Driving belt

A technology of transmission belt and transmission ratio, applied in the direction of V-belt, belt/chain/gear, mechanical equipment, etc., can solve problems such as failure of transmission belt, and achieve the effect of reducing transverse bending stress and transverse bending amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

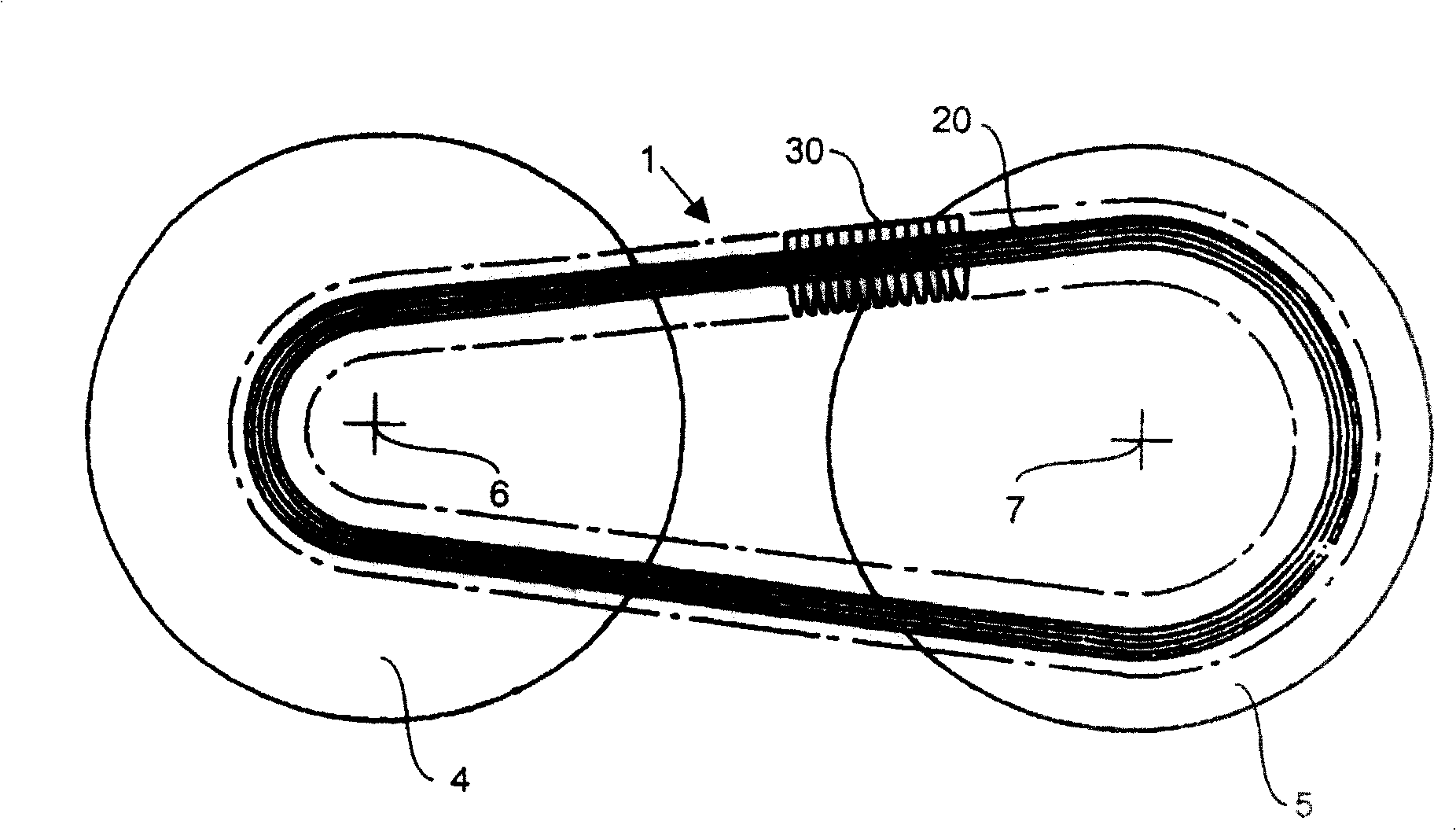

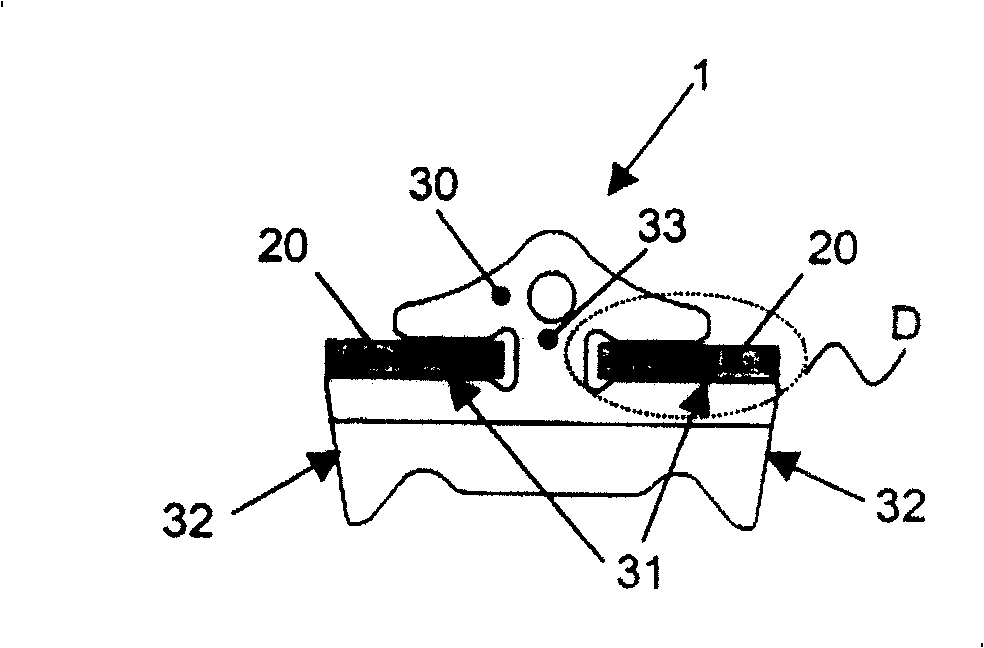

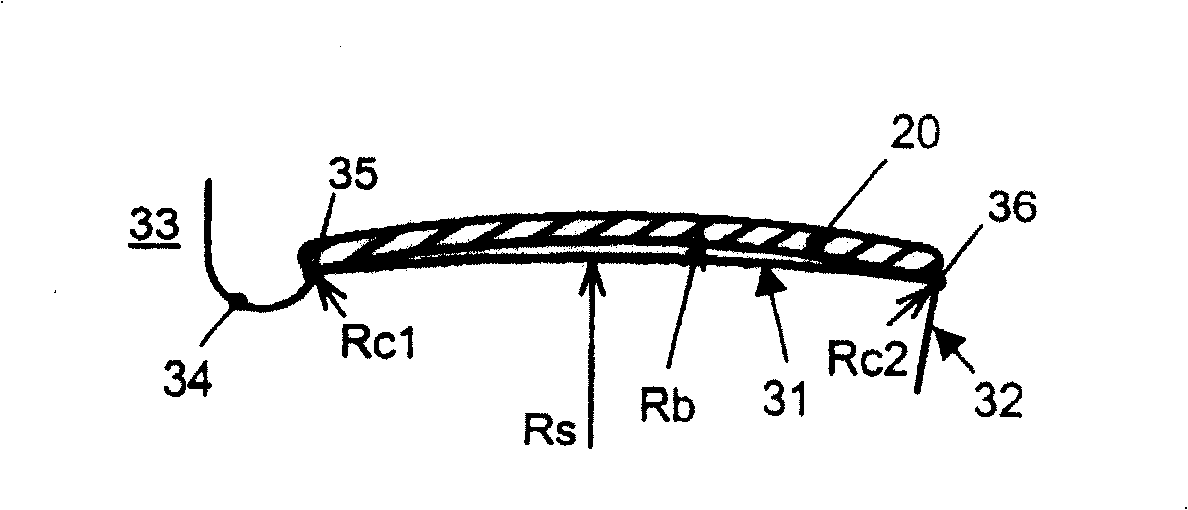

[0024] figure 1 Represents a schematic cross-section of a continuously variable transmission or CVT having a drive belt 1 comprising a tensioning device 20 comprising a number of radially nested, thinner continuous belts shape, so that the stretching device 20 can be relatively easily bent in its longitudinal direction; The innermost strip, this contact surface 31 is hereinafter referred to as the saddle surface 31 . The drive belt 1 is positioned around and between a set of pulley pulleys 4, 5, each pulley having a respective axis of rotation 6, 7. In order to transmit torque between the pulleys 4, 5 by means of friction, the drive belt 1 is clamped to each of the pulleys 4, 5 by moving the sheaves of the pulleys 4, 5 axially towards each other Between the two sheaves of the belt, and then exert a clamping force on the transmission belt 1. In order to carry this clamping force, the crossing elements 30 of the drive belt 1 are provided with sides 32, which are mainly transv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com