Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

271 results about "Interfacial shear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bone cement composite containing particles in a non-uniform spatial distribution and devices for implementation

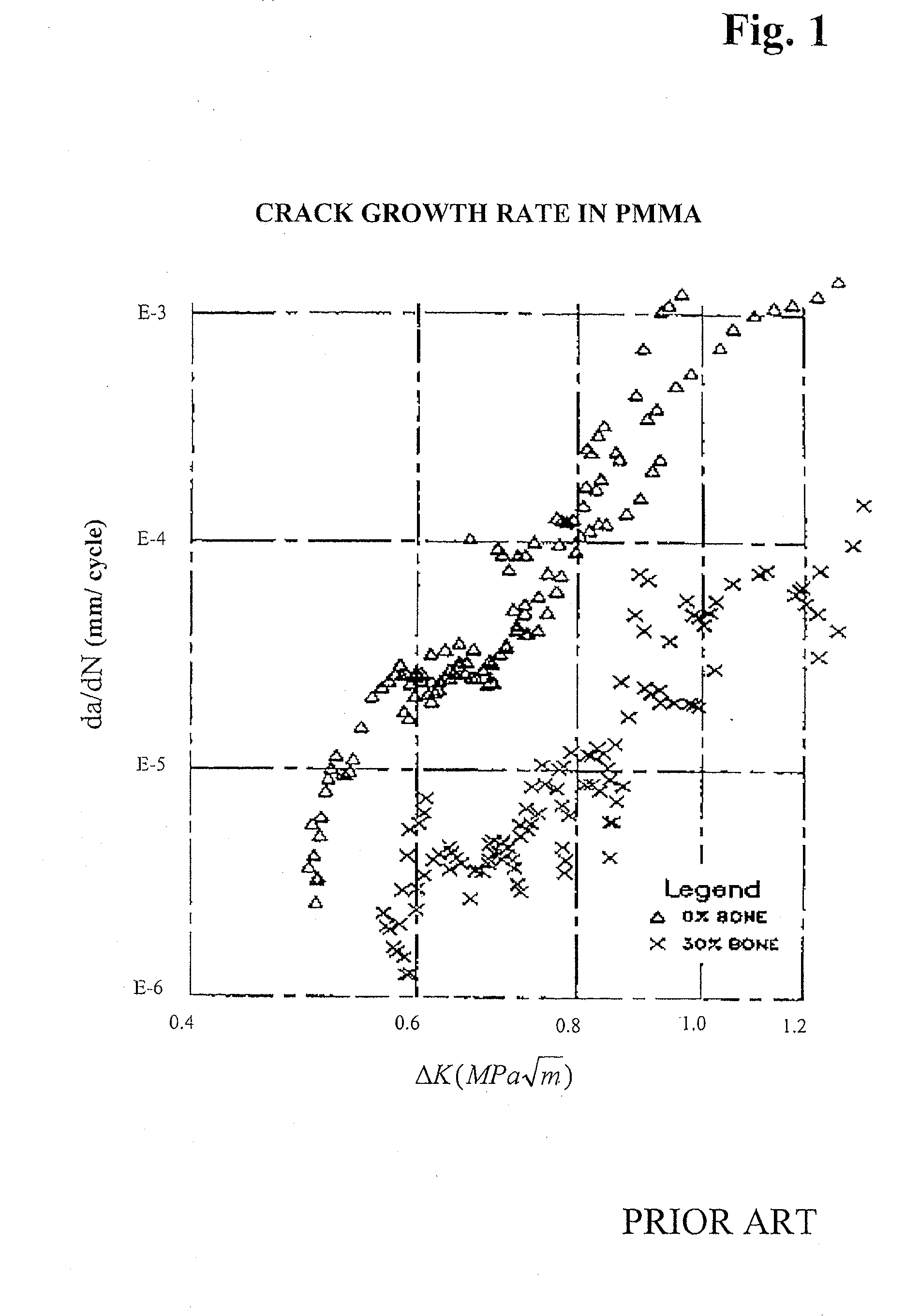

InactiveUS20070185231A1Avoid compressionReduce cavity volumeImpression capsSurgical adhesivesNatural boneControl manner

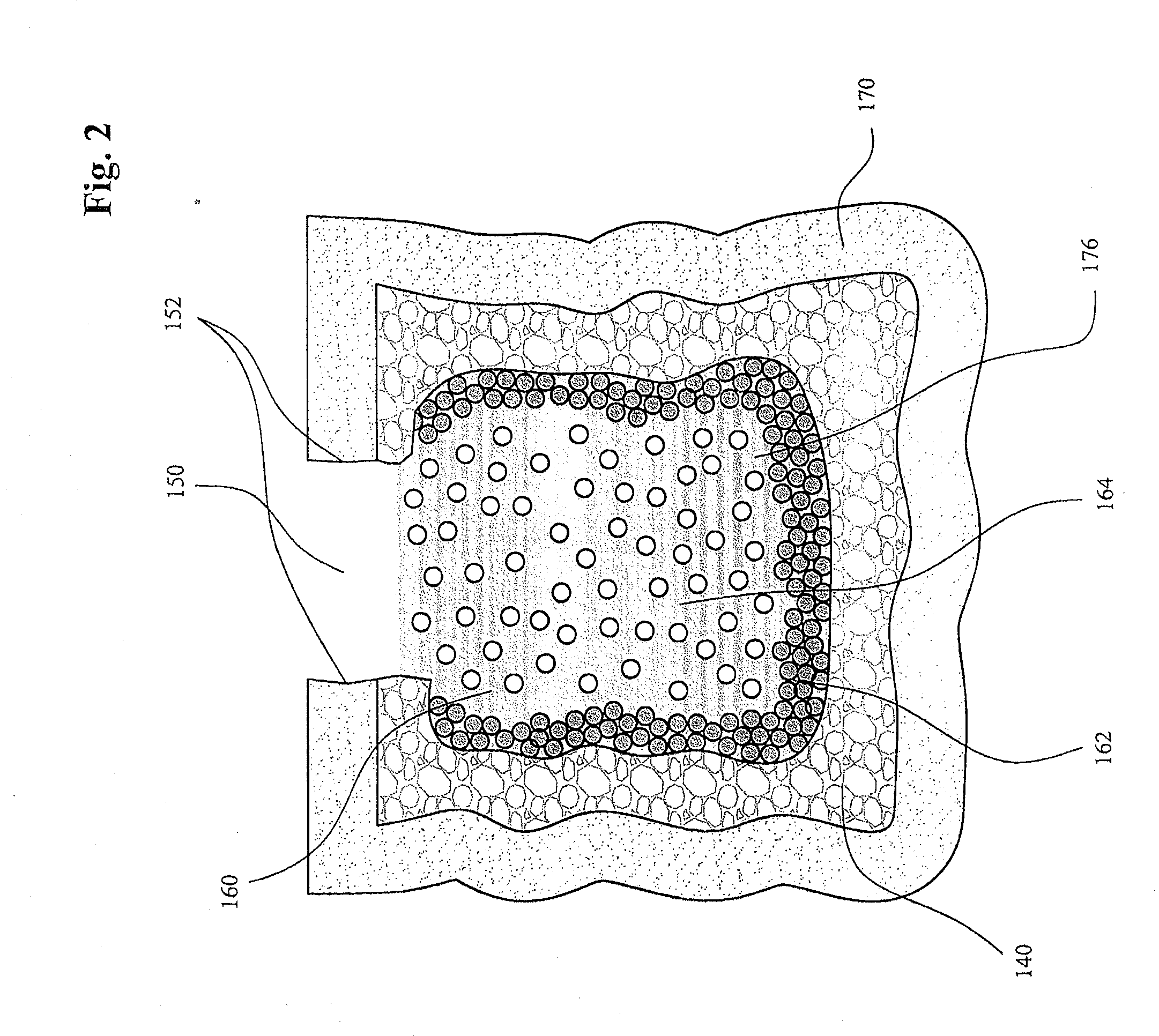

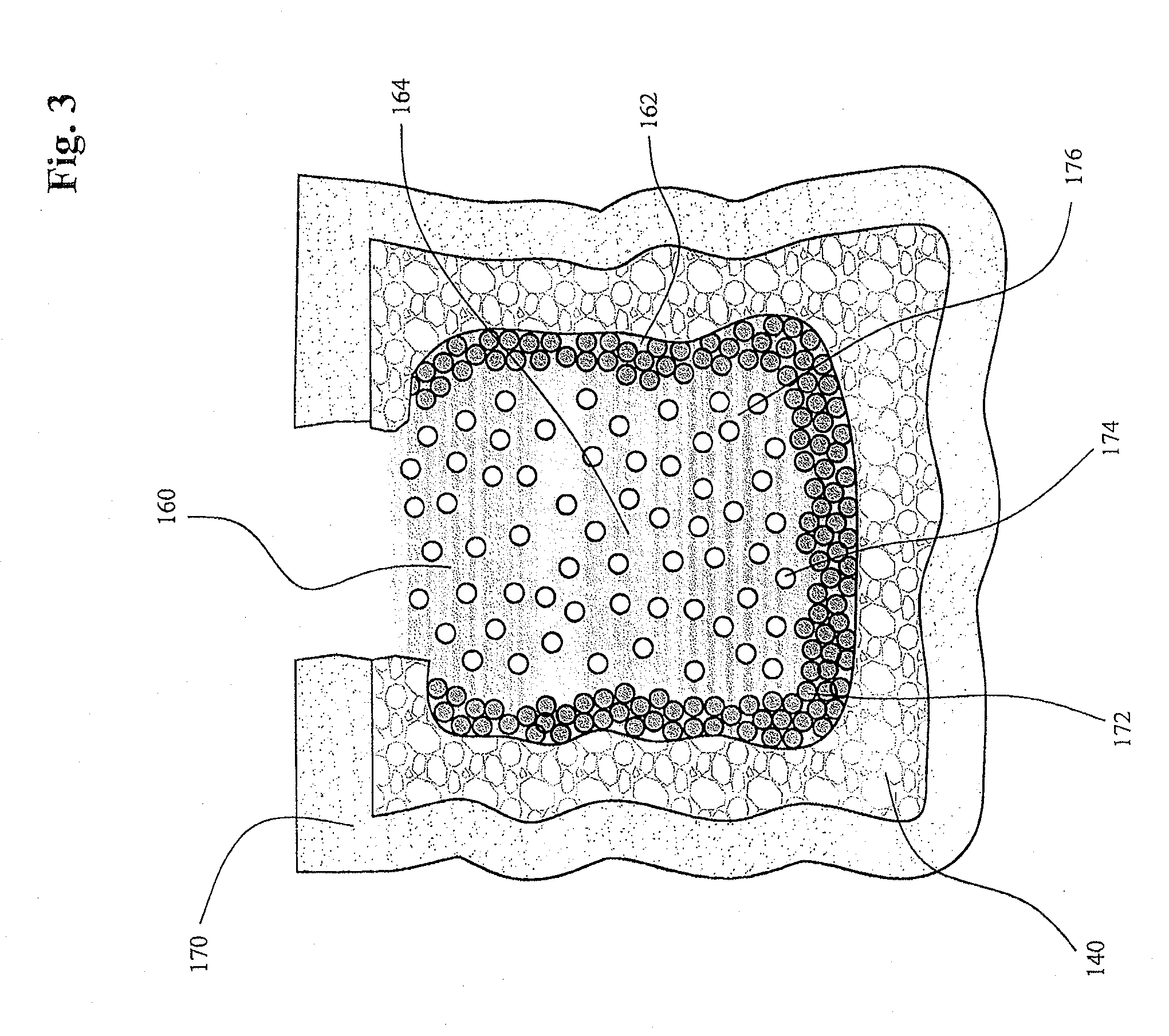

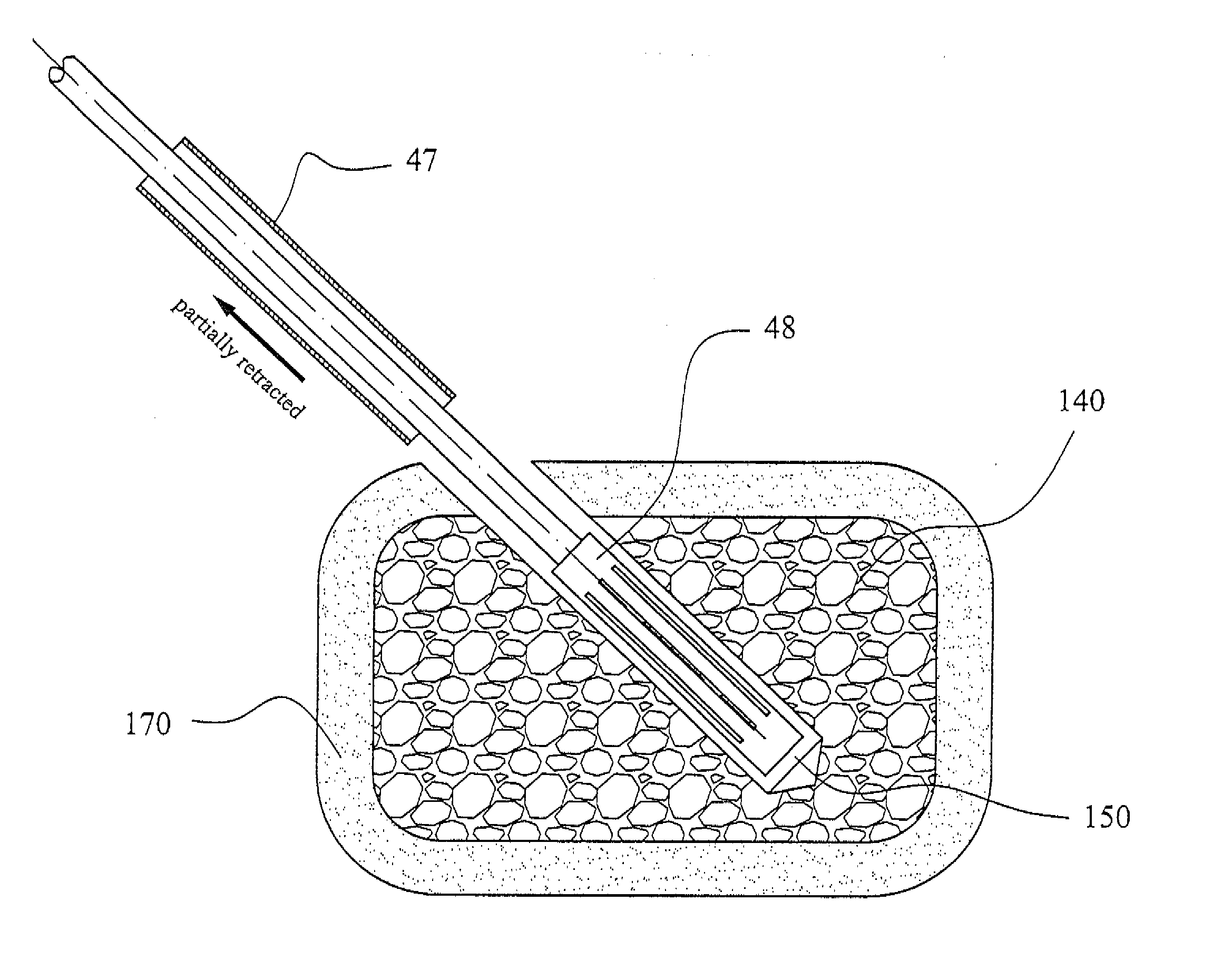

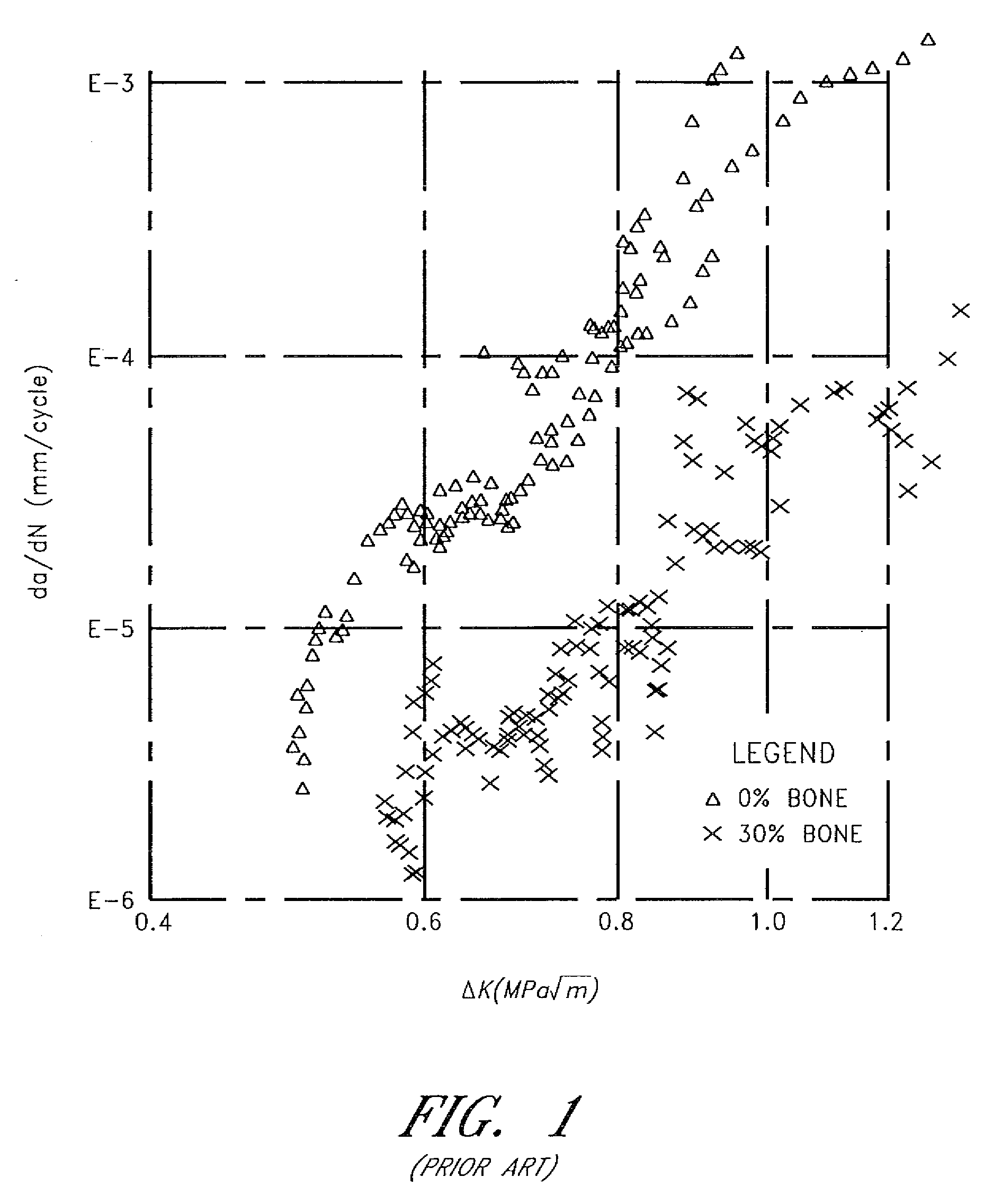

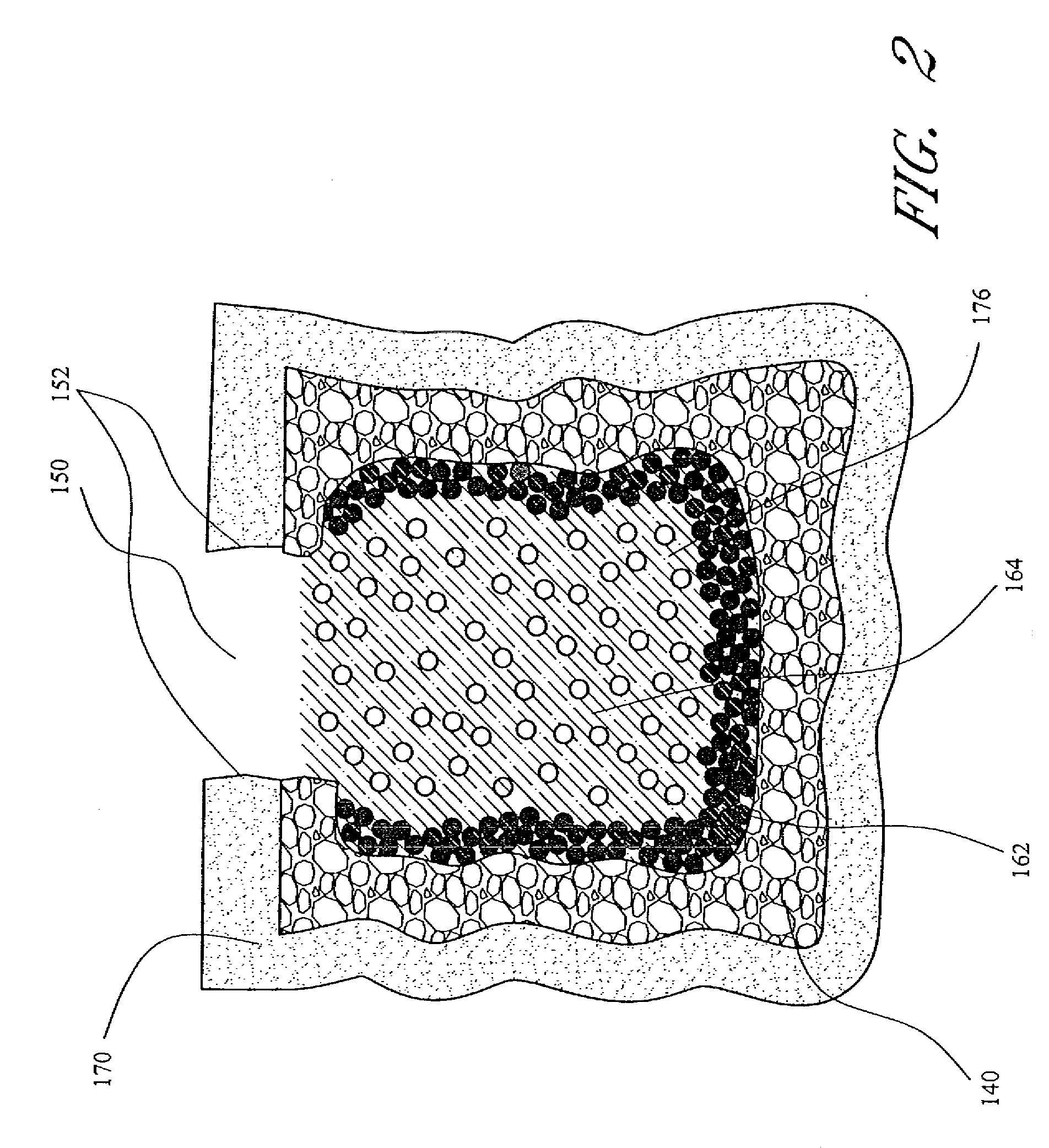

One embodiment of the invention comprises a differential composite in which bone cement everywhere or substantially everywhere contains at least some non-zero volume fraction of particles, and in which the local volume fraction of particles may vary from place to place in the composite in a controlled manner. The variation may be by identifiable region or may be in the form of a gradient of the local volume fraction of particles. In at least some places, the local volume fraction of particles may be such that the particles act as crack arrestors. Close to the interface with natural bone, the local volume fraction of particles may be greater. In at least some places adjoining natural bone, the local volume fraction of particles may be such as to allow bone ingrowth into appropriate region(s) of the composite, resulting in improved interfacial shear strength. Methods and apparatuses for producing and delivering the composite are also disclosed, which may include use of an introducer and an expandable basket-type device.

Owner:OSSEON THERAPEUTICS

Vertebroplasty methods with optimized shear strength and crack propagation resistance

InactiveUS20080195112A1Reduce cavity volumeImpression capsSurgical adhesivesNatural boneControl manner

Owner:LIU Y KING +3

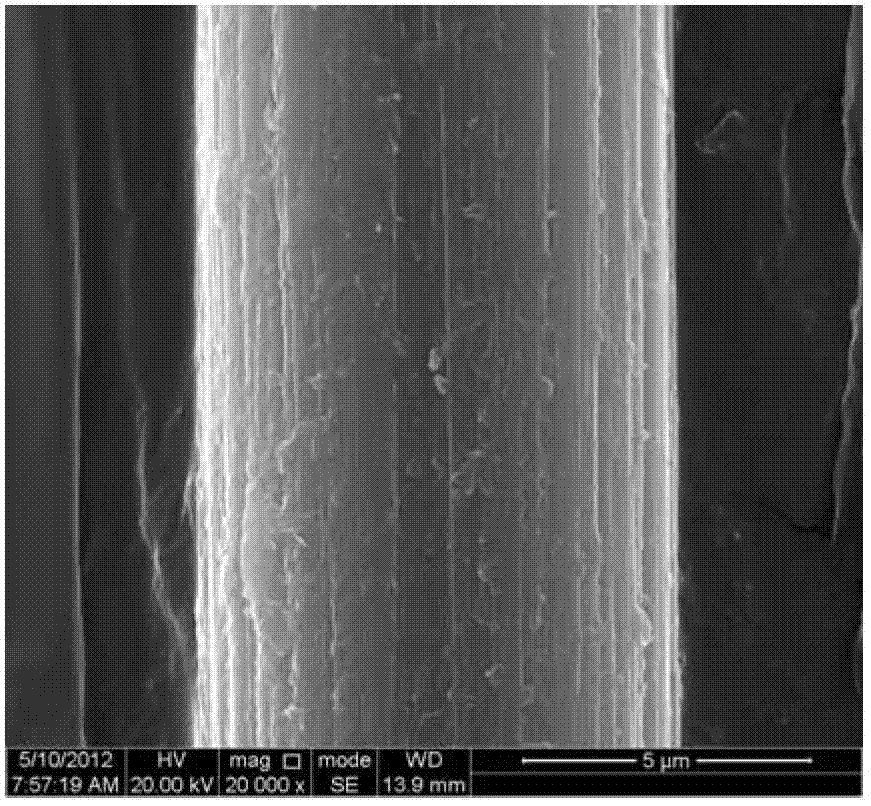

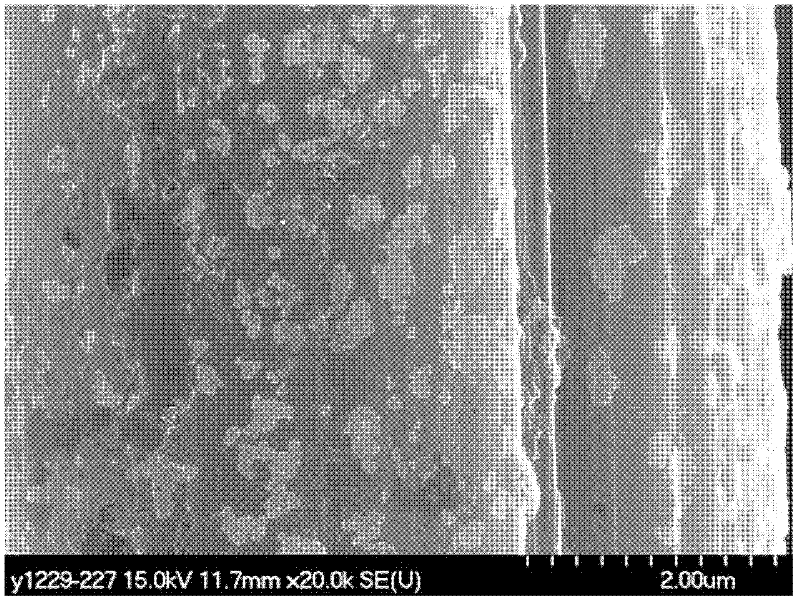

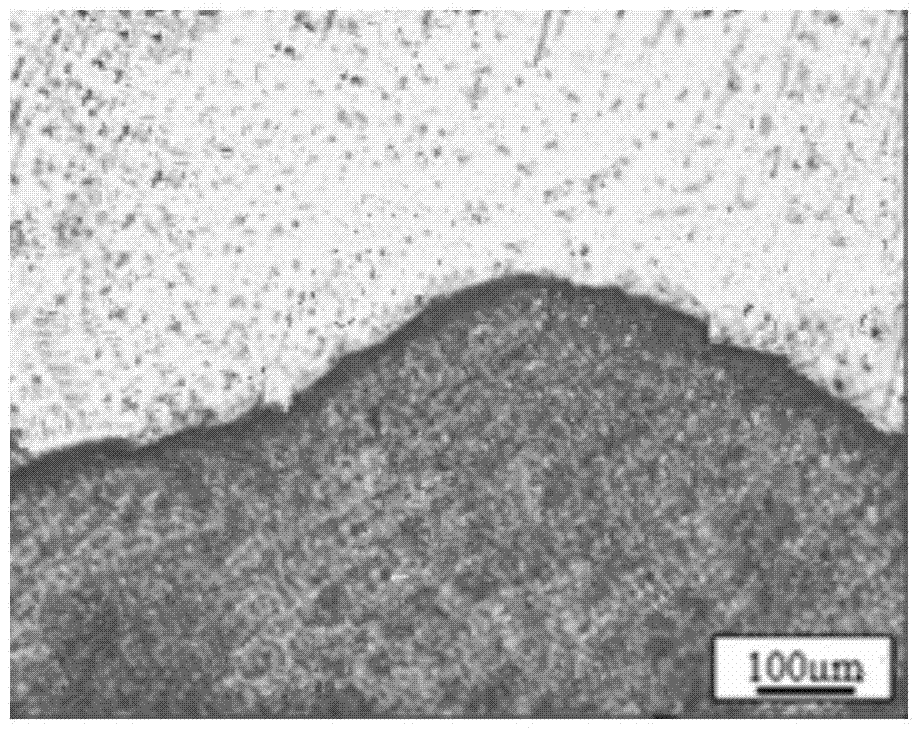

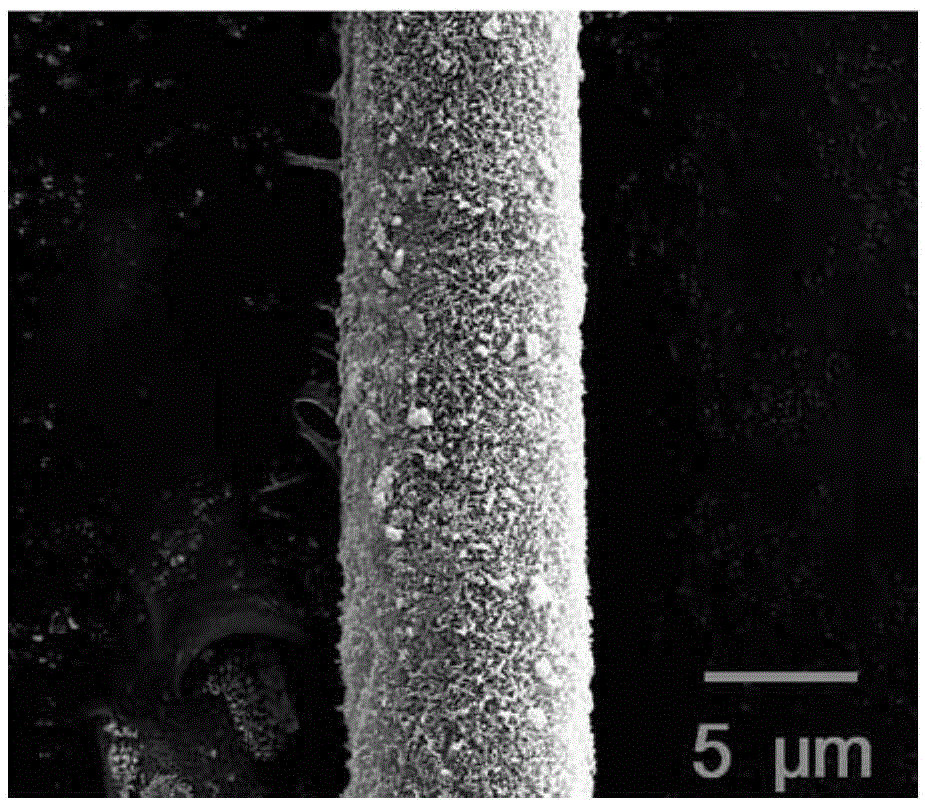

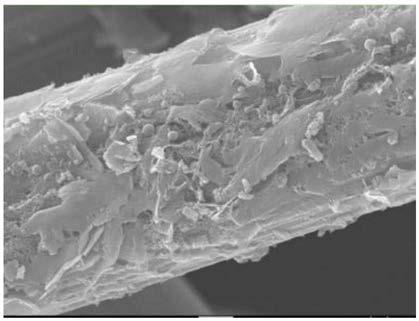

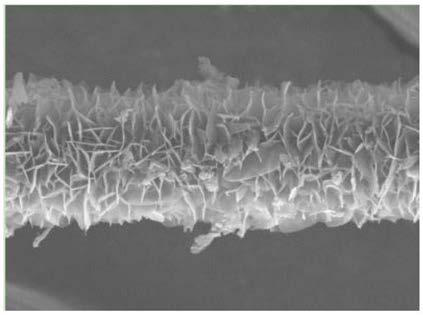

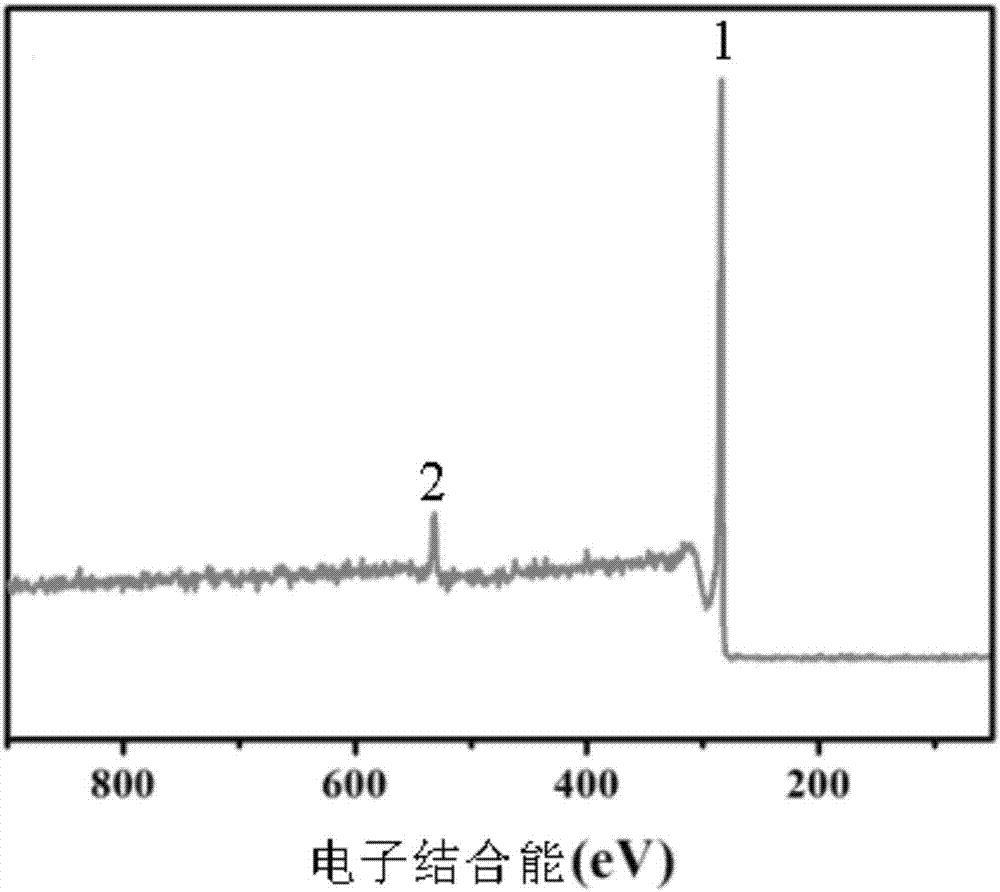

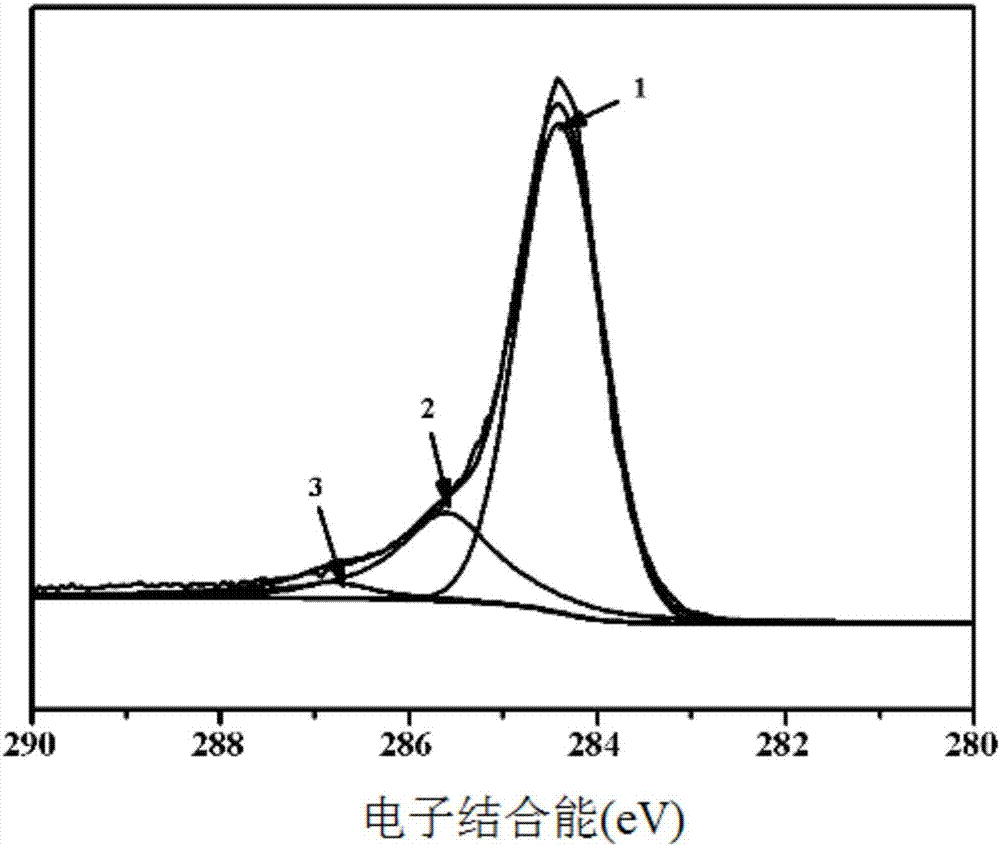

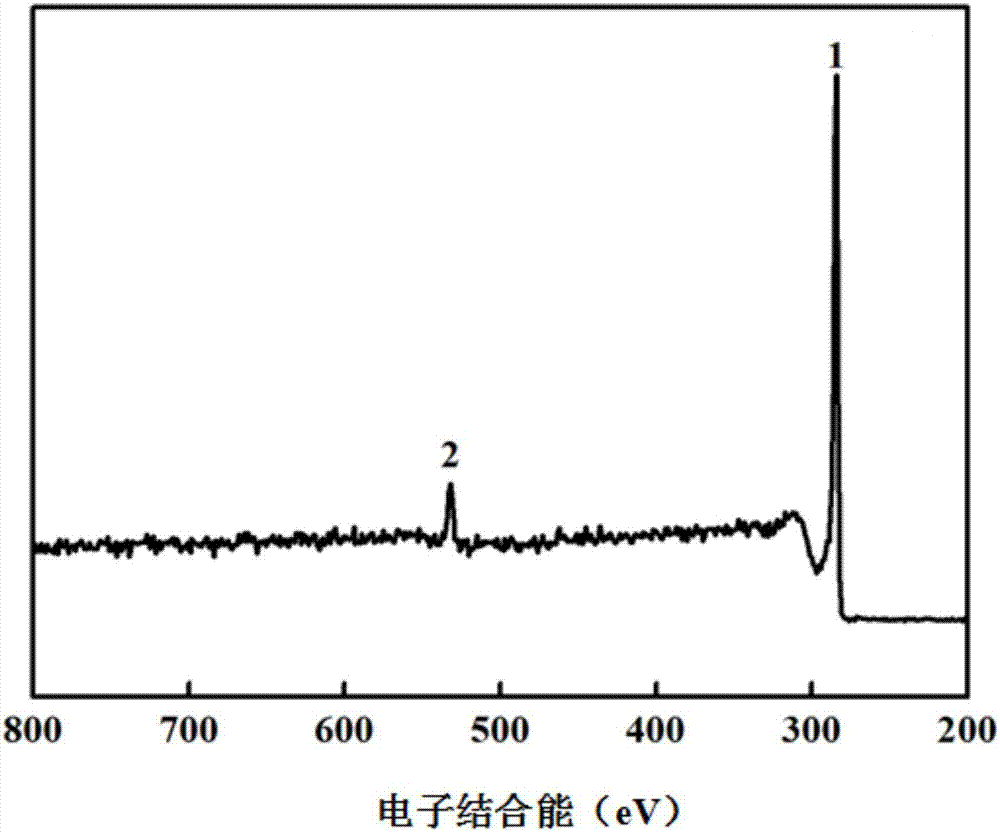

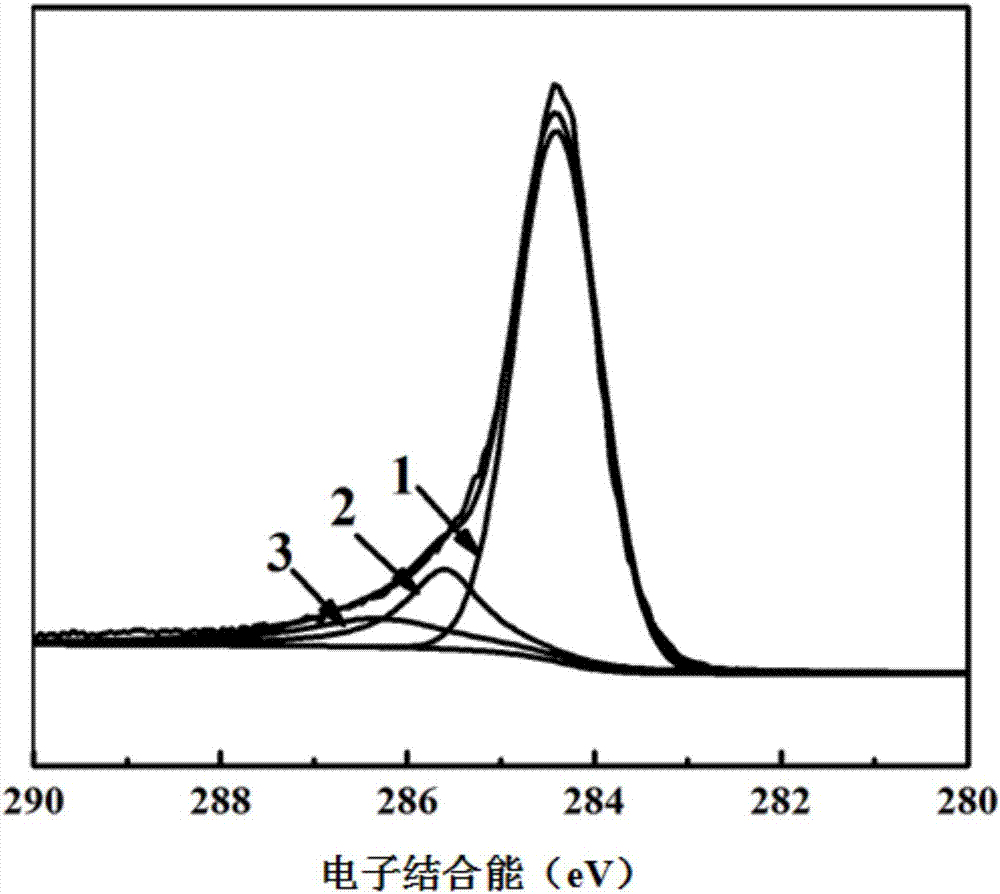

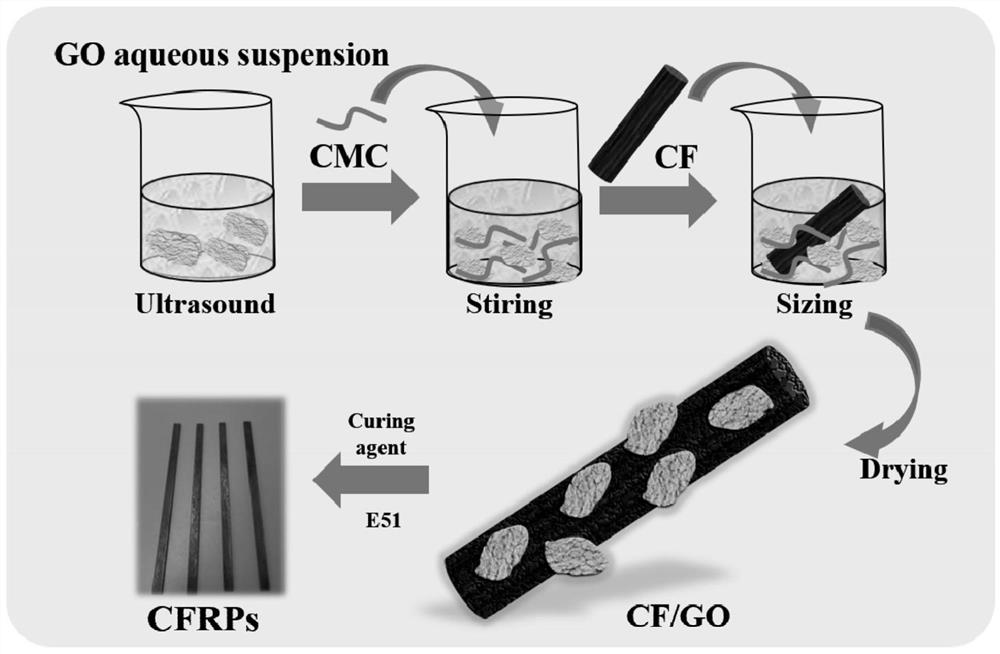

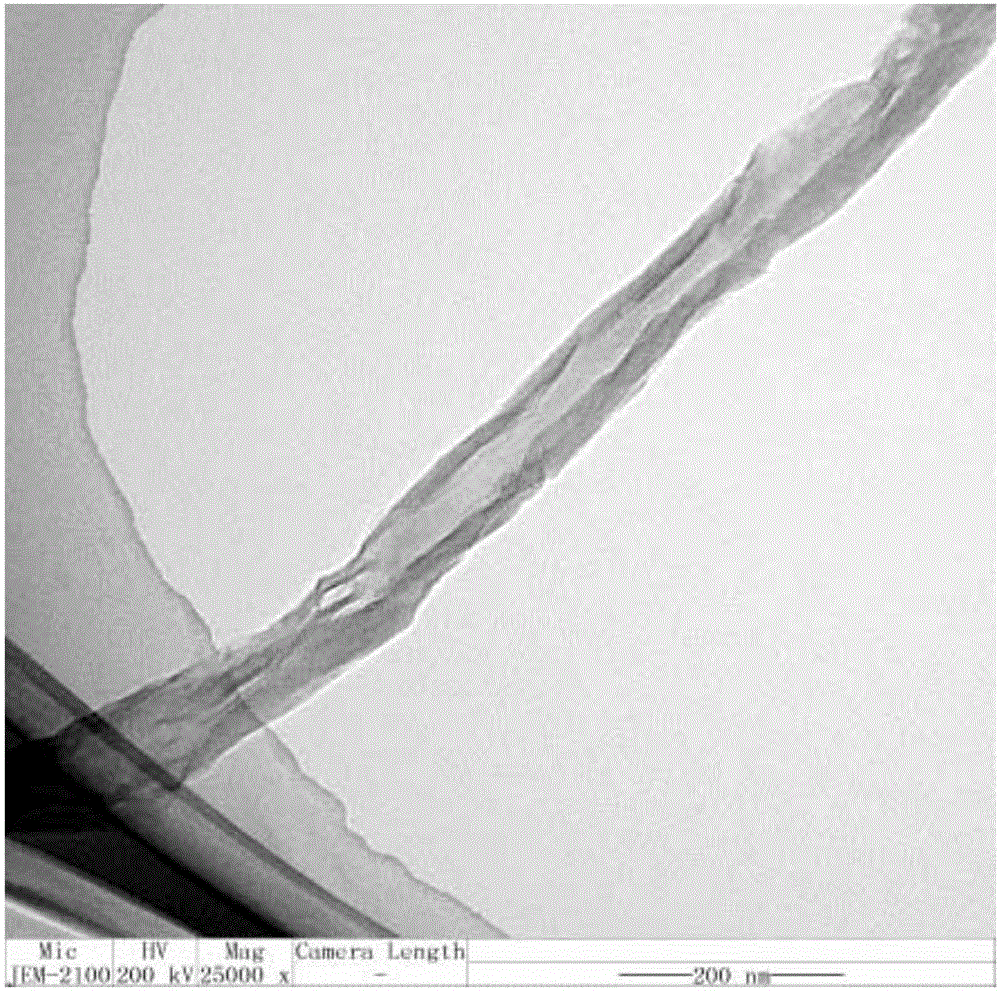

Method for preparing graphene oxide grafting surface modification carbon fiber

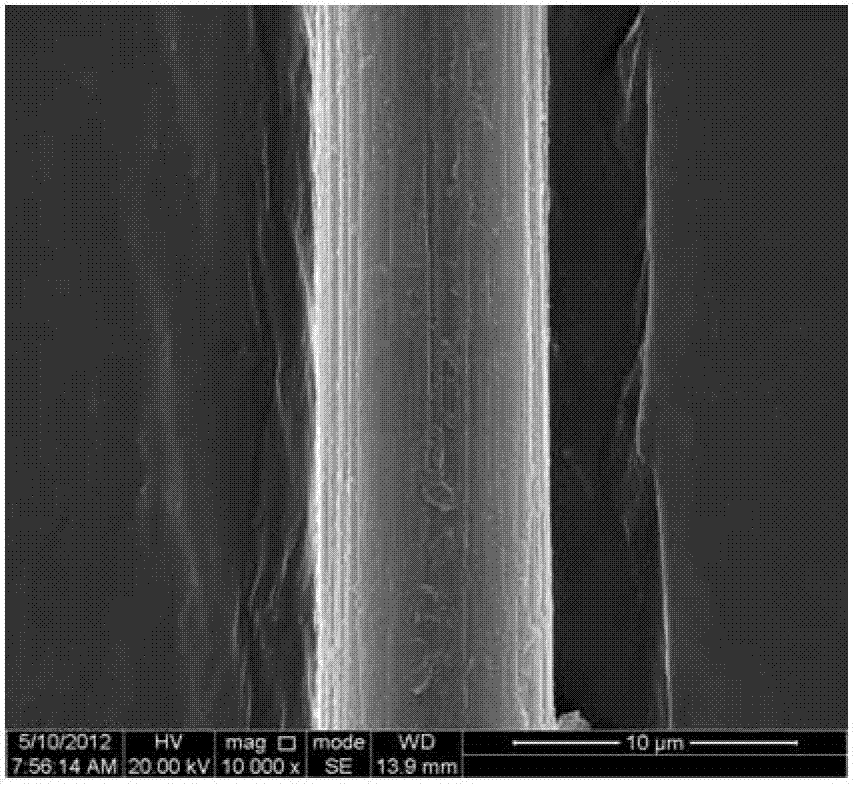

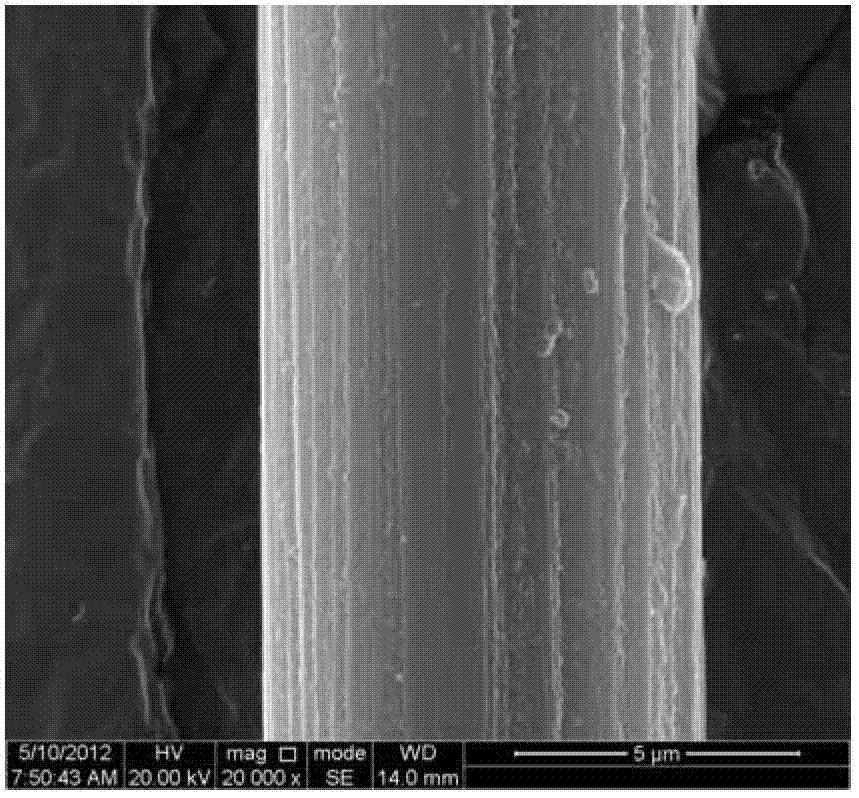

ActiveCN102787488AIncrease roughnessImprove interface performanceCarbon compoundsCarbon fibresCarbon compositesResin matrix

A method for preparing a graphene oxide grafting surface modification carbon fiber relates to a carbon fiber modification method, and is used for solving the technical problems that the existing carbon fiber has low surface activity, reduced surface tension and poor wettability with a resin matrix, and the interlaminar shear strength of a composite material is caused to reduce. The method comprises the steps as follows: 1, graphite oxidization; 2, separation of graphite oxide mother liquor; 3, functionalization of graphite oxide; 4, carbon fiber surface functionalization; and 5, carbon fiber surface graphite oxide treatment. The graphite oxide uniformly covers the carbon fiber surface, the roughness of the carbon fiber surface can be greatly improved, and accordingly, the interfacial properties of a carbon fiber reinforced composite material can be improved by an anchoring action. The interfacial shear strength of the surface grafting graphene oxide carbon fiber / carbon composite material which is prepared through graphene oxide grafting modification can be improved by 25% in comparison with that of the untreated surface grafting graphene oxide carbon fiber / carbon composite material.

Owner:HARBIN INST OF TECH

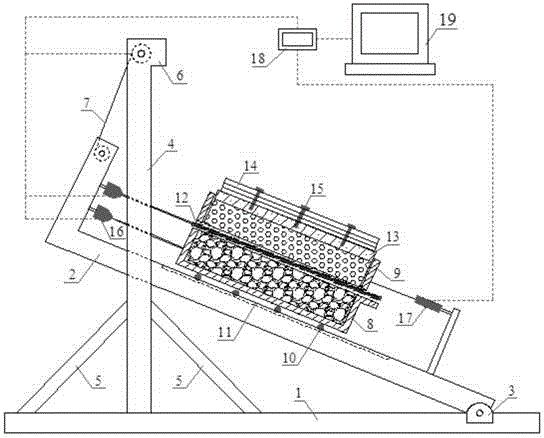

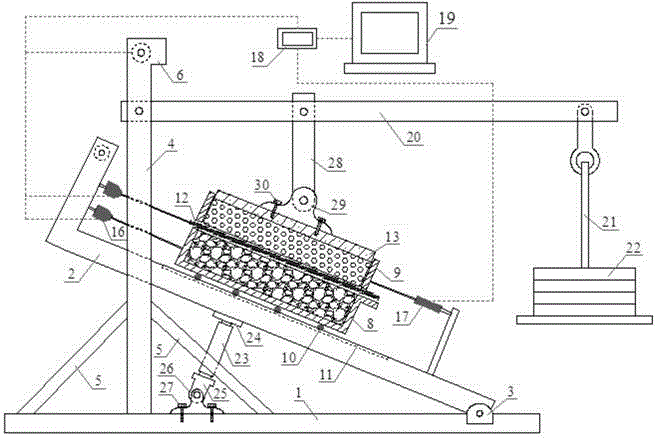

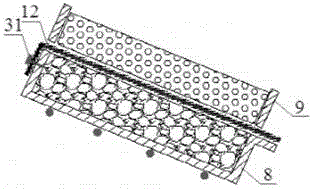

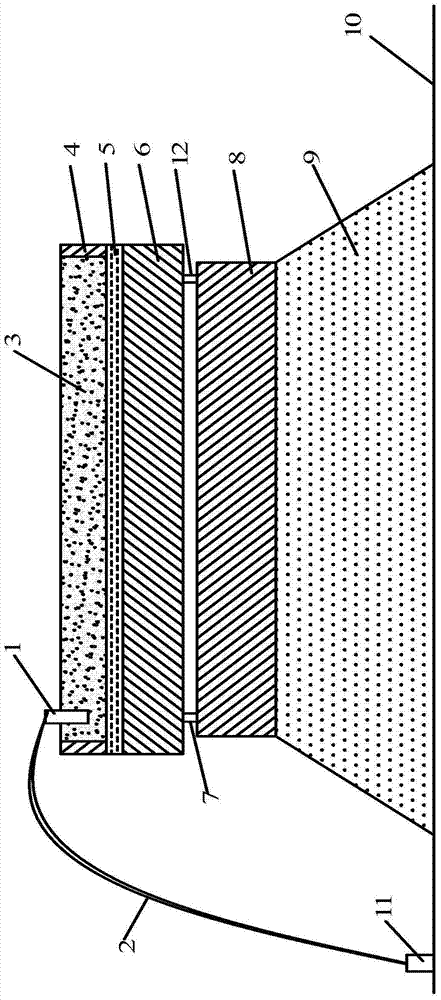

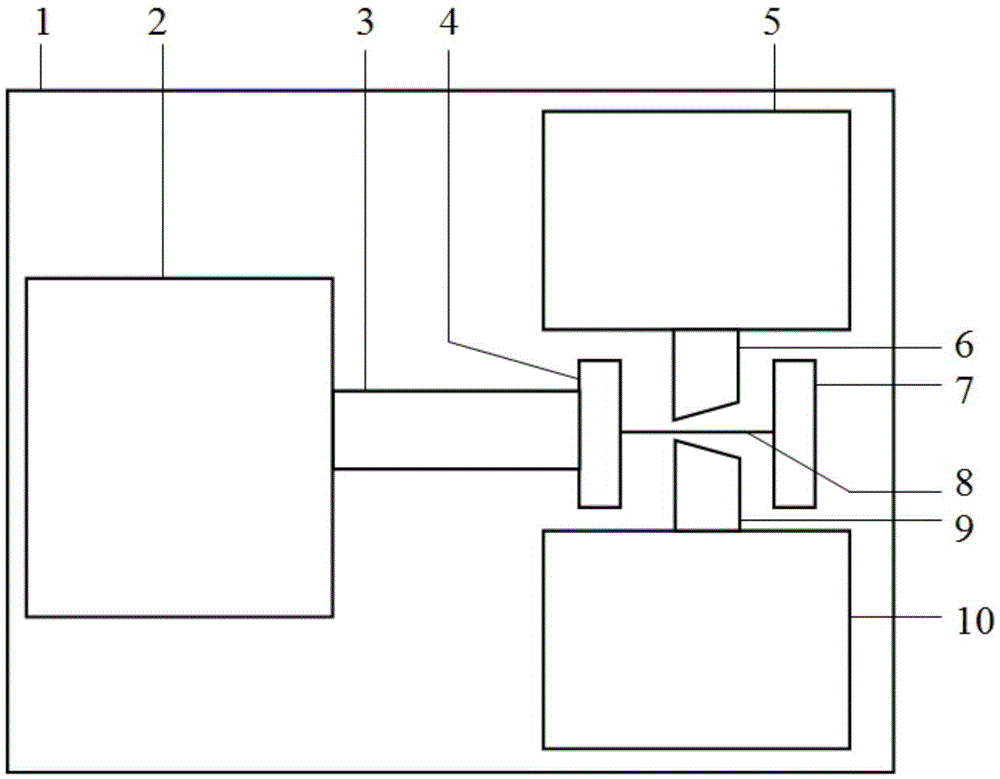

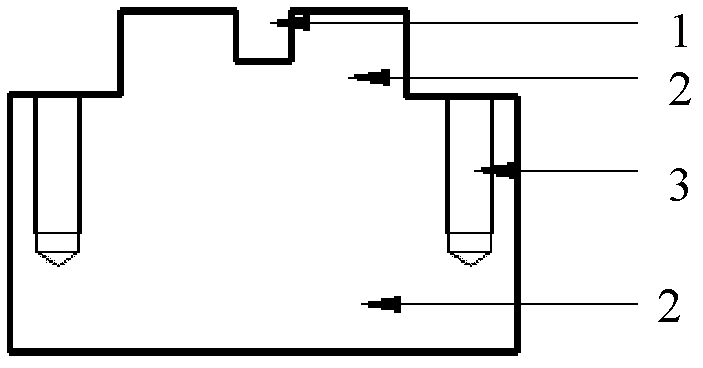

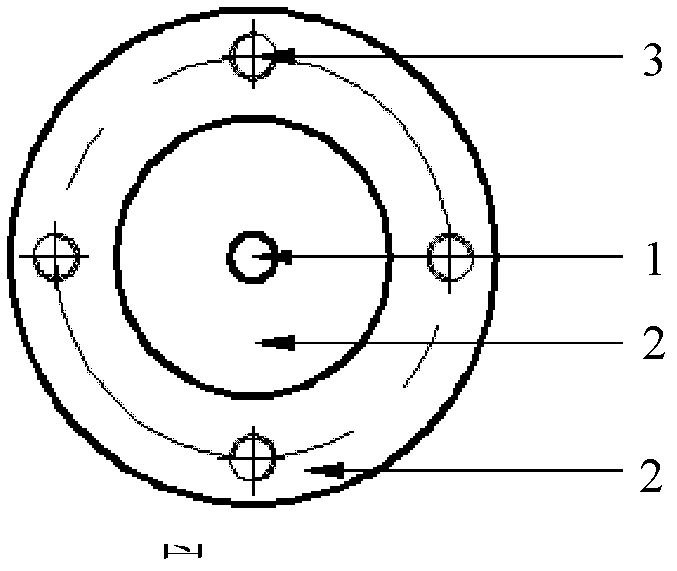

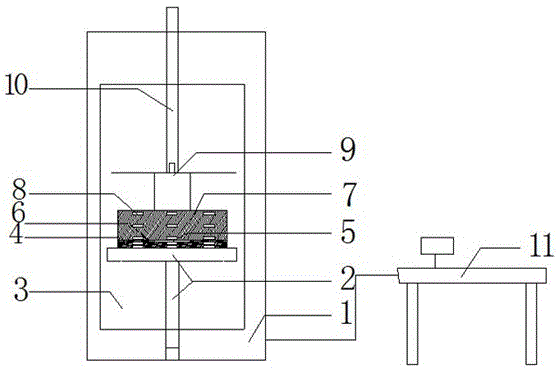

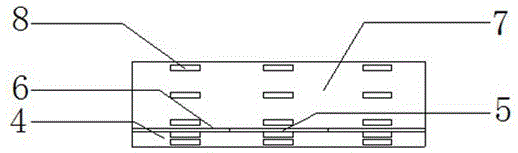

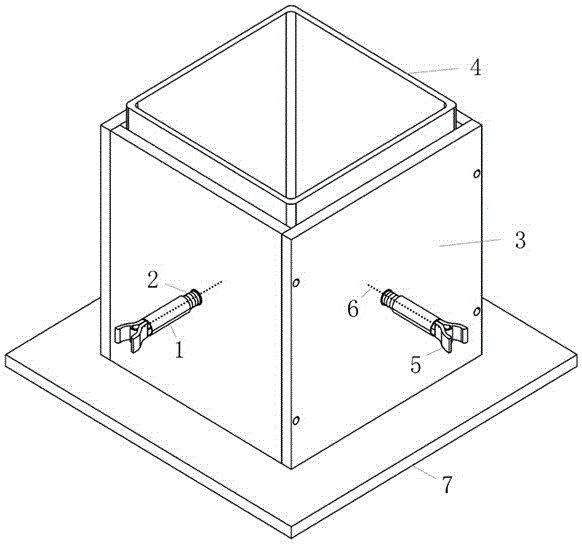

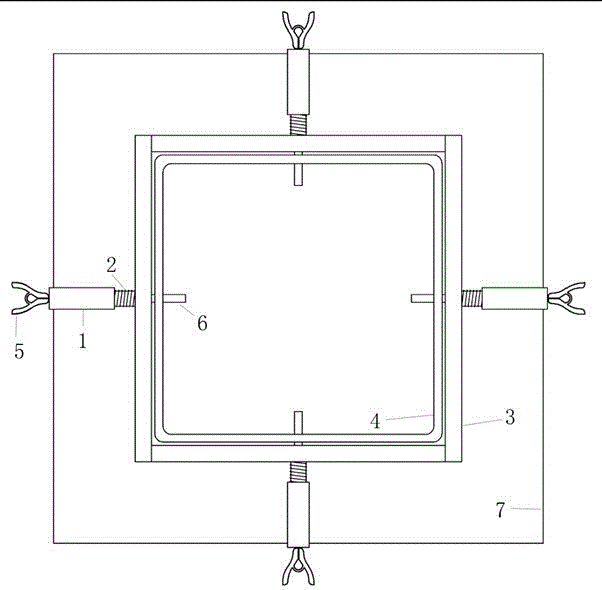

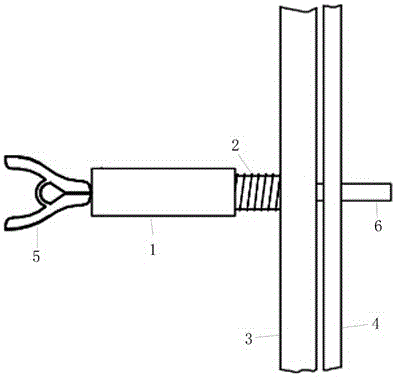

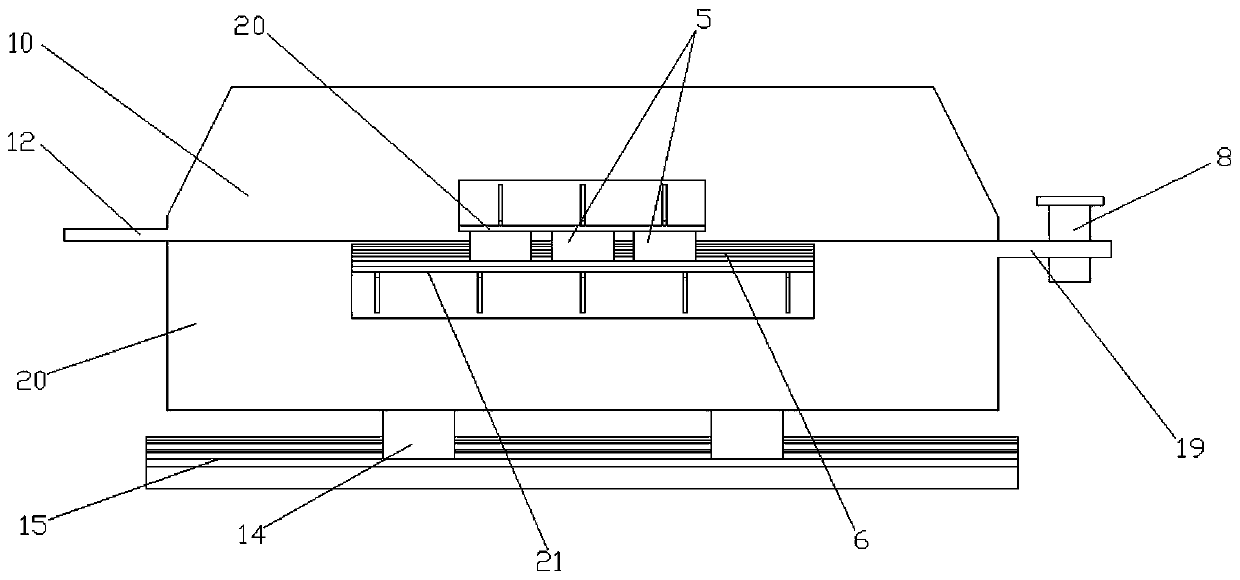

Multifunctional tilt table device used for testing interfacial shear strength characteristics of geotechnical synthetic material

InactiveCN104007025AEliminate the effects ofHigh degree of automatic test controlMaterial strength using steady shearing forcesSynthetic materialsControl system

The invention discloses a multifunctional tilt table device used for testing the interfacial shear strength characteristics of a geotechnical synthetic material. The multifunctional tilt table device comprises a testing stand, an inclined plane control mechanism, a shearing box unit, a vertical loading mechanism and a measurement and control system, wherein the inclined plane control mechanism drives a tilted plate of the testing stand through a motor so as to allow the tilted plate to rotate to any inclination angle and can fix the tilted plate at a certain inclination angle through hydraulic jacks, shearing boxes are placed on concave guide rails on the surface of the tilted plate, a geotechnical synthetic material sample is installed between upper and lower shearing boxes, multiple layers of inclined shearing interfaces are formed through rotation of the tilted plate, the vertical loading mechanism comprises two loading devices used for short-term and long-term characteristic testing of the interfaces, the measurement and control system composed of a sensor, a control and acquisition system and a computer carries out real-time monitoring on stress and displacement of the upper and lower shearing boxes and the sample, determines a critical interface instability inclination angle according to displacement and pull-up curve abrupt change points and calculates shear strength of each interface according to stress analysis. The multifunctional tilt table device can be used for short-term and long-term characteristic testing of a single layer or multiple layers of interfaces.

Owner:HOHAI UNIV

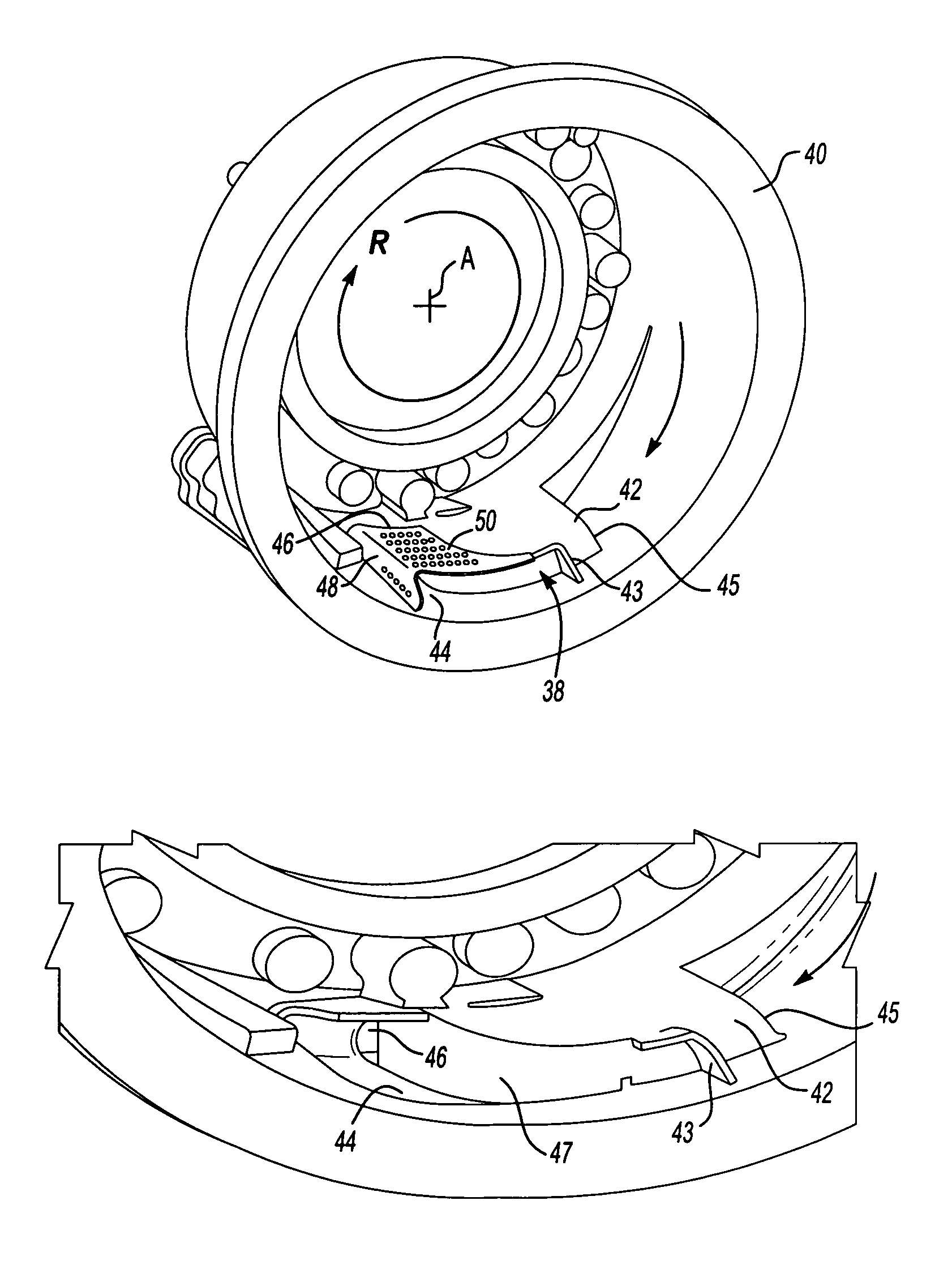

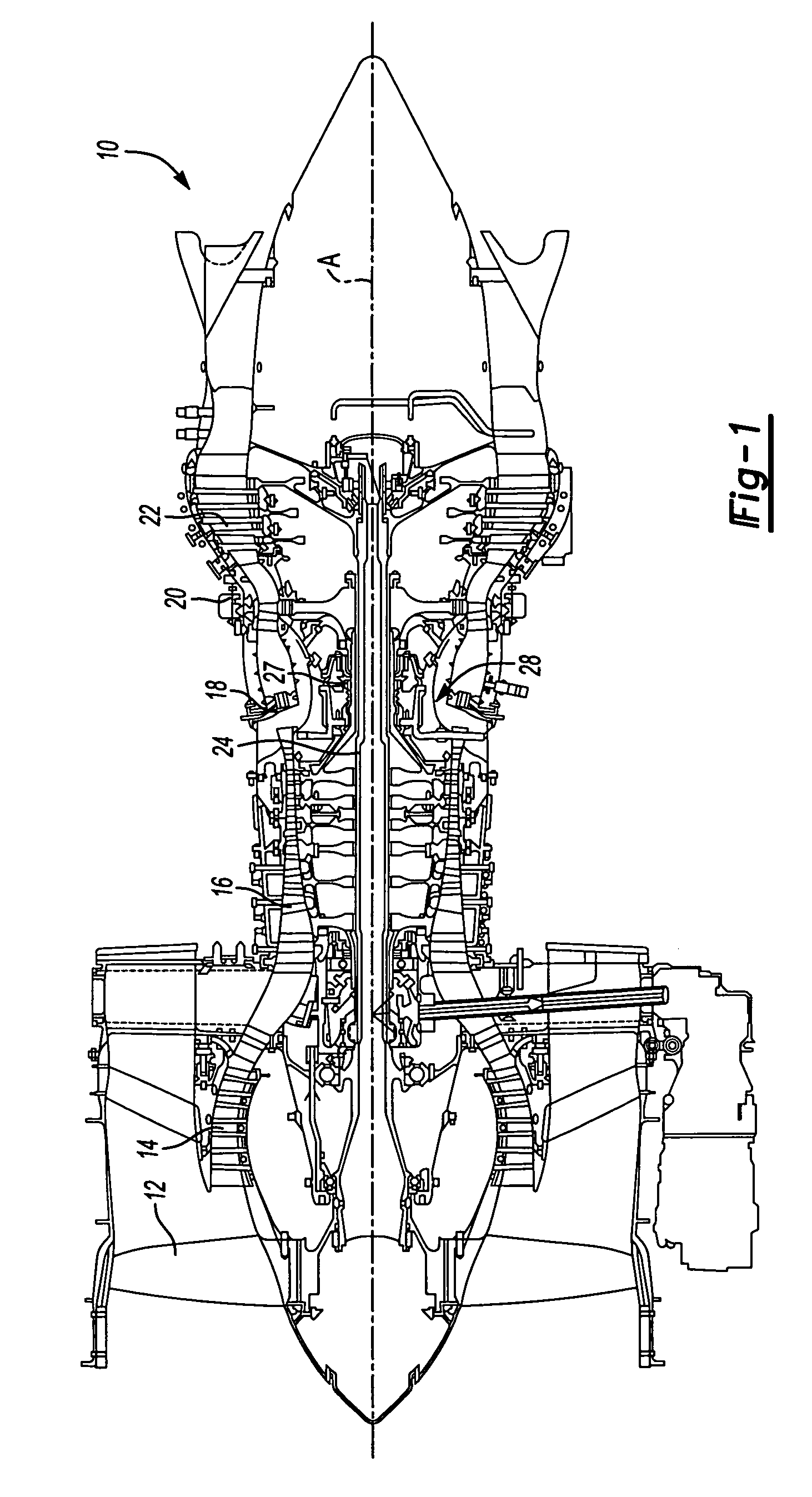

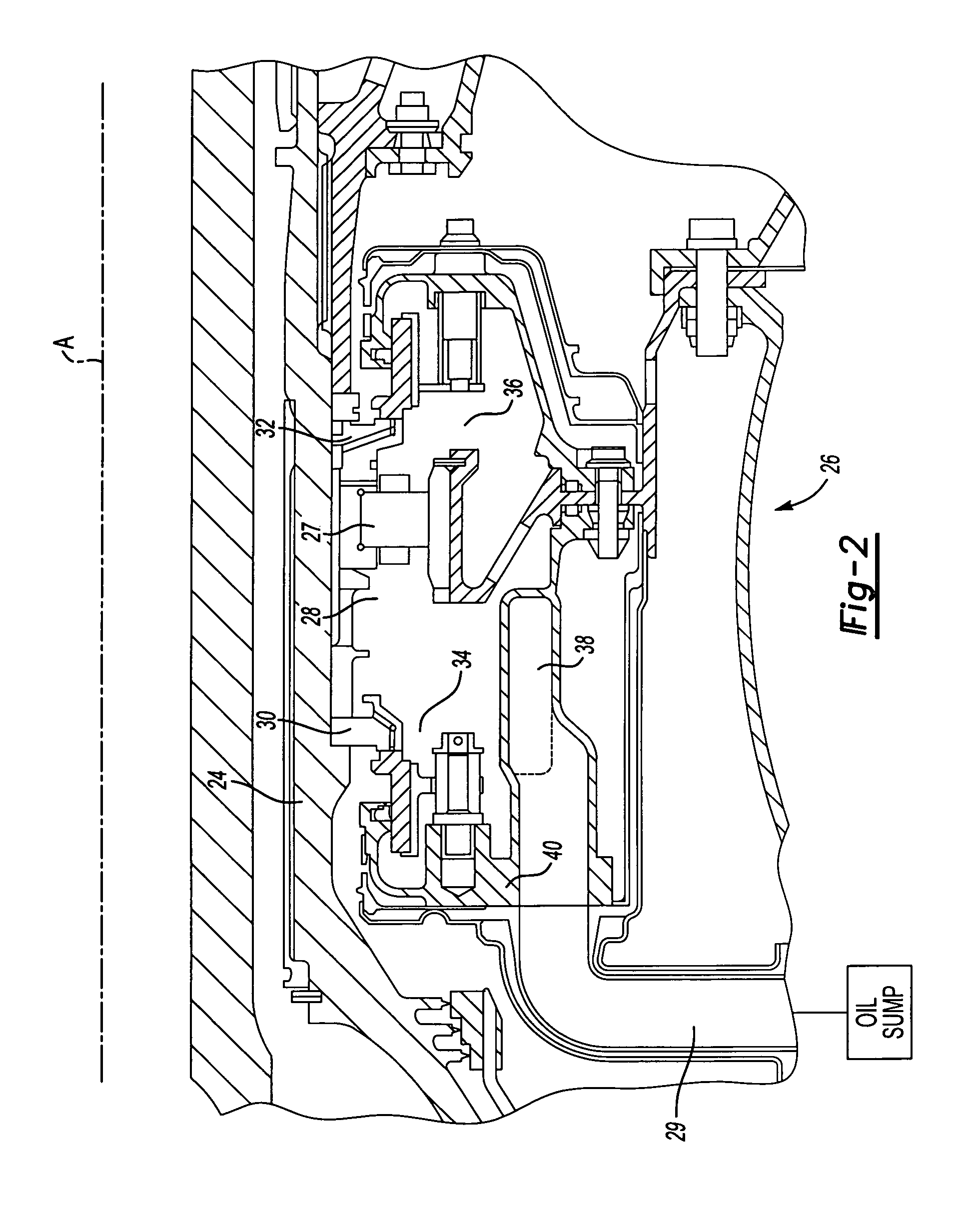

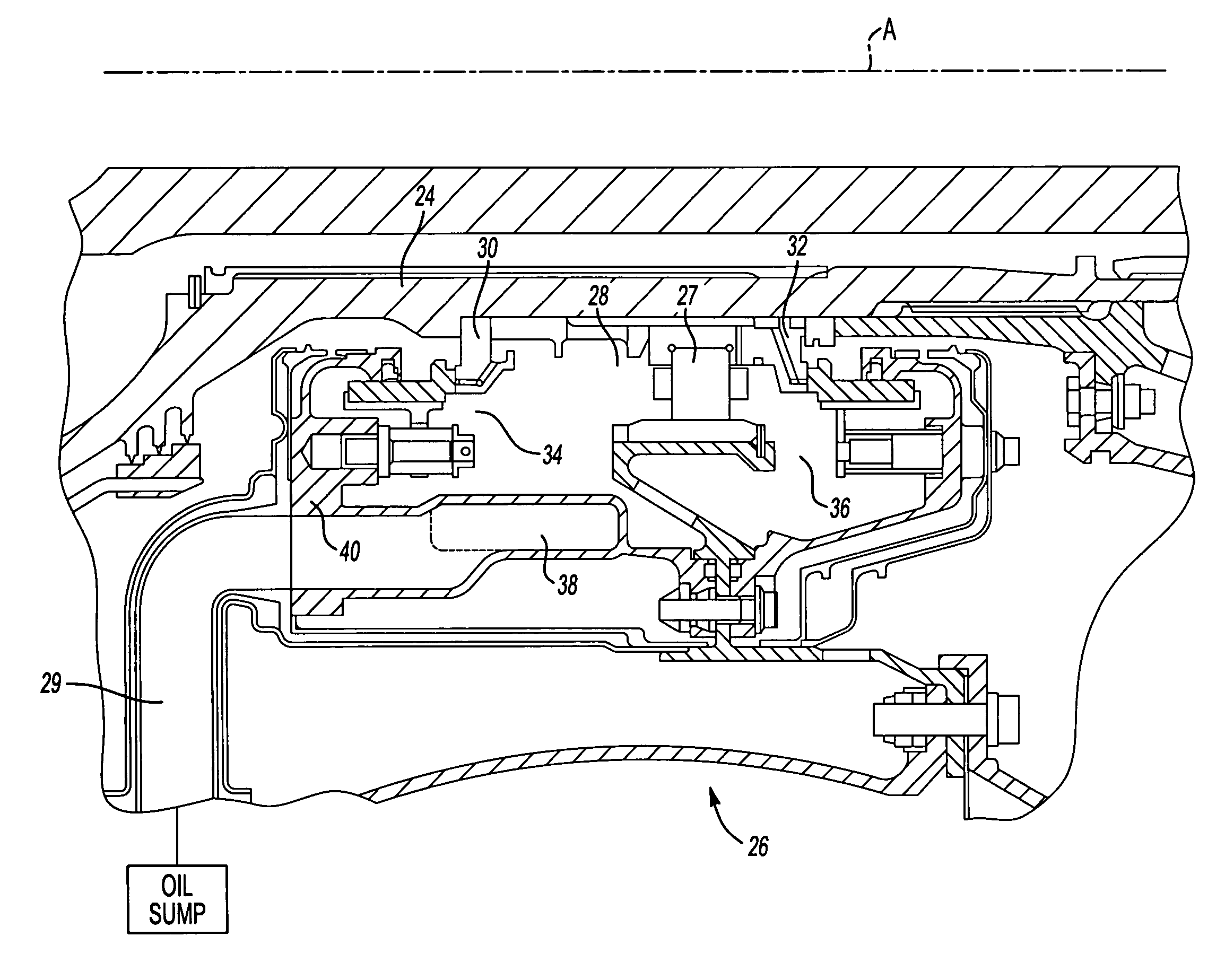

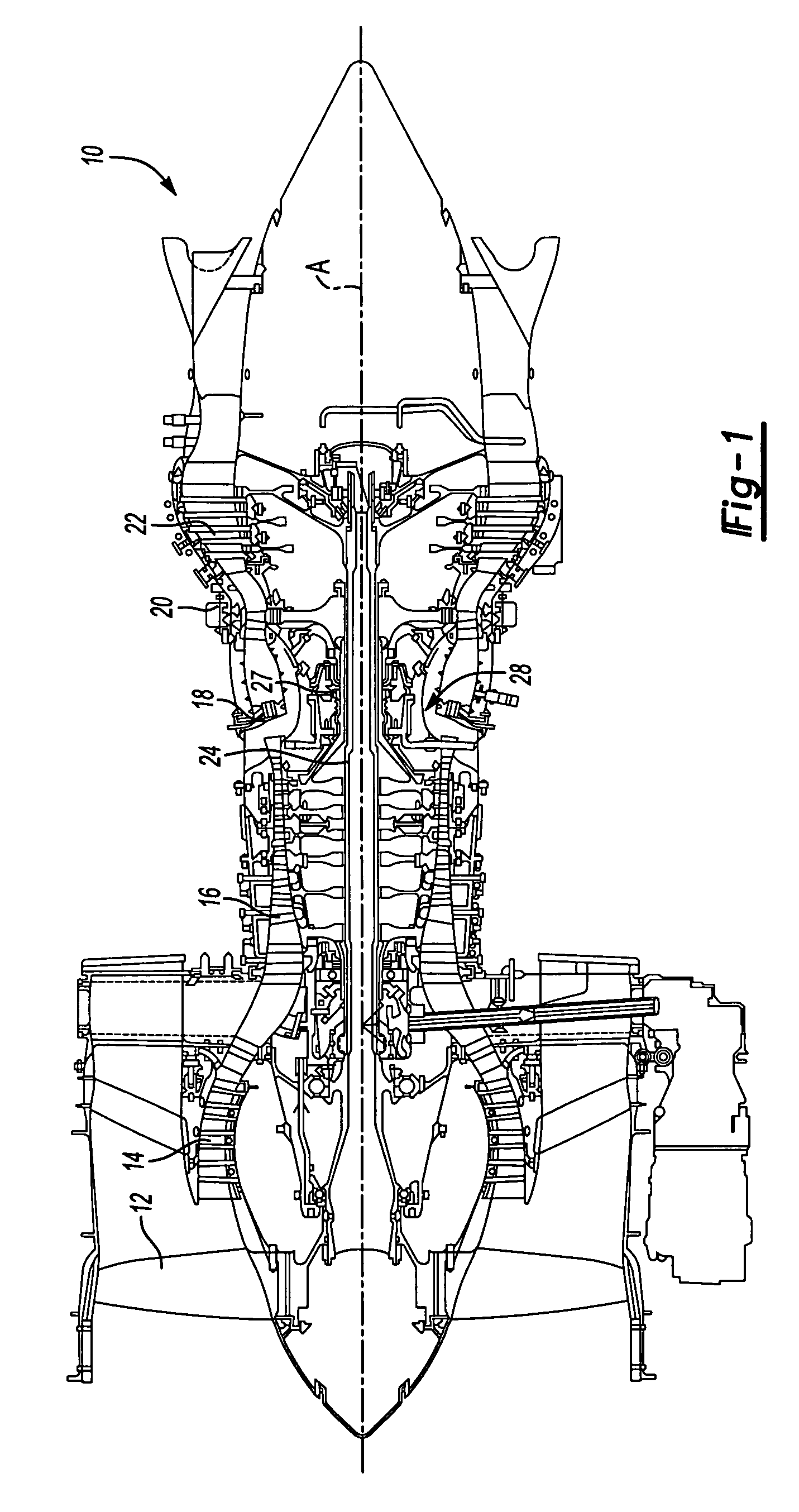

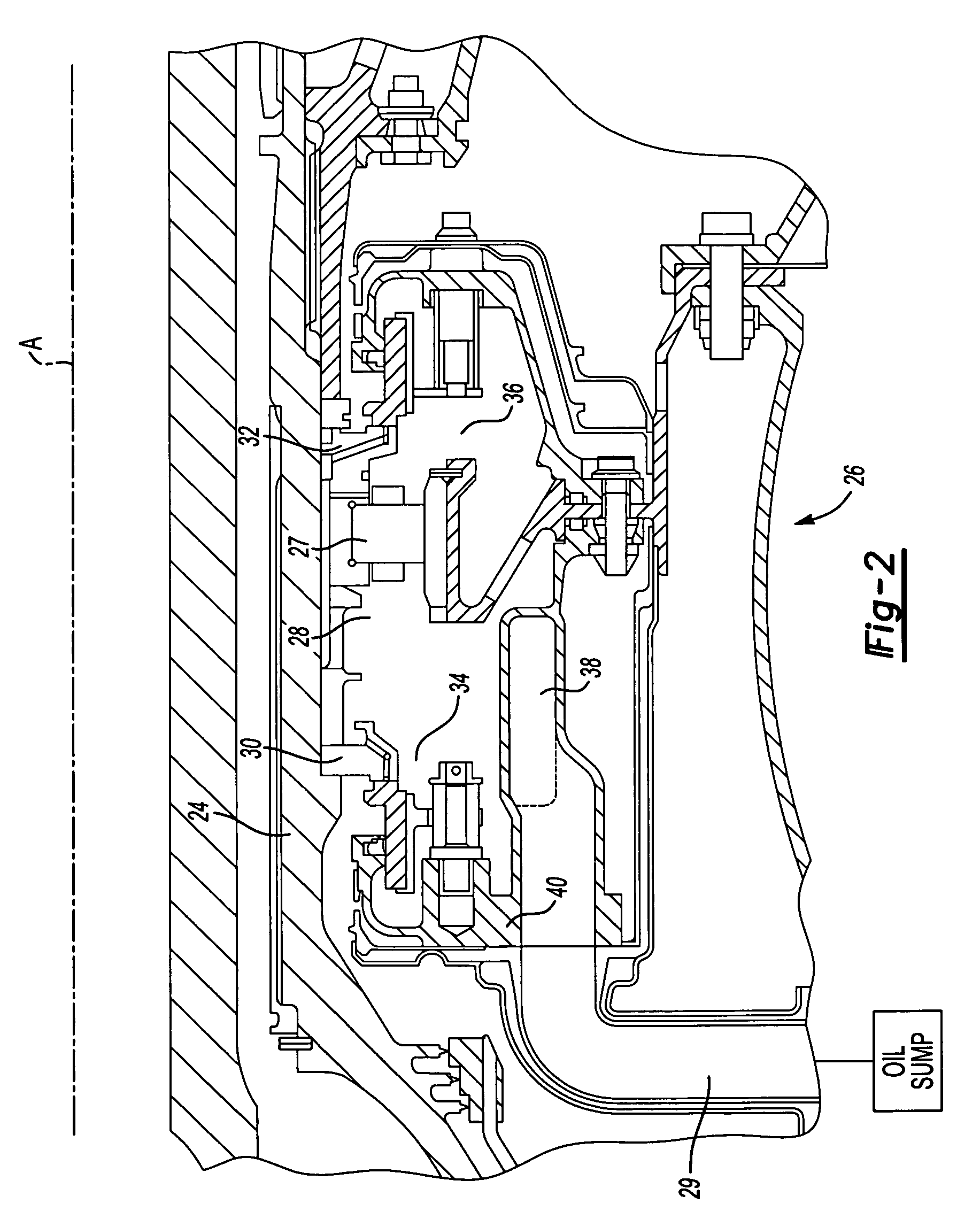

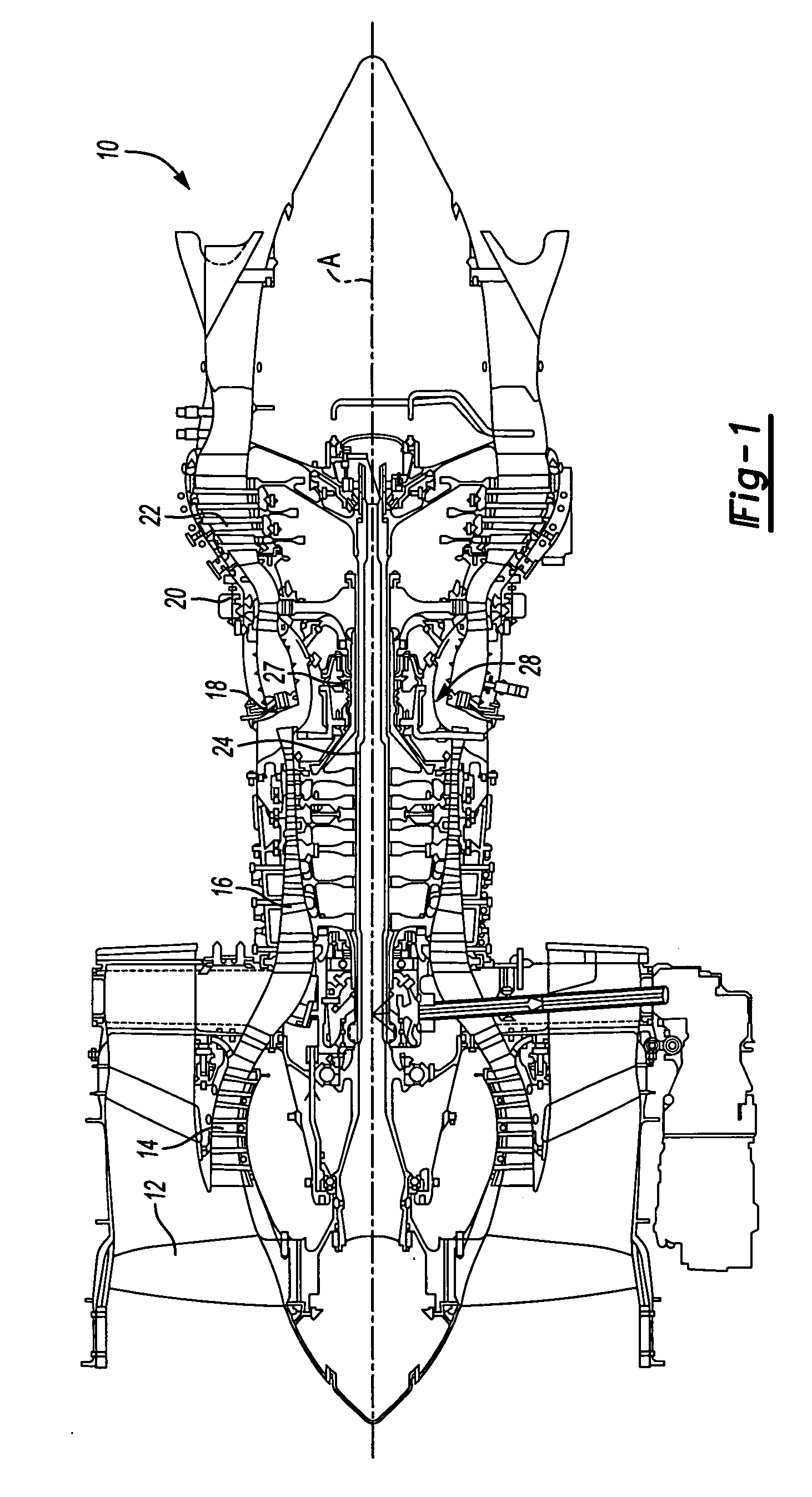

Bifurcated oil scavenge system for a gas turbine engine

An oil scavenge system includes a tangential scavenge scoop and a settling area adjacent thereto which separately communicate with a duct which feeds oil into an oil flow path and back to an oil sump. A shield is mounted over the settling area to at least partially shield the collecting liquid oil from interfacial shear. A multiple of apertures are located through the shield to permit oil flow through the shield and into the duct. The scavenge scoop forms a partition which separates the duct into a first portion and a second portion. The first portion processes upstream air / oil mixture that is captured by the tangential scoop while the second portion receives the oil collected in the settling area.

Owner:RTX CORP

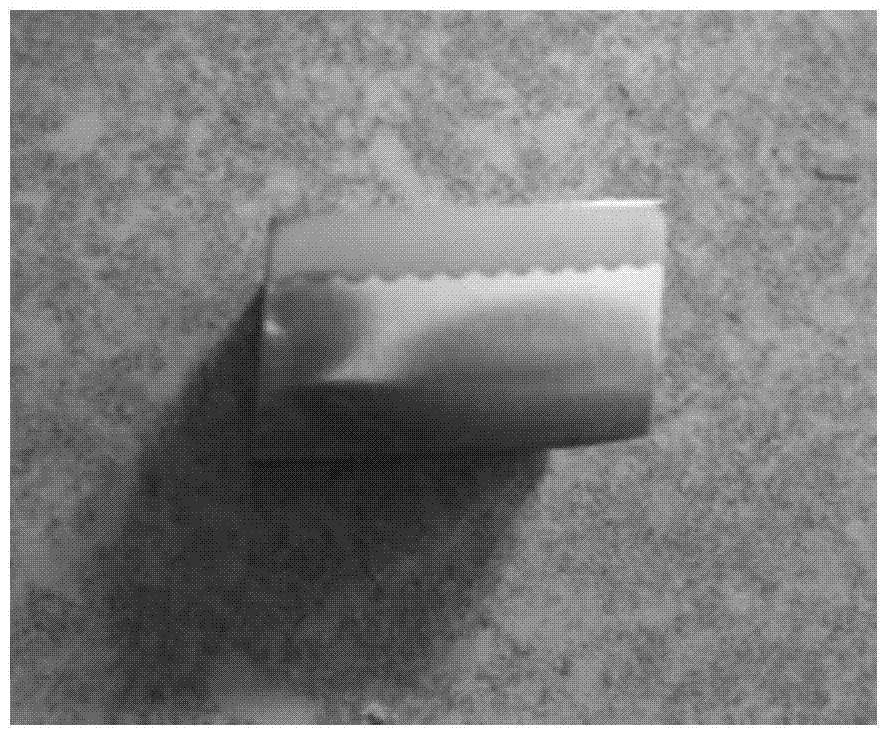

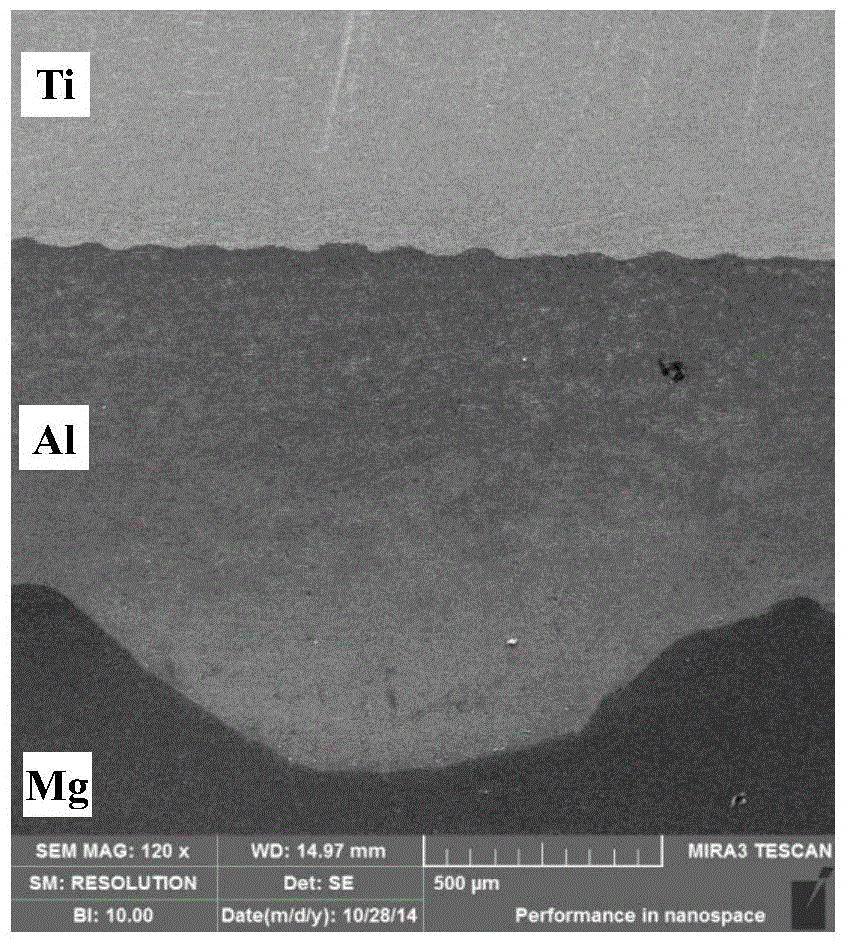

Post-treating method for steel-back aluminium-based semisolid-state clad plate

InactiveCN101117696AIncreased interfacial shear strengthSimple methodRoll mill control devicesMetal rolling arrangementsReduction rateRoom temperature

The present invention discloses a post-processing method for steel-back aluminum-base semisolid composite plates and relates to the post-processing research field of interfacial mechanical characteristic of steel-back aluminum-base semisolid composite plates. At room temperature, a steel-back aluminum-base semisolid composite plate is rolled with the reduction rate of 0.5-1.6 percent on a precision rolling mill, and the difference between shrinkages of the aluminum-base coating and the steel base in the coagulating and cooling process of the composition is redeemed by the difference between the deformation of the aluminum-base coating and the steel base produced in the rolling process, thereby, reducing the additional interfacial stress of the composite plate, simply and conveniently improving the interfacial shear strength of the composite plate, and solving the technical problems of large energy consumption and small increase amplitude of interfacial shear strength in post-processing method of diffusion annealing of aluminum-base semisolid composite plates.

Owner:BEIJING JIAOTONG UNIV

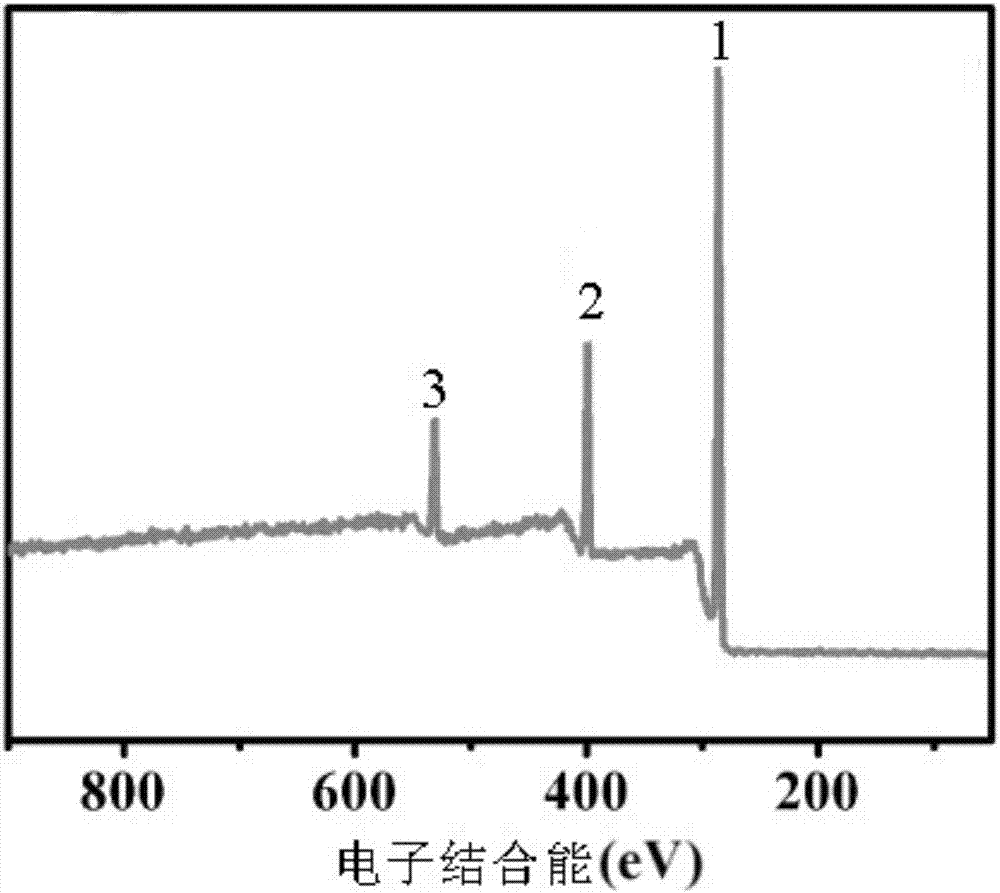

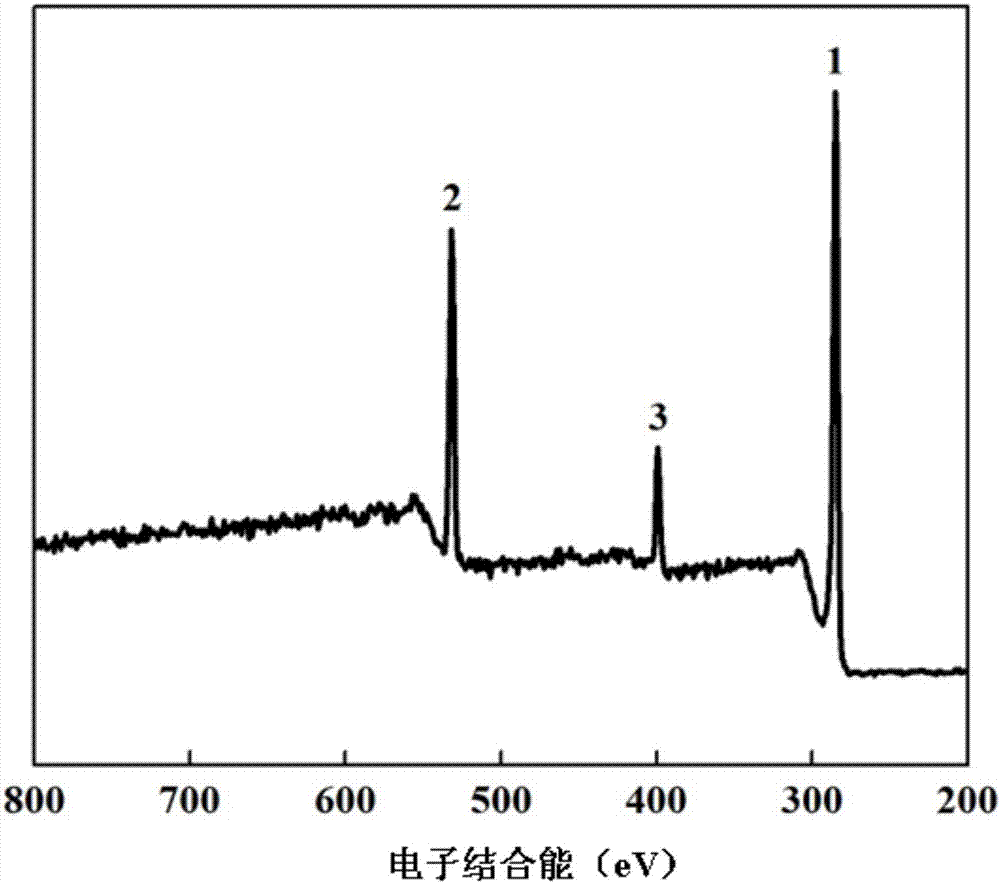

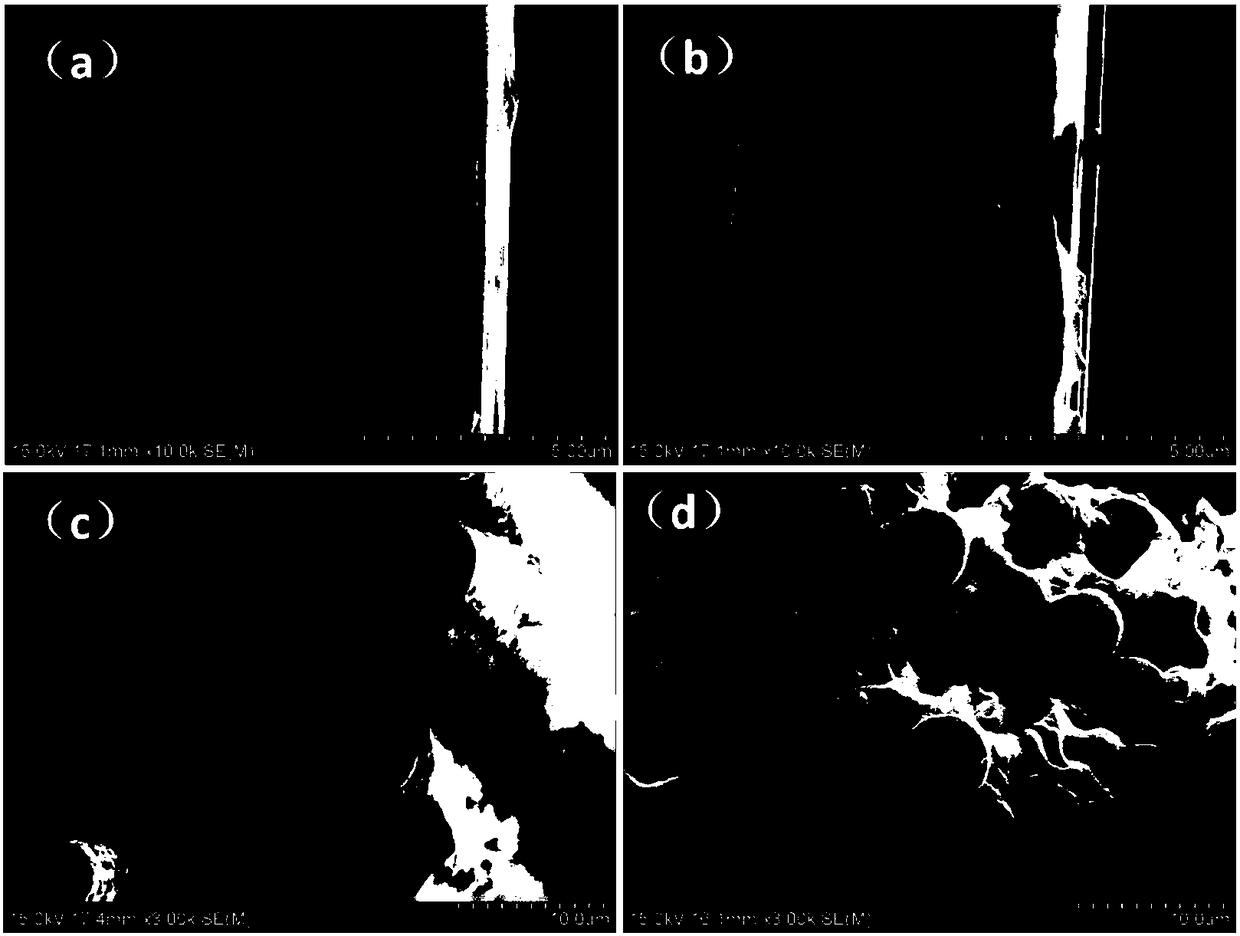

Preparation method of carbon fiber reinforcement grafted by graphene oxide

A preparation method of a carbon fiber reinforcement grafted by graphene oxide relates to a preparation method of a carbon fiber reinforcement grafted by graphene oxide. The invention solves the problems of harsh process conditions, long process period, toxic process, and difficult industrial production for current carbon fiber surface modification methods. The invention adopts a 'grafting' method, and grafts graphene oxide on acidified carbon fiber surfaces through an acylation reaction by using polyamide-amine with a lot of amido active groups; the invention has low cost, is simple, practical, environment-friendly, and nontoxic, and can be completed within a short period. The method particularly comprises the following steps: mixing acidified carbon fibers and a polyamide-amine methanolsolution, reacting to prepare carbon fibers modified by polyamide-amine, adding the prepared carbon fibers in a graphene oxide acetone suspension, mixing, reacting, filtering, drying the precipitatestill the weight is constant. The obtained carbon fiber reinforcement has interfacial shear strength with epoxy resin of up to 79.77-105.50 MPa which is improved.

Owner:HARBIN INST OF TECH

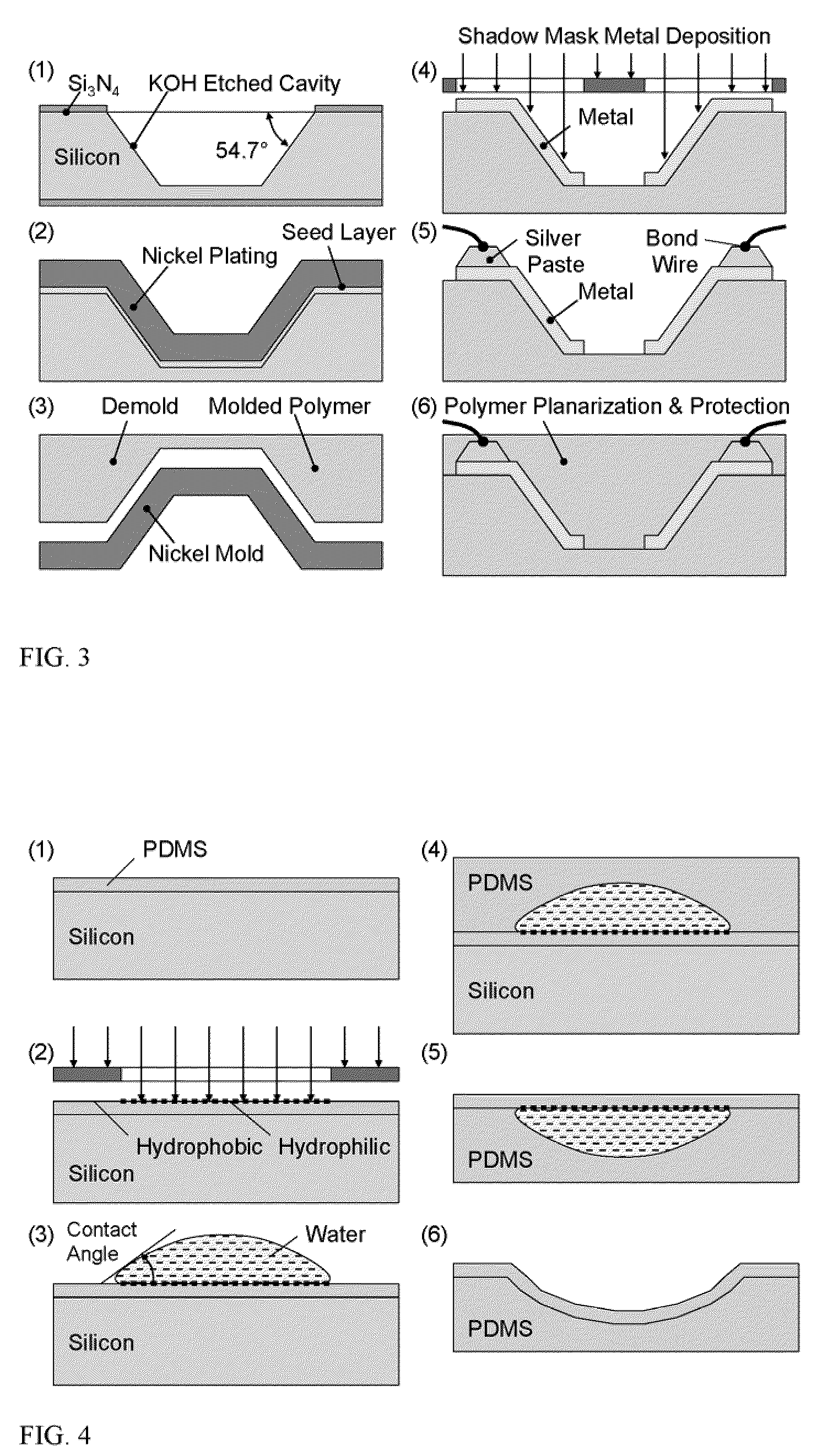

Flexible piezoresistive interfacial shear and normal force sensor and sensor array

ActiveUS20090282930A1Force measurement using piezo-resistive materialsDiagnostic recording/measuringSensor arrayContact pad

A force sensor includes a polymeric substrate including a cavity with a tilt plane, at least two metal piezoresistors on the tilt plane, and a contact pad connected to the metal piezoresistors. The tilt plane may include a measured interface of from 15° to 75°.

Owner:THE HONG KONG POLYTECHNIC UNIV

Method of scavenging oil within a gas turbine engine

Owner:RTX CORP

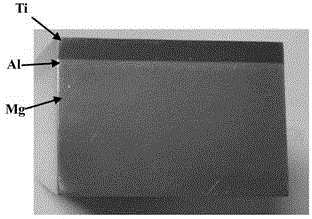

Explosive welding forming method of magnesium and aluminum alloy composite plates

InactiveCN103586574AImprove compactnessAdvancedMetal working apparatusNon-electric welding apparatusAlloy compositeFuel oil

The invention relates to an explosive welding forming method of magnesium and aluminum alloy composite plates. The explosive welding is performed according to the performance requirements of the magnesium and aluminum alloy composite plates, ammonium nitrate fuel oil mixture is adopted, and long-distance instantaneous explosive form is performed on a ground sand base. The welding method is high in forming speed, welding line is firm and is good in metallographic structure compactness, the combined rate is up to 99.5%, the interfacial shear strength is 120MPa, on the premise of strict operation, the welding process is safe and reliable, and the method is reliable and effective in magnesium and aluminum alloy composite plate production.

Owner:TAIYUAN UNIV OF TECH

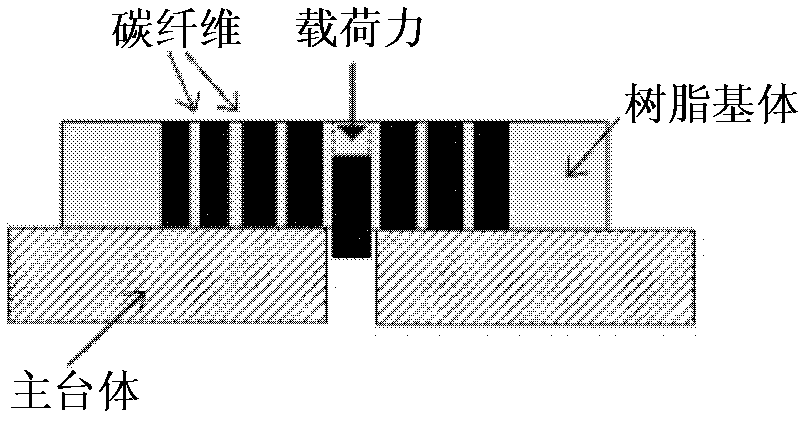

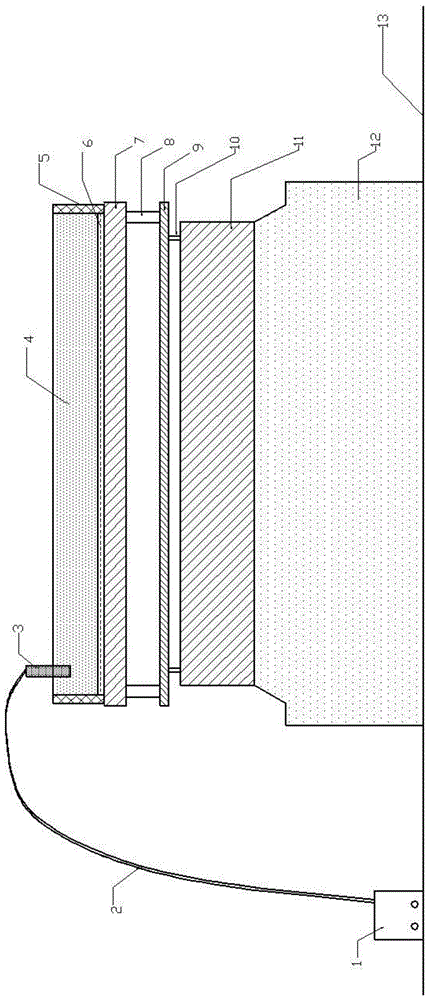

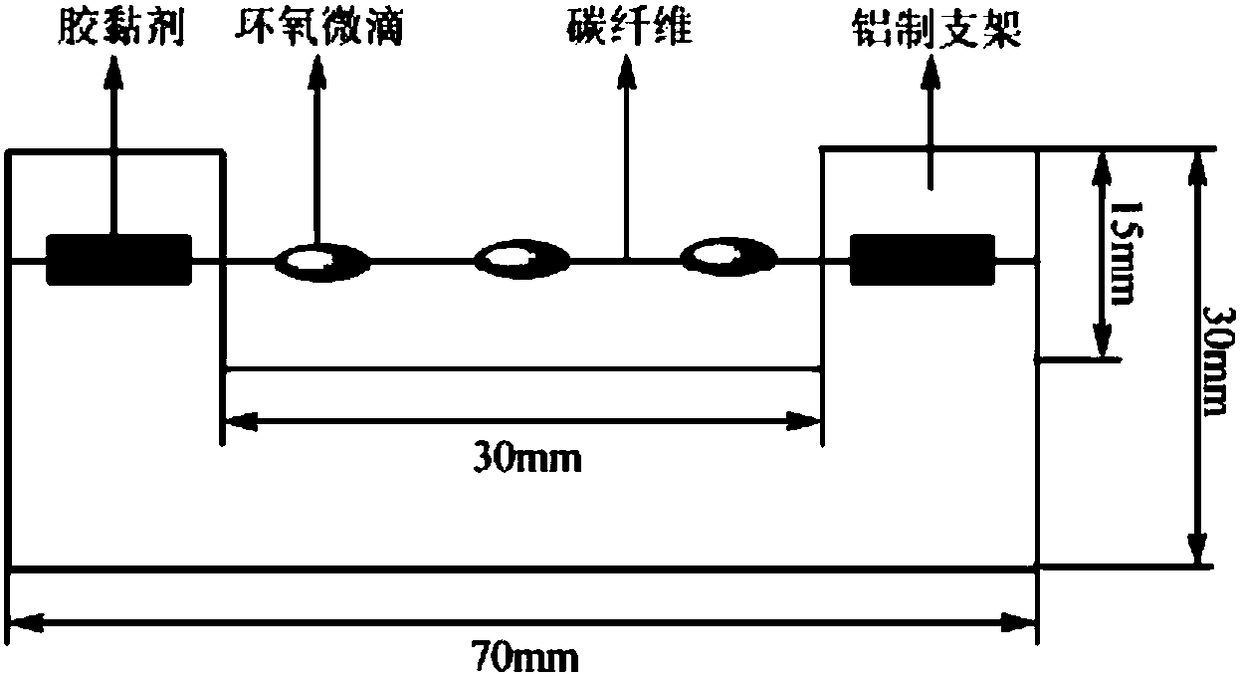

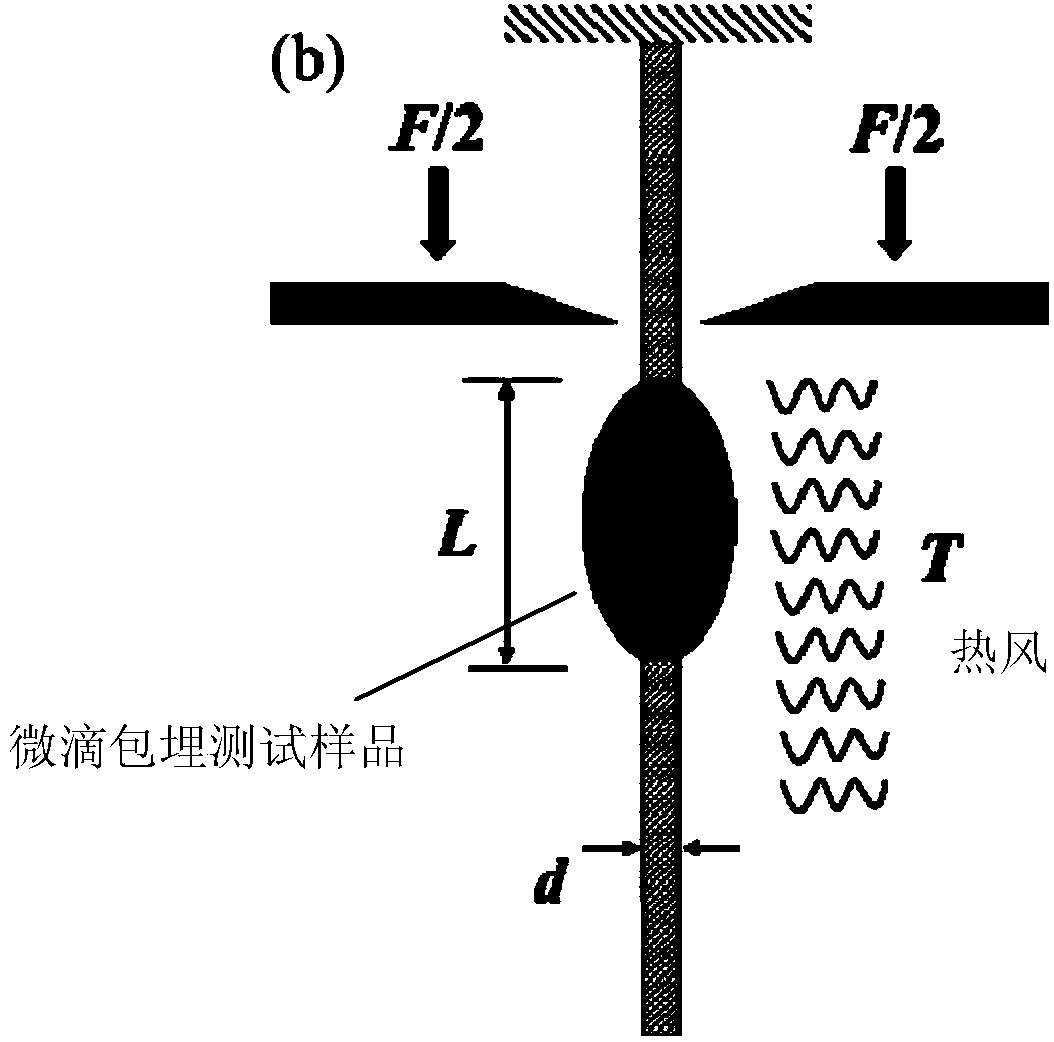

Compact device for testing interfacial shear strength of composite material and method for testing interfacial shear strength of composite material through device

InactiveCN105547851AReduce volumeHigh precisionMaterial strength using tensile/compressive forcesMicrosphereUltimate tensile strength

Disclosed are a compact device for testing the interfacial shear strength of a composite material and a method for testing the interfacial shear strength of the composite material through the device. The invention relates to the device and method for testing the interfacial shear strength of a composite material. An object of the invention is to solve the problems that a conventional micro-debonding test device which is unique for pure quantitative detection of the interfacial shear strength of an actual to-be-tested composite material sample is hard to be integrated in a low-temperature environment chamber because of the over size and cannot be used for testing the interfacial shear strength of a composite material in a low-temperature environment. The device comprises a fixed pedestal, a micro-extension test system, and a microsphere holding system. The method comprises: 1, preparation of a sample for an interfacial shear strength test; 2, interfacial shear strength test; and 3, calculation of the interfacial shear strength tau of the composite material according to a formula defined in the description. According to the invention, the compact device for testing the interfacial shear strength of a composite material and the method for testing the interfacial shear strength of the composite material through the device are obtained.

Owner:HARBIN INST OF TECH

Method for testing processing residual stress of 'through-silicon via'-Cu structure

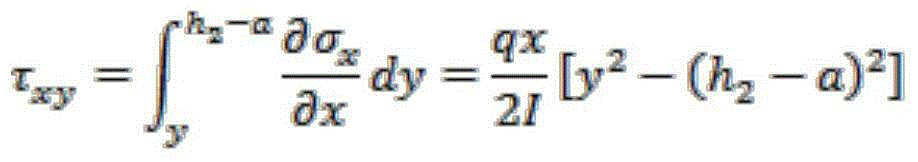

InactiveCN102818765AIntegrity guaranteedThe test result is accurateUsing mechanical meansApparatus for force/torque/work measurementCopper platingShear stress

The invention discloses a method for testing processing residual stress of a 'through-silicon via'-Cu structure, and belongs to the technical field of electronic information. The method includes downwardly squeezing a copper cylinder in a through-silicon via in a test sample by a pressure head, simultaneously recording the displacement and the pressure F when the pressure head acts downwardly to obtain a pressure F and displacement curve and a threshold value of the pressure F when the pressure F is reduced, and substituting the threshold value of the pressure F in a pressure and interfacial shear stress conversion formula to obtain a shear stress threshold value tau 0 when a copper and silicon interface in the TSV-Cu structure manufactured by a copper plating process slips; and computing to obtain the to-be-measured residual stress of the 'through-silicon via' TSV-Cu structure via the shear stress threshold value tau 0. The method has the advantages that completeness of the test sample is kept to the greatest extent, operation, such as cutting the test sample, which affects release of the residual stress, is omitted, and a test result is accurate; and a residual stress computing method is simple and reliable, and the positive or negative property of the residual stress can be visually judged.

Owner:BEIJING UNIV OF TECH

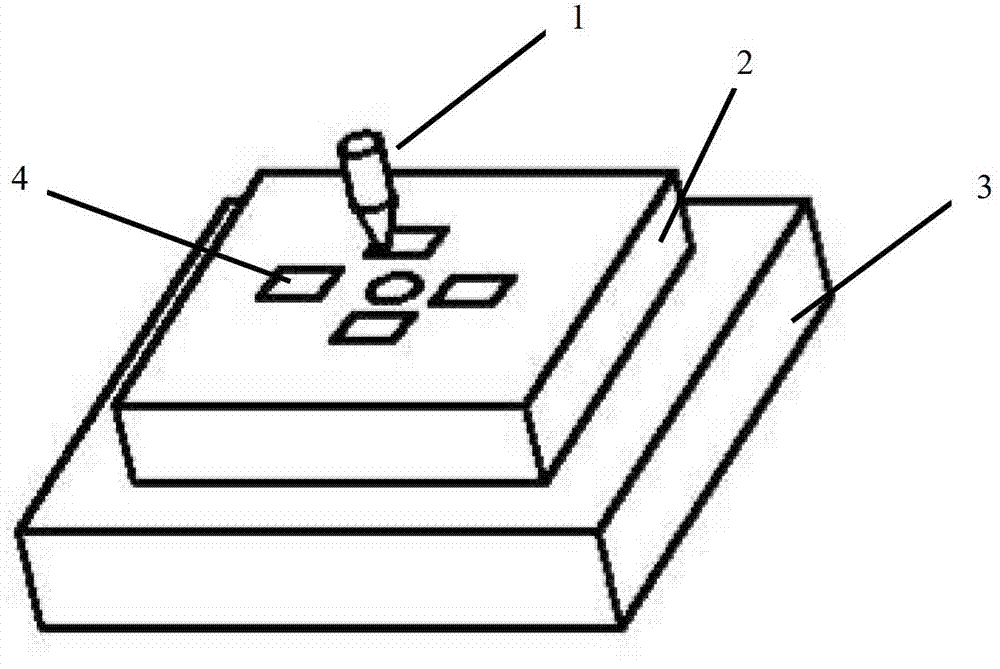

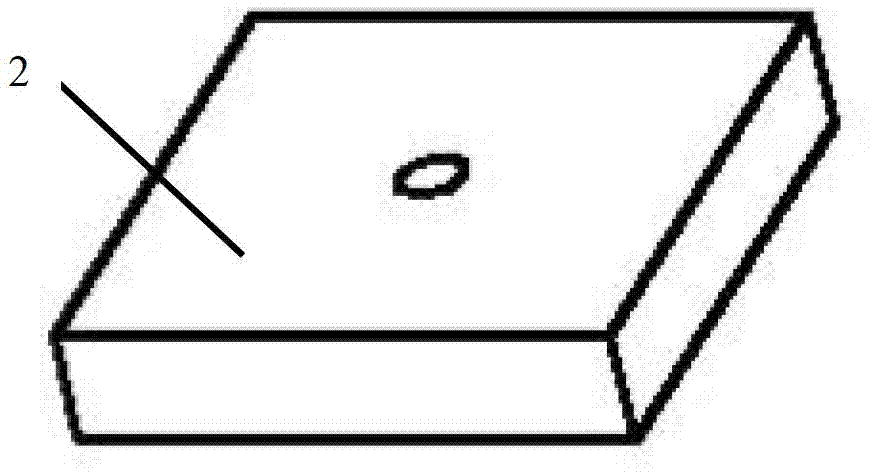

Nanoindentation test desk and experimental method for interfacial shear force of carbon fiber composite

InactiveCN102607947ABuckling controlMaterial strength using tensile/compressive forcesExperimental methodsSingle fiber

A nanoindentation test desk and an experimental method for interfacial shear force of a carbon fiber composite belong to the technical field of experimental devices and methods. The nanoindentation test desk comprises a desk body and a pressing plate component, wherein a main desk body and a pressing plate are fixed in a normal direction to form a normal loading device. A convex part is arranged in the middle of the main desk body, and a circular hole is arranged at the center of the convex part. A convex part is arranged in the middle of the pressing plate, a circular hole is arranged at the center of the convex part, and the circular hole in the pressing plate is larger than that in the main desk body in diameter and is a through hole. A rubber layer gasket is placed at the bottom of the pressing plate and is a circle of which the center is provided with a circular hole, and the circular hole is aligned to the circular hole in the pressing plate. The test desk and the method realize testing for in situ interfacial mechanical property of an actual composite material without special manufacturing of an experimental sample, and accomplish monitoring for a whole single fiber pressing-out process; a fiber debonding process can be obtained through analysis of loading and unloading curves obtained in an experiment; and the test desk and the method achieve the control of bending of fibrous composite sheets in a press-in process.

Owner:BEIJING UNIV OF TECH

Explosive welding forming method for magnesia-alumina-titanium alloy composite board

ActiveCN104526151AAdvancedApparent molding speedSolid-state devicesWelding/soldering/cutting articlesInterfacial shearControllability

The invention relates to an explosive welding forming method for a magnesia-alumina-titanium alloy composite board, which is performed aiming at the performance requirements of a magnesium alloy board, an aluminum alloy board and a titanium alloy board; an ammonium nitrate fuel oil mixture is adopted for performing remote instant explosive welding forming on a sand substrate on the ground; the welding forming method is quick in speed, firm in interface bonding, good in interfacial shear strength and high in boding rate; the magnesia-alumina-titanium alloy composite board achieves the shear strength of 150MPa, the explosive welding bonding rate is 96.8%, the controllability is good, the welding process is safe and reliable, and thereby the explosive welding forming method is a reliable and effectively method for preparing the magnesia-alumina-titanium alloy composite board.

Owner:TAIYUAN UNIV OF TECH

Bifurcated oil scavenge system for a gas turbine engine

ActiveUS20050132710A1Efficiently directsVelocity increasesEngine fuctionsShaftsGuide tubeGas turbines

An oil scavenge system includes a tangential scavenge scoop and a settling area adjacent thereto which separately communicate with a duct which feeds oil into an oil flow path and back to an oil sump. A shield is mounted over the settling area to at least partially shield the collecting liquid oil from interfacial shear. A multiple of apertures are located through the shield to permit oil flow through the shield and into the duct. The scavenge scoop forms a partition which separates the duct into a first portion and a second portion. The first portion processes upstream air / oil mixture that is captured by the tangential scoop while the second portion receives the oil collected in the settling area.

Owner:RAYTHEON TECH CORP

Preparation method and application of carbon nano tube modified carbon fiber enhanced SiBCN ceramic composite material

InactiveCN105272326AActive connectionEfficient deliveryCarbon nanotubeMechanical properties of carbon nanotubes

The invention relates to preparation methods and application of SiBCN ceramic composition materials, in particular to a preparation method and application of a carbon nano tube modified carbon fiber enhanced SiBCN ceramic composite material. The problem that an existing carbon fiber and SiBCN ceramic composite material is poor in mechanical property between carbon fiber and SiBCN ceramic is solved. The method comprises the steps that 1, the surface of the carbon fiber is oxidized to obtain oxidized carbon fiber; 2, a catalyst is attached to the surface of the carbon fiber; 3, a carbon nano tube modified carbon fiber enhanced body is prepared; 4, a carbon nano tube modified carbon fiber enhanced SiBCN ceramic precursor is prepared; 5, the carbon nano tube modified carbon fiber enhanced SiBCN ceramic composite material is prepared. The shearing strength of the obtained composite material can reach 61.99-68.01 MPa, and the obtained composite material is used for the field of ceramic materials.

Owner:HARBIN INST OF TECH

Preparation method of carbon nanotube-carbon fiber mixed enhanced epoxy resin composite material

The invention provides a preparation method of a carbon nanotube-carbon fiber mixed enhanced epoxy resin composite material. The preparation method comprises the following steps: carrying out modification treatment on surfaces of carbon fibers; preparing a sizing agent of carbon-containing nanotubes; preparing a carbon nanotube-carbon fiber enhanced body; preparing a carbon-containing nanotube enhanced epoxy resin matrix; and preparing the carbon nanotube-carbon fiber mixed enhanced epoxy resin composite material and the like. Compared with a traditional carbon fiber enhanced epoxy resin composite material, the carbon nanotube-carbon fiber mixed enhanced epoxy resin composite material has the advantages that the mechanical properties are obviously improved; and the interfacial shear strength is improved by 34 to 42 percent and the inter-laminar shear strength of the composite material is improved by 31 to 34 percent. The preparation method of the composite material, provided by the invention, has the advantages of simple molding technology, excellent mechanical properties and the like.

Owner:CIVIL AVIATION UNIV OF CHINA

Method and Apparatus for Evaluation and Improvement of Mechanical and Thermal Properties of CNT/CNF Arrays

ActiveUS20080096293A1Increasing of Young 's modulusReduce thermal resistanceMaterial nanotechnologySemiconductor/solid-state device testing/measurementInterfacial thermal resistanceCarbon nanofiber

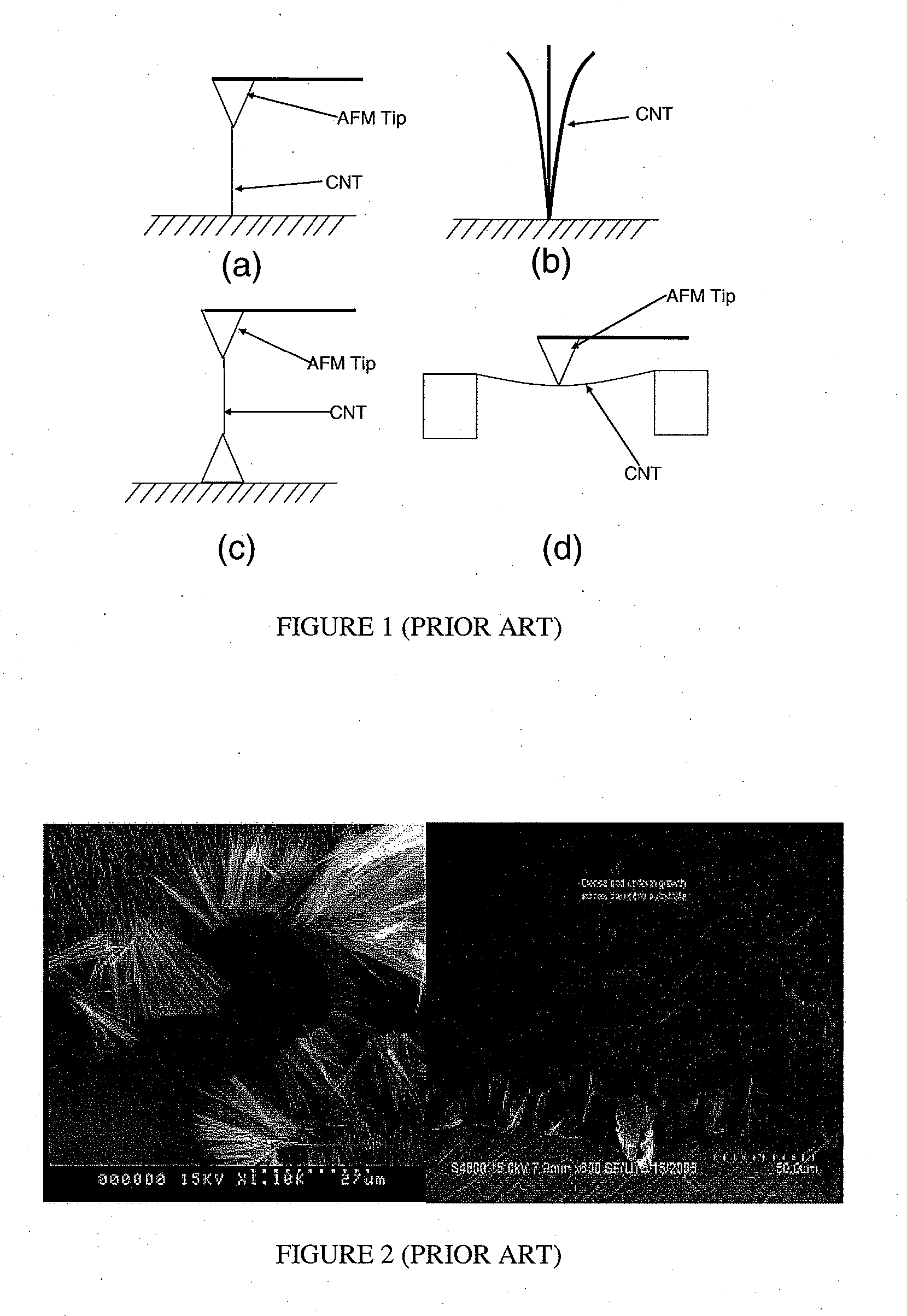

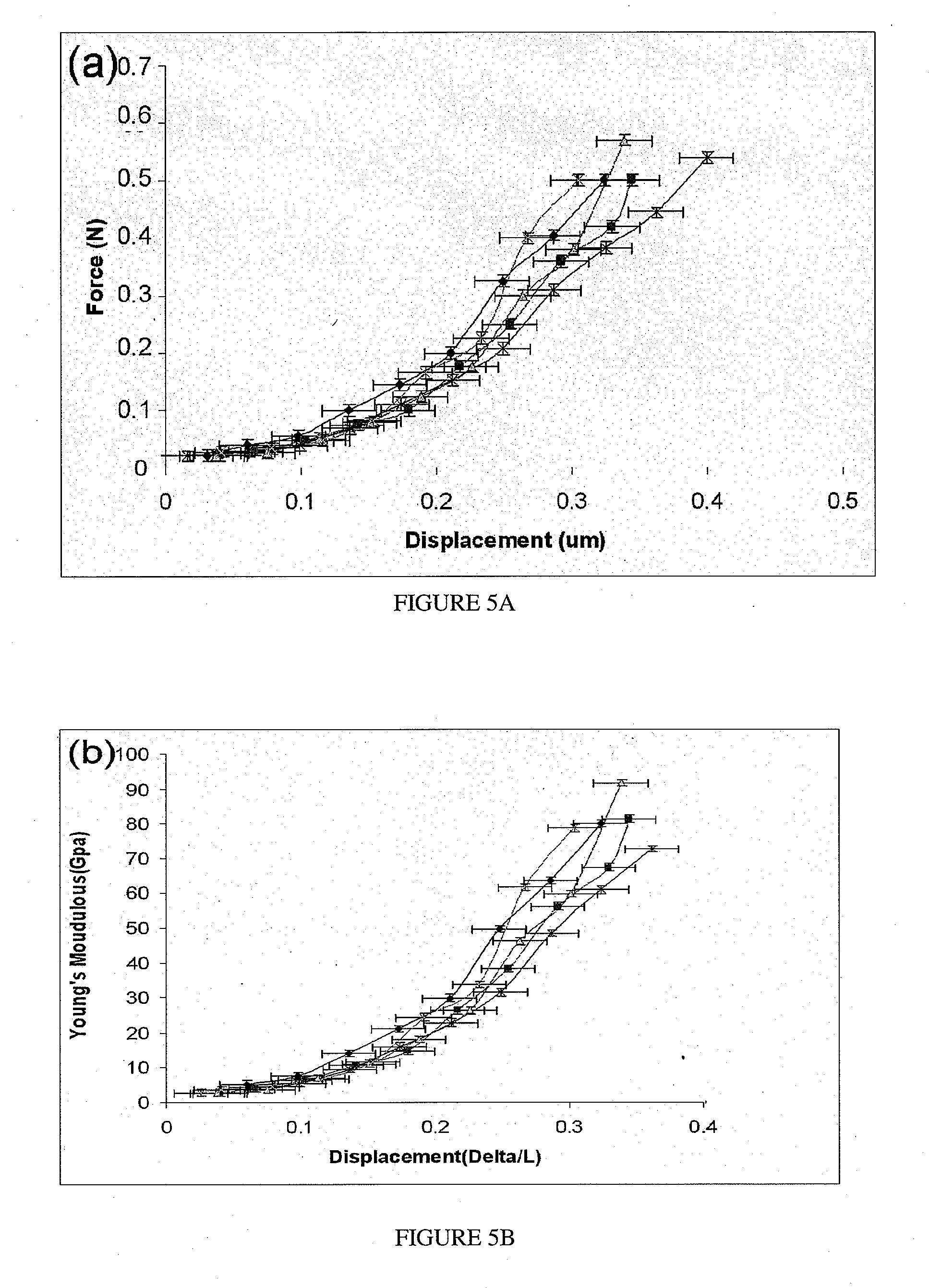

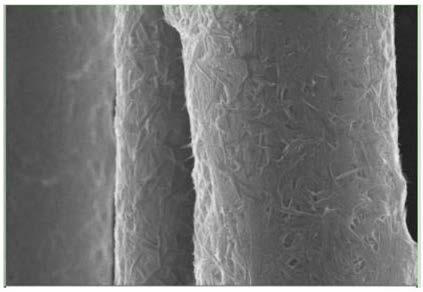

A method and apparatus for the evaluation and improvement of the mechanical and thermal properties of carbon-nanotube (CNT) and carbon nanofiber (CNF) arrays grown on a substrate is disclosed. The Young's modulus of a CNT / CNF material is measured by applying an axial compressive force on the CNT / CNF array and measuring the applied forces and the induced displacements. Also disclosed are the evaluation of the nonlinear stress-strain relationship of the CNT / CNF material, increasing of the Young's modulus and decreasing the thermal resistance by application of a compressive load, the application of rapid thermal annealing to improve the quality of the CNT / CNF material and to reduce the interfacial thermal resistance, improvement of the bonding strength of the CNT / CNF array to a substrate, evaluation of the bonding strength of the CNT / CNF array to a substrate, evaluation of the shearing force at failure, and an analytical stress model that enables one to predict the interfacial shearing stress from the measured force.

Owner:SAMSUNG ELECTRONICS CO LTD

Method for modifying carbon fiber surface by assembly of aromatic fused ring molecules and preparation method of carbon fiber interface reinforced resin matrix composite

The invention provides a method for modifying a carbon fiber surface by assembly of aromatic fused ring molecules and belongs to the technical field of carbon fiber modification. The method comprisesthe following steps: aromatic fused ring dianhydride and diamine are subjected to imidization, and an aromatic fused ring imide molecule assembly liquid is obtained; carbon fibers are soaked in the aromatic fused ring imide molecule assembly liquid, the aromatic fused ring imide molecules are combined with the carbon fibers, and the carbon fibers with surfaces subjected to assembly modification are obtained. Chemical activity of the surfaces of the carbon fibers can be improved with the modification method. The invention further provides a preparation method of a carbon fiber interface reinforced resin matrix composite. The obtained carbon fibers with the surfaces subjected to assembly modification are compositely cured with resin, and the aromatic fused ring molecule assembly-modified carbon fiber interface reinforced resin matrix composite is obtained. The interface reinforced resin matrix composite obtained with the preparation method has good interfacial adhesion strength and interfacial shear strength.

Owner:BEIJING UNIV OF CHEM TECH

Method and device for shearing test on interface between steel bridge deck and pavement layer

InactiveCN105115893AAdjust load sizeAdjustable temperatureUsing mechanical meansMaterial analysisStress conditionsShear stress

The invention discloses a method and device for a shearing test on the interface between the steel bridge deck and the pavement layer, and relates to the technical field of highway steel bridge deck pavement. The technical scheme includes the following key points: the test method includes test piece manufacture, heat preservation of the test piece, shearing test, and deduction of the relationship between the shearing stress and shearing strain of the interfacial layer according to the linear strain measured using a strain gage on the test piece. The invention also discloses a device for realizing the test method, and the device includes a material testing machine and a console; an environmental chamber is arranged on the inner side of the material testing machine; a loading rod, a three-point loading mold and a support platform are arranged on the inner side of the environmental chamber; in the working state, the test piece is placed between the three-point loading mold and the support platform. The test method and device, provided by the invention, are compatible with various experimental conditions; in addition, the device for the shearing test on the interface between the steel bridge deck and the pavement layer is simple in structure; the testing method is easy to operate, can accurately measure the shearing strain under different shearing stress conditions, and provides basis for the studying on shearing characteristics of the interface in a nonlinear bonding and slipping state.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Method for green grafting of polyether amine on carbon fiber surface

ActiveCN107142730AImprove interface performanceThe method steps are simpleCarbon fibresDry-cleaning apparatus for textilesUltimate tensile strengthInterfacial bonding

Relating to a carbon fiber surface grafting method, the invention provides a method for green grafting of polyether amine on a carbon fiber surface. The invention aims to solve the problems of great loss of loaded carbon fiber body strength and low interfacial bonding strength of a carbon fiber composite material in existing carbon fiber surface modification methods. The method includes: 1. cleaning; 2. oxidation; 3. carbon fiber grafting treatment, thus obtaining carbon fiber with a surface grafted with polyether amine, i.e. accomplishing the method for green grafting of polyether amine on the carbon fiber surface. The interfacial shear strength of the carbon fiber with the surface grafted with polyether amine prepared by the method provided by the invention is increased from the 48.8MPa of protofilament to 76.6Mpa-82.3MPa, and is improved by more than 57.4%. The tensile strength of the carbon fiber with the surface grafted with polyether amine prepared by the method provided by the invention is enhanced from 3.80GPa to 3.89Gpa-3.92GPa, and is improved by 2.4%-3.2%. The invention can acquire the method for green grafting of polyether amine on a carbon fiber surface.

Owner:青岛碳智新材料科技有限公司

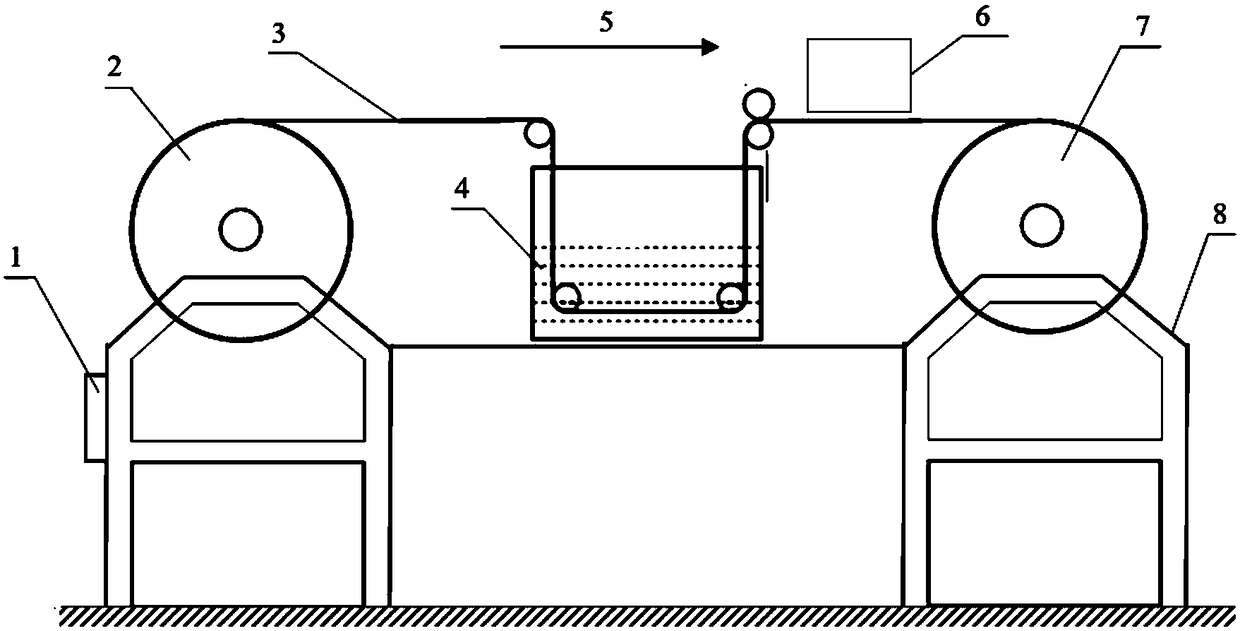

Composite technique for rolling semi-solid state copper-lead bearing alloy/steel bi-metal

InactiveCN101244430ASolve the problem of lead segregationPromote interdiffusionTemperature control deviceWork treatment devicesRare earthComposite plate

The invention relates to a roll-bonding process for semisolid copper-lead bearing alloys / steel bimetals. The weight content percentage of the lead in the copper-lead bearing alloy is 10.0 to 30.0%. In order to refine the crystalline grain of the lead and improve the mechanical property of the alloy, sulfur, tin, nickel, manganese, rare earth and other the third alloy elements can be added in the copper-lead alloy. The process comprises four steps: pretreatment of steel plates, preparation of semisolid sizing agent, roll bounding and water cooling. The detailed process comprises the following steps: performing mechanical agitation to the melted copper-lead bearing alloys at 930 to 1050 DEG C to obtain the semisolid sizing agent; pouring the semisolid sizing agent on the pretreated steel plates; synchronously feeding the semisolid copper-lead bearing alloys and solid steel plates in to a mill for rolling; spraying water for cooling to obtain the bimetallic composite plate. The invention effectively overcomes the defect of lead segregation in the production of the copper-lead bearing alloys in the prior art, therefore, metallographic structure with fine lead particle and even distribution is obtained. According to mechanical test results, the interfacial shear strength of the copper-lead bearing alloys / steel bimetallic slabs prepared using the process is more than 60Mpa, increased by about 10Mpa.

Owner:UNIV OF SCI & TECH BEIJING

Method for efficiently preparing carbon fiber-grafted polymer

The invention discloses a method for efficiently preparing a carbon fiber-grafted polymer and relates to a carbon fiber surface modifying method. The invention aims to solve the problems of high energy consumption, environment pollution, low grafting degree, serious damage to the main bodies of carbon fibers, and low interfacial strength of the modified carbon fibers of the current carbon fiber modifying method. The method comprises the following steps of 1, extracting the carbon fibers; 2, oxidizing the carbon fibers; and 3, grafting PEI (Polyetherimide) to the carbon fibers to obtain the carbon fiber grafted polyethyleneimine. Content of nitrogen element of the carbon fiber-grafted polyethyleneimine prepared by the method is up to 15.51 to 17.84 percent; compared with the carbon fibers, the carbon fiber-grafted polyethyleneimine prepared by the method is obviously improved in interfacial shear strength, and the interfacial shear strength is improved to 73.7MPa to 89.6MPa from 48.8MPa of the carbon fibers and is improved by 51 to 83.6 percent. An efficient carbon fiber-grafted polymer can be obtained by the method.

Owner:QINGDAO UNIV

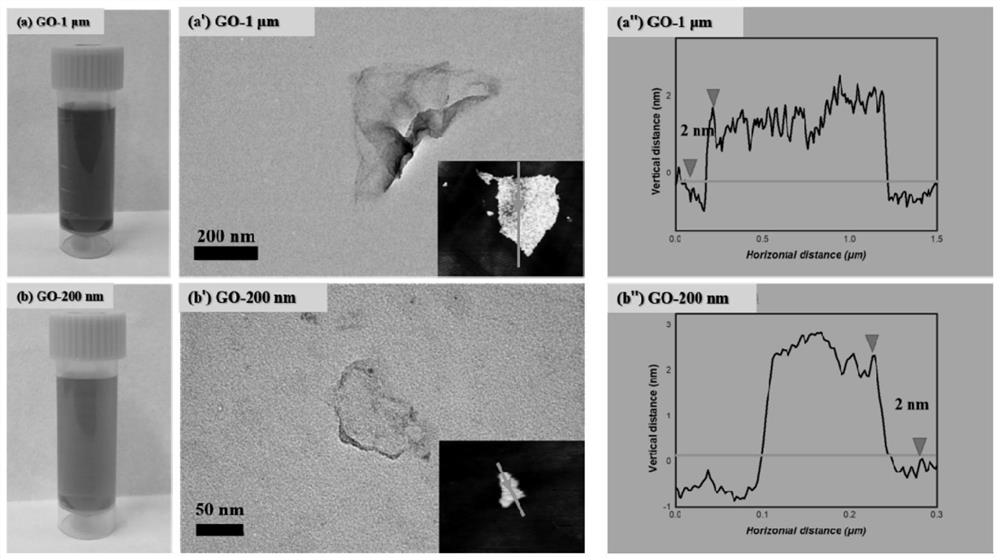

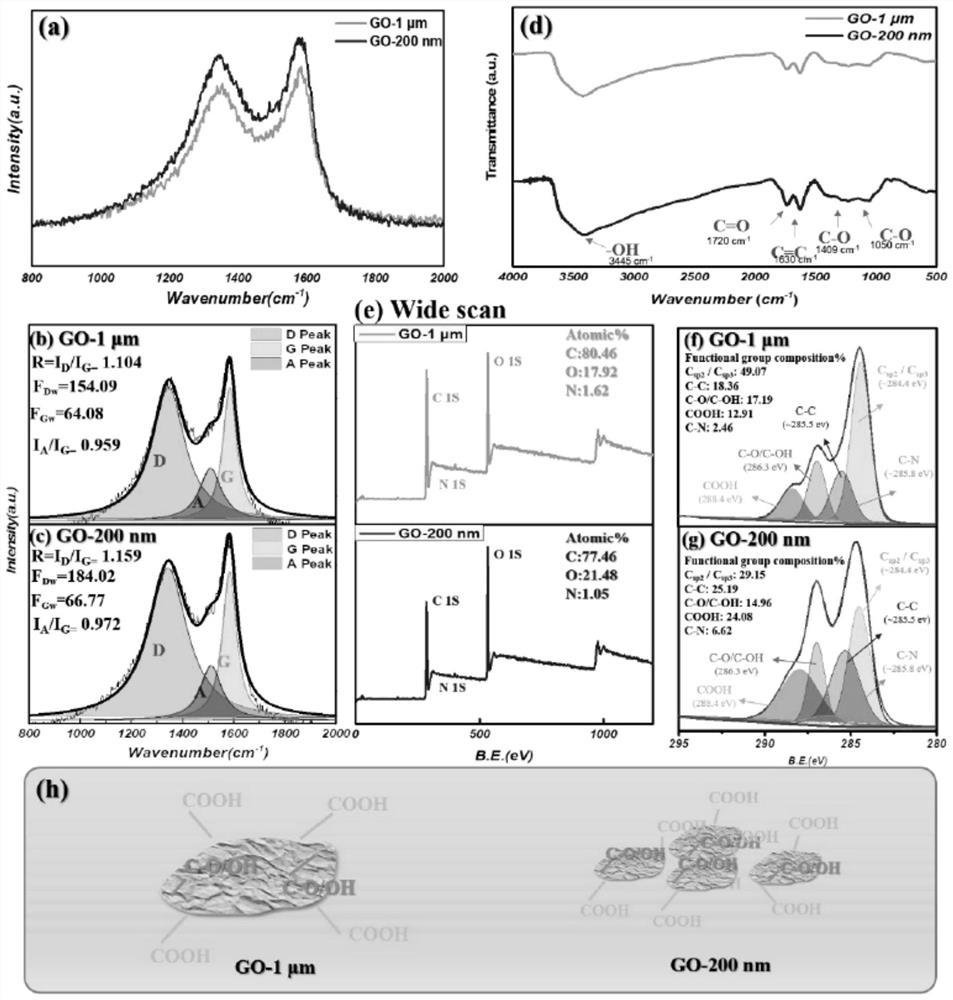

Method for improving interface performance of resin matrix and carbon fibers

ActiveCN113293605AImprove interface performanceSimple preparation processCarbon fibresModified carbonInterlaminar shear

The invention discloses a method for improving the interface performance of a resin matrix and carbon fibers, and belongs to the field of composite materials. Graphene oxide is adopted to modify the surface interface of the carbon fibers, so that a carbon fiber reinforced resin matrix composite material with high interface shear strength and interlayer shear strength is obtained. The carbon fiber reinforced resin-based composite material is prepared from graphene oxide modified carbon fibers, a resin matrix and a curing agent as raw materials, and the graphene oxide modified carbon fibers are obtained from graphene oxide modified carbon fibers with the transverse size of 50-50000 nm. The method has outstanding advantages in the aspect of enhancing the interface performance of the carbon fiber composite material, can meet the high-temperature forming requirement of high-heat-resistance resin, and has important application prospects in preparation of various high-performance resin-based composite materials. The graphene oxide modified carbon fiber reinforced resin matrix composite material is excellent in interlaminar shear performance and can be applied to the fields of aerospace, rail transit, automobiles, energy sources, ships and the like.

Owner:SICHUAN UNIV

Device and method for testing interfacial shear strength of fiber reinforced thermosetting resin composite materials

InactiveCN105928800AIncreased interfacial shear strengthRealize simultaneous sample preparationMaterial strength using steady shearing forcesSingle fiberResin-Based Composite

The invention relates to a device and method for testing interfacial shear strength of fiber reinforced thermosetting resin composite materials. The device comprises a resin die, support plates, hollow screw rods, sleeves, spring clips, and a bottom support plate; the hollow screw rods and the support plates are connected in rigid connection, the sleeves and the hollow screw rods are connected through internal screw threads, the support plates are vertically placed on the bottom support plates and fixed with screws, the resin die is embedded in the middle part of the support plates and is placed on the bottom support plate, a fiber is introduced to pass through the hollow screw rod and impale a wall of the resin die by a steel needle, a certain length of the fiber is embedded, and the spring clip clamps a free end of the fiber outside the sleeve. The testing method is based on single fiber pull-out technology, and the method comprises the following steps: fibers are embedded into the resin die, and the embedding length is regulated; resin is cast in order to prepare a testing sample; demoulding is carried out for a single fiber pull-out test, and the interfacial shear strength of the composite material is calculated. The device has a simple structure, and can be used for solving difficulties of sample preparation for the single fiber pull-out test of fiber and the like; the interface test method is convenient and rapid to operate.

Owner:TONGJI UNIV

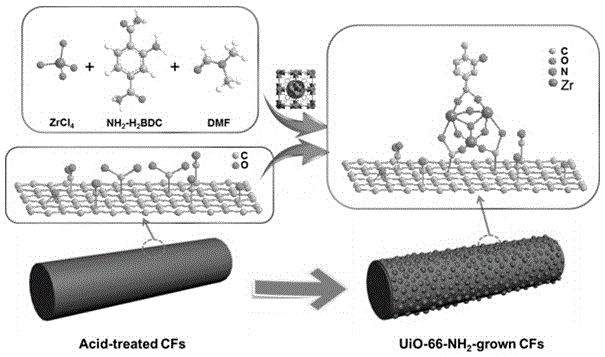

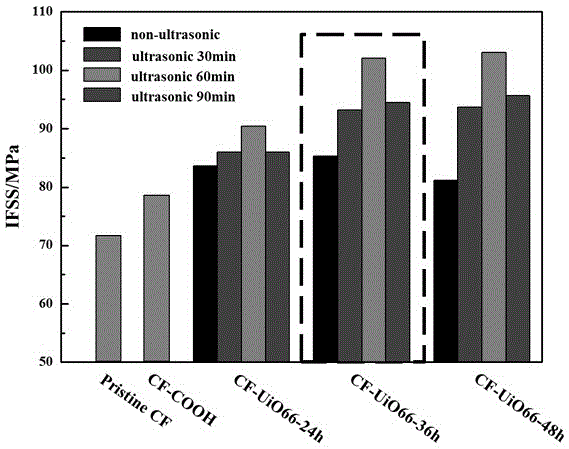

Method for modification of carbon fiber surface by use of metal organic framework

ActiveCN105133317AImprove surface propertiesHigh tensile strengthFibre treatmentCarbon fibersModified carbon

A method for modification of carbon fiber surface by use of a metal organic framework belongs to the field of composite material interfacial modification. By combination of a new metal organic framework nanomaterial, a new carbon fiber surface modification method is provided, the main purpose is to solve the problem of carbon fiber body strength loss while improvement of carbon fiber surface energy of carbon fiber surface modification methods in the prior art. The preparation process is as follows: first, cleaning carbon fiber surface; second, pretreating the cleaned carbon fiber surface; third, grafting the pretreated carbon fiber surface with metal organic framework UiO-66-NH2; and fourth, ultrasonically processing the modified carbon fiber. Interfacial shear strength of the composite material prepared from the carbon fiber and epoxy E51 is increased by 44%, meanwhile the tensile strength of the carbon fiber is increased by 25%, and the composite material is used in aerospace, automotive, transportation, construction, chemical engineering and other fields.

Owner:宜兴环保产业有限公司

Preparation method of silane coupling agent assisted electrophoresis deposition initiated graphene oxide modified carbon fibers

ActiveCN108286187AImprove the deposition effectSolve reunionCarbon fibresCarbon fibersModified carbon

The invention discloses a preparation method of silane coupling agent assisted electrophoresis deposition initiated graphene oxide modified carbon fibers. The preparation method comprises the following steps: placing desized carbon fibers into an aqueous solution which contains amino propyl triethoxysilane (APTES) and ethanol for hydrolysis amination pretreatment to obtain carbon fibers treated bya silane coupling agent, connecting the carbon fibers treated by the silane coupling agent to a positive electrode of a power supply, connecting a copper sheet to a negative electrode of the power supply, and performing electrophoresis deposition by a graphene oxide aqueous solution used as an electrophoresis deposition solution to obtain the silane coupling agent assisted electrophoresis deposition initiated graphene oxide modified carbon fibers. The preparation method can effectively enhance the interfacial shear strength of a carbon fiber enhanced resin-based composite material, and can beapplied to a surface modification process of homemade carbon fiber.

Owner:SHANDONG UNIV

Graphene nanoribbon interface-modified PBO (polyparaphenylene benzobisoxazole) fiber and preparation method thereof

The invention relates to a modification method of a PBO (polyparaphenylene benzobisoxazole) fiber, in particular to a graphene nanoribbon interface-modified PBO fiber and a preparation method thereof, aiming at solving the problem that the existing modification method of the PBO fiber enables the tensile strength of a PBO fiber body to be greatly reduced. The structure of the graphene nanoribbon interface-modified PBO fiber is described in the description. The preparation method comprises the steps of 1, preparing a graphene nanoribbon; 2, treating the graphene nanoribbon by carboxylation; 3, treating the surface of PBO by carboxylation; 4, using the carboxylic graphene nanoribbon interface-modified PBO fiber to obtain the graphene nanoribbon interface-modified PBO fiber. Compared with the untreated PBO fiber, the tensile strength of the modified PBO fiber is only reduced by 5-10 percent; compared with an epoxy resin composite material prepared by the unmodified PBO fiber, the interfacial shear strength of an epoxy resin composite material prepared by the modified PBO fiber is improved by 20-41 percent. The graphene nanoribbon interface-modified PBO fiber can be taken as a reinforcing material for preparing composite materials.

Owner:HARBIN INST OF TECH

Soil layer interfacial shear testing machine and soil layer interfacial shear testing box

PendingCN109580387AImpact measurementMaterial strength using steady shearing forcesEngineeringSoil horizon

The invention relates to a soil layer interfacial shear testing machine and a soil layer interfacial shear testing box. The soil layer interfacial shear testing box comprises an upper box body and a lower box body, the lower box body is provided with an inner cavity communicating with the upper box body for filling a testing soil layer, or the lower box body is provided with a resistance plate used for making friction contact with the testing soil layer in the upper box body, the upper end of the upper box body is open, an upper pressing plate used for pressing the testing soil layer in the upper box body is arranged at the power output end of a vertical loading mechanism, a lower guiding structure with the transverse guiding direction is arranged between the lower box body and a device frame, an upper guiding structure with the transverse guiding direction is arranged between the upper box body and the lower box body, and the power output end of a transverse loading mechanism is in transmission connection with the lower box body. The soil layer interfacial shear testing machine capable of testing soil layer interfacial shearing force, and the soil layer interfacial shear testing box used in the soil layer interfacial shear testing machine are provided by the invention.

Owner:ZHENGZHOU UNIV

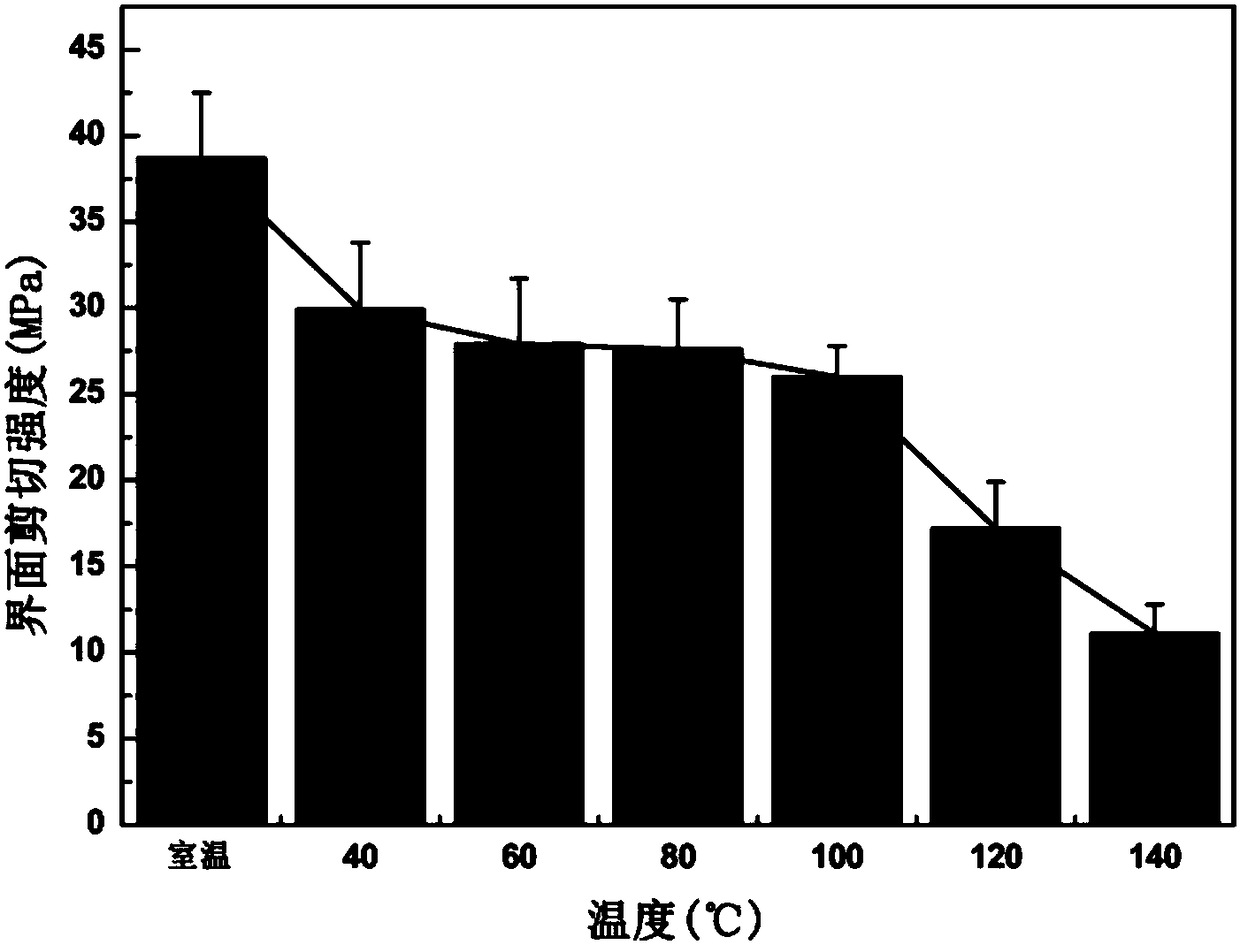

Methods for testing and improving interfacial shearing performance of fiber-resin composite under high temperature condition

InactiveCN108120670AImproved interfacial shear propertiesSimple processUsing mechanical meansMaterial analysisPorous fiberMaterials science

Owner:SHANGHAI UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com