Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

26969 results about "Distillation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Distillation is the process of separating the components or substances from a liquid mixture by using selective boiling and condensation. Distillation may result in essentially complete separation (nearly pure components), or it may be a partial separation that increases the concentration of selected components in the mixture. In either case, the process exploits differences in the relative volatility of the mixture's components. In industrial chemistry, distillation is a unit operation of practically universal importance, but it is a physical separation process, not a chemical reaction.

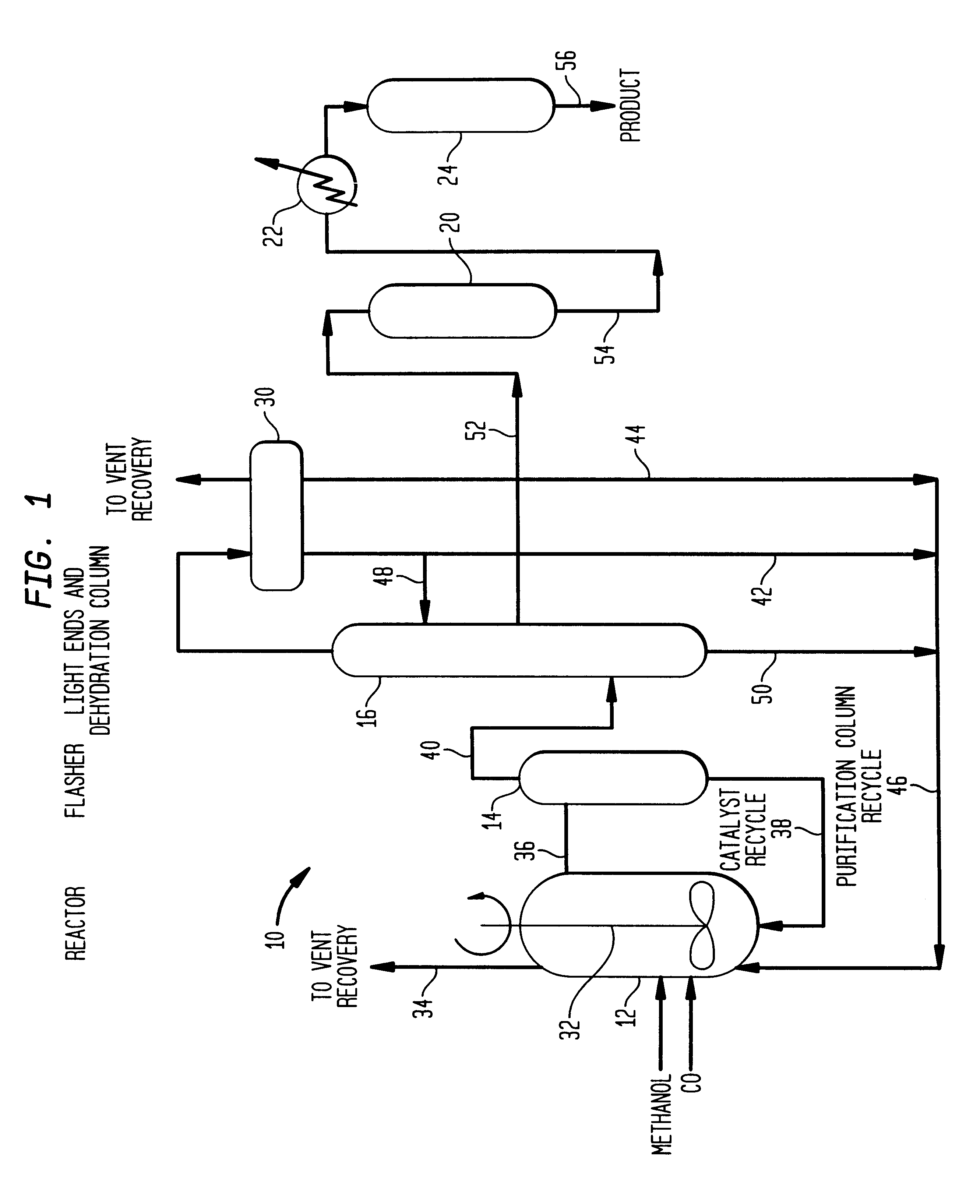

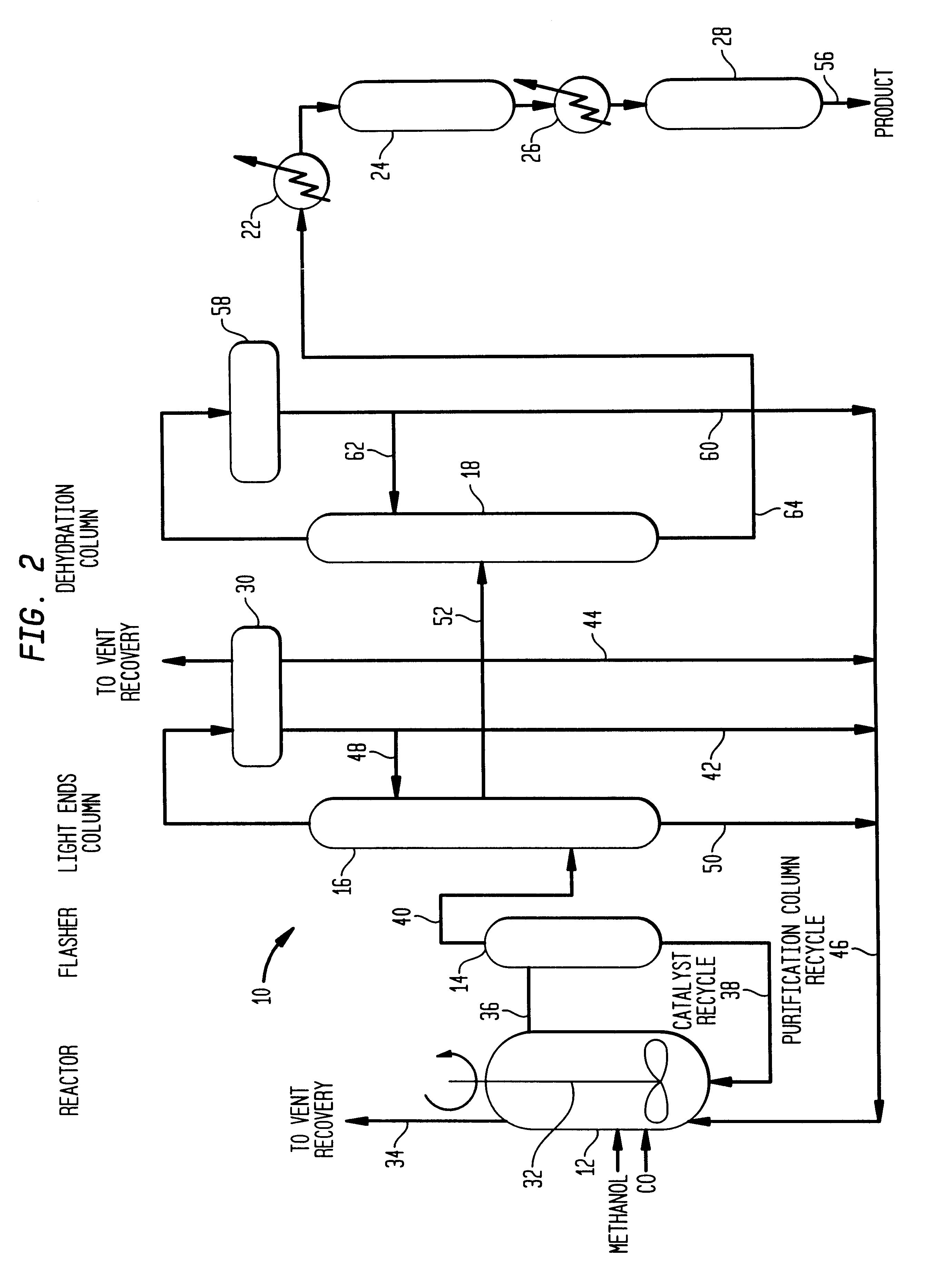

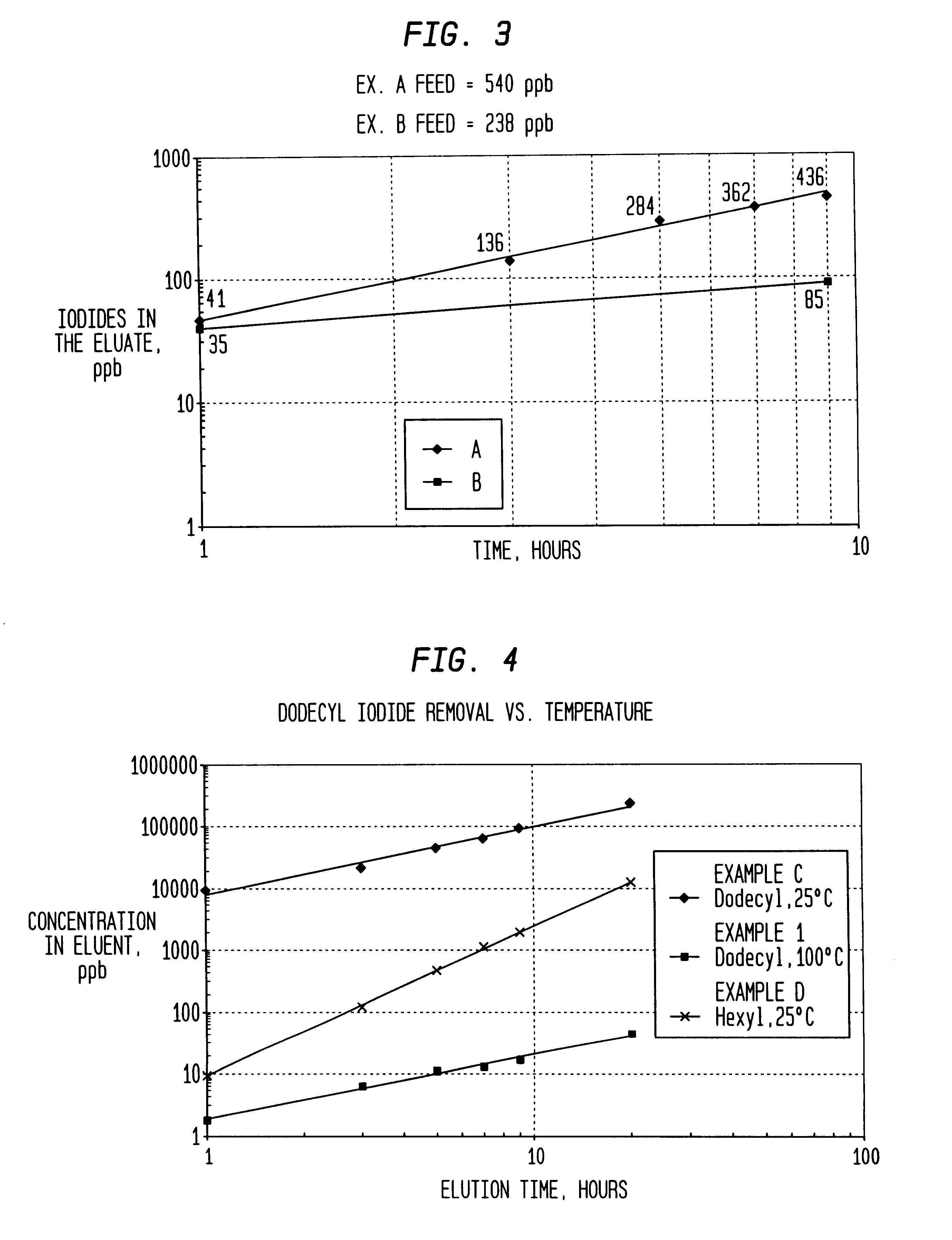

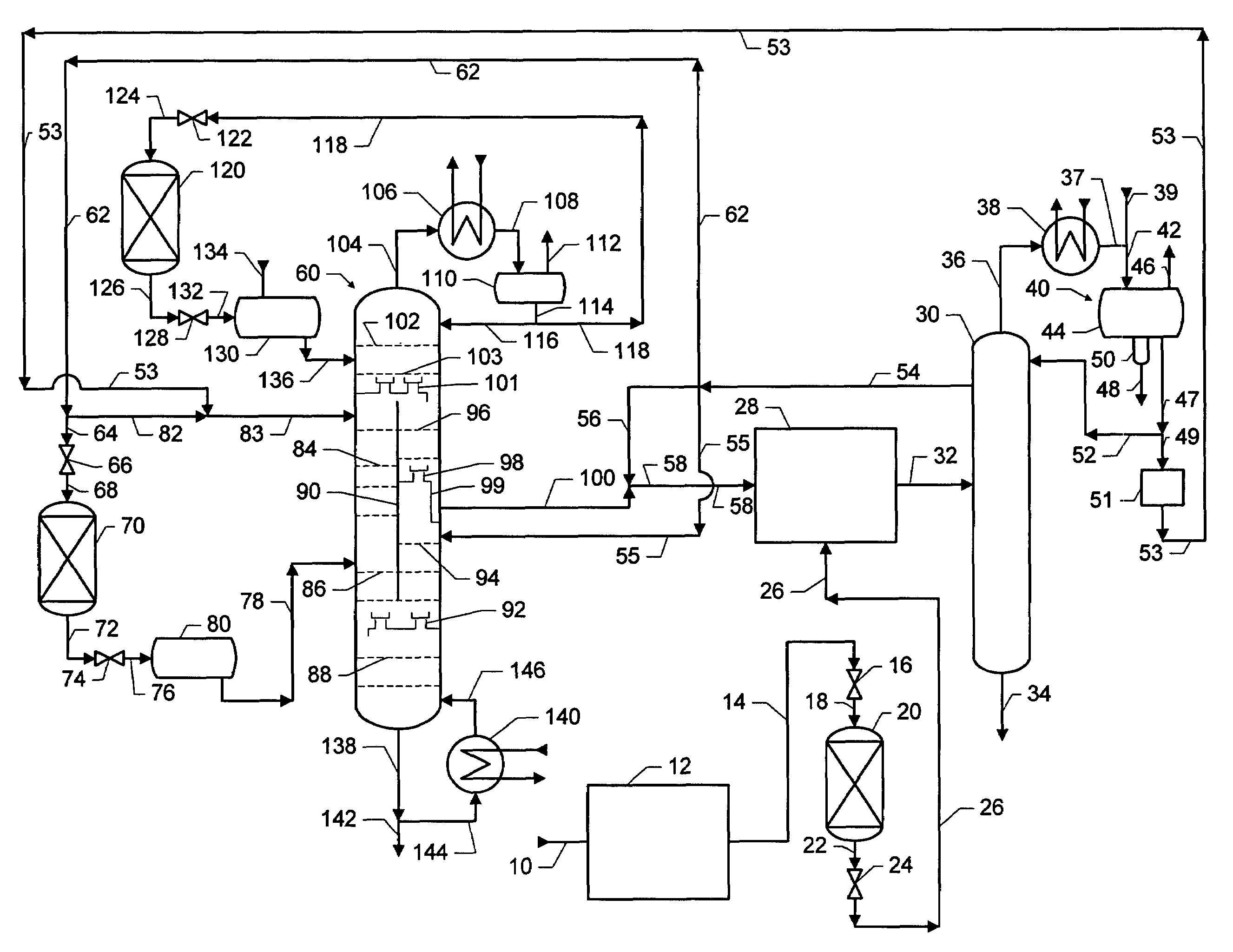

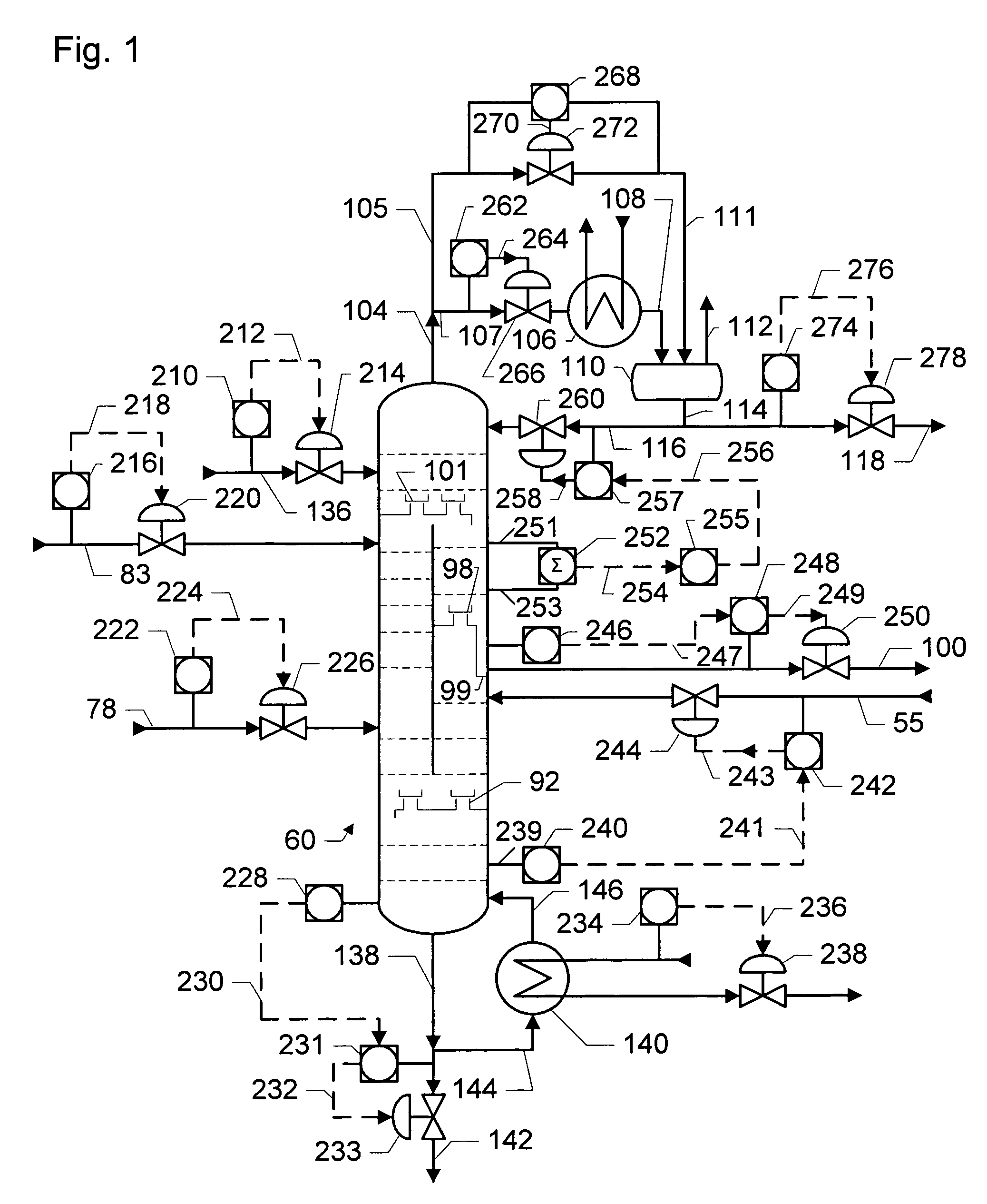

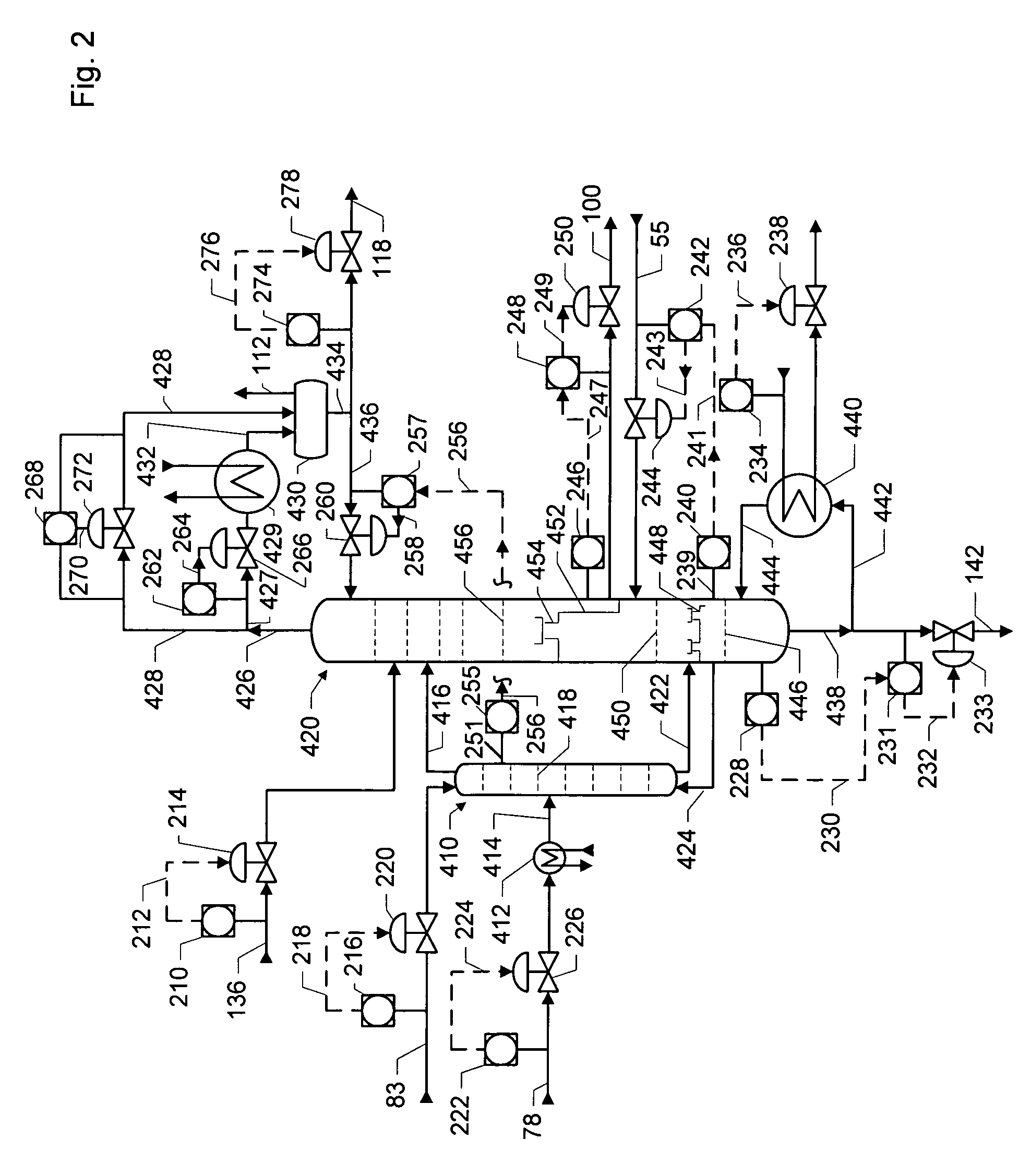

Low energy carbonylation process

InactiveUS6657078B2Weaken energyHigh purityOrganic compound preparationOrganic chemistry methodsPropanoic acidIodide

A low energy process for producing acetic acid by the carbonylation of methanol is disclosed. The process involves a rhodium-catalyzed system operated at less than about 14% water utilizing up to 2 distillation columns. The process is preferably controlled such that the product stream has a low level of propionic acid impurity and the level of aldehyde impurities is minimized by way of aldehyde removal or minimizing aldehyde generation. The level of iodides is controlled by contacting the product, at elevated temperatures, with ion exchange resins. In preferred embodiments, at least one silver or mercury exchanged macroreticular strong acid ion exchange resin is used to purify the product. The high temperature treatment provides the added benefit of controlling the Color Value (Pt-Co units) of the product stream.

Owner:CELANESE INT CORP

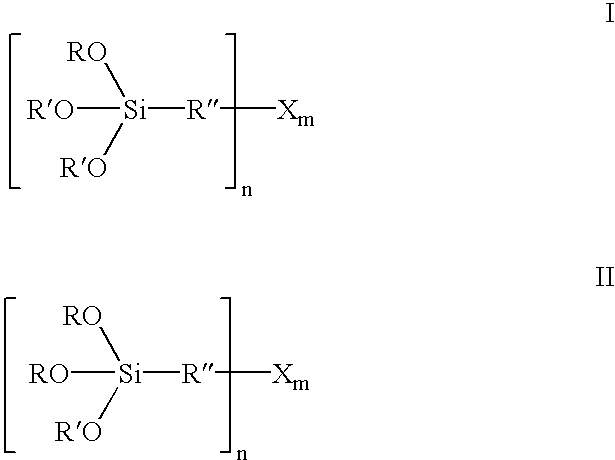

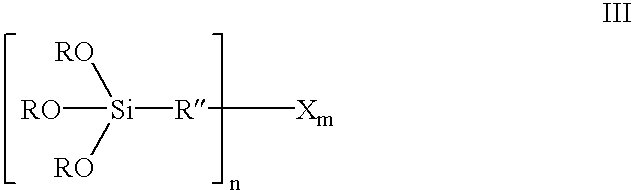

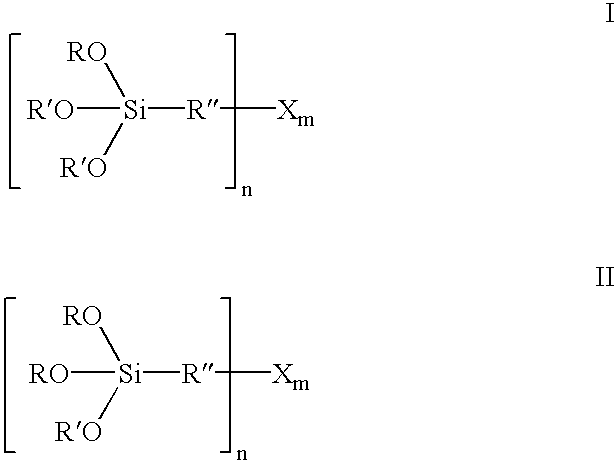

Organosilicon compounds

InactiveUS6849754B2Improve bindingAvoid large quantitiesSilicon organic compoundsOrganic chemistry methodsAlcoholSilanes

Organosilicon compounds of the general formula I and / or II are produced by reacting silanes of the general formula III with alcohols of the general formula R′—OH, with elimination of R—OH, wherein R—OH may be continuously separated from the reaction mixture by distillation. The organosilicon compounds may be used in rubber mixtures. Compounds, such as rubbers, produced using such organosilicon compounds.

Owner:EVONIK DEGUSSA GMBH

Method for producing fluorinated organic compounds

ActiveUS20070197842A1Preparation by hydrogen halide split-offPreparation by halogen replacementPtru catalystDistillation

Disclosed are processes for the production of fluorinated olefins, preferably adapted to commercialization of CF3CF═CH2 (1234yf). Three steps may be used in preferred embodiments in which a feedstock such as CCl2═CClCH2Cl (which may be purchased or synthesized from 1,2,3-trichloropropane) is fluorinated (preferably with HF in gas-phase in the presence of a catalyst) to synthesize a compound such as CF3CCl═CH2, preferably in a 80-96% selectivity. The CF3CCl═CH2 is preferably converted to CF3CFClCH3 (244-isomer) using a SbCl5 as the catalyst which is then transformed selectively to 1234yf, preferably in a gas-phase catalytic reaction using activated carbon as the catalyst. For the first step, a mixture of Cr2O3 and FeCl3 / C is preferably used as the catalyst to achieve high selectivity to CF3CCl═CH2 (96%). In the second step, SbCl5 / C is preferably used as the selective catalyst for transforming 1233xf to 244-isomer, CF3CFClCH3. The intermediates are preferably isolated and purified by distillation and used in the next step without further purification, preferably to a purity level of greater than about 95%.

Owner:HONEYWELL INT INC

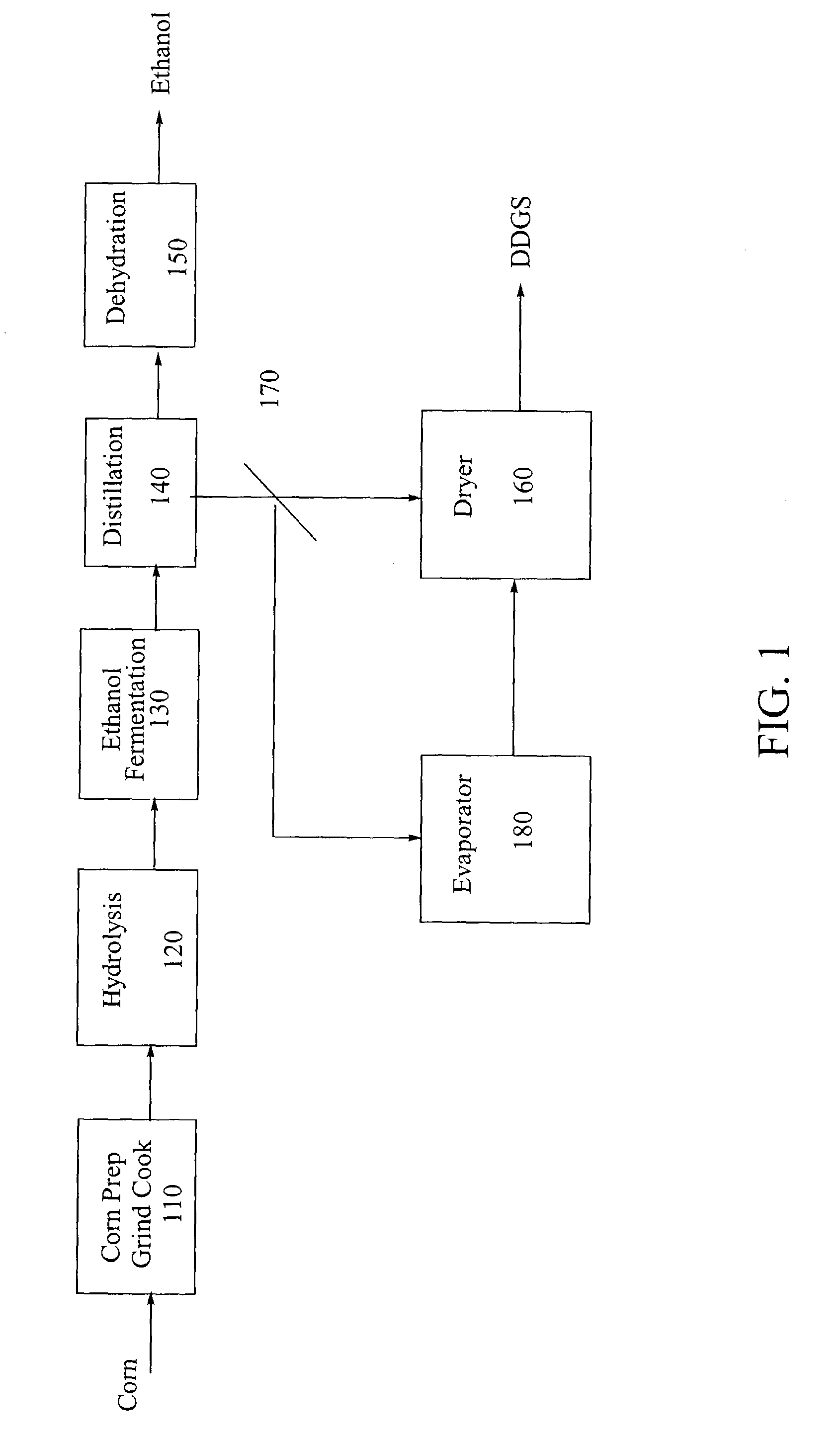

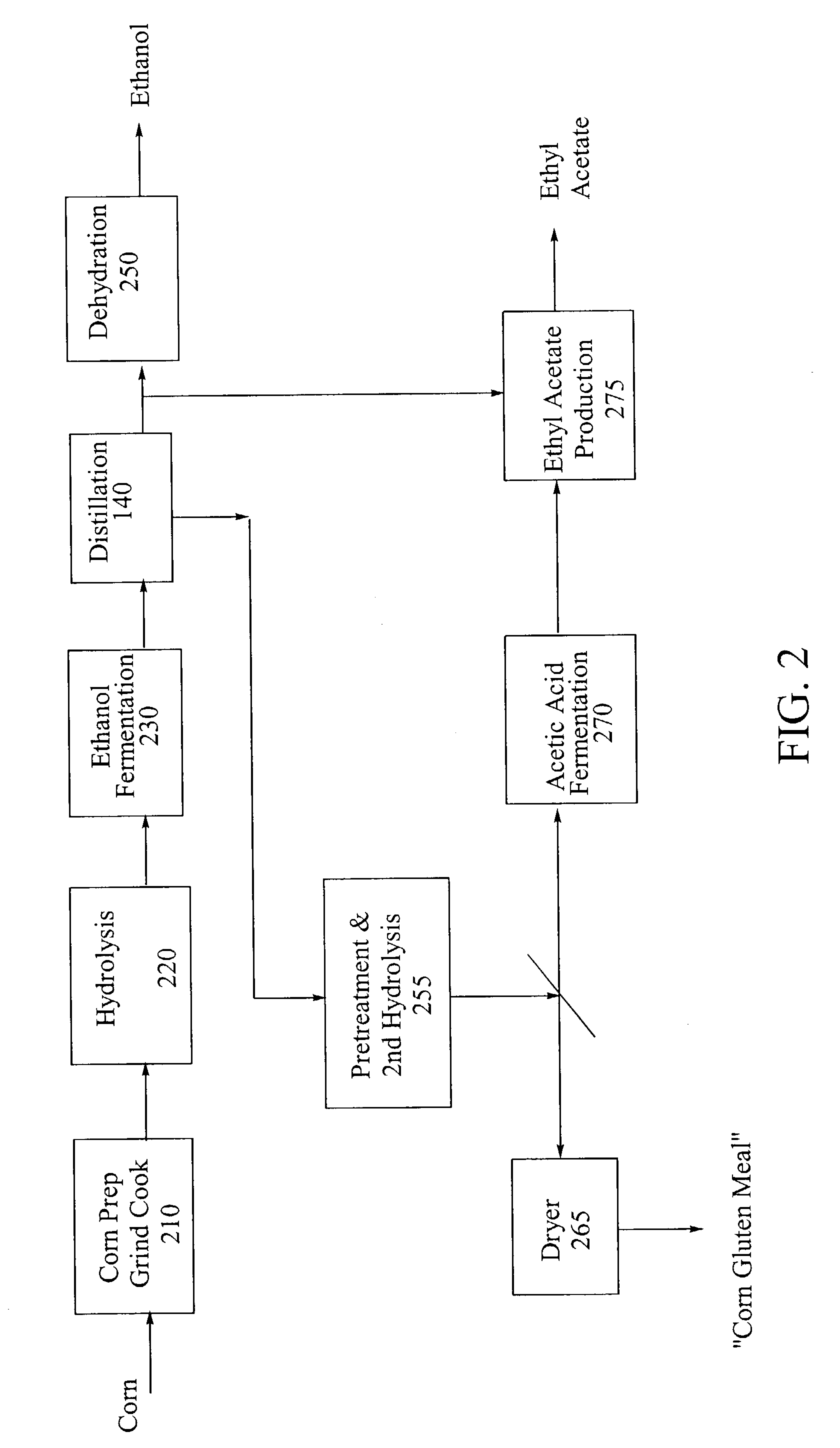

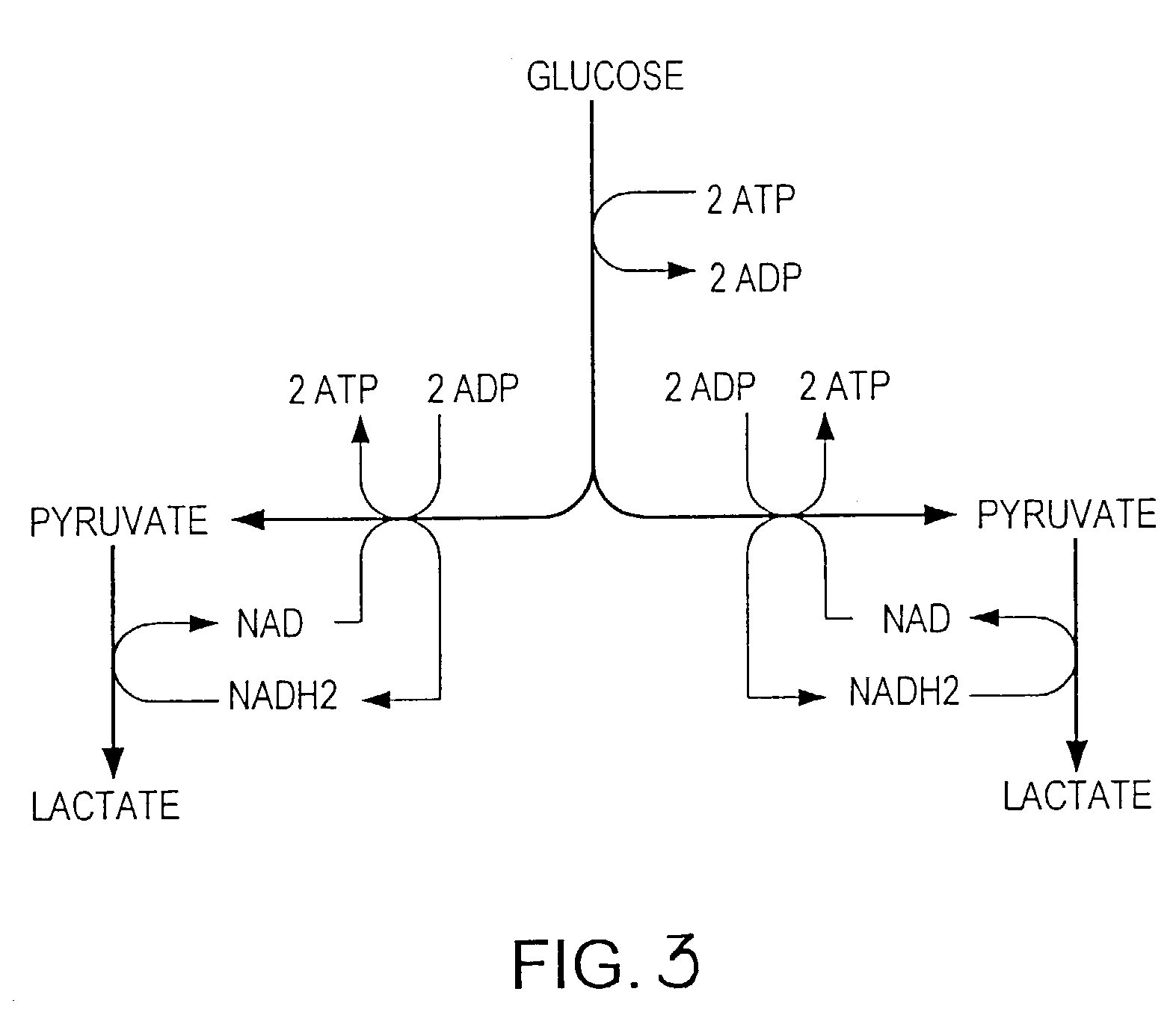

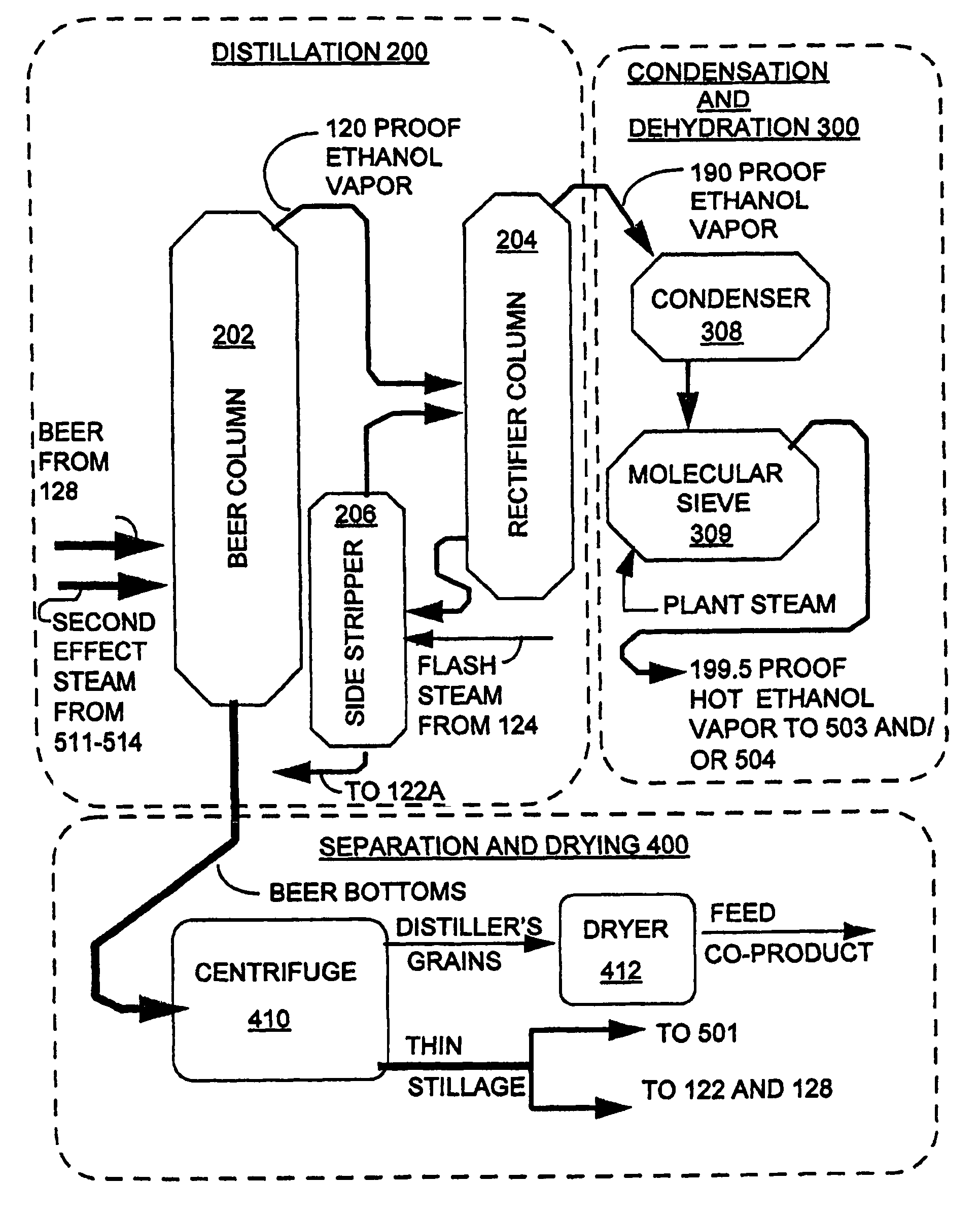

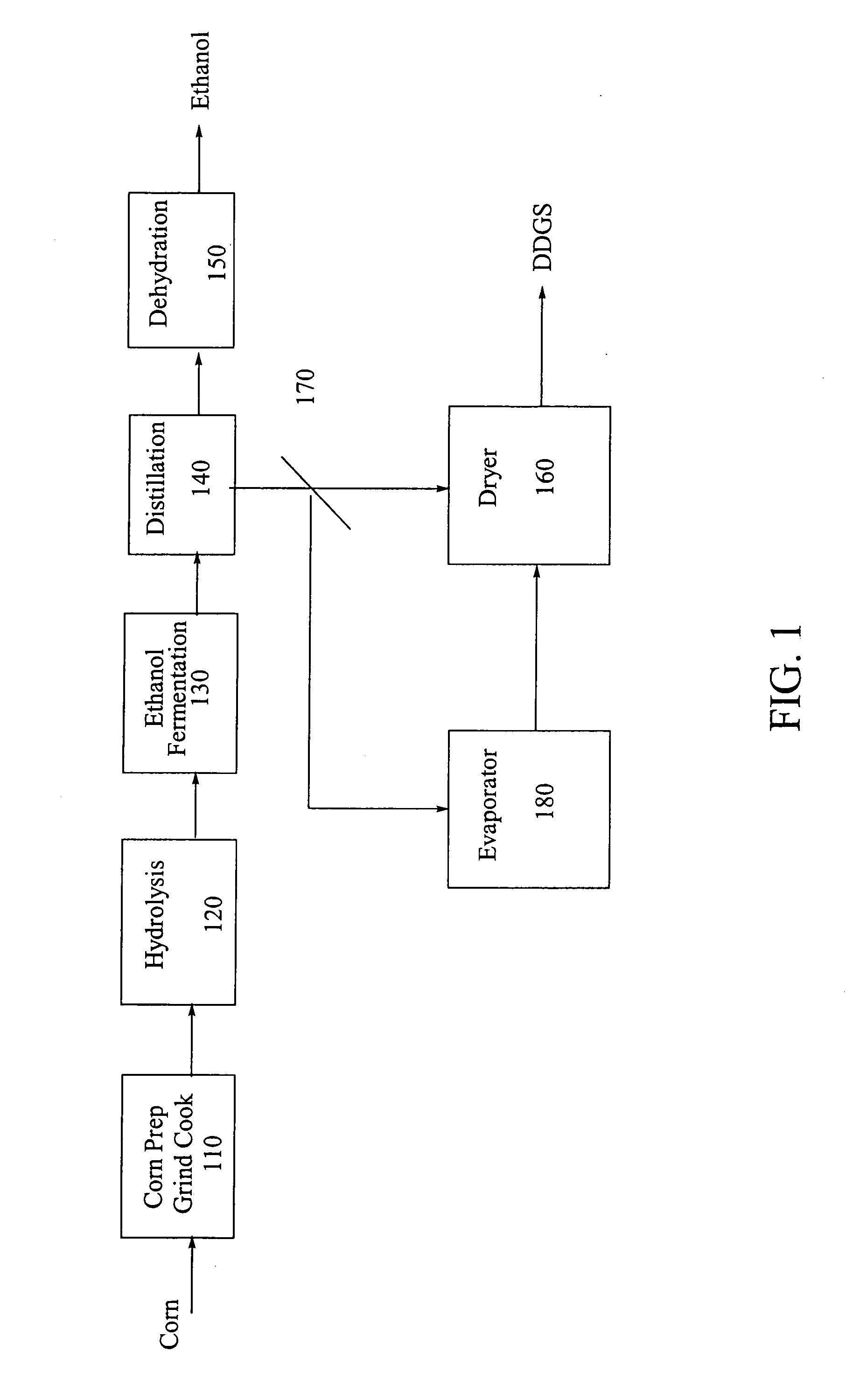

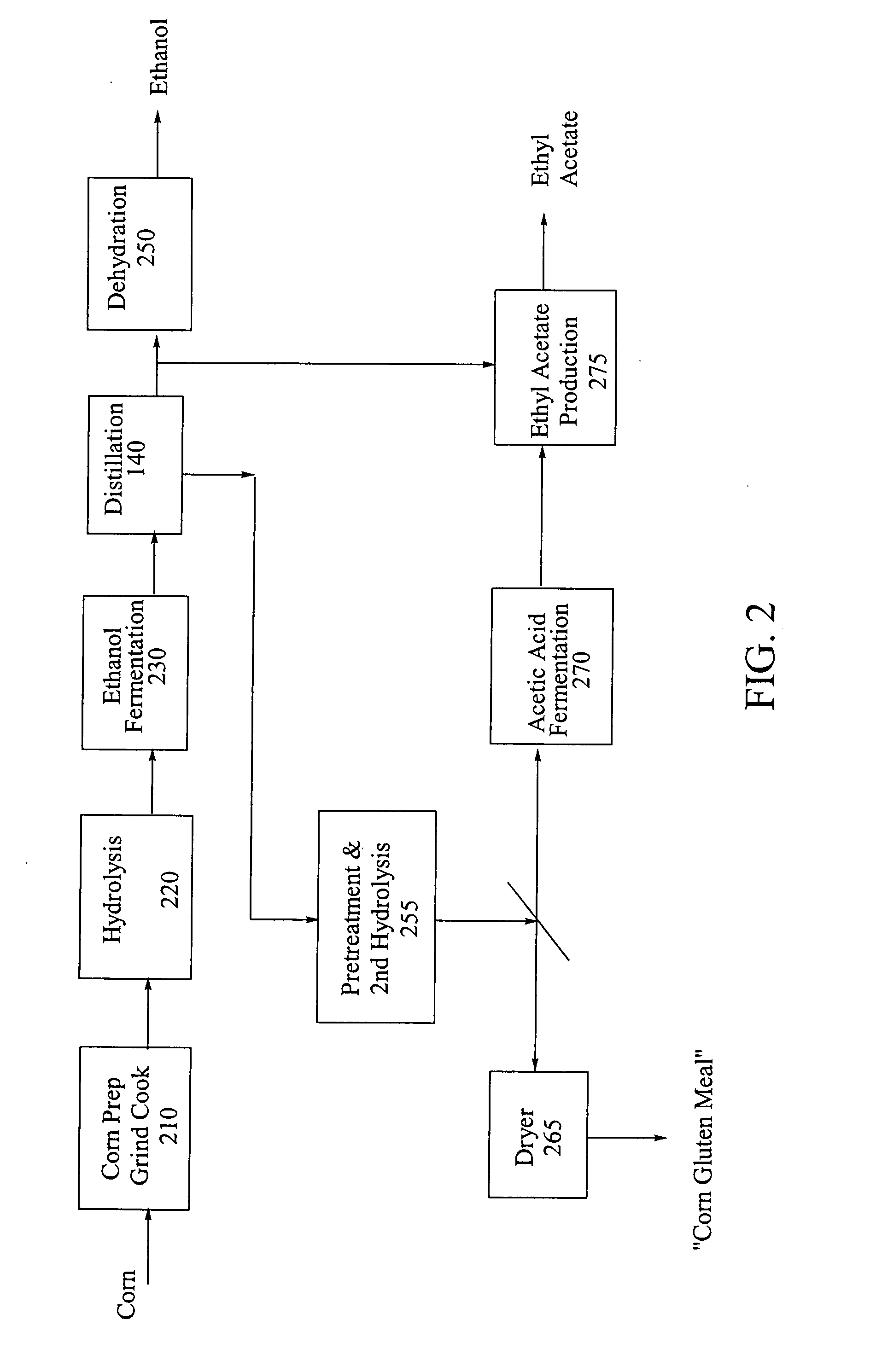

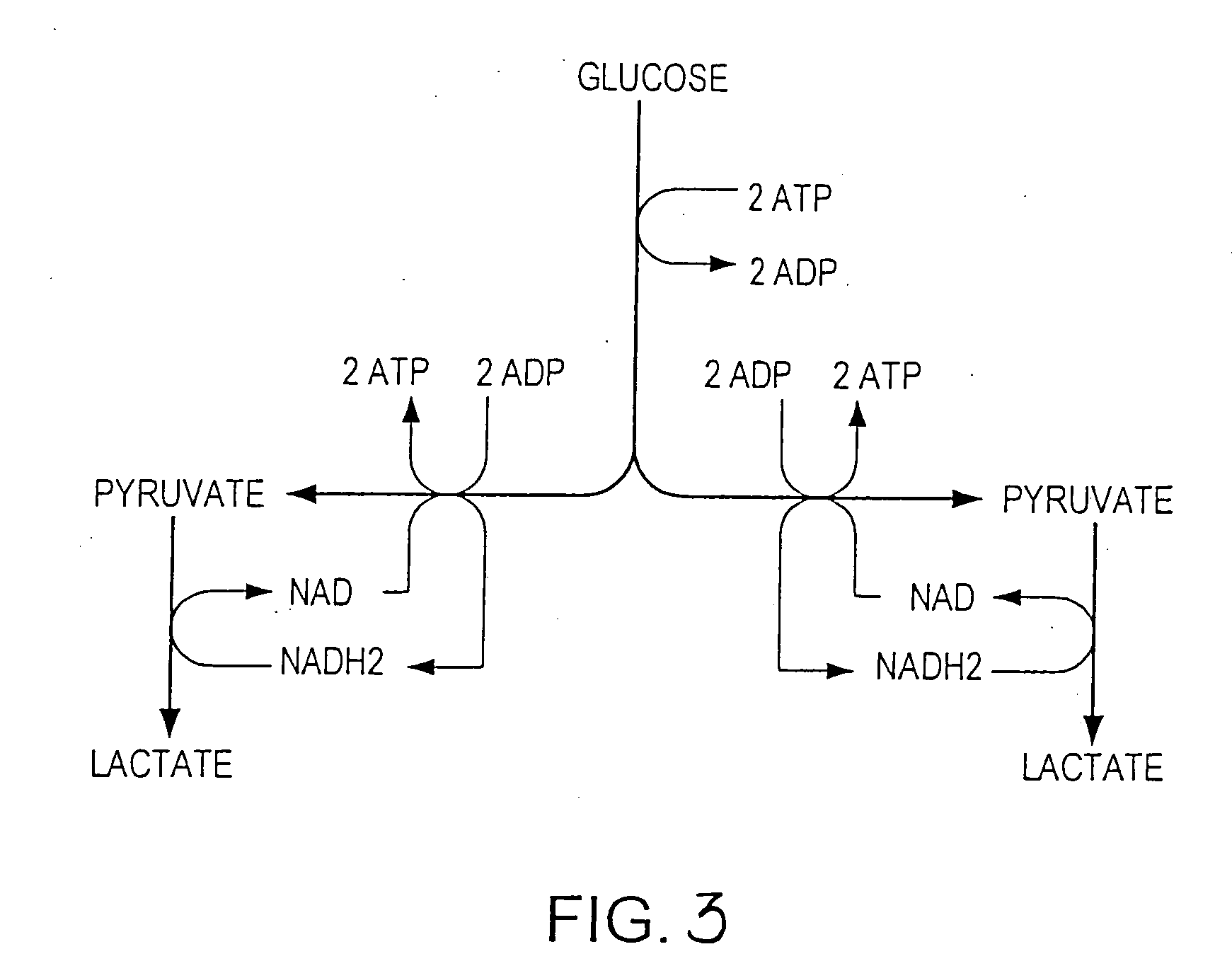

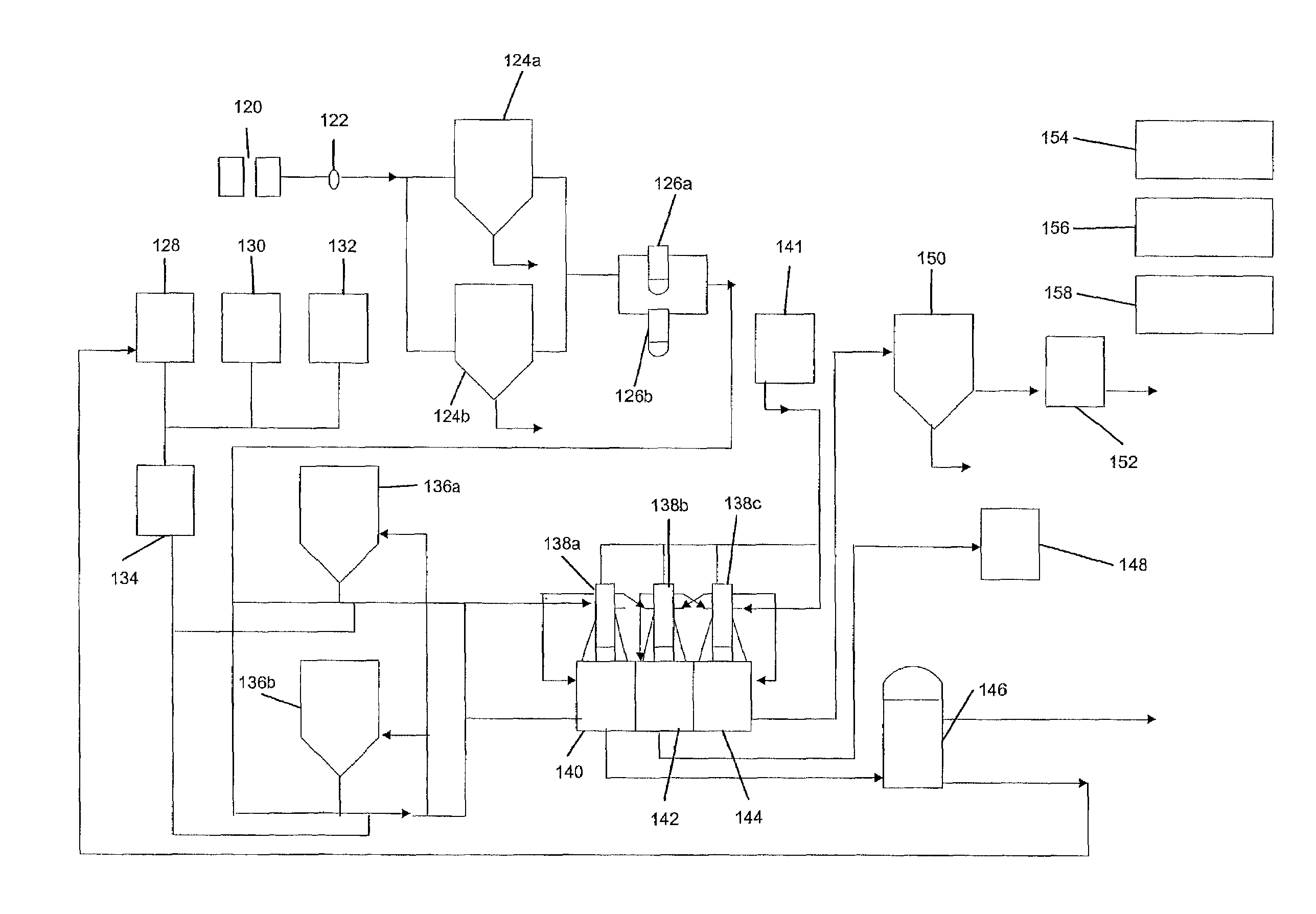

Process for producing ethanol from corn dry milling

InactiveUS7074603B2Fermented solutions distillation/rectificationOrganic compound preparationAcetic acidHydrogenation reaction

A process for producing ethanol by the conversion of carbohydrates from a corn dry milling process in which the bottoms fraction from distillation of ethanol in a conventional yeast fermentation is used in a process including a combination of biochemical and synthetic conversions. The process results in high yield ethanol production with concurrent production of high value coproducts. An acetic acid intermediate is produced from bottoms fraction, followed by conversion of the acetic acid into ethanol using esterification and hydrogenation reactions. Coproducts of the process include a high protein content solids fraction produced in the fermentation.

Owner:ZEACHEM

Purification of biologically-produced 1,3-propanediol

InactiveUS20050069997A1Reduce the amount of waterFermented solutions distillation/rectificationMembranesEscherichia coliDistillation

A process for purifying 1,3-propanediol from the fermentation broth of a cultured E. coli that has been bioengineered to synthesize 1,3-propanediol from sugar is provided. The basic process entails filtration, ion exchange and distillation of the fermentation broth product stream, preferably including chemical reduction of the product during the distillation procedure. Also provided are highly purified compositions of 1,3-propanediol.

Owner:DUPONT IND BIOSCIENCES USA LLC +1

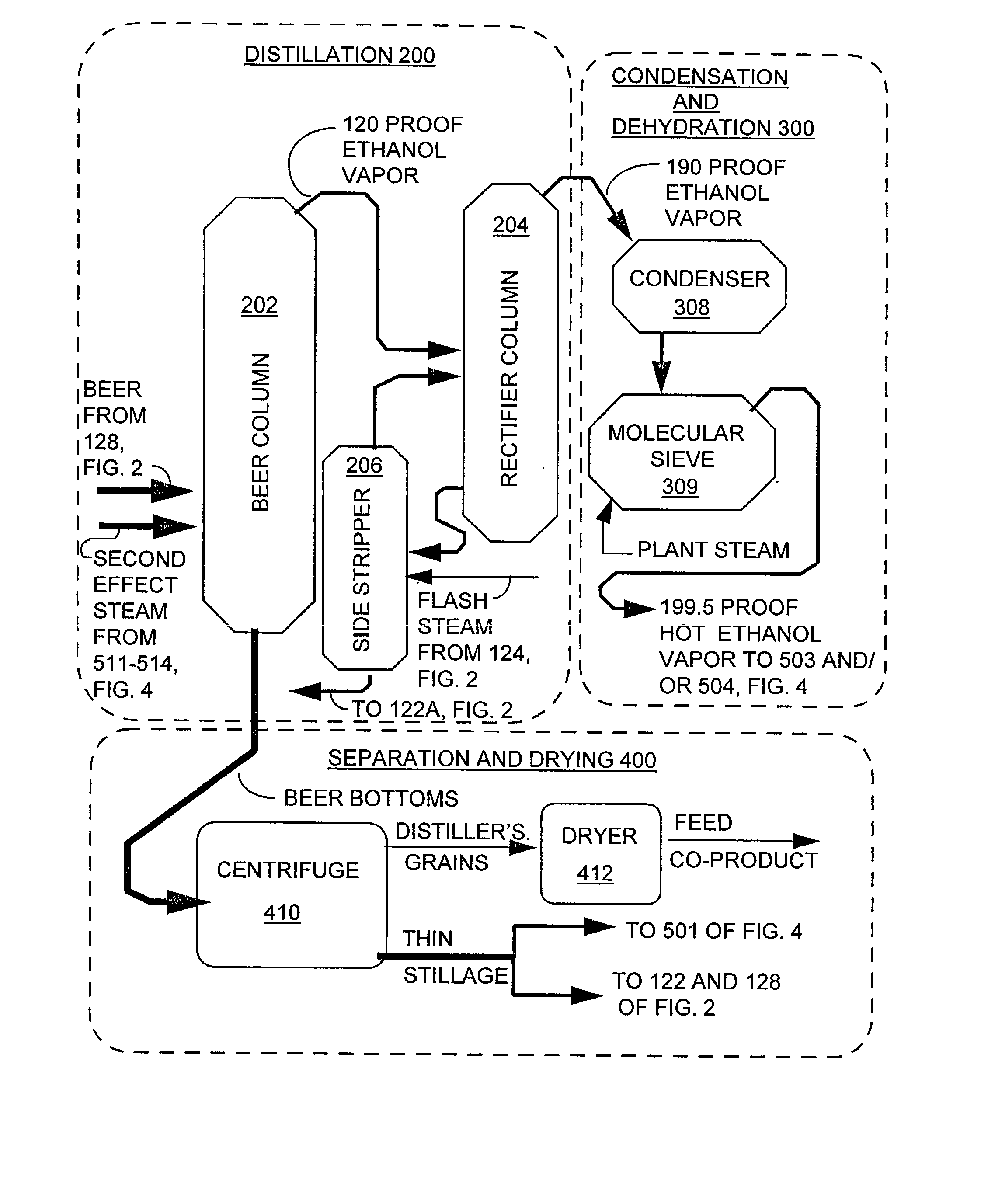

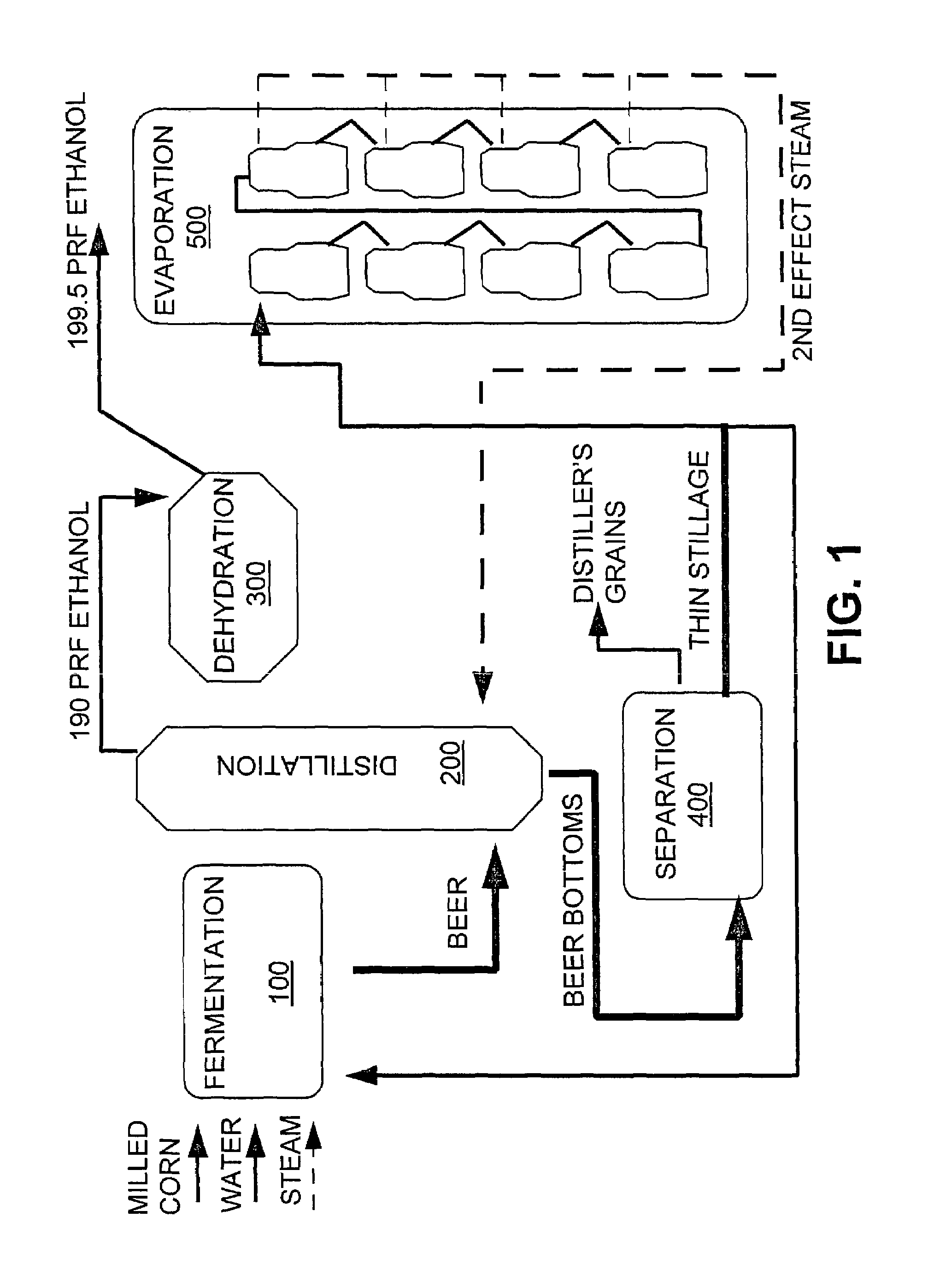

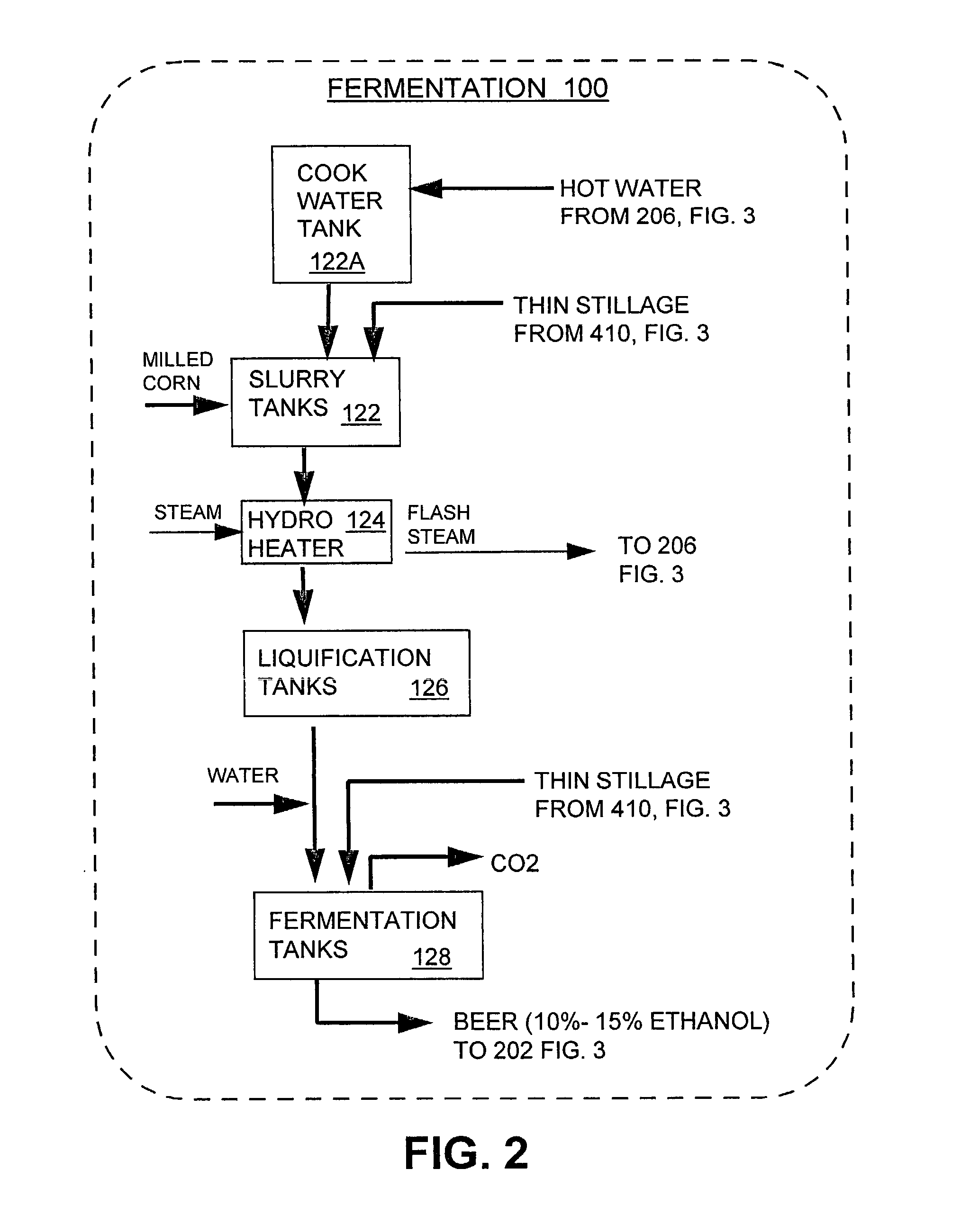

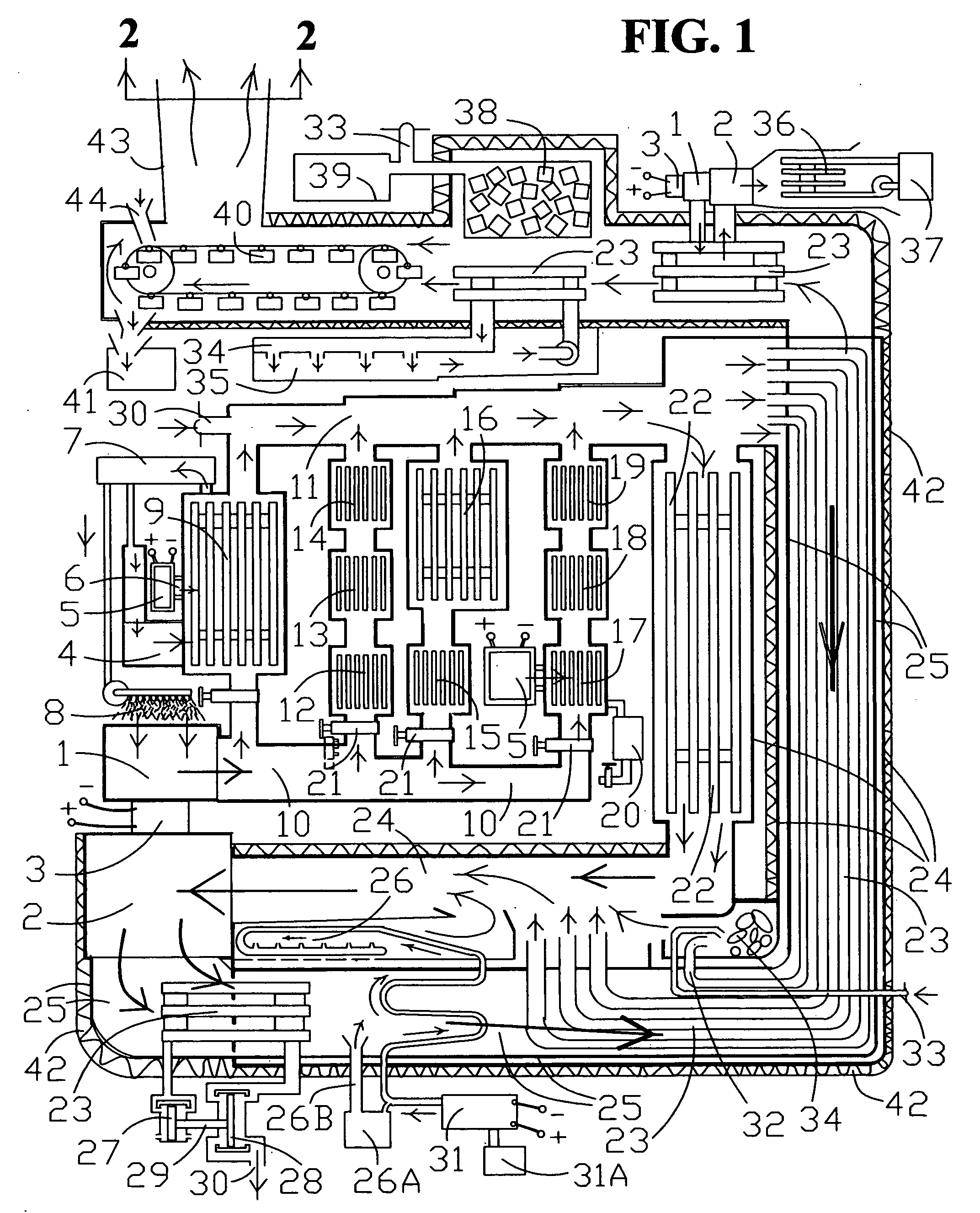

Ethanol distillation process

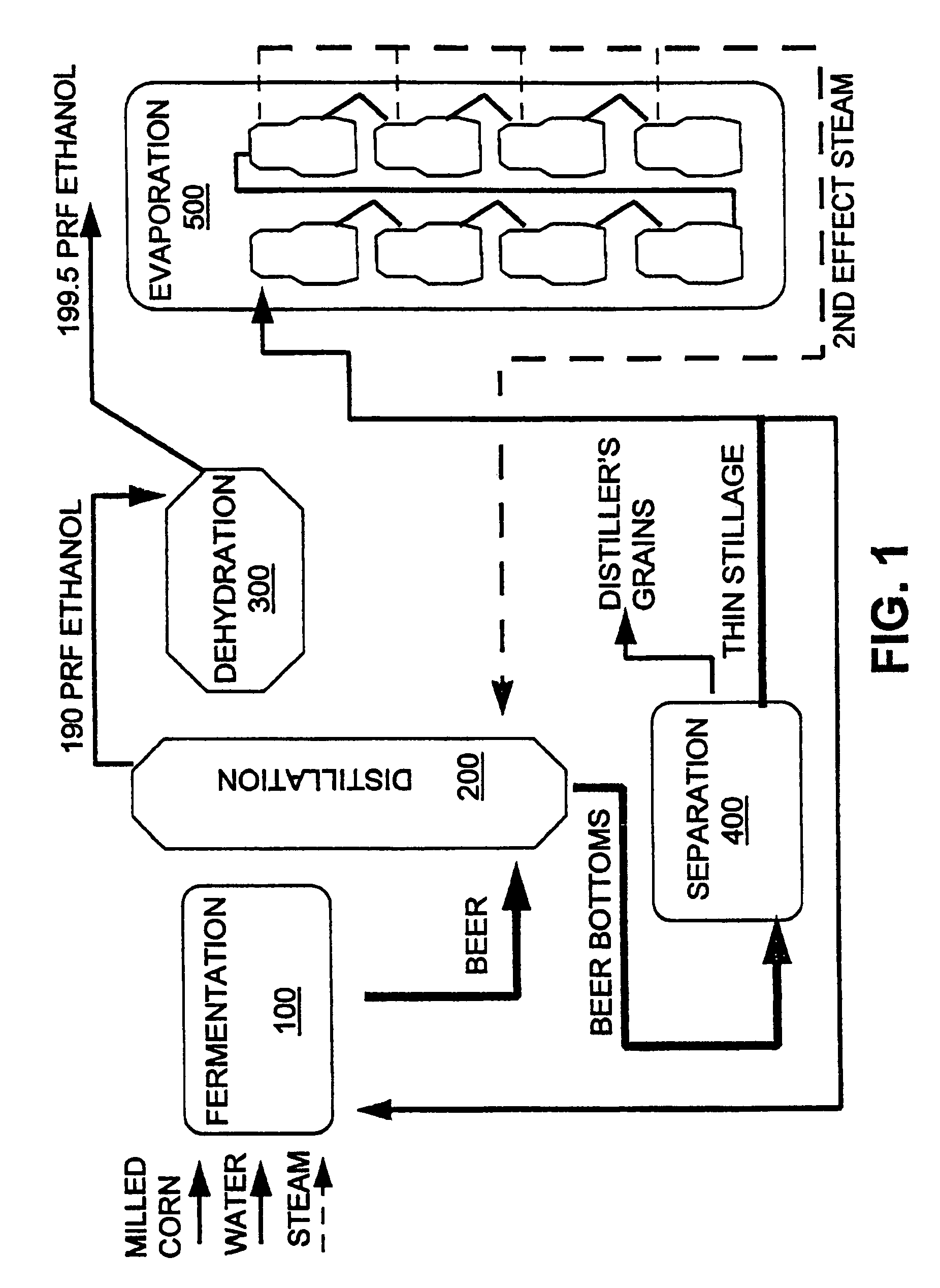

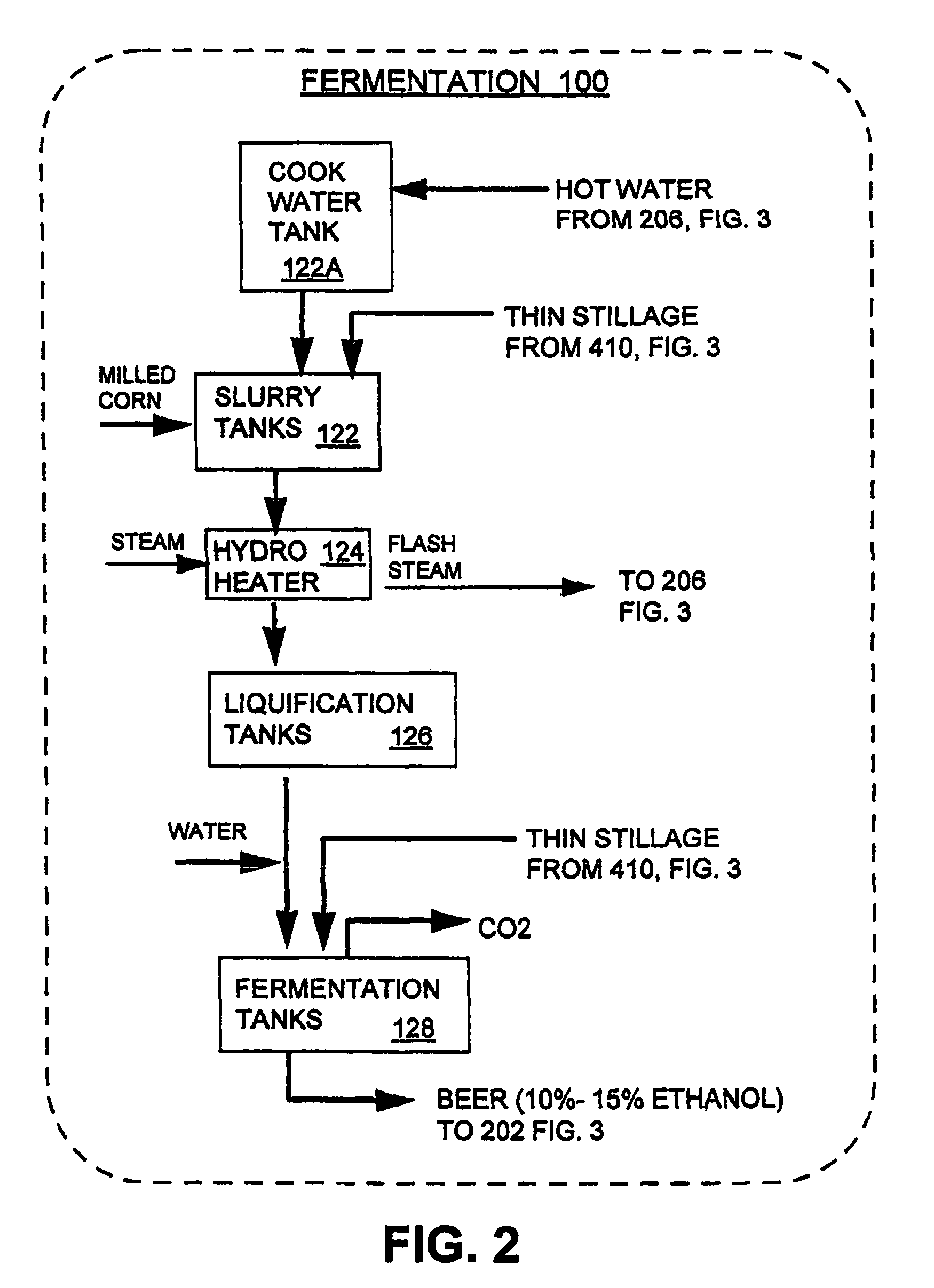

InactiveUS7297236B1Avoid insufficient heatingShorten the timeFermented solutions distillation/rectificationDistillation in boilers/stillsDistillationEvaporation

A process arrangement for distilling fuel grade ethanol includes a fermentation portion, a distillation portion, a condensation and dehydration portion, a separation and drying portion and an evaporation portion. The fermentation portion produces beer. The distillation portion, the condensation and dehydration portion and the separation and drying portion receives beer from the fermentation portion and produces hot ethanol vapor and thin stillage. In the evaporation portion, a set of first effect evaporators which are heated either by plant steam or hot ethanol vapor, concentrate thin stillage into mid stillage while producing first effect steam. The first effect steam from the first effect evaporators provides heat to a set of second effect evaporators which concentrate the mid stillage into a syrup for further drying. The second effect evaporators produce second effect steam which is used to heat the distillation portion of the process arrangement. The multiple evaporators of the first and second effects of the evaporation portion can be selectively taken off-line for maintenance while the evaporation portion and the remainder of the process arrangement continue to operate at full capacity.

Owner:ICM

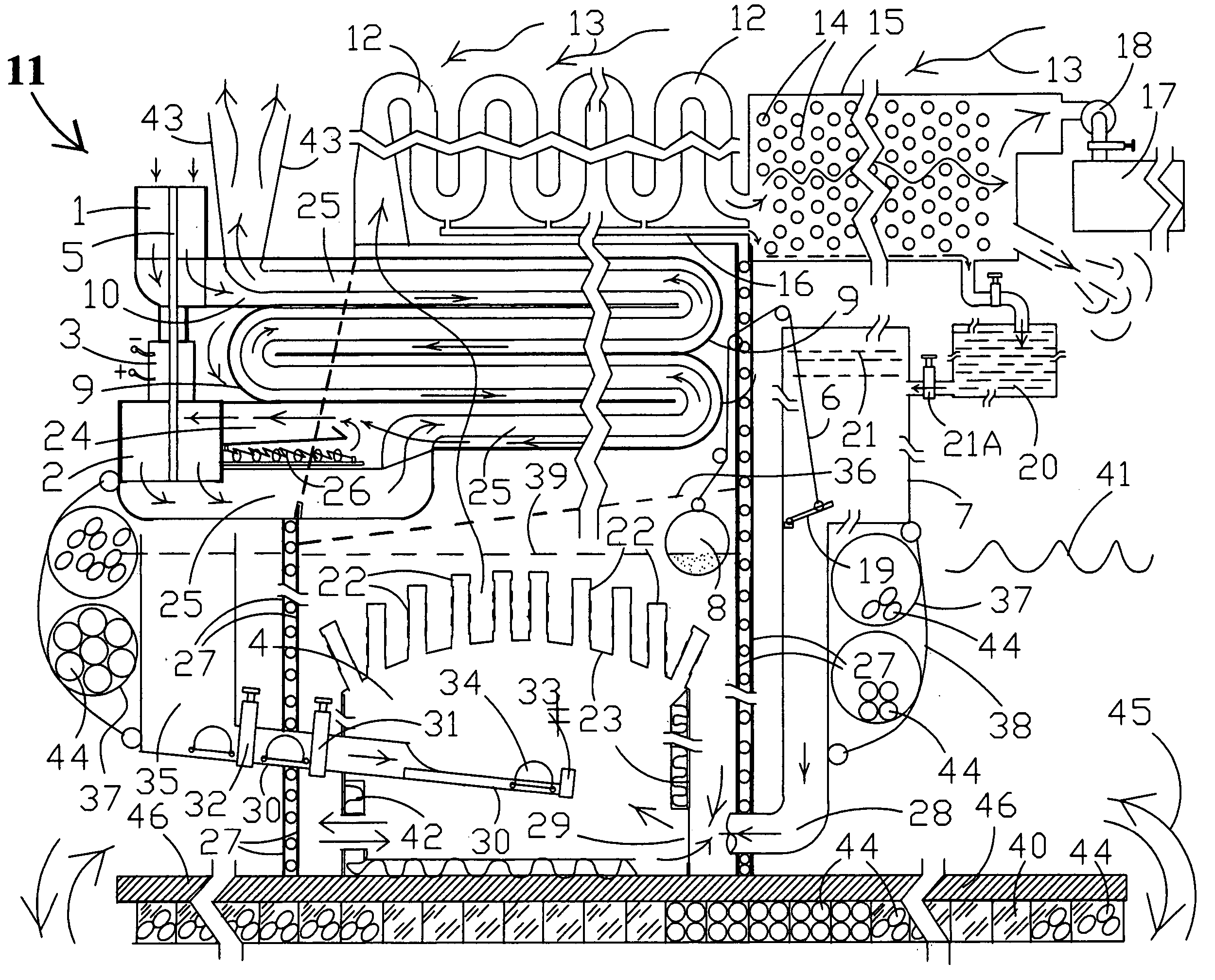

Heat energy recapture and recycle and its new applications

InactiveUS20050120715A1Increase the atmosphereGood sunshineEngine fuctionsEfficient propulsion technologiesThermal energyDistillation

What has been created is a plurality and a variety of processes and a variety of devices correspondingly supportive to each process, wherein, a new partnership between; (1) a heat absorbing radiator compressed air pipes / tubes and (2) a gas turbine engine or a reciprocating piston engine,—is used to recapture and reconvert the, otherwise wasted, heat energies expelled by engines, by factories, by smelting plants, by distillation plants, by chillers / coolers / freezers, by cooking ovens, by lamps / stoves, by trash burners, and the heat energies created by the solar heat on the desert / ocean water,—into electric power and finally into hydrogen-deuterium fuel,—by having the engine's tailpipes submerged in cold compressed air inside the heat absorbing radiator pipes in reverse air flow, to further drive and re-drive the same engine; wherein, in order to capture fusion heat energy the hydrogen bomb is detonated in the deep ocean to catch the flames by the water and the hot water is used to energize the compressed air inside the heat absorbing radiator pipes; wherein, in order to produce fusion energy, an abundant electric arc is passed across liquid deuterium or across gaseous deuterium by the electro-plasma torch and sparkplug in the internal combustion engine, and by detonating a dynamite inside a liquid deuterium; wherein diamond is produced by placing carbon inside the hydrogen bomb; and wherein, deuterium fusion flame is used first in smelting glass to large sizes before running an engine.

Owner:CHRISTIAN SCHOOL OF TECH CHARITABLE FOUND TRUST

Ethanol distillation process

InactiveUS7572353B1Shorten the timeLess rapidlyFermented solutions distillation/rectificationOrganic compound preparationDistillationEvaporation

Owner:ICM

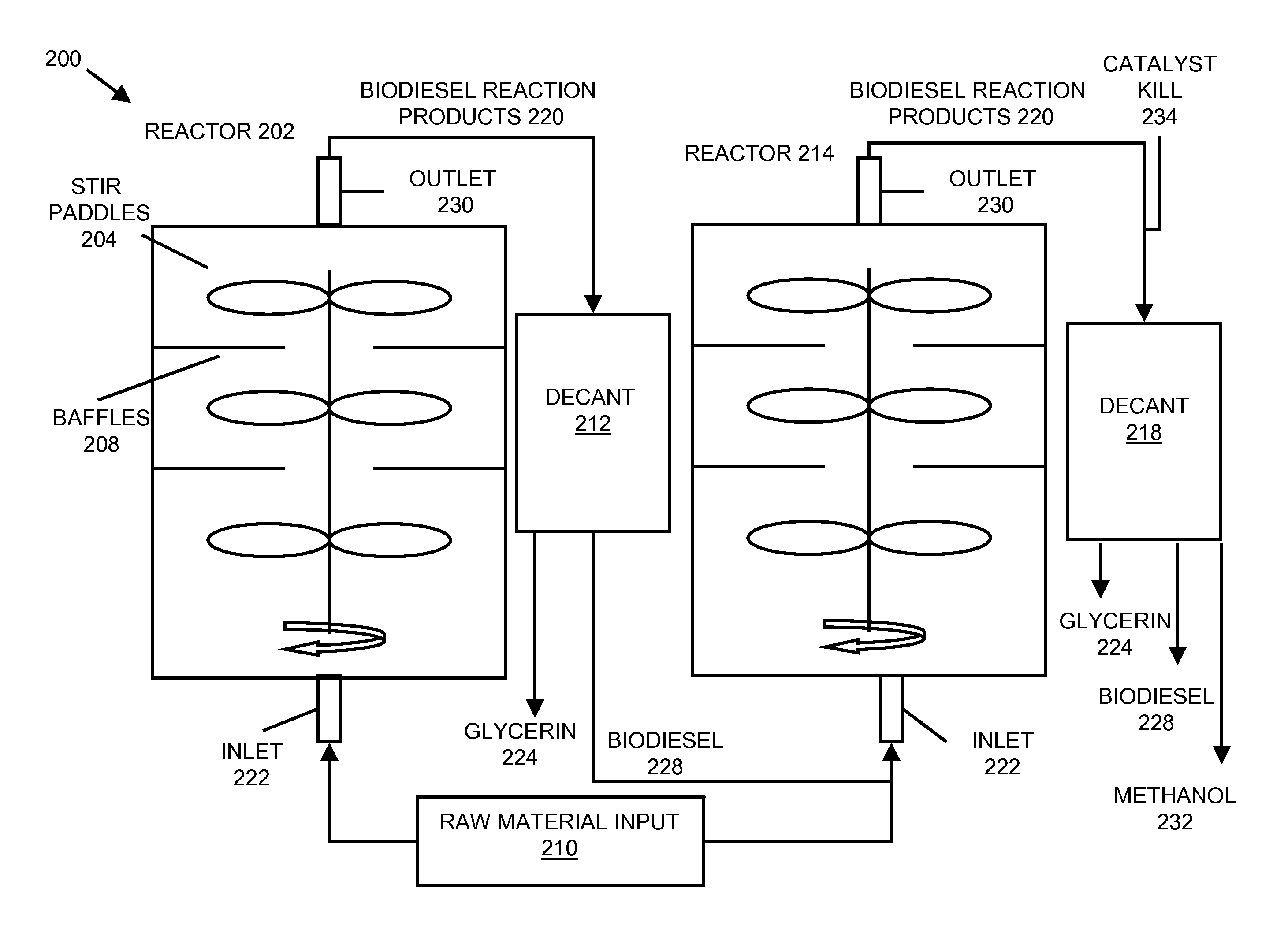

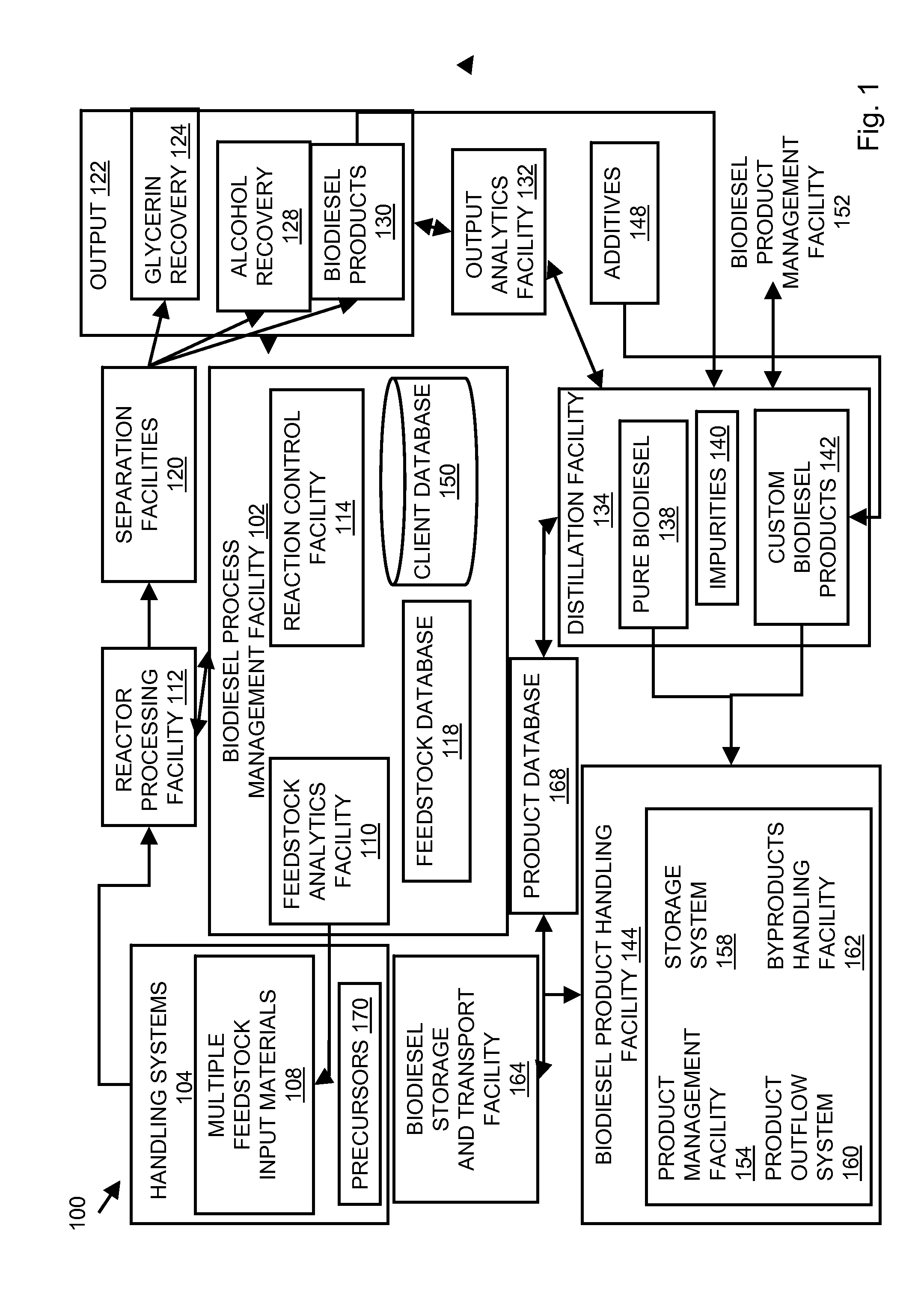

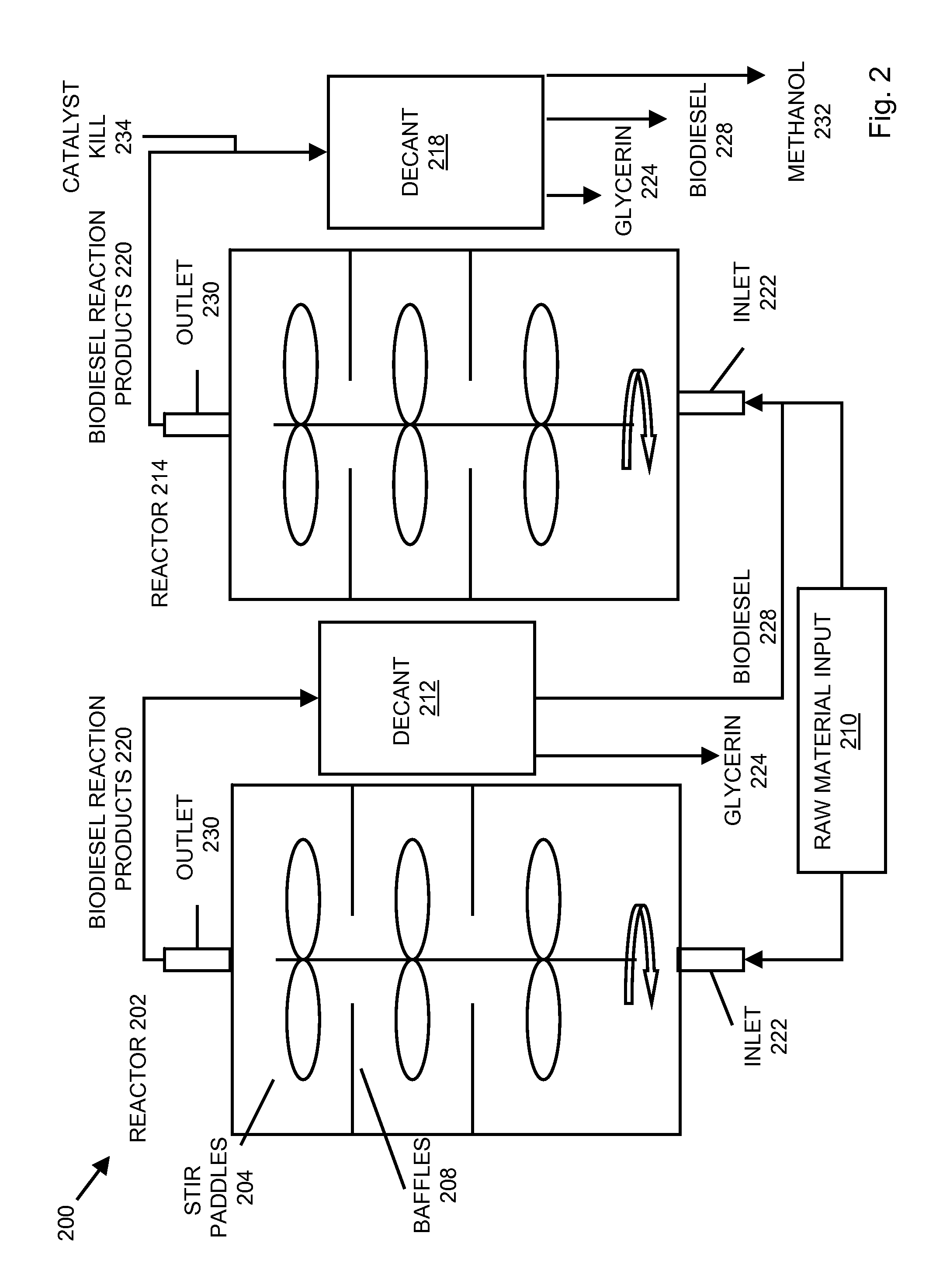

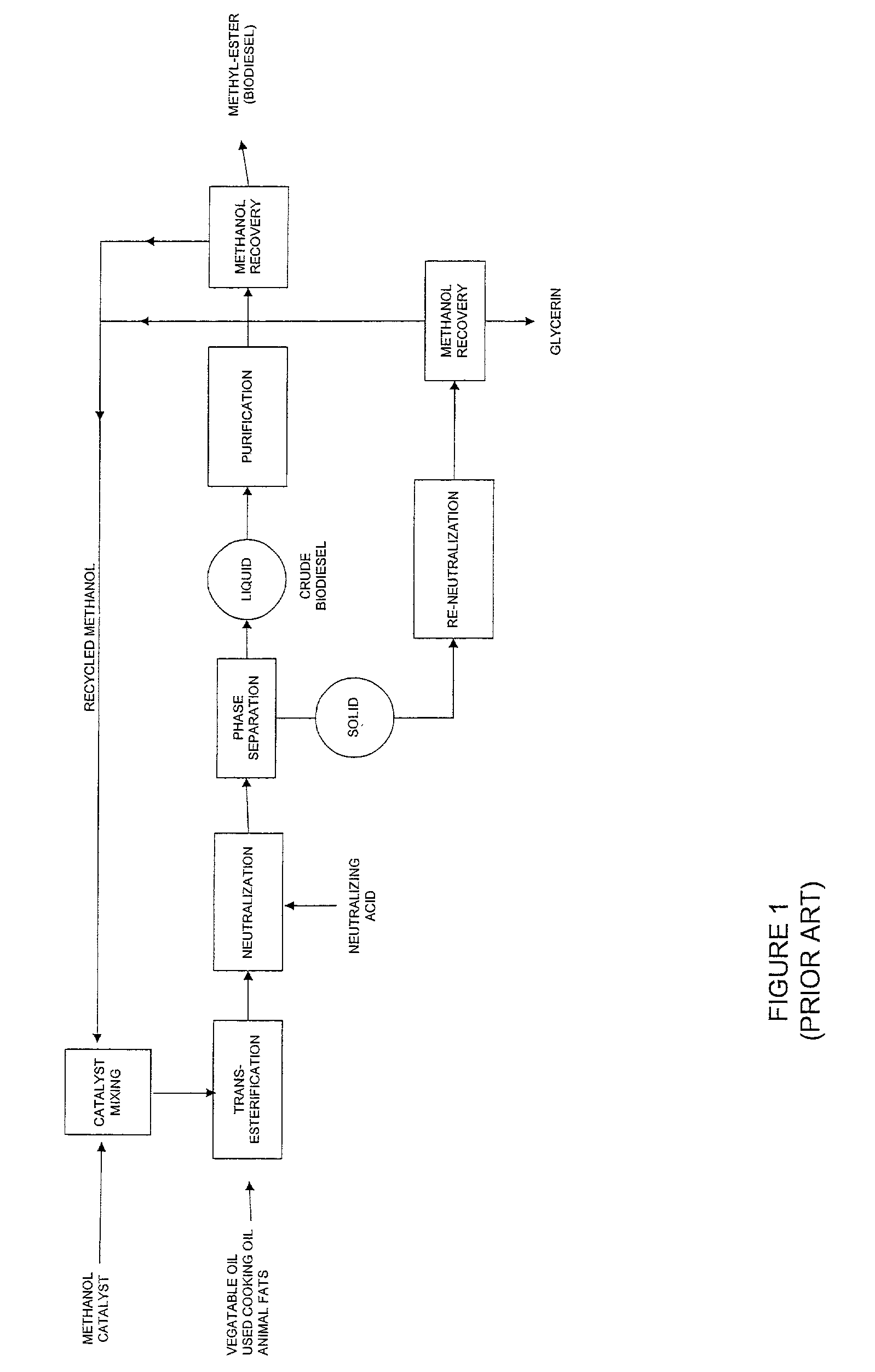

System and process for producing biodiesel

InactiveUS20080282606A1Reducing filter blocking tendencyEnhance biodiesel stabilityFatty acid esterificationFatty acids production/refiningBiodieselDistillation

In embodiments of the present invention, systems for producing a biodiesel product from multiple feedstocks may include a biodiesel reactor, a decanter, a flash evaporator and a distillation column. In other embodiments of the present invention, a process for producing a biodiesel comprises distilling a biodiesel reaction product to remove tocopherols and sterol glucosides and, optionally, adding biodiesel stabilizers to the resultant biodiesel to enhance thermal stability. The components of the system are interrelated so that parameters may be regulated to allow production of a custom biodiesel product.

Owner:IMPERIUM PROCESS TECH

Process for producing ethanol from corn dry milling

InactiveUS20060127999A1Speed up the conversion processFermented solutions distillation/rectificationOrganic compound preparationAcetic acidDistillation

A process for producing ethanol by the conversion of carbohydrates from a corn dry milling process in which the bottoms fraction from distillation of ethanol in a conventional yeast fermentation is used in a process including a combination of biochemical and synthetic conversions. The process results in high yield ethanol production with concurrent production of high value coproducts. An acetic acid intermediate is produced from bottoms fraction, followed by conversion of the acetic acid into ethanol using esterification and hydrogenation reactions. Coproducts of the process include a high protein content solids fraction produced in the fermentation.

Owner:ZEACHEM

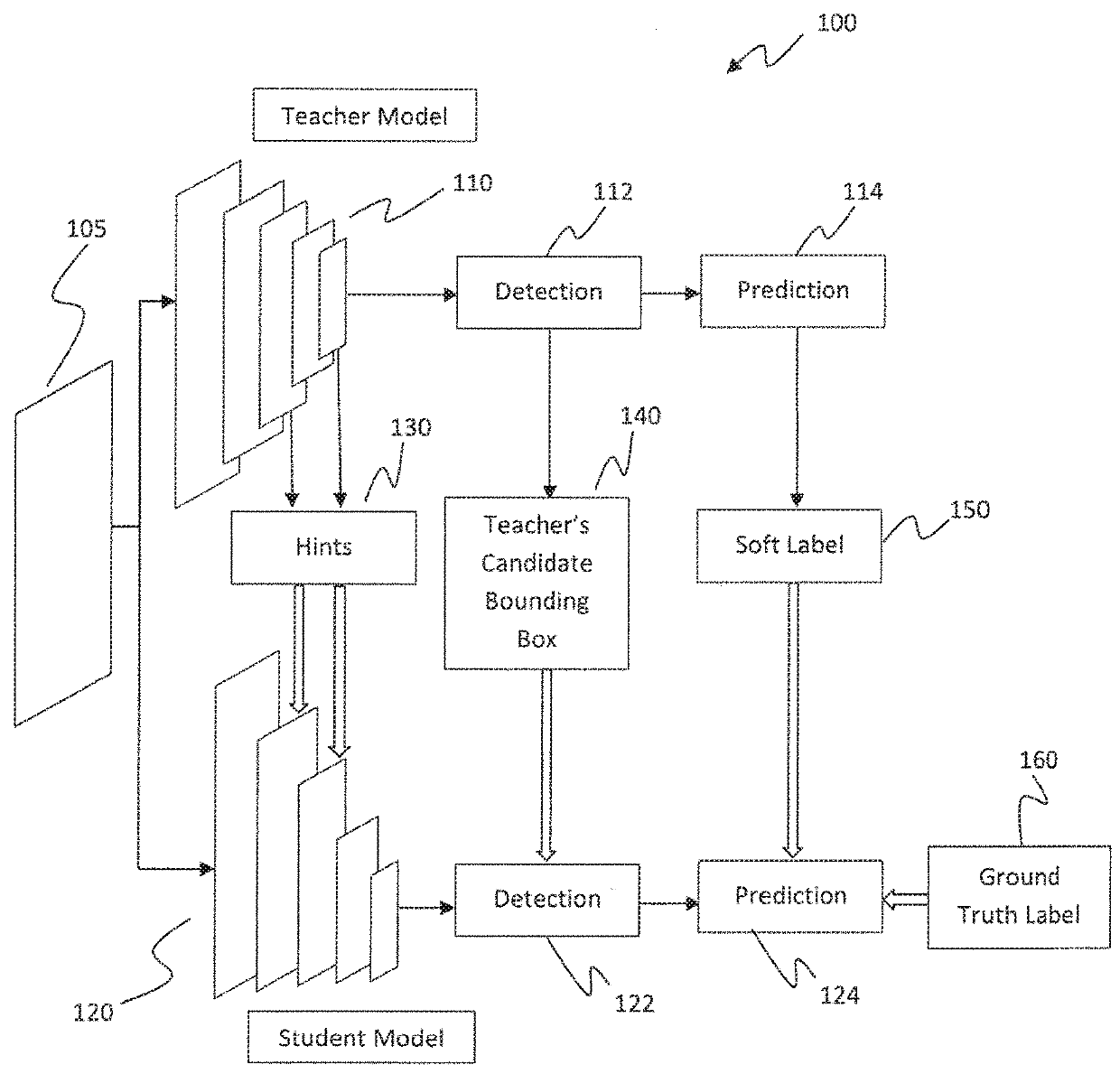

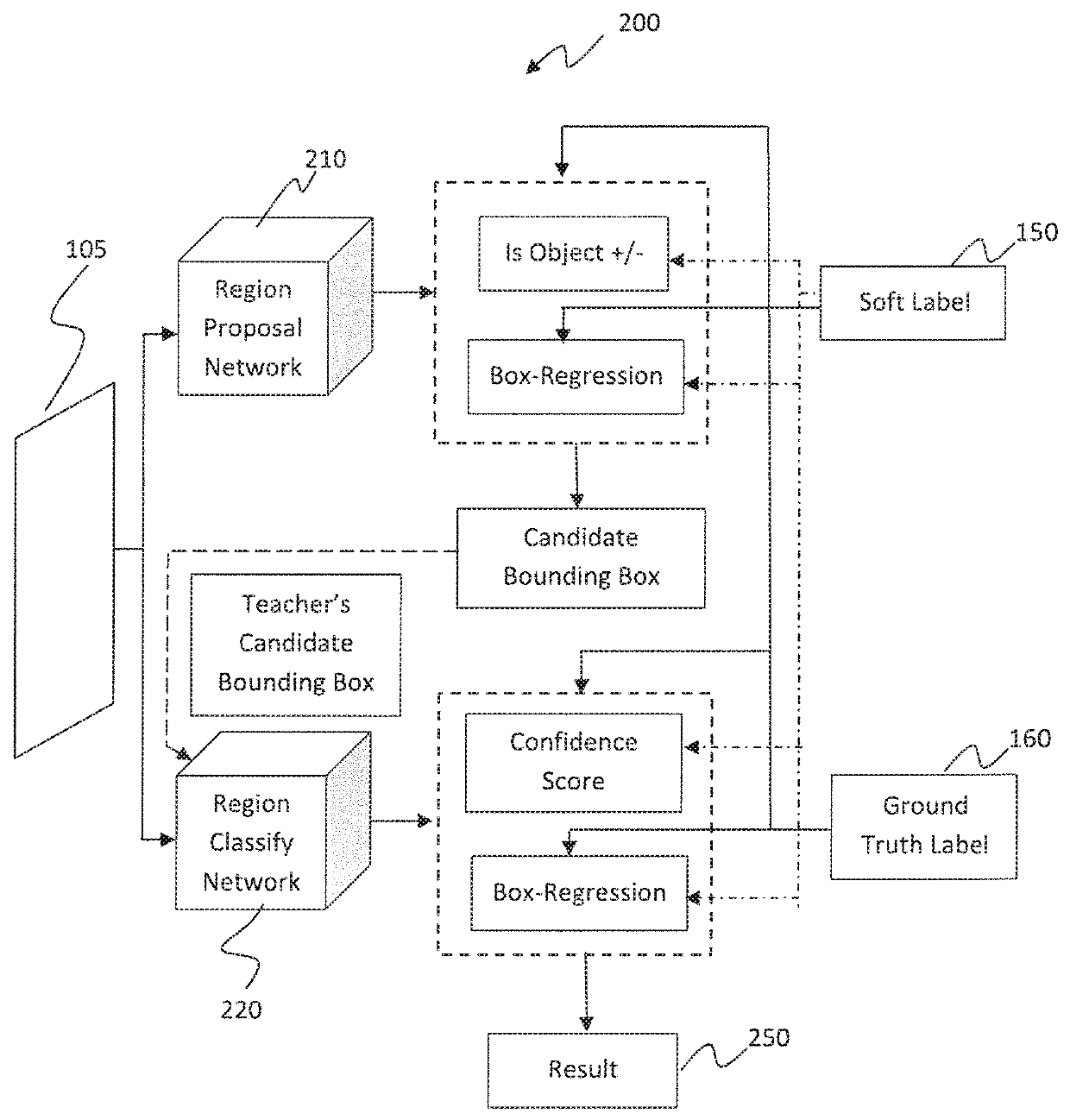

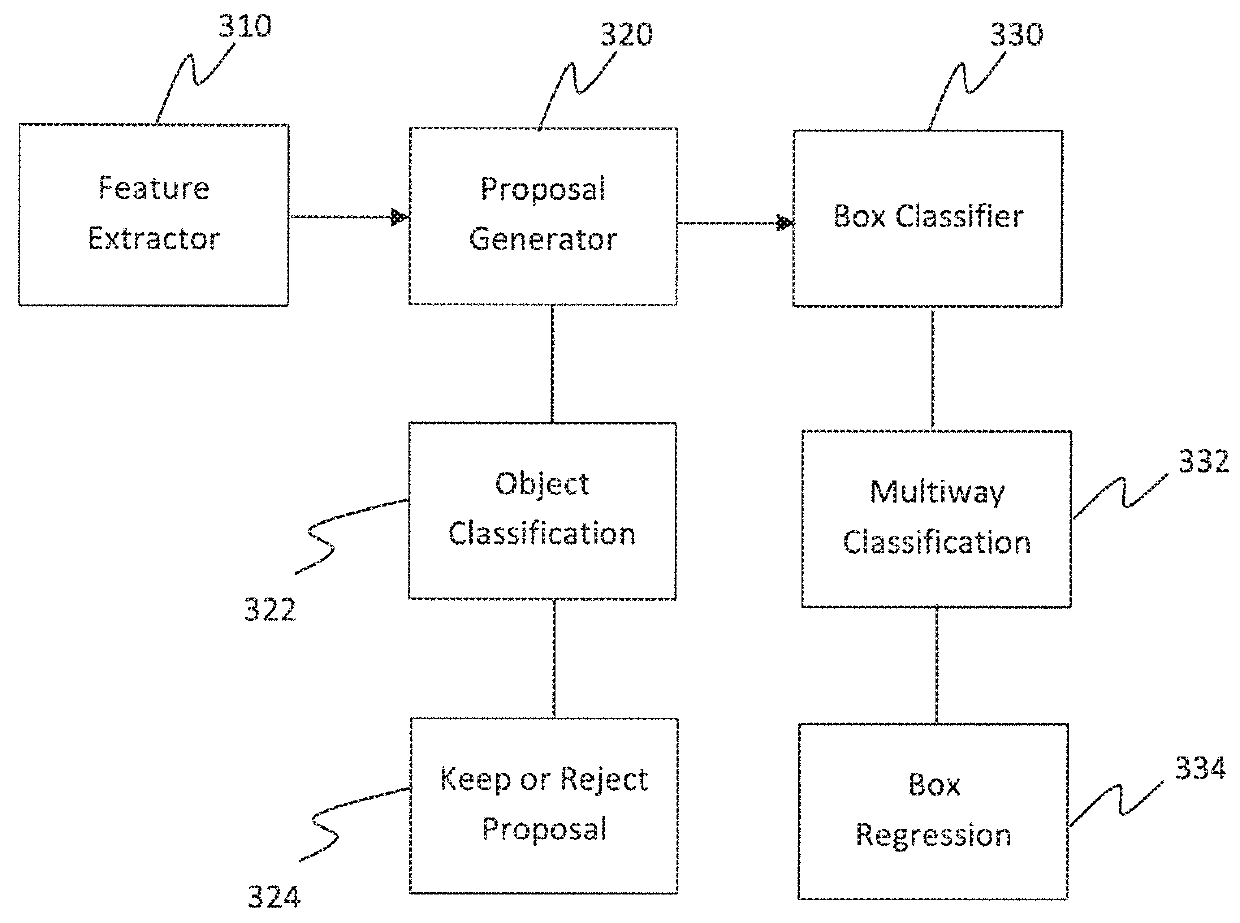

Learning efficient object detection models with knowledge distillation

InactiveUS20180268292A1Character and pattern recognitionNeural learning methodsObject ClassDistillation

A computer-implemented method executed by at least one processor for training fast models for real-time object detection with knowledge transfer is presented. The method includes employing a Faster Region-based Convolutional Neural Network (R-CNN) as an objection detection framework for performing the real-time object detection, inputting a plurality of images into the Faster R-CNN, and training the Faster R-CNN by learning a student model from a teacher model by employing a weighted cross-entropy loss layer for classification accounting for an imbalance between background classes and object classes, employing a boundary loss layer to enable transfer of knowledge of bounding box regression from the teacher model to the student model, and employing a confidence-weighted binary activation loss layer to train intermediate layers of the student model to achieve similar distribution of neurons as achieved by the teacher model.

Owner:NEC LAB AMERICA

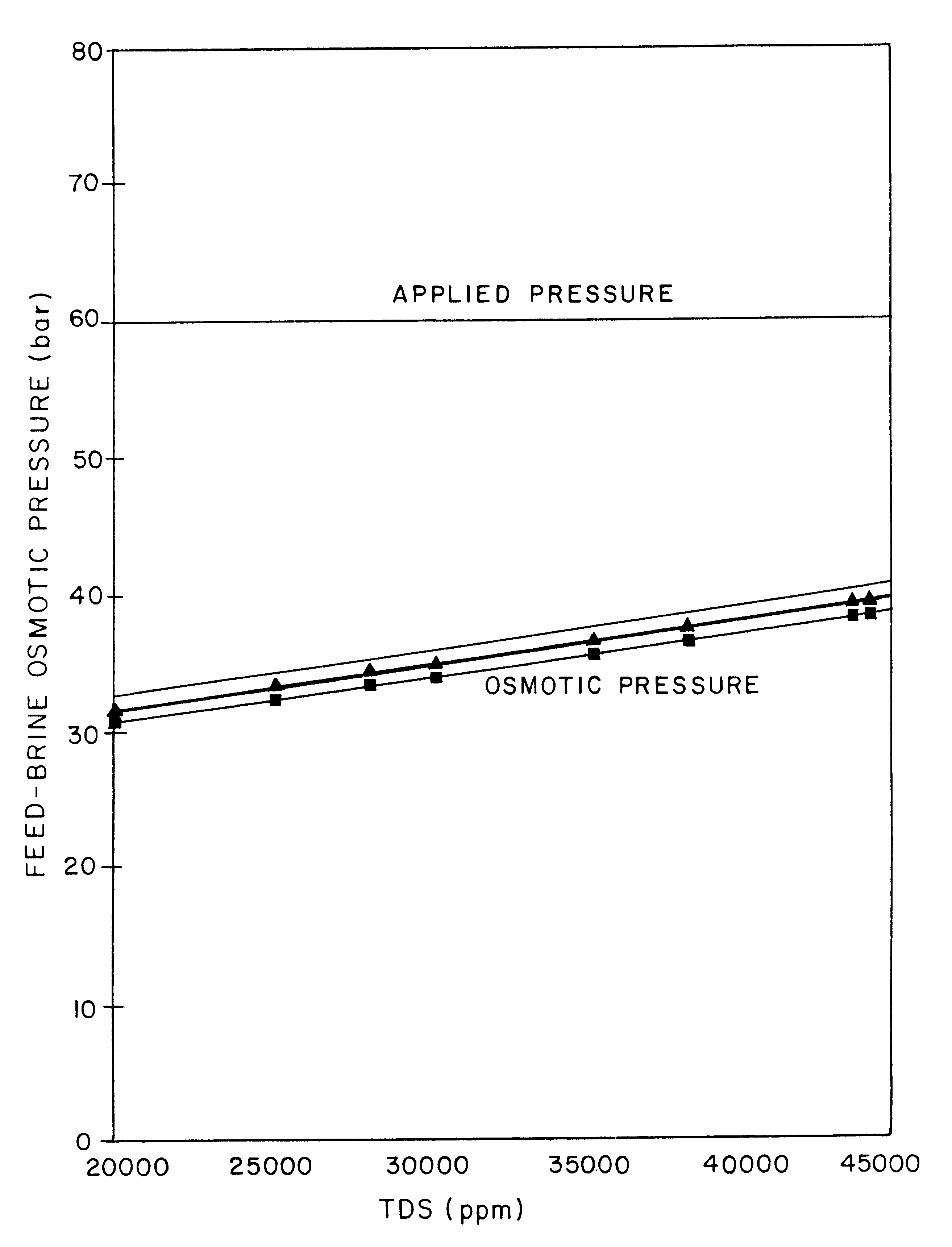

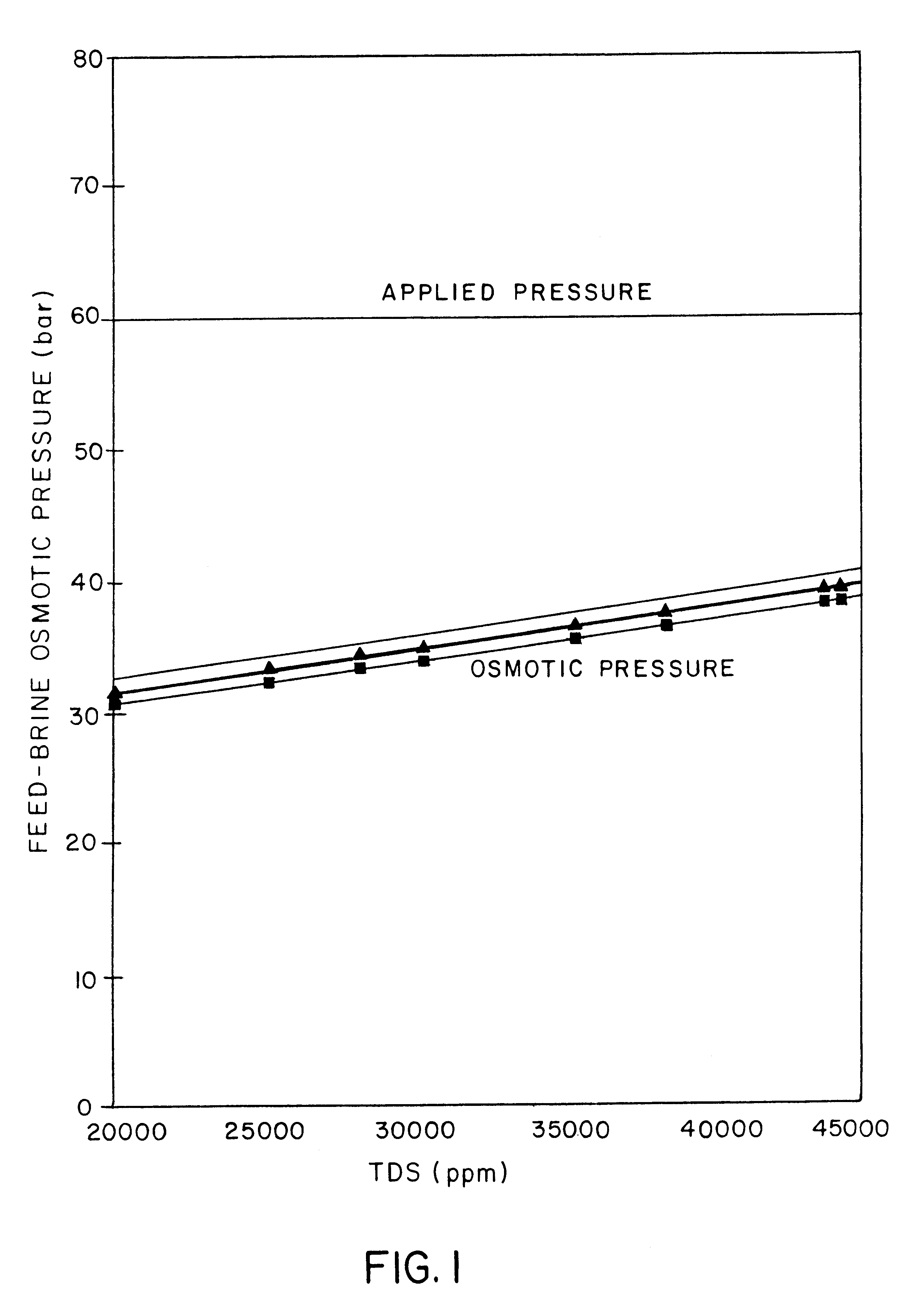

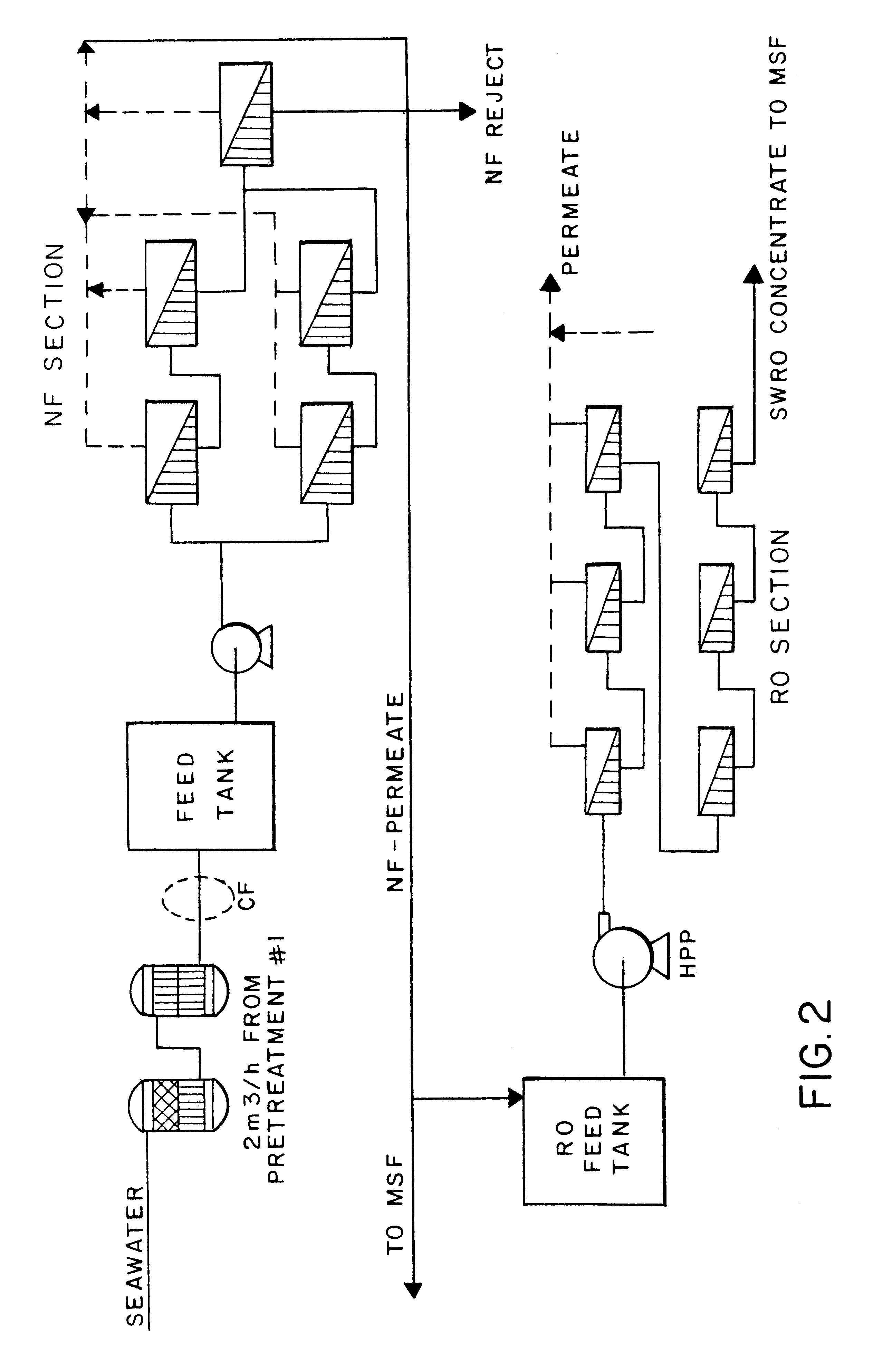

Process for desalination of saline water, especially water, having increased product yield and quality

InactiveUS6508936B1General water supply conservationSeawater treatmentTotal dissolved solidsDistillation

A desalination process is disclosed which combining two or more substantially different water treatment processes in a unique manner to desalinate saline water, especially sea water, to produce a high yield of high quality fresh water, including potable water, at an energy consumption equivalent to or less than much less efficient prior art desalination processes. In this process a nanofiltration step is synergistically combined with at least one of sea water reverse osmosis, multistage flash distillation. multieffect distillation of vapor compression distillation to provide an integrated desalination system by which sea water can be efficiently and economically converted to high quality potable water in yields which are at least 70%-80% greater than the yields available from the prior art processes. Typically a process of this invention using the nanofiltration initial step will produce, with respect to sea water feed properties, calcium, magnesium, sulfate and bicarbonate ion content reductions of 63%-94%, pH decreases of about 0.4-0.5 units and total dissolved solids content reductions of 35%-50%.

Owner:SALINE WATER CONVERSION CORP

Method for producing fluorinated organic compounds

ActiveUS8084653B2Preparation by hydrogen halide split-offPreparation by halogen replacementActivated carbonGas phase

Disclosed are processes for the production of fluorinated olefins, preferably adapted to commercialization of CF3CF═CH2 (1234yf). Three steps may be used in preferred embodiments in which a feedstock such as CCl2═CClCH2Cl (which may be purchased or synthesized from 1,2,3-trichloropropane) is fluorinated (preferably with HF in gas-phase in the presence of a catalyst) to synthesize a compound such as CF3CCl═CH2, preferably in a 80-96% selectivity. The CF3CCl═CH2 is preferably converted to CF3CFClCH3 (244-isomer) using a SbCl5 as the catalyst which is then transformed selectively to 1234yf, preferably in a gas-phase catalytic reaction using activated carbon as the catalyst. For the first step, a mixture of Cr2O3 and FeCl3 / C is preferably used as the catalyst to achieve high selectivity to CF3CCl═CH2 (96%). In the second step, SbCl5 / C is preferably used as the selective catalyst for transforming 1233xf to 244-isomer, CF3CFClCH3. The intermediates are preferably isolated and purified by distillation and used in the next step without further purification, preferably to a purity level of greater than about 95%.

Owner:HONEYWELL INT INC

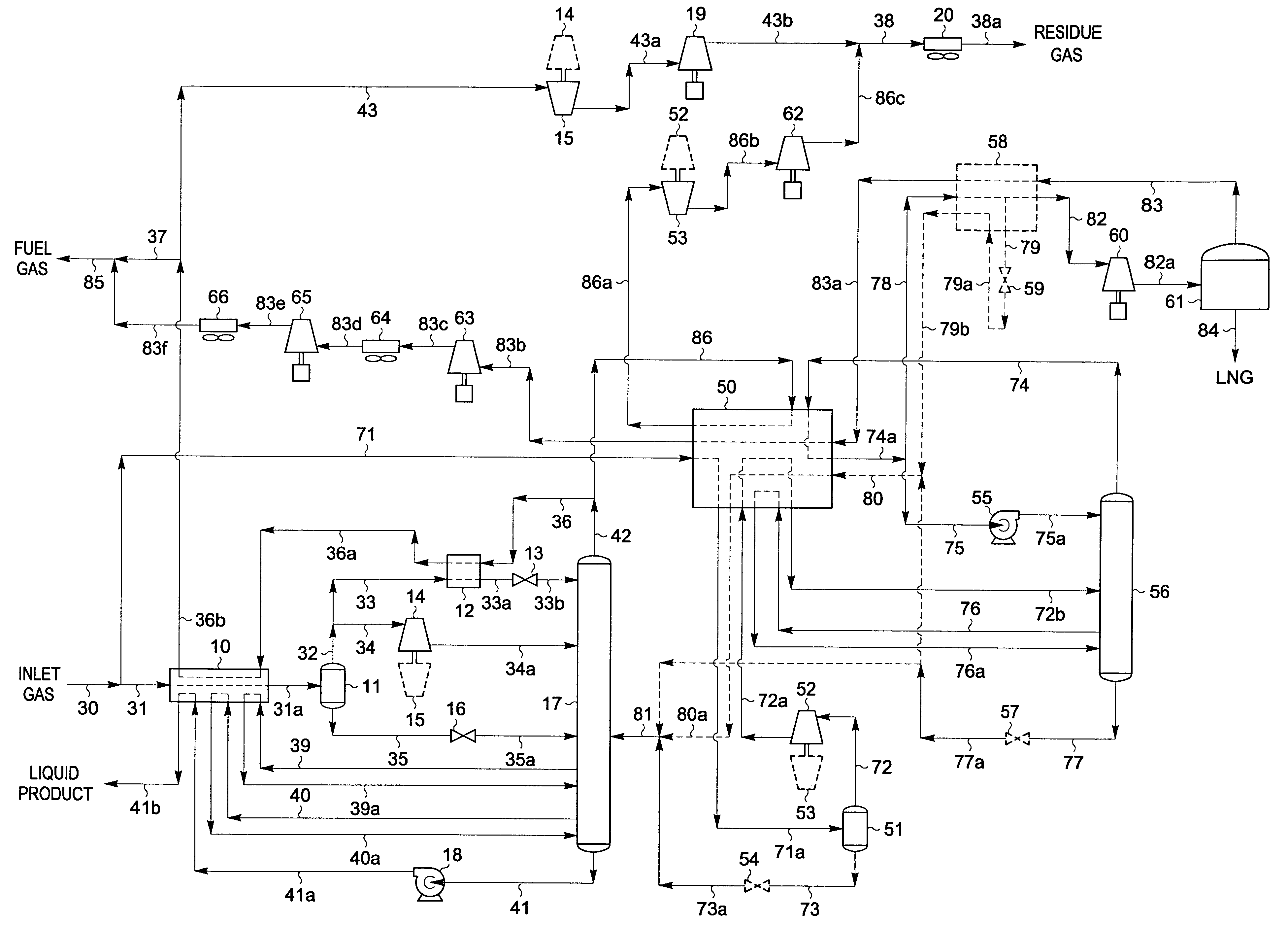

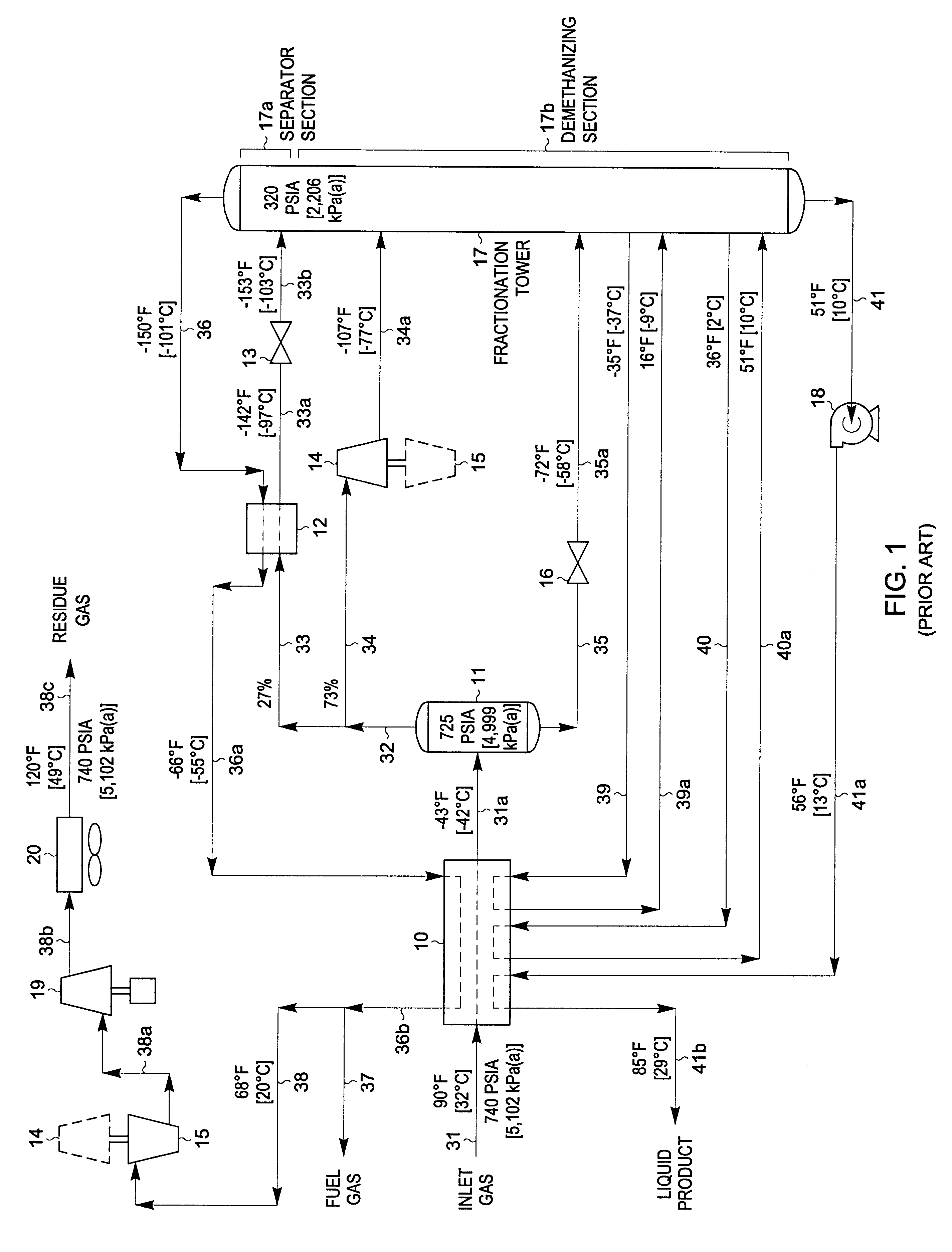

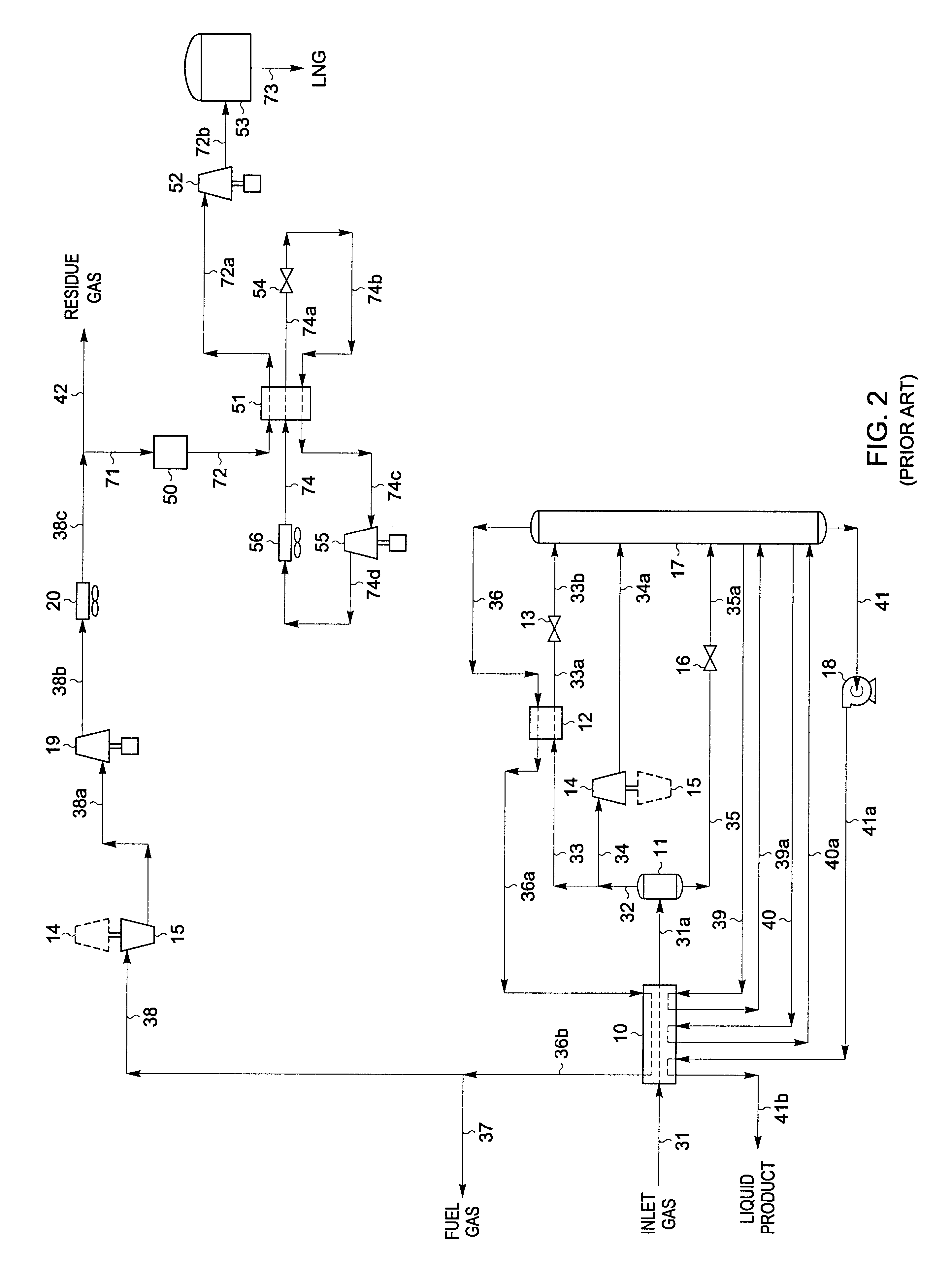

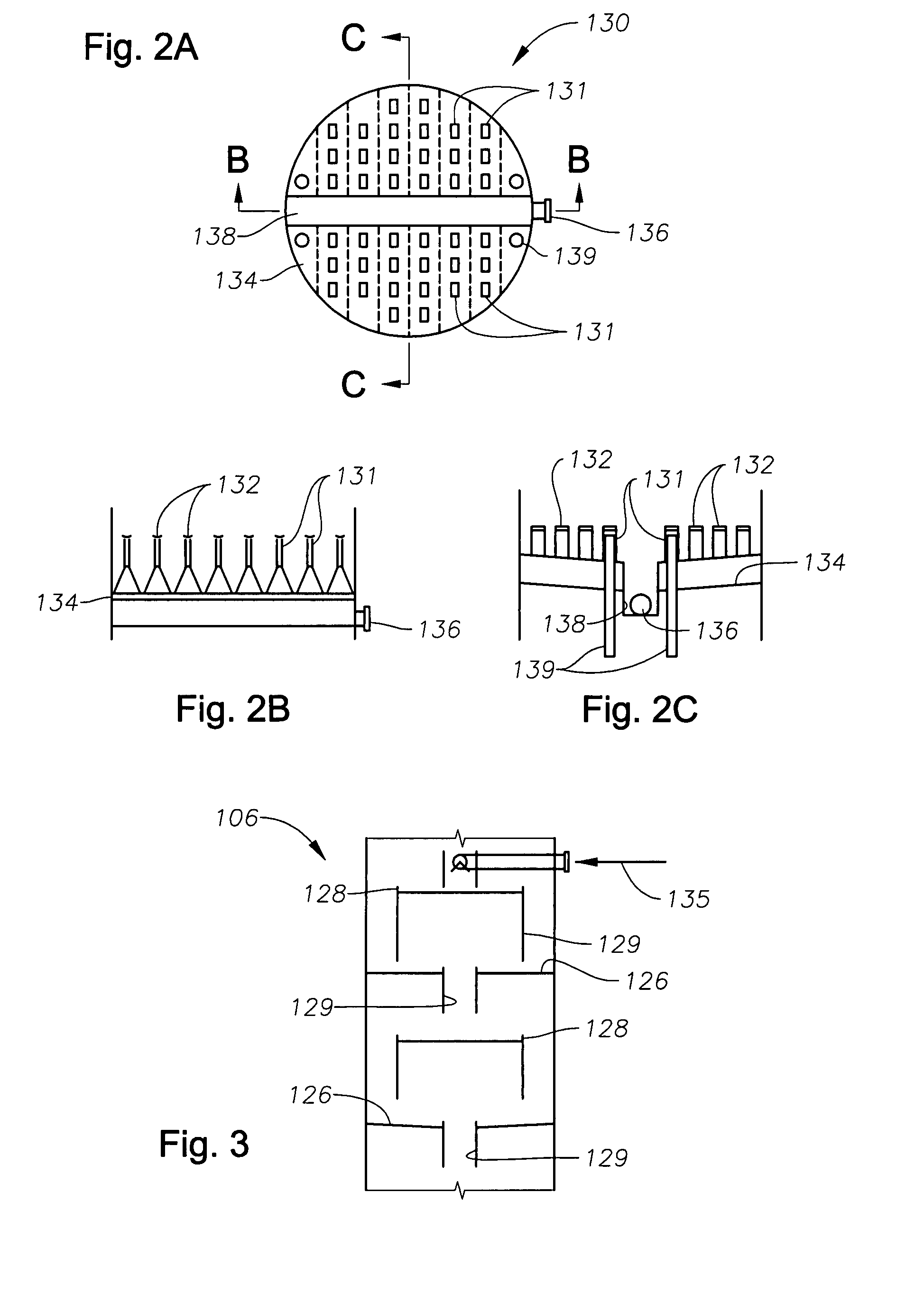

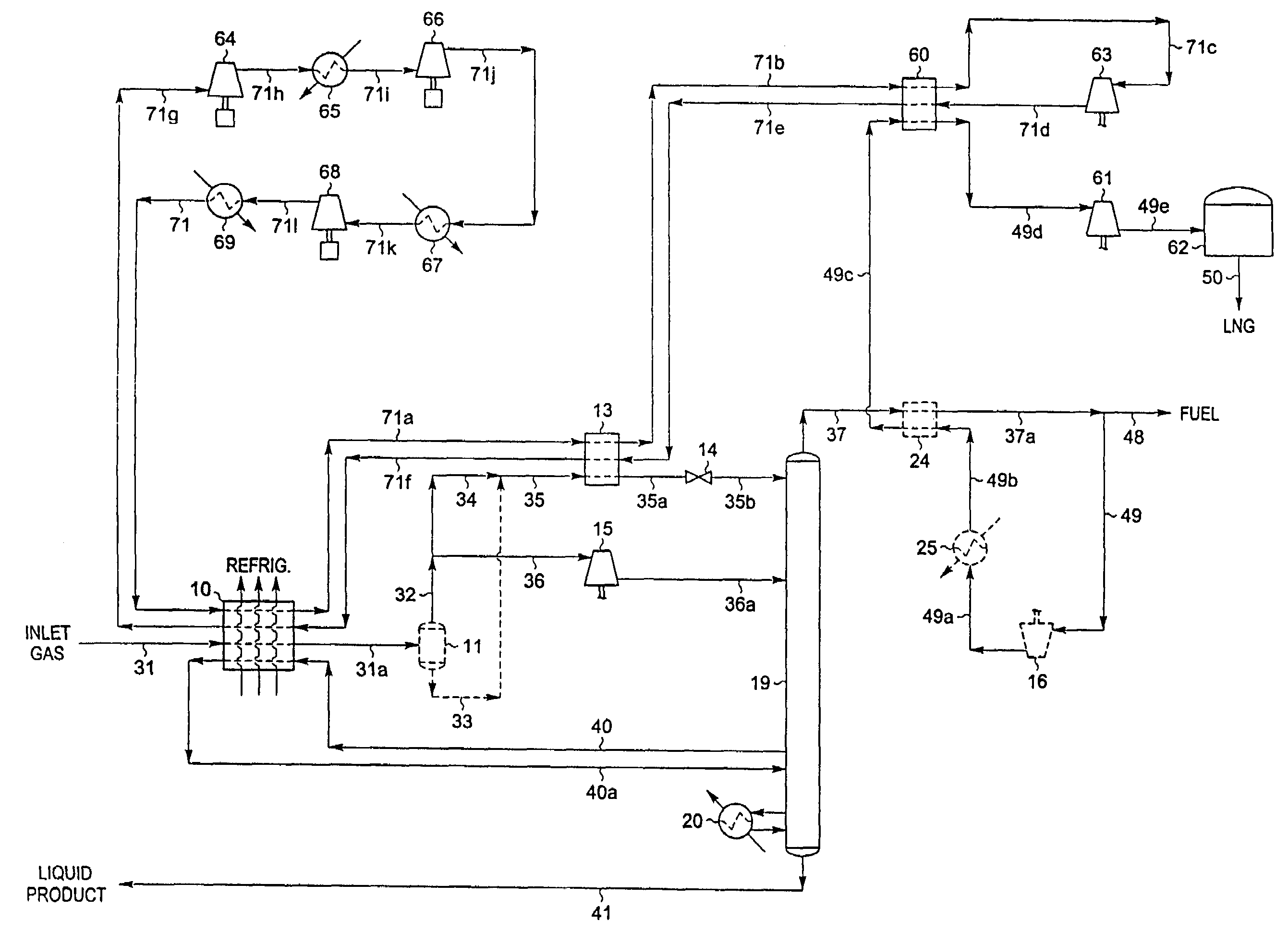

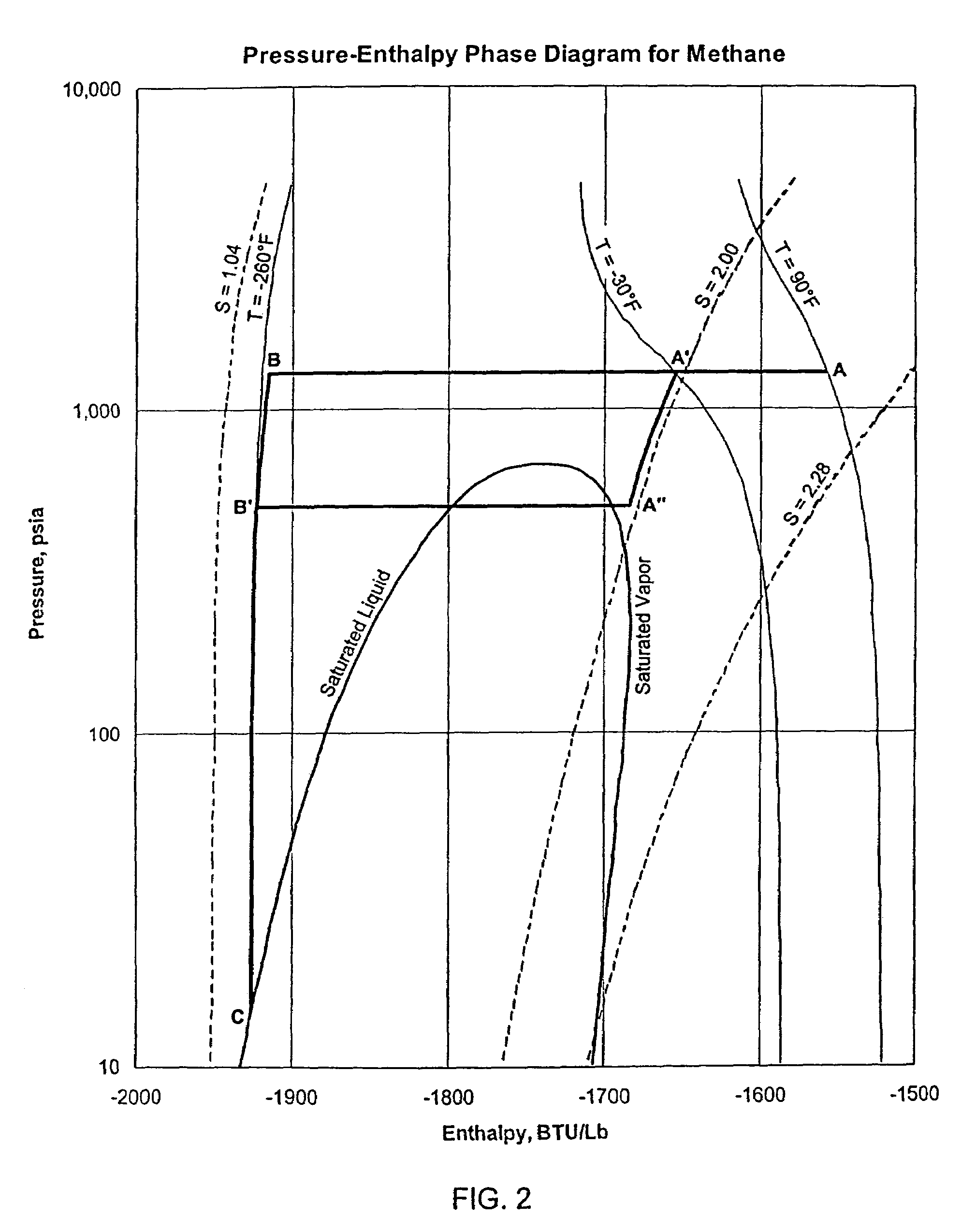

LNG production in cryogenic natural gas processing plants

A process for liquefying natural gas in conjunction with processing natural gas to recover natural gas liquids (NGL) is disclosed. In the process, the natural gas stream to be liquefied is taken from one of the streams in the NGL recovery plant and cooled under pressure to condense it. A distillation stream is withdrawn from the NGL recovery plant to provide some of the cooling required to condense the natural gas stream. The condensed natural gas stream is expanded to an intermediate pressure and supplied to a mid-column feed point on a distillation column. The bottom product from this distillation column preferentially contains the majority of any hydrocarbons heavier than methane that would otherwise reduce the purity of the liquefied natural gas, and is routed to the NGL recovery plant so that these heavier hydrocarbons can be recovered in the NGL product. The overhead vapor from the distillation column is cooled and condensed, and a portion of the condensed stream is supplied to a top feed point on the distillation column to serve as reflux. A second portion of the condensed stream is expanded to low pressure to form the liquefied natural gas stream.

Owner:ORTLOFF ENGINEERS

Method for the manufacture of hydrocarbons

ActiveUS20060161032A1Reduce hydrogen consumptionMaterial nanotechnologyRefining to change hydrocarbon structural skeletonHydrogenDistillation

Feedstock originating from renewable sources is converted to hydrocarbons in diesel fuel distillation range by contacting with a supported catalyst comprising VIII group metal / metals, whereby the consumption of hydrogen is decreased.

Owner:NESTE OIL OY

Process for the manufacture of hydrocarbons

ActiveUS20070135669A1Quality improvementImprove low temperature performanceFatty acid chemical modificationBiofuelsDeoxygenationDistillation

A feedstock originating from renewable sources is converted to branched and saturated hydrocarbons without heteroatoms in the diesel fuel distillation range by skeletal isomerisation and deoxygenation carried out by hydrodeoxygenation or alternatively by combined decarboxylation and decarbonylation reactions, whereby the consumption of hydrogen is decreased.

Owner:NESTE OIL OY

Wide-cut synthetic isoparaffinic lubricating oils

A wide-cut lubricant base stock is made by hydroisomerizing and then catalytically dewaxing a waxy Fischer-Tropsch synthesized hydrocarbon fraction feed and comprises the entire dewaxate having an initial boiling point in the 650-75O° F.+ range. Formulated lubricating oils made by admixing the base stock with a commercial automotive additive package meet all specifications, including low temperature properties, for multigrade internal combustion engine crankcase oils. The waxy feed has an initial boiling point in the 650-750° F. range and continuously boils to an end point of at least 1050° F.+. Lower boiling hydrocarbons produced by the process are separated from the base stock by simple flash distillation. The base stock comprises the entire dewaxate having an initial boiling point in the 650-750° F. range.

Owner:EXXON RES & ENG CO

Process for the production of acetic acid

Owner:CELANESE INT CORP

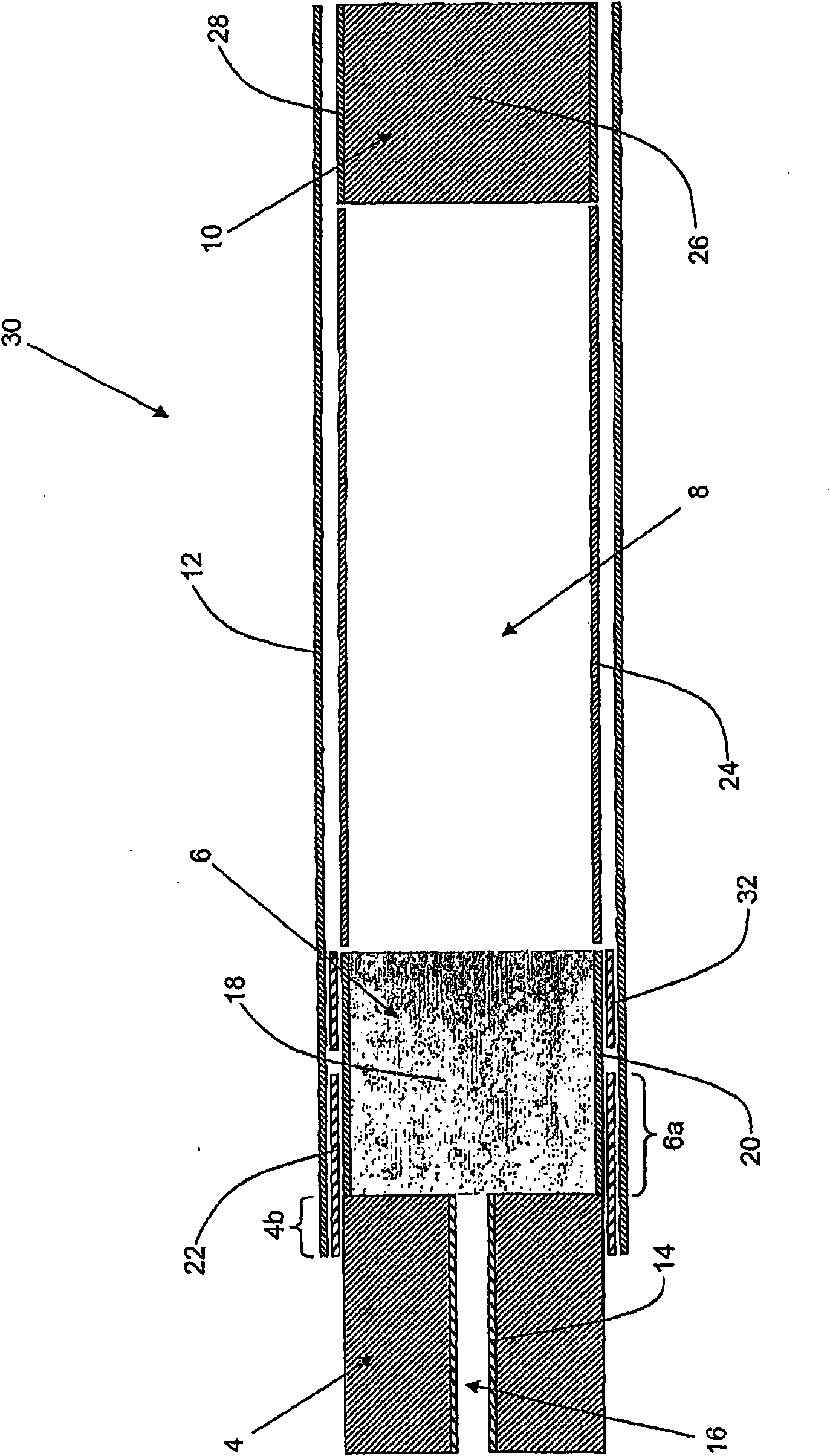

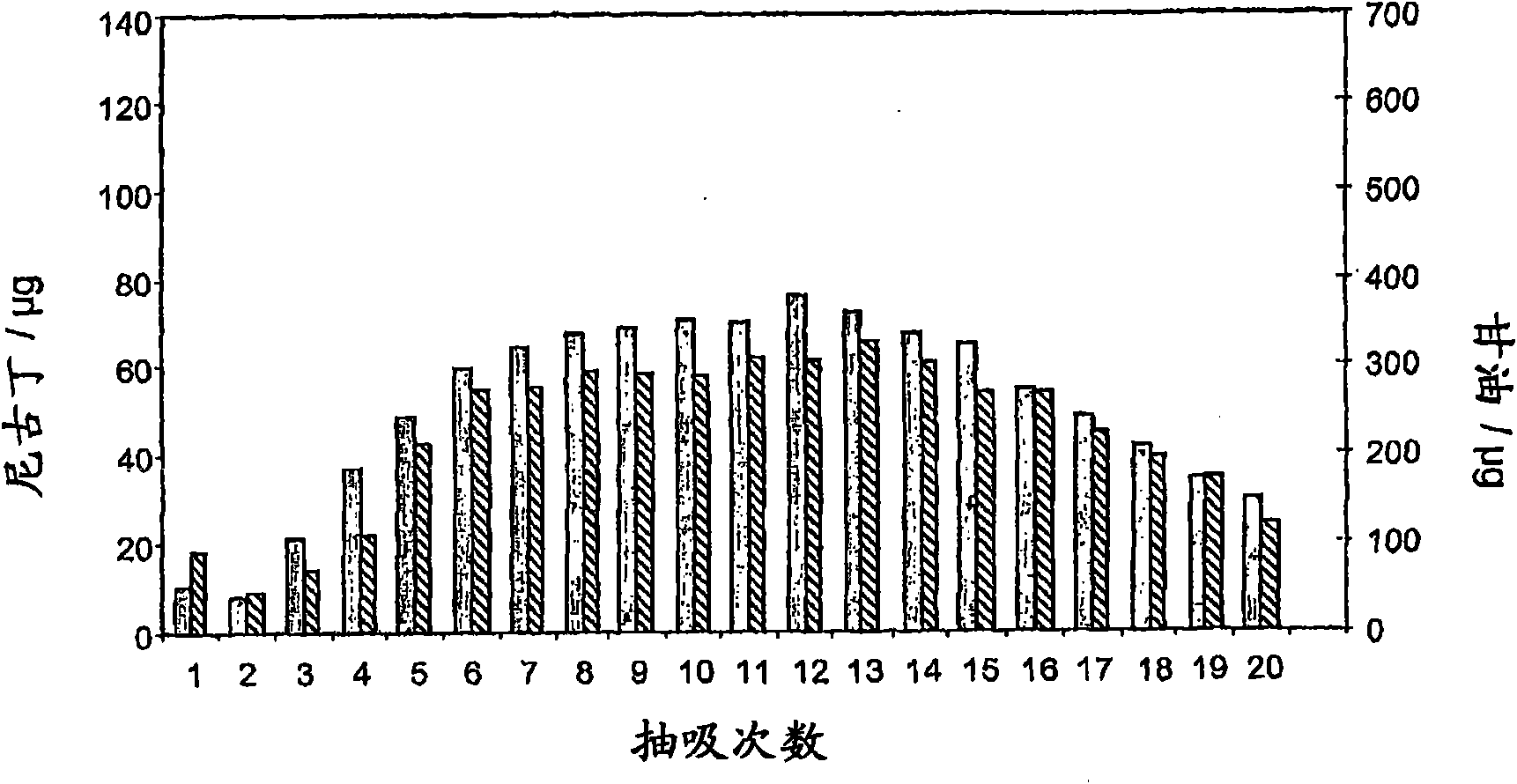

Distillation-based smoking article

Owner:PHILIP MORRIS PROD SA

Method for the manufacture of hydrocarbons

ActiveUS7491858B2Reduce hydrogen consumptionMaterial nanotechnologyRefining to change hydrocarbon structural skeletonHydrogenDistillation

Feedstock originating from renewable sources is converted to hydrocarbons in diesel fuel distillation range by contacting with a supported catalyst comprising VIII group metal / metals, whereby the consumption of hydrogen is decreased.

Owner:NESTE OIL OY

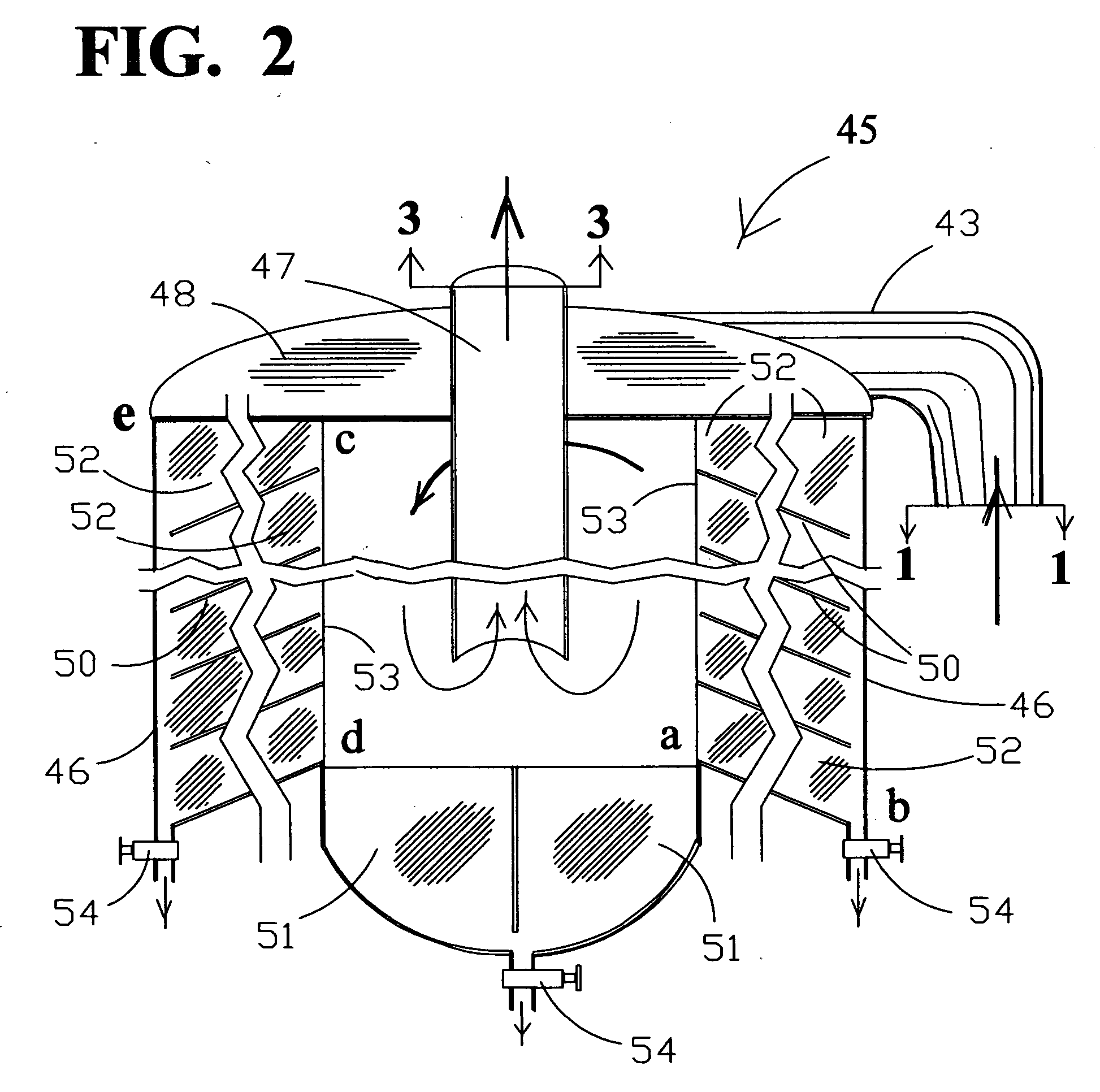

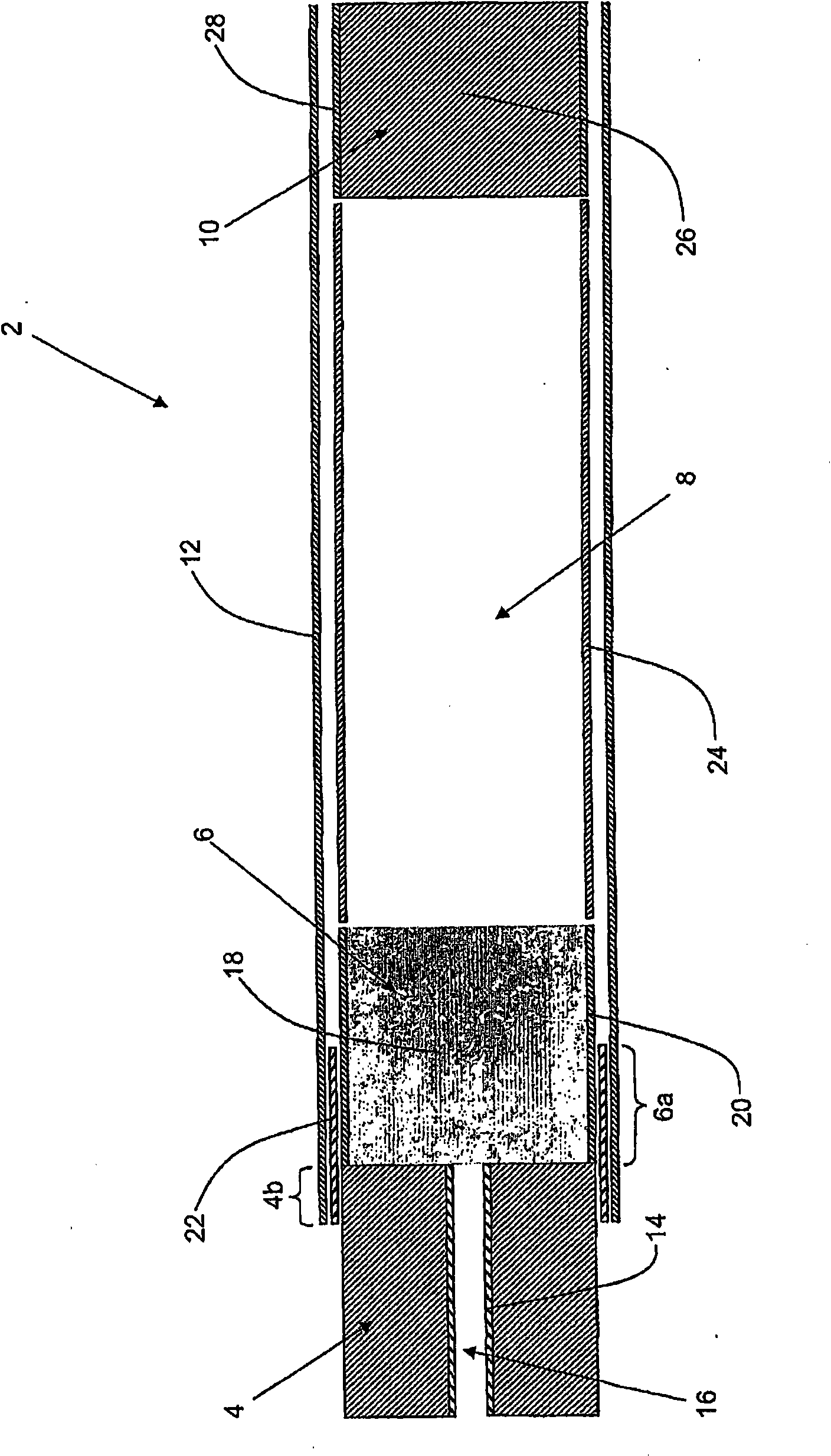

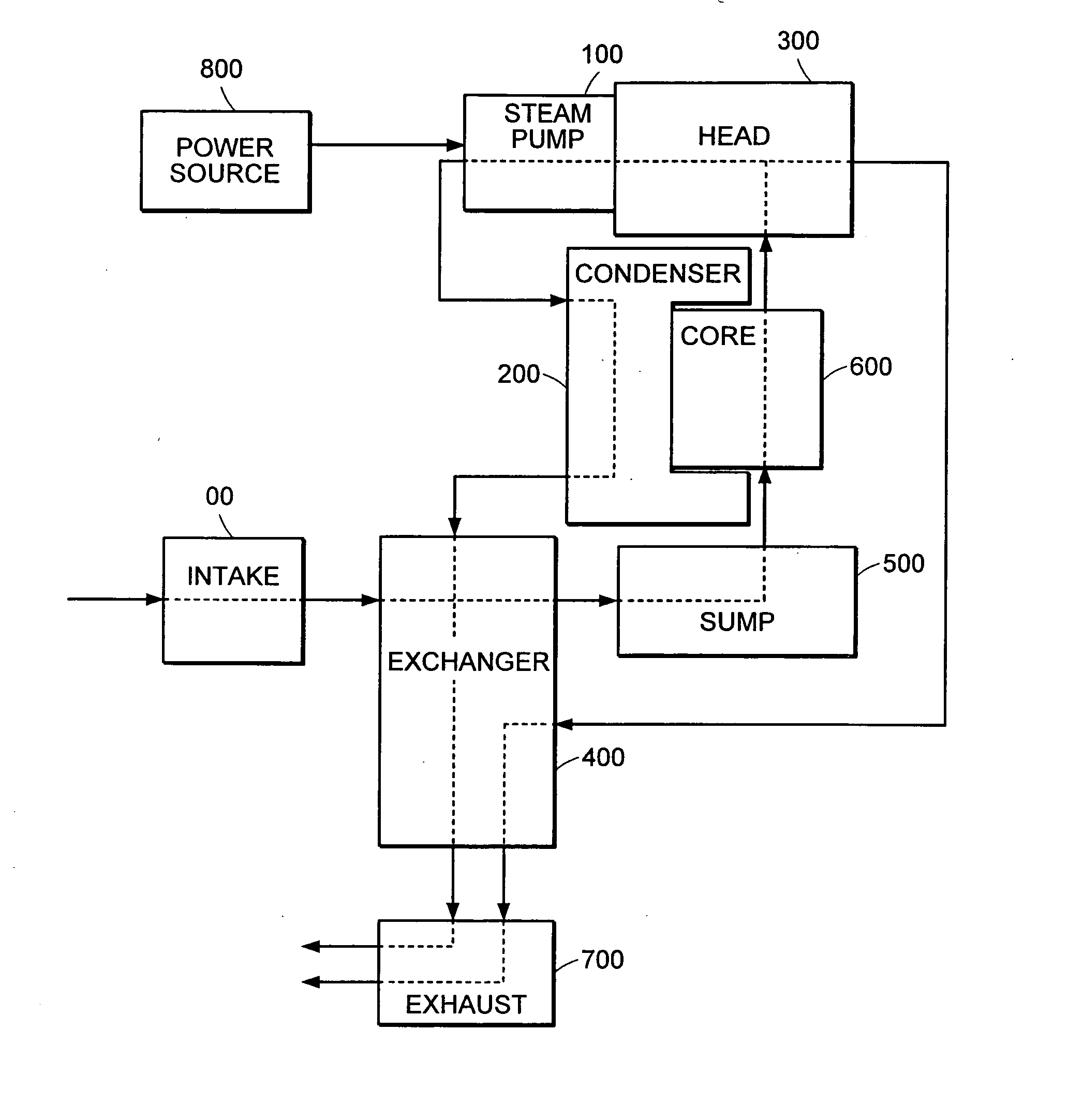

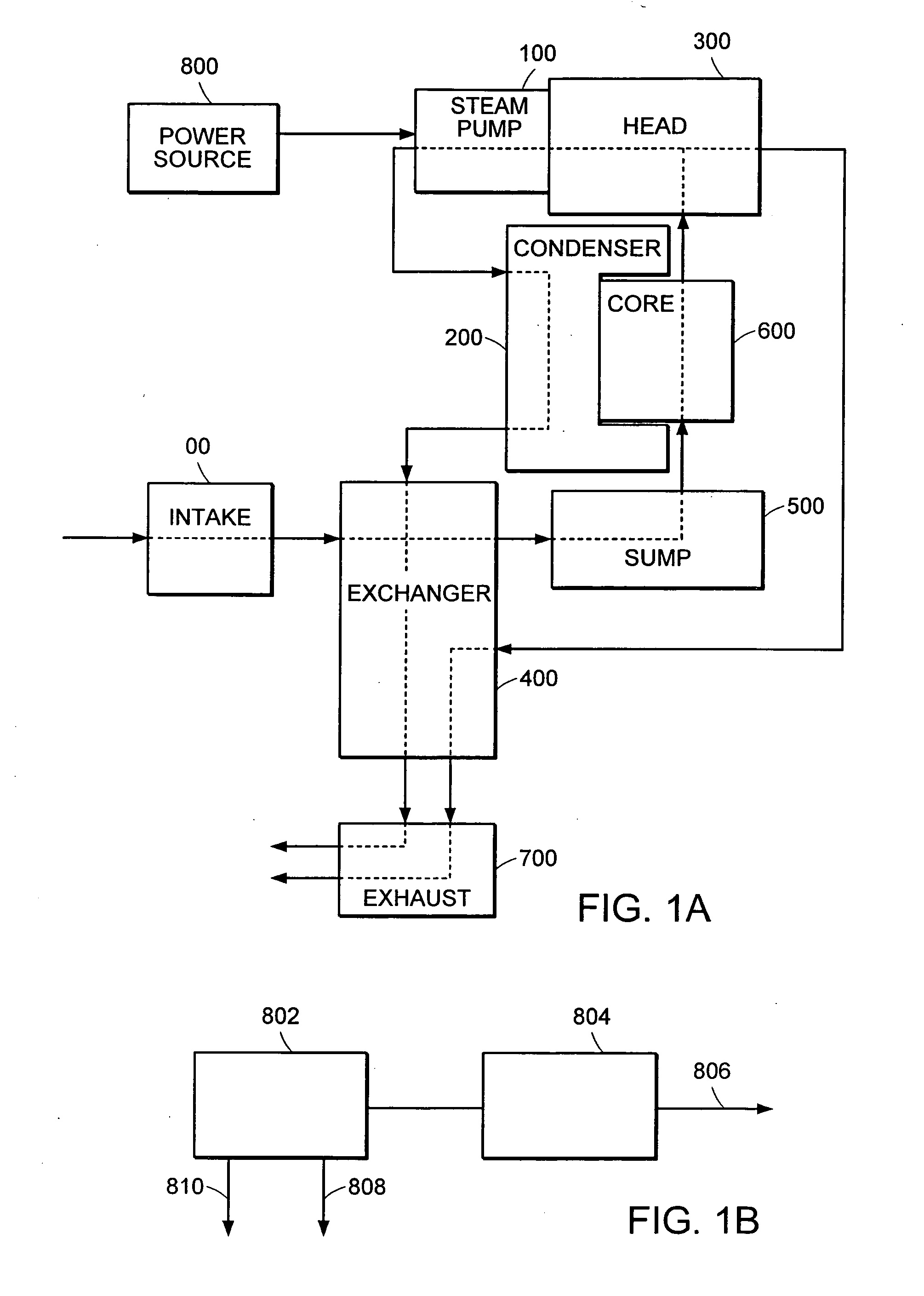

Pressurized vapor cycle liquid distillation

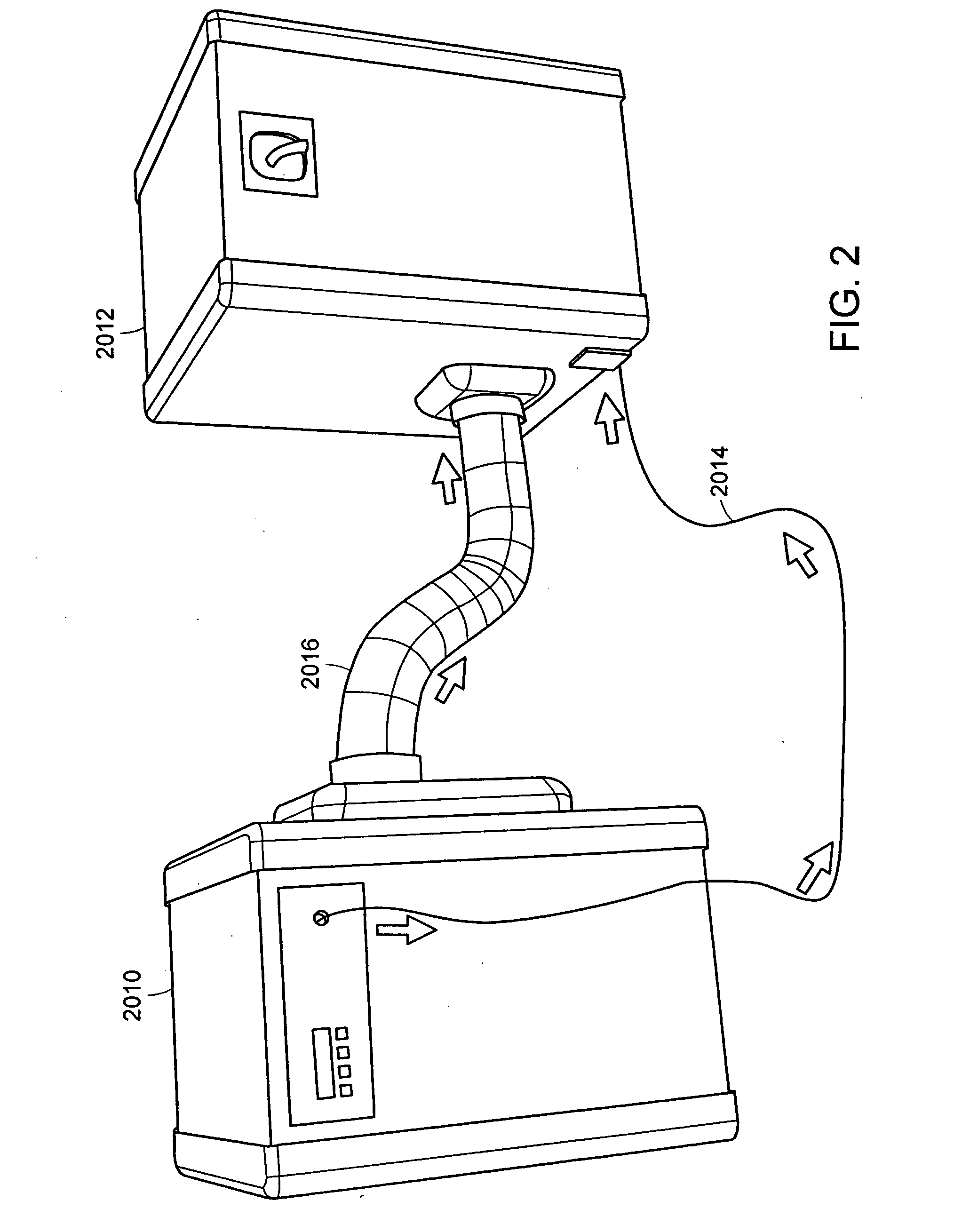

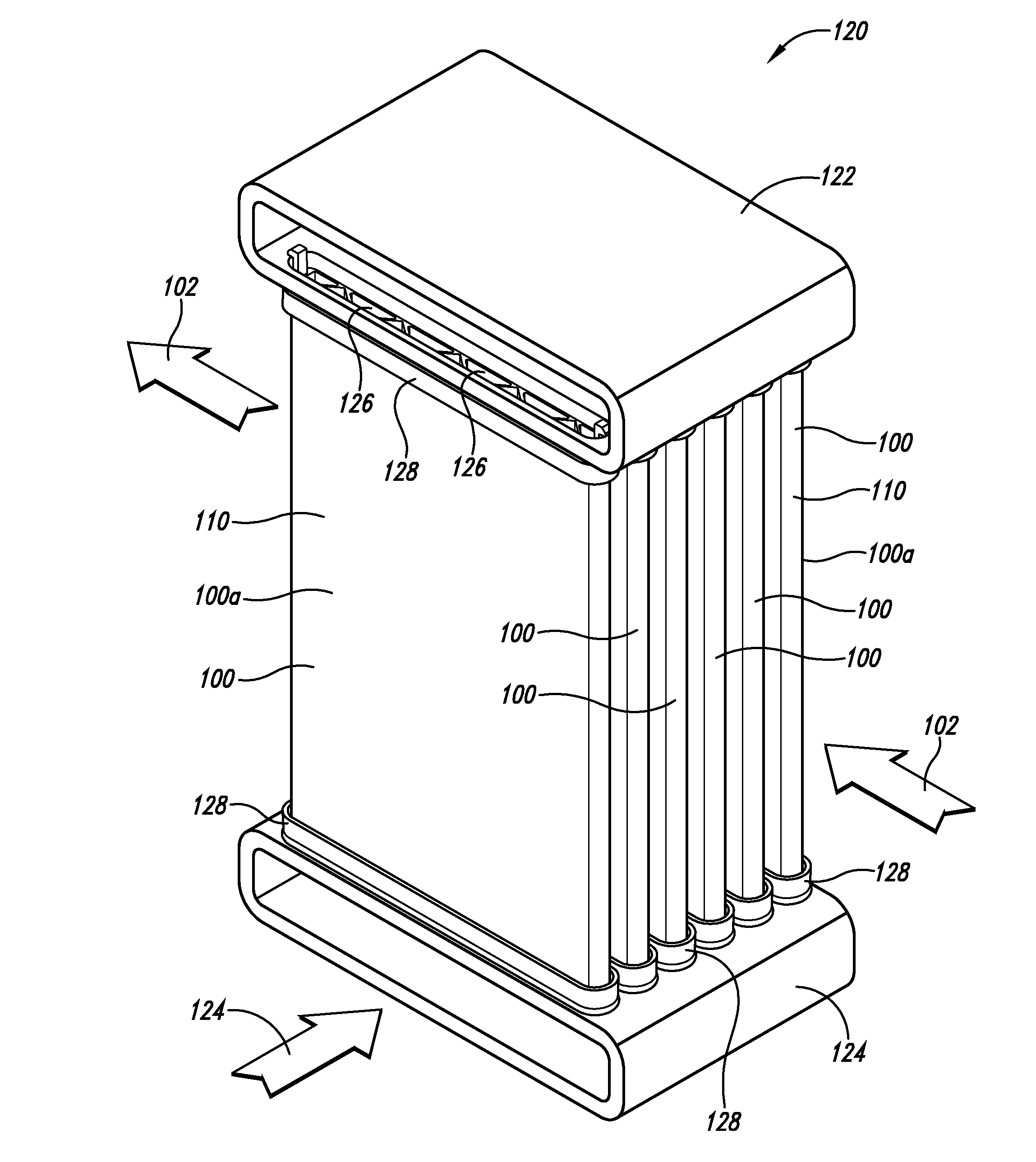

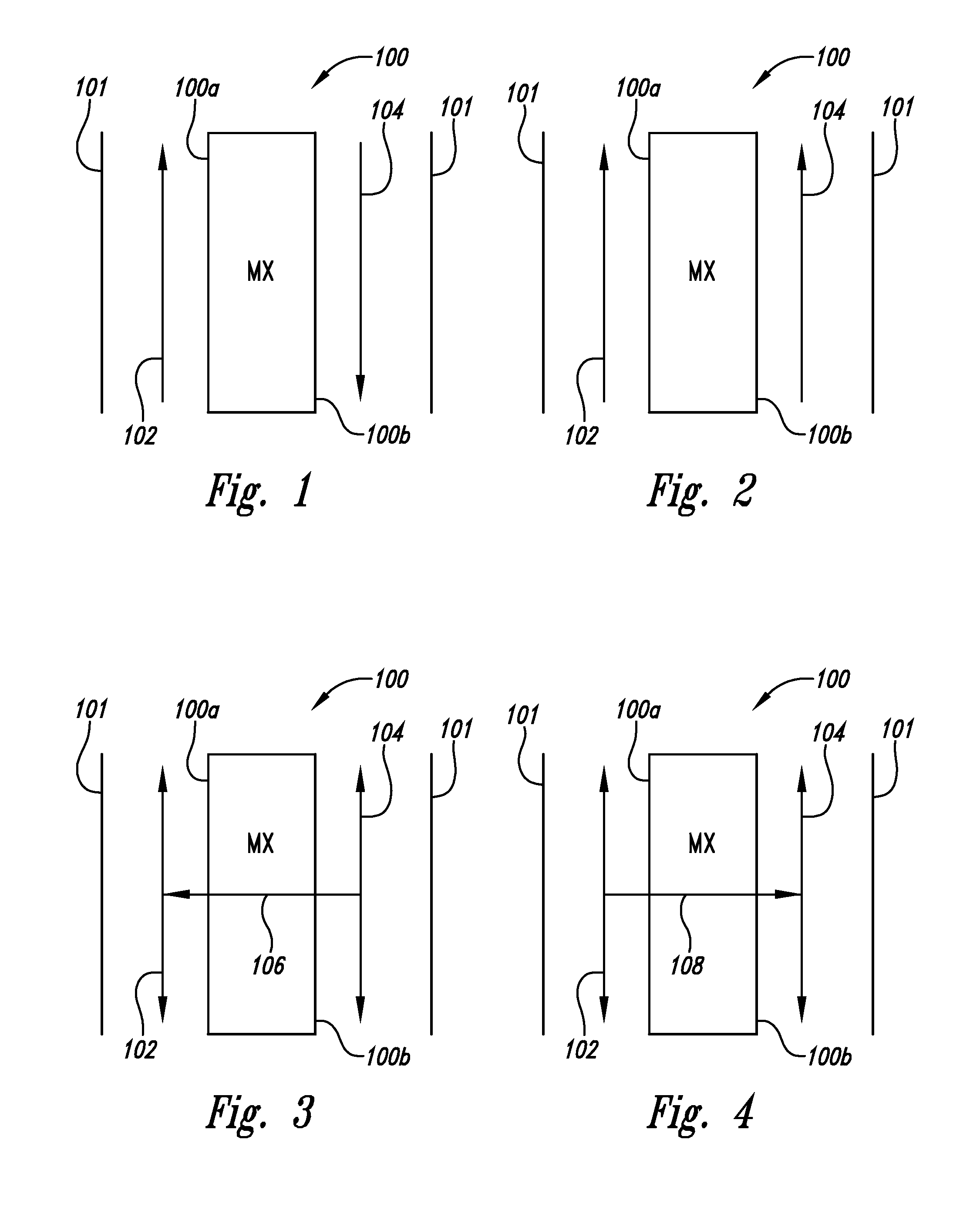

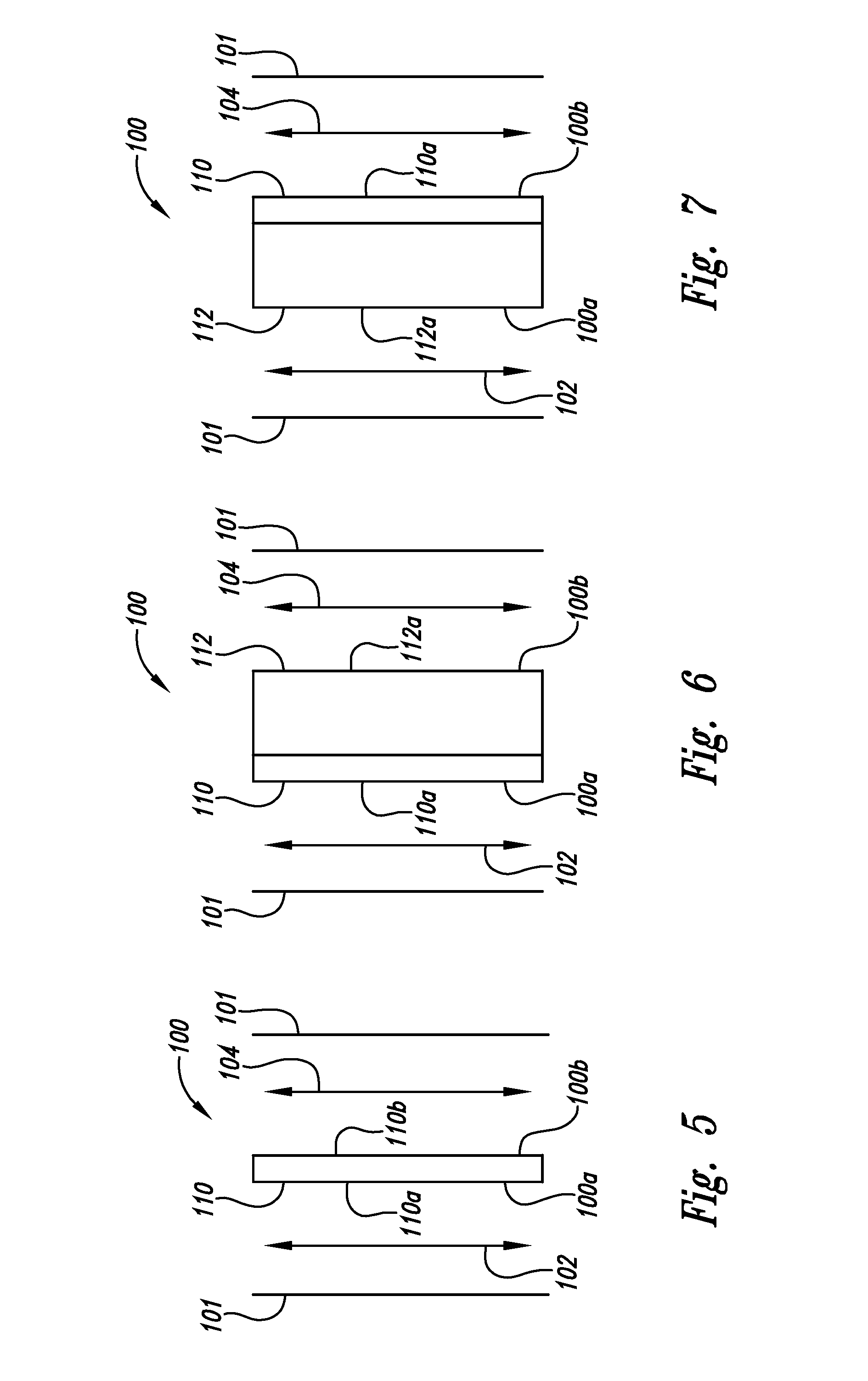

ActiveUS20050016828A1Easy maintenanceMaximize energy efficiencyDistillation regulation/controlUsing liquid separation agentHeat managementDrive shaft

Embodiments of the invention are directed toward a novel pressurized vapor cycle for distilling liquids. In some embodiments of the invention, a liquid purification system is revealed, including the elements of an input for receiving untreated liquid, a vaporizer coupled to the input for transforming the liquid to vapor, a head chamber for collecting the vapor, a vapor pump with an internal drive shaft and an eccentric rotor with a rotatable housing for compressing vapor, and a condenser in communication with the vapor pump for transforming the compressed vapor into a distilled product. Other embodiments of the invention are directed toward heat management, and other process enhancements for making the system especially efficient.

Owner:DEKA PROD LLP

Multi-phase selective mass transfer through a membrane

Disclosed herein are embodiments relating to particular systems comprising a selective transfer membrane that can be utilized in material separation. In certain embodiments, the membrane assembly comprises part of a desalination, distillation, liquid purification, and / or heating and cooling system. Other particular embodiments allow for a high rate of thermal capture by way of the system utilizing a selective transfer membrane. Certain preferred embodiments include a selective transfer membrane comprising an ionomeric polymer that is permeable to high dipole materials.

Owner:TANGREDI PATRICIA

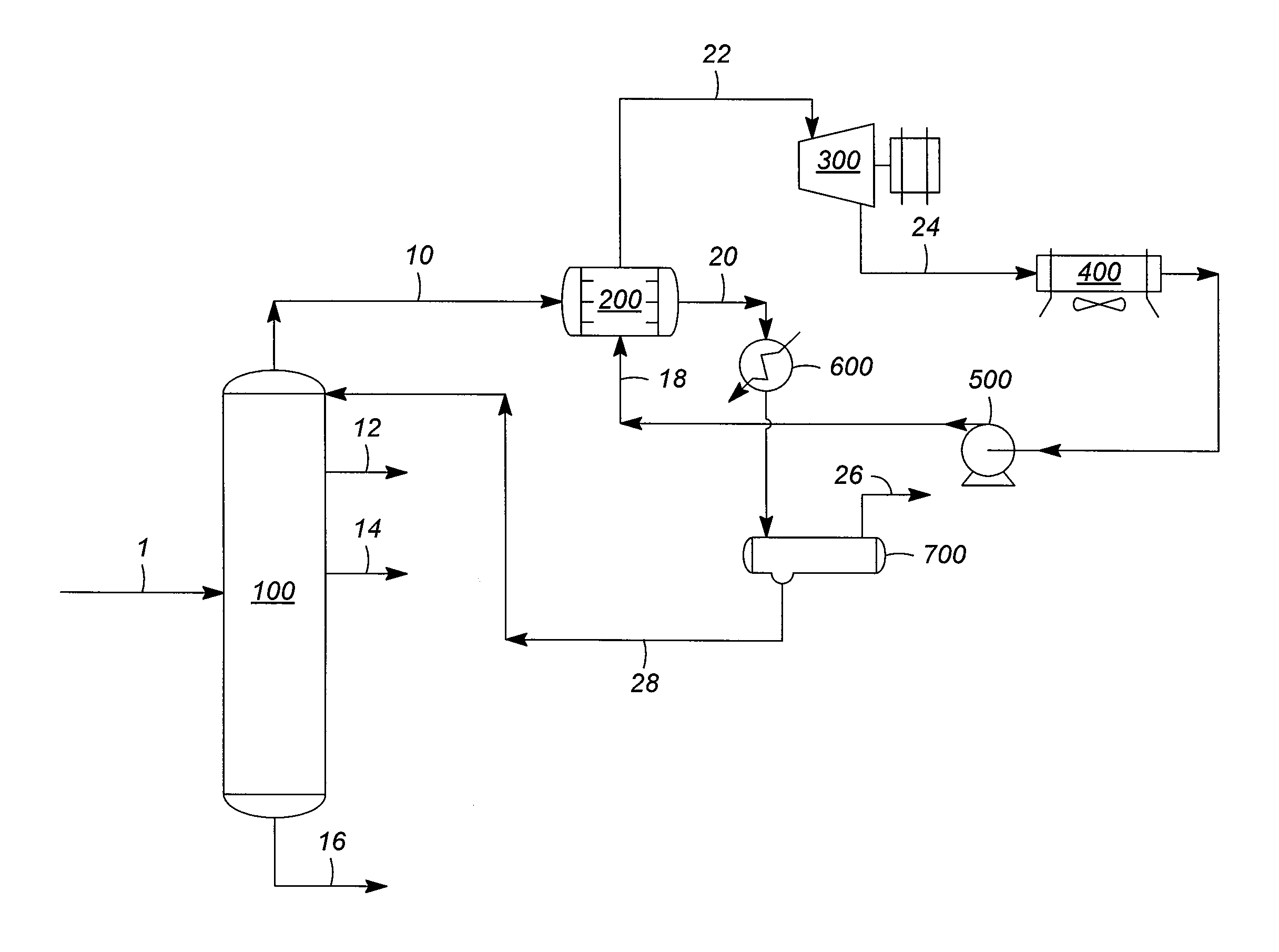

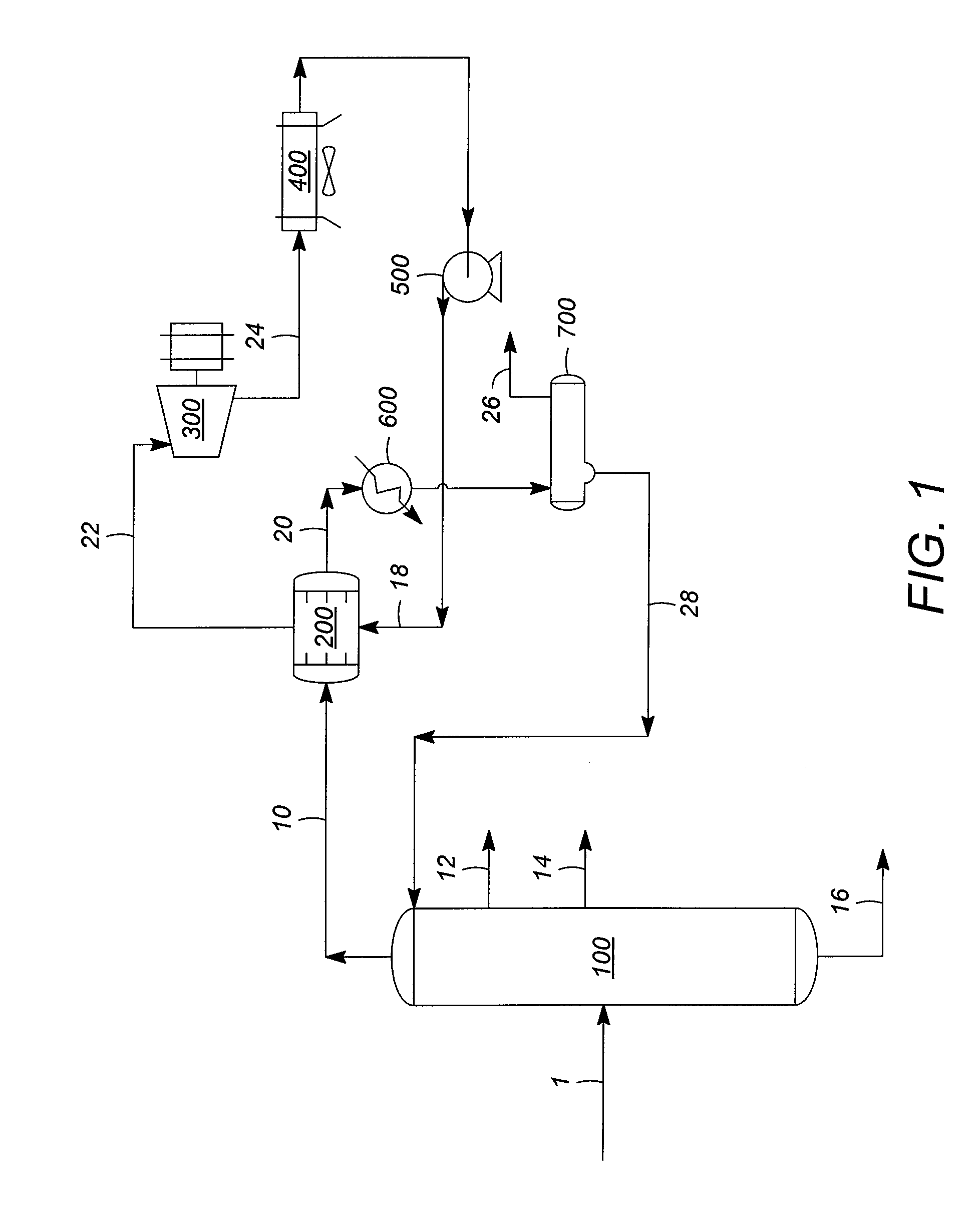

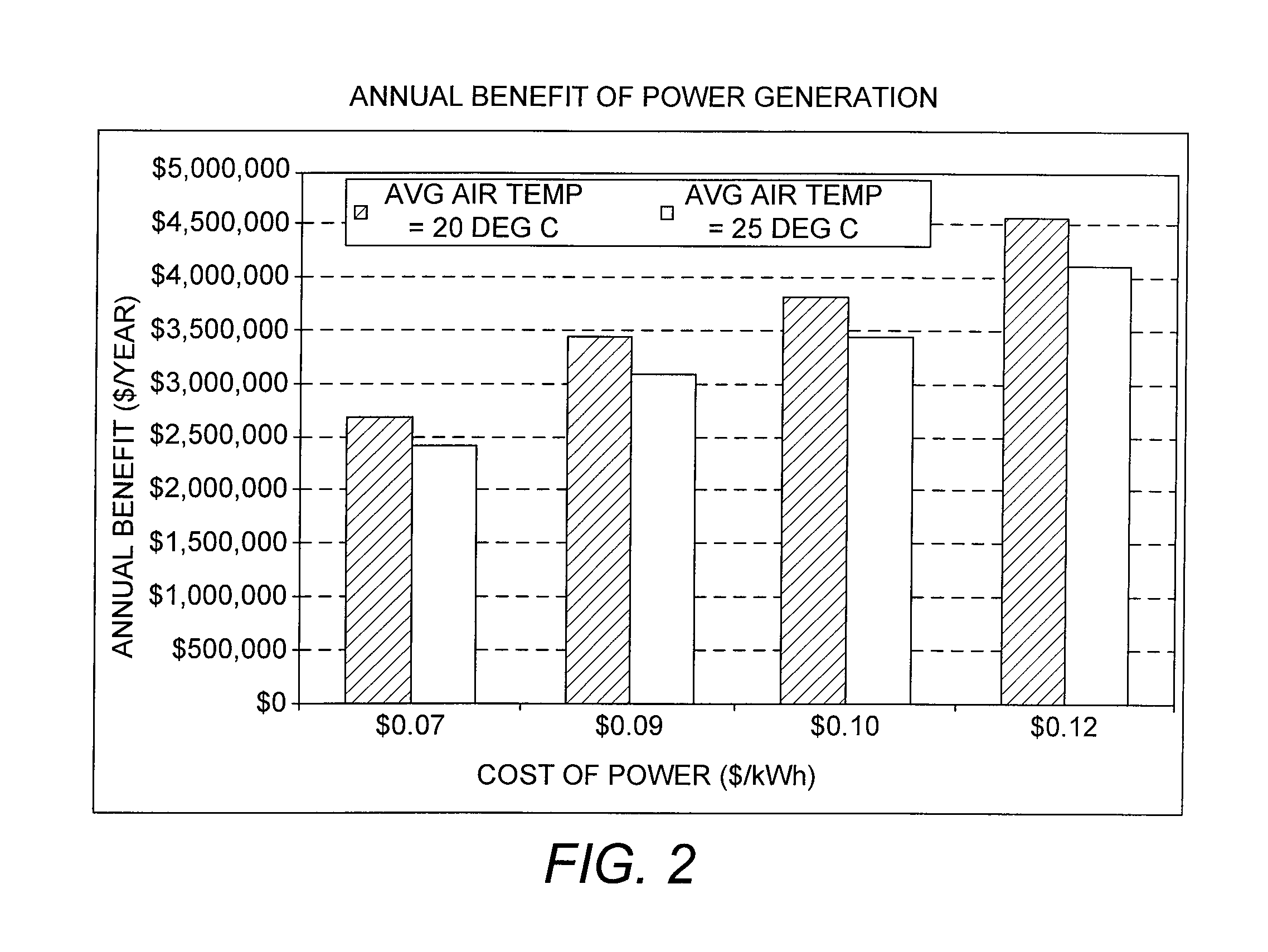

Low Grade Heat Recovery from Process Streams for Power Generation

InactiveUS20120031096A1Improve efficiencyImproves flexibility in designFeed water supplySteam engine plantsVapor liquidWorking fluid

Methods are described for generating electrical power from low grade heat sources from refining and petrochemical processes, including overhead vapors from vapor-liquid contacting apparatuses such as distillation columns, absorbers, strippers, quenching towers, scrubbers, etc. In many cases, these overhead vapors exit the apparatuses at a temperature from about 90° C. (194° F.) to about 175° C. (347° F.). Rather than rejecting the low temperature heat contained in these vapors to cooling air and / or cooling water, the vapors may instead be used to evaporate an organic working fluid. The vapors of the working fluid may then be sent to a turbine to drive a generator or other load.

Owner:UOP LLC

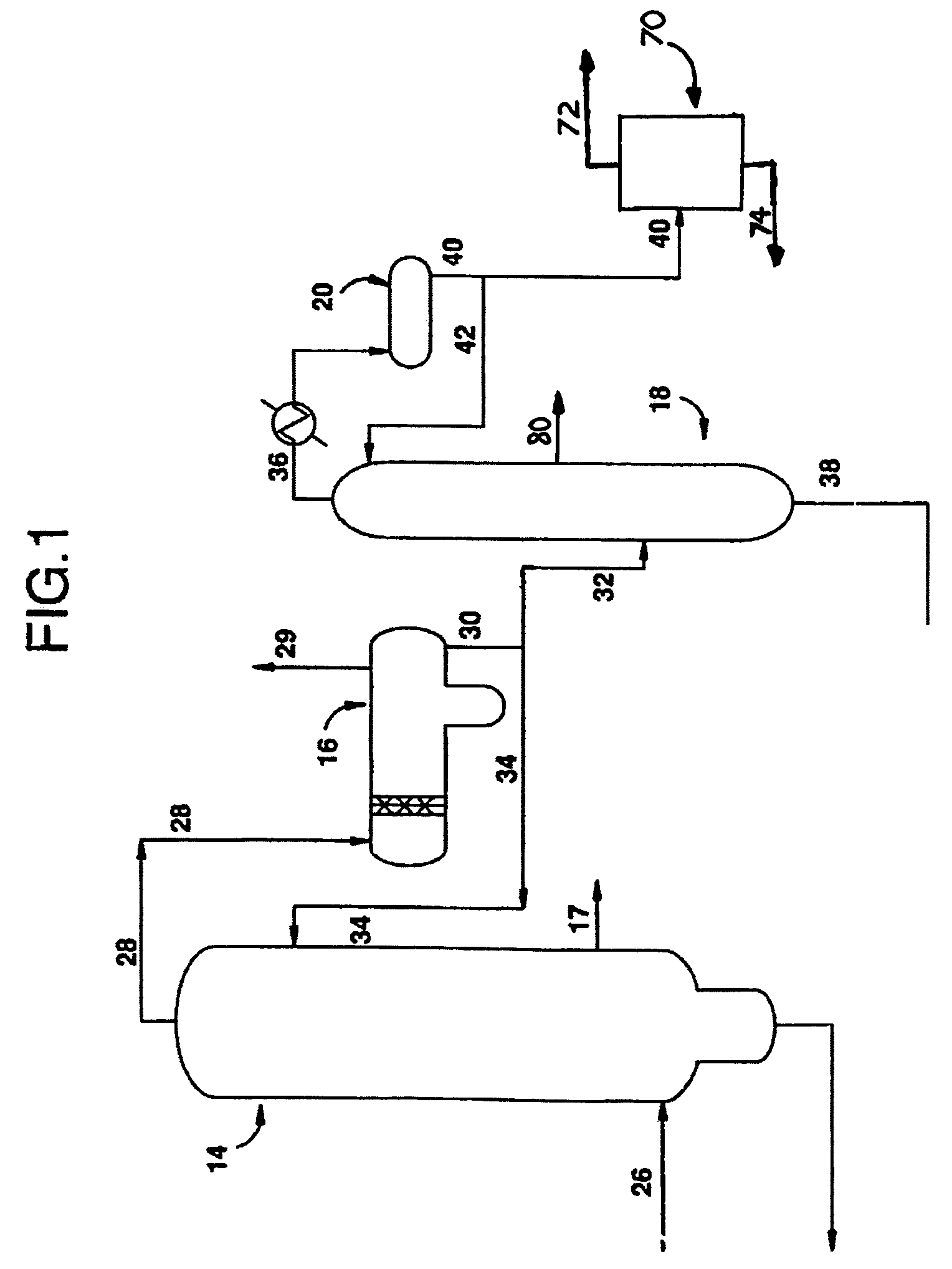

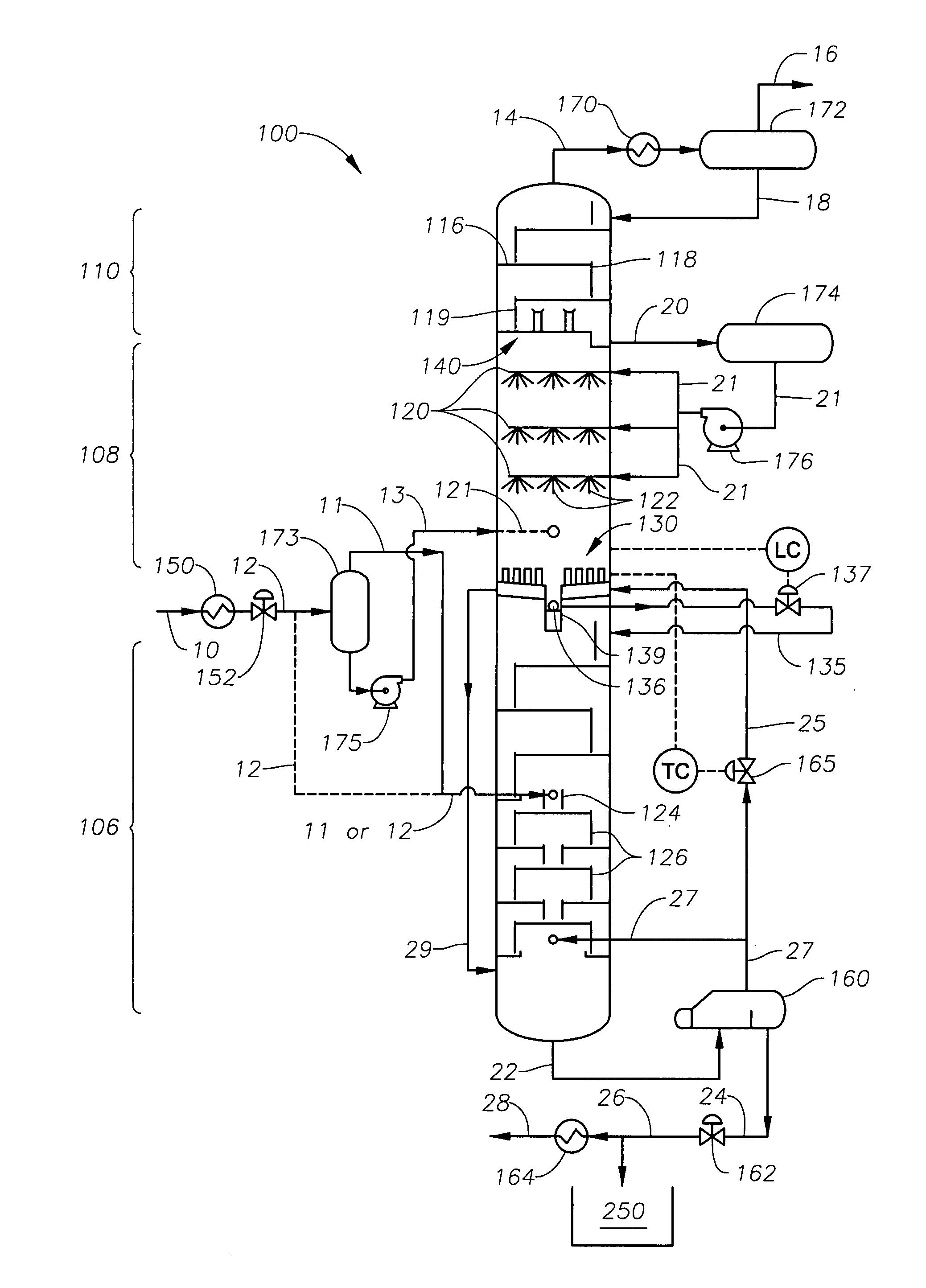

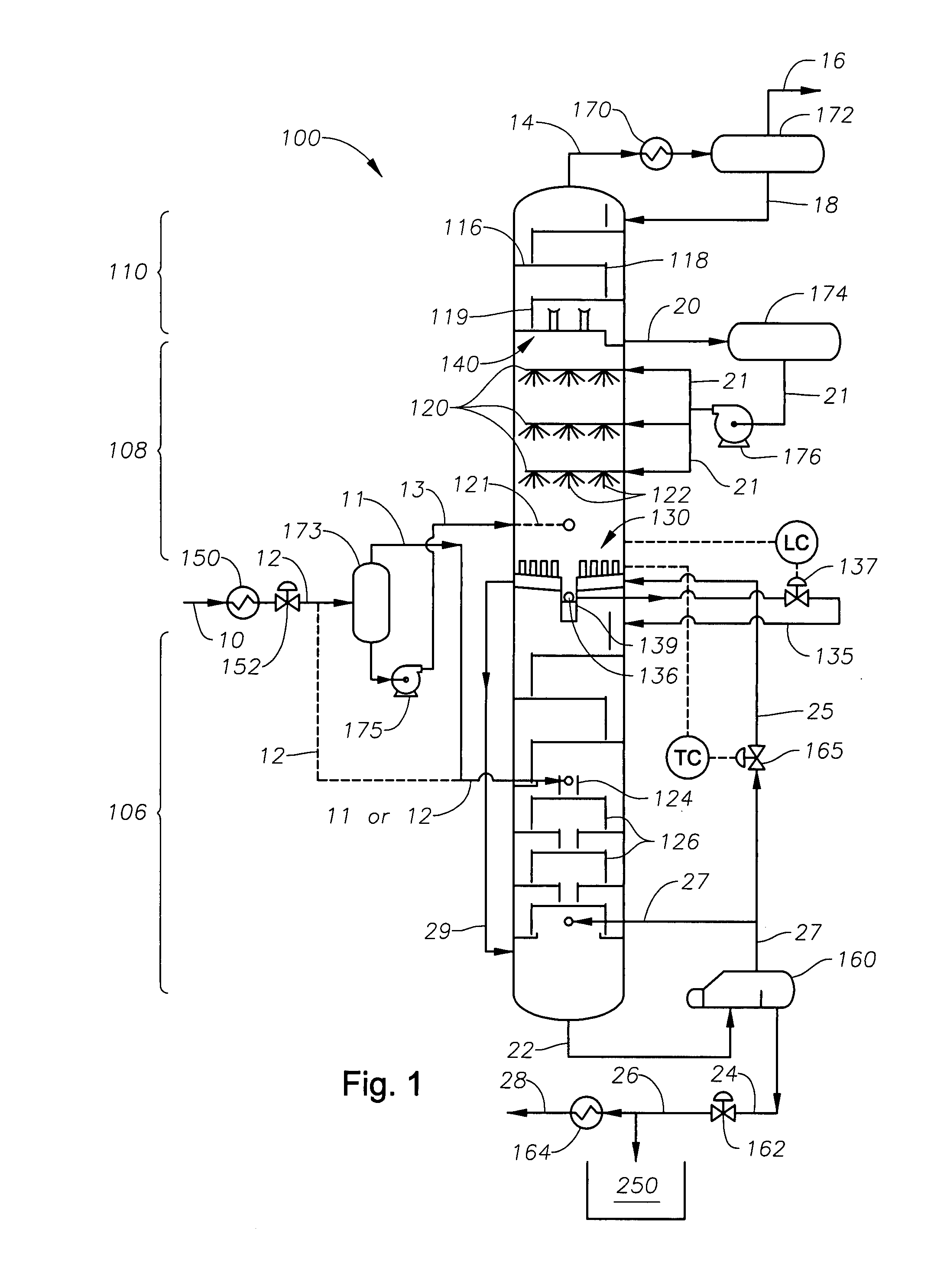

Controlled Freeze Zone Tower

A cryogenic distillation tower is provided for the separation of a fluid stream containing at least methane and carbon dioxide. The cryogenic distillation tower has a lower stripping section, an upper rectification section, and an intermediate spray section. The intermediate spray section includes a plurality of spray nozzles that inject a liquid freeze zone stream. The nozzles are configured such that substantial liquid coverage is provided across the inner diameter of the intermediate spray section. The liquid freeze zone stream generally includes methane at a temperature and pressure whereby both solid carbon dioxide particles and a methane-enriched vapor stream are formed. The tower may further include one or more baffles below the nozzles to create frictional resistance to the gravitational flow of the liquid freeze zone stream. This aids in the breakout and recovery of methane gas. Additional internal components are provided to improve heat transfer and to facilitate the breakout of methane gas.

Owner:FIELER ELEANOR R +3

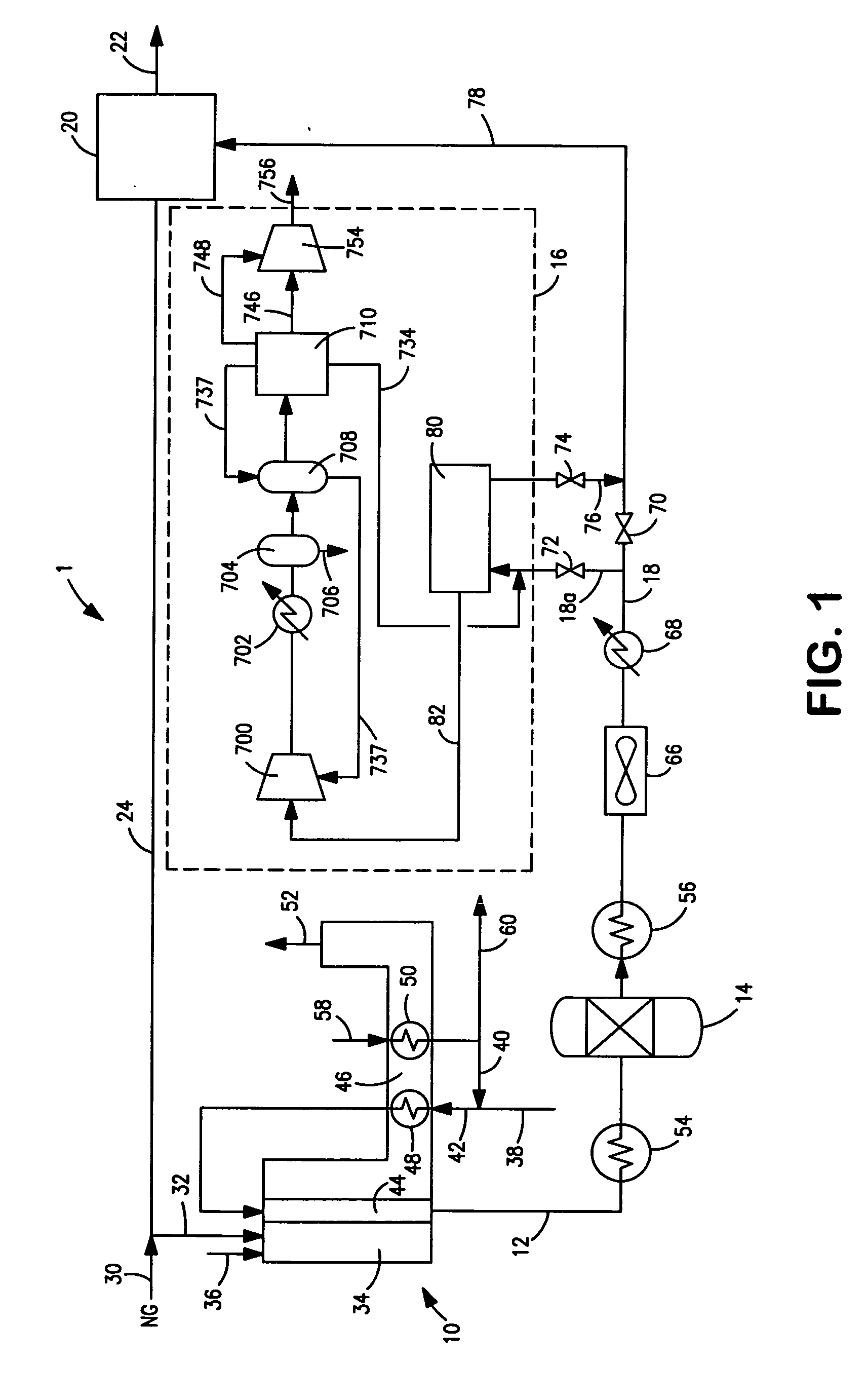

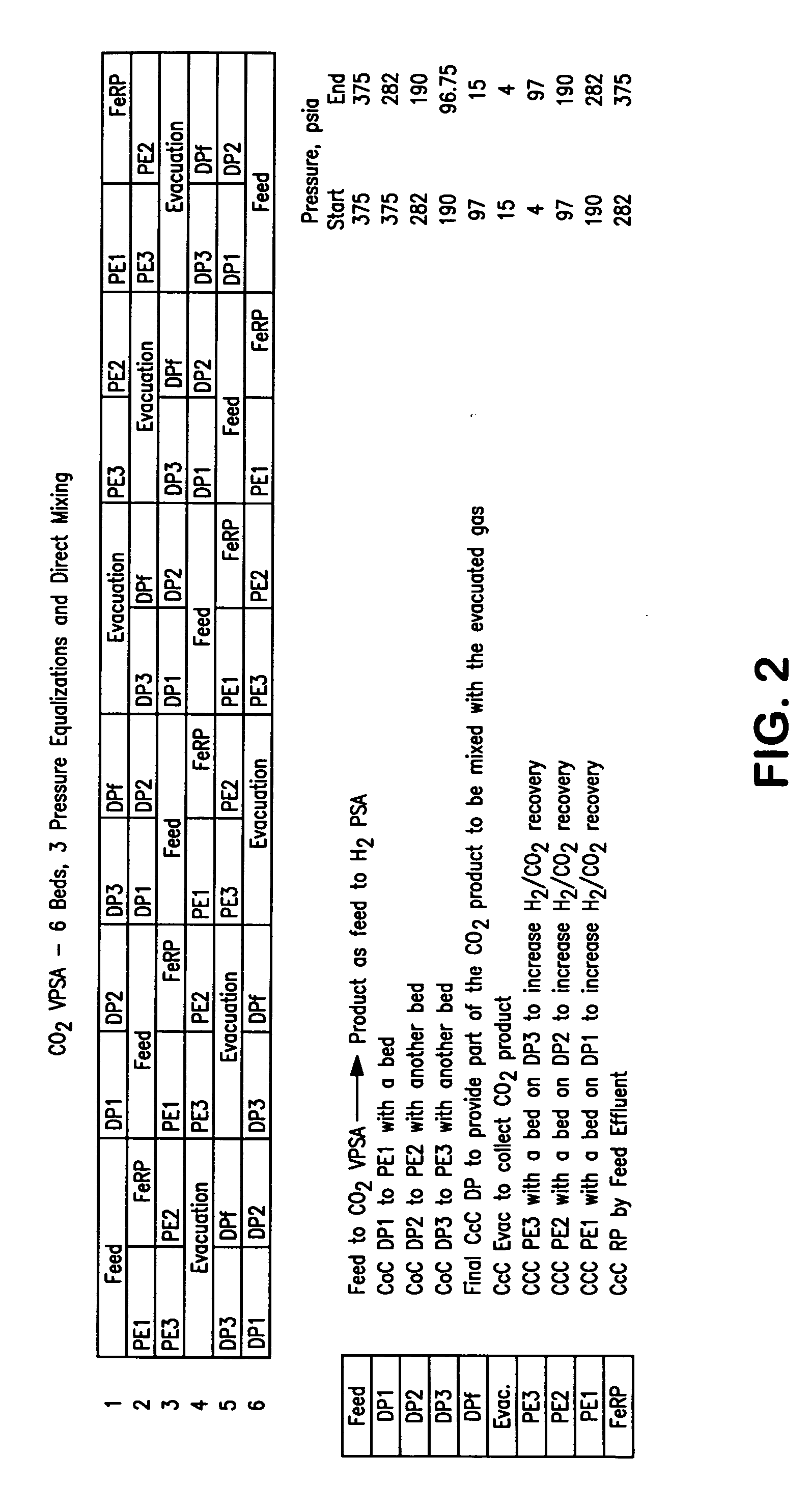

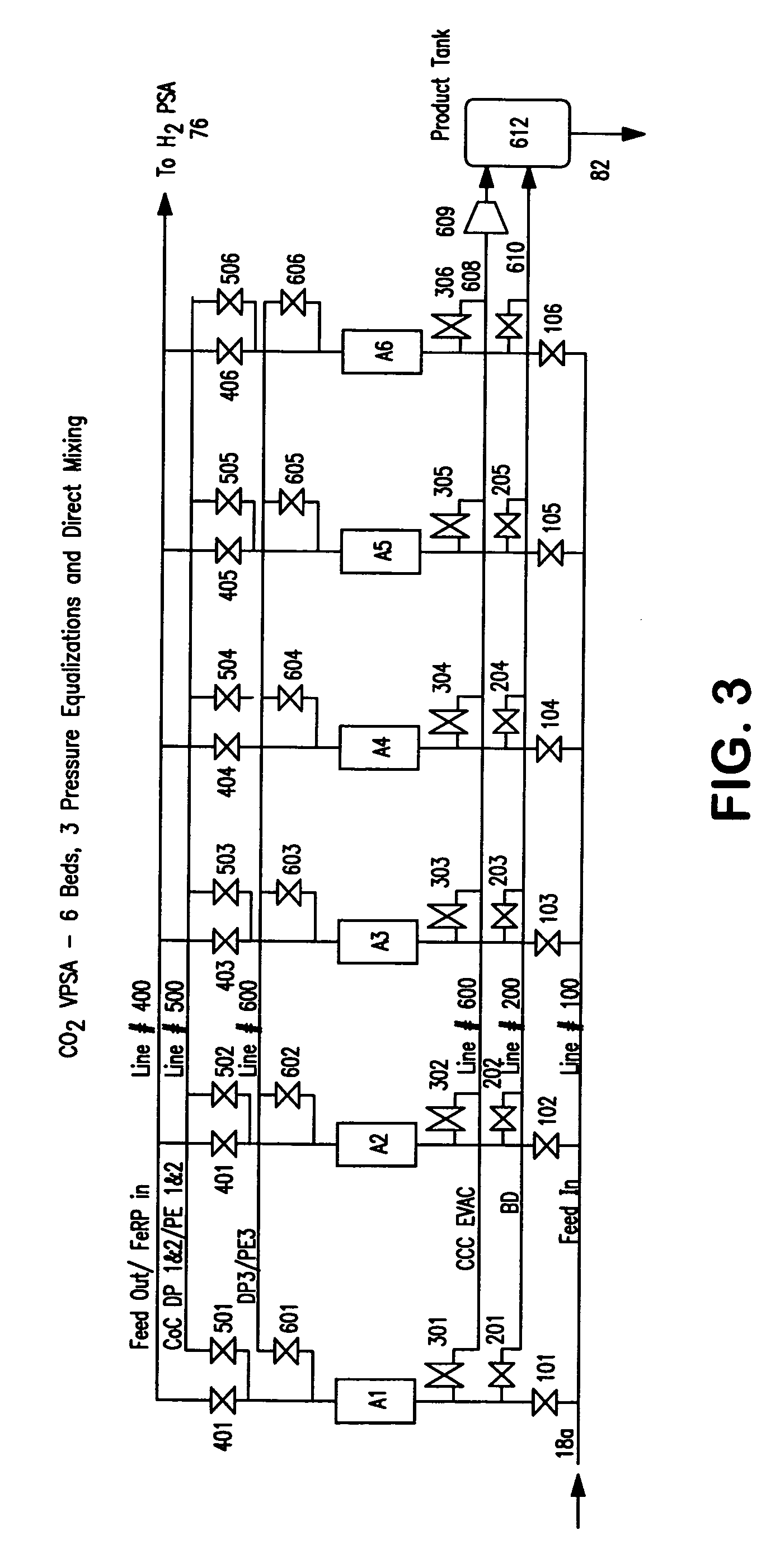

Carbon dioxide production method

ActiveUS20070232706A1Increased hydrogen recoveryPromote recoverySolidificationLiquefactionVacuum pressureCarbon dioxide production

A method of producing a carbon dioxide product stream from a synthesis gas stream formed within a hydrogen plant having a synthesis gas reactor, a water-gas shift reactor, located downstream of the synthesis gas reactor to form the synthesis gas stream and a hydrogen pressure swing adsorption unit to produce a hydrogen product recovered from the synthesis gas stream. In accordance with the method the carbon dioxide from the synthesis gas stream by separating the carbon dioxide from the synthesis gas stream in a vacuum pressure swing adsorption system, thereby to produce a hydrogen-rich synthesis gas stream and a crude carbon dioxide stream and then purifying the crude carbon dioxide stream by a sub-ambient temperature distillation process thereby to produce the carbon dioxide product. A hydrogen synthesis gas feed stream to the hydrogen pressure swing adsorption unit is formed at least in part from the hydrogen rich stream.

Owner:PRAXAIR TECH INC

Process for the manufacture of hydrocarbons

A feedstock originating from renewable sources is converted to branched and saturated hydrocarbons without heteroatoms in the diesel fuel distillation range by skeletal isomerisation and deoxygenation carried out by hydrodeoxygenation or alternatively by combined decarboxylation and decarbonylation reactions, whereby the consumption of hydrogen is decreased.

Owner:NESTE OIL OY

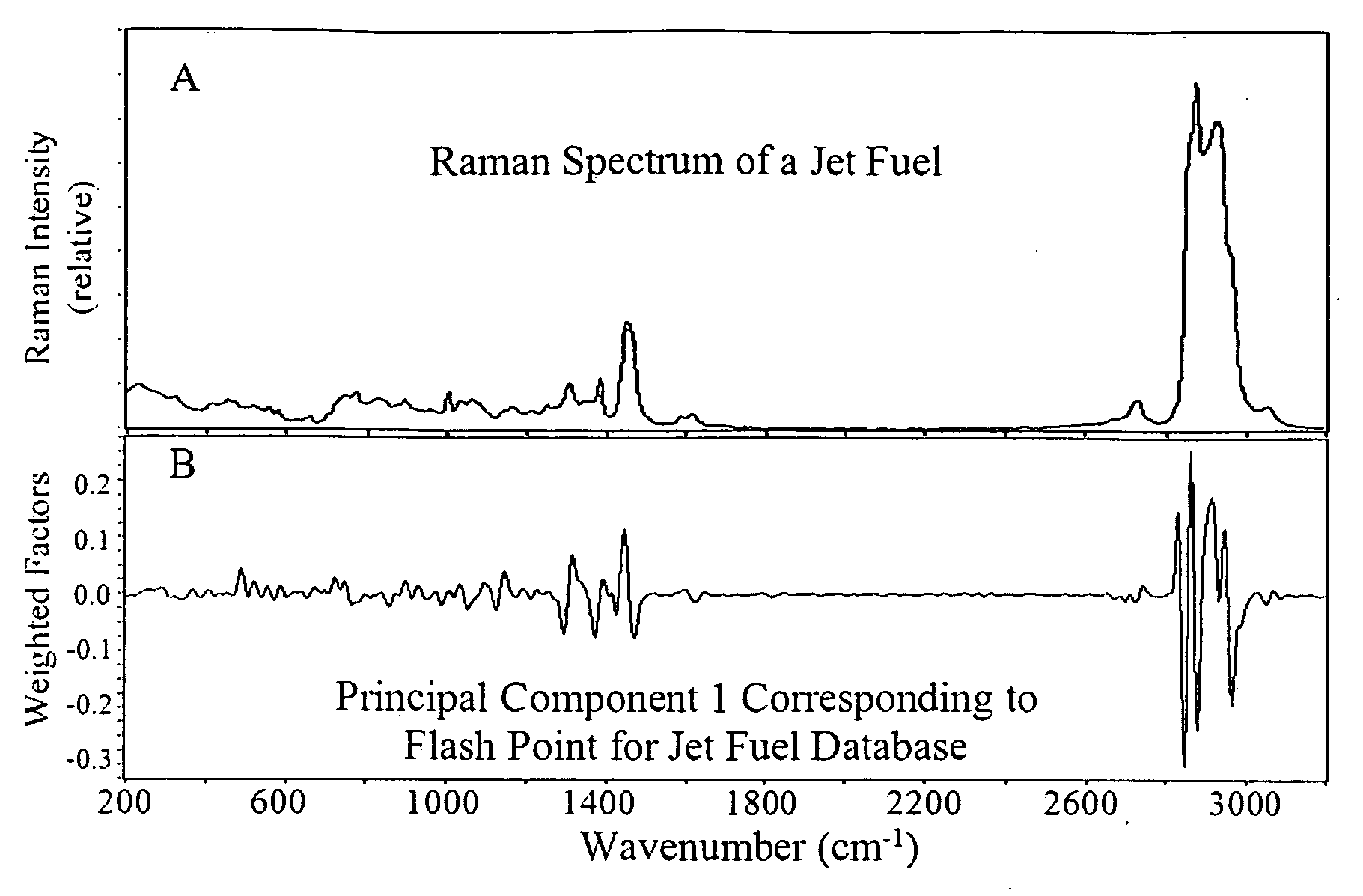

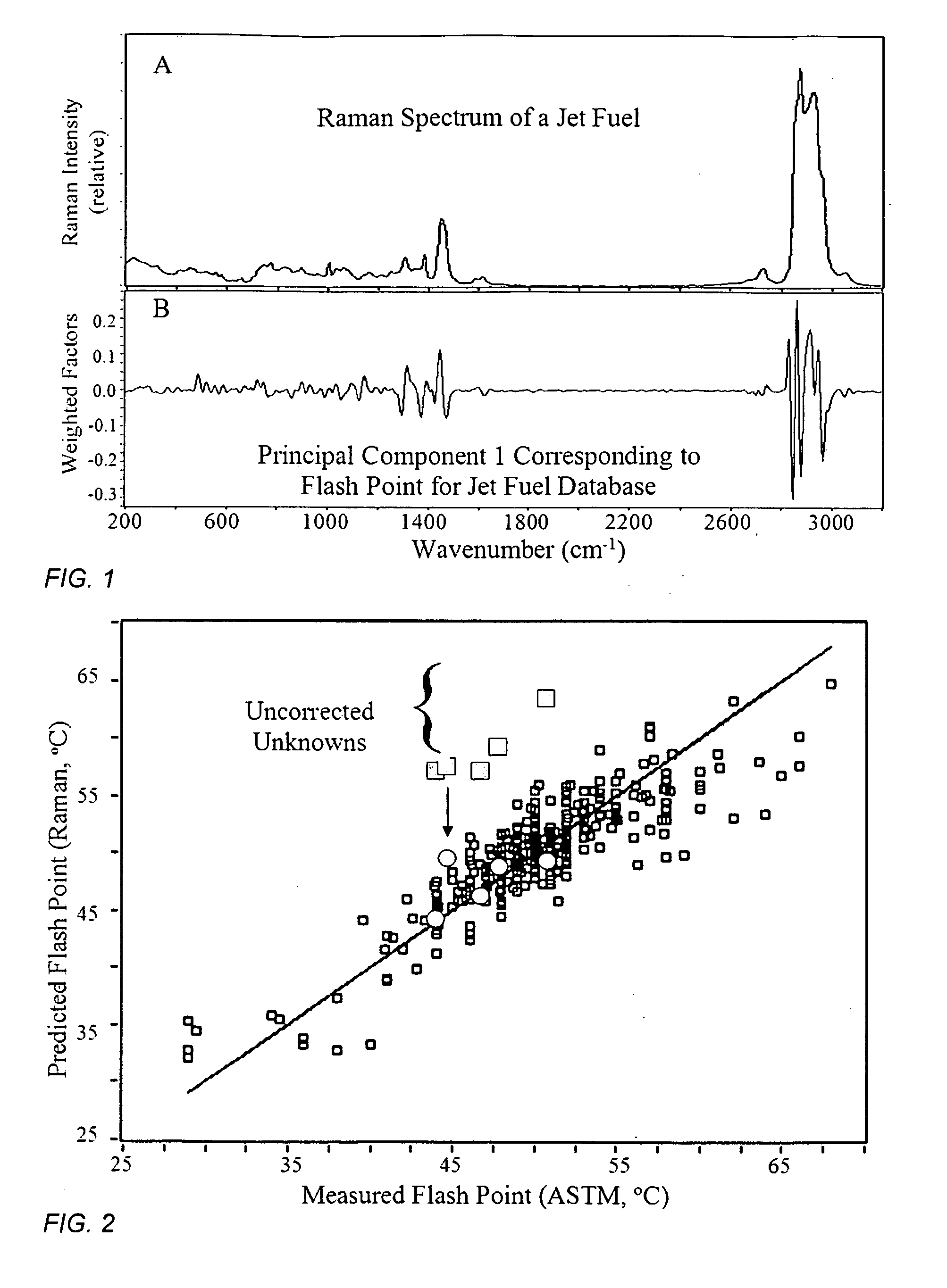

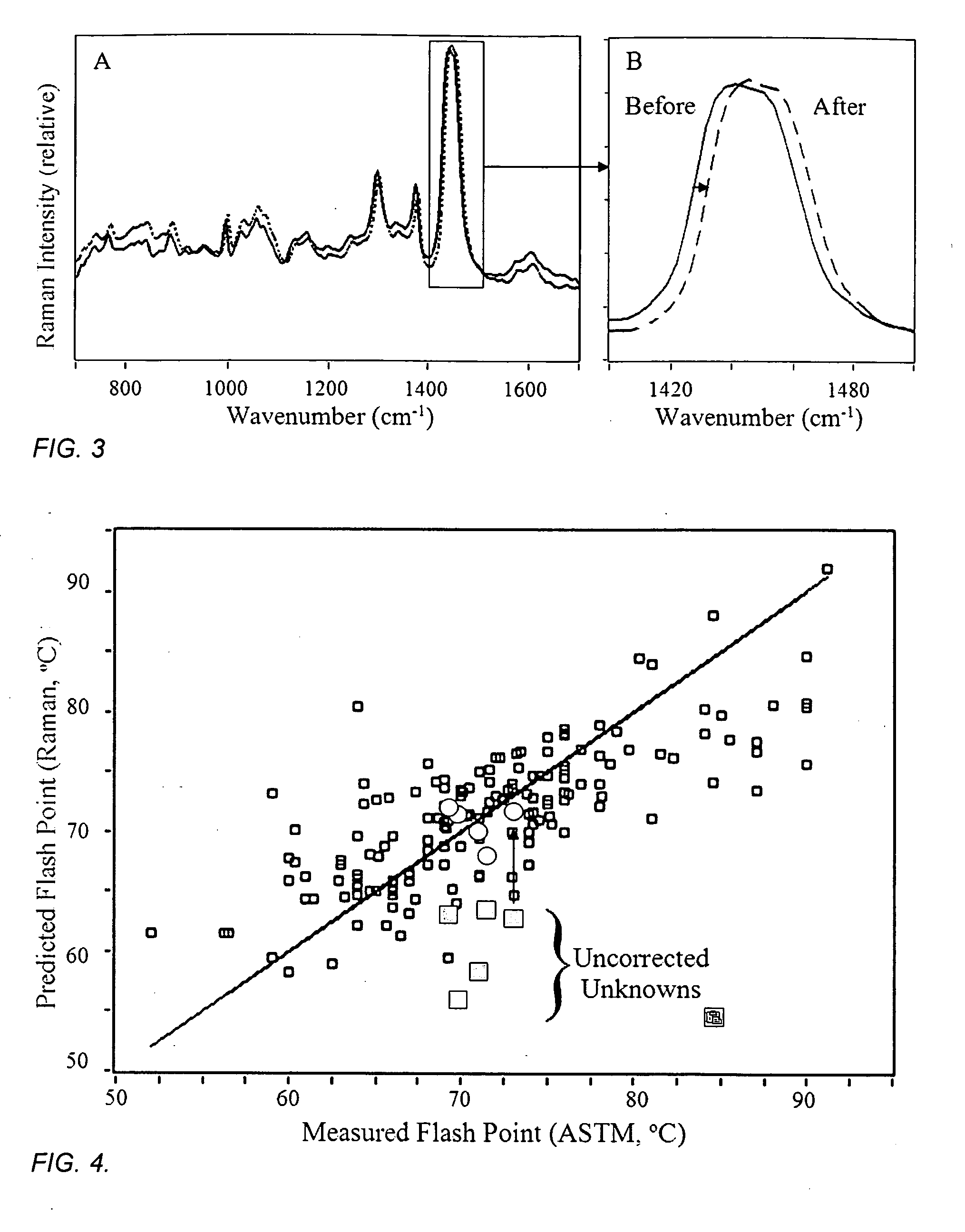

Method and apparatus for determining properties of fuels

ActiveUS20100211329A1Easy to operateRaman scatteringSpecial data processing applicationsPresent methodDistillation

The method and apparatus are used to determine class, grade and properties of fuel samples, regardless of ambient, instrument, or sample temperature, using mathematical correlations between fuel class, grade and properties and their spectra developed from a database of samples with measured properties and spectra. The ability to measure a fuel sample using the present method and apparatus is useful in identifying unknown fuel samples, determining suitability in equipment, and monitoring and controlling fuel processes, such as blending operations, distillation, and synthesis.

Owner:REAL TIME ANALYZERS

Dividing wall distillation column control apparatus

InactiveUS7267746B1Low costThermal non-catalytic crackingDistillation regulation/controlDistillationEngineering

A control apparatus and control method for controlling the separation in a dividing wall distillation column of at least two feeds into at least three products is disclosed. The apparatus uses a temperature measuring device to measure the temperature of fluid in the column, a controller, and a means for adjusting the temperature of fluid in the column. The temperature measuring device may be on either side of the dividing wall or above or below the dividing wall, and more than one such device may be used. The apparatus and method may be used in the production of alkylaromatic hydrocarbons by alkylating aromatic hydrocarbons with olefinic hydrocarbons.

Owner:UOP LLC

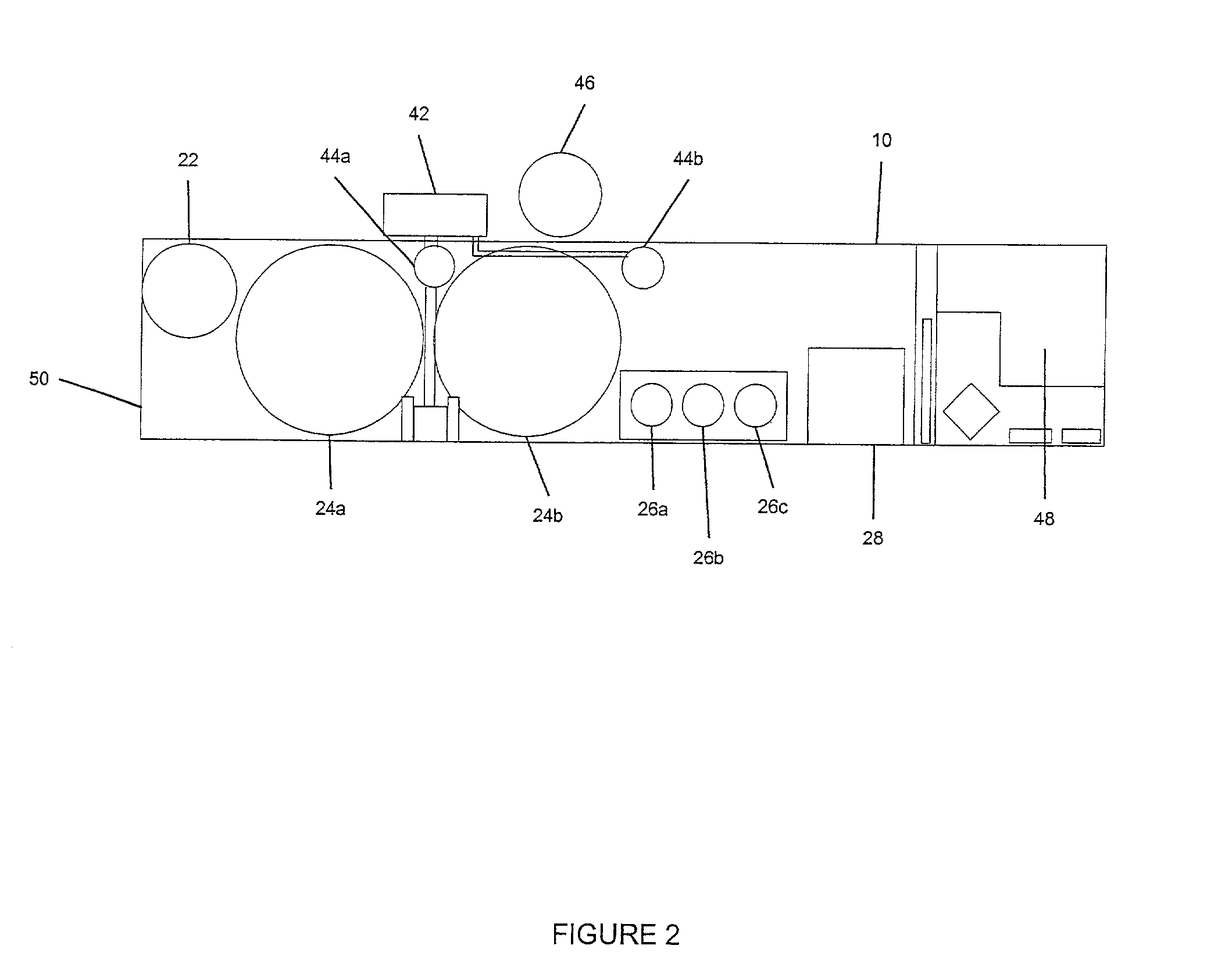

Biodiesel production unit

In a first aspect, systems and methods for producing biodiesel fuel include a modular production unit incorporated onto a single platform or into a housing for ease of relocatability. The modular production unit preferably includes a mixing unit, a reactor unit, a separation unit, a distillation unit, and a filtering unit, all incorporated onto or into a self-contained platform or housing that is able to be easily relocated. In a second aspect, the modular production unit is combined with additional fixed and / or relocatable components to provide a biodiesel processing plant. In a third aspect, a raw materials processing system and method includes a roller barrel adapted for recovery, transportation, and introduction of recycled oil feedstock into a biodiesel manufacturing process. The raw materials processing system preferably includes a hot box for filtering and heating the raw recycled oil feedstock.

Owner:BIODIESEL IND

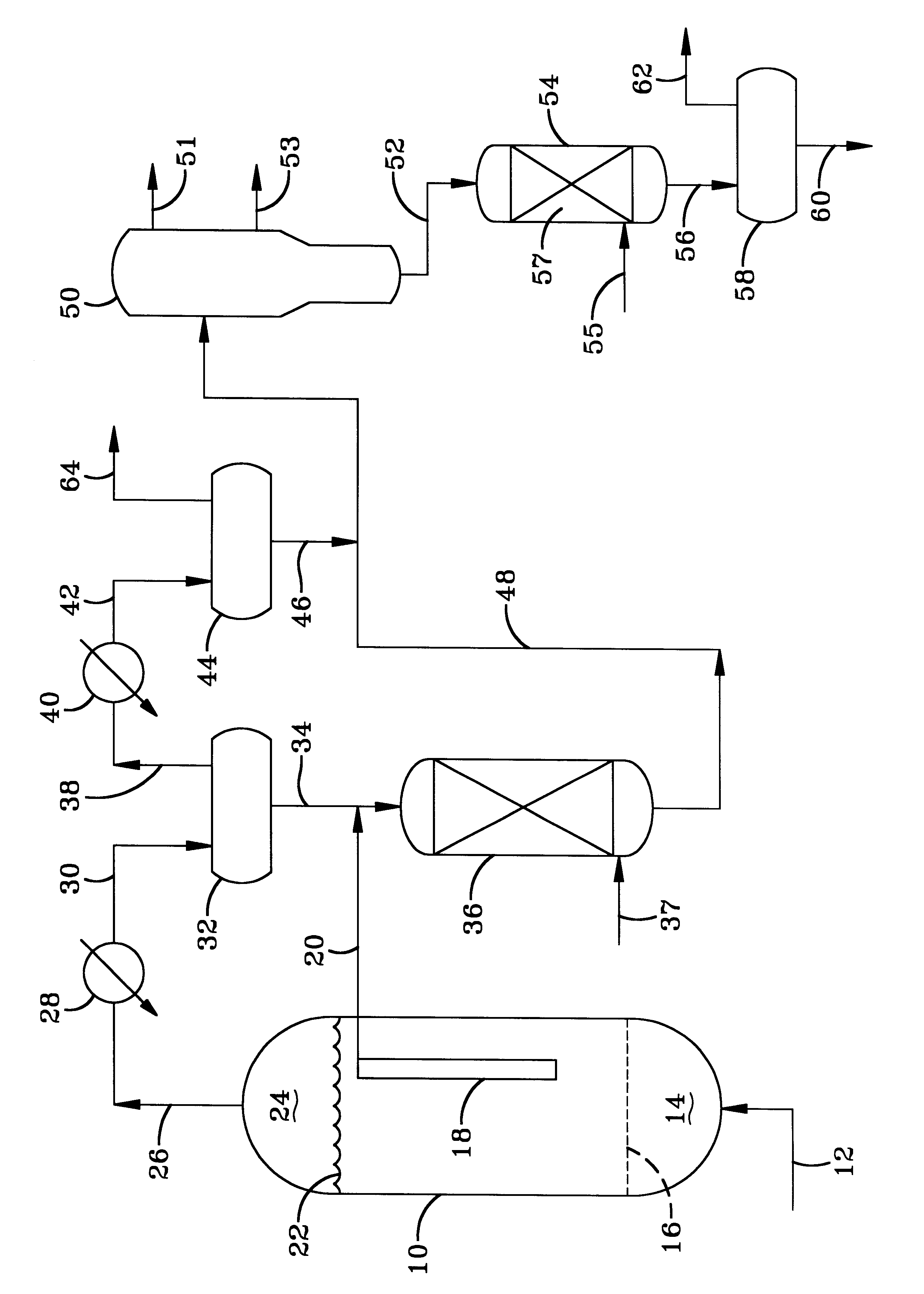

Natural gas liquefaction

A process for liquefying natural gas in conjunction with producing a liquid stream containing predominantly hydrocarbons heavier than methane is disclosed. In the process, the natural gas stream to be liquefied is partially cooled, expanded to an intermediate pressure, and supplied to a distillation column. The bottom product from this distillation column preferentially contains the majority of any hydrocarbons heavier than methane that would otherwise reduce the purity of the liquefied natural gas. The residual gas stream from the distillation column is compressed to a higher intermediate pressure, cooled under pressure to condense it, and then expanded to low pressure to form the liquefied natural gas stream.

Owner:UOP LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com