Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

13979 results about "Packaging machine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Packaging machinery is used throughout all packaging operations, involving primary packages to distribution packs. This includes many packaging processes: fabrication, cleaning, filling, sealing, combining, labeling, overwrapping, palletizing, etc.

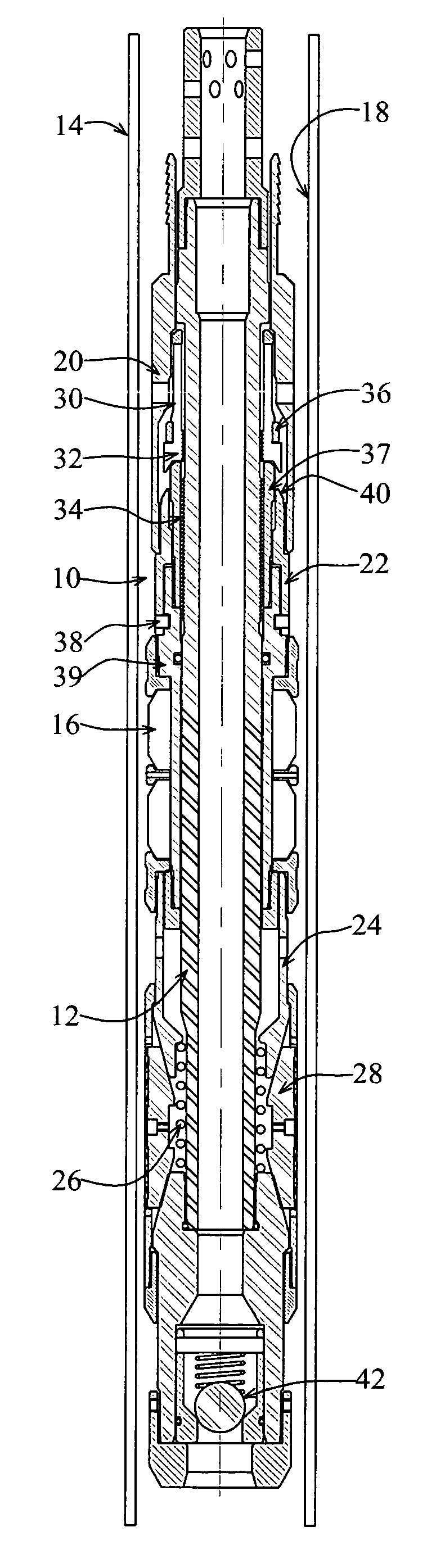

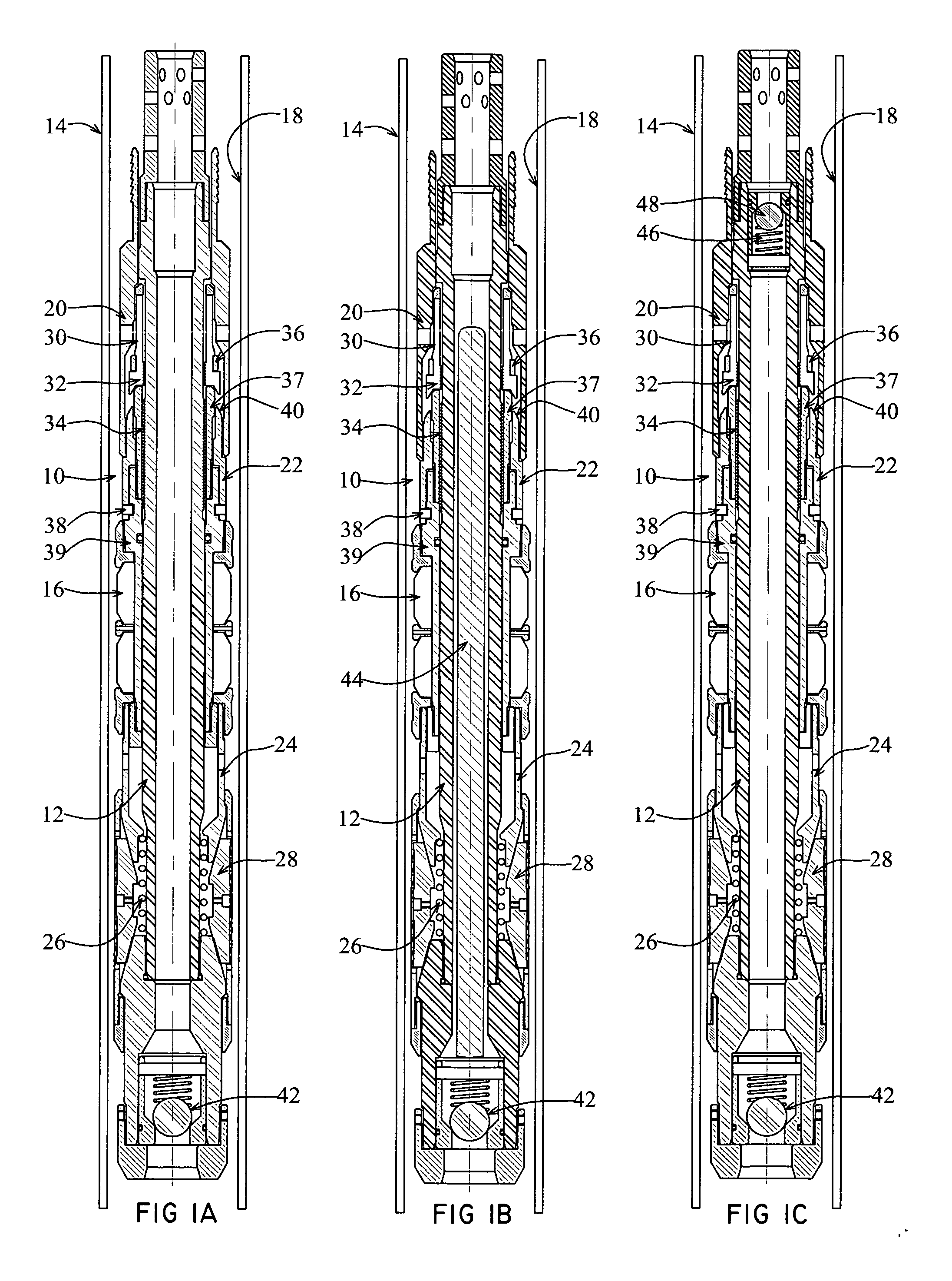

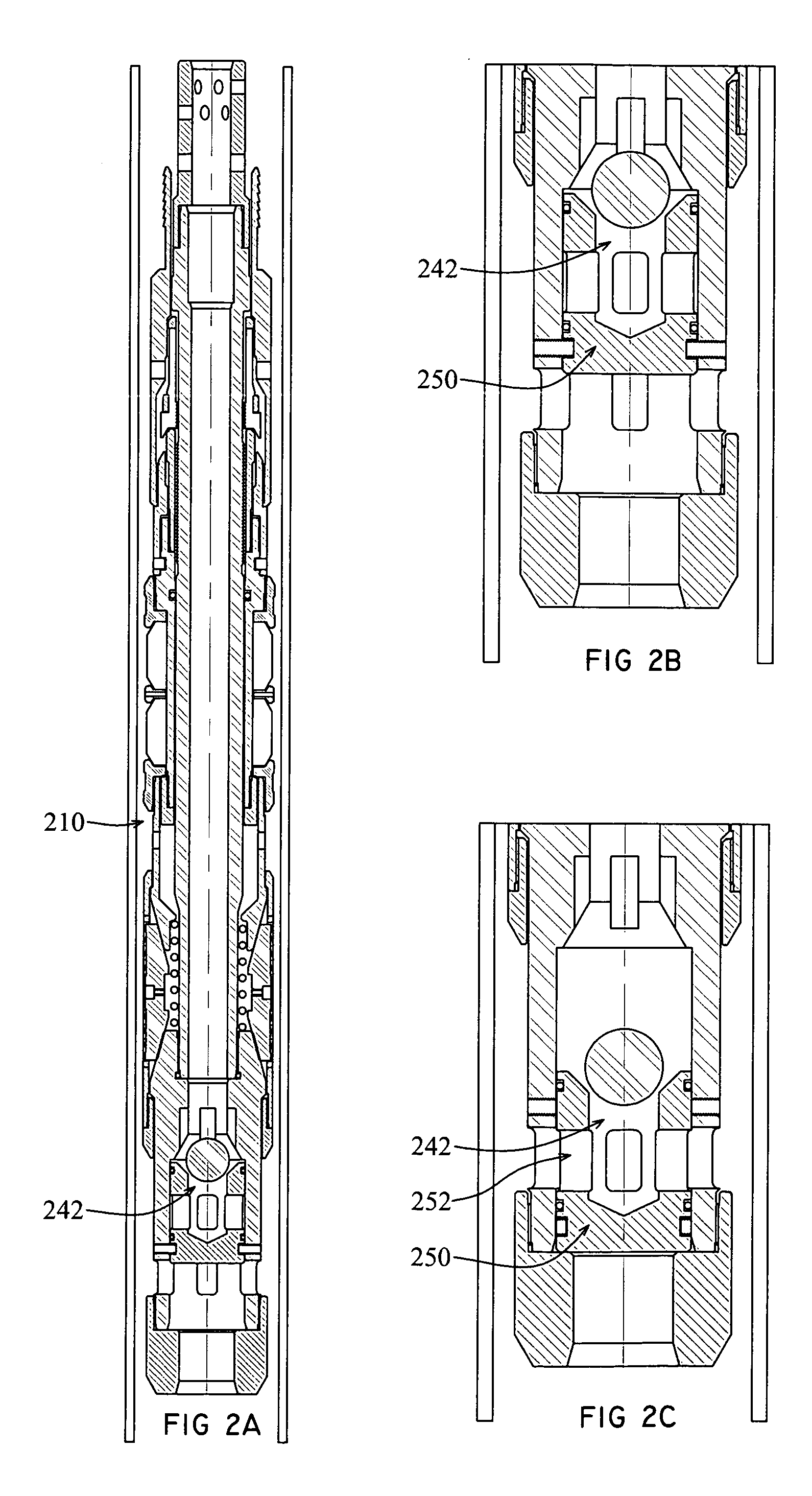

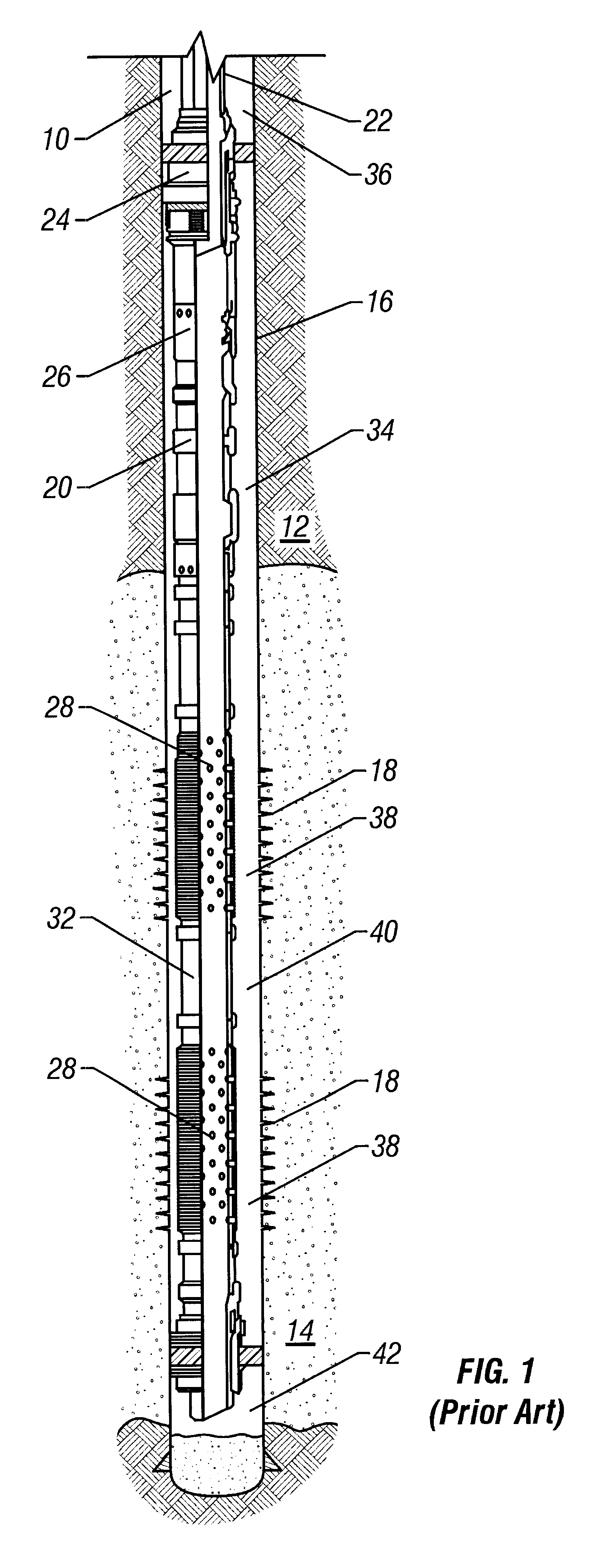

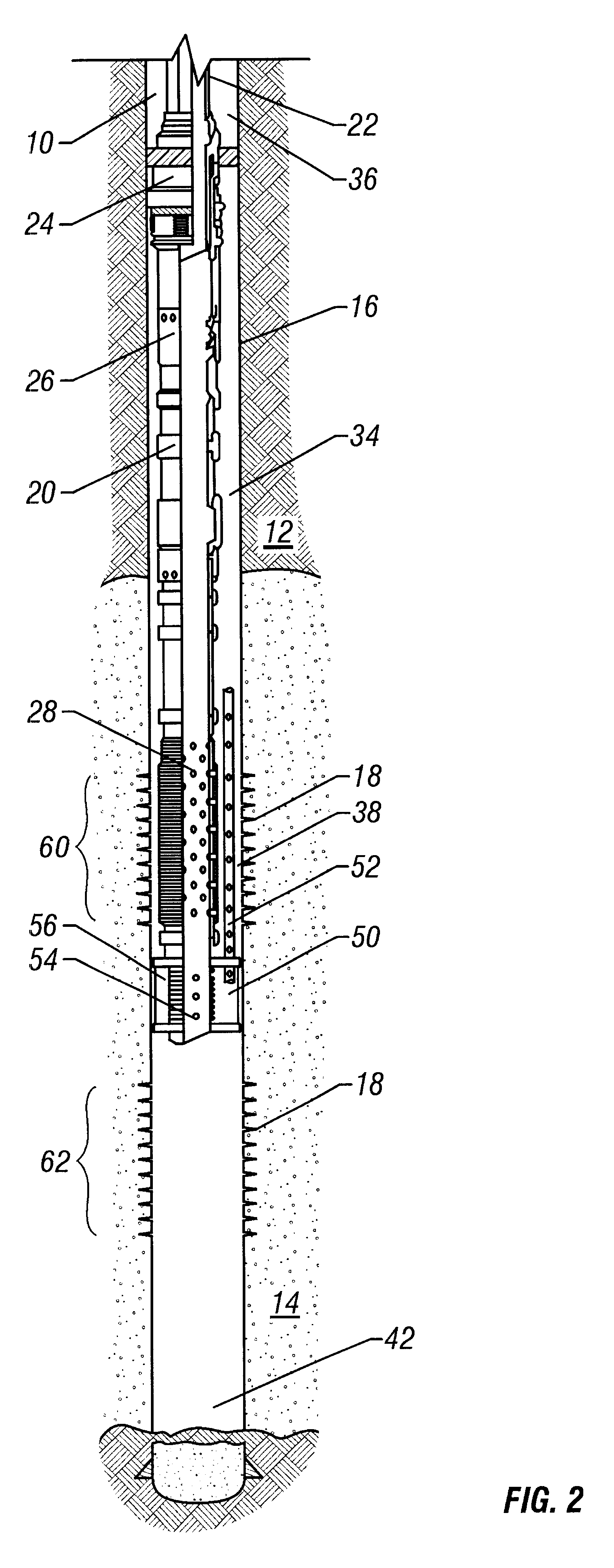

Retrievable frac packer

InactiveUS20070051521A1Reduce in quantityIncrease sealing forceFluid removalSealing/packingManufacturing engineeringProduction testing

A retrievable frac packer is provided which allows frac operations to be conducted with a single, retrievable tool, with the capability of providing positive zone production indications during production testing.

Owner:EAGLE DOWNHOLE SOLUTIONS

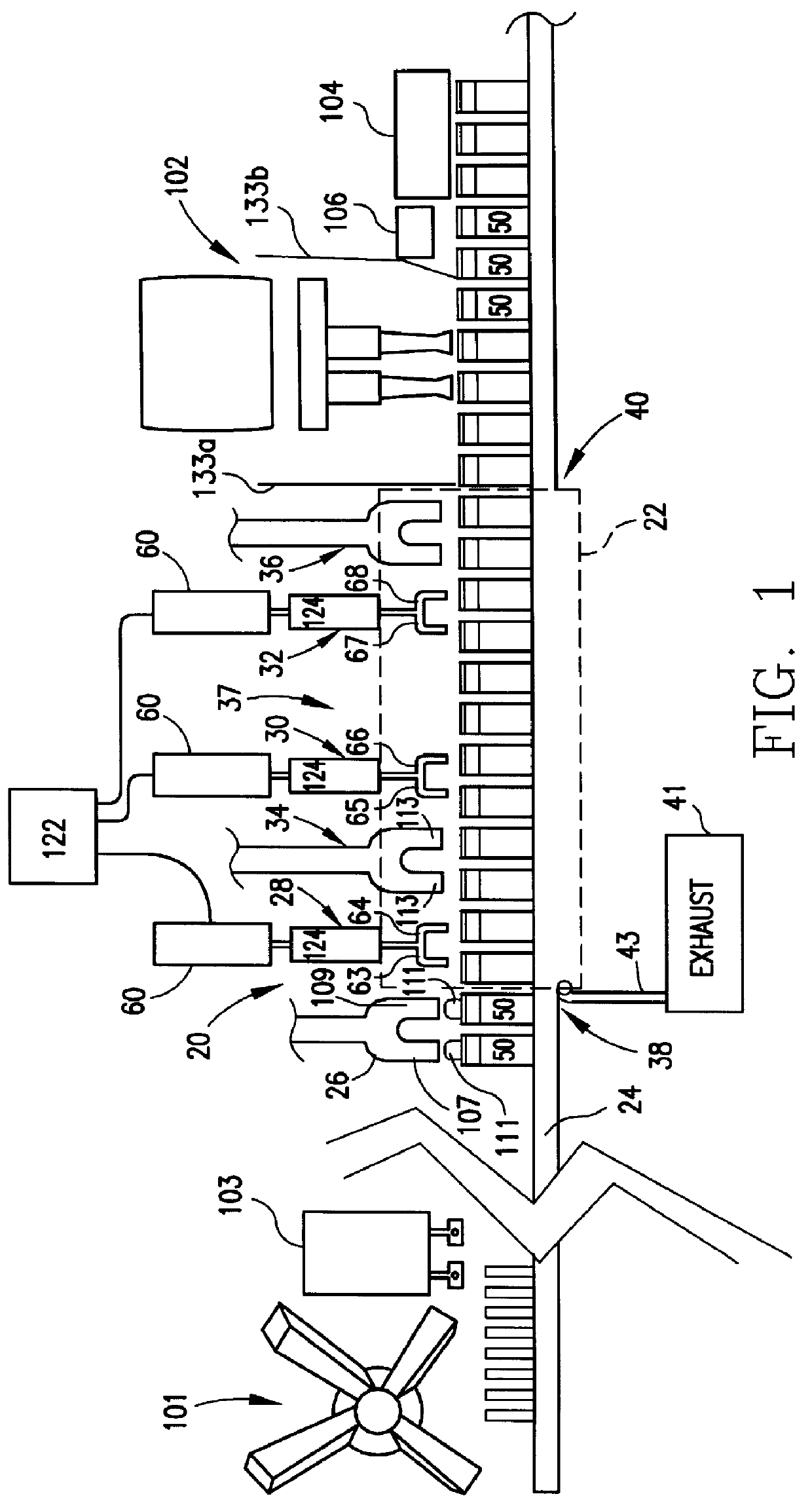

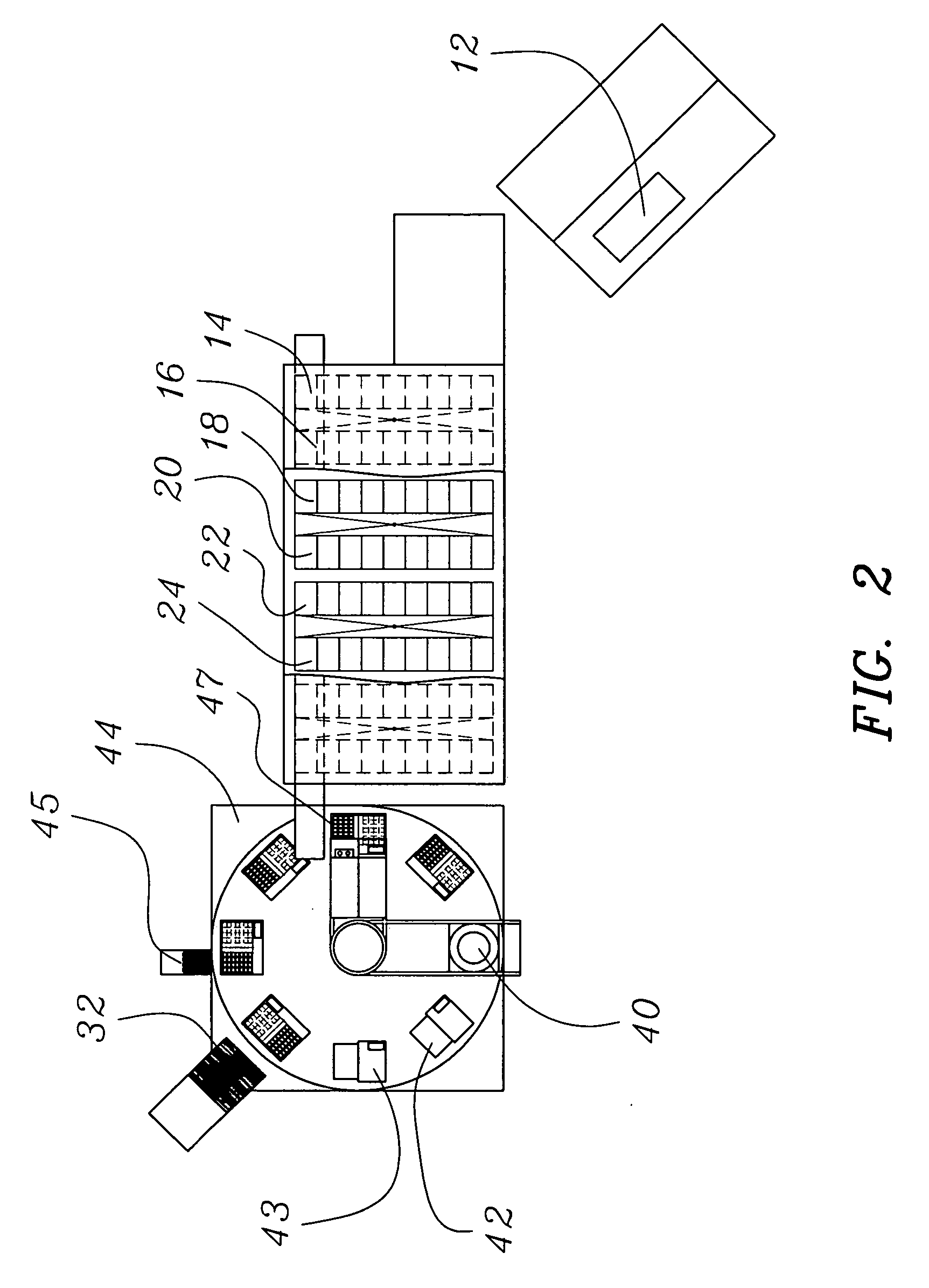

Heat and hydrogen peroxide gas sterilization of container

The present invention discloses a method and apparatus for sterilizing containers with gas-phase hydrogen peroxide and heat on a linear form, fill and seal packaging machine. A partially formed container is subjected to multiple applications of gaseous hydrogen peroxide and hot air within a sterilization tunnel. The sterilization tunnel is maintained at a temperature greater than the condensation temperature of hydrogen peroxide. The present invention sterilizes the container allowing for filling of the container with a high acid product such as orange juice for ambient distribution. The container may be any number of possibilities such as TETRA REX TM gable top cartons, plastic bottles, and the like. The invention allows for the efficacious use of hydrogen peroxide gas having a concentration of up to 53%.

Owner:TETRA LAVAL HLDG & FINANCE SA

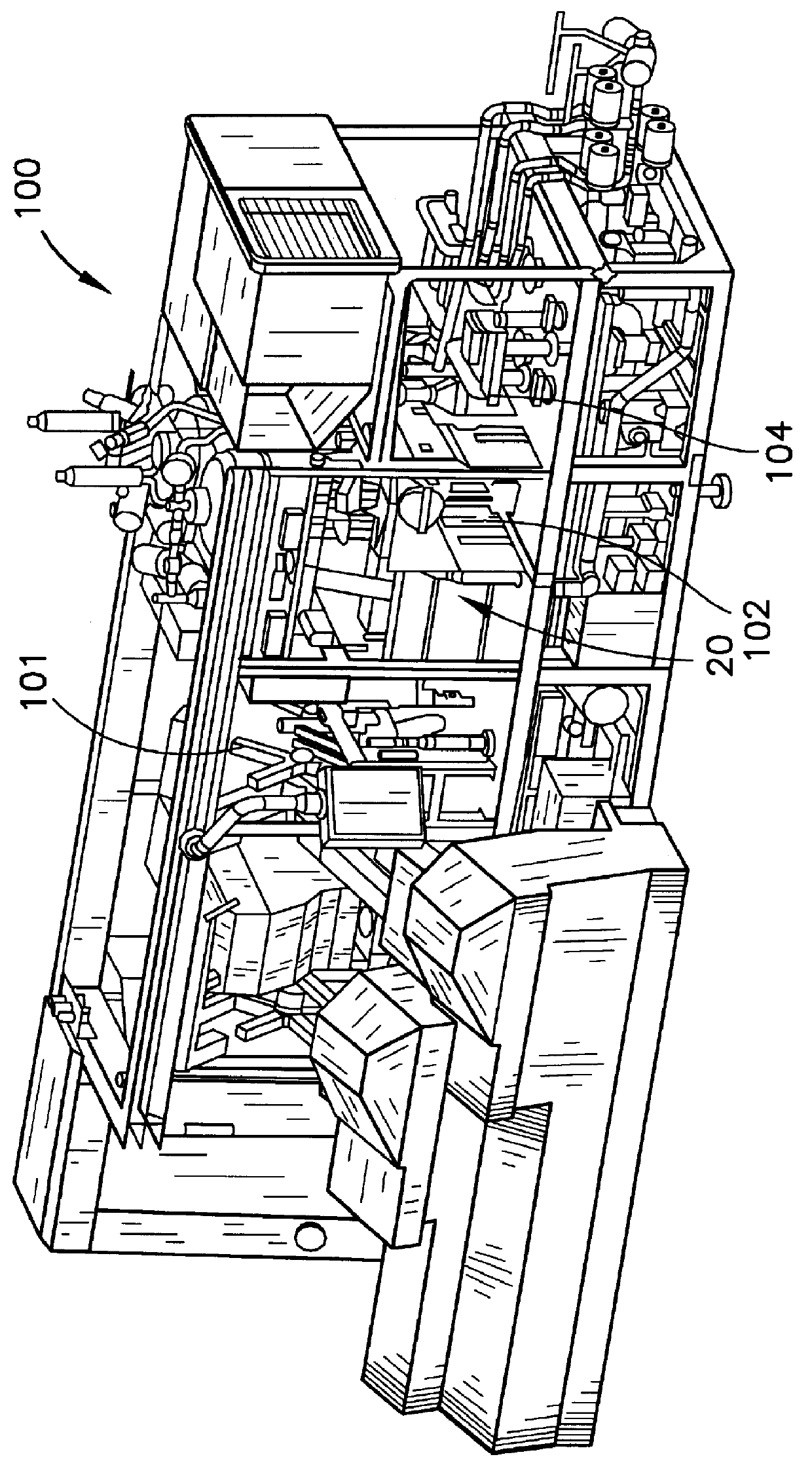

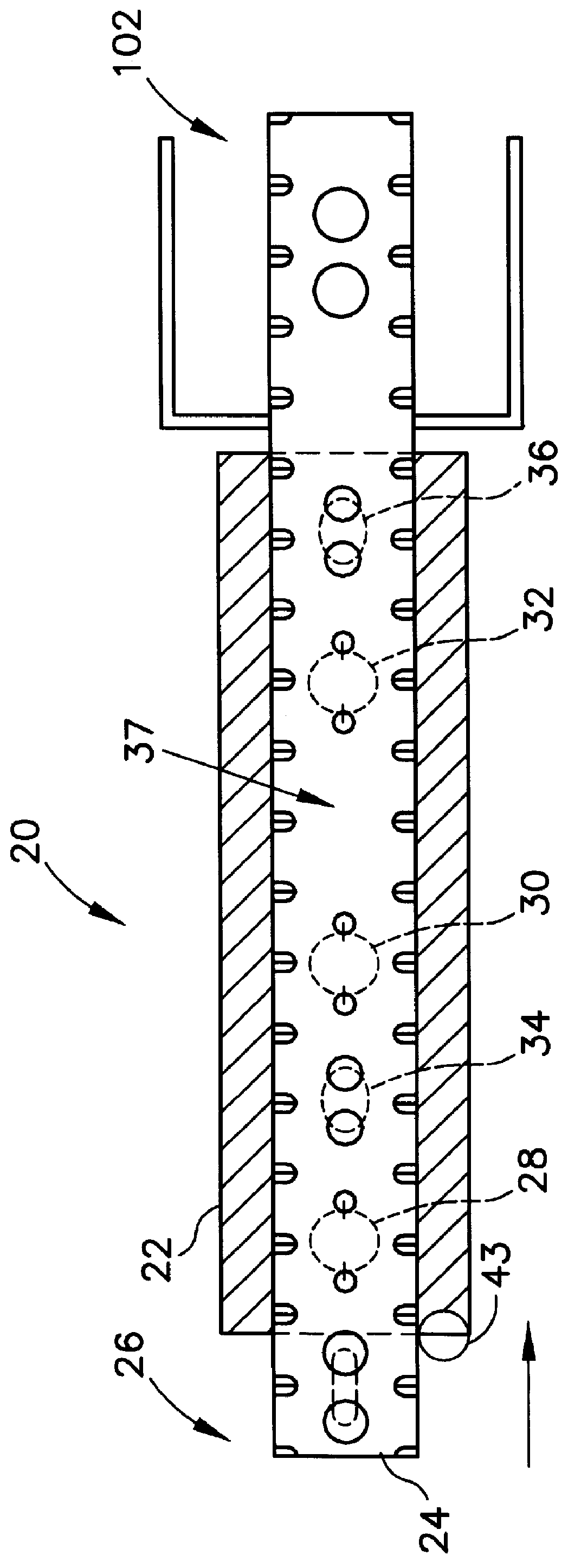

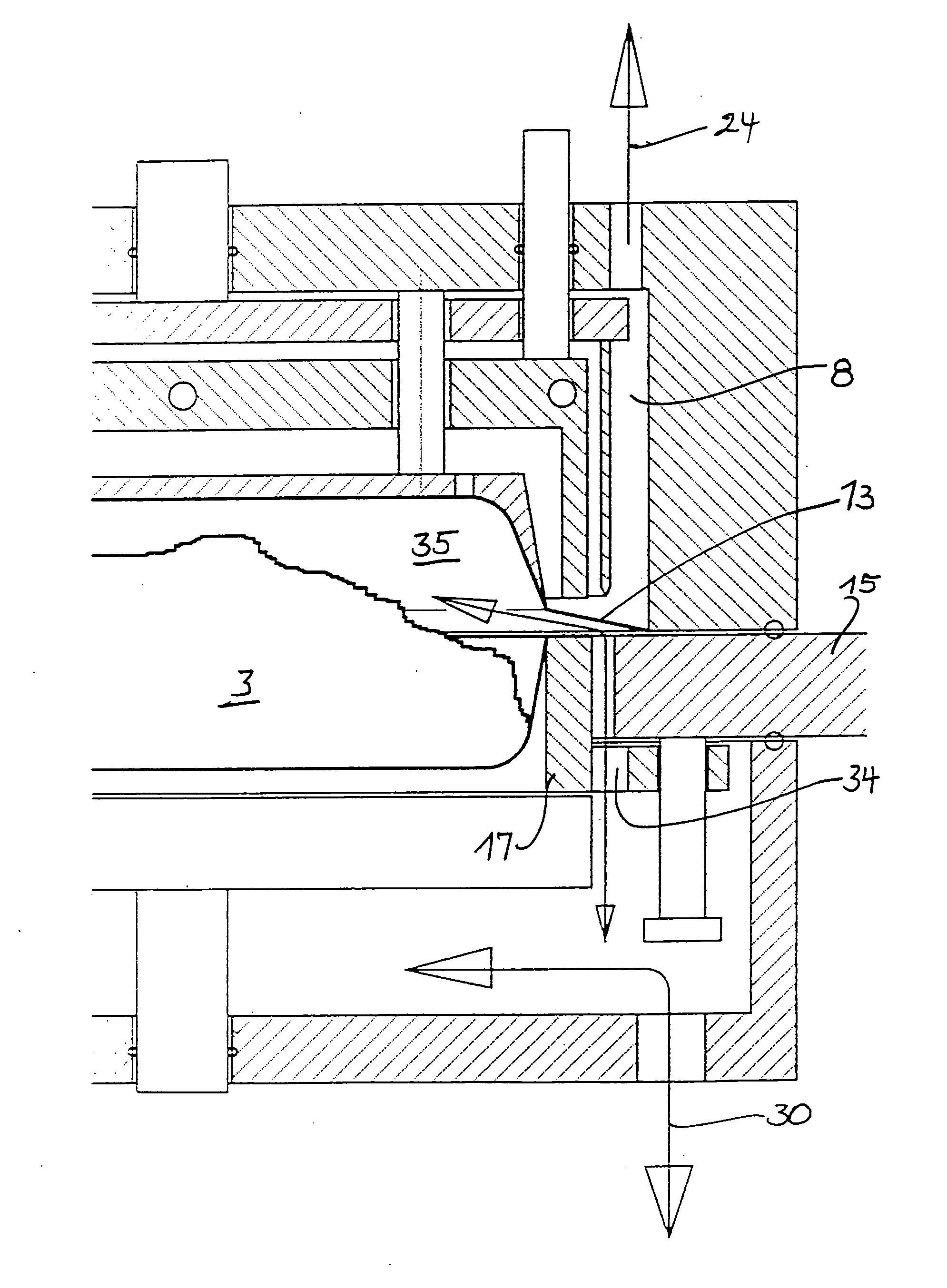

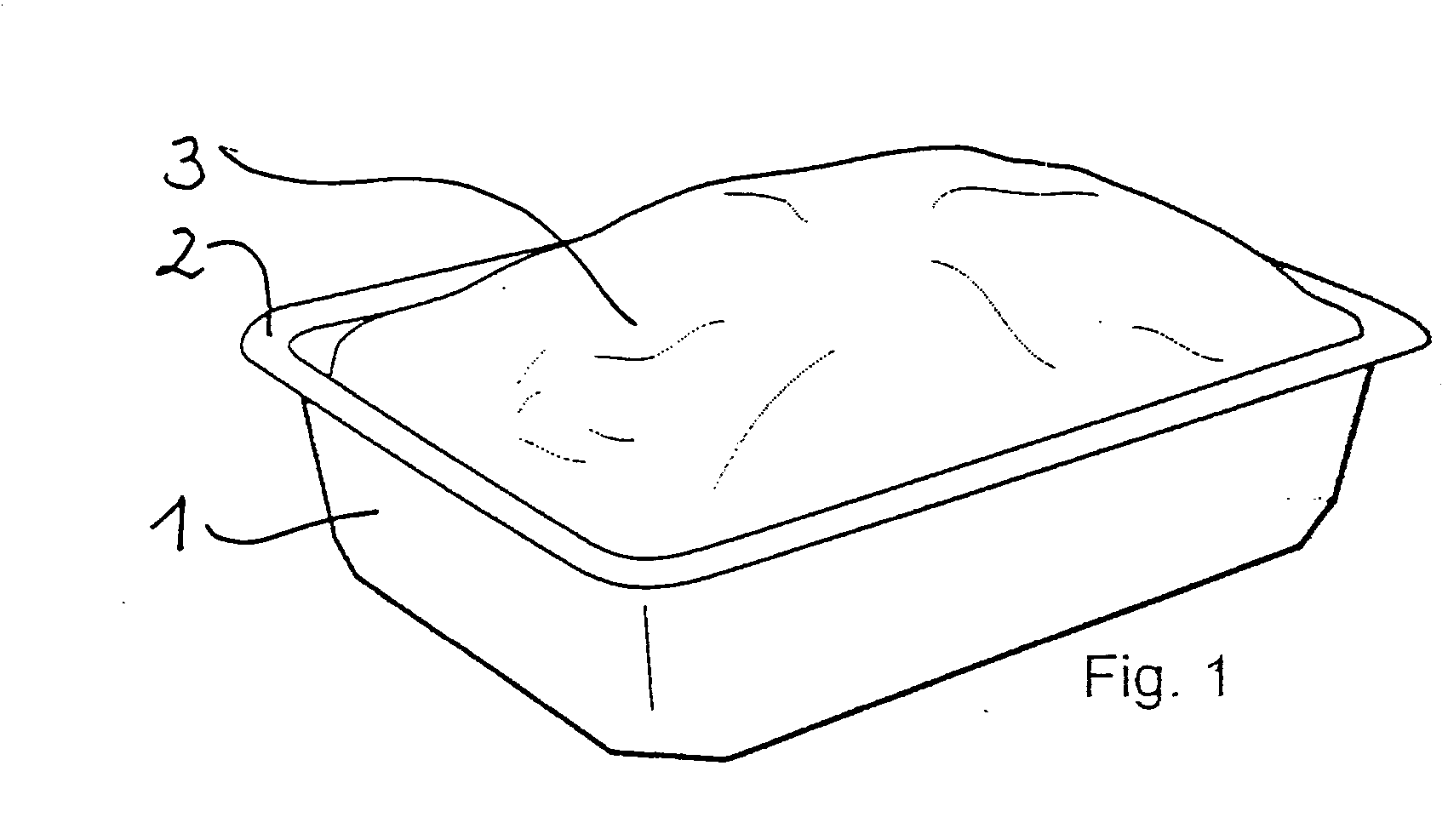

Method and packaging machine for packaging a product arranged in a tray

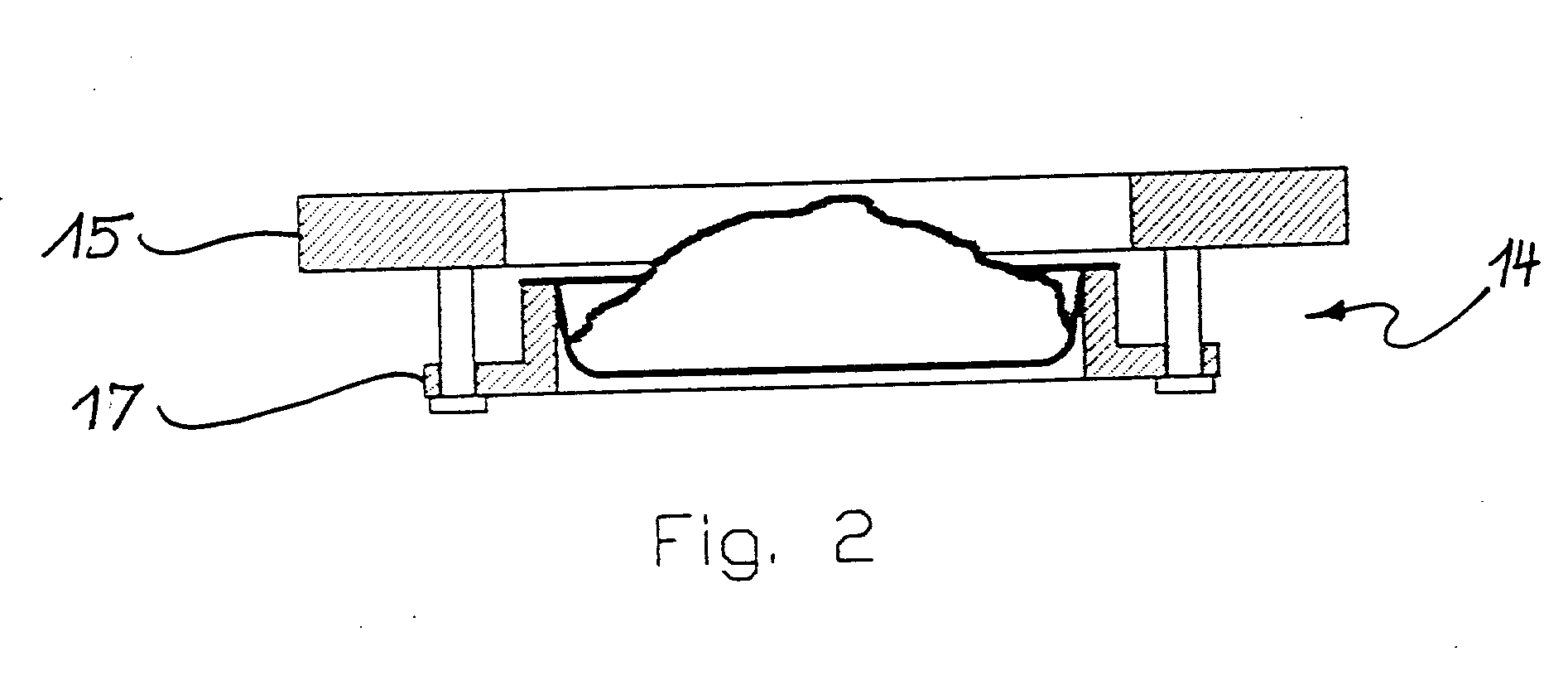

InactiveUS20050257501A1Reliable manufacturingImprove presentationPackaging by pressurising/gasifyingPackaging under vacuum/special atmosphereEngineeringPackaging machine

A method for packaging a product arranged in a tray is provided. An upper film located in a distance above the product is clamped along an edge surrounding the tray and is deformed in a direction extending away from the product. Subsequently, evacuating of the space surrounding the product is performed, then a raising of the tray towards the upper film and finally a sealing of the film and of the edge of the tray. In this way, the seam of the upper film and the edge of the tray is attained to be free from creases such that a long-living and good looking package is produced. Additionally, a packaging machine for performing the method is provided.

Owner:CREAVIS GES FUER TECH +1

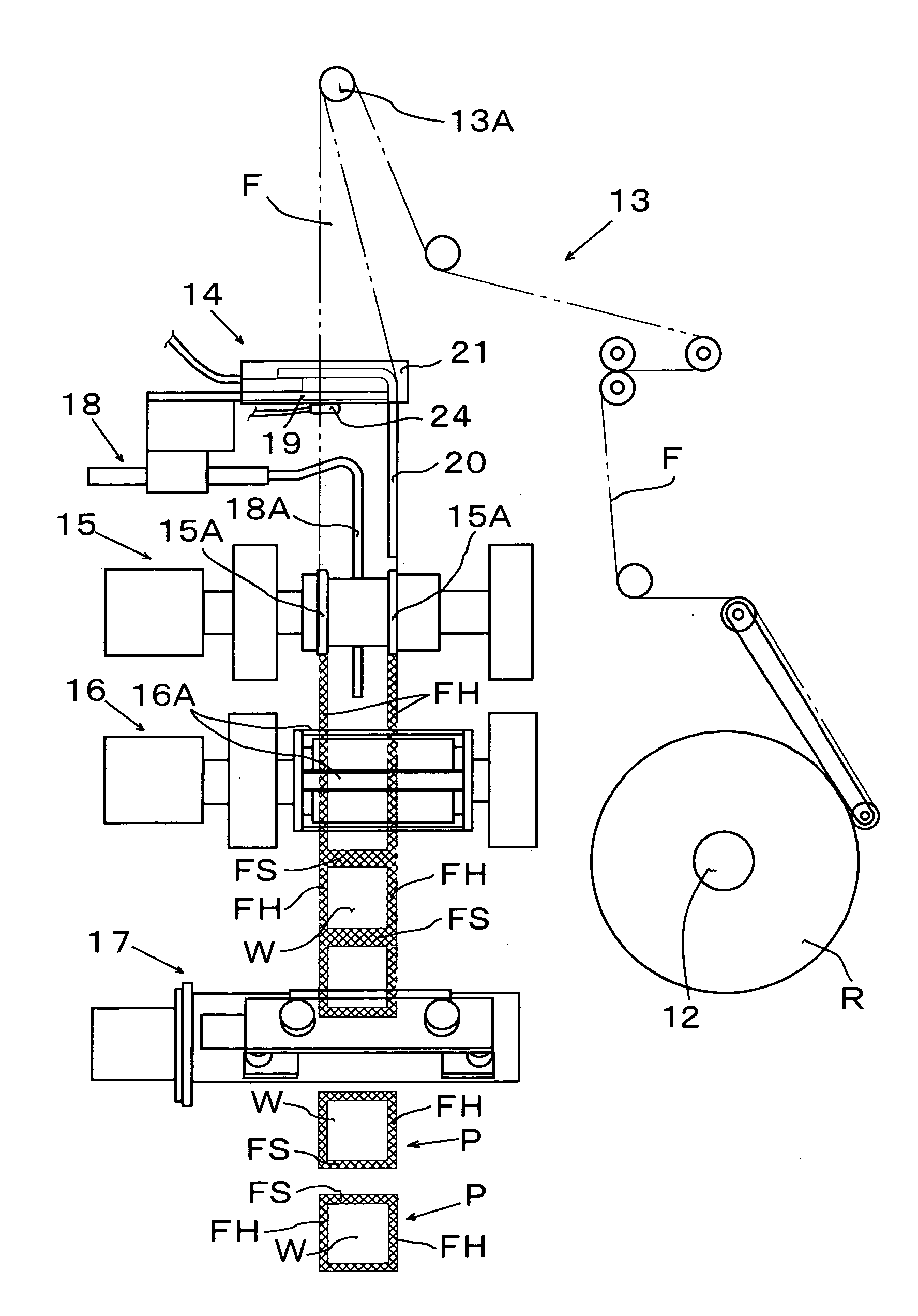

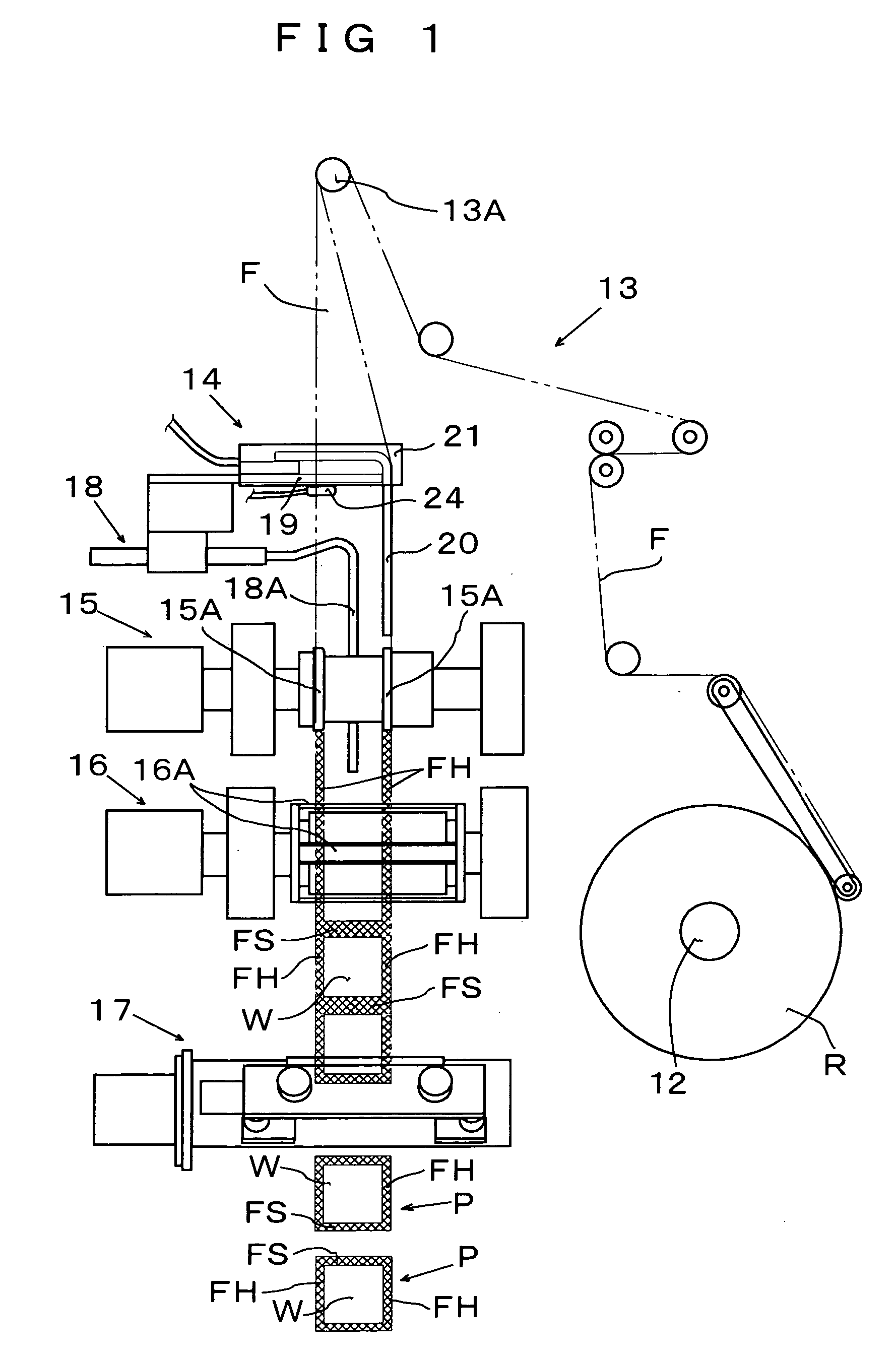

Filling and packaging machine

InactiveUS20060021300A1Melted excellentlyImperfect heat sealingWrappers shrinkagePaper-makingEngineeringSupport surface

A filling and packaging machine capable of supplementing the shortage of heat quality without lowering package speed when a film is heat-sealed while being pressurized by a vertical sealing mechanism, comprising a film folding mechanism having an inner surface guide member for guiding the film laterally, formed on the inner surface side of the film folded up into two parts, a pair of right and left pre-heating block members having tilted support surfaces or are support surfaces formed along the width-direction of the film on the outer surface side of the film through a specified interval from the inner surface guide member so that the interval on the upstream side of the film in feeding direction is larger than the interval on the downstream side, and heaters installed in the pre-heating block members.

Owner:NIPPON SEIKI CO LTD

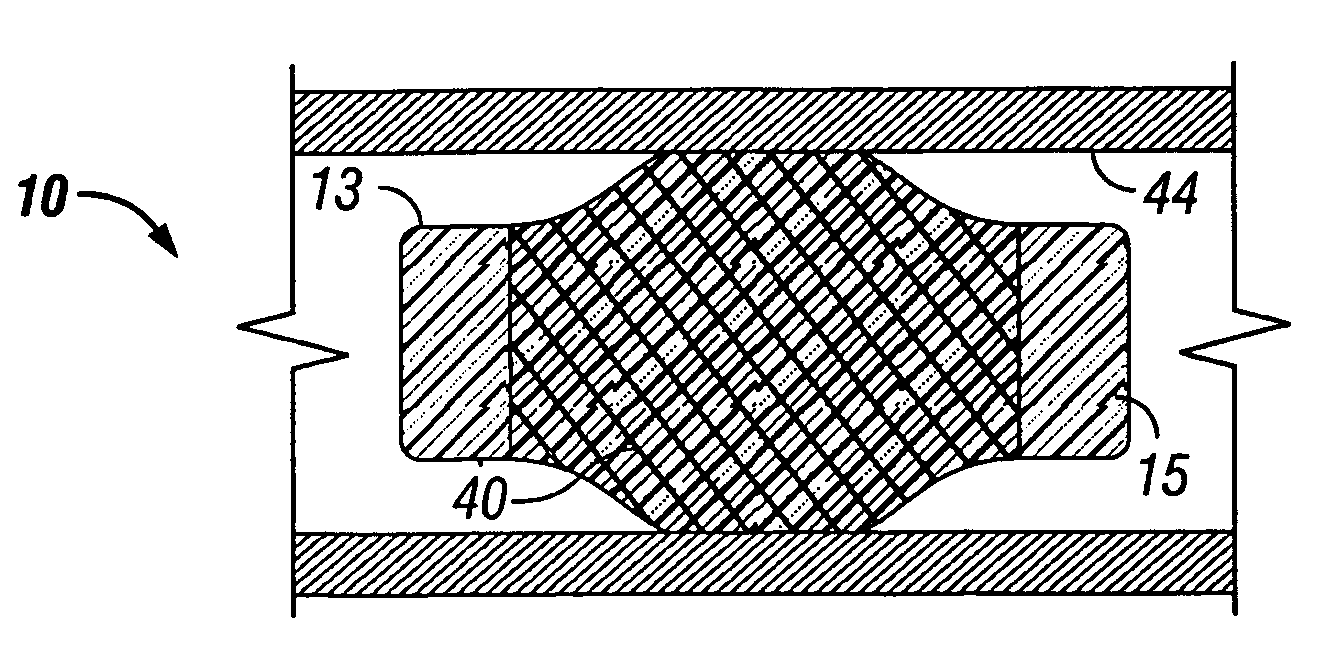

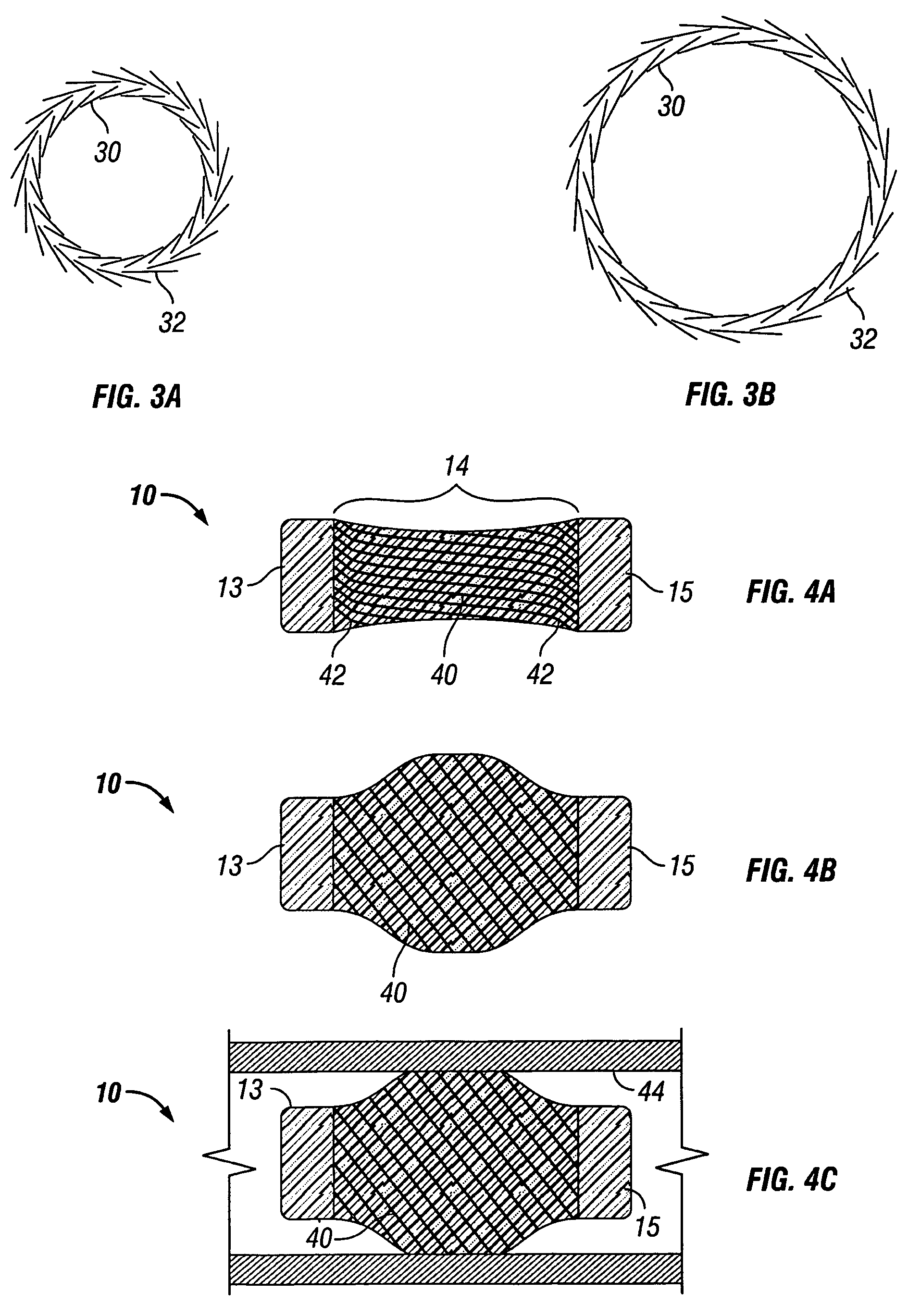

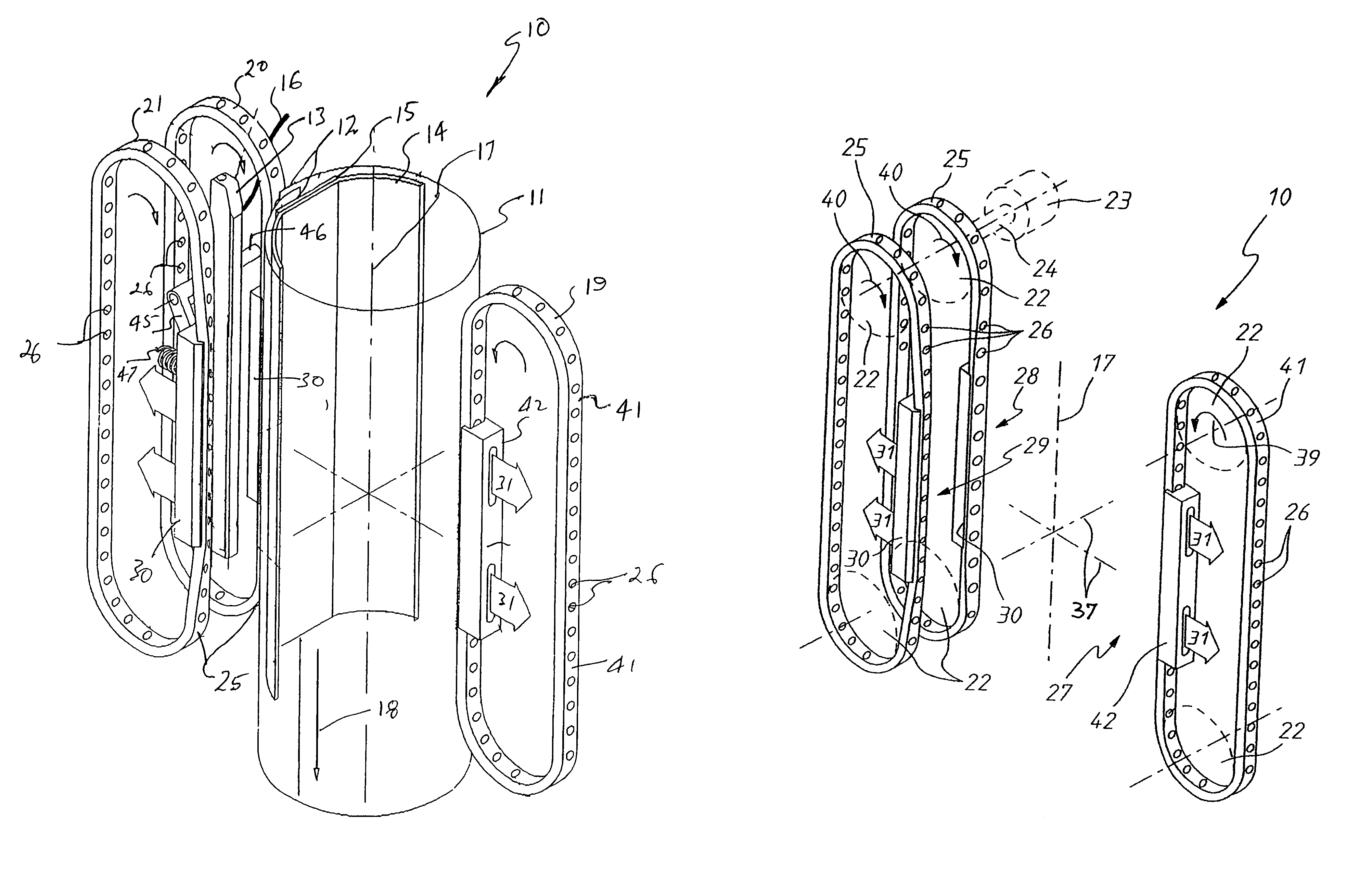

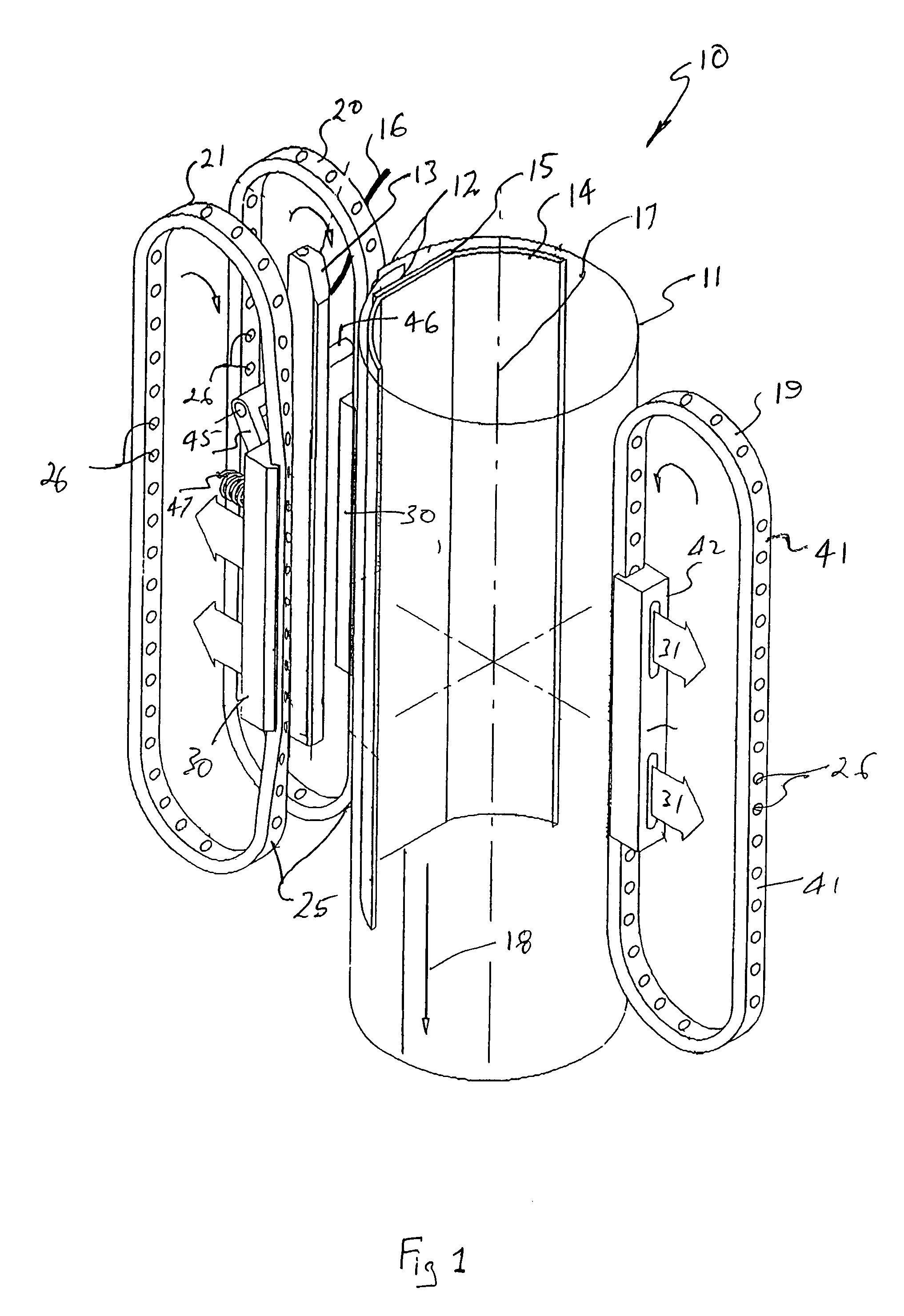

Expandable packer

InactiveUS7363970B2Improve scalabilityHigh strengthFluid removalSealing/packingNanoparticleNanofiber

An integral bodied composite packer is constructed entirely of a composite material. It can include an expandable middle portion with an elastomeric cover to engage an exterior surface of a well bore. The expandable portion can include continuous strands of polymeric fibers to reinforce the body and prevent extrusion. The packer body can have longitudinal cuts or slats to provide rigidity of the body after expansion. The slats can overlap. The packer can include an elastomeric cover or layer therein to engage the well bore. The expandable portion can include a reinforcement member in a laminar portion of the body made from high strength alloys, fiber-reinforced polymers and / or elastomers, nanofiber, nanoparticle, and nanotube reinforced polymers and / or elastomers.

Owner:SCHLUMBERGER TECH CORP

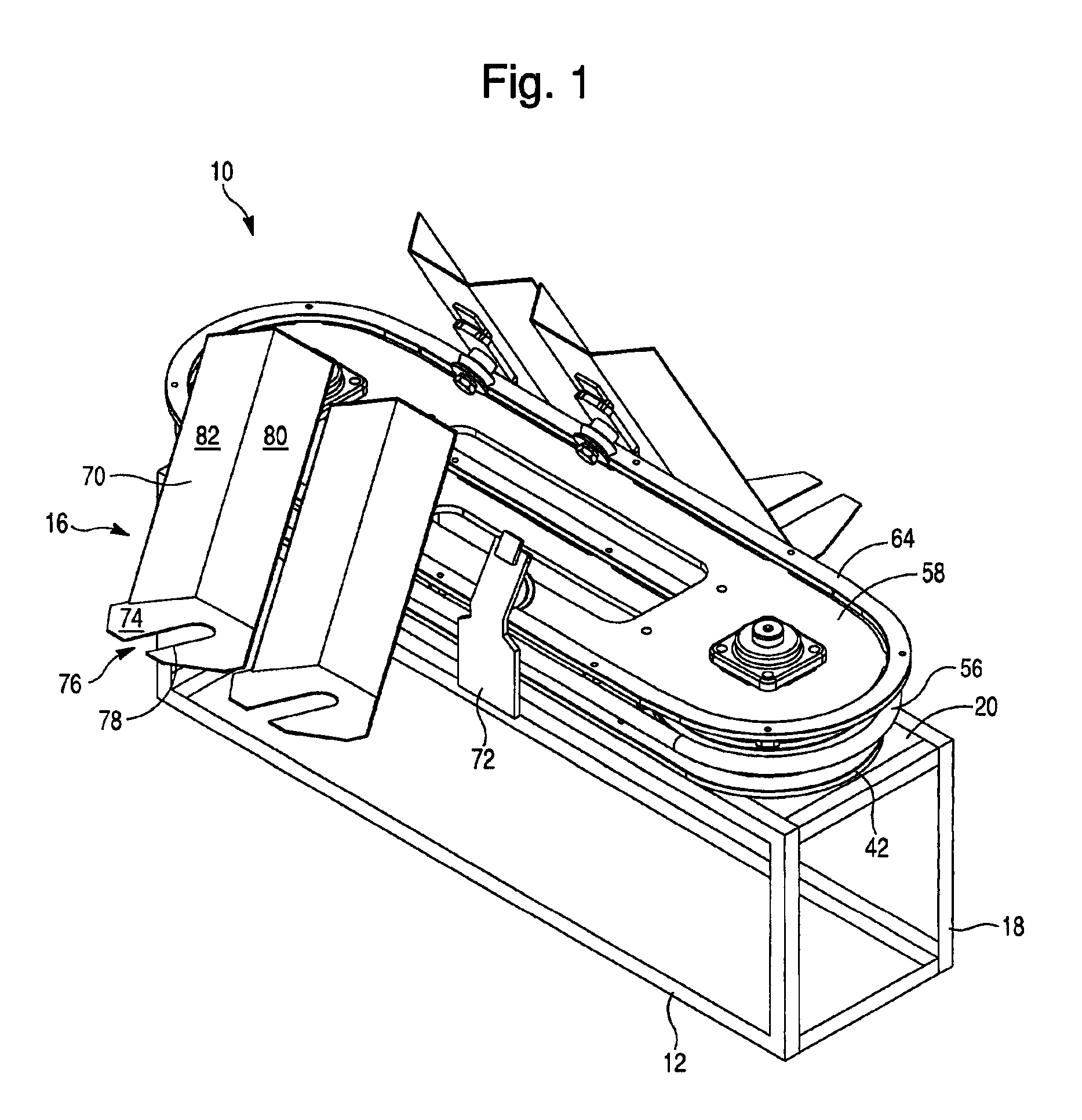

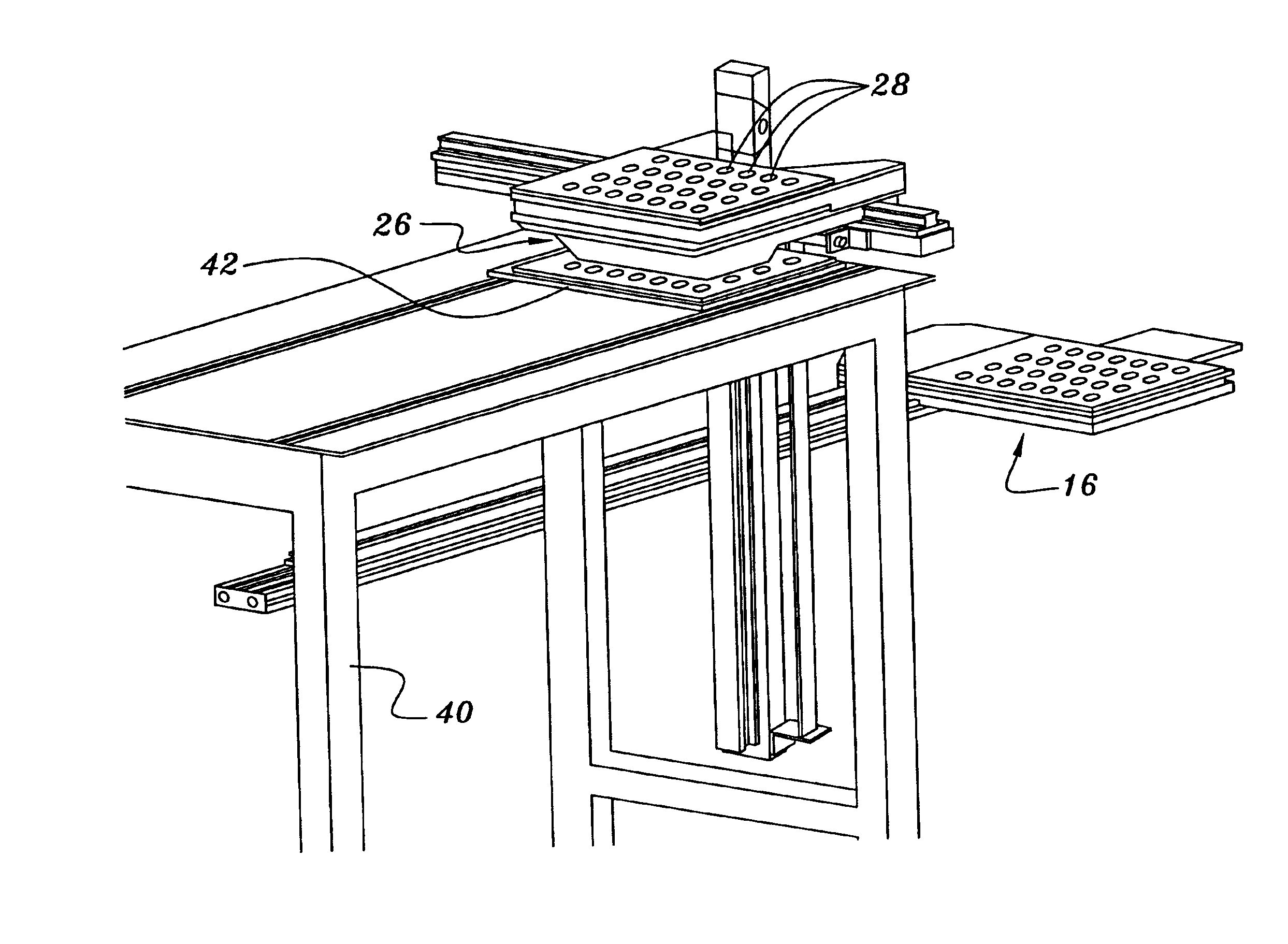

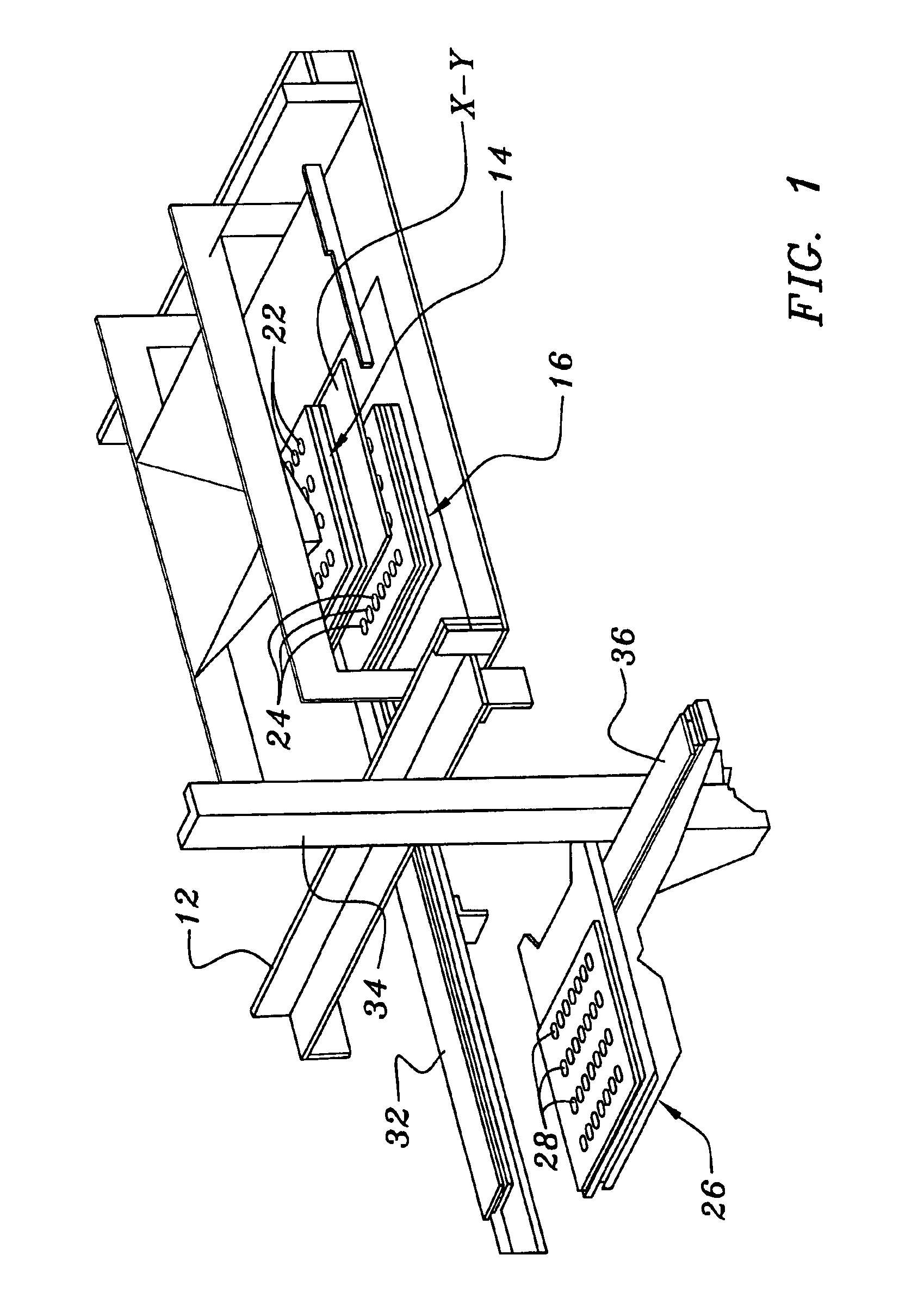

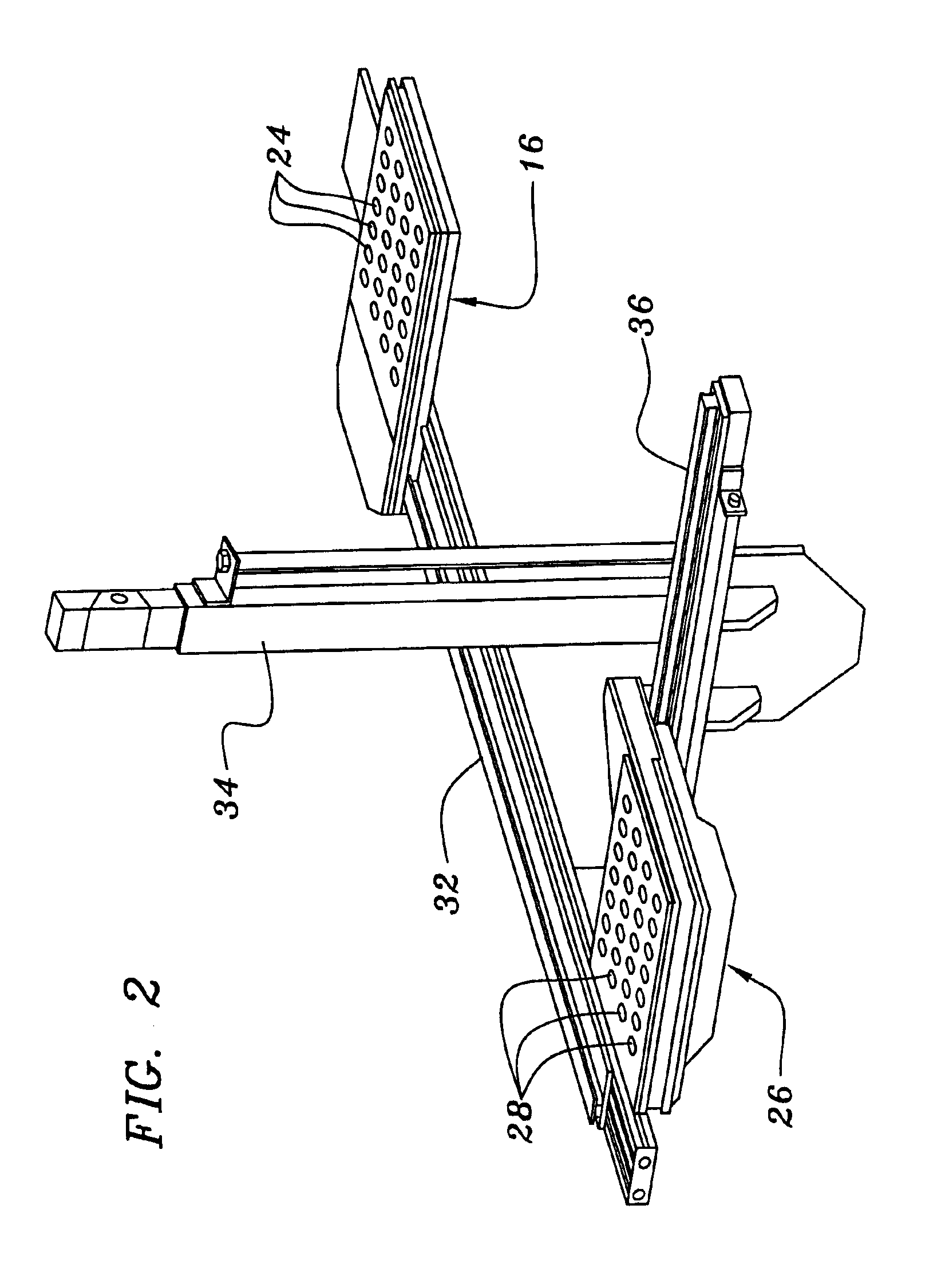

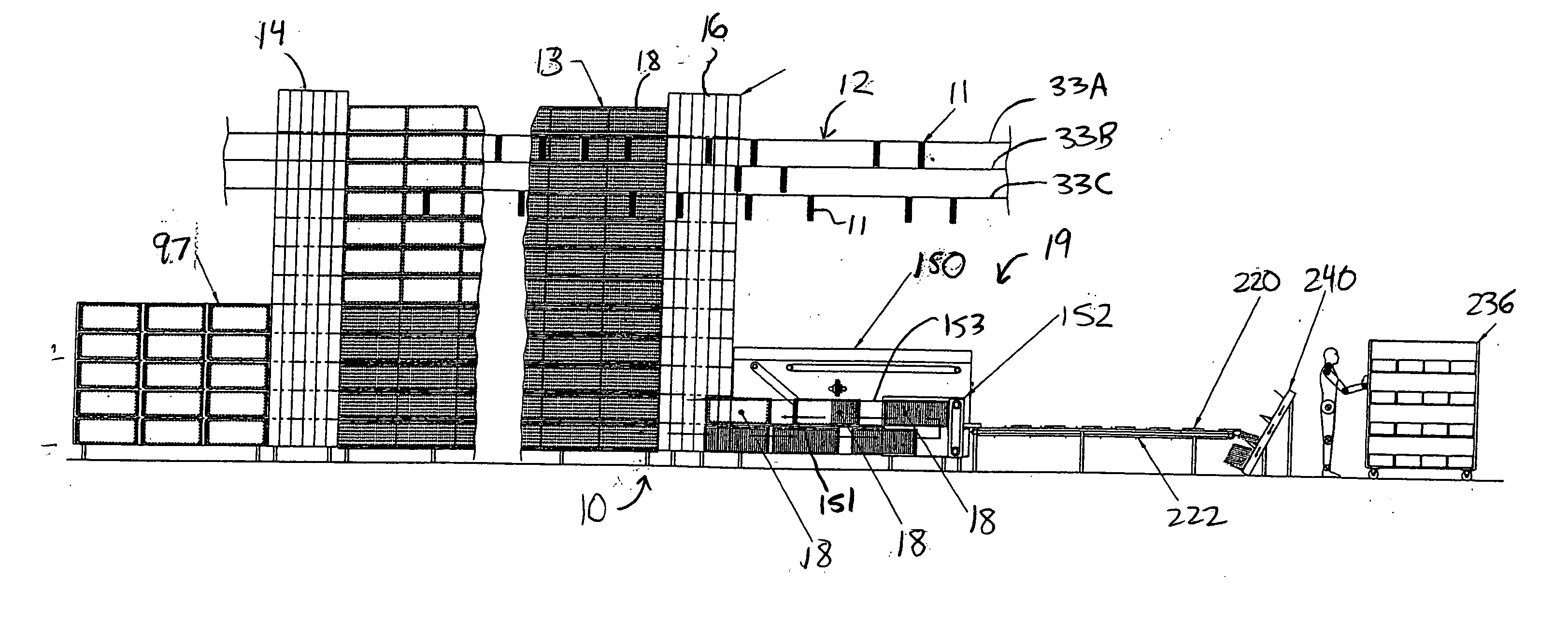

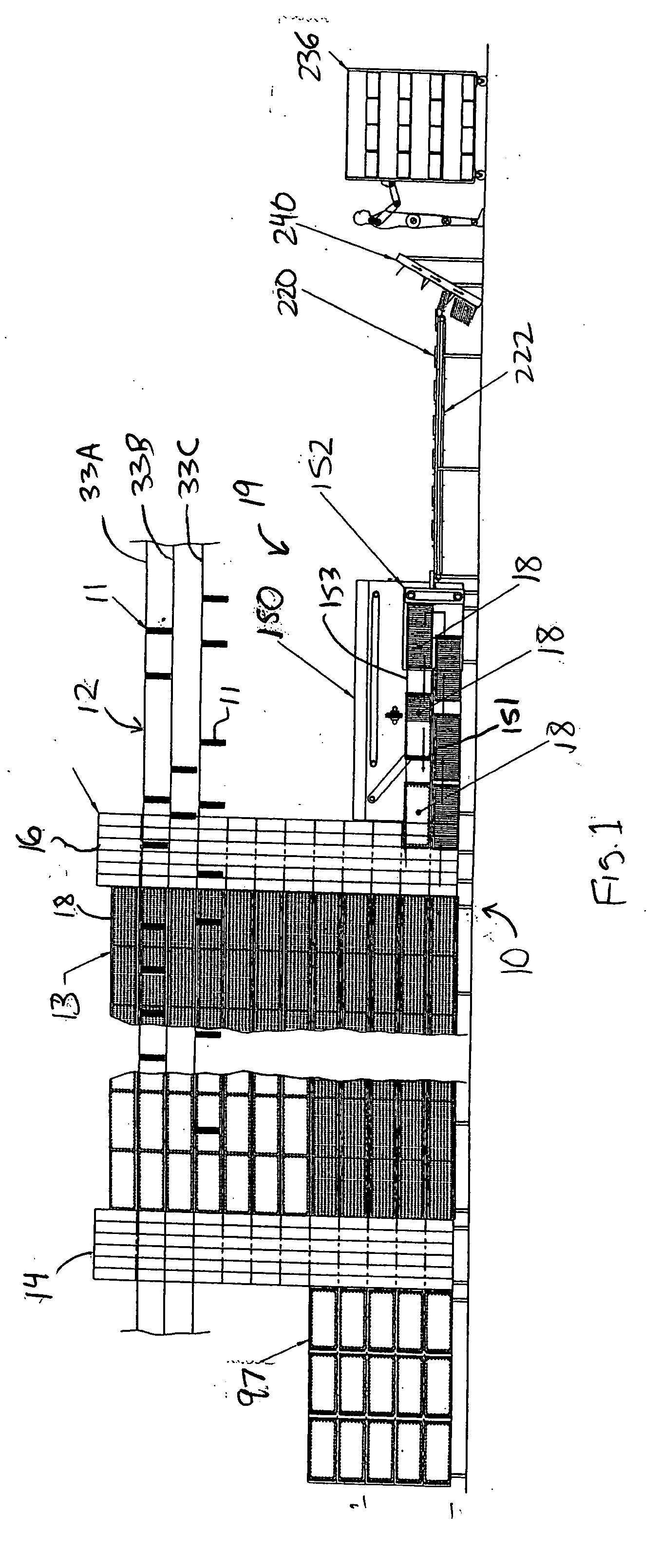

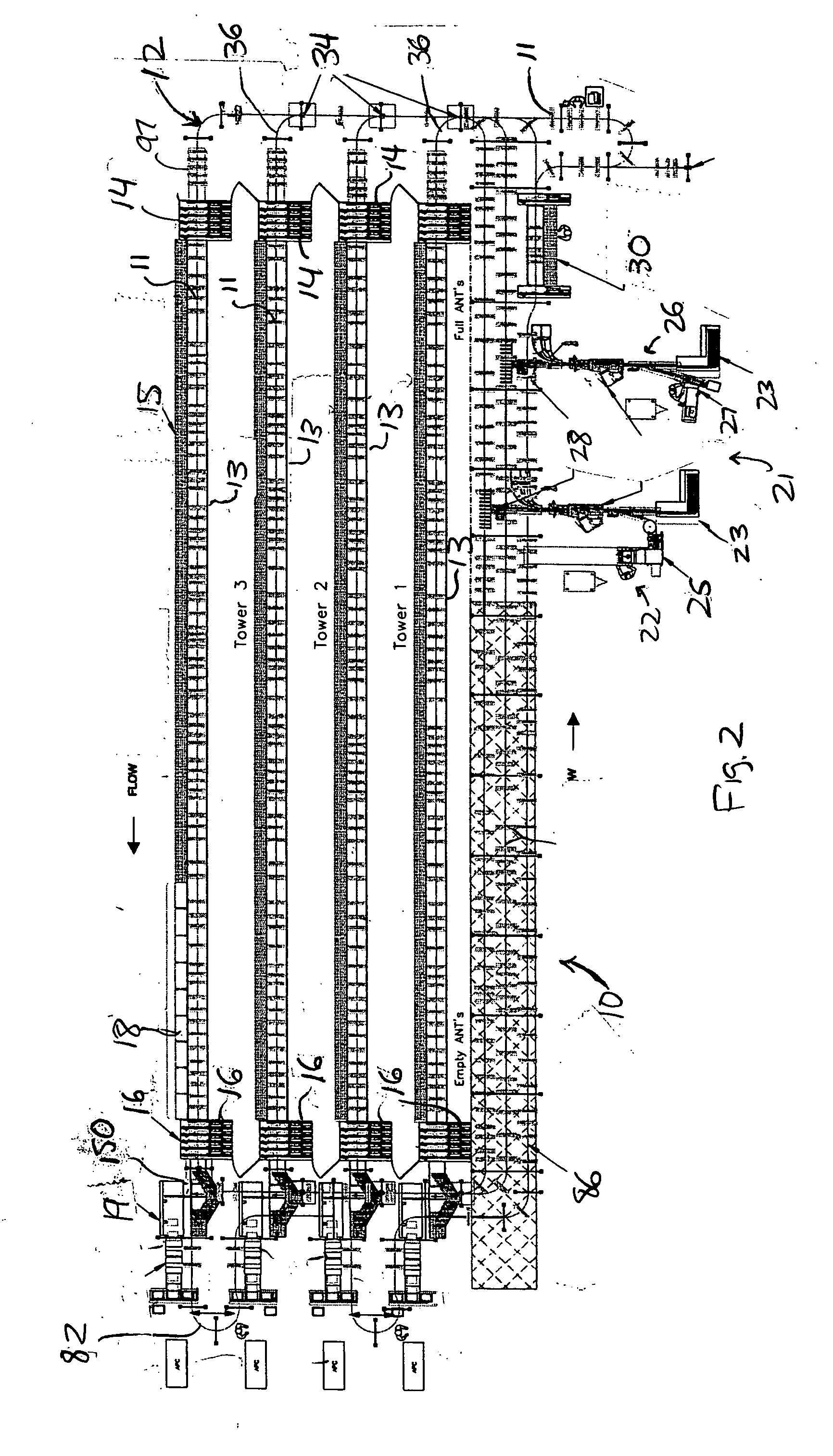

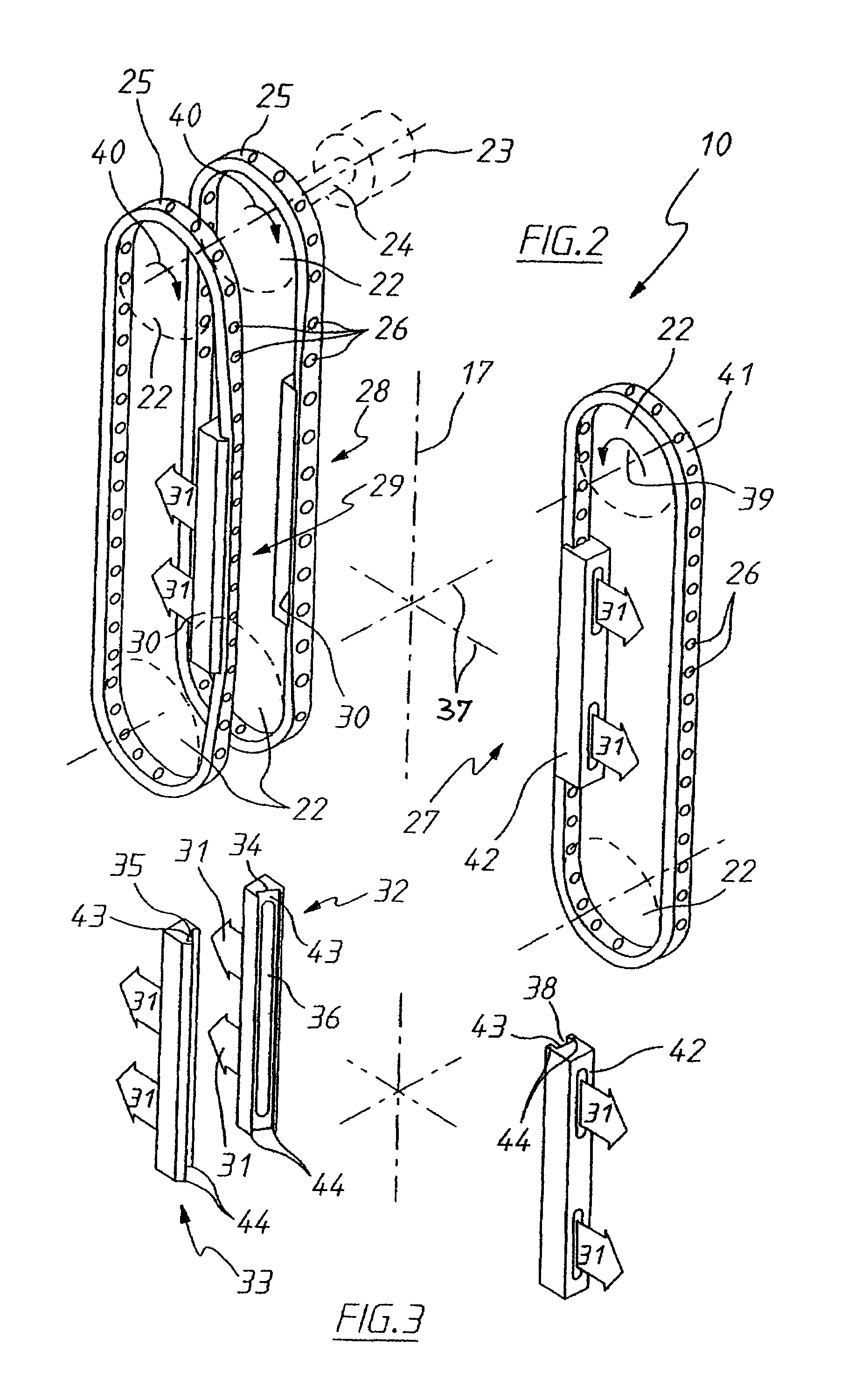

Method and apparatus for buffering a flow of objects

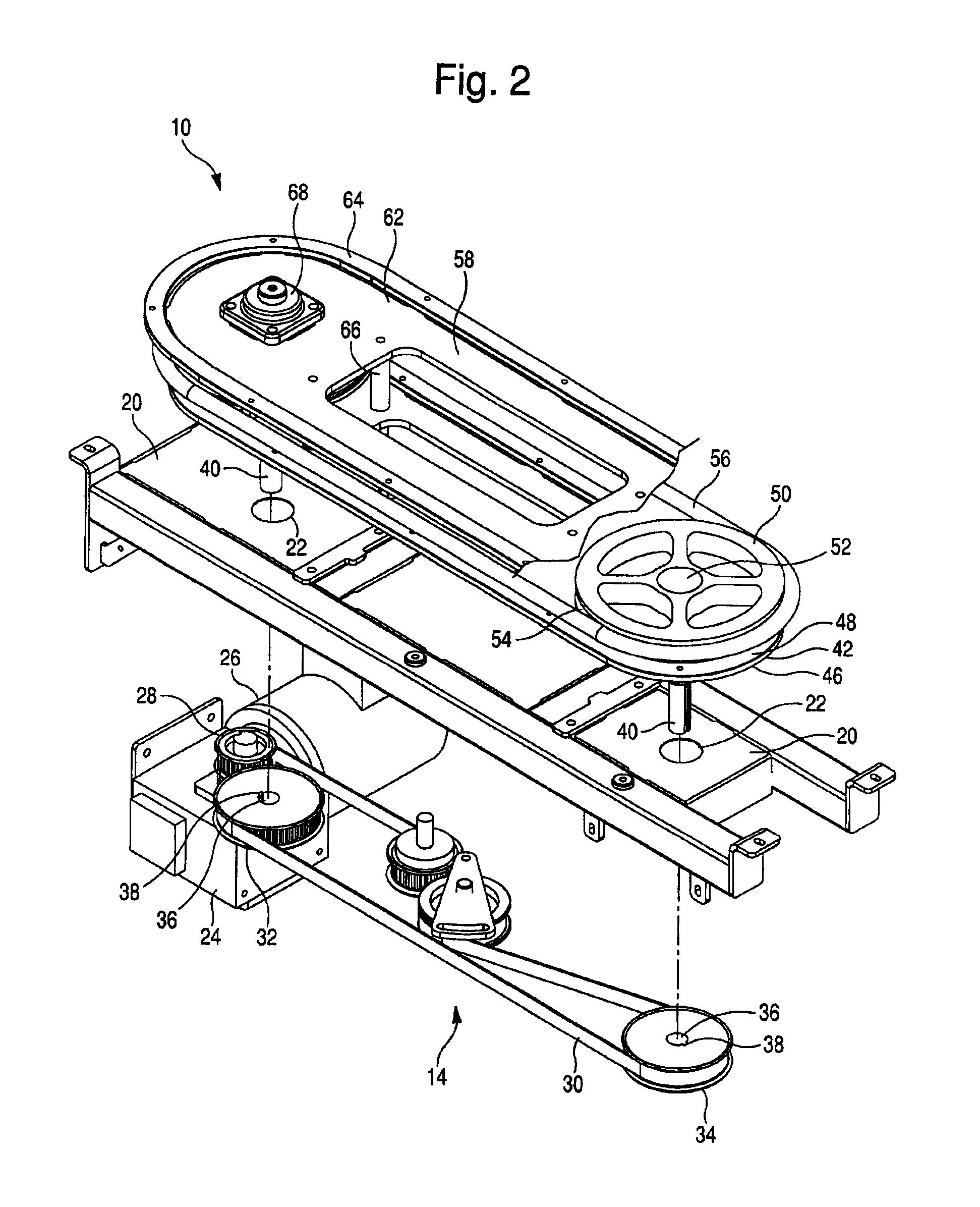

InactiveUS6957941B2Good flexibilityMinimize the numberPackaging meatCharge manipulationEngineeringPackaging machine

A buffer device for buffering a flow of stacks of discrete objects between a stacking machine and a packaging machine is disclosed which buffer includes a plurality of individual trays mounted on carriers which carriers are mounted on a frame and driven about the periphery of the frame by a drive. A first number of stacks of objects is placed on a first number of carriers on a first side of the frame and a second number of stacks are removed from a second number of carriers on a second side of the frame where the first number can be greater than, less than or equal to the first number. The carriers clamp onto a continuously moving drive belt in a manner that allow the drive belt to slip through the carrier clamps when motion of the carriers is obstructed. A method of using the buffer device is also disclosed.

Owner:F R DRAKE

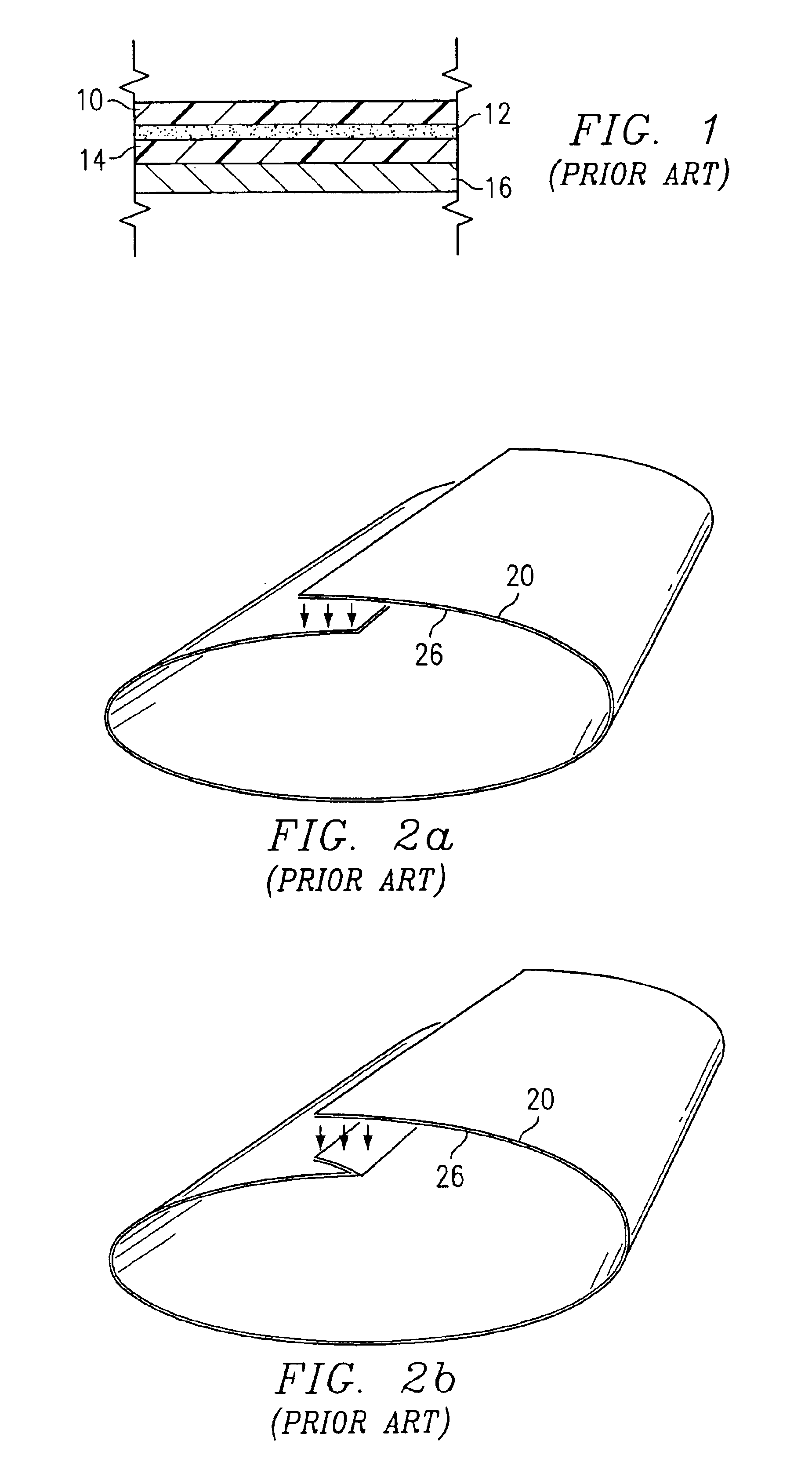

Two Side Cut Reseal With Pressure Sensitive Adhesive and the Method for Making Same

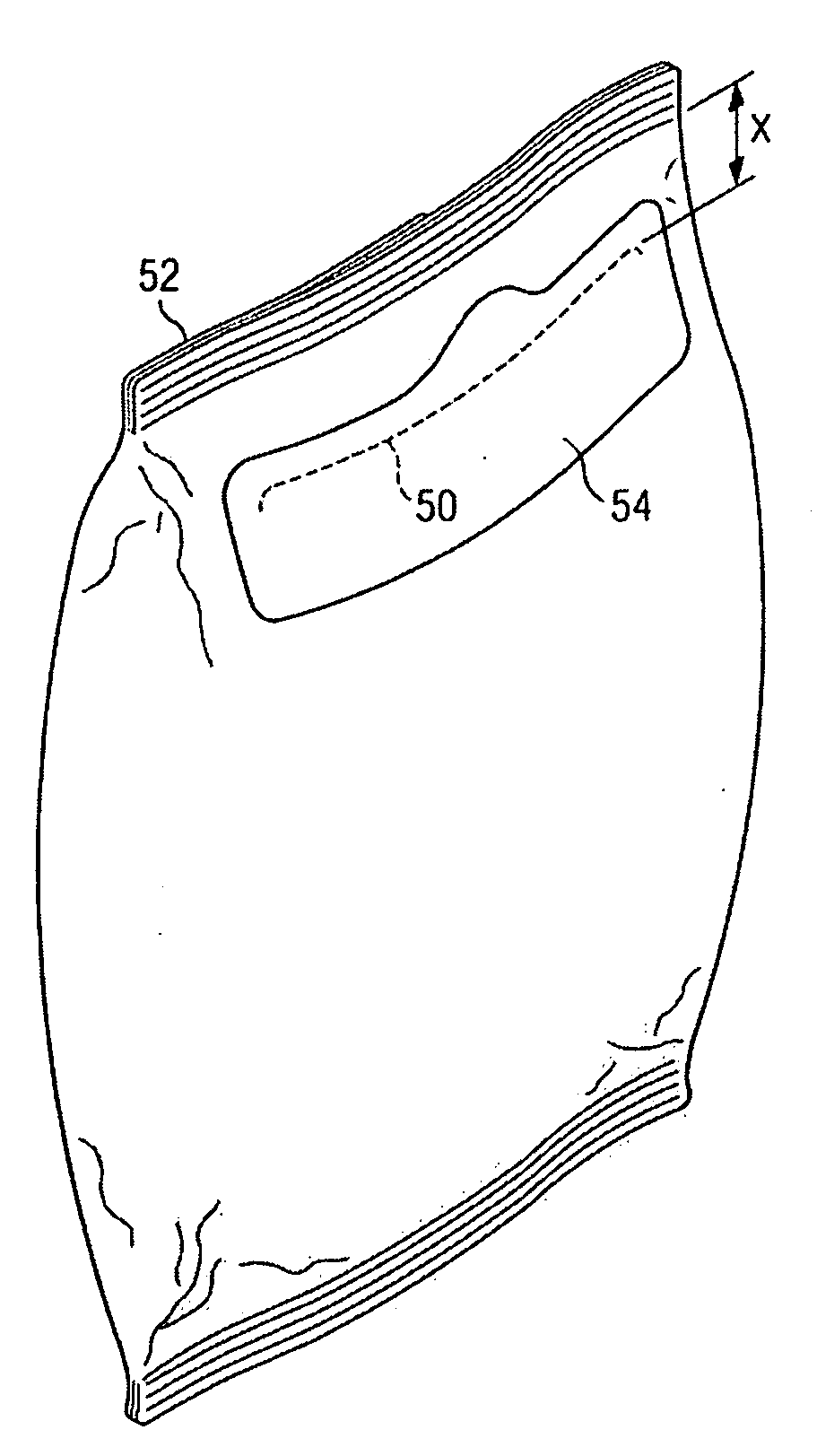

InactiveUS20100111453A1Prevent premature deterioration of qualityAvoid damageCapsDecorative coversSheet filmHermetic packaging

Two side cut reseal with pressure sensitive adhesive. A flexible package having a reseal integrated within the opposite layers of its film is constructed using existing vertical form fill and seal packaging machines. The invention involves a single sheet of flexible packaging film web having at least three layers. In a preferred embodiment, the reseal is comprised of two offsetting score lines on interior and exterior sides of the film and spaced apart by 0.5 to 1 inch. The scoring creates lines of weakness, which define an opening in the package. Upon opening, a pressure sensitive adhesive layer, which is pattern applied in between the offsetting score lines, is exposed from an interior side of the film. The adhesive releasably adheres the inner and outer layers of the film back together once separated by a consumer.

Owner:FRITO LAY NORTH AMERICA INC

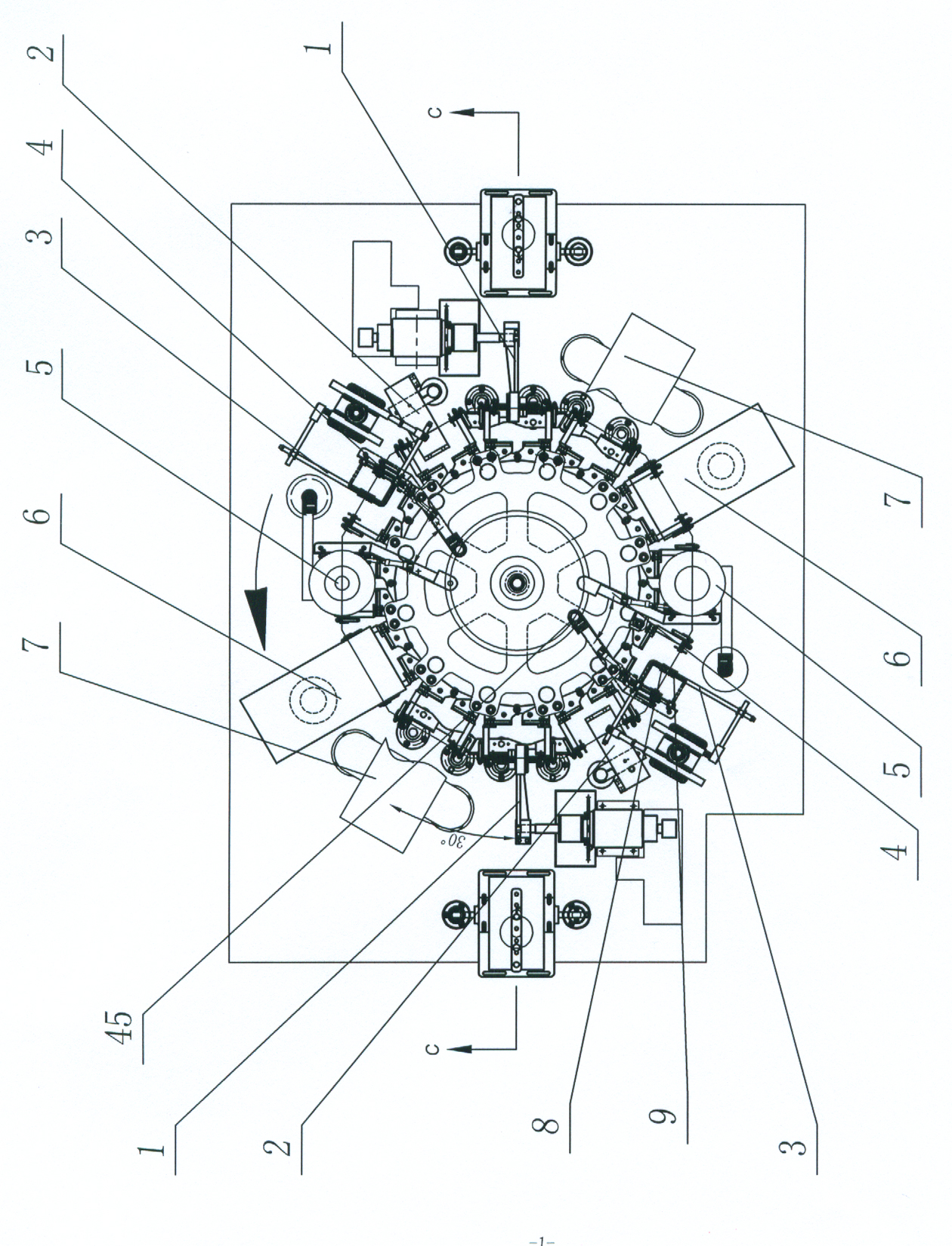

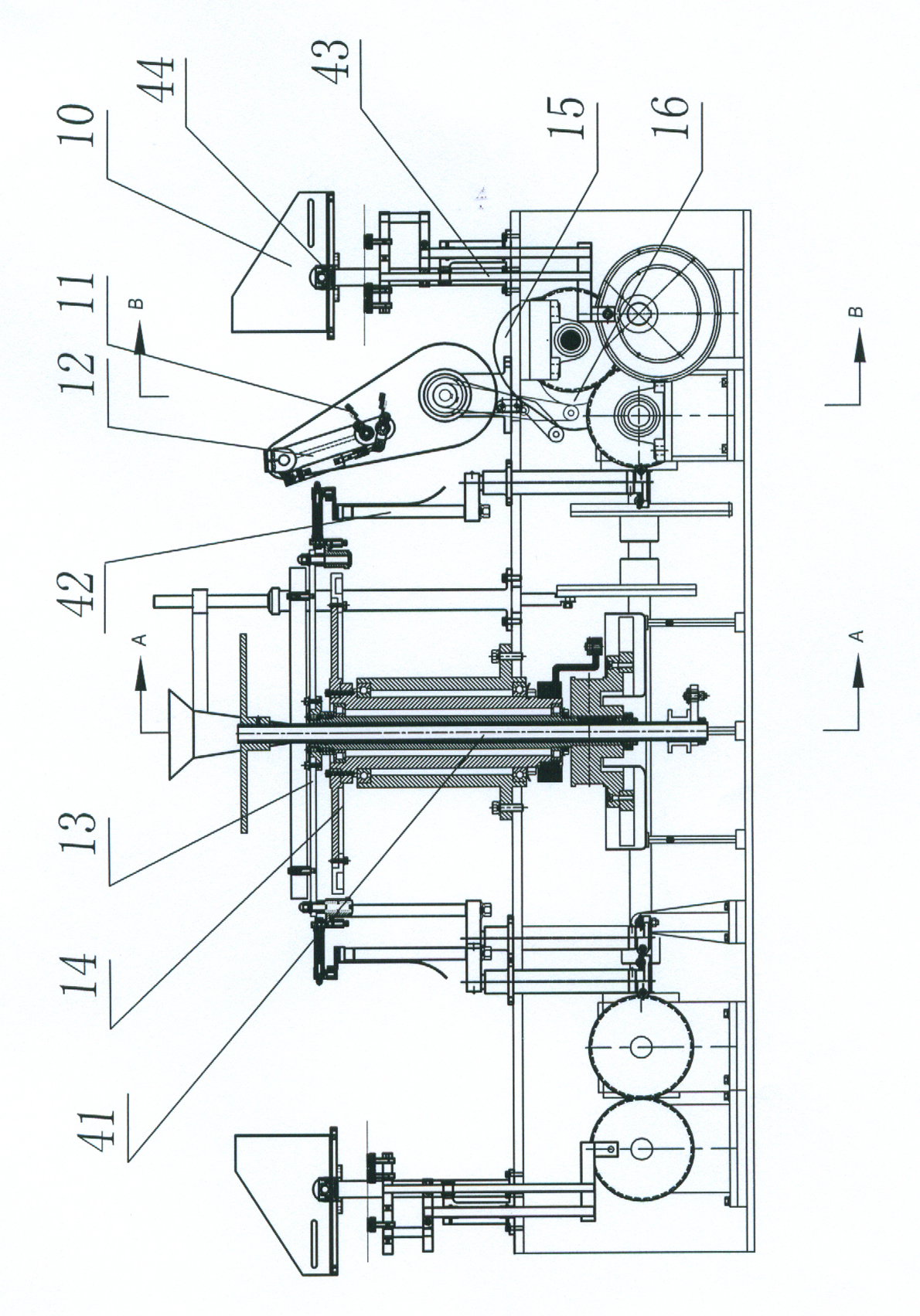

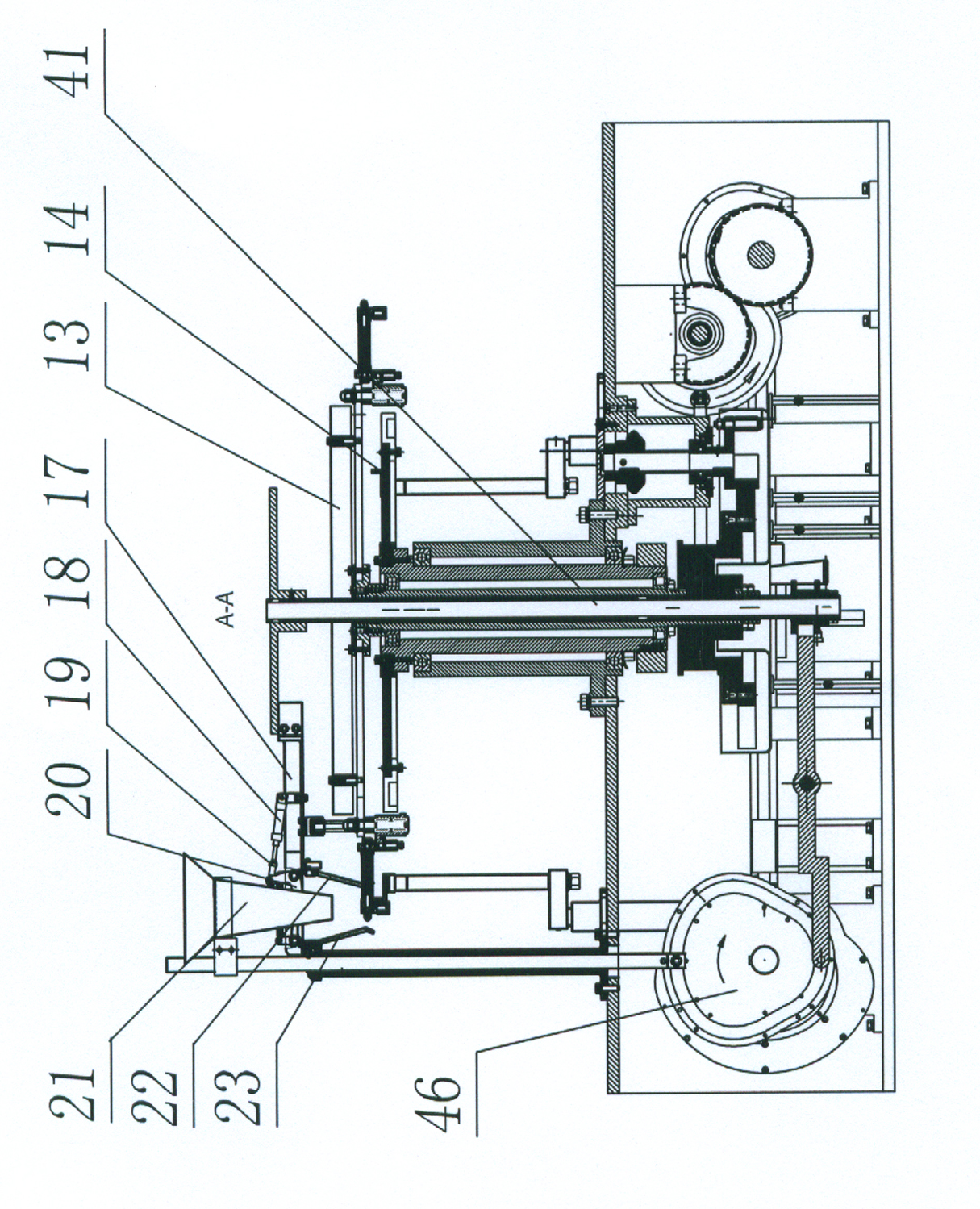

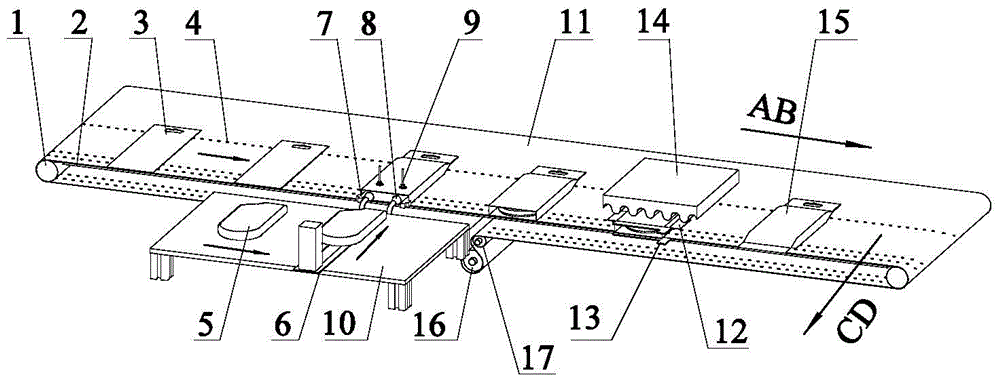

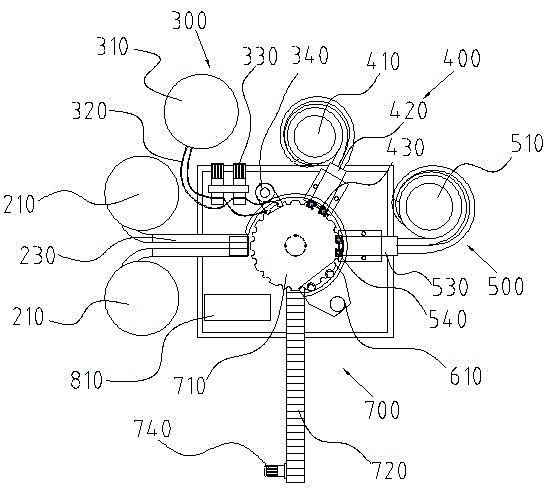

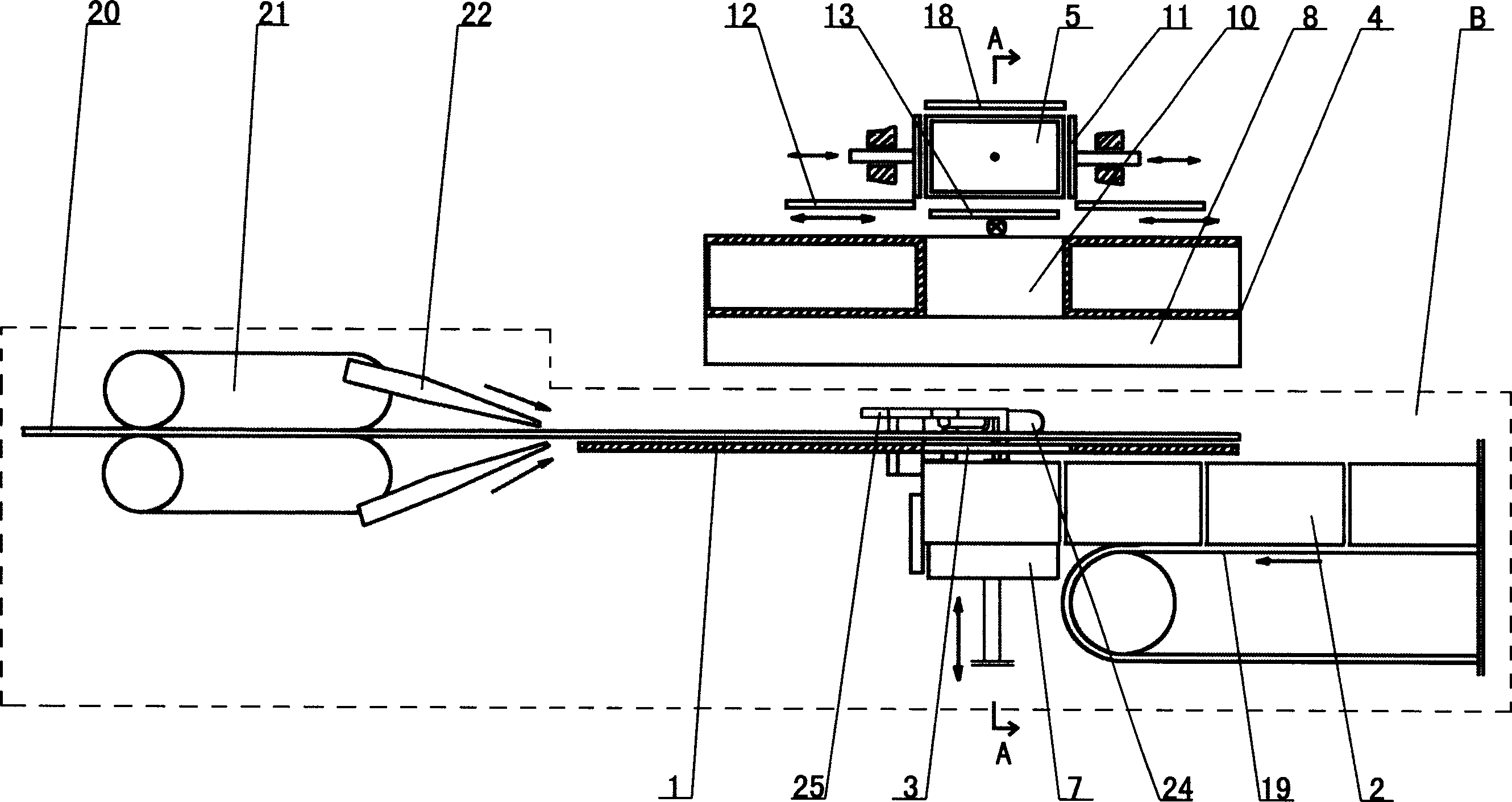

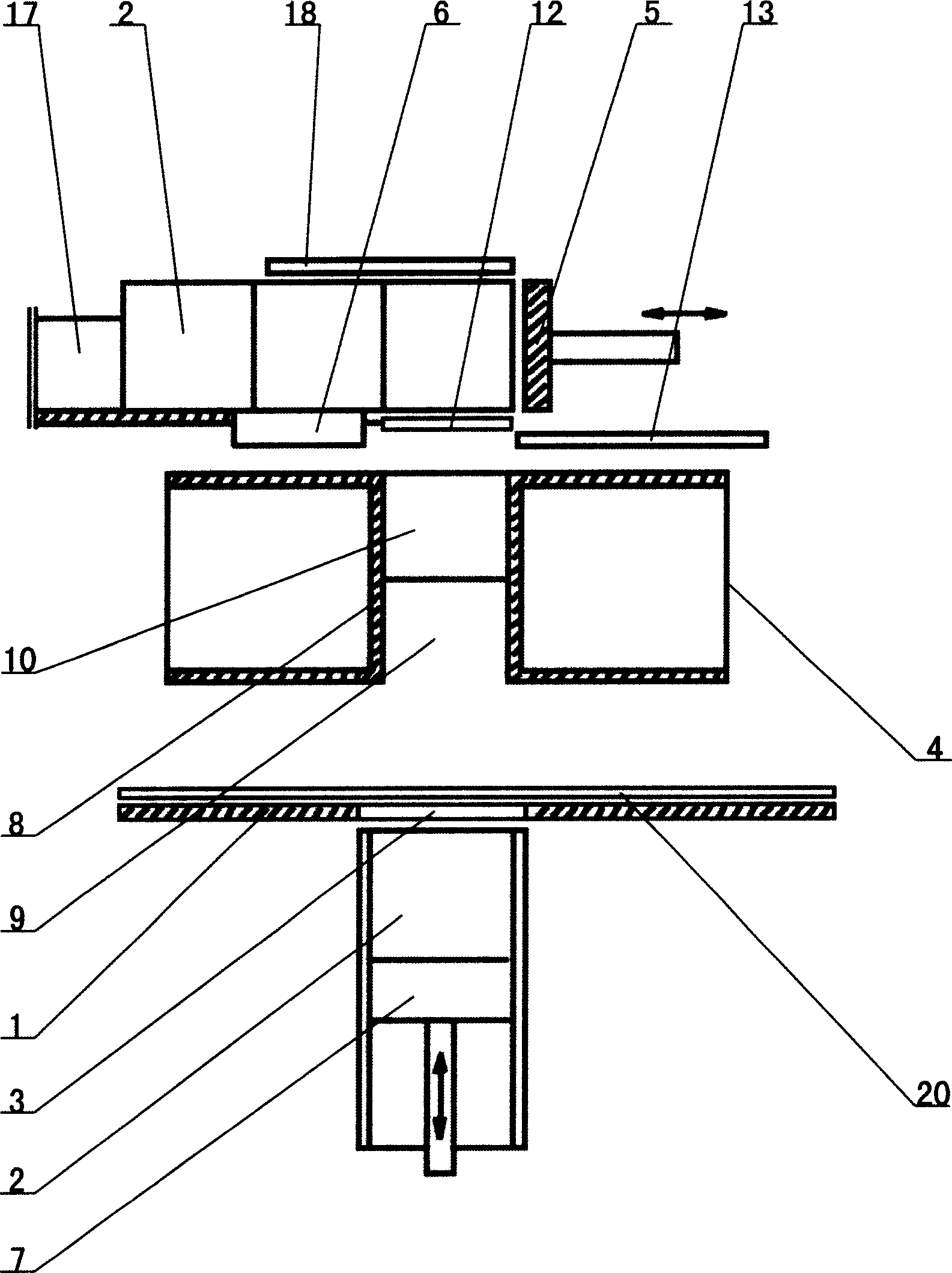

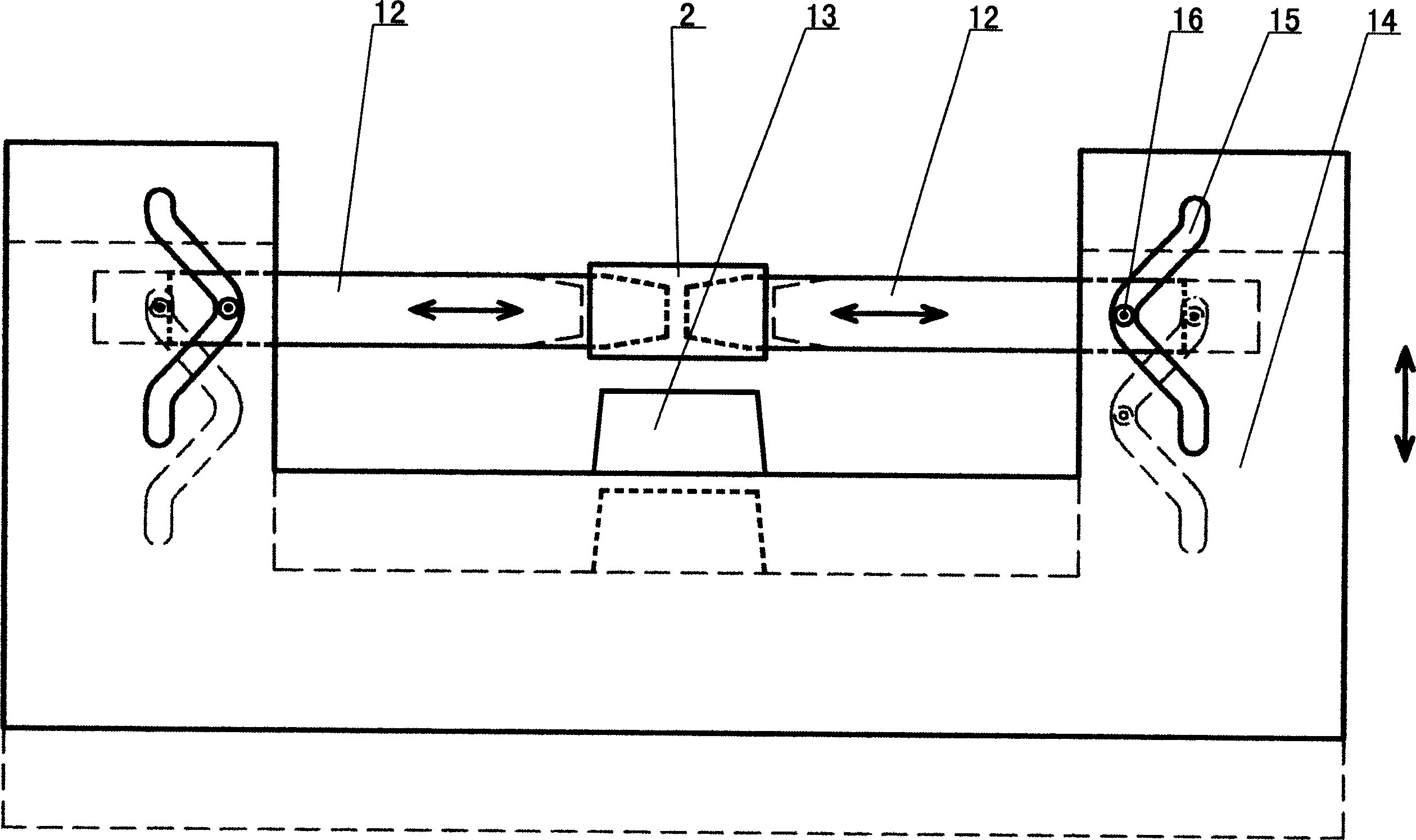

Full-automatic bag-feeding type packaging machine

InactiveCN101837845AImprove packaging efficiencyAvoid the problem of not being able to hold the bagWrapper supporting apparatusWrapper twisting/gatheringRotating discPackaging machine

The invention discloses a full-automatic bag-feeding type packaging machine, comprising a rotating disc (13), a large cam (14), a bag feeding device (1), a marking device (2), a bag opening device (3), a material charging device (5), a heat-sealing device (6), a bag discharging device (7) and a bag bracing device (4). A bag clamping device (39) is arranged at the edges of the rotating disc (13); the bag feeding device (1), the marking device (2), the bag opening device (3), the material charging device (5), the heat-sealing device (6) and the bag discharging device (7) are all arranged outside the rotating disc (13); and the bag bracing device (5) is of a swing arm type and is movably mounted on the rotating disc (13). The packaging machine is characterized in that the bag feeding device (1), the bag opening device (3), the material charging device (5), the heat-sealing device (6) and the bag discharging device (7) are symmetrically arranged around the central point of the rotating disc (13); and the bag bracing device (4) is symmetrically arranged around the central point of the rotating disc (13). The full-automatic bag-feeding type packaging machine with the structure has the advantages of stable performance and high production efficiency.

Owner:WENZHOU READOR MACHINERY

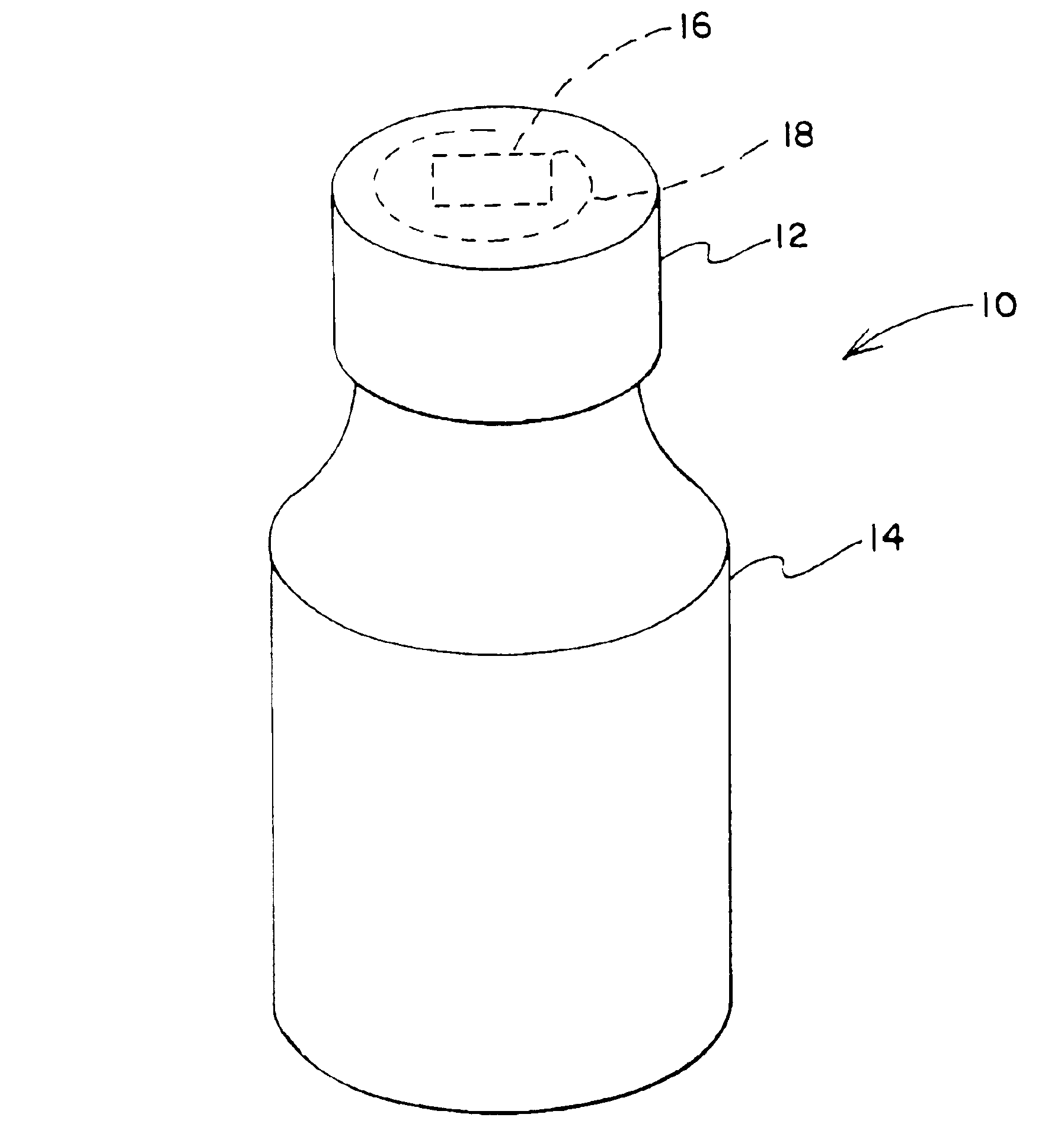

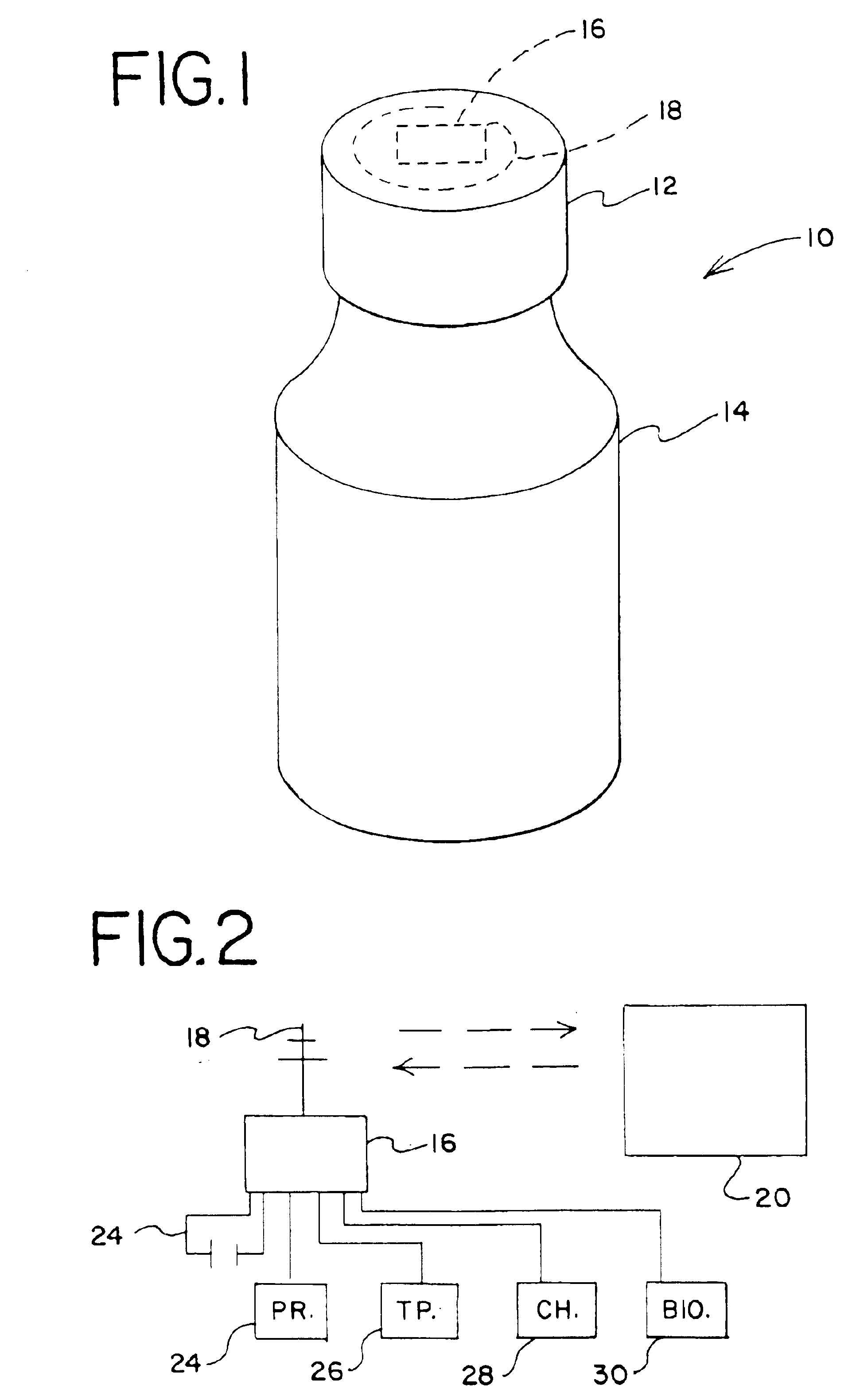

Interactive information package

InactiveUS6859745B2Eliminate needEnhanced disseminationContainer decorationsLevel indicationsQuality assuranceRadio frequency

A product package embodying the principles of the present invention includes an integrated circuit device which is configured for radio frequency interfacing with associated equipment. The package is configured such that the integrated circuit device is disposed within the package, thus assuring that the device remains associated with the package's contents. Notably, this arrangement facilitates use of the device for applications apart from product tracking and inventory control, including product promotions, storage, and dissemination of product information, and quality assurance including tamper-indication. A packaging machine for writing information on, and or reading information from, the integrated circuit device is also disclosed.

Owner:CREDIT SUISSE SYDNEY BRANCH

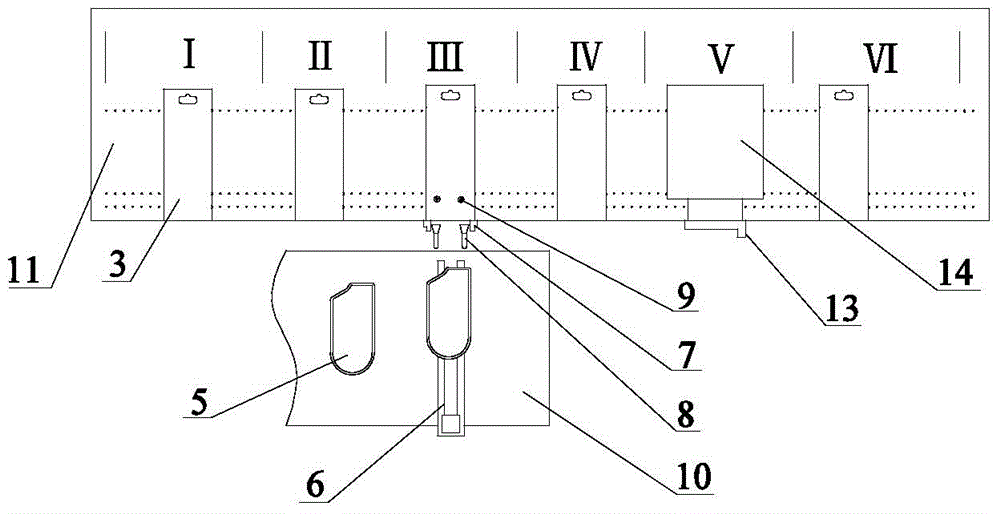

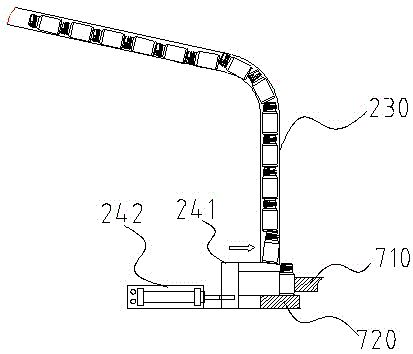

Bag-feeding pillow type packaging machine

ActiveCN103241409AHigh degree of automationIncrease productivityPackaging by pressurising/gasifyingWrapper twisting/gatheringEngineeringPackaging machine

Disclosed is a bag-feeding pillow type packaging machine. A horizontal bag conveyor is disposed between a bag feeder and a horizontal bag opener. A feeding part of the horizontal bag conveyor is located below the bag feeder. A discharge part of the horizontal bag conveyor is connected with the rear end of the horizontal bag opener. A bag picker is located below the horizontal bag conveyor. The bag picker extends into the bag feeder through the feeding part of the horizontal bag conveyor. The horizontal bag opener is disposed on the conveying direction of the horizontal bag conveyor, a conveying device is disposed in front of the horizontal bag opener, the conveying direction of the conveying device is perpendicular to that of the horizontal bag conveyor, a horizontal feeding device is disposed on one side of the conveying device and located on the conveying direction of the horizontal bag conveyor, a motion direction of the horizontal feeding device is perpendicular to the conveying direction of the conveying device, a sealing device is disposed on the horizontal bag opener, a finished product output device is disposed below the horizontal bag opener, and the conveying direction of the finished product output device is perpendicular to that of the horizontal bag conveyor.

Owner:广东宏川环宇智能装备有限公司

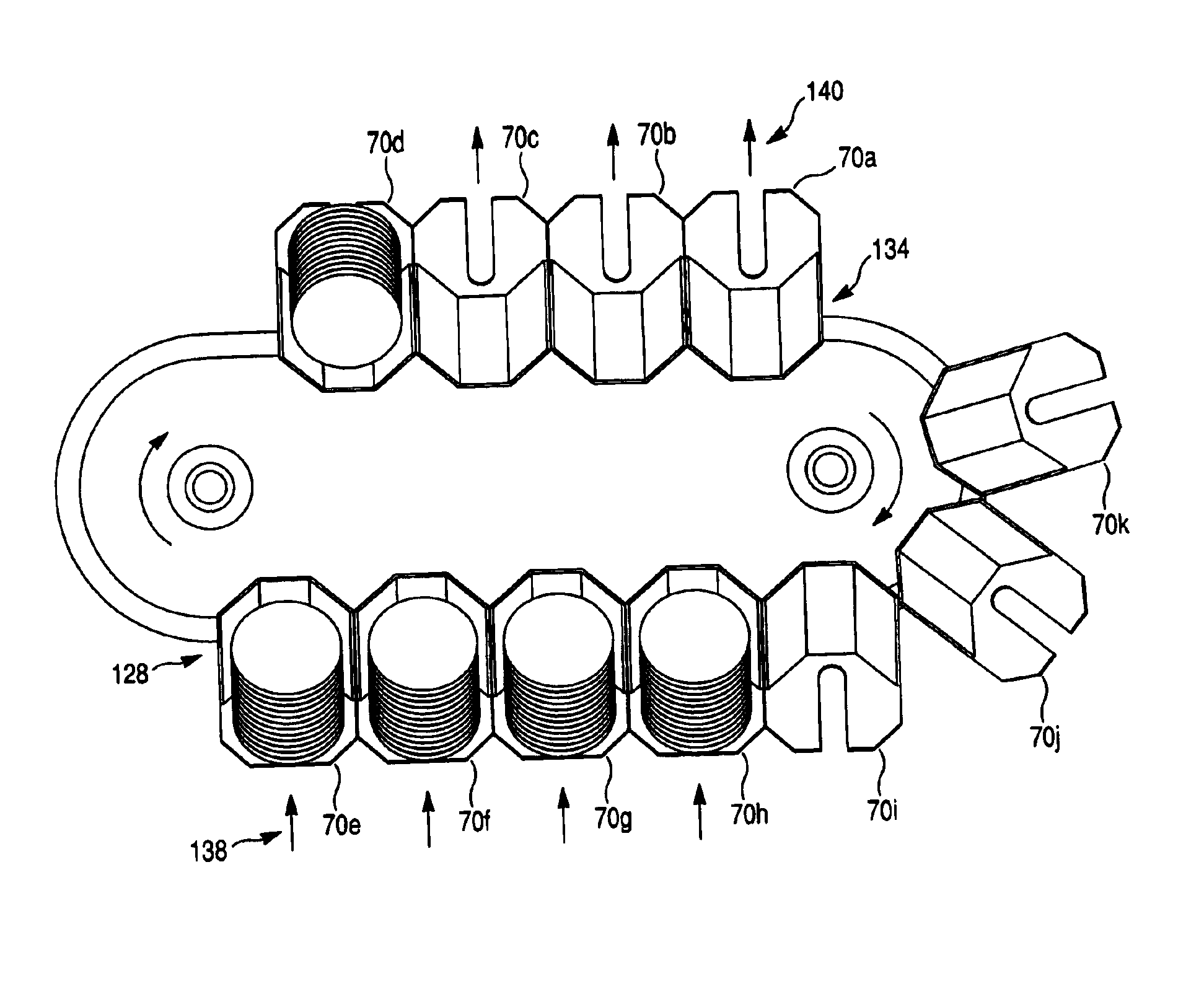

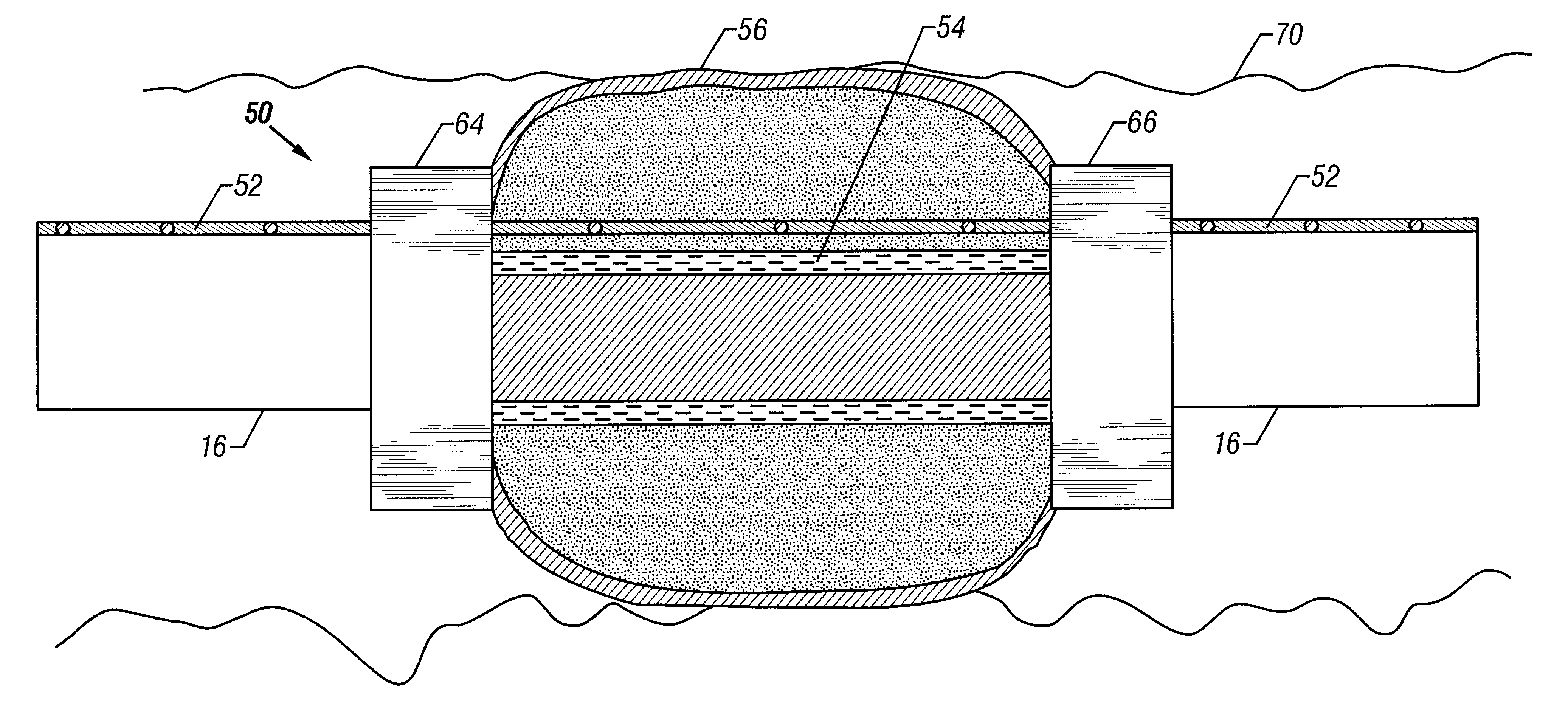

Gravel inflated isolation packer

The present invention discloses apparatus and methods for use in wellbores that comprise an inflatable element. The inflatable element is adapted for inflation by gravel. One embodiment of the invention is a method of sealing an annulus in a well that comprises expanding the inflatable element with a gravel laden slurry. The inflatable element comprises a passageway communicating between an exterior and an interior of the inflatable element. The inflatable element is capable of being connected to a sand screen and the inflatable element can be inflated with the gravel laden slurry during a gravel packing of the well.

Owner:SCHLUMBERGER TECH CORP

Packaging film

A film of biodegradable polylactic acid polymers and copolymers is produced by coextrusion which displays improved winding and manufacturability and end use performance. The film is coextruded from polylactic acid (PLA) polymers and copolymers and biaxially oriented. The surface layer(s) of the film is modified with a particle and displays improved COF, blocking resistance, reduced static generation, improved winding and improved package formation on packaging machines.

Owner:BIAX INT

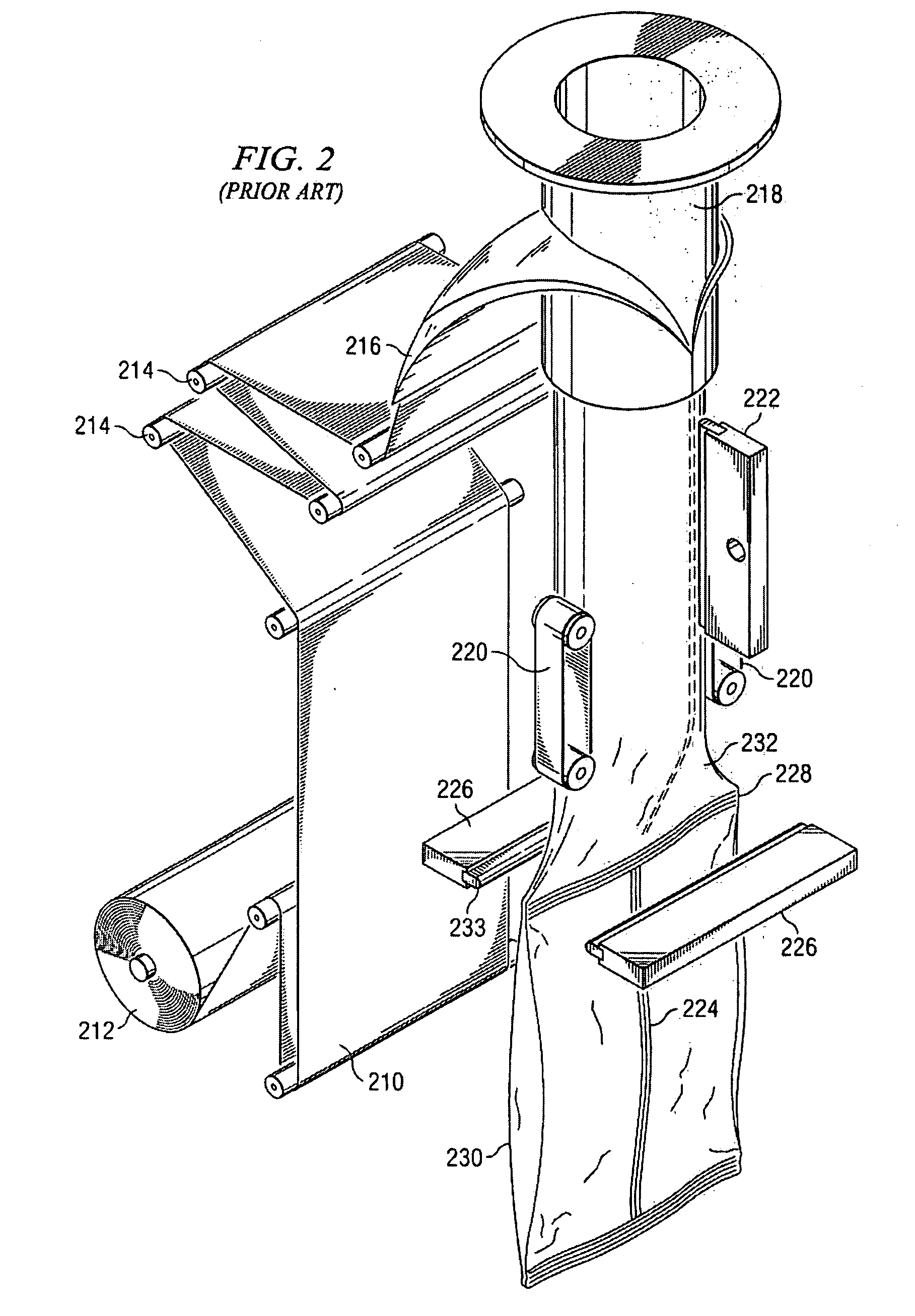

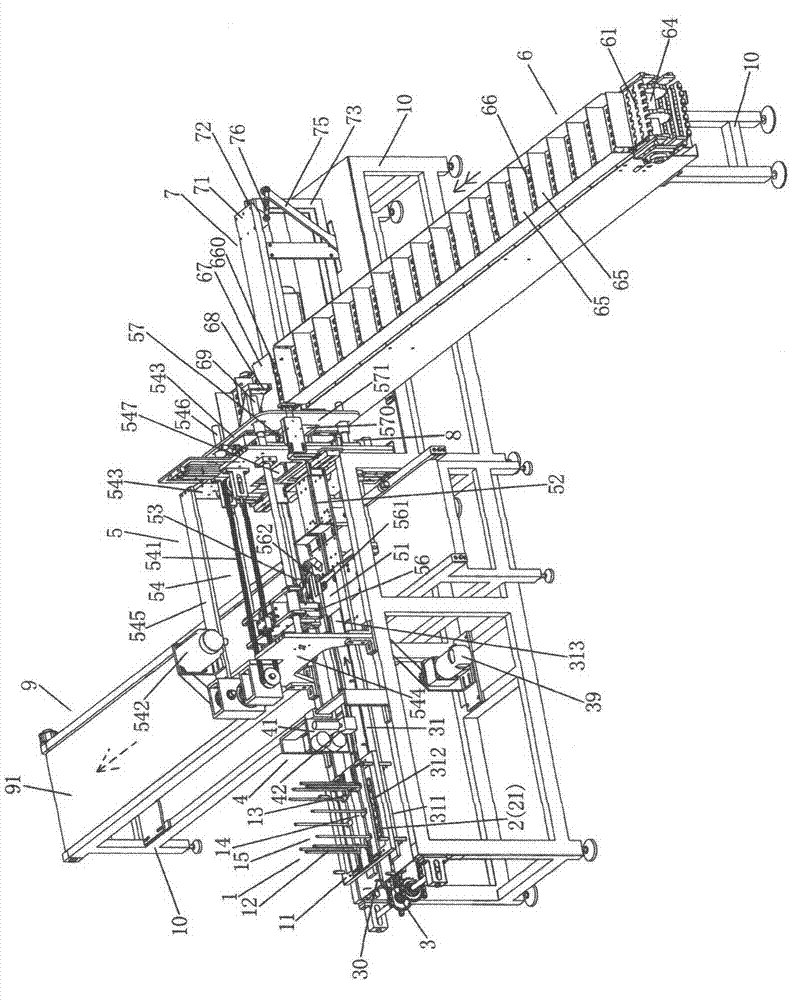

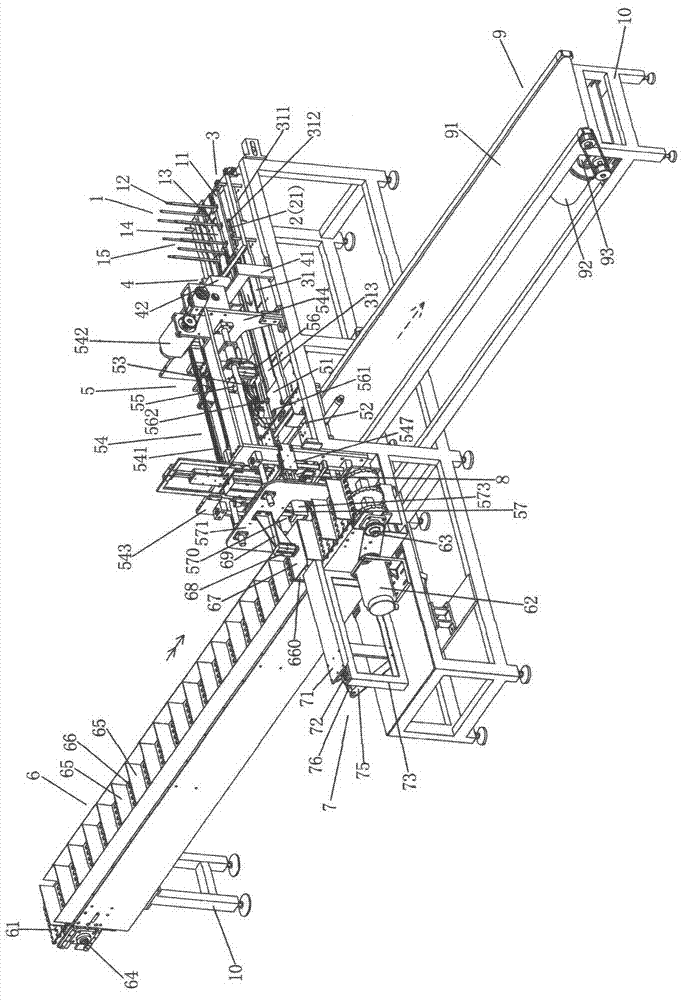

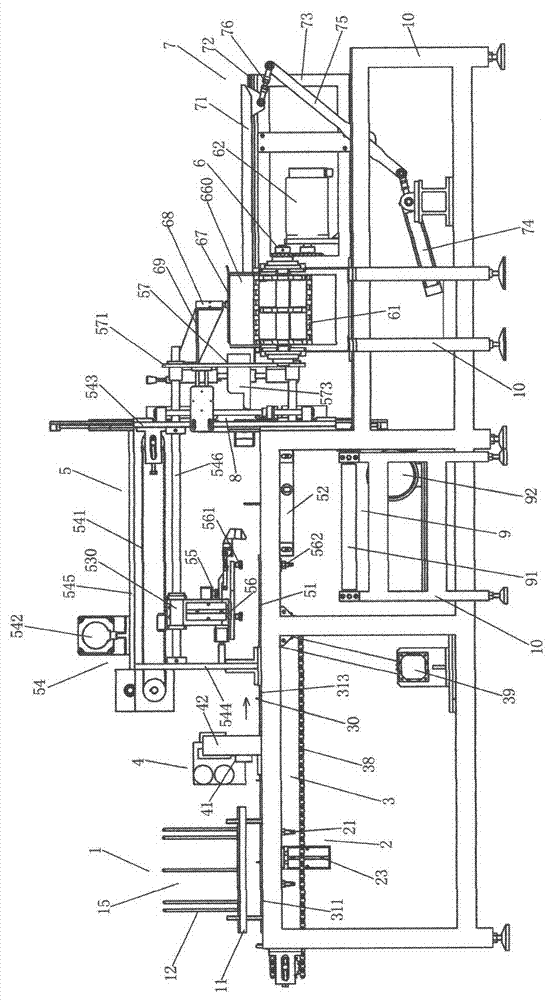

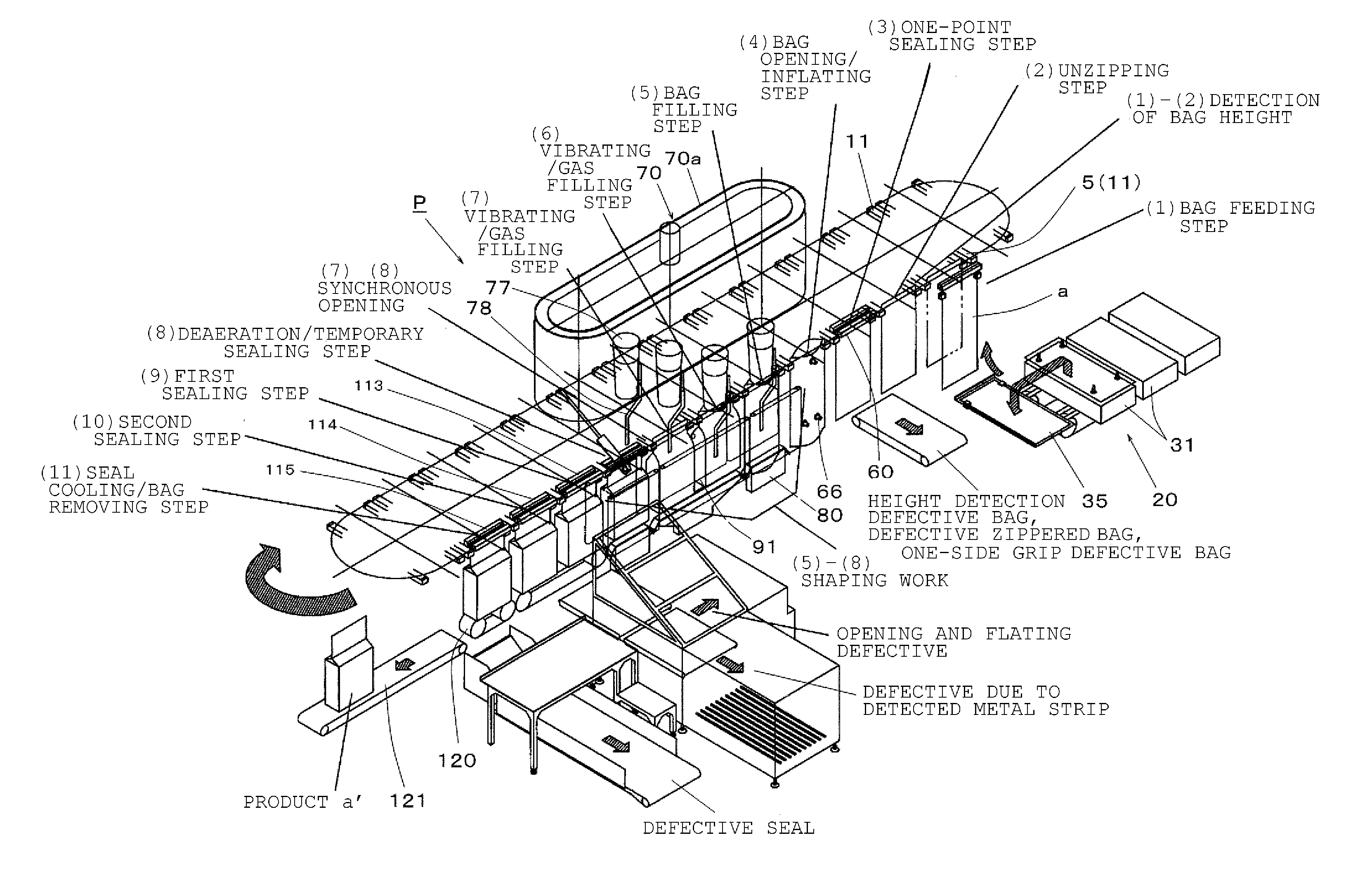

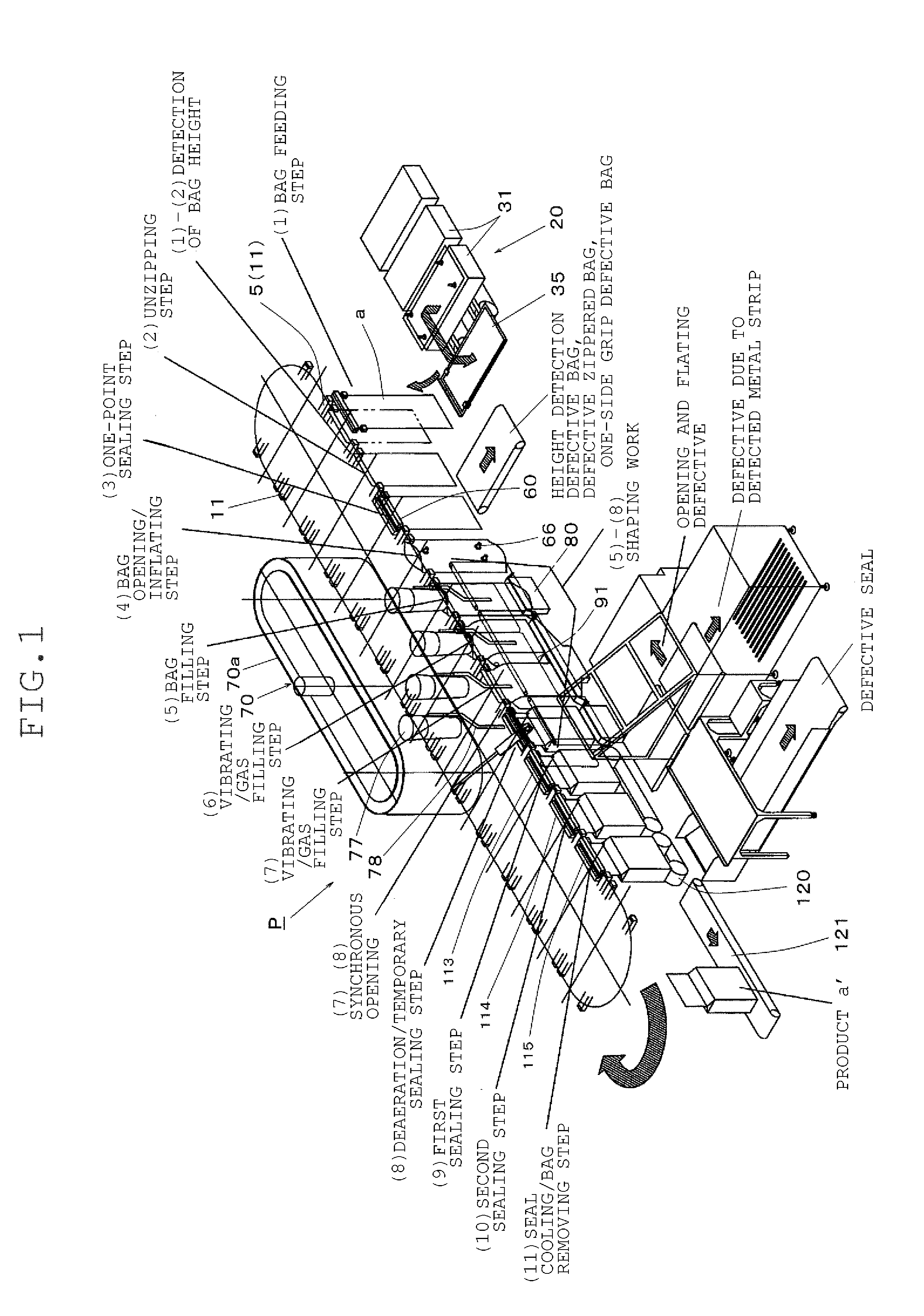

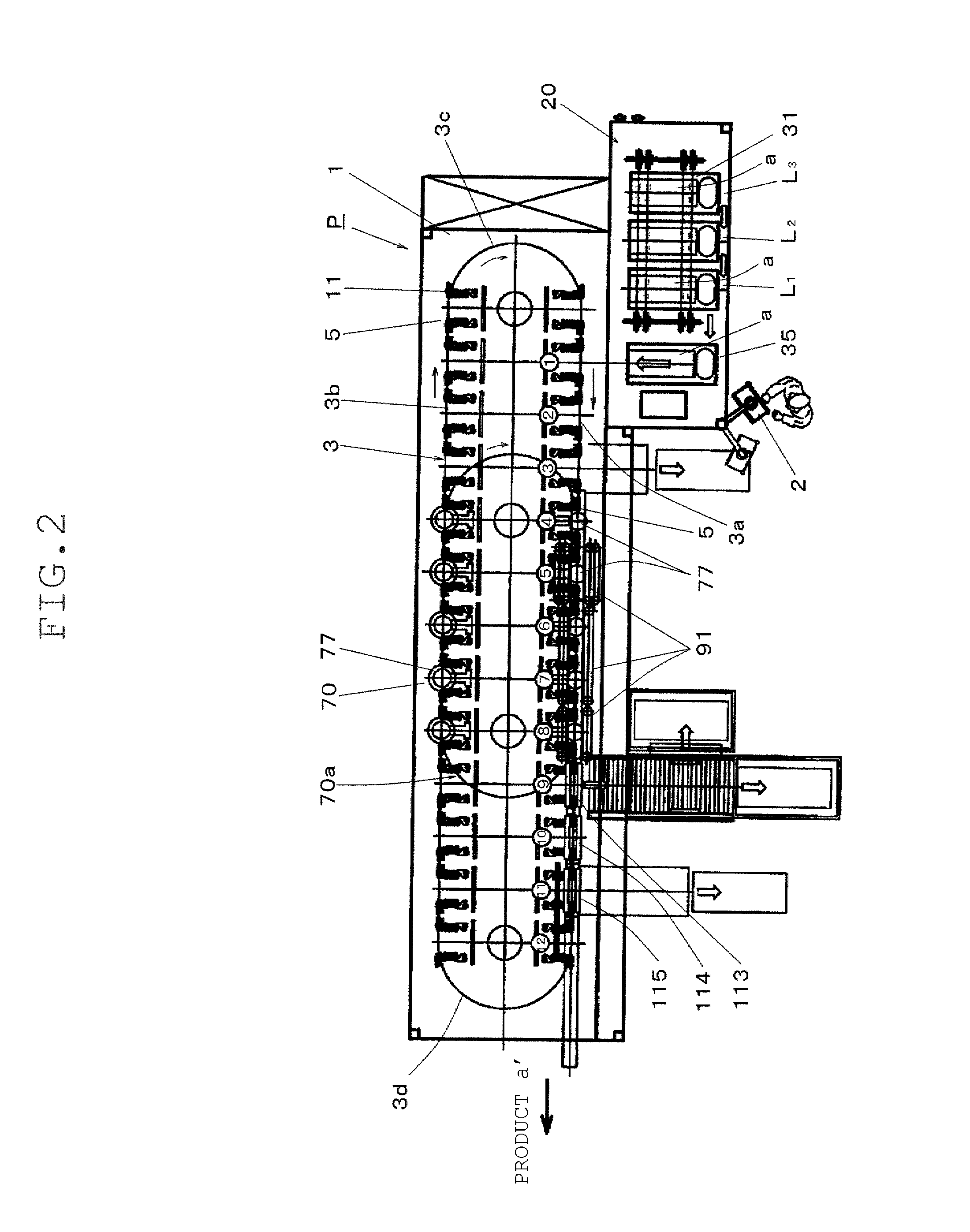

Gas-Filliing Packaging Method and Packaging Machine Therefor

InactiveUS20140331603A1Good quality and stabilityPackaging by pressurising/gasifyingWrapper twisting/gatheringPacking methodPackaging machine

A gas-filling packaging method using a track type gas-filling packaging machine includes a bag placing step in which a number of packaging bags set in a magazine in a stacked state are turned up one by one by a sucker and picking up and then passing the bag to a bag chuck, a bag opening / inflating step of opening the bag mouth and inflating the bottom of the bag by suckers, a bag filling step of lowering a synchronous funnel to be inserted into the bag and applying a receiving member of a bottom tapping unit to the bag, so that the bag is filled with a predetermined amount of article while the bottom is tapped, a deaeration / temporarily sealing step of inserting a deaeration nozzle into the bag to remove air in the bag and holding the bag mouth by a temporary heater.

Owner:GENERAL PACKER

Transparent, coated, shrinkable, oriented polypropylene film

InactiveUS20030157354A1Prevent shrinkageAvoid wrinklesSynthetic resin layered productsPackaging by pressurising/gasifyingWater basedEngineering

A transparent, coated, heat-shrinkable film having controlled shrinkability which includes a biaxially oriented substrate having a polypropylene blend core layer and a water based coating. The shrink during the application on packaging machines is achieved through the balanced MD-TD (machine direction and transverse direction) film retraction in and near the sealed areas. The substrate can also include outer layers of a propylene-ethylene-butylene terpolymer disposed on either side of the polypropylene core layer or on either side of additional intermediate layers that may be disposed between the outer layers and the core layer. The invention also includes a process for making this coated heat-shrinkable film. The coated film is formed under controlled temperature and tension conditions to produce a packaging film having shrinkage within a controlled shrinkability range.

Owner:EXXONMOBIL CORP (US)

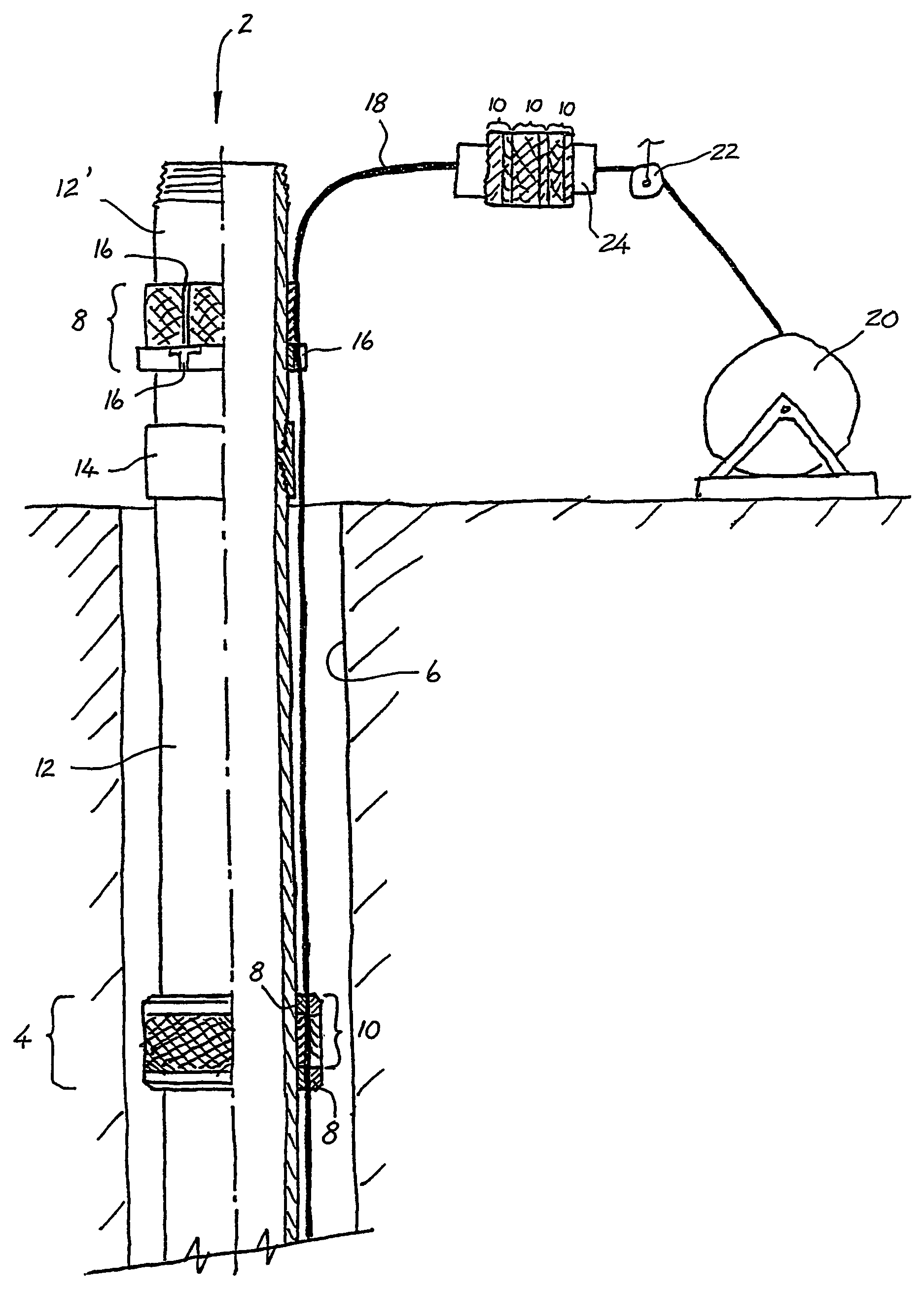

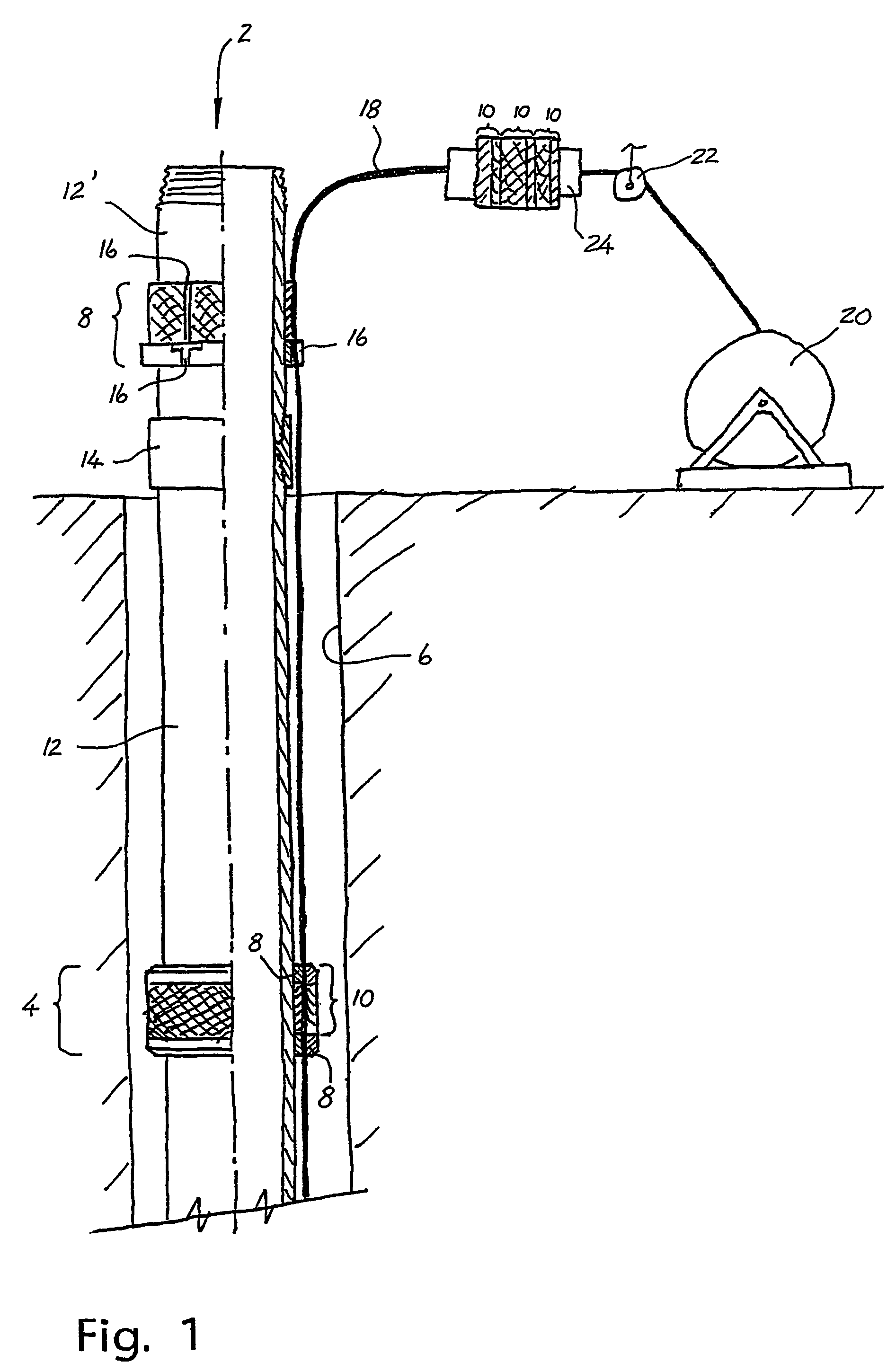

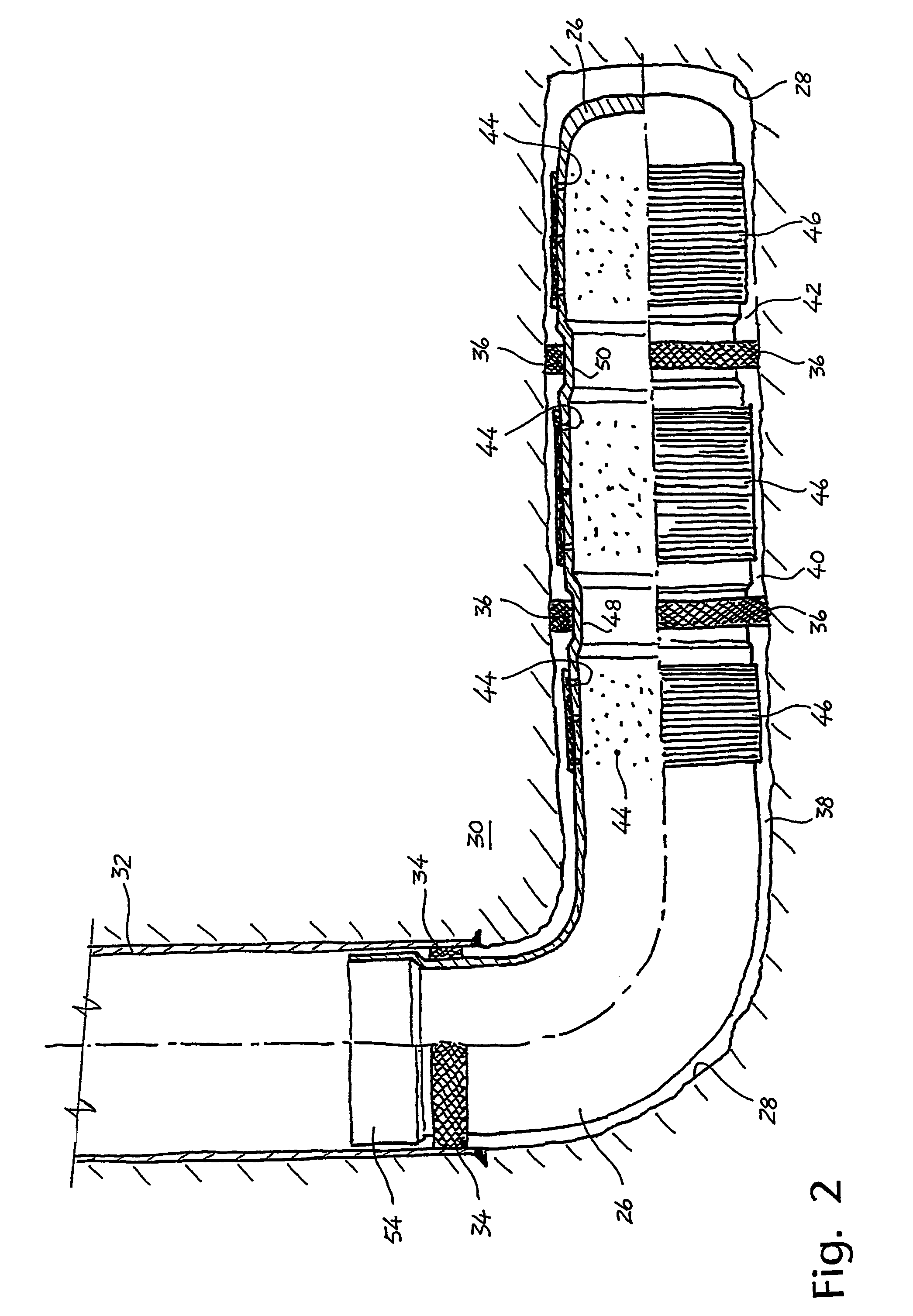

Well packer for a pipe string and a method of leading a line past the well packer

InactiveUS7264061B2Easy to controlDisadvantage is reduced and avoidedDrilling rodsFluid removalLine tubingEngineering

The invention concerns an external well packer (4, 4′, 4″) for a pipe string (2), and also a method of leading at least one line (18) seamlessly past at least one packer (4, 4′, 4″) along the pipe string (2). What is characteristic of the packer (4, 4′, 4″) is that it consists of a continuous inner packer ring (8) and a separate and continuous outer packer ring (10), which in the operating position encloses the inner packer ring (8) in a pressure tight manner. The fitting surface of at least one of the packer rings (8, 10) is provided with at least one through-going line slot (16, 16′), which in the operating position encloses a line (18) in a pressure tight manner. This allows continuous lines (18) to be stretched out past several such packers (4, 4′, 4″).

Owner:RESLINK

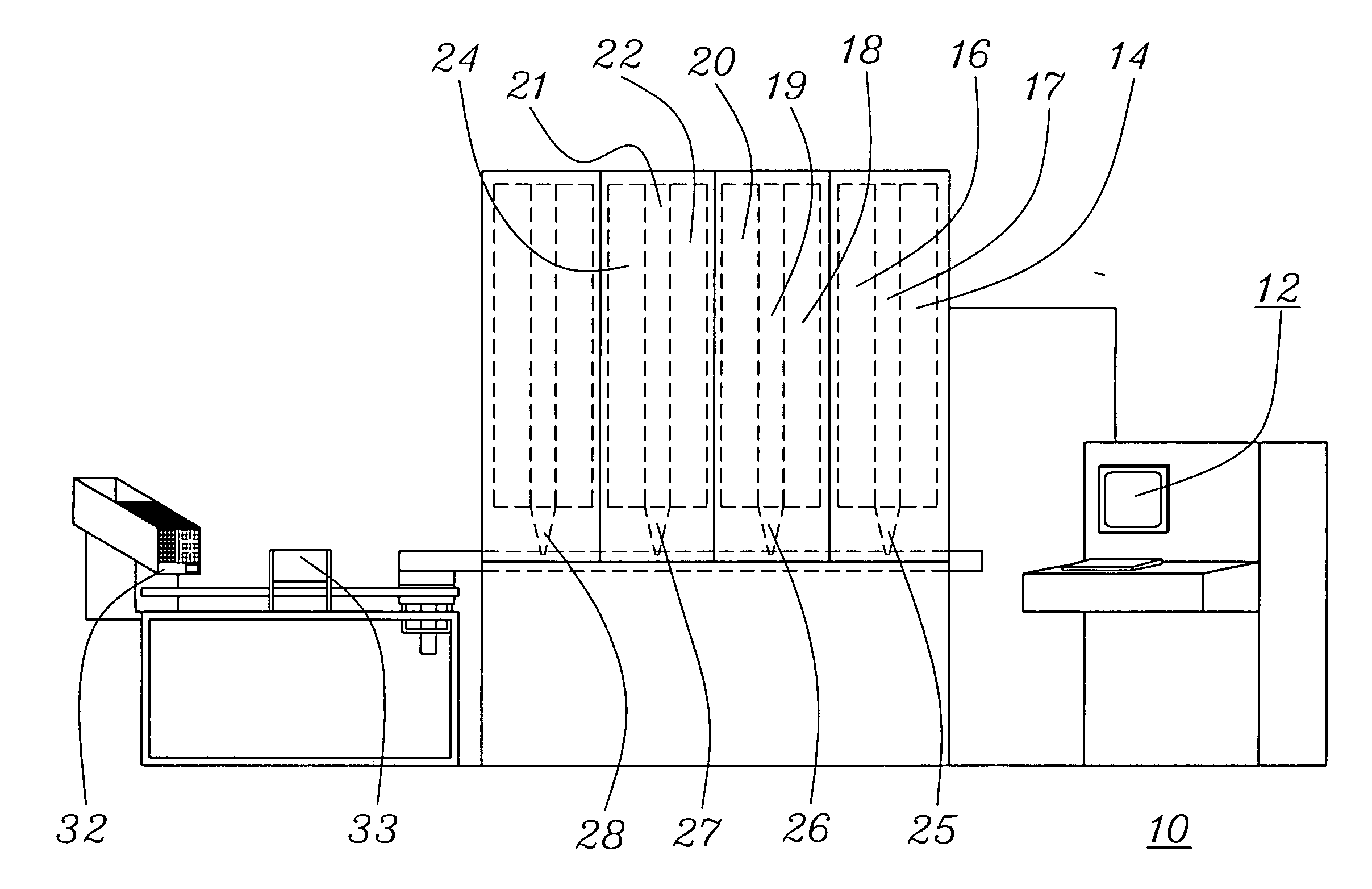

Compact structure for automatically filling solid pharmaceutical product packages

InactiveUS6925774B2Various kindsRun at high speedLiquid fillingSolid materialEngineeringTemporary storage

An automated solid pharmaceutical product packaging machine includes a plurality of temporary storage members for receiving a plurality of solid pharmaceutical products in a plurality of cavities. The use of the temporary storage cavities enables the machine to process several prescriptions simultaneously. Advantageously, at least one of the temporary storage members is capable of being automatically displaced in a vertical direction in order to increase the capacity of the overall filling system for processing a greater number of solid pharmaceutical products while minimizing the overall footprint of the device.

Owner:MTS MEDICATION TECH INC

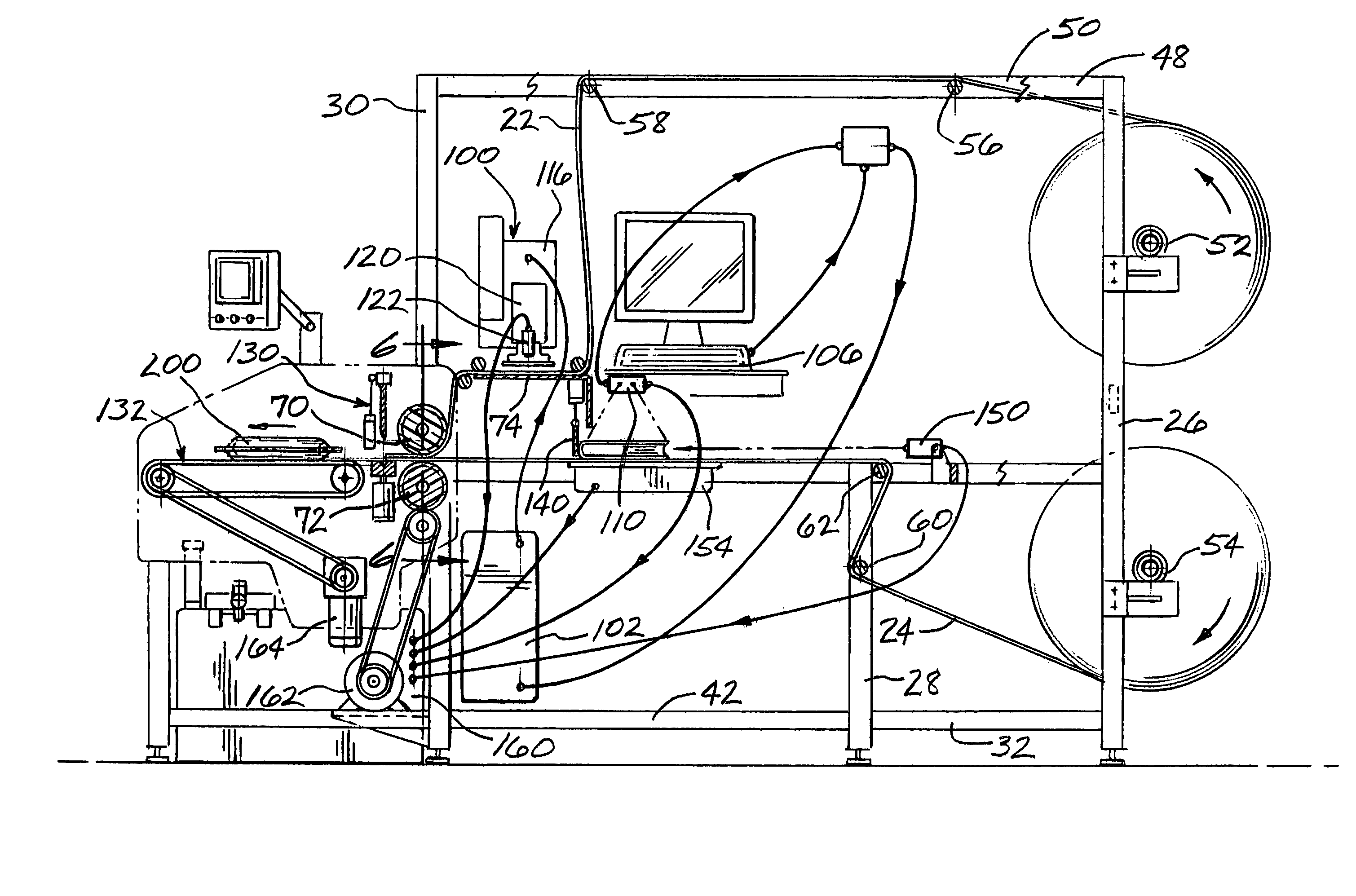

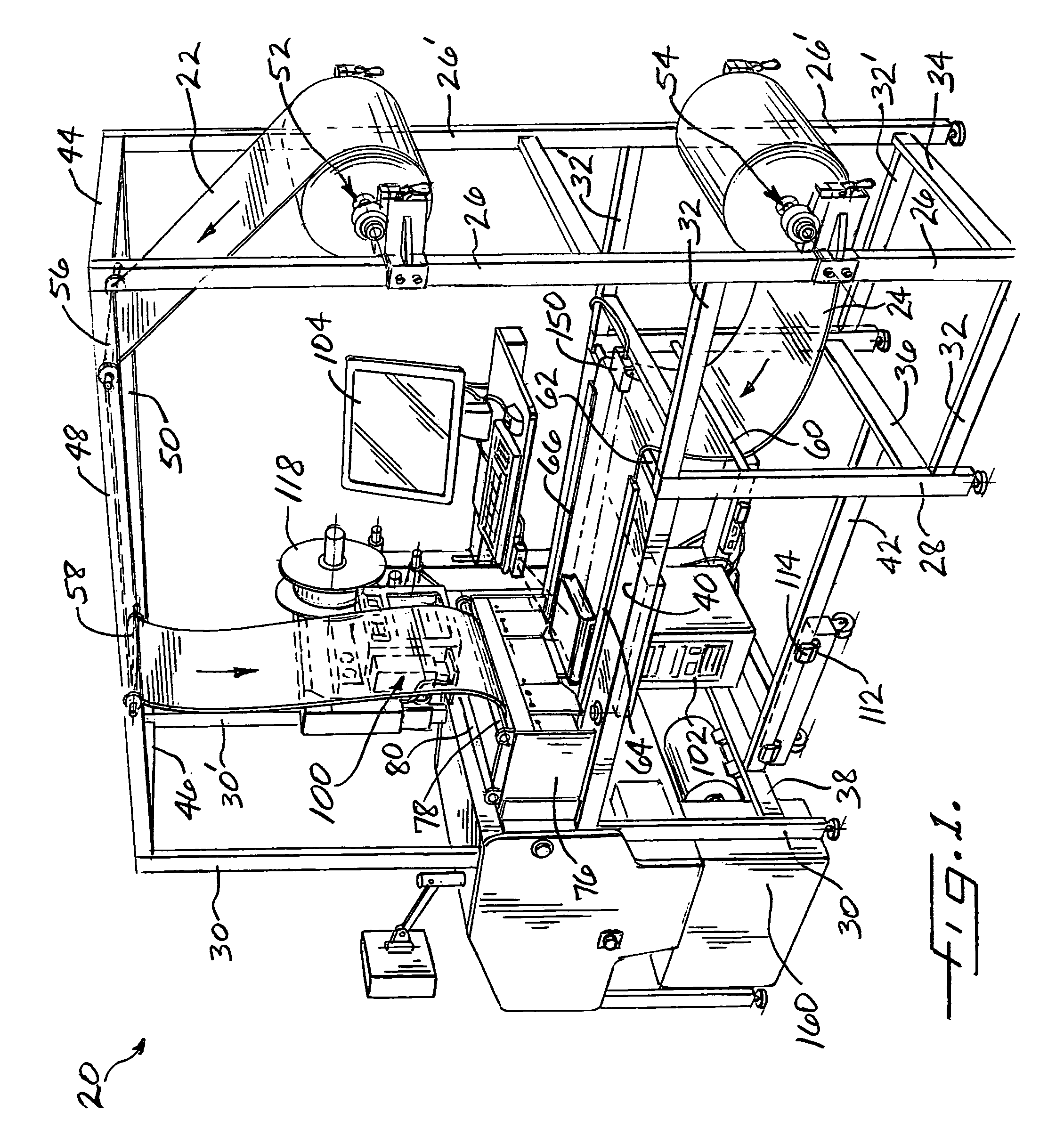

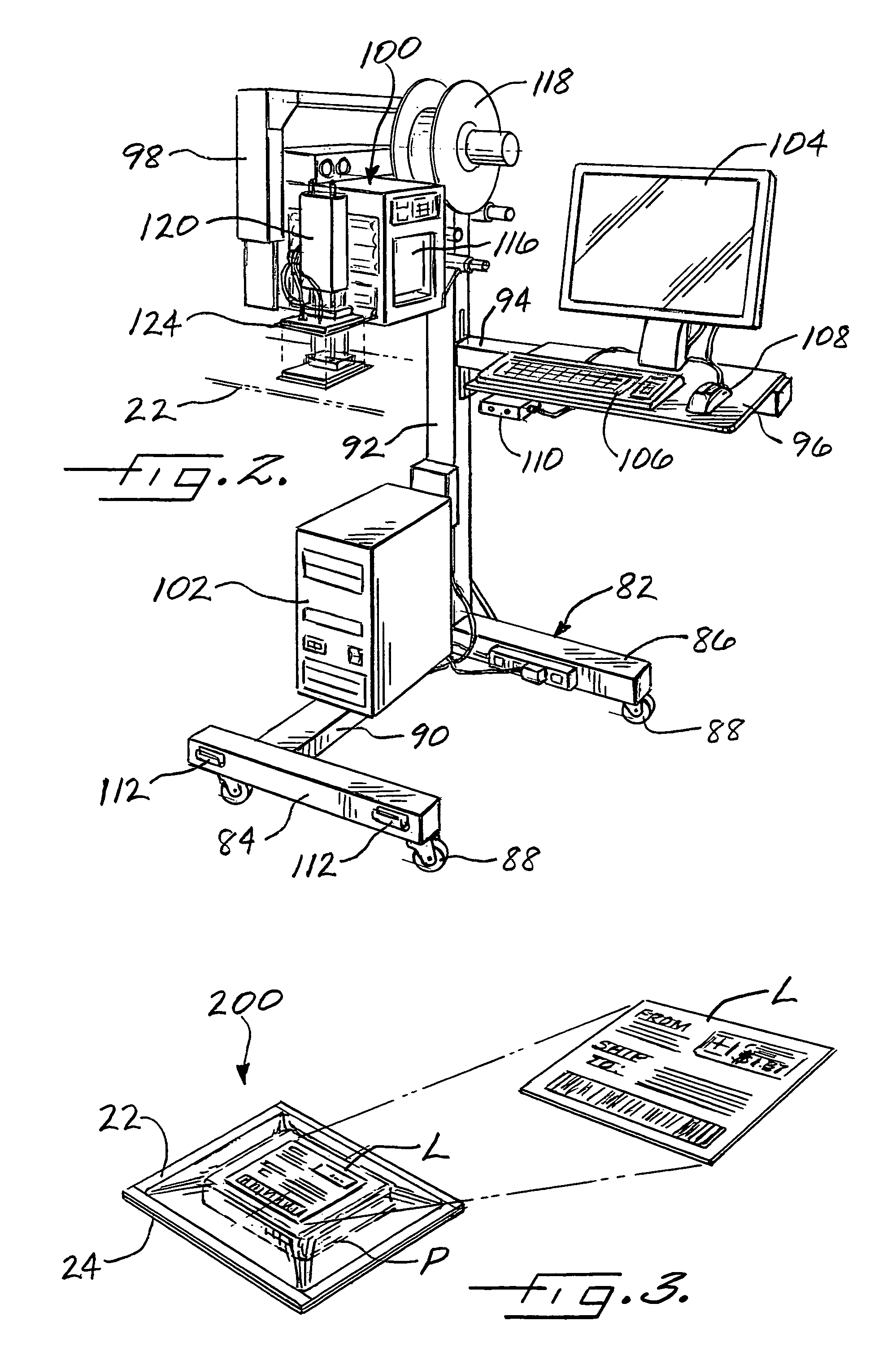

Packaging machine and method

ActiveUS7386968B2Facilitates automatic detectionPackaging cigarettePackaging cigarsProduct baseProcess engineering

A packaging method and apparatus wherein each product is packaged by enveloping the product in flexible packaging material. A programmed microprocessor calculates the length of flexible packaging material needed to package the product based on the physical dimensions of the product, calculates the weight of the flexible packaging material needed, and calculates a total package weight as the sum of the weight of the product and the calculated weight of the flexible packaging material. A printer prints information specific to the product that is being packaged onto a label that is then affixed to the flexible packaging material prior to the product being packaged. The information can be a function of the package weight, and the calculated total package weight can be communicated from the microprocessor to the printer. Finally, the product is packaged in the flexible packaging material having the label already affixed thereto.

Owner:SEALED AIR U S

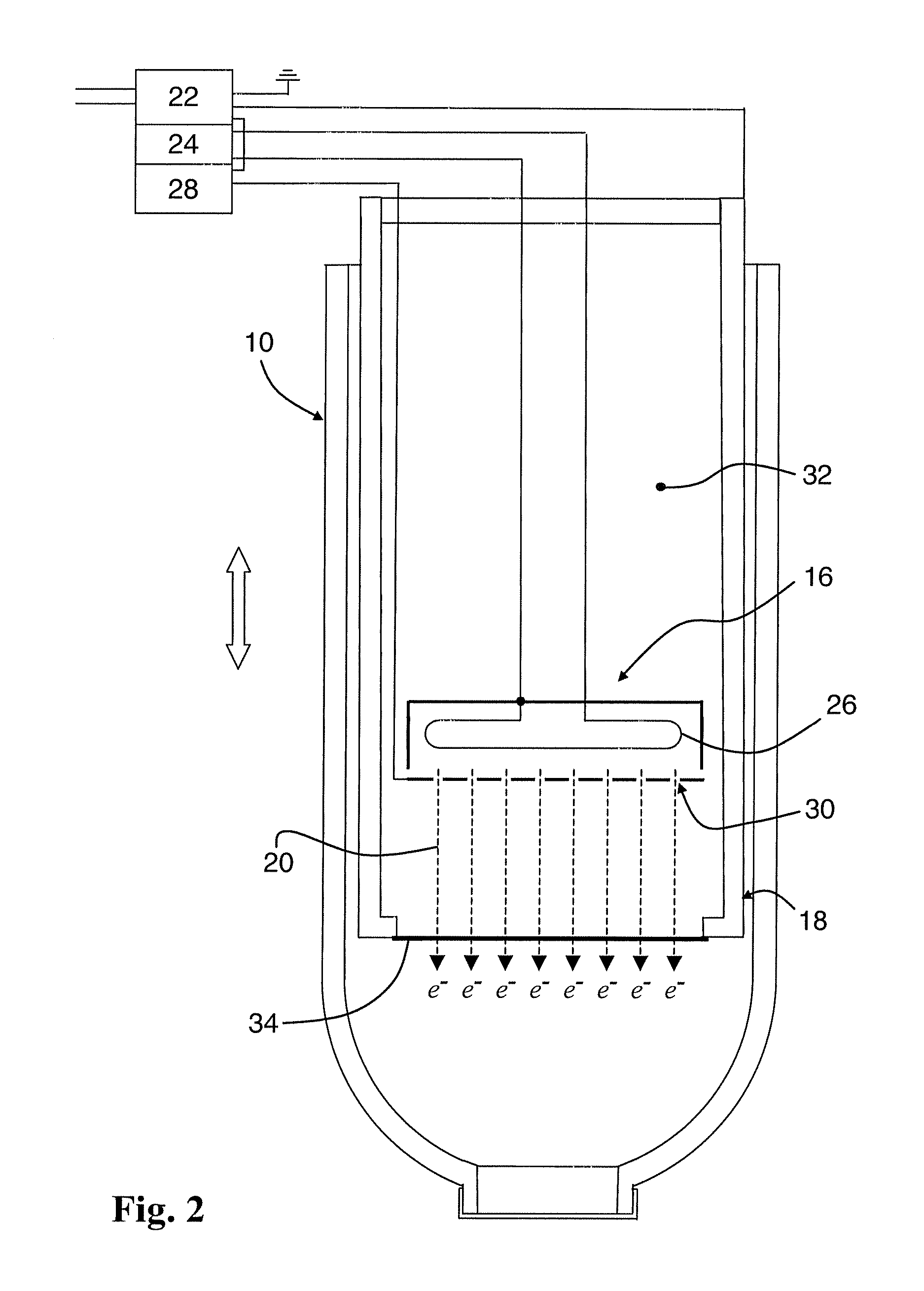

Method of sterilizing packages

ActiveUS20070283667A1Even dosePackage sterilisationLavatory sanitoryPhysicsElectron beam irradiation

A method for sterilizing at least partly formed packages with electron beam irradiation in a packaging machine involves sterilizing each of at least two at least partially separate areas of the package by way of a respective electron beam sterilizing device, with each of the sterilizing devices being adapted to characteristics of each respective one of the two areas, and also performing a respective relative movement between the package and each of the electron beam sterilizing devices, which movements are adapted for the sterilization of each respective one of the two areas with the sterilizing devices.

Owner:TETRA LAVAL HLDG & FINANCE SA

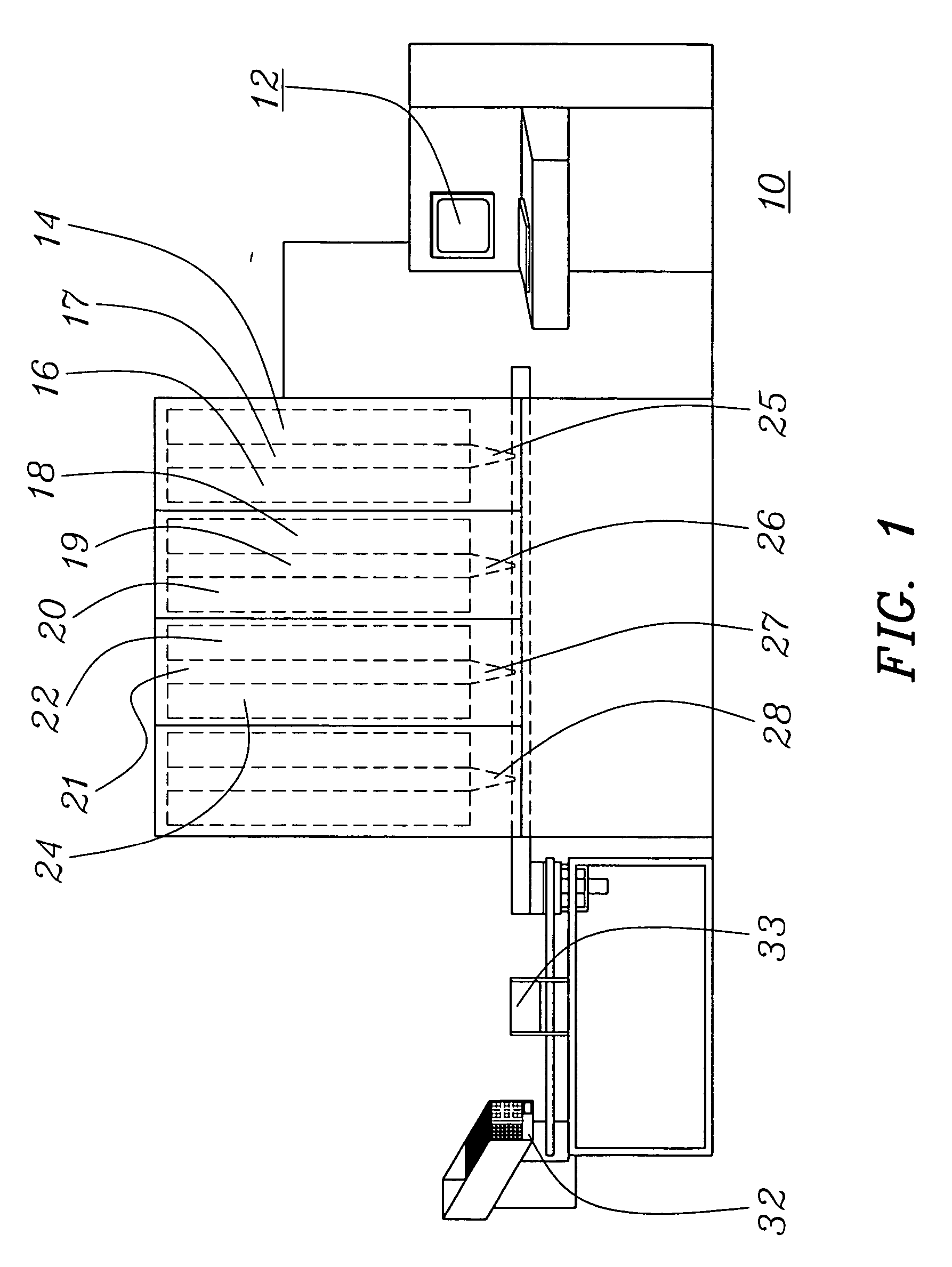

Single pass mail sorting system

InactiveUS20070017855A1Efficiently formedCharacter and pattern recognitionSortingDelivery systemIndustrial engineering

A method of mail sorting according to the invention includes the steps of sorting a batch of mail addressed to recipients in a common postal delivery zone with an automated single pass mail sorting machine into groups wherein the mail pieces in each group have a common delivery destination, transporting the groups of sorted mail using an automated conveying system to a delivery point packaging machine, and then packaging the groups of mail pieces with the delivery point packaging machine. Such a method is preferably part of a single pass sorting process wherein a batch of starting mail destined to a common zone is sorted into groups of mail for each destination that are then brought to the delivery point packaging machine in carrier delivery order.

Owner:SIEMENS LOGISTICS LLC

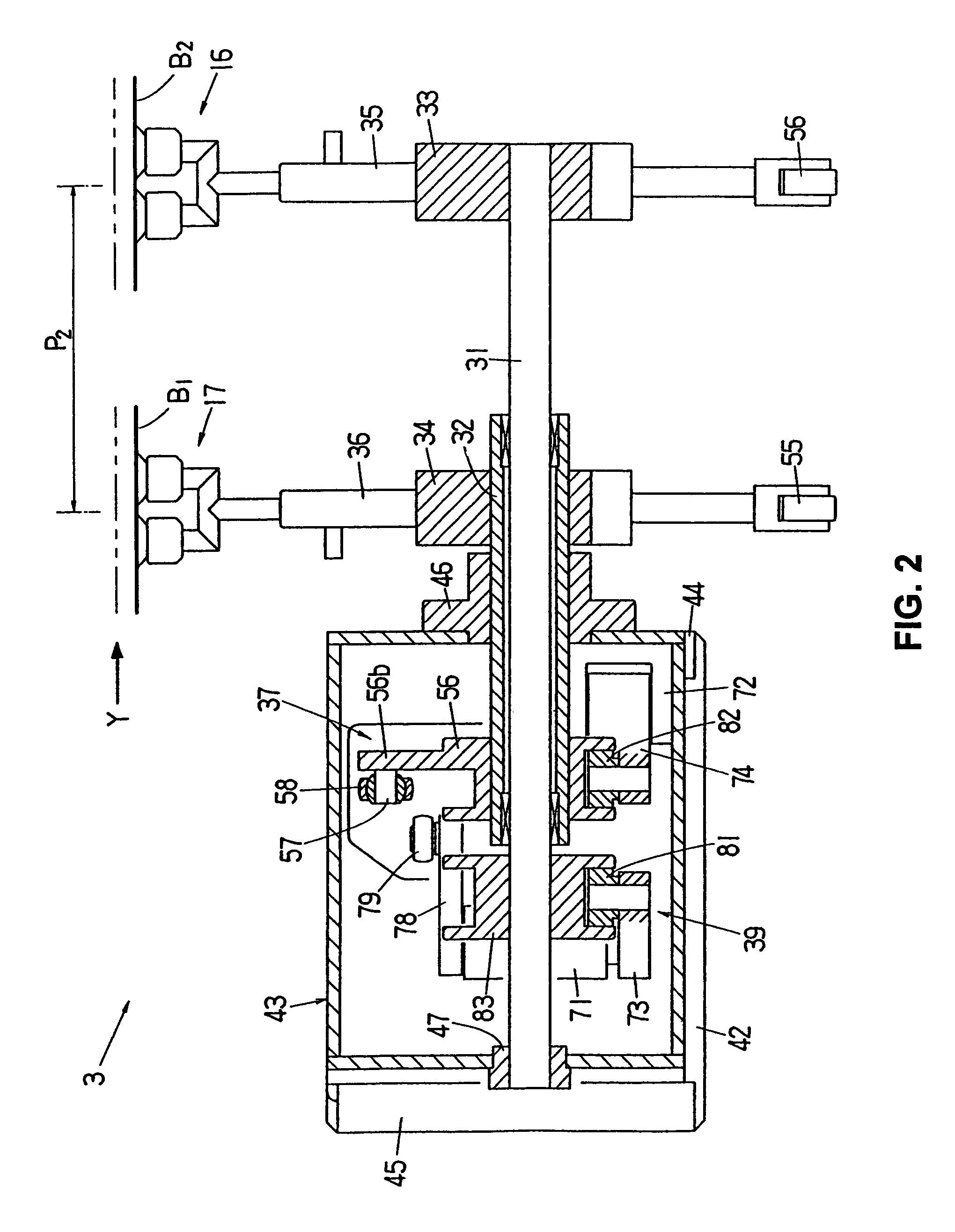

Process and packing machine for manufacturing filled drinking cups

InactiveUS6161367AReduce mechanical forceMinimized cover foil wasteCapsFlanged caps applicationPack materialEngineering

The invention is concerned with a process of manufacturing filled drinking cups closed by cover foil blanks heat-sealed thereto and formed by deep-drawing from a thermoplastic packing material strip, comprising a beaded peripheral flange, with the cover foil blanks being provided with a pull flap. According to the invention the method includes the following steps: cyclically feeding the packing material strip loaded with the deep-drawn and filled cups underneath a cover foil blank transfer means; taking up the cover foil blanks from the transfer means, with the pull flaps, during transfer of the cover foil blanks to the packing material strip, being positioned in a direction substantially vertical to the extension plane of the blanks, and the blanks with the upright pull flaps above the cup openings being applied to the packing material strip; sealing the margins of the cover foil blanks to the unmolded areas of the packing material strip about the cup openings; bending the upright flaps during the advance movement of the packing material strip; punching the cups from the packing material strip along a punching contour line extending in parallel to and at a space from the circumferential contour of the cover foil blanks; and transferring the punched cups into a beading means wherein the peripheral flange portion projecting relative to the cover foil blanks is downwardly beaded.

Owner:HASSIA VERPACKUNGSMASCHEN

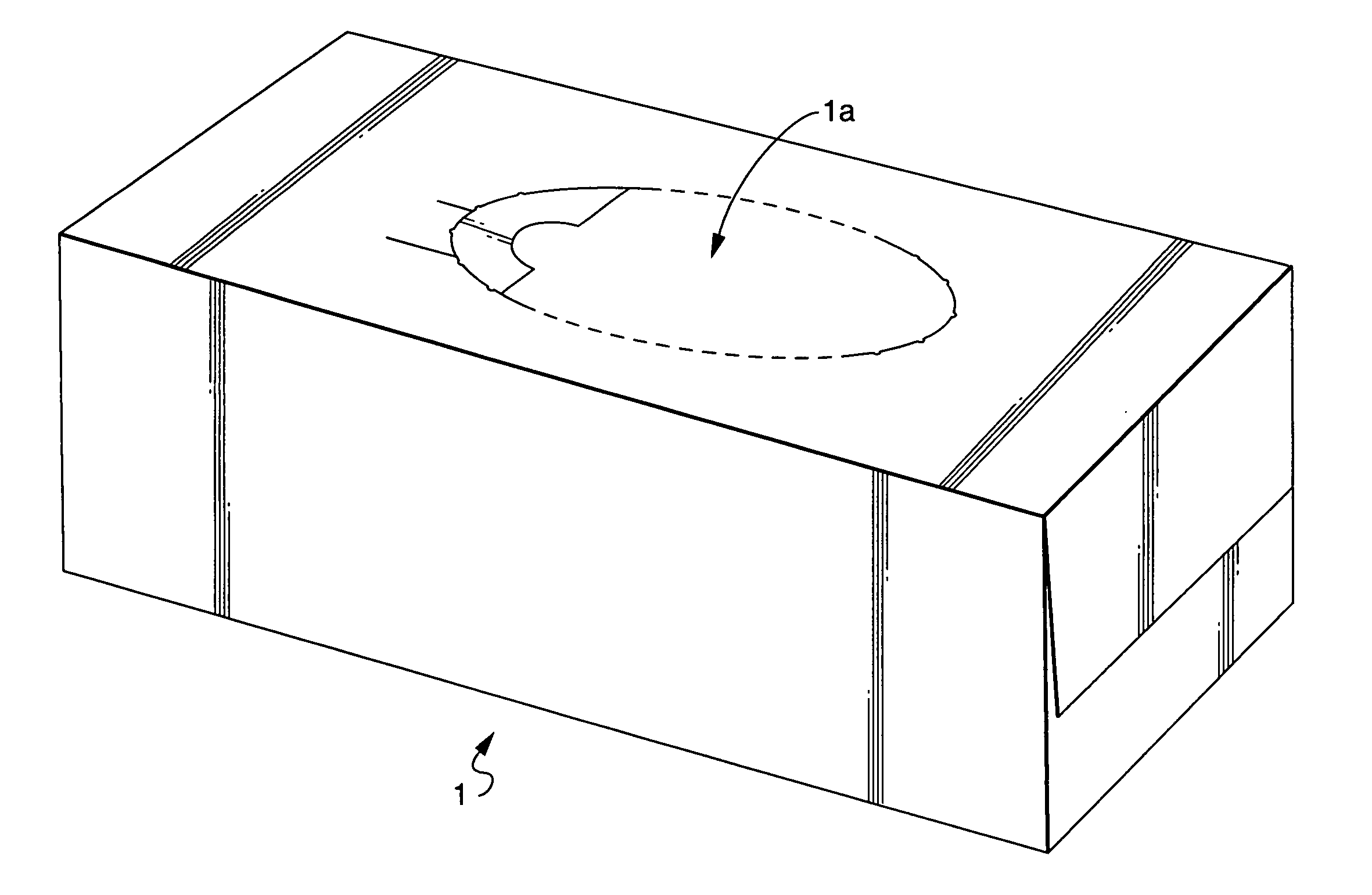

High-volume package dispenser

InactiveUS20070210096A1Easy accessAvoid pollutionDispensing apparatusRigid containersPackage designLarge capacity

A dispenser package system for protective articles, having a new substantially vertical product storage orientation and package design, is described. The package includes a double or multi-chambered dispenser unit that can provide within substantially the same footprint as a conventional dispenser container a greater volume of product. The package can store and dispense at least 50%, up to about 200% or greater capacity than conventional dispenser for protective article products such as gloves or face masks.

Owner:KIMBERLY-CLARK WORLDWIDE INC

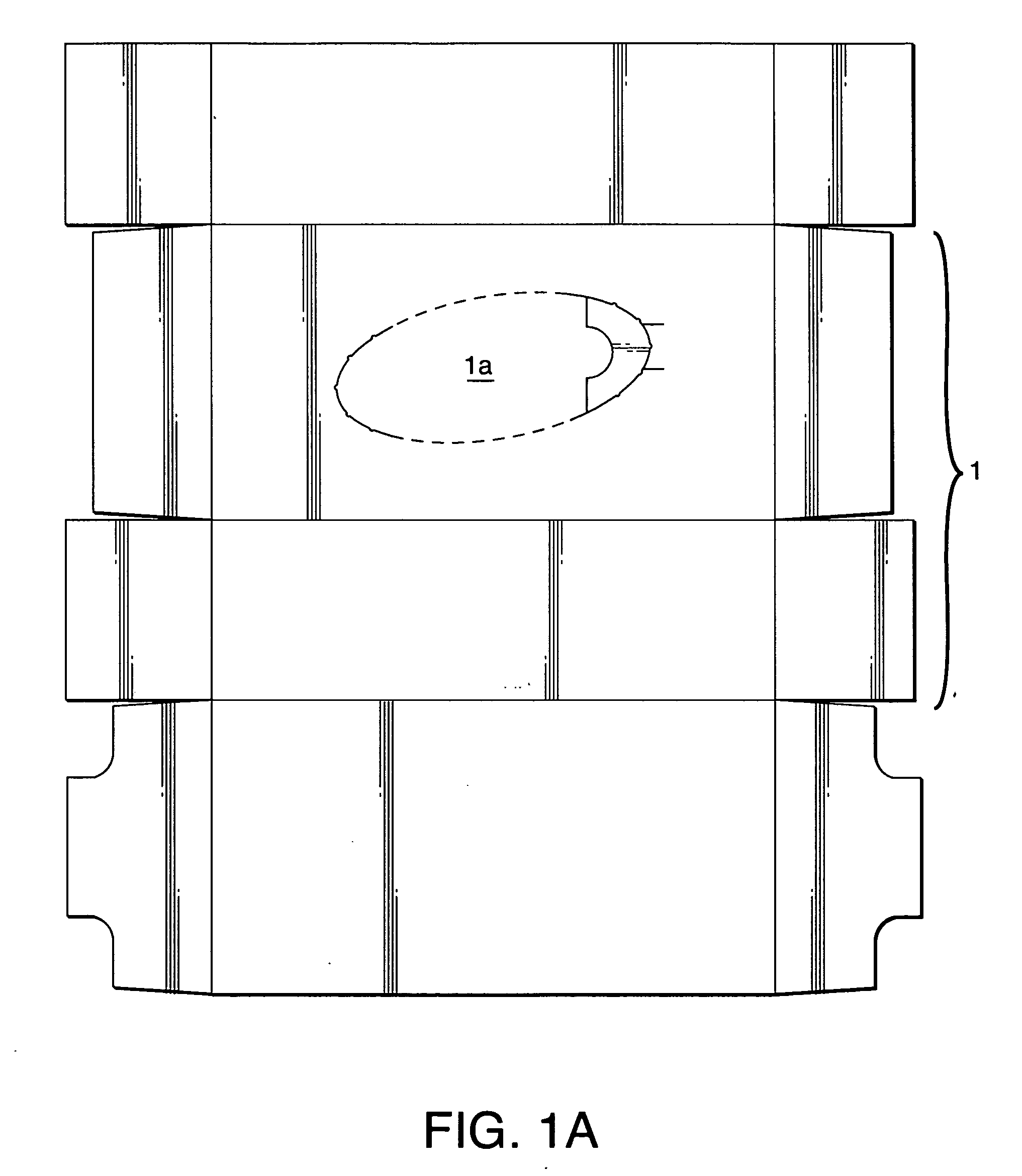

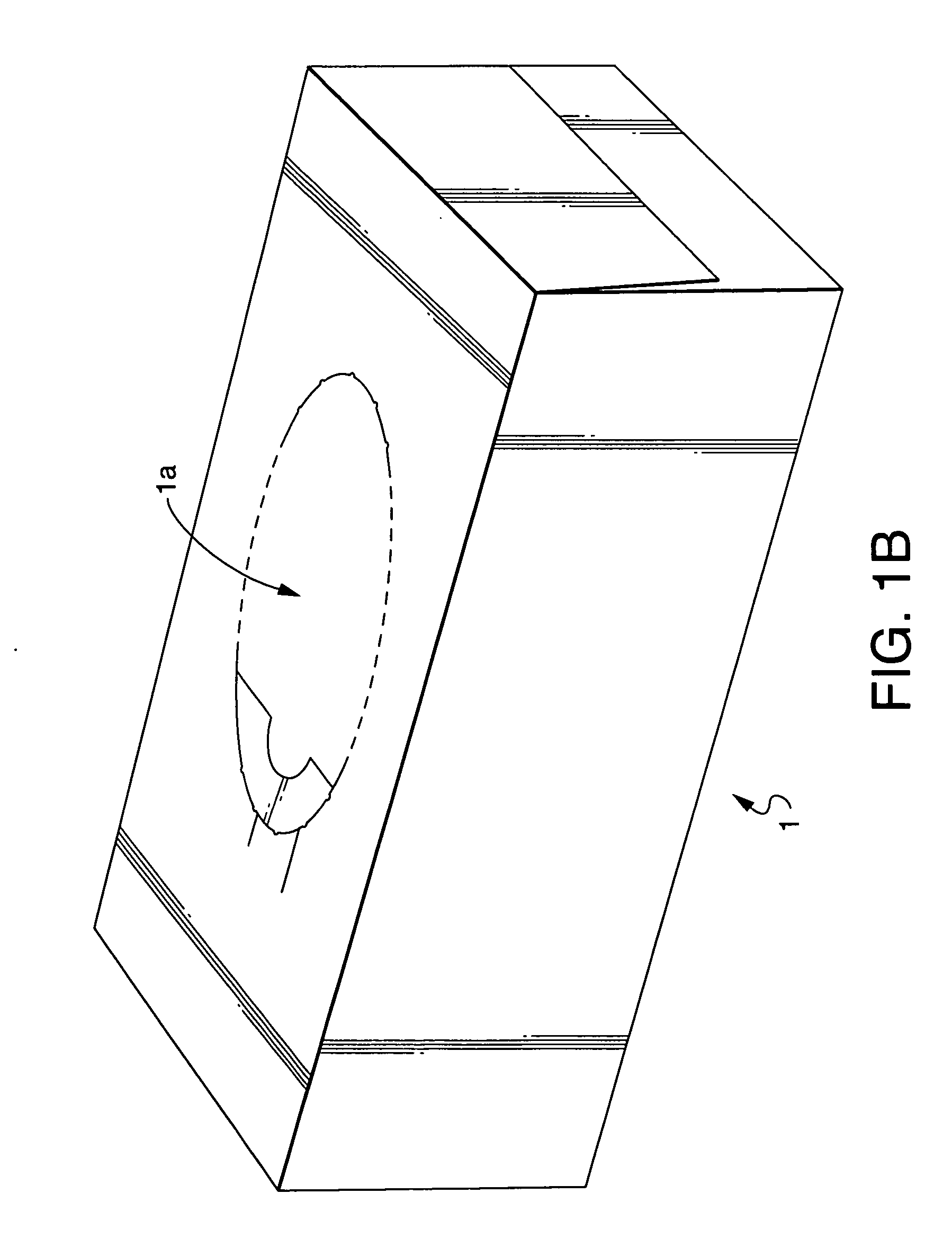

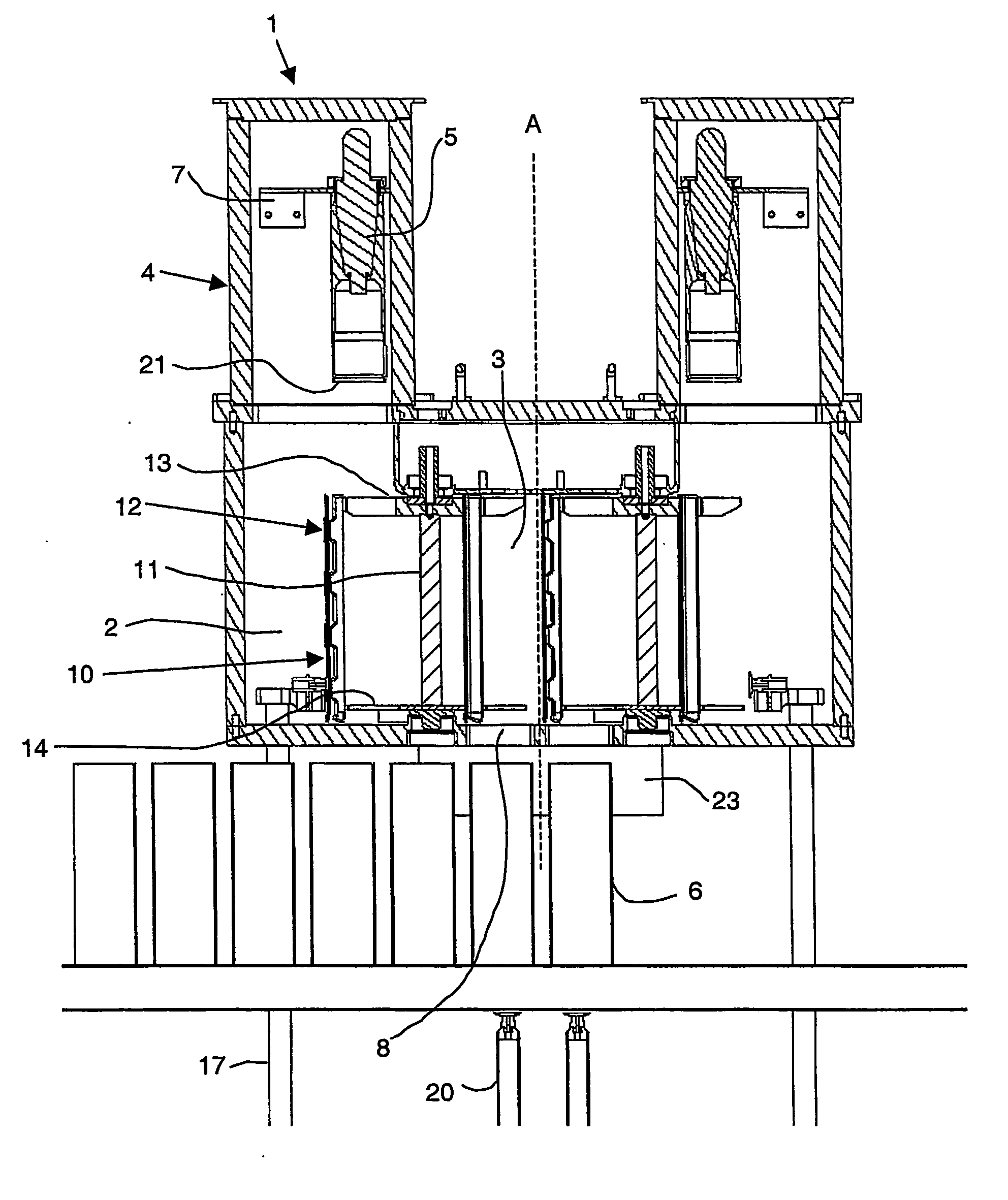

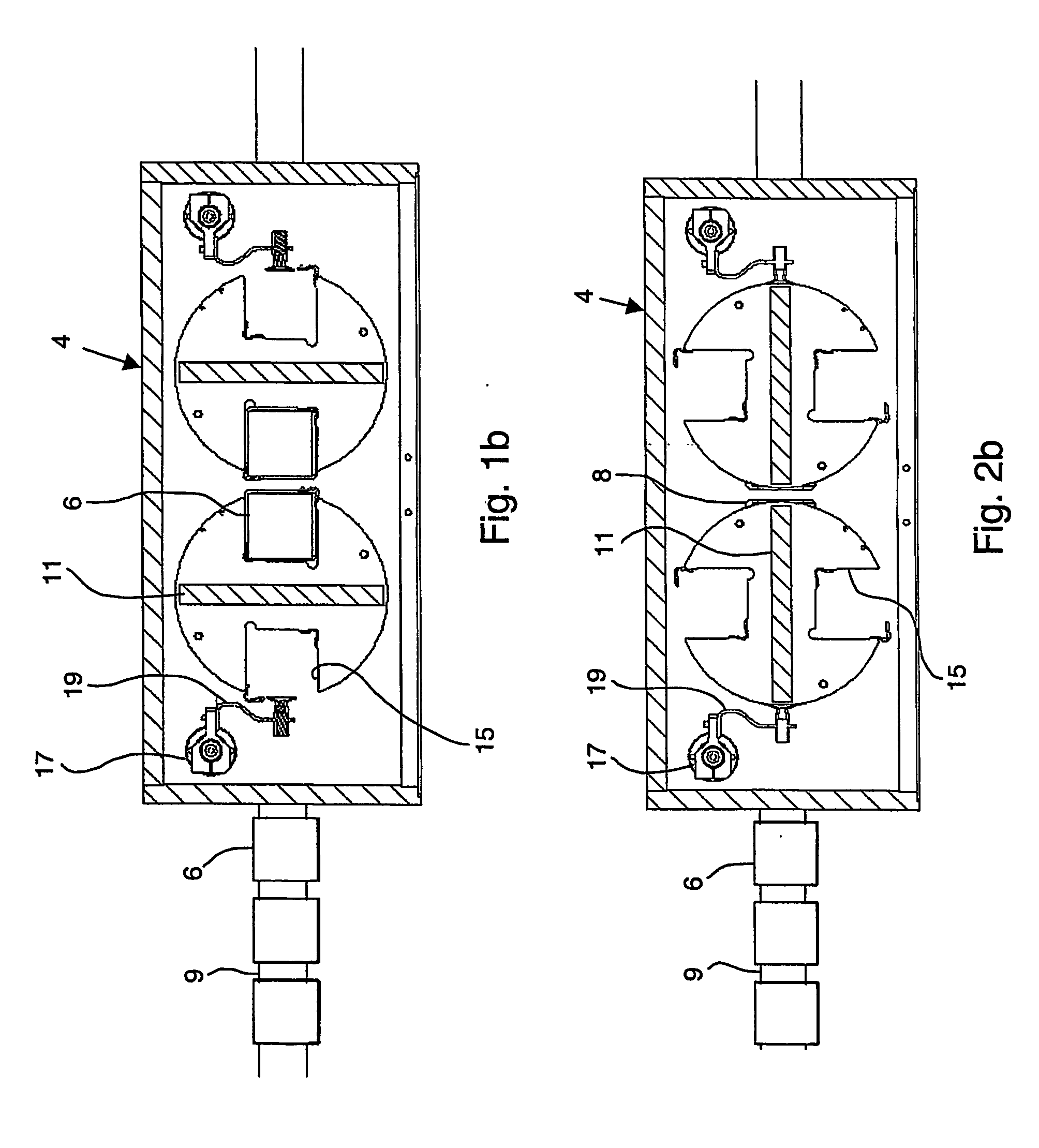

Device and method for sterilization

InactiveUS20060159583A1Risk minimizationEffectively and reliably dischargedElectrolysis componentsPackage sterilisationEngineeringBiomedical engineering

The invention refers to a device (1) and method for sterilizing partly formed packages (6) in a packaging machine. The device (1) comprises an inner chamber (2) and an outer chamber (3), the inner chamber (2) being provided with a sterilization unit (5). Further, it comprises a carrier unit (10), comprising a separating member (11) and a package carrying member (12), which is being adapted to rotate between a first position in which the package carrying member (12) is located in the outer chamber (3), and in which the separating member (11) separates the inner chamber (2) from the outer chamber (3), and a second position in which the carrier unit (10) has rotated a package (6) into the inner chamber (2) and in which the separating member (11) separates the inner chamber (2) from the outer chamber (3).

Owner:TETRA LAVAL HLDG & FINANCE SA

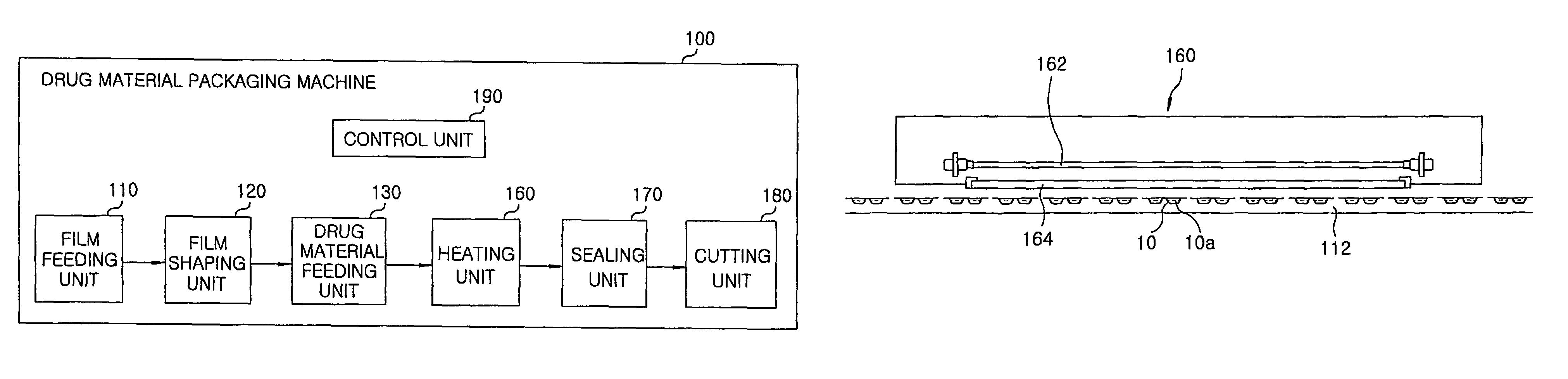

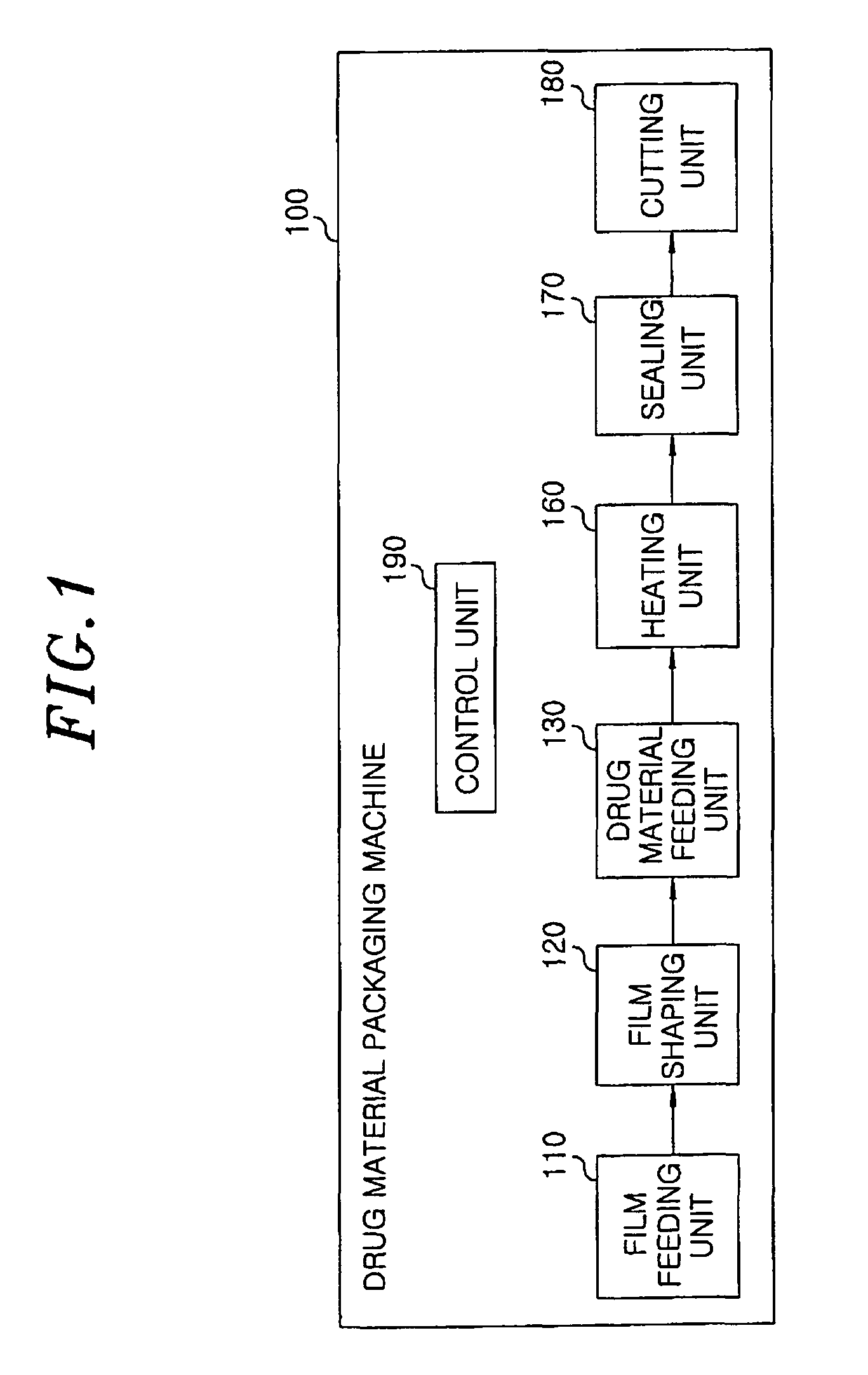

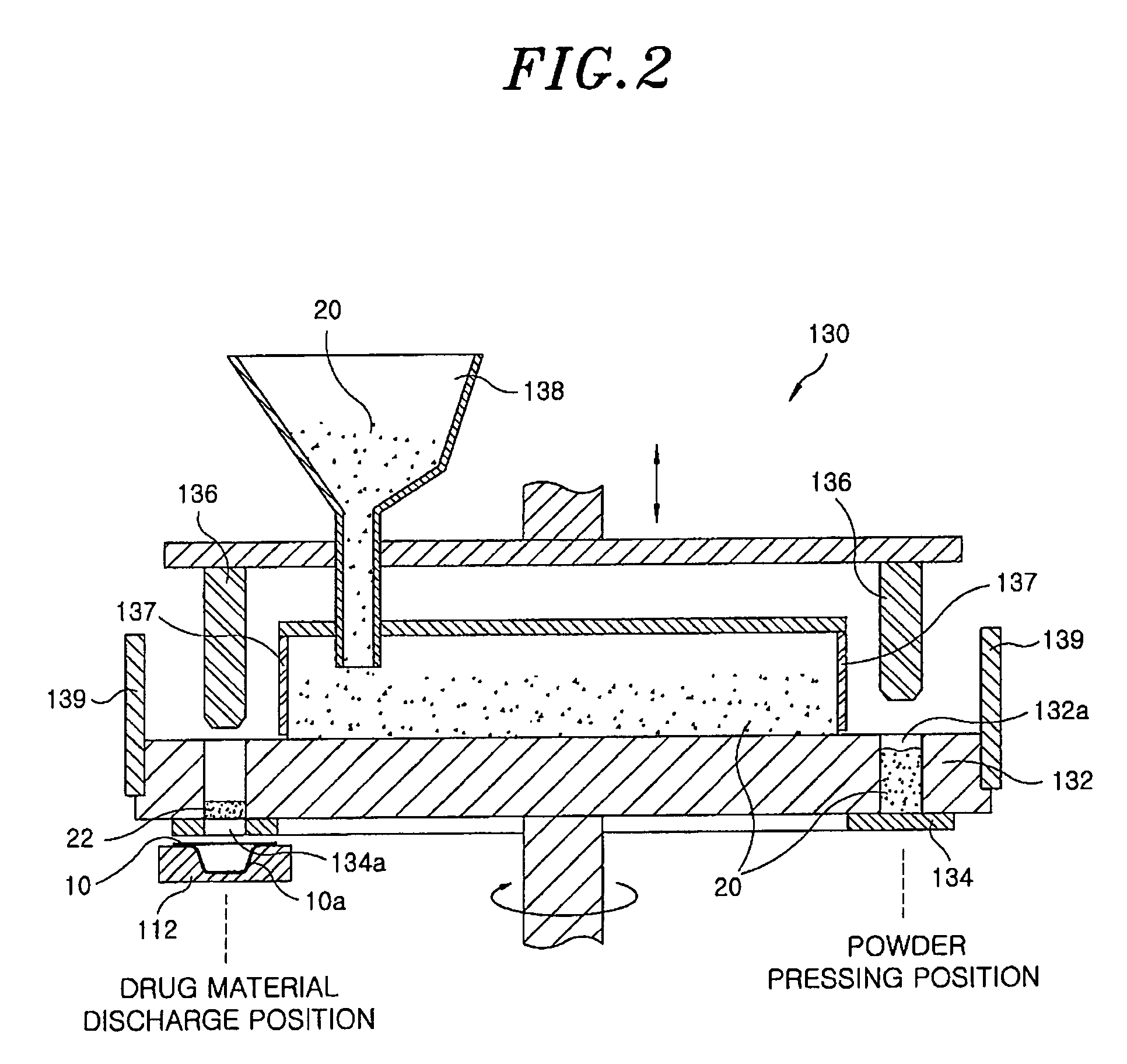

Method for preparing rapidly disintegrating formulation for oral administration and apparatus for preparing and packing the same

InactiveUS8127516B2Disintegrates quicklyEnhanced patient comfortAntibacterial agentsNervous disorderPowder mixtureOral medication

A method and packaging machine for preparing rapidly disintegrating formulations for oral administration are disclosed. The present invention is characterized in that a powdery mixture including a pharmaceutically active ingredient and a sugar or a sugar alcohol powder is filled into a packaging material and, thereafter, the mixture, filled in the packaging material, is heated. The present invention can simply and economically prepare an oral formulation which undergoes rapid disintegration in the oral cavity and provides for high-quality administration to patients.

Owner:HANMI PHARMA

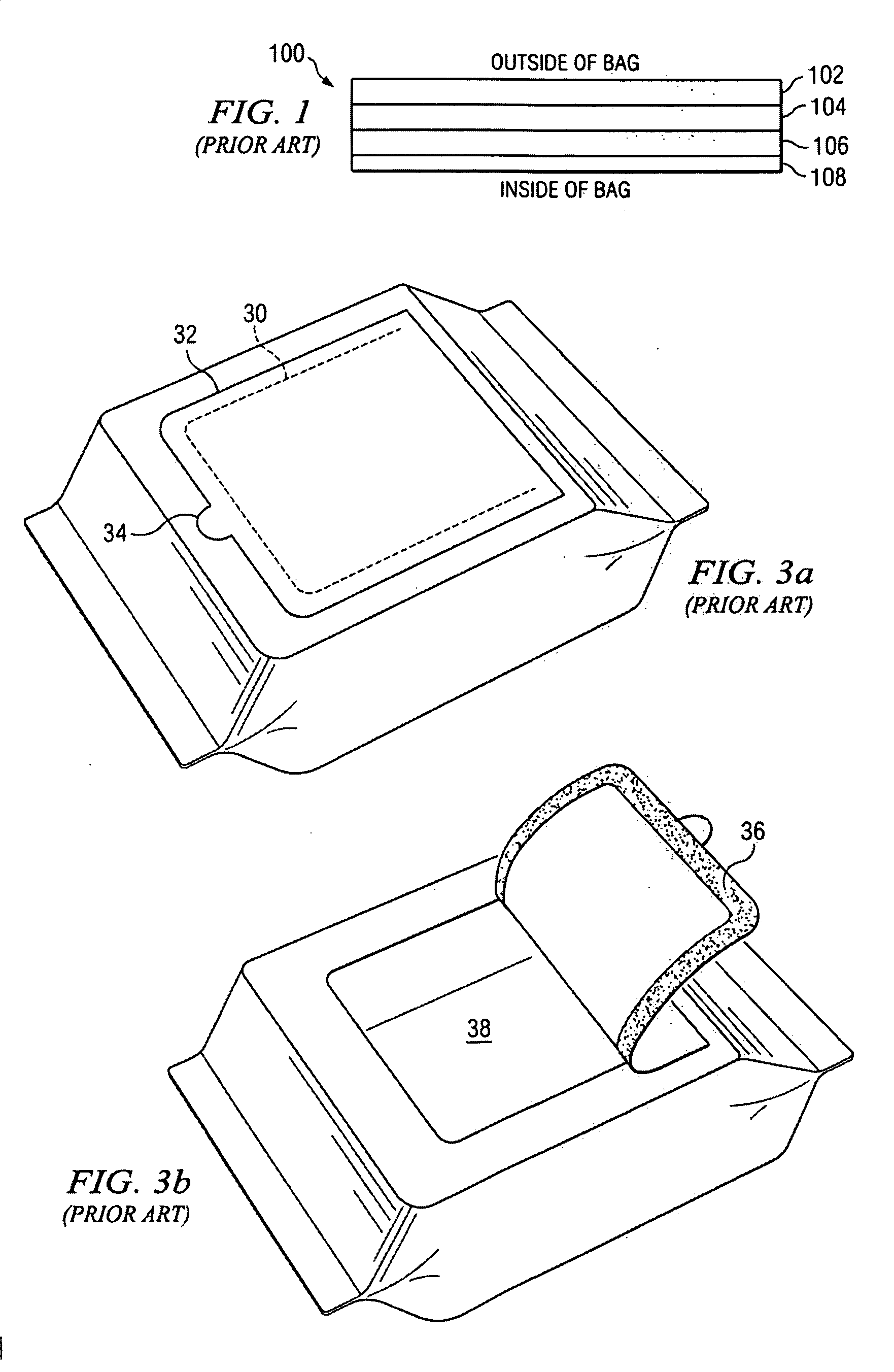

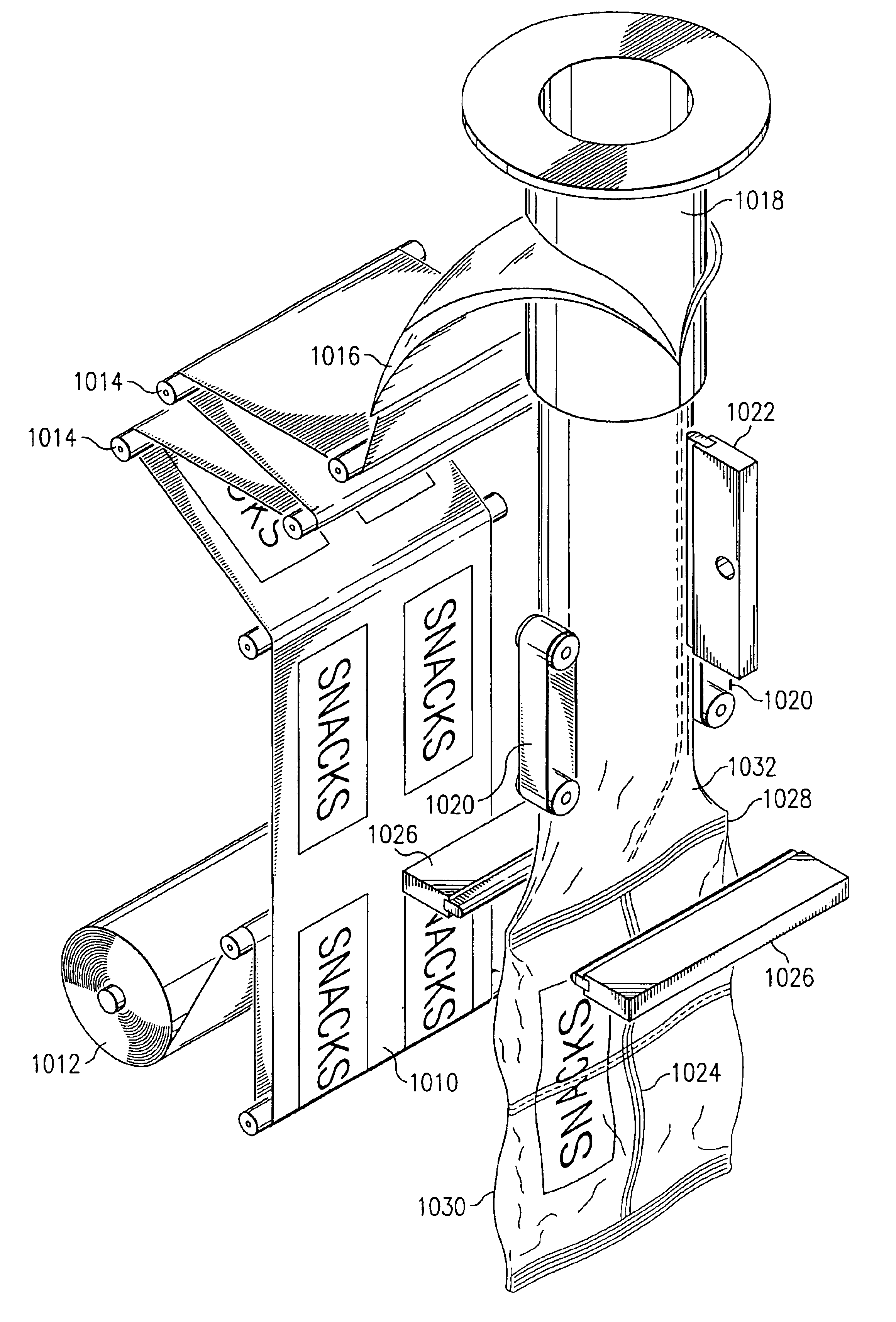

Double-bag package and perforation knife

A double-bag package, and method for manufacturing same, constructed by modification to existing vertical form and fill packaging machines and perforation knives. In a preferred embodiment, the invention involves producing a double-bag package from a single sheet of packaging film by feeding a roll of film having graphics printed sideways rather than vertically into a vertical form, fill and seal packaging machine and using a novel perforating / cutting knife to alternately cut and perforate transverse seals. The perforating / cutting knife has teeth in the shape of oblique triangular pyramids, with each tooth having three cutting edges. The perforating / cutting knife produces self-correcting T-shaped perforation patterns capable of capturing and redirecting errant tears for fail-safe directional separation.

Owner:FRITO LAY NORTH AMERICA INC

Automated solid pharmaceutical product packaging machine

InactiveUS20070084150A1Improve versatilityImprove efficiencyPackaging automatic controlSolid materialPharmaceutical packagingBiomedical engineering

An automated pharmaceutical product packaging machine simultaneously fills a plurality of product package templates in parallel with desired pharmaceutical dosing requirements. The templates are subsequently positioned over a temporary storage template having cavities for receiving solid pharmaceutical doses. A collector member is subsequently placed beneath the temporary storage template for receiving the pharmaceuticals which in turn is positioned over a solid pharmaceutical product package having a plurality of cavities which correspond to openings on the templates and wherein each of the templates fills a pharmaceutical package.

Owner:MTS MEDICATION TECH

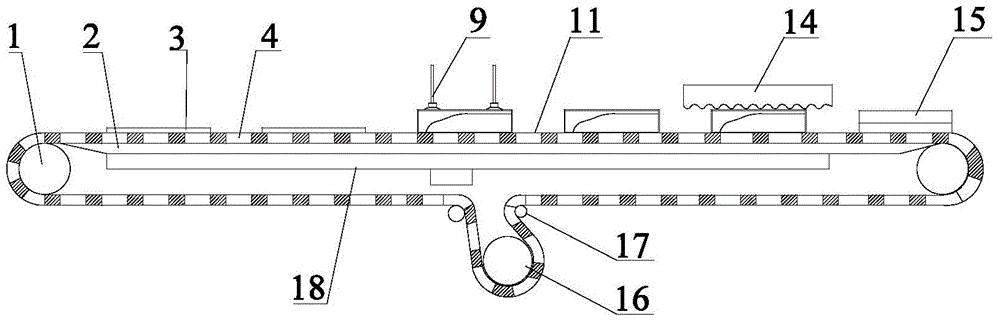

Automatic bagging packing machine

InactiveCN103979151AOptimize locationGood conditionWrapper folding/bending apparatusWrapper twisting/gatheringMaterial supplyPackaging machine

The invention relates to an automatic bagging packing machine. The automatic bagging packing machine comprises a packing matter supplying and conveying device, an absorbing and transmission device, a vacuum bag opening device, a leading-in type filling device and a side folding, exhausting and opening sealing device; a vacuum absorbing and bag opening device comprises a bag opening mechanism and a bag supporting and blowing mechanism; the material supplying and conveying device is arranged in parallel with the absorbing and transmission device; the absorbing and transmission device works by the vacuum absorbing and dynamic transmission mode; the vacuum absorbing and bag opening device and the side folding, exhausting and opening sealing device are arranged above the absorbing and transmission device; the leading-in type filling device is arranged above the packing matter supplying and conveying device. According to the automatic bagging packing machine, the intermittent packing and transmission mode is performed; the mechanical structures with a plurality of functions like absorbing and bag supplying, bag opening, bag supporting and blowing, leading-in type filling, and side folding, exhausting and opening sealing are integrated; the automatic bagging packing machine is novel in design, unique in structure, compact in processes, wide in product package applicability, high in packing quality, and high in production efficiency.

Owner:JIANGNAN UNIV

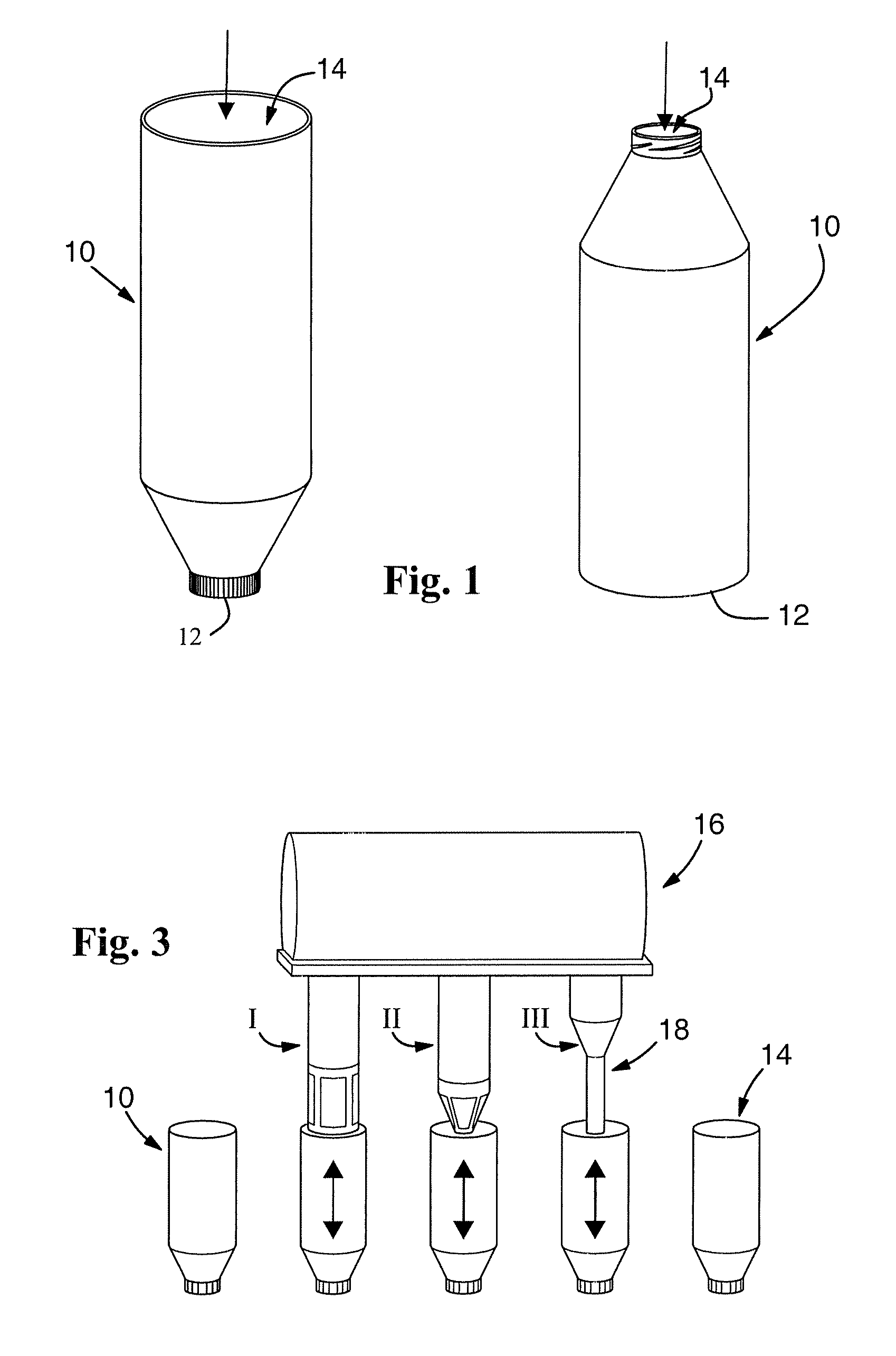

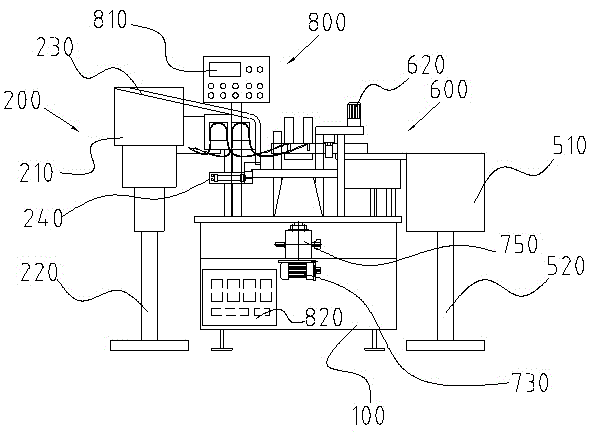

Automatic bottle feeding, filling, corking and capping integrated packaging machine

The invention discloses an automatic bottle feeding, filling, corking and capping integrated packaging machine which comprises a rack main body, a bottle arrangement and feeding system for arranging a bottle and placing the bottle on a bottle feeding station, an automatic filling system for filling the bottle on a filling station with a required material, an inner cork arrangement and corking system for pressing an inner cork in a bottle opening on a corking station, a bottle cap arrangement and capping system for capping the corked bottle opening on a capping station with a bottle cap, a cap twisting system for twisting the bottle cap arranged on the bottle opening on a cap twisting station on the bottle opening, a conveying system and a control system positioned in the rack main body. The automatic bottle feeding, filling, corking and capping integrated packaging machine is easy to operate, the great convenience is brought to a user, a product is high in quality consistency, and the systems and the mechanisms are compact and high in working efficiency, and sequentially act; the manual operation is replaced by the systems and the mechanisms, so that the risk of pollution is avoided.

Owner:GUANGZHOU BEAUTY STAR CO LTD

Vacuum belt assembly to drive tubular bag material

A vacuum belt assembly (10) to drive tubular bag material (11) through a packaging machine. The assembly (10) includes three belts (19, 20, 21) with the belts (19, 20, 21) being driven by rollers (22). The belts (20, 21) have respectively lengths (28, 29) being located in planes inclined by an angle greater than 0° but less than 180°, preferably an obtuse angle.

Owner:TNA AUSTRALIA

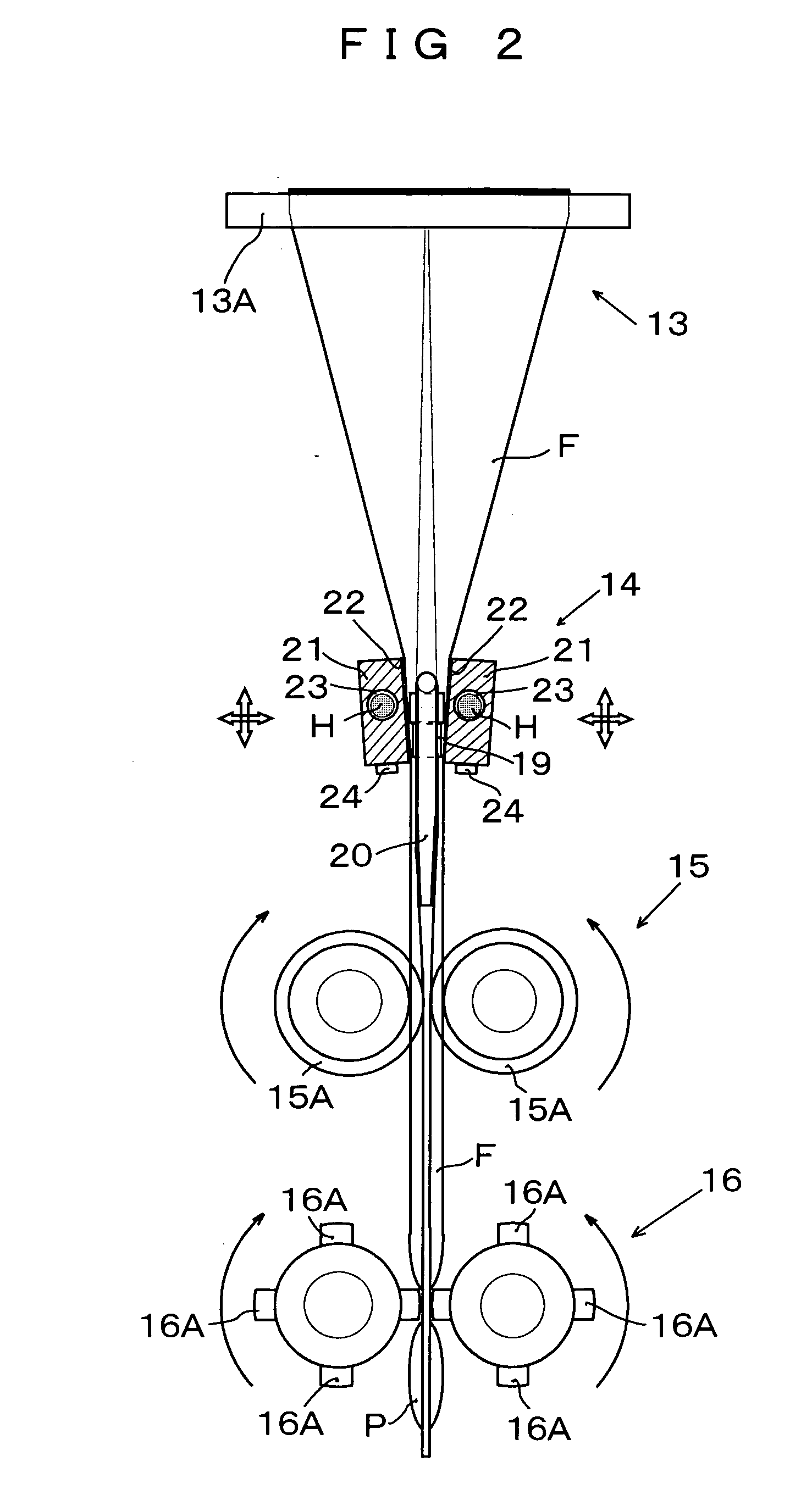

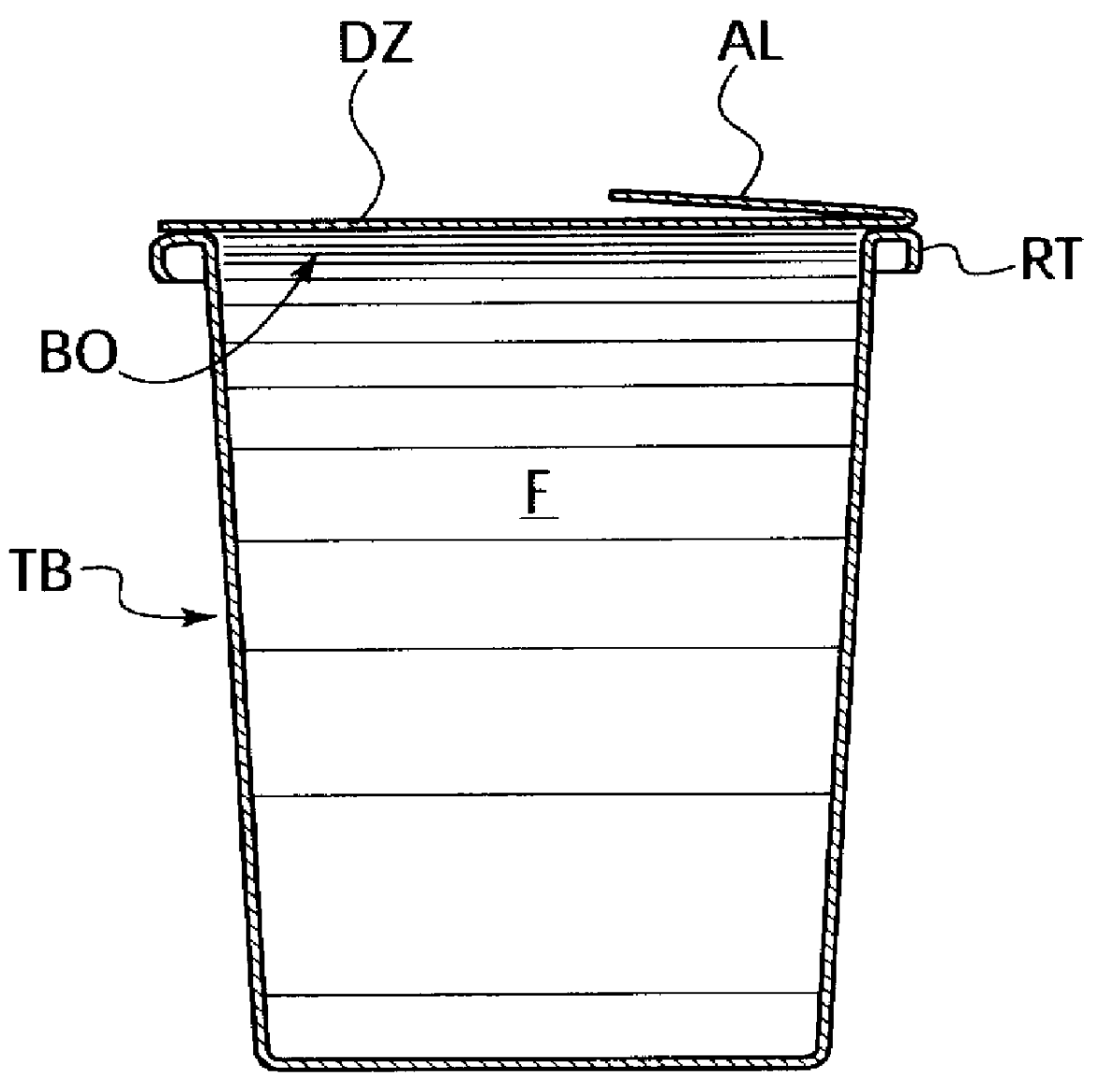

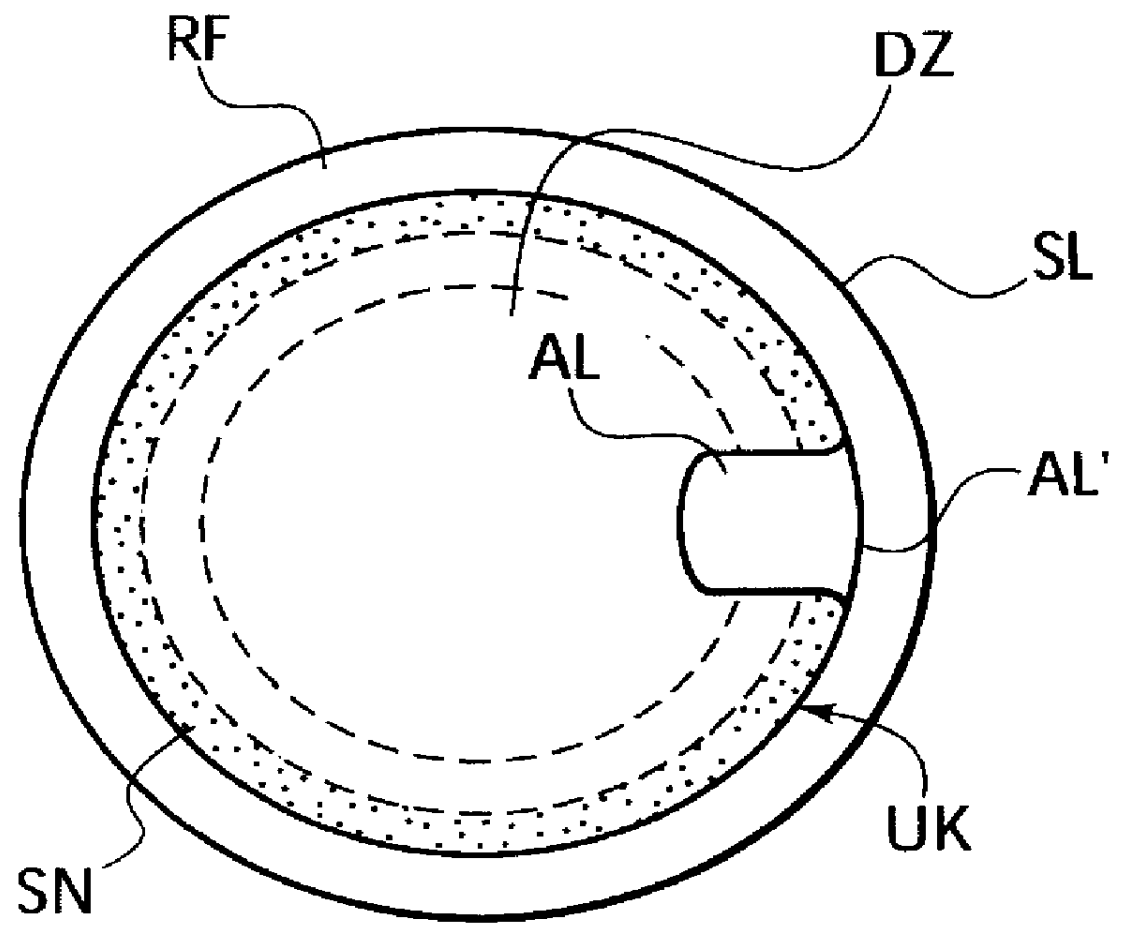

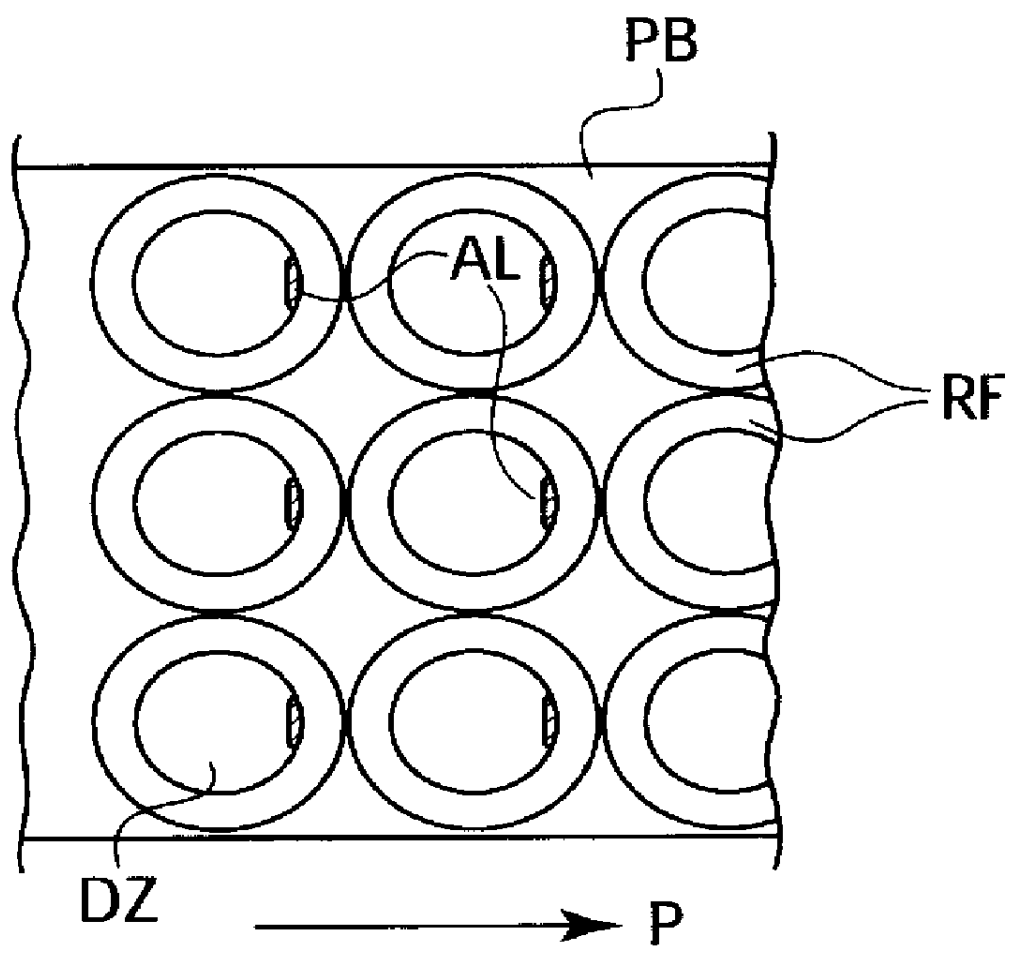

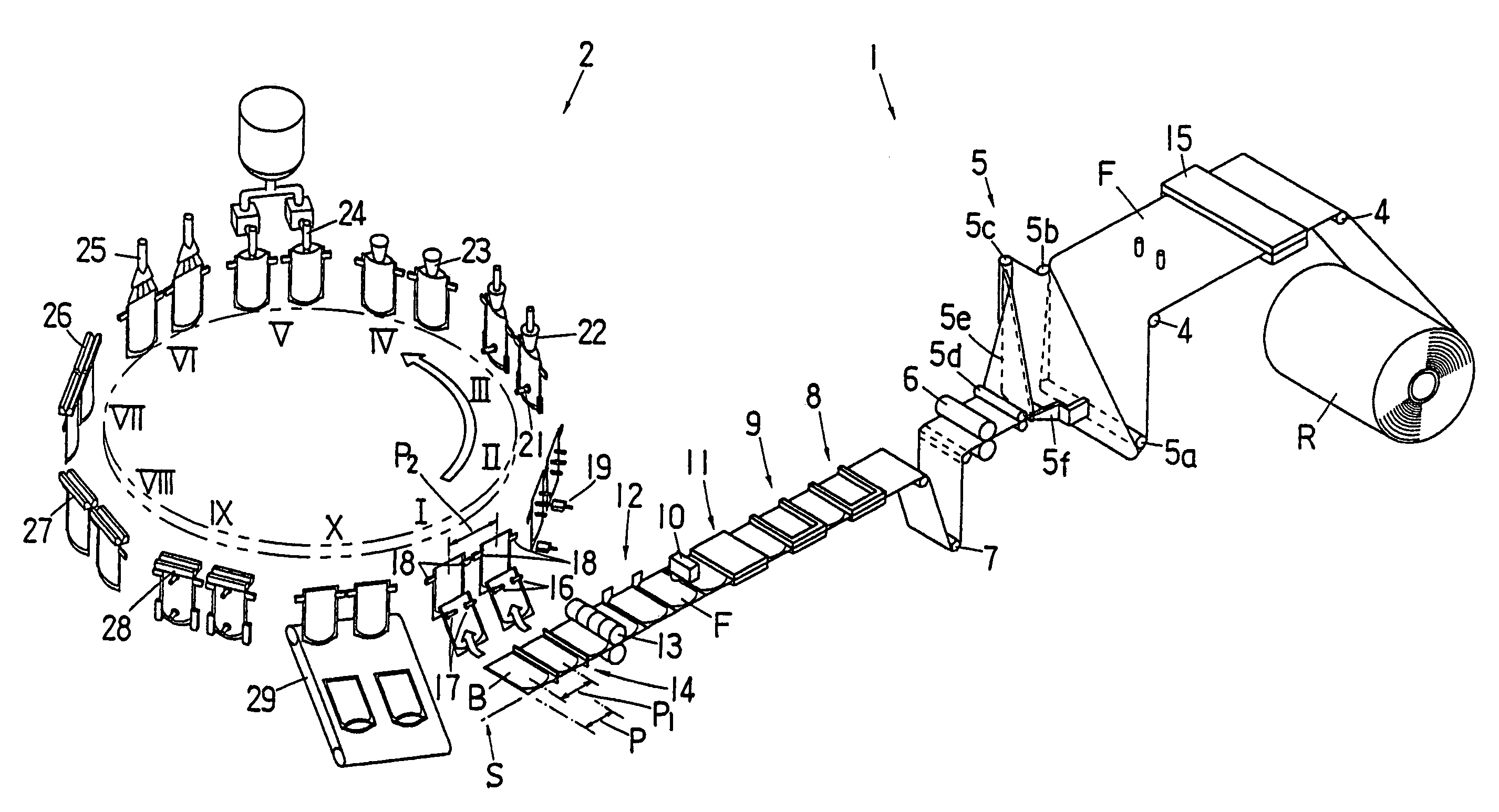

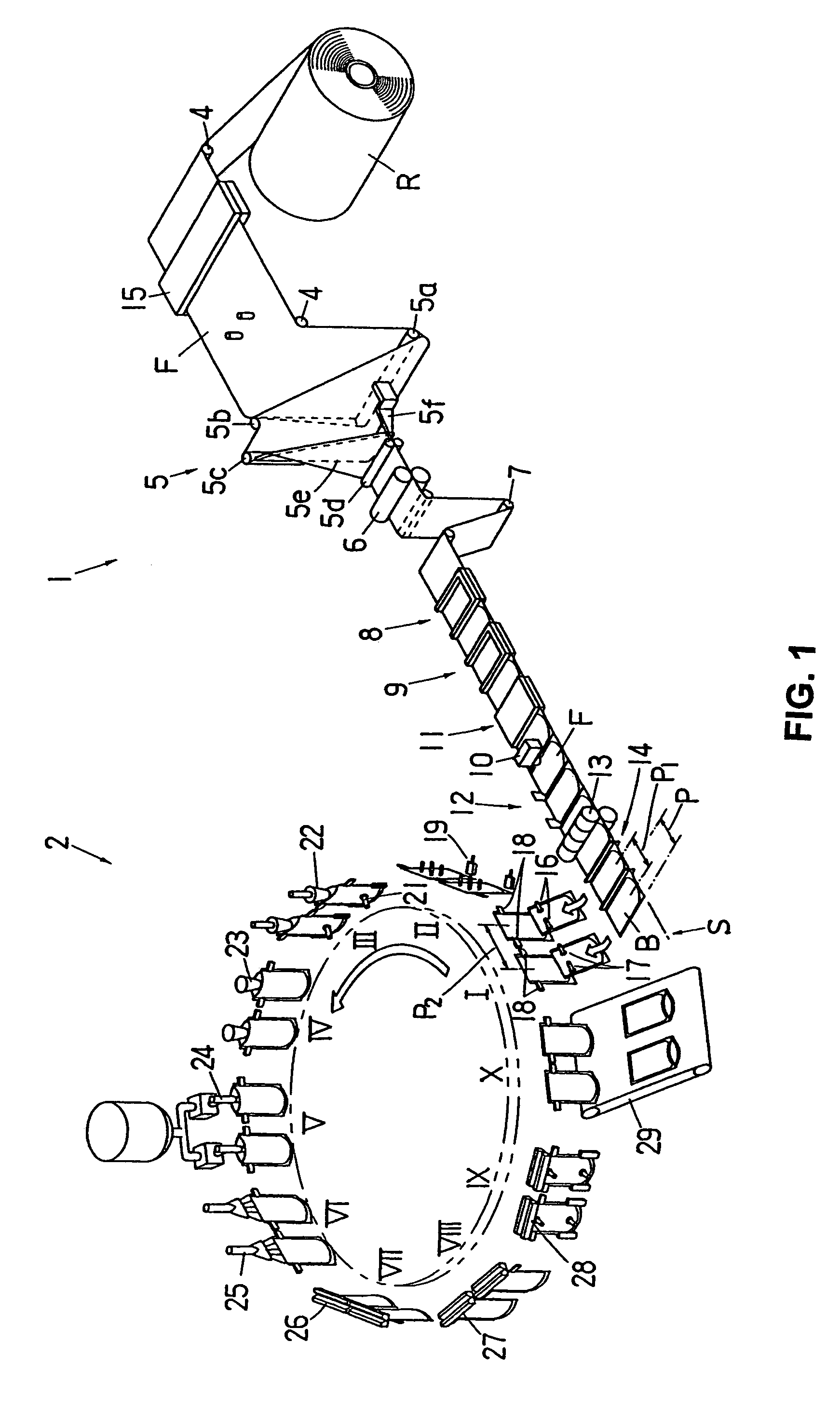

Bag-making and packaging machine

InactiveUS7021036B2Easy to handleEnvelopes/bags making machineryBox making operationsThin membraneEngineering

A bag-making and packaging machine including a bag-making apparatus 1, a bag-filling (packaging) apparatus 2, and a bag transfer apparatus. The bag-making apparatus 1 of a bag-making and packaging machine, while releasing a film F from a film roll disposed in the horizontal direction and feeding the film lengthwise, folds and overlaps the film in two in a horizontal attitude, performs sealing in locations corresponding to the bag bottom portions and side portions of the film in the horizontal attitude, and separates bags by cutting. The line corresponding to the bag bottom ends of the folded and overlapped film F (this position indicated by S) is set in the same position regardless of the bag length, and the respective apparatuses such as the forming apparatus 5, sealing apparatuses 8, 9 and 11, and cutting apparatus 14, etc. are disposed with reference to this position.

Owner:TOYO JIDOKI CO LTD

Materials packing machine

InactiveCN1736801AImprove packaging qualityImprove work efficiencyWrapping material feeding apparatusWrappingMaterials sciencePackaging machine

Disclosed is a material packing device, which contains a film feed device, a charging device and a packaging film forming enveloping device, and is characterized in that: said film feed device contains a film cutting mechanism; said packaging film forming enveloping device contains a packaging film supporting board fixed on the stand, the supporting board being equipped with material through-holes, all shapes and dimensions of which match with pre-packaging material; and the packaging film forming enveloping device contains a packaging film former above the material through-hole, a material fixing clamping part and material pushing part above the packaging film former, a group of material floor packaging hands and a scalding enveloping plate for enveloping packaging film of material floor between the packaging film former and the material clamping part, and a material lifting part which can send the material to material fixing clamping part from below the packaging film supporting board; the material fixing clamping part and material pushing part which moves vertically. The device can complete automatically the packaging of material, especially the rectangle material, the packaging quality perfect and stable, and the work efficiency high.

Owner:汕头市金海湾包装机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com