Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8876 results about "Knife holder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

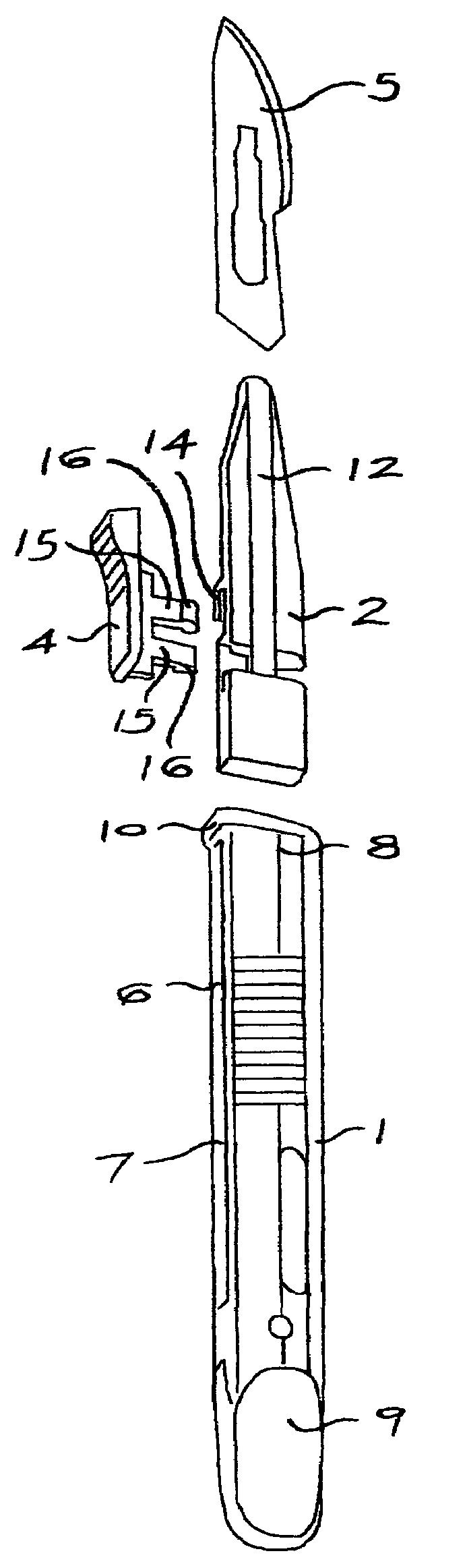

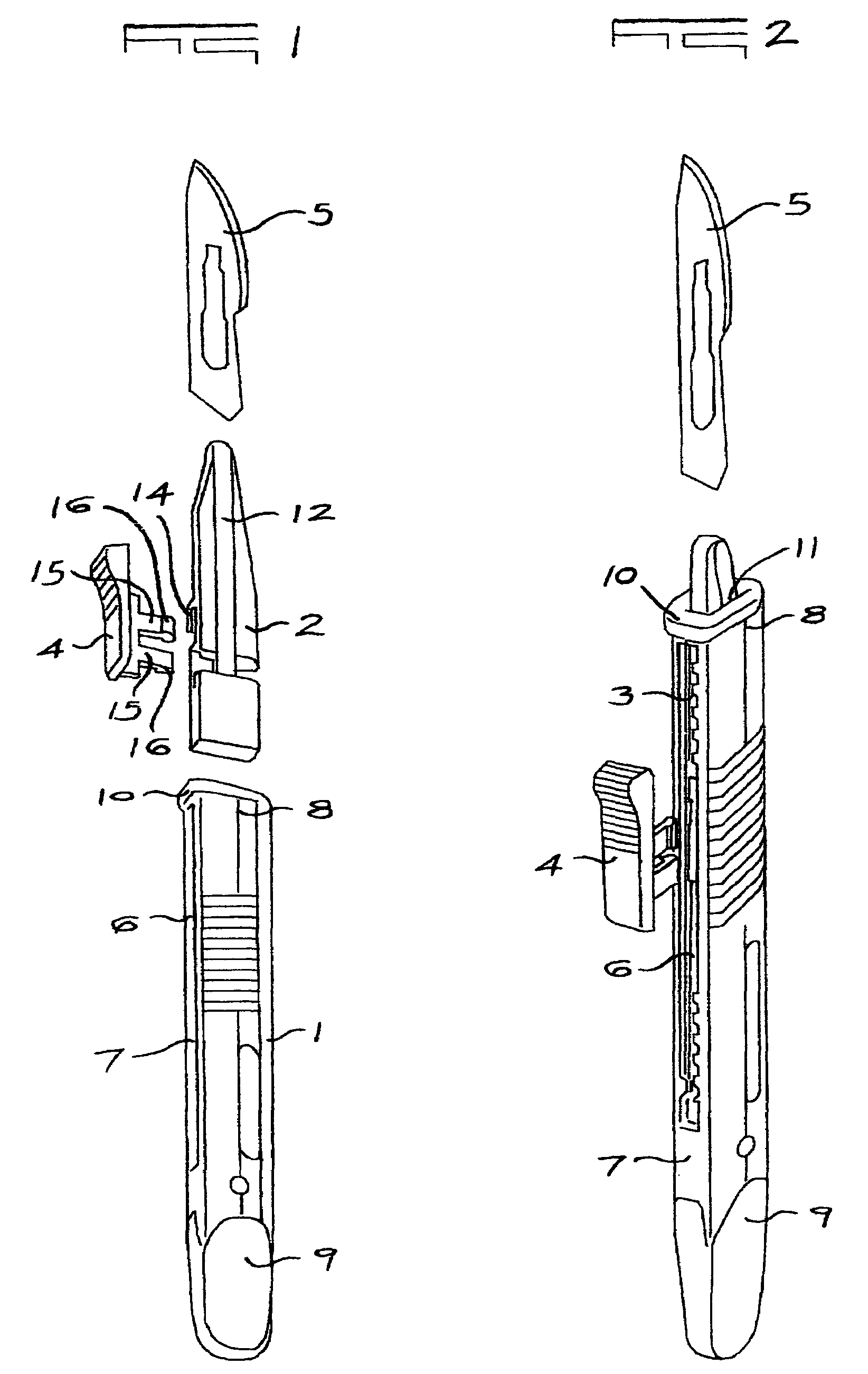

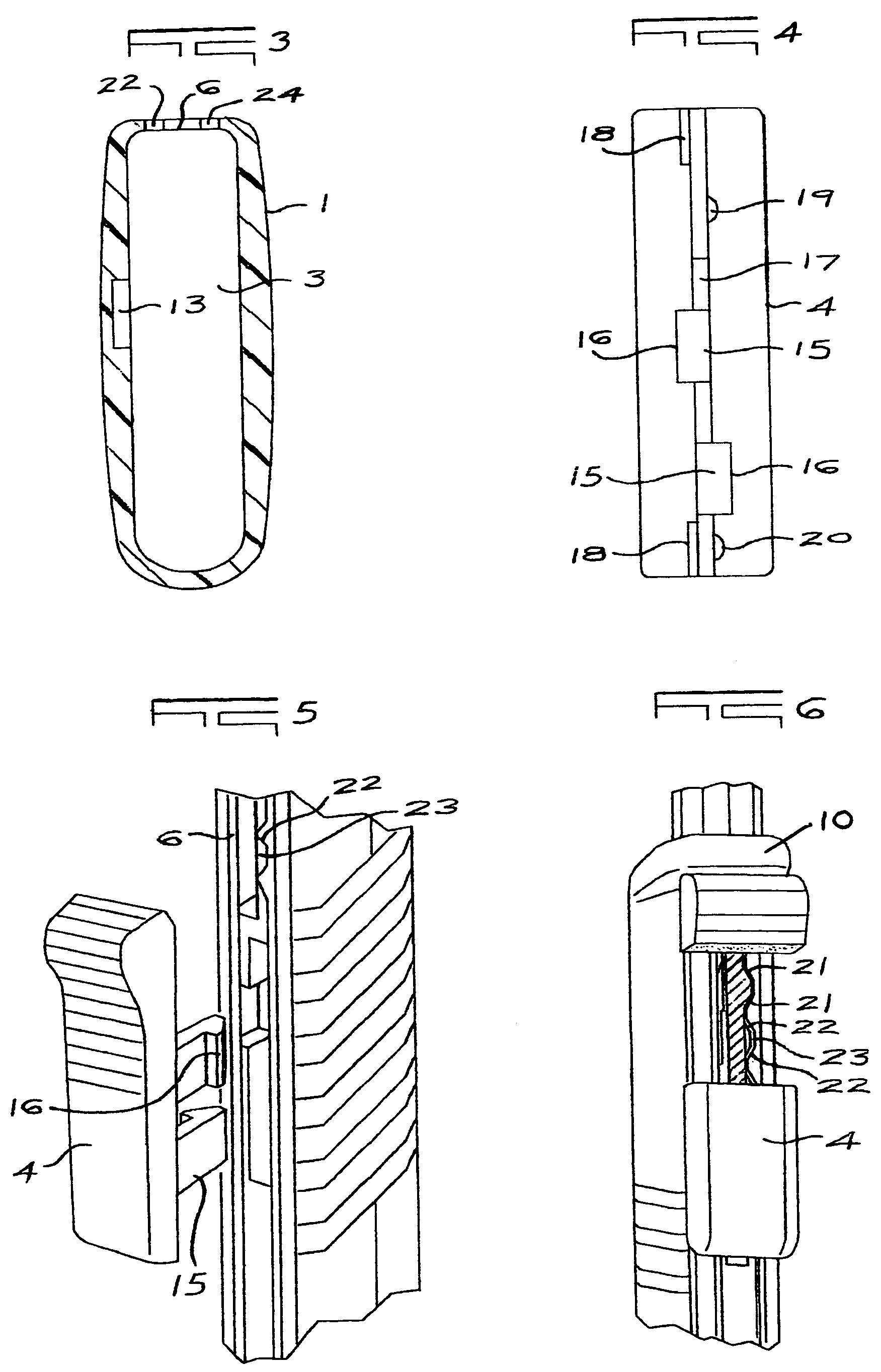

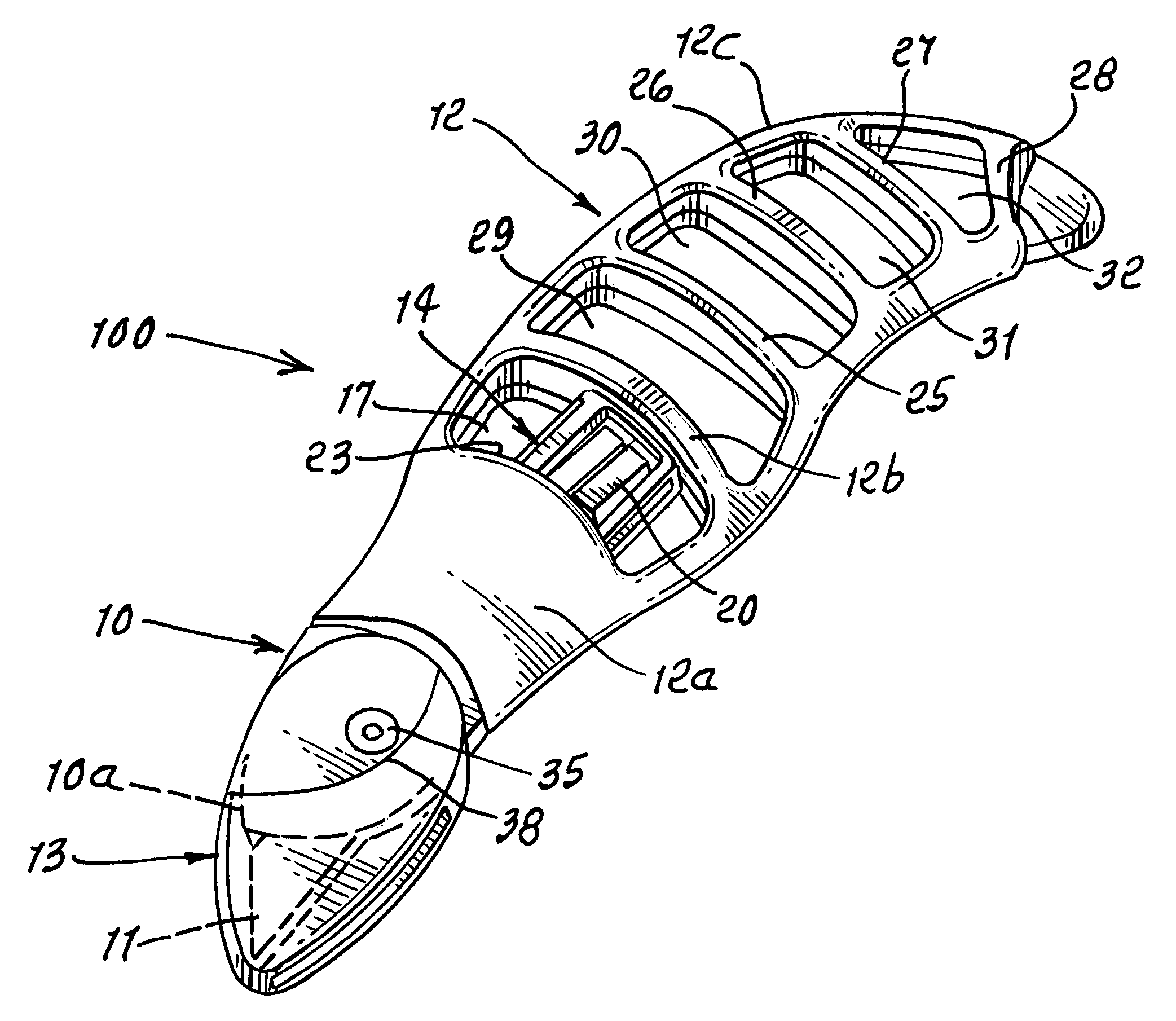

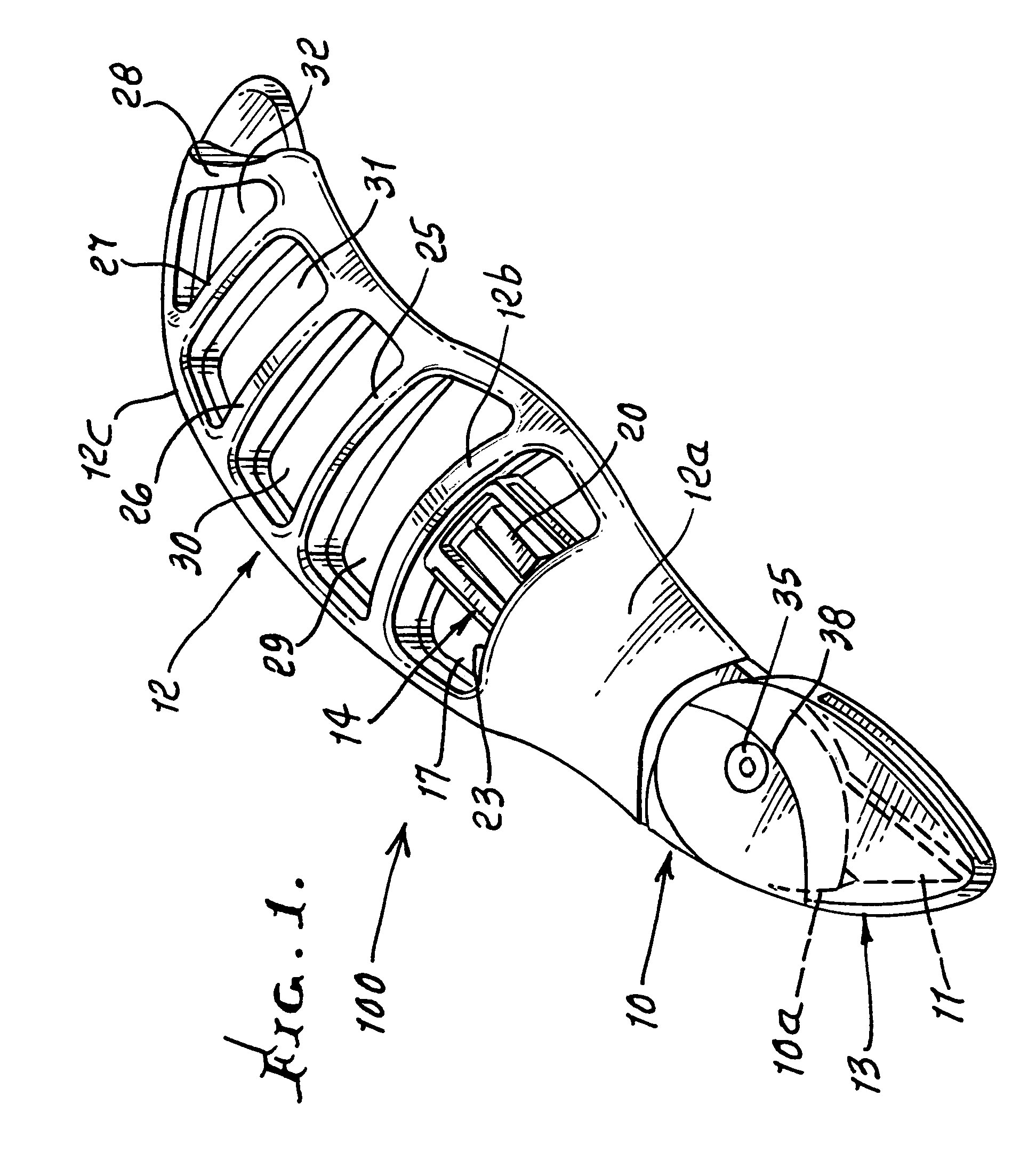

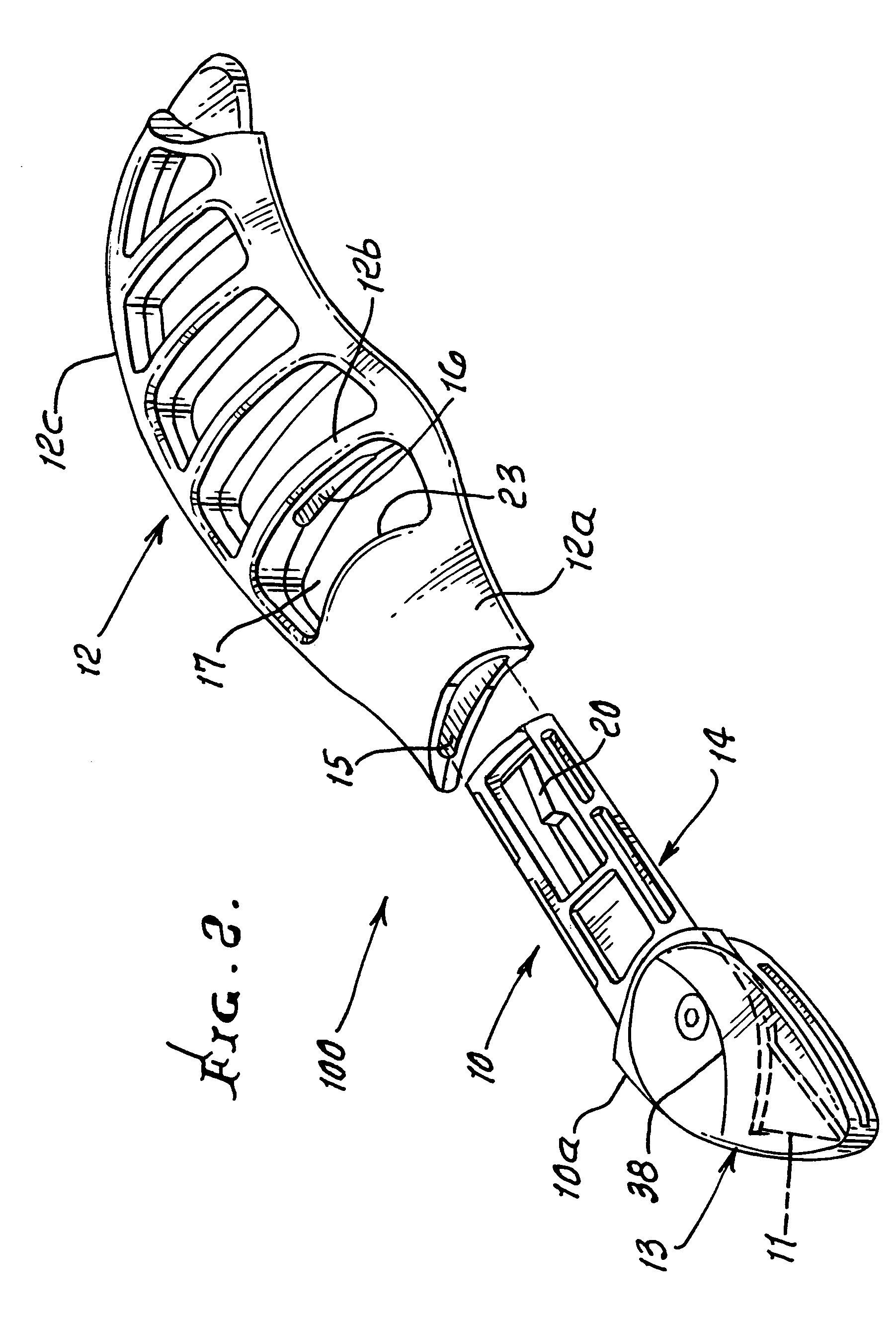

Disposable scalpel with retractable blade

A scalpel is provided having a handle with a longitudinally extending cavity therein, a blade carrier within the cavity and movable longitudinally relative to the handle between an operative position in which a blade carried thereby is exposed for use at an open end of the cavity and an inoperative position in which a blade carried thereby is retracted within the cavity in the handle, and a manually operable slider associated with the blade carrier and passing through a slot in a wall of the handle at an edge thereof, herein termed the top edge. The handle is moulded as a single piece moulding with an integral bridge defining an endless open end to the cavity through which the blade carrier is introduced into the cavity. The slider is formed as a separate part that snap fits to the blade carrier after its introduction through the open end of the cavity to form a blade carrier and slider assembly. “Click stops” are provided in the operative and inoperative positions by tooth and notch formations on the slider and slot. A final innermost permanently locked position is also preferably provided.

Owner:MILTON TREVOR JOHN

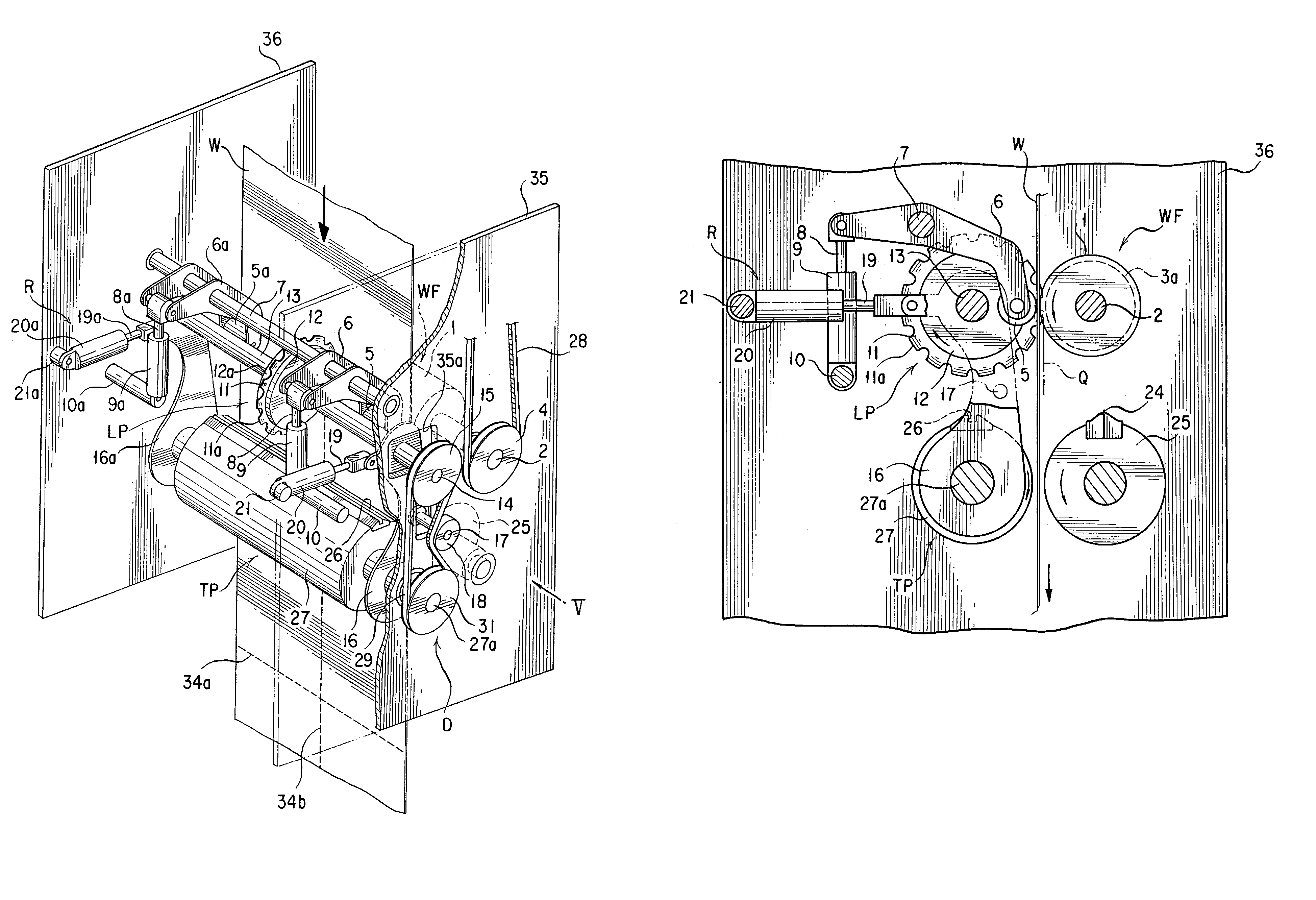

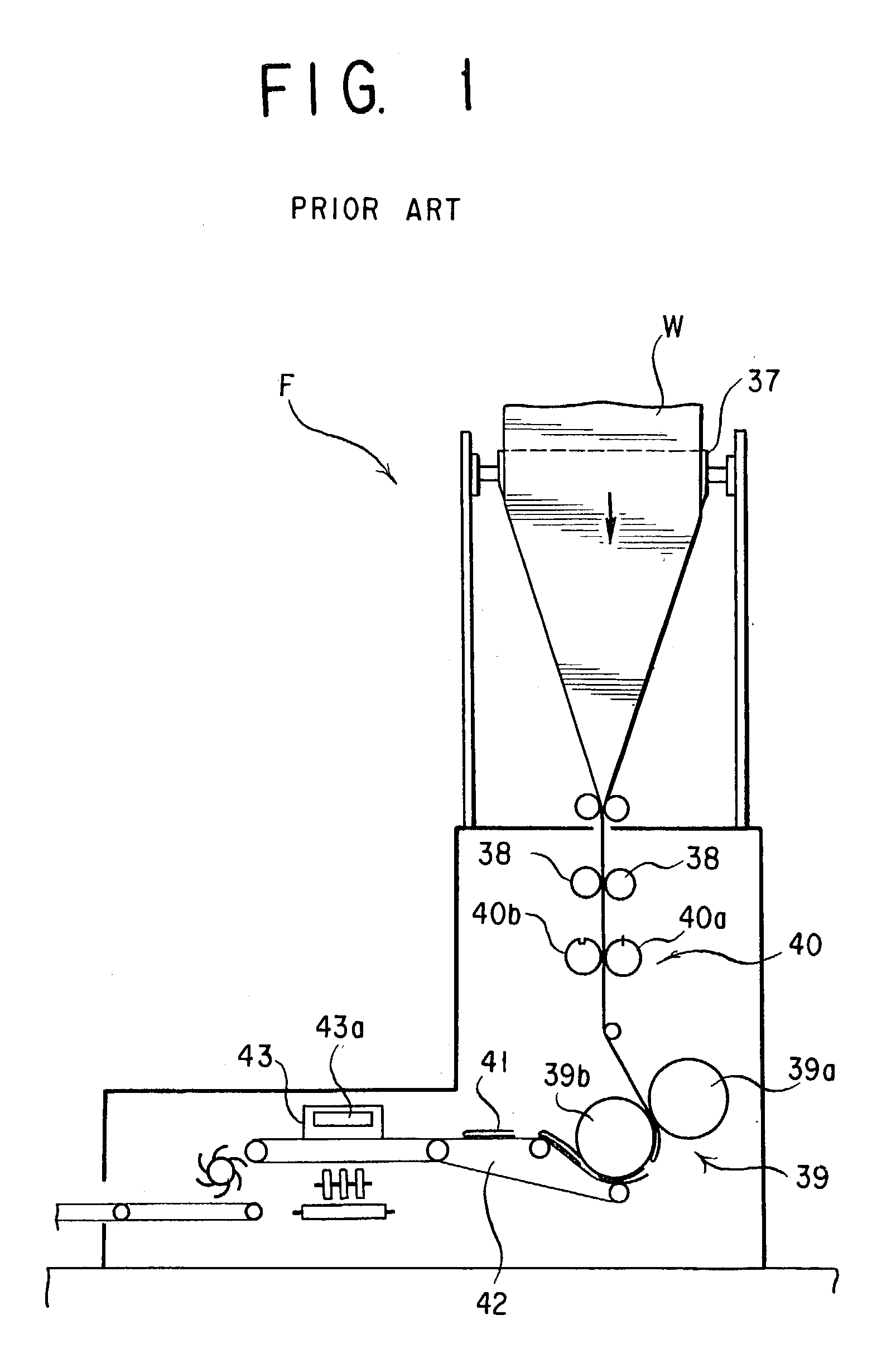

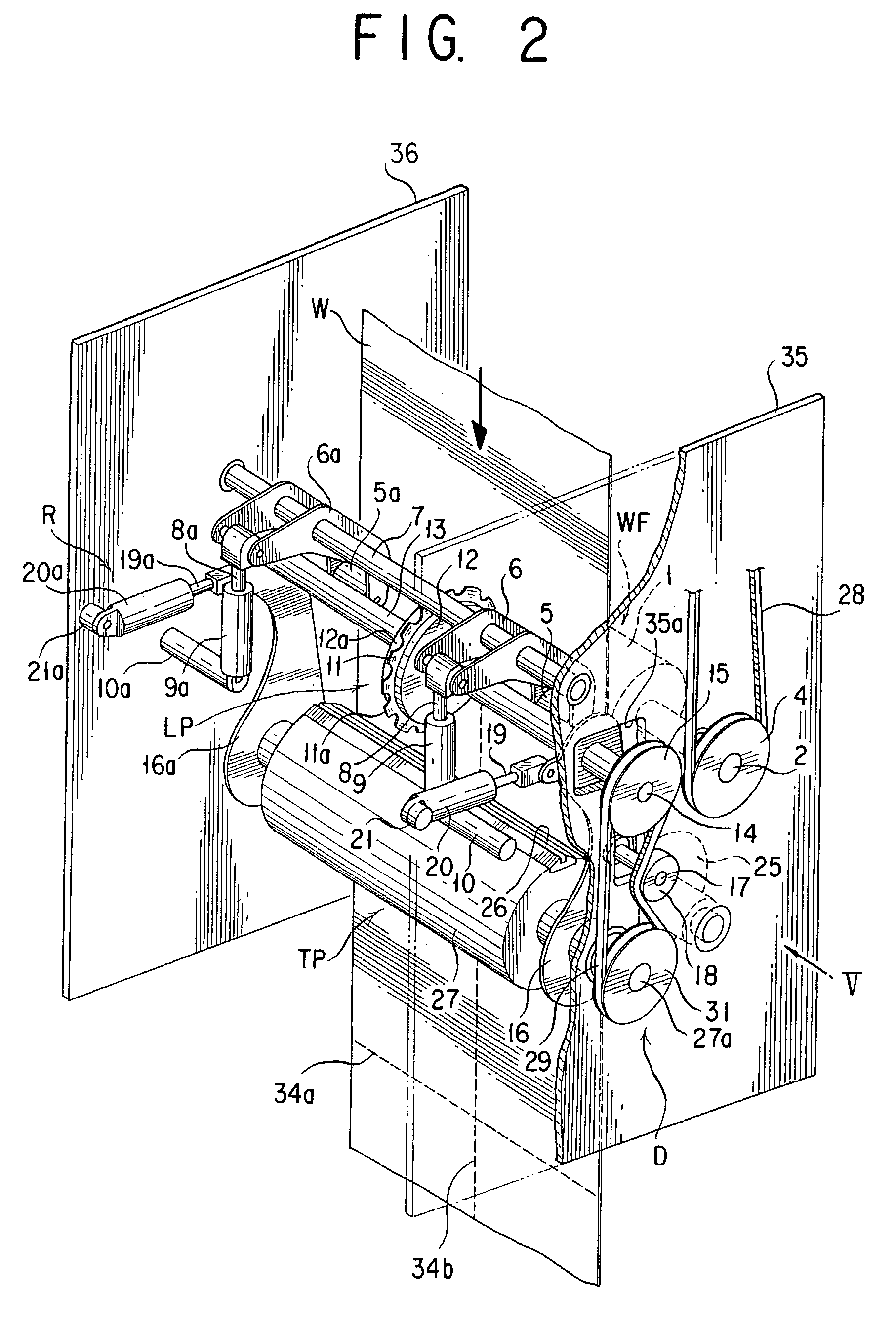

Apparatus for longitudinally perforating a web of paper in a rotary printing press

A rotary printing press has a folding station where the printed web is perforated both transversely and longitudinally in order to expedite subsequent folding thereof into signatures. In order to incorporate a longitudinal perforator into the folding station without adding to its size, a longitudinally perforating blade similar to a circular saw is mounted to a blade carrier shaft which is rotatably supported opposite a feed roller by which the web is frictionally fed into and through the folding station. An annular, longitudinally grooved anvil is formed circumferentially on the feed roller for engaging the longitudinally perforating blade via the web being thereby perforated. The longitudinally perforating blade is movable with the blade carrier shaft into and out of perforating engagement with the anvil on the feed roller.

Owner:TOKYO KIKAI SEISAKUCHI LTD

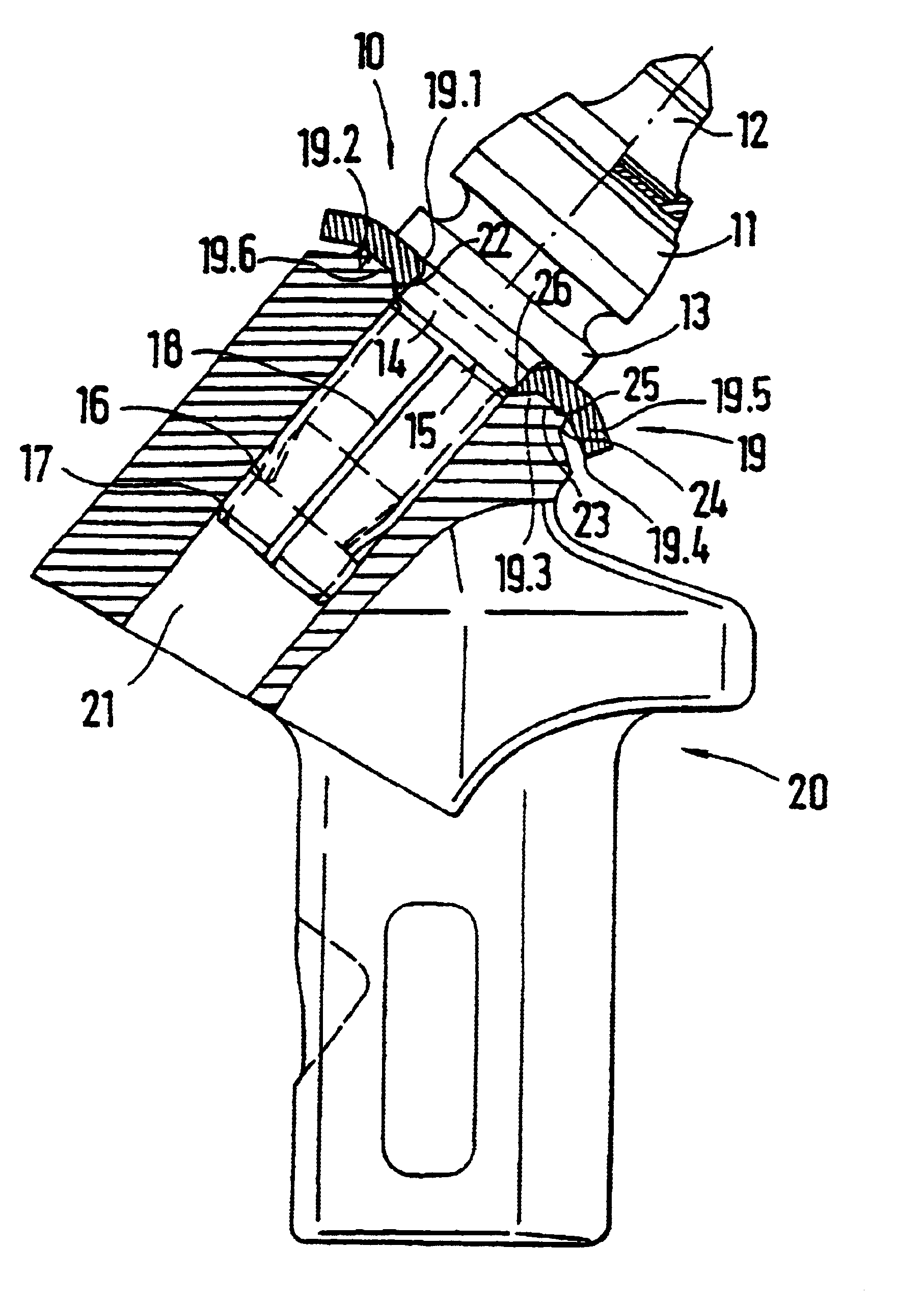

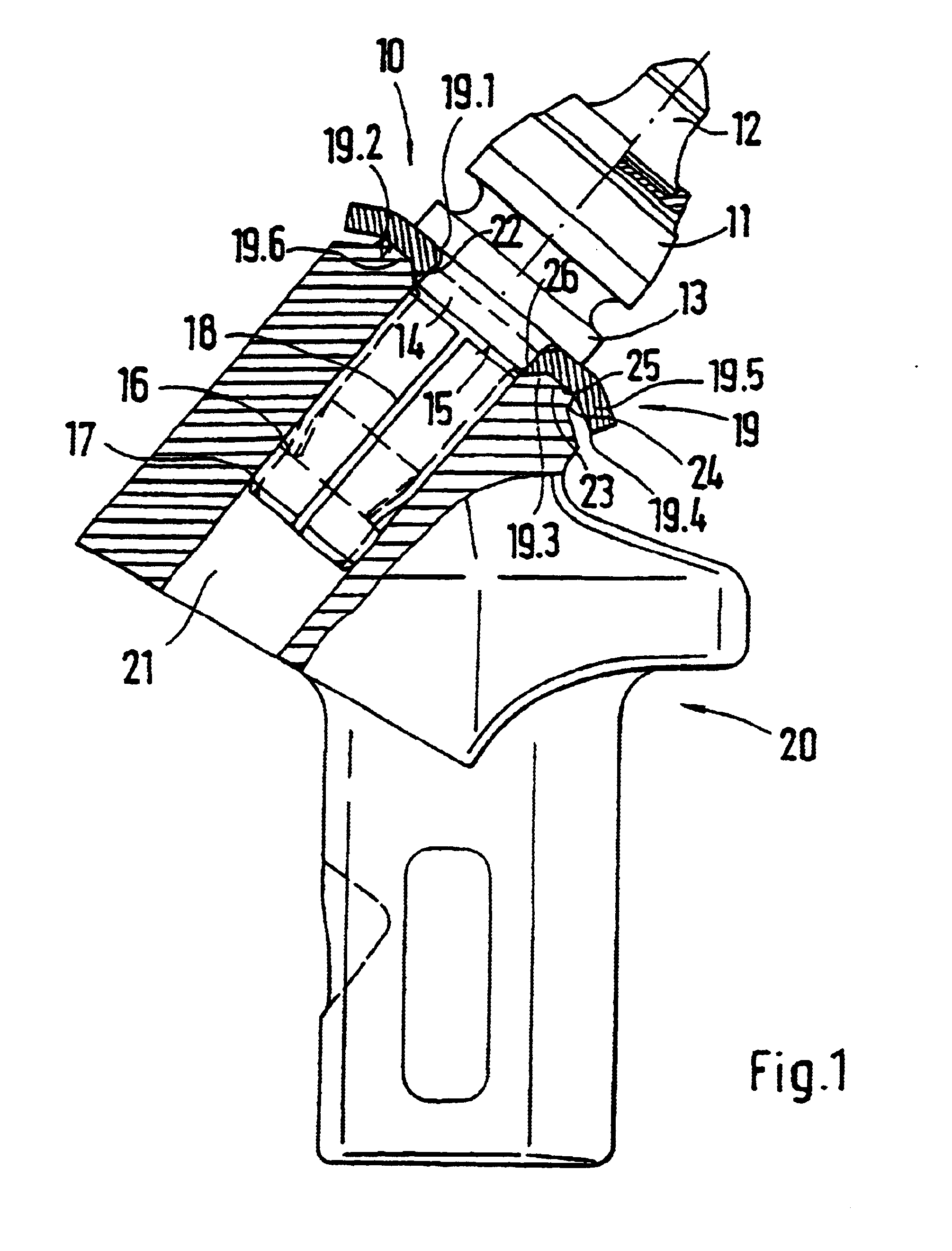

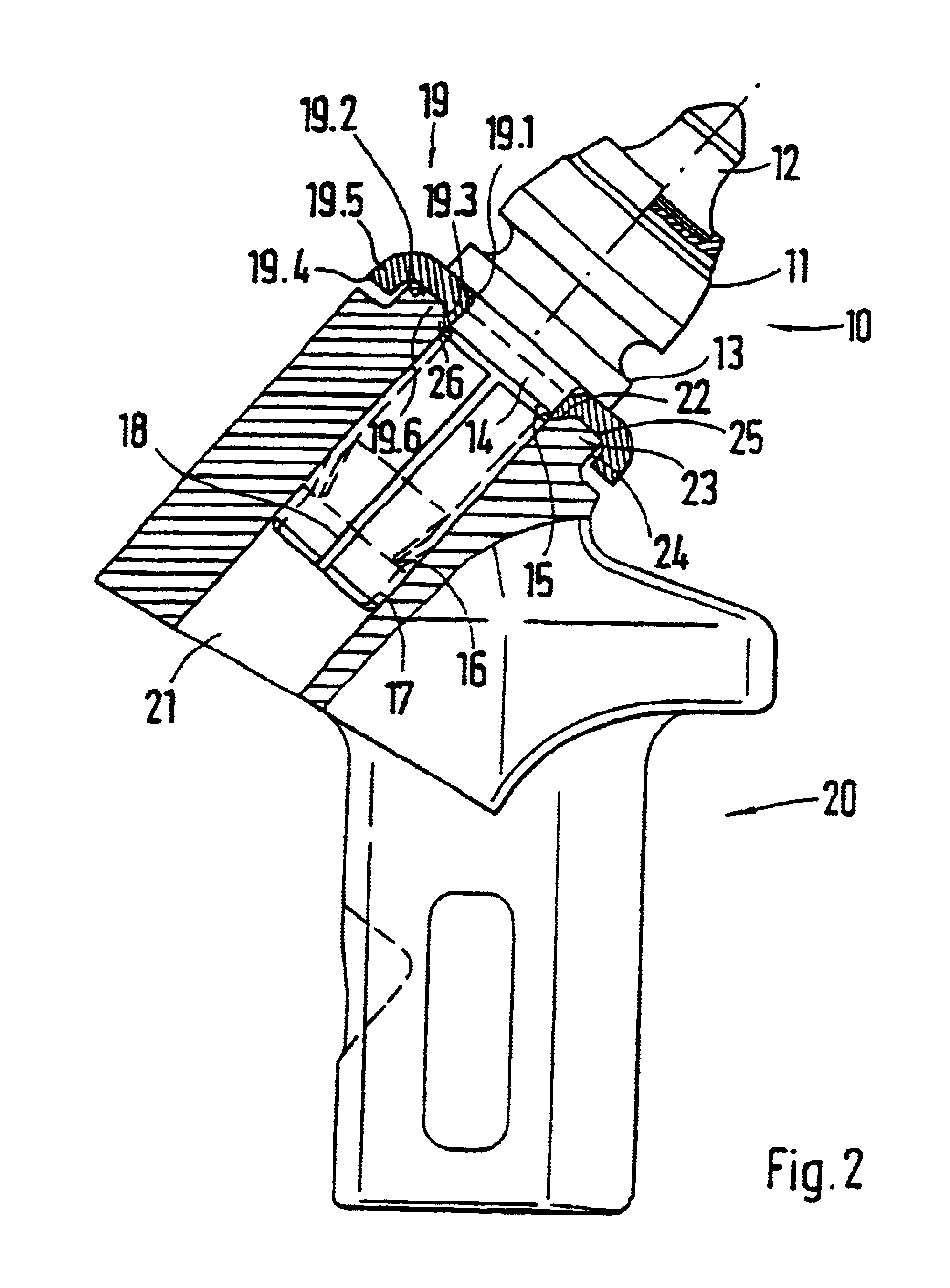

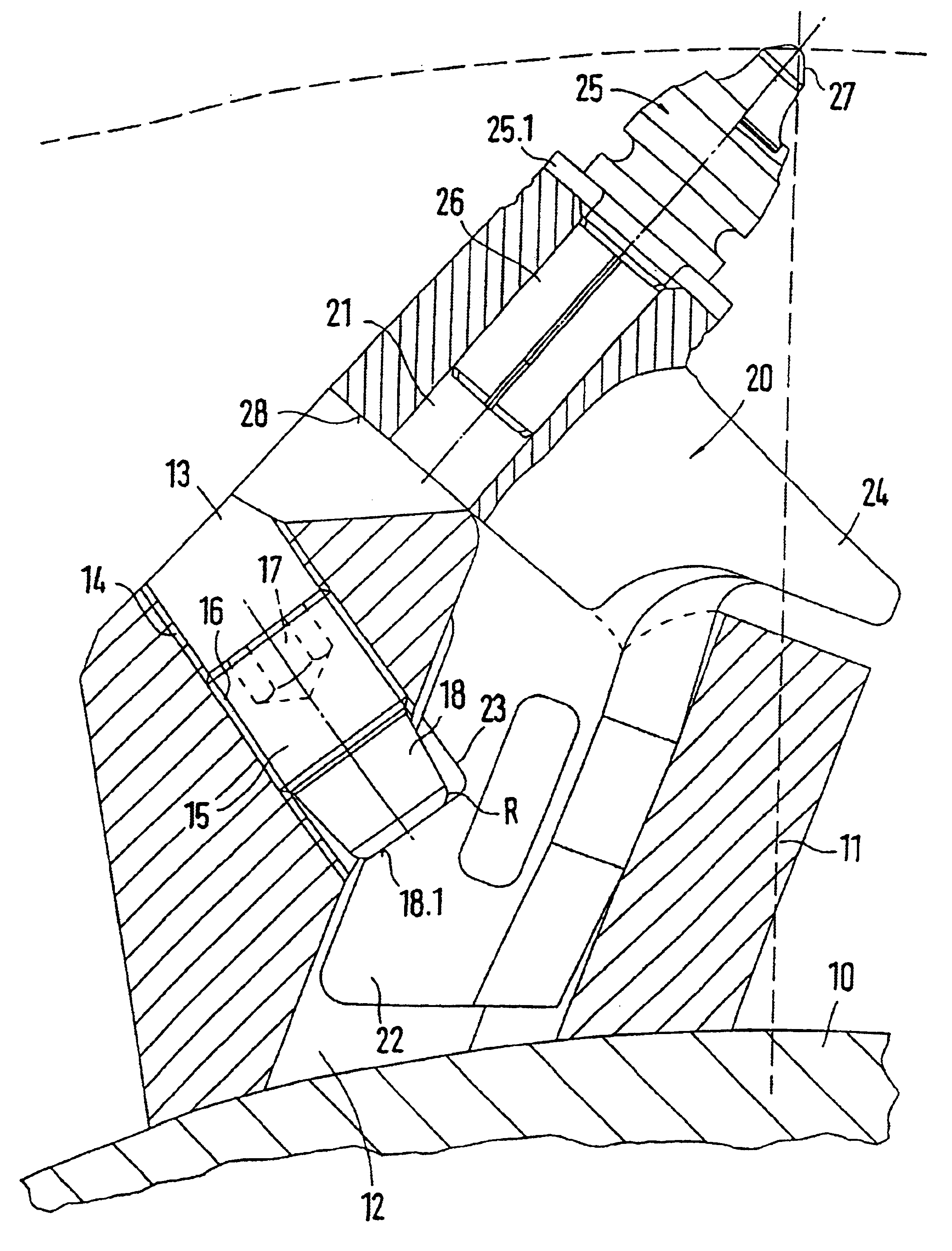

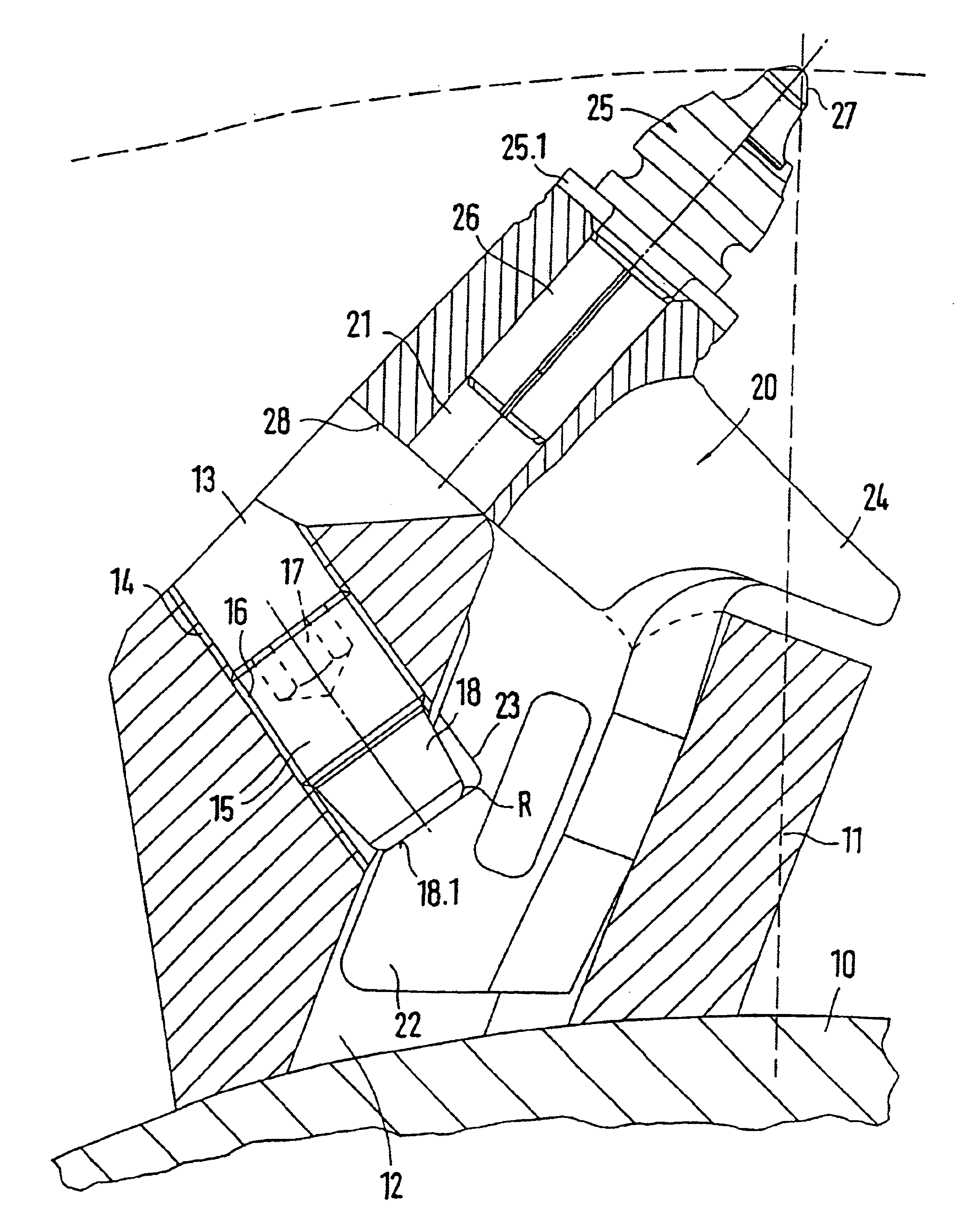

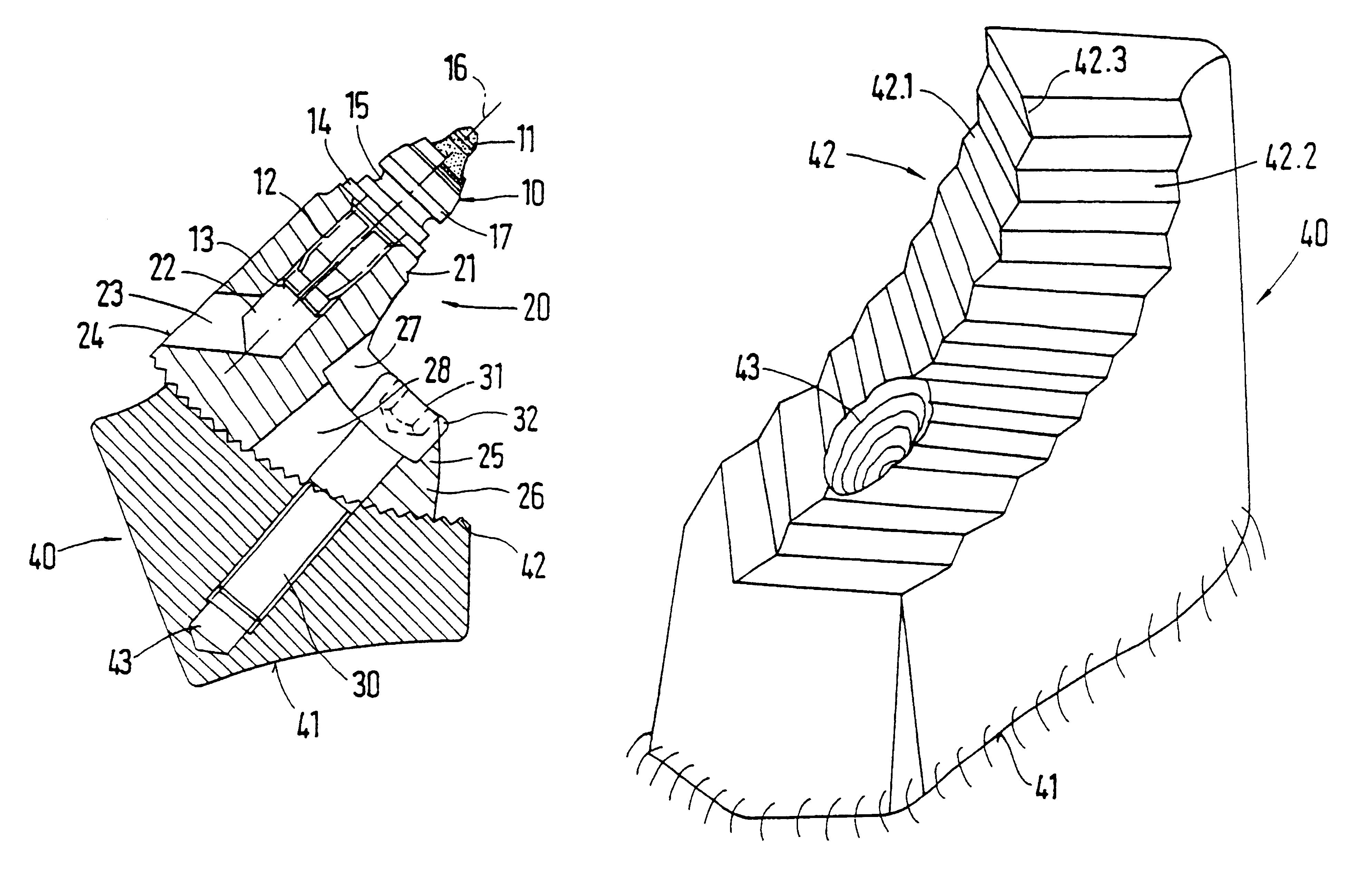

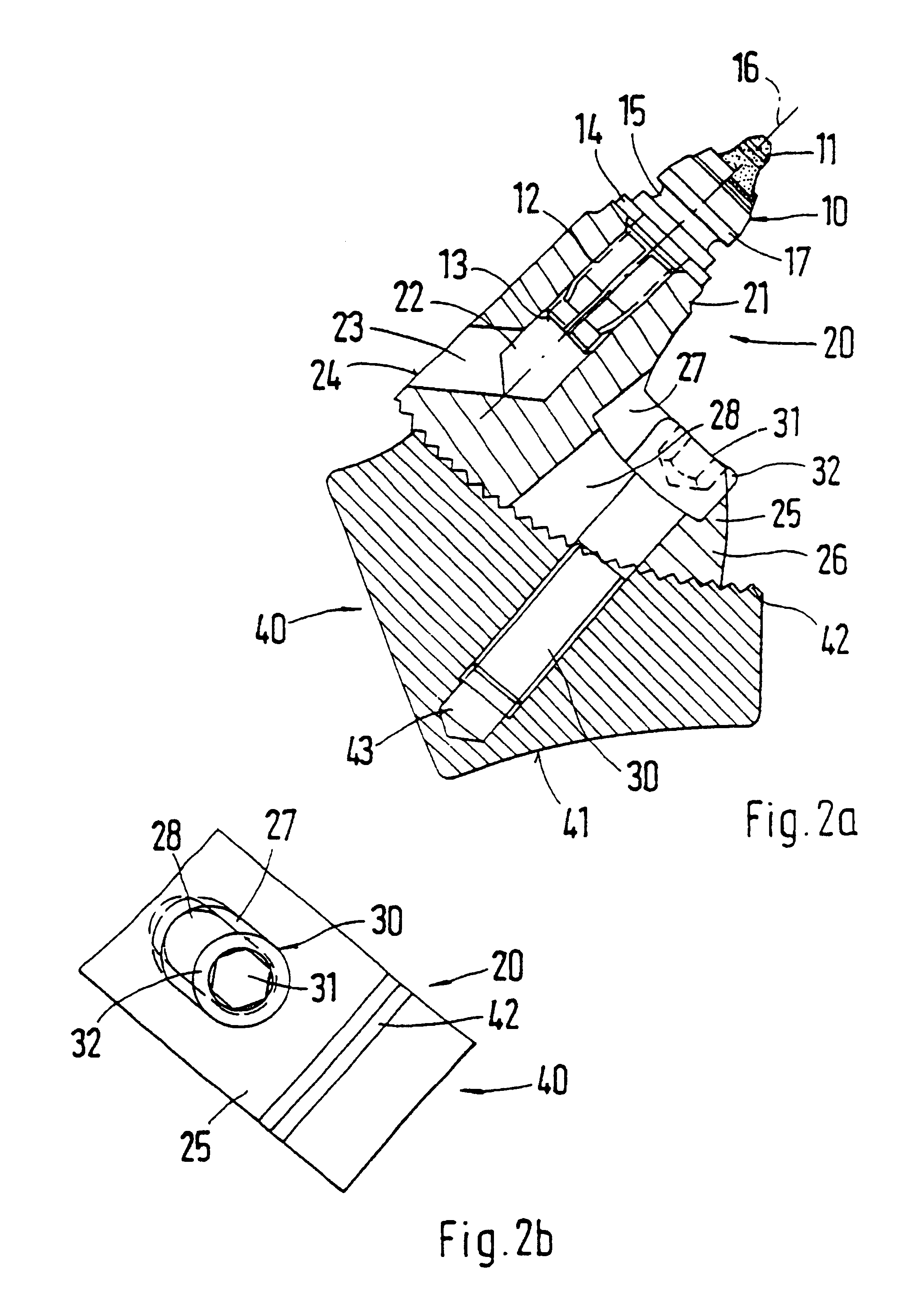

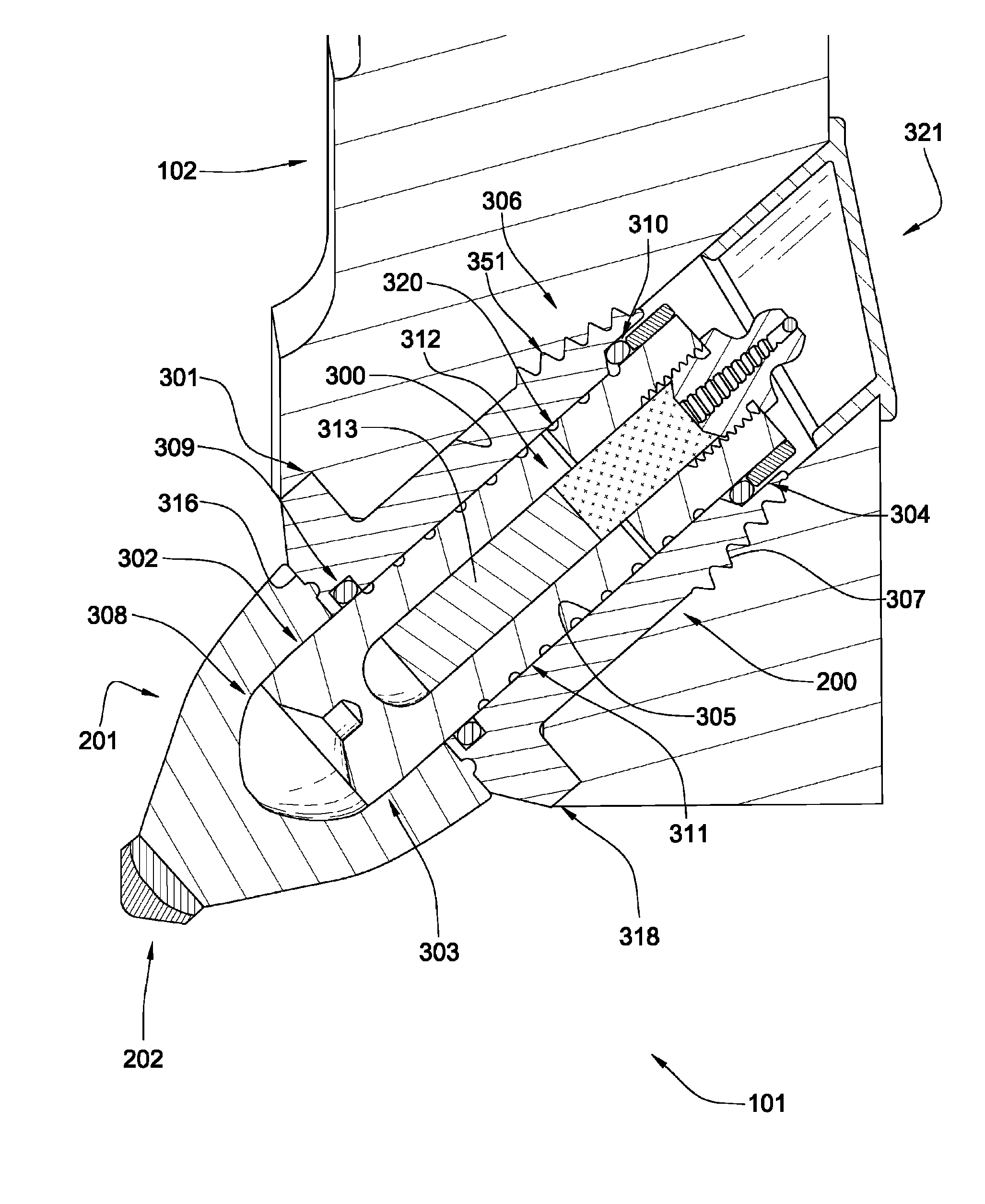

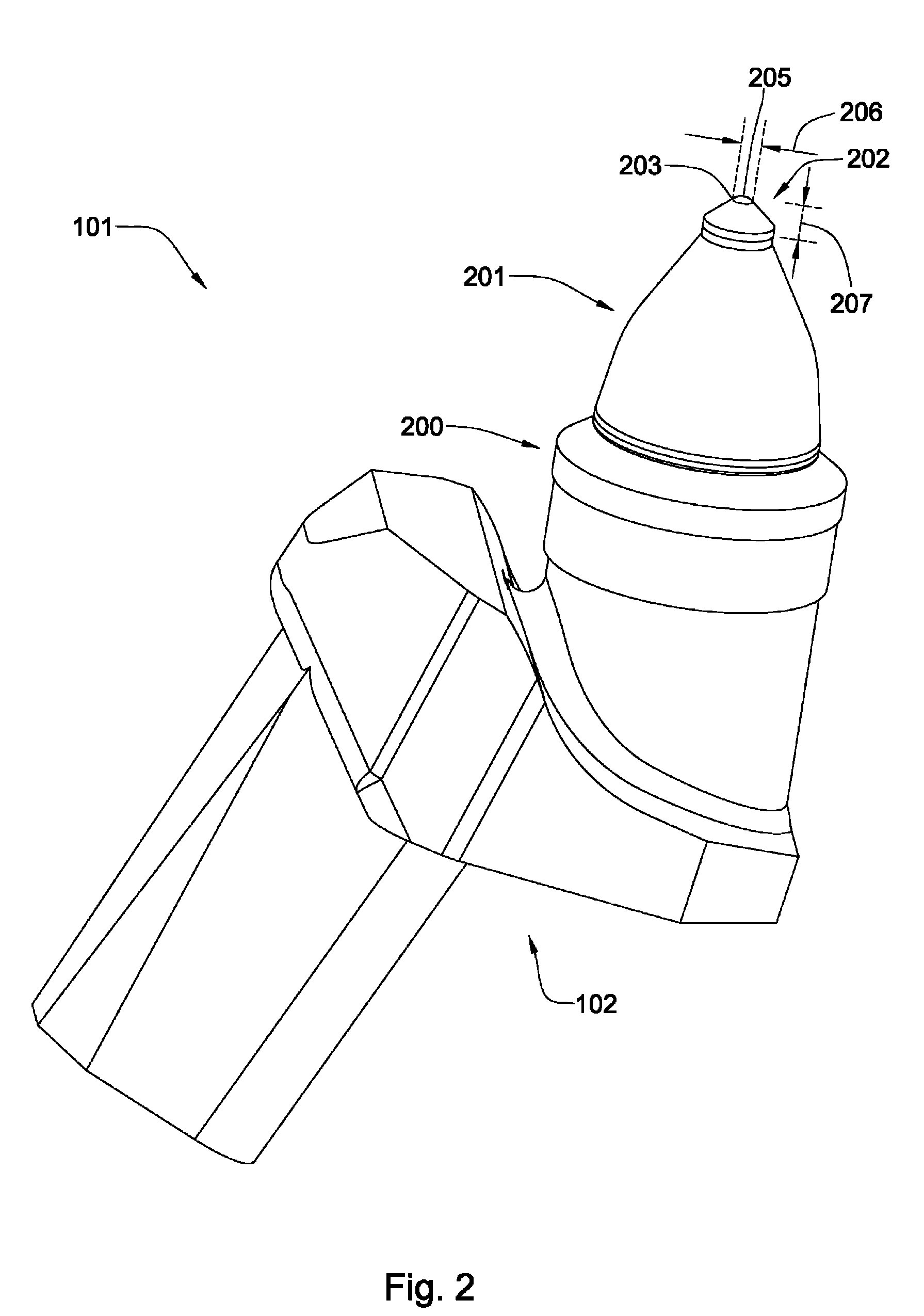

Fixture for a round shank chisel having a wearing protection disk

A fixture for attaching a round shank chisel to a road milling machine or the like. The round shank chisel has a chisel head and a chisel shank. With a bearing surface the chisel head rests upon a wearing protection disk which in turn rests on and is supported by a chisel holder. The chisel shank is accommodated by a location bore of the chisel holder. This invention prevents dirt from penetrating the area of the location bore of such a fixture and at the same time ensures that the free movability of the round shank chisel is not impaired. Thus, the chisel holder has a circumferential projection or a circumferential depression which extends along the location bore. Also, the wearing protection disk has a circumferential receiving groove or a circumferential shoulder and the projection or the depression of the chisel holder engages with the receiving groove or the depression of the wearing protection disk when the round shank chisel is assembled.

Owner:BETEK BERGBAU UND HARTMETALLTECHN KARL HEINZ SIMON

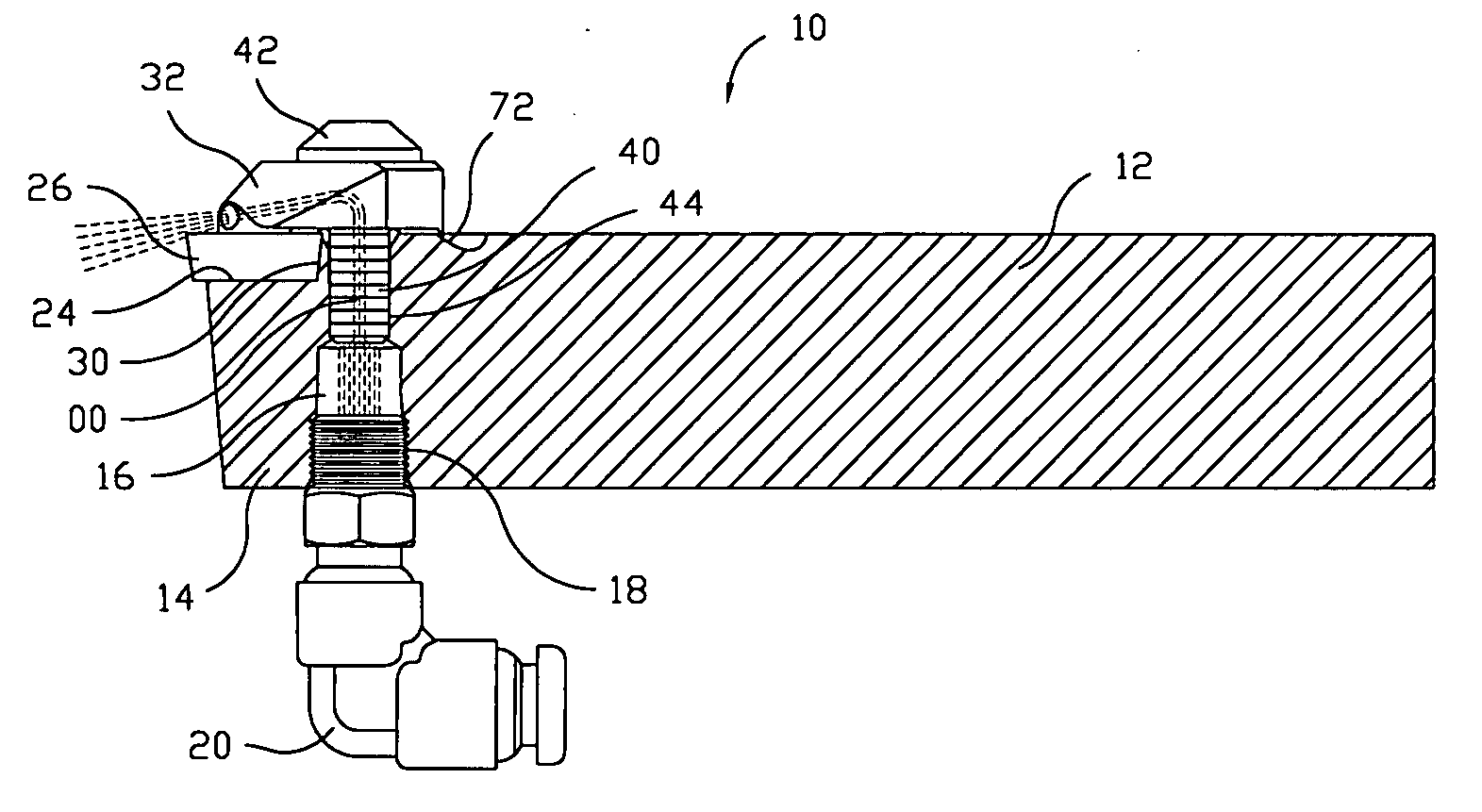

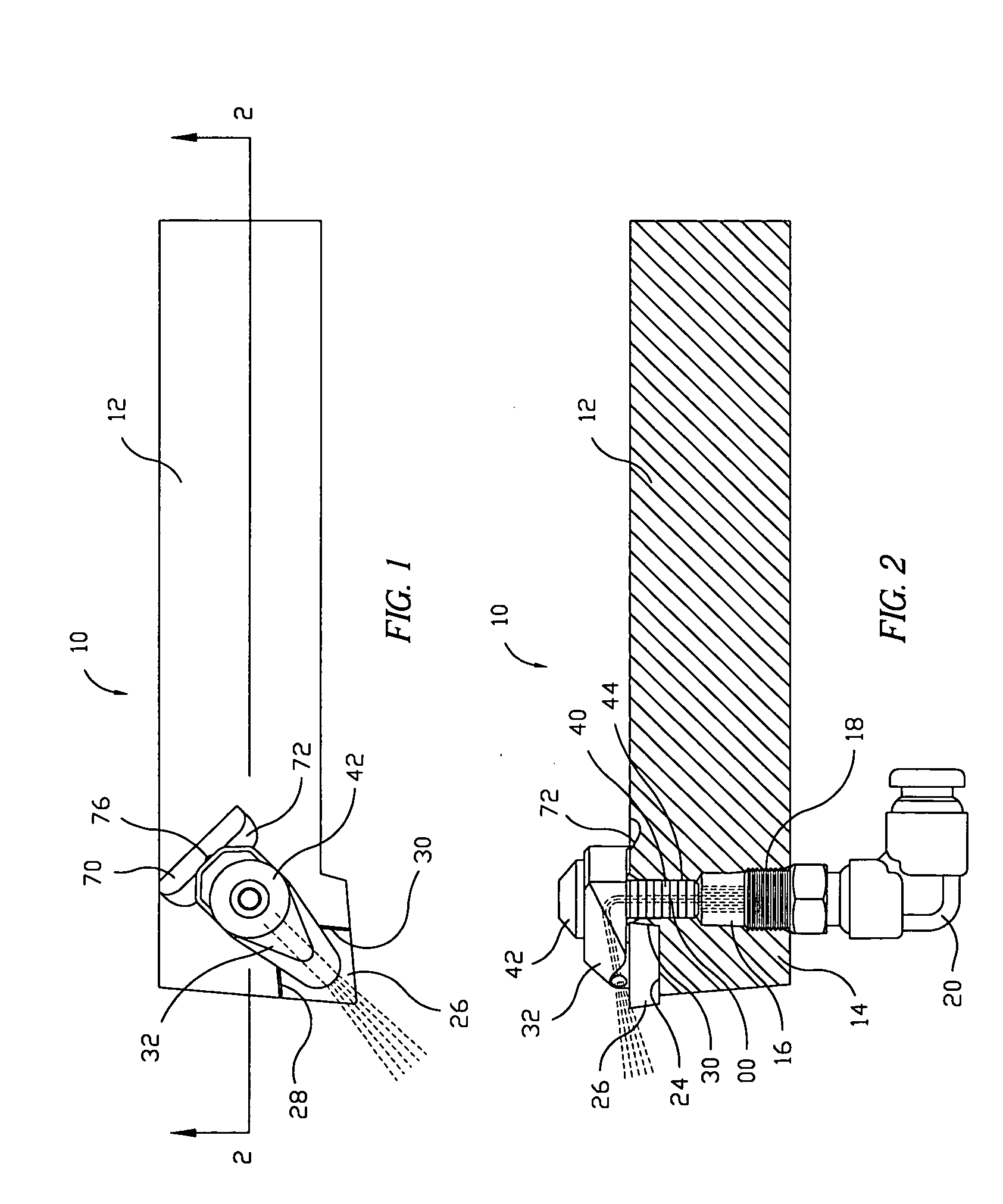

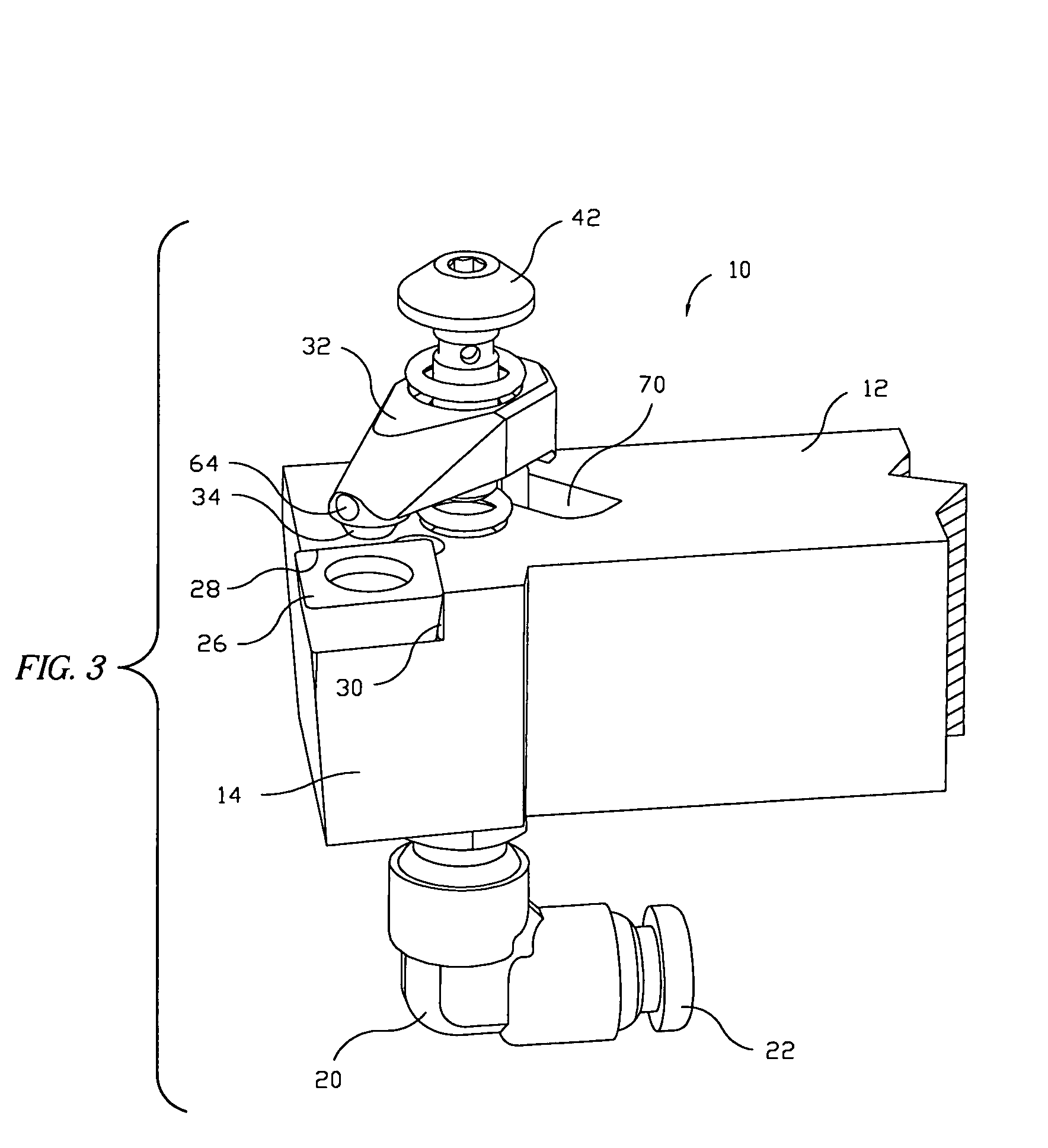

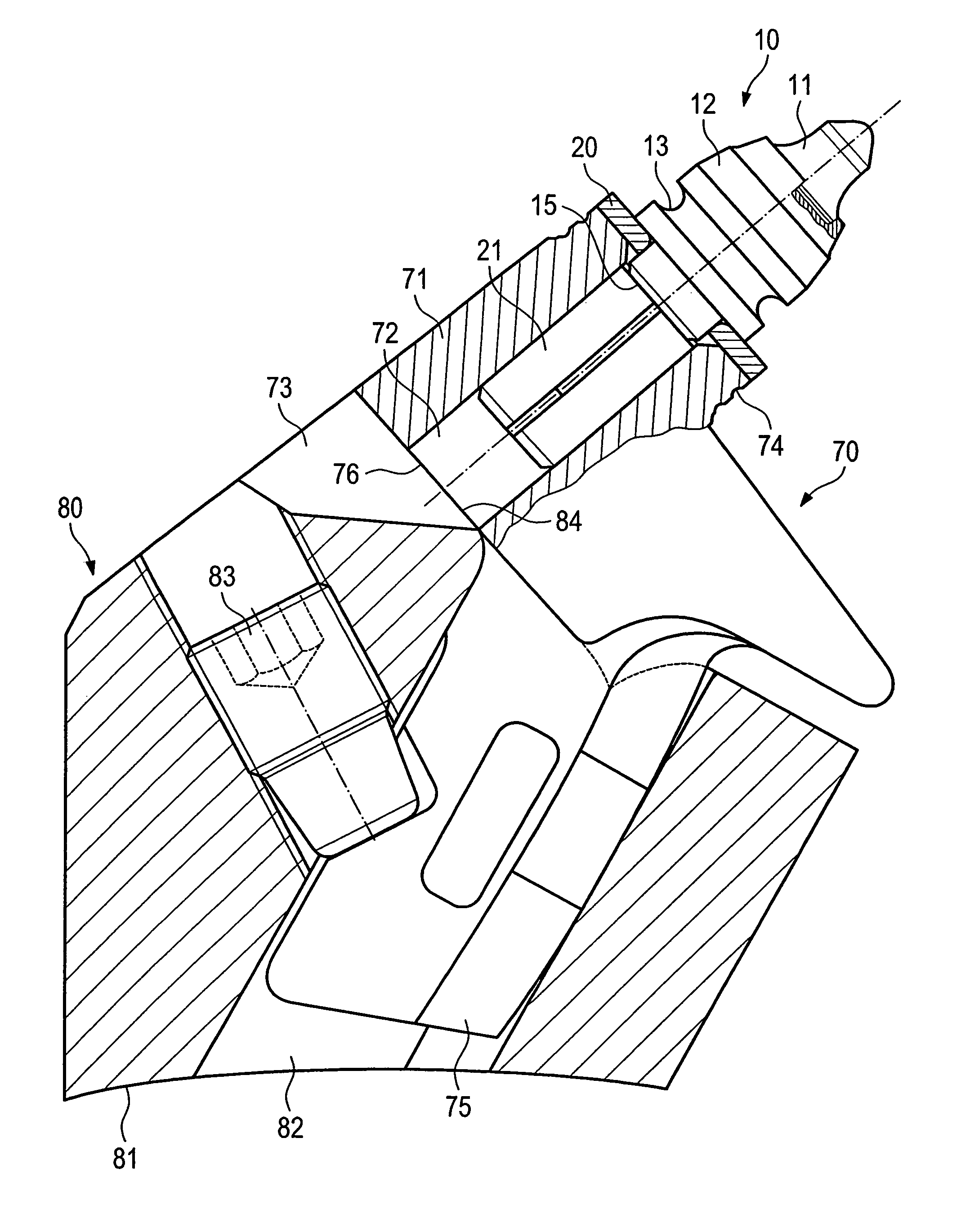

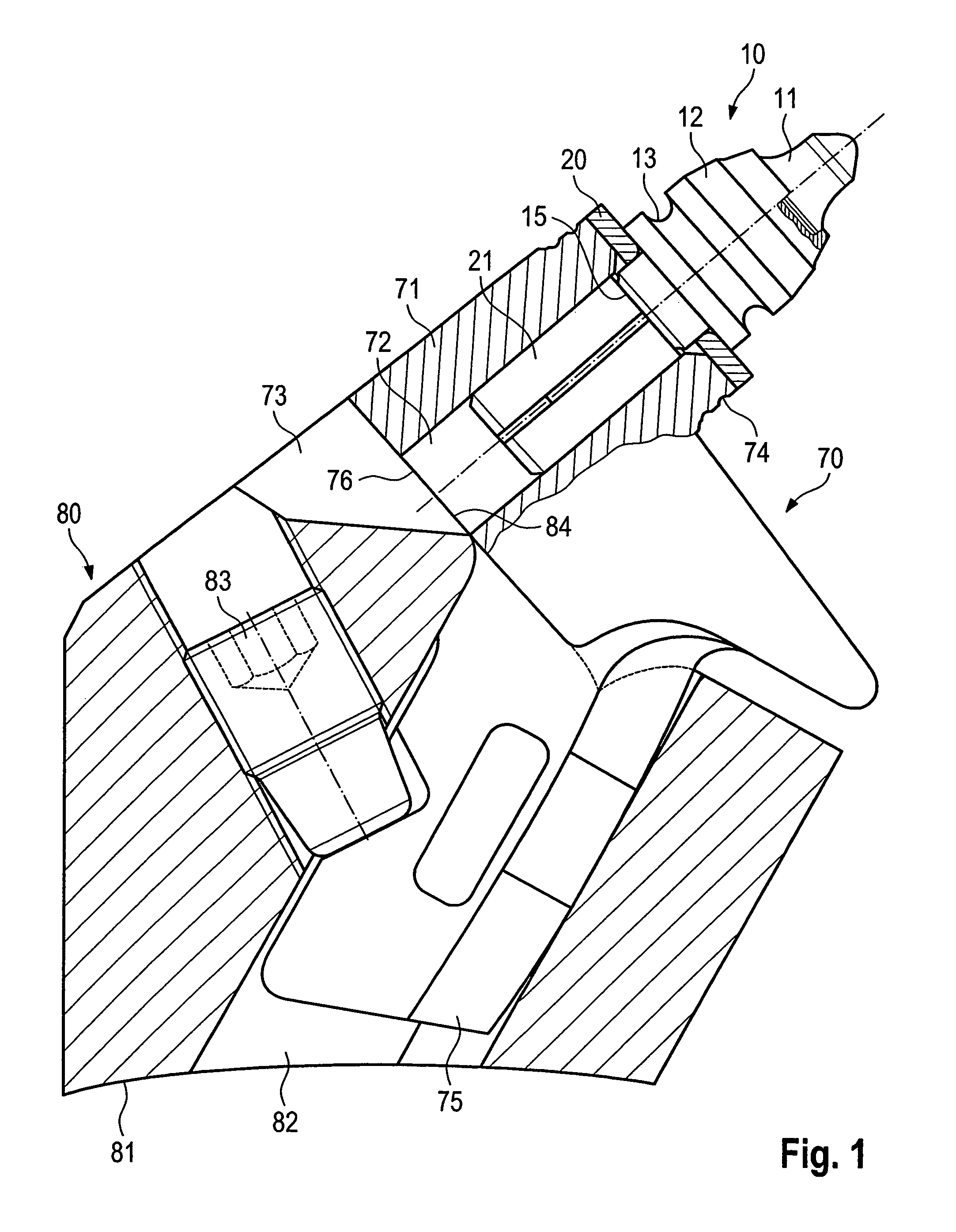

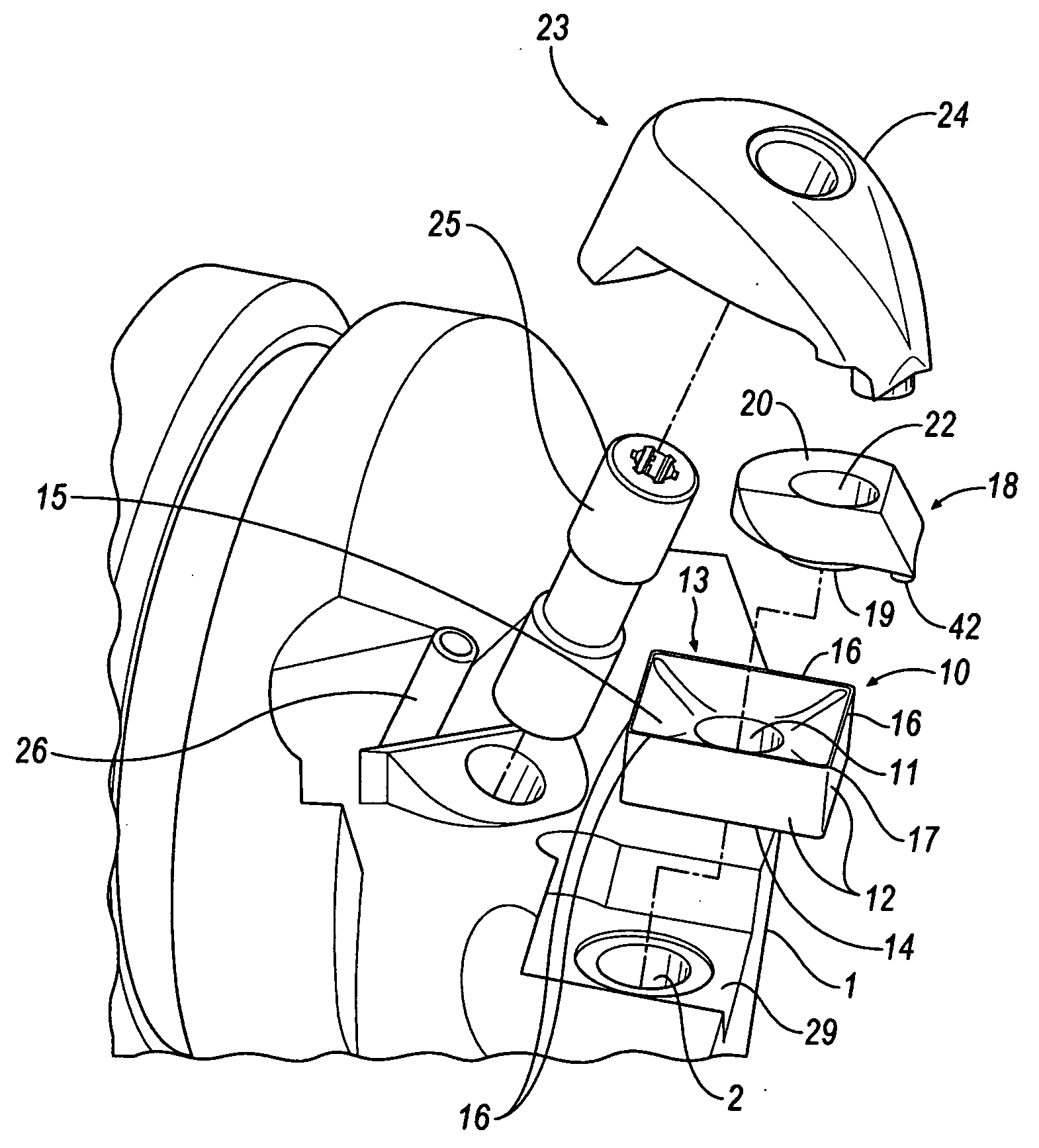

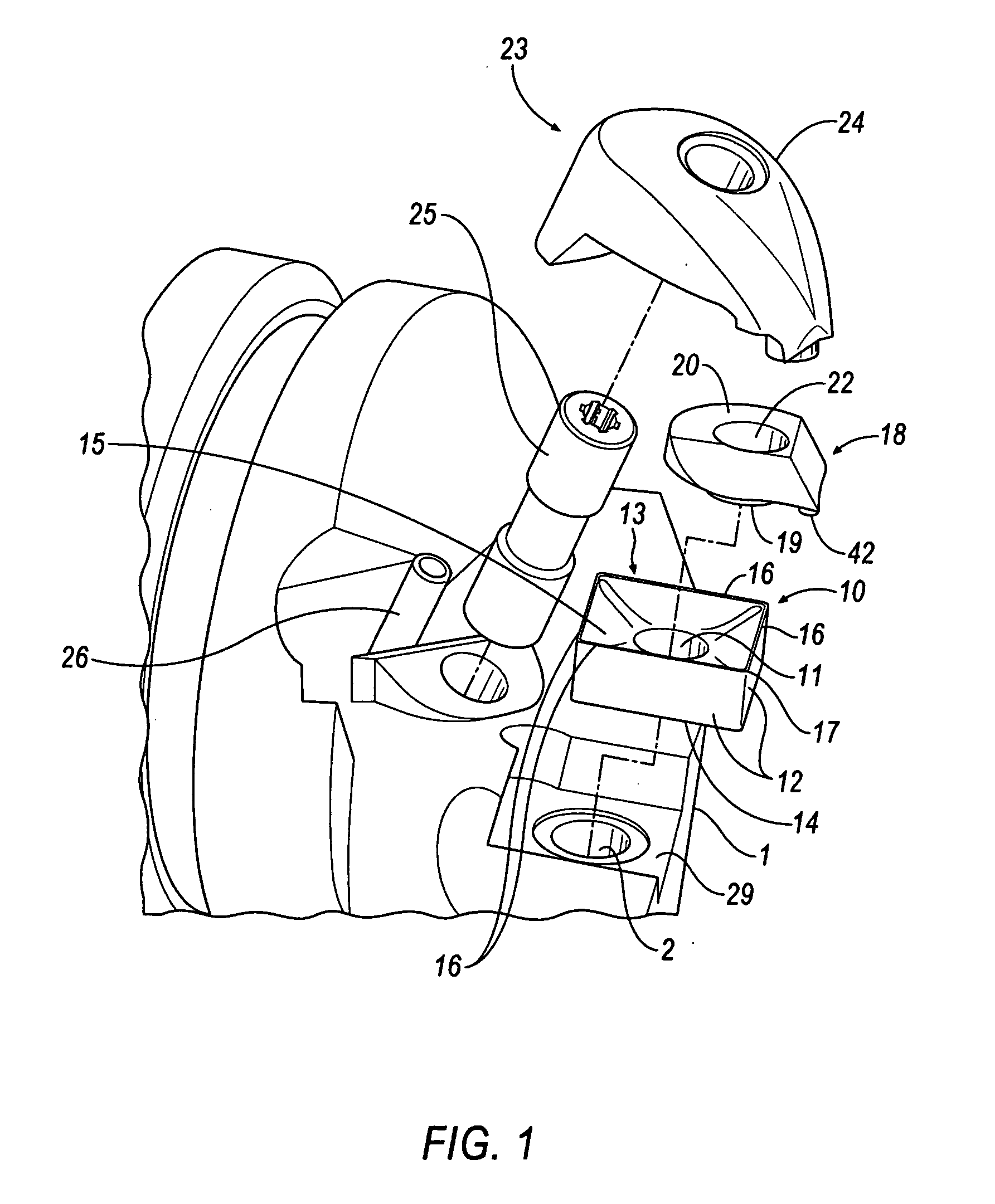

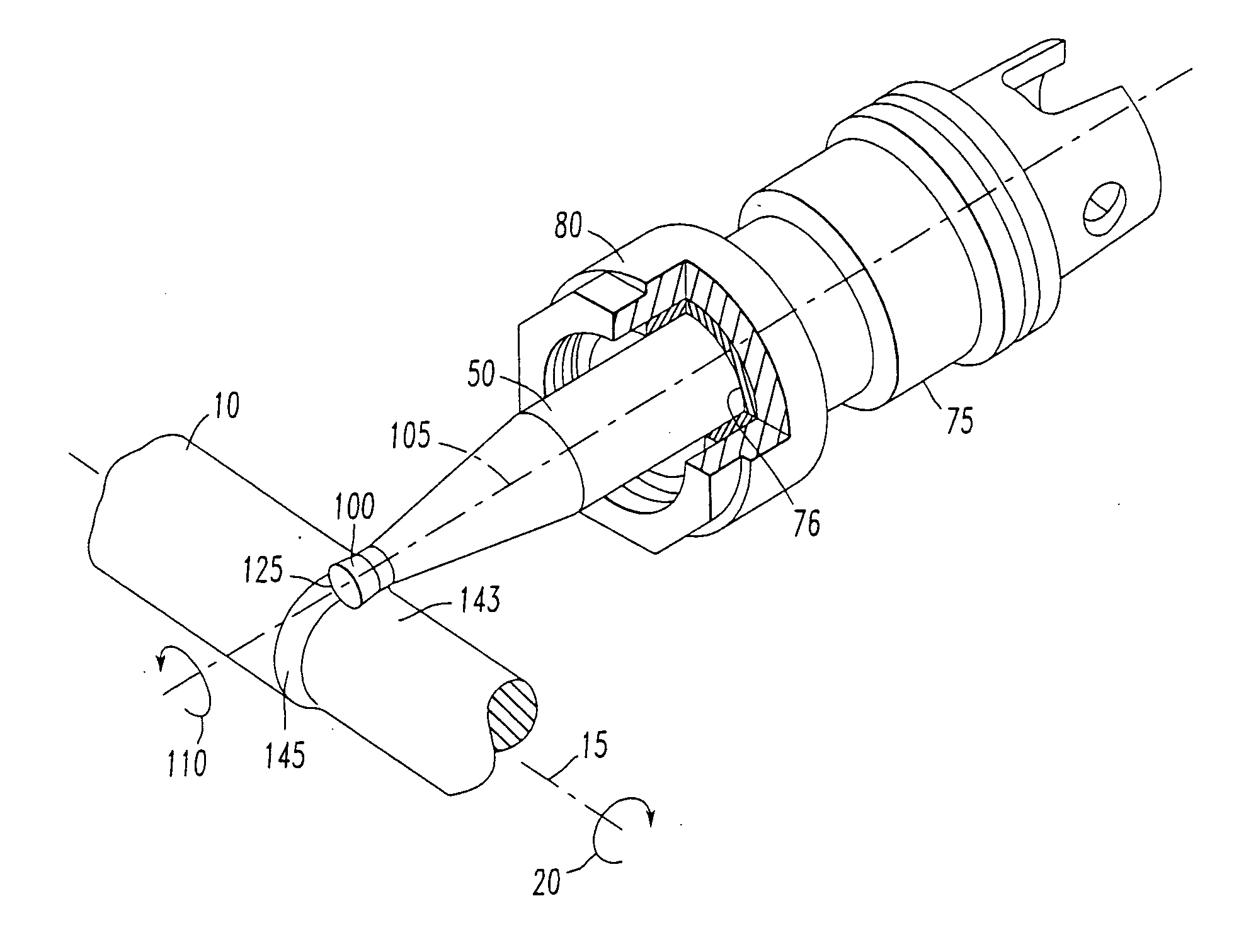

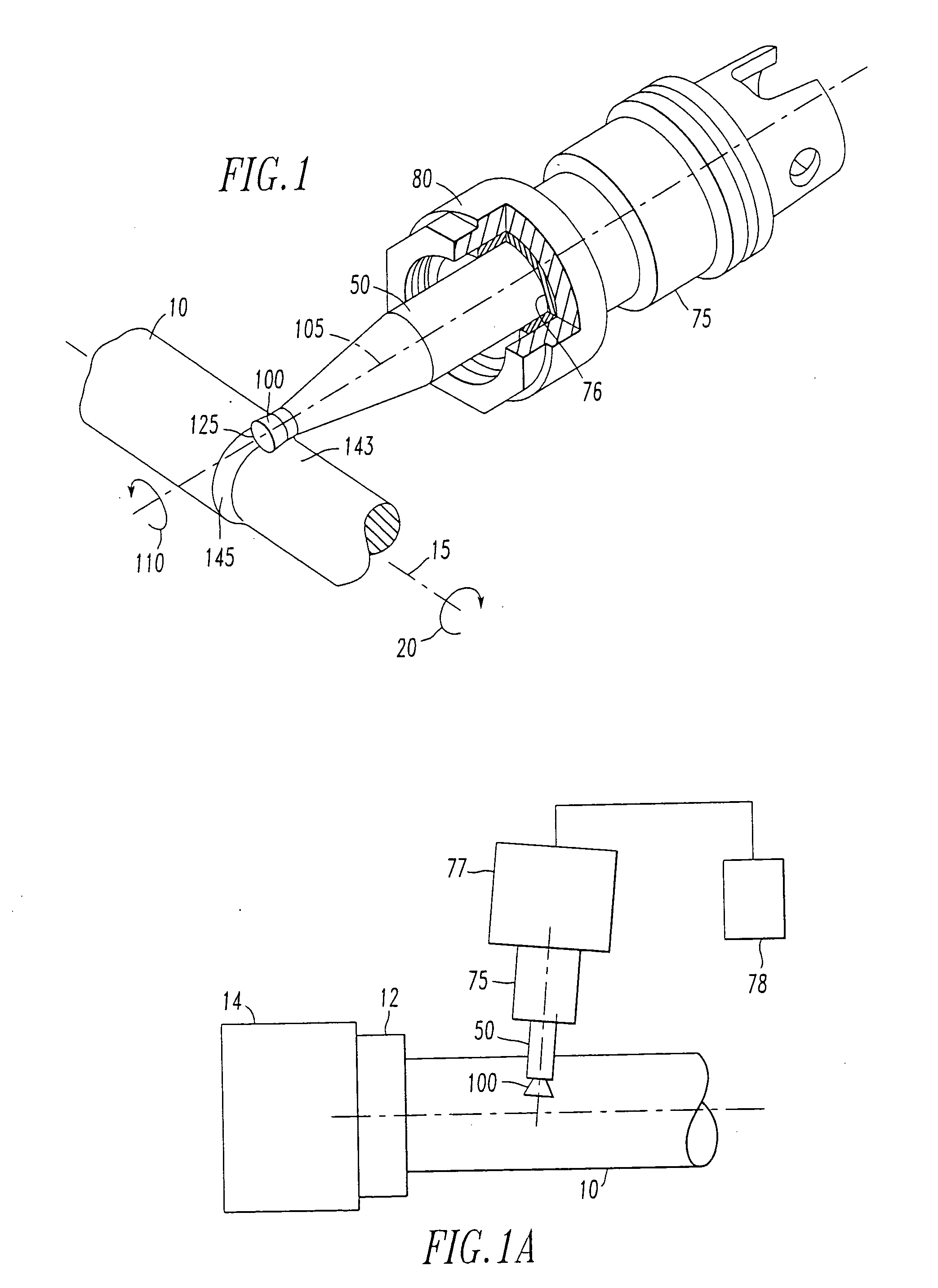

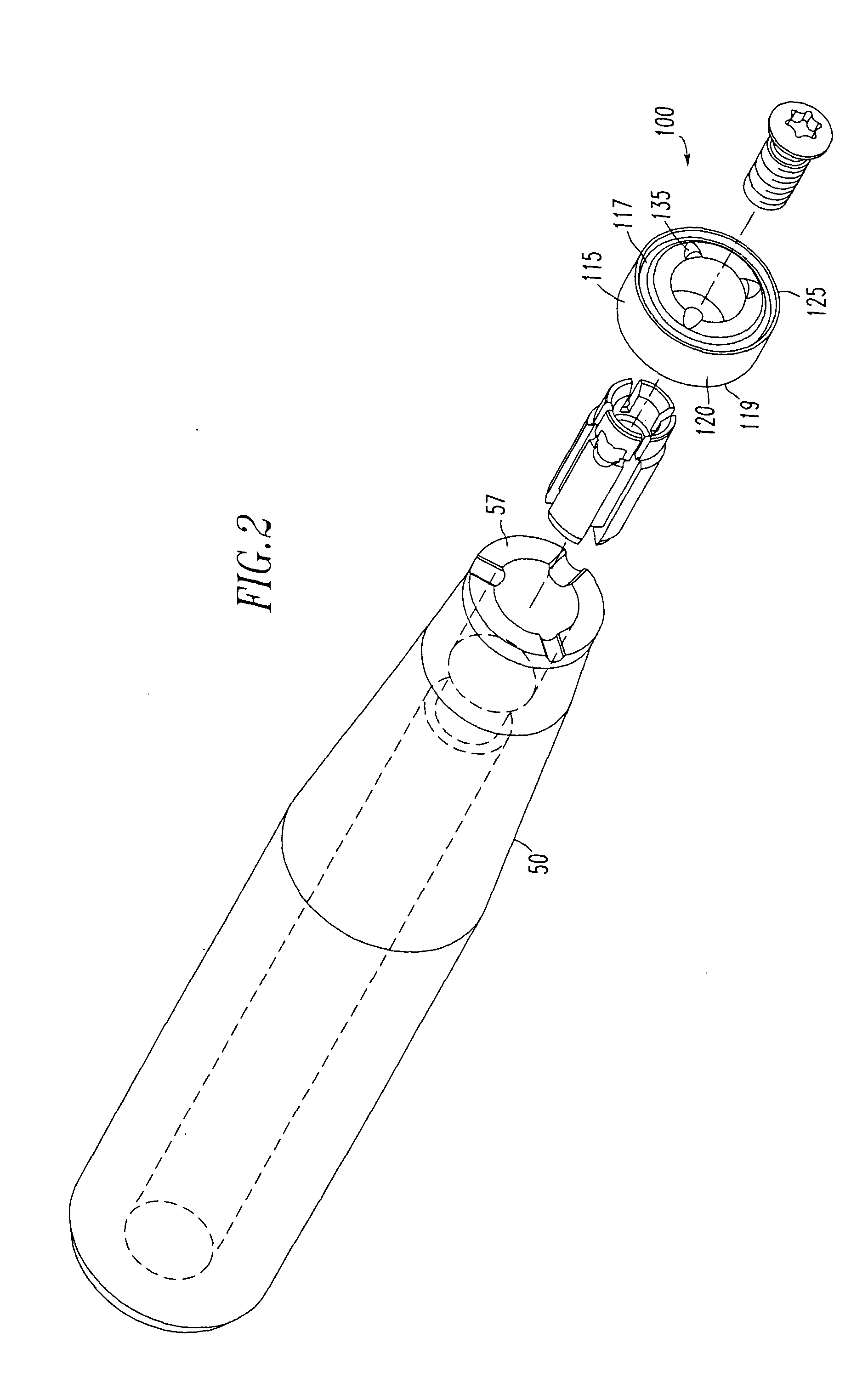

Machine tool holder having internal coolant supply and cutter retaining and coolant distribution cutter insert retaining clamp assembly

InactiveUS20070283794A1Minimizes heat induced wear and deteriorationExtended service lifeLathesCutting insertsCooling fluidMachine tool

A boring bar has a shank having a cutter support head at one end. A flow passage extends to the cutter support head and intersects a transverse flow passage that is defined in part by a clamp screw passage of the head. A metal cutting insert is clamped to the cutter support head by a clamp that is secured by a clamp screw being threaded into the clamp screw passage. The clamp screw defines an internal or external passage that communicates with the internal coolant fluid passage and completes a coolant distribution circuit. The clamp defines an internal coolant fluid passage having a discharge opening located and oriented to direct a jet of coolant fluid onto the metal cutting insert immediately at the site of cutting engagement within the rotating workpiece. The cutter support head also has a passage and chip removal jet nozzle that orients a jet of coolant fluid adjacent the cutter insert for remove metal chips during machining.

Owner:GIANNETTI ENRICO R

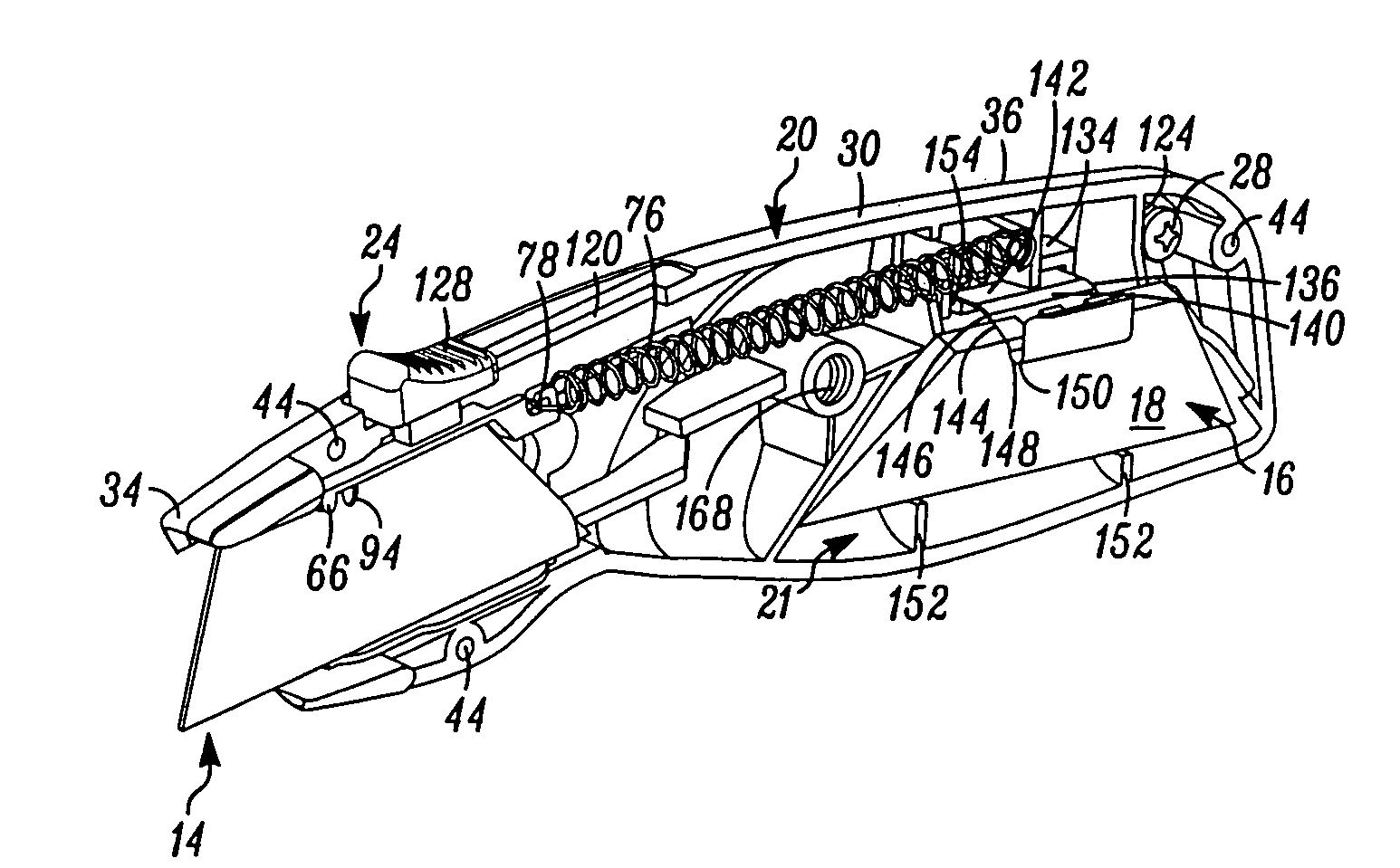

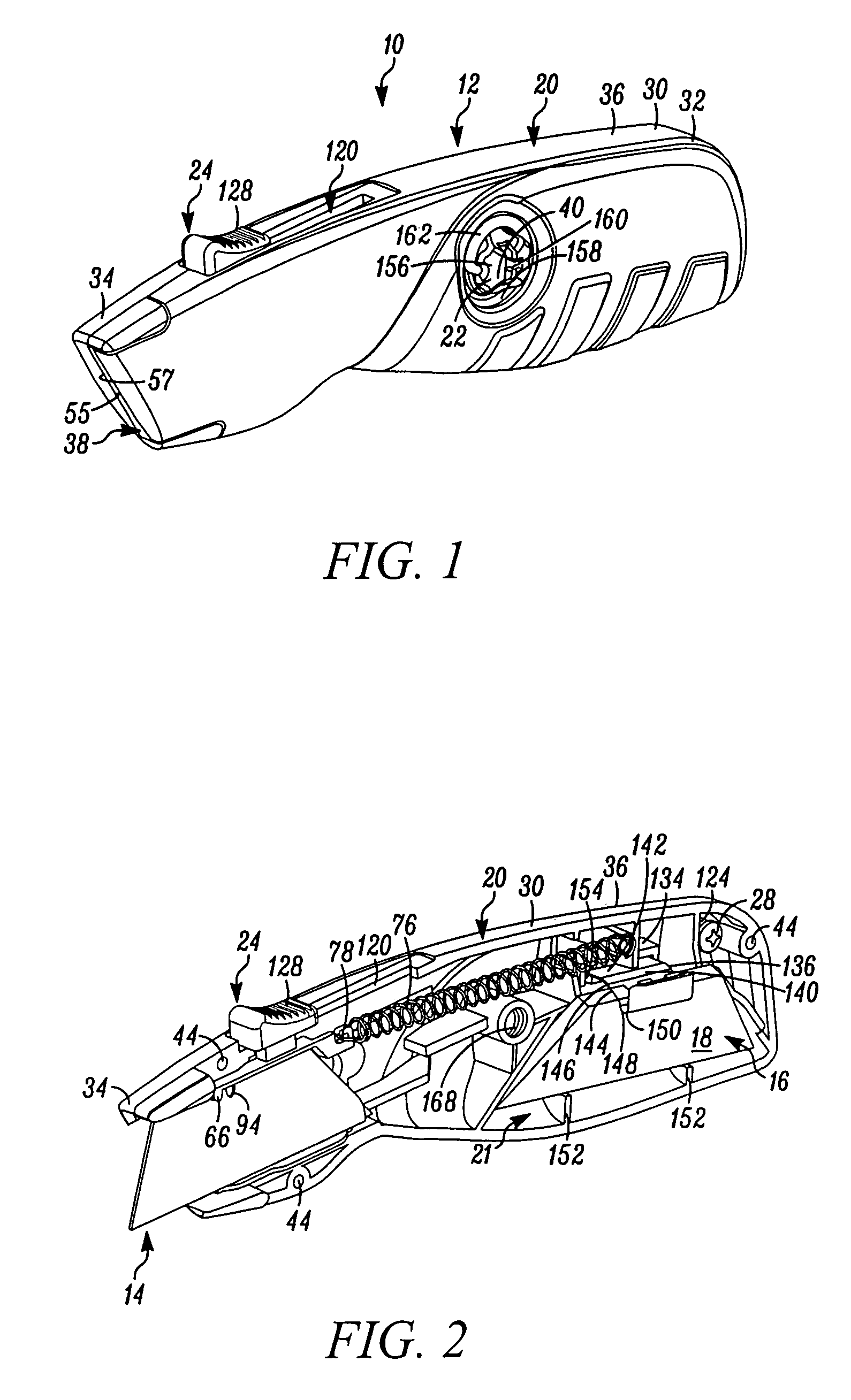

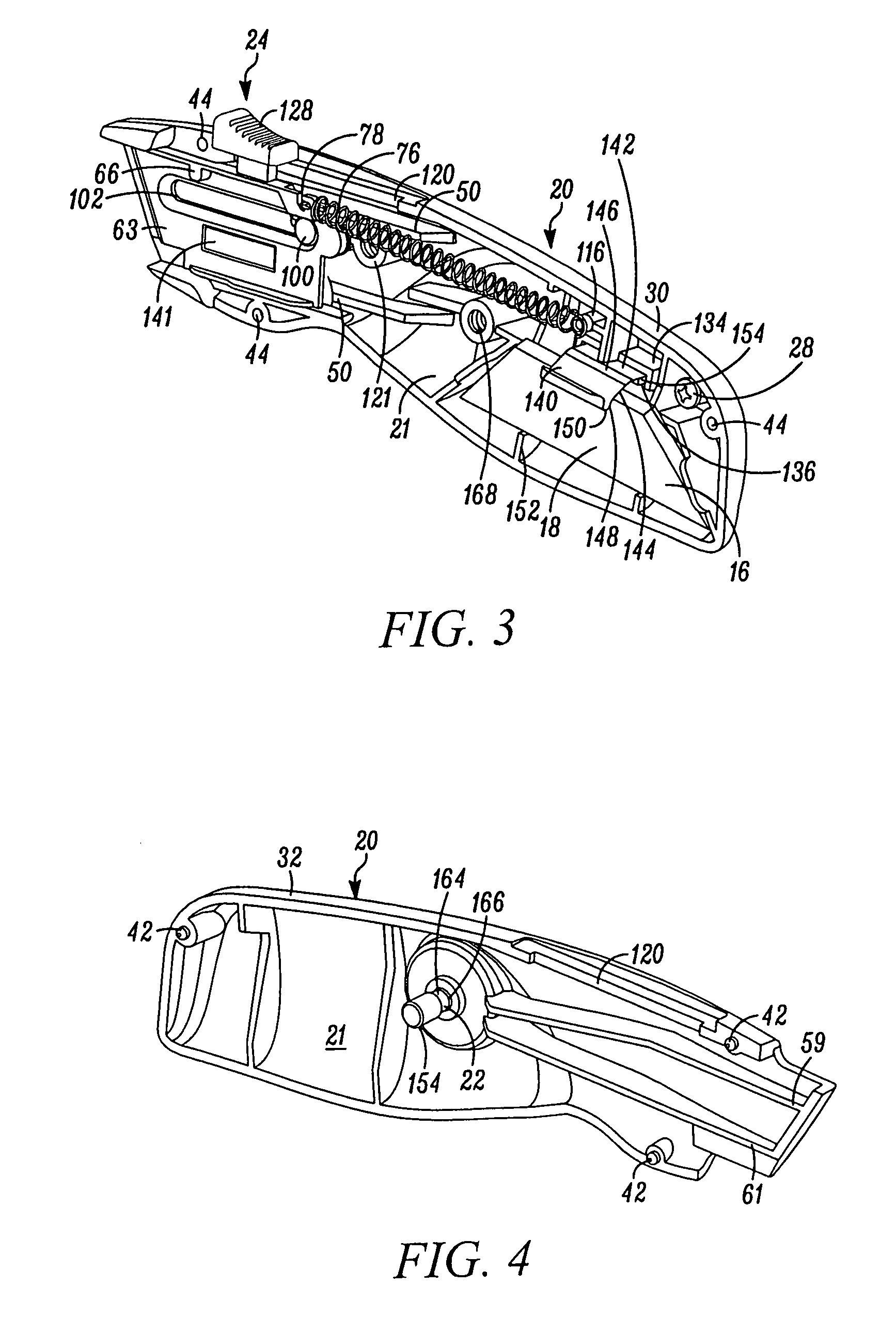

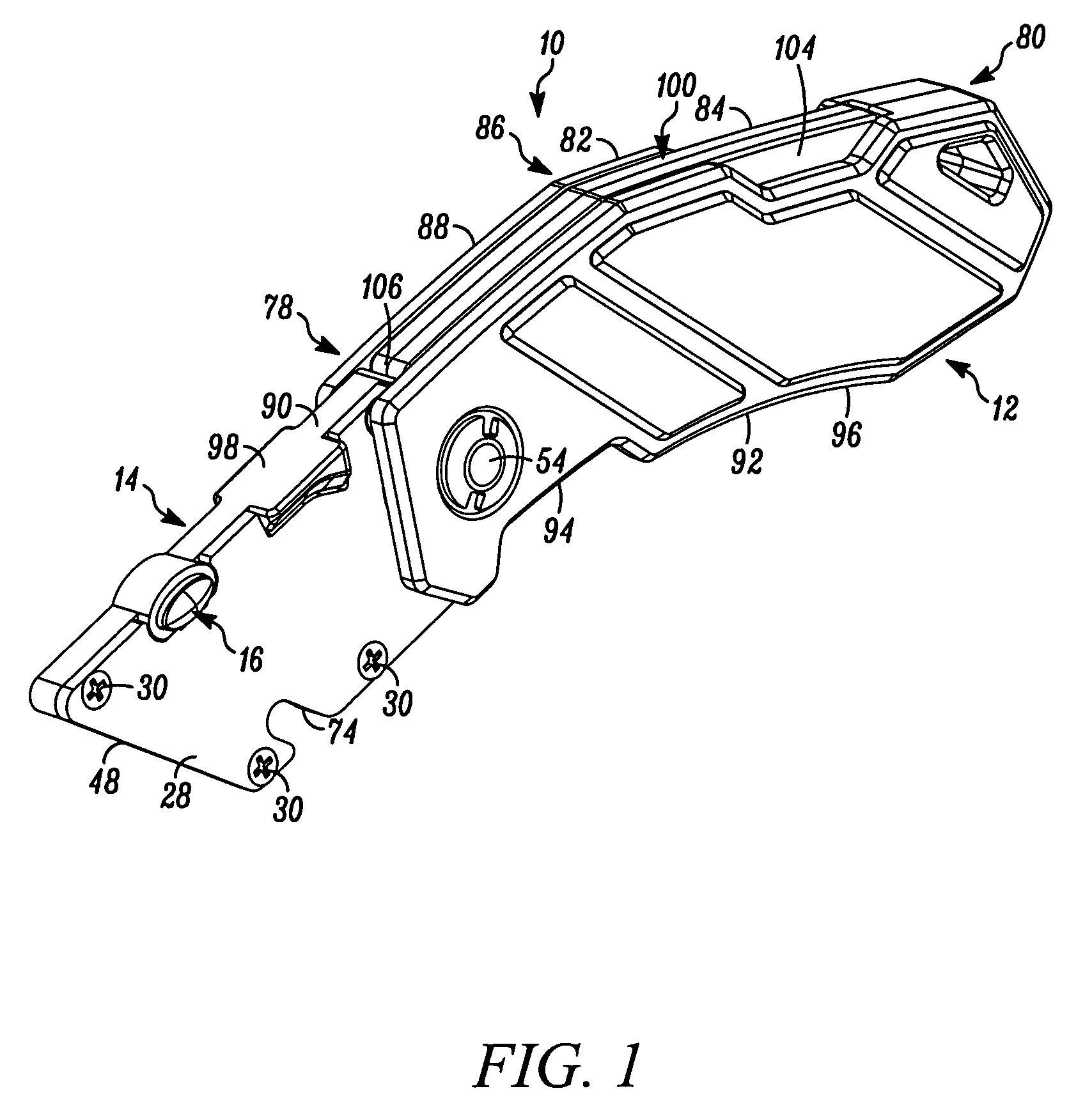

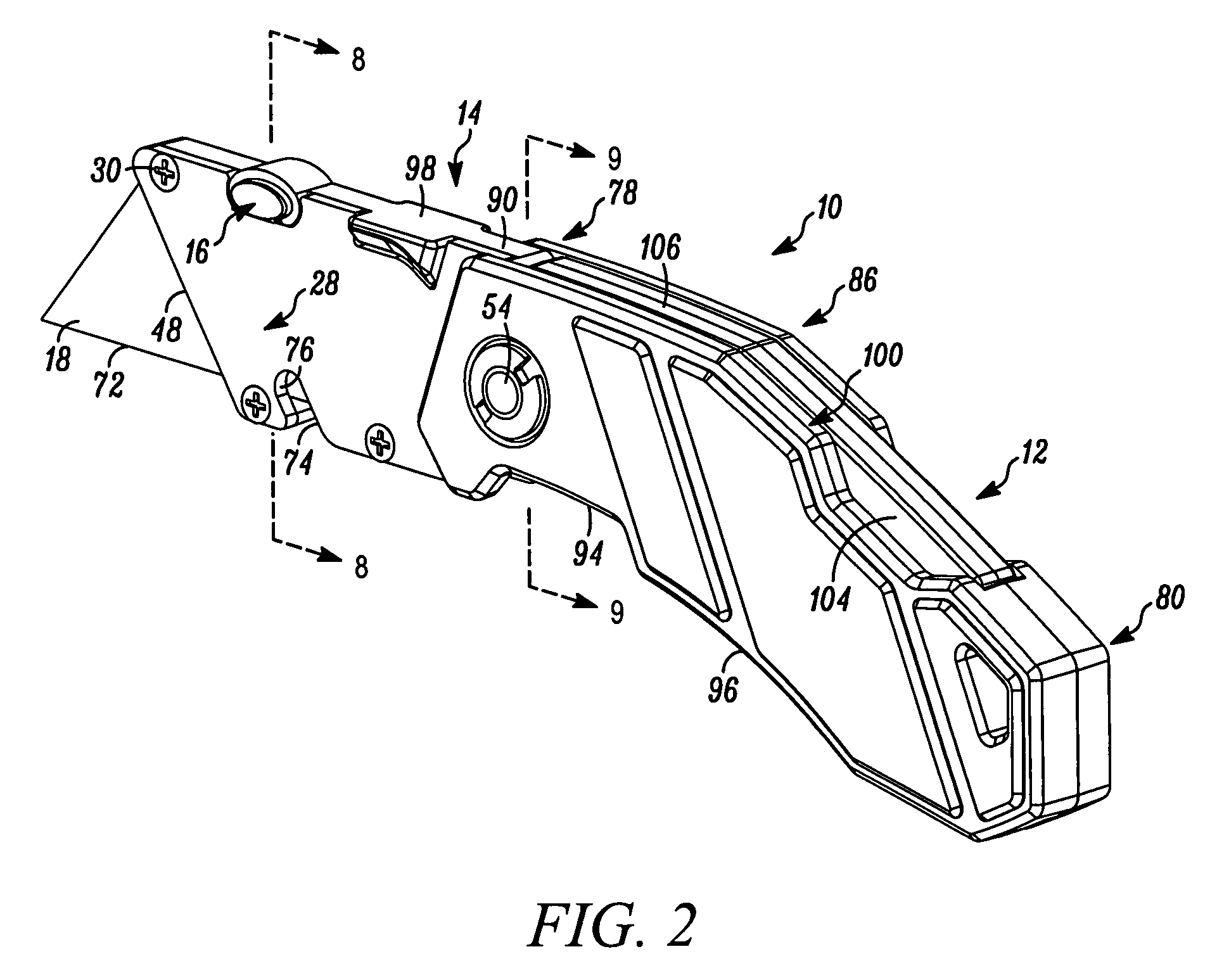

Self-retracting utility knife

ActiveUS7316070B2Avoid the needNarrow handleOpening closed containersBottle/container closureActuatorSupport surface

A utility knife includes a housing and a blade carrier movably mounted to the housing. The blade carrier includes a blade supporting surface for supporting a blade, wherein the blade carrier is movable between a retracted position with at least a substantial portion of the blade retracted in the housing, and a first extended position with at least a portion of the blade extending outwardly of the housing. An actuator is operably connected to the blade carrier and is operable to move the blade carrier between the retracted and extended positions to, in turn, move a blade located on the blade carrier between the retracted and extended positions. A biasing member biases the blade carrier toward the retracted position. A stop member is movable between a first position and a second position. In the first position, the stop member is engagable with the blade carrier to thereby limit extension of the blade carrier and blade located thereon to a second extended position spaced inwardly on the housing relative to the first extended position. In the second position of the stop member, the stop member is spaced away from the blade carrier to thereby permit movement of the blade carrier and blade located thereon to the first extended position.

Owner:BLACK & DECKER INC

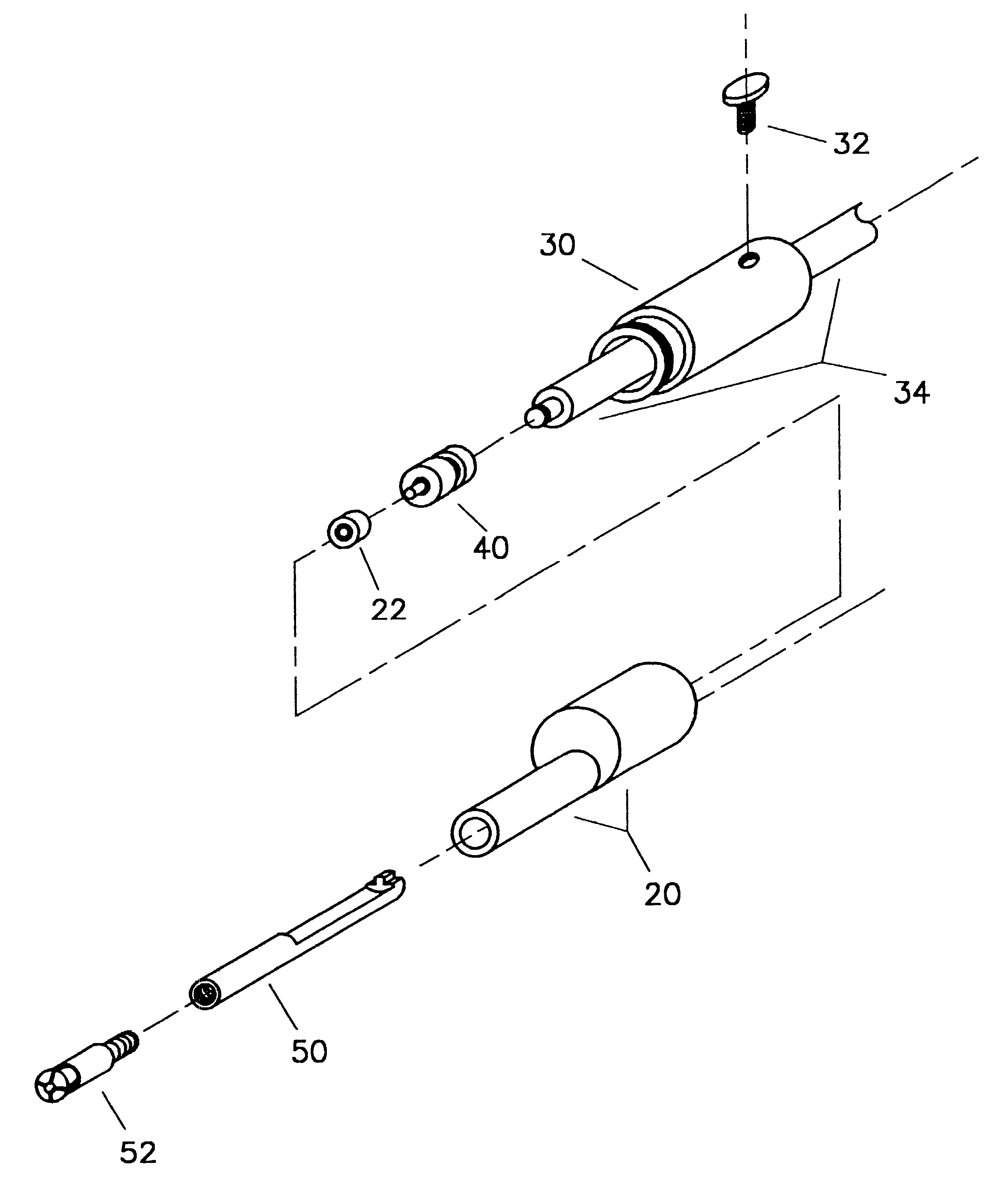

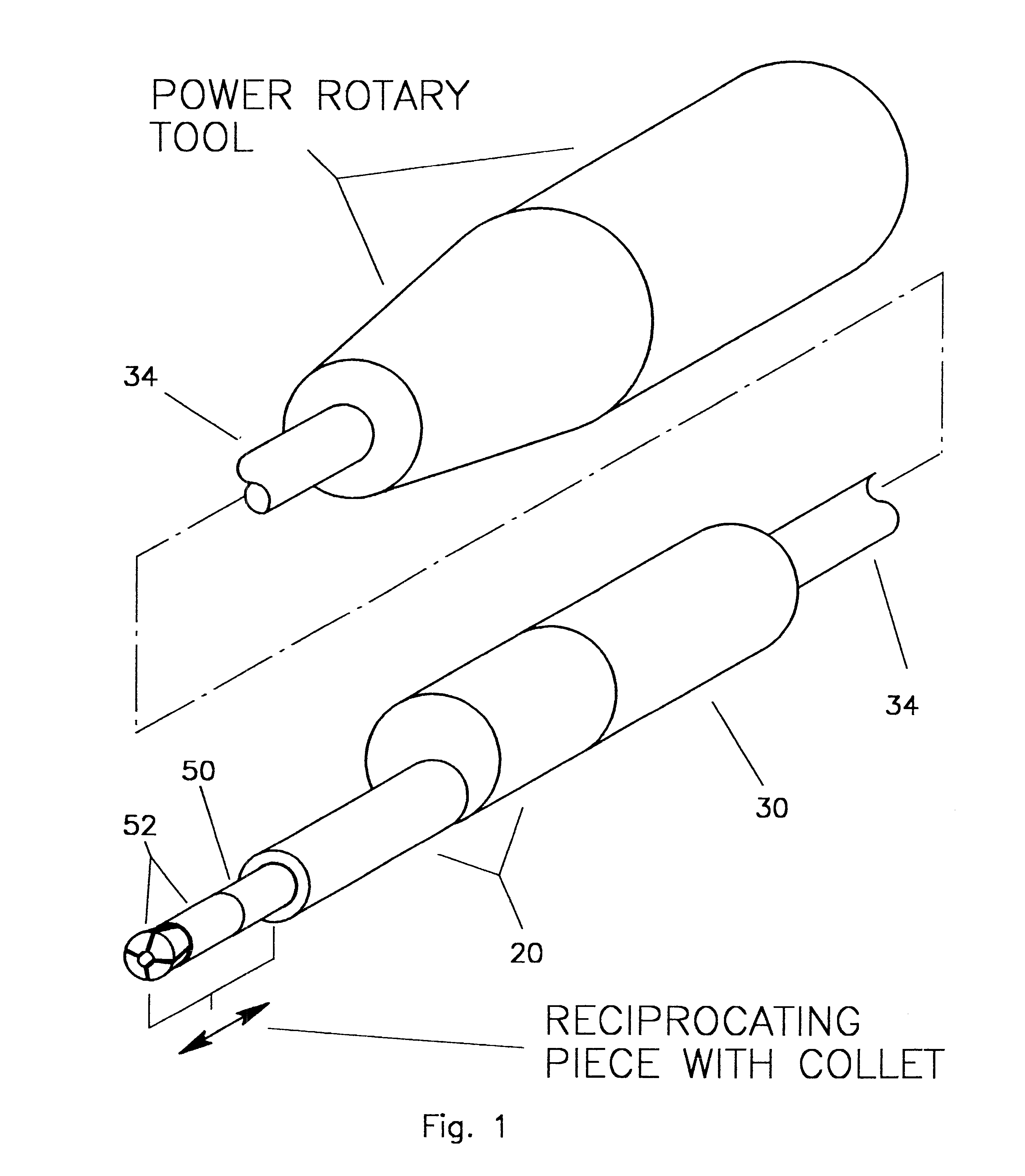

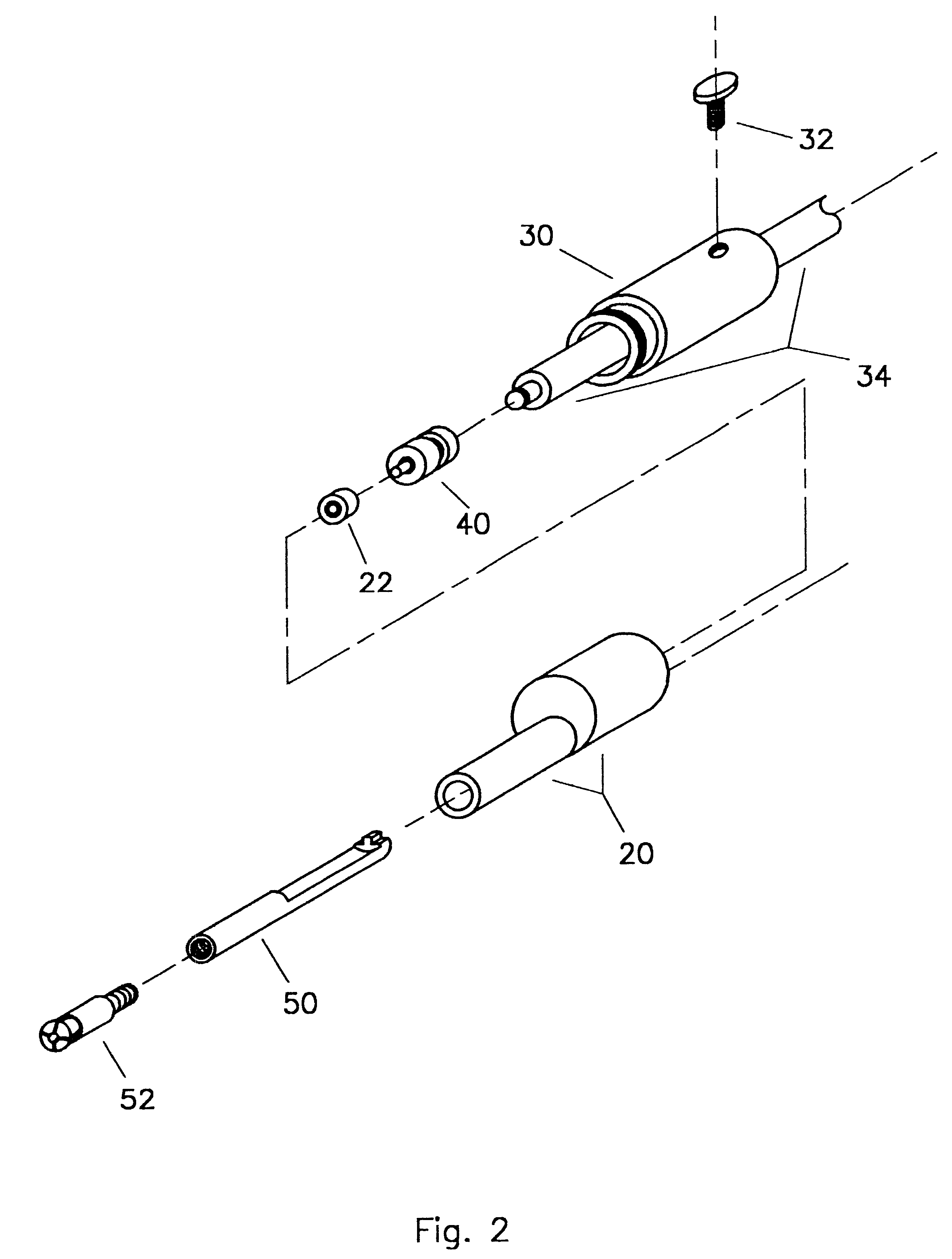

High-speed, hand-held reciprocating method for cutting, carving, sawing, chiseling, filing, sanding, and engraving

A high-speed, hand-held attachment for flex rotor shafts of power rotary tools, and also for direct attachment to power rotary tools without flex rotor shafts, that converts rotary motion to reciprocating motion for precision control of cutting, carving, sawing, chiseling, filing, sanding, and engraving on delicate work pieces. The attachment is one assembly comprising a one-piece front one-piece enclosure (20), a rear one-piece enclosure (30), a high-speed bearing (22), a one-piece rotating piece (40) with integral cam groove, a one-piece reciprocating piece (50) with an integral cam follower on one end and with its other, exposed end accomodating the attachment of a chuck or collet and with geometry to prevent rotation, and a thumbscrew (32). Rotating piece (40) attaches directly to the rotary power source and provides the cam action drive to reciprocating piece (50). Bearing (22) provides rotative support for the other end of rotating piece (40). Reciprocating piece (50) slidably mounts in front one-piece enclosure (20). Front one-piece enclosure (20) and rear one-piece enclosure (30) are attached to each other and maintain proper alignment for rotating piece (40), bearing (22), and reciprocating piece (50). Thumbscrew (32) secures the attachment to the flex rotor shaft of a power rotary tool. A tool holder / collet is attached to the exposed end of reciprocating piece (50) whereby numerous types of cutting tools may be utilized. Alternative versions of the rear one-piece enclosure, (30A) and (30B), described herein, allow for attachment directly to power rotary tools without flex rotor shafts. Alternative versions of the reciprocating piece, (50A), (50B), and (50C), and of the rotating piece, (40A), are also described herein.

Owner:JONES WILLIAM RANDOLPH

Method for determining the wear state

This invention relates to a method for determining a wear state of a chisel, a chisel holder, and / or a chisel holder replacement system equipped with a chisel and chisel holder. For this method to give the user qualitative and quantitative information about the wear, according to one embodiment of this invention, a position of at least one point of the chisel and / or the chisel holder is determined by a contactless measurement method and a corresponding measurement result is compared in a switching unit to a reference value stored in a memory device.

Owner:WIRTGEN GMBH

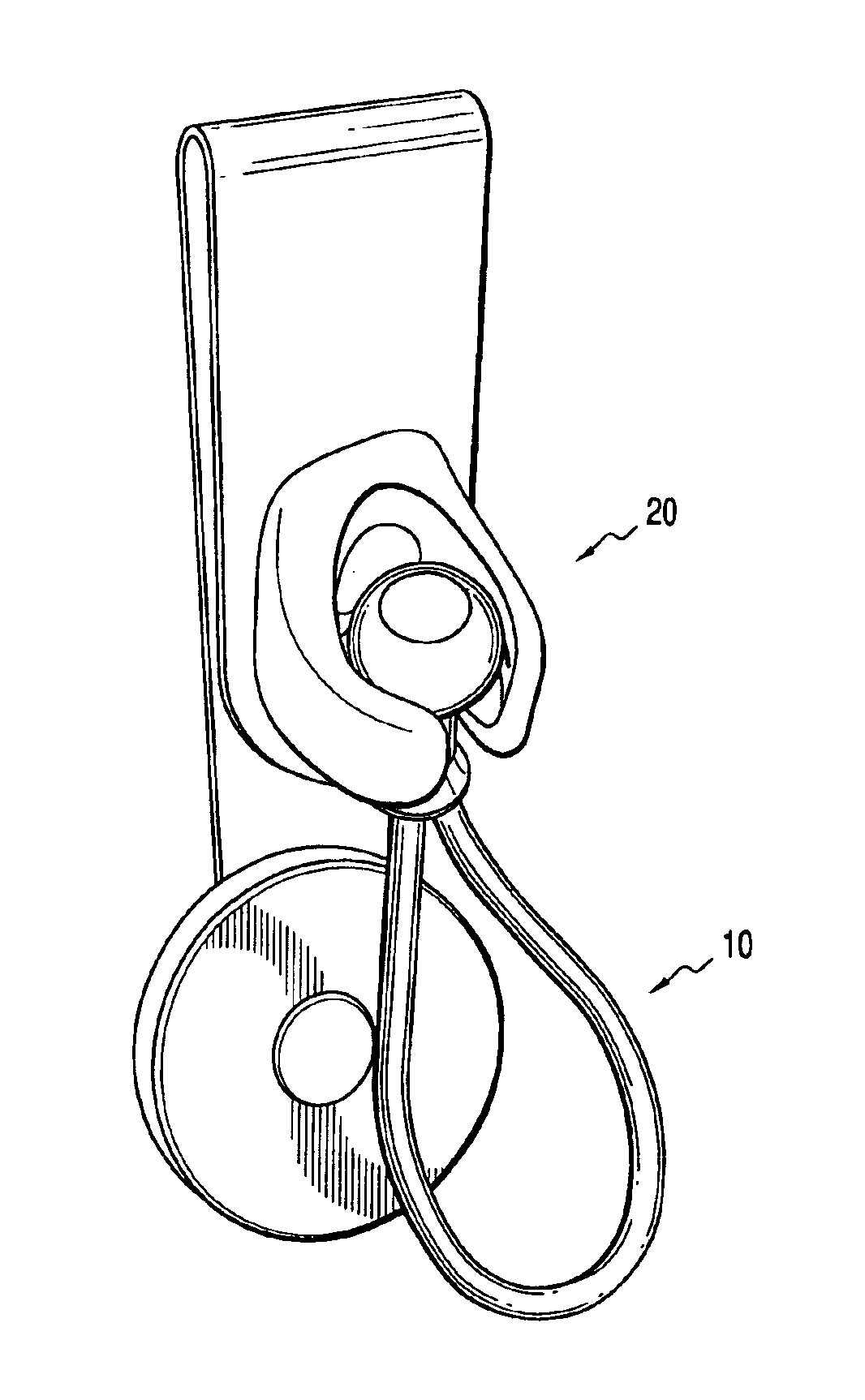

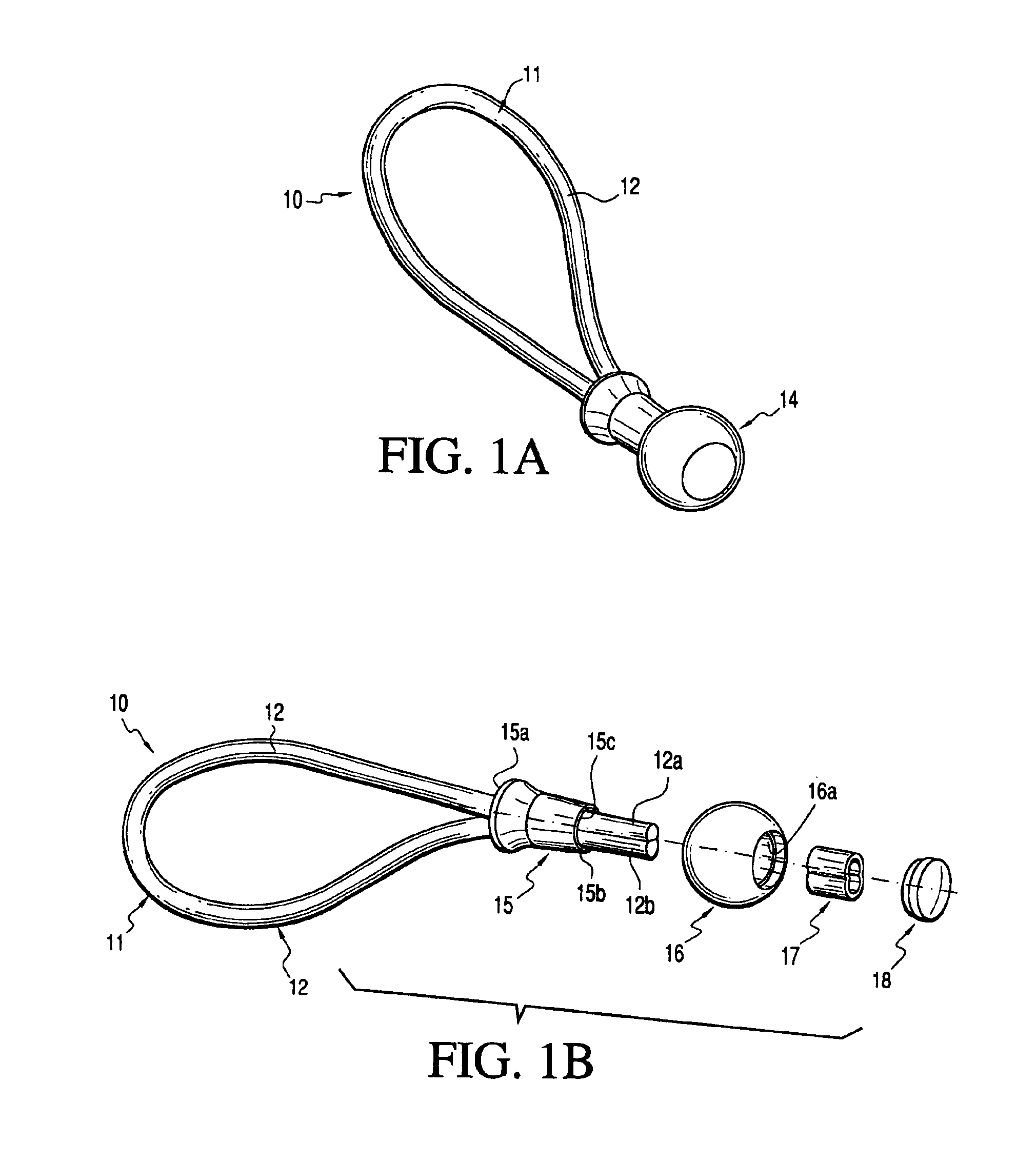

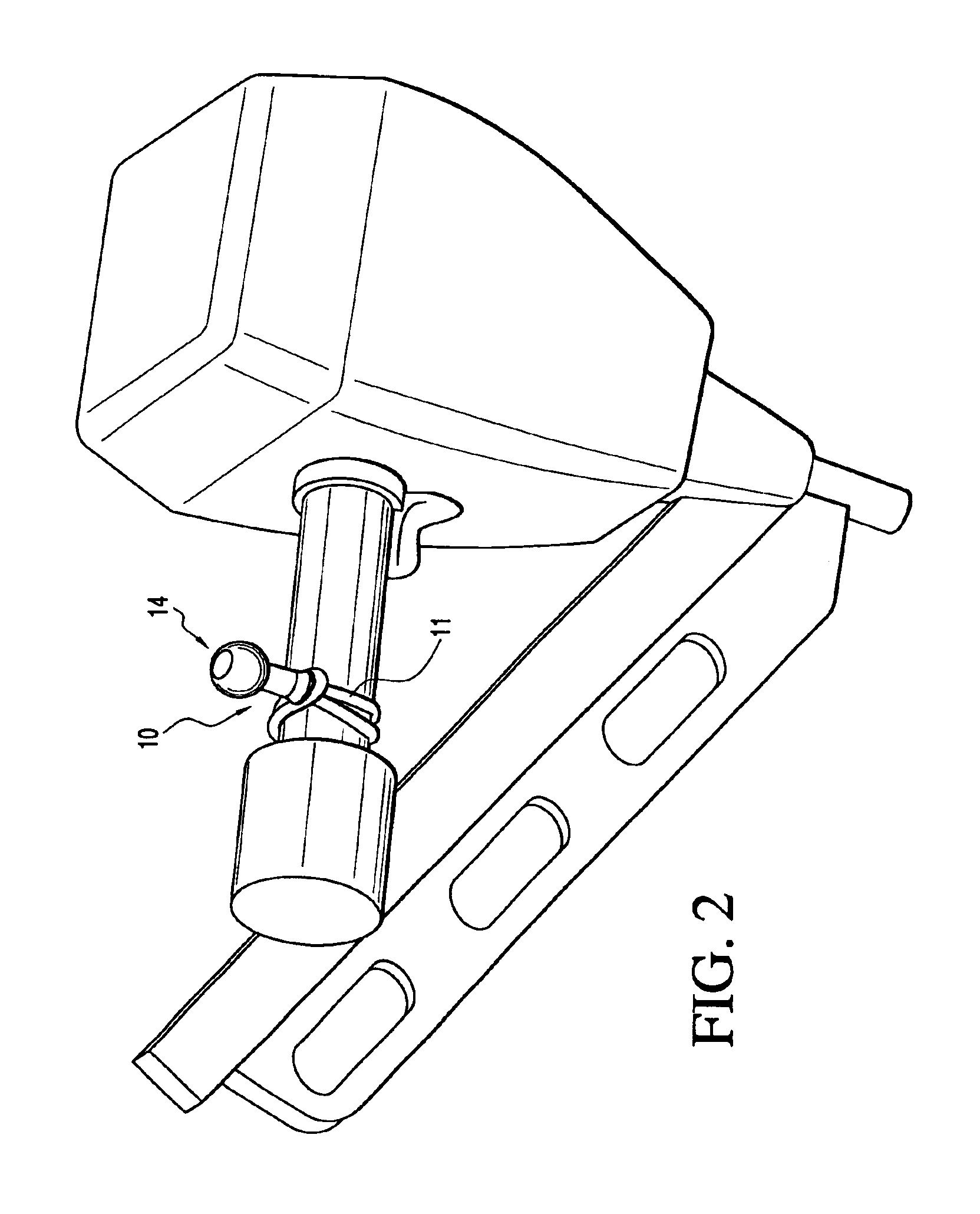

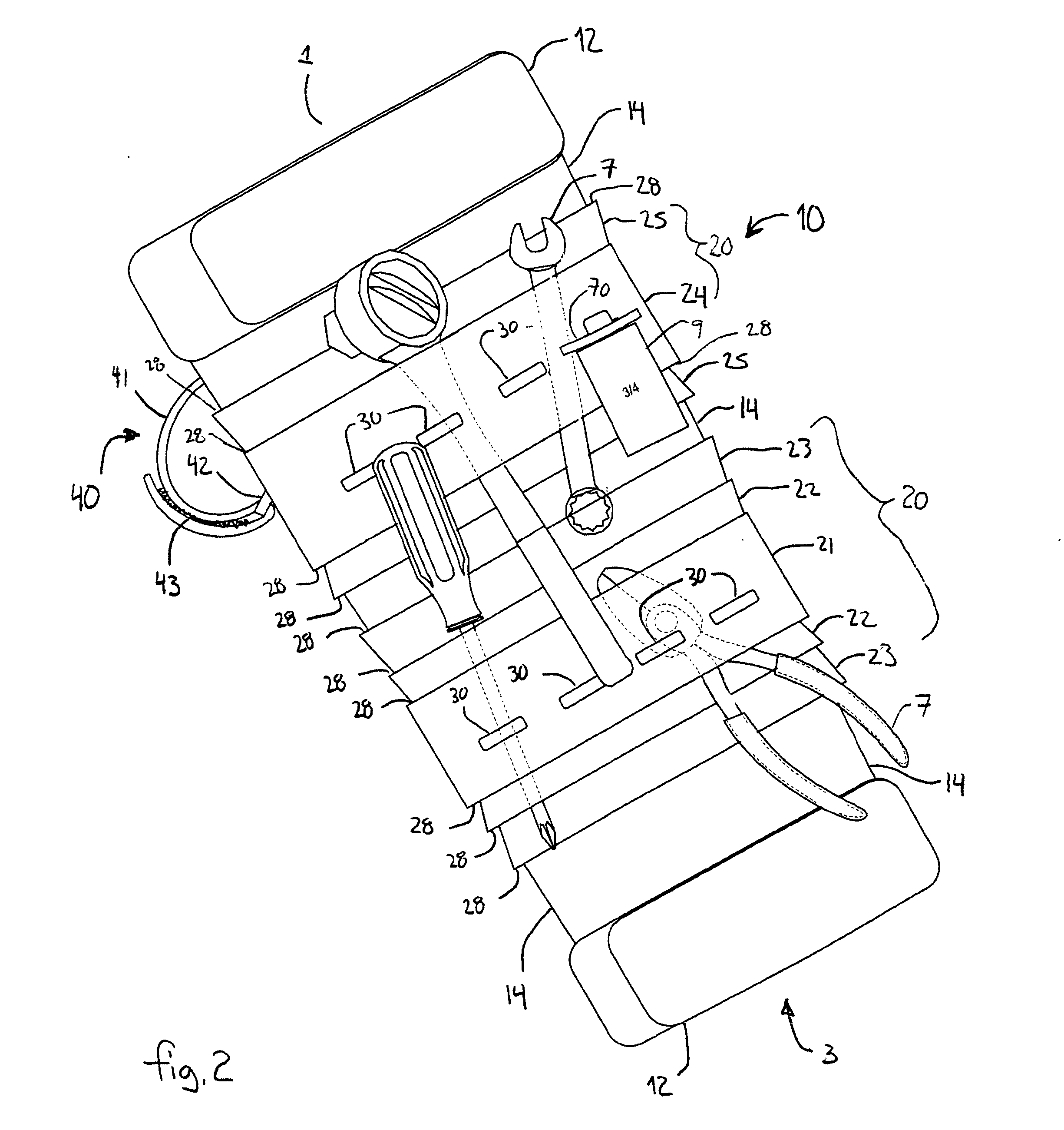

Universal tool holder

ActiveUS6880794B1Removably attachEasily and quickly introduced into retaining receiverSnap fastenersTravelling carriersDrillWall mount

A universal tool holder for carrying a tool or other article, for example, a cordless drill, nail gun, hammer or shovel is provided comprising a stretchable cord that is formed into a looped end and adapted to be wrapped about the handle of a tool in such a manner that it tightly engages the tool, and a second end having a retainable object, such as a ball, that is configured to be safely and securely held within a retaining receiver. The retaining receiver is in the form of a socket-type receiver configured to correspond to the geometrical shape of the retainable object such it can removably secure the retainable object. The socket-shaped retaining receiver can be incorporated into a variety of articles usefull in carrying and storing tools, including a belt clip, a wall mounting implement or a ladder mounting implement. By integrating the retaining receiver into such a variety of articles, any tool carried by the universal tool holder can be removably secured to the retaining receiver, thereby enabling a user to suspend the tool from a belt clip, ladder or wall.

Owner:KAHN PETER P

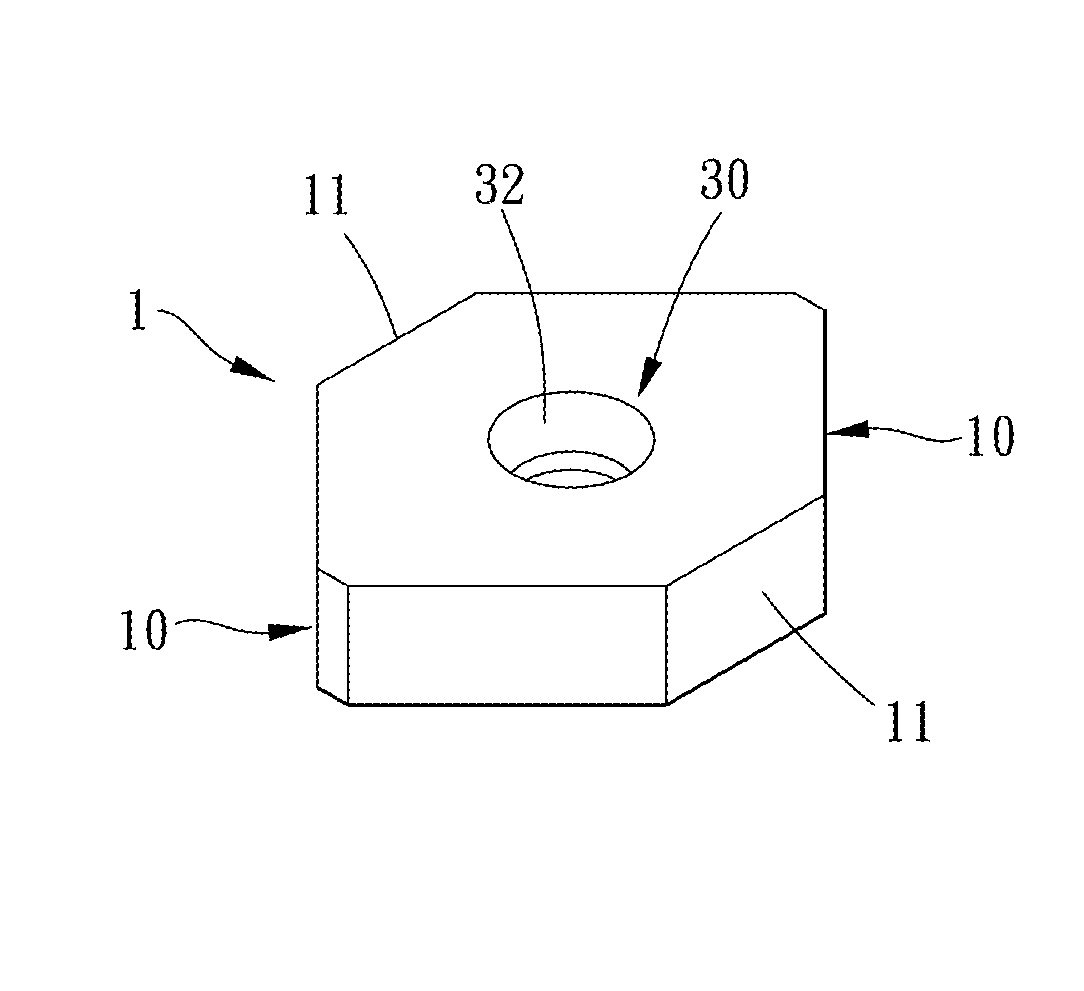

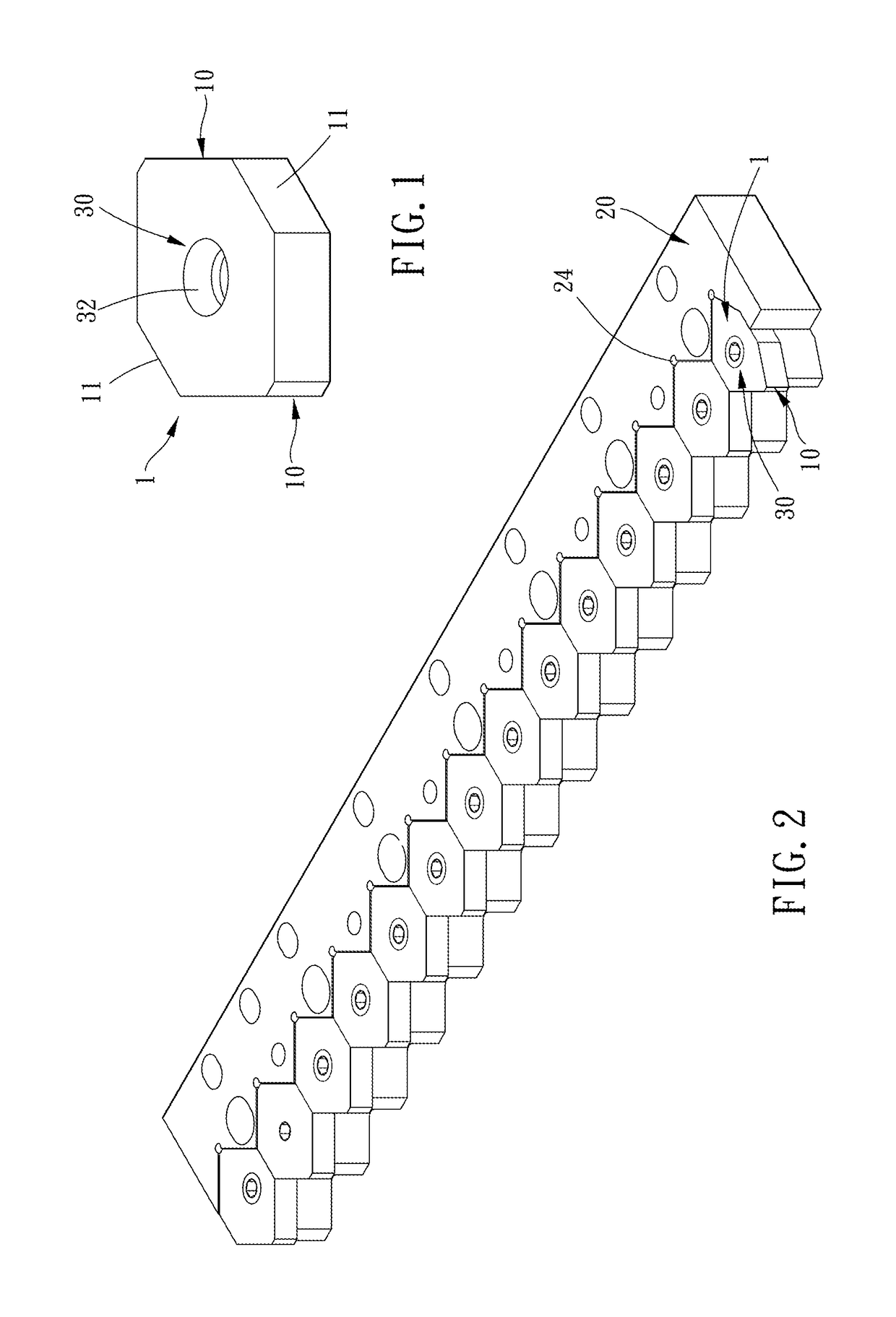

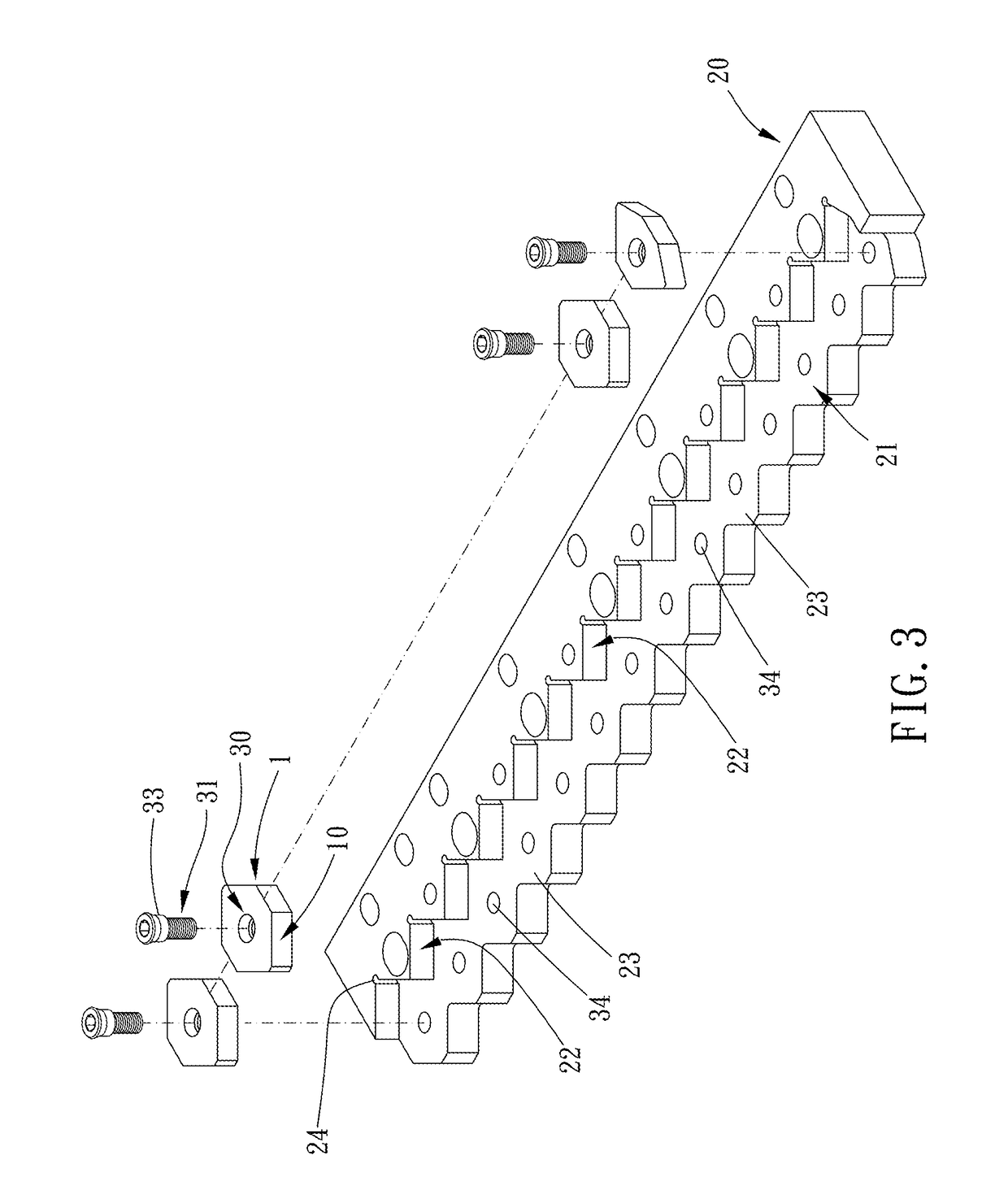

Crusher with cutter assembly and cutter thereof

ActiveUS10124343B2Prevent the crusher cutter from shakingImprove efficiencyGrain treatmentsEngineeringCrusher

A crusher includes a base, a cylinder pivoted to the base, cutting portions arranged on the cylinder. A crusher cutter assembly is further provided, including: a cutter base, for being assembled to the crusher, having receiving slots including an abutting recess and a bottom portion. A crusher cutter is further provided for assembling on the cutter base. The crusher cutter includes: two corner portions, disposed on two sides thereof, for being inserted in the abutting recess and fixed on the cutter base, two sides of the corner portion abutting against the abutting recess; two abutting portions, disposed on two opposite sides of the crusher cutter, for being positionably abutting against another crusher cutter; wherein when the crusher cutter is fixed on the cutter base, a part of the corner portion protrudes beyond the cutter base and is alternatively shifted with a part of the cutting portions.

Owner:KUN SHENG MACHINE

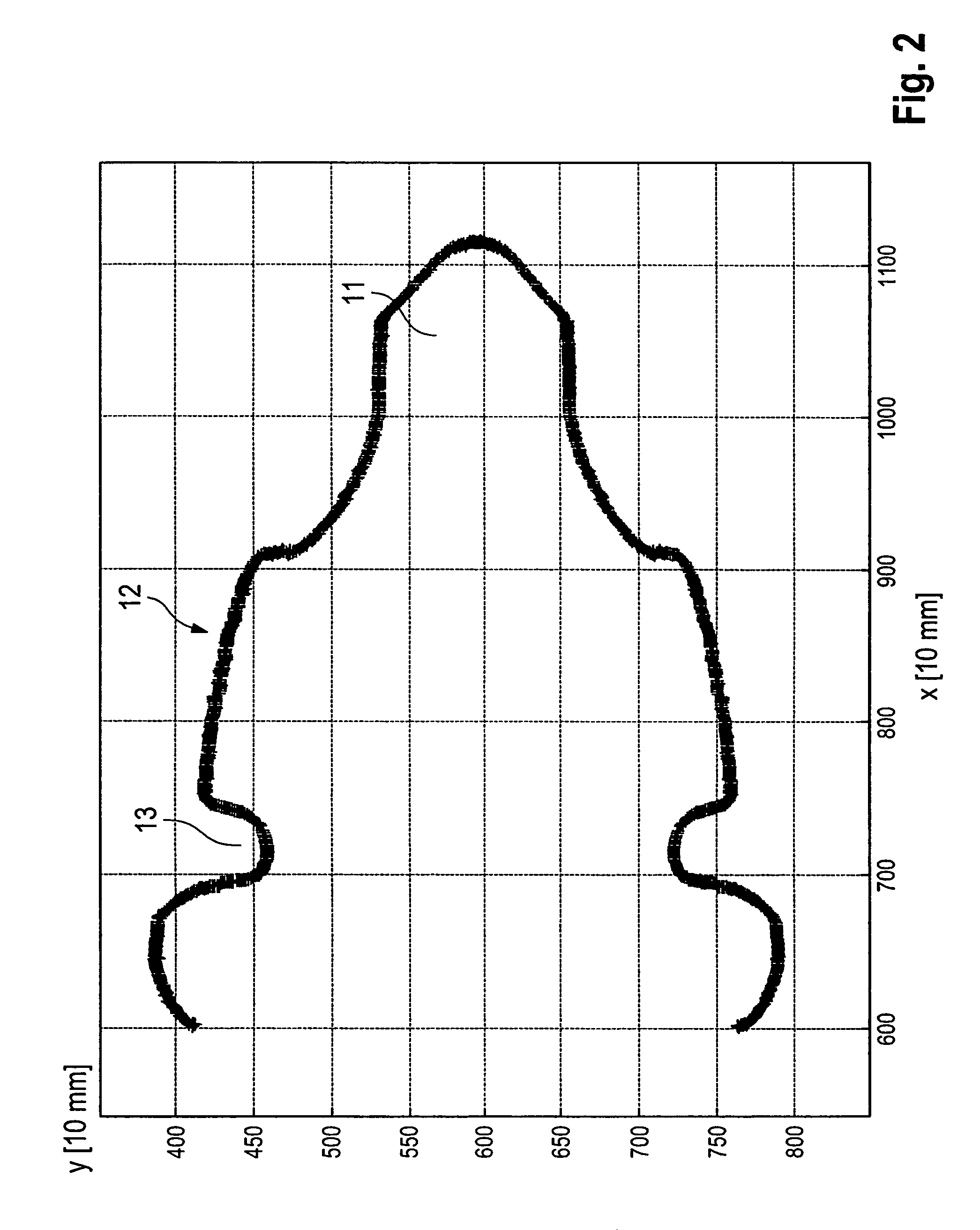

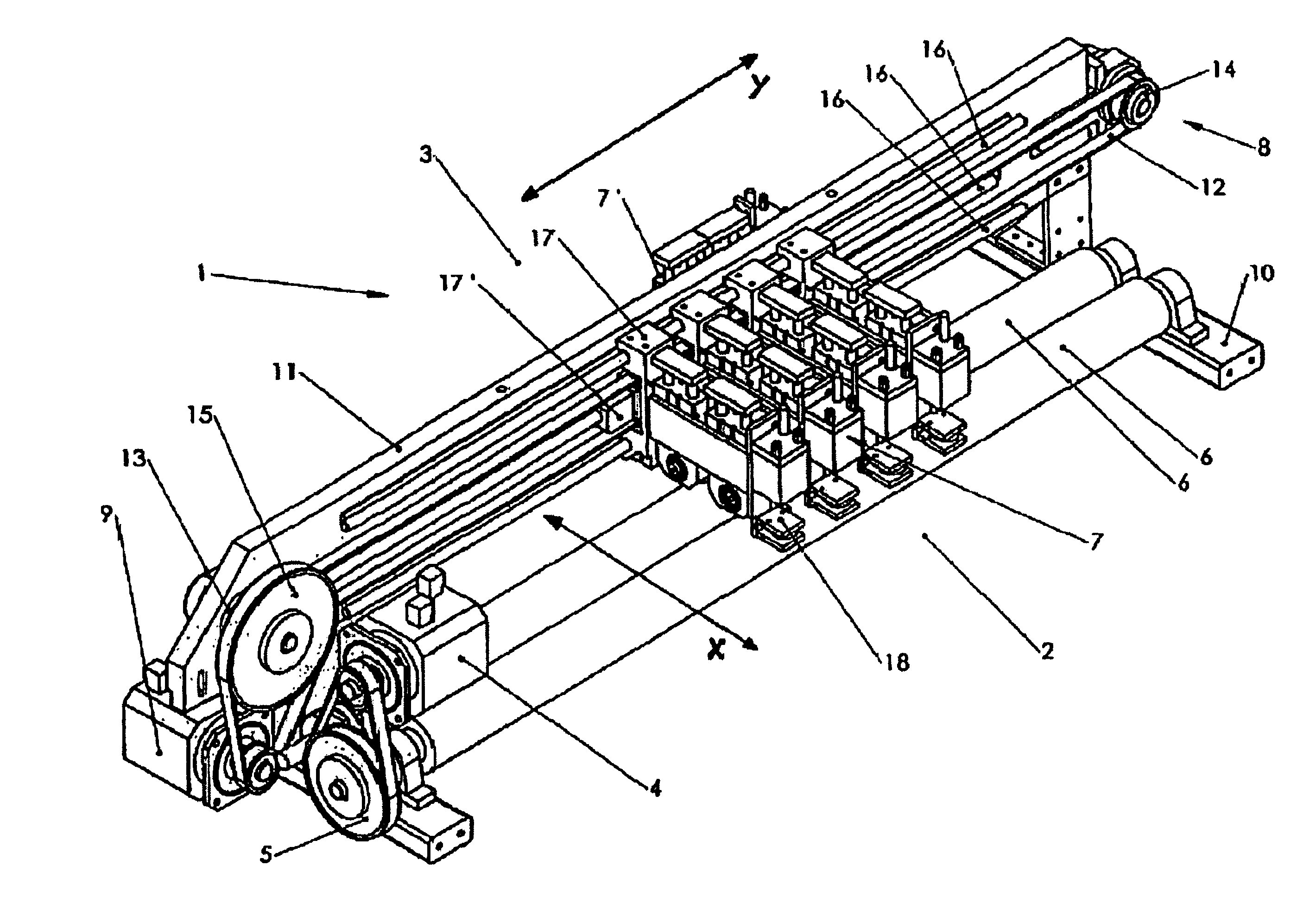

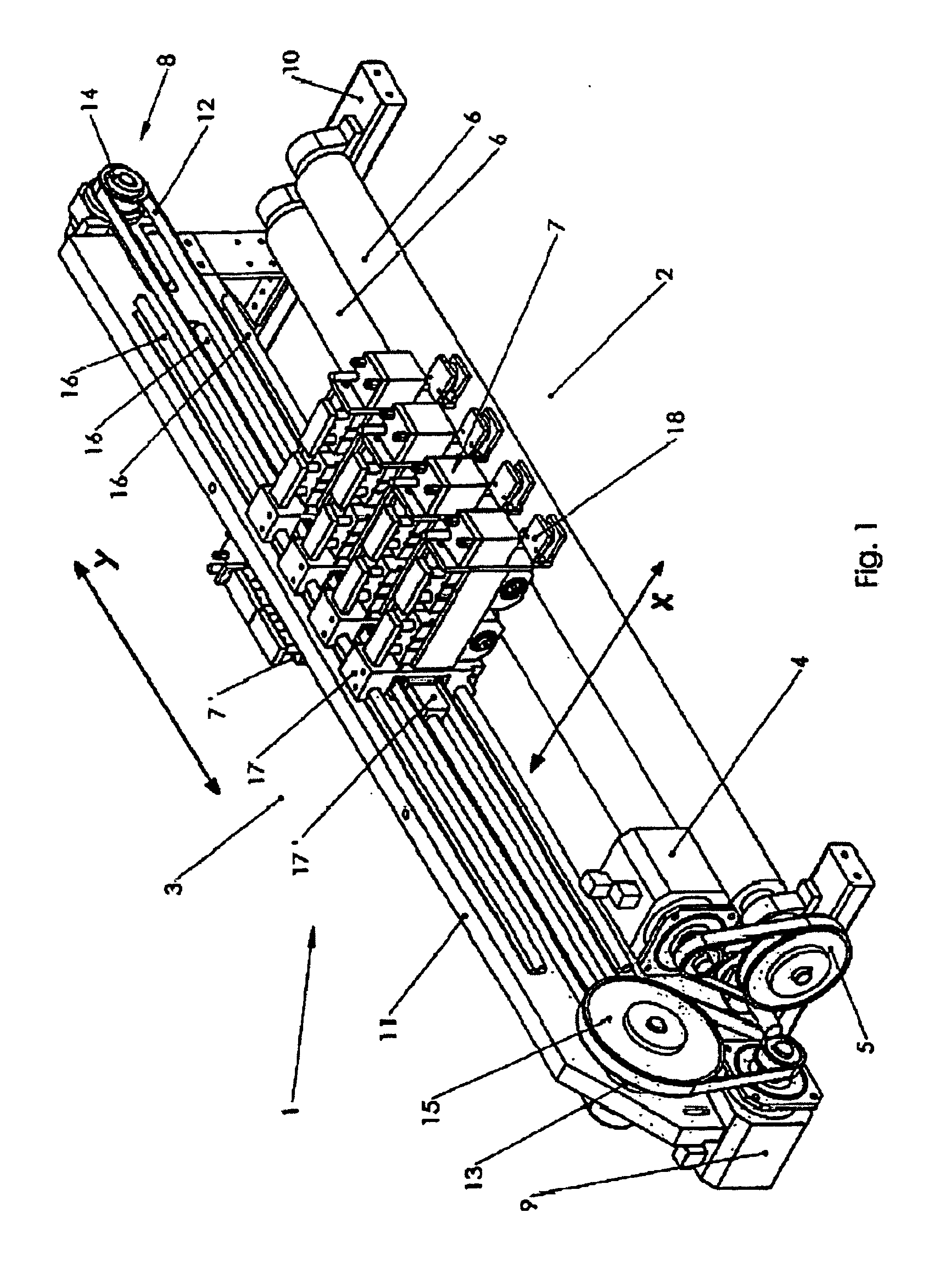

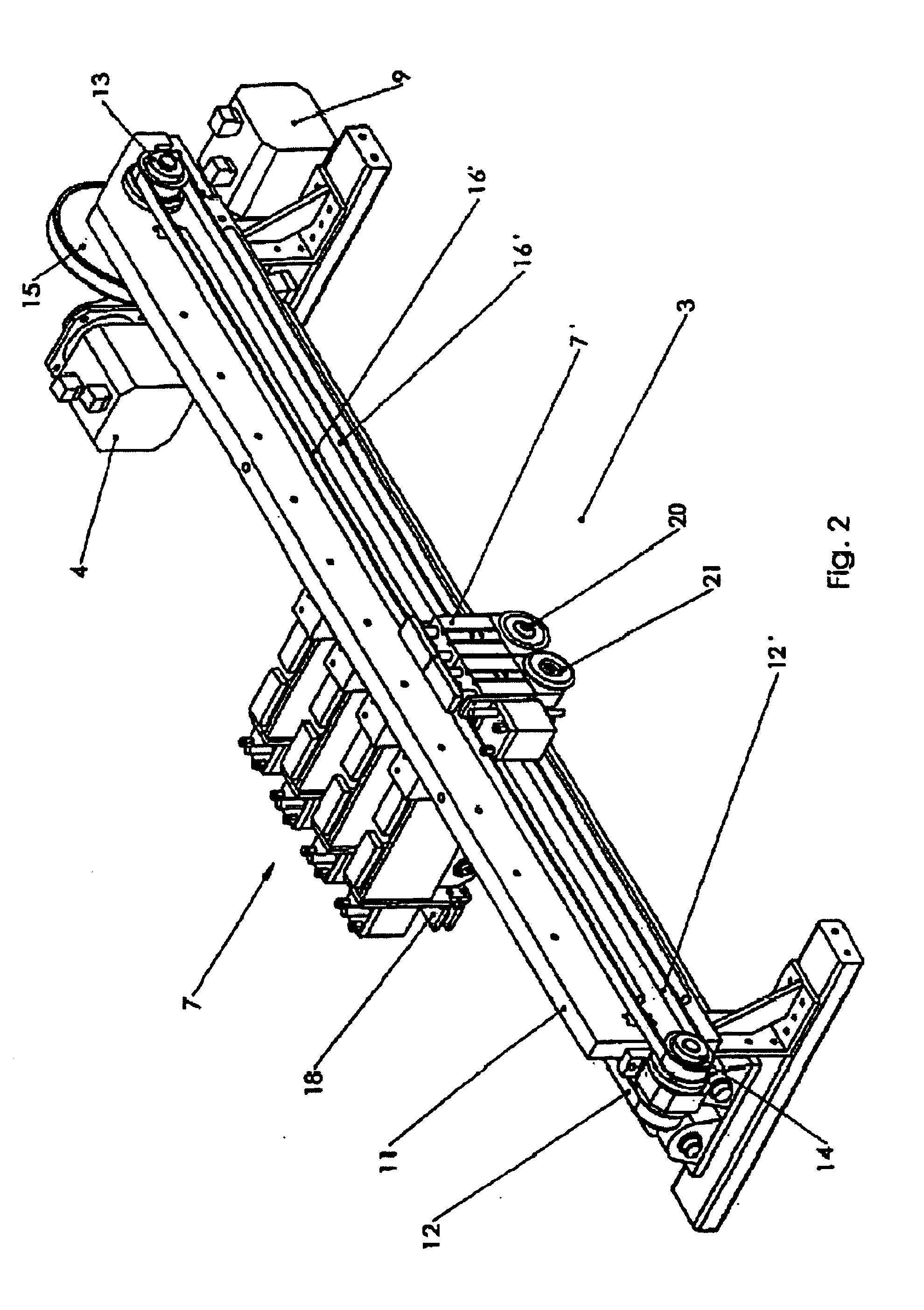

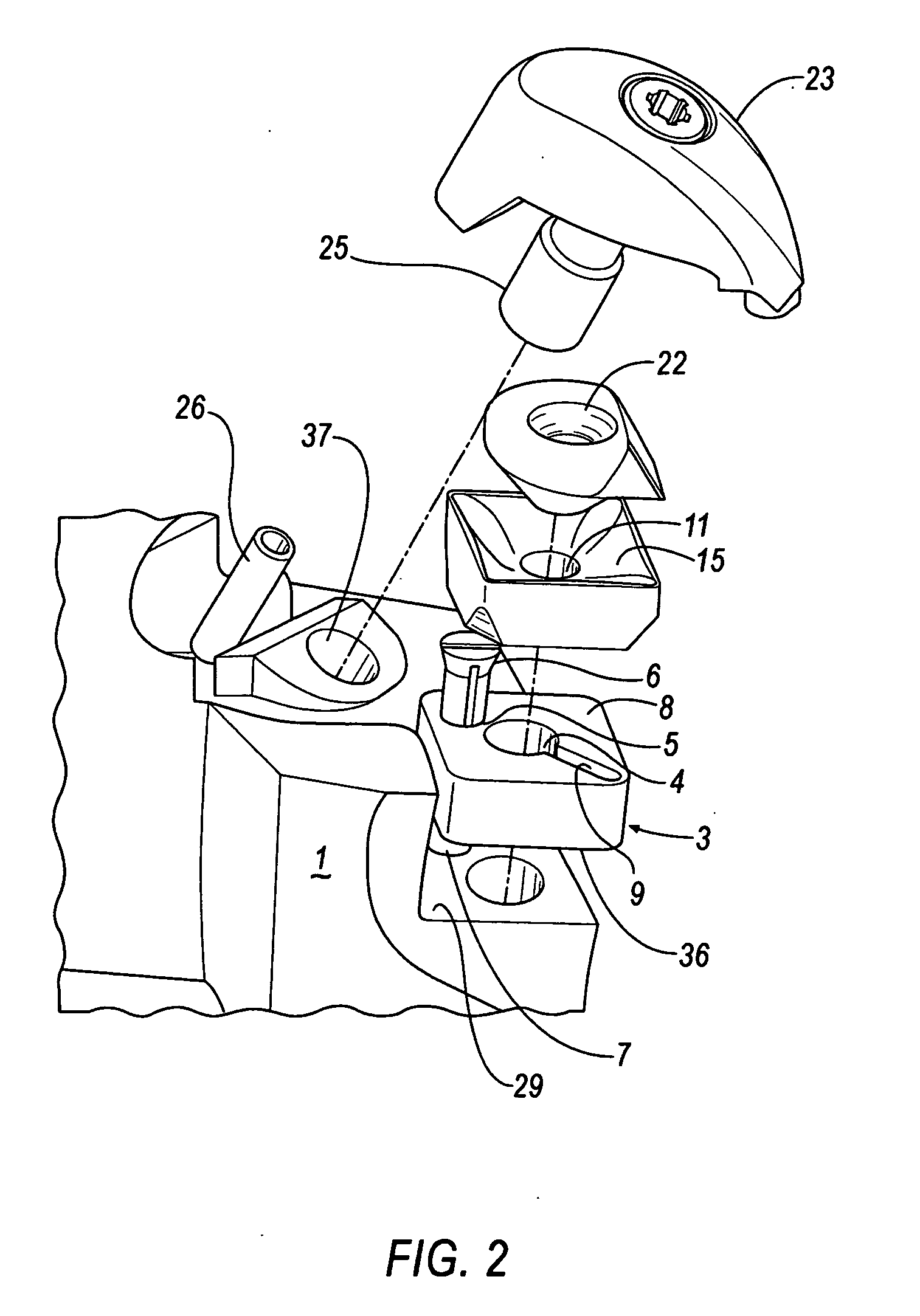

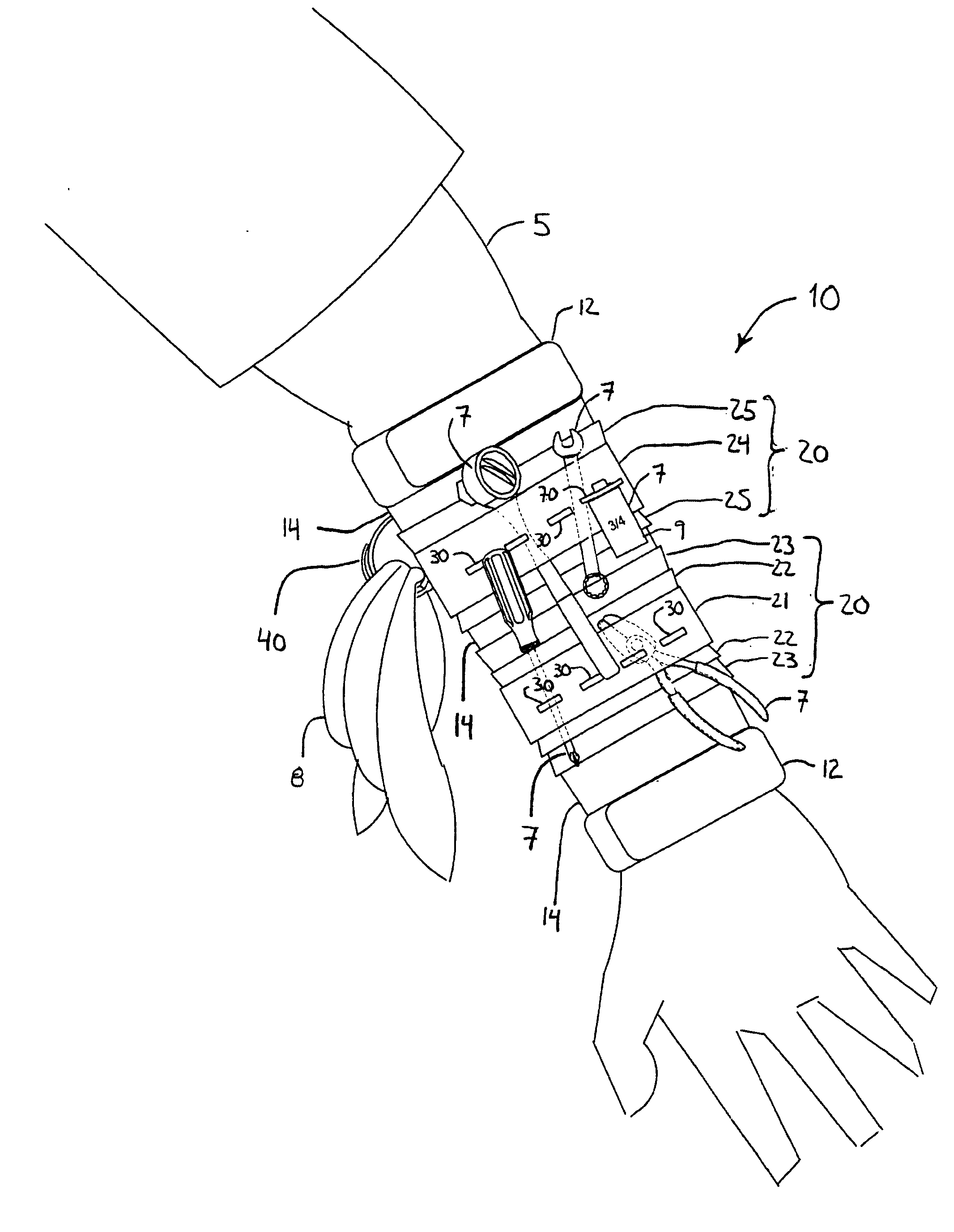

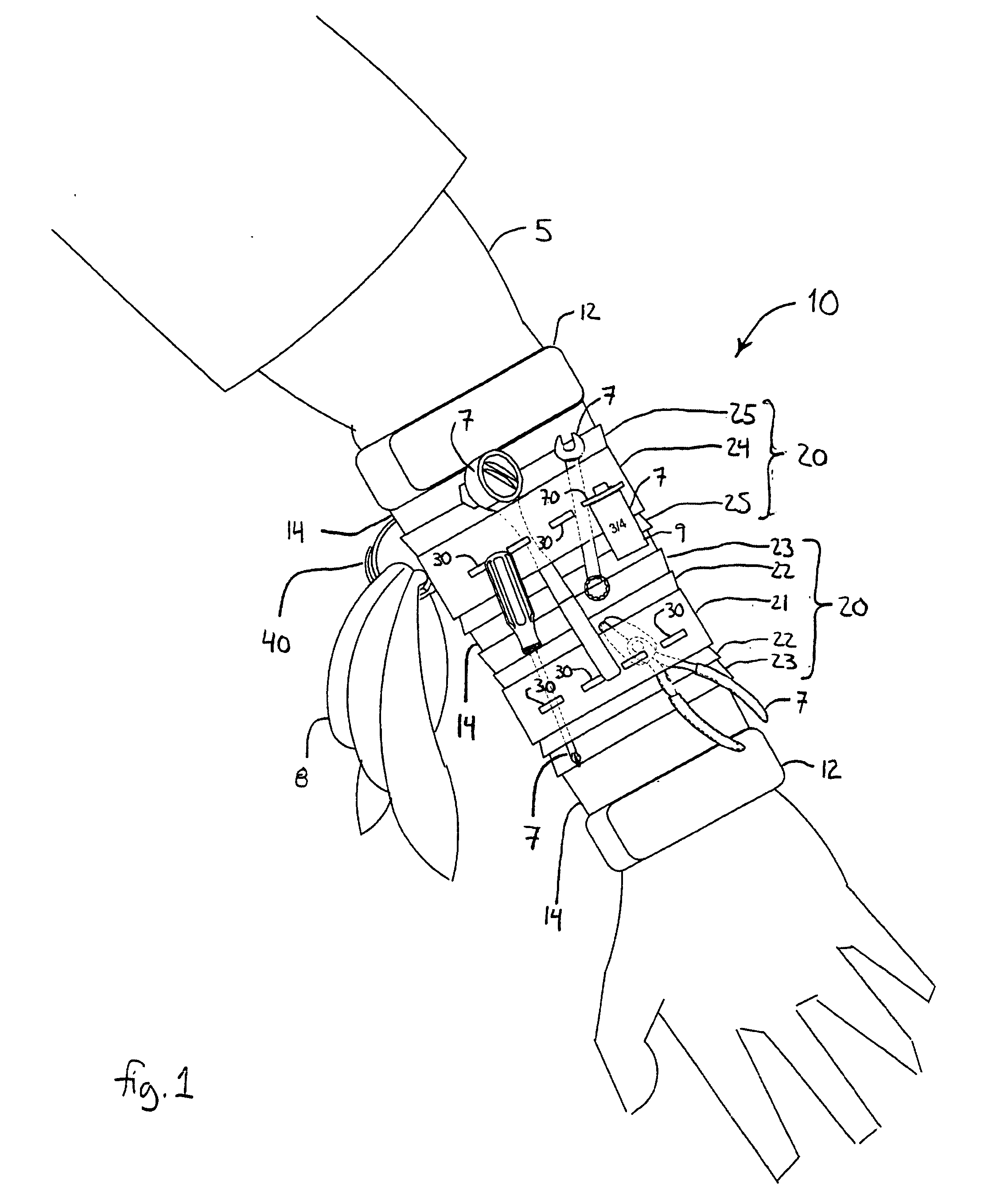

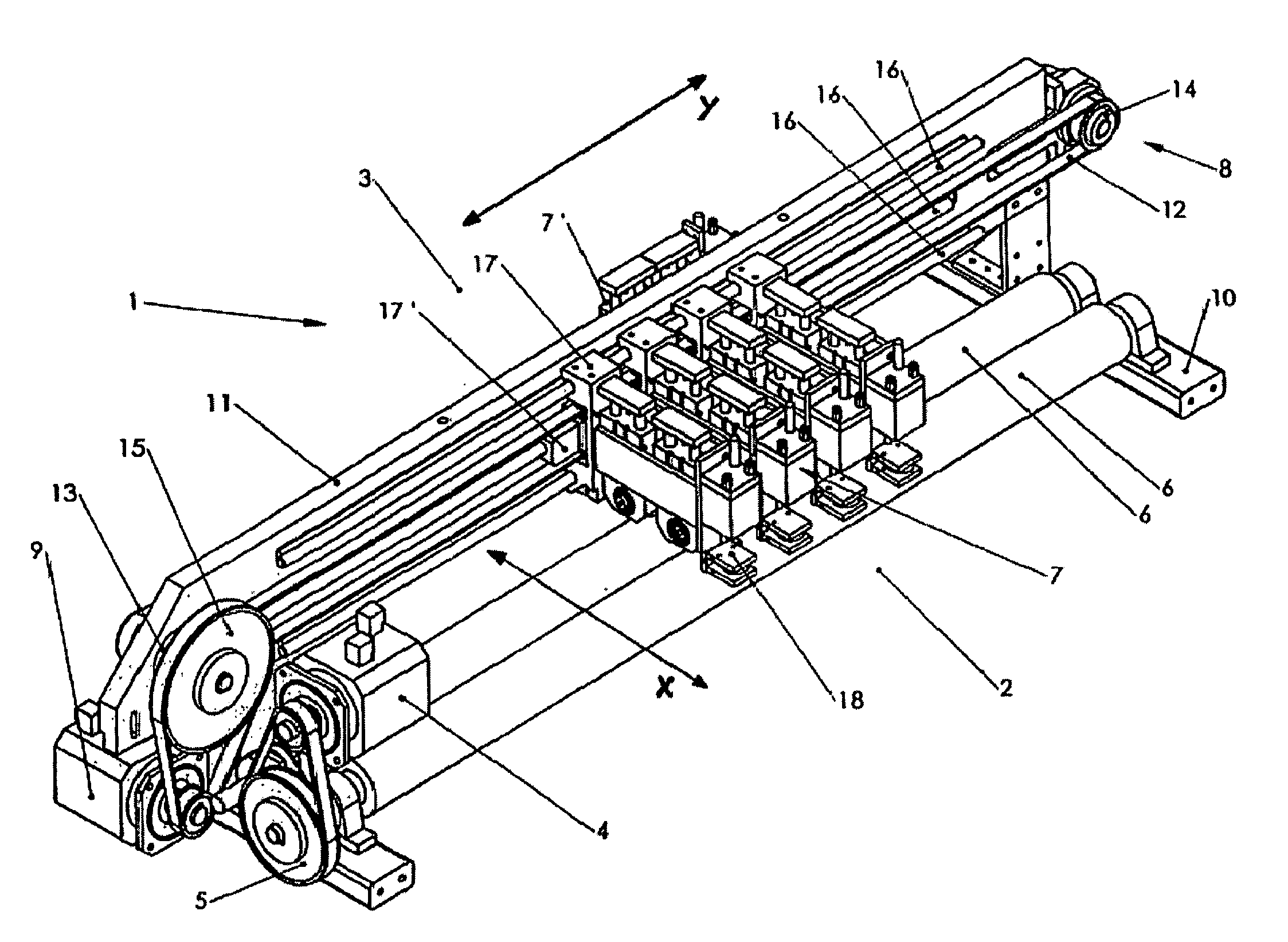

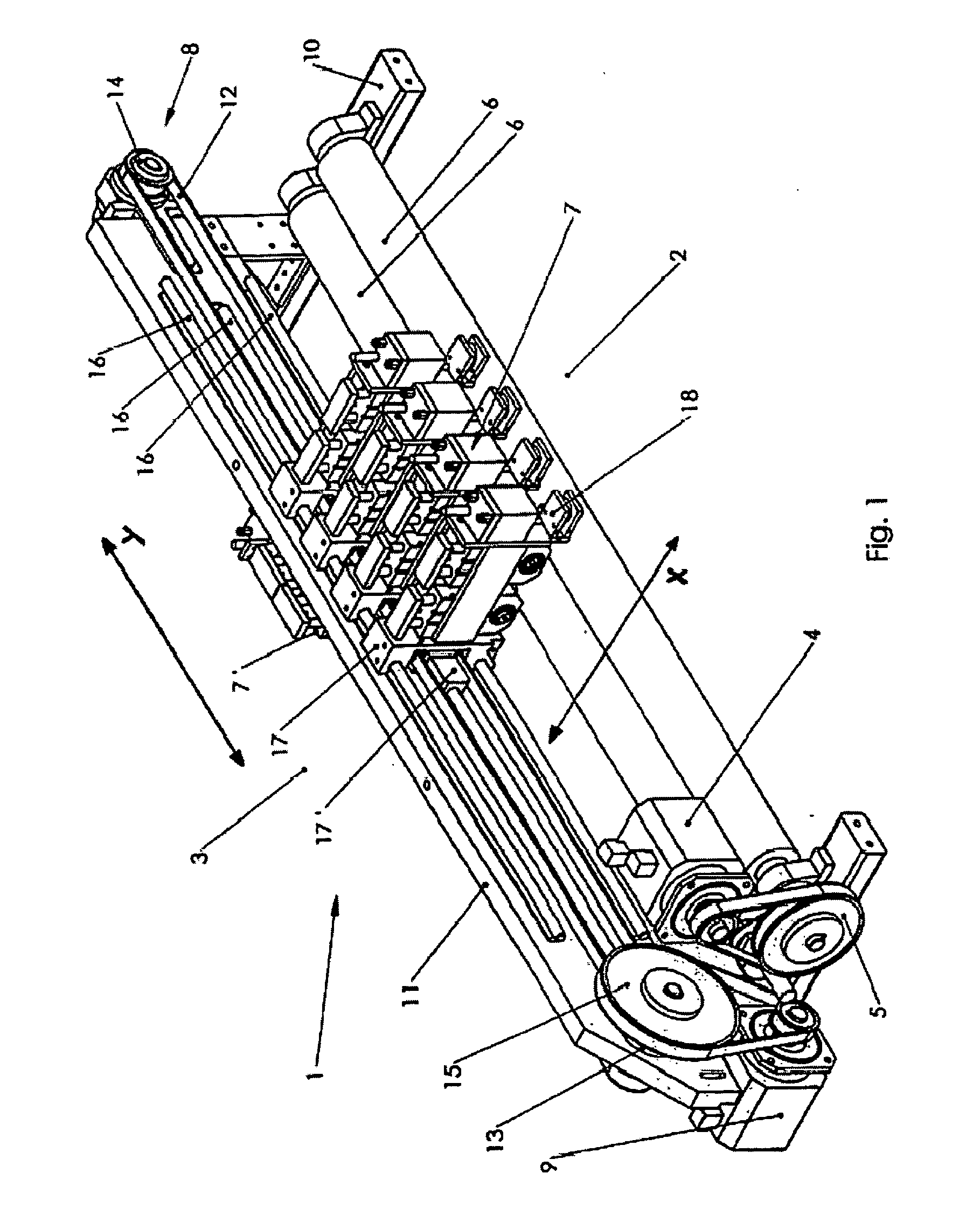

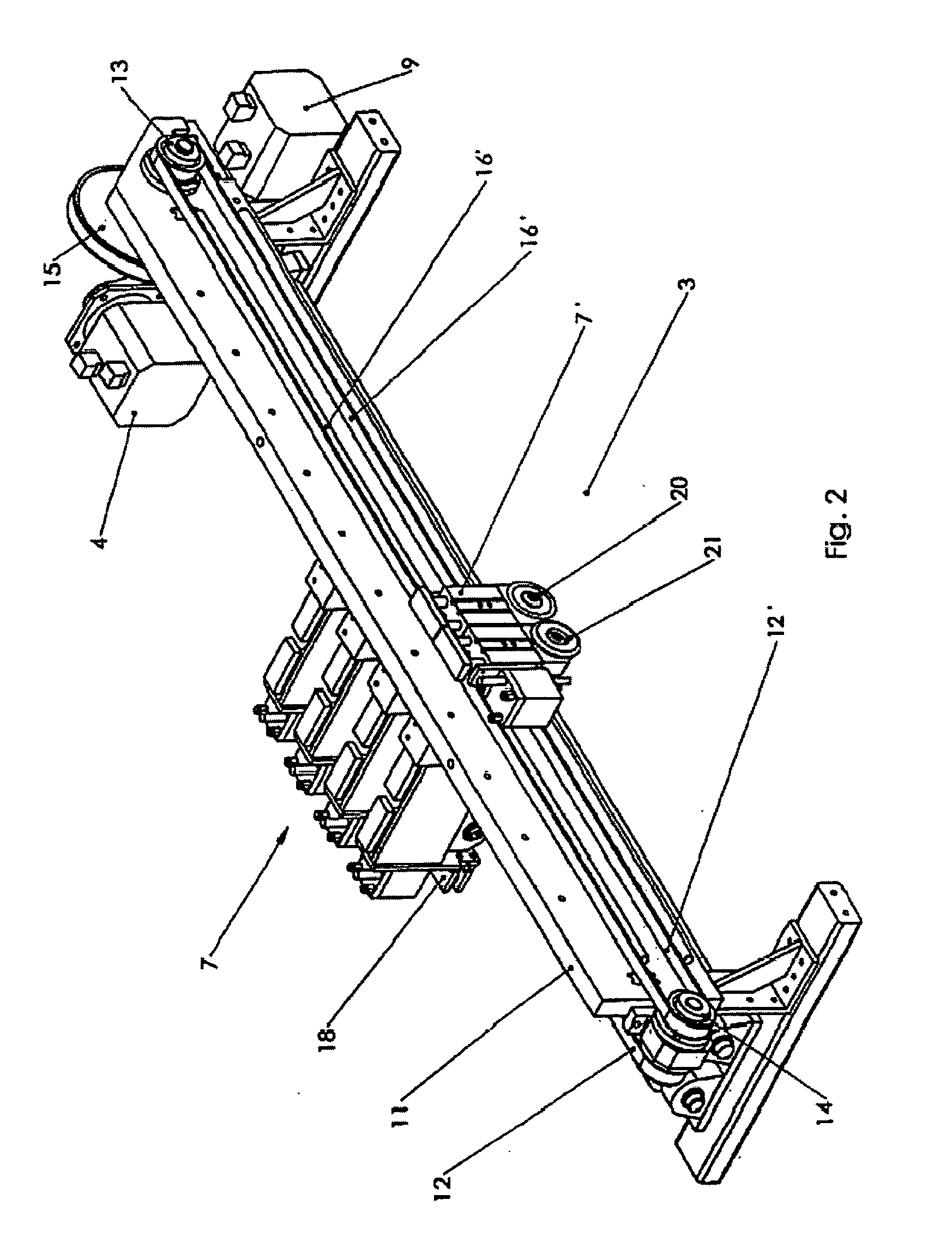

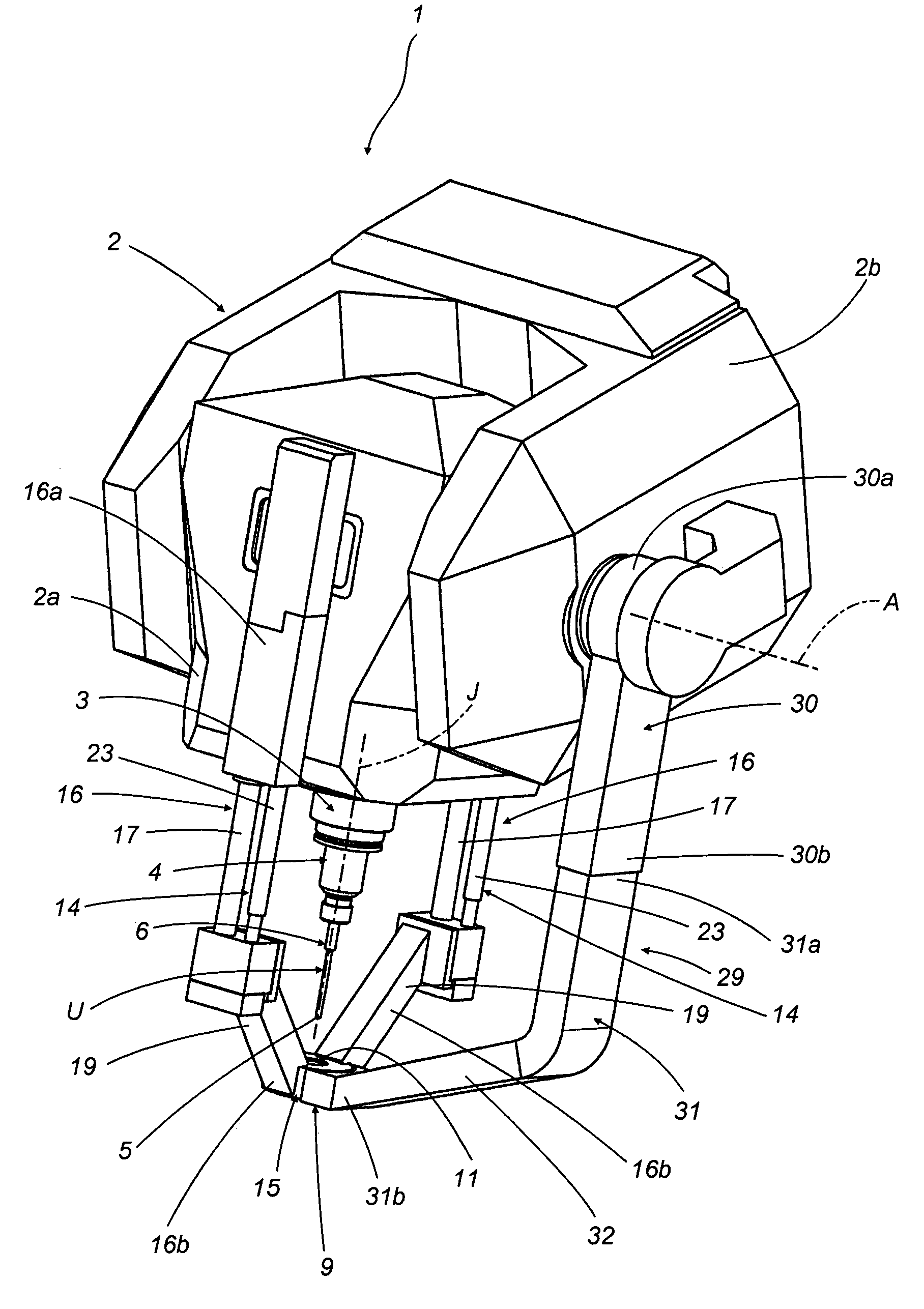

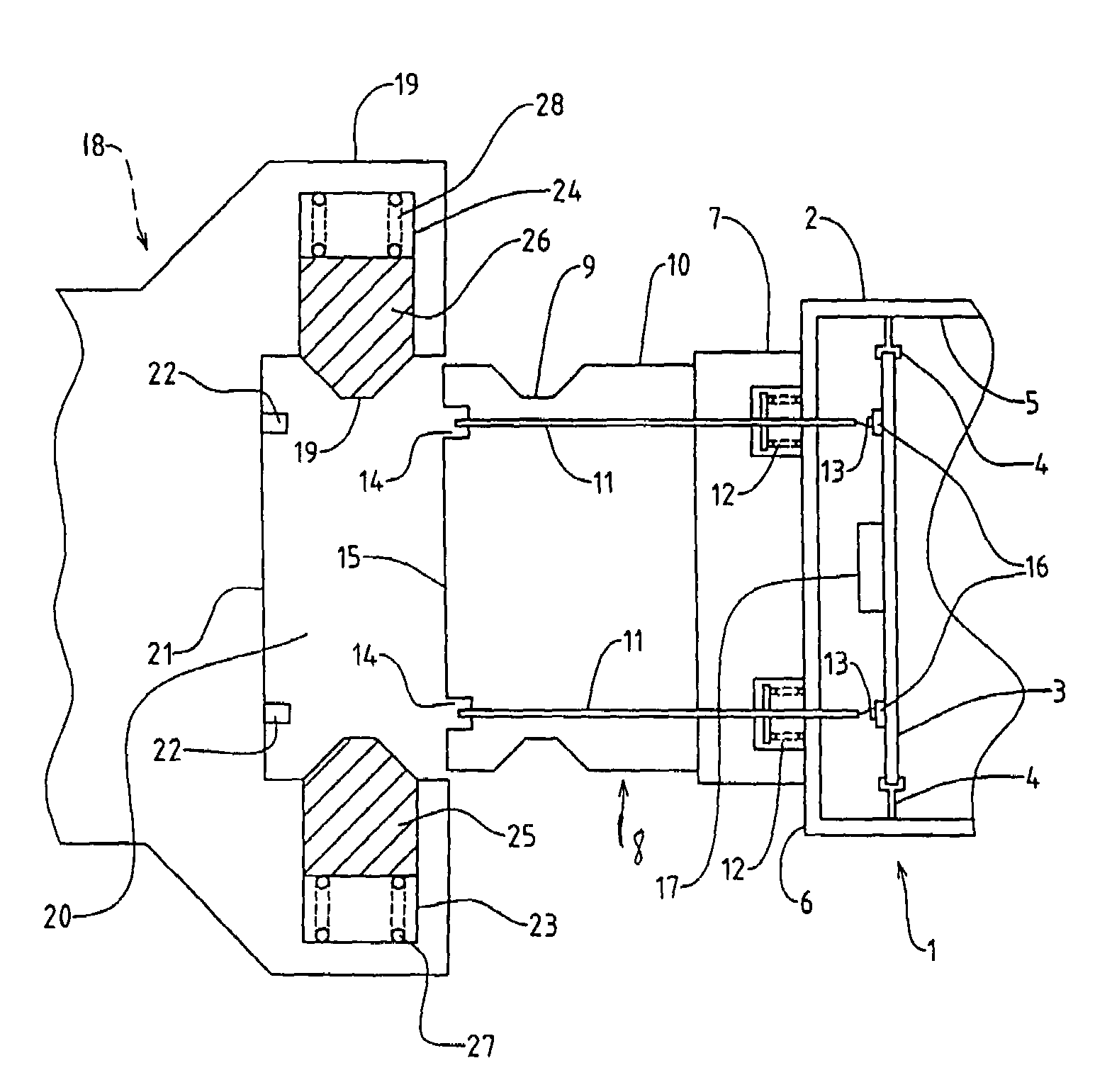

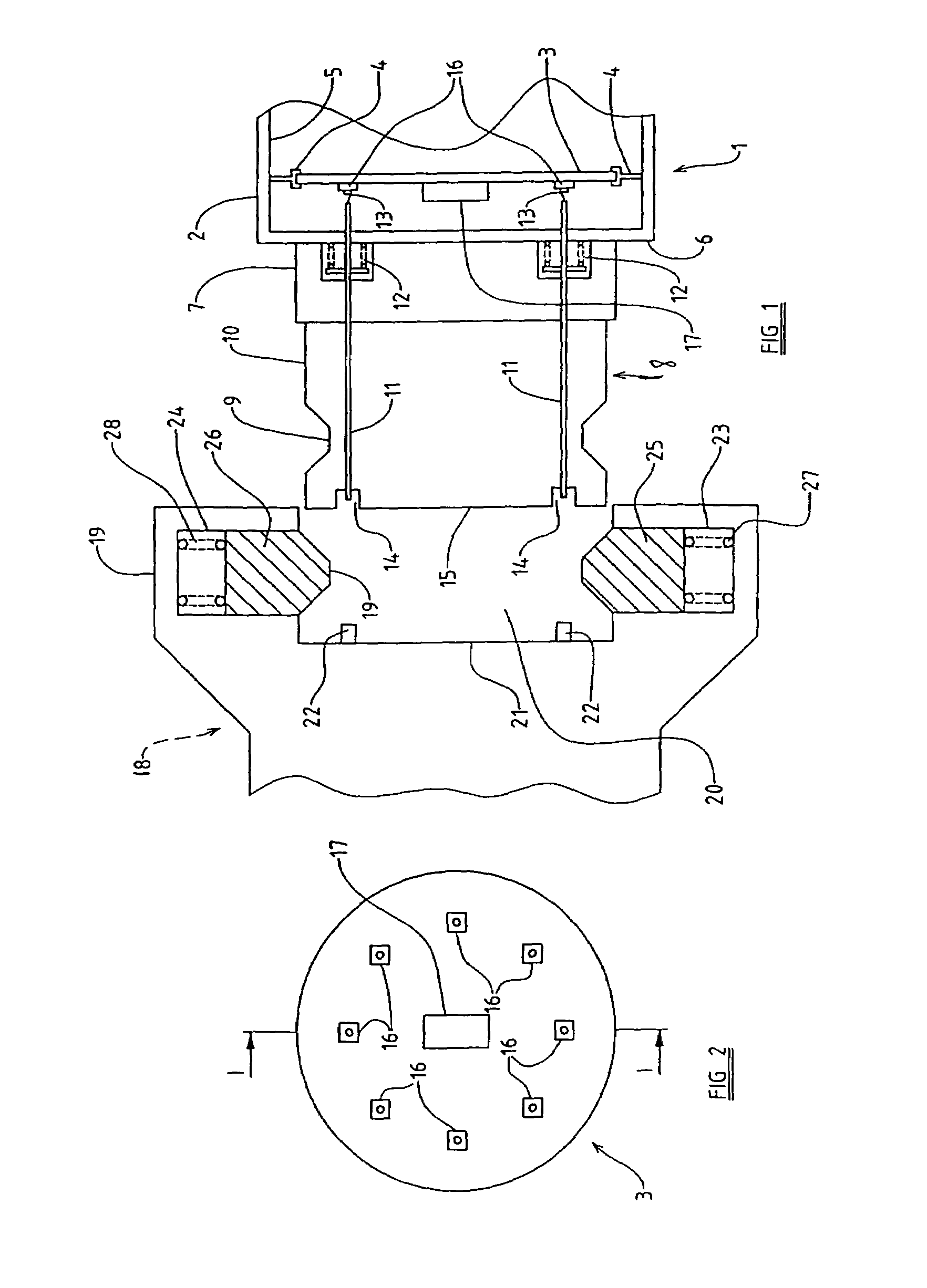

Apparatus for the positioning of a tool or a tool holder in a machine designed for processing a sheet material

InactiveUS6840898B2Accurate versatile controlled positioningEnvelopes/bags making machineryBox making operationsMachine designKnife holder

Arrangement for the positioning and shifting of tools, specifically the tools of a machine designed for shaping sheet material while being advanced relative to the arrangement, the arrangement having fixed guides (16,19) for guiding the tools in transverse motion relative to the travel direction (X) of the material, the tools or holders (7,7′) for the tools comprising means (22,23) by which a continuous or intermittently running drive (Y) across the material travel direction (X) is used for shifting the tool holders, individually or in combination, by alternately connecting one or several tool holders (7,7′) to the running drive.

Owner:PACKSIZE

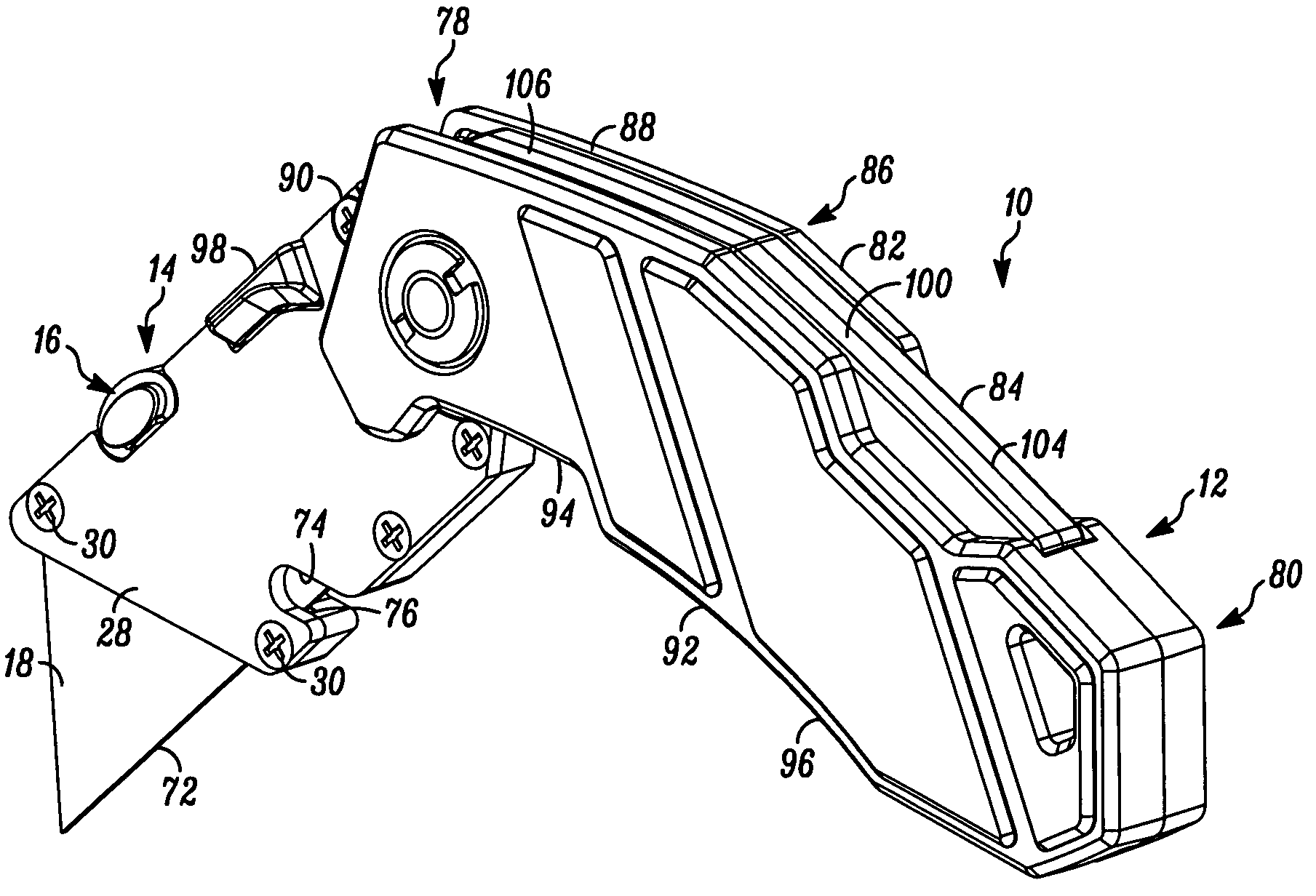

Folding utility knife

A folding utility knife has a handle and a blade holder pivotally mounted on he handle. The blade holder is movable between (i) a closed position with the blade holder pivoted inwardly toward the handle, (ii) a cutting position with the blade holder pivoted outwardly relative to the handle, and (iii) a blade release position located between the closed position and the cutting position. A blade release actuator is located on the blade holder and is movable between (i) a first position preventing release of a utility knife blade located on the blade holder, and (ii) a second position permitting release of a utility knife blade located on the blade holder. A locking member is movable between (i) a blade locking position with the blade holder located in the cutting position that prevents movement of the blade release actuator from the first position to the second position, and (ii) a blade release position with the blade holder located in the blade release position that permits movement of the blade release actuator from the first position to the second position to, in turn, release a utility knife blade from the blade holder.

Owner:BLACK & DECKER INC

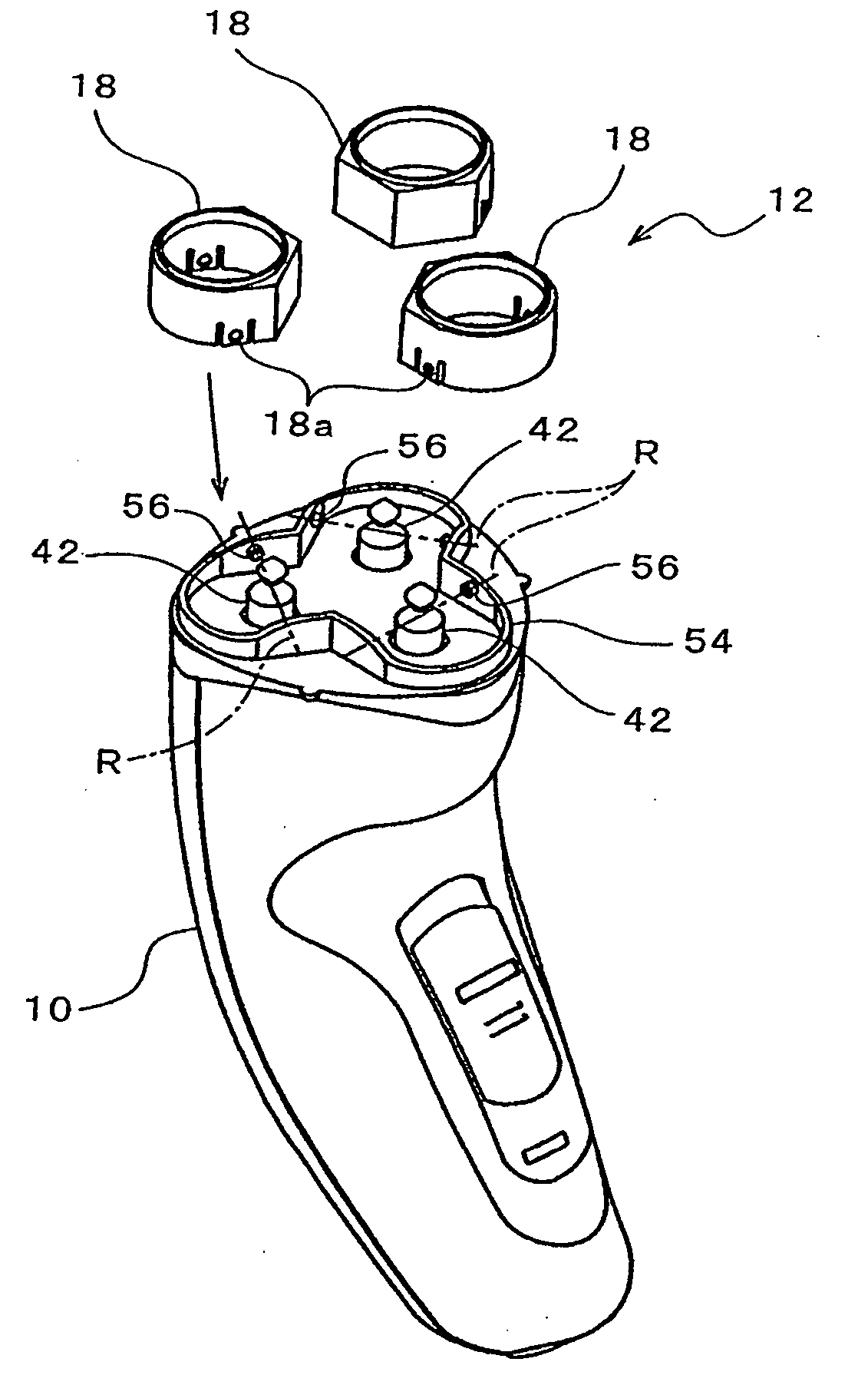

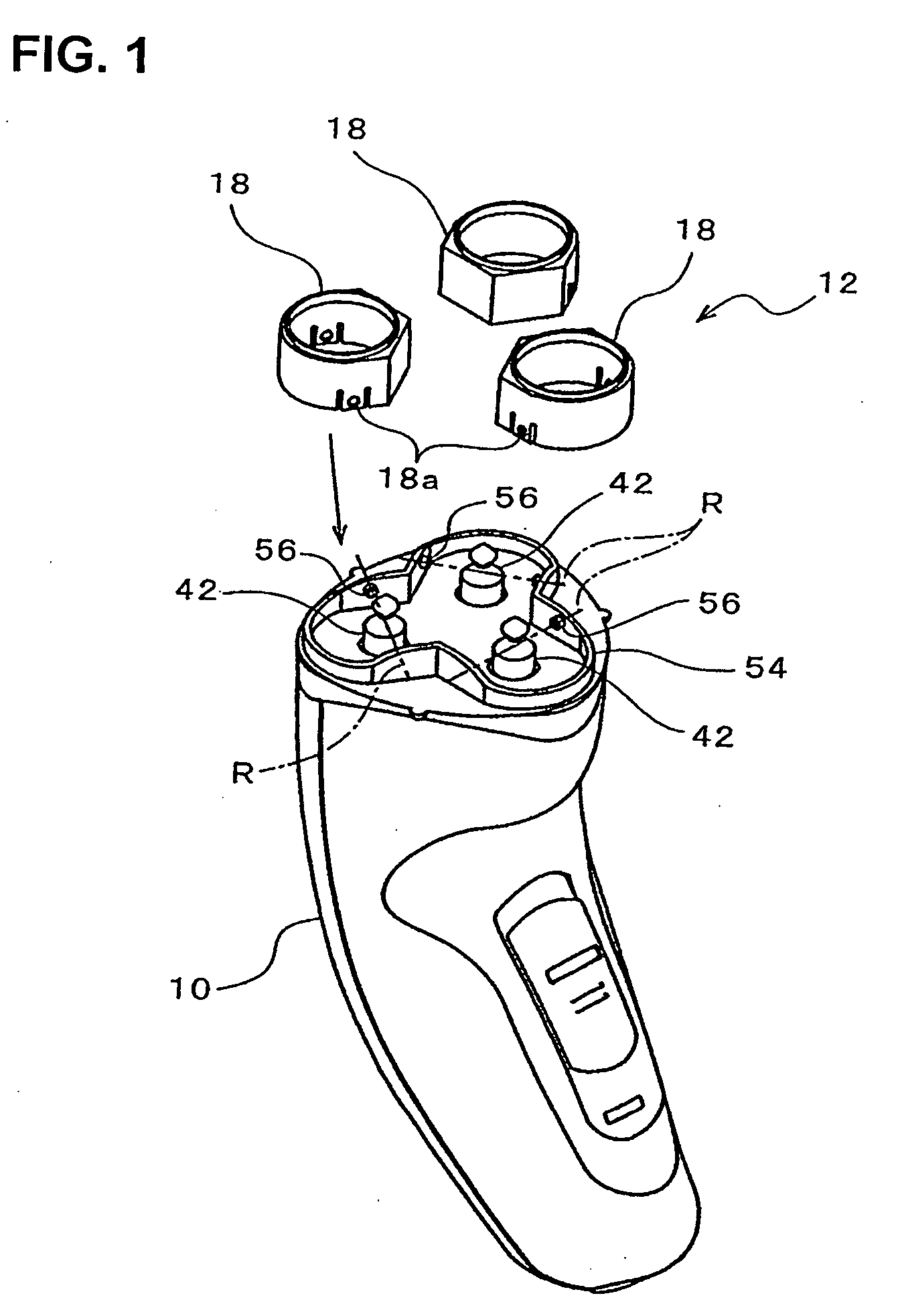

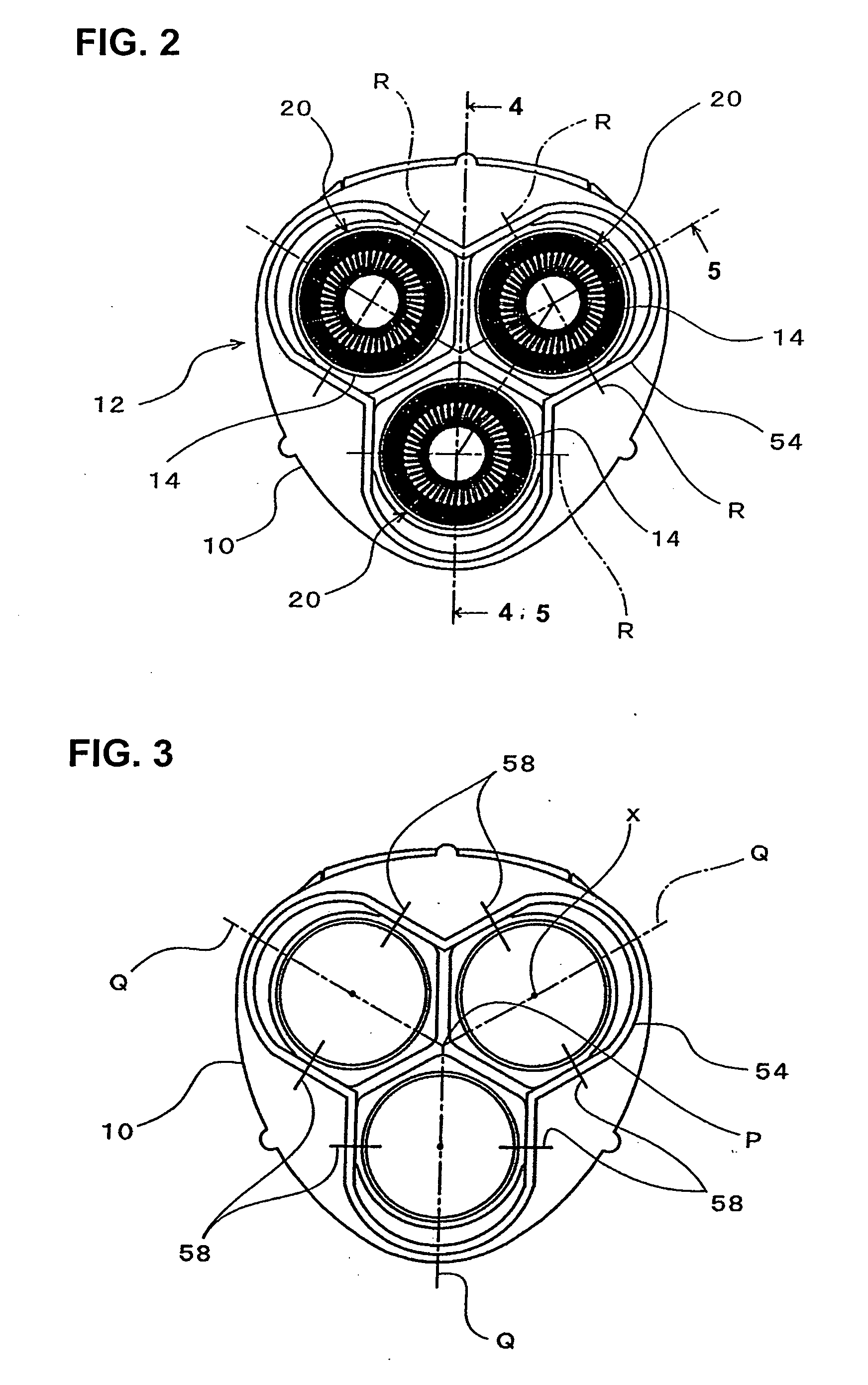

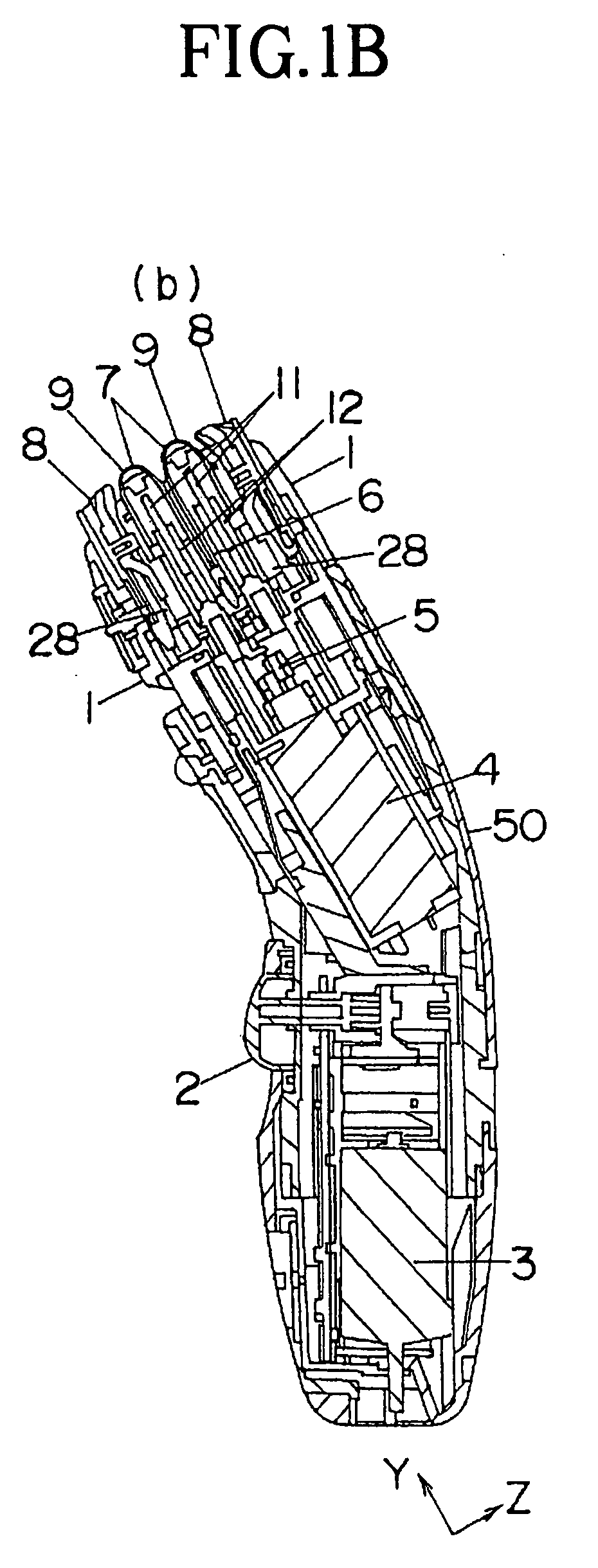

Rotary electric shaver

InactiveUS20070124936A1Extended angle rangeImprove contact tightnessMetal working apparatusElectric machineryEngineering

A rotary electric shaver including a plurality of substantially disc-shaped outer cutters, which are provided in the upper part of a shaver main body housing therein a motor, and inner cutters, which engage the outer cutters from below and are rotationally driven by the motor so as to cut hair entering into the hair introduction openings formed in the outer cutters; and in addition, substantially cylindrical cutter frames 18 for respectively holding the outer cutters in a depressible manner are provided so that cutter frames 18 can pivot in the upper surface of the shaver main body.

Owner:IZUMI PROD CO

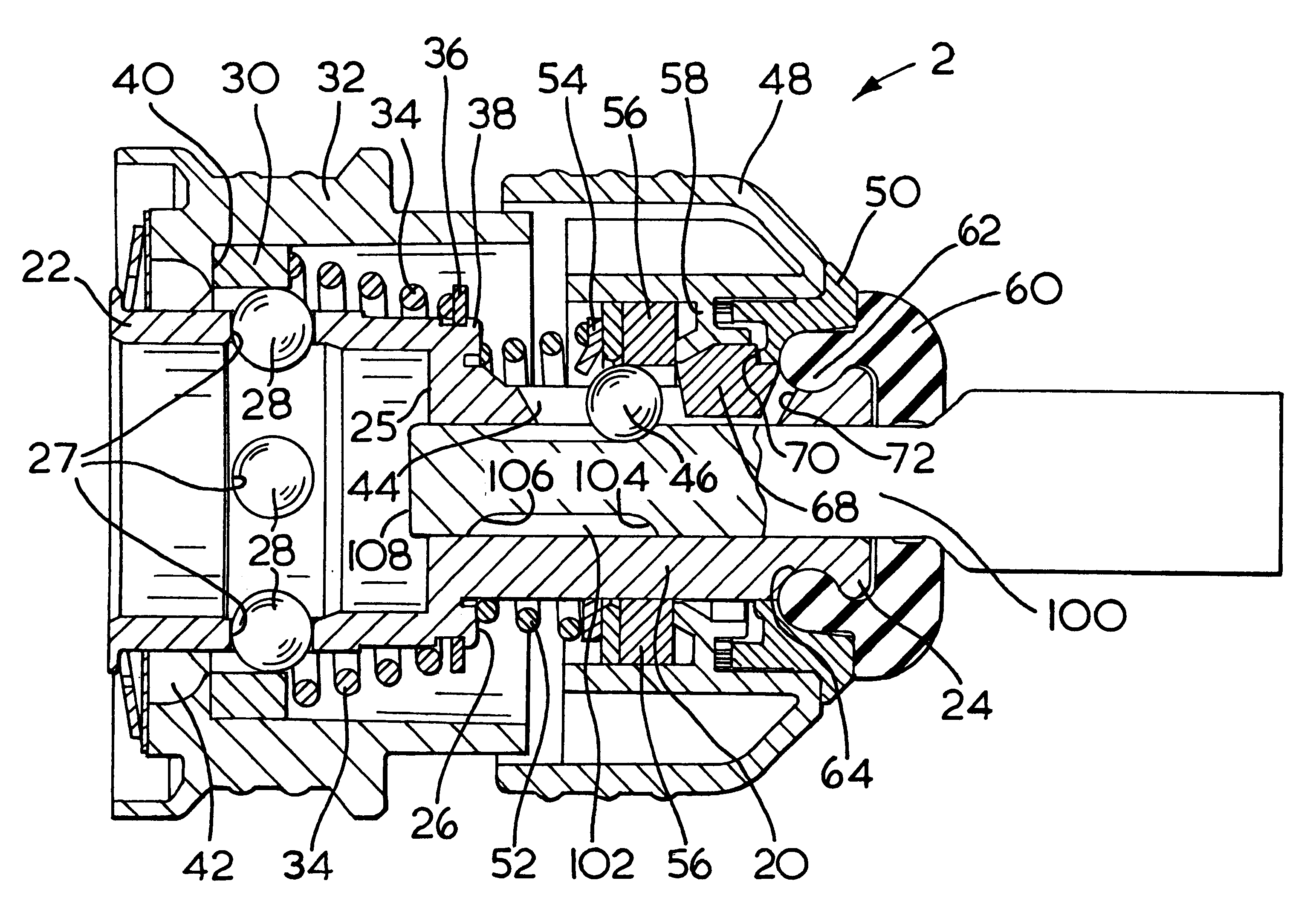

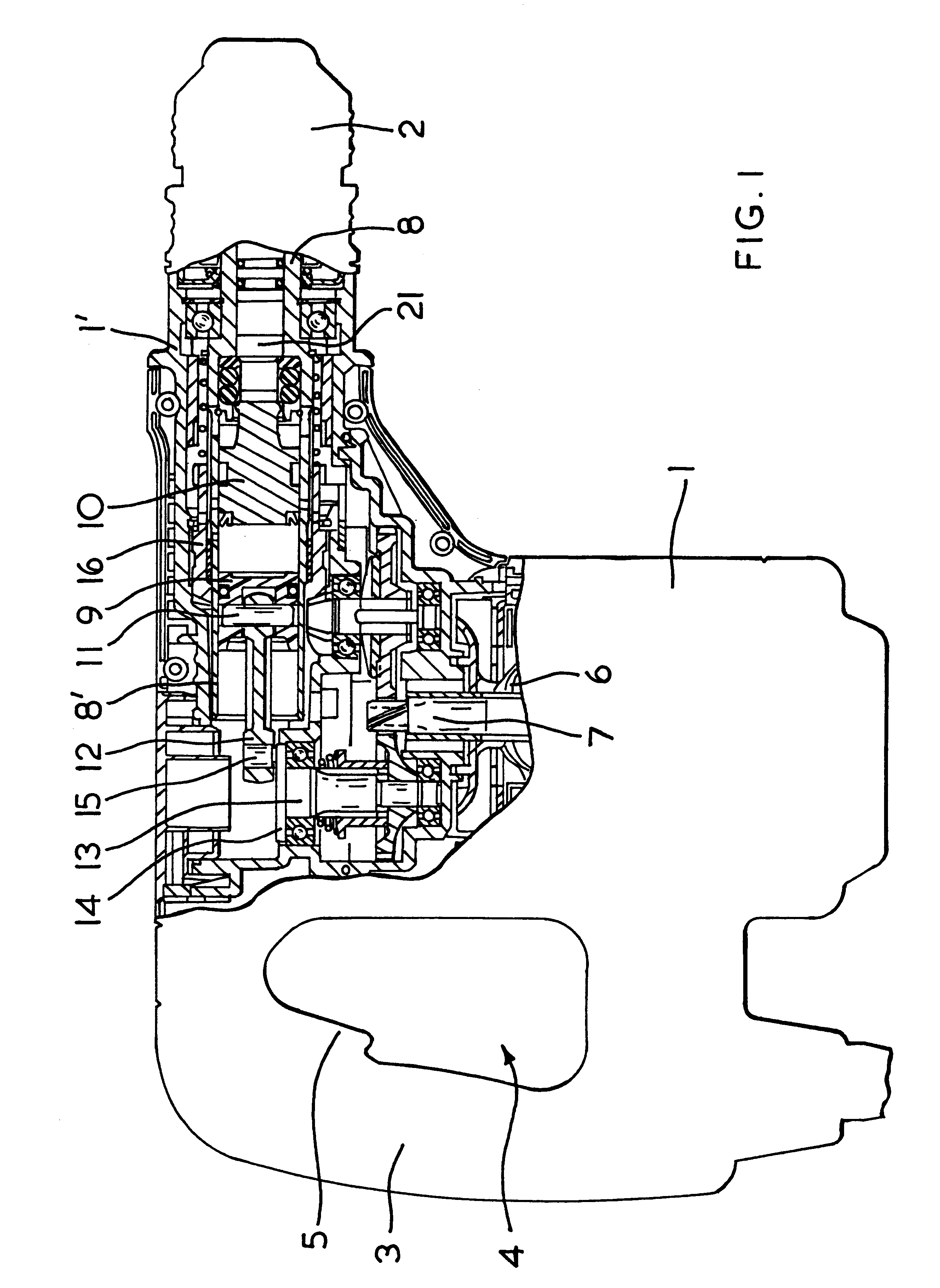

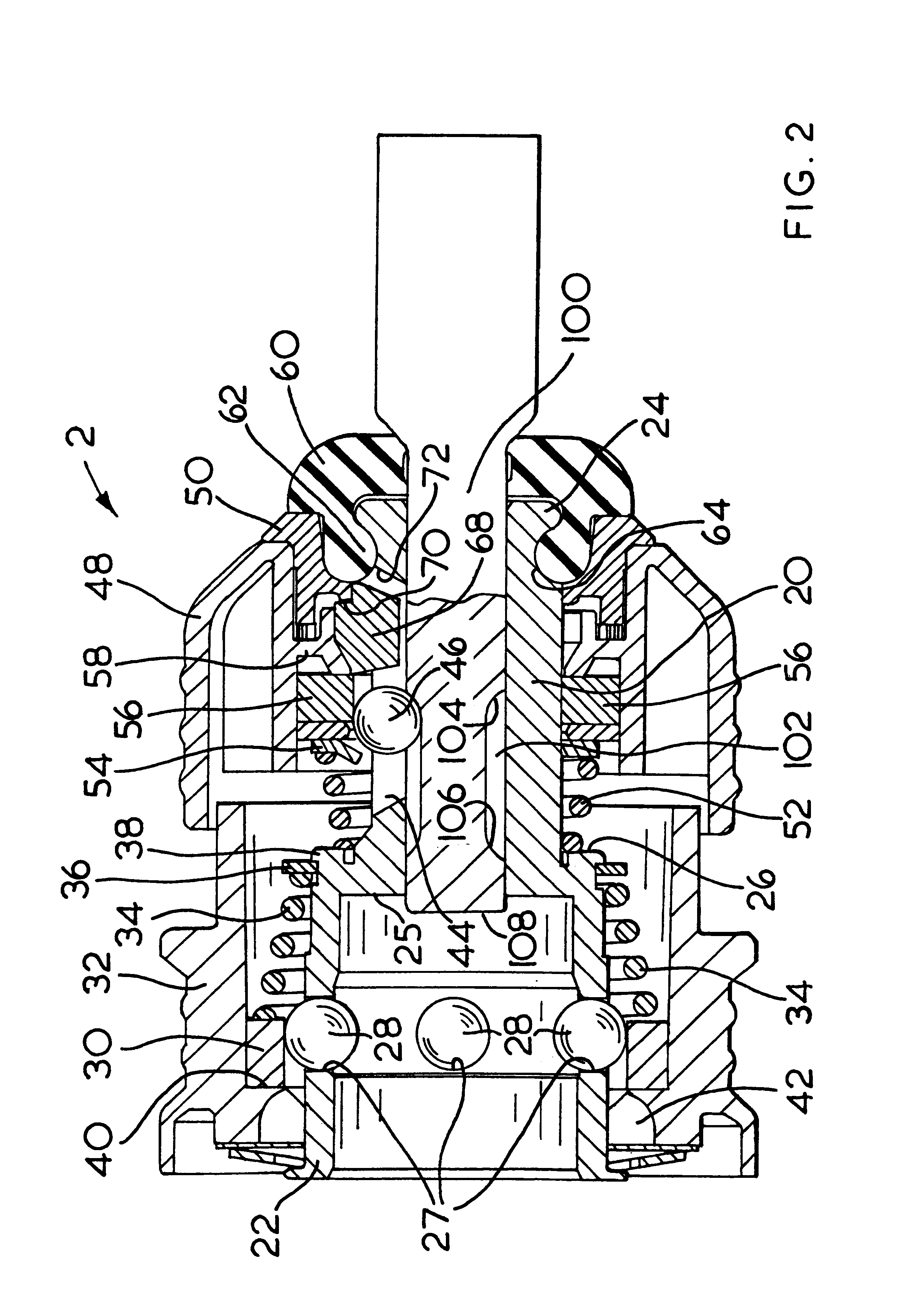

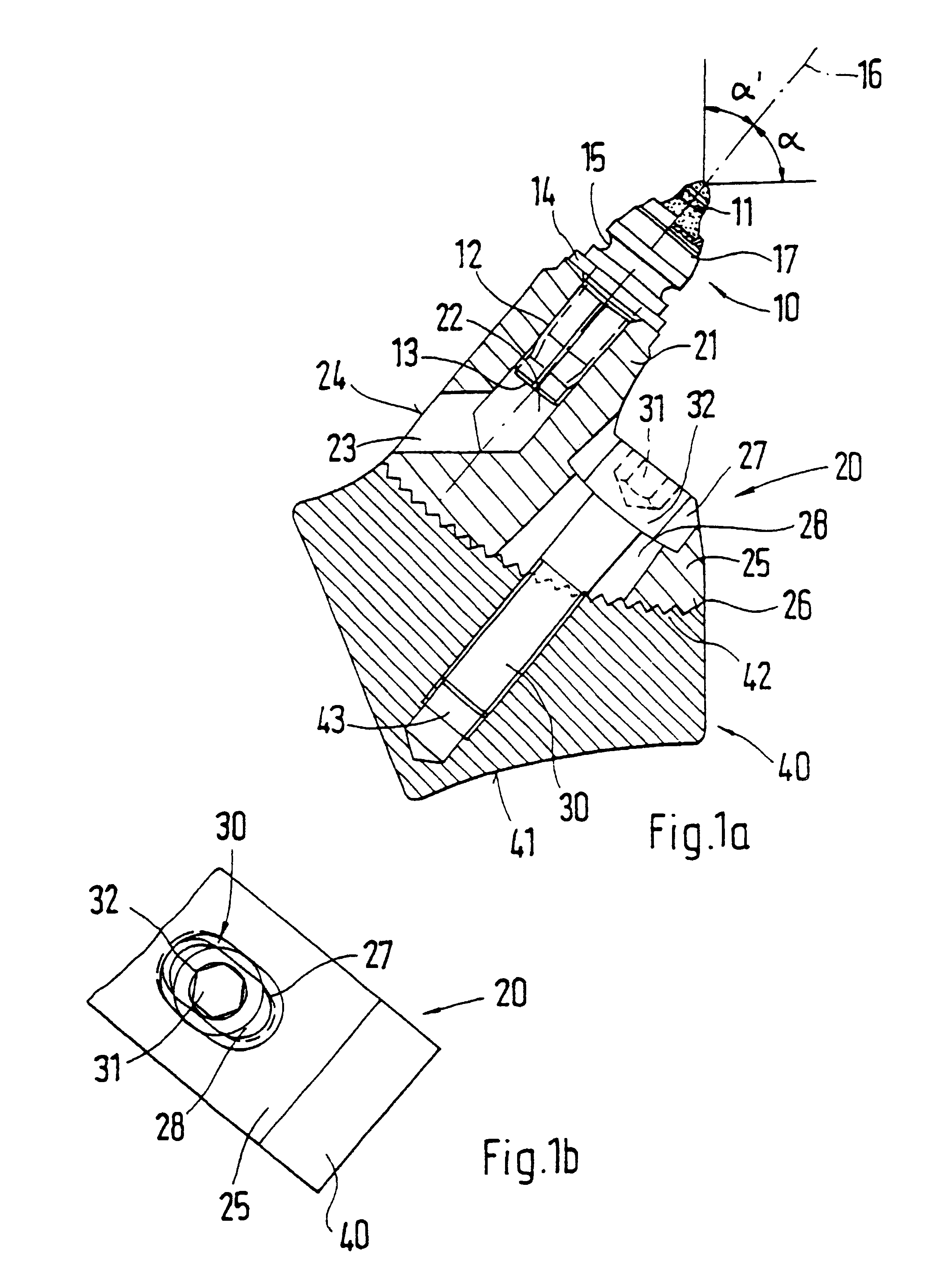

Rotary hammer

InactiveUS6241026B1Weakening rangeReduce risk of damageConstructionsChucksEngineeringFront and back ends

A tool holder attachable to a spindle of a hammer and which can receive a bit, the bit having a shank with at least one retaining groove extending along part of the shank, the retaining groove having a defined length, a front end and a rear end that limit axial movement of the bit in the tool holder, which tool holder comprises a hollow cylinder having an axis, an axial bore, a rear end that can be attached to the spindle of the hammer, and a front end that can receive the shank of the bit so that the bit is slidable within the cylinder in an axial direction, at least one retaining element that is located so that it can extend radially into the bore of the cylinder and into the at least one retaining groove of the bit so that the retaining element can be hit by the rear end of the retaining groove during the transition to idling and limit the extent of axial movement of the bit within the cylinder, at least one radial restraining element limiting movement of the retaining element in the radial direction, at least one axial restraining block limiting movement of the retaining element in the axial direction, when hit by the retaining element the axial restraining block movable to a limited extent in the axial direction with respect to the radial restraining element, and a resilient element located forward of the axial restraining block and arranged so as to attenuate the impact transmitted through the axial restraining block from the retaining element.

Owner:BLACK & DECKER INC

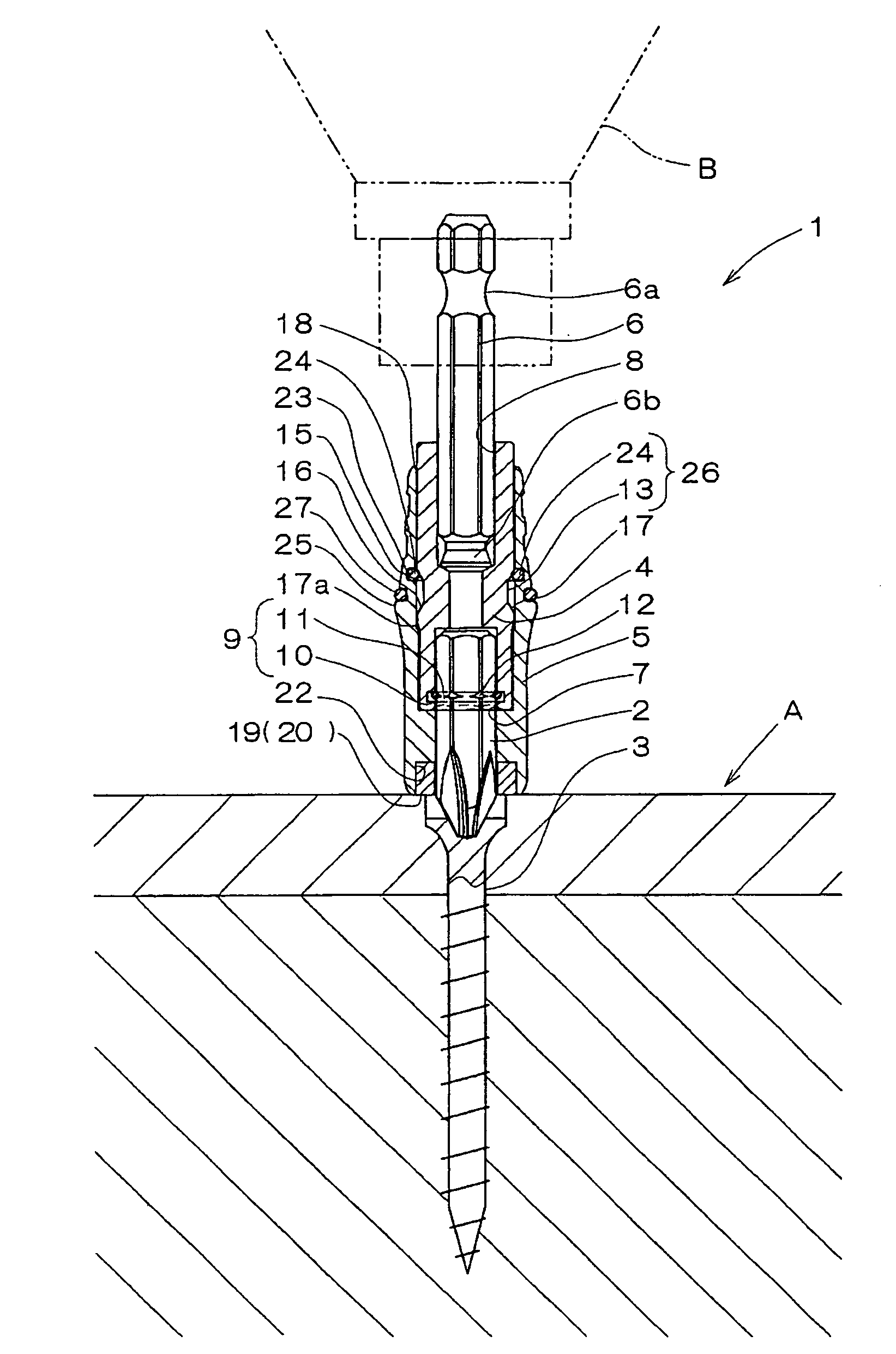

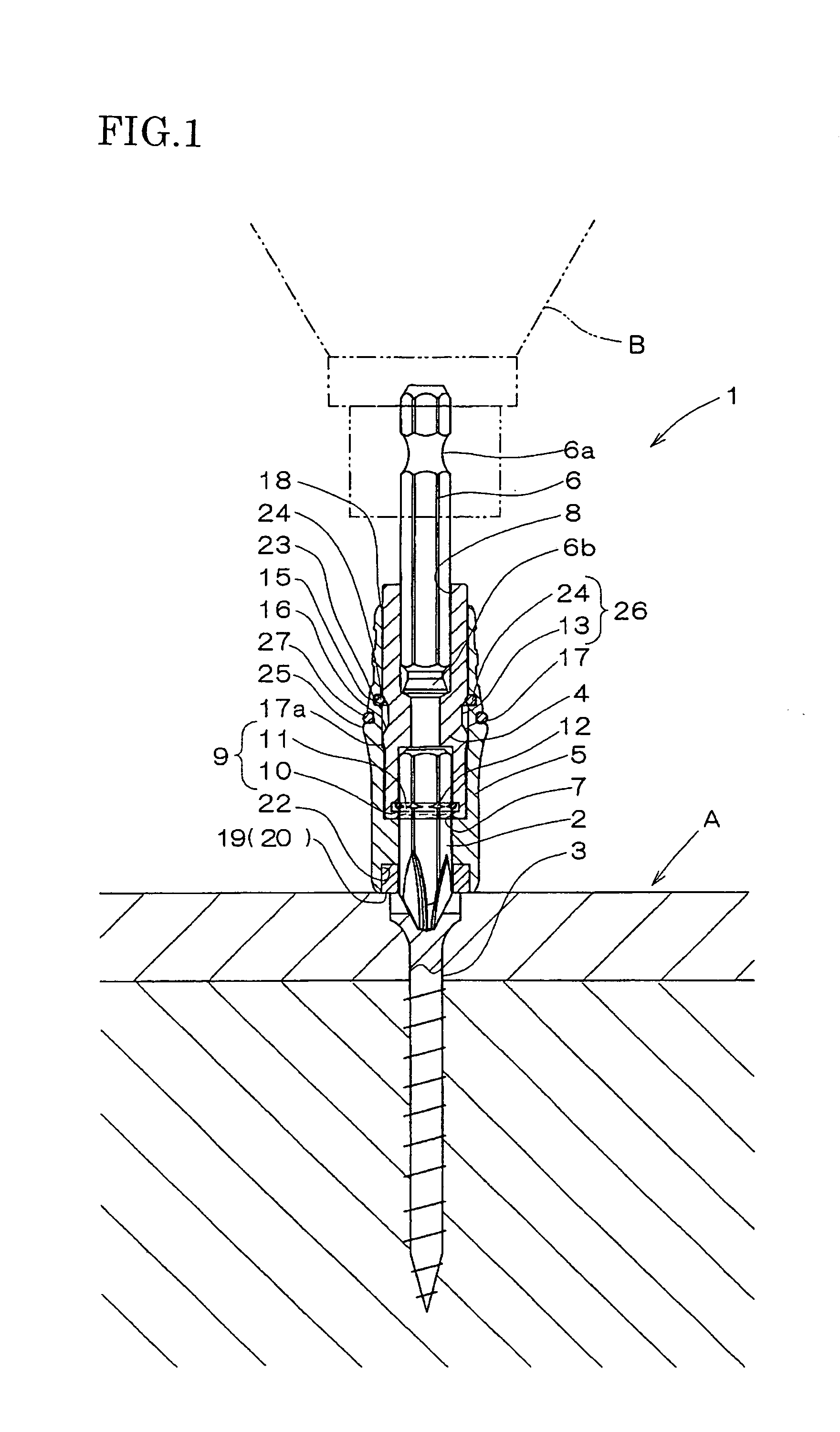

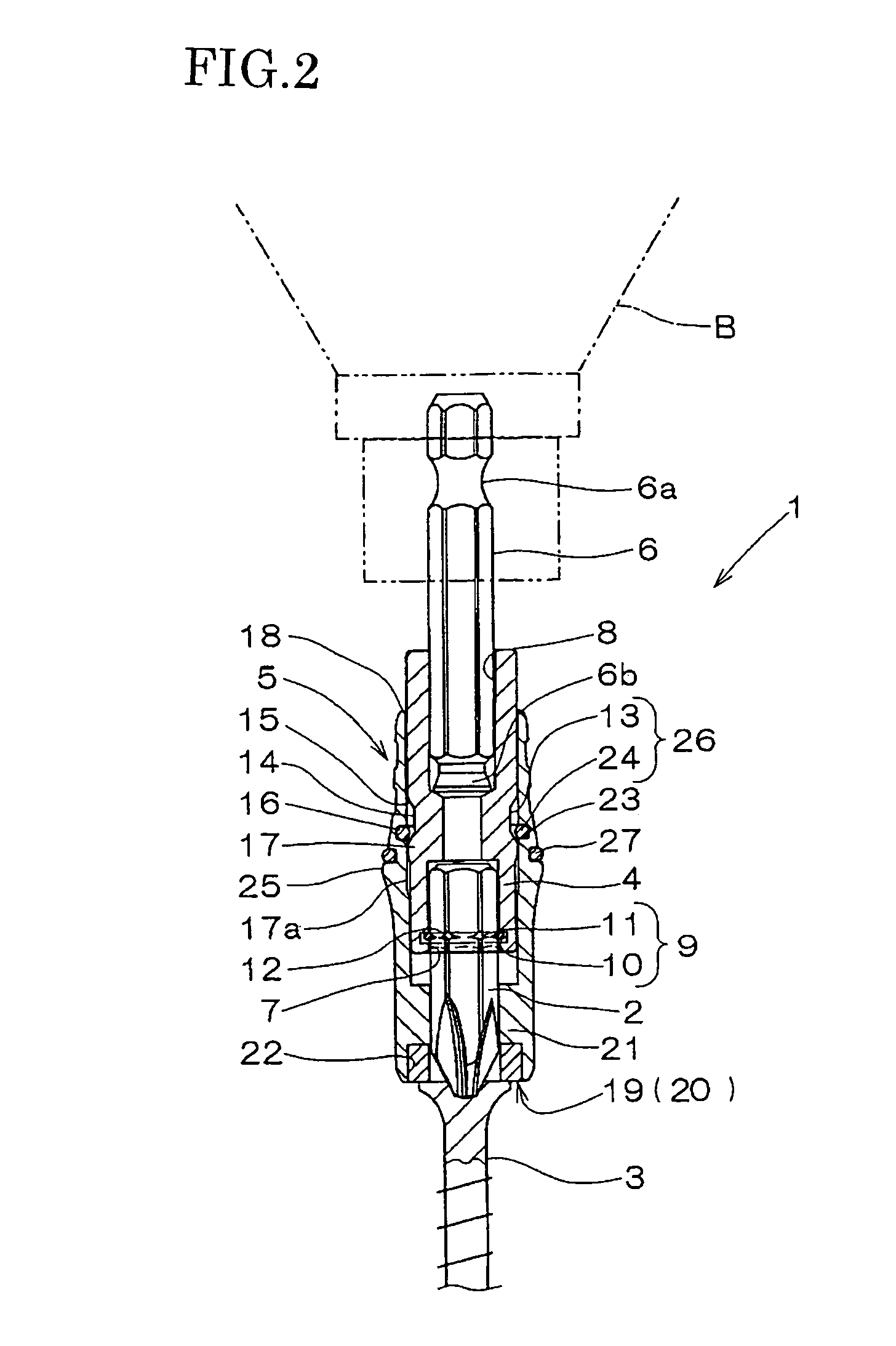

Bit holder device

Owner:VESSEL IND

Metal cutting system for effective coolant delivery

A metal cutting system with a tool holder, a shim, an insert with a top depression, a top piece and a clamp. A rake face cooling channel for fluid delivery is formed between the top piece and the depression in the insert. A primary discharge slot at the end of the rake face cooling channel delivers fluid from below the cutting edge of the insert. A second cooling channel for delivery of fluid to the flank face is formed between the insert and the shim or is formed between the shim and the tool holder with a portion of the cooling channel passing through the shim.

Owner:KENNAMETAL INC

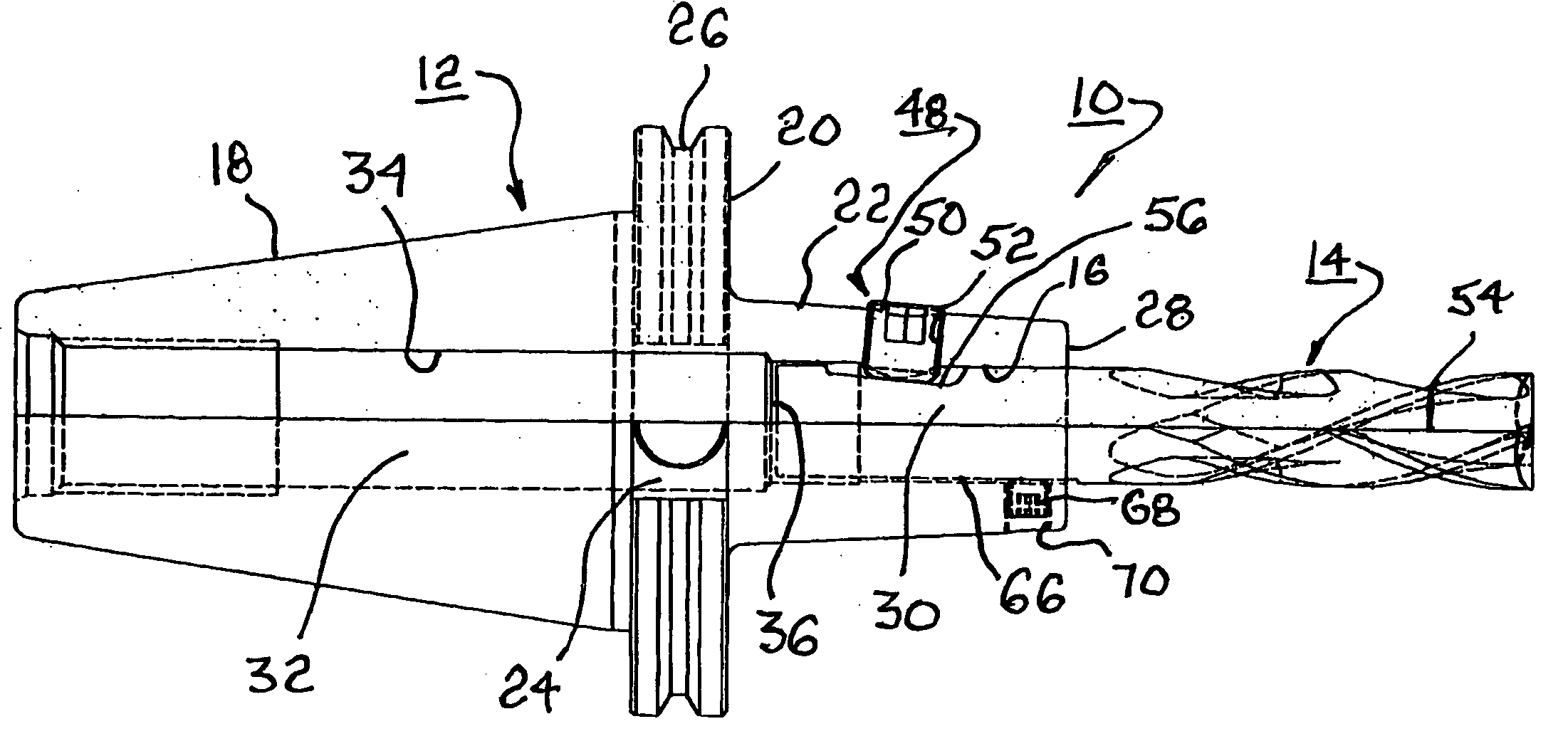

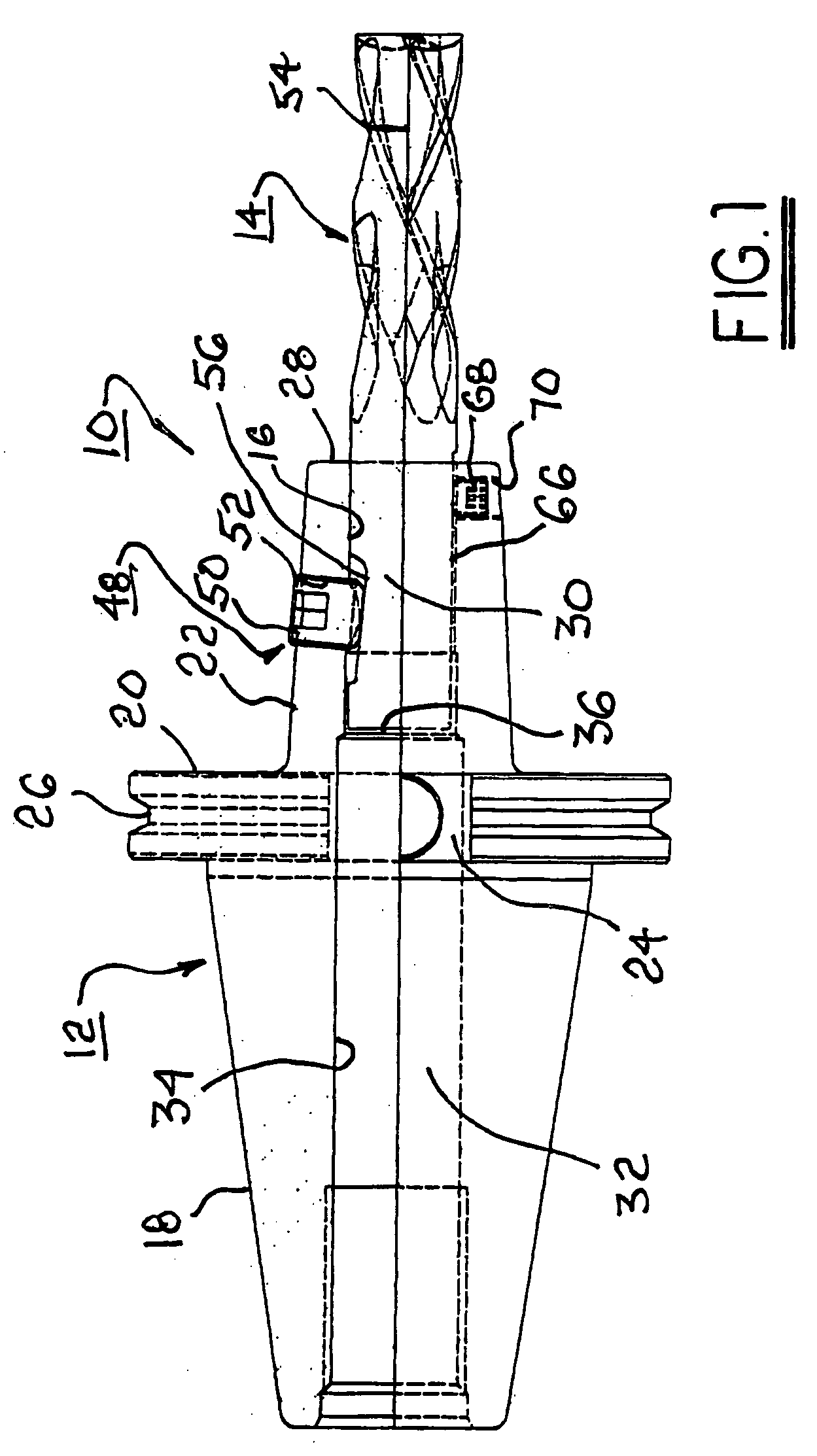

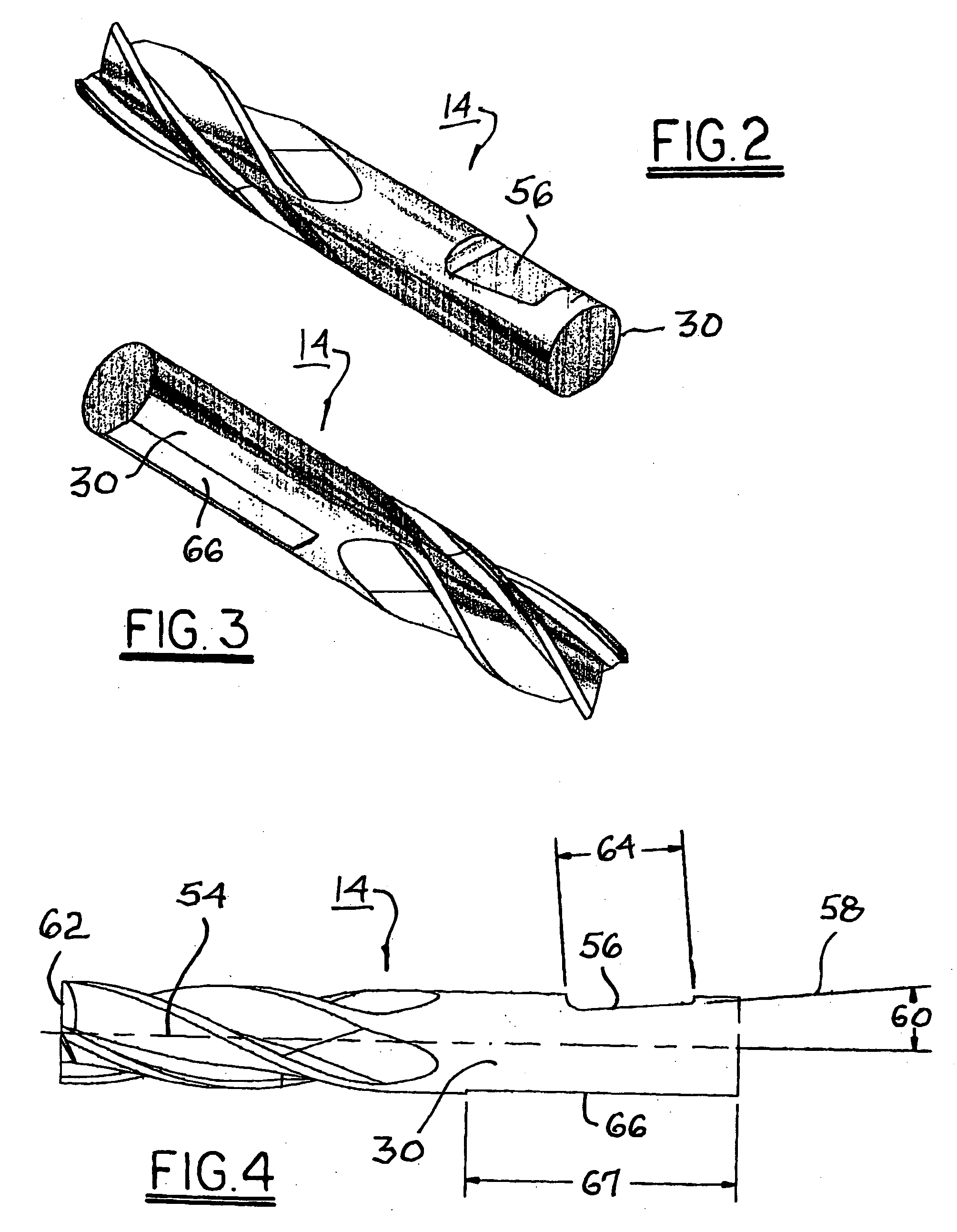

System for mounting a machine tool in a tool holder

InactiveUS20050238451A1Accurate centerAvoid turningSleeve/socket jointsTransportation and packagingSet screwEngineering

A system for mounting a tool in a tool holder combining a means for high-precision centering of the tool and a means for positive restraint of the tool from rotation within the tool holder. The tool holder includes a cylindrical aperture having a diameter slightly less than the diameter of the shank of a cylindrical tool. The tool is installed into the tool holder by heating the tool holder to a temperature sufficient to increase the pocket diameter sufficiently to accept the tool shank. In a first shrink-fit embodiment, the tool shank is further provided with an angular flat for engagement with a set screw to prevent the tool from being turned in the holder in use. In a second shrink-fit embodiment, a groove extending partially around the tool receives a tangential pin through a passage in the tool holder. The tool is rotated in the holder until the pin binds in the groove, thus preventing any further rotation of the tool in the holder during use.

Owner:PARLEC

Chisel holder changing system with chisel holder receivers

A chisel holder changing system having a base element with a chisel holder receiver, into which a chisel holder equipped with a chisel can be inserted, wherein the chisel holder is inserted with a holder shaft into the chisel holder receivers and is maintained therein with the aid of bracing screws. Bracing screws can be screwed into a threaded receiver of the base element and during this are supported under tension in a bracing receiver of the holder shaft of the chisel holder. If in a chisel holder changing system in accordance with this invention the surfaces of the outer screw thread of the bracing screw and / or of the inner screw thread of the threaded receivers of the chisel holder receivers have a metallic layer of zinc and aluminum lamellas and a mineral chromium oxide bonding agent, which is burned in after the application, the screw connections are improved so that larger prestressing forces / tightening torques can be transmitted without damage to the screw connections.

Owner:WIRTGEN GMBH

Wrist tool holder

The present invention comprises an apparatus for removably holding tools. The apparatus includes an armband arranged to removably fasten around a user's forearm. At least one tool holder is attached to the armband. The at least one tool holder is arranged to removably receive and hold a tool. In other aspects of the invention the tool holder includes a magnet as a band a tool can be removably slid under.

Owner:OHAIR KEITH

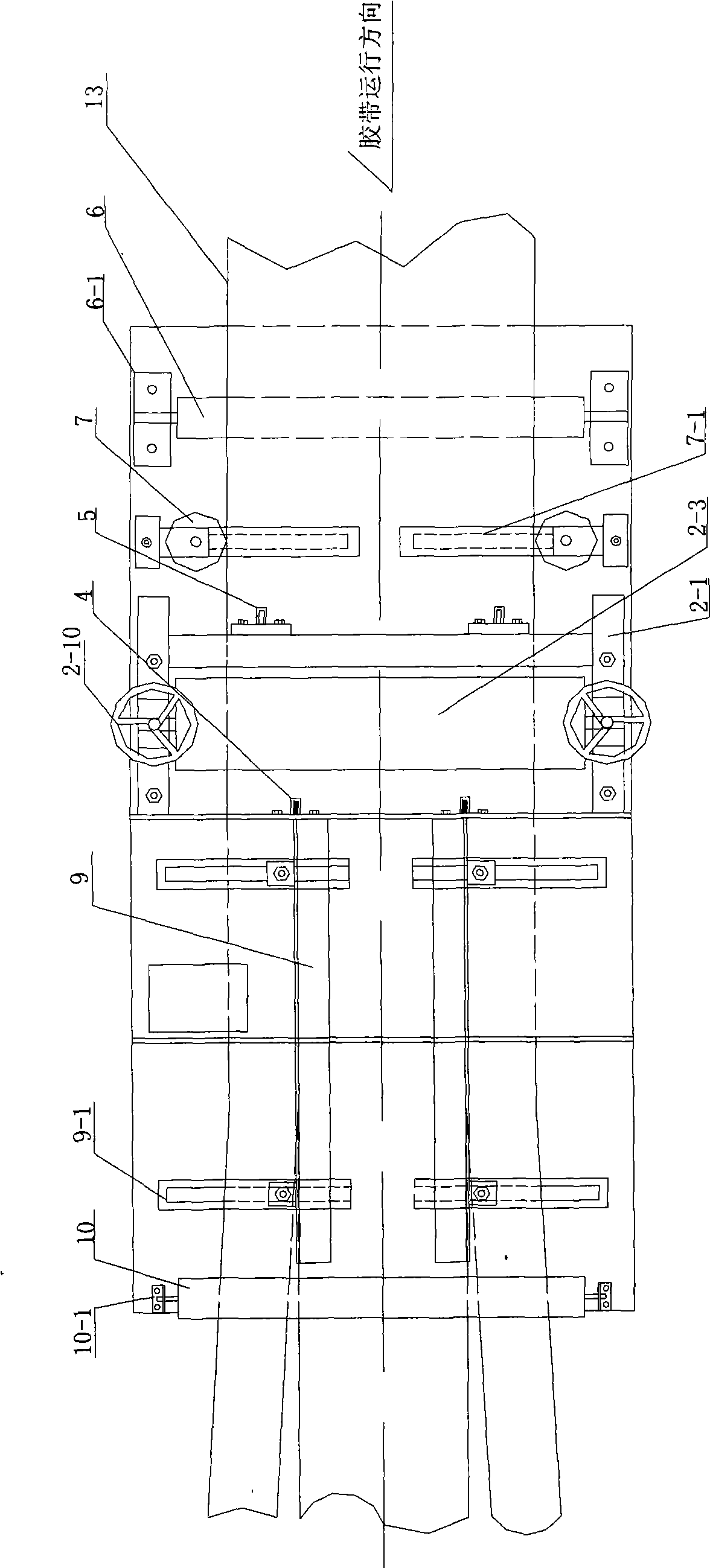

Apparatus for the positioning of a tool or a tool holder in a machine designed for processing a sheet material

InactiveUS20040082453A1Accurate versatile controlled positioningEnvelopes/bags making machineryBox making operationsEngineeringMachine design

Arrangement for the positioning and shifting of tools, specifically the tools of a machine designed for shaping sheet material while being advanced relative to the arrangement, the arrangement having fixed guides (16,19) for guiding the tools in transverse motion relative to the travel direction (X) of the material, the tools or holders (7,7') for the tools comprising means (22,23) by which a continuous or intermittently running drive (Y) across the material travel direction (X) is used for shifting the tool holders, individually or in combination, by alternately connecting one or several tool holders (7,7') to the running drive.

Owner:PACKSIZE

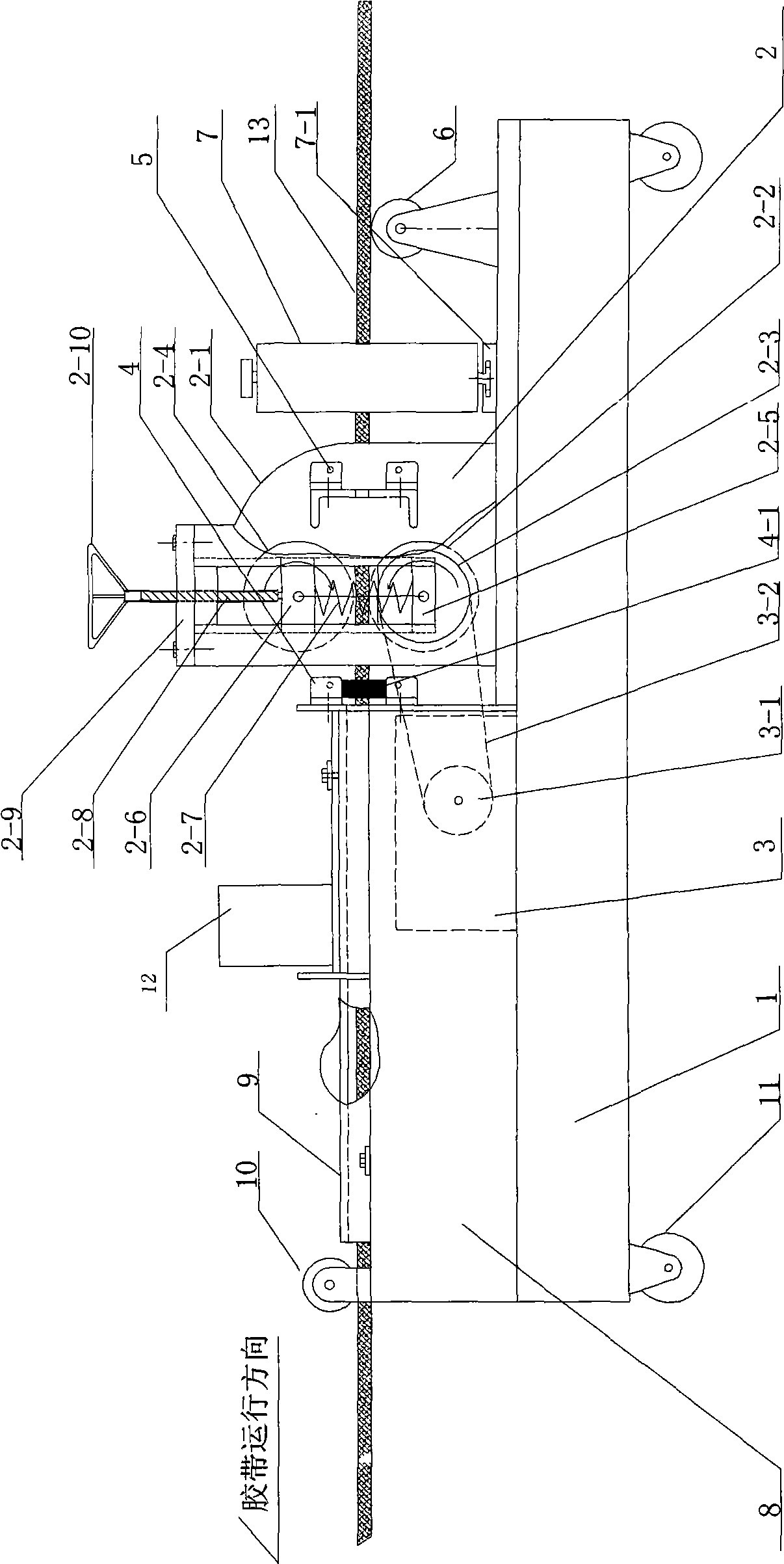

Cutting trimming device of conveyer belt

InactiveCN101508119ARealize comprehensive utilizationSave resourcesMetal working apparatusWebs handlingElectric machineryMechanical equipment

The invention relates to mining mechanical equipment, in particular to a conveyor belt cutting and dressing machine, which consists of a pedestal, a drive device, a conveyor belt device, a main tool post, an auxiliary tool post, a carrier roller, a guide wheel, a saddle, a guide groove, a belt hold roller and an electric control box; the drive device consists of an electric motor and a gear box; the conveyor belt device consists of an upright post bracket, a conveyor belt driving roller, a conveyor belt pressing roller and a feed screw nut; the gear box and the conveyor belt driving roller are connected through chains; the front end and the rear end of the drive device are provided with the main tool post and the auxiliary tool post; the tool posts are provided with cutting knives or saw bits driven by a small-power motor; the rear end of the auxiliary tool post is provided with the guide wheel; the rear end of the guide wheel is provided with the carrier roller; the saddle is arranged on the pedestal; the guide groove and the belt hold roller are arranged on the saddle; and a road wheel is arranged at the bottom of the pedestal. The mining mechanical equipment is used for the trimming, the reshaping and the width modification of the conveyor belt, realizes the waste utilization, saves energy resources, reduces the cost and labor intensity, improves the production efficiency, and has a simple structure and convenient operation.

Owner:兖矿能源集团股份有限公司

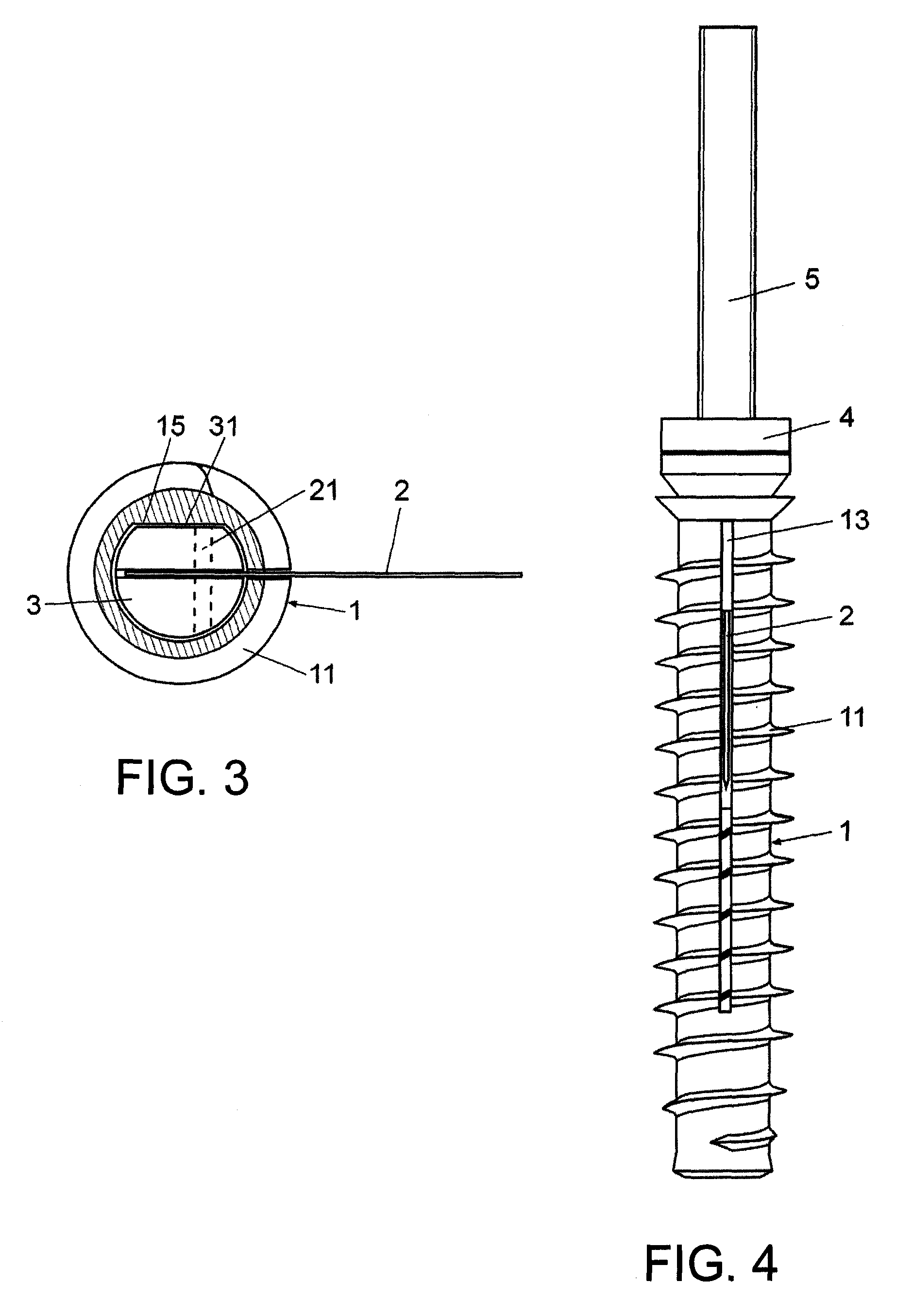

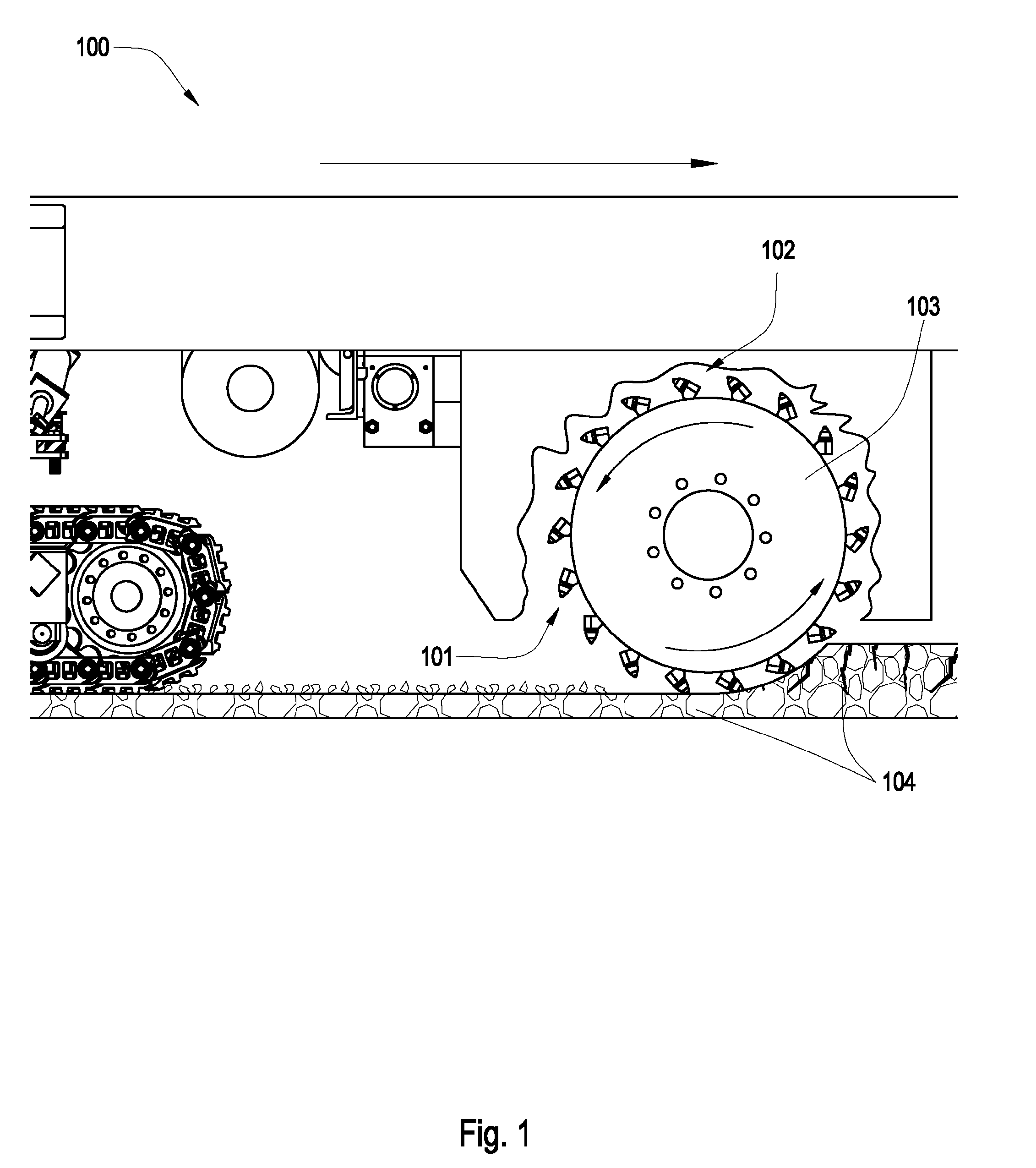

Chisel holder changing system

InactiveUS6619756B1Easy to changeGood and quick attachmentYielding couplingSlitting machinesChiselEngineering

A chisel-holder changing system for a road milling machine, a coal cutting machine or the like to which a chisel-holder is fastened in an exchangeable manner by means of a connecting mechanism. The chisel-holder accommodates at least one chisel that can be exchanged. The middle longitudinal axis of the chisel is set at an operating angle of less than 90° with respect to the surface to be worked. In order to be able to obtain varied removal results using such a chisel-holder changing system, the chisel-holder can be fixed in two or more configuring positions to the base part and in different attachment positions of the chisel, the middle longitudinal axis of the chisel is slanted at various working angles.

Owner:WIRTGEN GMBH

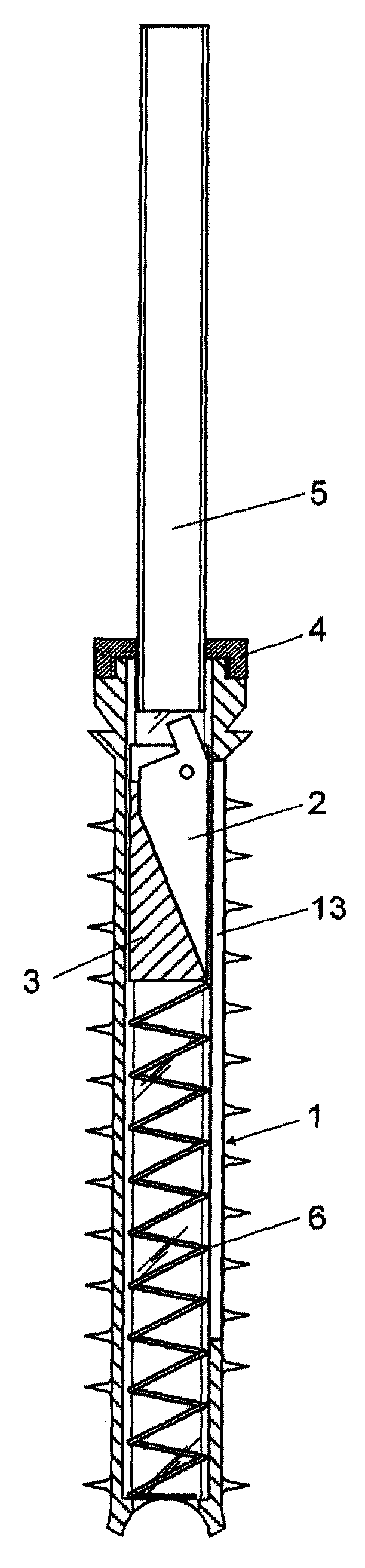

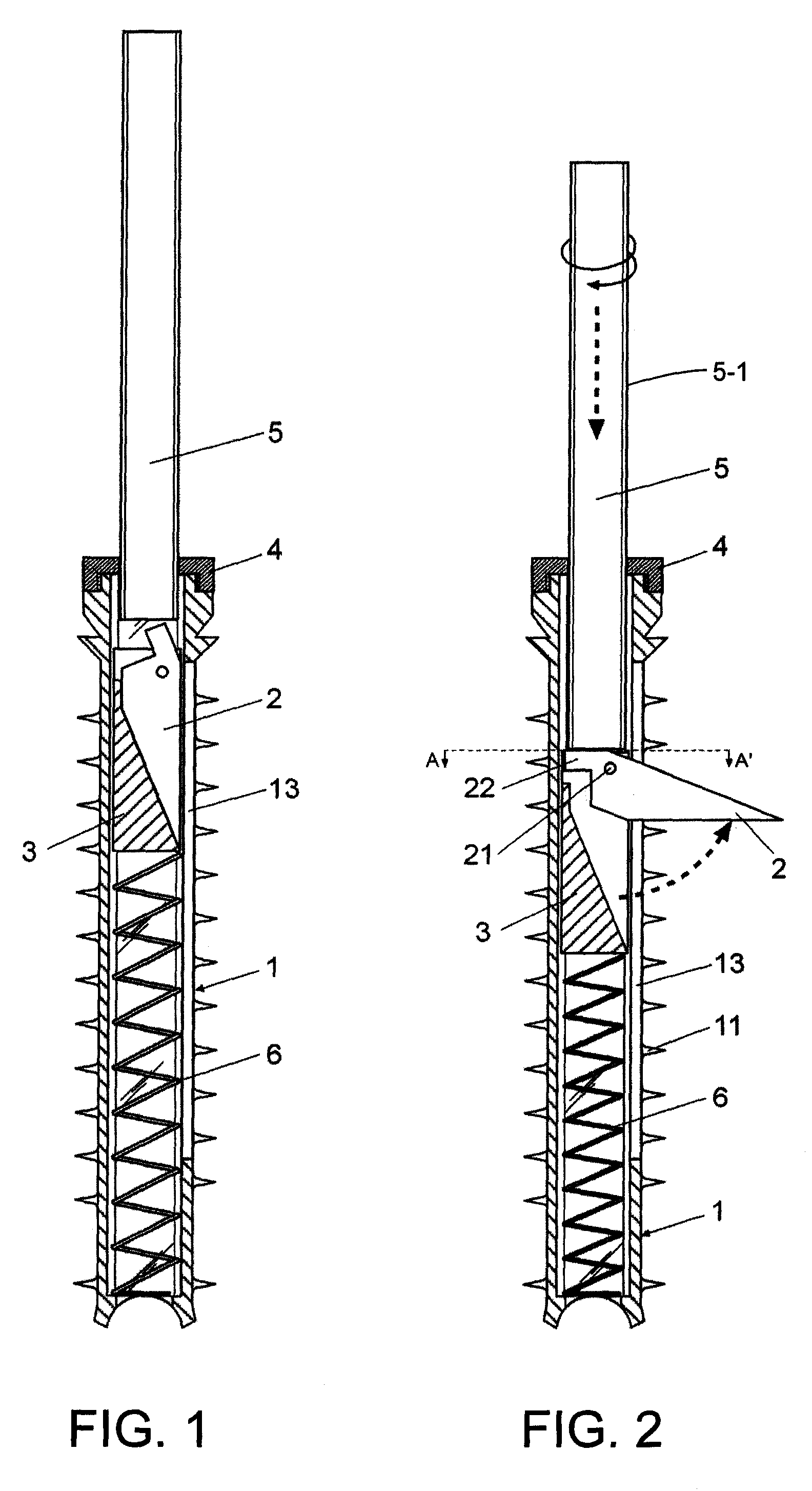

Cutting apparatus for performing osteotomy

InactiveUS20090254092A1Ensure correct executionPromote resultsExcision instrumentsNon-surgical orthopedic devicesEngineeringOsteotomy

For performing an osteotomy operation at a selected location on a patient's bone, a cutting apparatus comprising a screw device having a tubular shell with at least one longitudinal slot through said shell. A knife holder is slidable longitudinally in the bore to pivotally support at least one knife for displacement between a closed position and an opened position. In its closed position the knife is contained within the bore, and is pivotable to said opened position to project outwardly through the slot to perform the cutting operation, The knife is displaced longitudinally in the bore by an applicator operable to be telescopically displaced in the bore and operable upon its longitudinal displacement to contact an extended end of said knife and pivot the knife into its opened position through the slot, and thereafter to displace said knife holder toward the opposite end of said tubular shell. A spring is positioned between the knife holder and the opposite end of the bore to provide a bias resisting the longitudinal displacement of said knife holder, and upon retraction of said applicator, to return the knife to its closed position.

Owner:ALBIOL LLORACH AGUSTI

Method and assembly for rotating a cutting insert during a turning operation and inserts used therein

A cutting insert rotated about its axis may be utilized during a metalworking operation and applied against the rotating workpiece to enhance tool performance. A method, including an assembly with a rotatable insert mounted to a toolholder may be utilized to achieve this result.

Owner:KENNAMETAL INC

Disposable blade cartridge utility knife

ActiveUS7475480B2Low costEasy constructionOpening closed containersBottle/container closureEngineeringKnife blades

Owner:VOTOLATO LIVING TRUST DATED JUNE 1 1994 AS WHOLLY AMENDED THE

Tool holder sleeve

Owner:SCHLUMBERGER TECH CORP

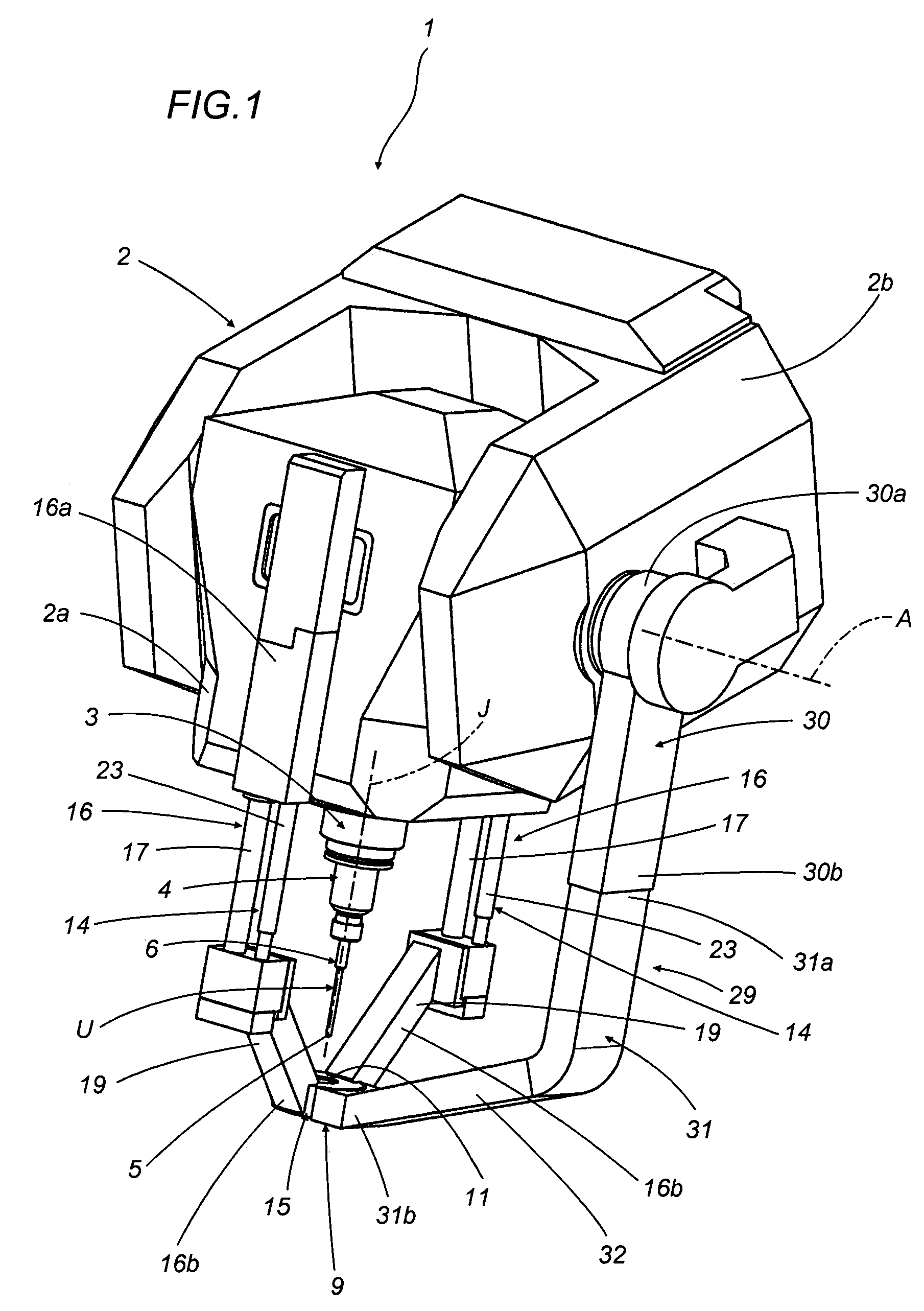

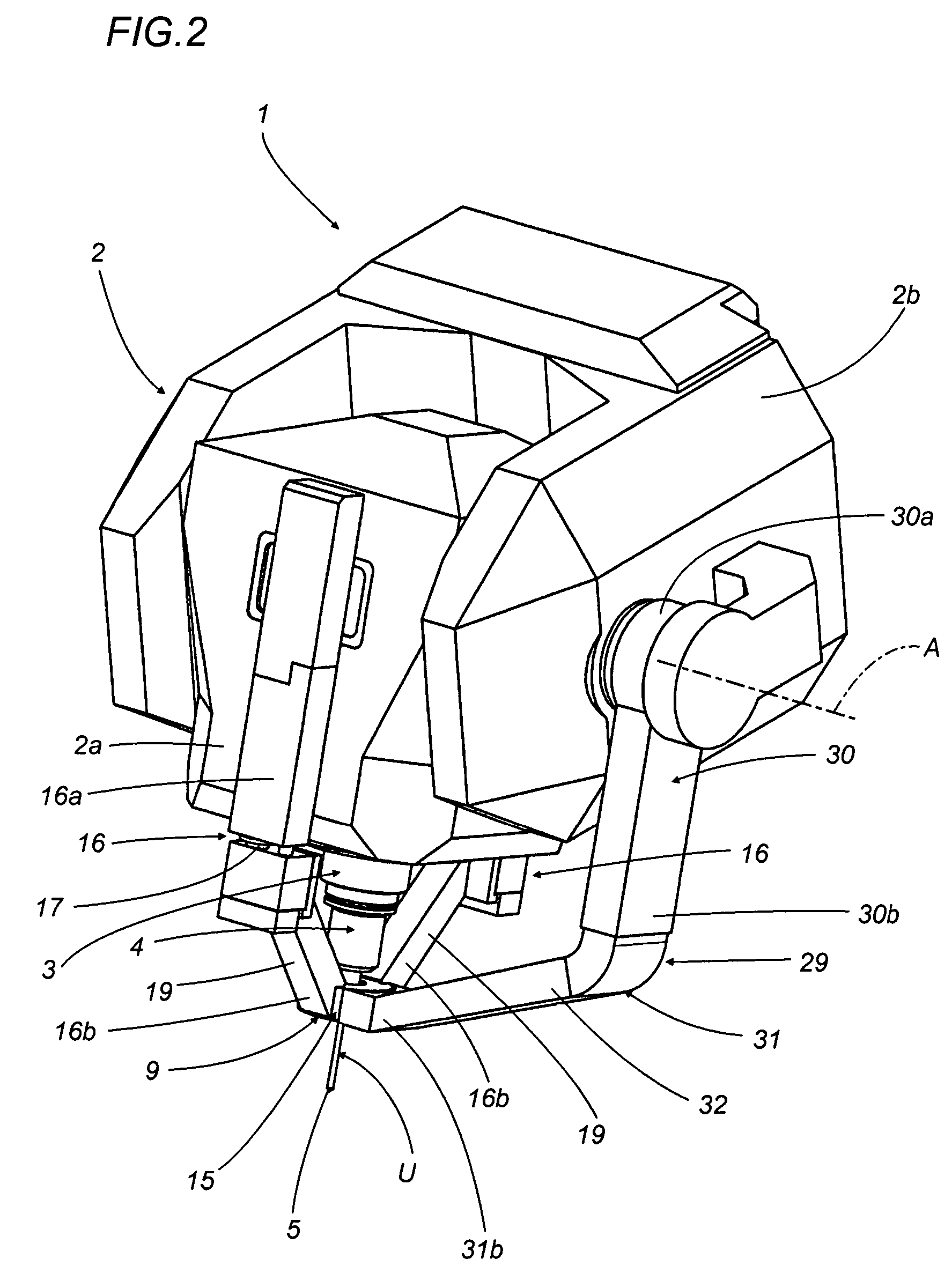

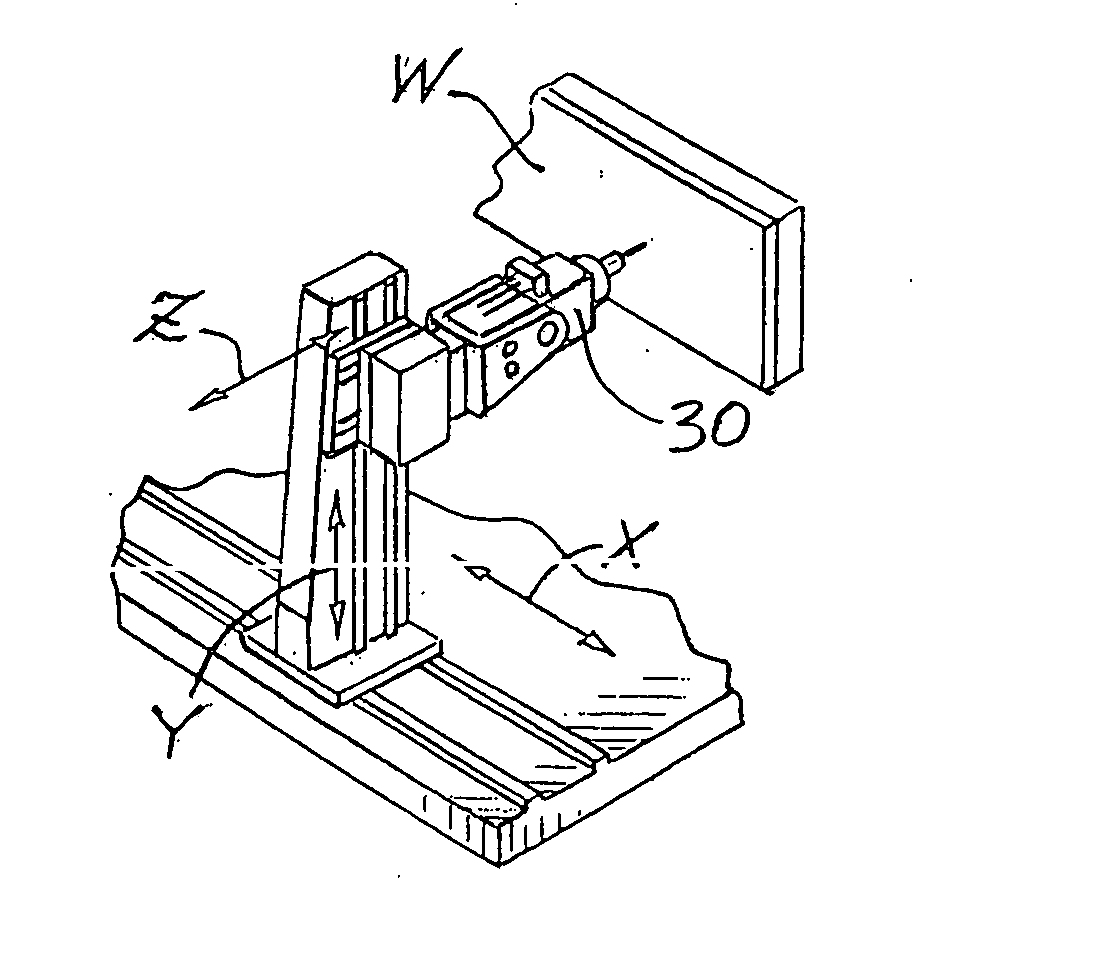

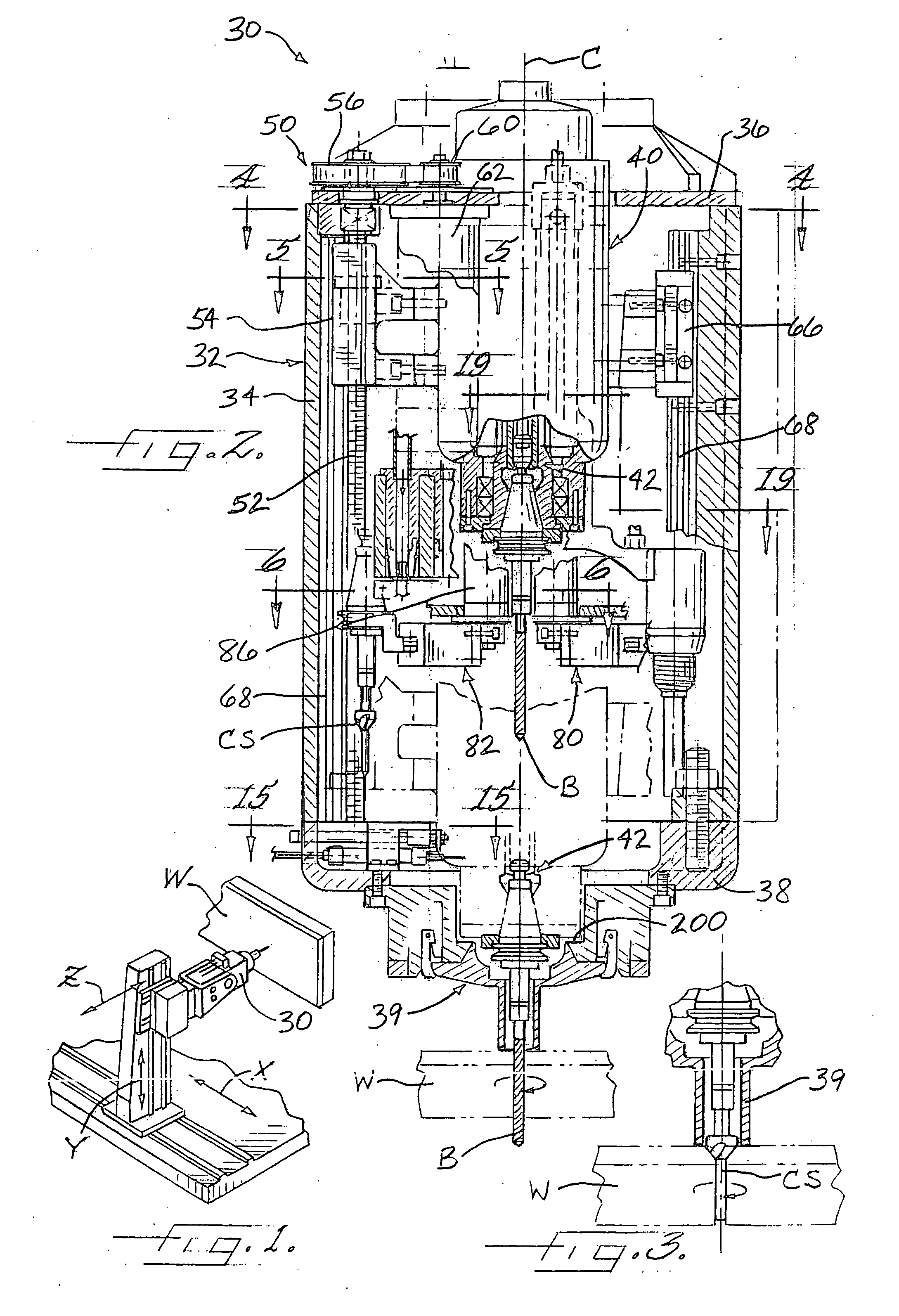

Toolhead for multi-axis machine tools

ActiveUS7220088B2Easy to getSmall and lightAircraft componentsDrilling/boring measurement devicesTransducerEngineering

Owner:JOBS SPA

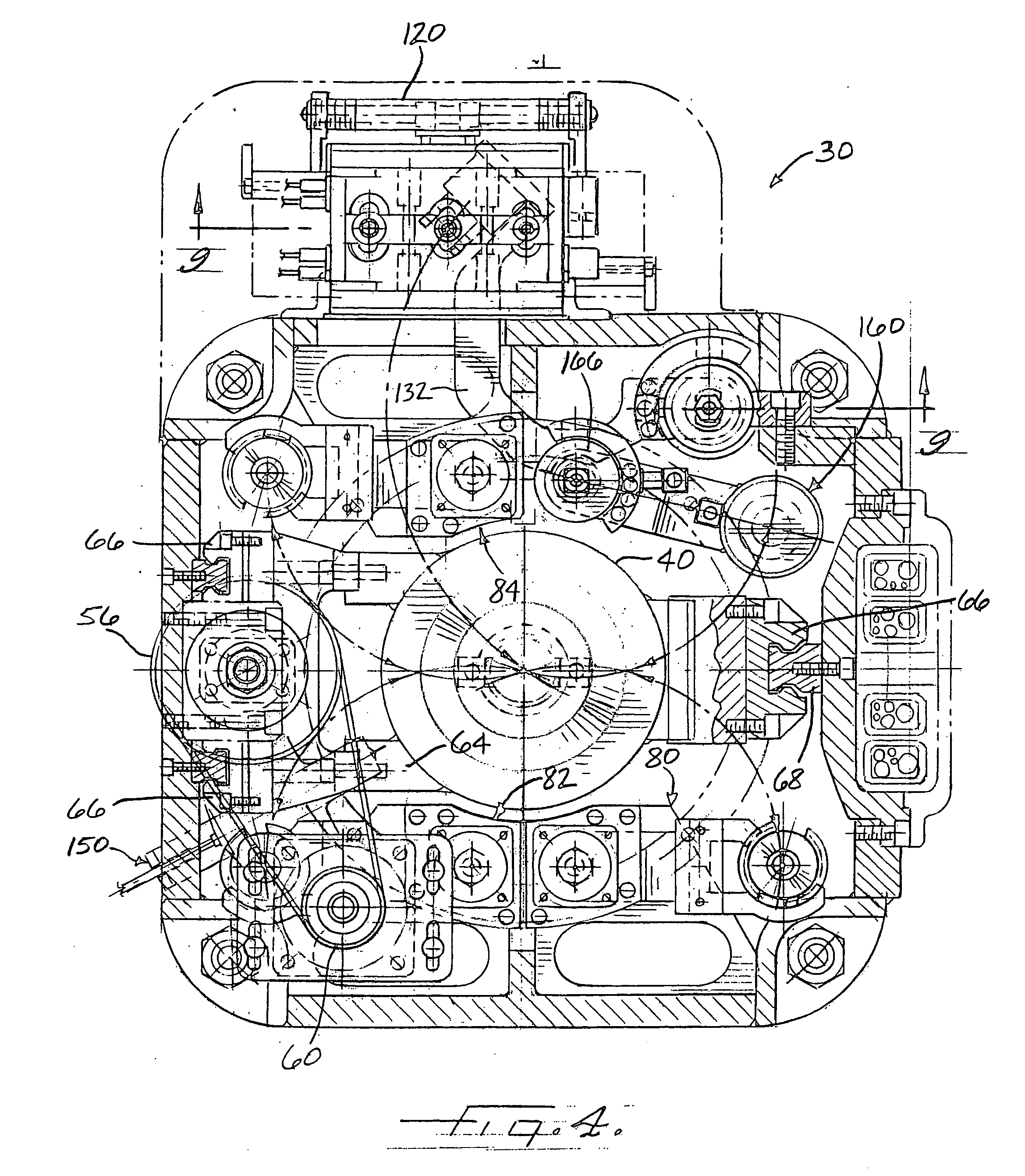

Multi-function end effector

A multi-function end effector includes a plurality of tool change mechanisms in a housing in which a spindle is also mounted for translation along an axis of the spindle. Each tool change mechanism has a gripper that releasably grips a tool holder in which a tool is mounted. The gripper of each tool change mechanism is movable between a stowed position to a tool-change position in which the gripper is coaxially aligned with the axis of the spindle for placing a tool holder held in the gripper in a position to be received by the spindle and for positioning the gripper to receive a tool holder from the spindle. The tools mounted in the tool holders include a drill bit, a countersink tool, and a fastener insertion tool. The end effector also includes a fastener feed system, a hammer device, and a sealant applicator.

Owner:THE BOEING CO

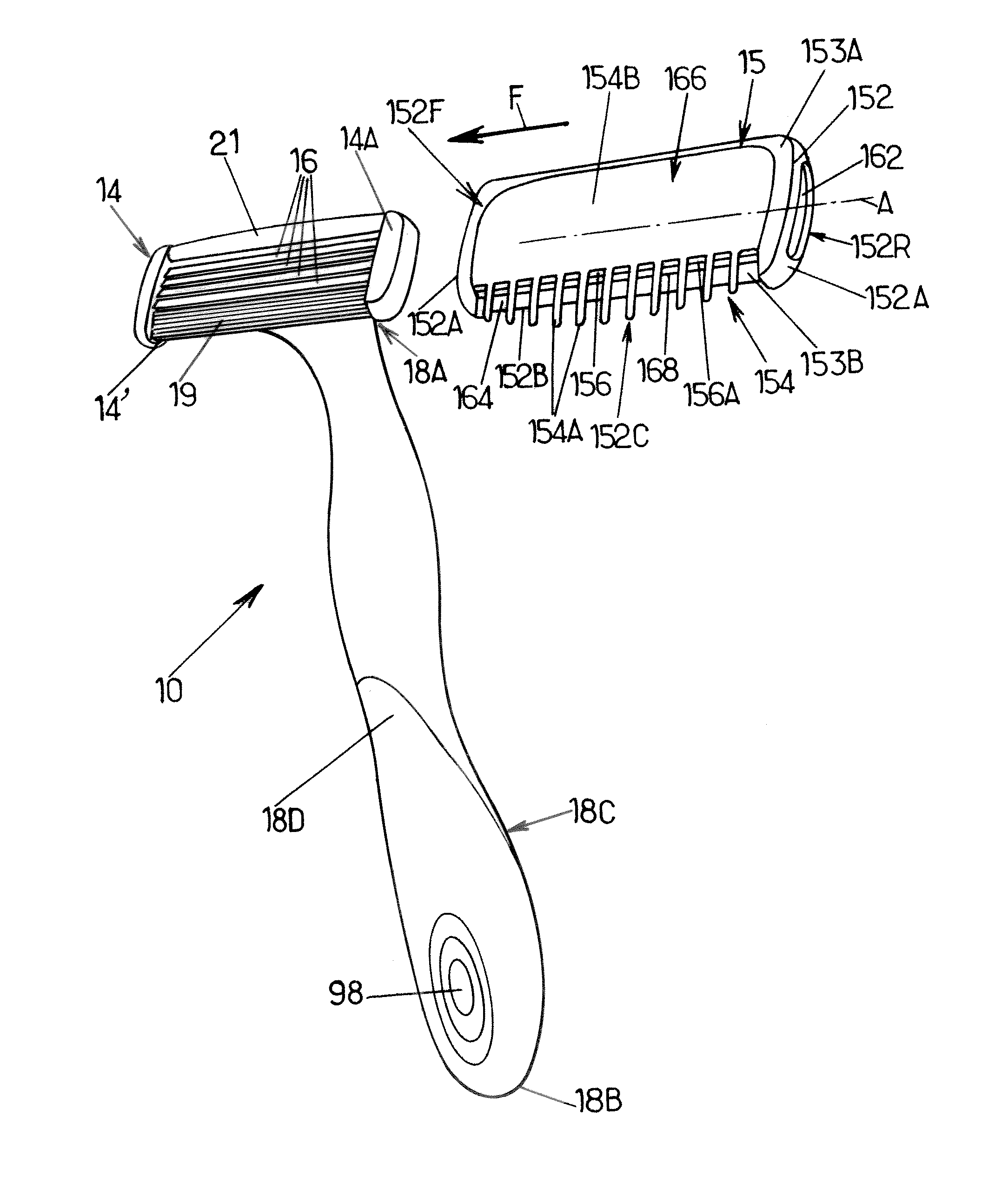

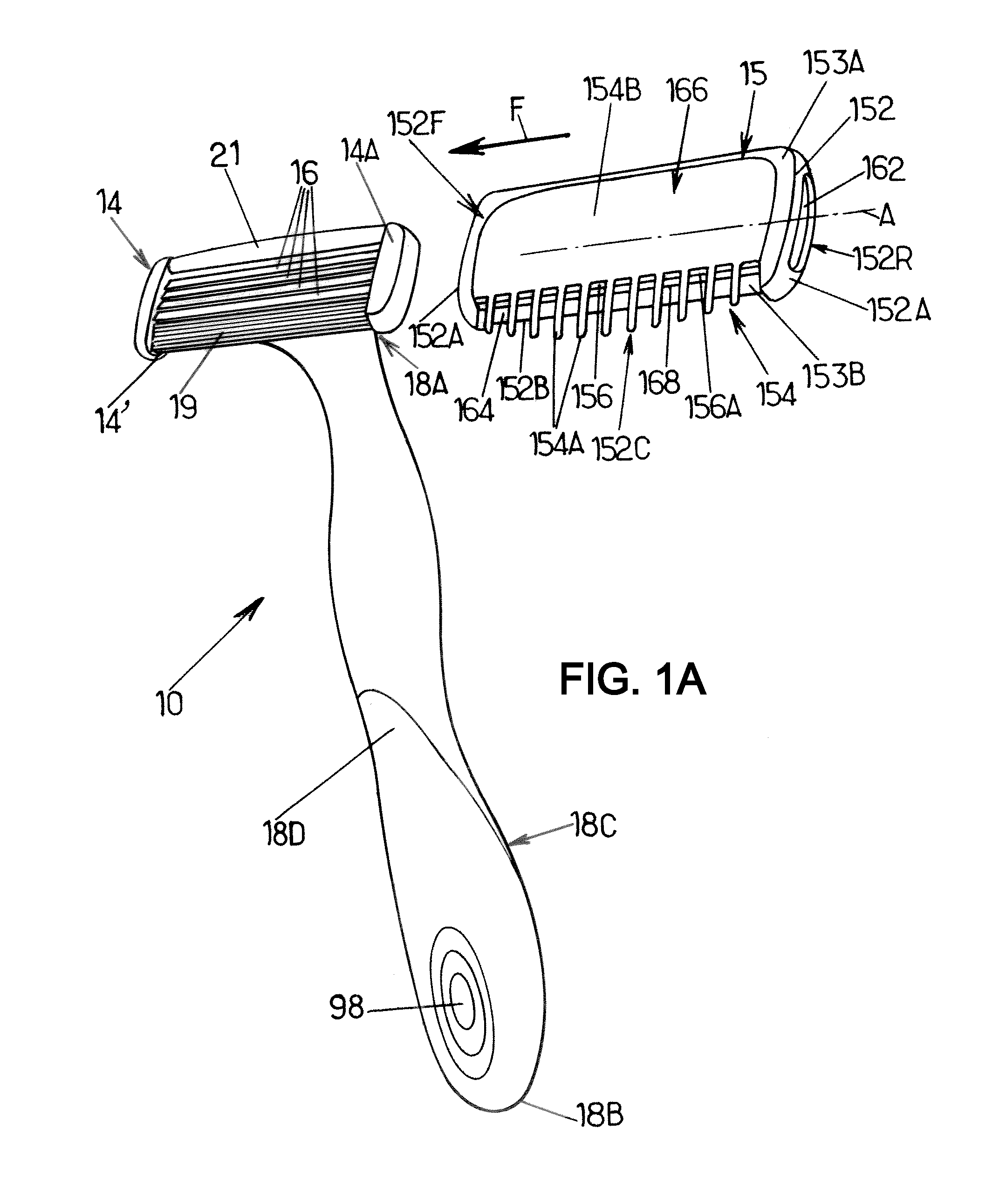

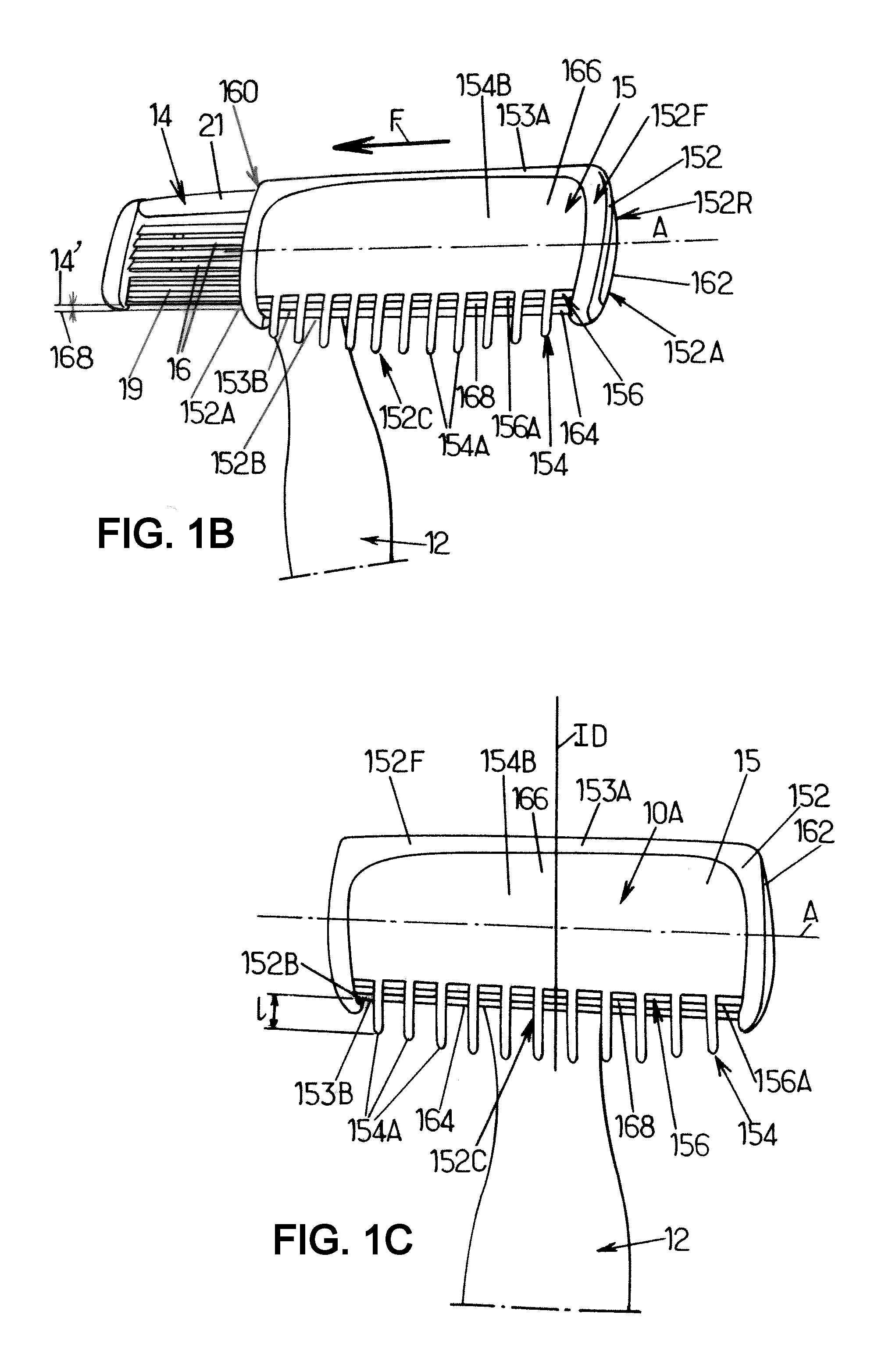

Protective cover for a shaving cartridge, a shaving assembly, a razor, a method of shaving with such a razor and a method of manufacturing a protective cover

A protective cover for a shaving cartridge, a shaving assembly including a cartridge and a protective cover, a razor having a razor handle and such a shaving assembly, a method of shaving with such a razor and a method of manufacturing such a protective cover. The protective cover includes a housing extending longitudinally along a longitudinal axis (A) and is provided with a comb and a trimming blade, the trimming blade having an elongated cutting edge and the comb having several teeth projecting obliquely to the longitudinal axis (A) and protruding forwardly with regard to the trimming blade.

Owner:BIC VIOLEX SA

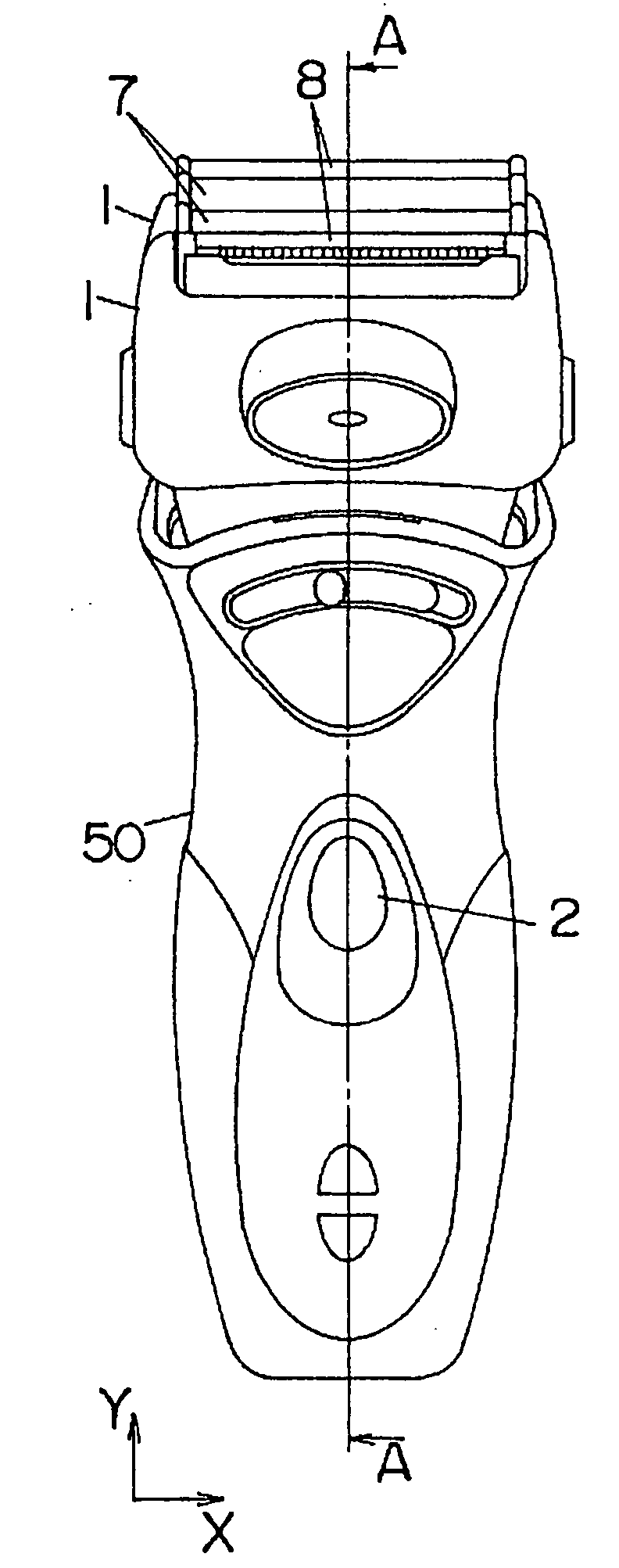

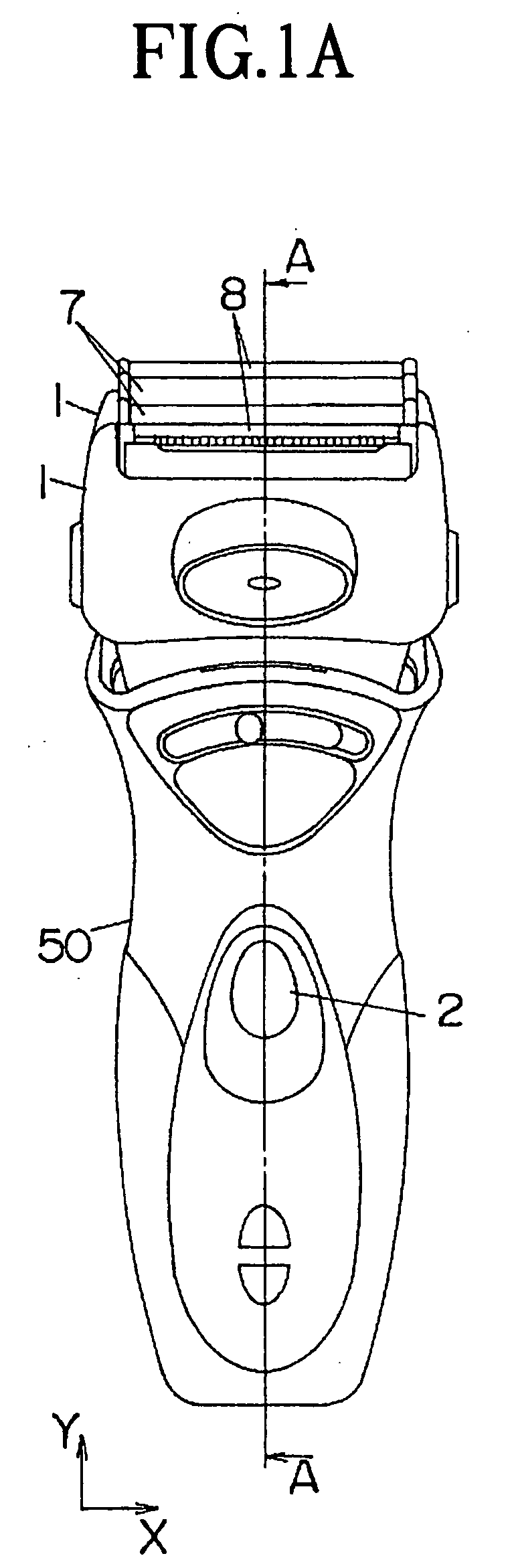

Electric shaver

InactiveUS20050016002A1Preventing uncut hairSoft skinMetal working apparatusShort hairElectric razors

An electric shaver includes a plurality of outer cutter frames connected to an electric shaver main body, for accommodating short hair cutter blocks and long hair cutter blocks. Each of the outer cutter frames is movable with respect to the electric shaver main body according to an amount of pressure applied to the outer cutter frame against the skin.

Owner:PANASONIC CORP

Tool holder arrangement

ActiveUS7008362B2Easy to understandDiagnosticsTool changing apparatusEngineeringIdentification system

A tool identification system has a tool holder allowing removable attachment thereto of any one of a plurality of tools; a sensor arrangement operable to sense features present on a tool attached to the tool holder; a processor operable to identify uniquely, from the sensed features, the type of the tool attached to the tool holder; and an insulation arrangement provided between the tool holder and the sensor arrangement, thereby electrically insulating the tool holder from the sensor arrangement.

Owner:PROSURGICS

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com