Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "Small frictional force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

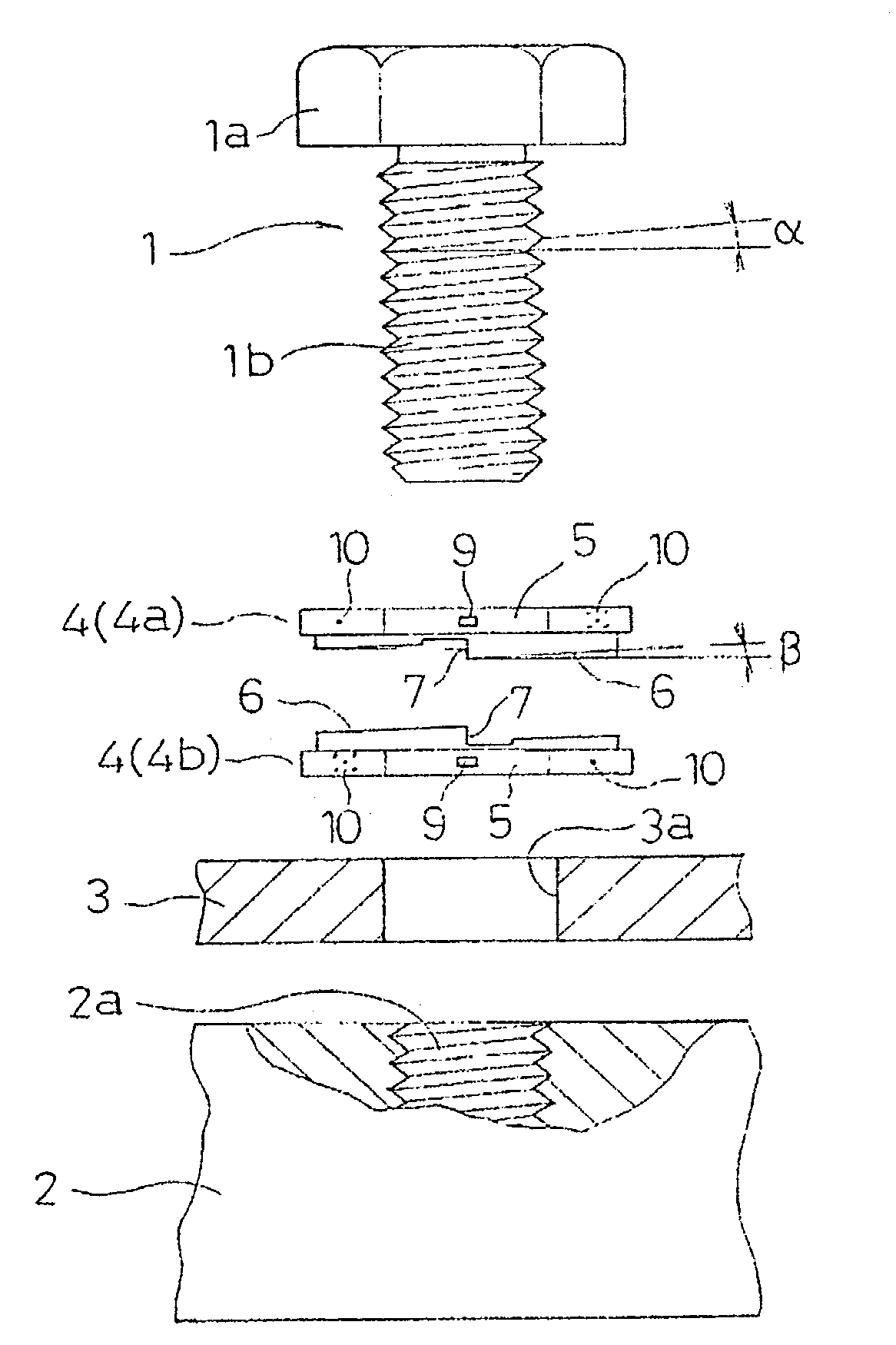

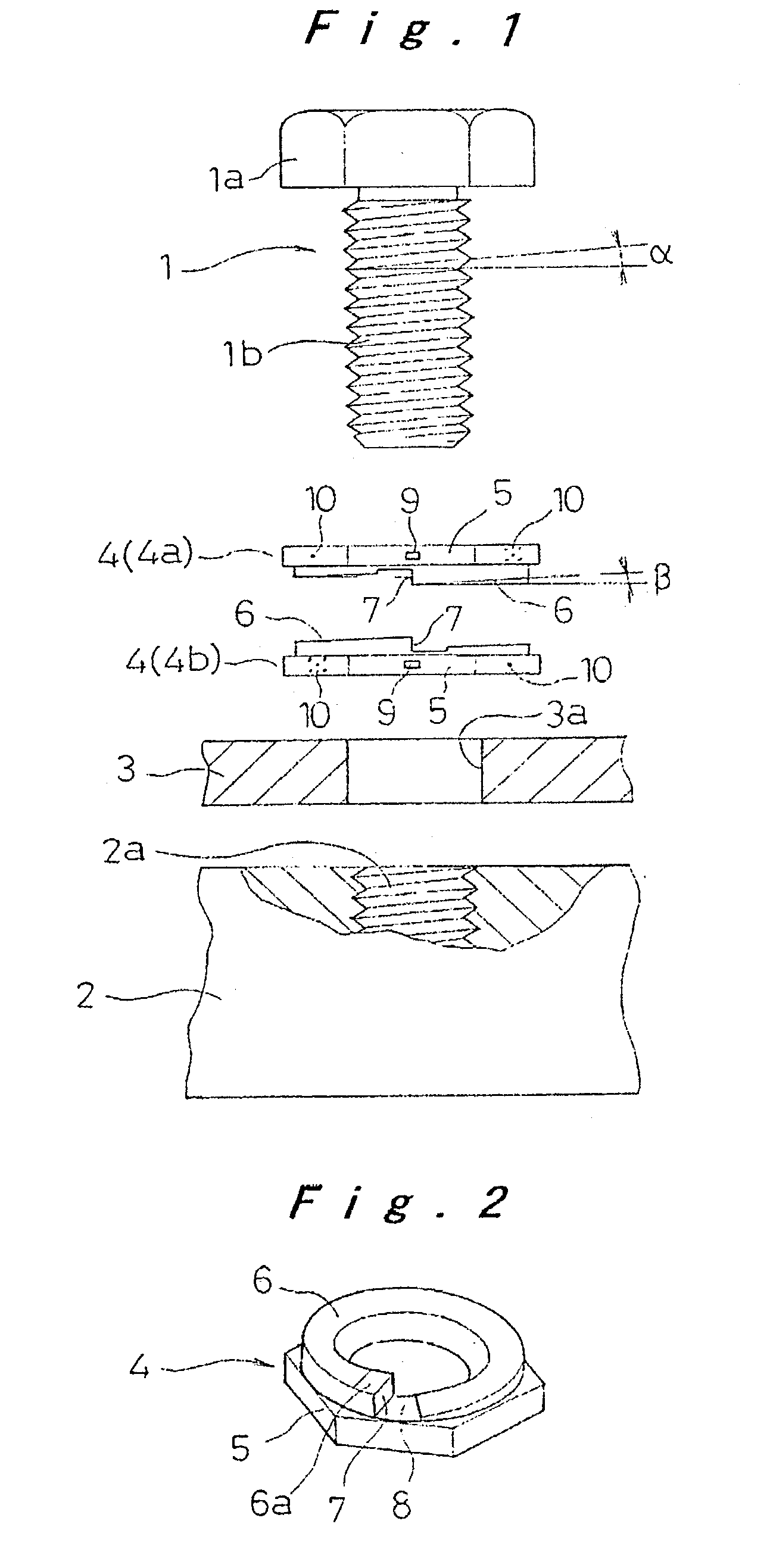

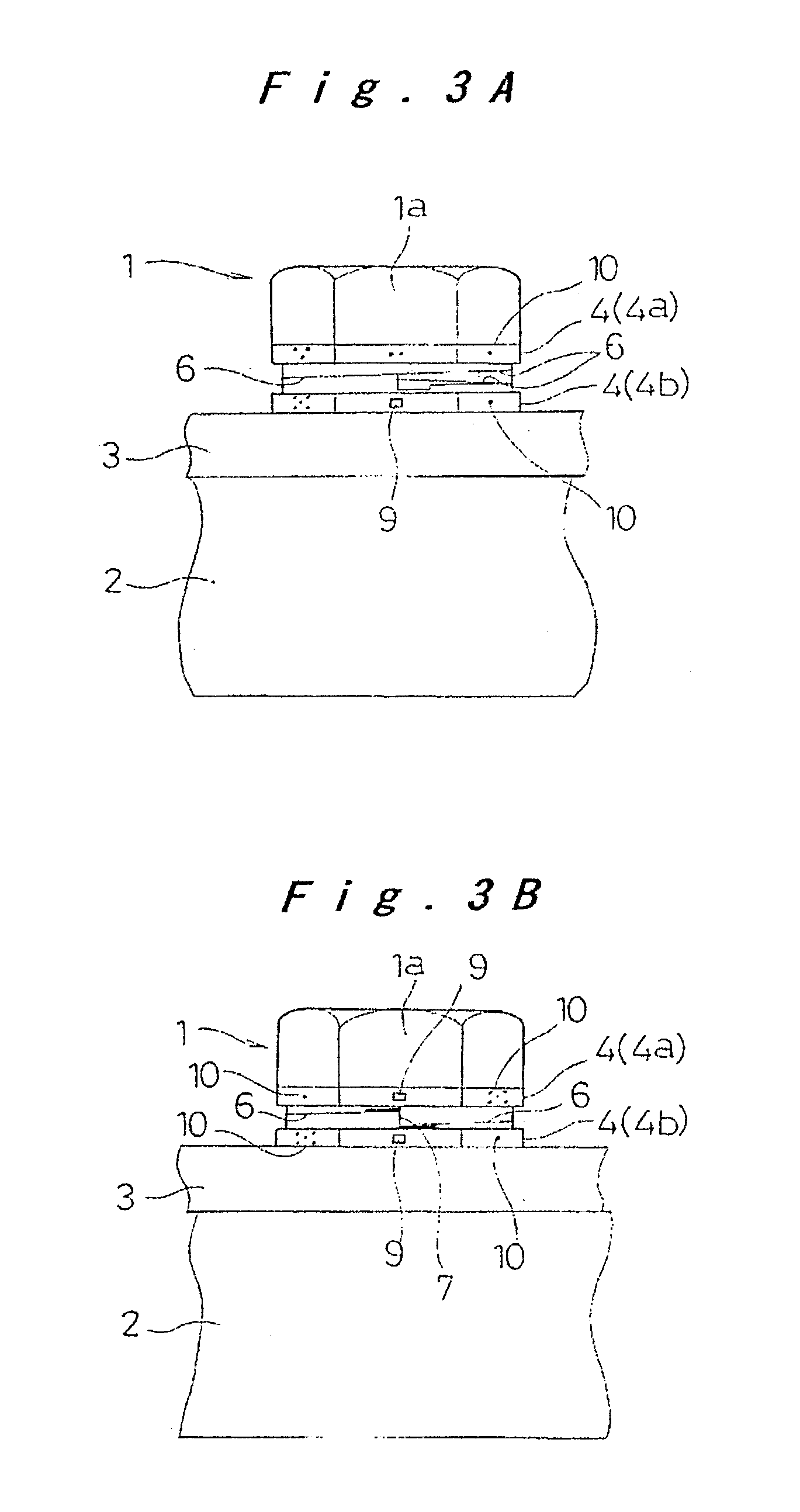

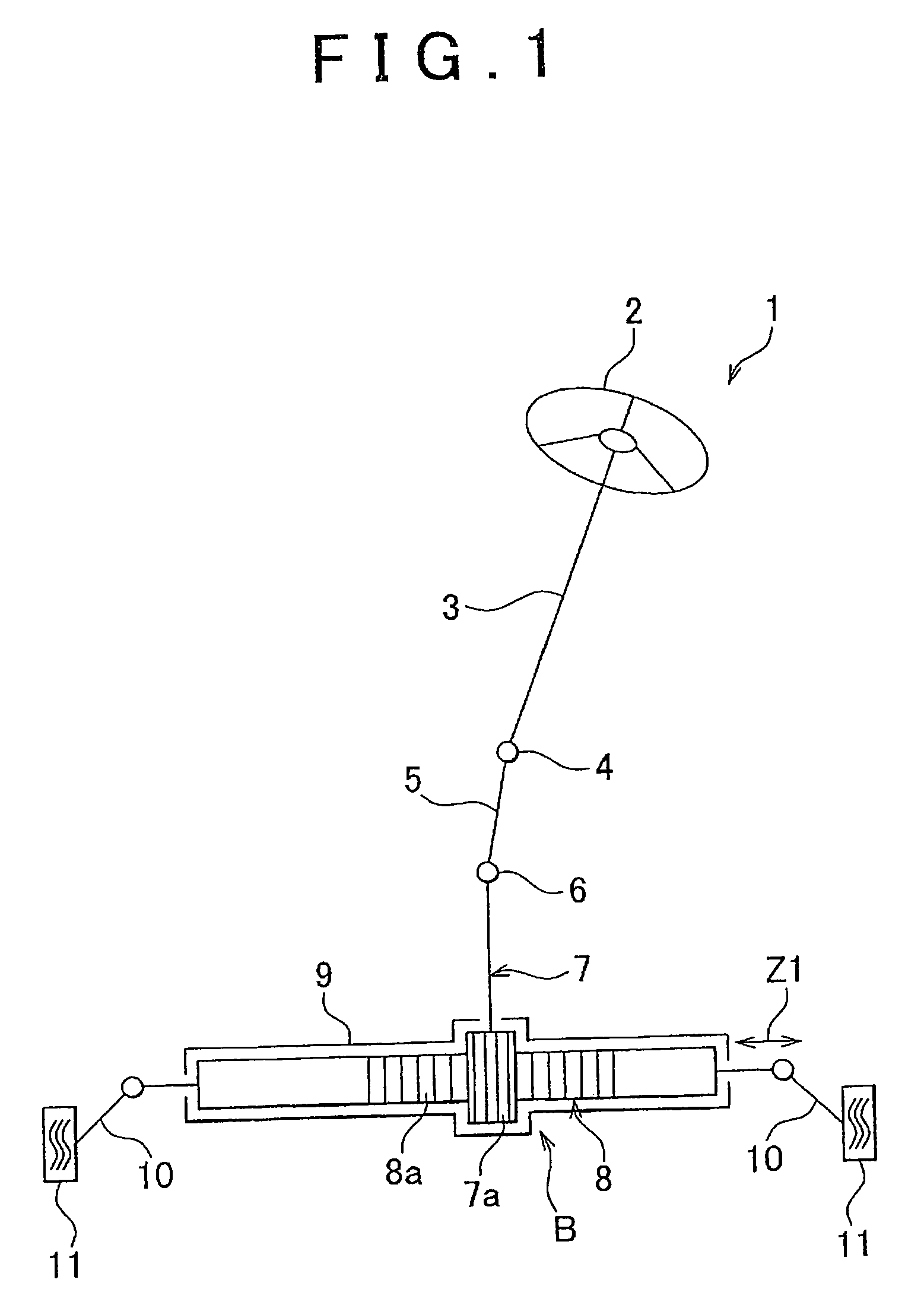

Screw mechanism

InactiveUS6966735B1Strong tightening forceThe implementation process is simpleWashersNutsEngineeringMechanical engineering

In a screw locking assembly a pair of washers having inclined surfaces are interposed between a screw member on a tightening side and a member to be tightened, with the inclined surfaces being mutually contacted. These inclined surfaces circle around once in spiral form with a lead angle β smaller than a lead angle α of the screw, and both ends thereof are connected with a tier face in the axial direction. By conducting an initial-tightening in a state with an interval of a preset angle maintained between the tier faces, and tightening and rotating the screw member on the tightening side until the tier faces come into contact with each other, a tightening force proportional to that angle is generated, and the tightening force is controlled surely with precision.

Owner:YAMAZAKI MASAKI

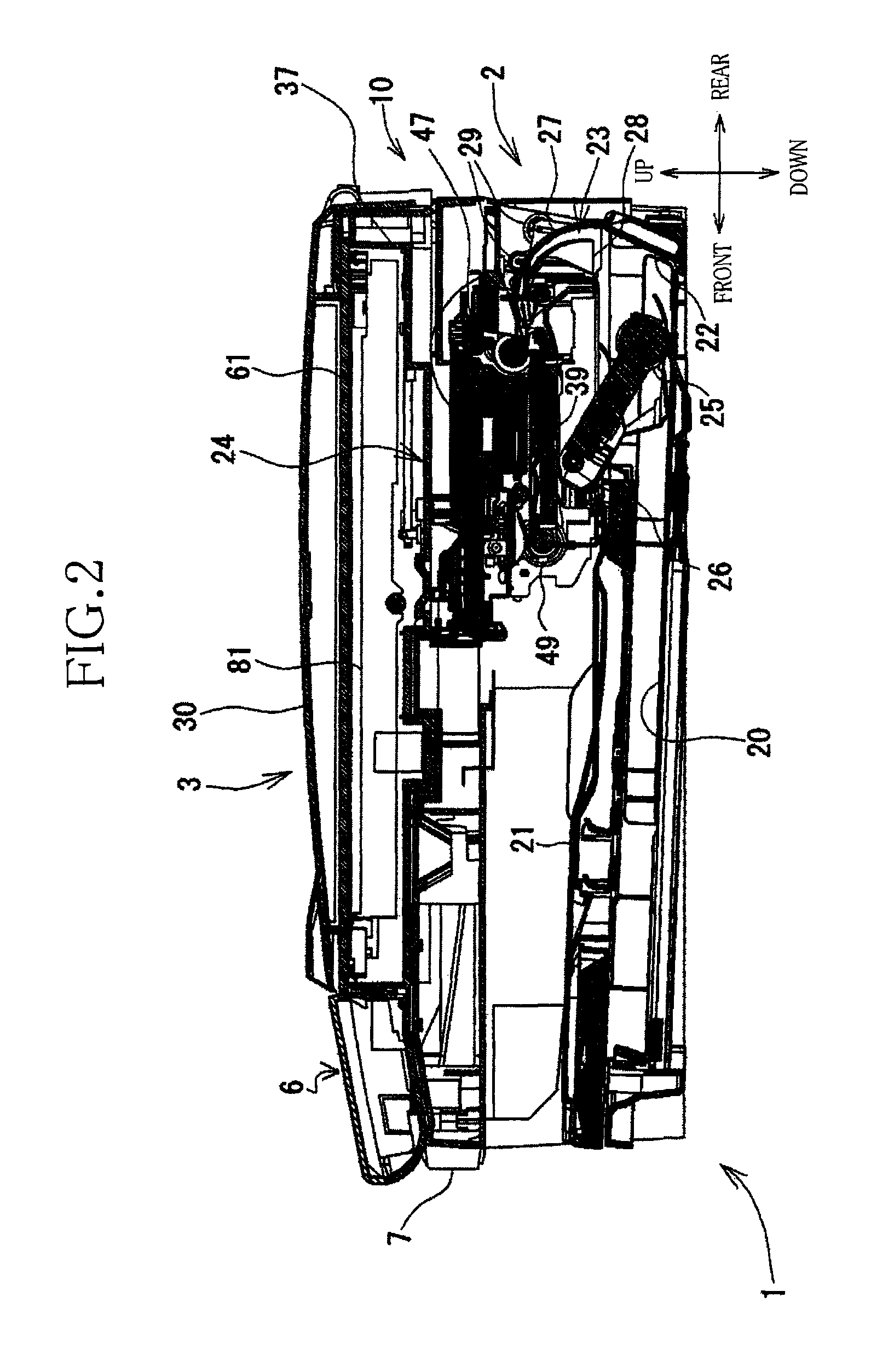

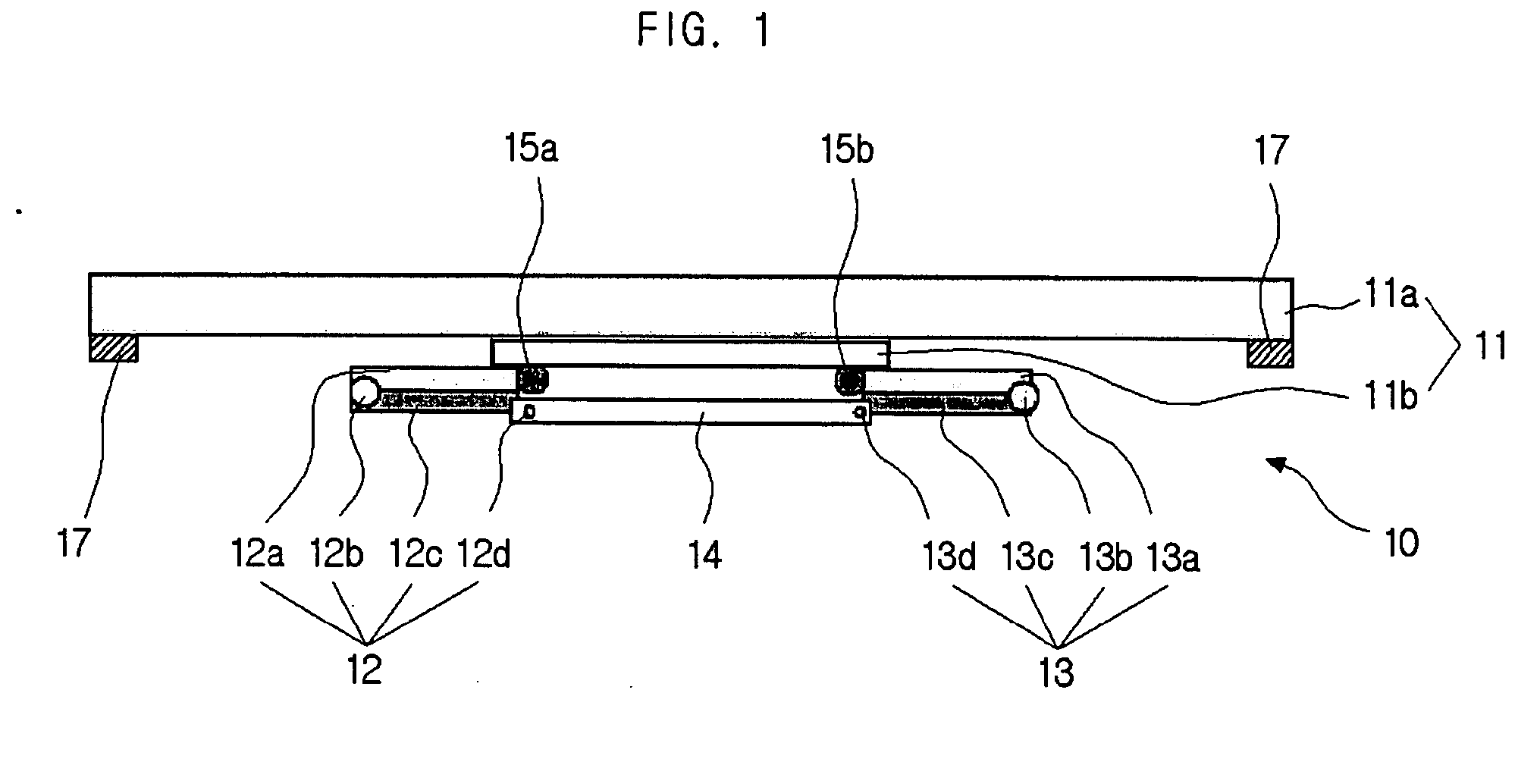

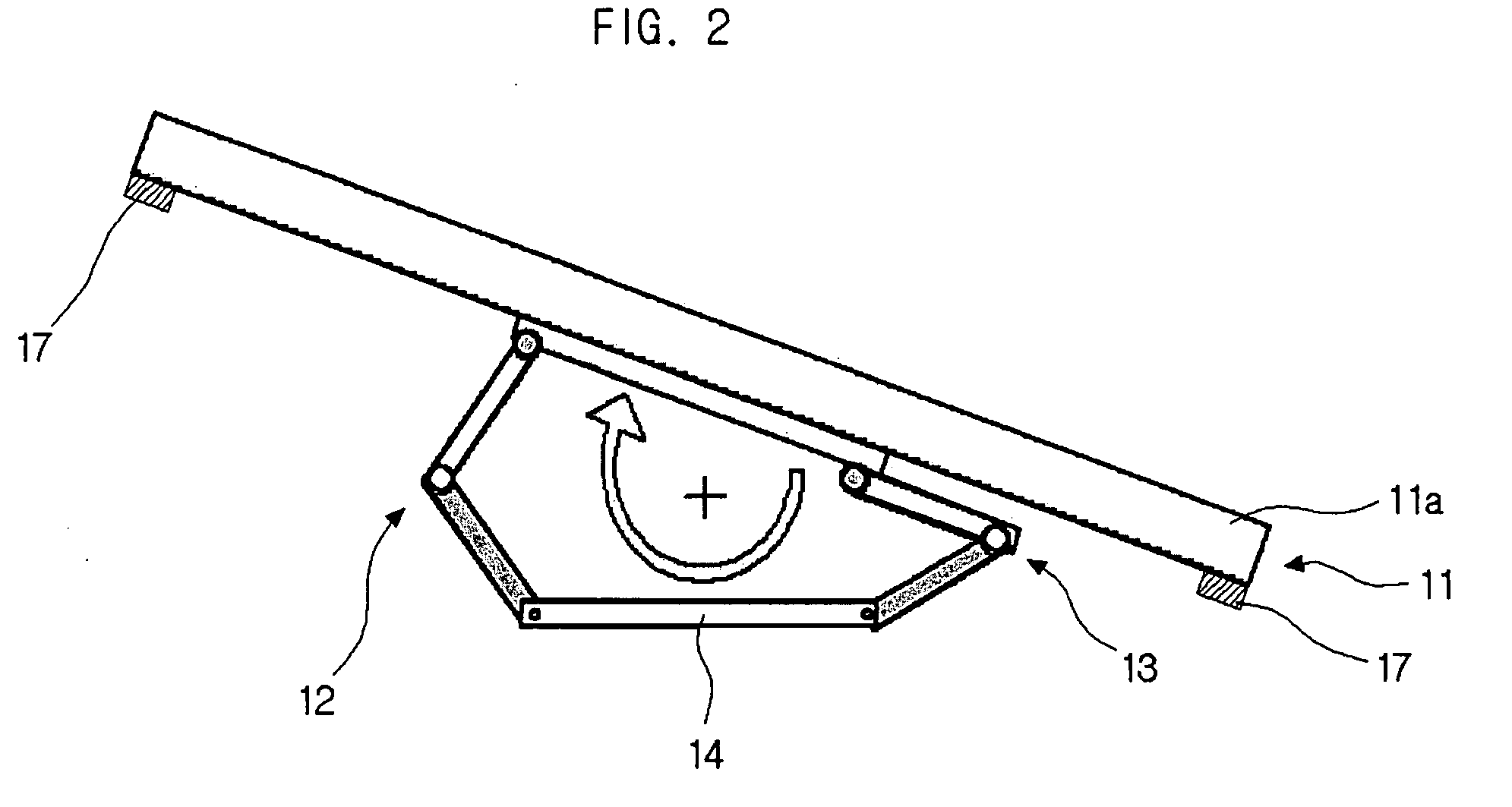

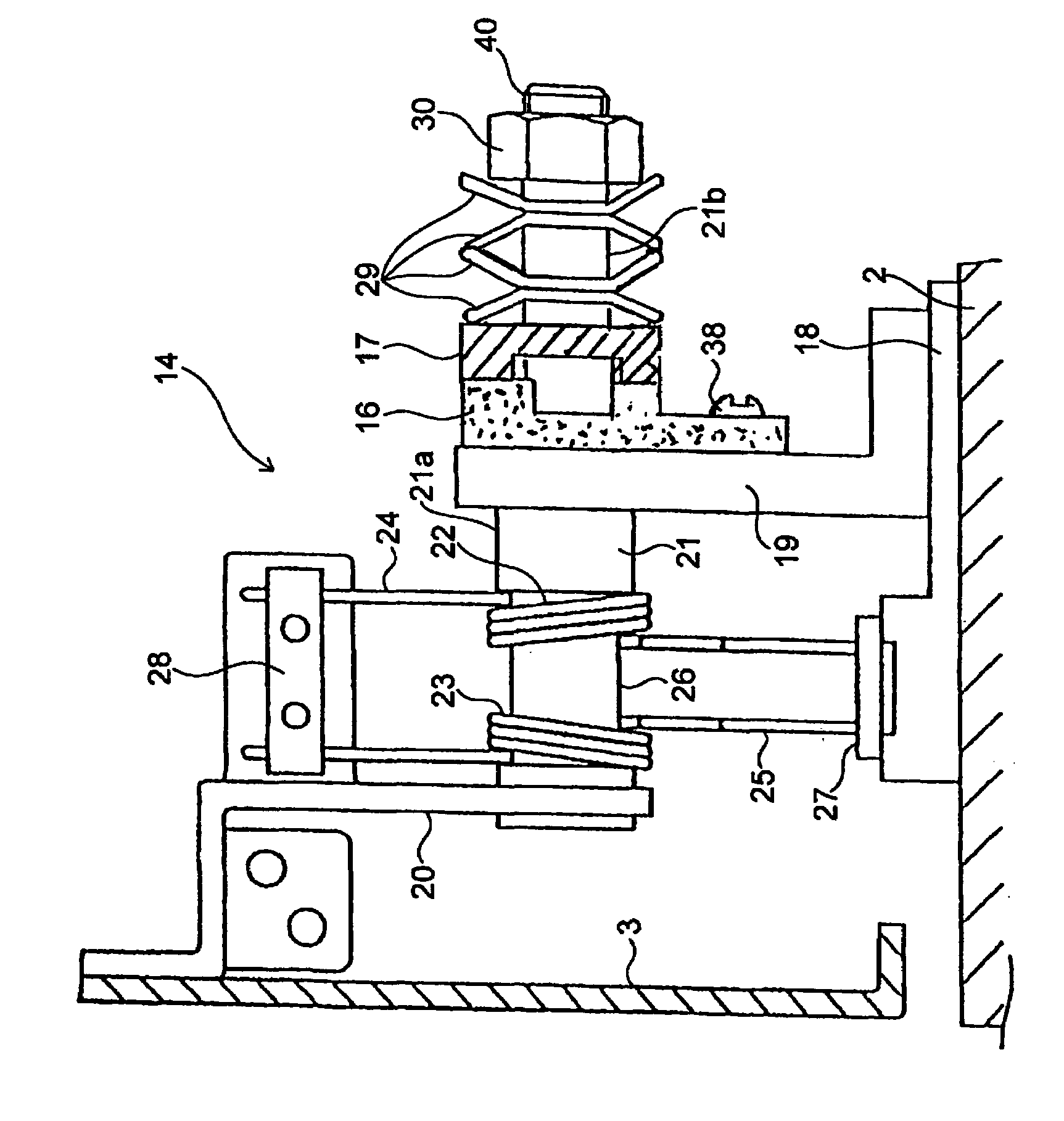

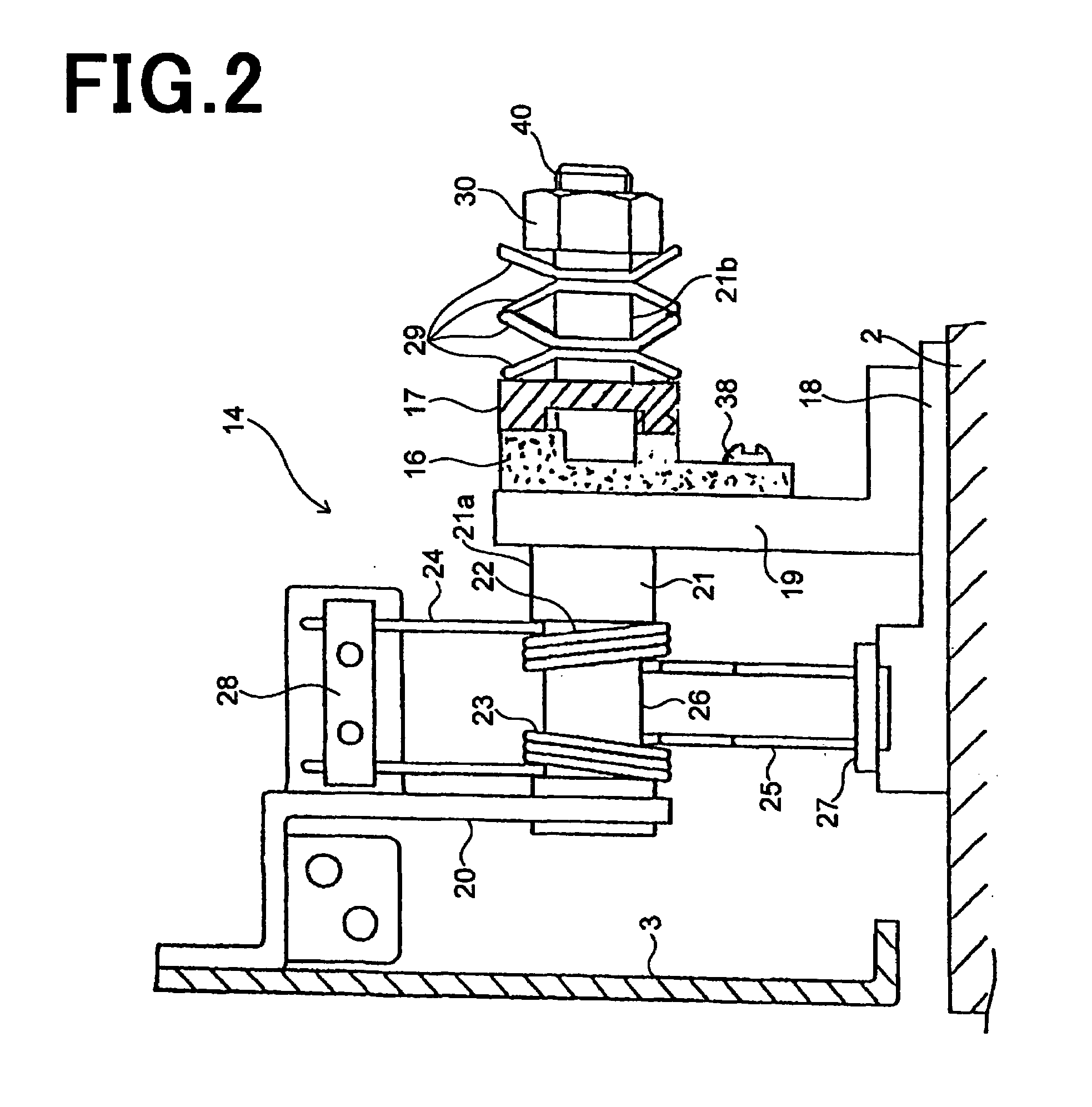

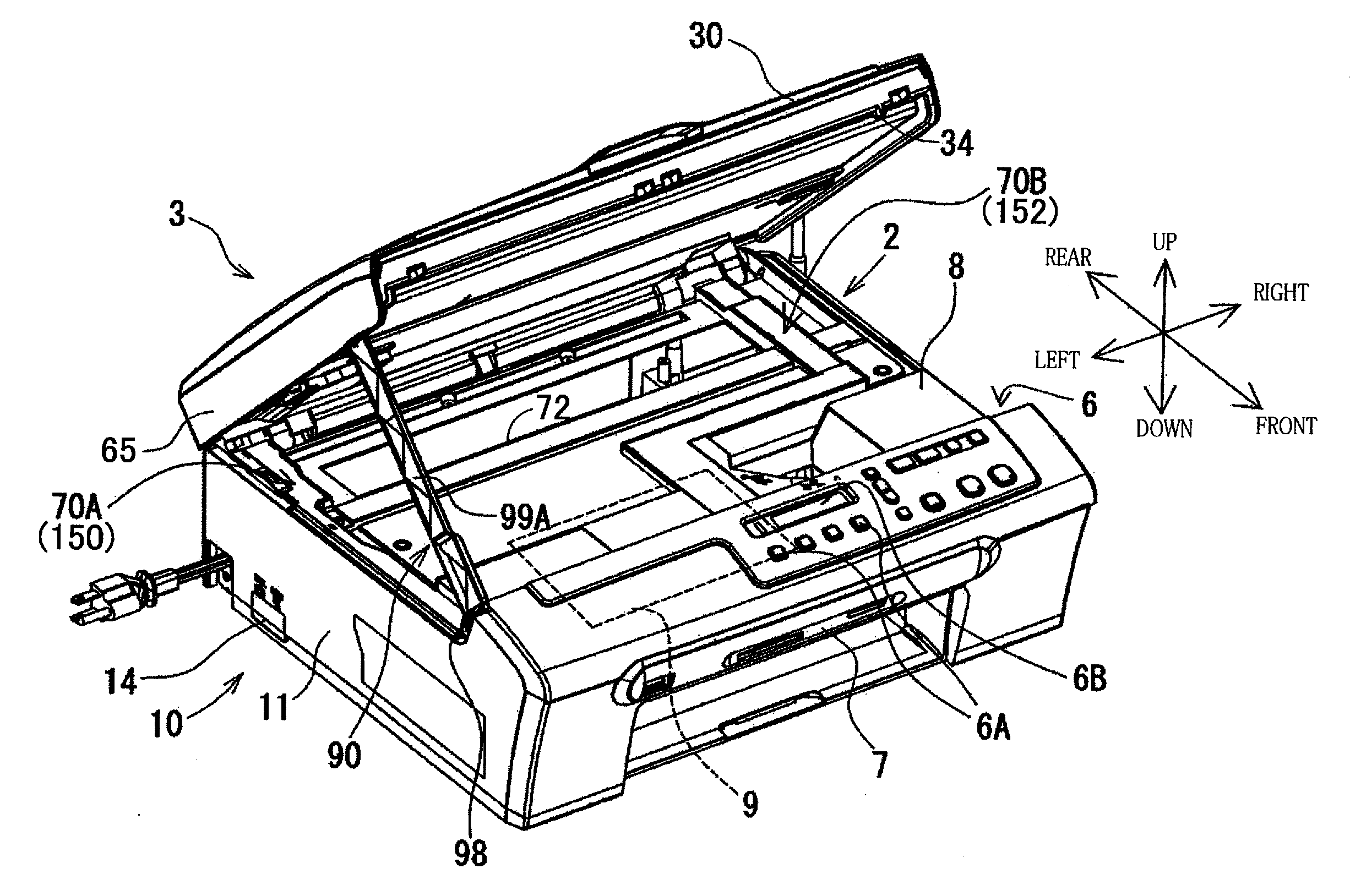

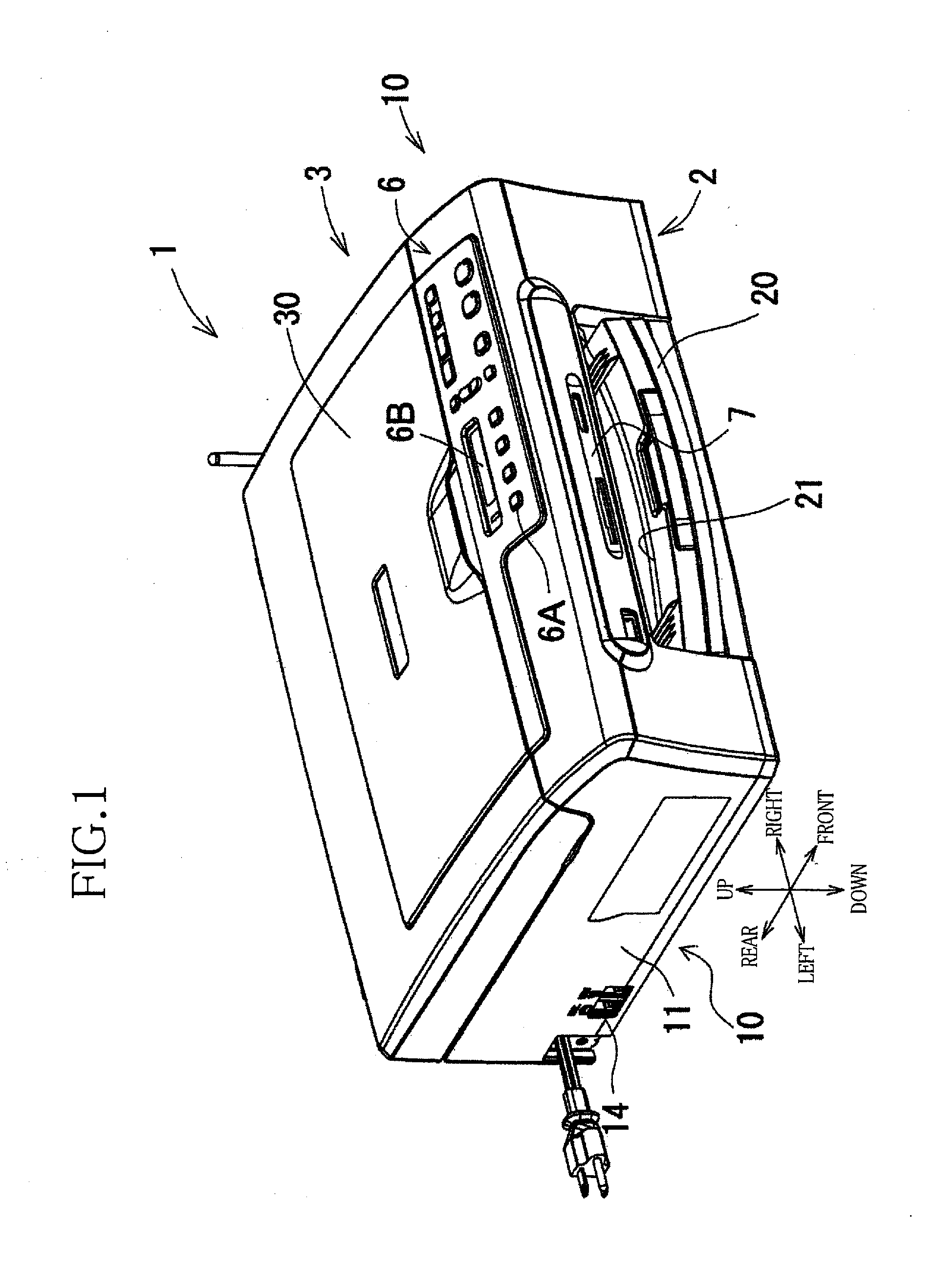

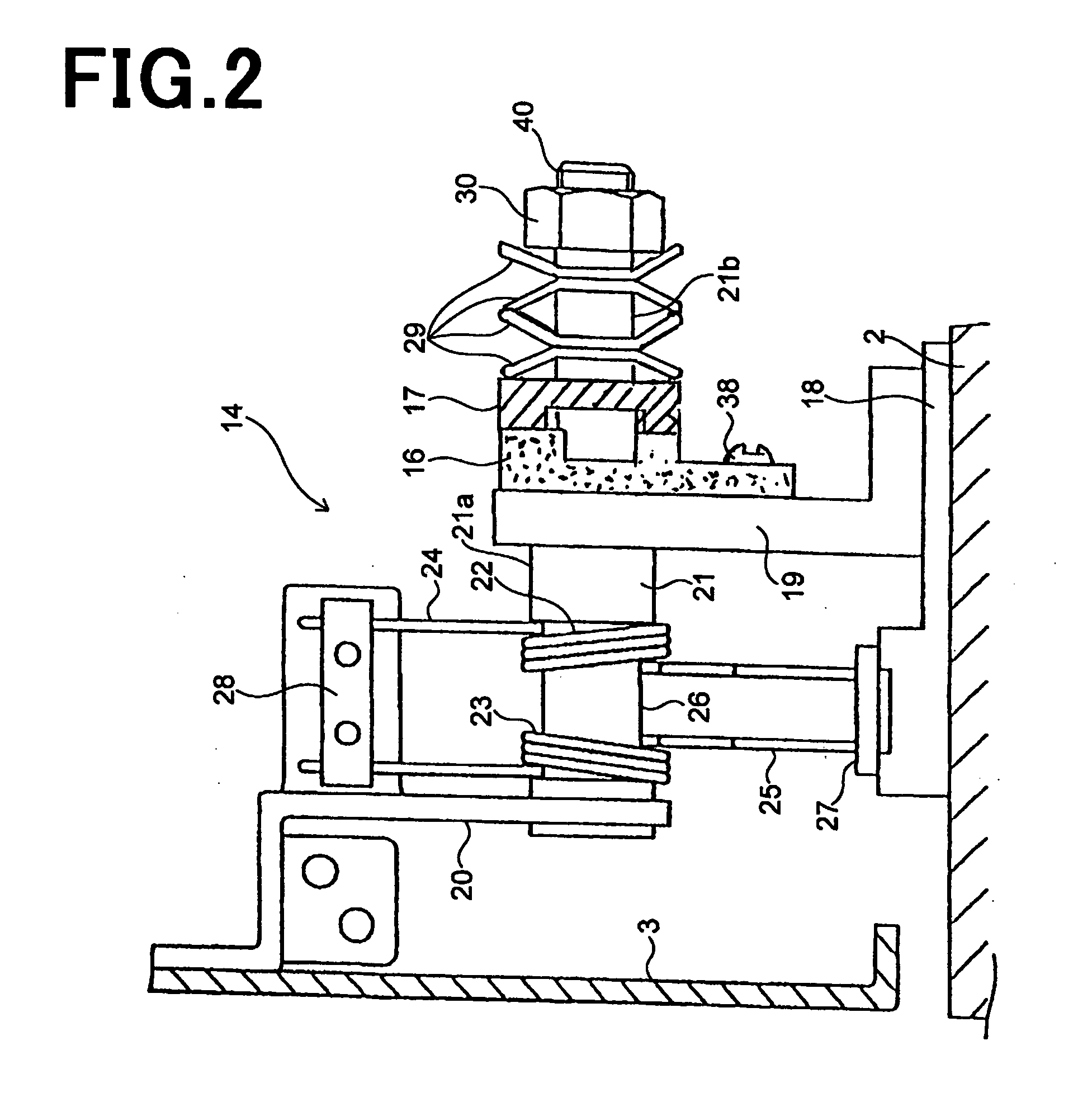

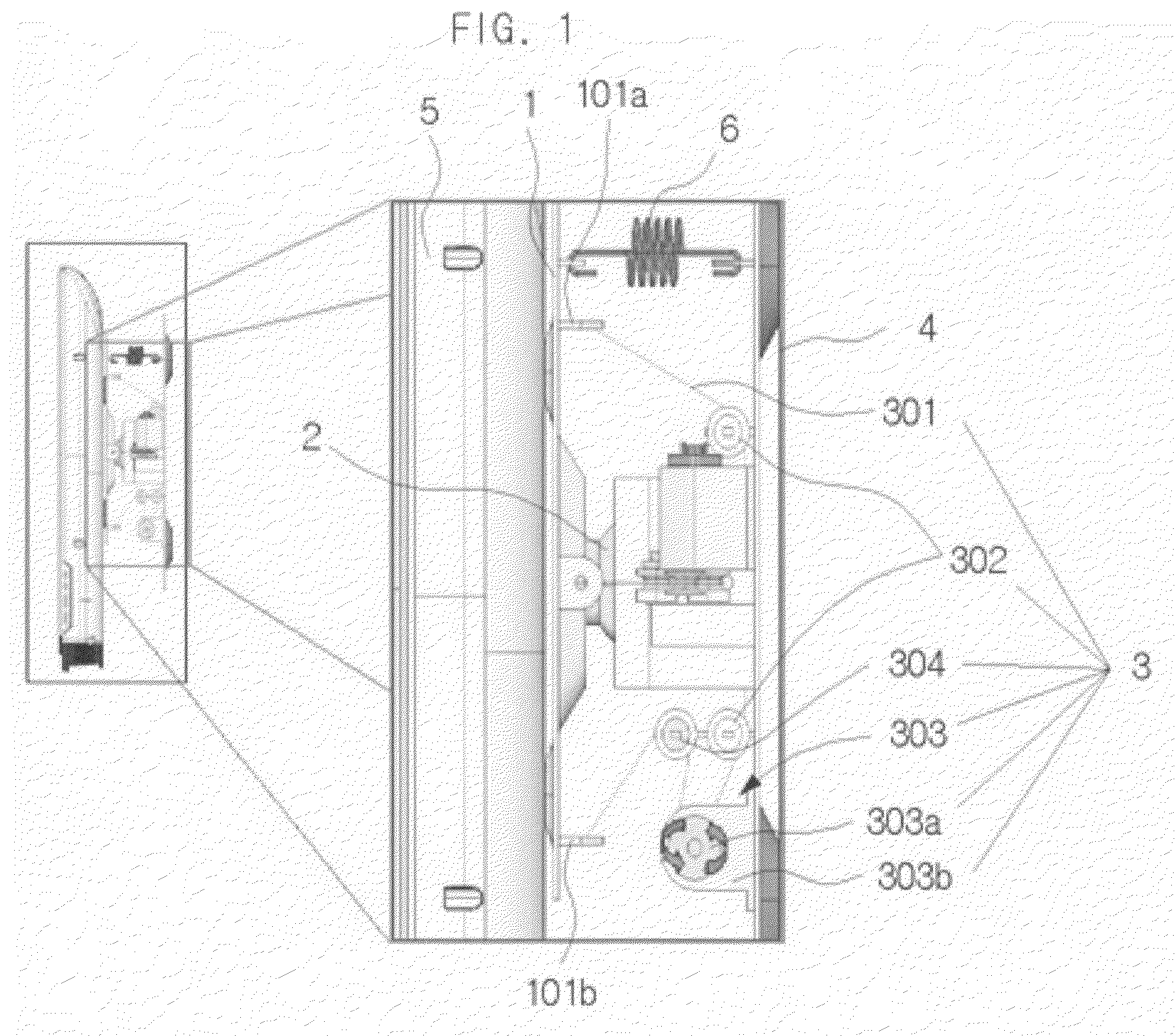

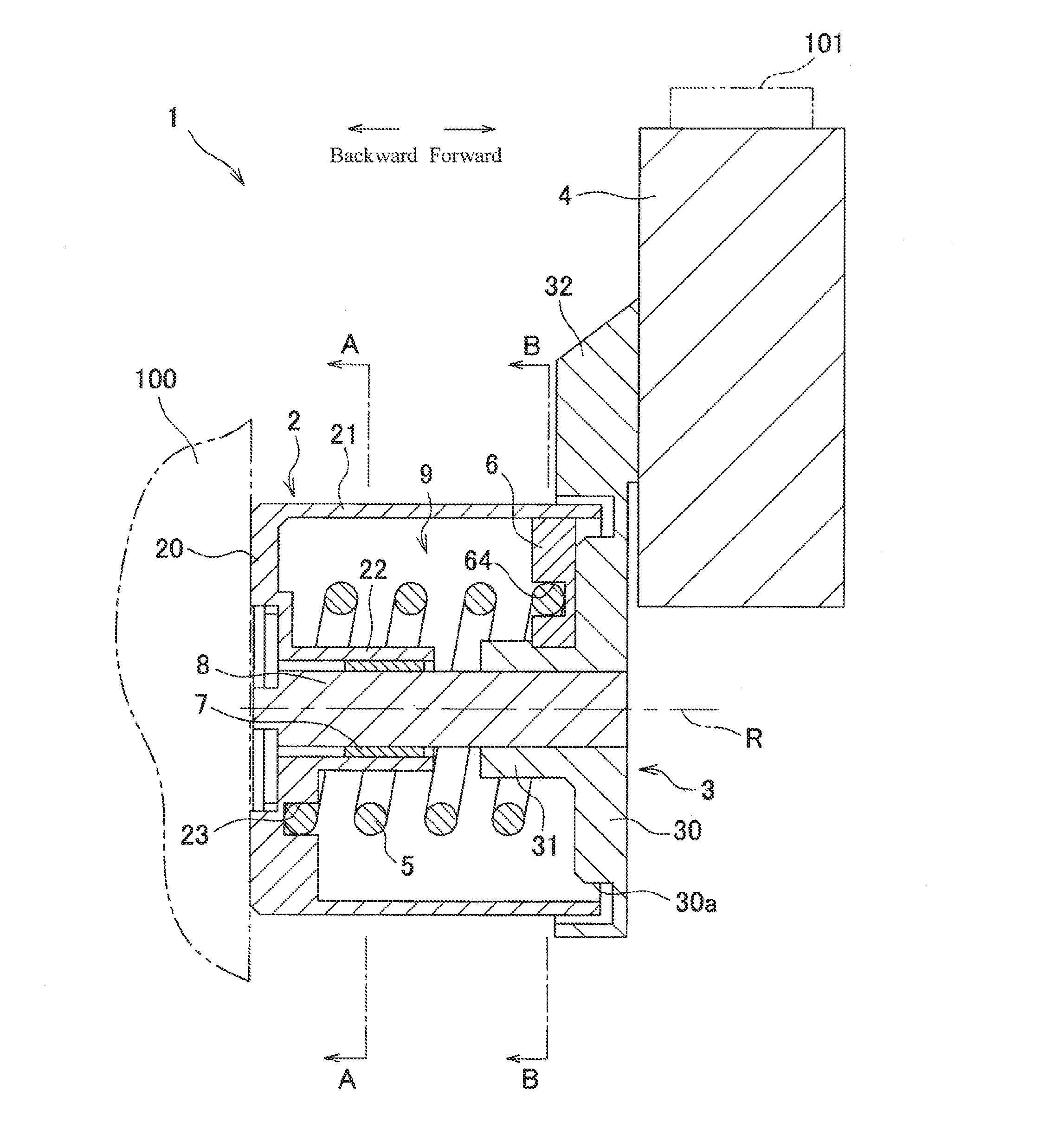

Opening and closing assembly, and multifunction device including the assembly

InactiveUS7778572B2Smoothly and quickly openedSmall frictional forceElectrographic process apparatusOther printing apparatusEngineering

An opening and closing assembly includes: (a) a first casing body; (b) a second casing body pivotable to be selectively placed in open and closed positions relative to the first casing body; and (c) a support stand for supporting the second casing body to maintain the open position. The support stand includes (c-1) a proximal end portion pivotably connected to one of the first and second casing bodies and (c-2) a distal end portion slidably connected to the other of the first and second casing bodies. The other of the first and second casing bodies includes (i) a guide portion for guiding the distal end portion of the support stand, and (ii) first and second wall portions cooperating with each other for gripping the distal end portion of the support stand. The distal end portion of the support stand includes a gripped portion having a thickness that is increased in a direction away from the distal end portion of the support stand toward the proximal end portion of the support stand.

Owner:BROTHER KOGYO KK

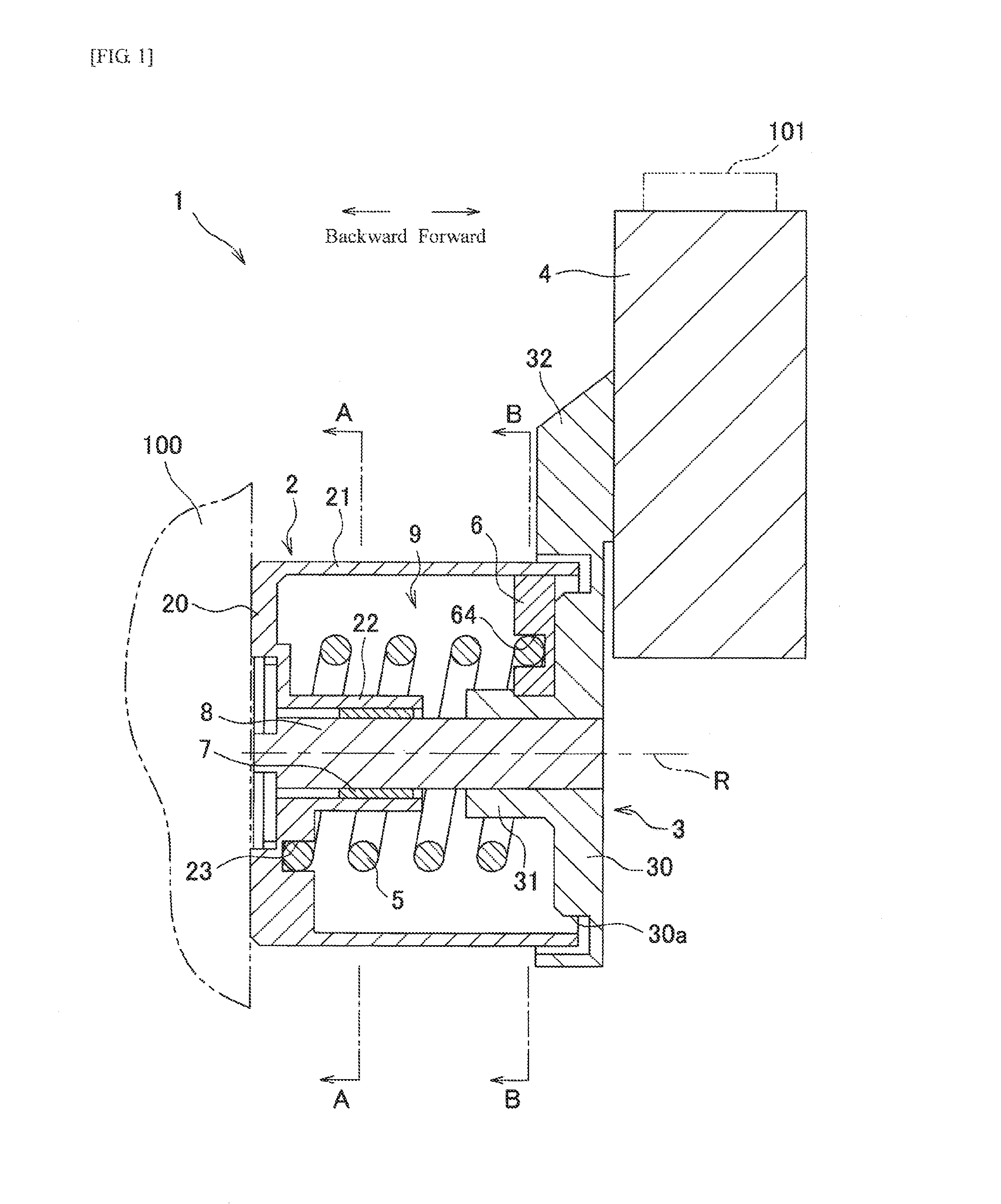

Rack shaft support device

ActiveUS20100024583A1Small frictional forceSmooth rotationPortable liftingToothed gearingsEngineeringCam

A rack shaft support device includes: a rack shaft support member that is accommodated inside a retention hole formed in a housing so as to slide in an axial direction of the retention hole, and slidably supports a rack shaft; a sealing member fixed to an inlet port of the retention hole; an intermediate member that is interposed between the rack shaft support member and the sealing member; a torsion spring that couples the sealing member and the intermediate member; a cam mechanism that converts a rotational force of the intermediate member induced by untwisting of the torsion spring to a force by which the intermediate member pushes the rack shaft support member; an opposing portion that opposes a rear surface of the rack shaft support member; and an annular elastic member that is interposed between the rear surface of the rack shaft support member and the opposing portion.

Owner:JTEKT CORP

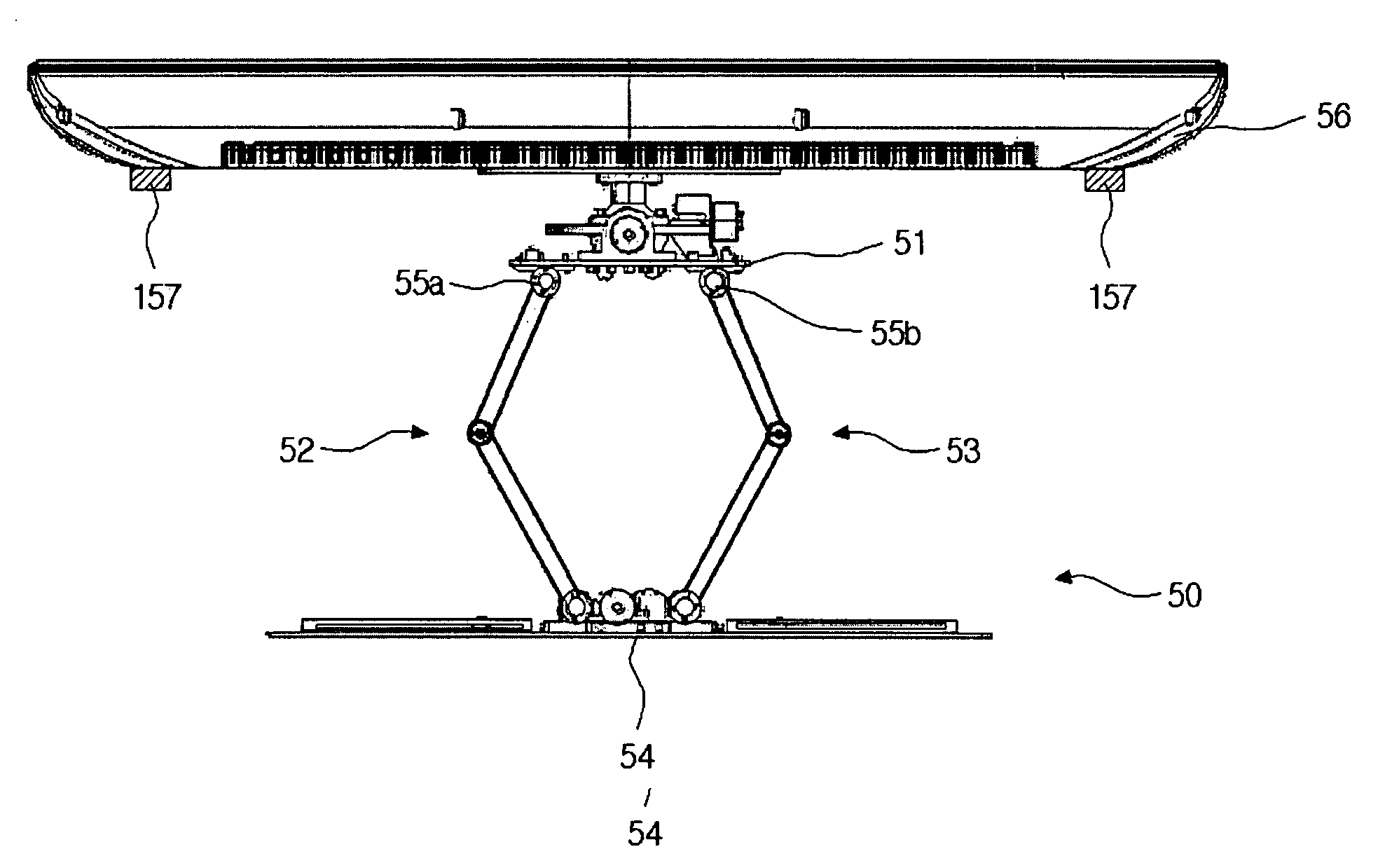

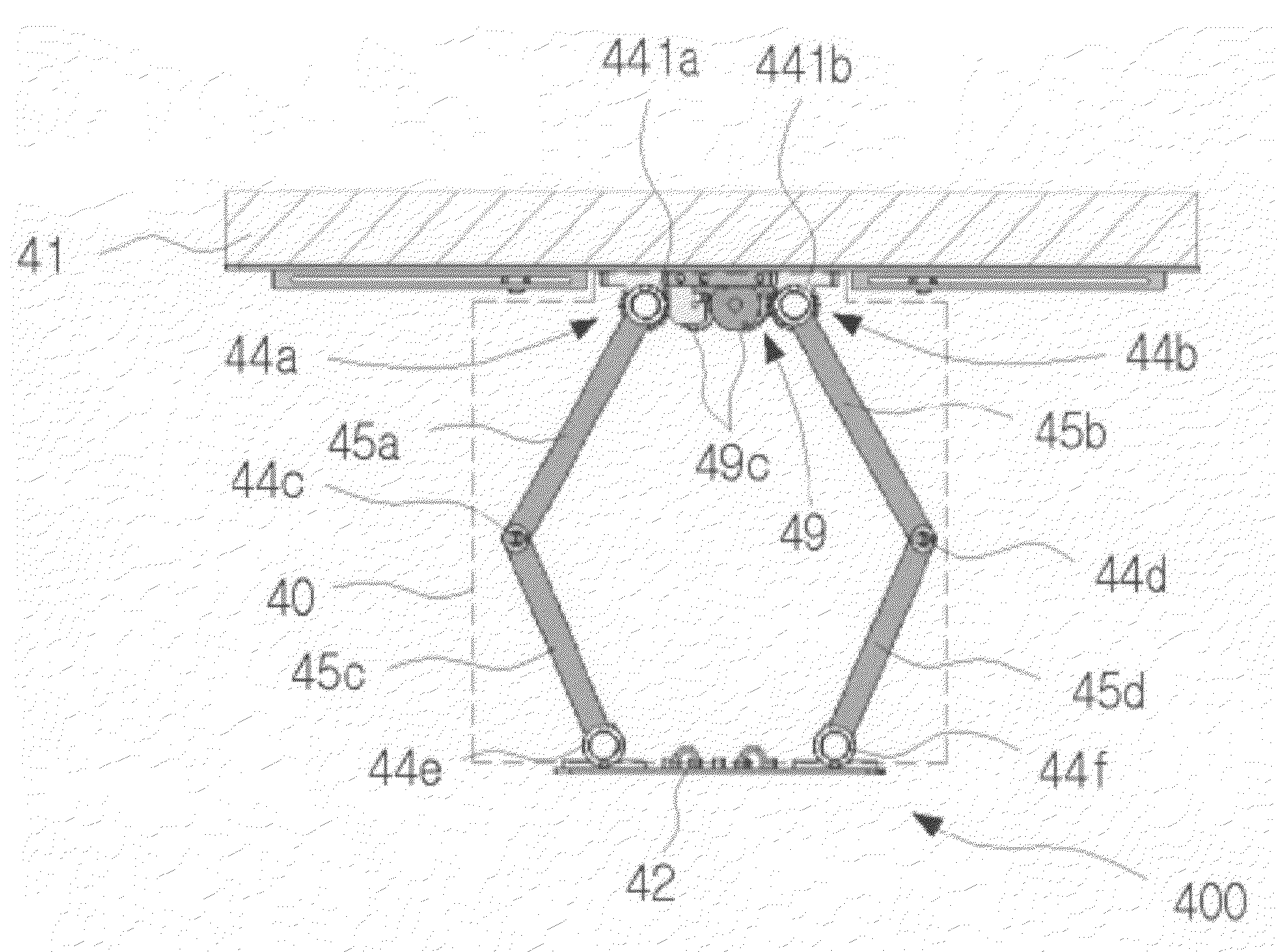

Display rotation appatatus and rotating method thereof

InactiveUS20080001048A1Large viewing angleEfficient use ofTelevision system detailsFurniture partsRotation methodDisplay device

A display rotation apparatus and rotating method thereof are disclosed. A display rotation apparatus, interposed between a fixed body and a moving body and rotating the moving body about the fixed body, comprising plural joint parts coupled to the moving body; plural arm parts, one end coupled to the joint part and the other end coupled to the fixed body, comprising a link member and a hinge member configured to joint act; and a driving part, coupled to the hinge member, rotating the arm part can rotate the display in variable directions.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

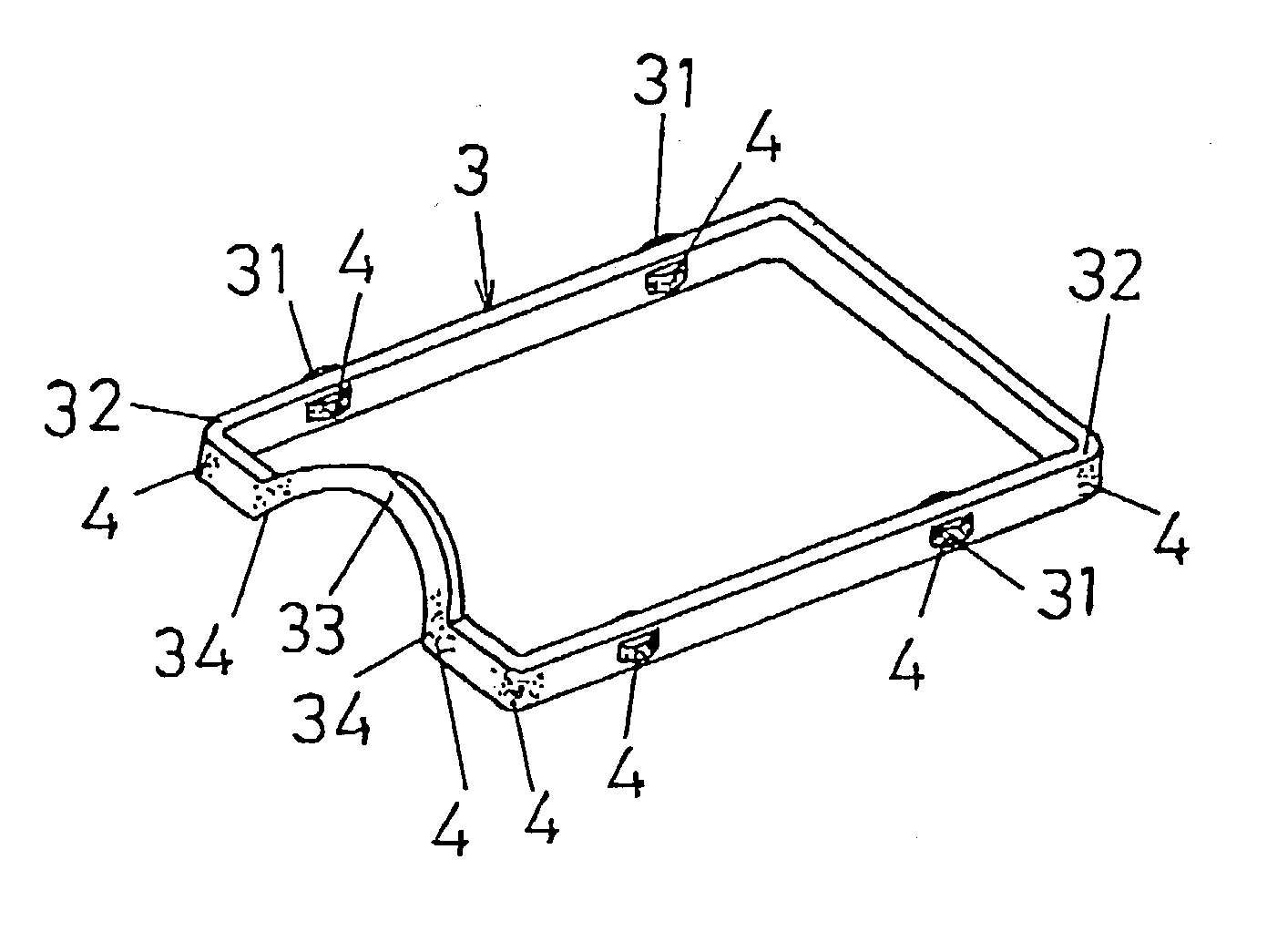

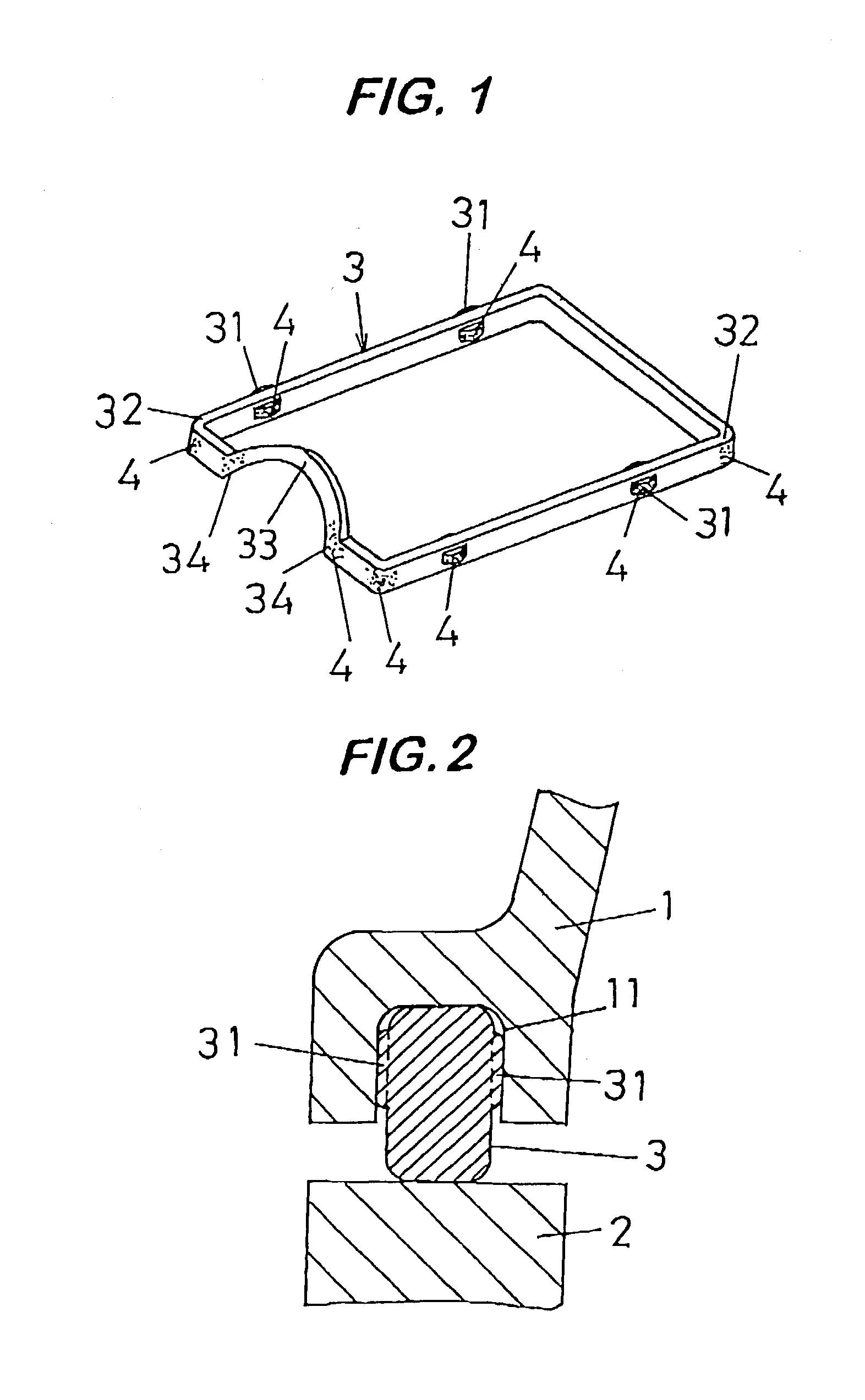

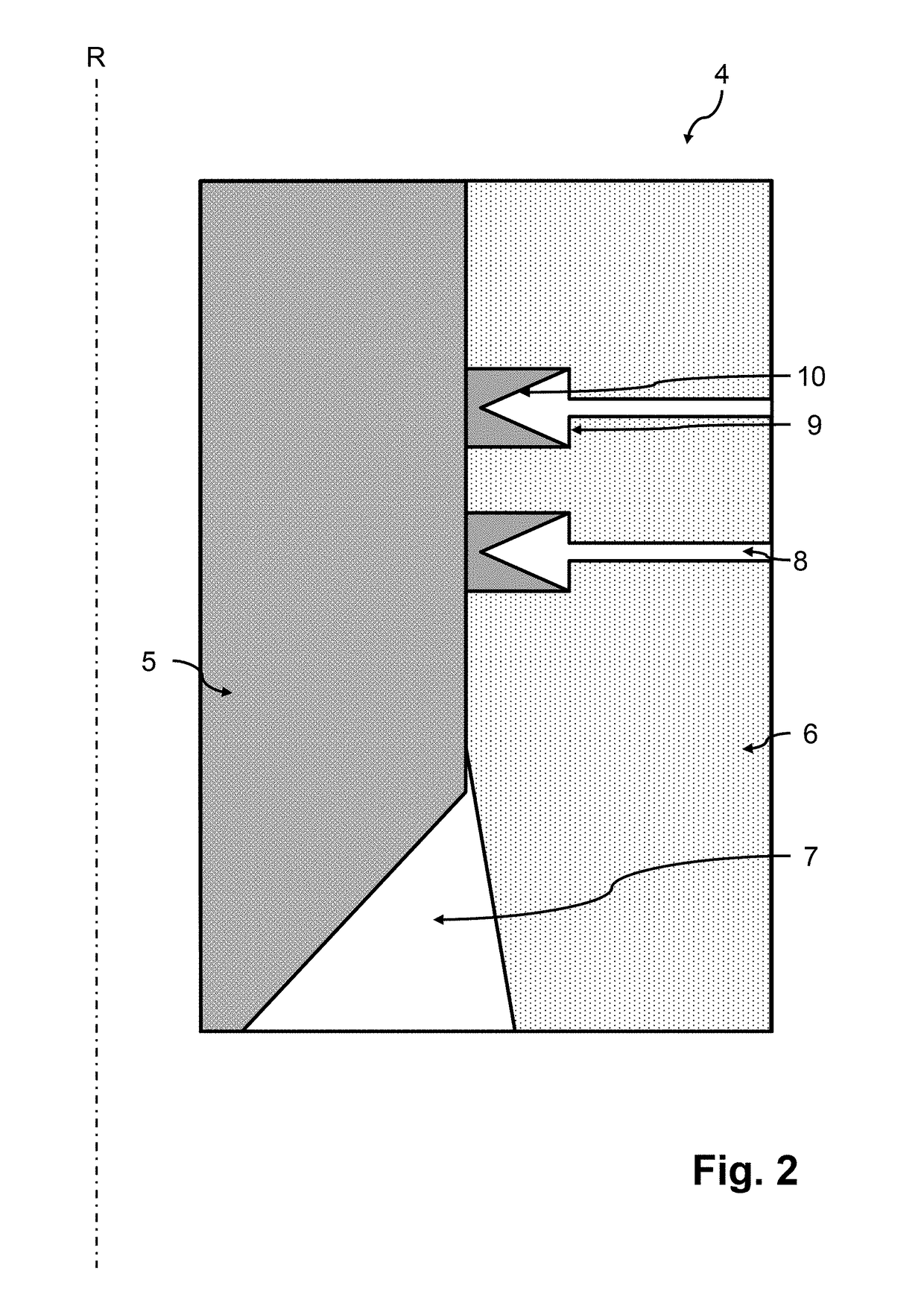

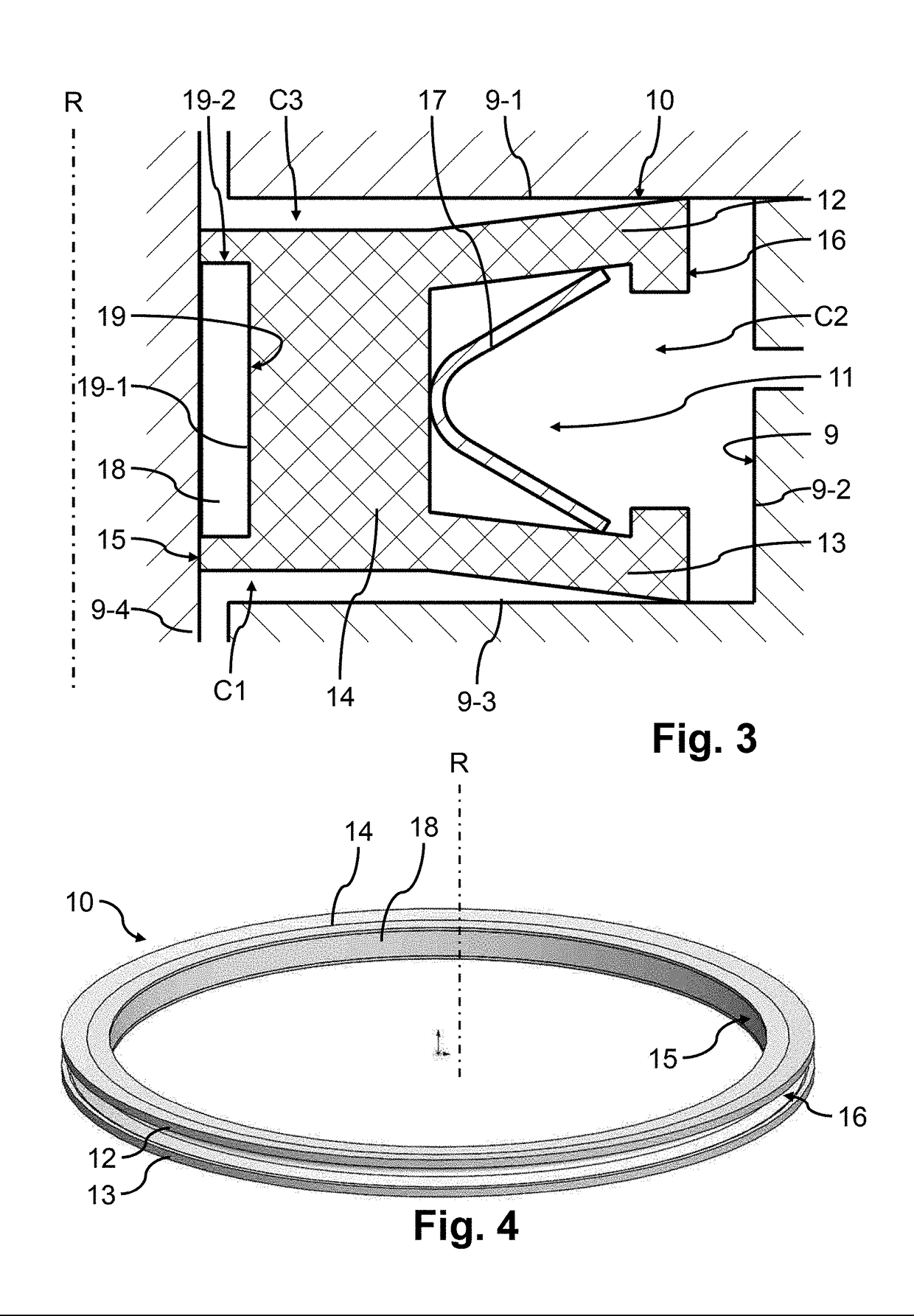

Gasket

InactiveUS20030184025A1Small frictional forceSmoothly and safely insertCasingsEngine sealsGasketEngineering

Owner:UCHIYAMA MFG

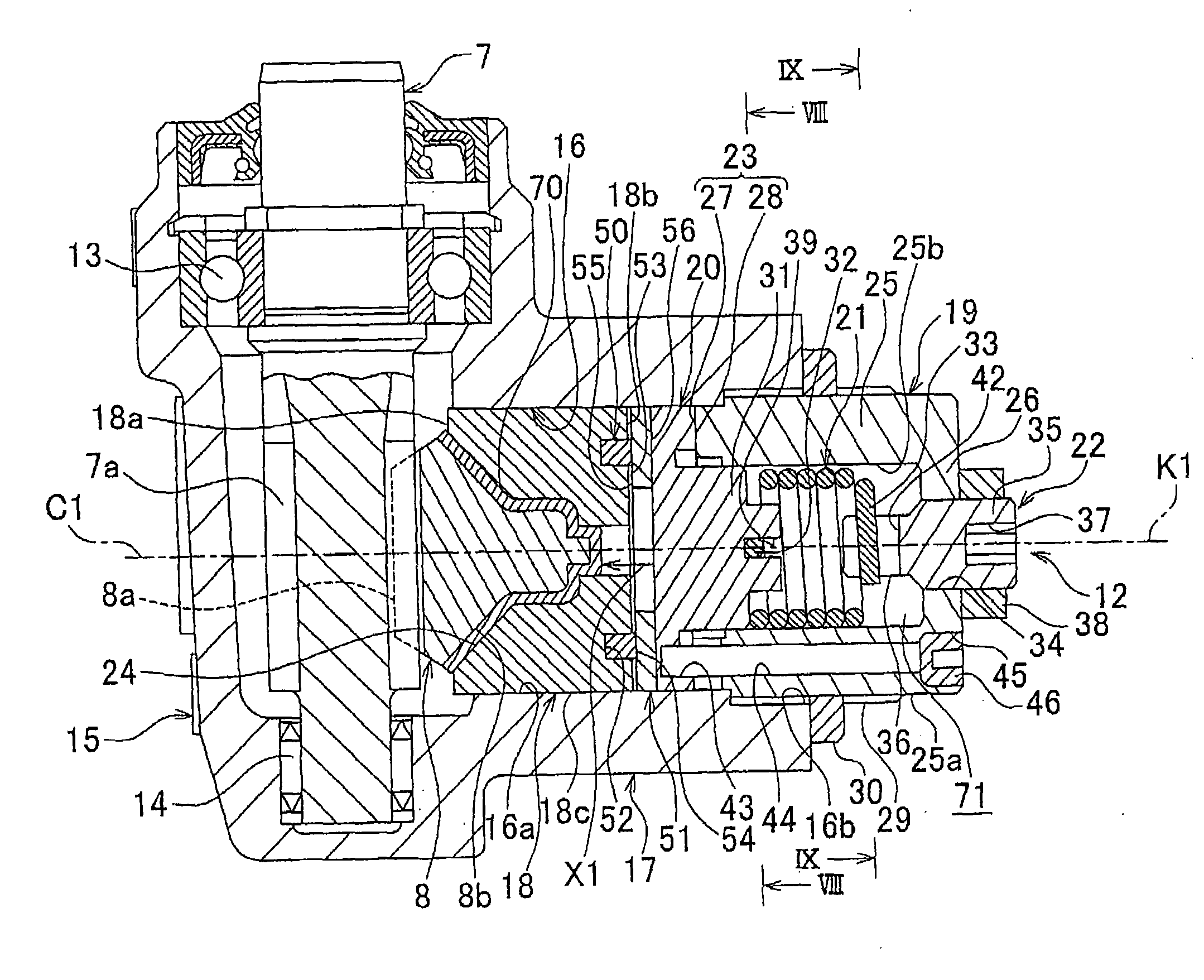

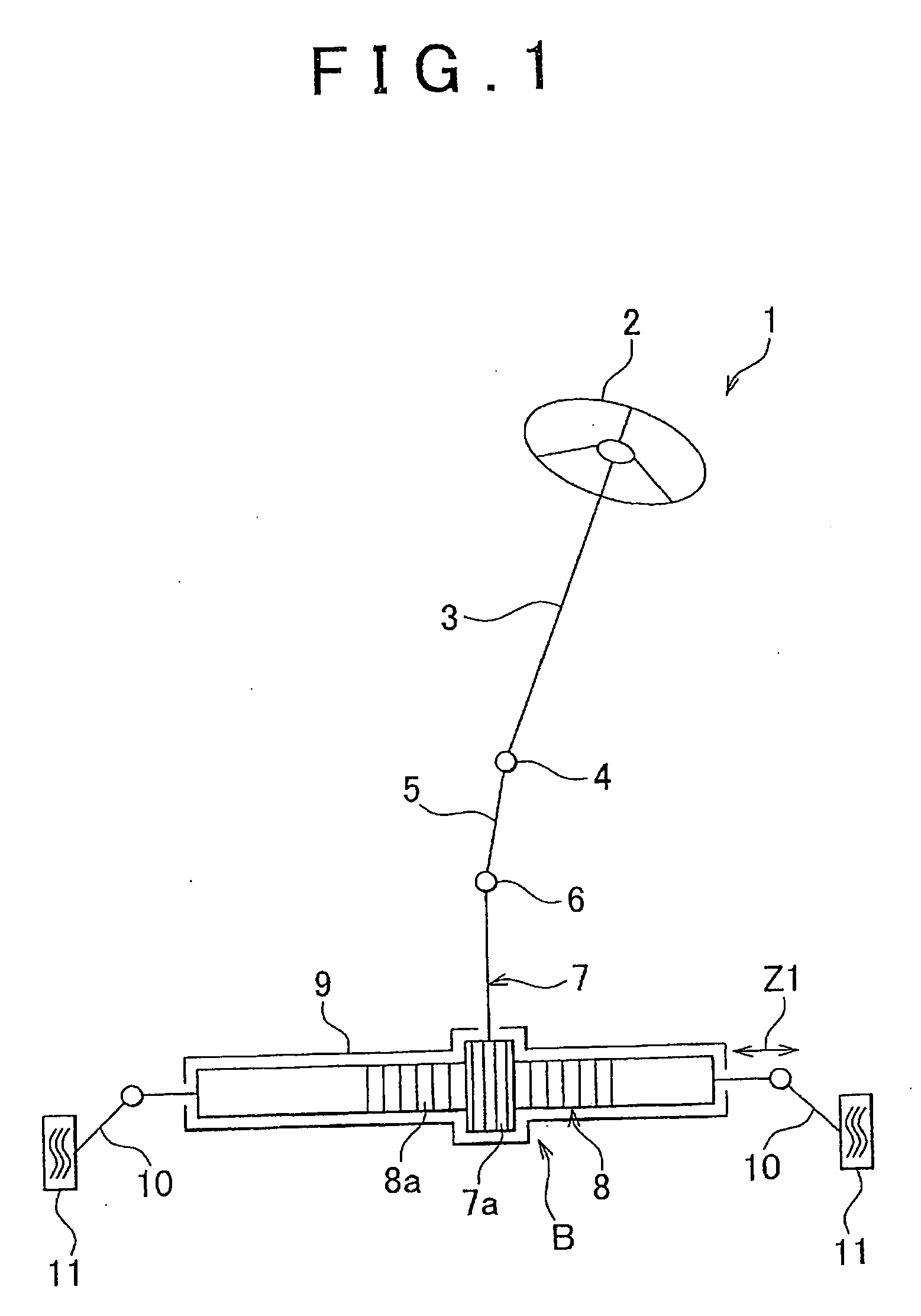

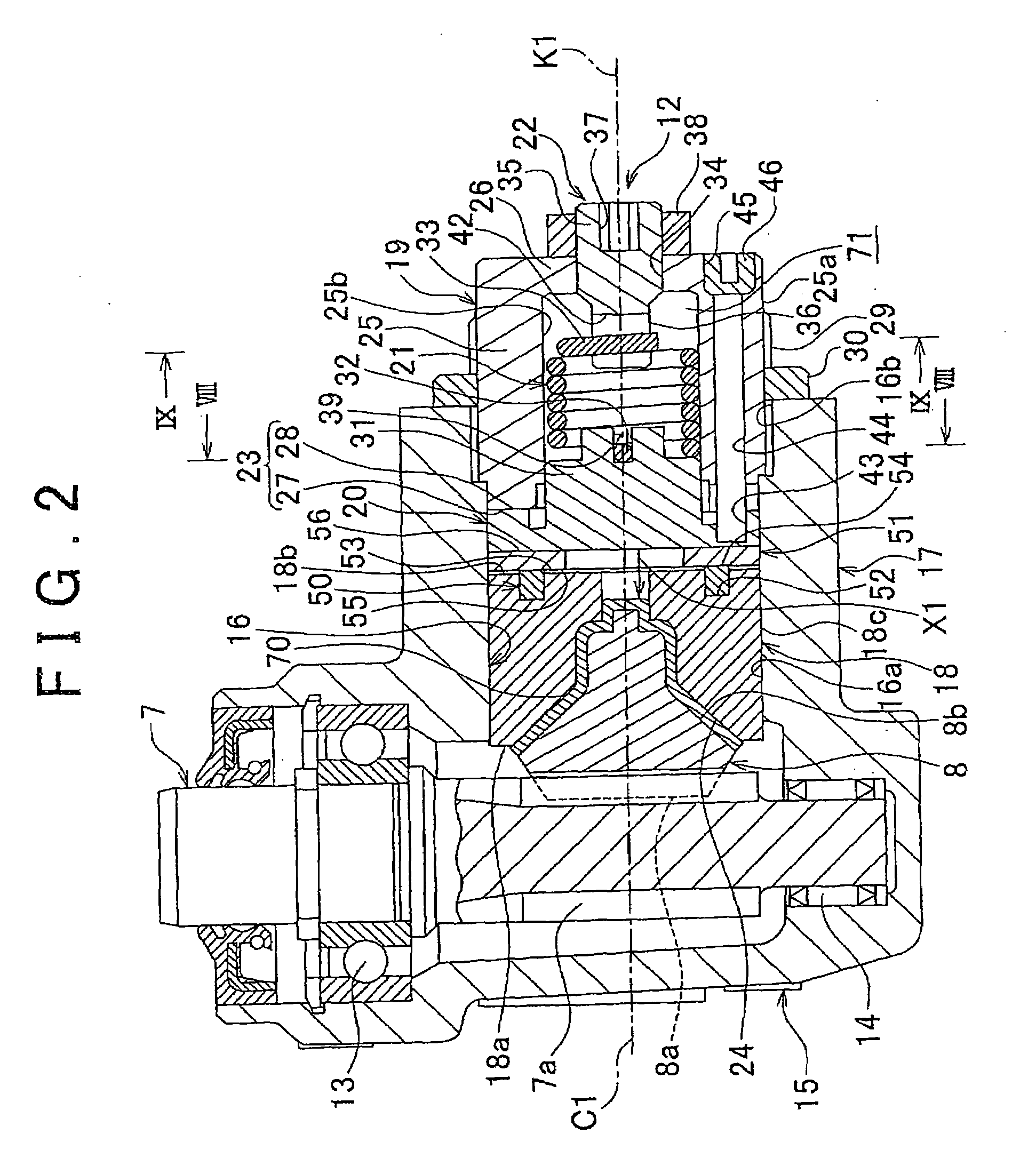

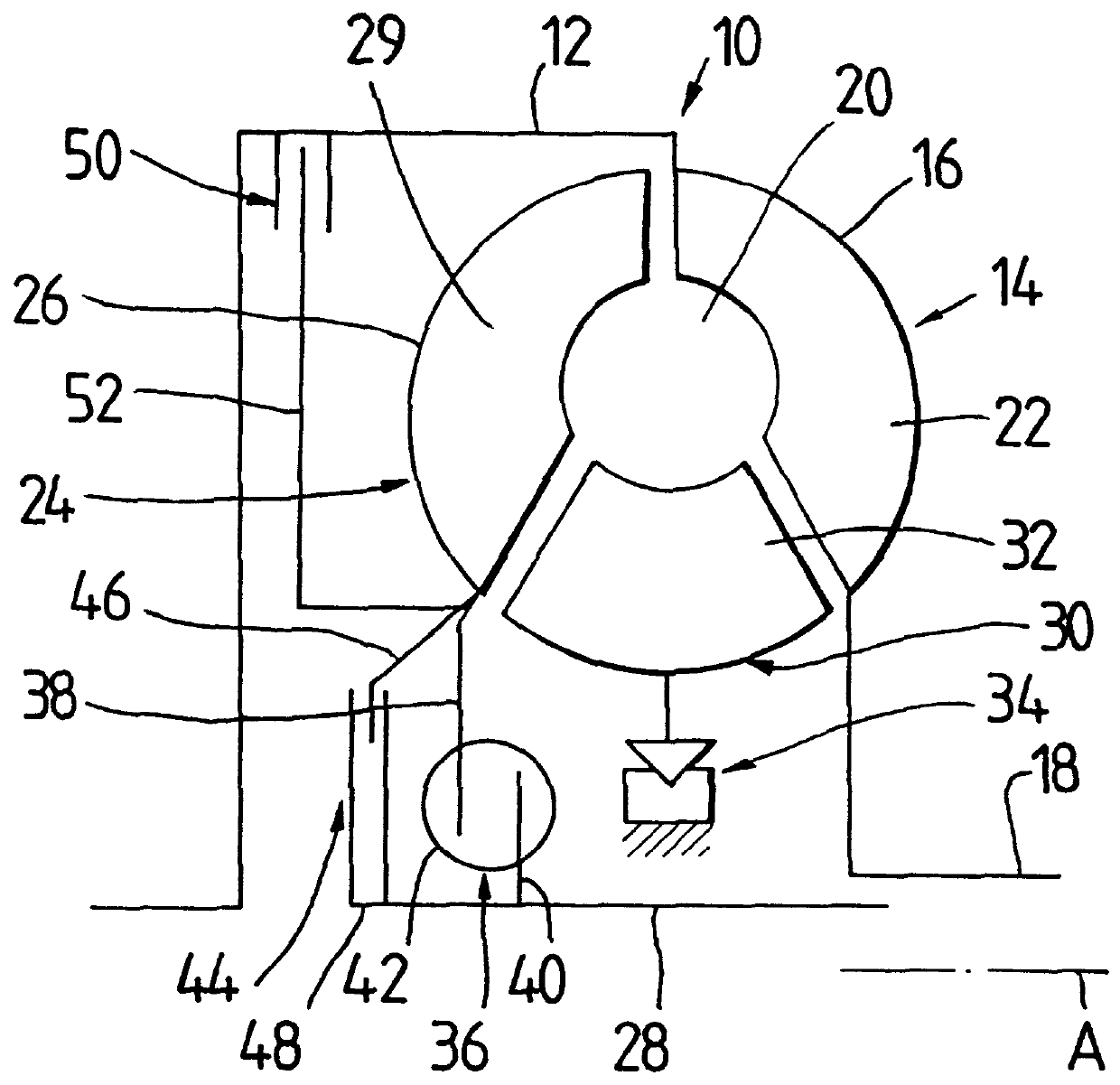

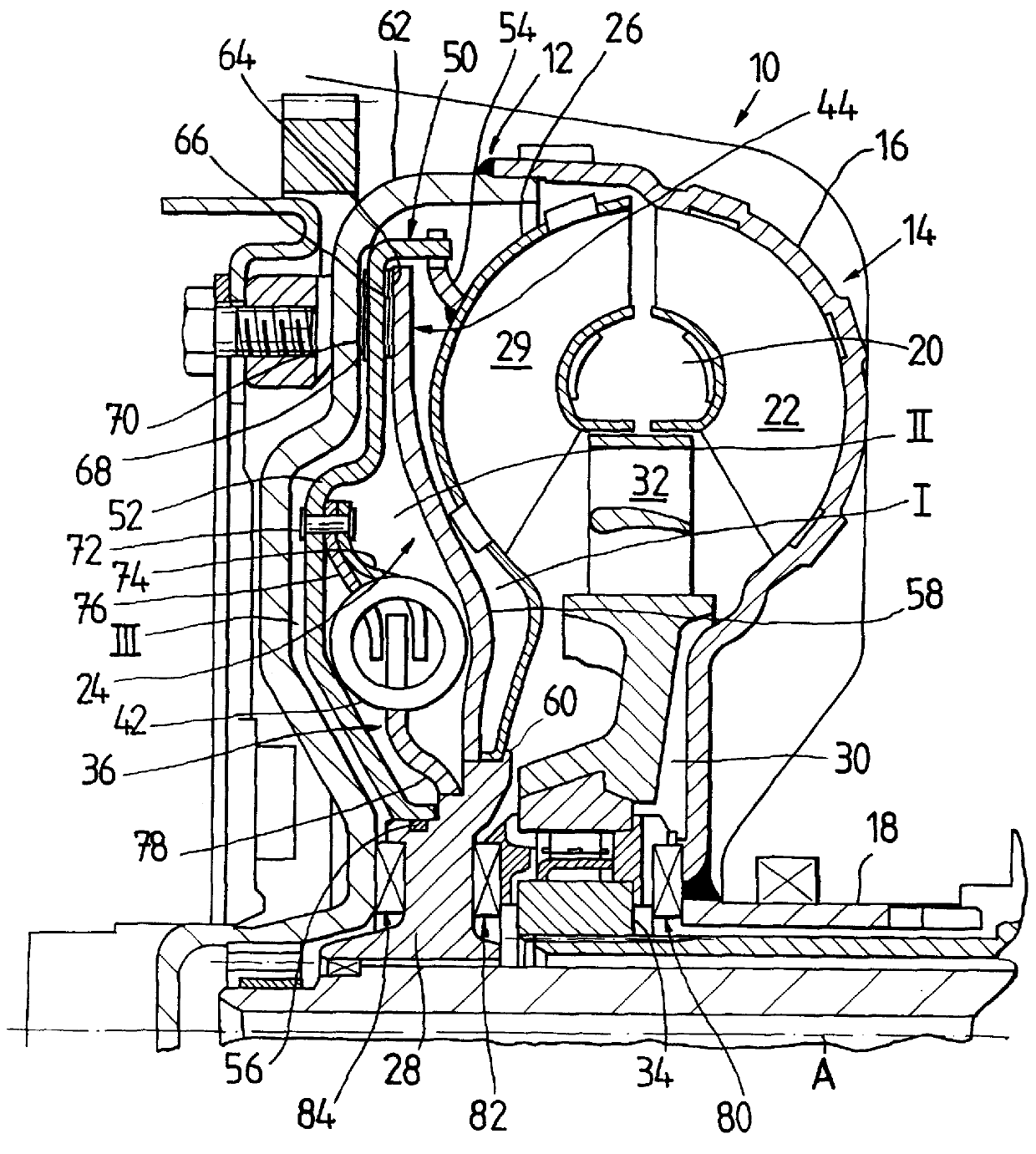

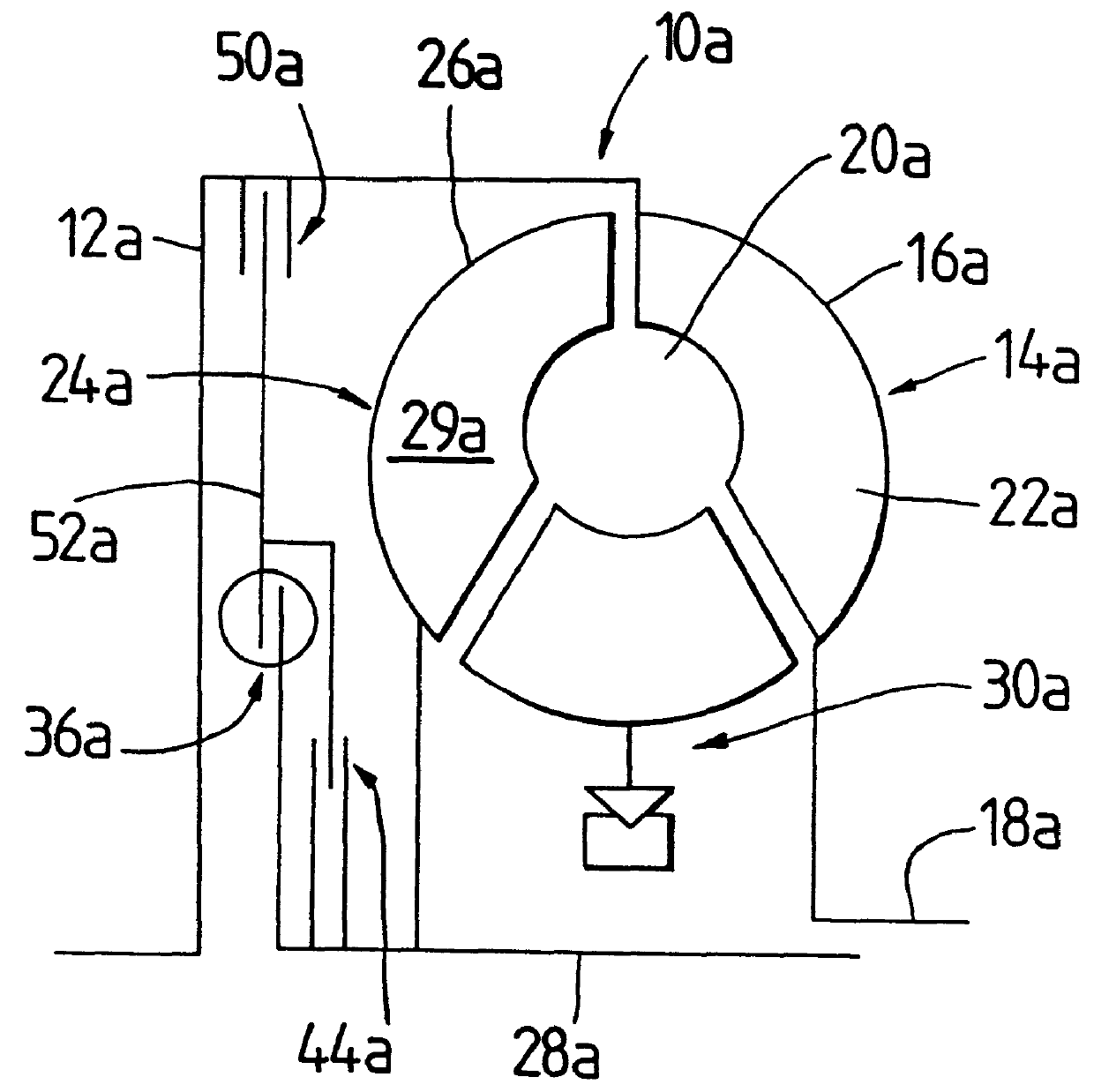

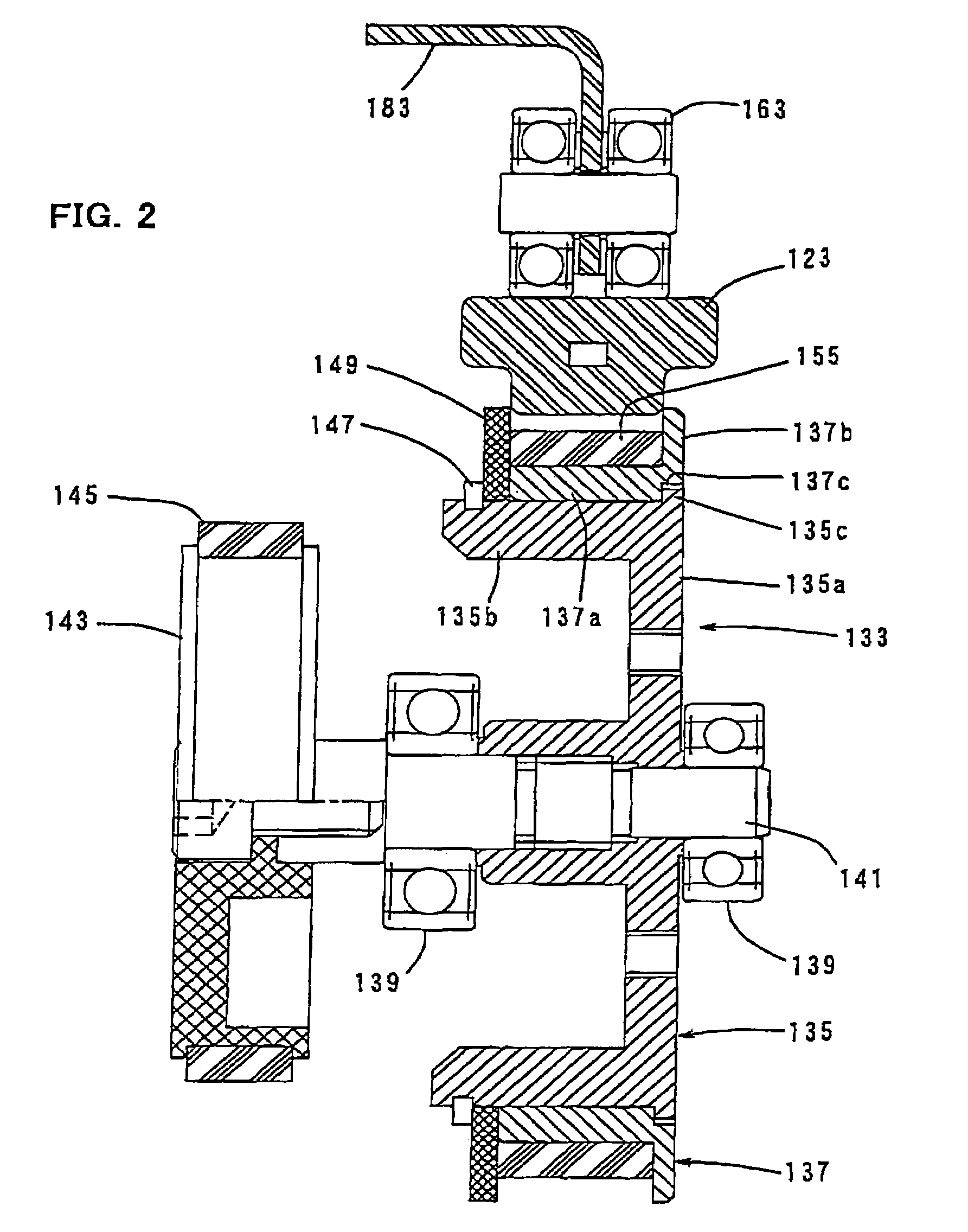

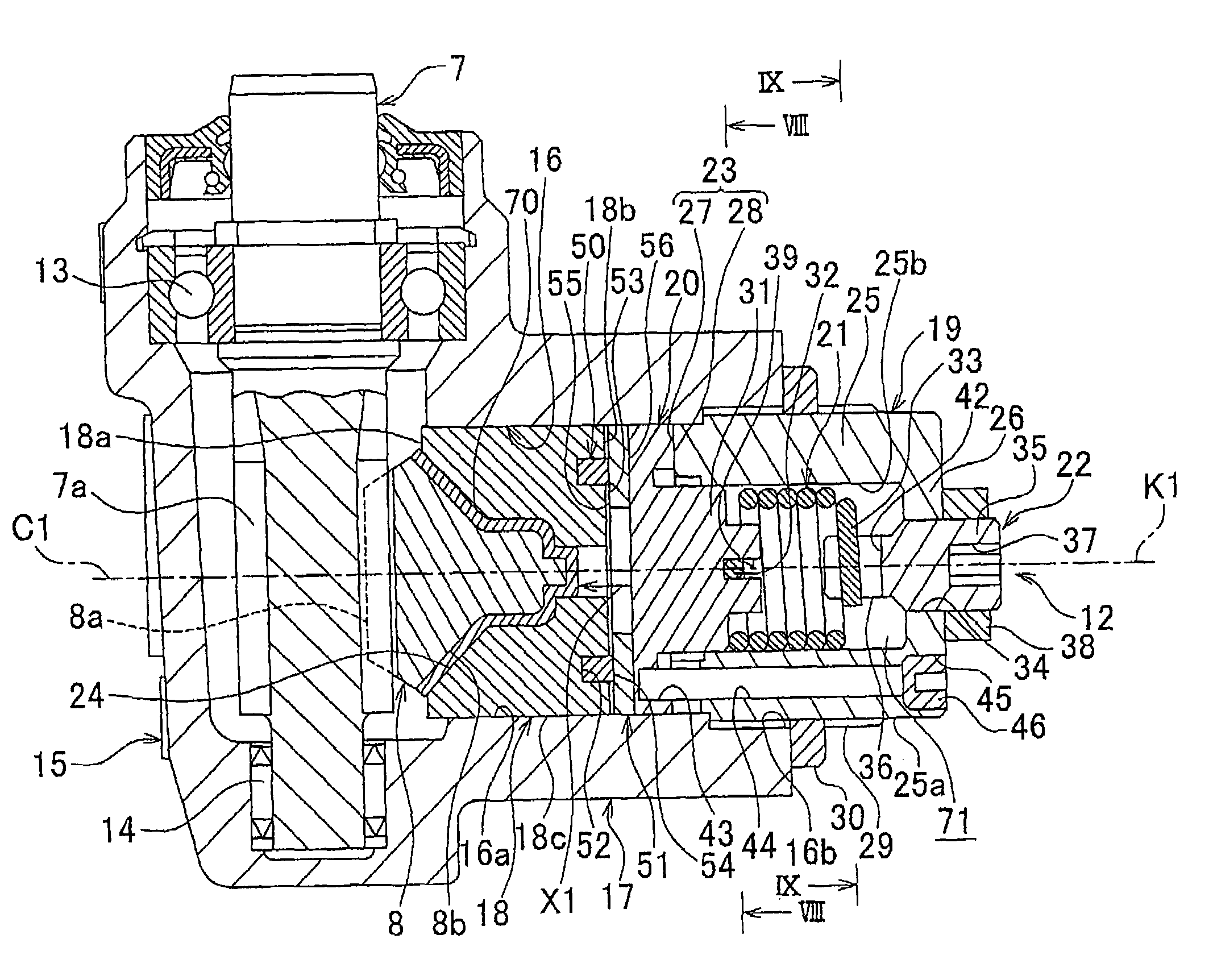

Torque converter

InactiveUS6070704APrevent slippingSmall frictional forceRotary clutchesFluid gearingsImpellerTurbine wheel

A torque converter having a converter housing which is coupled to a driving unit, a turbine wheel which is arranged in the converter housing and is rotatable with respect to the converter housing about an axis of rotation and has a turbine wheel shell and a turbine wheel hub which is connected with the turbine wheel shell and which can be coupled with or is coupled with a converter driven shaft. A lockup clutch provides selectable rotational coupling of the converter housing with the turbine wheel, and a torsional vibration damper arrangement is provided in the power transmission path between the converter housing and the turbine wheel hub and / or between the turbine wheel shell and the turbine wheel hub. A friction device is connected parallel to the torsional vibration damper arrangement in the power transmission path for generating a frictional force which may be changed in a selected manner.

Owner:ZF FRIEDRICHSHAFEN AG

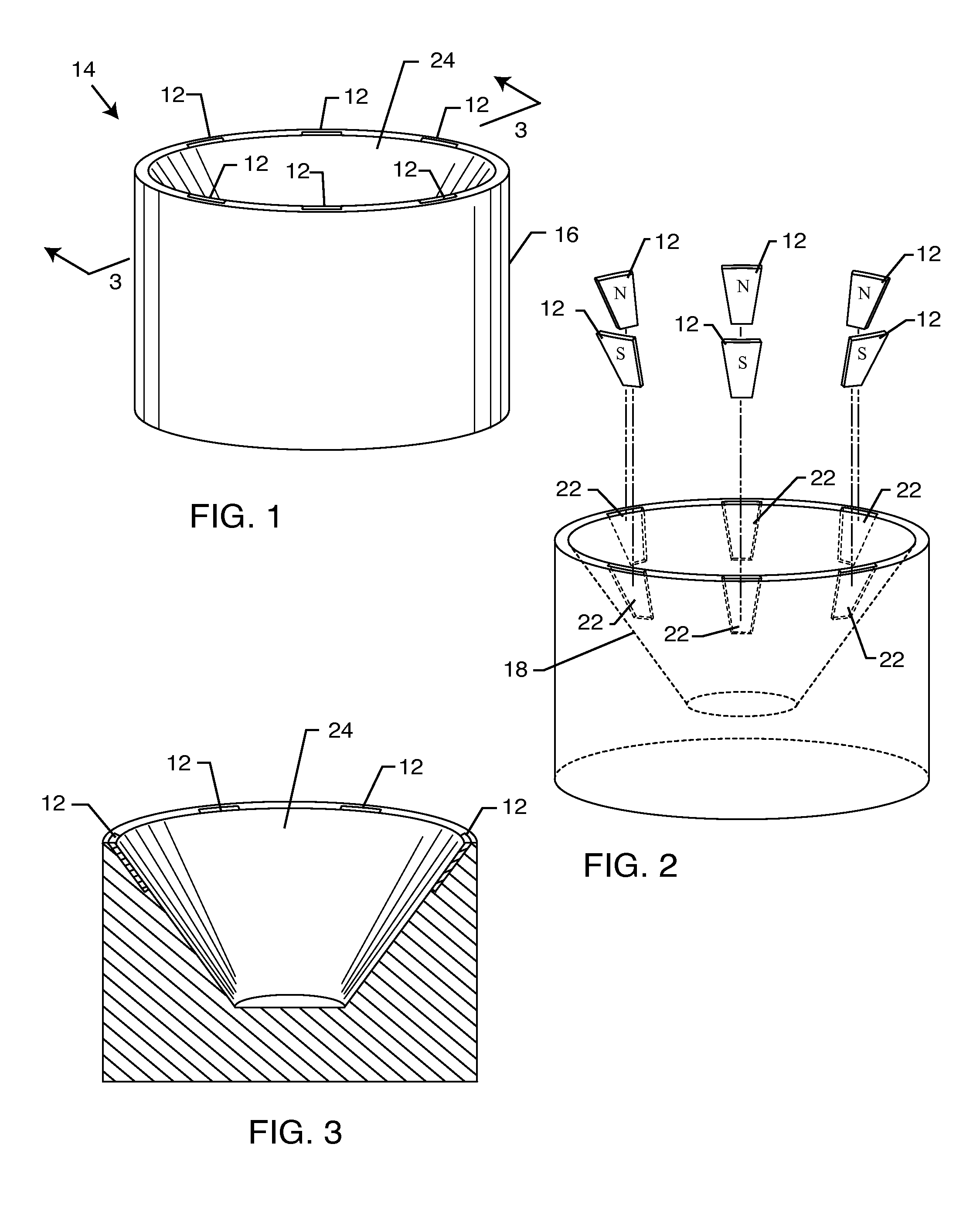

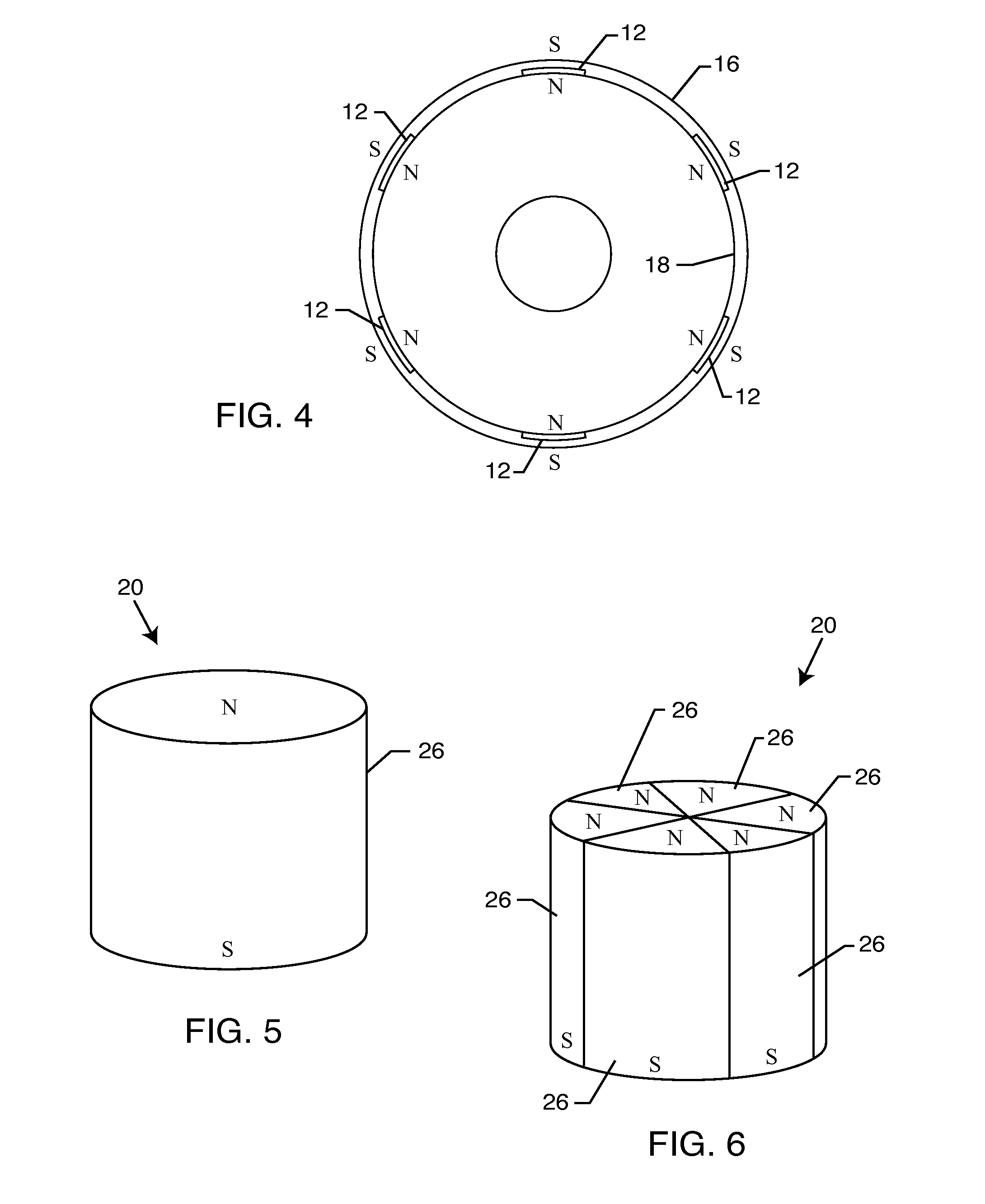

Permanent magnetic male and female levitation supports

InactiveUS7501922B2Eliminate needAvoid smallElectromagnets without armaturesPermanent magnetsLevitationClassical mechanics

A permanent magnetic male and female levitation support has a first part with a cavity and a plurality of retainment mechanisms incorporated therein, and a plurality of first permanent magnets evenly distributed around the perimeter of the cavity and held in place by the retainment mechanisms, wherein the first permanent magnets produce a first rotationally invariant magnetic field around a first axis. A second part is rigidly connected to a base and produces a second rotationally invariant magnetic field around a second axis. When the first axis is aligned with the second axis, the first magnetic field and the second magnetic field simultaneously produce a repulsive force and a restorative force to levitate the first part relative to the second part.

Owner:KAZADI SANZA T

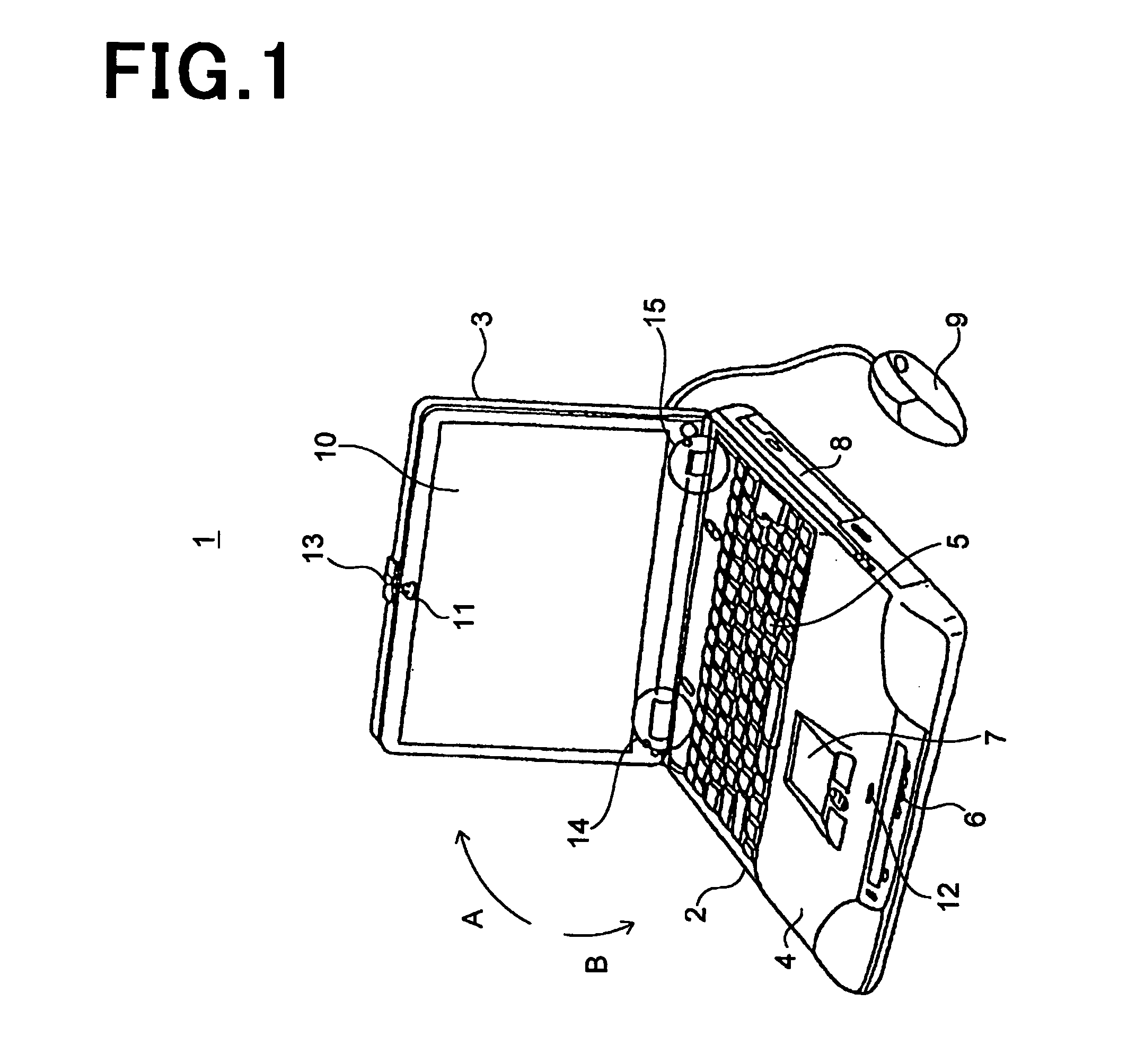

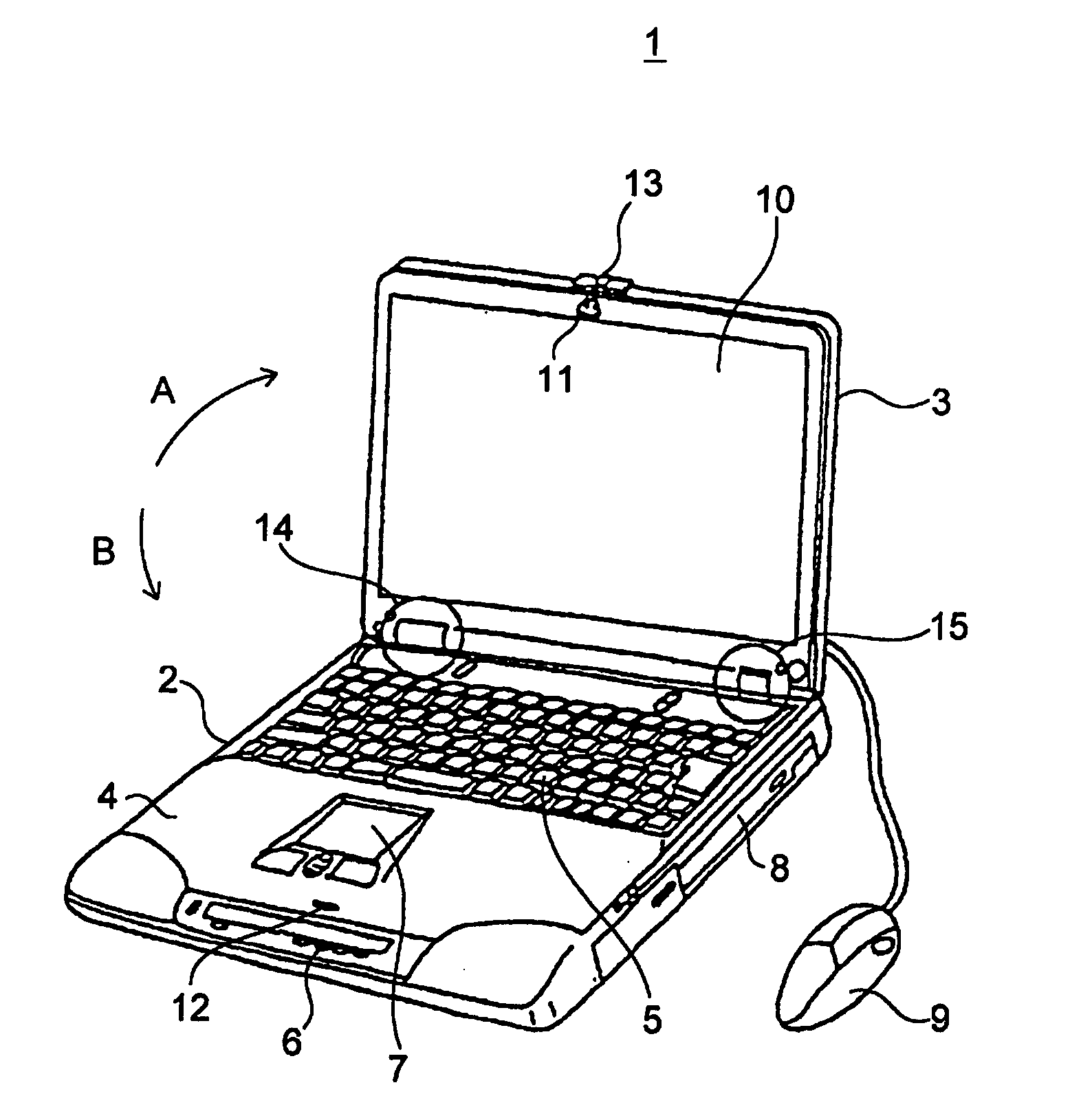

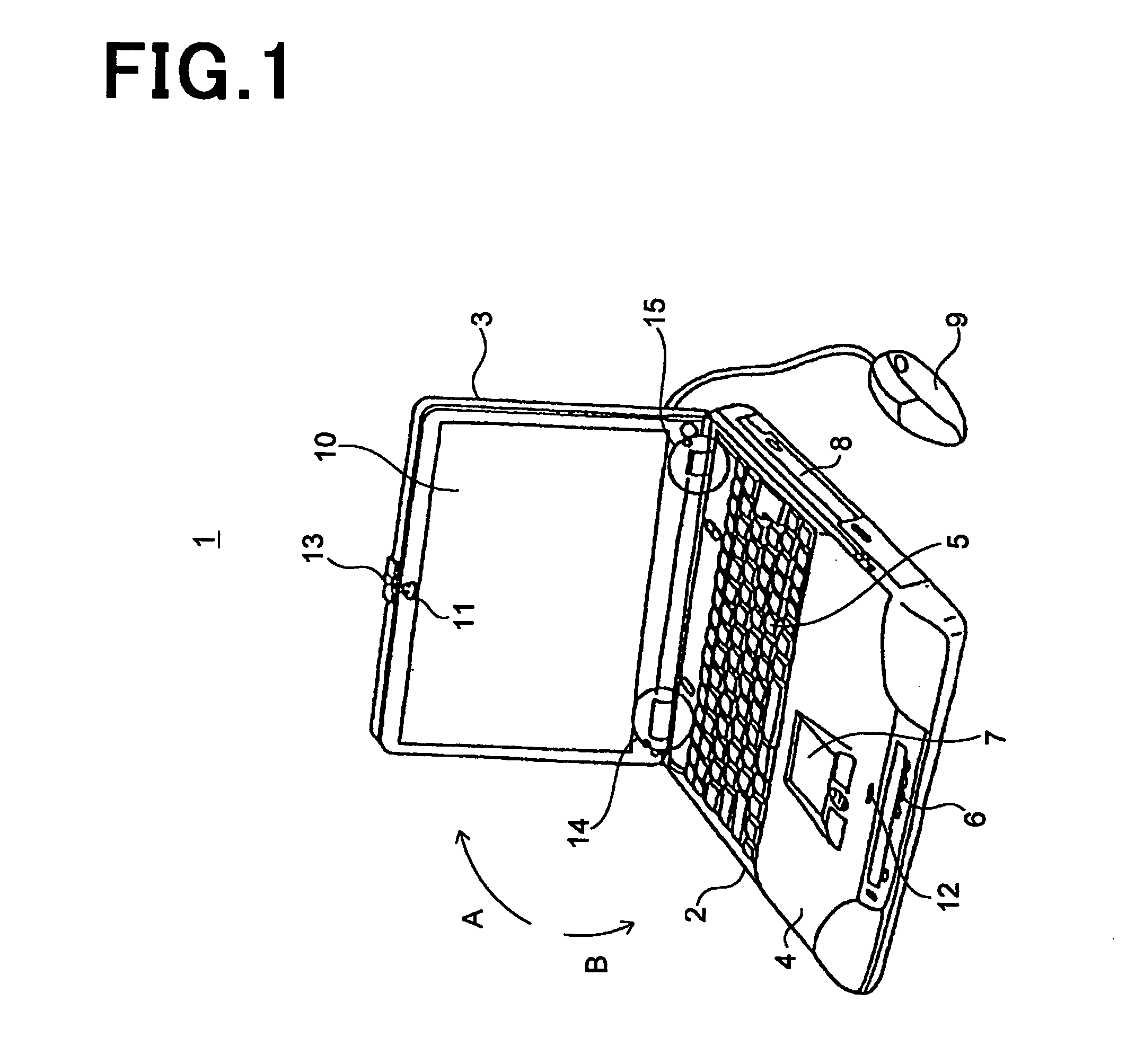

Hinge system used for personal computer and personal computer including the same

InactiveUS7219393B2Close smoothlyOpen smoothlyCasings/cabinets/drawers detailsWing fastenersPersonal computerMechanical engineering

Owner:KIDA MAKOTO

Opening and closing assembly, and multifunction device including the assembly

InactiveUS20070292159A1Smoothly and quickly openedGuaranteed to workElectrographic process apparatusOther printing apparatusEngineeringSupport plane

An opening and closing assembly includes: (a) a first casing body; (b) a second casing body pivotable to be selectively placed in open and closed positions relative to the first casing body; and (c) a support stand for supporting the second casing body to maintain the open position. The support stand includes (c-1) a proximal end portion pivotably connected to one of the first and second casing bodies and (c-2) a distal end portion slidably connected to the other of the first and second casing bodies. The other of the first and second casing bodies includes (i) a guide portion for guiding the distal end portion of the support stand, and (ii) first and second wall portions cooperating with each other for gripping the distal end portion of the support stand. The distal end portion of the support stand includes a gripped portion having a thickness that is increased in a direction away from the distal end portion of the support stand toward the proximal end portion of the support stand.

Owner:BROTHER KOGYO KK

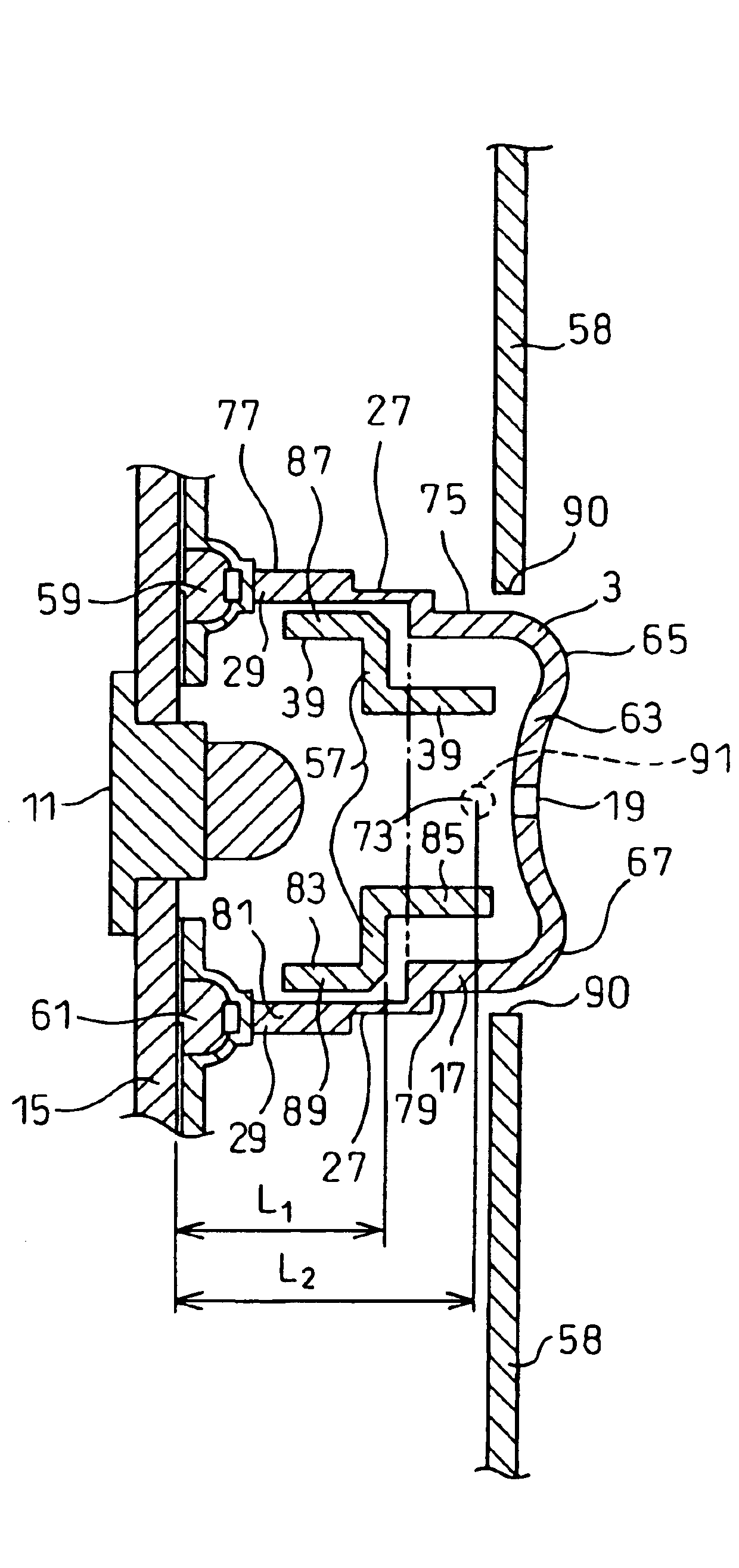

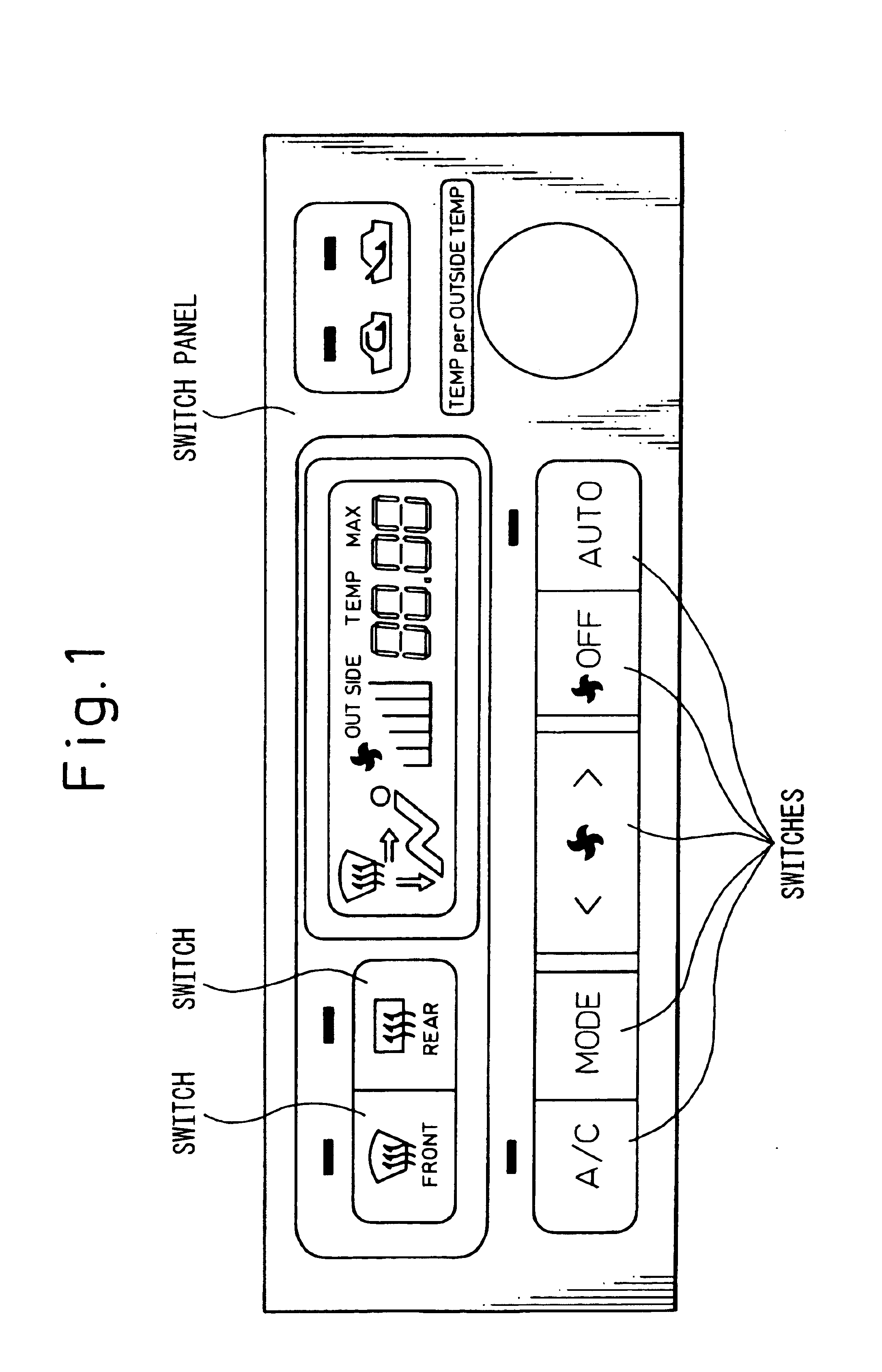

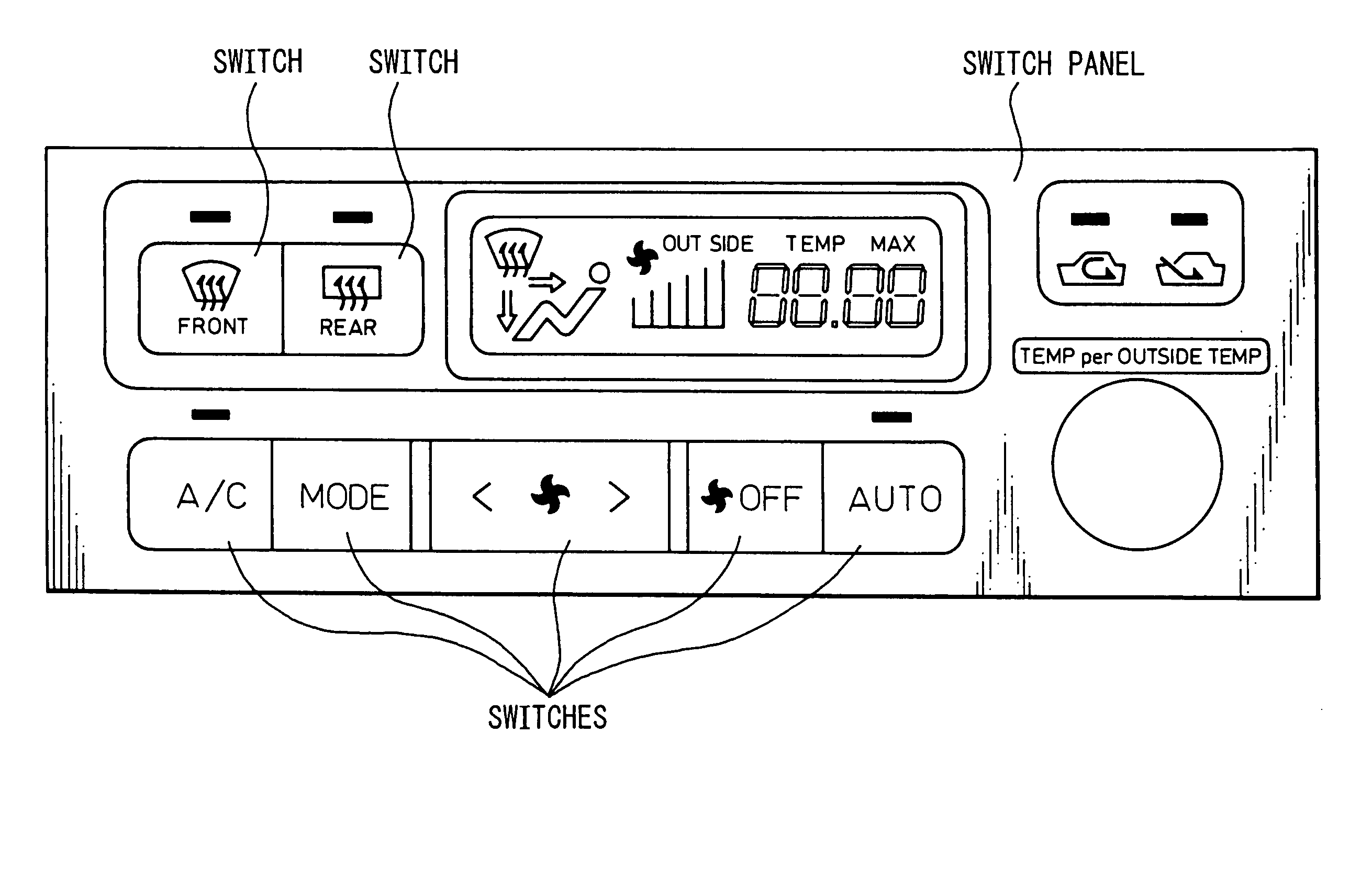

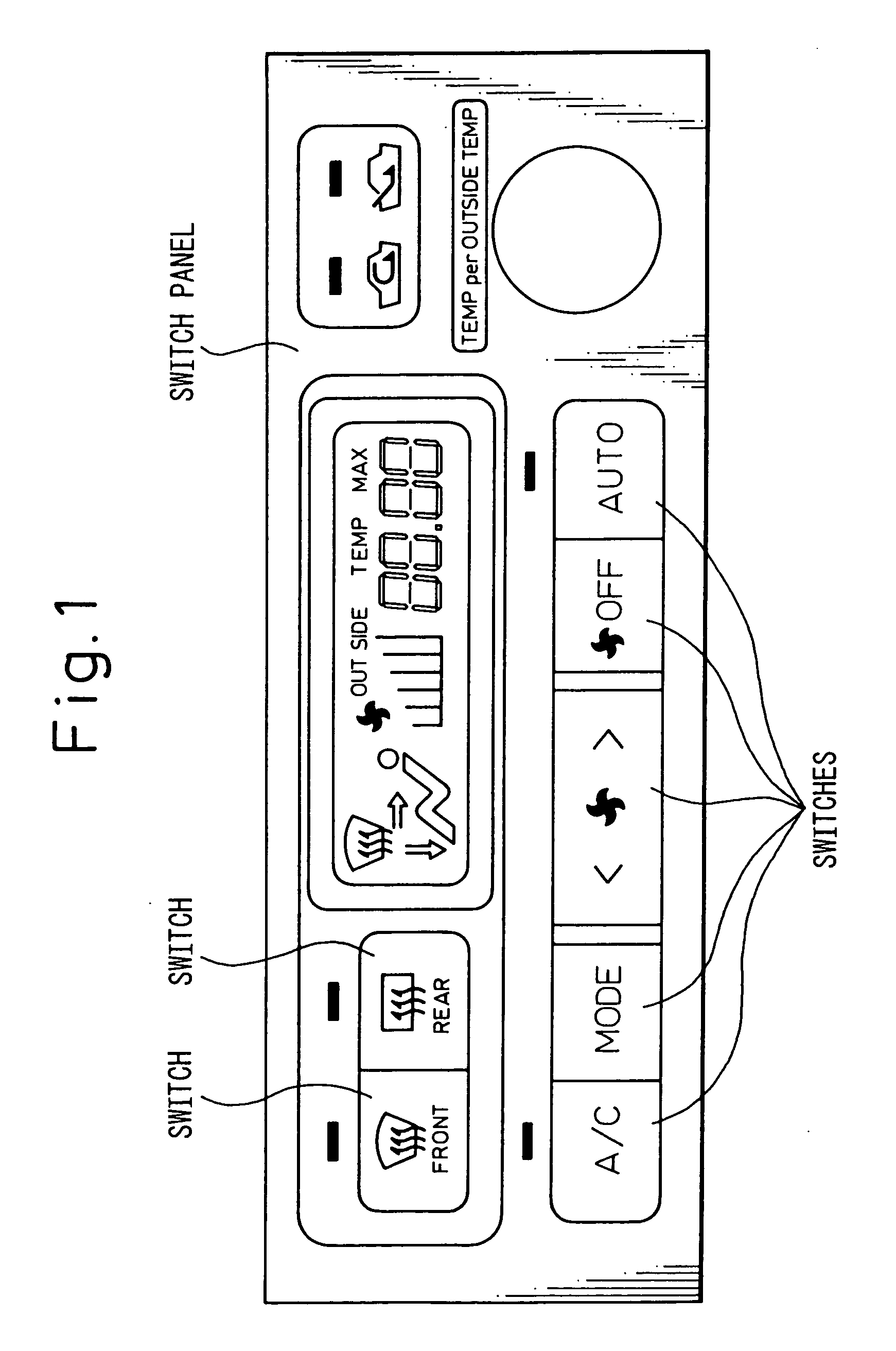

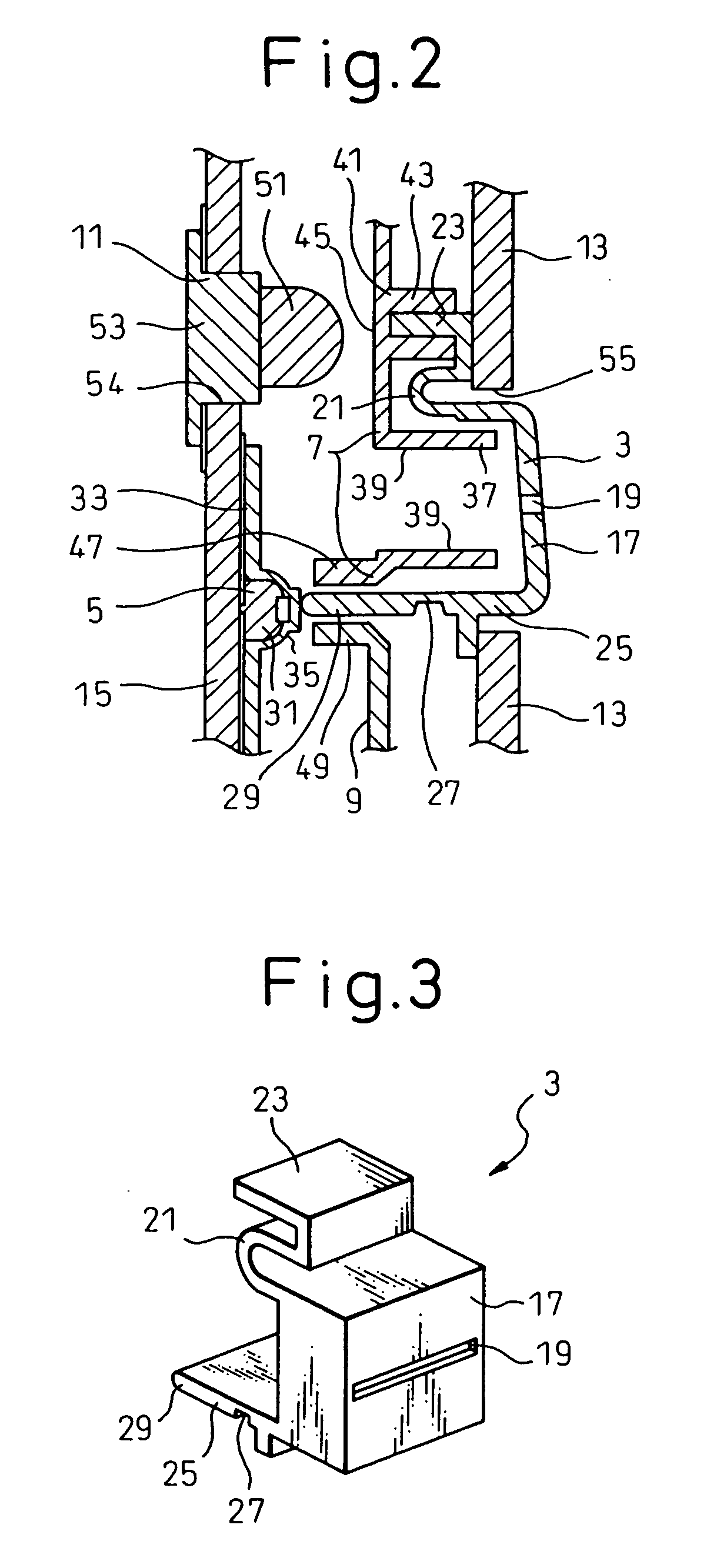

Switch structure

InactiveUS6809273B2Easy to operateIncreased durabilityEmergency actuatorsContact mechanismsEngineeringCircuit switching

A switch structure comprising a switch element (5, 59, 61) performing circuit switching operation by pushing and a push button section (3) attached rotationally movably to a supporting member (7, 91) and having a push rod section (25, 77, 81) pushing the switch element and integrally formed thereto, wherein a switching operation is performed when the push button section (3) is rotationally moved by pushing and push rod section pushes the switch element, wherein the push rod section is provided with a flexible portion (27) able to bend when pushed, and wherein a guide section (47, 57, 49) is provided which comes into contact with the push rod section to bend the flexible portion and, at the same time, guides the push rod section to push the switch element in the normal direction when the push button section is rotationally moved by pushing.

Owner:DENSO CORP

Hinge system used for personal computer and personal computer including the same

InactiveUS20050117284A1Close smoothlyOpen smoothlyCasings/cabinets/drawers detailsDetails for portable computersPersonal computerMechanical engineering

Owner:KIDA MAKOTO

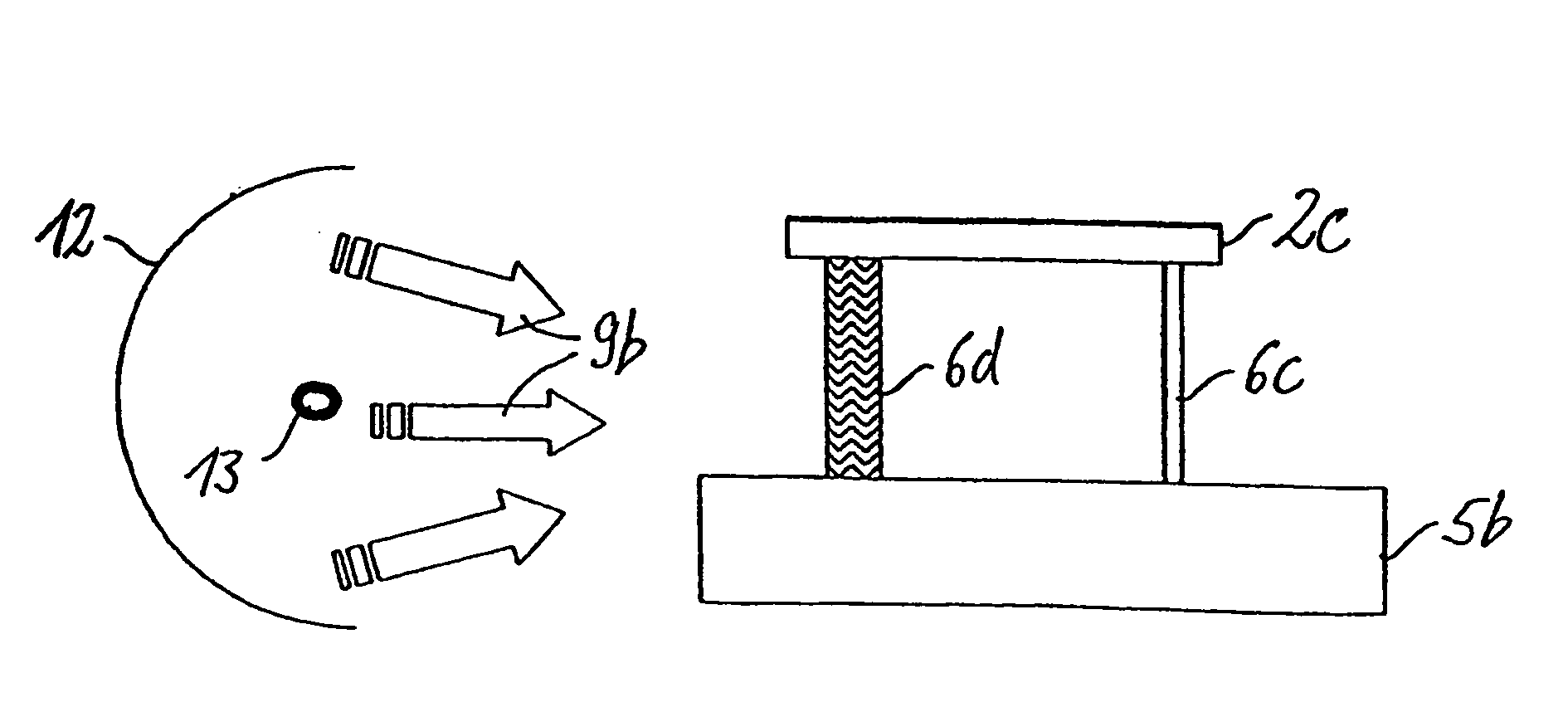

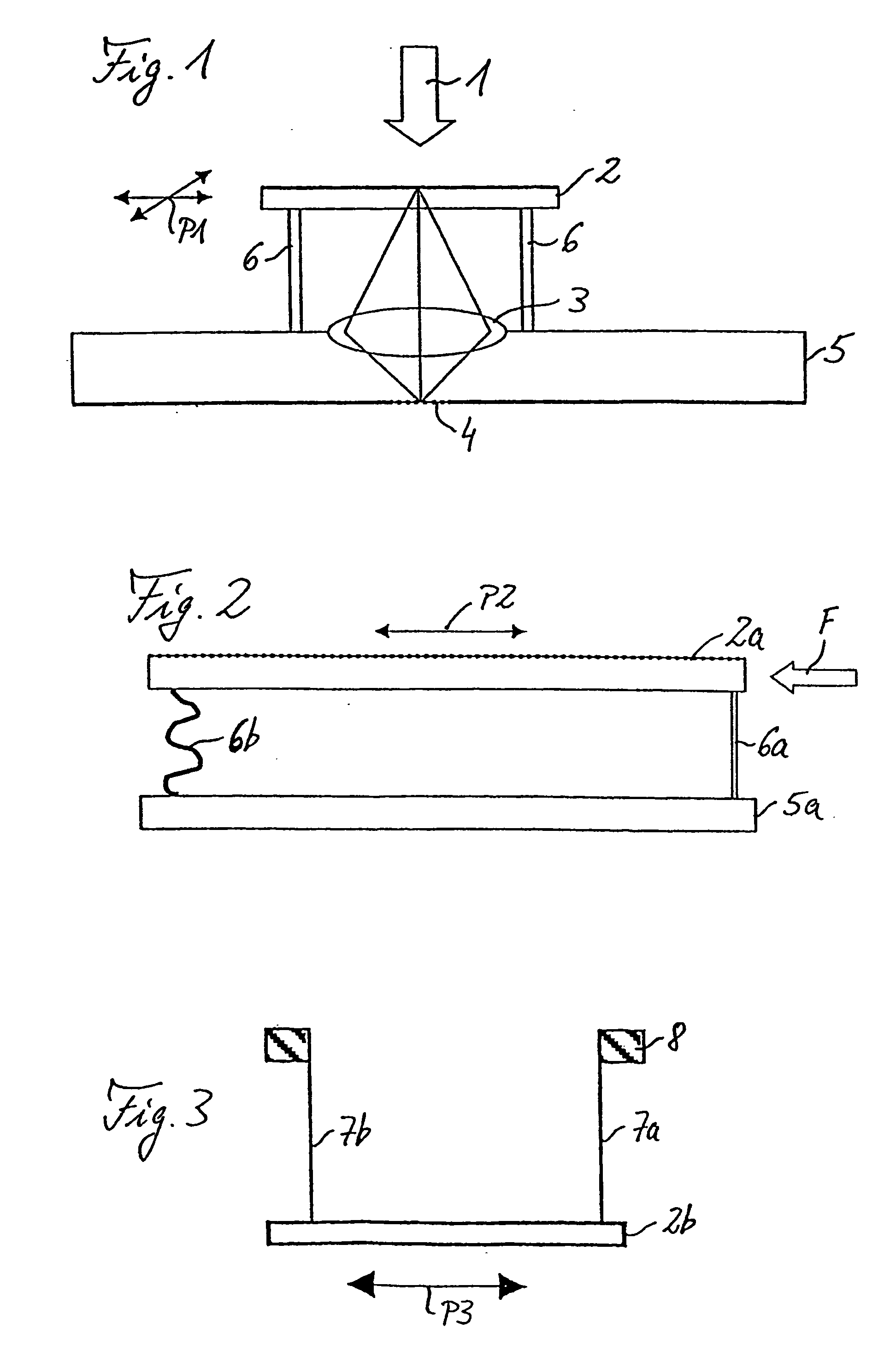

Illuminating system having a diffuser element

InactiveUS20050002102A1Reduce spendingSmall installation spaceDiffusing elementsPhotomechanical exposure apparatusWavefrontLight beam

An illuminating system having a diffuser element (2) that is introduced into an illuminating beam path (1) and is arranged movably, in particular for oscillatory movement. Such system has applicability, for example, in microlithography projection exposure machines and associated wavefront measurement interferometers.

Owner:CARL ZEISS SMT GMBH

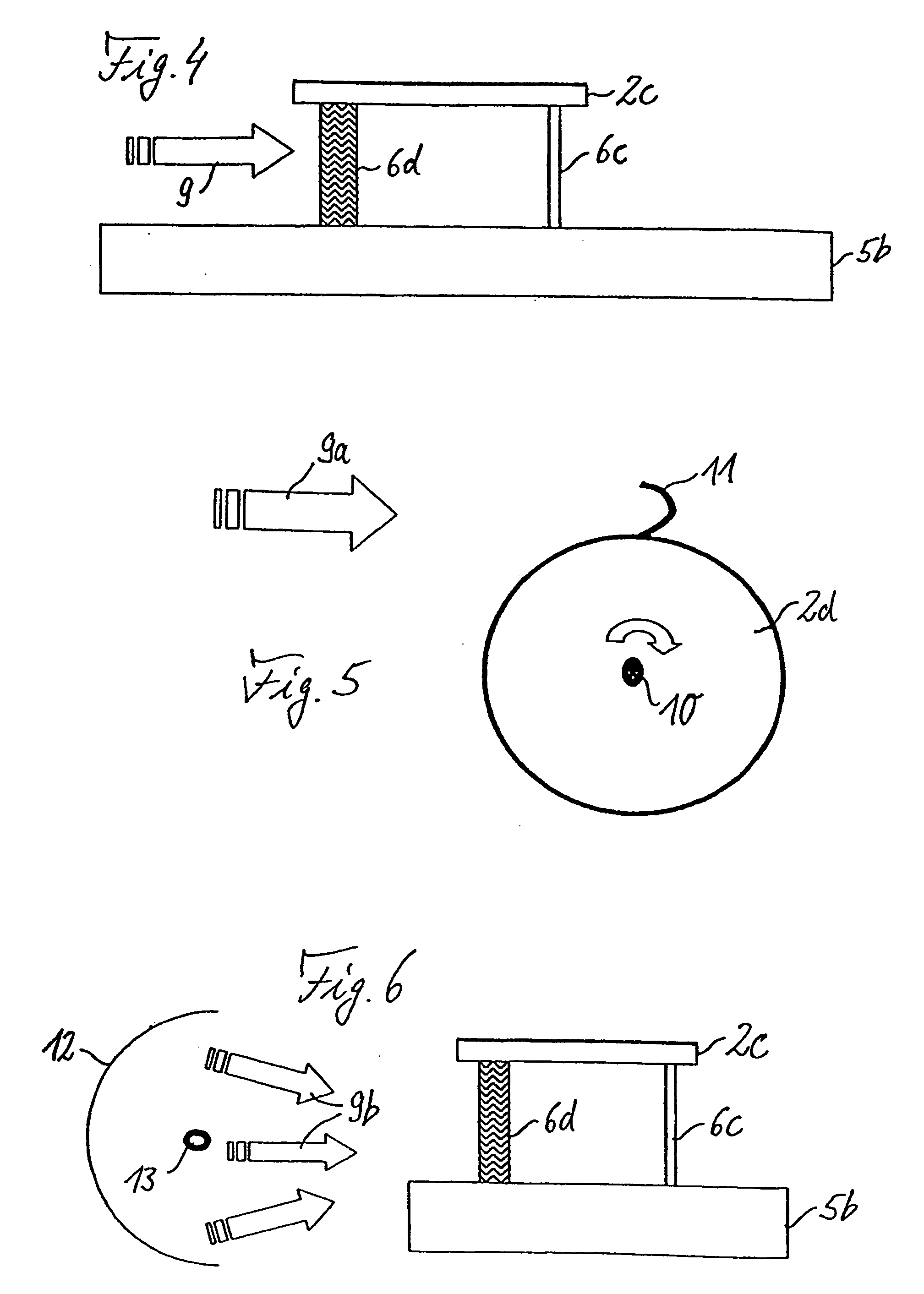

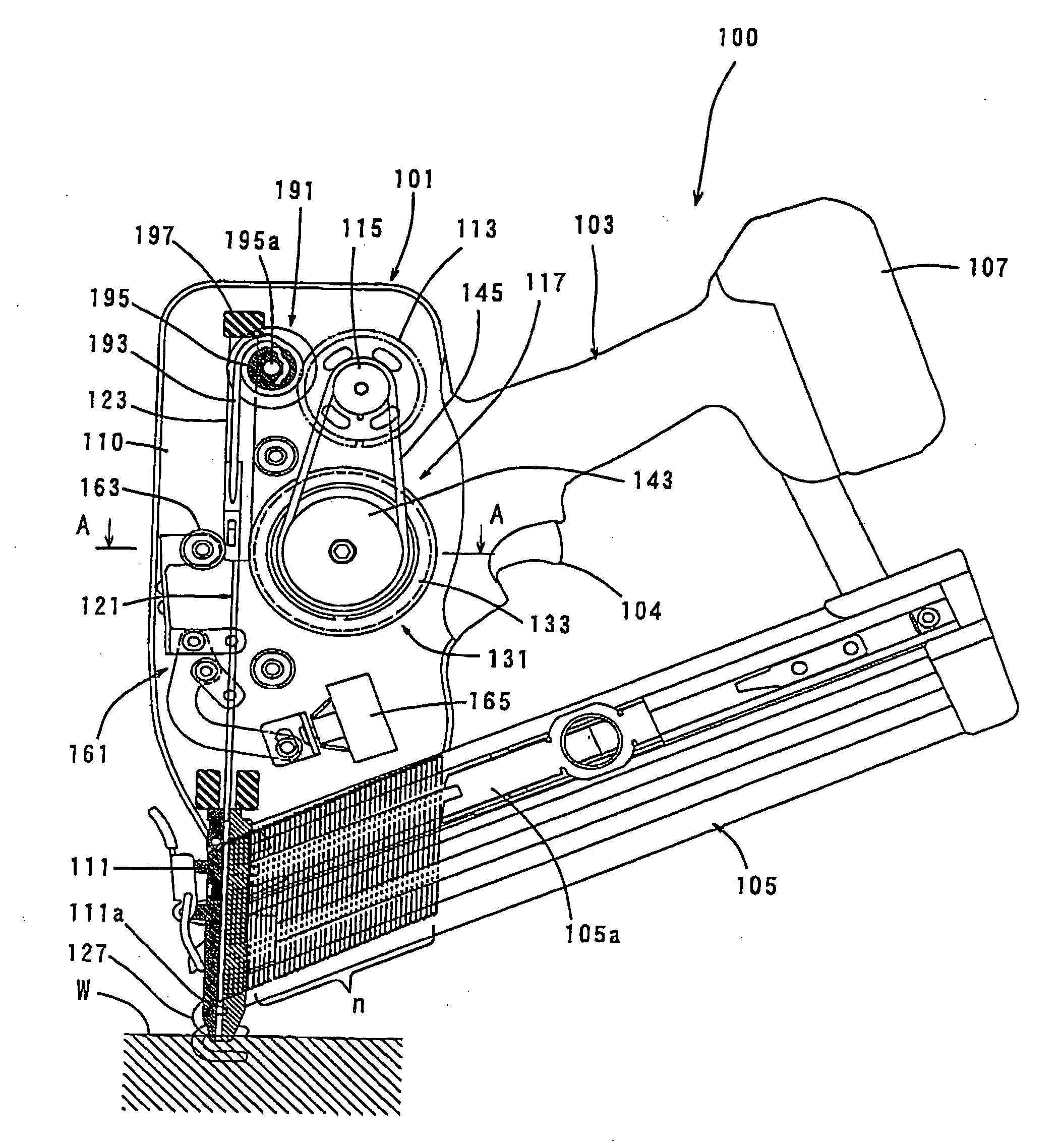

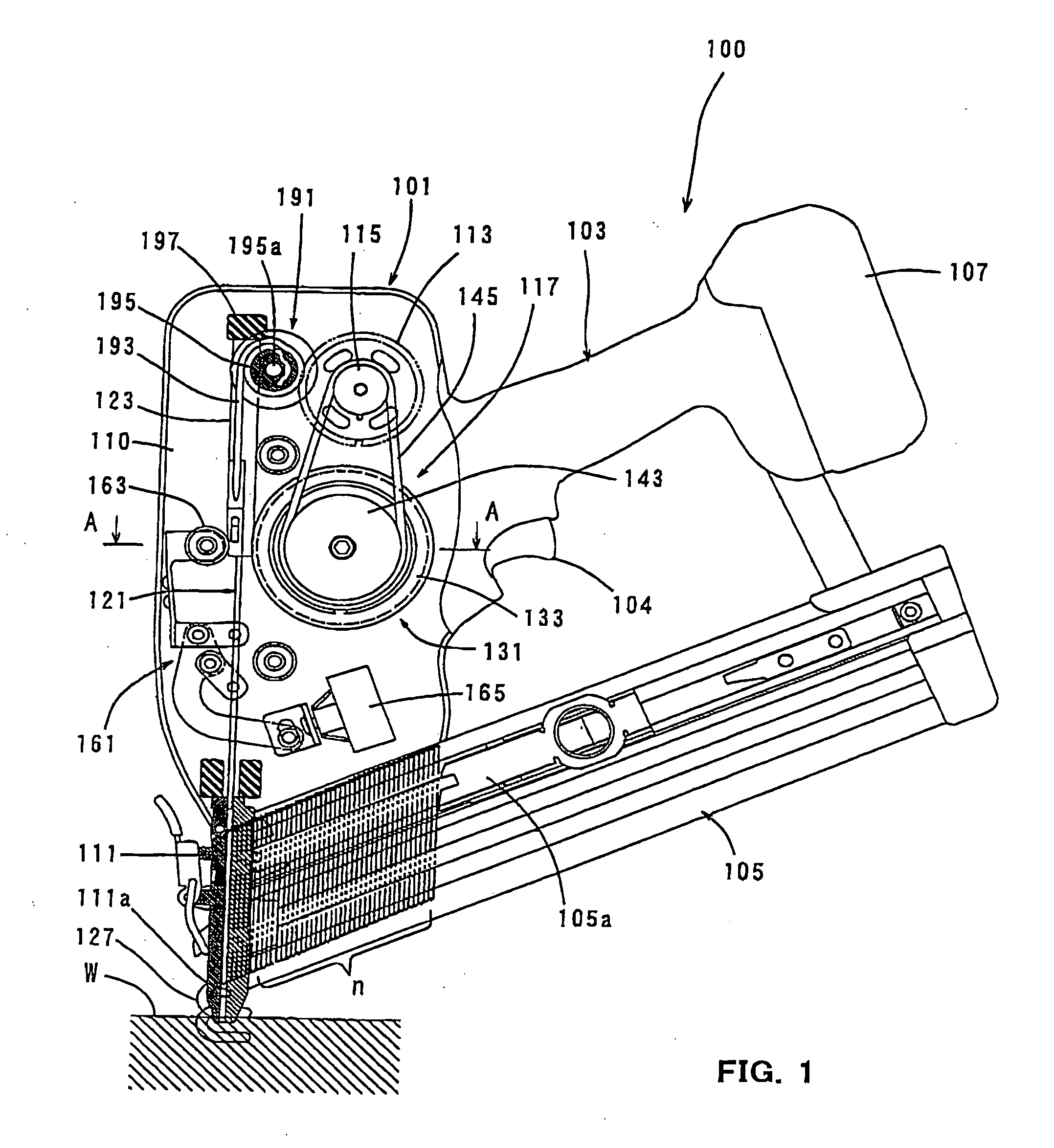

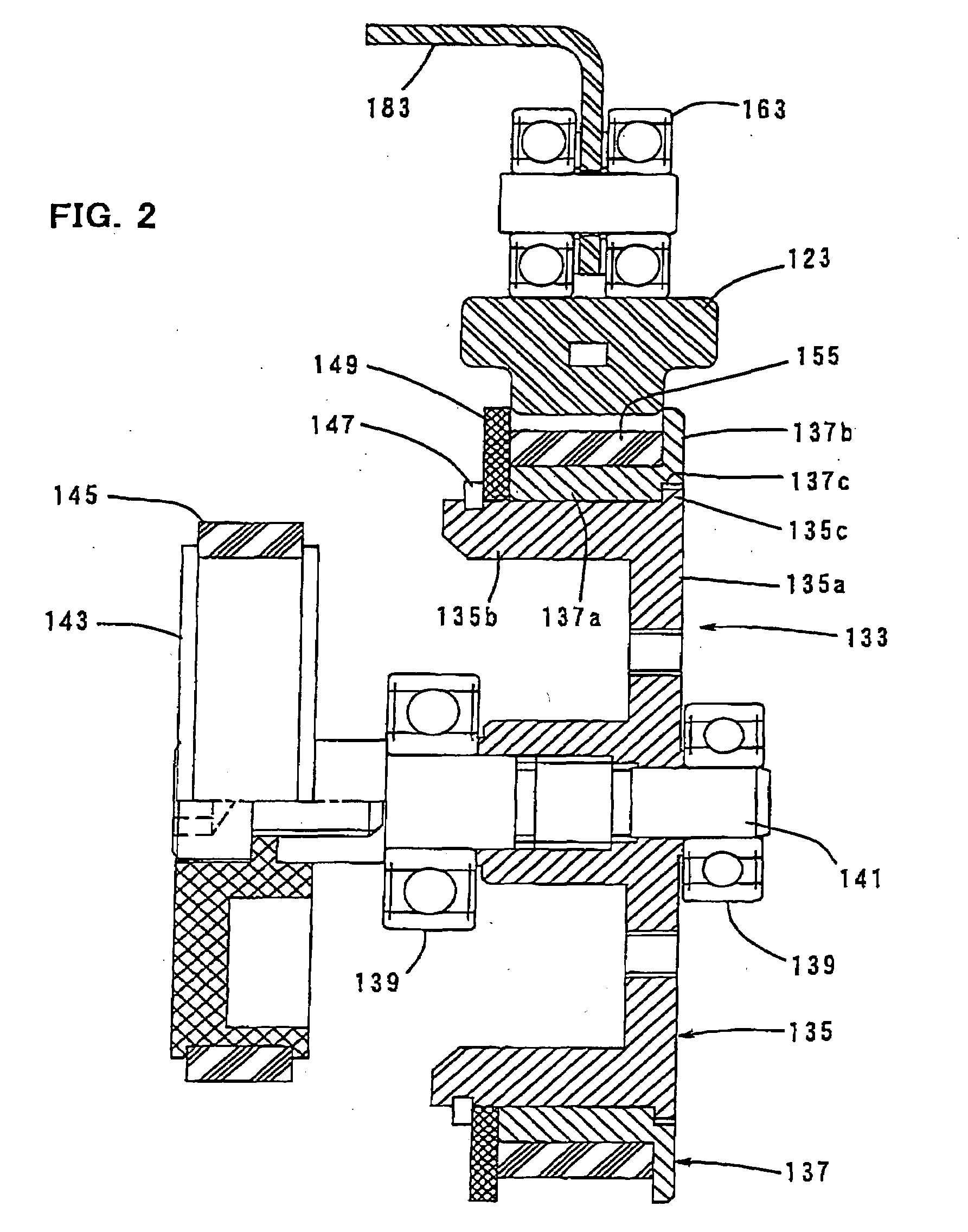

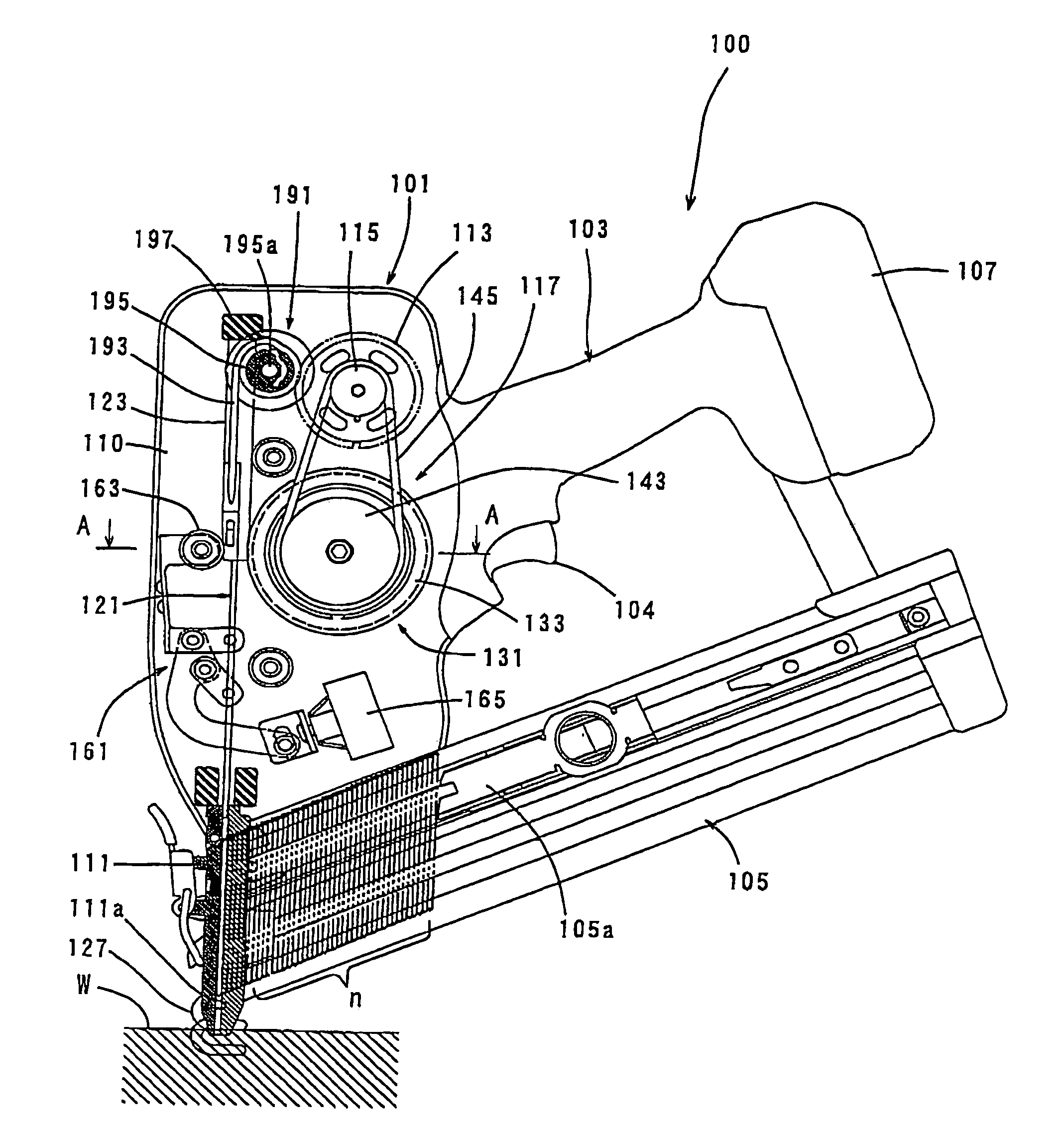

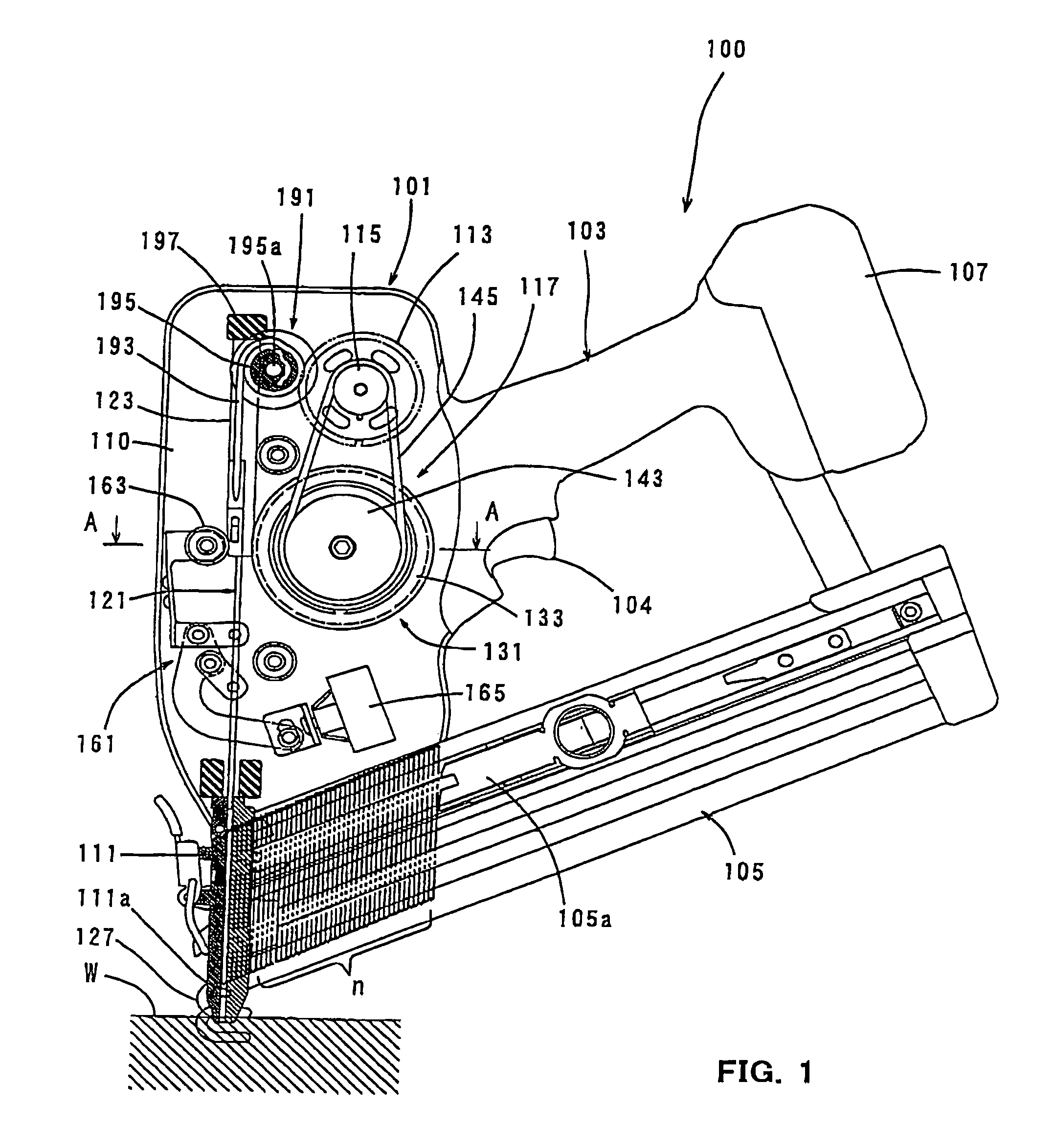

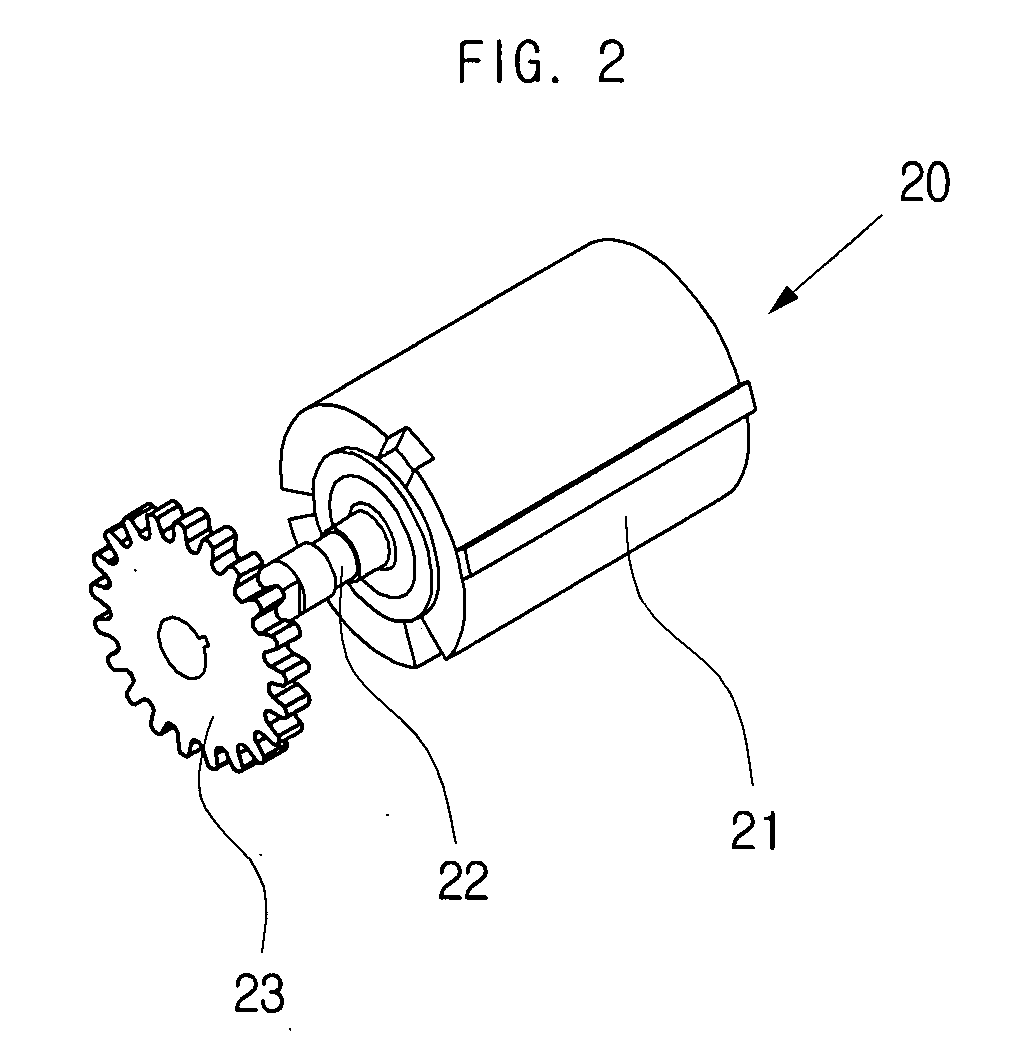

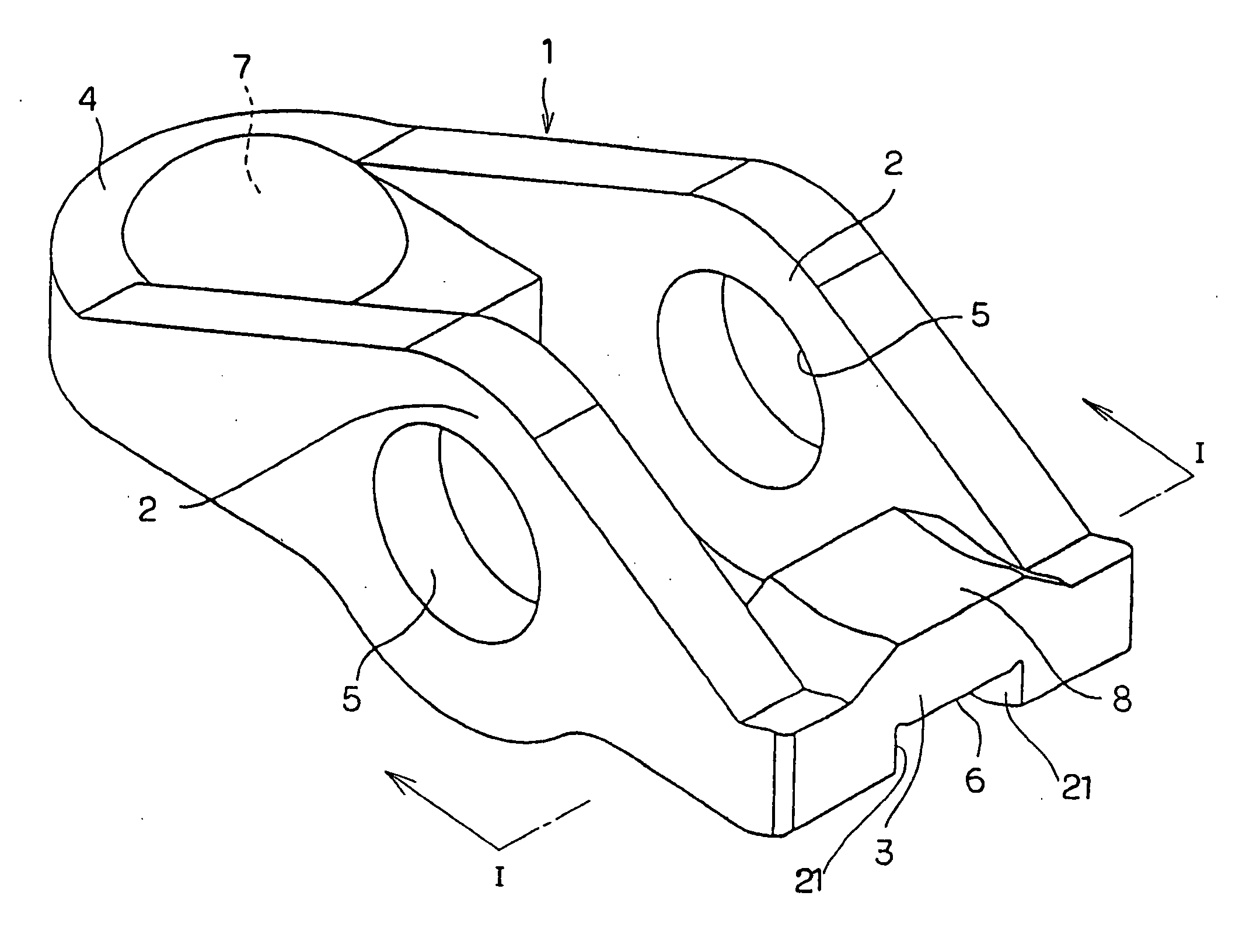

Driving tool

InactiveUS20080257933A1Increased durabilitySolve the small frictionStapling toolsNailing toolsFreewheelFlywheel

It is an object of the present invention to increase durability of a driving tool. A representative driving tool comprises an elongated operating member that drives in a driving material and a drive mechanism that drives the operating member. The drive mechanism comprises a rotating flywheel and the flywheel includes an inner wheel and an outer wheel which are concentrically disposed to each other. The inner circumferential surface of the outer wheel is fitted on an outer circumferential surface of the inner wheel. The outer circumferential surface of the outer wheel directly contacts the operating member and thus, the rotational force of the flywheel is transmitted from the inner wheel to the operating member via the outer wheel and the drive mechanism linearly moves. A frictional force between the outer circumferential surface of the inner wheel and the inner circumferential surface of the outer wheel is set to be smaller than a frictional force between the outer circumferential surface of the outer wheel and the operating member. With such construction, when the operating member contacts the rotating flywheel, slippage is caused between the inner wheel and the outer wheel such that only a smaller frictional force may be produced between the inner wheel and the outer wheel. Therefore, stress which acts upon the inner wheel and the outer wheel can be alleviated and as a result, wear of the flywheel and the operating member can be reduced to increase the durability.

Owner:MAKITA CORP

Driving tool having a two-part flywheel

InactiveUS7637408B2Increased durabilitySolve the small frictionStapling toolsNailing toolsFreewheelEngineering

Owner:MAKITA CORP

Magnetic head slider and disk drive with reduced damage to recording medium

InactiveUS20060139810A1Small in friction coefficientSmall frictional forceRecord information storageFluid-dynamic spacing of headsBearing surfaceMagnetic disks

Embodiments of the invention reduce damage to a disk recording medium when a slider flying above the disk recording medium inside a magnetic disk drive comes into contact with the disk recording medium due to slider vibration. In one embodiment, a magnetic head slider includes a front pad, a rear pad, and carbon protective films. The front pad includes a step bearing surface disposed on the side of a leading end and leading side rail surfaces formed on the step bearing surface. The rear pad includes a rear step bearing surface disposed across a deep groove surface from the front pad and a trailing side rail surface formed on the rear step bearing surface. The carbon protective films are formed on regions including vertices of slider corner portions, respectively. The leading side rail surfaces and the trailing side rail surface are formed substantially on the same level. The carbon protective films are harder than a slider base material and have a small coefficient of friction. The films have a film thickness of about 10 nm or more.

Owner:WESTERN DIGITAL TECH INC

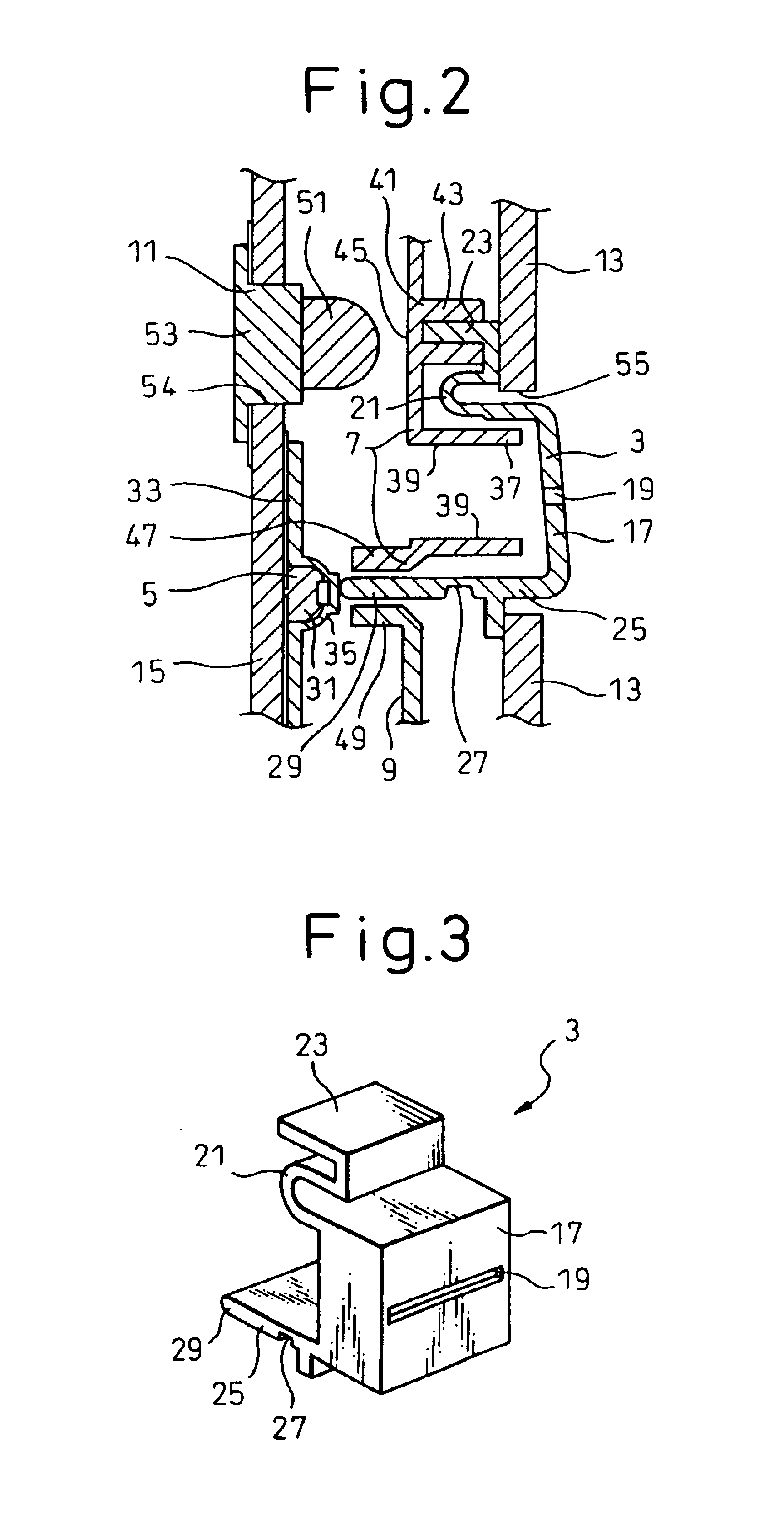

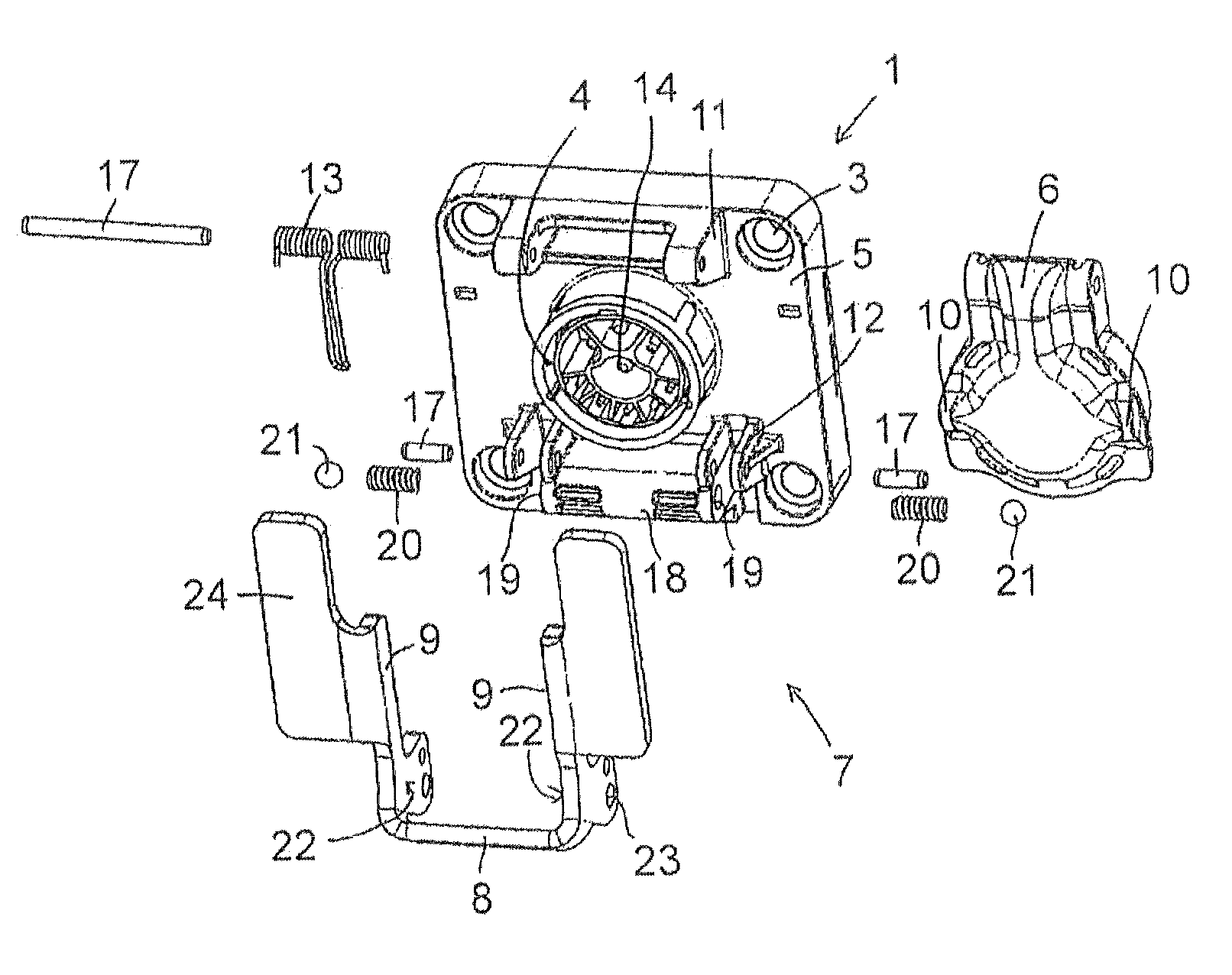

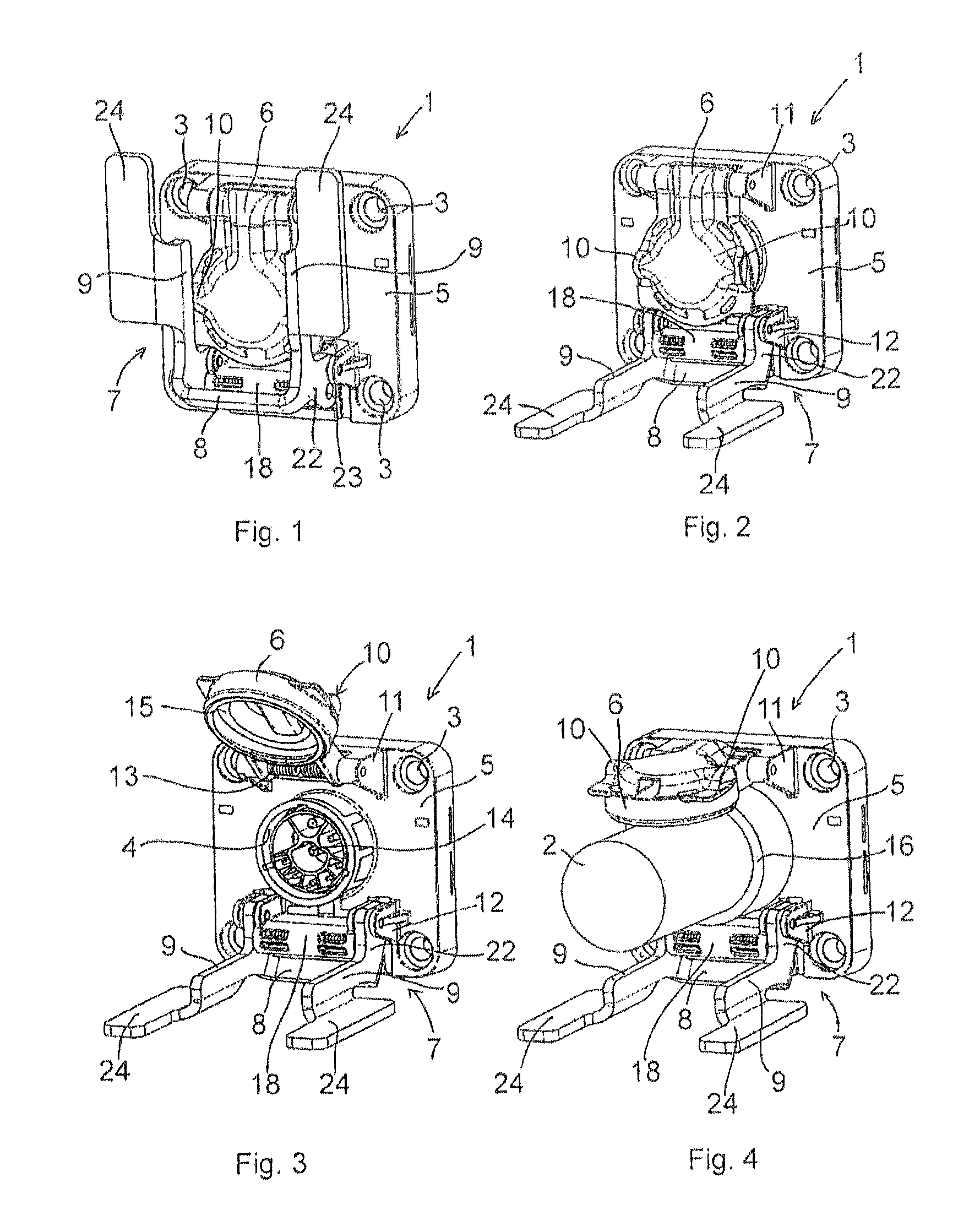

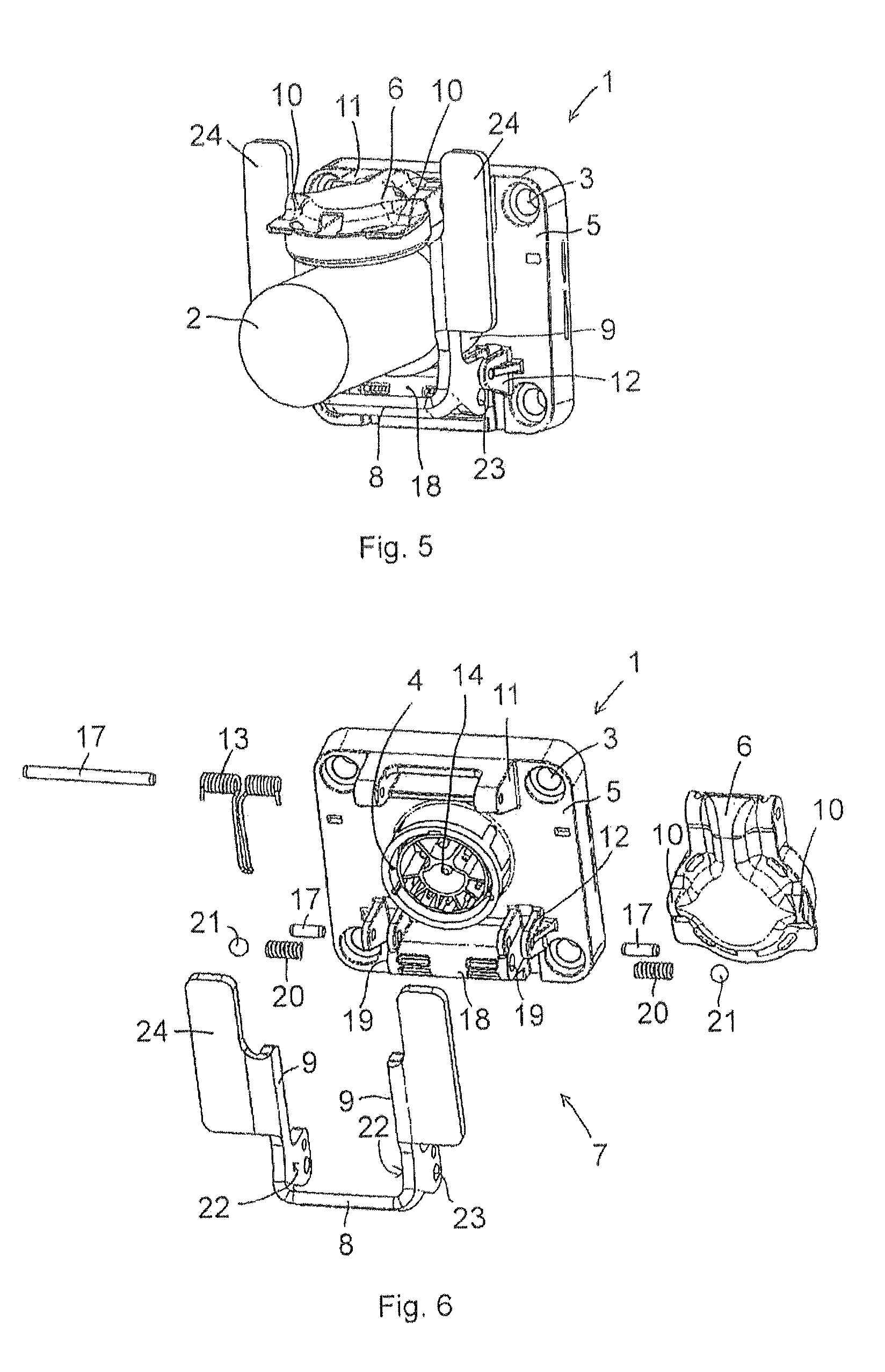

Socket

ActiveUS8888515B2Simple designEasy to set upVehicle connectorsCouplings bases/casesEngineeringElectric contact

The present invention relates to a socket for connecting a plug in the external region of a motor vehicle, comprising a socket housing, in which a plug-receiving opening having electric contacts for plugging in a plug and establishing an electric connection is formed, and comprising a cover, which is hinge-mounted on the socket housing and closes the plug-receiving opening in the closed position of the cover and which is preloaded in the closing direction, wherein a hold-closed mechanism that increases the holding force of the cover in the closed position thereof is provided.

Owner:ERICH JAEGER GMBH & CO KG

Switch structure

InactiveUS20040003986A1Easy to operateIncreased durabilityEmergency actuatorsContact mechanismsEngineeringCircuit switching

A switch structure comprising a switch element (5, 59, 61) performing circuit switching operation by pushing and a push button section (3) attached rotationally movably to a supporting member (7, 91) and having a push rod section (25, 77, 81) pushing the switch element and integrally formed thereto, wherein a switching operation is performed when the push button section (3) is rotationally moved by pushing and push rod section pushes the switch element, wherein the push rod section is provided with a flexible portion (27) able to bend when pushed, and wherein a guide section (47, 57, 49) is provided which comes into contact with the push rod section to bend the flexible portion and, at the same time, guides the push rod section to push the switch element in the normal direction when the push button section is rotationally moved by pushing.

Owner:DENSO CORP

Rack shaft support device

ActiveUS8511191B2Reliably inhibit generation of soundFluctuation in meshingToothed gearingsPortable liftingEngineeringCam

A rack shaft support device includes: a rack shaft support member that is accommodated inside a retention hole formed in a housing so as to slide in an axial direction of the retention hole, and slidably supports a rack shaft; a sealing member fixed to an inlet port of the retention hole; an intermediate member that is interposed between the rack shaft support member and the sealing member; a torsion spring that couples the sealing member and the intermediate member; a cam mechanism that converts a rotational force of the intermediate member induced by untwisting of the torsion spring to a force by which the intermediate member pushes the rack shaft support member; an opposing portion that opposes a rear surface of the rack shaft support member; and an annular elastic member that is interposed between the rear surface of the rack shaft support member and the opposing portion.

Owner:JTEKT CORP

Power Switchgear

ActiveUS20160035501A1Contact resistanceImprove insulation performanceSwitch lubricationContacts enclosures/screensElectrical conductorSwitchgear

Disclosed is a power switch gear that includes: a fixed electrode and a movable electrode disposed opposite to each other in a tank filled with insulting gas; and a movable conductor electrically connecting the fixed electrode and the movable electrode together. The fixed electrode and the movable electrode have a contactor through which current flows to the movable conductor. At least one of the fixed electrode and the movable electrode has ring-shaped sliding members, the ring-shaped sliding members being disposed, on both sides of the contactor. At least one grease pool is provided between the contactor and the sliding members.

Owner:HITACHI LTD

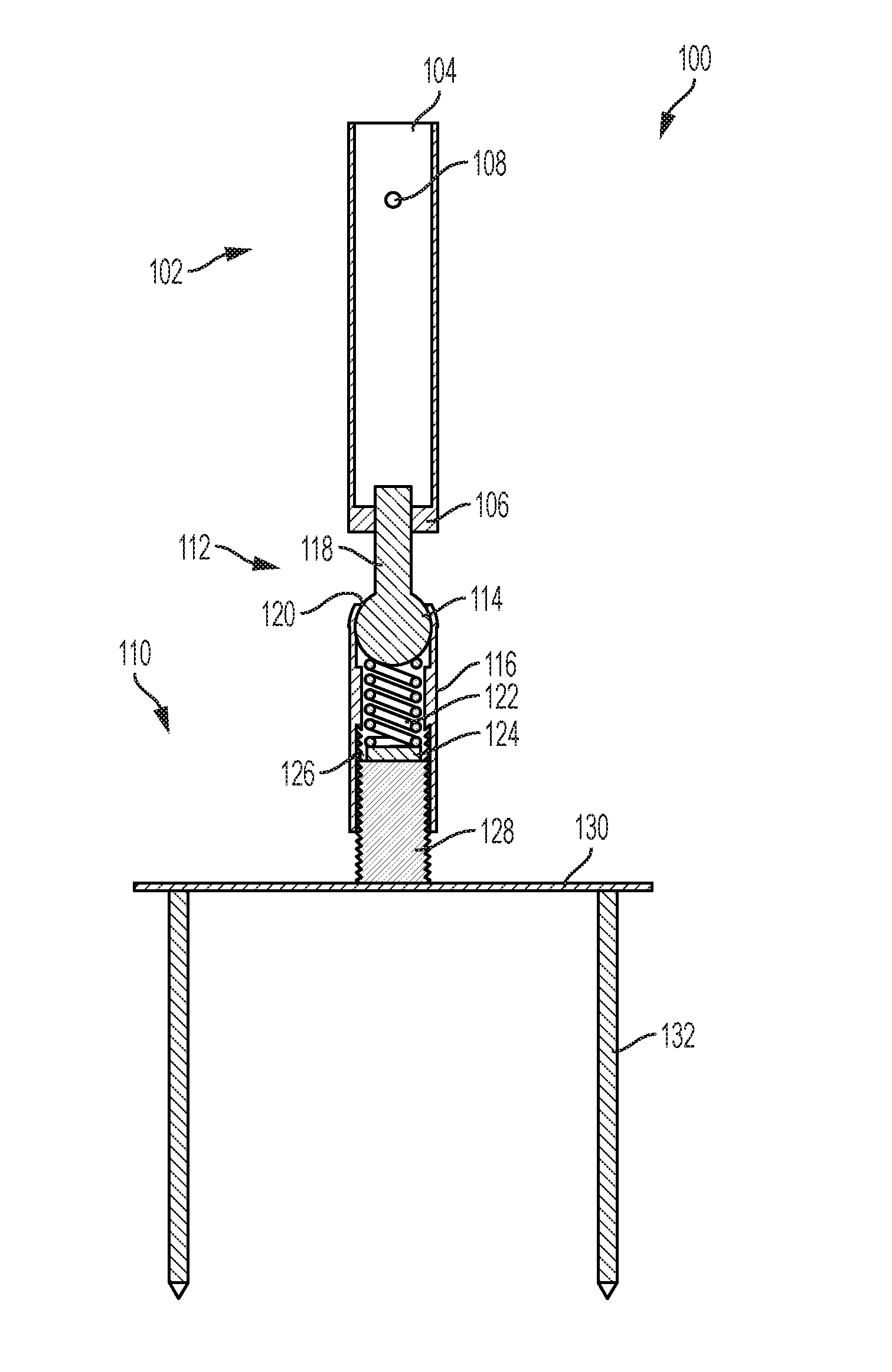

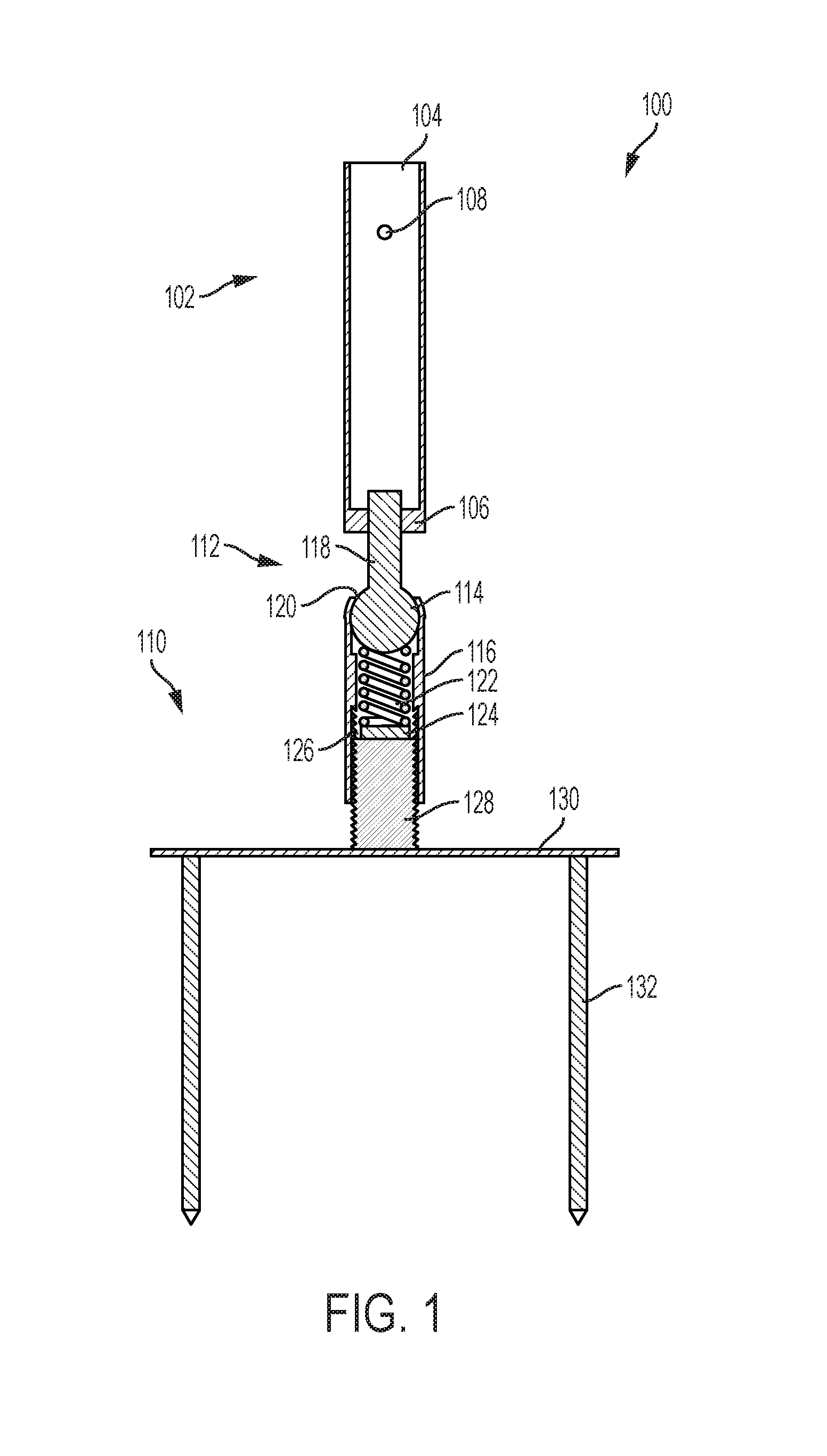

Adjustable umbrella base

Owner:NGU HAO THU

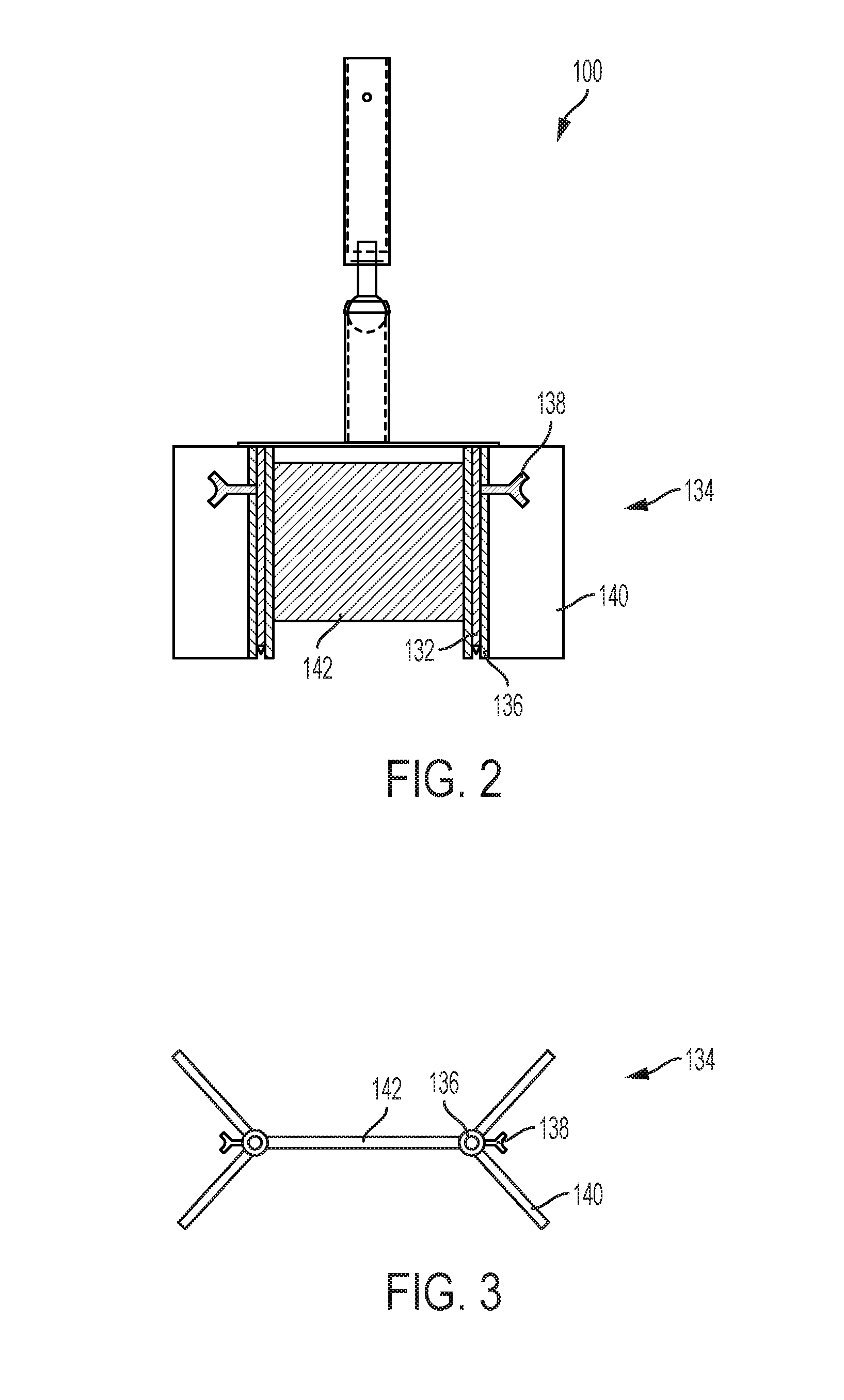

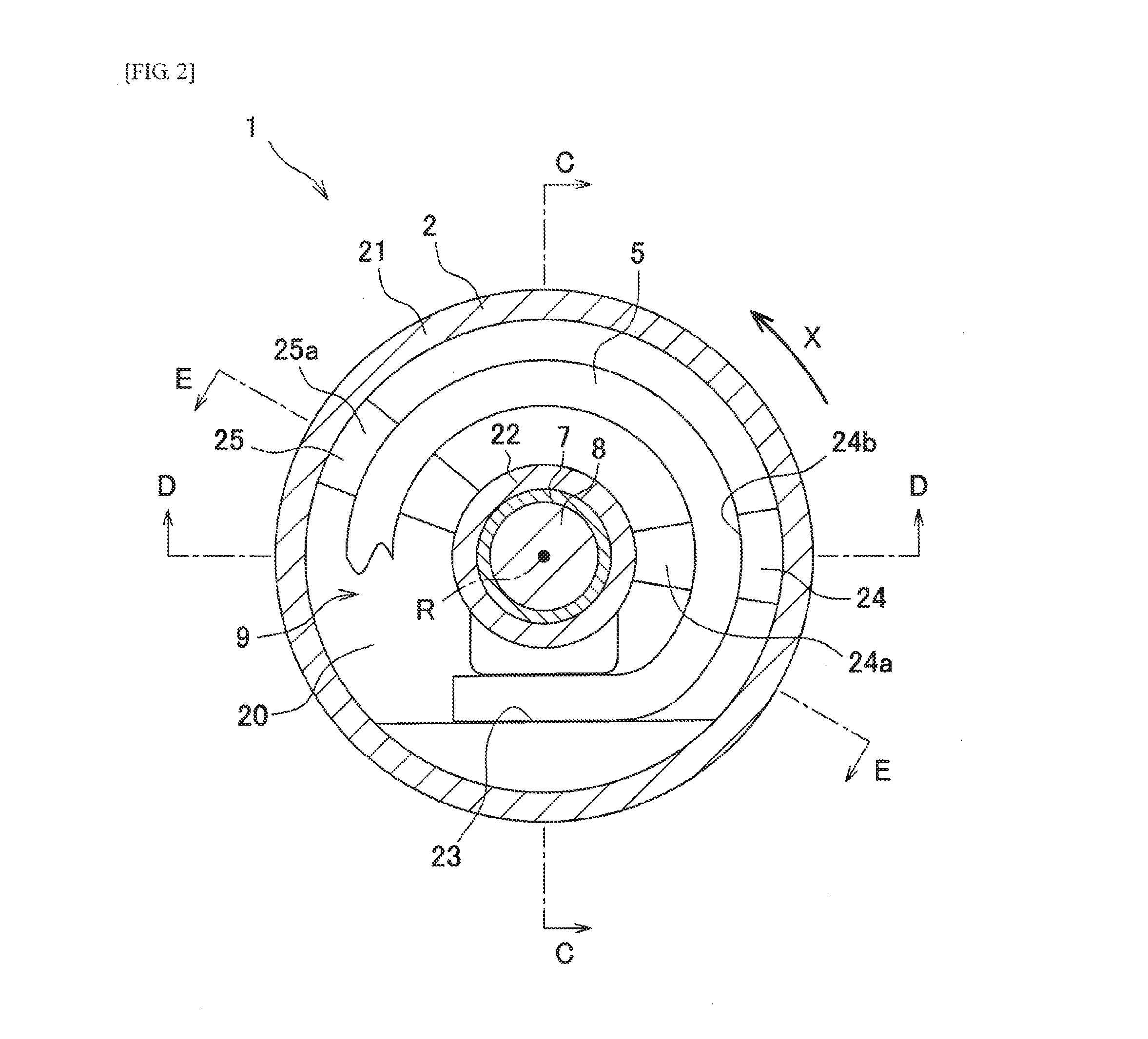

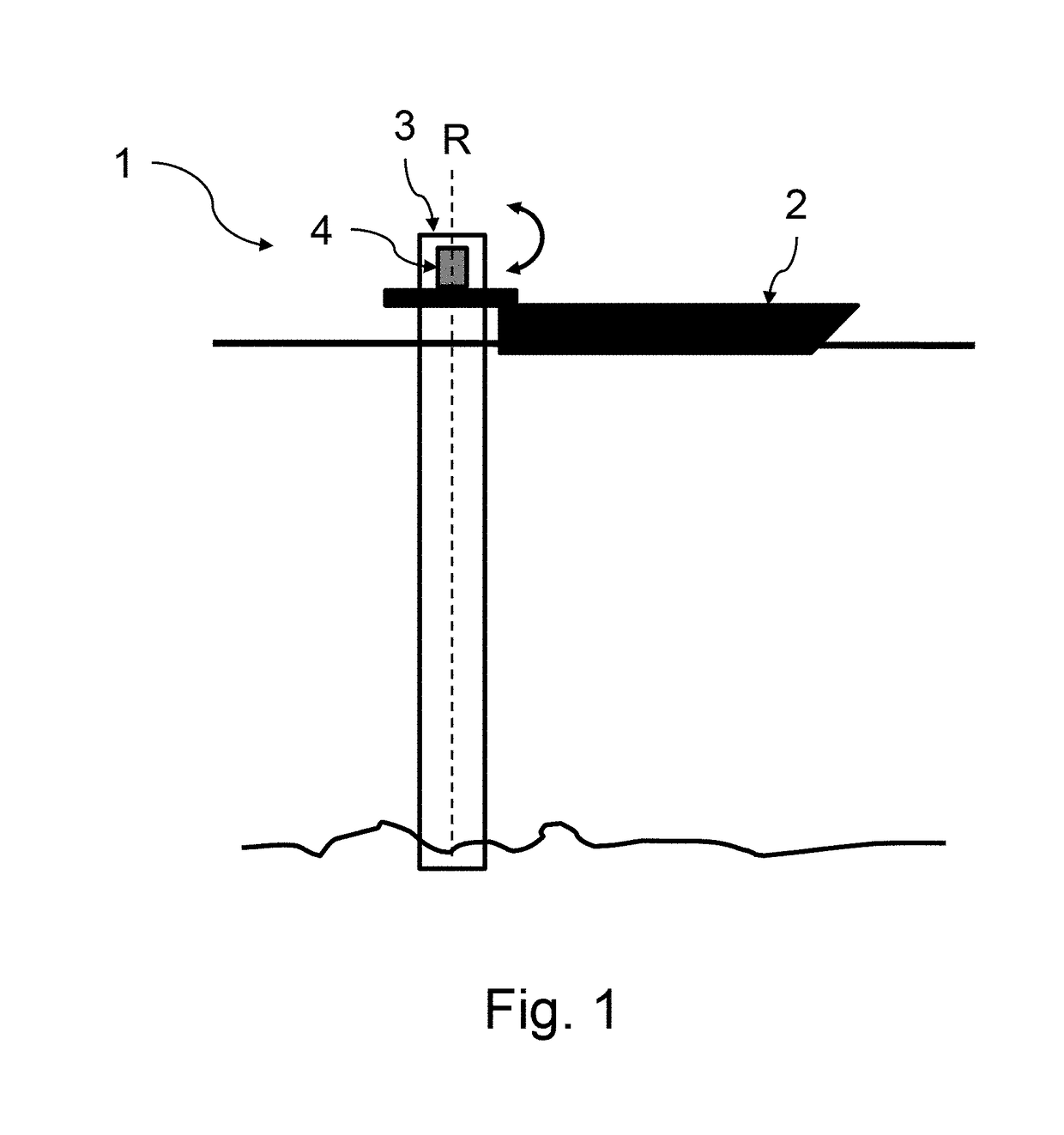

Display rotation apparatus

InactiveUS20070222776A1Small driving forceSmall frictional forceTelevision system detailsCathode-ray tube indicatorsEngineeringDisplay device

The present invention relates to a display rotation apparatus. The present invention provides a display rotation apparatus, including a support, a universal joint coupled to the support, a movable body coupled to the universal joint, a driving part coupled to the movable body for rotating the movable body about the universal joint.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

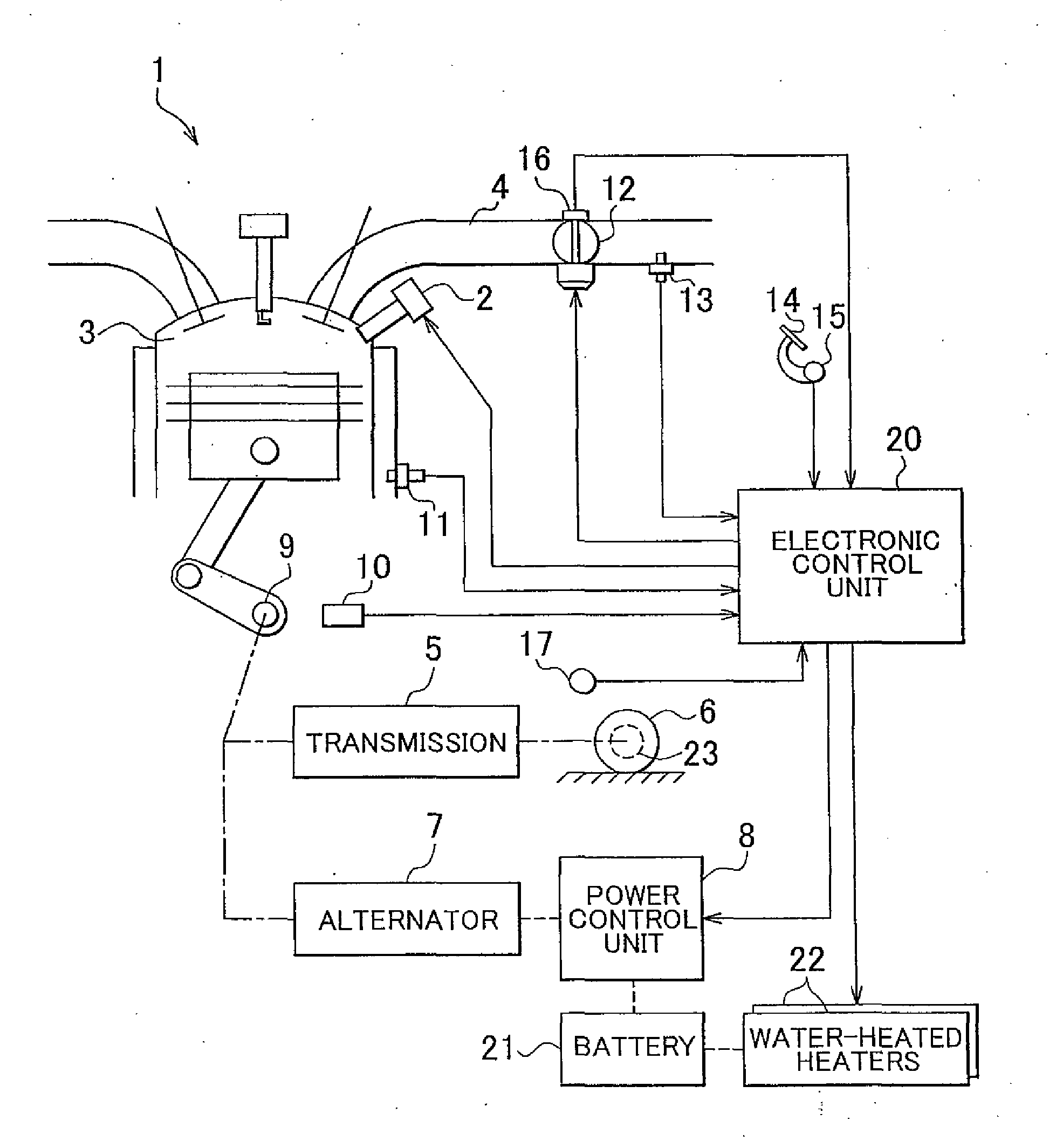

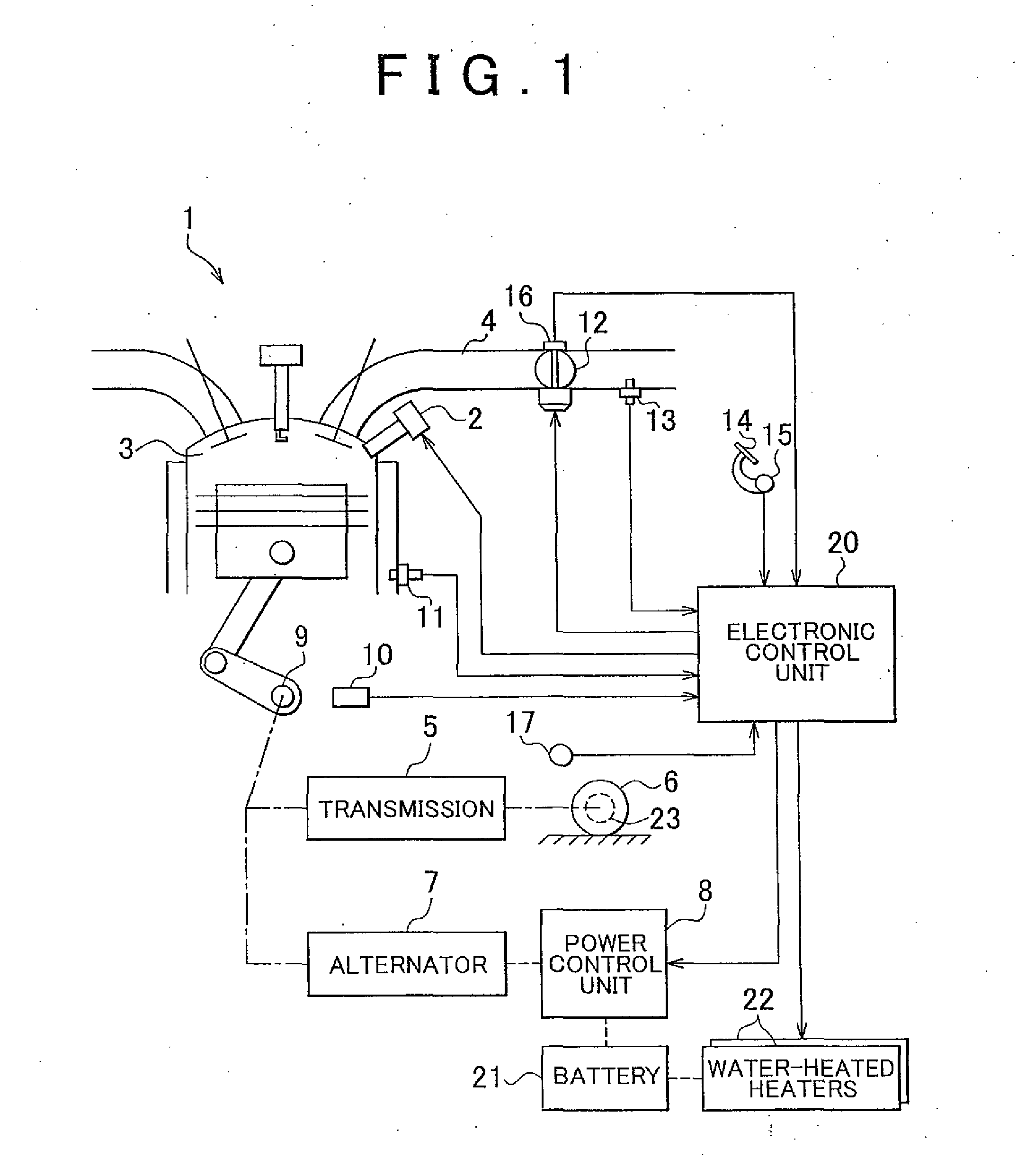

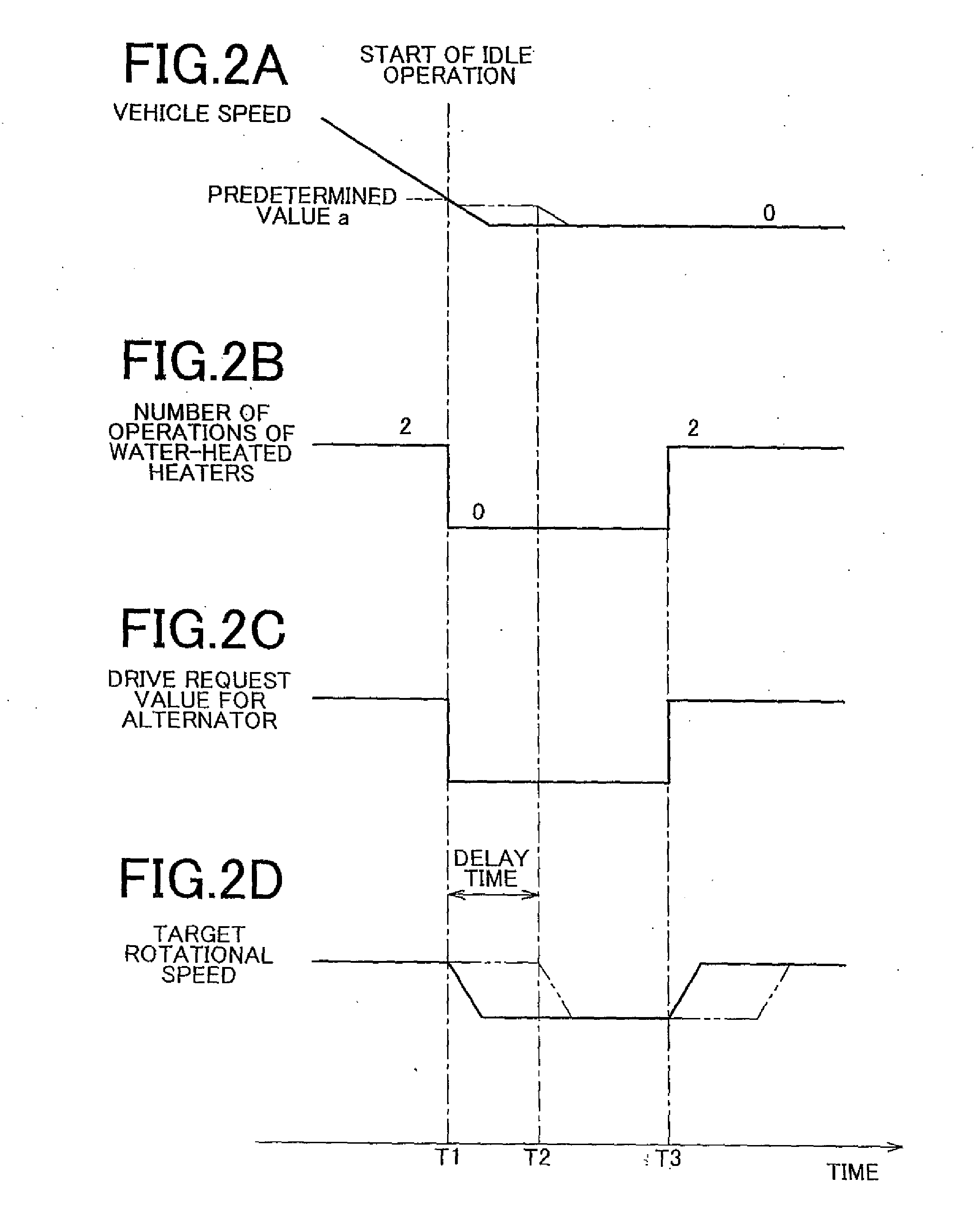

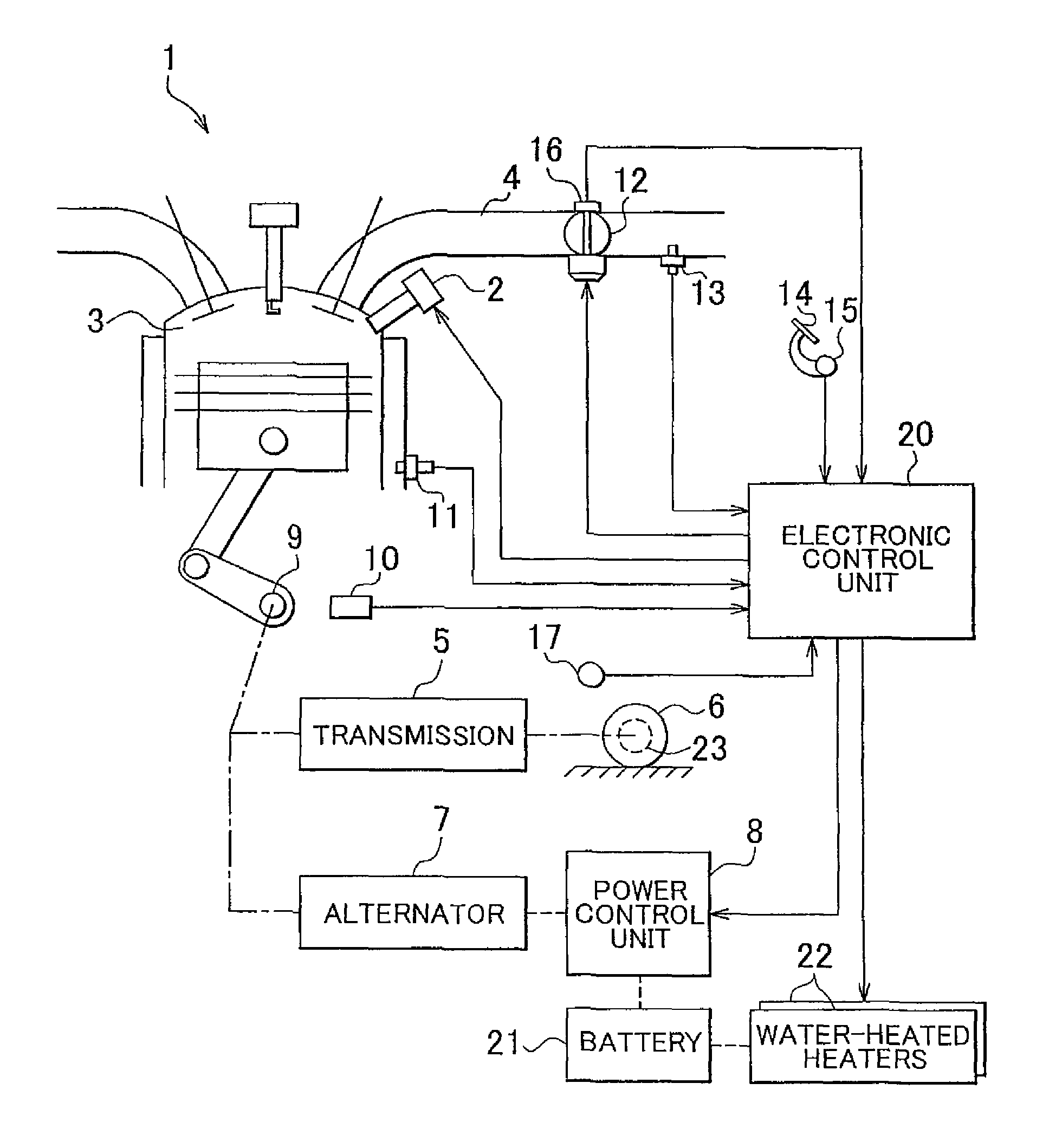

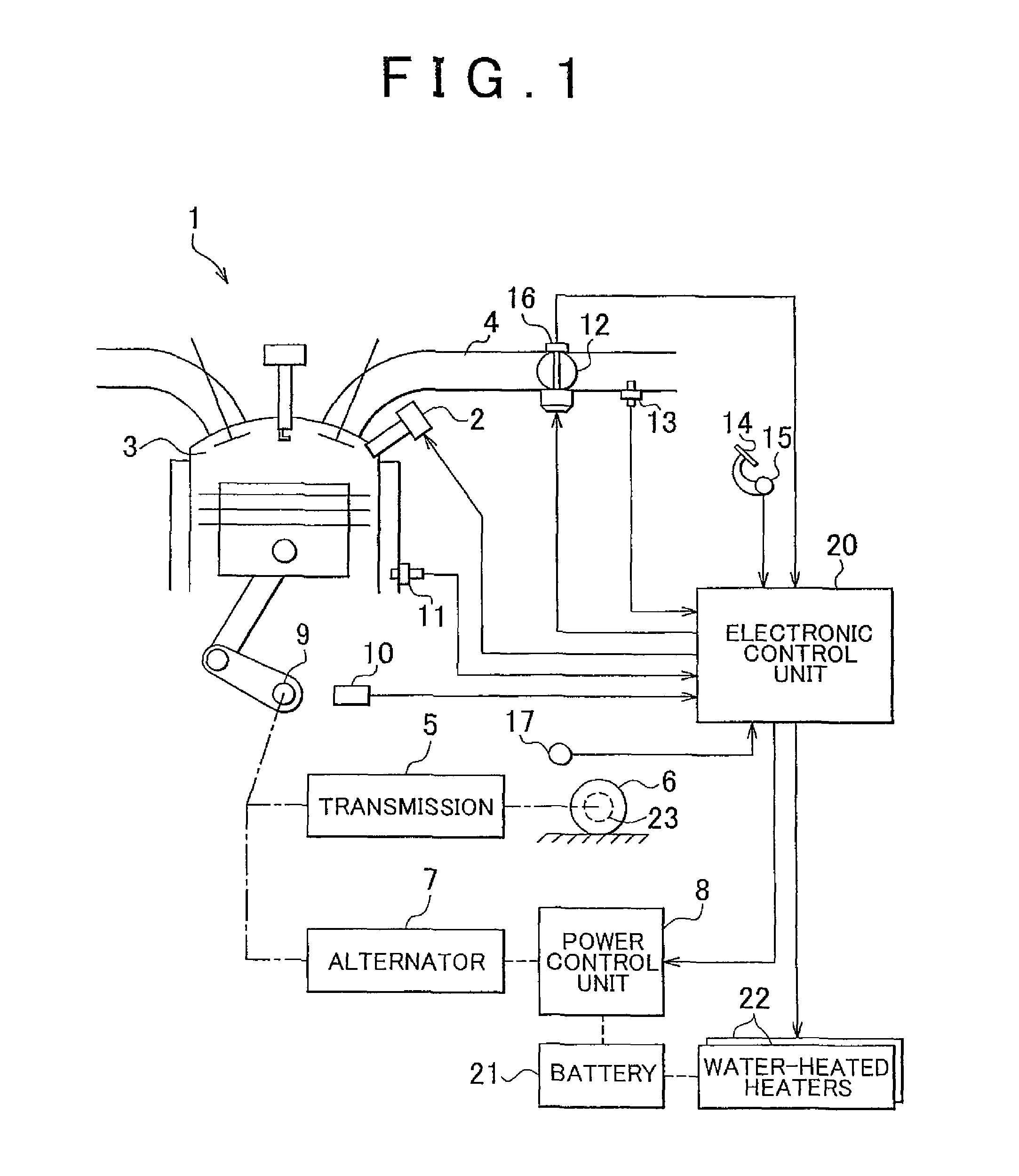

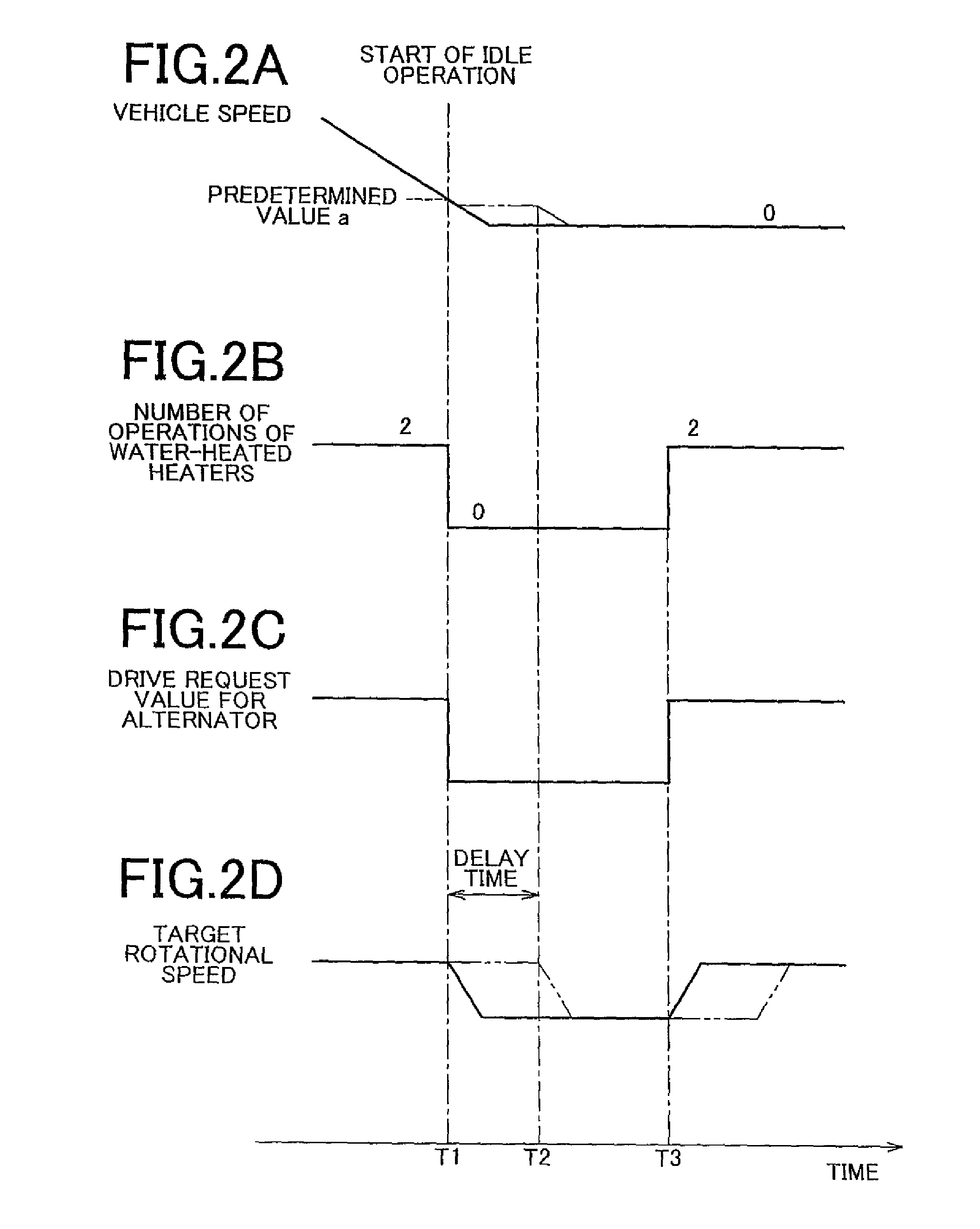

Control apparatus and method of controlling internal combustion engine mounted on vehicle

InactiveUS20100206266A1Shorten speedReduce coefficient of frictionElectrical controlIdling devicesIdle speedRoad surface

When an automobile is traveling on a road surface with a low friction coefficient upon a shift of an engine to idle operation in the process of stopping the automobile from traveling, a target engine speed of the engine is reduced by a value equivalent to a reduction in a drive request value for any auxiliary at a time point corresponding to start of reduction of the drive request value.

Owner:TOYOTA JIDOSHA KK

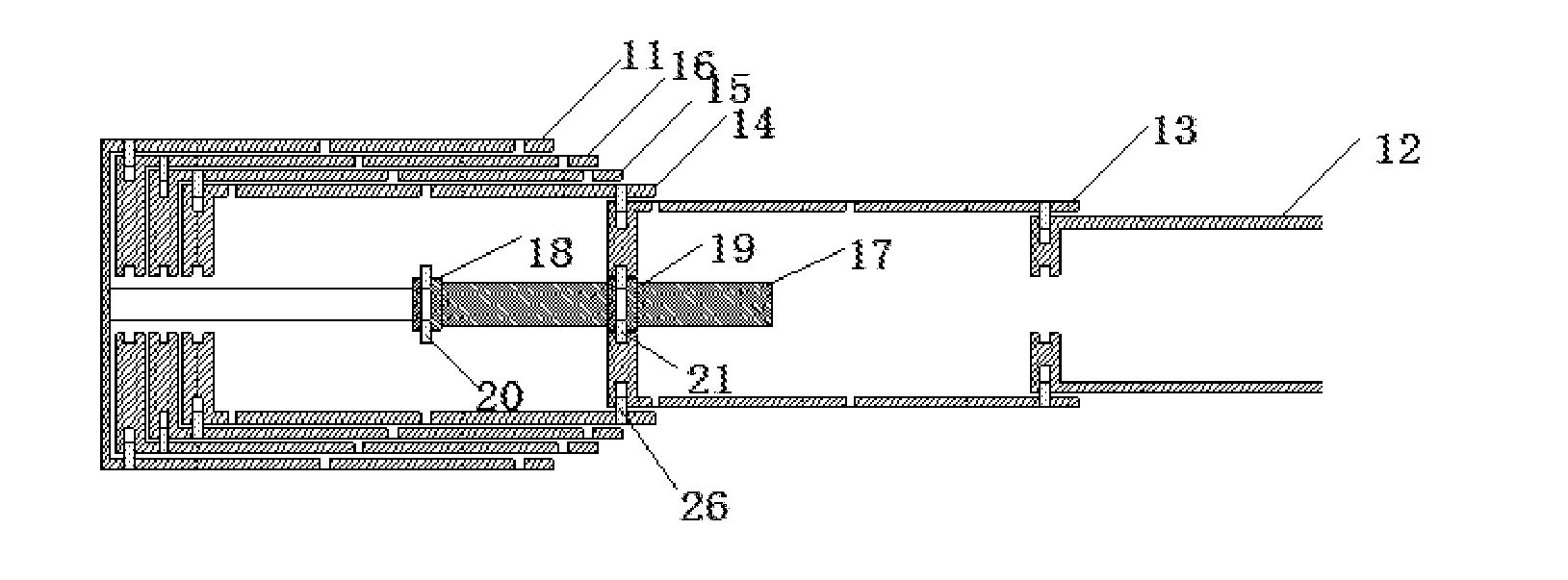

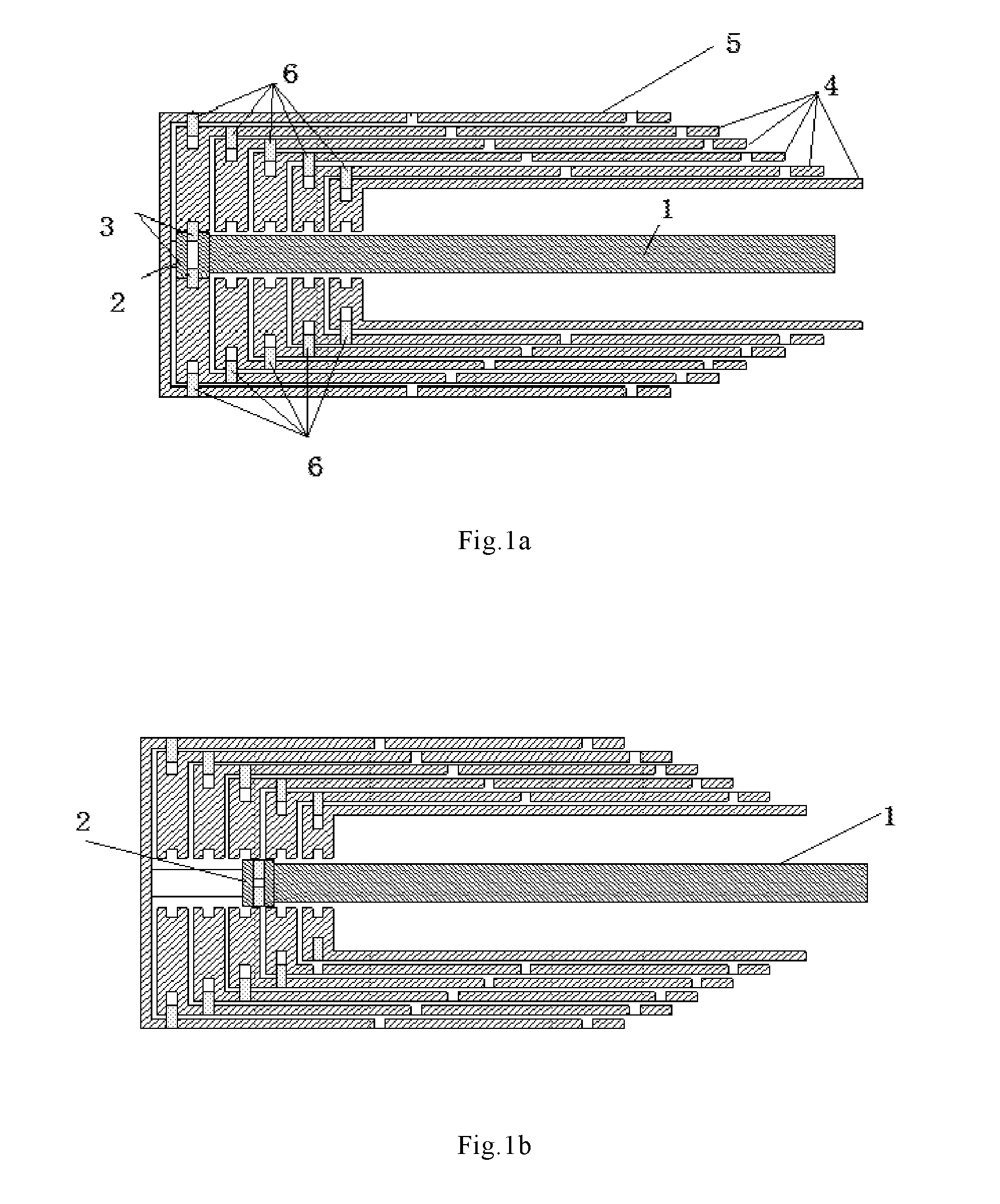

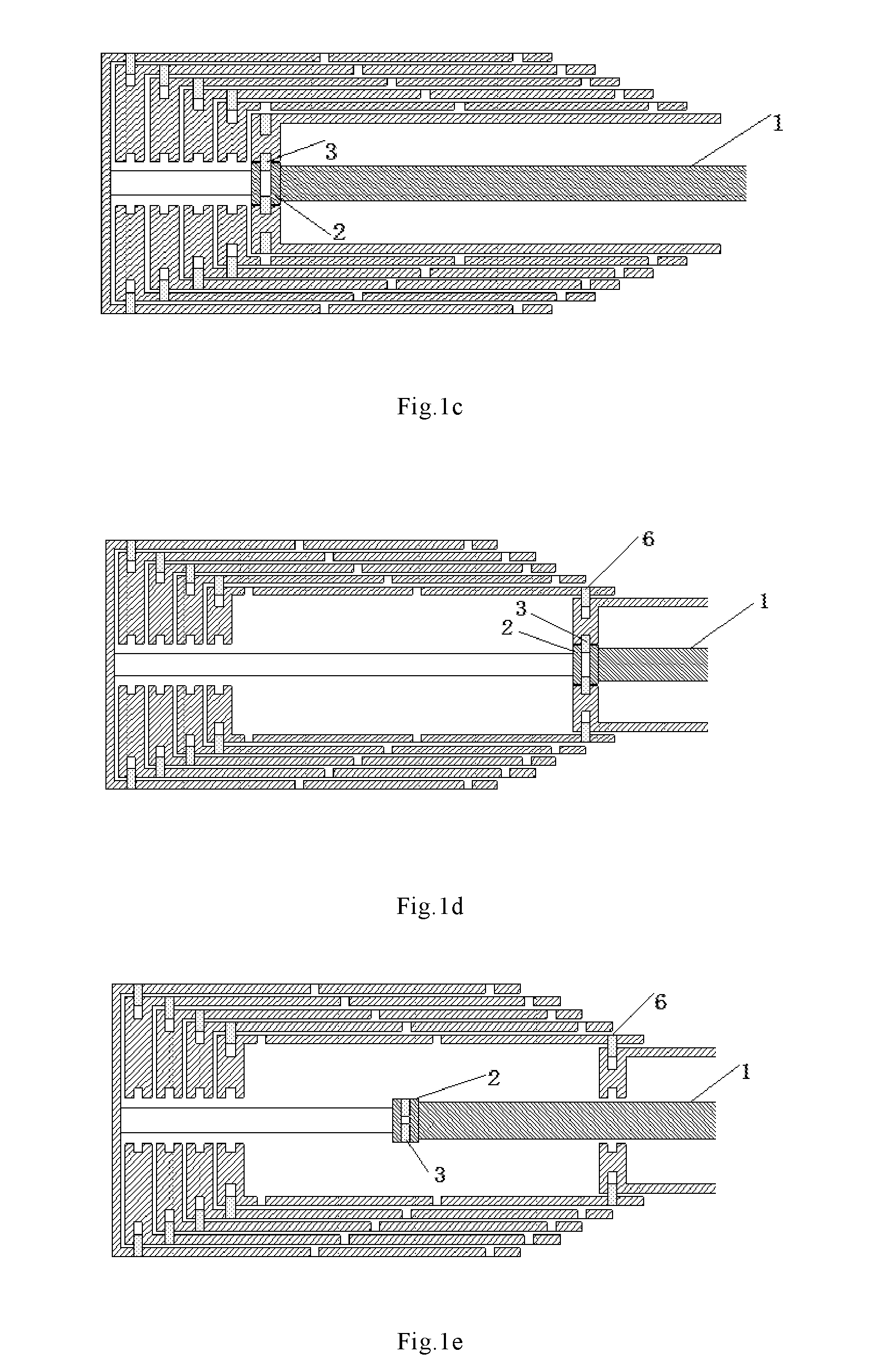

Single-cylinder plug pin type telescopic arm, telescopic method thereof and crane having telescopic arm

The present invention relates to a single-cylinder plug pin type telescopic arm, a crane and a telescopic method thereof. The single-cylinder plug pin type telescopic arm includes a basic arm and at least one telescopic arm sleeved in the basic arm, wherein coaxial center holes are formed in the tails of the telescopic arms, and a telescopic oil cylinder is arranged in the center holes; the telescopic oil cylinder includes a cylinder rod and a cylinder barrel, at least two cylinder heads are fixedly sleeved on the outer side of the cylinder barrel in the longitudinal direction, and at least three arm pin holes are formed in each of the basic arm and the telescopic arms in the longitudinal direction. The single-cylinder plug pin type telescopic arm provided by the present invention adopts one telescopic oil cylinder and at least two cylinder heads, each cylinder head is adapted to lock and unlock the telescopic oil cylinder and any telescopic arm, the telescopic arms are extended out or retracted in a relay transmission manner to achieve the extension and retraction of the single-cylinder plug pin type telescopic arm, the length of the oil cylinder is shortened, the cylinder diameter and the rod diameter of the oil cylinder are decreased, the cost of the oil cylinder is lowered, the upperstructure weight is reduced, the lifting capacity is improved, and there are more crane design spaces.

Owner:XUZHOU HEAVY MASCH CO LTD

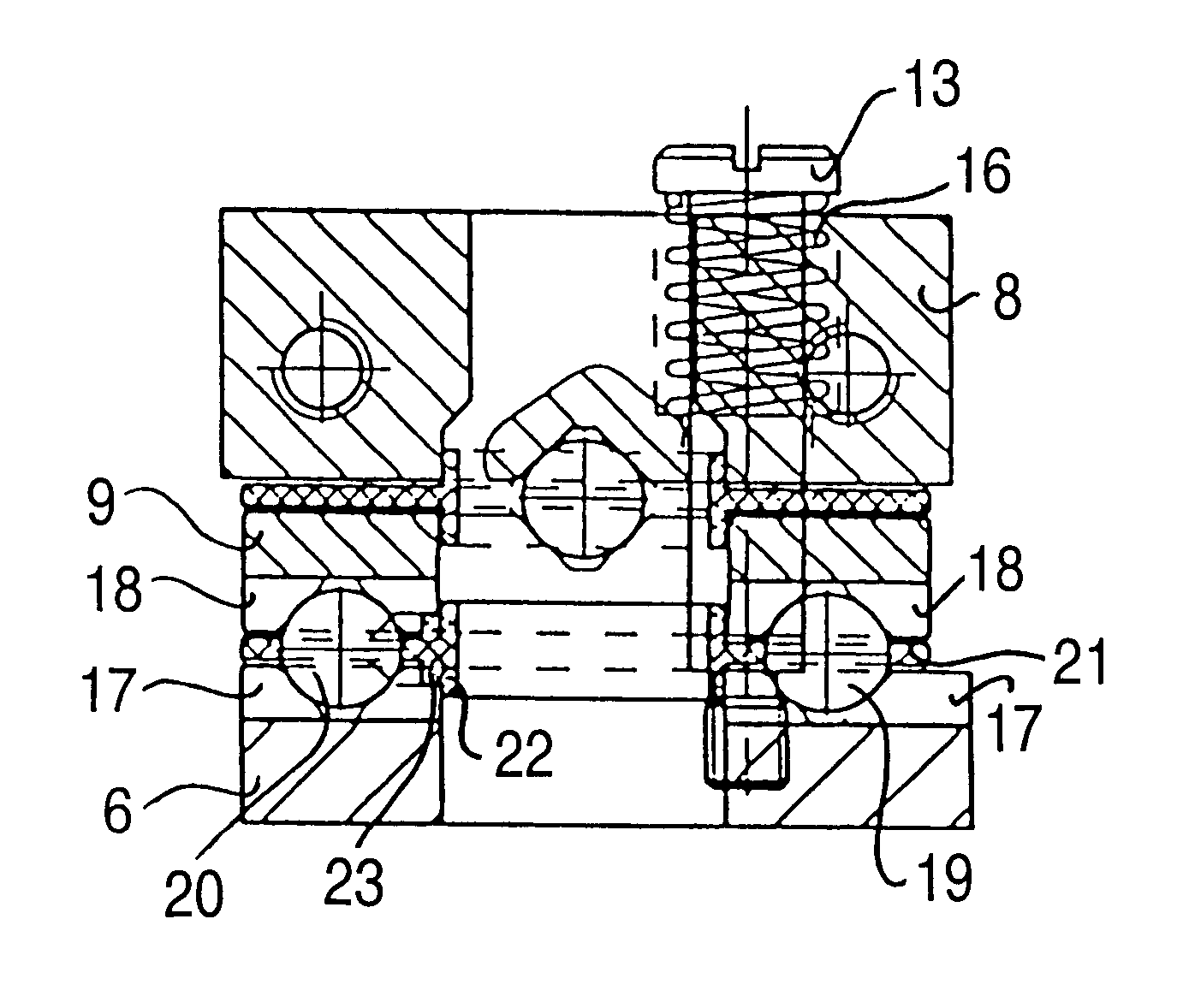

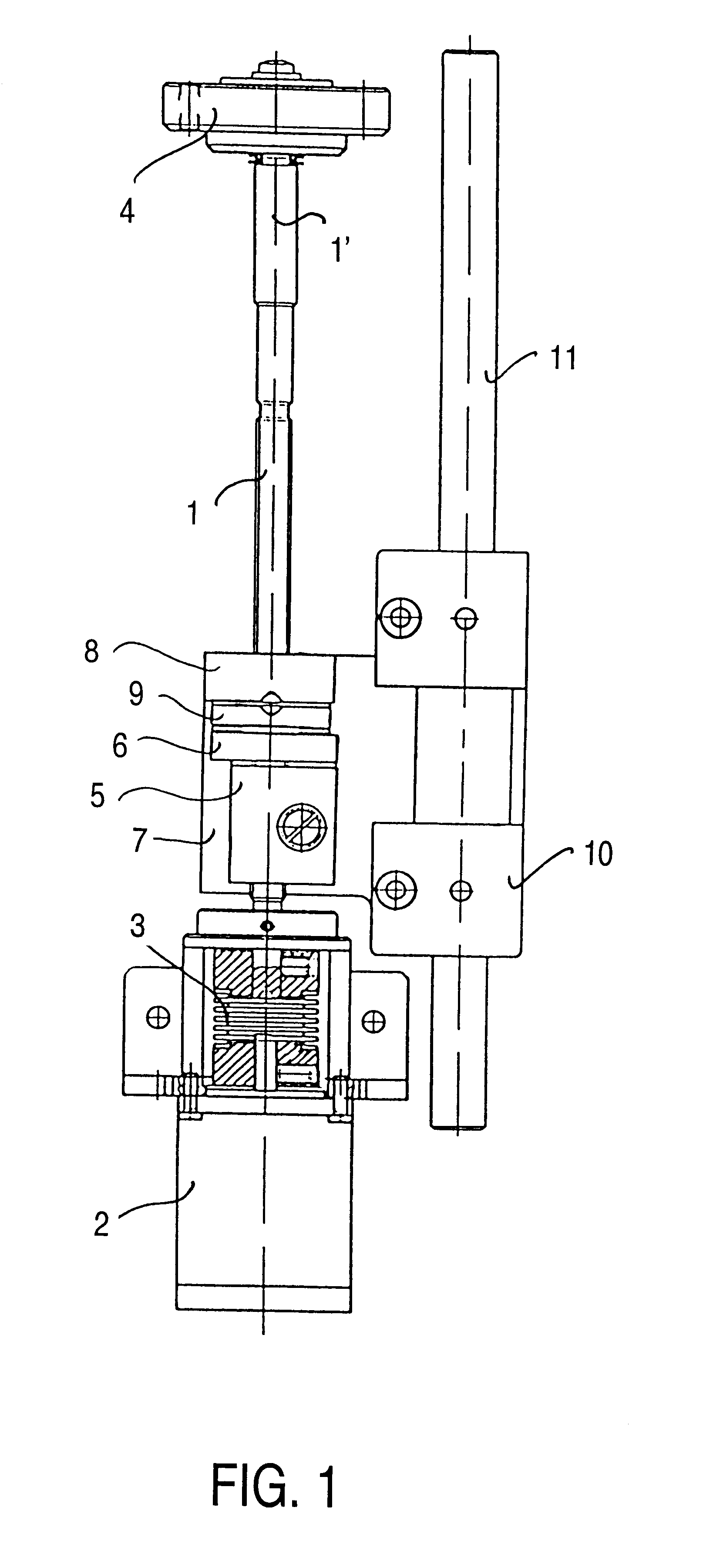

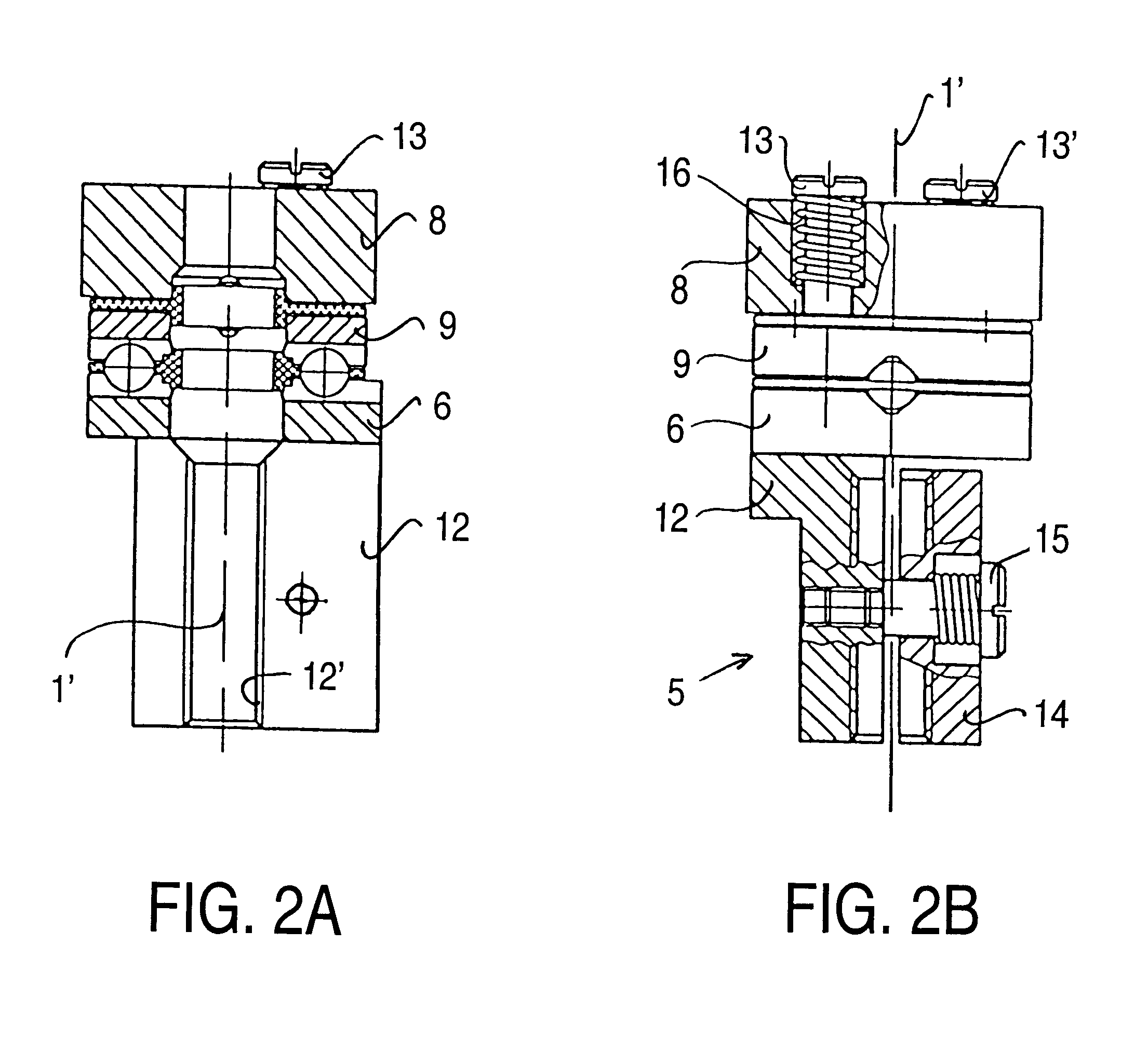

Helical gear

Screw mechanism having a spindle (1) which is secured in the axial direction and has a spindle axis (1'), and a spindle nut (5) which is connected to a slide (7) which can be driven and is guided in the axial direction, a joint being provided between the spindle nut (5) and the slide (7) in order to compensate for relative transverse movements and tilting between the spindle nut (5) and slide (7), said joint being formed symmetrically to the spindle axis (1') and having two joint axes which are perpendicular to each other, intersect on the spindle axis (1') and are assigned at one end to the transverse movement of a bearing plate (6), which is connected to the spindle nut (5), and at the other end to the transverse movement of a bearing plate (8), which is connected to the slide (7), and said joint containing an intermediate plate (9) via which the bearing plates (6, 8) are connected pivotably to each other in order to compensate for any tilting of their joint axes. The joint axes are each formed by two balls (19, 20; 19', 20') which are arranged aligned with one another on opposite sides of the spindle axis (1'), are mounted in mutually opposite prism grooves (17, 18; 17', 18') in the bearing plates (6, 8) and the intermediate plate (9), and bear against one another under spring pressure (13, 16; 13', 16').

Owner:LEICA GEOSYSTEMS AG

Thin-slotting lifting synchronous grouting device and its usage method

ActiveUS20200256031A1Little disturbanceReduce frictionSoil preservationSpray nozzleStructural engineering

A thin-slotting lifting synchronous grouting device and its usage method are provided, The device includes a hollow force-bearing column through which a feeding pipe passes; wherein: left and right cutting plates are respectively fixedly arranged on each side of the hollow force-bearing column; a left connecting plate is fixedly arranged on an outside of the left cutting plate; a right guiding column is fixedly arranged on an outside of the right cutting plate; center lines of the left connecting plate, the right guiding column and the hollow force-bearing column are in a same plane; a top end of to the feeding pipe is connected to a grouting device, and a bottom end is connected to a spraying device; a spraying nozzle of the spraying device stretches out along the hollow force-bearing column; and a lower end of the hollow force-bearing column is connected with a disposable conical head.

Owner:INFRASTRUCTURE RENEWAL INST OF SOUTHERN CHINA +1

Control apparatus and method of controlling internal combustion engine mounted on vehicle

InactiveUS8408182B2Shorten speedReduce coefficient of frictionElectrical controlIdling devicesIdle speedRoad surface

When an automobile is traveling on a road surface with a low friction coefficient upon a shift of an engine to idle operation in the process of stopping the automobile from traveling, a target engine speed of the engine is reduced by a value equivalent to a reduction in a drive request value for any auxiliary at a time point corresponding to start of reduction of the drive request value.

Owner:TOYOTA JIDOSHA KK

Lifting type venetian blind

A lifting Venetian blind having a rope lock device is equipped at an end of a head rail, a side cover is equipped at another end of the head rail, a piece of transverse shaft is equipped in a head rail assembly system, an end of the piece of transverse shaft is loaded in the rope lock device, and another end of the piece of transverse shaft is equipped with elevator components, which include an elevator connection seat, a ladder belt cover wheel brake shaft, a cloth wheel stop bit elastic device, a ladder belt cover wheel, a bearing block, a bearing, and an elevator belt rotating wheel. It solves a problem of light leaking through a hole on a blind slat to the greatest extent possible. When the blind is raised or lowered, an elevator belt is easily on and off and not mutually winding knot without noise.

Owner:LANDER IND (ZHEJIANG) CO LTD

Auto Tensioner

The present invention relates to an auto-tensioner containing a base having a cylindrical part, a rotating member supported rotatably to the base, a pulley provided at the rotating member, a friction member sandwiched between the cylindrical part and the rotating member, and a coil spring locked to the friction member and the base and disposed in a state of being compressed in an axial direction, thereby biasing the rotating member in one direction, in which the friction member has an arcuate surface capable of sliding along the cylindrical part, a first locking part located further toward the one direction side than the arcuate surface in a circumferential direction of the cylindrical part and locked to the rotating member, and a second locking part locked to one end of the coil spring.

Owner:MITSUBOSHI BELTING LTD

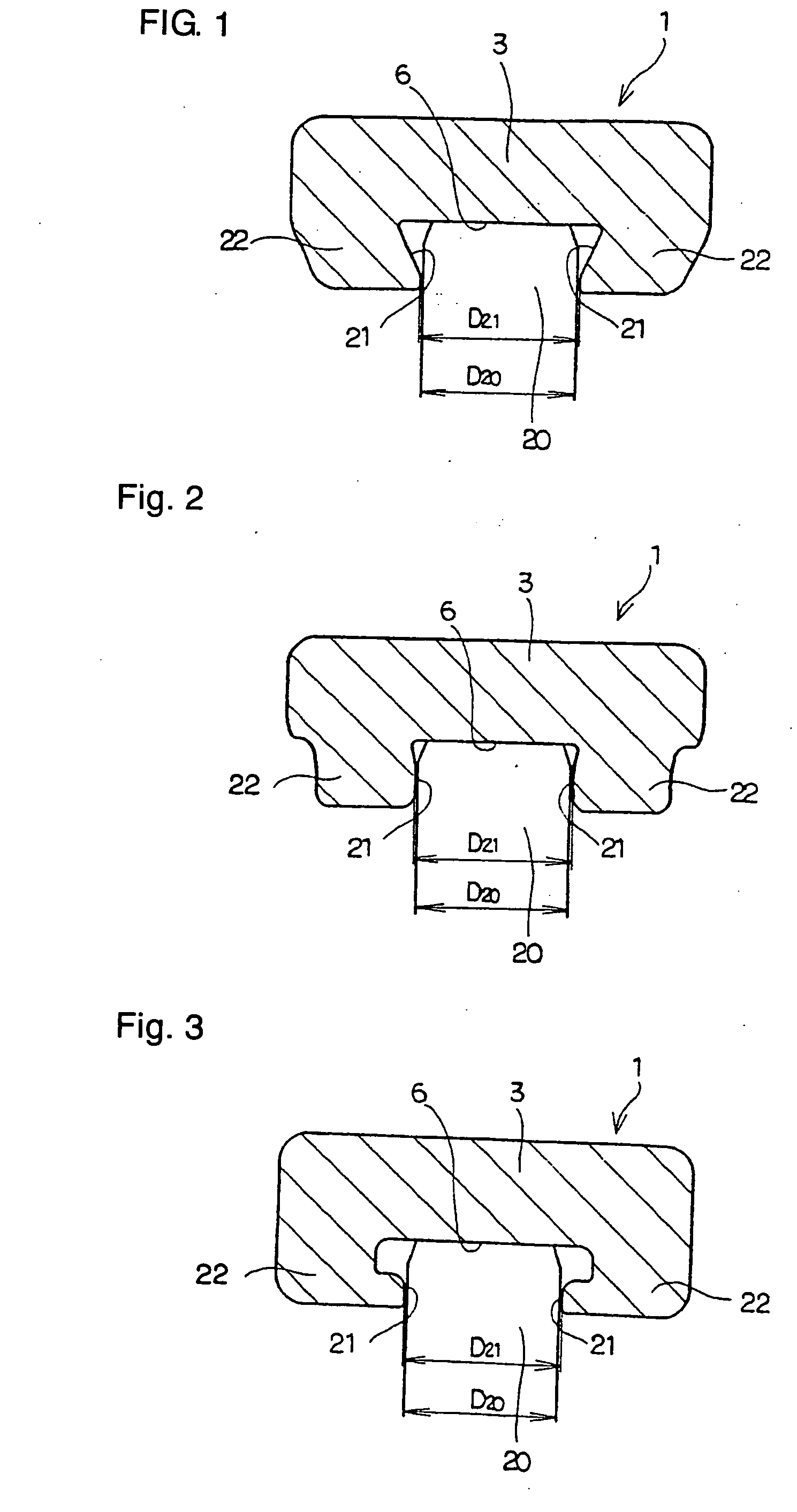

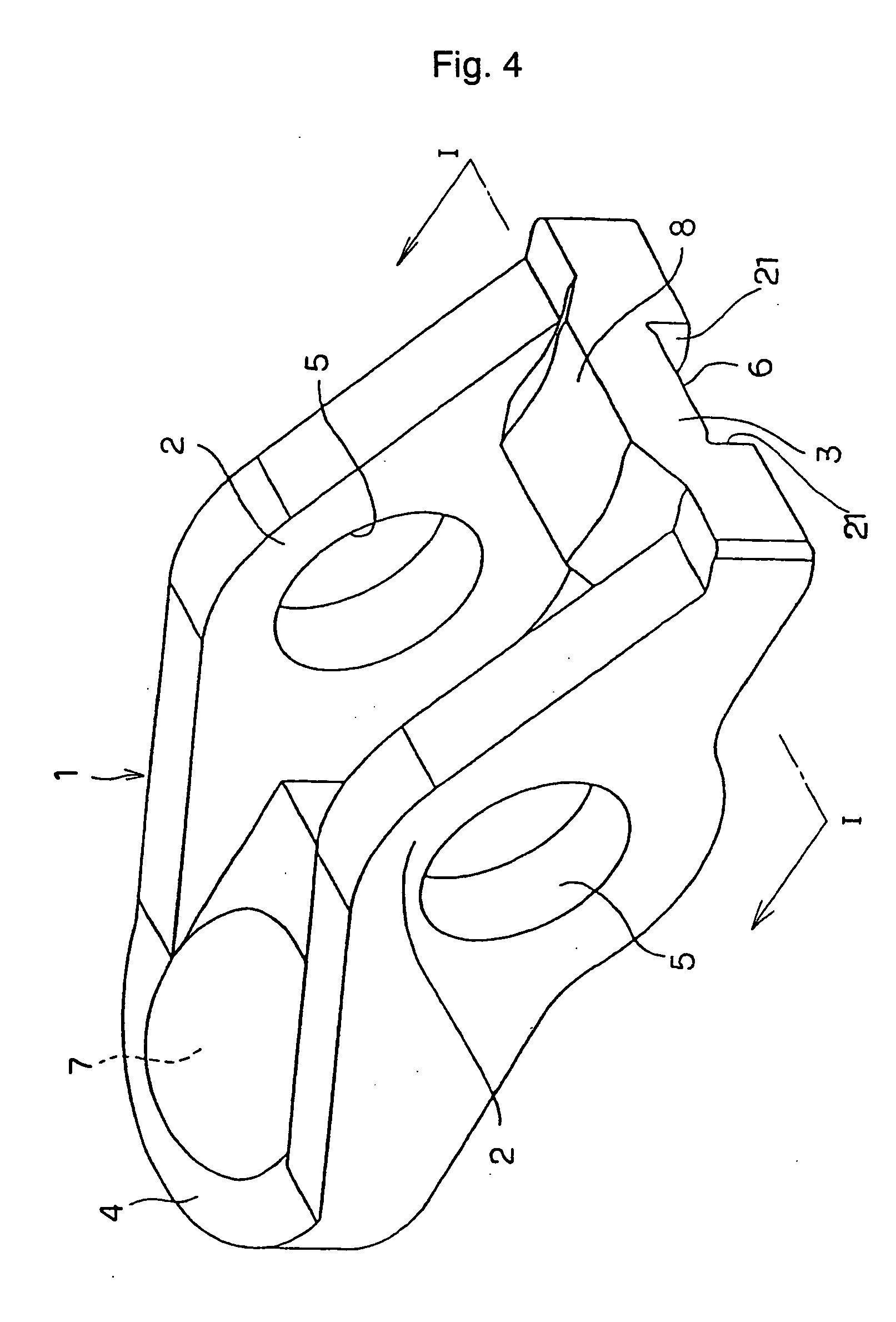

Rocker arm

InactiveUS20050034696A1Improve the lubrication effectEasy to keep small resistanceValve arrangementsMachines/enginesEngineeringLubrication

The rocker arm 1 has a fitting surface 6 on the opposite sides of which guide surfaces 21 are formed, such that the guide surfaces 21 are inclined to be closer to each other toward their tip ends. Even when the valve stem 20 is displaced in the widthwise direction of the fitting surface 6, the outer peripheral surface of the base end portion of the valve stem 20 comes into contact with only the tip end of one of the guide surfaces 21. Consequently, lubrication is improved and friction moment is decreased in the contact area, so that friction resistance is suppressed between the guide surfaces 21 and the outer peripheral surface of the base end of the valve stem 20 to easily obtain high performance of the engine.

Owner:NSK LTD

Dynamic sealing device

ActiveUS20190085980A1Improve performanceLimit premature wearEngine sealsEngineeringMechanical engineering

Disclosed is a dynamic sealing device configured to provide sealing between at least a first part and at least a second part having a relative rotational movement in relation to the first part. The device includes a seal provided with a first lip and with a second lip extending from a body portion, the first lip facing the second lip, the seal being formed from a first predetermined material having a first coefficient of friction, and a ring formed from a second predetermined material different from the first predetermined material and having a second coefficient of friction different from the first coefficient of friction. The ring is securely connected with the seal at the location of the body portion and the first coefficient of friction of the first predetermined material forming the seal is greater than the second coefficient of friction of the second predetermined material forming the ring.

Owner:ETI GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com