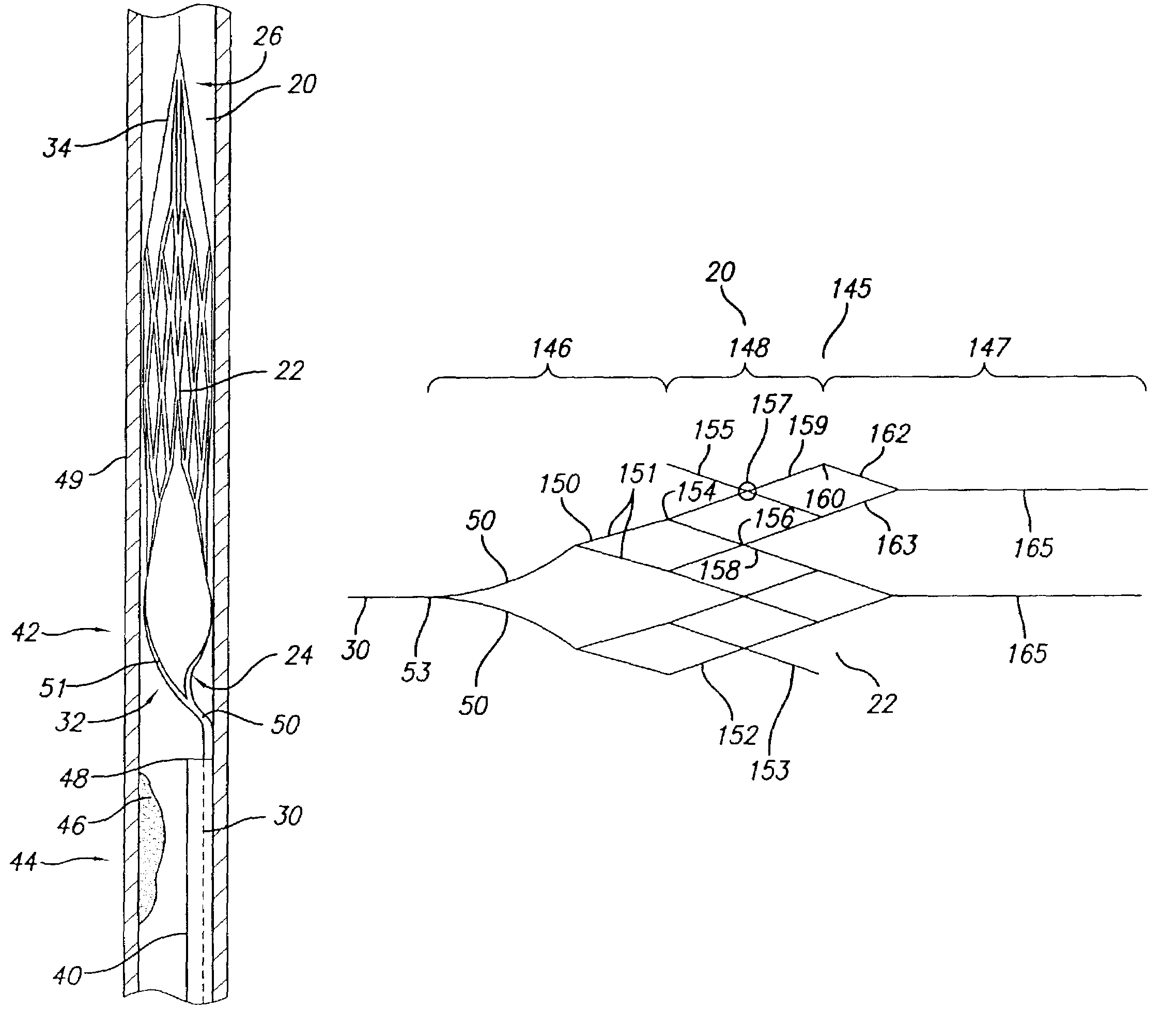

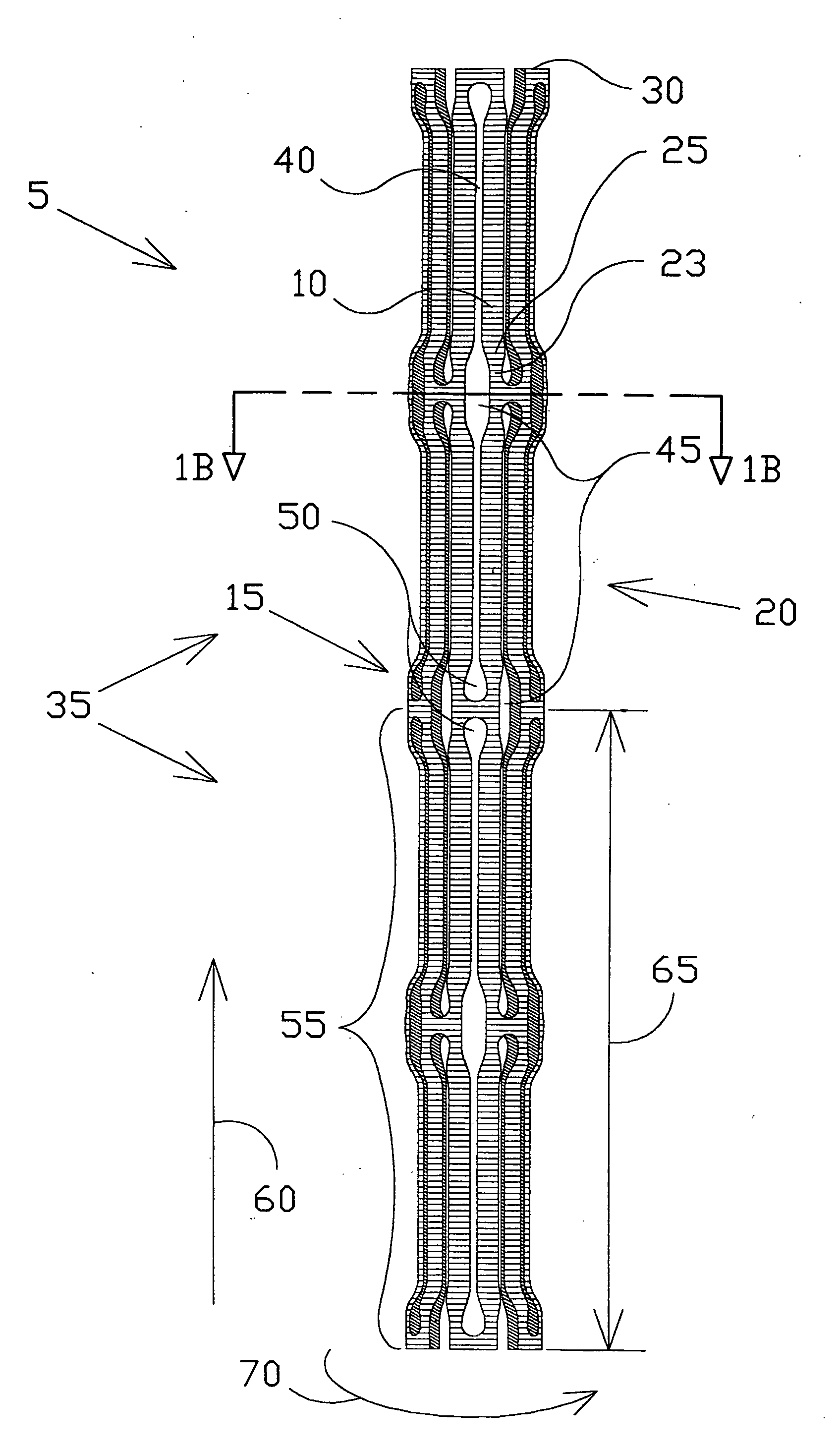

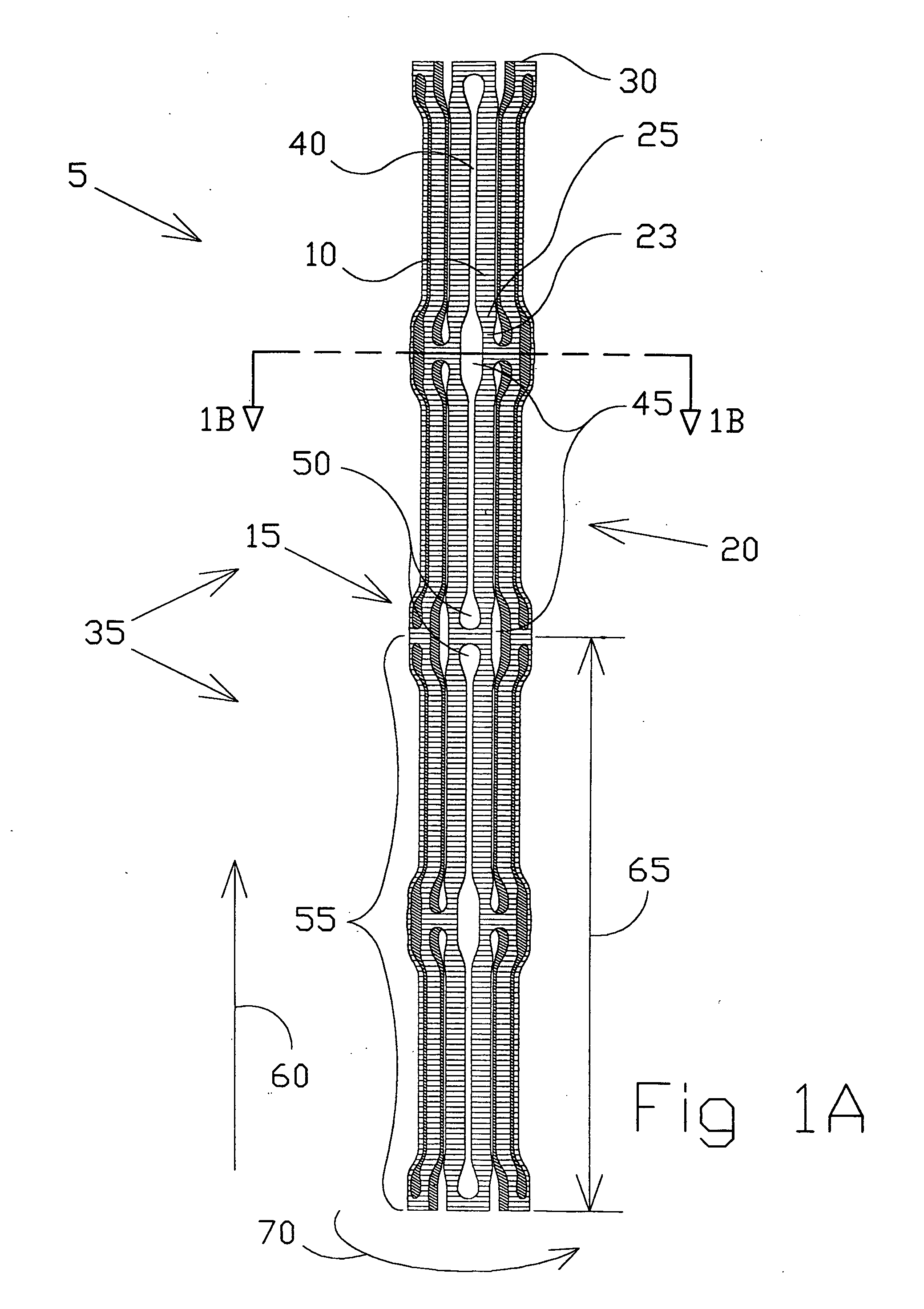

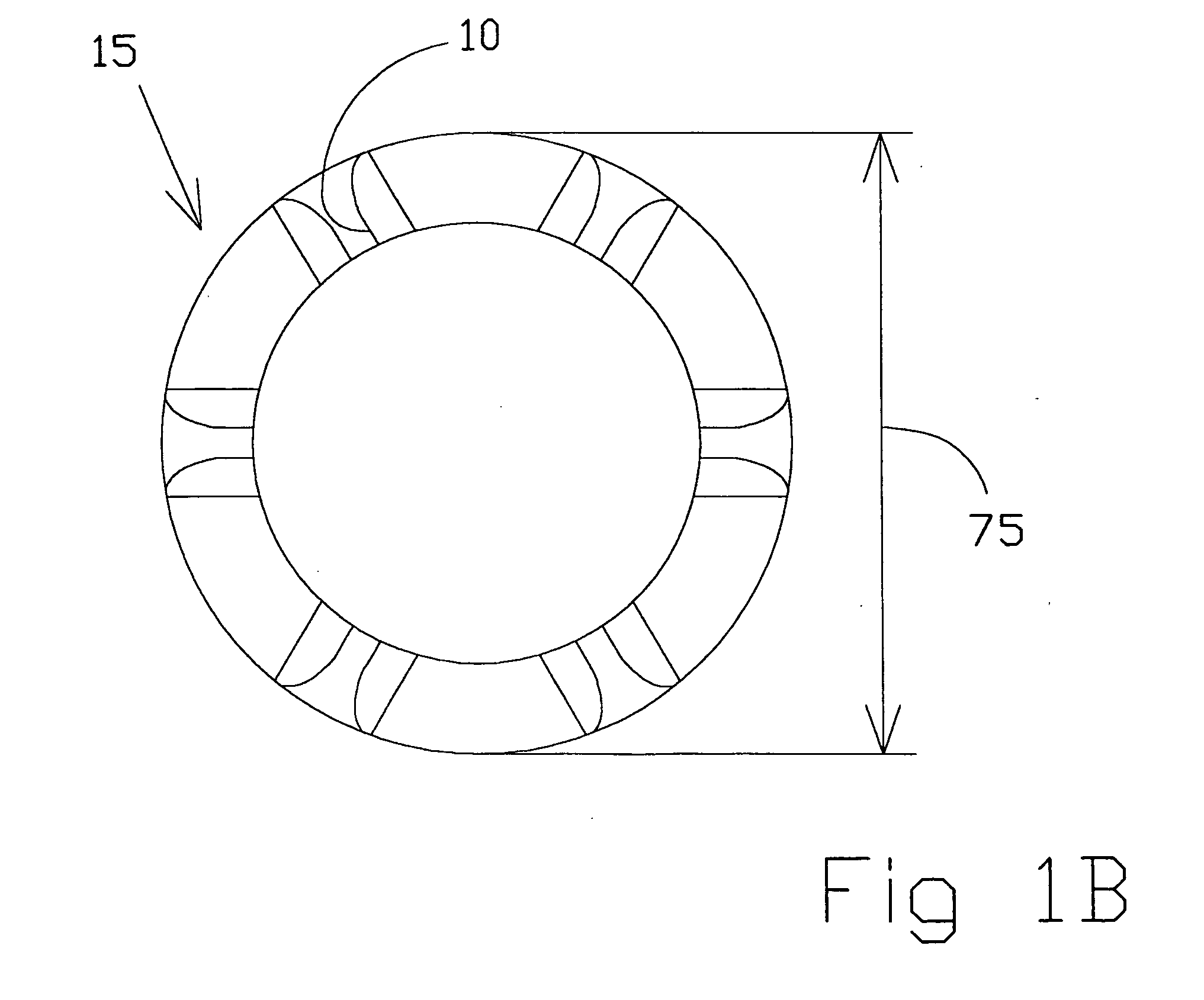

Intravascular hinge stent

A balloon or self expandable endoprosthesis formed of a single or multiple joined stent sections. Each section has a node and strut structure extending throughout in order to uncouple expansion forces of the stent to hold a blood vessel outward from crush forces that resist the formation of an oval shape during crush deformation. The hinge can bend in the direction of a uniformly curved surface of the stent but not in the radial direction. The strut can bend in the radial direction but not in the uniformly curved surface of the stent. The widths, lengths, and radial dimensions of the hinges and struts provide a balloon-expandable hinge stent that is non-crushable. For a self-expanding stent the hinge and strut dimensions provide expansion forces that are controlled independently from crush forces. Expansion properties are determined by the hinge dimensions and crush properties are determined independently by strut dimensions.

Owner:DRASLER WILLIAM JOSEPH +1

Phase change memory devices with contact surface area to a phase changeable material defined by a sidewall of an electrode hole and methods of forming the same

ActiveUS20050110983A1Small widthTransistorSolid-state devicesPhase-change materialPhase-change memory

Phase change memory devices and methods of making phase changeable memory devices including a heating electrode disposed on a substrate are provided. The heating electrode includes an electrode hole in the heating electrode. A phase change material pattern is provided in the electrode hole and contacts a sidewall of the electrode hole. In some embodiments, the electrode hole extends through the heating electrode. In some embodiments, the phase changeable material pattern only contacts the electrode at a sidewall of the electrode hole

Owner:SAMSUNG ELECTRONICS CO LTD

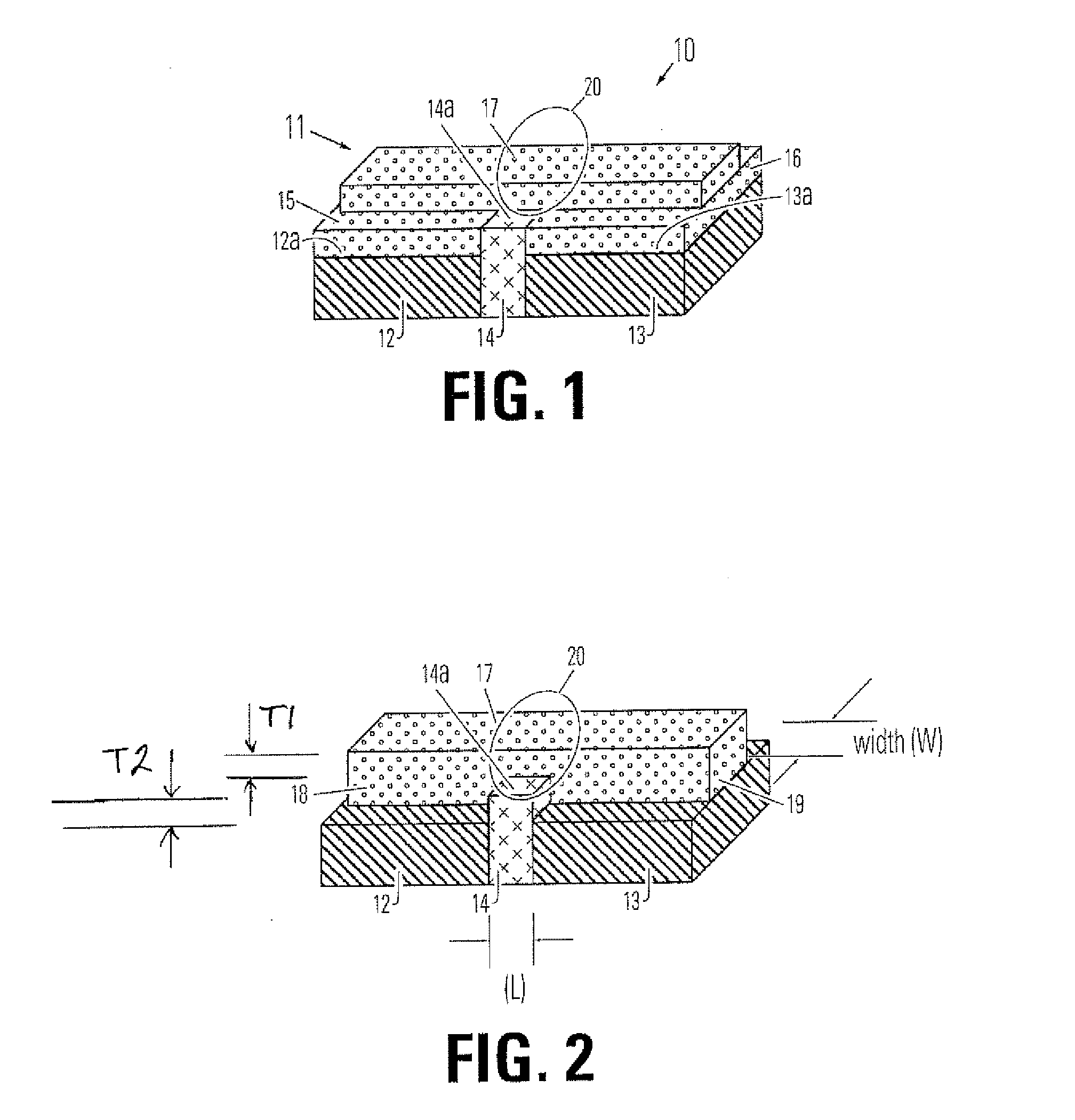

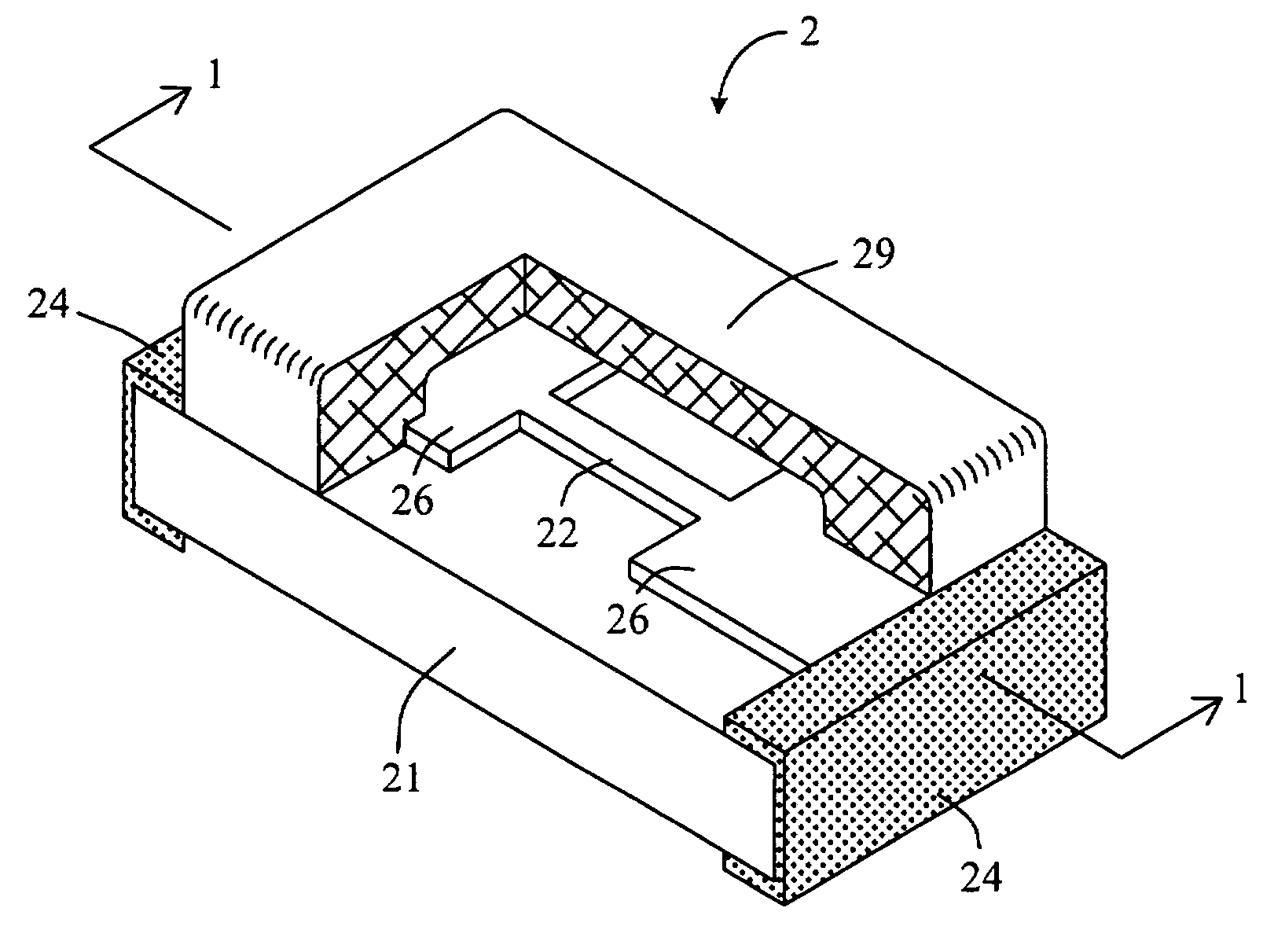

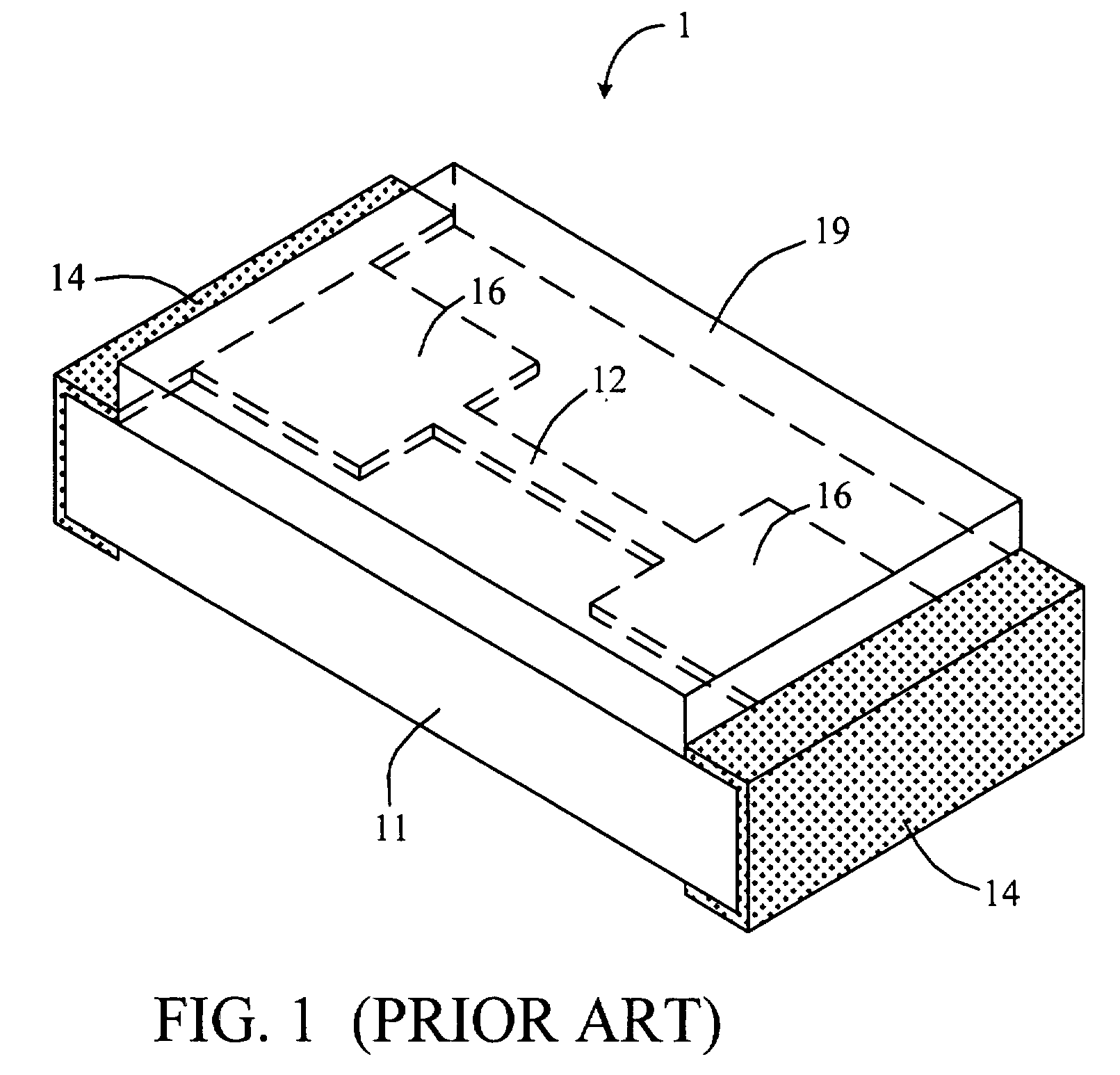

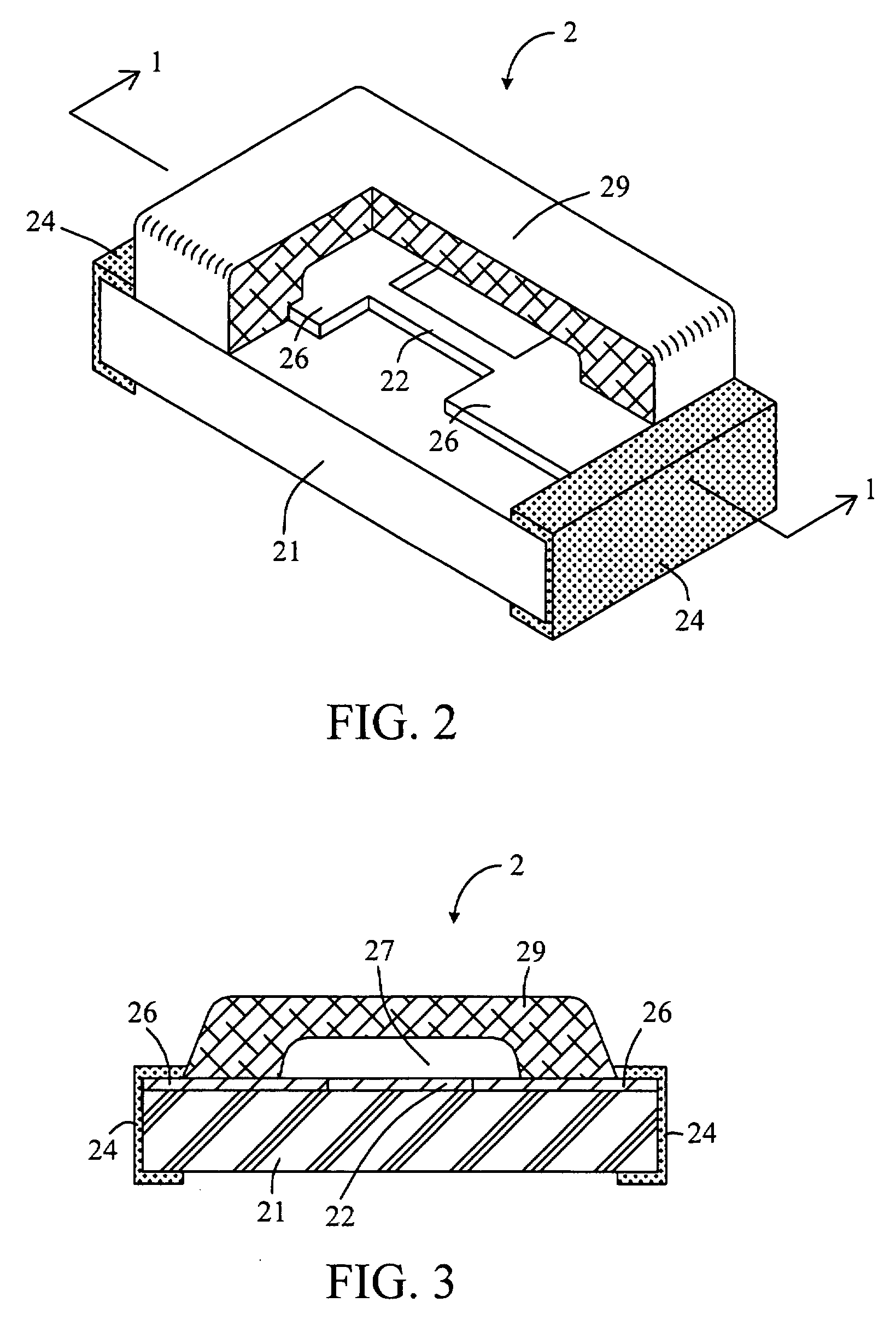

Chip-type fuse and method of manufacturing the same

InactiveUS20080191832A1Ensure long-term reliabilityLow costFuse device manufactureElectrical and Electronics engineeringFuse cutout

A chip-type fuse is based on an electrically insulating substrate and fusible element is disposed thereon. A protective layer is formed over the fusible element and adheres to the substrate around the fusible element so as to define a cavity between the protective layer and the fusible element. The cavity isolates the protective layer from direct contact with the fusible element so that the protective layer will not be melted or breached by the excessive heat and arc generated by the fusible element under overload condition. Further, the cavity can be hermetically sealed to enclose a gas of pressure less than one atmosphere. A thermally insulating layer and an arc suppressive layer may be incorporated to reduce the response time and arc intensity of the chip-type fuse respectively under overload condition. The method of manufacturing chip-type fuse, particularly the method of forming fusible element and cavity, is described too.

Owner:BESDON TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com