Automatic guide control system

A control system and automatic guidance technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve problems such as damaged components and adverse effects on component performance, and achieve the effects of convenient sorting, simple structure and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

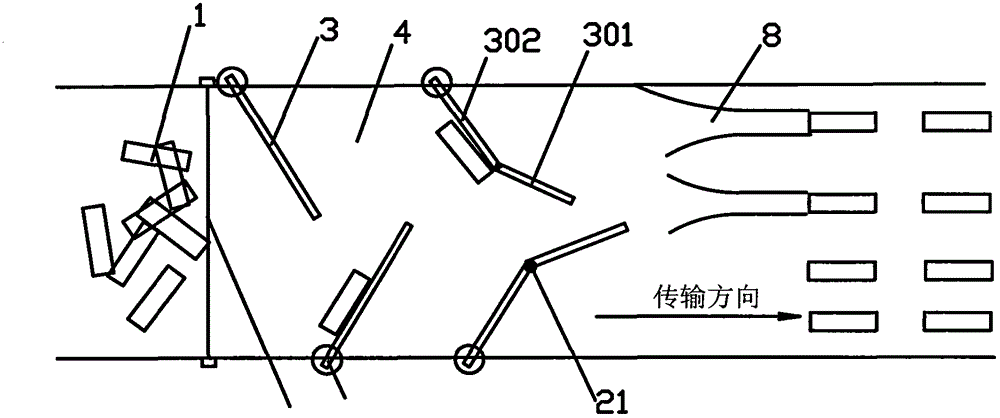

[0028] Such as figure 1 , An automatic guide control system, including: conveyor belt 4, guide arm 3, control device, height guide arm 5;

[0029] The conveyor belt is used for conveying objects in a certain direction, as shown in the figure;

[0030] The guide arms are installed on both sides of the conveyor belt through the guide arm mounting ends 30 to adjust the direction of conveying objects. The guide arms 3 can be divided into a single arm shape and a big arm shape, and multiple groups are arranged on the conveyor belt. The guide arm is inclined along the direction of object transmission, and the angle can be adjusted as required;

[0031] Among them, the single-arm guiding arm is a strip or rod shape without joint structure;

[0032] The height control arm 5 is a gantry structure for controlling the non-overlapping transmission of transmission objects;

[0033] The automatic guiding control system also includes guiding grooves 8, which can be arranged side by side in multiple g...

Embodiment 2

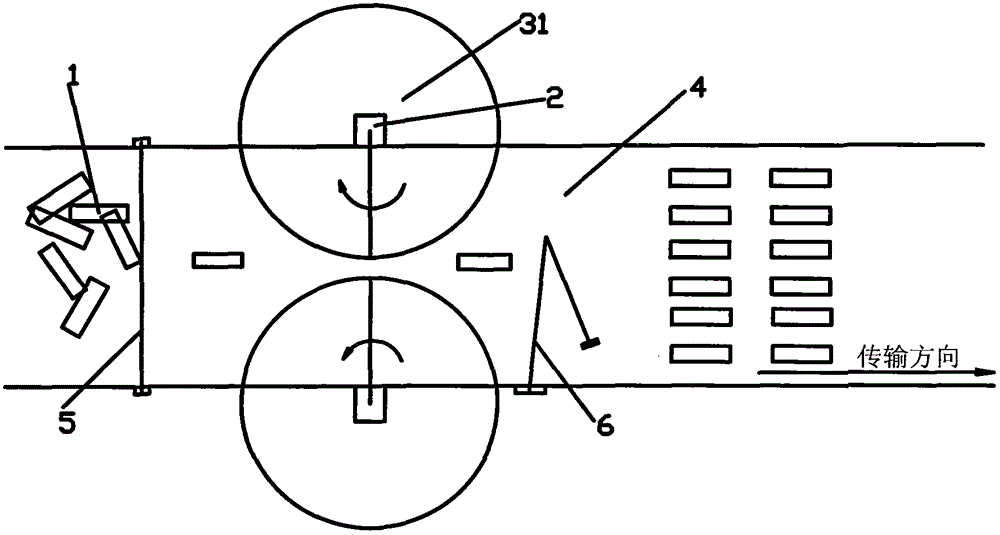

[0038] Such as figure 2 , An automatic guidance control system, including: conveyor belt 4, guide arm 3, motor 2, control device, height guide arm 5;

[0039] The conveyor belt is used for conveying objects in a certain direction, as shown in the figure;

[0040] The guide arm is installed on both sides of the conveyor belt through the guide arm mounting end 30, and the minimum distance between the two arms can accommodate the conveyed objects to pass through. The guide arm mounting end is connected to the motor 2 and can be driven by the motor The transmission direction of the conveyor belt swings;

[0041] The control device is used to control the movement of the guide arm;

[0042] The height control arm 5 is a gantry structure for controlling the non-overlapping transmission of transmission objects;

[0043] The stray and disordered objects 1 are transported by the conveyor belt 4, and after passing through the height guide arm 5, the multi-layer overlapping objects are eliminated...

Embodiment 3

[0048] On the basis of the second embodiment, the guide arm is set as Figure 5 The big arm 302 and the small arm 301 are shown connected, the joint motor 302 is fixedly connected to the big arm, the joint motor is connected to the small arm 301 and drives the small arm 301 to swing, which can ensure that the guide arm is too long and swings when the transmission belt is wide. Normal control of amplitude and speed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com