Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63 results about "Saddle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

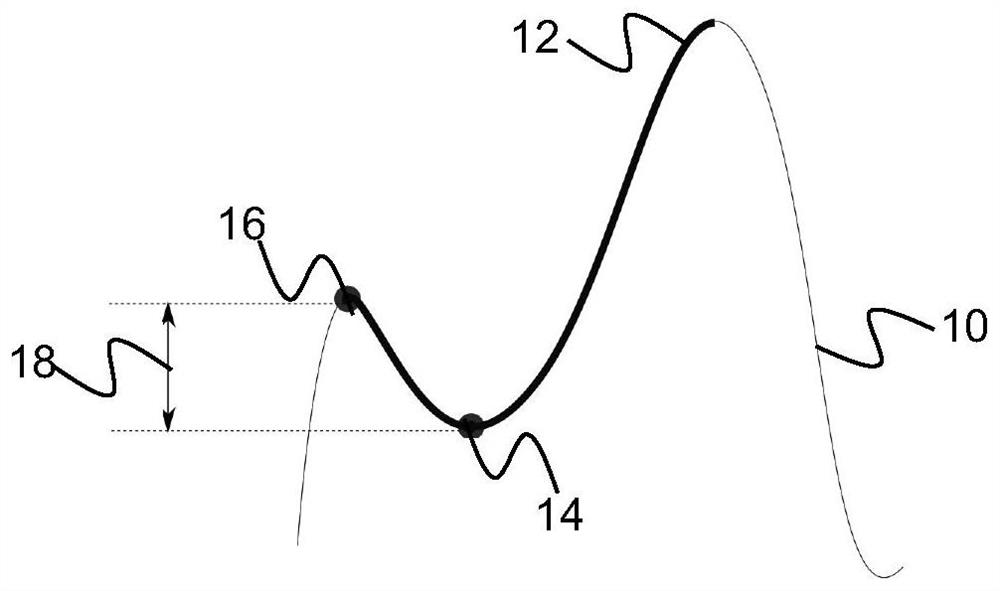

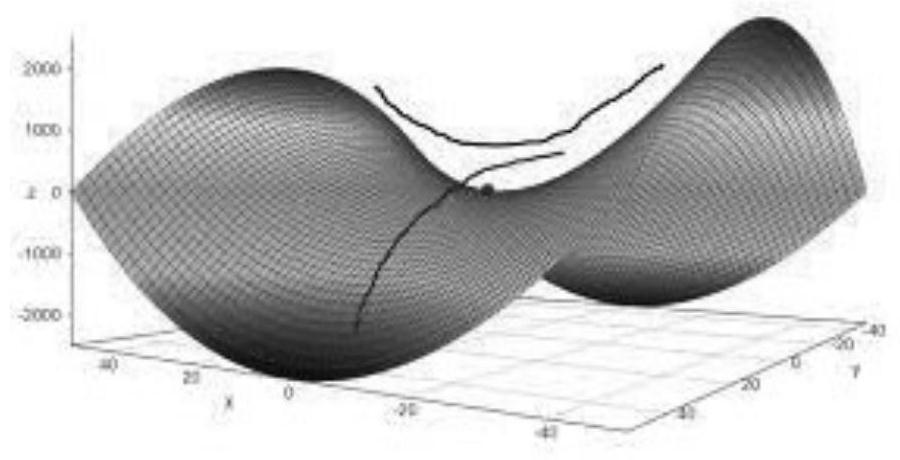

The saddle between two hills (or mountains) is the region surrounding the highest point of the lowest point on the line tracing the drainage divide (the col) connecting the peaks. When, and if, the saddle is navigable, even if only on foot, the saddle of a (optimal) pass between the two massifs, is the area generally found around the lowest route on which one could pass between the two summits, which includes that point which is a mathematically when graphed a relative high along one axis, and a relative low in the perpendicular axis, simultaneously; that point being by definition the col of the saddle.

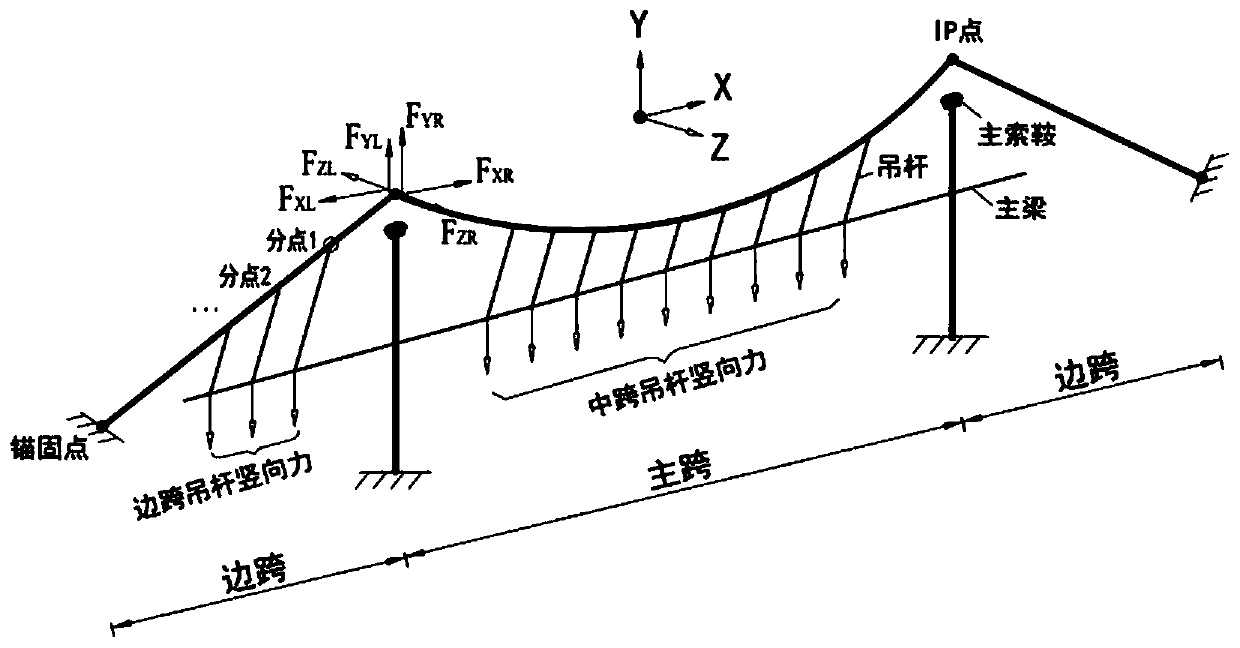

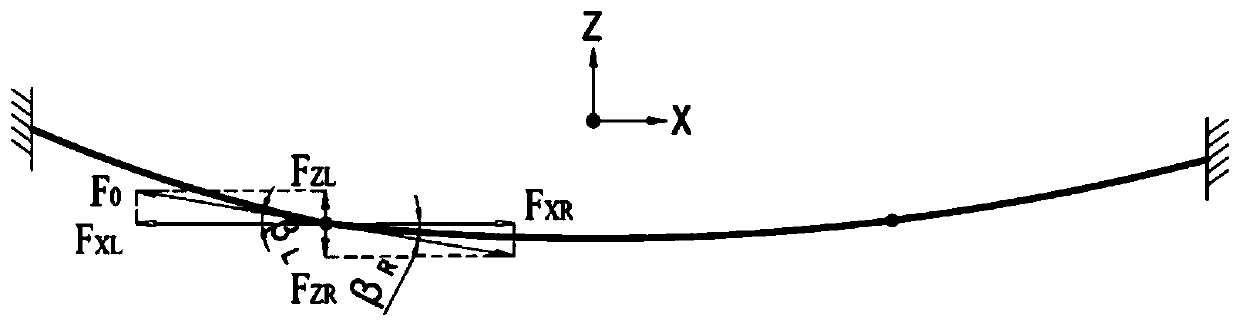

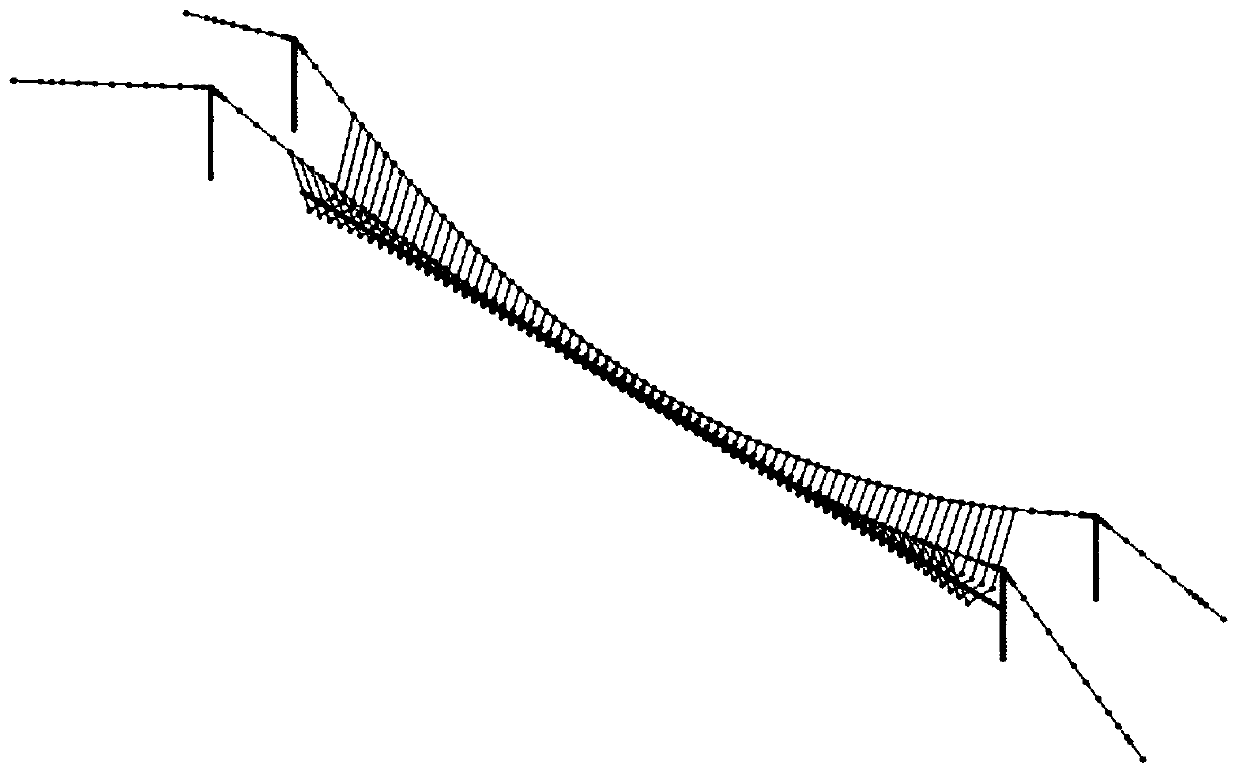

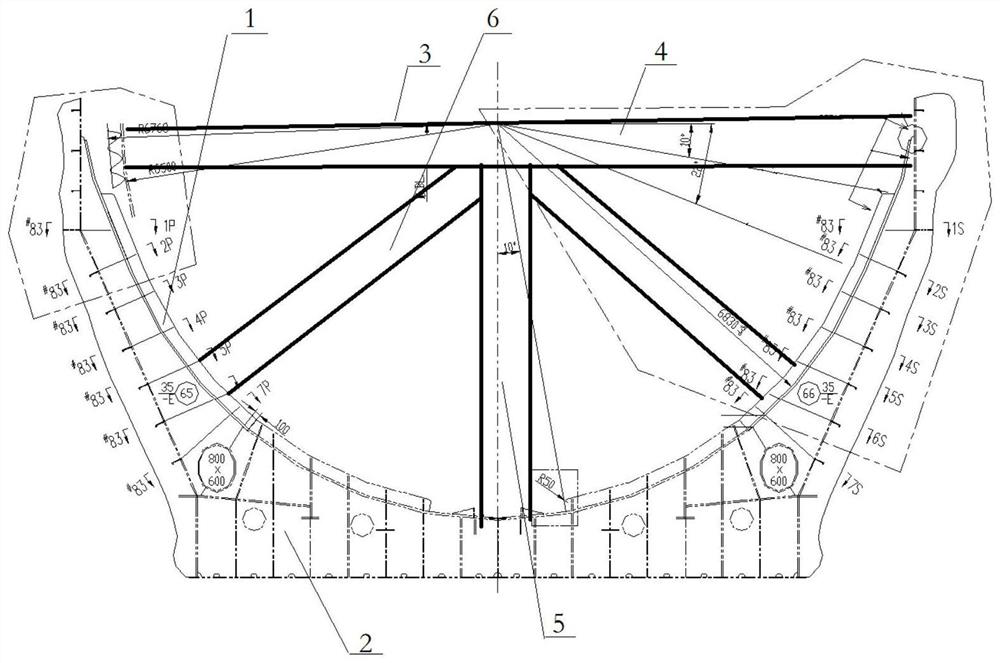

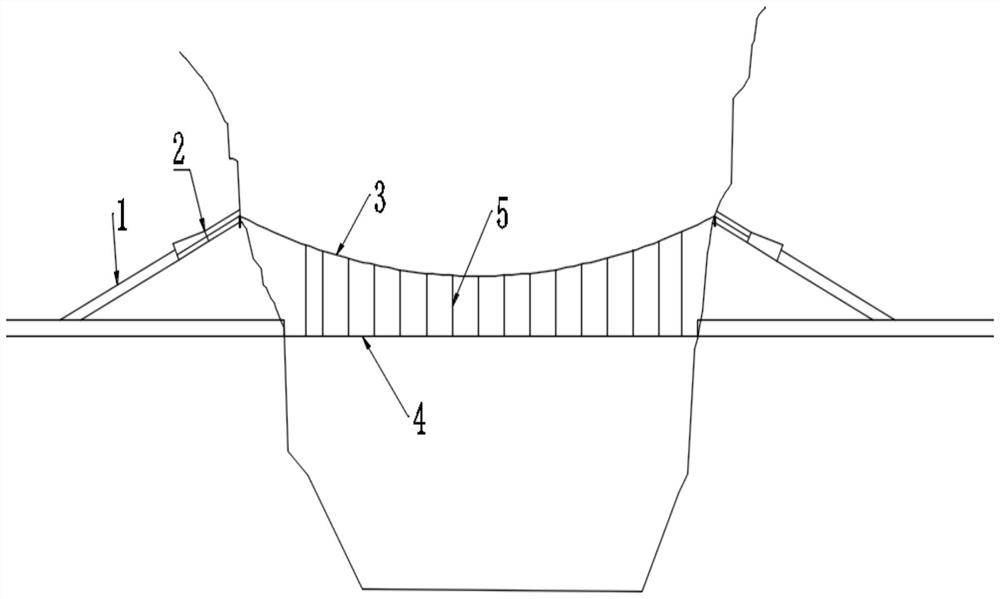

Side span shape finding method adopting resultant force control in horizontal plane

ActiveCN110990913AAccurate calculationSimple designGeometric CADData processing applicationsTowerControl theory

The invention discloses a side span shape finding method adopting resultant force control in a horizontal plane. The method comprises the following steps: taking a vertical component force of a side span main cable at a theoretical vertex as an iterative variable, taking a vertical coordinate of the theoretical vertex or an anchoring point at a splay saddle as an iterative target, adding a new control item, i.e., an included angle between a resultant force in a horizontal plane and a longitudinal axis of a side span end part, and carrying out loop iteration on a side span cable system until aprecision requirement is met. According to the side span shape finding method, it is guaranteed that the longitudinal component force and the transverse component force of the cable force on the towertop are equal, in other words, the resultant force in the horizontal plane is equal, the bridge tower can be completely vertical, the obtained side span line shape and the obtained middle span line shape do not have folded angles on the tower top, and the transverse coordinates of the theoretical vertex or the anchoring point of the splay saddle can be accurately calculated. When the bridge forming state of the space cable suspension bridge is determined, the side span shape finding method controlled by the resultant force in the horizontal plane is successfully applied to the design of a large canyon glass bridge with the main span of 430 m.

Owner:CHINA MAJOR BRIDGE ENERGINEERING

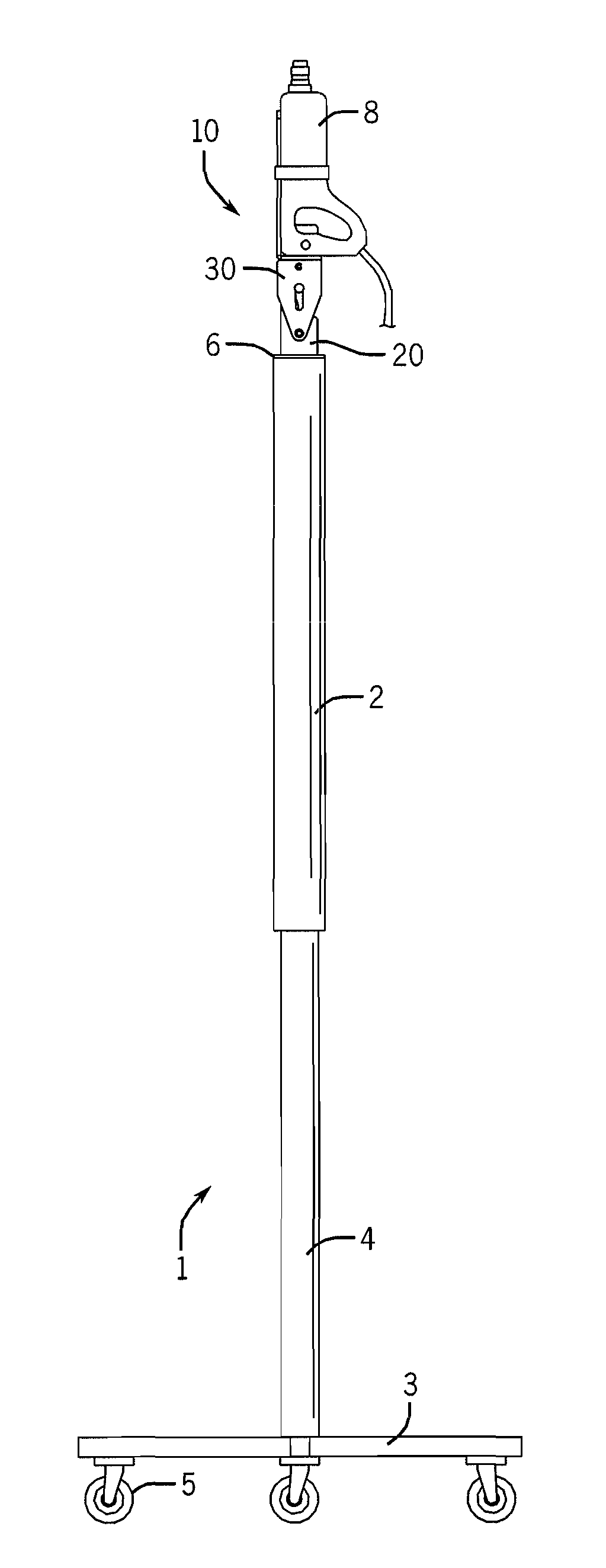

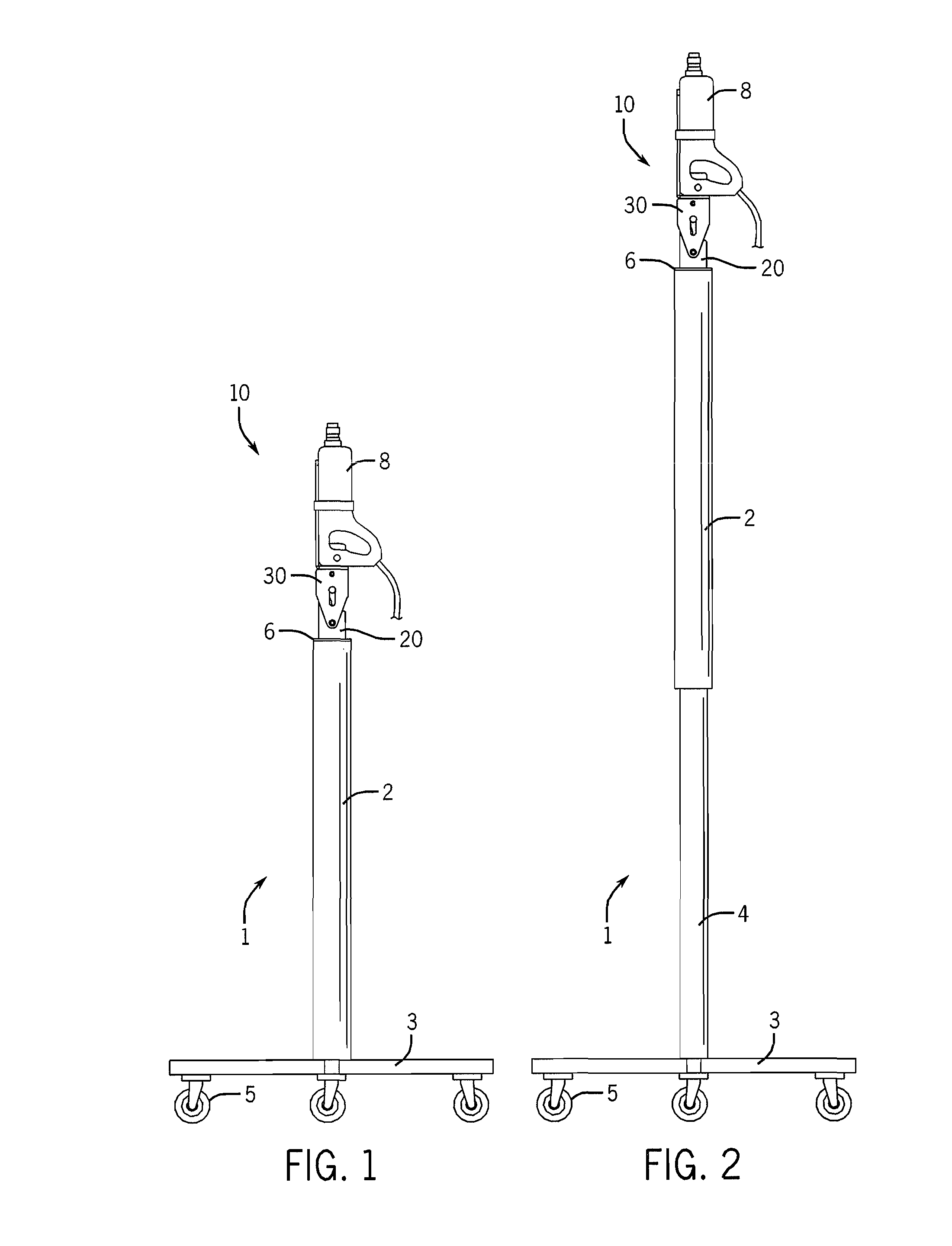

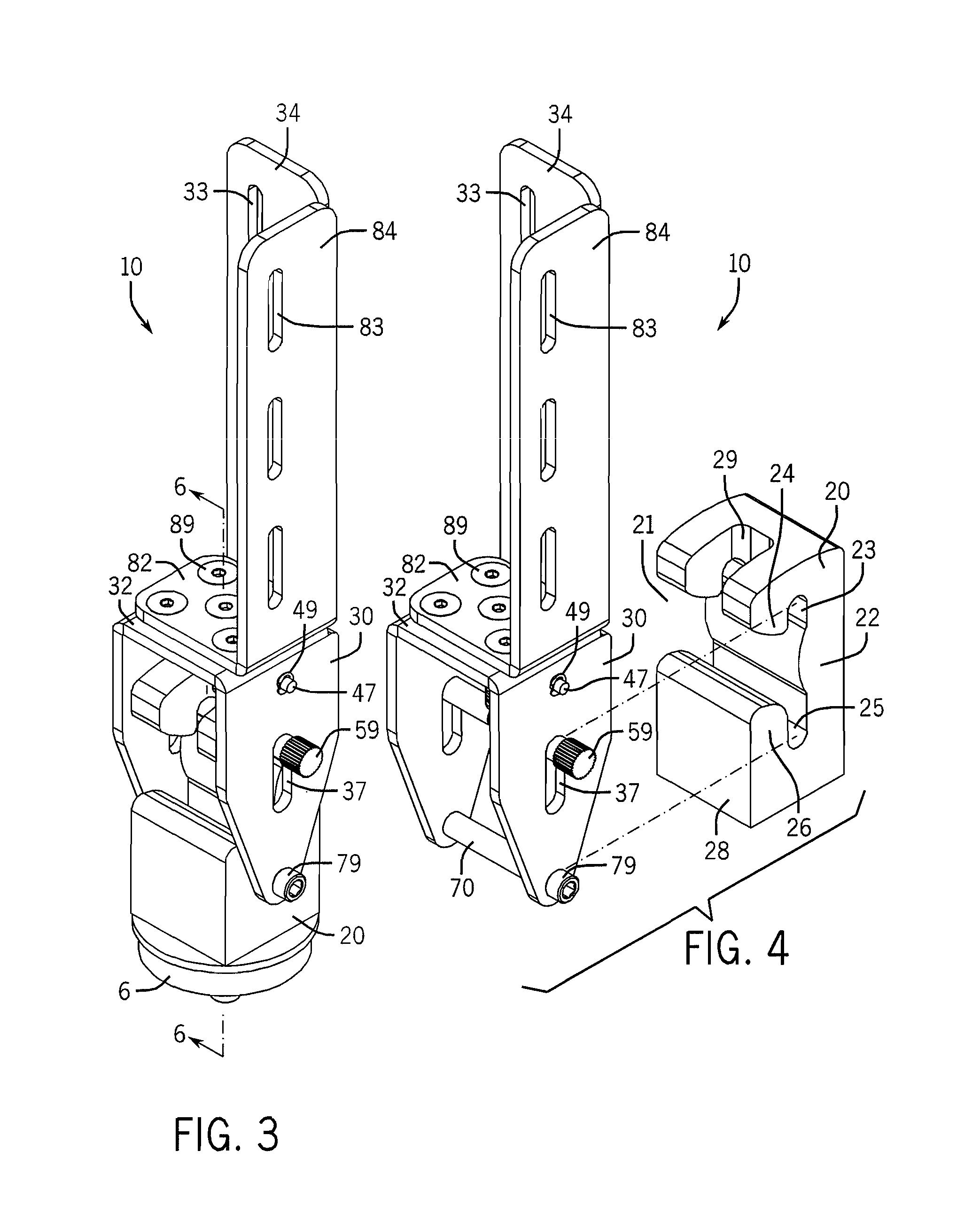

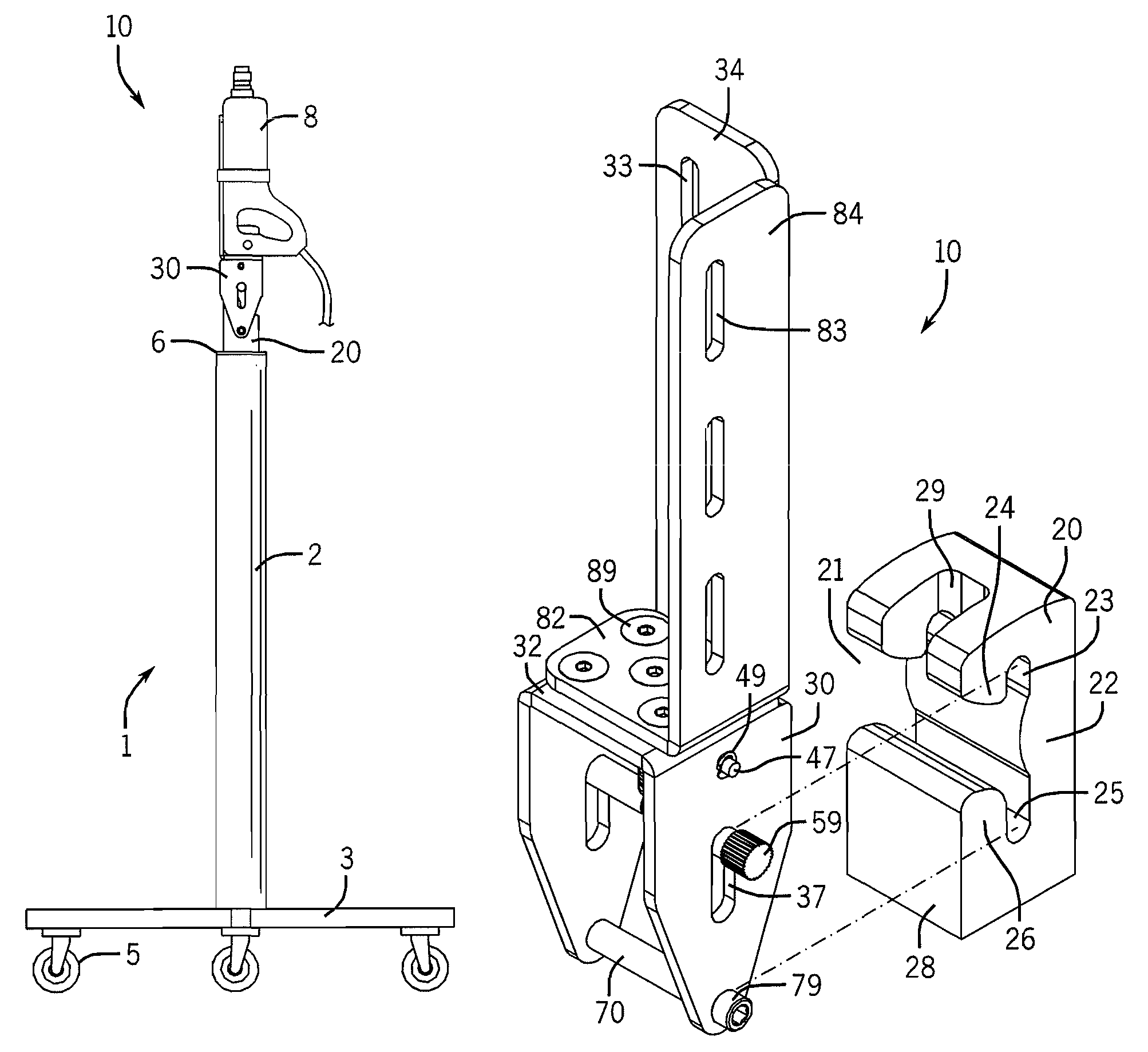

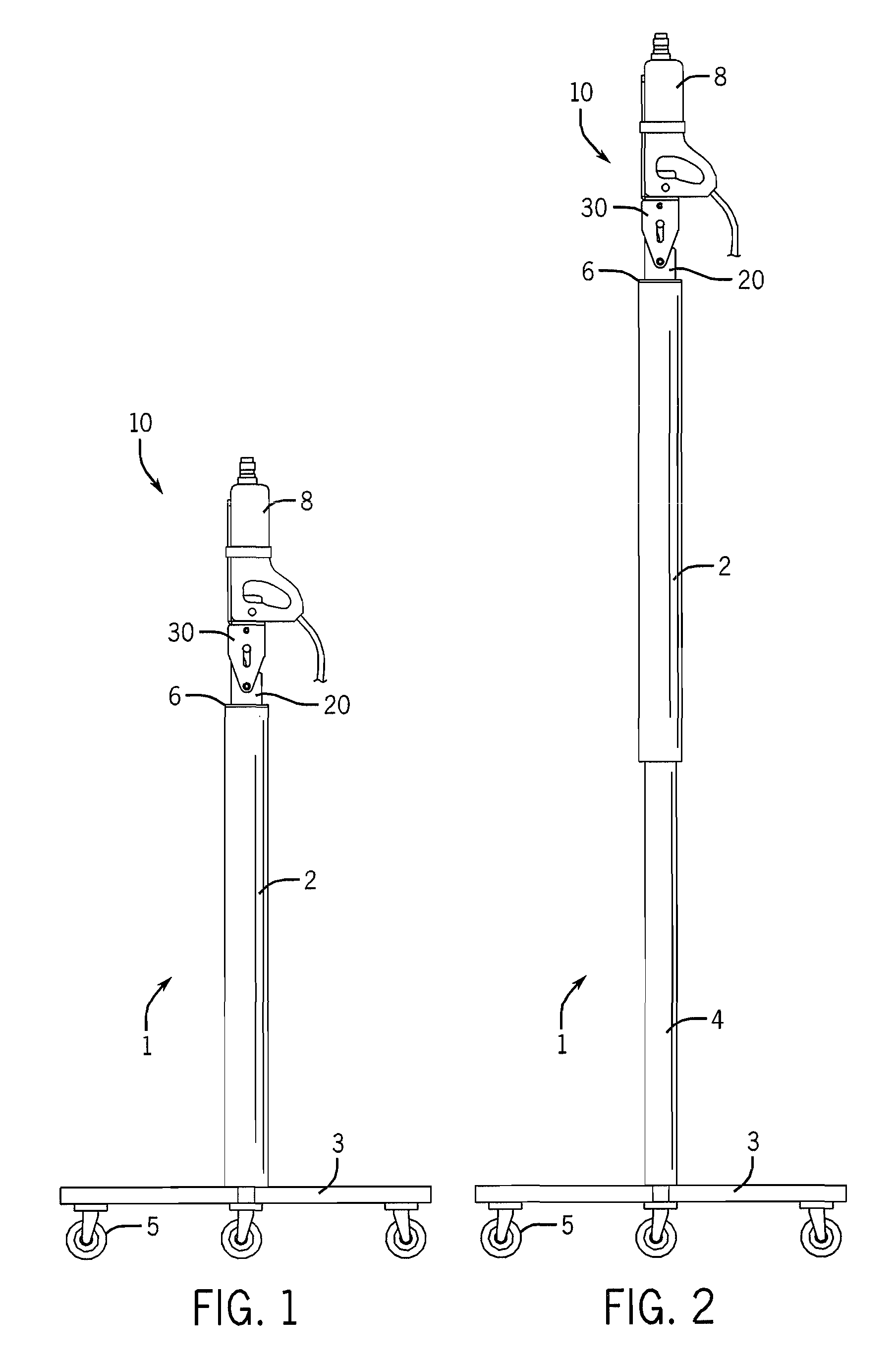

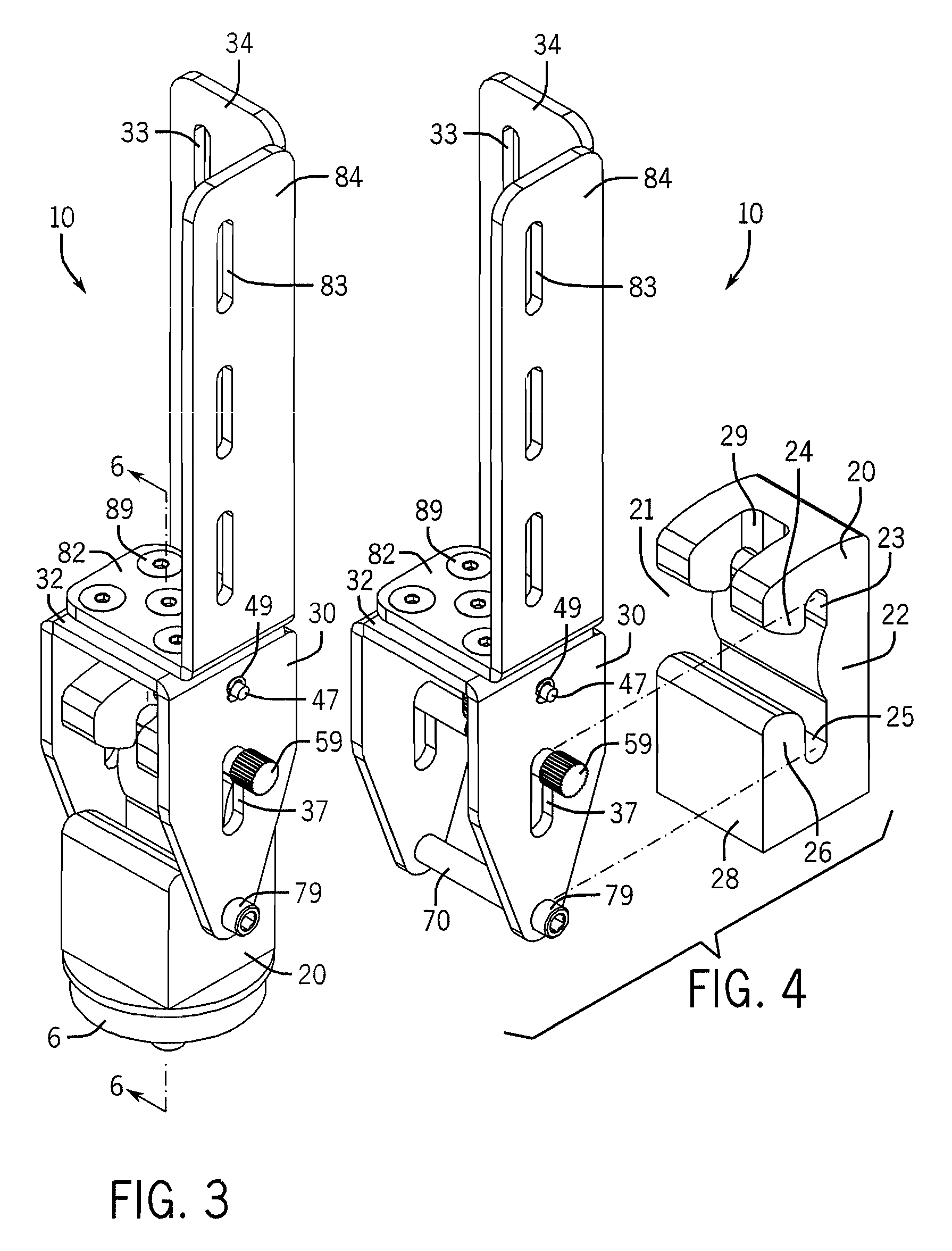

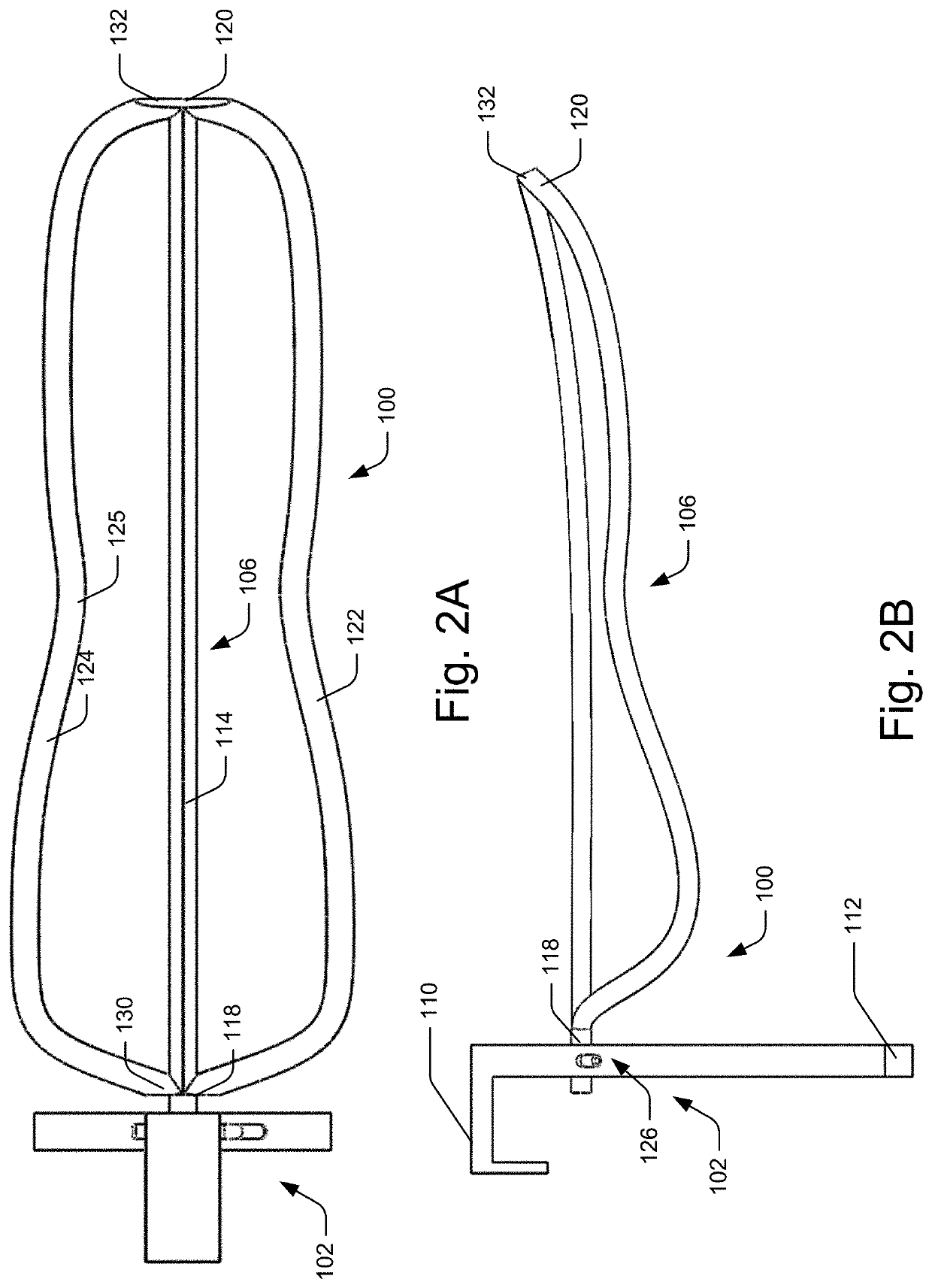

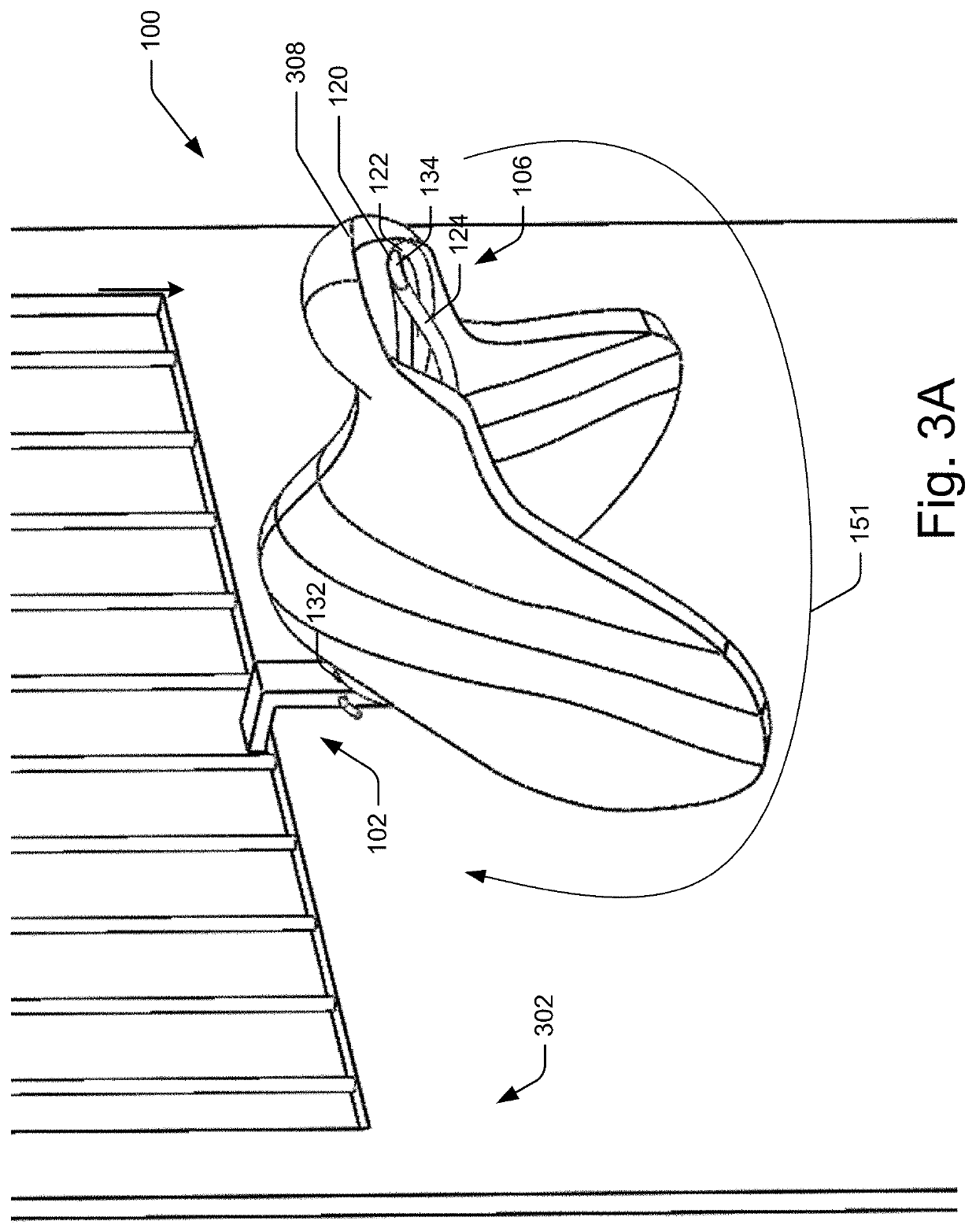

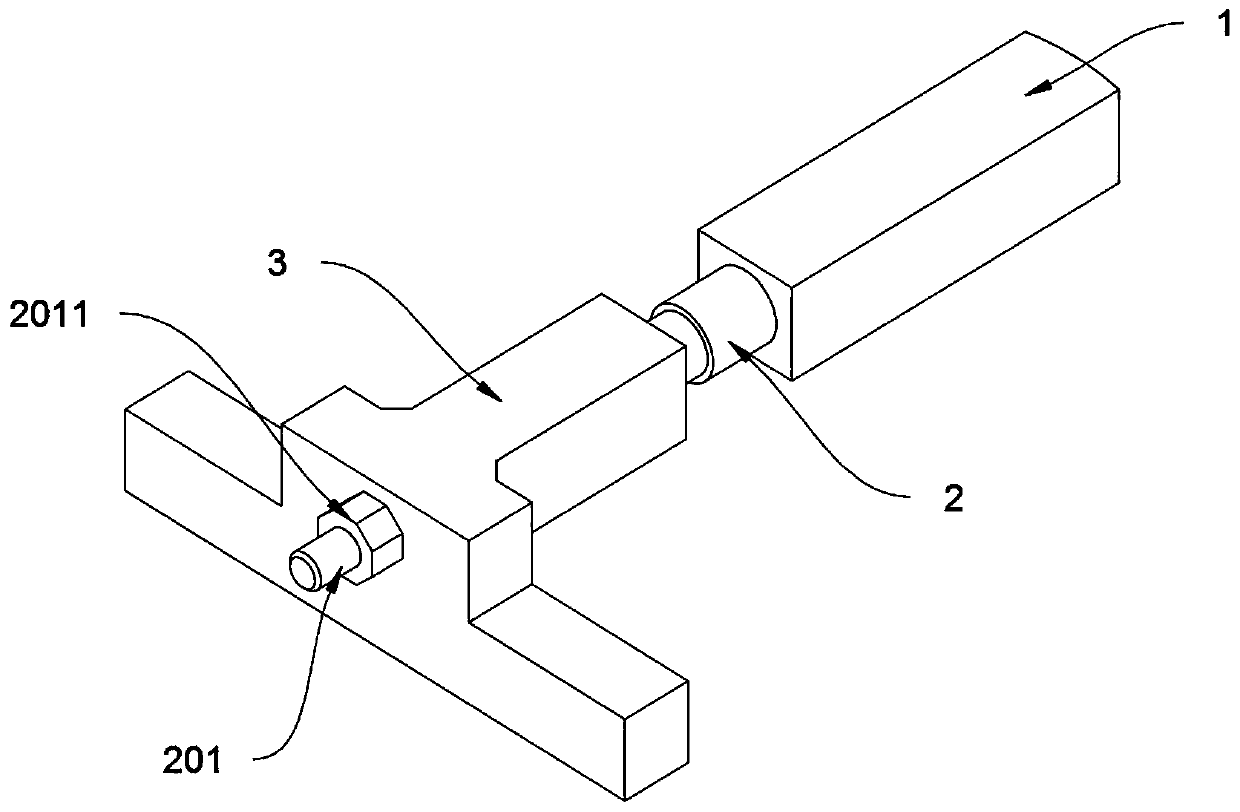

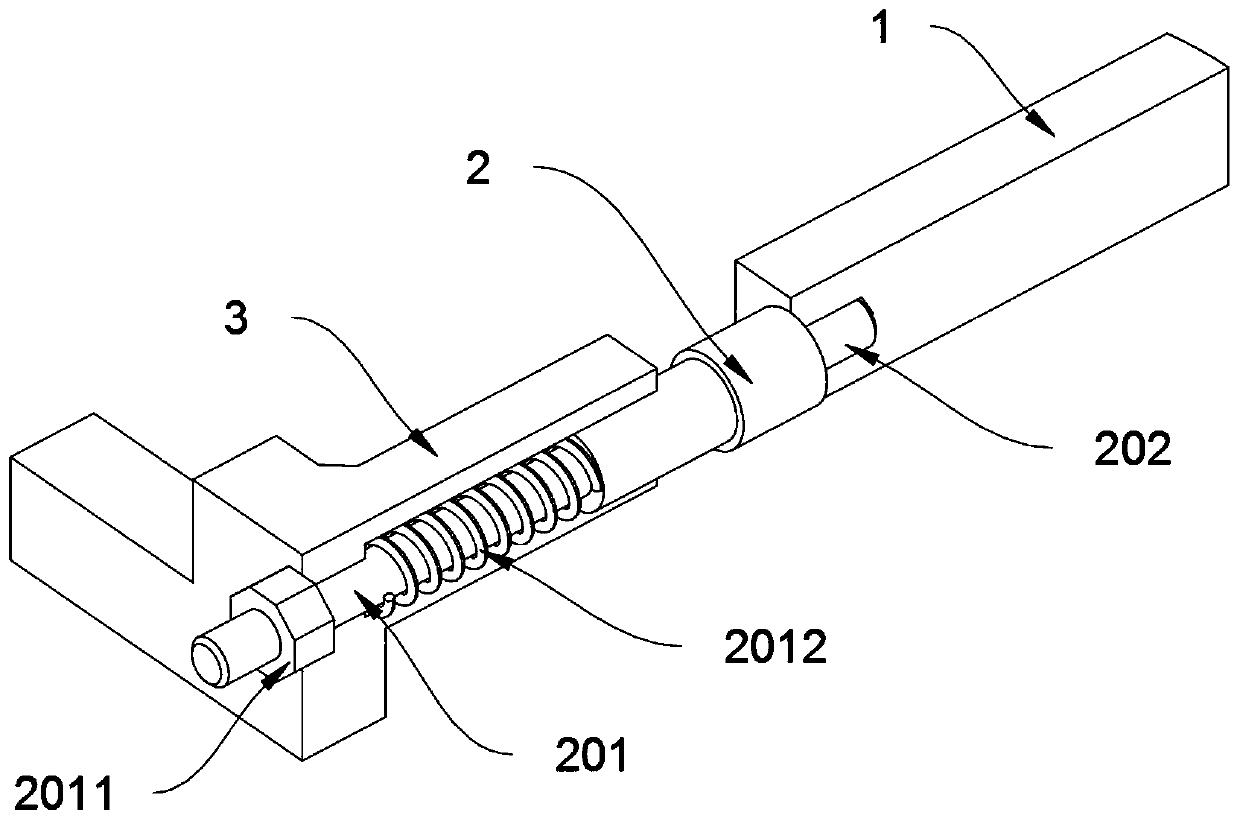

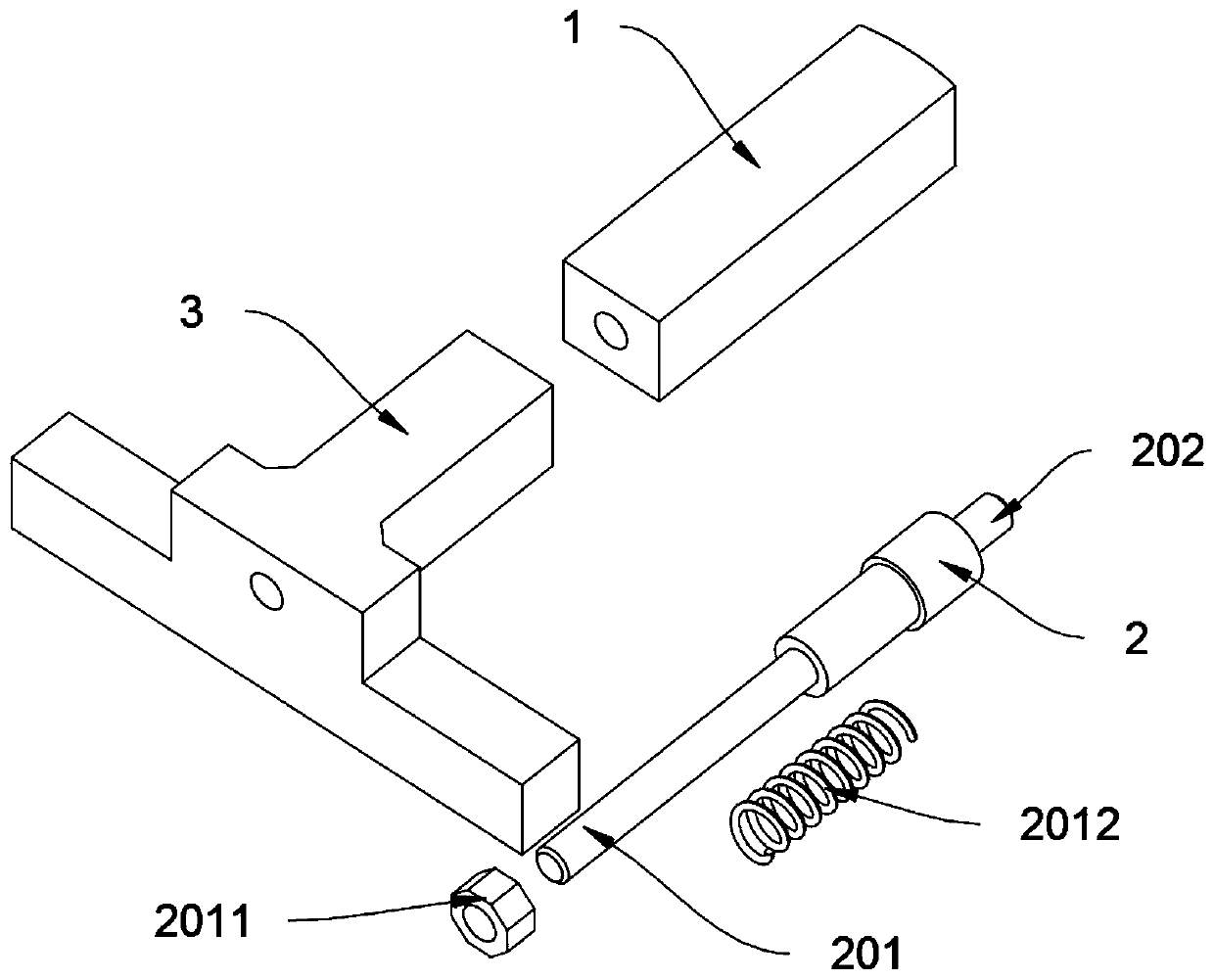

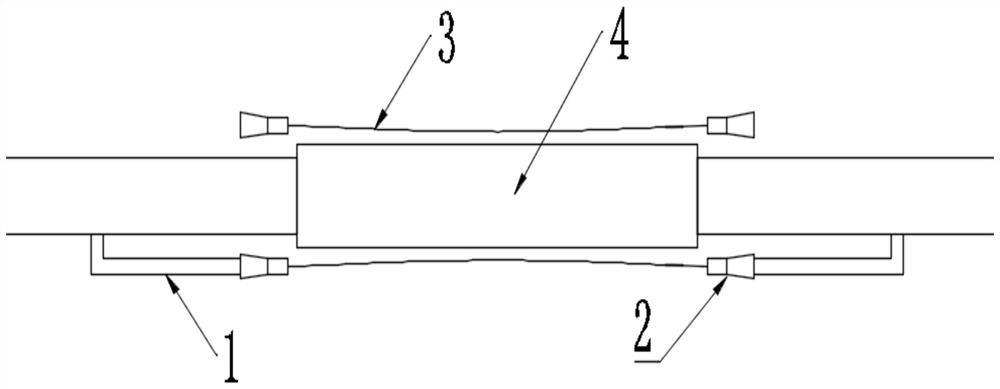

Saddle coupling and saddle base assembly for use with power hand tools

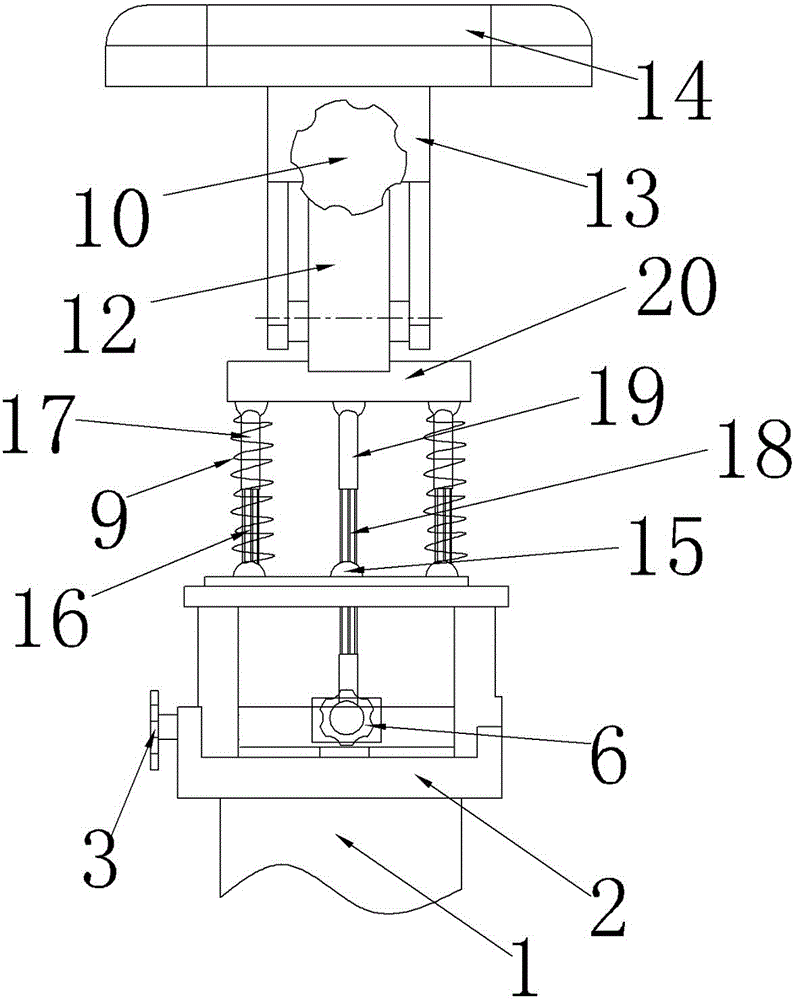

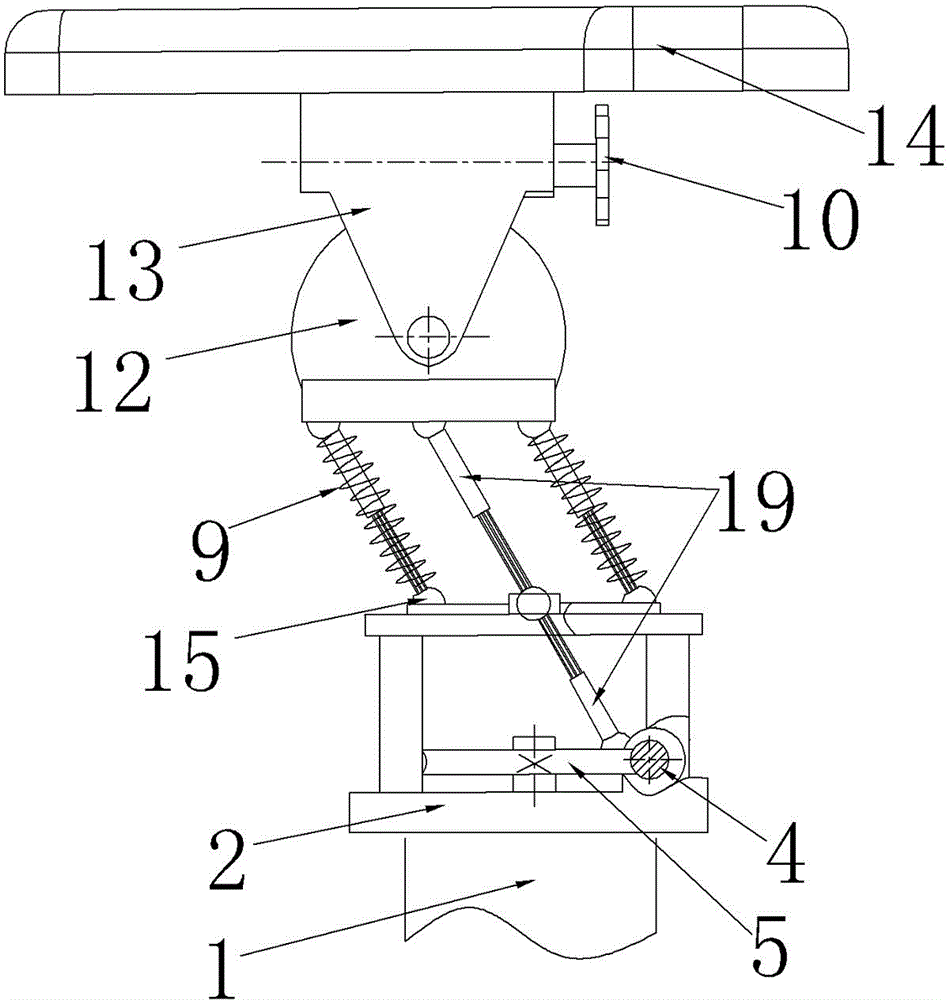

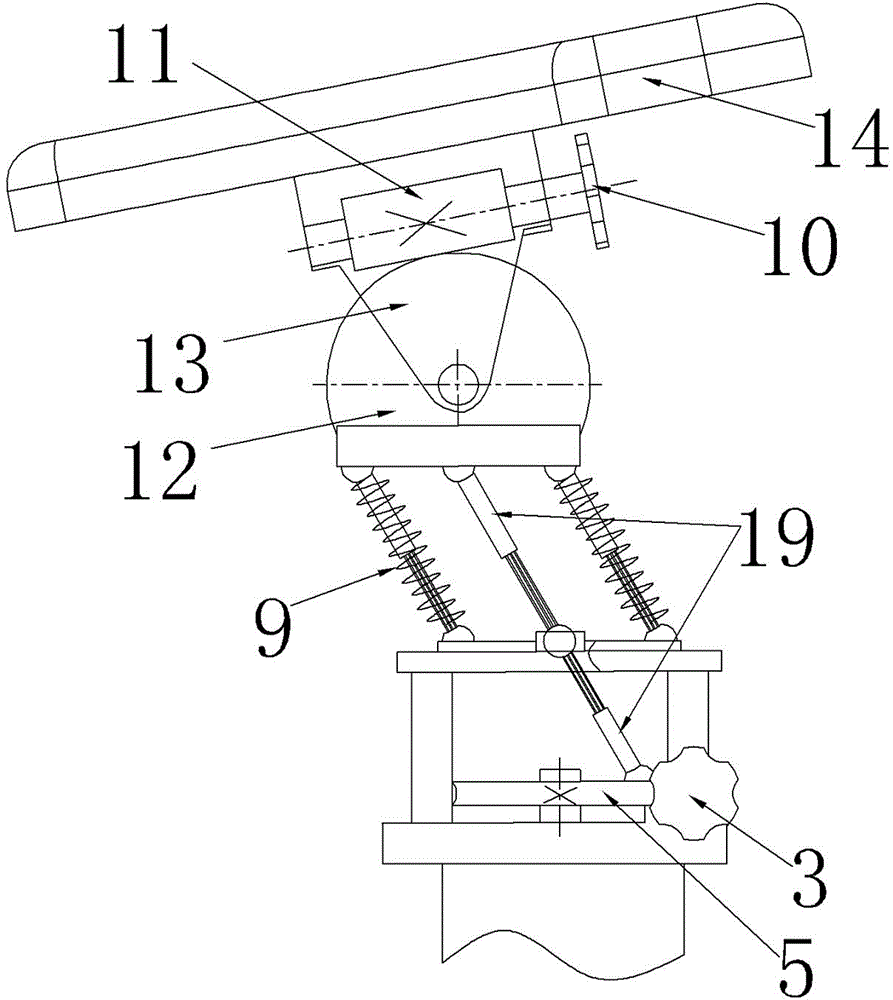

A saddle coupling and saddle base assembly is provided for use with power hand tools. The assembly is mounted atop a variably-adjustable stand for drilling holes or inserting fasteners into concrete ceilings, drywall ceilings or other overhead surfaces. The assembly comprises a saddle base and a saddle coupling that is removably attachable to the saddle base. The saddle coupling is configured to attach a single power hand tool or a plurality of power hand tools to the coupling. A plurality of like-configured saddle couplings can be attached to different power hand tools to allow the user to quickly and easily remove one saddle coupling and power hand tool and replace it for another. A spring-loaded locking feature is included in the assembly as a primary securement means for the assembly. A secondary securement means is also provided in the event of a failure of the primary means.

Owner:BUCHNER DAVID

Saddle coupling and saddle base assembly for use with power hand tools

A saddle coupling and saddle base assembly is provided for use with power hand tools. The assembly is mounted atop a variably-adjustable stand for drilling holes or inserting fasteners into concrete ceilings, drywall ceilings or other overhead surfaces. The assembly comprises a saddle base and a saddle coupling that is removably attachable to the saddle base. The saddle coupling is configured to attach a single power hand tool or a plurality of power hand tools to the coupling. A plurality of like-configured saddle couplings can be attached to different power hand tools to allow the user to quickly and easily remove one saddle coupling and power hand tool and replace it for another. A spring-loaded locking feature is included in the assembly as a primary securement means for the assembly. A secondary securement means is also provided in the event of a failure of the primary means.

Owner:BUCHNER DAVID

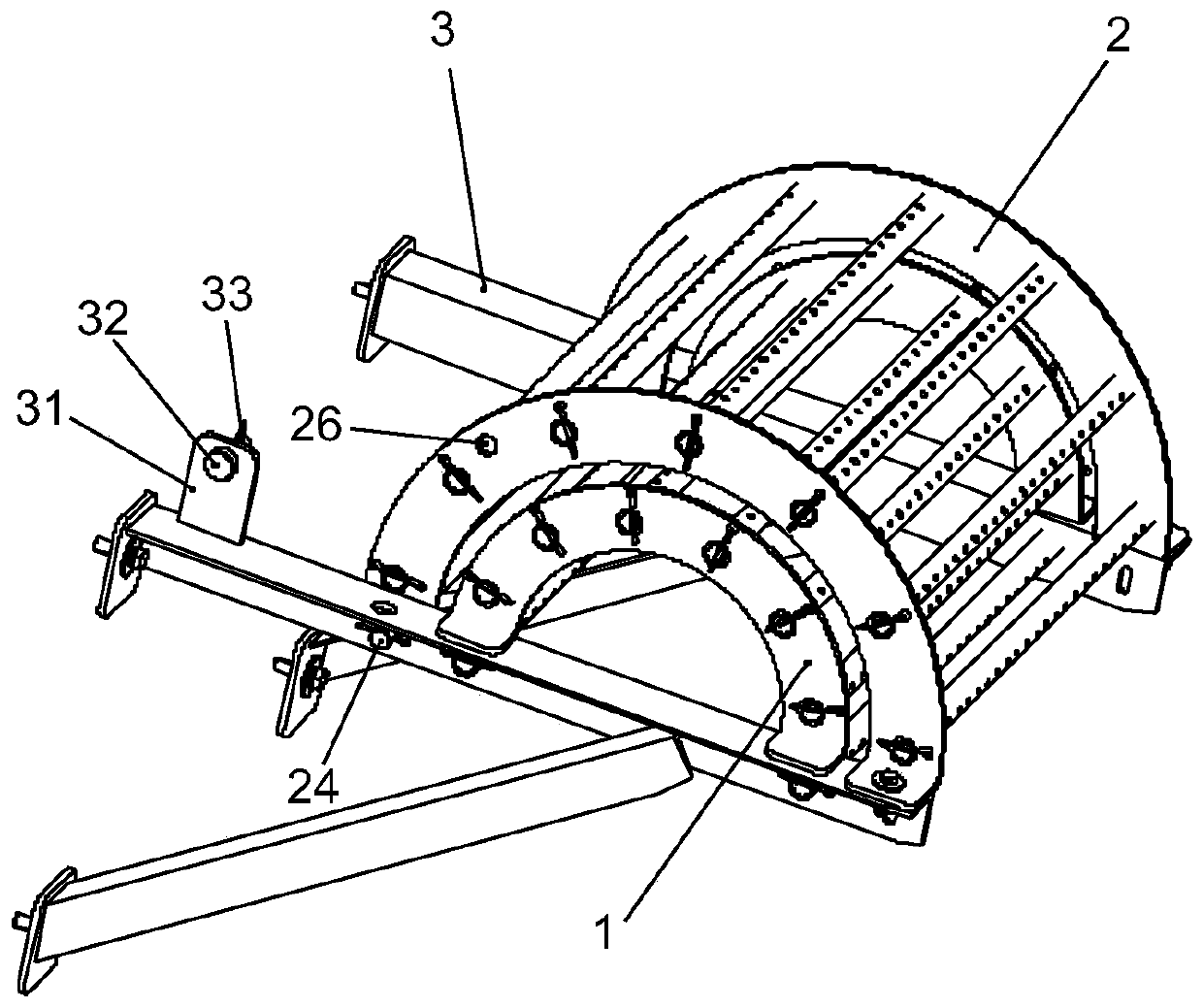

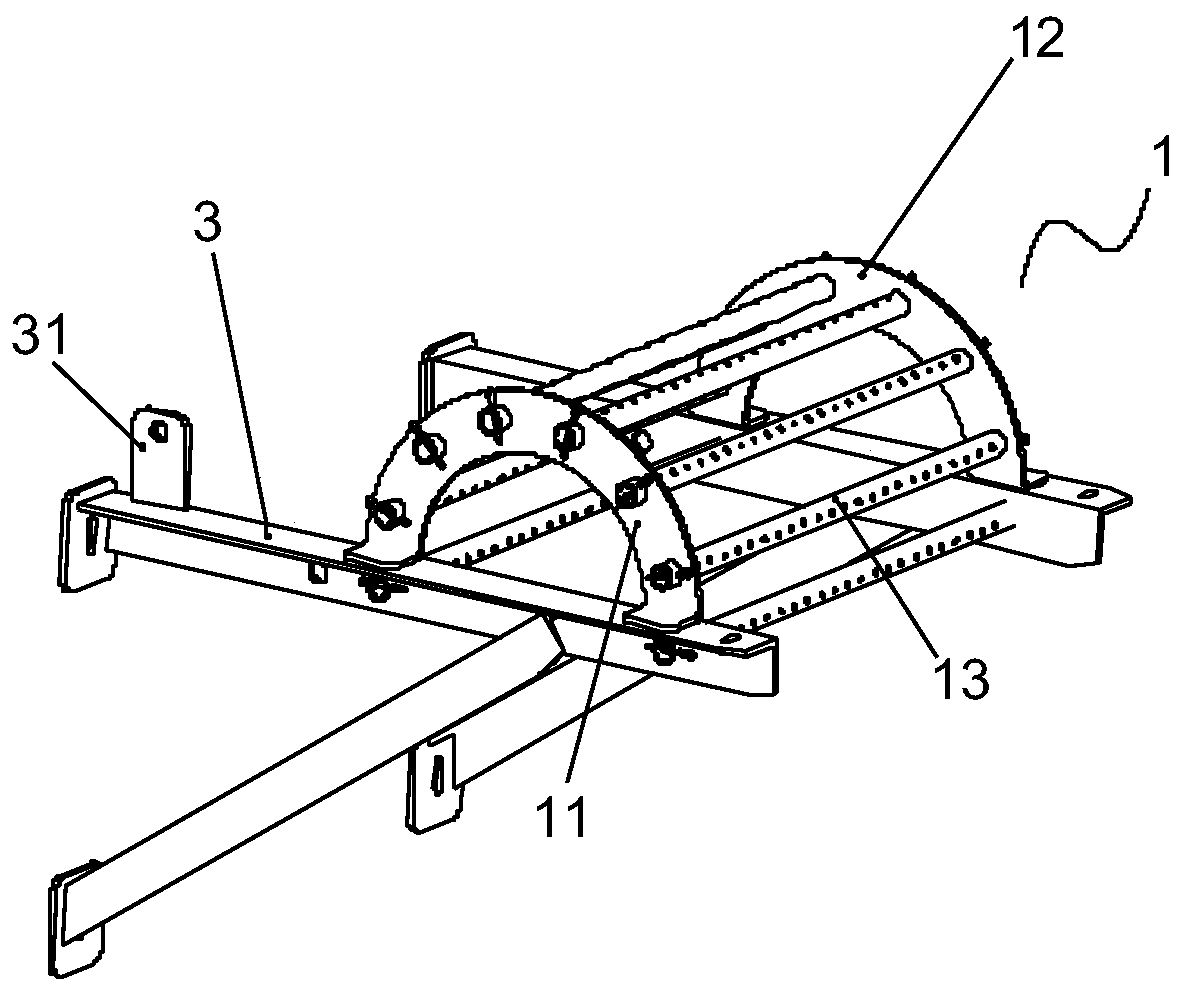

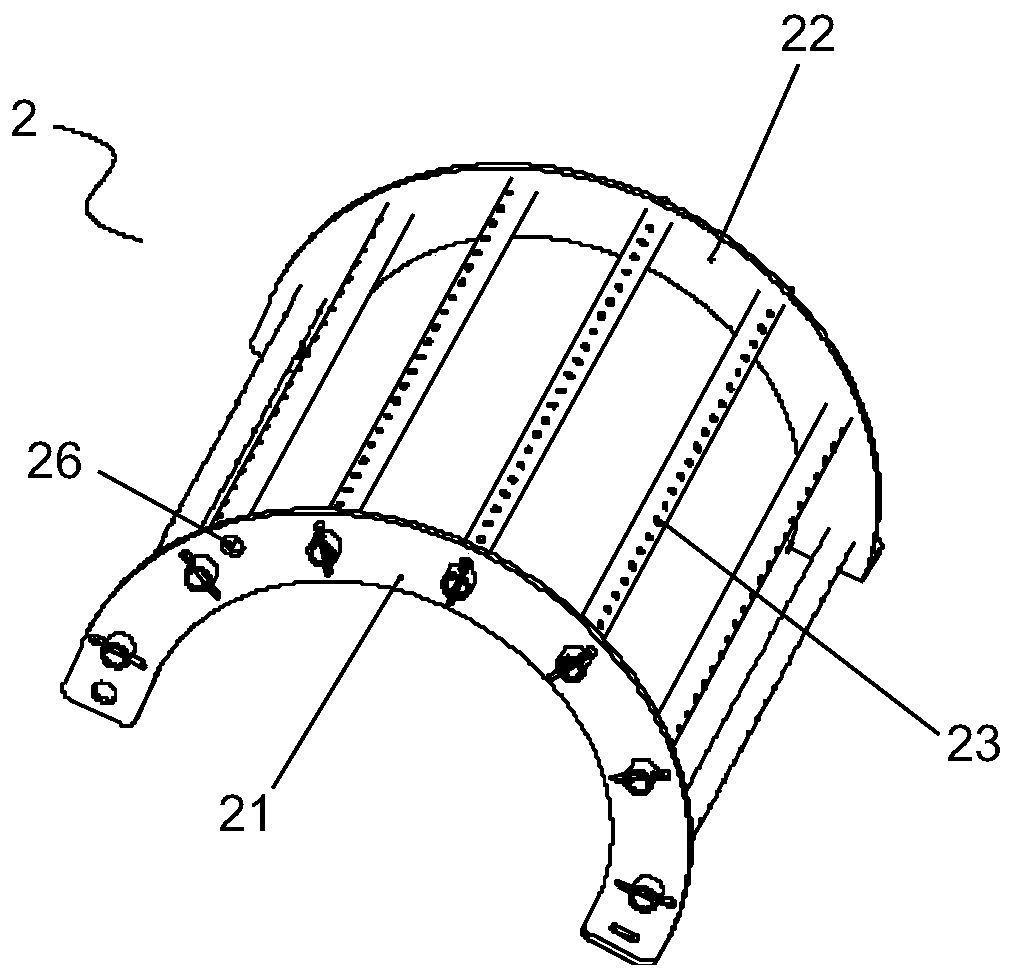

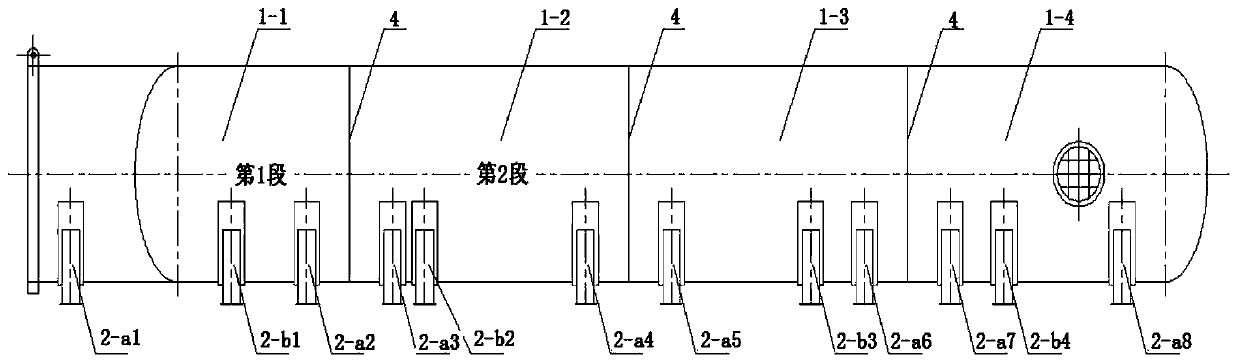

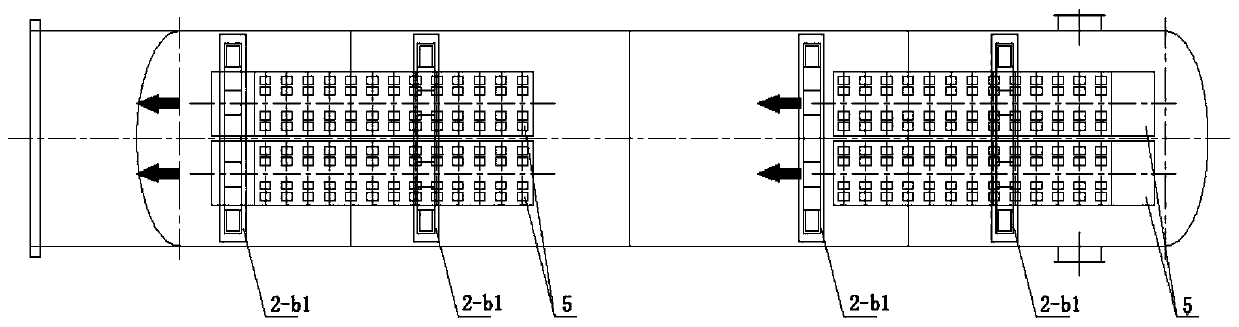

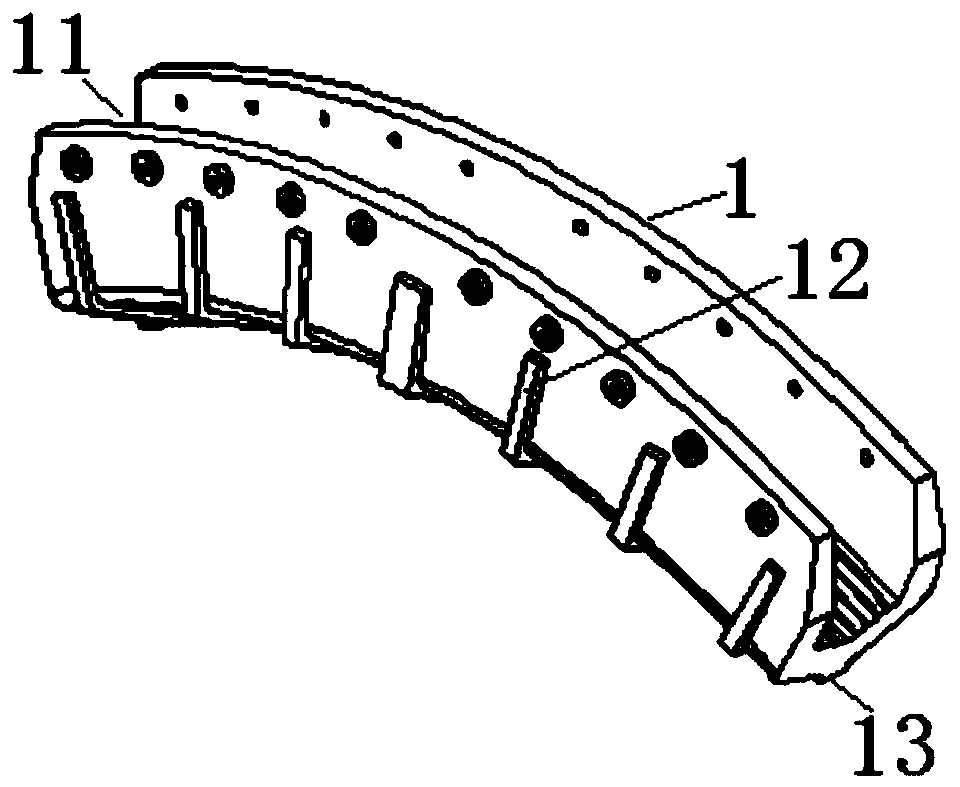

Installation precision control method of C-shaped saddle of LNG filling ship

The invention discloses an installation precision control method of a C-shaped saddle of an LNG filling ship. The installation precision control method comprises the steps of manufacturing the C-shaped saddle and installing the C-shaped saddle. C-shaped saddle manufacturing comprises the following steps of S11, a precision design of the C-shaped saddle; S12, C-shaped saddle manufacturing; S13, datum line drawing; S14, precision detection; and S15, C-shaped saddle transportation. C-shaped saddle installation comprises the following steps of S21, C-shaped saddle arc center point determination; S22, datum line reinspection; S23, C-shaped saddle positioning; and S24, C-shaped saddle installation. The manufacturing precision and the installation precision of the C-shaped saddle are monitored inthe whole process in the manufacturing and installation stages so that an actual mounting position of the liquid tank in the cargo hold is adjusted, the liquid tank is supported and fixed, stabilityof a liquid tank installation system is improved, and operation safety of the LNG filling ship is guaranteed.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

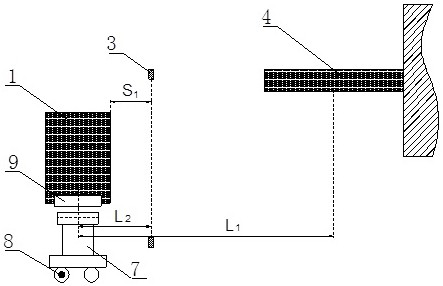

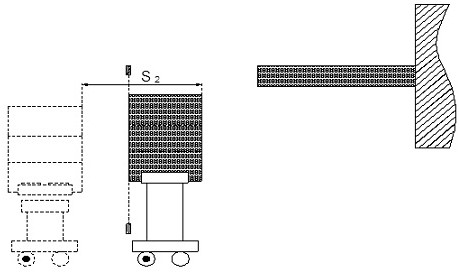

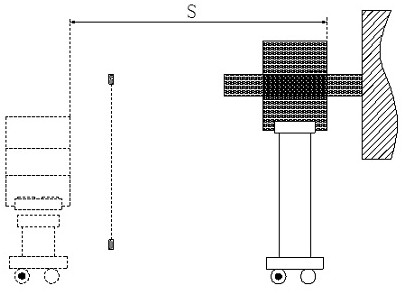

Steel coil feeding and centering method

The invention relates to a steel coil feeding and centering method. After a steel coil is lifted from a saddle to the height of a running position by a coil feeding trolley, the steel coil is draggedto move to the direction of an uncoiling machine mandrel to pass through a grating, and according to a formula epsilon= L2-(S1 + S2) / 2, the deviation epsilon between the center line of the saddle andthe center line of the steel coil when the steel coil is placed on the saddle is calculated, S1 is the distance between the edge of the steel coil and the grating, L1 is the distance between the center of the saddle and the center of the of the uncoiling machine mandrel, S2 is the distance traveled by the trolley when the steel coil moves out of the grating, and the distance S required to move forcentering the steel coil and a rolling line is L1-epsilon, that is, S = L1-L2 +(S1 + S2) / 2, and L2 is the distance between the center of the saddle and the grating. The method is simple, and the horizontal moving distance of the coil feeding trolley can be automatically calculated.

Owner:WEIER AUTOMATION CO LTD TANGSHAN IRON & STEELGRP +1

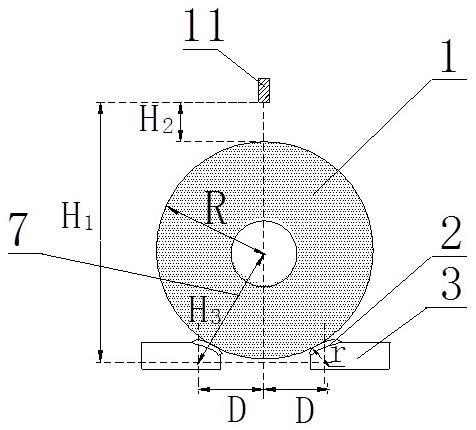

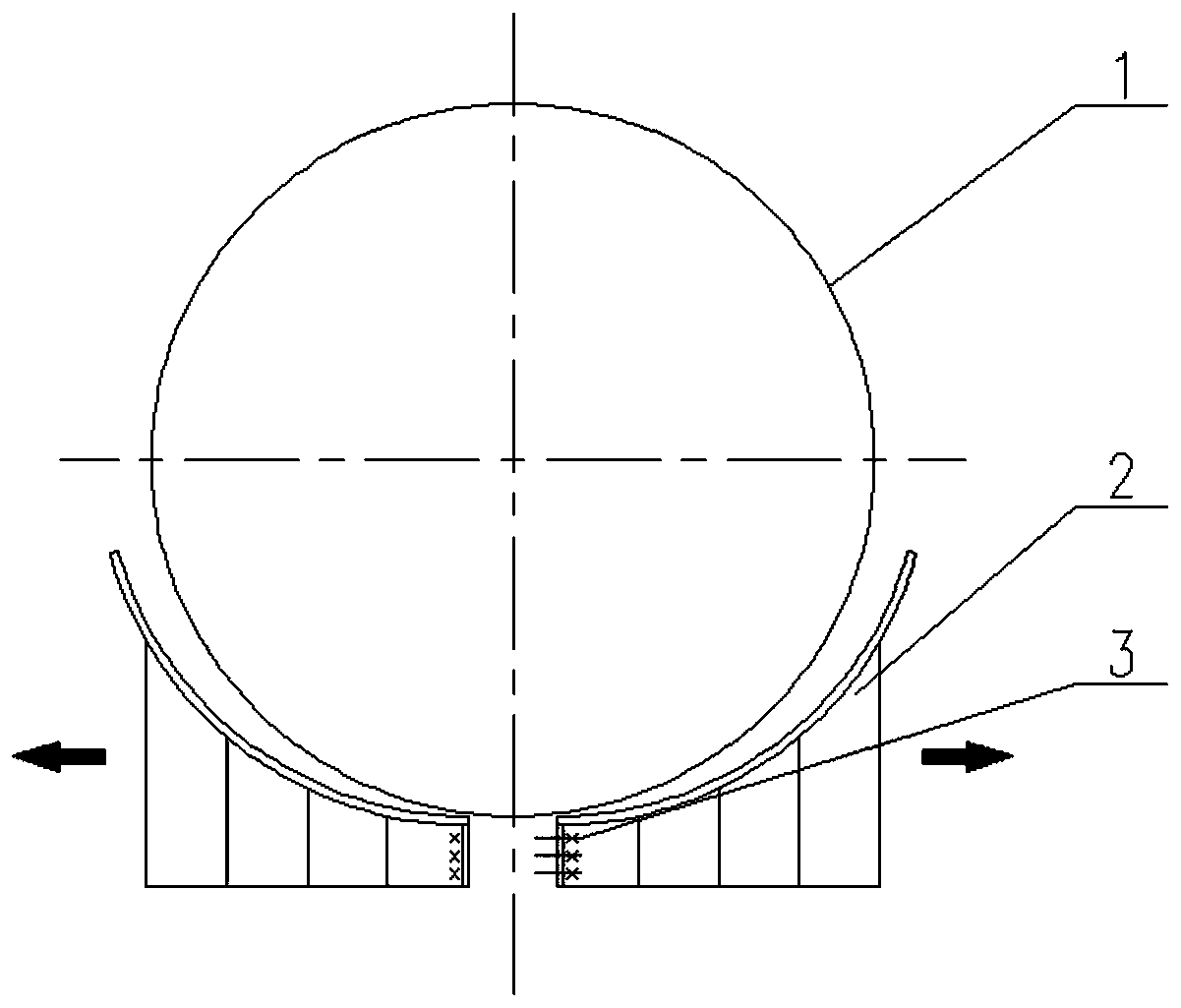

Steel coil diameter calculation method

ActiveCN111981992AReduce labor intensityReduce labor costsUsing optical meansLaser rangingLaser sensor

The invention relates to a steel coil diameter calculation method; a seat lining plate is of an arc structure, a laser distance measuring sensor is mounted over the center position of the connecting line of the circle centers of two saddle lining plates, and the distance between the laser distance measuring sensor and the bottom face of a saddle is larger than the maximum steel coil diameter; thediameter of the steel coil is obtained through a formula R=(H1<2>+H2<2>-2*H1*H2-r<2>+D<2>) / 2(H1-H2+r) according to the distance H2 between the laser distance measuring sensor and the surface of the steel coil measured by the laser distance measuring sensor, wherein R is the radius of the steel coil, H1 is the vertical distance of the circle center connecting line of the laser ranging sensor and the saddle lining plates, H2 is the distance between the laser ranging sensor and the top of the steel coil and is the actual measurement value of the laser sensor, r is the radius of the saddle liningplates, and D is half of the distance of the circle center connecting line of the two saddle lining plates. The method can automatically measure the diameter of the steel coil, and improves the production efficiency.

Owner:WEIER AUTOMATION CO LTD TANGSHAN IRON & STEELGRP +1

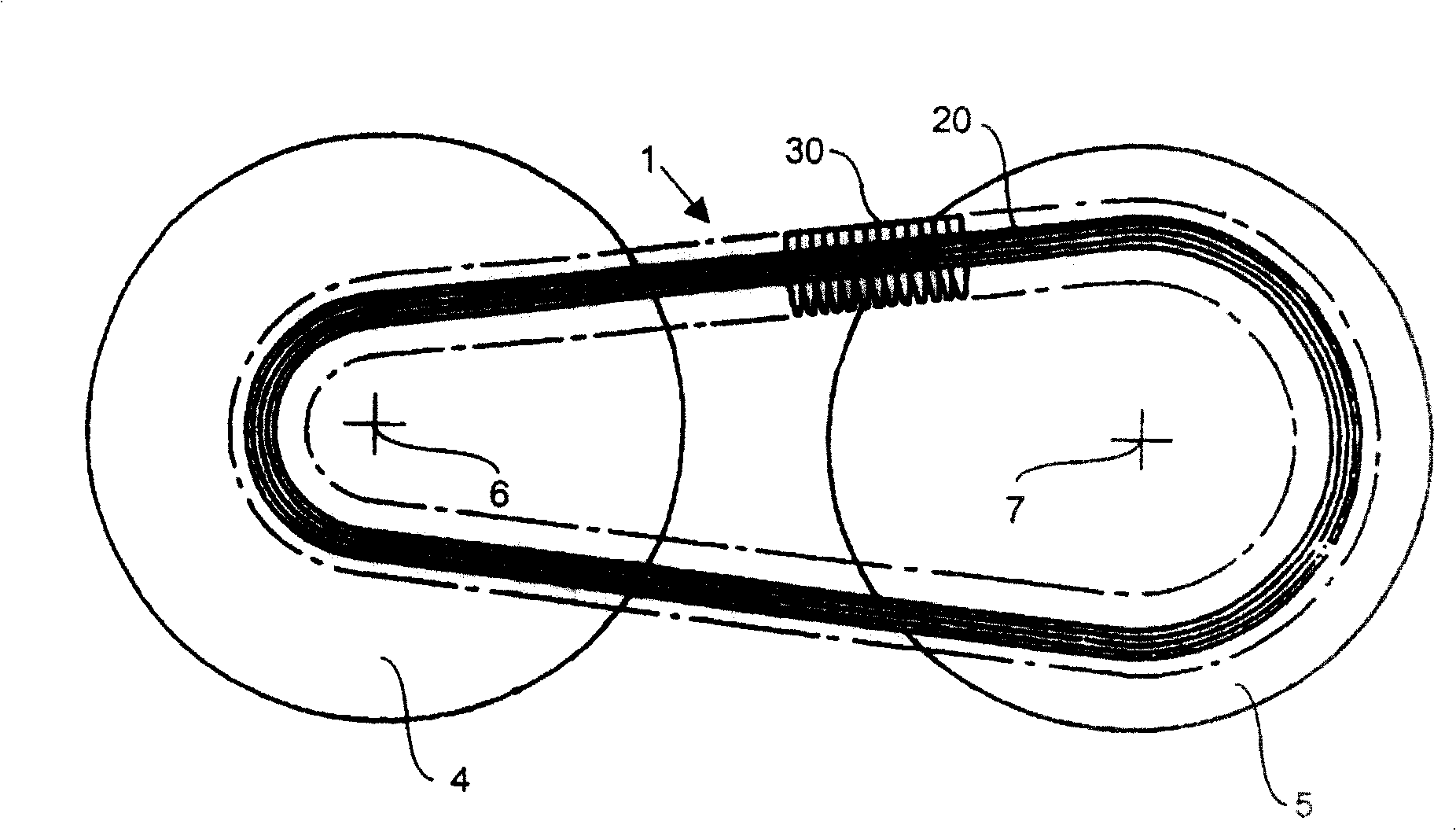

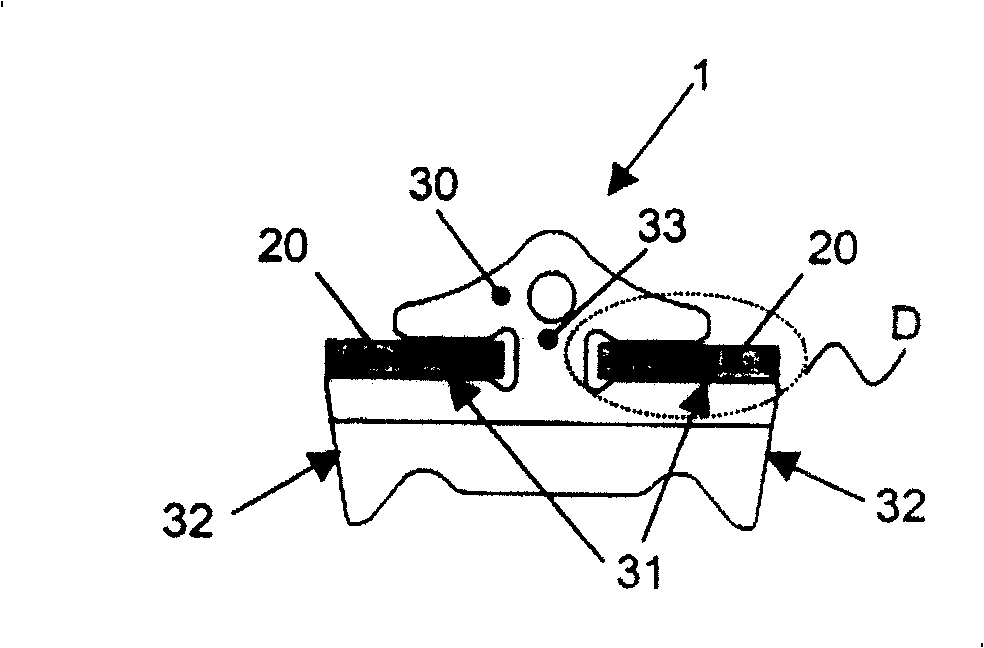

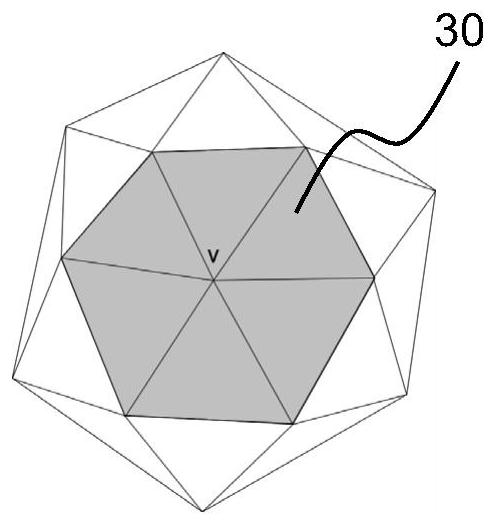

Driving belt

ActiveCN100451381CReduce the amount of lateral bendingReduced transverse bending stressV-beltsEngineeringSaddle shape

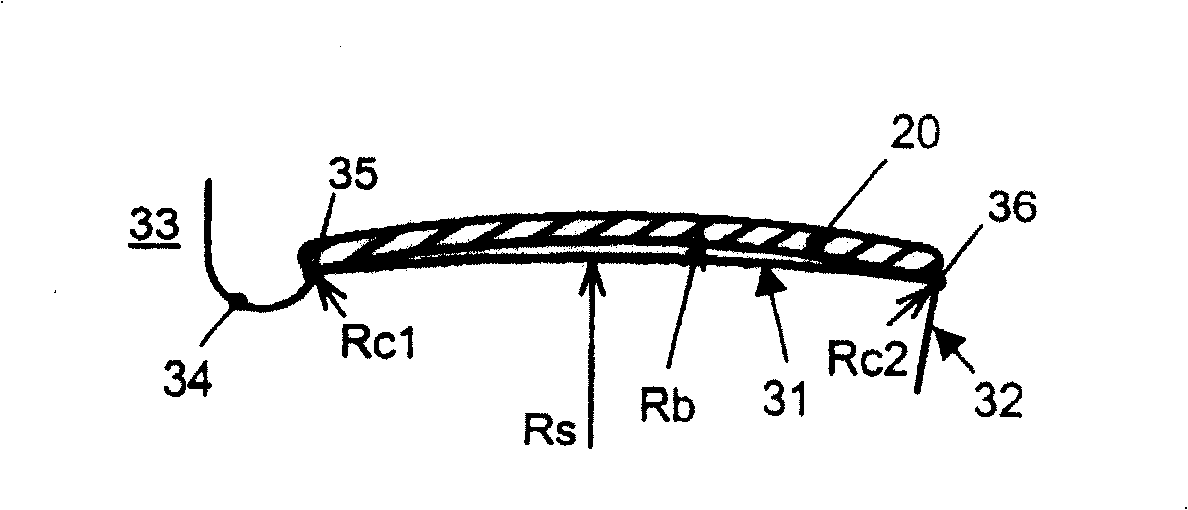

Drive belt (1) comprising at least one continuous band (21) and a number of cross elements (30) having a transversely curved saddle surface (31) of saddle radius (Rs) for interacting with an inwardly oriented main face of the continuous band (21) that at a first lateral side thereof adjacent a pillar part (33) of the element (30) connects to a concavely recessed surface part (34) through a first convexely curved transition surface part (35). The drive belt further incorporating the features that: a transverse width (W) of the continuous band (21) is larger than a transverse width of the saddle surface (31); the saddle radius (Rs) is essentially constant throughout the transverse width of the saddle surface (31); the saddle radius (Rs) is smaller than a so-called band radius (Rb) of a transverse curvature of the band (21) in an unloaded state thereof, irrespective of an amount of bending in the longitudinal direction of the band (21); and the first transition surface part (35) forms a relatively sharp edge. <IMAGE>

Owner:ROBERT BOSCH GMBH

Continuous hot extrusion saddle-shaped barrel section butt joint assembling method

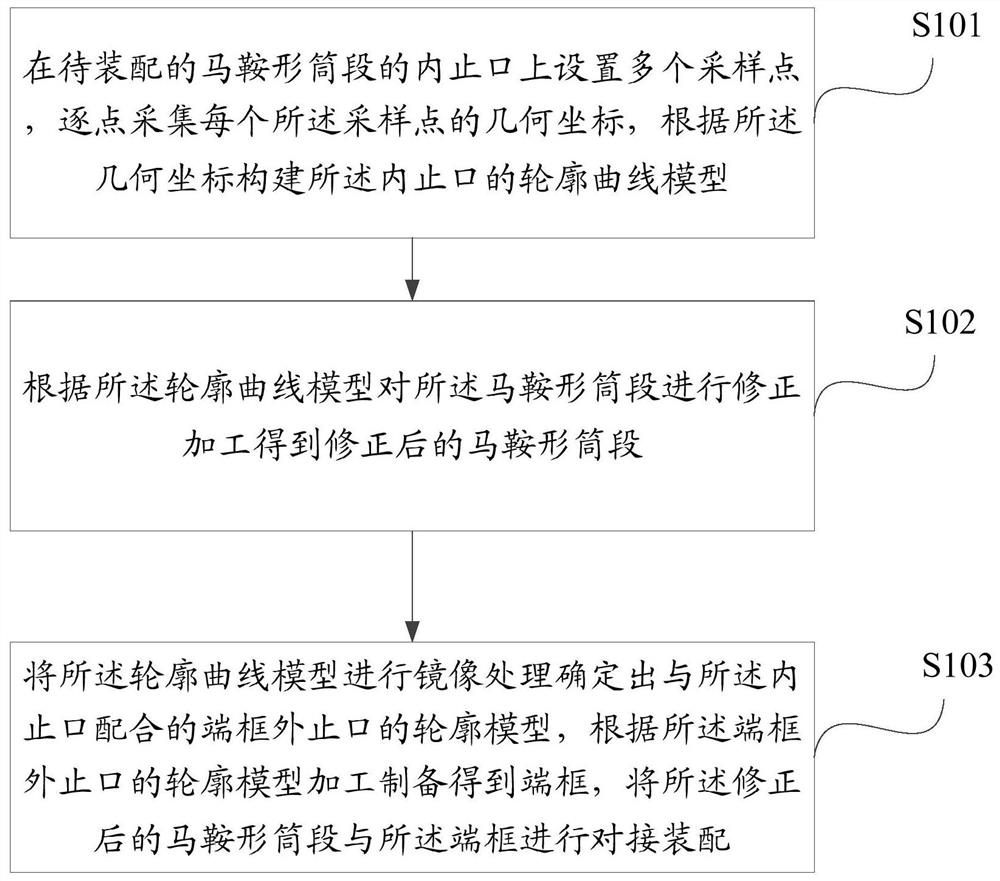

The invention discloses a continuous hot extrusion saddle-shaped barrel section butt joint assembling method. The method comprises the steps that a plurality of sampling points are arranged on an inner spigot of a saddle-shaped barrel section to be assembled, geometric coordinates of each sampling point are collected point by point, and a contour curve model of the inner spigot is constructed according to the geometric coordinates; the saddle-shaped barrel section is corrected according to the contour curve model to obtain a corrected saddle-shaped barrel section; and mirror image processing is performed on the contour curve model to determine a contour model of an end frame outer spigot matched with the inner spigot, an end frame is prepared according to the contour model of the end frame outer spigot, and butt joint assembly is performed on the corrected saddle-shaped barrel section and the end frame. The technical problems of difficult butt joint and poor butt joint precision of a hot extrusion saddle-shaped barrel section and an end frame in the actual butt joint process in the prior art are solved.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

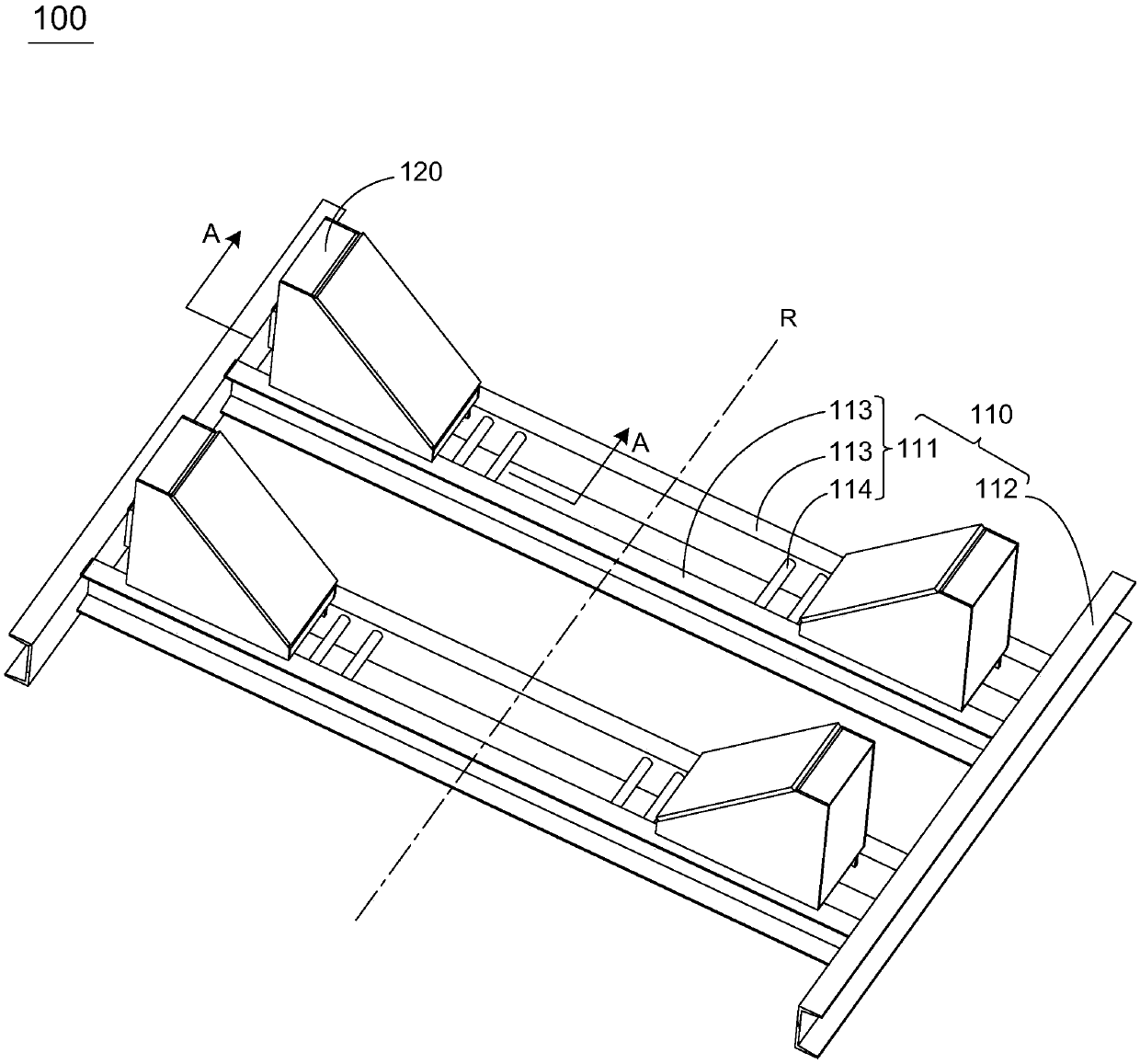

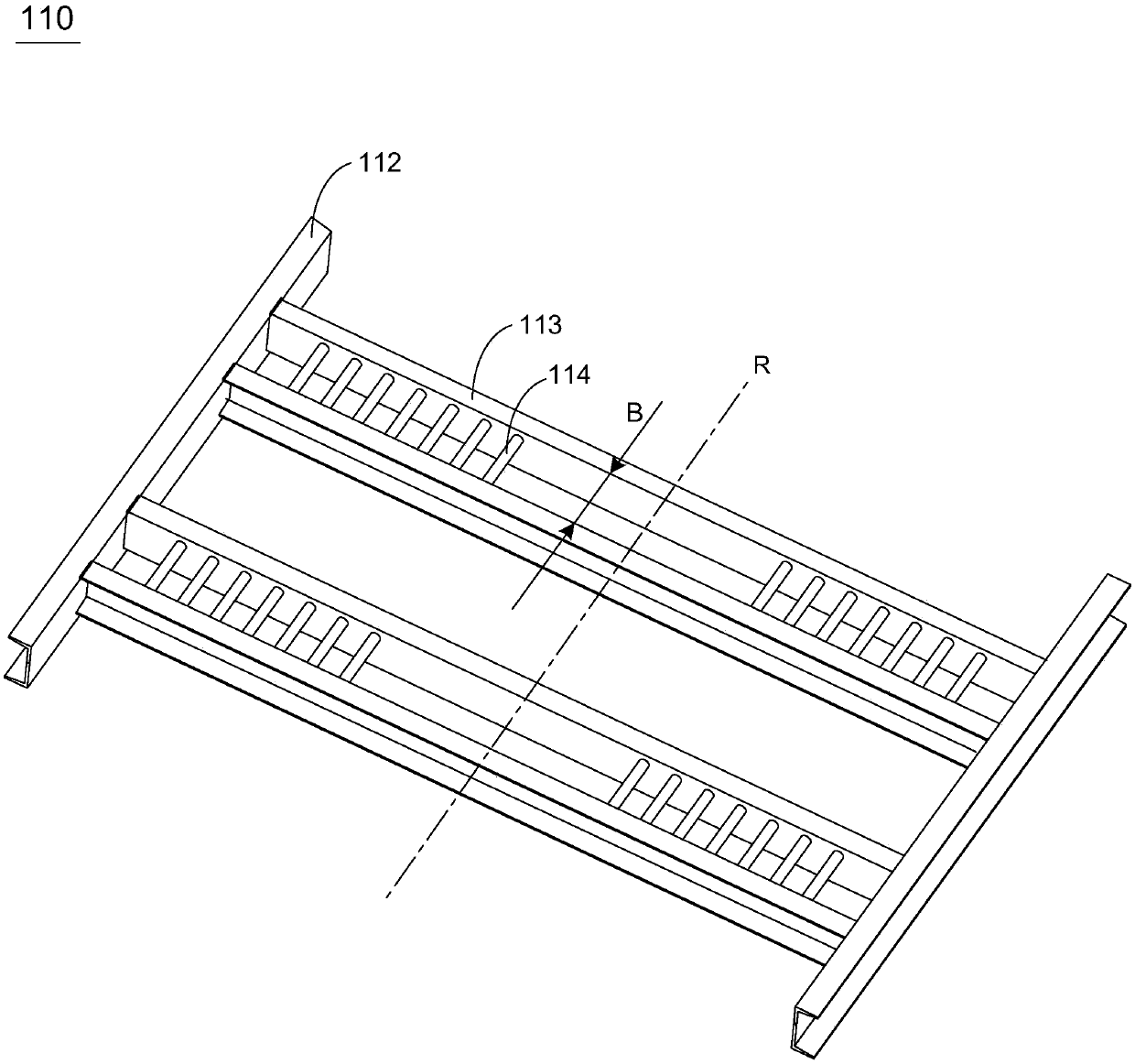

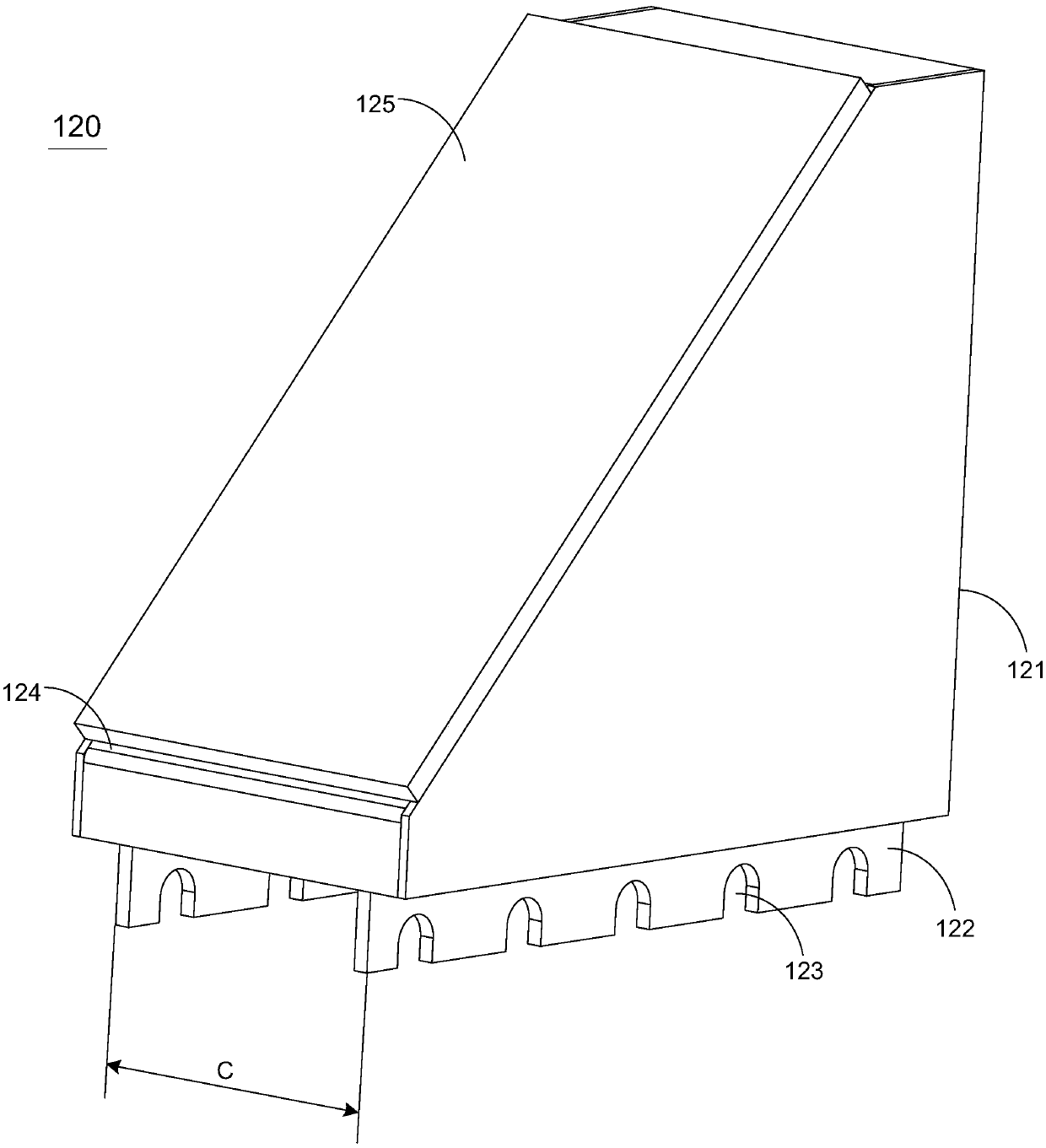

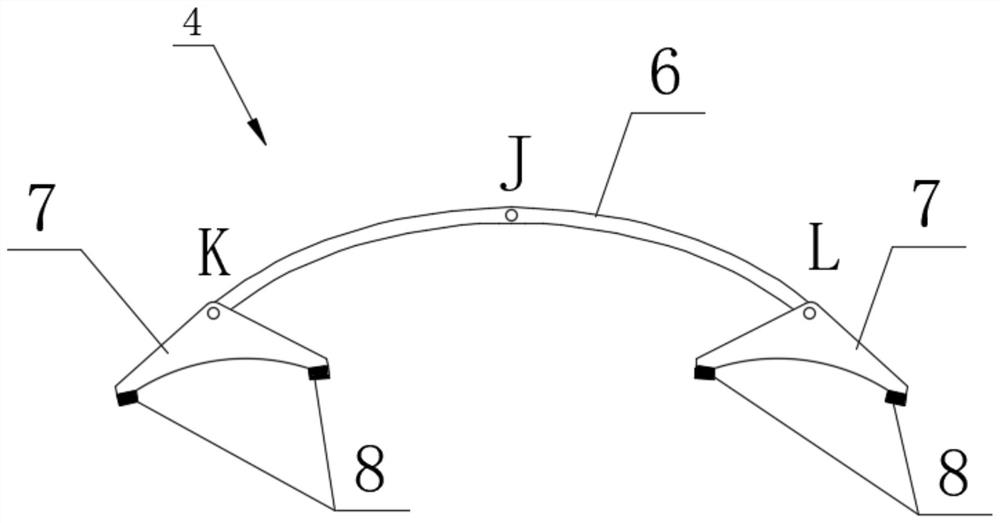

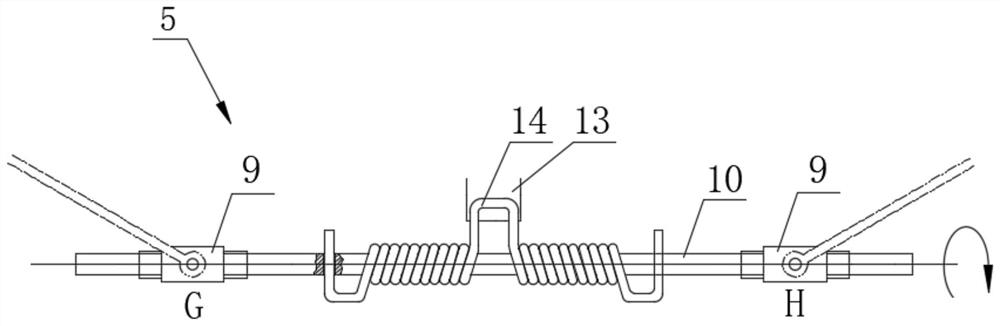

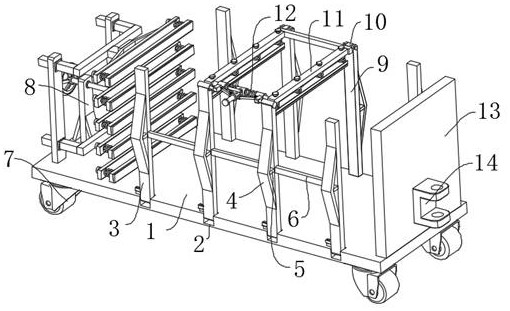

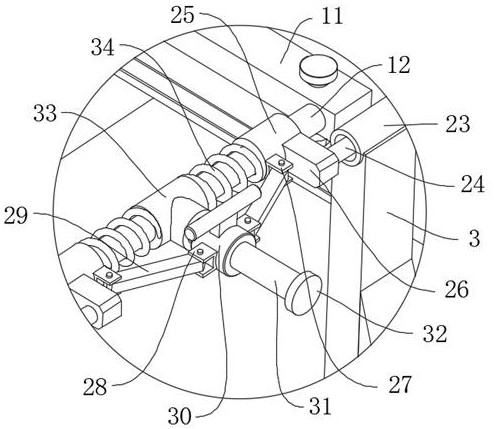

Support

The invention provides a support for transporting roll goods. The support comprises a base and at least one pair of saddles. The base comprises at least one supporting beam, and each supporting beam comprises a pair of cross beams and a plurality of positioning parts located between the pair of cross beams. At least one pair of saddles are oppositely arranged above the supporting beams, each saddle is provided with a limiting groove with a downward opening, and in the state that the saddles are supported on the supporting beams, the positioning parts are at least partially contained in the limiting grooves so as to prevent the saddles from moving in the horizontal direction relative to the supporting beam; and the saddles are matched with the positioning parts through the limiting groovesso as to be positioned at at least two different positions, so that the distance between the pair of saddles is changed. According to the support, the saddles can be positioned at at least two different positions through cooperation of the limiting grooves and the positioning parts so that the distance between the saddles can be changed, the roll goods of different specifications and sizes can beloaded, and the support has the advantages of being wide in adaptability, simple in structure, low in cost, firm, reliable and good in stability.

Owner:DALIAN CIMC SPECIAL LOGISTICS EQUIP CO LTD +3

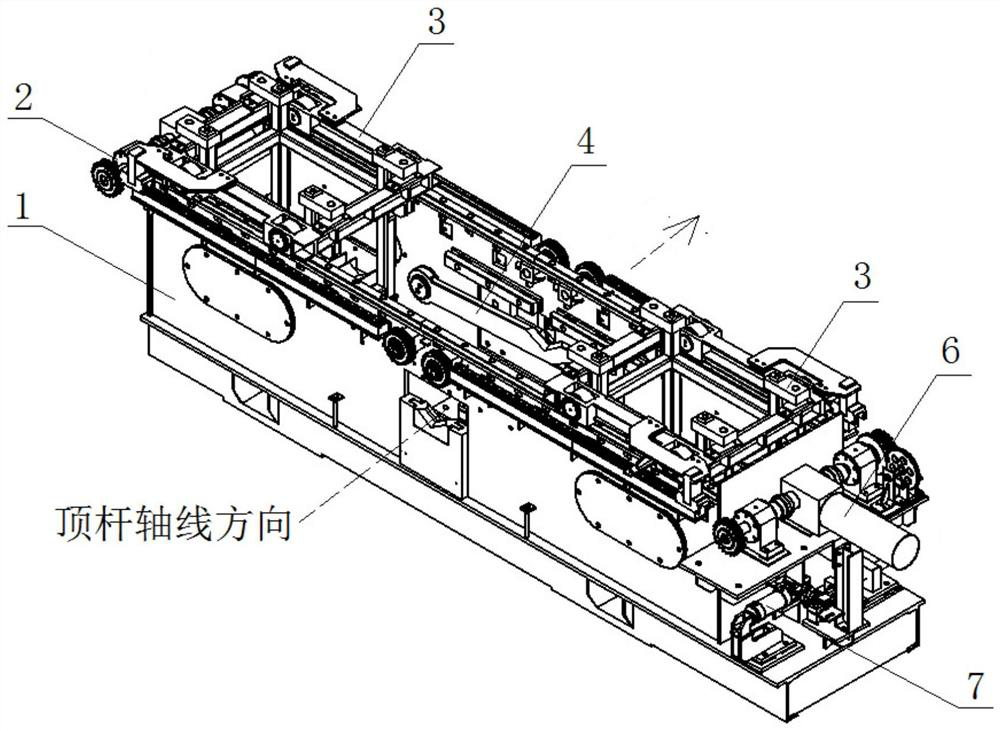

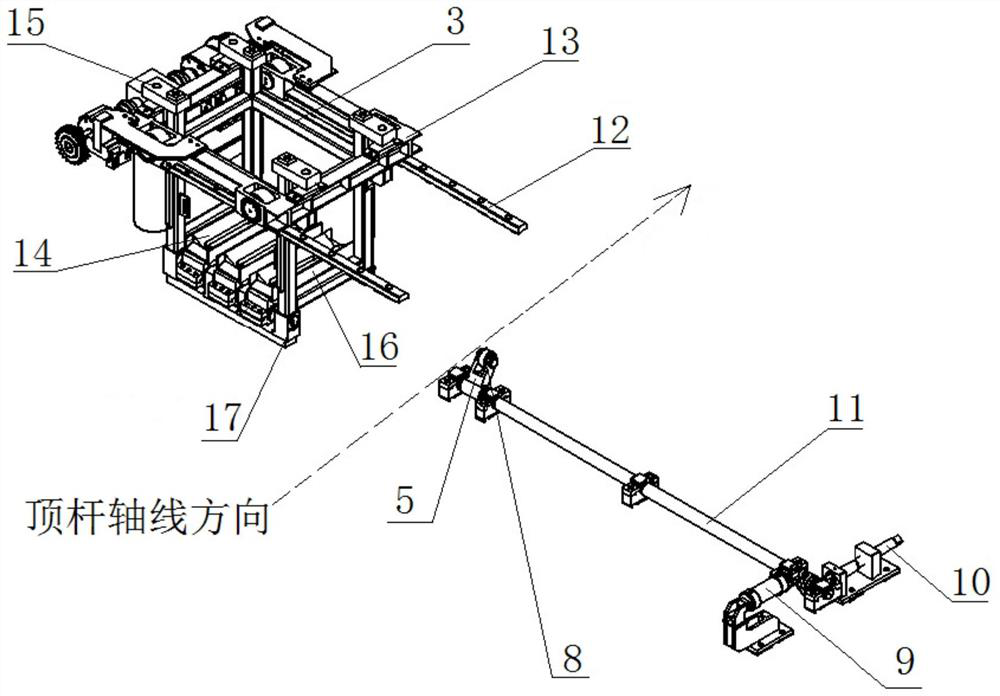

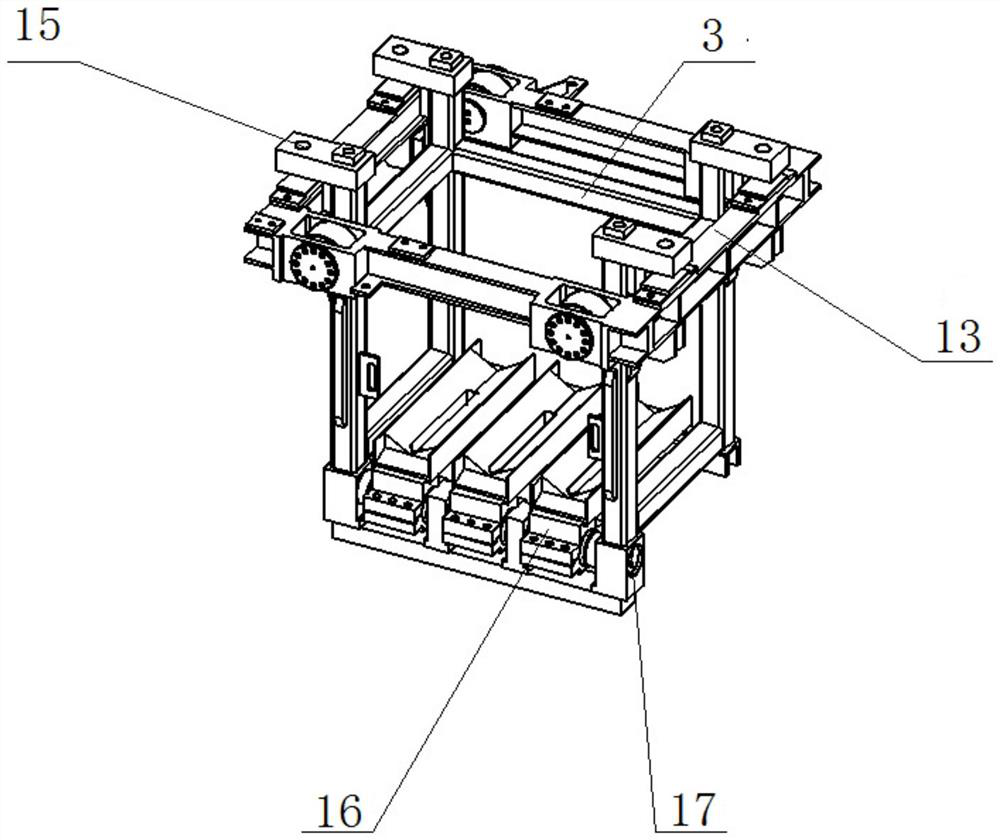

Circular-replacing device for perforator top head

PendingCN111618099AHigh precisionIncrease success rateMandrelsMetal rolling arrangementsIndustrial engineeringSaddle

The invention relates to a circular-replacing device for a perforator top head, and belongs to the field of hot-rolling seamless steel pipe production equipment. The circular-replacing device comprises a replacing device and a lifting-centering device, wherein a plurality of saddles are arranged in the replacing device; a containing groove used for containing the top head is arranged above the saddles; on end of each saddle is rotatably arranged on the replacing device; the lifting-centering device acts on the other end of each saddle; and the top head rotates along with the saddles under thedriving of the lifting-centering device. In the circular-replacing device, one end of each saddle is rotatably arranged, the lifting-centering device acts on the other end of each saddle, the lifting-centering device directly acts on the lower saddle to eliminate an influence of the shape of the top head on lifting-centering height, and top head lifting-centering accuracy is improved so as to be favorable for a supporting rod to successfully and correctly penetrate into the top head, a top head replacement success rate is improved, and a top head falling accident is reduced.

Owner:CISDI ENG CO LTD

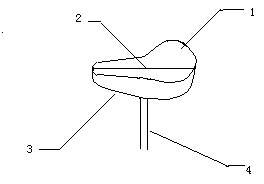

Rotation type rain-proof saddle

InactiveCN103273996ATake the hassle out of cyclingTake the hassle out of riding wetCycle saddlesEngineeringSaddle

The invention discloses a rotation type rain-proof saddle. According to the technical scheme, the rotation type rain-proof saddle comprises a double-face saddle body, a central rotary shaft, a supporting frame and a supporting rod and is characterized in that the central rotary shaft penetrates through the double-face saddle body so that the double-face saddle body can rotate around the central rotary shaft, the central rotary shaft is fixed on the supporting frame, and the supporting frame is fixed on the supporting rod.

Owner:SICHUAN UNIV

Multipurpose Cleaning Saddle Rack

Owner:ROBLES OLIVIA ISABEL

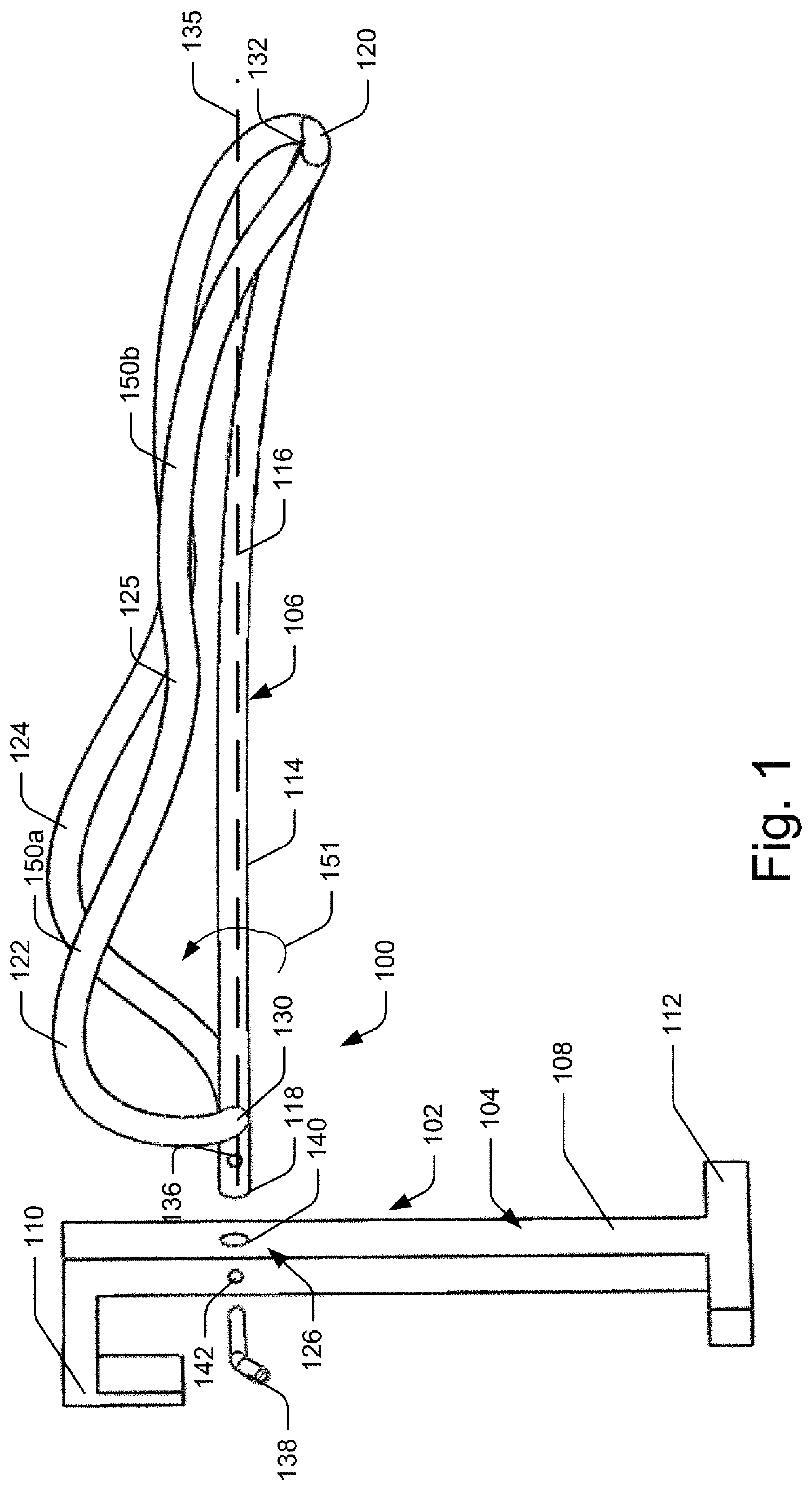

Wind generating set and cable transition device

PendingCN111525467AIncrease the laying spaceMeet the laying spacing requirementsMachines/enginesWind energy generationElectric cablesSaddle

The invention discloses a cable transition device, which comprises a mounting seat and at least two layers of saddle supports, the at least two layers of saddle supports are sleeved on the mounting seat layer by layer, and the saddle support arranged on the outer layer can be opened relative to the saddle support arranged on the inner layer and is used for reserving a cable laying operation spacefor the saddle support arranged on the inner layer. By arranging at least two layers of saddle supports, the cable laying space is greatly enlarged, the spacing requirement of cable laying can be wellmet, the current-carrying capacity of the cable is improved, the heat dissipation problem of the cable is synchronously solved, the current-carrying capacity of the cable is further improved, and theservice life of the cable is further prolonged. Besides, the saddle supports are installed in a layer-by-layer sleeving mode, the installation occupied space is further reduced, the outer-layer saddle support can be opened relative to the inner-layer saddle support, the structure is easy to achieve, and cable laying operation is convenient.

Owner:SANY ELECTRIC CO LTD

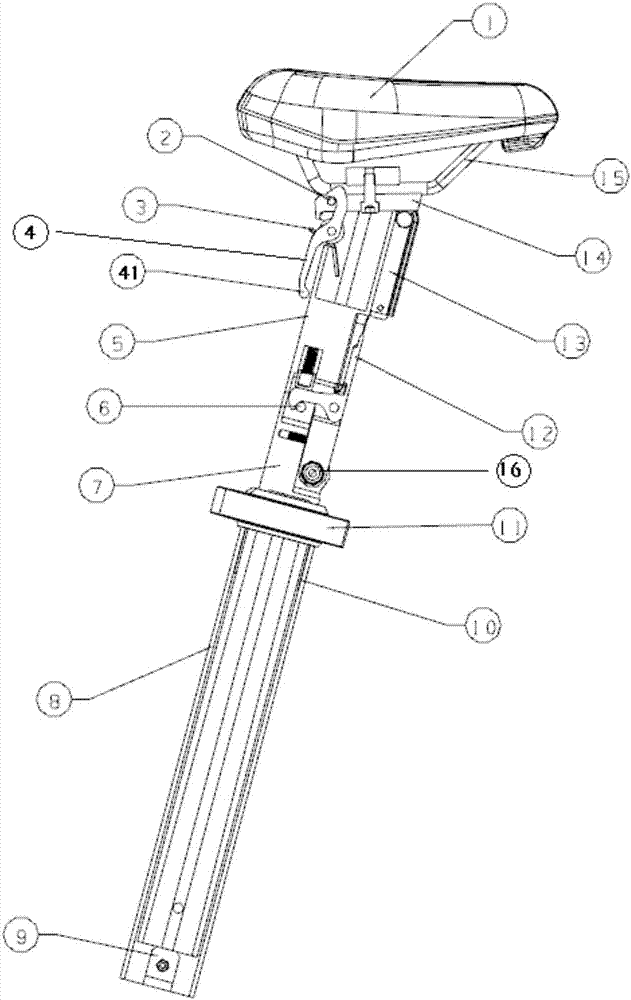

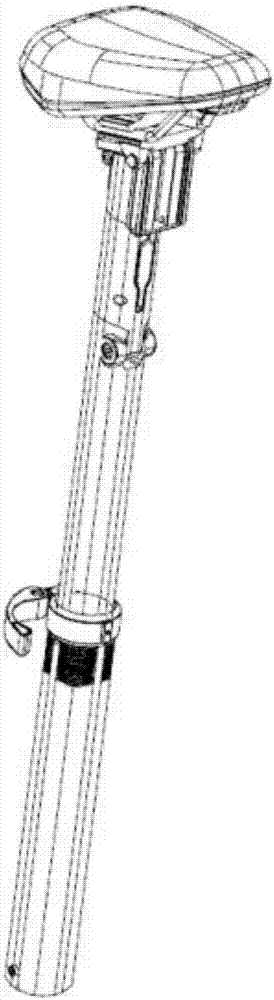

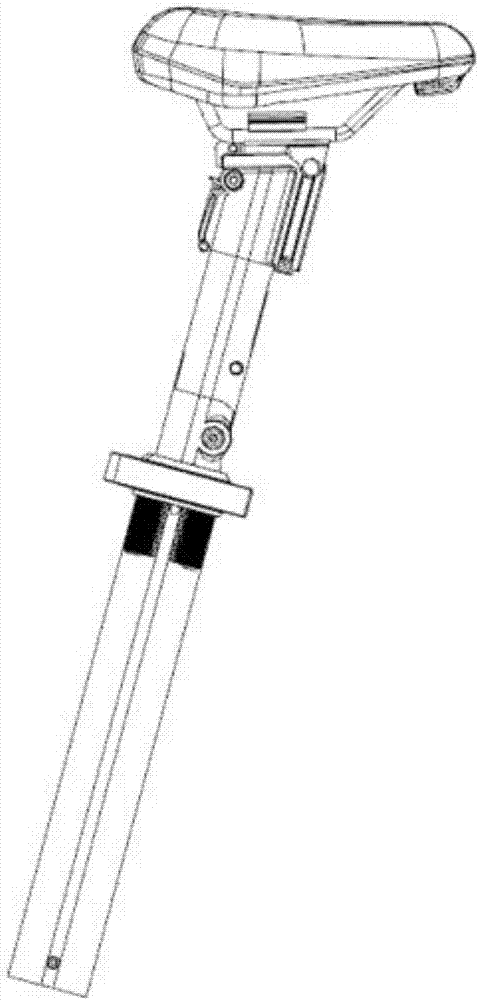

Foldable saddle integrated with saddle tube and folding and unfolding method of foldable saddle

The invention relates to the technical field of foldable electric vehicles and folding methods thereof, in particular to a foldable saddle integrated with a saddle tube and a folding and unfolding method of the foldable saddle. A saddle fixing mechanism is arranged at the bottom of the saddle, a vertically arranged long-strip-shaped through hole is formed in one side of the upper portion of an upper saddle tube to form a slide way, a shaft is arranged in the slide way, and the shaft is connected with the saddle fixing mechanism; the saddle can turn over along the shaft and move up and down in the slide way along with the shaft, a saddle hanging hook is fixed to the top of the upper saddle tube, a saddle hanging rod corresponding to the saddle hanging hook is arranged on the saddle fixing mechanism, the lower portion of the saddle hanging hook is a longitudinal protruding spanner, and the upper portion of the saddle hanging hook is a hanging hook body matched with the hanging rod in shape; and a hinge pin is arranged on the saddle fixing mechanism, and fixing of the saddle is achieved through cooperation of the saddle hanging hook and the hinge pin of the saddle fixing mechanism. Compared with the prior art, the foldable saddle integrated with the saddle tube and the folding and unfolding method of the of foldable saddle have the advantages that the structure of the integrally designed saddle is more stable, folding can be achieved only by pulling the spanner, using is convenient, and the folding form of a product is smaller and more exquisite.

Owner:黄嘉文 +3

Adjustable saddle

The invention relates to a saddle, specifically to an adjustable saddle. The adjustable saddle comprises a saddle shaft, a support frame, a first hand wheel, a first worm, a first worm wheel, a second hand wheel, a screw, a screw nut, a short shaft flexible component, a damper spring, a long shaft flexible component, a third hand wheel, a third worm, a third worm wheel, a saddle face hinging base, and a saddle face; the first hand wheel drives the first worm and the first worm wheel in turn; the first worm wheel drives the long shaft flexible component to be moved during the rotation; the front and back, left and right positions of the saddle face can be randomly changed; while the first worm wheel stops the rotation, the second hand wheel and the screw are rotated, the screw net is moved on the screw, the long shaft flexible component is driven to be moved, the inclined angle of the long shaft flexible component is changed, and the height of the saddle face can be flexibly changed; and the third hand wheel is rotated at the same time, the third hand wheel drives the third worm to be rotated, and the inclined angle of the saddle face is further adjusted. The adjustable saddle can be adjusted in all directions, the structure is simple, and the operation is convenient and reliable.

Owner:郭子鑫

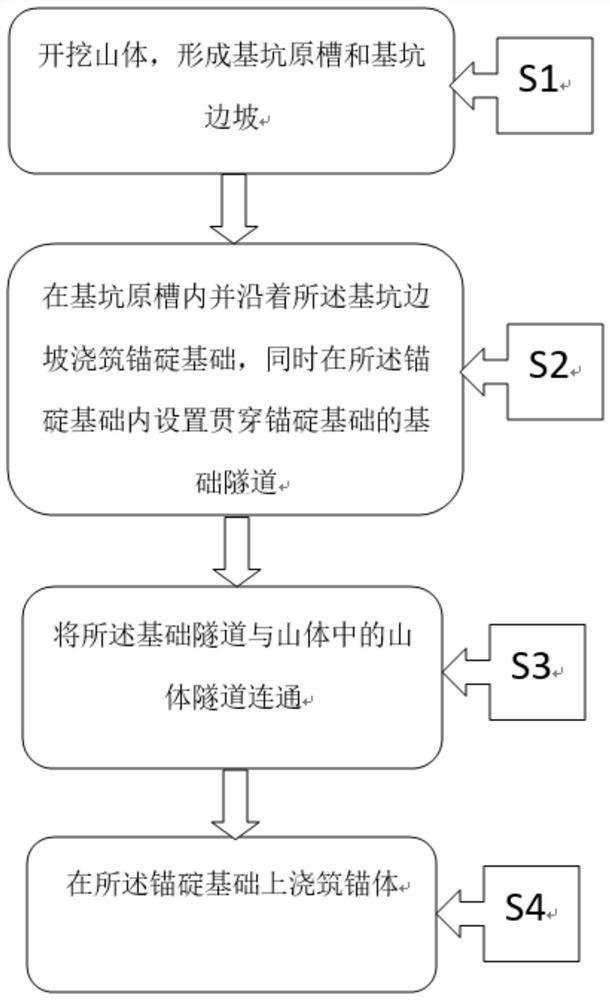

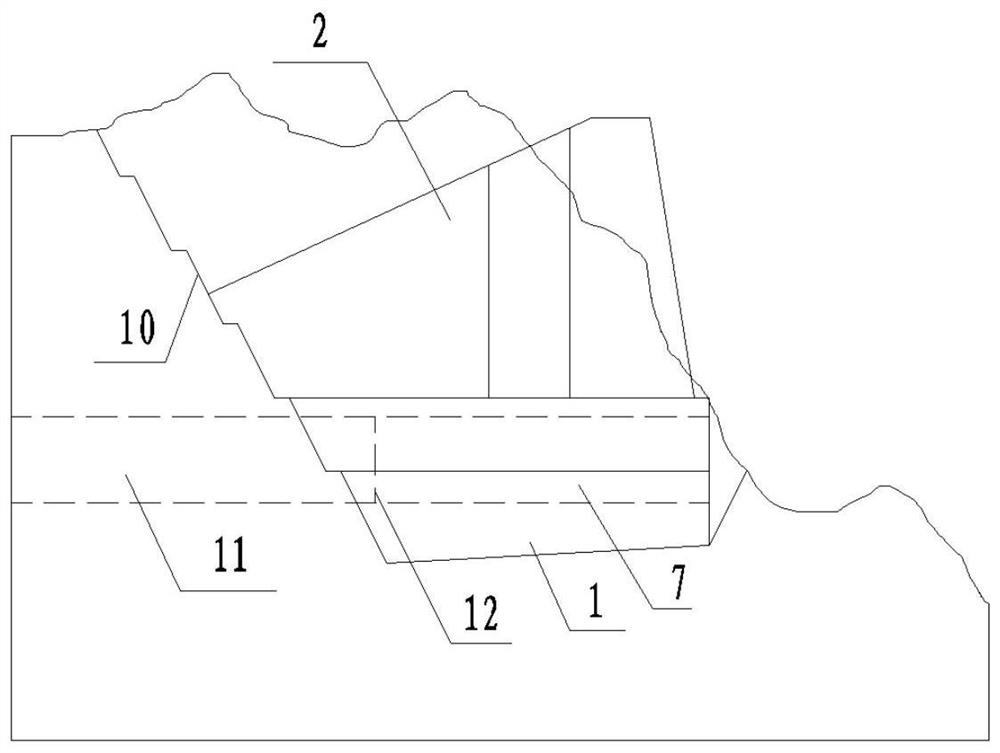

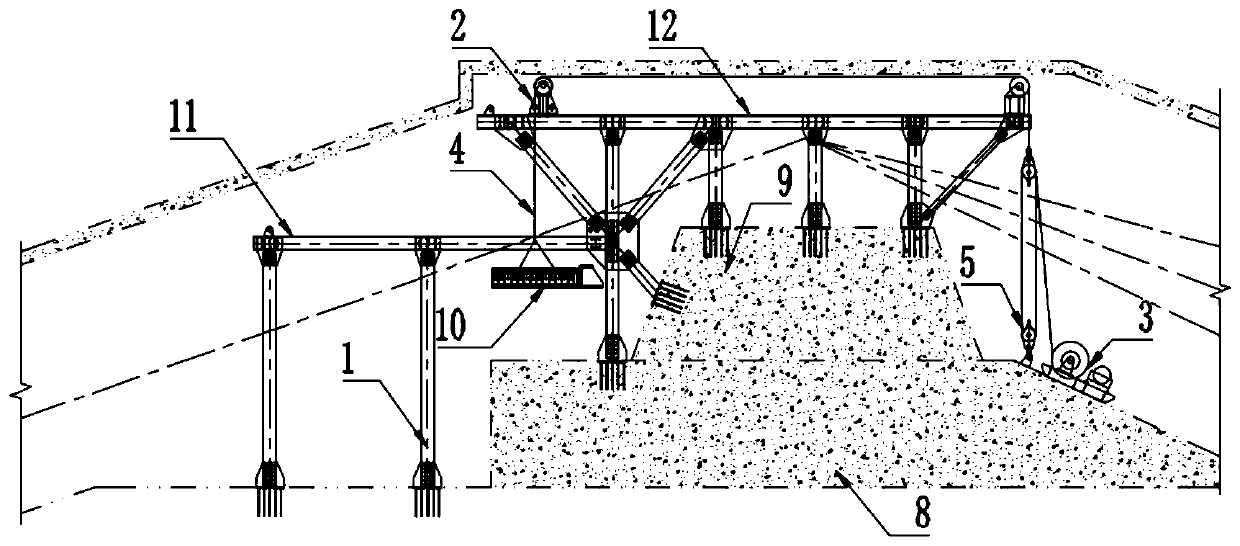

Suspension bridge gravity type anchorage and tunnel combined structure and co-construction method thereof

InactiveCN113389130AReduce excavationReduce disturbanceSuspension bridgeBridge structural detailsBridge engineeringButtress

The invention discloses a suspension bridge gravity type anchorage and tunnel combined structure and a co-construction method thereof, and relates to the technical field of bridge engineering. The co-construction method comprises the steps: excavating a foundation pit in a mountain; then, pouring an anchorage foundation with a tunnel into the foundation pit; communicating the tunnel in the anchorage foundation with the tunnel in the mountain; and finally, pouring an anchor body on the foundation. The anchor body comprises an anchor block which is located above the foundation and used for anchoring a main cable strand, a splay cable saddle buttress which is supported at the front end of the anchorage foundation and used for supporting a splay cable saddle structure, and an anchor chamber which is located between the anchor block and the splay cable saddle buttress and used for protecting a main cable structure. According to the method, the tunnel and the anchorage are built together, and compared with a conventional gravity type anchorage building scheme, the foundation excavation amount is saved, and disturbance to the environment in the construction process is relatively small.

Owner:CHINA MAJOR BRIDGE ENERGINEERING

Assembly method for saddle of large tower equipment

InactiveCN110877181AReduced maximum lifting capacityLower requirementWelding/cutting auxillary devicesAuxillary welding devicesLifting capacityJackscrew

The invention discloses an assembly method for saddles of large tower equipment. The assembly method is characterized in that the large tower equipment is manufactured in sections according to the weight, and then the saddles are assembled; the straightness of the tower equipment is adjusted by a hydraulic jack during the assembly; the detachable saddles are adopted, and after the welding of the assembly ring weld joint is completed, the saddle position is readjusted, and redundant saddles are removed; after the assembly is completed, the saddles are lifted from both sides by the hydraulic jack; and a transport vehicle enters the lower part of the transport saddle from the middle of the jack, and the loading work is completed. According to the assembly method, the requirements of the maximum lifting capacity of a crown block and the bearing capacity of a foundation are lowered, the number of required saddles is decreased, and the manufacturing time and manufacturing cost are saved.

Owner:HUALU ENG & TECH

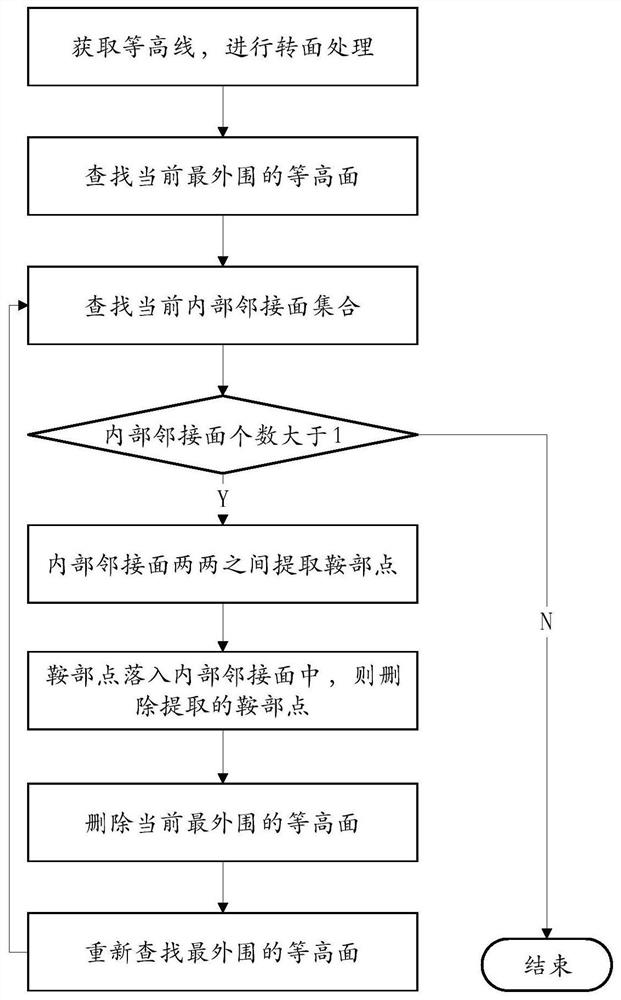

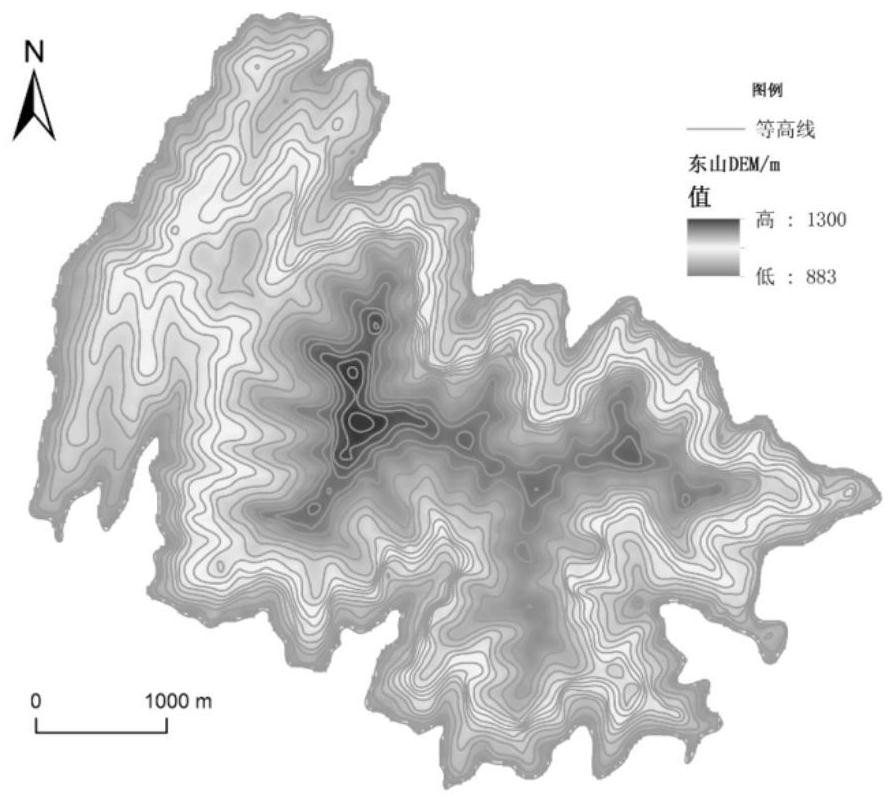

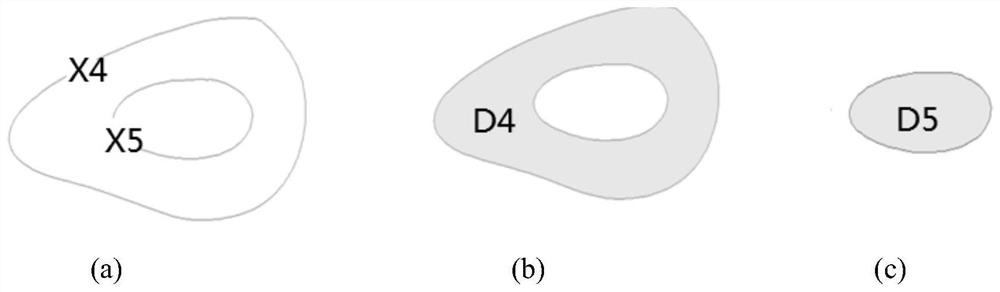

A Saddle Point Extraction Method Based on Contour Model

ActiveCN109739942BImprove extraction accuracySolve the problem of false saddle pointsGeographical information databasesEngineeringExtraction methods

The invention discloses a contour line model-based saddle point extraction method, which comprises the following steps of: 1, acquiring contour line data and carrying out line-to-surface processing toobtain a surface set S; 2, finding the outermost equal-height surface s from the S; 3, traversing the set S, finding out all faces which are located in an area surrounded by the faces s and are adjacent to the faces s, and forming an internal adjacent face set T; wherein the internal adjacent surfaces with the elevation values greater than the elevation values of the surfaces s in the set T forma set W; 4, extracting saddle points between every two internal adjacent surfaces in the set W to form a set U; Adding a saddle point which is not located in any internal adjacent surface in the set Uinto the set Us; 5, deleting the surface s from the surface set S, and repeating the steps 2-5; and 4, the number of the internal adjacent surfaces in the current outermost contour surface is smallerthan 2. According to the method, the topographic characteristics of the saddle points and the spatial characteristics of the saddle points in the contour line are fully utilized, the problem that pseudo saddle points are generated in the traditional saddle point extraction process is solved, and the extraction precision of the saddle points is improved.

Owner:南京泛在地理信息产业研究院有限公司 +1

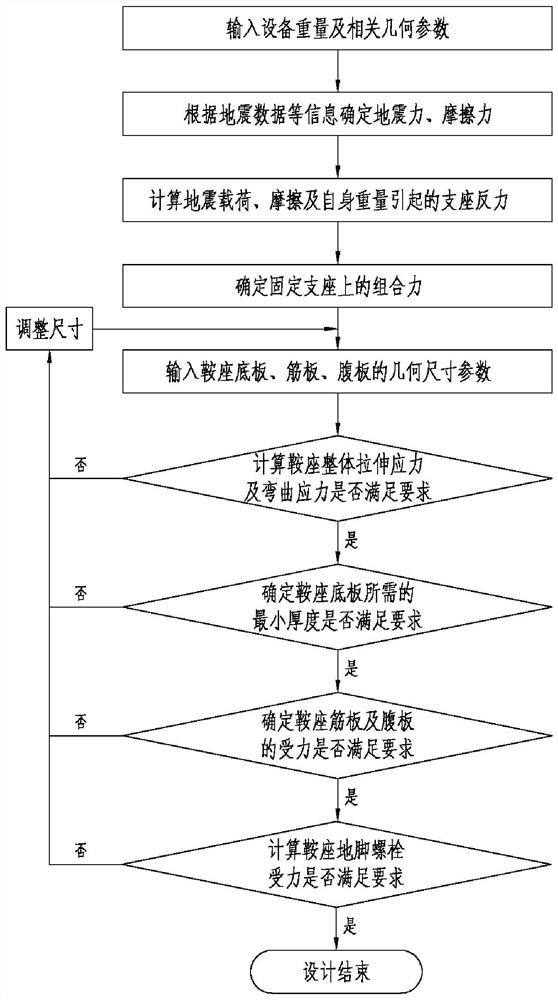

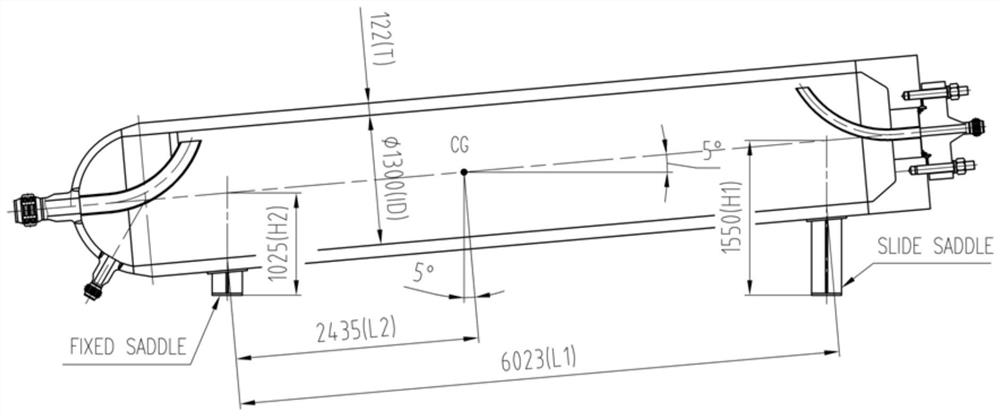

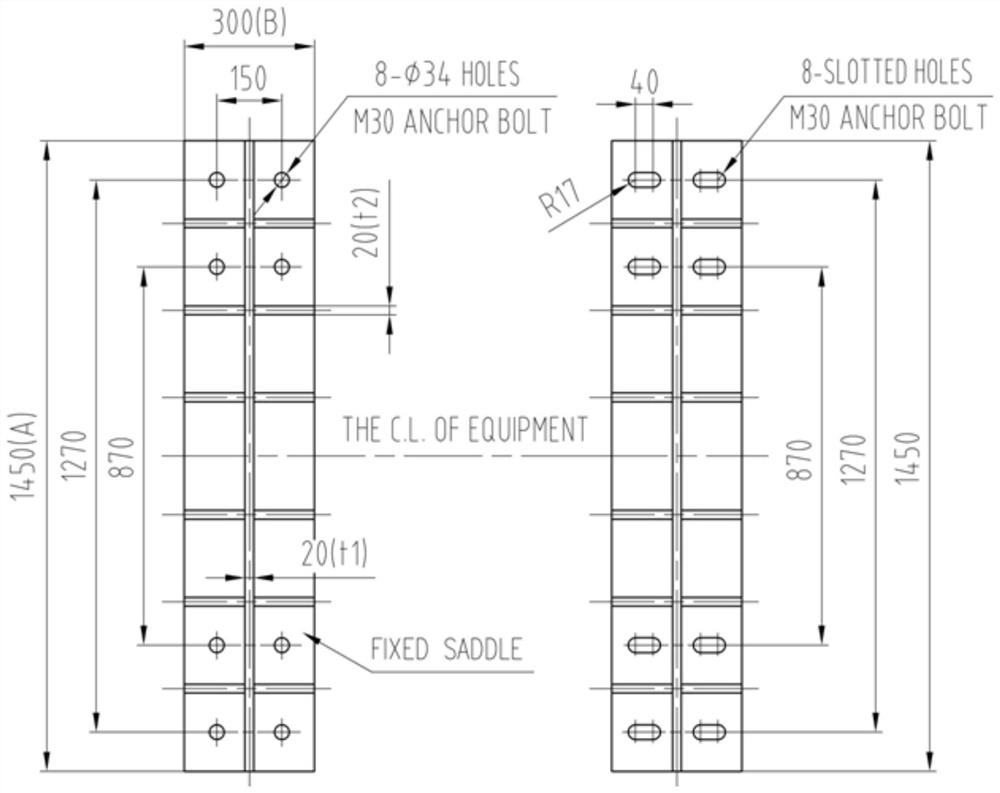

Method for calculating saddles with different heights on two sides

PendingCN112364457ATroubleshoot Strength CalculationsImprove accuracyGeometric CADDesign optimisation/simulationFrictional coefficientUltimate tensile strength

The invention provides a method for calculating saddles with different heights on two sides. The method comprises the following steps: obtaining the total weight of container equipment; obtaining seismic load data and friction coefficients, and calculating friction force and seismic force borne by the container equipment; calculating saddle reaction force and combined force; and respectively calculating the overall tensile stress and bending stress of the saddle, the minimum thickness of a bottom plate of the saddle, the stress of a rib plate and a web plate of the saddle and the stress of a foundation bolt of the saddle. According to the method, the problem of saddle strength calculation of the inclined horizontal container with the two sides supported by saddles with different heights issuccessfully solved, and checking can be automatically completed. The defect that existing software designs the horizontal container according to domestic and overseas standards is overcome, the accuracy of saddle support design calculation is improved and programmed, the complexity of saddle support design calculation is avoided, the equipment design efficiency is improved, and the method has certain universality and practicability.

Owner:DALIAN DESIGN INST CO LTD CHINA FIRST HEAVY IND +1

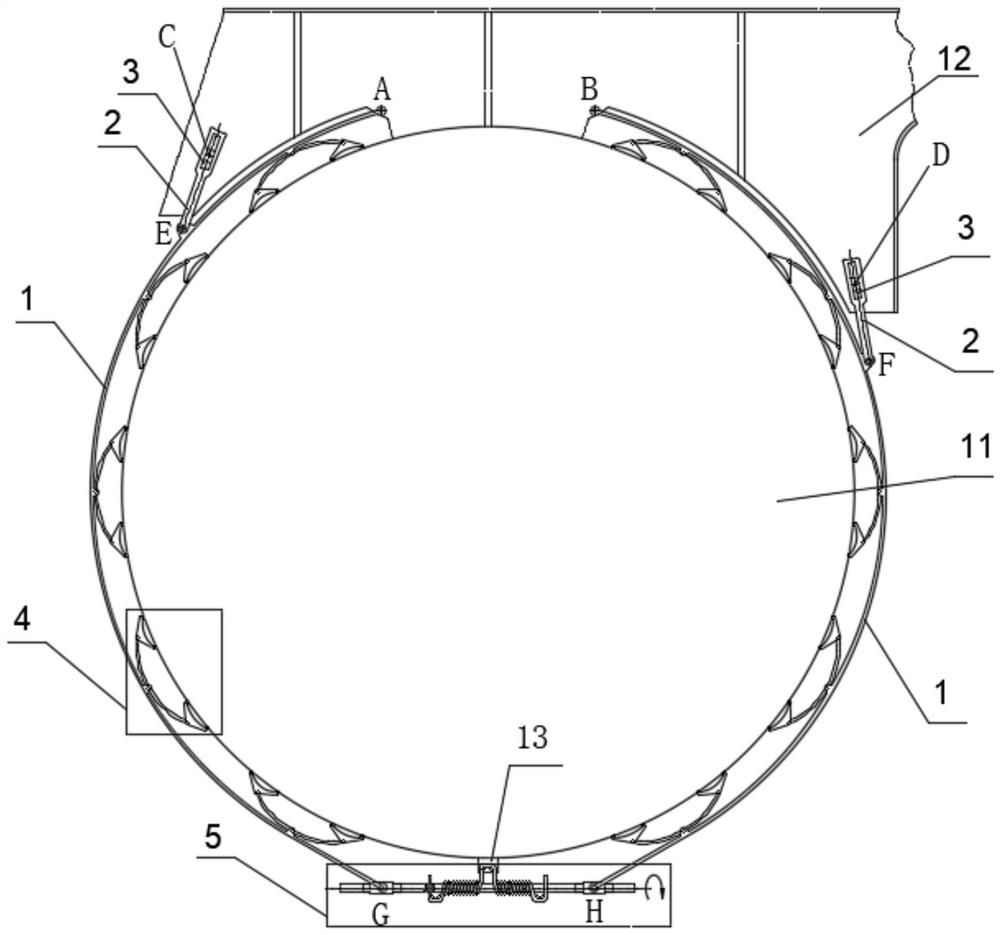

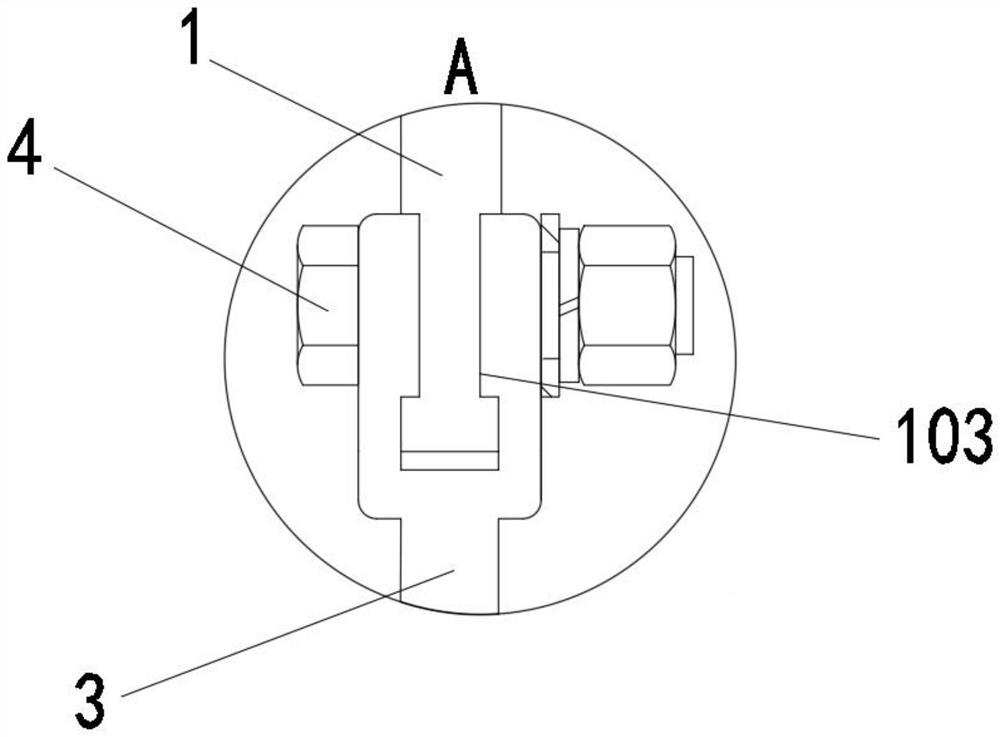

A brake mechanism for detachable saddle of deep-sea carrier platform

ActiveCN111412205BAchieving Adaptive ClampingPrevent overload failureFriction grip releasable fasteningsUnderwater vesselsMechanicsBraking system

The invention relates to a brake mechanism for a detachable saddle of a deep-sea carrier platform, comprising a saddle, the bottom of the saddle is provided with a pressure-resistant shell, and the two sides of the outer circumferential surface of the pressure-resistant shell are arranged symmetrically. The tops of the two strips are respectively hinged on the saddle, the bottoms of the two strips are connected by an elastic connection assembly, and a stopper is provided at the middle of the bottom of the pressure-resistant shell, and the elastic connection assembly is connected to the block connection; the two ends of the saddle are respectively hinged with guide blocks, and the outer side of the upper part of the plate belt is hinged with a guide rod, and the guide rod is provided with a guide groove, and the guide block slides freely in the guide groove; the plate The inner side of the belt is evenly spaced with gate block assemblies, one end of a single gate block assembly is hinged to the inner side of the plate belt, and the other end is pressed against the outer peripheral surface of the pressure-resistant shell. The work is stable and reliable.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

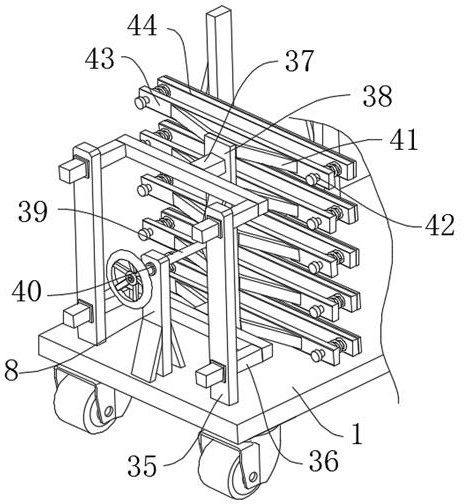

Auxiliary protection structure of steel pipe conveying device

The invention relates to the field of steel pipe conveying, in particular to a steel pipe conveying device auxiliary protection structure which comprises a saddle, stoppers are mounted at the front edge and the rear edge of the upper end of the saddle, pressing pieces are mounted at the ends of the stoppers, a frame is mounted at the edge of one side of the upper end of the saddle, and a traction frame extends from the side face of the frame. Wheels are installed at the corners of the lower end face of the saddle, and a jacking piece is installed on the edge of the other side of the upper end of the saddle. According to the steel pipe conveying device, the steel pipe protection performance during conveying is improved, noise is reduced, the steel pipe conveying device can adapt to steel pipes of different lengths, and the conveyed steel pipes can be conveniently unloaded.

Owner:SHANDONG KAITAI SHOT BLASTING MACHINERY +1

Adjustable special gauge for measuring space sizes of saddle baffles

InactiveCN111457824AGuaranteed accuracyReduce labor intensityMechanical clearance measurementsClassical mechanicsControl theory

The invention discloses an adjustable special gauge for measuring the spacing space sizes of saddle baffles, relates to the technical field of special gauges for saddles, and solves the problems of low detection efficiency and low measurement precision due to the fact that the size of an existing saddle needs to be measured manually. The adjustable special gauge comprises a pressure head, and thepressure head is movably connected to the front end of the adjusting shaft. The adjustable special gauge is based on structural characteristics of parts; a special measuring gauge is manufactured to ensure the measurement accuracy and efficiency, during measurement, after the positioning nut and the pressure head are adjusted to be completely attached to the diameter of the central bottom plate according to the actual size, the adjustable special gauge is taken out and then measured through a measuring tool, the accuracy of measured data is guaranteed, the measurement precision is improved, the labor intensity of staff can be relieved when the adjustable special gauge is used for measuring and detecting the saddle, and staff operation is facilitated.

Owner:DONGFENG SPECIAL PURPOSE VEHICLE

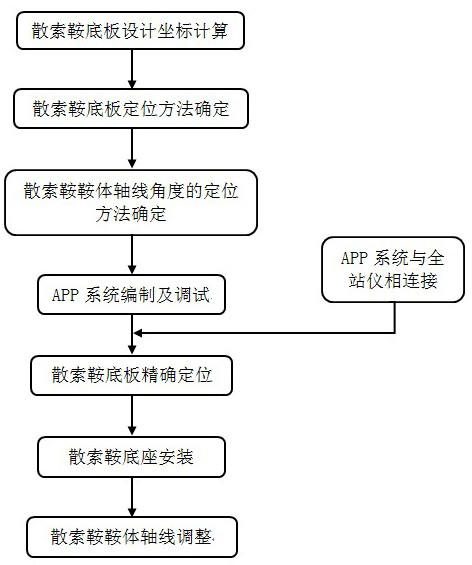

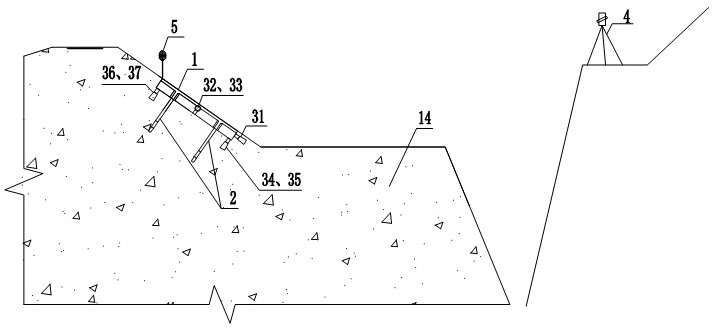

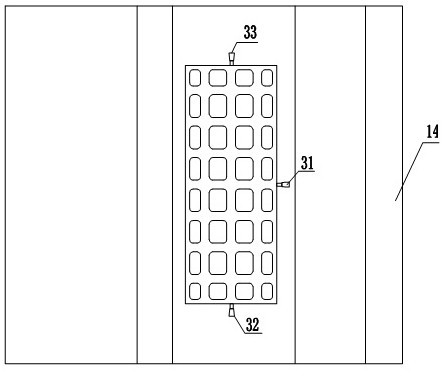

Suspension bridge splay saddle accurate positioning method based on APP system

ActiveCN112525170AEasy to operateAccurate adjustment positionGeometric CADSurveying instrumentsClassical mechanicsEngineering

The invention provides a splay saddle accurate positioning method based on an APP system. The method comprises the following steps of calculating the coordinates of a splay saddle bottom plate designcross curve through employing a coordinate positive algorithm and the spatial position relation of a splay saddle bottom plate; drawing a 1: 1 three-dimensional diagram of the splay saddle, and performing coordinate rechecking; an APP system being compiled, the system connecting the total station with the APP system through Bluetooth, measured data of the total station being transmitted to the APPsystem in real time, and adjustment parameters of the bottom plate and the saddle body of the splay saddle being automatically calculated; adjusting parameters of the splay saddle bottom plate beingcalculated according to the position relation from space points to lines, and the splay saddle bottom plate being adjusted through jacks at all parts. The method is advantaged in that the measured angle of the axis of the saddle body is reflected through a dihedral angle between a measured plane and a designed plane of the splay saddle body, and the angle of the axis of the saddle body is adjustedthrough a lifting appliance on a splay saddle gantry.

Owner:THE 5TH ENG MBEC

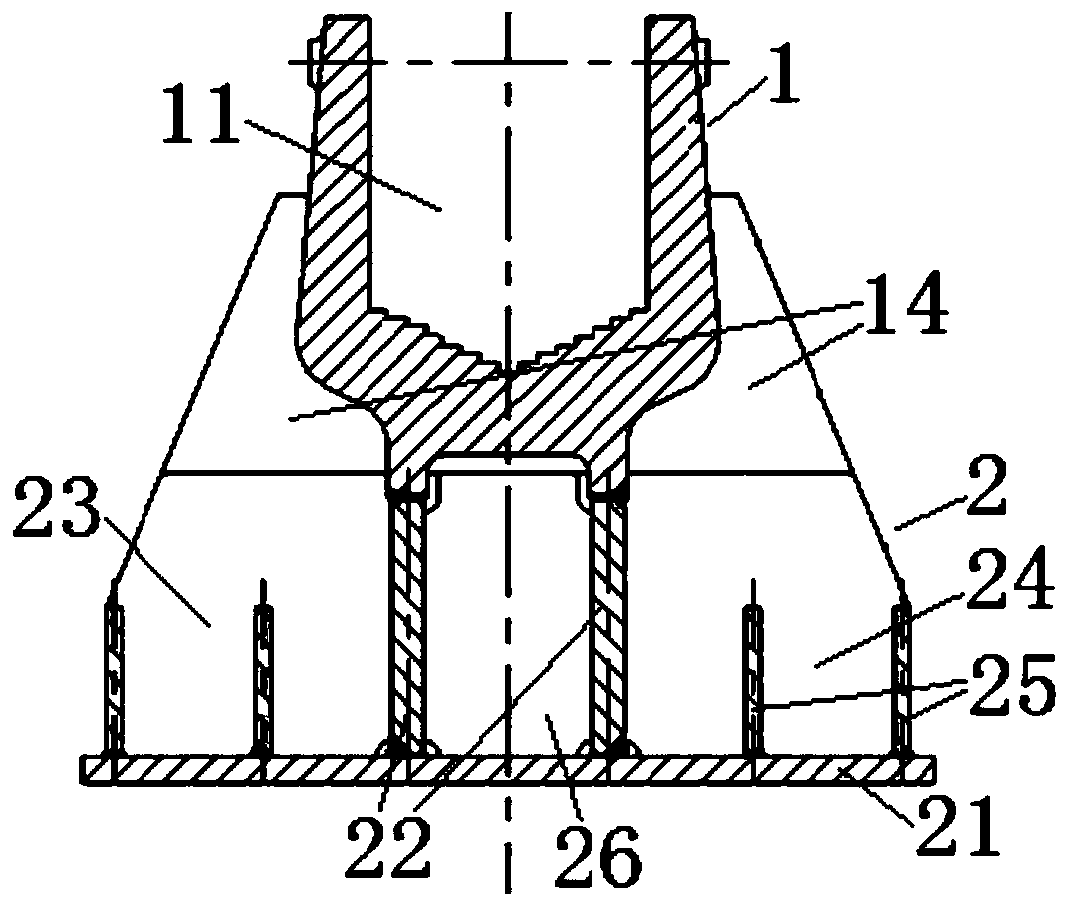

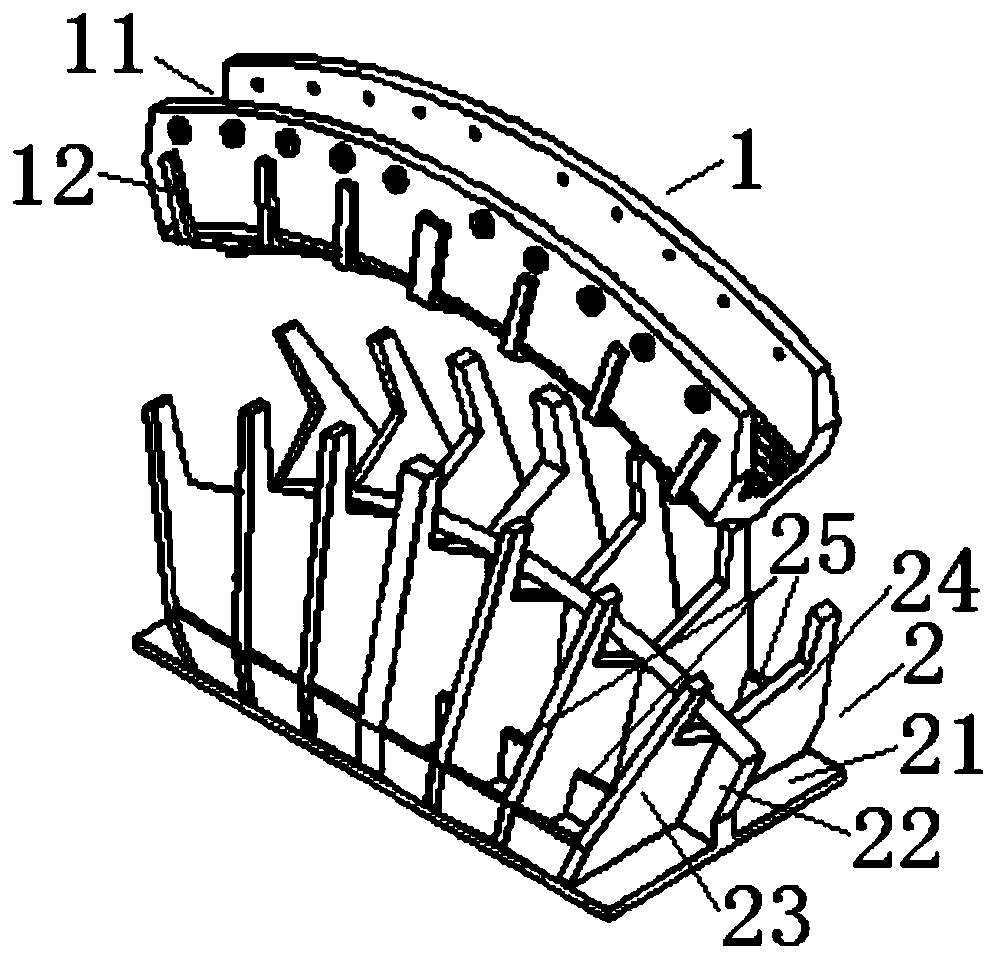

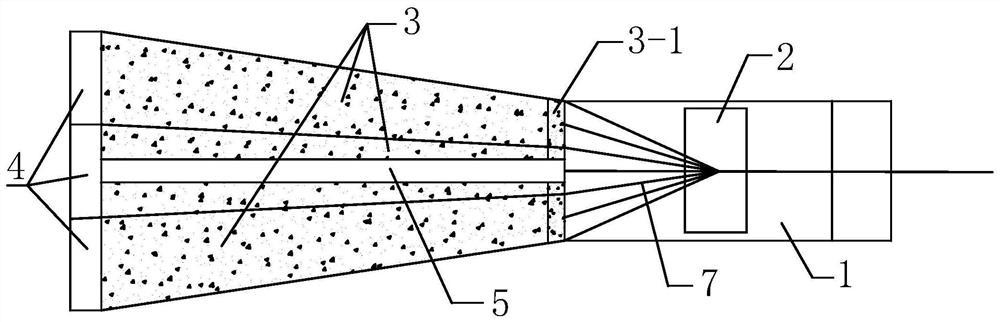

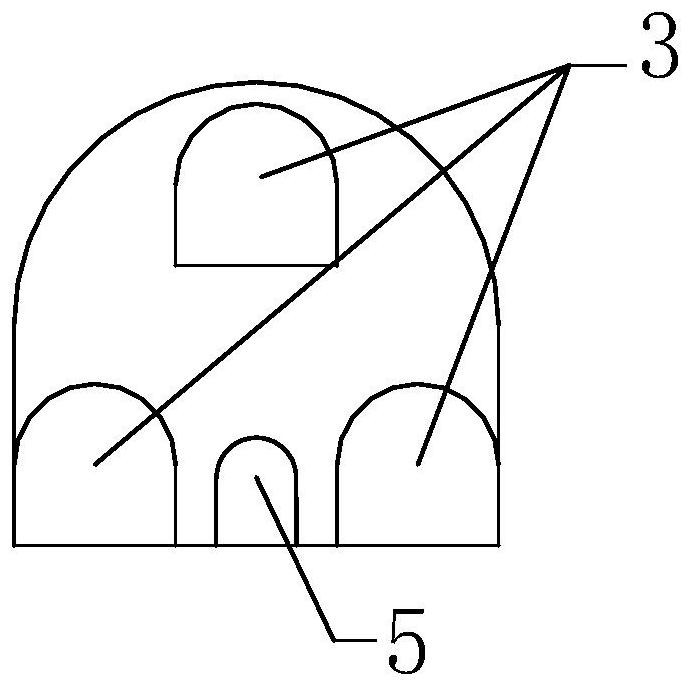

Cast-weld combined type cable saddle forming structure

PendingCN111535176AImprove bearing strengthImprove structural stabilityBridge structural detailsPolishingUltimate tensile strength

The invention discloses a cast-weld combined type cable saddle forming structure which comprises a saddle head of a casting structure and a saddle of a weldment structure. The saddle head is assembledon the saddle through a polishing abutting fit structure. The saddle head of the casting structure and the saddle of the weldment structure are assembled together through the polishing abutting fit structure, complex, high-difficulty and high-residual-stress penetration welding treatment does not need to be adopted, assembling and forming are convenient, bearing strength of the joint between thesaddle head and the saddle can be greatly improved, and then overall structural stability of the cable saddle is improved.

Owner:DEYANG TIANYUAN HEAVY IND +1

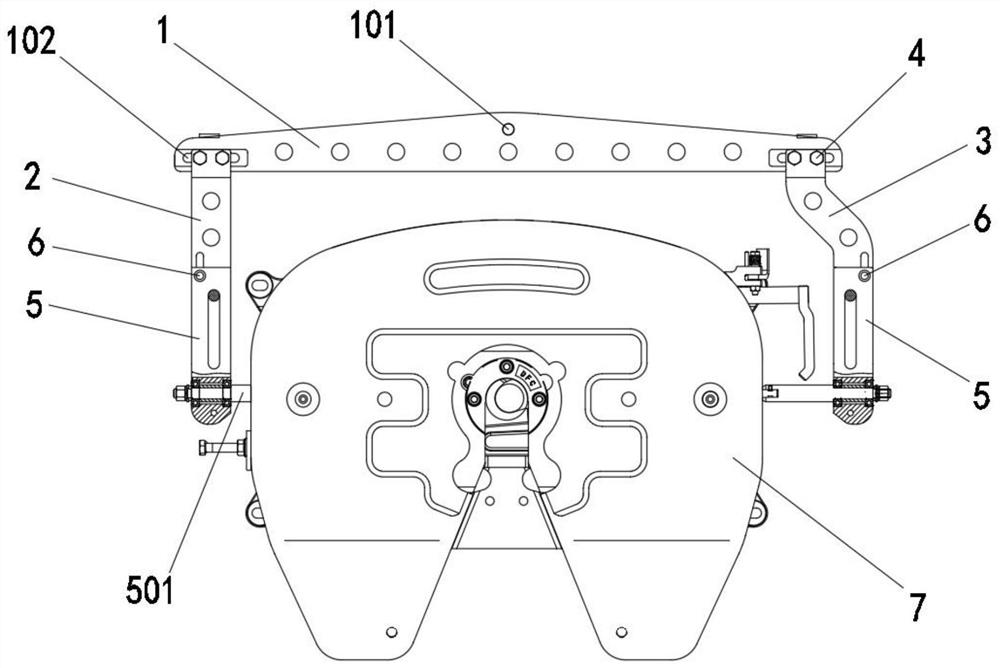

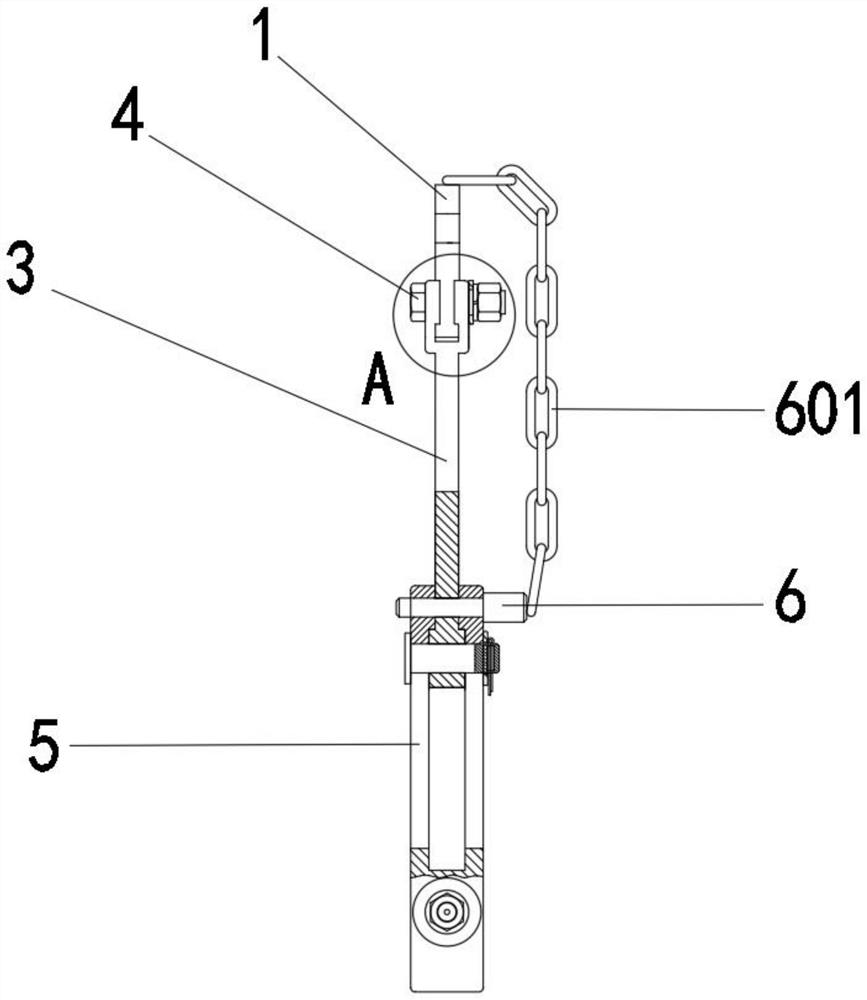

Universal lifting appliance for lifting and overturning saddle assembly

The invention provides a universal lifting appliance for lifting and overturning a saddle assembly, belongs to the technical field of overturning lifting appliances, and aims at solving the problems that when an existing lifting appliance overturns a saddle, due to the fact that a lifting arm on the lifting appliance hinders a handle rod on the saddle, the lifting appliance cannot meet the overturning operation of the saddle in the lifting process, and then the overturning operation of the saddle is difficult and the production efficiency is low. The universal lifting appliance for lifting andoverturning the saddle assembly comprises a cross arm, a vertical straight arm and a vertical bent arm are slidably connected to the bottoms of the left end and the right end of the cross arm correspondingly, and two adjusting bolts penetrating through the cross arm are connected to the upper end of the vertical straight arm and the upper end of the vertical bent arm correspondingly. The lower end of the vertical bent arm is arranged to be of the bent structure, so that the vertical bent arm does not hinder the handle rod on a saddle assembly main body, the lifting appliance can meet the requirement for overturning operation of the saddle assembly main body in the lifting process, and then the phenomena that the saddle assembly main body is difficult to turn over and low in production efficiency are avoided.

Owner:DONGFENG SPECIAL PURPOSE VEHICLE

Watershed segmentation in civil engineering

The invention relates to a computer-implemented method for civil engineering. The method comprises providing a mesh representing a terrain. The method further comprises computing a watershed segmentation of the terrain based on the mesh. The computing of the watershed segmentation includes identifying one or more saddle points on the mesh. The computing of the watershed segmentation further includes, for each identified saddle point, identifying paths each ascending from the saddle point according to a direction of a local maximal slope around the saddle point, and a path descending from the saddle point according to a direction of a steepest slope around the saddle point. The identified ascending paths divide the mesh into connected components. The computing of the watershed segmentation further includes, for each identified saddle point, merging each connected component of which bottom point is the saddle point with a connected component comprising the identified path descending from the saddle point according to a direction of a steepest slope around the saddle point. The merging yields at least a part of a basin.

Owner:DASSAULT SYSTEMES

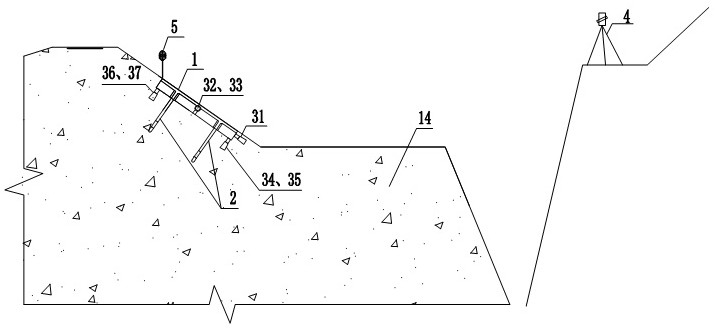

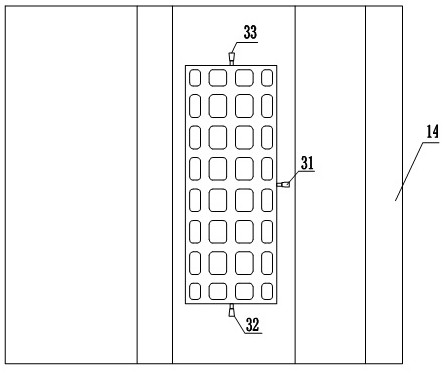

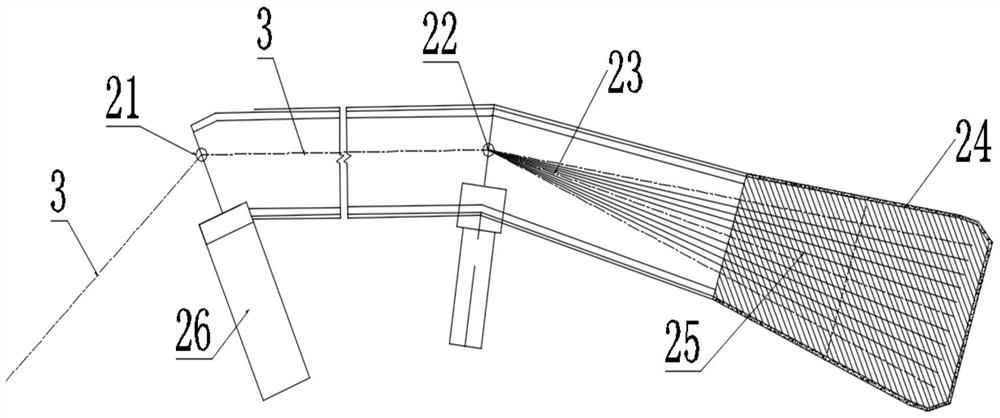

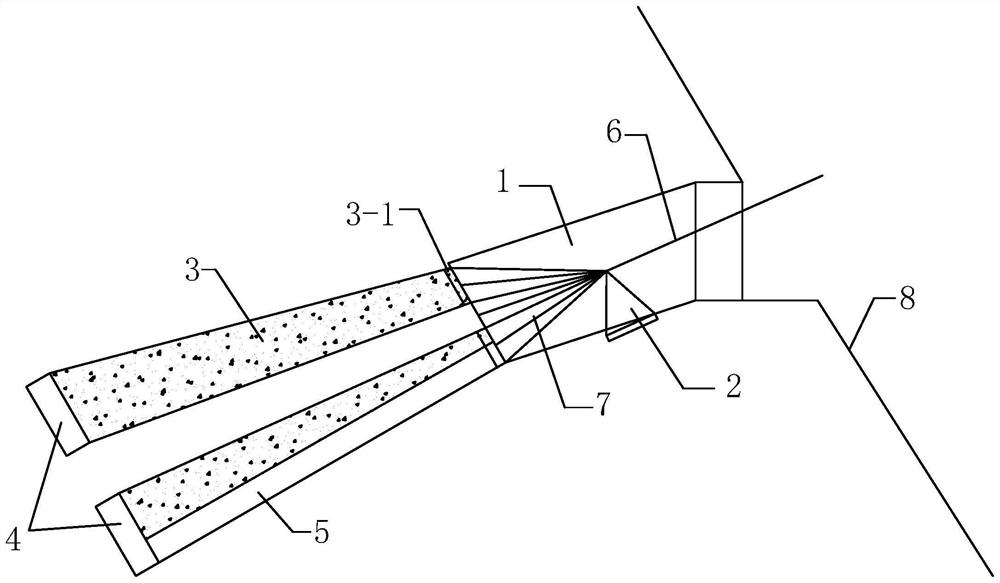

Main-tower-free suspension bridge suitable for wide and deep canyons and construction scheme

PendingCN112663476AReduce the difficulty of buildingReduce construction costsSuspension bridgeBridge erection/assemblyCanyonArchitectural engineering

The invention discloses a main-tower-free suspension bridge suitable for a wide and deep canyons and a construction scheme. The construction scheme comprises: performing inclined shaft construction; installing an anchoring body; installing a main cable saddle; installing a loose cable saddle; installing a cable fixing device; installing main cables; installing cables; and performing main beam and sling construction. The main-tower-free suspension bridge comprises an inclined shaft, an anchoring structure, a main cable, a main beam and slings, wherein the main beam is erected between canyons; the inclined shafts are arranged at two sides of the tunnel portal, and two inclined shafts are arranged at the tunnel portal at two ends; the anchoring device is combined with the inclined shaft and is fixed at the front end of the inclined shaft; the two main cables are connected with the corresponding anchoring structures at the two ends of the canyon correspondingly. One end of the sling is connected with the main cable and the other end is vertically connected with the girder. Mountains on the two banks of the canyon are fully utilized, anchoring structures are arranged in the mountains, the mountains are used for fixing main cables of the suspension bridge, so that arrangement of a main tower is avoided, the construction difficulty of the suspension bridge is further reduced, and meanwhile the construction cost of the suspension bridge is also reduced.

Owner:四川省交通勘察设计研究院有限公司

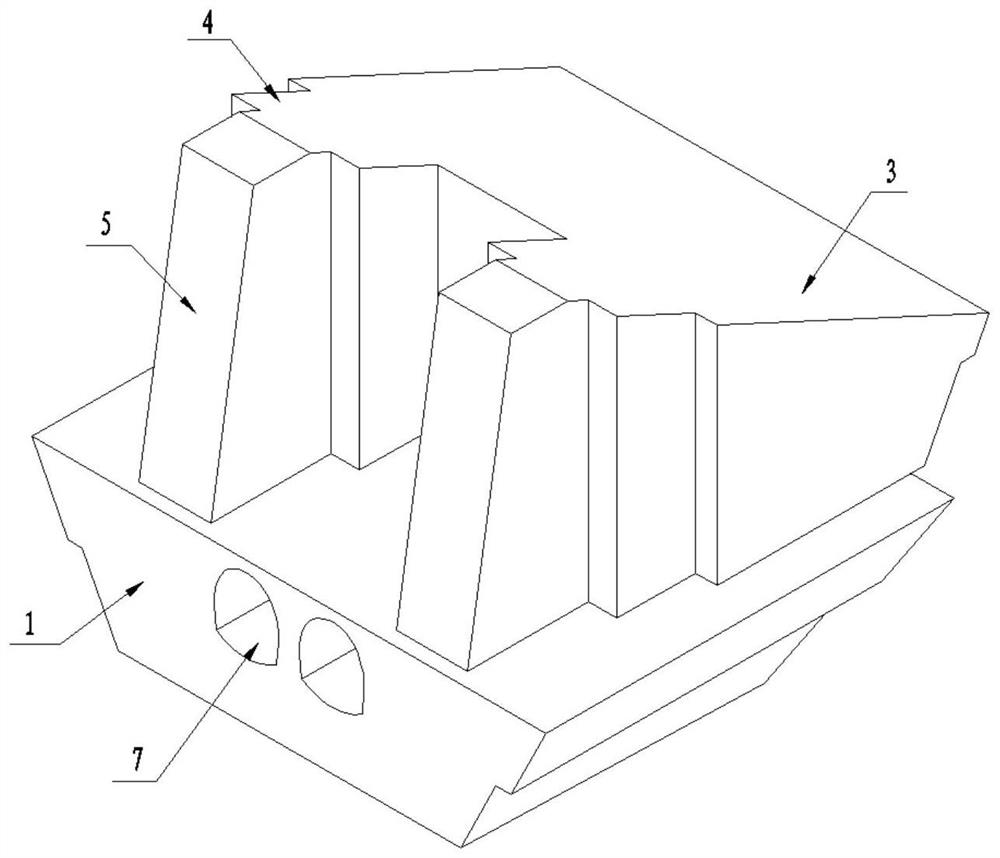

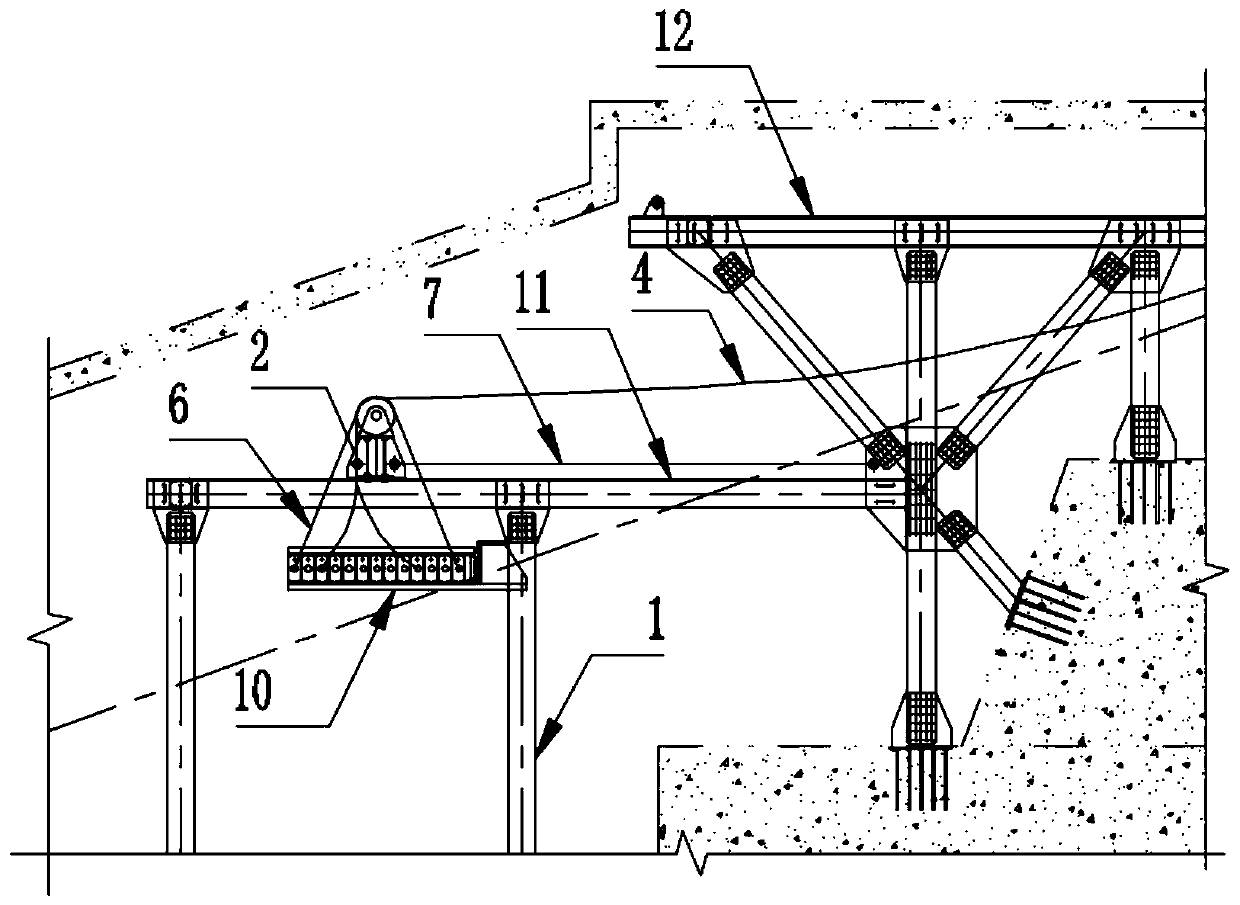

Method for installing composite cable saddle in anchor hole of a mountainous area suspension bridge tunnel s

ActiveCN110886242ASolve the problem of difficult to install above the mastReduce investmentSuspension bridgeBridge structural detailsArchitectural engineeringPortal frame

The invention discloses a method for installing a composite cable saddle in an anchor hole of a mountainous area suspension bridge tunnel, and belongs to the technical field of bridge construction. The method comprises the following steps: transporting components of the composite cable saddle to the side of a composite cable saddle buttress foundation; hoisting the components of the composite cable saddle to be higher than the top surface of the composite cable saddle buttress foundation by using a winch and a portal; horizontally moving the components of the composite cable saddle to the position above the top face of the composite cable saddle buttress foundation on the portal frame; lifting the components of the composite cable saddle to be higher than the top face of the composite cable saddle buttress again through the winch and the portal; translating the components of the composite cable saddle again on the portal to the upper part of the top surface of the composite cable saddle buttress; and lowering the components of the composite cable saddle to a set position on the top surface of the composite cable saddle buttress by using a winch. According to the method, in a narrowtunnel anchor hole, the portal, the winch and other devices are used for moving the component of the composite cable saddle with the single body weight reaching 50 t to the set position of the top face of the composite cable saddle buttress, and the device investment is small, and operation is convenient, and the construction cost is reduced.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD +1

An accurate positioning method for loose cable saddles of suspension bridges based on app system

ActiveCN112525170BEasy to operateAccurate adjustment positionGeometric CADSurveying instrumentsTotal stationControl theory

Owner:THE 5TH ENG MBEC

A composite anchorage of suspension bridge tunnel anchor and its construction method

ActiveCN107724236BInto the hole easyReduce usageBridge structural detailsBridge erection/assemblySocial benefitsEconomic benefits

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com