Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1752results about "Distillation regulation/control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

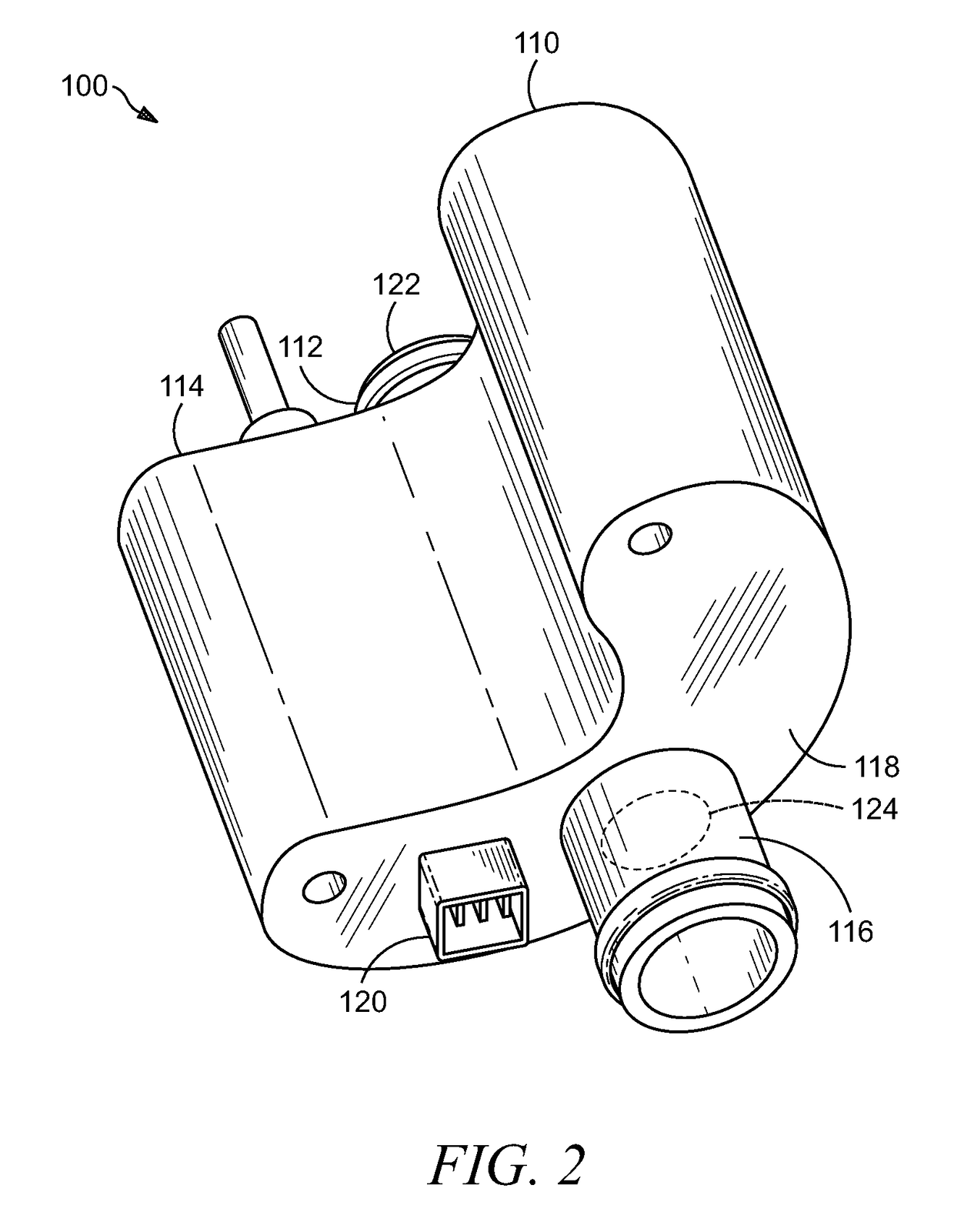

Swappable Sets of Partial-Mapping Tables in a Flash-Memory System With A Command Queue for Combining Flash Writes

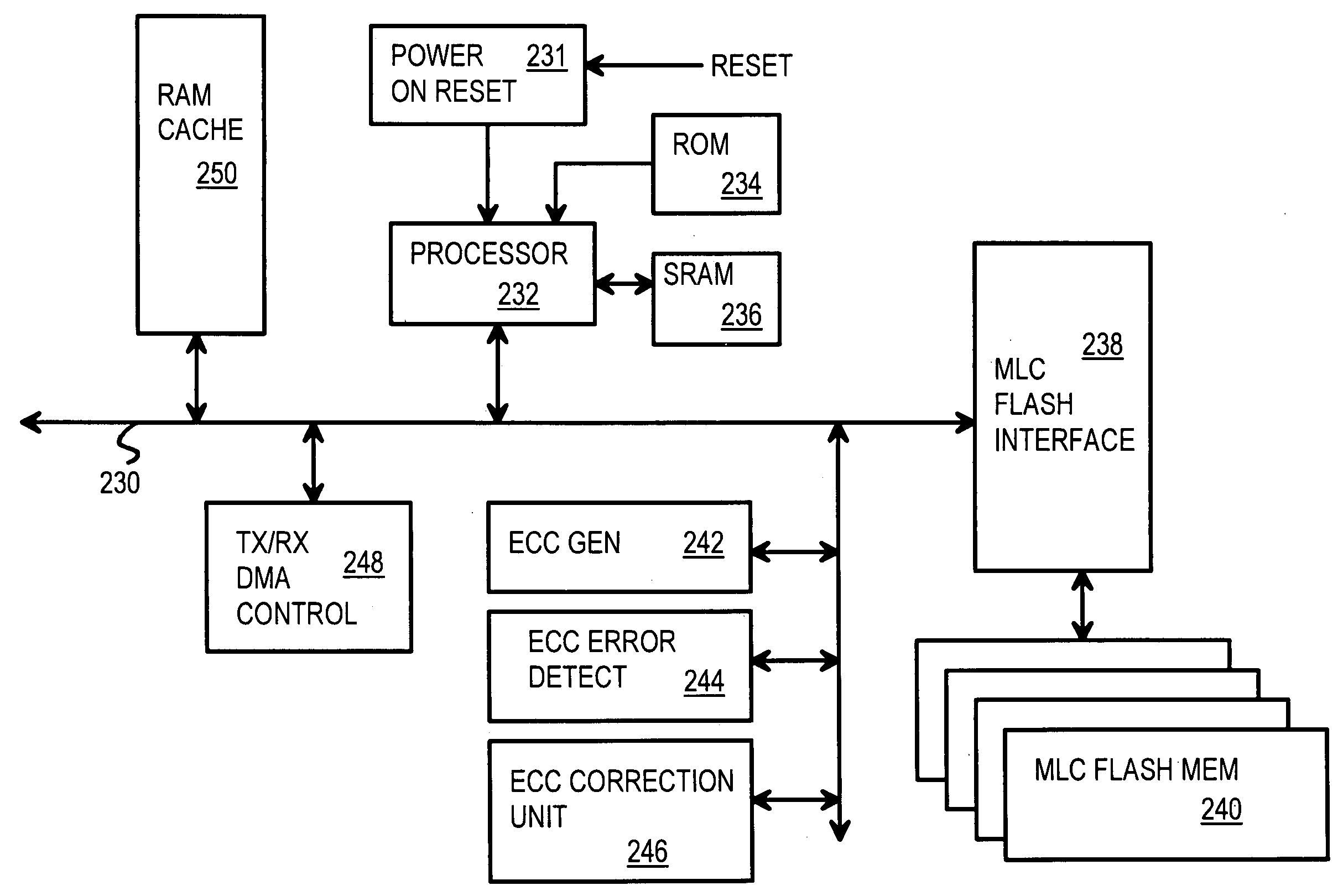

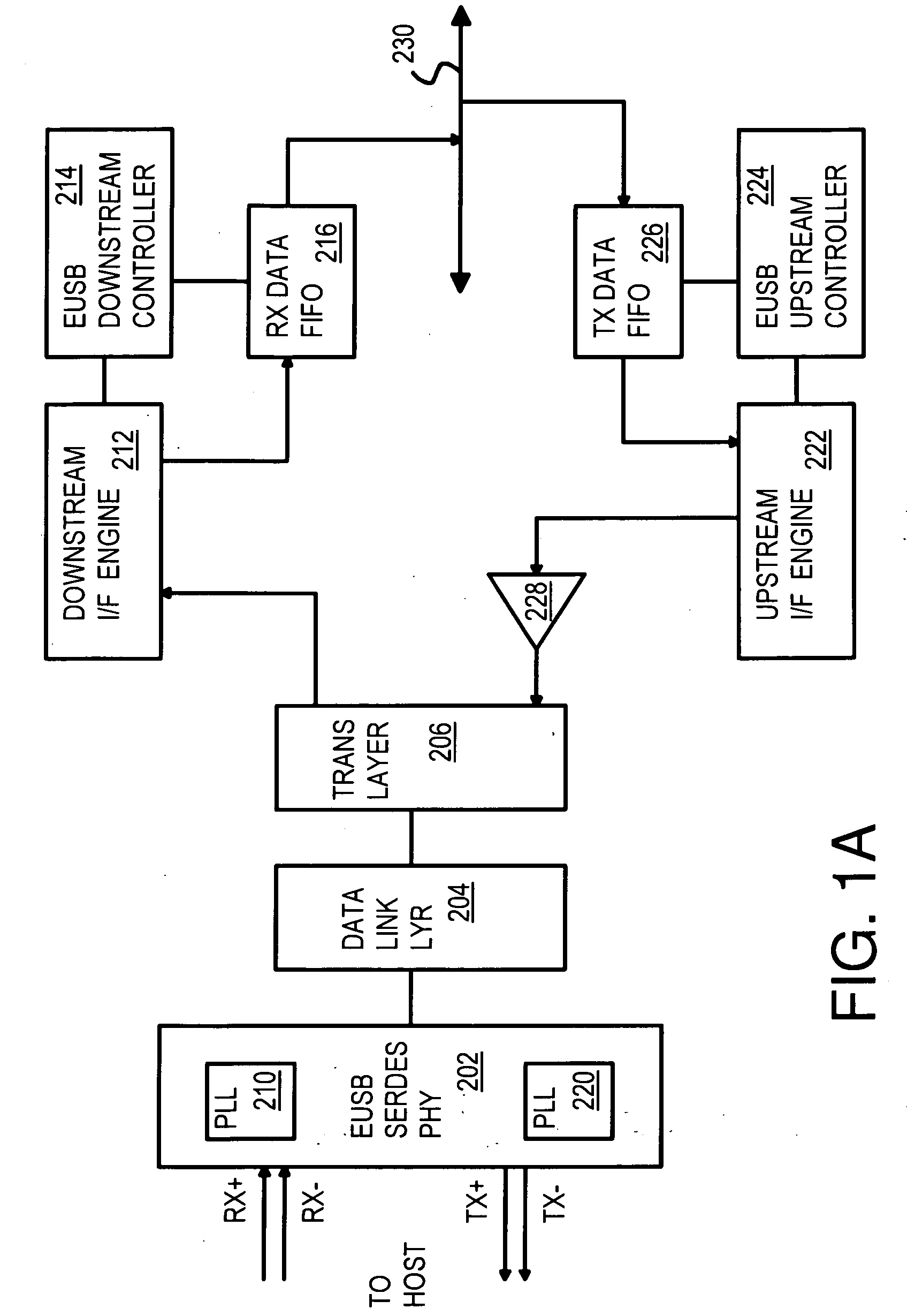

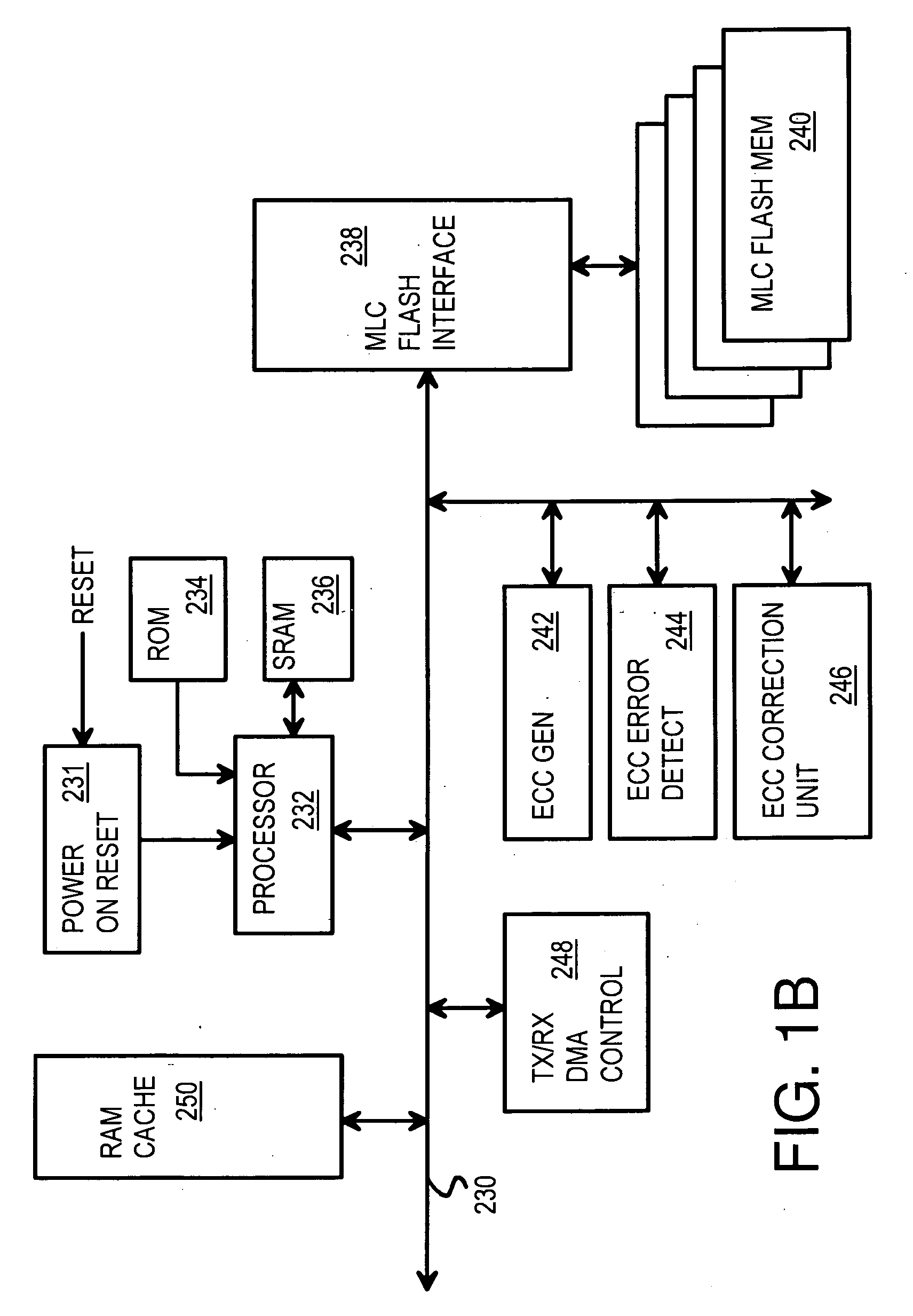

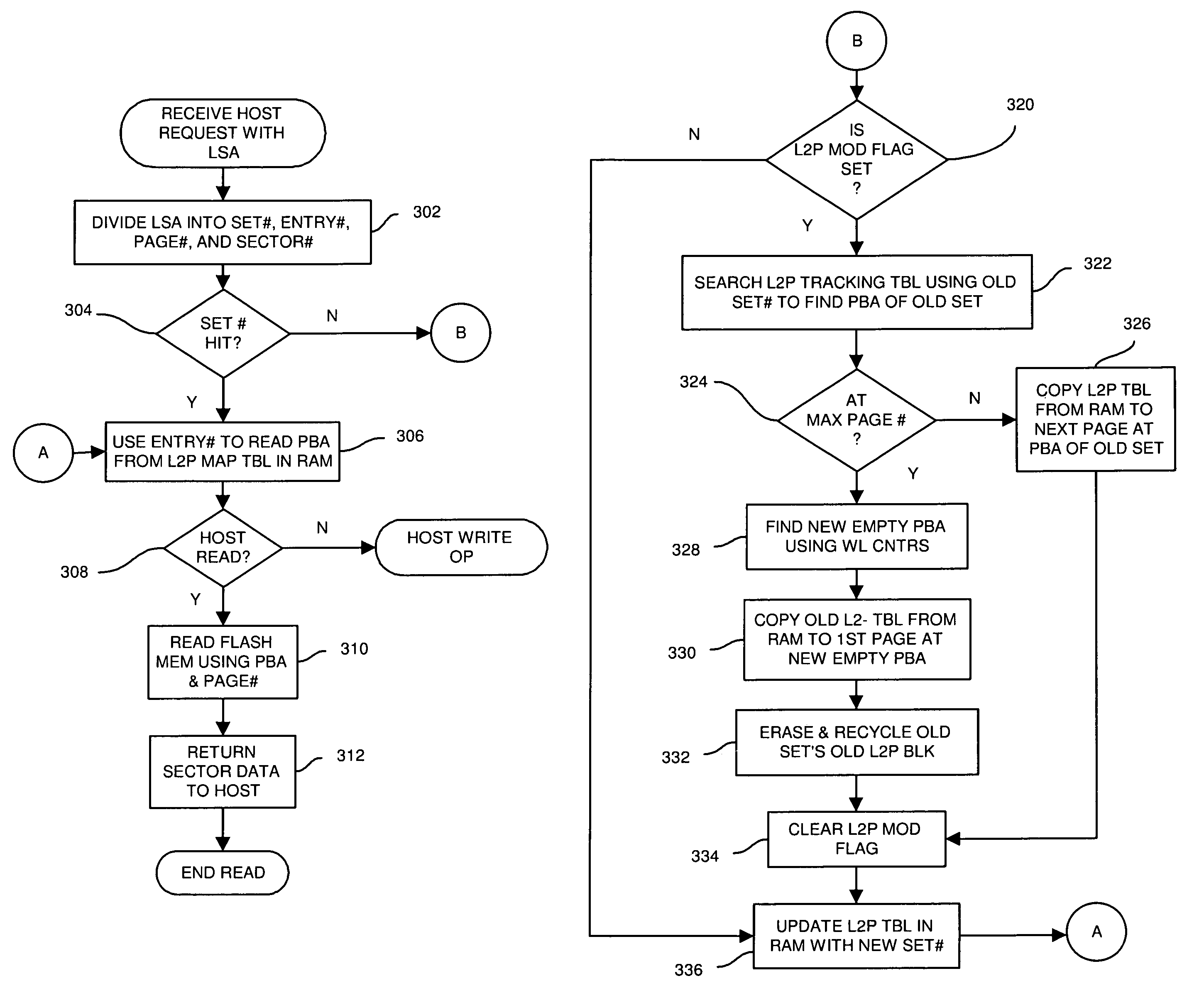

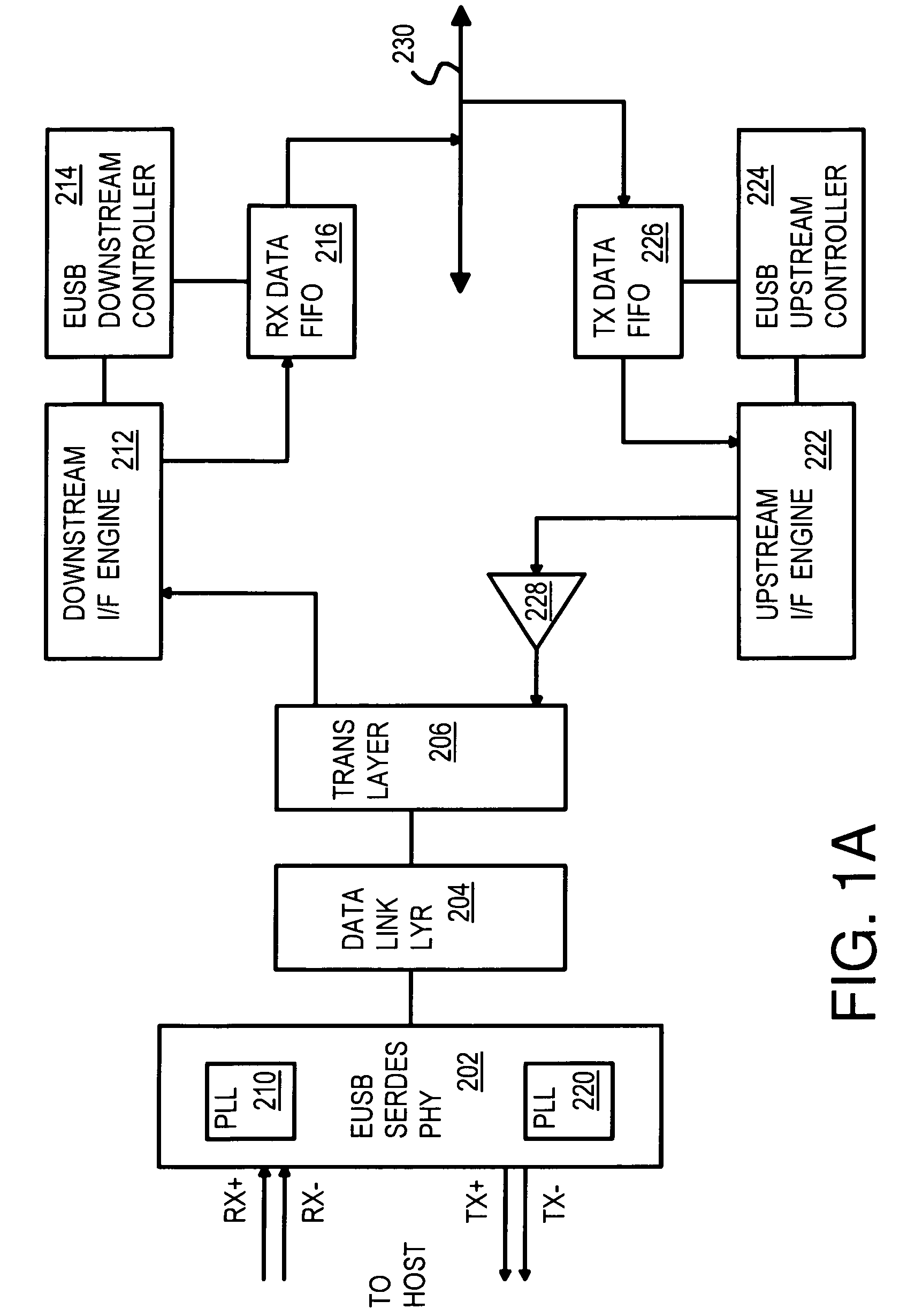

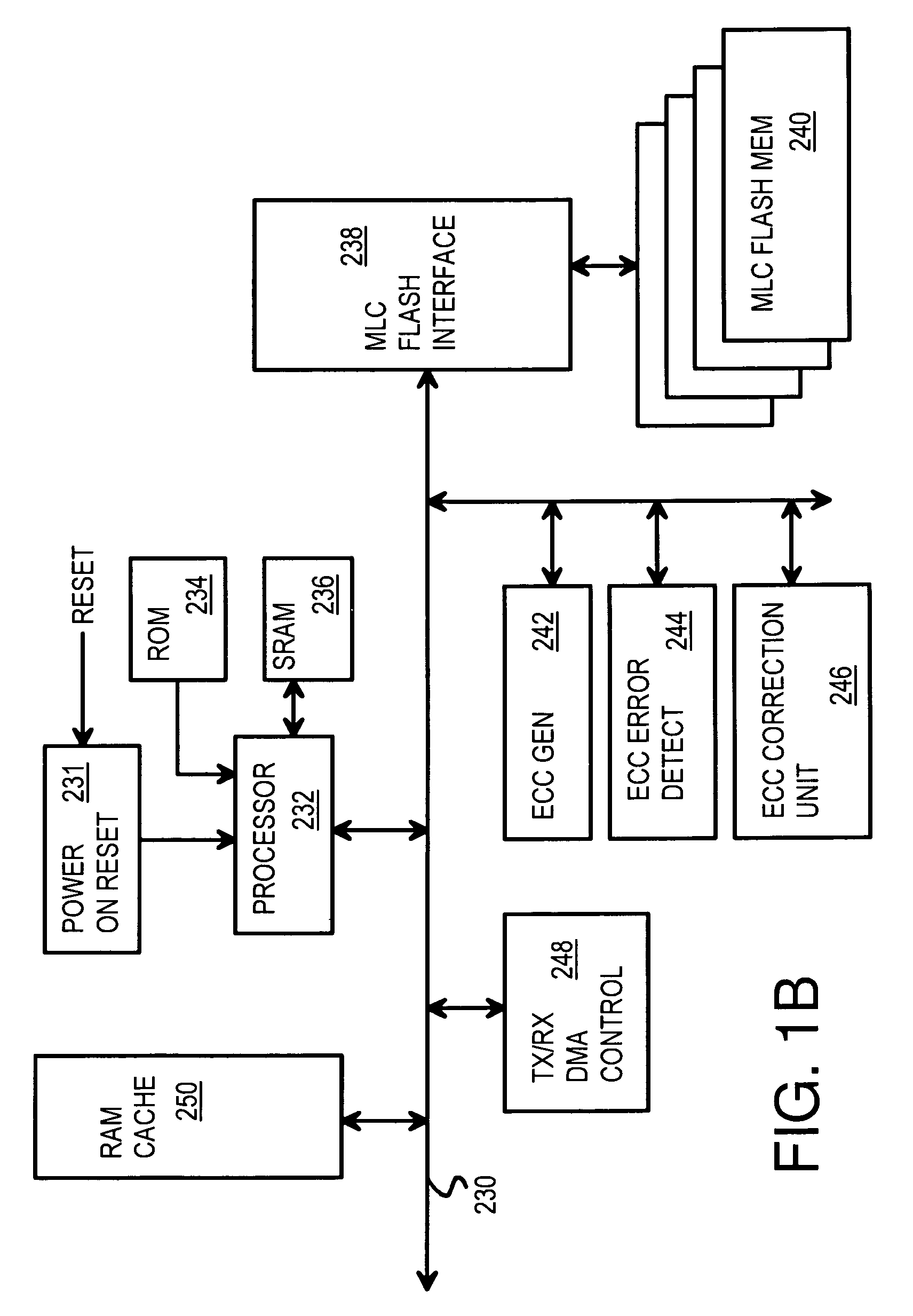

InactiveUS20090113121A1Memory architecture accessing/allocationDistillation regulation/controlFlash memory controllerMulti-level cell

A flash controller has a flash interface accessing physical blocks of multi-level-cell (MLC) flash memory. An Extended Universal-Serial-Bus (EUSB) interface loads host commands into a command queue where writes are re-ordered and combined to reduce flash writes. A partial logical-to-physical L2P mapping table in a RAM has entries for only 1 of N sets of L2P mapping tables. The other N−1 sets are stored in flash memory and fetched into the RAM when a L2P table miss occurs. The RAM required for mapping is greatly reduced. A data buffer stores one page of host write data. Sector writes are merged using the data buffer. The data buffer is flushed to flash when a different page is written, while the partial logical-to-physical mapping table is flushed to flash when a L2P table miss occurs, when the host address is to a different one of the N sets of L2P mapping tables.

Owner:SUPER TALENT TECH CORP

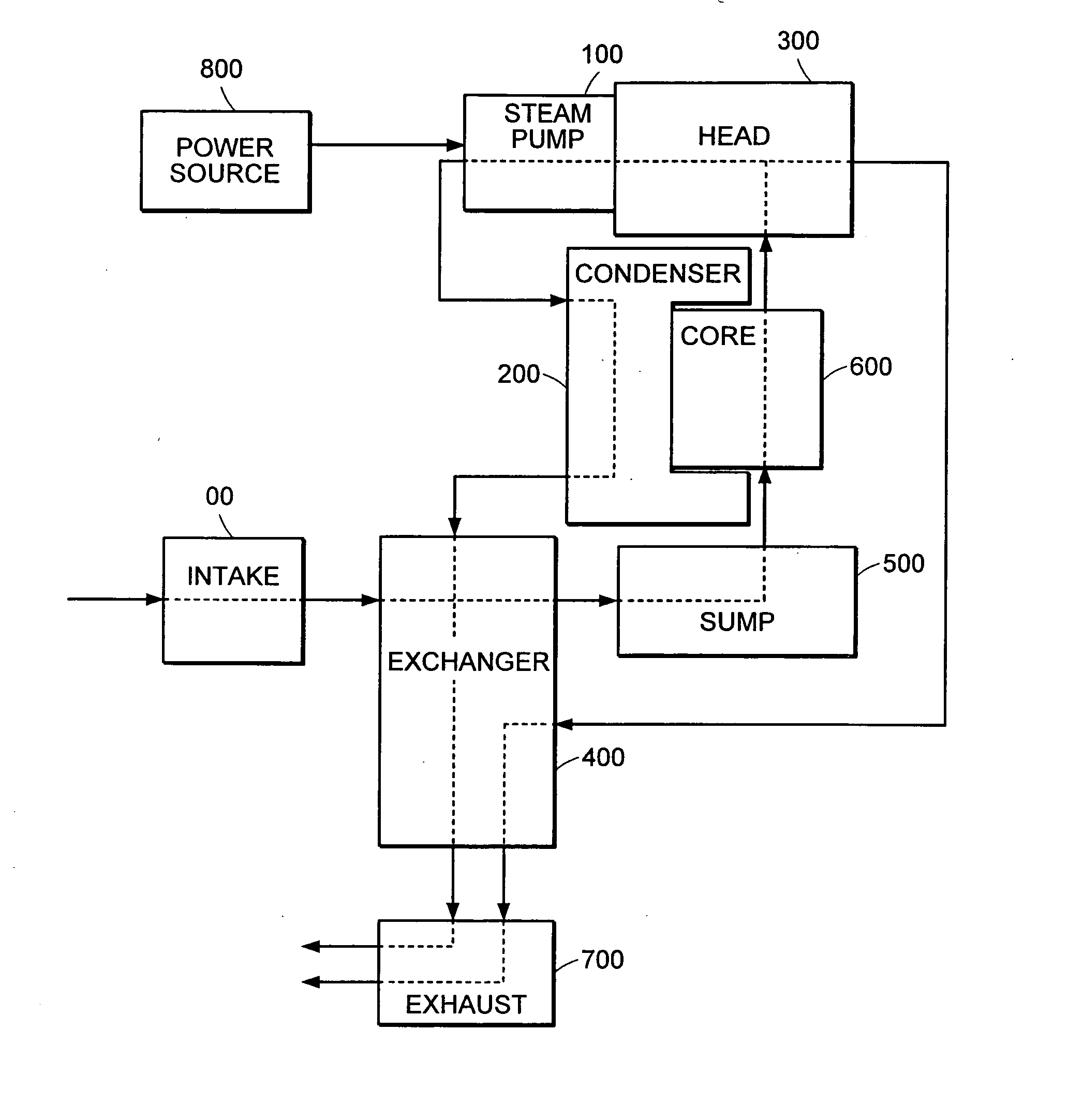

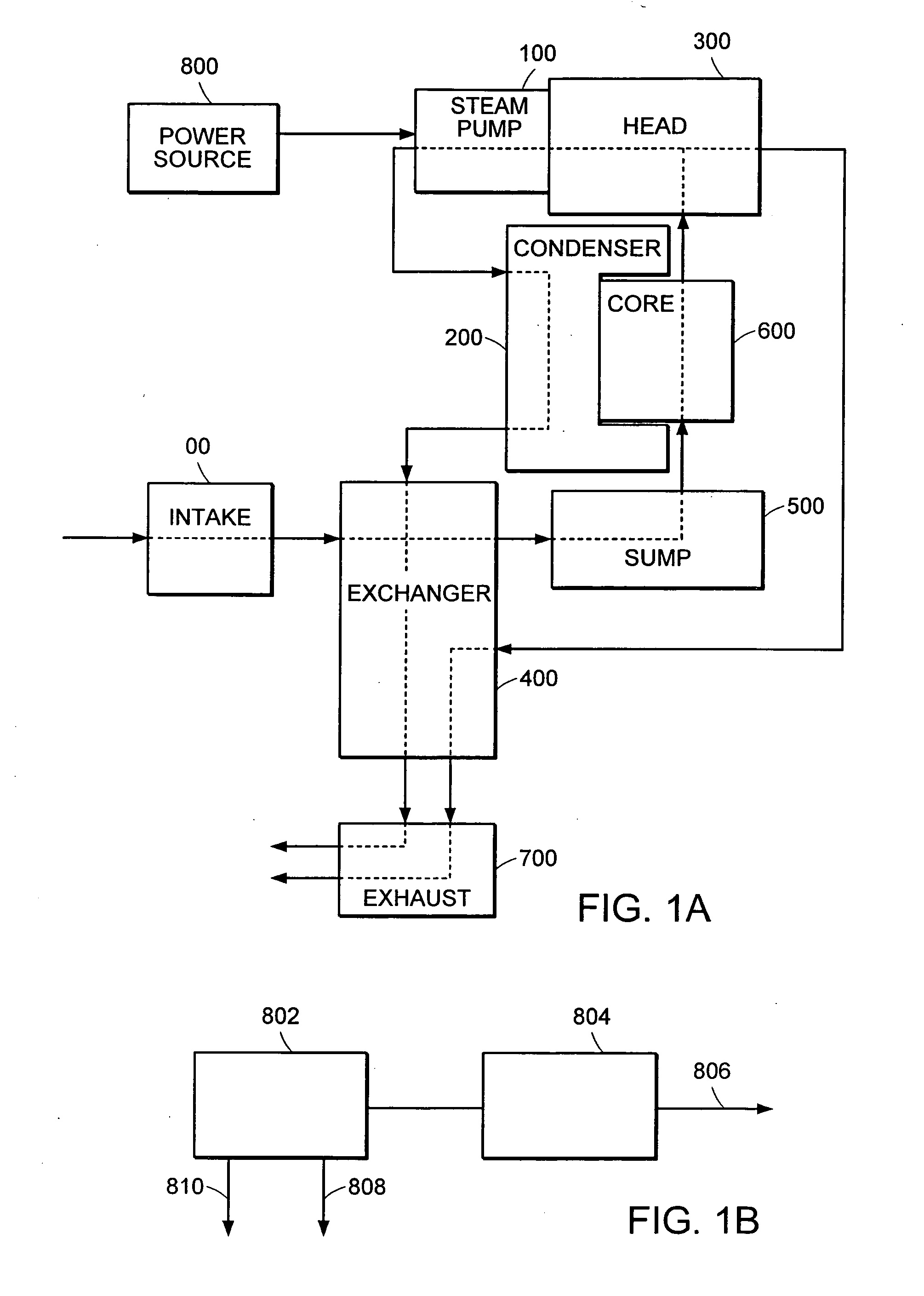

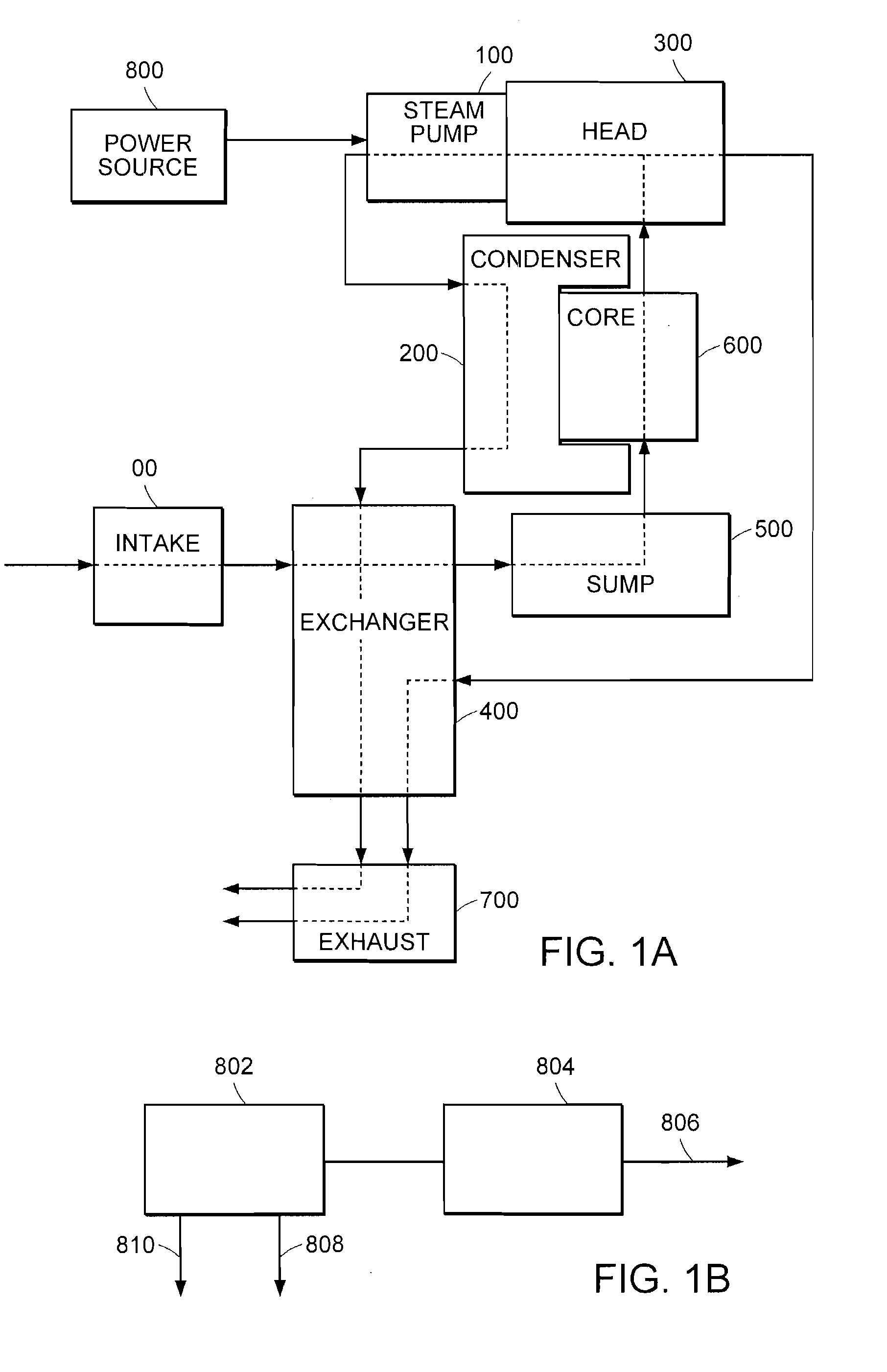

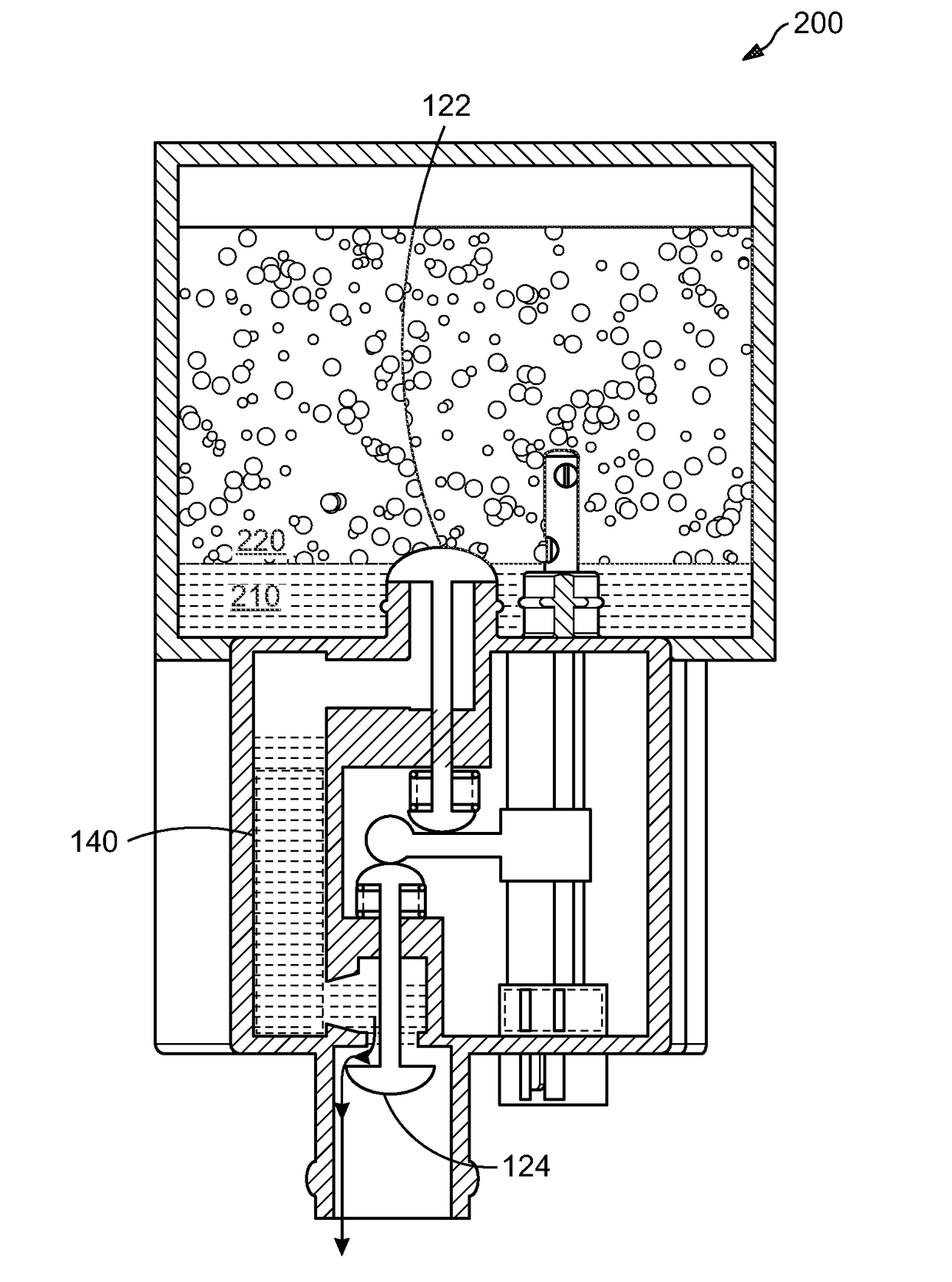

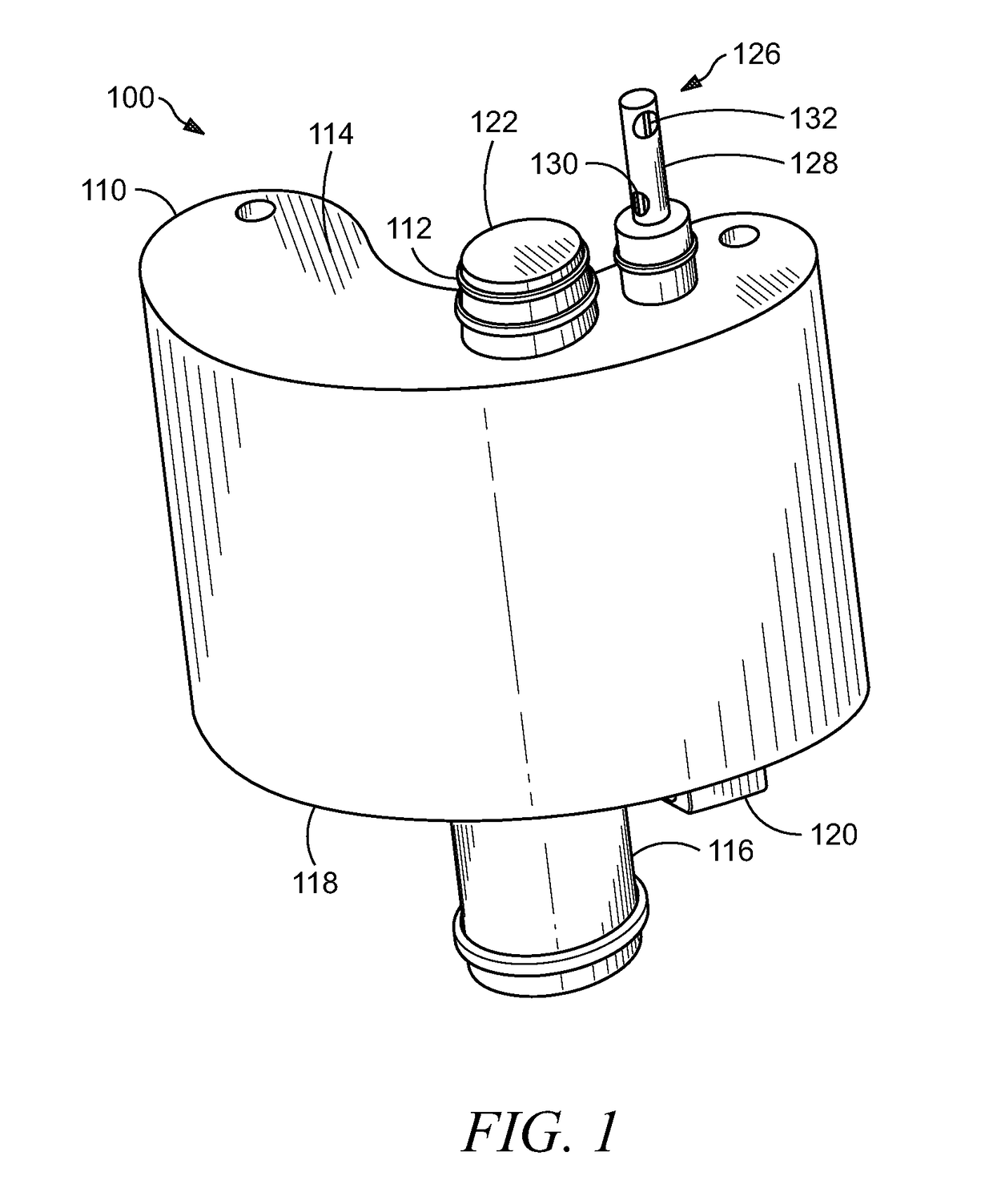

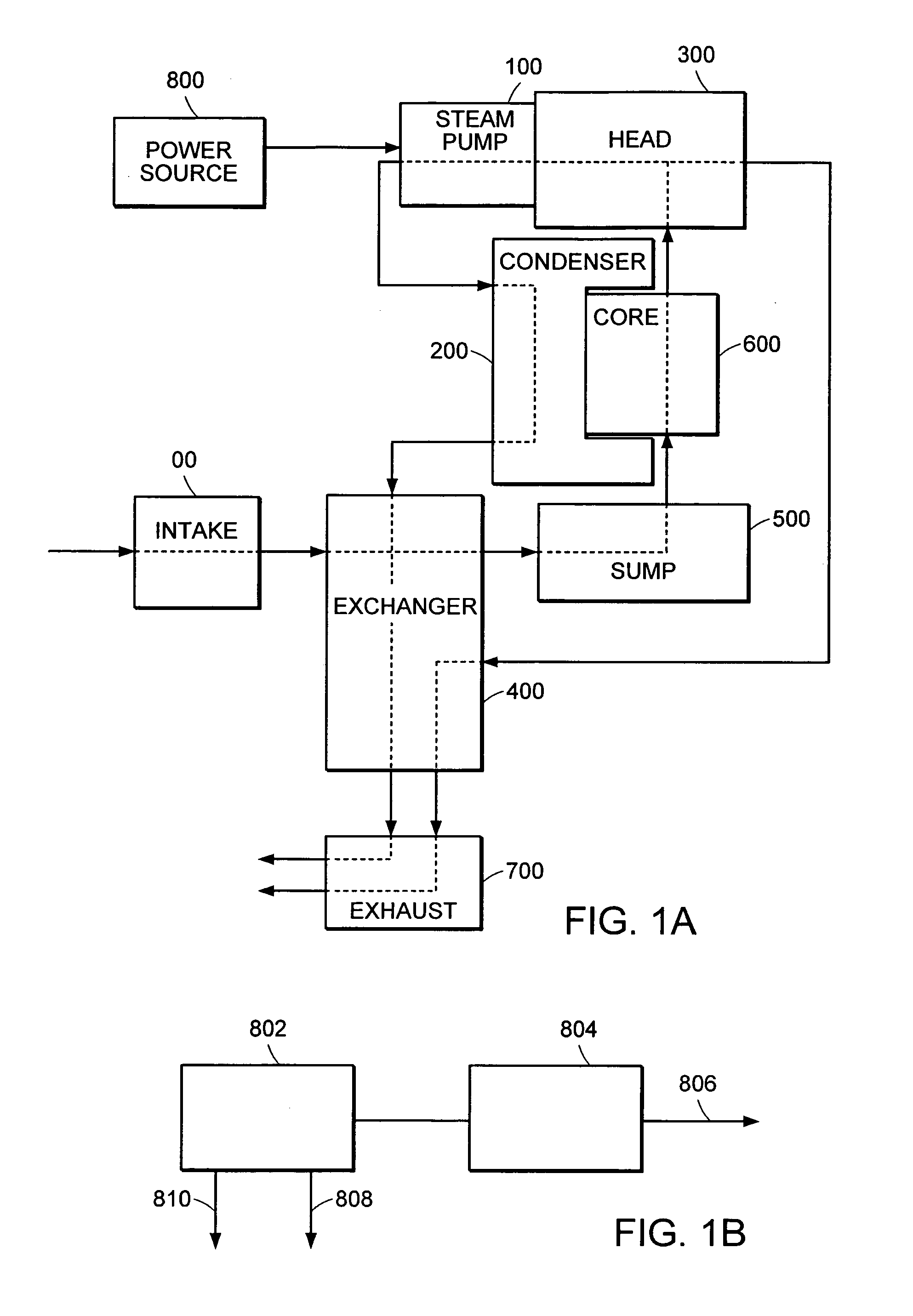

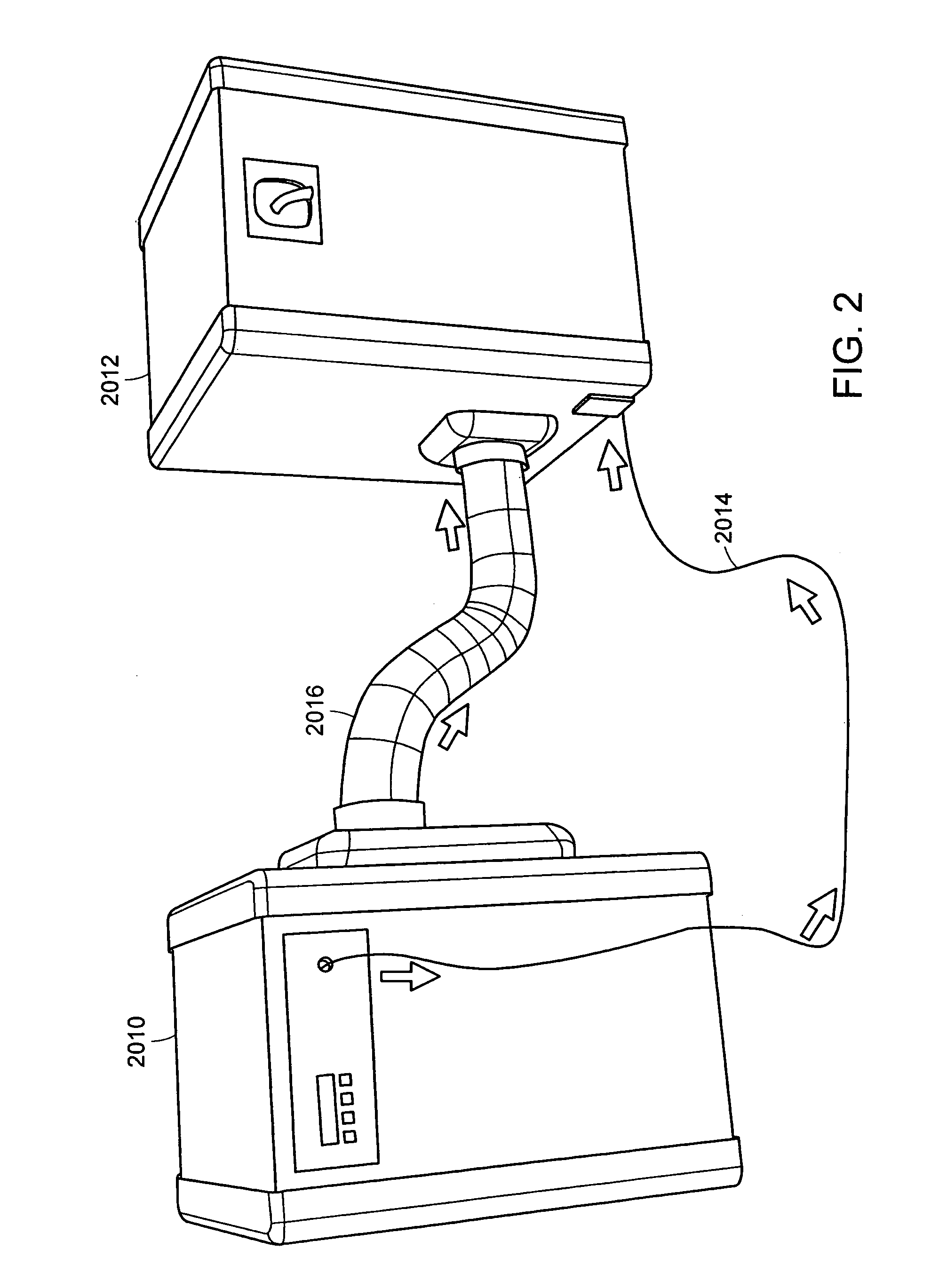

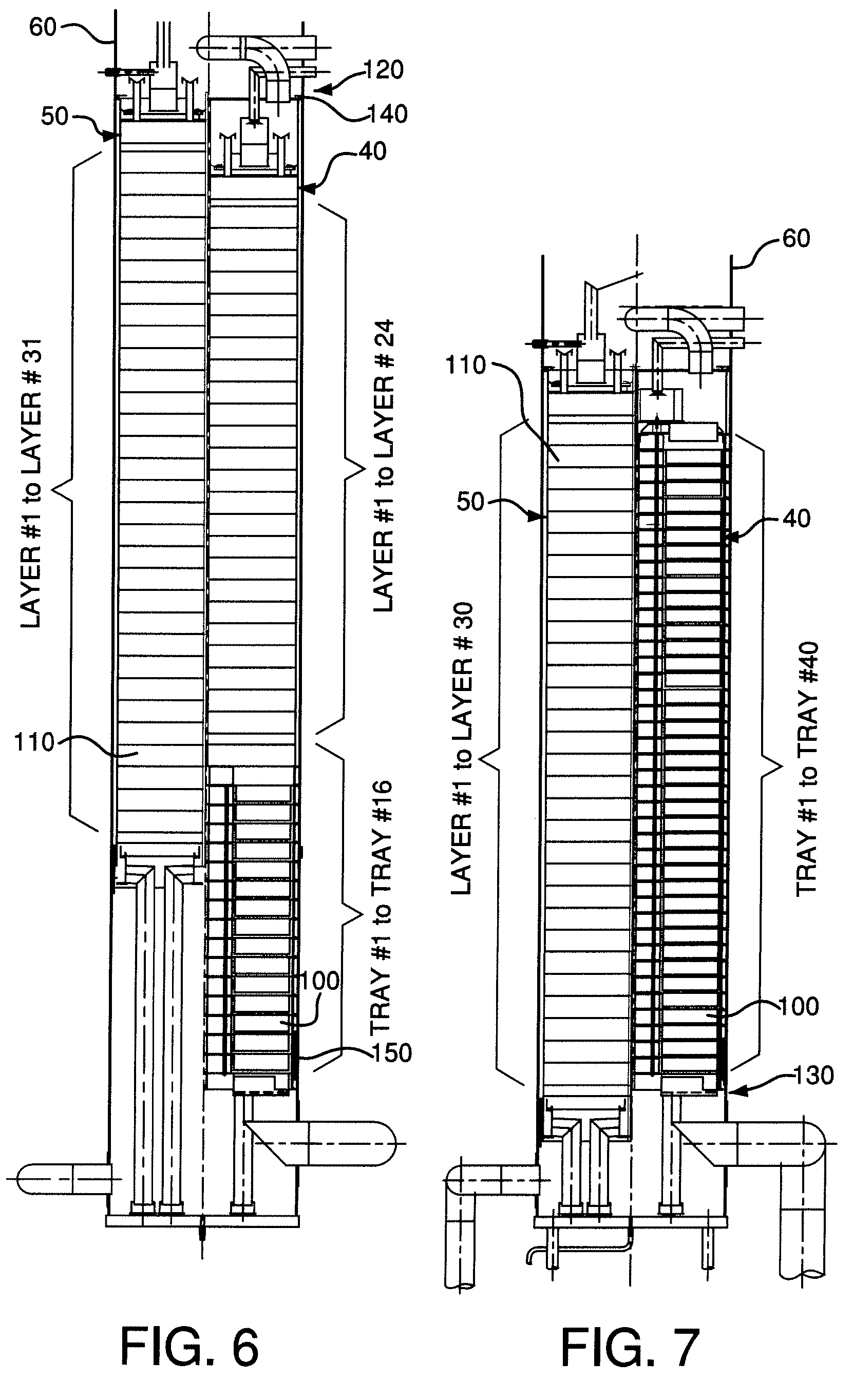

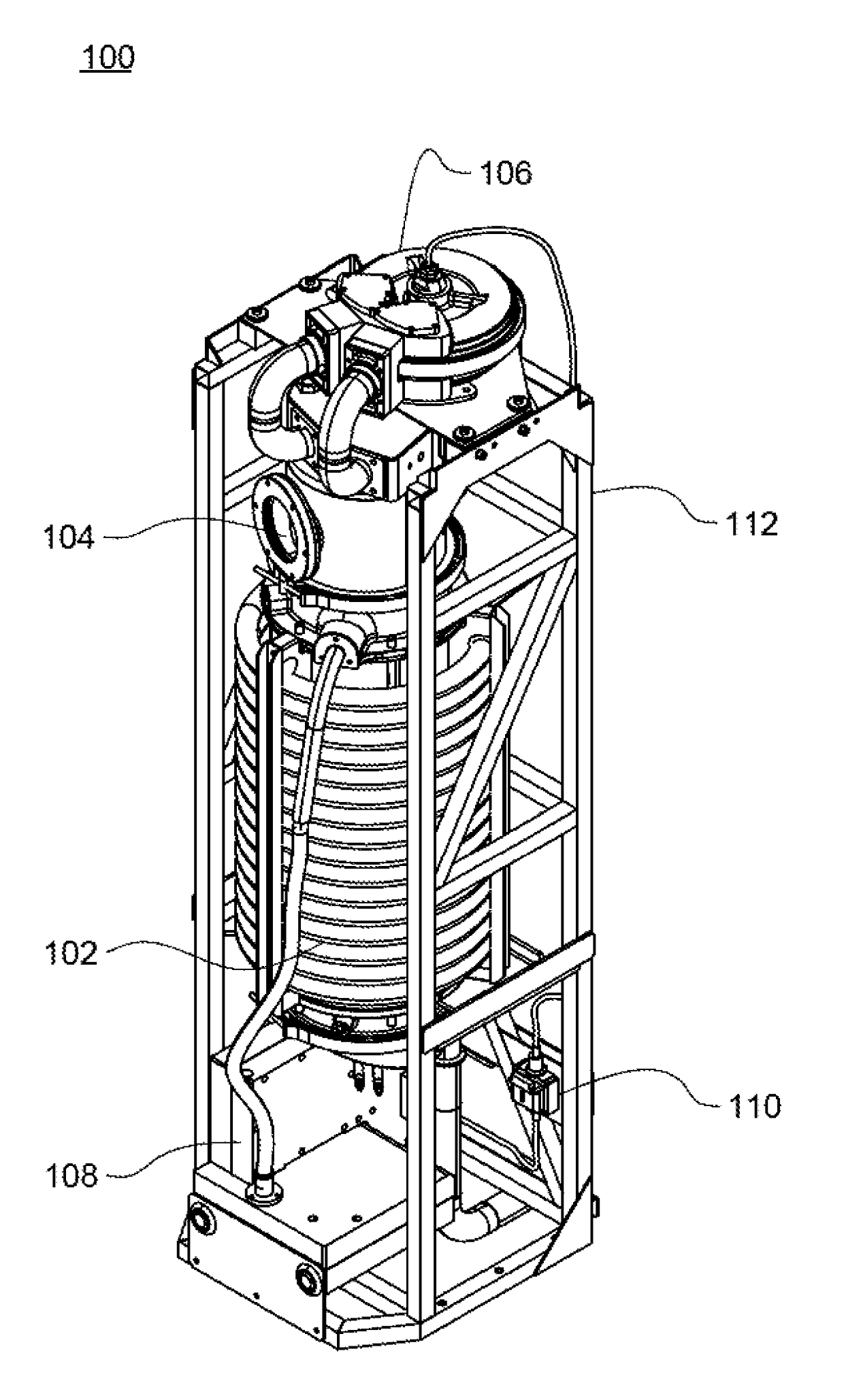

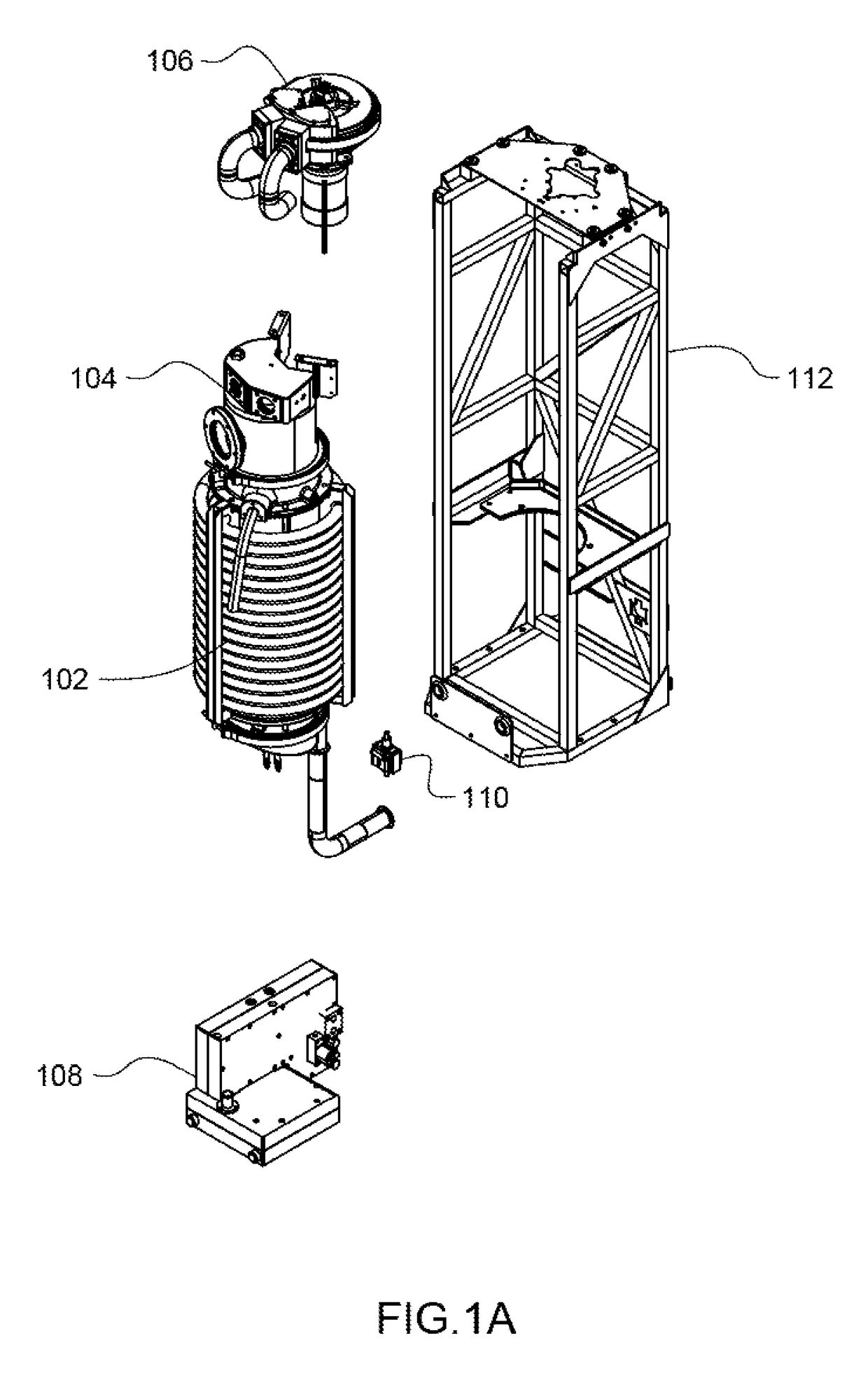

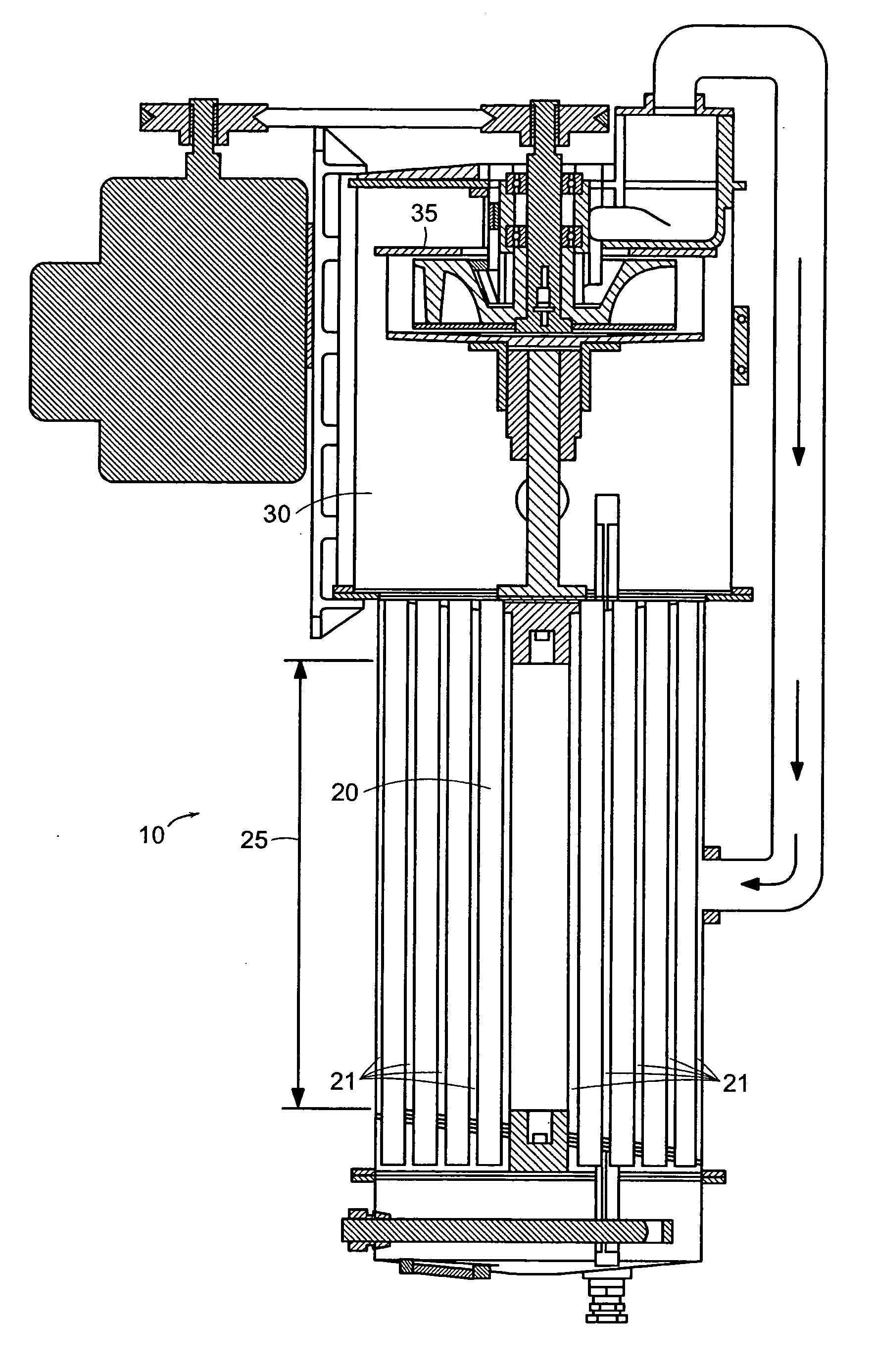

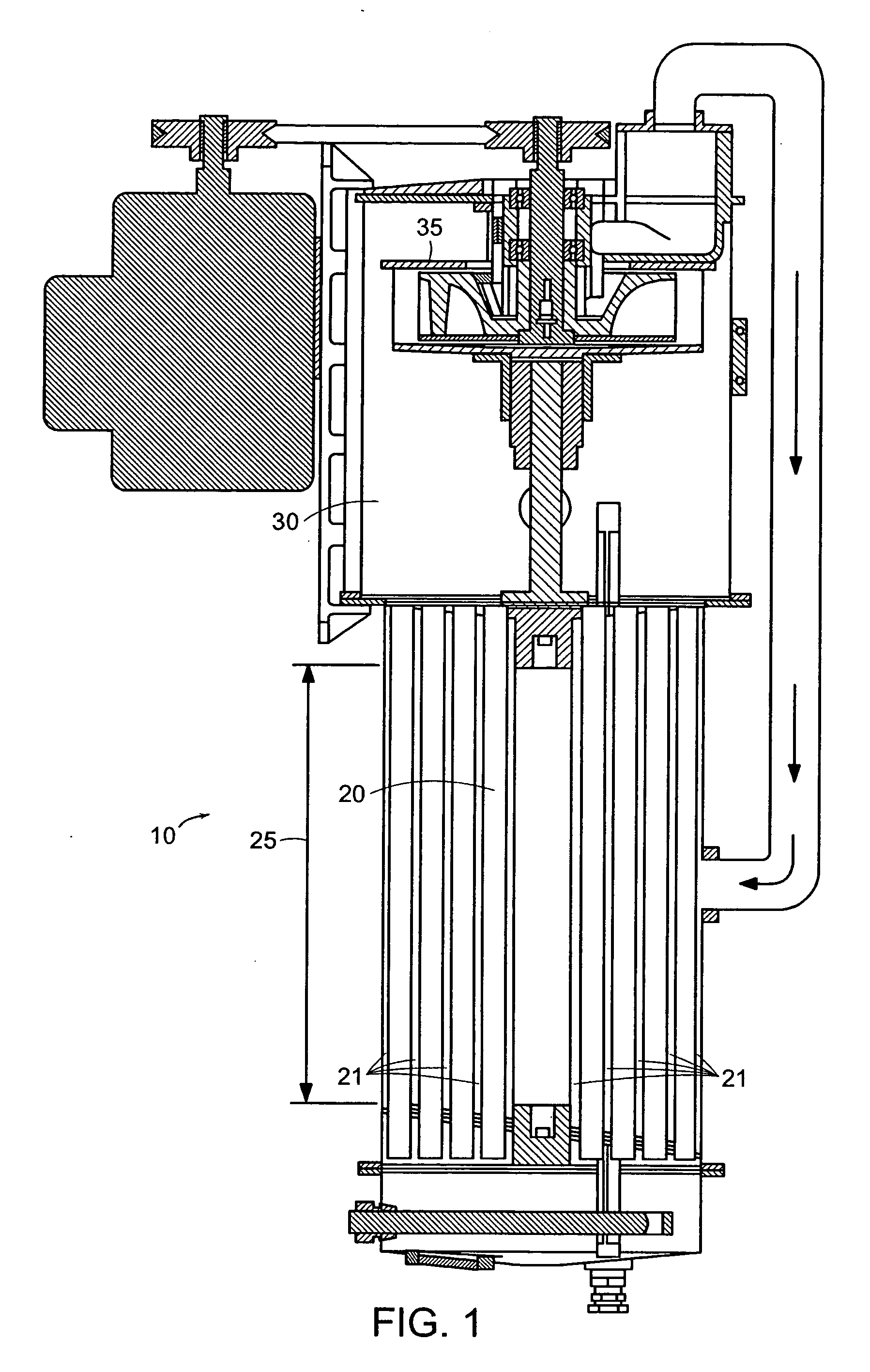

Pressurized vapor cycle liquid distillation

ActiveUS20050016828A1Easy maintenanceMaximize energy efficiencyDistillation regulation/controlUsing liquid separation agentHeat managementDrive shaft

Embodiments of the invention are directed toward a novel pressurized vapor cycle for distilling liquids. In some embodiments of the invention, a liquid purification system is revealed, including the elements of an input for receiving untreated liquid, a vaporizer coupled to the input for transforming the liquid to vapor, a head chamber for collecting the vapor, a vapor pump with an internal drive shaft and an eccentric rotor with a rotatable housing for compressing vapor, and a condenser in communication with the vapor pump for transforming the compressed vapor into a distilled product. Other embodiments of the invention are directed toward heat management, and other process enhancements for making the system especially efficient.

Owner:DEKA PROD LLP

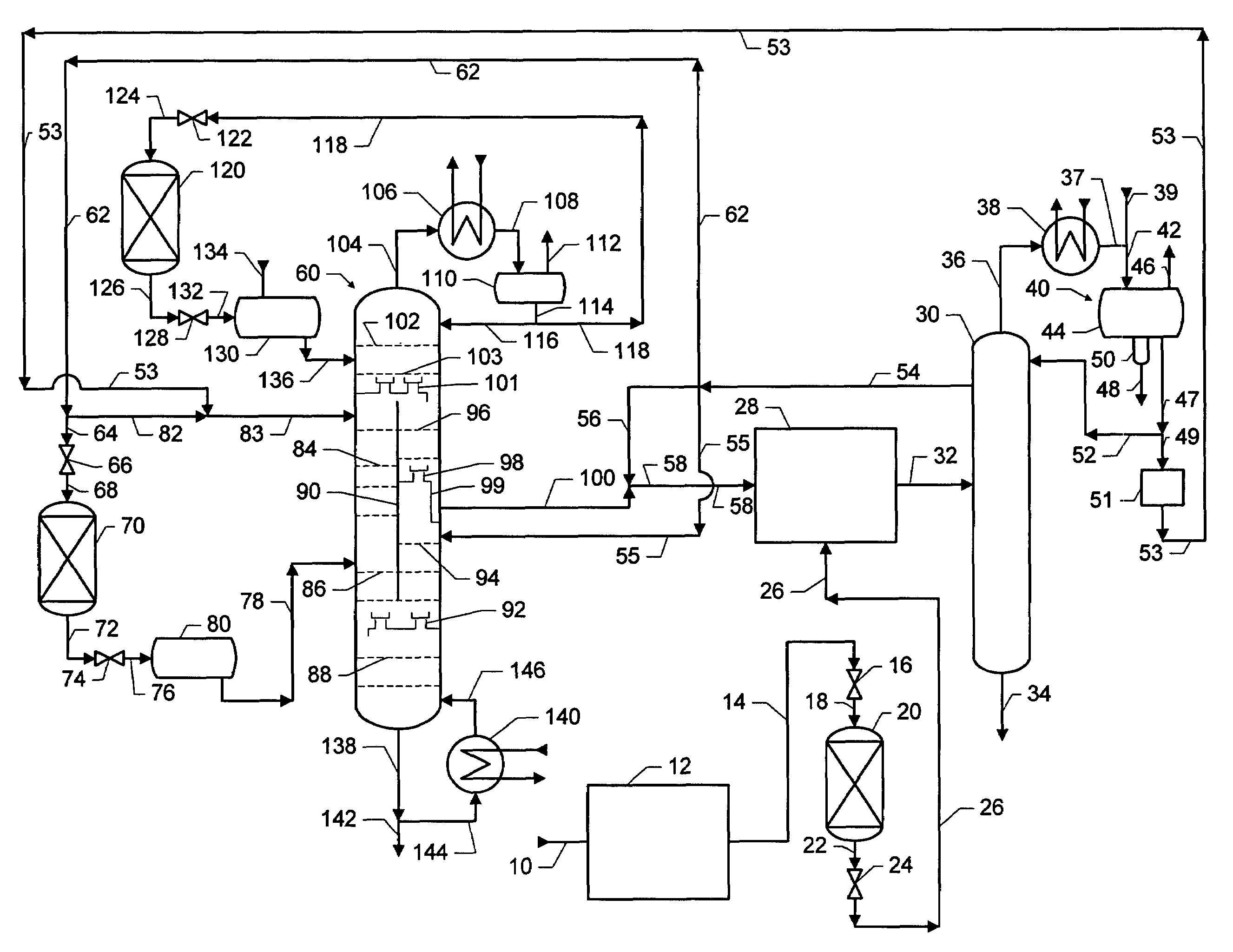

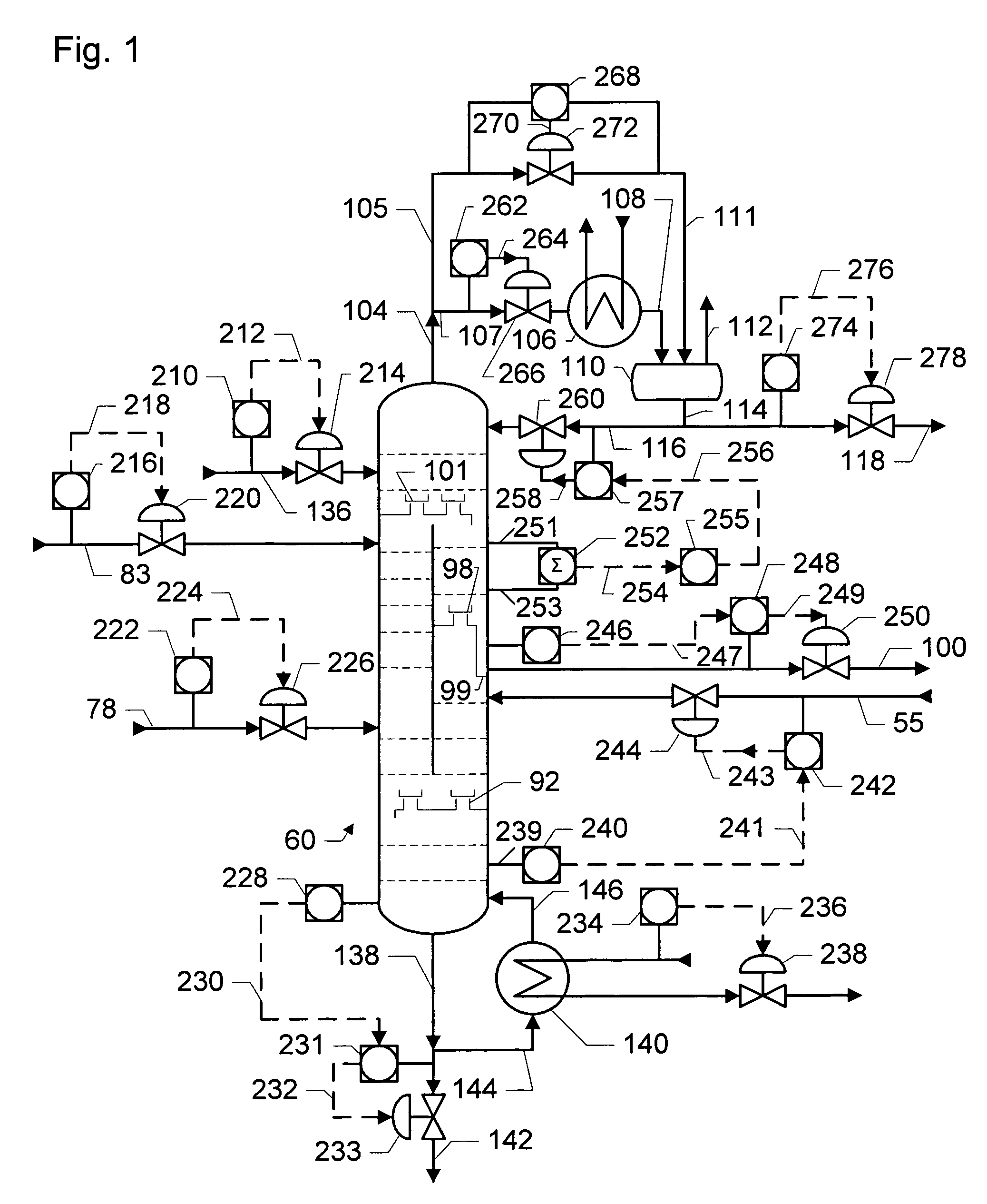

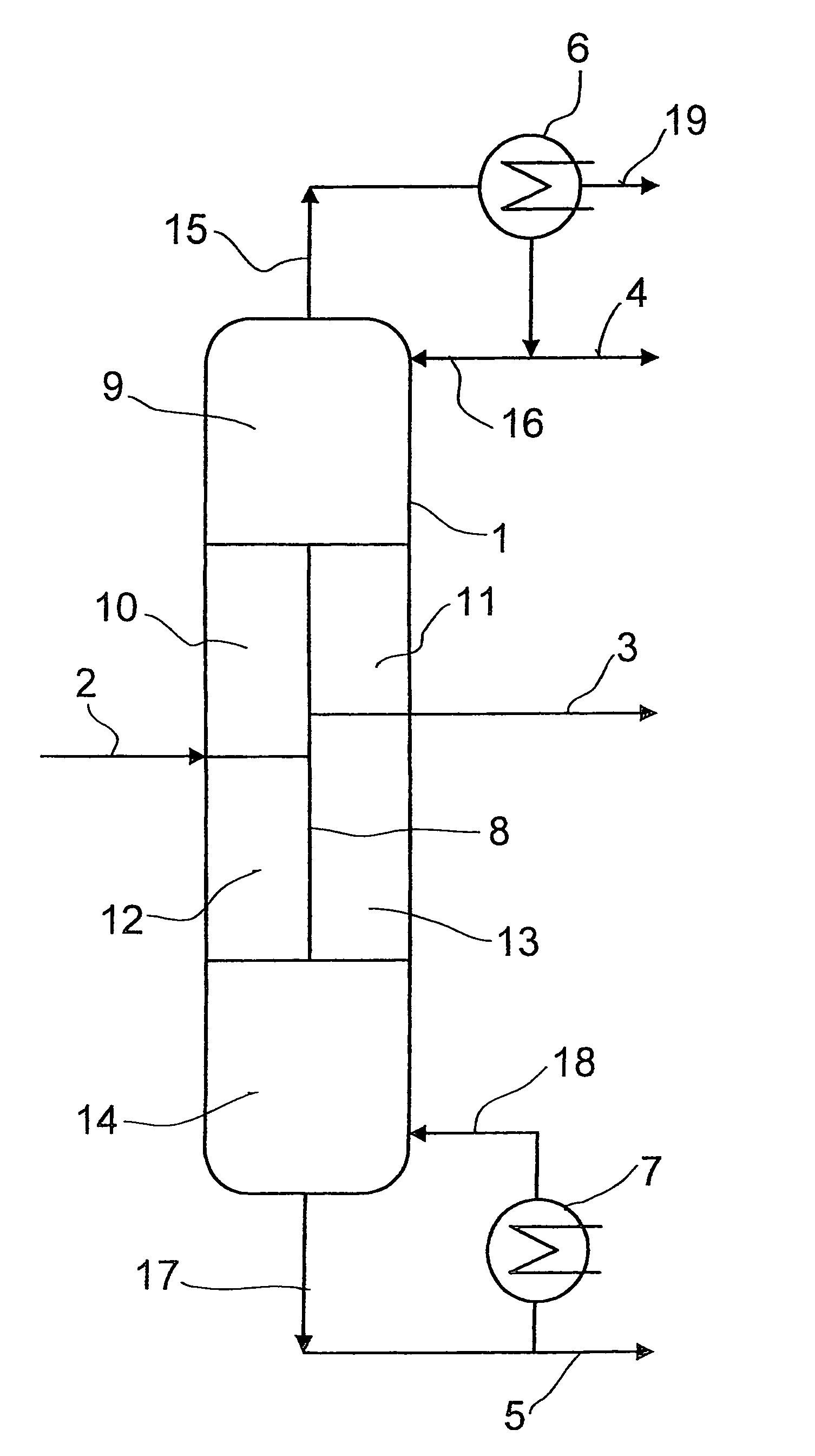

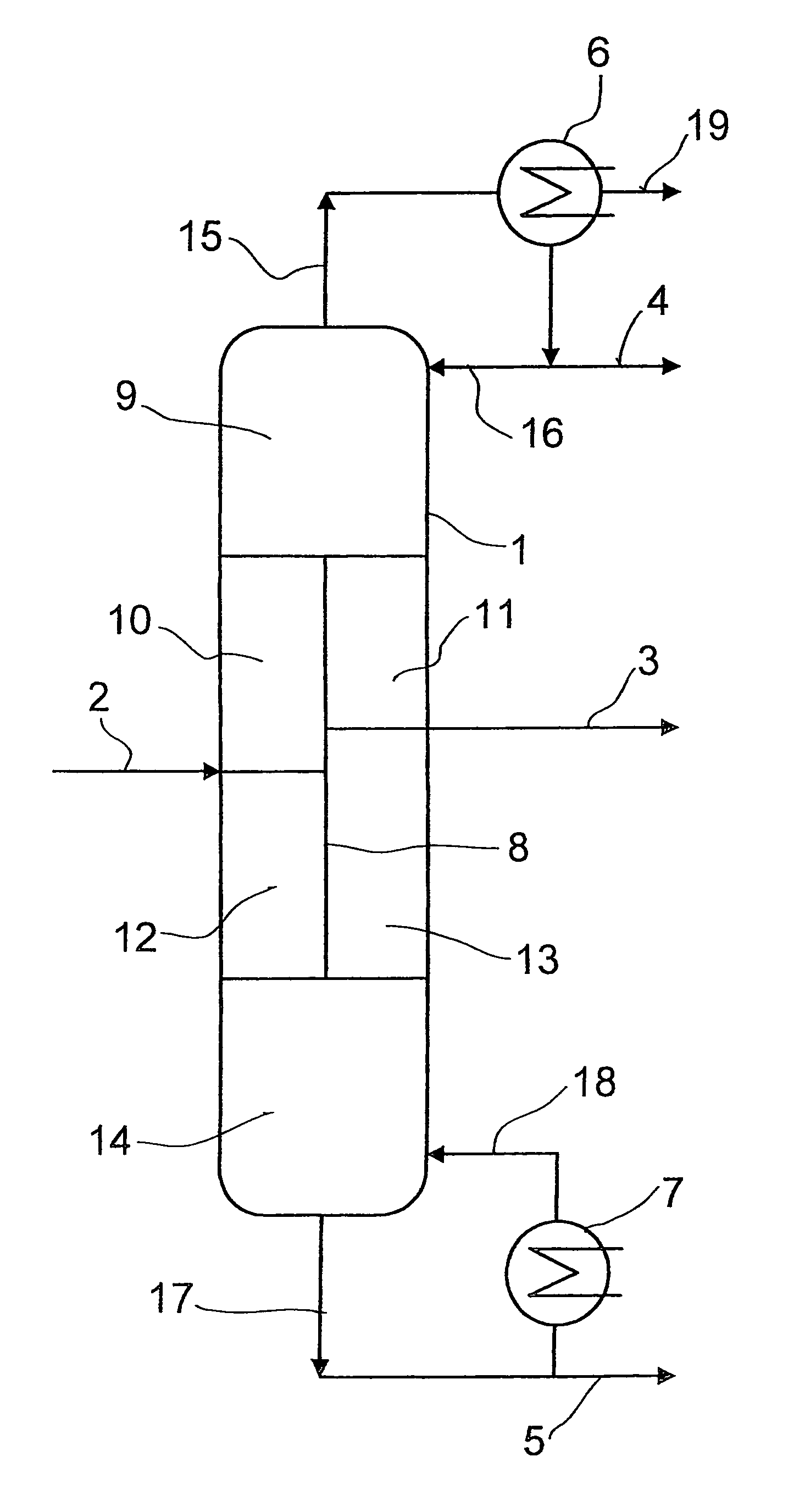

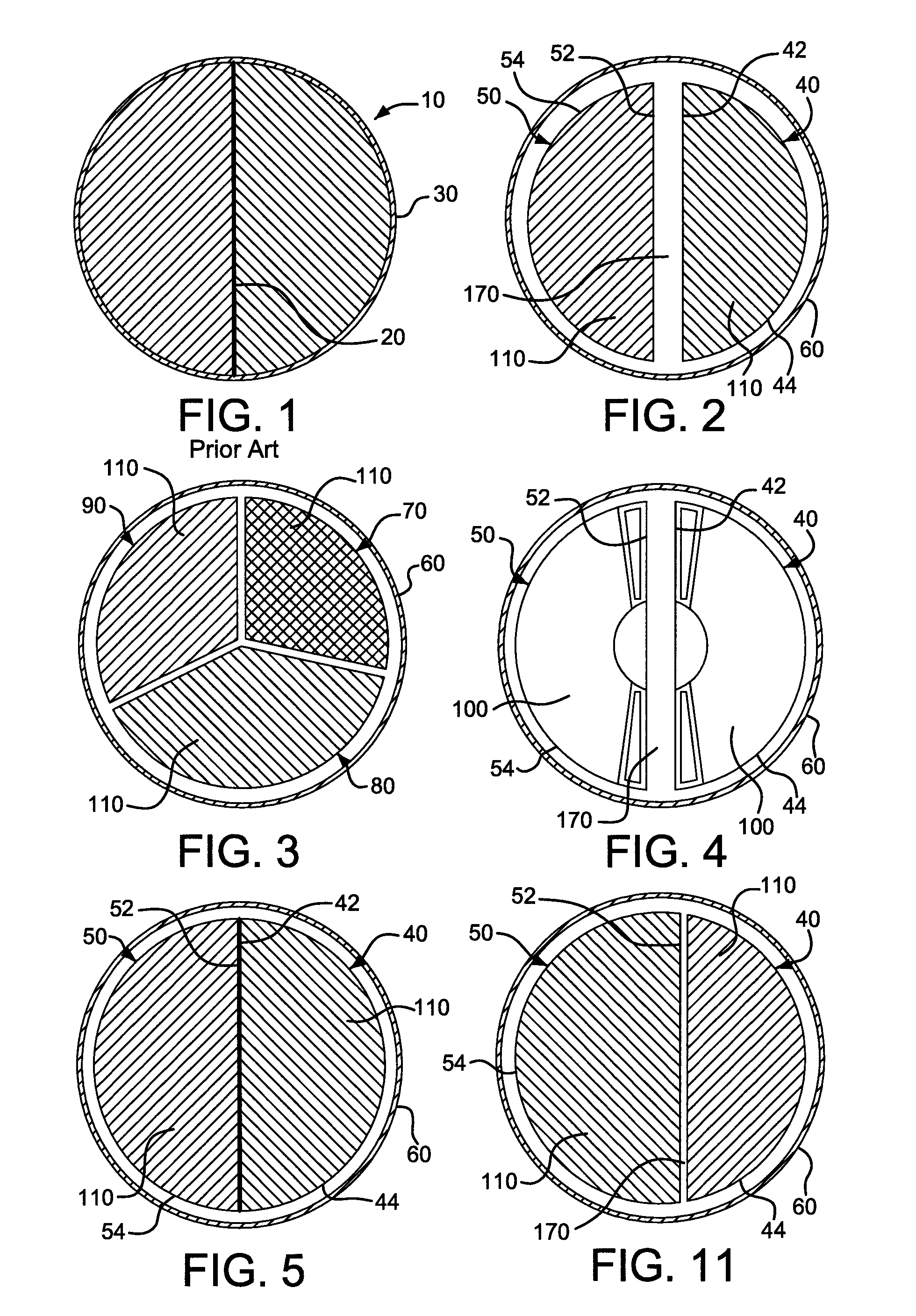

Dividing wall distillation column control apparatus

InactiveUS7267746B1Low costThermal non-catalytic crackingDistillation regulation/controlDistillationEngineering

A control apparatus and control method for controlling the separation in a dividing wall distillation column of at least two feeds into at least three products is disclosed. The apparatus uses a temperature measuring device to measure the temperature of fluid in the column, a controller, and a means for adjusting the temperature of fluid in the column. The temperature measuring device may be on either side of the dividing wall or above or below the dividing wall, and more than one such device may be used. The apparatus and method may be used in the production of alkylaromatic hydrocarbons by alkylating aromatic hydrocarbons with olefinic hydrocarbons.

Owner:UOP LLC

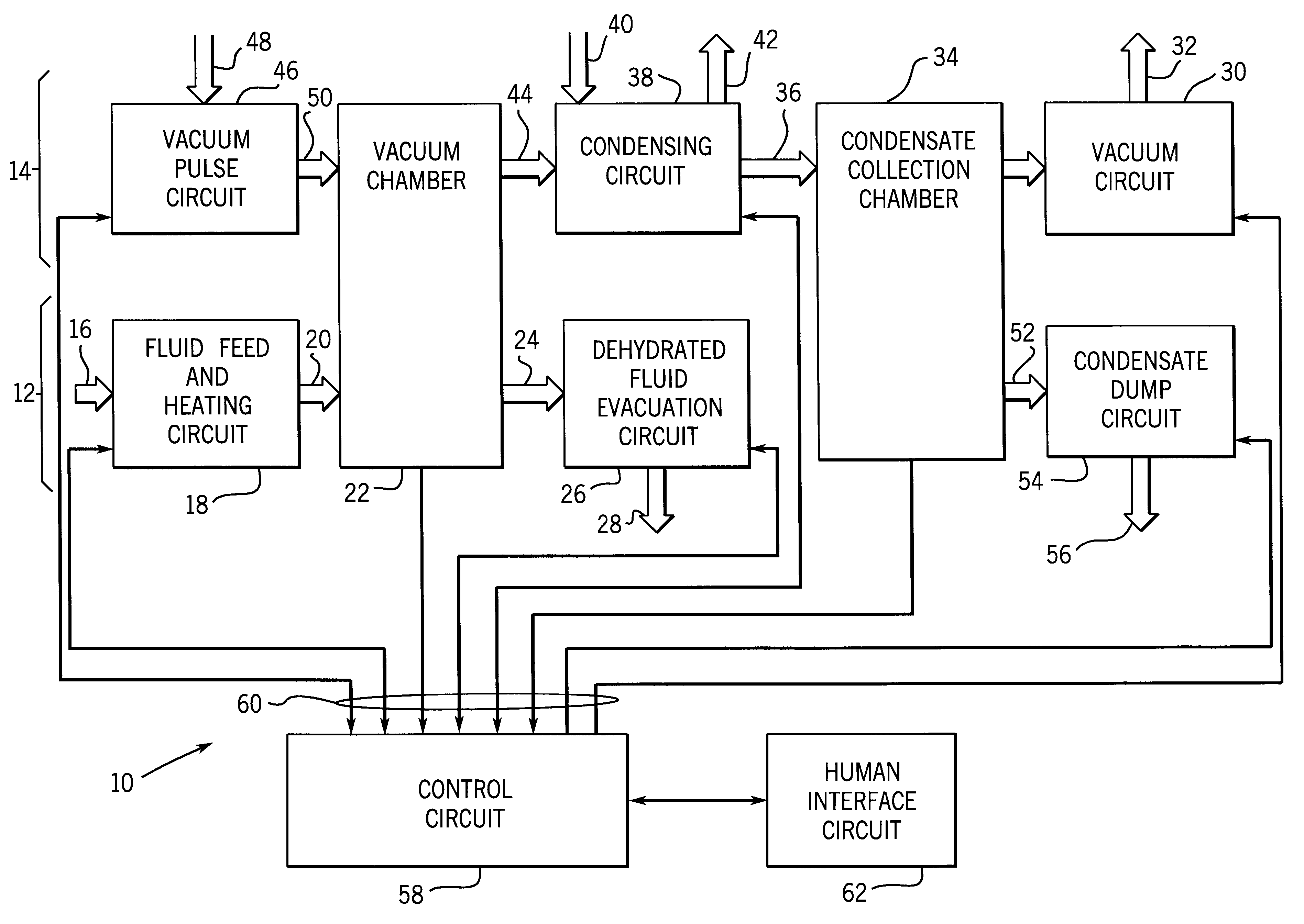

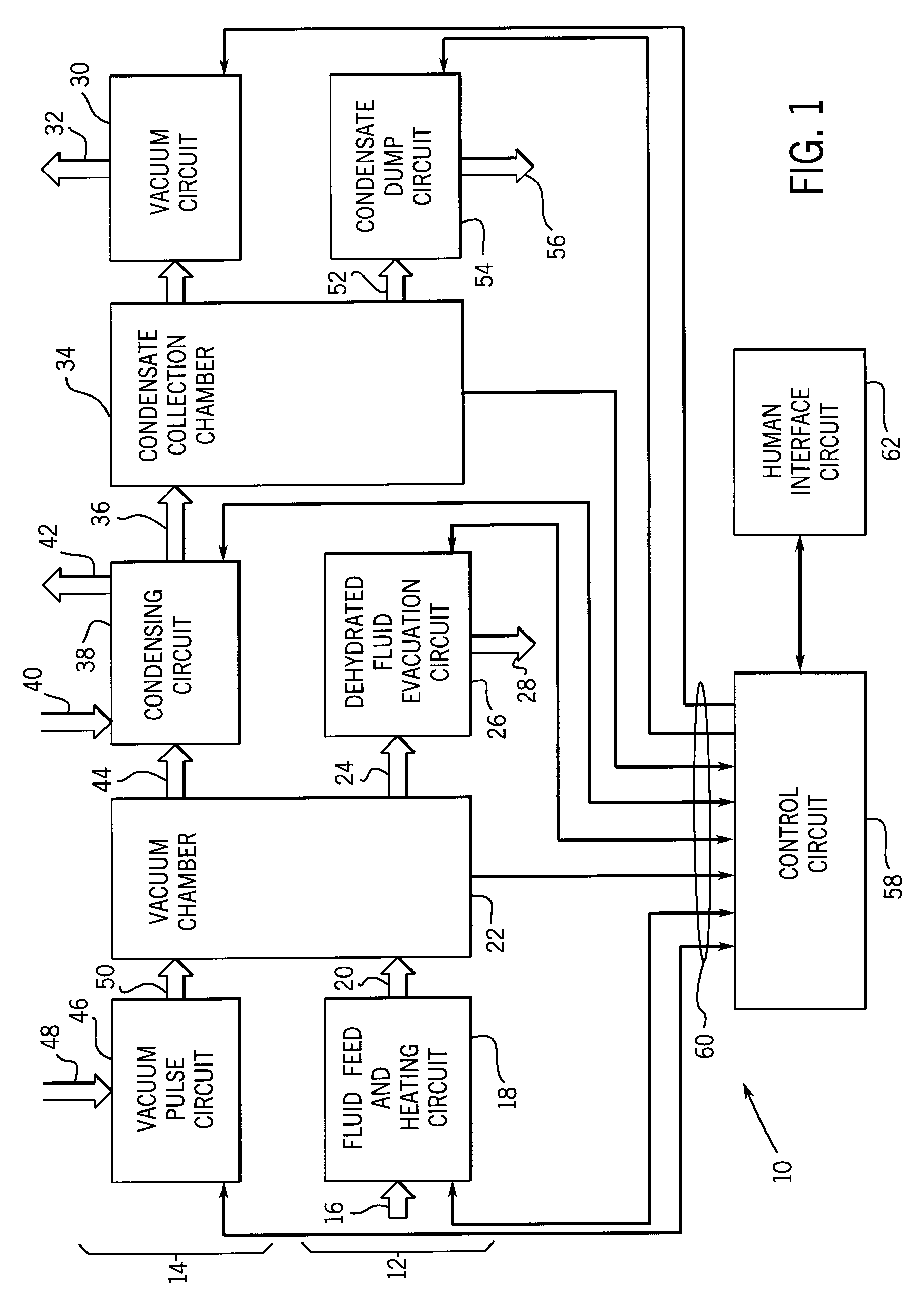

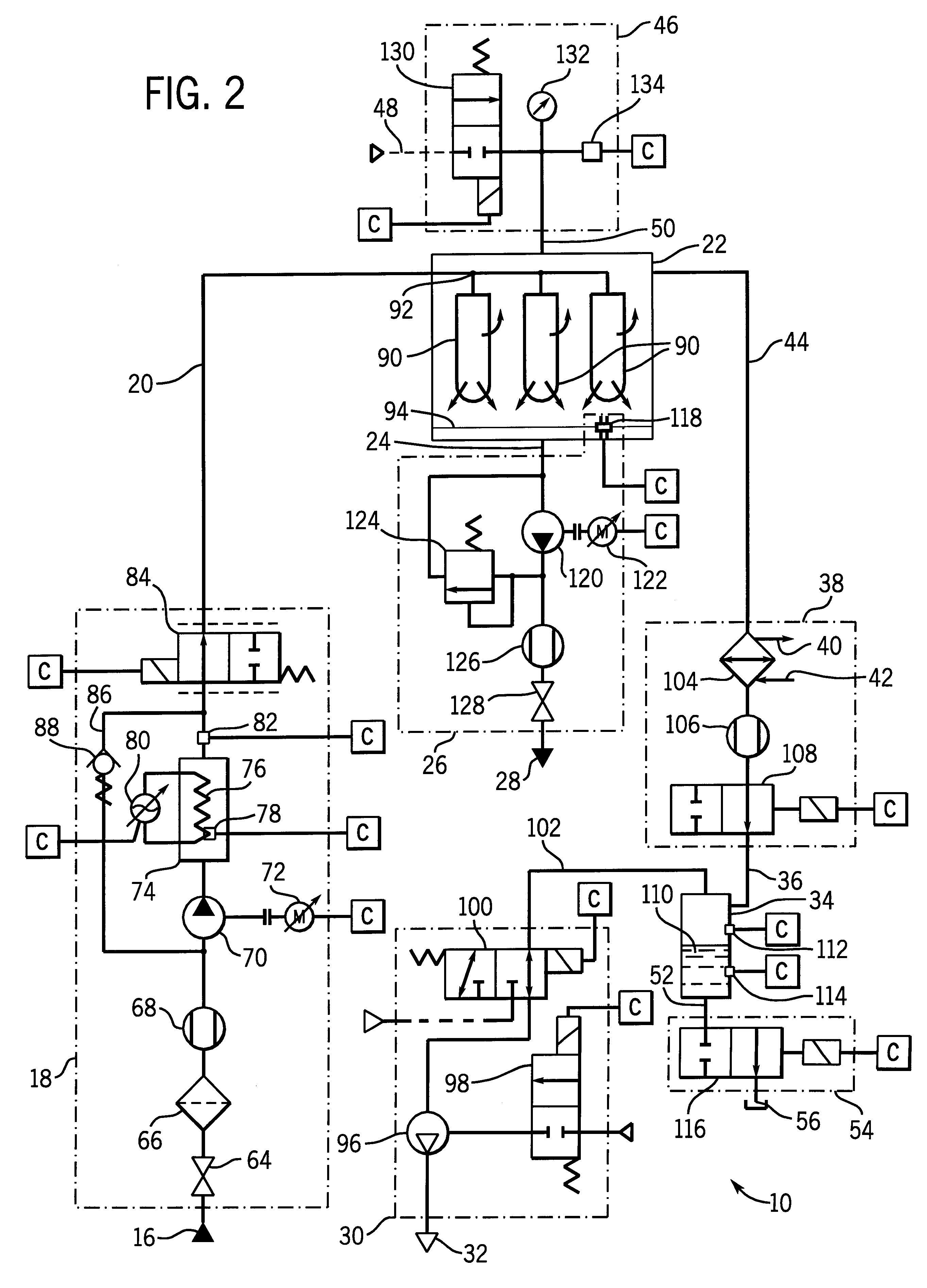

Apparatus for dehydrating oil

InactiveUS6224716B1Distillation regulation/controlEvaporation with vapour compressionVacuum pressureClosed loop

A system for dehydrating lubricating and hydraulic fluids includes a heating circuit and circuitry for creating a vacuum. The heating circuitry introduces a stream of heated fluid into a vacuum chamber in which a partial vacuum is drawn by the vacuum circuit. Aqueous components of the fluid stream are flashed in the vacuum chamber by virtue of the elevated temperature and reduced pressure. Dehydrated fluid is then collected and evacuated from the vacuum chamber. Vapor from the vacuum chamber, including the aqueous components of the fluid stream are collected, condensed and separately evacuated. The heating circuit limits surface temperature of a heating element in a closed-loop manner to avoid degradation of the fluid. The fluid stream is introduced into the vacuum chamber or is recirculated through the heating circuit to maintain a desired level of fluid temperature in a closed-loop manner. The system includes circuits for evacuating dehydrated fluid in a closed-loop manner and for automatically discharging condensate. The technique avoids undesirable foaming of dehydrated fluid within the vacuum chamber. A vacuum pulsing circuit is provided for periodically pulsing vacuum pressure within the vacuum chamber to aid in flashing aqueous components from the heated fluid stream.

Owner:OILQUIP

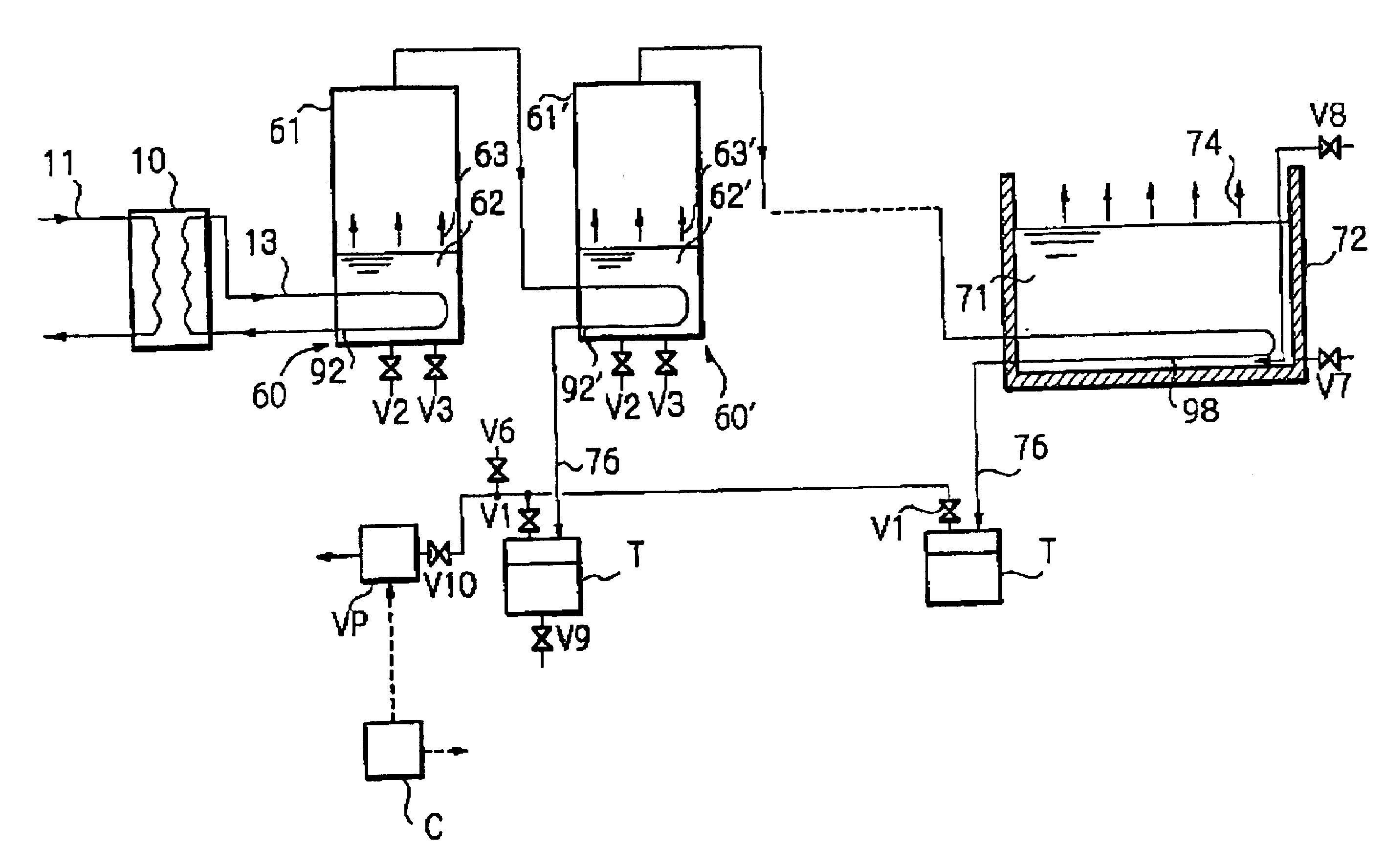

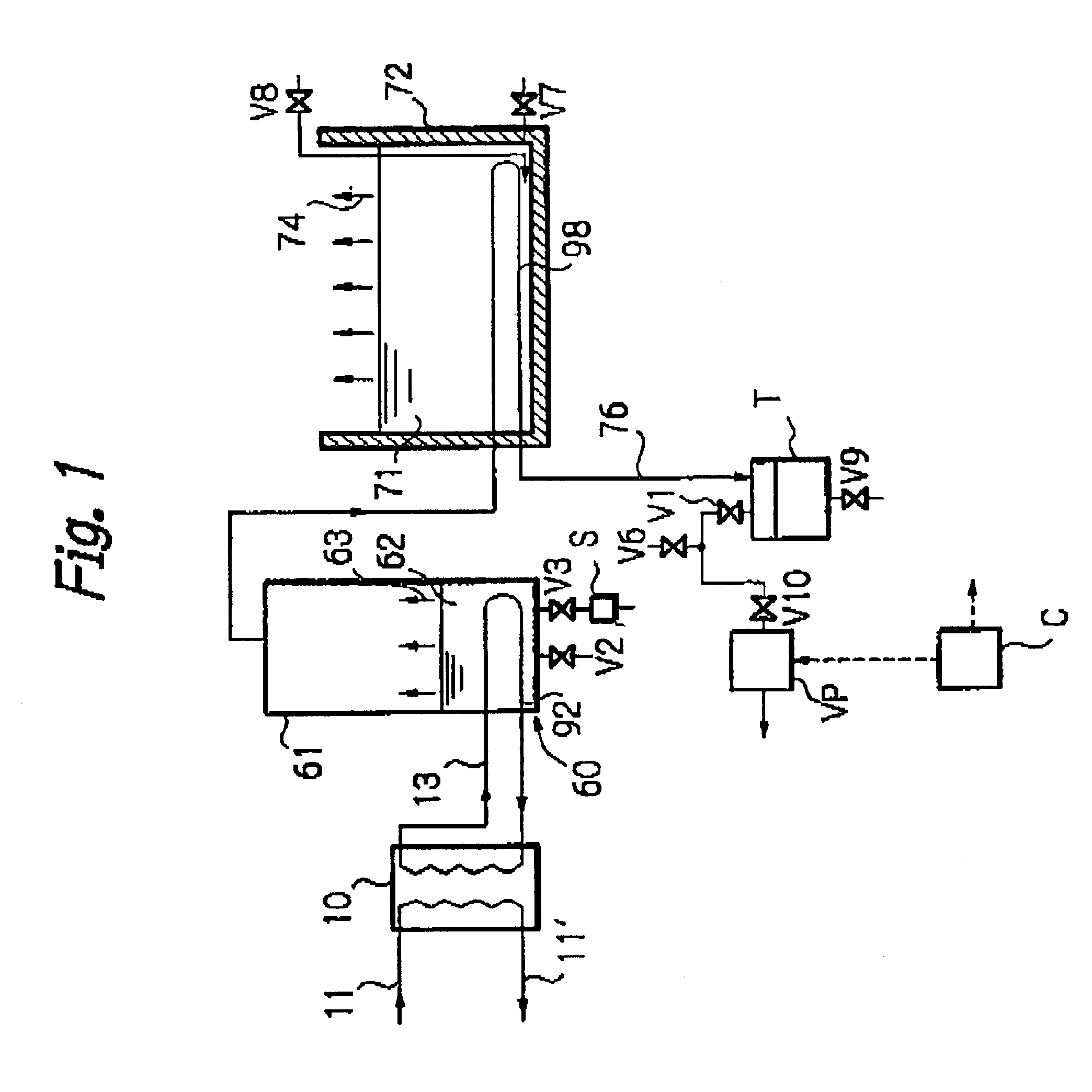

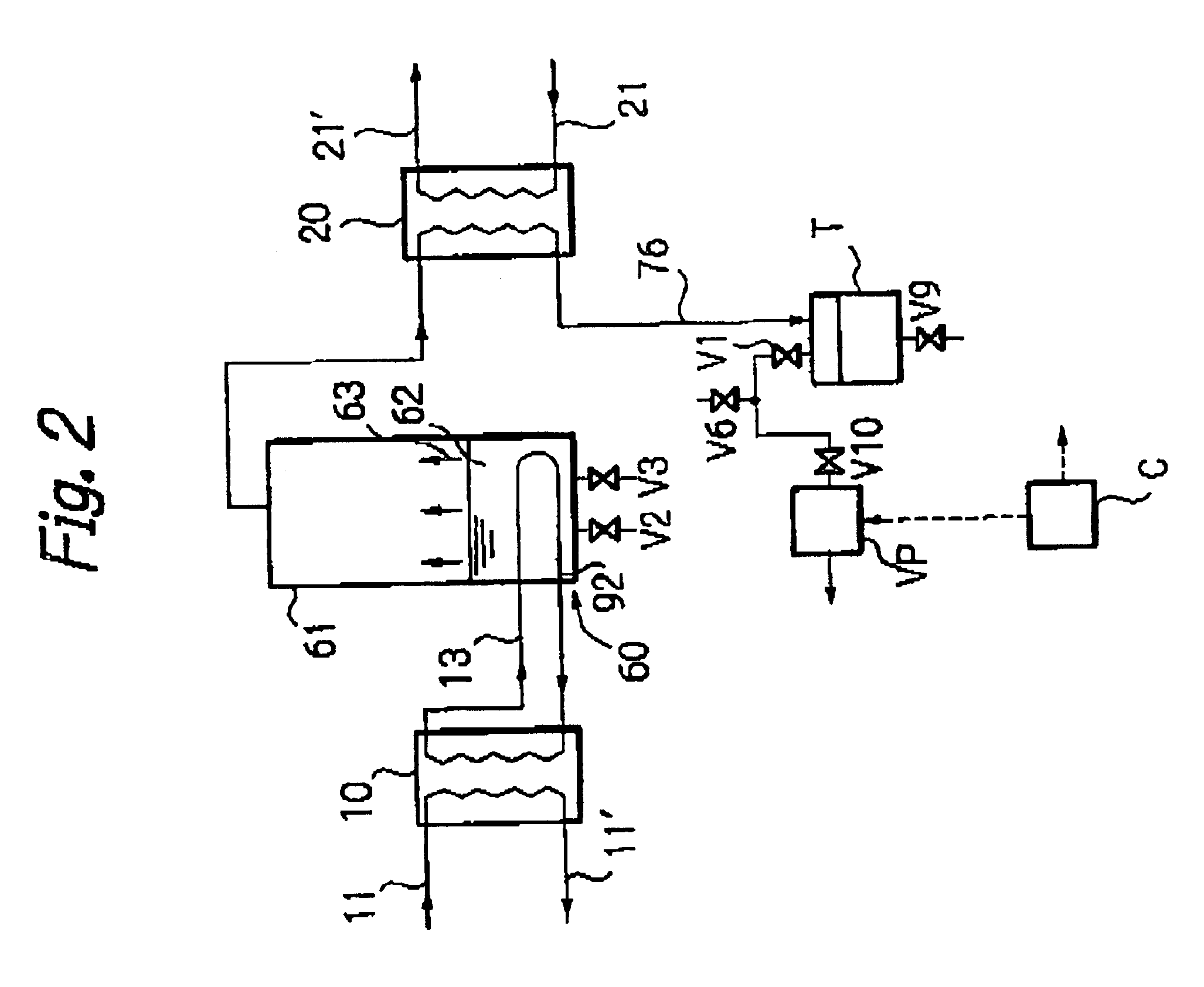

Desalination method and desalination apparatus

InactiveUS6833056B1Number of stage increasingIncrease the number ofAuxillariesGeneral water supply conservationDesalinationDistilled water

A desalination apparatus capable of obtaining fresh water stably at low cost by utilizing low-temperature waste, wherein the desalination apparatus including a heat exchanger 92 cooperating with an evaporation can 60 so as to subject a low-temperature waste heat 11 and raw water 62 in the evaporation can 60 to heat exchange and generate water vapor 63 in the evaporation can 60; a condenser 98 cooperating with a raw water tank 72 so as to receive the water vapor 63 from the evaporation can 60, cool the water vapor 63 by subjecting the water vapor 63 and raw water 71 in the raw water tank 72 to heat exchange and obtain distilled water 76; a distilled water tank for storing the distilled water 76; vacuum means for evacuating the evaporation can 60 and depressurizing the inside thereof so as to promote generation of water vapor 63 in the evaporation can 60; and raw water supply means for supplying raw water to the evaporation can.

Owner:EBARA CORP

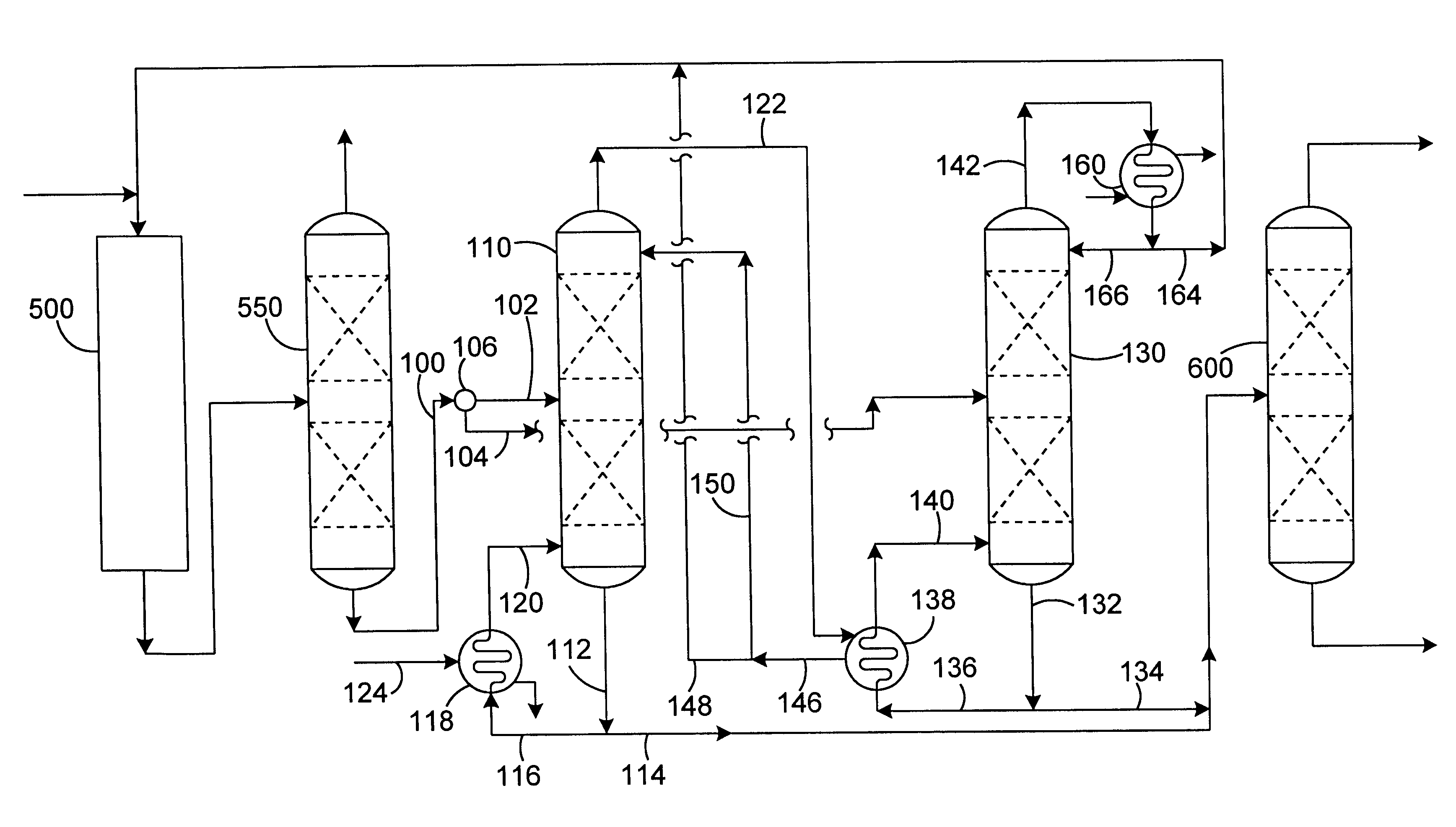

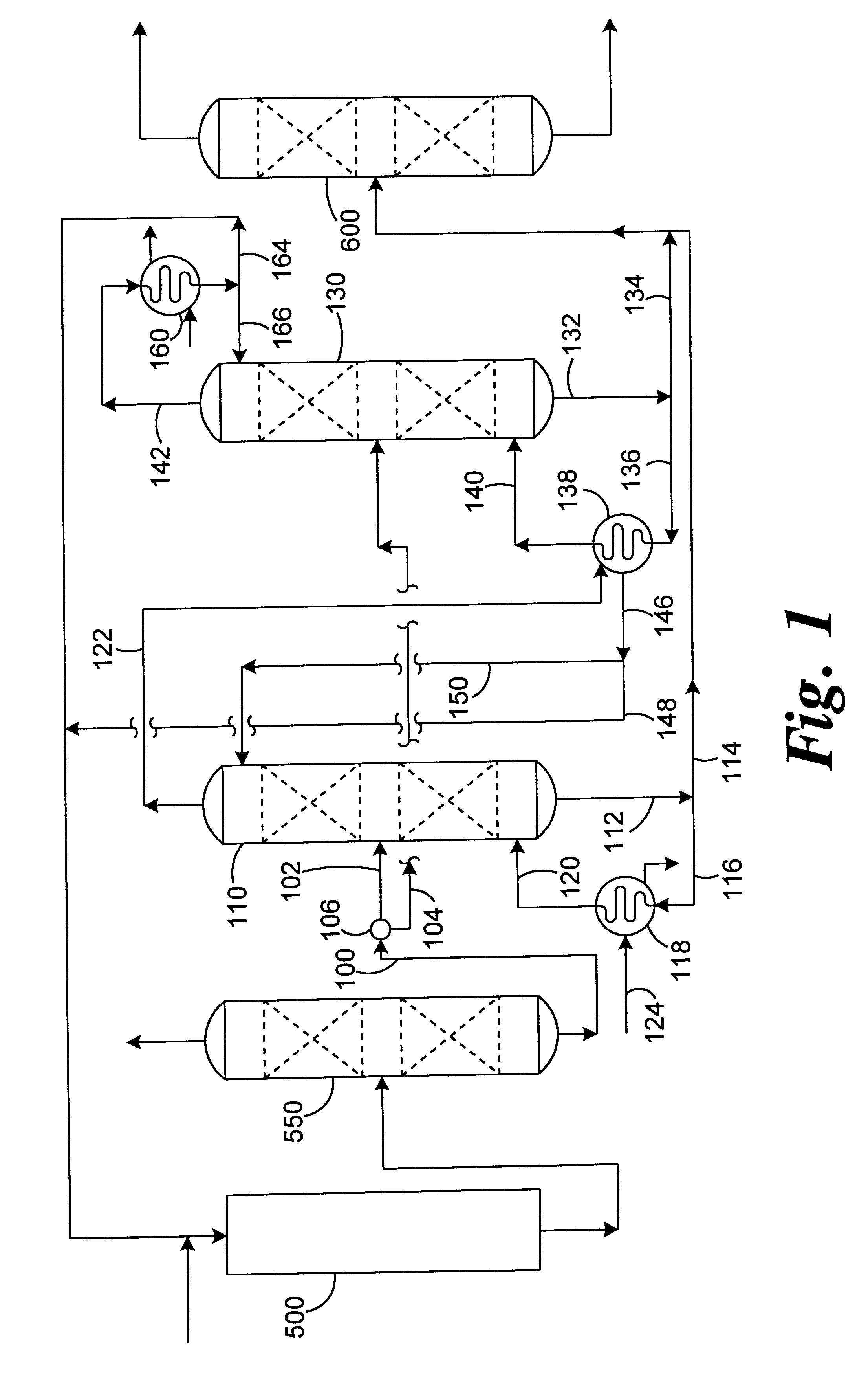

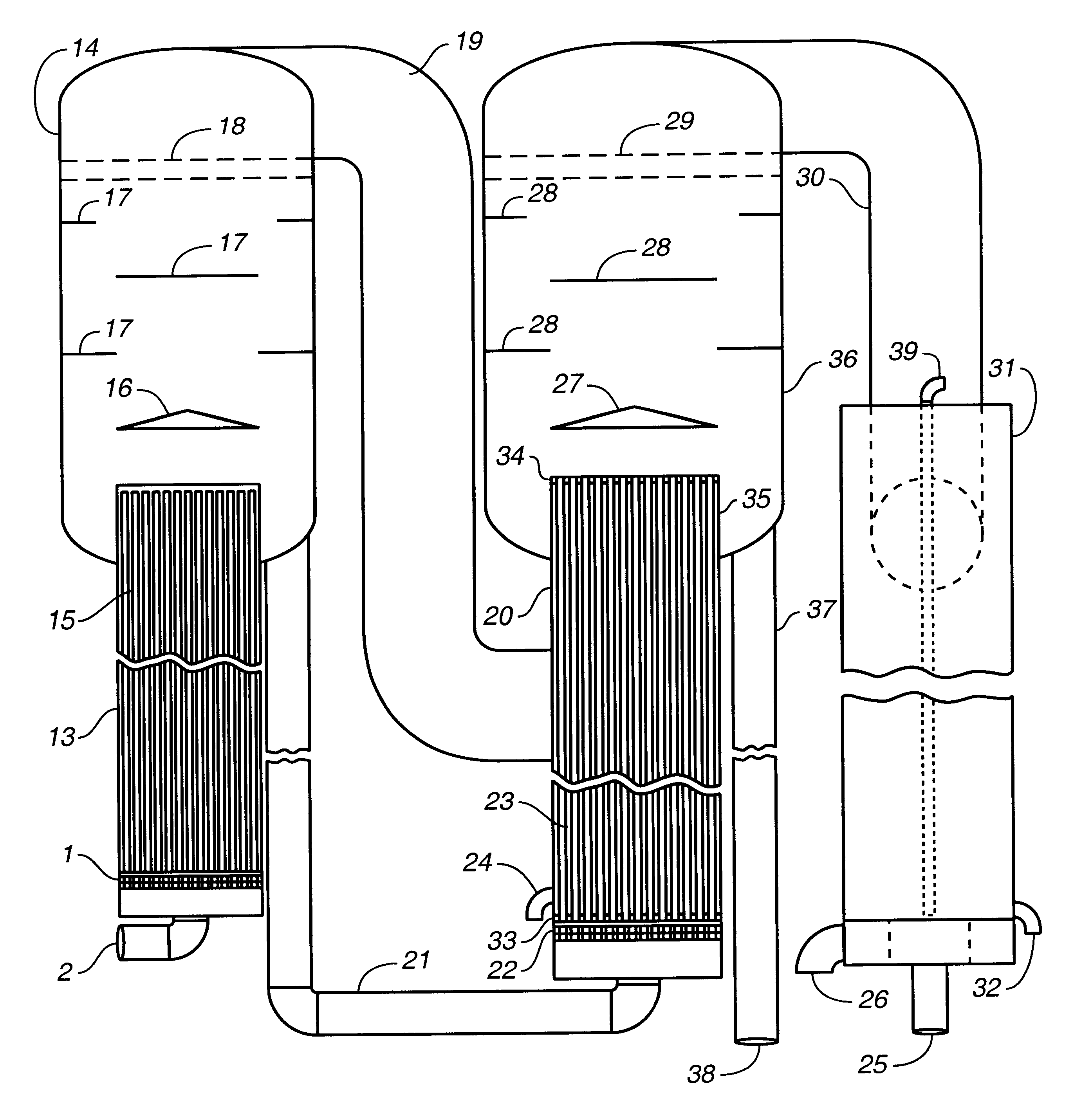

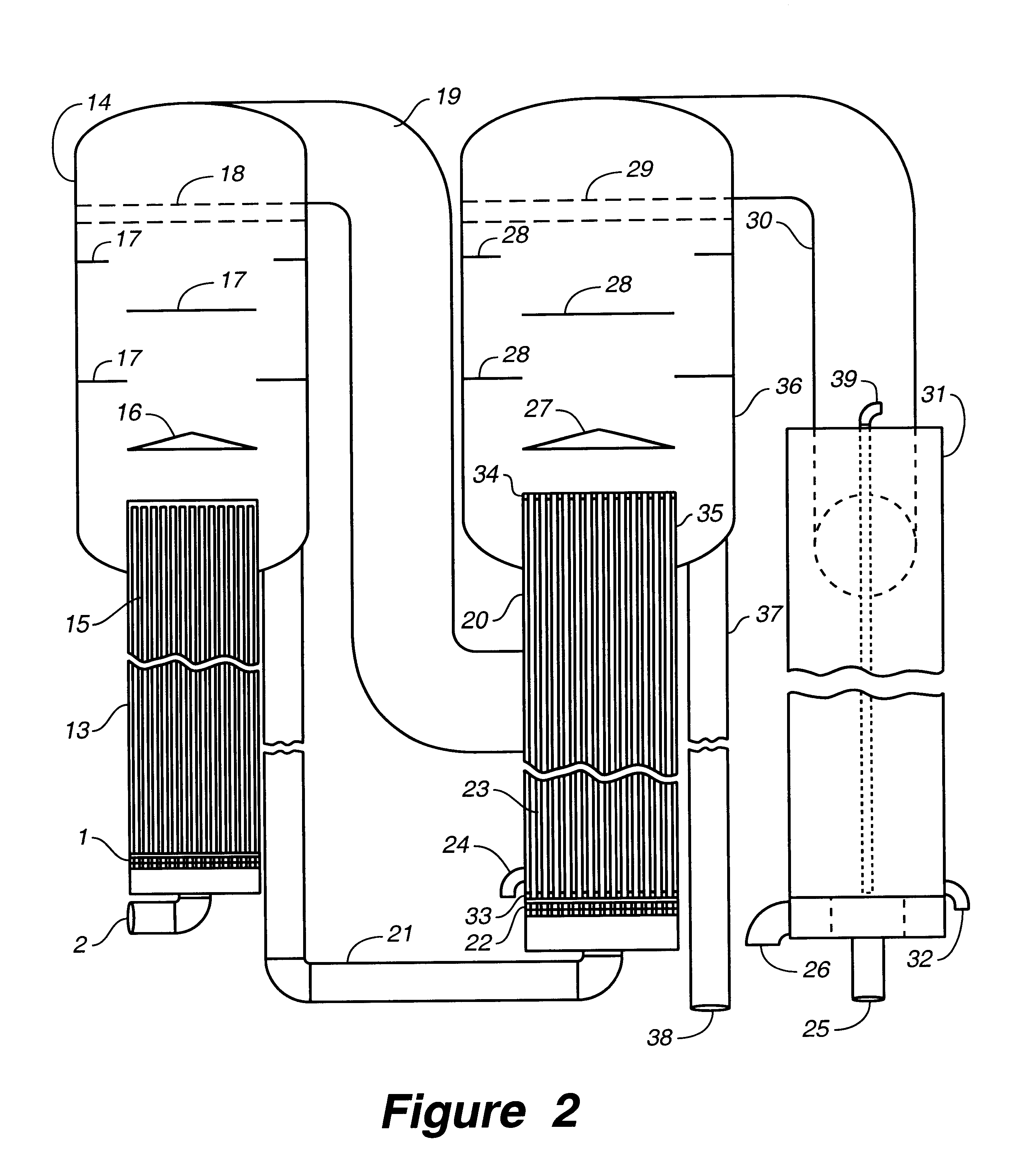

Cascade reboiling of ethylbenzene/styrene columns

InactiveUS6171449B1Reduce use costEfficient and economical approachDistillation regulation/controlDistillation in boilers/stillsCascadeEngineering

Apparatus and process are disclosed for the distillation separation of styrene monomer from ethylbenzene utilizing a split feed to two distillation columns in conjunction with cascade reboiling utilizing thermal energy from the overhead of one column to supply heat to the second.

Owner:STONE & WEBSTER PROCESS TECH

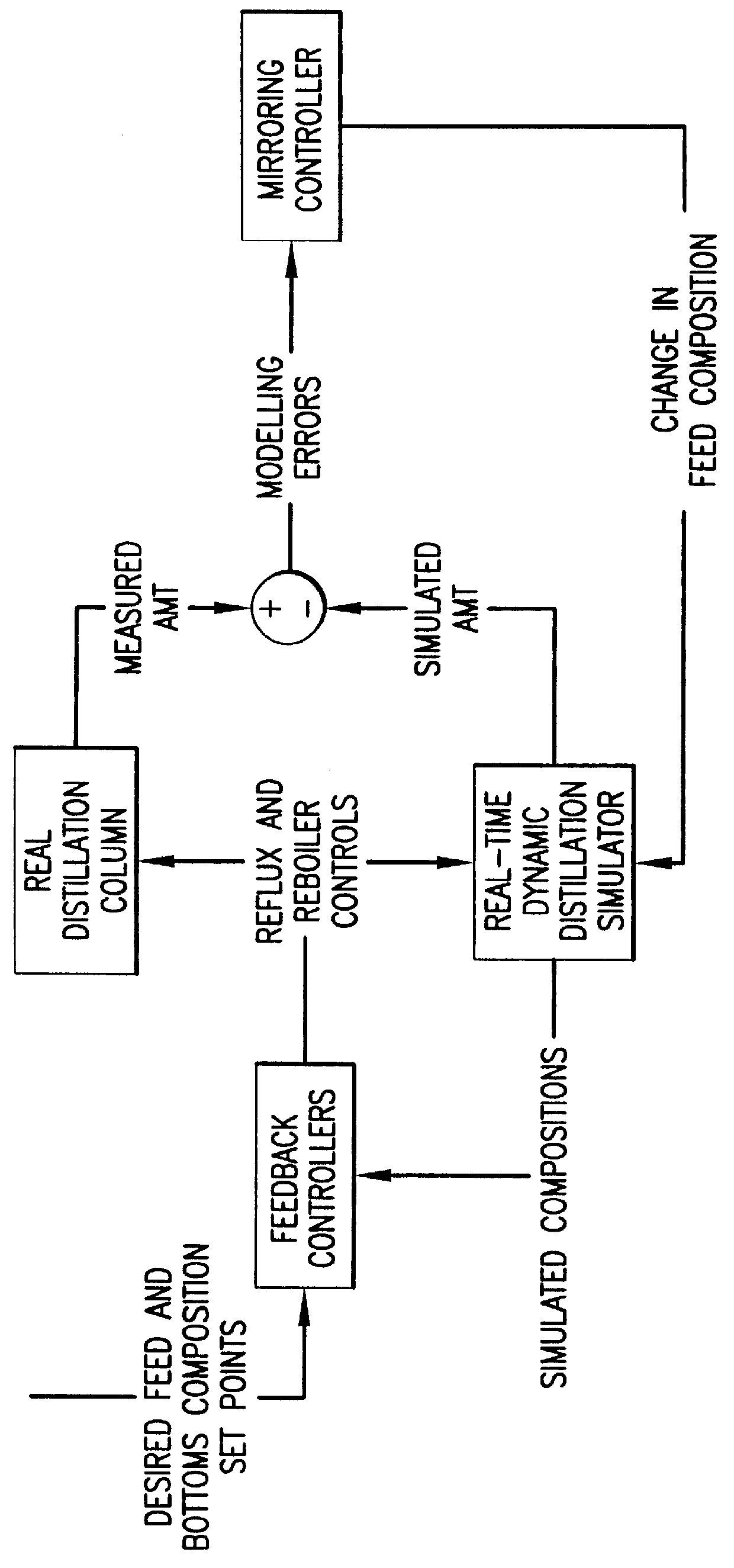

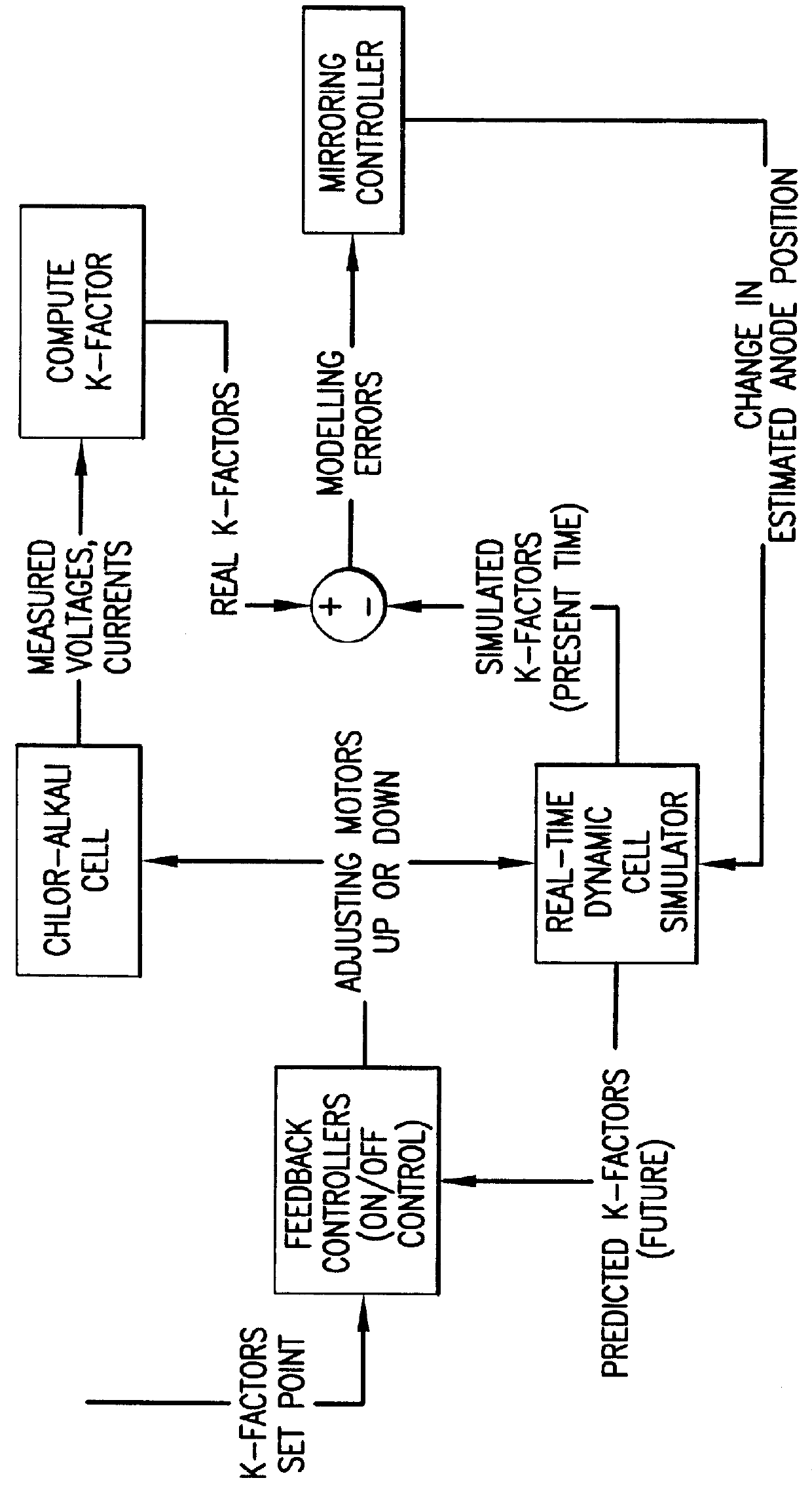

Automatic control system for unit operation

InactiveUS6088630AImprove stabilityAccurate predictionSampled-variable control systemsPhotography auxillary processesAutomatic controlAutomatic train control

Automatic control systems, and corresponding processes, for controlling either an anode adjuster in a chlor / alkali cell or at least one average middle temperature of a distillation column wherein the combination of feedback control from at least one real unit operation variable and an embedded real-time dynamic simulation of that variable are used.

Owner:OLIN CORP

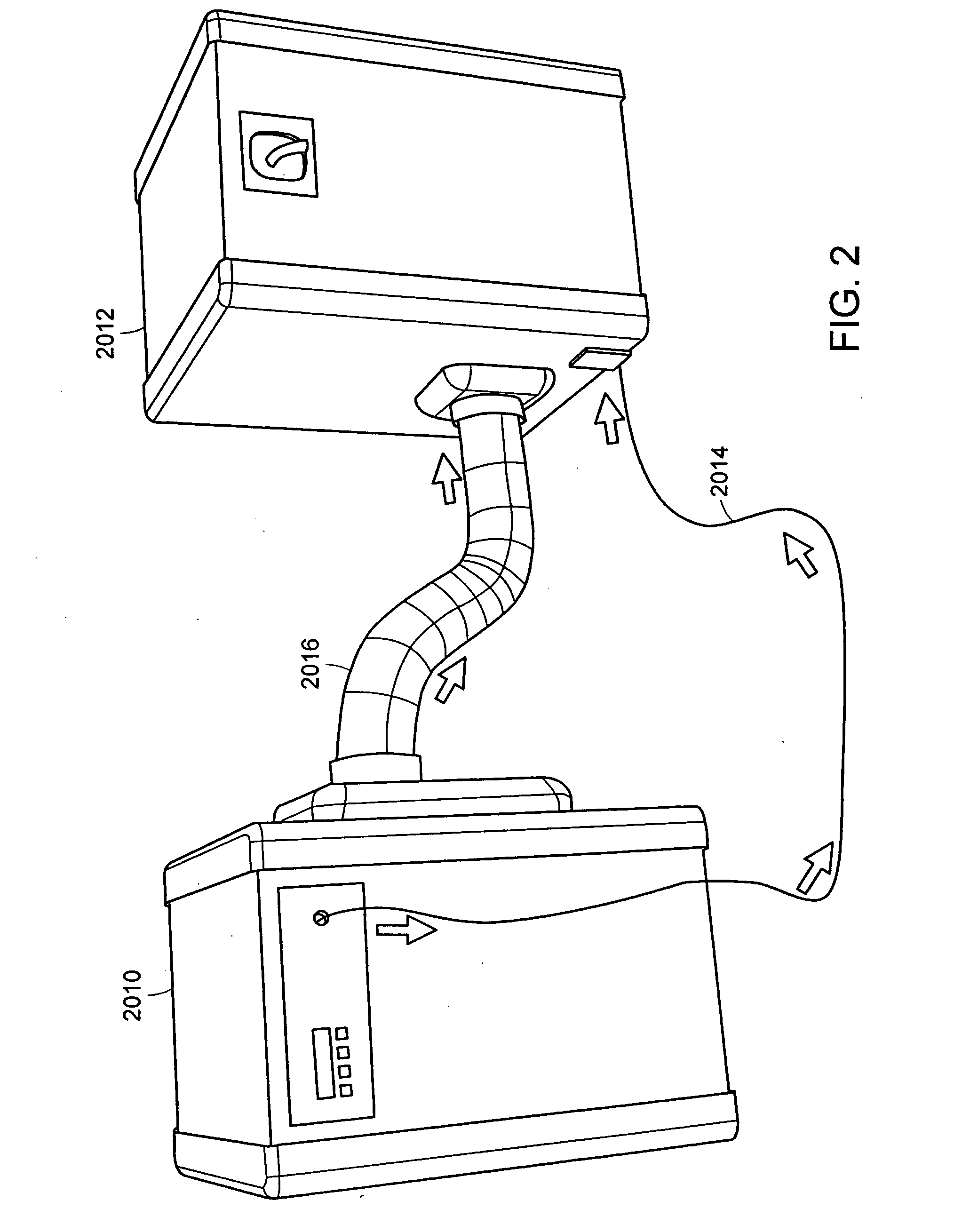

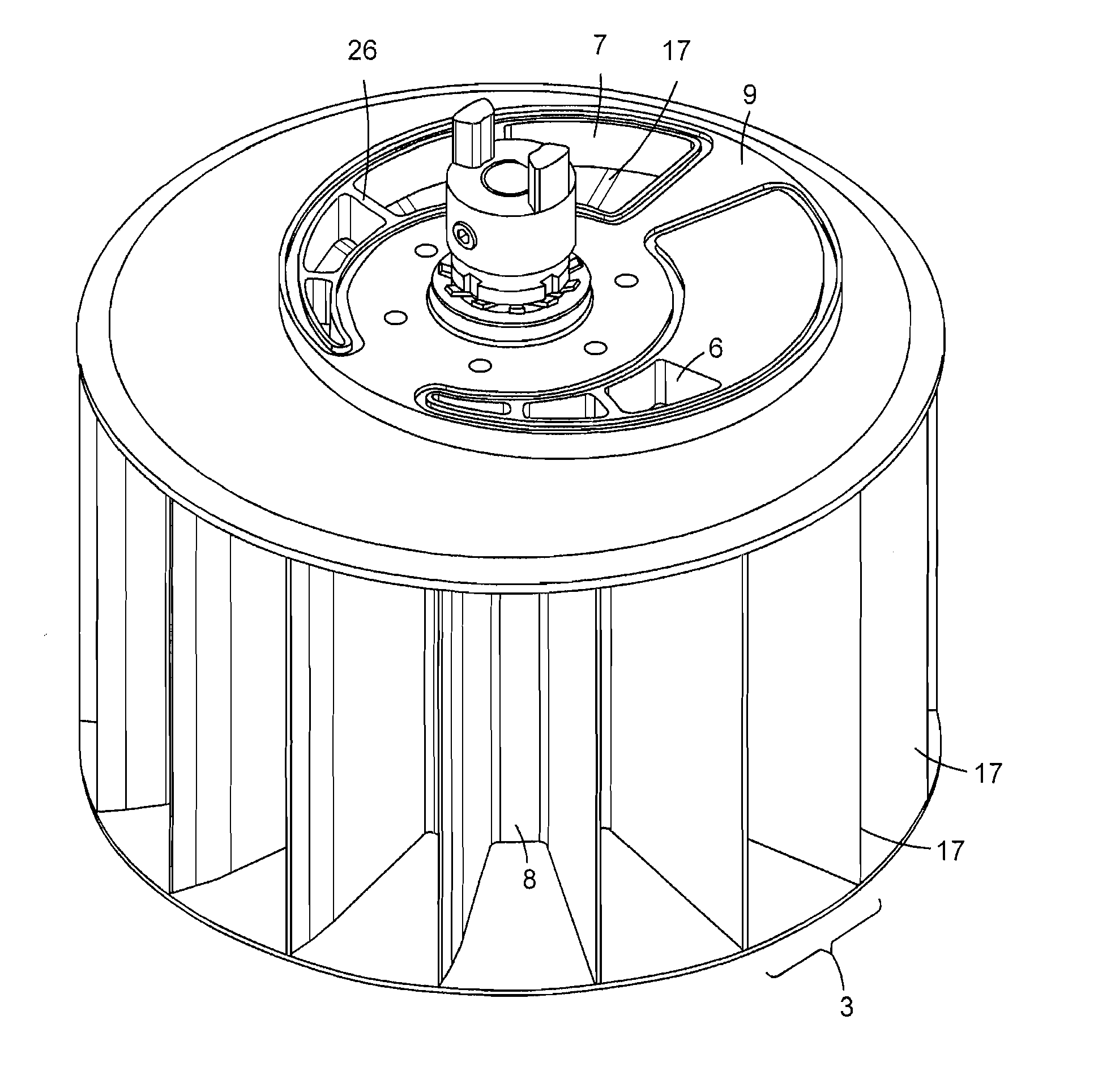

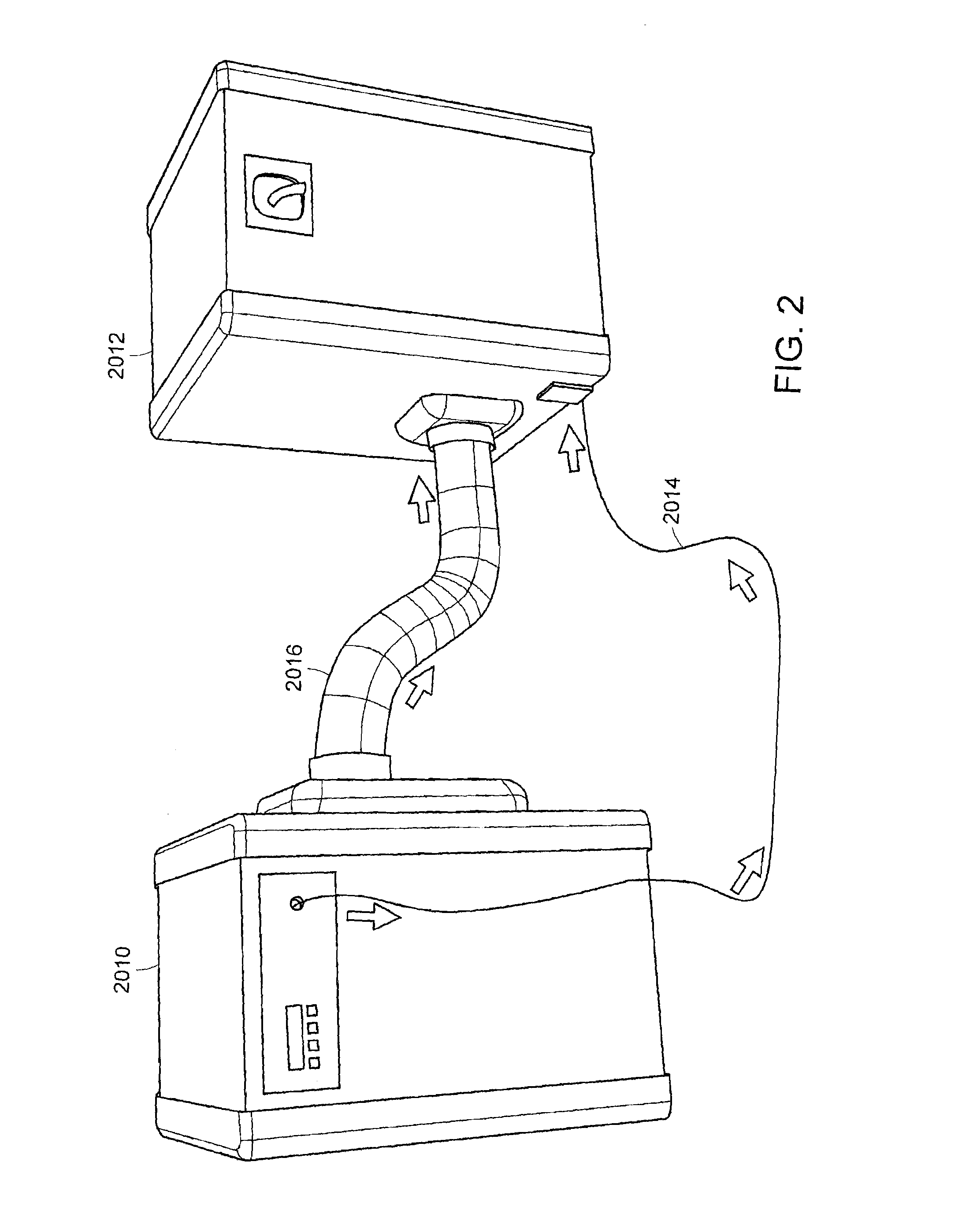

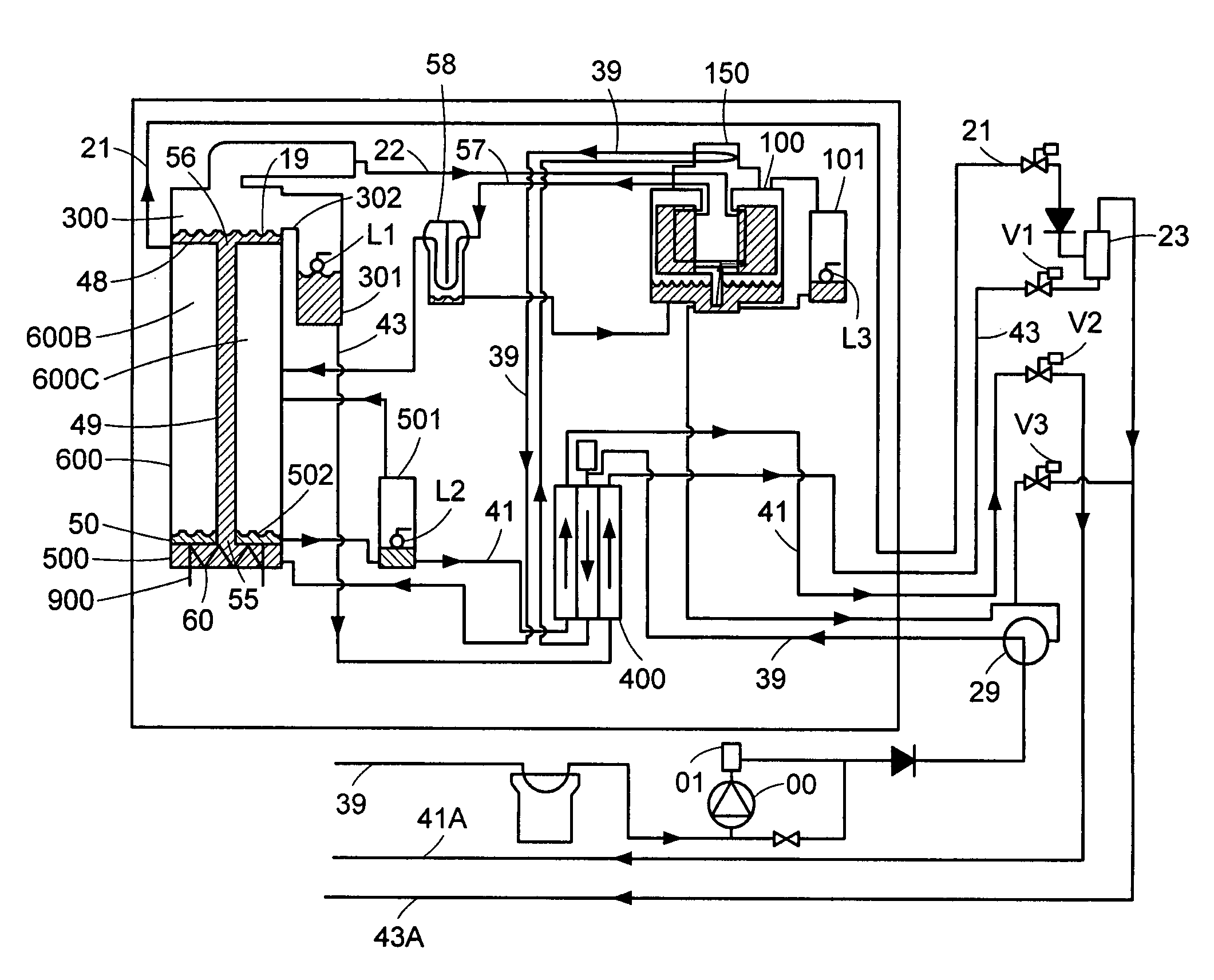

Pressurized vapor cycle liquid distillation

ActiveUS20070017192A1Easy maintenanceImprove efficiencyCombination devicesDrying using combination processesHeat managementDistillation

Embodiments of the invention are directed toward a novel pressurized vapor cycle for distilling liquids. In some embodiments of the invention, a liquid purification system is revealed, including the elements of an input for receiving untreated liquid, a vaporizer coupled to the input for transforming the liquid to vapor, a head chamber for collecting the vapor, a vapor pump with an internal drive shaft and an eccentric rotor with a rotatable housing for compressing vapor, and a condenser in communication with the vapor pump for transforming the compressed vapor into a distilled product. Other embodiments of the invention are directed toward heat management, and other process enhancements for making the system especially efficient.

Owner:DEKA PROD LLP

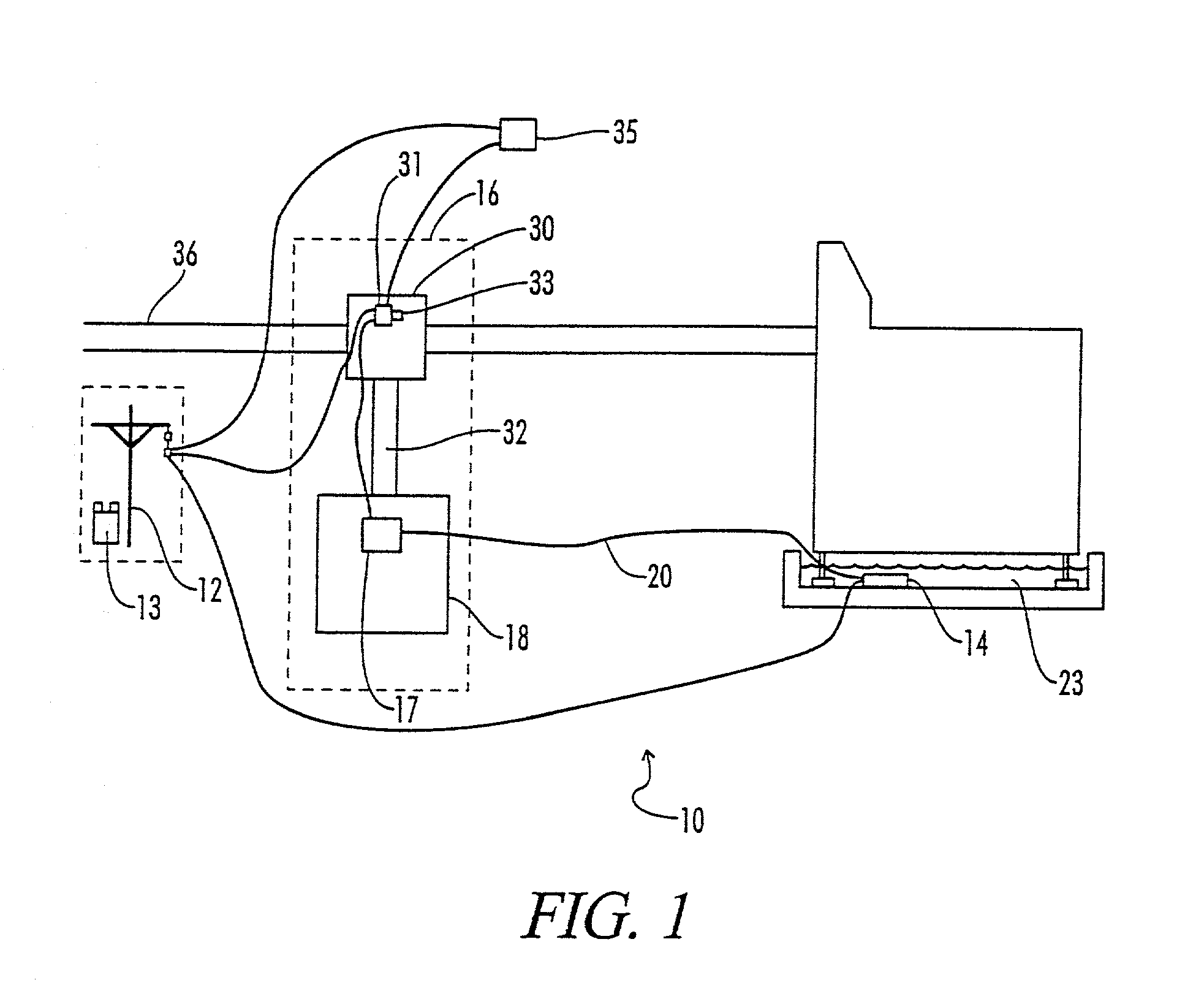

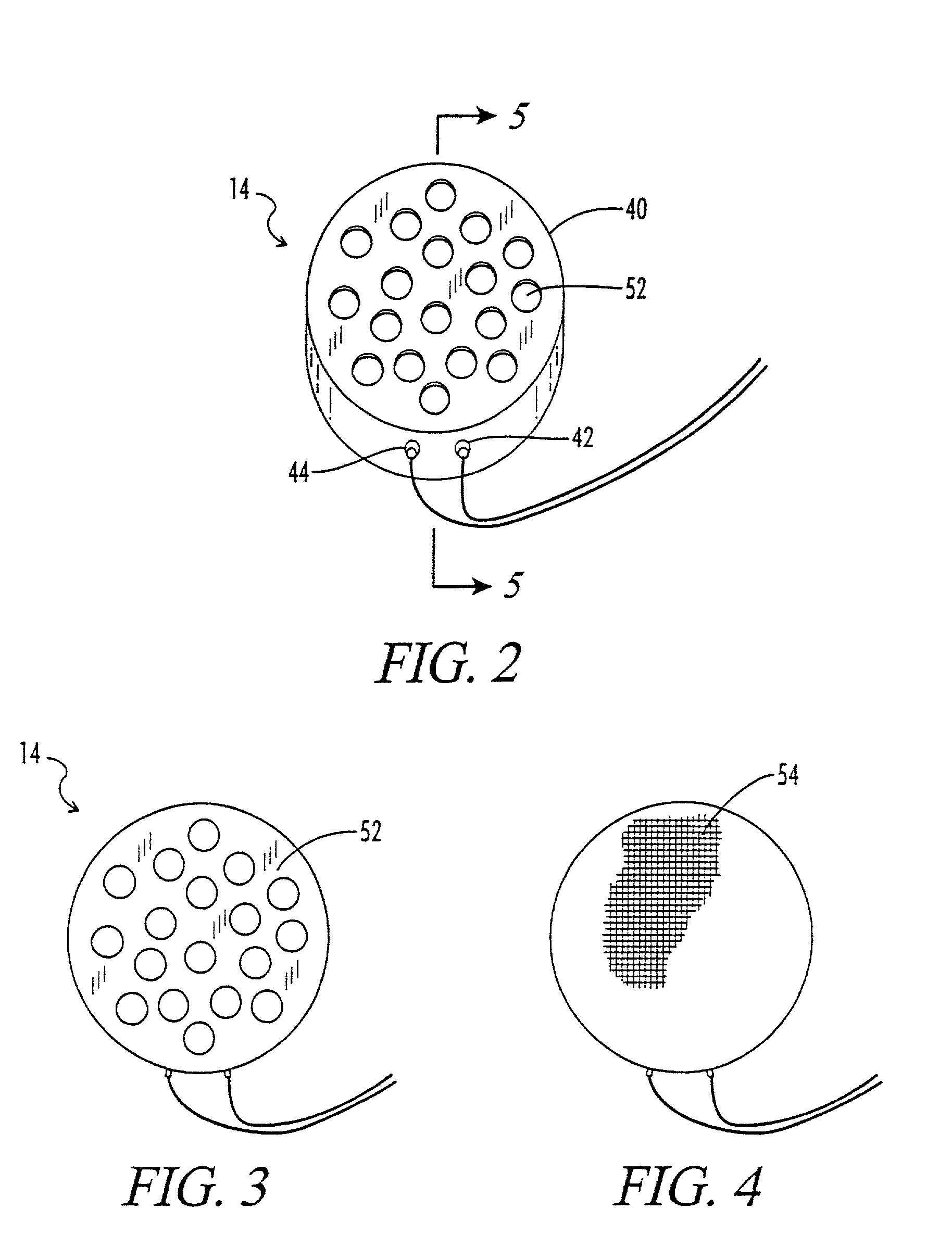

Automatic drain for fuel processor

An automatic water drain apparatus includes a reservoir, a fluid inlet, and a fluid outlet. A first valve member is moveable between an open position for admitting fluid to the reservoir via the fluid inlet and a closed position for preventing admission of fluid to the reservoir. A second valve member is moveable between an open position for exhausting fluid from the reservoir and a closed position for preventing exhaust of fluid from the reservoir. At least one actuator is operable to move the fluid inlet and the fluid outlet between their respective open and closed positions. A sensor is disposed outside the reservoir and is operable to produce a first sensor output signal in response to detection of the presence of water, wherein the at least one actuator moves the first valve to the open position in response to the first sensor output signal.

Owner:DAVCO TECH

Barometric evaporation process and evaporator

InactiveUS6254734B1Reduce and minimize amountIncrease supplyDrying using combination processesDistillation regulation/controlChemistryVapor phase

A process for the evaporation of an available warm or hot liquid under a vacuum by applying a pressure drop thereon initiating flash-down evaporation, and followed by further flash-down evaporation under an applied pressure gradient whereby the residual liquid is raised by the vapor produced to an elevation sufficient for subsequently discharging the residual liquid from vacuum without a pump; and by separating the vapor phase from the residual liquid phase before condensing the vapor produced into distilled liquid.

Owner:SEPHTON HUGO H

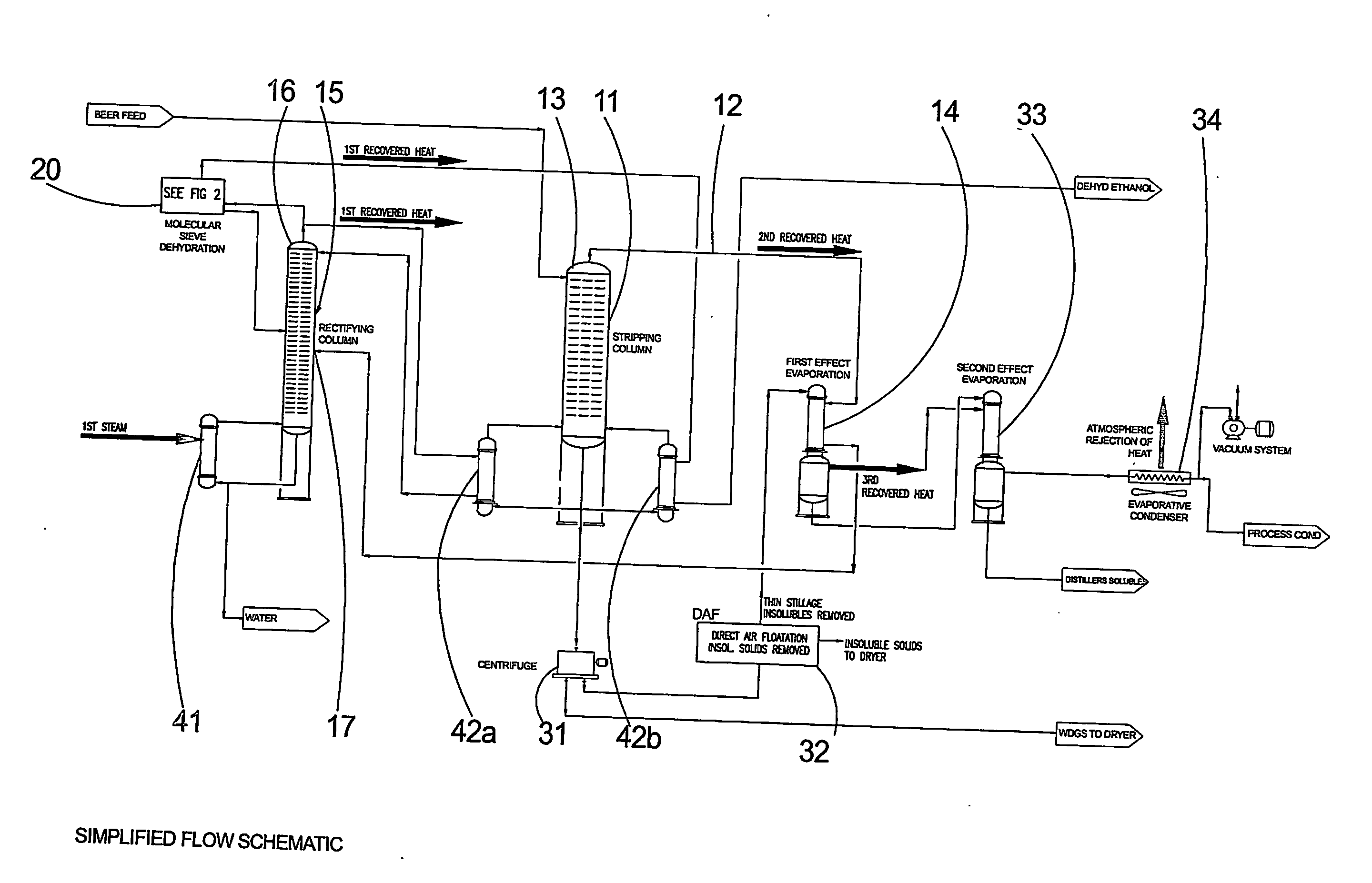

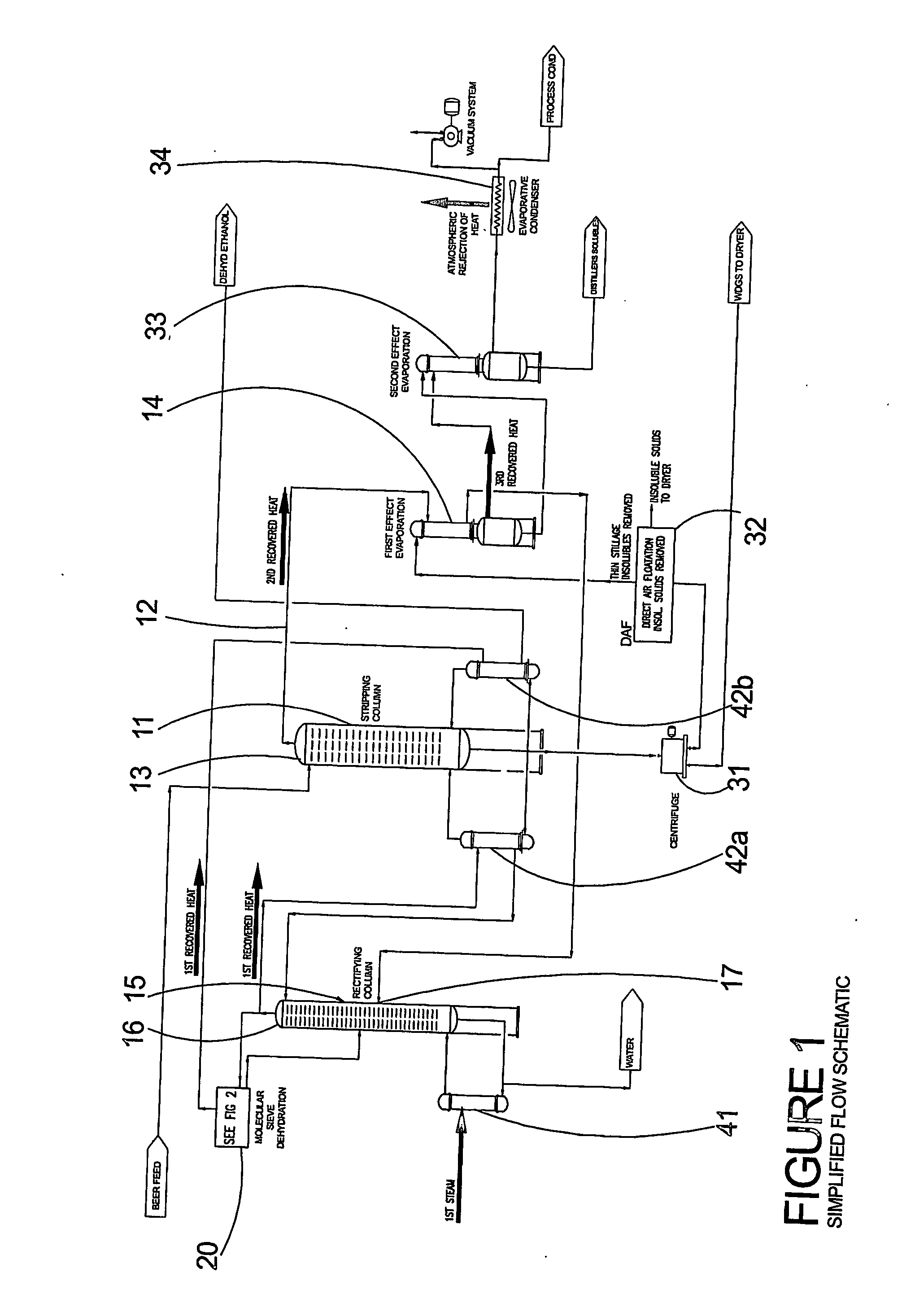

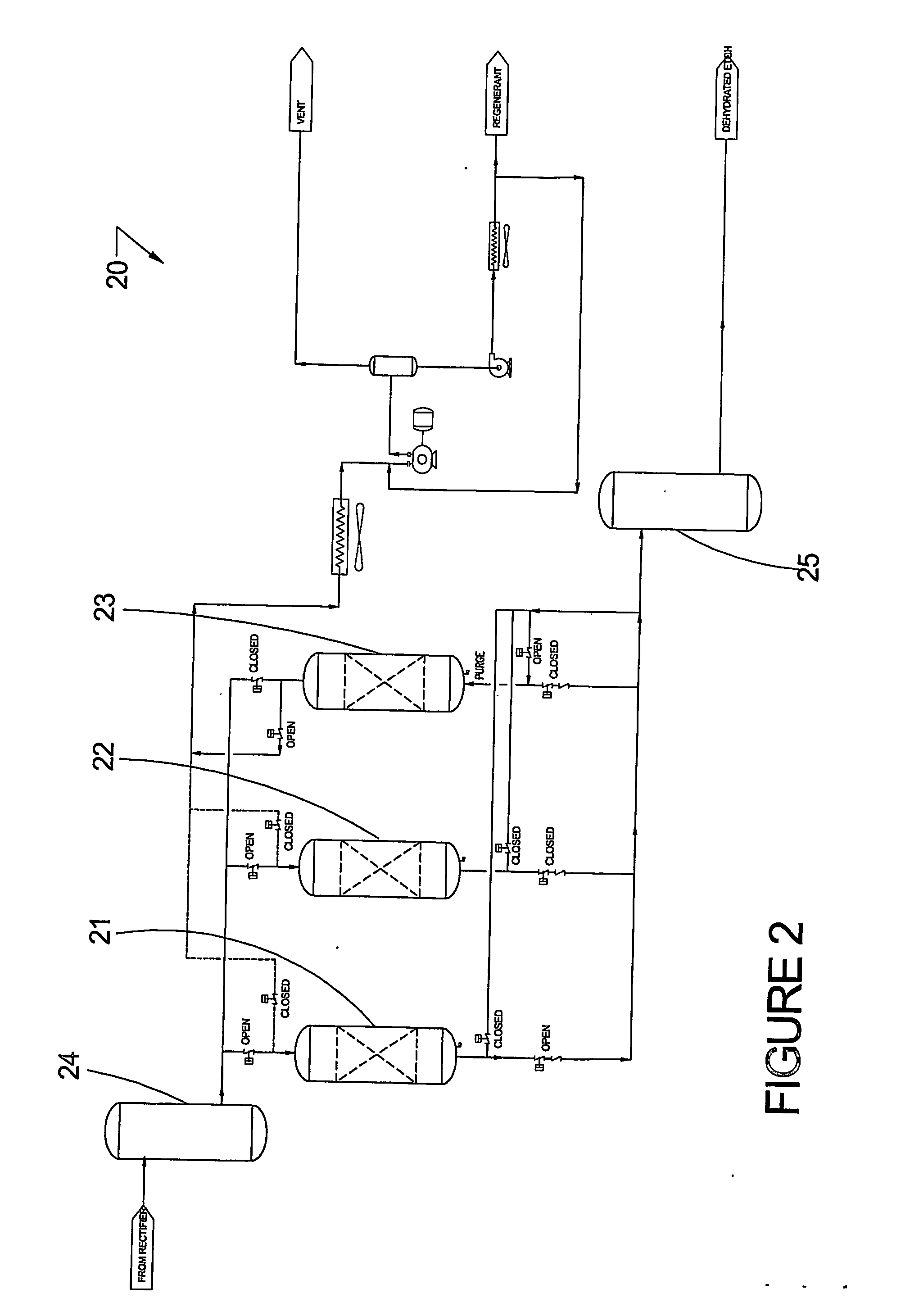

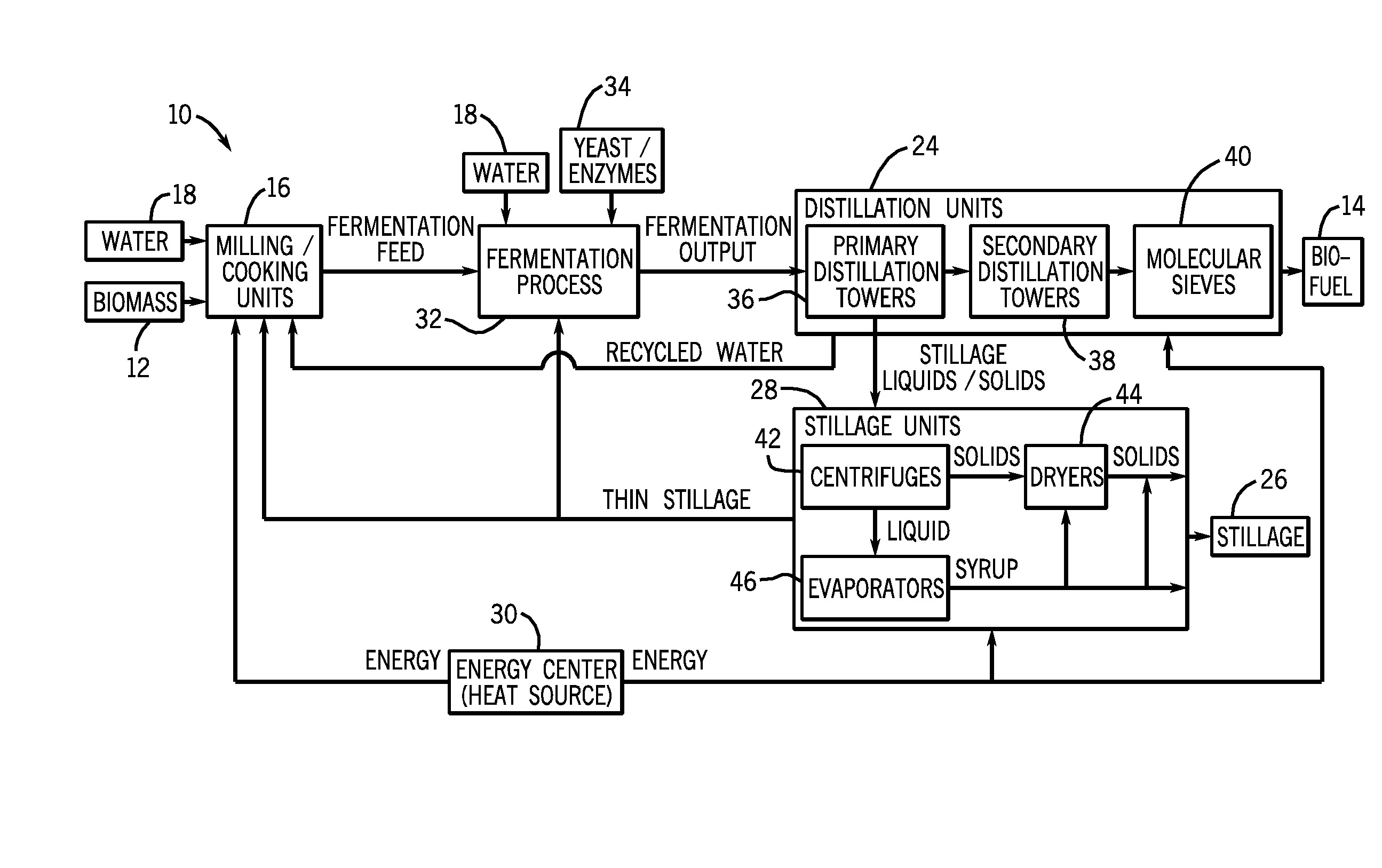

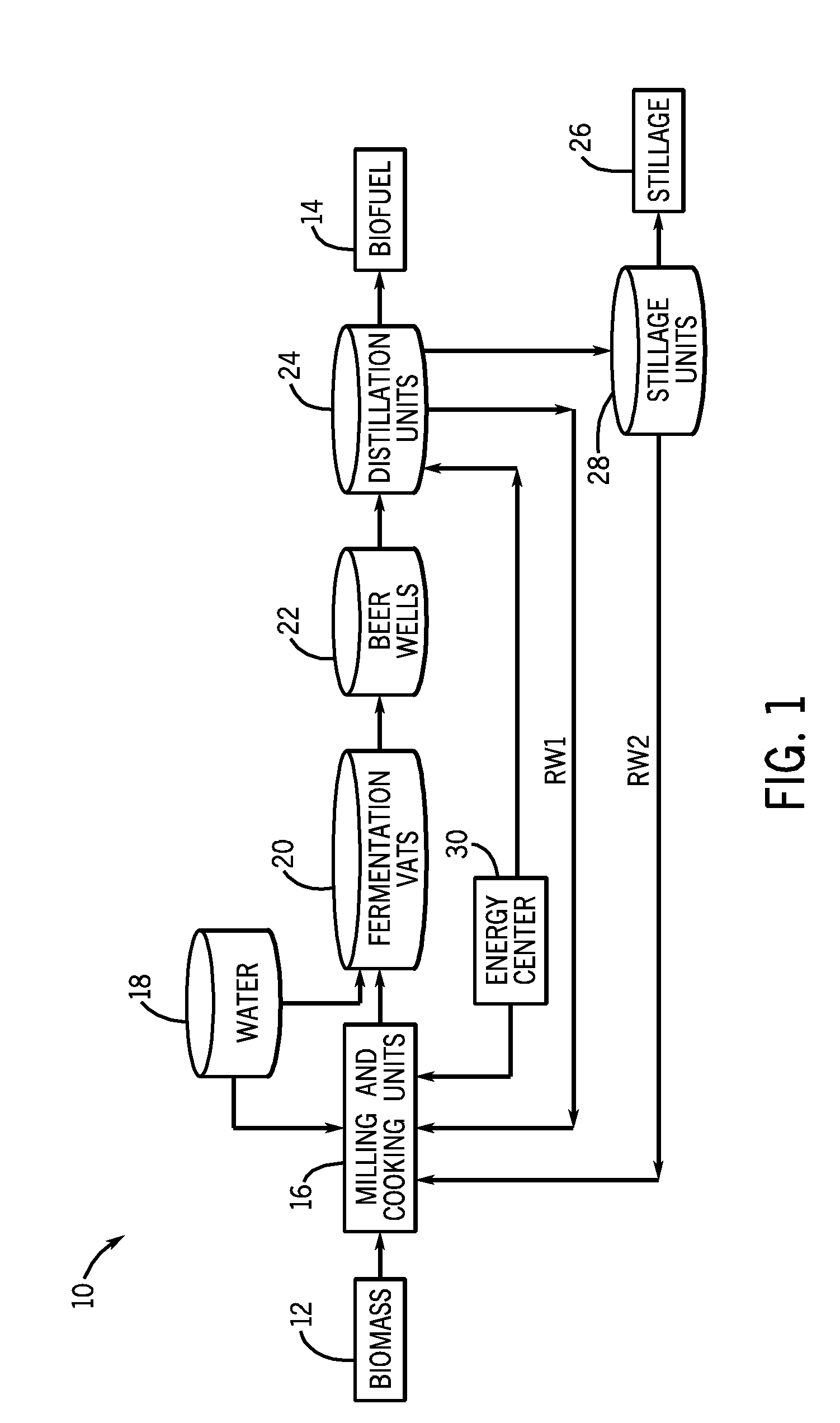

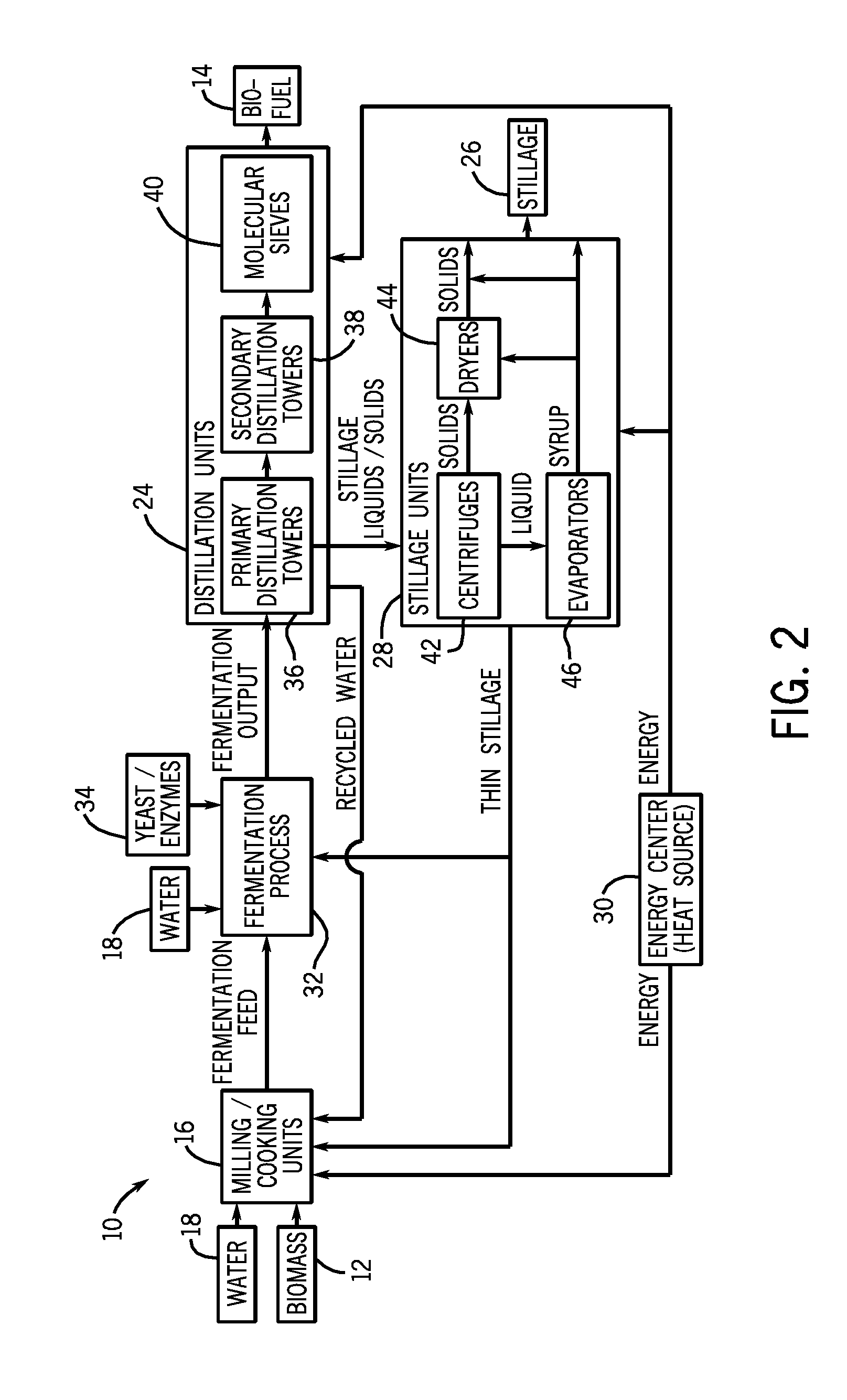

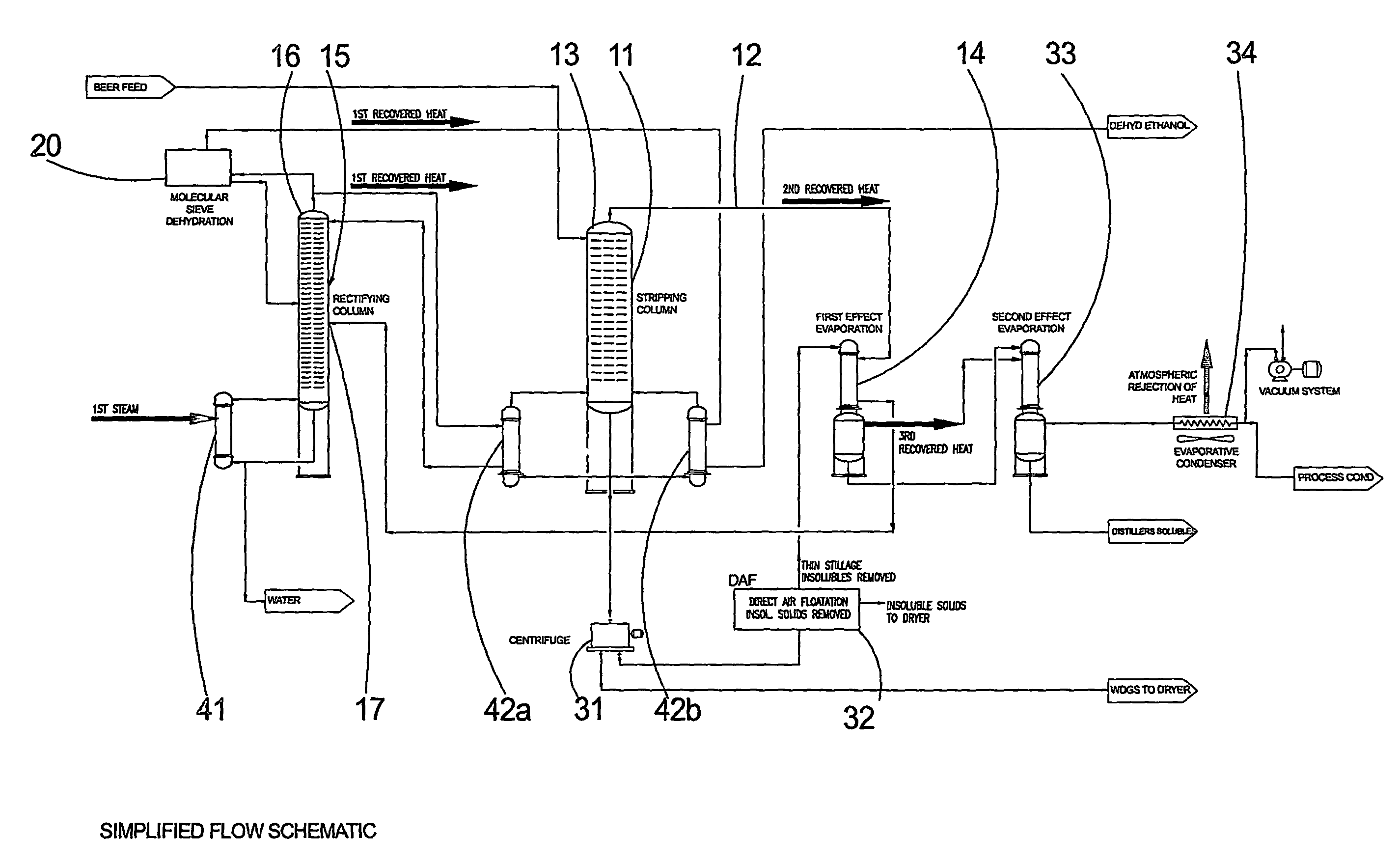

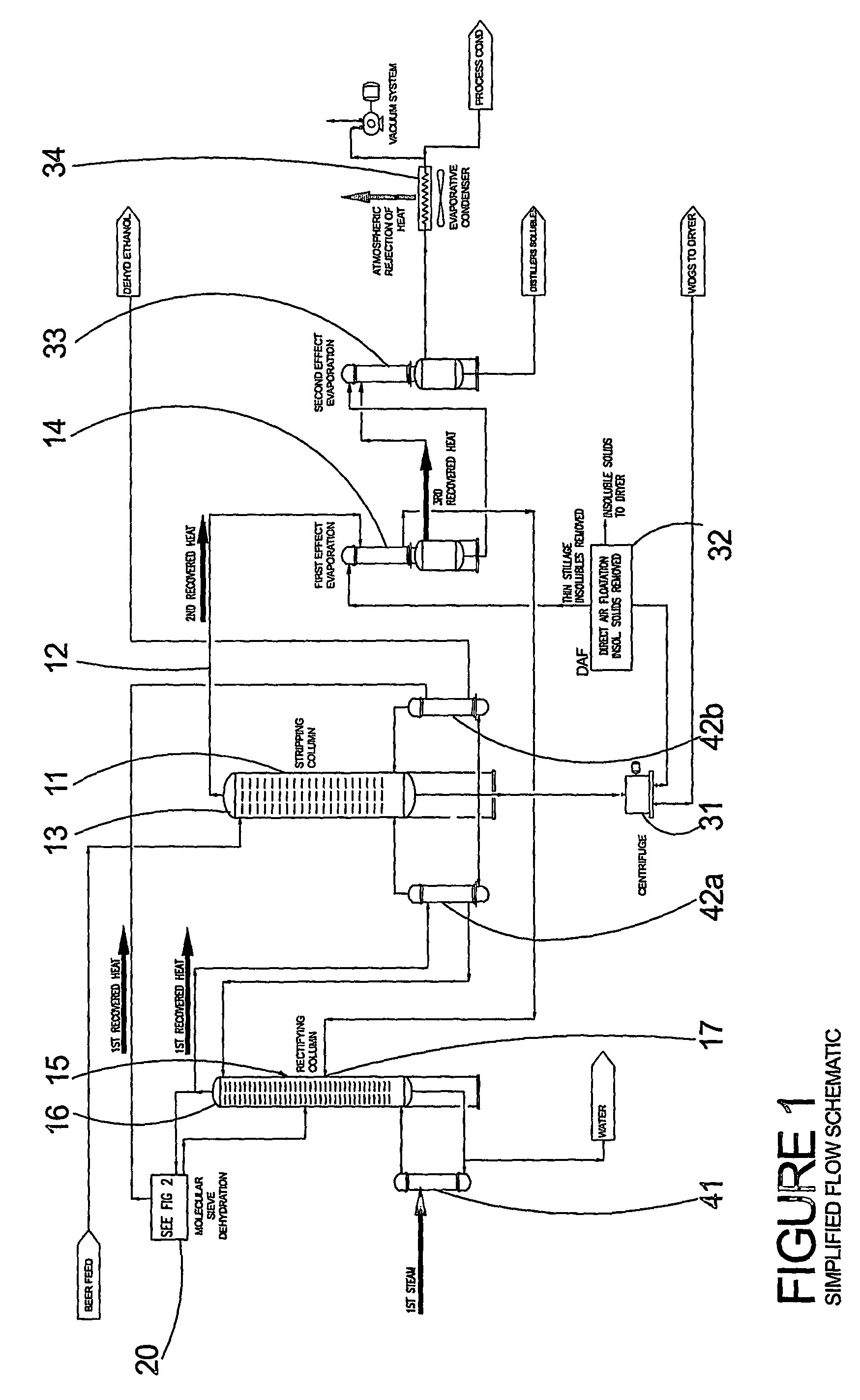

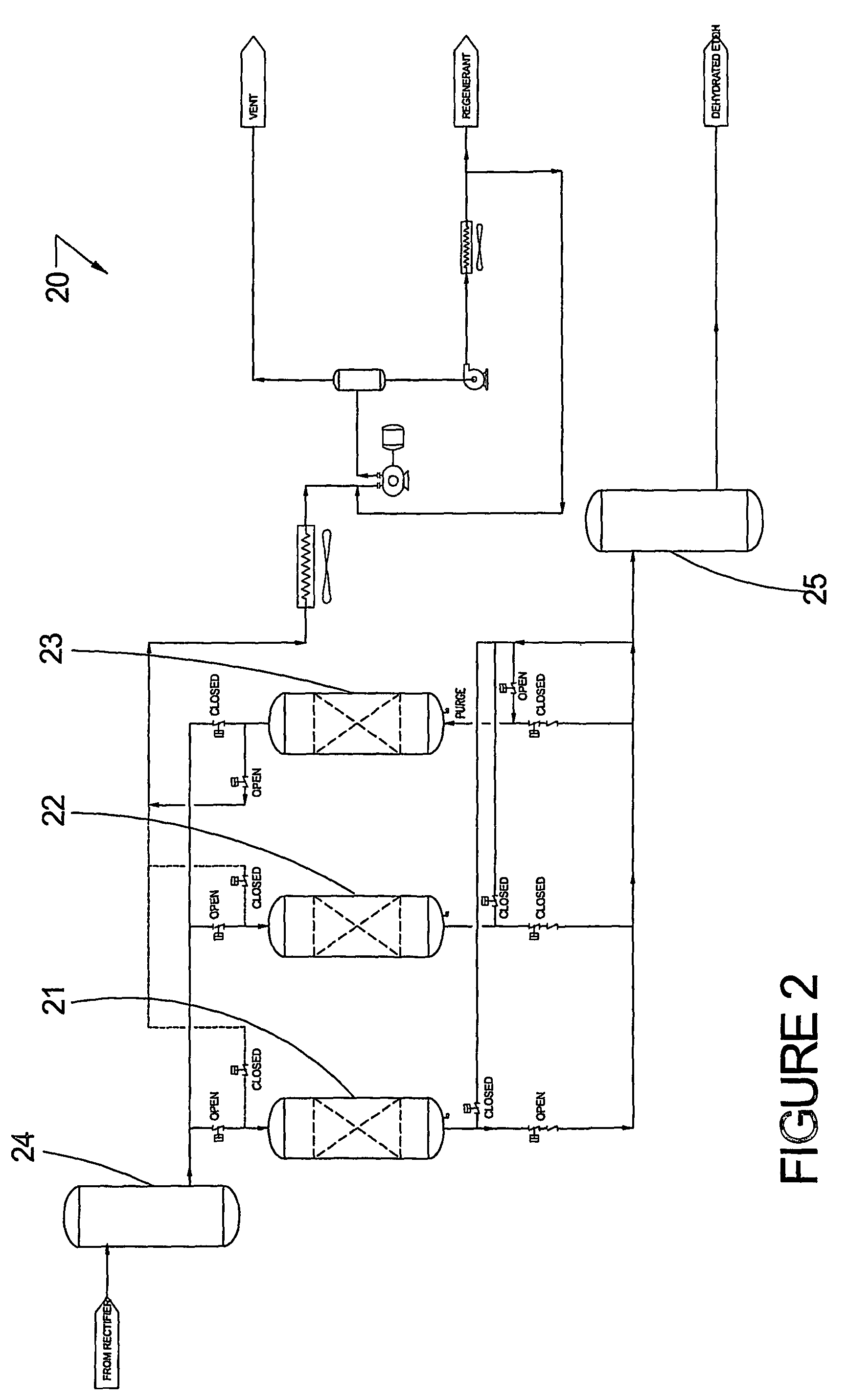

Ethanol distillation with distillers soluble solids recovery apparatus

ActiveUS20070000769A1High operating temperatureReduce drying loadDistillation regulation/controlBiofuelsMolecular sieveAnhydrous ethanol

The present invention relates to a system for producing ethanol from an organic source and that operates to purify and dry ethanol from a beer source. The system for producing substantially anhydrous ethanol comprises: (a) a first distillation stripping column that operates between 160 to 220 degrees F.; (b) a second distillation rectifying column having a higher operating temperature than said stripping column; (c) a molecular sieve dehydration means in fluid communication with said rectifying column; and (d) an energy control means.

Owner:RCM TECH USA INC

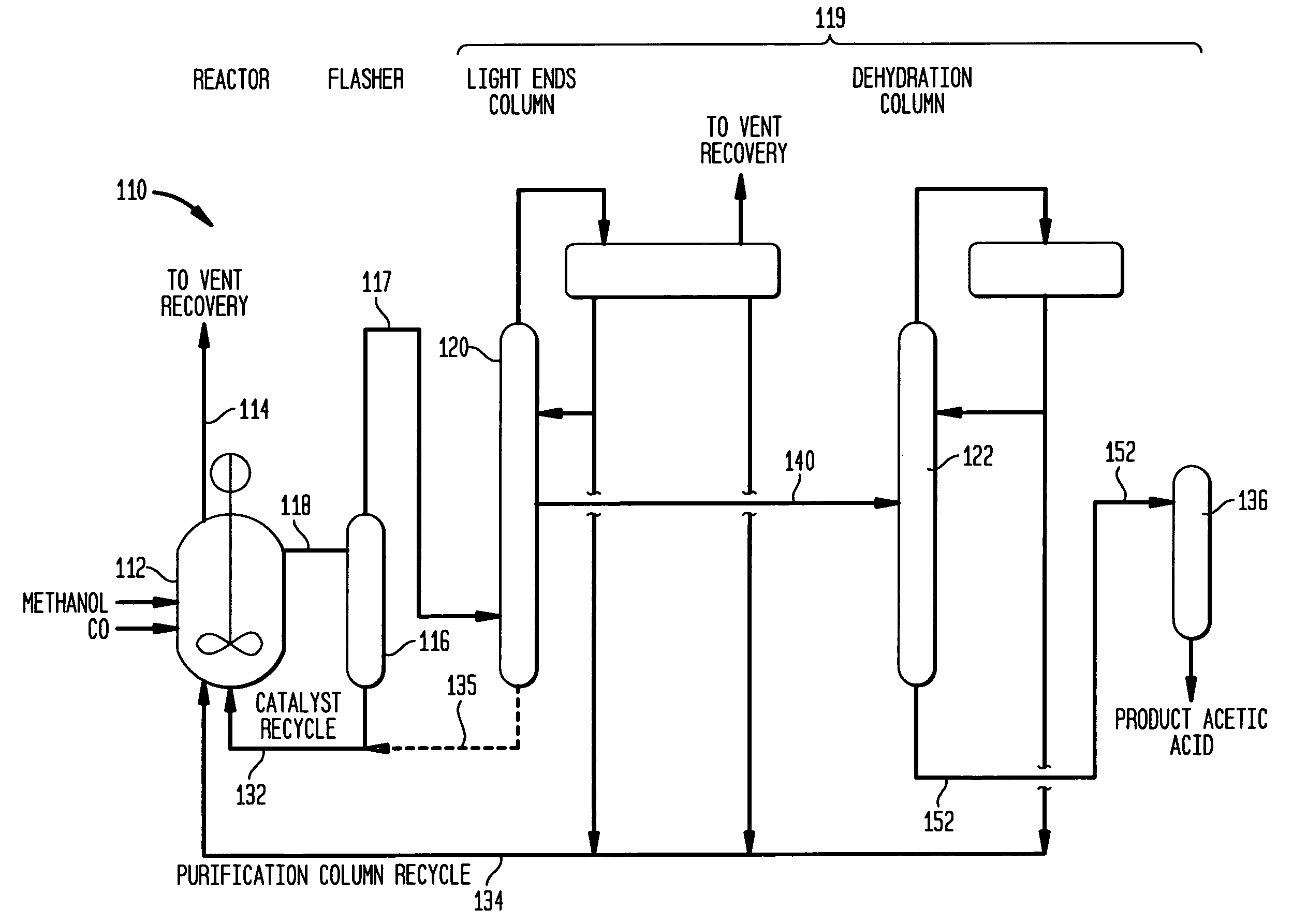

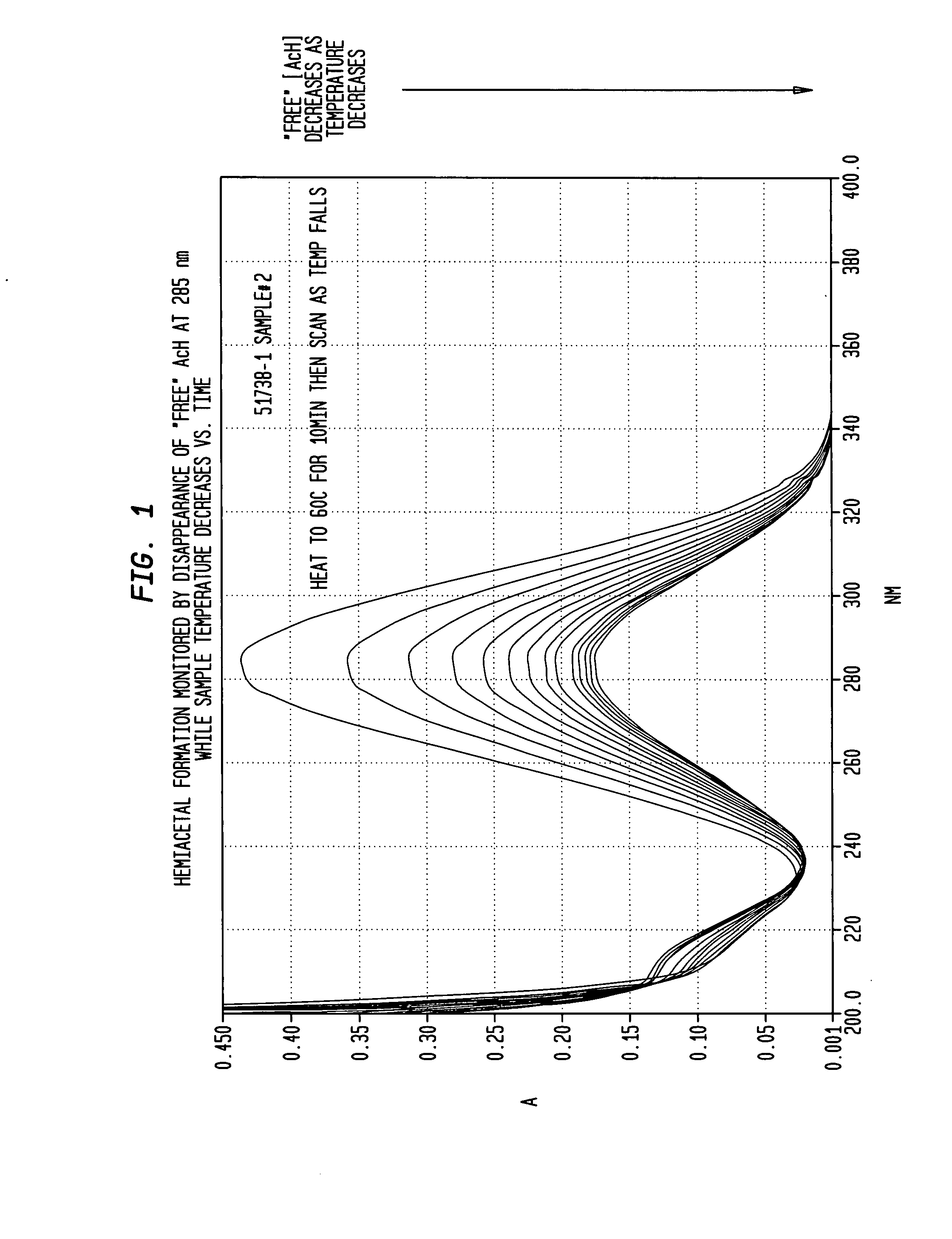

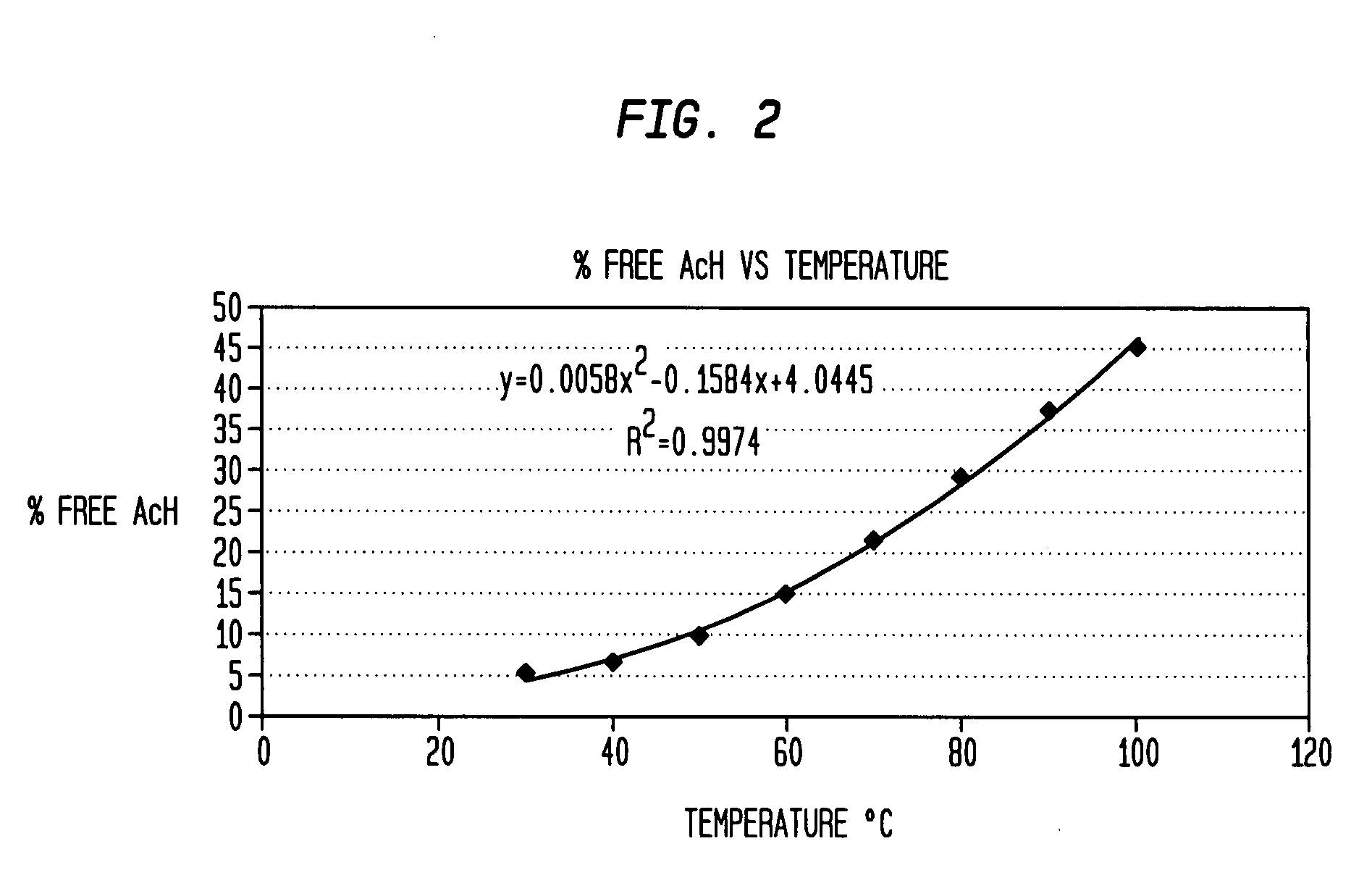

Acetaldehyde removal from methyl acetate by distillation at elevated pressure

ActiveUS20090107833A1Low in acetaldehydeEfficient AcH removalOrganic compound preparationDistillation regulation/controlChemistryDistillation

A method for removing acetaldehyde from a mixture of methyl acetate, methanol and acetaldehyde includes: (a) feeding the mixture of methyl acetate, methanol and acetaldehyde to a distillation column; (b) distilling the feed mixture of methyl acetate methanol and acetaldehyde at a pressure of 10 psig or more to generate an overhead vapor stream enriched in acetaldehyde as compared with the feed mixture and a residue stream depleted in acetaldehyde as compared with the feed mixture; and (c) withdrawing the residue stream depleted in acetaldehyde from the distillation column.

Owner:CELANESE INT CORP

Liquid ring pumps with hermetically sealed motor rotors

ActiveUS7465375B2Easy maintenanceMaximize energy efficiencyGeneral water supply conservationDistillation regulation/controlDrive shaftDistillation

Owner:DEKA PROD LLP

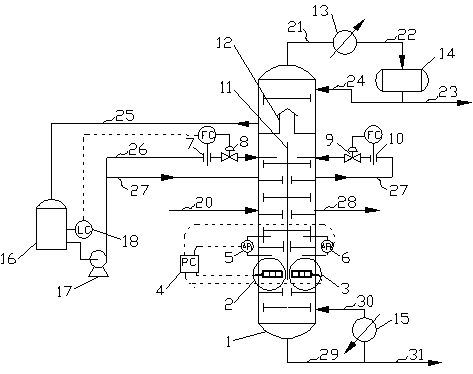

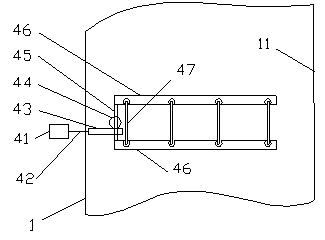

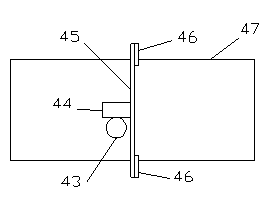

Dividing wall rectifying tower

ActiveCN102872609AEasy to controlRealize continuous adjustmentDistillation regulation/controlFractional distillationDistribution controlControl system

The invention discloses a dividing wall rectifying tower. In the rectifying tower, a spliter plate is arranged along the vertical direction of the tower, and the inner space of the rectifying tower is divided into a tower top combination zone, a dividing wall zone charging side, a dividing wall zone delivery side and a tower bottom combination zone. The rectifying tower also comprises a liquid intermediate section reflux distribution system and a tower bottom rising gas distribution control system. The dividing wall rectifying tower can be used to flexibly adjust liquid reflux distribution ratio and gas distribution ratio at the two sides of the spliter plate of the dividing wall tower, thus achieving an ideal product separation effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

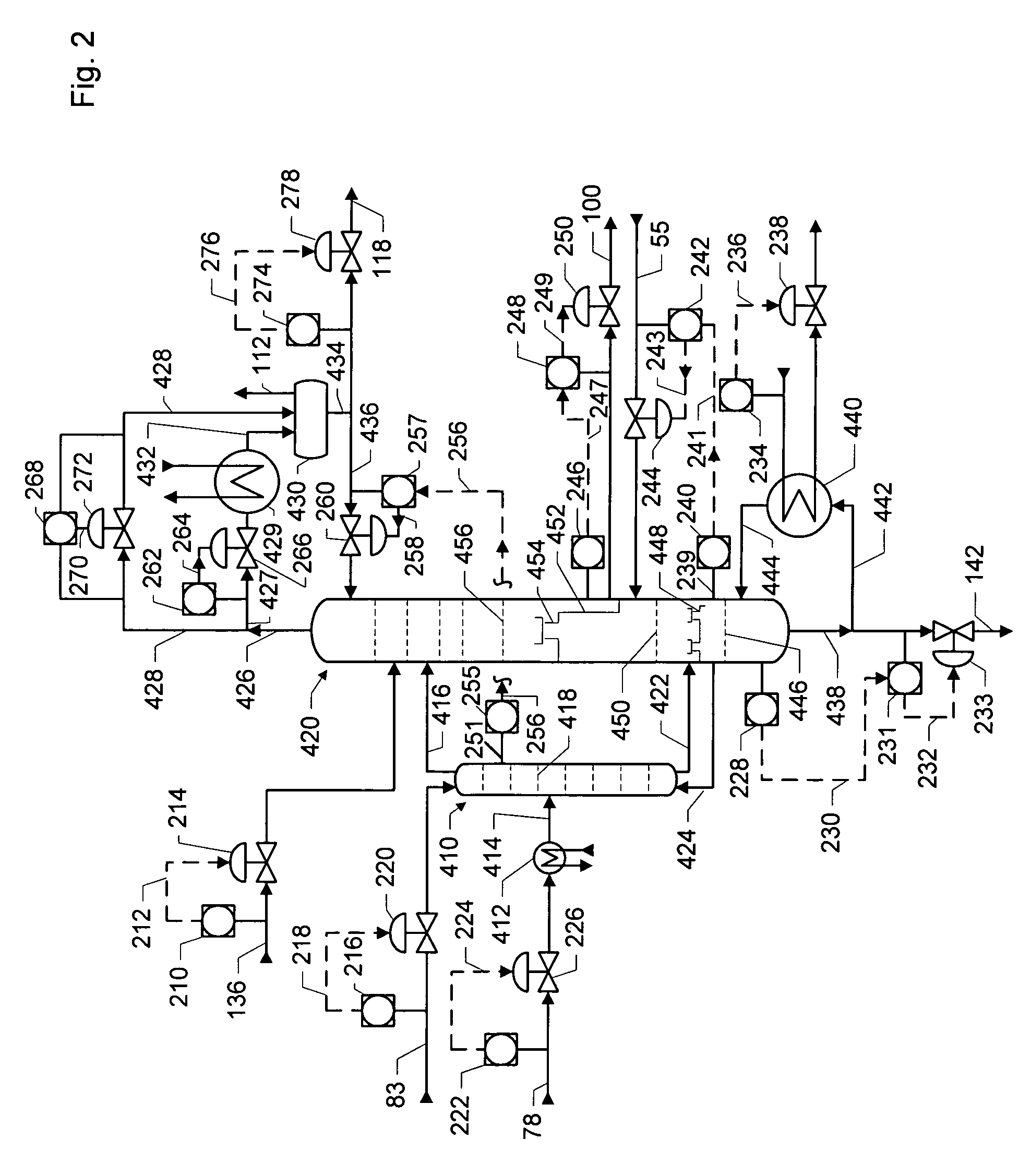

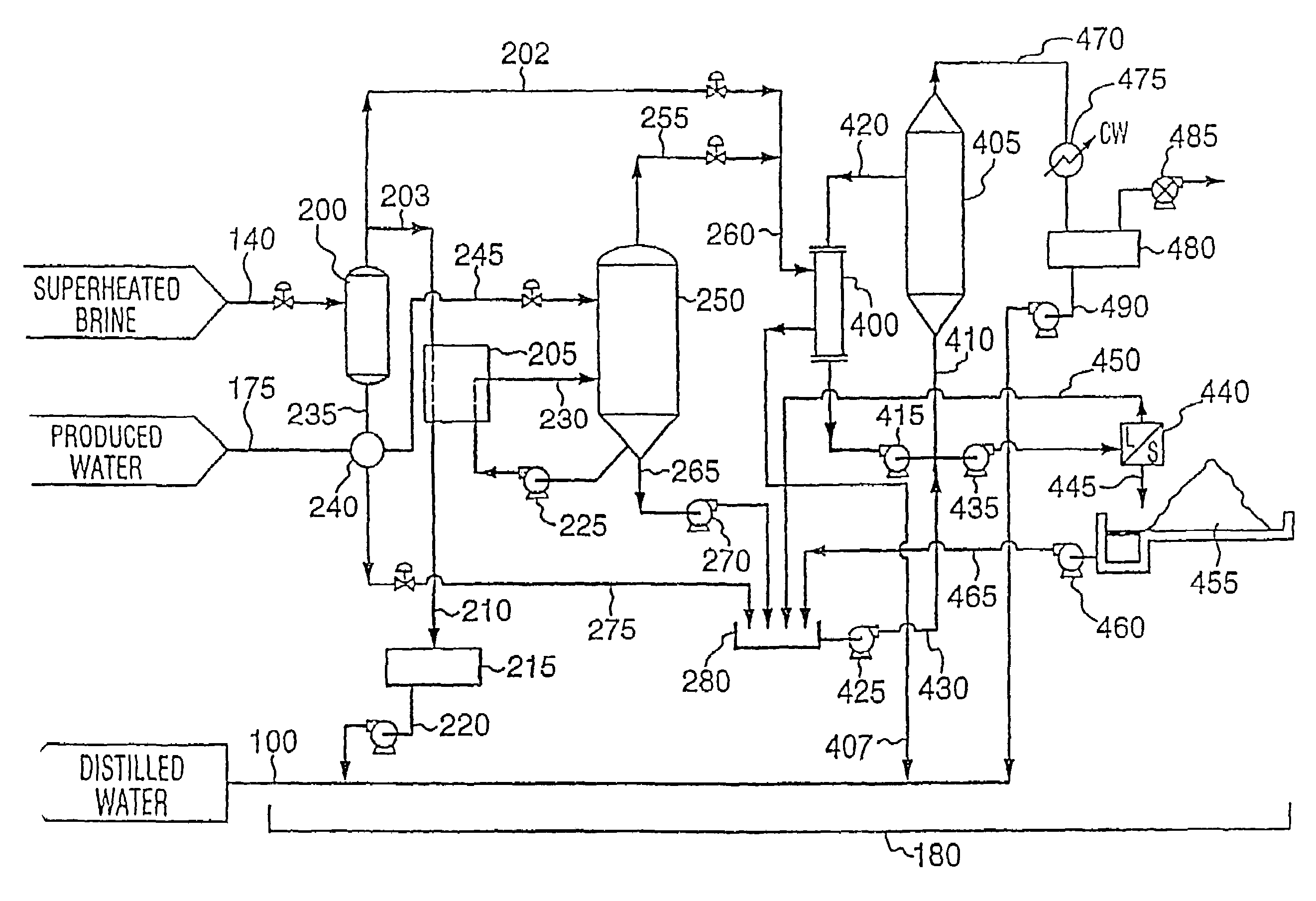

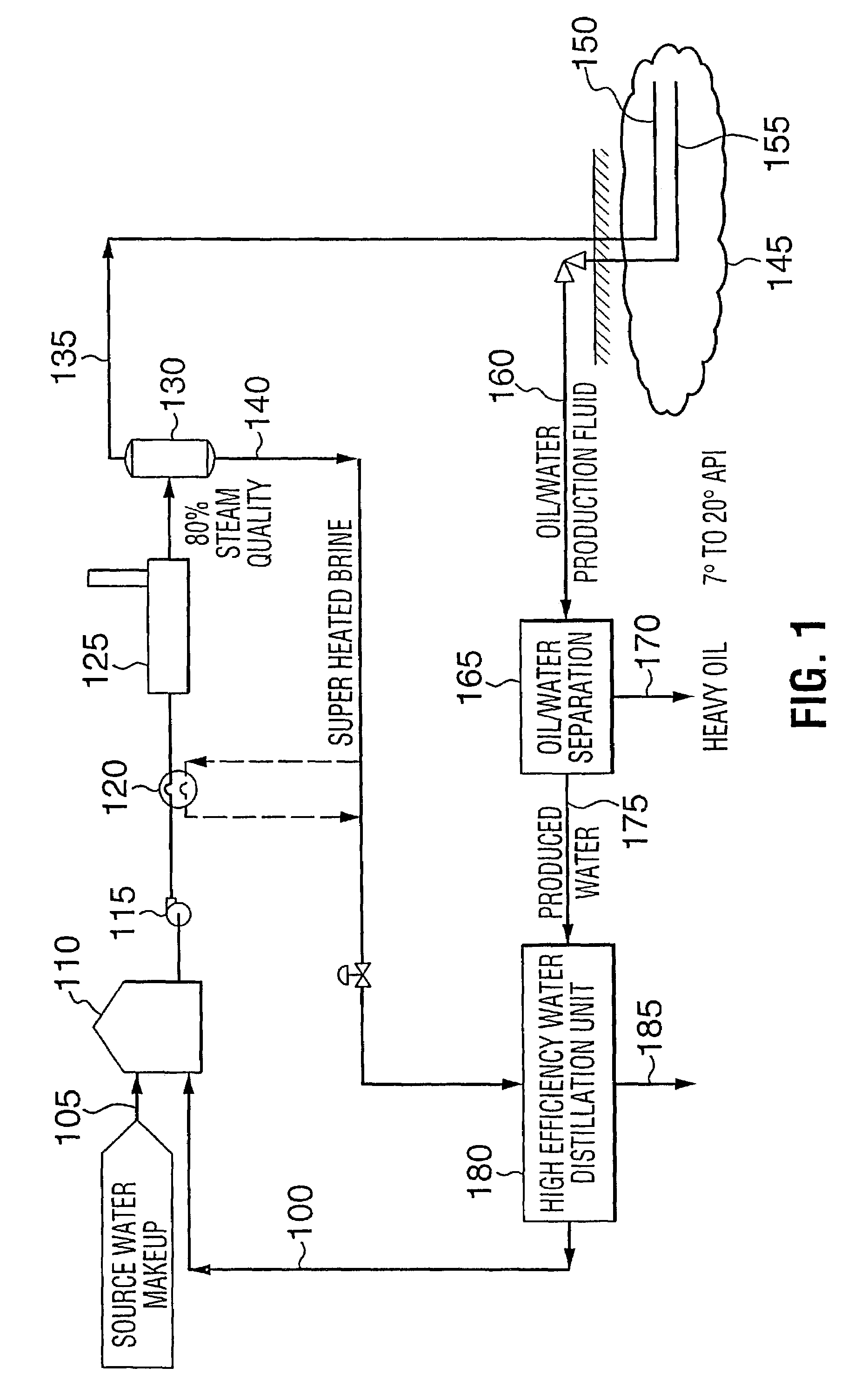

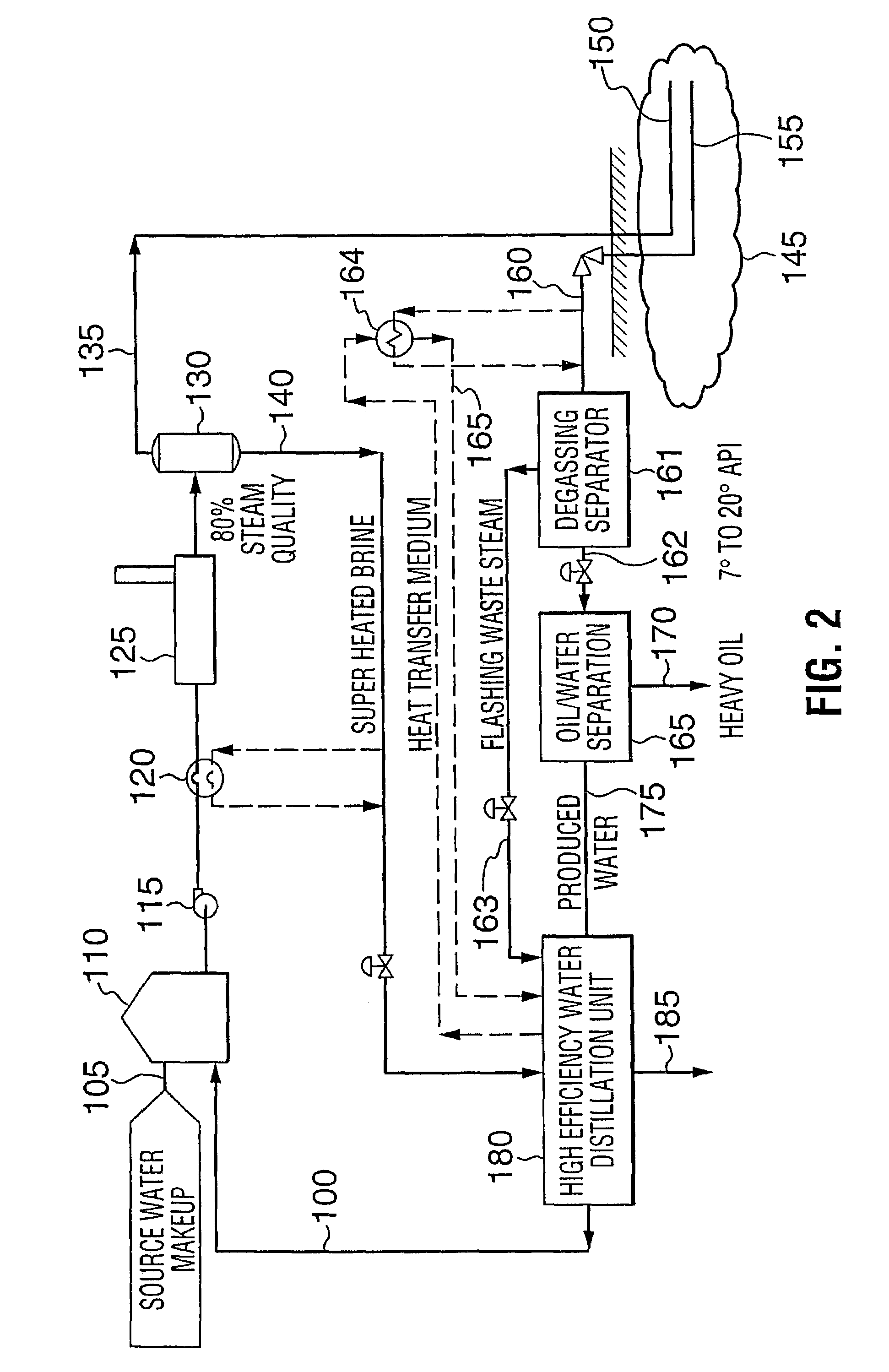

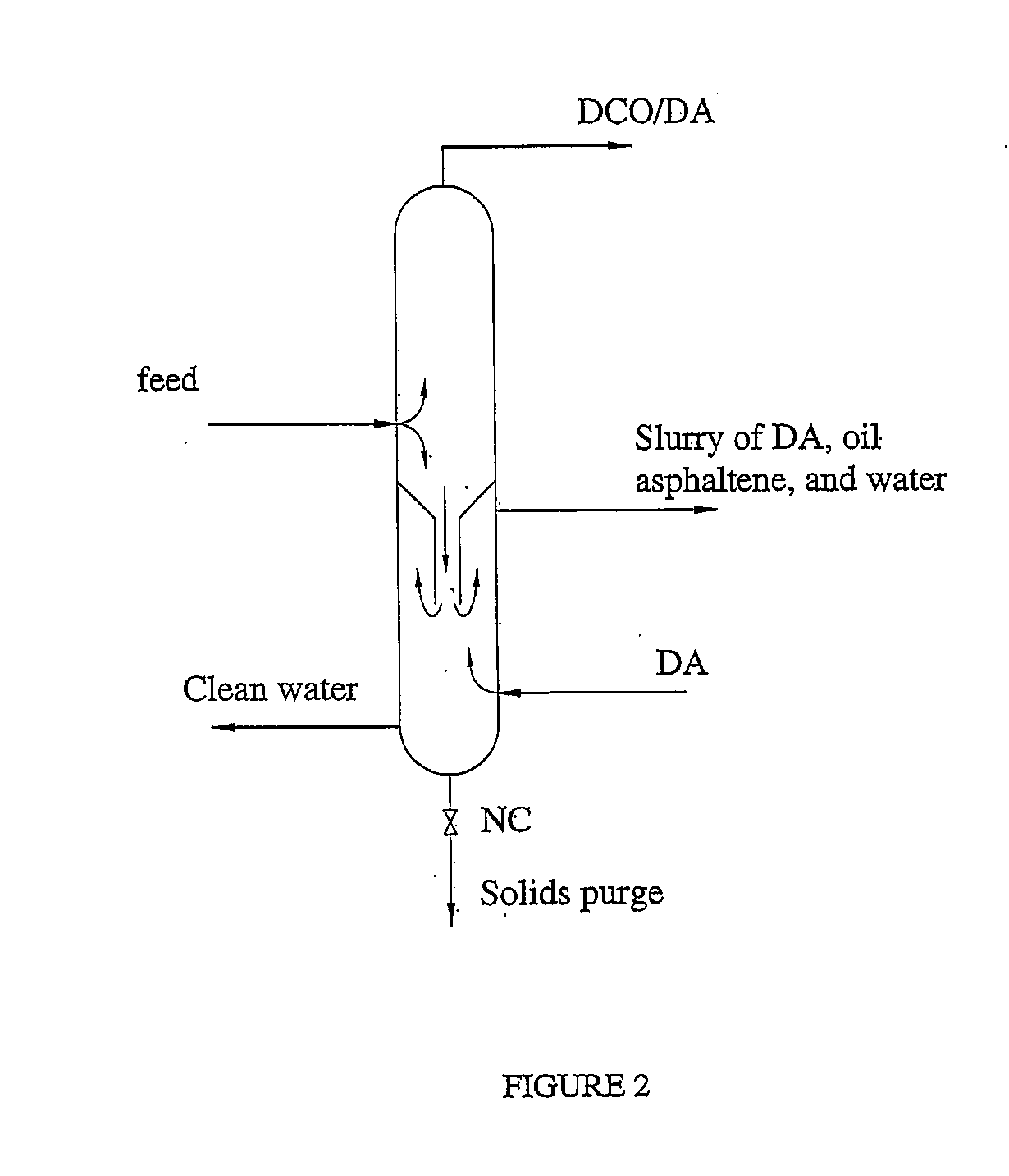

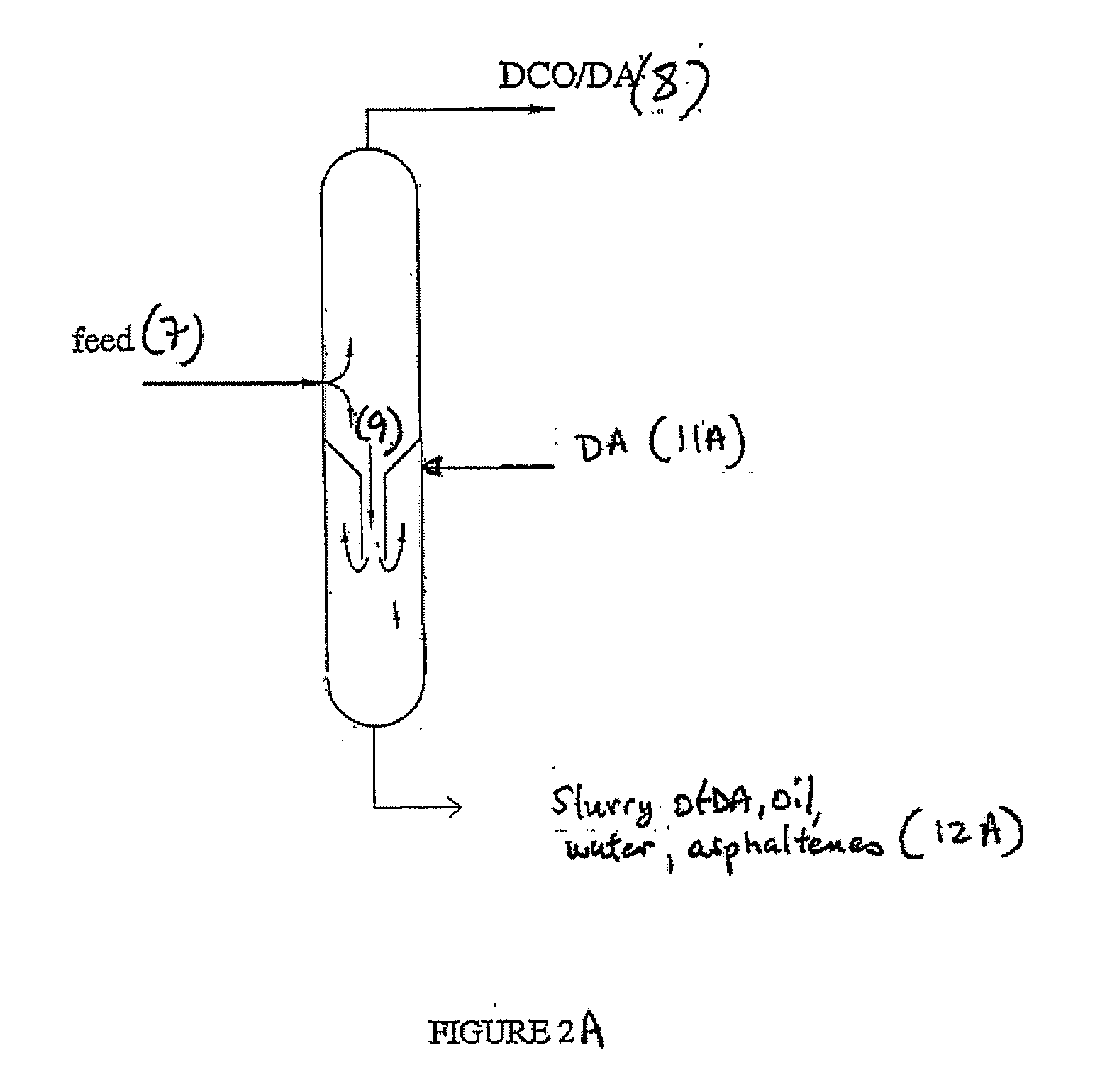

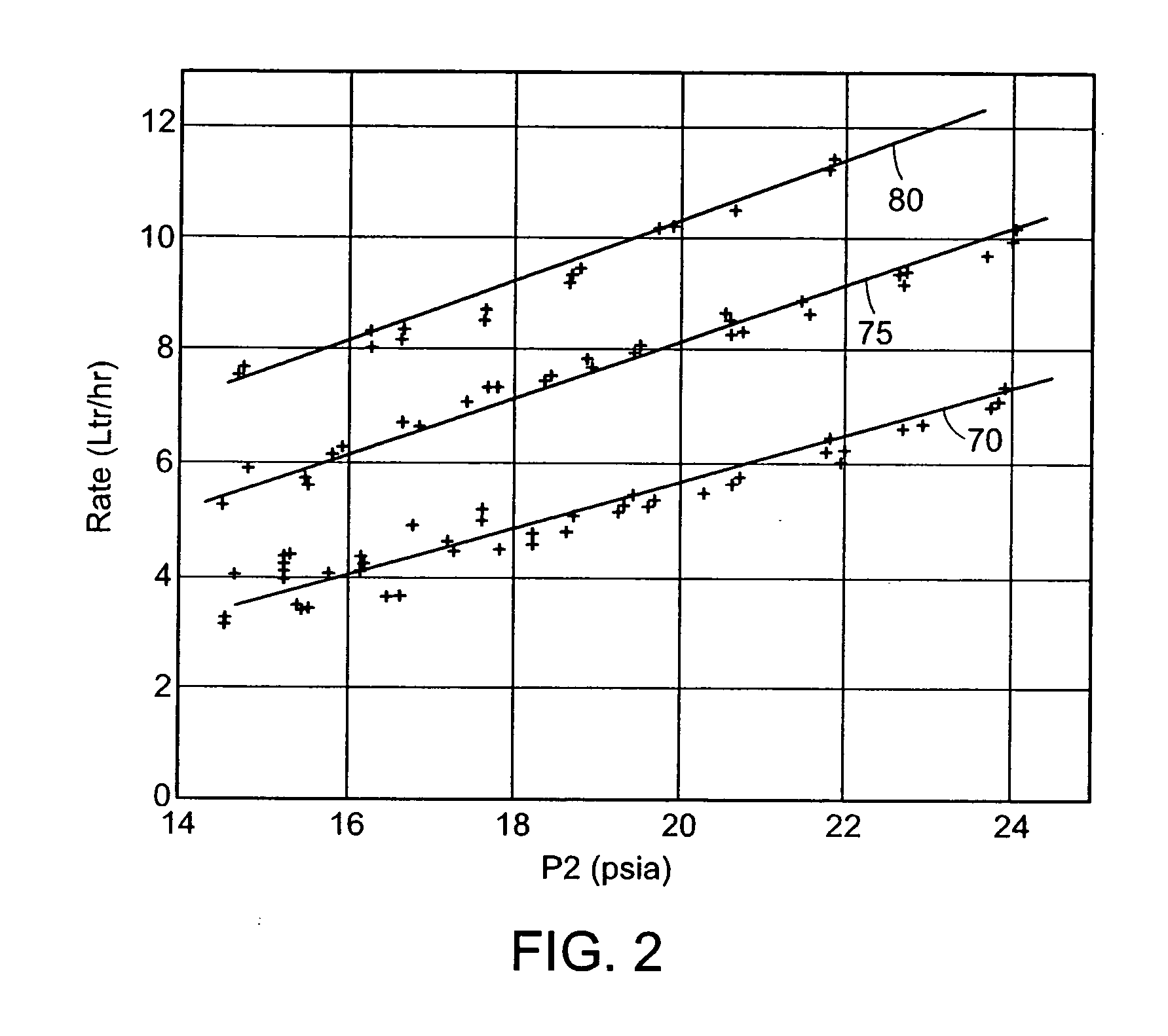

Water treatment process for thermal heavy oil recovery

There is disclosed a method and apparatus for treating produced water from a heavy oil thermal recovery unit to achieve water recovery and recycle levels of greater than 80% and as high as 100% to achieve zero discharge criteria. The method includes the initial steps of capturing the waste heat energy from the high pressure steam separator located downstream of the steam generators. Further, transferring the heat energy into a heated separator and reboiler exchanger to distill oil reservoir produced water and recover distilled water and a concentrated brine or solid product. The heated separator concentrated stream is circulated through the reboiler exchanger to maintain from 1% to about 50% mass vapour in the stream returning to the heated separator and prevent fouling and scaling. The apparatus includes a low pressure waste energy separator, heated separator and vapour compressor in combination with a forced circulation circuit to generate the distilled water.

Owner:FOUNTAIN QUAIL WATER MANAGEMENT LLC +1

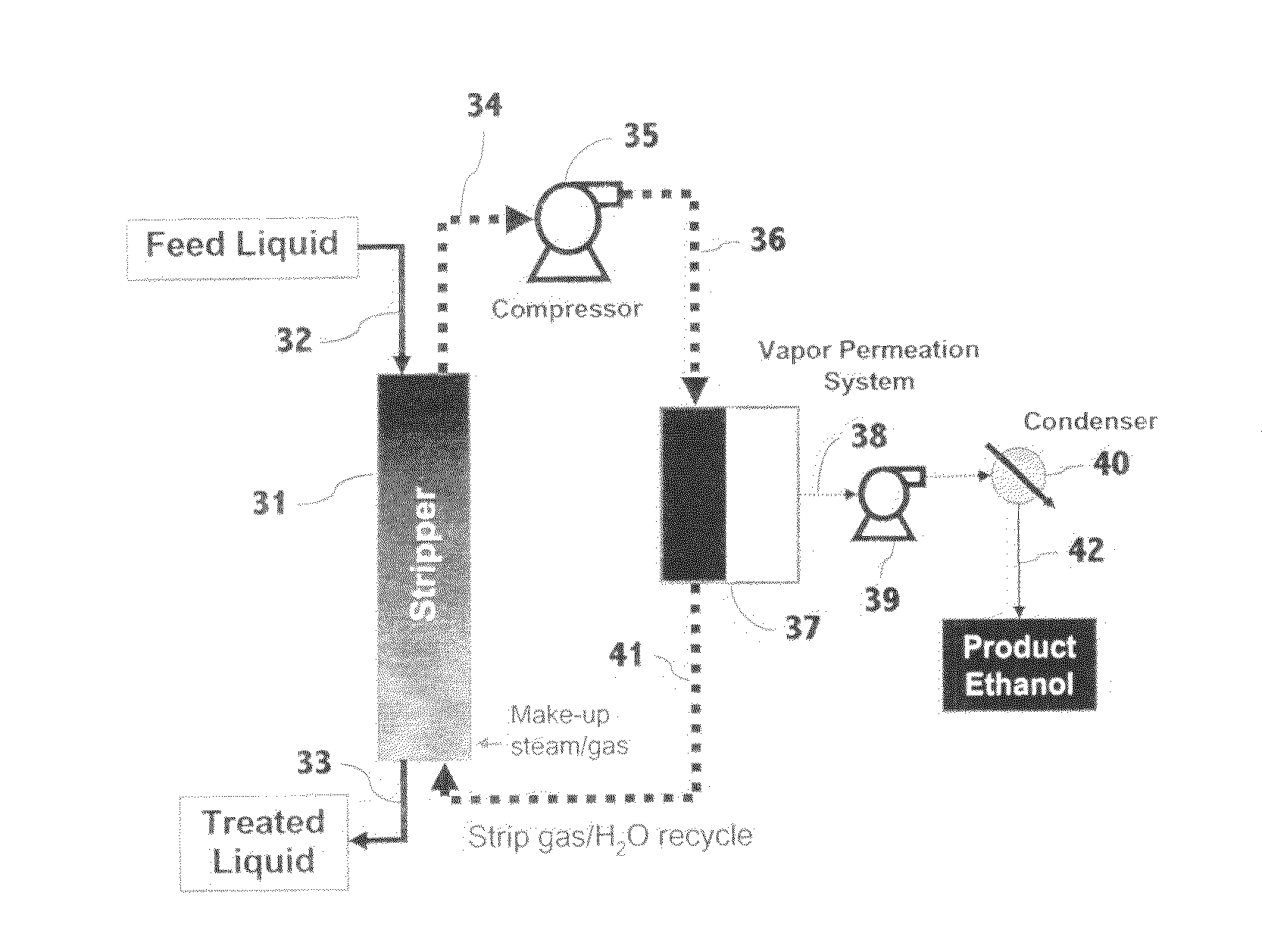

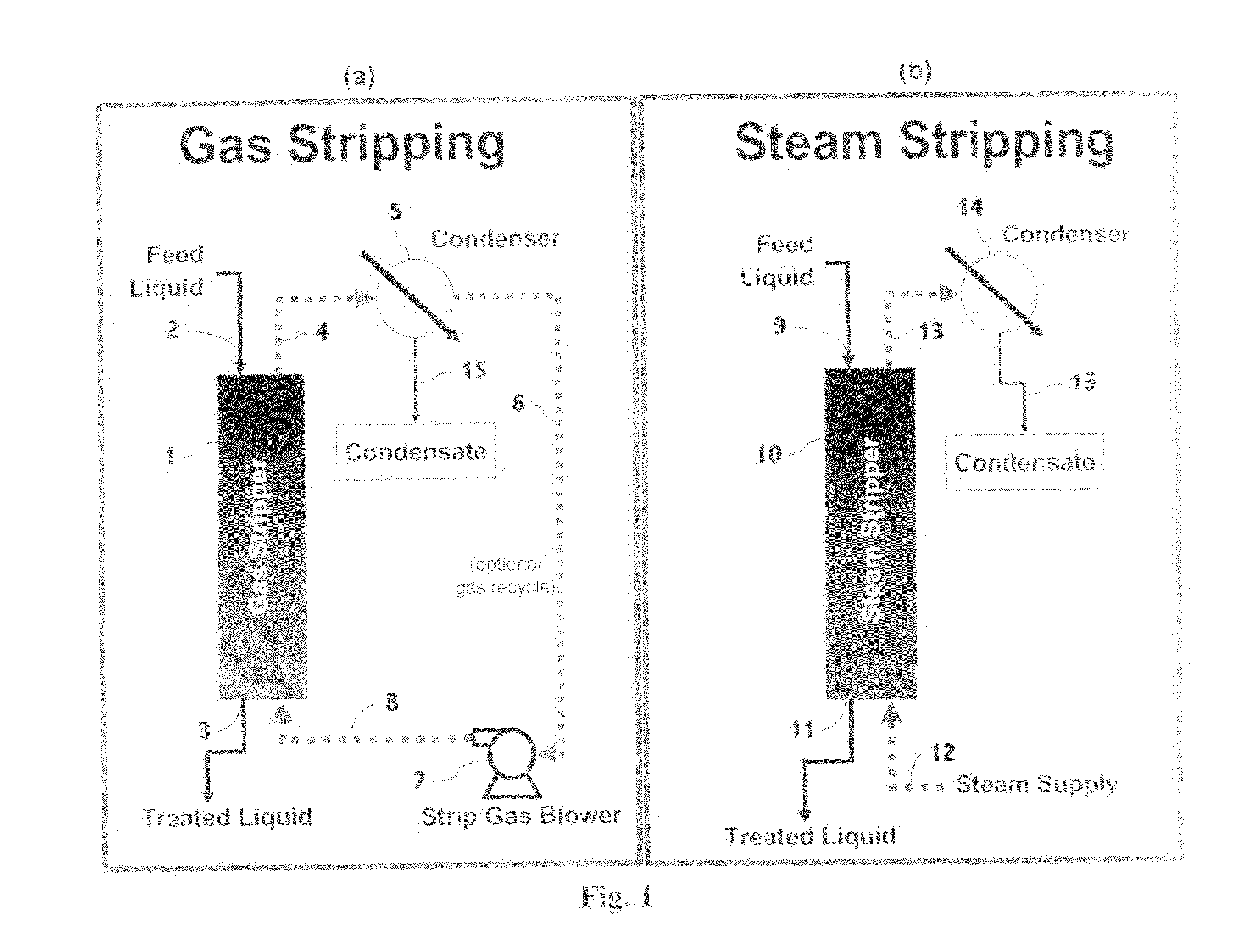

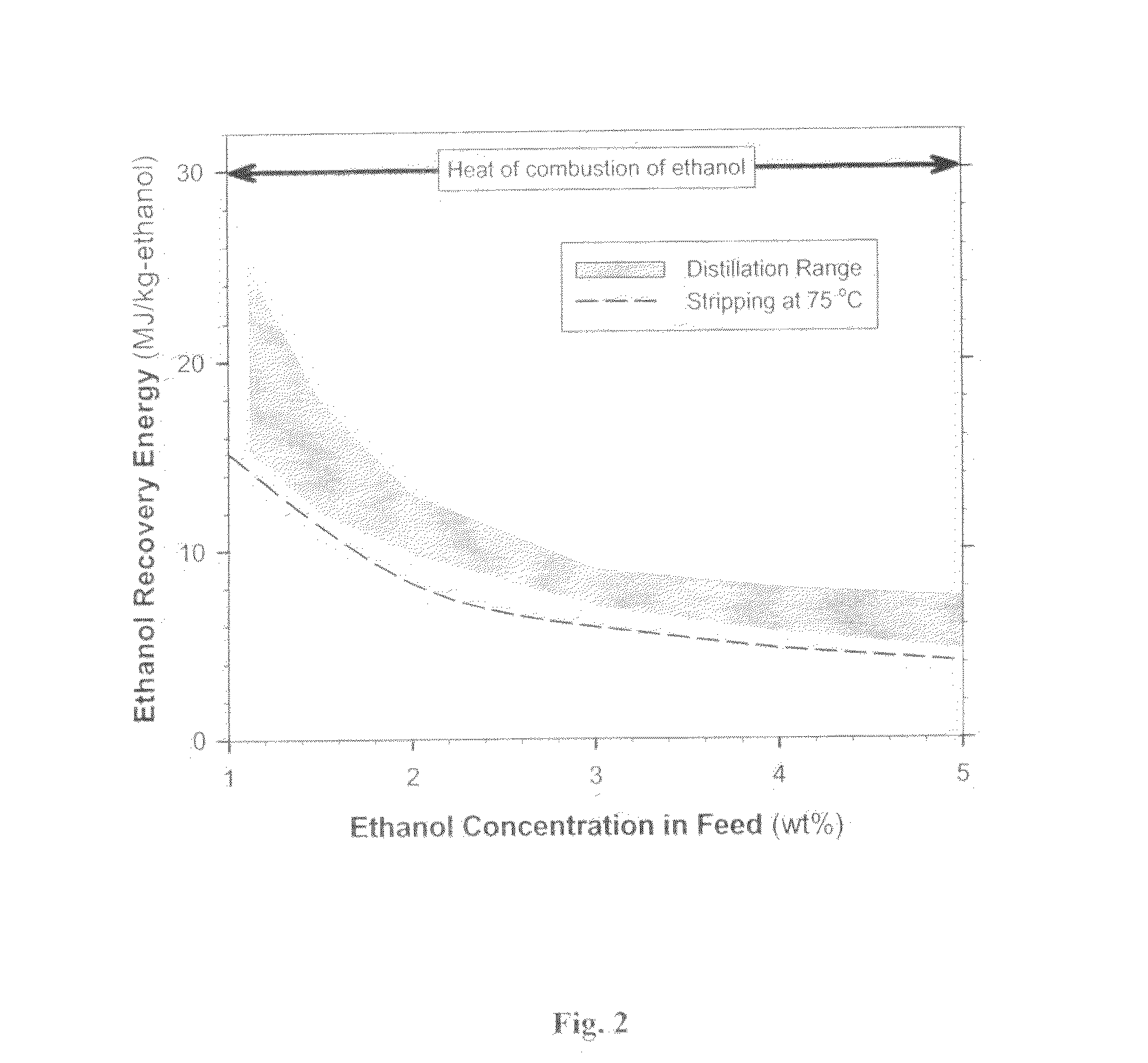

Liquid separation by membrane assisted vapor stripping process

InactiveUS20090057128A1Distillation regulation/controlUsing liquid separation agentImproved methodPermeation

An improved process for separation of liquid mixtures involves vapor stripping followed by mechanical compression of the vapor which is then exposed to a permeation membrane for separation of the compressed vapor.

Owner:VANE LELAND +1

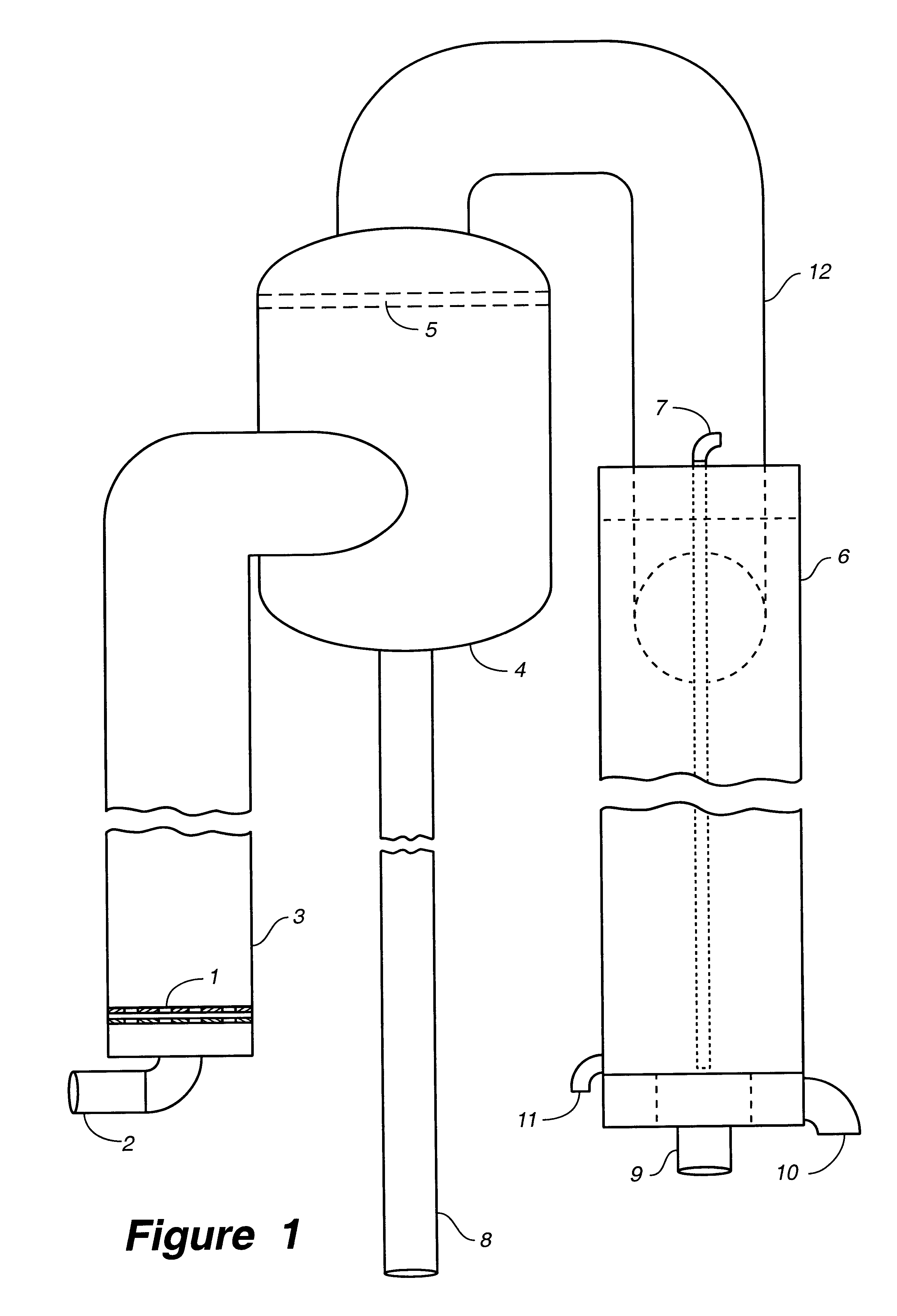

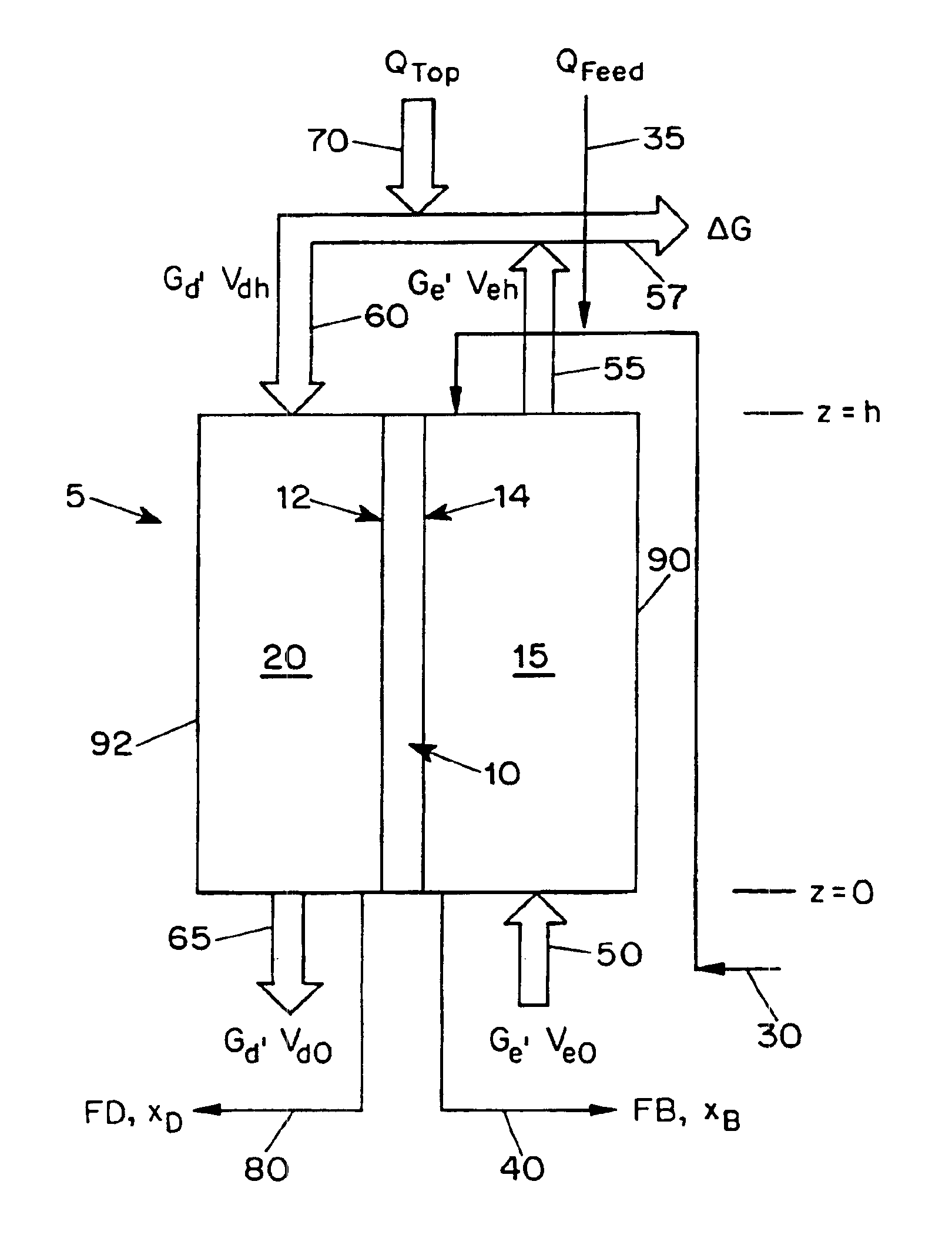

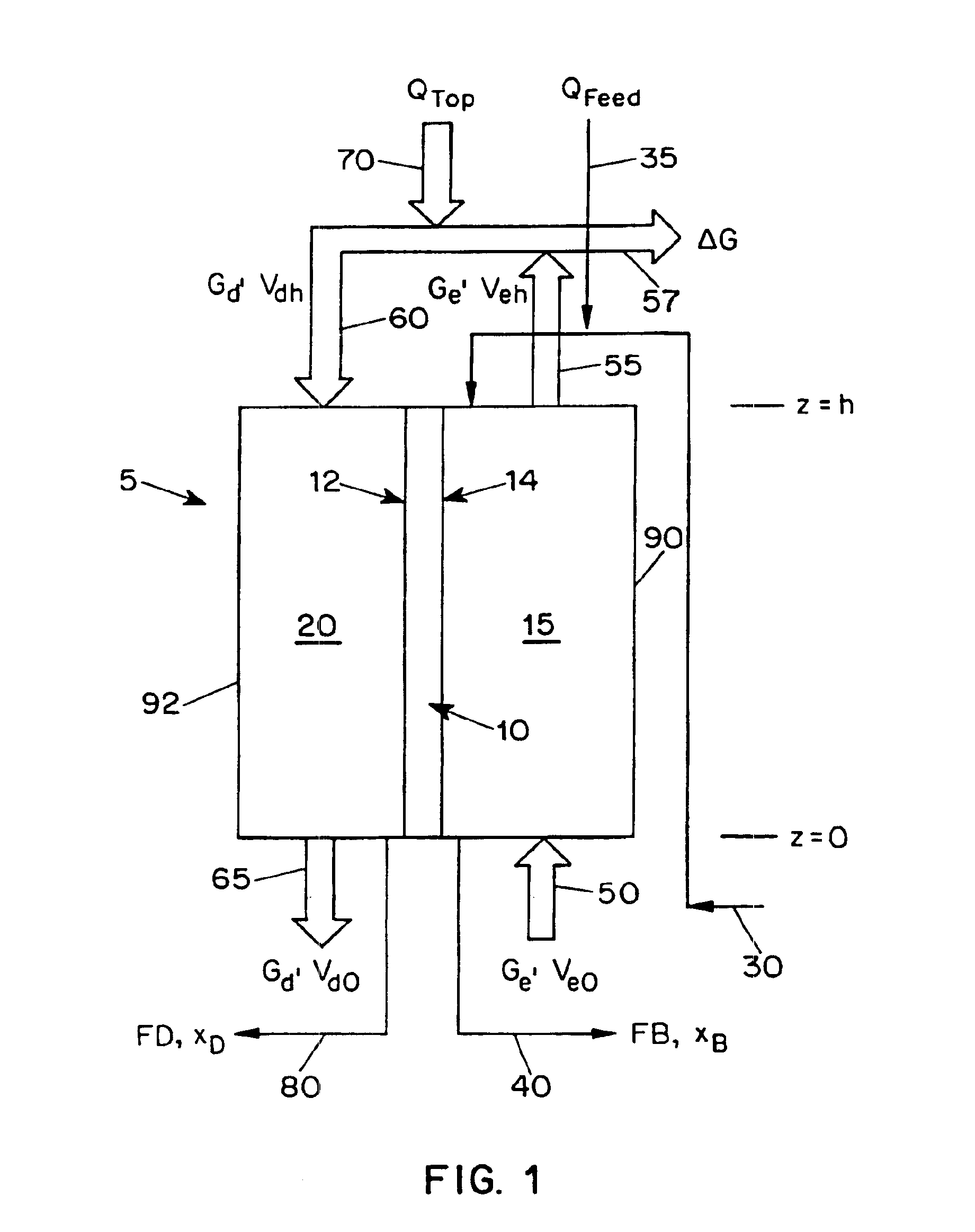

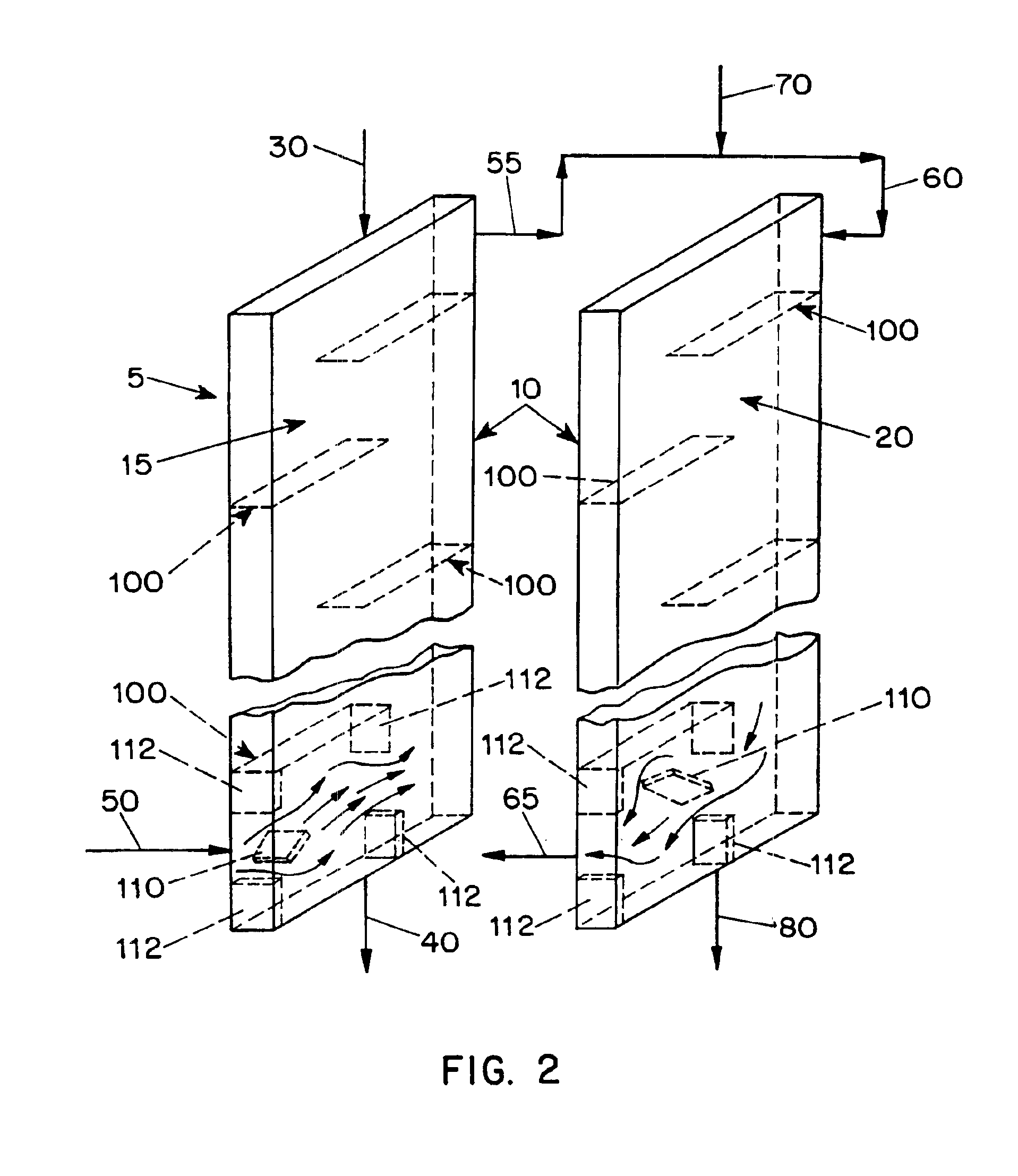

Method and apparatus for simultaneous heat and mass transfer utilizing a carrier-gas

InactiveUS6911121B1Improve concentrationDistillation regulation/controlEnergy based wastewater treatmentDewEvaporation chamber

The present application is directed to a continuous contacting apparatus for separating a liquid component from a liquid mixture. The apparatus comprises: (i) an evaporation chamber (15) having first and second ends, an inlet (50) and an outlet (55) for a carrier gas, and an inlet (30) and an outlet (40) for a liquid mixture, wherein the inlet (30) for the liquid mixture and the outlet (55) of the carrier gas are located on the first end of the evaporation chamber (15); (ii) a dew-formation chamber (20) having an inlet (60) and an outlet (65) for a carrier gas and an outlet for the separable liquid component (80), wherein the inlet for the carrier gas (60) of the dew-formation chamber (20) is situated in a countercurrent manner to the inlet for the carrier gas of the evaporation chamber; (iii) a common heat transfer wall (10) providing thermal communication between the evaporation chamber (15) and the dew-formation chamber (20); (iv) a feeding device for providing the liquid mixture onto the evaporation side of the heat transfer wall; (v) an air mover for controlling a flow of a carrier gas through the chambers, wherein the gas flow in the evaporation chamber is countercurrent to the gas flow in the dew-formation chamber; and (vi) a heating apparatus for heating the carrier gas from the outlet of the evaporation chamber, wherein the heated carrier gas is directed to flow into the inlet of the dew-formation chamber. Also described is a process for separating a liquid component from a liquid mixture in a continuous contacting manner comprising employing such an apparatus for such separation.

Owner:THE ARIZONA BOARD OF REGENTS ON BEHALF OF THE UNIV OF ARIZONA +1

Method and device for obtaining 1,3 pure butadiene from 1,3 raw butadiene by distillation

InactiveUS7132038B2Meet specificationsThermal non-catalytic crackingDistillation regulation/controlDistillationChemistry

A process for obtaining pure 1,3-butadiene from crude 1,3-butadiene by distillation is carried out in a dividing wall column in which a dividing wall is located in the longitudinal direction of the column to form an upper common column region, a lower common column region, a feed section and an offtake section.

Owner:BASF AG

Apparatus and method for protection against appliance leaking

A water protection system apparatus for detecting and stopping a flow of water which includes a power supply, a water ionization switch, and a controlled valve assembly. The water ionization switch selectively conducts electricity when exposed to water and includes an initially dry non-conductive crystallized compound. The compound ionizes when exposed to water to form an electrolyte which conducts electricity. This switch is connected to a controlled valve assembly to stop the flow of water in response to the detection of water by the switch. Other refinements include modifications to the switch housing and condition indicators for monitoring the system and signaling water detection and shutdown operations.

Owner:STAY DRY INT

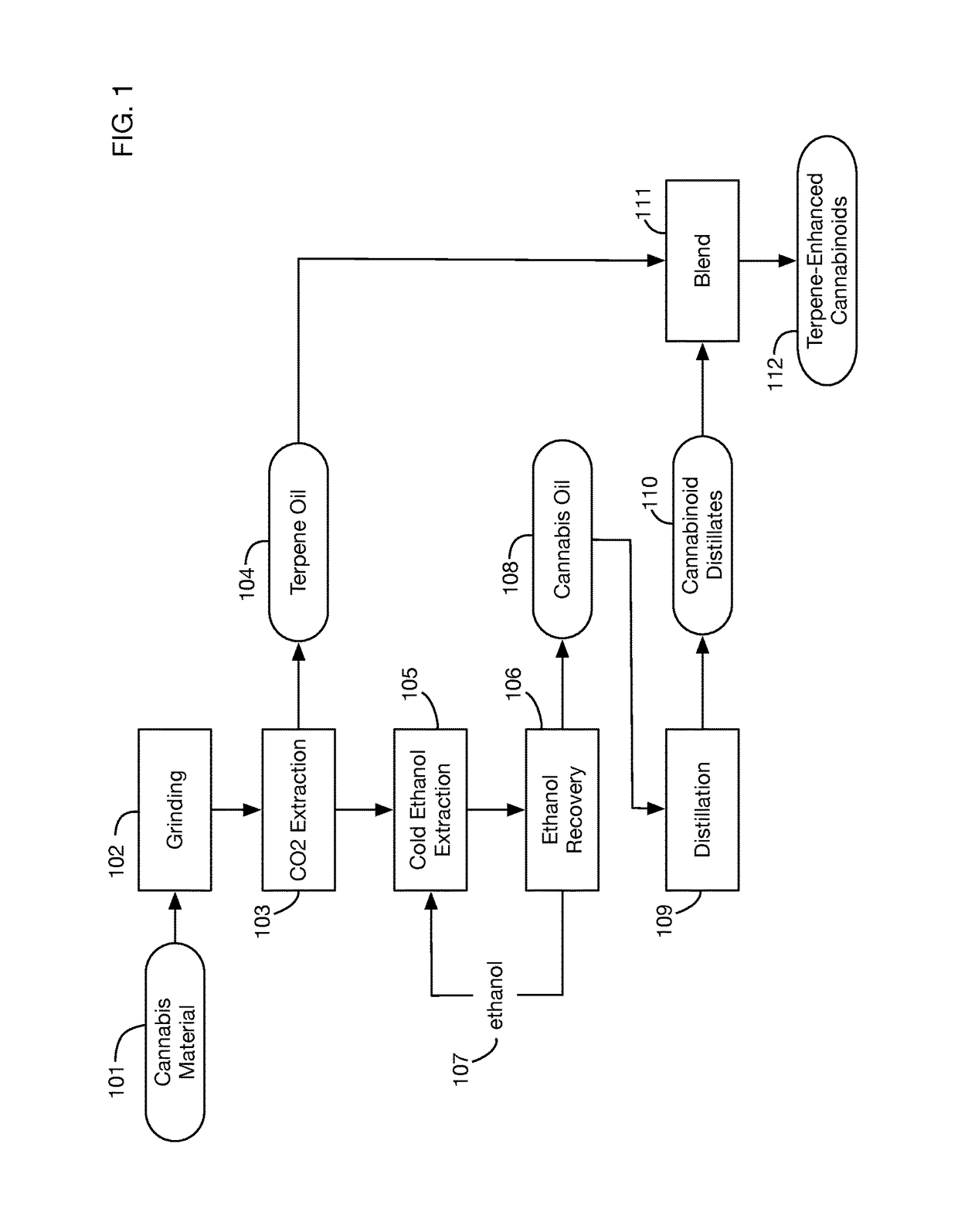

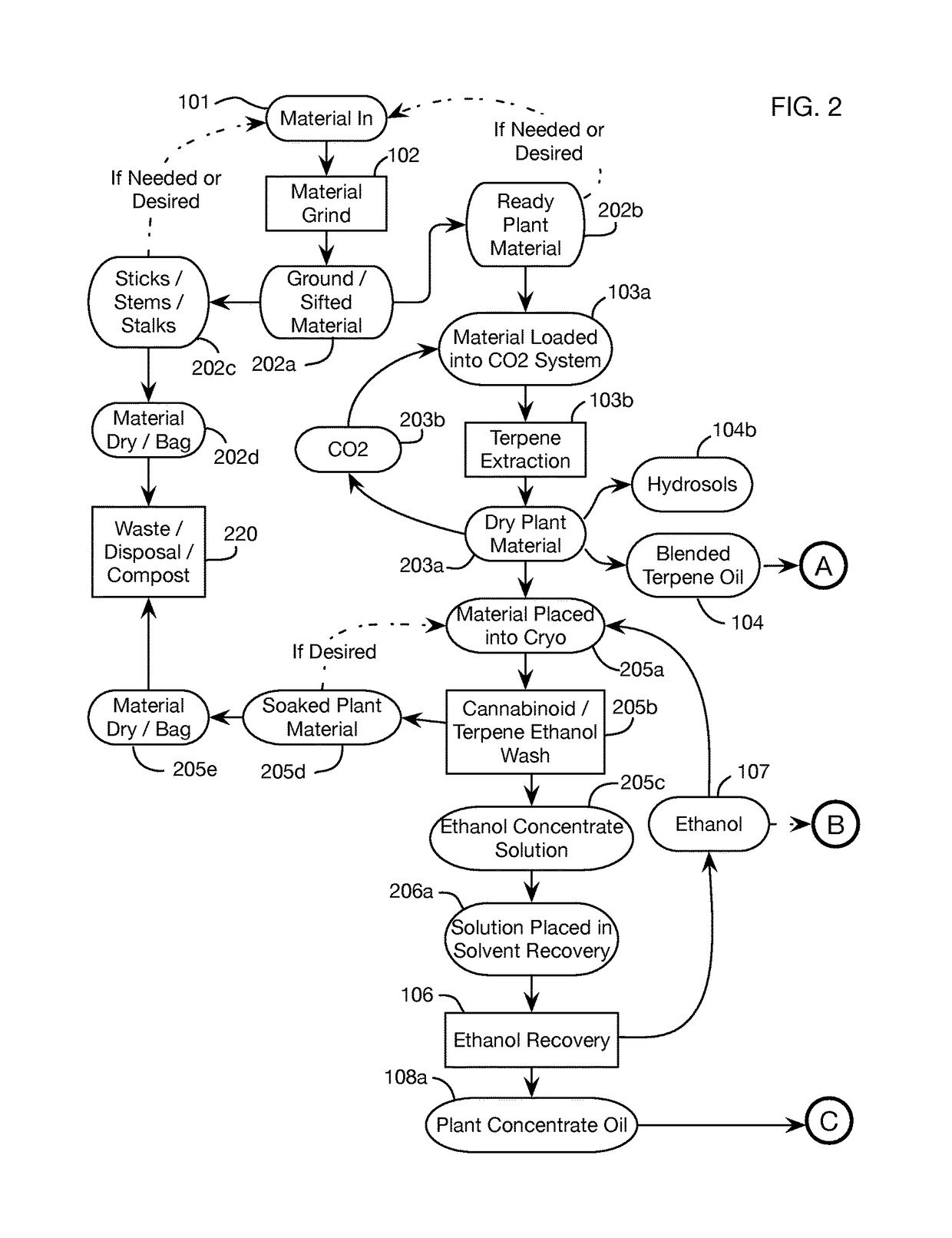

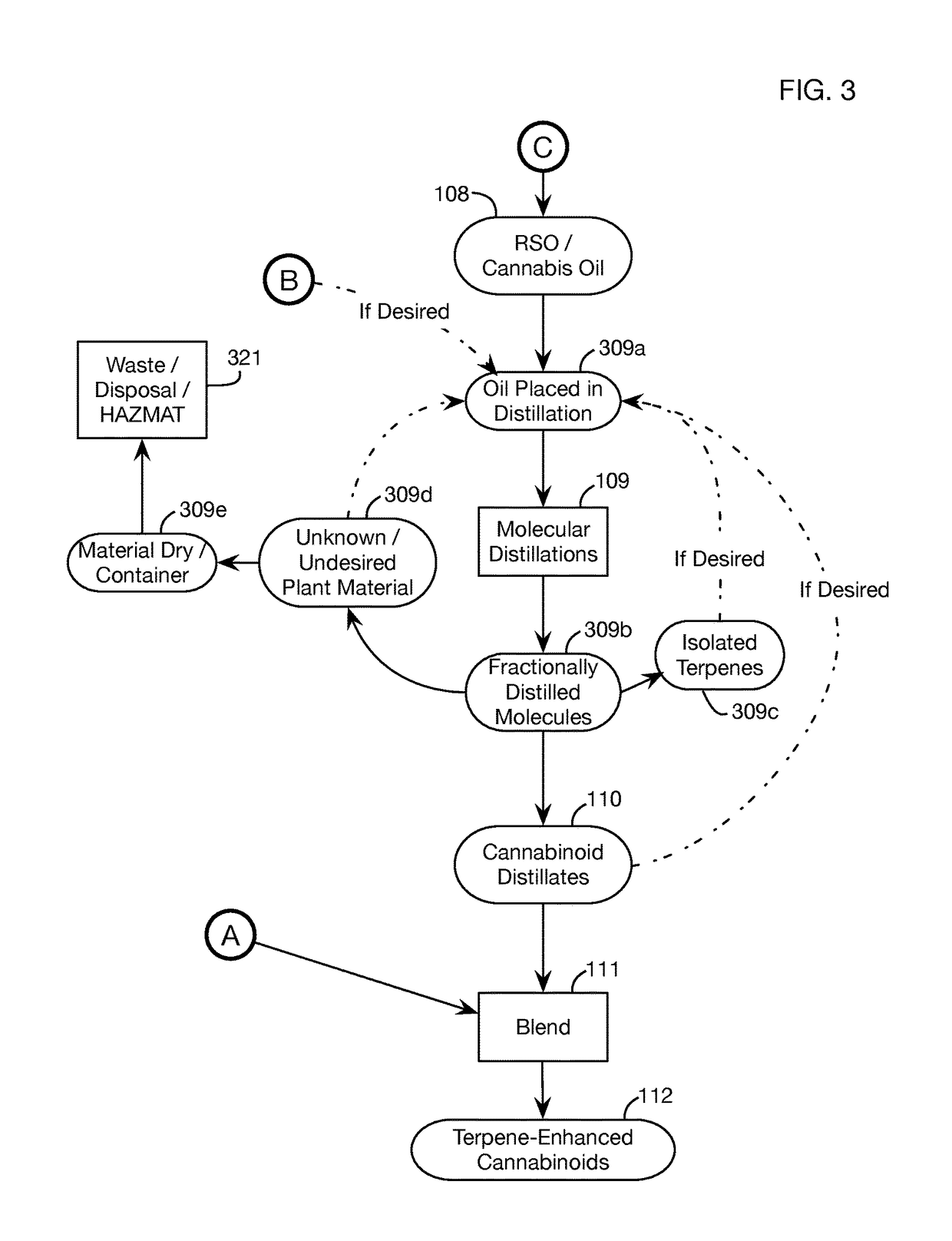

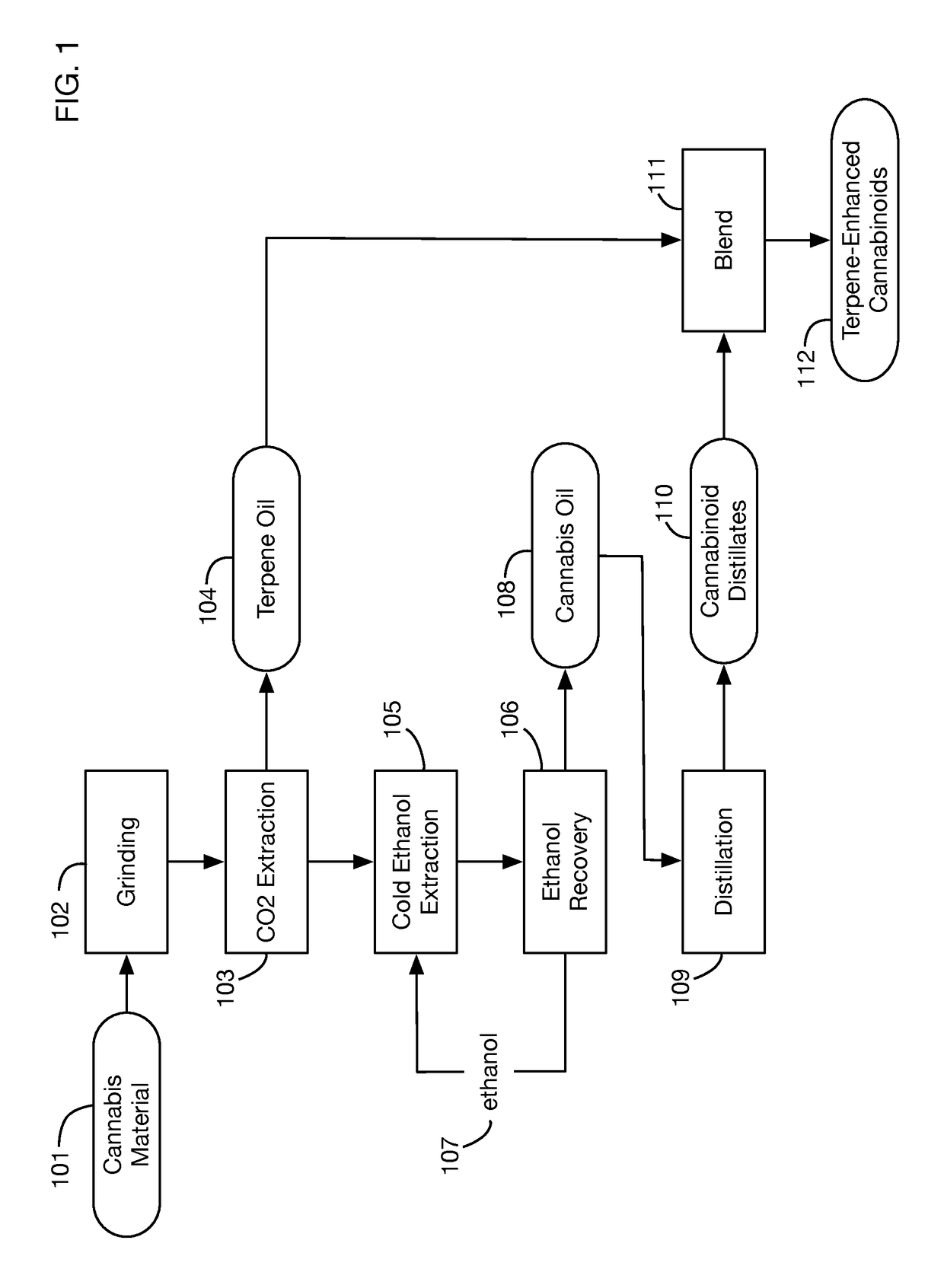

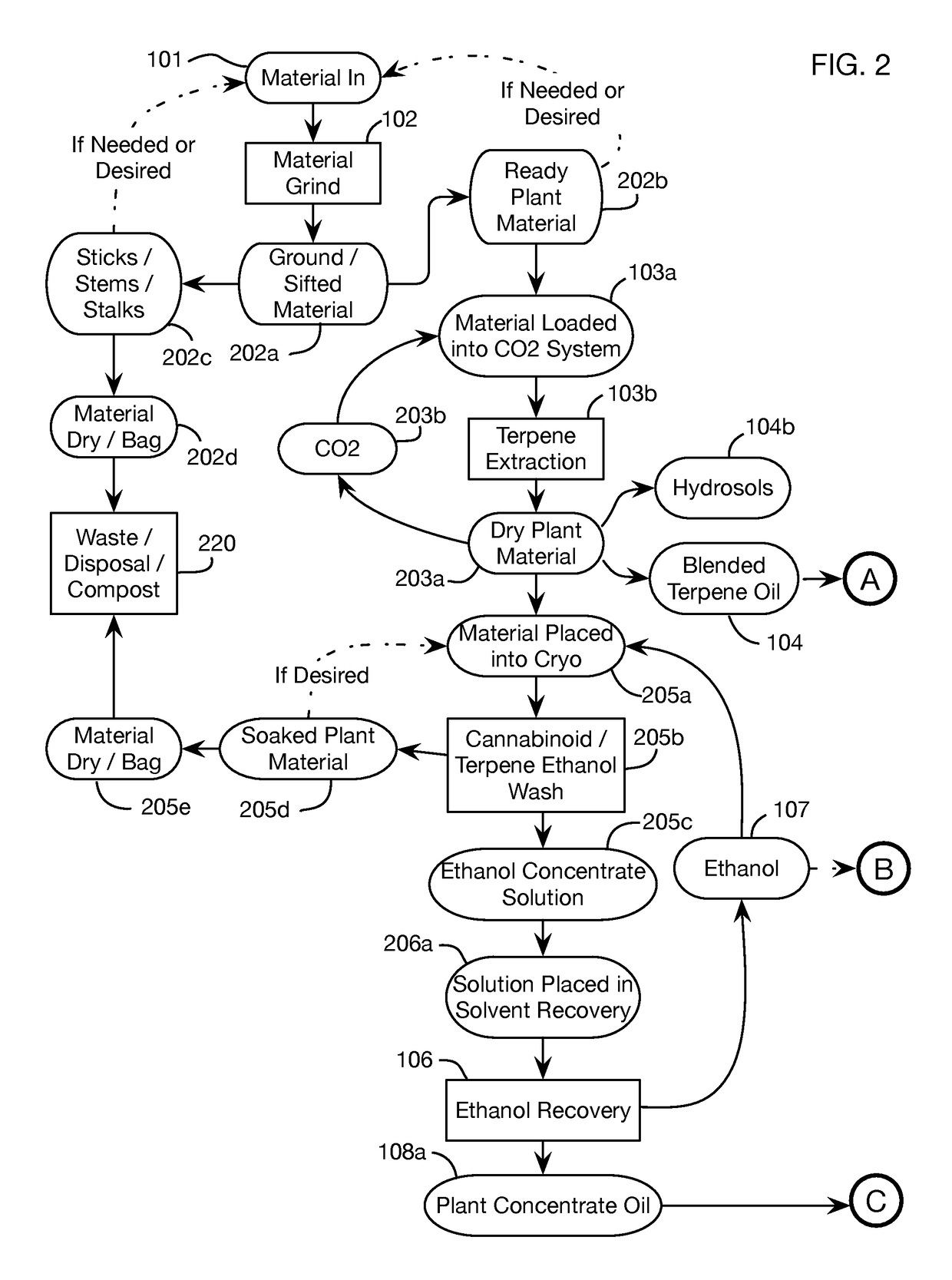

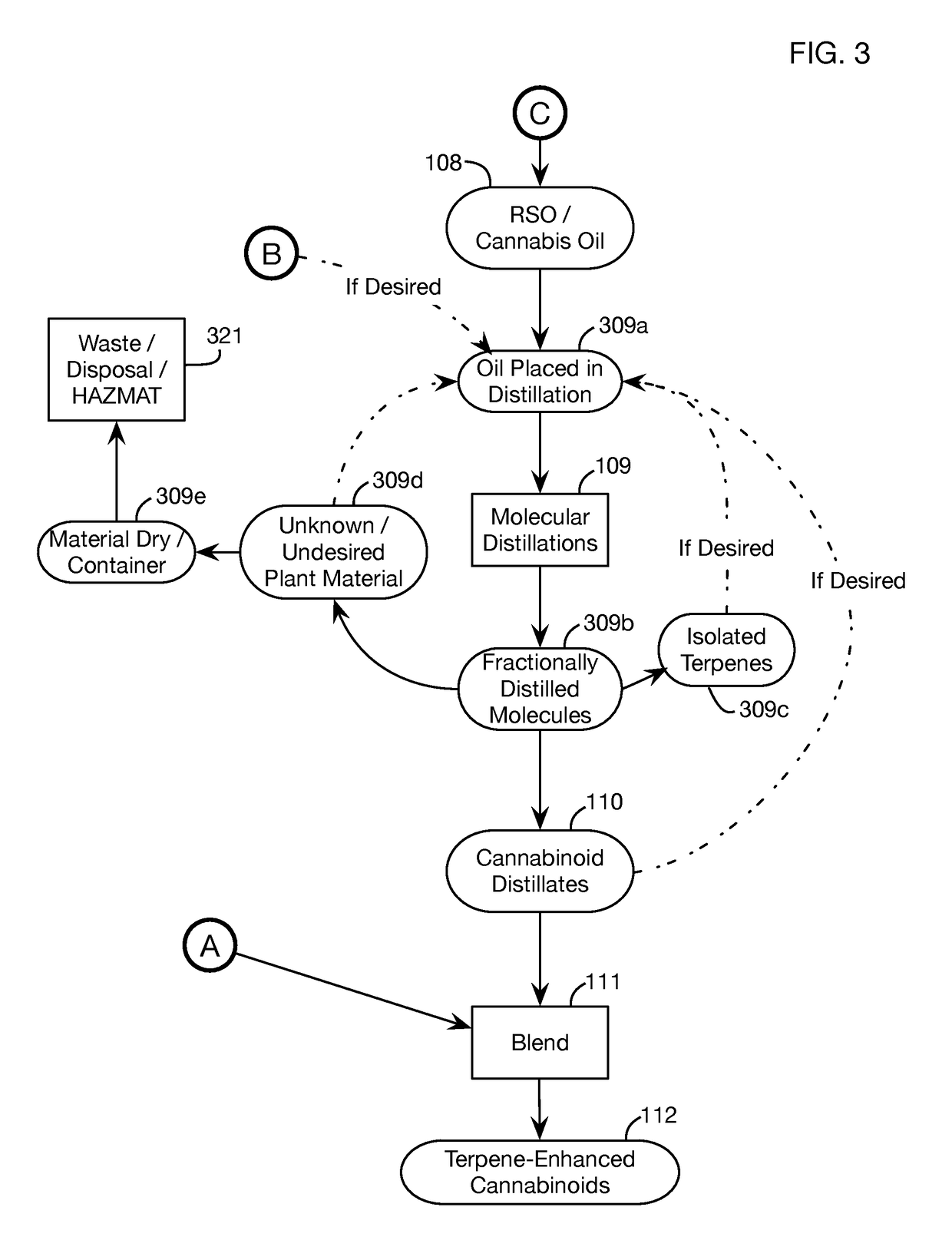

System and method for producing a terpene-enhanced cannibinoid concentrate

A system and method of producing a blended extract of cannabinoids and terpenes, which extracts terpenes using supercritical CO2, and extracts a cannabinoid concentrate from the residual material using a cold ethanol flush followed by distillation; the CO2-extracted terpenes are then added back to the cannabinoid concentrate in a final blending step. Blending terpenes at the end of extraction may enhance the flavor and effectiveness of the cannabinoid concentrate. By separately extracting terpenes and cannabinoids, optimal processes and parameters may be used for each step. Blending may combine terpenes and cannabinoids in any desired ratio; for example, a terpene-to-cannabinoid ratio of approximately 1:10 may be used. The ethanol used in the cold ethanol extraction of cannabinoids may be recovered and reused for subsequent batches. Cannabinoid concentrates may be redistilled multiple times to enhance their concentration, followed by terpene blending.

Owner:THE HOUSE OF GREEN

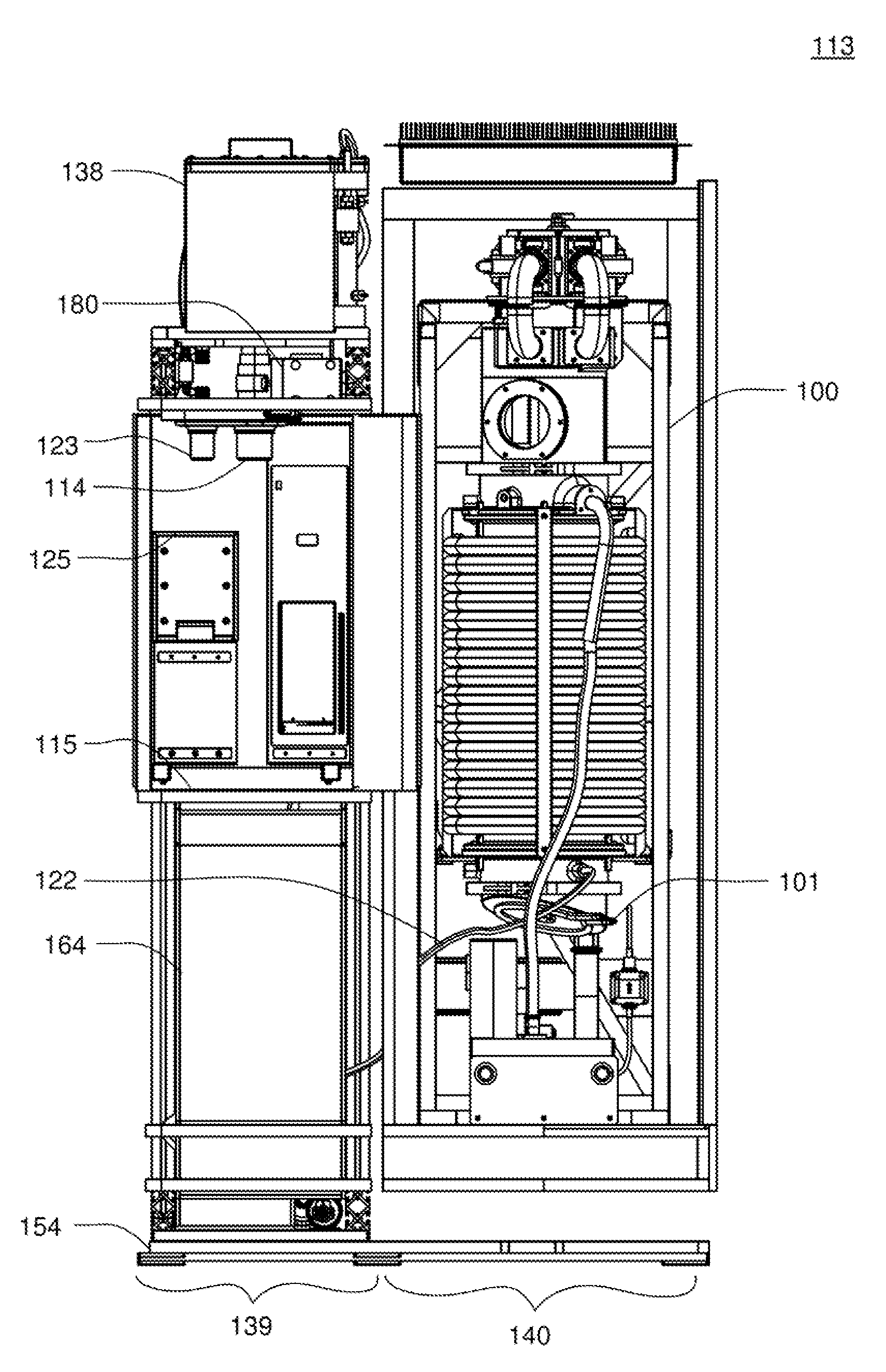

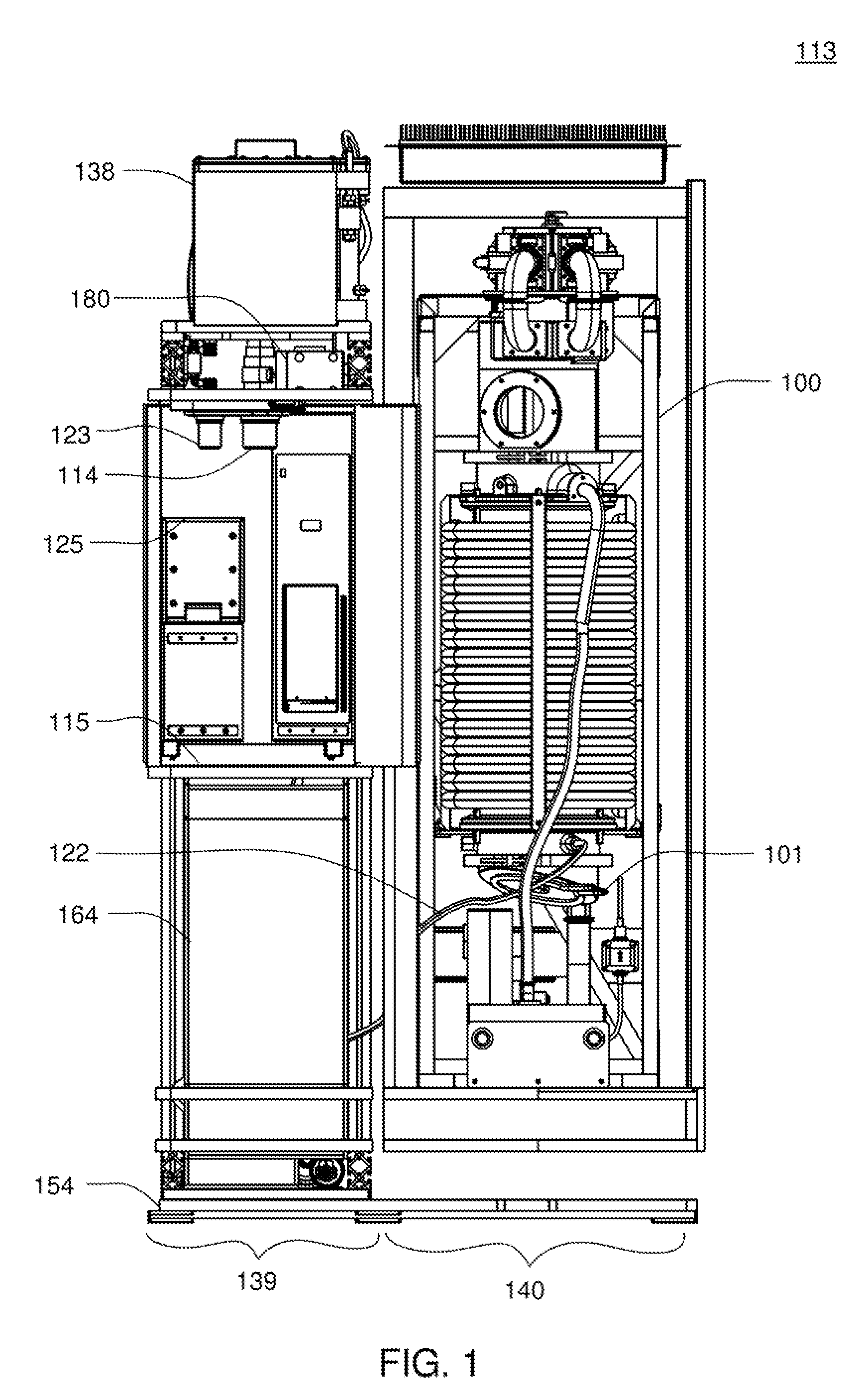

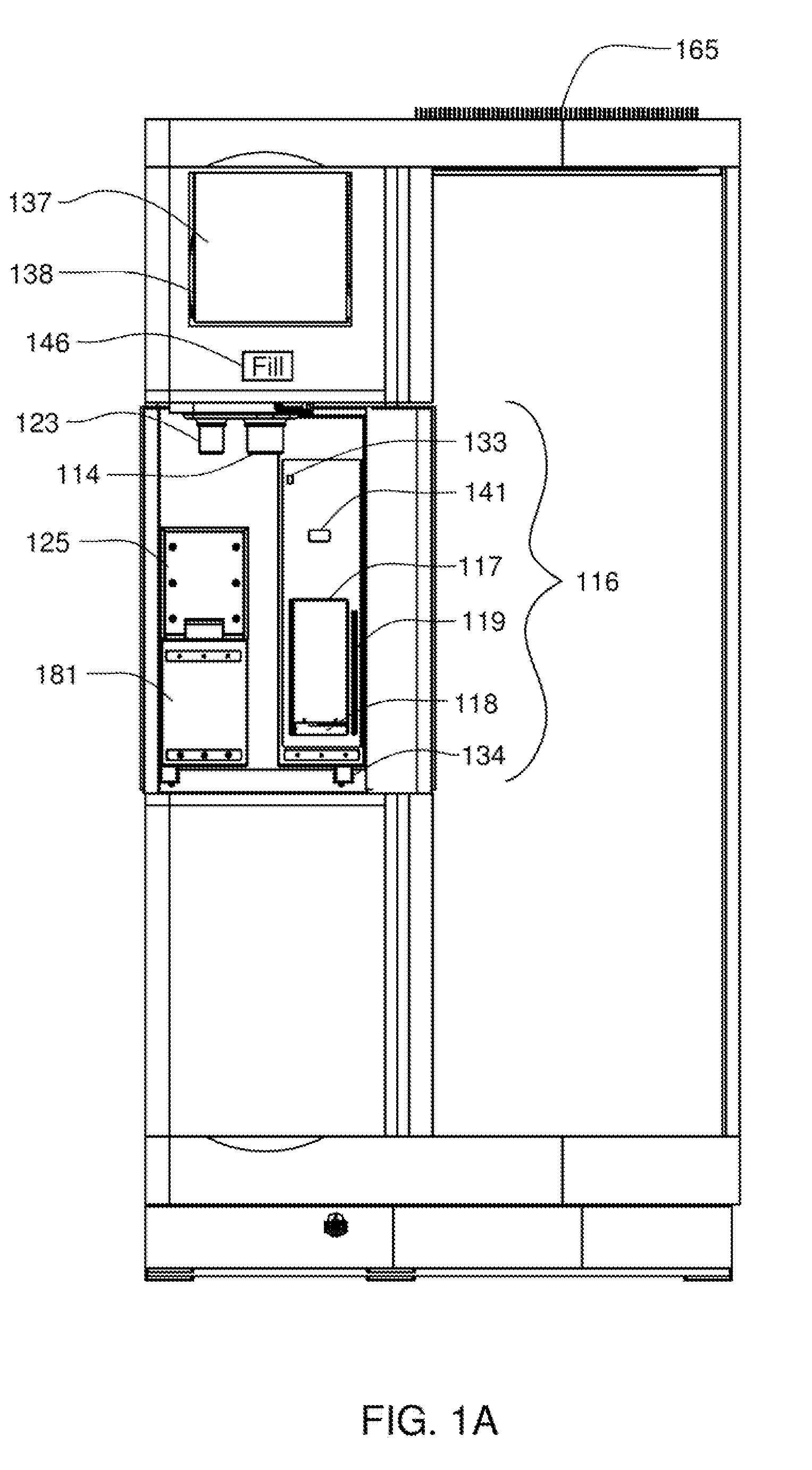

Water Vending Apparatus

ActiveUS20100101929A1Less production ratePrevents sediment buildupWater/sewage treatment by irradiationLighting and heating apparatusWater vaporSteam distillation

A water vending apparatus is disclosed. The water vending system includes a water vapor distillation apparatus and a dispensing device. The dispensing device is in fluid communication with the fluid vapor distillation apparatus and the product water from the fluid vapor distillation apparatus is dispensed by the dispensing device.

Owner:DEKA PROD LLP

Swappable sets of partial-mapping tables in a flash-memory system with a command queue for combining flash writes

InactiveUS8112574B2Memory architecture accessing/allocationDistillation regulation/controlFlash memory controllerMulti-level cell

A flash controller has a flash interface accessing physical blocks of multi-level-cell (MLC) flash memory. An Extended Universal-Serial-Bus (EUSB) interface loads host commands into a command queue where writes are re-ordered and combined to reduce flash writes. A partial logical-to-physical L2P mapping table in a RAM has entries for only 1 of N sets of L2P mapping tables. The other N−1 sets are stored in flash memory and fetched into the RAM when a L2P table miss occurs. The RAM required for mapping is greatly reduced. A data buffer stores one page of host write data. Sector writes are merged using the data buffer. The data buffer is flushed to flash when a different page is written, while the partial logical-to-physical mapping table is flushed to flash when a L2P table miss occurs, when the host address is to a different one of the N sets of L2P mapping tables.

Owner:SUPER TALENT TECH CORP

Optimizing product drying through parallel lines of centrifuges and dryer process units

Owner:ROCKWELL AUTOMATION TECH

System for producing a terpene-enhanced cannabinoid concentrate

A system for producing a blended extract of cannabinoids and terpenes, which extracts terpenes using supercritical CO2, and extracts a cannabinoid concentrate from the residual material using a cold ethanol flush followed by distillation; the CO2-extracted terpenes are then added back to the cannabinoid concentrate in a final blending step. Blending terpenes at the end of extraction may enhance the flavor and effectiveness of the cannabinoid concentrate. By separately extracting terpenes and cannabinoids, optimal processes and parameters may be used for each step. Blending may combine terpenes and cannabinoids in any desired ratio; for example, a terpene-to-cannabinoid ratio of approximately 1:10 may be used. The ethanol used in the cold ethanol extraction of cannabinoids may be recovered and reused for subsequent batches. Cannabinoid concentrates may be redistilled multiple times to enhance their concentration, followed by terpene blending.

Owner:OAK & CRANE LLC

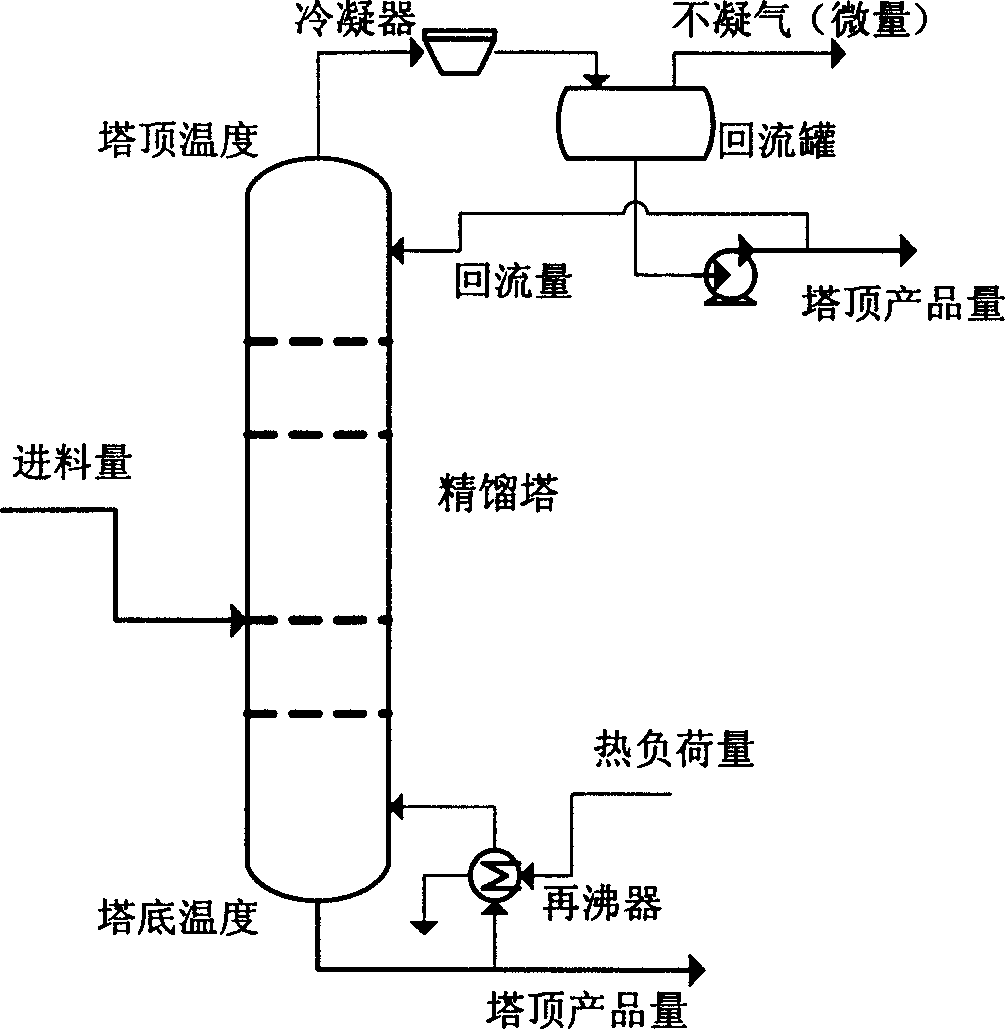

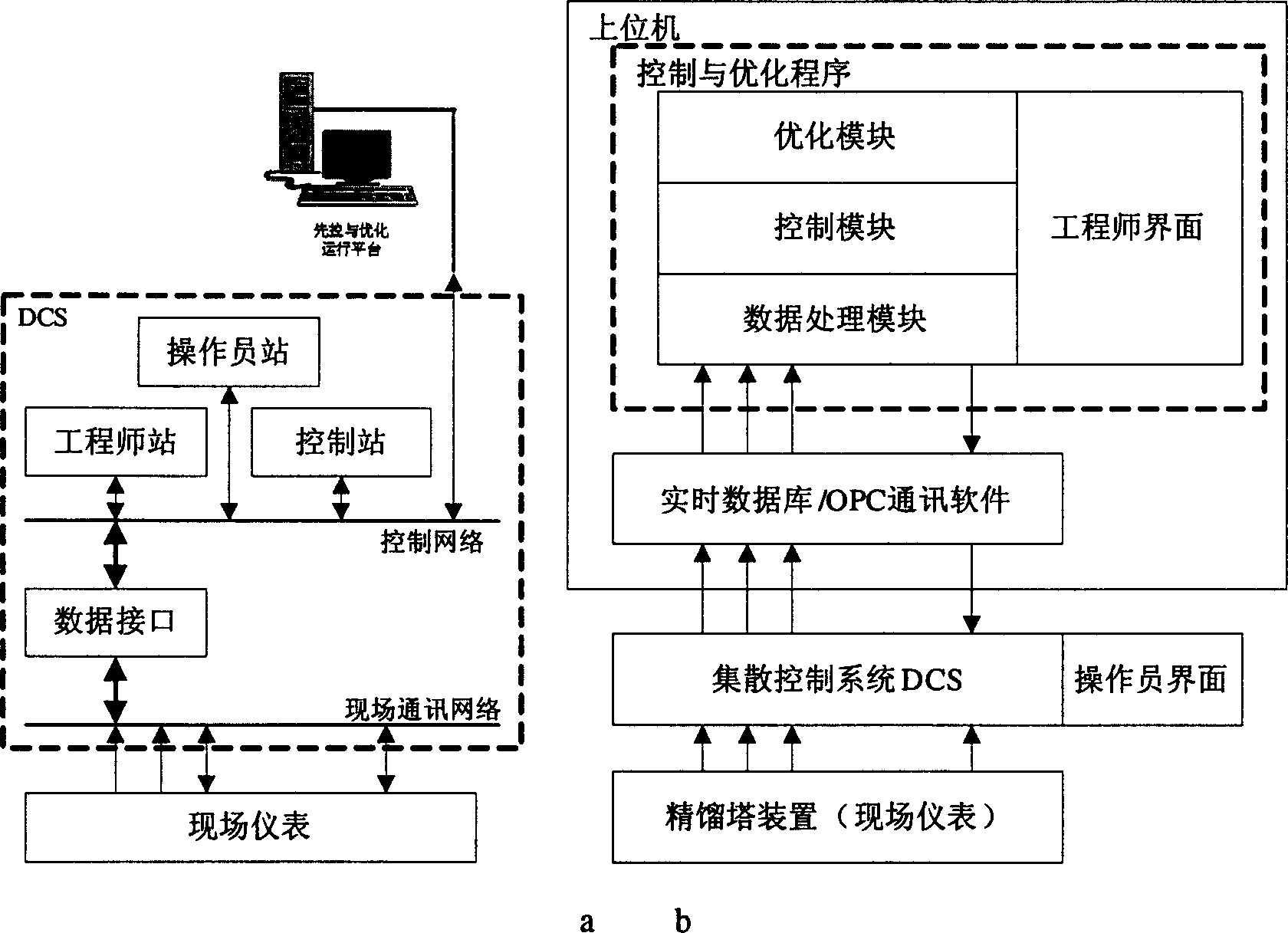

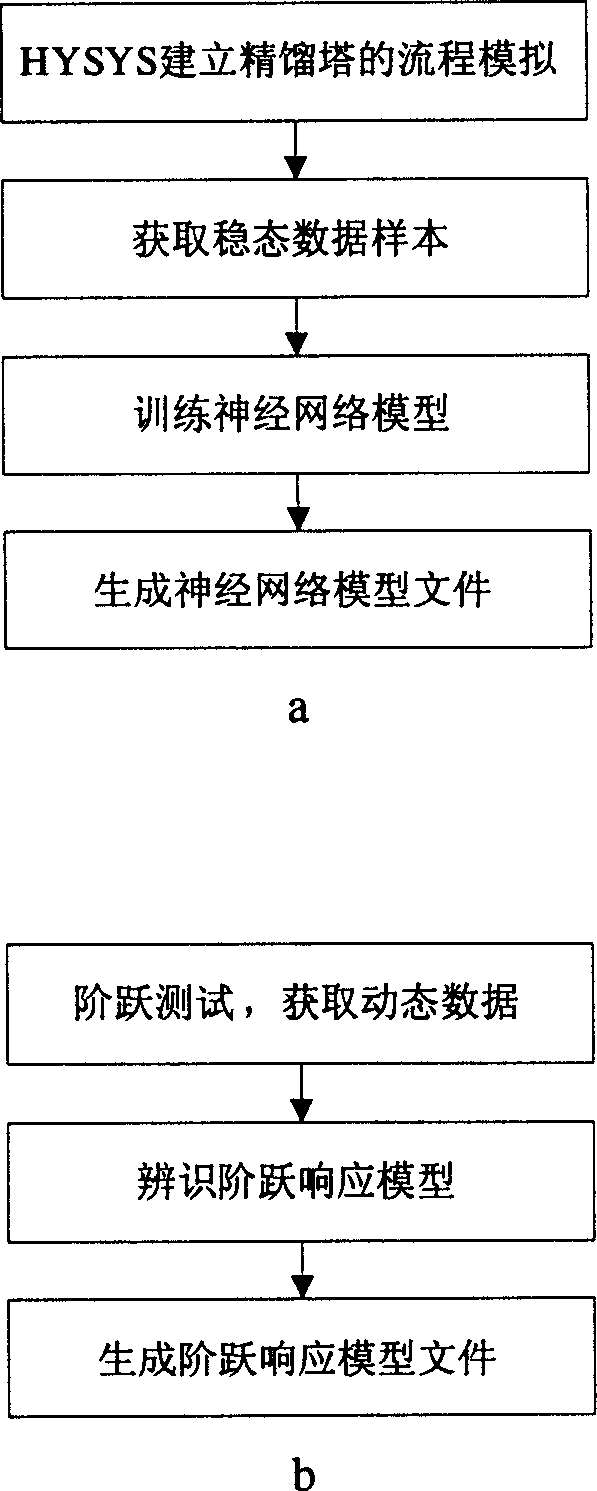

Rectification tower automatic control and optimization method

InactiveCN1762525AEasy to operateLess impuritiesDistillation regulation/controlAutomatic controlMaterial balance

The invention relates to a method for controlling and optimizing the distillation tower. It controls the distillation tower in dependence on the material balance relation and component balance relation, optimizes the distillation tower by using representative model. Employing the abstraction proportion between the light product on the top of the tower and heavy product in the bottom of the tower (in following, taking the proportion between light and heavy product for abbreviation) as main controlled variable depending on the distillation principle, the material balance and component balance in the distillation tower, controlling the proportion between the light and heavy product, temperature, reflux ratio to realize stable operation by regulating the quantity of reflux and heat load of re-boiler. Simulating the practical course through the technological process simulation software, and training the nerve net model to become the representative model for the course optimization. Optimizing the operation with the representative model by using the analytical data for the raw material and product to realize the product Ka bian optimization, increasing the productivity of product with high value on the condition of guaranteeing the product quality and realizing the device energy saving and consumption reduction.

Owner:TSINGHUA UNIV

Ethanol distillation with distillers soluble solids recovery apparatus

ActiveUS7867365B2Reduce energy useIncrease concentrationDrying using combination processesDistillation regulation/controlMolecular sieveAnhydrous ethanol

The present invention relates to a system for producing ethanol from an organic source and that operates to purify and dry ethanol from a beer source. The system for producing substantially anhydrous ethanol comprises: (a) a first distillation stripping column; (b) a second distillation rectifying column having a higher operating temperature than said stripping column; (c) a molecular sieve dehydration means in fluid communication with said rectifying column. Heat from the overhead of the second distillation rectifying column and the molecular sieve dehydration are used to heat the first distillation stripping column.

Owner:RCM TECH USA INC

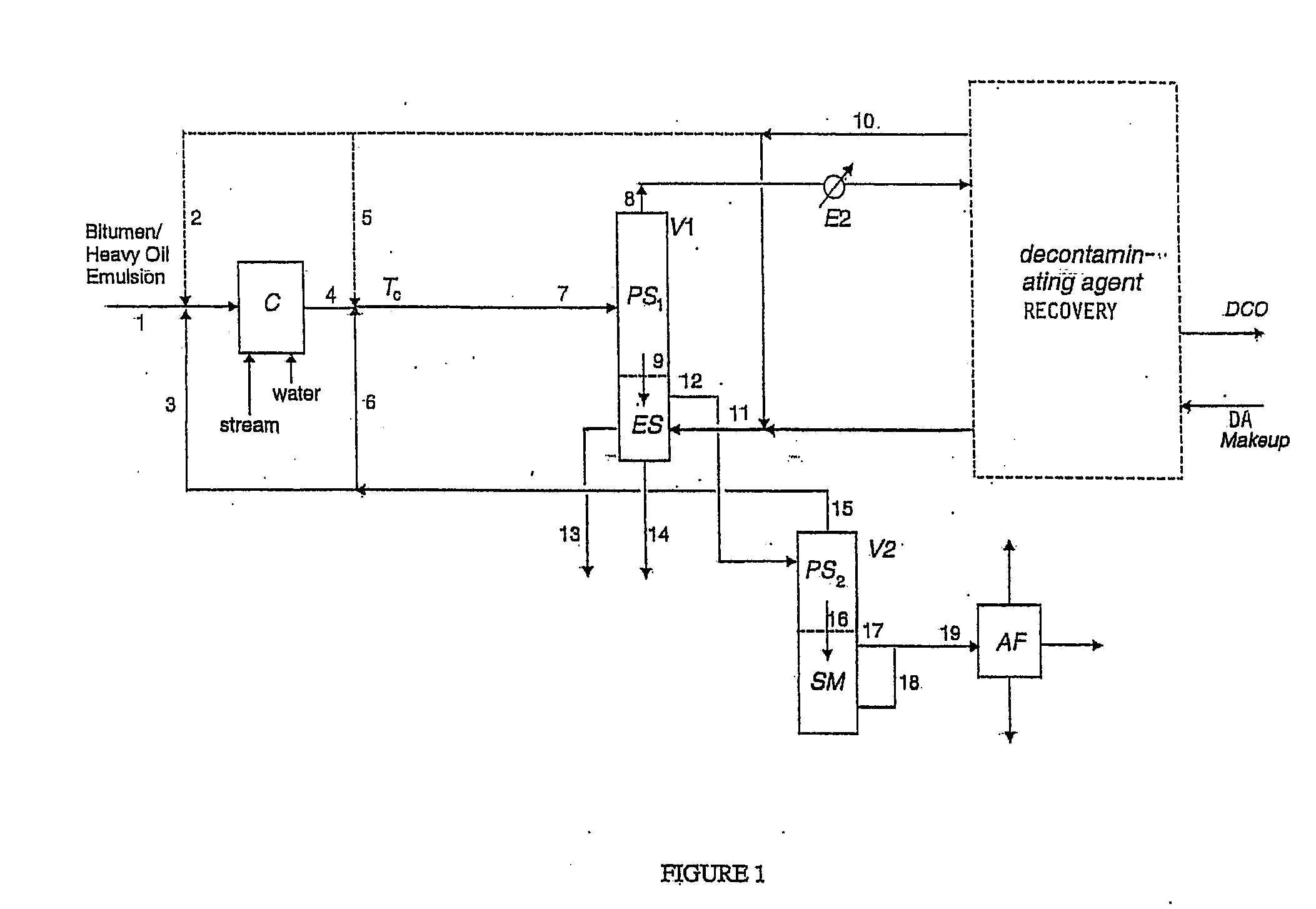

Decontamination of asphaltic heavy oil and bitumen

ActiveUS20060260980A1Distillation regulation/controlHydrocarbon distillationPetroleum productFuel oil

Owner:VALUE CREATION +1

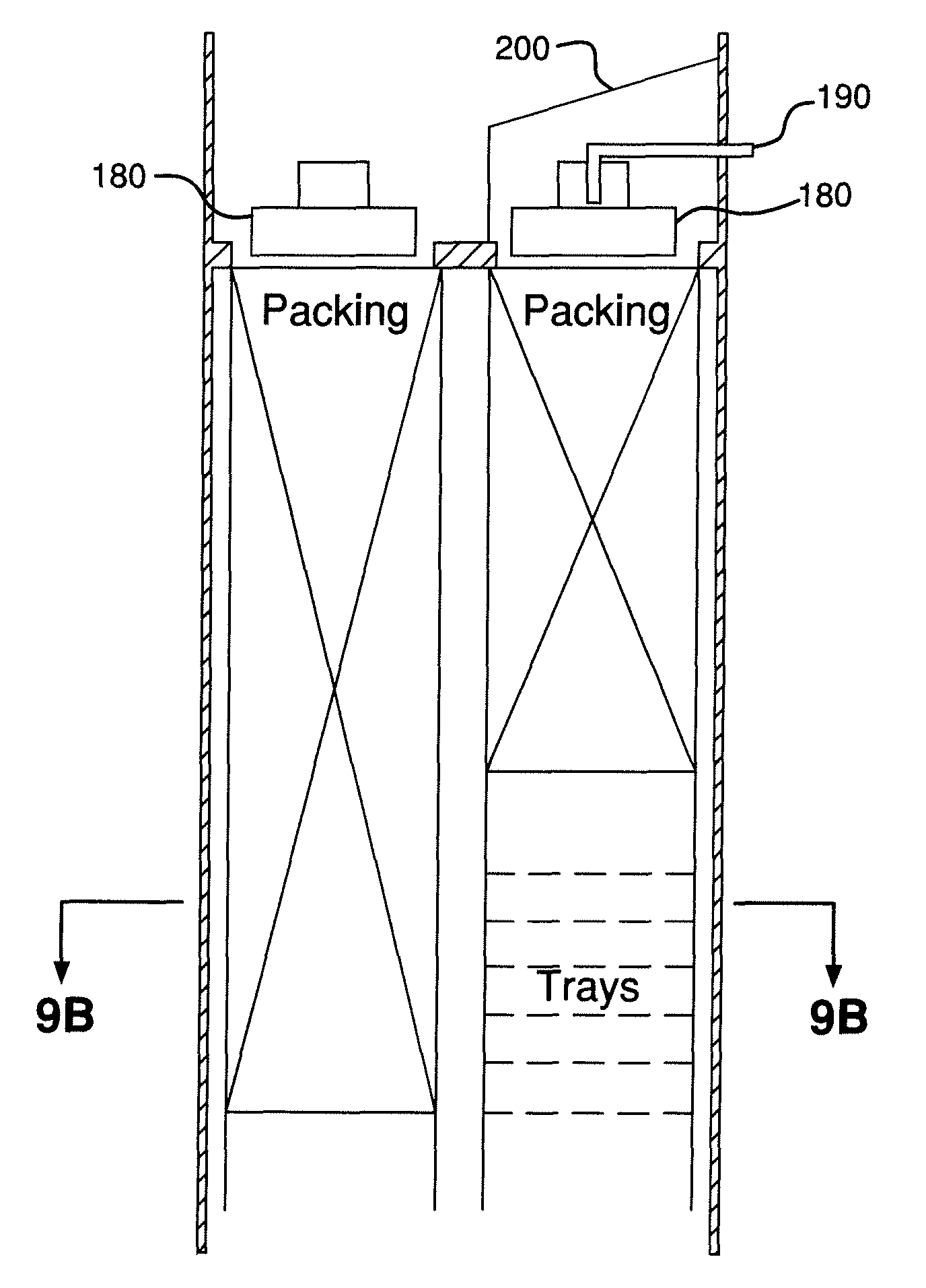

Divided wall columns for smaller sized plants

ActiveUS8480860B2Small diameterEasy to useThermal non-catalytic crackingSolidificationInterior spaceStructural engineering

A divided exchange column includes a shell column having a first longitudinal axis, a cylindrical wall spaced apart from and surrounding the first longitudinal axis and defining a first interior space, a first divided wall column having a second longitudinal axis substantially parallel to the first longitudinal axis, and a second divided wall column having a third longitudinal axis substantially parallel to the first and the second longitudinal axes, where the first divided wall column and the second divided wall column are positioned in the first interior space of the shell column.

Owner:AIR PROD & CHEM INC

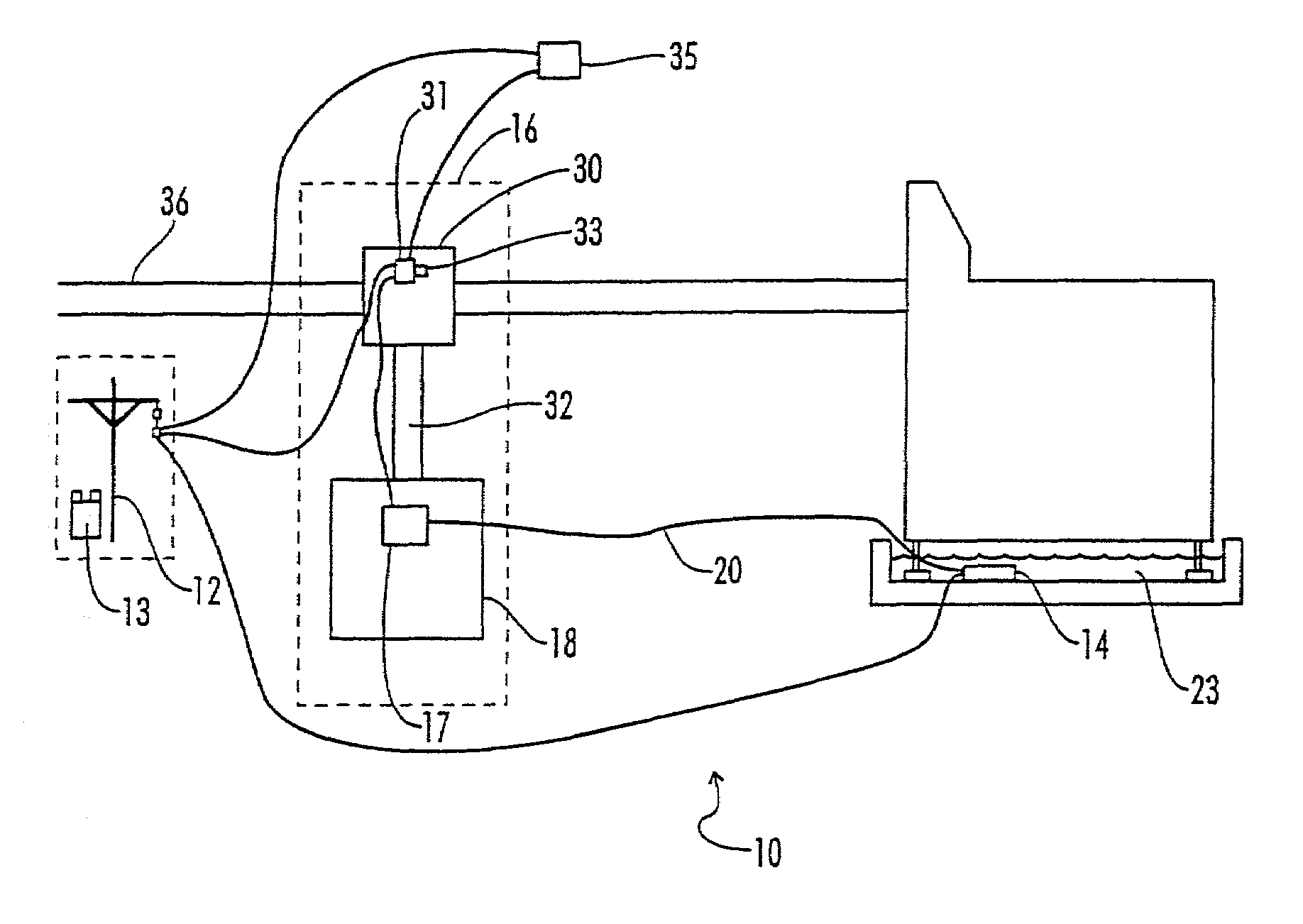

Water vapor distillation apparatus, method and system

ActiveUS9604858B2Water treatment parameter controlDistillation regulation/controlWater vaporControl system

A fluid vapor distillation system. The system includes a control system for controlling a fluid vapor distillation apparatus including a blow down controller for controlling a blow down valve, a source flow controller for controlling a source flow valve, and a blow down level sensor in communication with a blow down controller and a source flow controller, the blow down level sensor sends signals related to the blow down level to the blow down controller and the source flow controller indicative of the blow down level, wherein the source flow controller actuates the source flow valve based at least on the blow down level sensor signals, and wherein the blow down controller actuates the blow down valve based at least on the blow down level sensor signals, whereby the blow down level and the source flow level are maintained using the blow down level sensor signals as input.

Owner:DEKA PROD LLP

Method and apparatus for phase change enhancement

ActiveUS20050183832A1Distillation regulation/controlVacuum distillation separationEngineeringPhase change

A method of operating an evaporator is described. In evaporator feed water, a Taylor bubble is developed which has an outer surface including a thin film in contact with an inner surface of an outer wall of an evaporator tube. The Taylor bubble is heated as it rises within the evaporator tube so that liquid in the thin film transitions into vapor within the bubble.

Owner:DEKA PROD LLP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com