Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1490 results about "Turbine wheel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

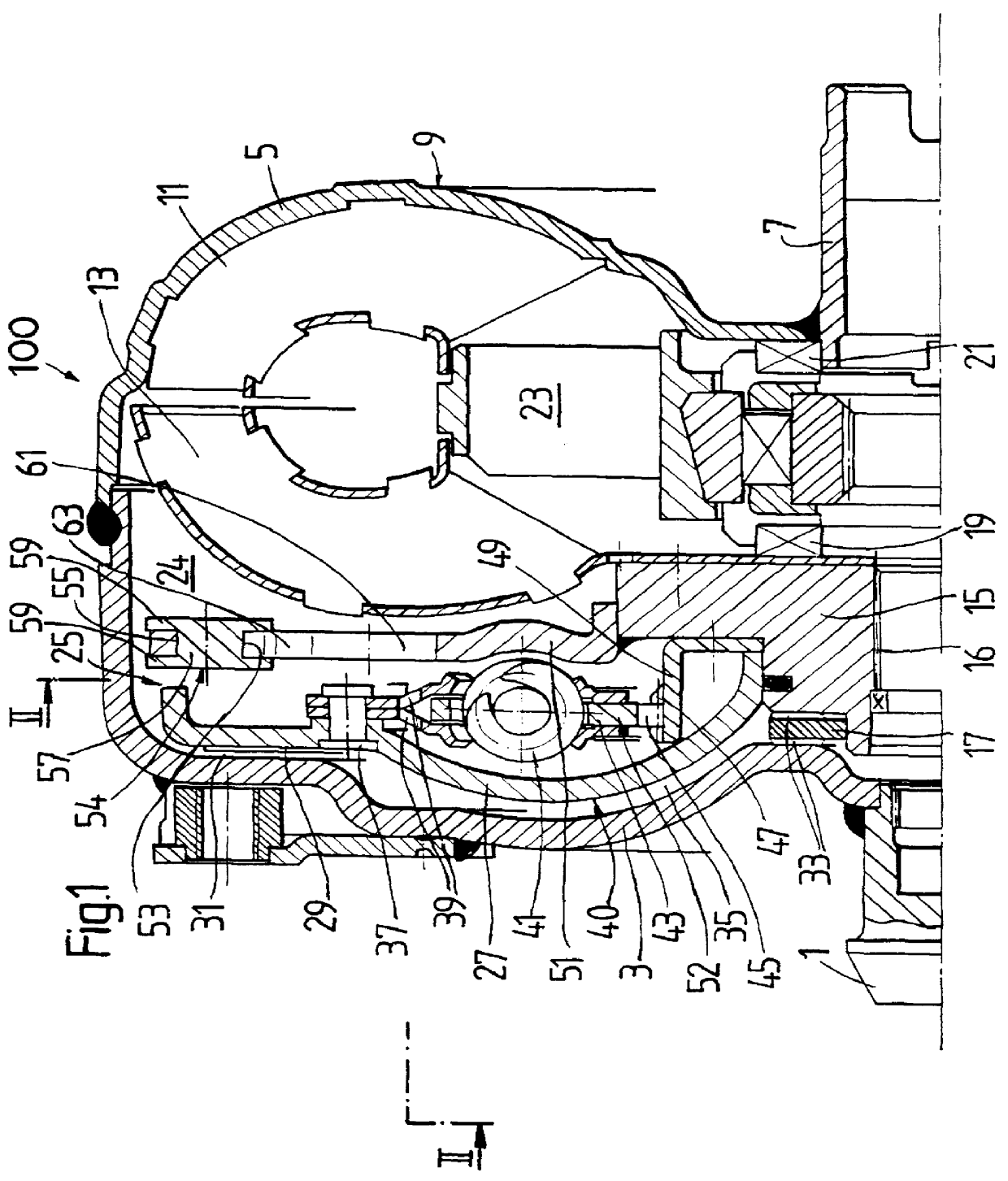

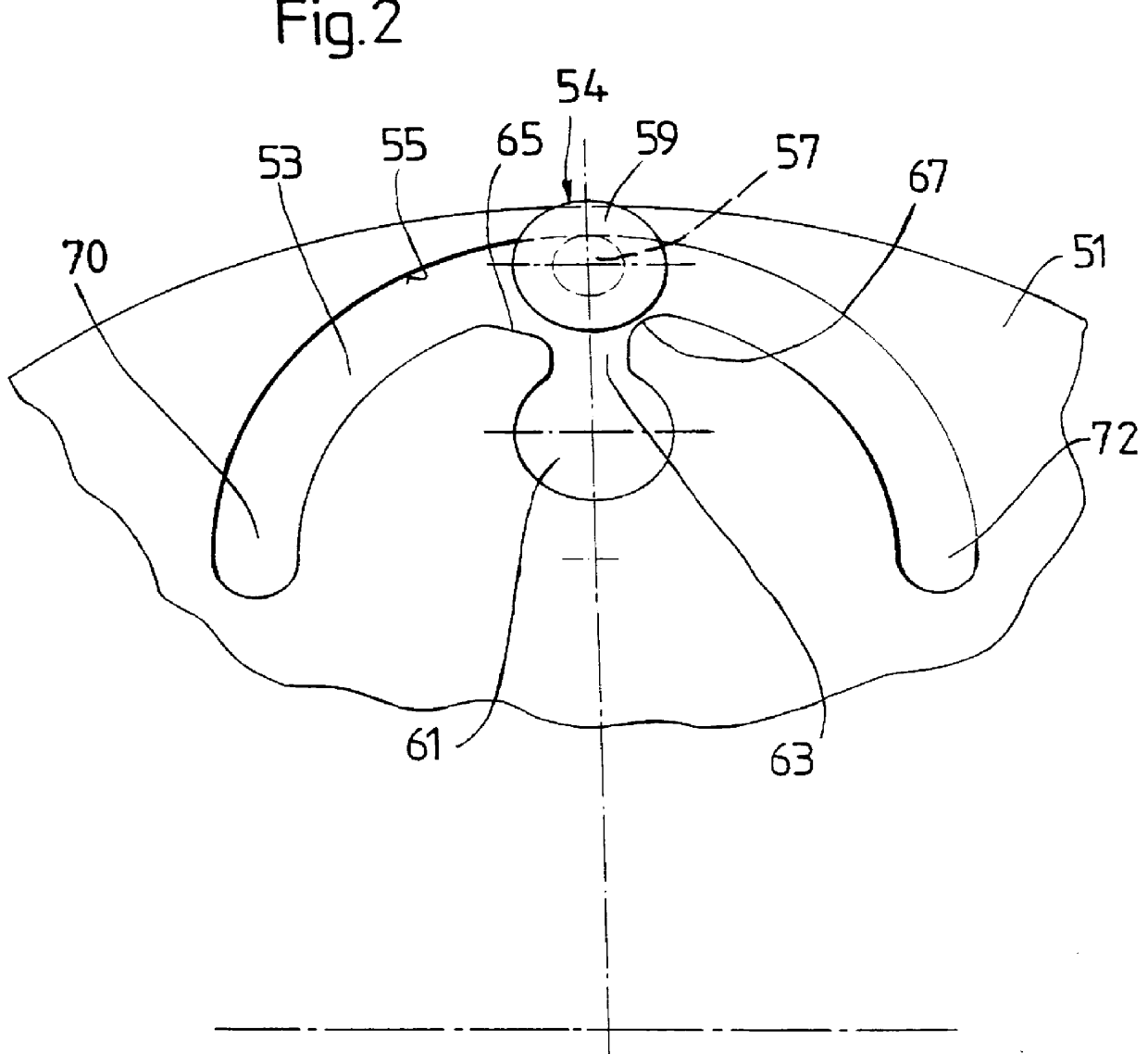

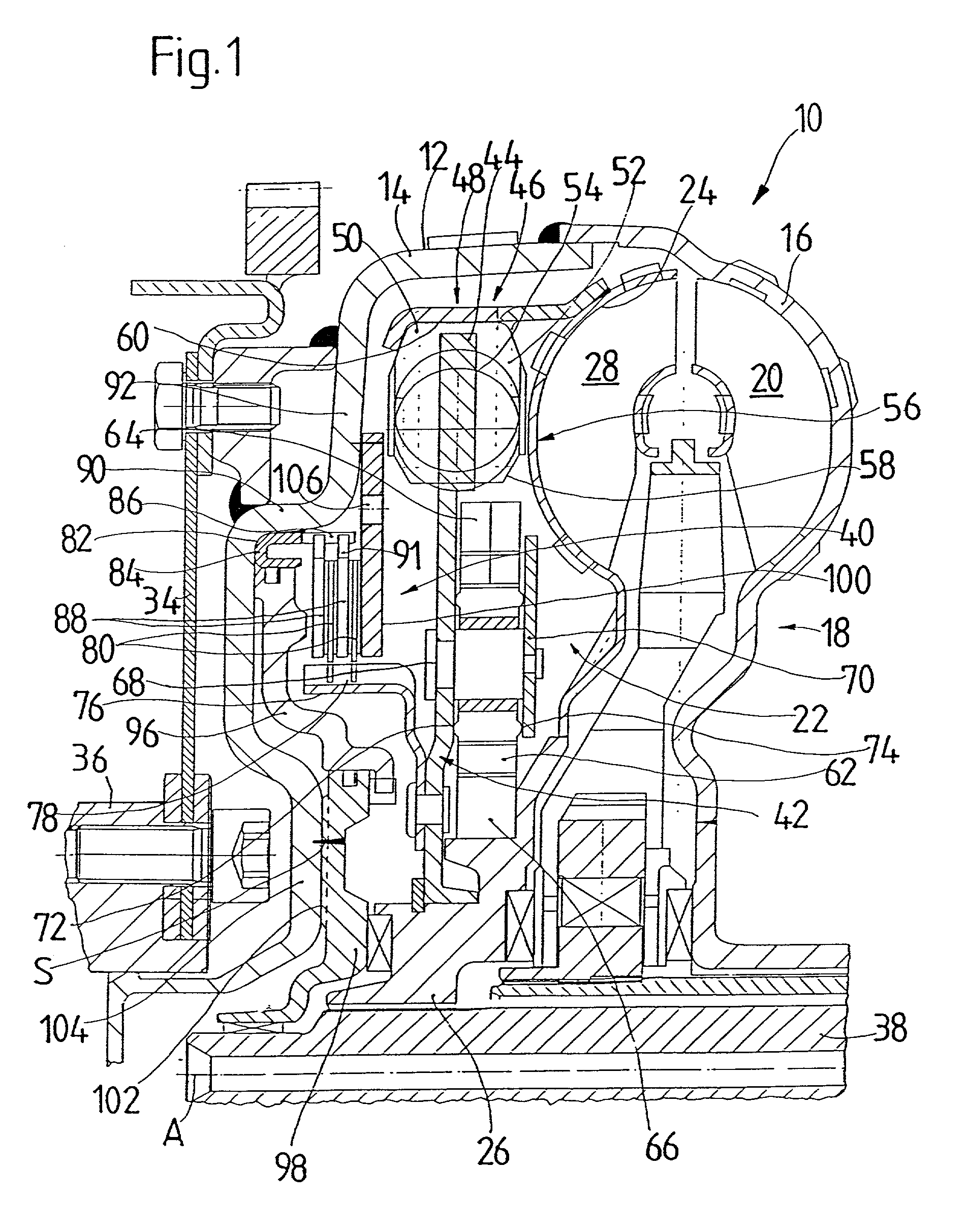

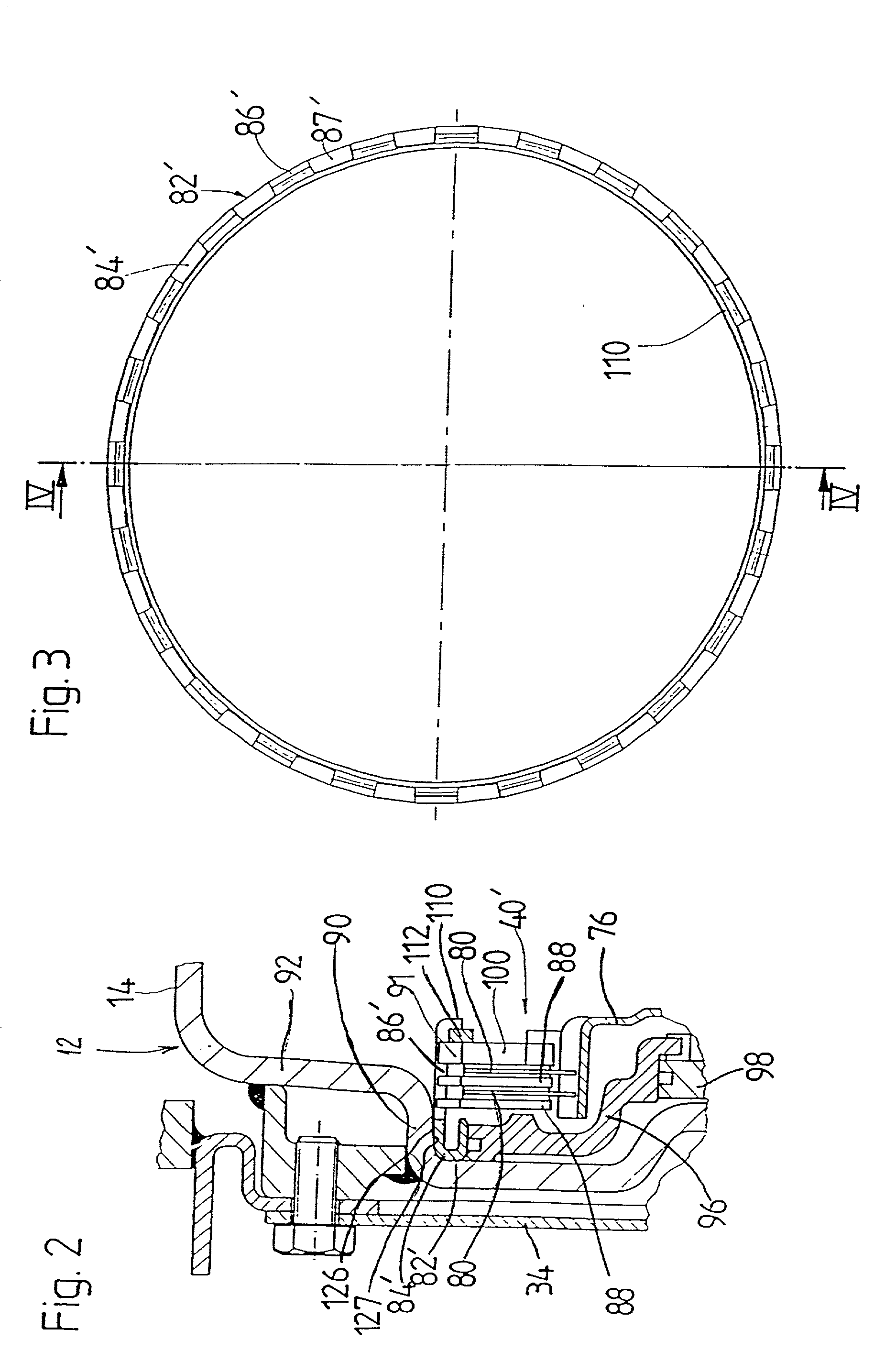

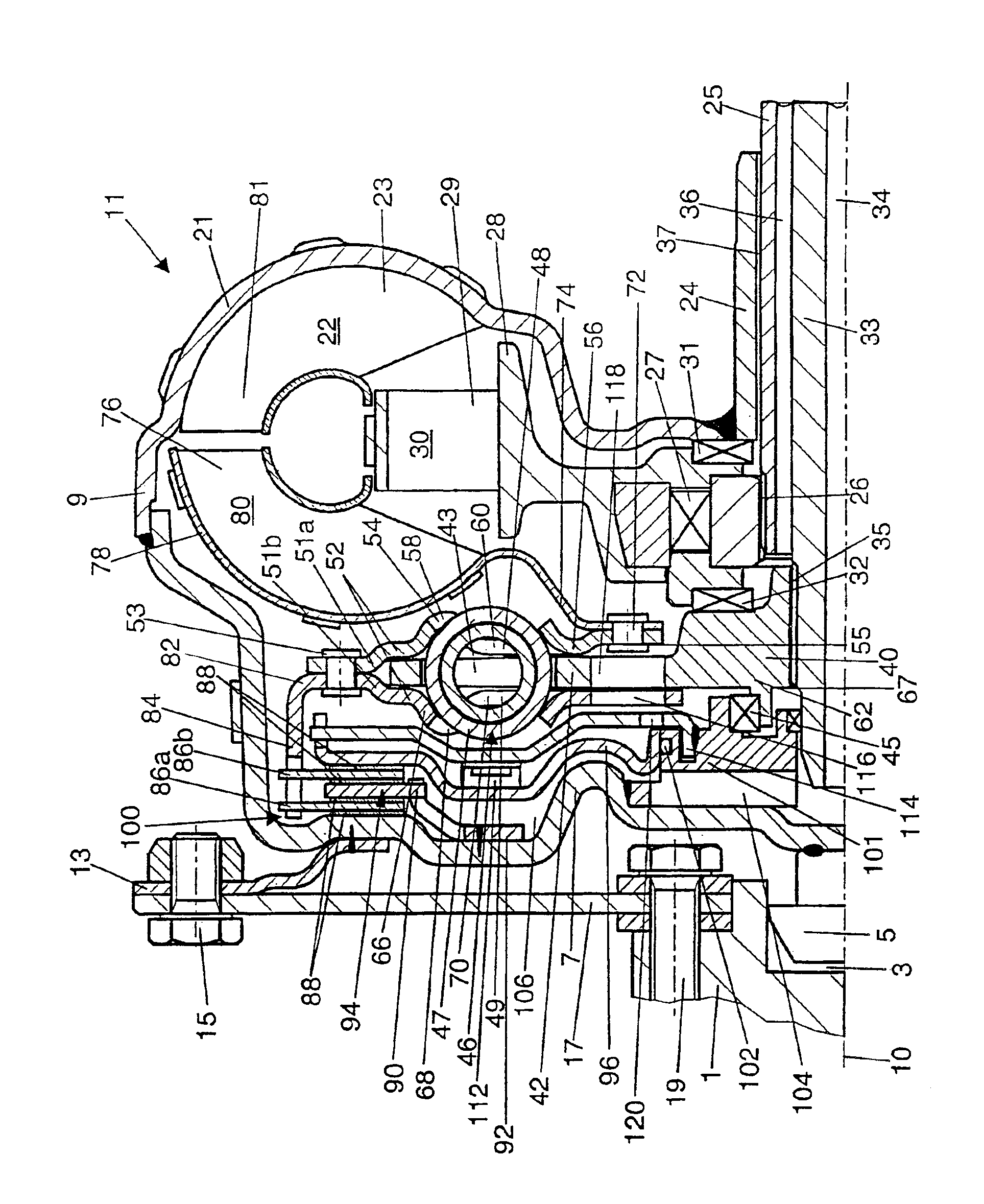

Lockup clutch with a compensation flywheel mass at the torsional vibration damper

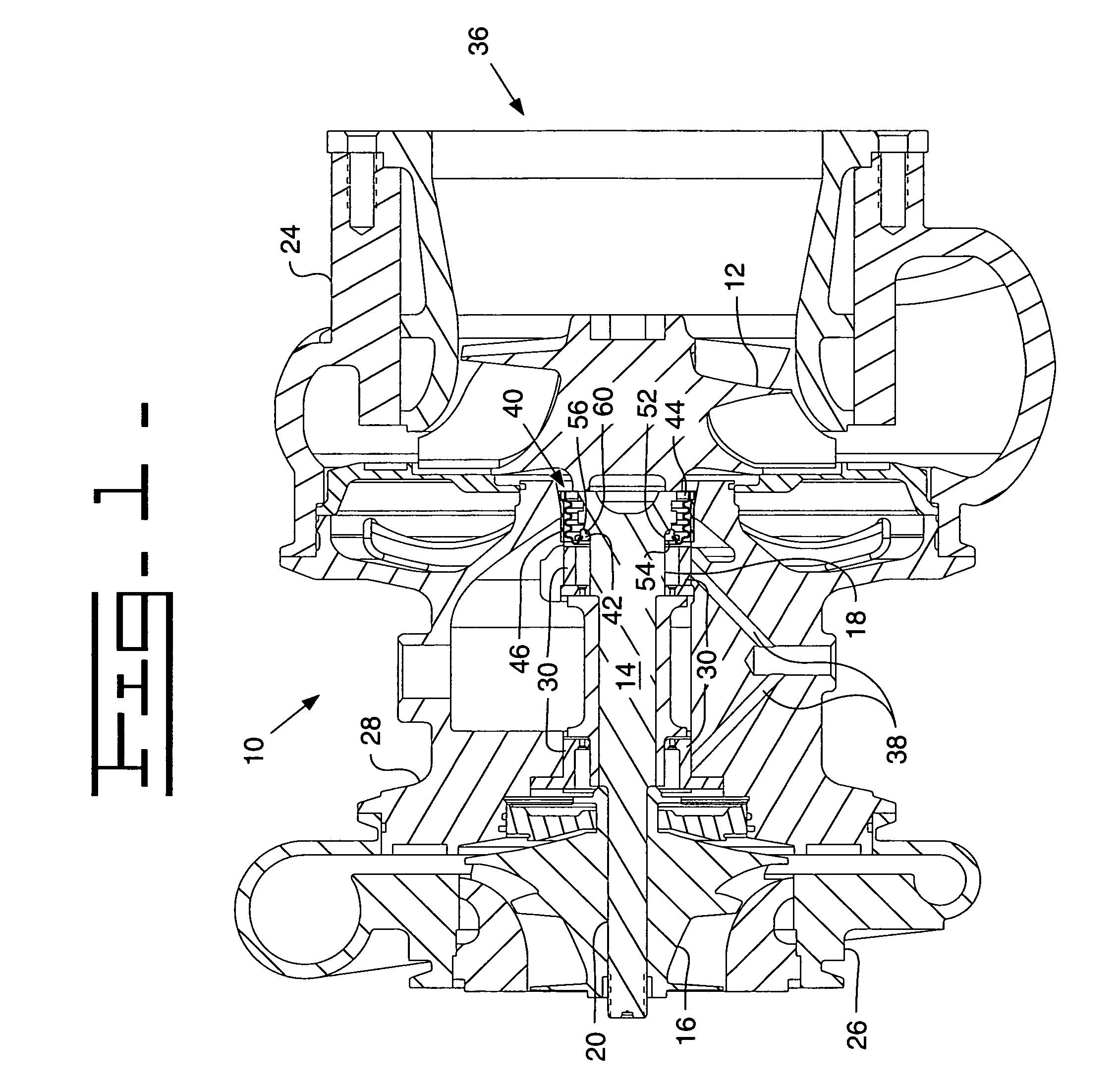

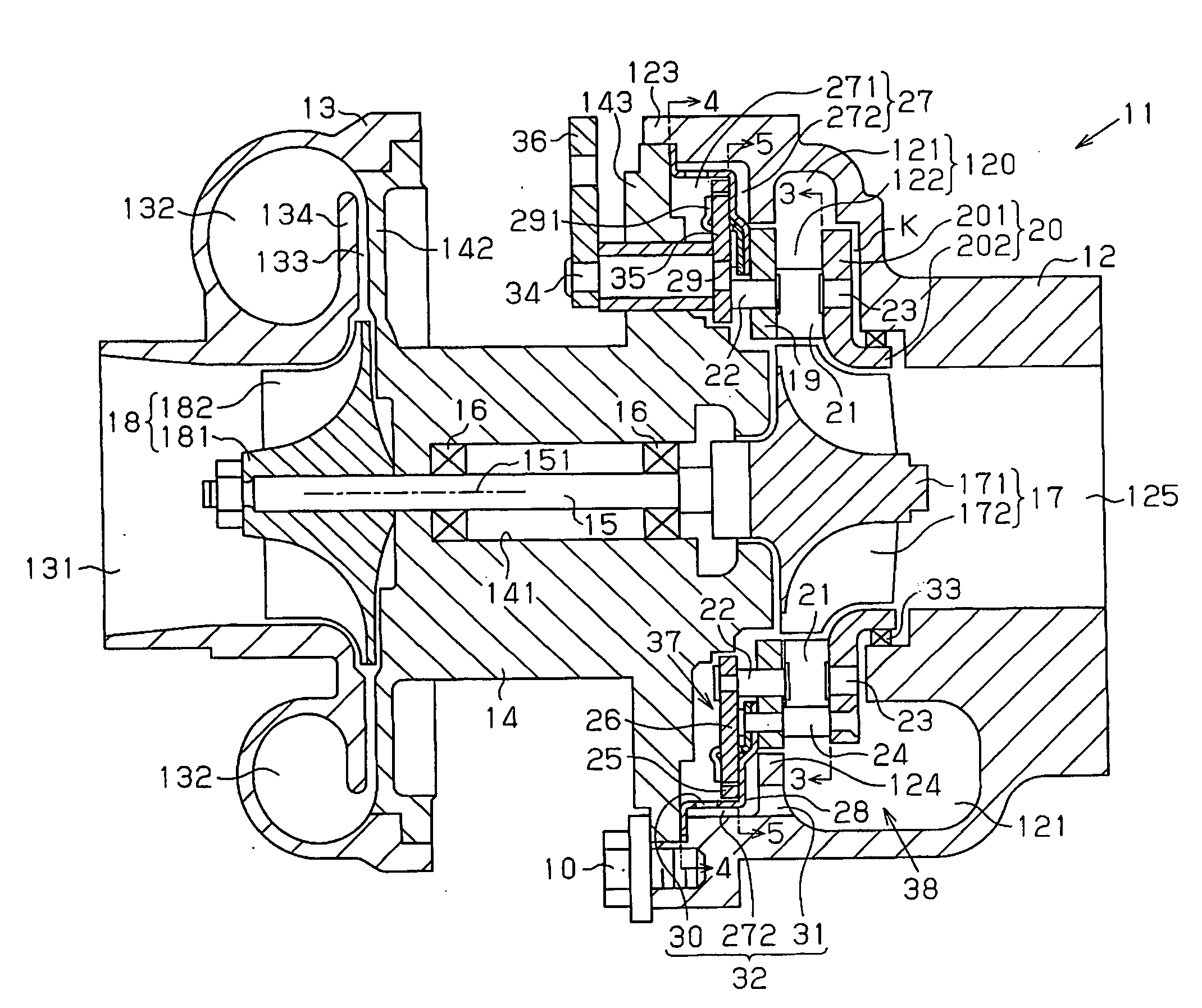

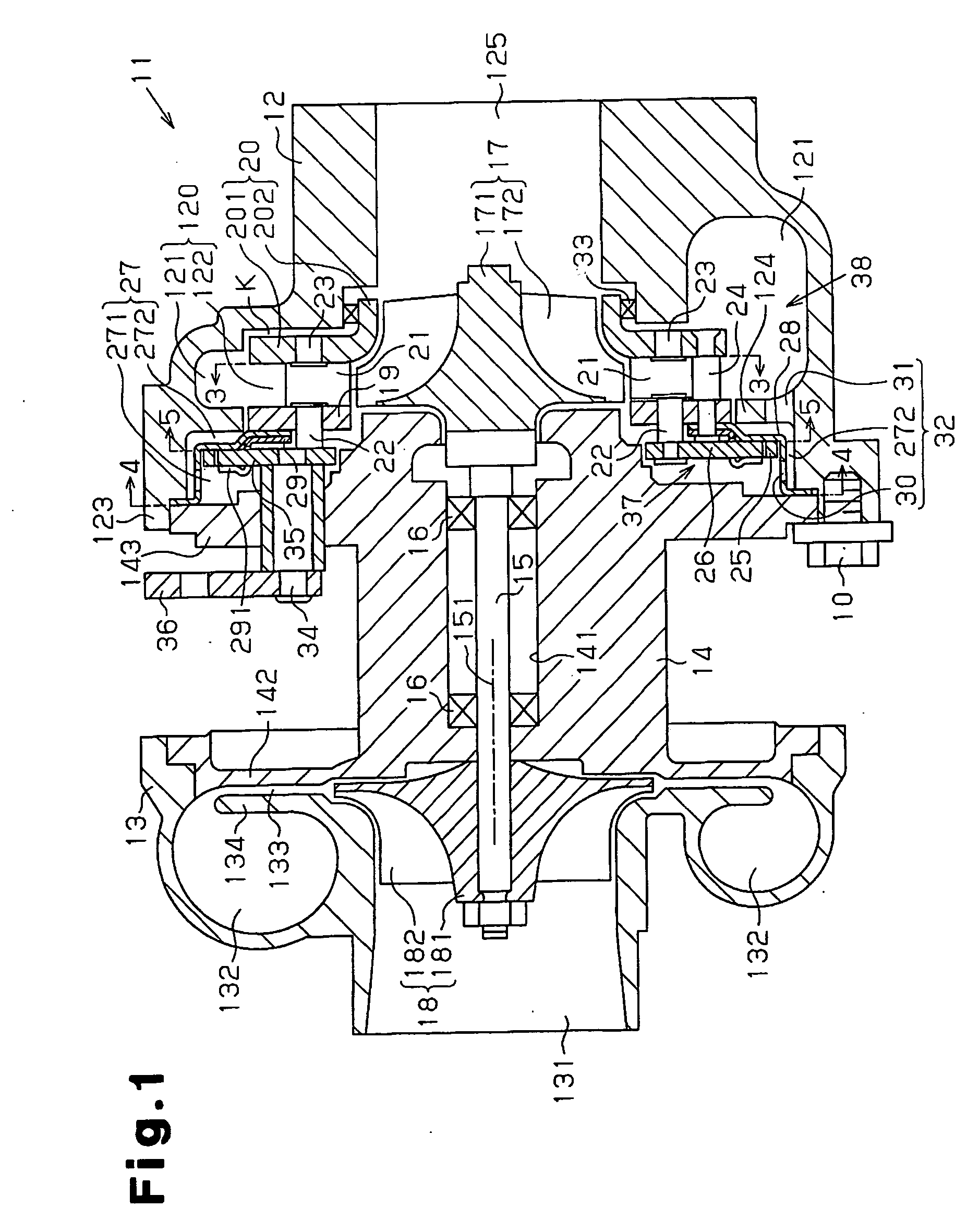

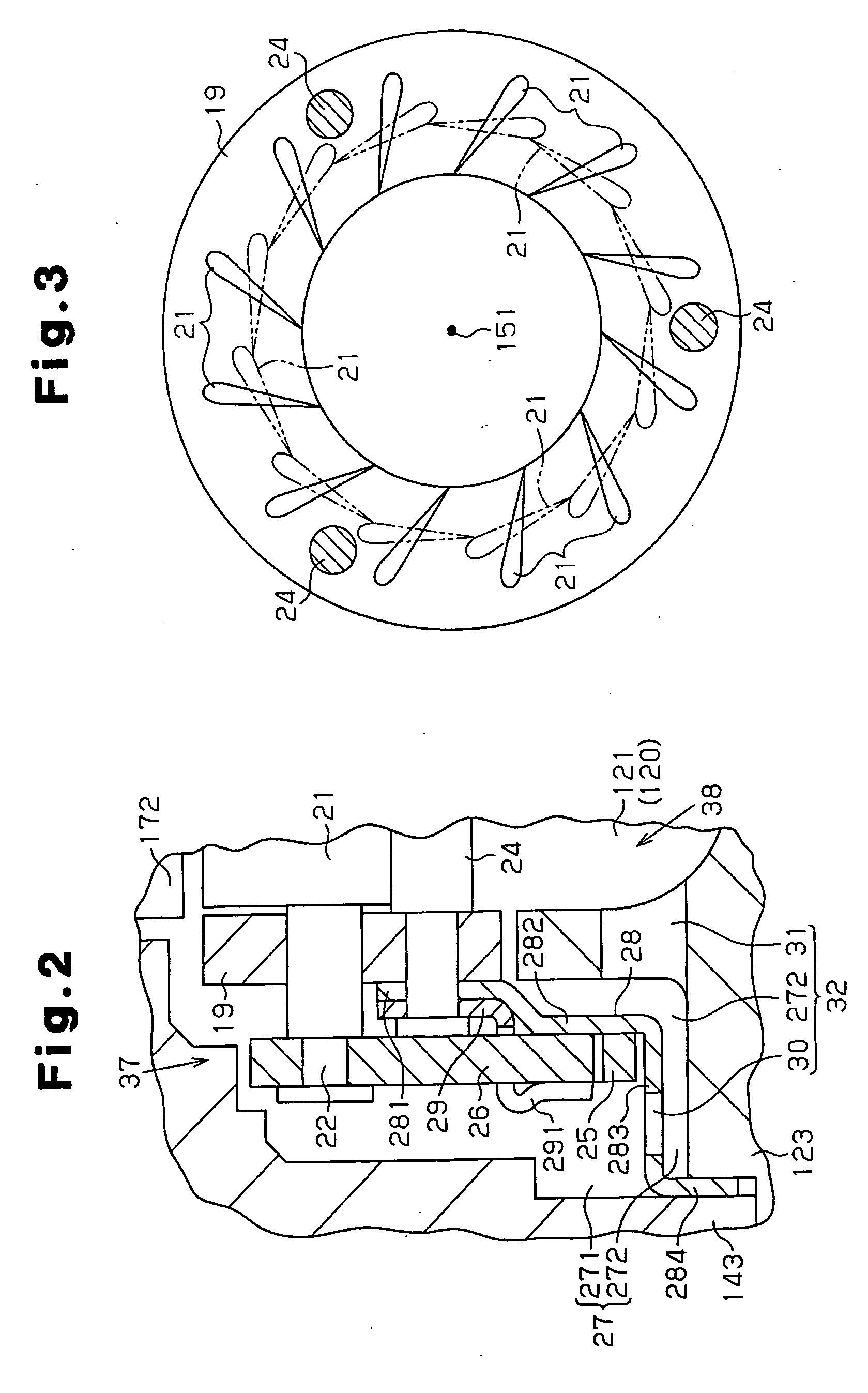

A lockup clutch at a hydrodynamic torque converter is constructed with a torsional vibration damper which has a drive-side transmission element and a driven-side transmission element which is rotatable relative to the latter. Both of the transmission elements are provided with driving devices for driving elastic elements of a damping device. A carrier for a compensation flywheel mass is associated with the driven-side transmission element, wherein the carrier is connected with the turbine wheel on the one hand and with the driven-side driving device of the elastic elements on the other hand so as to be fixed with respect to rotation relative thereto and is provided at least with a cutout for receiving the compensation flywheel mass. The cutout has a guide path at least in its area of contact with the compensation flywheel mass, which guide path allows a movement of the compensation flywheel mass with at least one component perpendicular to the radial direction at the carrier.

Owner:ZF FRIEDRICHSHAFEN AG

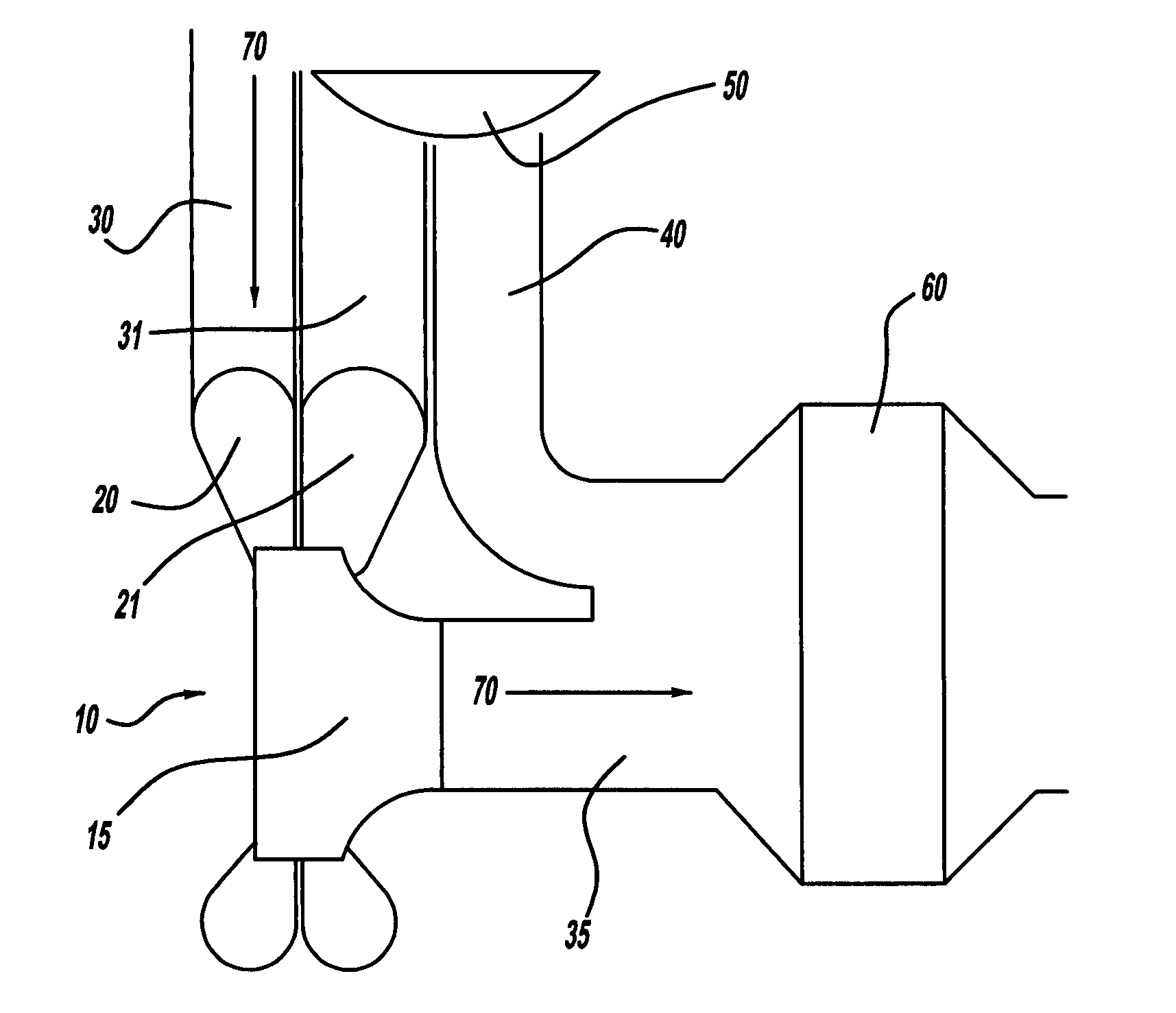

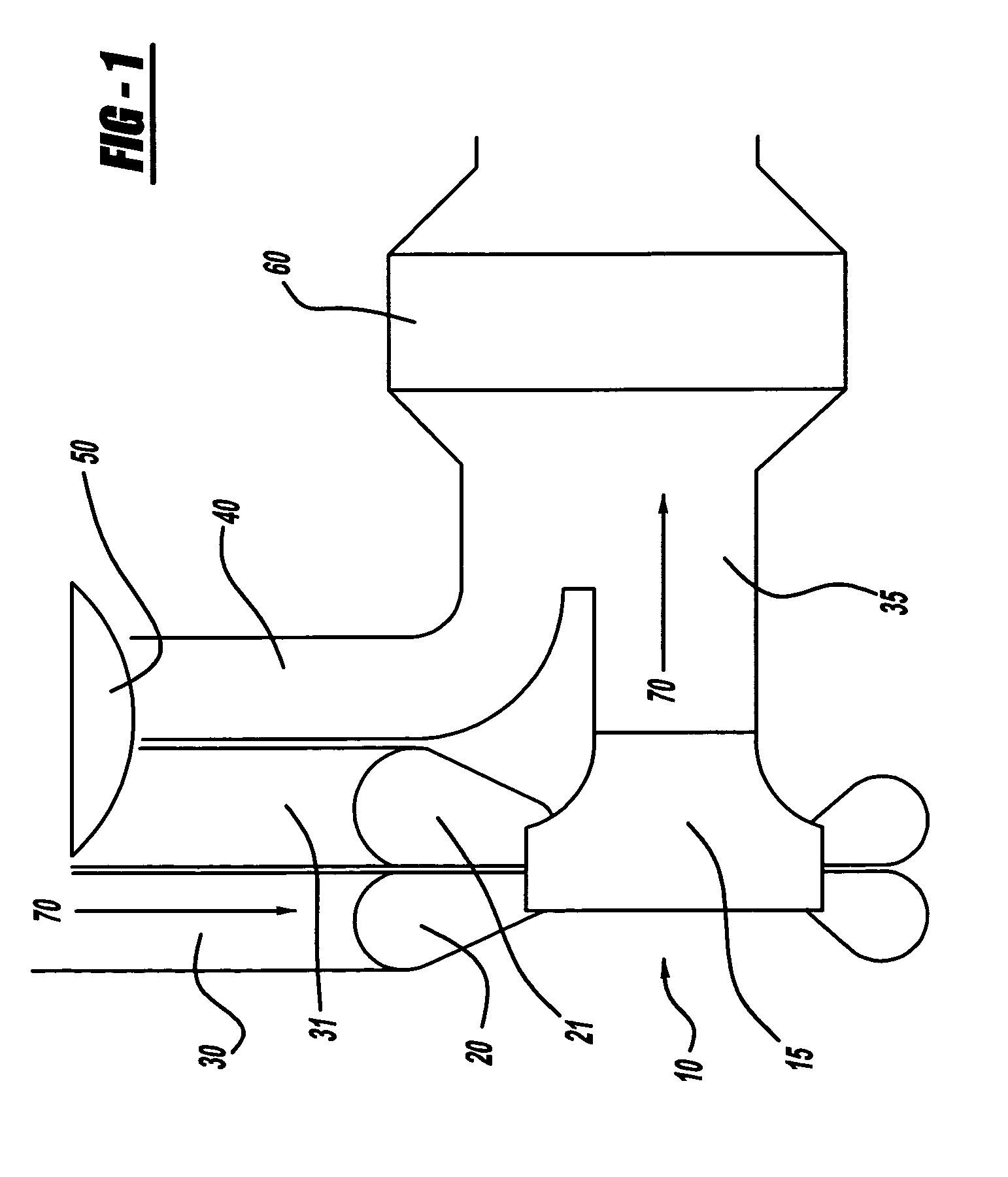

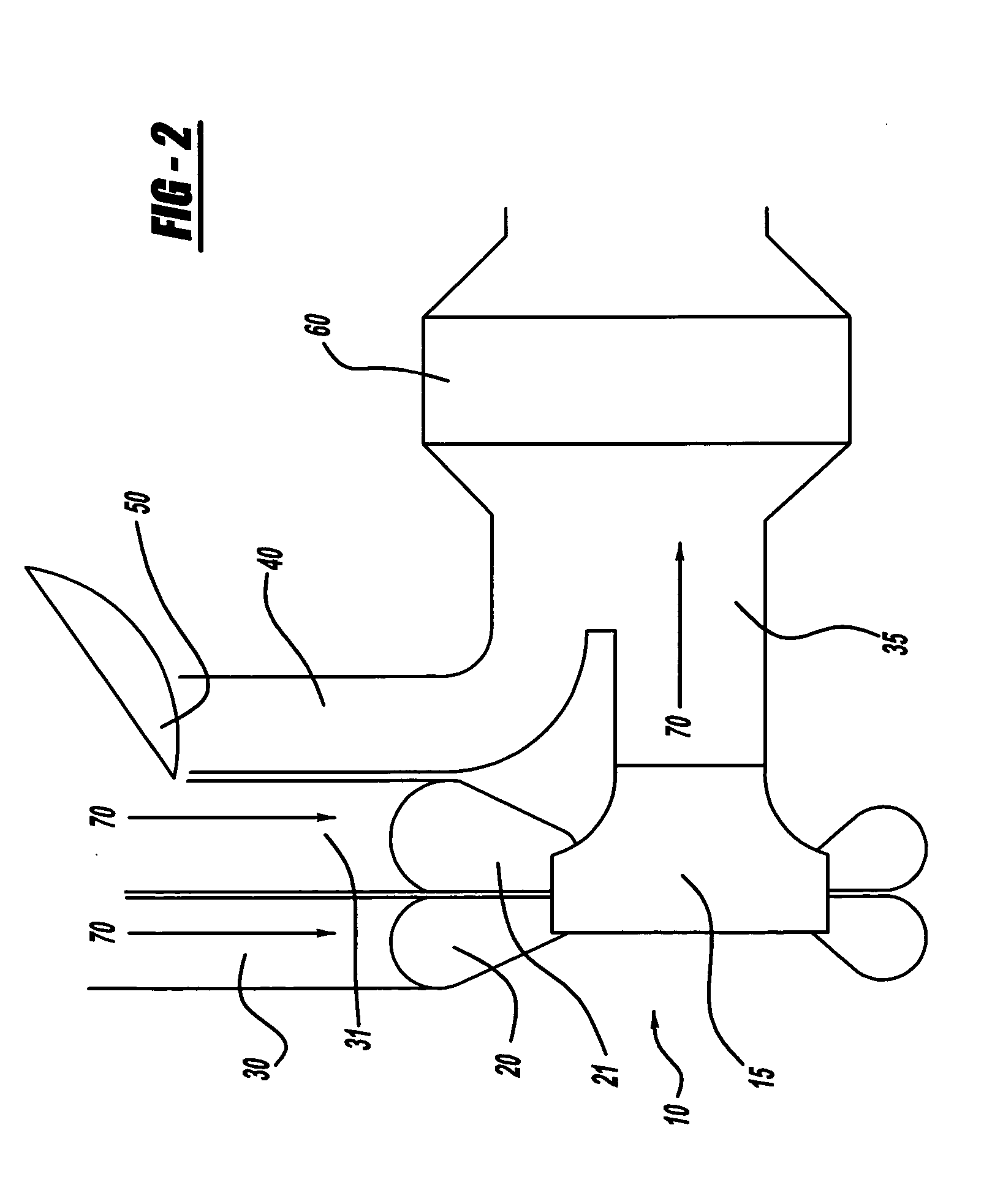

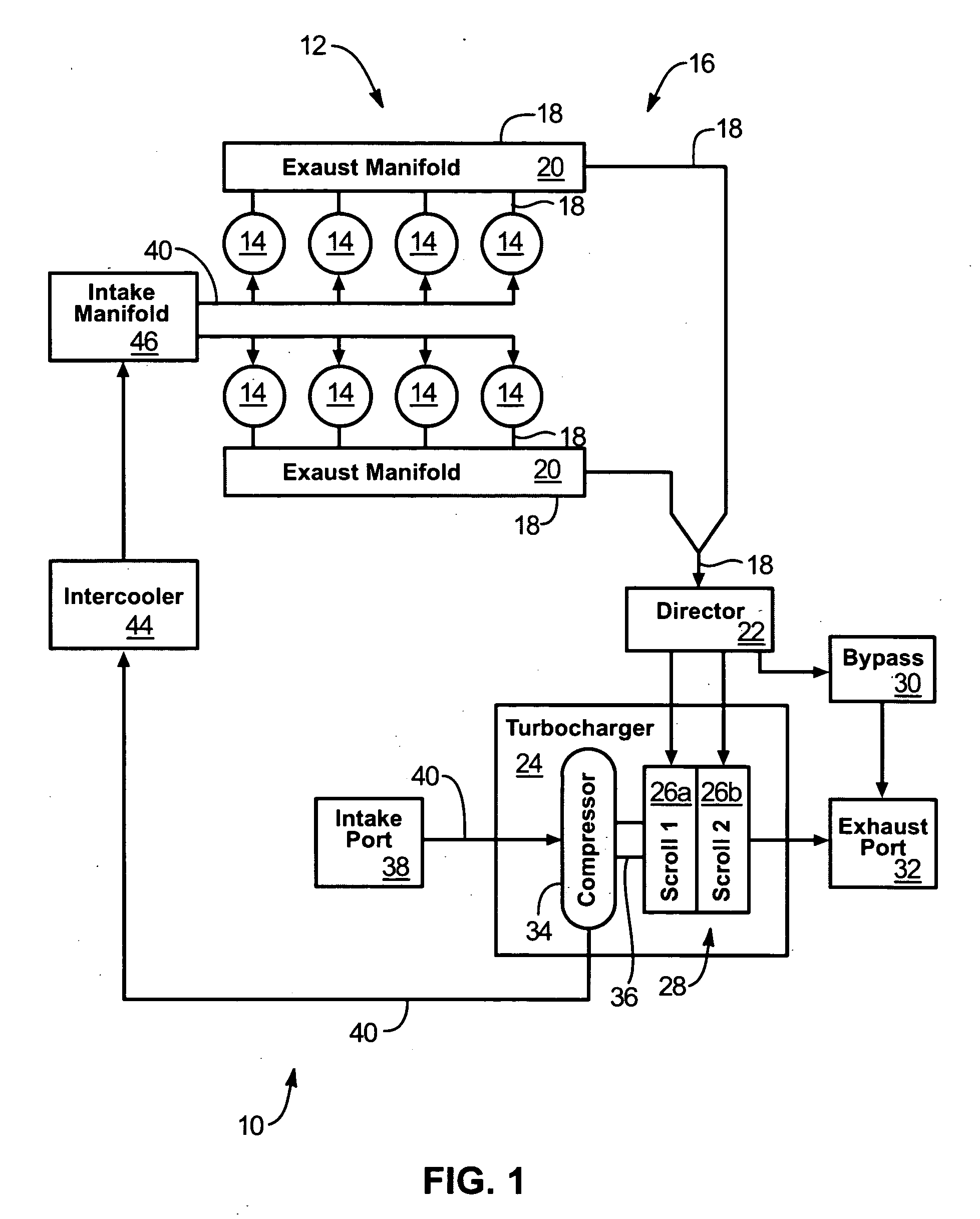

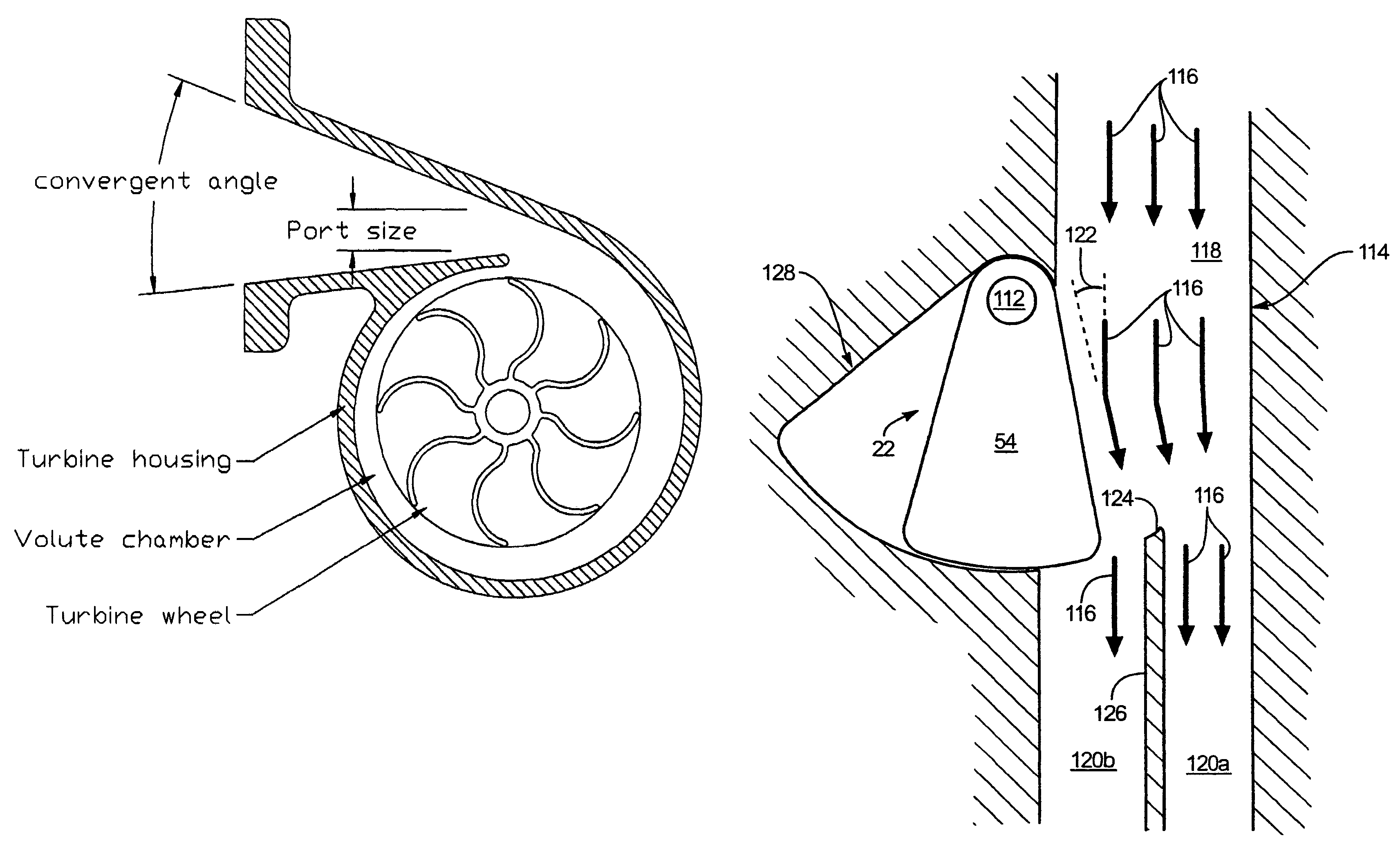

Integrated bypass and variable geometry configuration for an exhaust gas turbocharger

ActiveUS20050086936A1Suitable for operationSimple and durableInternal combustion piston enginesWind motor controlImpellerTurbine wheel

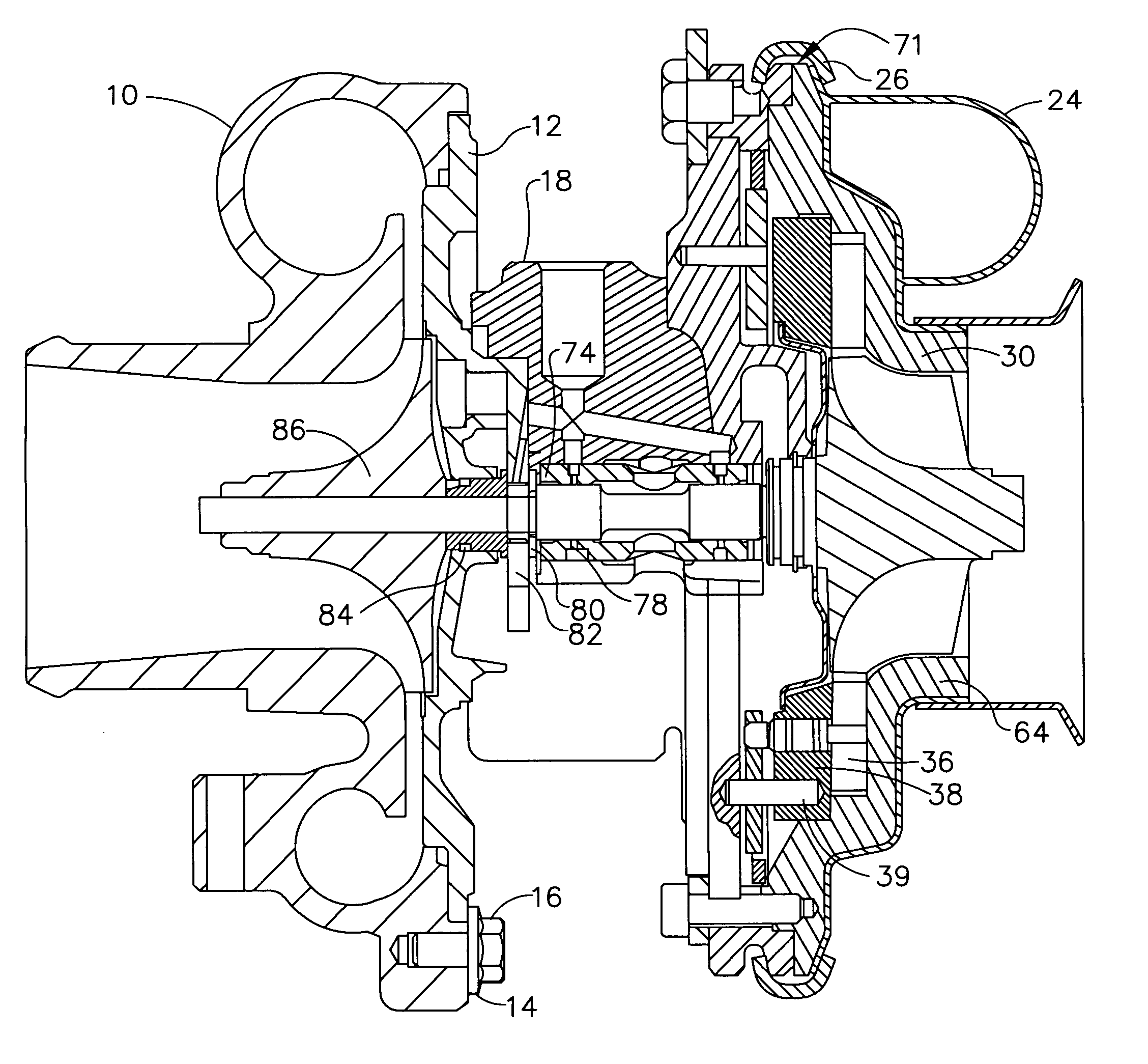

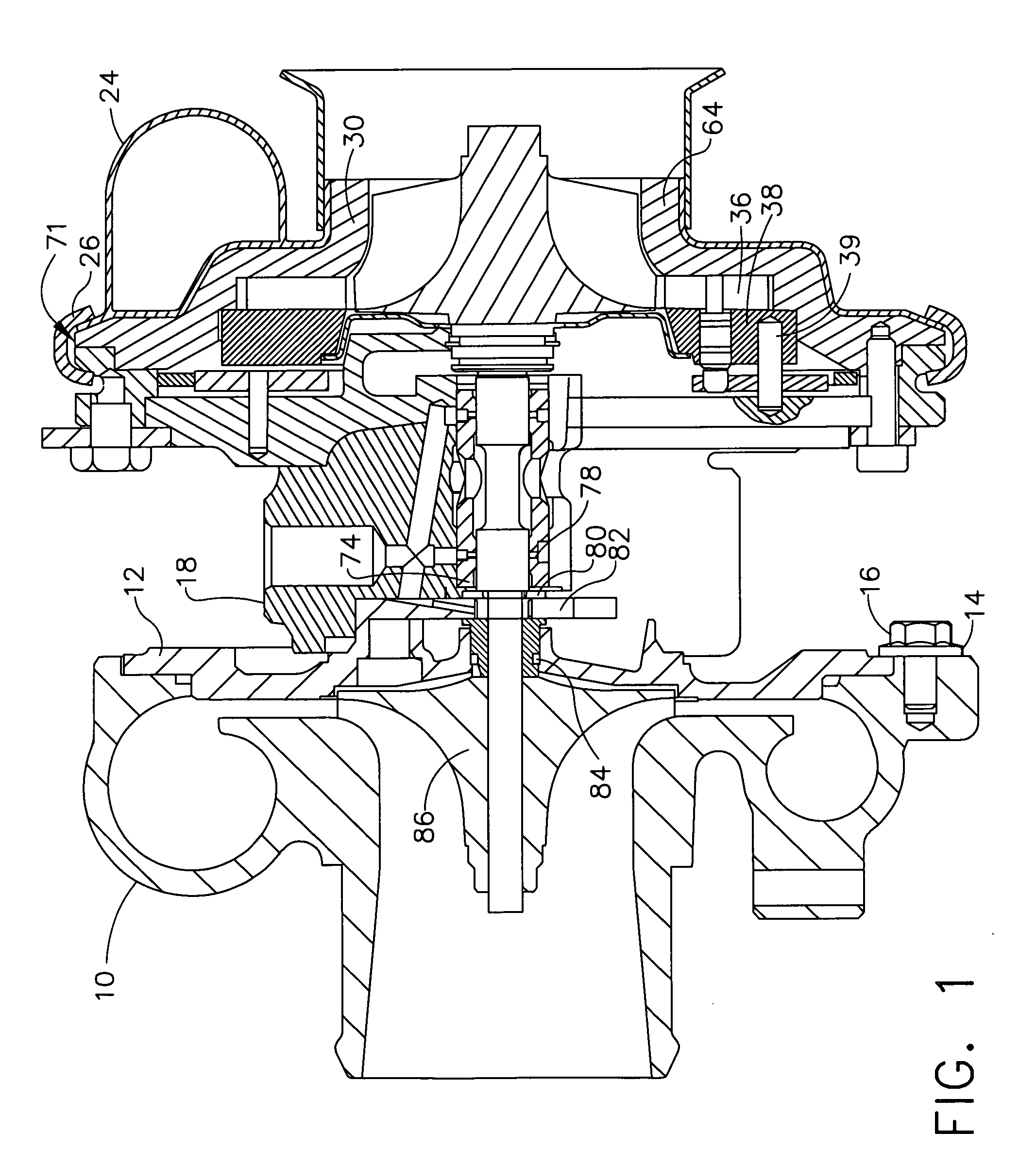

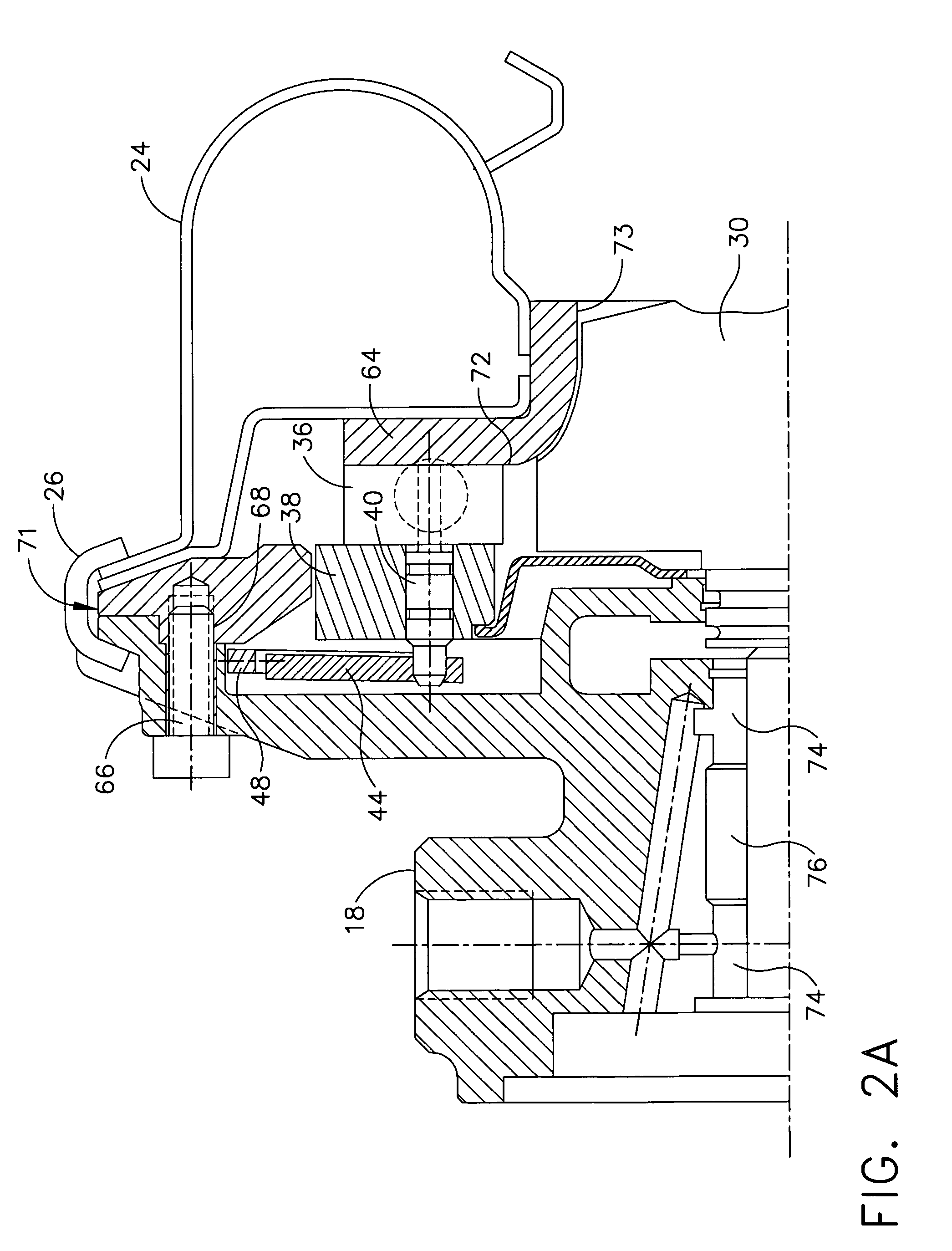

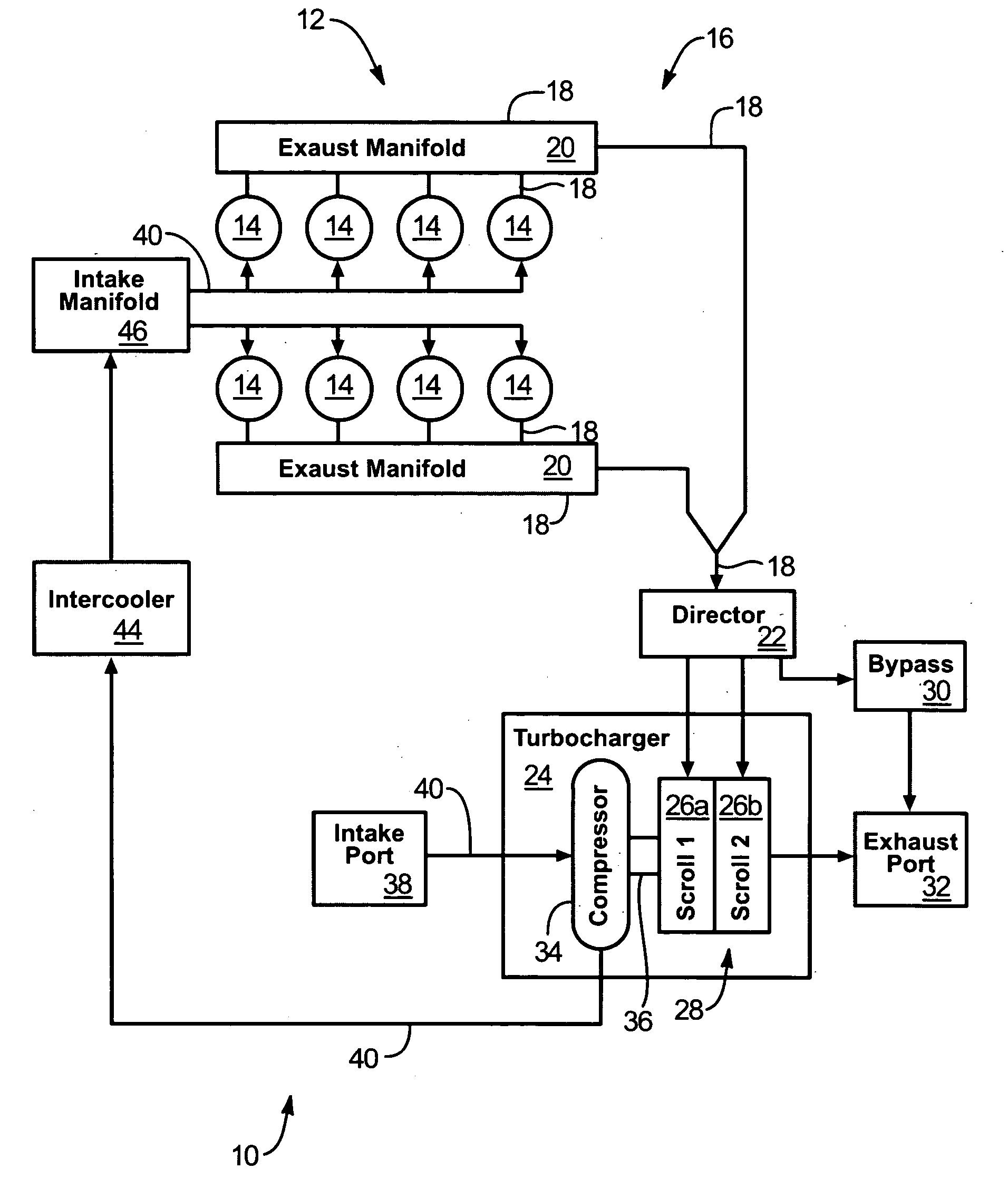

An exhaust gas turbocharger comprising: a twin scroll turbine housing; a turbine wheel positioned in the twin scroll housing; an exhaust gas inlet, operatively connected to port exhaust gas through each side of the twin scroll turbine housing and onto the turbine wheel; a bypass, operatively connected to the exhaust gas inlet to port exhaust gas around the twin scroll turbine housing to bypass the turbine wheel; and a valve, operatively positioned to control exhaust gas flow to each side of the twin scroll turbine housing and the bypass.

Owner:FCA US

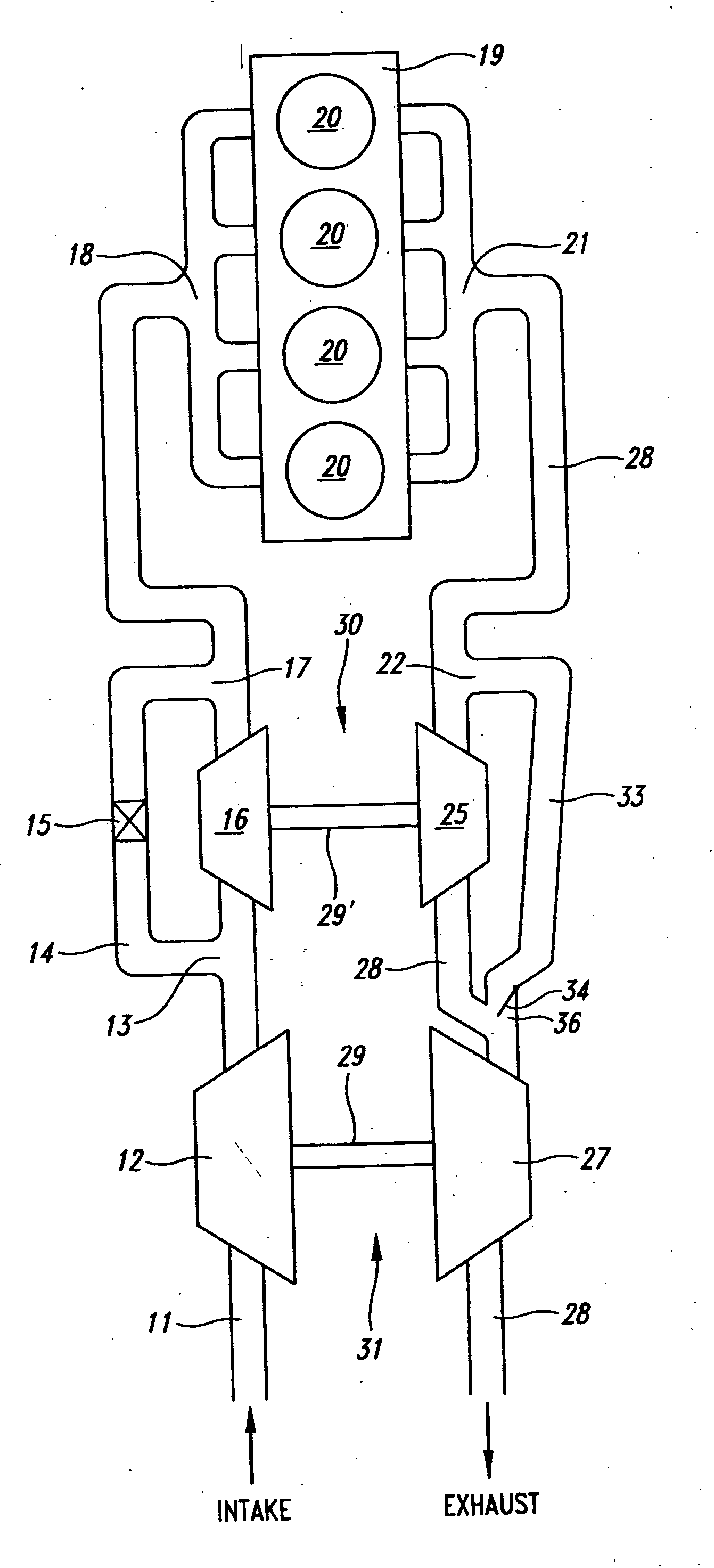

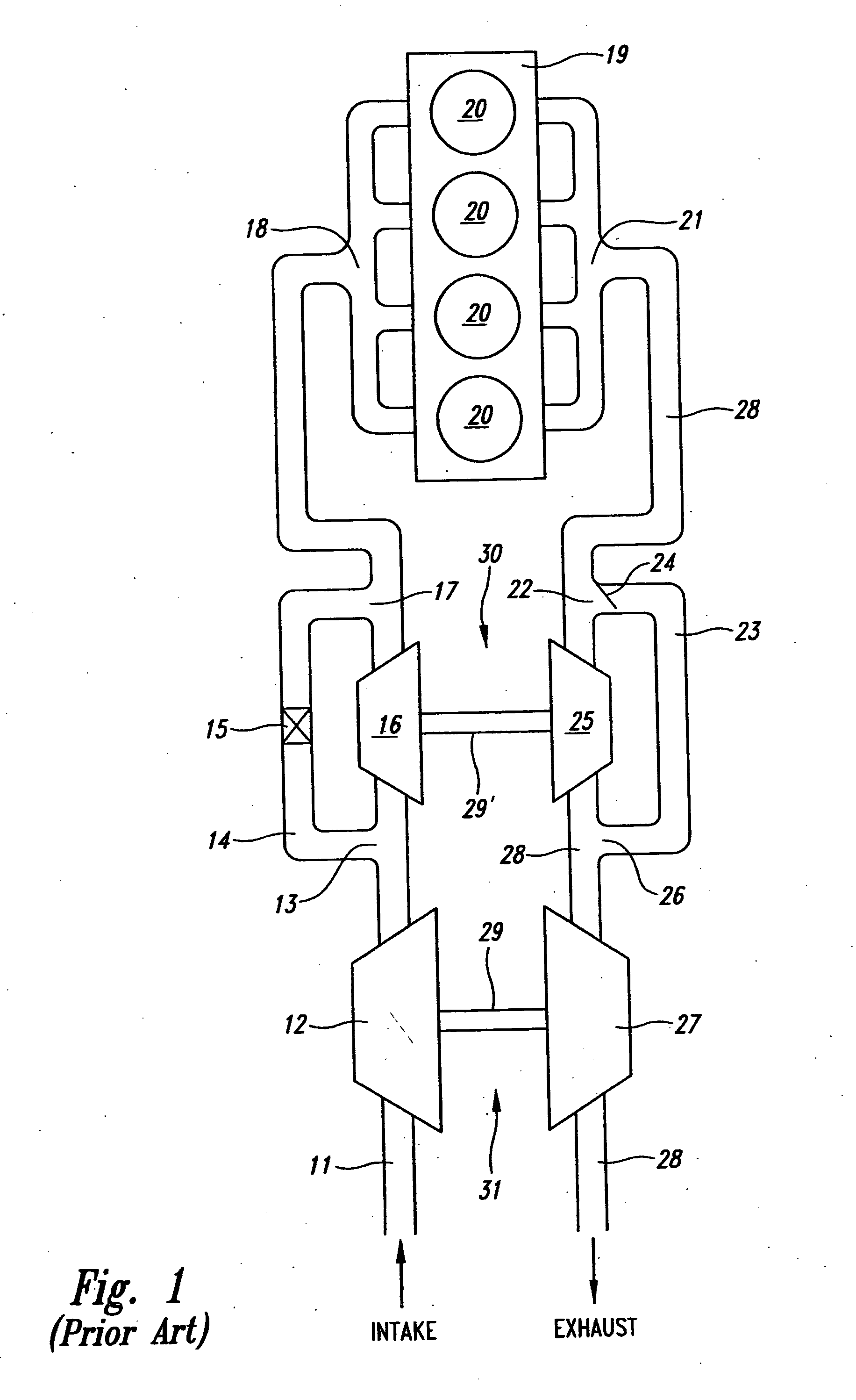

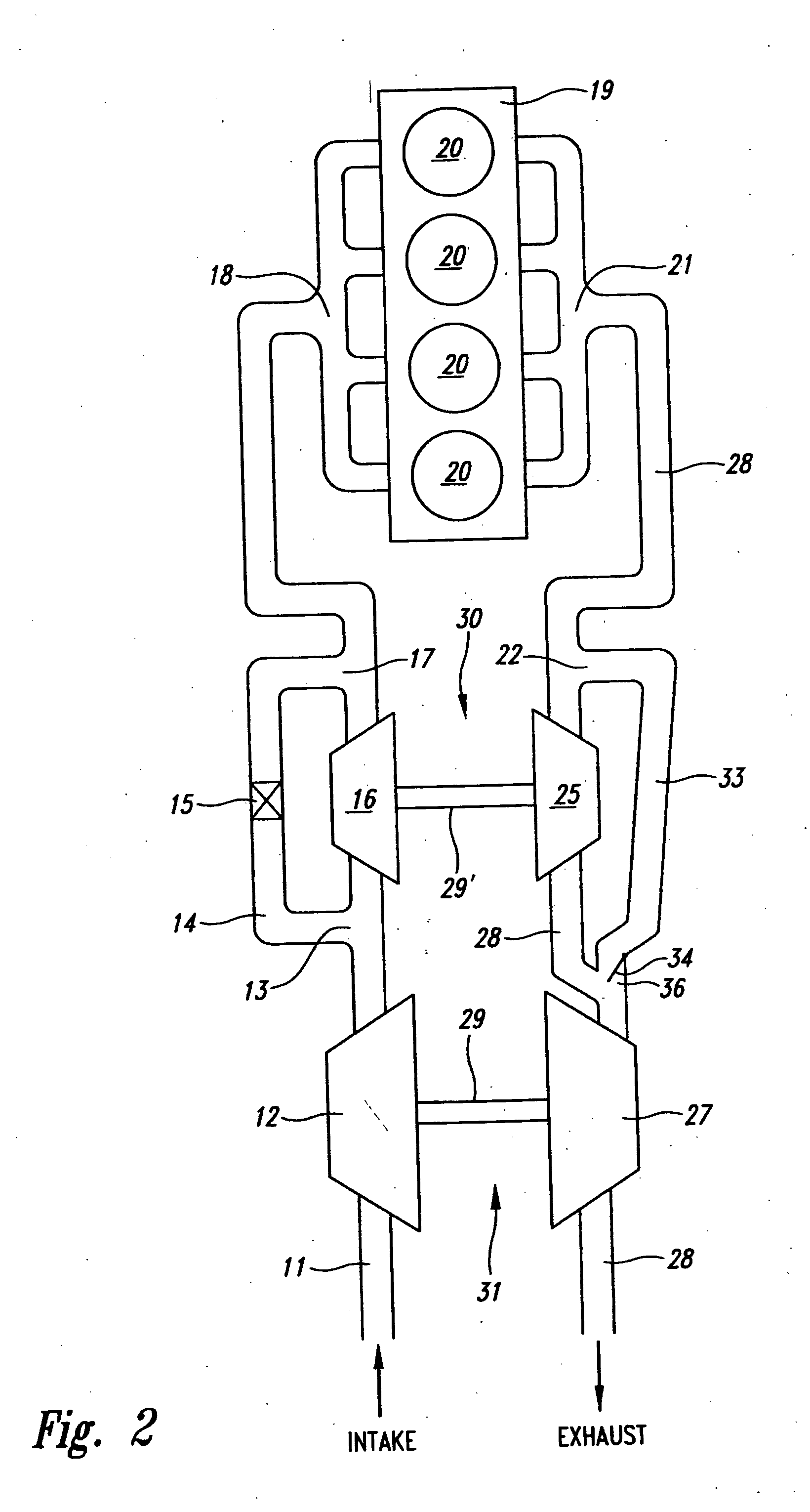

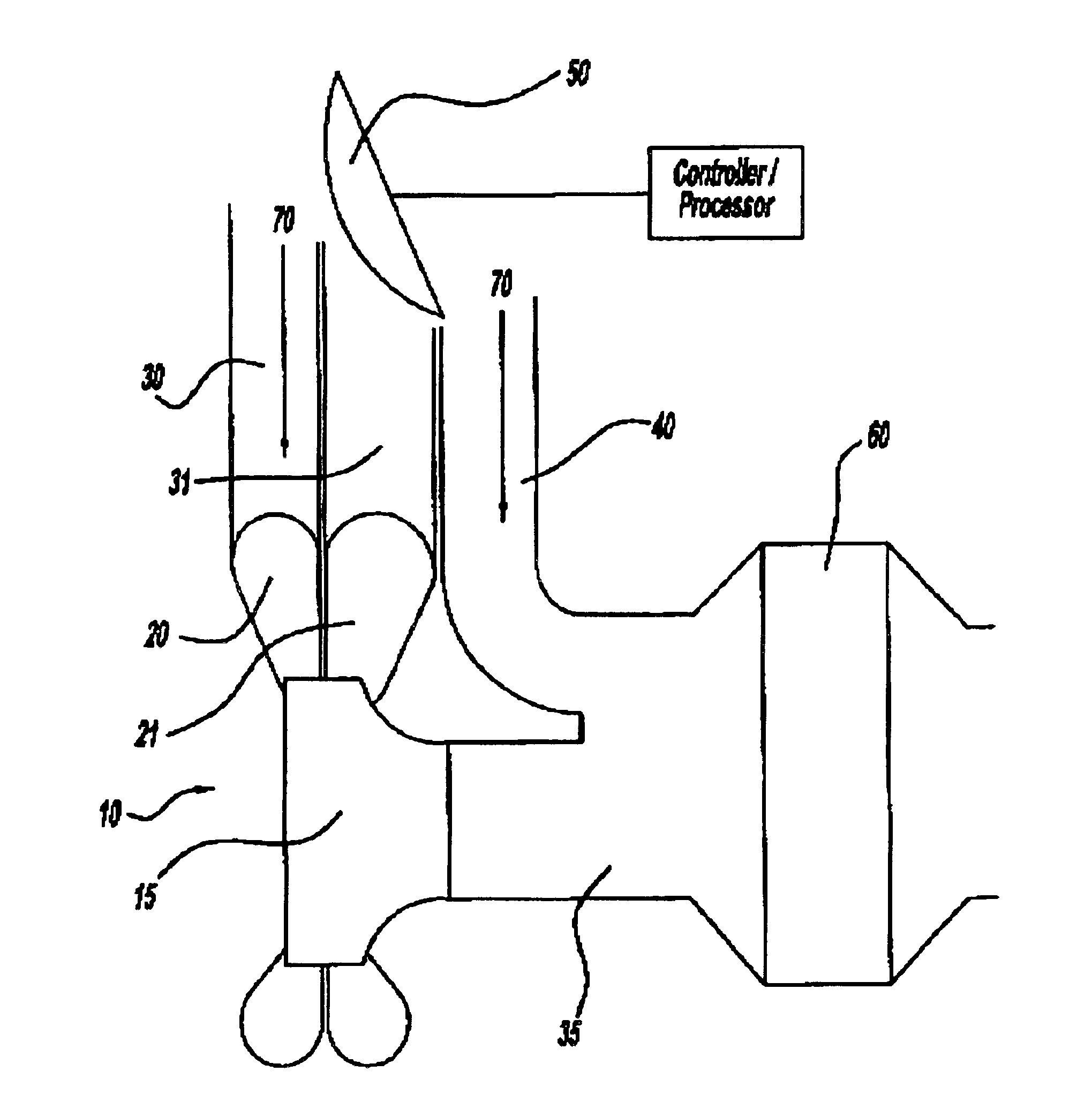

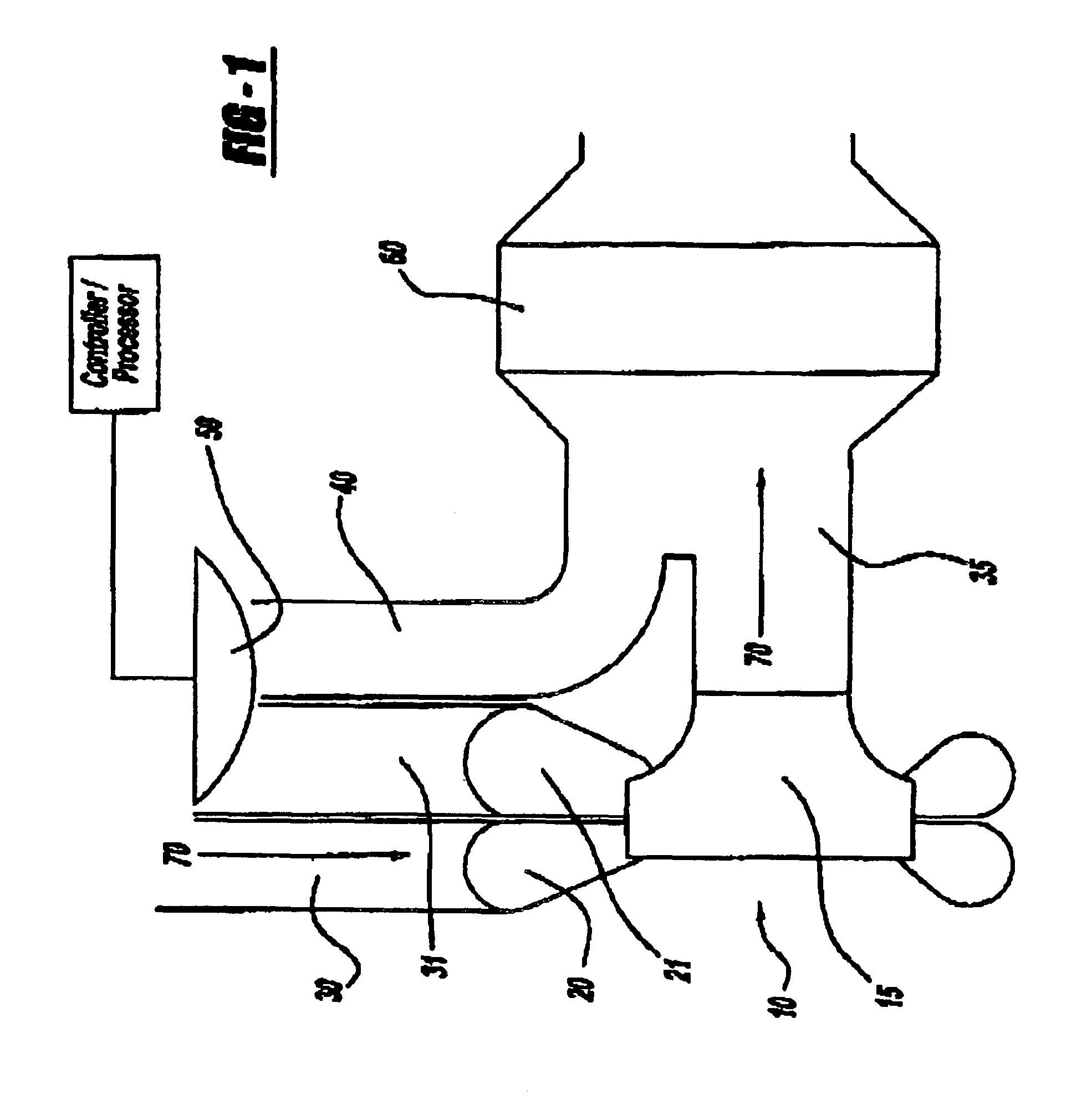

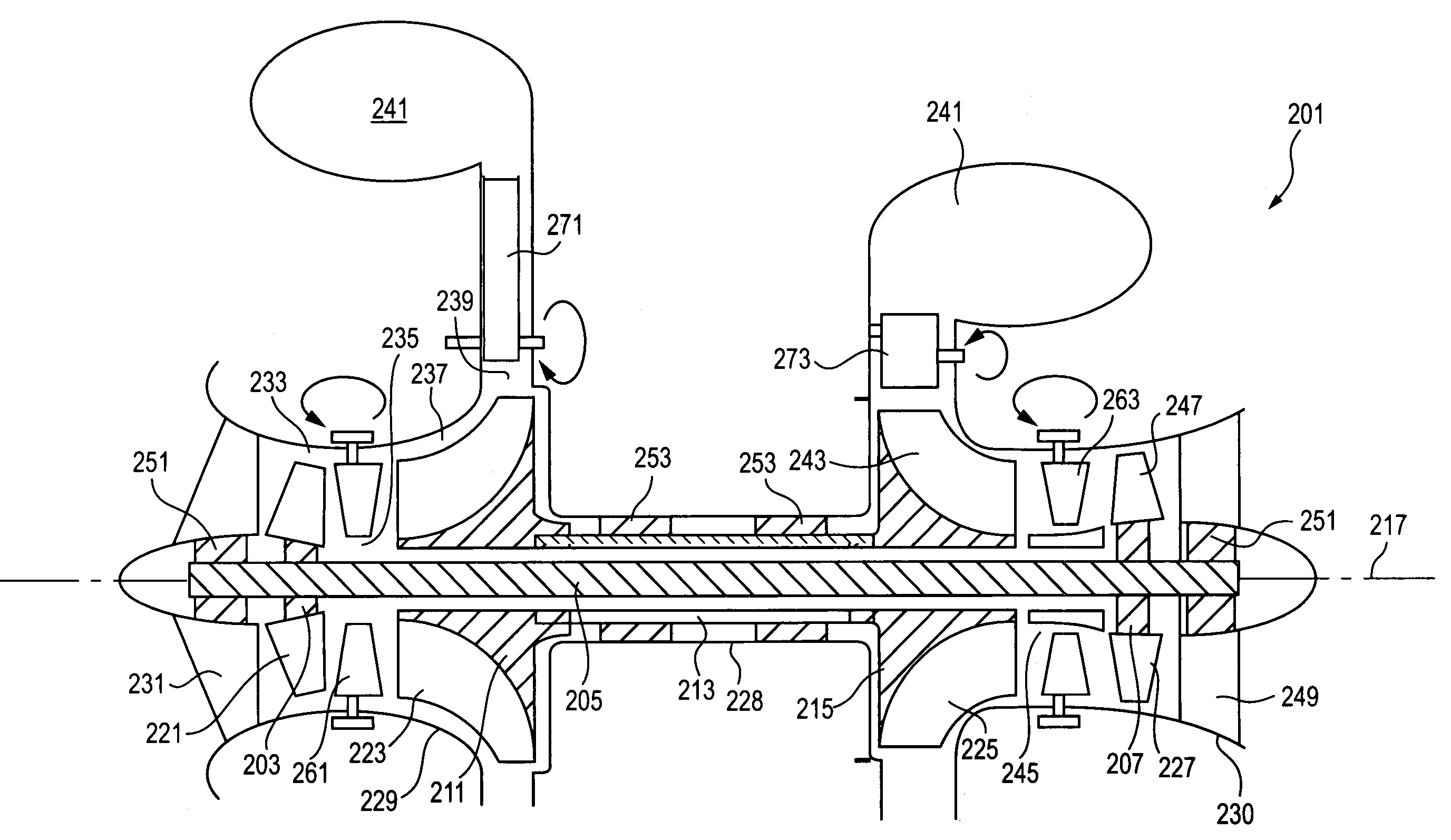

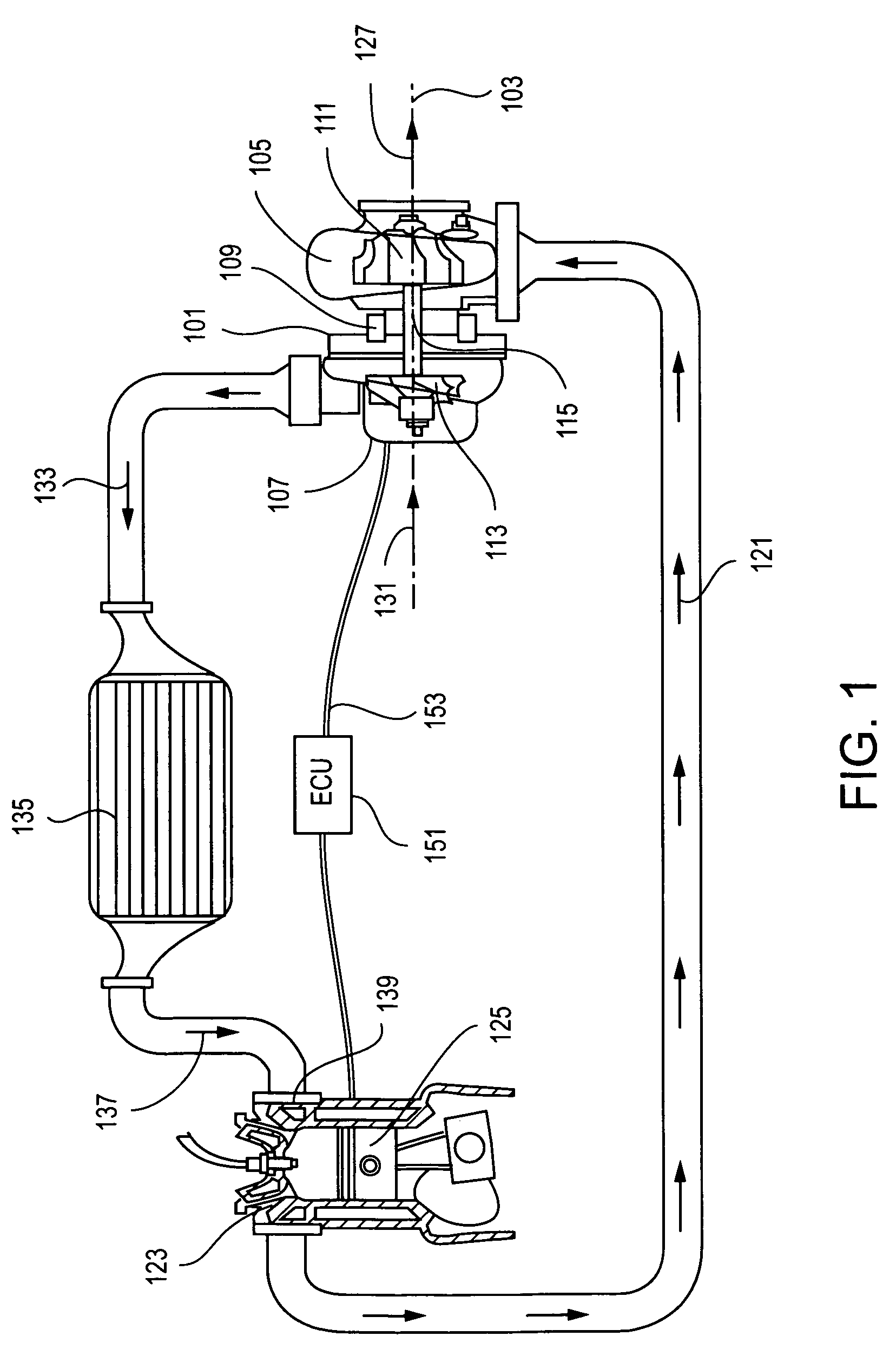

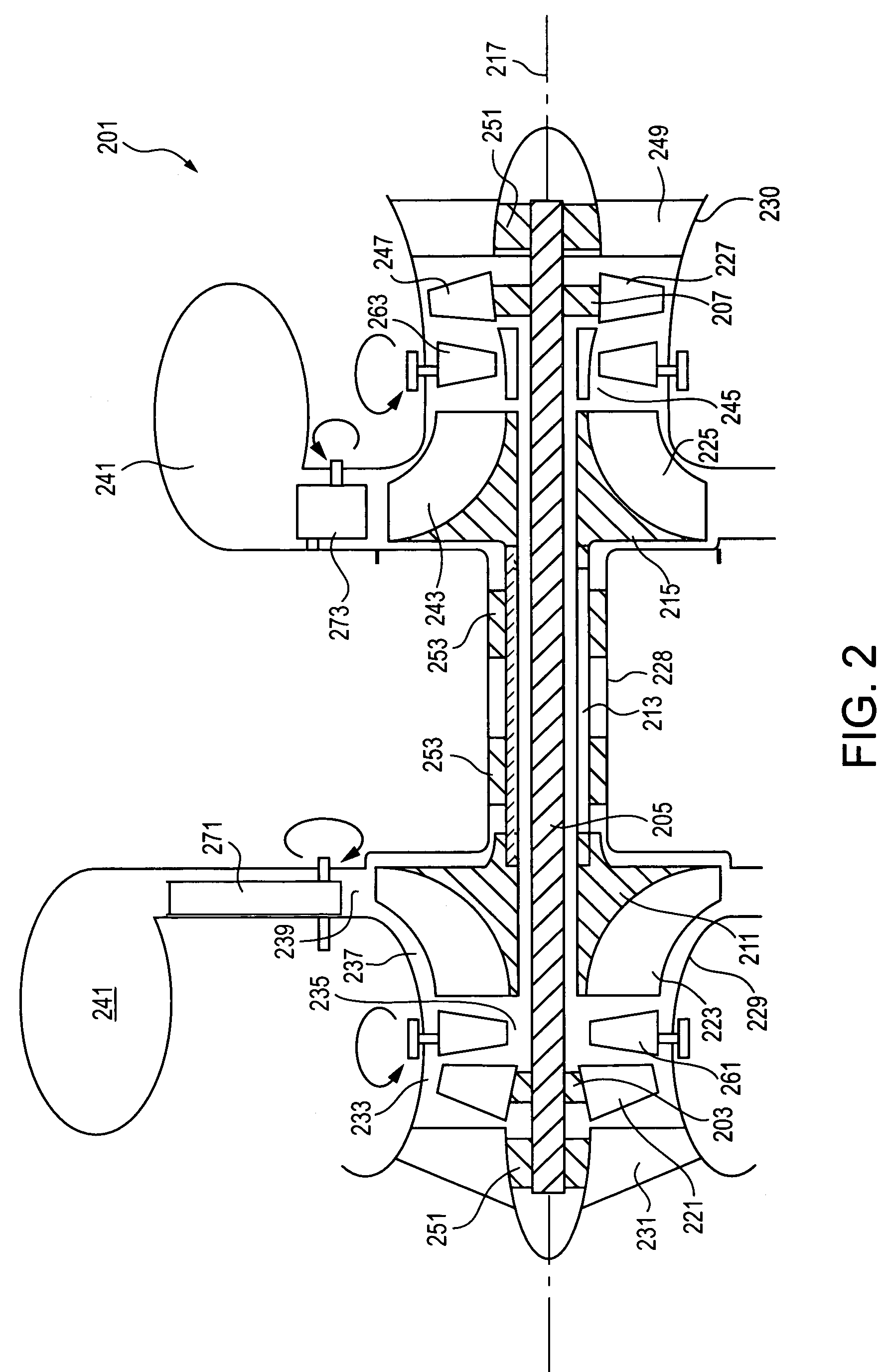

Multi-stage turbocharging system with efficient bypass

InactiveUS20060042247A1Improve efficiencyLoss of useful energyNon-fuel substance addition to fuelInternal combustion piston enginesImpellerTurbine wheel

A more efficient multi-stage turbocharging system and method for internal combustion engine systems is set forth. The present invention recovers the loss of a portion of exhaust energy that conventionally occurs in bypassing exhaust flow from one stage to another in a multi-stage turbocharging system. The preferred method of preserving such exhaust energy is through converting a portion of the exhaust energy of the bypassed flow from pressure to kinetic energy (velocity) by passing the bypassed flow through a VGT vane outlet or other variable geometry valve / nozzle, and then not allowing the accelerated flow to dissipate energy before reaching the subsequent stage's turbine wheel, where the accelerated flow may then be converted to a mechanical rotational force by the lower pressure turbine's wheel. Preferred hardware for achieving the object of the invention is also set forth, including a preferred two-volute low pressure turbocharging system with a VGT mechanism in one turbine volute only, or an alternative low pressure turbocharger with two low pressure turbines on a common shaft (again, preferably, with a VGT mechanism in one turbine only).

Owner:ENVIRONMENTAL PROTECTION AGENCY US

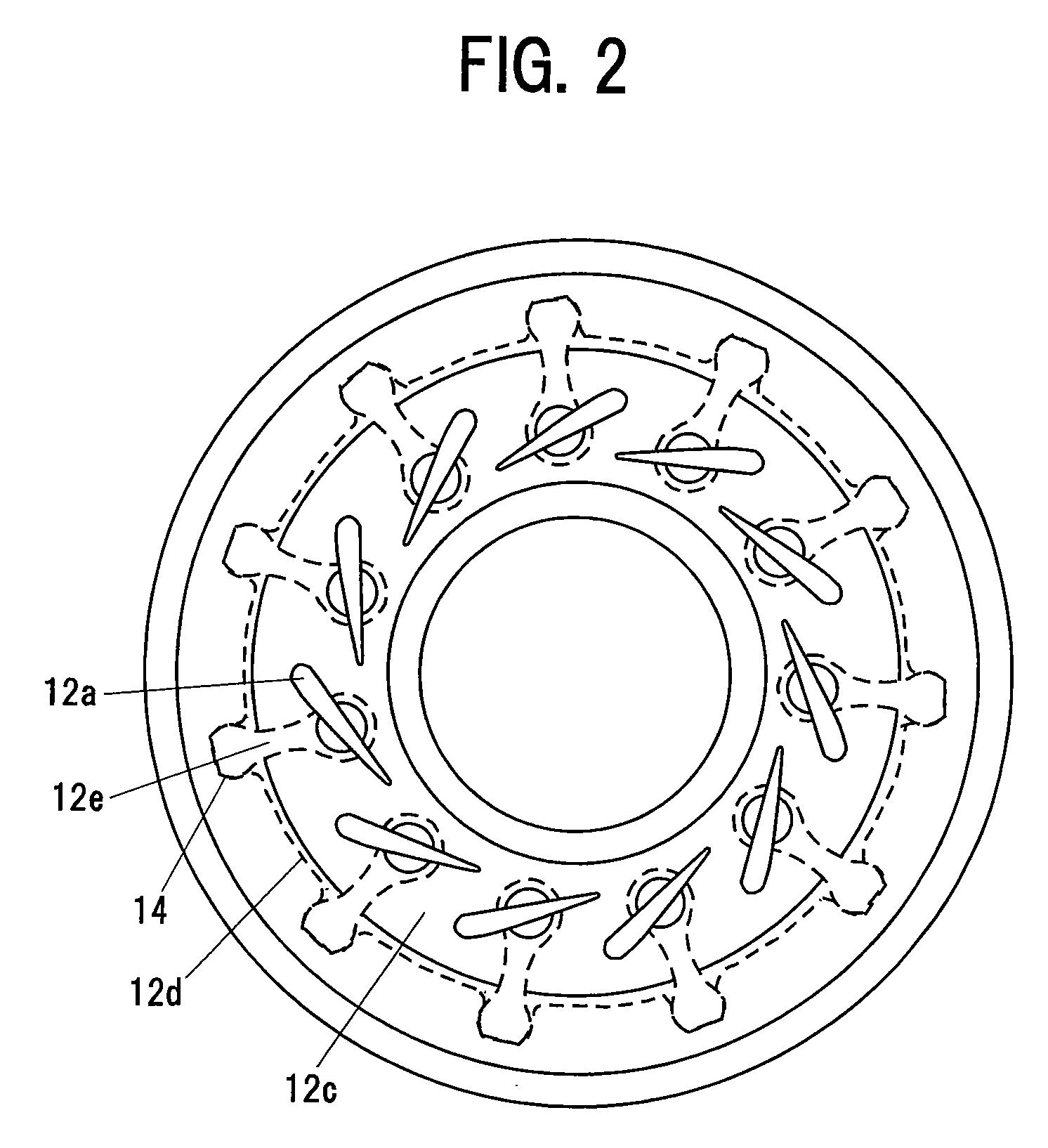

Variable geometry turbocharger

A cartridge is formed by an insert fixed to a base to form turbine intake nozzles in which vanes are rotatably mounted, and the base is fixed to a center housing. A separate exhaust housing which is formed from sheet metal is fixed to the cartridge outside of the insert in order to provide an intake and an outlet for exhaust gases driving a turbine wheel on a shaft journaled in the center housing.

Owner:GARRETT TRANSPORATION I INC

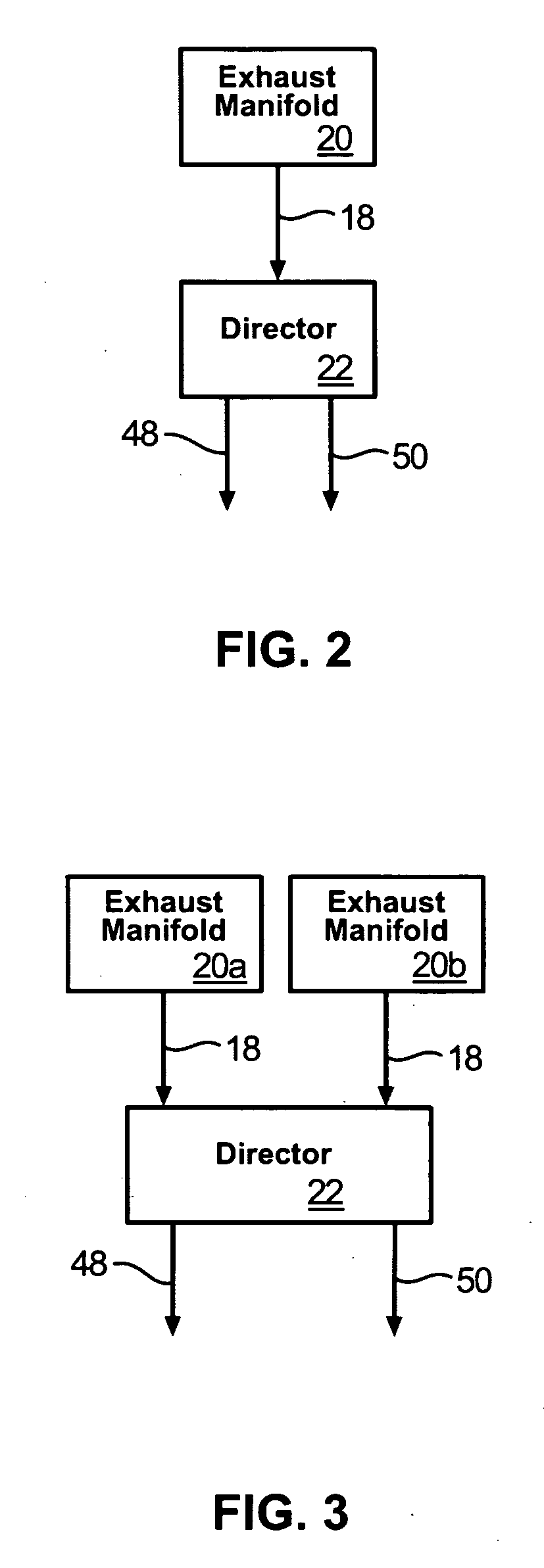

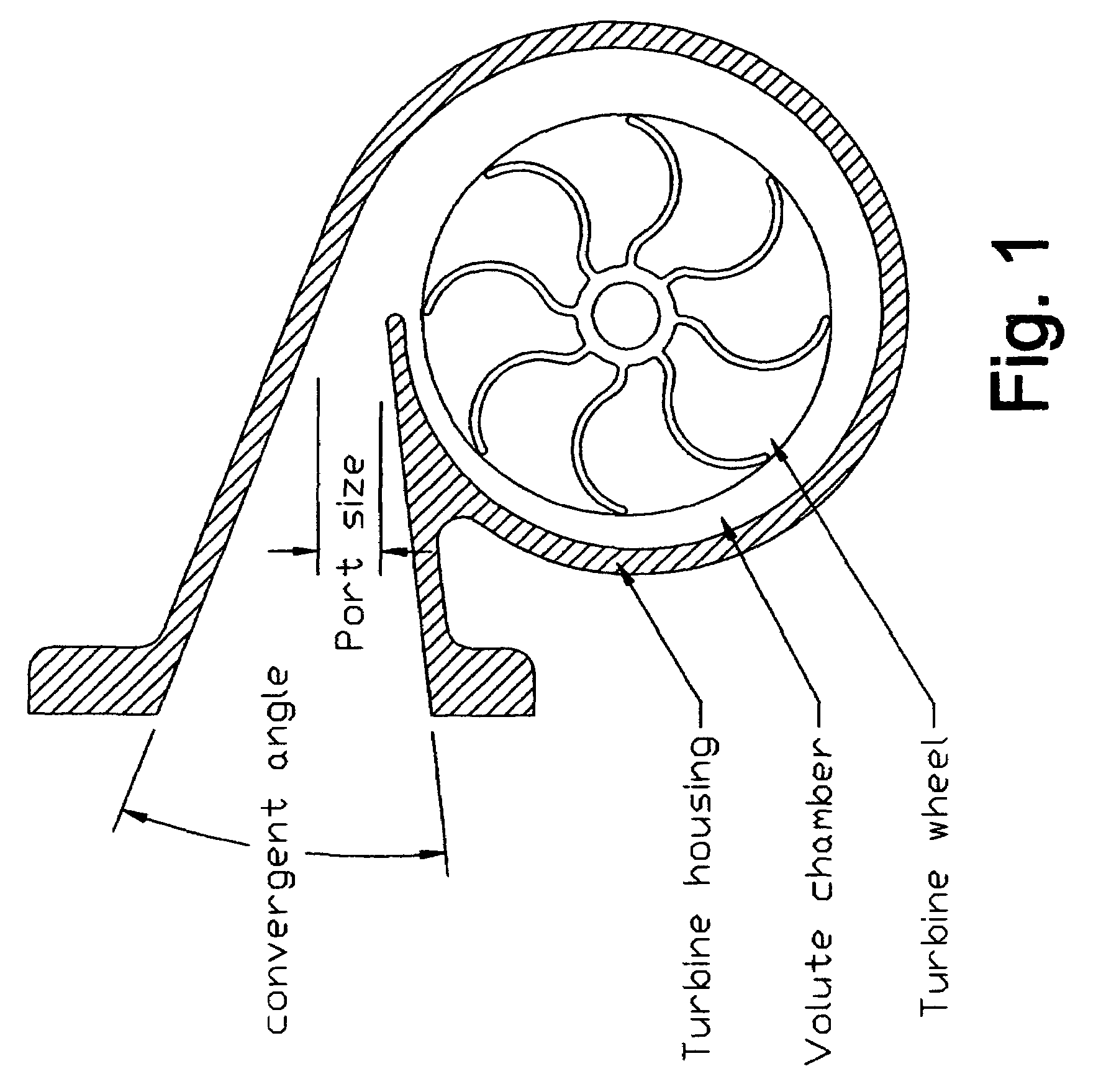

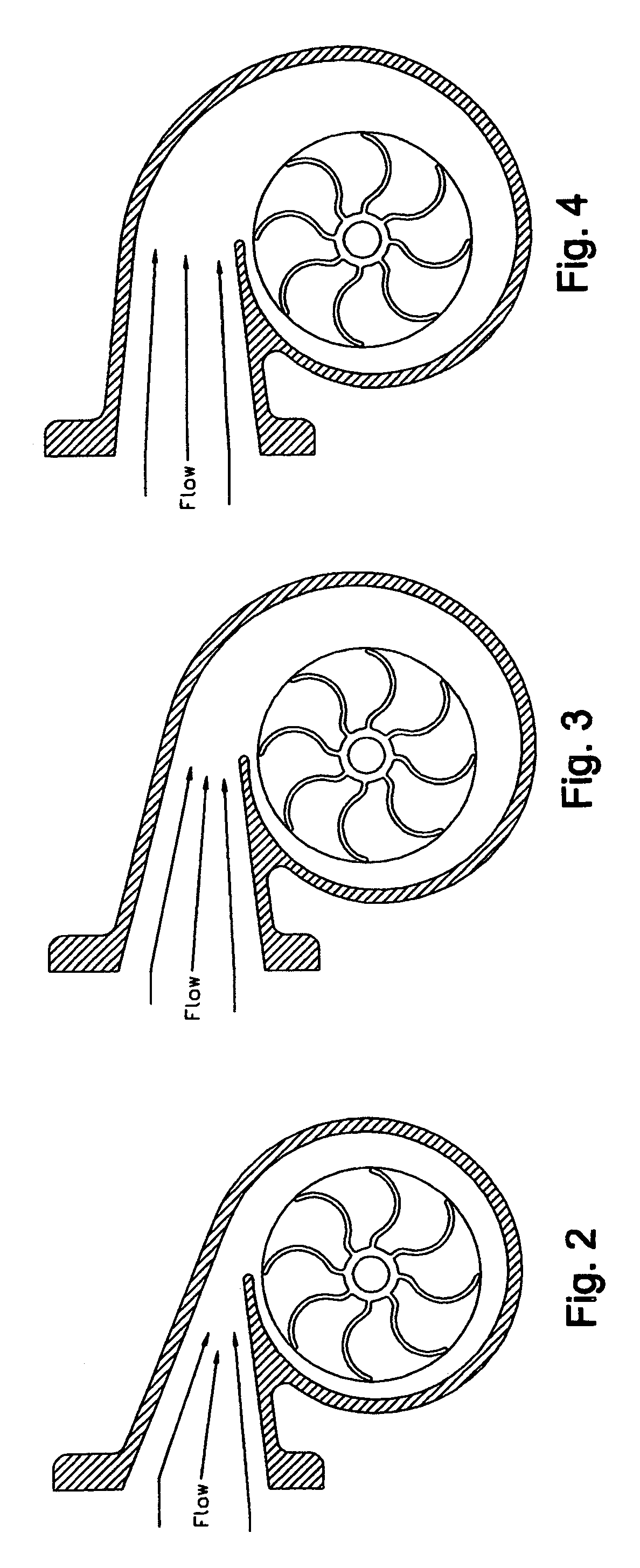

Staged turbocharger

InactiveUS20050247058A1Reduce impact speedControl back pressureInternal combustion piston enginesExhaust apparatusImpellerTurbine wheel

A turbocharger comprising a turbine, director, and compressor. The turbine may be formed as a turbine wheel surrounded by at least two scrolls. The at least two scrolls may direct exhaust gases supplied thereto toward the turbine wheel to cause rotation thereof. The director may control distribution of the exhaust gases between the at least two scrolls to optimize circumferential velocity in the scroll or volute, and thus impingement velocity on the turbine. The compressor may be driven by the turbine.

Owner:PRECISION INDS

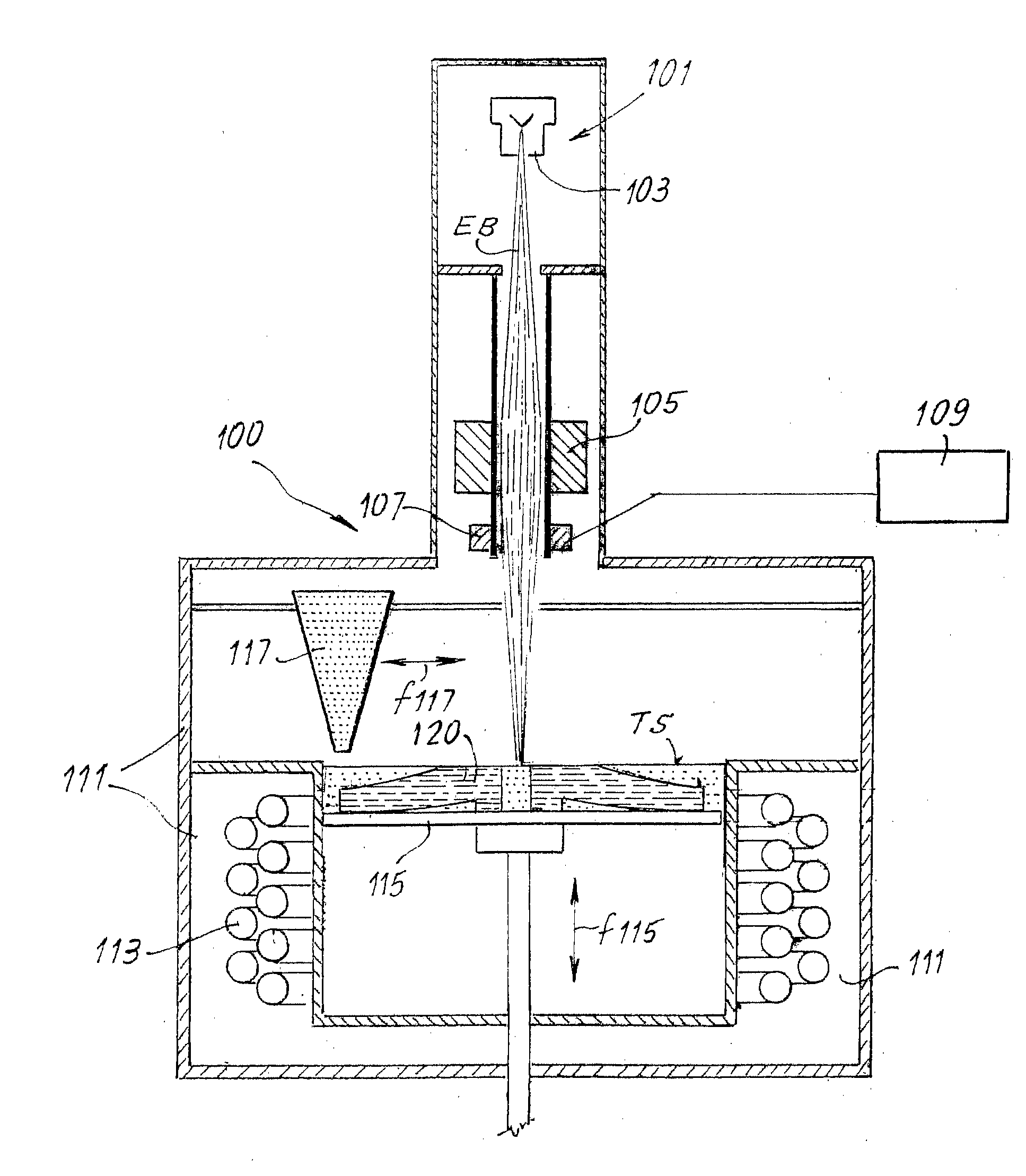

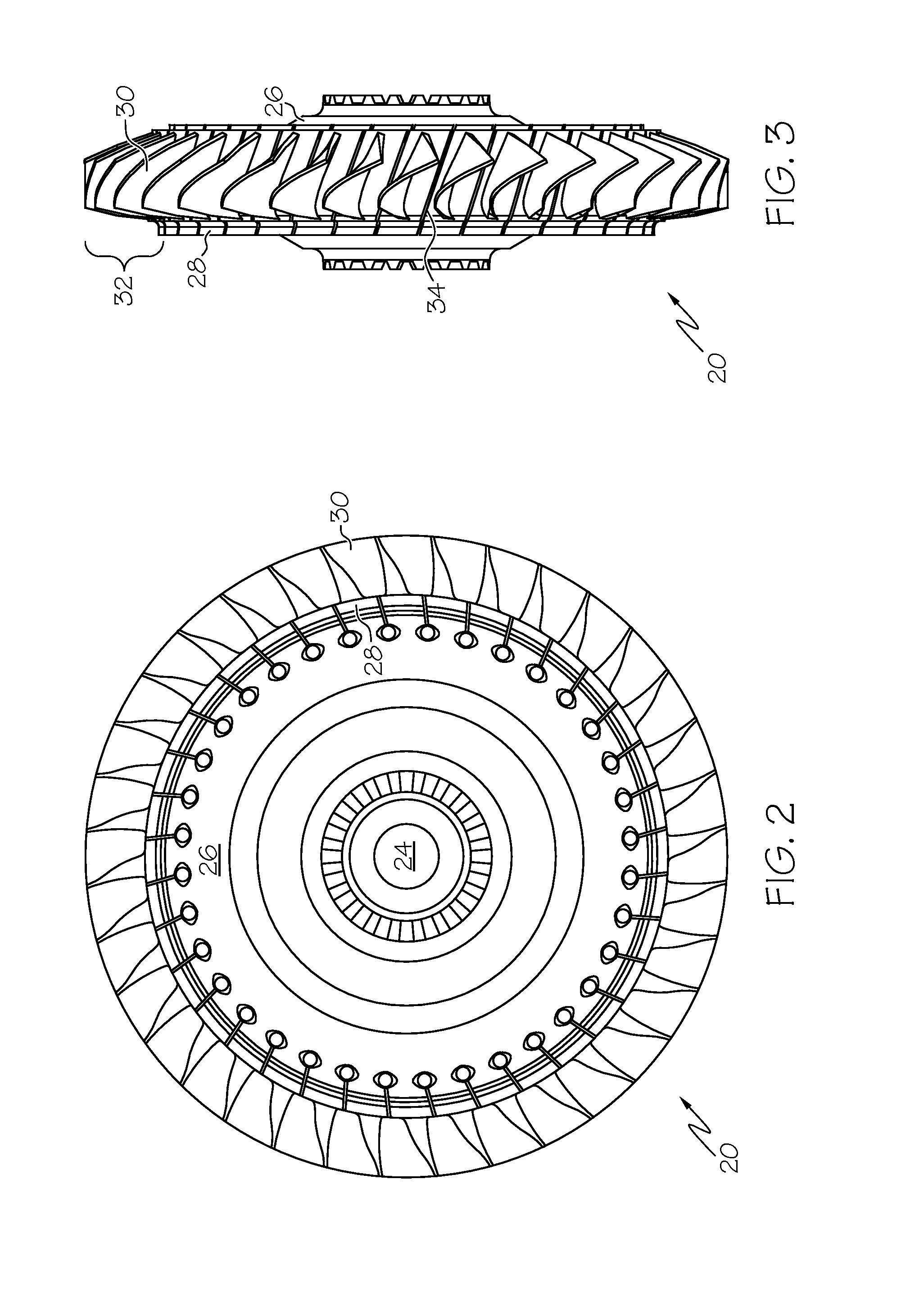

Turbo-machine impeller manufacturing

A method of manufacturing a turbo-machine impeller, which includes a hub and a plurality of blades, using powder material in an additive-manufacturing process. The method includes: applying energy to the powder material by way of a high energy source, and solidifying the powder material. At least one bulky portion of the hub is irradiated such that the powder material solidifies in a lattice structure surrounded by an outer solid skin structure enclosing the lattice structure.

Owner:NUOVO PIGNONE TECH SRL

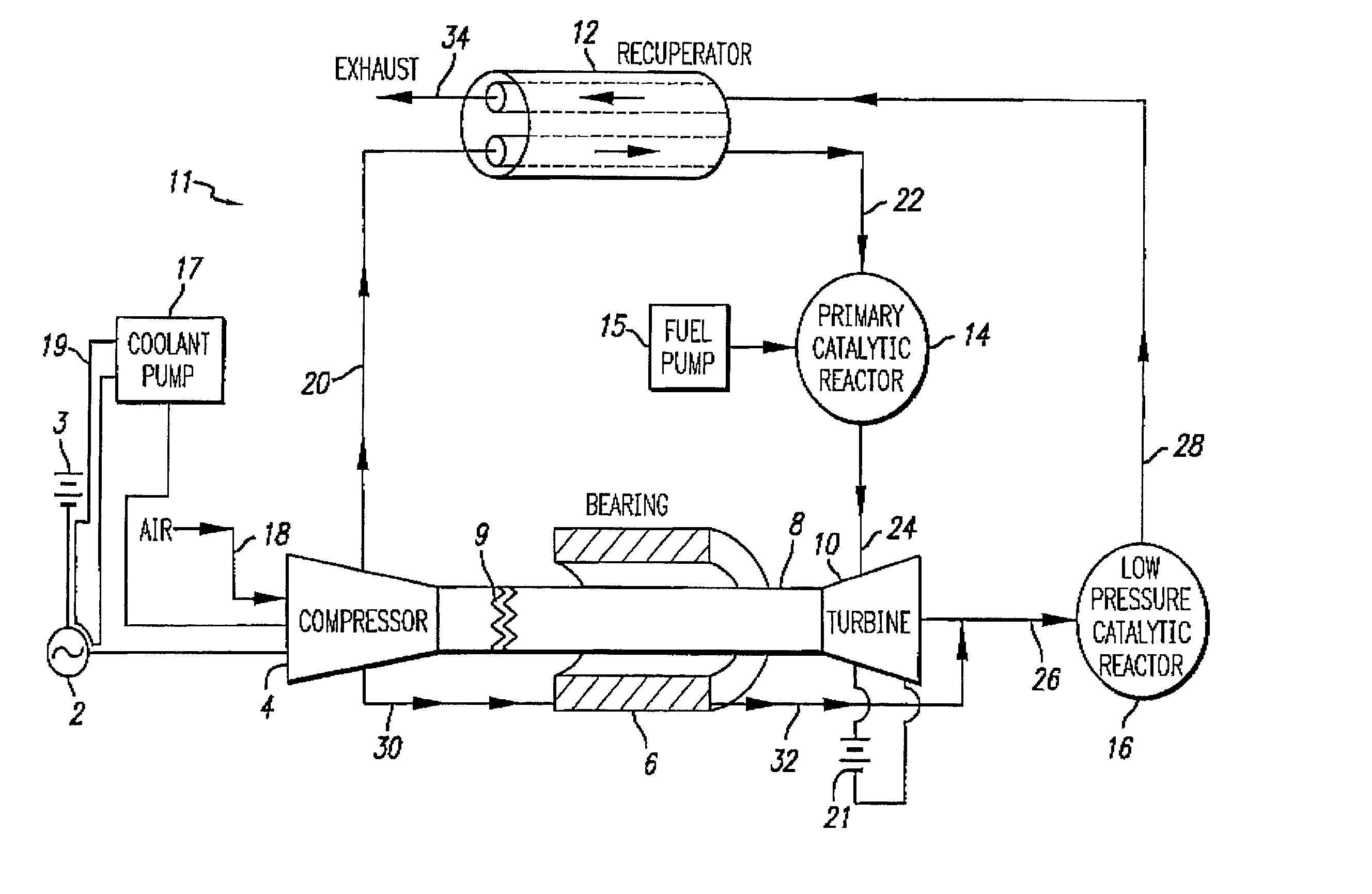

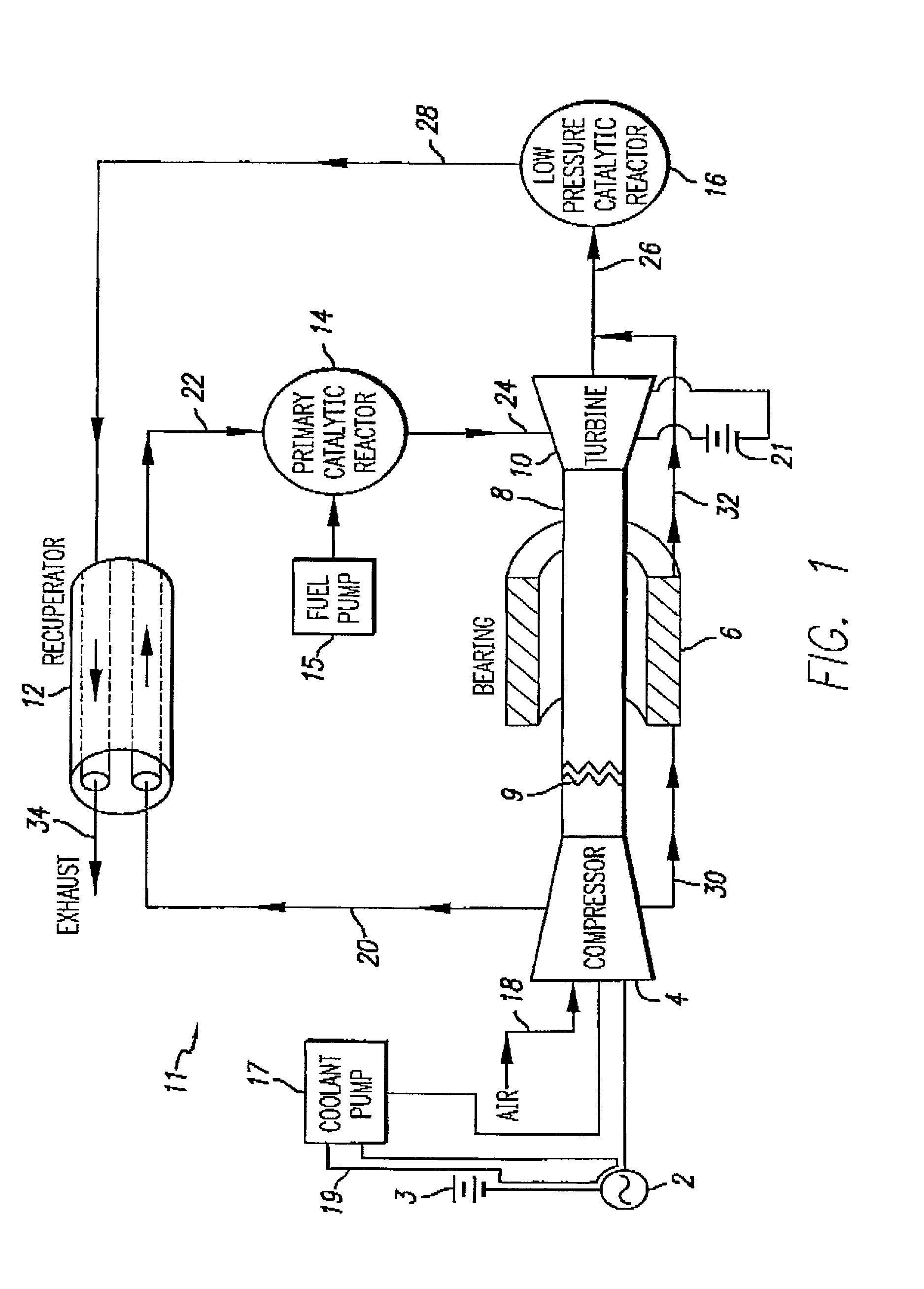

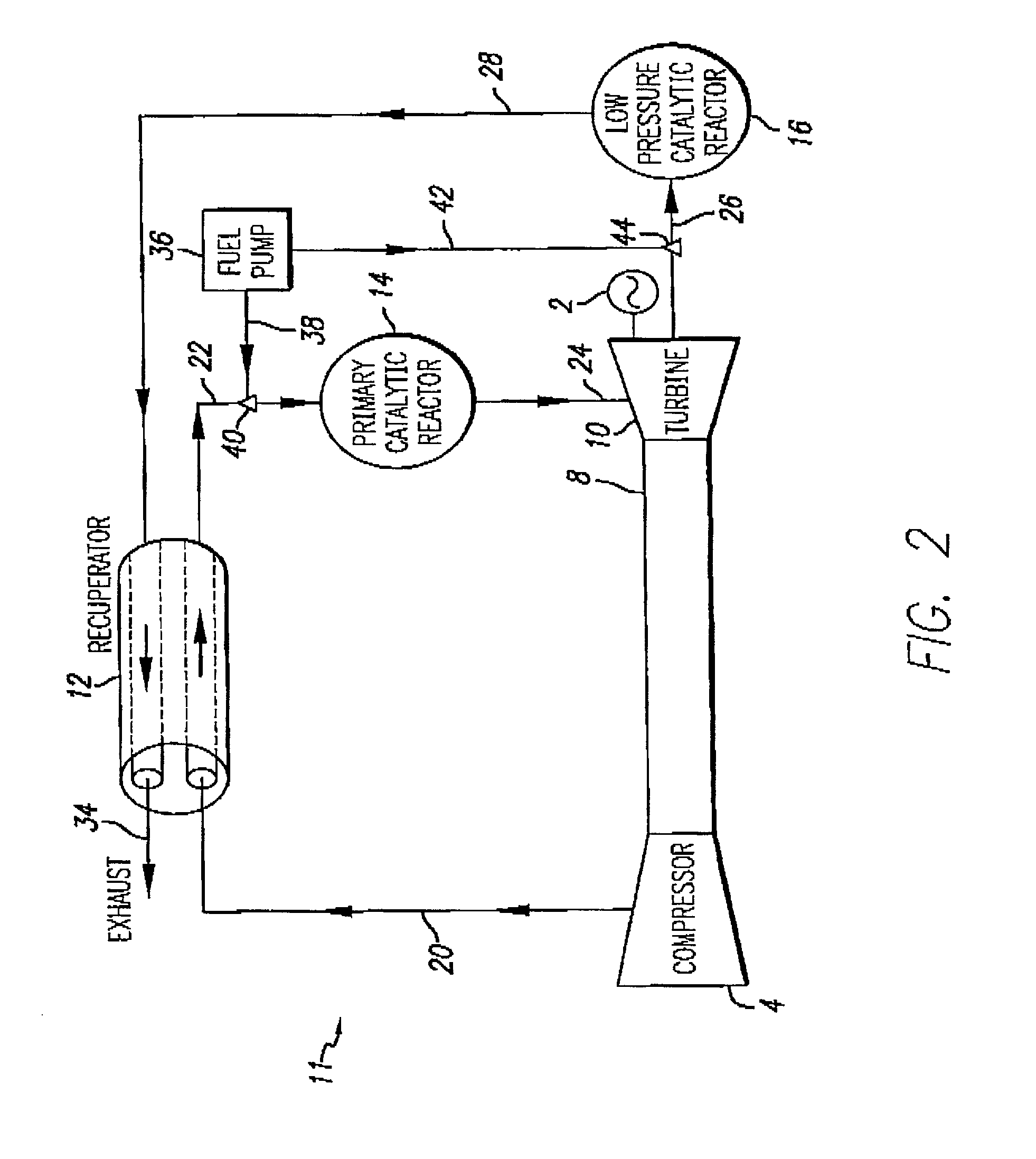

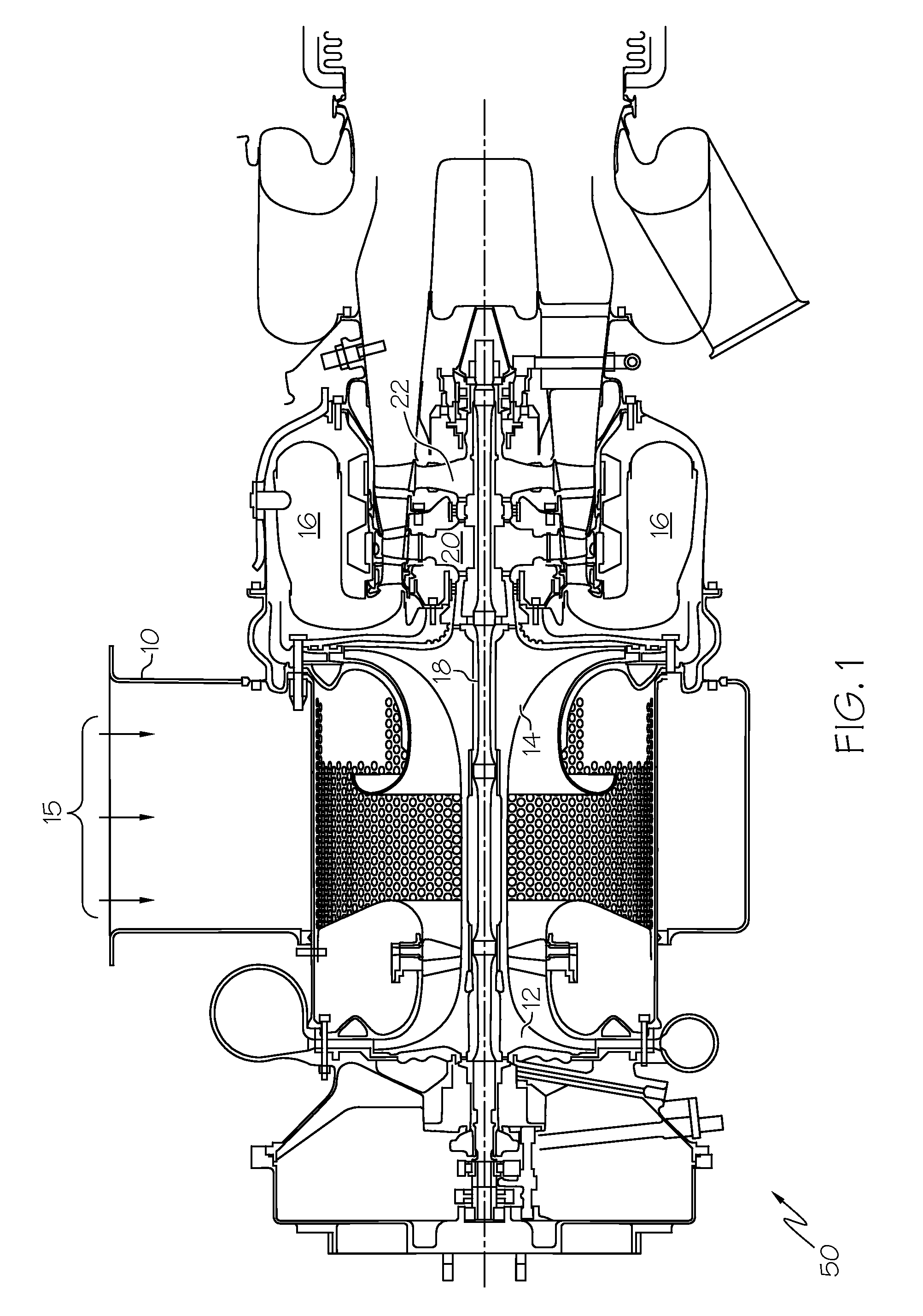

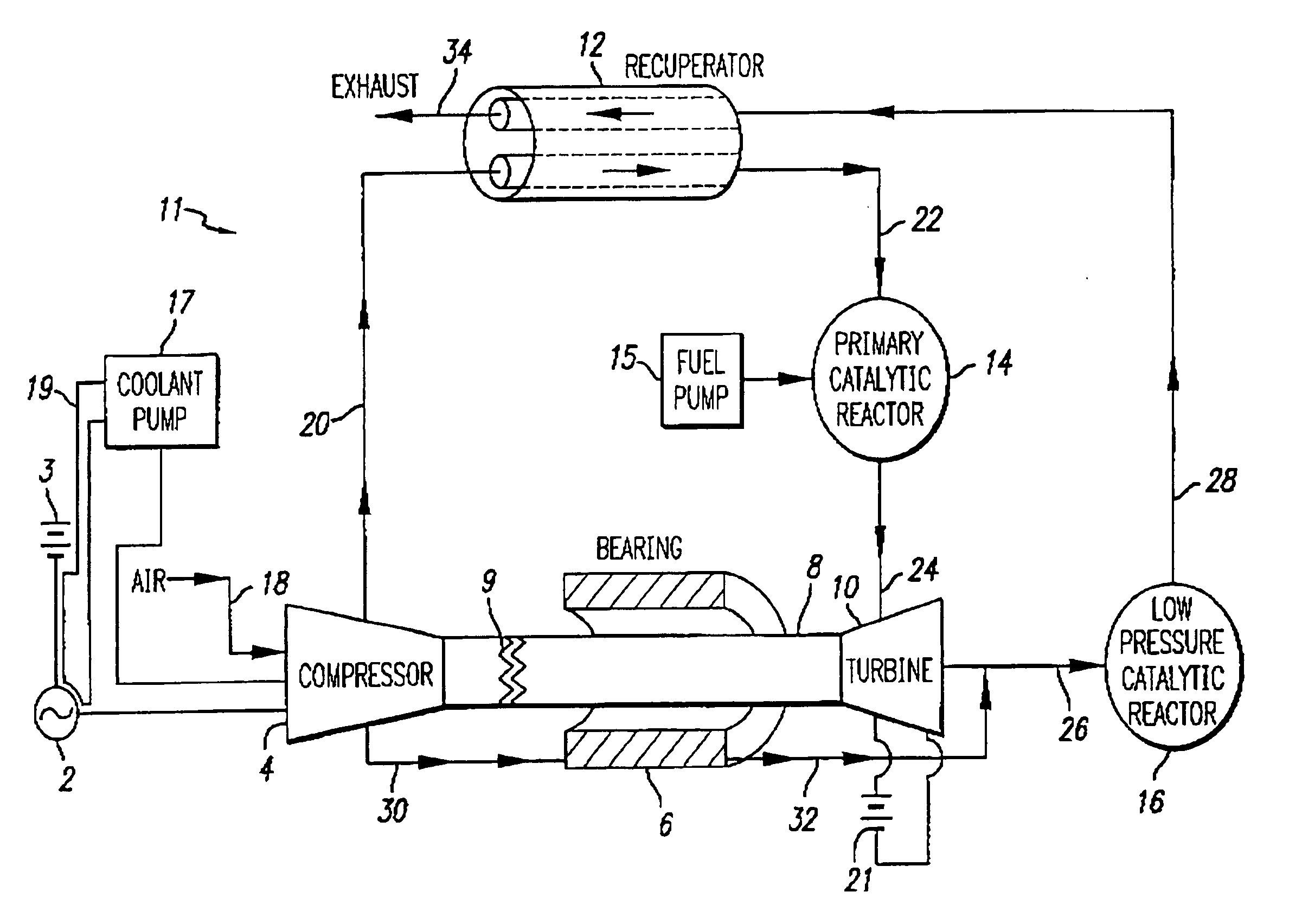

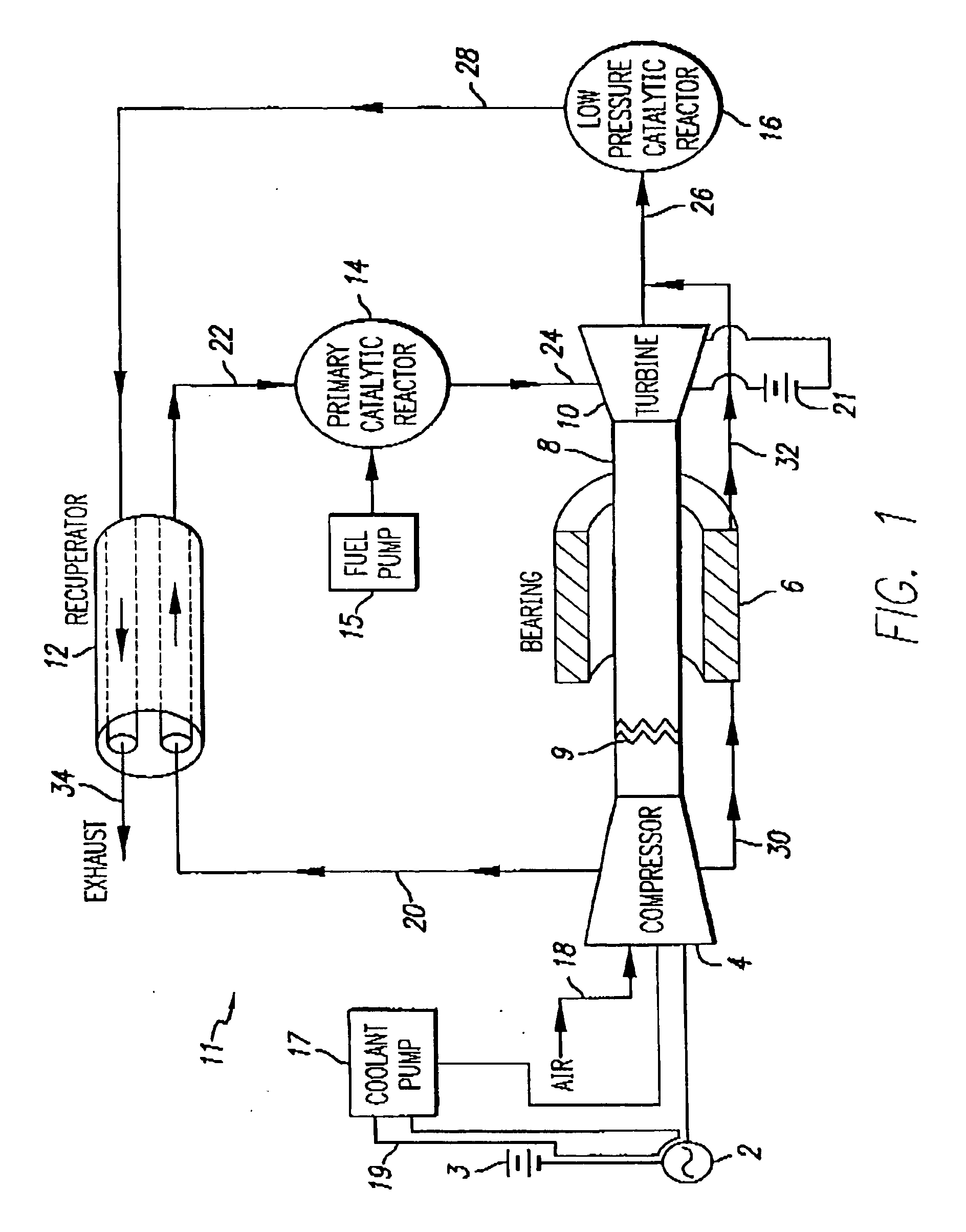

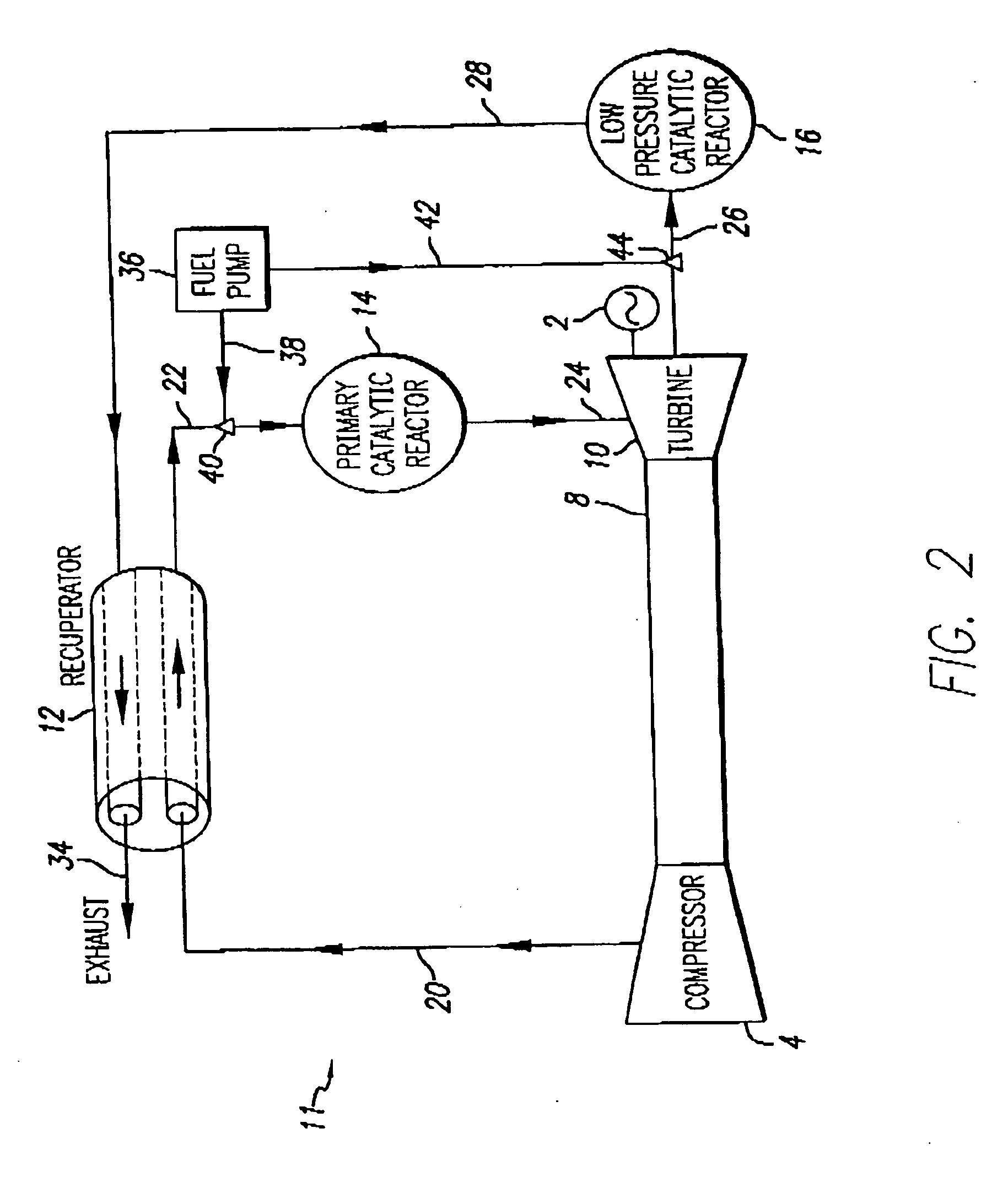

Integrated turbine power generation system having low pressure supplemental catalytic reactor

InactiveUS20020166324A1Continuous combustion chamberTurbine/propulsion engine ignitionImpellerTurbine wheel

The invention provides integrated turbogenerators having a turbine wheel, a compressor impeller, and a motor generator mounted to or mechanically constrained to a common shaft, and improved components and configurations thereof.

Owner:CAPSTONE TURBINE

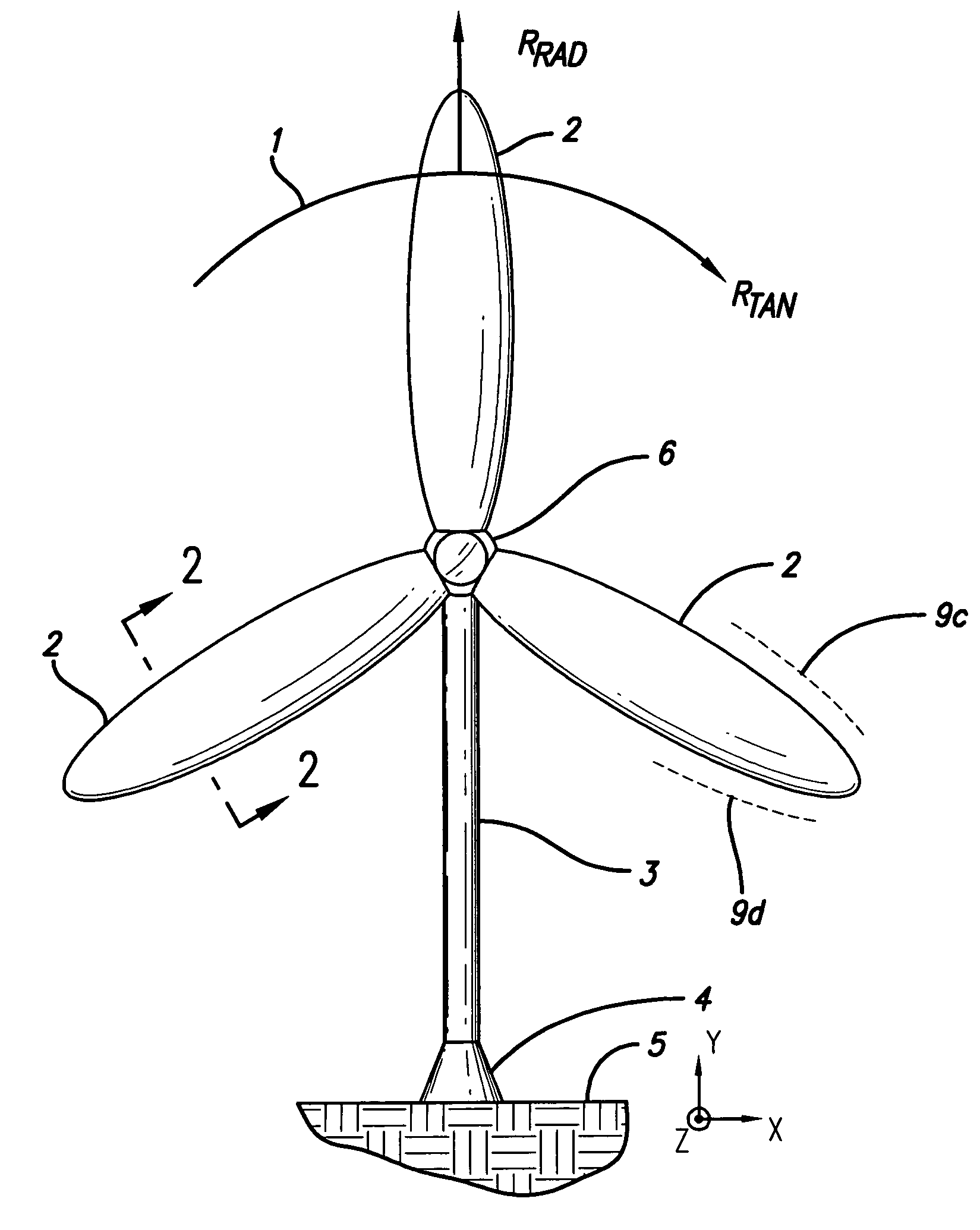

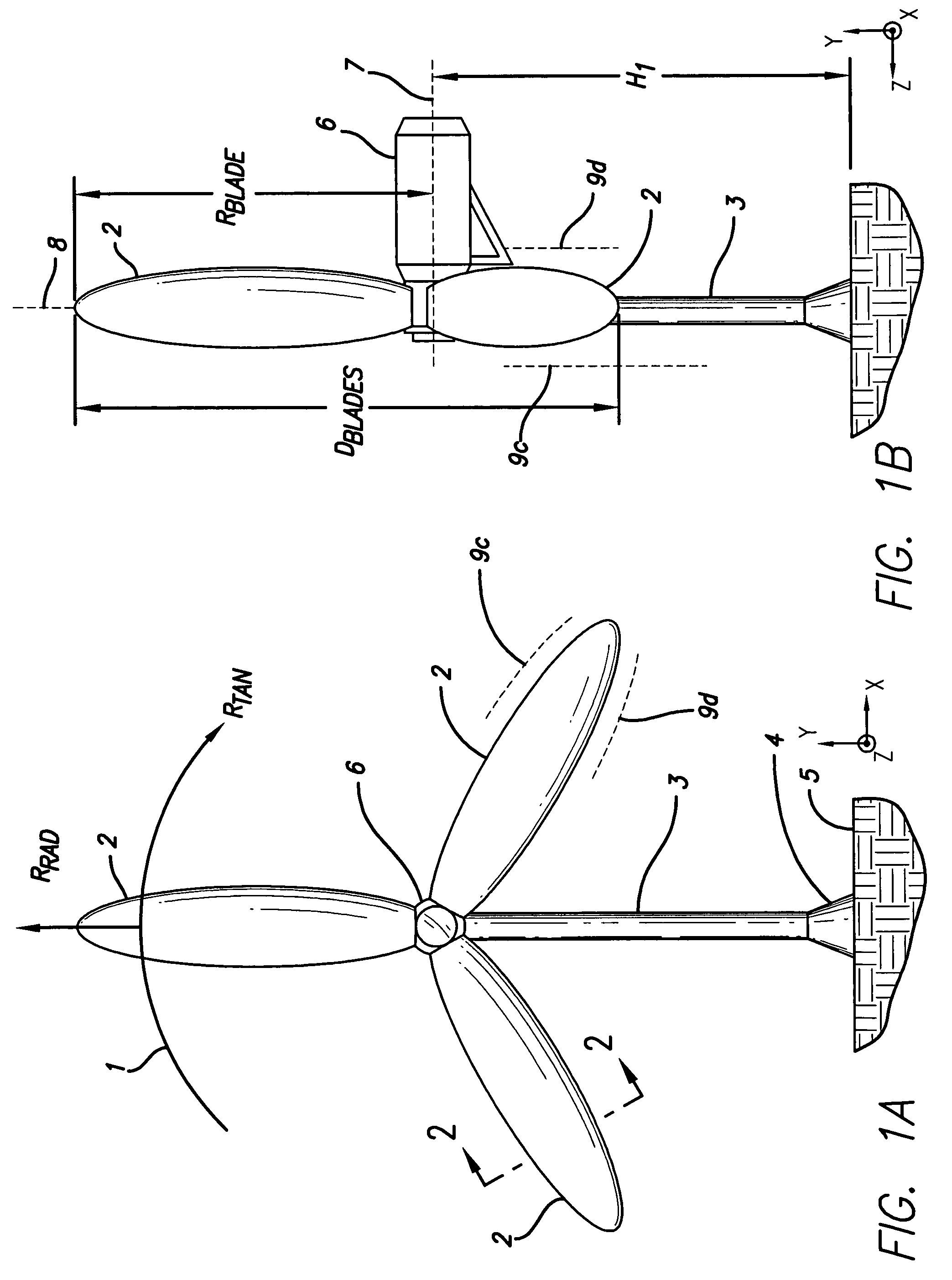

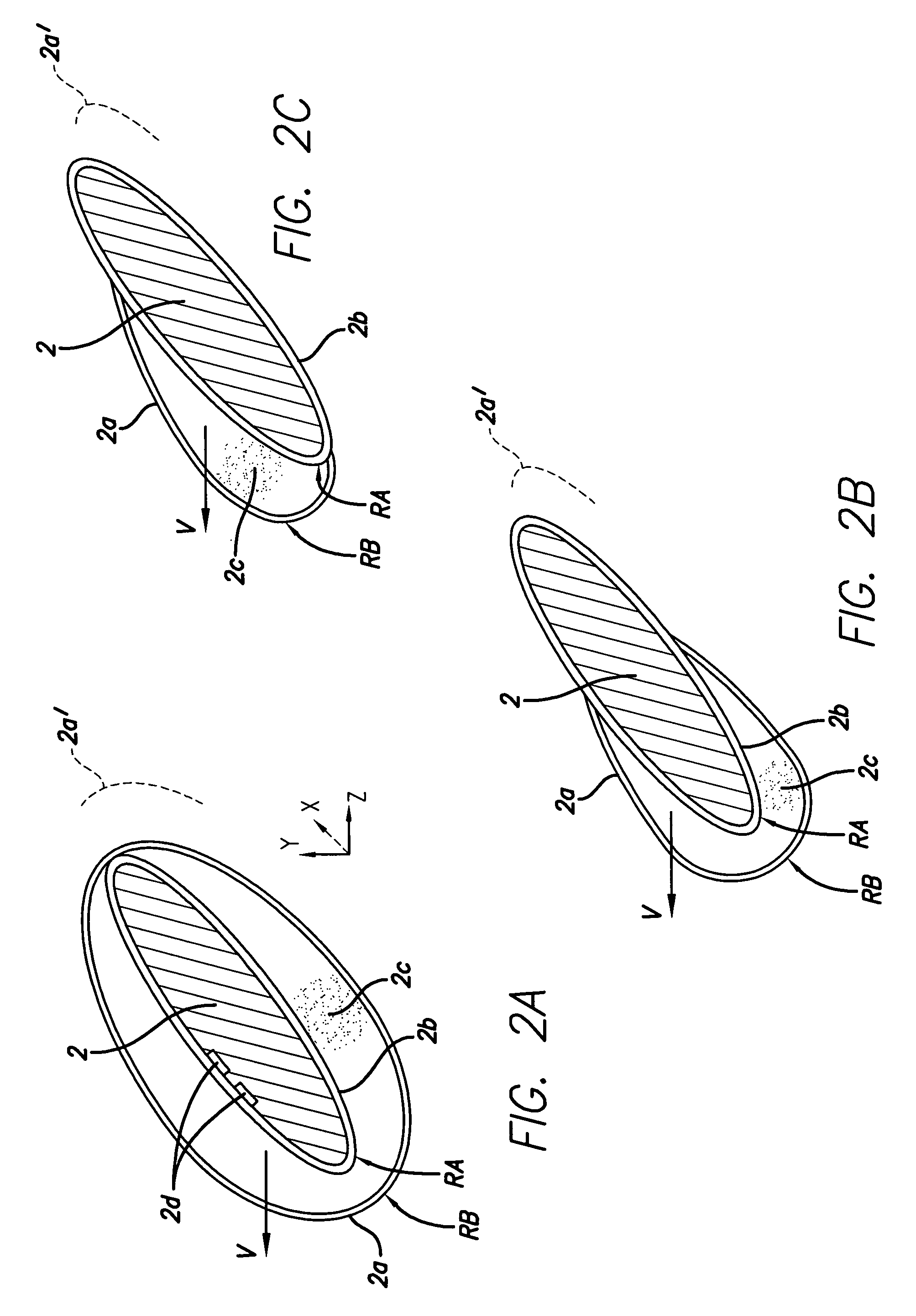

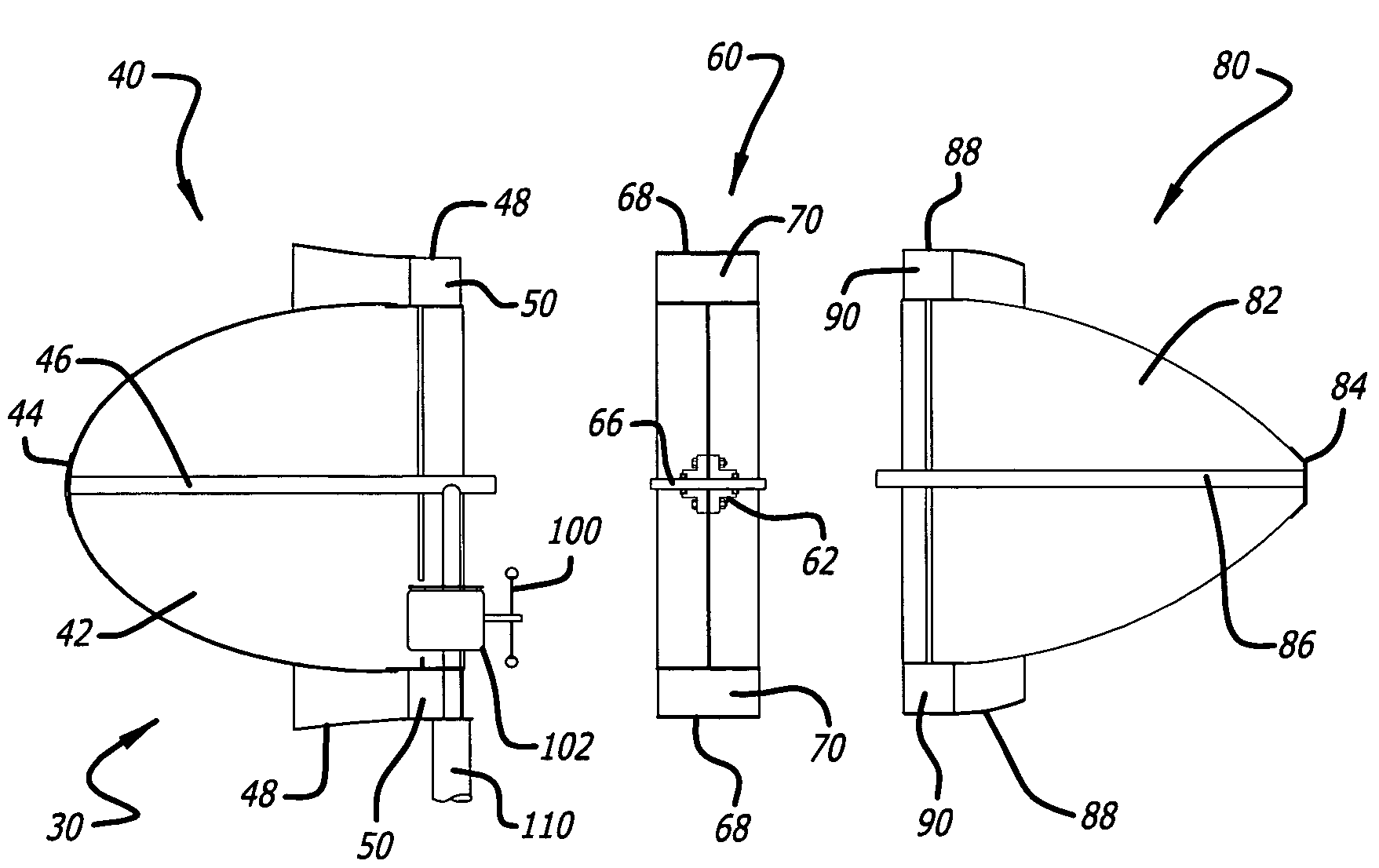

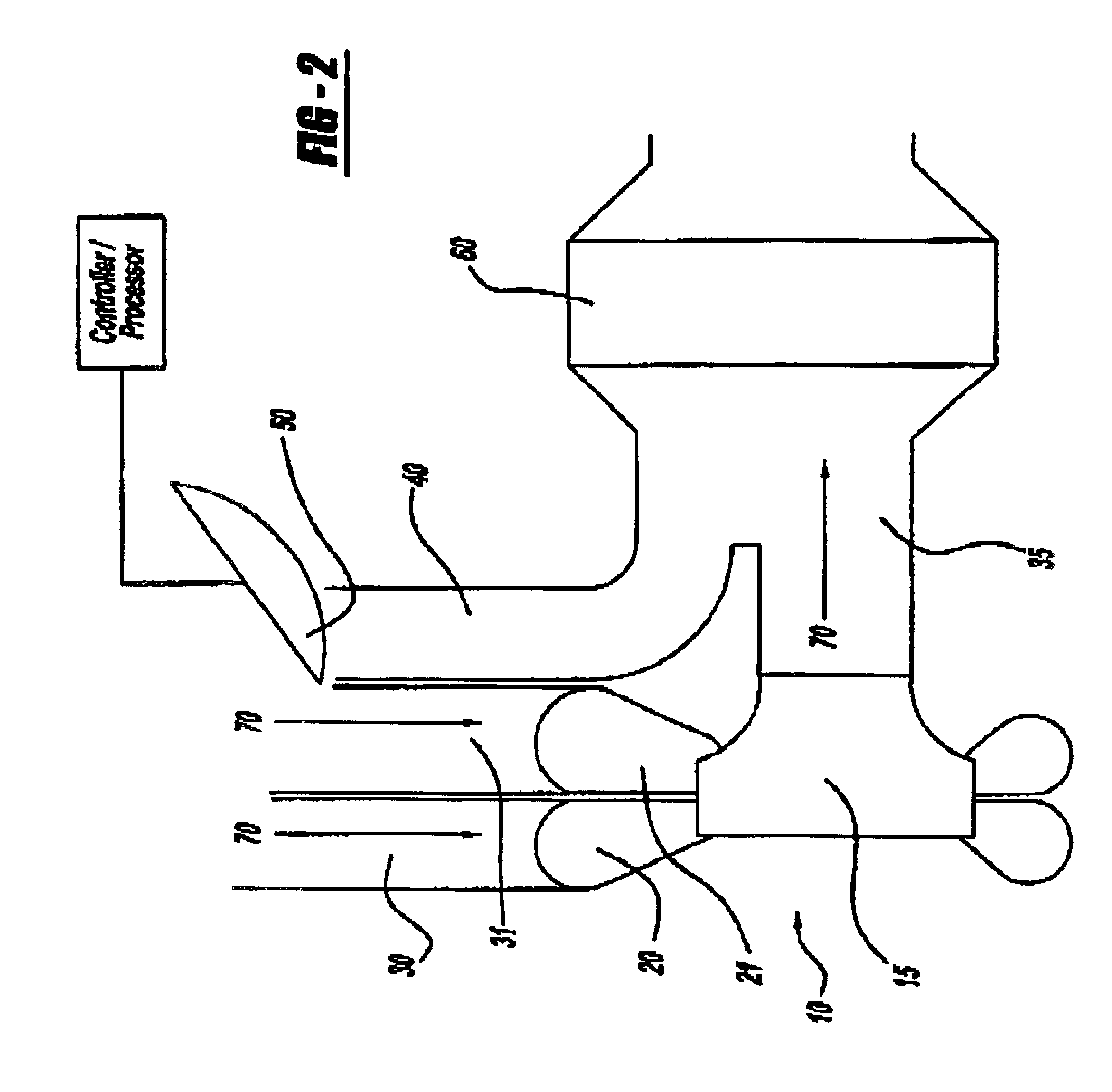

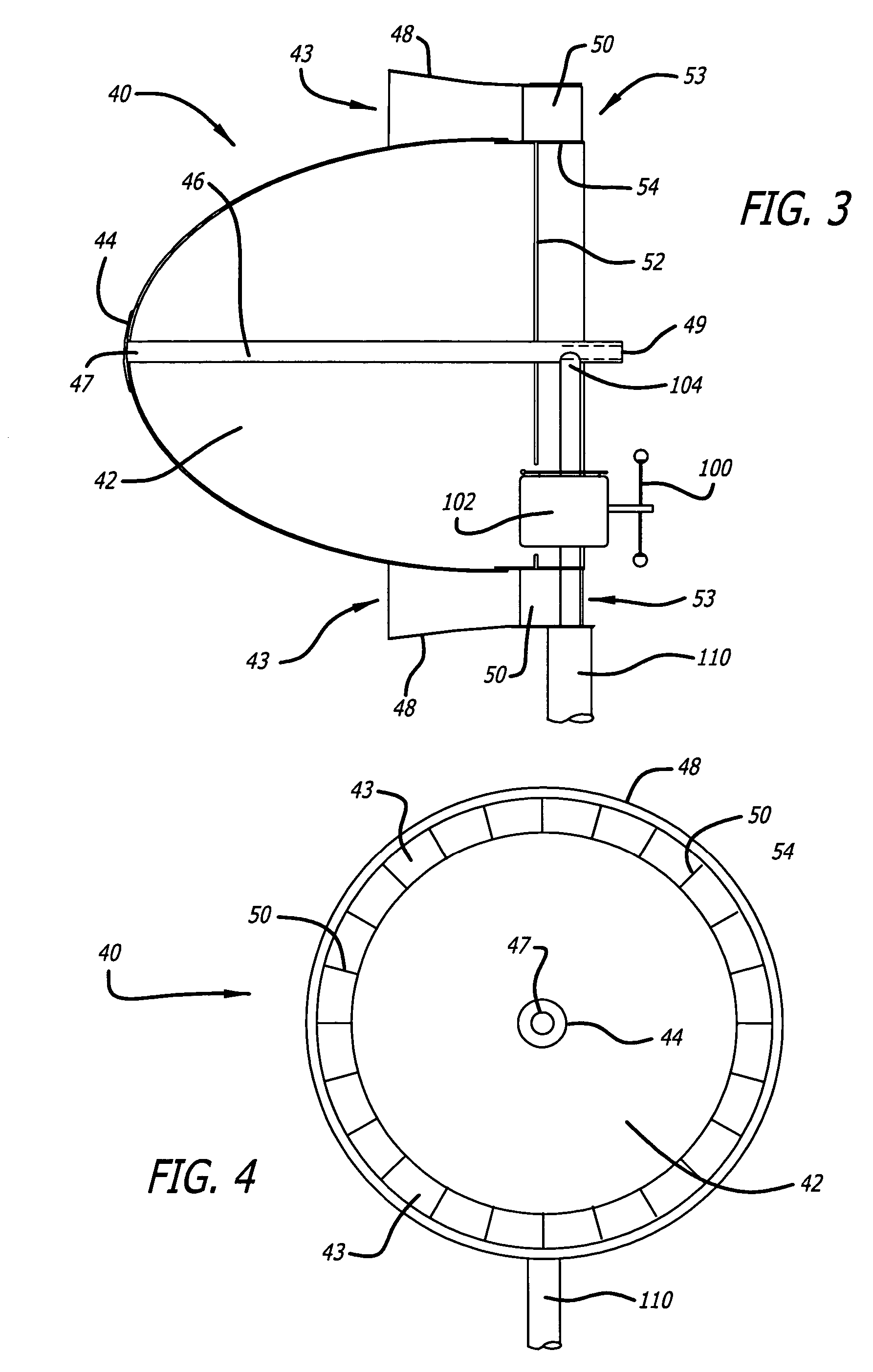

Method and apparatus for reducing bird and fish injuries and deaths at wind and water-turbine power-generation sites

A simple system is provided to dramatically reduce the number of bird fatalities and injuries, as these are bird-kills that man should be able to do something about. Essentially, the inventive apparatus comprises one or more instantaneously inflatable mini-airbags on turbine blade leading edges which, in the “stowed position” are tightly conformally elastically wrapped around or juxtaposed to the turbine blade surface(s) and / or edges(s) thereby not affecting the blade's aerodynamic efficiency. The airbag(s) can be activated and restowed or recollapsed very rapidly, thereby not significantly negatively impacting the operational efficiency of the wind machine. In a similar manner, fish-kills or injuries taking place in the turbine impellers of hydroelectric power-generator facilities may be avoided (as opposed to ameliorated) using another inventive system and method taught herein, this one being primarily a collision avoidance system which does not require the problematic alteration of the turbine blades themselves.

Owner:I P FOUNDRY

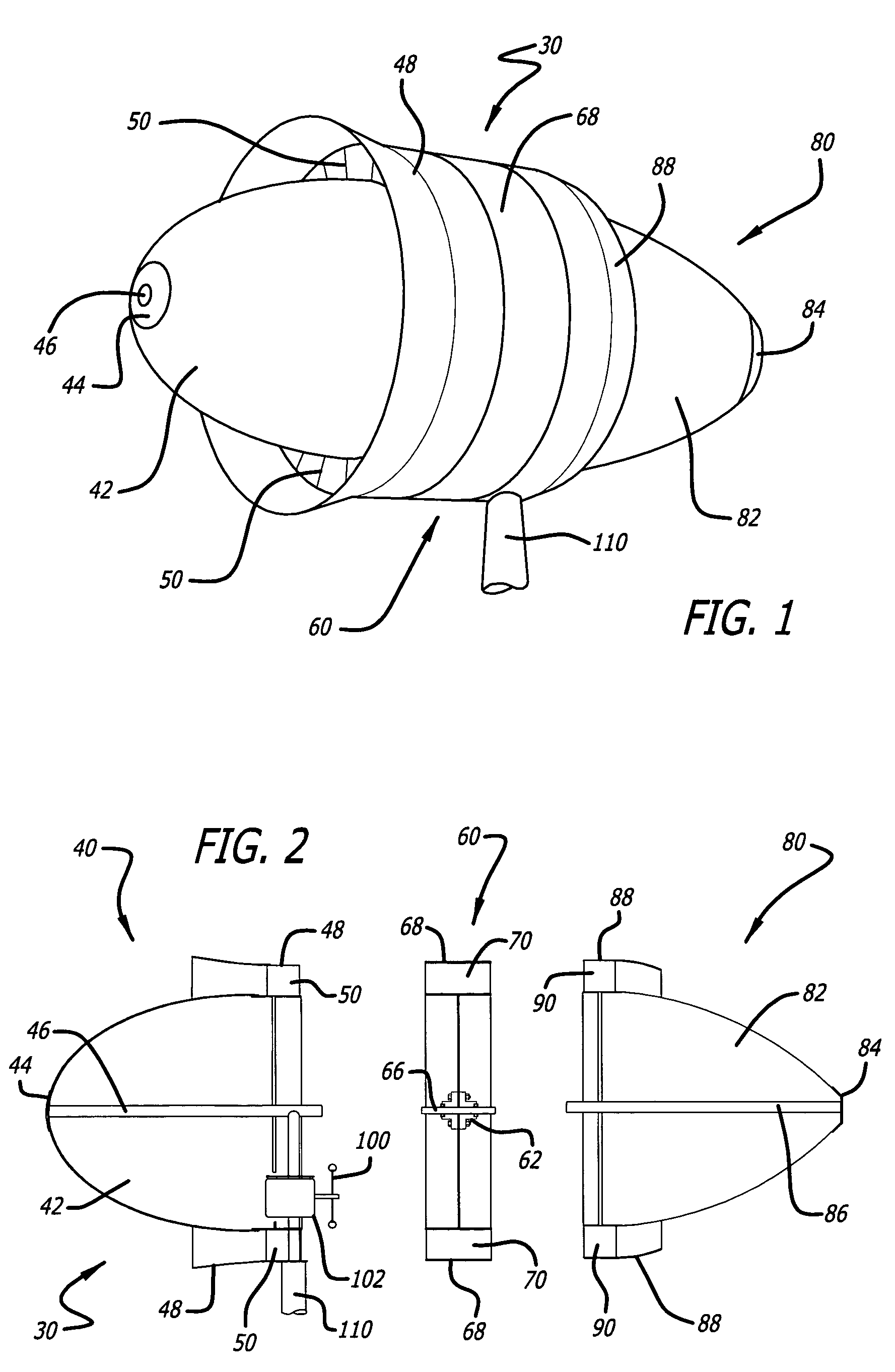

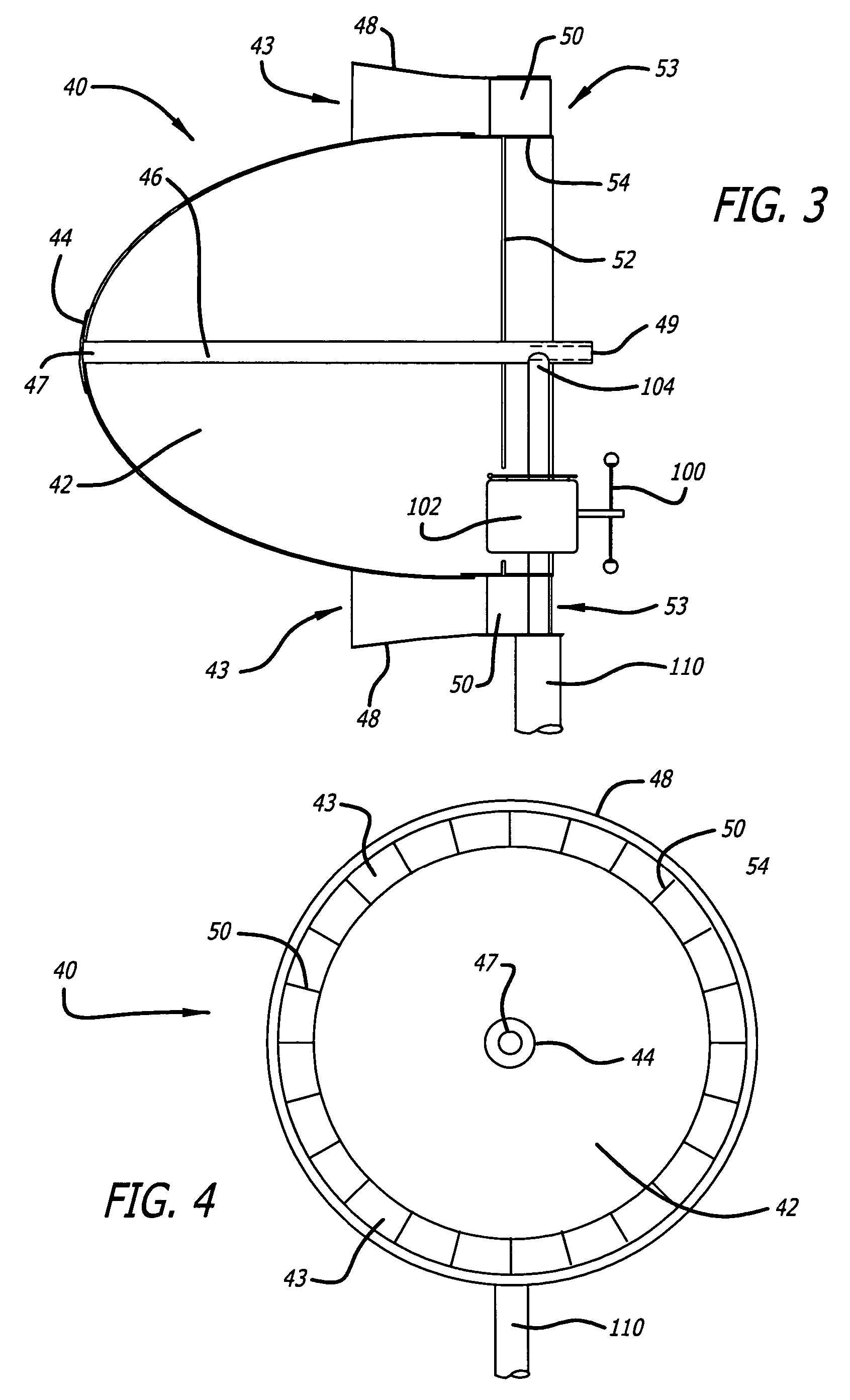

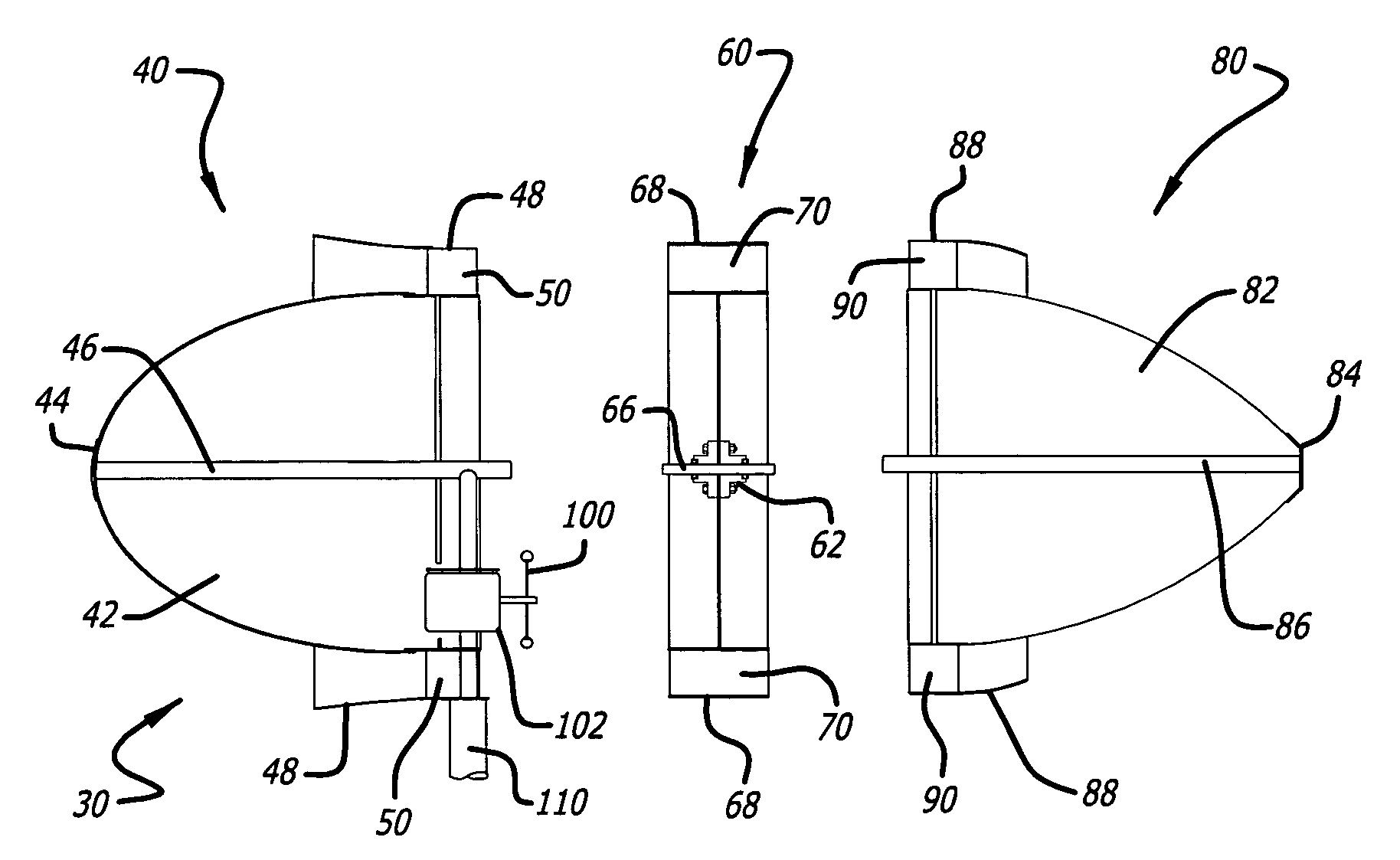

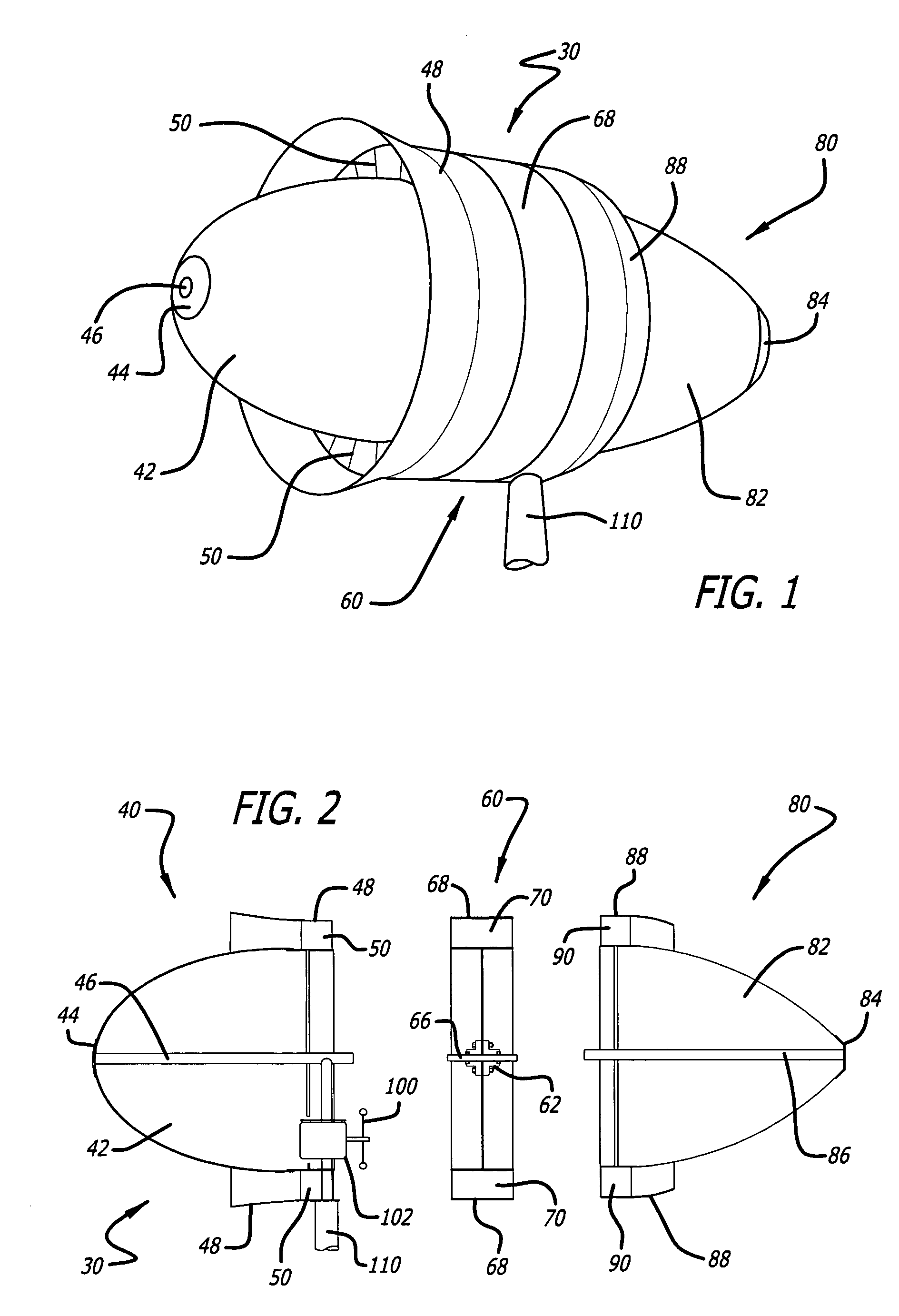

Laminar air turbine

InactiveUS7214029B2Low costMaximize rotational forcePump componentsWind motor controlWind drivenTurbine wheel

The windmill assembly is a low drag, streamlined body of revolution that captures the kinetic energy content of the accelerated laminar air surrounding the body. The assembly includes a power-generating, wind-driven turbine that is compact, lightweight and capable of producing a substantially greater output than a conventional windmill with a comparable size rotor. The turbine includes a protruding aerodynamic nose and outer cowling that provide a streamlined, wind-collecting inlet section that constricts the incoming air stream and increases its velocity through the turbine blades. The turbine further includes an exit section designed to exhaust the air stream with a minimum of turbulence. One or more generators are coupled to a turbine wheel, and are electrically switched on and off to maximize the energy capture over the full range of ambient winds. The wind turbine assembly may be configured around a blimp-type body having counter-rotating turbine assemblies.

Owner:RICHTER DONALD L

Integrated bypass and variable geometry configuration for an exhaust gas turbocharger

InactiveUS6941755B2Suitable for operationSimple and durableInternal combustion piston enginesWind motor controlImpellerTurbine wheel

Owner:FCA US

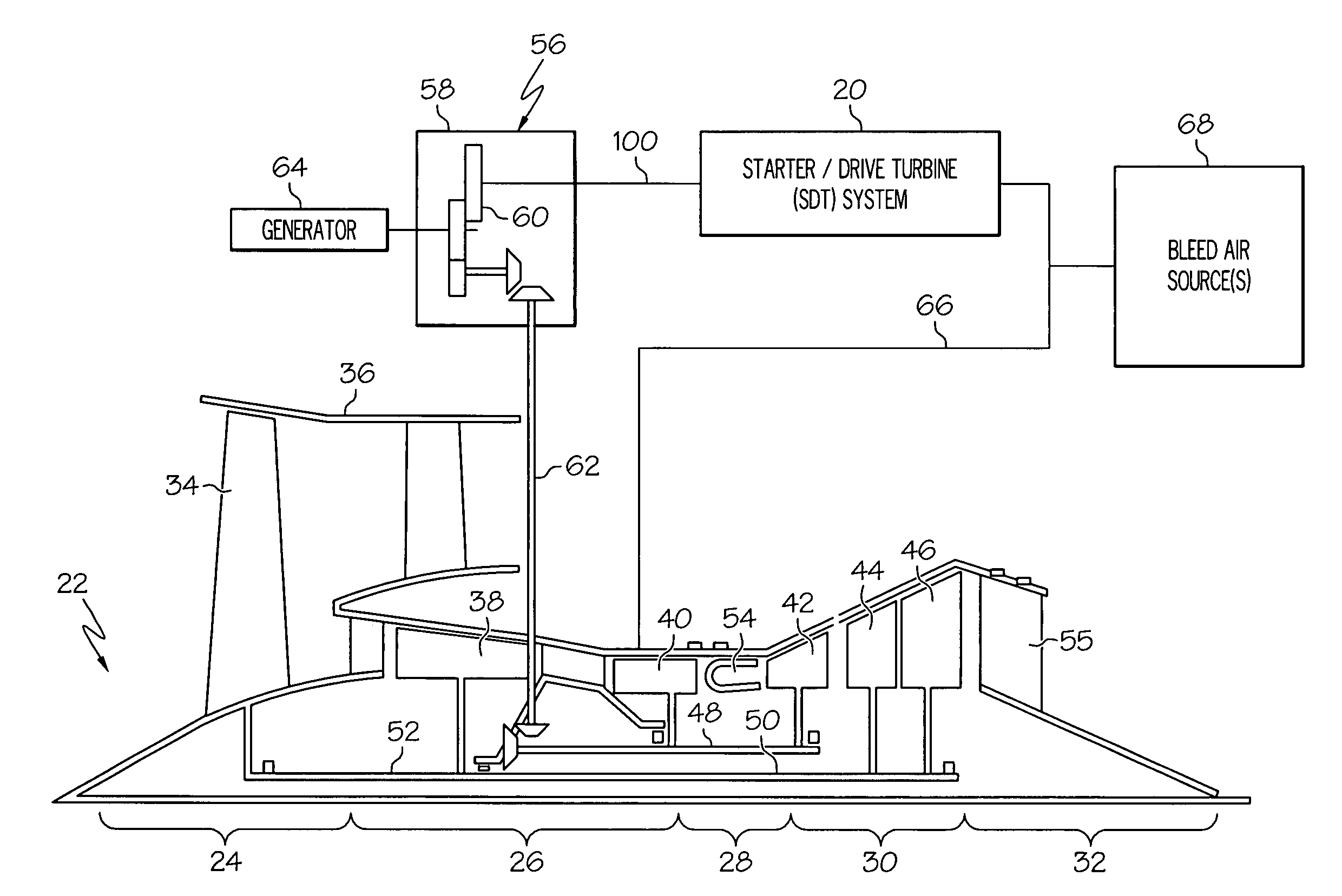

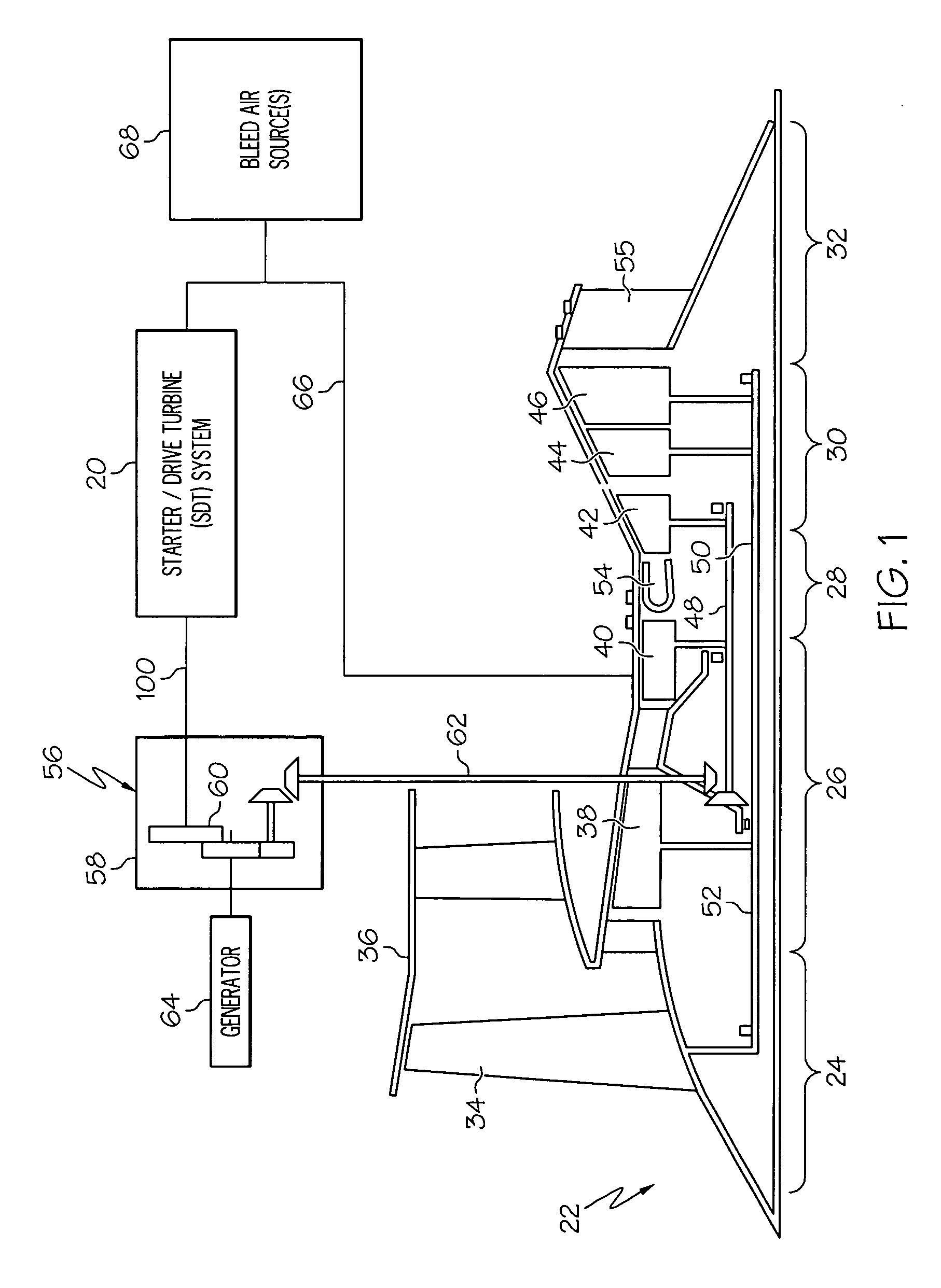

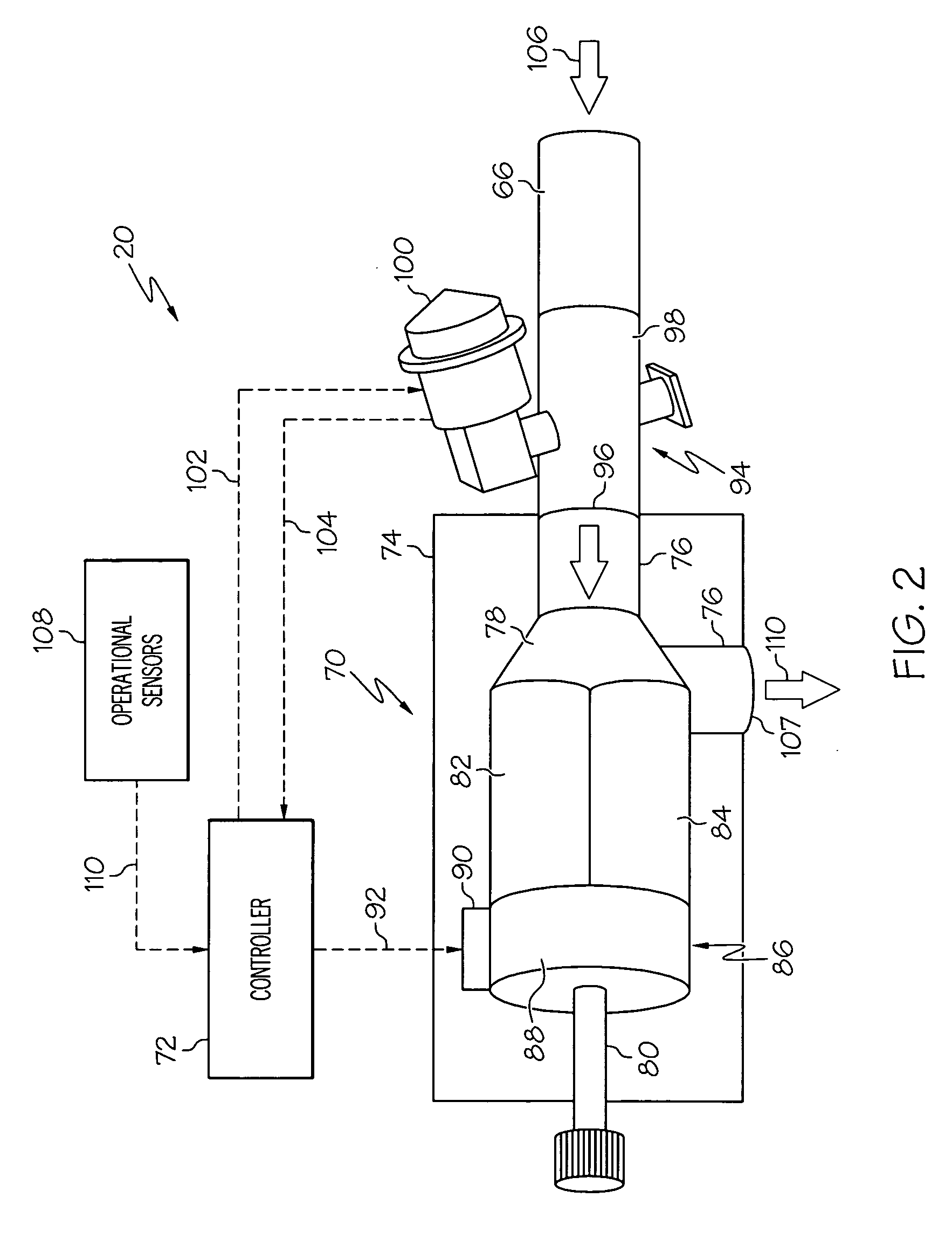

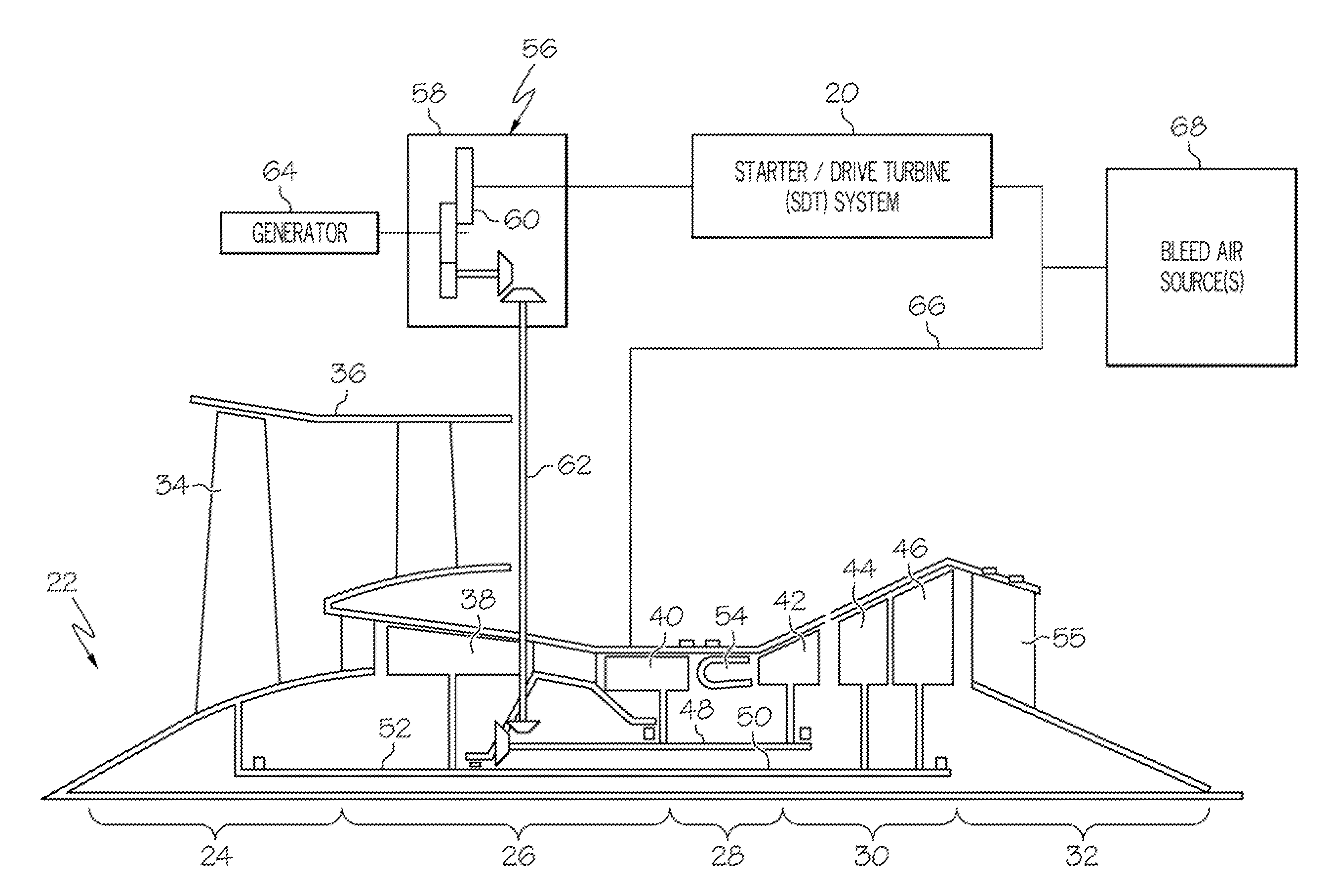

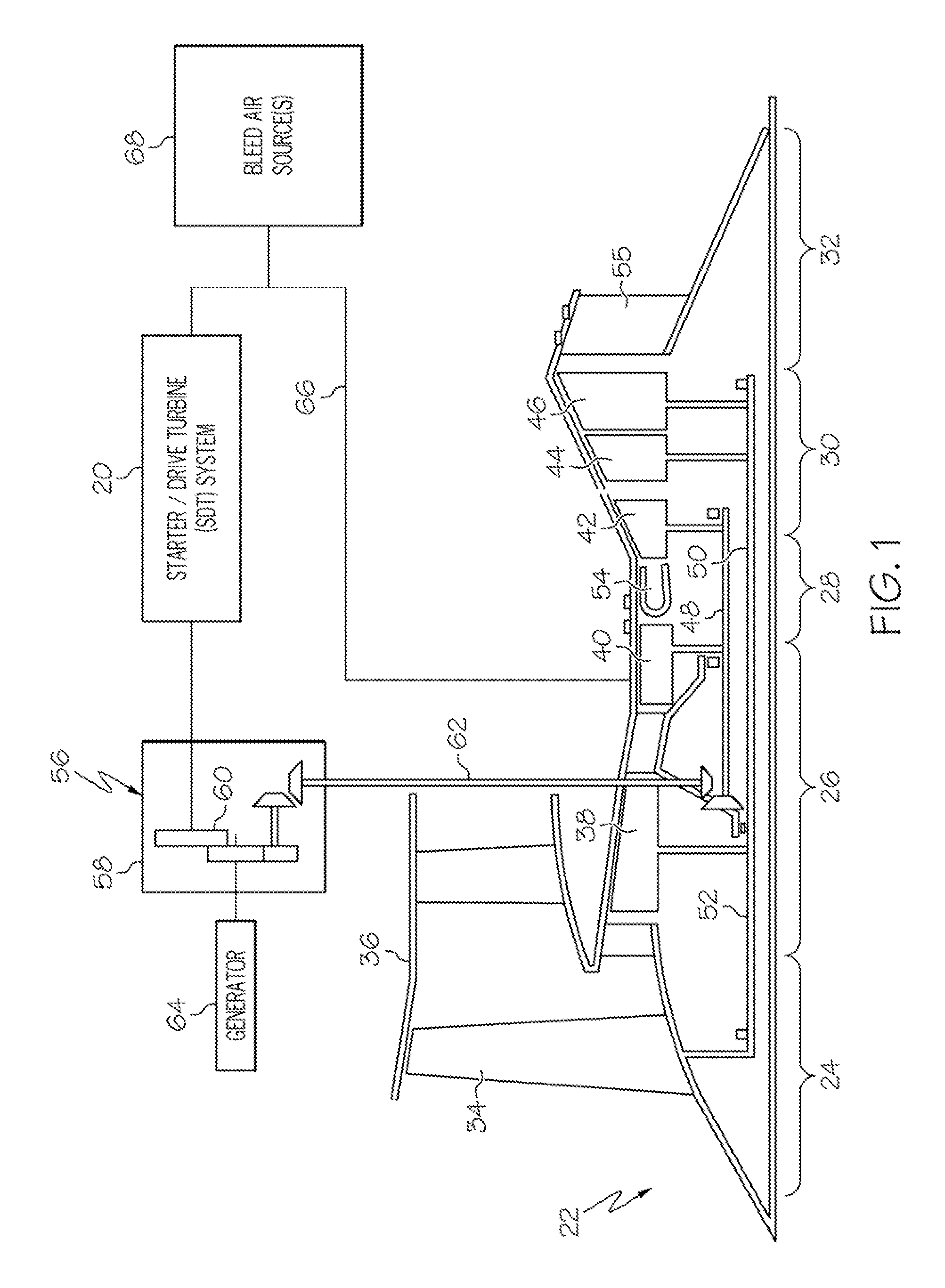

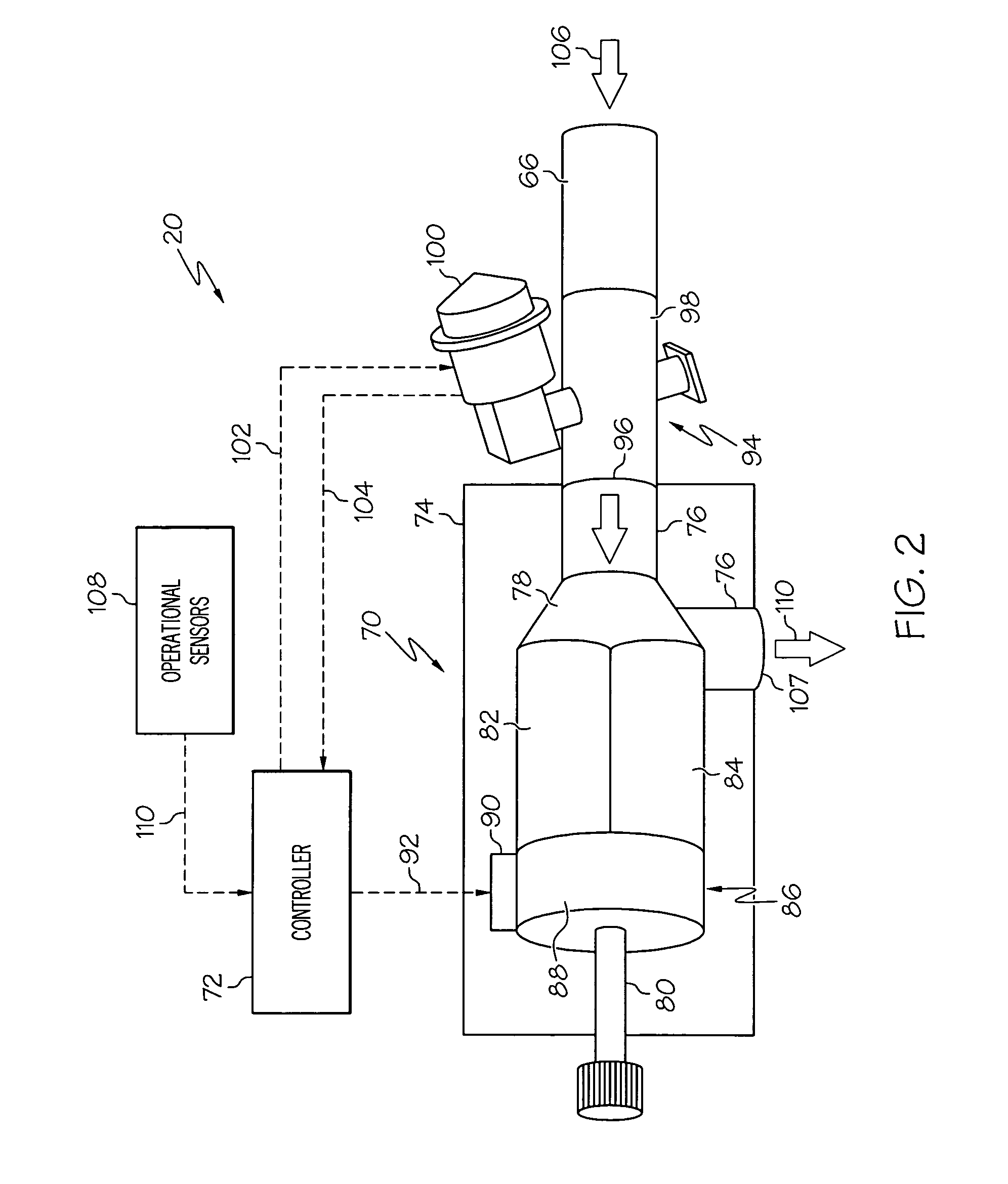

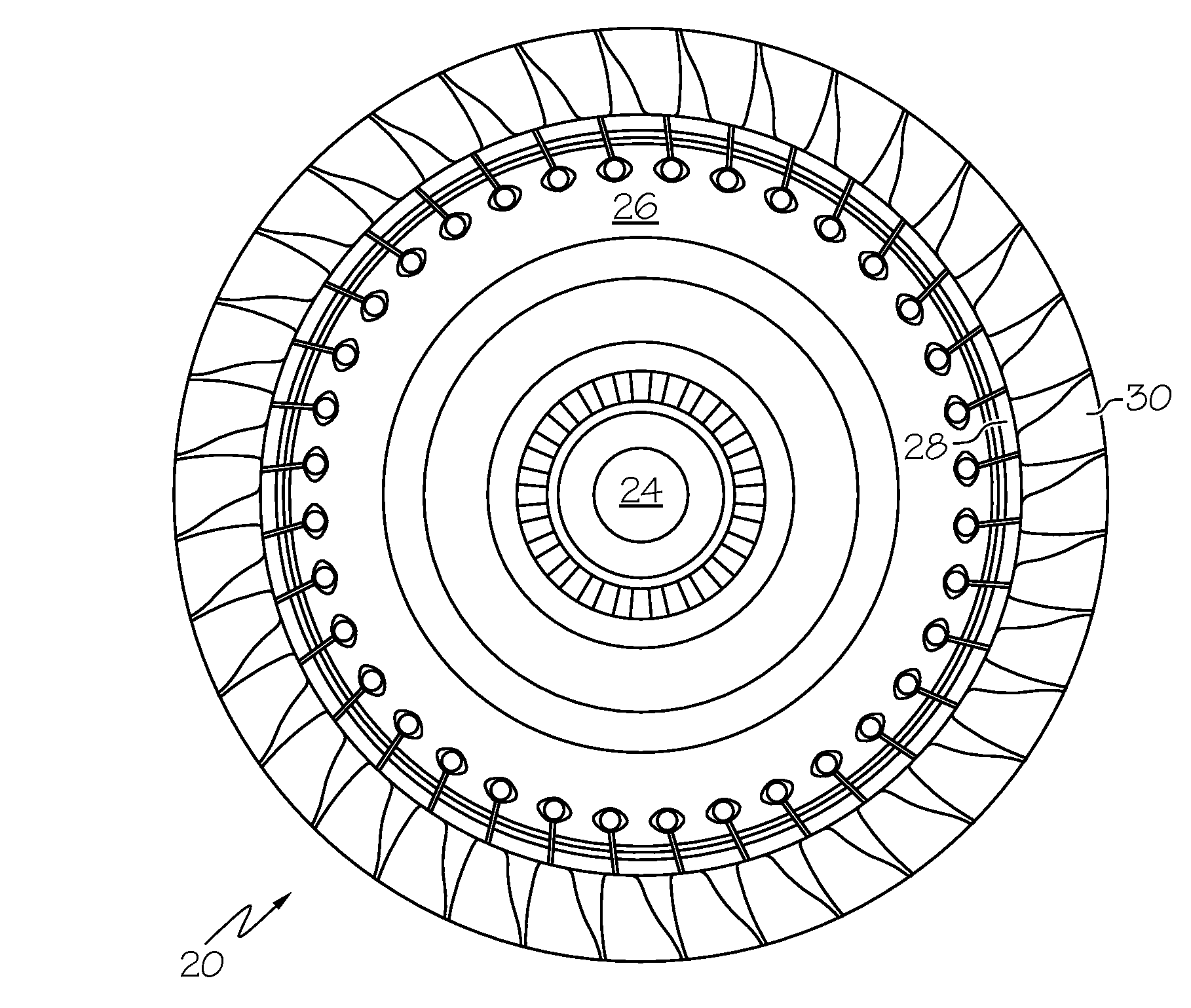

Bi-modal turbine assembly and starter / drive turbine system employing the same

A bi-modal turbine assembly is provided for use in conjunction with a gas turbine engine. In one embodiment, the bi-modal turbine assembly includes a housing assembly having a flow passage therethrough, a turbine wheel rotatably mounted in the housing assembly and positioned so as to be driven by pressurized air flowing through the flow passage, an output shaft rotatably mounted in the housing assembly, and first and second gear trains disposed in the housing assembly. A switching device is also disposed in the housing assembly and configured to mechanically couple: (i) the first gear train between the turbine wheel and the output shaft in a first operational mode, and (ii) the second gear train between the turbine wheel and the output shaft in a second operational mode.

Owner:HONEYWELL INT INC

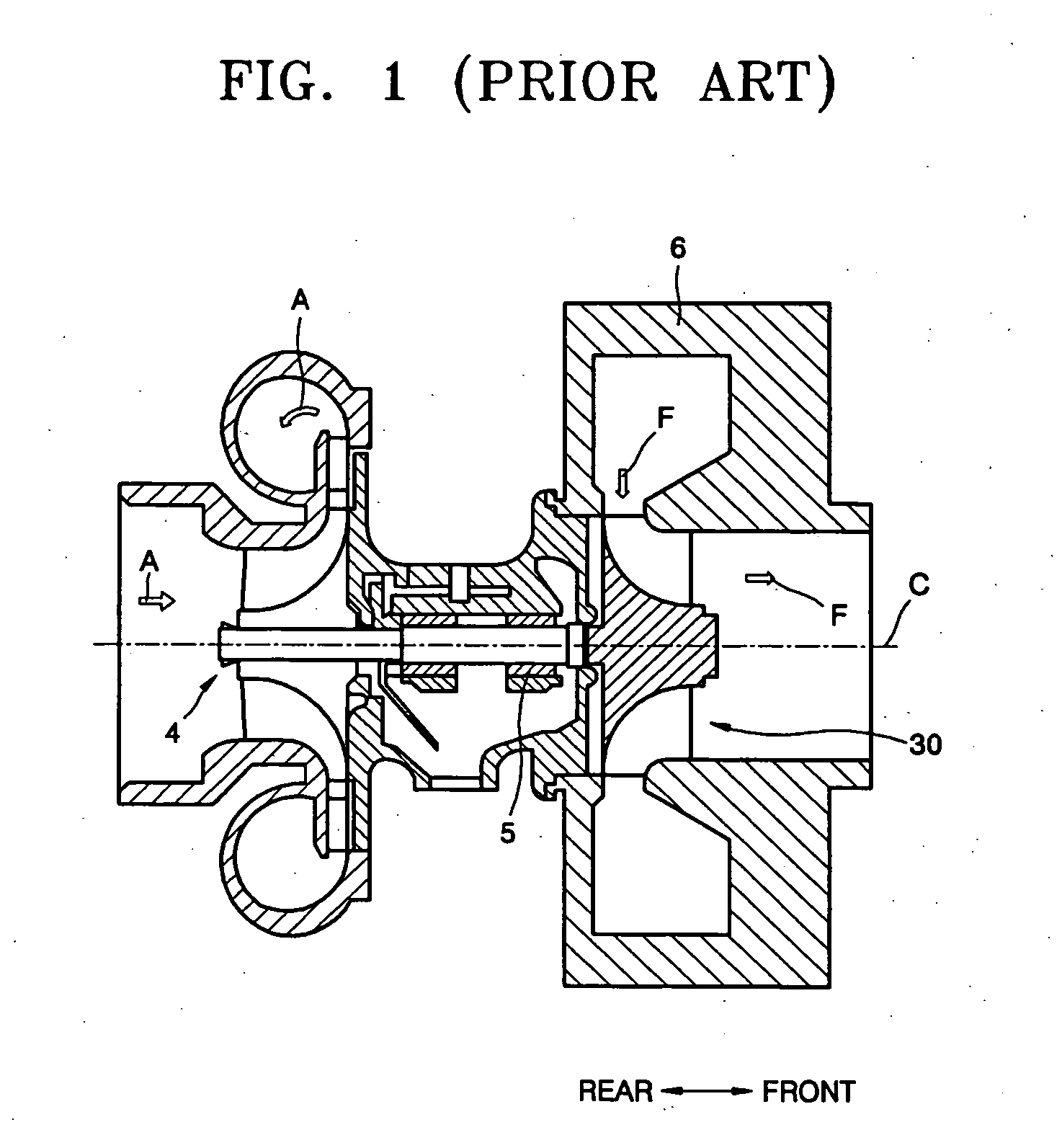

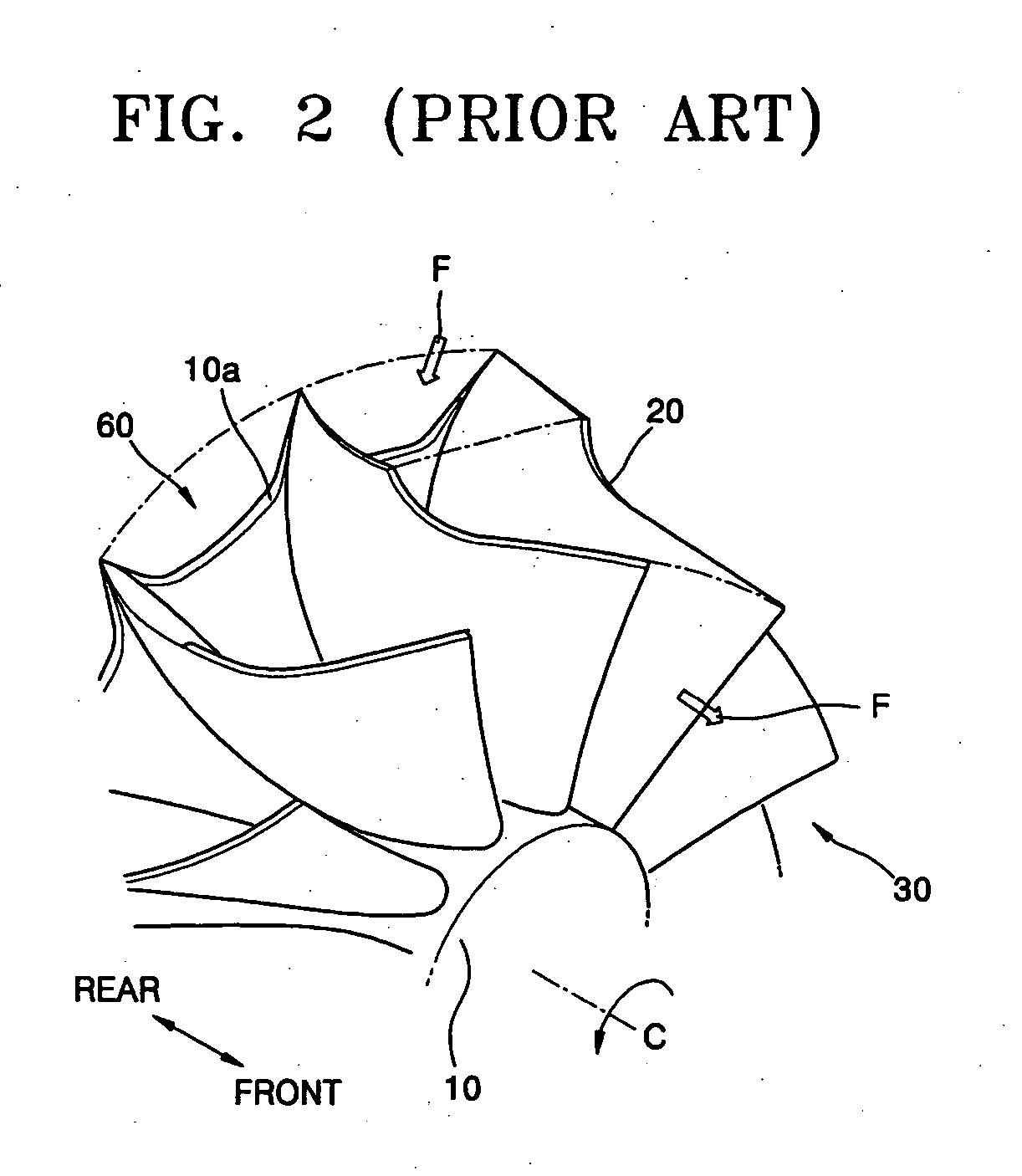

Sealing device for a turbocharger

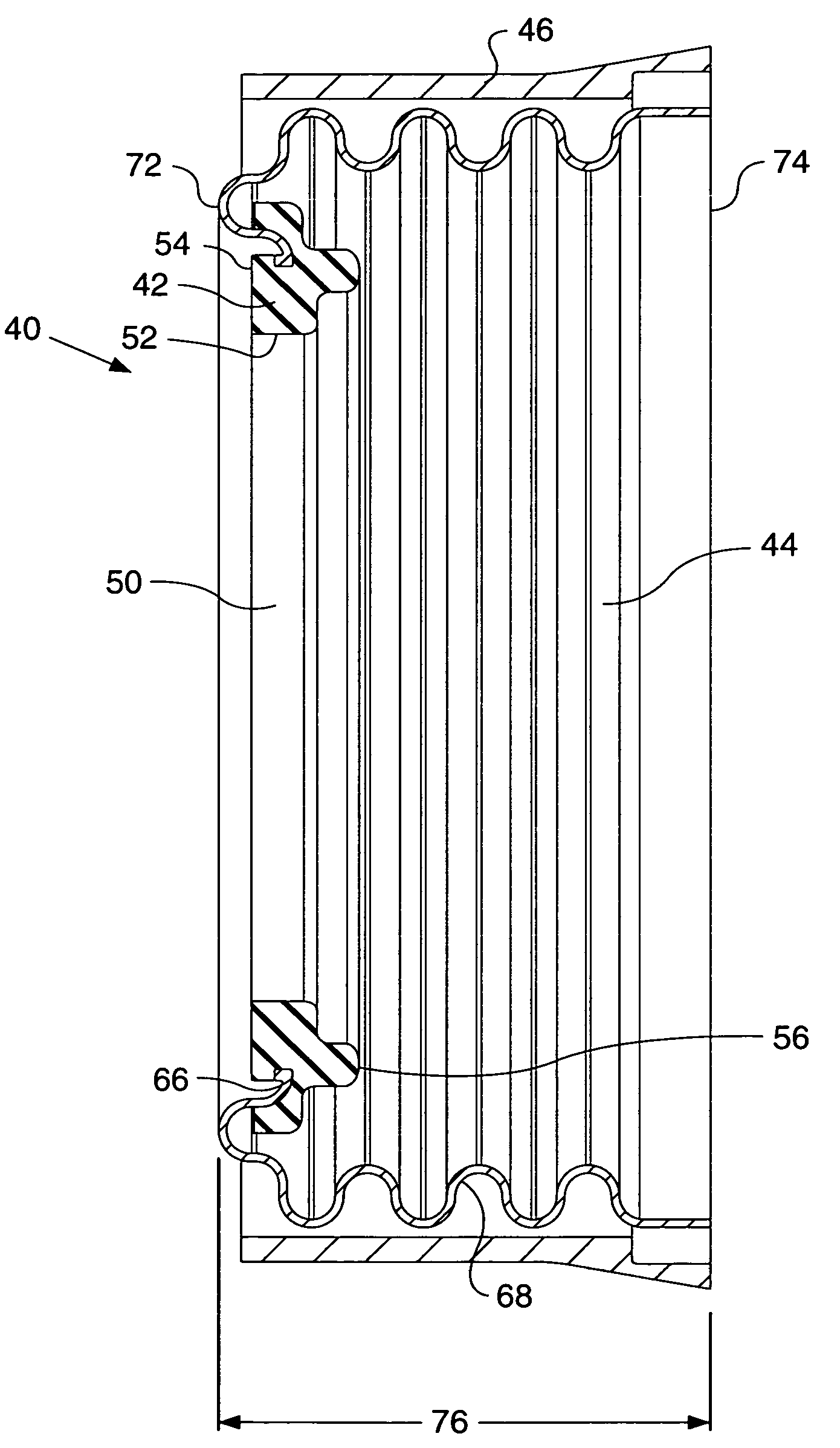

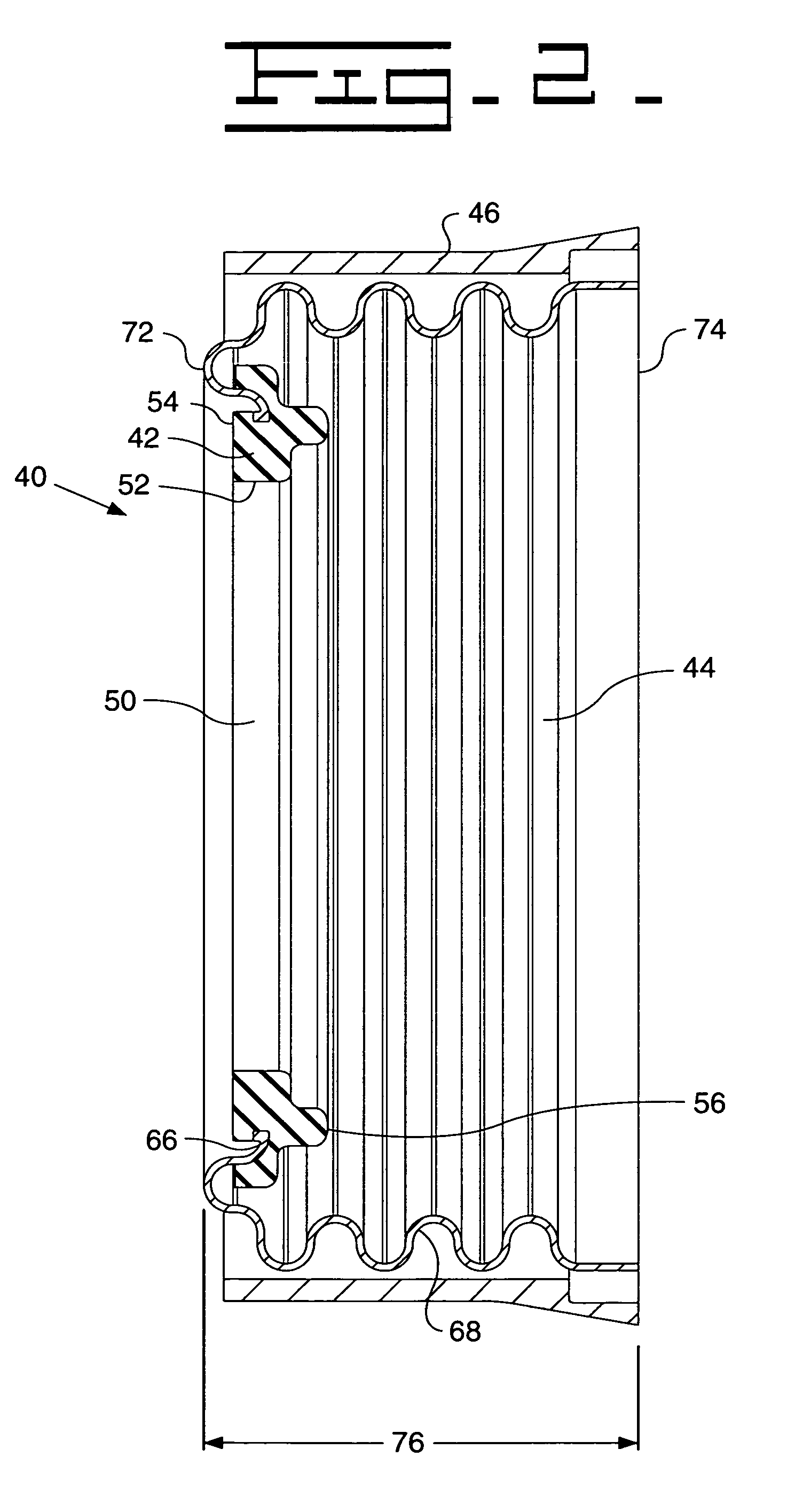

A sealing device has a seal ring and a cylindrical bellows portion connected to the seal ring. The cylindrical bellows portion has a corrugated outer surface. A turbocharger utilizing the sealing device has a turbine wheel connected to a shaft and a compressor wheel connected to the shaft. The sealing device is sealingly engaged with the shaft. The sealing device provides a seal between a bearing housing of the turbocharger and either a turbine housing or a compressor housing.

Owner:CATERPILLAR INC

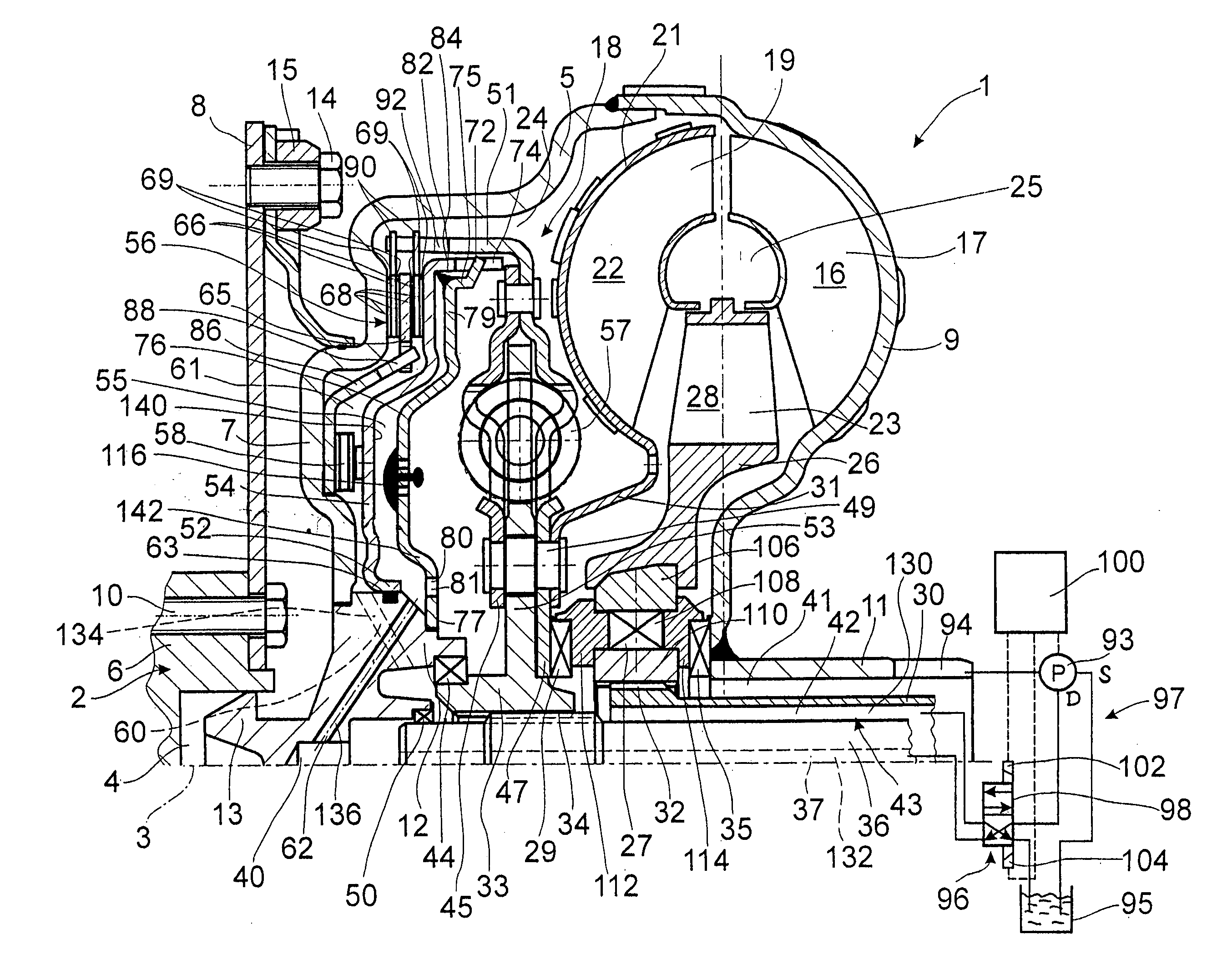

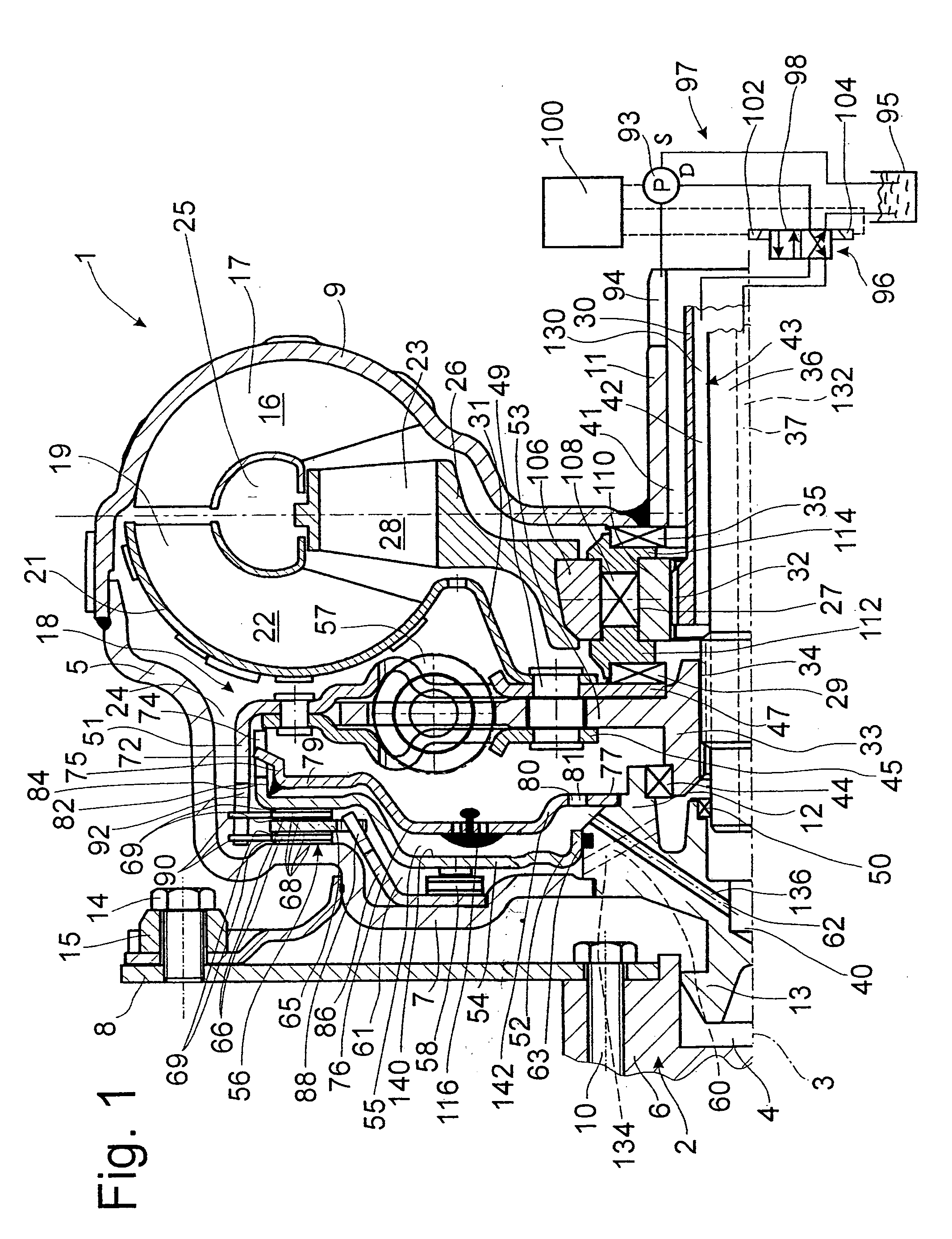

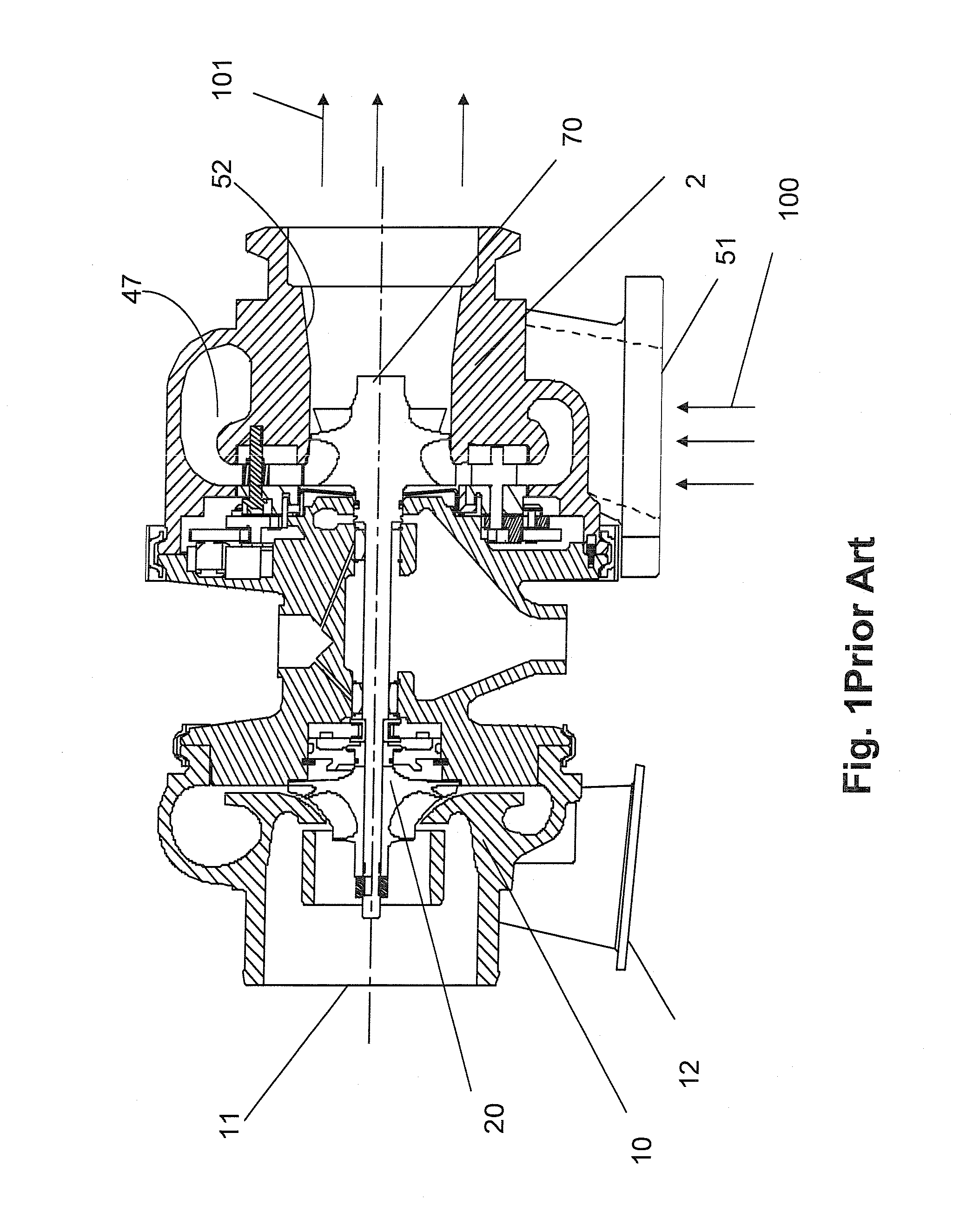

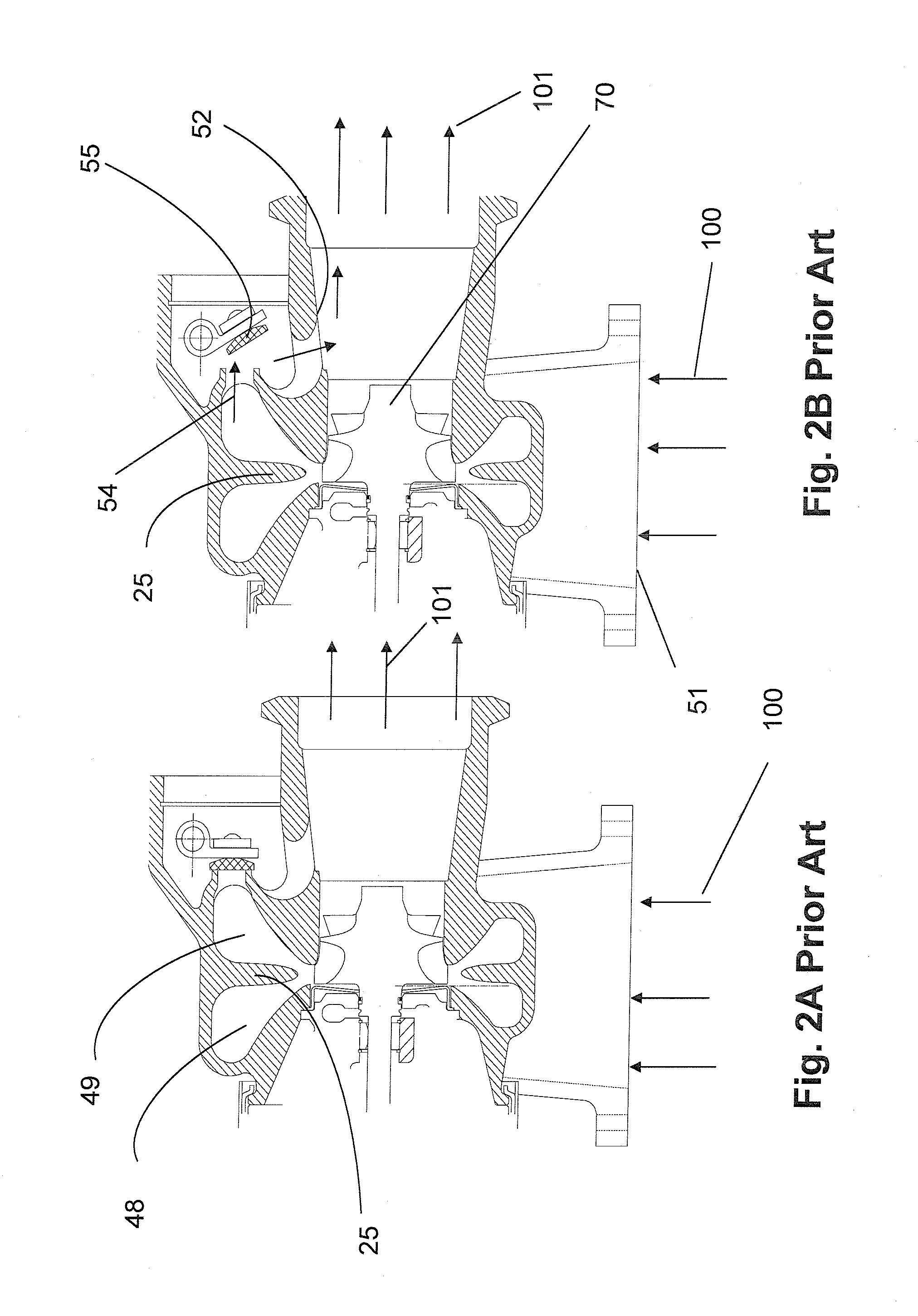

Hydrodynamic torque converter

InactiveUS20020033310A1Improve performanceSimple and accurate mannerRotary clutchesFluid actuated clutchesRotational axisImpeller

A hydrodynamic torque converter includes a converter housing and a turbine wheel which is arranged in the converter housing and is rotatable with respect to the converter housing about a rotational axis of the converter. The torque converter further includes a lockup clutch for producing a torque transmission connection between the converter housing and the turbine wheel. The lockup clutch has a first friction surface arrangement held by a first friction surface carrier arrangement substantially fixed with respect to rotation relative to the converter housing, a second friction surface arrangement is held by a second friction surface carrier arrangement substantially fixed with respect to rotation relative to the turbine wheel, a contact pressing arrangement for pressing the first and the second friction surface arrangement against one another in frictional contact, and an abutment arrangement at which the first and second friction surface arrangement can be supported substantially in the direction of the axis of rotation when pressed by the contact pressure arrangement. The first friction surface carrier arrangement has a substantially annular body region connected either directly or indirectly with the converter housing and driver projections which are arranged at a distance from one another in the circumferential direction proceeding from the body region. Respective counter-driver projections at the first friction surface arrangement engage between these driver projections.

Owner:ZF FRIEDRICHSHAFEN AG

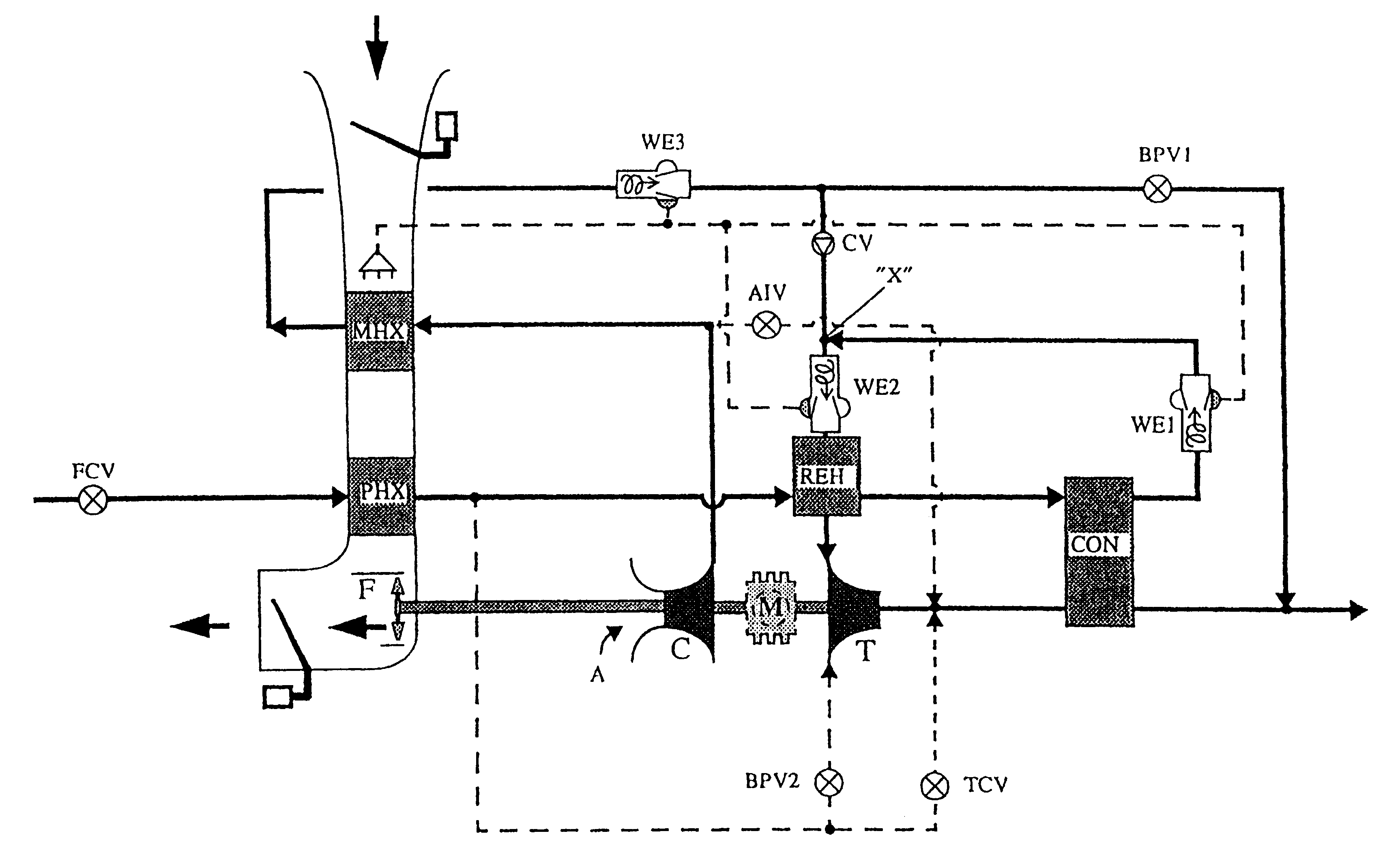

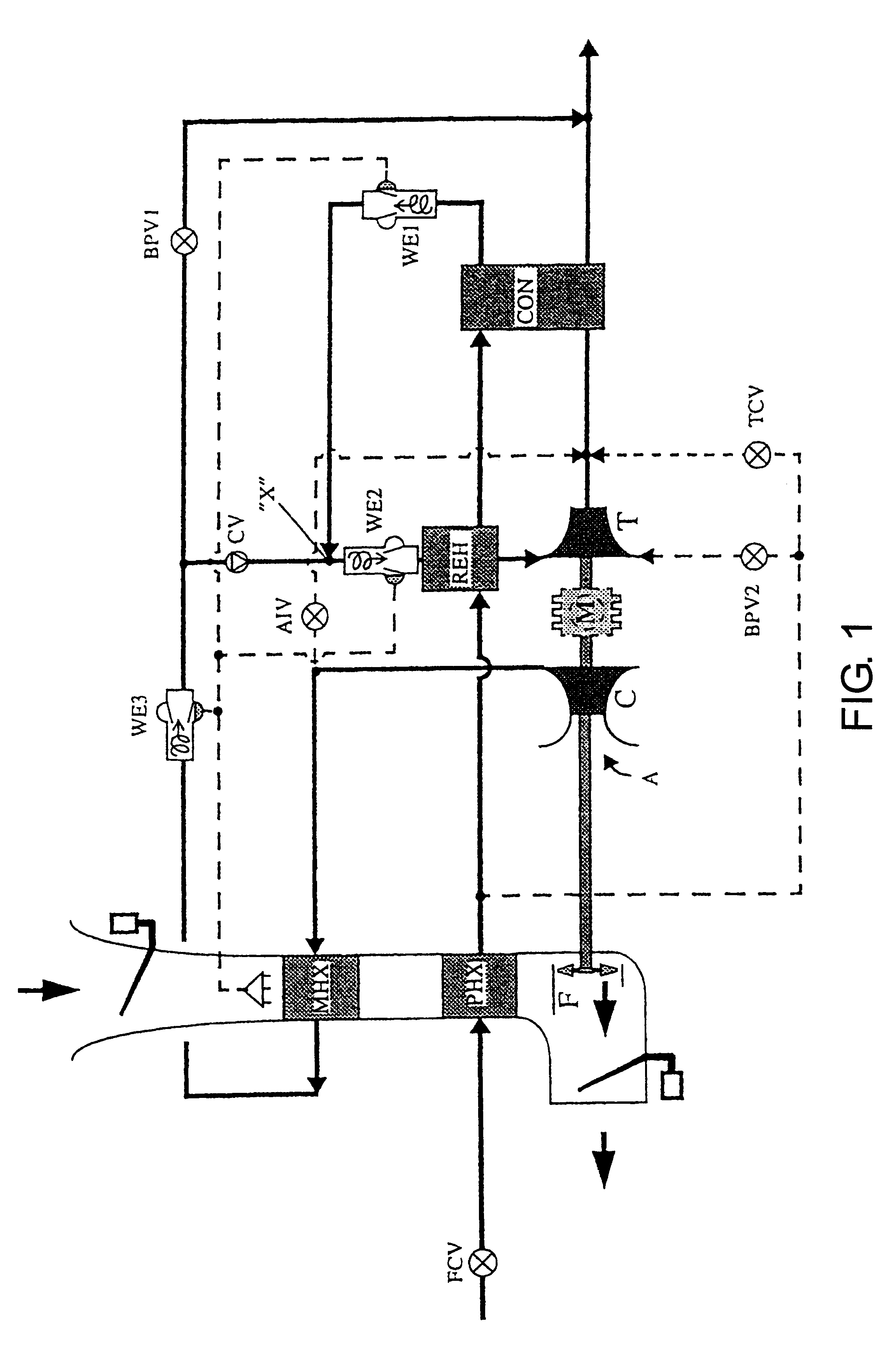

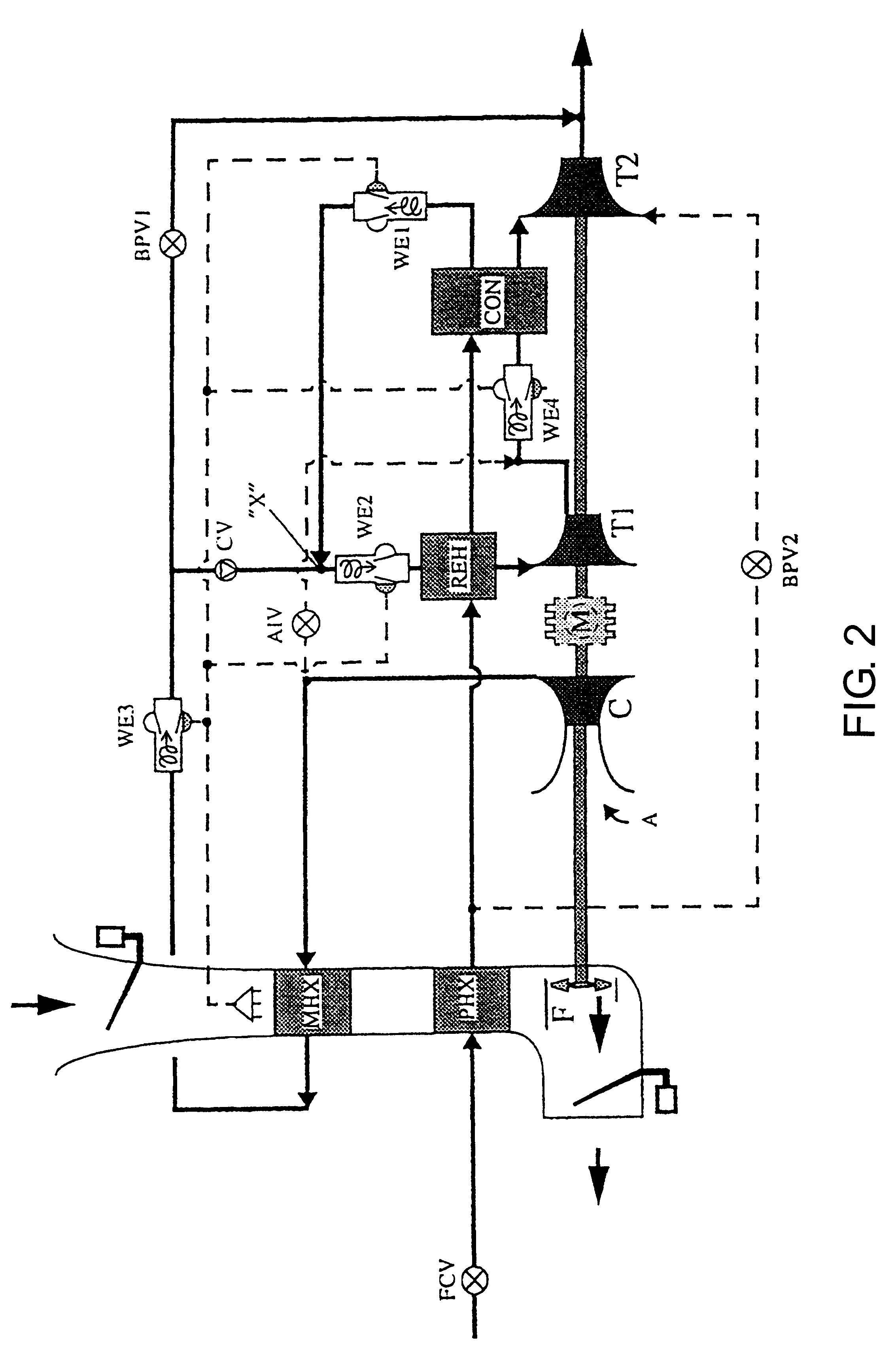

Air-conditioning system for airplane cabin

InactiveUS6519969B2Provide goodDomestic cooling apparatusAir-treatment apparatus arrangementsTurbine wheelEngineering

An air-conditioning system for airplanes is proposed in which a portion of the fresh airflow to be prepared is tapped at high pressure from a power unit and another portion is sucked in from the surroundings. The energy potential of the tapped airflow is utilized to compress the ambient air. The compressed ambient air and the tapped air are mixed into a mixed airflow before the mixed airflow's pressure is expanded in one or more turbine stages (T1, T2). Water is separated from the mixed airflow between the mixing point (X) and the first turbine stage 1 (T1). In order to cool down the tapped airflow to a temperature at which water can be separated at all, the tapped airflow is guided past the entire cooler mixed airflow, preferably in two steps (REH, CON), namely once before the pressure expansion and another time after the pressure expansion of the mixed airflow in the first turbine stage (T1) . In a preferred form of execution, the ambient air is compressed in two steps, in connection with which in each case a compressor wheel (C1, C2) and a turbine wheel (T2, T1) (two-step pressure expansion) are mounted together on a shaft.

Owner:LIEBHERR AEROSPACE LINDENBERG

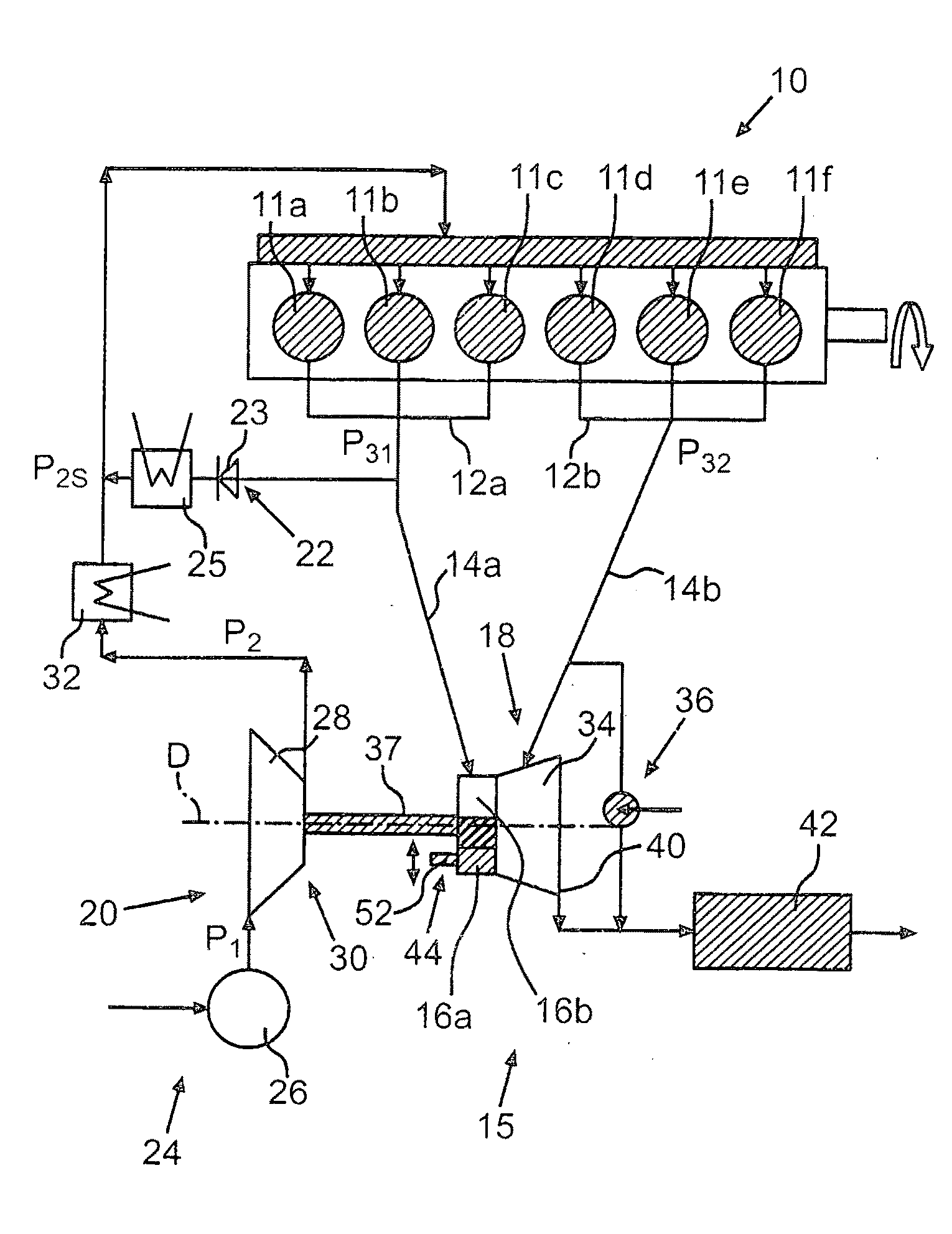

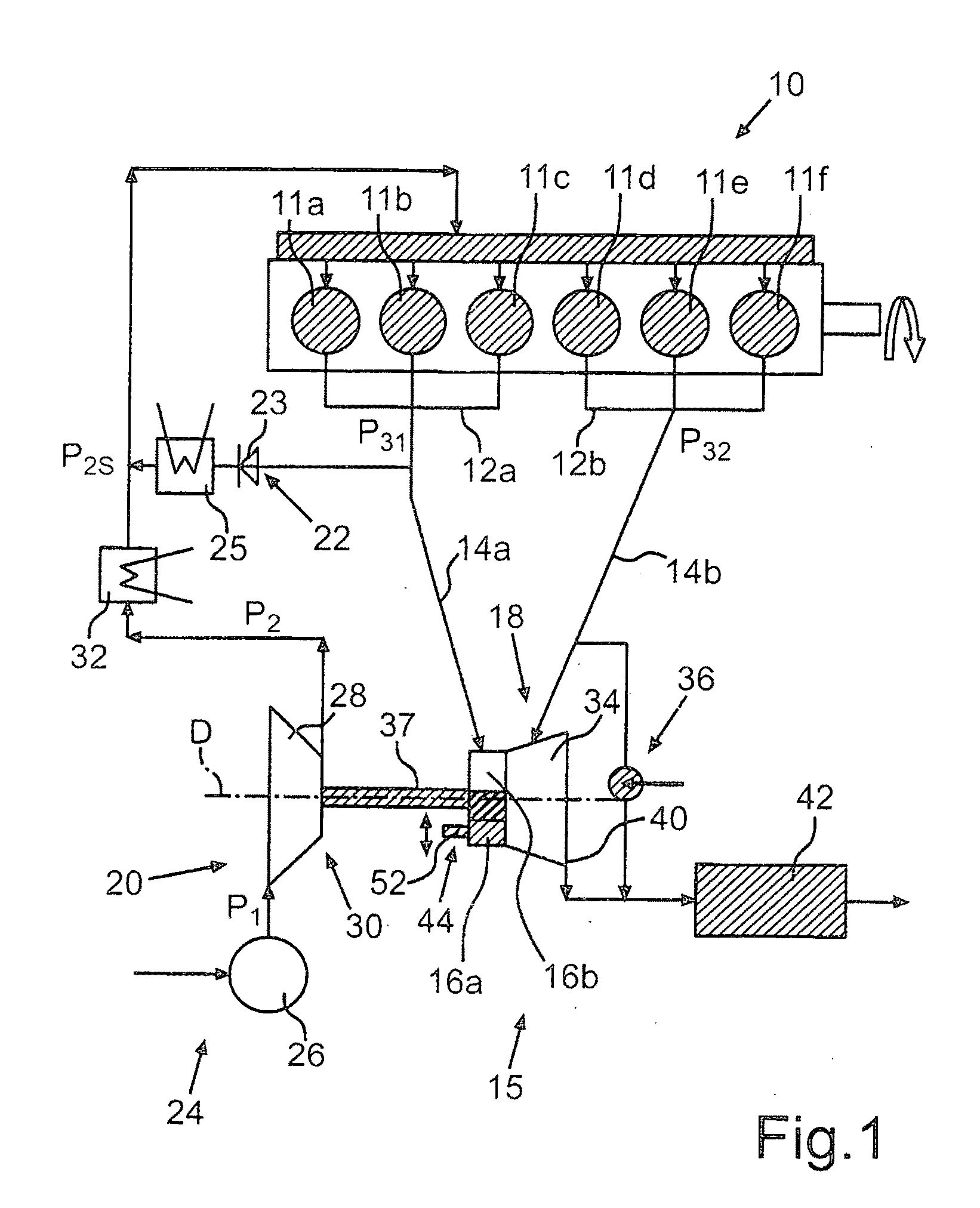

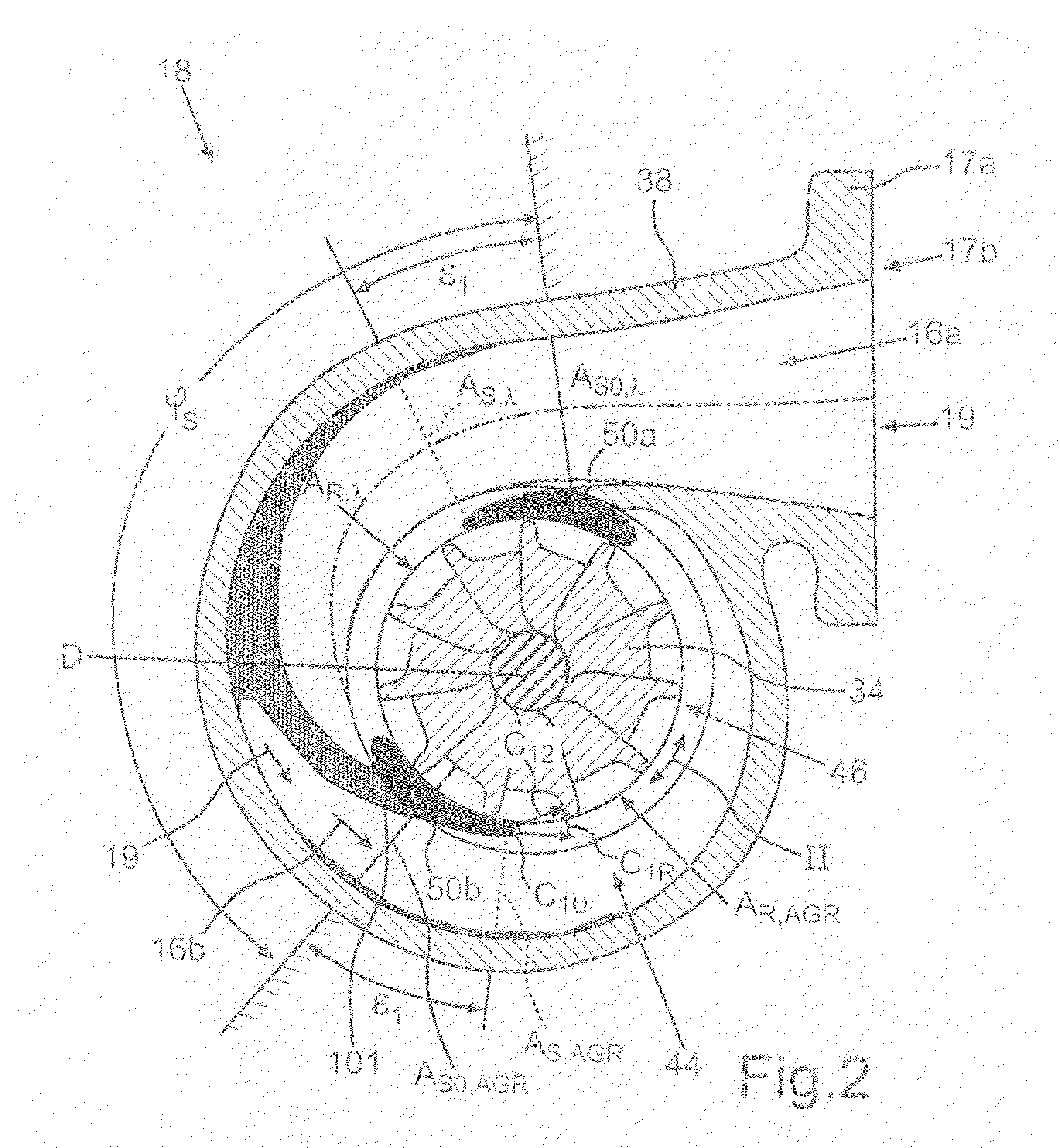

Internal combustion engine with an exhaust gas turbocharger

InactiveUS20110067397A1Improve efficiencyLarge operating regionInternal combustion piston enginesNon-fuel substance addition to fuelTurbine wheelInlet channel

In an internal combustion engine for a motor vehicle having an exhaust gas turbo-charger comprising a compressor arranged in an intake tract of the internal combustion engine and a turbine arranged in an exhaust gas tract of the internal combustion engine, with a turbine wheel disposed the turbine housing, an adjustment device is provided by means of which a spiral inlet cross section of a spiral turbine inlet channel and a nozzle cross section of the spiral inlet channel to the turbine wheel are jointly adjustable by a common adjustment device. The invention further relates to an exhaust gas turbocharger, a motor vehicle having an internal combustion engine and a method for operating an internal combustion engine having an exhaust gas turbocharger.

Owner:DAIMLER AG

Bi-modal turbine assembly and starter / drive turbine system employing the same

A bi-modal turbine assembly is provided for use in conjunction with a gas turbine engine. In one embodiment, the bi-modal turbine assembly includes a housing assembly having a flow passage therethrough, a turbine wheel rotatably mounted in the housing assembly and positioned so as to be driven by pressurized air flowing through the flow passage, an output shaft rotatably mounted in the housing assembly, and first and second gear trains disposed in the housing assembly. A switching device is also disposed in the housing assembly and configured to mechanically couple: (i) the first gear train between the turbine wheel and the output shaft in a first operational mode, and (ii) the second gear train between the turbine wheel and the output shaft in a second operational mode.

Owner:HONEYWELL INT INC

First stage dual-alloy turbine wheel

A first-stage turbine that is adapted for receiving high energy air directly from a combustion chamber in a gas turbine engine auxiliary power unit includes a disk formed from a first alloy and having an outer surface, and a unitary blade wheel formed from a second alloy that is different than the first alloy. The unitary blade wheel includes an annular member having an inner surface that is joined to the disk, and blades that are integrally formed with the annular member.

Owner:HONEYWELL INT INC

Laminar air turbine

InactiveUS20060002786A1Low costMaximize rotational forceWind motor controlPump componentsWind drivenTurbine wheel

The windmill assembly is a low drag, streamlined body of revolution that captures the kinetic energy content of the accelerated laminar air surrounding the body. The assembly includes a power-generating, wind-driven turbine that is compact, lightweight and capable of producing a substantially greater output than a conventional windmill with a comparable size rotor. The turbine includes a protruding aerodynamic nose and outer cowling that provide a streamlined, wind-collecting inlet section that constricts the incoming air stream and increases its velocity through the turbine blades. The turbine further includes an exit section designed to exhaust the air stream with a minimum of turbulence. One or more generators are coupled to a turbine wheel, and are electrically switched on and off to maximize the energy capture over the full range of ambient winds. The wind turbine assembly may be configured around a blimp-type body having counter-rotating turbine assemblies.

Owner:RICHTER DONALD L

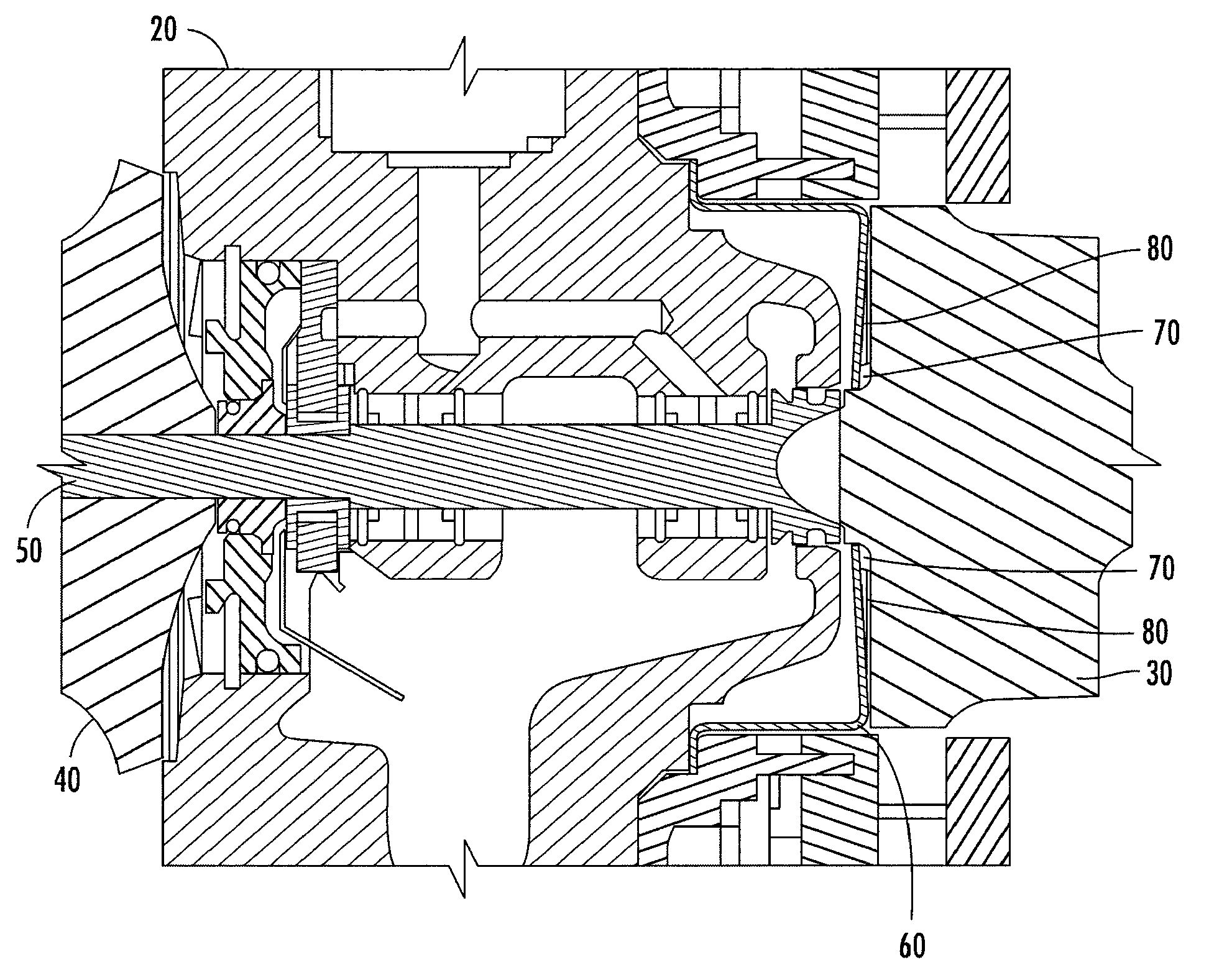

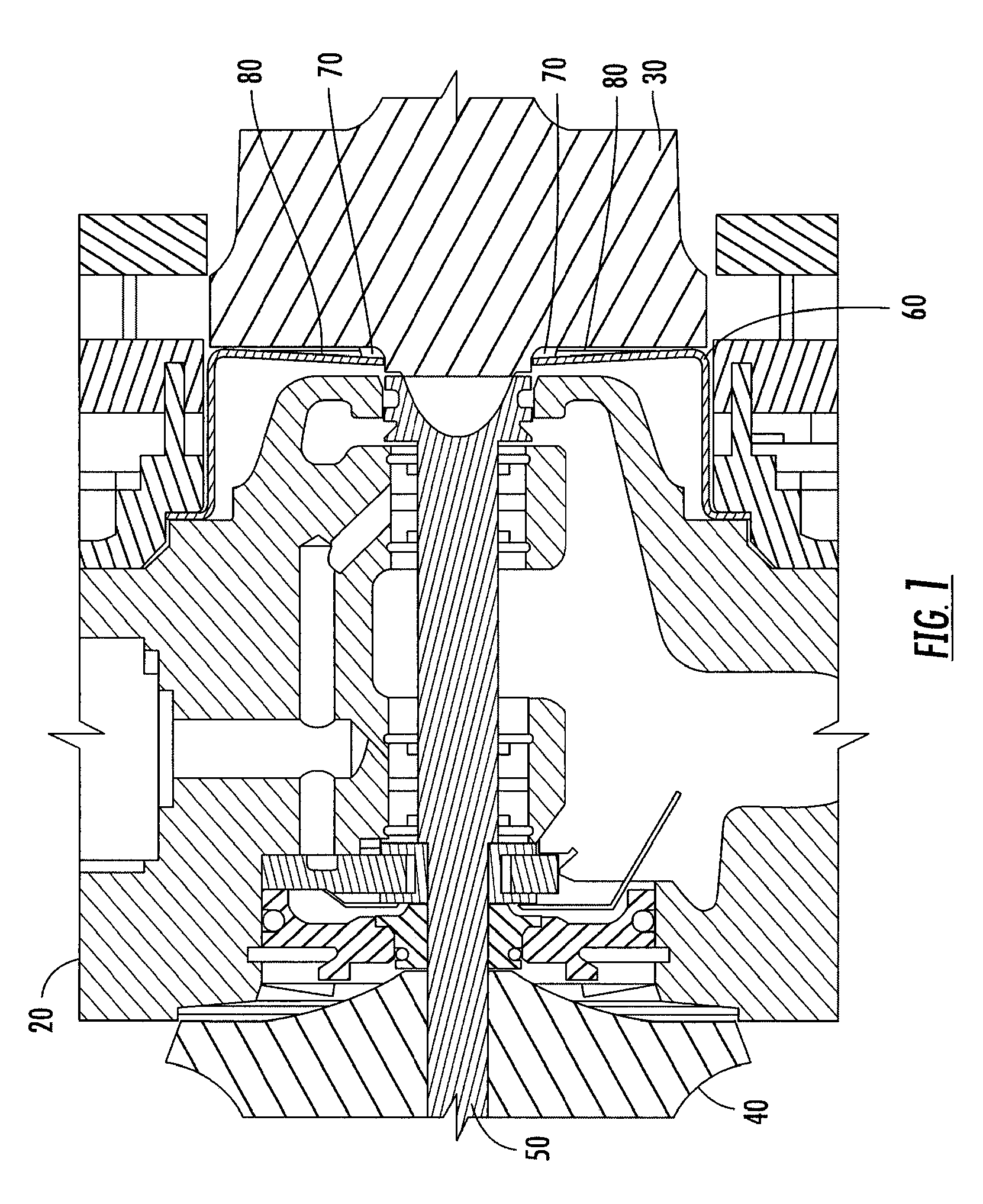

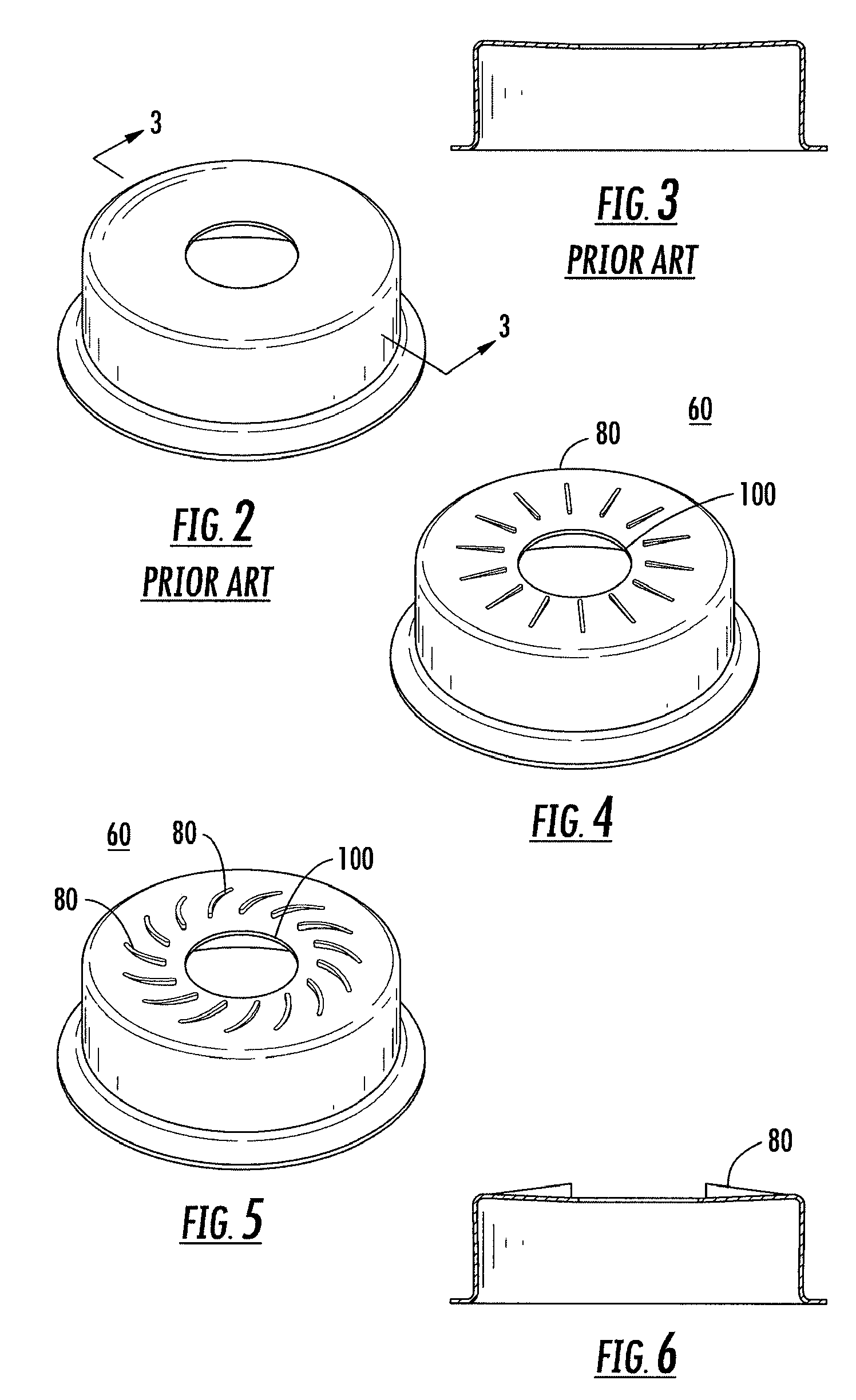

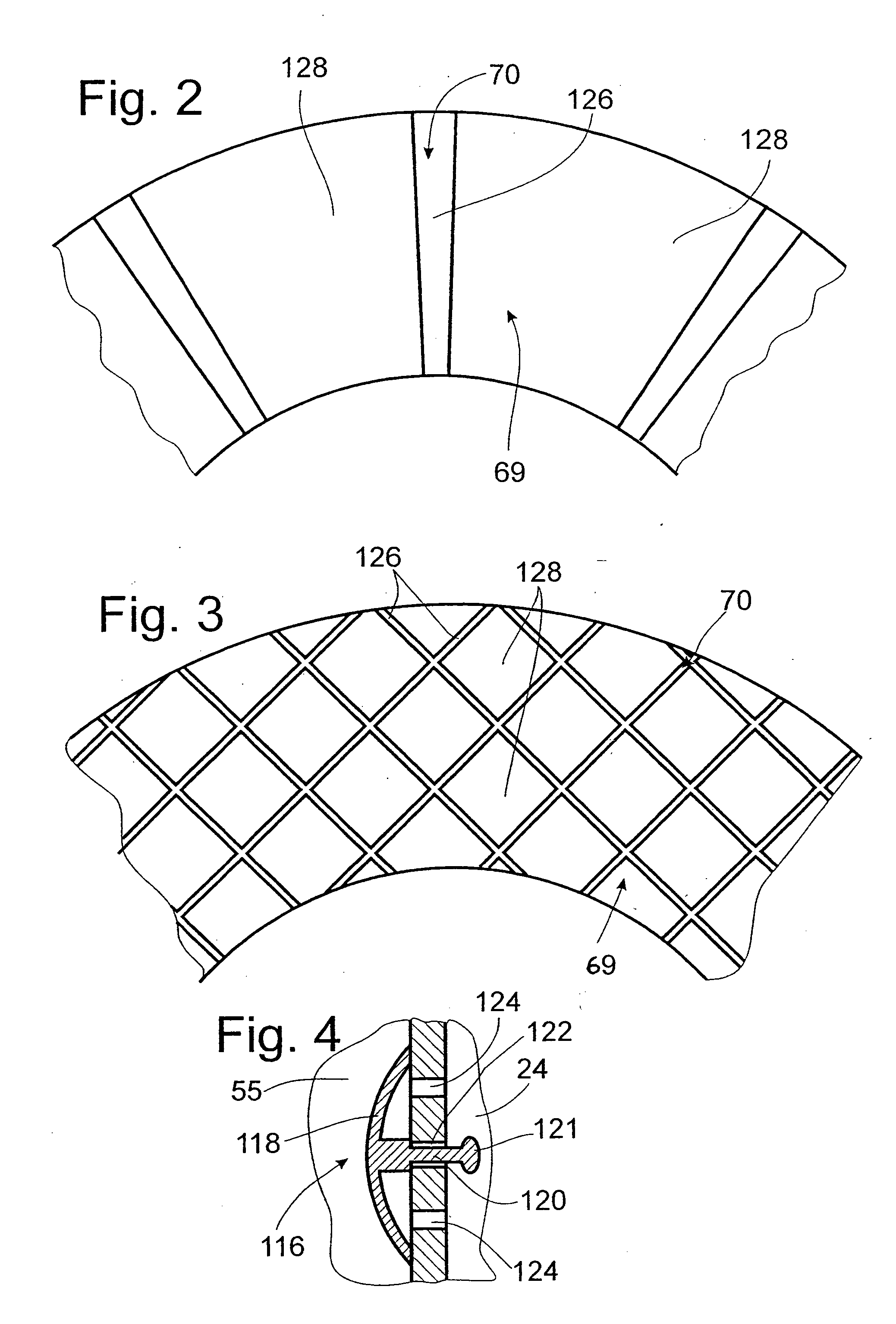

Turbine heat shield with ribs

ActiveUS7631497B2Prevent lubricant leakageReduce flowEngine manufactureCombustion enginesTurbine wheelEngineering

A turbocharger (10) with a heat shield (60) positioned between the turbine wheel (30) and the bearing housing (20), wherein the heat shield defines a gap (70) between the turbine wheel (30). The heat shield (60) and is provided with at least one rib (80) extending into the gap. In this gap, in the case of a conventional flat heat shield, the turbine wheel backface may act in the manner of a centrifugal pumping, pumping gas out from within the gap, creating a region of reduced pressure adjacent the outboard side of the turbine shaft bearing, drawing oil out the shaft bearing and into the space between the turbine wheel backface and the heat shield. The inventive heat shield has raised structures designed to interfere with the rotational and centrifugal flow of gas in the gap between heat shield and turbine wheel backface, thus prevent oil bypass.

Owner:BORGWARNER INC

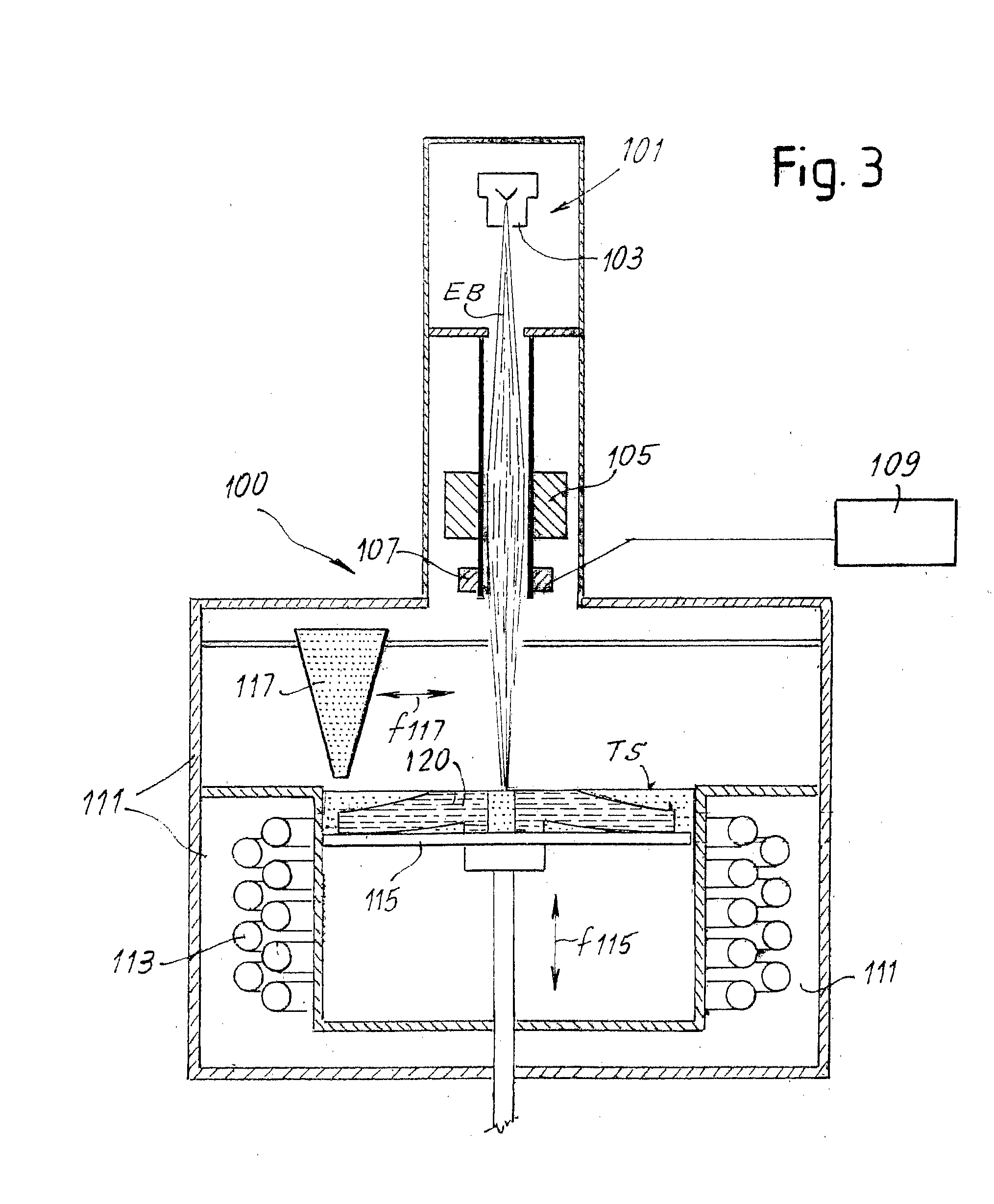

Integrated turbine power generation system with catalytic reactor

InactiveUS20040100101A1Turbine/propulsion fuel deliveryLoad balancing in dc networkImpellerTurbine wheel

Owner:CAPSTONE TURBINE

Staged turbocharger

InactiveUS7269950B2High speedShorten speedInternal combustion piston enginesExhaust apparatusImpellerTurbine wheel

A turbocharger comprising a turbine, director, and compressor. The turbine may be formed as a turbine wheel surrounded by at least two scrolls. The at least two scrolls may direct exhaust gases supplied thereto toward the turbine wheel to cause rotation thereof. The director may control distribution of the exhaust gases between the at least two scrolls to optimize circumferential velocity in the scroll or volute, and thus impingement velocity on the turbine. The compressor may be driven by the turbine.

Owner:PRECISION INDS

Radial turbine wheel with locally curved trailing edge tip

The present invention provides a turbine wheel with locally curved trailing edge blade tips on the blades of the turbine wheel. The locally curved trailing edge may increase the blade vibration mode natural frequency which may in turn result in longer blade fatigue lifetimes. It may also eliminate vortex shedding. Methods for increasing the blade vibration mode natural frequencies using the turbine wheel of the present invention are also provided.

Owner:HONEYWELL INT INC

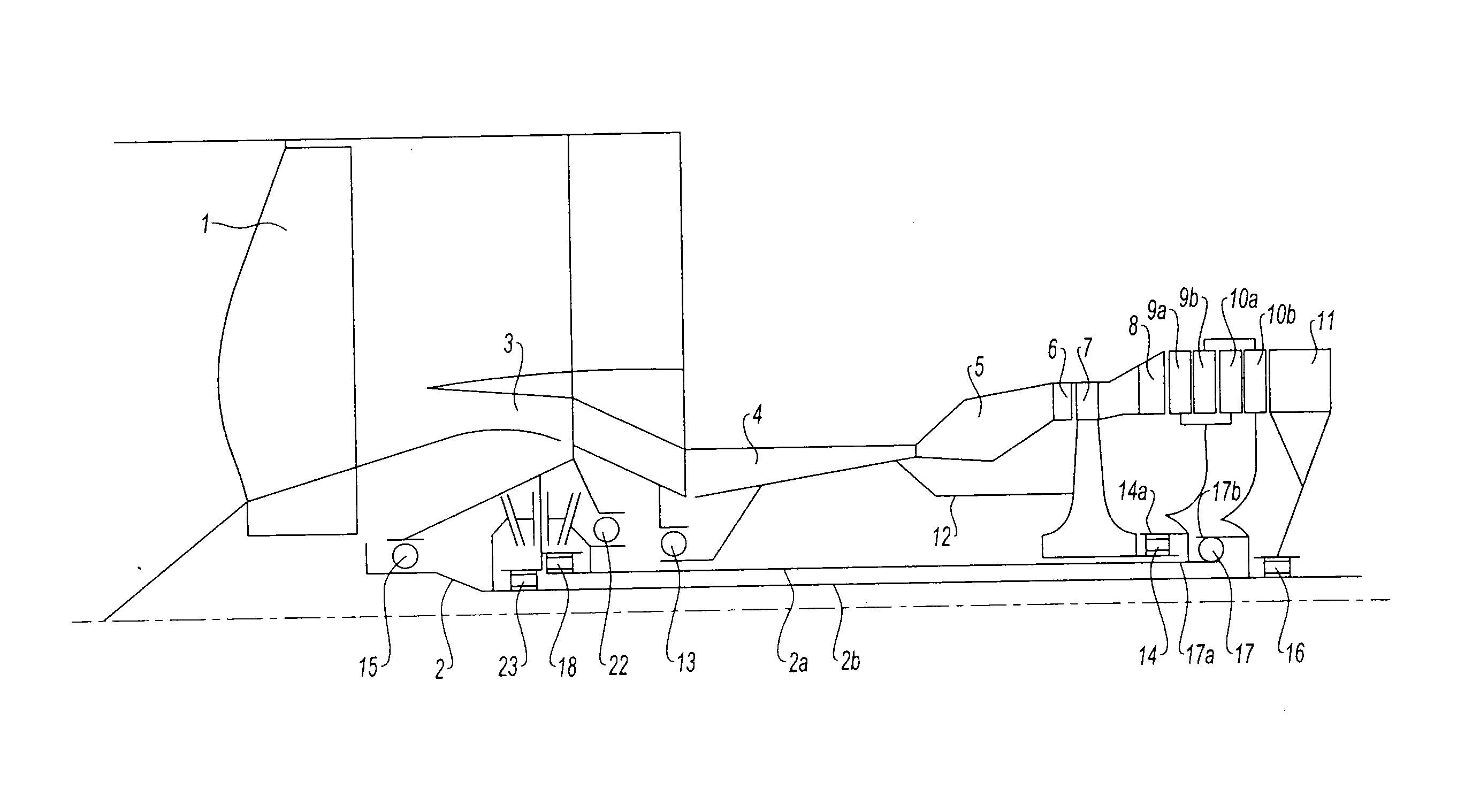

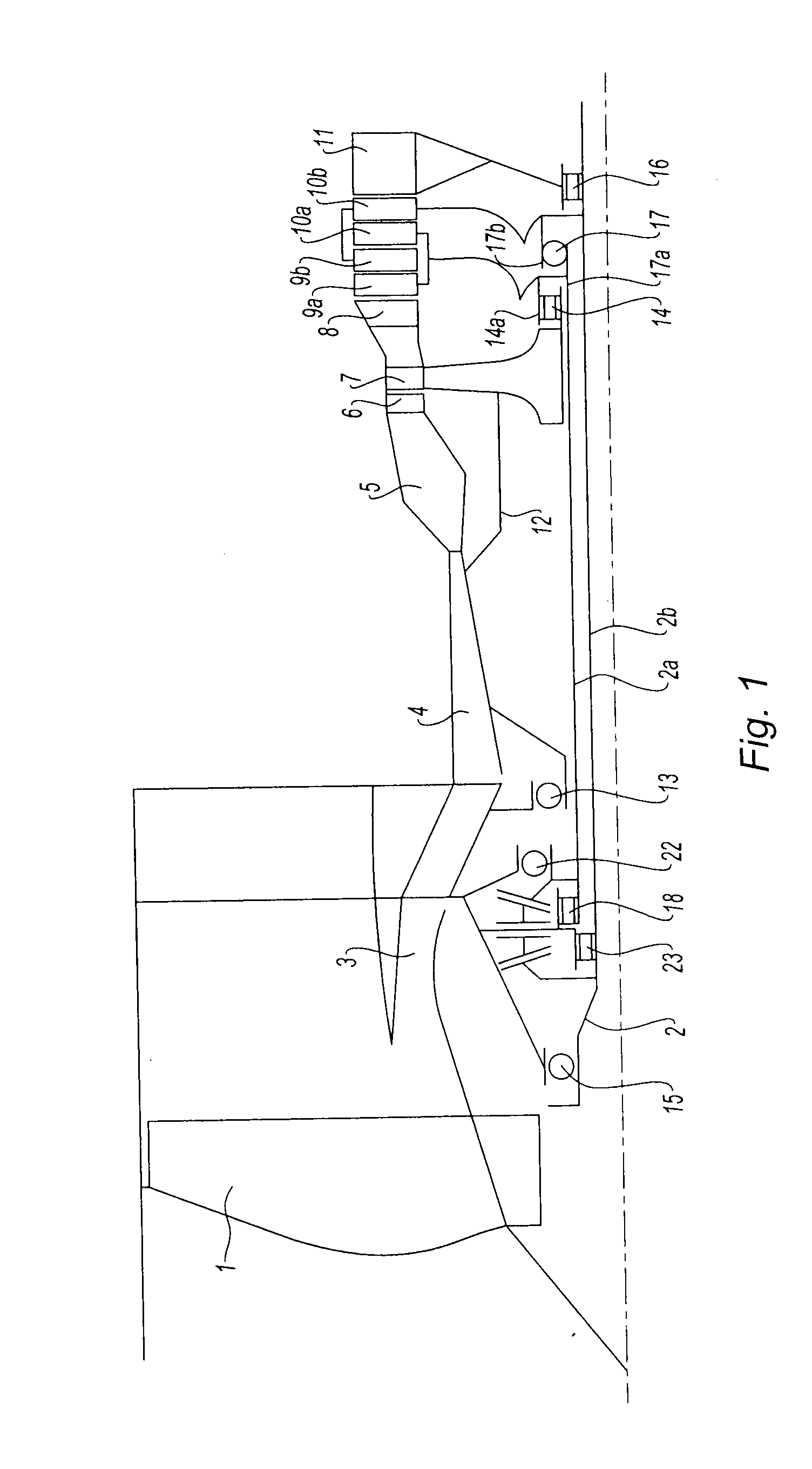

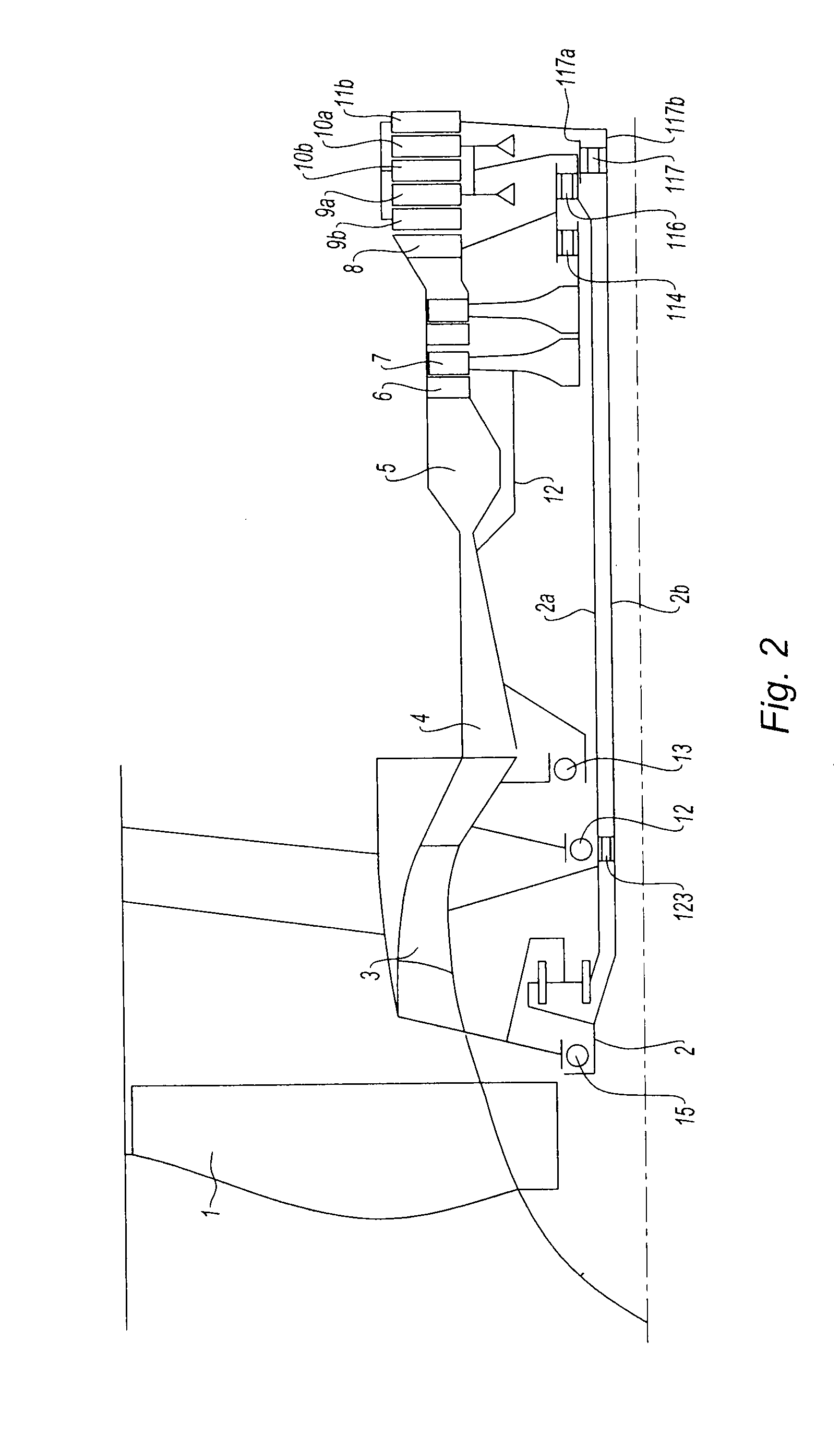

Bypass engine with contrarotating turbine wheels

ActiveUS20100205934A1High mechanical stressSmall sizeEngine fuctionsBlade accessoriesTurbine wheelCombustion chamber

Bypass aeronautical engine comprising a fan (1), an LP compressor (3) and an HP compressor (4), a combustion chamber (5), an HP turbine and at least one LP turbine stage, said LP stage comprising a first movable bladed wheel (9a, 10a) carried by a first turbine shaft and a second movable bladed wheel (9b, 10b, 11b) turning in the opposite direction to said first wheel, said fan being driven by said second wheel via a second turbine shaft (2b) and by said first shaft (2a) via a module for reversing its direction of rotation, wherein the reversing module is produced with the aid of two bevel pinions (19, 21) of the same size, carried respectively by the first and second LP turbine shafts, and with the aid of a reversing pinion (20), the two turbine shafts (2a, 2b) turning in absolute value at the same speed of rotation.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

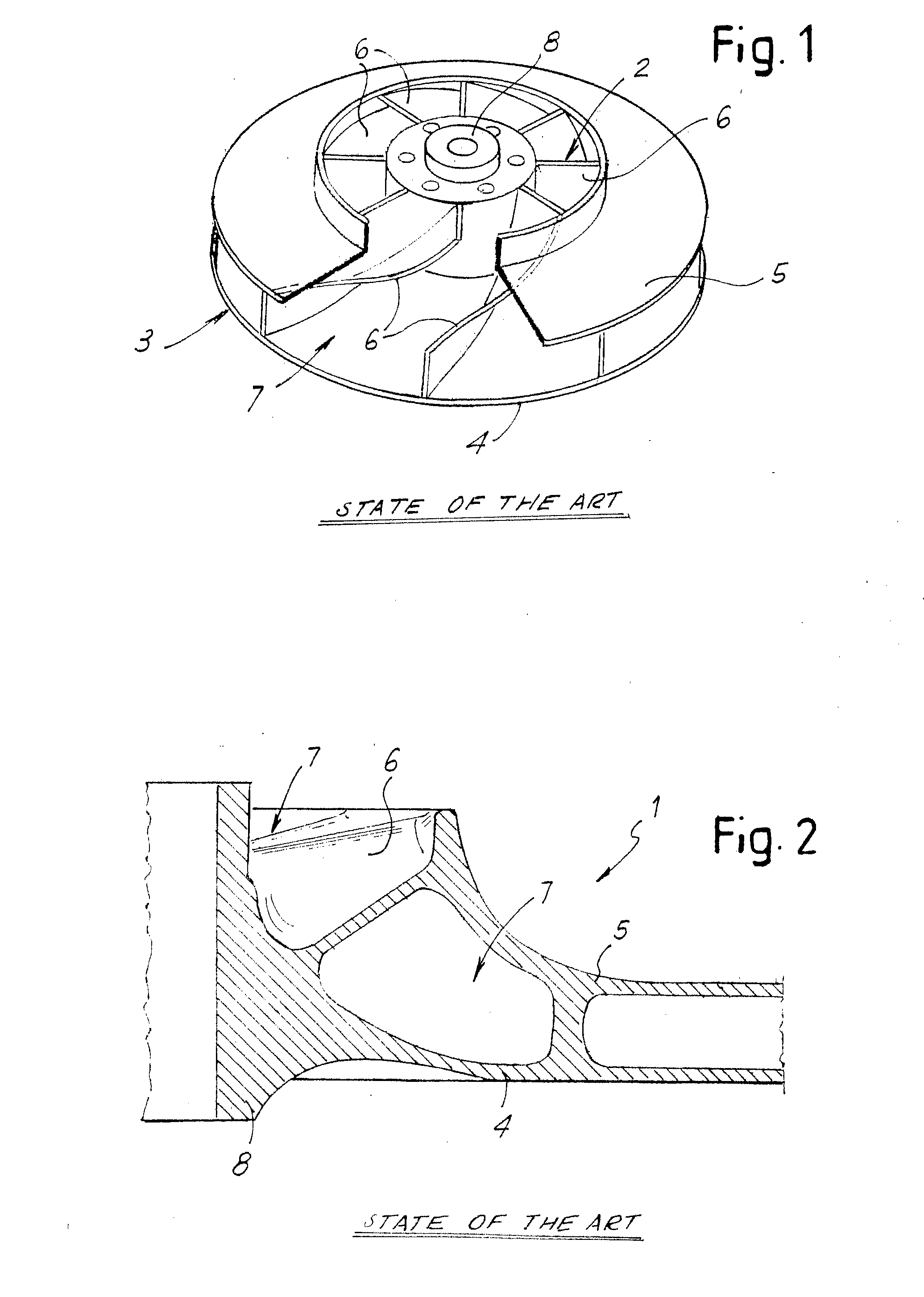

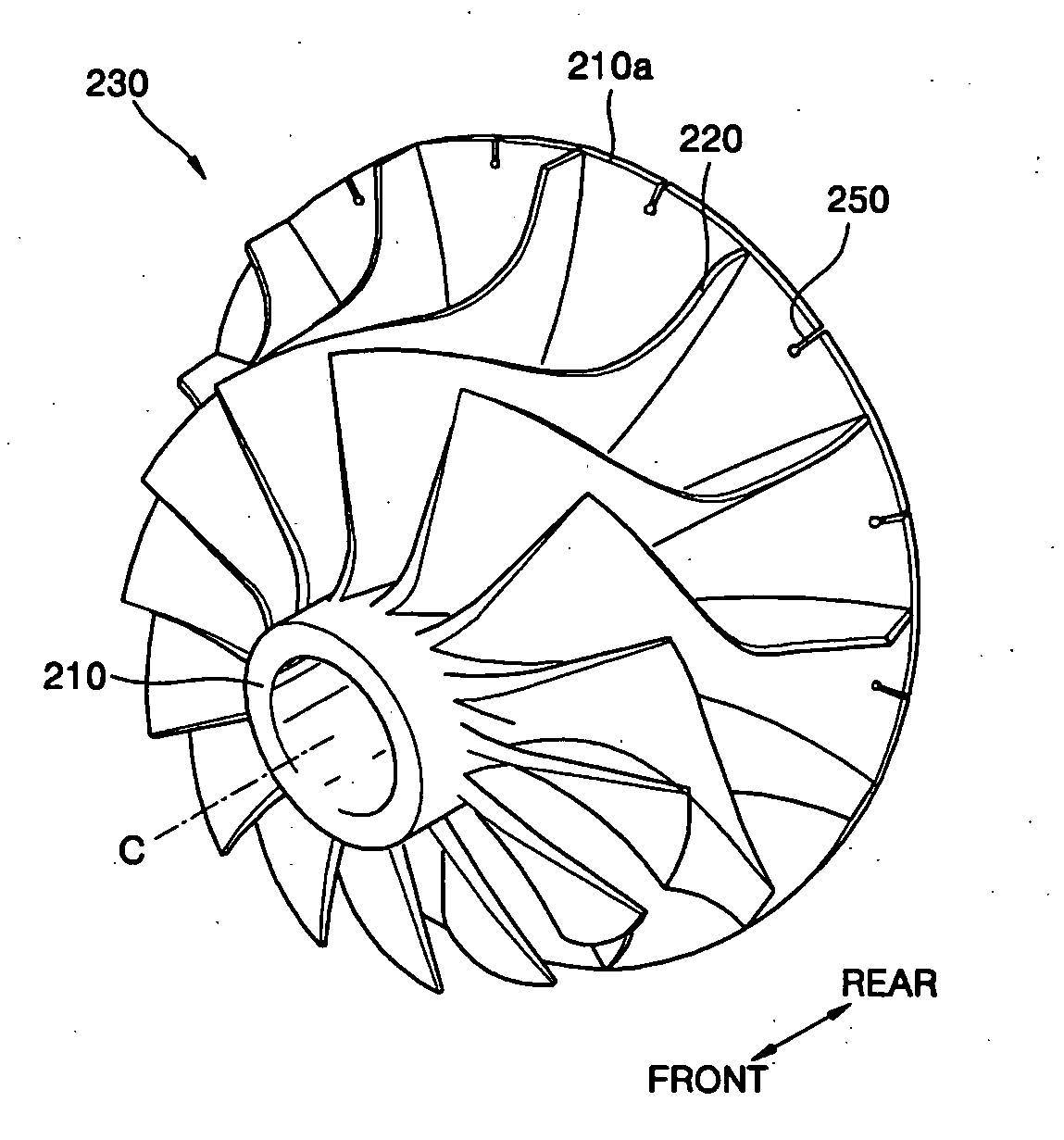

Radial-flow turbine wheel

InactiveUS20060039791A1Improve turbine efficiencyAvoid creatingPropellersEngine manufactureImpellerTurbine wheel

A radial-flow turbine wheel is provided. The radial-flow turbine wheel includes a hub having an outer radius gradually increasing from a front end to a rear end, a rear periphery of the hub being radially extended in a plane generally perpendicular to a center axis, and a plurality of turbine blades formed around the hub at constant intervals. A plurality of slots is formed by inward cut at the rear periphery of the hub between the turbine blades of the hub. The turbine wheel restrains creation and propagation of crack due to thermal stress, as well as improving a turbine efficiency.

Owner:HANWHA POWER SYST CO LTD

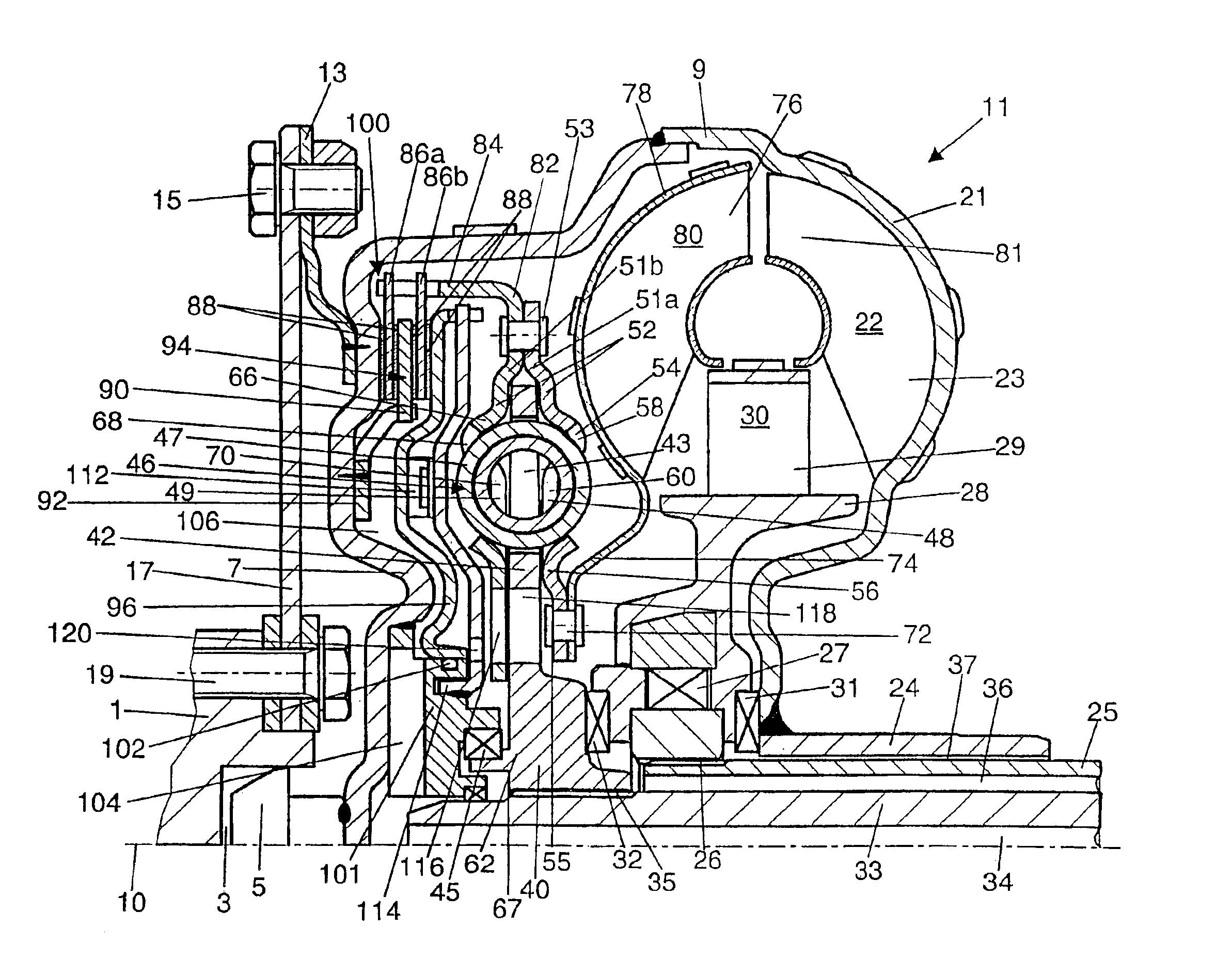

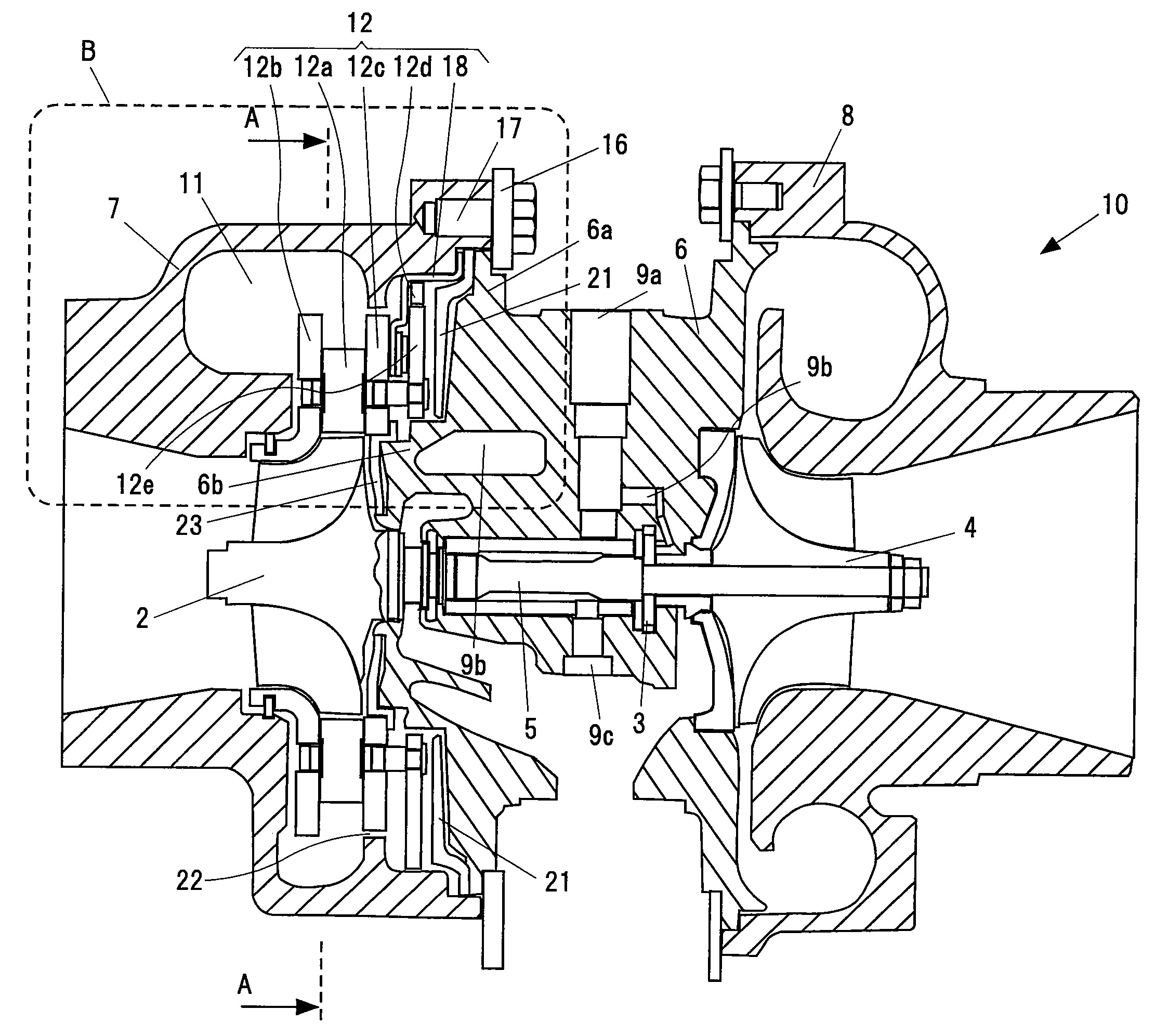

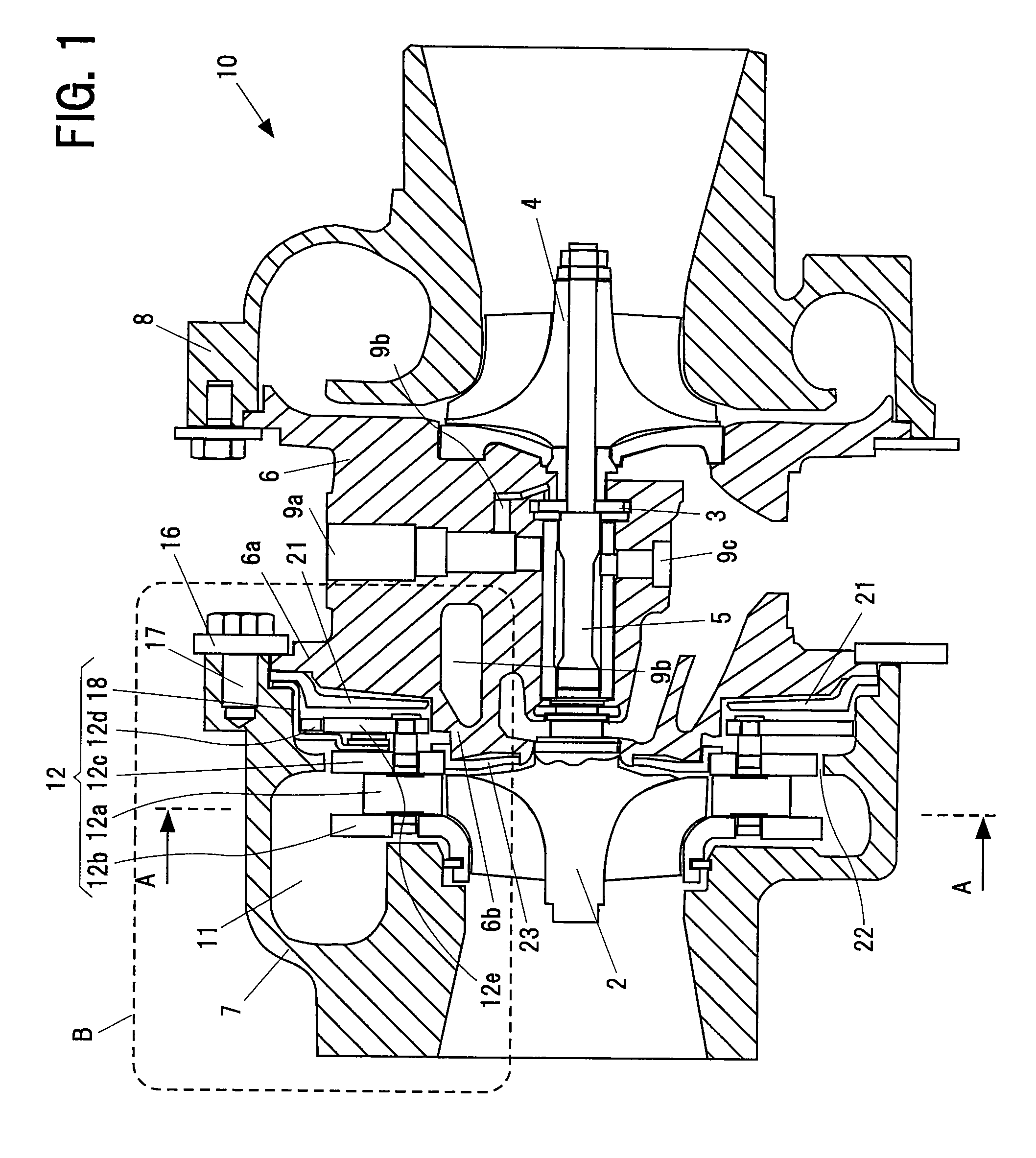

Turbocharger with variable nozzle mechanism

A turbocharger having a variable nozzle mechanism, which is accommodated in an accommodating chamber, is disclosed. The variable nozzle mechanism has a nozzle ring, a nozzle vane, a nozzle vane drive mechanism, and a support ring. The nozzle ring defines a gas passage through which exhaust gas is guided to a turbine wheel. The nozzle vane is supported by the nozzle ring and varies the flow area of the gas passage. The nozzle vane drive mechanism drives the nozzle vane. The support ring is connected to the nozzle ring. The nozzle vane drive mechanism is accommodated in the accommodating chamber as spaced from the nozzle ring through the support ring. The turbocharger has a drain passage that extends through a lower portion of the support ring and reaches the gas passage. The drain passage is located downward from the nozzle vane drive mechanism.

Owner:TOYOTA IND CORP +1

Bridging clutch

InactiveUS6915886B2Precise positioningIncrease stiffnessYielding couplingRotary clutchesImpellerTurbine wheel

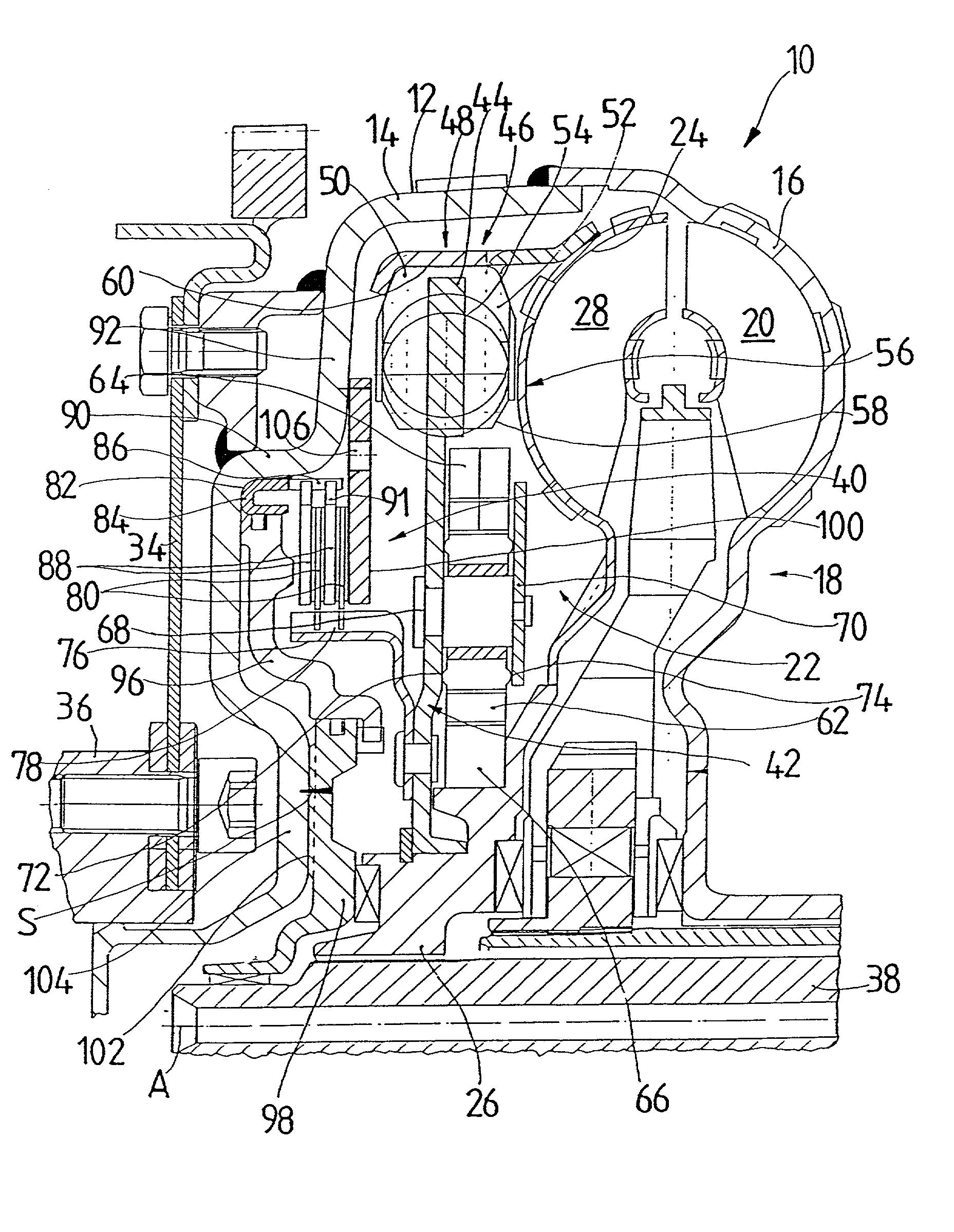

A bridging clutch is installed in a fluid medium-filled housing of a hydrodynamic coupling device located between a drive shaft and a transmission input shaft, the coupling device also containing a pump wheel and a turbine wheel. The bridging clutch is provided with a piston, which, when moved into a first axial position, brings at least one friction element into working connection with at least one friction surface, and when moved into a second axial position, at least partially releases this working connection, and with a torsional vibration damper, which is designed with at least one drive element and with at least one takeoff element, at least one of which has openings for circumferential springs and actuating areas for these springs. At least one of the takeoff elements acts a carrier element for the turbine wheel, which is held otherwise without radial support in the housing. At least one of these elements, namely, either the drive element or the takeoff element, has at least one radial area which is brought up in the axial direction essentially without play to the other one of the elements in question, which radial area serves as axial support for the positioning of the turbine wheel in this direction with respect to the housing of the coupling device.

Owner:ZF SACHS AG

Hydrodynamic clutch device

InactiveUS20060124420A1Small surface areaLoss of areaRotary clutchesGearing controlTurbine wheelLine tubing

A hydrodynamic clutch device includes a clutch housing connected to a drive, a pump wheel connected to the clutch housing, and a turbine wheel connected to a takeoff, the turbine wheel and the pump wheel forming a hydrodynamic circuit. A bridging clutch which is essentially surrounded by the hydrodynamic circuit includes a piston and at least one friction surface which can be acted on by the piston to connect the drive to the takeoff independently of the hydrodynamic circuit, the piston having one surface facing the hydrodynamic circuit and an opposite surface facing a pressure space. A pressure circuit includes a first pressure medium line to supply the hydrodynamic circuit with clutch fluid and a second pressure medium line to supply the pressure space with clutch fluid. A seal at least reduces the exchange of fluid between the hydrodynamic circuit and the pressure space, and a throttle allows a defined exchange of fluid between the hydrodynamic circuit and the pressure space.

Owner:ZF FRIEDRICHSHAFEN AG

Two-shaft turbocharger

InactiveUS7571607B2Easy to controlIncrease pressure ratioInternal combustion piston enginesCombination enginesAxial compressorImpeller

Owner:HONEYWELL INT INC

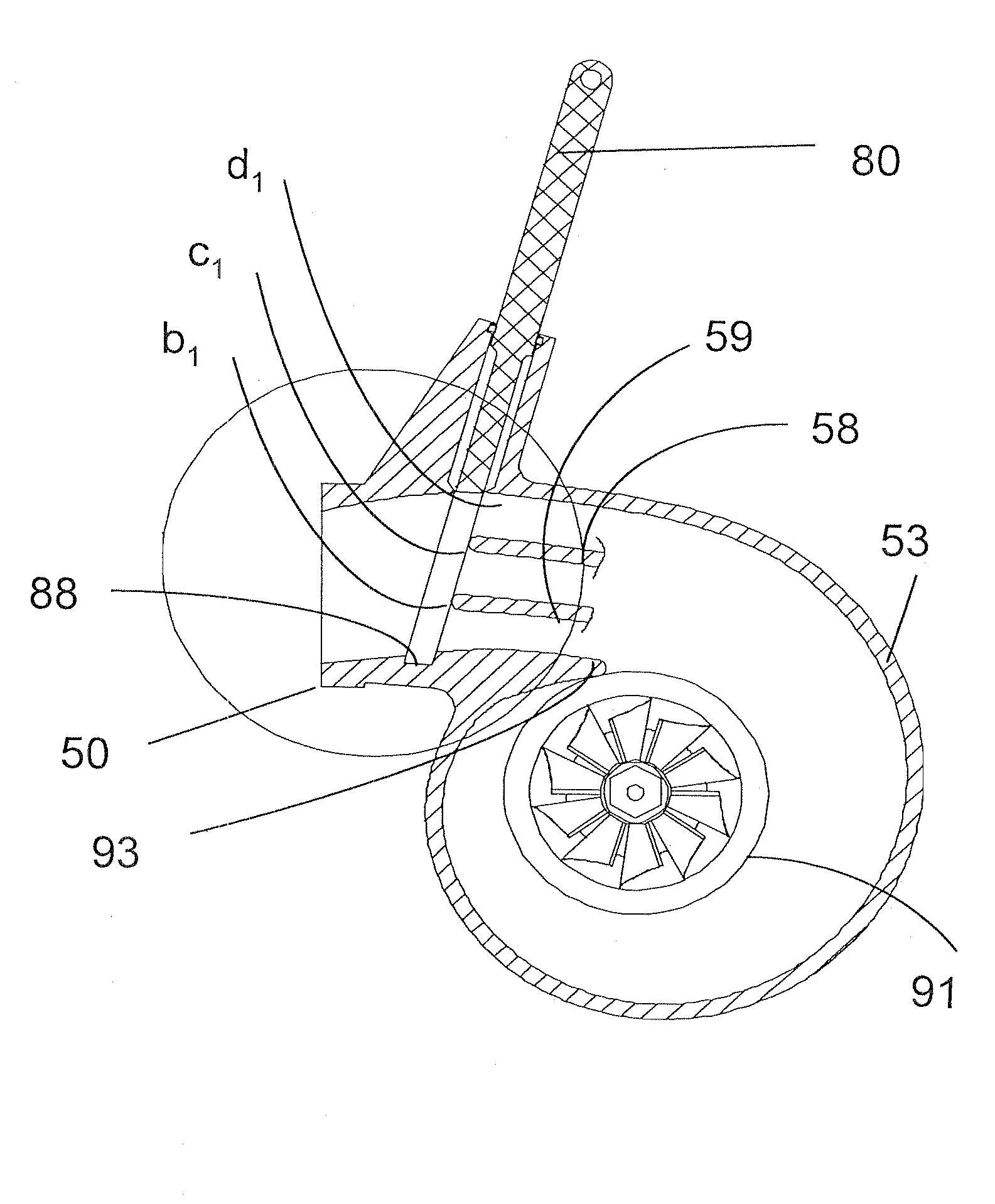

Simplified variable geometry turbocharger with sliding gate and multiple volutes

A simplified, low cost, turbine flow controlling device, using a sliding gate, with an actuator to control exhaust flow to multiple volutes, which volutes have perforated transverse divider walls. By moving the sliding gate (80) from a closed position (88) through a displacement of “a” to the next position b1; and then from position b1 through a displacement of “b” to the next position c1, each a discreet movement, by a simple actuator, an increasing number of volutes are opened for flow from the exhaust manifold, via the volutes with perforated transverse divider walls, to the turbine wheel, without the attenuation of pulse energy usually seen in VTGs, at a cost lower than that of a VTG.

Owner:BORGWARNER INC

Turbocharger with variable nozzle

ActiveUS20070175216A1Good adhesionHeat suppressionWind motor controlPump componentsImpellerTurbine wheel

A turbocharger with a variable nozzle has a turbine impeller, a compressor impeller, a shaft coupling the turbine impeller and the compressor impeller, a bearing housing rotatably supporting the shaft, and a turbine housing accommodating the turbine impeller. The turbocharger further includes a variable nozzle mechanism, provided in a compressor impeller side in a radial-direction outer side of the turbine impeller, for adjusting a flow rate of an exhaust gas directed to the turbine impeller. The bearing housing has a radially expanded portion that extends to a radial-direction outer side to be coupled to the turbine housing at a radial-direction outer side portion thereof such that the variable nozzle mechanism is accommodated between the turbine housing and the radially expanded portion. Between the variable nozzle mechanism and the radially expanded portion, a heat shield plate is provided for preventing a heat transmission between them.

Owner:IHI CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com