Full-automatic bag-feeding type packaging machine

A fully automatic packaging machine and bag feeding technology, which is applied in packaging, transportation packaging, transportation and packaging, etc. It can solve the problems that it is not easy to align the mouth of the film bag, the process cannot be completed, and the bag cannot be opened.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

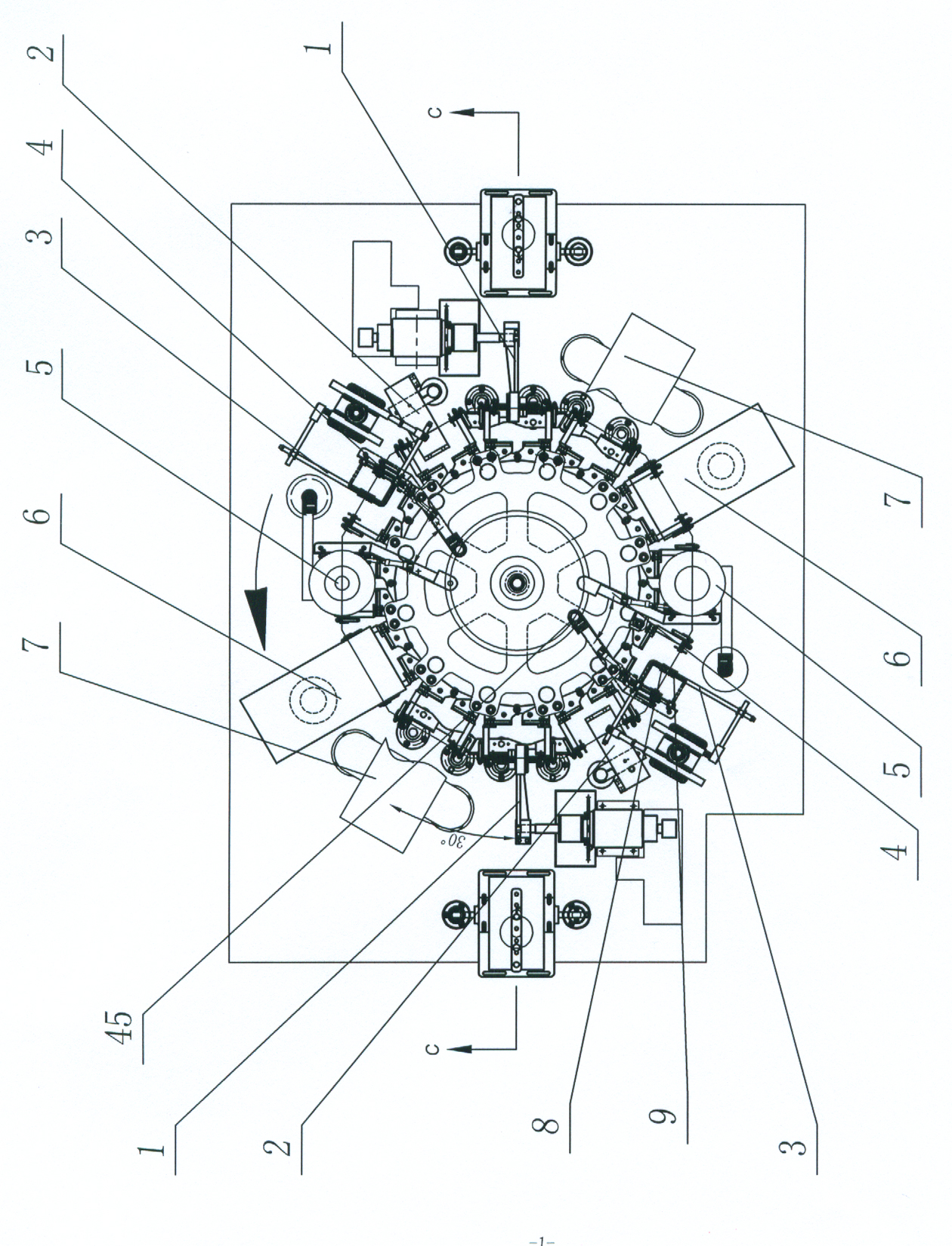

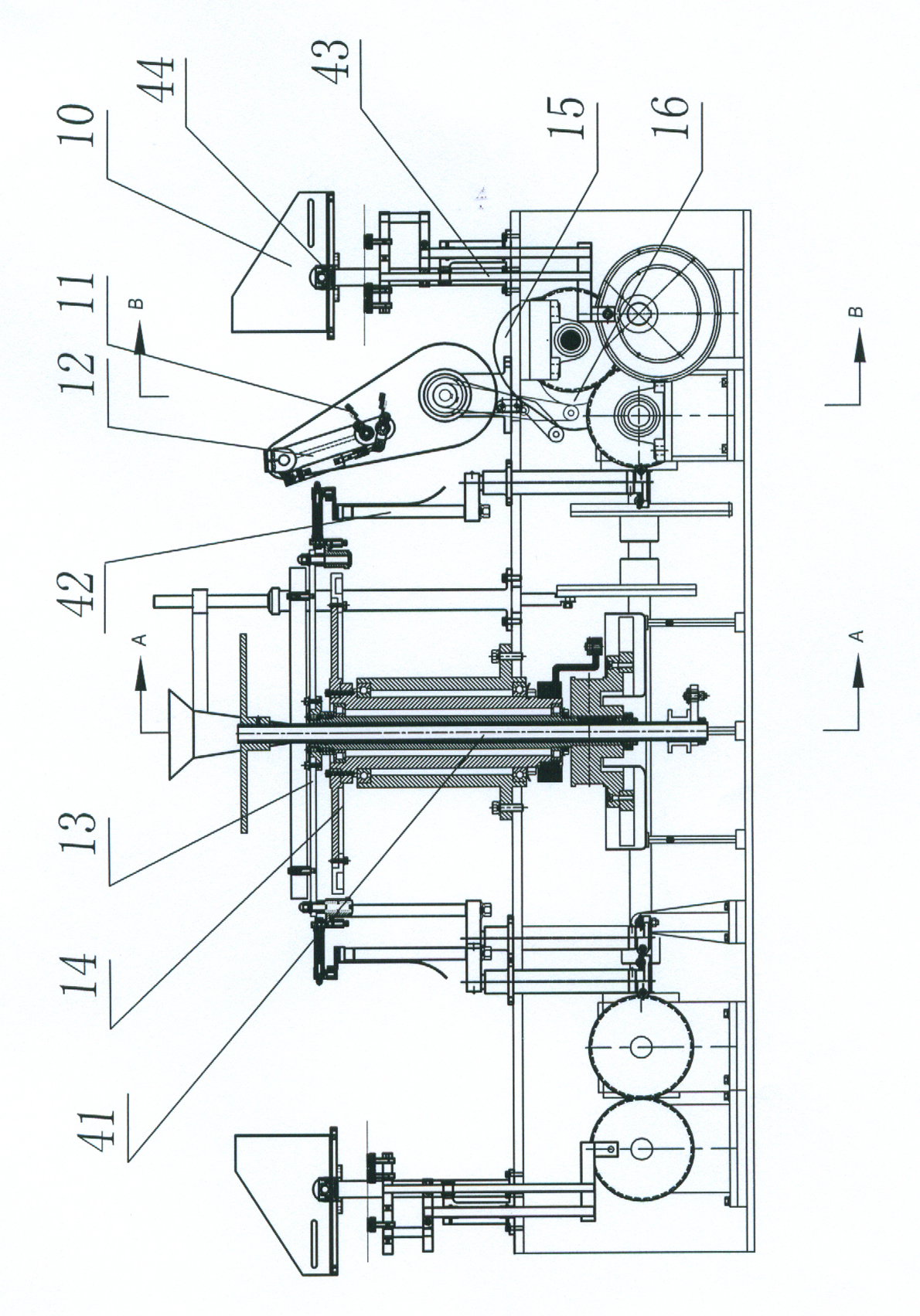

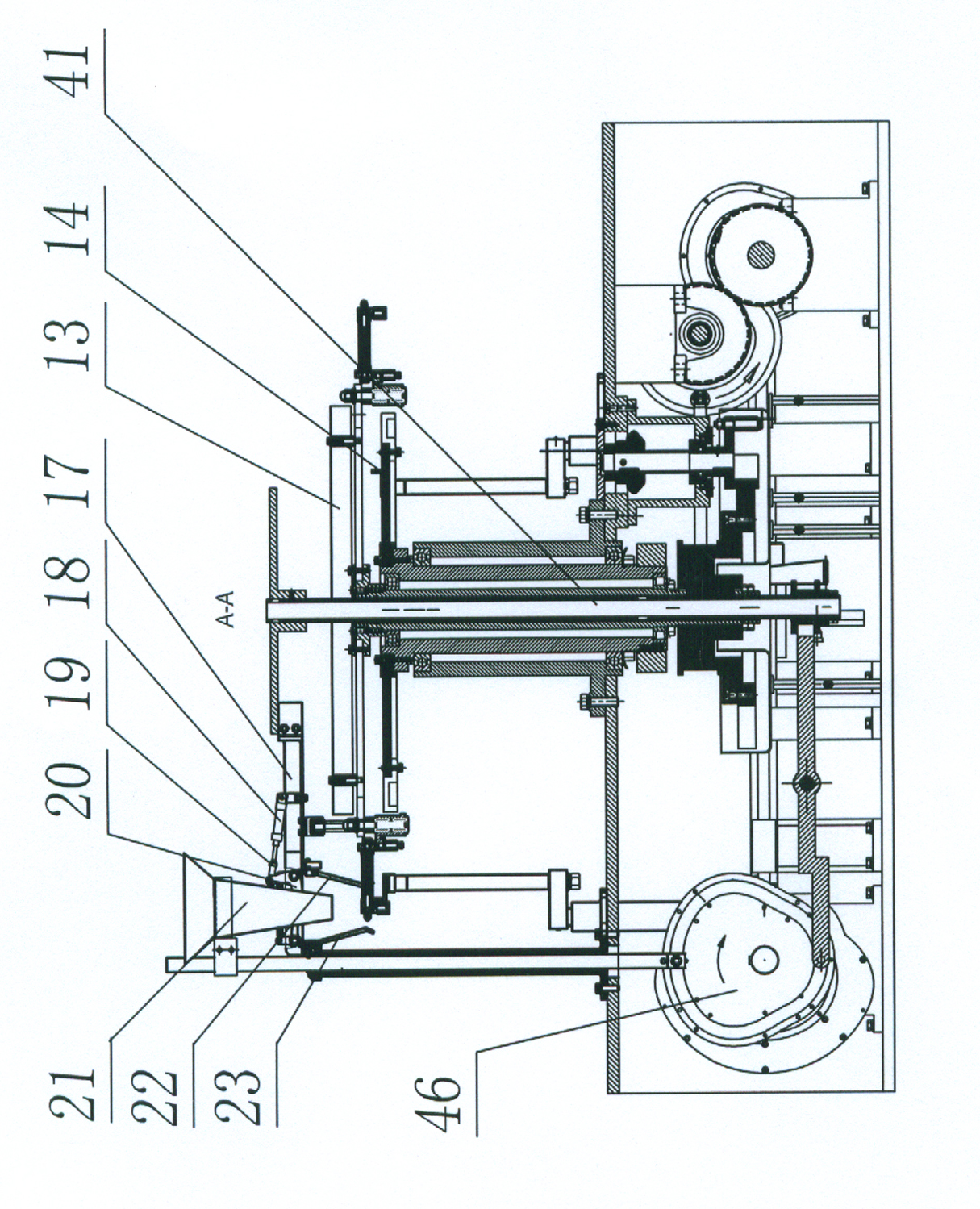

[0019]Referring to the accompanying drawings, this bag-feeding type automatic packaging machine includes a turntable 13, a large cam 14, a bag loading device 1, a coding device 2, a bag opening device 3, a feeding device 5, a heat sealing device 6, and a bag unloading device. 7 and the bag supporting device 4, the turntable 13 is fixedly installed on the main shaft 41 of the packaging machine, the large cam 14 is installed below the turntable 13, and is sleeved on the main shaft 41, the turntable 13 The bag clamping device 39 is evenly arranged on the edge of the carousel, and the bag loading device 1, coding device 2, bag opening device 3, feeding device 5, heat sealing device 6 and bag unloading device 7 are all set on the outside of the turntable 13 , the bag-holding device 4 is movably installed on the turntable 13, and how to move will be described below. The bag loading device 1, coding device 2, bag opening device 3, feeding device 5, heat sealing device 6 and bag unloa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com