Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6461 results about "Carbon composites" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

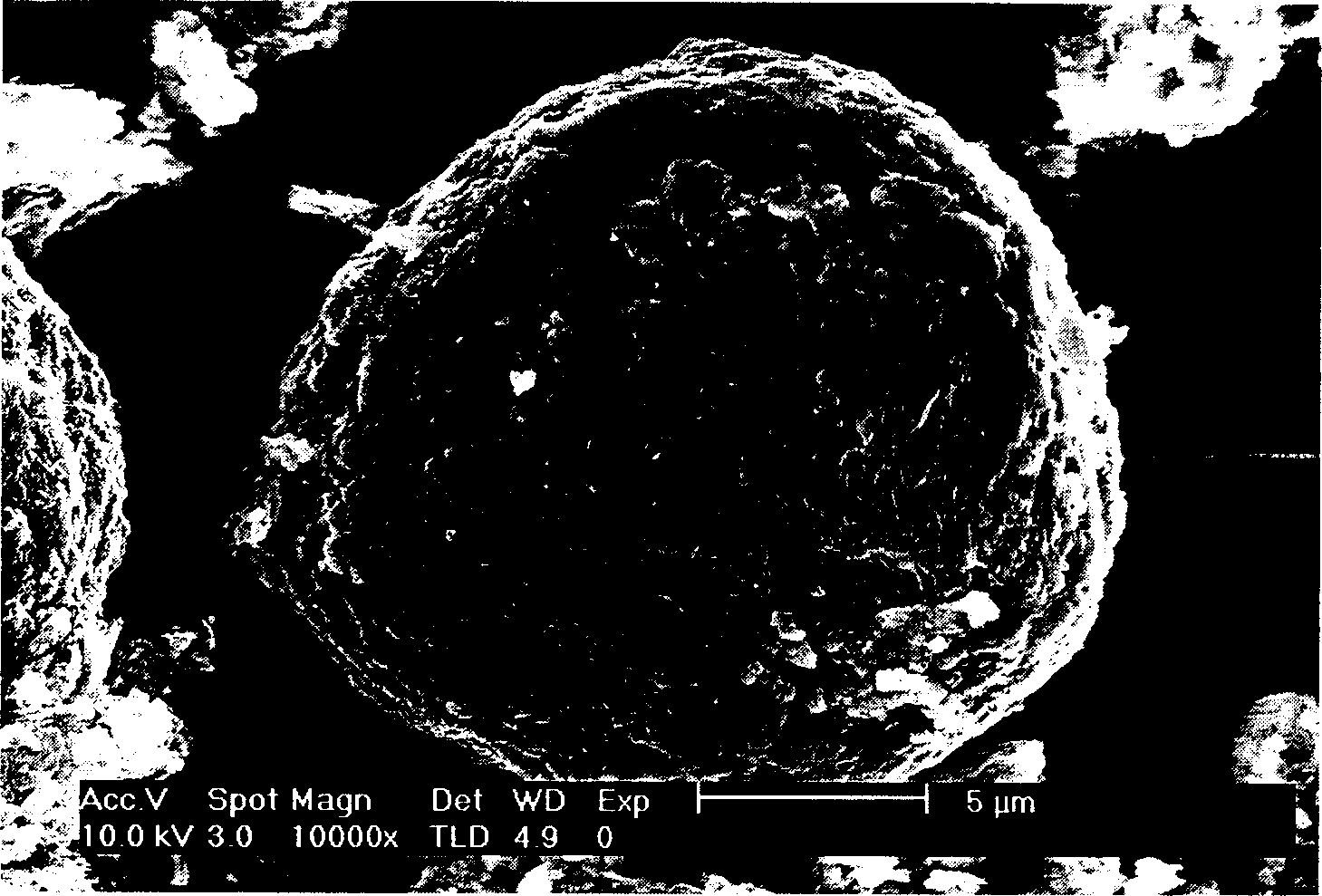

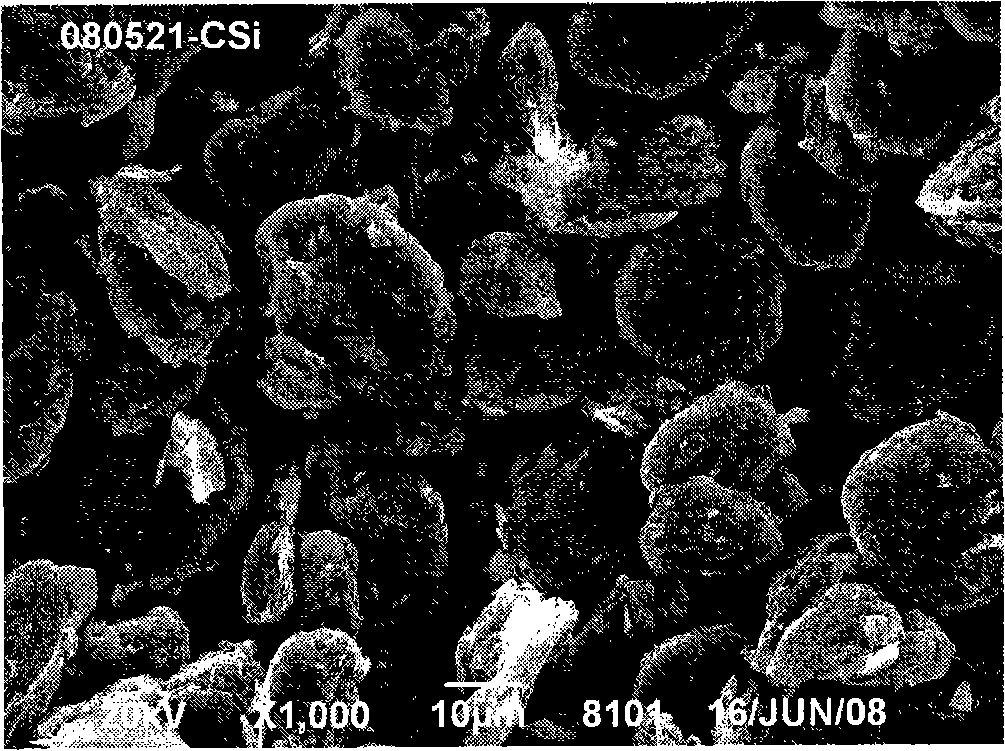

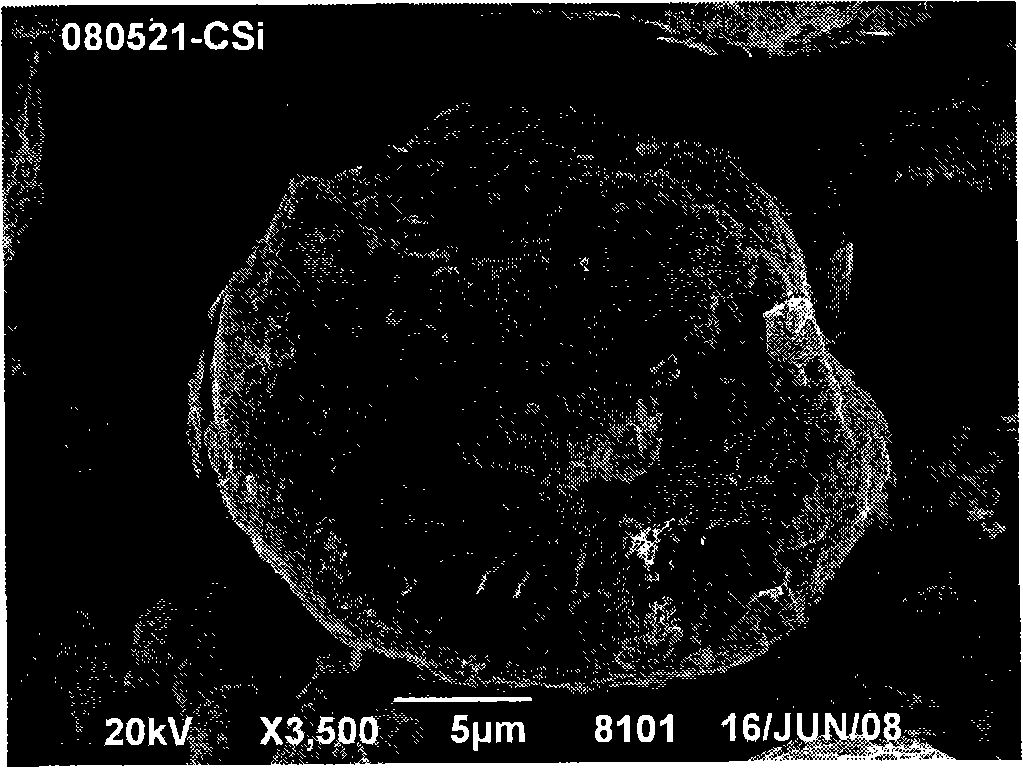

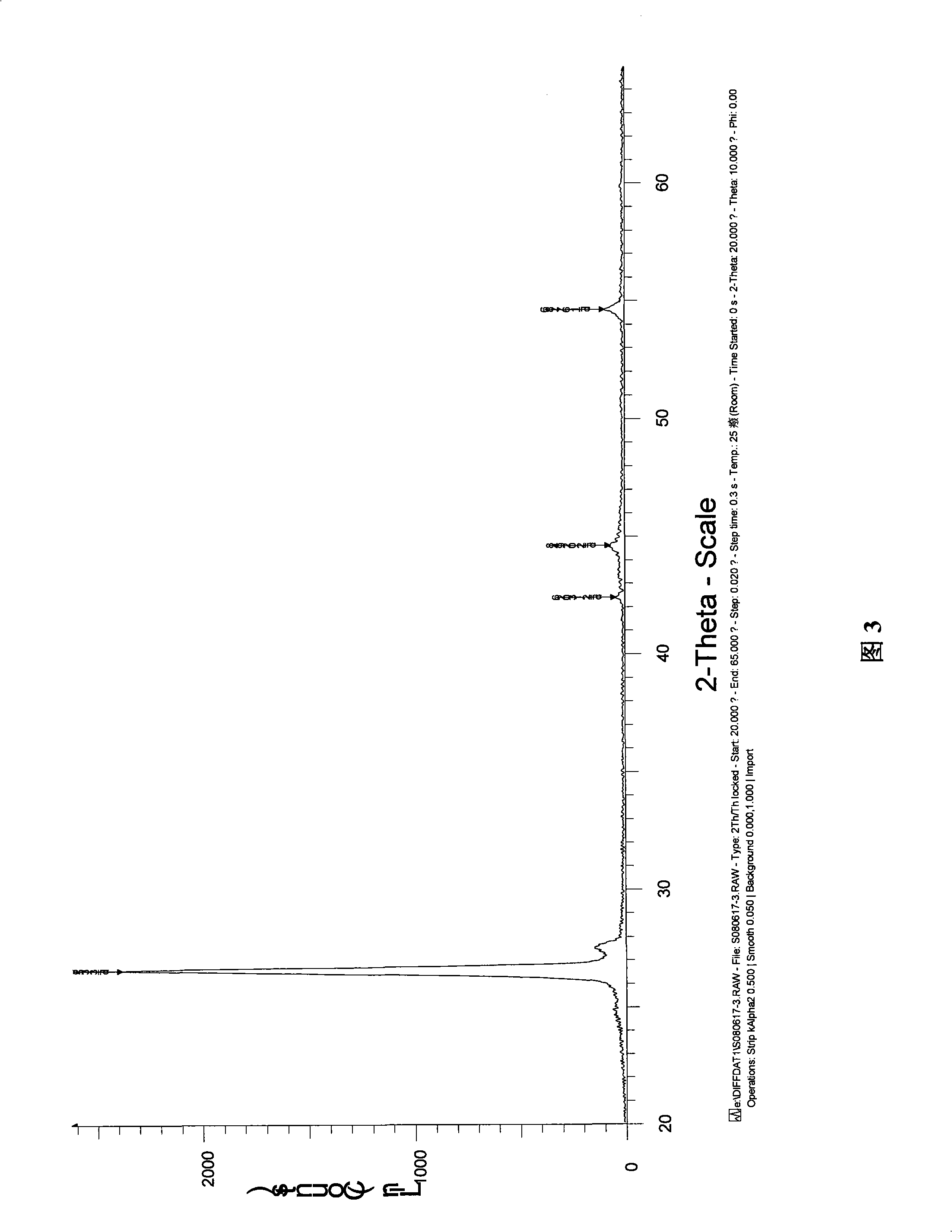

Carbon-coated silicon particle power as the anode material for lithium batteries and the method of making the same

InactiveUS20050136330A1Large capacityImprove efficiencyElectrode thermal treatmentElectrode carriers/collectorsCarbon compositesSilicon particle

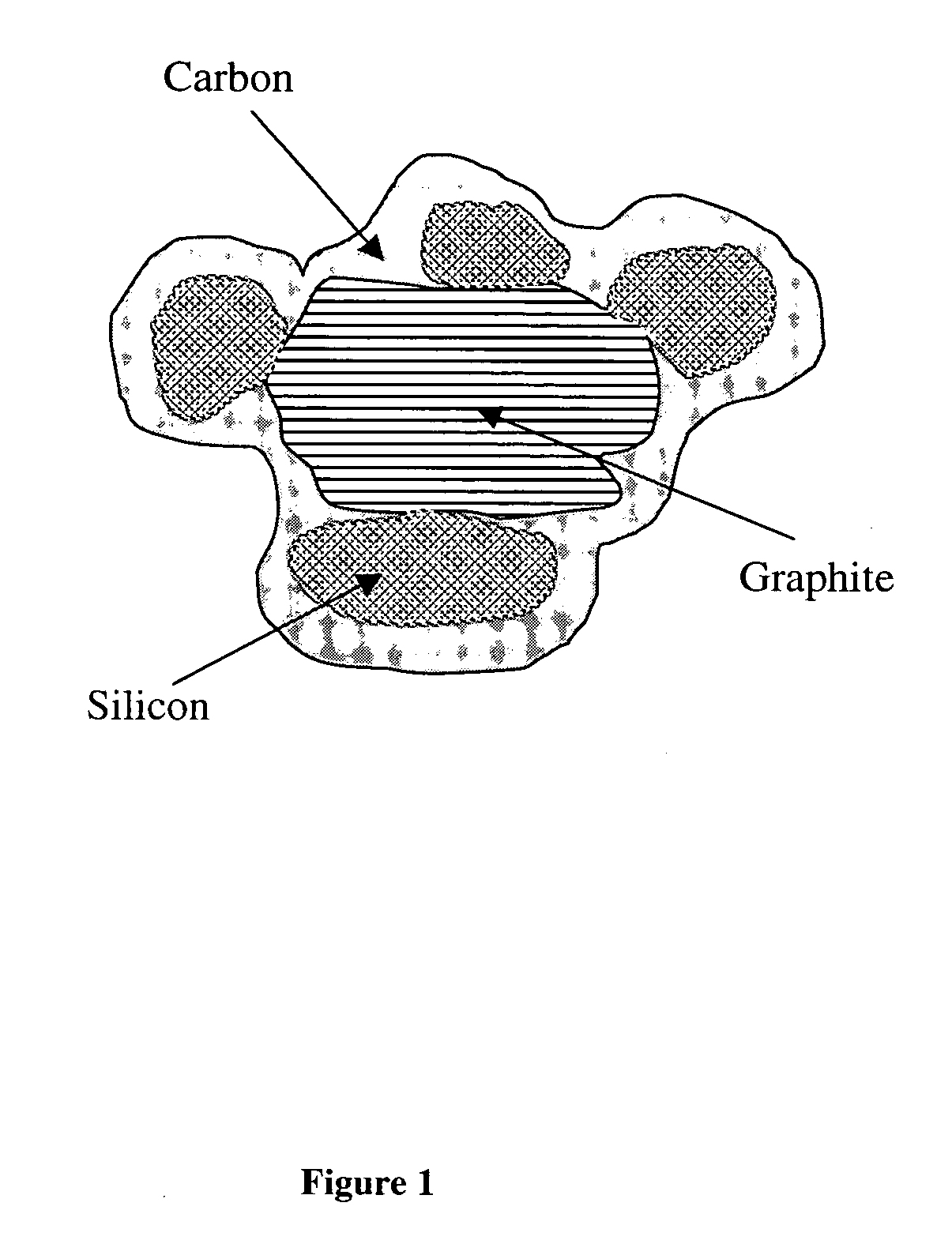

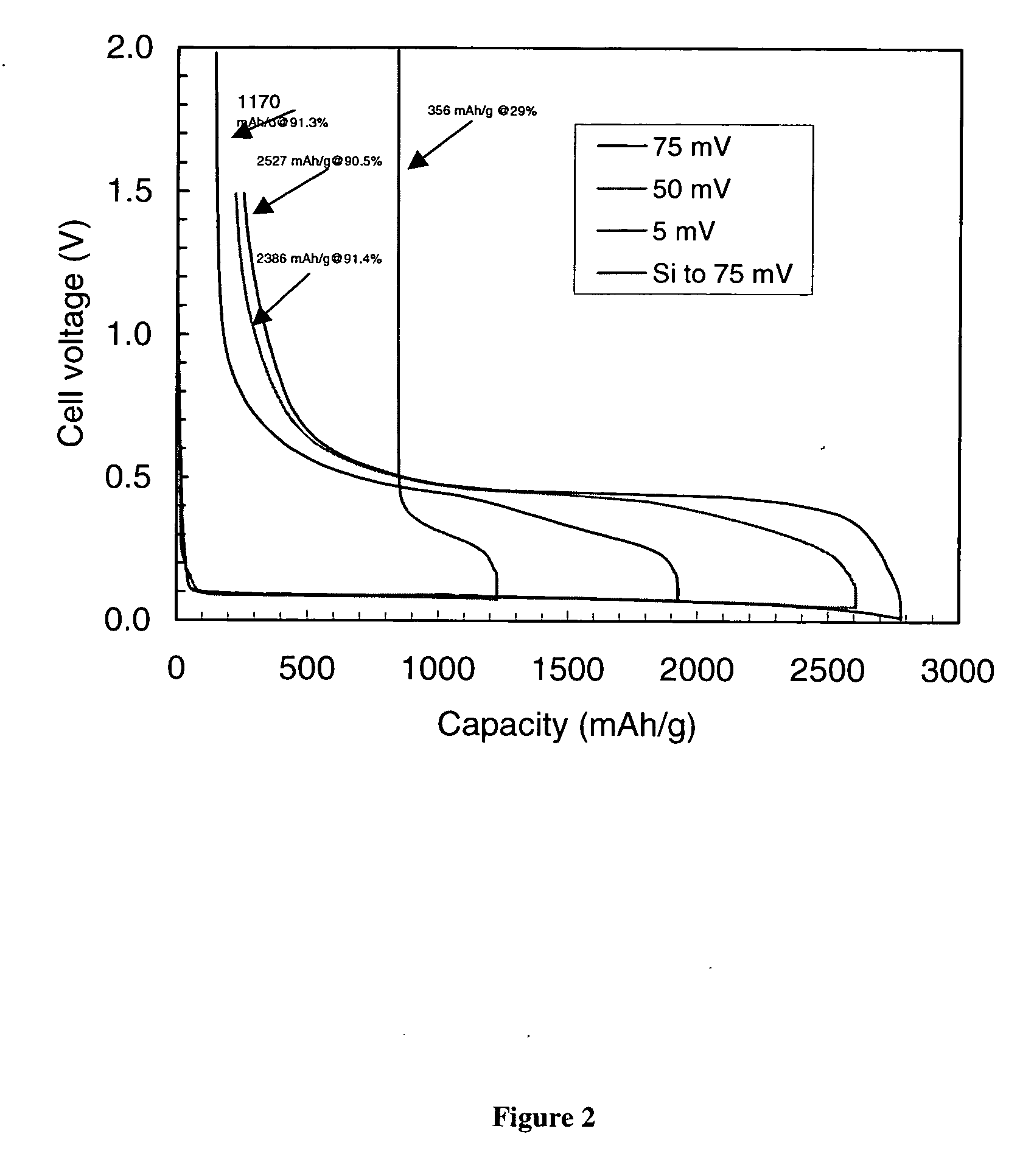

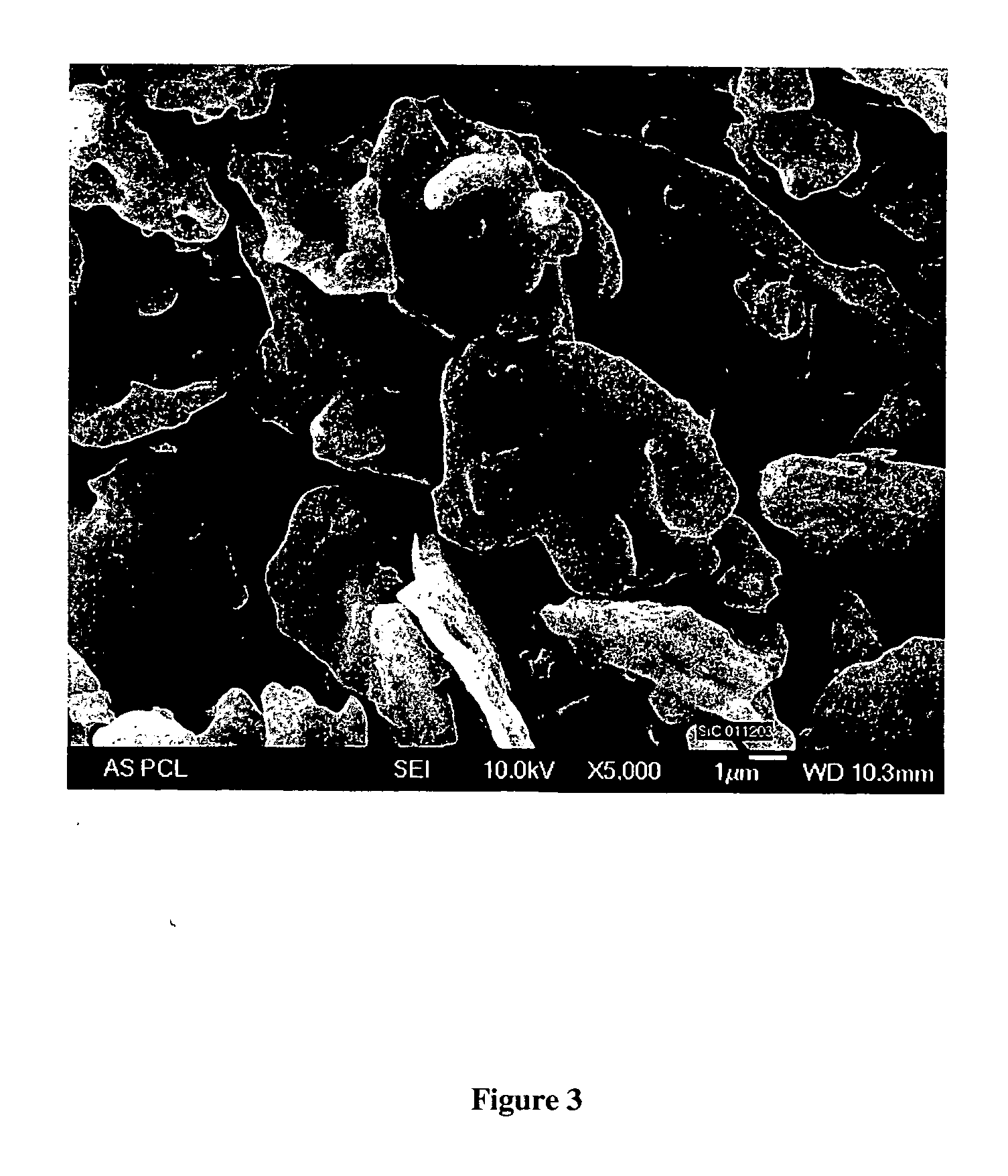

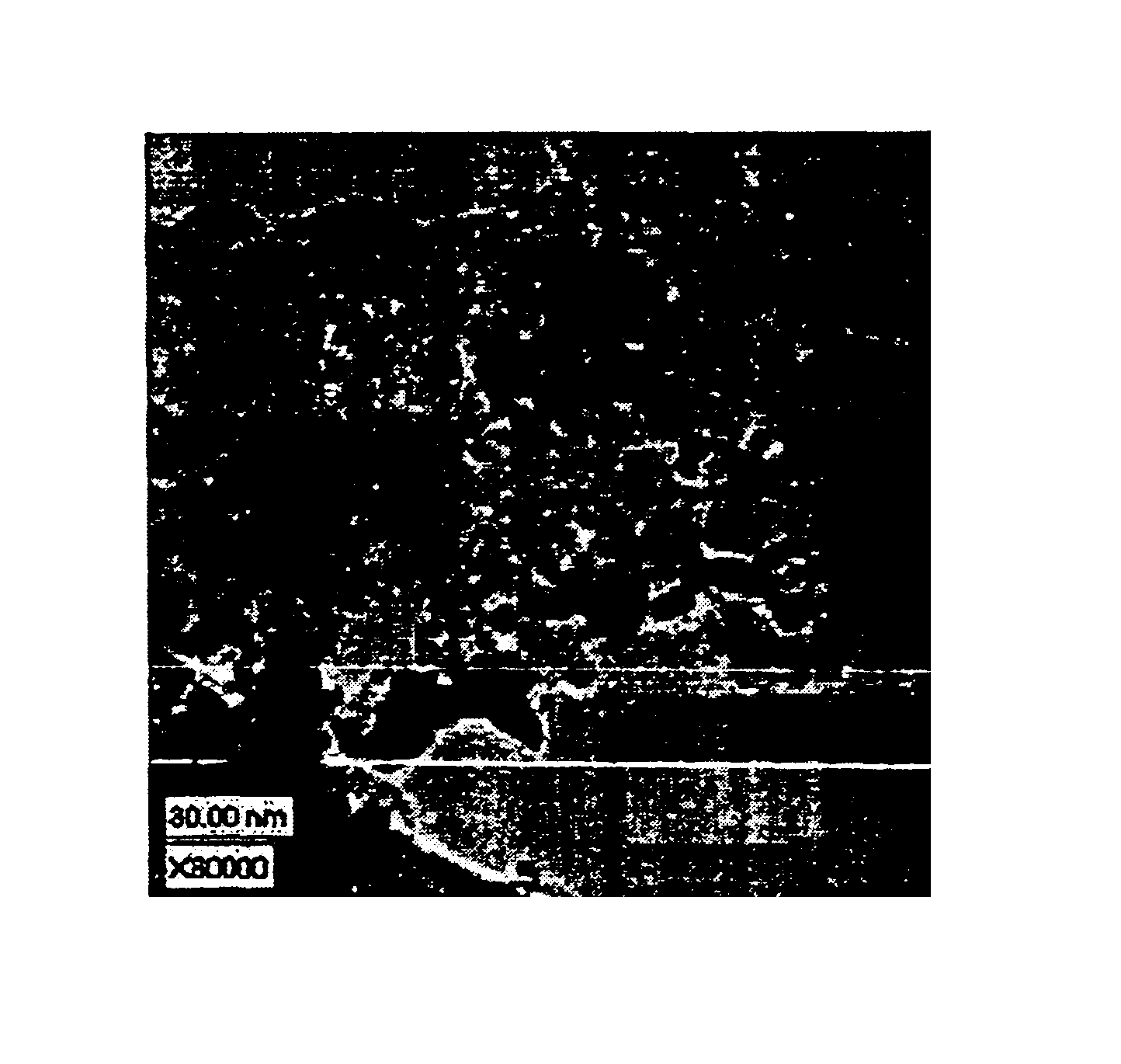

A process for the production of coated silicon / carbon particles comprising: providing a carbon residue forming material; providing silicon particles; coating said silicon particles with said carbon residue forming material to form coated silicon particles; providing particles of a carbonaceous material; coating said particles of carbonaceous material with said carbon residue forming material to form coated carbonaceous particles; embedding said coated silicon particles onto said coated carbonaceous particles to form silicon / carbon composite particles; coating said silicon / carbon composite particles with said carbon residue forming material to form coated silicon / carbon composite particles; and stabilizing the coated composite particles by subjecting said coated composite particles to an oxidation reaction. The coated composite particles will have a substantially smooth coating. The particles may be coated with multiple layers of carbon residue forming material /

Owner:PYROTECK INC

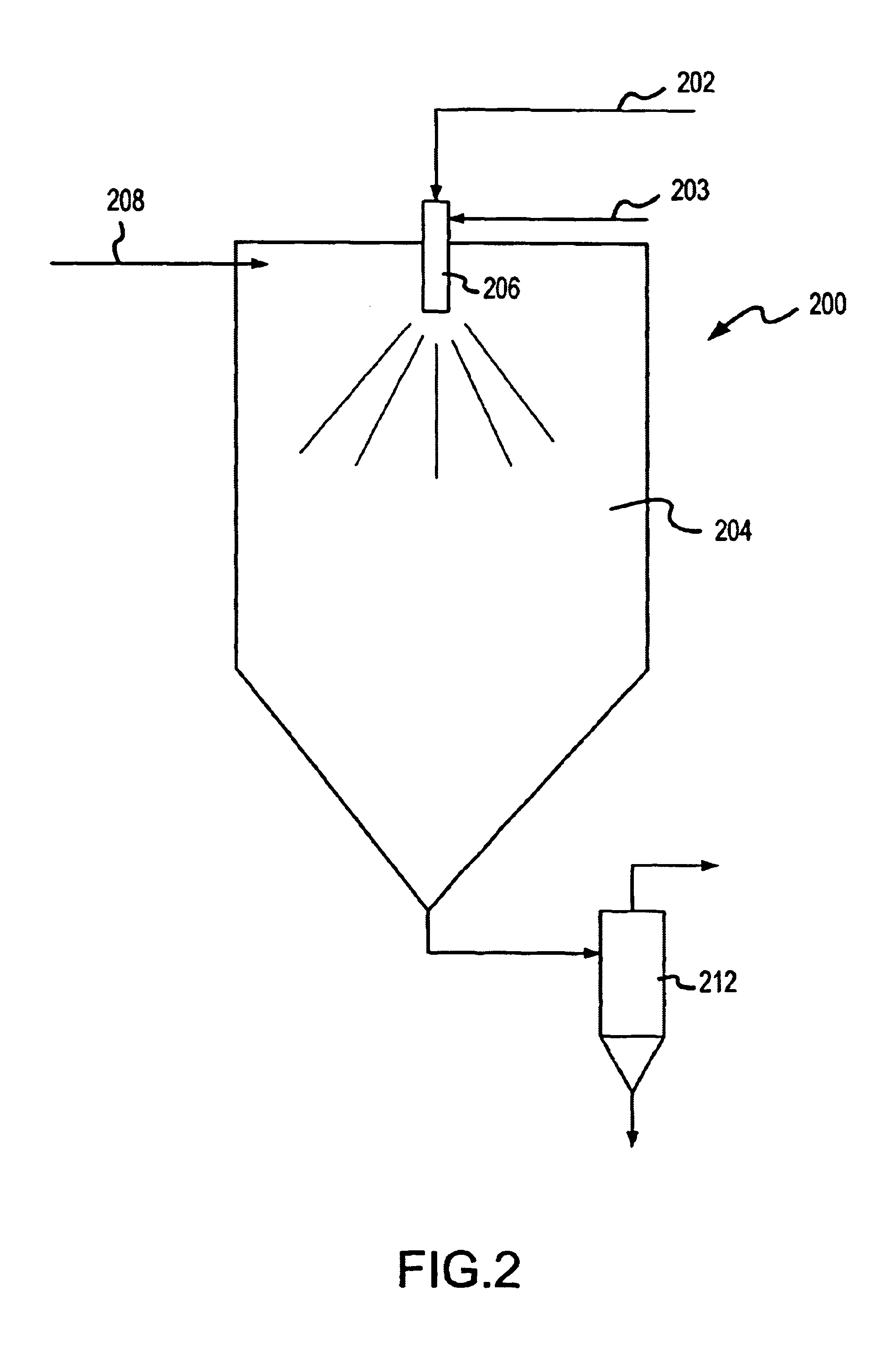

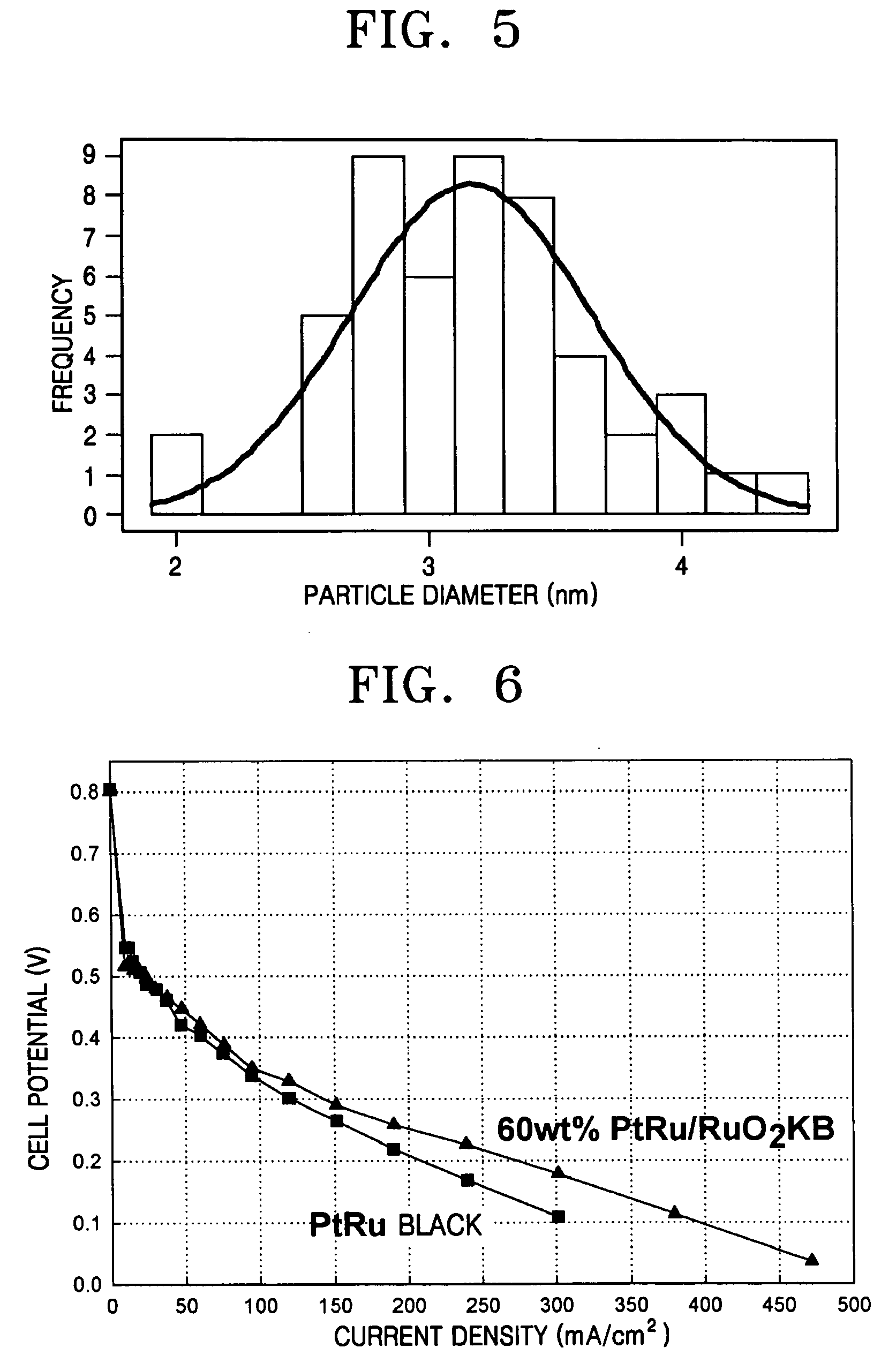

Electrocatalyst powders, methods for producing powders and devices fabricated from same

Electrocatalyst powders and methods for producing electrocatalyst powders, such as carbon composite electrocatalyst powders. The powders have a well-controlled microstructure and morphology. The method includes forming the particles from an aerosol of precursors by heating the aerosol to a relatively low temperature, such as not greater than about 400° C.

Owner:CABOT CORP

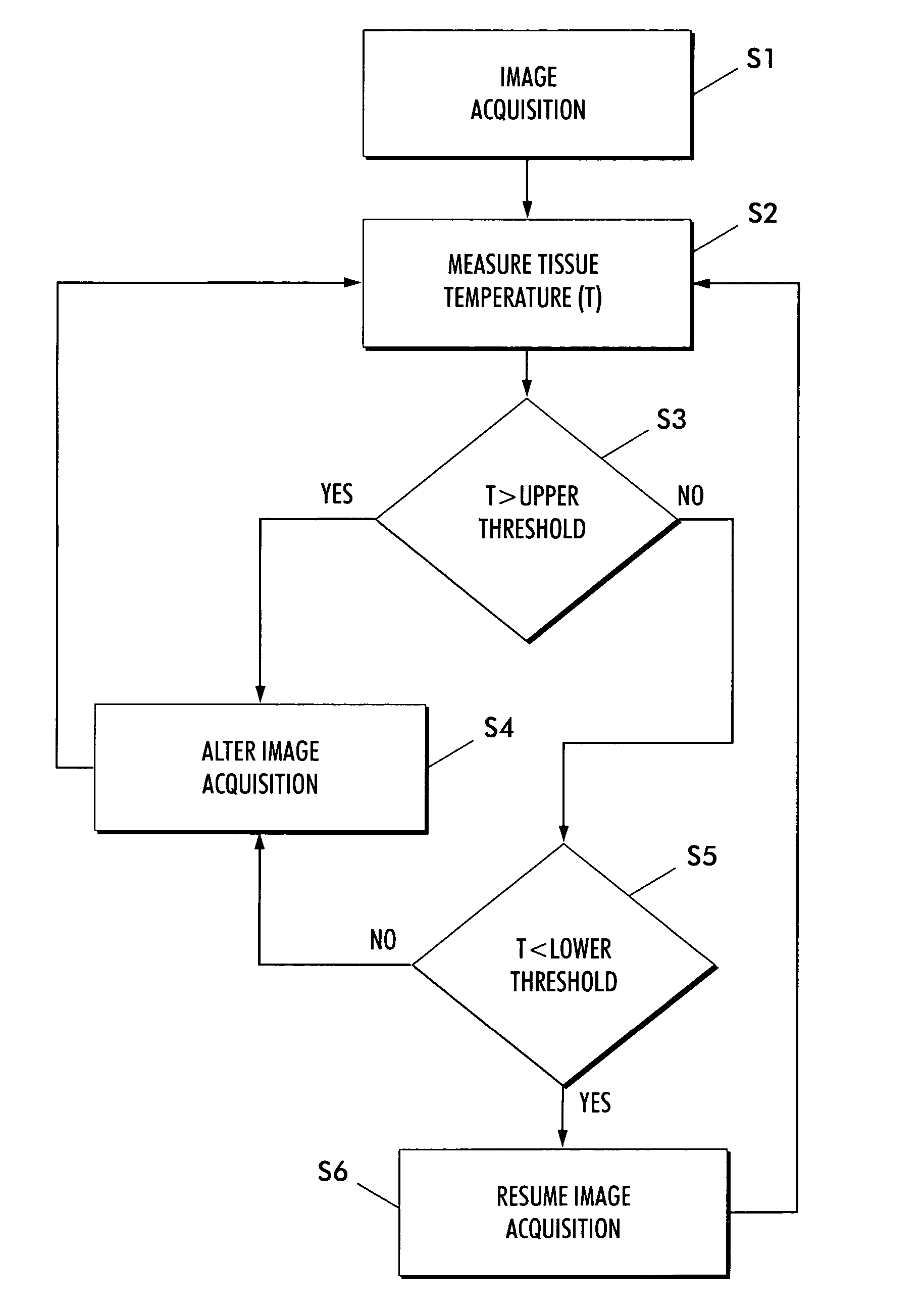

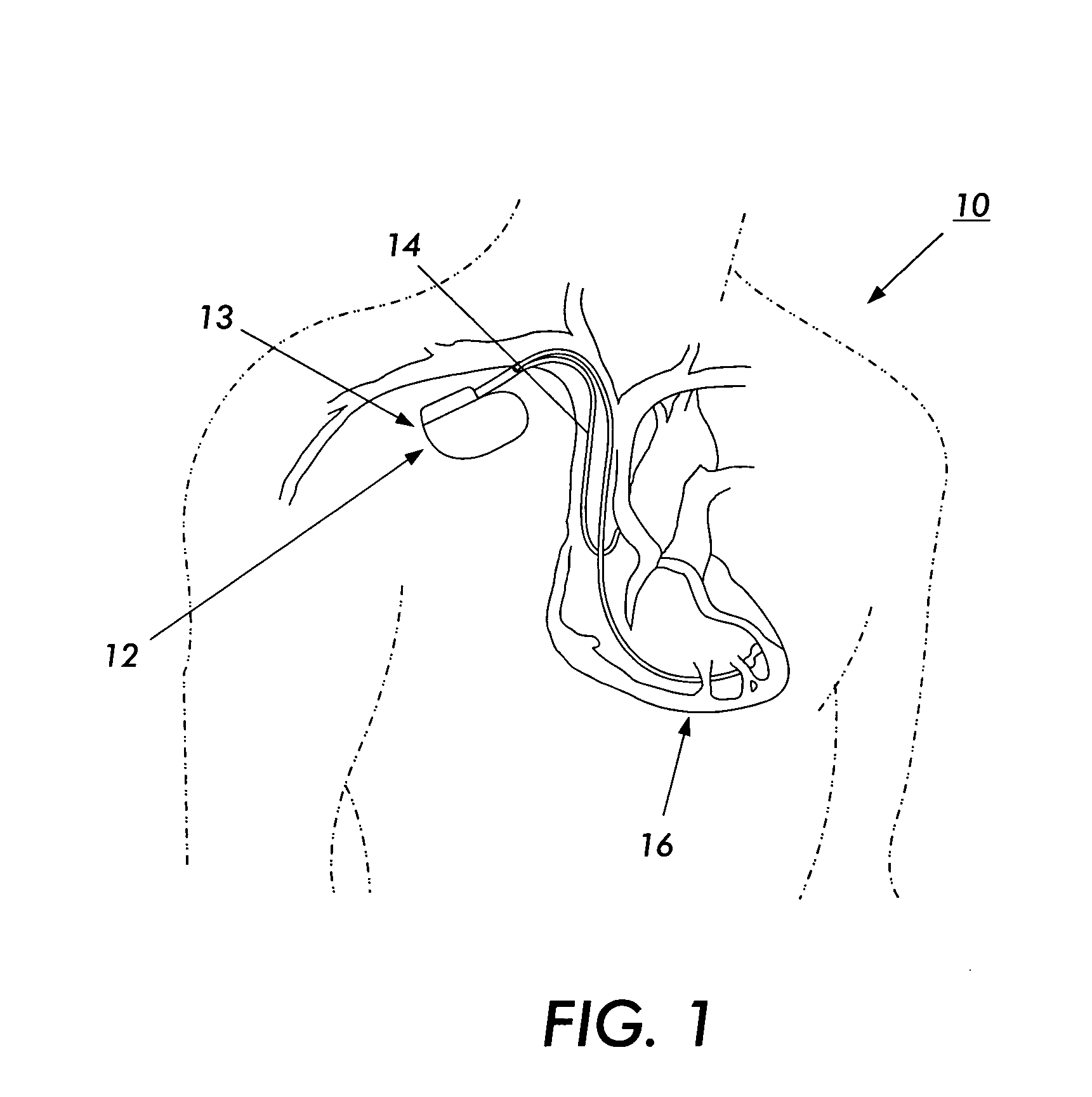

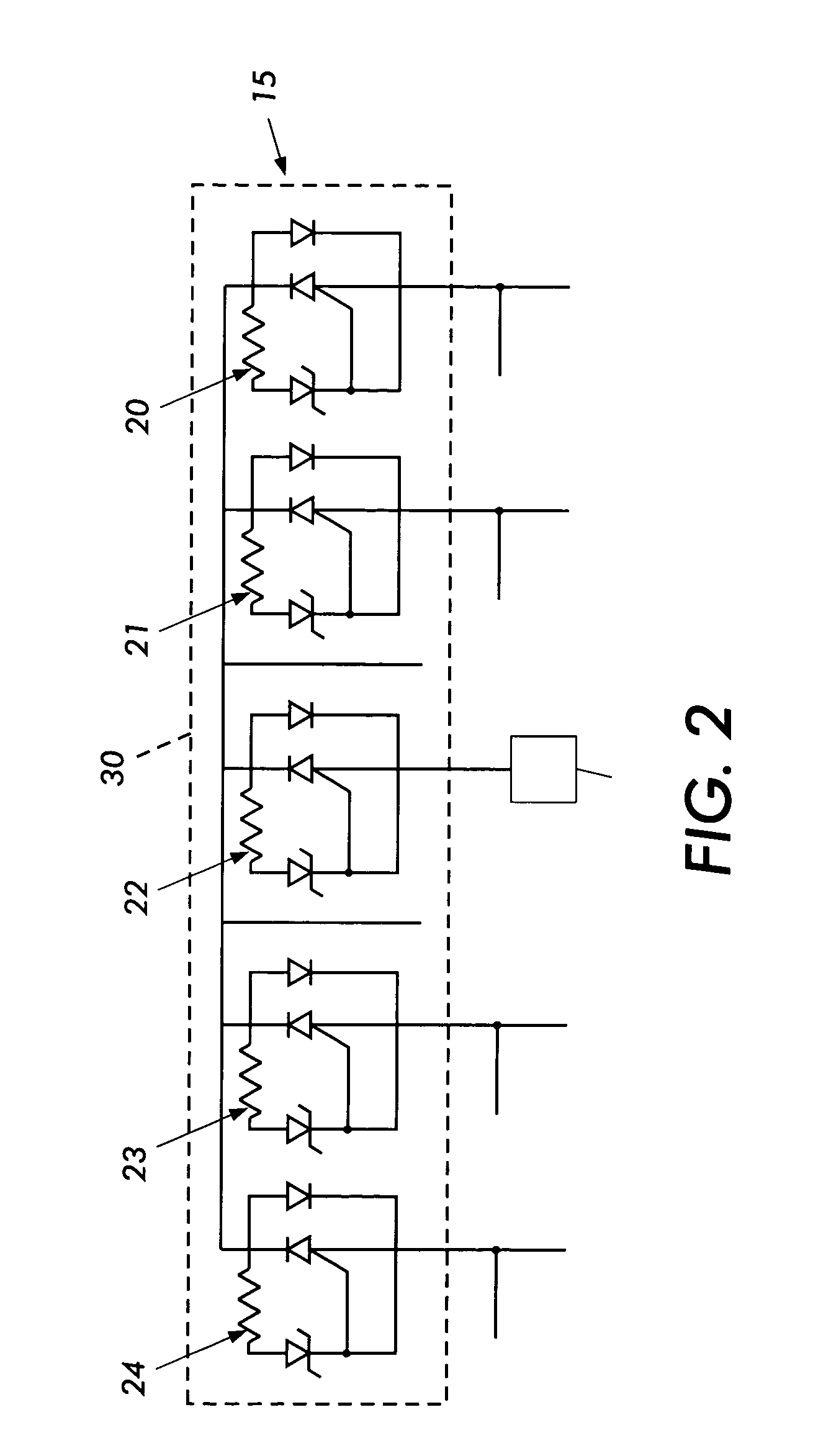

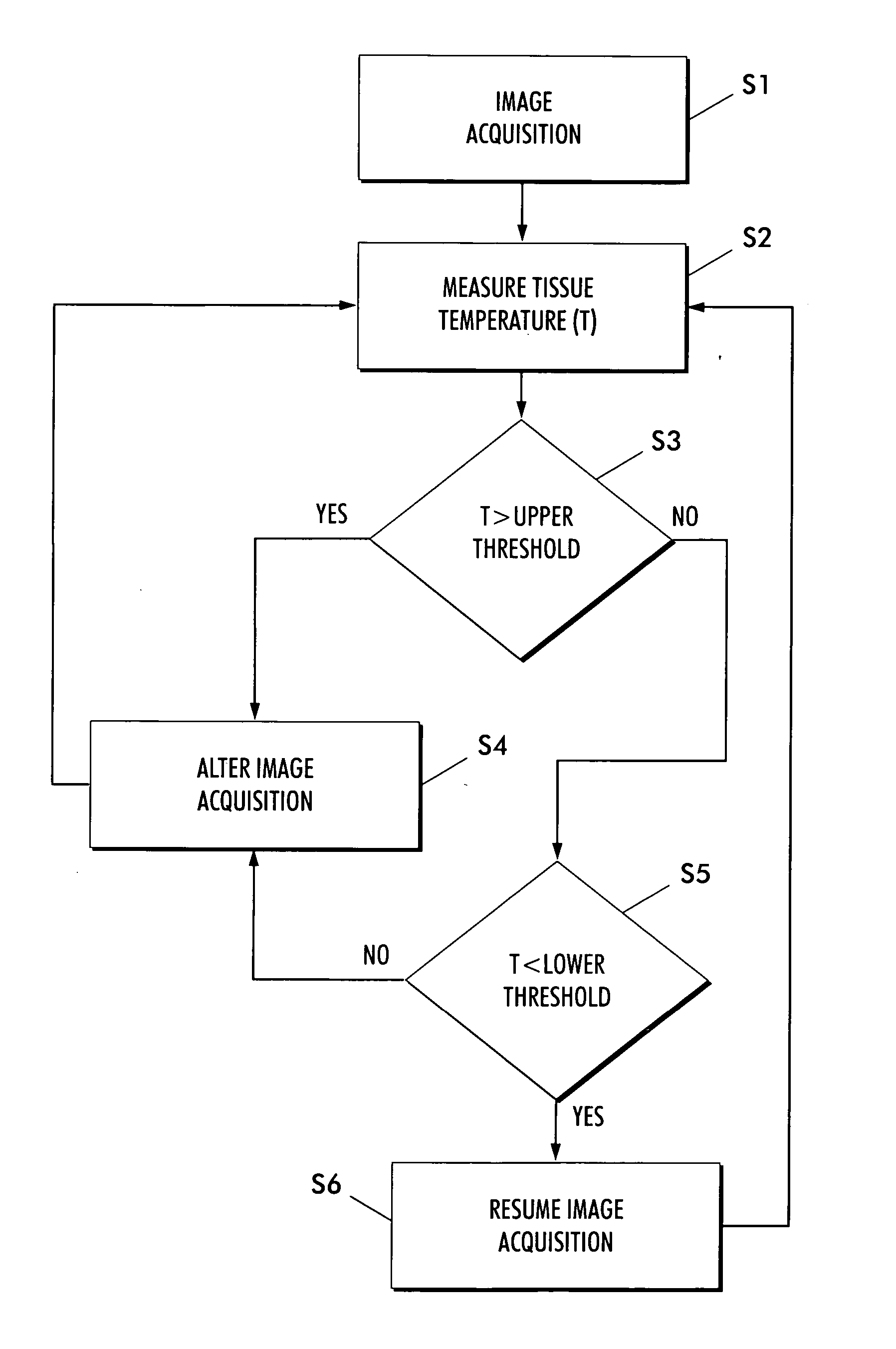

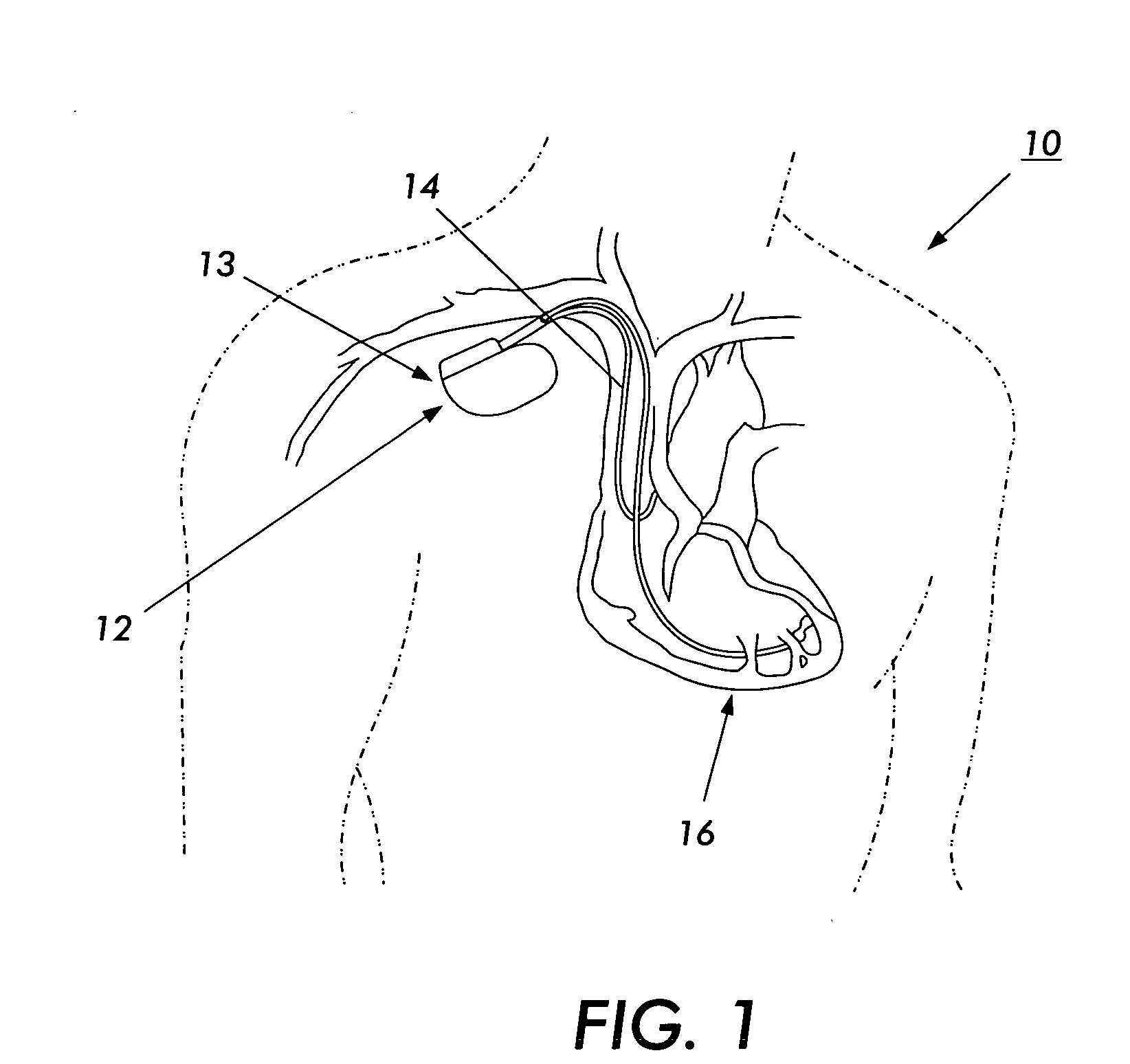

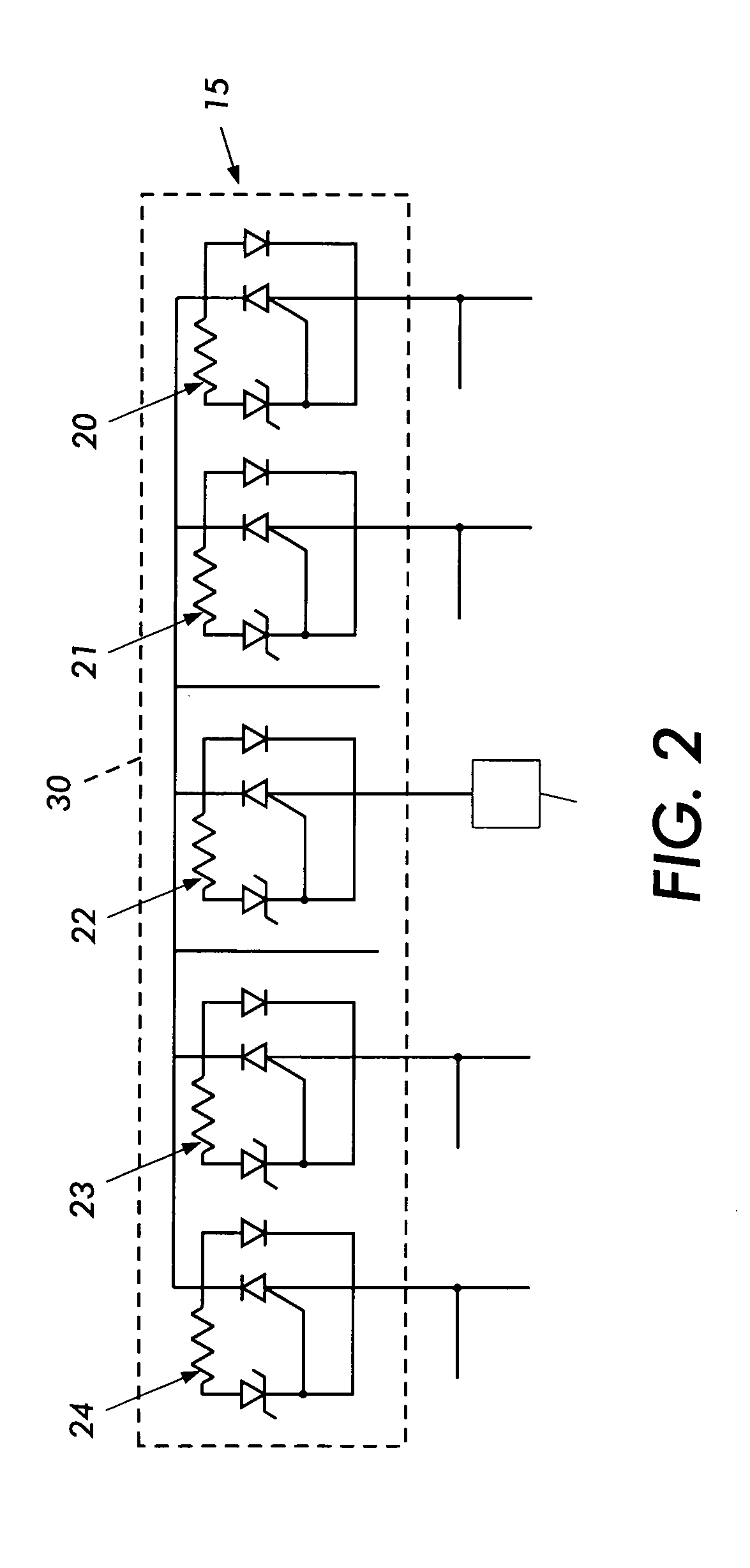

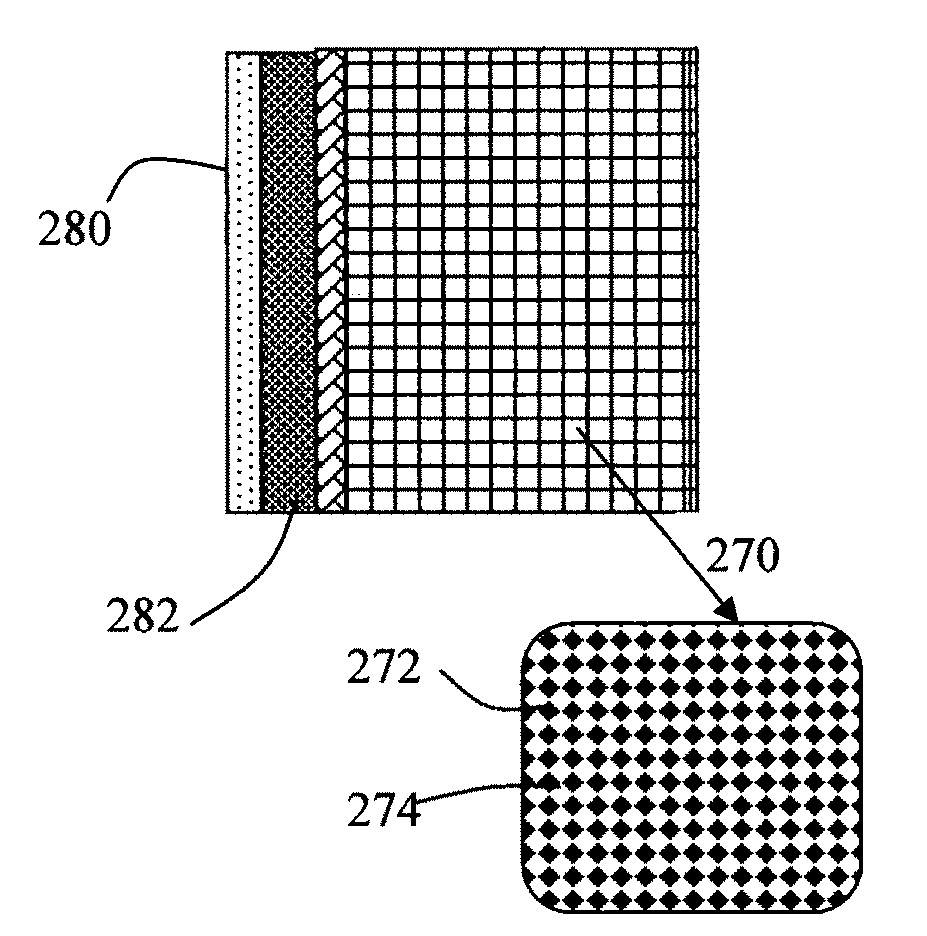

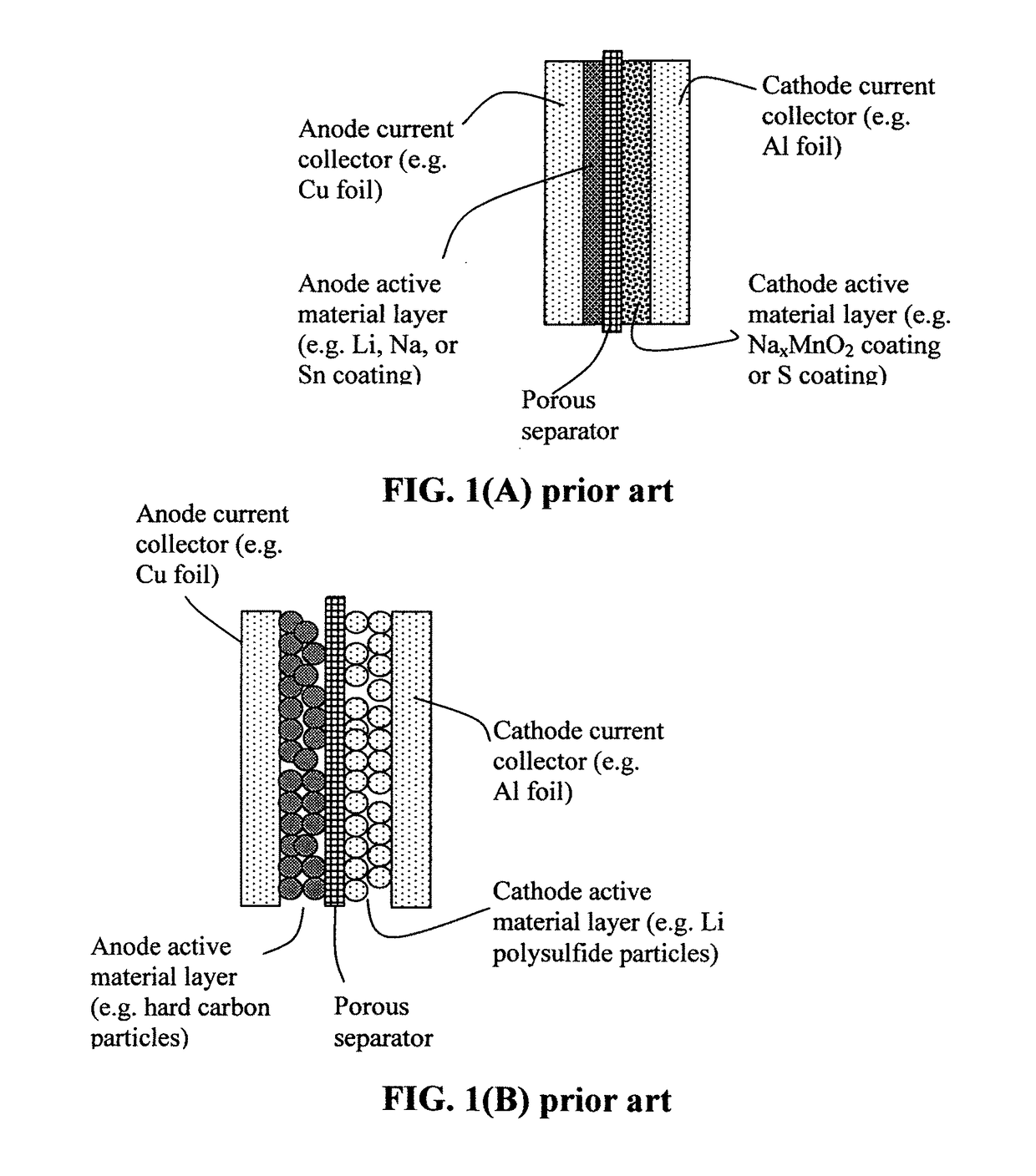

Device and method for preventing magnetic resonance imaging induced damage

An electromagnetic shield has a first patterned or apertured layer having non-conductive materials and conductive material and a second patterned or apertured layer having non-conductive materials and conductive material. The conductive material may be a metal, a carbon composite, or a polymer composite. The non-conductive materials in the first patterned or apertured layer may be randomly located or located in a predetermined segmented pattern such that the non-conductive materials in the first patterned or apertured layer are located in a predetermined segmented pattern with respect to locations of the non-conductive materials in the second patterned or apertured layer.

Owner:MEDTRONIC INC

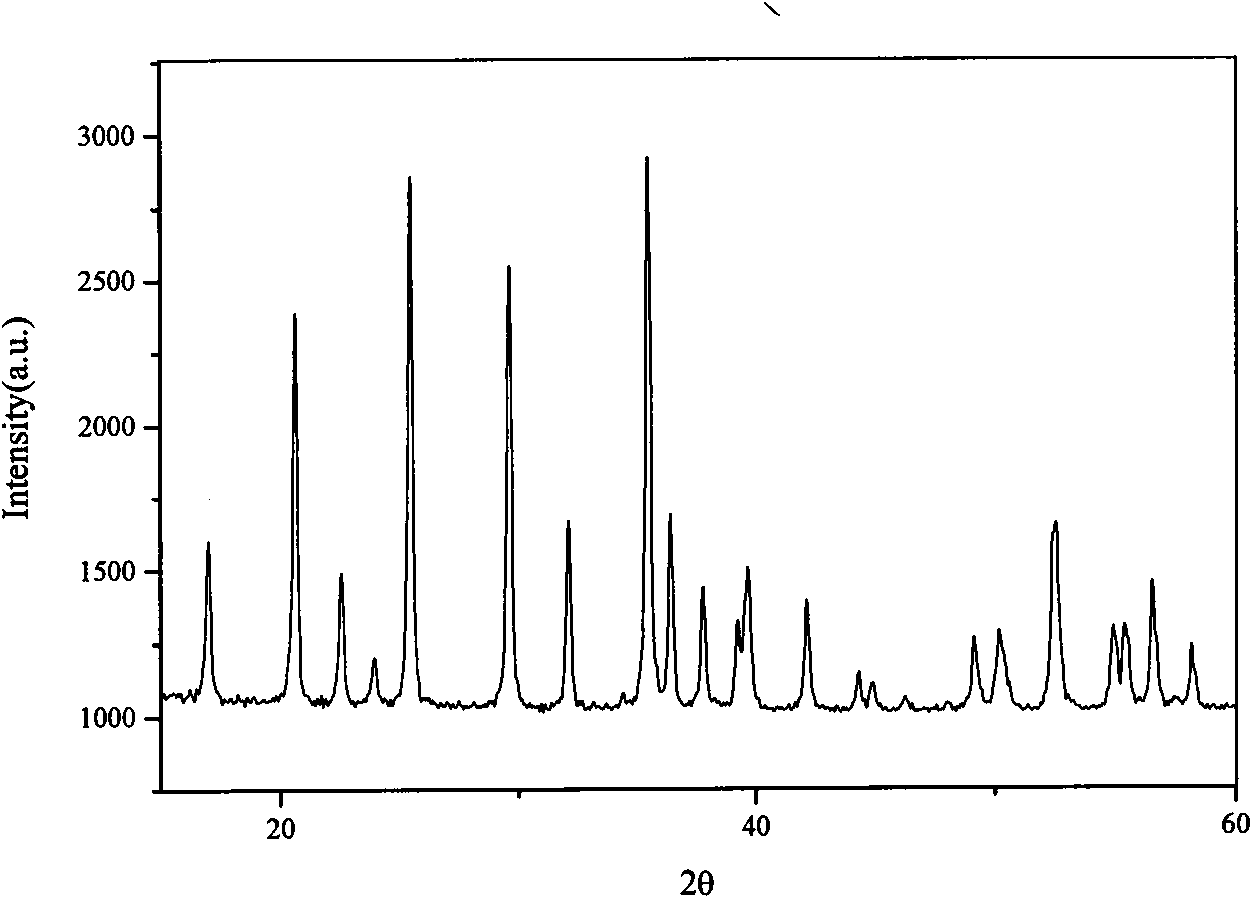

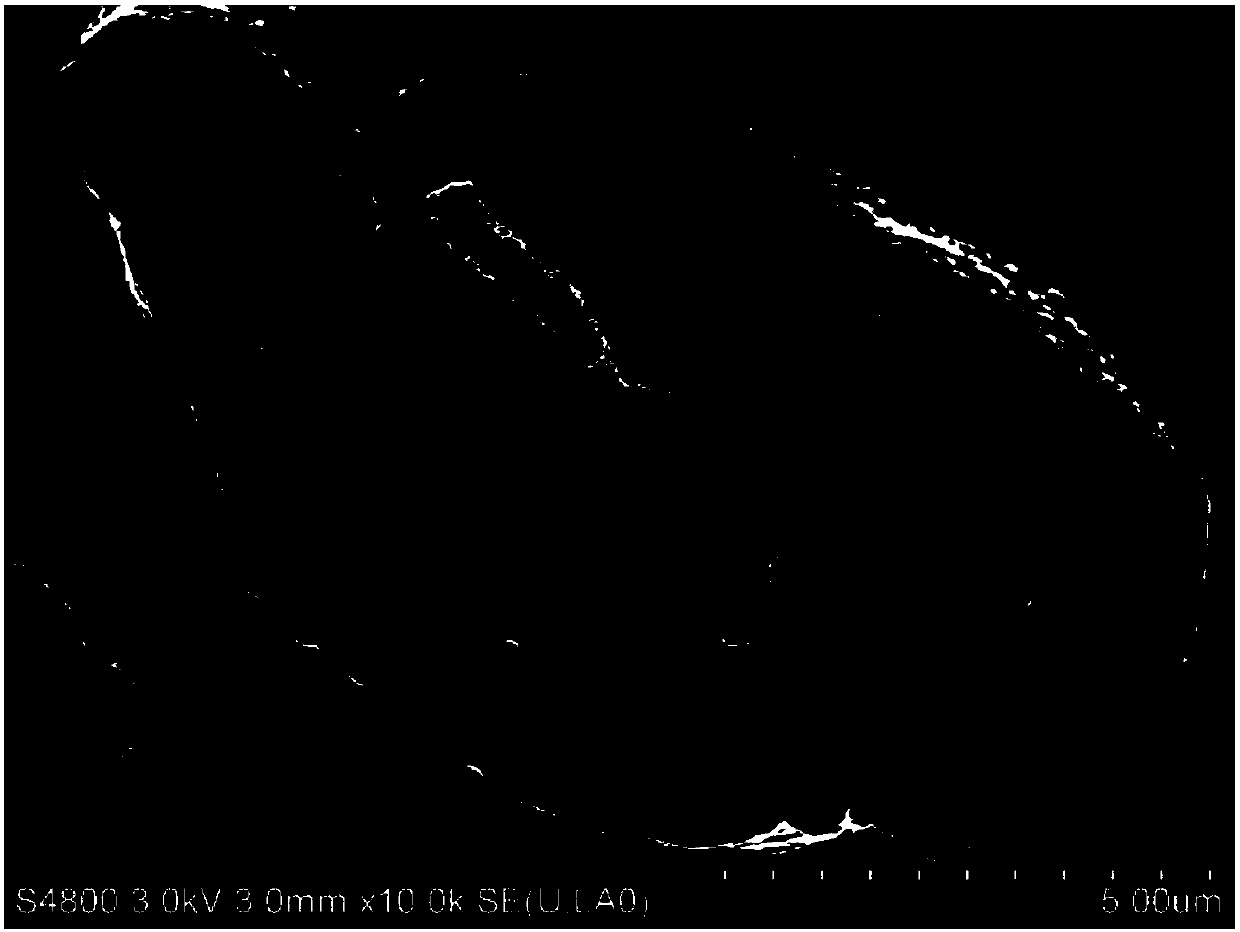

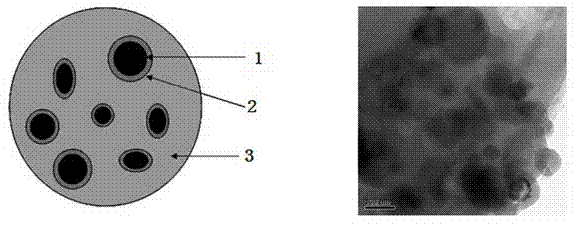

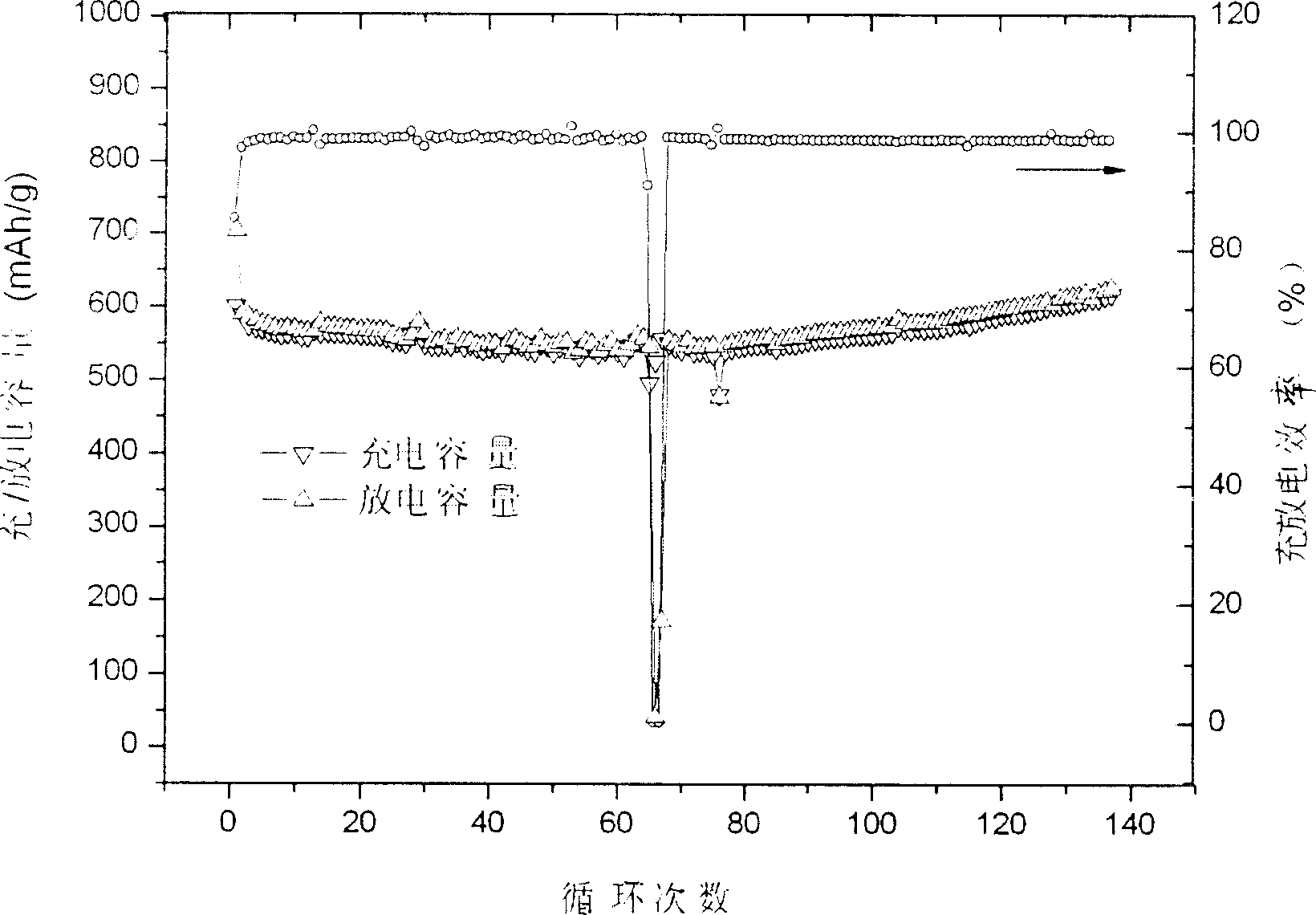

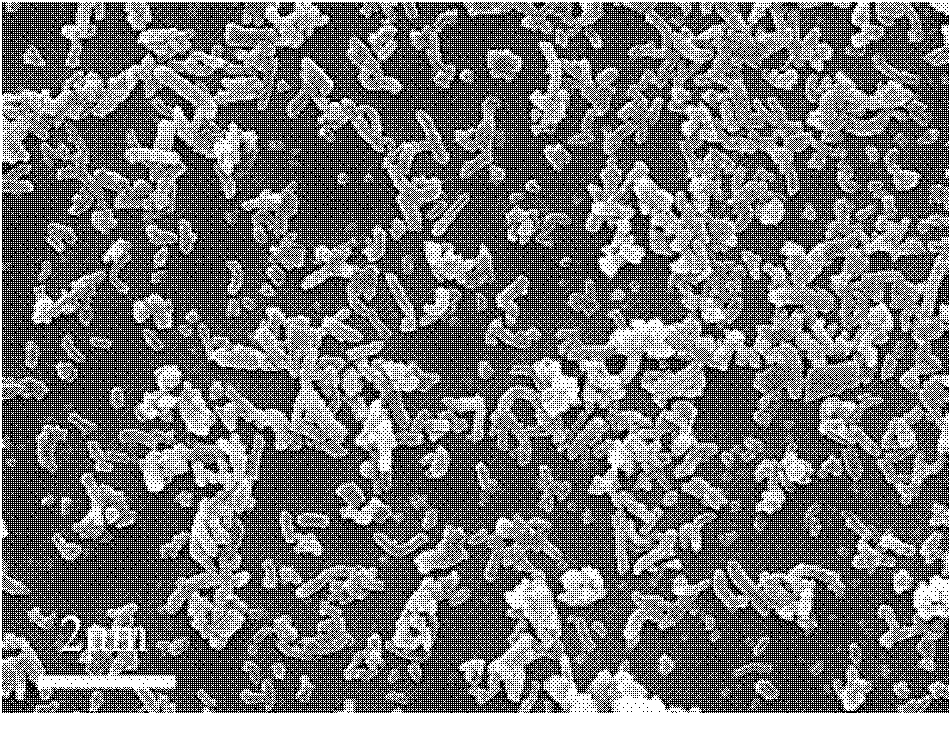

Carbon/silicon/carbon nano composite structure cathode material and preparation method thereof

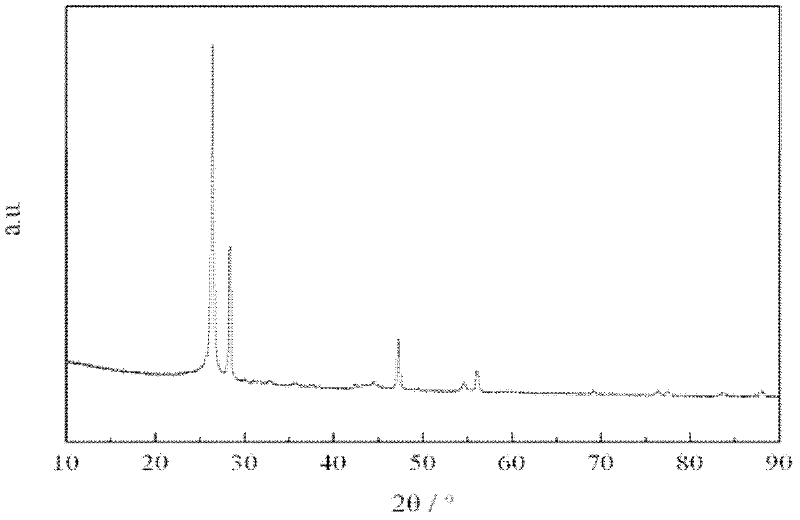

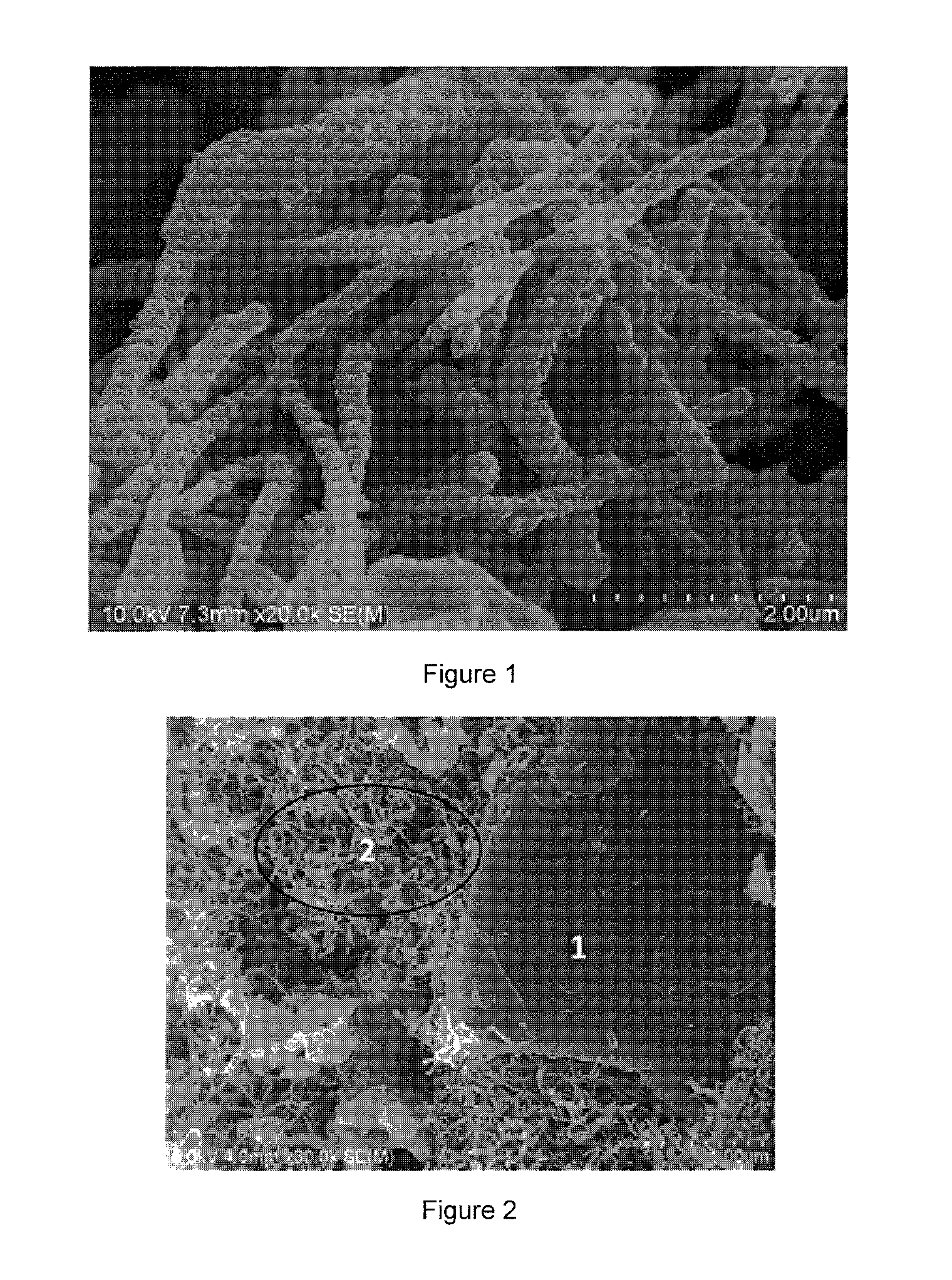

The invention discloses a carbon / silicon / carbon nano composite structure cathode material and a preparation method thereof, belonging to the technical field of electrochemical power supply technologies. The cathode material consists of a carbon-based conductive substrate, nano silicon and a nano carbon coating layer, wherein the nano silicon is uniformly distributed on the carbon-based conductive substrate; the nano carbon coating layer is arranged on the surface of the nano silicon; the carbon-based conductive substrate is porous carbon, a carbon nanotube or graphene; the nano silicon exists in the state of nanoparticles or nano films; the weight percentage of the nano silicon in the cathode material is 10-90 percent; and the thickness of the nano carbon coating layer is 0.1-10 nanometers. The preparation method comprises the following steps of: depositing nano silicon on the carbon substrate in a reaction space in oxygen-free atmosphere by adopting a chemical vapor deposition process; and coating nano carbon on the surface of the nano silicon by adopting the chemical vapor deposition process. In the obtained carbon / silicon / carbon composite cathode material, the volume change of a silicon electrode material is controlled effectively in the charging and discharging processes, the electrode structure is kept complete, the circulation volume is large, the circulation service life is long, and the electrochemical performance is high.

Owner:TSINGHUA UNIV

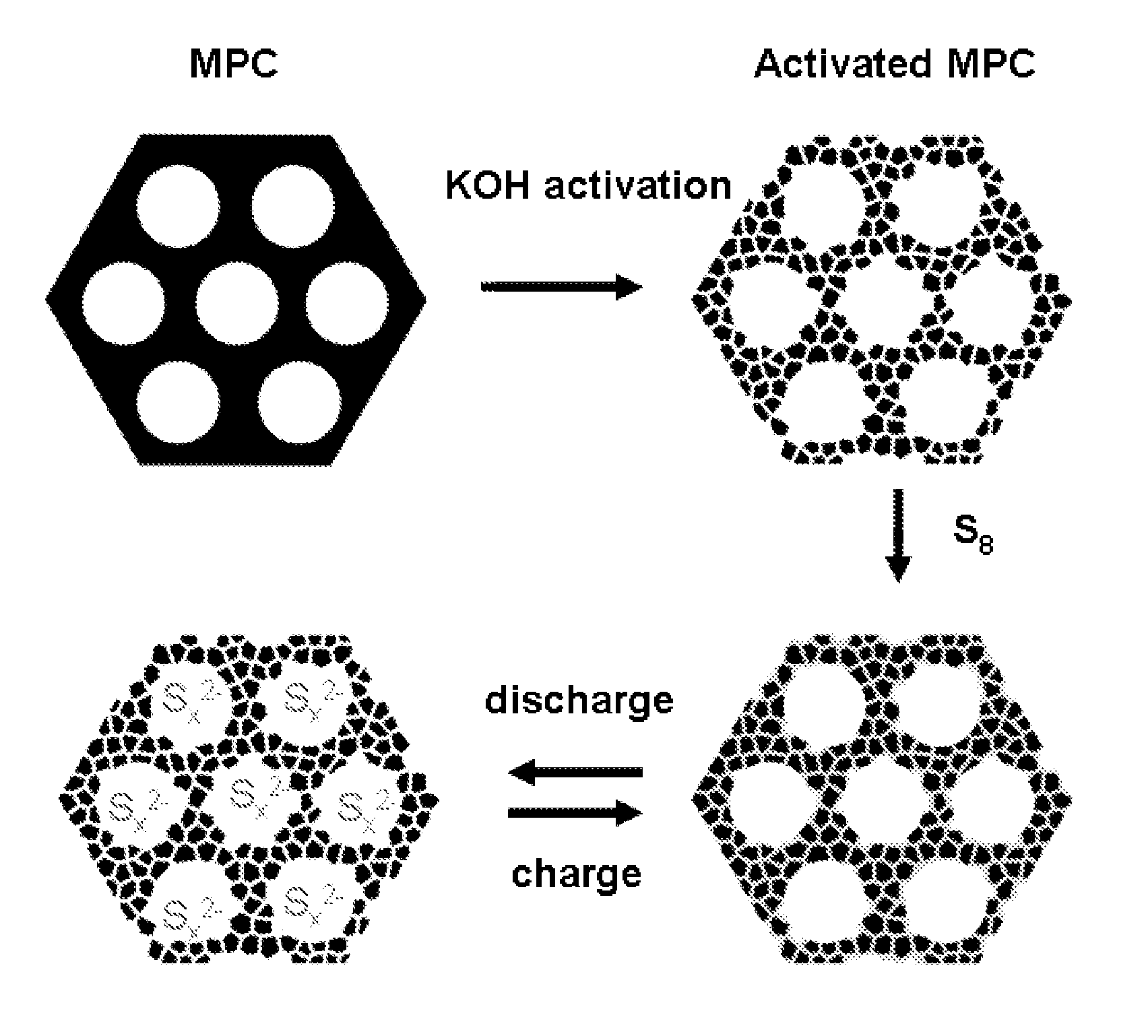

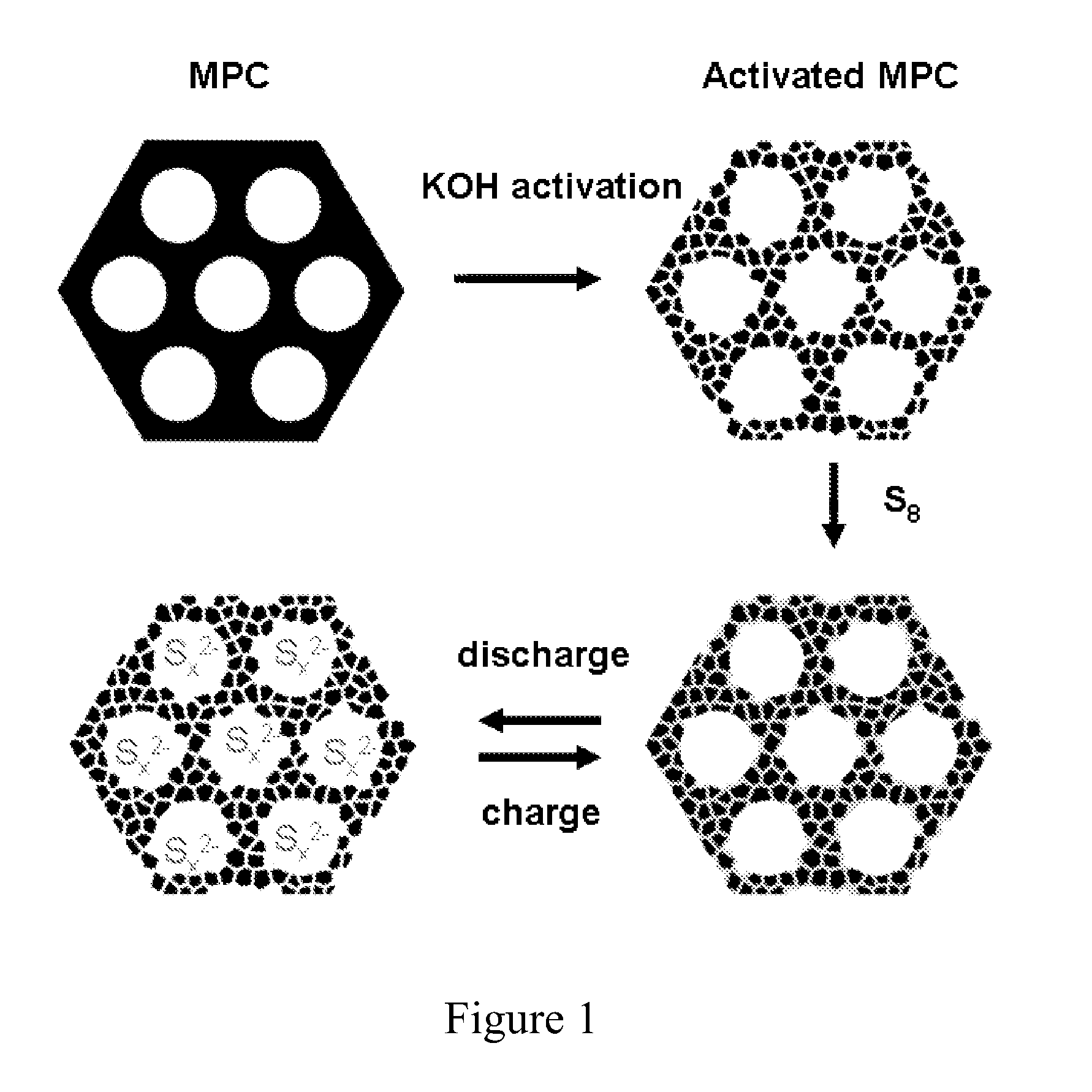

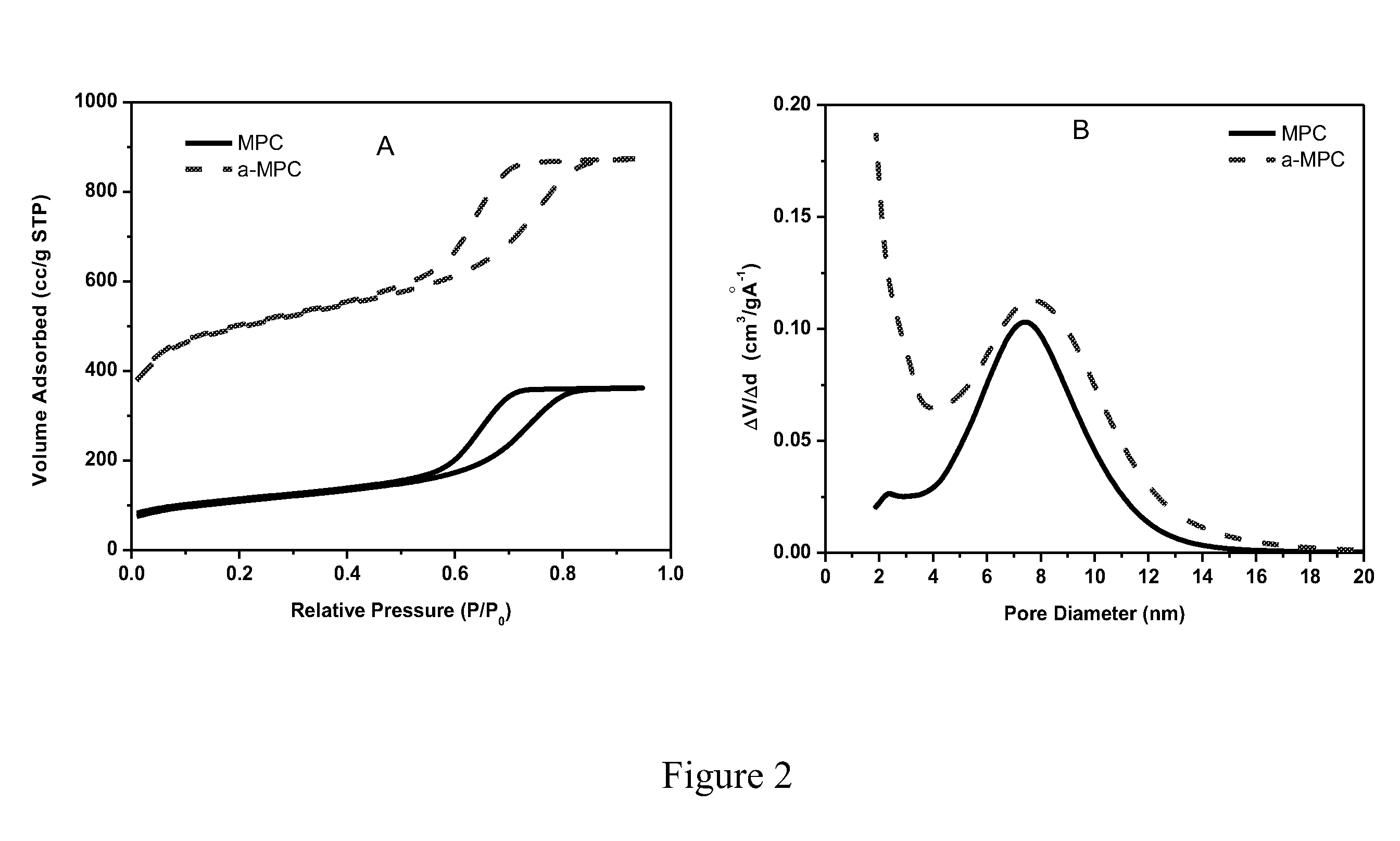

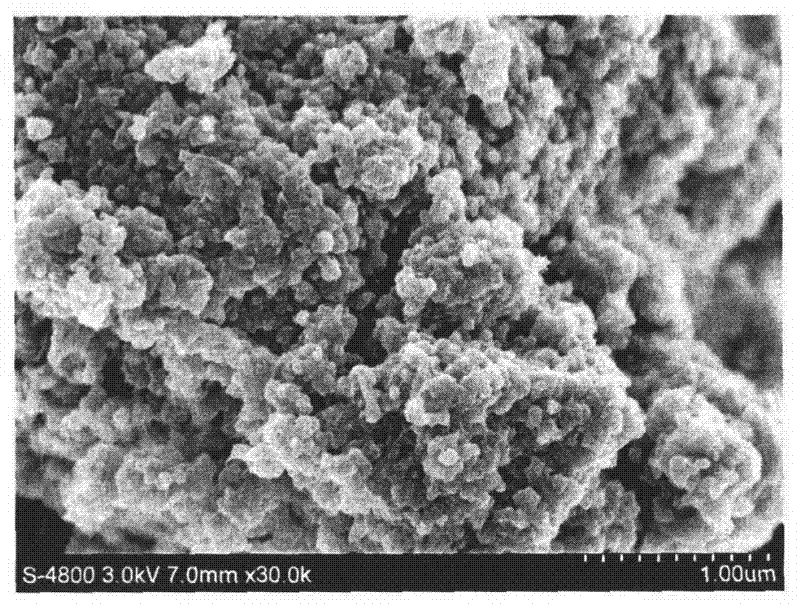

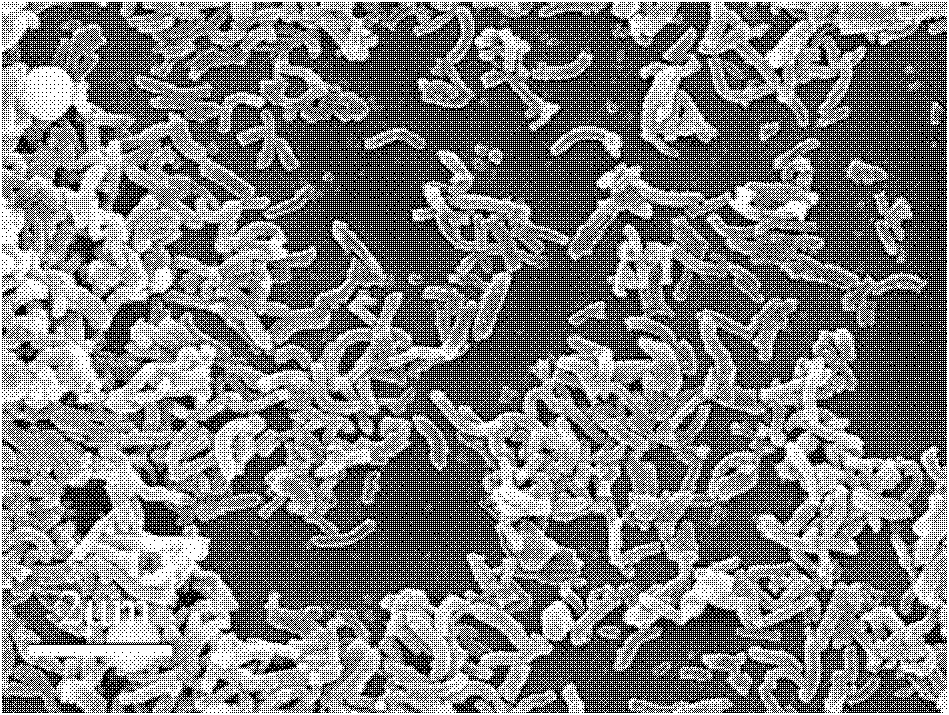

Sulfur-carbon nanocomposites and their application as cathode materials in lithium-sulfur batteries

ActiveUS20110052998A1Minimize formationEasy to transportAlkaline accumulatorsElectrode thermal treatmentCarbon compositesPorous carbon

The invention is directed in a first aspect to a sulfur-carbon composite material comprising: (i) a bimodal porous carbon component containing therein a first mode of pores which are mesopores, and a second mode of pores which are micropores; and (ii) elemental sulfur contained in at least a portion of said micropores. The invention is also directed to the aforesaid sulfur-carbon composite as a layer on a current collector material; a lithium ion battery containing the sulfur-carbon composite in a cathode therein; as well as a method for preparing the sulfur-composite material.

Owner:UT BATTELLE LLC

Device and method for preventing magnetic-resonance imaging induced damage

An electromagnetic shield has a first patterned or apertured layer having non-conductive materials and conductive material and a second patterned or apertured layer having non-conductive materials and conductive material. The conductive material may be a metal, a carbon composite, or a polymer composite. The non-conductive materials in the first patterned or apertured layer may be randomly located or located in a predetermined segmented pattern such that the non-conductive materials in the first patterned or apertured layer are located in a predetermined segmented pattern with respect to locations of the non-conductive materials in the second patterned or apertured layer.

Owner:MEDTRONIC INC

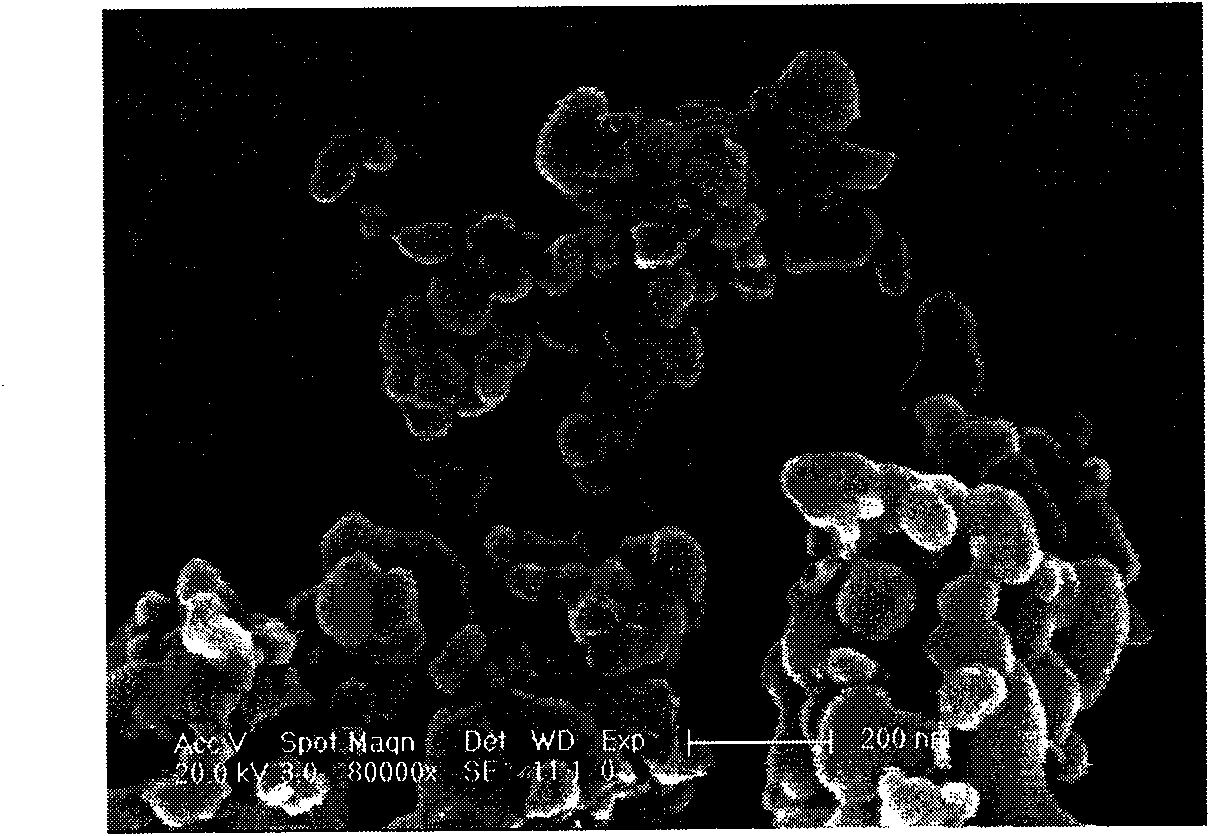

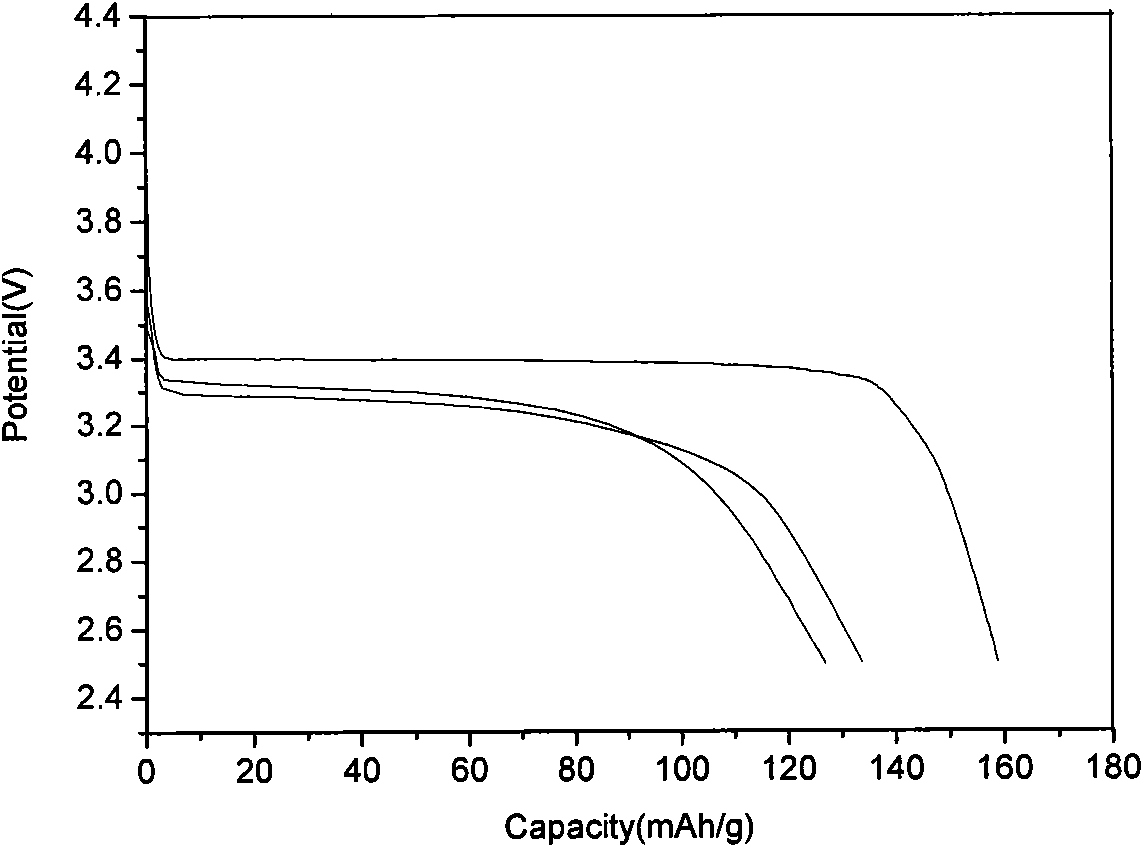

Method for preparing nanometer ferrous phosphate lithium /carbon composite material

InactiveCN101582498ARich sourcesLow priceElectrode manufacturing processesCapacitanceCarbon composites

The invention belongs to energy materials, particularly relating to a method for preparing nanometer ferrous phosphate lithium / carbon composite material. In the invention, ferrous source, lithium source, phosphorus source are mixed with a small quantity of doped metal salt and organic macromolecular polymer carbon source according to certain ratio followed by the steps of ball milling, parching and calcining. High temperature sintering is carried out on the above mixture in the atmosphere of non-oxidation gas to obtain nanometer lithium iron phosphate LiMxFe(1-x)PO4 / C coated with carbon and LiFe(1-x)NxPO4 / C material, and the particle sizes of which are remarkably reduced and are less than 100nm. When the material is applied to battery assemble, 0.2C multiplying power discharge capacity can reach above 160mAh / g at room temperature, 1C multiplying power discharge capacity can be 140-155mAh / g, and 5C multiplying power discharge capacity is 130-150mAh / g. the initial capacity is 120-140mAh / g under the large multiplying power of 10C, and remains more than 90% through thousands of cycles, demonstrating good multiplying power and cycle properties. The invention features low cost, simple production process and fine safety. The prepared nanometer ferrous phosphate lithium / carbon composite material can be widely applied into manufacturing of convenient and fast equipment, electric vehicles and the like.

Owner:NORTHEAST NORMAL UNIVERSITY

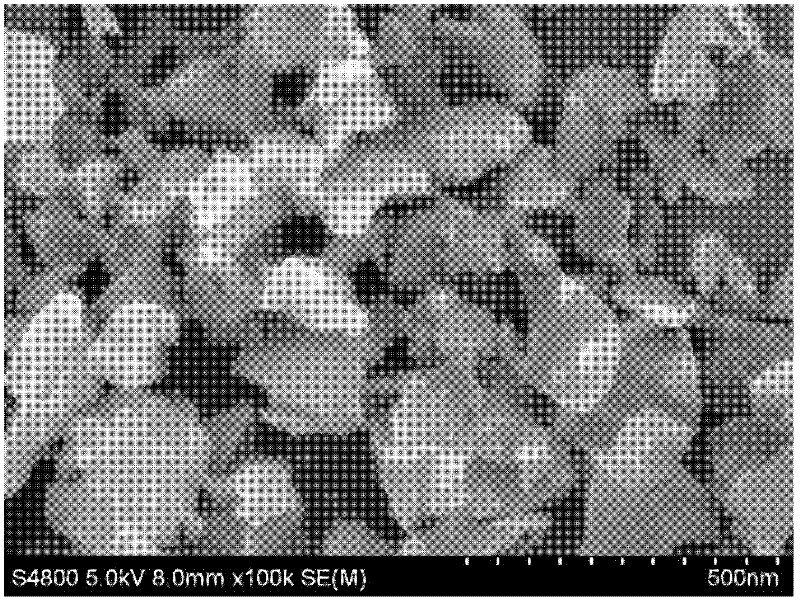

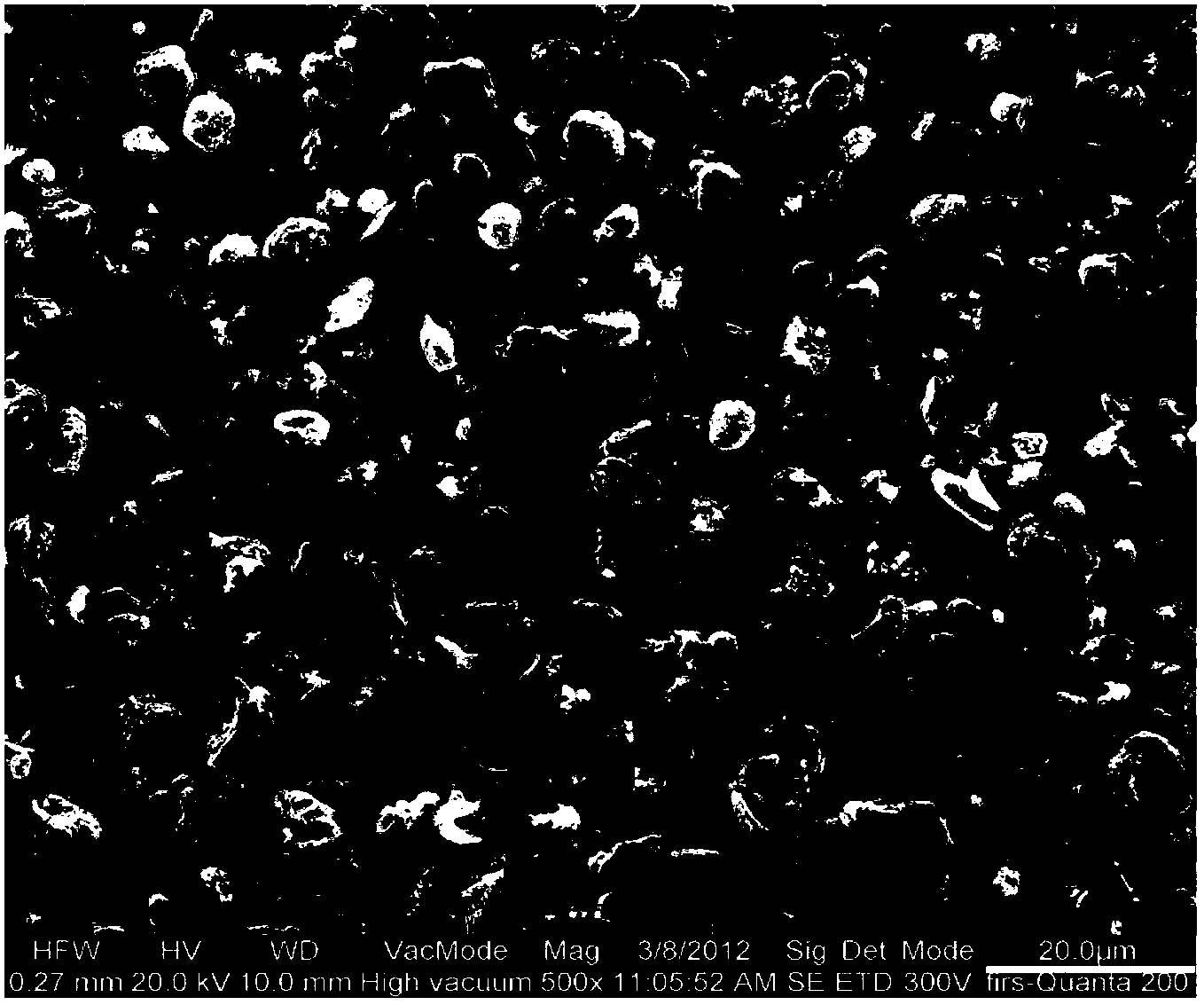

Silicon-carbon composite negative electrode material for lithium ion battery and preparation method thereof

ActiveCN103474667AImprove cycle performanceHigh charge and discharge capacityMaterial nanotechnologyCell electrodesCarbon compositesCarbon layer

The invention relates to a silicon-carbon composite negative electrode material and a preparation method thereof. The silicon-carbon composite negative electrode material successively comprises nano silicon / graphite particles, a first carbon coating layer and an organic cracking carbon layer from inside to outside. The nano silicon / graphite particles are globular or globular-like composite particles formed by employing graphite as an inner core of a volume expansion buffer substrate and coating a nano silicon particle layer; the first carbon coating layer comprises carbon nanotubes and / or amorphous carbon, the carbon nanotubes and / or amorphous carbon are interspersed in a gap network formed by gaps of the nano silicon particles and / or are coated outside the nano silicon particle layer, so that the nano silicon is tightly wrapped between the carbon nanotubes and / or between the carbon nanotubes and the graphite substrate, and besides, the material ion conductivity is effectively enhanced; the organic cracking carbon layer is an outermost coating layer of the silicon-carbon composite negative electrode material. The silicon-carbon composite negative electrode material has excellent cycle performance, excellent multiplying power charging and discharging performance and lower volume expansion effect.

Owner:BTR NEW MATERIAL GRP CO LTD

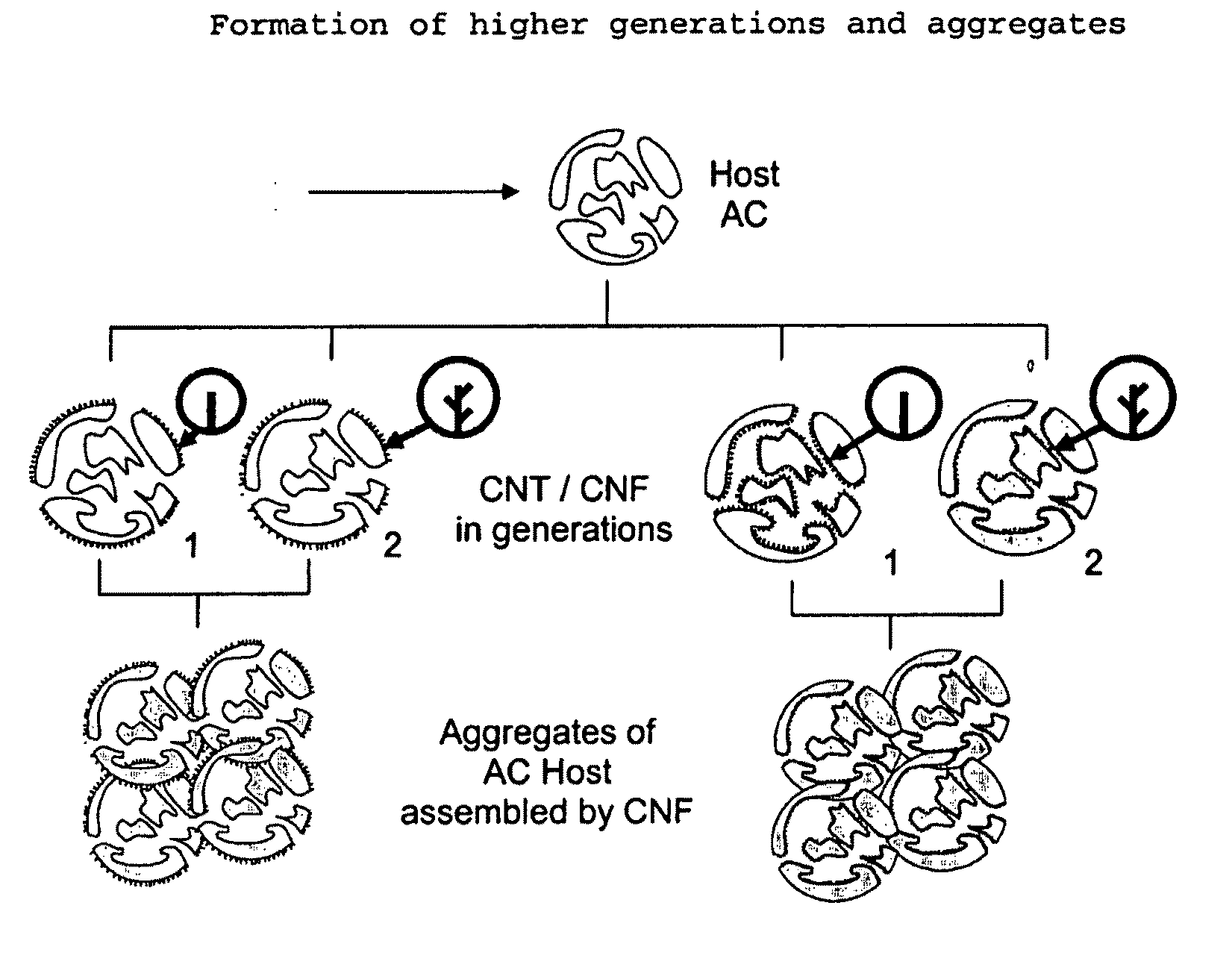

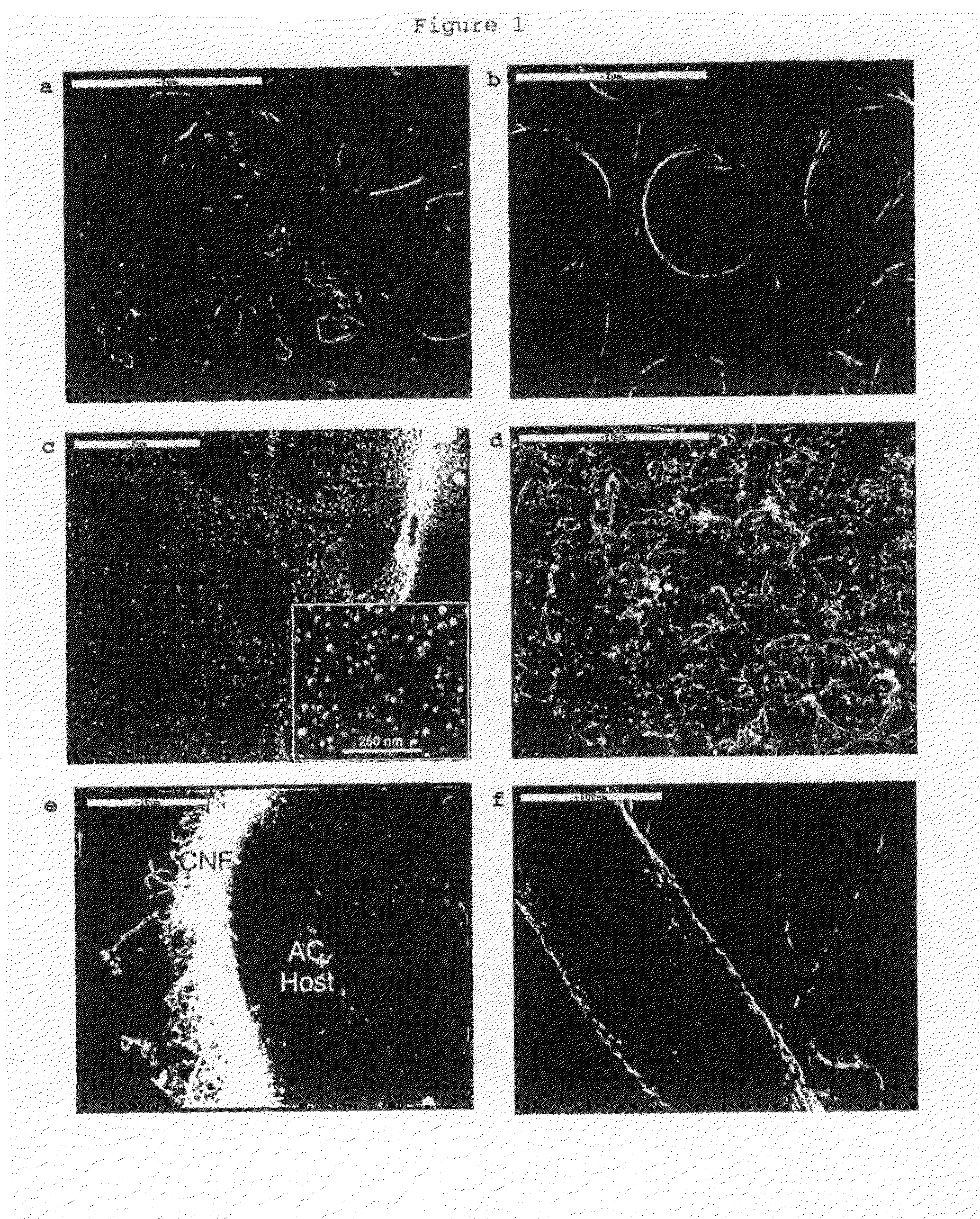

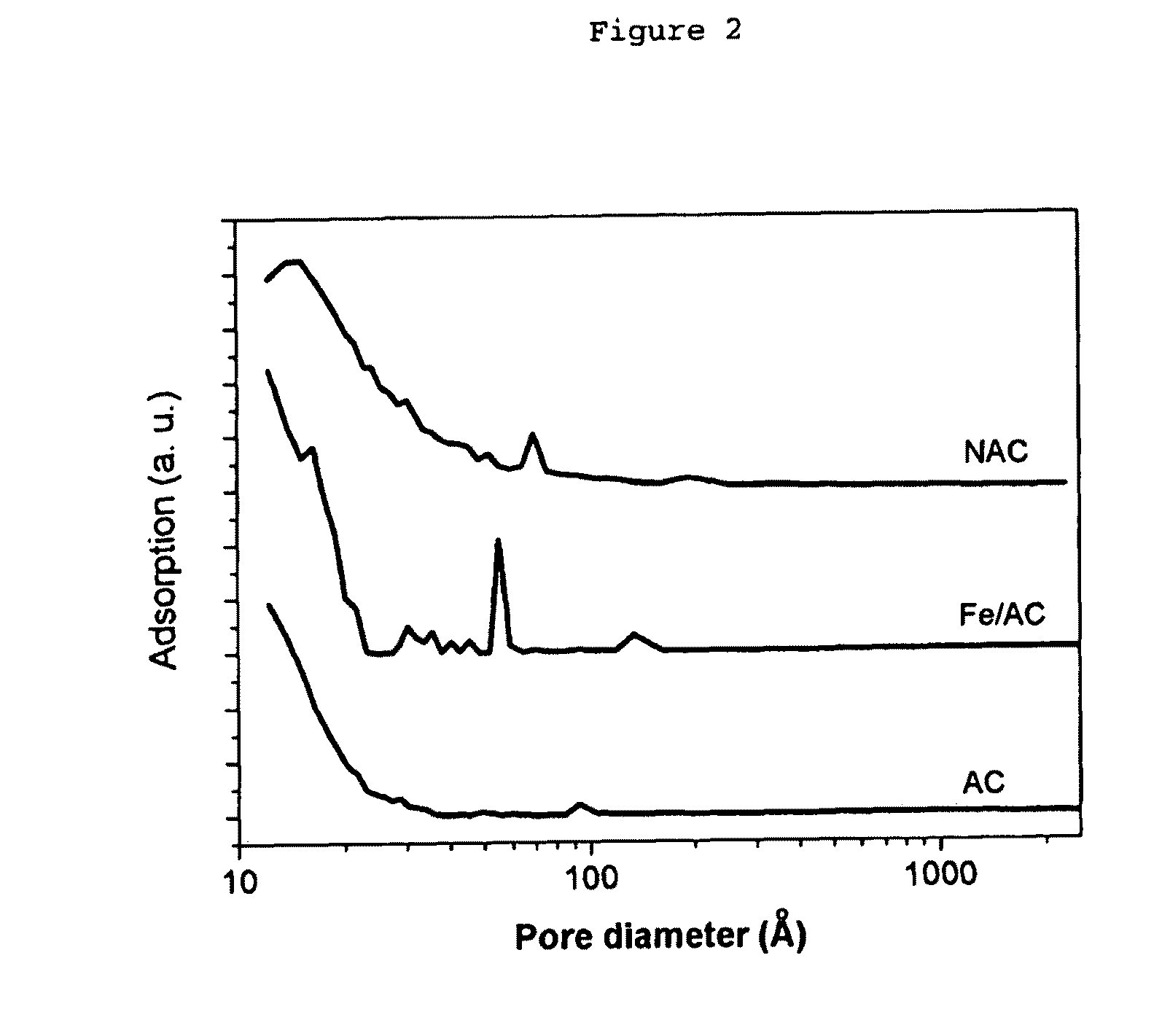

Nanocarbon-activated carbon composite

InactiveUS20090220767A1Percolation limitAvoid combiningPigmenting treatmentMaterial nanotechnologyCarbon compositesPorosity

The present invention relates to carbon-carbon composite material comprising a carbonaceous carrier and nanosize carbon structures (e.g. CNT or CNF), wherein the nanosize carbon structures are grown on the carbonaceous carrier. The carrier may be porous, as in activated carbon or consists of carbon black particles. In accordance with the invention, nanocarbon growth in the pores of porous carriers can be realized. The process for the manufacture of a this carbon-carbon-composite material comprises the steps of treating a carbonaceous carrier material with a metal-containing catalyst material, said metal being capable of forming nanosize carbon structures, and growing nanosize carbon structures by means of a CVD (chemical vapour deposition) method on the treated carrier in a gas atmosphere comprising a carbon-containing gas, followed by an optional surface modification step. This process allows optimising porosity, hydrodynamical properties and surface chemistry independently from each other, which is particularly beneficial in respect of the use of the composite for water purification. Carbon black-based composites are particularly useful for filler applications.

Owner:SUD CHEM IP GMBH & CO KG

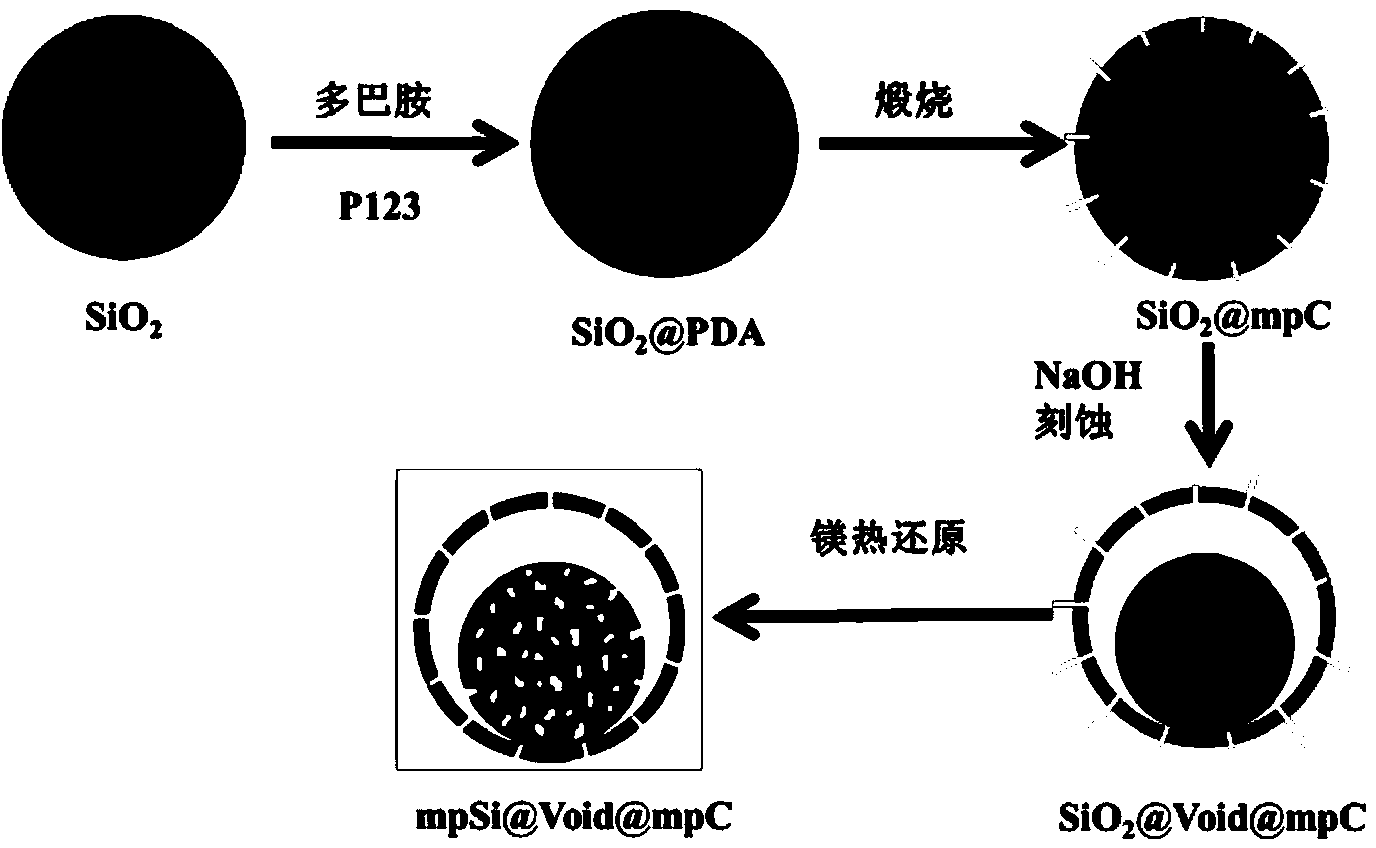

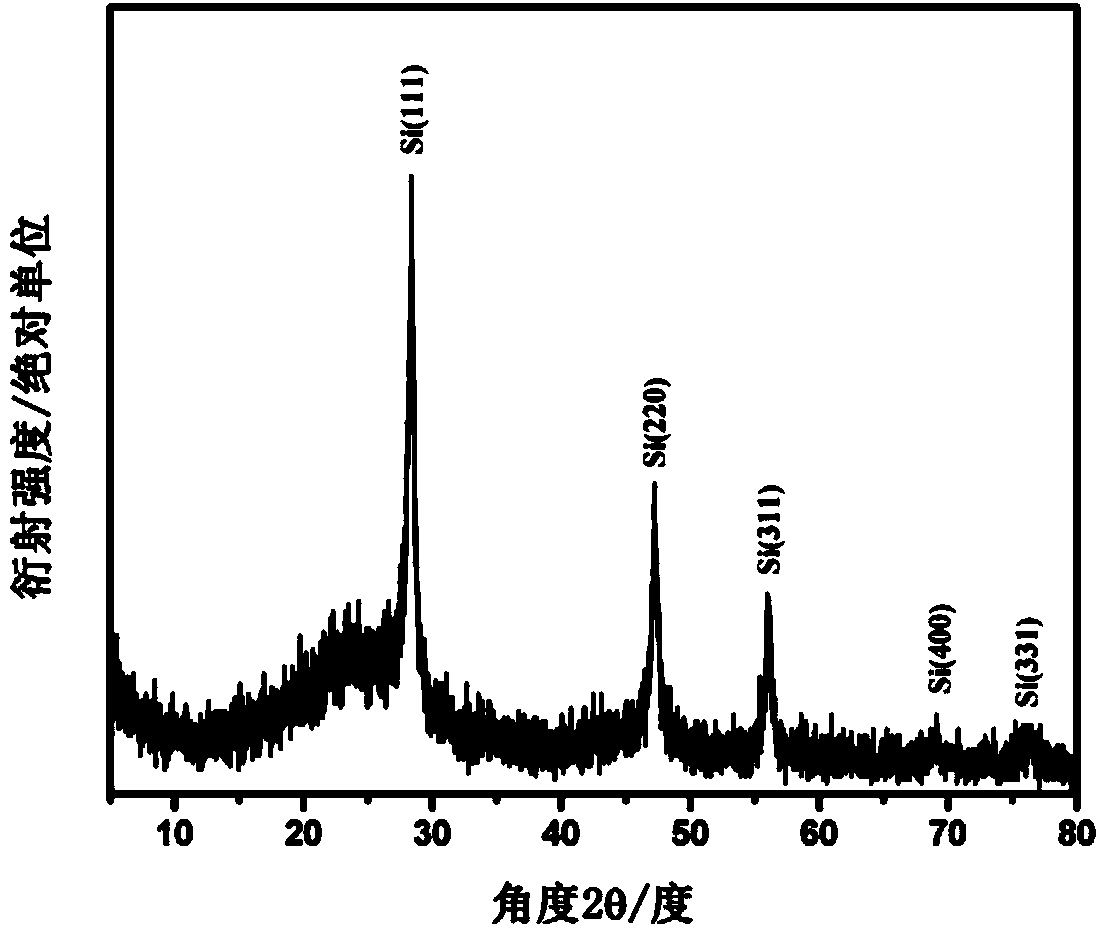

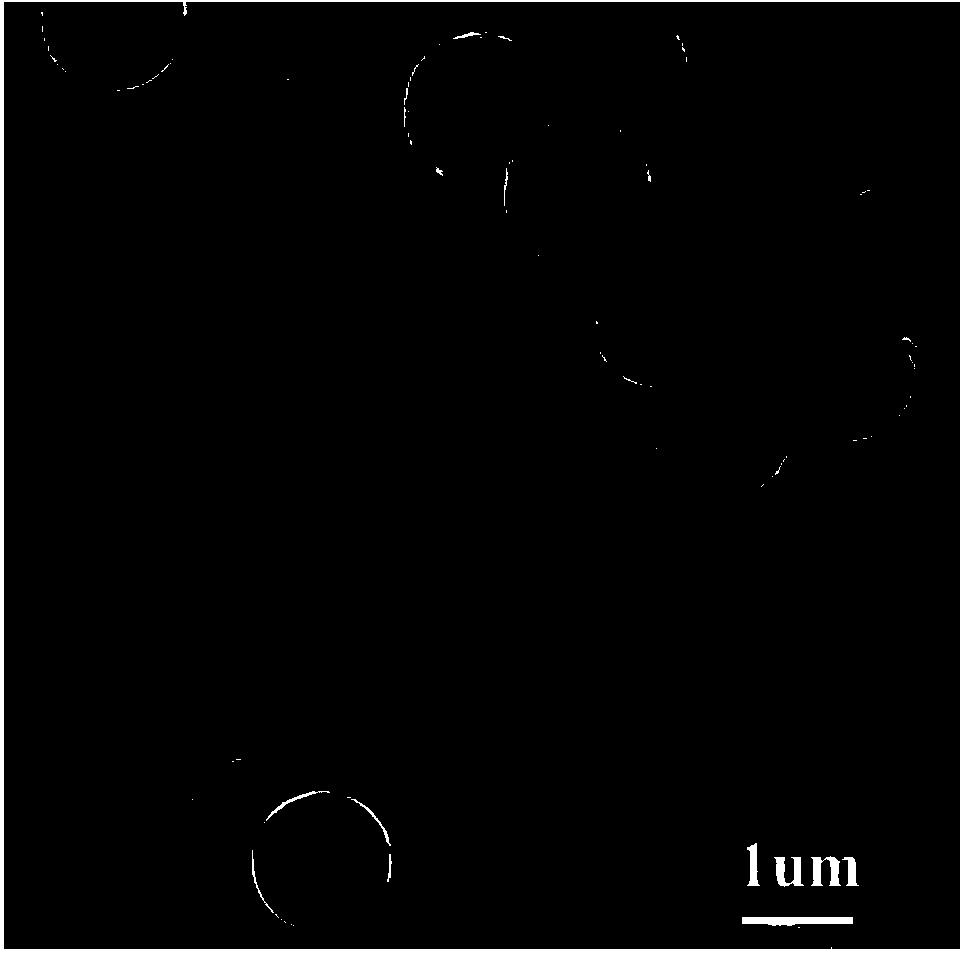

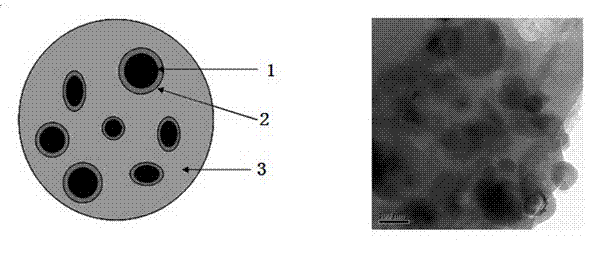

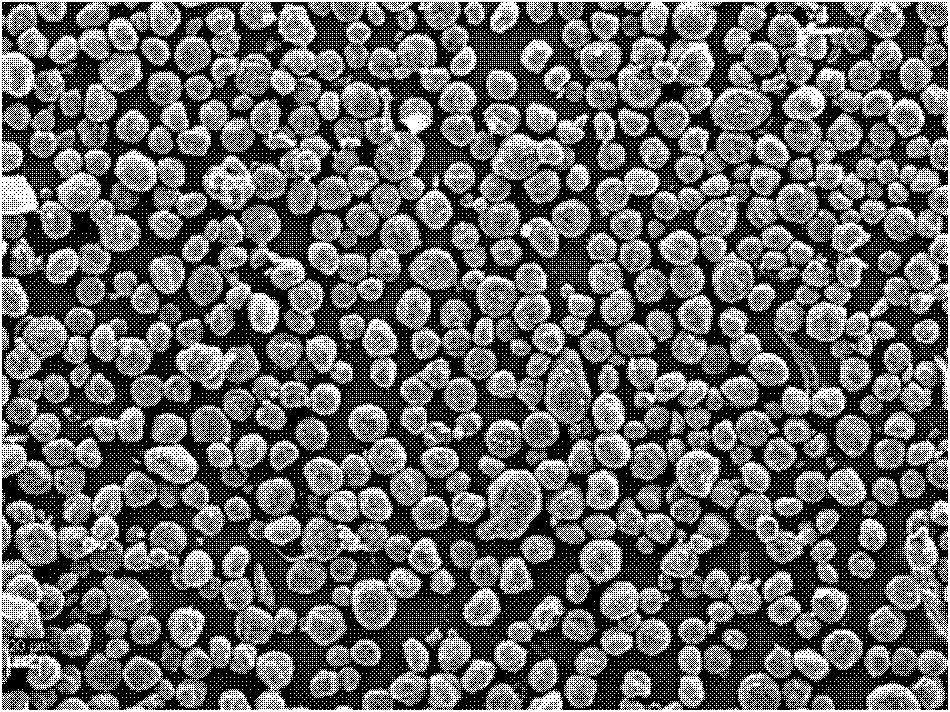

Porous silicon carbon composite microsphere with yolk-eggshell structure and preparation method therefor

InactiveCN103531760AEase of mass productionPromote infiltrationMaterial nanotechnologyCell electrodesCarbon compositesYolk

The invention provides a porous silicon carbon composite microsphere with a yolk-eggshell structure and a preparation method therefor, and belongs to the lithium ion battery electrode material technology field. The porous silicon carbon composite microsphere takes a porous submicron silicon sphere mpSi as a core with a diameter of 400-900 nm, and takes porous carbon mpC as a shell with a thickness of 10-60 nm. The inner diameter of a cavity Void is 800-1400 nm. The composition of the silicon carbon composite microsphere can be described as mpSi@Void@mpC. In addition, In the preparation method, cheap silicon dioxide is taken as a silicon source, silicon dioxide is conversed into silicon materials with electrochemical activities through a magnesiothermic reduction method. The size of gaps can be regulated and controlled through control of etching conditions. The preparation method is advantaged in that the material structure can be controlled, the cost is low, the process is simple, and the composite microsphere is convenient for large-scale production.

Owner:BEIJING UNIV OF CHEM TECH

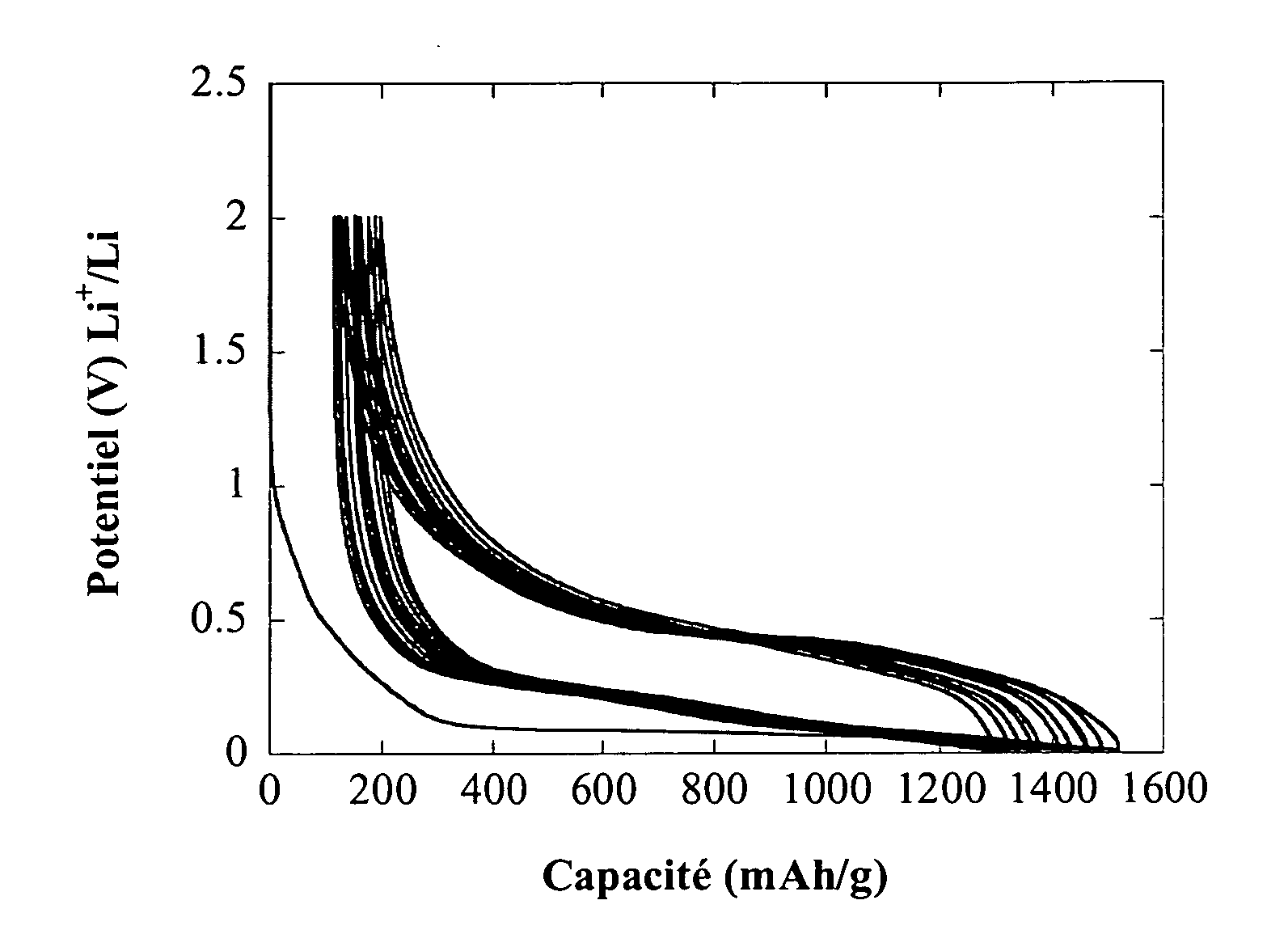

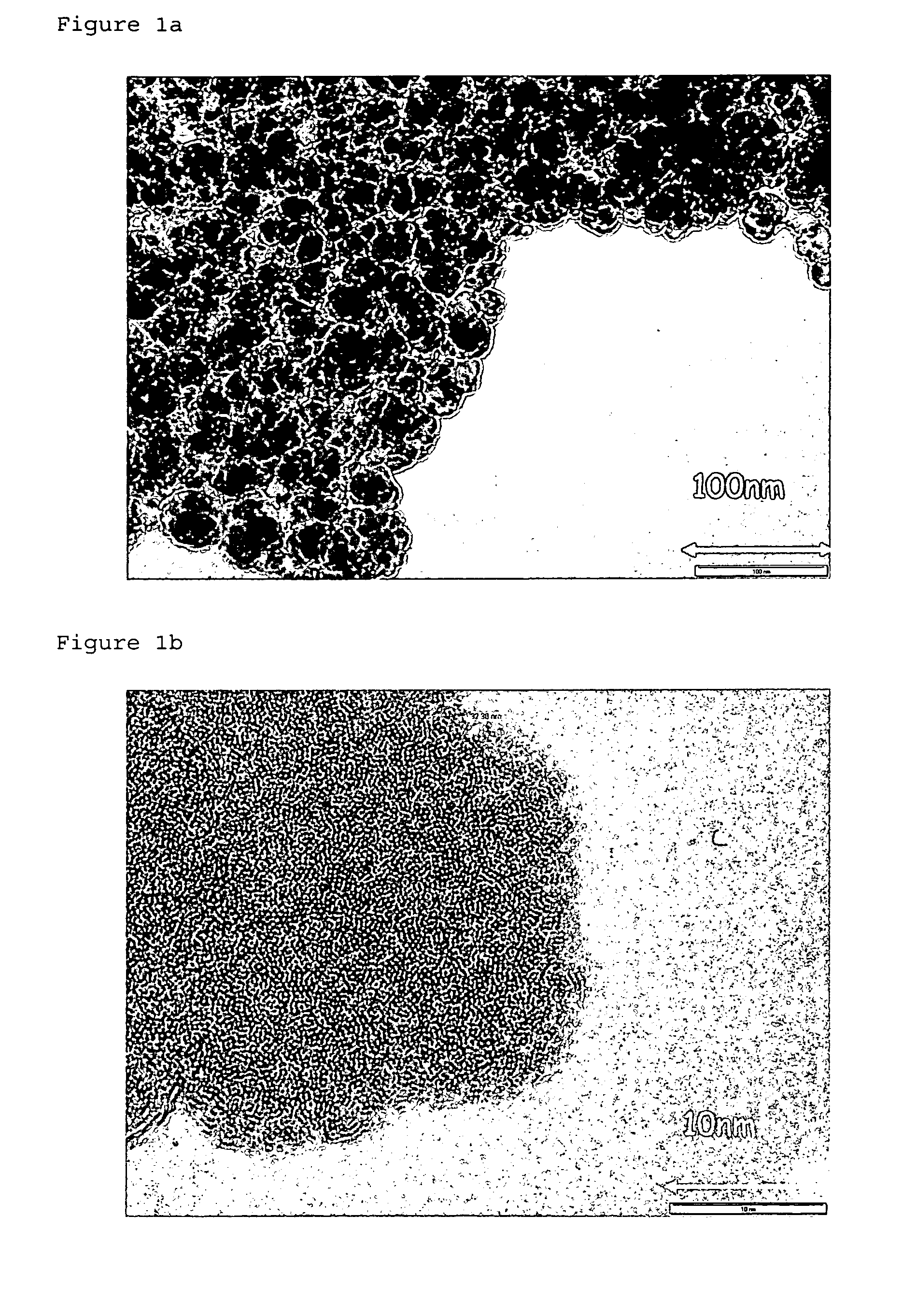

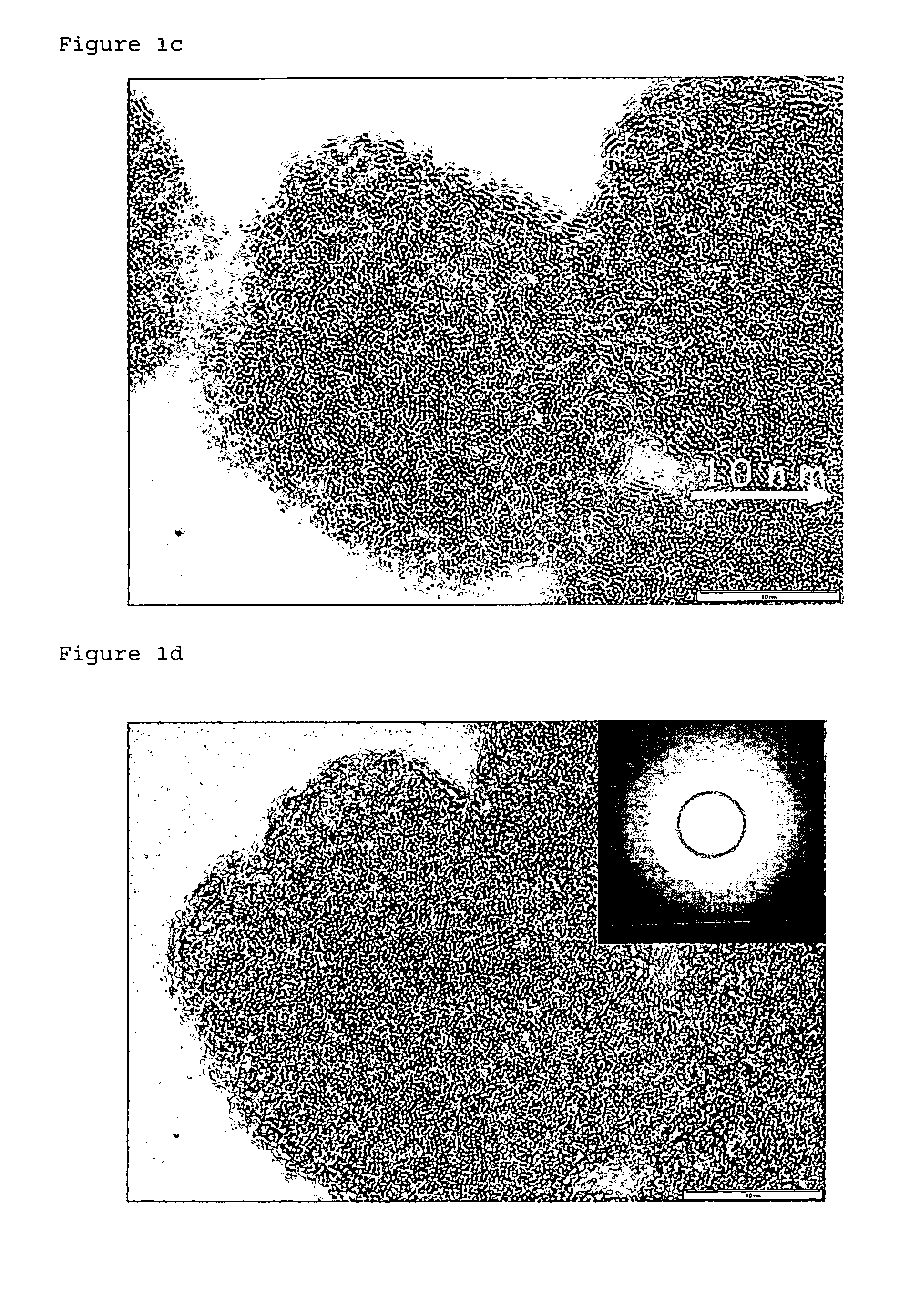

Nanocomposite material for the anode of a lithium cell

ActiveUS20060275668A1Material nanotechnologyLiquid surface applicatorsCarbon compositesChemical vapor deposition

The subject of the invention is an anode material of the silicon-carbon composite type, for a lithium cell, having a high mass capacity and good cycling stability. This material is obtained by a preparation method comprising the steps consisting of: a) providing a silicon powder obtained by the plasma-enhanced chemical vapour deposition (PECVD) technique or by CO2 laser, the size of the silicon particles being less than 100 nm; b) mixing the silicon powder with a carbon-containing polymer, and c) carrying out the pyrolysis of the mixture. The invention also proposes a lithium cell containing at least one anode the material of which contains the nanocomposite material produced by this method.

Owner:SAFT GRP SA

Silicon-carbon composite anode material and preparing method thereof

ActiveCN102509781AHigh specific capacityImprove cycle performanceCell electrodesCarbon compositesPorous carbon

The invention provides a silicon-carbon composite anode material, which comprises a nuclear shell structure and a support substrate, wherein particle size of the silicon-carbon composite anode material is 1-200 micrometers, and porous carbon serving as the support substrate is obtained through decomposition of biomass materials. The invention further provides a preparing method of the silicon-carbon composite anode material, which includes the following steps: 1 reaming the biomass materials in physical activation or chemical activation mode to prepare the porous carbon, or preparing small molecular organics serving as a precursor of the porous carbon in hydrolyzing mode; 2 mixing silica particles and the obtained porous carbon or the precursor of the porous carbon in solution and performing ultrasonic treatment; 3 evaporating the solution mixture to dry so as to obtain solid-state powder; and 4 drying the solid-state powder, and performing thermal treatment, crushing and sieving on the solid-state powder to obtain the silicon-carbon composite anode material. The silicon-carbon composite anode material and the preparing method thereof are simple in process, short in flow path, easy to operate and low in cost, and lithium ion batteries manufactured by the silicon-carbon composite anode material are suitable for various mobile electronic equipment or devices driven by mobile energy.

Owner:SHANGHAI JIAO TONG UNIV

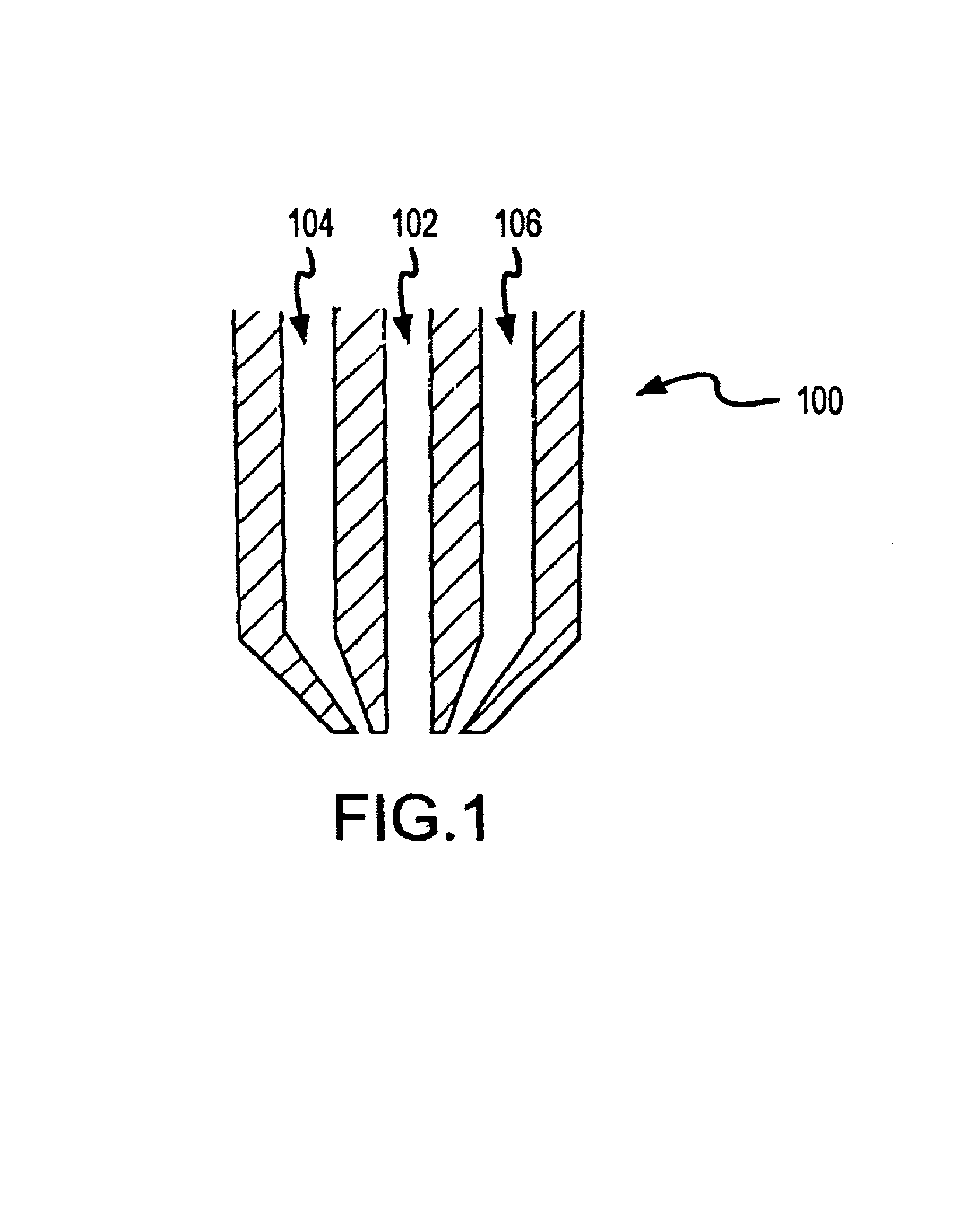

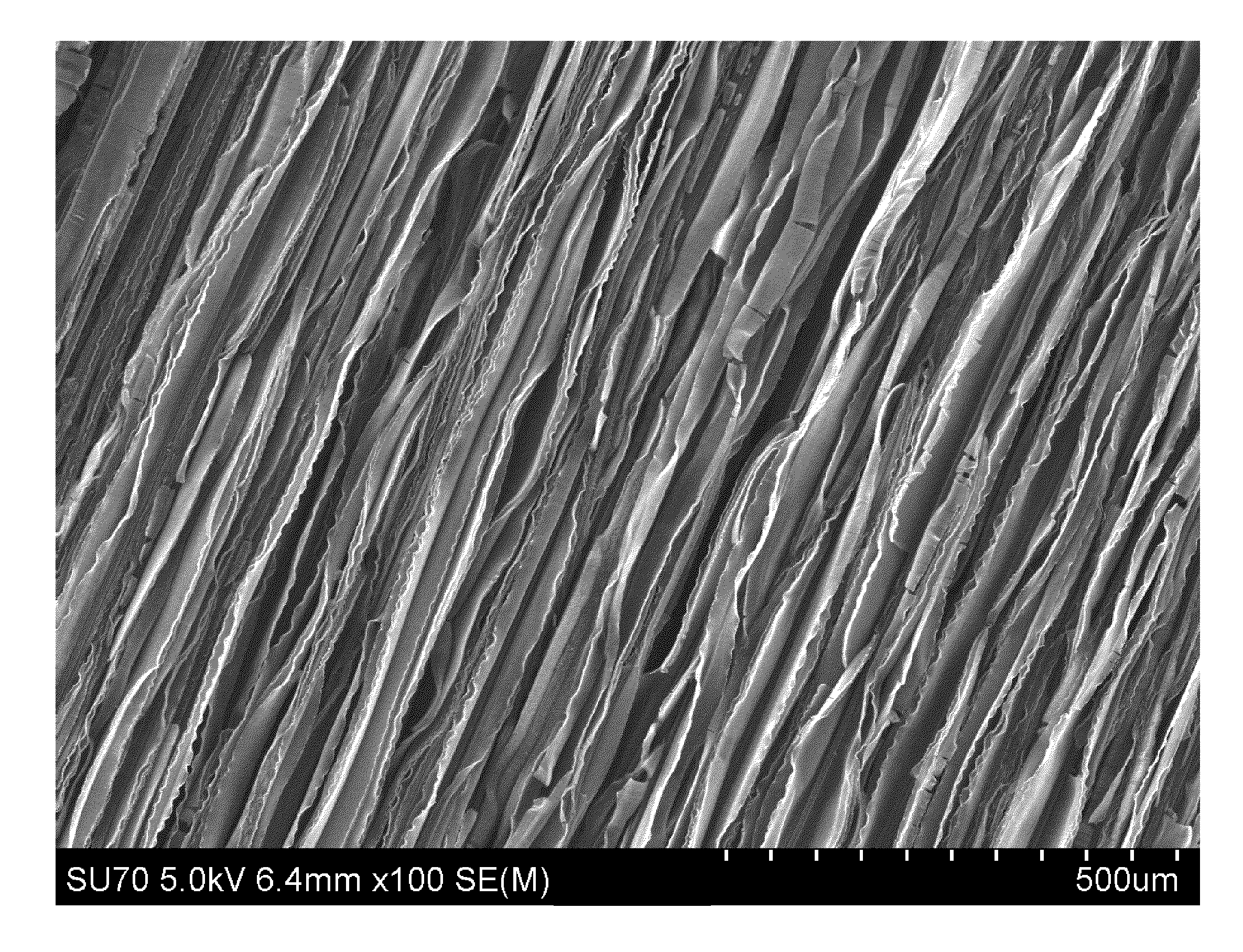

Cnt-infused fibers in carbon-carbon composites

A carbon / carbon (C / C) composite includes a carbon matrix and a non-woven, carbon nanotube (CNT)-infused carbon fiber material. Where woven materials are employed, CNTs are infused on a parent carbon fiber material in a non-woven state. A C / C composite includes a barrier coating on the CNT-infused fiber material. An article is constructed from these (C / C) composites. A method of making a C / C composite includes winding a continuous CNT-infused carbon fiber about a template structure and forming a carbon matrix to provide an initial C / C composite or by dispersing chopped CNT-infused carbon fibers in a carbon matrix precursor to provide a mixture, placing the mixture in a mold, and forming a carbon matrix to provide an initial C / C composite.

Owner:APPL NANOSTRUCTURED SOLUTIONS LLC

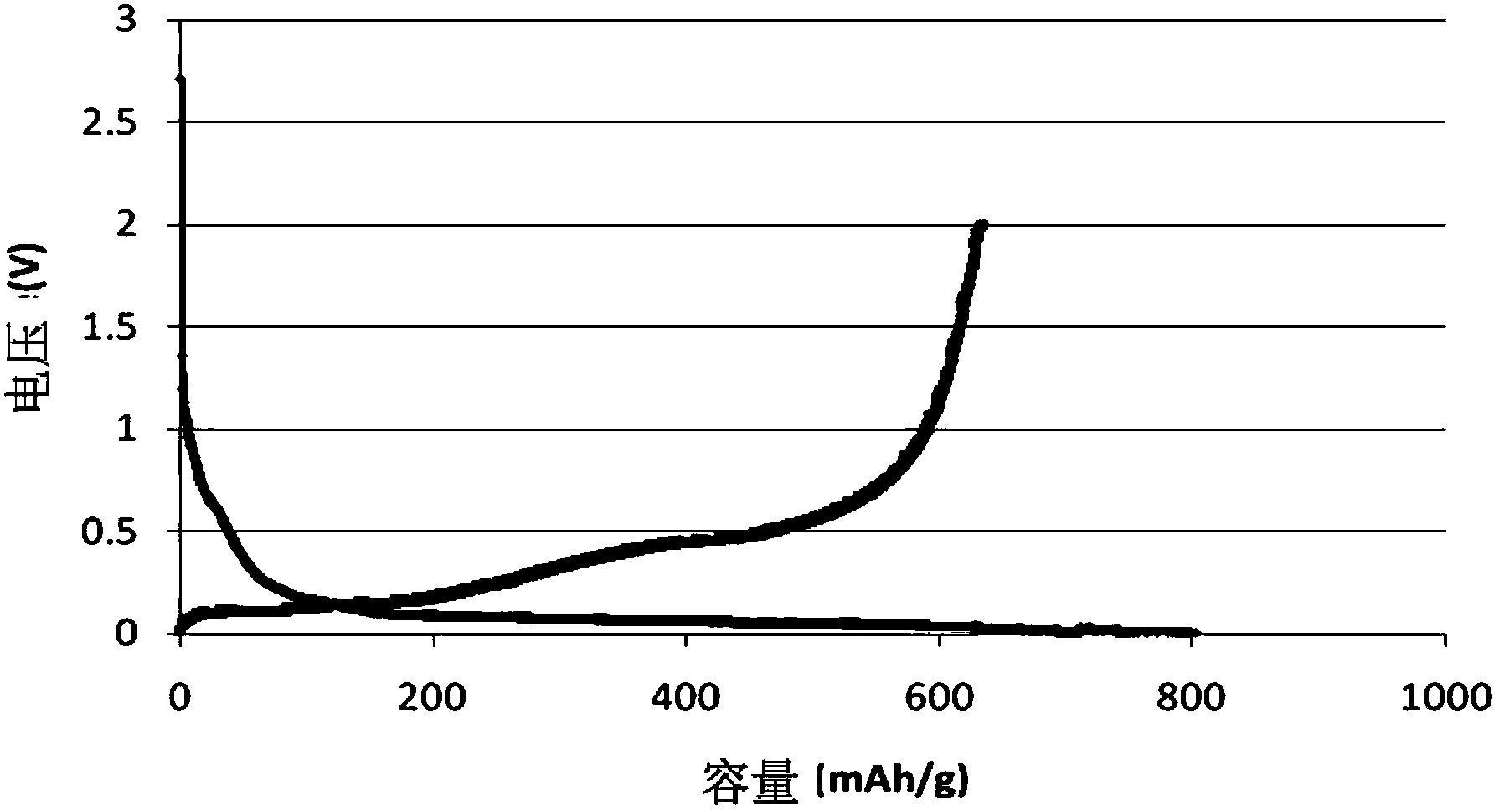

Silicon-carbon Composite Anode Material for Lithium Ion Batteries and A Preparation Method Thereof

ActiveUS20140147751A1Large capacityImprove cycle stability performanceMechanical vibrations separationLiquid/solution decomposition chemical coatingCarbon compositesCarbon coating

Disclosed in the invention are a silicon-carbon composite anode material for lithium ion batteries and a preparation method thereof The material consists of a porous silicon substrate and a carbon coating layer. The preparation method of the material comprises preparing a porous silicon substrate and a carbon coating layer. The silicon-carbon composite anode material for lithium ion batteries has the advantages of high reversible capacity, good cycle performance and good rate performance. The material respectively shows reversible capacities of 1,556 mAh, 1,290 mAh, 877 mAh and 474 mAh / g at 0.2 C, 1 C, 4 C and 15 C rates; the specific capacity remains above 1,500 mAh after 40 cycles at the rate of 0.2 C and the reversible capacity retention rate is up to 90 percent.

Owner:BOSCH CHINA INVESTMENT

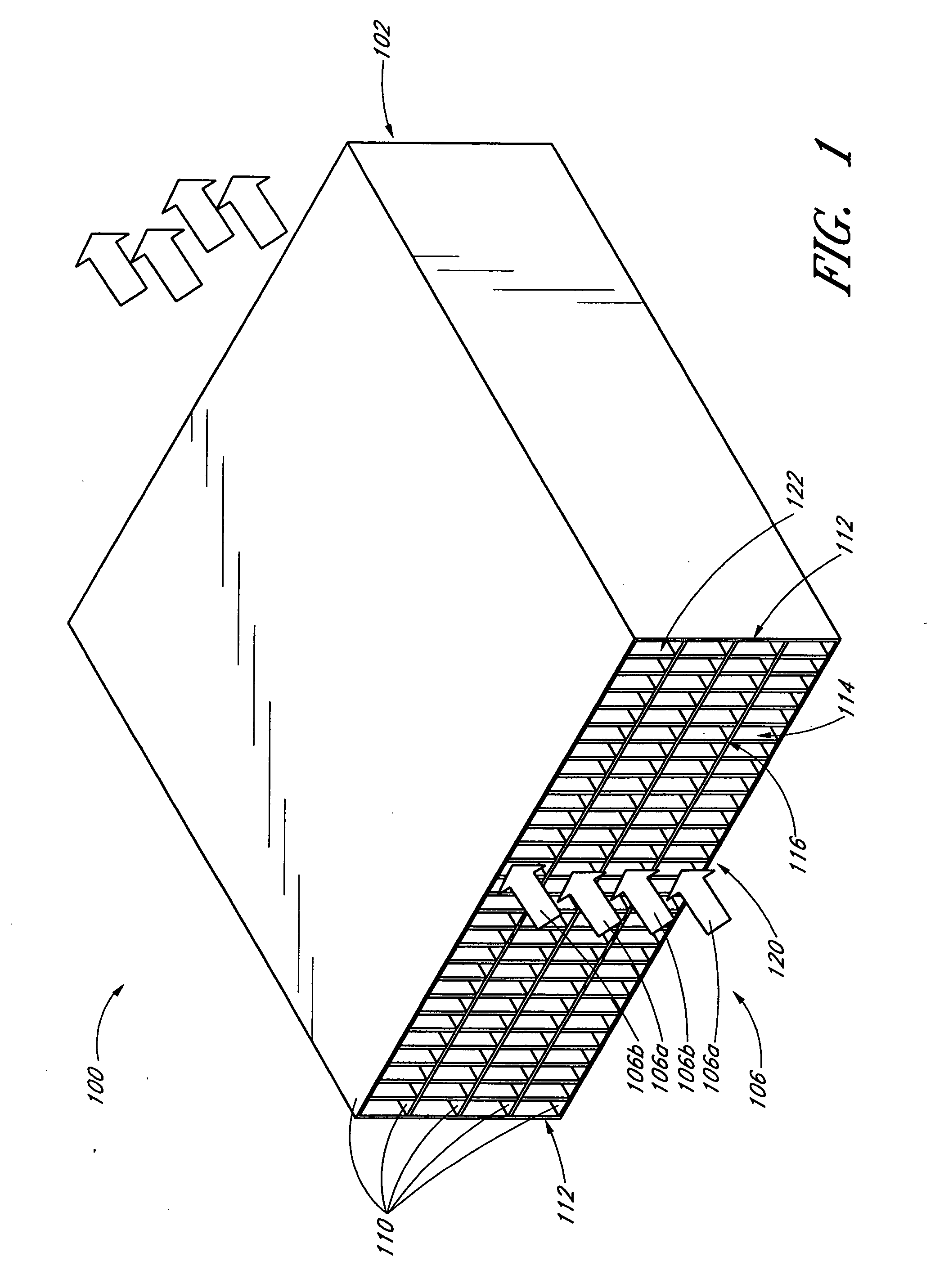

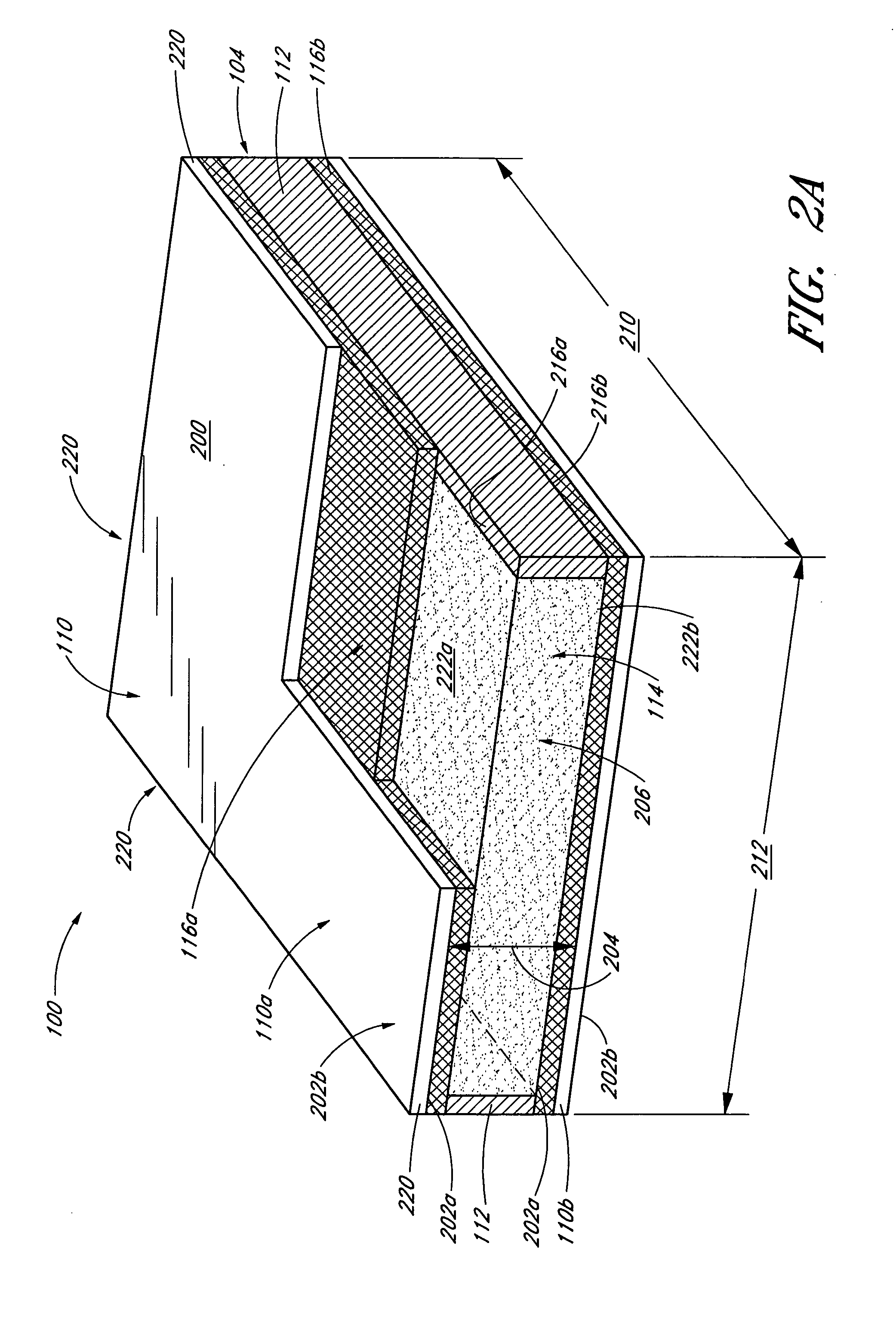

Hybrid heat exchangers

InactiveUS20070284095A1Improve mechanical durabilityLow densityReinforcing meansStationary tubular conduit assembliesCarbon compositesCore component

A light weight hybrid heat exchanger core possessing low density and improved thermal conductivity is disclosed. The hybrid core is comprised of a plurality of parting sheets and interposed by a plurality of high thermal conductivity, light weight bridging elements and enclosure bars. These core members are comprised of dissimilar materials. The parting sheets and bridging elements are interconnected by a specially tailored joint which forms form a substantially strong, high thermal conductivity bond. In particular embodiments, carbon-based bridging elements are bonded to metallic parting sheets using a brazed joint. The parting sheets, in certain embodiments, may comprise titanium or Ni-based superalloys or carbon composites, while the carbon-based bridging elements may comprise fiber-reinforced composites. The carbon-based bridging elements reduce the core weight and increase the core thermal conductivity over conventional all-metal designs, while the brazed joint provides for improved leak resistance over all-composite designs.

Owner:ALLCOMP

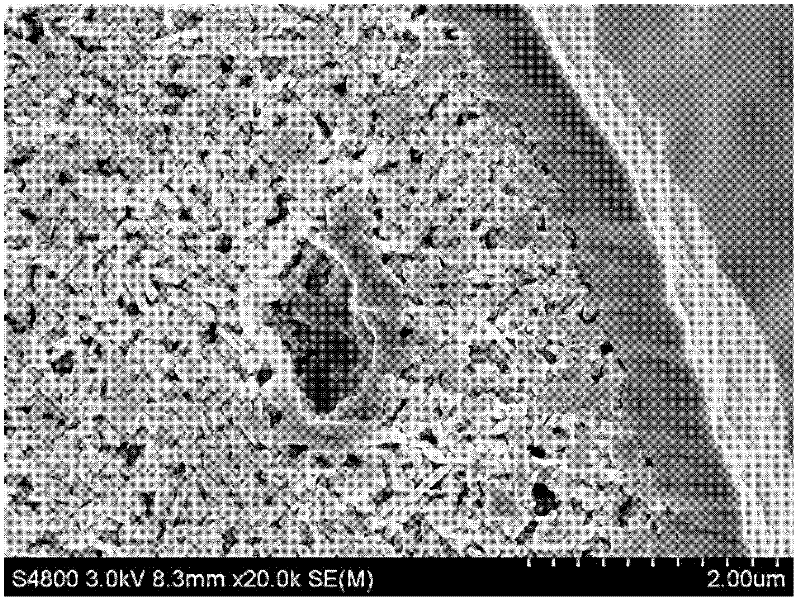

Carbon-silicon composite material with spherical nucleocapsid, and its preparing method and use

This invention relates to a kind of silicon&carbon composite material with a spherical appearance and core-shell structure in spherical particles with a mean diameter of 1.2~53 micron and a 'core-shell' structure, there are silicon particles 5~50wt% and carbon particles 50~95wt%, the core of which is spherical carbon particles with a mean diameter of 1~45 micron. The carbon particles are the mixture of one, two or three kinds of mesophase carbon graphite balls, hard carbon balls and spherical graphite ball. The thickness of the shell is 0.1~4 microns composed of carbon and silicon grains with the average size of 10 nm~4 micron. The carbon&silicon composite materials are achieved through thermal decomposition and chemical vapor deposition after the spherical carbon particles are coated with silicon and carbon composite ultrafine silica slurry.

Owner:LIYANG TIANMU PILOT BATTERY MATERIAL TECH CO LTD

Method for preparing porous silicon/carbon composite material by using diatomite as raw material and application

The invention provides a method for preparing a porous silicon / carbon composite material by using diatomite as the raw material, which is characterized by comprising the following steps of: with the diatomite as the raw material, performing simple refinement and purification processing to obtain silicon with a porous structure by means of metallothermic reduction; performing mechanical ball-milling with the carbon materials and / or precursors of carbon, hydro-thermal carbonization, pyrolytic carbonization or chemical vapor deposition to prepare the porous silicon / carbon composite material. Thecomposite material can be directly used as the cathode of the lithium ion battery, or can be mixed with other cathode materials to be used as the cathode materials of the lithium ion battery. Compared with a pure silicon material as the cathode material of the lithium ion battery, the porous silicon / carbon composite material has the advantages that the first reversible capacity and the circulation stability of the material are greatly improved. In the method, the inexpensive and accessible natural minerals are used as the raw materials, thus the cost is low and the preparation method is simple.

Owner:UNIV OF SCI & TECH BEIJING

Metal oxide-carbon composite catalyst support and fuel cell comprising the same

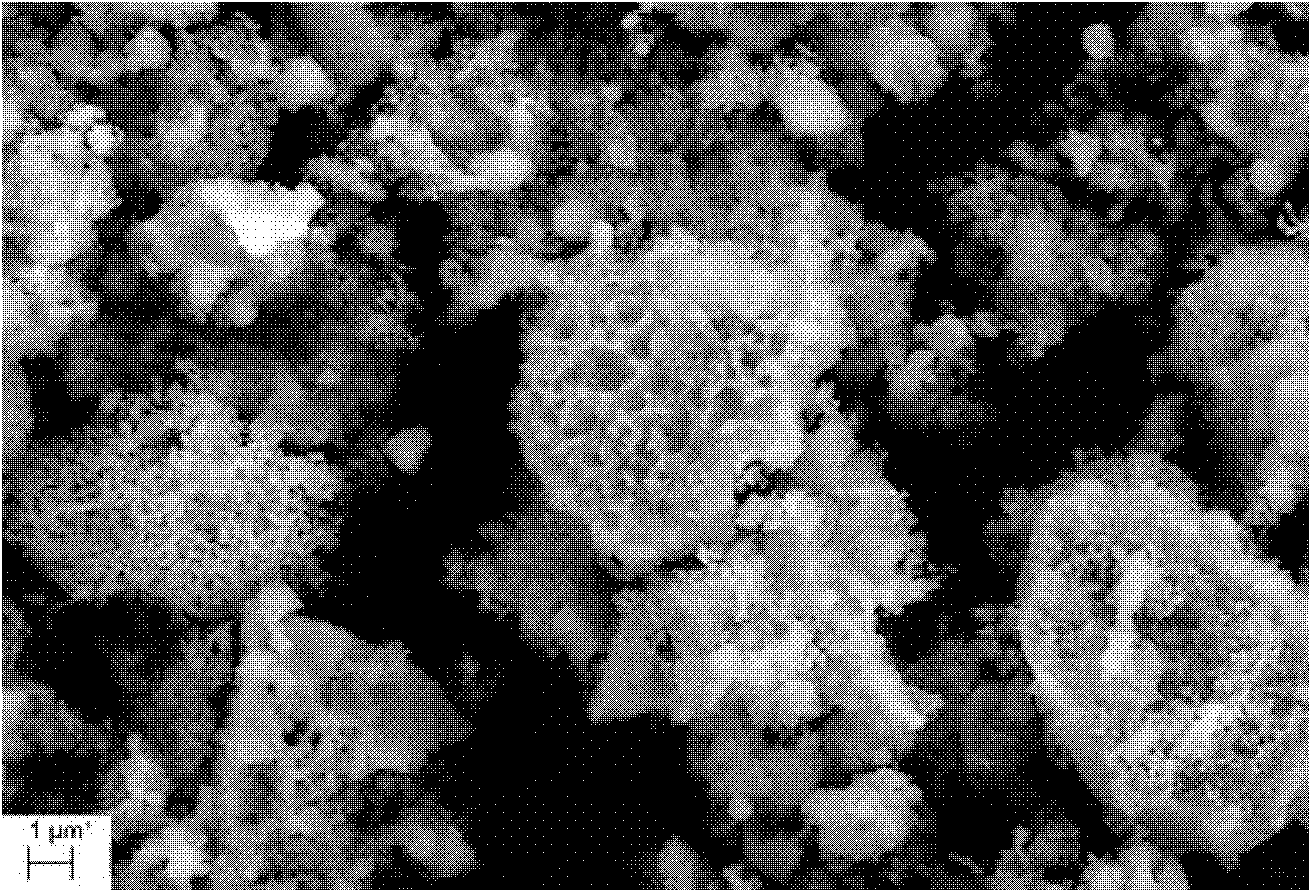

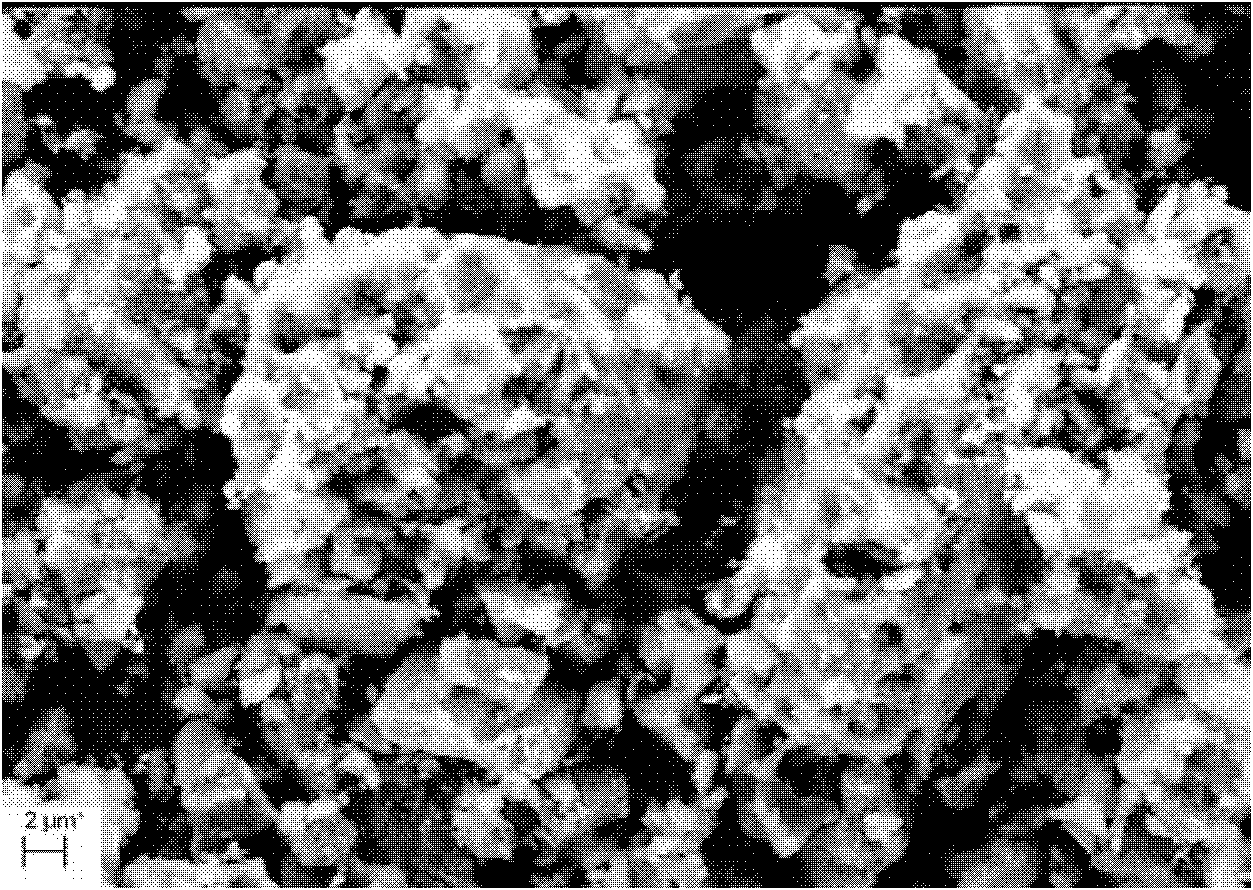

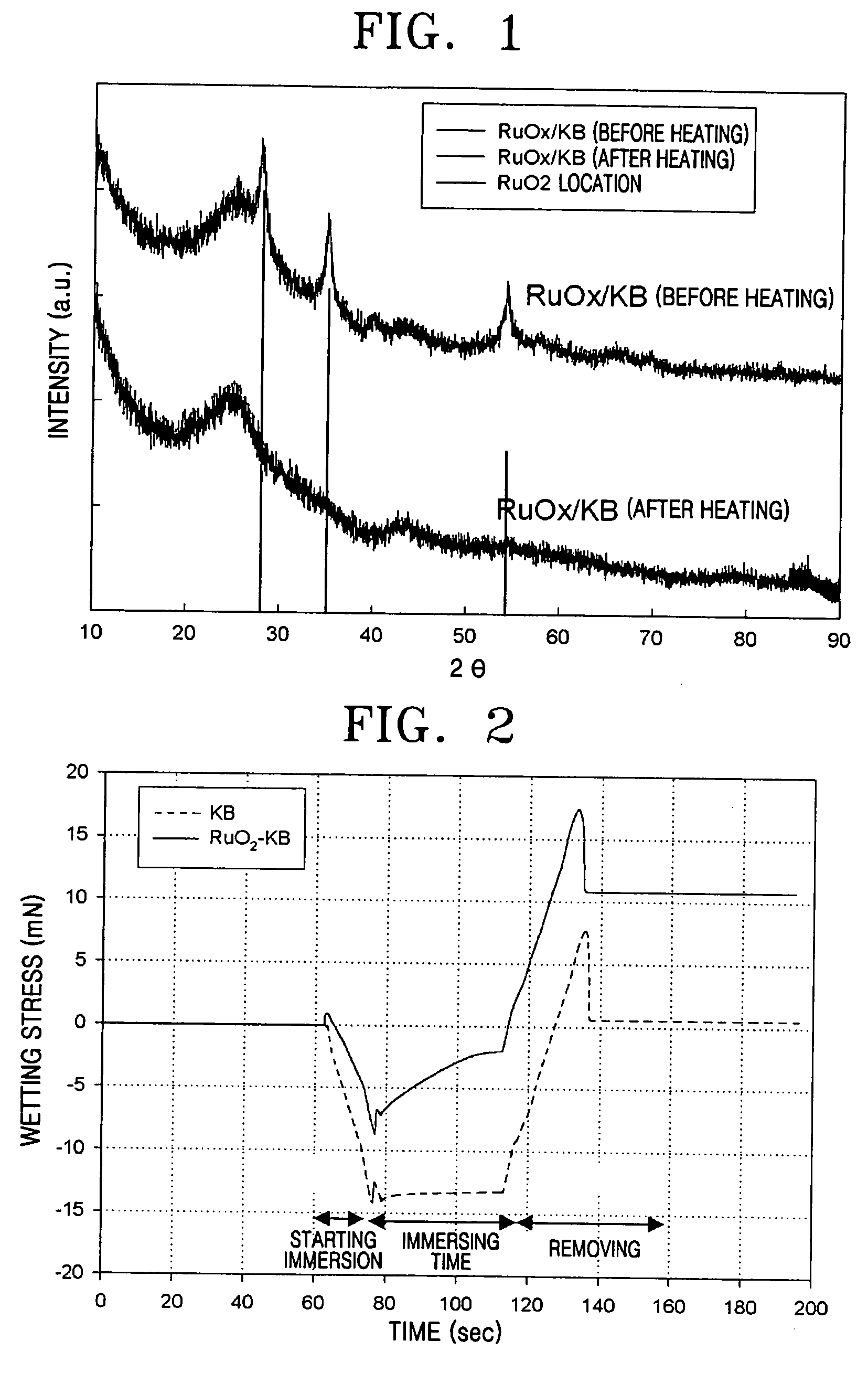

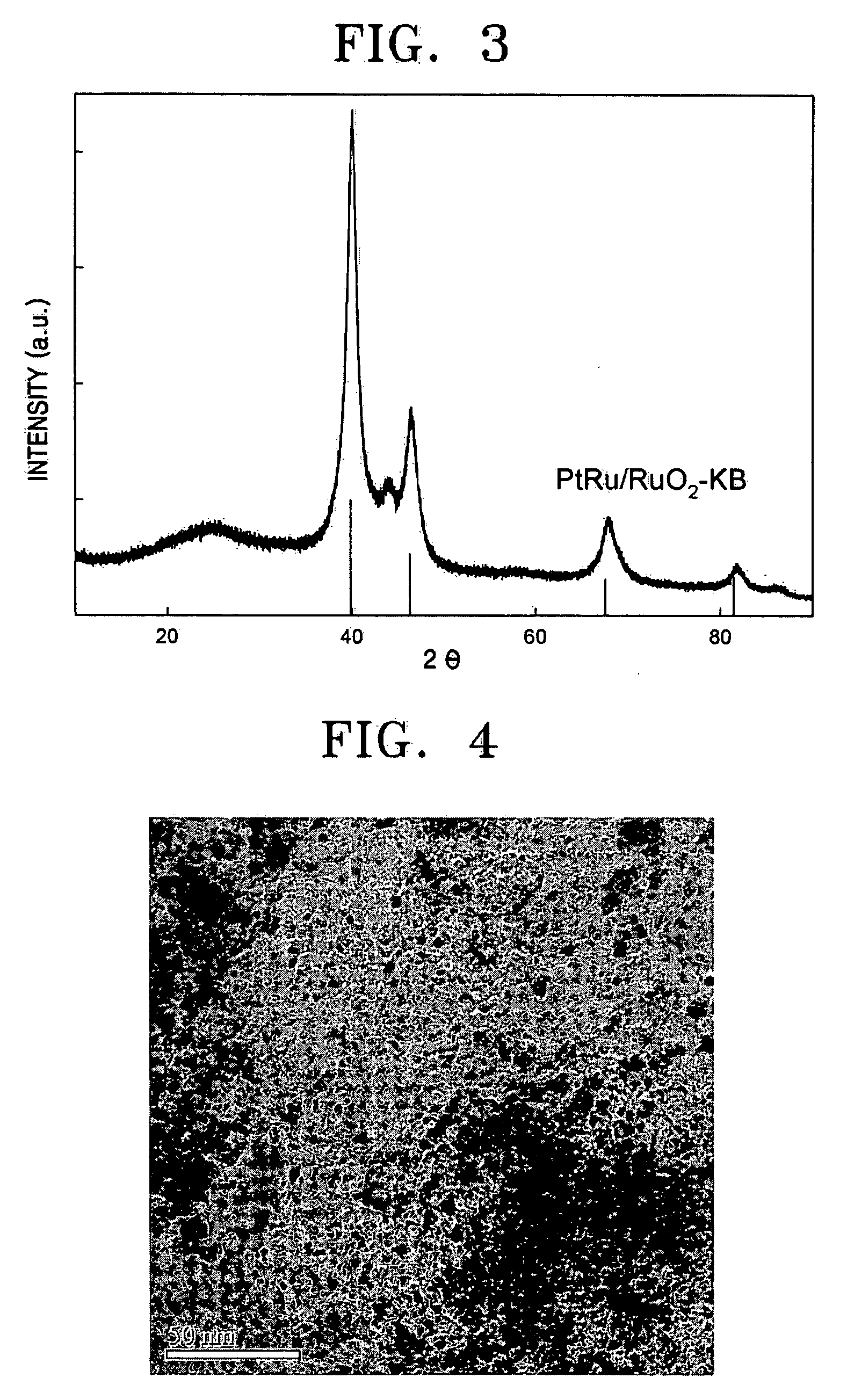

InactiveUS20050112451A1Increased electroconductivityImprove hydrophilicityMaterial nanotechnologyActive material electrodesCarbon compositesFuel cells

A catalyst support for a fuel cell, having good hydrophilic property and electroconductivity, an anode including the same, and a fuel cell including the anode are provided. The catalyst support is composed of a metal oxide-carbon composite.

Owner:SAMSUNG SDI CO LTD

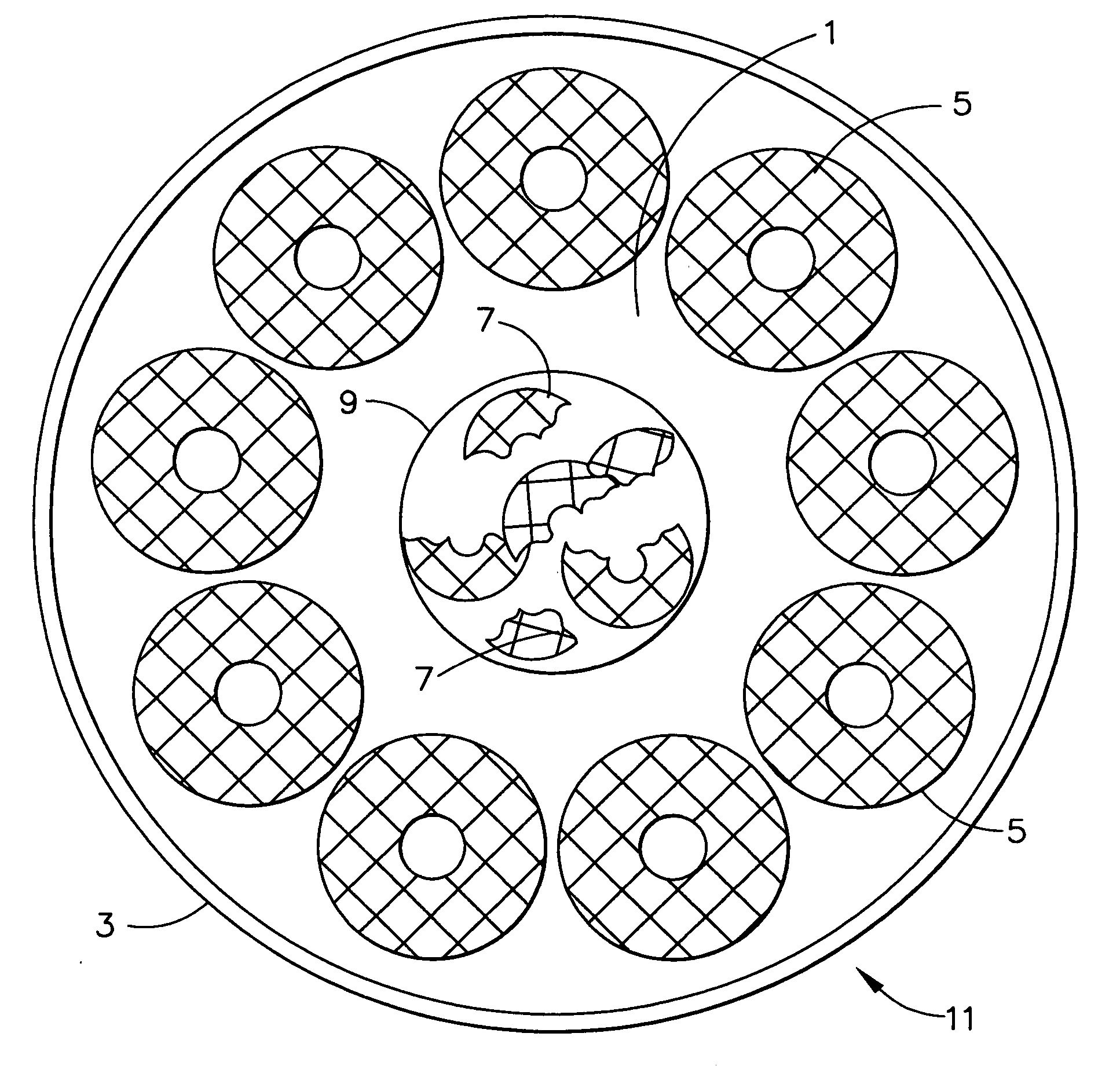

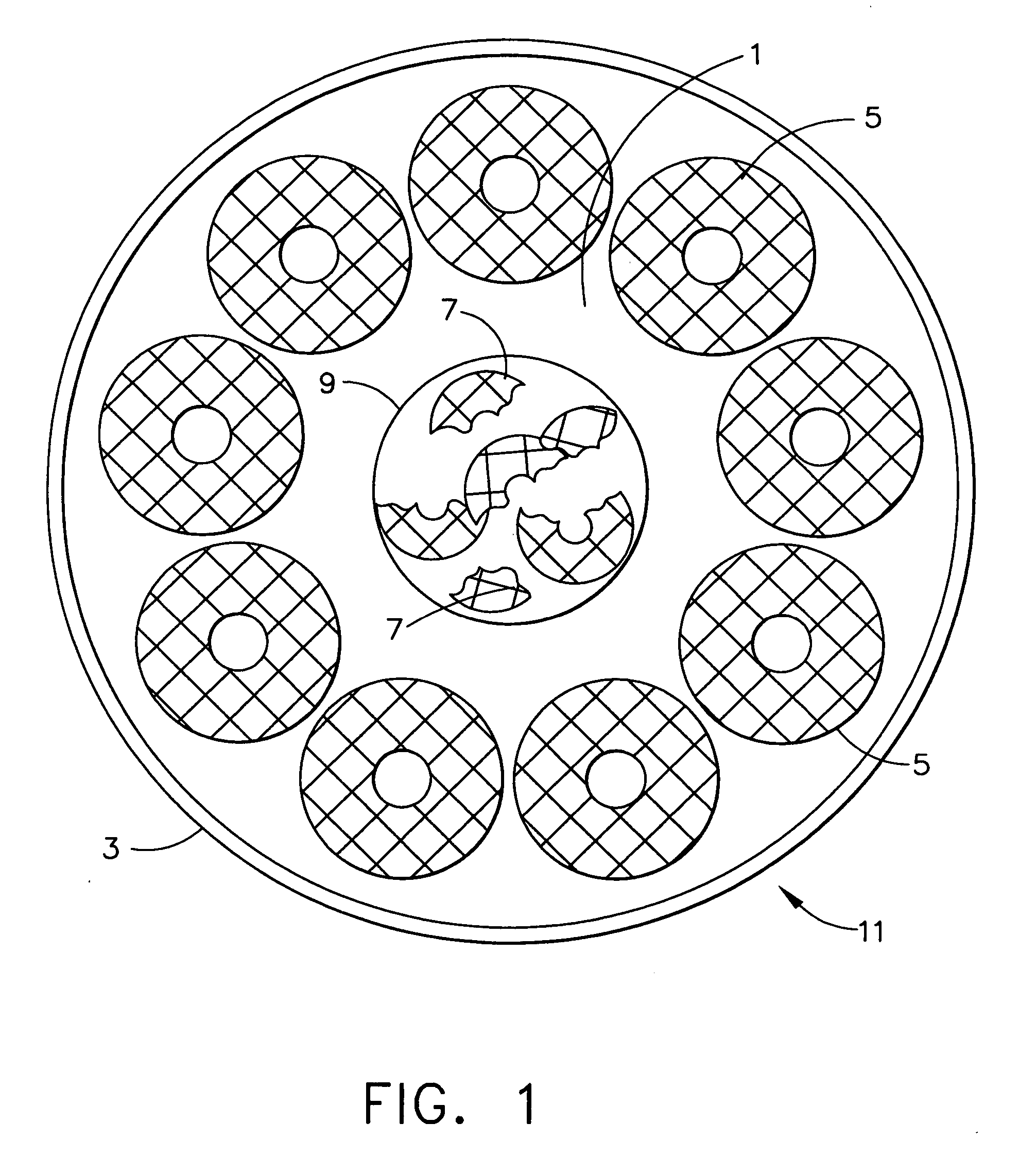

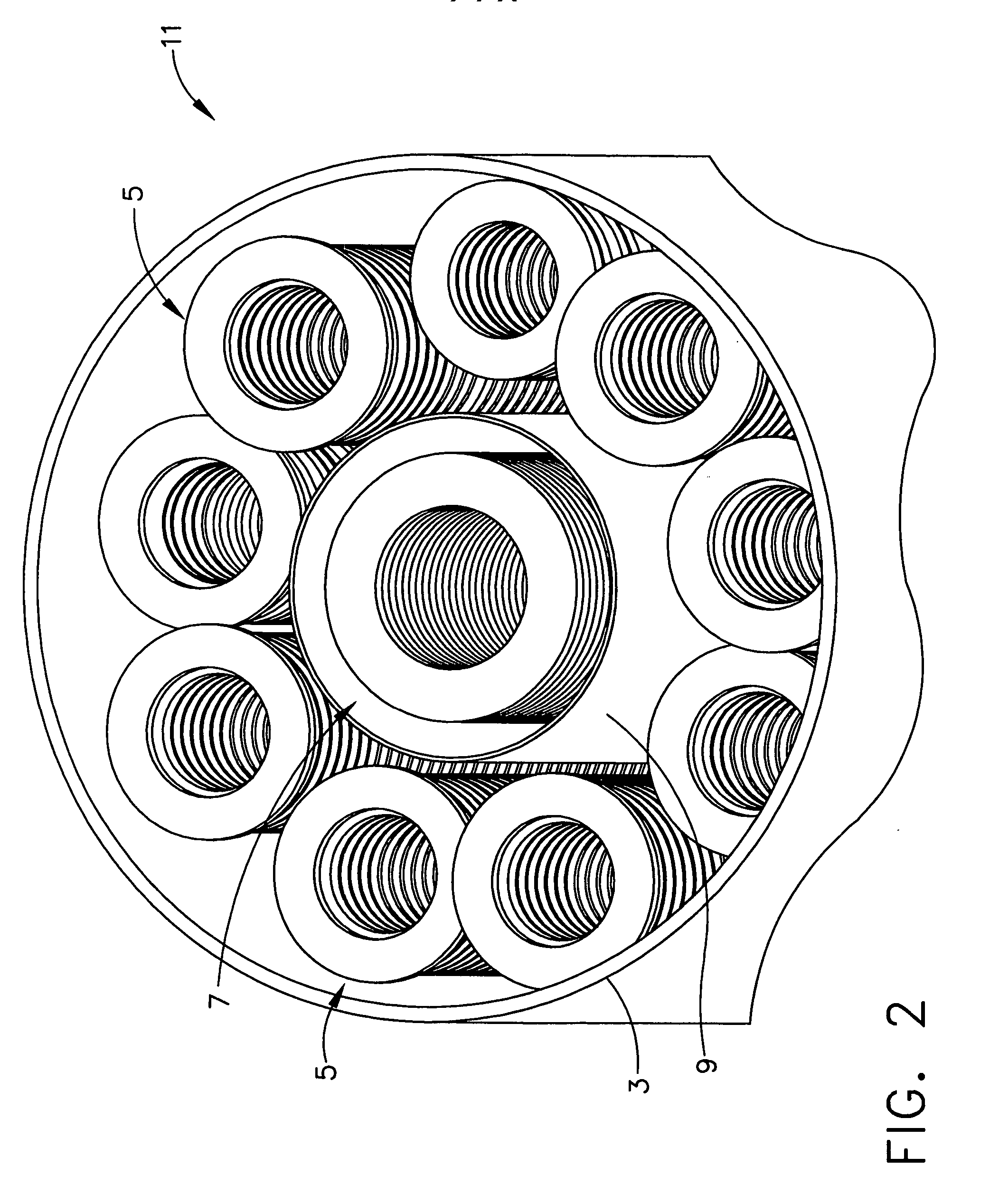

Chemical vapor deposition apparatus and method

InactiveUS20060046059A1High densityGreat and uniform weightLayered productsChemical vapor deposition coatingCarbon compositesCircular disc

Apparatus such as a furnace muffle (11) for use in a CVI / CVD furnace. The apparatus includes a bottom (12), a top (13), and an outer wall (3) defining an interior space (1) in the apparatus, and a passive heat distribution element (7, 9) located within the interior space (1) and apart from the outer wall (3). Preferably, the bottom (12) and top (12) include perforated plates and the outer wall (3) is cylindrical in shape and all are made of graphite or carbon-carbon composite material and the passive heat distribution element (7, 9) is cylindrical in shape and includes graphite or carbon-carbon composite discs having no spacers therebetween. Also, a method for densifying a porous carbon preform (5), which method includes the steps of: (a) providing the apparatus (11); (b) charging the apparatus (11) with a plurality of stacks of annular porous carbon preforms (5), the preforms being separated from one another by spacers (15); (c) locating the charged apparatus (11) in a furnace at a temperature in the range of 950-1100° C. and a pressure in the range of 5-40 torr; and (d) circulating a natural gas reactant blended with up to 15% propane through the apparatus for 150-900 hours. Also, a batch of carbon-carbon composite preforms made by the method, wherein the density of the batch of preforms is at least 0.5 g / cc higher than the density of a batch of preforms made by an otherwise identical process in which the apparatus does not contain a passive heat distribution element located within its interior. The preforms may be configured as aircraft landing system brake discs or racing car brake discs.

Owner:HONEYWELL INT INC

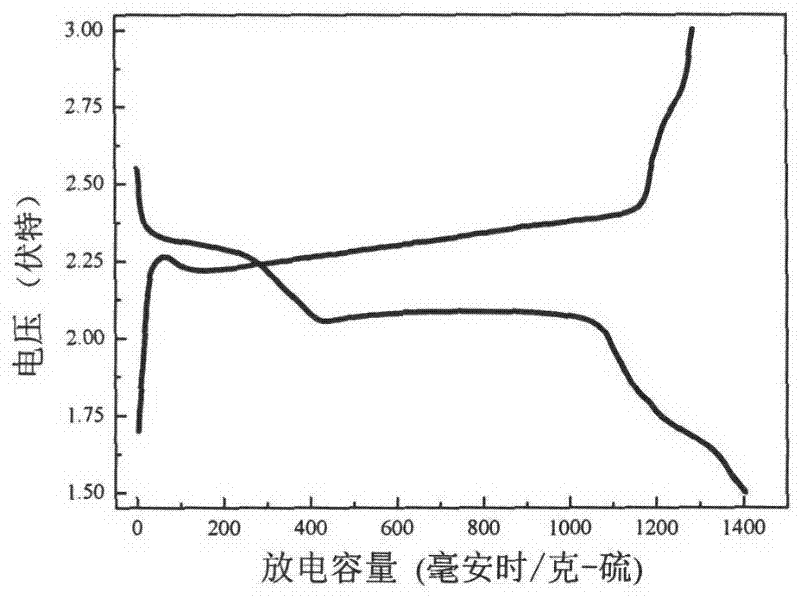

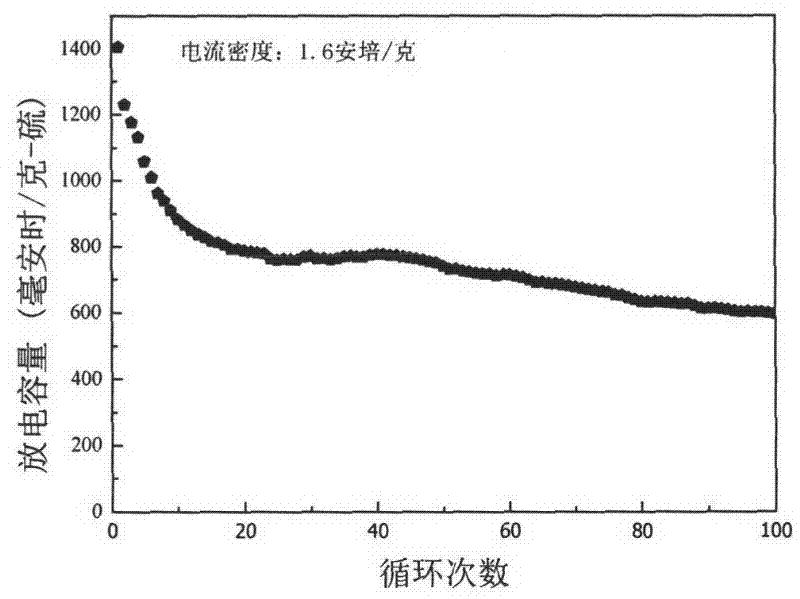

Lithium battery with polymer-coated sulfur/carbon composite material as anode

InactiveCN102447113AImprove cycle performanceImprove conductivityCell electrodesSecondary cellsCarbon compositesMass ratio

The invention relates to a lithium battery with a polymer-coated sulfur / carbon composite material as an anode. According to the invention, sublimed sulfur or sulfur powder and a conductive carbon material are mixed according to a mass ratio of 3:7-8:2; the mixture is subject to ball milling, such that a sulfur / carbon composite material is obtained; the composite material is dispersed in a solution, and a polymer monomer is added to the solution; under a low temperature and the protection of inert gas, an oxidizing agent is added for initiating polymerization; the material is centrifuged, washed, and dried; the obtained polymer-coated elemental sulfur / carbon composite material, acetylene black and PTFE are mixed; a dispersant is added to the mixture, and the mixture is sufficiently mixed by stirring; the mixture is rolled into a sheet, and is vacuum-dried under a temperature of 55 DEG C, such that an electrode sheet is obtained. The prepared electrode sheet is adopted as an anode, metal lithium is adopted as a cathode, and a solvent type organic solution system containing 0.2mol / L of a waterless lithium nitrate additive is adopted as electrolyte, and a battery is assembled. With the electrode material, the assembled lithium battery is advantaged in high specific capacity, good circulation stability, and excellent heavy-current charge / discharge performances. The preparation method is advantaged in simple process, low cost, and good repeatability.

Owner:NANKAI UNIV

Porous silicon/carbon composite material and preparation method thereof

ActiveCN102208634AHigh specific capacityImprove cycle stabilityCell electrodesCarbon compositesNew energy

The invention discloses a porous silicon / carbon composite material and a preparation method thereof, and belongs to the fields of electrochemistry and new energy materials. The method comprises the following steps of: preparing porous silicon dioxide by using ethyl orthosilicate, silicon tetrachloride, methyl silicone oil and sodium silicide as raw materials, reducing the porous silicon dioxide into porous silicon, coating the porous silicon by adopting an organic carbon source, and performing thermal treatment under an inert atmosphere to prepare the porous silicon / carbon composite material. The material can be directly used as the lithium ion battery cathode material, the first discharge specific capacity of the material can reach 1,245mAh / g, the specific capacity can also reach 1,230mAh / g after 30 cycles, and the material has excellent charge / discharge performance.

Owner:SUZHOU QINGTAO NEW ENERGY TECH CO LTD

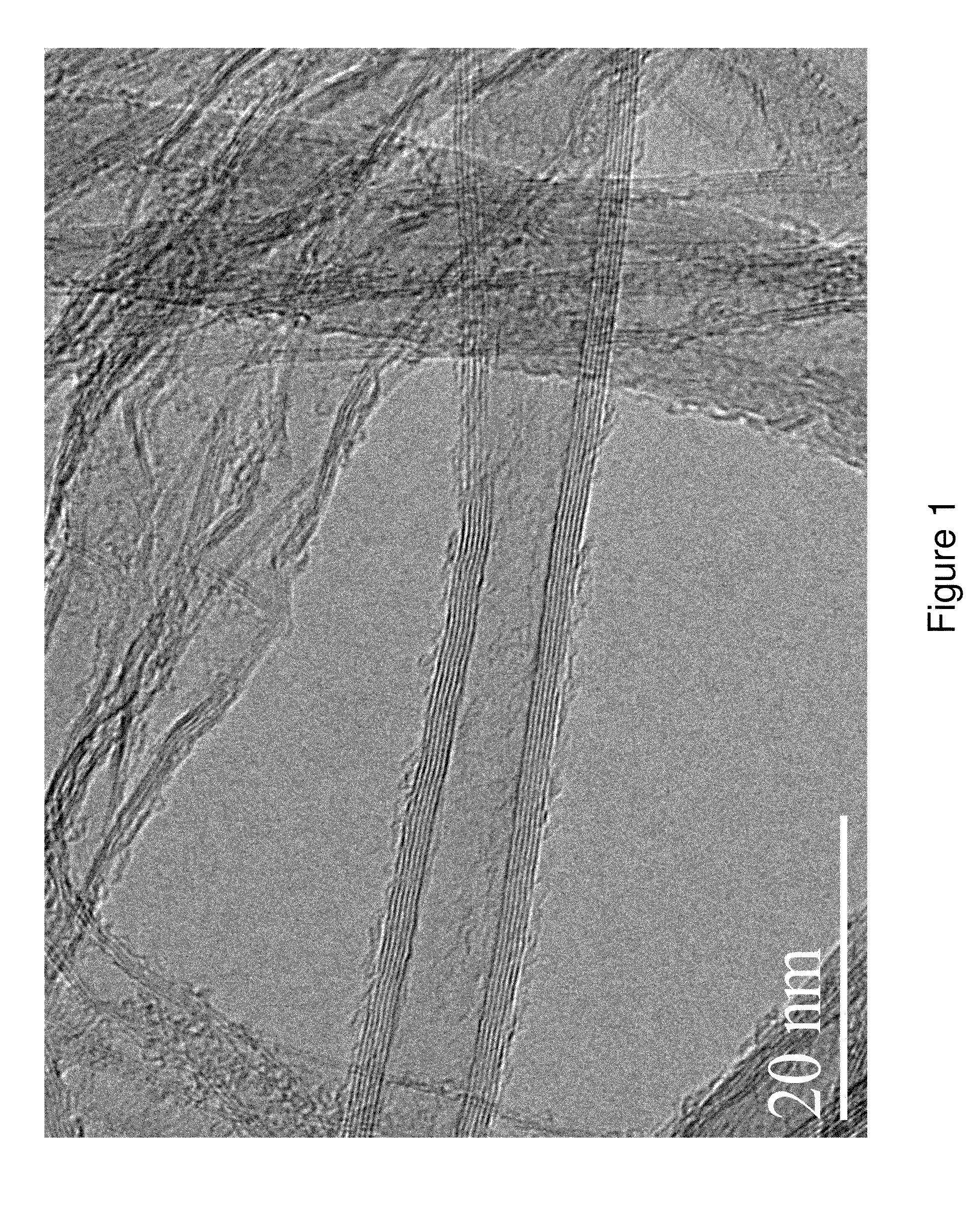

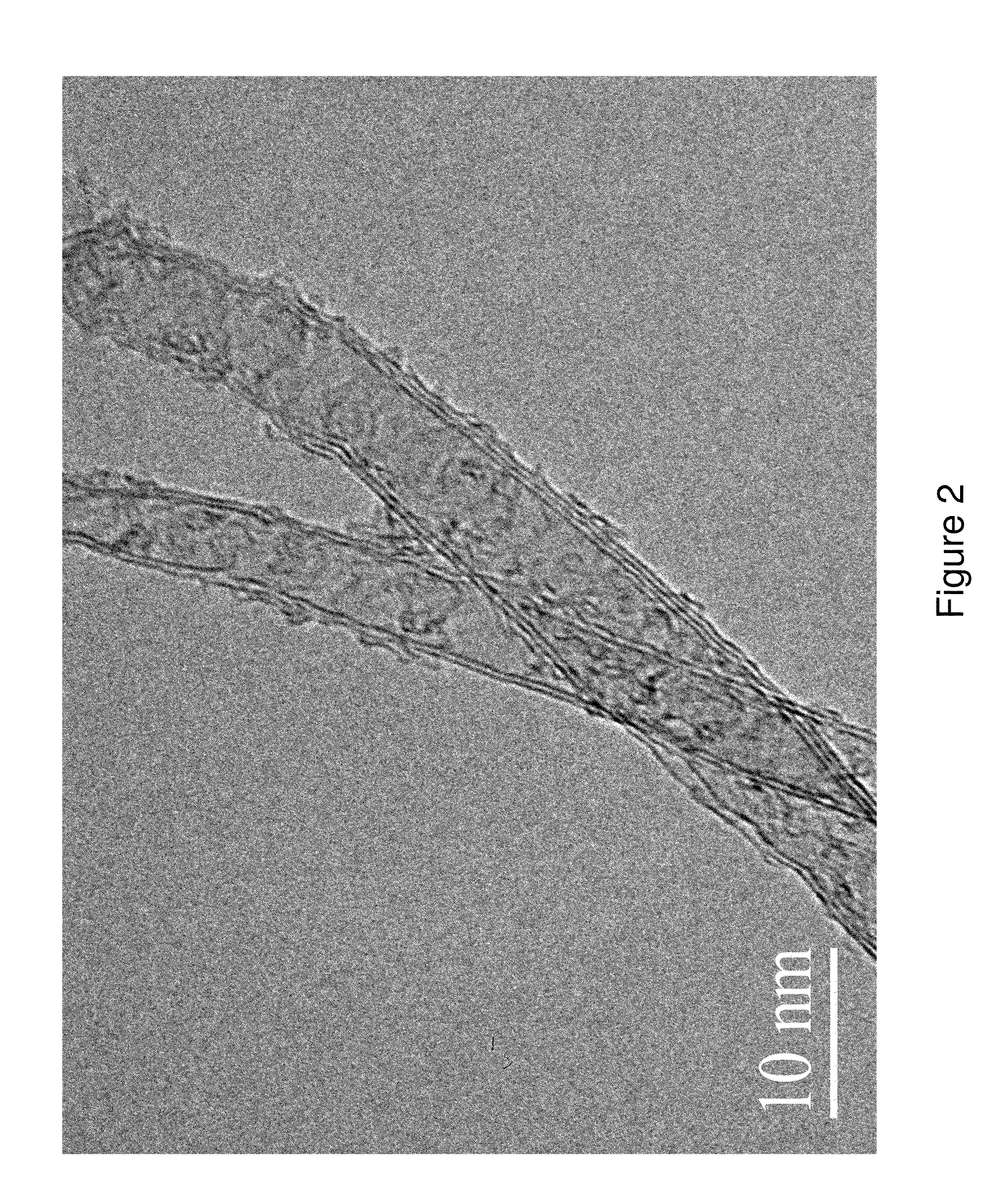

Silicon-carbon negative electrode material of lithium ion battery and preparation method thereof

ActiveCN102394287AExcellent intercalation and delithiation abilityImprove cycle stabilityCell electrodesFiberCarbon composites

The invention discloses a silicon-carbon negative electrode material of a lithium ion battery and a preparation method thereof, and solves the technological problem of improving the charge and discharge cycling stability of the electrode material. The silicon-carbon negative electrode material is prepared by mixing a silicon-carbon composite material and a natural graphite material, wherein the weight of the silicon-carbon composite material is 7-20% and the silicon-carbon composite material is prepared by depositing carbon nanotube and / or carbon nanofiber on the surface of nanometer silica fume and / or embedding into the nanometer silica fume to form core, the surface of which is covered with 3-15wt% of a carbon layer. The preparation method provided by the invention comprises steps of: precursor silicon powder preparation; chemical vapor deposition; liquid-coating roasting; crushing; and mixing. In comparison with the prior art, the reversible specific capacity of the silicon-carbon composite negative electrode material is greater than 500mAh / g; the coulombic efficiency for a first cycle is greater than 80%; the capacity conservation rate of cycling for 50 weeks is greater than 95%. The preparation method is simple, is easy to operate, requires low cost and is suitable for a high-volume negative electrode material of lithium ion batteries used for various portable devices.

Owner:BTR NEW MATERIAL GRP CO LTD

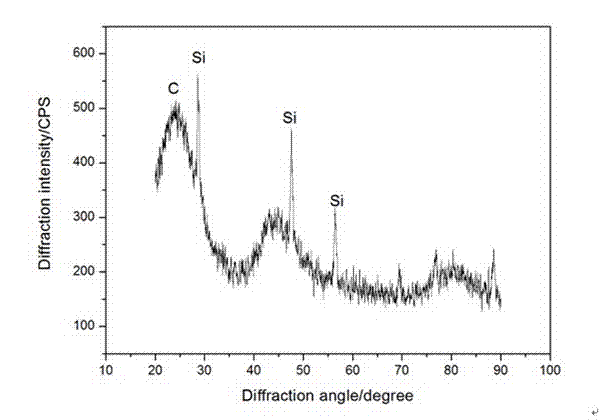

NANO silicon-carbon composite material and preparation method thereof

ActiveUS20140302396A1Improve cycle stabilityShort production processMaterial nanotechnologyElectrolysis componentsCarbon compositesSilicon dioxide

The invention relates to a nano silicon-carbon composite negative material for lithium ion batteries and a preparation method thereof. A porous electrode composed of silica and carbon is taken as a raw material, and a nano silicon-carbon composite material of carbon-loaded nano silicon is formed by a molten salt electrolysis method in a manner of silica in-situ electrochemical reduction. Silicon and carbon of the material are connected by nano silicon carbide, and are metallurgical-grade combination, so that the electrochemical cycle stability of the nano silicon-carbon composite material is improved. The preparation method of the nano silicon-carbon composite material provided by the invention comprises the following steps: compounding a porous block composed of carbon and silica powder with a conductive cathode collector as a cathode; using graphite or an inert anode as an anode, and putting the cathode and anode into CaCl2 electrolyte or mixed salt melt electrolyte containing CaCl2 to form an electrolytic cell; applying voltage between the cathode and the anode; controlling the electrolytic voltage, the electrolytic current density and the electrolytic quantity, so that silica in the porous block is deoxidized into nano silicon by electrolytic reduction, and the nano silicon-carbon composite material for lithium ion batteries is prepared at the cathode.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

Silicon-carbon composite material, lithium ion battery, and preparation method and application of silicon-carbon composite material

ActiveCN103633295AAlleviate volume expansionAvoid direct contactCell electrodesSecondary cellsCarbon compositesSilicon monoxide

The invention discloses a silicon-carbon composite material, a lithium ion battery, and a preparation method and application of the silicon-carbon composite material. The preparation method of the silicon-carbon composite material comprises the steps: uniformly mixing silicon powder and silicon monoxide powder, then mixing with a solution containing an organic carbon source dispersant, and performing wet-process ball milling to obtain a slurry; uniformly mixing the slurry, graphite and a conductive agent, and performing spray drying to obtain spherical-like particles, wherein graphite is synthetic graphite and / or intermediate-phase graphite; mixing the spherical-like particles and asphalt, performing cladding processing under the inert atmosphere to obtain a cladded material; and then performing carbonizing processing to obtain the silicon-carbon composite material, wherein silicon powder, silicon monoxide powder, graphite and asphalt respectively accounts for 5-15%, 3-10%, 45-75% and 5-40% by weight of the sum of the above materials, and the organic carbon source dispersant and the conductive agent both accounts for 0.1-2% by weight of the sum of silicon powder, silicon monoxide powder and graphite. The silicon-carbon composite material has relatively good cycle performance, and can be directly used as a cathode material of the lithium ion battery. The preparation method is simple in technology, low in cost and applicable to industrial production.

Owner:SHANGHAI SHANSHAN TECH CO LTD

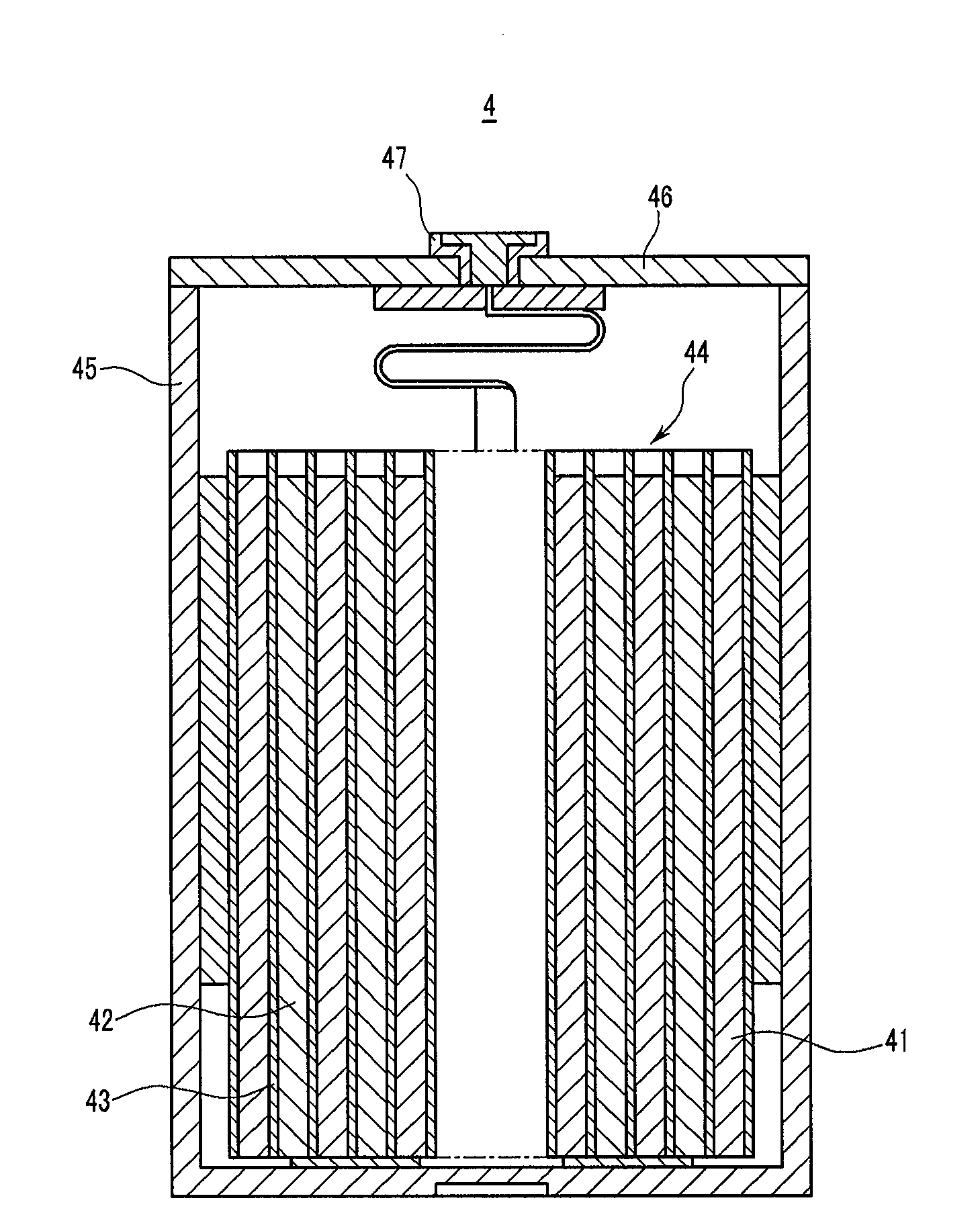

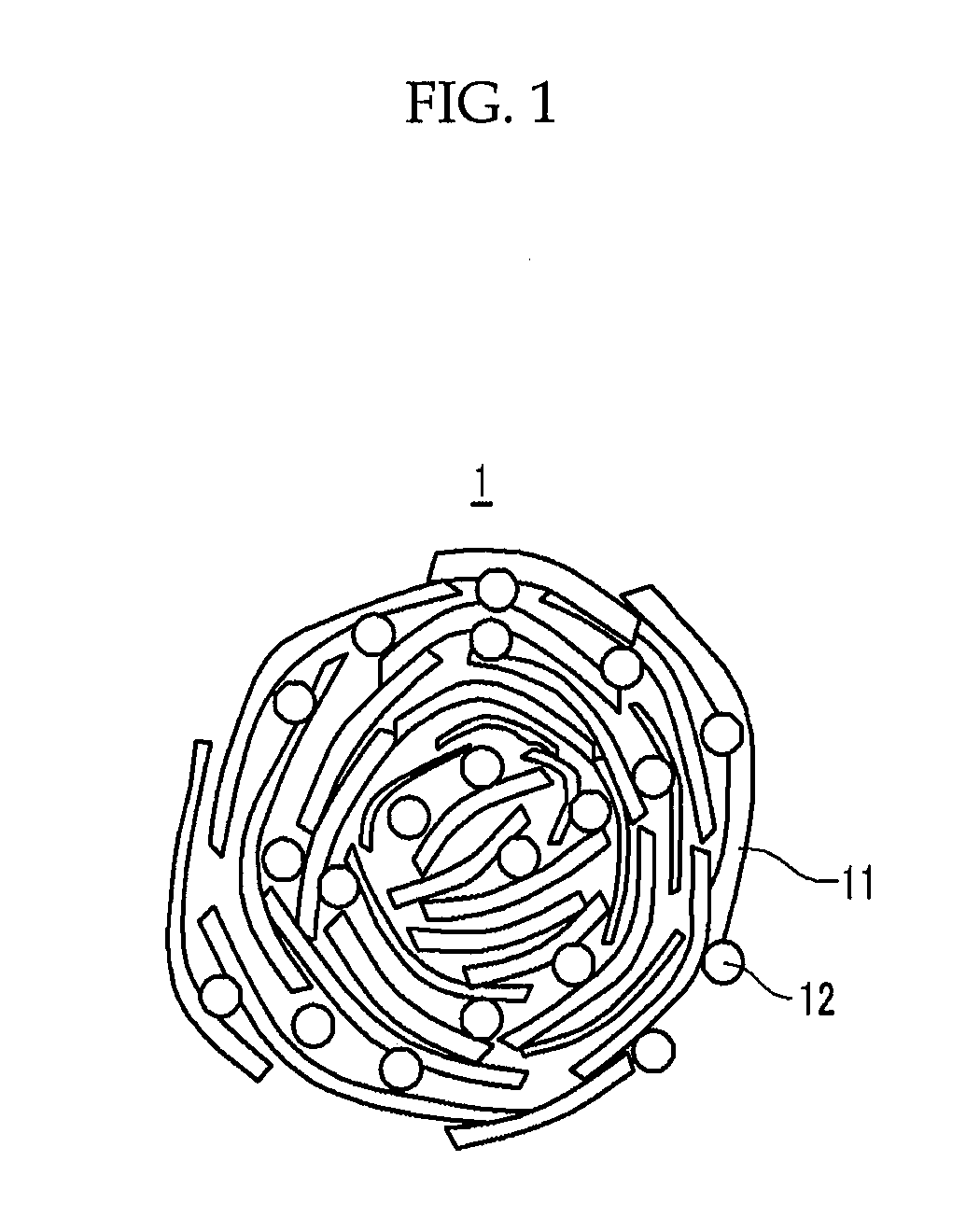

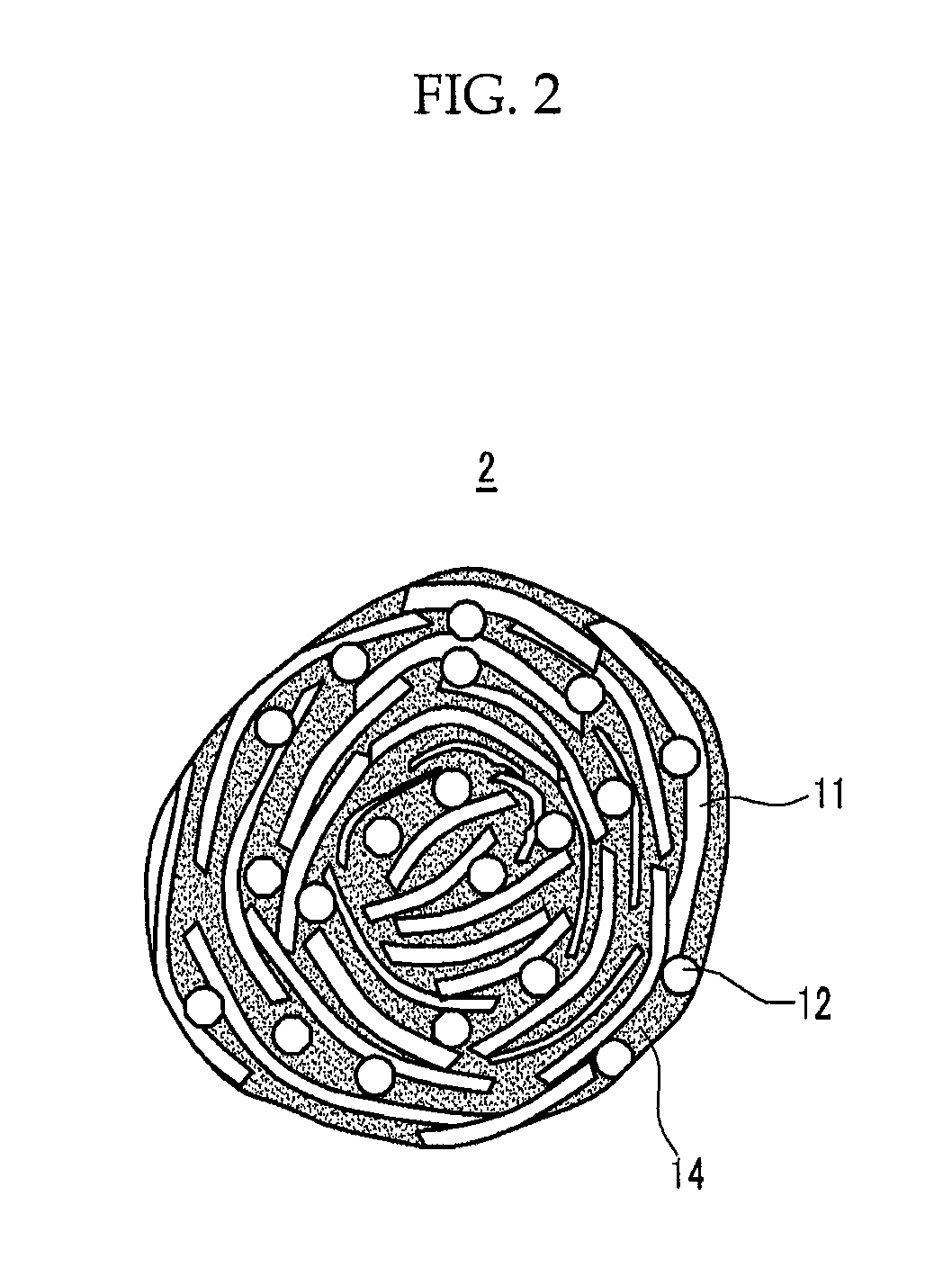

Negative electrode active material for an electricity storage device and method for manufacturing the same

InactiveUS20080220329A1Improve conductivityIncrease electrode densityMaterial nanotechnologyElectrode manufacturing processesElectricityCarbon composites

To provide a negative electrode active material for an electricity storage device, which has considerably enhanced low-temperature characteristic, increased energy density, and increased output power. A negative electrode active material is made of a carbon composite containing carbon particles as a core and a fibrous carbon having a graphene structure, which is formed on the surfaces and / or the inside of the carbon particles, wherein the carbon composite has a volume of all mesopores within 0.005 to 1.0 cm3 / g, and a volume of the mesopores each with a pore diameter ranging from 100 to 400 Å of not less than 25% of the volume of all mesopores.

Owner:SUBARU CORP

Negative active material for lithium secondary battery, method for preparing the same, negative electrode comprising the same, and lithium secondary battery comprising same

ActiveUS20100273058A1Effective supervisionImprove responseFinal product manufactureSecondary cellsCarbon compositesGraphite particle

The present invention relates to a negative active material for a rechargeable lithium battery, a method of manufacturing the negative active material, and a rechargeable lithium battery including the negative active material. The negative active material includes a sphere-shaped first graphite particle that a first particle precursor, a flake-shaped graphite piece, is linked to each other; and at least one second particle dispersed between the flake-shaped graphite pieces inside the sphere-shaped first graphite particle and selected from the group consisting of at least one element particle selected from the group consisting of Si, Sn, Al, Ge, Pb, and combinations thereof; at least one element compound particle selected from the group consisting of Si, Sn, Al, Ge, Pb, and combinations thereof; a composite particle including at least one element selected from the group consisting of Si, Sn, Al, Ge, Pb, and combinations thereof; a carbon composite particle including at least one element selected from the group consisting of Si, Sn, Al, Ge, Pb, and combinations thereof; and a combination particle thereof.

Owner:SAMSUNG ELECTRONICS CO LTD

Silicon-carbon composite cathode material of lithium ion battery and preparation thereof

InactiveCN101339987AImprove battery energy densityImprove cycle performanceElectrode manufacturing processesChemical/physical/physico-chemical processesCarbon compositesCarbonization

The invention provides a silicon-carbon composite cathode material for preparing a lithium-ion battery at the room temperature and a preparation method thereof. The composite cathode material is a material with a nuclear shell structure and comprises the following proportional elements: 0.01-10% of simple substance silicon and 90-99.9% of carbon. With regard to the preparation method, silicon powder and graphite are mixed for ball grinding and then added with bitumen or polymer cladding material for ball grinding again, after the treatment of carbonization, the mixture is crushed and sieved to obtain the material containing 0.01-10wt% of silicon and 10-99.9% of carbon. The capacity of the material is more than 350mAh / g, the cycle efficiency of the material is larger than 90% for the first time, and keeps larger than 80% after 200 cycles, and the material has good charging and discharging property.

Owner:湖南海容新材料有限责任公司

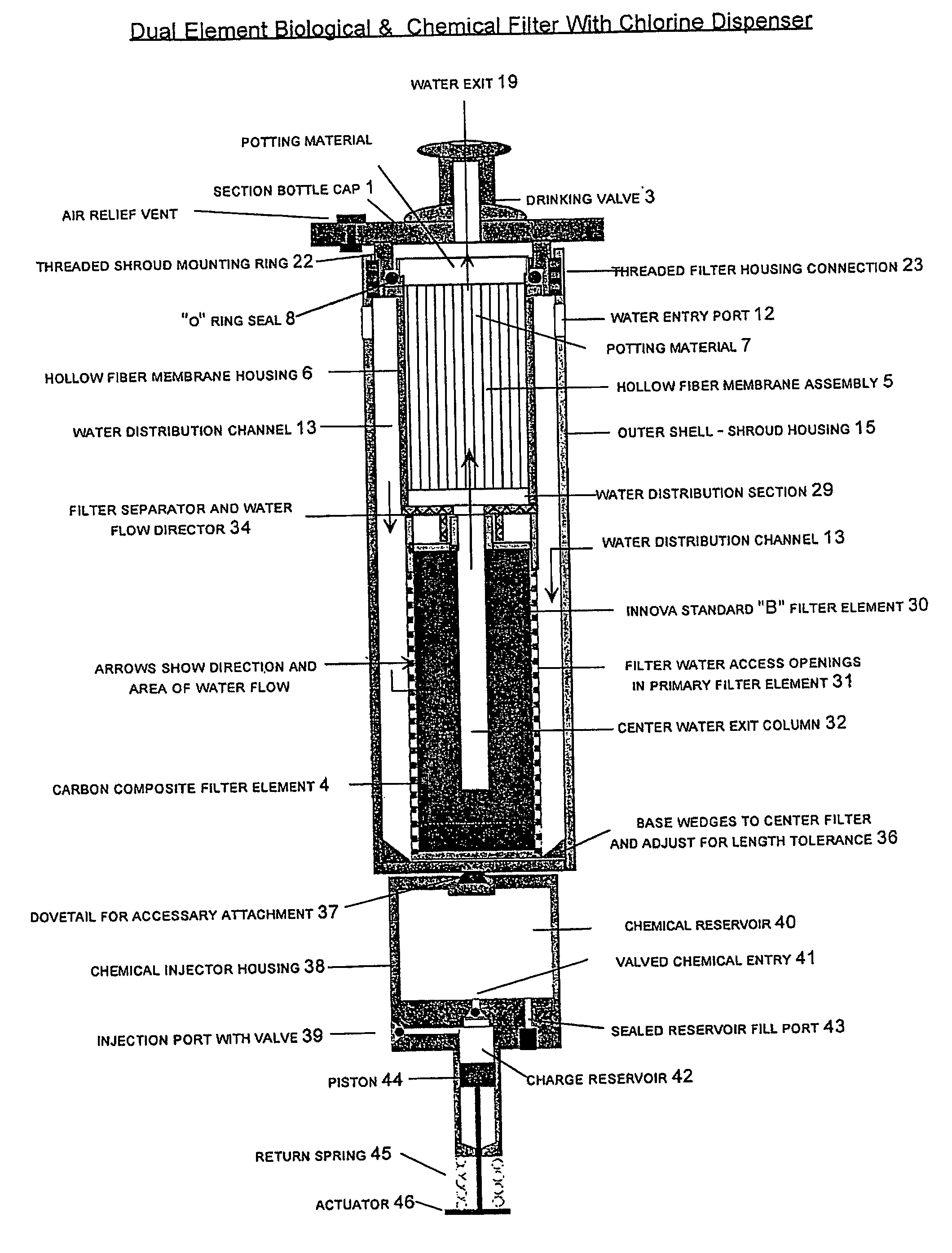

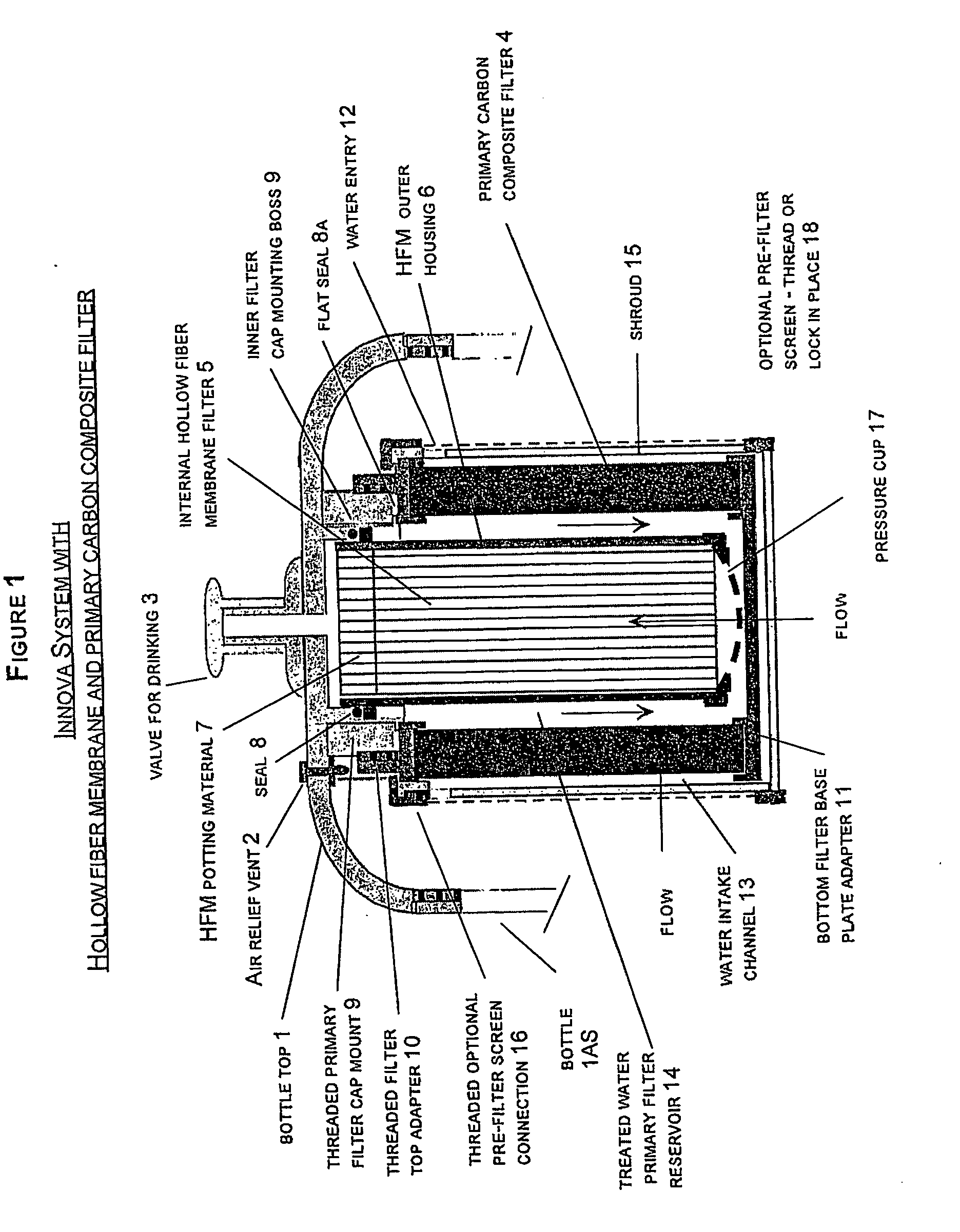

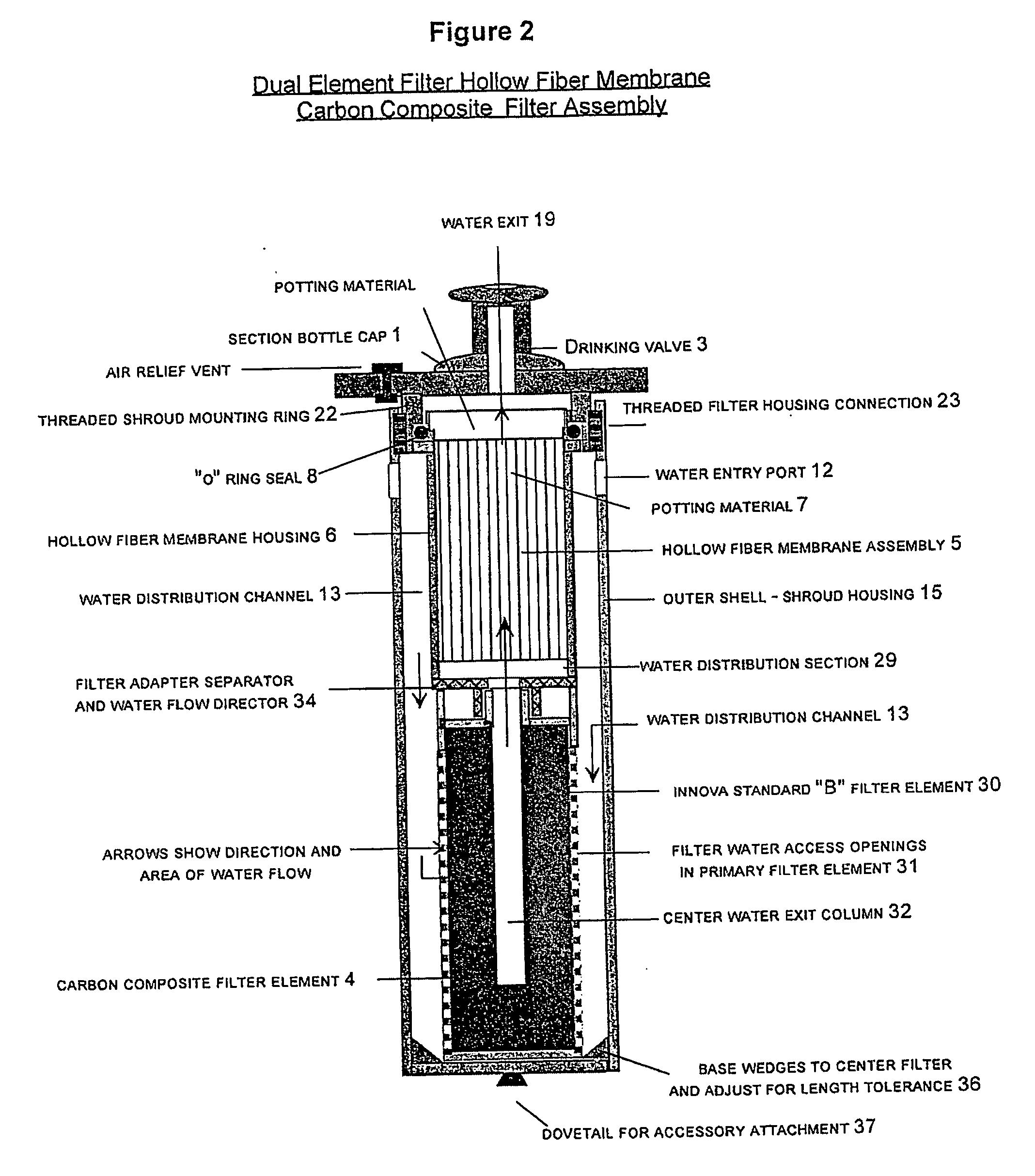

Hollow fiber membrane filters in various containers

InactiveUS20050035041A1Eliminate the problemAvoid accumulationTravelling sacksUltrafiltrationCarbon compositesWater filter

A water filter cooperable with a water container includes both a carbon composite filter (30) and a bundle of micro porous hollow fiber membranes (5) in fluid communication with the carbon composite filter (30). An influent side of the hollow fiber membrane (5) is continuously immersed in water whereby air is prevented from being reintroduced to the hollow fiber membrane (5).

Owner:INNOVAPURE WATER

Method for preparing graphene oxide grafting surface modification carbon fiber

ActiveCN102787488AIncrease roughnessImprove interface performanceCarbon compoundsCarbon fibresCarbon compositesResin matrix

A method for preparing a graphene oxide grafting surface modification carbon fiber relates to a carbon fiber modification method, and is used for solving the technical problems that the existing carbon fiber has low surface activity, reduced surface tension and poor wettability with a resin matrix, and the interlaminar shear strength of a composite material is caused to reduce. The method comprises the steps as follows: 1, graphite oxidization; 2, separation of graphite oxide mother liquor; 3, functionalization of graphite oxide; 4, carbon fiber surface functionalization; and 5, carbon fiber surface graphite oxide treatment. The graphite oxide uniformly covers the carbon fiber surface, the roughness of the carbon fiber surface can be greatly improved, and accordingly, the interfacial properties of a carbon fiber reinforced composite material can be improved by an anchoring action. The interfacial shear strength of the surface grafting graphene oxide carbon fiber / carbon composite material which is prepared through graphene oxide grafting modification can be improved by 25% in comparison with that of the untreated surface grafting graphene oxide carbon fiber / carbon composite material.

Owner:HARBIN INST OF TECH

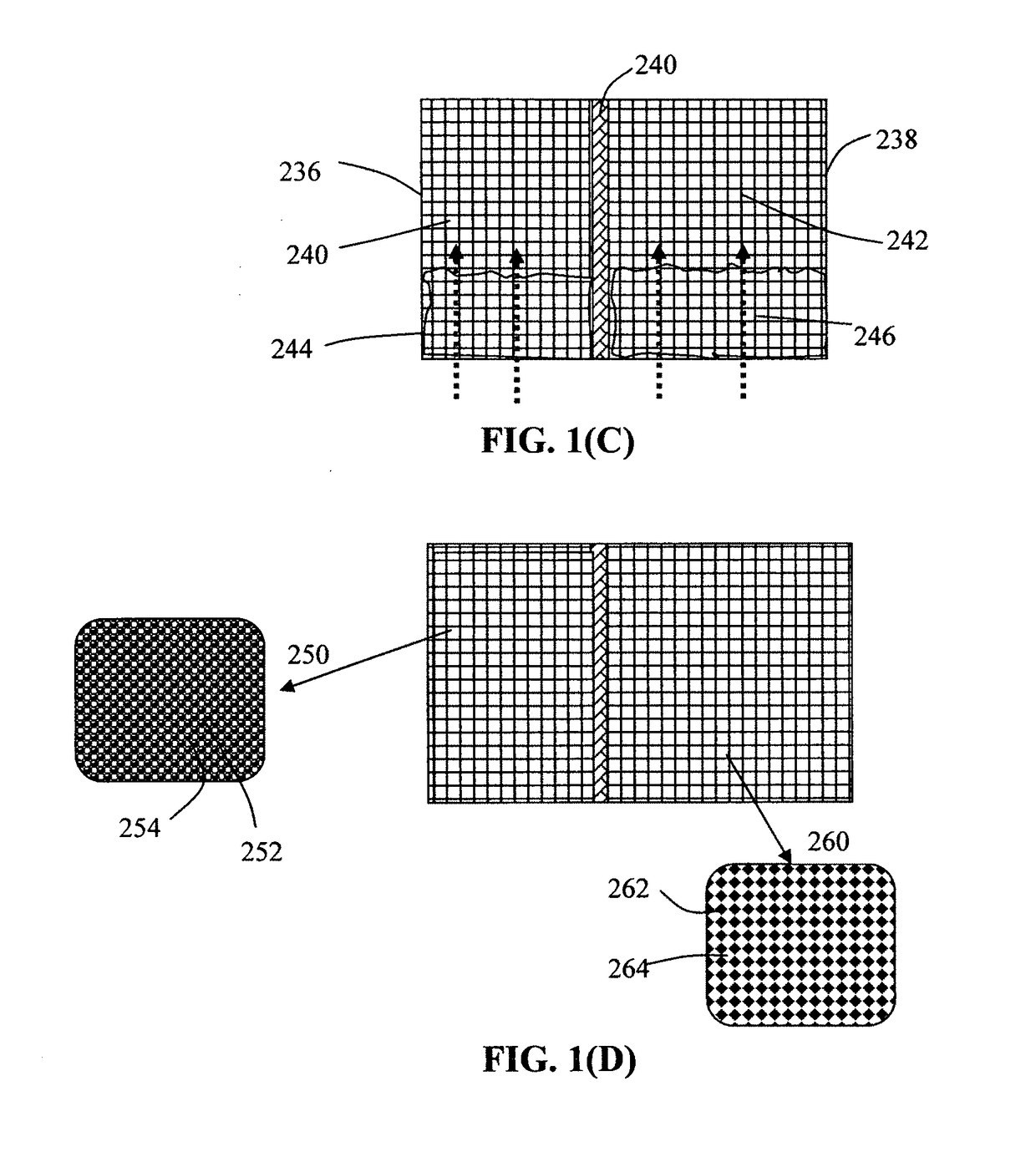

Alkali Metal-Sulfur Batteries Having High Volumetric and Gravimetric Energy Densities

ActiveUS20170207484A1Large capacityImprove the immunityFinal product manufactureElectrode carriers/collectorsCarbon compositesSlurry

Provided is an alkali metal-sulfur battery, comprising: (a) an anode; (b) a cathode having (i) a cathode active material slurry comprising a cathode active material dispersed in an electrolyte and (ii) a conductive porous structure acting as a 3D cathode current collector having at least 70% by volume of pores and wherein cathode active material slurry is disposed in pores of the conductive porous structure, wherein the cathode active material is selected from sulfur, lithium polysulfide, sodium polysulfide, sulfur-polymer composite, sulfur-carbon composite, sulfur-graphene composite, or a combination thereof; and (c) a separator disposed between the anode and the cathode; wherein the cathode thickness-to-cathode current collector thickness ratio is from 0.8 / 1 to 1 / 0.8, and / or the cathode active material constitutes an electrode active material loading greater than 15 mg / cm2, and the 3D porous cathode current collector has a thickness no less than 200 μm (preferably thicker than 500 μm).

Owner:GLOBAL GRAPHENE GRP INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com