Method for modification of carbon fiber surface by use of metal organic framework

A metal-organic framework and fiber surface technology, which is applied in fiber processing, textiles and papermaking, can solve the problems of lower body strength, achieve the effect of improving surface properties and increasing tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1. Clean the carbon fiber surface: put 2g of carbon fiber bundles into a Soxhlet extractor, add 150ml of acetone, wash at 70°C for 48h, put the cleaned carbon fiber in a vacuum oven and dry at 70°C for 10h.

[0020] 2. Surface pretreatment of the cleaned carbon fiber: Put the dried carbon fiber bundle into a single-mouth bottle, pour 100ml of concentrated nitric acid, completely immerse the carbon fiber in the concentrated nitric acid, and react at 80°C for 4 hours. The oxidized carbon fibers were taken out and washed repeatedly with clean water until neutral, and then put into a vacuum oven and dried at 70°C for 10 hours.

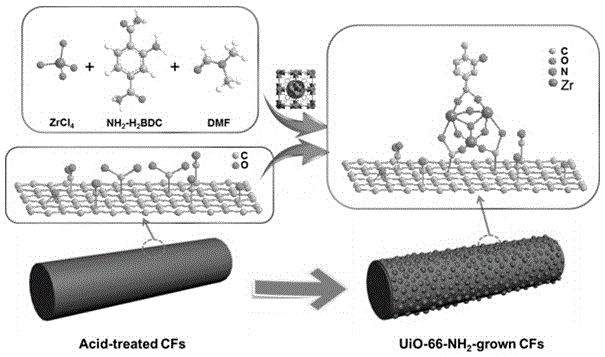

[0021] 3. Grafting metal-organic framework UiO-66-NH on the surface of pretreated carbon fibers 2 : put the carbon fiber bundle after surface pretreatment into ZrCl 4 And 2-aminoterephthalic acid in DMF solution, heated to 80 ° C for 24h. Rinse the treated carbon fiber bundles under clean water repeatedly.

[0022] 4. Ultrasonic treatment of mod...

Embodiment 2~9

[0023] Embodiment 2~9: with reference to embodiment 1, change parameter:

[0024]

[0025] Depend on figure 1 It can be seen that the surface of carbon fiber has polar groups such as -COOH and -OH after being oxidized by nitric acid. By working with UiO-66-NH 2 The precursor undergoes a coordination reaction, so that UiO-66-NH 2 grafted onto the carbon fiber surface.

[0026] Depend on figure 2 It can be seen that dense UiO-66-NH appeared on the surface of the grafted carbon fiber 2 Crystal particles, after EDX elemental analysis, mainly contain elements such as Zr, C, N and O.

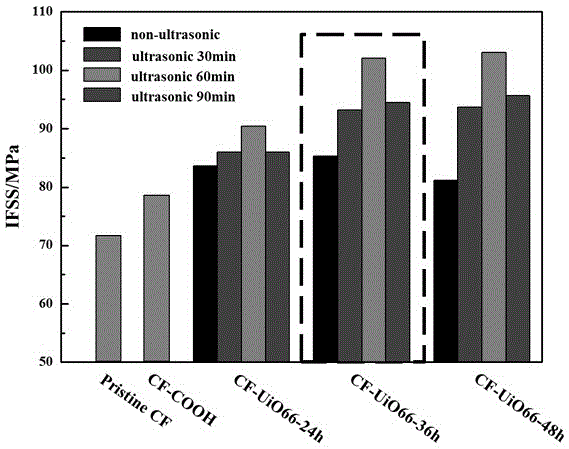

[0027] Depend on image 3 It can be seen that the interfacial shear strength of the modified carbon fiber is increased by 44% and 32% respectively compared with the original carbon fiber and the nitrated carbon fiber.

[0028] Depend on Figure 4 It can be seen that the single filament tensile strength of the modified carbon fiber is increased by 25% and 30% respectively compared with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com