Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

13669 results about "Transmission belt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A transmission belt is a Leninist concept developed to create a figurative model of the relationship between Bolshevik vanguard party, the mass of the proletariat, and from the mass of working people as a whole.

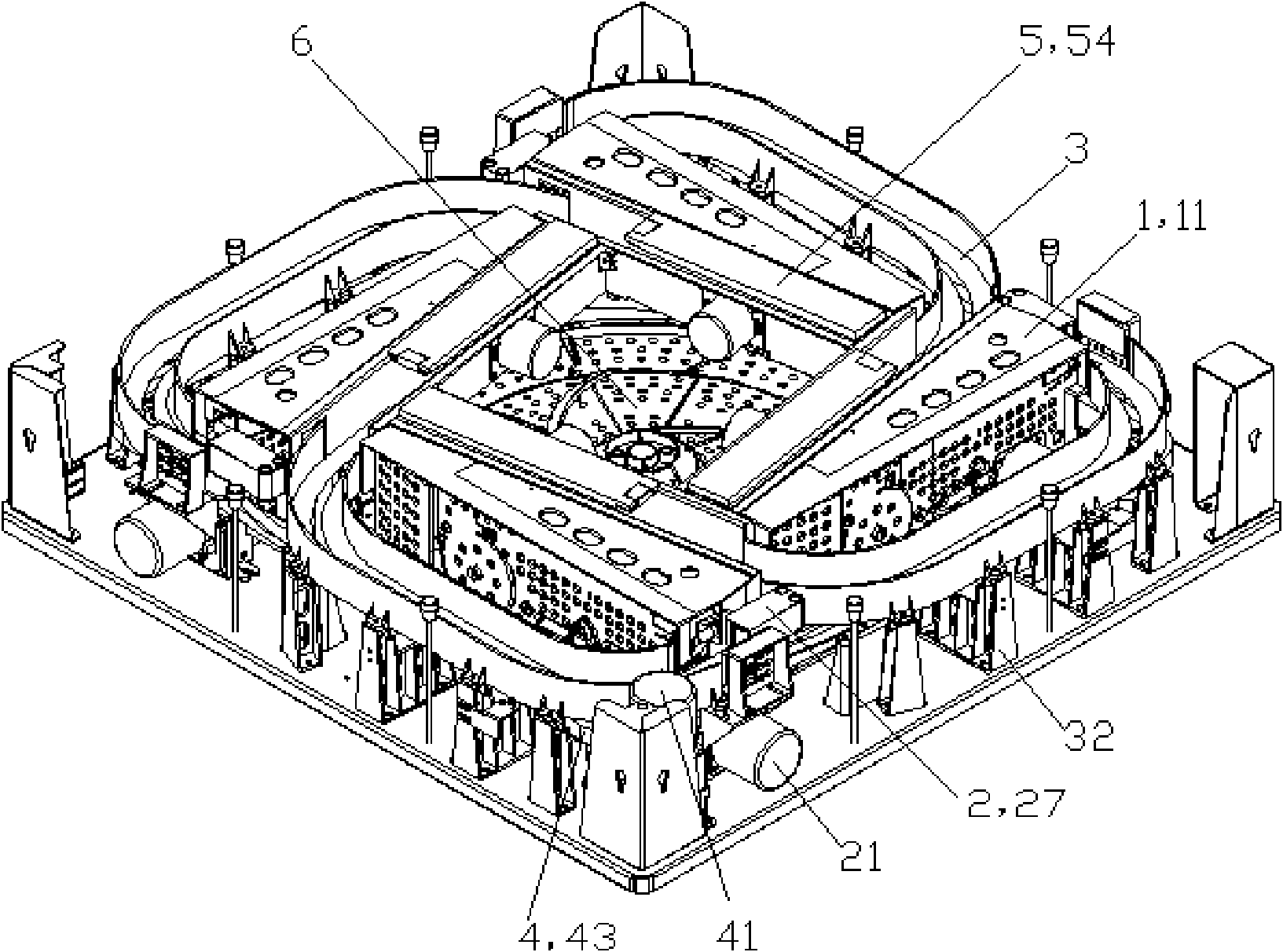

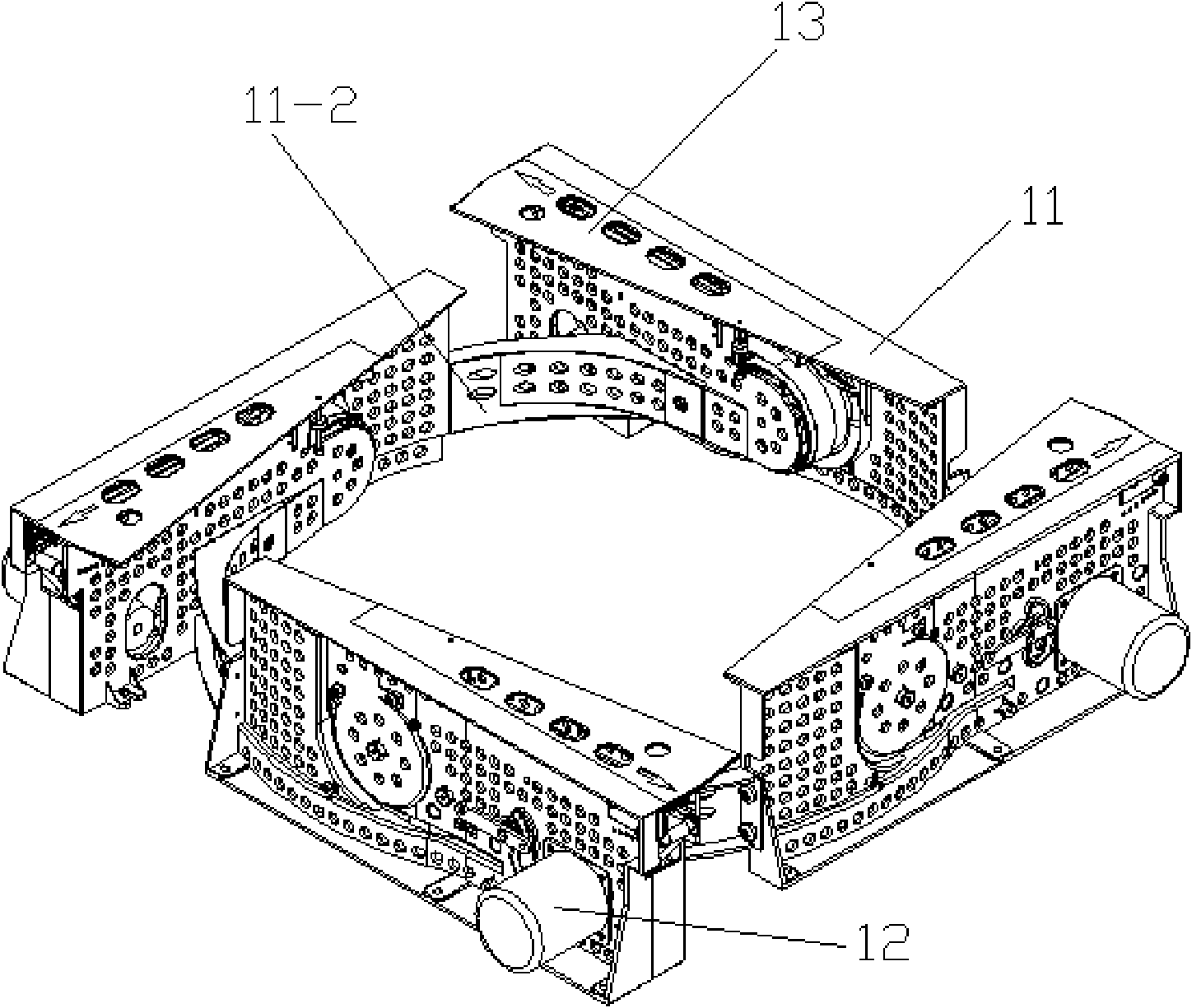

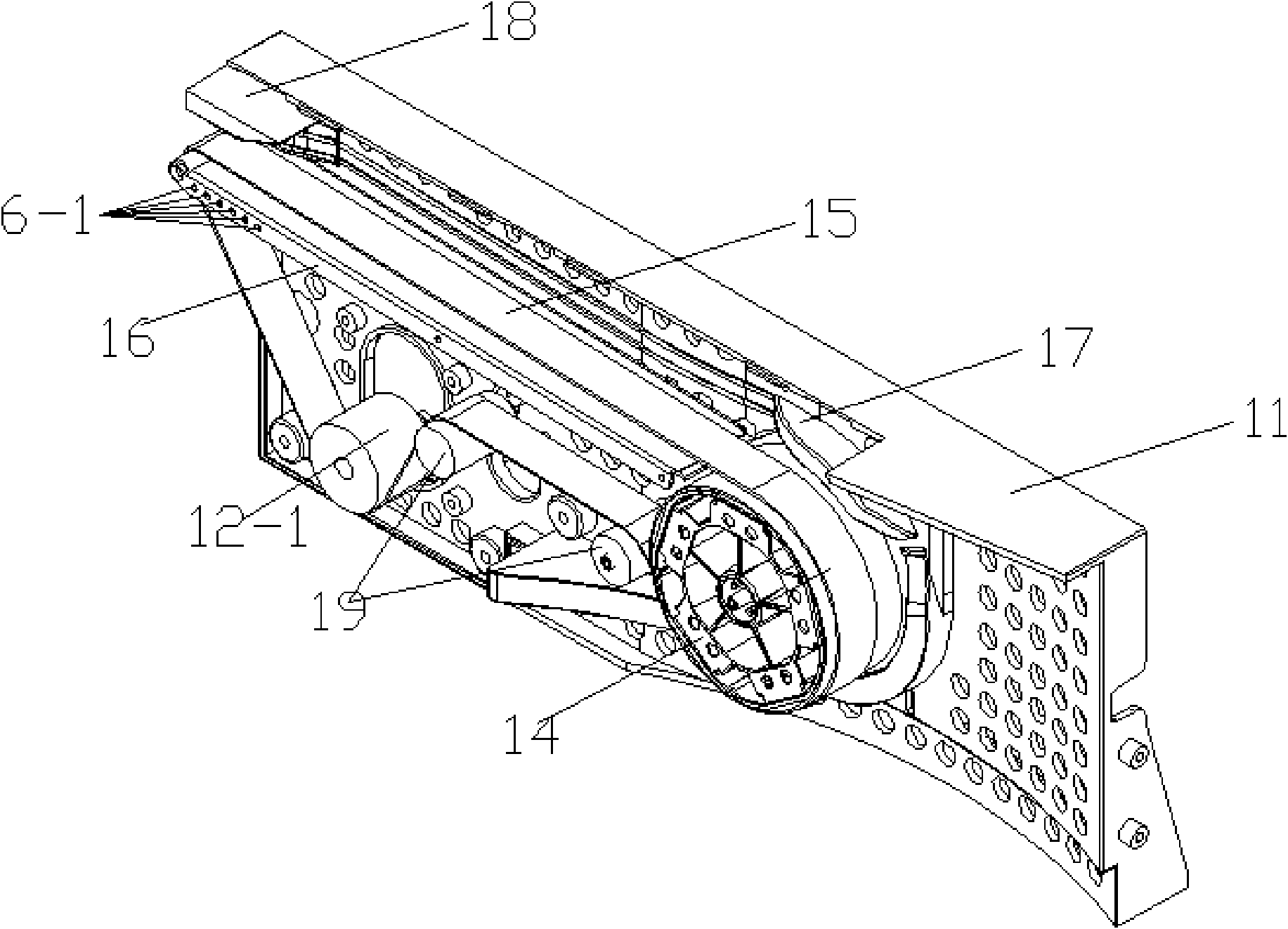

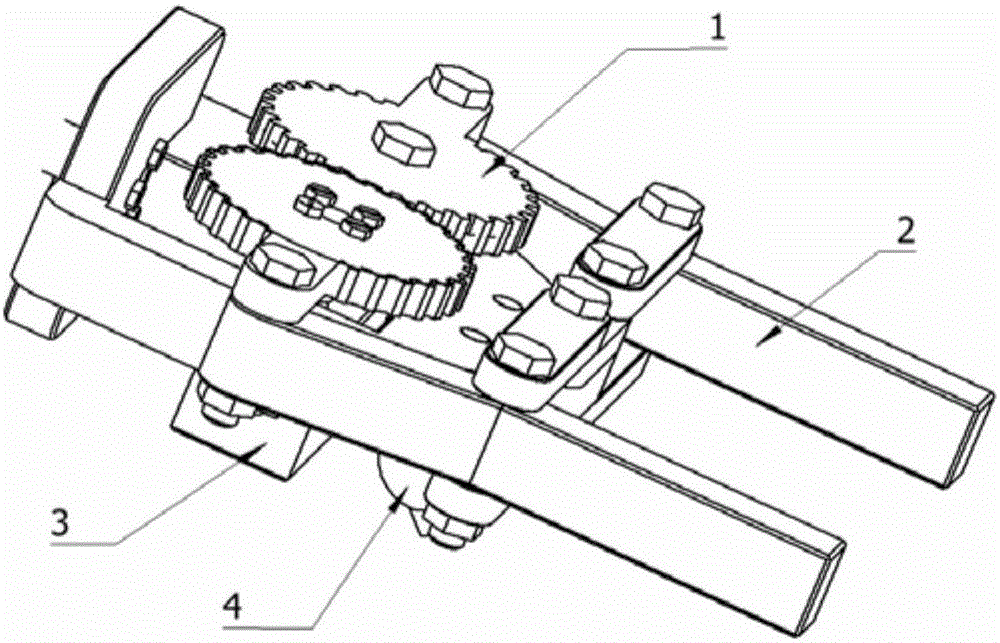

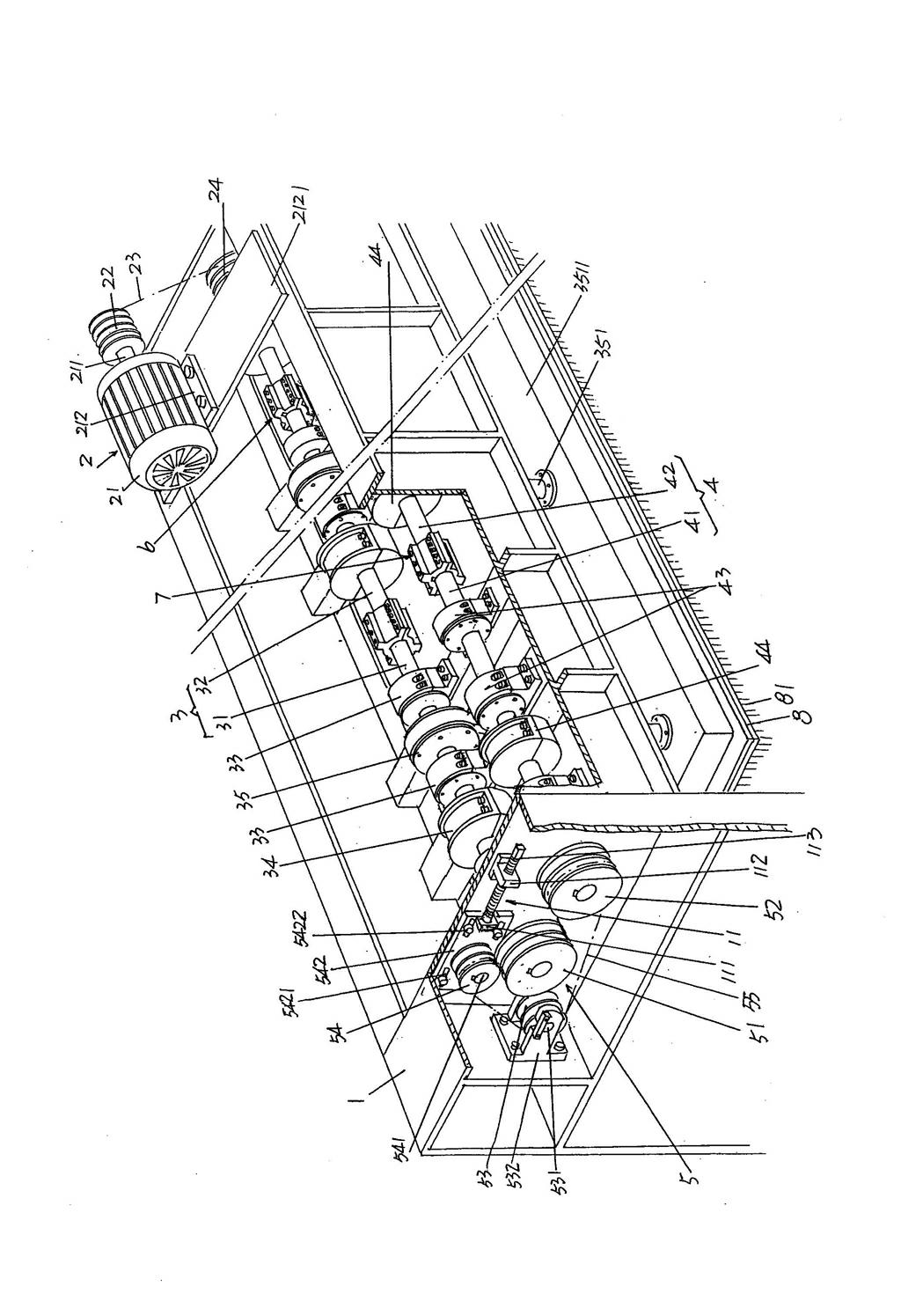

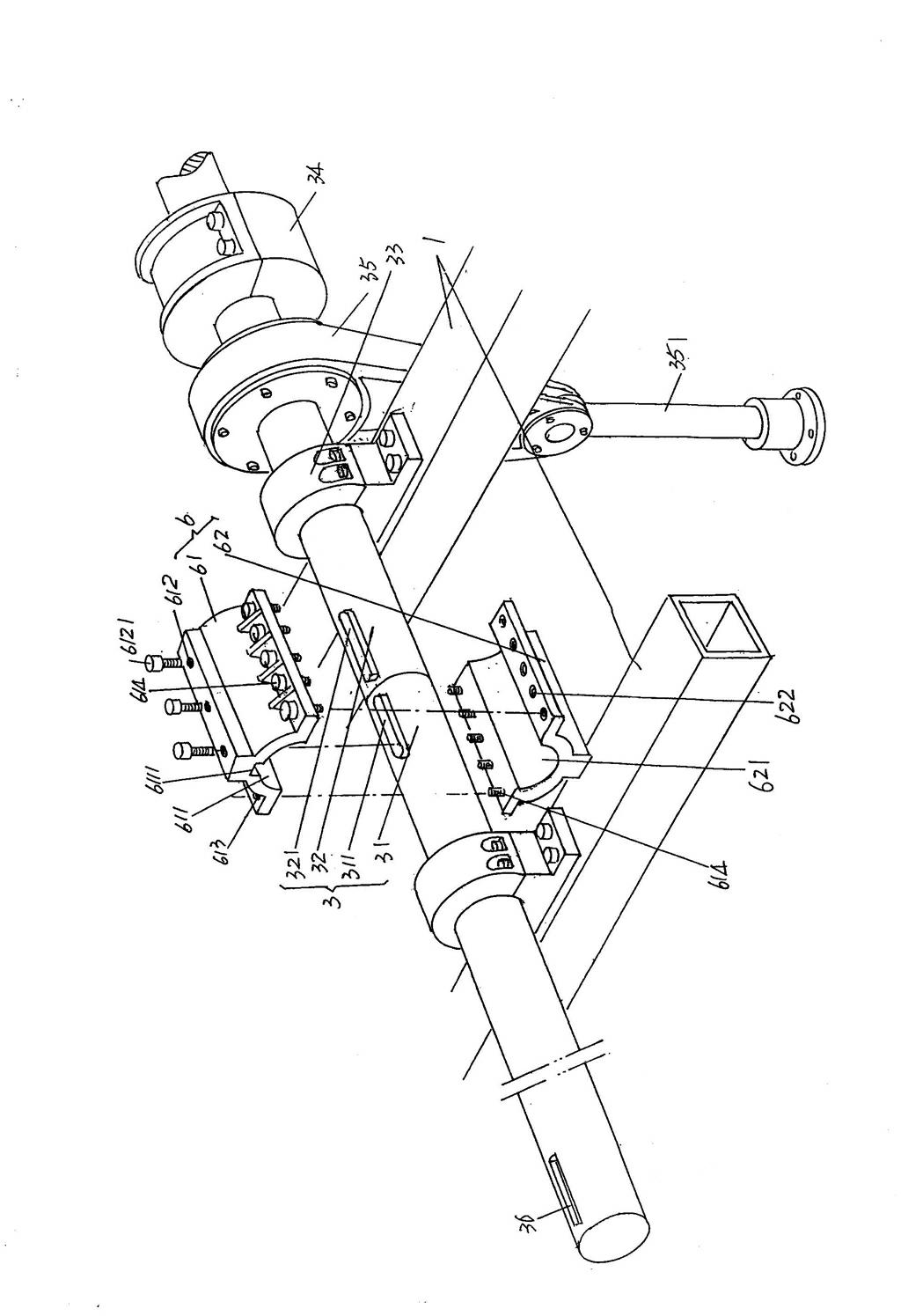

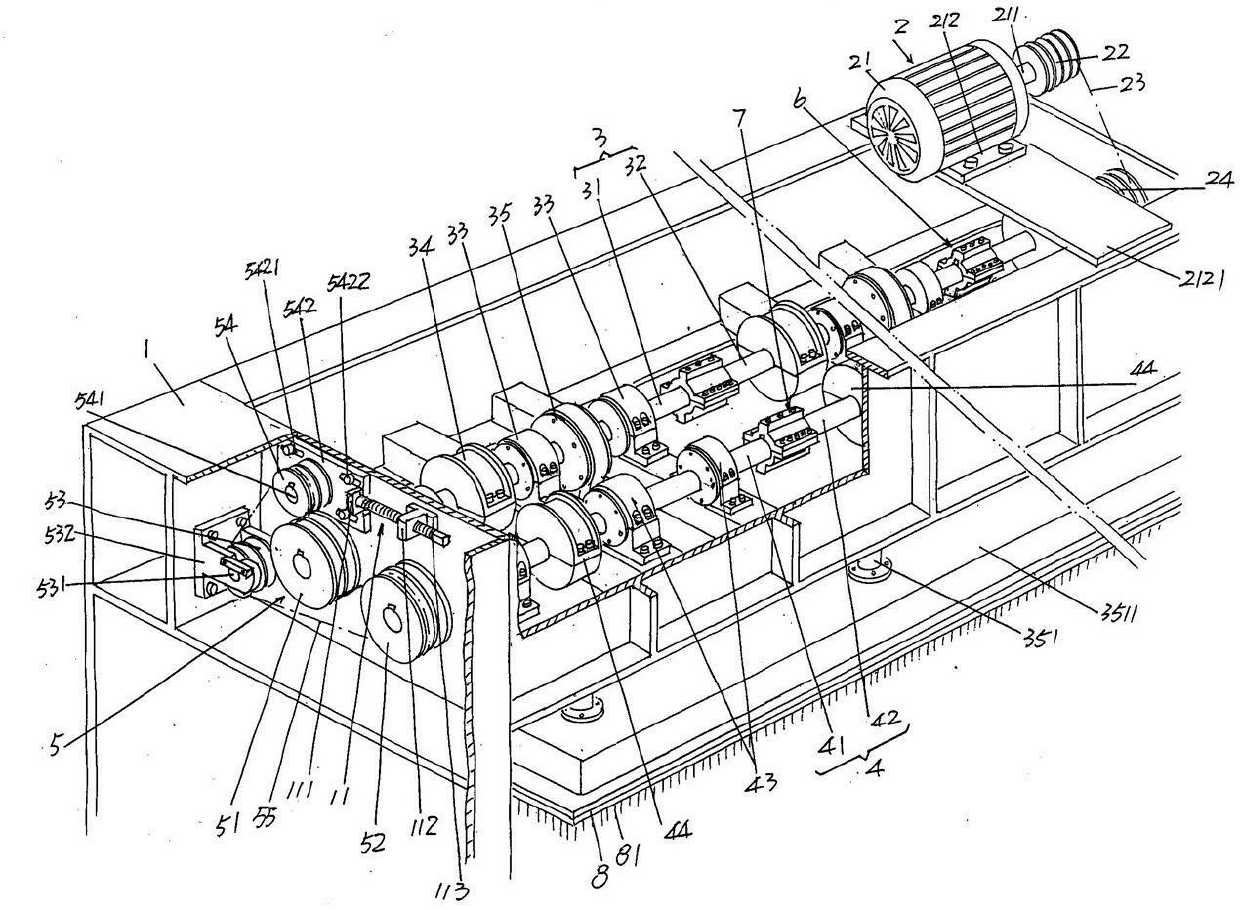

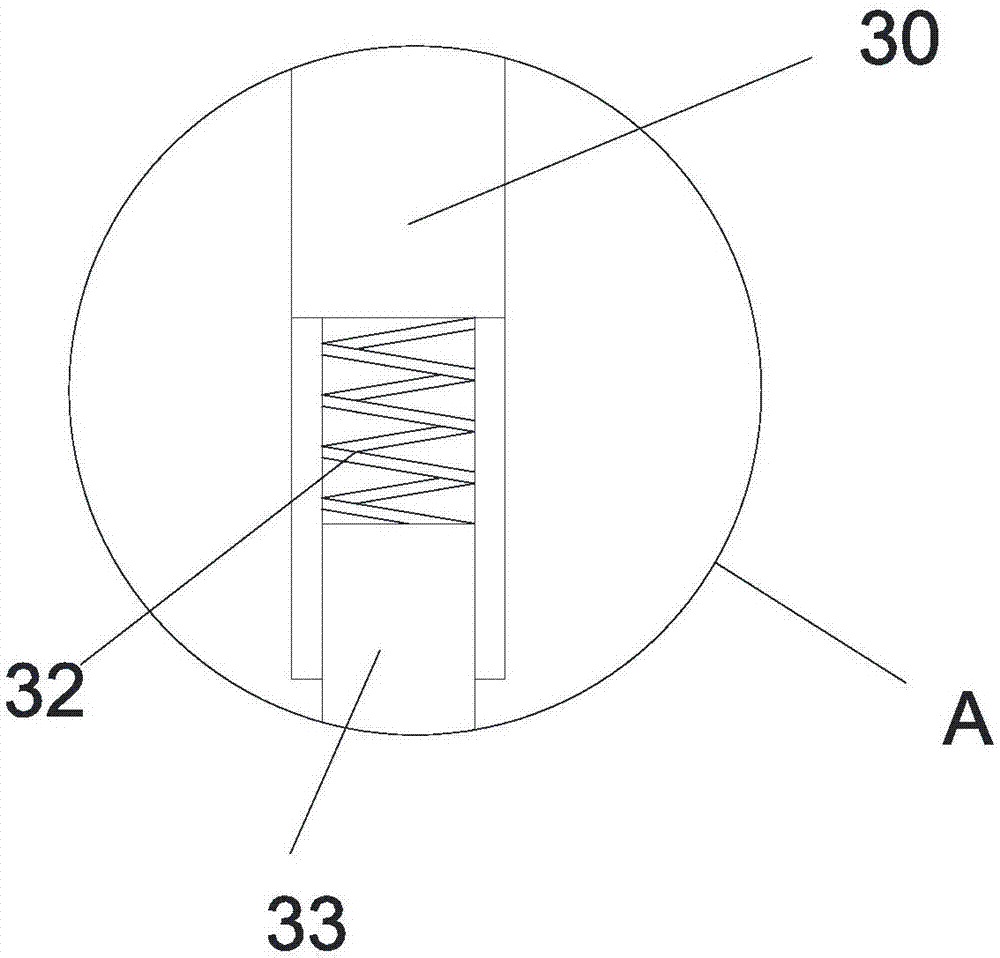

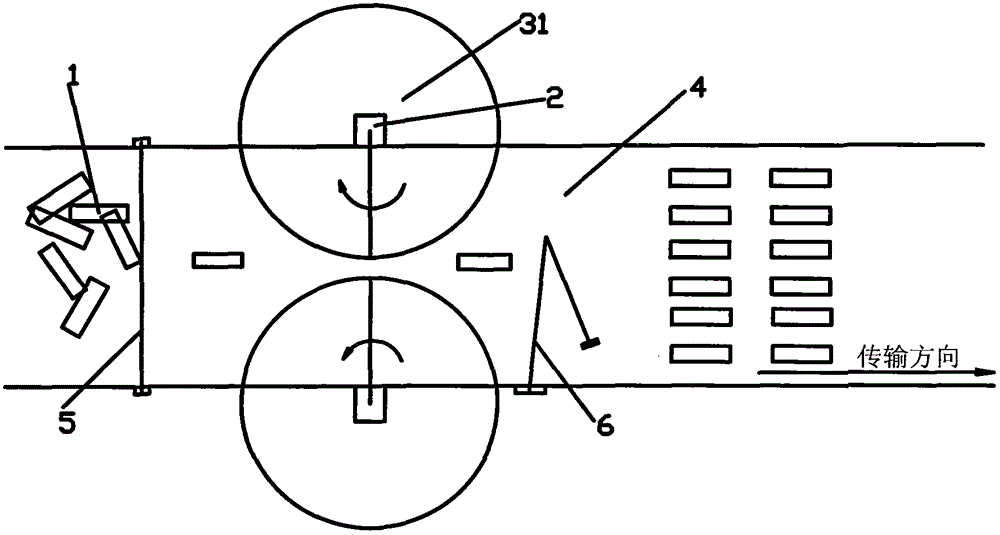

Fully-automatic mahjong machine

InactiveCN102133480AReduce manufacturing costGuaranteed uptimeIndoor gamesInlet channelTransmission belt

The invention relates to a fully-automatic mahjong machine comprising a board sending system, a board loading system, a board lifting system and a large shuffling disc. The board sending system comprises four board sending mechanisms, each board sending mechanism comprises a transmission rack, and a board sending motor, a board absorbing wheel, a transmission belt, a transmission platform, a board inlet guiding piece and a board outlet guiding piece fixed on the transmission rack; a board sending channel is arranged at the upper end of the transmission platform, the board absorbing wheel is tightly attached at the lower end of a board inlet opening of the board sending channel, the board inlet guiding piece is positioned above the board absorbing wheel, the board outlet guiding piece is positioned at a board outlet opening of the board inlet channel, the board sending motor is used for driving a motor guiding wheel, the motor guiding wheel is positioned below the transmission platform, and the transmission belt loops the motor guiding wheel, the board absorbing wheel and the transmission platform. In the invention, for the mahjong boards with different widths, the board sending mechanism of the mahjong machine can run normally by only replacing the corresponding board inlet guiding piece and the board outlet guiding piece, and a transmission rack cover does not need to be changed, so that the operation is simple and convenient, and the board inlet guiding piece and the board outlet guiding piece has extremely low production cost relative to the transmission rack cover.

Owner:程亮星

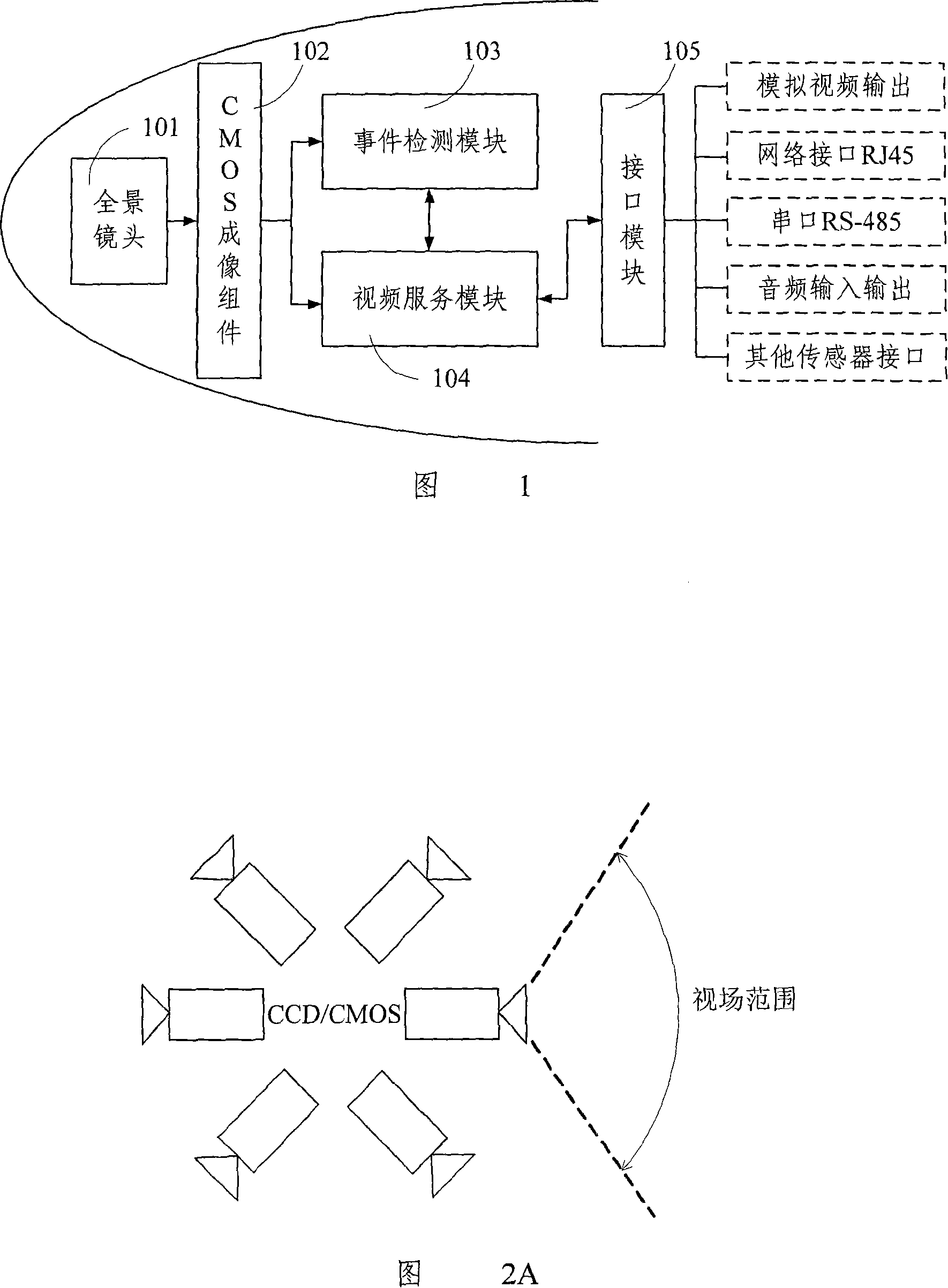

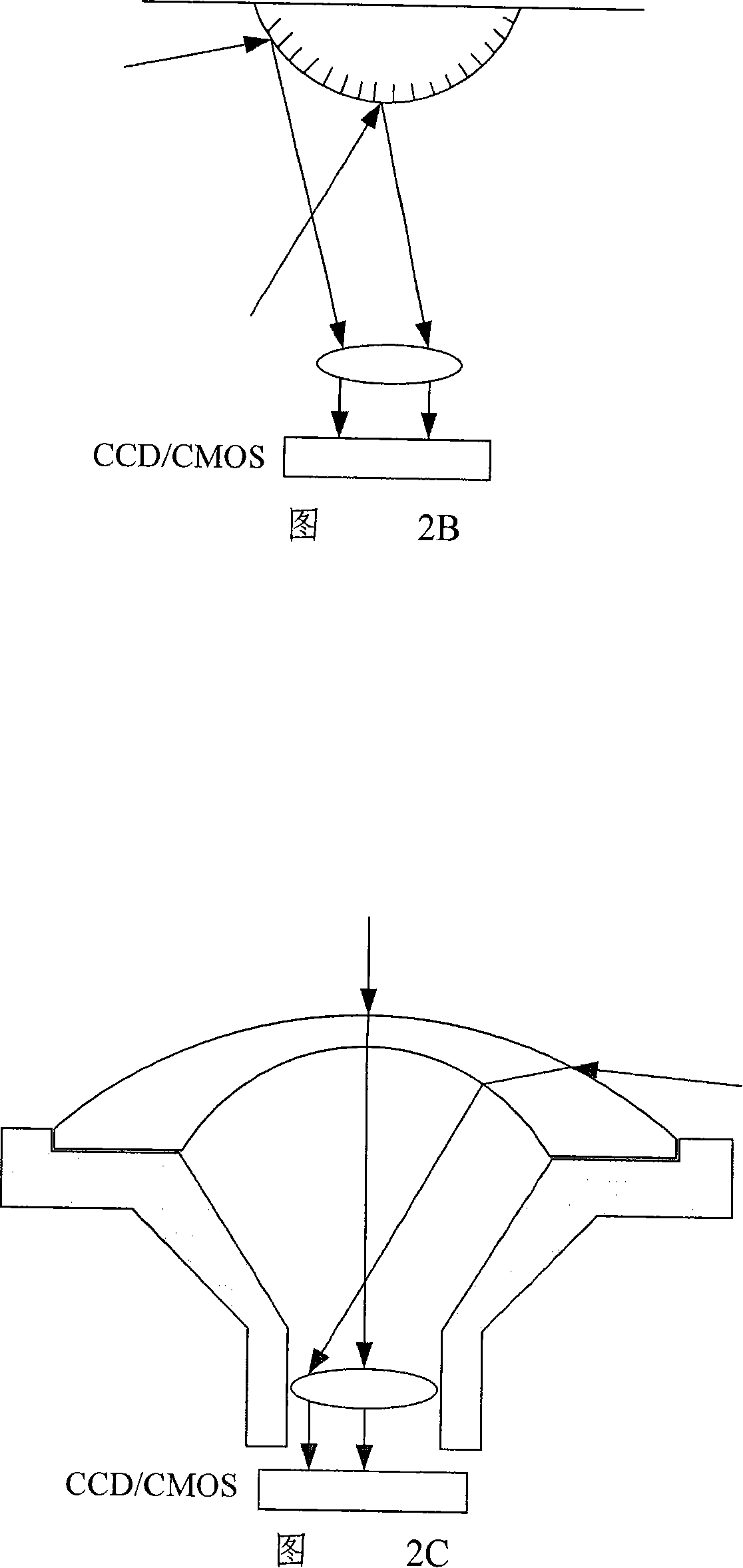

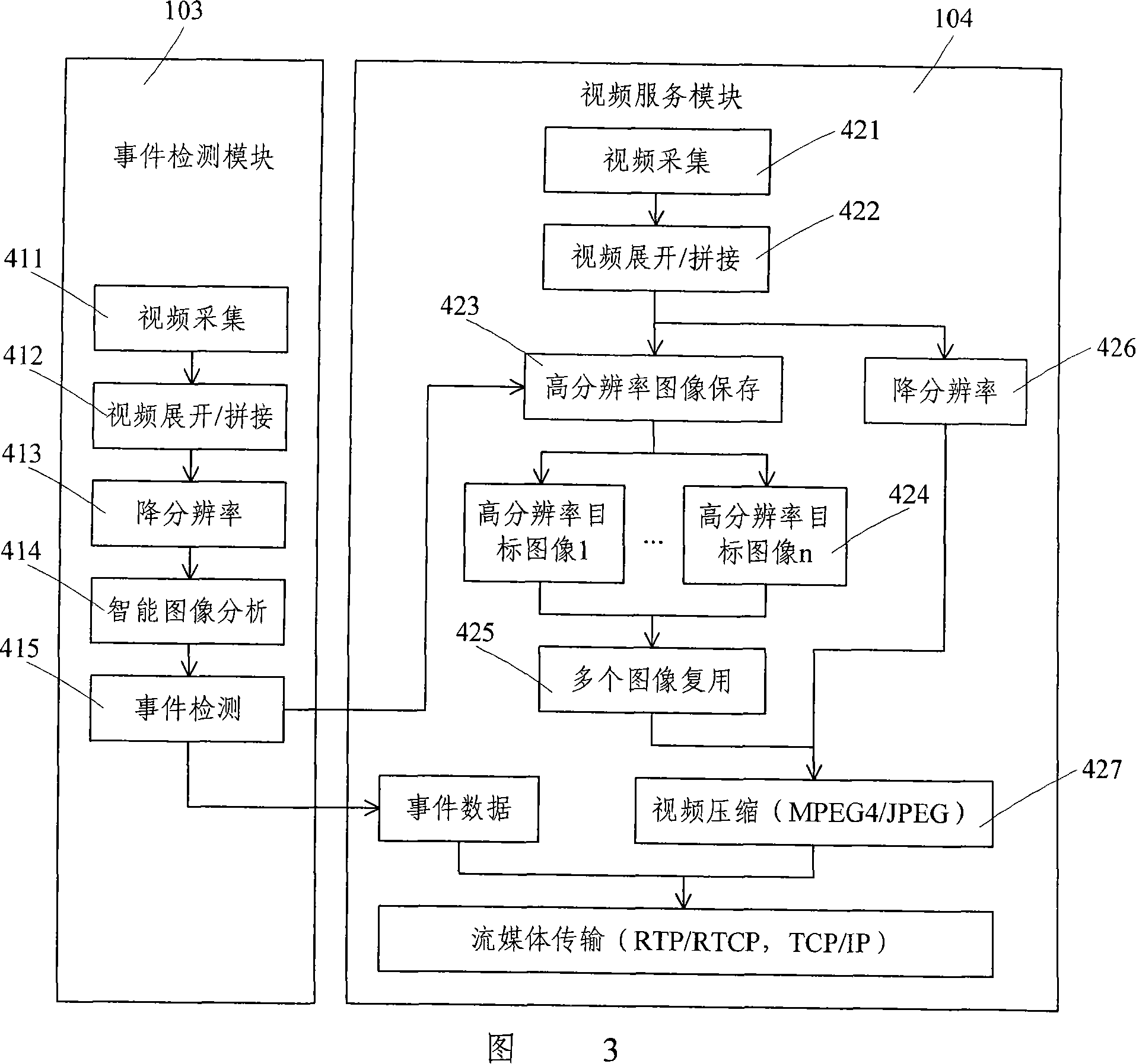

Overall view monitoring method and apparatus

InactiveCN101119482ALess investmentLower requirementImage analysisClosed circuit television systemsCamera lensMonitoring site

The present invention relates to a panorama monitoring method and device, wherein, the panorama camera lens and the imaging component are combined to get the panorama video frequency information of the monitoring scene, and the affair checking module is used for holding intelligent image analyzing for the panorama video frequency information, and according to the obtained intelligent analyzing result to judge whether having the affair to produce in accordance with the advancedly setting alarming condition, and producing affair checking report. The video frequency module is used for using the intelligent analyzing result to realize multi-aim suppositional PTZ following and providing a repeatedly used processing and transmission mechanism for the resolution aiming image, which not only solves the problem of seeing clearly and seeing fully, but also effectively reduces the requirement for the transmission belt width to realize high effective transmission. The interface module is used for applying all the interfaces for the connecting of panorama monitoring device and the outside. According to the proposal of the present invention, the present invention realizes continuously monitoring 360 degrees panorama space without missing out or missing any accident affair, realizing the intelligent monitoring without blind point and dead angle.

Owner:无锡安科兴业科技有限公司

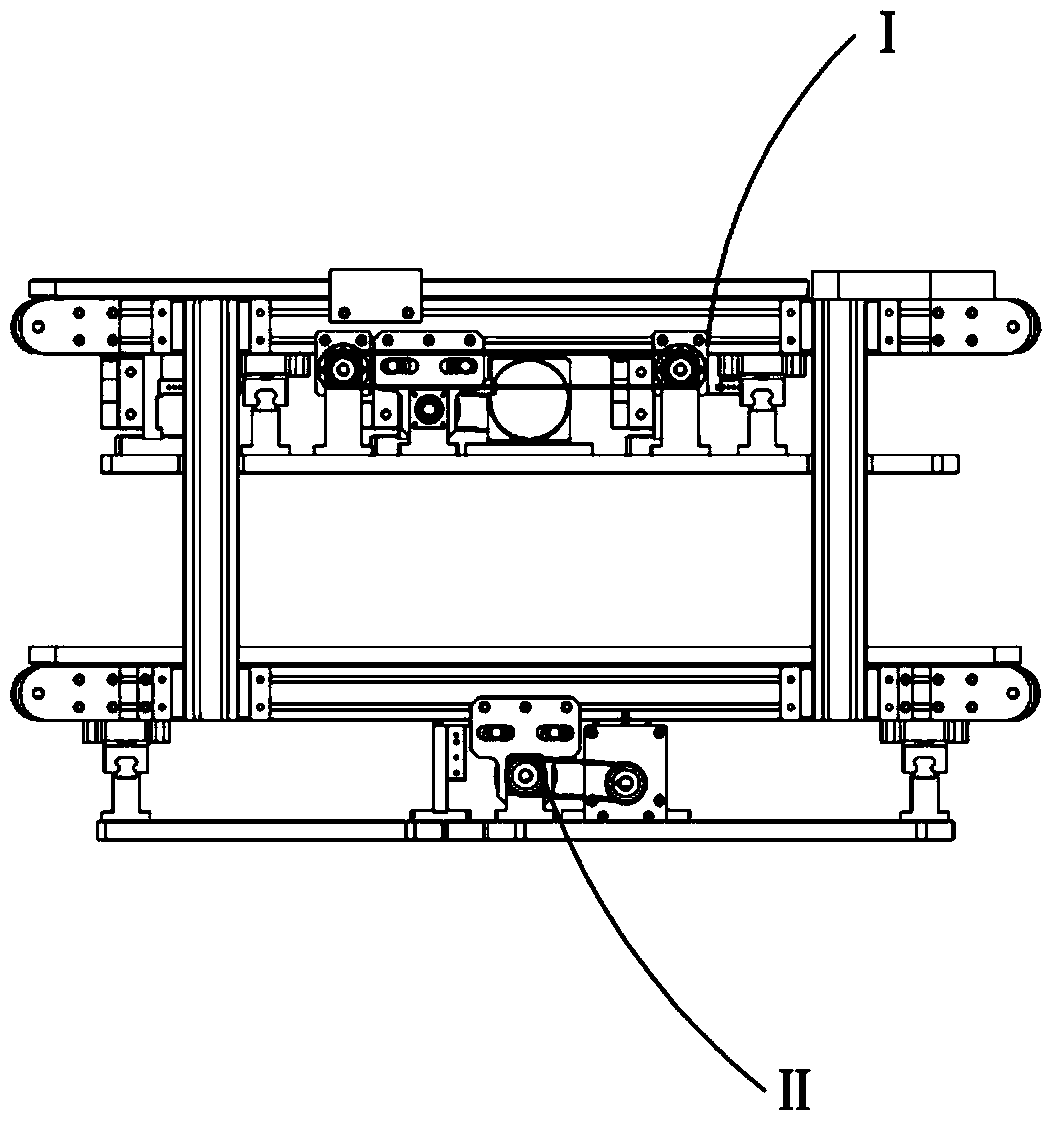

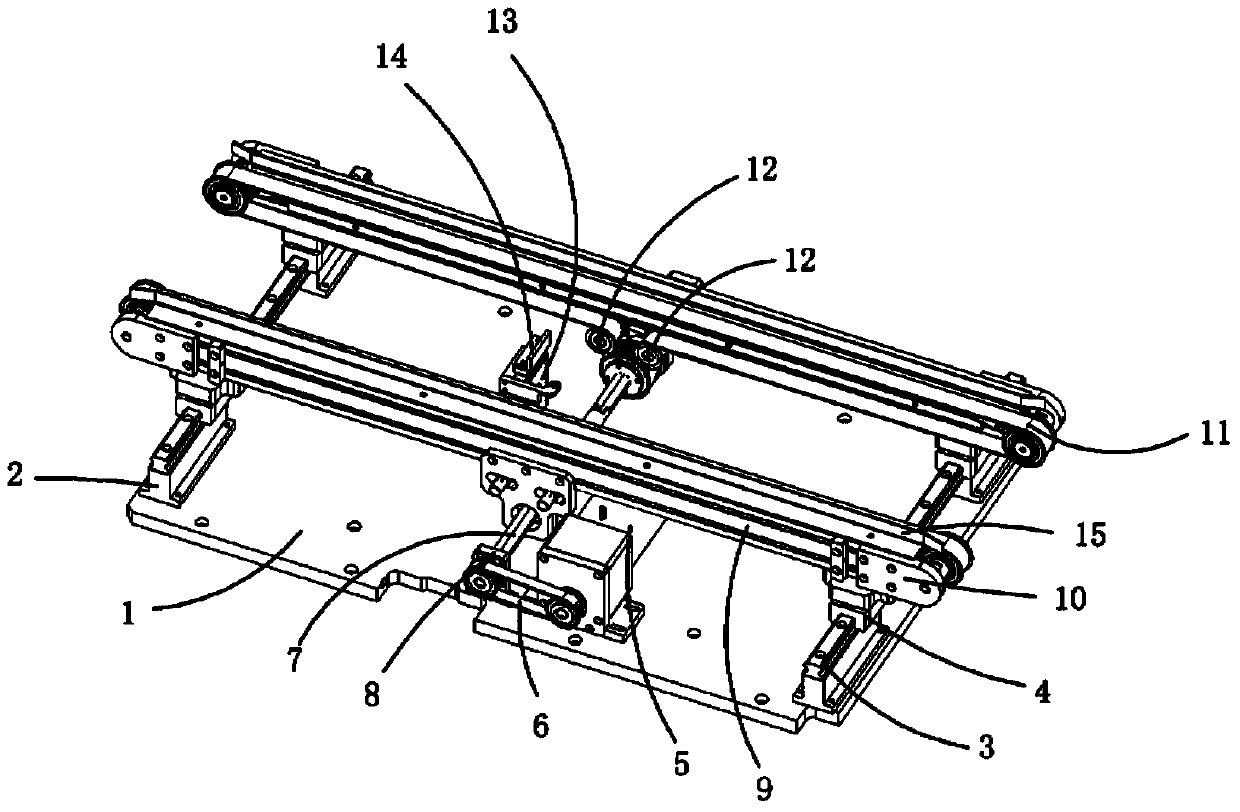

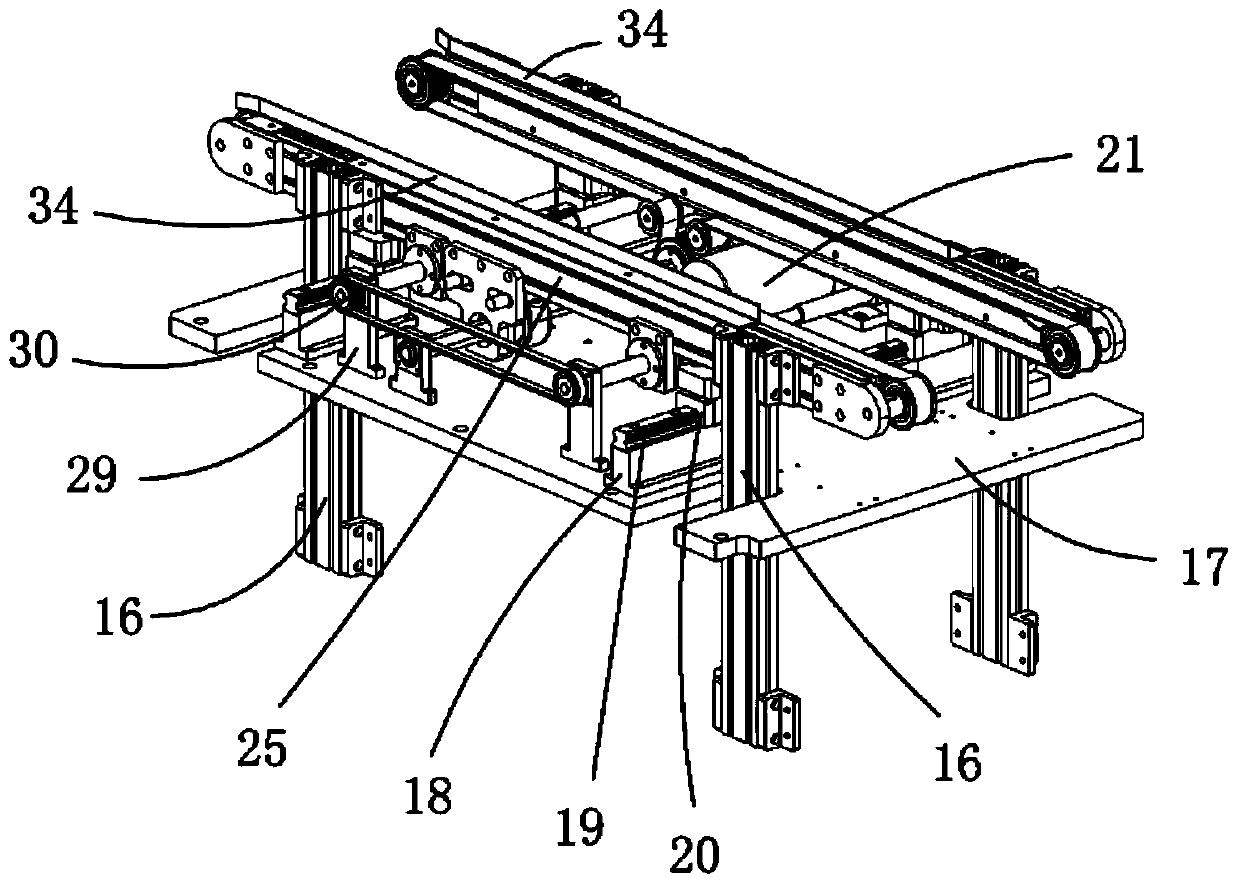

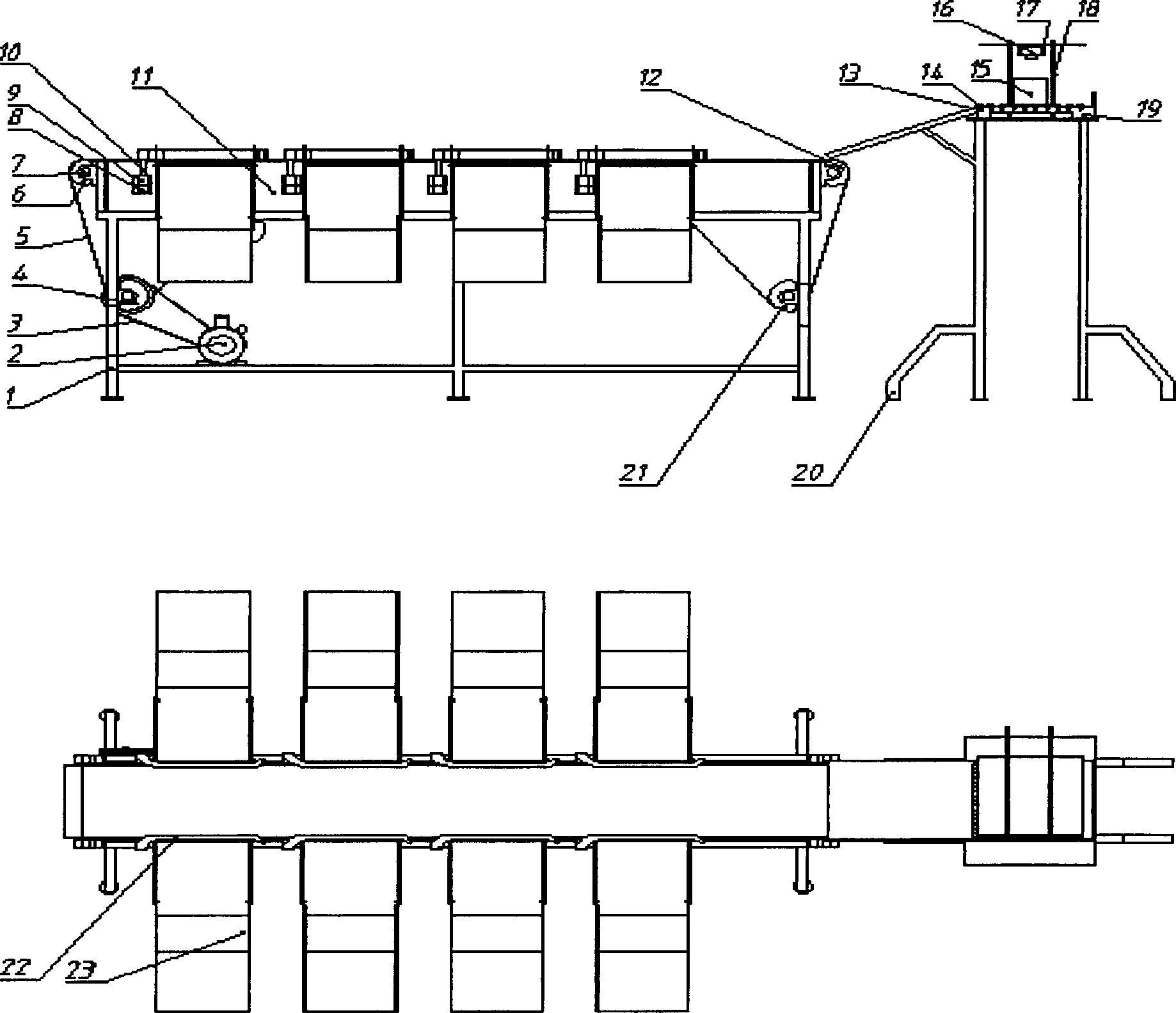

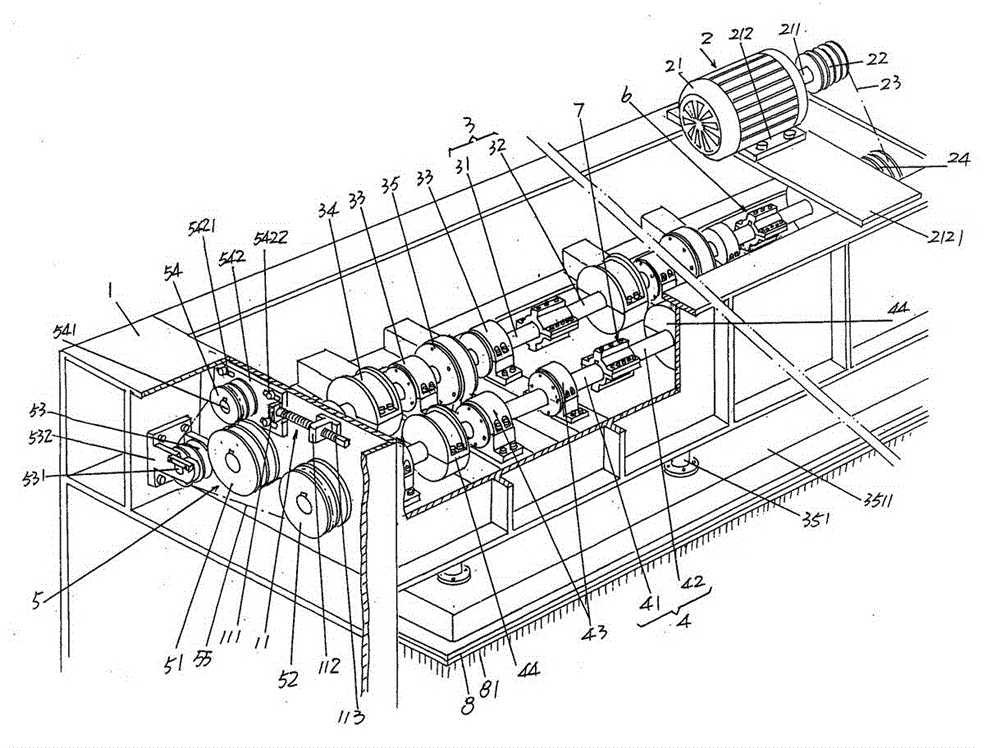

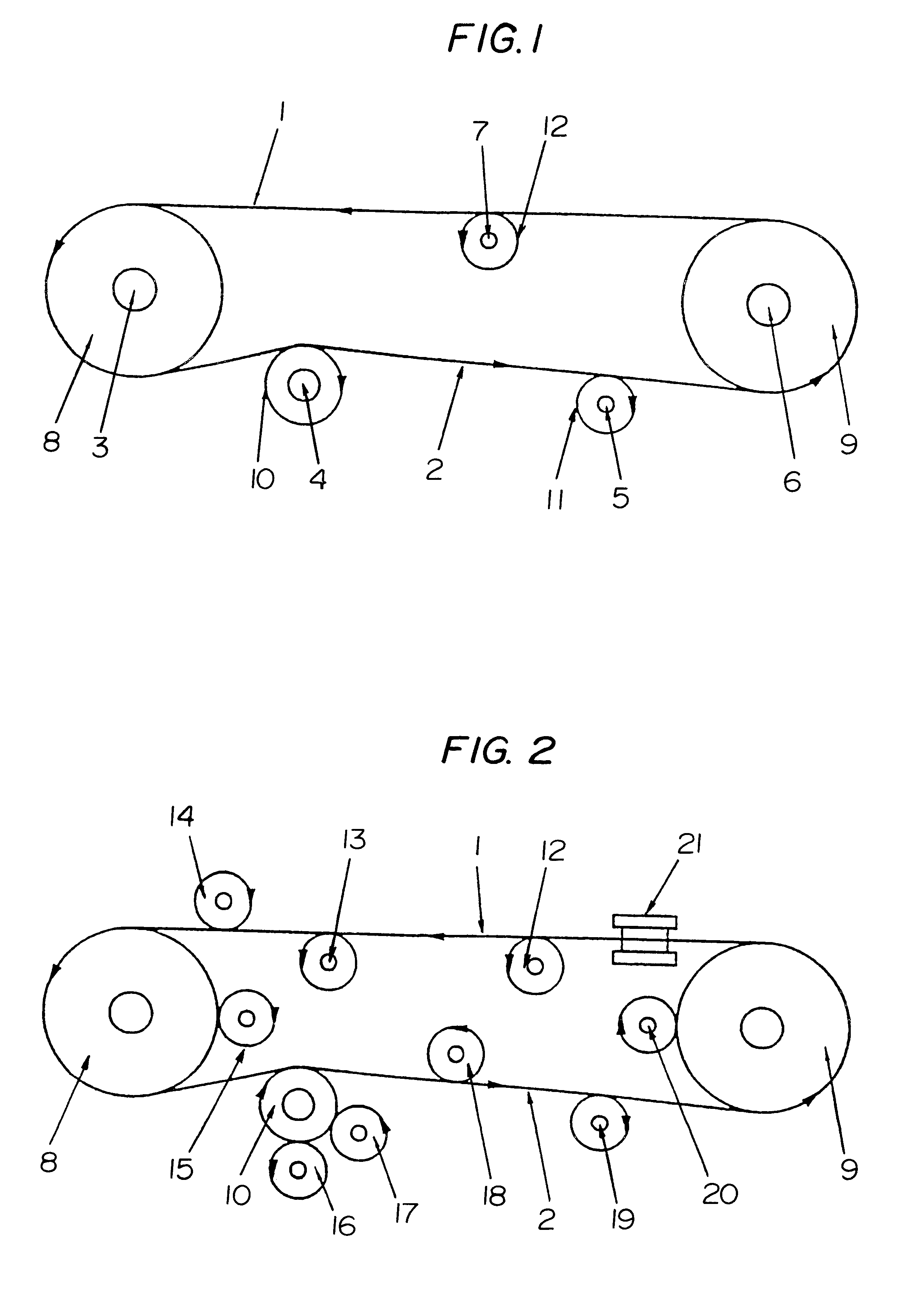

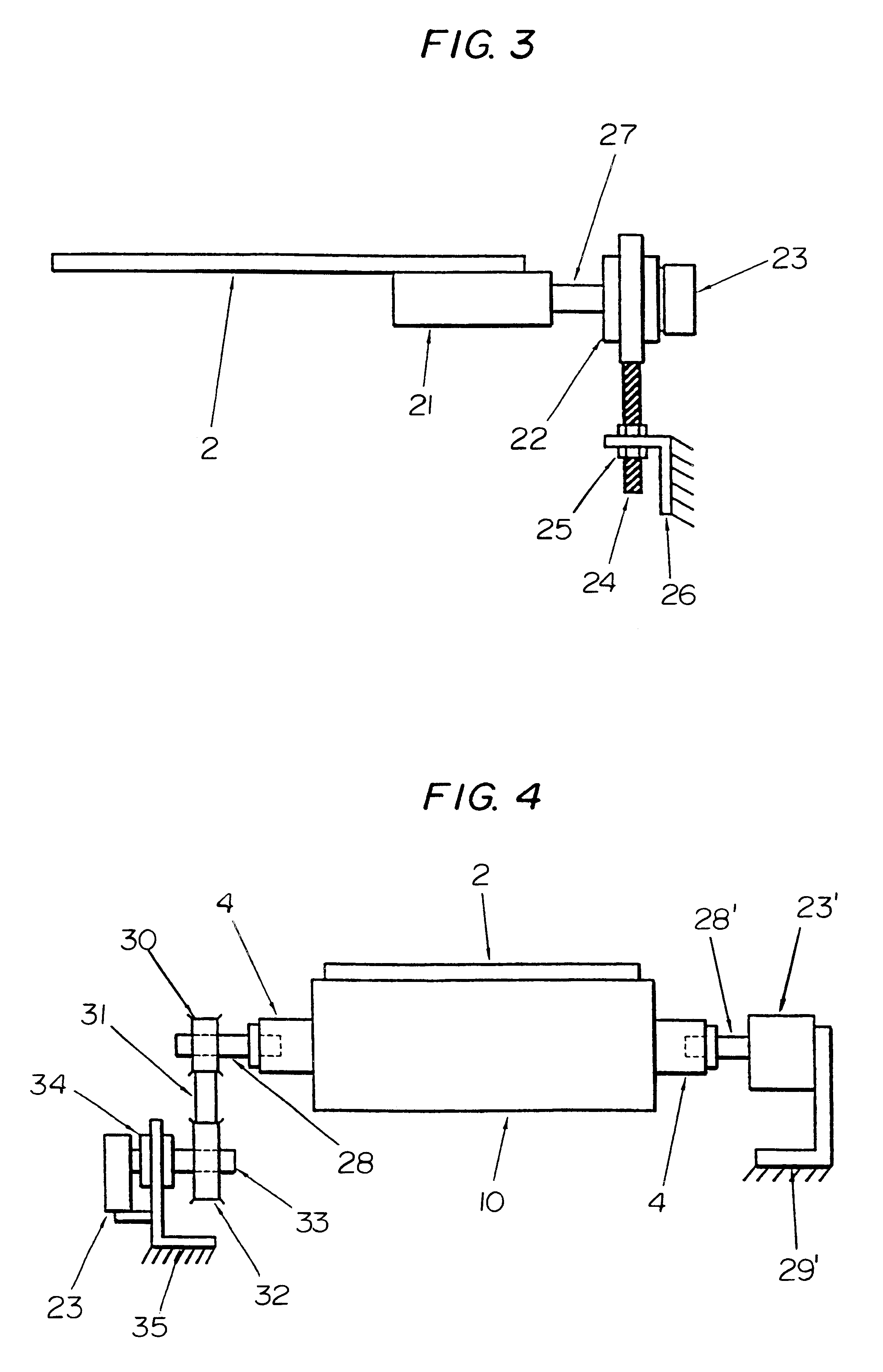

Double-layer assembly line with interval adjustable

ActiveCN103787025AAdjustable distanceGuaranteed uptimeConveyorsConveyor partsTransmission beltAssembly line

The invention relates to a double-layer assembly line with the interval adjustable. An upper layer adjustable assembly line of the double-layer assembly line with the interval adjustable is installed on a lower layer adjustable assembly line. When an adjusting screw rod is rotated, two upper belt mounting plates can move outwards or inwards simultaneously under the action of synchronizing wheels, meanwhile, under the action of four connecting frames, lower belt mounting plates can be driven to move outwards or inwards simultaneously under the action of lower sliders, thus, the distance between upper transmission belt wheels and lower transmission belt wheels can be adjusted simultaneously to adapt to carriers with various widths, three carrier lifting mechanisms and three carrier stopping mechanisms are installed on an upper plate of the upper layer adjustable assembly line, the carriers are jacked and positioned by the carrier lifting mechanisms after being stopped, and then each carrier can act in a corresponding station and flow to the next station after the action is completed; lifting air cylinders are installed on a lower plate of the lower layer adjustable assembly line, and stop dogs are connected to the lifting air cylinders. The double-layer assembly line with the interval adjustable is used for transporting product carriers, the carriers can stop in any position of the assembly line for machining, and thus the double-layer assembly line with the interval adjustable can adapt to different products.

Owner:BOZHON PRECISION IND TECH CO LTD

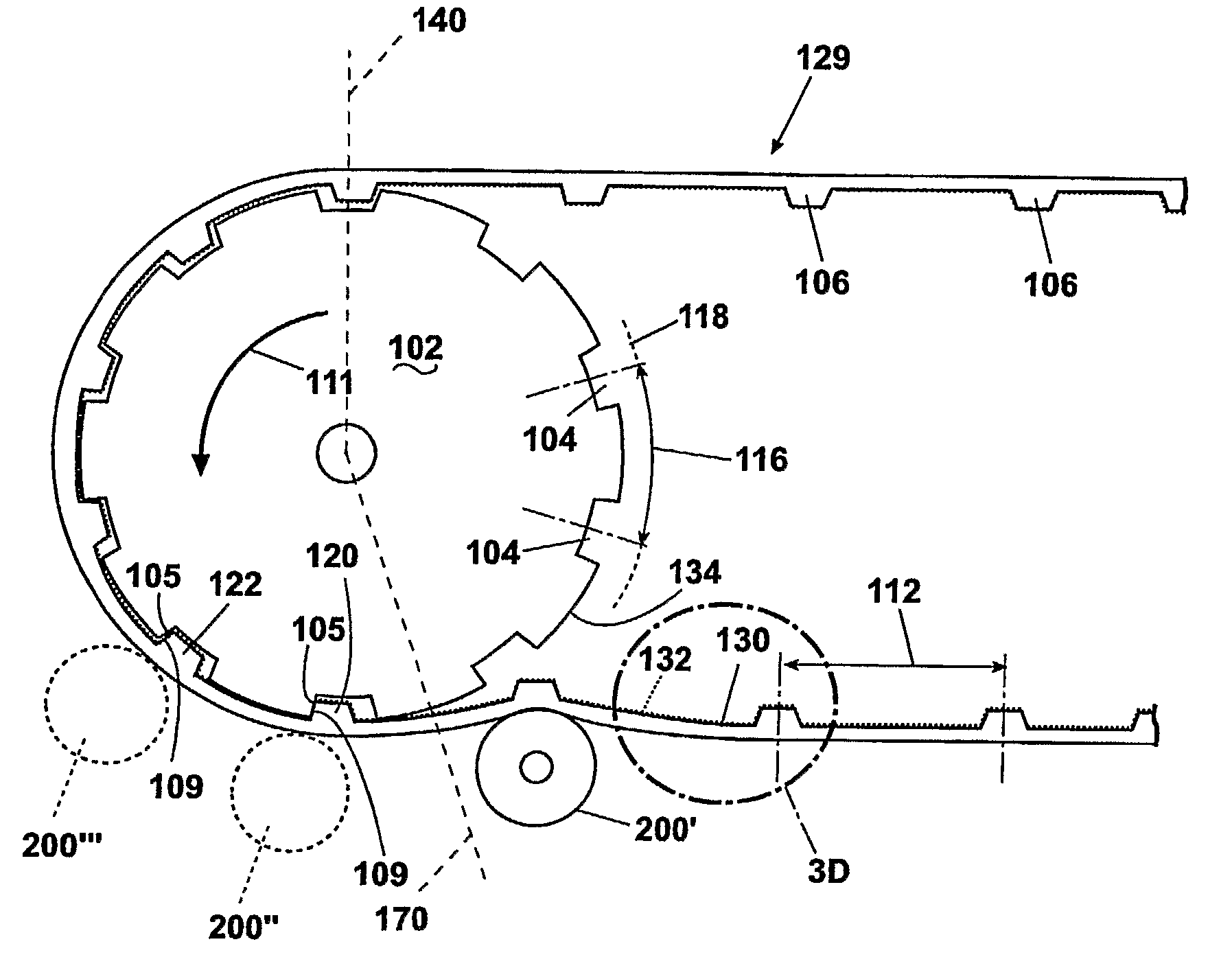

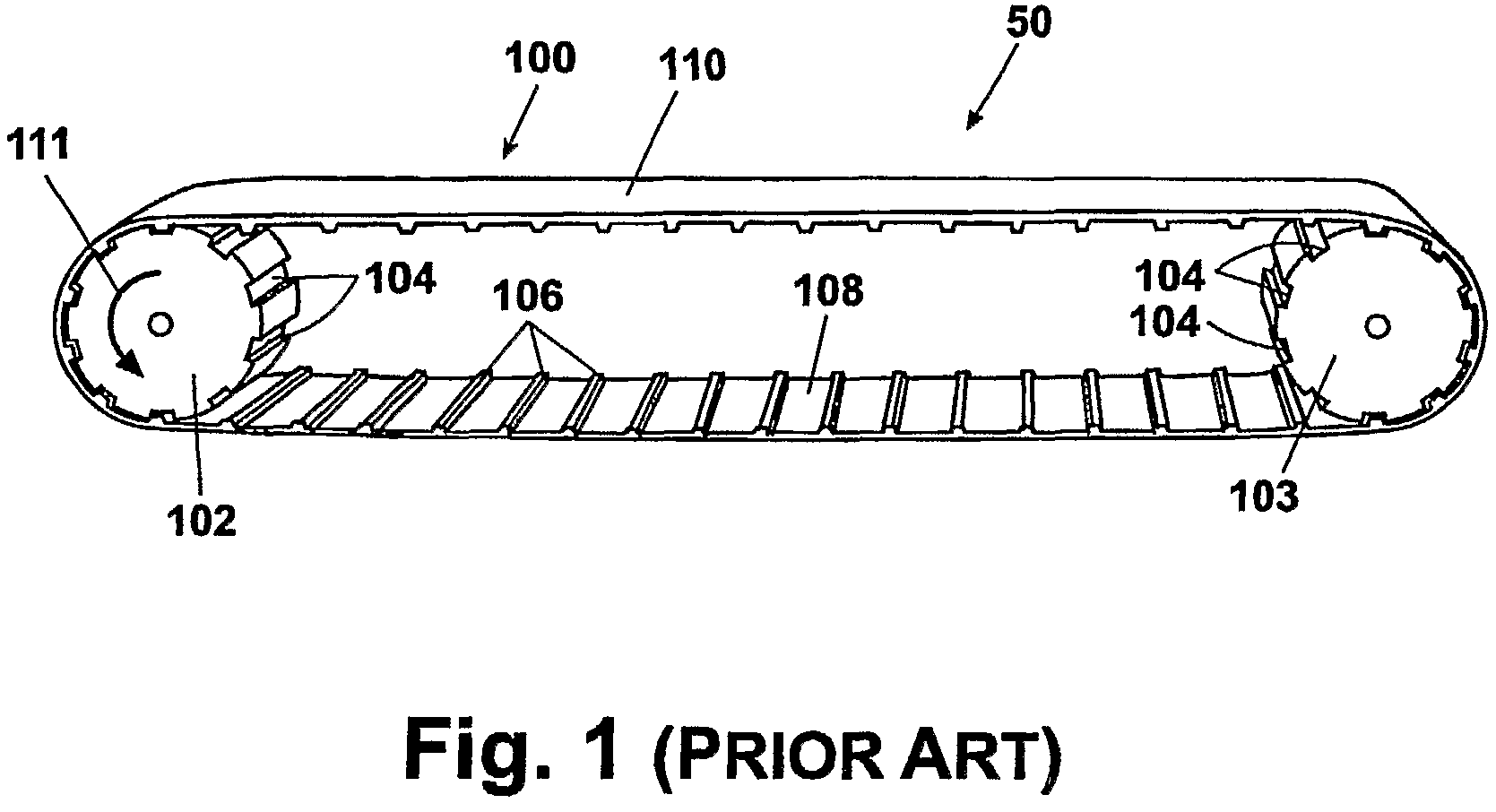

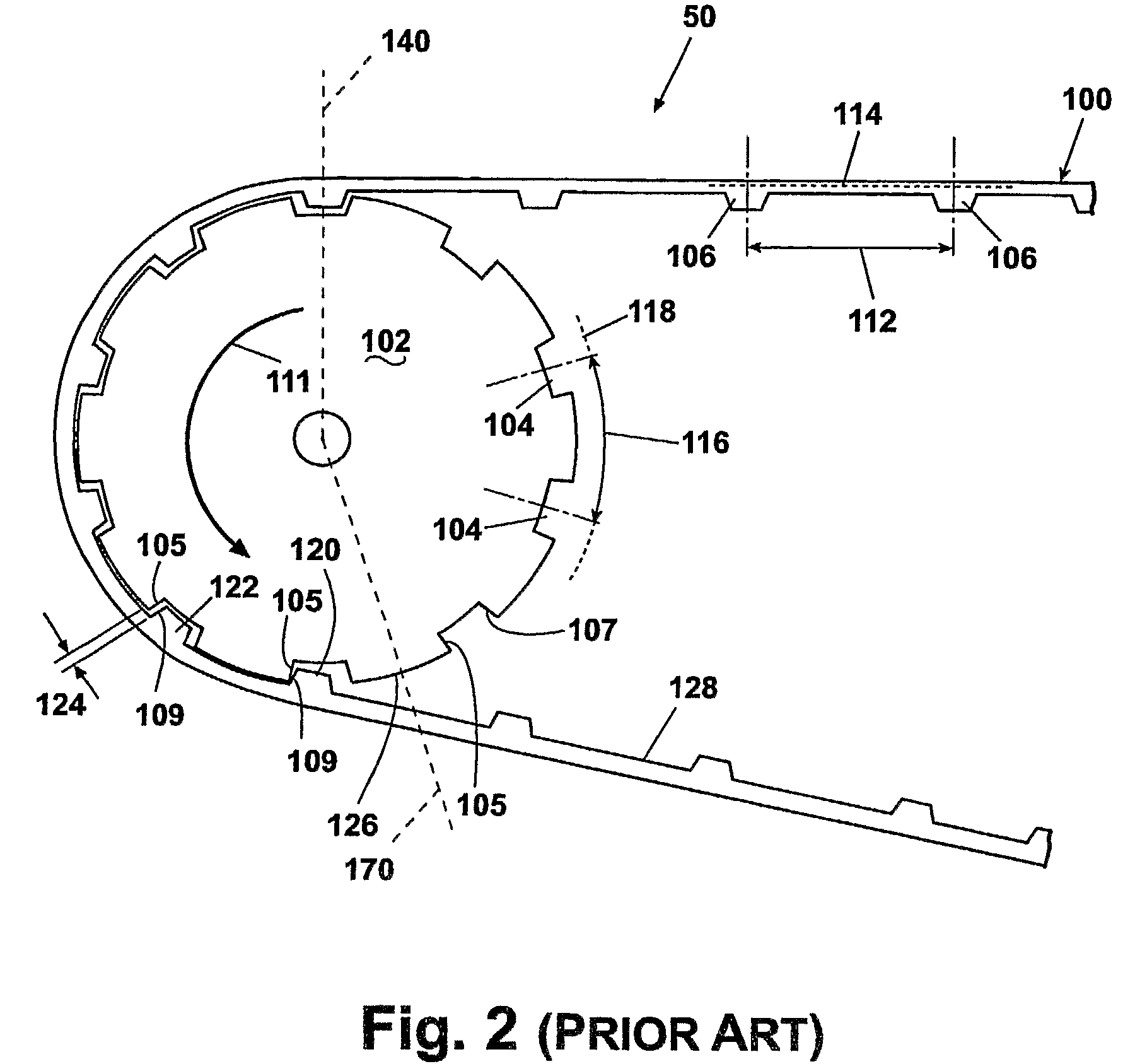

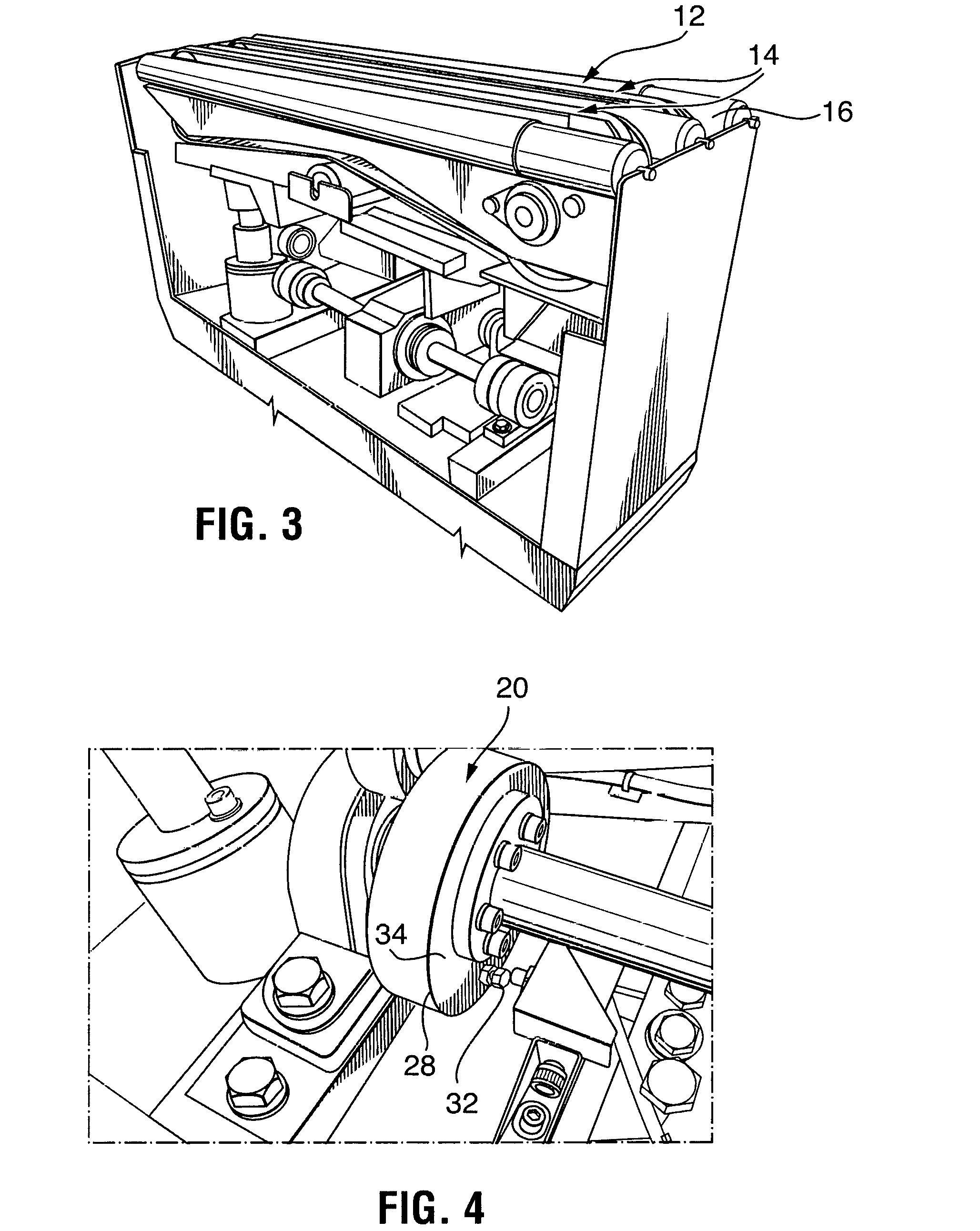

Low friction, direct drive conveyor belt

A thermoplastic endless belt (100) has a smooth outer surface substantially free of discontinuities and an inner surface with a plurality of teeth (106) at a given belt pitch. The teeth are adapted to engage a pulley (102) with circumferentially spaced sheaves (104) at a pulley pitch greater than the belt pitch. The belt is slightly stretchable so that the pulley can drive the endless belt when engaging the teeth within a range of load on the belt. Means (132, 136, 138) are provided to minimize friction between the belt and the drive pulley. Also, a position limiter (200) ensures that the driven tooth stays engaged optimally with the drive sheave.

Owner:LAITRAM LLC

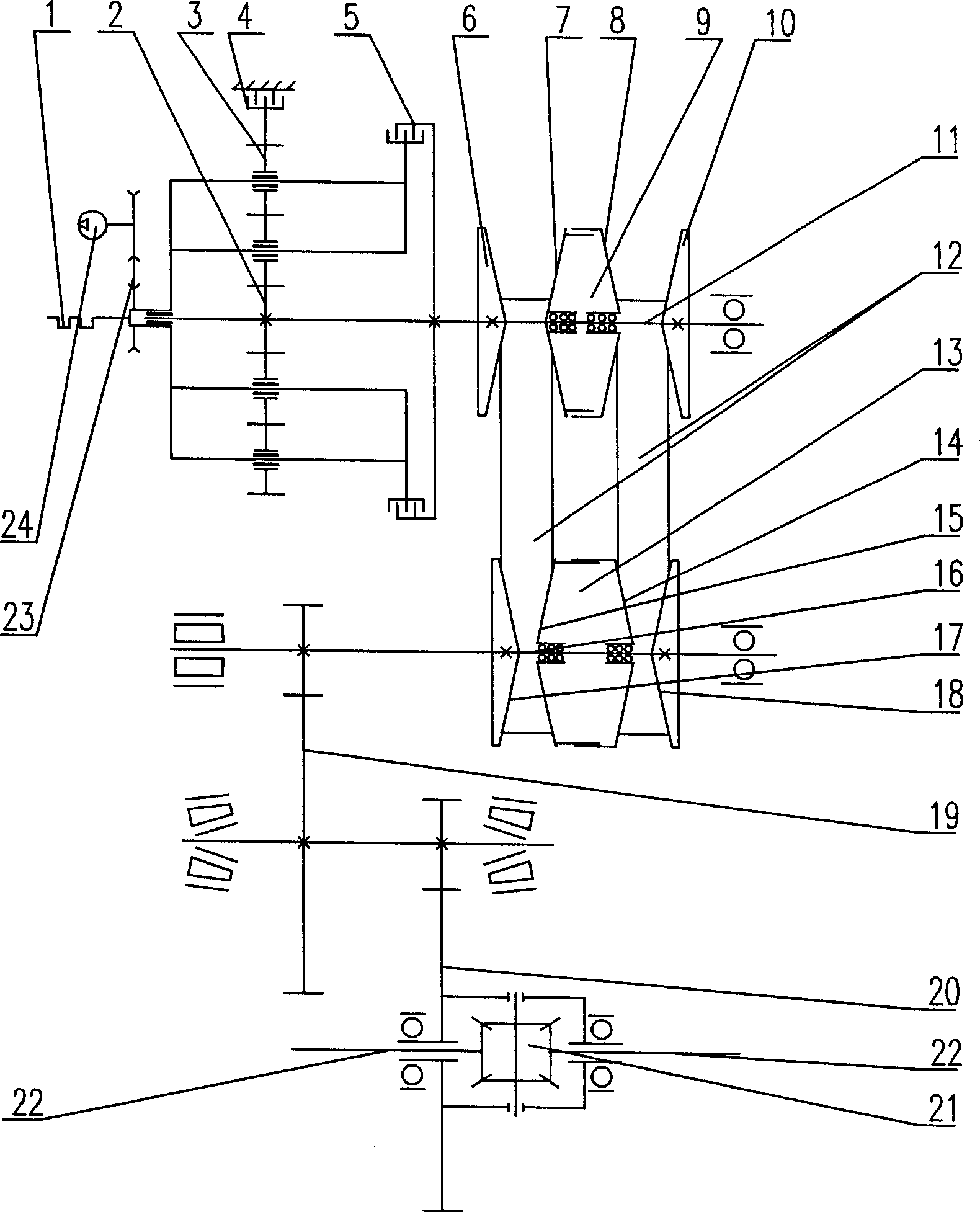

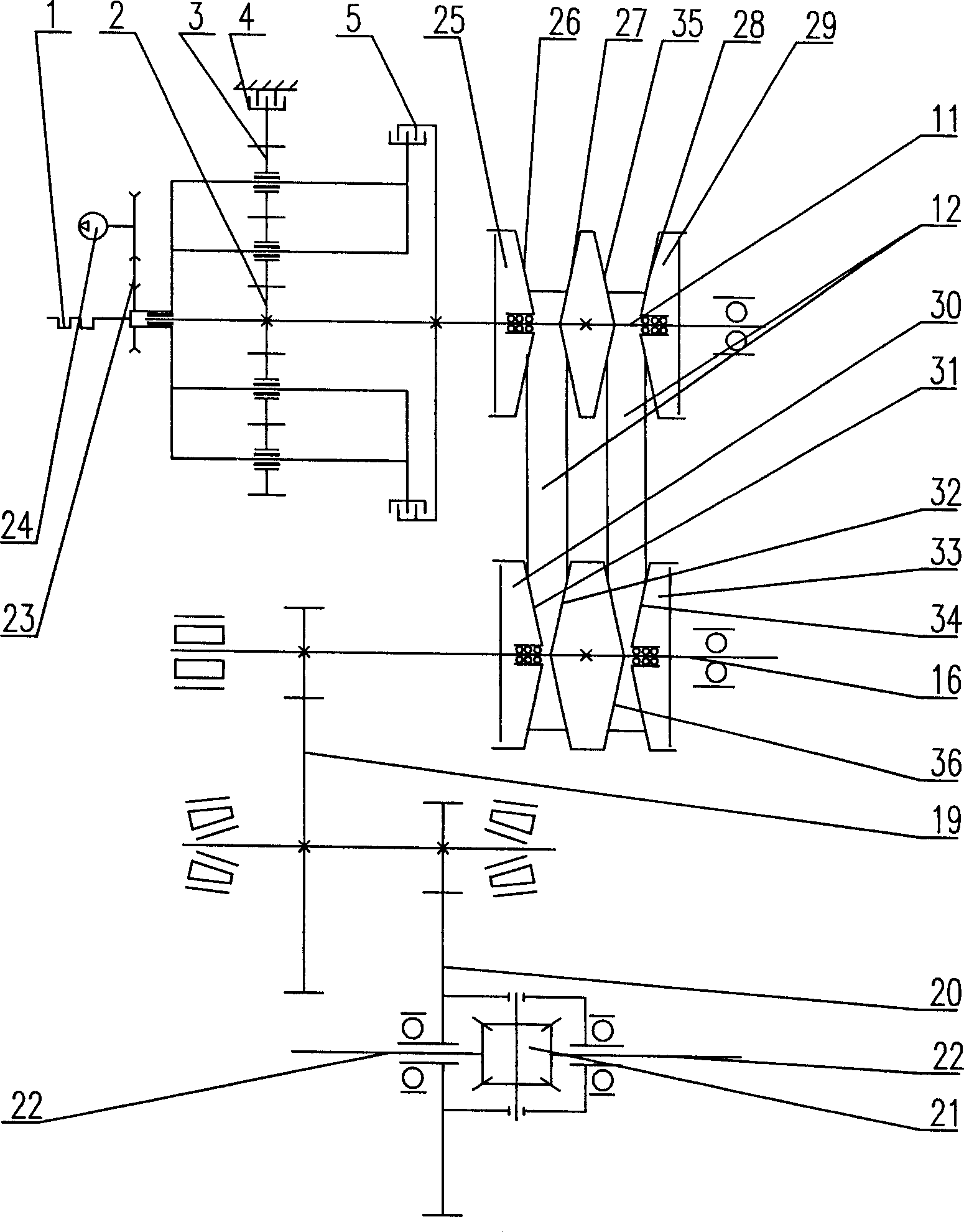

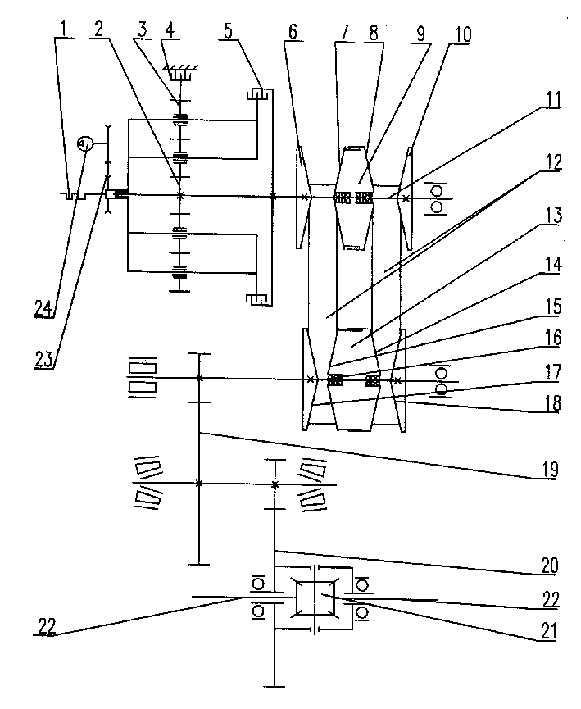

Multiple transmission pair stepless speed variation transmission device

The present invention provides a multiple transmission pair stepless variable drive, mainly including reverse brake and forward gear clutch which are set in the gear shifting box and driving cone disk portion, driven cone disk portion and transmission belt. Said invention is characterized by that the driving cone disk and driven cone disk portions are respectively formed from two or more than twofixed cone disks and several moving cone disks correspondent to them. The driving cone disk portion is coupled with main shaft of gear shifting box and the driven cone disk portion is coupled with driven shaft of gear shifting box, and they can be synchronously rotated with them, between driving cone disk portion and driven cone disk portion two or more than two parllelly arranged transmission belts are set and connected between them so as to form two grups or more than two groups of transmission pairs structure.

Owner:刘亚军

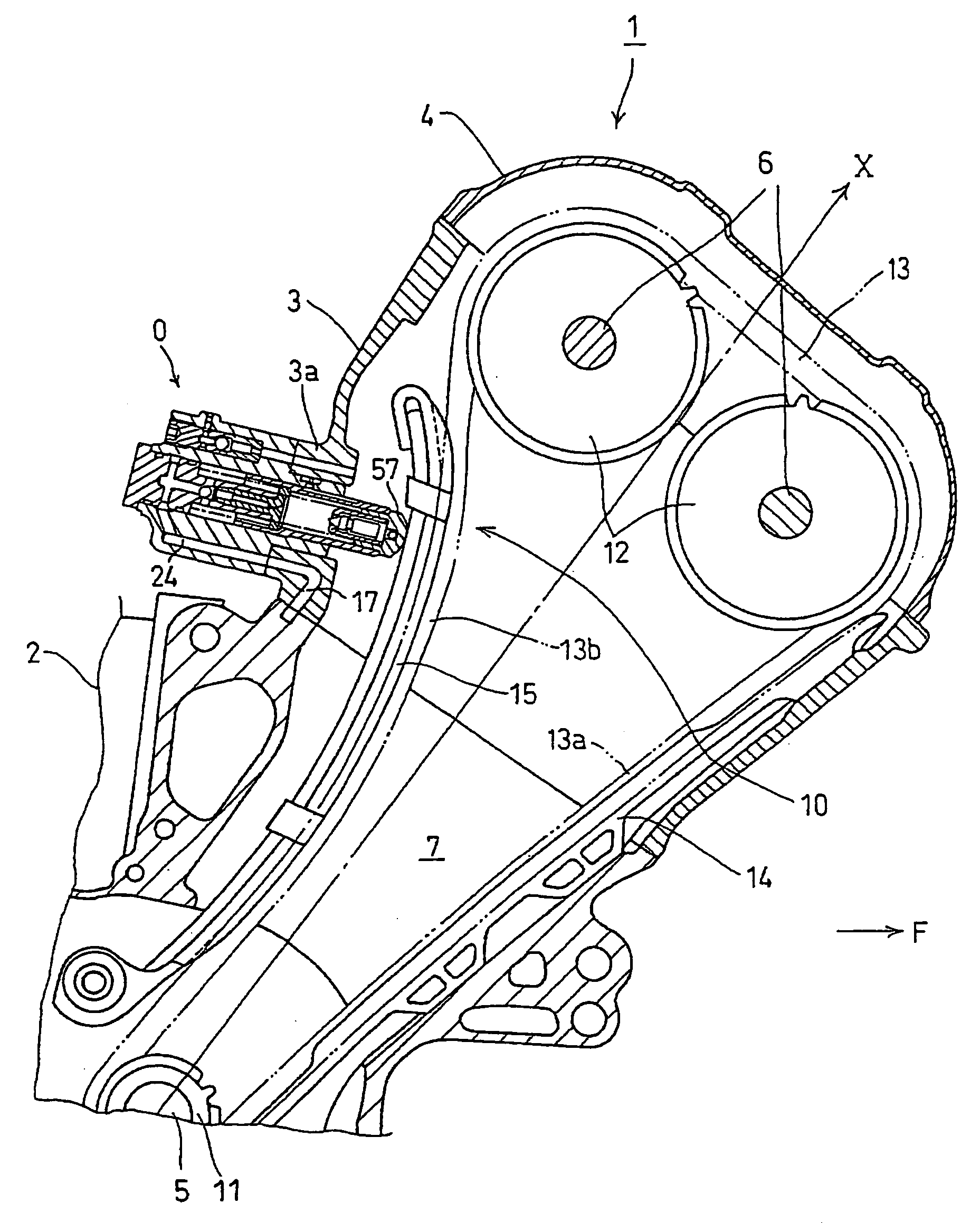

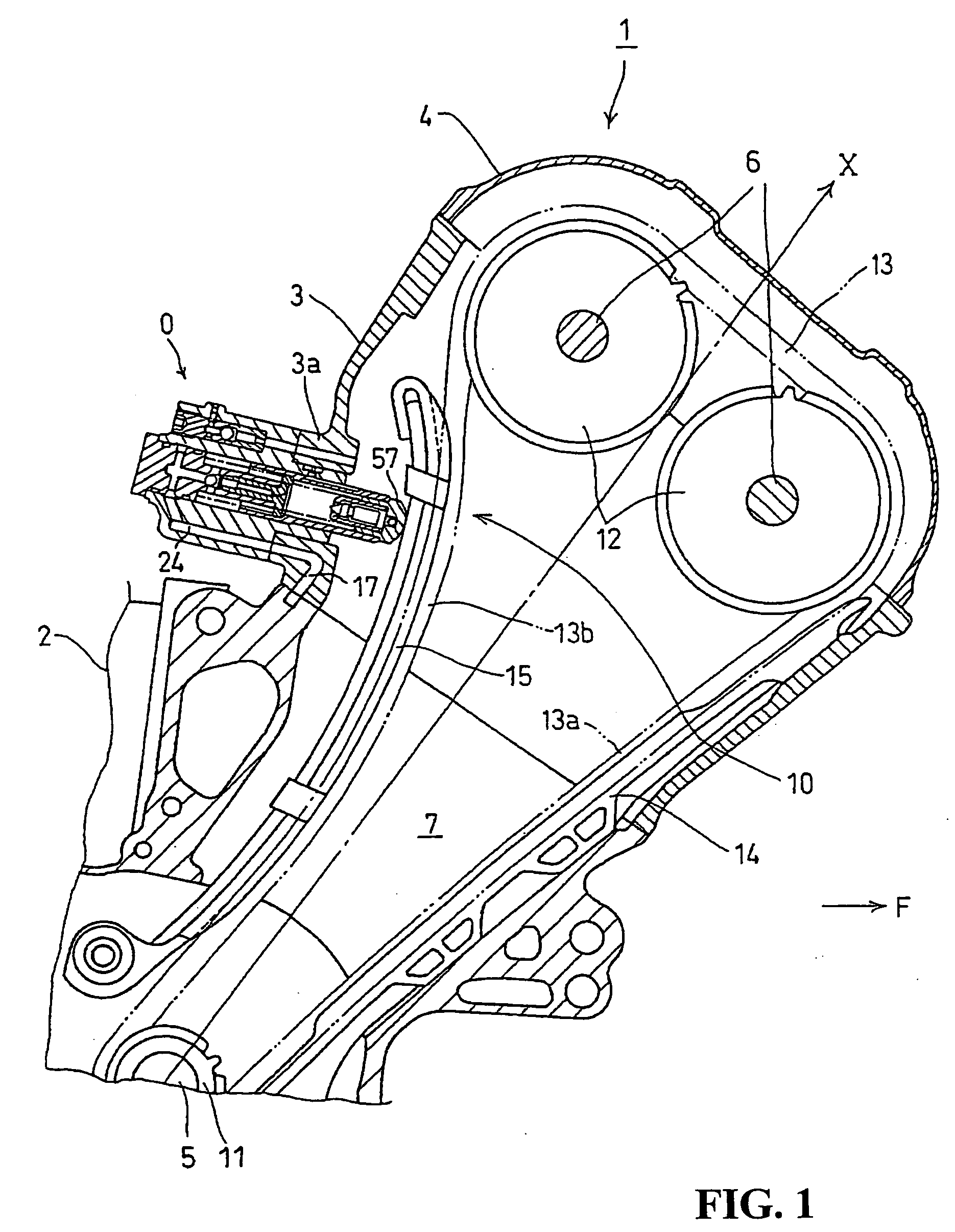

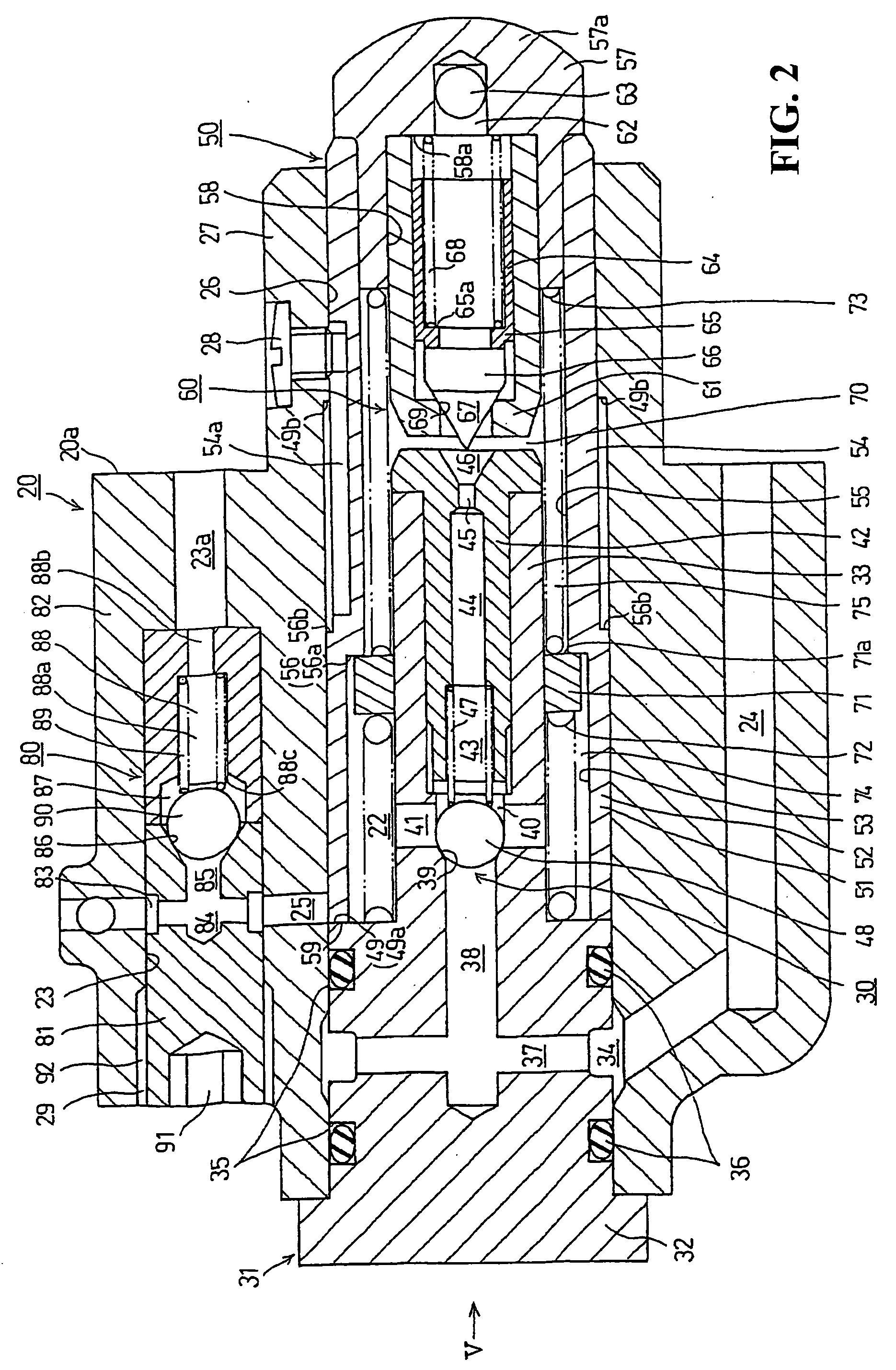

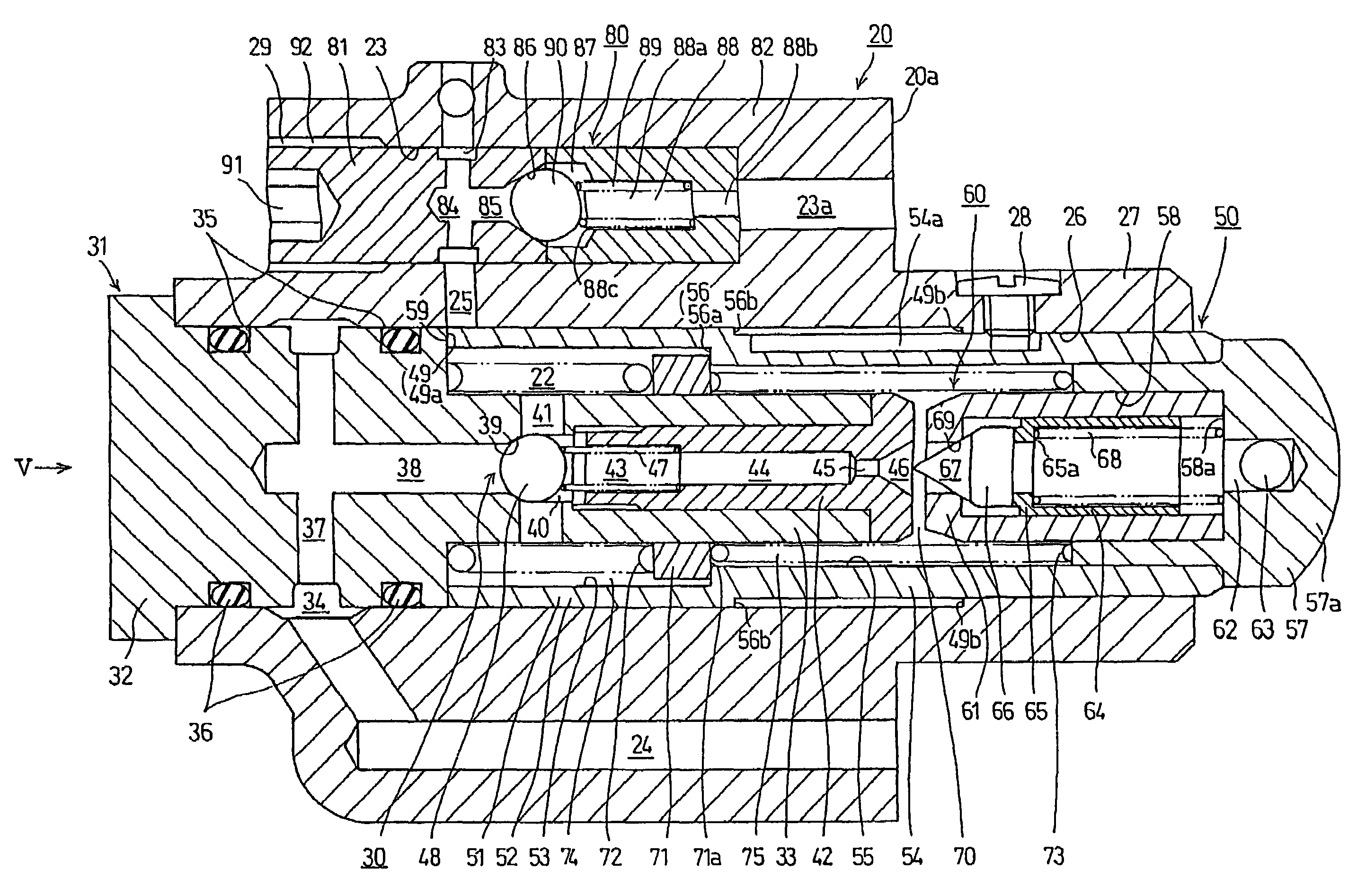

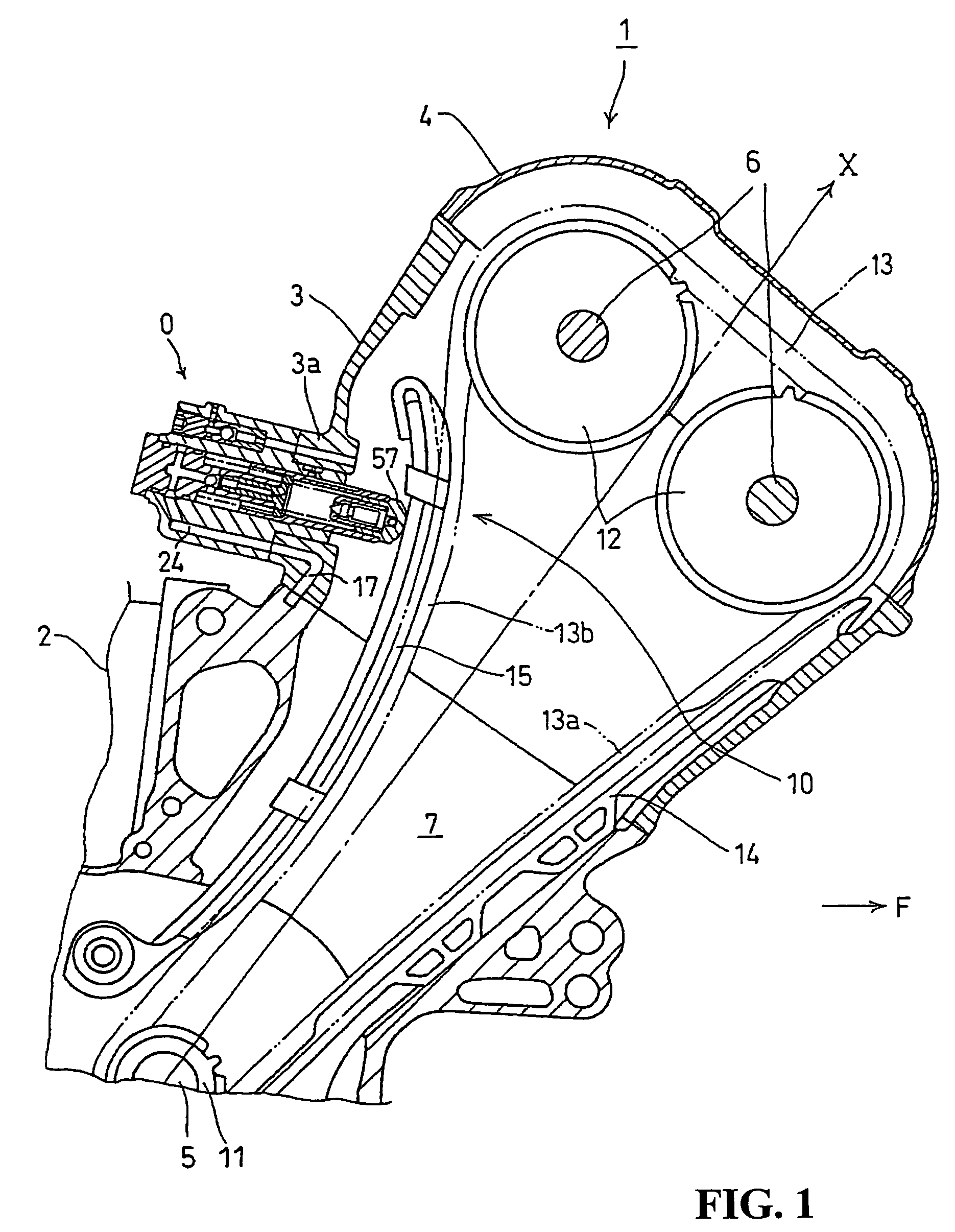

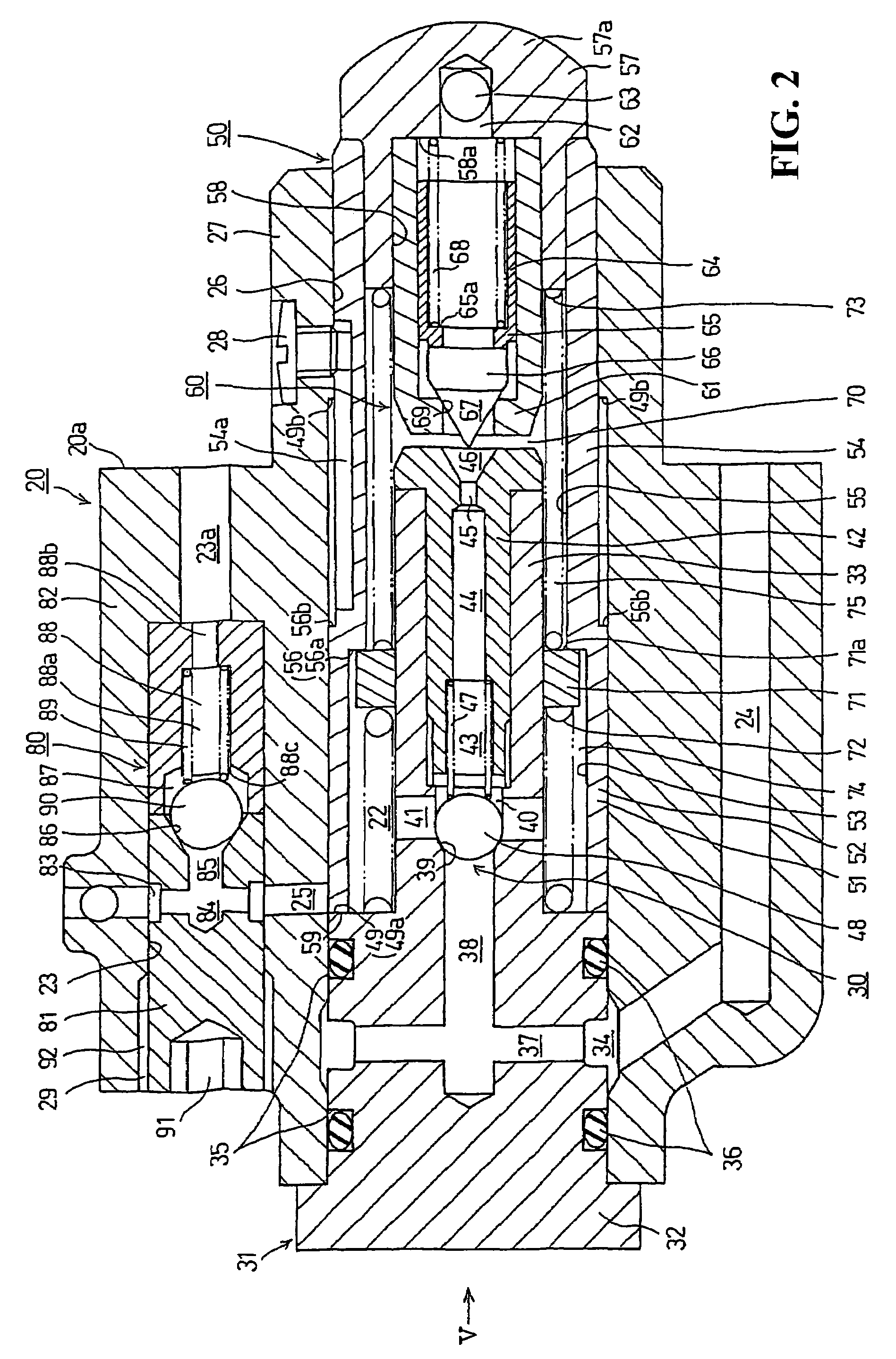

Hydraulic tensioner lifter

To provide an adequate biasing load to an endless transmission belt by biasing forces of a plurality of springs with different biasing forces and oil pressure biasing force to permit an easy adjustment. In a structure which includes an almost cylindrical plunger, a tensioner body into which the plunger is fitted, high pressure oil chambers are formed by the tensioner body and the plunger and supplied with oil pressure. Two tensioner springs, a rigid spring and a soft spring are supported by the tensioner body and are arranged in series for biasing the plunger. The plunger in its fully stretched state is supported by the serially arranged rigid and soft tensioner springs. In a condition when the plunger is pushed back from this fully stretched state by a prescribed amount or further, the plunger is supported by the rigid tensioner spring.

Owner:HONDA MOTOR CO LTD

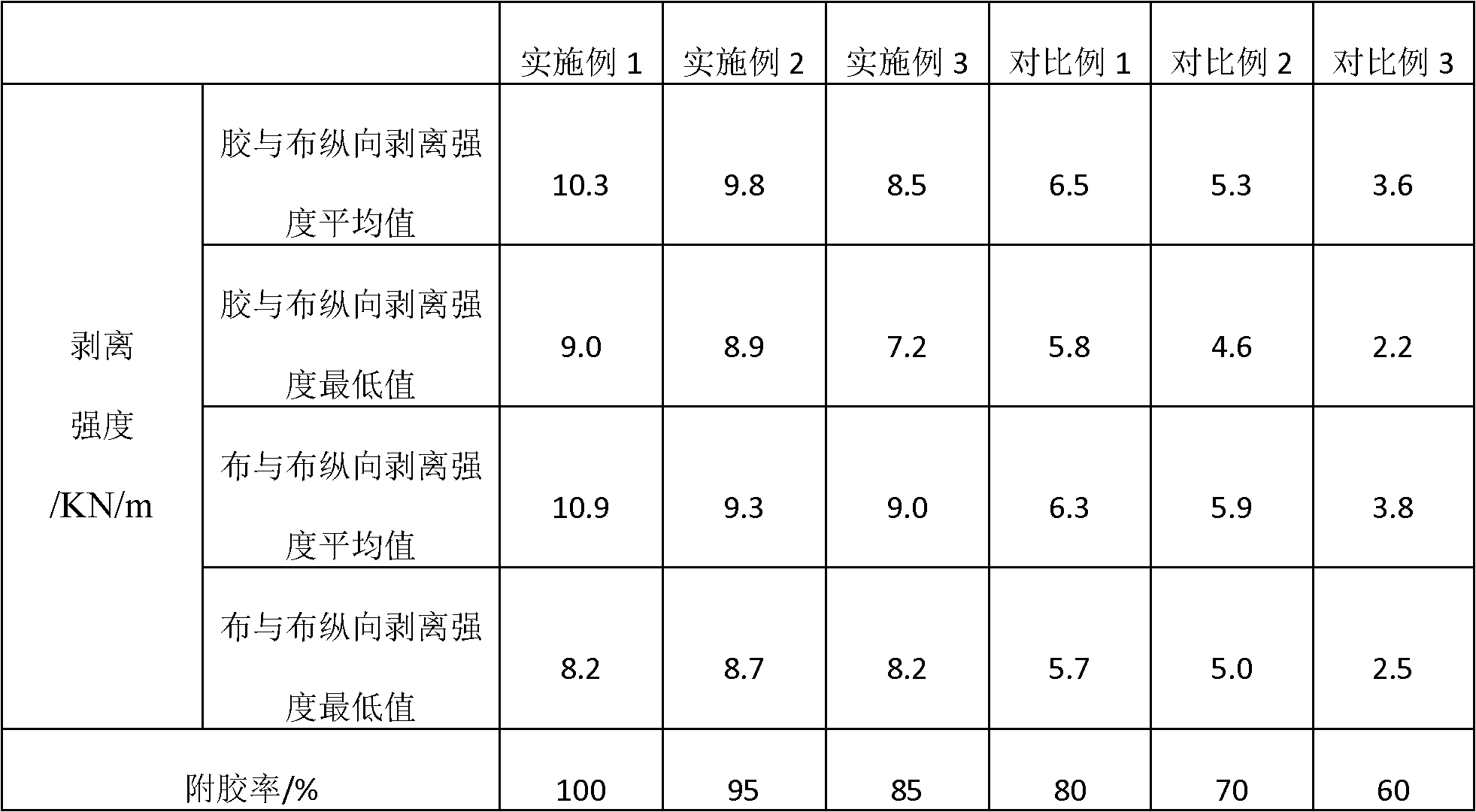

Method for pretreating fibers

The invention relates to a method for pretreating fibers, comprising the following steps of: performing surface activation on fibers by a dopamine hydrochloride biomimetic modification method, and then performing impregnation treatment on the fibers by using impregnation solution composed of rubber latex and phenolic resin, aiming to improve the interface adhesion property of the fibers with rubber so that the fibers are more suitable for tyres, conveyor belts, high-pressure rubber tubes and transmission belts. The method solves the experimental problem caused by high toxicity of isocyanate and avoids damage on the fibers caused by high-temperature treatment; and the process flow is simplified and the production cost is reduced.

Owner:BEIJING UNIV OF CHEM TECH

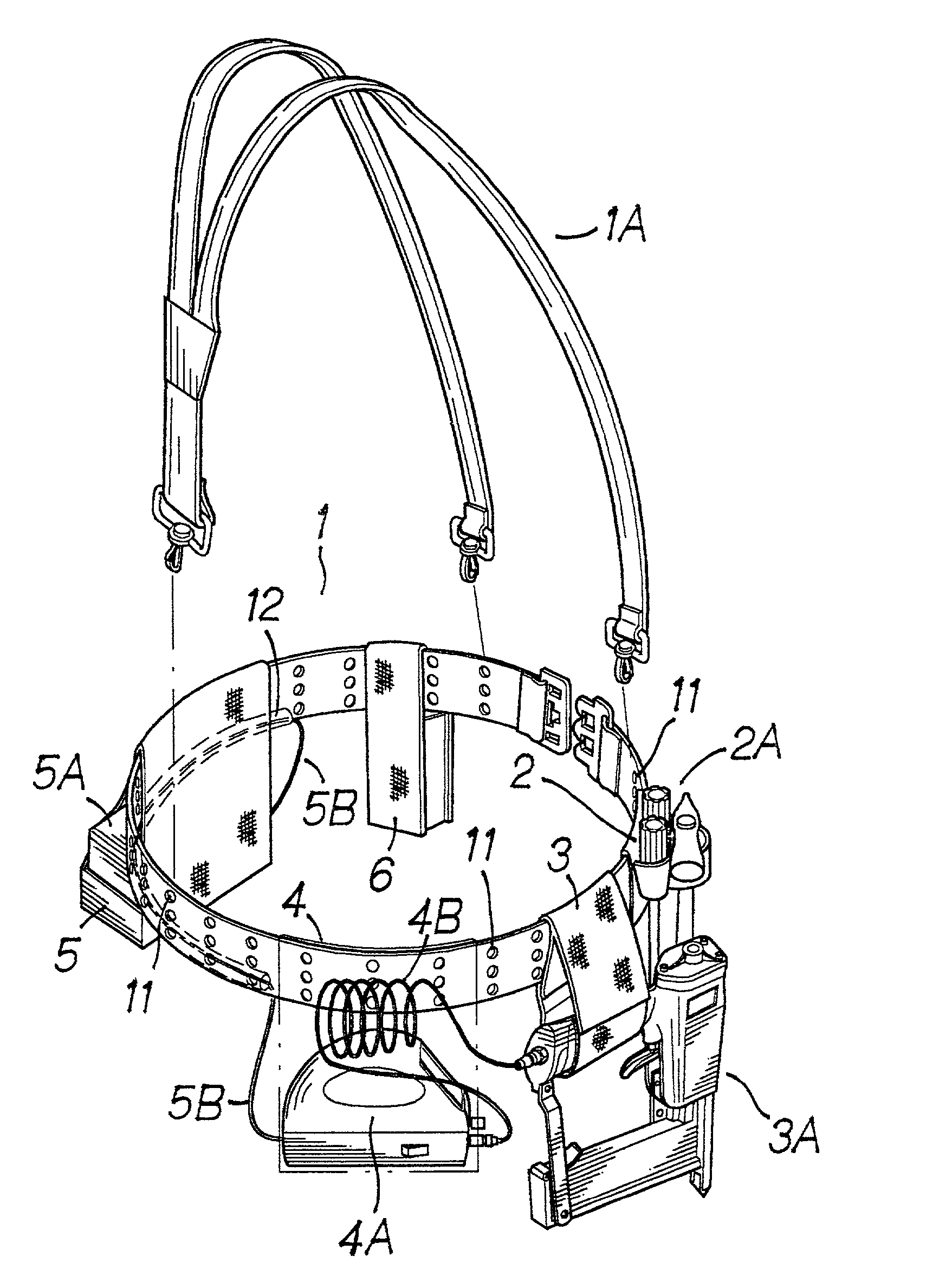

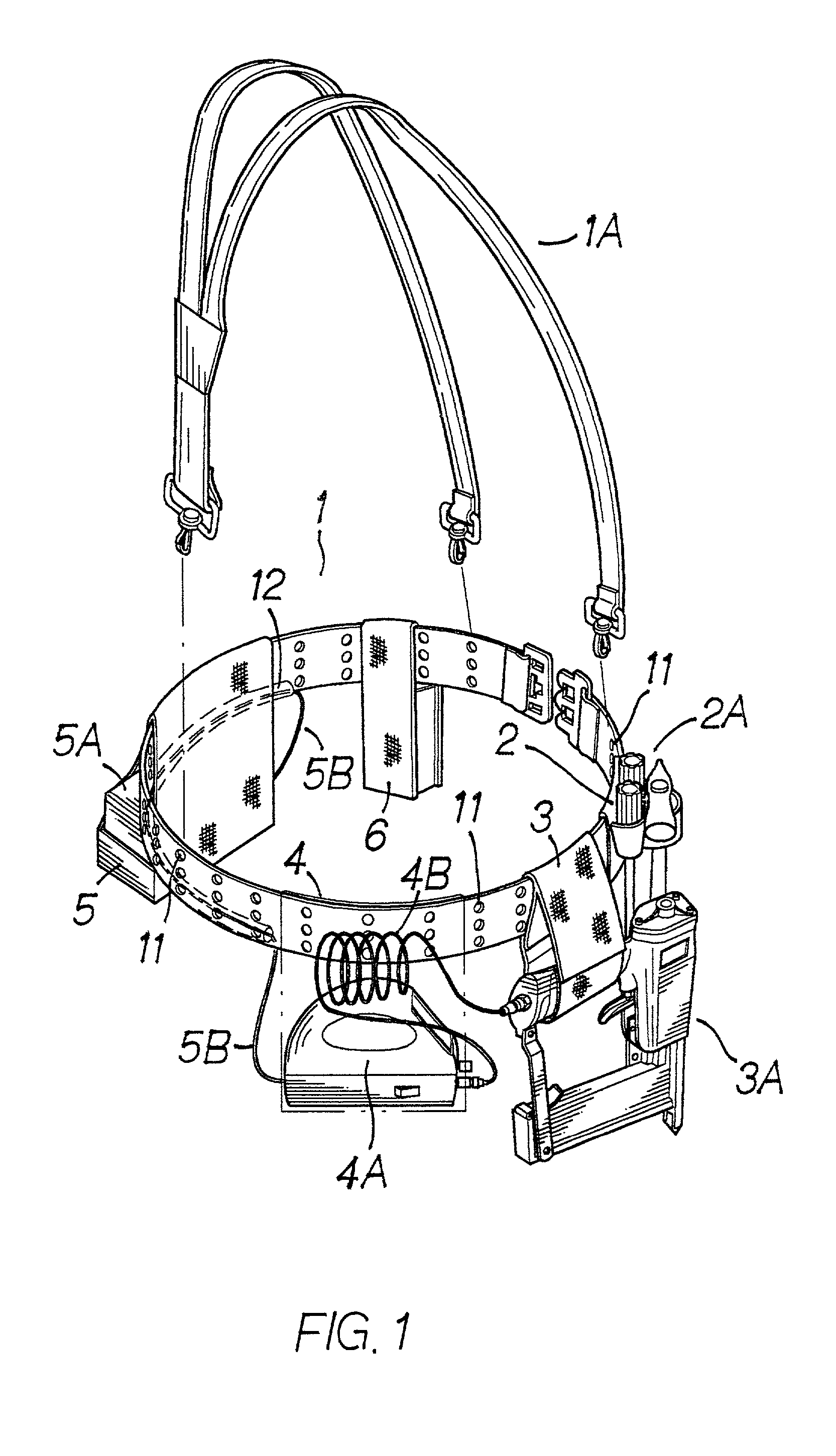

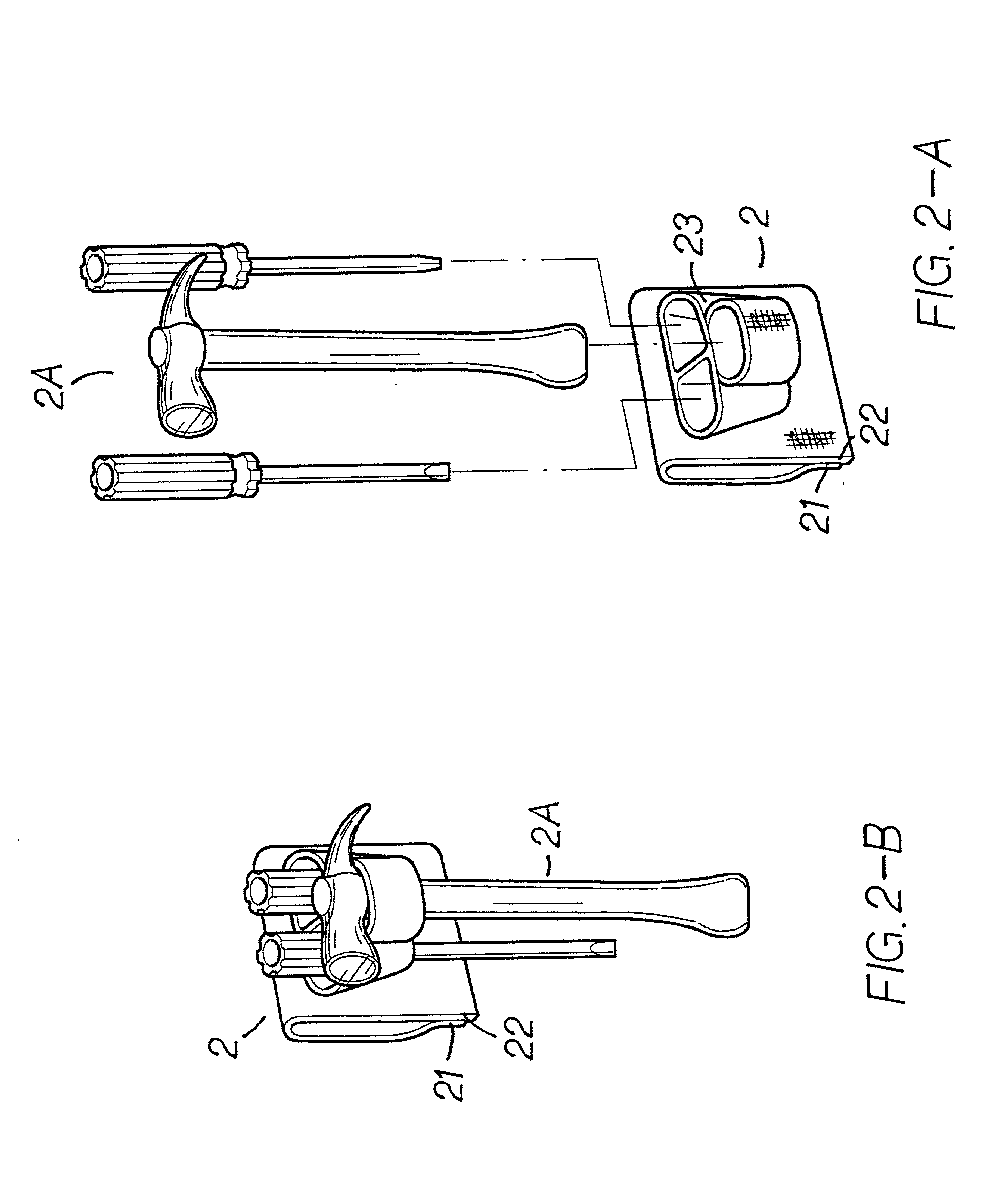

Pneumatic tool system operation and carrier belt

A pneumatic tool system operation and carrier belt comprised of a band worn around the waist of the user and from which is suspended a plurality of cinctures that respectively hold a set of hand tools, a pneumatic tool, a mini compressor, a small battery, and goggles, wherein the pneumatic tool, the mini compressor, and the small battery are interconnected. As such, the user goes to the work site only wearing the carrier belt holding the entire pneumatic tool system and operates the pneumatic tools directly from the belt because the power supply and compressed air source are built in, which improves upon the conventional need to connect a confusing array of equipment cables and hoses. Furthermore, the present invention does not hinder work and prevents accidental injury and other hazardous situations, and thereby provides a carrier belt that facilitates construction and manual dexterity.

Owner:VIVA ENTERPRISE

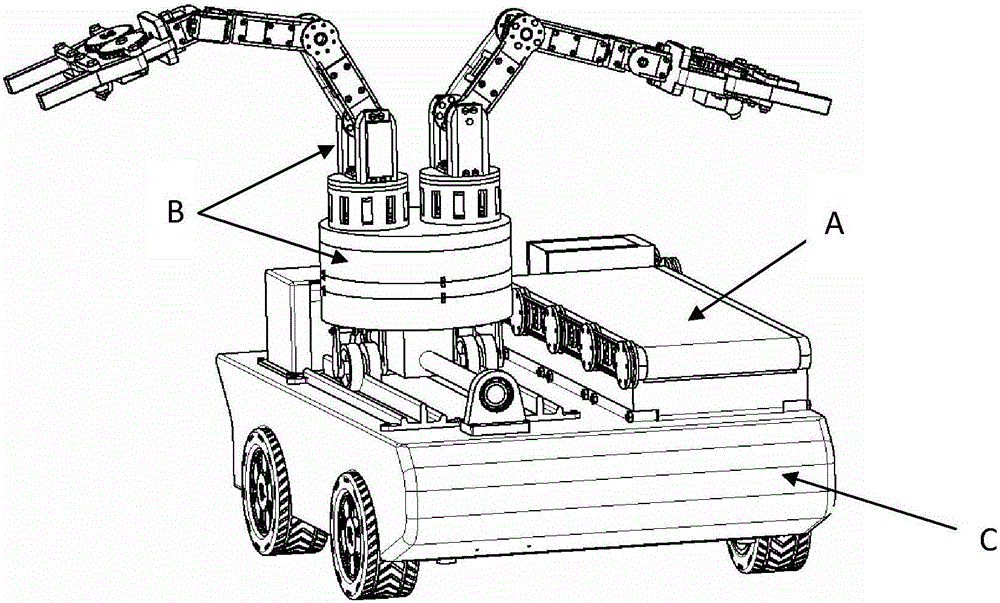

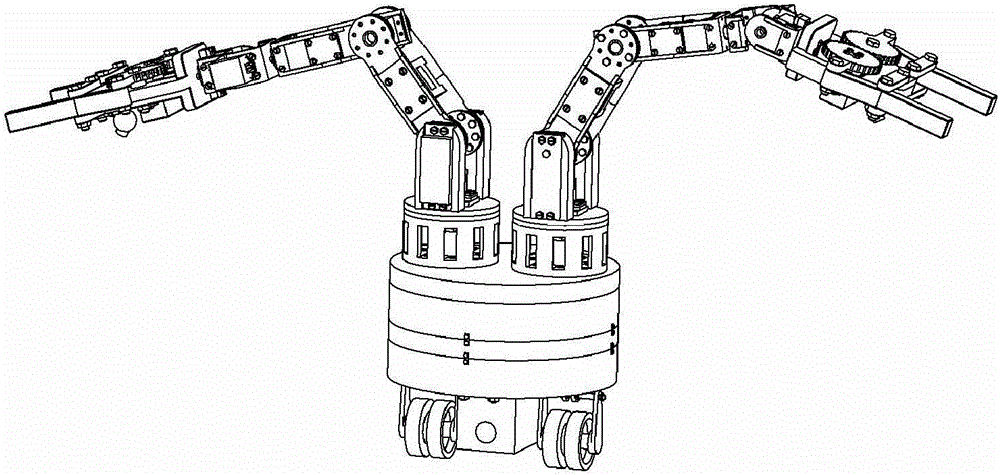

Double-arm loading and transferring robot

ActiveCN106112952AUninterrupted gripping of packagesImprove securityProgramme-controlled manipulatorCircular discTransmission belt

The invention discloses a double-arm loading and transferring robot and belongs to the field of robot structure design. Fast package loading during air transportation is achieved through the double-arm loading and transferring robot. The robot comprises a clamping module composed of mechanical arms, a disc mechanism and a guide rail mechanism, a conveying belt module used for transferring, a chassis module capable of making the robot move freely, and a sorting module located at the transferring terminal point. During transferring, a double-arm rotary structure is adopted by the robot, the two mechanical arms are fixed to a rotatable disc, the included angle between the two mechanical arms is 180 degrees, after a package is clamped by one mechanical arm, 180-degree fixed-angle rotation of the rotatable disc is achieved through the cooperation of a clutch and an incomplete gear mechanism in the disc, the package is placed onto a small conveying belt, the other mechanical arm starts clamping simultaneously, and in this way, the double mechanical arms can conduct clamping and placing alternately so that the packages can be clamped continuously. Meanwhile, the clamped packages are transferred through the conveying belt, and the efficiency is improved. After the packages reach a transfer location, the conveying belt can be in lap joint with an airport large conveying belt by adjusting the angle and heights, and the packages are separated from a sorting device and moved to a cabin.

Owner:BEIJING UNIV OF TECH

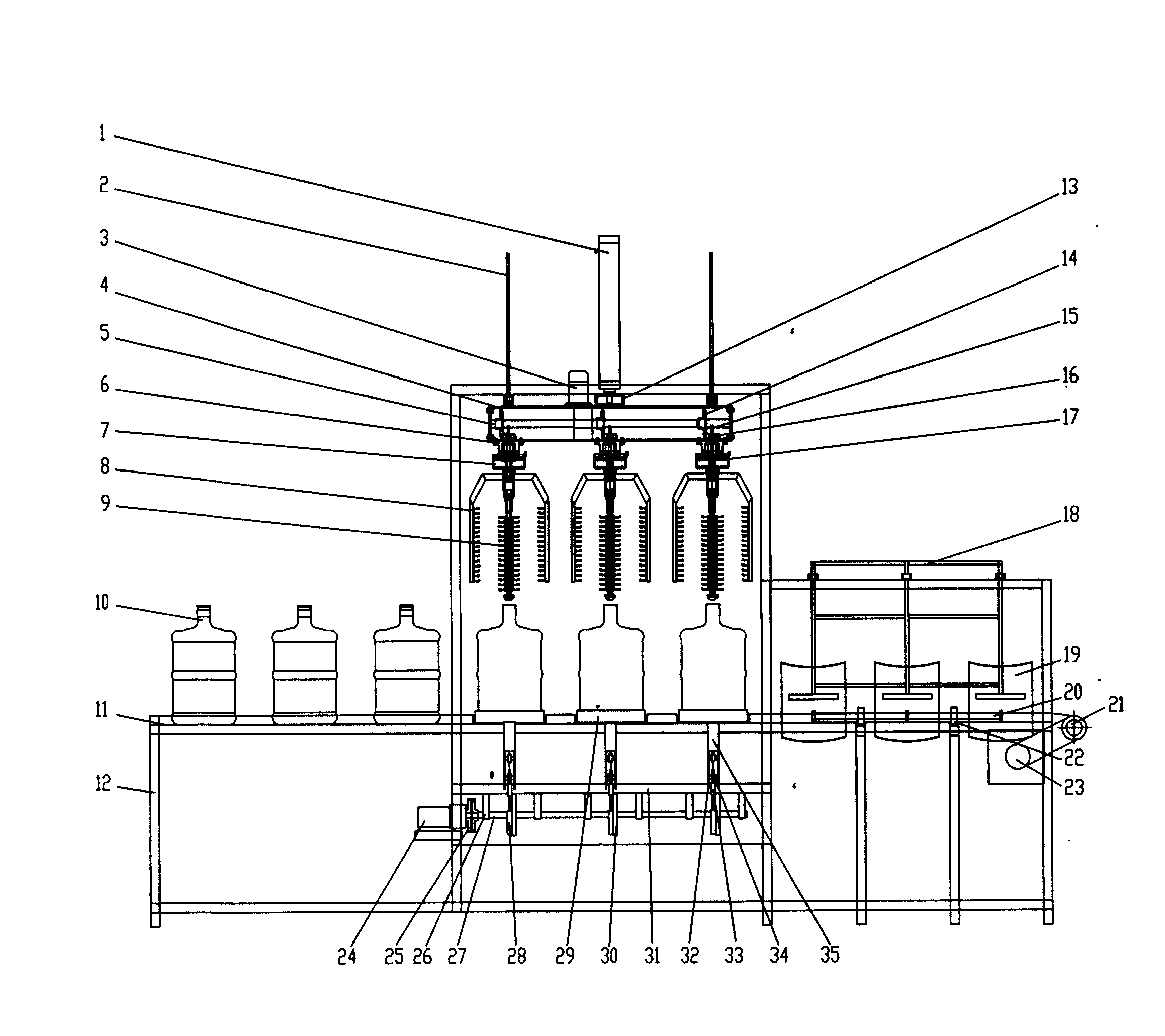

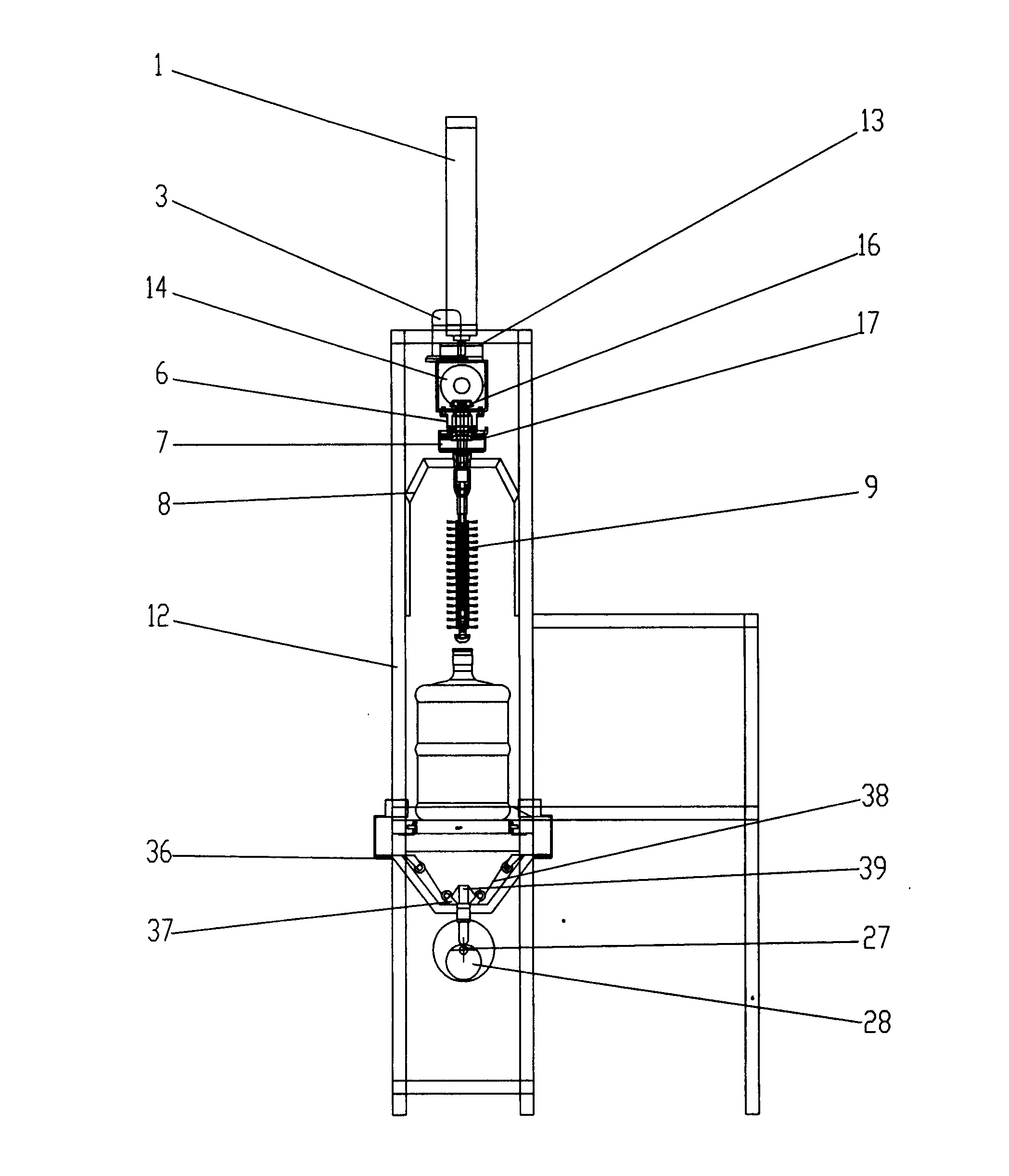

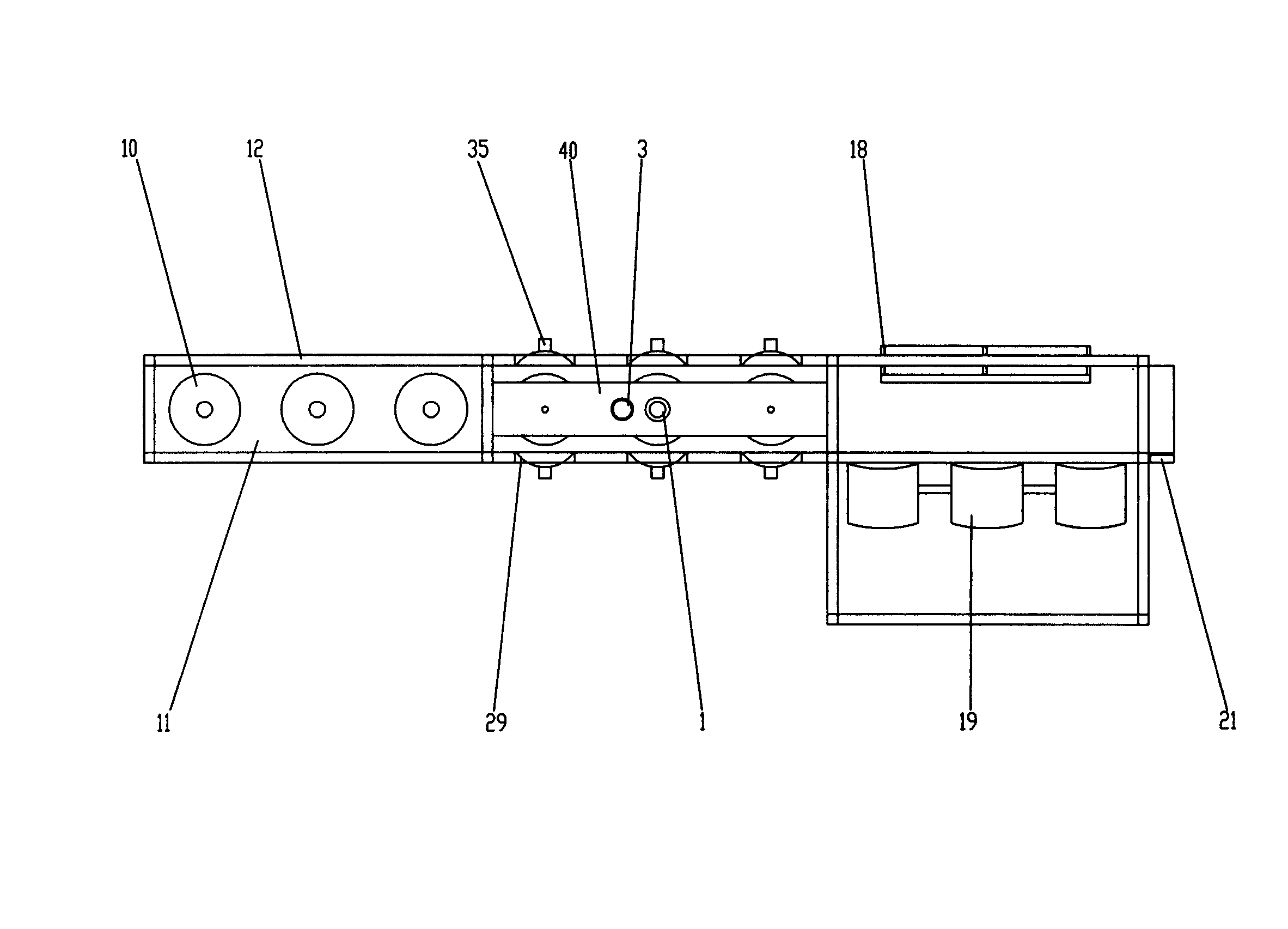

Automatic cleaning machine of water bucket

InactiveCN102553872ARealize cleaning integration operationAdvanced technologyHollow article cleaningTransmission beltClutch

The invention provides an automatic cleaning machine of a water bucket, relates to automatic cleaning equipment of a pure water bucket, and in particular relates to the automatic cleaning machine of the water bucket which can wash inside and outside simultaneously, aiming to solve the problems that the recycled water buckets cannot be washed from inside to outside by all national manufacturers of bucketed pure water in the existing background technology, particularly, bacteria are easy to breed in the water bucket at a high temperature in summer and the water bucket is polluted, and blots in the bucket are difficult to clean and the bucket only can be cleaned by manually binding a piece of cloth on an iron rod. The technical scheme for solving the technical problems is as follows: the automatic cleaning machine of the water bucket mainly comprises an air cylinder, a motor, a transmission box, a clutch cover, a transmission belt, a frame body, a positioning bracket, a fixed bracket, a bucket tray, a positioning eccentric shaft, an inner hairbrush, an outer hairbrush and the like. The inside and outside of the water bucket are completely cleaned by the cleaning machine and no blind angles exist; and the automatic cleaning machine of the water bucket can be matched with other disinfection equipment and the integral work of washing the inside and outside of the water bucket can be realized according to the washing quantity needing to be allocated.

Owner:宋树建

Hydraulic tensioner lifter

To provide an adequate biasing load to an endless transmission belt by biasing forces of a plurality of springs with different biasing forces and oil pressure biasing force to permit an easy adjustment. In a structure which includes an almost cylindrical plunger, a tensioner body into which the plunger is fitted, high pressure oil chambers are formed by the tensioner body and the plunger and supplied with oil pressure. Two tensioner springs, a rigid spring and a soft spring are supported by the tensioner body and are arranged in series for biasing the plunger. The plunger in its fully stretched state is supported by the serially arranged rigid and soft tensioner springs. In a condition when the plunger is pushed back from this fully stretched state by a prescribed amount or further, the plunger is supported by the rigid tensioner spring.

Owner:HONDA MOTOR CO LTD

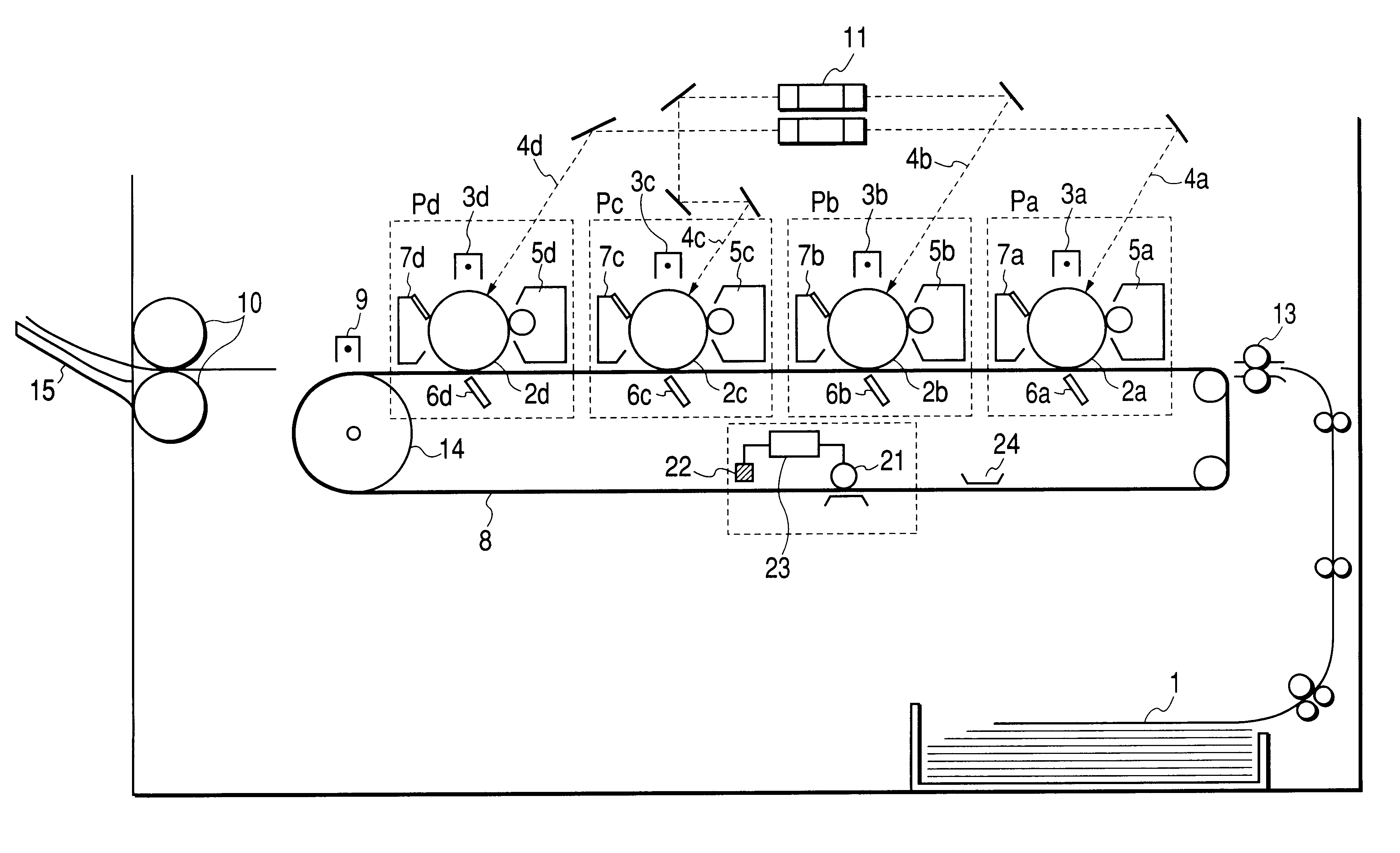

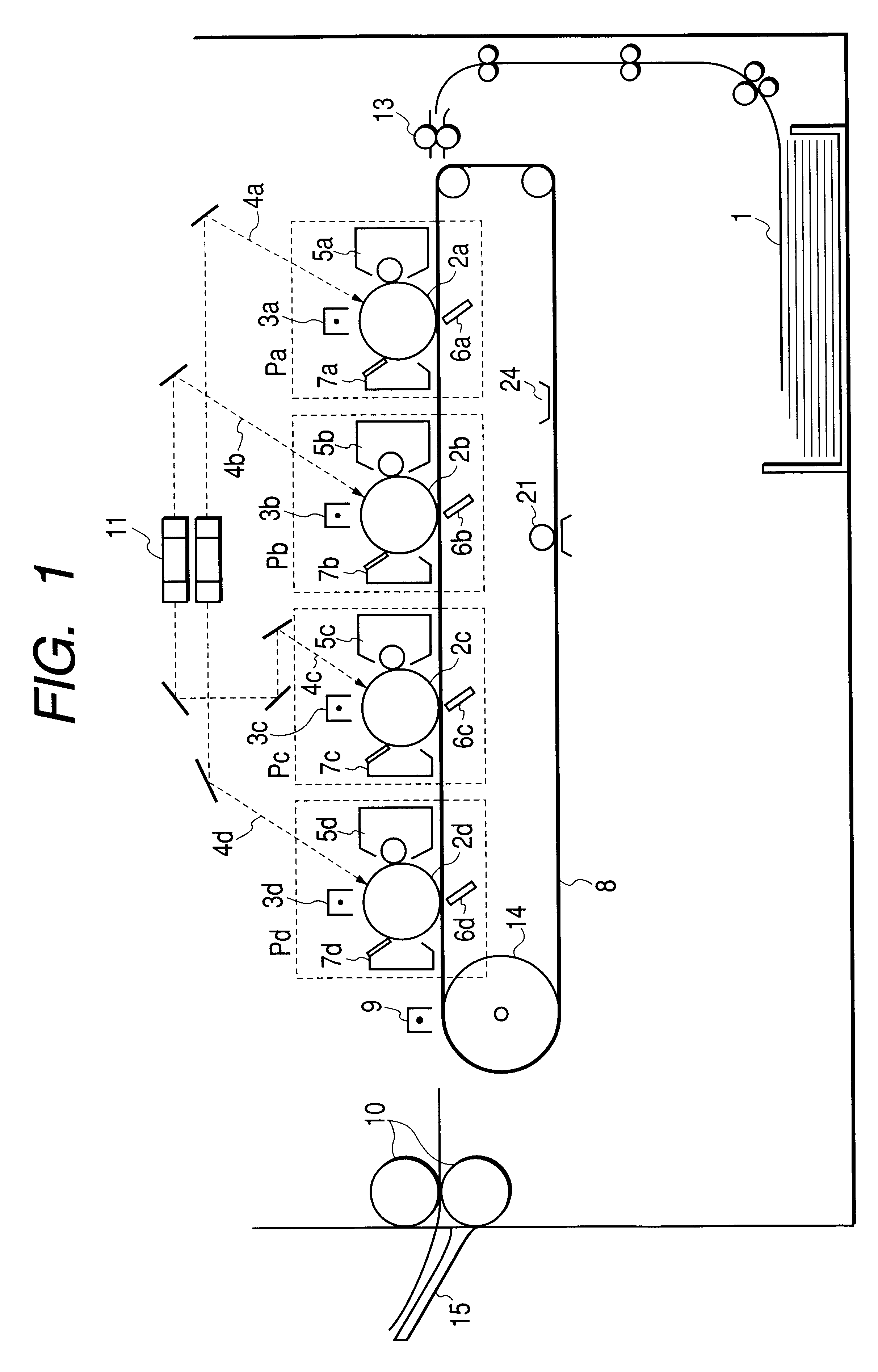

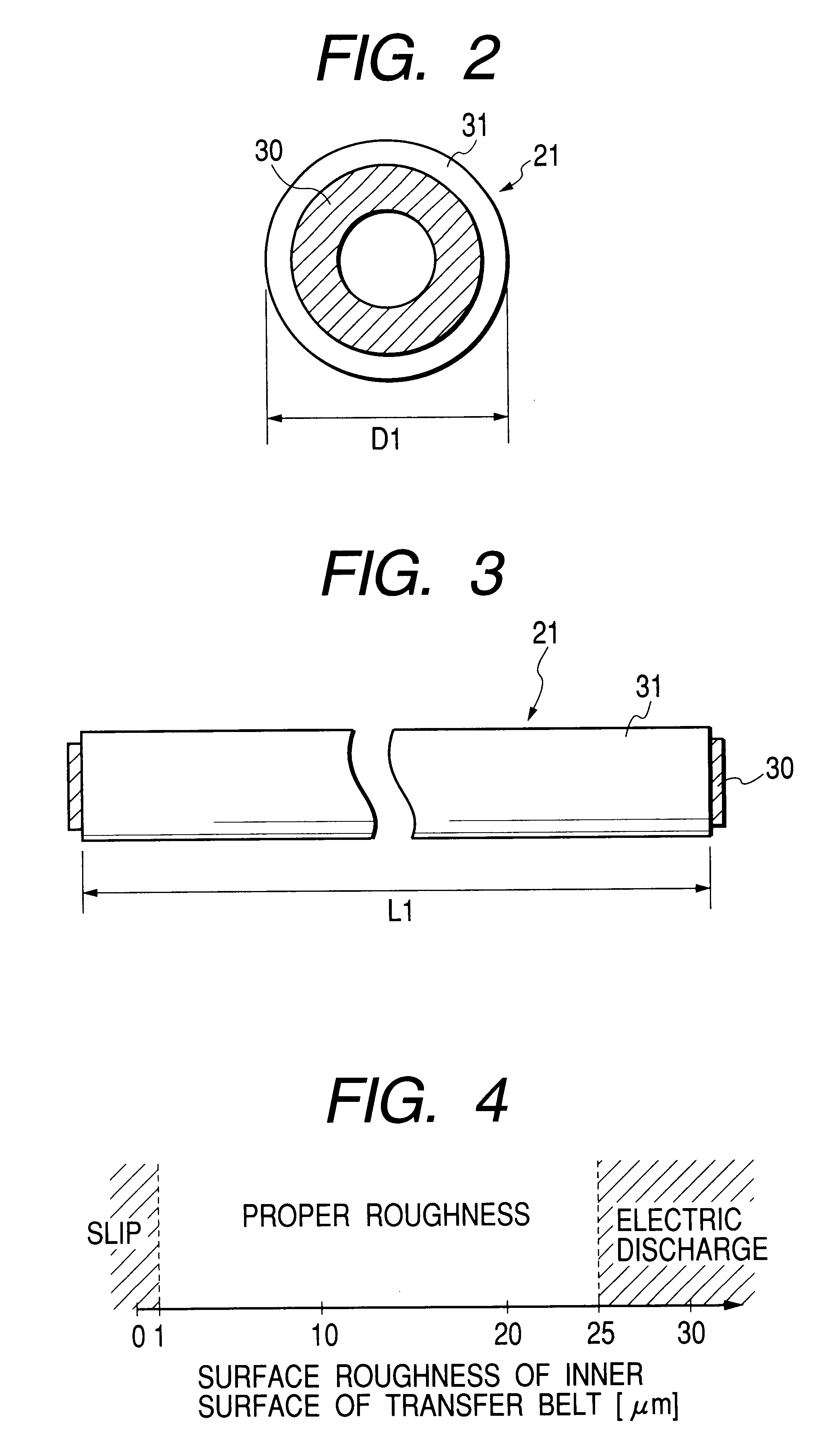

Image forming apparatus

In an image forming apparatus wherein the slip of a transporting belt relative to a driving device due to a change in the surface state the inner surface of the transporting belt and a bad image can be reliably prevented, and having a photosensitive drum on the surface of which a toner image is formed, a transfer belt and a driving roller for driving the transfer belt, wherein the toner image formed on the surface of the photosensitive drum is transferred onto the transfer belt or a recording material borne on the transfer belt, an abrasive roller is provided at a position, in contact with a surface on which the driving roller abuts against the transfer belt.

Owner:CANON KK

Double-shaft needling machine

The invention discloses a double-shaft needling machine, belonging to the technical field of non-woven textile machinery. The machine comprises a rack, a power transmission mechanism, a main shaft, an auxiliary shaft and an auxiliary shaft transition transmission mechanism. The machine is characterized in that the auxiliary shaft transition transmission mechanism comprises a first belt wheel, a second belt wheel, a transition belt wheel, a tension belt wheel and a transmission belt, wherein the first belt wheel is fixed at the other end part of the main shaft; the second belt wheel is fixed on the auxiliary shaft and corresponds to the first belt wheel; the transition belt wheel and the tension belt wheel are arranged on the rack; the transmission belt is sleeved on the first and second belt wheels, the transition belt wheel and the tension belt wheel; and the transition belt wheel, the tension belt wheel and the first belt wheel are in a triangular positional relation. The double-shaft needling machine disclosed by the invention has the advantages of avoiding noise, reducing the manufacturing and mounting difficulty, being beneficial to maintaining and replacing a bearing, shortening the shutdown time, ensuring the operation efficiency, saving resources and lowering the cost.

Owner:常熟市伟成非织造成套设备有限公司

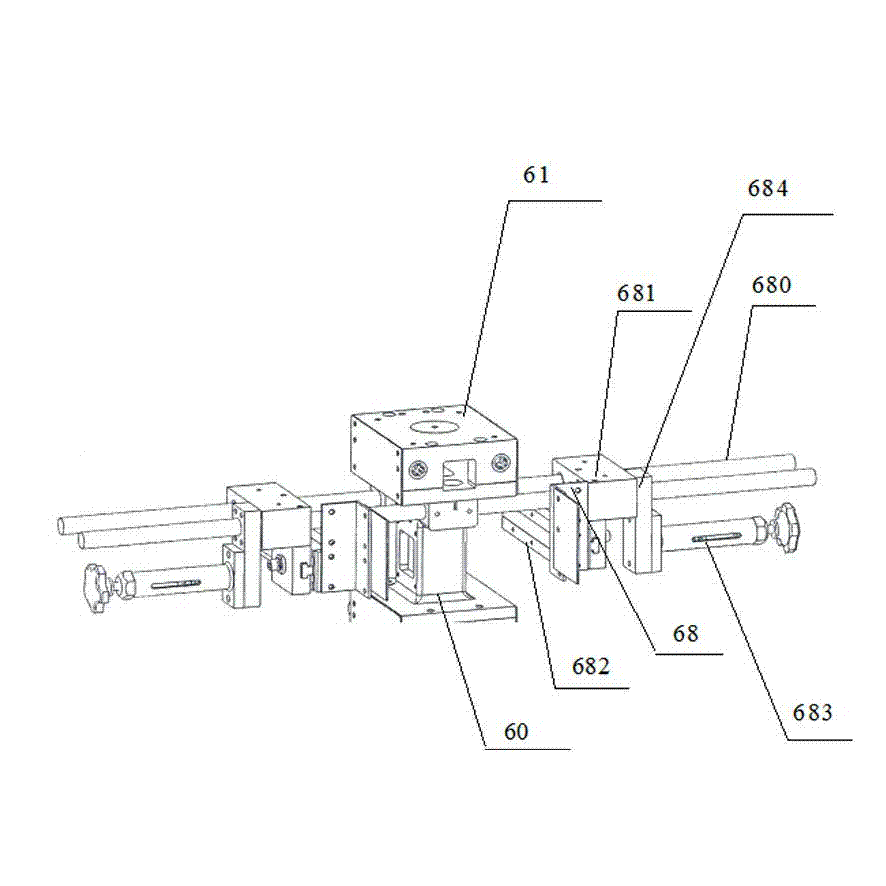

Extruding granulation device for feed processing

InactiveCN107397052AImprove the efficiency of processing and granulationMix and stirWorking-up animal fodderDrive shaftTransmission belt

The invention discloses an extrusion granulation device for feed processing, which comprises a granulation box, a drive motor is arranged on the top of the granulation box, a transmission shaft is connected to the output shaft of the drive motor, and a coaxial fixed installation is installed on the transmission shaft. The driving pulley and the turntable, the connecting rod is hinged at the side edge of the turntable; the driven pulley is rotated on the granulation box, and the driving belt is wound between the driven pulley and the driving pulley, and the driven pulley is the same The shaft is fixedly installed with a driving bevel gear; the surface of the rotating shaft is provided with a helical blade; the extrusion die is installed horizontally in the granulation box, the horizontal limit sleeve is horizontally installed on the inner wall of the right side of the granulation box, and the left end of the slider is connected with a Several cutting blades are arranged parallel to each other, and the baffle is in contact with the disc cam; the slider drives the cutting blades to cut the feed extruded from the extrusion die, making the feed more refined and uniform, and effectively avoiding feed blockage The extrusion die head greatly improves the efficiency of feed processing and granulation.

Owner:南宁众创空间科技有限公司

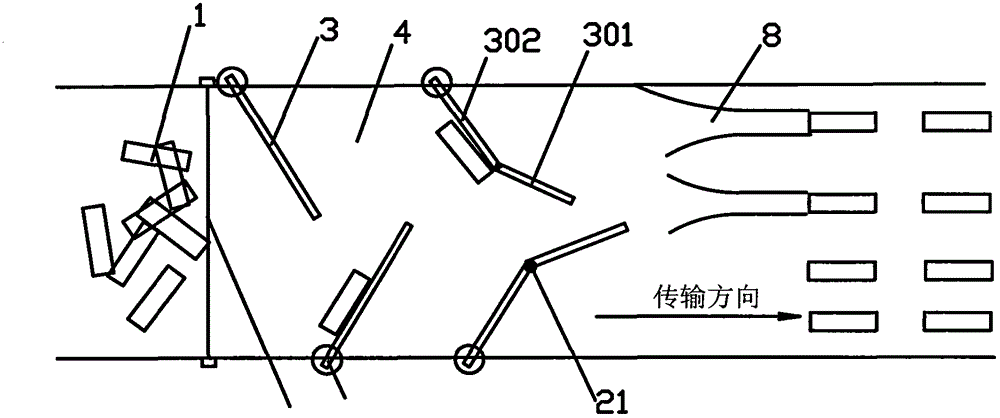

Small multifunctional sorting machine for sorting expresses

The invention discloses a small multifunctional express sorting machine, comprising a sorting mechanism and a scanning mechanism, wherein the sorting mechanism comprises a main transmission belt, a driving belt, a motor, an air cylinder and a moving block; the scanning mechanism comprises a scanning lifting frame, a scanning gun mounting fixture, an auxiliary roller wheel and an auxiliary sliding chute; a scanning frame can be adjusted up and down by regulating the position of a spring bulge via a scanning frame lifting mechanism; the roller and the auxiliary sliding chute are used for conveying expresses to the sorting mechanism after express scanning is completed; in the sorting mechanism, the main transmission belt is driven to move via the motor, the moving block can be rotated for 70 degrees under the control of a program so as to realize sorting of the expresses. The small multifunctional express sorting machine is simple in structure, low in cost, easy to operate and high in sorting efficiency, the sorting speed can be realized by only adjusting the rotating speed of the motor, and meanwhile the small multifunctional express sorting machine has broad use prospect.

Owner:JIANGNAN UNIV

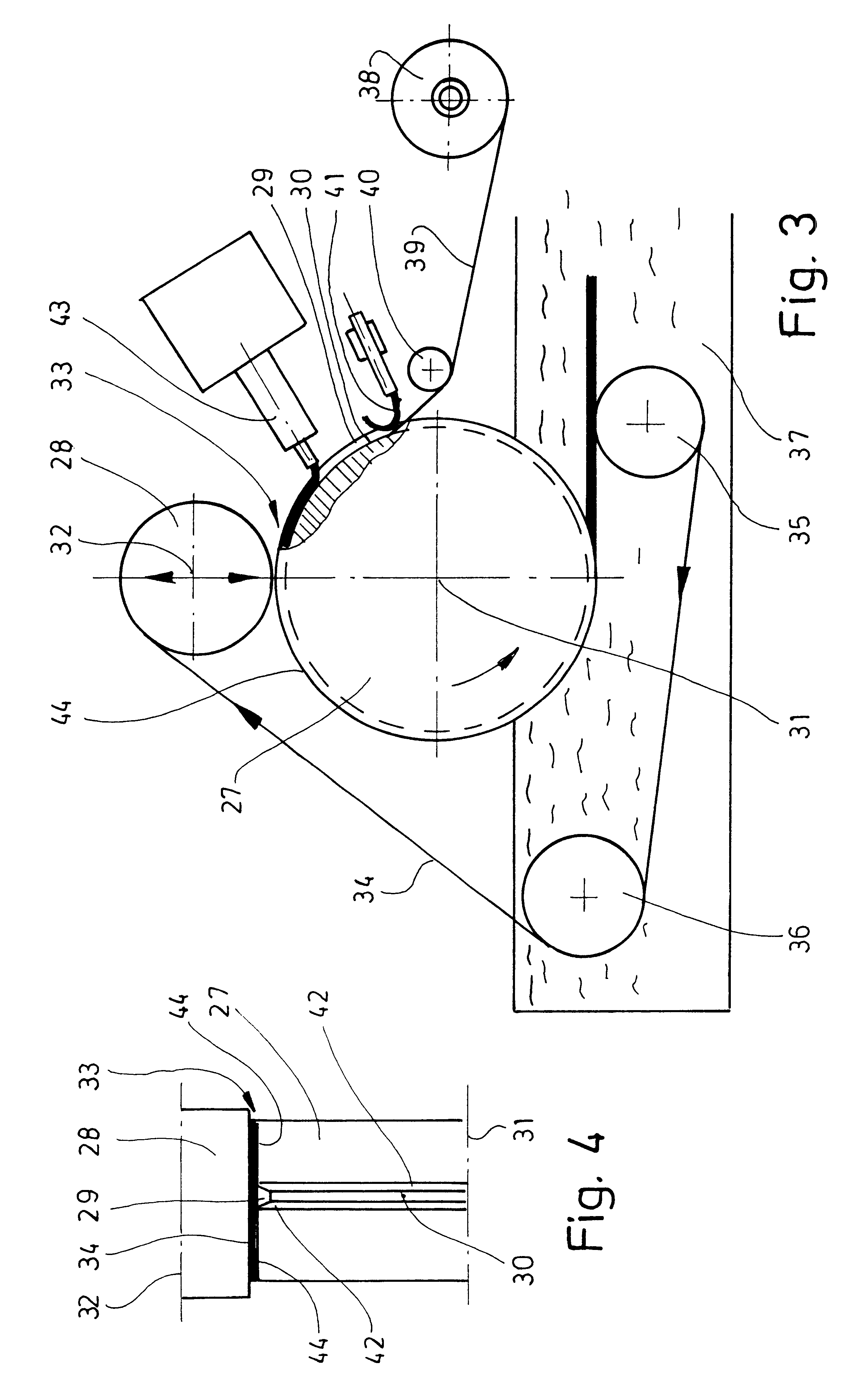

Stripping device for the return run area of conveyor belts

Apparatus for stripping a belt in conveyor belt assemblies includes a stripping element on a system carrier, the stripping element having a stripping lamella on a lamella holder, the stripping lamella contacting the belt in a peeling position, wherein the stripping element has a swivel mount coupled to the lamella holder and a swivel axis parallel to a plane of the belt, a spring for pressing the stripping lamella against the belt such that the lamella holder in the peeling position is swiveled about the horizontal axis, and when obstructions adhering to the belt impact the stripping lamella, the lamella holder deflects and returns a working position, wherein the stripping lamella is swivel mounted at the lamella holder by a swivel mount having an axis parallel to a plane of the belt and is held and spring biased by a top spring is counter to the bottom swivel mount spring.

Owner:KILL FRECH CORNELIA

Automatic guide control system

InactiveCN102718053AEfficient sortingSimple structureConveyor partsAutomatic train controlAutomatic control

The invention discloses an automatic guide control system which comprises a transmission belt, guide arms, a control device and a height control arm, wherein the transmission belt is used for transmitting objects along a determined direction; the guide arms are arranged on the two sides of the transmission belt through guide arm installing ends and used for regulating the direction of the objects to be transmitted; the control device can control the movement of the transmission belt; the height of the height control arm can be set, and the height control arm is used for controlling that the objects to be transmitted are not transmitted in an overlapping manner; and the guide arms are arranged to be single or in a large arm-small arm connection manner and can be arranged side by side in multiple groups. The automatic guide control system also comprises guide grooves which are used for guiding the objects passing through the guide arms into specified lines and are arranged side by side in multiple groups. The automatic guide control system has the advantages of simple structure, convenience and effectiveness for sequencing the disordered and scattered materials, strong applicability and high precision.

Owner:ADTECH SHENZHEN TECH

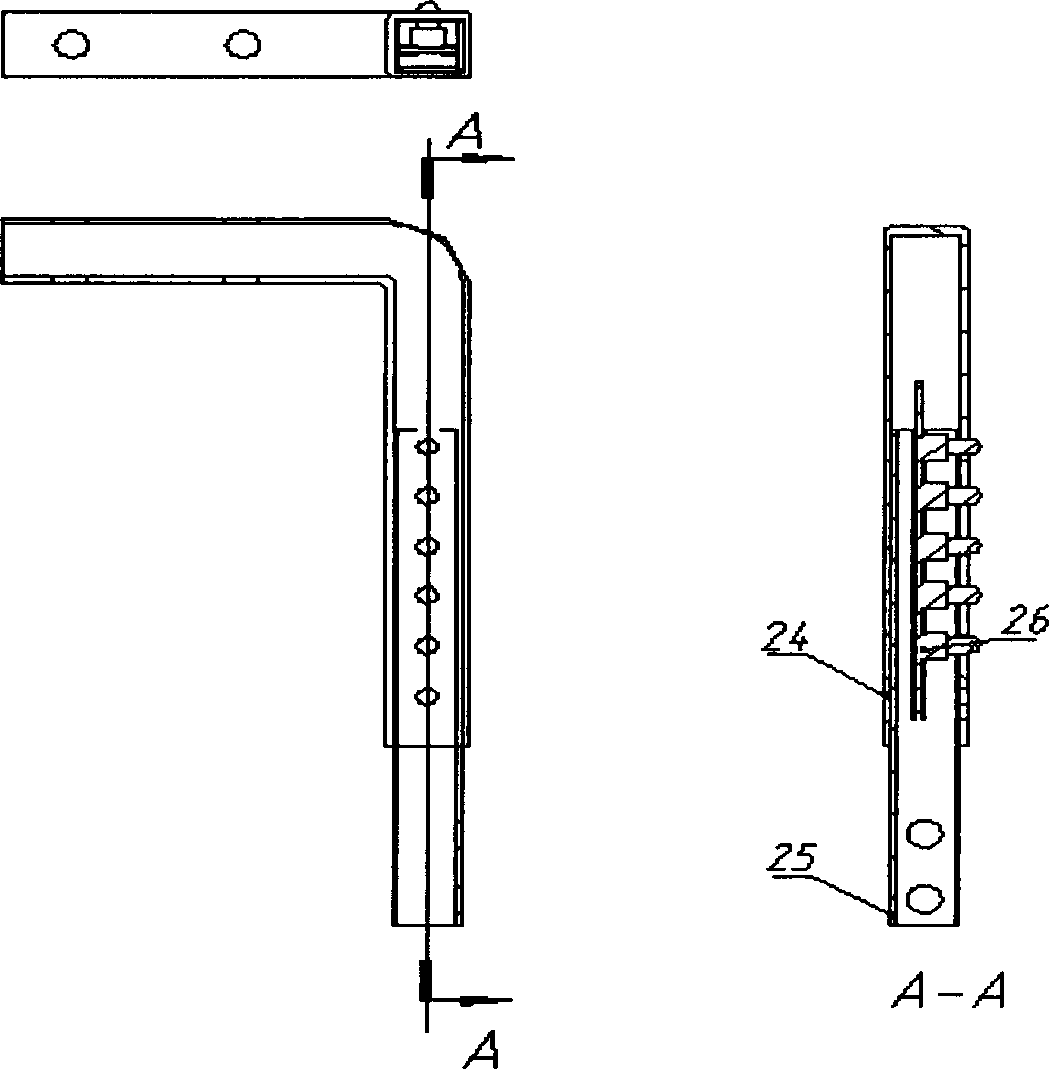

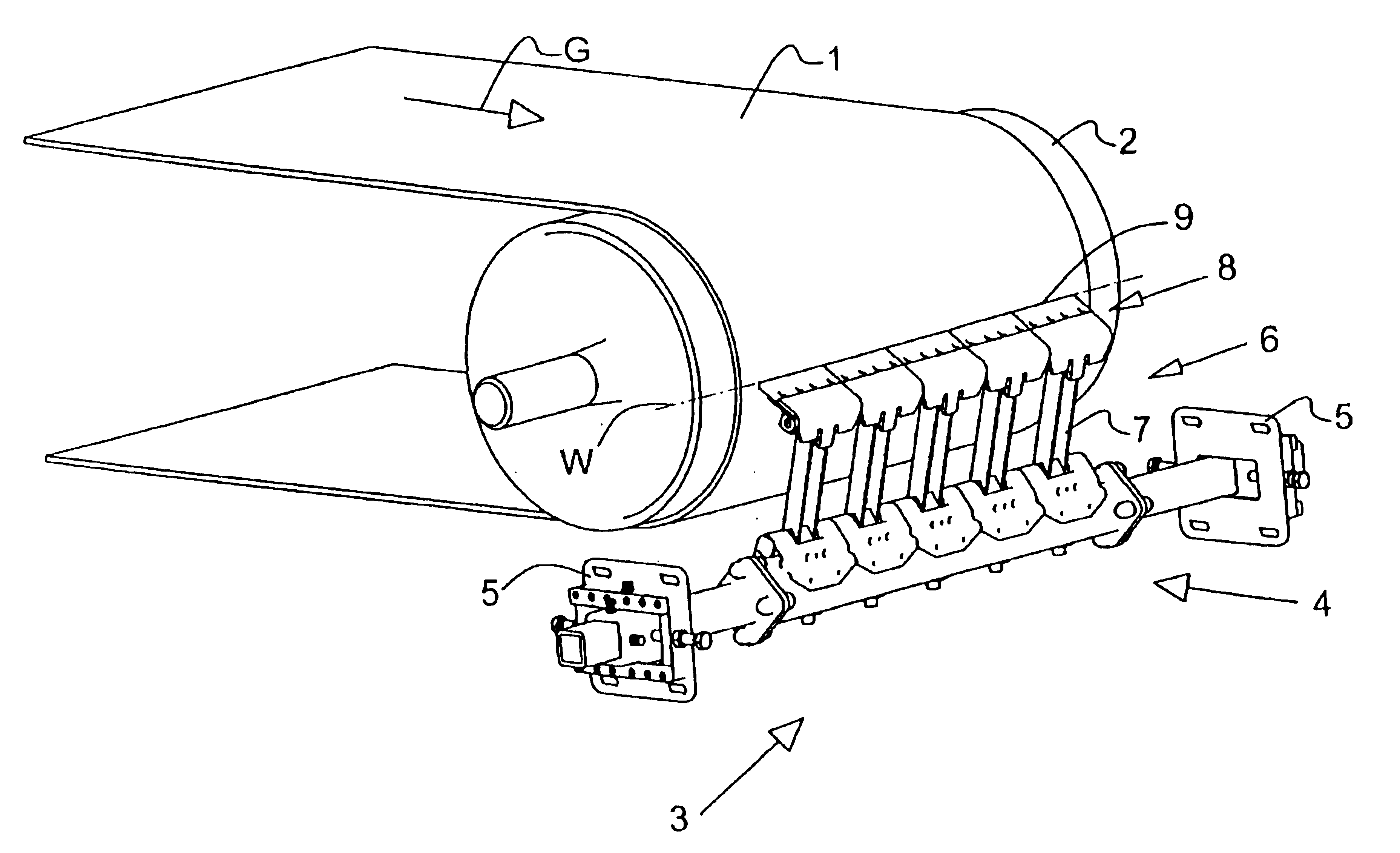

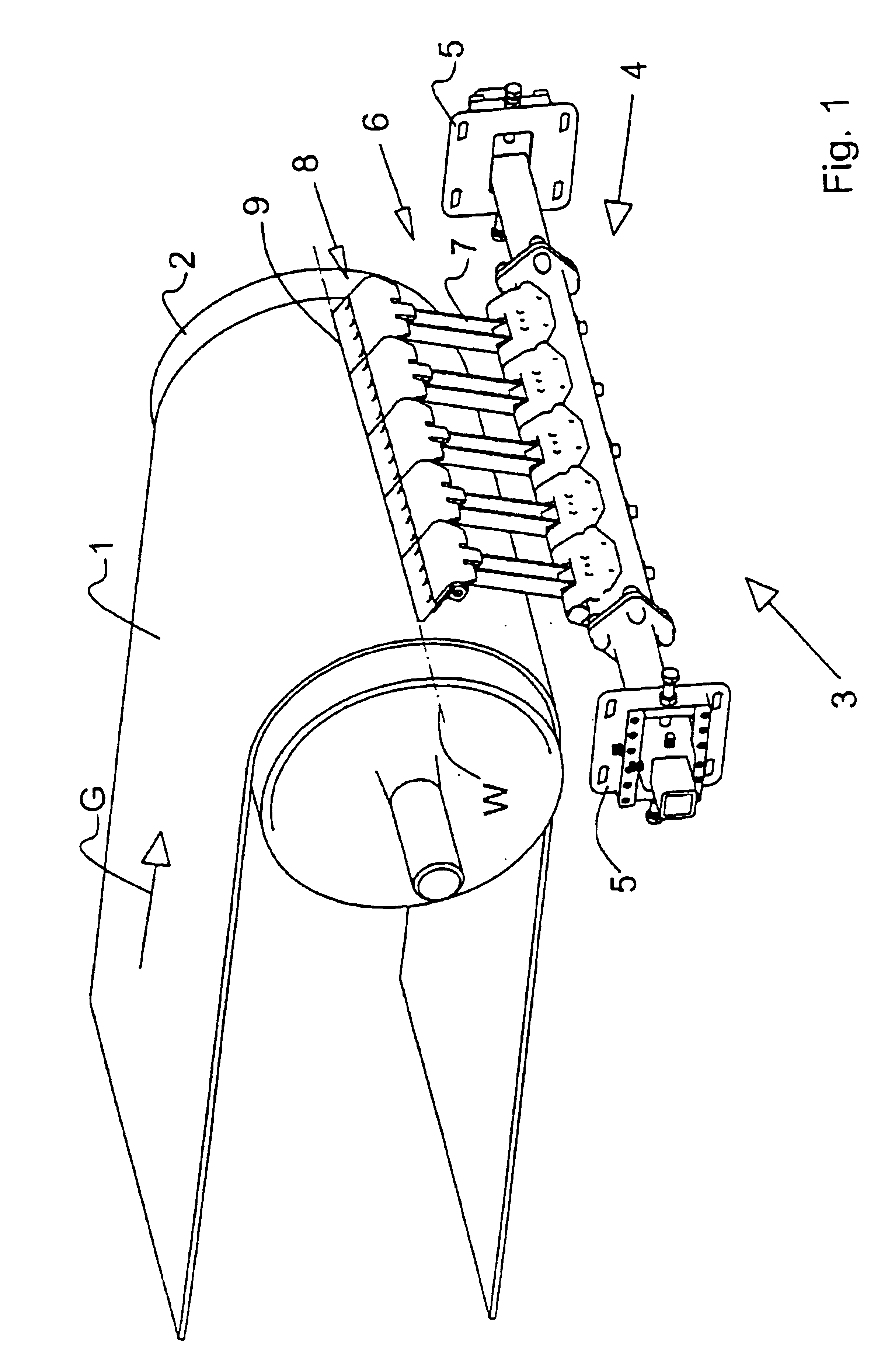

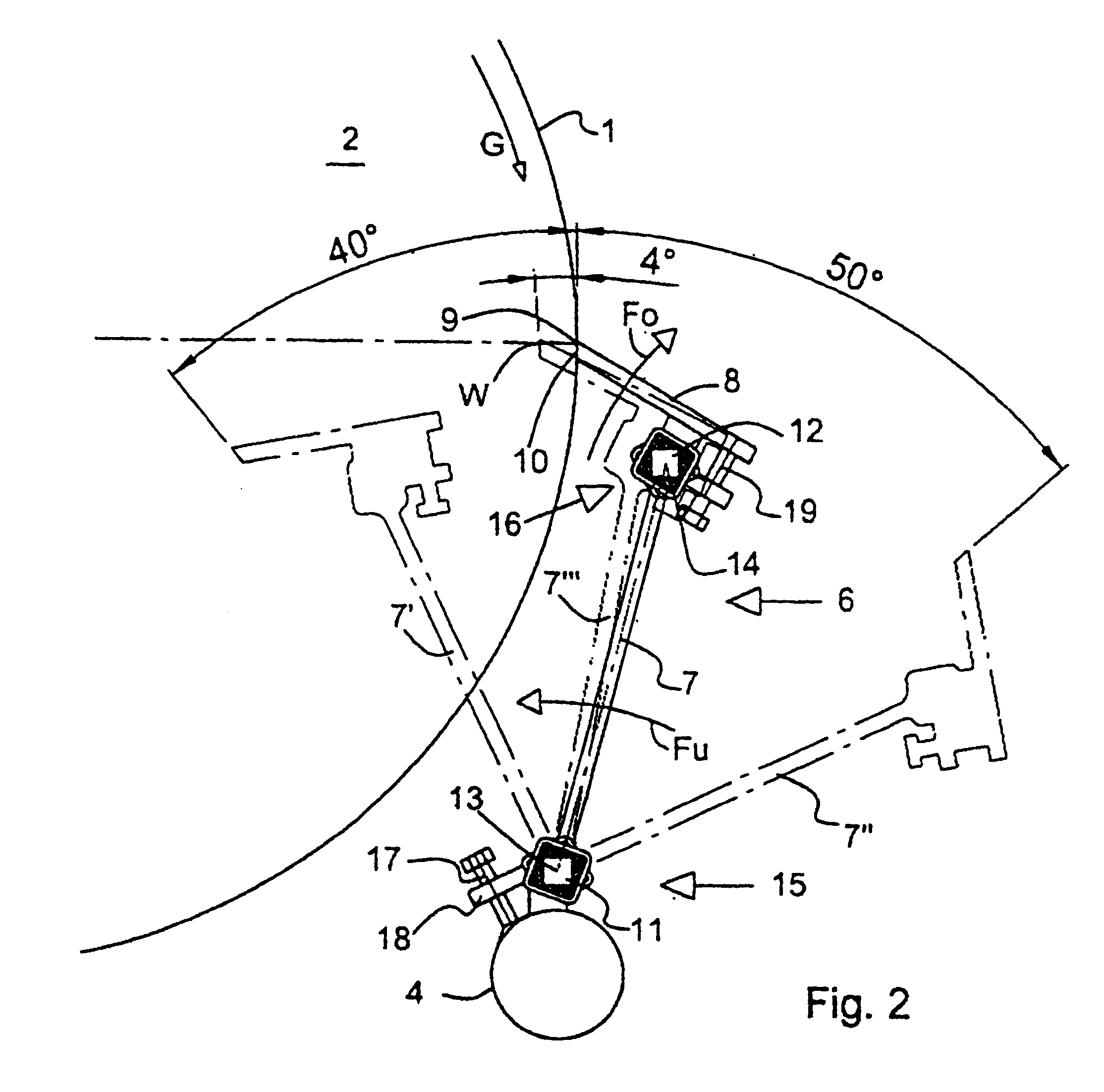

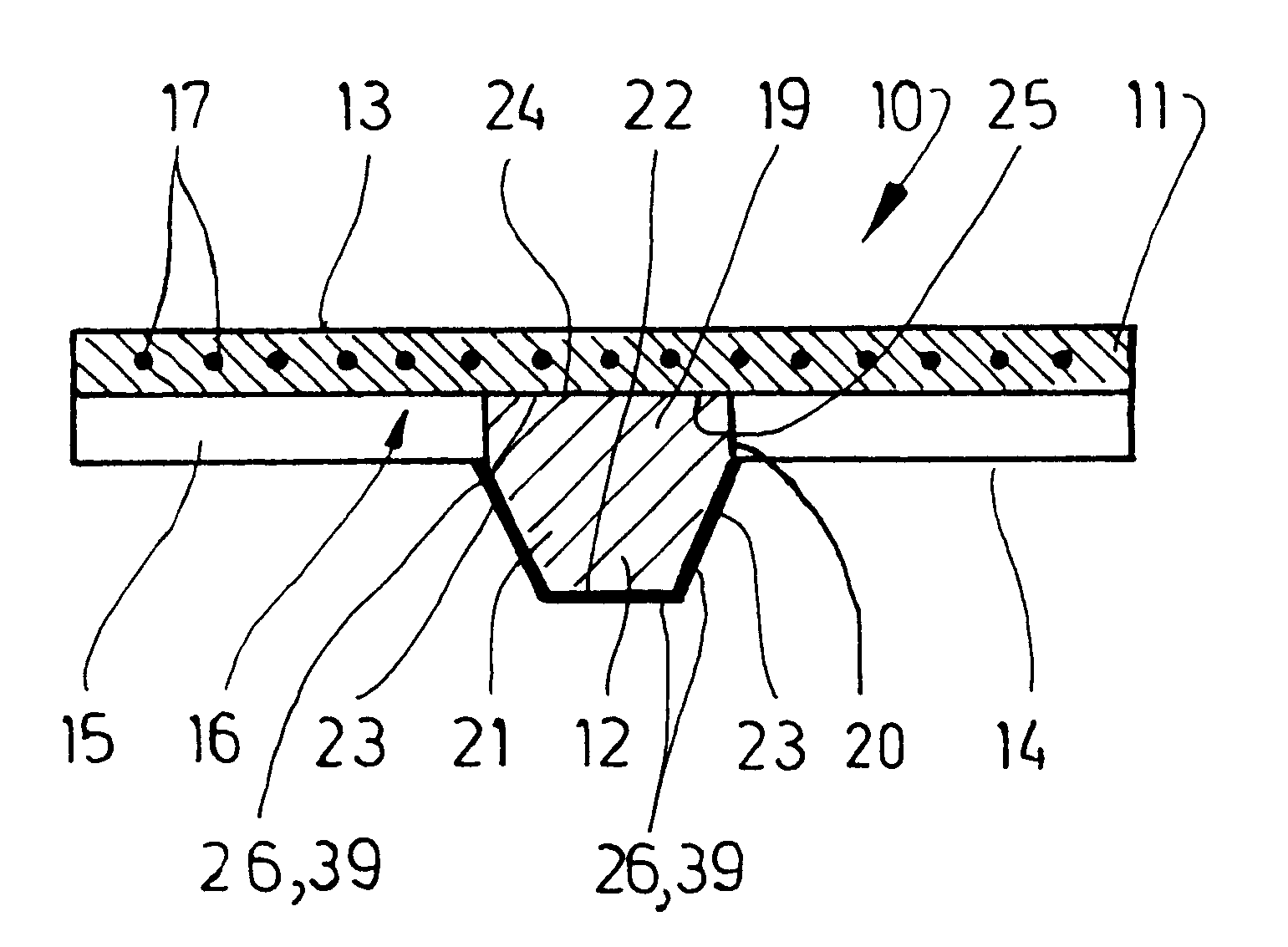

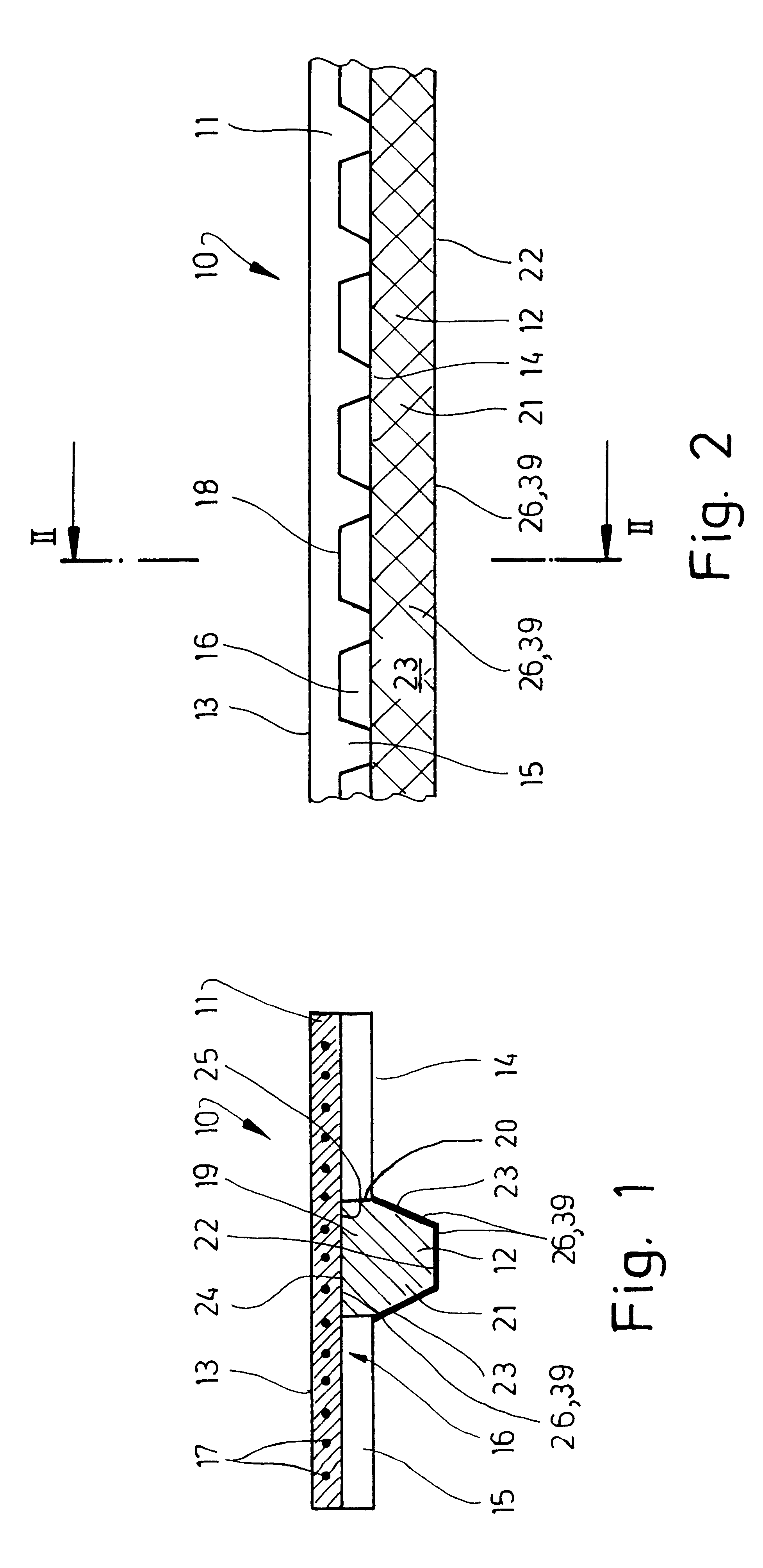

Belt, especially conveyer belt and method for manufacturing same

InactiveUS6561344B1Reduce noiseReduce the valueConveyorsDriving beltsTransmission beltStructural engineering

Conveyer belts (10) are deflected many times along a conveying path of the objects to be conveyed. It has been shown that unpleasant squeaking noises are generated in the region of this deflection between the guide means (12) of the conveyer belt (10) and guide rollers or guide drums.The invention is based on the knowledge that the squeaking noises are caused by the relatively high friction value of the material of the conveyer belt (10). The design according to the invention therefore proposes that at least the outer side of the guide means (12) of the conveyer belt (10) is provided with a coating (26) made from a material with a lower frictional value. As a result, it has been shown that undesirable squeaking noices can be effectively avoided.

Owner:NORDDEUTSCHE SEEKABELWERKE AG

Improved-structure double-shaft needling machine

The utility model relates to a structurally improved double-shaft needle loom, which belongs to the technical field of non-woven machinery. Including frame, power transmission mechanism, main shaft, auxiliary shaft and auxiliary shaft transition transmission mechanism, features: auxiliary shaft transition transmission mechanism includes first and second pulleys, transition pulleys, tension pulleys and transmission belts, the first pulley is fixed on the main shaft The end of the second pulley is fixed on the auxiliary shaft, the transition pulley and the tension pulley are set on the frame; the transition pulley is set on the transition pulley shaft seat, and the transition pulley shaft seat is fixed on the frame; the tension pulley is set on On the shaft seat of the tensioning pulley, an adjusting device for the shaft seat of the tensioning pulley is arranged on the frame; a pair of adjusting screw slots are respectively set on the upper and lower parts of the shaft seat of the tensioning pulley, and adjusting screws are arranged at the positions of each adjusting screw slot; The tensioning pulley shaft seat adjusting device comprises a screw nut, a screw seat and a screw rod. Advantages: Avoid noise and improve the environment of the job site.

Owner:常熟市伟成非织造成套设备有限公司

Power take off from an endless conveyor

A hydraulic power take off device for an endless conveyor belt system having an upper material run and a lower return run, said device being arranged to generate hydraulic fluid at pressure to maintain a self adjusting force to belt cleaning equipment, and other equipment that can utilize fluid pressure. The take off device is driven directly or indirectly from the motion of the conveyor belt or from the motion of other components fitted to the endless system. The power take off comprises a hydraulic pump which is rotated by the motion of the endless conveyor and generates fluid at pressure via an adjustable relief valve and maintains a constant self adjusting force of actuators, automatically compensating for wear that takes place on the equipment being operated and providing an automatic and interlocked source of power, generating pressure only when the conveyor belt system operates.

Owner:MARTIN BULK HANDLING SOLUTIONS (PTY) LTD

Indoor vehicle ABS test-bed with variable adhesion coefficient

InactiveCN101183046AEasy to detectAvoid lostVehicle testingApparatus for force/torque/work measurementAdhesion coefficientIn vehicle

The invention discloses a vehicle ABS test bed with changeable attachment coefficient and comprises a front and a back shaft frames, a front and a back fly wheel shafts, a transmission box and a telescopic transmission shaft; the front and the back shaft frames are respectively and symmetrically provided with a front left wheel, a front right wheel, a back left wheel and a back right wheel roller group and the front left wheel, the front right wheel, the back left wheel and the back right wheel roller group are totally uniform; each roller group is respectively connected with the output end of a torque controller through a transmission belt in correspondence and the input end of the torque controller is respectively and rigidly connected with the front and the back fly wheel shafts; the front and the back fly wheel shafts are connected with the telescopic transmission shaft through the transmission box to realize mutual synchronization; each fly wheel shaft is rigidly and symmetrically provided with two fly wheels with same turning inertia; the braking force of the wheel of the measured vehicle can be changed by controlling magnetizing current of the torque controller when the wheel is in lock braking and then the attachment coefficient of the road can be simulated. The invention can be widely applied in vehicle examination, ABS research and development, vehicle maintenance and service industry.

Owner:CHANGAN UNIV

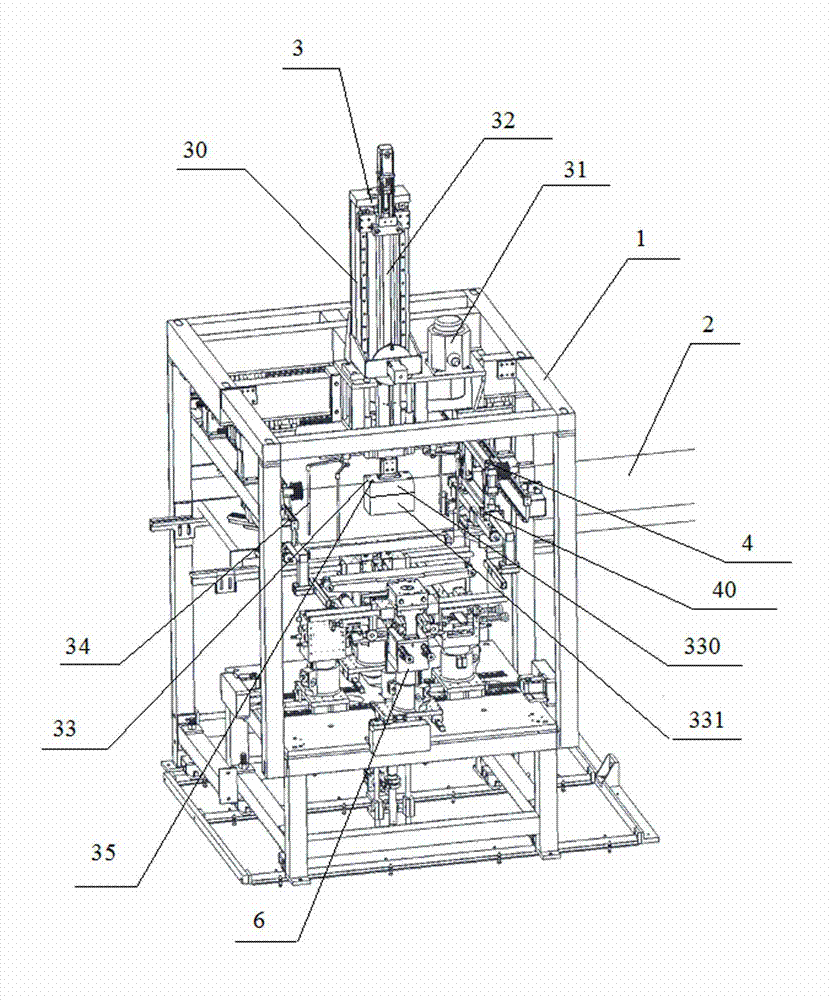

Fully automatic carton molding machine

InactiveCN103085316AStable jobWork flexiblyContainer making machineryMolding machineProgrammable logic controller

Provided is a fully automatic carton molding machine. The fully automatic carton molding machine comprises a rack, a transmission belt which is arranged on the rack and extends outward, a box pressing device which is arranged above the transmission melt, a box holding device which is arranged on two sides of the box pressing device, and a molding machine head device which is arranged below the transmission belt. The fully automatic carton molding machine further comprises a programmable logic controller (PLC) controlling system for controlling the transmission belt, the box pressing device, the box holding device, and the molding machine head device. The molding machine head device comprises four molding machine heads and the molding machine heads can independently complete molding work, so that the fully automatic carton molding machine is stable at work. Lifting-dropping barrel bodies are arranged on all the molding machine heads, the lifting-dropping barrel bodies can independently lift and drop, a shovel device and a plate pressing device of the molding machine heads can rotate and tilt, and thus the fully automatic carton molding machine is flexible at work. Due to the fact that the PLC controlling system for controlling is the transmission belt, the box pressing device, and the molding machine head device, automatic production is achieved, and thus production efficiency and product pass percent are improved.

Owner:广东力顺源智能自动化有限公司

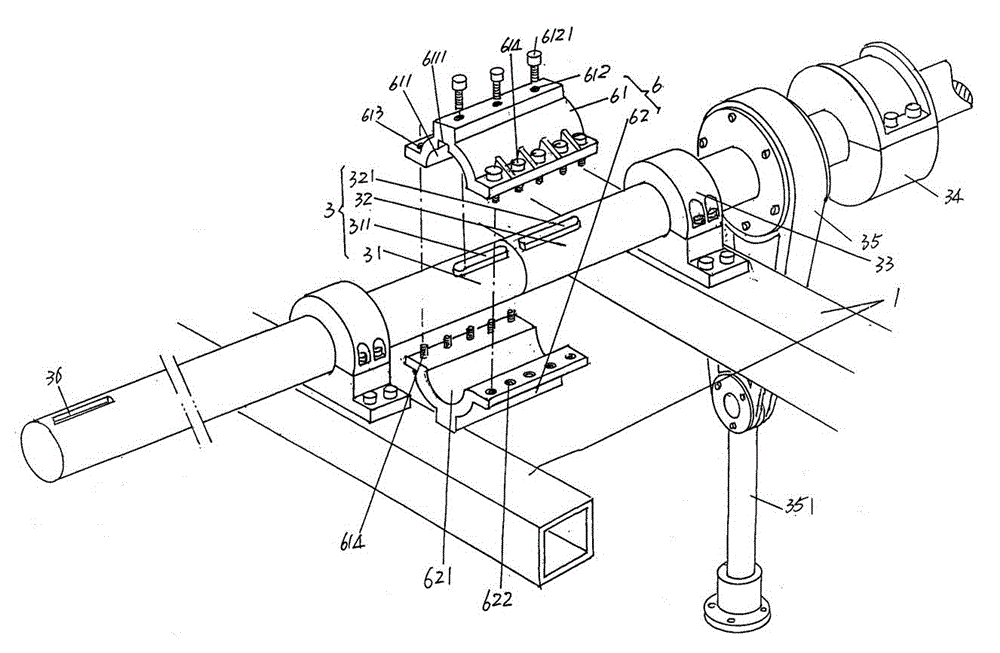

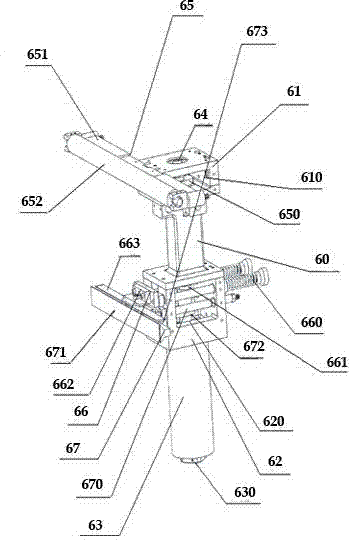

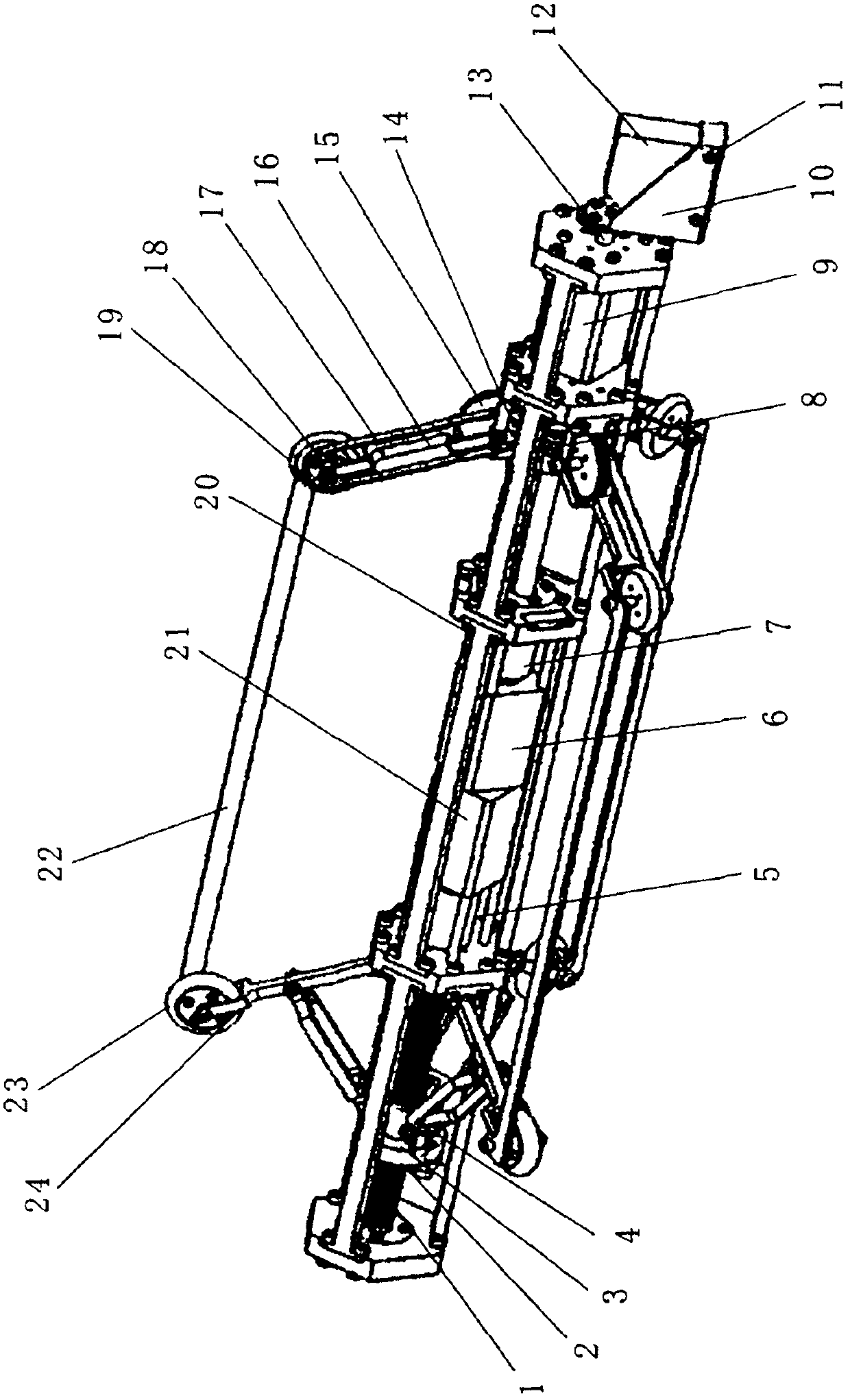

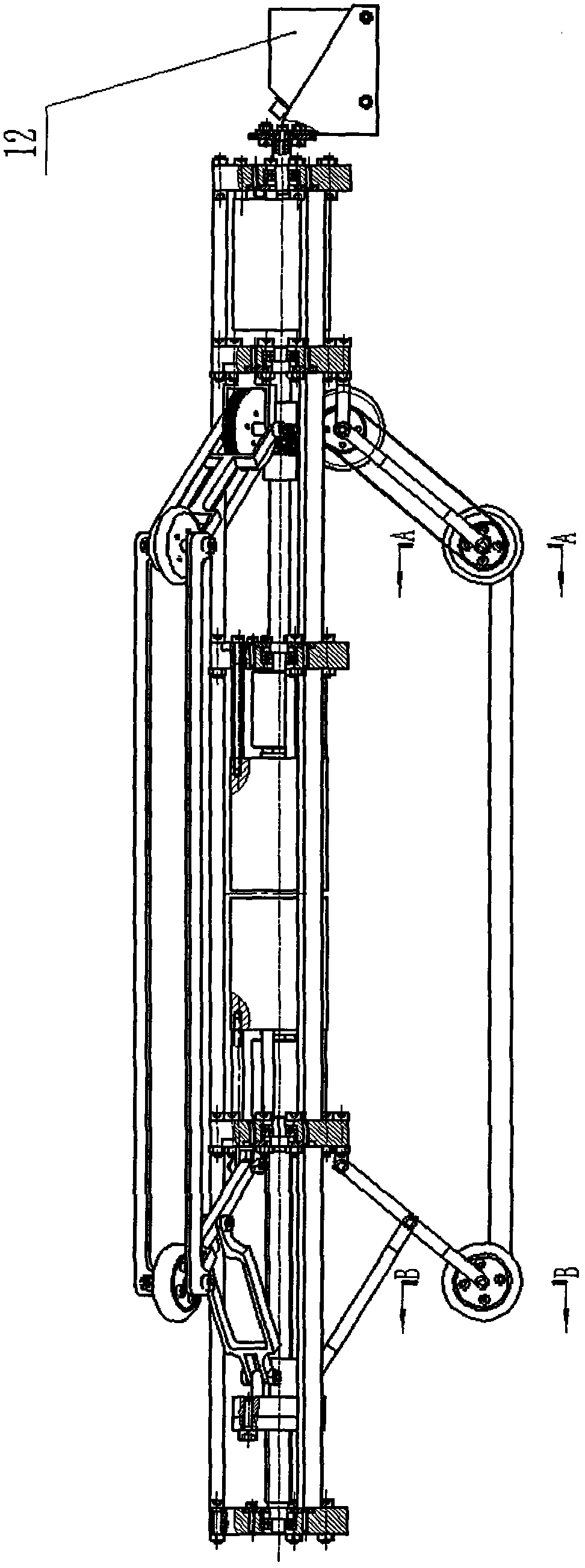

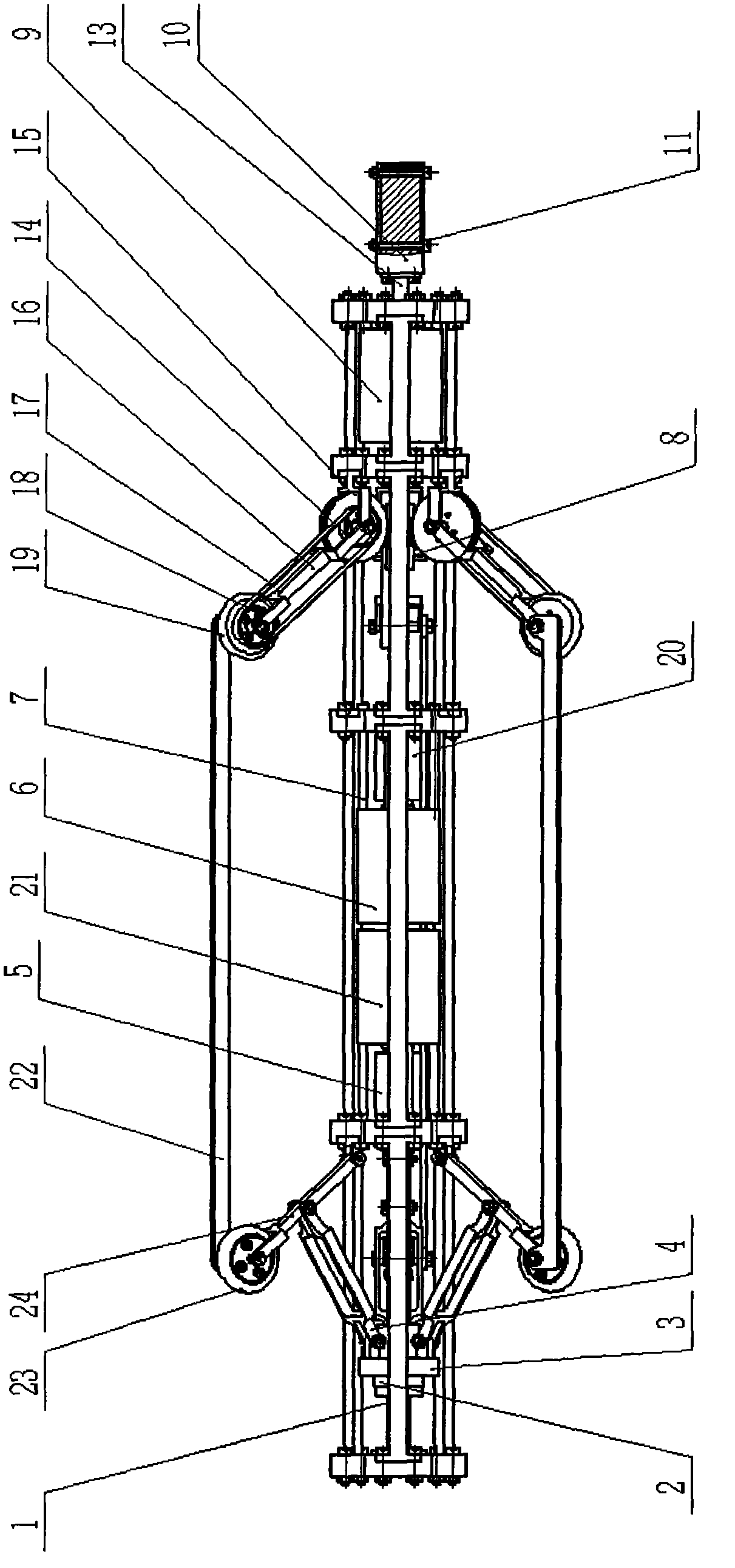

Pipeline robot for internal diameter measurement

InactiveCN103398665ASuitable for measurement requirementsHigh measurement accuracyUsing optical meansPigs/molesTransmission beltBall screw

The invention relates to a pipeline robot for internal diameter measurement. The pipeline robot for the internal diameter measurement comprises a supporting mechanism, a main driving mechanism and a laser measurement mechanism, wherein the supporting mechanism mainly consists of a nut for a ball screw, a step motor I, wheels, a connection rod, a push rod and the like; the main driving mechanism mainly consists of a worm gear, a worm rod, a belt wheel, a transmission belt and the like; and the linear movement of the pipeline robot can be realized through the driving of a step motor II. The laser measurement mechanism is mainly composed of a sensing measuring head, a sensor bracket and a step motor III. The pipeline robot provided by the invention can be used for measuring an internal diameter of a long pipeline, and can particularly meet the measurement requirement of thin and long pipes with the larger range of the internal diameter. The pipeline robot provided by the invention not only can be used for carrying out non-contact measurement on the internal diameters of the pipelines with different sizes but also can realize various measurements by means of replacing a measurement head of a sensor, such as flaw detection and the like. The pipeline robot has the advantages of high measurement precision and convenience in use.

Owner:INNER MONGOLIA UNIV OF TECH

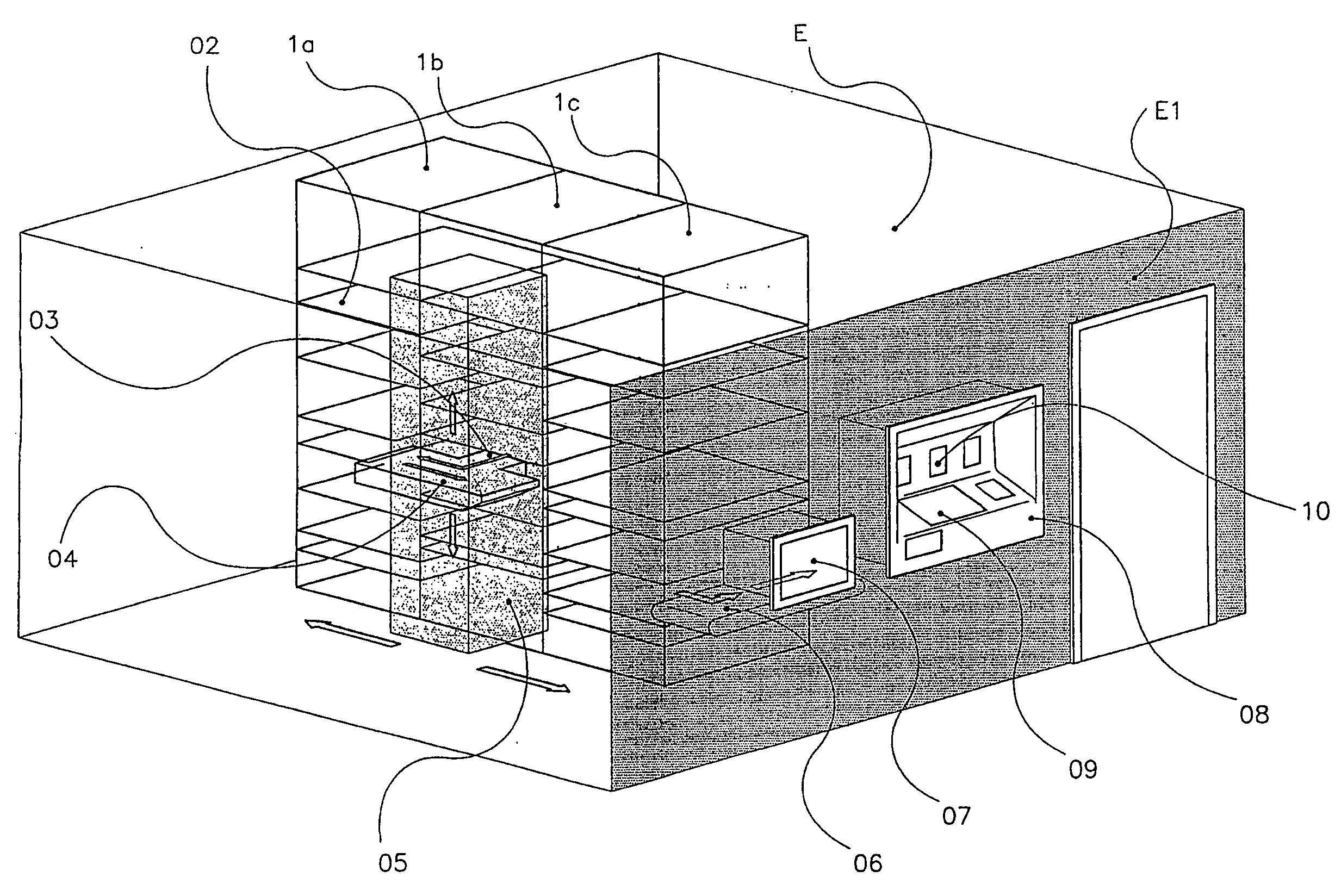

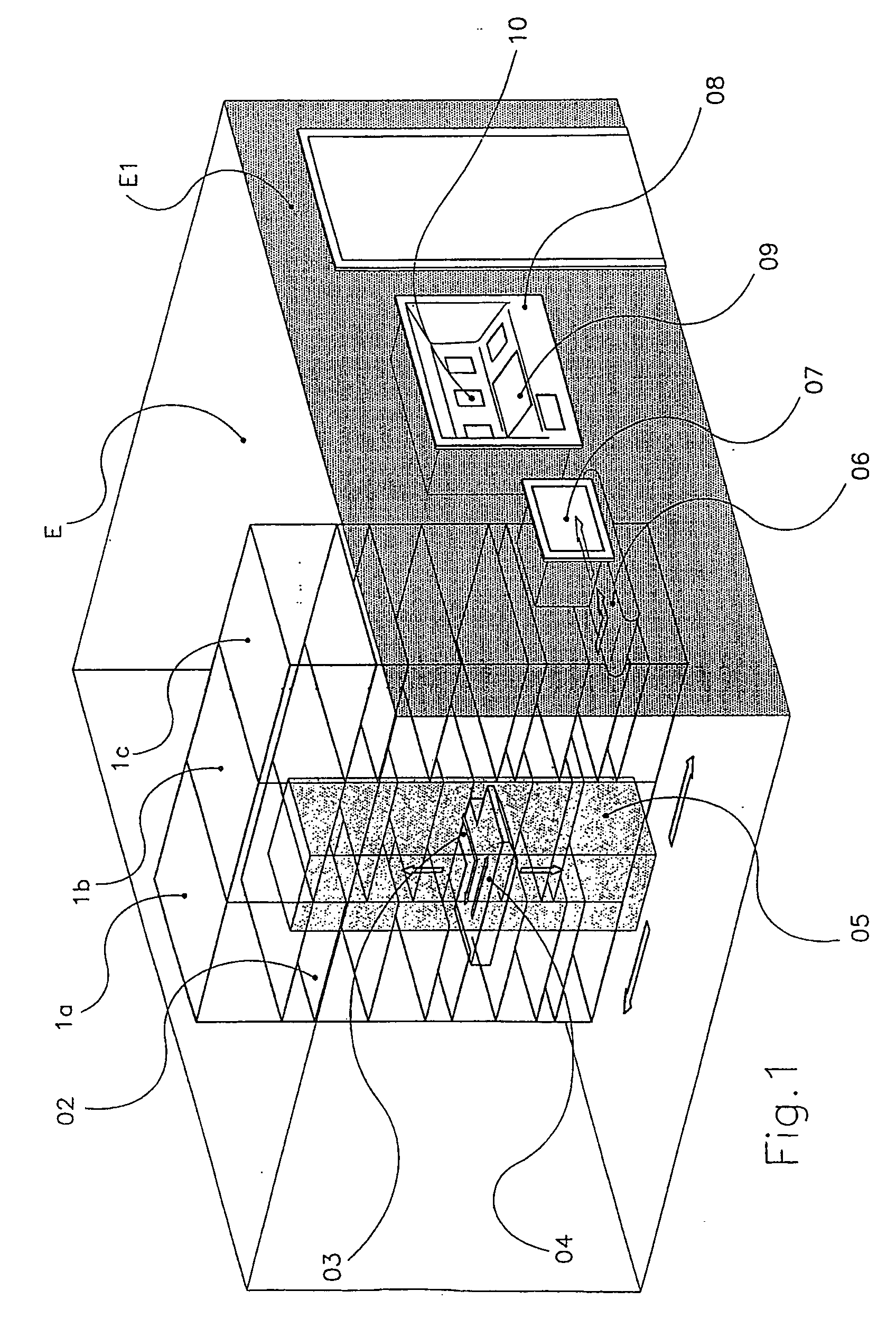

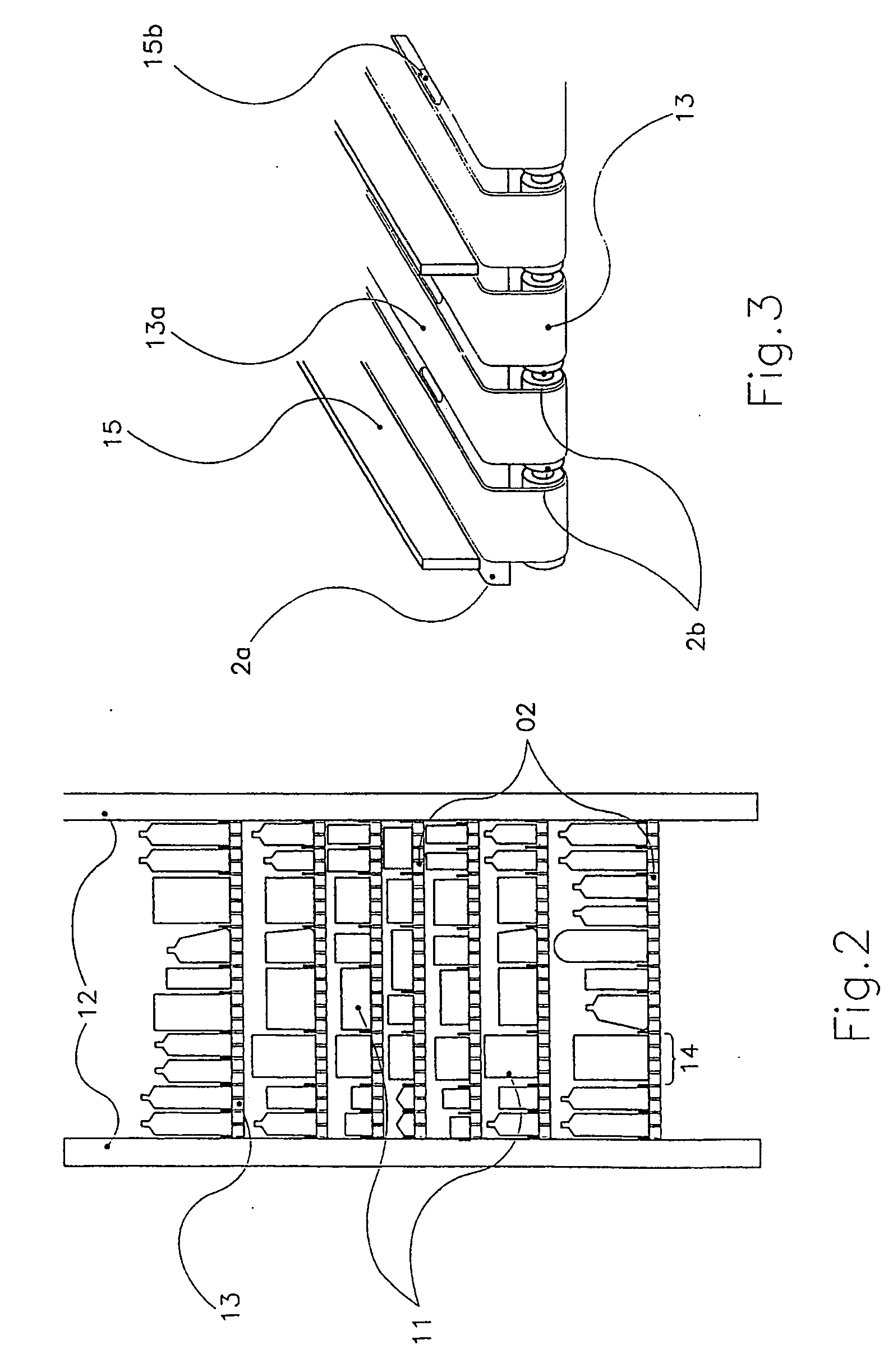

Method and automated system for storing and distributing various objects or articles

InactiveUS20050063801A1Quickly availableShorten the construction periodCoin-freed apparatus detailsLoading/unloadingTransmission beltCommand system

A method for storing and distributing various articles, according to which the objects are stored on the trays of a rack structure. A suitable extraction system driven by a control and command system is movable in front of the rack structure in such a way that the extraction system is aligned in front of the bay of a tray carrying the stock of articles corresponding to the selected object so as to remove at least one of the articles. Objects or articles having the same reference are stored adjacent to each other on the upper side of one or several freely moving continuous conveyor belts, the conveyor belt(s) forming the receiving surface for one of the different bays of a storage tray. The conveyor belts are selectively motorized, causing the articles carried by the conveyor belts to be moved in the direction of a point of removal. The selective motorization is obtained by operating moving wheels mounted on a mobile extractor, which is movable in front of the storage rack and transports the conveyor belt(s) of the bay holding the selected or ordered articles by friction in such a way that at least the first one of the articles is transferred to a receiving surface of the extractor.

Owner:B PLUS DEVMENT

Travelling mechanism of track inspection robot

The invention discloses a travelling mechanism of a track inspection robot. The travelling mechanism comprises a track and a driving mechanism, the driving mechanism moves along the track, and the inspection robot is installed on the driving mechanism; the track comprises an aluminum profile and a chain which is arranged under the aluminum profile in parallel; the driving mechanism comprises suspension arms, a cross beam, a steady wheel set, a chain wheel, a driving motor and a steering device, a U-shaped structure is formed by the two suspension arms and the cross beam, the suspension arms make slideable contact with the aluminum profile through the steady wheel set, the chain wheel is horizontally arranged and rotationally connected with the cross beam, the chain wheel meshes with the chain, a torque input shaft of the chain is fixedly connected with a torque output shaft of the driving motor through a transmission belt, and the driving motor is fixedly connected with the cross beam.In the travelling mechanism, the standard industrial aluminum profile is used as the track, the chain is used as a path, the chain wheel is used as a driving wheel, and a chain-drive mode is adoptedso that precise positioning can be achieved, and turning and climbing can be easily achieved; the steering shaft is adopted as a steering knuckle so that the requirements for small-radius turning canbe met.

Owner:SHENZHEN LAUNCH DIGITAL TECH

Multi-shaft aircraft

InactiveCN103786878ALow costReduce weightRemote controlled aircraftRotocraftMotor driveFlight vehicle

The invention discloses a multi-shaft aircraft. The multi-shaft aircraft comprises a bracket and a driving system; the bracket comprises a first side rod, a second side rod, and a main rod, wherein the first side rod and the second side rod are arranged in parallel; the main rod is fixed between the first side rod and the second side rod; two ends of the main rod are respectively fixed in the middle parts of the first side rod and the second side rod; the driving system is mounted on the bracket and comprises a motor and four rotor wings, wherein the four rotor wings are respectively mounted at four end parts of the first side rod and the second side rod; the motor drives a plurality of rotor wings to rotate through a synchronous transmission mechanism; the synchronous transmission mechanism comprises a main shaft which is driven to rotate through the motor; a synchronous transmission belt is arranged between the main shaft and each of the rotor wings; the synchronous transmission belt is arranged in the first side rod or the second side rod. According to the multi-shaft aircraft, the synchronous transmission belt is arranged in cavity body between the first side rod and the second side rod, a first synchronous belt wheel is arranged in a first protection space of a first support, and thus the synchronous transmission belt and the first synchronous belt wheel can be effectively protected once the aircraft collides by accident.

Owner:张家港锐泰智能科技有限公司

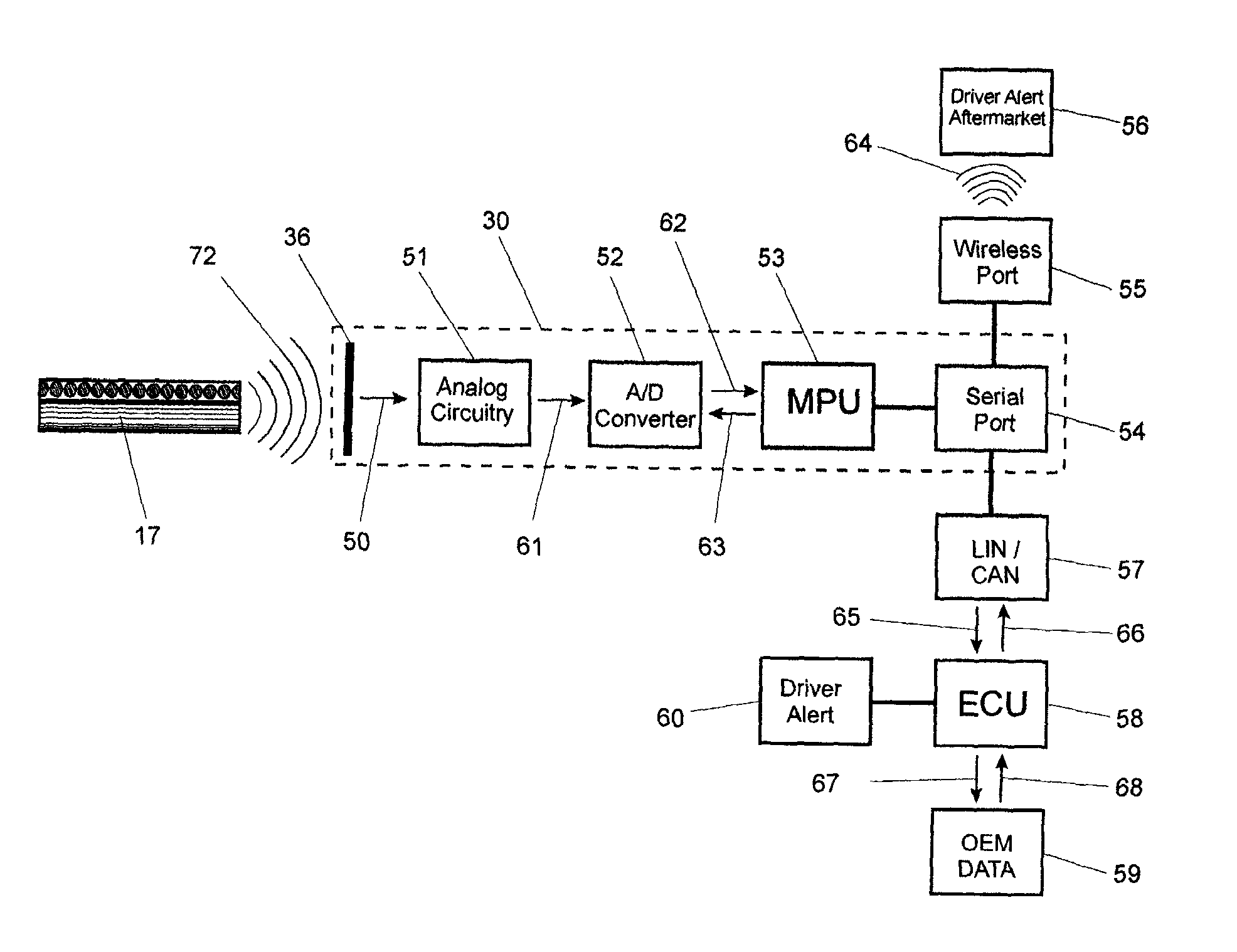

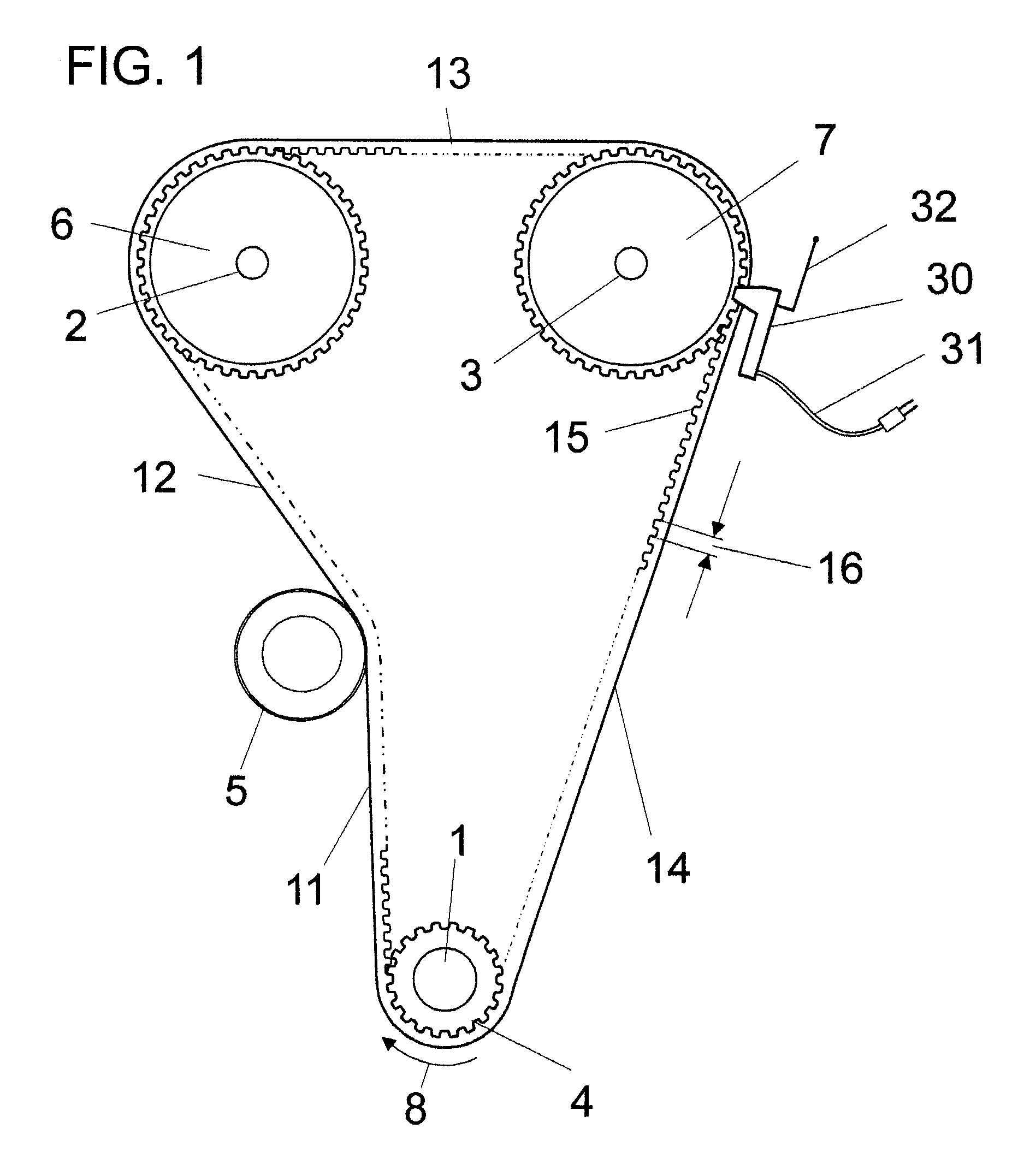

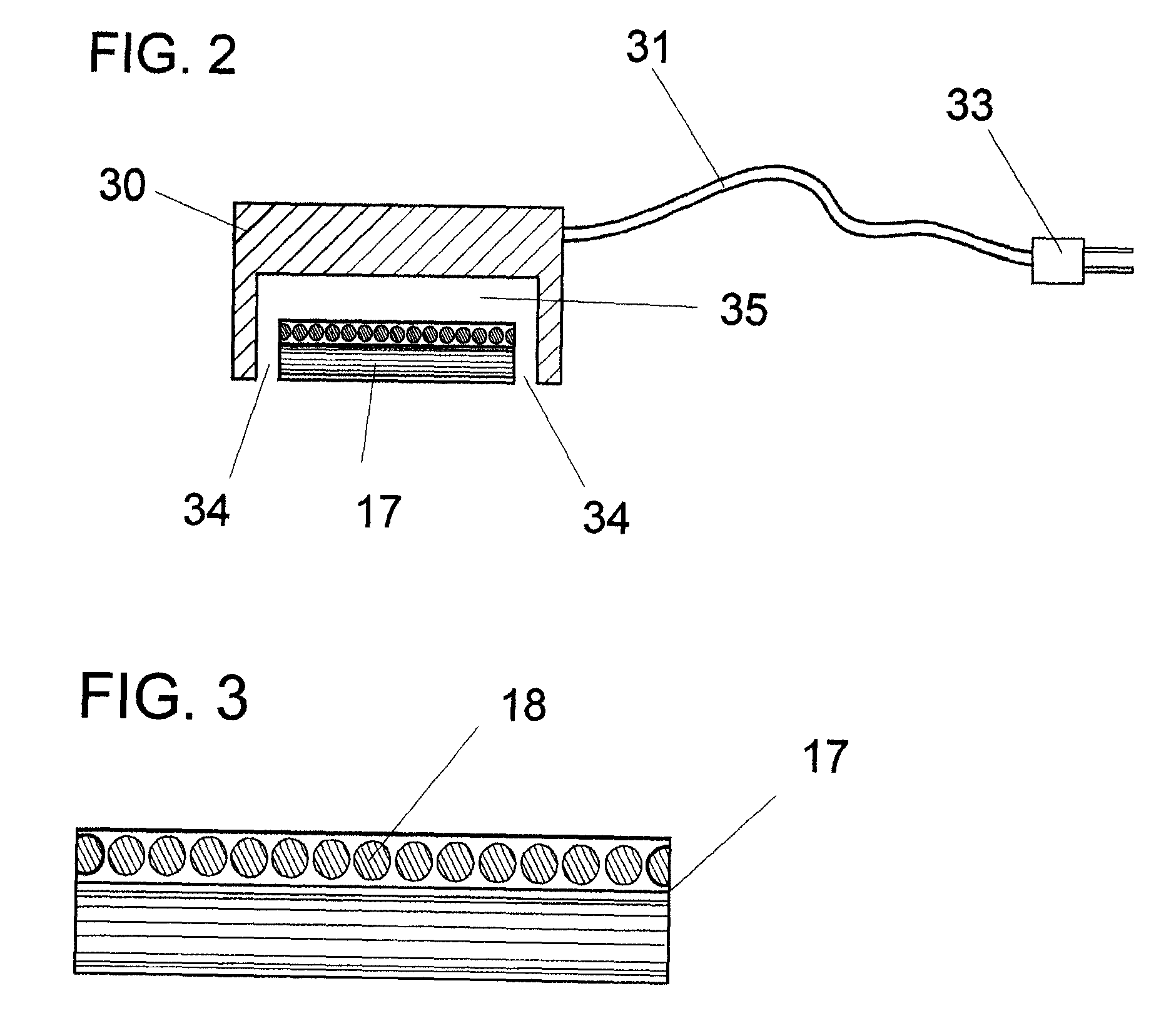

Apparatus And Method For Detecting Transmission Belt Wear And Monitoring Belt Drive System Performance

InactiveUS20090303065A1Improve system qualityPremature failureVehicle testingMachine gearing/transmission testingMicrocontrollerFiber

An apparatus and method to monitor endless belts and related belt drive systems by non-contact sensors for wear or an anomalous function, determining the state of belt drive system and detecting early stages of belt and system failure. A sensing unit featuring one or several independent sensor elements is placed near a belt of a polymer matrix with a fiber cord load bearing core to monitor several simultaneously occurring normal modes of operation. The sensor can determine soundness of the whole timing drive continuously by processing the collected signal and detecting structural damage. The collected data is processed by a microcontroller integrated with the sensor. The apparatus and method uses a non-contacting capacitor array having sensing element(s) connected to electronic circuitry that is adapted to sense the dynamic capacitance change coupled with electrocapacitive and piezoelectric effects exhibited by the belt. The sensor continuously monitors the belt during normal operation.

Owner:LIPOWSKI MATS

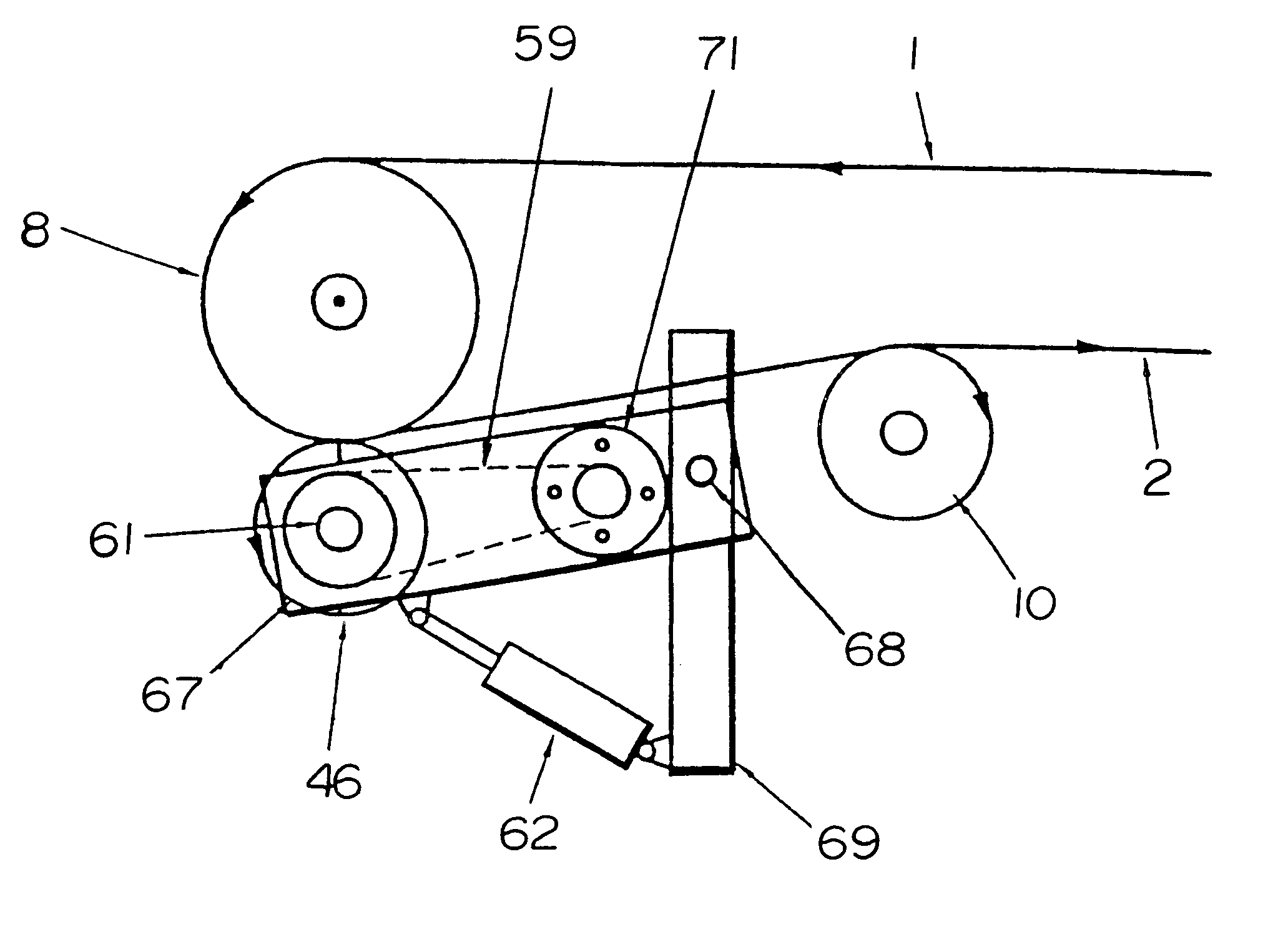

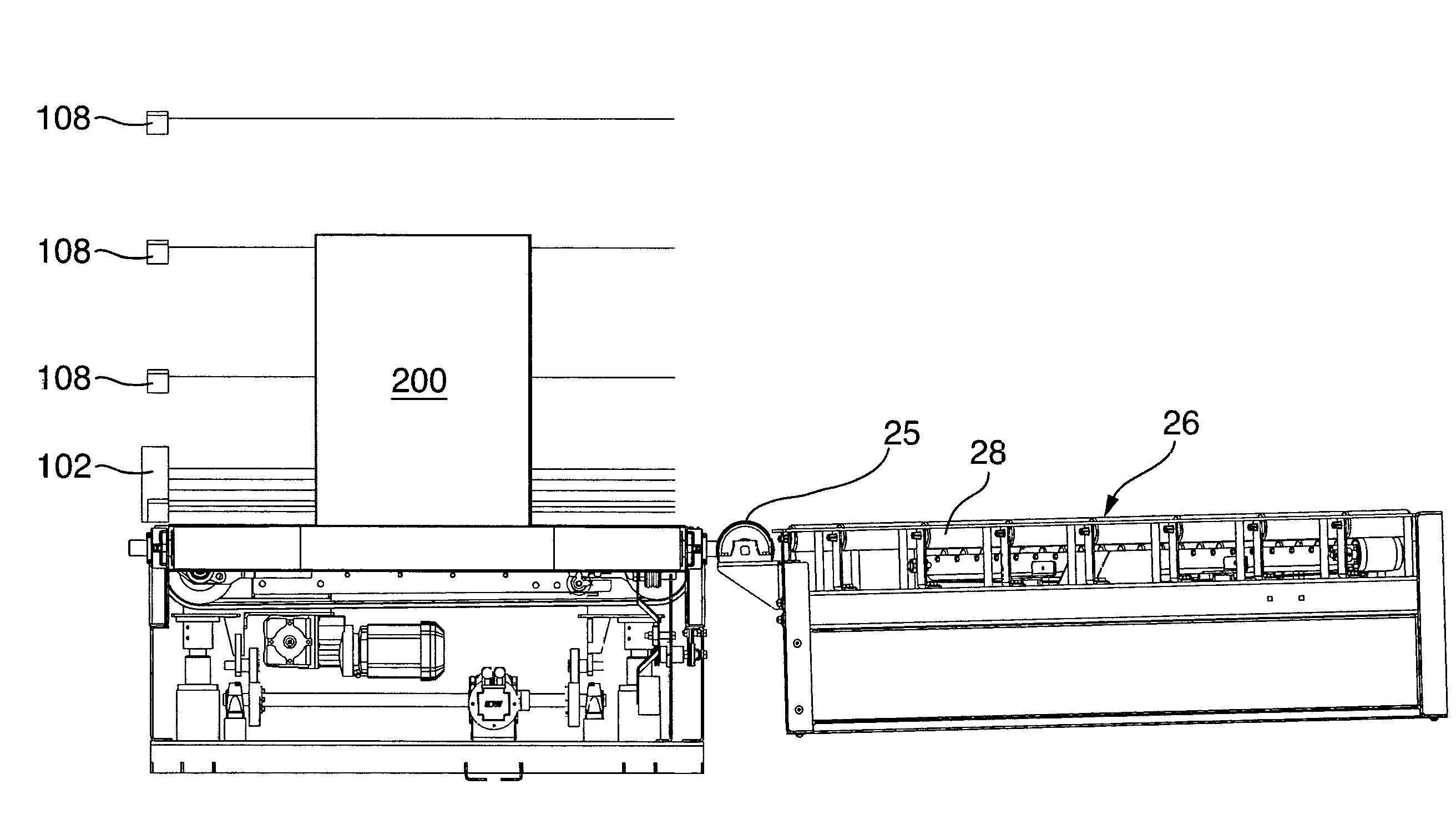

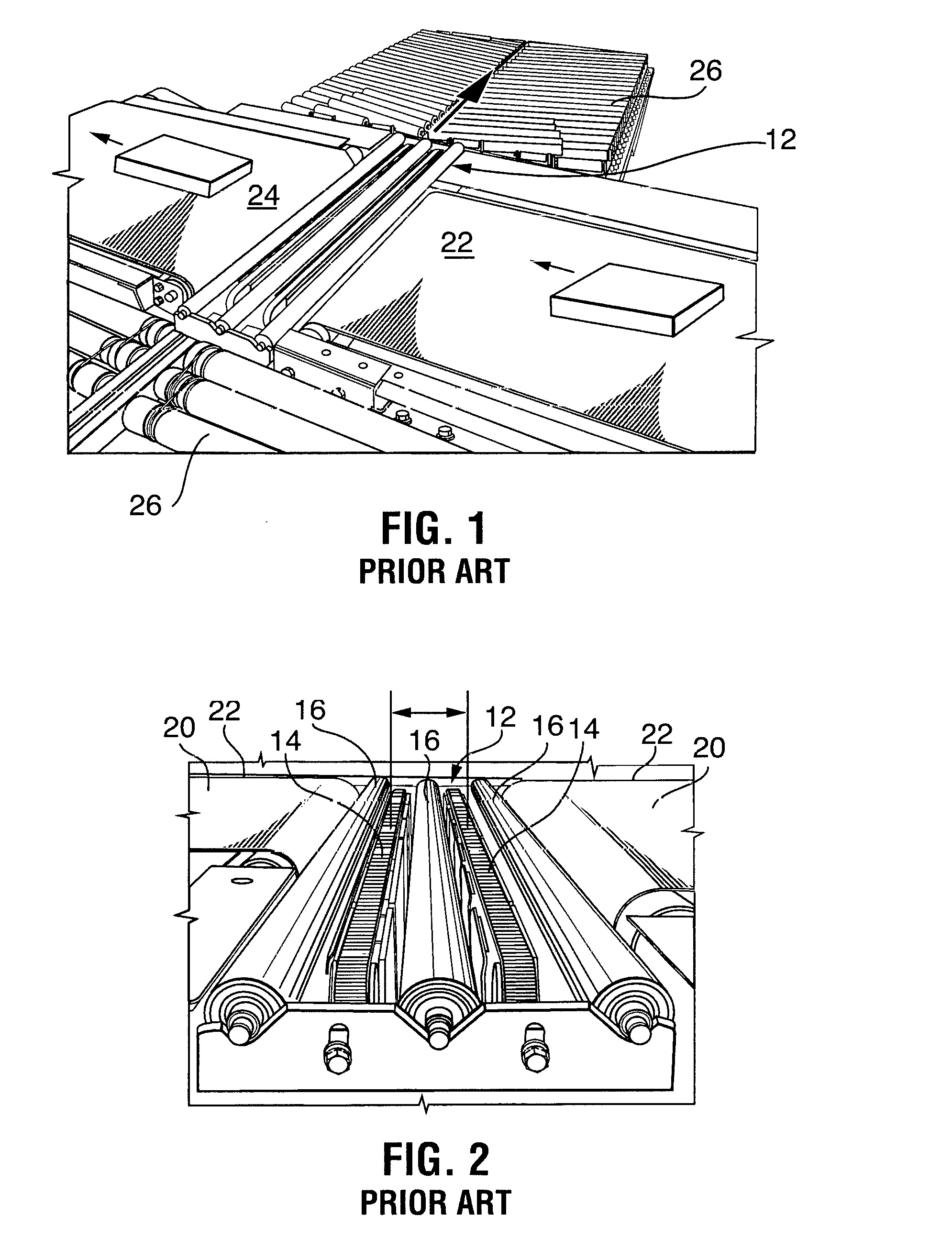

Slide sorter pop-up diverting conveyor with transfer rate based on article characteristics

ActiveUS20160221766A1Efficient loadingControl devices for conveyorsSortingTransmission beltEngineering

This invention relates generally to a conveyor system including a speed control slide sorter system disposed perpendicular to a pass through conveyor wherein the speed control improves efficiency in loading and utilizing available area on the belt and selects the conveyor speed to induce a diverter action according to sensors which detect portions of the irregular shaped packages, parcels, and bags which can be engaged by the pop-up belt at a selected time to slow the conveyor and engage the pop-up transfer conveyor without stopping the conveyor.

Owner:FIVES INTRALOGISTICS SA

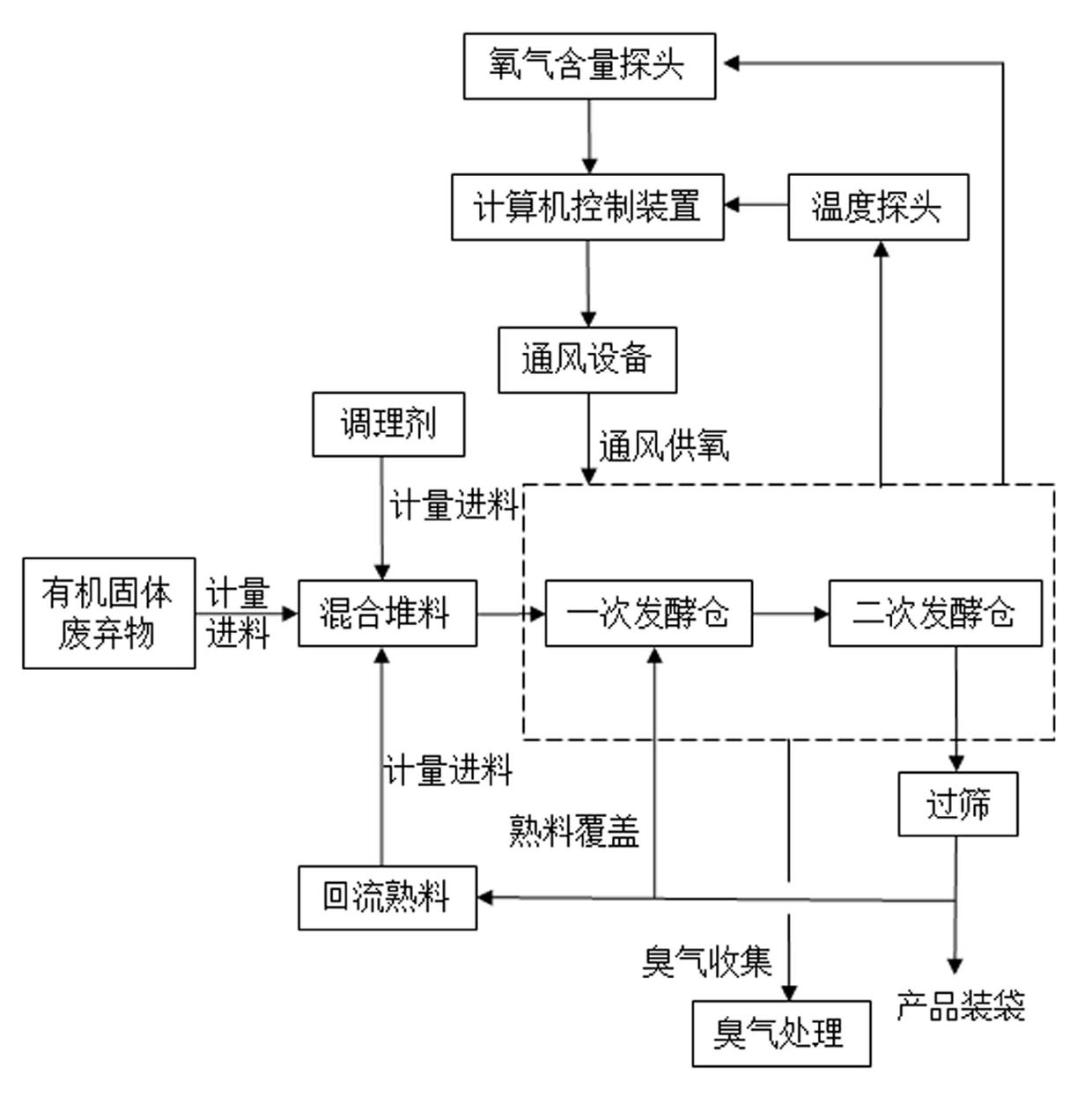

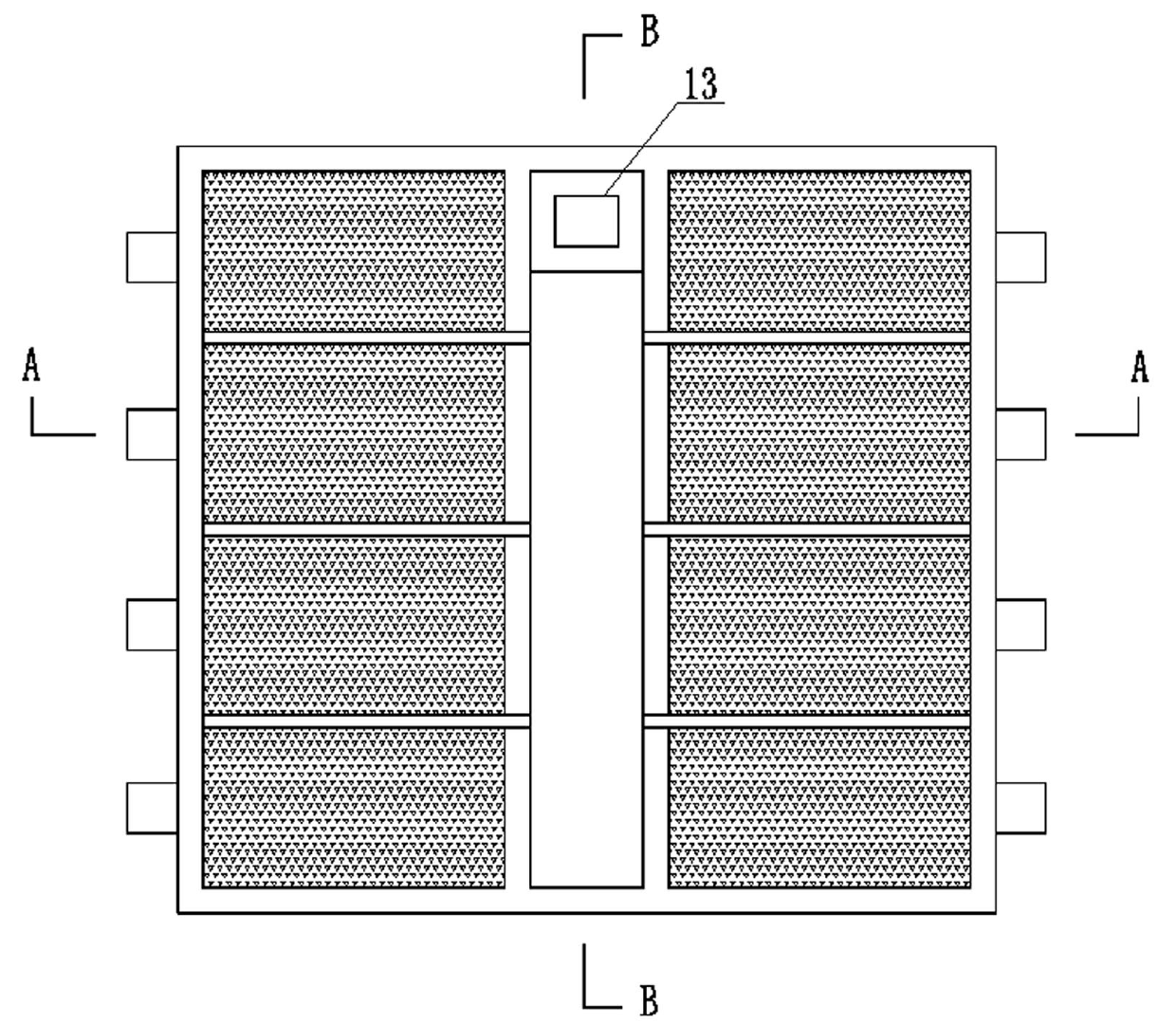

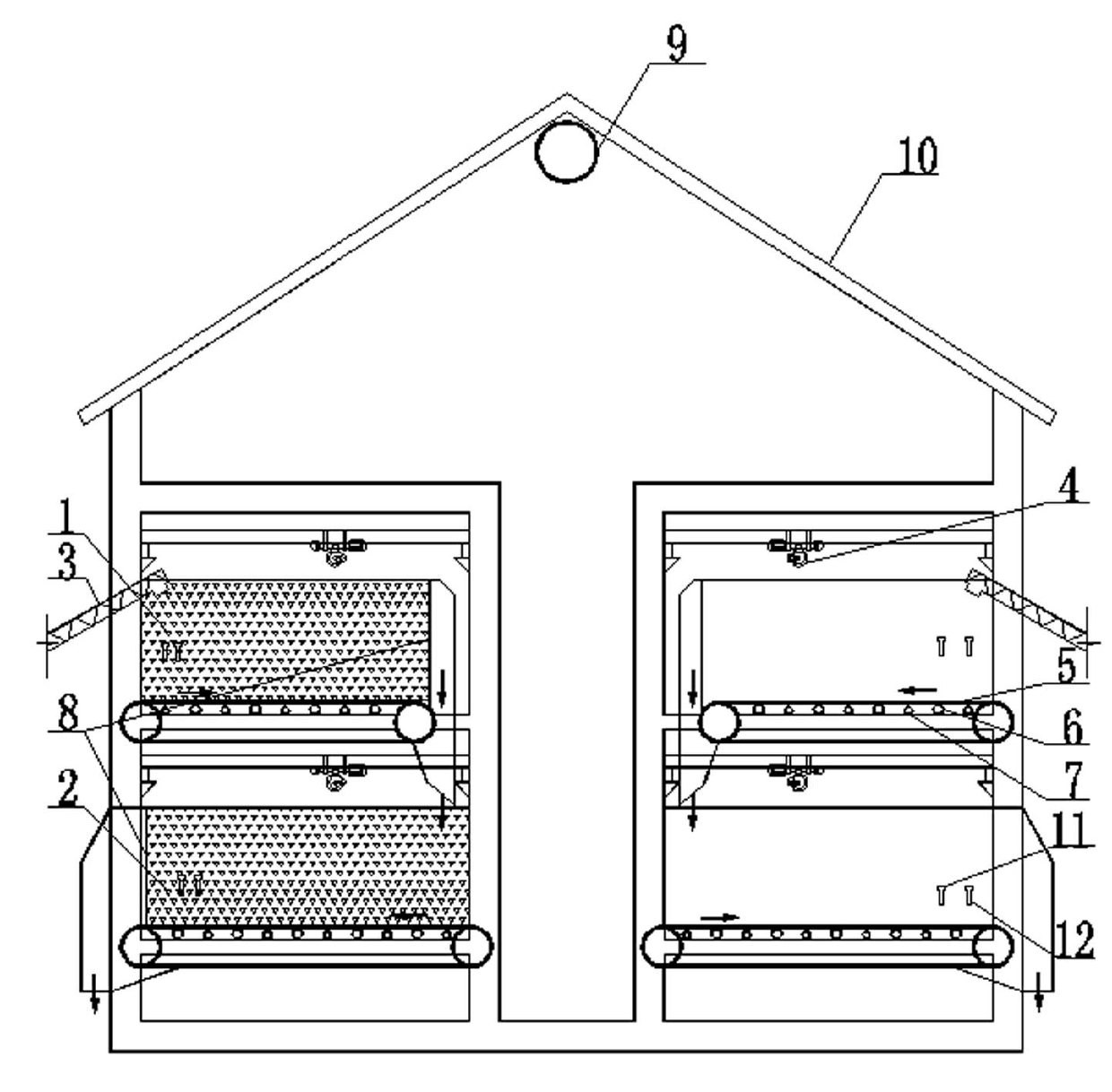

Aerobic fermentation fertilizer making device for organic solid waste and method thereof

InactiveCN102603384ARealize resource utilizationShort fermentation cycleBio-organic fraction processingClimate change adaptationTransmission beltEngineering

The invention discloses an aerobic fermentation fertilizer making device for organic solid waste, which comprises fermentation cabins, a plant, multifunctional pile turning machines, a feeding device and a screening machine, wherein multiple groups of fermentation cabins are arranged in the plant; each group of fermentation cabin comprises a primary fermentation cabin and a secondary fermentation cabin which are correspondingly arranged on an upper position and a lower position; the bottoms of the two fermentation cabins are respectively provided with a transmission belt, an idler wheel and an aeration pipe; the discharging end of the feeding device is positioned on the primary fermentation cabin; the multifunctional pile turning machines are arranged in the two fermentation cabins; the bottoms of the two fermentation cabins are respectively provided with a movable baffle; one end of the transmission belt of each fermentation cabin corresponds to the position of the movable baffle of the fermentation cabin; the outlet of the movable baffle of the primary fermentation cabin is positioned above the transmission belt of the secondary fermentation cabin; the outlet of the movable baffle of the secondary fermentation cabin is positioned above the screening machine; the top of the plant is provided with an odor centralizing pipe provided with a plurality of air inlets; and the odor centralizing pipe is connected with a deodorization device arranged out of the plant. The aerobic fermentation fertilizer making device for the organic solid waste has the advantages of small occupied land, high mechanized degree and low operation cost and is simple to operate.

Owner:中国市政工程西北设计研究院有限公司

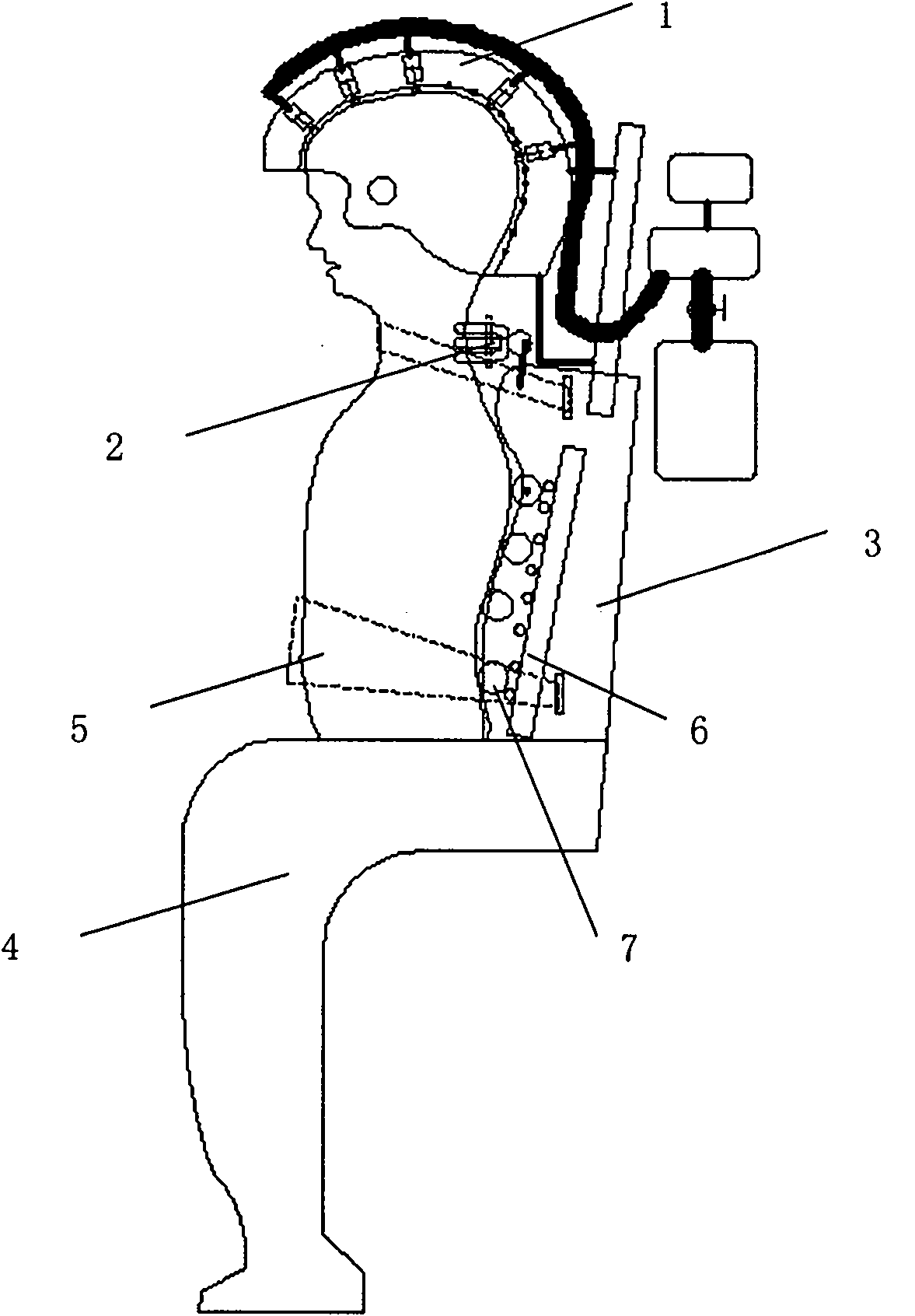

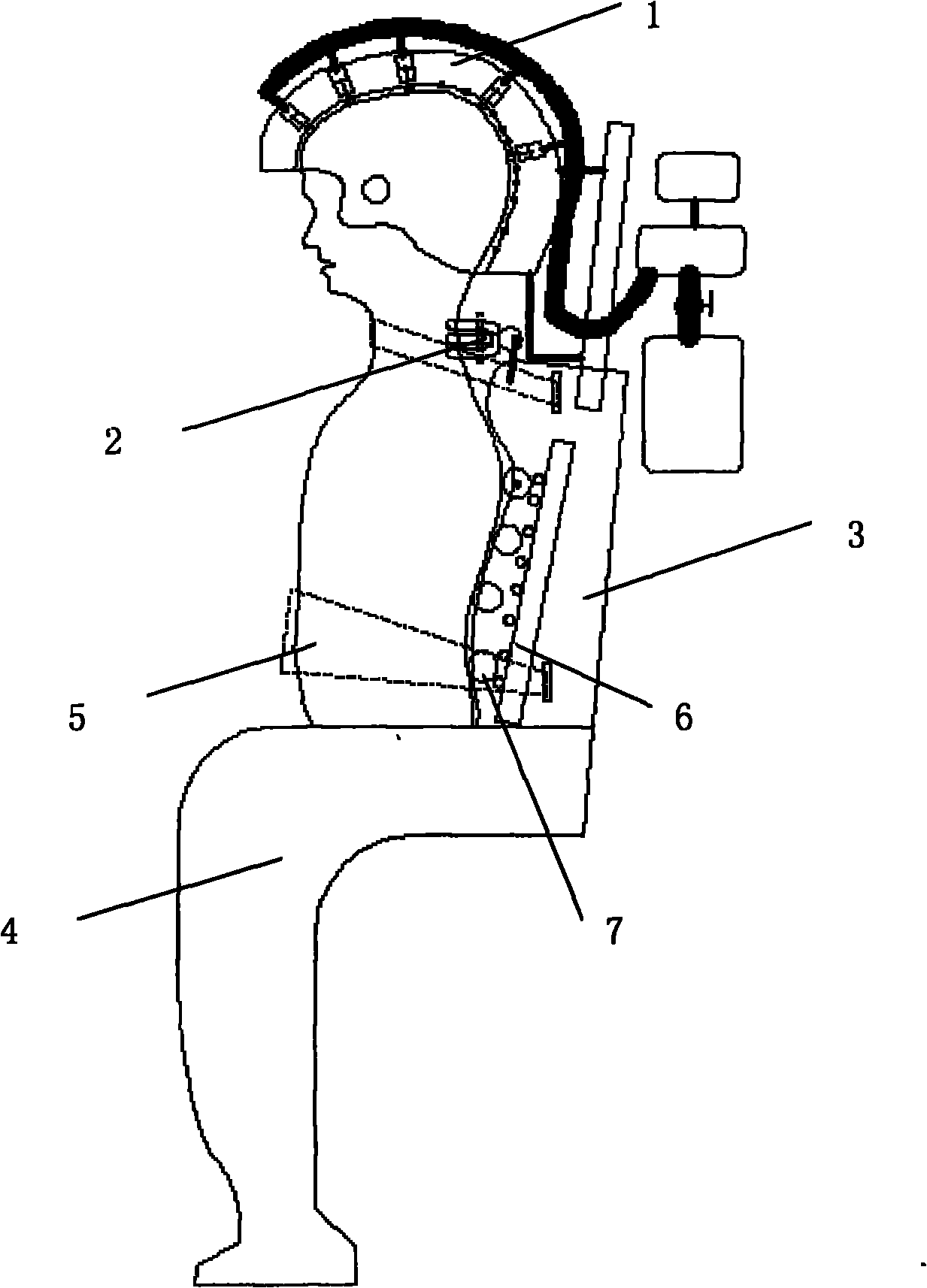

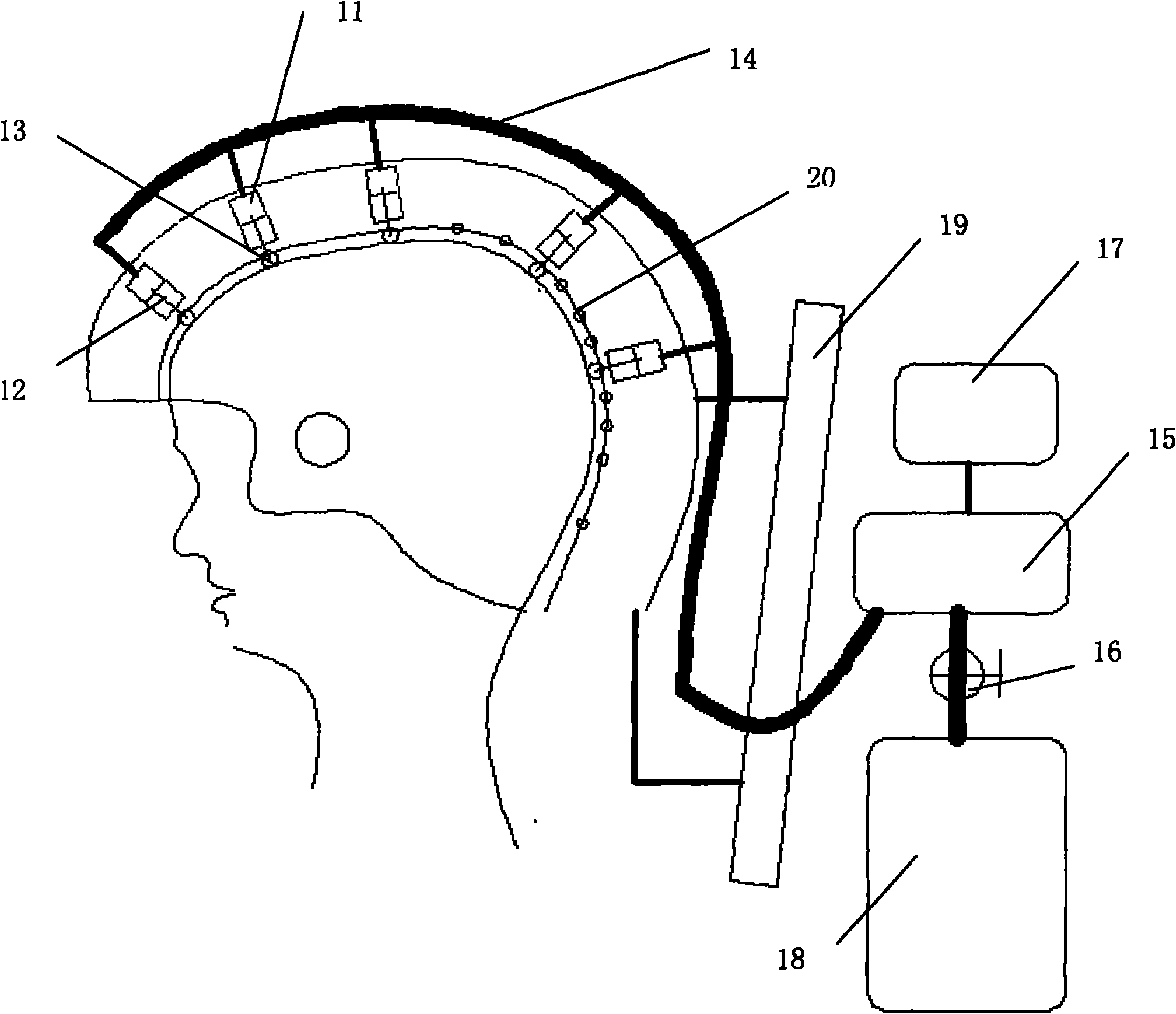

Multifunctional detachable physiotherapy massage device

InactiveCN101810538AGood health effectElectrotherapyDevices for pressing relfex pointsDrive wheelAir pump

The invention provides a multifunctional detachable physiotherapy massage device which comprises a massage helmet, a neck mechanism, a backrest and a leg mechanism. The massage helmet is internally provided with a plurality of cylinders similar to the curve of the head part, a piston, a massage head and a physiotherapy device; the cylinders are connected with an air distributing valve, an air pressure adjusting valve, an air pump and a control circuit through air ducts; the top end of the backrest is provided with the neck mechanism; the neck mechanism comprises two groups of symmetrical herringbone massage heads, eccentric cams and drive motors; the shape of the backrest is similar to the shape of the waist of the human body, the backrest is provided with a plurality of bulges and connected with a physiotherapy belt capable of automatically folding and unfolding and a plurality of massage wheels connected with an up-down moving control device, the lower end of the backrest is connected with a chair and the leg mechanism, the leg mechanism is provided with a power shaft and the eccentric wheels connected with the power shaft; and the eccentric wheels are connected with a connecting rod which is connected with a transmission belt, the transmission belt is connected with a drive wheel and a massage wheel, and the massage wheel is arranged in a slide rail.

Owner:徐克林

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com