Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5476results about "Stationary plate conduit assemblies" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

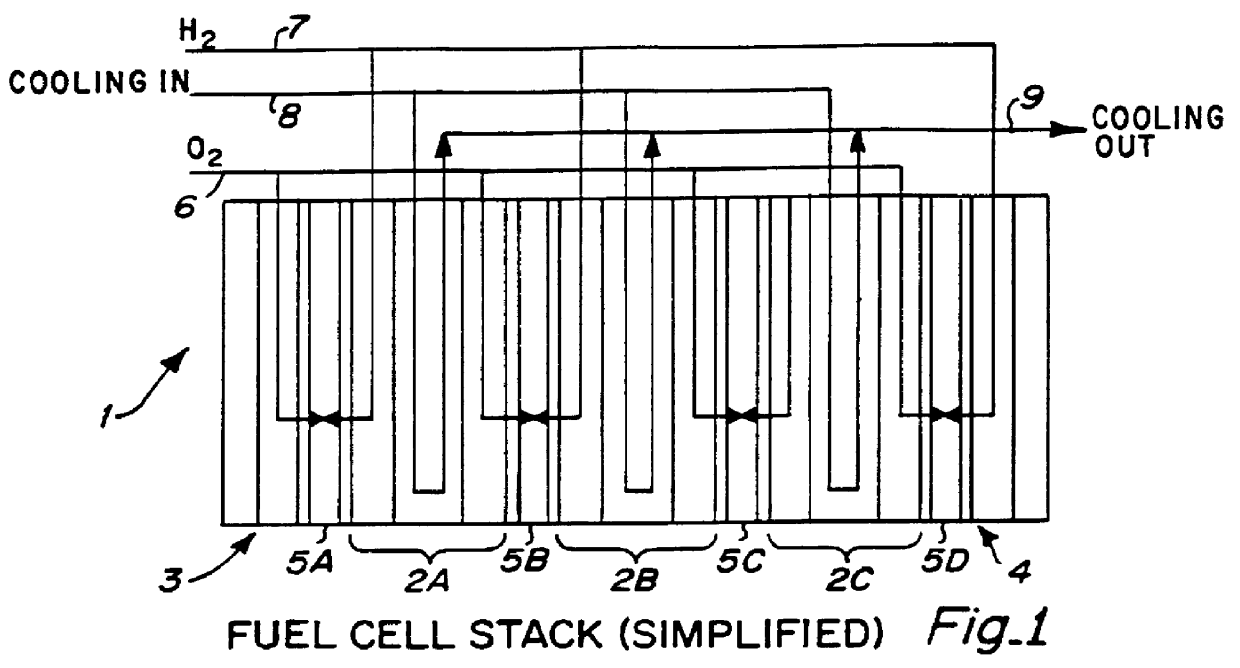

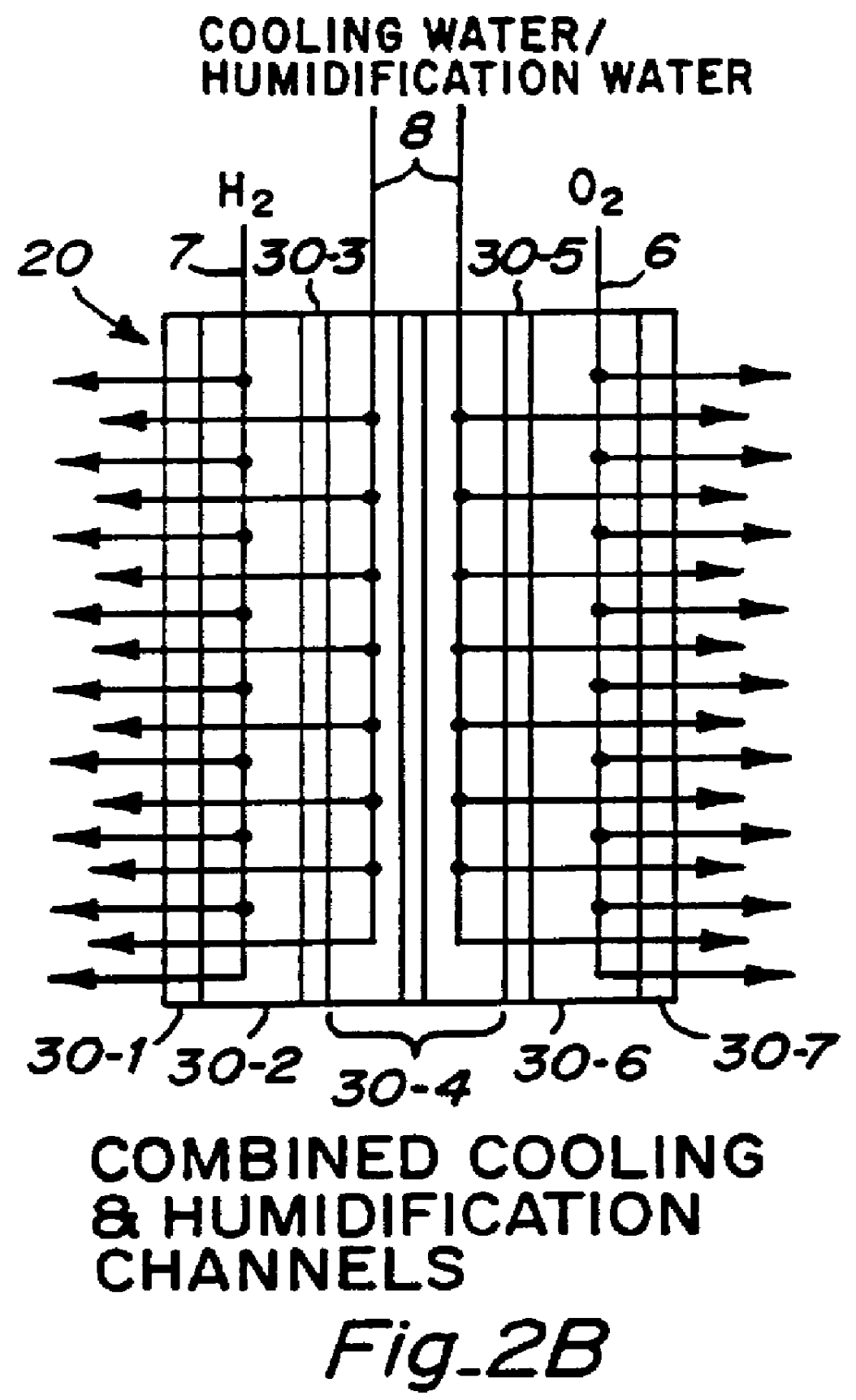

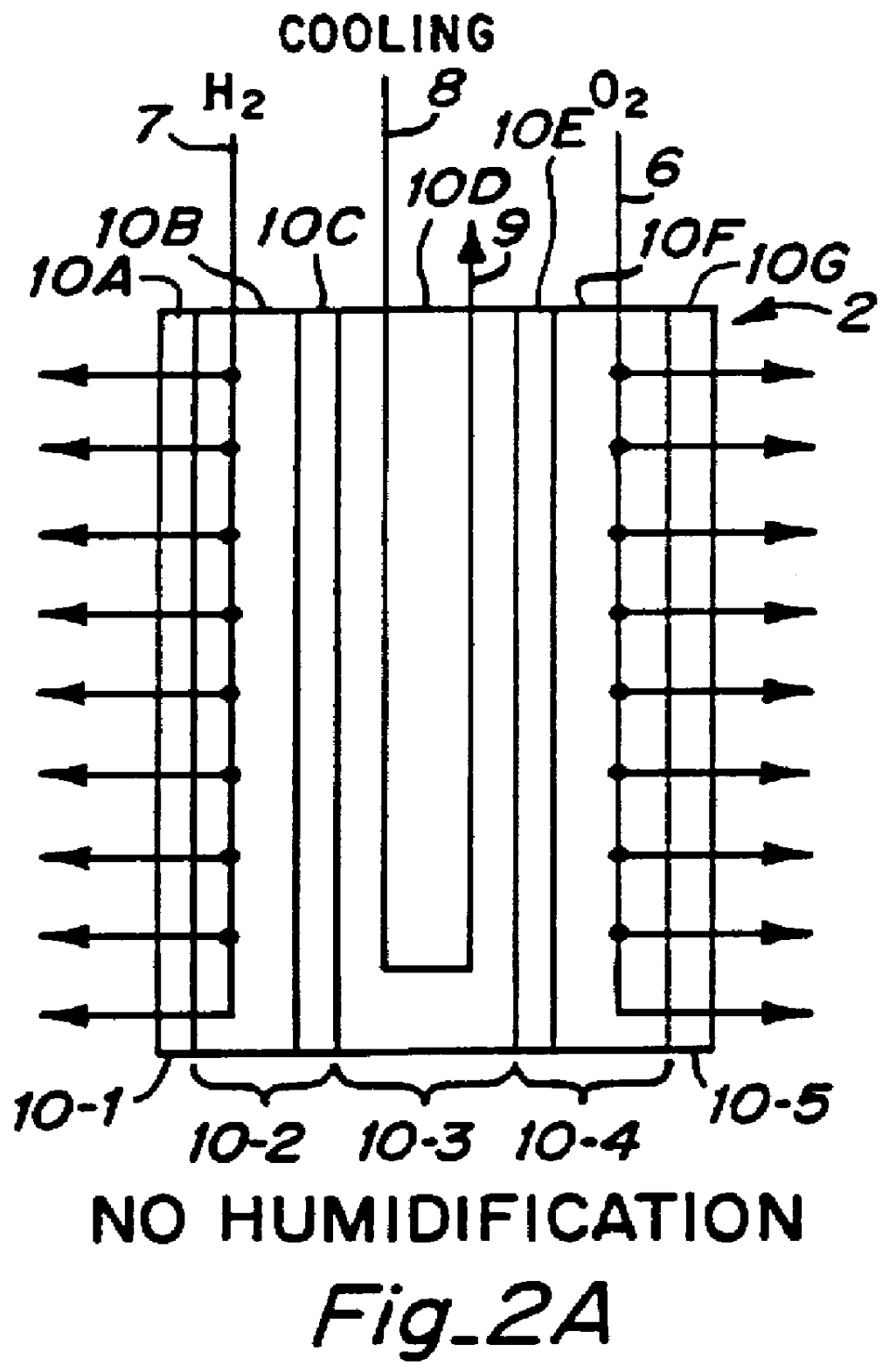

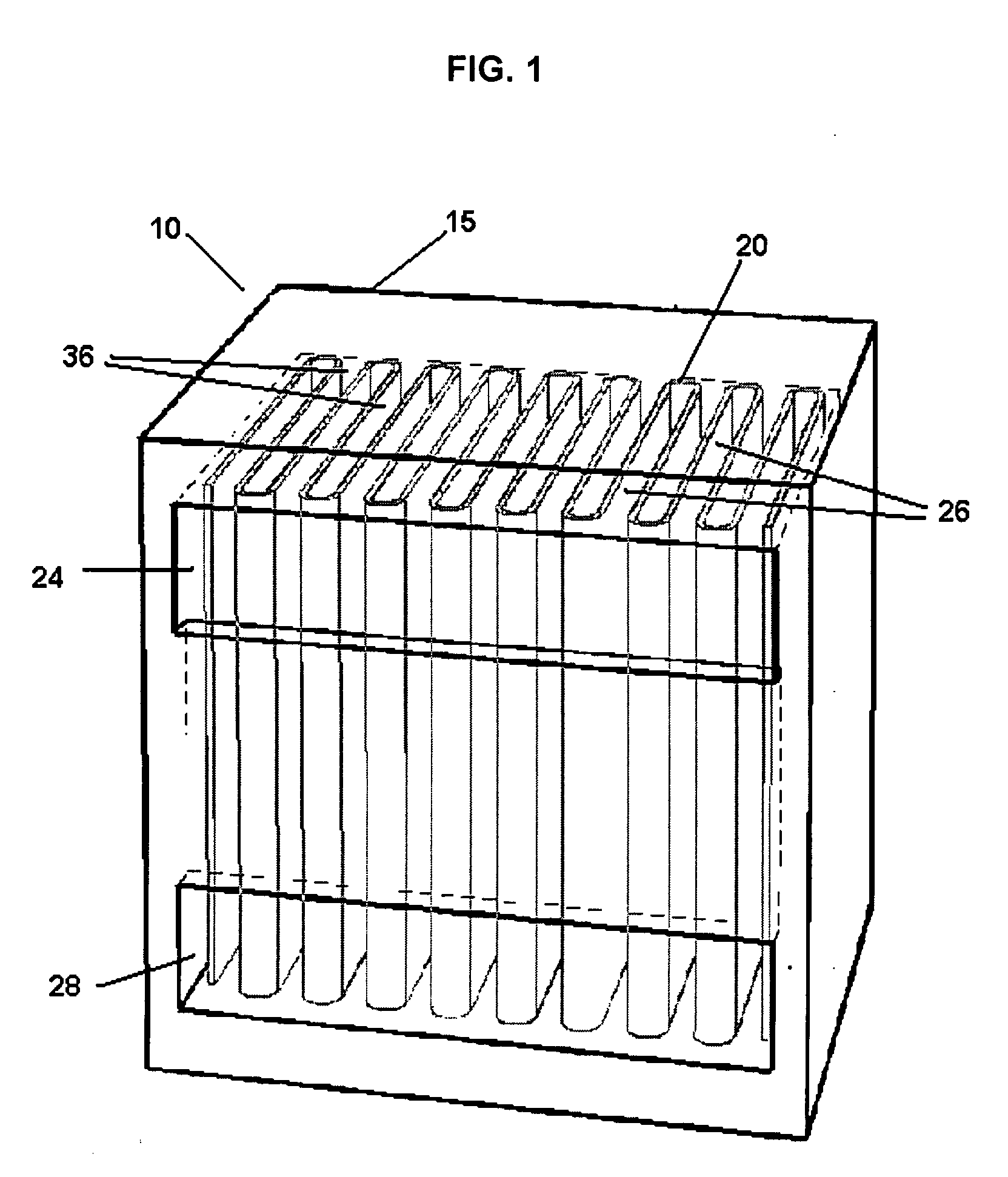

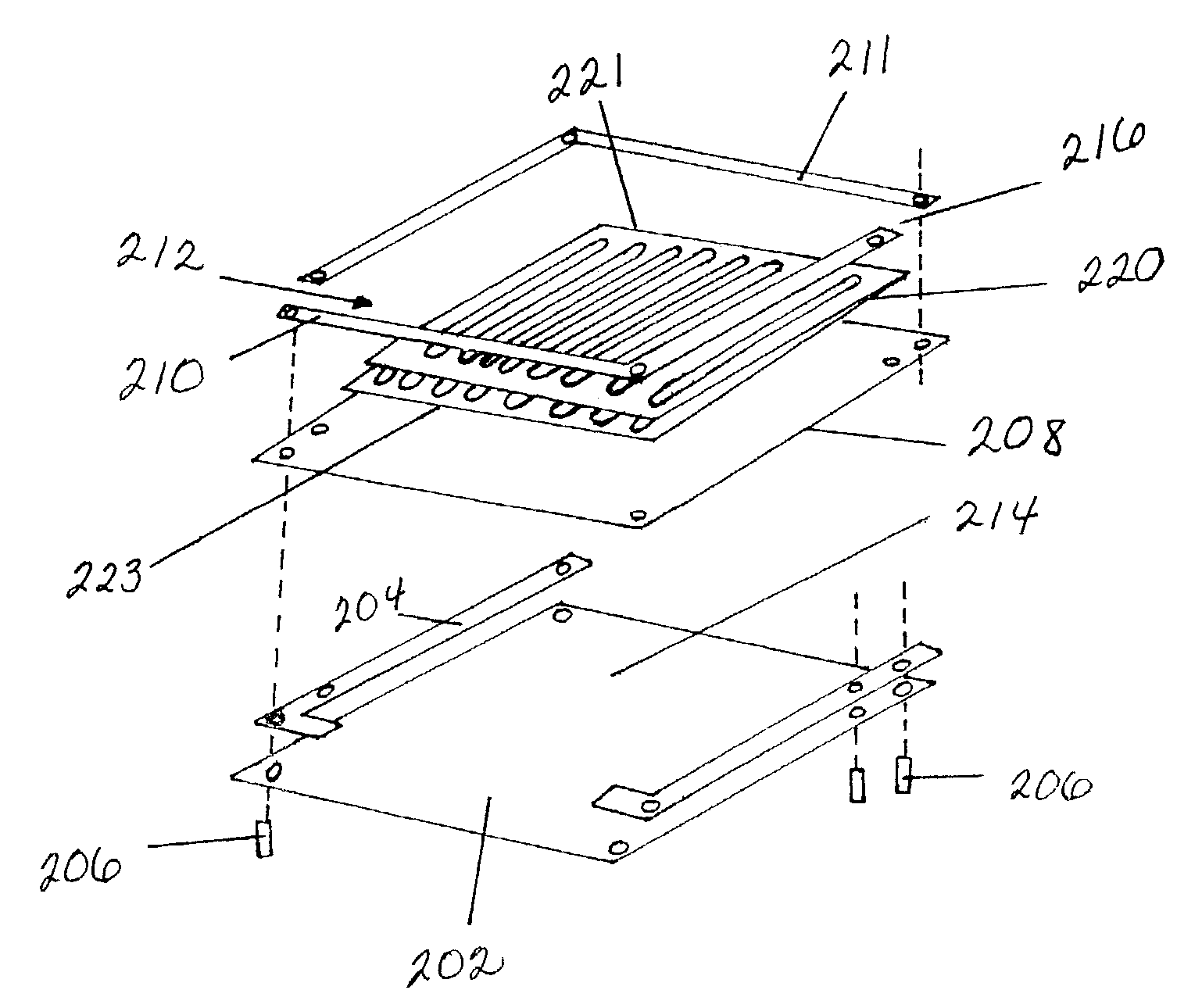

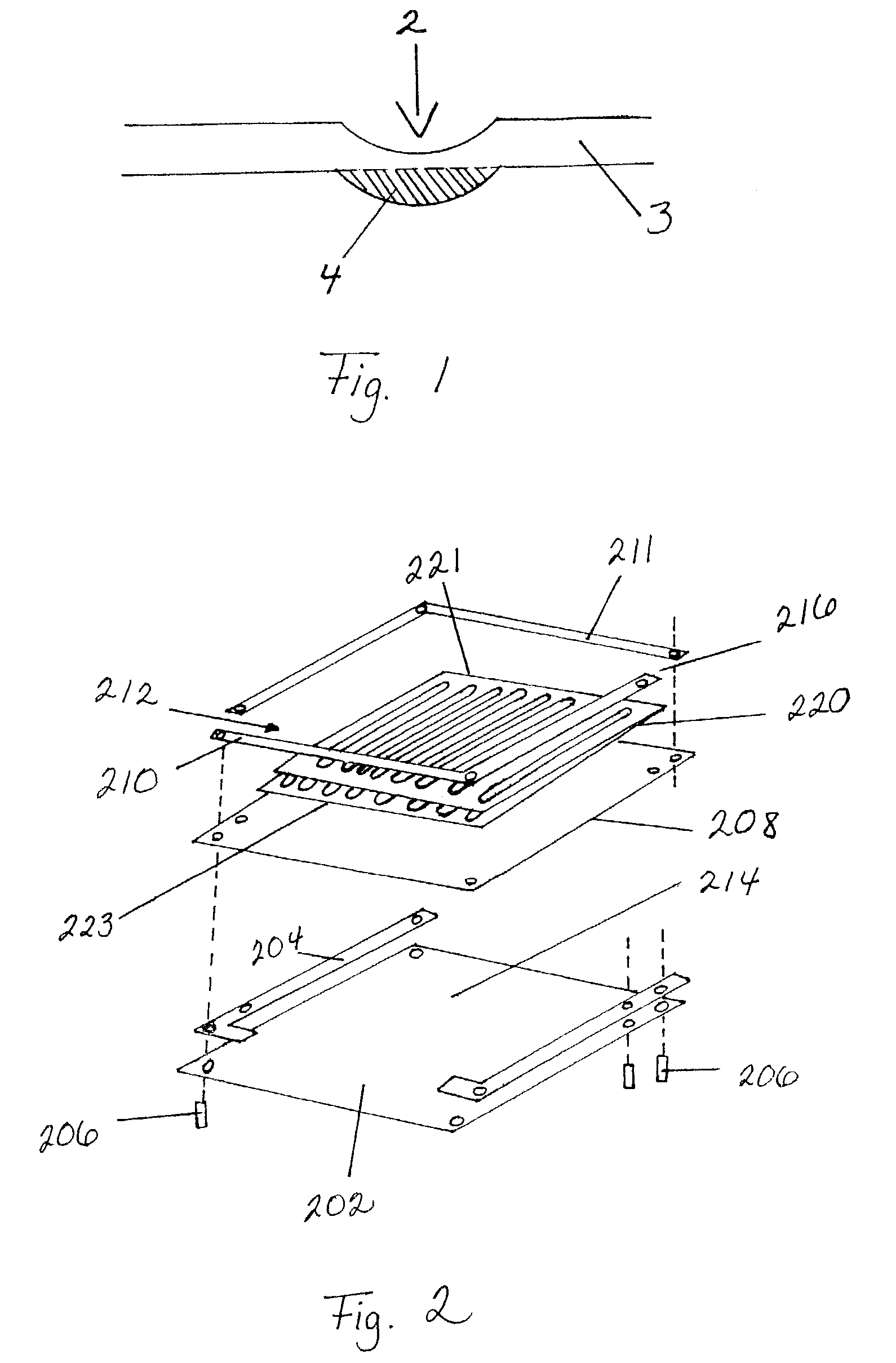

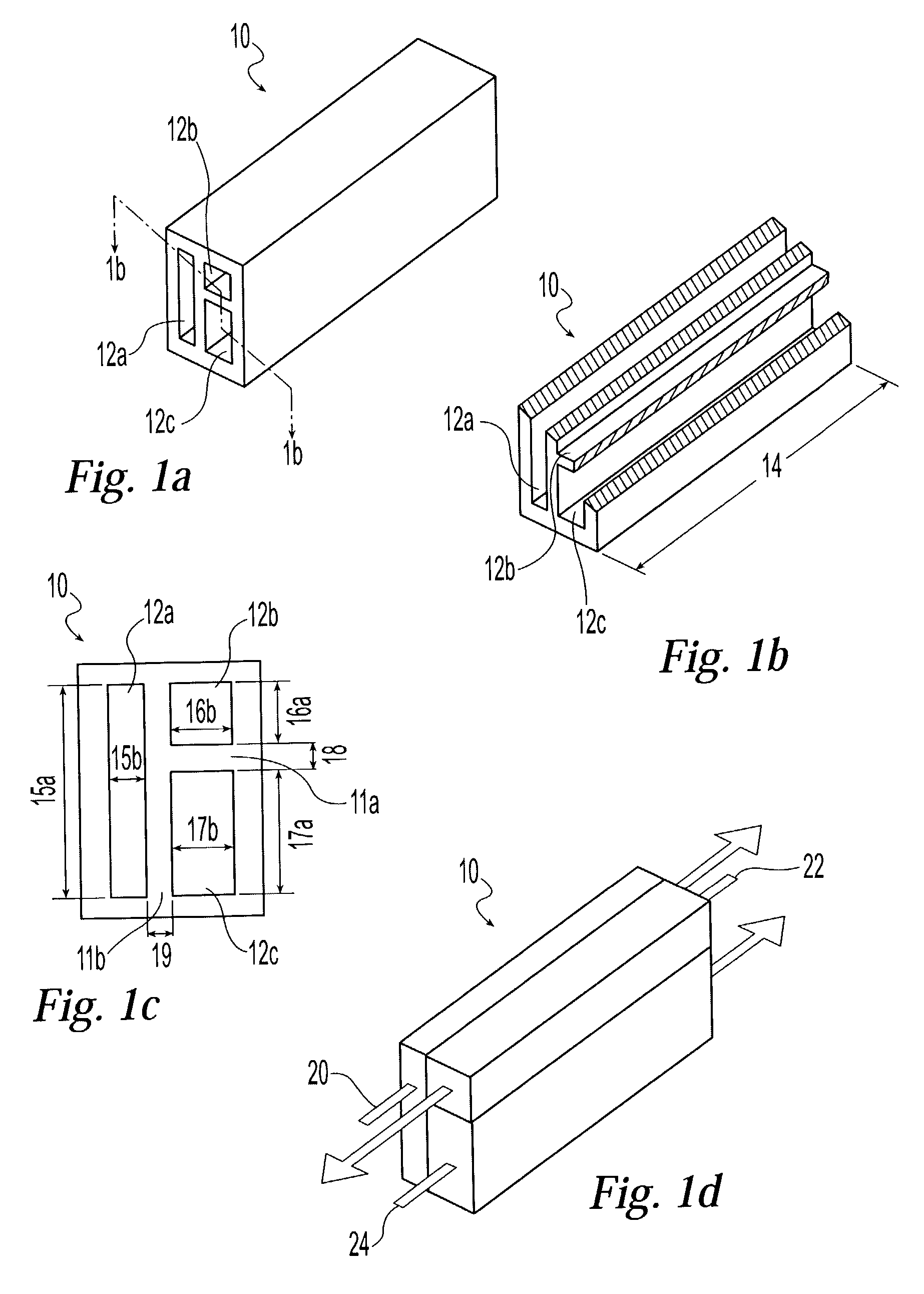

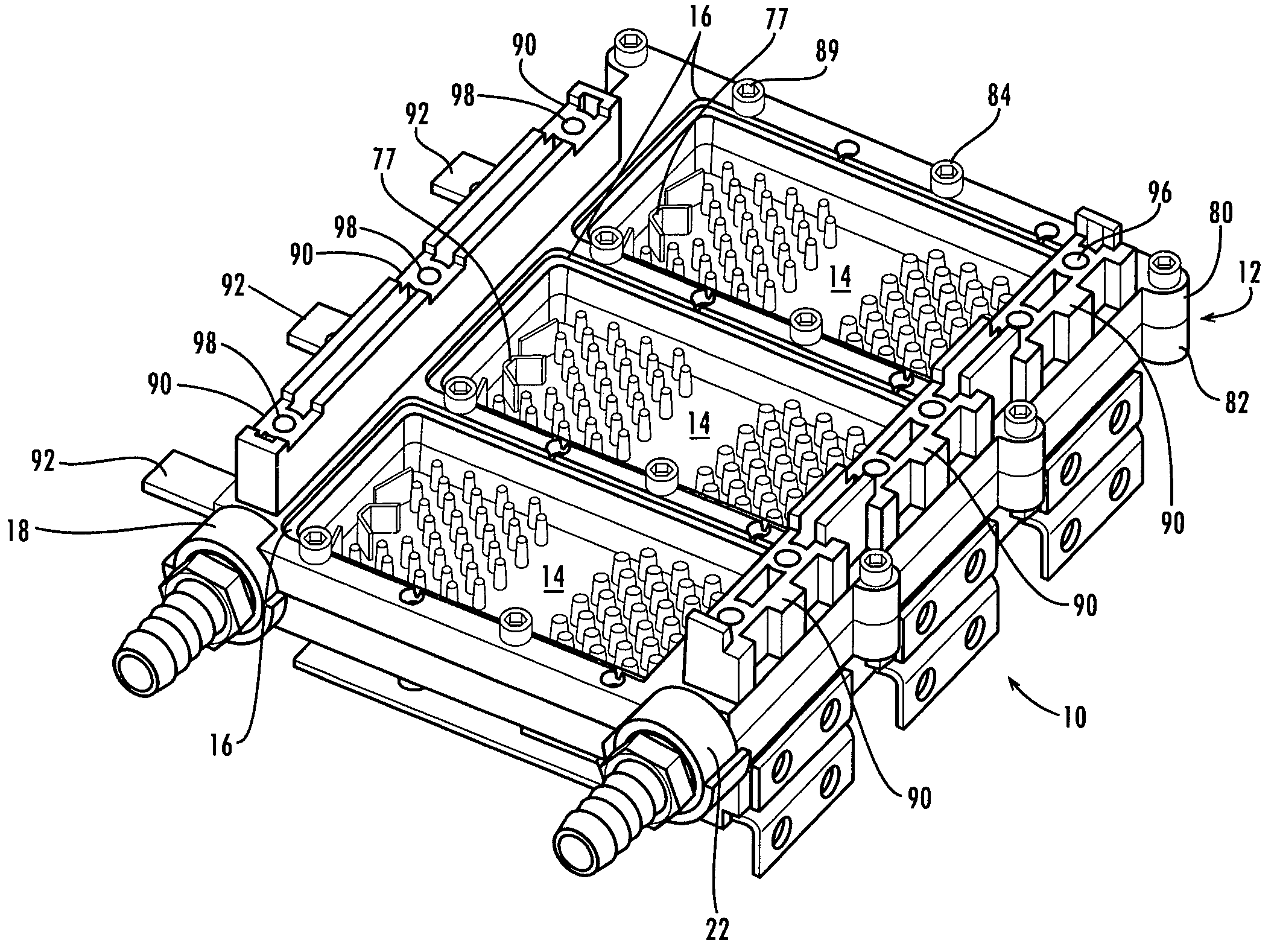

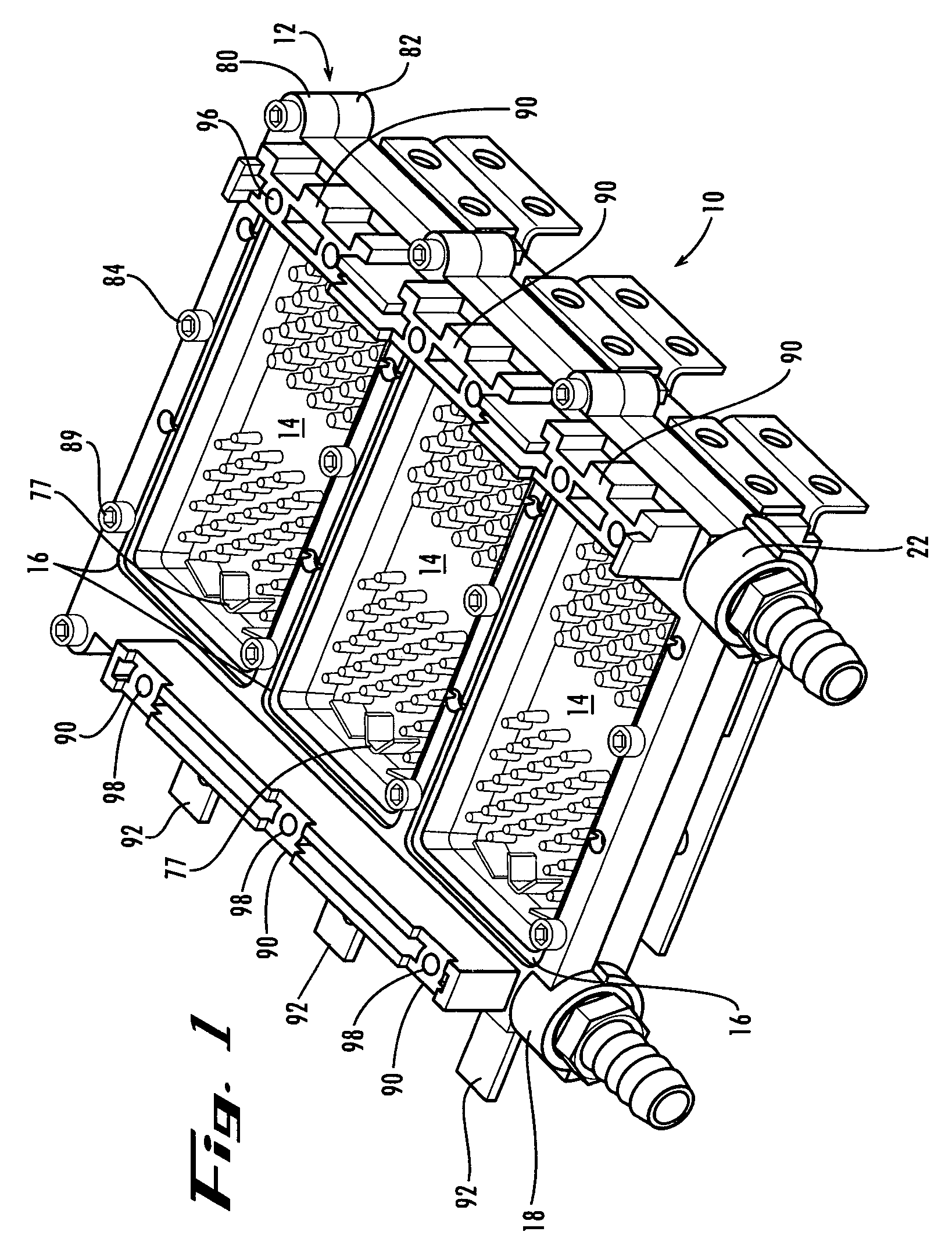

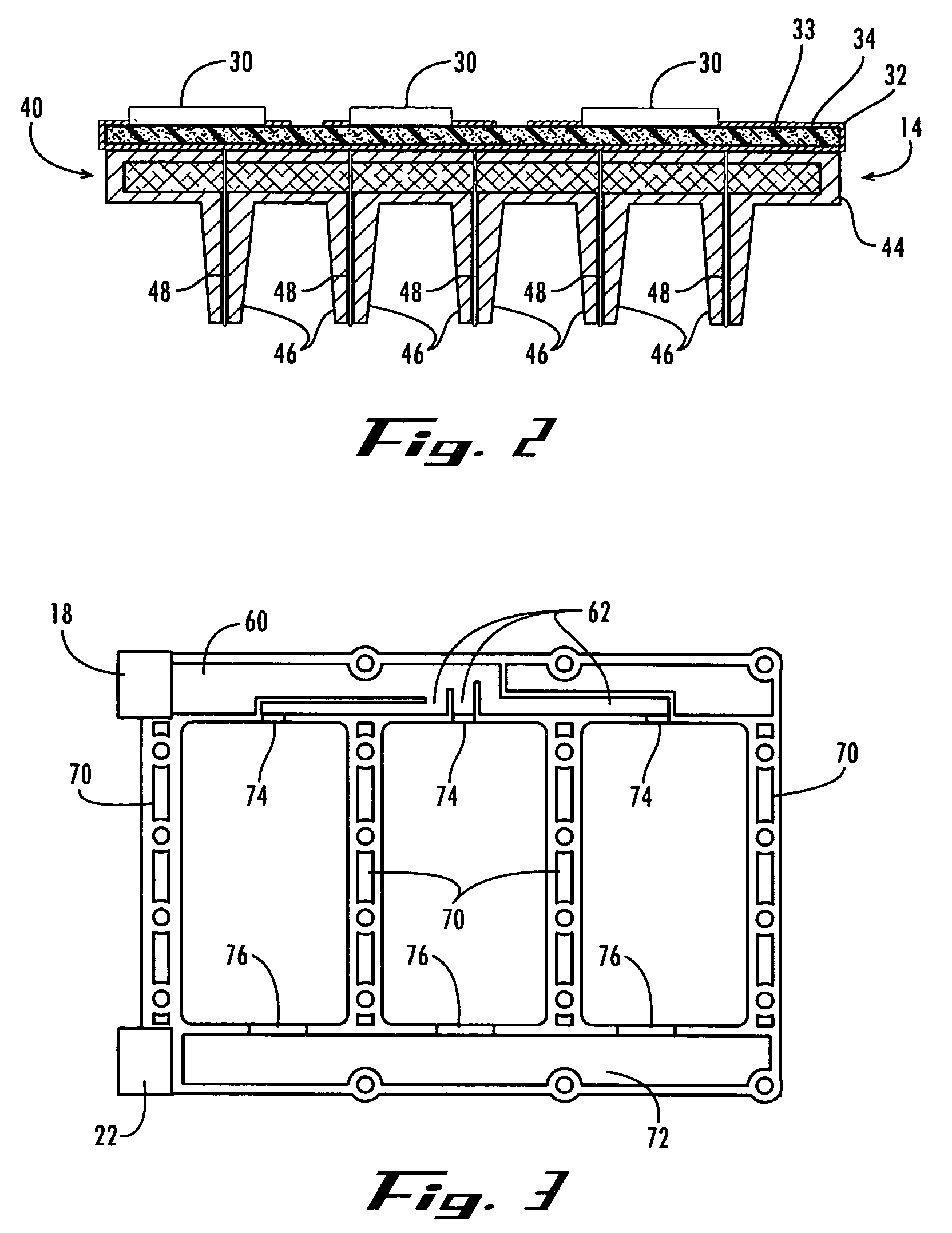

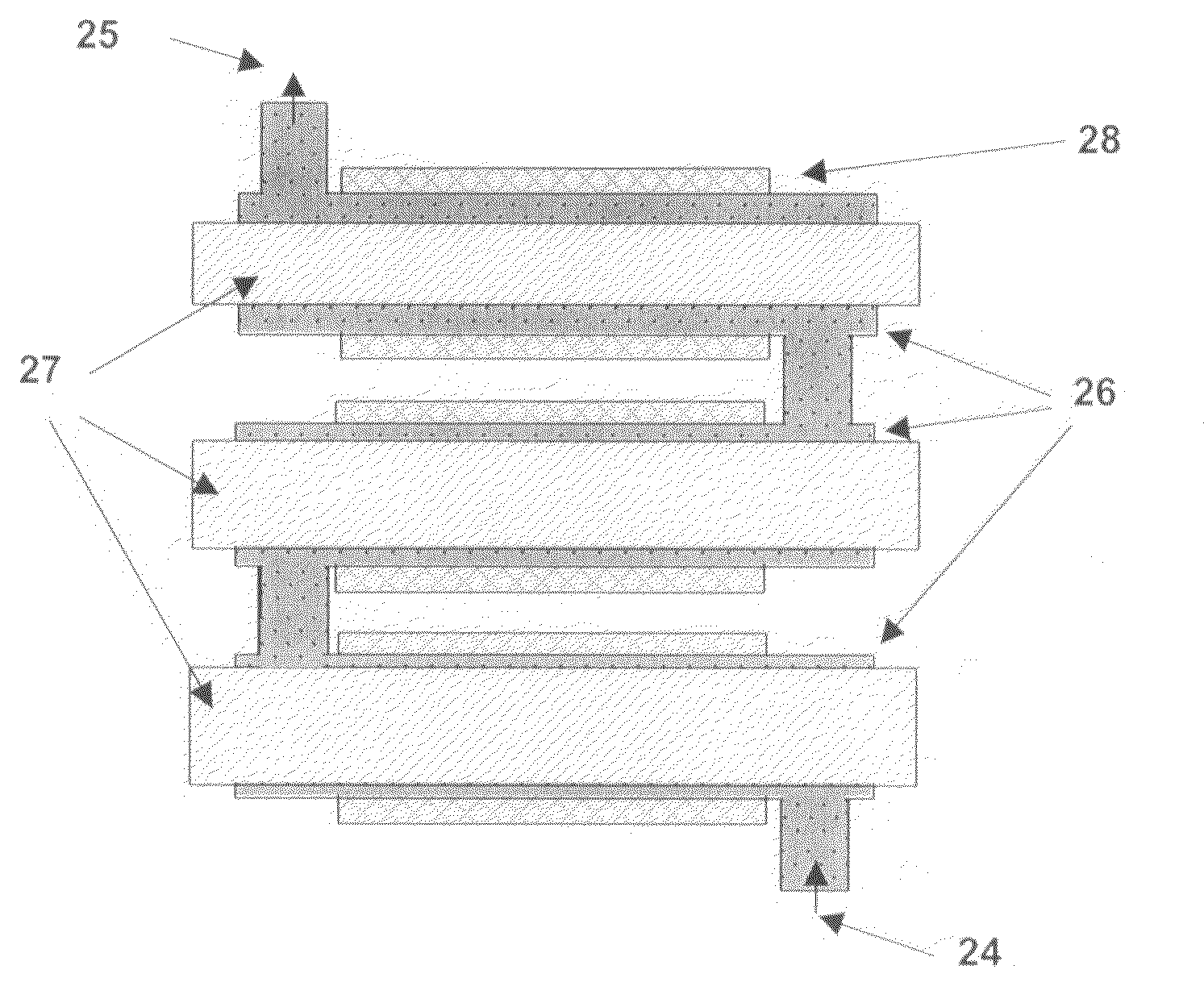

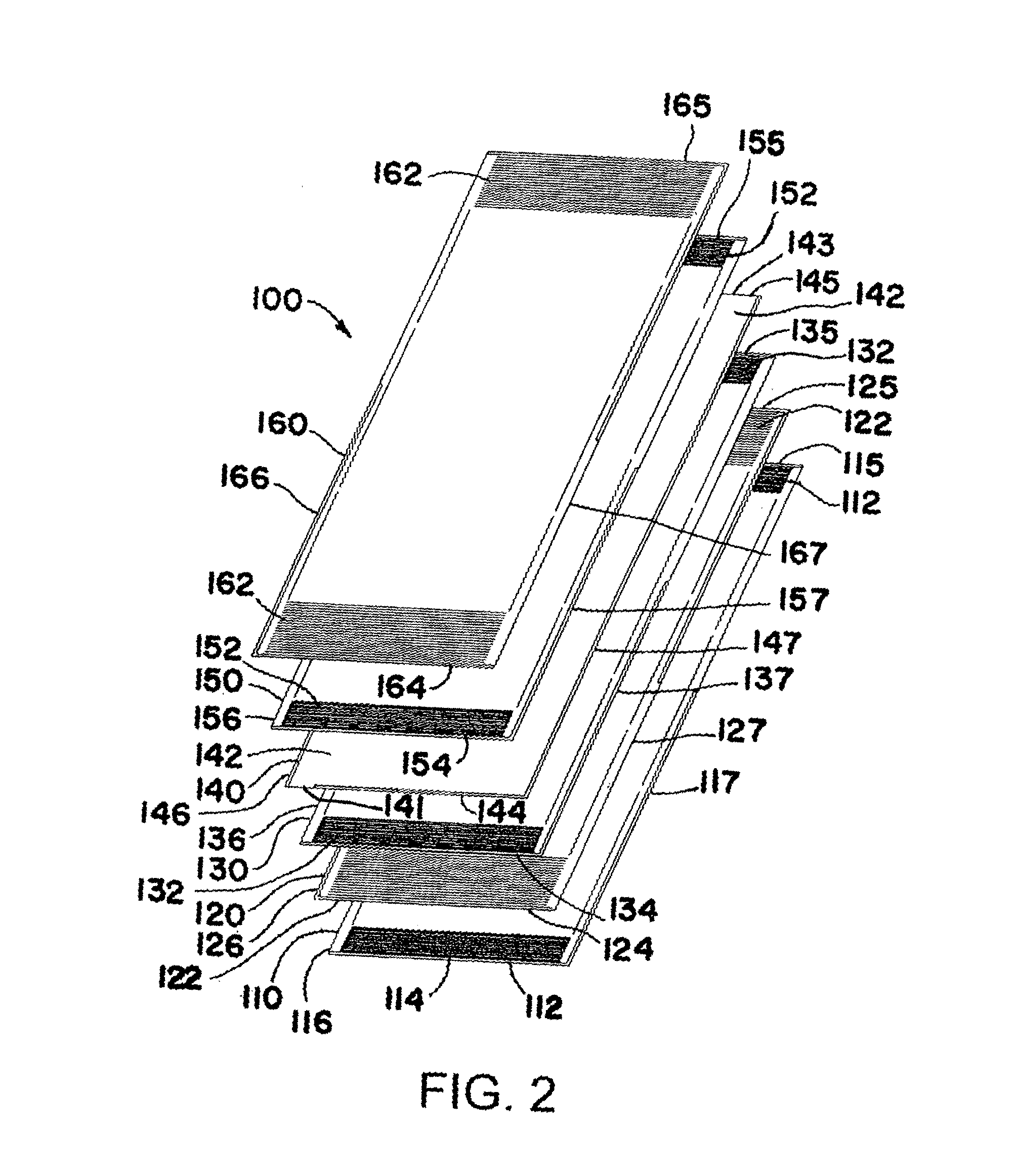

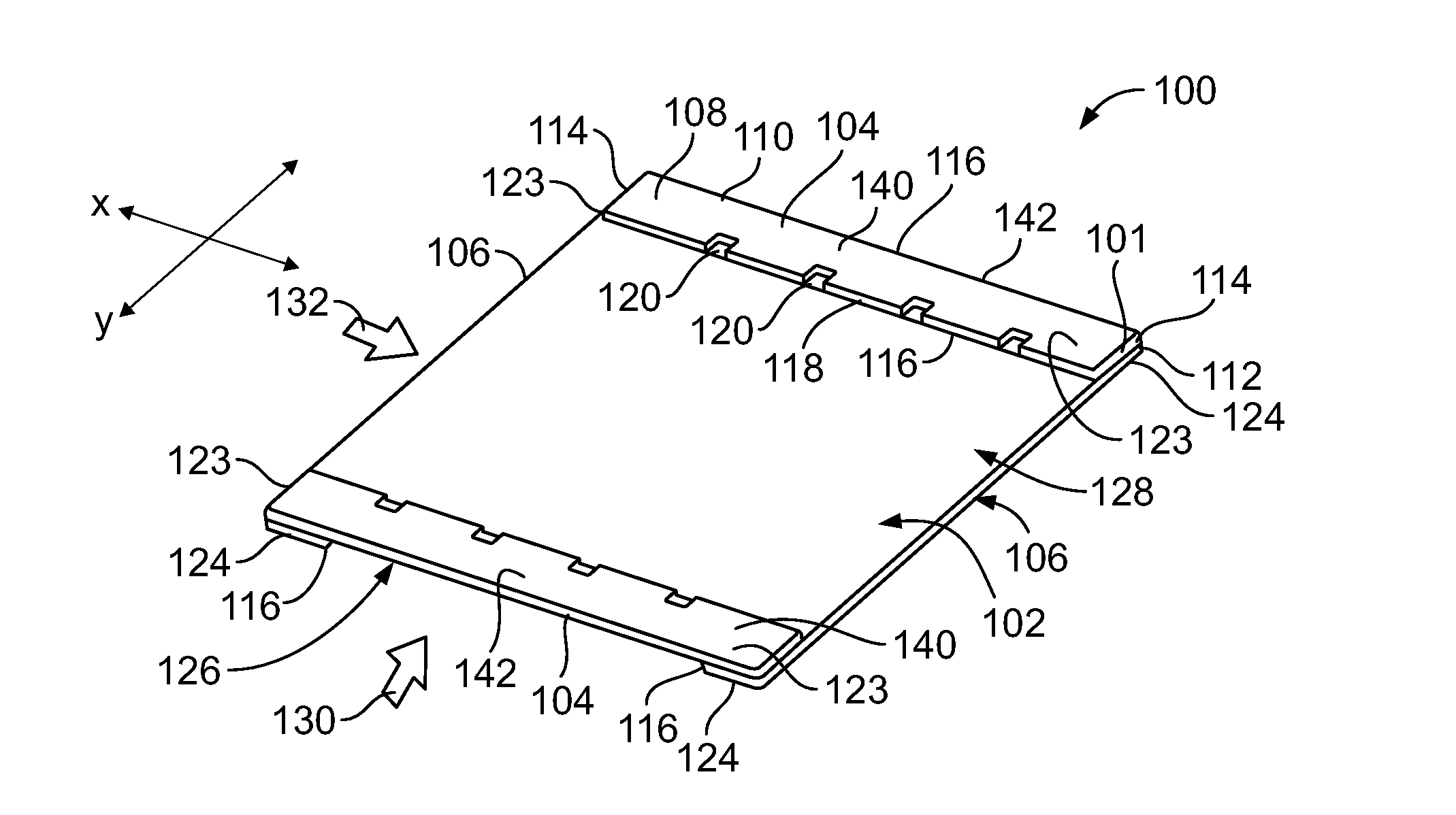

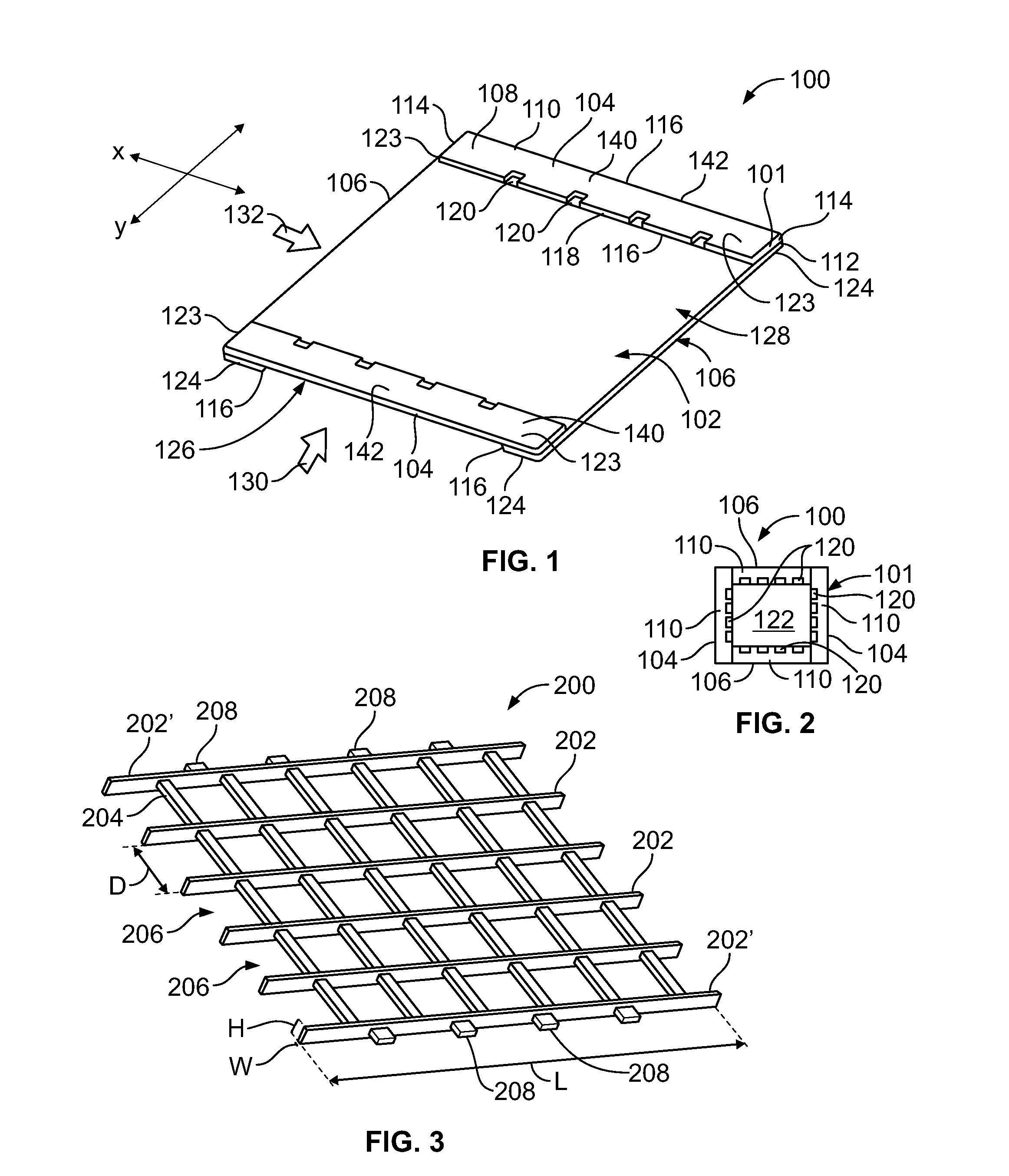

Fuel cell platelet separators having coordinate features

InactiveUS6051331ASimple designEvenly distributedSolid electrolytesFuel cells groupingLaser etchingFuel cells

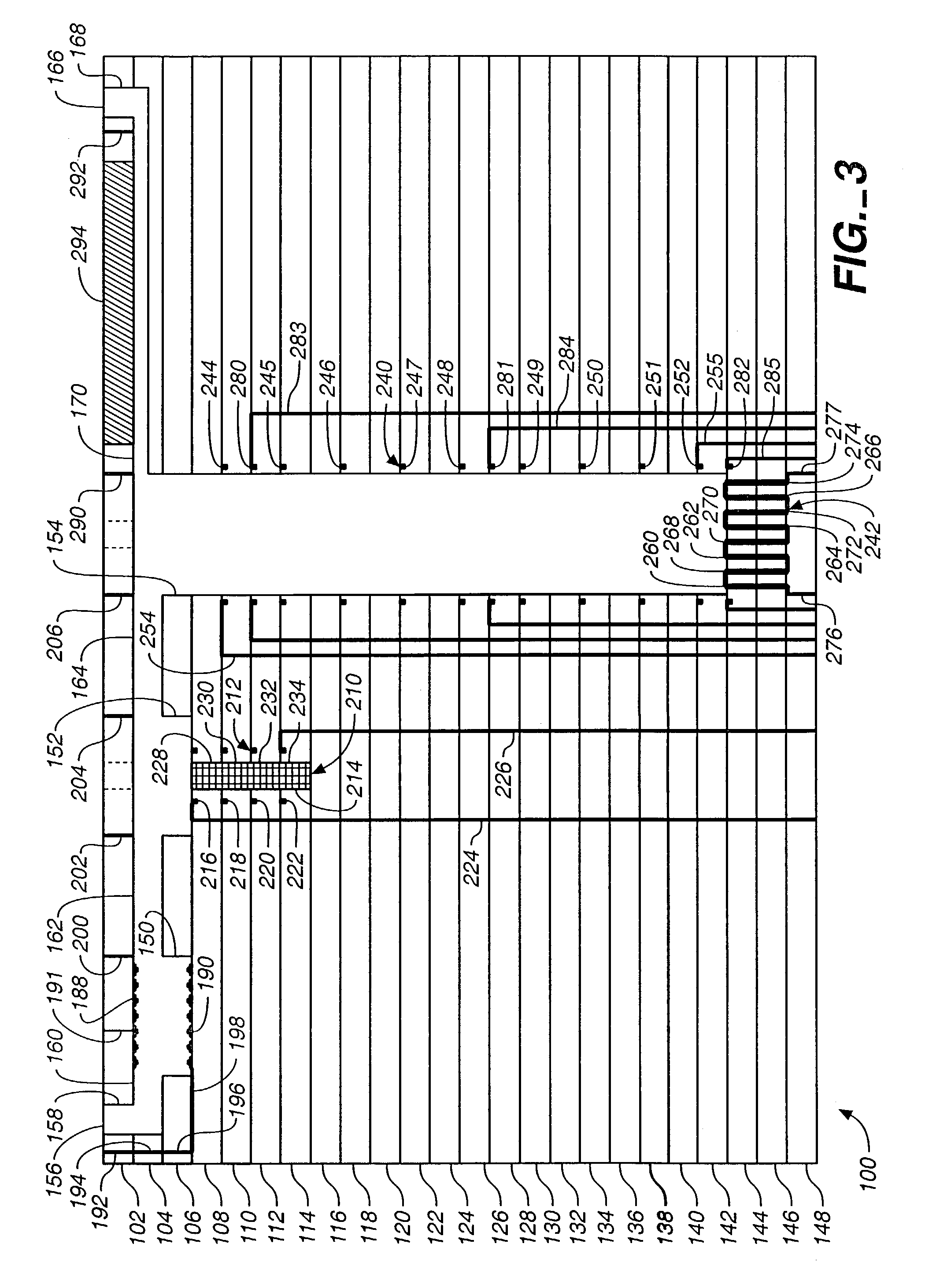

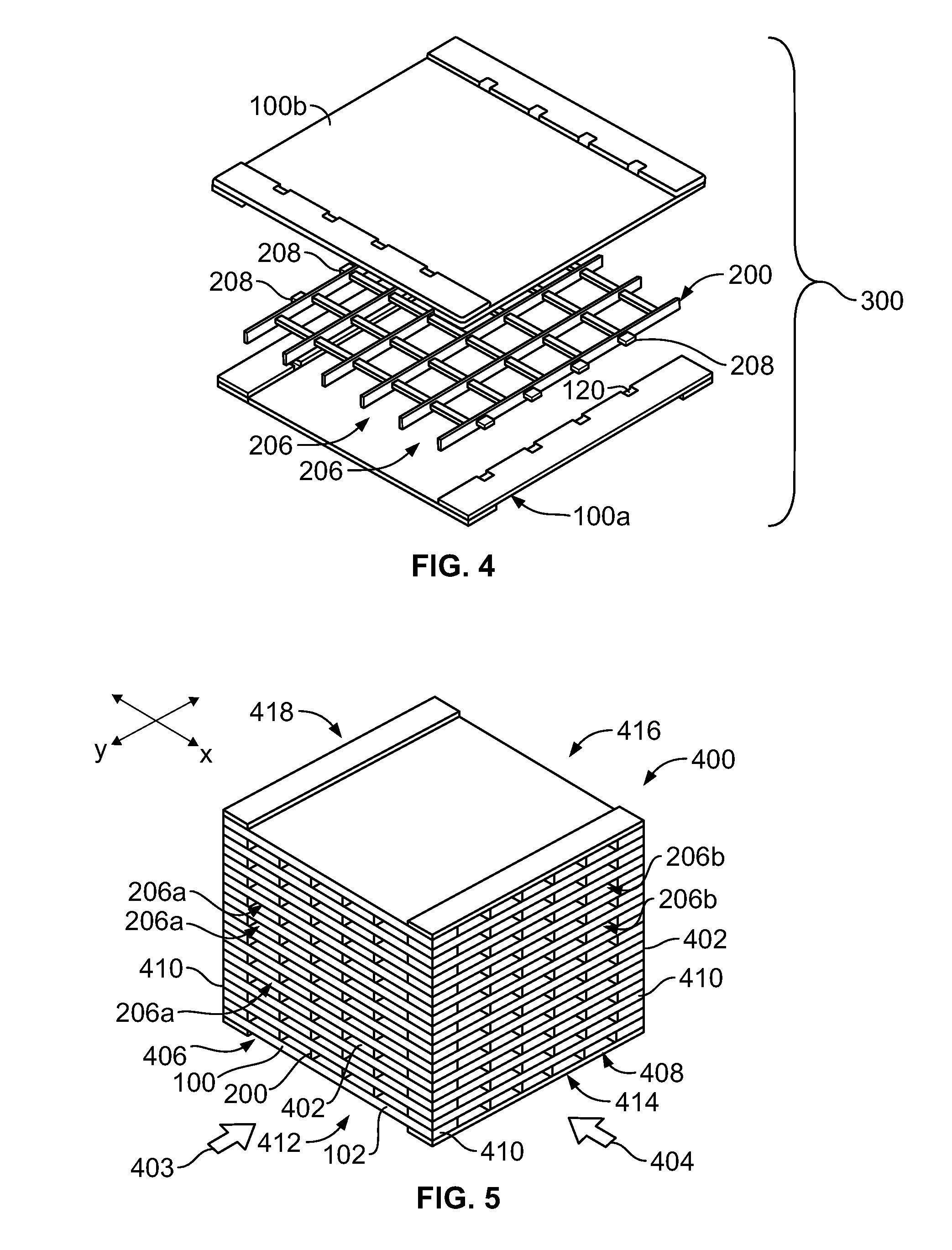

PCT No. PCT / US95 / 13325 Sec. 371 Date Sep. 28, 1997 Sec. 102(e) Date Sep. 28, 1997 PCT Filed Oct. 10, 1995 PCT Pub. No. WO96 / 12316 PCT Pub. Date Apr. 25, 1996Fuel cell stacks comprising stacked separator / membrane electrode assembly fuel cells in which the separators comprise a series of thin sheet platelets, having individually configured serpentine micro-channel reactant gas humidification active areas and cooling fields therein. The individual platelets are stacked with coordinate features aligned in contact with adjacent platelets and bonded to form a monolithic separator. Post-bonding processing includes passivation, such as nitriding. Preferred platelet material is 4-25 mil Ti, in which the features, serpentine channels, tabs, lands, vias, manifolds and holes, are formed by chemical and laser etching, cutting, pressing or embossing, with combinations of depth and through etching preferred. The platelet manufacturing process is continuous and fast. By employing CAD based platelet design and photolithography, rapid change in feature design can accommodate a wide range of thermal management and humidification techniques. One hundred H2-O2 / PEM fuel cell stacks of this IFMT platelet design will exhibit outputs on the order of 0.75 kW / kg, some 3-6 times greater than the current graphite plate PEM stacks.

Owner:H POWER

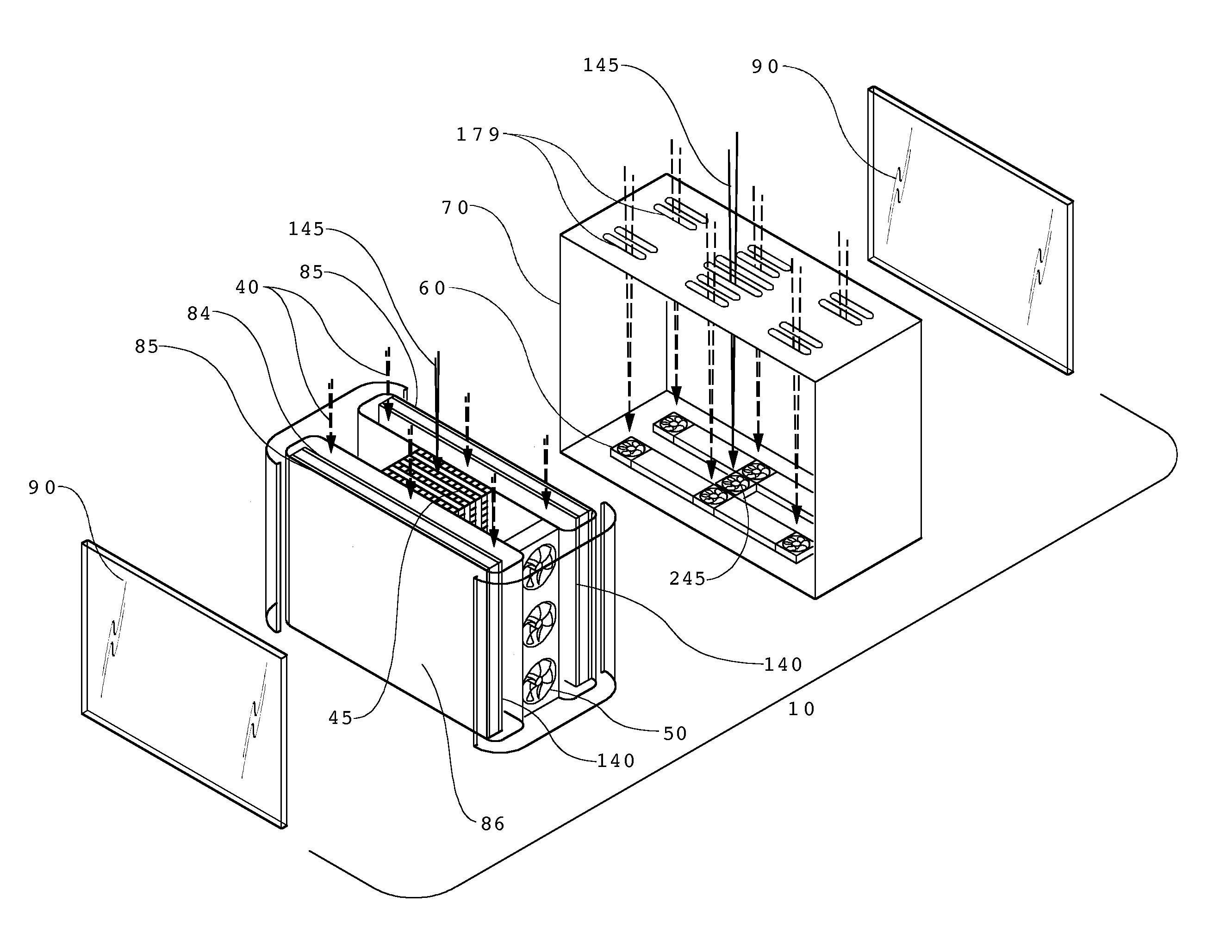

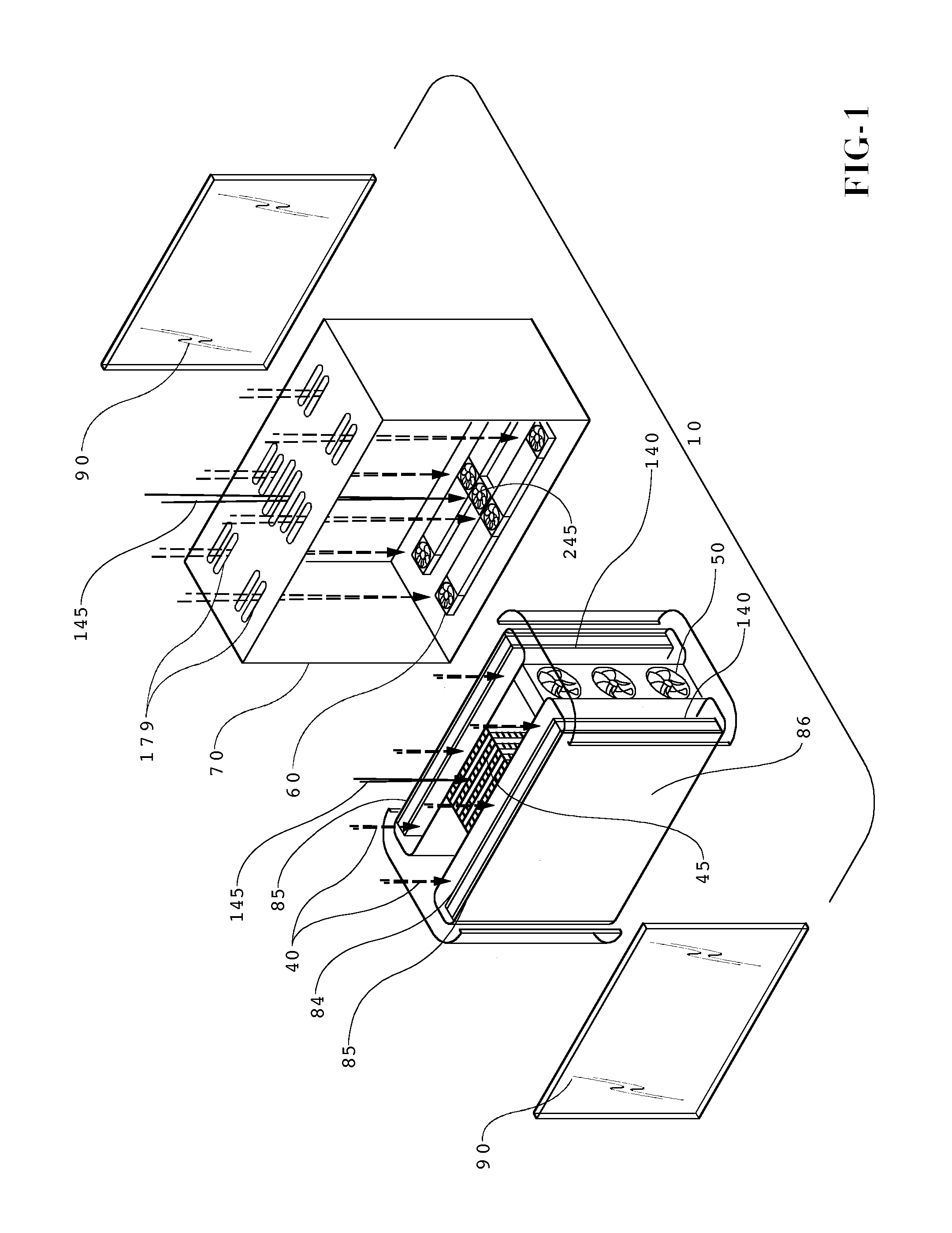

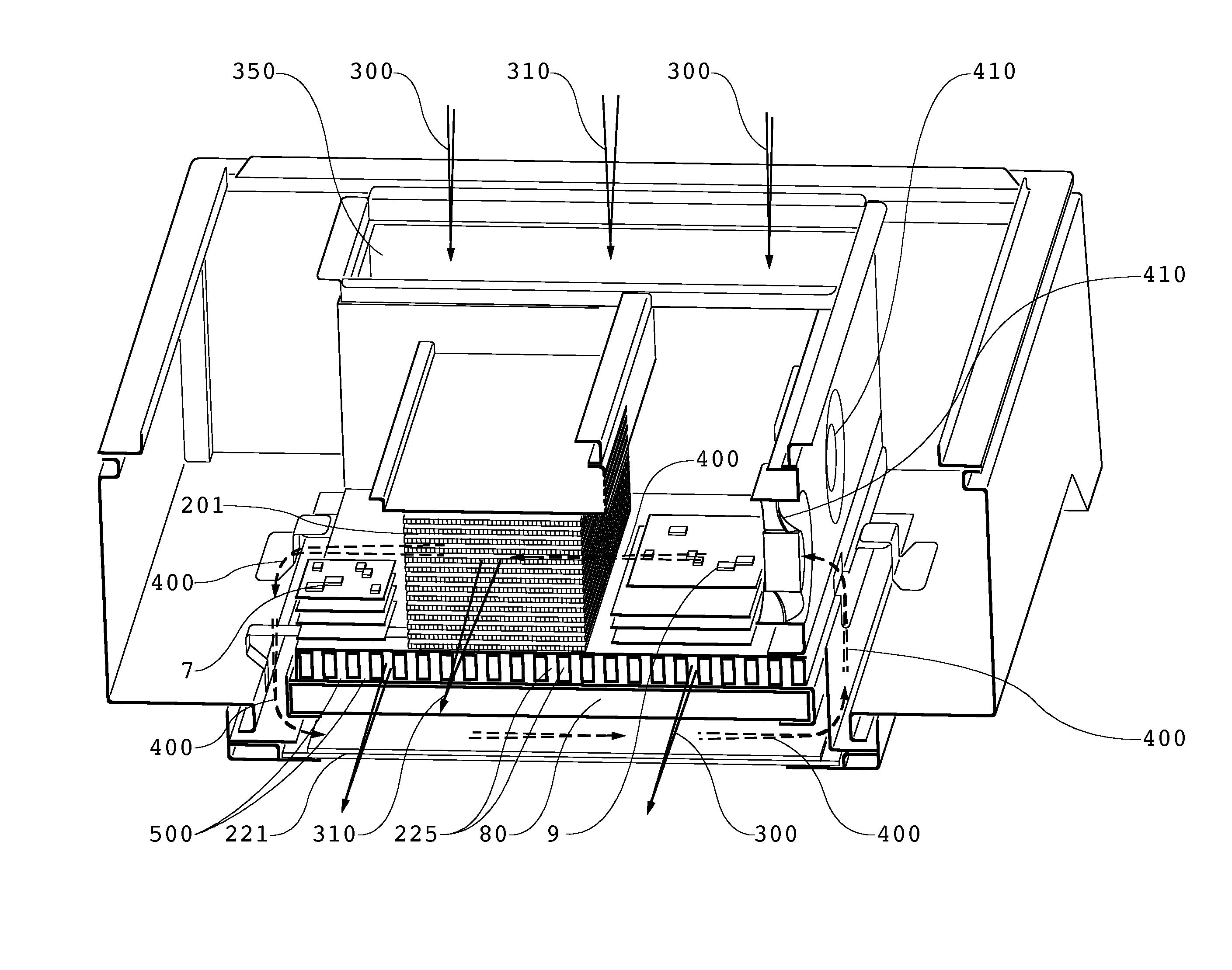

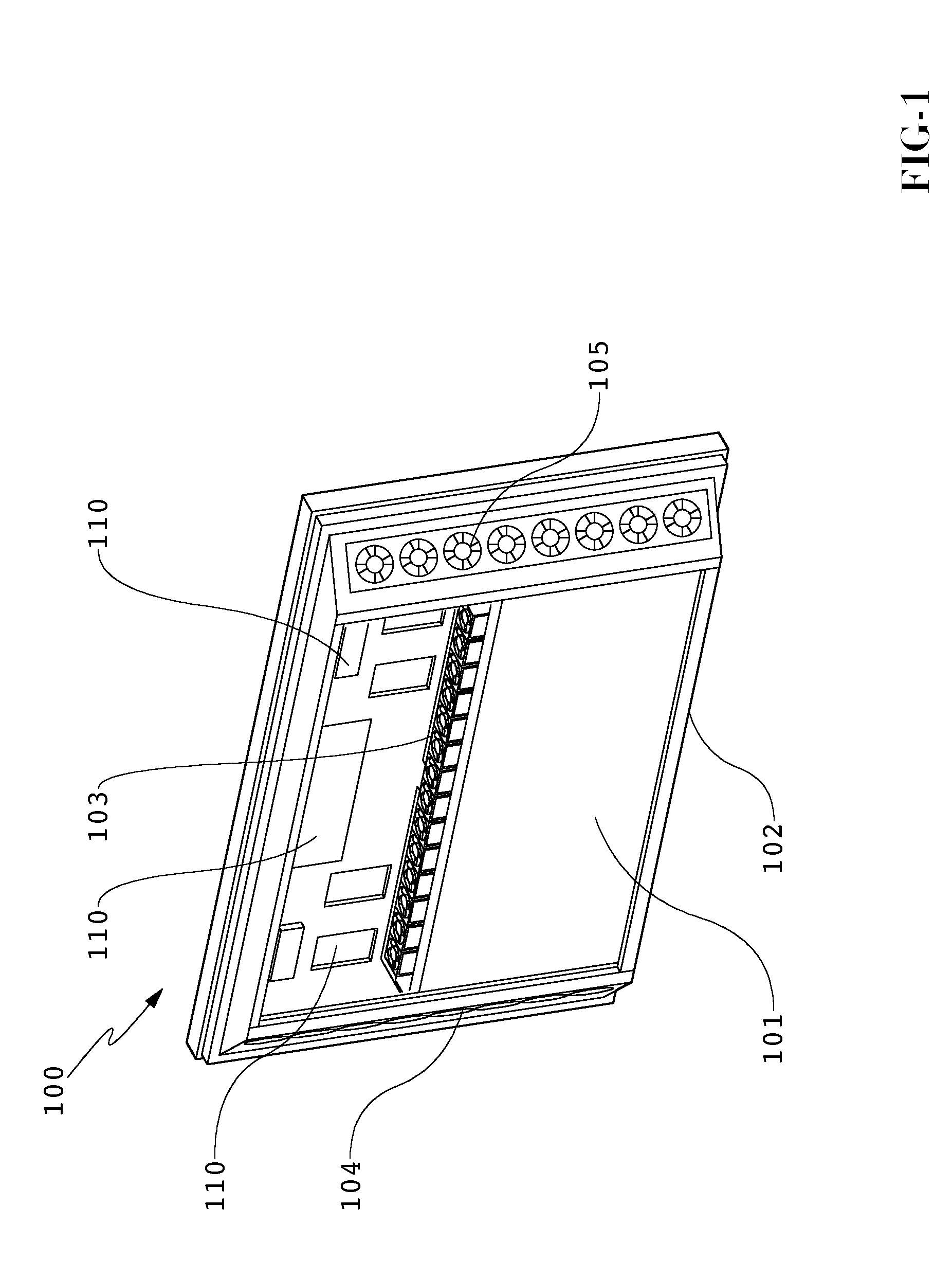

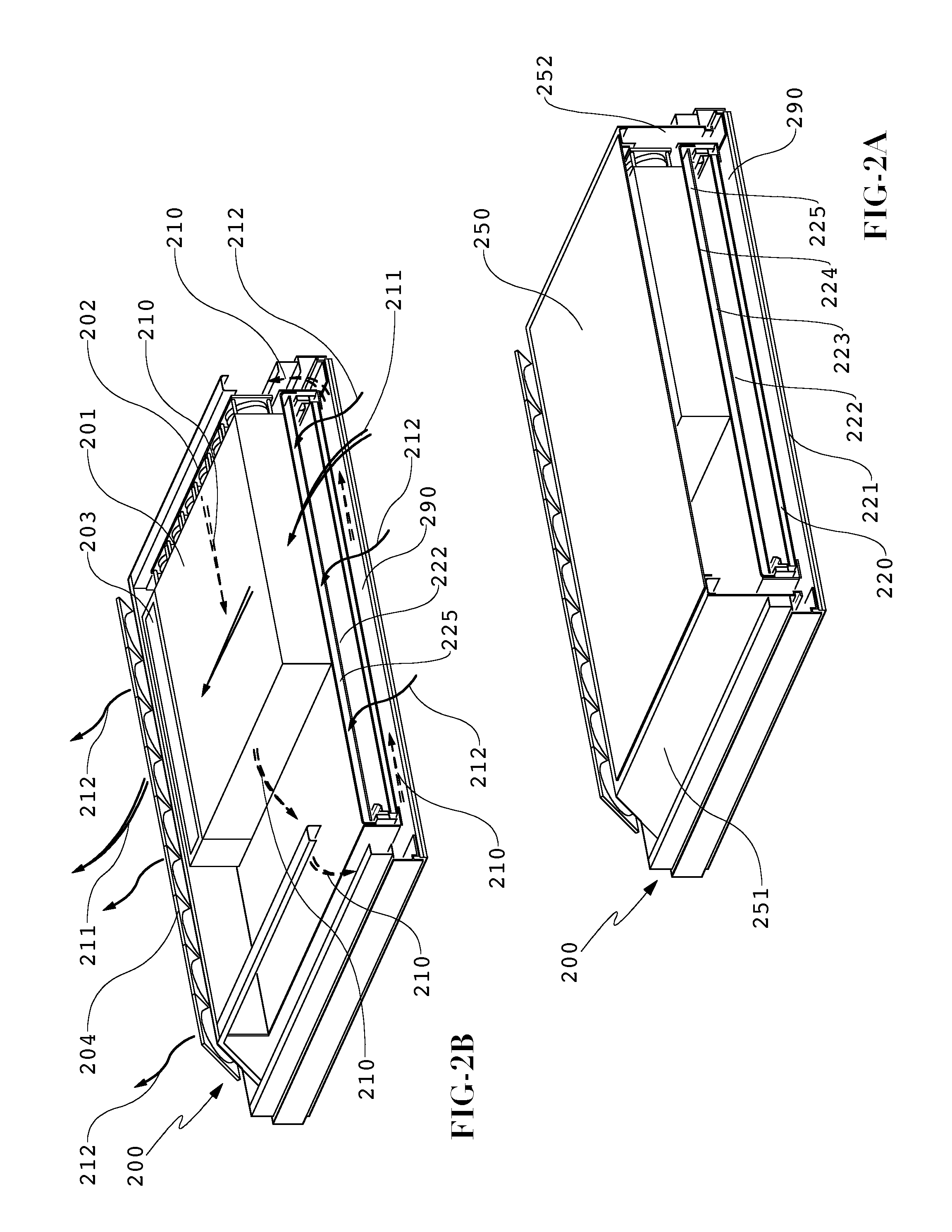

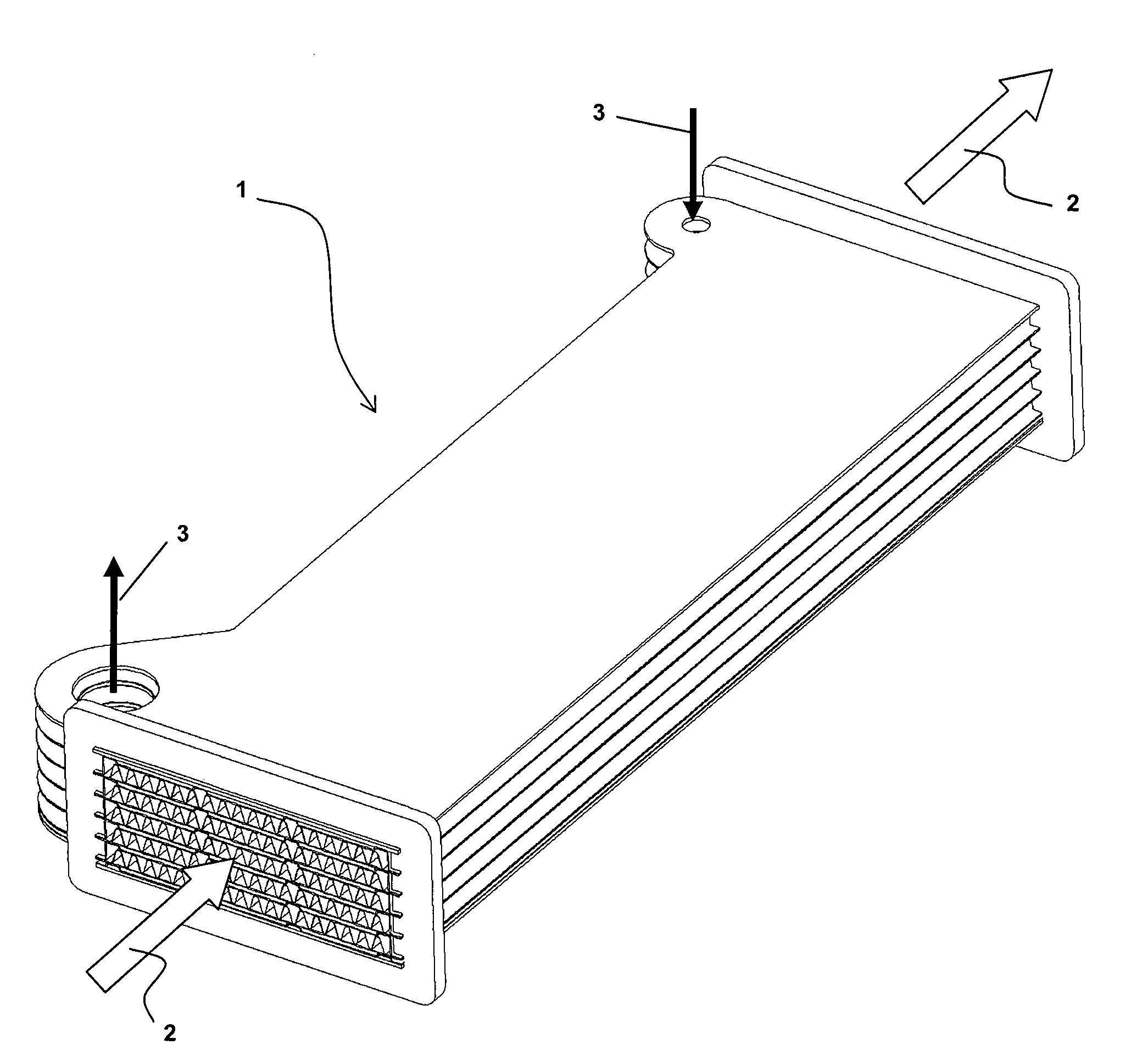

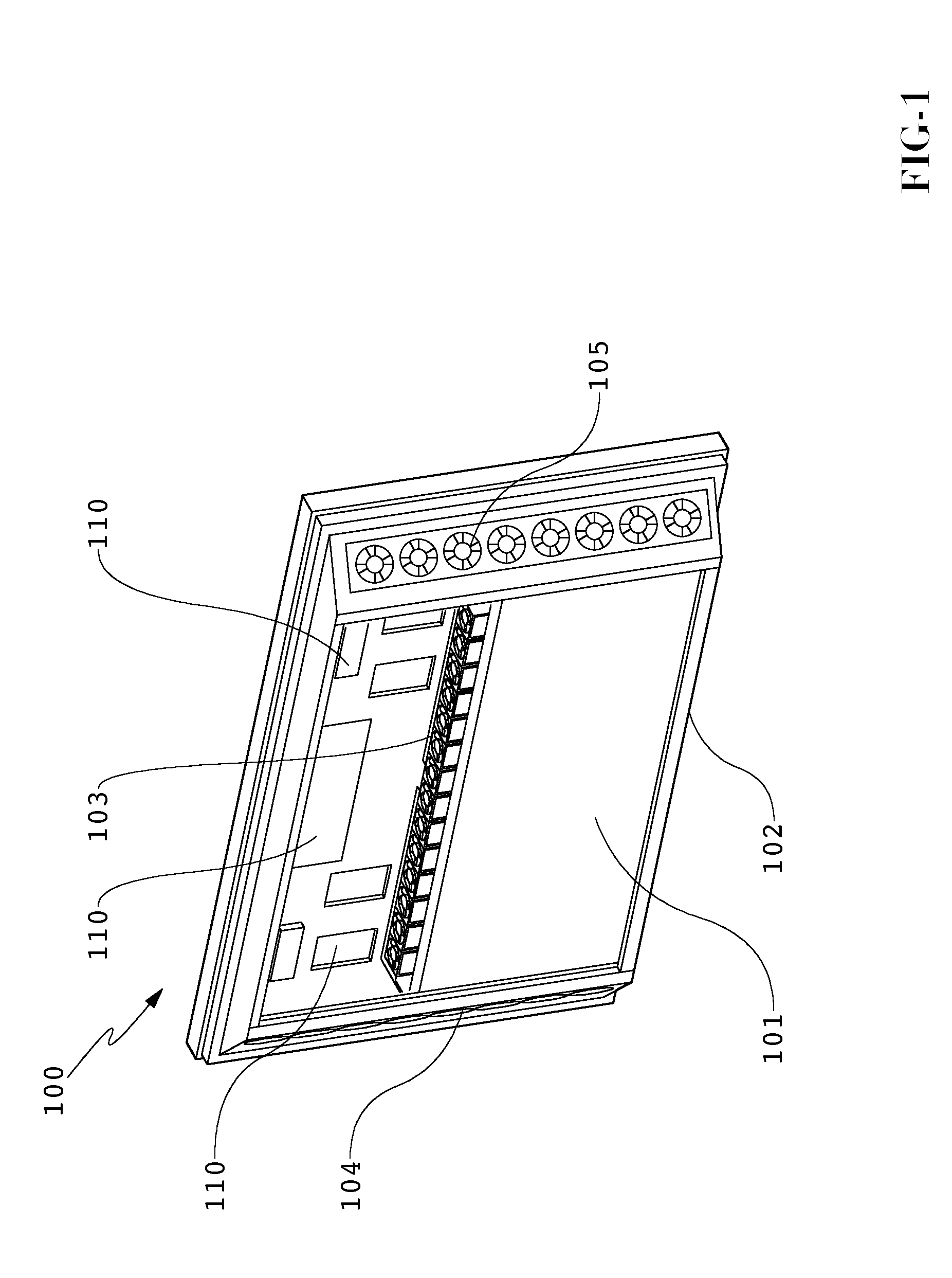

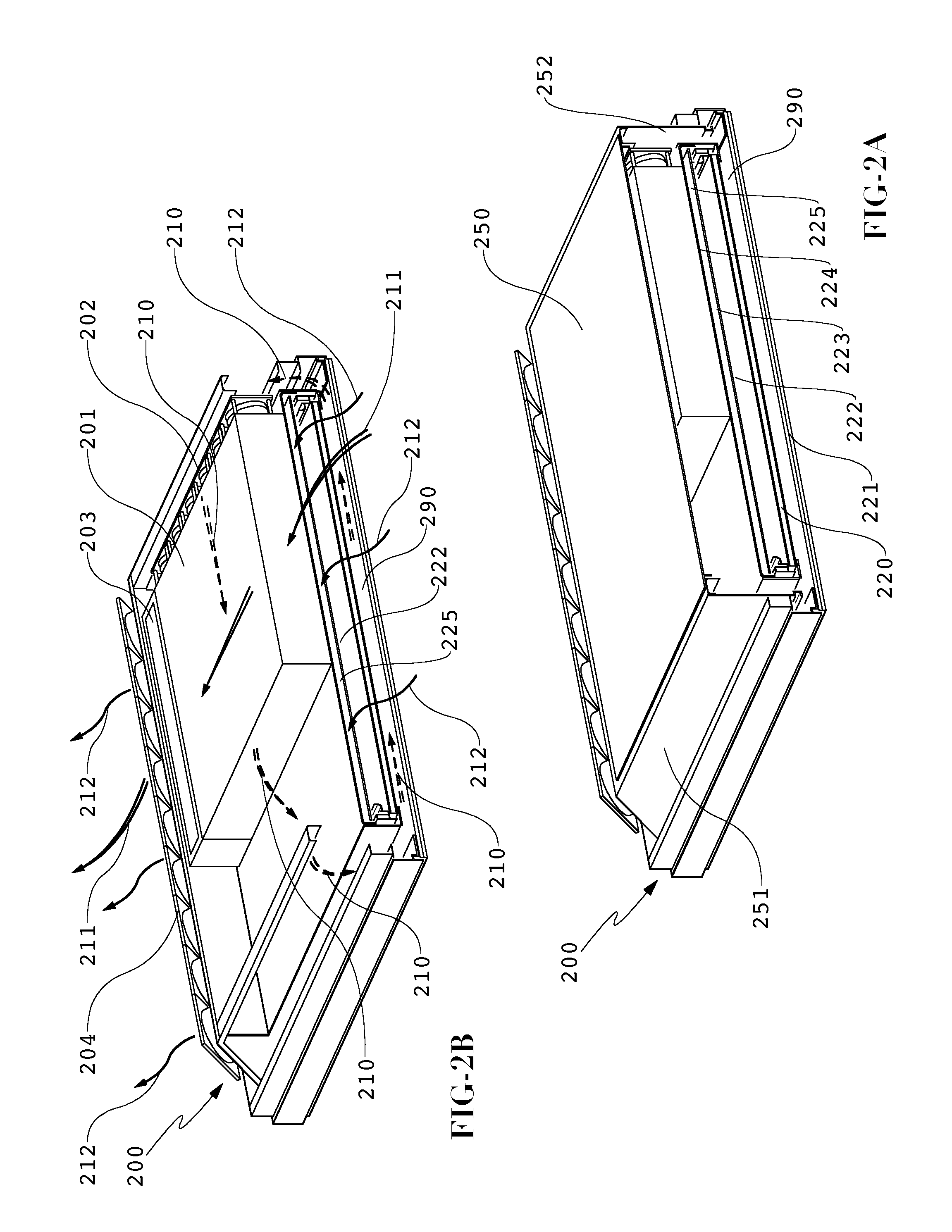

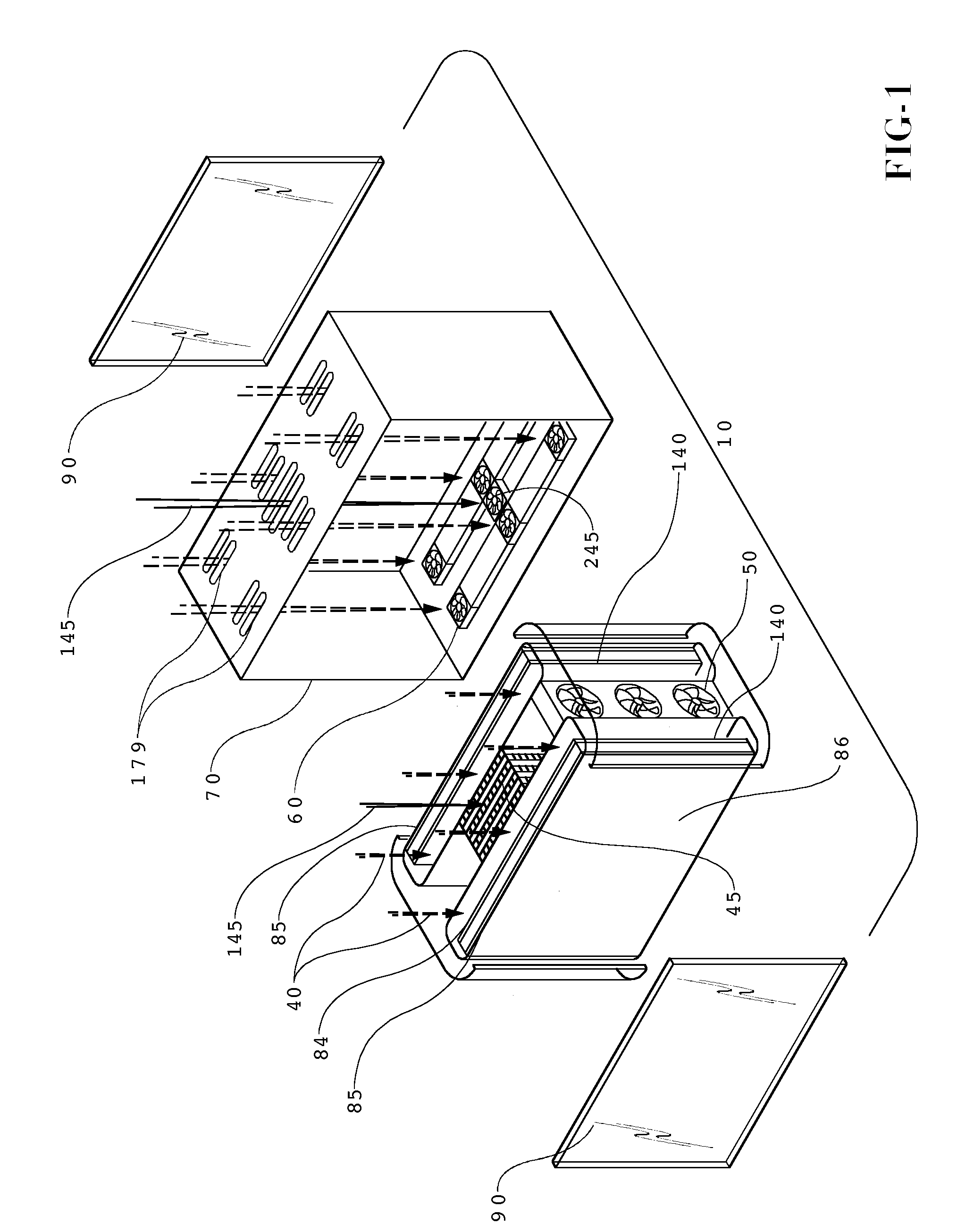

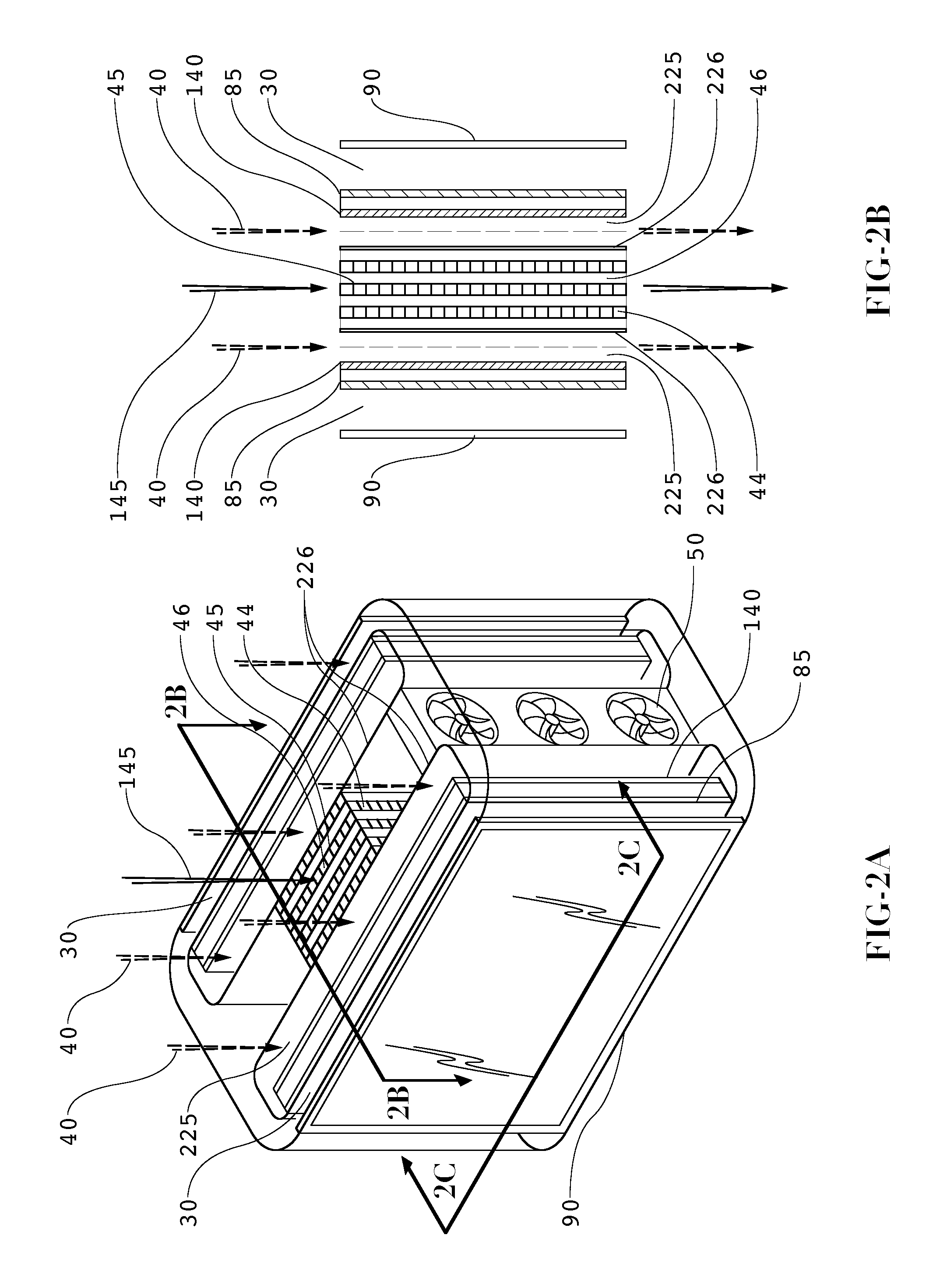

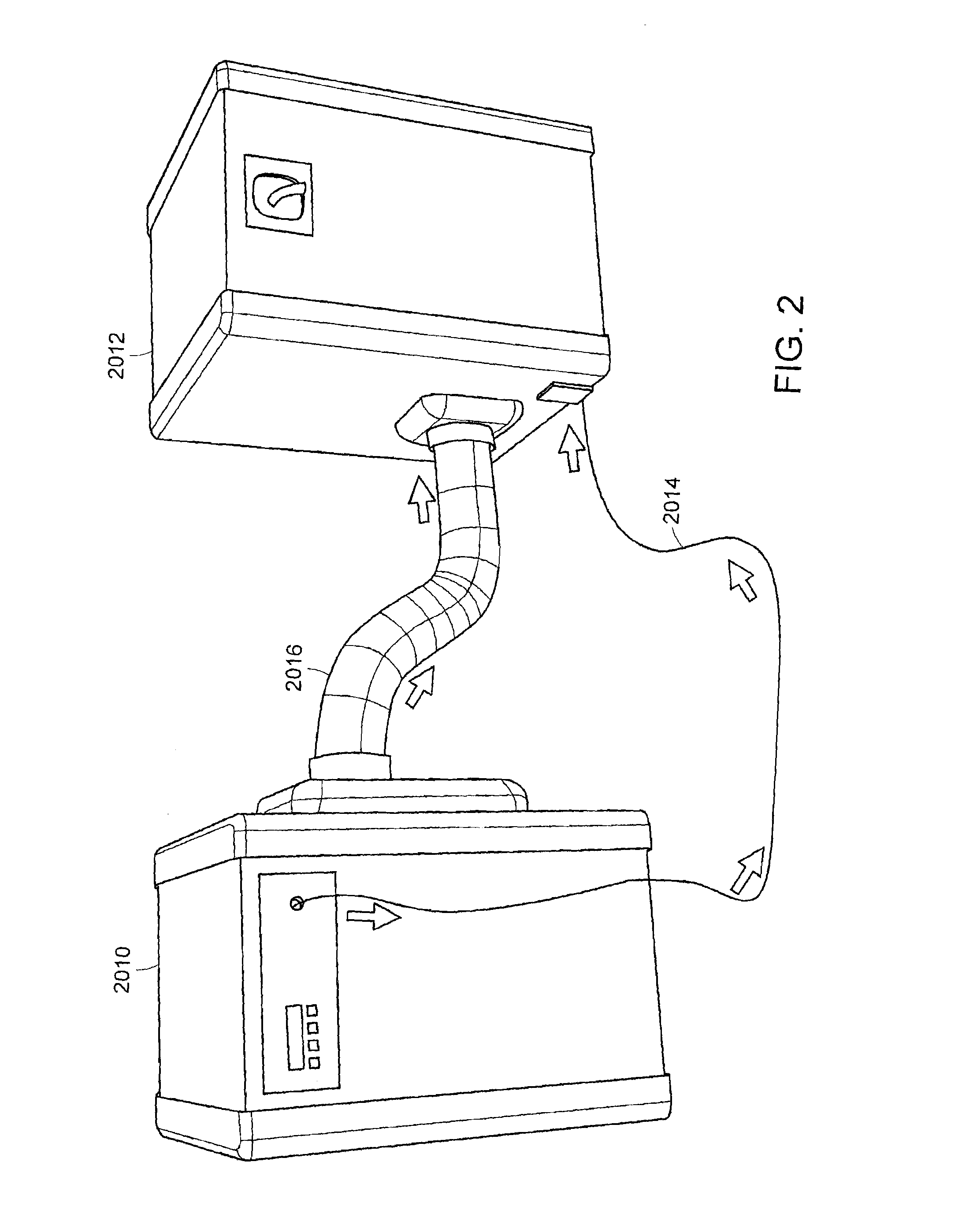

Heat Exchanger for Back to Back Electronic Displays

ActiveUS20110085301A1Digital data processing detailsLighting heating/cooling arrangementsEngineeringElectronic assemblies

A cooling assembly for a dual electronic image assembly having an open and closed gaseous loop. A closed gaseous loop allows circulating gas to travel across the front surface of a pair of electronic image assemblies and through a heat exchanger. An open loop allows ambient gas to pass through the heat exchanger and extract heat from the circulating gas. An optional additional open loop may be used to cool the back portion of the electronic image assembly (optionally a backlight). The cooling assembly can be used with any type of electronic assembly for producing an image. Some embodiments use cross-flow heat exchangers comprised of corrugated plastic.

Owner:MFG RESOURCES INT INC

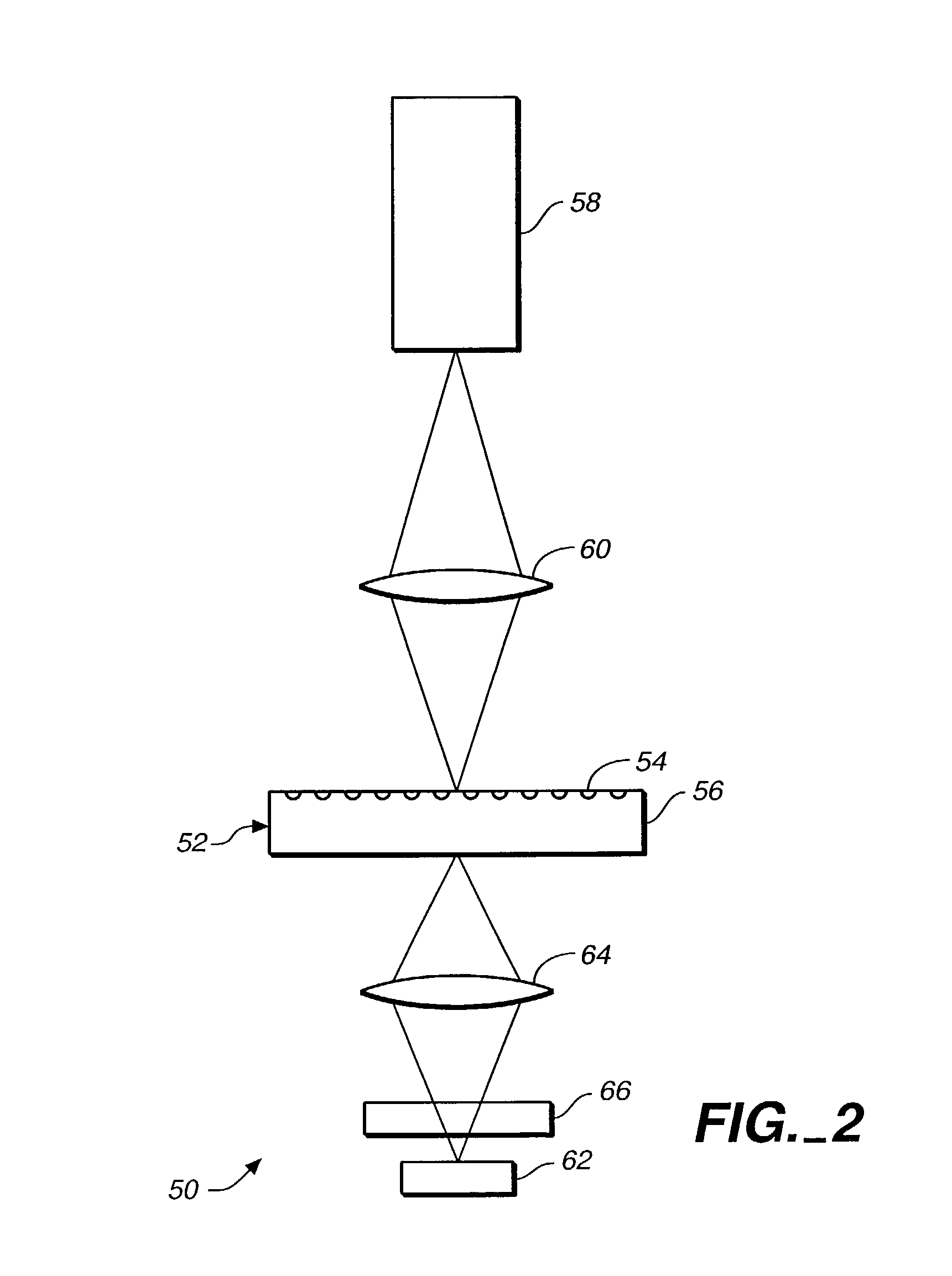

Multilayered microfluidic DNA analysis system and method

A multilayered microfluidic DNA analysis system includes a cell lysis chamber, a DNA separation chamber, a DNA amplification chamber, and a DNA detection system. The multilayered microfluidic DNA analysis system is provided as a substantially monolithic structure formed from a plurality of green-sheet layers sintered together. The substantially monolithic structure has defined therein a means for heating the DNA amplification chamber and a means for cooling the DNA amplification chamber. The means for heating and means for cooling operate to cycle the temperature of the DNA amplification chamber as required for performing a DNA amplification process, such as PCR.

Owner:GOOGLE TECH HLDG LLC

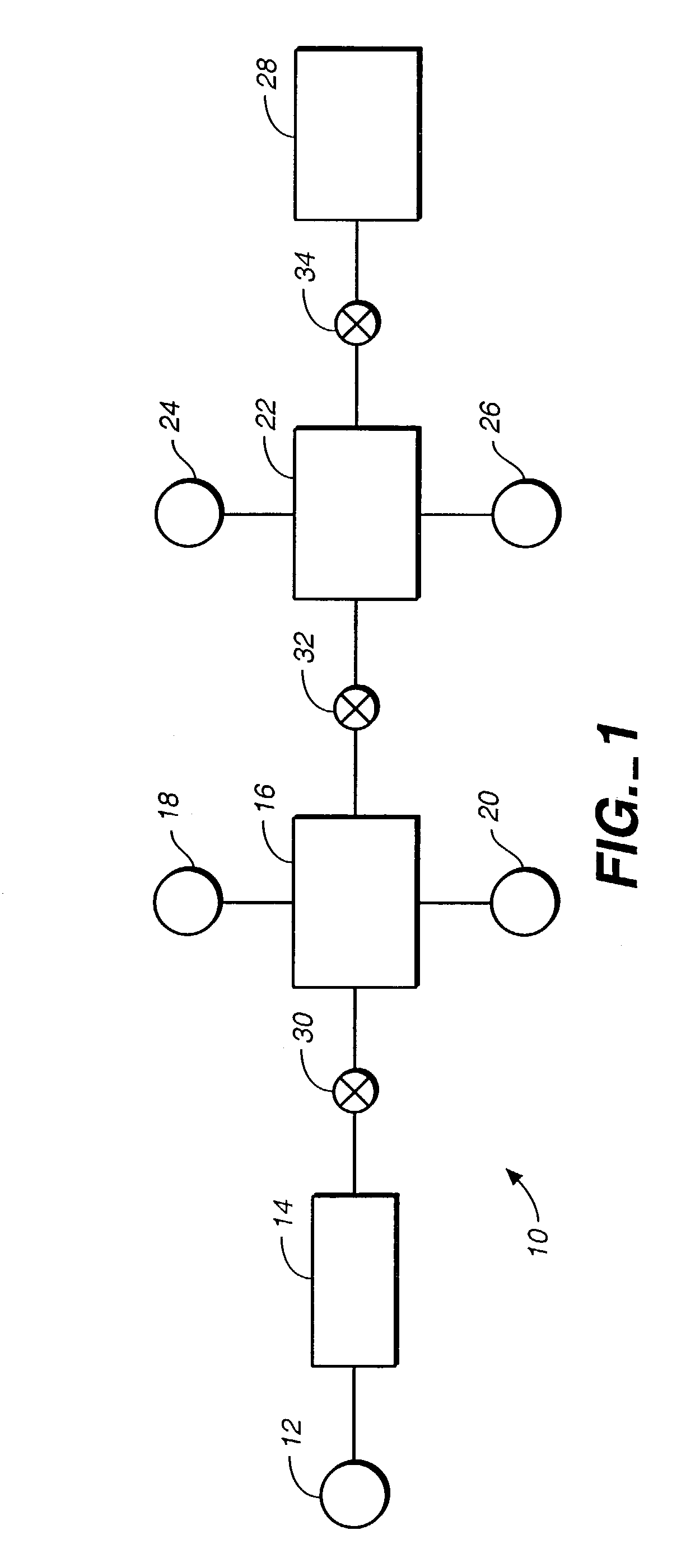

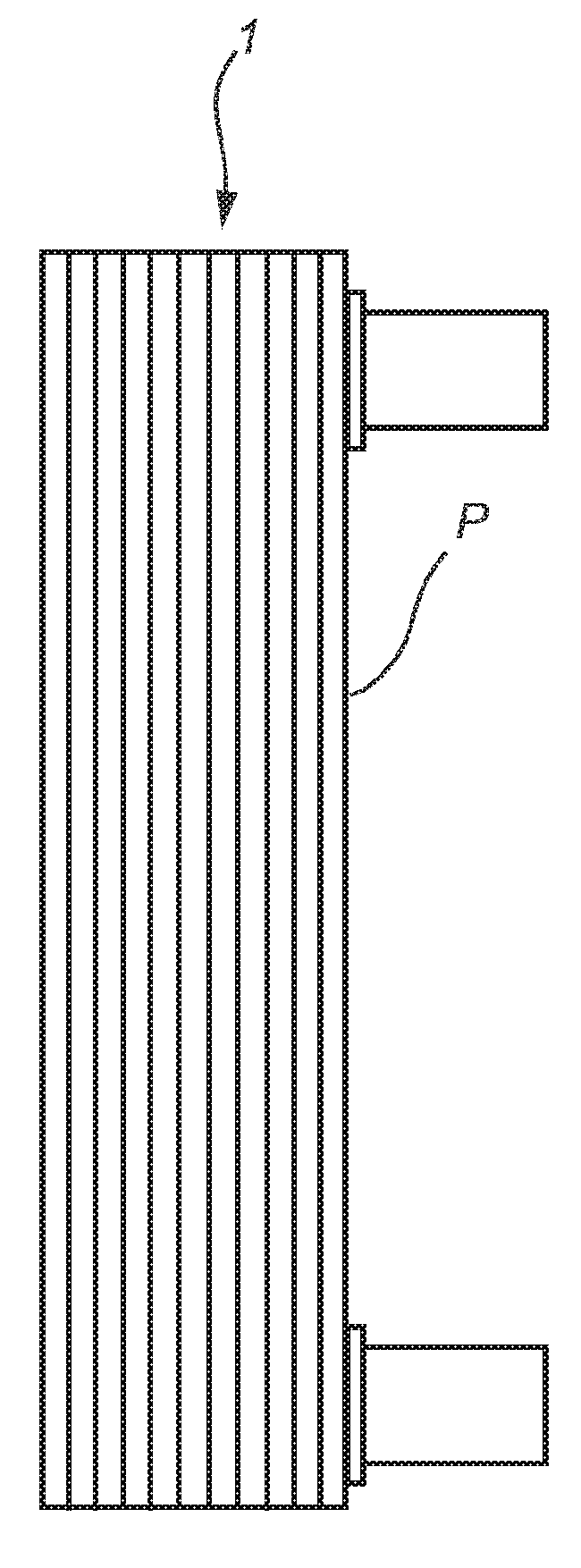

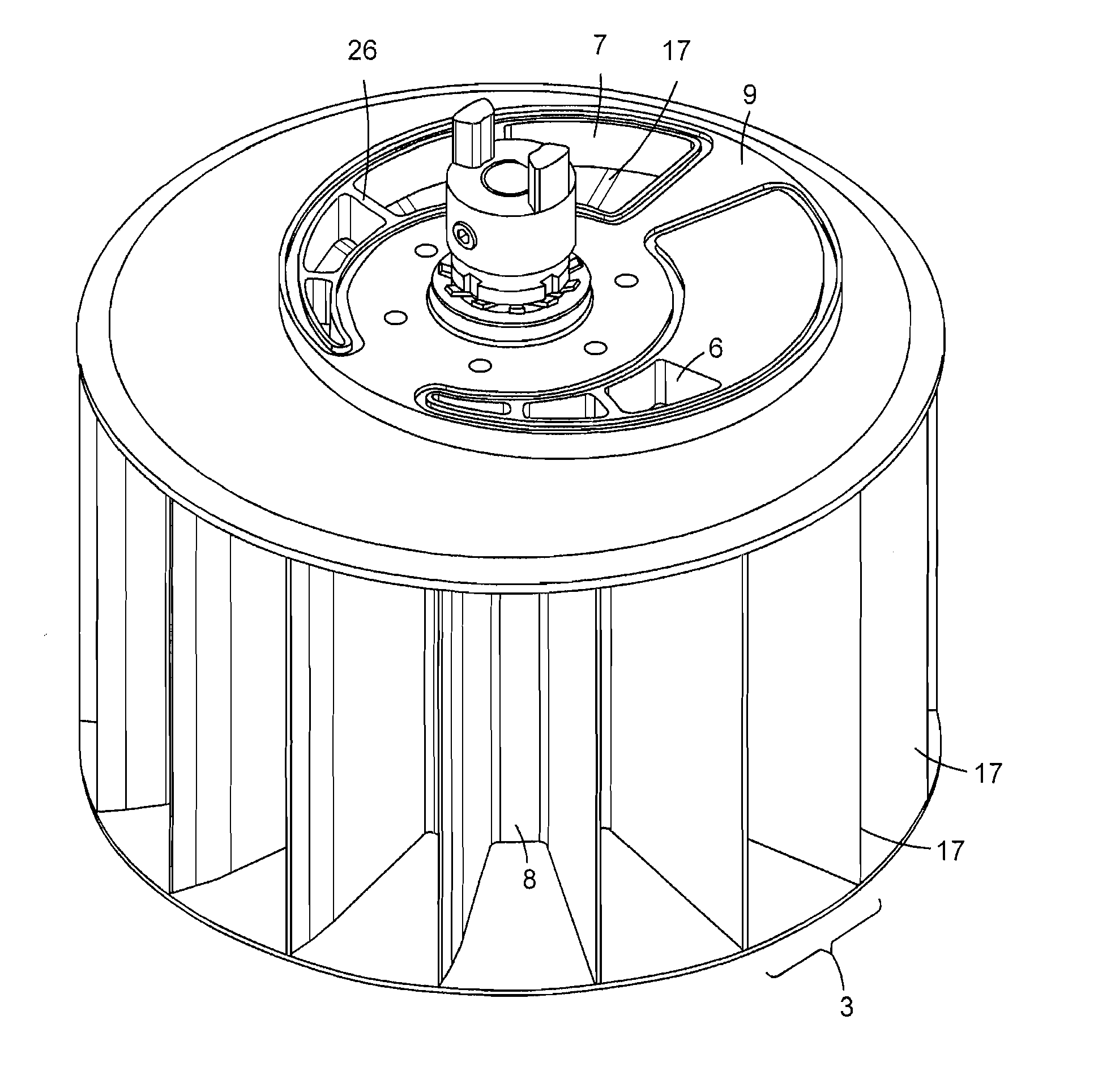

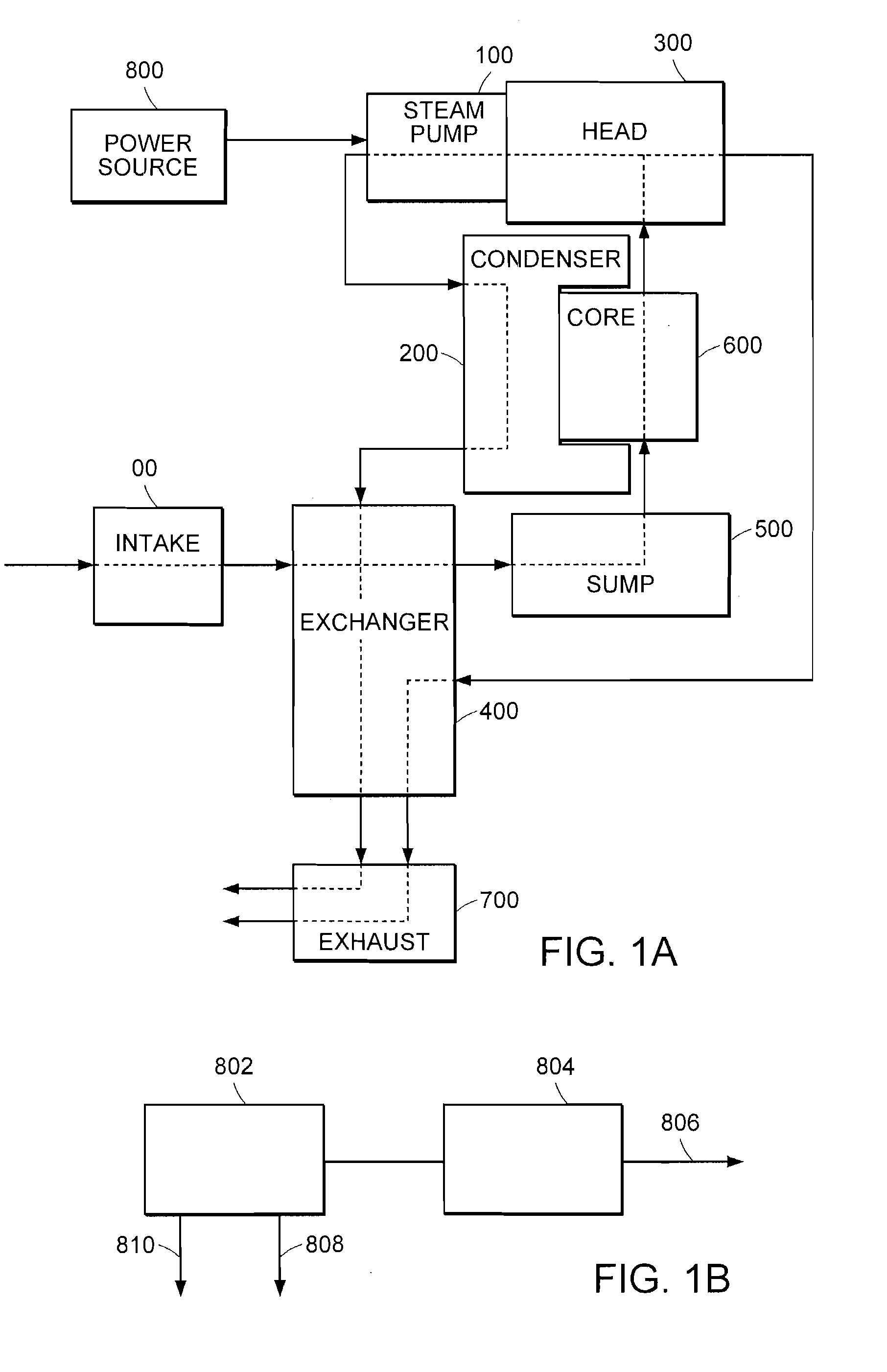

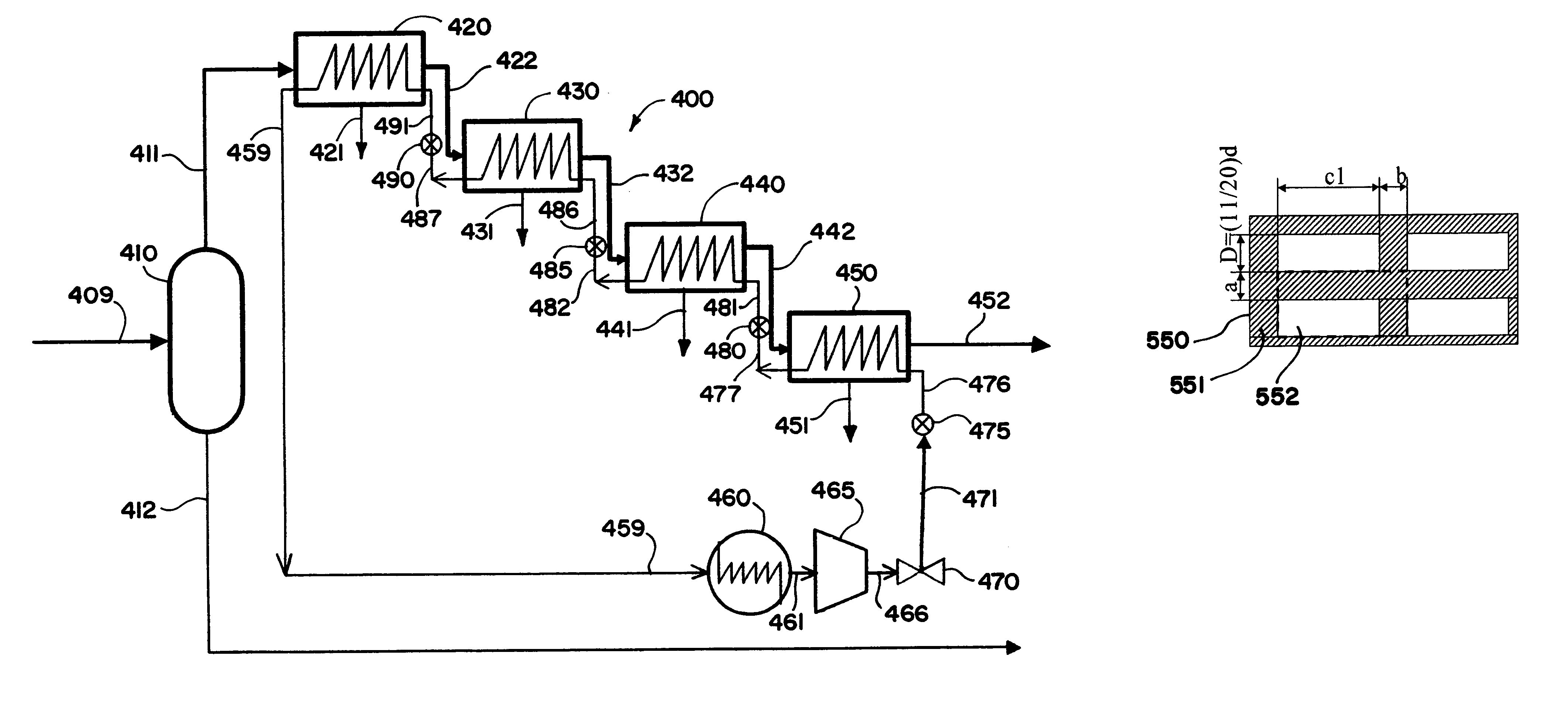

Pressurized vapor cycle liquid distillation

ActiveUS20050016828A1Easy maintenanceMaximize energy efficiencyDistillation regulation/controlUsing liquid separation agentHeat managementDrive shaft

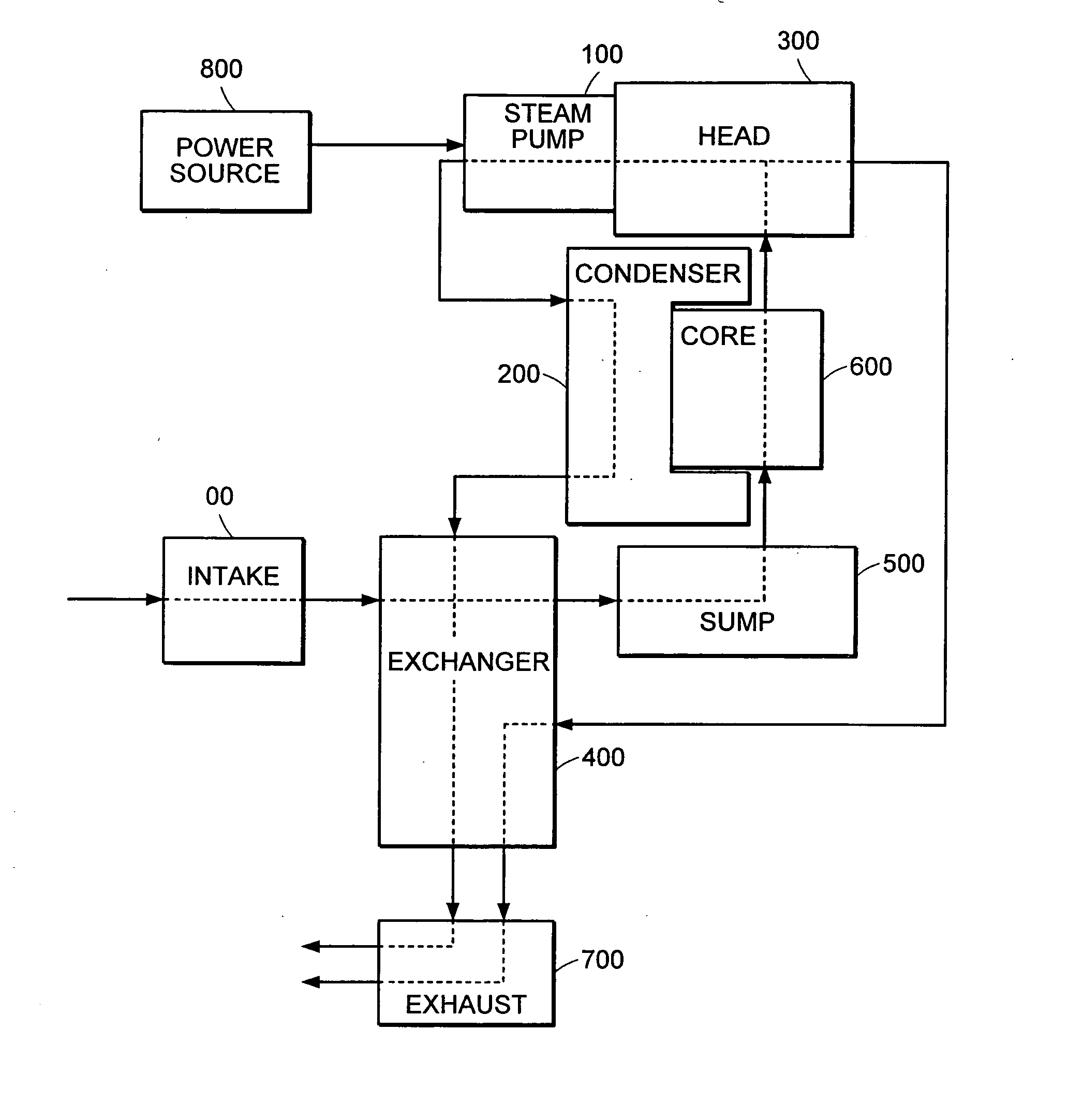

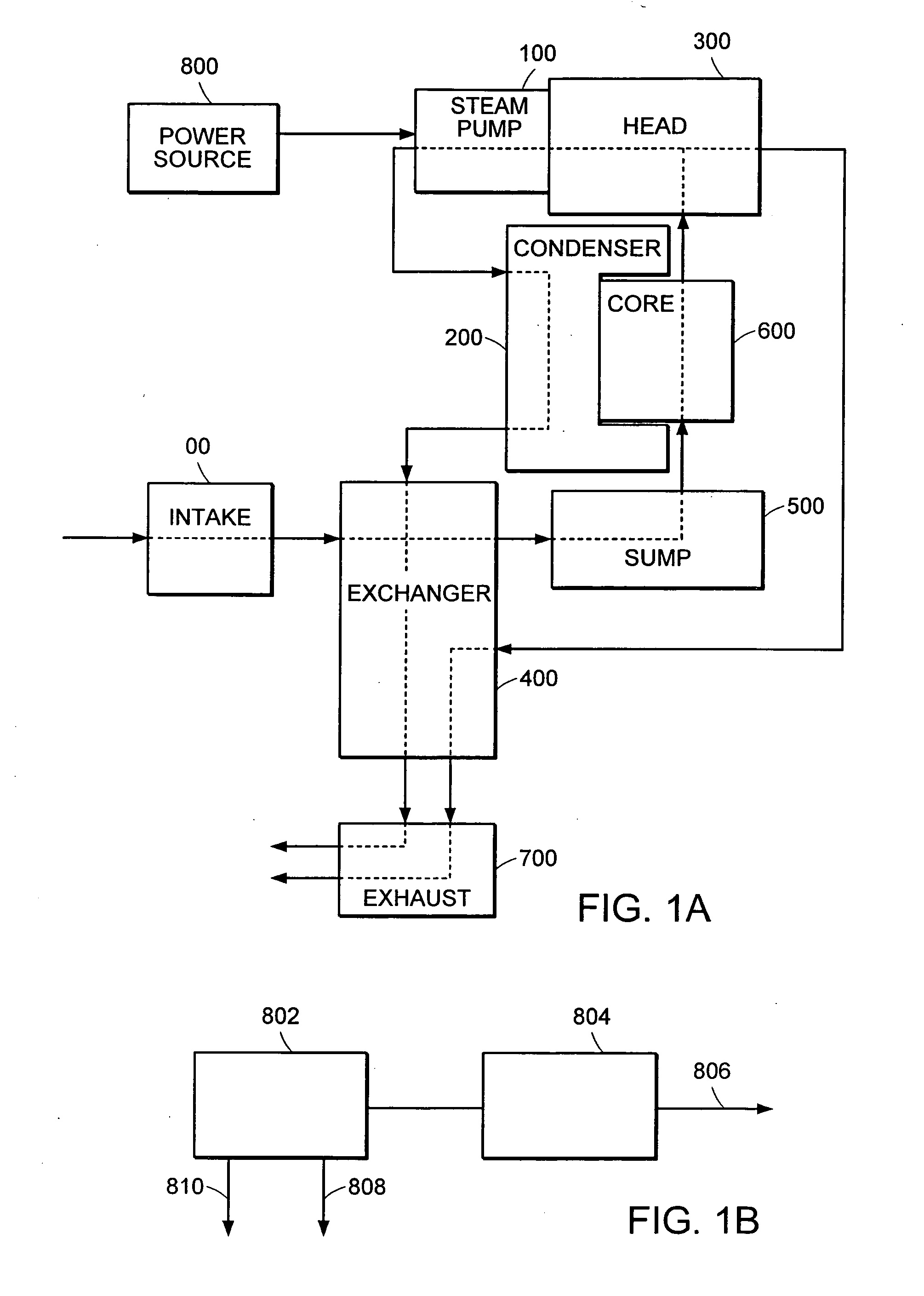

Embodiments of the invention are directed toward a novel pressurized vapor cycle for distilling liquids. In some embodiments of the invention, a liquid purification system is revealed, including the elements of an input for receiving untreated liquid, a vaporizer coupled to the input for transforming the liquid to vapor, a head chamber for collecting the vapor, a vapor pump with an internal drive shaft and an eccentric rotor with a rotatable housing for compressing vapor, and a condenser in communication with the vapor pump for transforming the compressed vapor into a distilled product. Other embodiments of the invention are directed toward heat management, and other process enhancements for making the system especially efficient.

Owner:DEKA PROD LLP

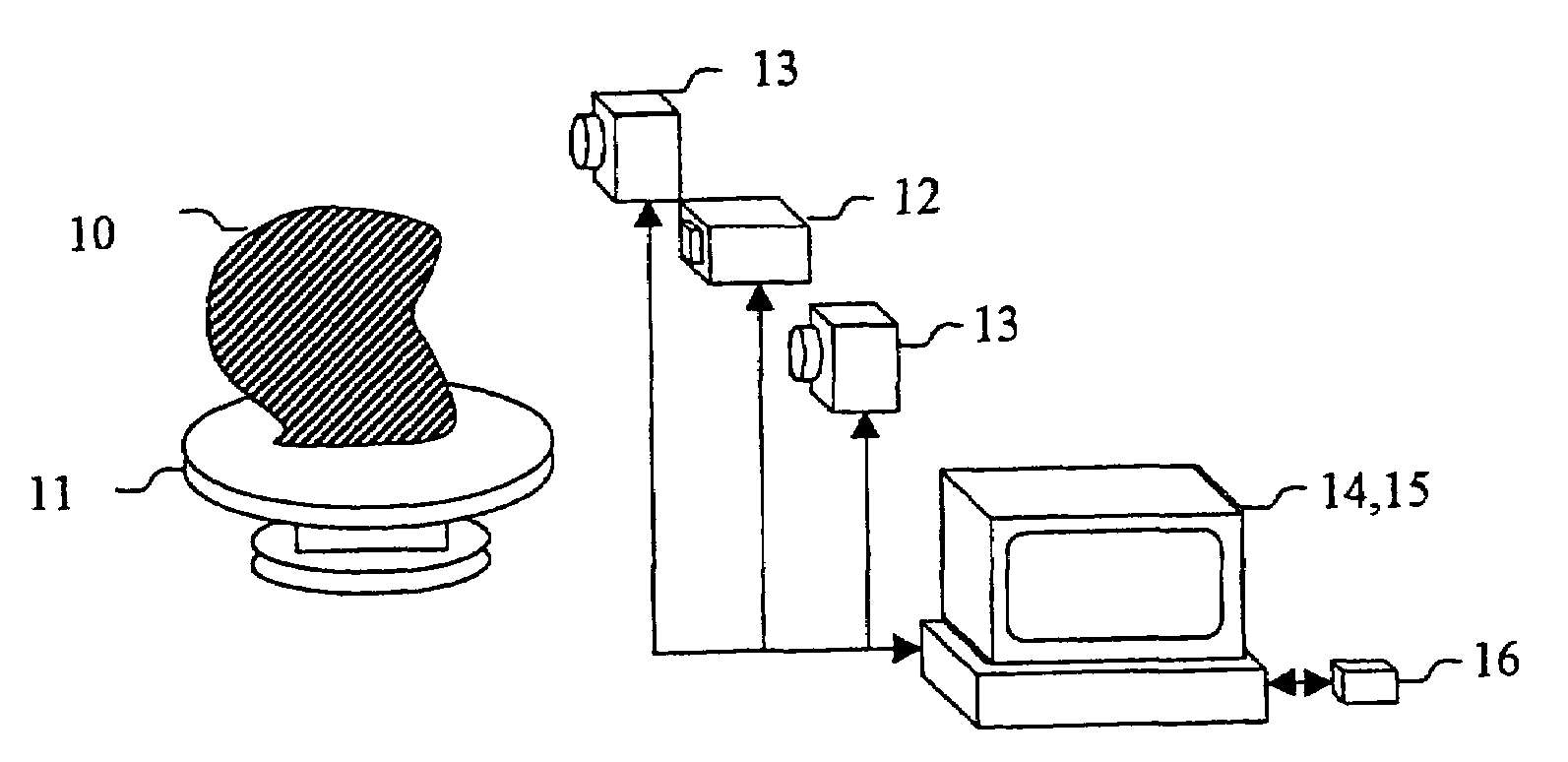

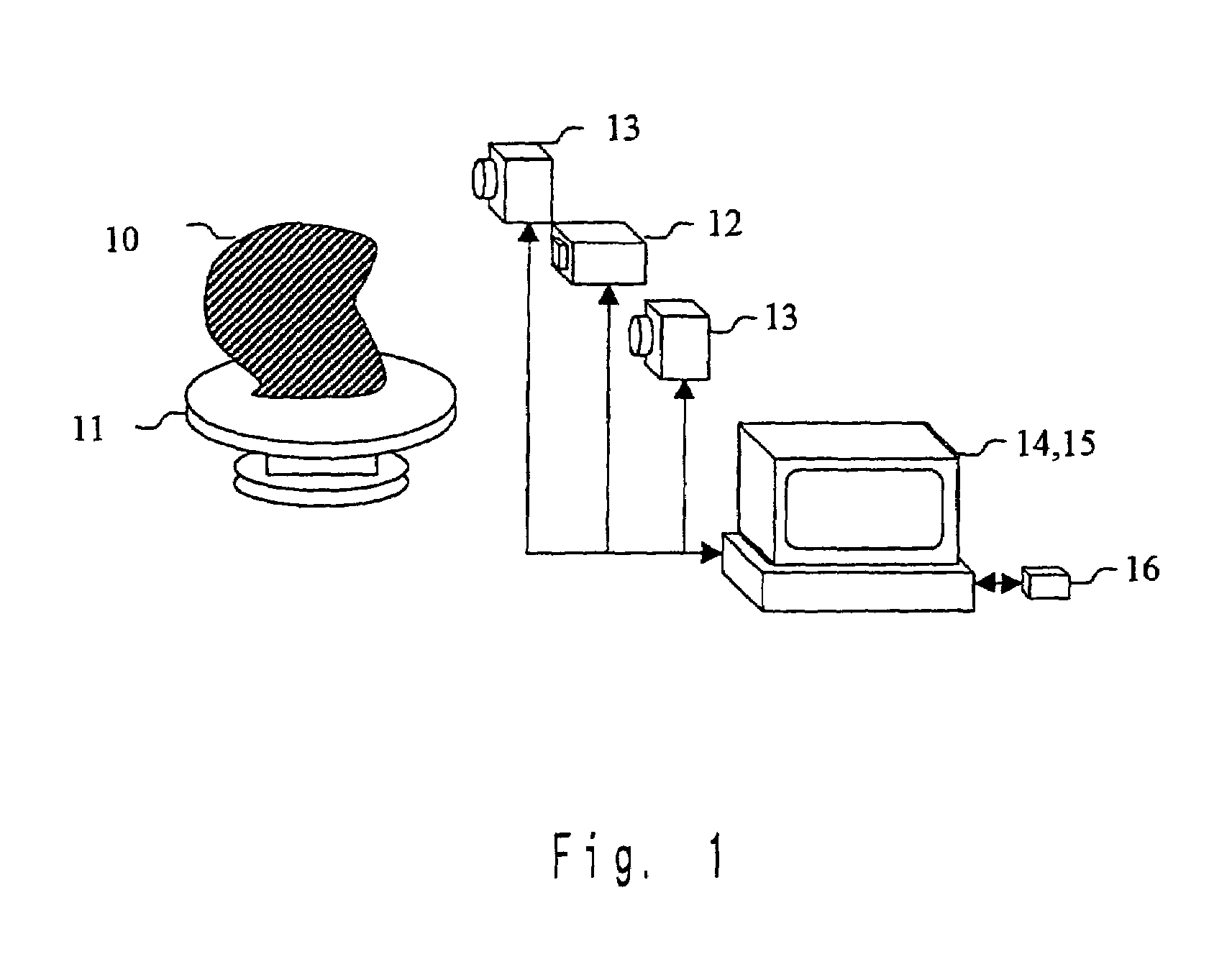

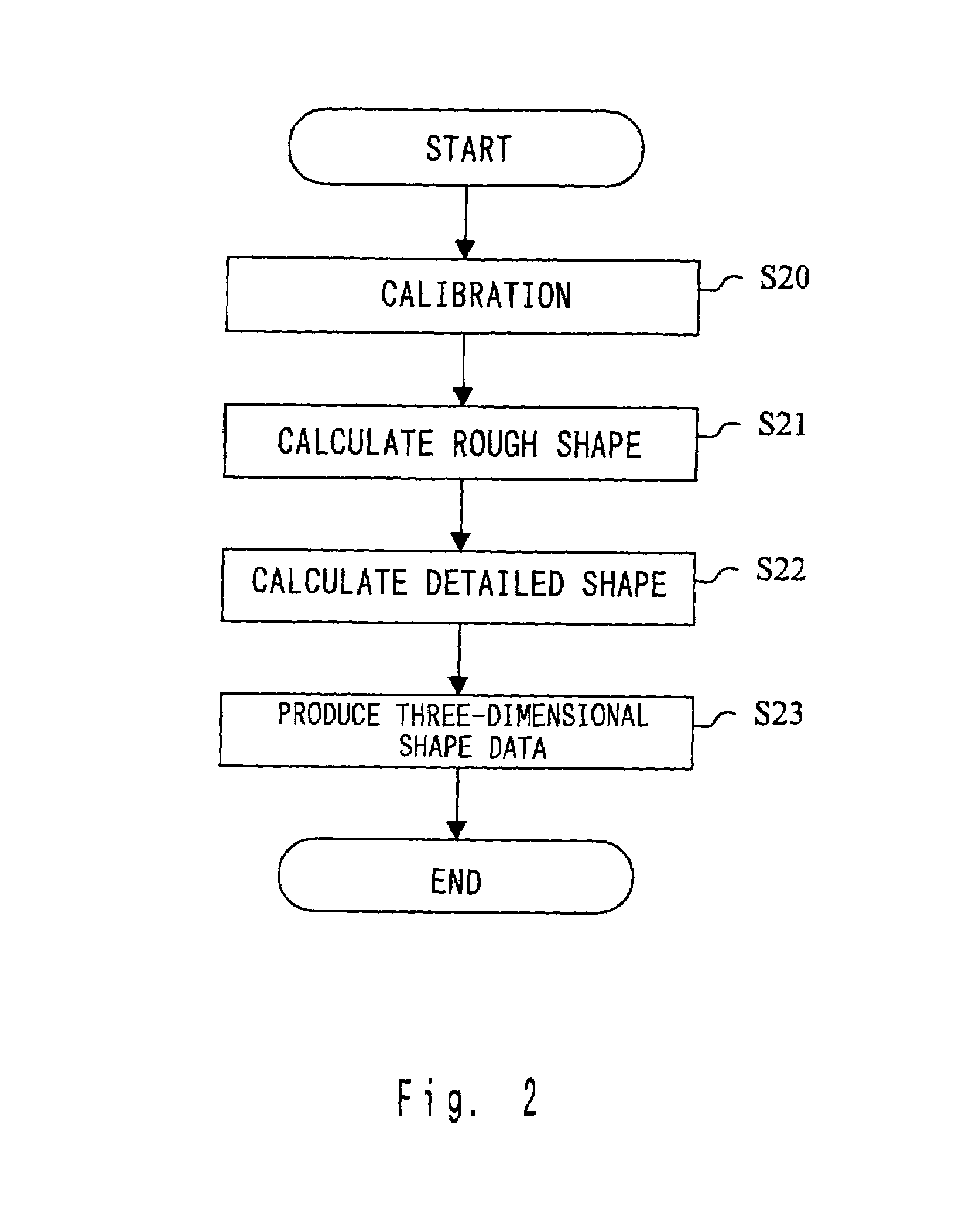

Three-dimensional modeling apparatus, method, and medium, and three-dimensional shape data recording apparatus, method, and medium

InactiveUS6965690B2Increase investmentOptical rangefindersFuel cell auxillariesTriangulationThree dimensional shape

A three-dimensional shape modeling of a real object that reduces the limitations on the target shape and color. The rough shape of the target object is determined by a silhouette method (which has limitation on the target shape) and, at the same time, the detailed shape of the target object is determined by a triangulation method or the like (which has limitation on the target color). By using both sets of information, the consistency between the rough and detailed shape information are checked. For the portions where the consistency is not satisfied (points where detailed shape information is absent or points where detailed shape section is present outside the rough shape), rough shape is assumed to be the final object information and for other portions, the detailed shape is taken as the final object information. In this manner, three-dimensional shape modeling with reduced limitations on the target shape and color can be performed.

Owner:OL SECURITY LIABILITY CO

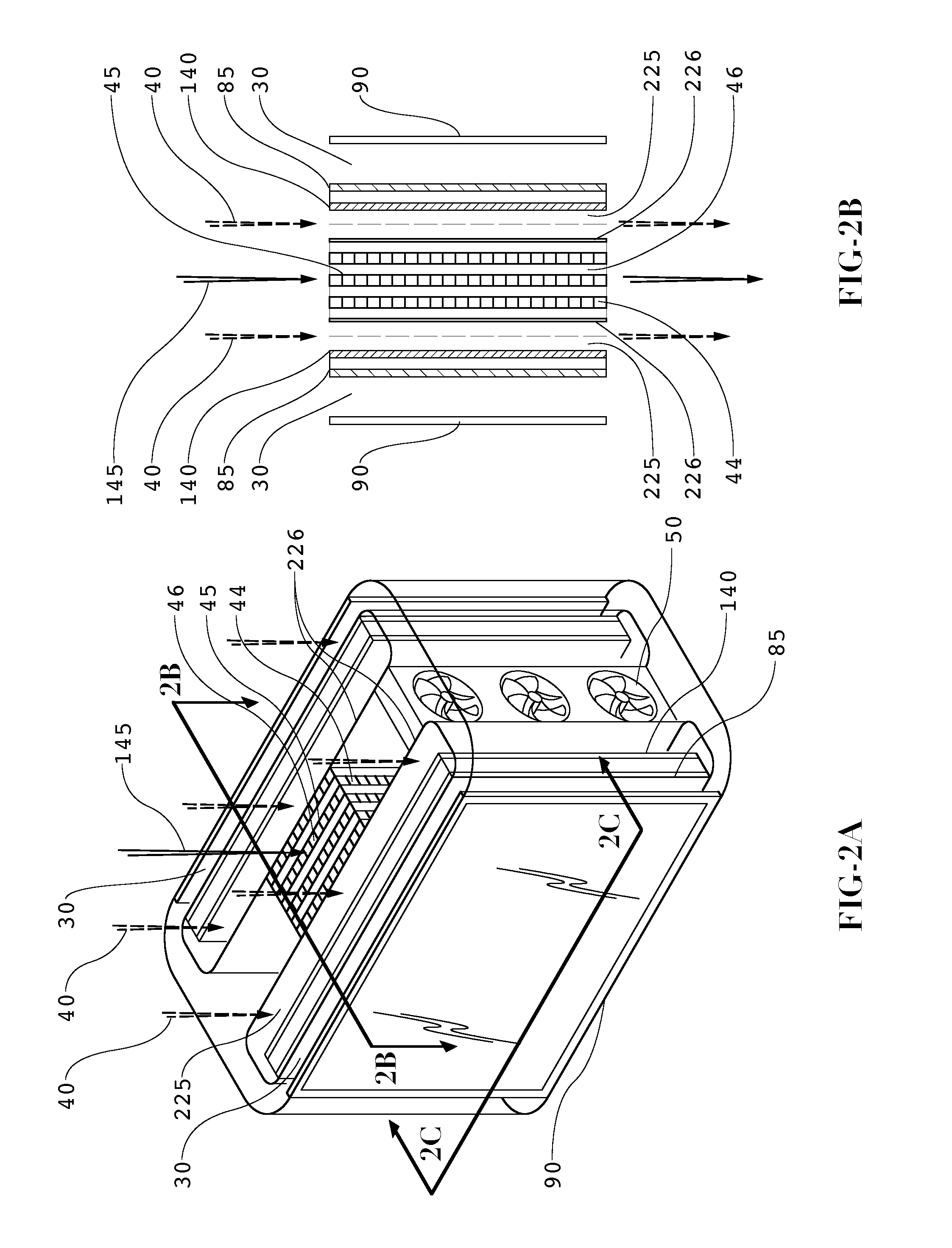

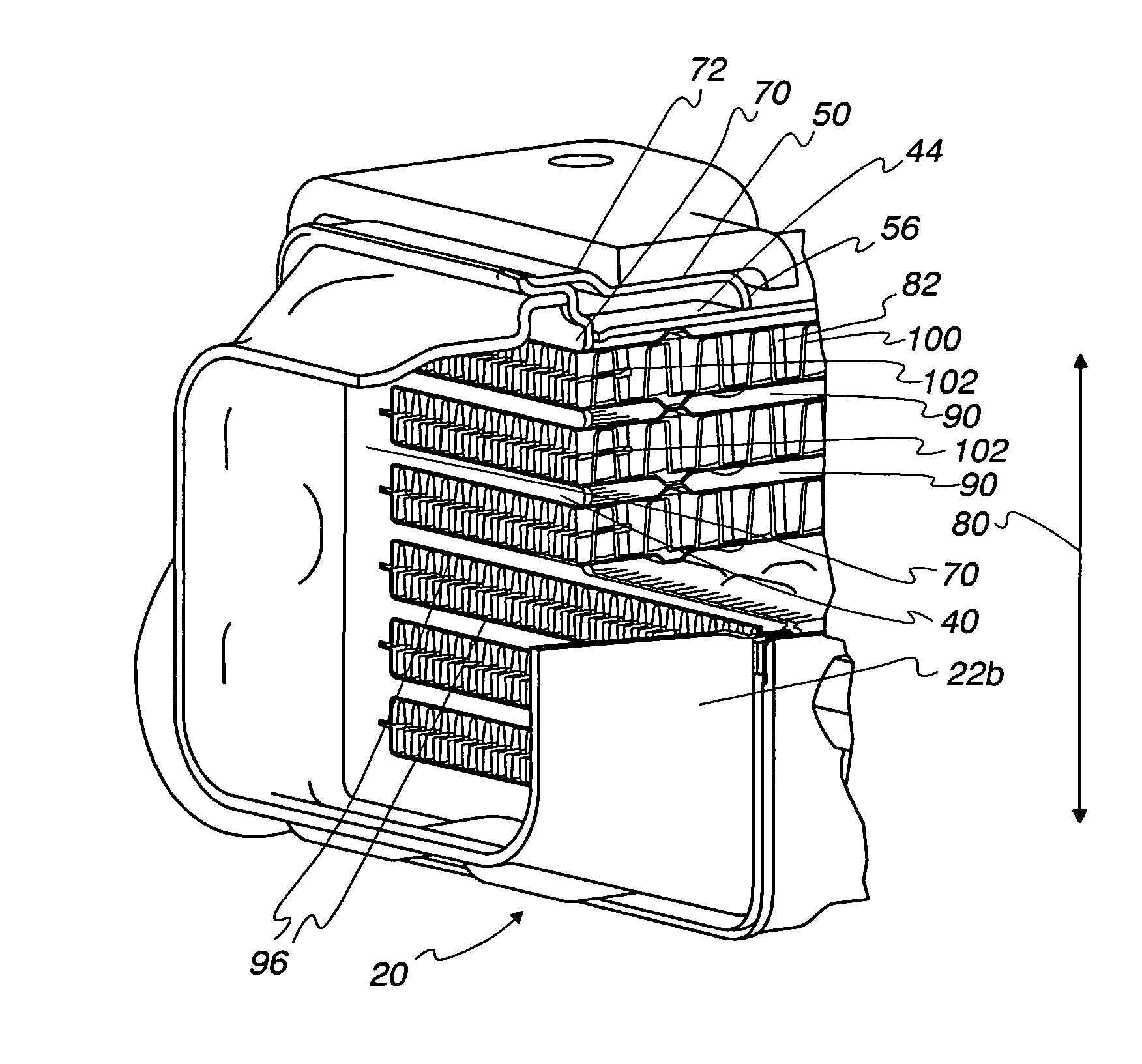

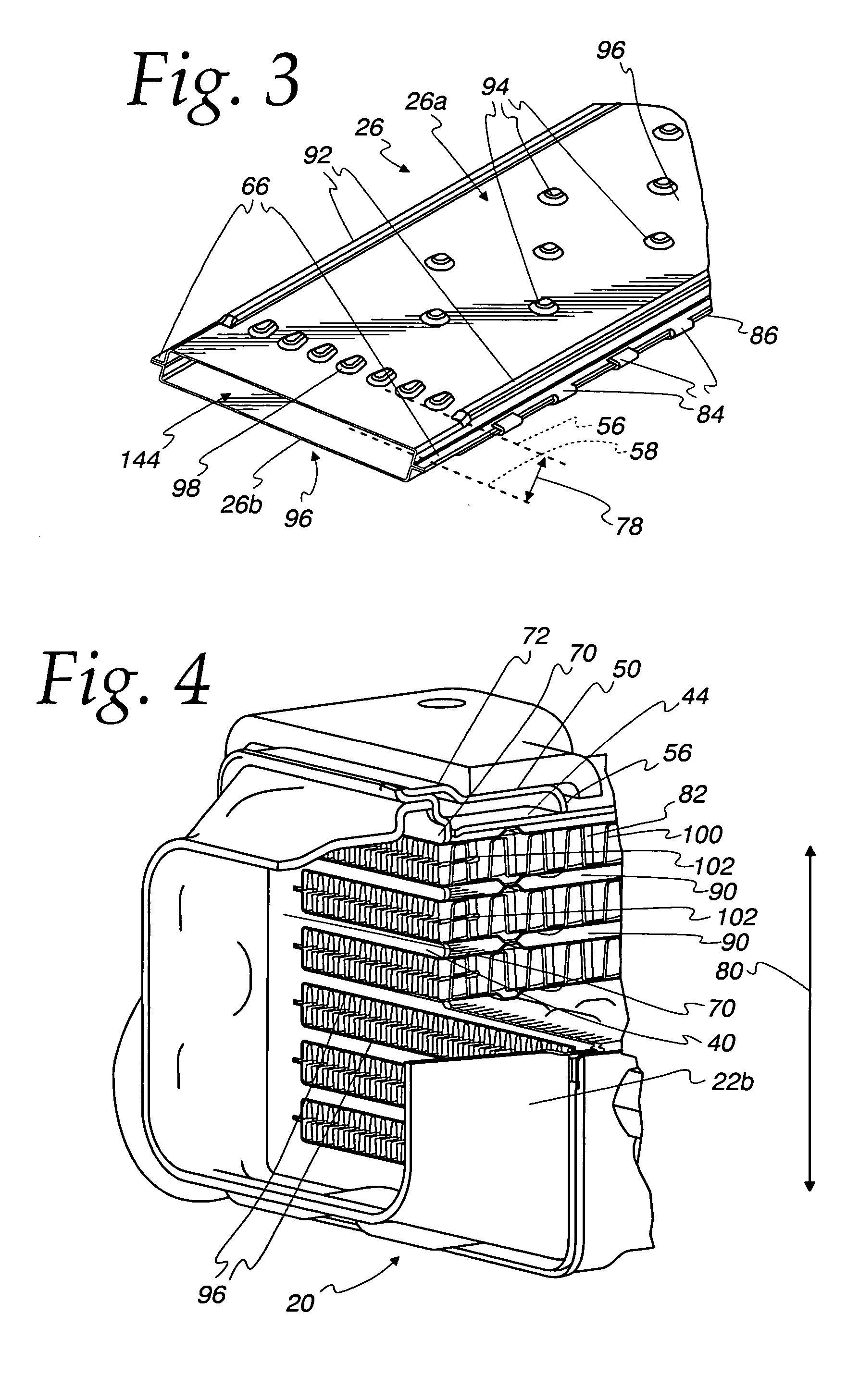

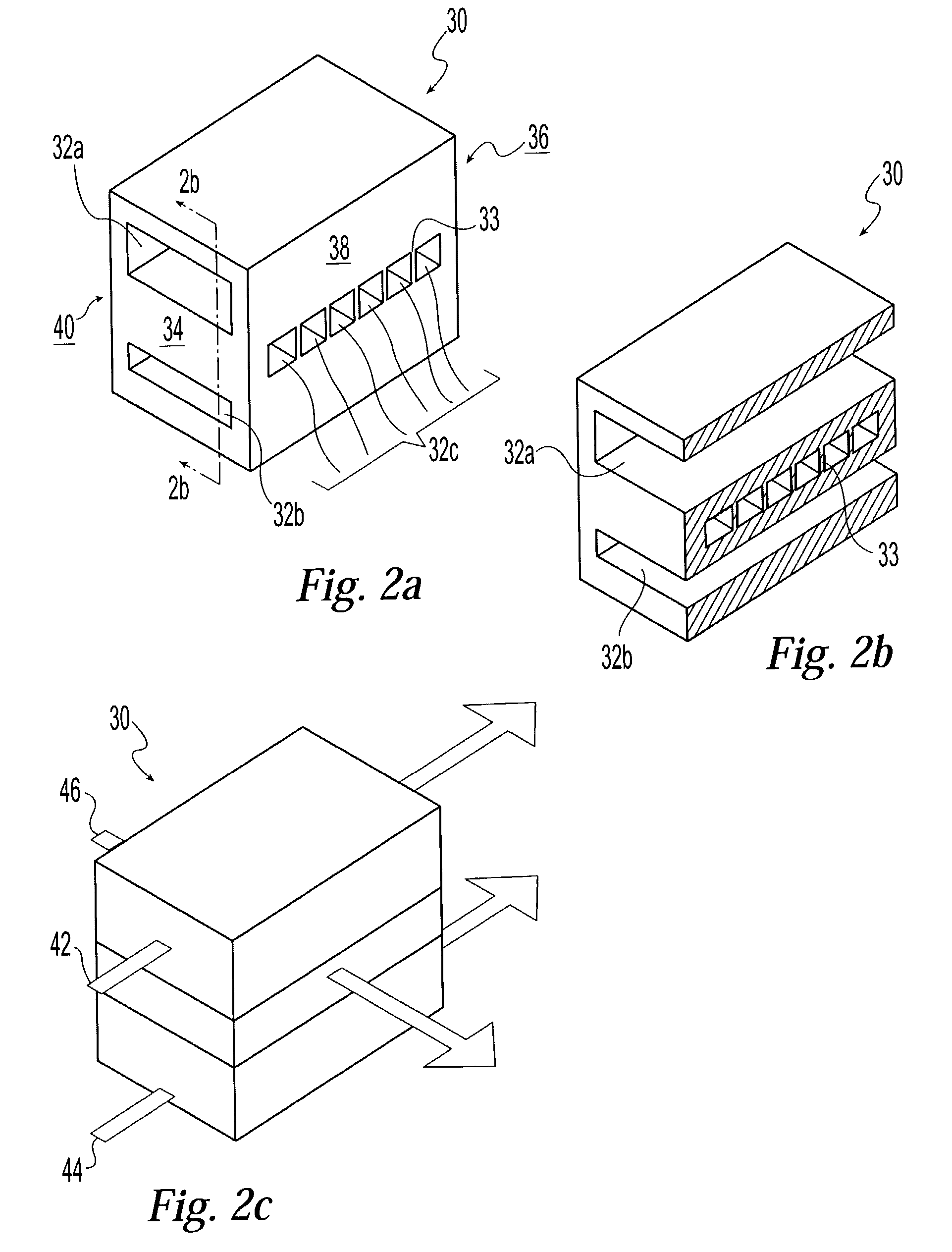

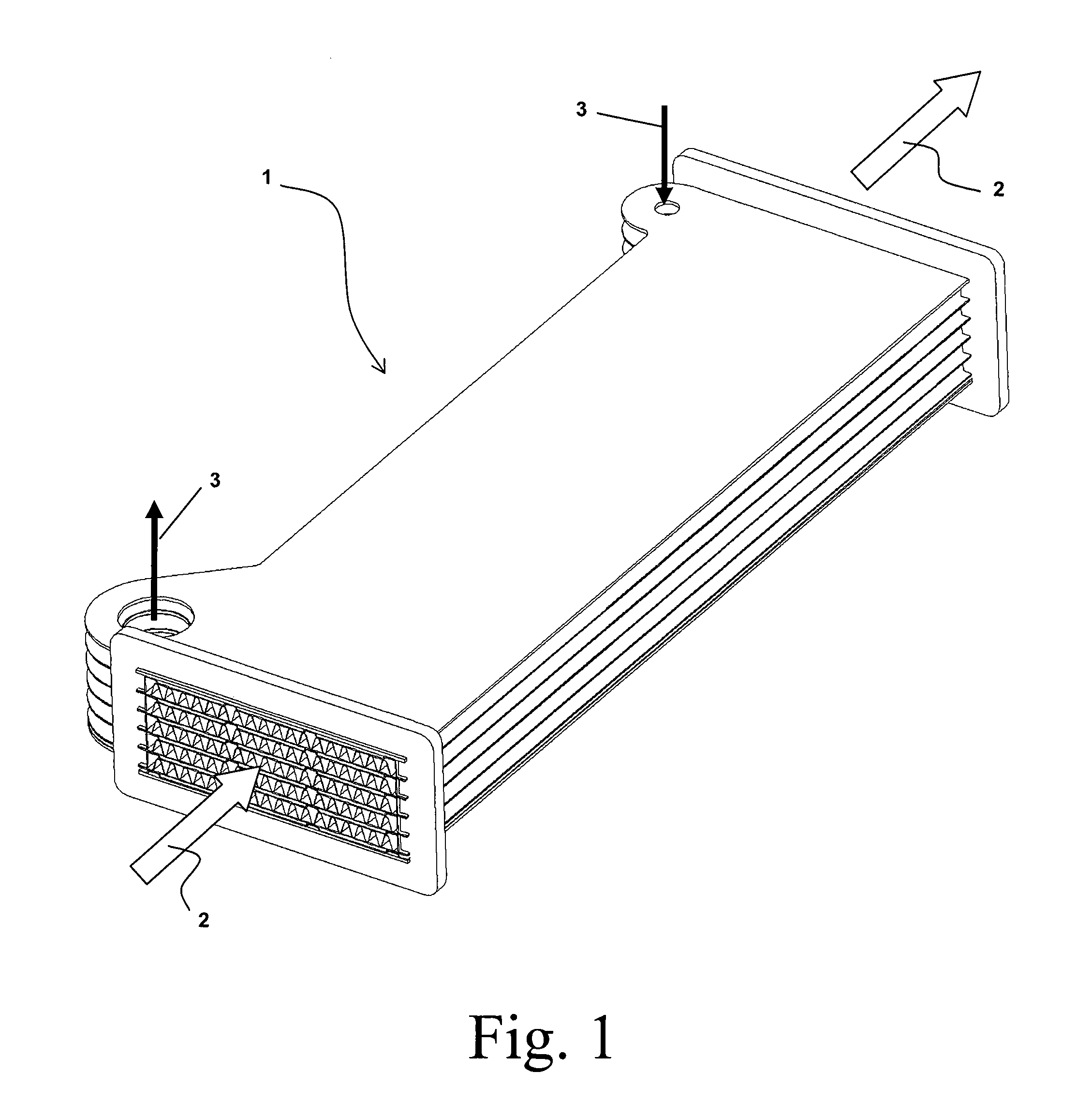

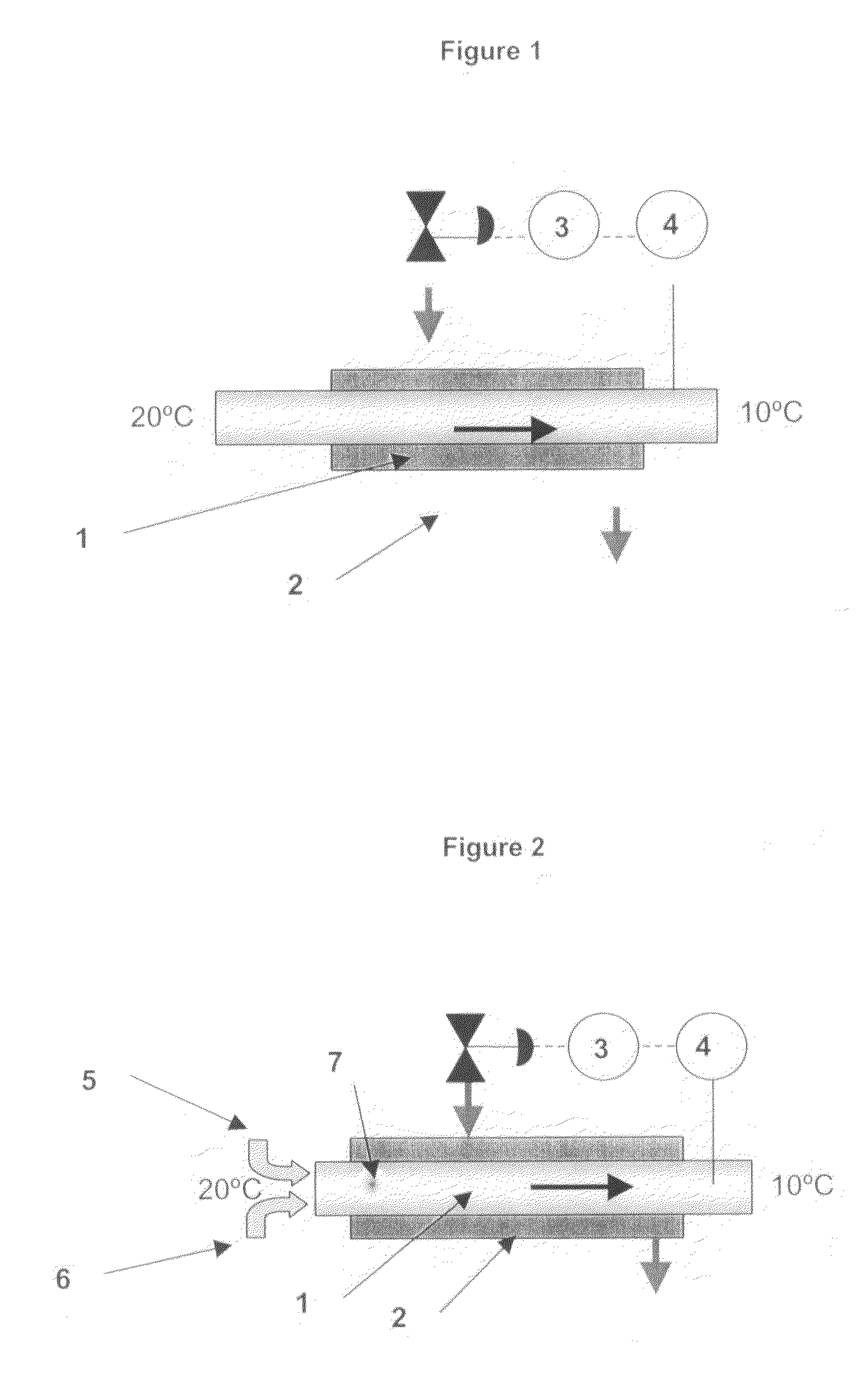

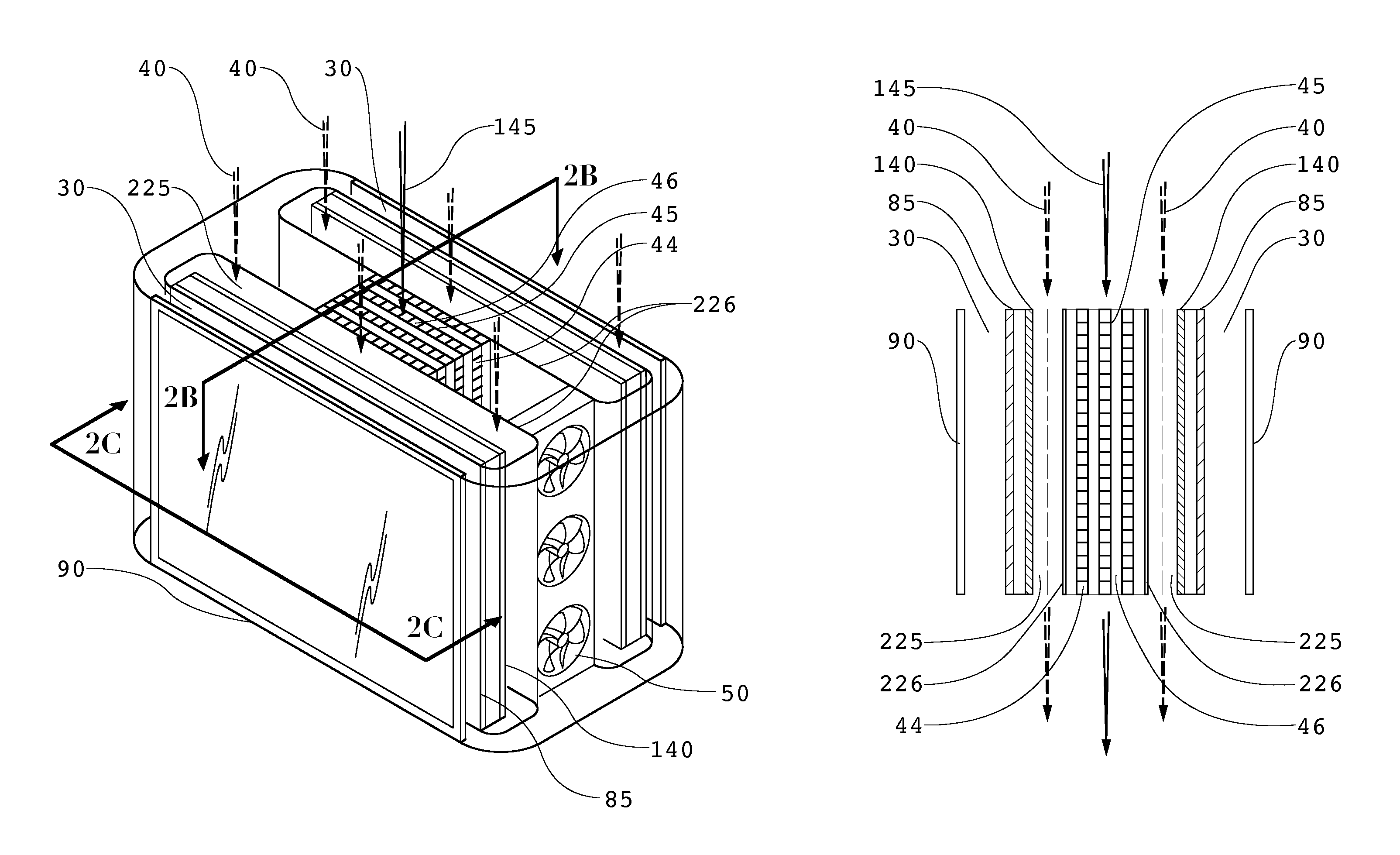

Heat Exchanger for an Electronic Display

ActiveUS20110013114A1Non-linear opticsCooling/ventilation/heating modificationsEngineeringElectronic assemblies

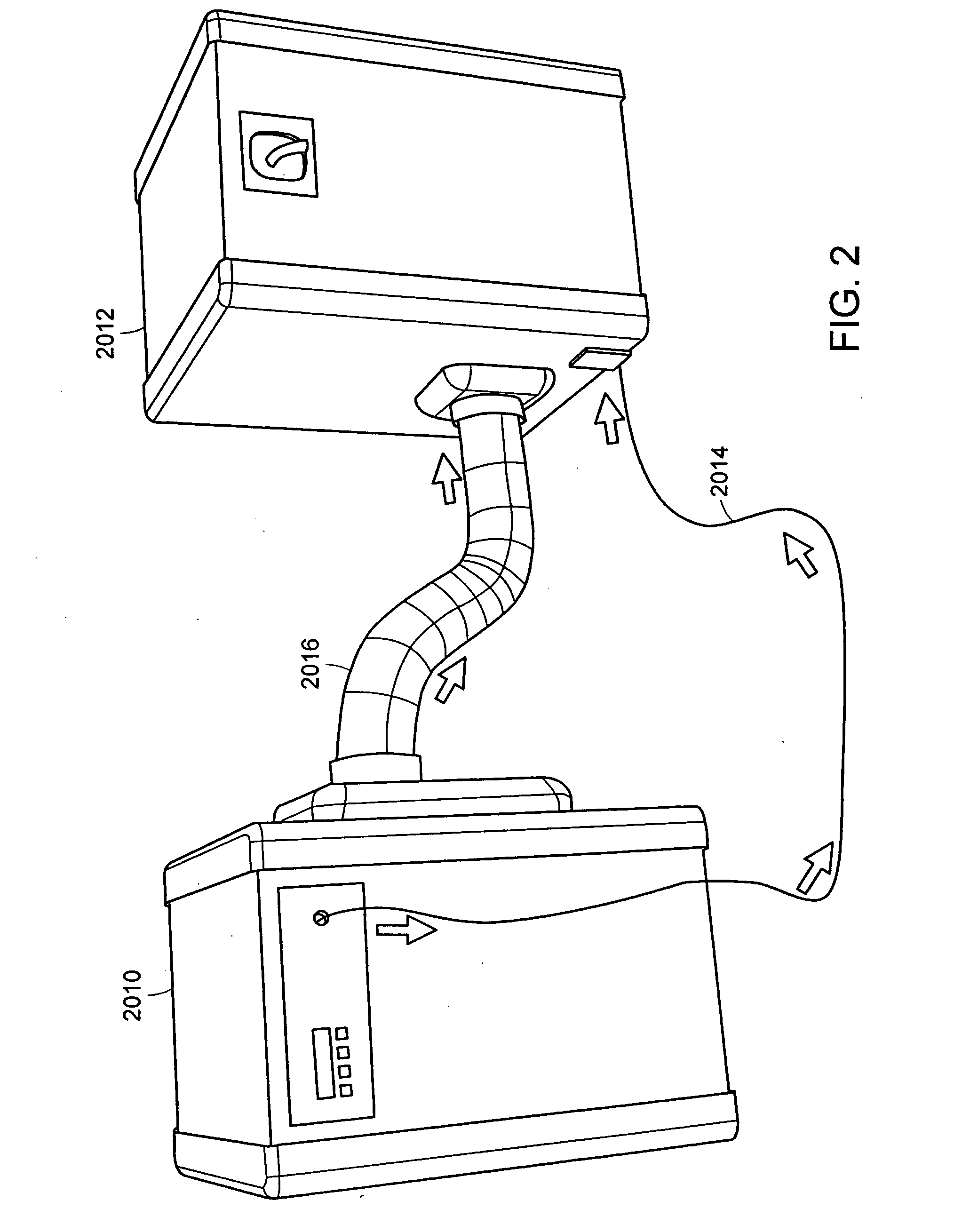

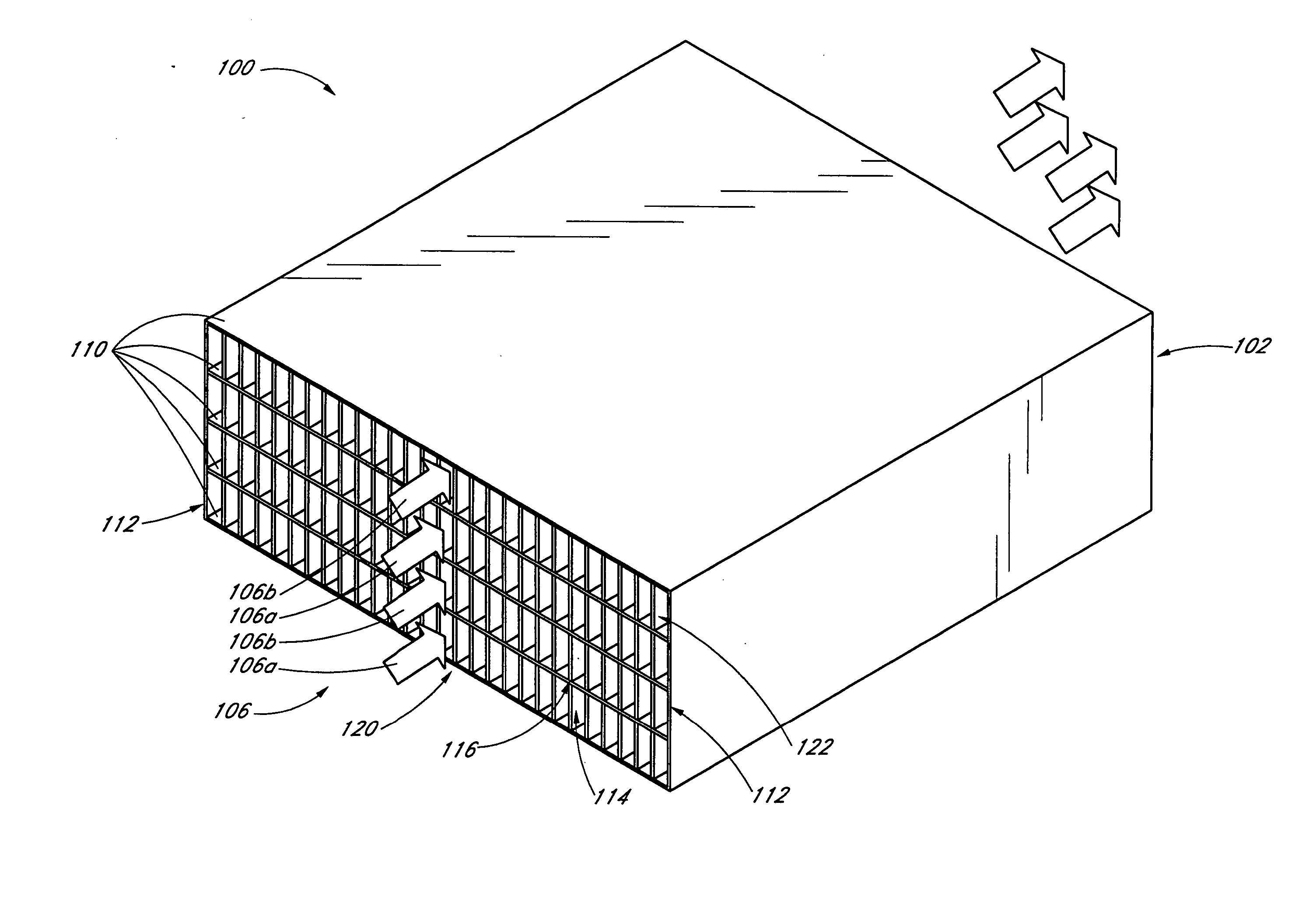

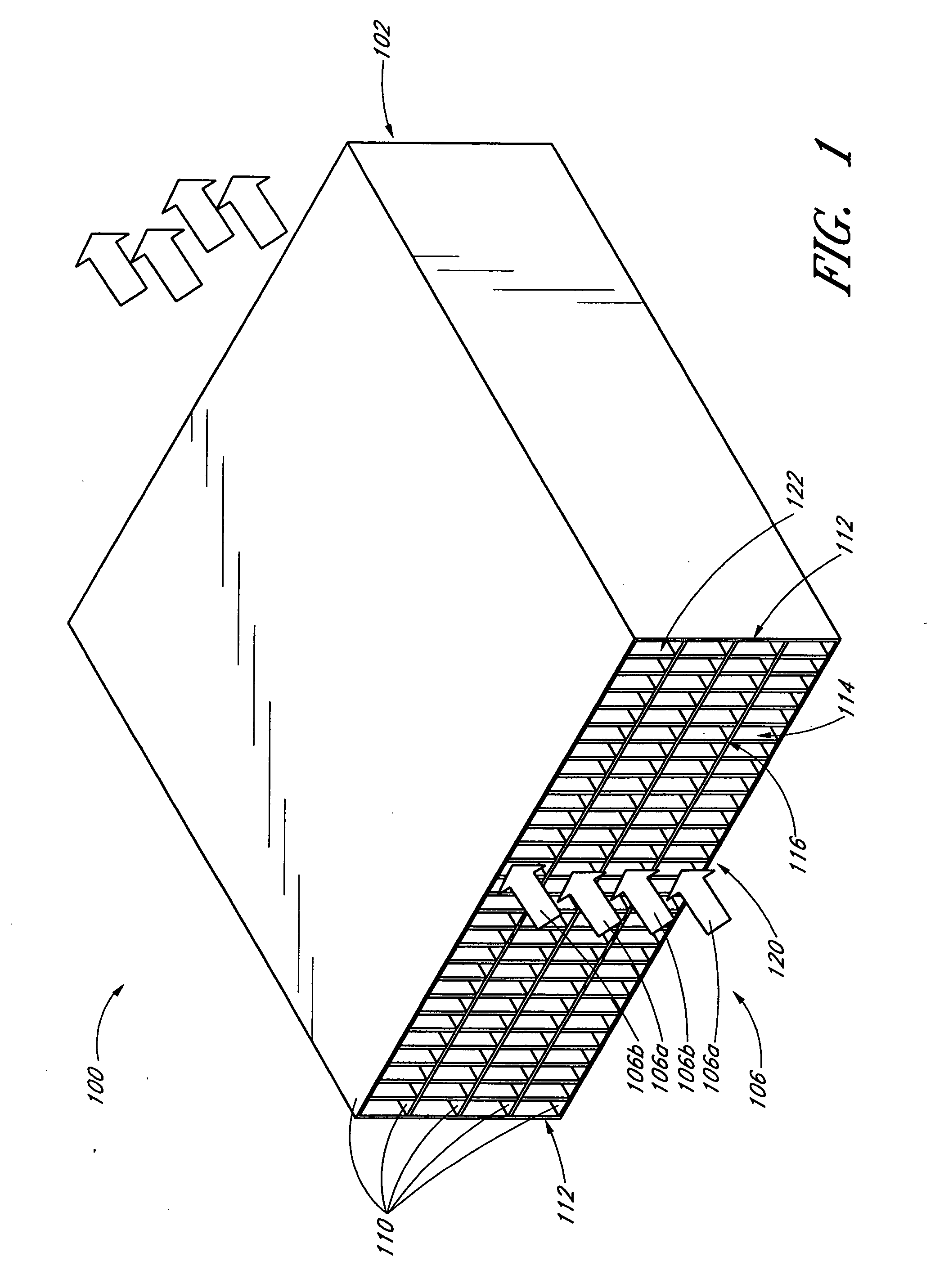

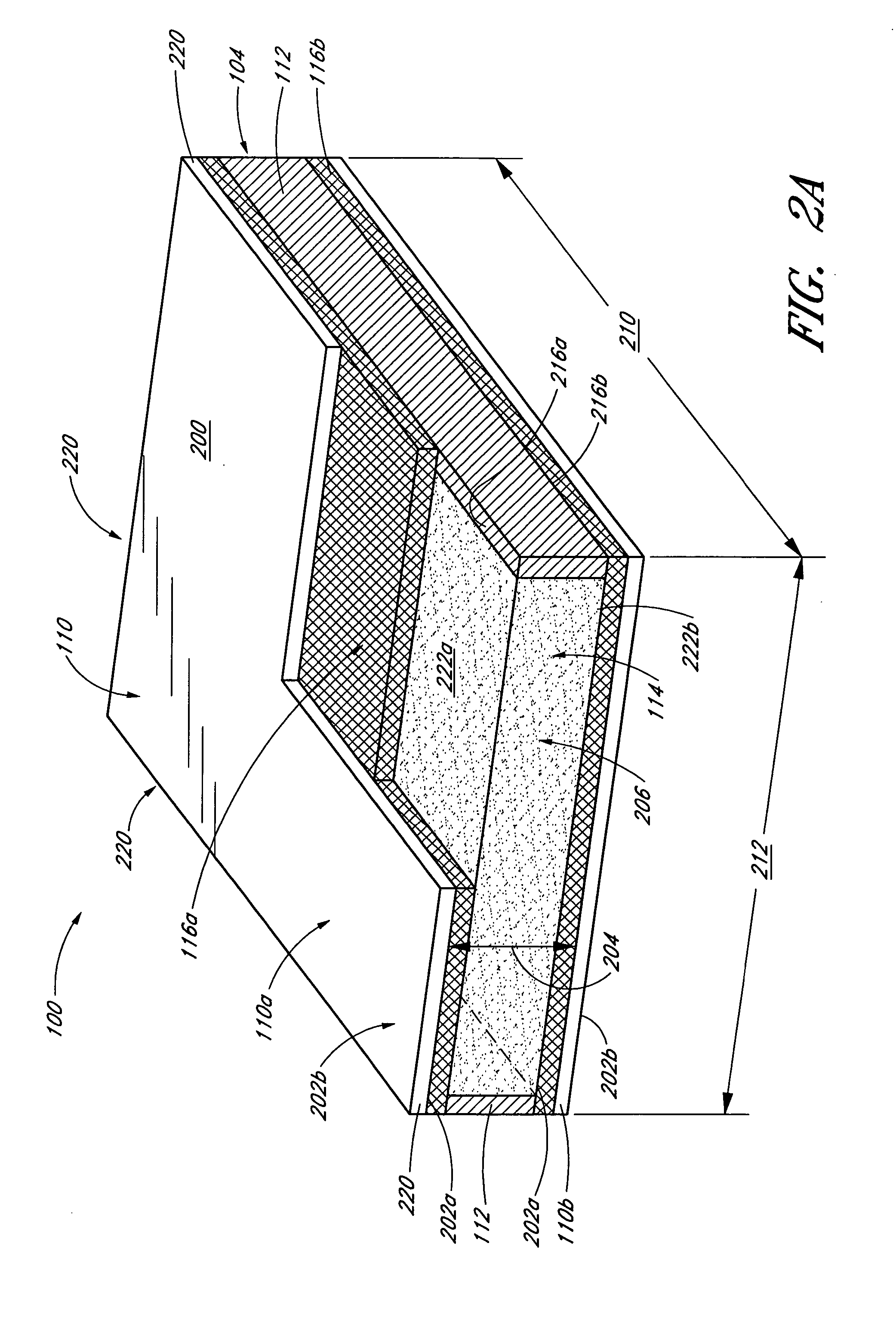

A cooling assembly for an electronic image assembly having an open and closed gaseous loop. A closed gaseous loop allows circulating gas to travel across the front surface of an image assembly and through a heat exchanger. An open loop allows ambient gas to pass through the heat exchanger and extract heat from the circulating gas. An optional additional open loop may be used to cool the back portion of the image assembly (optionally a backlight). Ribs may be placed within the optional additional open loop to facilitate the heat transfer to the ambient gas. The cooling assembly can be used with any type of electronic assembly for producing an image.

Owner:MFG RESOURCES INT INC

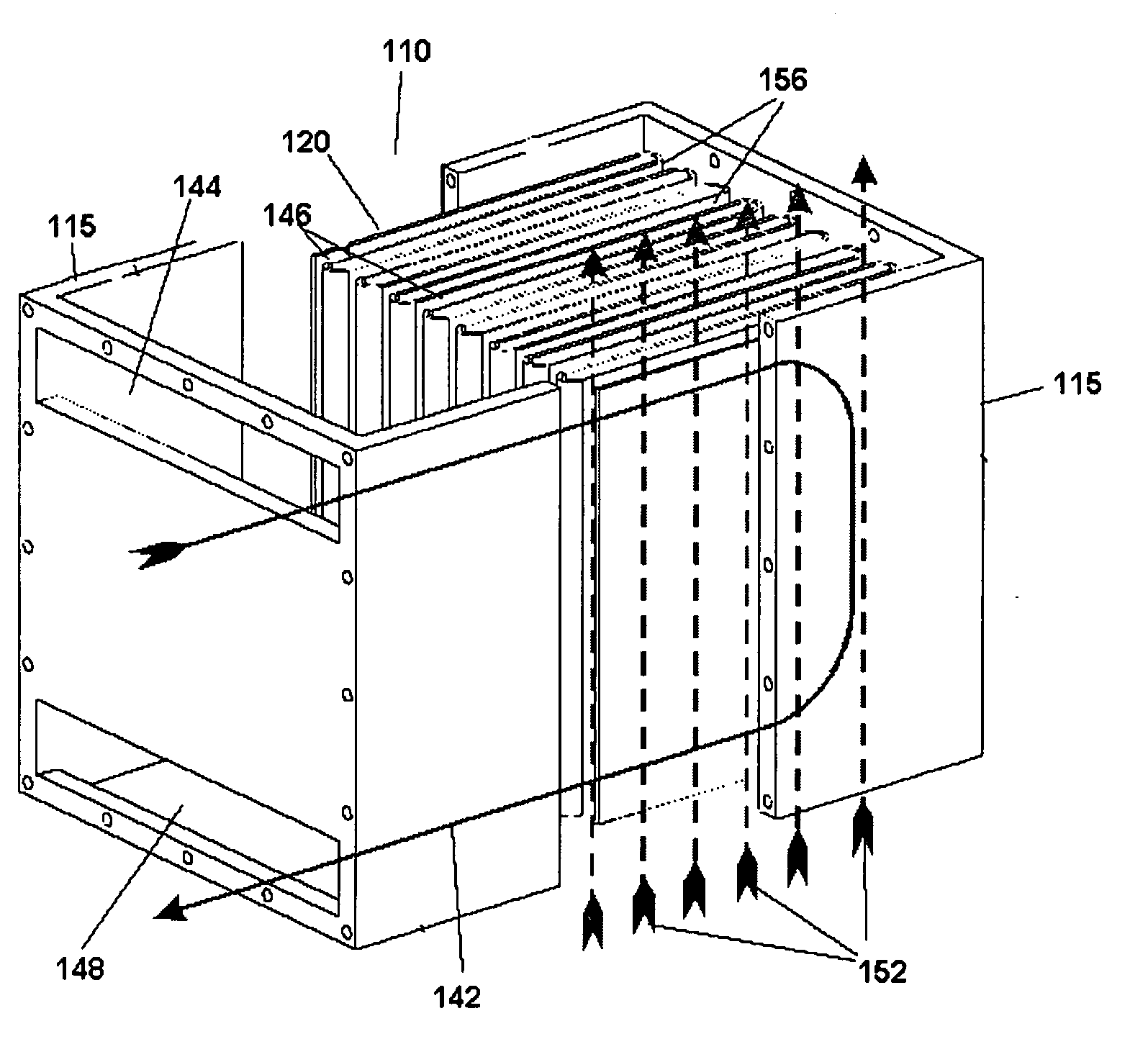

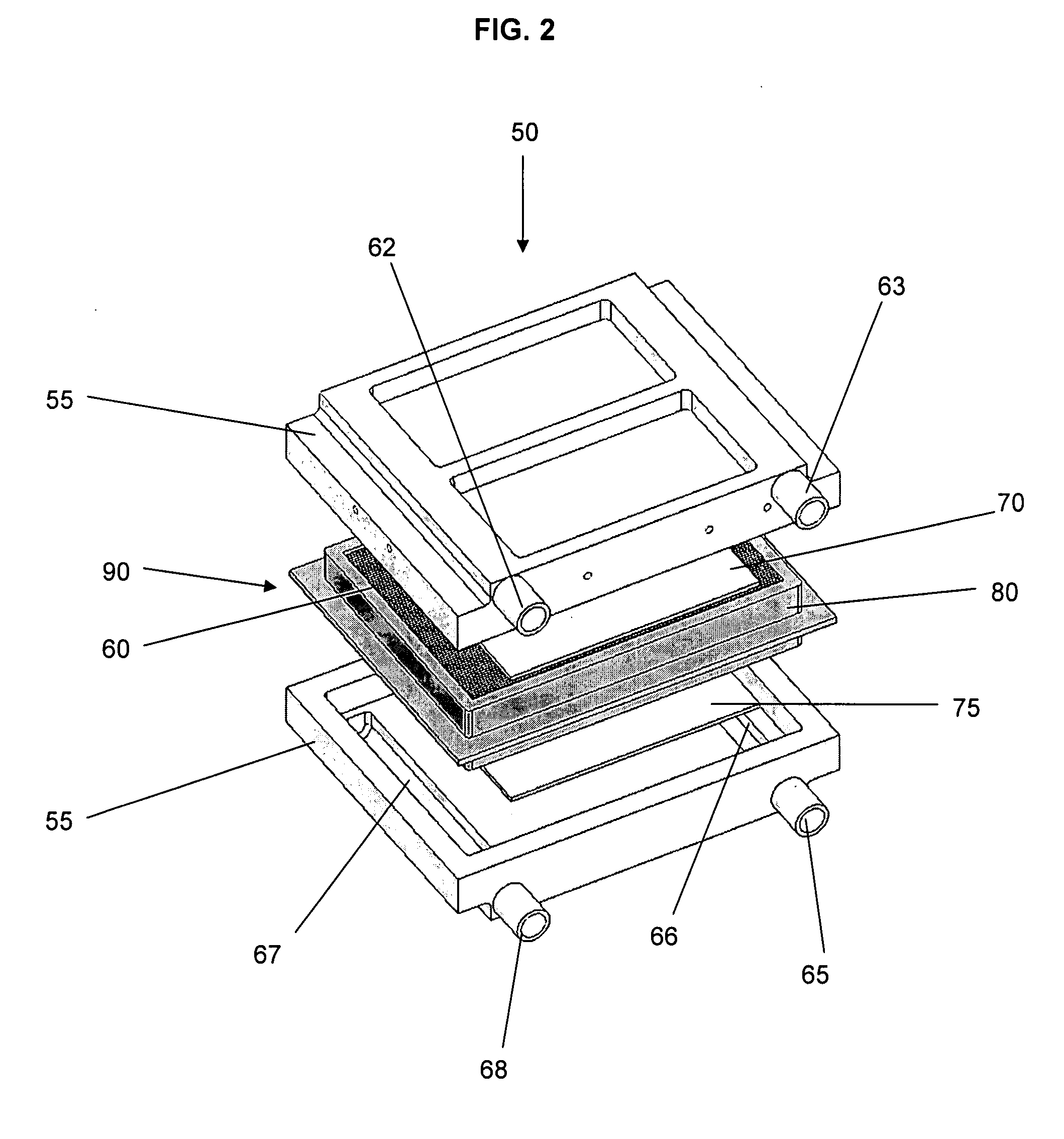

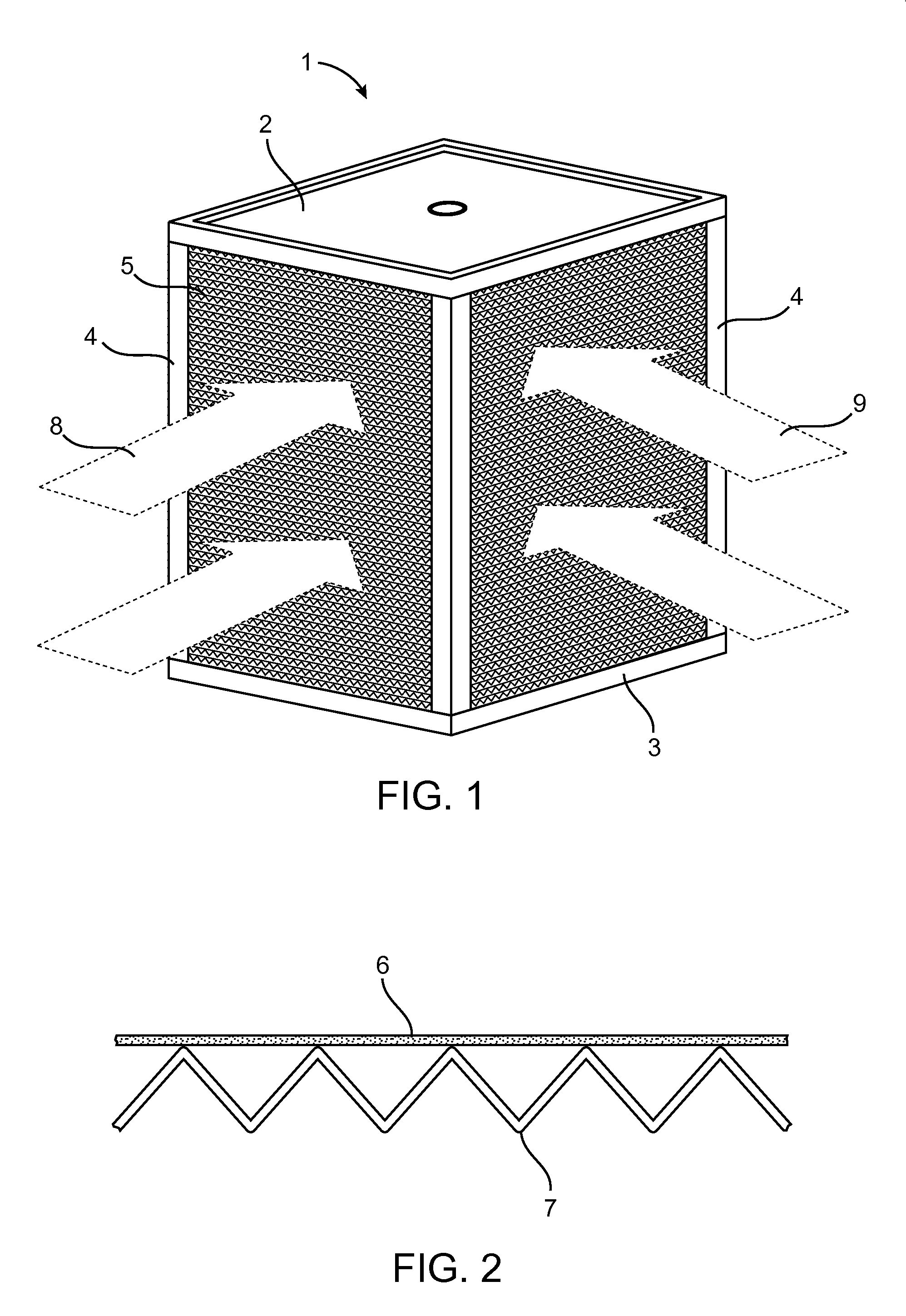

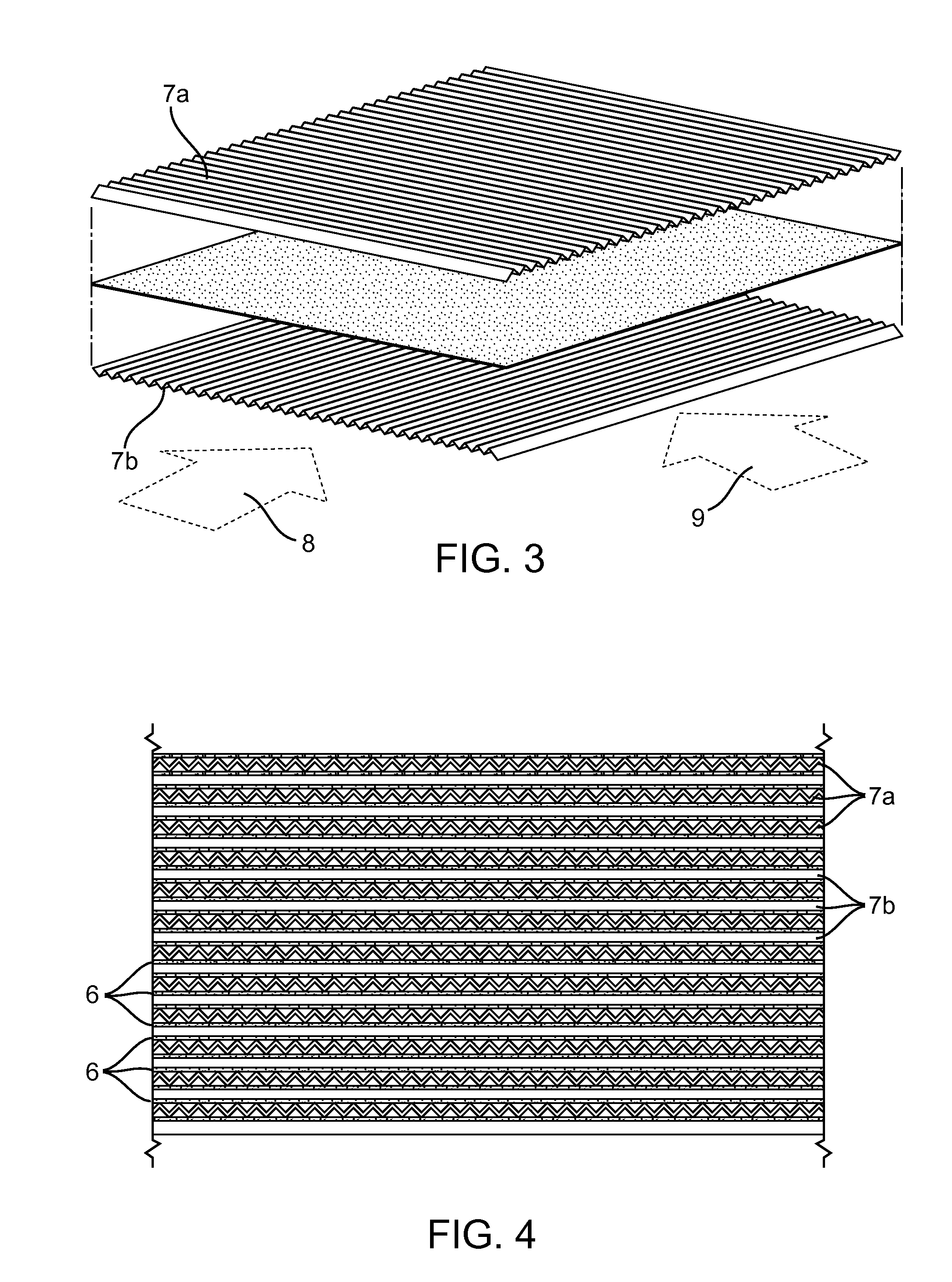

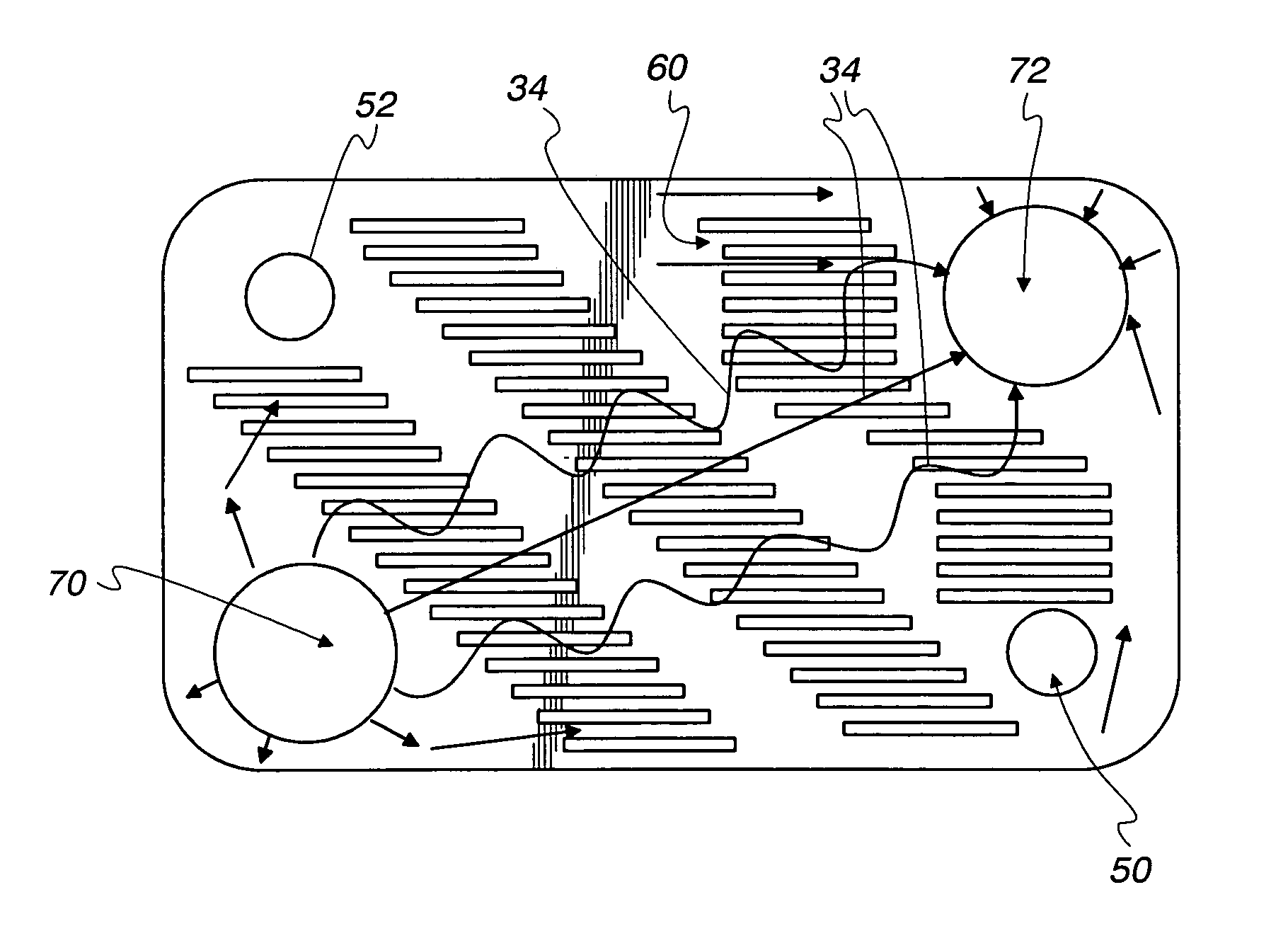

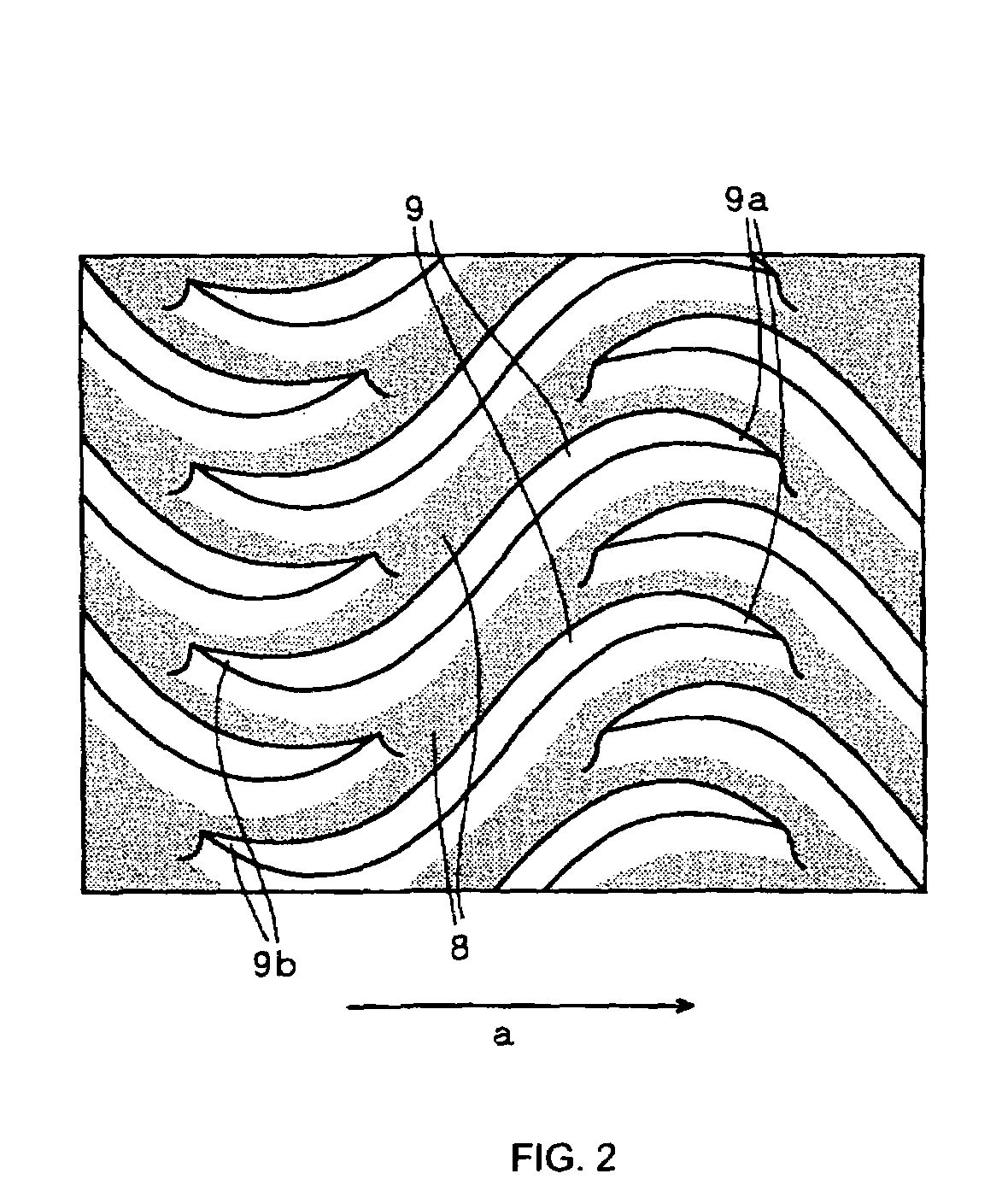

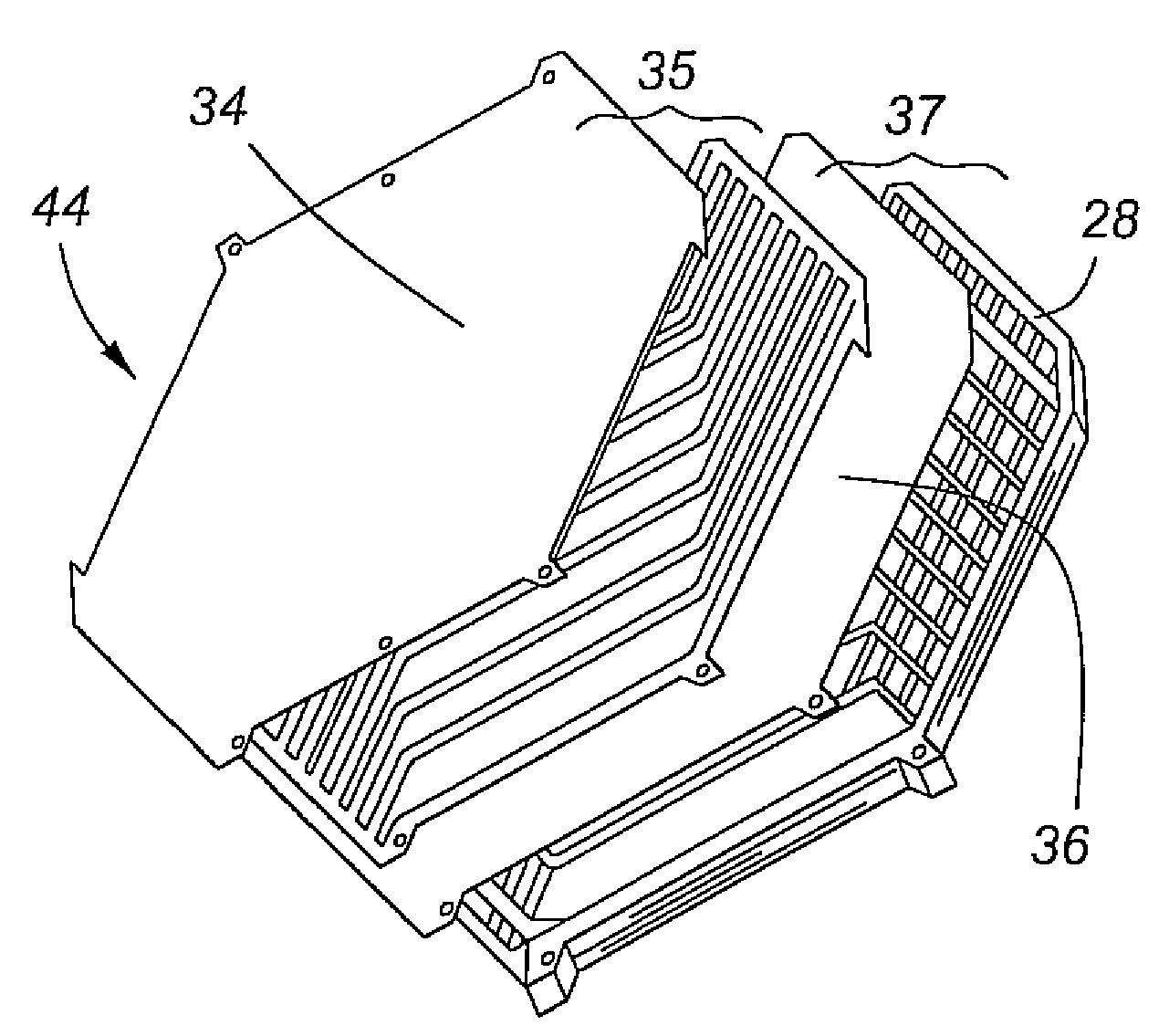

Pleated heat and humidity exchanger with flow field elements

InactiveUS20080085437A1Fuel cell heat exchangeUsing liquid separation agentFuel cellsMembrane surface

A heat and humidity exchanger comprises a pleated membrane cartridge disposed in a housing. The cartridge comprises a pleated water-permeable membrane via which heat and humidity can be transferred between two fluid streams. A flow field element is disposed within some or all of the folds of the pleated membrane, for directing the stream over the inner surfaces of the folds. The flow field path defined by the flow field element enhances flow distribution across one or both membrane surfaces, controlling the relative flow paths of the two streams on opposite sides of the membrane and reducing the pressure drop across the heat and humidity exchanger. The flow field elements provide improved water transfer and allow for a more compact device. The flow field elements can also assist in supporting the pleated membrane and controlling the pleat spacing within the pleated membrane cartridge. The heat and humidity exchanger is particularly suitable for fuel cell and energy recovery ventilator (ERV) applications.

Owner:DPOINT TECH

Heat exchanger with flat tubes

ActiveUS20050161206A1Reinforcing meansInternal combustion piston enginesElectrical and Electronics engineeringHeat exchanger

A heat exchanger with a plurality of stacked flat tubes and a collecting tank having a wall extending around the entire periphery of, and connected to, the end of the stacked flat tubes. A first medium may be distributed through the collecting tank and flat tubes. Internal inserts are in the flat tubes, with the inserts being bonded between the broad sides of the tubes and, in the region of connection of the tubes to the collecting tank, being configured to compensate for length changes in the stacking direction caused by temperature changes, as by recesses in connectors such as wave flanks or by corrugated wave flanks. The flat tubes with inserts such as described may be separately provided for use in manufacture of heat exchangers.

Owner:MODINE MFG CO

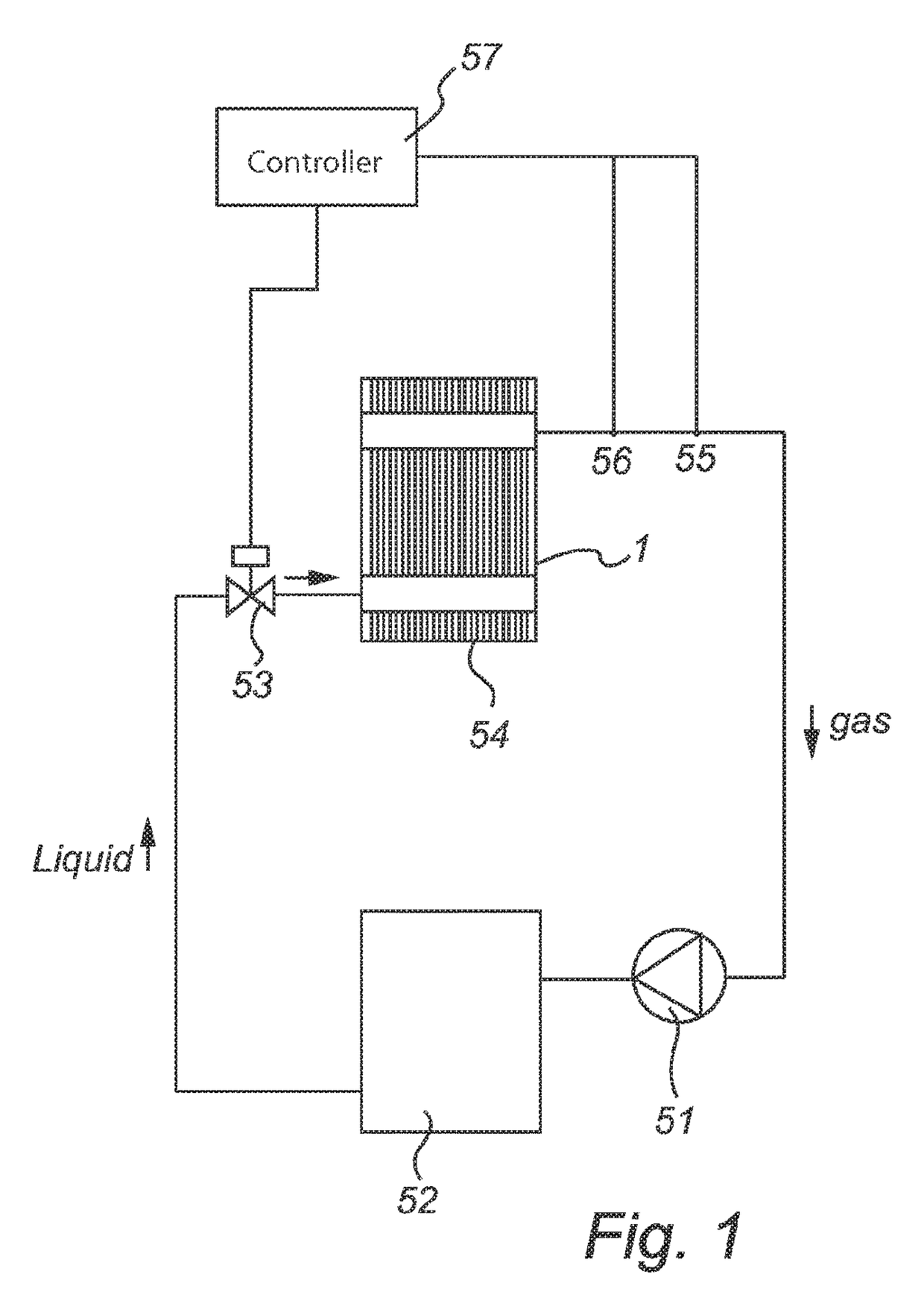

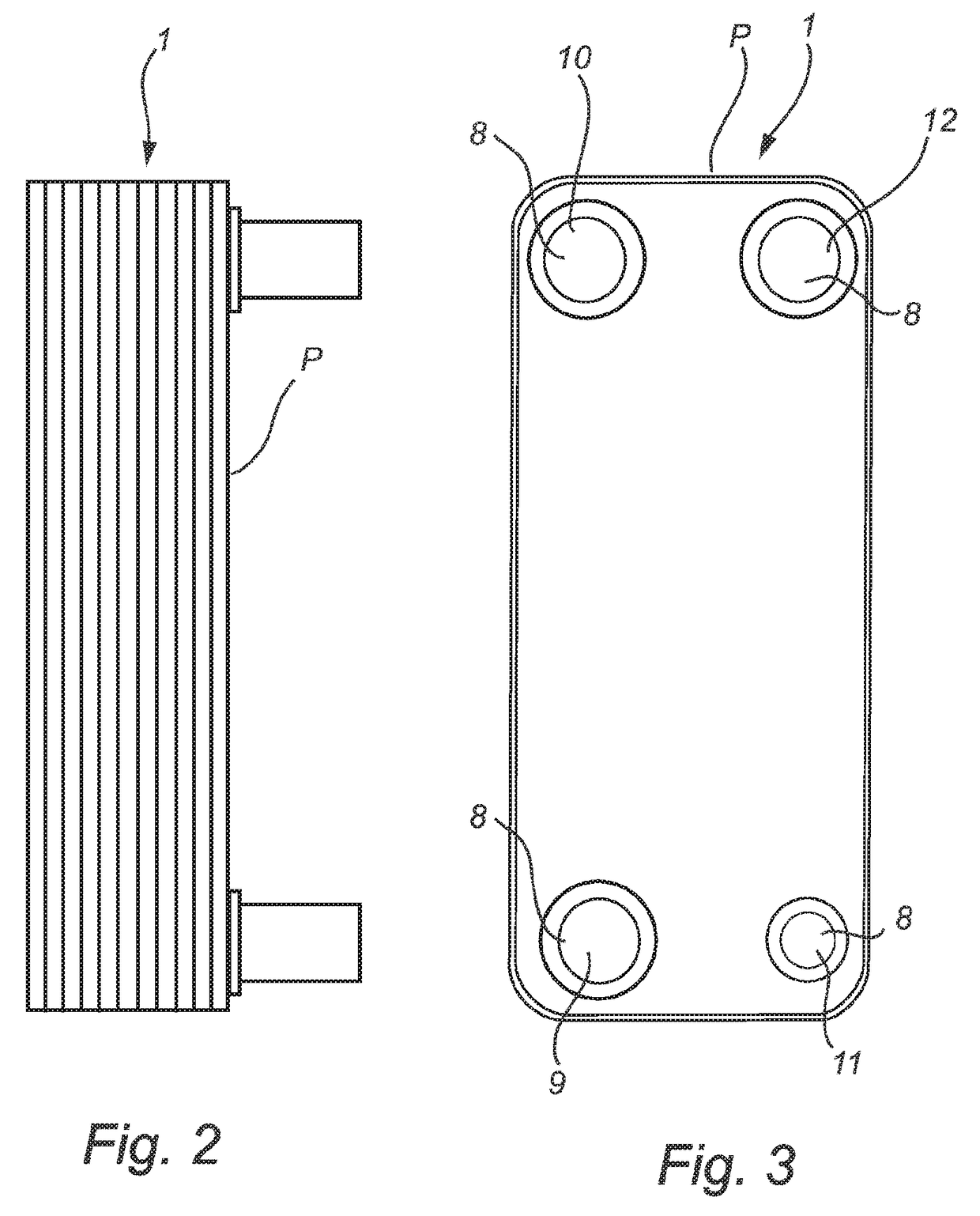

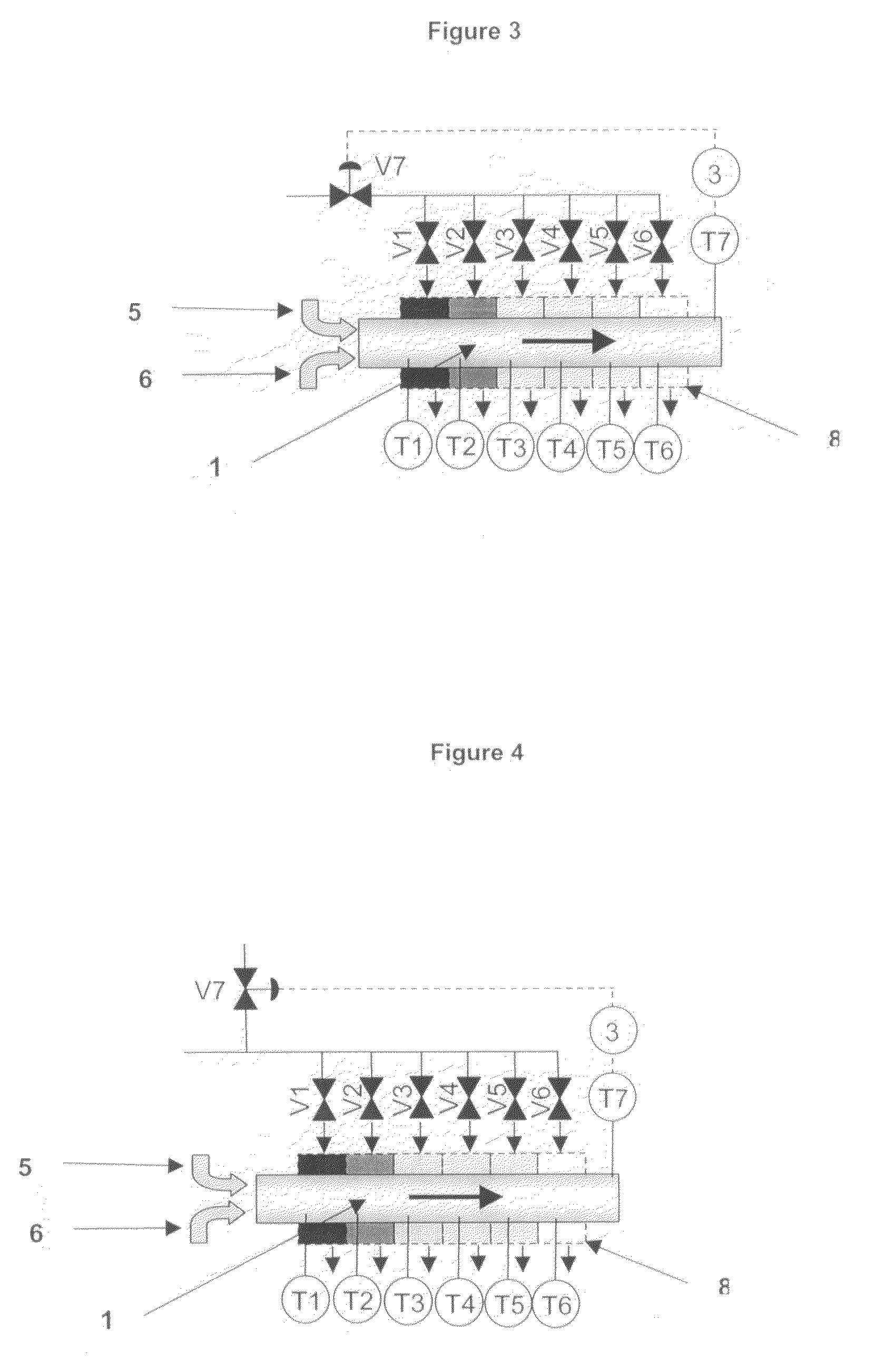

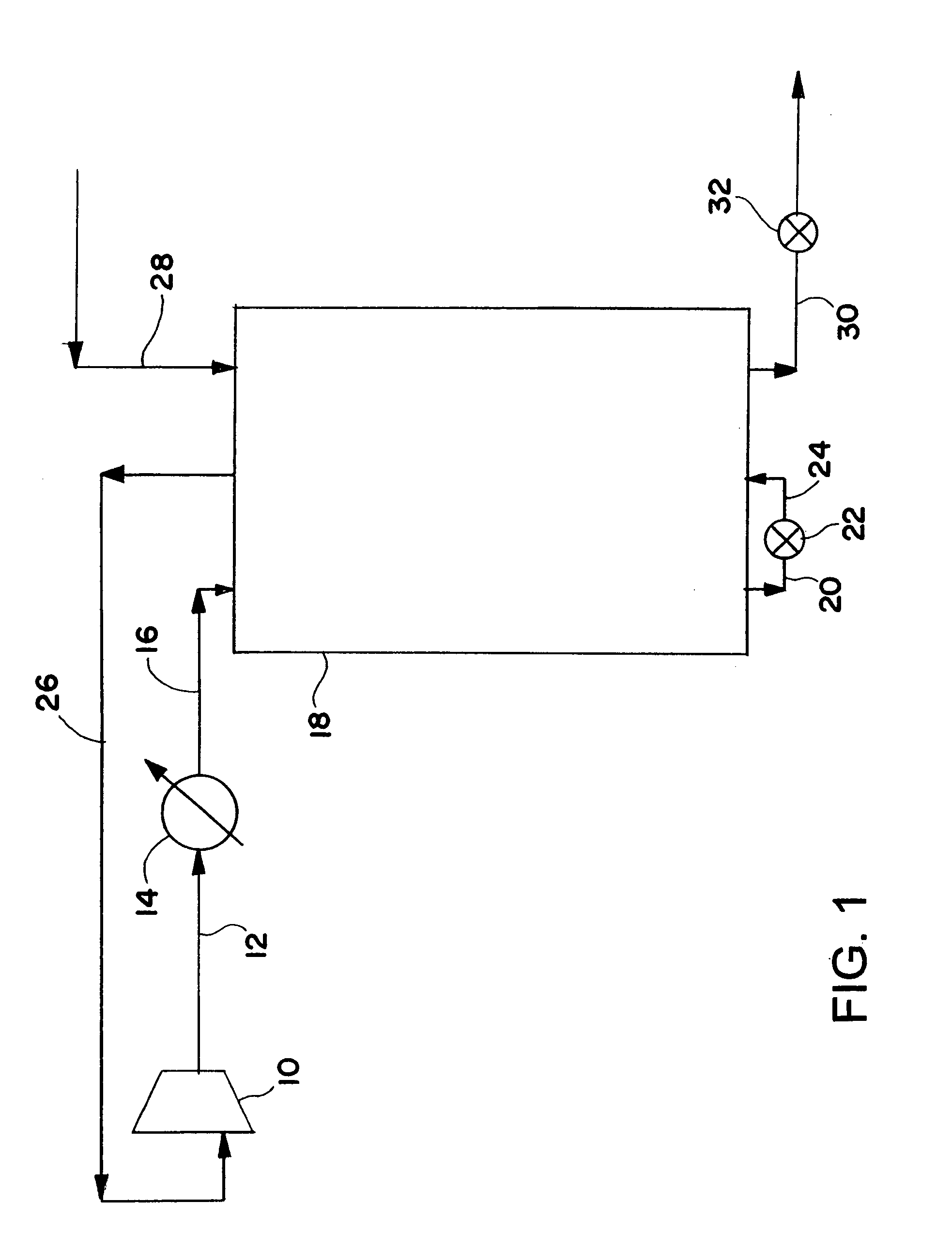

System and method for dynamic control of a heat exchanger

InactiveUS20170167810A1Easy to controlImprove plating efficiencyMechanical apparatusEvaporators/condensersProcess engineeringFluid supply

The present application relates to a system for dynamic control of the operation of a heat exchanger, the system comprising a heat exchanger, a plurality of injector arrangements, a local sensor arrangement, and a controller, wherein the local sensor arrangement comprises a plurality of local temperature sensors being arranged to measure temperature values; and wherein the controller is arranged to determine a difference between the measured temperature values and is further arranged to communicate with the valves of the plurality of injector arrangements to adjust the local amount of first fluid supplied by at least one of the injector arrangements in order to even out the determined difference. The application also relates to a method for the dynamic control of the operation of a heat exchanger in such a system.

Owner:ALFA LAVAL CORP AB

Microchannel apparatus, methods of making microchannel apparatus, and processes of conducting unit operations

InactiveUS6989134B2Low costReduce wasteFlow mixersTransportation and packagingUnit operationEngineering

Novel methods of making laminated, microchannel devices are described. Examples include: assembly from thin strips rather than sheets; and hot isostatic pressing (HIPing) to form devices with a hermetically sealed wall. Laminated microchannel articles having novel features are also described. The invention includes processes conducted using any of the articles described.

Owner:VELOCYS CORPORATION

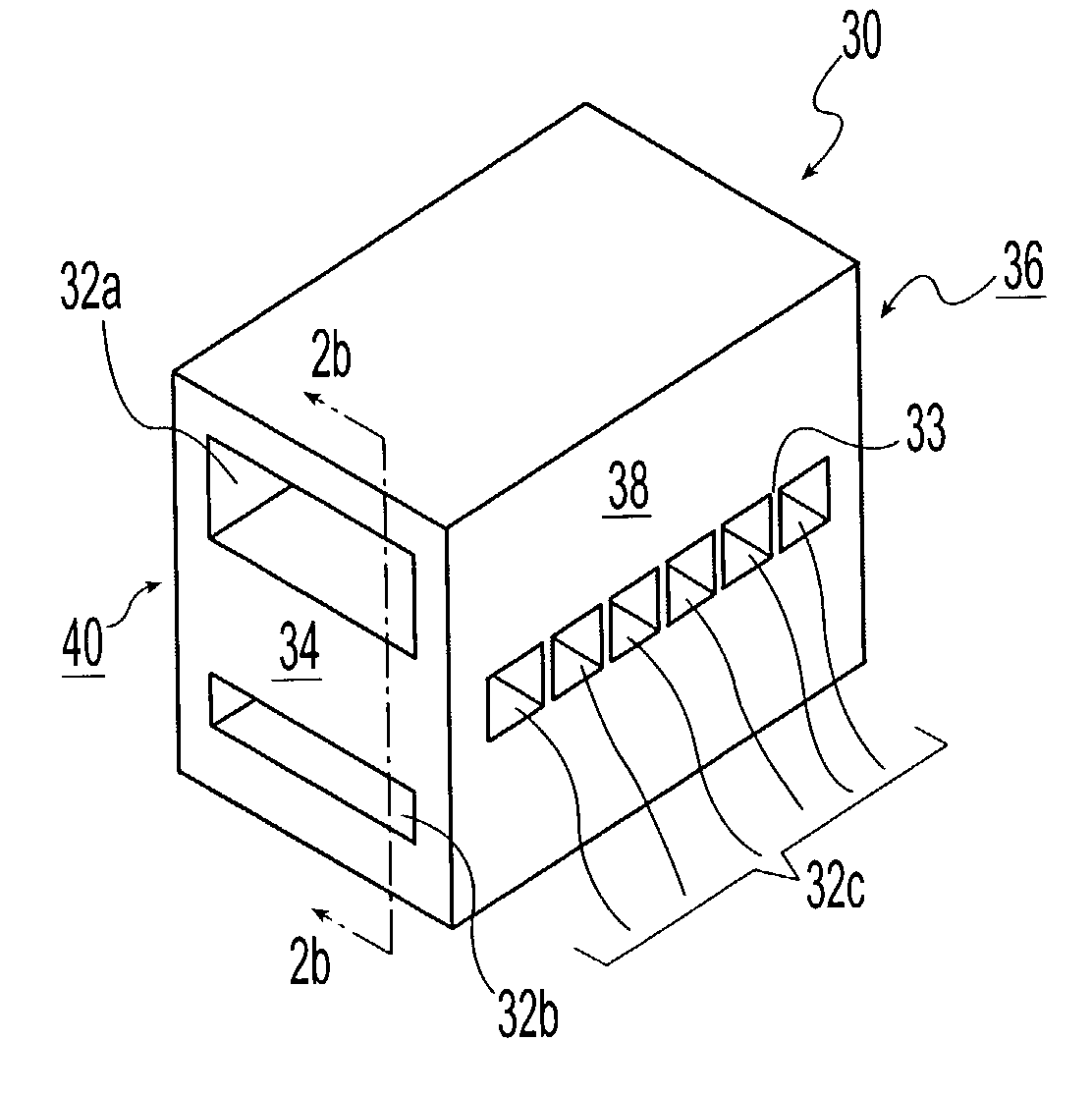

Hybrid heat exchangers

InactiveUS20070284095A1Improve mechanical durabilityLow densityReinforcing meansStationary tubular conduit assembliesCarbon compositesCore component

A light weight hybrid heat exchanger core possessing low density and improved thermal conductivity is disclosed. The hybrid core is comprised of a plurality of parting sheets and interposed by a plurality of high thermal conductivity, light weight bridging elements and enclosure bars. These core members are comprised of dissimilar materials. The parting sheets and bridging elements are interconnected by a specially tailored joint which forms form a substantially strong, high thermal conductivity bond. In particular embodiments, carbon-based bridging elements are bonded to metallic parting sheets using a brazed joint. The parting sheets, in certain embodiments, may comprise titanium or Ni-based superalloys or carbon composites, while the carbon-based bridging elements may comprise fiber-reinforced composites. The carbon-based bridging elements reduce the core weight and increase the core thermal conductivity over conventional all-metal designs, while the brazed joint provides for improved leak resistance over all-composite designs.

Owner:ALLCOMP

Multi-stream microchannel device

InactiveUS7014835B2Large-scale operationImproved profileHydrogenPhysical/chemical process catalystsMulti streamProcess engineering

The invention is a process and device for exchanging heat energy between three or more streams in a microchannel heat exchanger which can be integrated with a microchannel reactor to form an integrated microchannel processing unit. The invention enables the combining of a plurality of integrated microchannel devices to provide the benefits of large-scale operation. In particular, the microchannel heat exchanger of the present invention enables flexible heat transfer between multiple streams and total heat transfer rates of about 1 Watt or more per core unit volume expressed as W / cc.

Owner:VELOCYS CORPORATION

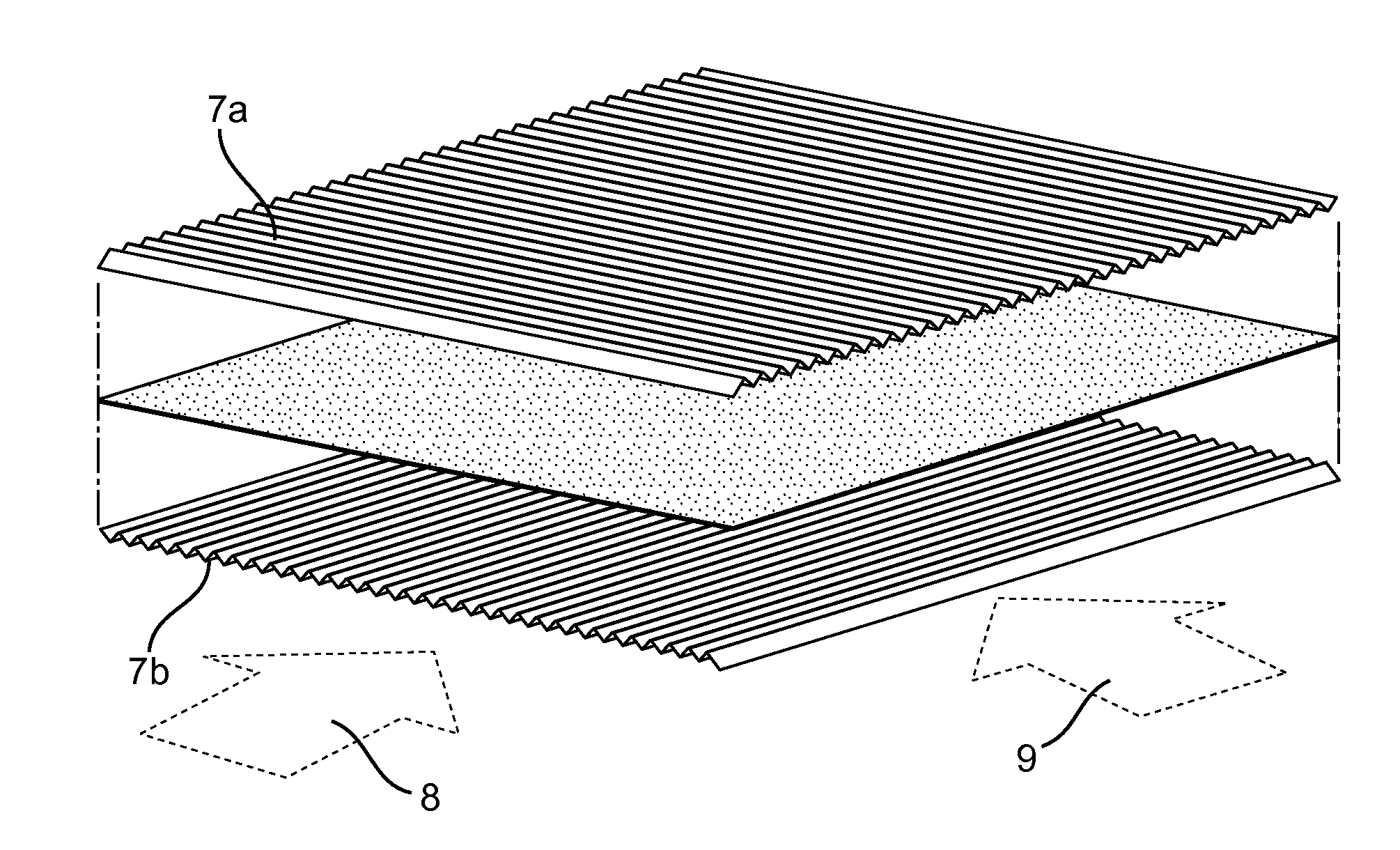

Energy Recovery Ventilation Sulfonated Block Copolymer Laminate Membrane

ActiveUS20120073791A1Improved sensible and latent heat exchangeHigh water vapor transport rateEnergy recovery in ventilation and heatingSemi-permeable membranesPolymer scienceEnergy recovery

A core unit for an energy recovery system for exchanging heat and vapor between two independent intake and exhaust airstreams without intermixing thereof, the core unit having a fibrous microporous support substrate and a sulfonated block copolymer having at least one end block A and at least one interior block B wherein each A block contains essentially no sulfonic acid or sulfonate ester functional groups and each B block is a polymer block containing from about 10 to about 100 mol percent sulfonic acid or sulfonate ester functional groups based on the number of monomer units, and wherein the sulfonated block copolymer is laminated on the microporous support substrate

Owner:KRATON POLYMERS US LLC

Fluid cooled electrical assembly

ActiveUS7173823B1Cooling/ventilation/heating modificationsLaminated elementsElectrical devicesEngineering

A heat producing, fluid cooled assembly that includes a housing made of liquid-impermeable material, which defines a fluid inlet and a fluid outlet and an opening. Also included is an electrical package having a set of semiconductor electrical devices supported on a substrate and the second major surface is a heat sink adapted to express heat generated from the electrical apparatus and wherein the second major surface defines a rim that is fit to the opening. Further, the housing is constructed so that as fluid travels from the fluid inlet to the fluid outlet it is constrained to flow past the opening thereby placing the fluid in contact with the heat sink.

Owner:RINEHART MOTION SYST

Heat exchanger and method of operating the same

ActiveUS20100084120A1Remarkable effectIncrease heatStationary conduit assembliesFlash steam boilersPlate heat exchangerEngineering

An evaporative heat exchanger including a plurality of parallel flow passages extending through the heat exchanger and together defining a first fluid flow path, and a plurality of substantially parallel stacked plates interleaved with the parallel flow passages. Each plate can have first, second, and third sets of flow channels, a first collection manifold adjacent to an end of the plate and connecting the first and second passes, and a second collection manifold. The second collection manifold can intersect the second set of flow channels and at least some of the third set of flow channels. The plate separates the first set of flow channels from the second collection manifold.

Owner:MODINE MFG CO

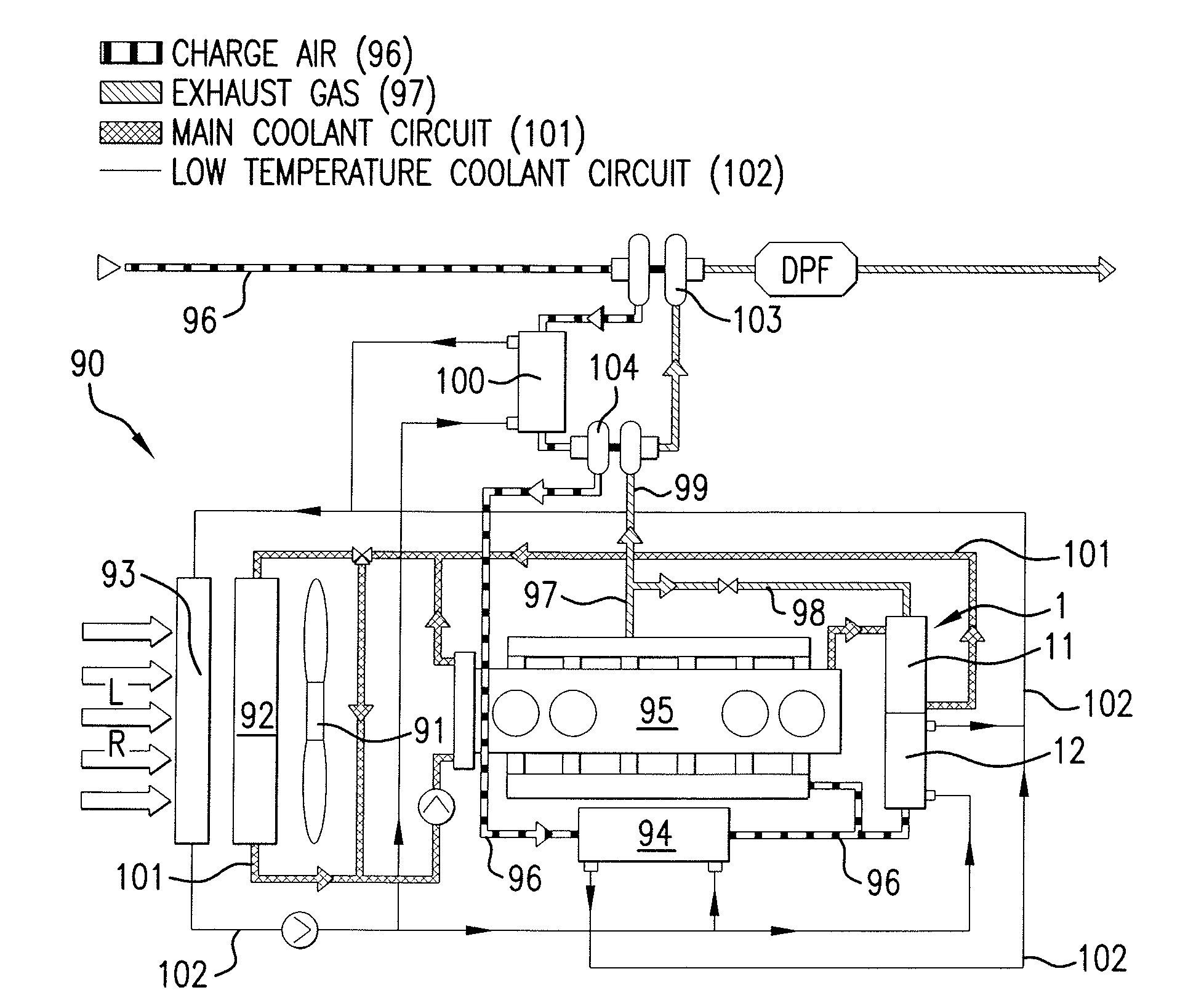

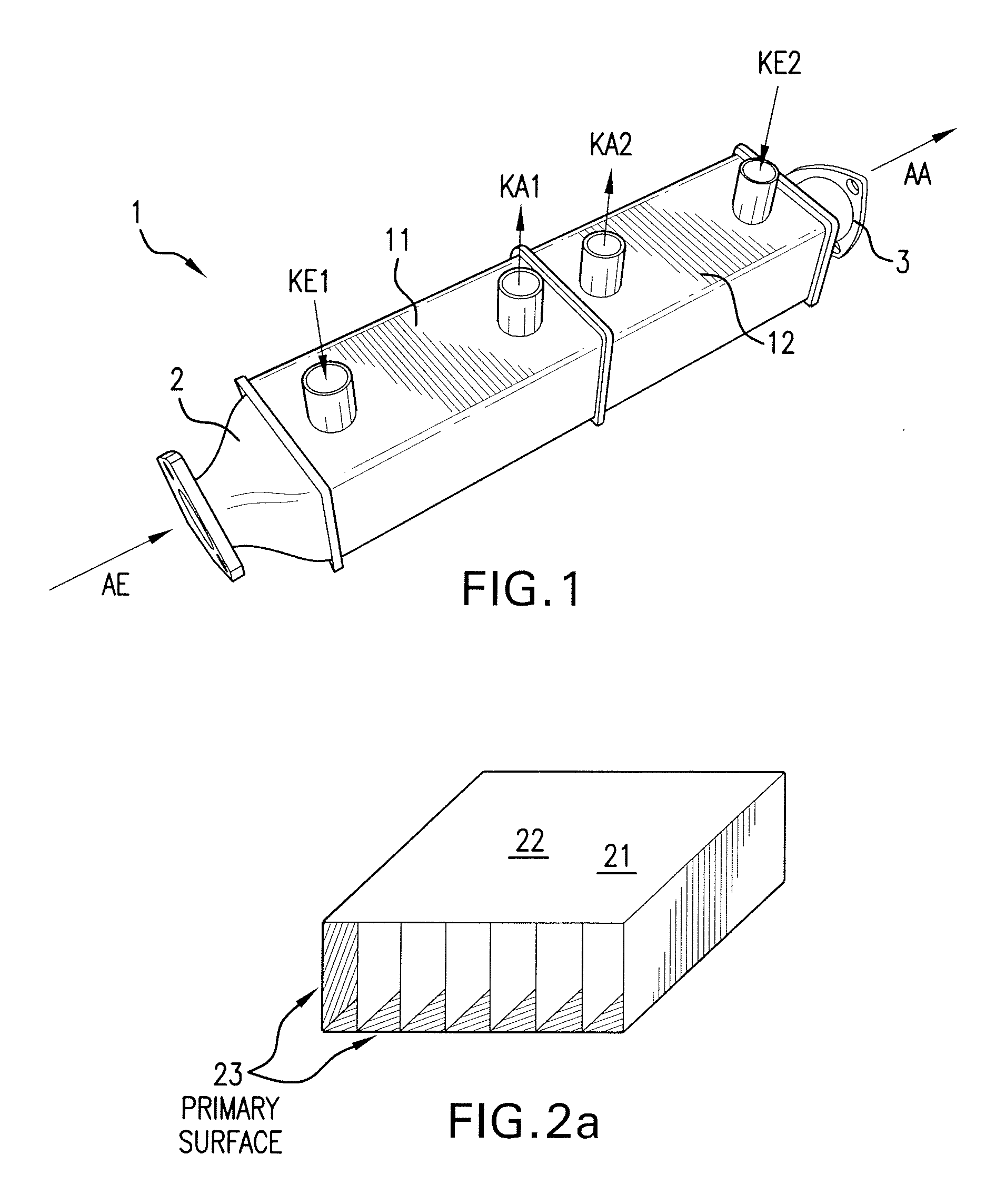

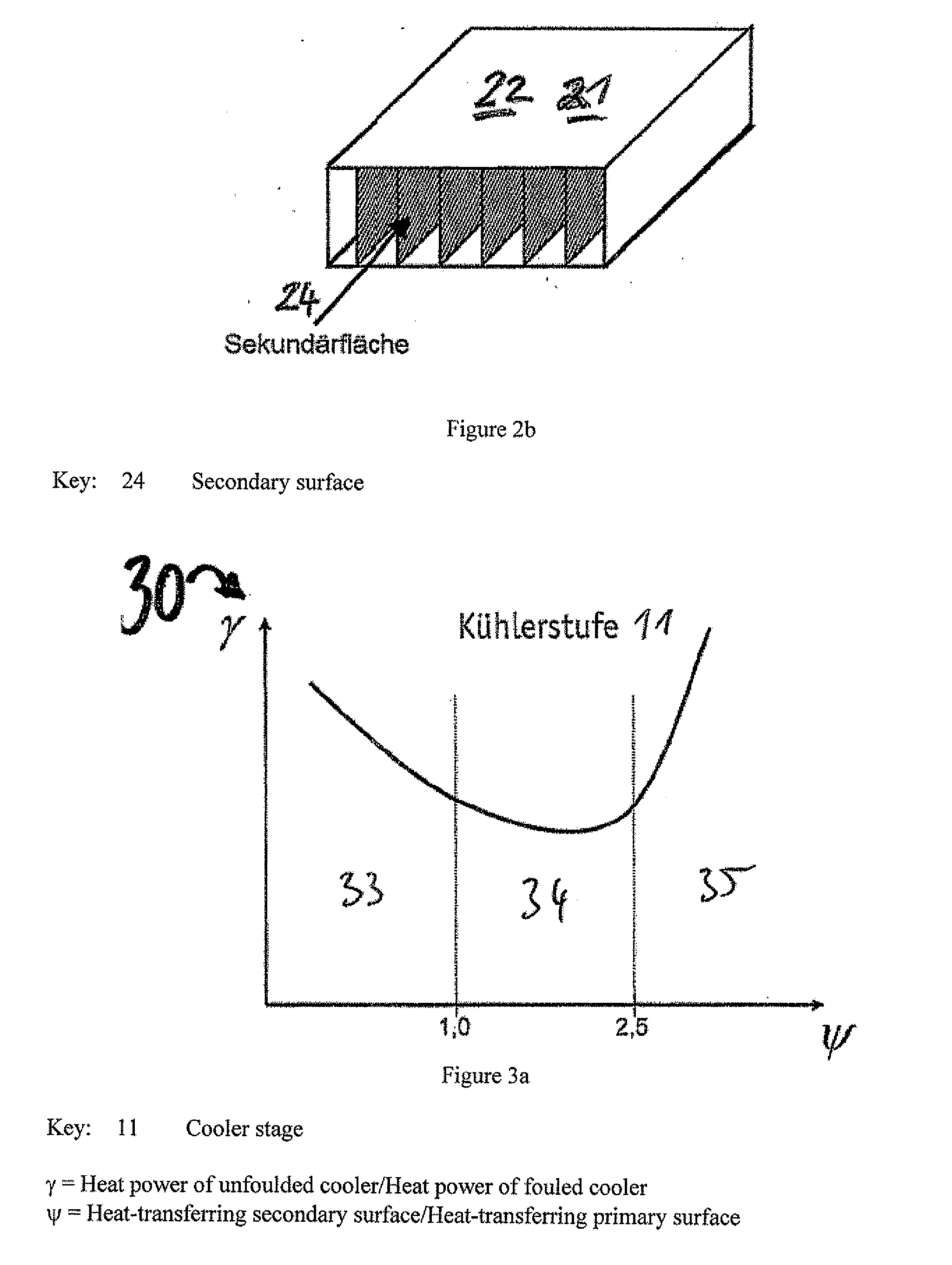

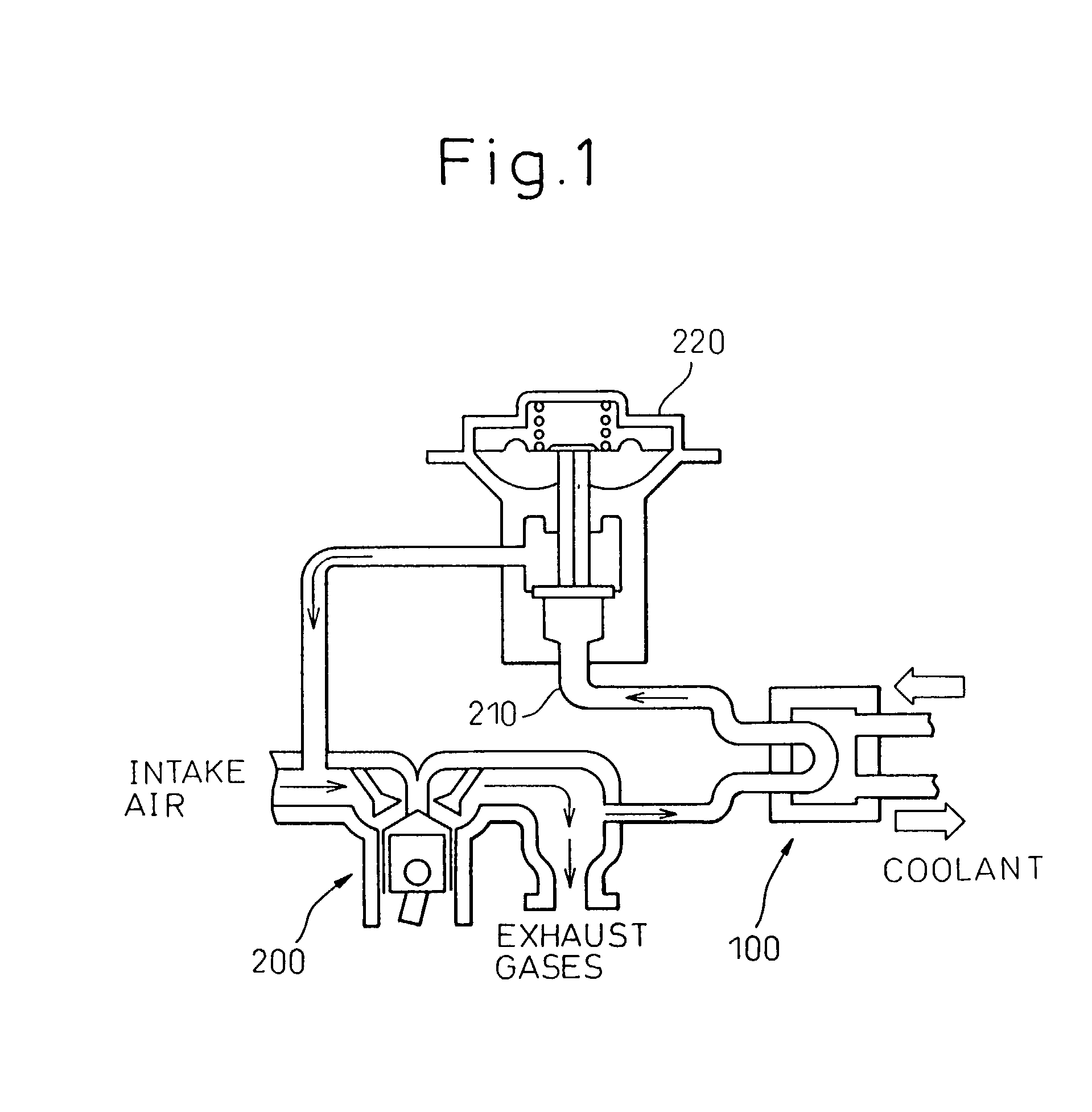

Heat exchanger for exhaust gas cooling; method for operating a heat exchanger; system with a heat exchanger for exhaust gas cooling

InactiveUS20080264609A1Prevent scalingLower performance requirementsNon-fuel substance addition to fuelInternal combustion piston enginesCoolant flowExhaust fumes

A heat exchanger, in particular for cooling the exhaust of a motor vehicle internal combustion engine, is disclosed, the heat exchanger comprising a first partial heat exchanger with at least one first flow channel through which a medium to be cooled is to flow and at least one third flow channel through which a first coolant is to flow, at least one second partial heat exchanger with at least one second flow channel through which a medium to be cooled is to flow and at least one fourth flow channel through which a second coolant is to flow, wherein the at least one first flow channel and the at least one second flow channel are fluidly connected, and the at least one first flow channel and the at least one second flow channel have at least one first specific heat transfer surface and at least one second heat transfer surface, wherein second specific heat transfer surface area, divided by first specific heat transfer surface area, yields a quotient (ψ), the at least one first flow channel having a larger quotient (ψ) than second flow channel.

Owner:BEHR GMBH & CO KG

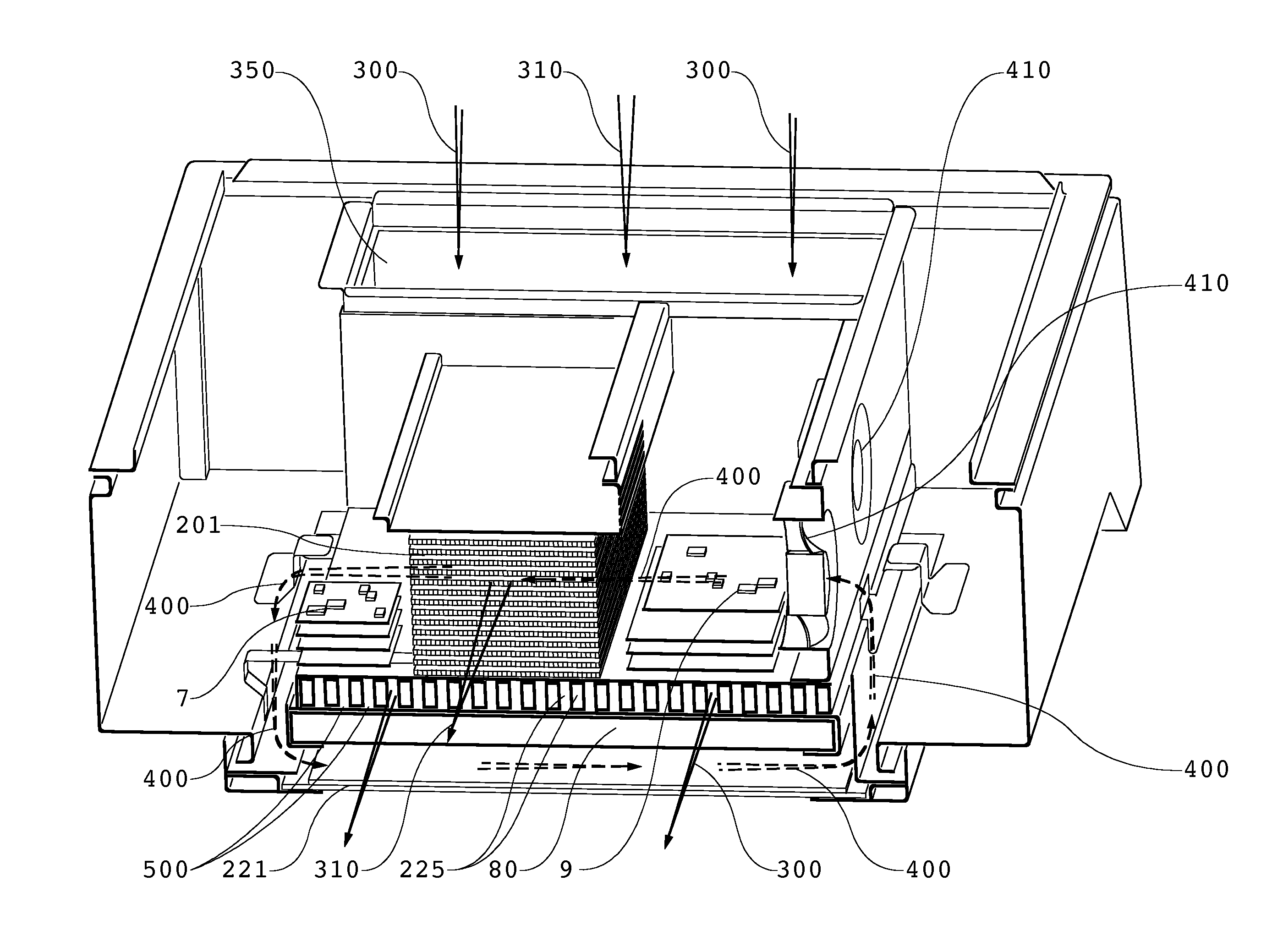

Heat exchanger for an electronic display

ActiveUS8654302B2Semiconductor/solid-state device detailsSolid-state devicesElectronic assembliesMicro heat exchanger

A cooling assembly for an electronic image assembly having an open and closed gaseous loop. A closed gaseous loop allows circulating gas to travel across the front surface of an image assembly and through a heat exchanger. An open loop allows ambient gas to pass through the heat exchanger and extract heat from the circulating gas. An optional additional open loop may be used to cool the back portion of the image assembly (optionally a backlight). Ribs may be placed within the optional additional open loop to facilitate the heat transfer to the ambient gas. The cooling assembly can be used with any type of electronic assembly for producing an image.

Owner:MFG RESOURCES INT INC

Variable heat flux heat exchangers

InactiveUS20090120629A1Easy to adaptMinimal modificationChemical/physical/physico-chemical processesHeat transfer modificationHeat fluxHeat transmission

A system for heat exchange is provided in which process material flows through a heat exchanger comprising multiple heat transfer stages and the heating and or cooling power applied to each stage can be modified independently. The system comprises a unitary heat exchanger comprising a heat transfer surface comprising a plurality of elements or zones over which a process material can flow wherein each element or zone has independent means to set or control the level of heating or cooling within that zone.

Owner:ASHE MORRIS LTD

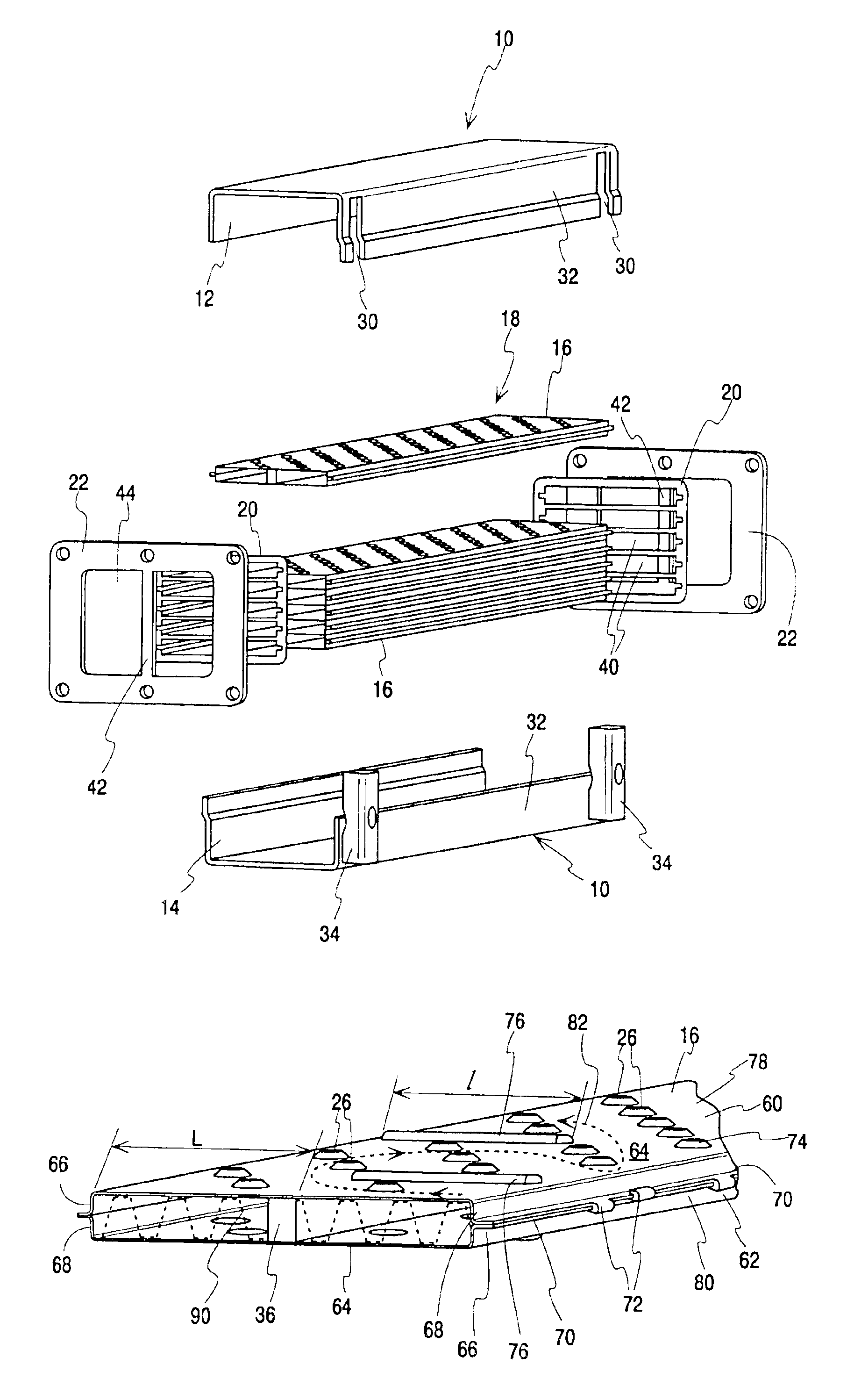

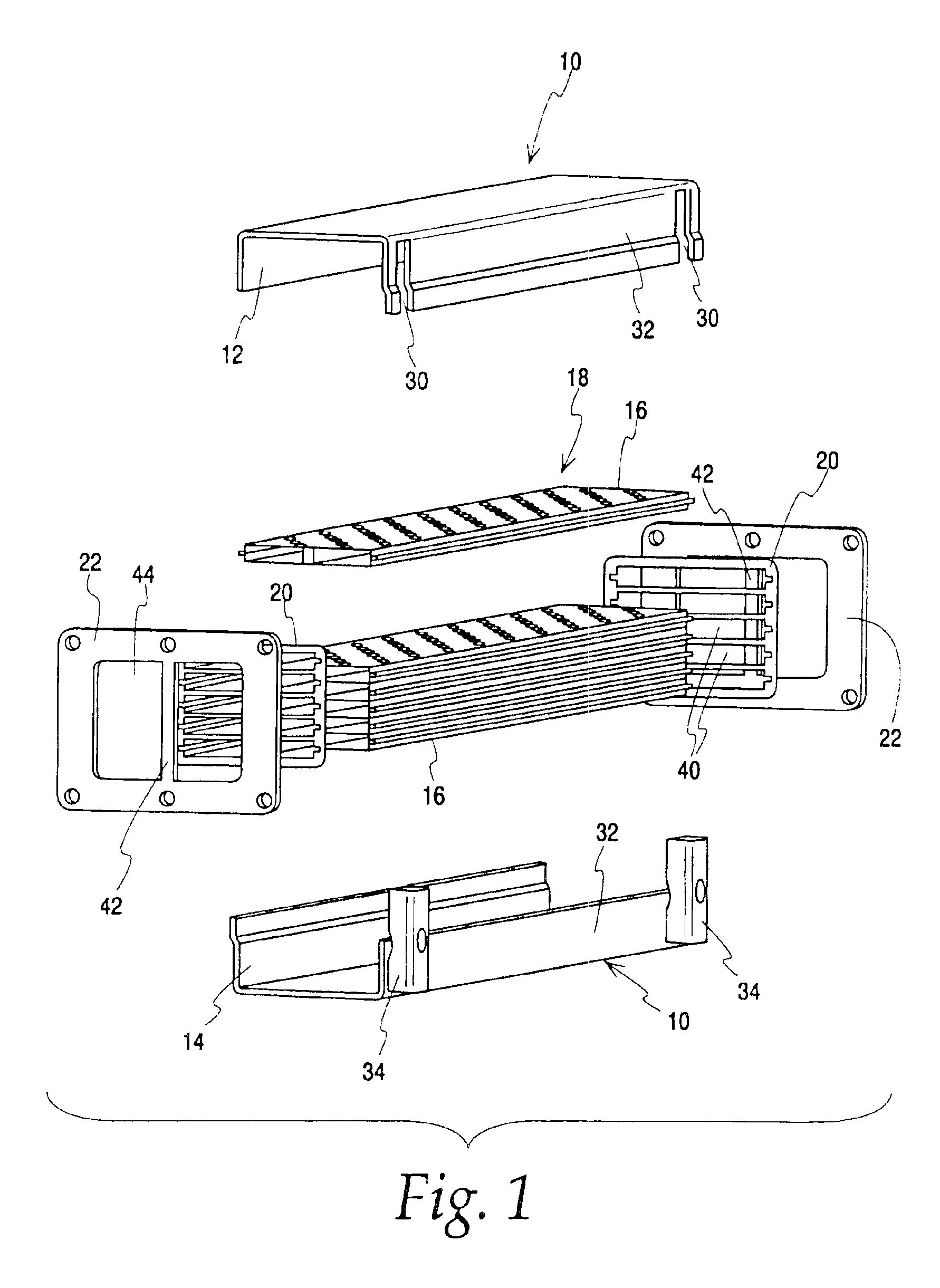

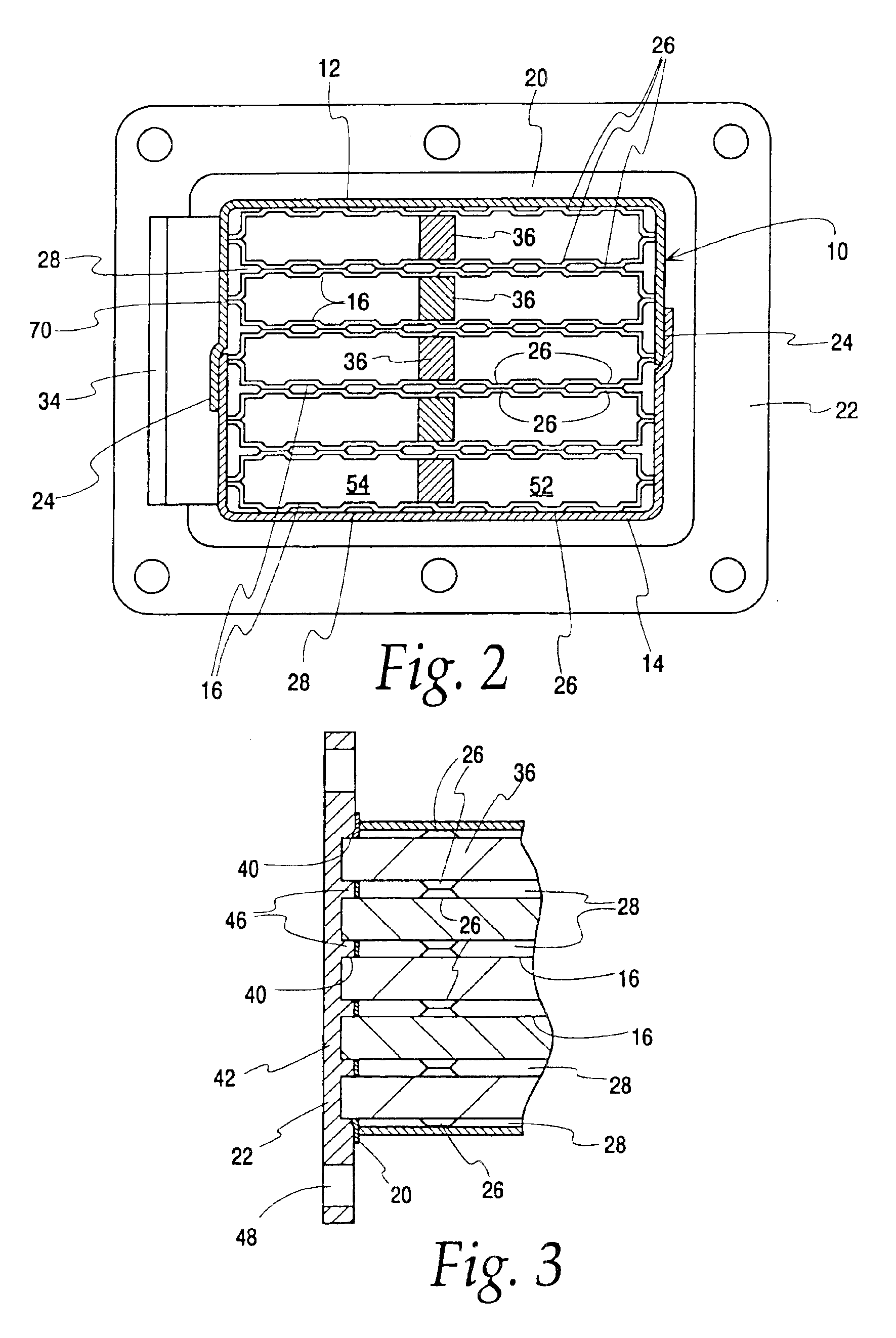

Heat exchanger

An economically manufactured heat exchanger is provided and includes a plurality of elongated, straight, flat tubes (16), each formed of two identical halves (78,80) joined to each other in mirror image fashion and each having opposed open ends and all arranged in a stack (18). At least one spacer wall (36) is disposed within each tube and extends generally from end to end thereof to define at least two side-by-side first fluid flow paths within a tube. An elongated housing (10) contains the stack and includes spaced headers (20,22) with each header including a tube slot for the adjacent end of each tube (16) in the stack (18). Spacers (26) in the stack separate adjacent tubes in the stack from one another and the spacers include ribs defining a serpentine flow path for a second fluid. An opening (30) is located in the housing (10) near each end thereof and is in fluid communication with the second fluid flow path (28).

Owner:MODINE MFG CO

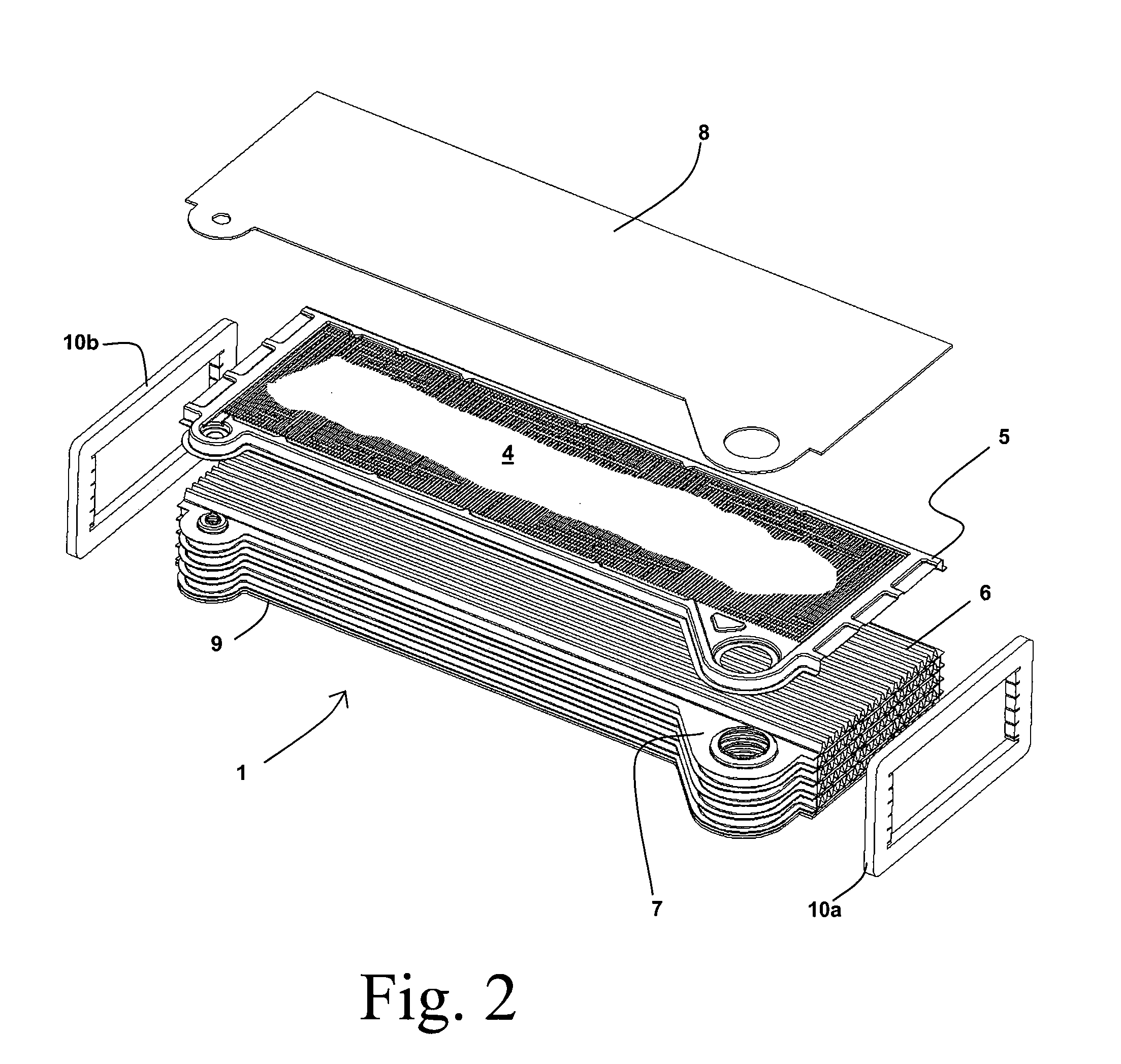

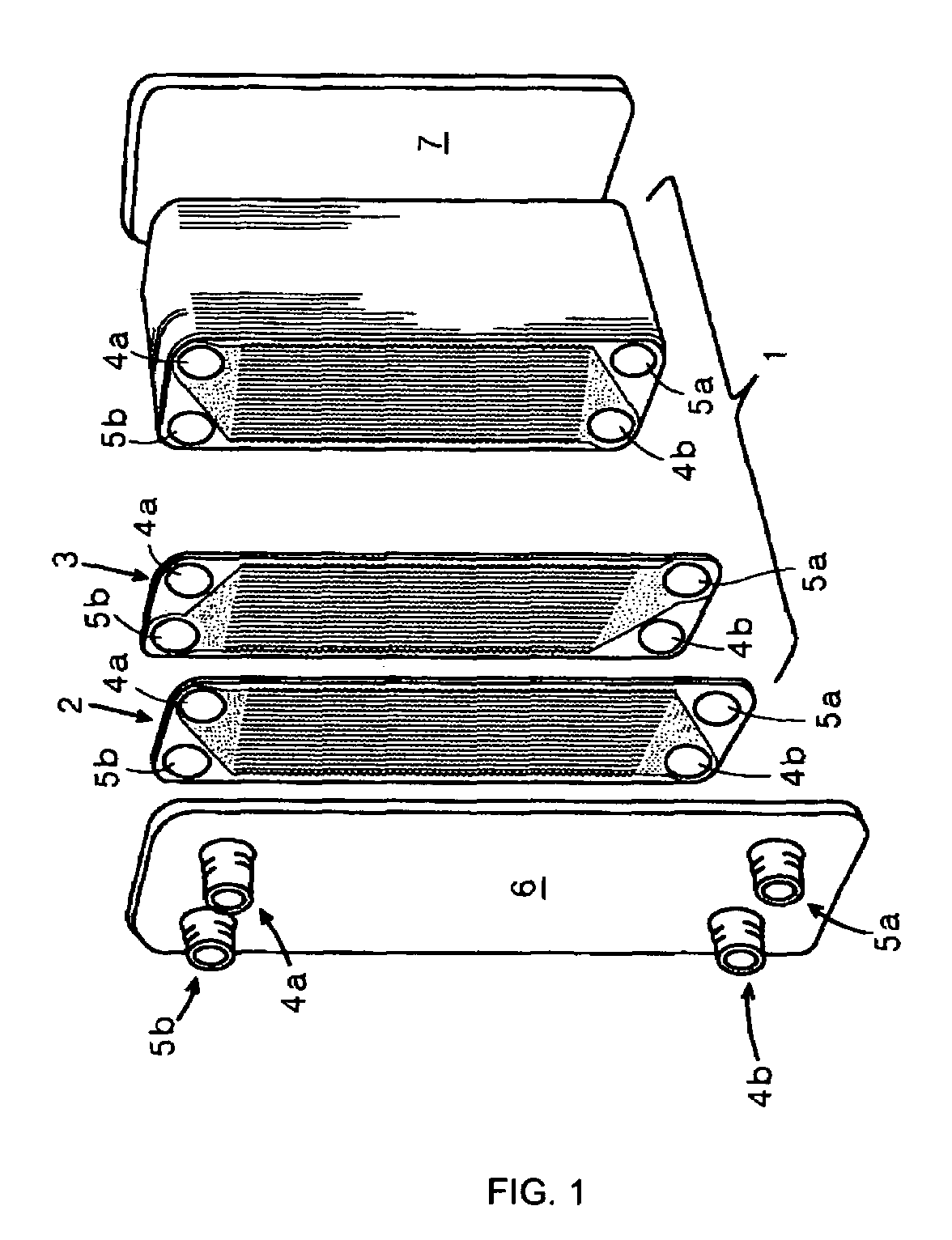

Brazed plate high pressure heat exchanger

InactiveUS20050155749A1Compression machinesGas cycle refrigeration machinesPlate heat exchangerEngineering

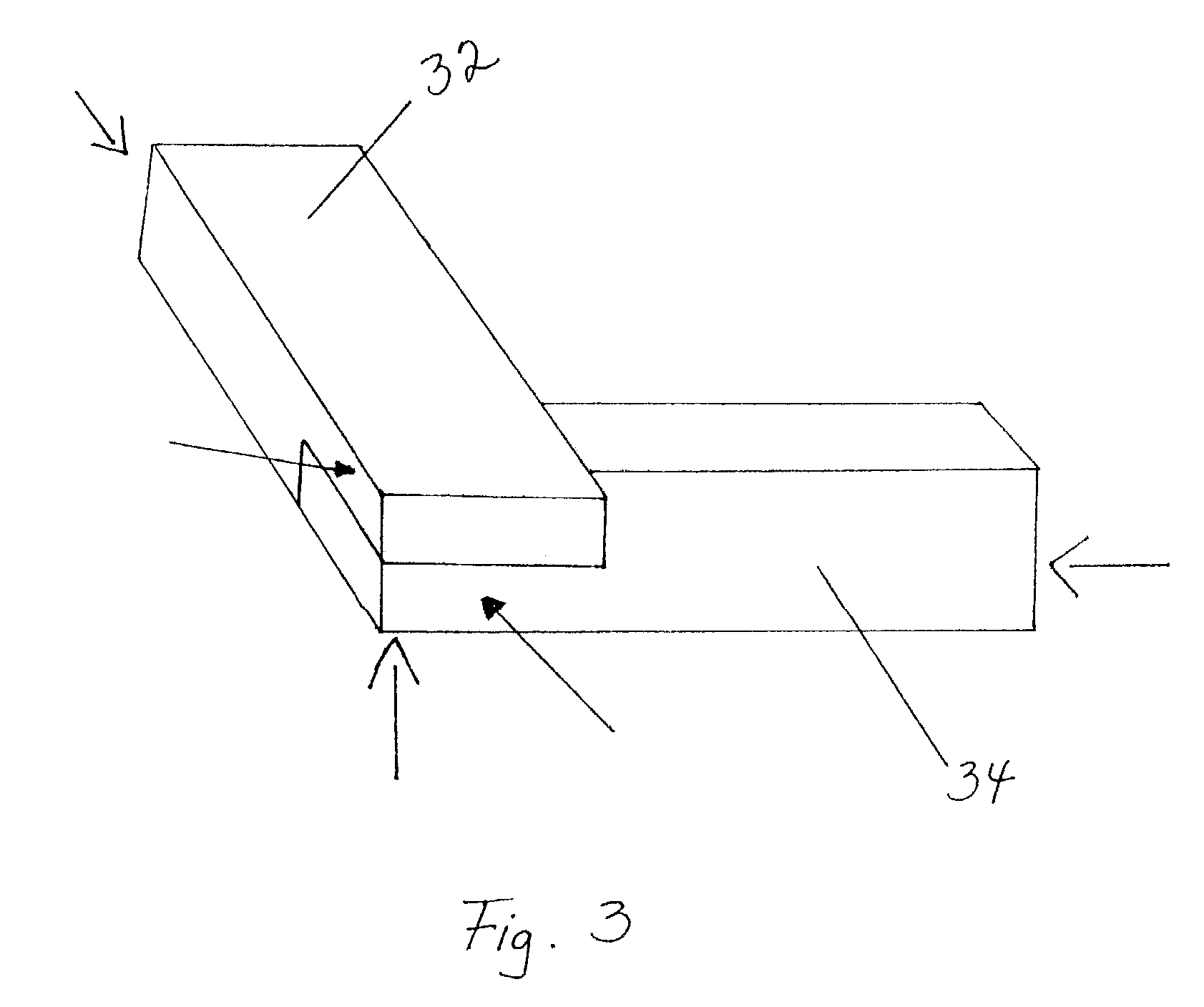

A brazed plate heat exchanger (30) is provided for transferring heat between a first fluid (32) and a second fluid (34), with the first fluid (32) being pressurized to a relatively high pressure. The heat exchanger includes plate pairs (41), with each pair (41) defining a plurality of flow channels (56) for the first fluid (32). Each of the flow channels (56) has a hydraulic diameter less than 1 mm. Reinforcements (62) are provided between each of the plate pairs (41) and are aligned with inlet and outlet openings (46,48) to define inlet and outlet manifolds (50,52) for the first fluid (32).

Owner:MODINE MFG CO

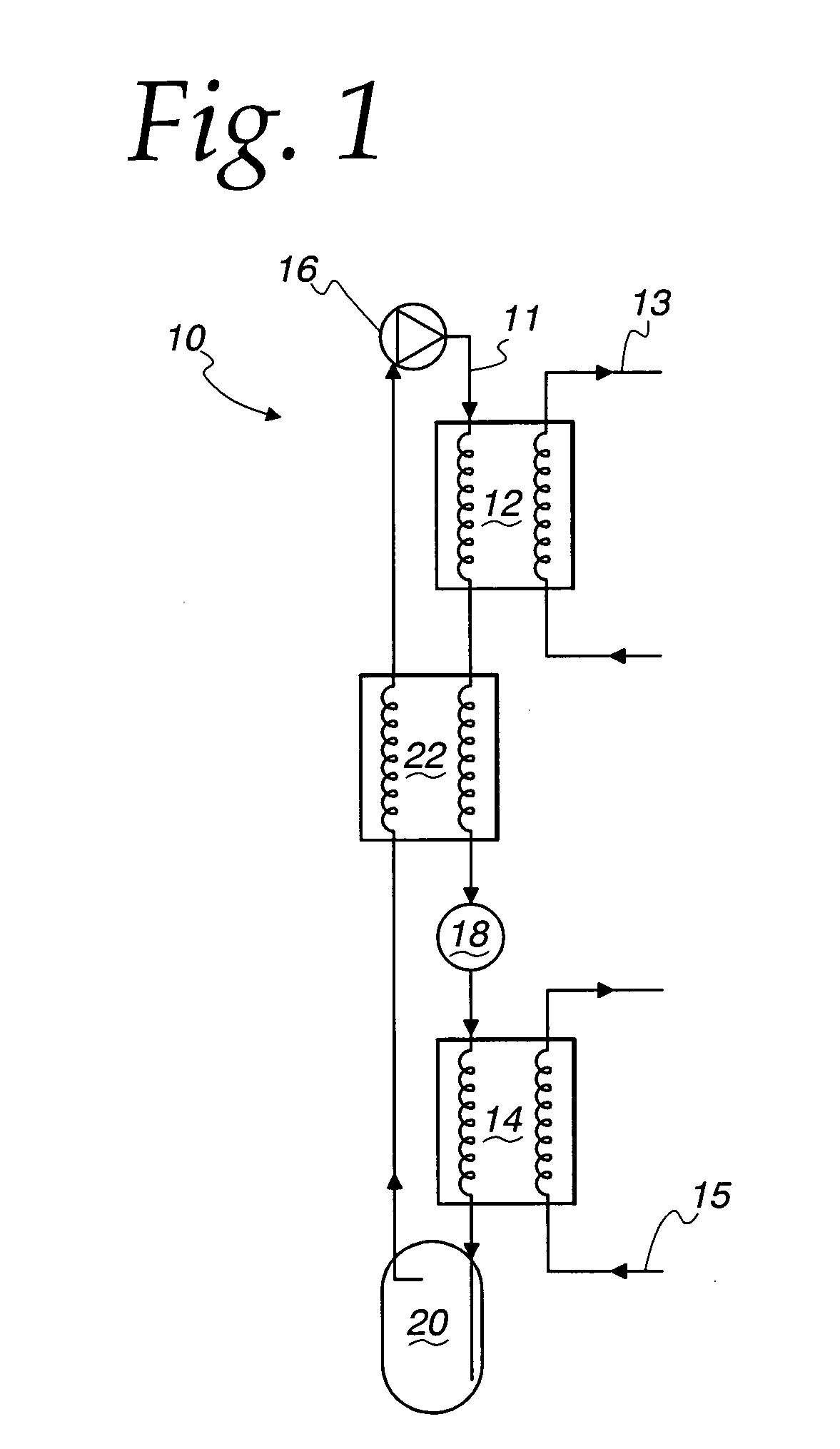

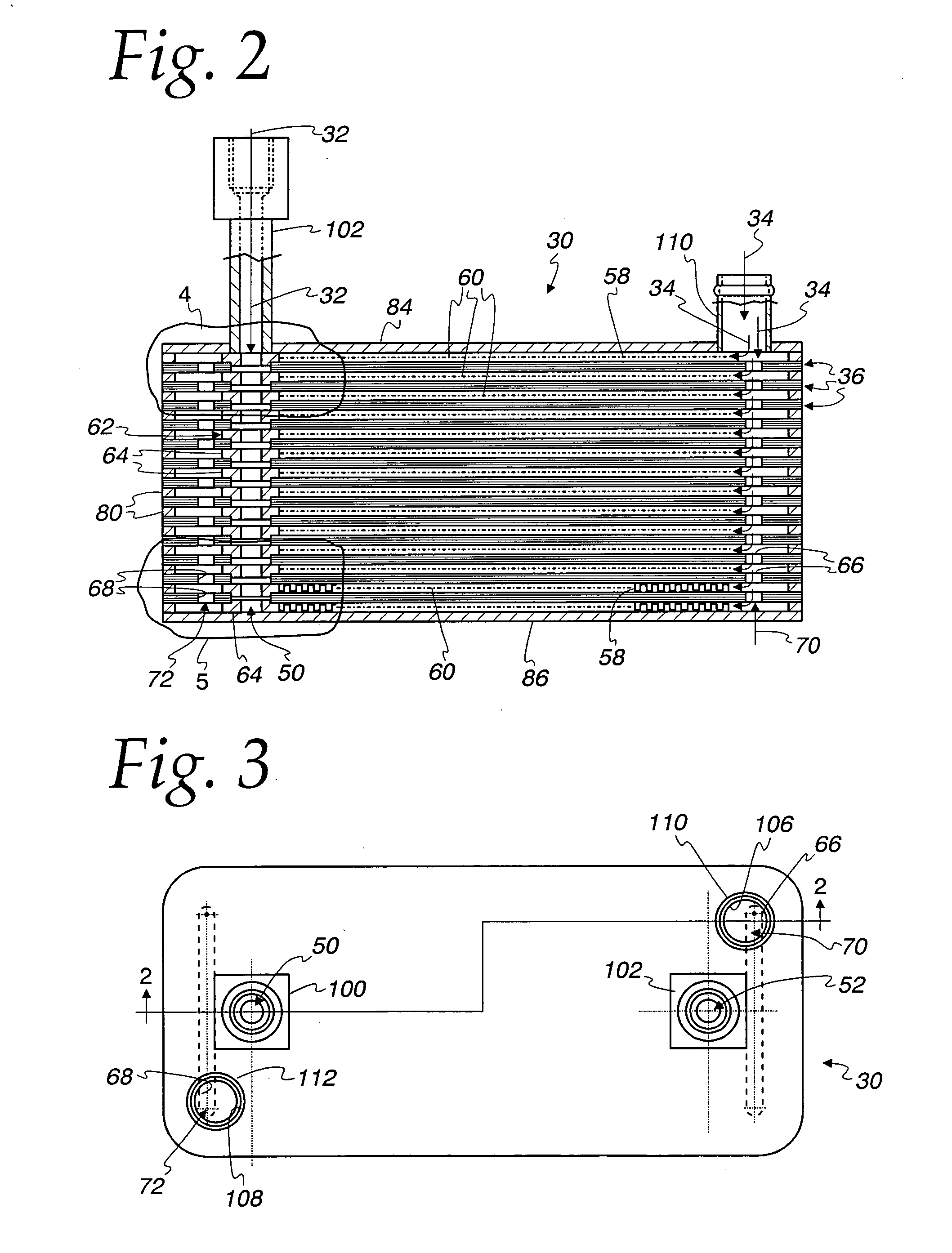

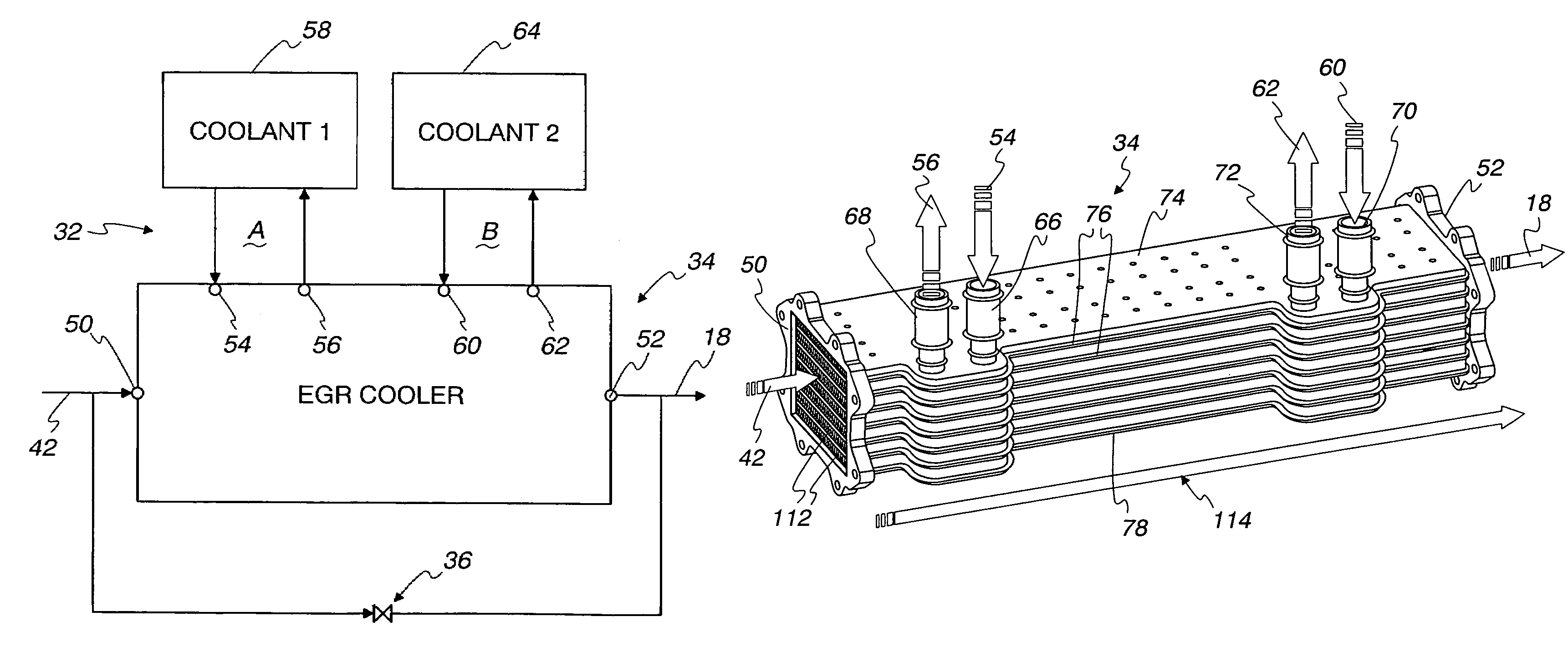

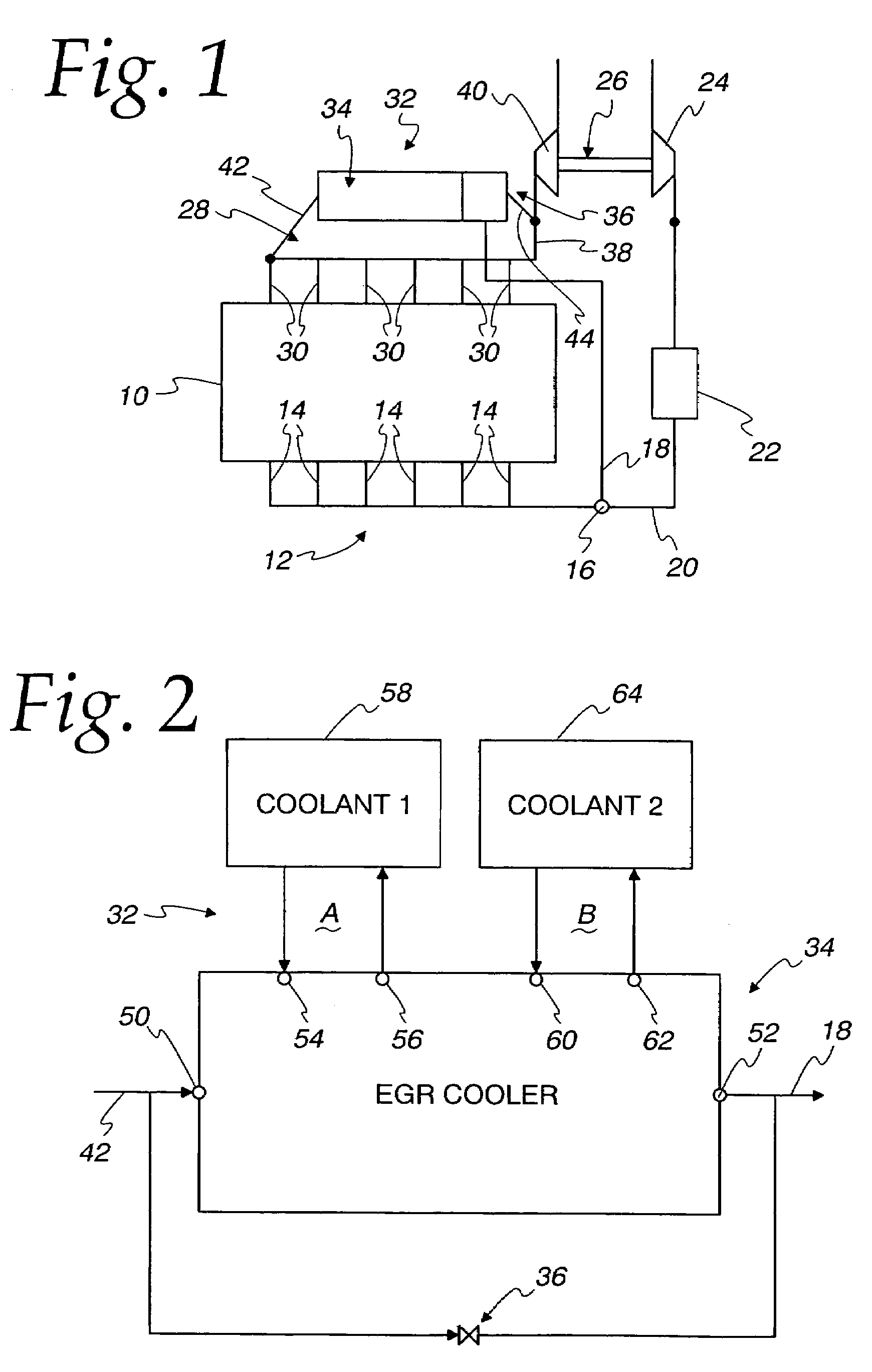

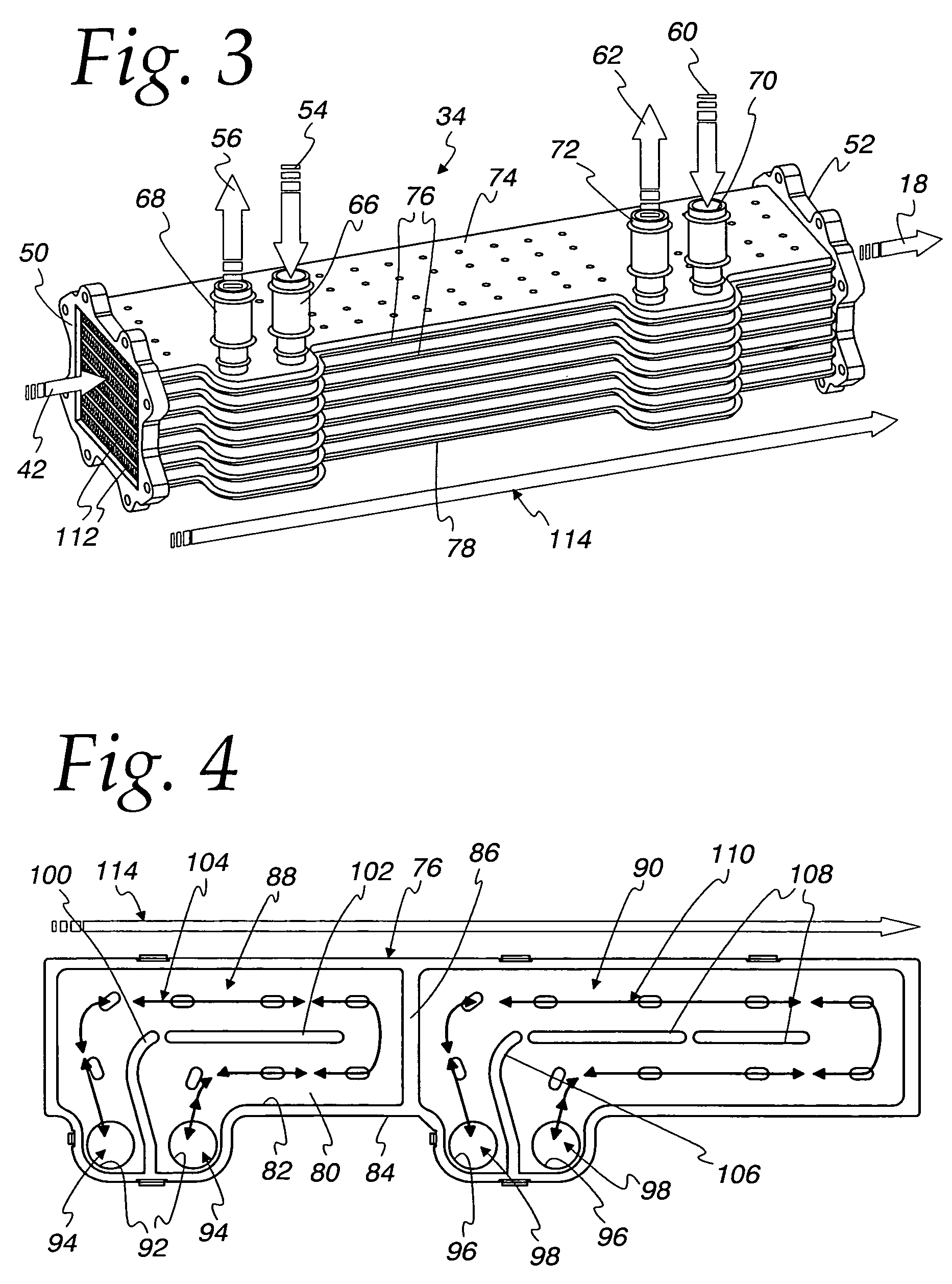

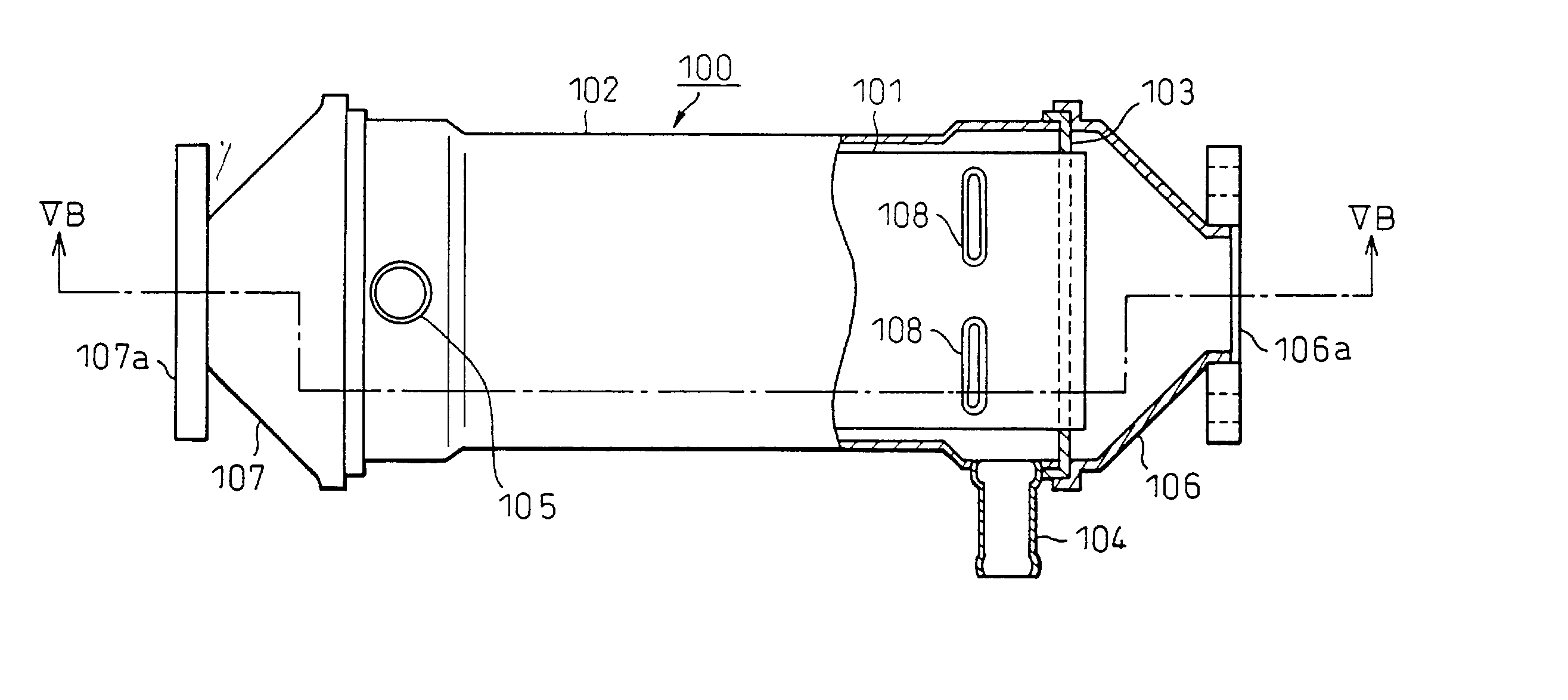

EGR cooler with dual coolant loop

InactiveUS7380544B2Internal combustion piston enginesNon-fuel substance addition to fuelCoolant flowExhaust fumes

An integrated exhaust gas recirculation (EGR) cooler with dual coolant loops comprises an exhaust gas inlet and an exhaust gas outlet for recirculating exhaust gas. An exhaust gas flow path extends between the exhaust gas inlet and the exhaust gas outlet to direct recirculating exhaust gas from the exhaust gas inlet to the exhaust gas outlet. A first coolant flow path extends between a first coolant inlet and a first coolant outlet to direct a first coolant flow from the EGR cooler in heat exchange relation with the exhaust gas flow path. A second coolant flow path extends between a second coolant inlet and a second coolant outlet to direct a second coolant flow through the EGR cooler in heat exchange relation with the exhaust gas flow path.

Owner:MODINE MFG CO

Heat exchanger for back to back electronic displays

ActiveUS8351014B2Digital data processing detailsLighting heating/cooling arrangementsElectronic assembliesElectron

A cooling assembly for a dual electronic image assembly having an open and closed gaseous loop. A closed gaseous loop allows circulating gas to travel across the front surface of a pair of electronic image assemblies and through a heat exchanger. An open loop allows ambient gas to pass through the heat exchanger and extract heat from the circulating gas. An optional additional open loop may be used to cool the back portion of the electronic image assembly (optionally a backlight). The cooling assembly can be used with any type of electronic assembly for producing an image. Some embodiments use cross-flow heat exchangers comprised of corrugated plastic.

Owner:MFG RESOURCES INT INC

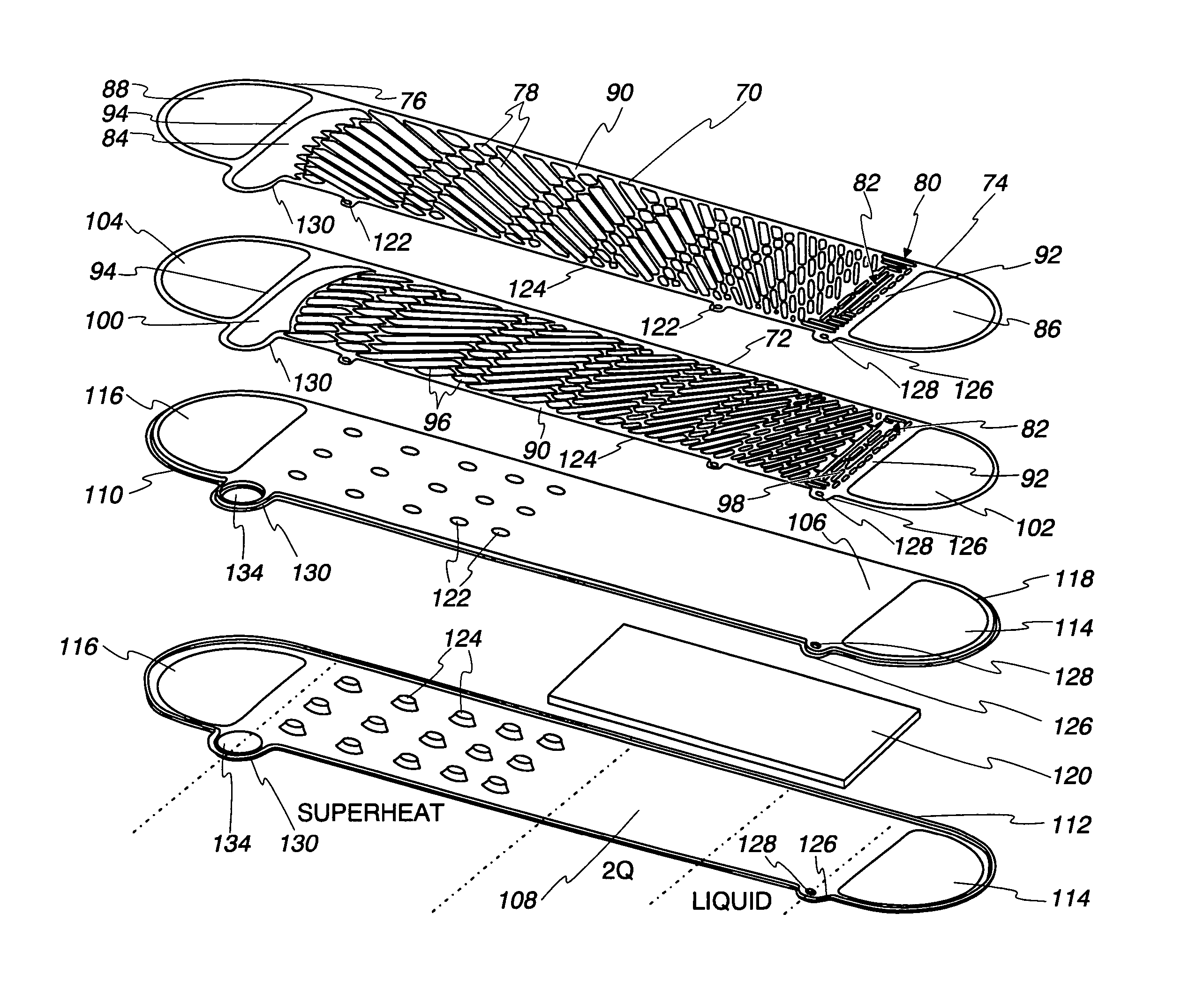

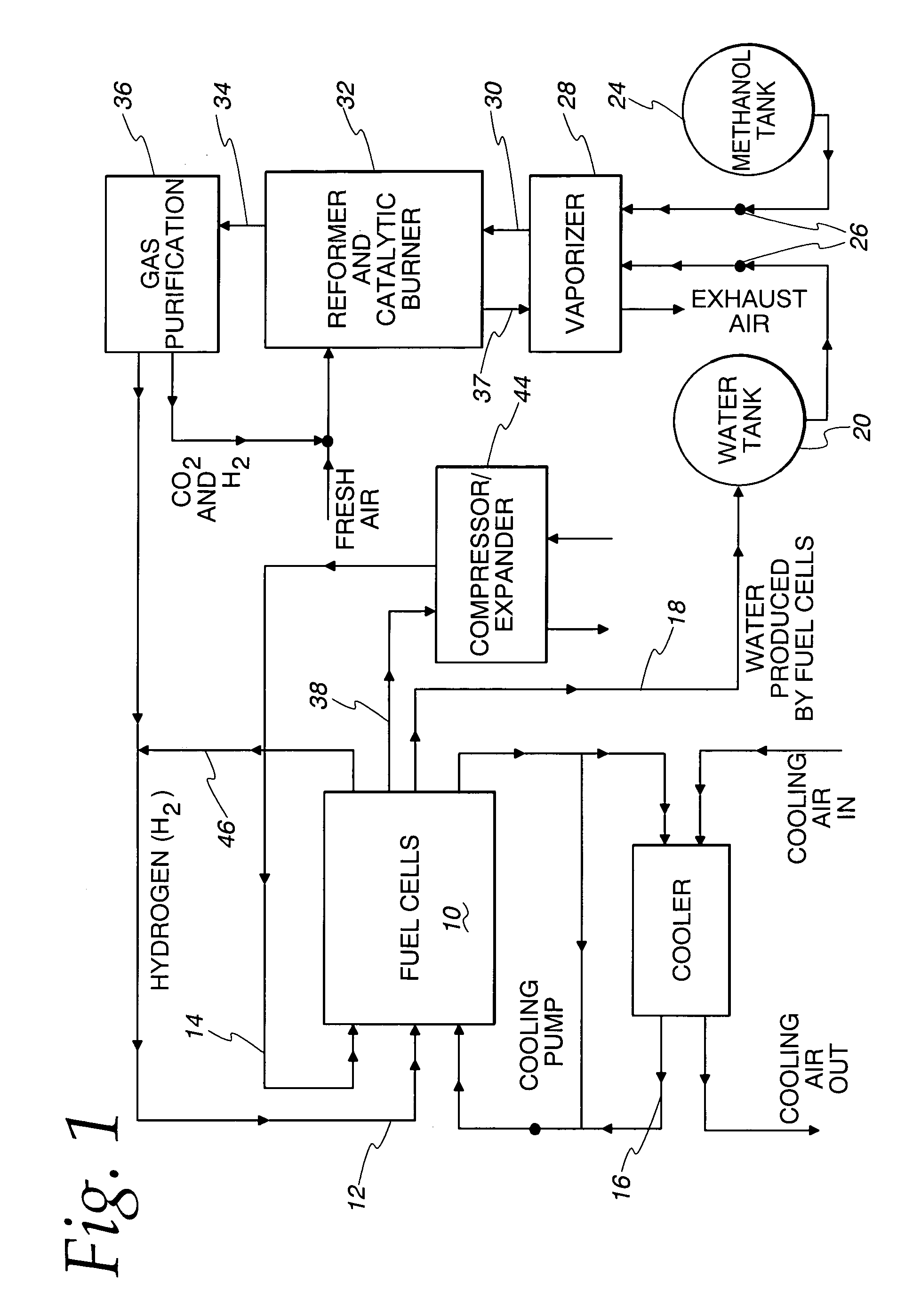

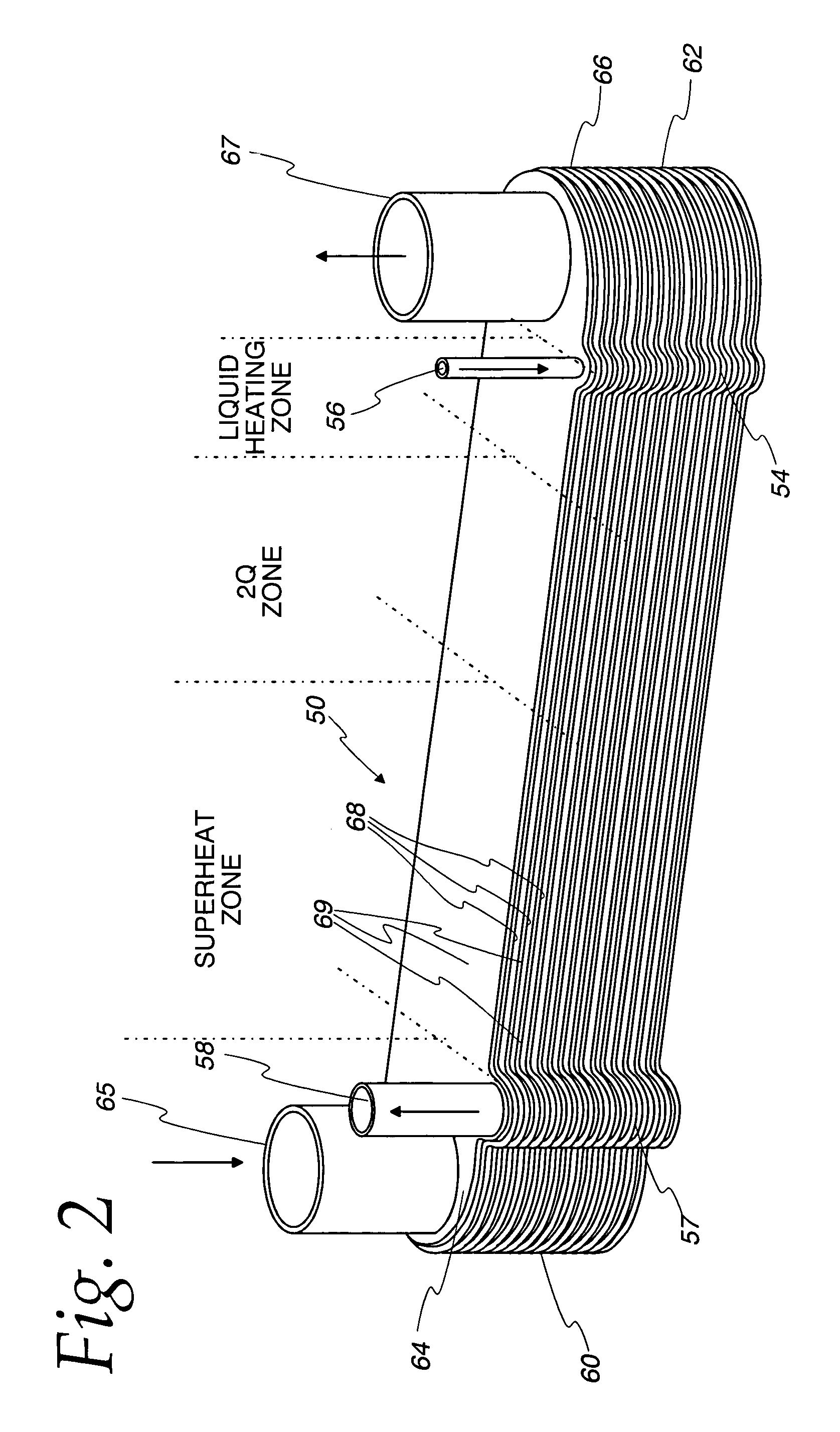

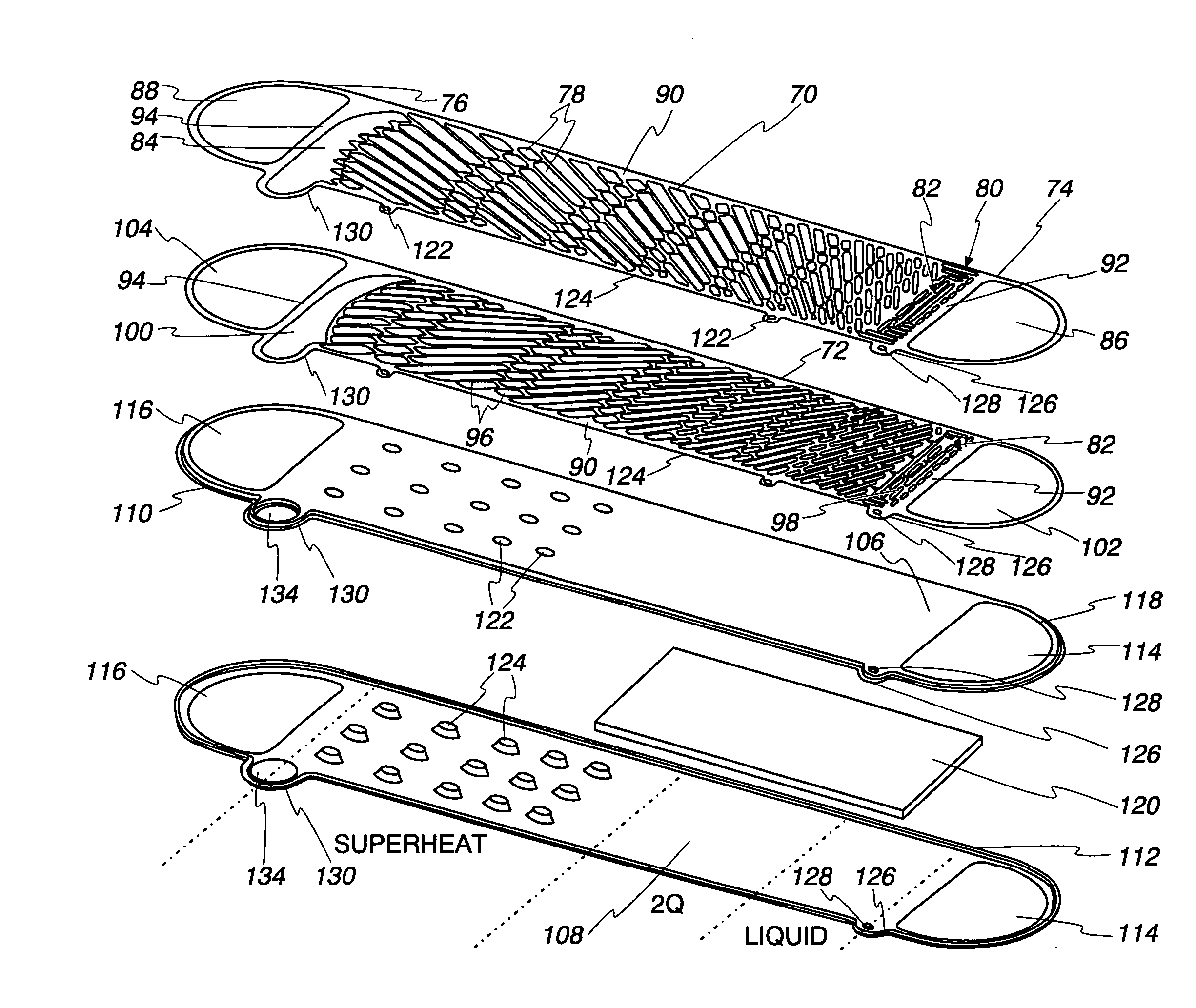

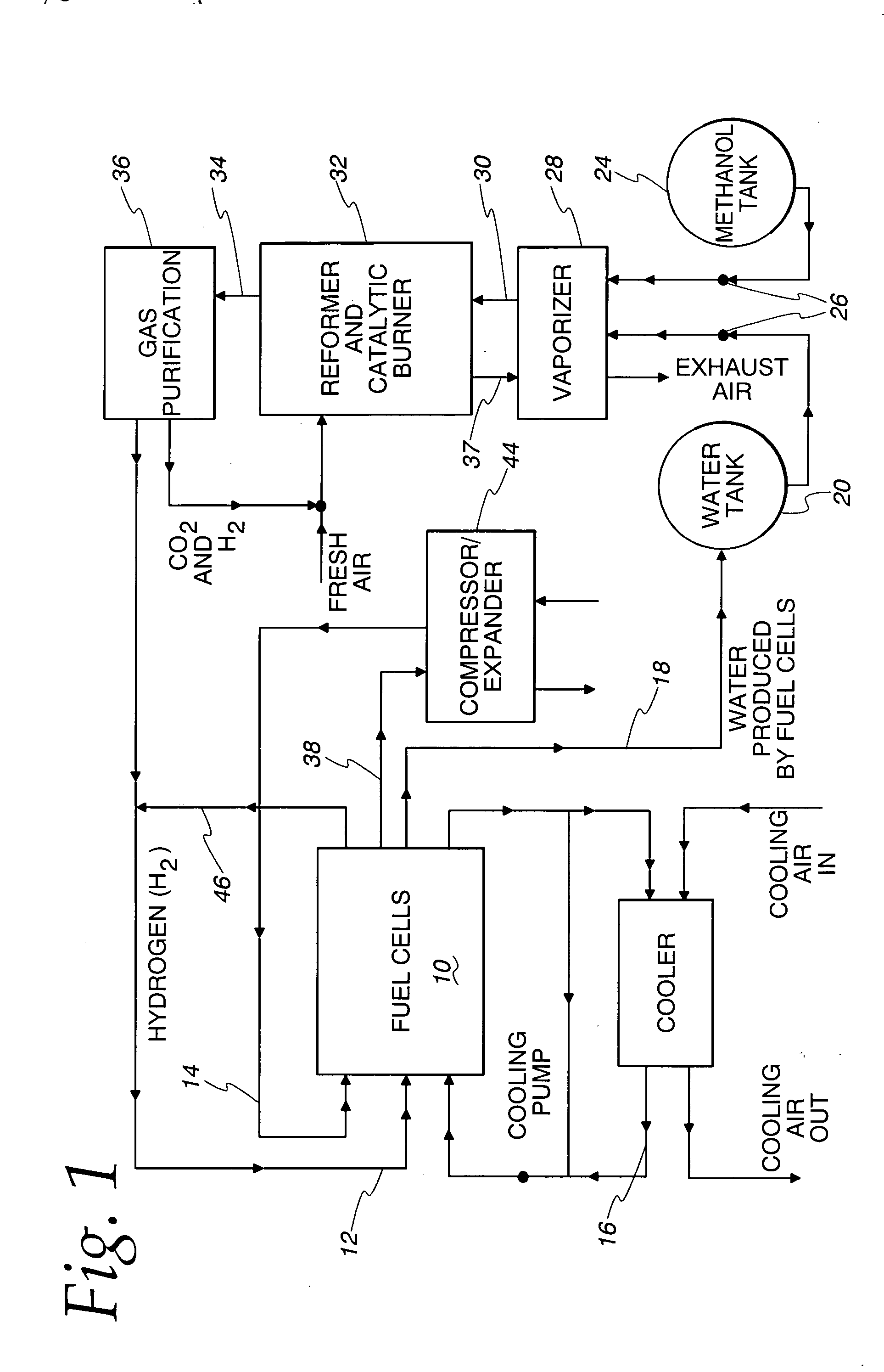

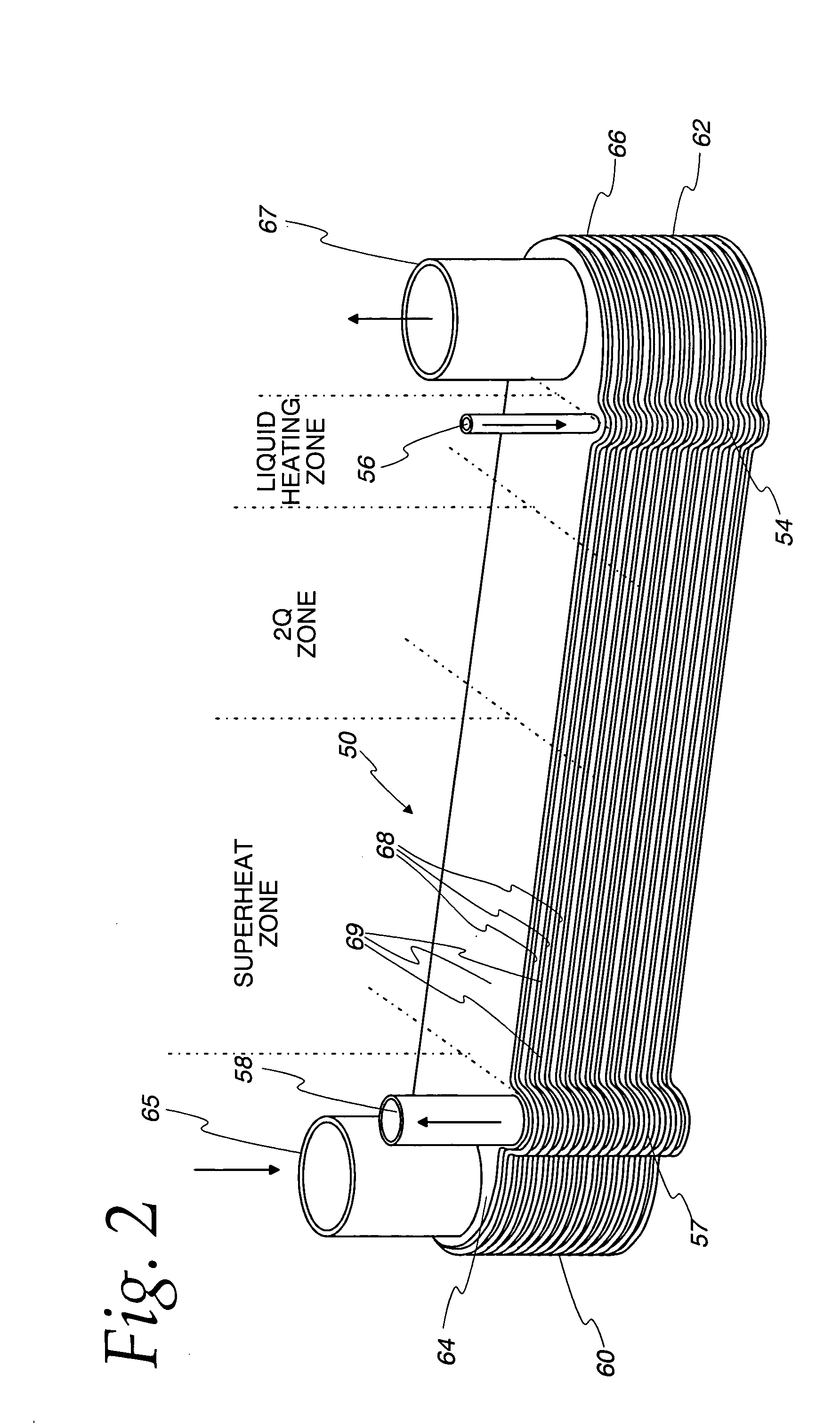

Fuel vaporizer for a reformer type fuel cell system

InactiveUS7063047B2Short response timeReduced effectivenessFuel cell heat exchangeHeat transfer modificationFuel cellsWater flow

Large thermal stresses are avoided and the fuel charge reduced in a vaporizer particularly suited for use in a reformer type fuel cell system and having a construction that includes alternating fuel / water flow path defining cells (68) and hot gas flow path cells (69) by providing heat transfer augmentation, such as a lanced and offset fin (120), only in that part of the gas flow path structure (69) adjacent the regions in the fuel / water flow path cells (68) where heating of the liquid fuel / water and vaporizing of the fuel / water where the mixture exists is a two phase material occurs and not in the area adjacent those parts of the fuel / water flow path structure (68) in which superheating of the vaporized fuel / water mixture is occurring.

Owner:MODINE MFG CO

Pressurized vapor cycle liquid distillation

ActiveUS20070017192A1Easy maintenanceImprove efficiencyCombination devicesDrying using combination processesHeat managementDistillation

Embodiments of the invention are directed toward a novel pressurized vapor cycle for distilling liquids. In some embodiments of the invention, a liquid purification system is revealed, including the elements of an input for receiving untreated liquid, a vaporizer coupled to the input for transforming the liquid to vapor, a head chamber for collecting the vapor, a vapor pump with an internal drive shaft and an eccentric rotor with a rotatable housing for compressing vapor, and a condenser in communication with the vapor pump for transforming the compressed vapor into a distilled product. Other embodiments of the invention are directed toward heat management, and other process enhancements for making the system especially efficient.

Owner:DEKA PROD LLP

Process for cooling a product in a heat exchanger employing microchannels

InactiveUS7000427B2Reduced Power RequirementsLower overall pressure dropSolidificationLiquefactionProcess engineeringRefrigerant

This invention relates to a process for cooling or liquefying a fluid product (e.g., natural gas) in a heat exchanger, the process comprising: flowing a fluid refrigerant through a set of refrigerant microchannels in the heat exchanger; and flowing the product through a set of product microchannels in the heat exchanger, the product flowing through the product microchannels exchanging heat with the refrigerant flowing through the refrigerant microchannels, the product exiting the set of product microchannels being cooler than the product entering the set of product microchannels. The process has a wide range of applications, including liquefying natural gas.

Owner:VELOCYS CORPORATION

Heat exchanger

InactiveUS7334631B2Without impairment of heat transfer characteristicIncreased pressure lossHeat transfer modificationLaminated elementsThin metalPlate heat exchanger

To reduce pressure loss on a heat-exchanger fluid while downsizing a heat exchange and reducing the production cost of the heat exchanger without impairment of the heat transfer performance of the heat exchanger by forming a fluid channel in surfaces of thin metal plates such as stainless steel plates through the use of an etching technique or the like and by improving the shape of the fluid channel. In a heat exchanger in which a plurality of heat exchanger fins are provided in thin metal plates by using an etching technique or the like and a fluid channel for a heat-exchanger fluid is formed between the two opposed thin metal plates by alternately stacking the thin metal plates, the area of the fluid channel, through which the fluid flows between the heat exchanger fins, is made substantially uniform by forming the heat exchanger fins so as to have a curved cross-sectional shape from the front end thereof to the rear end.

Owner:KATO YASUYOSHI

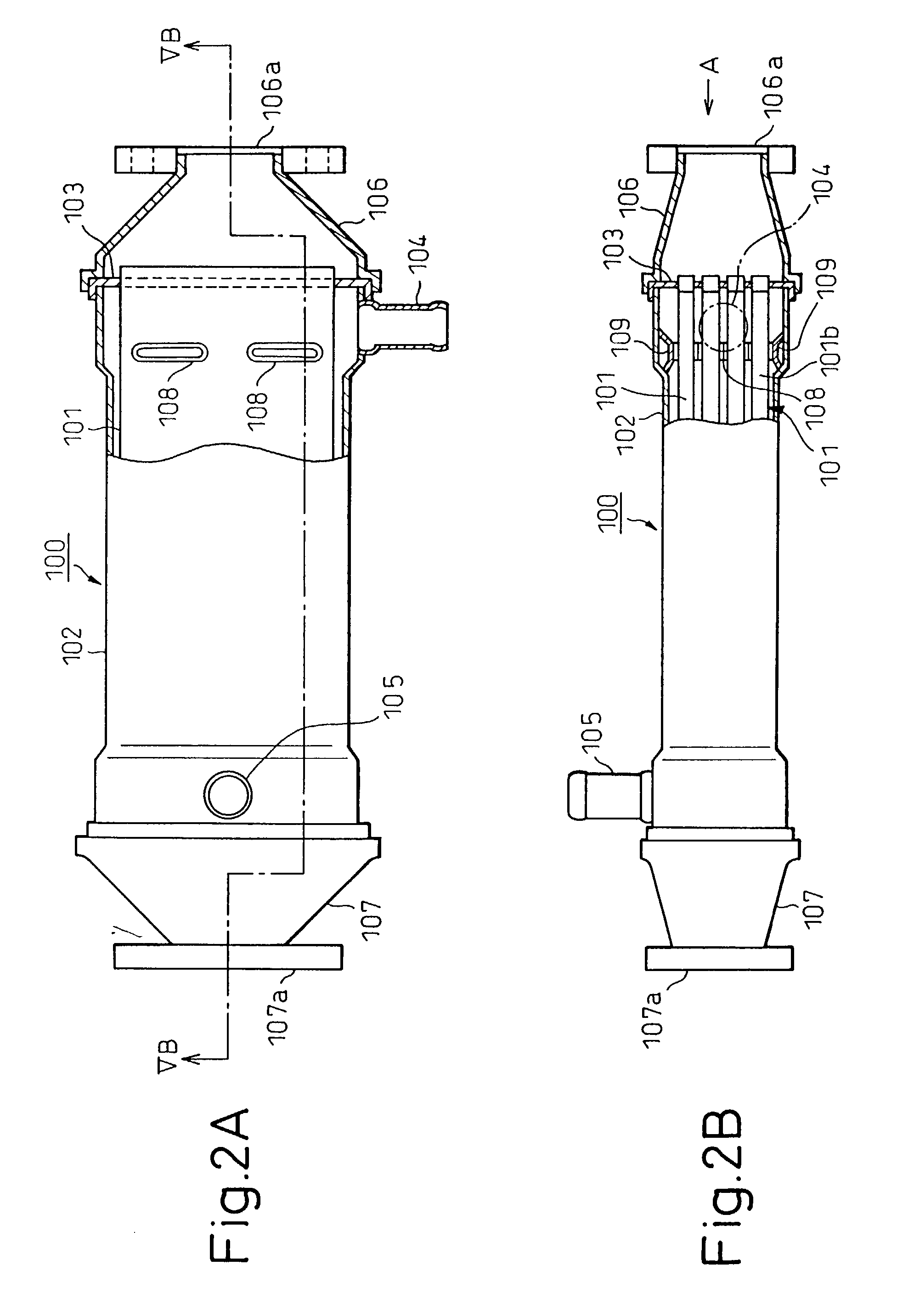

Exhaust gas heat exchanger

InactiveUS20030010480A1Spacing meansNon-fuel substance addition to fuelEngineeringMechanical engineering

A tube 101 is constituted by a pair of plates 111a, 111b which are fitted with each other in such a manner as to put an inner fin 101b between the plate 111a and the plate 111b. Differences in level 111c are formed on the second plate 111b, which fits inside, which differences in level each protrude inwardly by a distance equal to the thickness of the first plate 111a, whereby the outer wall surface of the tube 101 is made substantially level thereover. A gap which is formed between the outer wall surface of the tube 101 and a core plate, when the tube is passed through the core plate, can be as small as possible whereby the brazing properties can be improved.

Owner:DENSO CORP

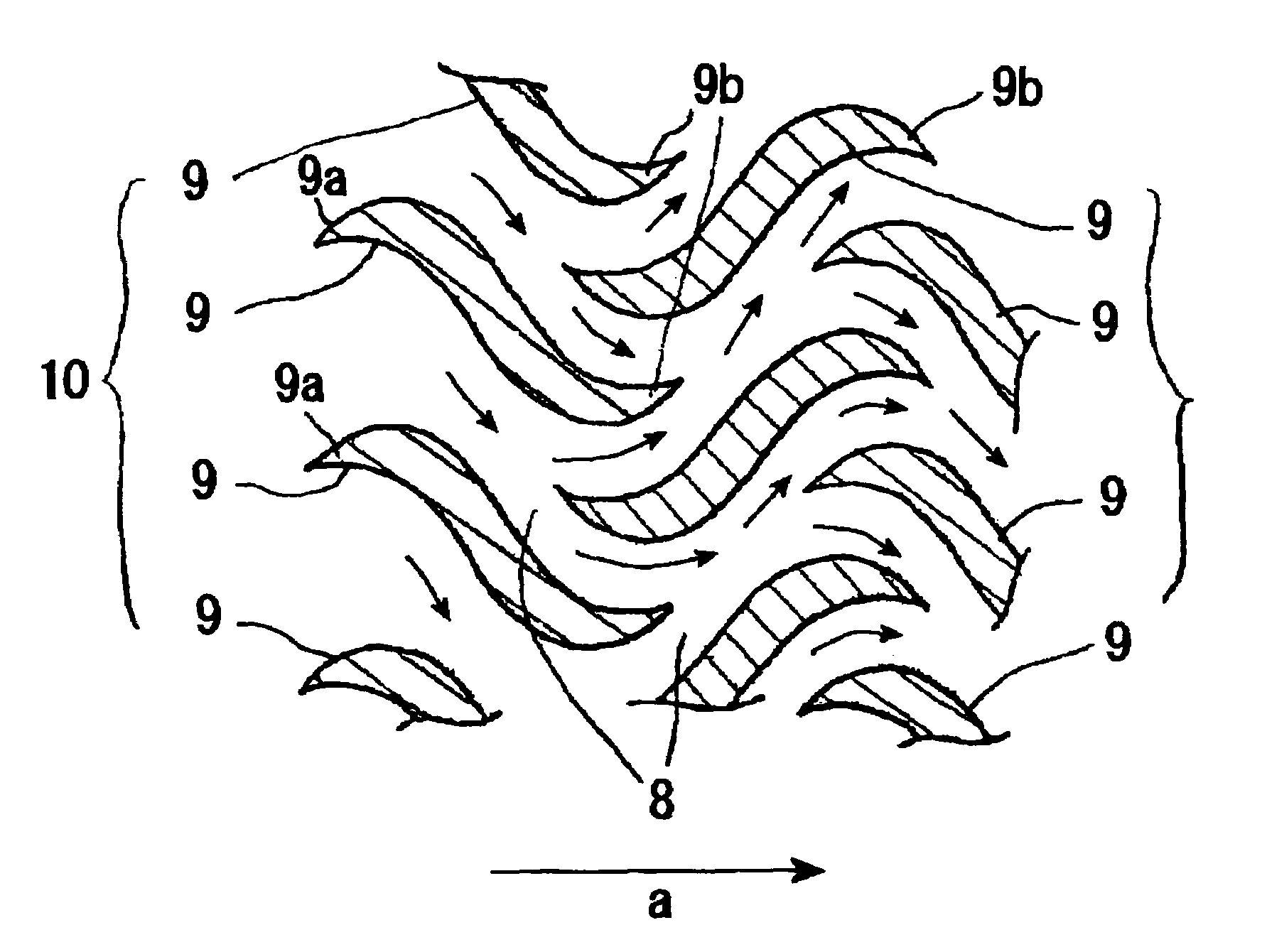

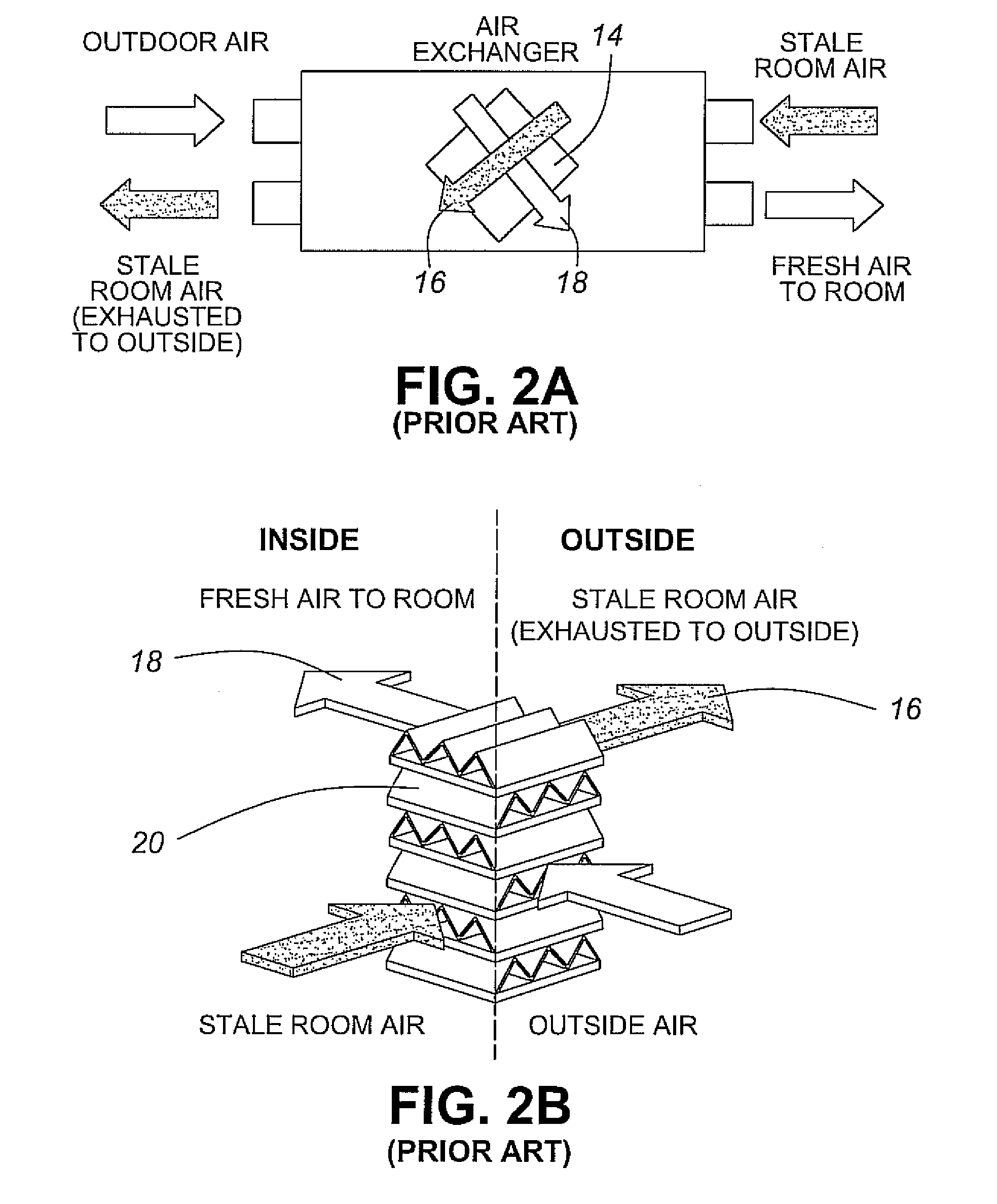

Flat plate heat and moisture exchanger

ActiveUS20090314480A1Easy to manufactureOperationally efficientFuel cell heat exchangeHeat exchanger casingsHeat and moisture exchangerEnergy recovery

This invention relates in general to air exchange systems and, in particular, to an improved energy recovery ventilator, a cross flow plate core associated therewith and a method of conditioning air for a building. In one aspect, the invention provides a cross flow plate core comprising: a left hand wafer comprising a left hand spacer with a first of a plurality of membranes bonded thereto, the left hand spacer comprising a plurality of parallel curvilinear rails which form channels for receiving a first stream of air; and a right hand wafer comprising a right hand spacer with a second of the plurality of membranes bonded thereto, the right hand spacer comprising a plurality of parallel curvilinear rails which form channels for receiving a second stream of air, wherein the left hand spacer of the left hand wafer is bonded to the top of the membrane of the right hand wafer.

Owner:ZEHNDER VERKAUFS UND VERW

Fuel vaporizer for a reformer type fuel cell system

InactiveUS20050056412A1Short response timeReduced effectivenessFuel cell heat exchangeHeat transfer modificationFuel cellsWater flow

Large thermal stresses are avoided and the fuel charge reduced in a vaporizer particularly suited for use in a reformer type fuel cell system and having a construction that includes alternating fuel / water flow path defining cells (68) and hot gas flow path cells (69) by providing heat transfer augmentation, such as a lanced and offset fin (120), only in that part of the gas flow path structure (69) adjacent the regions in the fuel / water flow path cells (68) where heating of the liquid fuel / water and vaporizing of the fuel / water where the mixture exists is a two phase material occurs and not in the area adjacent those parts of the fuel / water flow path structure (68) in which superheating of the vaporized fuel / water mixture is occurring.

Owner:MODINE MFG CO

Membrane-integrated energy exchange assembly

A method of forming a membrane panel configured to be secured within an energy exchange assembly may include forming an outer frame defining a central opening, and integrating a membrane sheet with the outer frame. The membrane sheet spans across the central opening, and is configured to transfer one or both of sensible energy or latent energy therethrough. The integrating operation may include injection-molding the outer frame to edge portions of the membrane sheet. Alternatively, the integrating operation may include laser-bonding, ultrasonically bonding, heat-sealing, or the like, the membrane sheet to the outer frame.

Owner:NORTEK AIR SOLUTIONS CANADA INC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com