Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2389 results about "Automatic train control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automatic train control (ATC) is a general class of train protection systems for railways that involves a speed control mechanism in response to external inputs. For example, a system could effect an emergency brake application if the driver does not react to a signal at danger. ATC systems tend to integrate various cab signalling technologies and they use more granular deceleration patterns in lieu of the rigid stops encountered with the older automatic train stop technology. ATC can also be used with automatic train operation (ATO) and is usually considered to be the safety-critical part of the system.

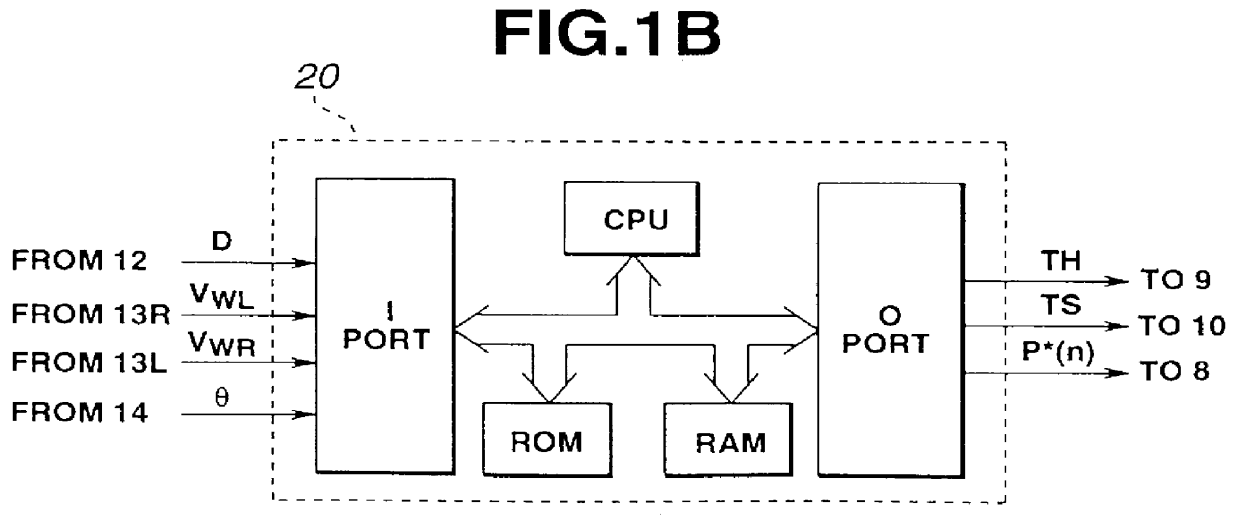

Method and system for automatic control of vehicles based on carrier phase differential GPS

InactiveUS6052647AImprove system stabilitySimple processDigital data processing detailsPosition fixationAutomatic train controlAutomatic control

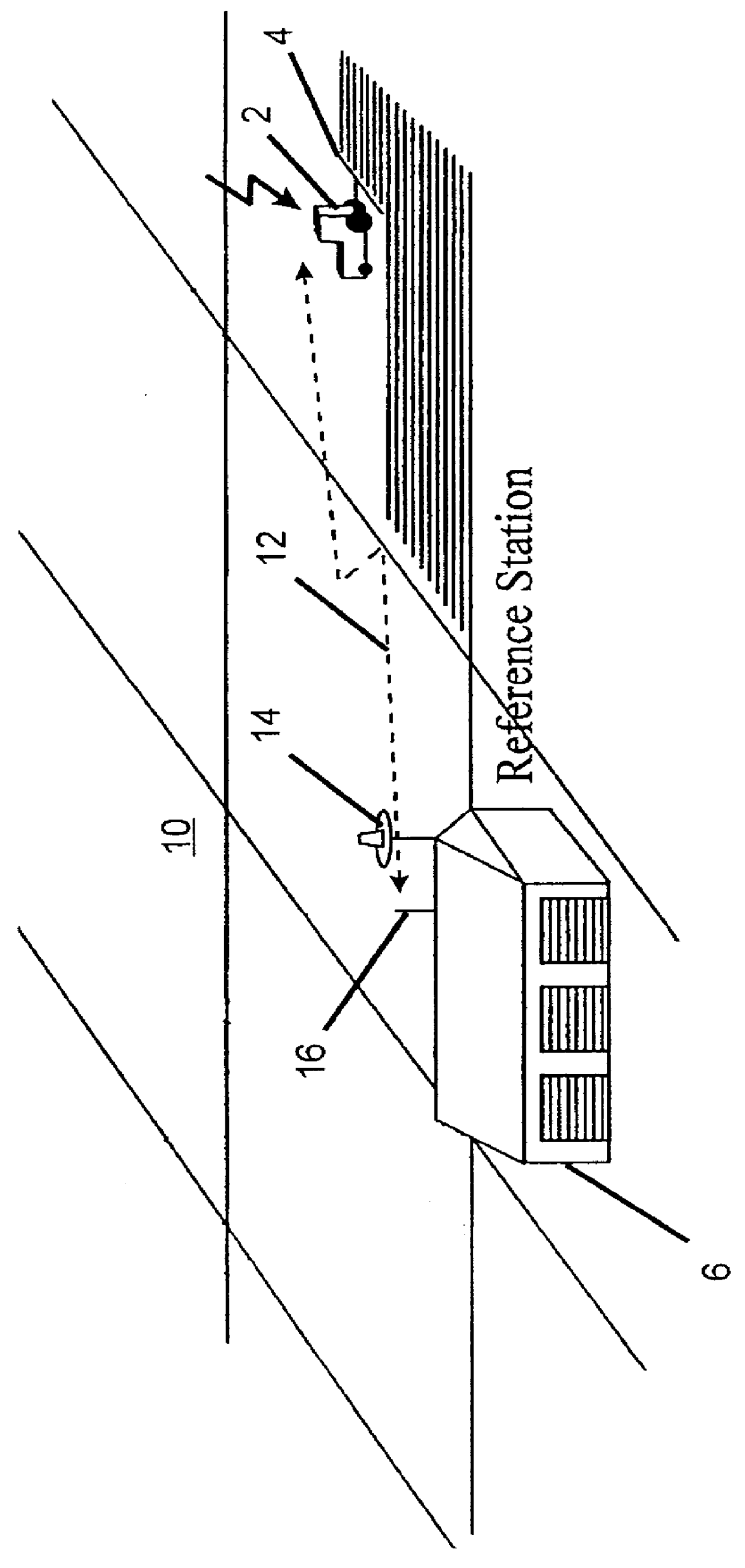

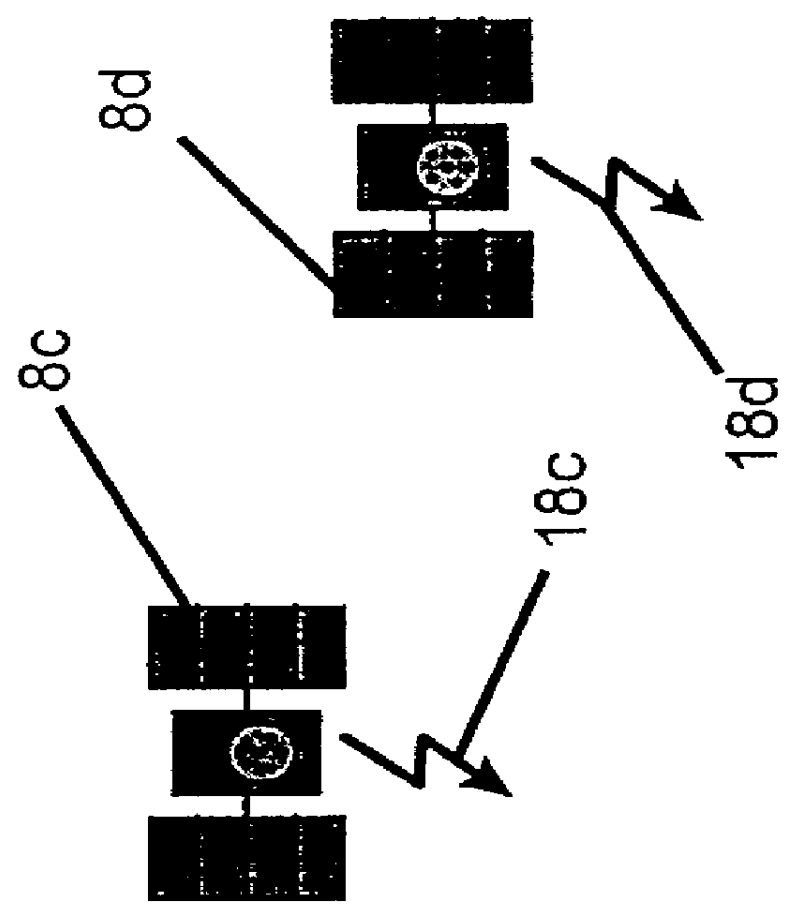

Described is an automatic control system for land (and possible marine) vehicles based on carrier phase differential GPS (CPGPS). The system relies on CPGPS to determine vehicle position and attitude very precisely (position to within 1 cm and attitude to within 0.1 DEG ). A system incorporates a technique to calculate and compensate for antenna motion due to vehicle roll and pitch. One aspect of the system utilizes an intelligent vehicle controller that recognizes and adapts to changing conditions, such as vehicle speed, implements towed by the vehicle, soil conditions, and disturbance level. The system provides the capability to control the vehicle on various paths, including straight lines and arbitrary curves. Also described is a technique for initialization and vehicle control using only a single pseudolite.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV +1

Automatic frequency control of multiple channels

ActiveUS7218901B1Broadband local area networksHybrid switching systemsCable transmissionMultiplexing

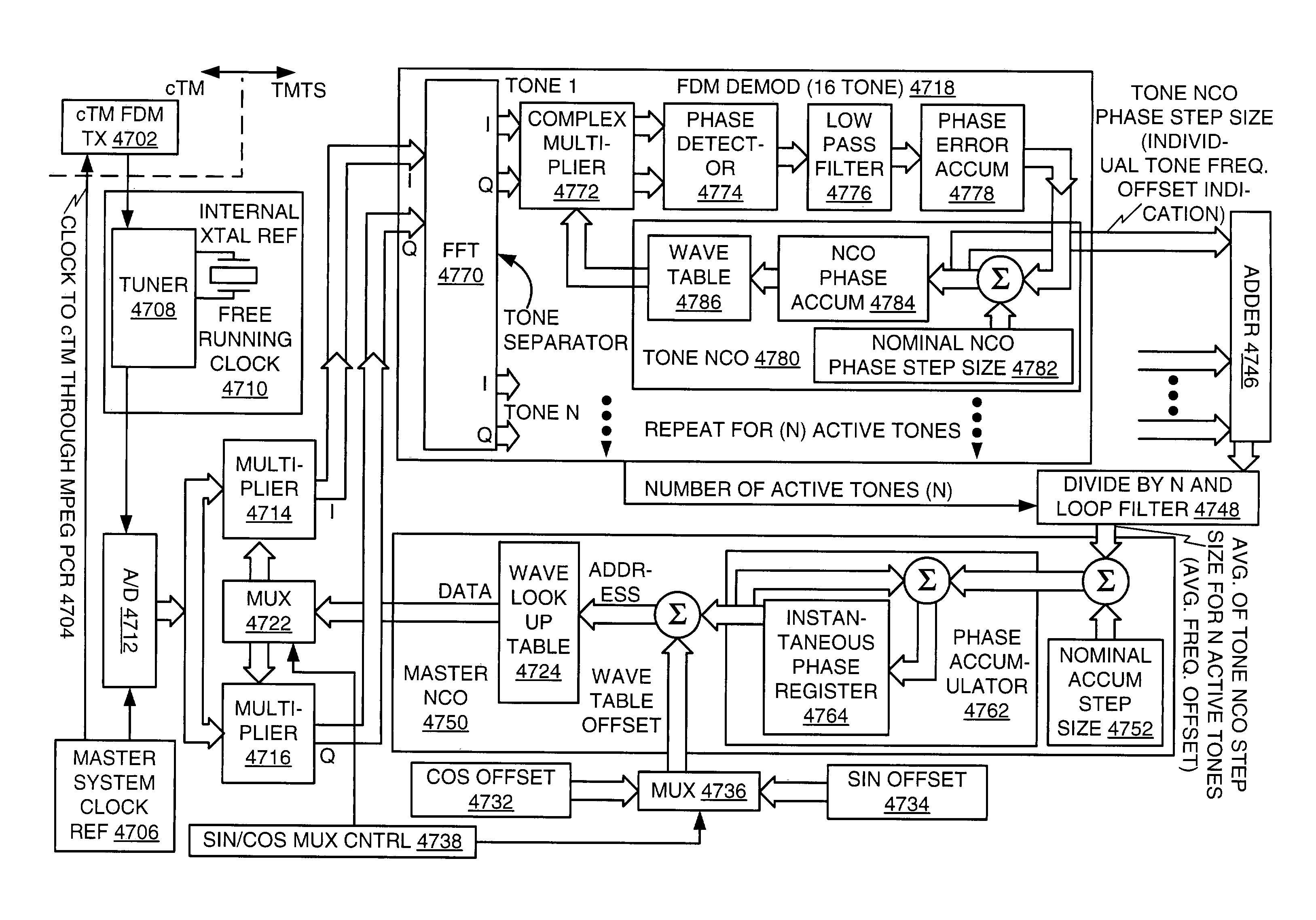

An architecture for providing high-speed access over frequency-division multiplexed (FDM) channels allows transmission of ethernet frames and / or other data across a cable transmission network or other form of FDM transport. The architecture involves downstream and upstream FDM multiplexing techniques to allow contemporaneous, parallel communications across a plurality of frequency channels. Moreover, an automatic frequency control resolves some issues of a free-running clock in an upstream tuner of the central concentrator by performing adjustments based on the average frequency error of a number of active upstream tones. In the preferred embodiments of the present invention, the automatic frequency control (AFC) utilizes a feedback loop for at least each active upstream tone. Also, the average of the active upstream tones is determined and is utilized in providing feedback to adjust the automatic frequency control (AFC).

Owner:CISCO TECH INC

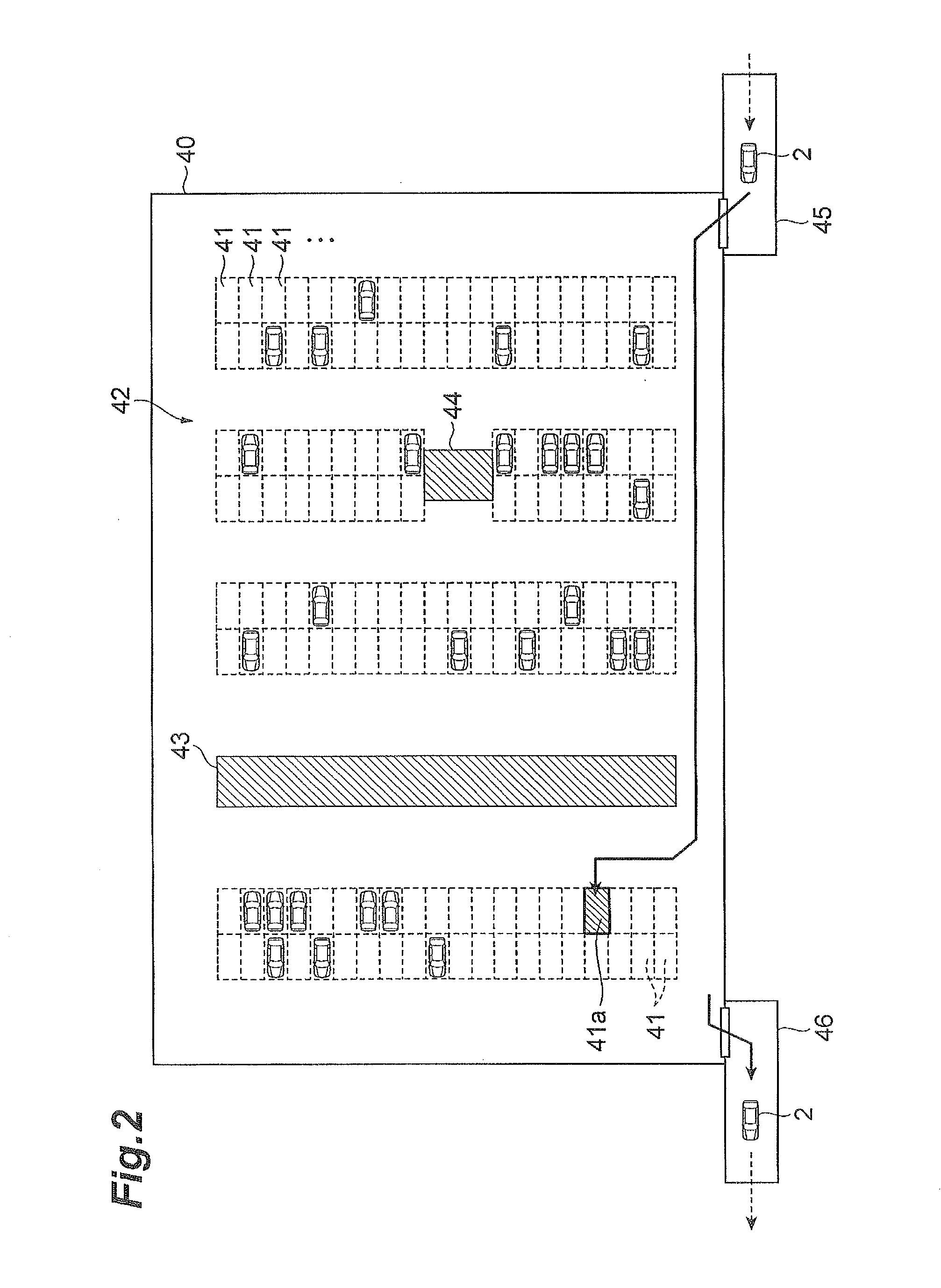

Automatic parking system

ActiveUS20150353080A1Automatic securing/unlockingSteering partsAutomatic controlAutomatic train control

An automatic parking system is disclosed. The automatic parking system includes: a monitoring device configured to monitor a parking space and a traveling path in a parking lot; an automatic drive unit configured to perform an automatic drive control for a vehicle in the parking lot to move from a current position to a predetermined target position in the parking lot based on a monitoring result of the monitoring device; and a contact determination unit configured to perform a contact determination between the vehicle in the automatic drive control and an obstacle, based on the monitoring result, or the like. In a case where the contact determination is performed by the contact determination unit, the automatic drive unit causes the vehicle to stop, and then, causes the vehicle to move to a removal position and to be parked using the automatic drive control.

Owner:TOYOTA JIDOSHA KK

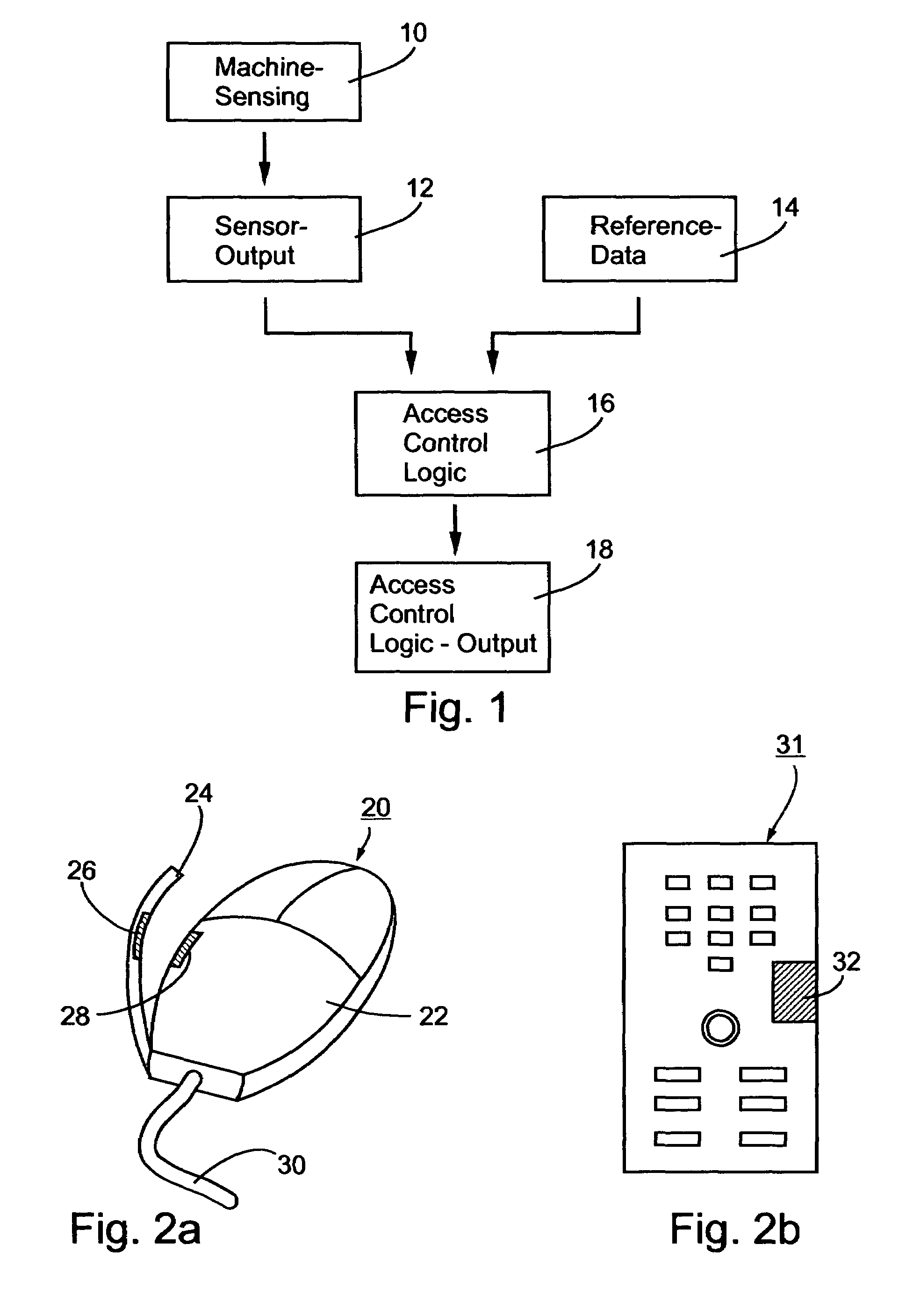

Method and apparatus for automatic control of access

InactiveUS7370208B2Easy to understandOrgan movement/changes detectionPerson identificationAutomatic train controlChat room

A method and apparatus for controlling access of individuals to a service, device or location in order to restrict access to members of a particular age and / or gender category, by machine-sensing a predetermined biometric characteristic of the individual indicative of the particular age and / or gender category, and utilizing the machine-sensed characteristic for automatically controlling access of the individual. The method and apparatus are particularly suited to controlling access of children to certain Internet sites, TV programs, chat rooms, or other places inappropriate to children.

Owner:LEVIN SHMUEL

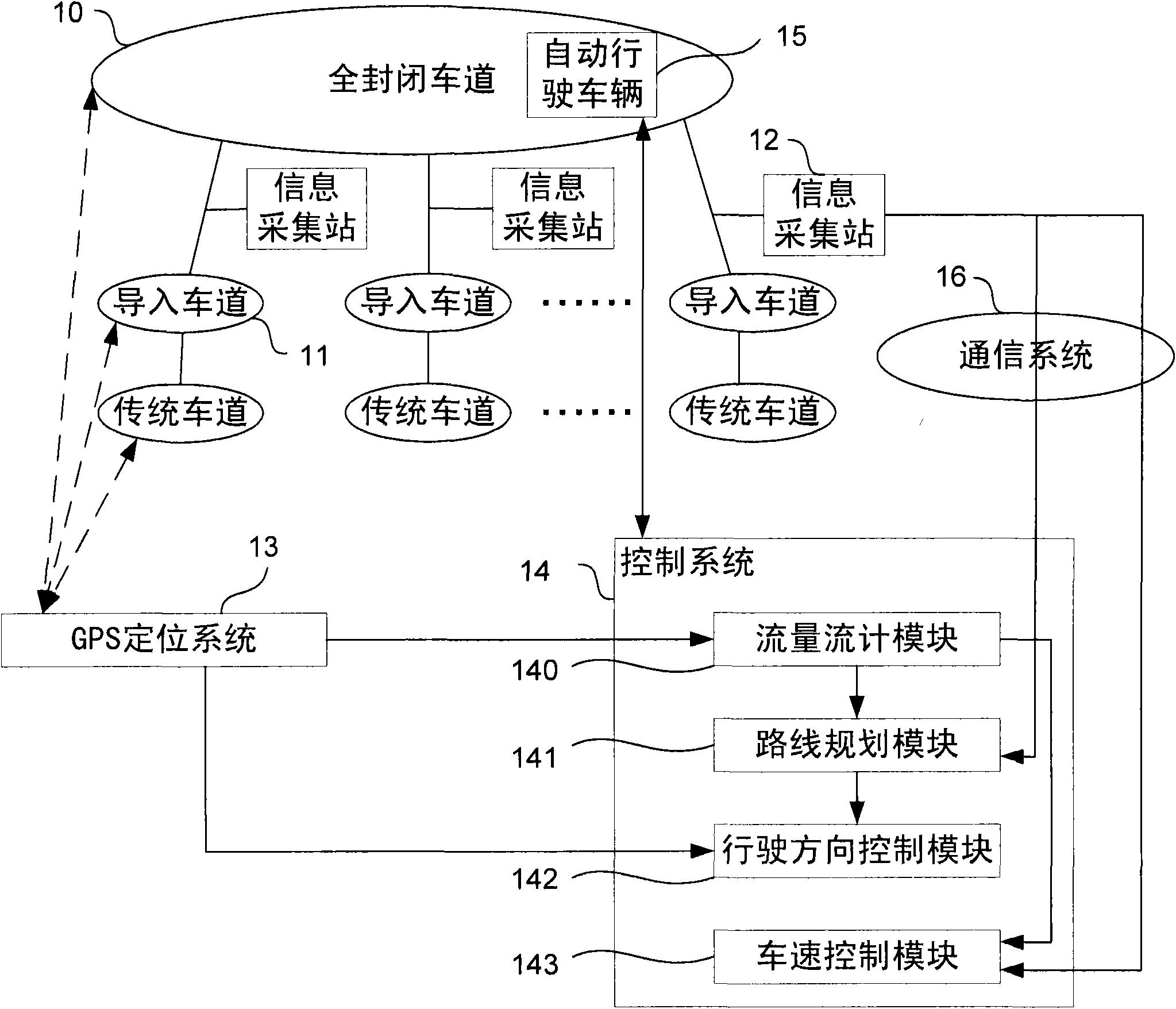

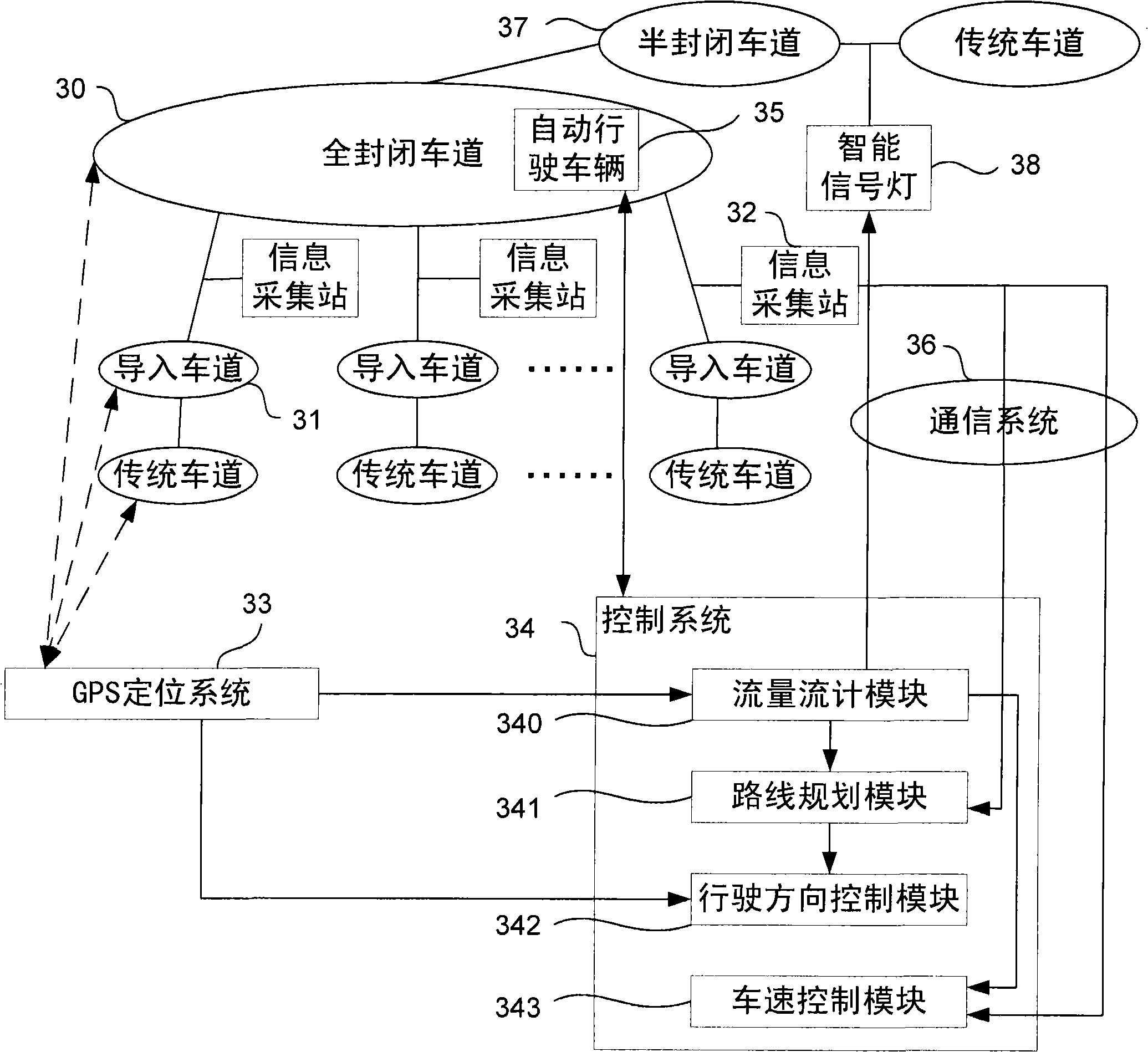

Intelligent traffic system

ActiveCN101799977AControlling traffic signalsDetection of traffic movementInformatizationAutomatic control

The invention discloses an intelligent traffic system, which reduces traffic jam, environmental pollution, accident rate and the load of drivers and achieves the aims of ensuring security, improving efficiency and environment and saving energy resources. The technical scheme is that the invention adopts the intelligent traffic system which is formed by a road system composed of a lead-in lane and a totally-closed lane, a GPS positioning system, a 3G or 4G communication system, a control system and automatic travel vehicles. After using the intelligent traffic system, the driver can give up autonomic driving and uses automatic driving controlled by the system to reach the destination. The intelligent traffic system uses advanced information technology, data communication transmission technology, global positioning technology, geographic information system technology, electric control technology and computer processing technology, is a novel transportation system integrating informatization, intelligent and socialization and makes traffic infrastructure exert the largest efficacy.

Owner:马正方 +1

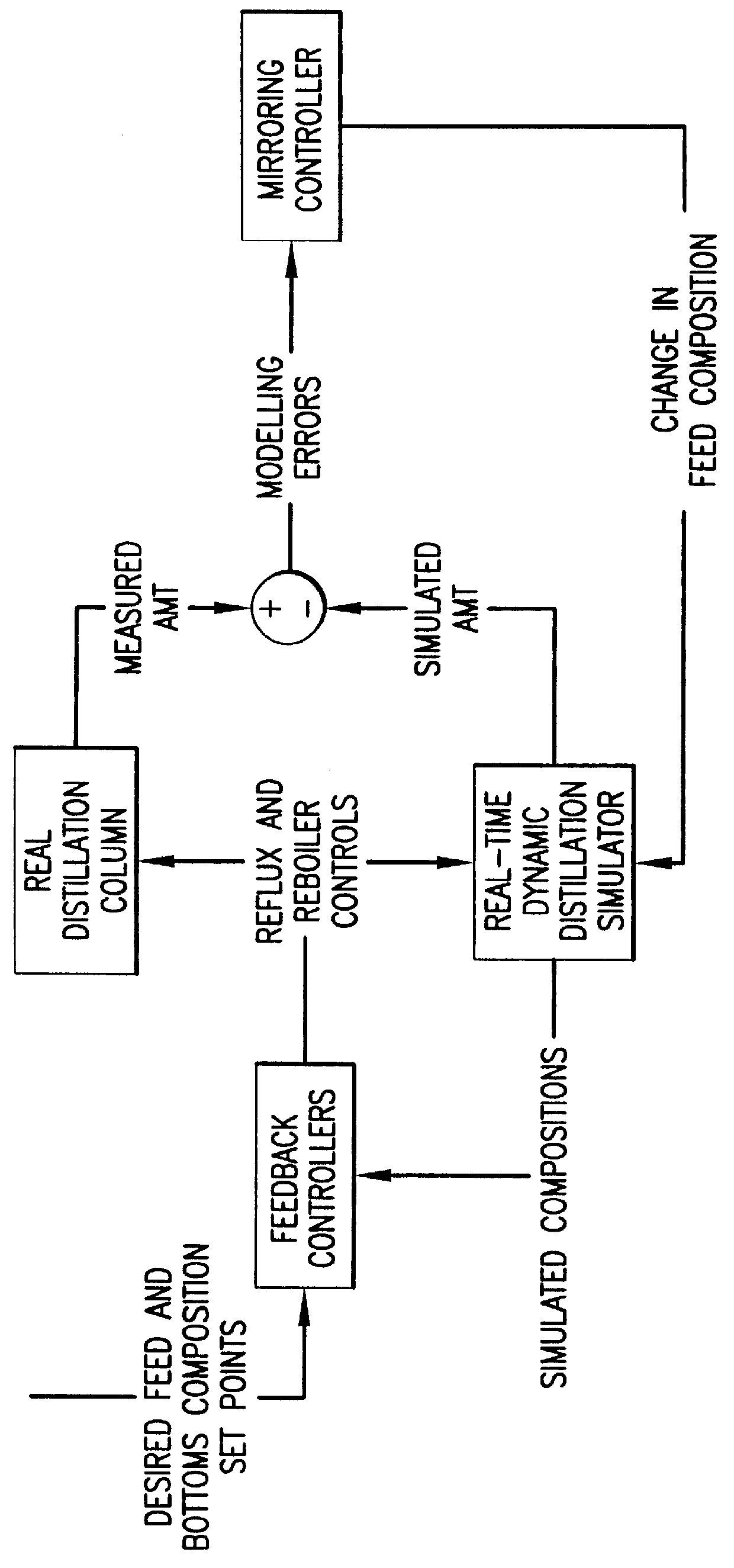

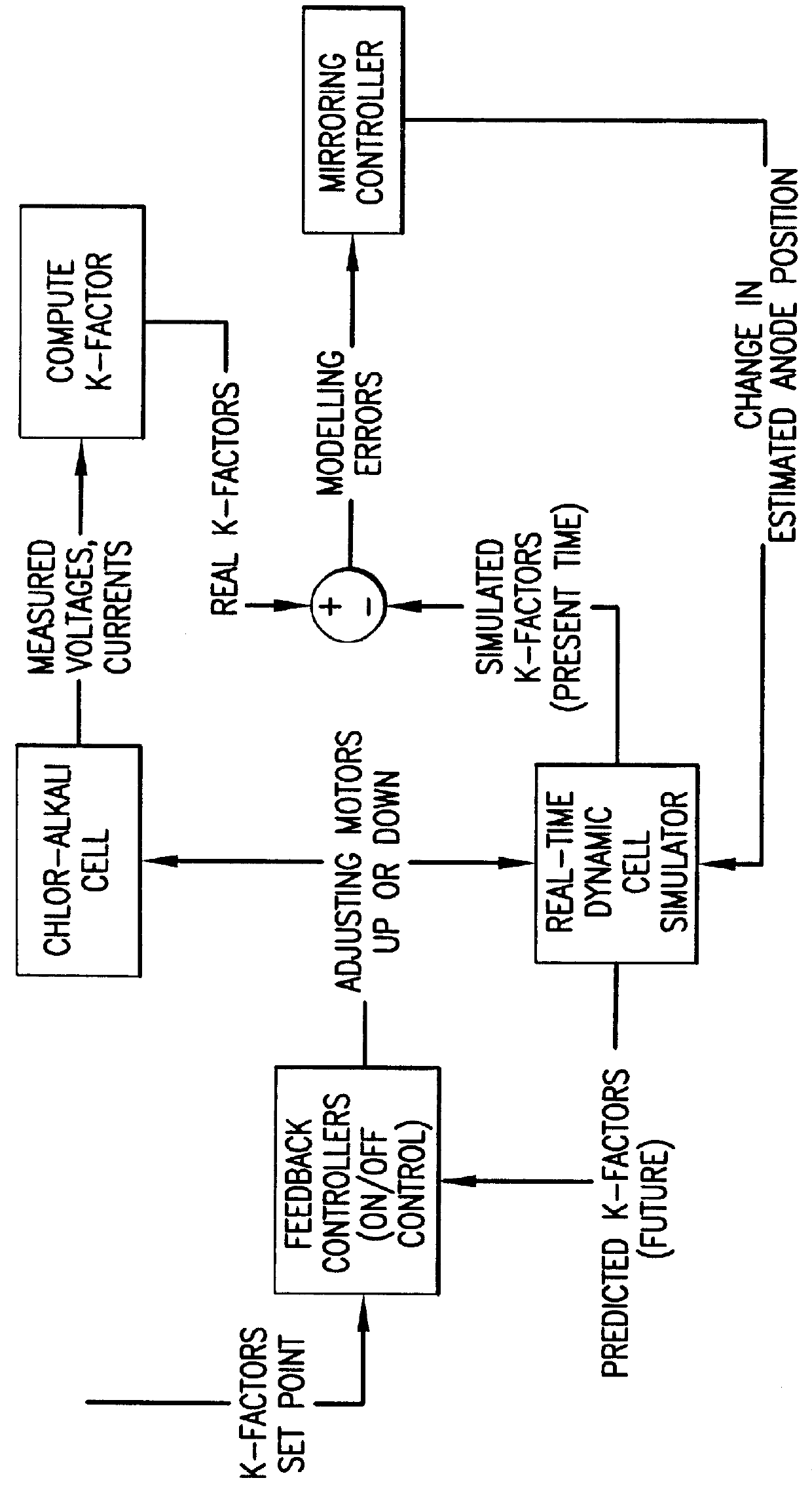

Automatic control system for unit operation

InactiveUS6088630AImprove stabilityAccurate predictionSampled-variable control systemsPhotography auxillary processesAutomatic controlAutomatic train control

Automatic control systems, and corresponding processes, for controlling either an anode adjuster in a chlor / alkali cell or at least one average middle temperature of a distillation column wherein the combination of feedback control from at least one real unit operation variable and an embedded real-time dynamic simulation of that variable are used.

Owner:OLIN CORP

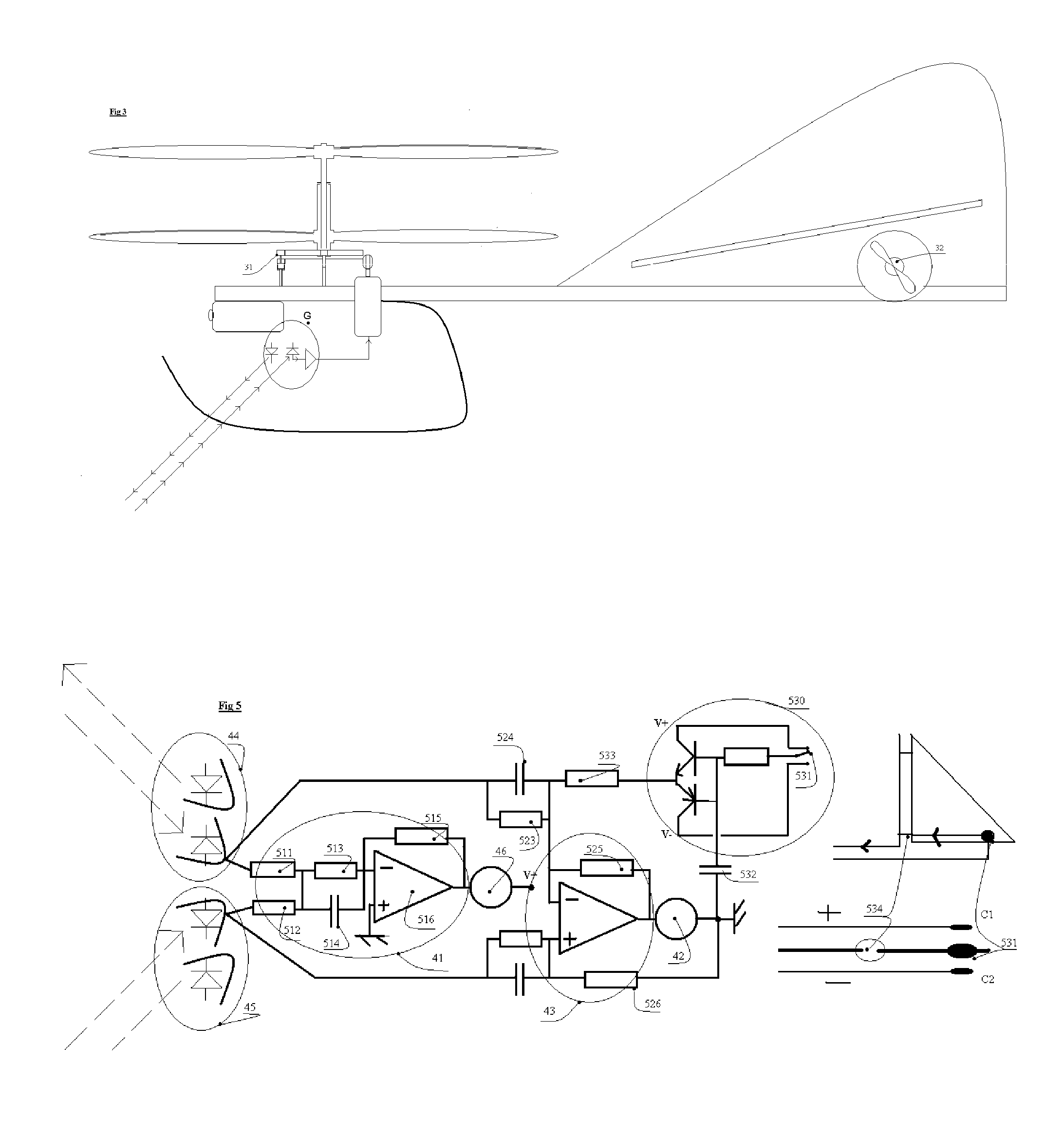

Automatic flight control helicopter

InactiveUS20100161155A1Unmanned aerial vehiclesDigital data processing detailsAutomatic controlAutomatic train control

The invention relates to an autonomous helicopter for recreational purposes or for a swarm-type surveillance system, characterised in that the helicopter has a complete automatic flight control, and in that the flight thereof is stable and automatic due to a device for the automatic control of the altitude, comprising at least two optical receivers, at least one optical emitter, at least two channels for processing signals of the receivers, and at least two motors controlling at least two propellers, at a speed proportional to the total amount of signals received. Said helicopter avoids obstacles by means of an orientation device controlled by the difference between the signals of the two receivers. It advances at a regular speed by means of a shift of the centre of gravity thereof in front of the axis of the two lifting propellers.

Owner:JM CONCEPTS

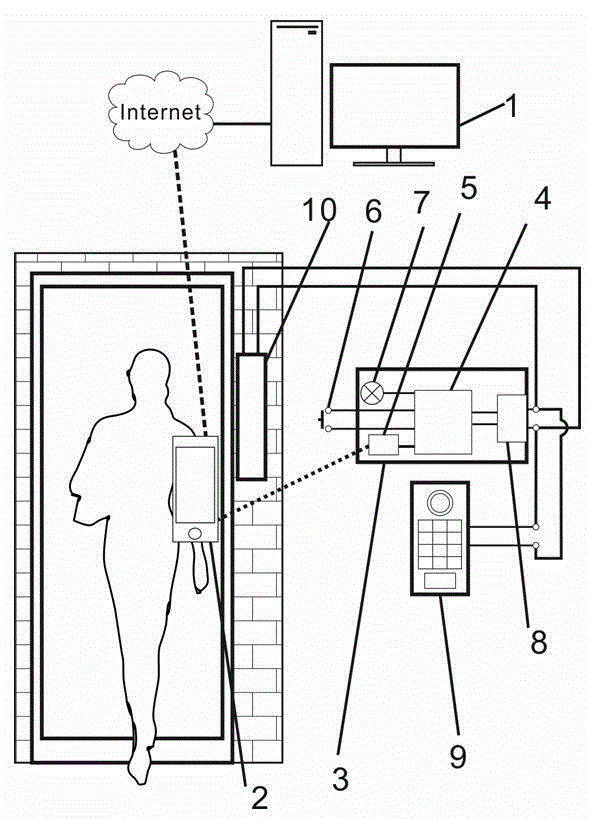

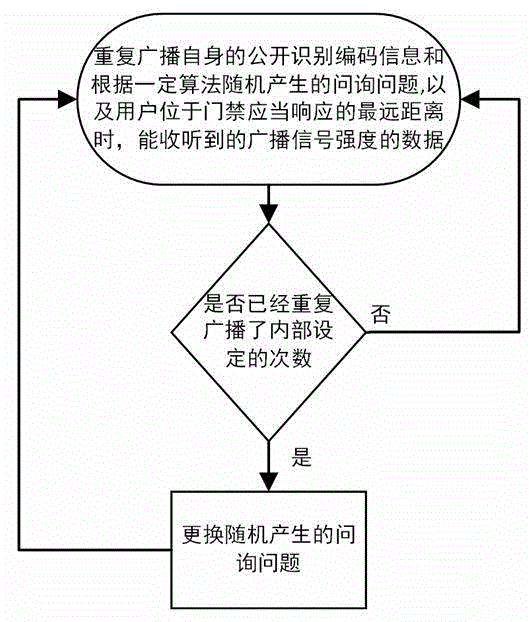

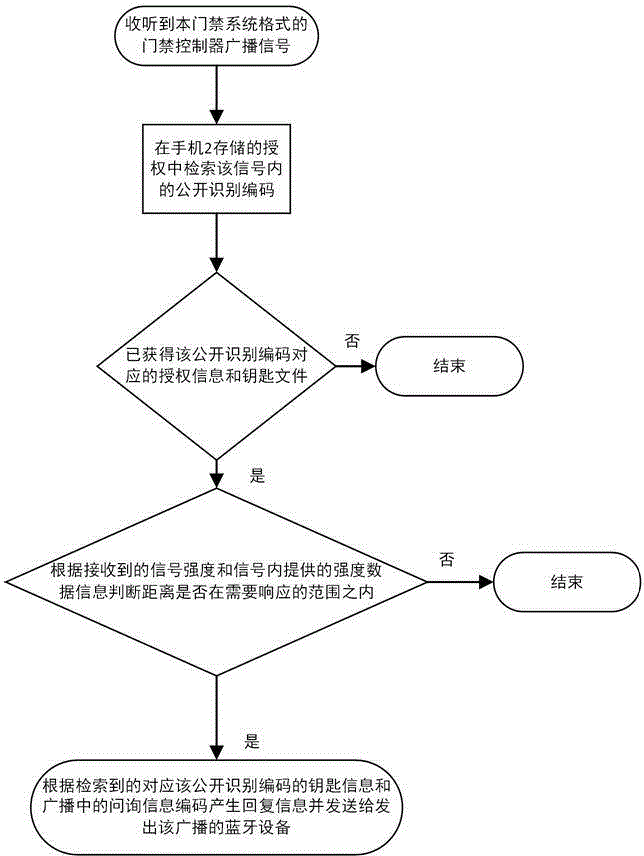

Automatic access control system based on mobile phone Bluetooth communication and implementation method thereof

InactiveCN104103111AReduce workloadIncrease internal clockIndividual entry/exit registersAutomatic controlAutomatic train control

The invention discloses an automatic access control system based on mobile phone Bluetooth communication and an implementation method thereof. The automatic access control system comprises an access controller mounted at an entrance, a mobile phone, an access control program, a remote management server and the like, wherein a Bluetooth communication module, a data processing unit and a relay control circuit are arranged in the access controller; after the mobile phone of a user is equipped with the access control program, the user can obtain authorization and key information provided by the management server according to the user identity; when the user is located near the Bluetooth access controller, the mobile phone and the access controller are communicated through a Bluetooth signal; the Bluetooth access controller judges whether the door can be opened according to communication content, if the door can be opened, the access controller controls a relay to open the door automatically, or a door opening switch is activated, and the relay can be controlled to open the door once the user presses the switch; and if the communication content is inconsistent with the setting of the Bluetooth access controller, no reaction is performed. Therefore, the door is opened without operation, and convenience is provided for the user.

Owner:张明

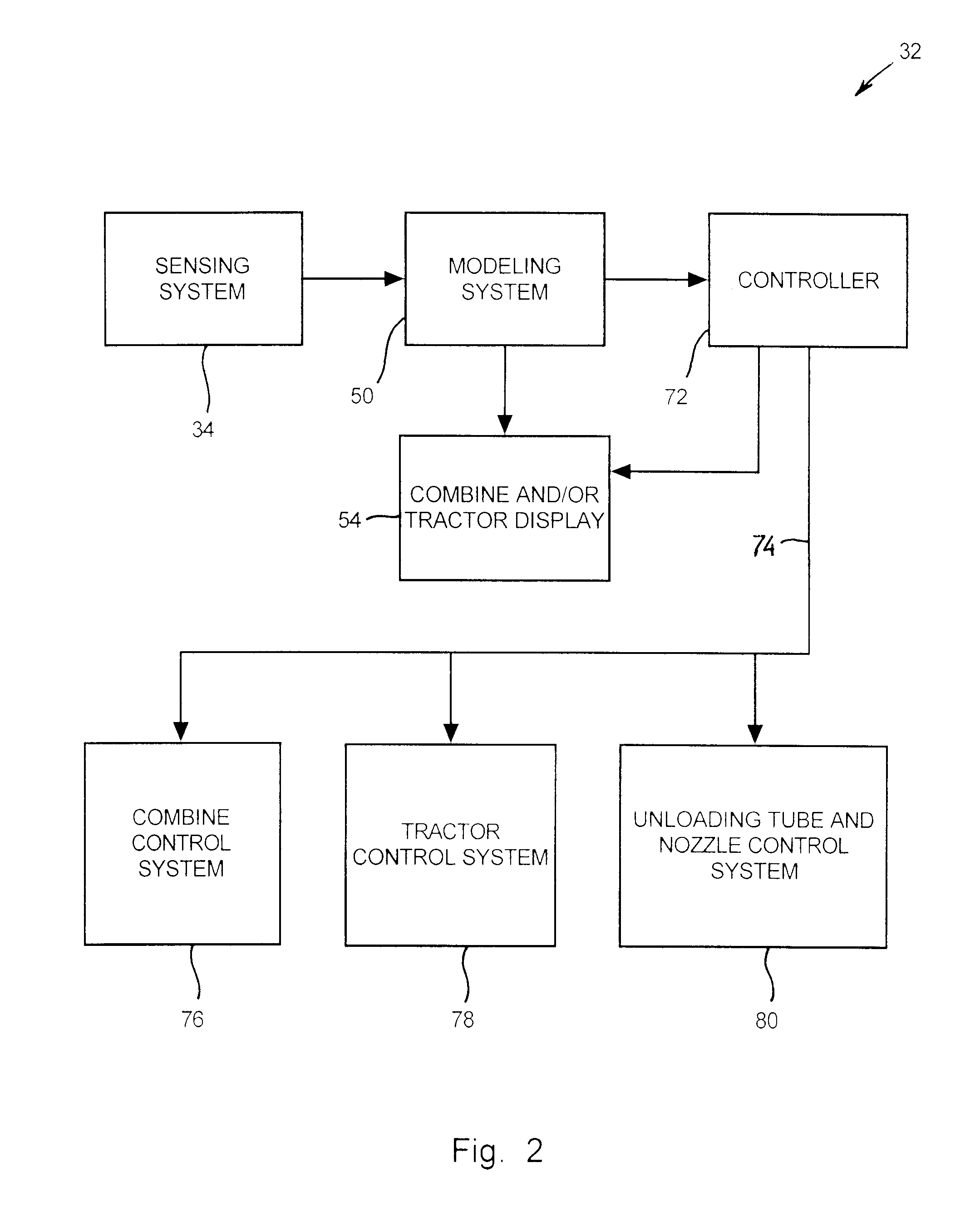

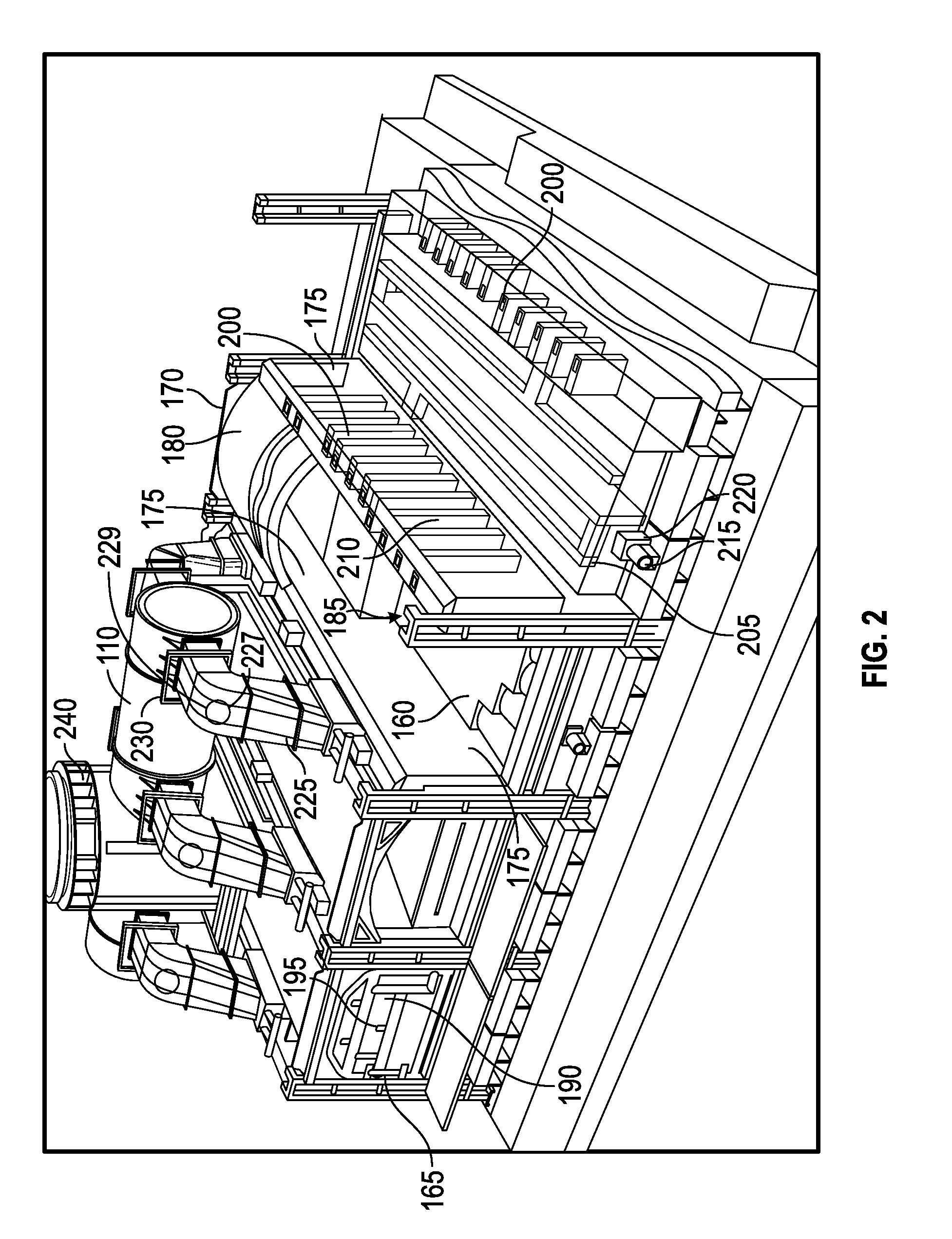

Automatic grain transfer control system based on real time modeling of a fill level profile for regions of the receiving container

A grain transfer control system for automatically controlling relative positions of an unloading system discharge nozzle of a work machine and a receiving container based on a real time model of a fill level profile for regions of the receiving container, the profile being modeled using known or estimated rates of flow of grain and positions of the nozzle relative to regions of the receiving container as a function of time, the system adjusting the relative positions of the nozzle and the receiving container to effect a generally even fill of the receiving container.

Owner:CNH IND AMERICA LLC

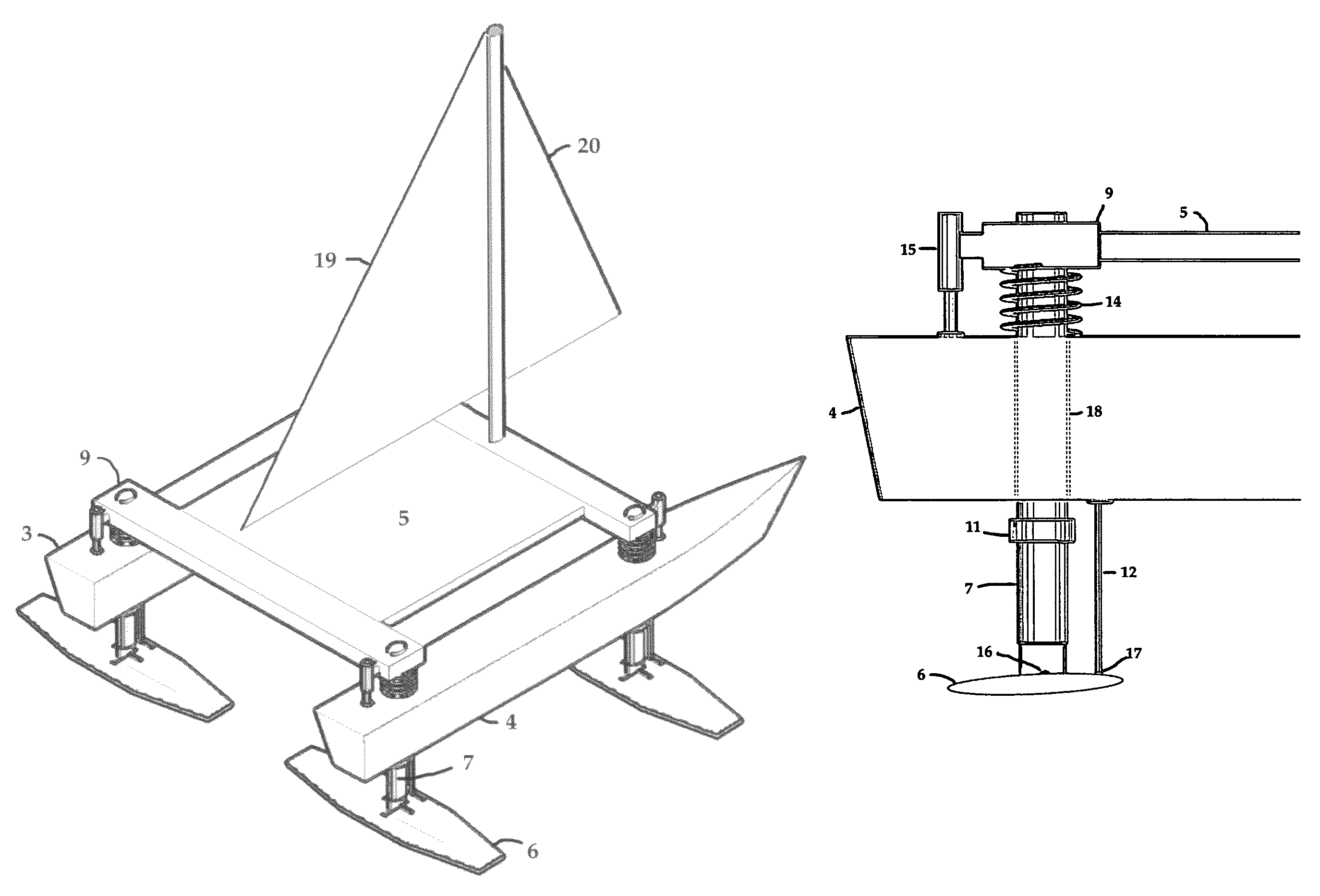

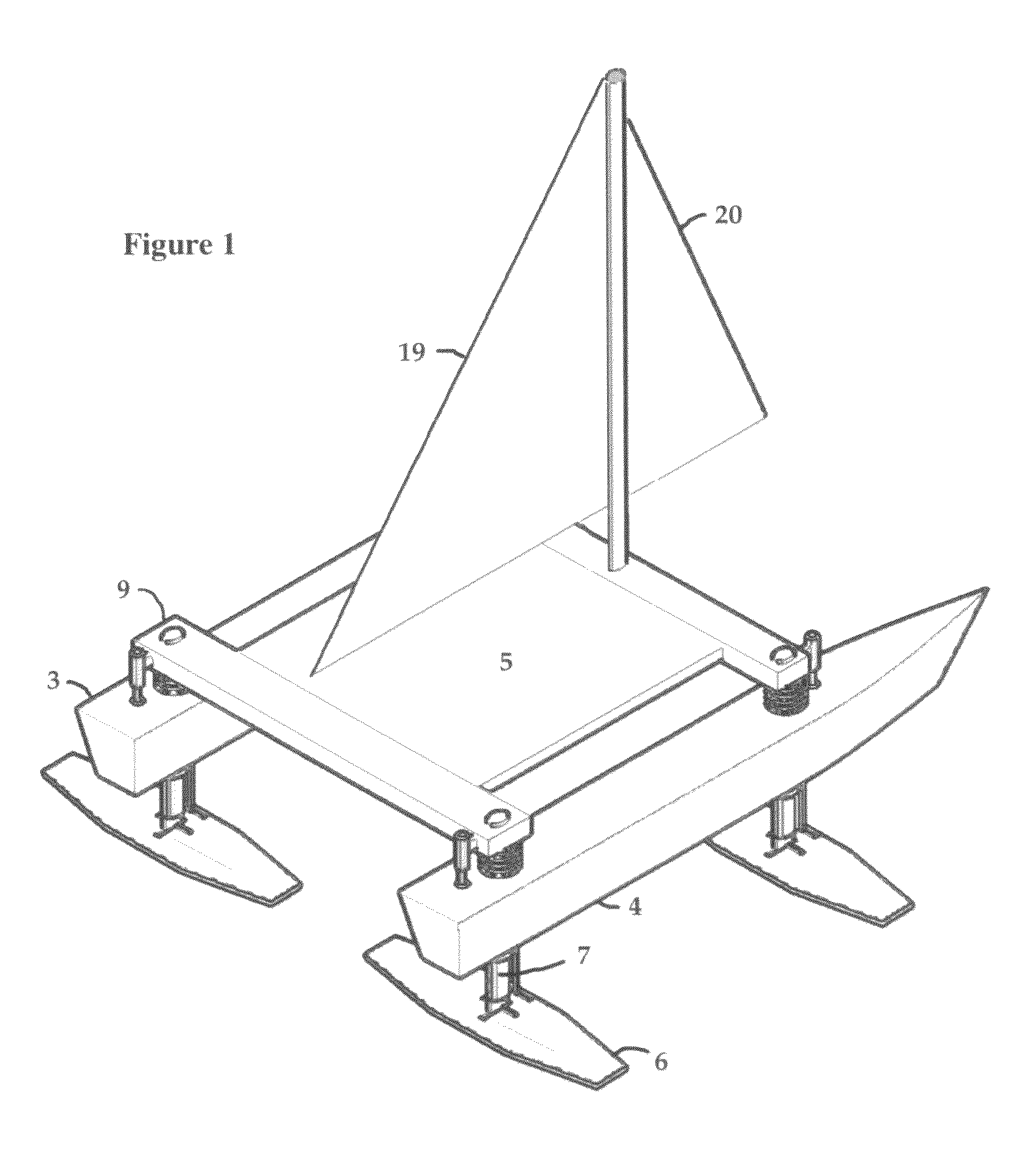

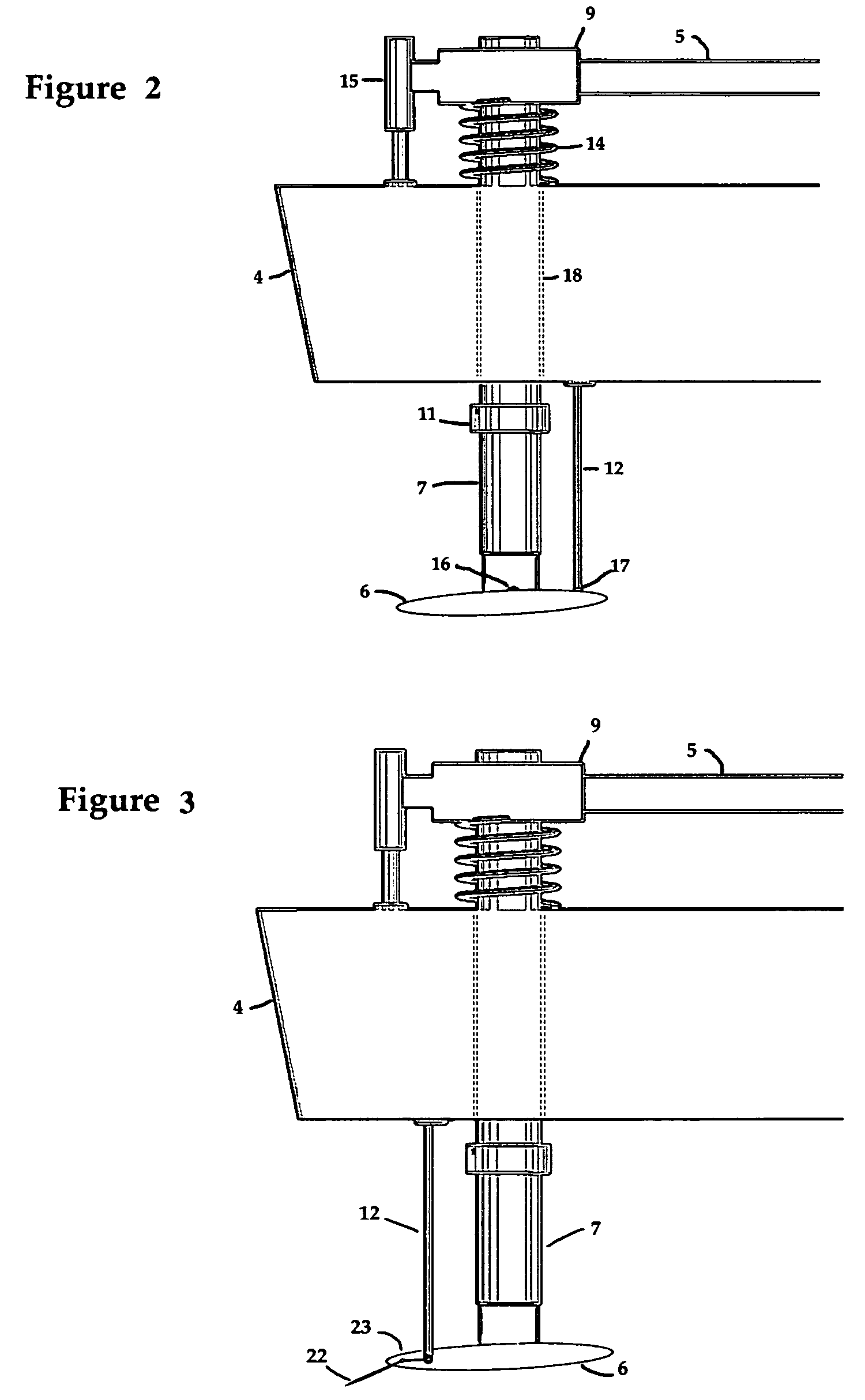

Multihull hydrofoil watercraft

InactiveUS7743720B1Reduce angle of attackReduce lifting forceVessel partsVessel movement reduction by foilsAutomatic controlAutomatic train control

A multihull hydrofoil watercraft incorporates a stabilization system wherein the buoyancy of the hulls is used as a sensing and control mechanism for the hydrofoils. The use of hull buoyancy to adjust the hydrofoil lift provides for automatic control of altitude, pitch and roll, and allows the craft to accommodate varying weather and sea conditions while providing a smooth ride for passengers. The stabilization technique eliminates the need for extraneous sensing mechanisms placed in or on the water surface which are subject to fouling, damage, or disruption by localized surface disturbances.

Owner:SALANI STEVEN JOHN

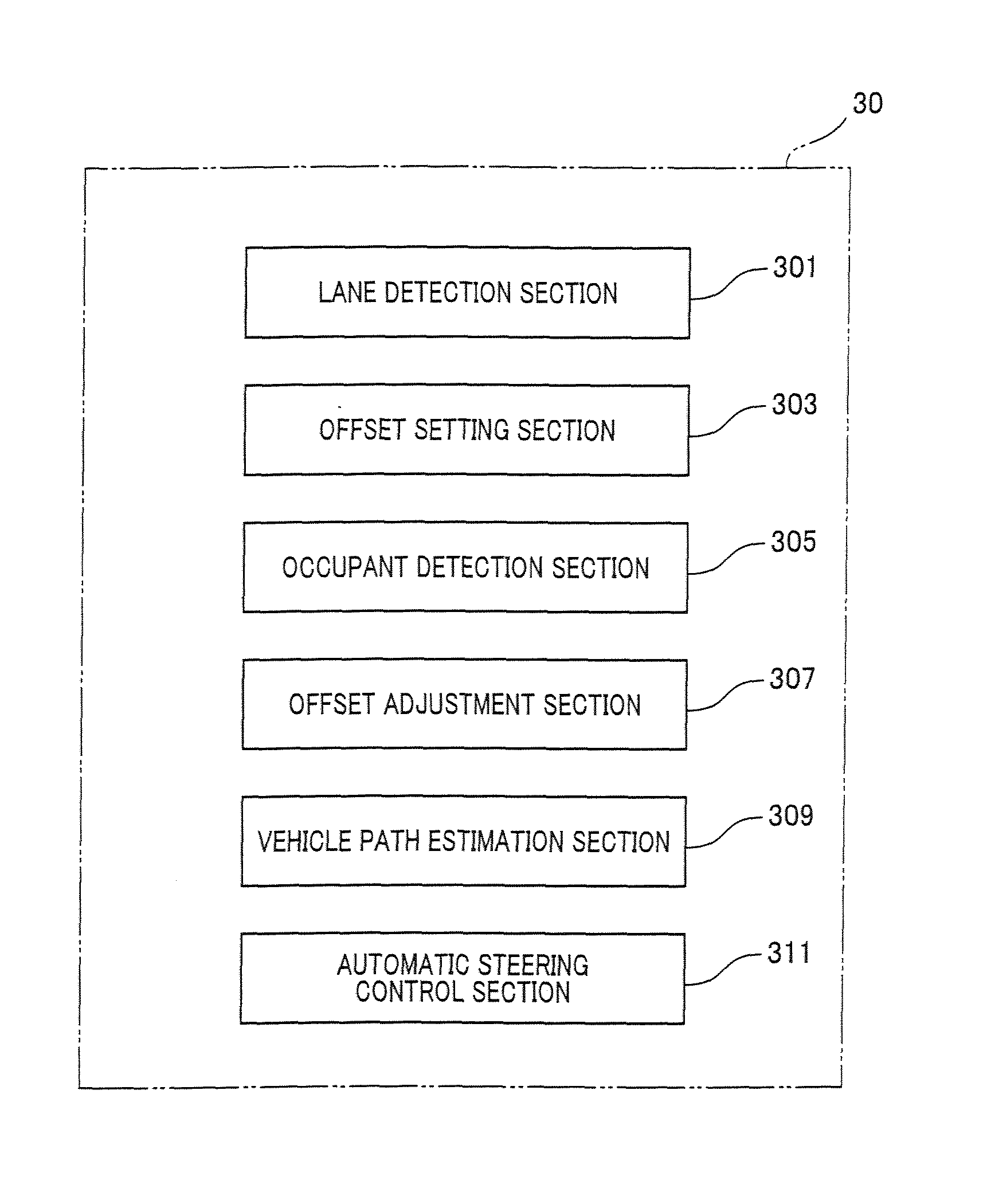

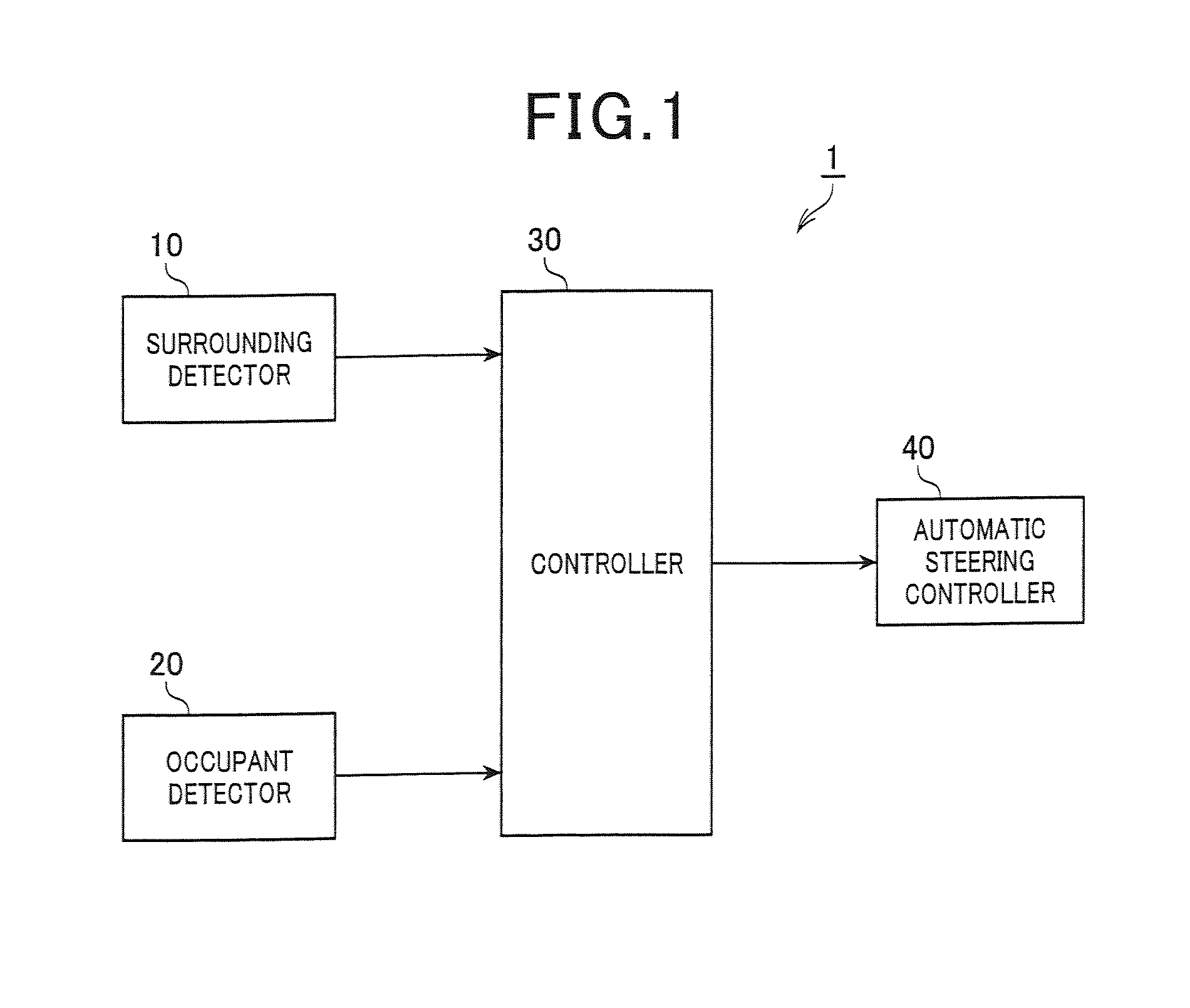

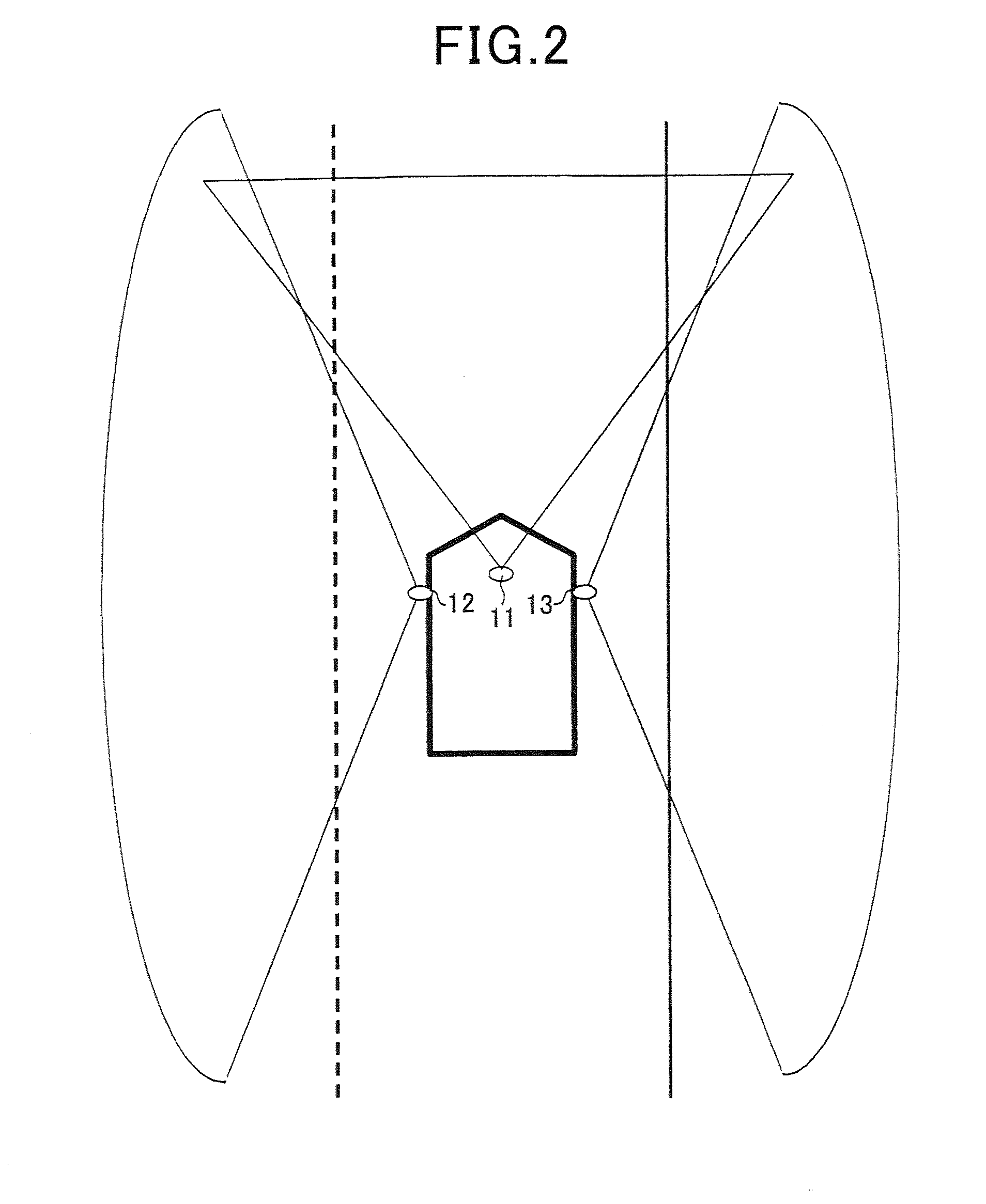

Vehicle control apparatus

InactiveUS20130226406A1Easy to adjustPrevent unnecessary steering controlDigital data processing detailsSteering initiationsAutomatic train controlAutomatic steering

A vehicle control apparatus capable of automatic steering control while reducing discomfort or stress on vehicle occupants. In the apparatus, a lane detection unit detects a lane in which the vehicle is traveling. An offset setting unit sets an offset within the lane suitable for making a driver feel less stressed. An occupant detection unit detects the presence of a designated occupant of a seat opposite a driver's seat. An offset adjustment unit, when the designated occupant is detected, adjusts the offset set by the offset setting unit to be decreased. A vehicle-path estimation unit estimates a vehicle path in the lane such that the vehicle can travel along the vehicle path from a current lateral position to a target lateral position of the vehicle. An automatic steering control unit automatically controls steering so that the vehicle travels along the estimated vehicle.

Owner:DENSO CORP +1

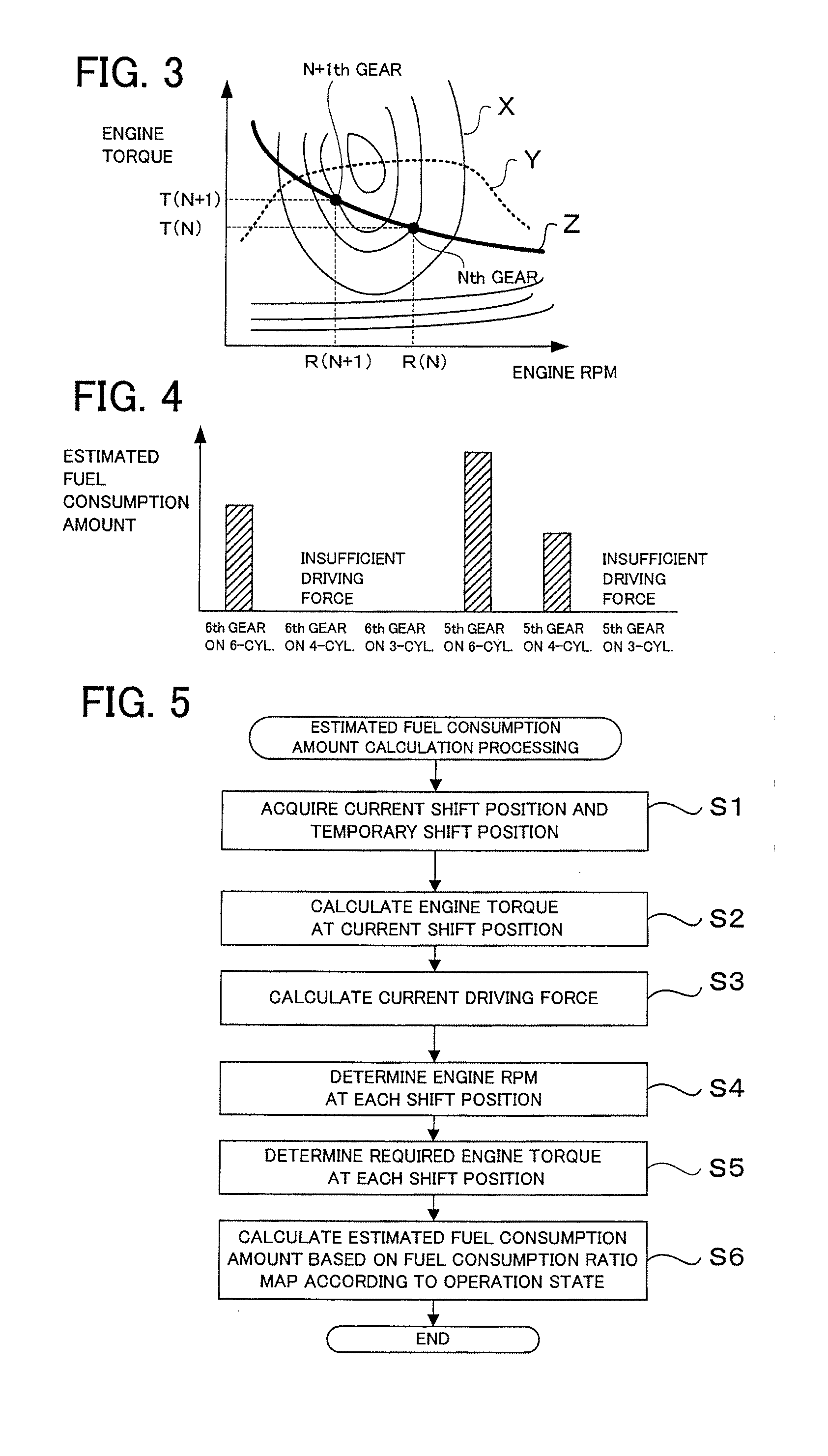

Control device for automatic transmission

ActiveUS20130184949A1Reduce fuel consumptionSmall fuel consumption amountDigital data processing detailsRoad transportAutomatic train controlAutomatic control

For each engine operation state to which a variable cylinder engine can be switched, a fuel consumption amount to be consumed to generate a driving force required to maintain a current traveling state of a vehicle for each of a current gear and a new gear after a possible shift-up is calculated. An automatic shift control of shifting up to the new gear is performed in a condition that a calculated fuel consumption amount of the new gear after the possible shift-up is smaller than a calculated fuel consumption amount of the current gear. In this way, the fuel consumption amount can be optimally reduced and the shift control can be performed without degrading the traveling performance, even in the vehicle equipped with the variable cylinder engine.

Owner:HONDA MOTOR CO LTD

Method and system for automatic camera control

ActiveUS8169463B2Television system detailsTelevision conference systemsCamera controlAutomatic control

A method for automatically determining an orientation and zoom of an image pickup device associated with a video conferencing system, wherein the method includes the steps of: generating, at the image pickup device, an image signal representative of an image framed by the image pickup device; processing the image signal to identify objects plural users of the video conferencing system in the image; steering the image pickup device to an initial orientation; determining a location of all the identified objects relative to a reference point and determining respective sizes of the identified objects; defining an area of interest in the image, wherein the area of interest includes all the identified objects; and steering the image pickup device to frame the defined area of interest including all the identified objects where a center of the frame substantially coincides with a center of all the identified objects.

Owner:CISCO TECH INC

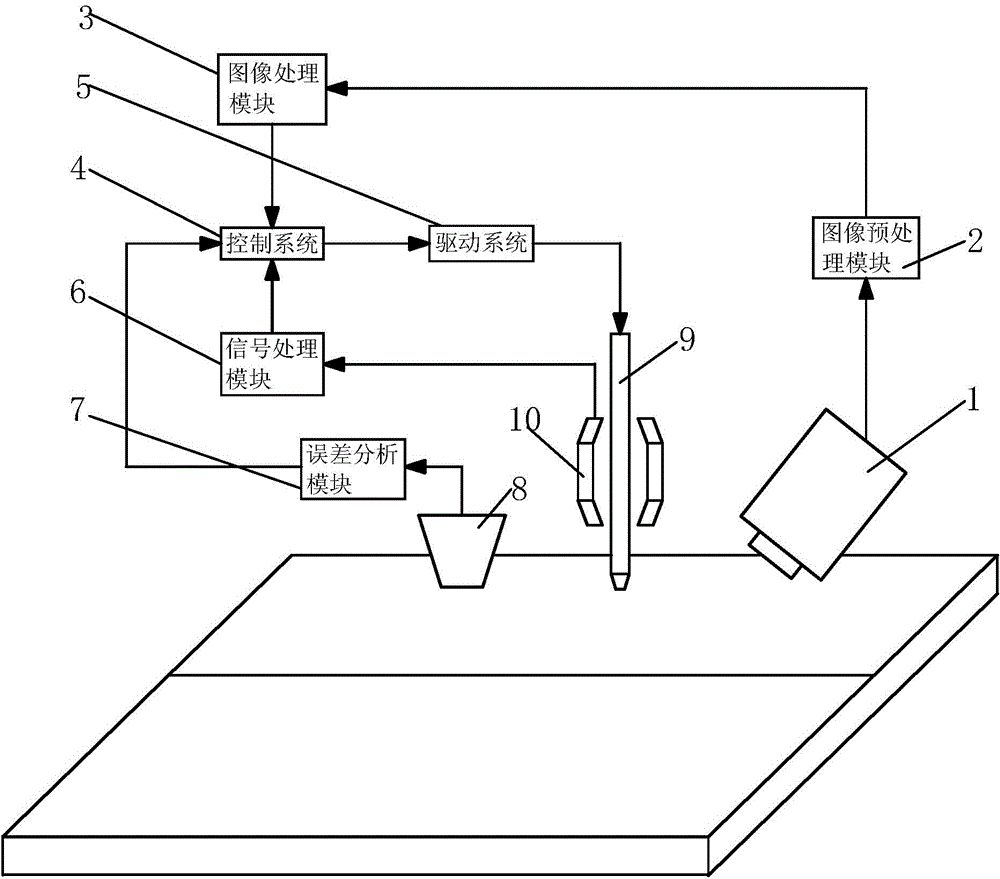

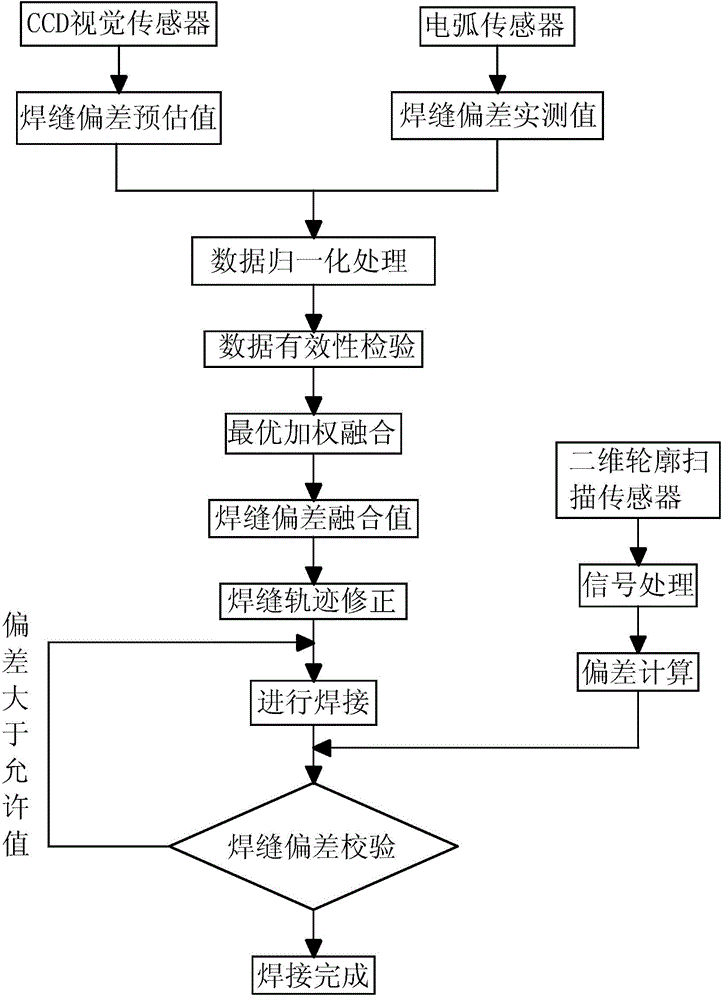

Automatic tracking control and online correction system with welding gun and control method thereof

The invention relates to an automatic tracking control and online correction system with a welding gun and a control method thereof and belongs to the technical field of robotic arc welding. The automatic tracking and control and online correction system comprises a vision sensing system, an image processing system, a tracking control system and an online correction system, wherein the vision sensing system comprises a CCD (Charge Coupled Device) vision sensor; the image processing system comprises an image preprocessing module and an image processing module; the tracking control system comprises the welding gun, a control system, a driving system, a signal processing module and an arc sensor; the online correction system comprises a laser two-dimensional outline scanning sensor and an error analysis module. According to the automatic tracking control and online correction system, butt-welded seams are predicated, tracked and corrected respectively a prewelding stage, a welding stage and a post-welding stage by virtue of error online fusion of three sensors, namely the CCD vision sensor, the arc sensor and the laser two-dimensional outline scanning sensor, so that the welded seam tracking precision and the fault tolerance of the system are improved, the welding production efficiency and the welding quality are improved, and the automatic tracking control and online correction system has generality.

Owner:WUHU ANPU ROBOT IND TECH RES INST

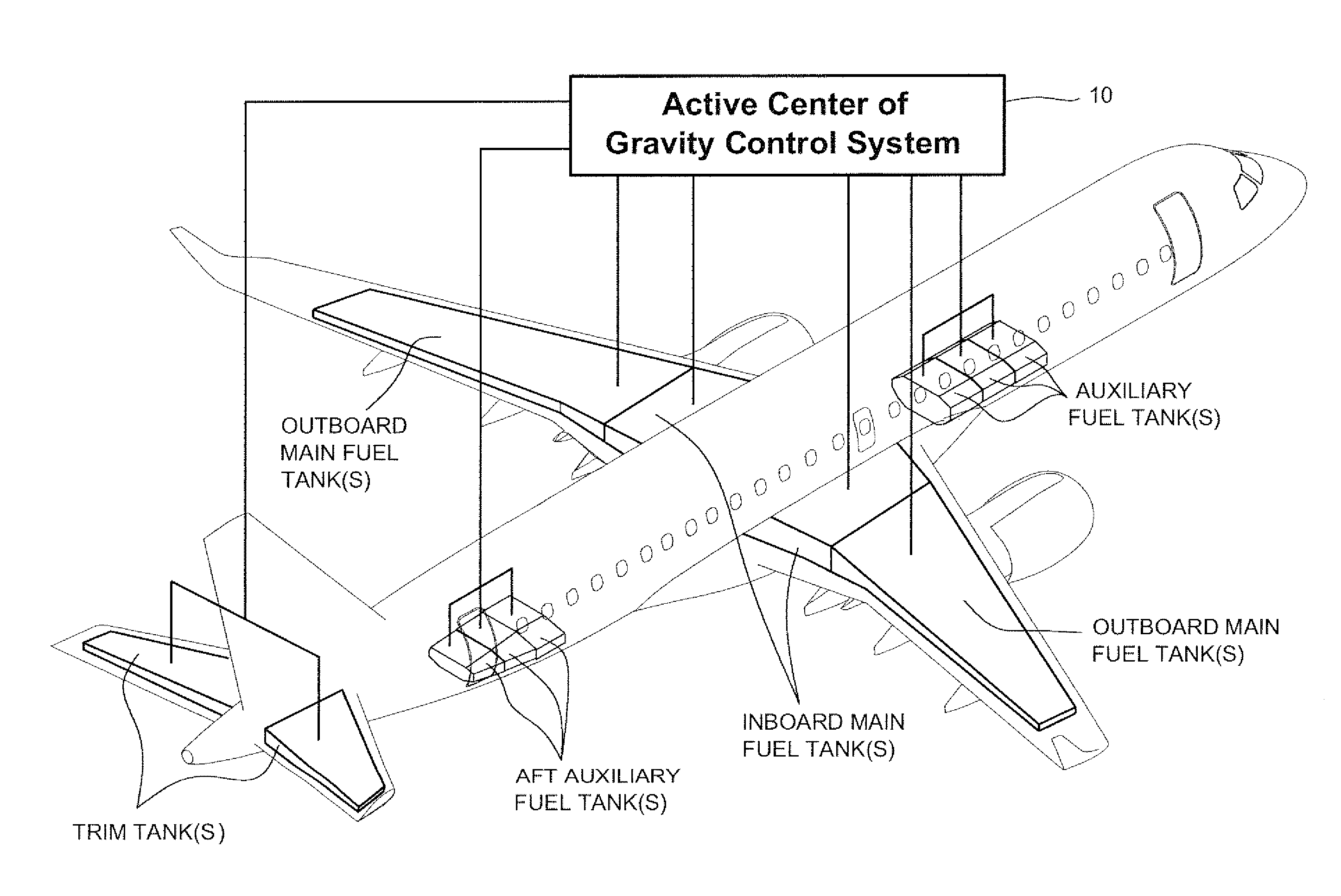

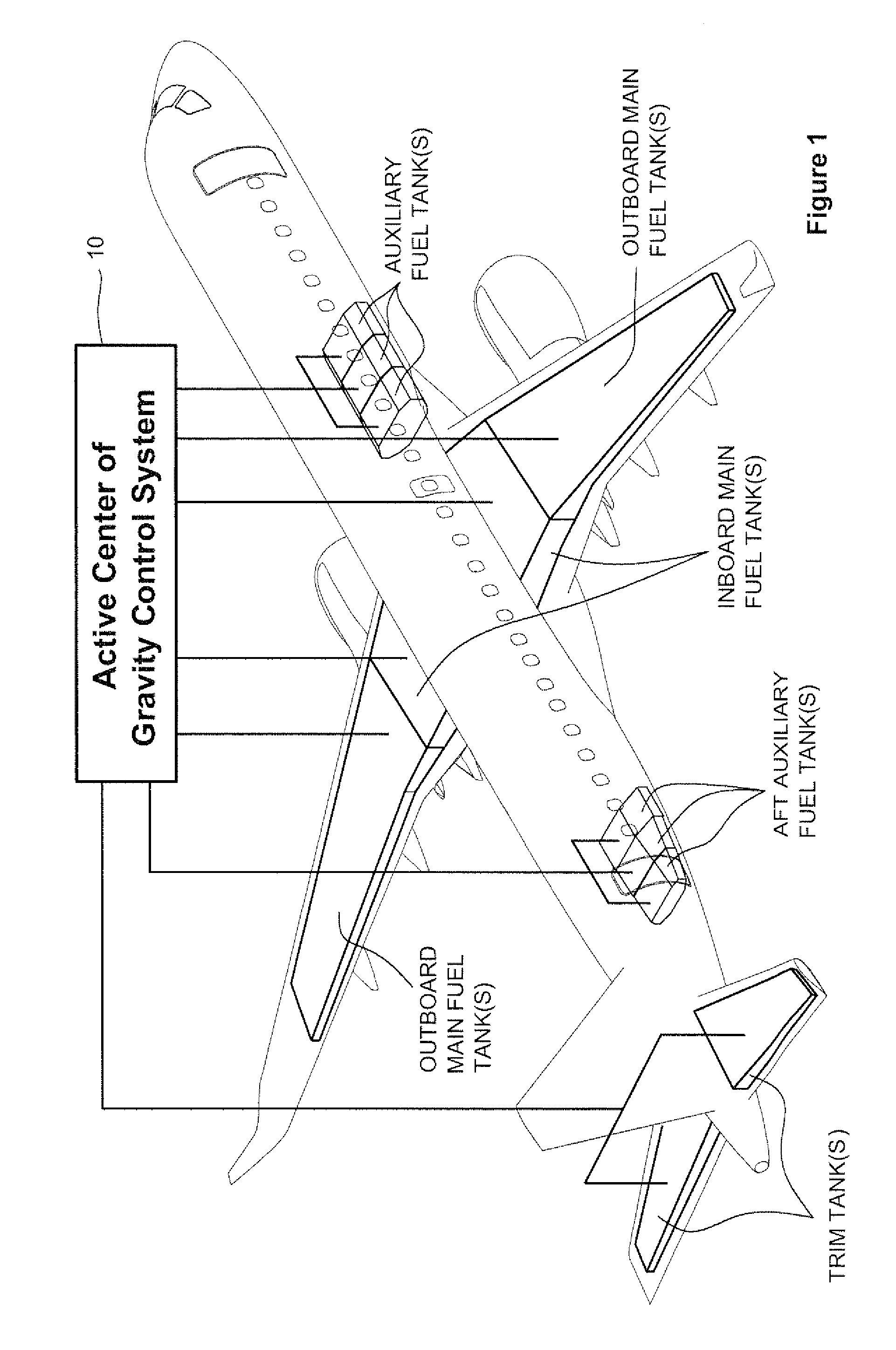

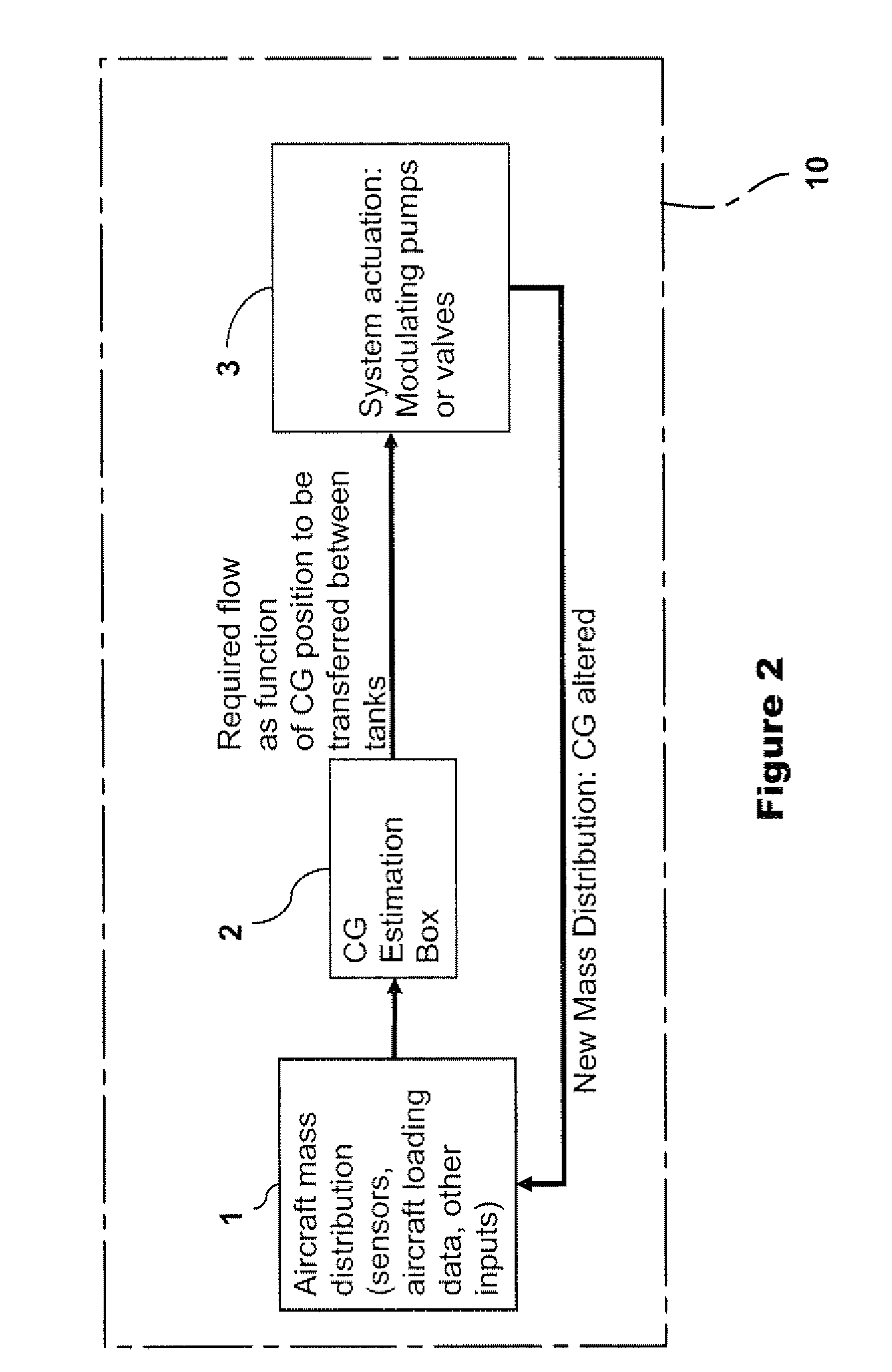

Continuous fuel management system for automatic control of aircraft center of gravity

ActiveUS8226040B2Power plant fuel tanksAircraft stabilisationAutomatic controlAutomatic train control

Owner:EMBRAER SA

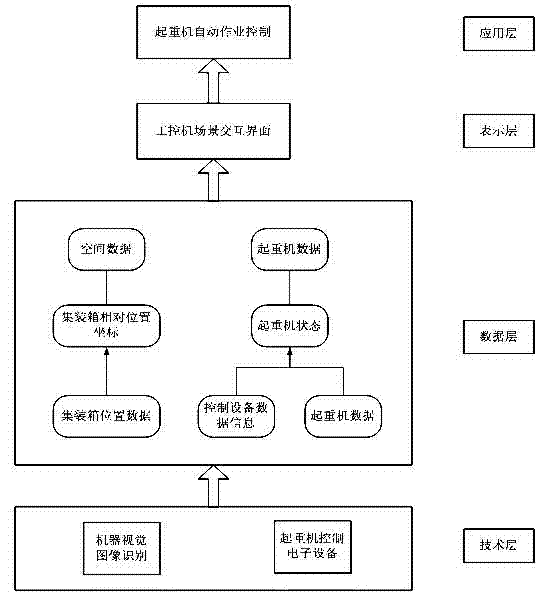

Automatic control system of efficient handing operation of container crane

InactiveCN102923578APrecise positioningMovement precisionLoad-engaging elementsLoop controlAutomatic control

The invention provides an automatic control system of an efficient handing operation of a container crane, and relates to the technical field of operation and production of container cranes. The machine vision and image recognition location technology is used to locate the relative position of a container and a lifting appliance, an image processing result is transmitted to a crane control system, a bar code location system is mounted near a crane cart track and a crane trolley track to accurately locate the position of the lifting appliance of the crane, then a position closed loop feedback control system is formed, and therefore an image recognition location method and an image recognition location device of the container crane are achieved, a lifting appliance movement closed loop control method of the container crane is achieved, and an automatic container grabbing method and an container grabbing device of the lifting appliance of the crane are achieved.

Owner:YANGZHOU CITY HUATAI ENVIRONMENT PROTECTION EQUIP MFG

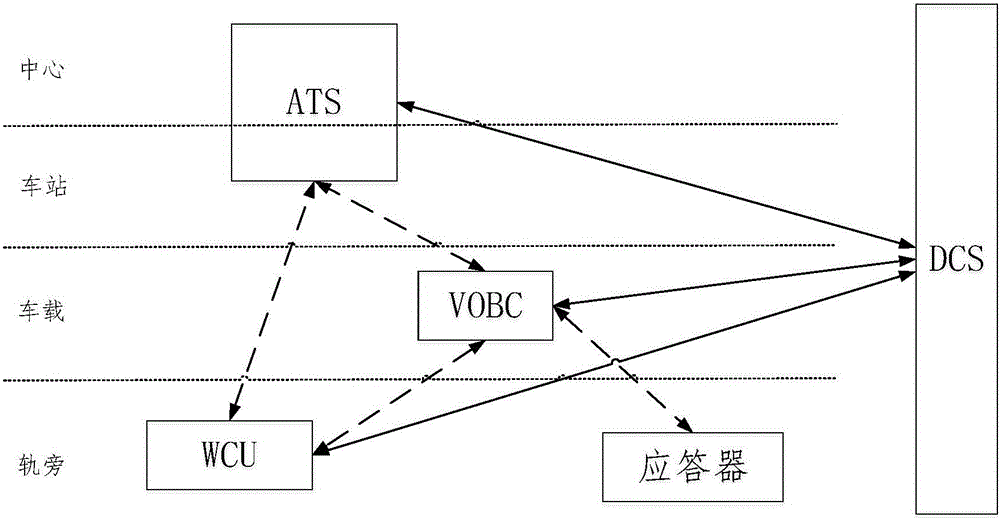

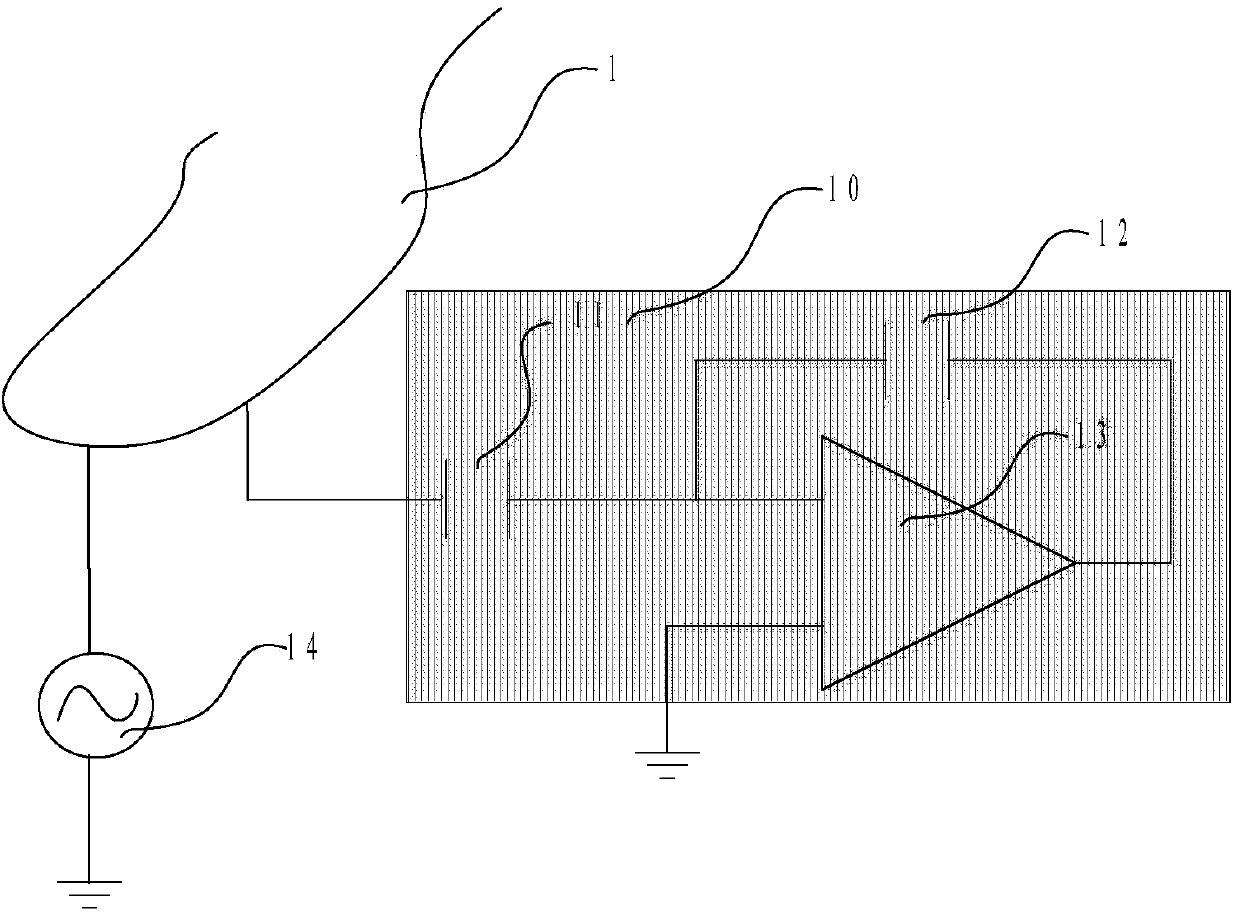

Train operation control system

ActiveCN105101094AImprove tracking efficiencyLow costNetwork traffic/resource managementWireless commuication servicesAutomatic controlAutomatic train control

The embodiment of the invention provides a train operation control system. The system comprises that a train operation plan is generated, issued and adjusted by a train automatic control system; high-precision train autonomous positioning is realized by a vehicle-mounted controller through correction of a train autonomous positioning system and a trackside transponder; a trackside controller receives commands which are transmitted by the vehicle-mounted controller and used for operating trackside equipment and controls the corresponding trackside equipment to actuate and lock to the corresponding position according to the command requirements; and a data communication subsystem performs data communication with each set of ground equipment via a redundant backbone network and realizes wireless transmitting and receiving of trackside controller information and vehicle-mounted controller information via a wireless communication antenna. CI and ground ATP equipment are reduced and WCU equipment is increased, and mutual resource coordination is performed via a mode of direct communication between adjacent trains and between the trains and the WCU so that system cost is reduced and train tracking efficiency is enhanced.

Owner:BEIJING JIAOTONG UNIV

Automatic draft control system for coke plants

ActiveUS20140048402A1Change positionCombustible gas coke oven heatingHorizontal chamber coke ovensAutomatic controlAutomatic train control

A coke oven includes an oven chamber, an uptake duct in fluid communication with the oven chamber, the uptake duct being configured to receive exhaust gases from the oven chamber, an uptake damper in fluid communication with the uptake duct, the uptake damper being positioned at any one of multiple positions, the uptake damper configured to control an oven draft, an actuator configured to alter the position of the uptake damper between the positions in response to a position instruction, a sensor configured to detect an operating condition of the coke oven, wherein the sensor includes one of a draft sensor, a temperature sensor configured to detect an uptake duct temperature or a sole flue temperature, and an oxygen sensor, and a controller being configured to provide the position instruction to the actuator in response to the operating condition detected by the sensor.

Owner:SUNCOKE TECH & DEV LLC

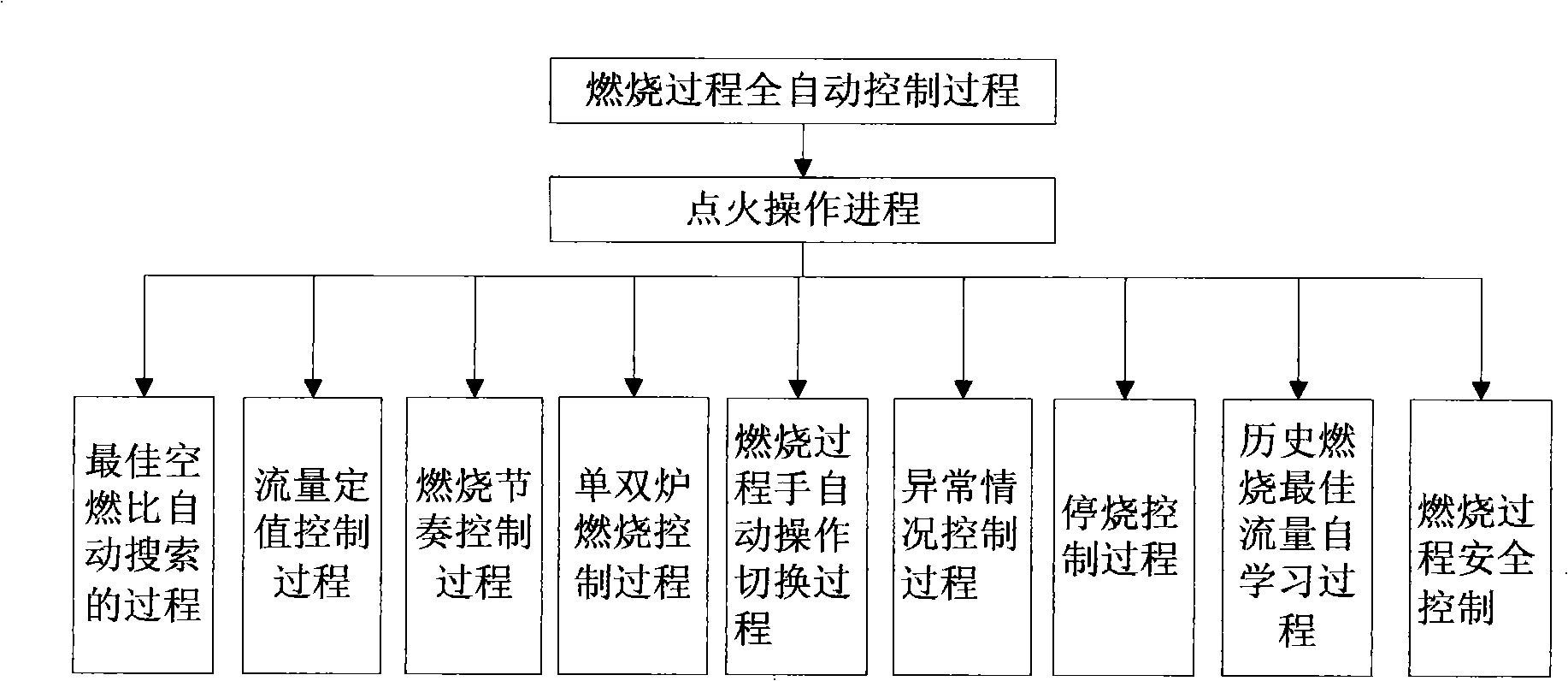

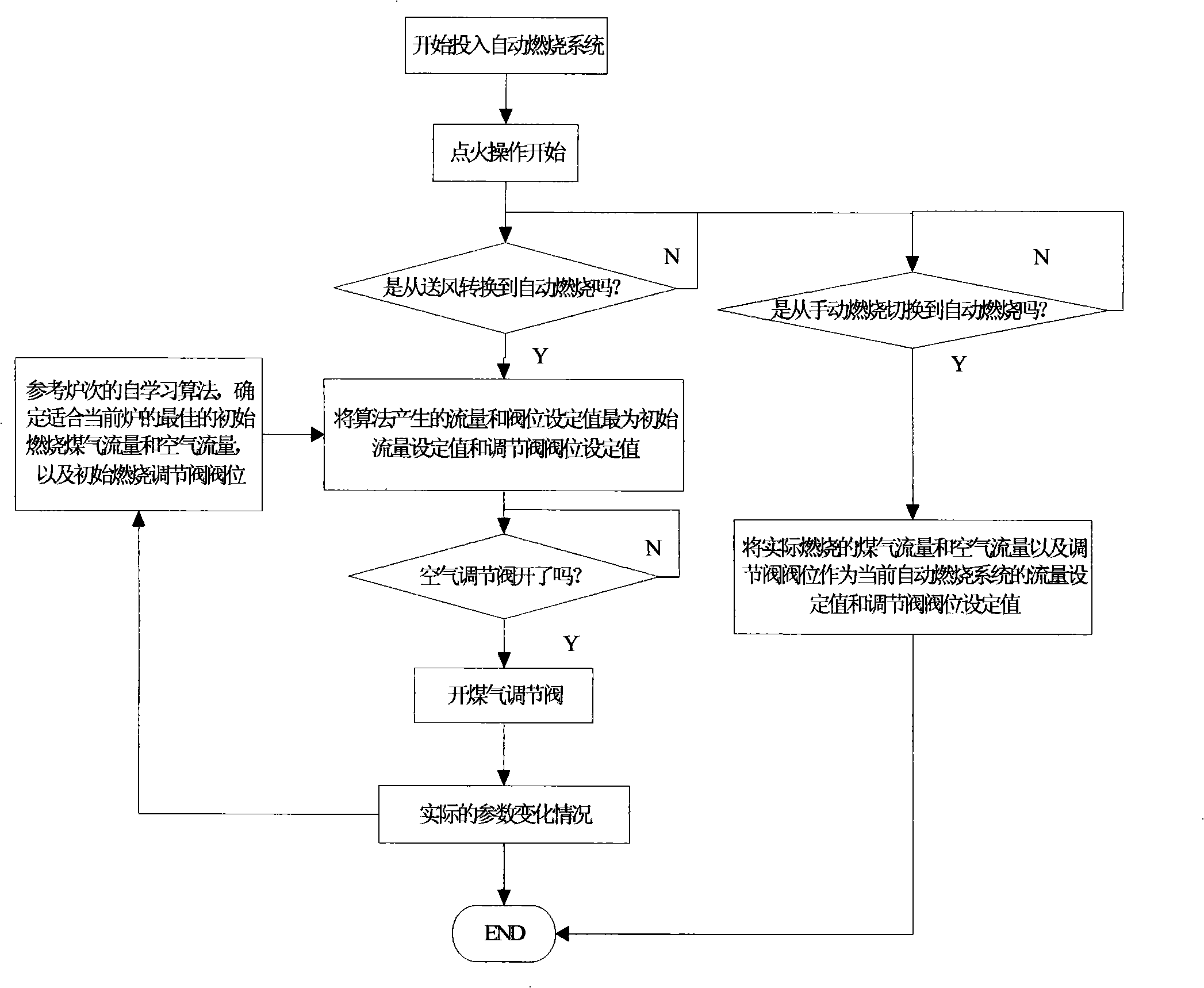

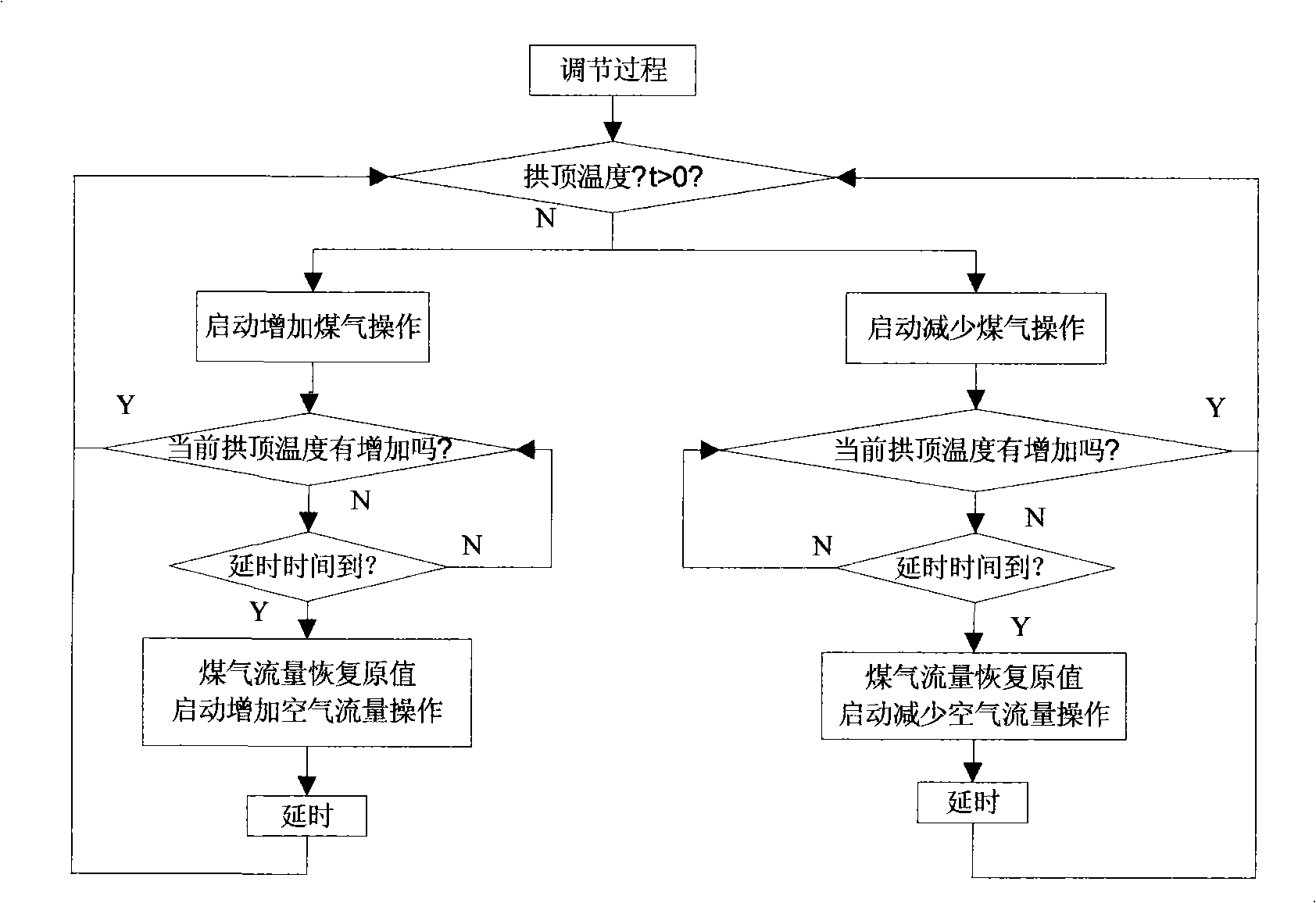

Automatic control system of blast furnace hot blast stove combustion process

ActiveCN101408314AGuaranteed air-fuel ratioQuick controlFuel supply regulationCombustion chamberAutomatic control

The invention relates to an automatic control system during the combustion process of a hot air furnace of a blast furnace, belonging to the field of automatic combustion control technique of the hot air furnace of the blast furnace. Firstly, the system self-learns the historical combustion data of the furnace according to the specified conditions, and determines the best coal gas and air flux of the furnace and the best initial openness of an adjusting valve to be as the initial parameters of the next combustion period. During the normal combustion stage, a control method that fuzzy control is combined with self-optimization control is adopted, the fastest increment of the temperature at the arch is taken as the object, and the air combustion proportion coefficient is quickly optimized according to the temperature change of the combustion chamber. Simultaneously, by adopting a non-difference self-adaptive single closed ring control system combined with the methods such as fuzzy control, self-learning and pulse driving and the like, the action of the adjusting valve can be effectively controlled, and precise and quick adjustment and control of the flux are realized. According to the trend change of the temperature of the waste gas, the system adopts the fuzzy control arithmetic to control the combustion rhythm. Simultaneously, the system comprehensively summarizes the manual combustion experience and achieves the object of completely automatic control without man-watching during the whole combustion process.

Owner:SHOUGANG CORPORATION +1

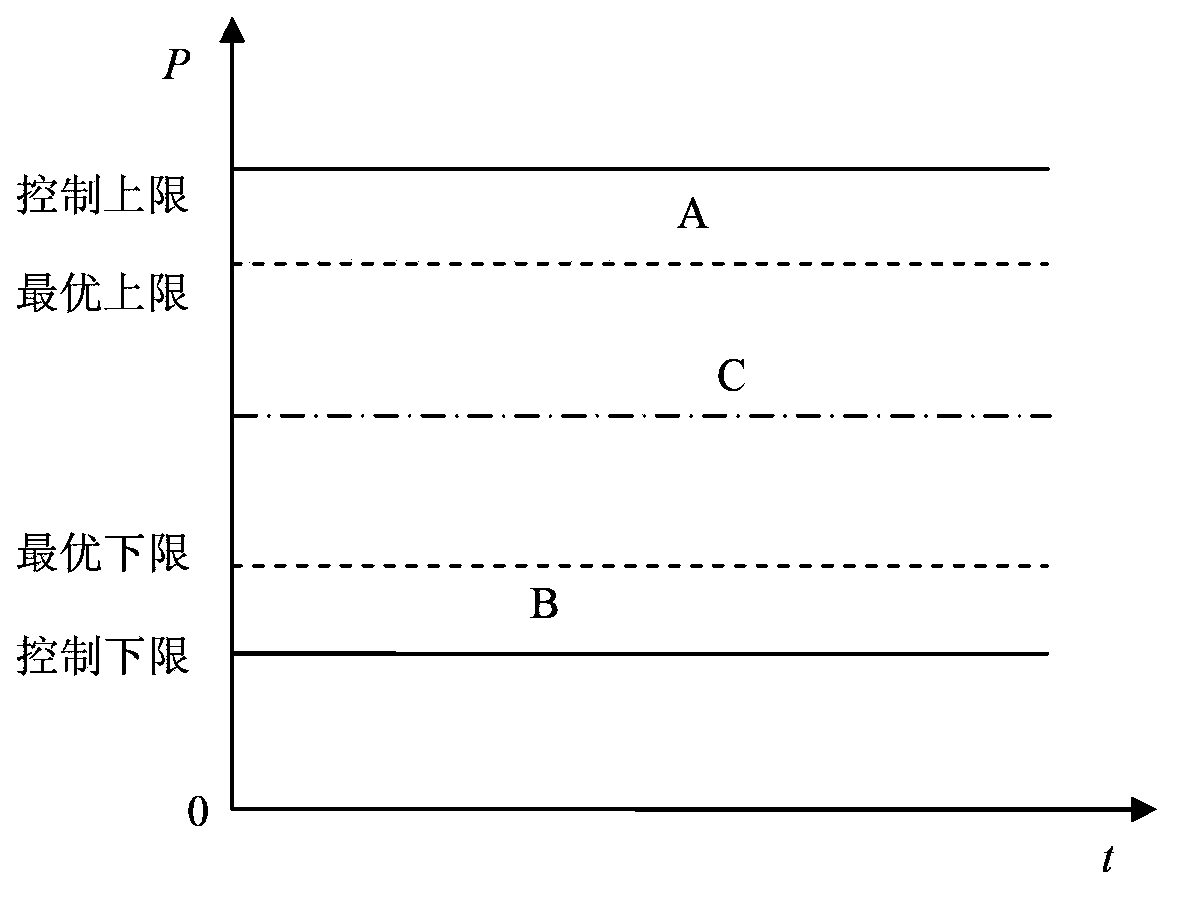

System limits of an automatic control

InactiveUS20180292820A1Control process safetyImprove securityVehicle position/course/altitude controlDriver input parametersAutomatic train controlAutomatic control

A method for transferring control from an automatic control to an operator includes the steps of detecting a first time period in which the automatic control may probably be maintained, of determining a second time period which the operator needs to take over control, and of outputting a message to the operator if the first time period is longer than the second time period by less than a predetermined interval. For this purpose, the second time period is determined as a function of a situation of the operator.

Owner:ROBERT BOSCH GMBH

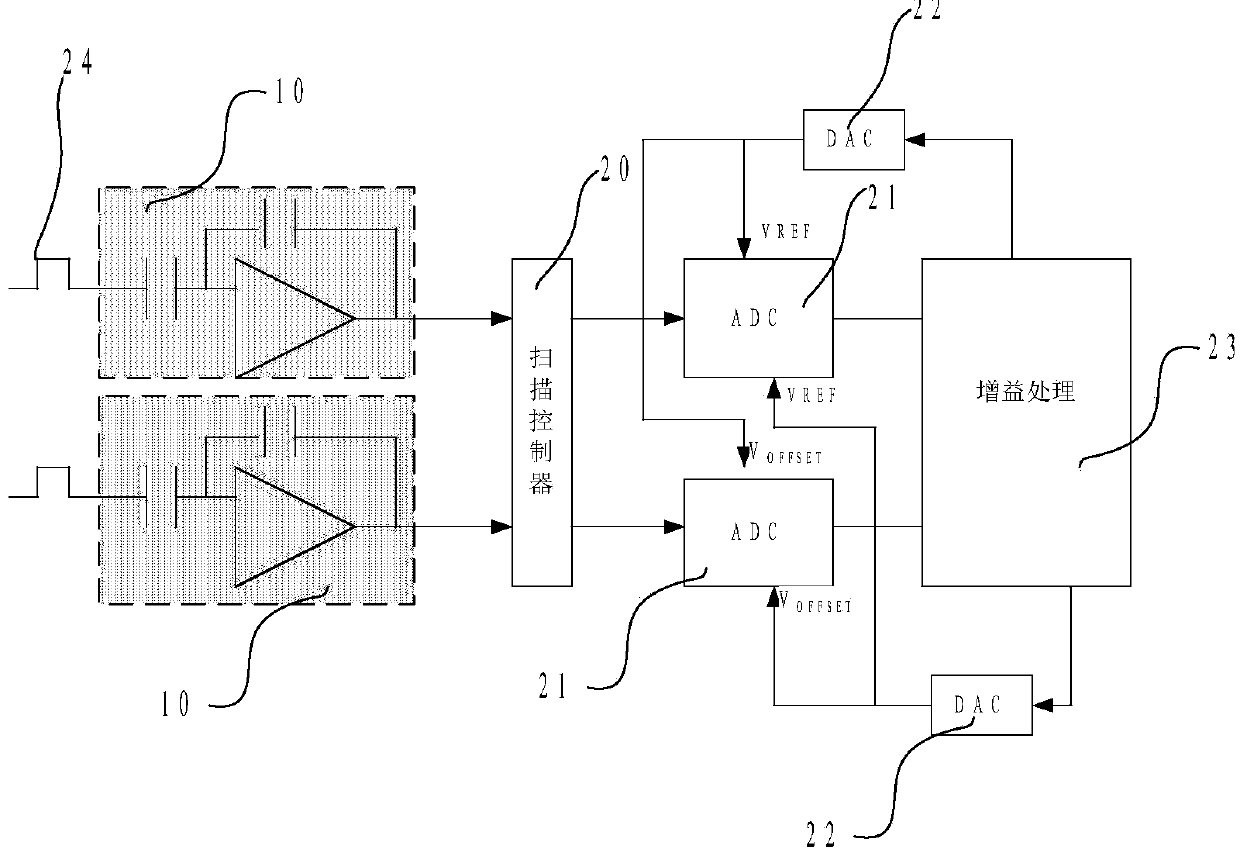

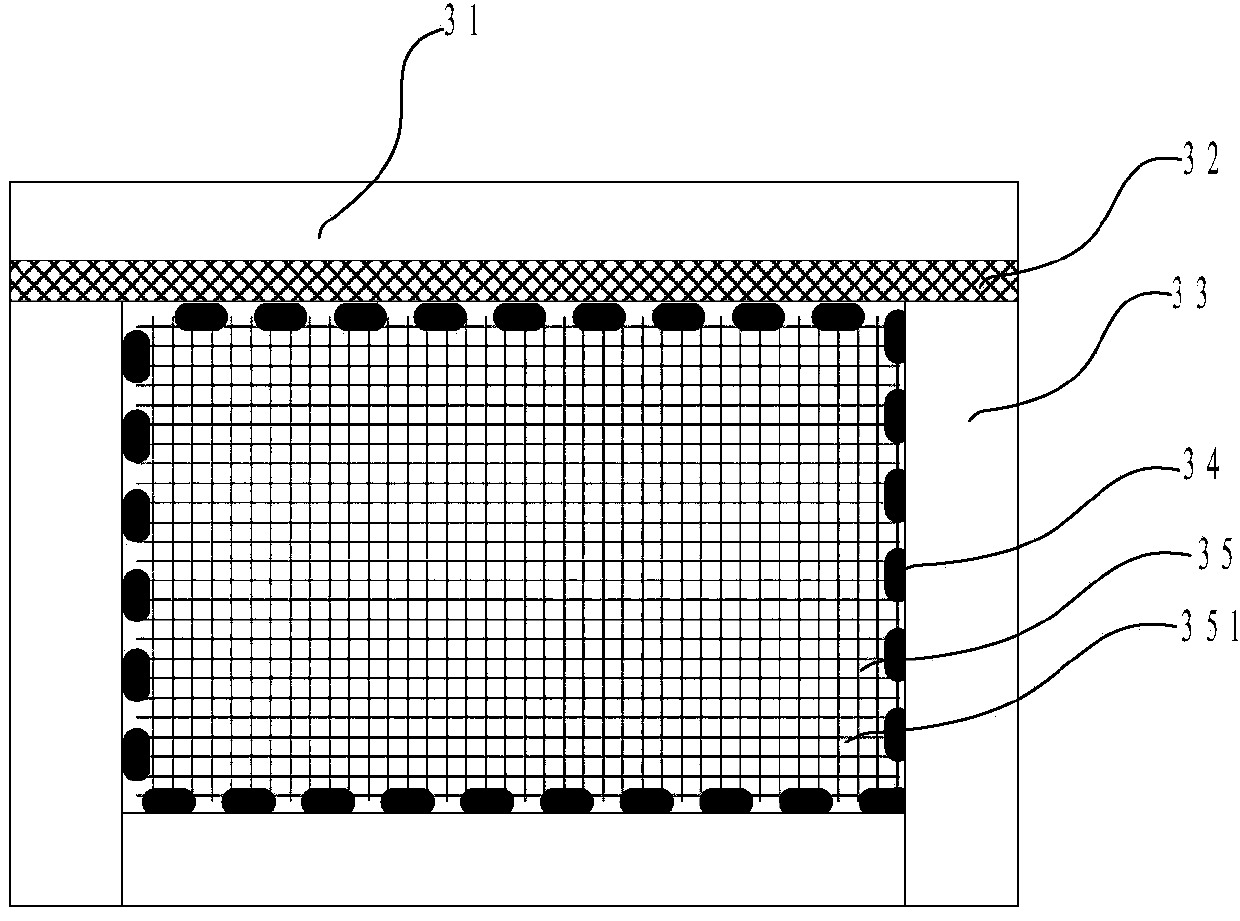

Fingerprint detection system having automatic gain control function and automatic gain control method thereof

ActiveCN103778420AImprove stabilityImprove consistencyCharacter and pattern recognitionAutomatic train controlGray level

The invention relates to a fingerprint detection system having an automatic gain control function. The fingerprint detection system comprises a fingerprint sensor which comprises a fingerprint sensing unit array comprising a plurality of sensing units, a rapid scanning control circuit for selecting at least a part of the sensing units in the fingerprint sensing unit array as effective sensing units, a gain control circuit which comprises an ADC (Analog to Digital Converter) array and is used for converting an electric signal into digital fingerprint image information, an image gray value counting unit for counting the gray level distribution information of a fingerprint image, and an adaptive judging circuit for defining the type of the fingerprint image according to the gray level distribution information of the fingerprint image, wherein the gain control circuit is further used for receiving the output of the adaptive judging circuit and adjusting the gain of each effective sensing unit according to the type of the fingerprint image in order to correct the digital fingerprint image information and outputting the corrected information. The fingerprint detection system is wide in application range, high in stability and consistence and low in power consumption.

Owner:成都费恩格尔微电子技术有限公司 +1

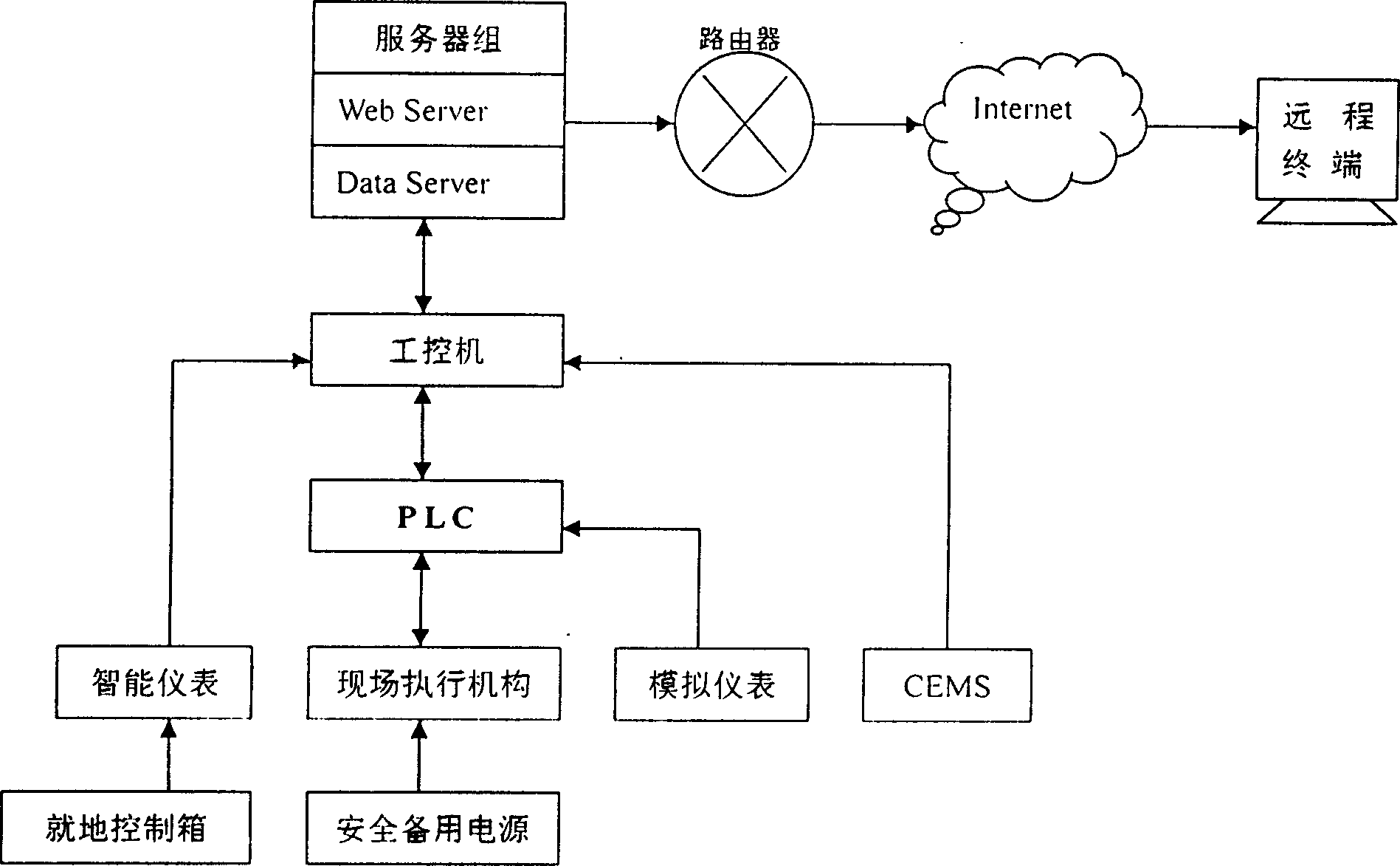

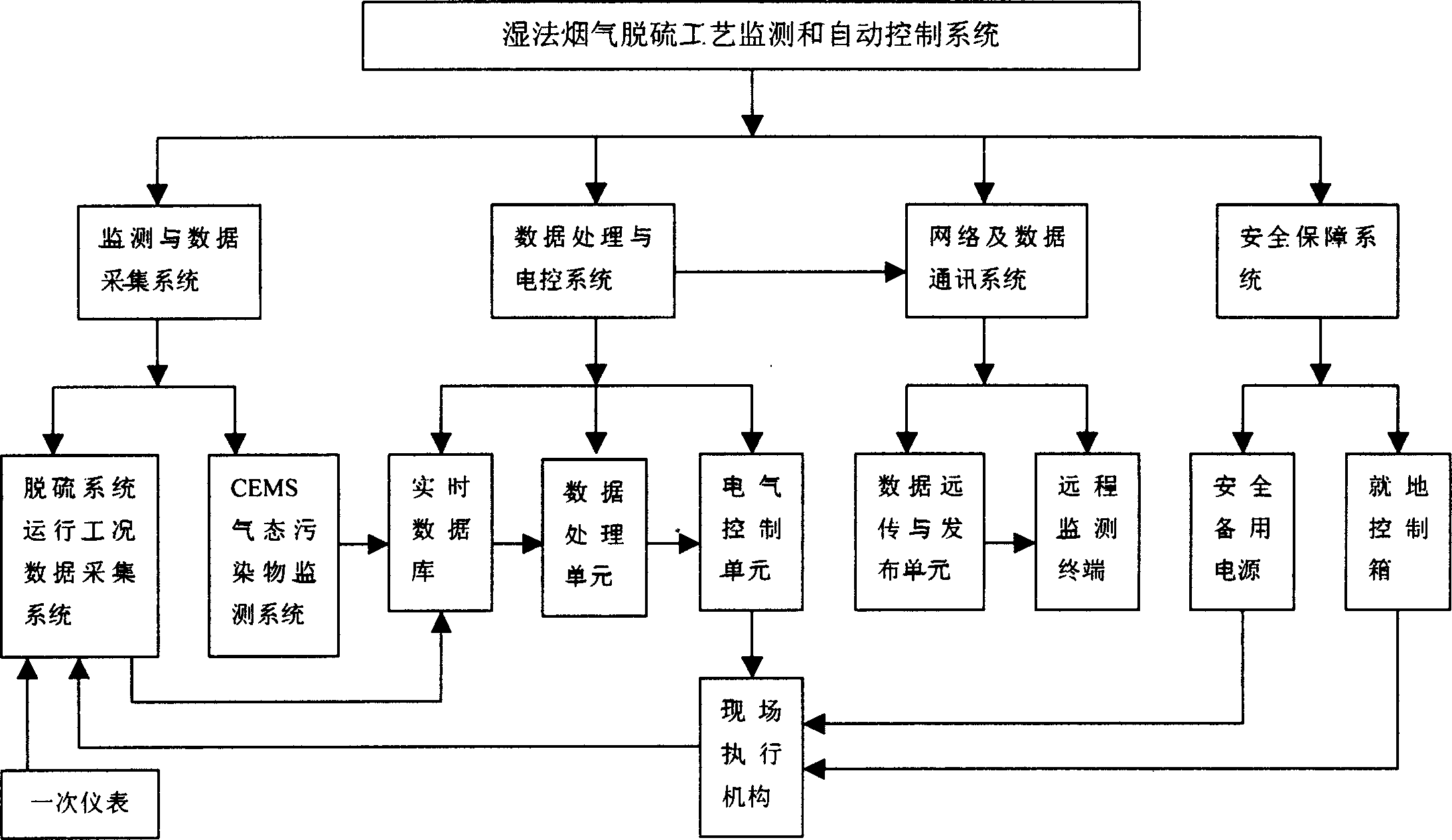

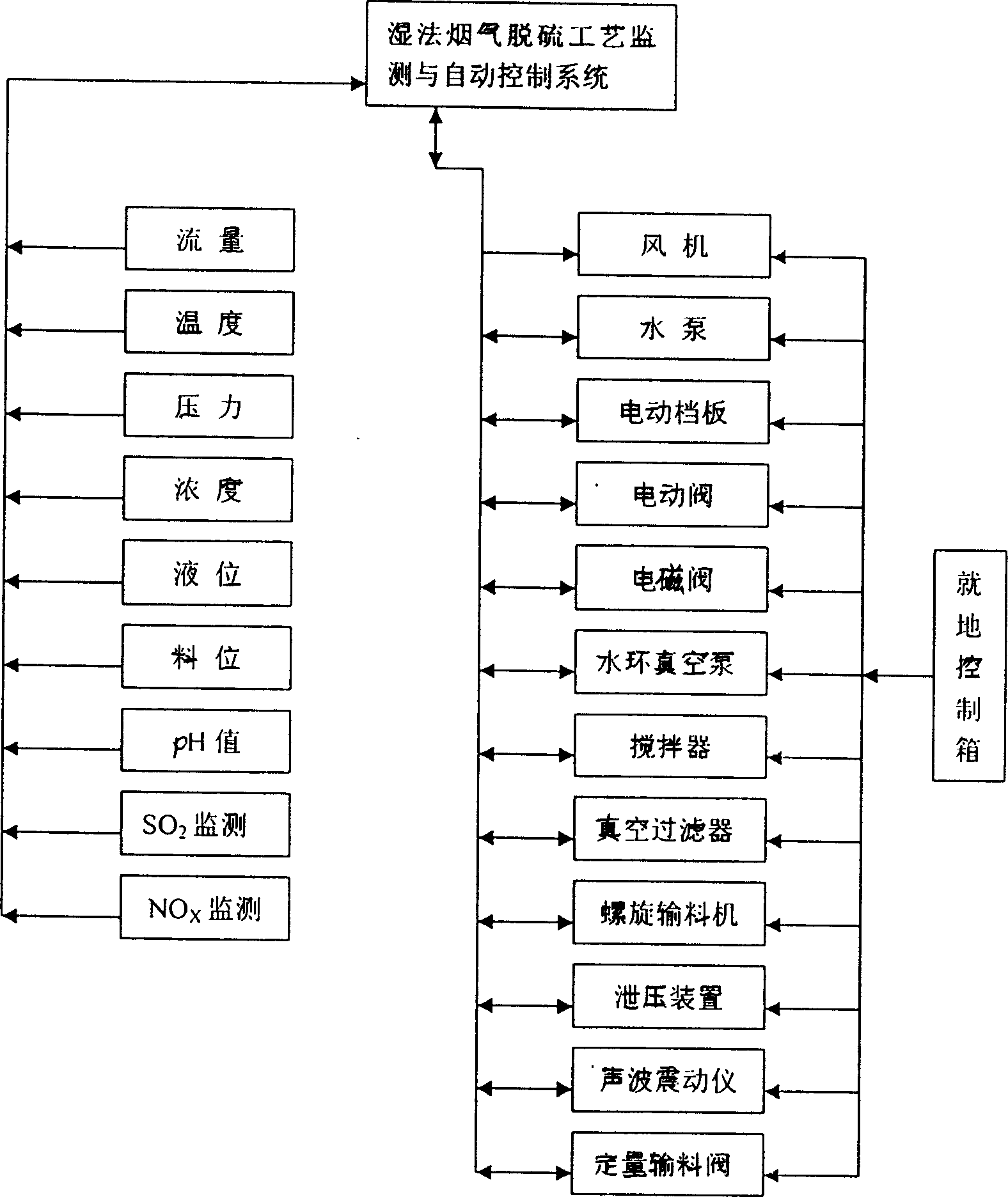

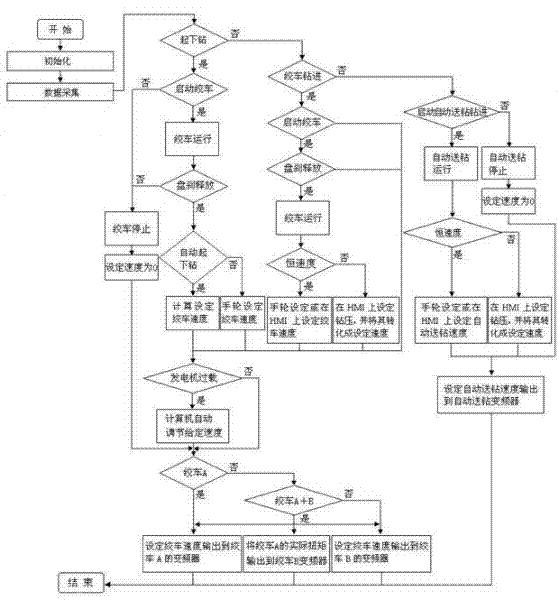

Monitoring and automatic control system for wet method flue gas desulfurization technology

InactiveCN1593726AGuaranteed uptimeEconomical and energy efficient operationDispersed particle separationAutomatic controlThe Internet

The invention relates to a kind of wet-form stack-gas desulfurizing industrial art monitoring and auto-control system, which can be used in desulfurizing industrial art by spraying lime powder or size mixture of lime to stack gases in order to forming high purity gypsum. The hardware of the invention contains industrial cybertron, PLC, group of server, router, Internet system and remote terminal. And the feature of it is that it contains the subsystems as follows: the monitoring and data acquisition subsystem, which includes the intelligence instrument; the simulated instrument and the observation system of the air pollutant that is CEMS; the data processing and electrical control system, which controls the on-the-spot actuating mechanism by PLC; the network and data communication subsystem and the safety control subsystem, which include the safety emergency power supply and the control cabinet on the spot of the subject equipment. The industrial cybertron works for data processing and central control, which uses PLC to control spot actuating mechanism, and it can manifest the data of equipment state at the right moment and can type all kinds of report form, in order to realize auto-control and remote control at the right moment.

Owner:樊金鑫

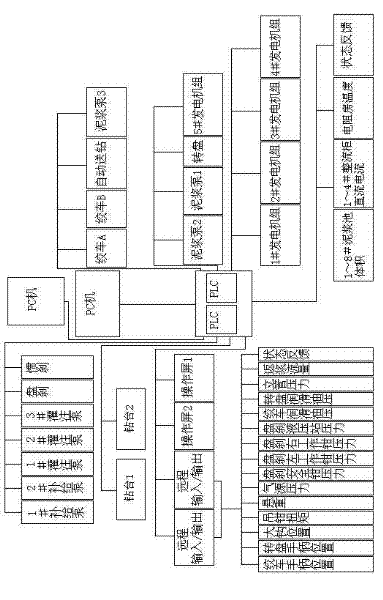

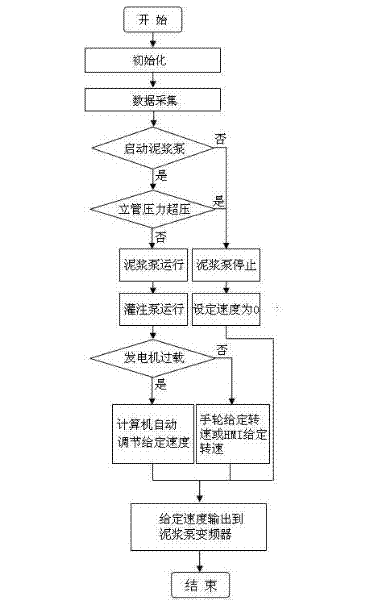

Automatic control system and method of petroleum drilling machine

ActiveCN102305059AEasy to operateRealize centralized controlFlushingAutomatic control for drillingAutomatic controlAutomatic train control

The invention relates to the field of oil-field drilling operation and provides an automatic control system and method of a petroleum drilling machine. The automatic control system comprises a master station and a plurality of slave stations, wherein a winch, an automatic driller, a rotary table and a mud pump are centrally controlled so that processes of well drilling operation can be dynamically, accurately and automatically controlled and good operation environment and work environment are provided for operating personnel.

Owner:四机赛瓦石油钻采设备有限公司

Vehicular drive assist device, and vehicular drive assist method

Owner:NISSAN MOTOR CO LTD

Apparatus and method for performing automatic control over velocity of automotive vehicle

InactiveUS6154168AVehicle fittingsDirection finders using radio wavesMobile vehicleAutomatic train control

In automatic velocity controlling apparatus and method for an automotive vehicle, an inter-vehicle distance detector is provided for detecting an inter-vehicle distance from the vehicle to another vehicle which is running at the detected inter-vehicle distance with respect to the vehicle. A vehicular running controller is provided for effecting a vehicular running control such that the vehicle follows up the other vehicle maintaining the inter-vehicle distance to the other vehicle at a predetermined inter-vehicle distance. An inter-vehicle distance determinator is provided for determining whether the inter-vehicle distance detector transfers from a first state in which the inter-vehicle distance to the other vehicle is detected to a second state in which the inter-vehicle distance to the other vehicle is undetected. A deceleration controlled state determinator is provided for determining whether the vehicle is in a deceleration controlled state when the inter-vehicle distance determinator determines that the vehicle has transferred from the first state to the second state. A deceleration keep command generator is provided for generating and outputting a vehicular deceleration keep command to the vehicular running controller to maintain a vehicular deceleration at a value which is immediately before the inter-vehicle distance determinator determines that the inter-vehicle distance detector has transferred from the first state to the second state when the deceleration controlled state determinator determines that the vehicle is in the deceleration controlled state.

Owner:NISSAN MOTOR CO LTD

Diversified energy automatic generation control method considering wind power acceptance

ActiveCN103390905AFully explore the ability of active frequency regulationReduced FM StandbySingle network parallel feeding arrangementsWind energy generationAutomatic Generation ControlElectricity

The invention relates to the field of electric power systems, and particularly to a diversified energy automatic generation control method considering wind power acceptance. The method comprises the following steps: classifying units according to different AGC adjustment performances and unit types, and dividing load changing tendencies (rising / declining / stable) by combining with a load prediction result; calculating an area control error ACE of a current region, and defining a zone (dead zone / help zone / secondary emergency zone / emergency zone) which the area control error ACE of the current region belongs to; and adopting different ACG adjustment tactics according to the differences of the load tendencies and ACEs. The method conducts classification on all units; the units match with each other to carry out the water-fire-wind combined automatic generation control; the frequency adjustment ability of a system is fully excavated to lower the frequency regulation reserve of the system; and the purpose of more accepting the wind power output is realized while the control quality is ensured.

Owner:STATE GRID CORP OF CHINA +2

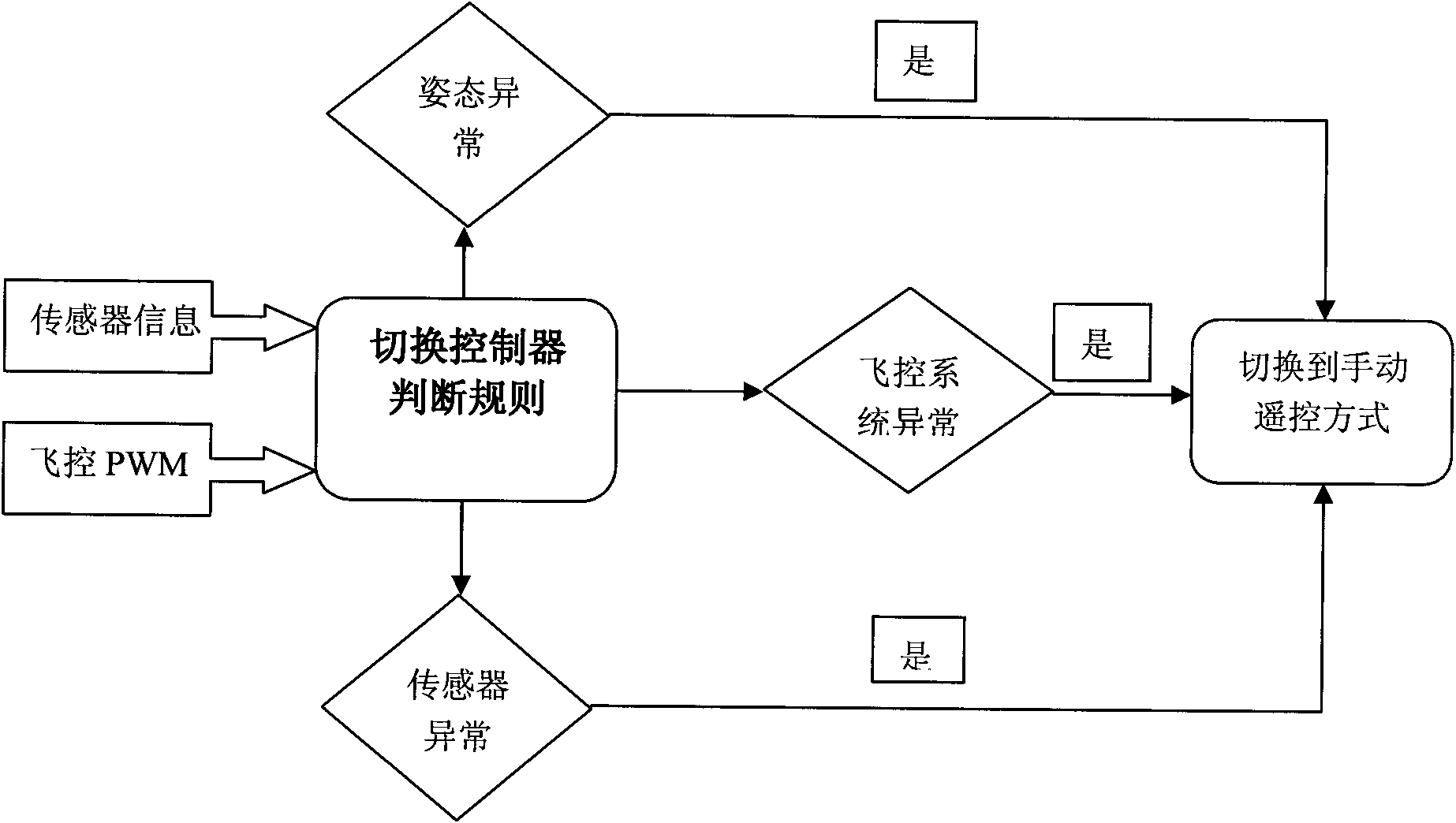

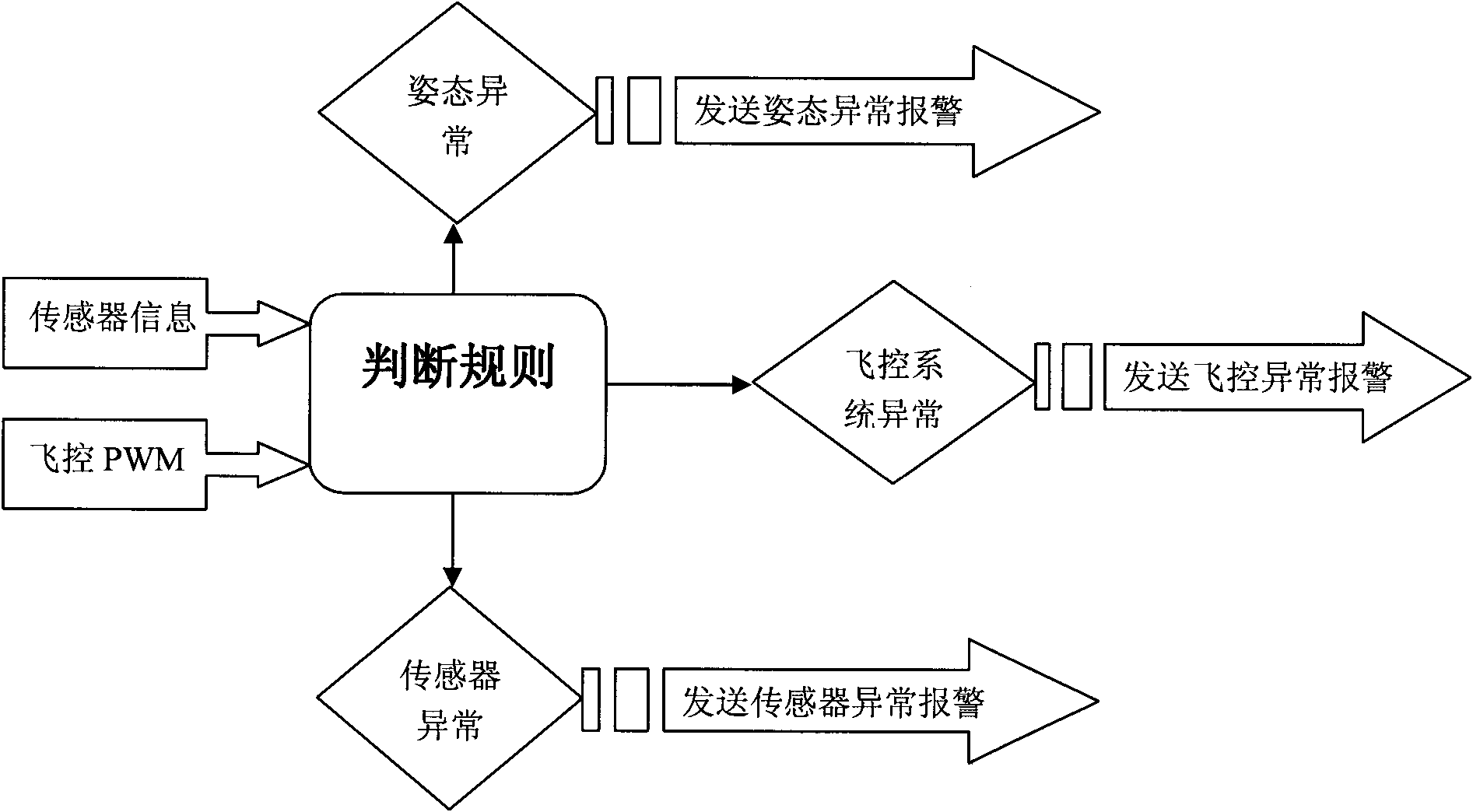

Method for switching automatic flight mode and manual remotely-controlled flight mode of miniature unmanned helicopter

The invention discloses a method for switching the automatic flight mode and the manual remotely-controlled flight mode of a miniature unmanned helicopter, and belongs to the field of automatic control of an aircraft. A switching controller module receives the PWM (pulse-width modulation) steering gear control signal and the sensor information of the flight control system of the miniature unmanned helicopter, judges the PWM steering gear control signal and the sensor information of the automatic flight control system according to the preset judgment rule, and switches the PWM steering gear control signal to the remotely-controlled PWM steering gear control signal from the automatic control signal if the PWM steering gear signal or the sensor information of the automatic flight control system is judged to be abnormal. The switching method adopted by the invention detects the flight condition of the miniature unmanned helicopter without intermittences, switches the automatic control flight mode into the manual remotely-controlled flight mode at once if the abnormity of the flight condition is detected, and informs operating personnel on the ground to remotely control the helicopter to fly and guide the helicopter to safely land.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

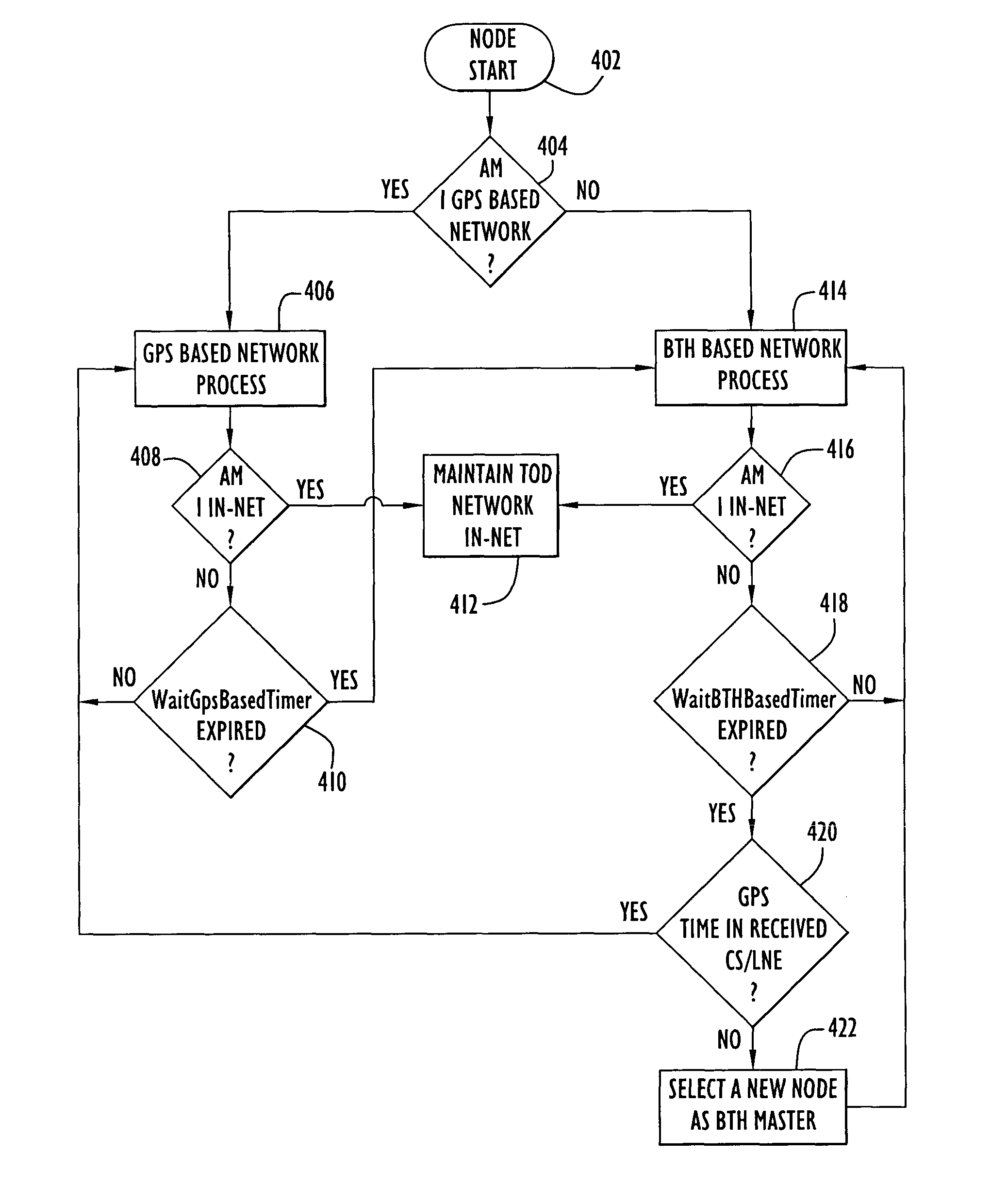

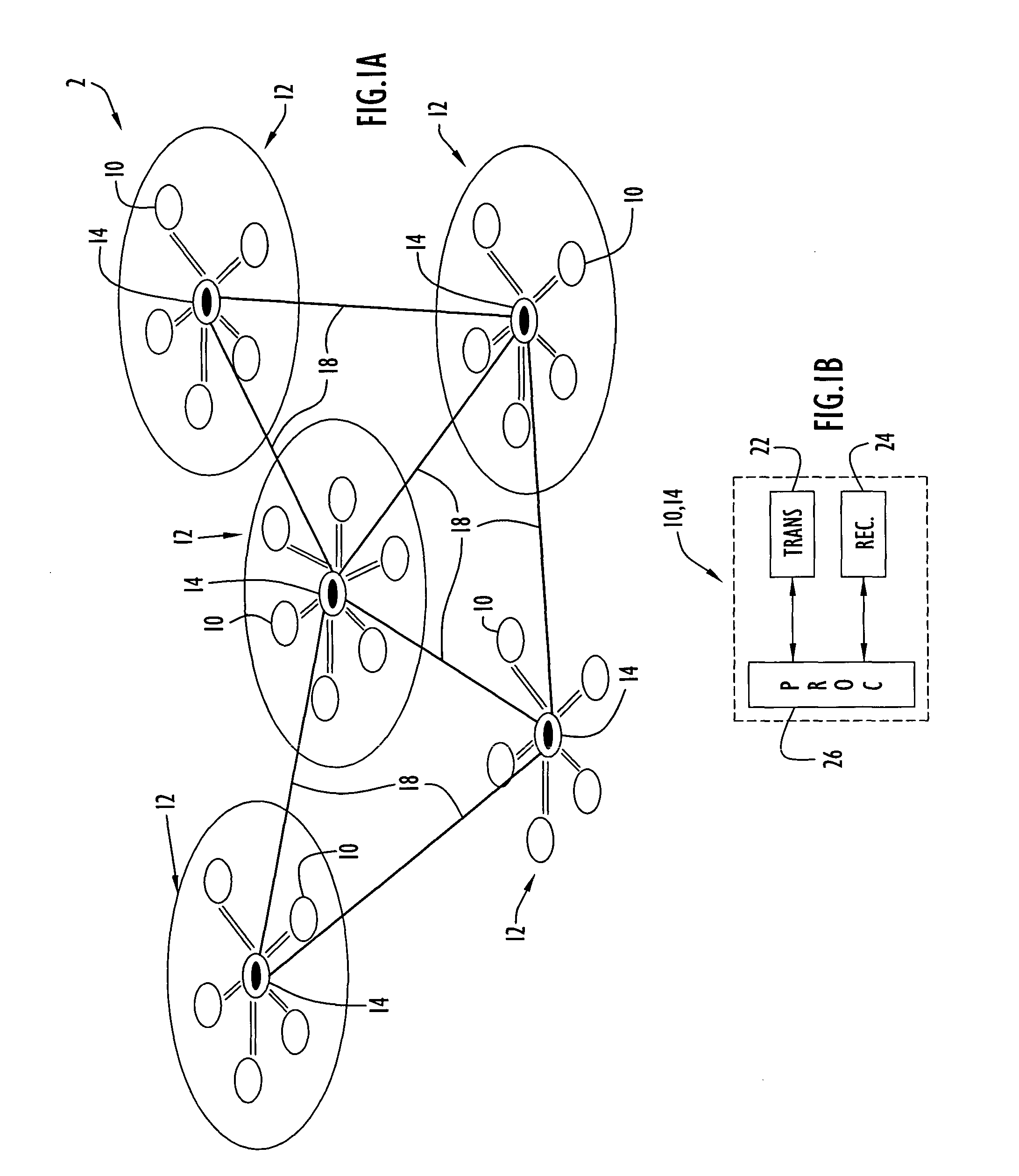

Method and apparatus for automatic control of time-of-day synchronization and merging of networks

ActiveUS8014378B1Control impactLittle and no degradation in performanceTime-division multiplexRadio transmissionAutomatic train controlRadio networks

A method and apparatus for synchronizing time of day (TOD) information between radio nodes of a network and for detecting and merging otherwise isolated radio networks. In this manner individual isolated networks are able start when they are ready and once connectivity is detected with another network, the two networks can merge. Radio nodes within each network periodically send out TOD messages and periodically receive TOD messages issued by other nodes look to identify networks within communication range. Upon detecting another network a radio node informs a central control node that uses network detection information received from its members to determine the extent of the connectivity between the two networks and whether to merge the two networks. Network searching is optimized to limit impact on the overall network performance, resulting in little or no degradation in network performance.

Owner:HARRIS GLOBAL COMM INC

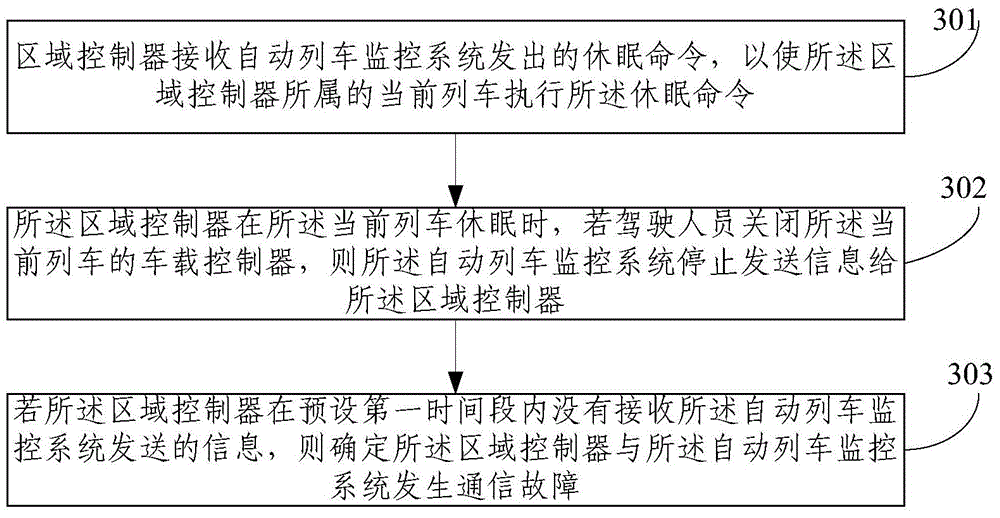

Zone controller-based train position memorizing method and checking method

ActiveCN104442928AImprove securityManual driving mode reductionRailway signalling and safetyDriving safetyAutomatic train control

The invention provides a zone controller-based train position memorizing method and checking method. The memorizing method comprises the steps that a zone controller receives a dormancy command given out by an automatic train monitoring system, so that a current train to which the zone controller belongs carries out the dormancy command; whether communication failure occurs between the zone controller and the automatic train monitoring system or not is judged by the zone controller when the current train is dormant, and when communication failure occurs between the zone controller and the automatic train monitoring system, the zone controller carries out movement authority on the current train according to the manual driving mode. The zone controller-based train position memorizing method and checking method can automatically finish train returning to a storage, train delivery from the storage and train stopping and starting through the zone controller, manual intervention is reduced, and the train driving safety is improved at the same time.

Owner:TRAFFIC CONTROL TECH CO LTD

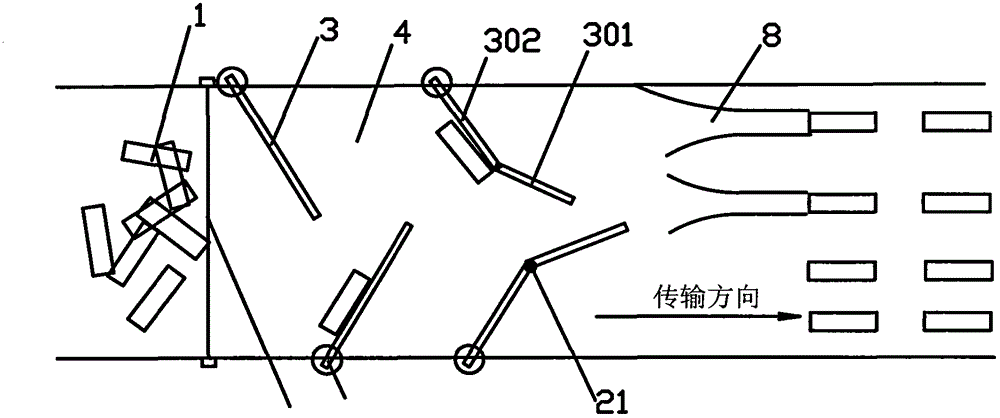

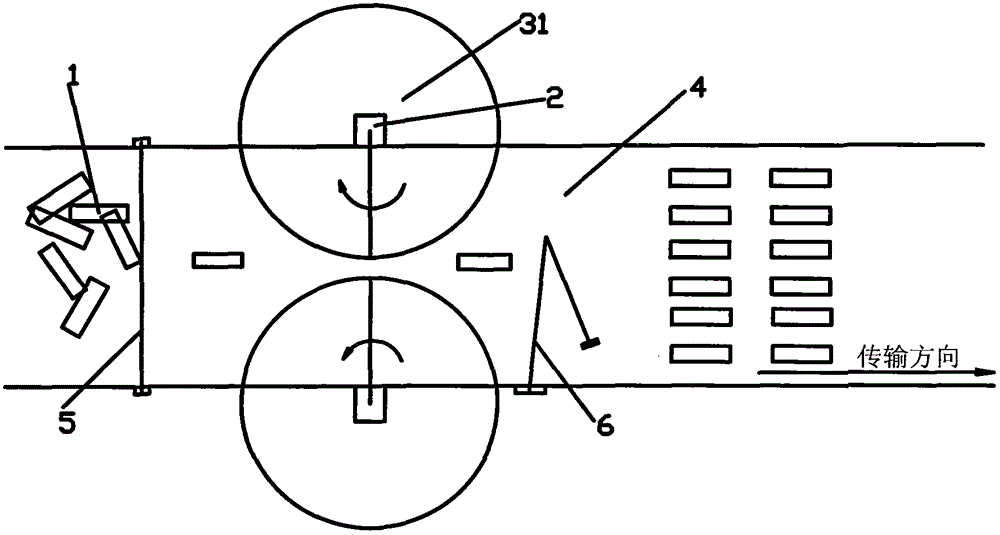

Automatic guide control system

InactiveCN102718053AEfficient sortingSimple structureConveyor partsAutomatic train controlAutomatic control

The invention discloses an automatic guide control system which comprises a transmission belt, guide arms, a control device and a height control arm, wherein the transmission belt is used for transmitting objects along a determined direction; the guide arms are arranged on the two sides of the transmission belt through guide arm installing ends and used for regulating the direction of the objects to be transmitted; the control device can control the movement of the transmission belt; the height of the height control arm can be set, and the height control arm is used for controlling that the objects to be transmitted are not transmitted in an overlapping manner; and the guide arms are arranged to be single or in a large arm-small arm connection manner and can be arranged side by side in multiple groups. The automatic guide control system also comprises guide grooves which are used for guiding the objects passing through the guide arms into specified lines and are arranged side by side in multiple groups. The automatic guide control system has the advantages of simple structure, convenience and effectiveness for sequencing the disordered and scattered materials, strong applicability and high precision.

Owner:ADTECH SHENZHEN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com