Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6744results about "Combustion engines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

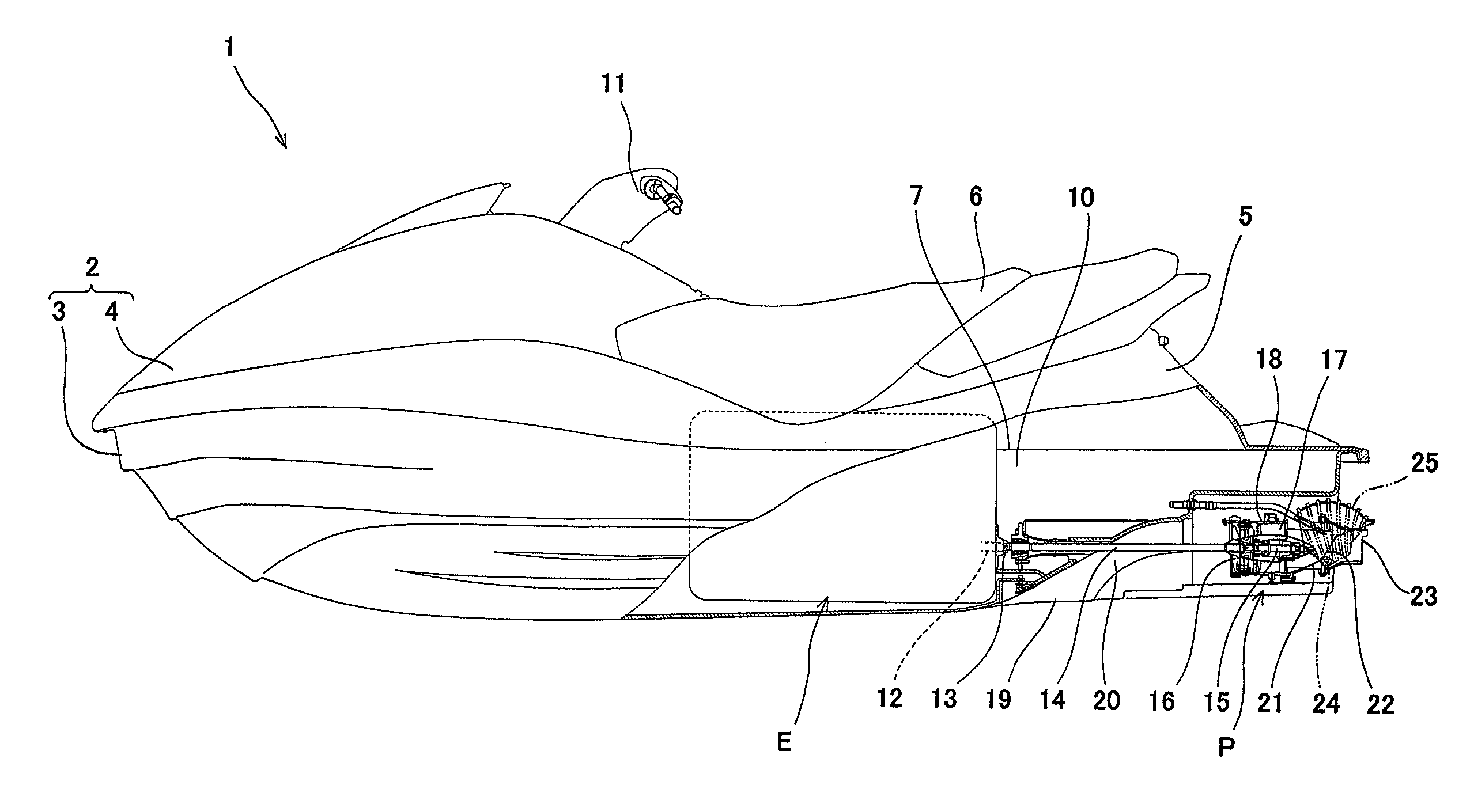

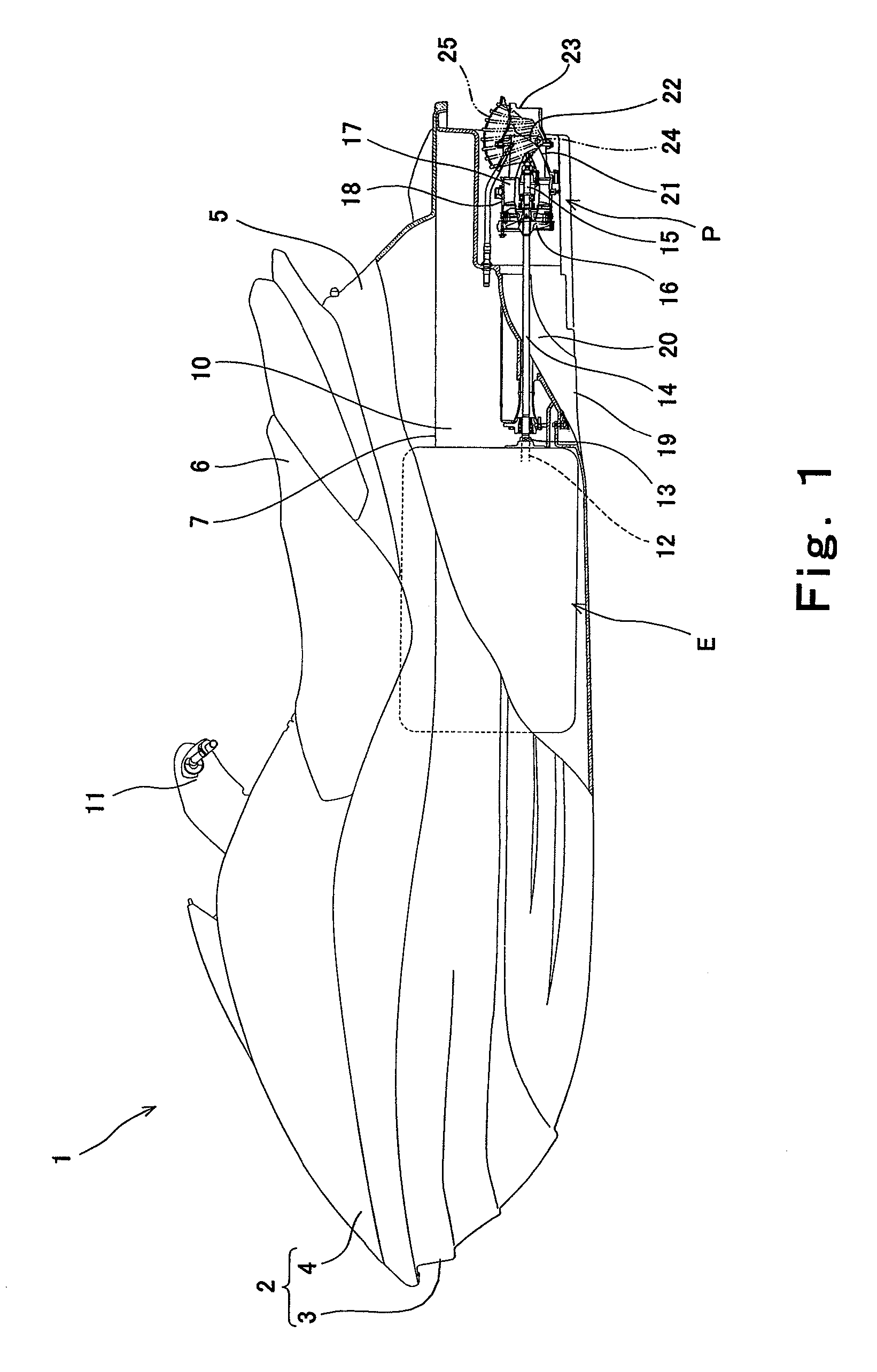

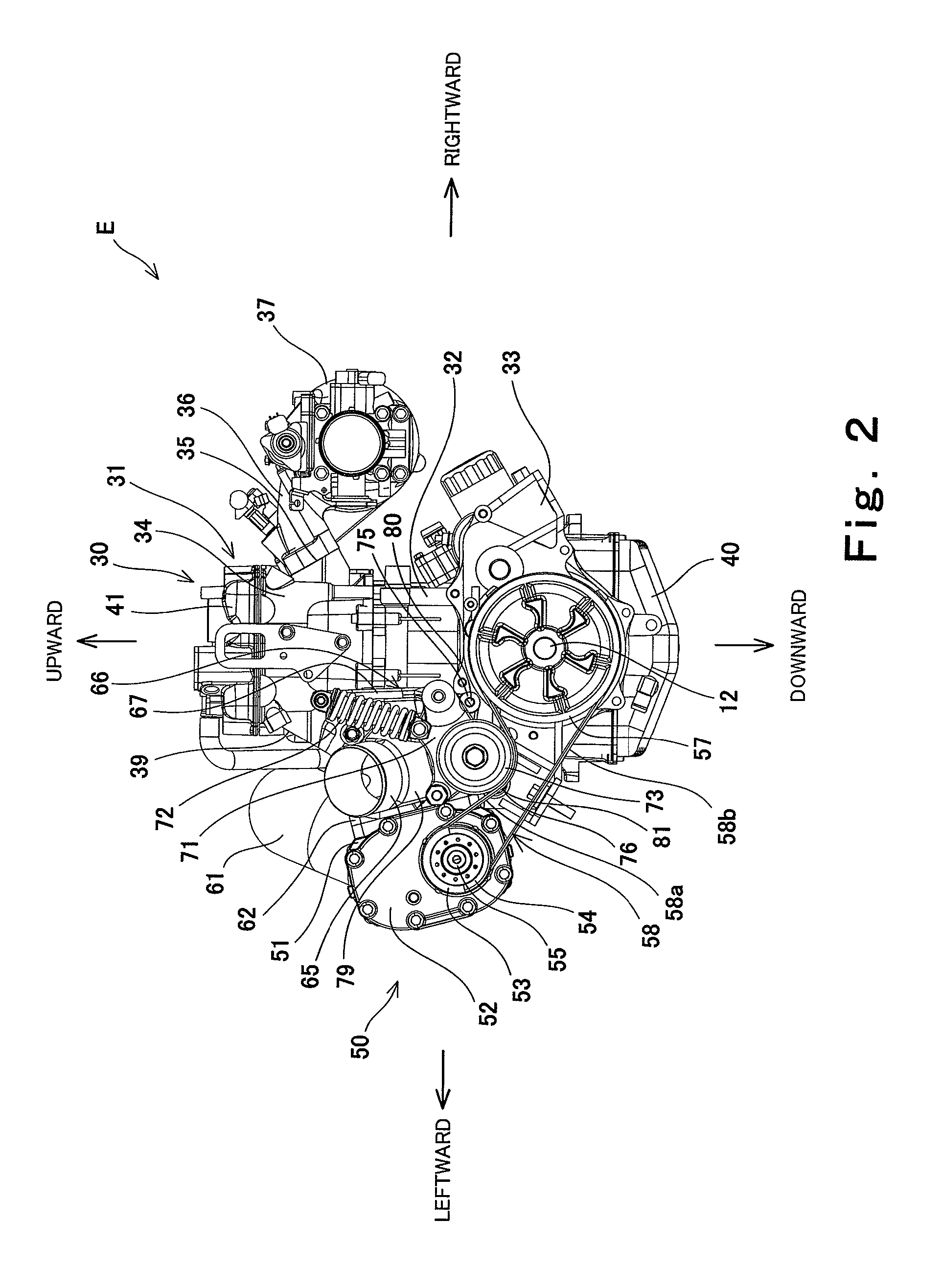

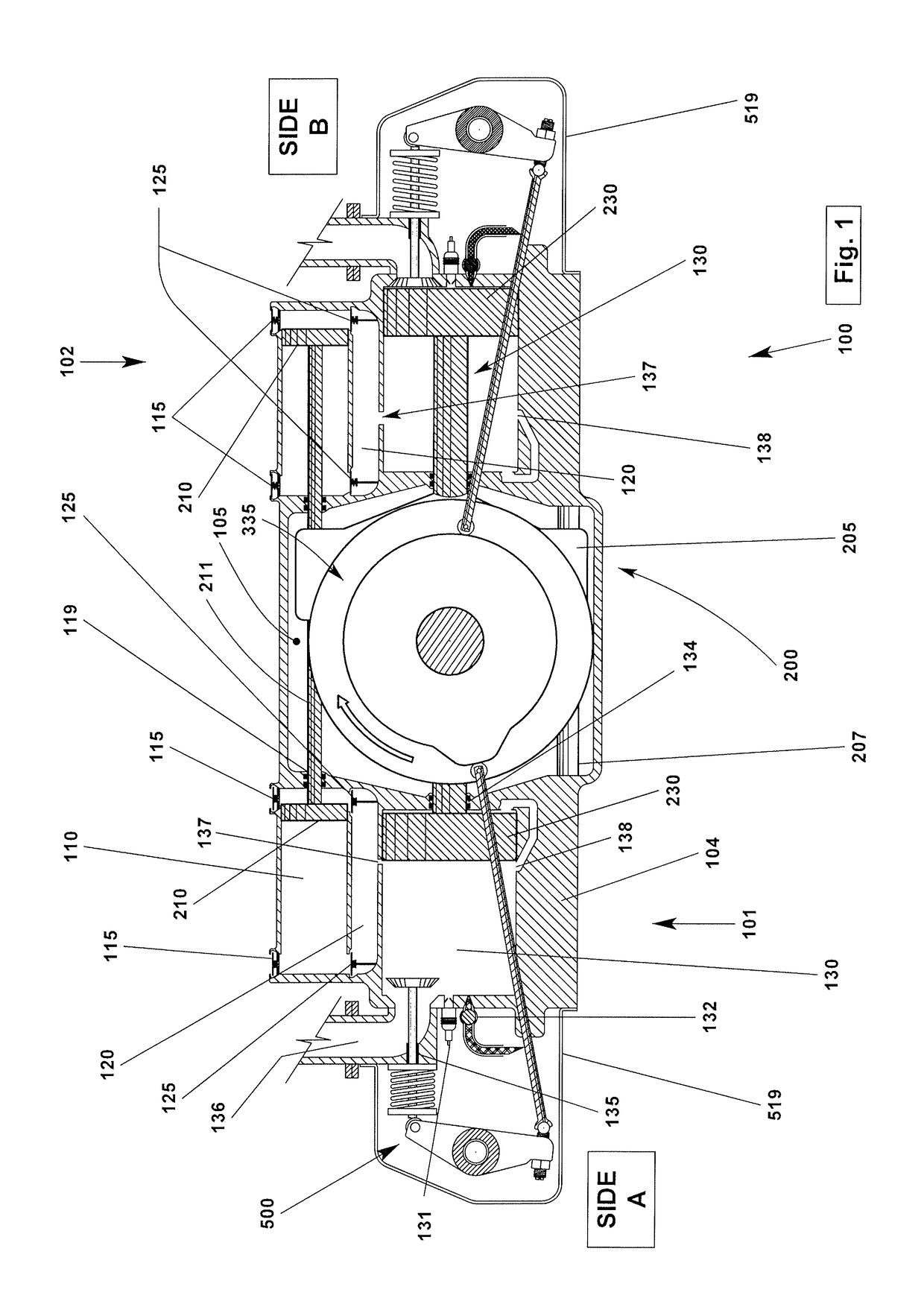

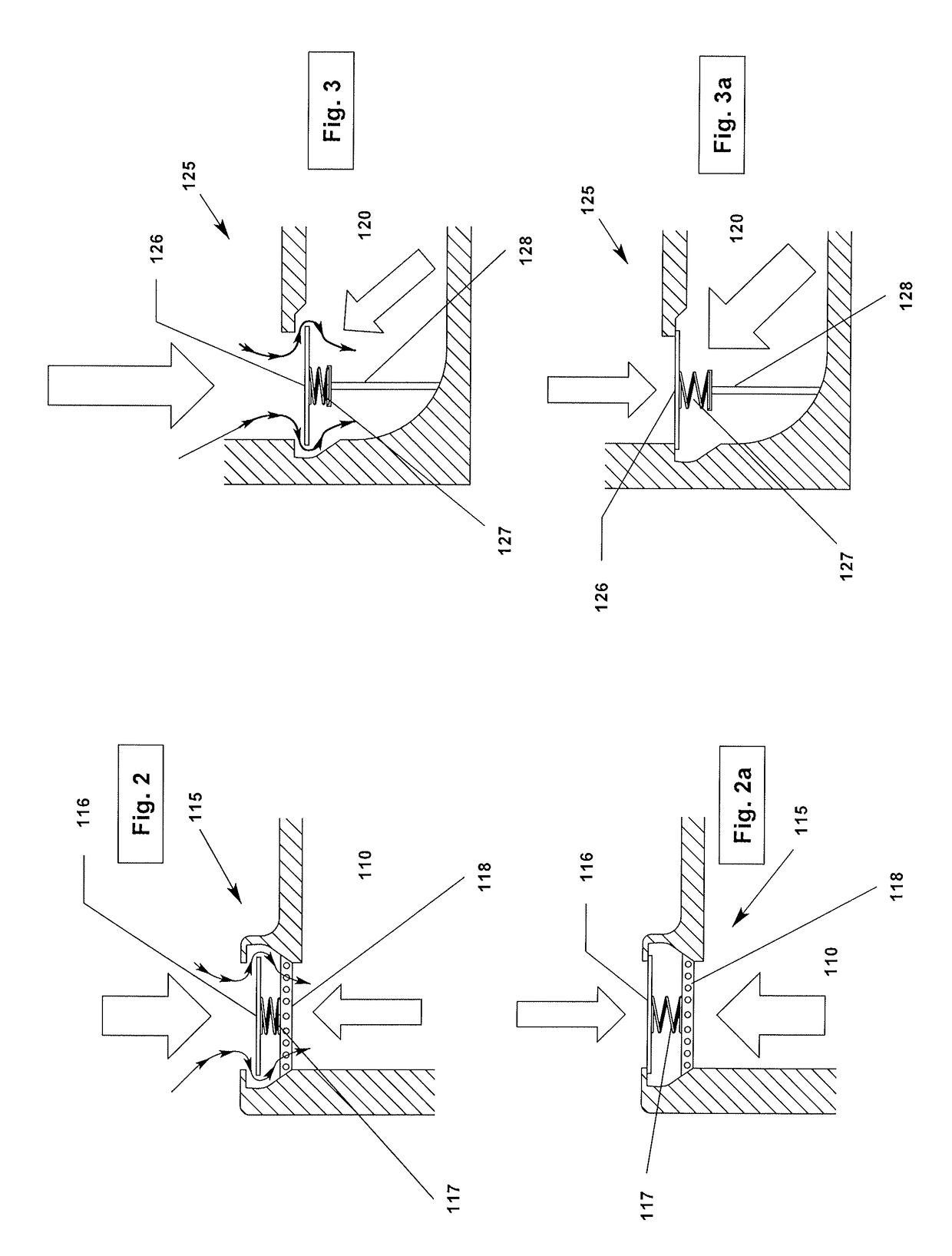

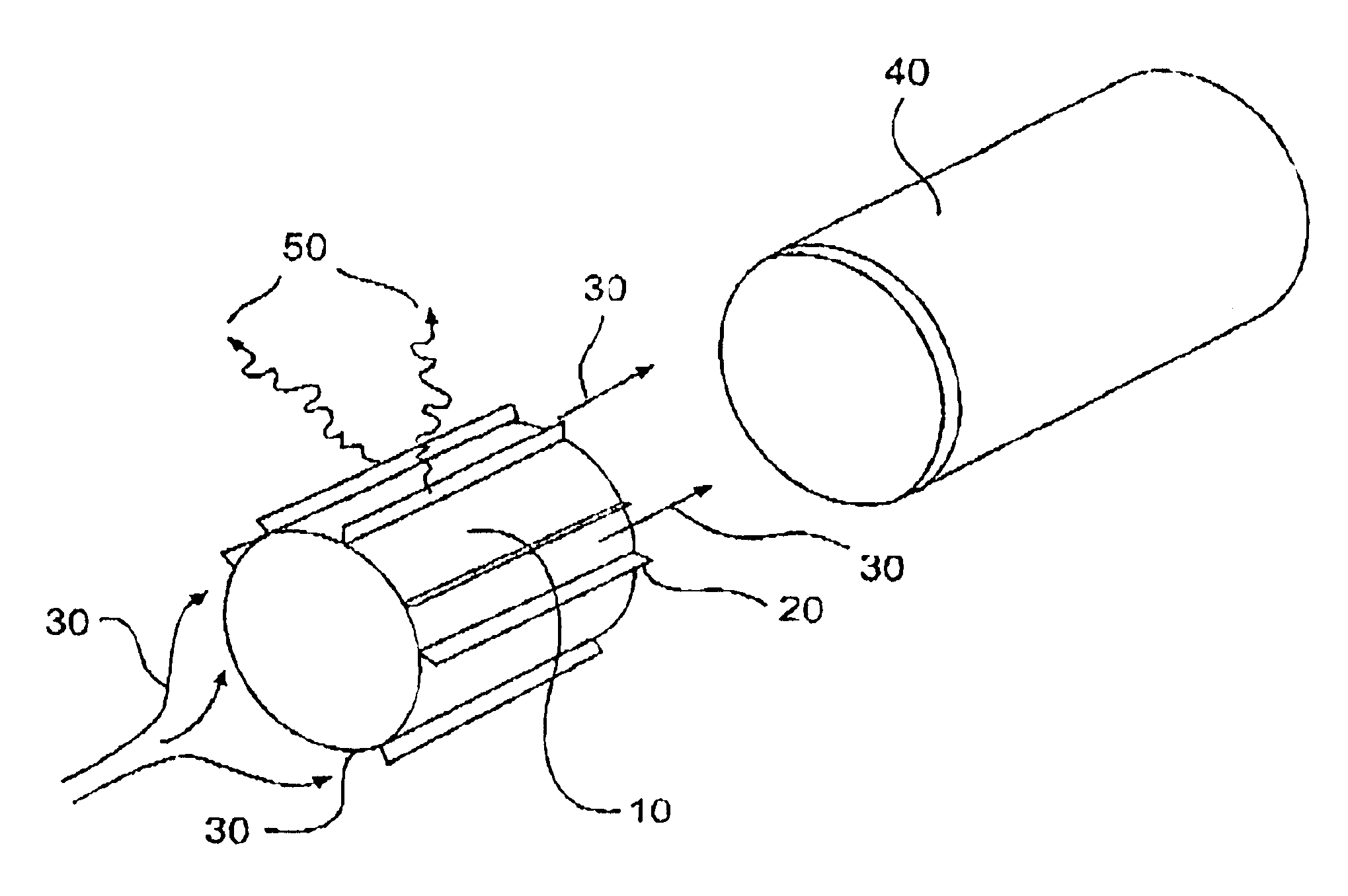

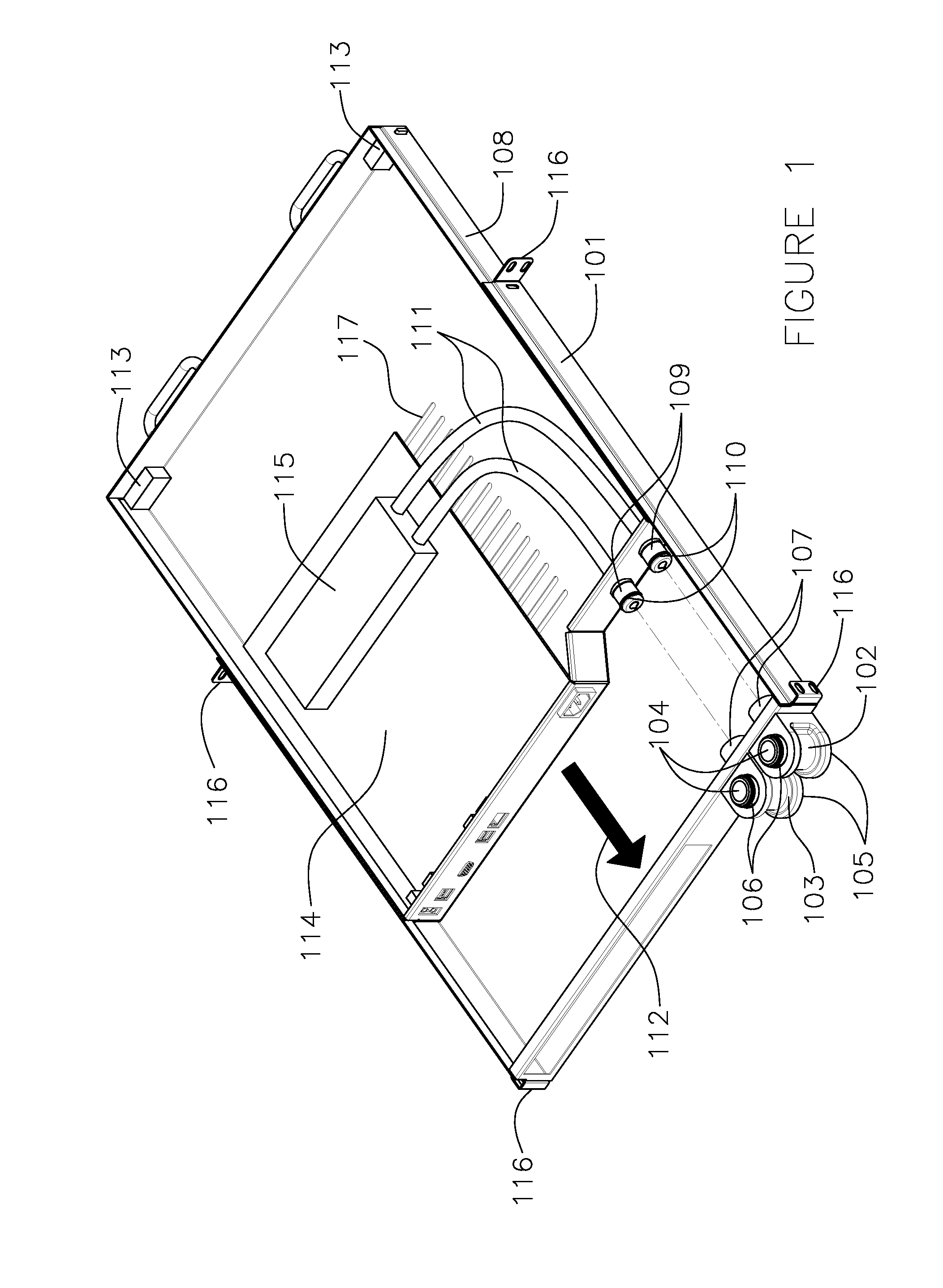

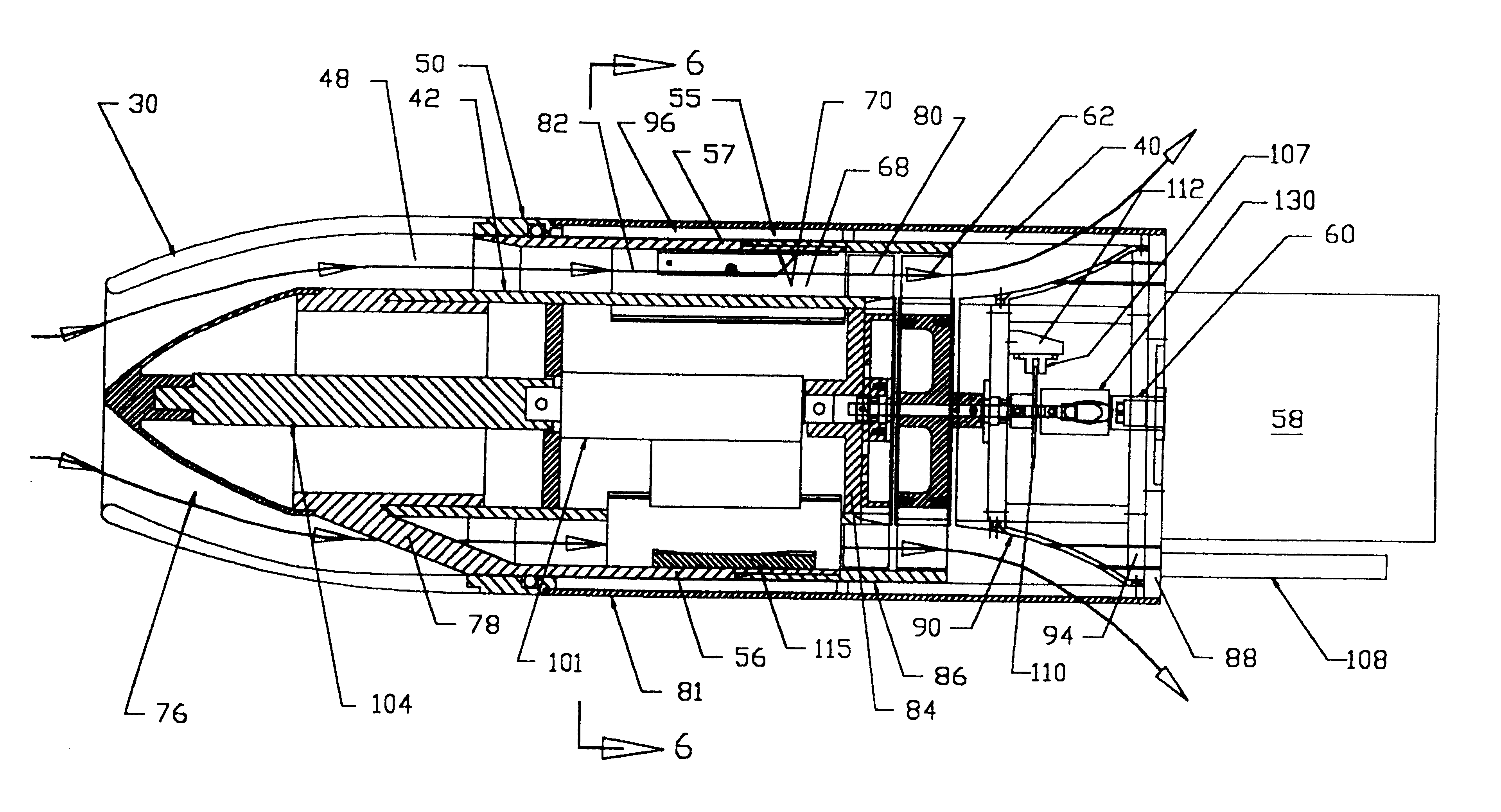

Opposed piston internal combustion engine with inviscid layer sealing

InactiveUS9909492B2Close toleranceAccurate concentricityCombustion enginesReciprocating piston enginesDetonationCombustion

An opposed-piston engine that forms an inviscid layer between pistons and the respective cylinder walls. In an aspect, the opposed-piston engine utilizes a Scotch yoke assembly that includes rigidly connected opposed combustion pistons. In an aspect, the Scotch yoke assembly is configured to transfer power from the combustion pistons to a crankshaft assembly. In an aspect, the crankshaft assembly can be configured to have dual flywheels that are internal to the engine, and can be configured to assist with an exhaust system, a detonation system, and / or a lubrication system.

Owner:PRIME GRP ALLIANCE

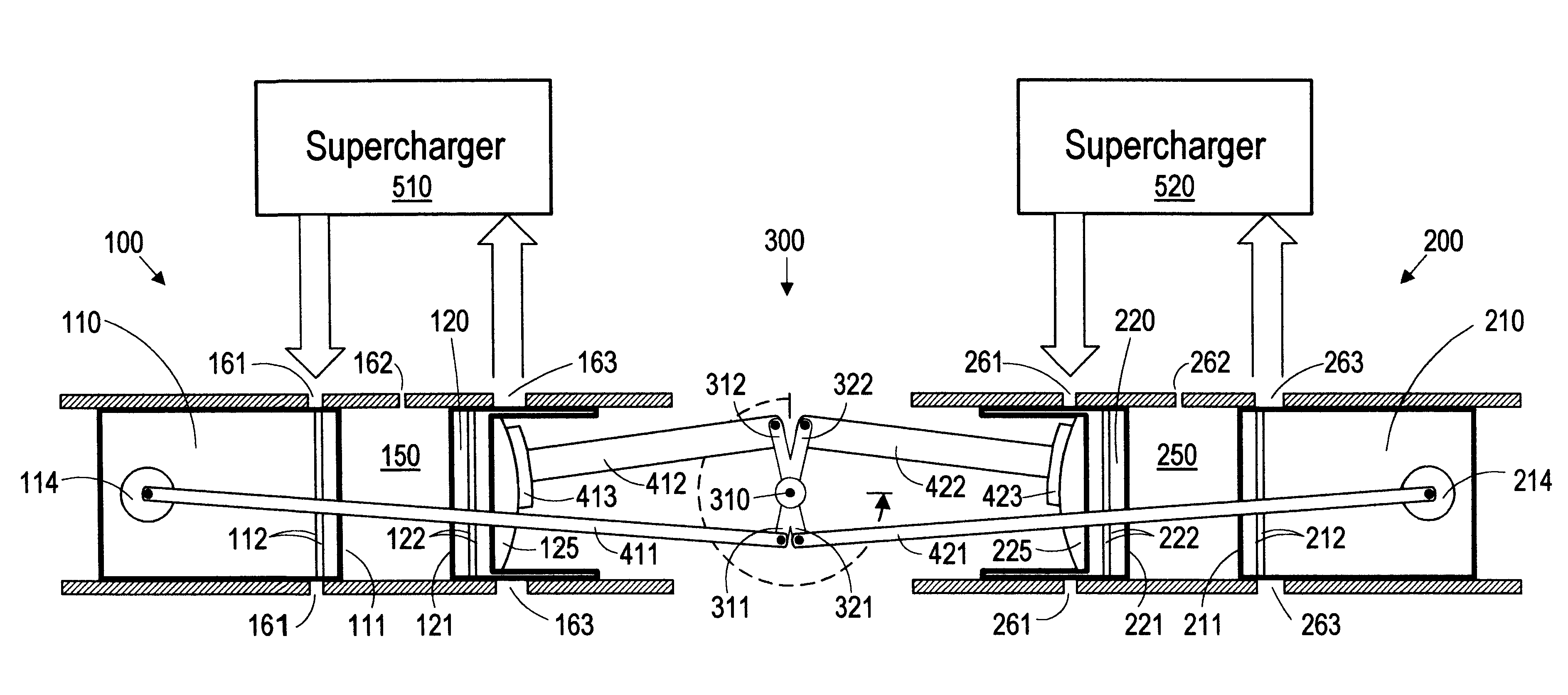

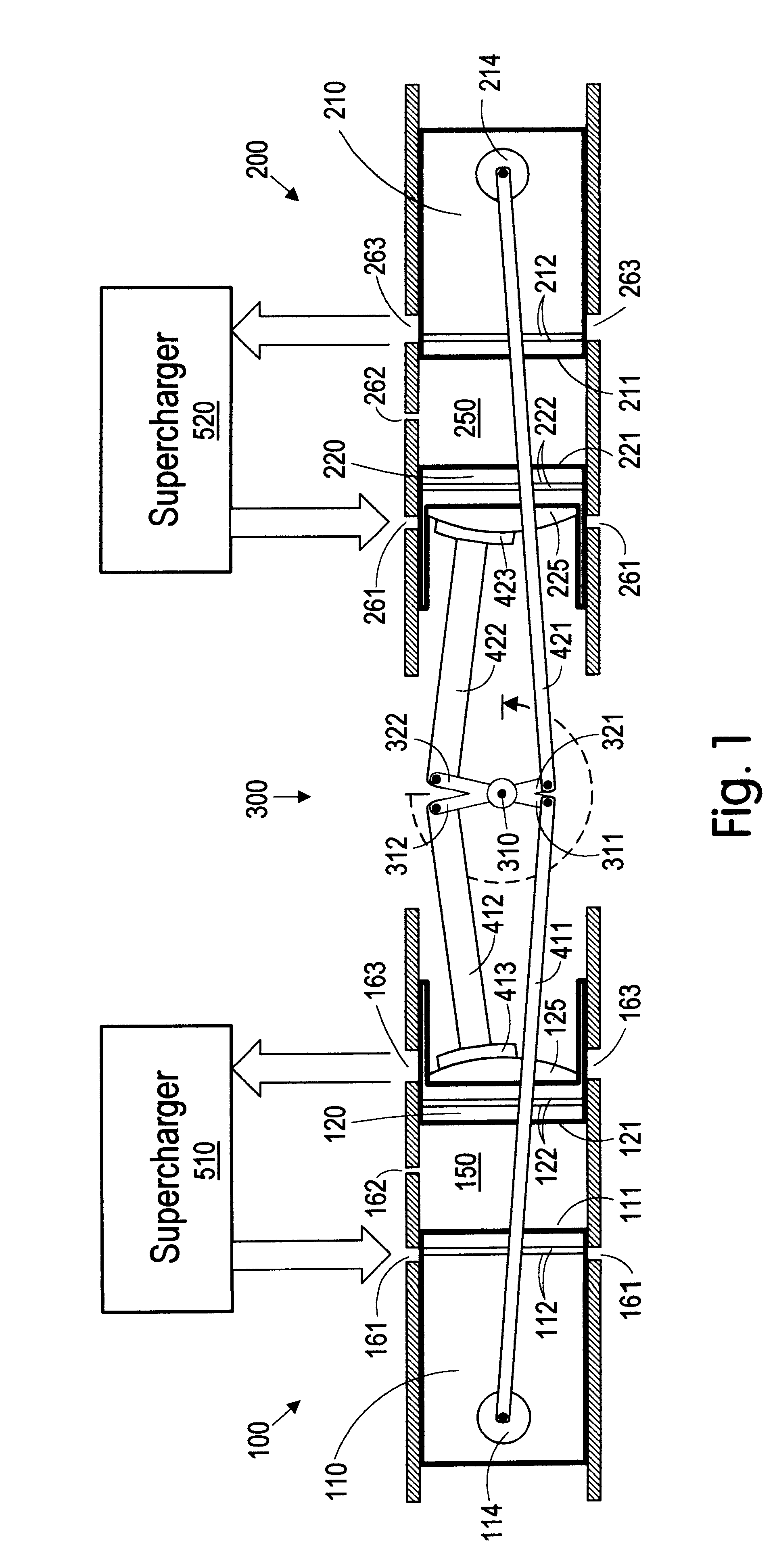

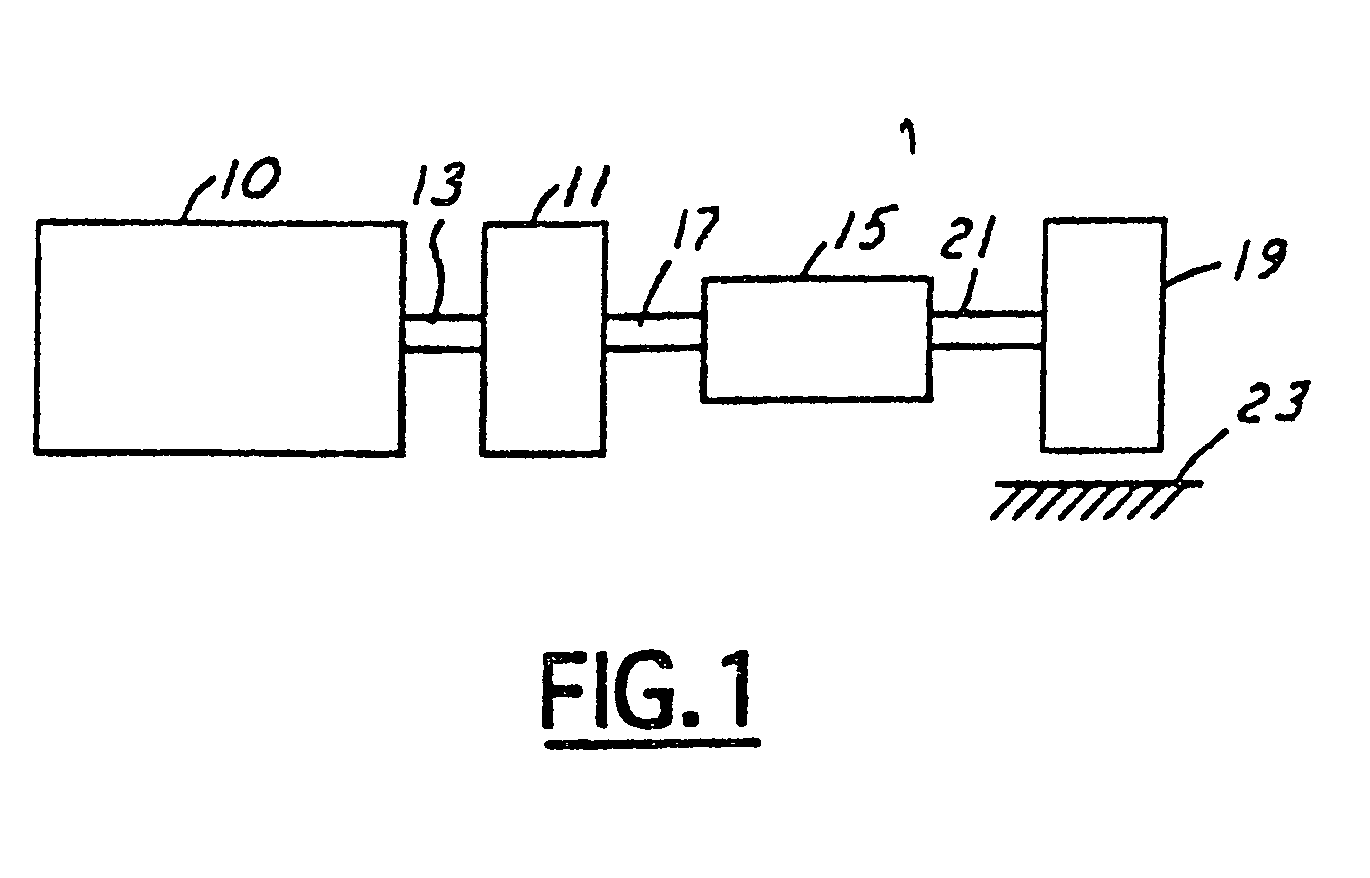

Internal combustion engine with a single crankshaft and having opposed cylinders with opposed pistons

InactiveUS6170443B1MiniaturizationEliminates dynamic imbalanceCombustion enginesReciprocating piston enginesExternal combustion engineEngineering

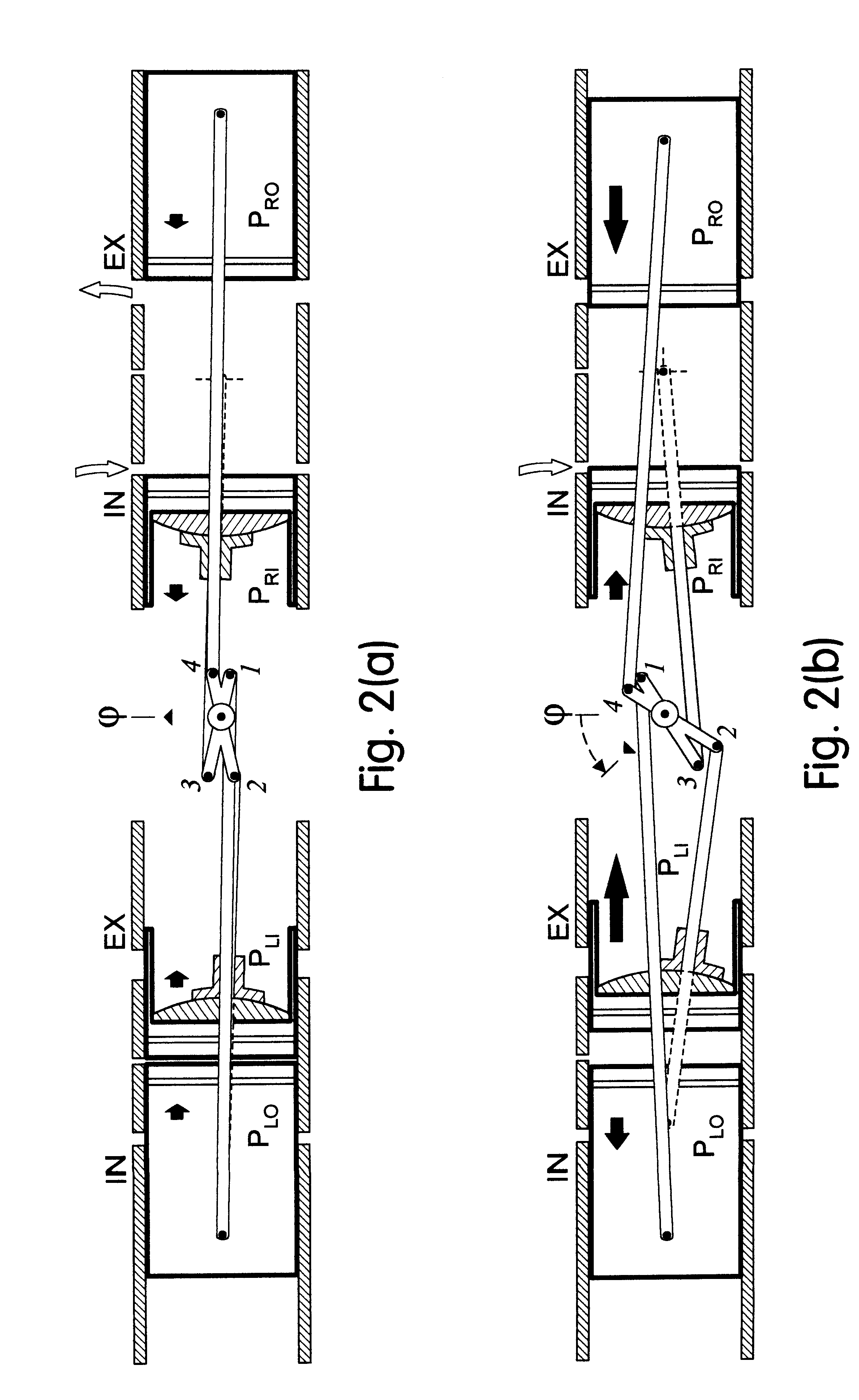

A two-stroke internal combustion engine is disclosed having opposed cylinders, each cylinder having a pair of opposed pistons, with all the pistons connected to a common central crankshaft. The inboard pistons of each cylinder are connected to the crankshaft with pushrods and the outboard pistons are connected to the crankshaft with pullrods. This configuration results in a compact engine with a very low profile, in which the free mass forces can be essentially totally balanced. The engine configuration also allows for asymmetrical timing of the intake and exhaust ports through independent angular positioning of the eccentrics on the crankshaft, making the engine suitable for supercharging.

Owner:ADVANCED PROPULSION TECH +1

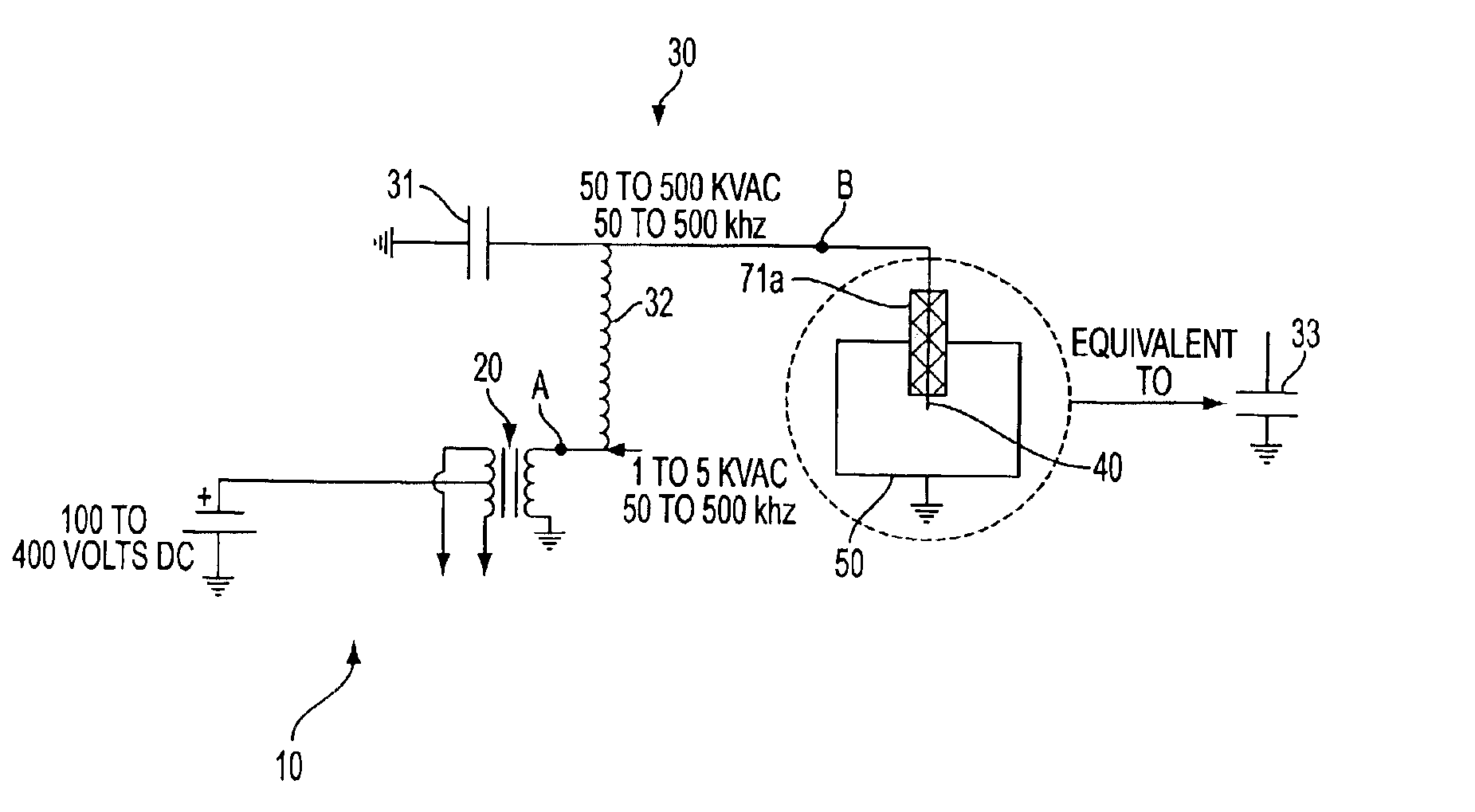

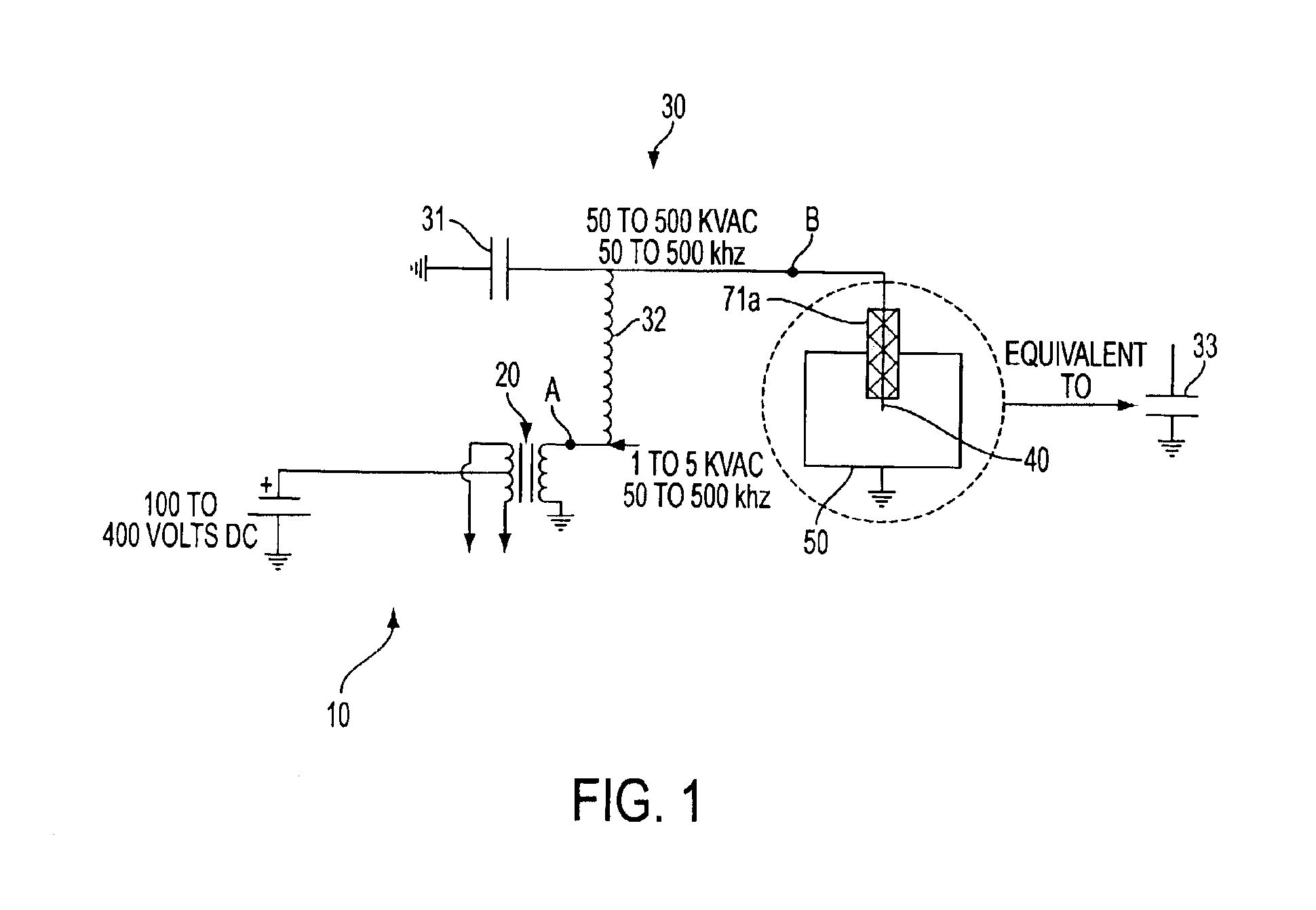

System and method for generating and sustaining a corona electric discharge for igniting a combustible gaseous mixture

InactiveUS6883507B2Sufficient energySparking plugsCombustion enginesCombustion chamberElectric discharge

The invention relates to a system for igniting a fuel-air mixture in a combustion chamber with a corona discharge. The system comprises an electrode inside of the combustion chamber, an electric circuit which provides radio frequency electric power to the electrode, and a ground formed by the combustion chamber walls. A radio frequency voltage differential formed between the electrode and the ground produces a radio frequency electric field therebetween which causes a fuel-air mixture to ionize resulting in combustion of the fuel-air mixture. The system can be utilized in engines such as internal combustion engines or gas turbine engines, for example.

Owner:BORGWARNER INC

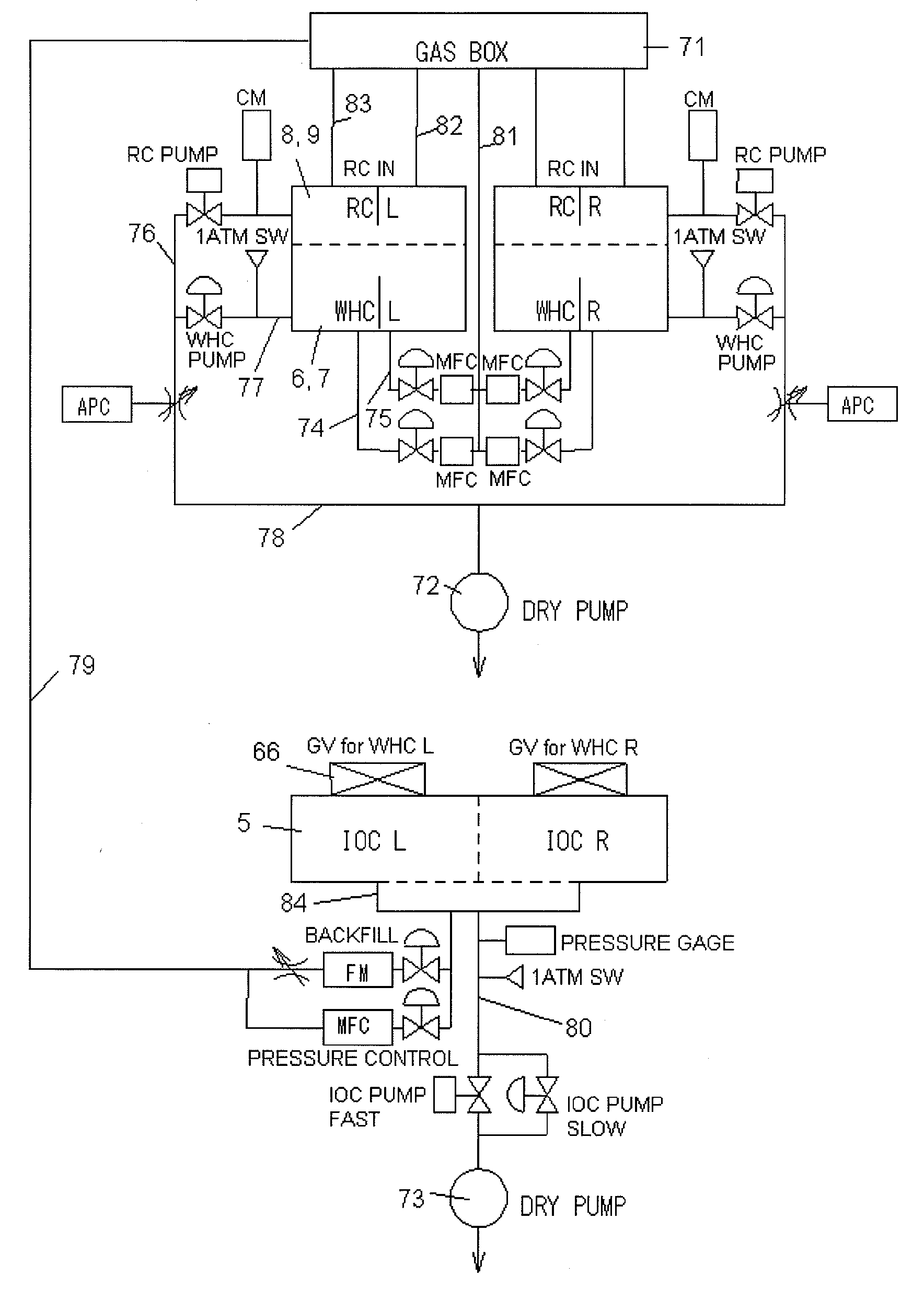

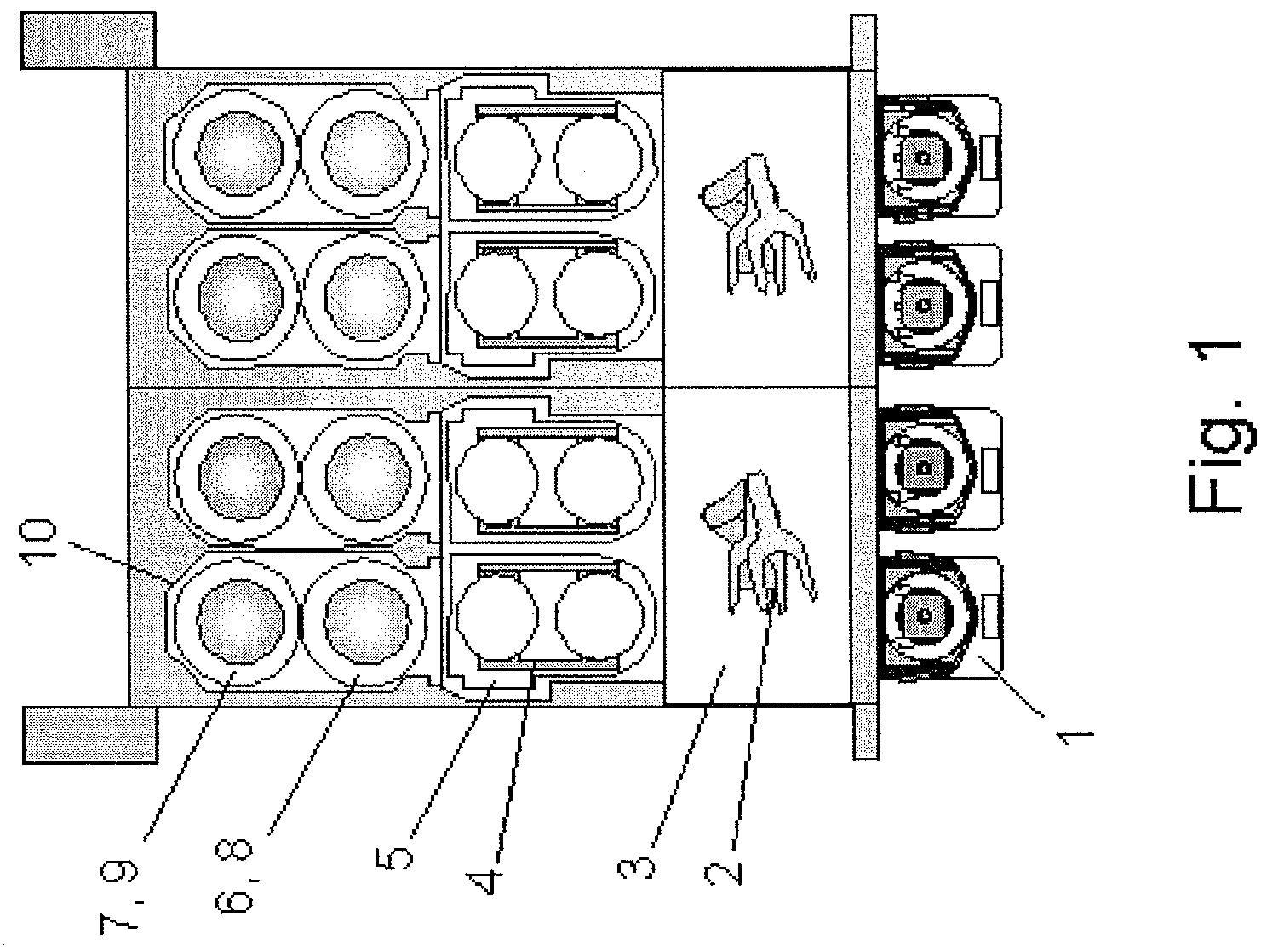

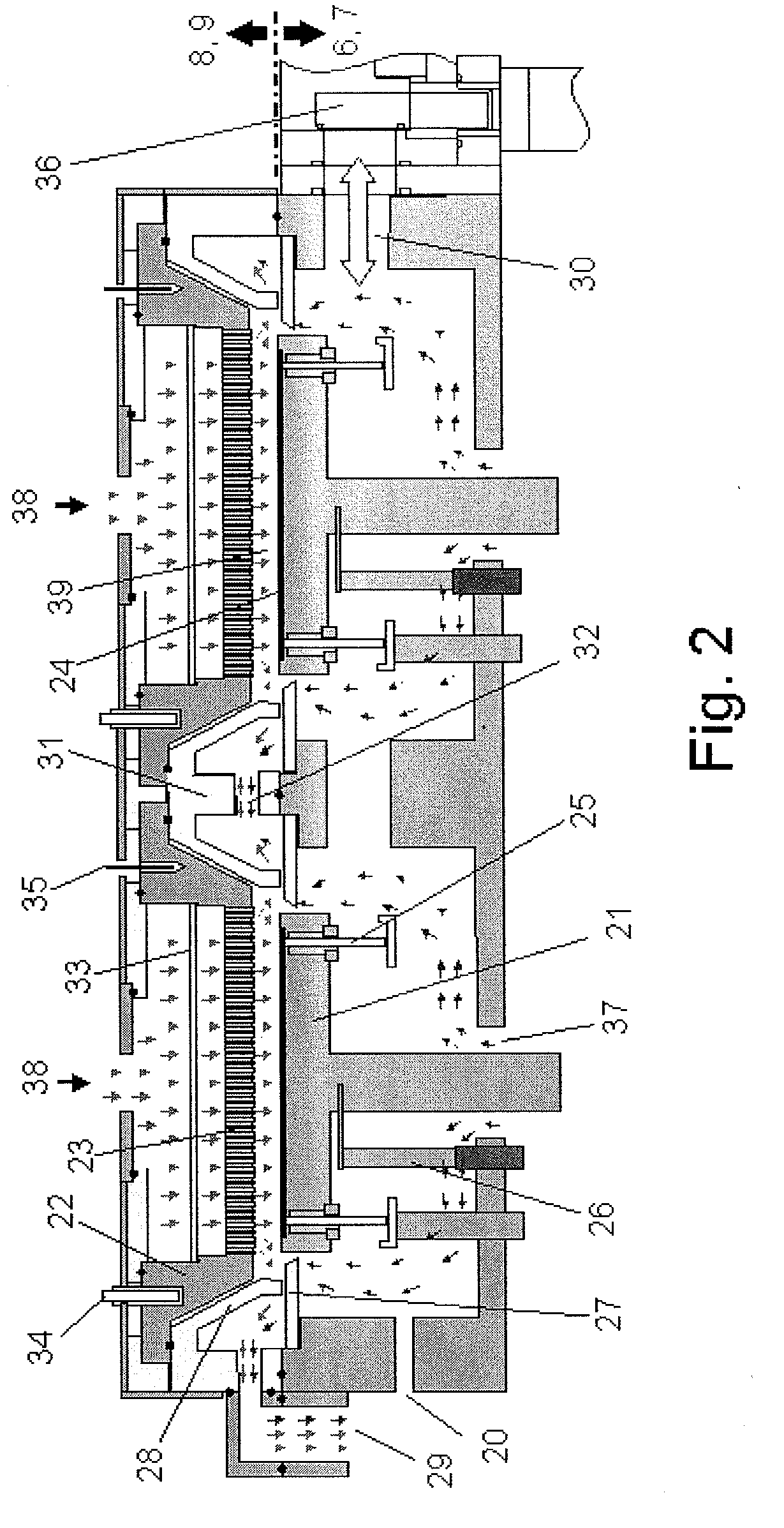

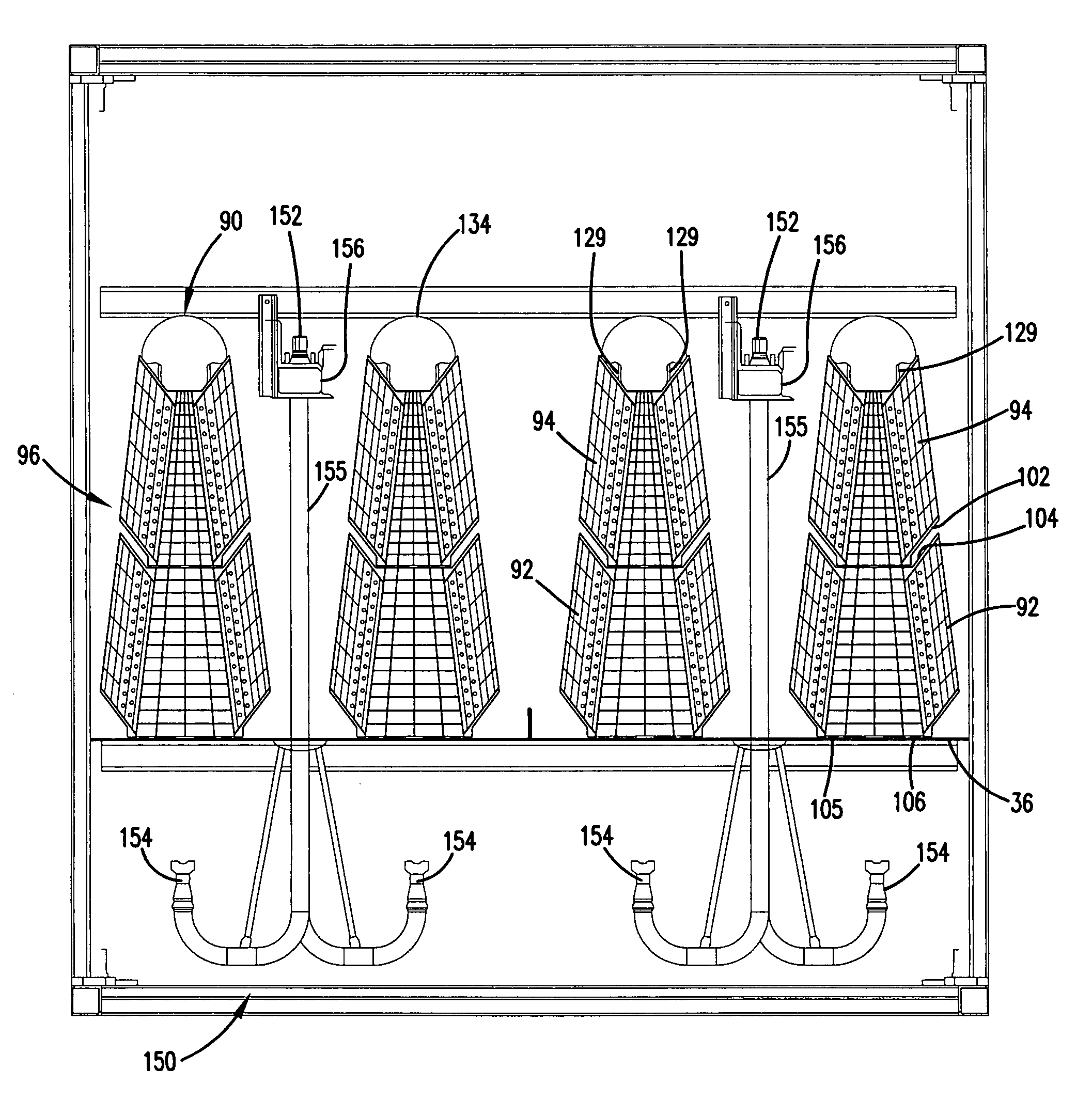

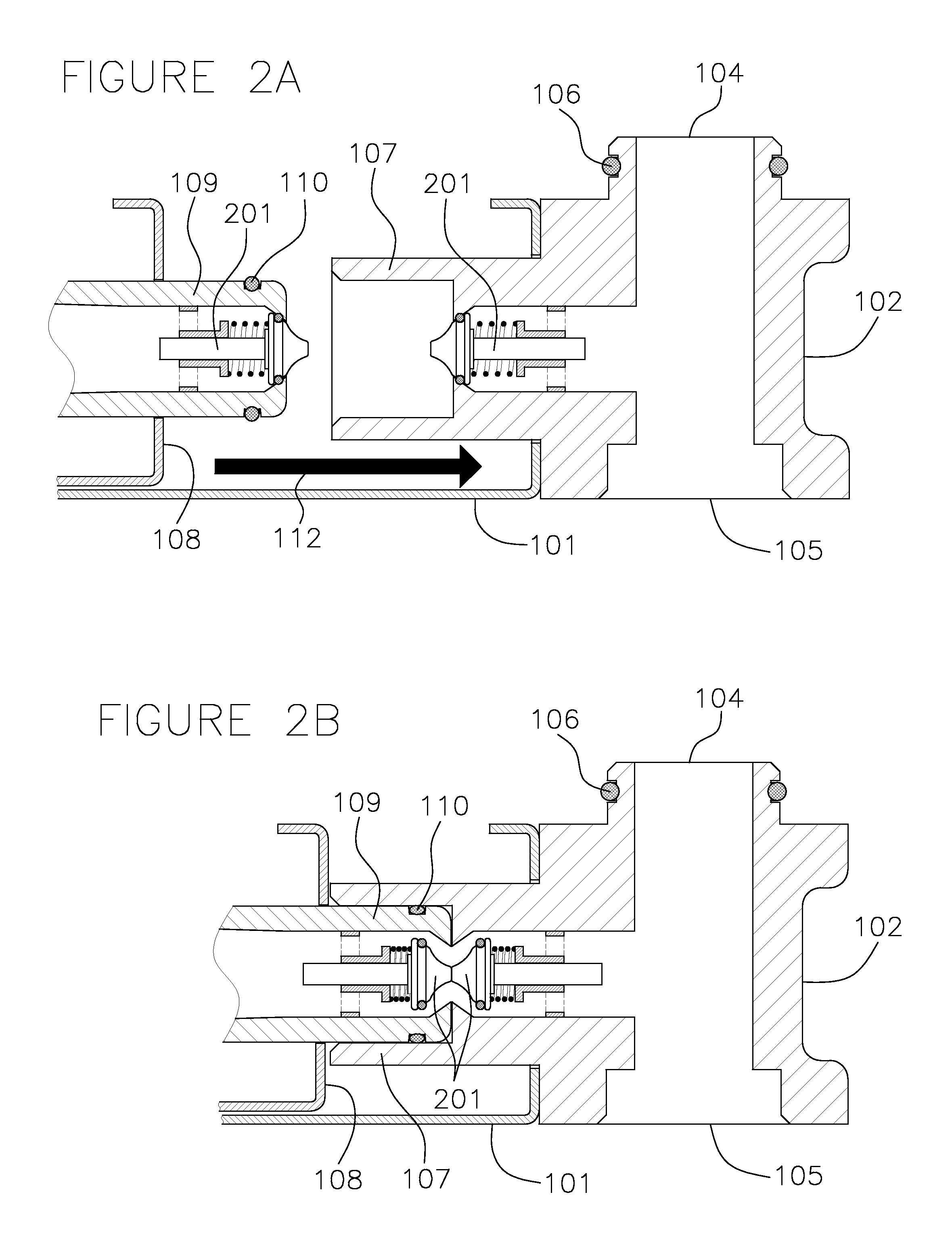

Multiple-Substrate Transfer Apparatus and Multiple-Substrate Processing Apparatus

InactiveUS20100147396A1Cost per throughputSmall footprintHollow article cleaningCombustion enginesEngineeringMechanical engineering

A multiple-substrate processing apparatus includes: a reaction chamber comprised of two discrete reaction stations aligned one behind the other for simultaneously processing two substrates; a transfer chamber disposed underneath the reaction chamber, for loading and unloading substrates to and from the reaction stations simultaneously; and a load lock chamber disposed next to the transfer chamber. The transfer arm includes one or more end-effectors for simultaneously supporting two substrates one behind the other as viewed in the substrate-loading / unloading direction.

Owner:ASM JAPAN +1

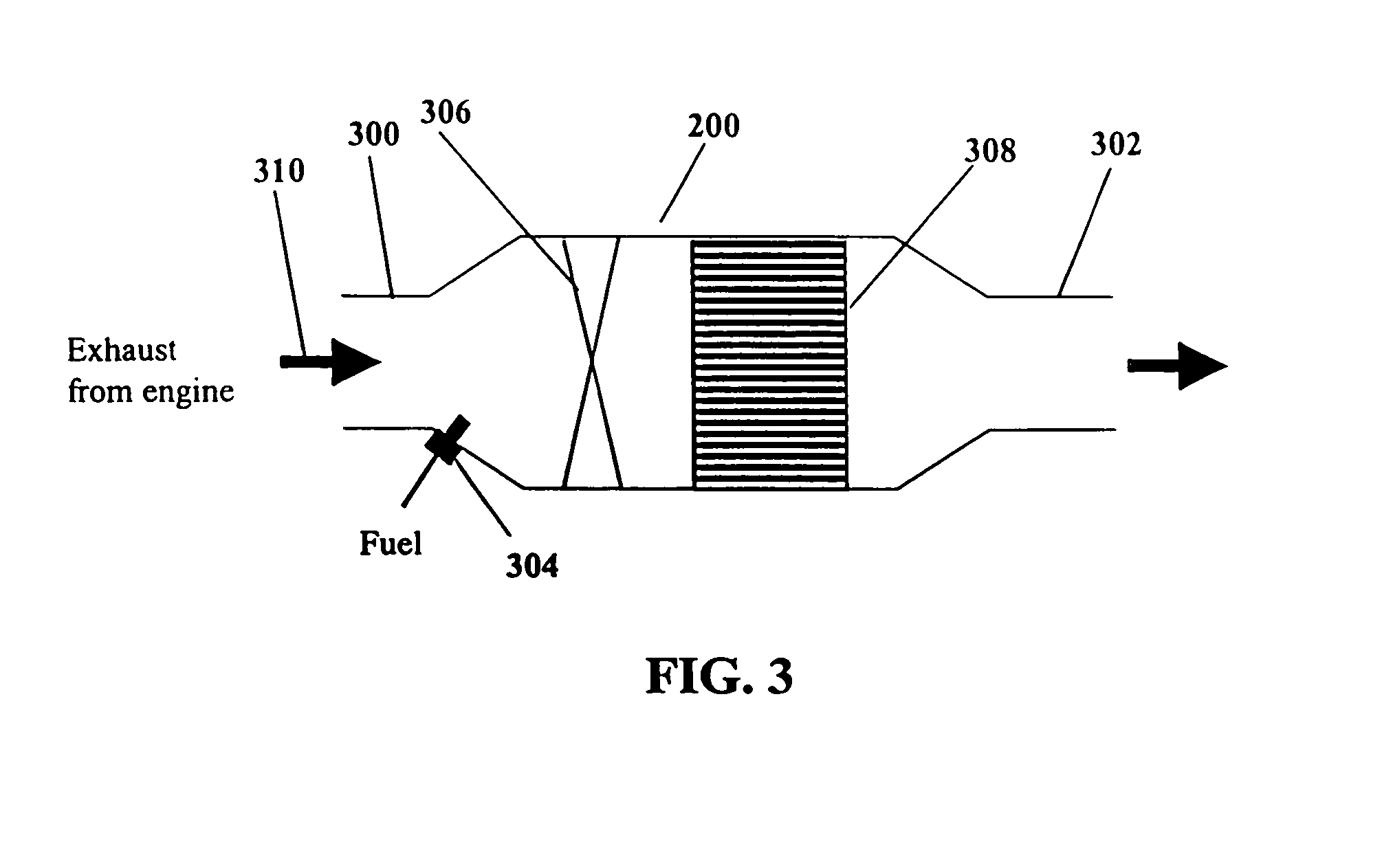

Method and apparatus to increase combustion efficiency and to reduce exhaust gas pollutants from combustion of a fuel

InactiveUS6851413B1Improve combustion efficiencyFacilitate fuel combustionBurnersLiquid fuel feeder/distributionCombustorExhaust fumes

A method and apparatus is disclosed for increasing combustion efficiency in internal combustion engines and external combustors resulting in increased fuel economy and reduced exhaust pollutants. The same principles and apparatus of the invention are used in the exhaust stream to further reduce pollutants.

Owner:RONNELL

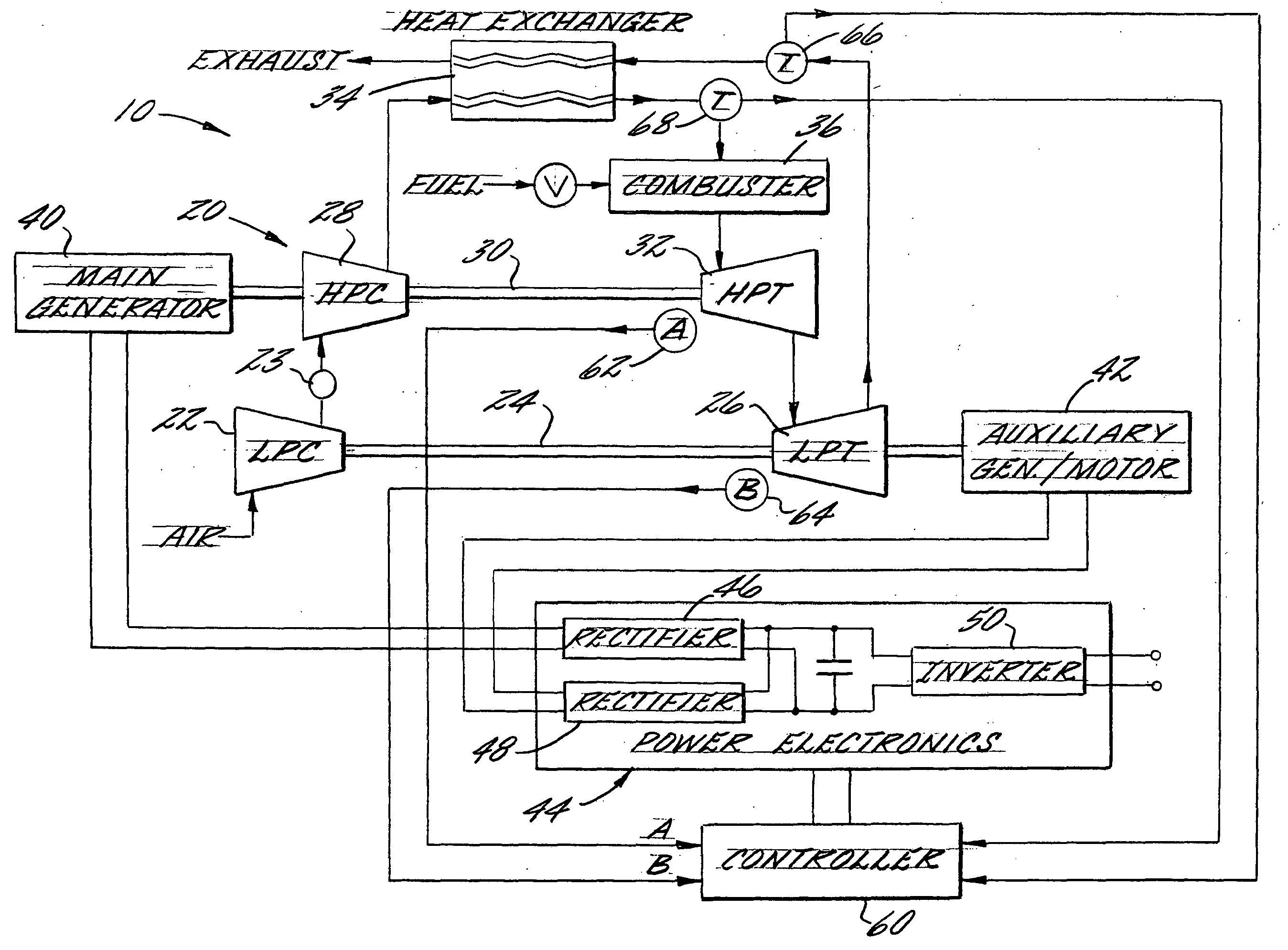

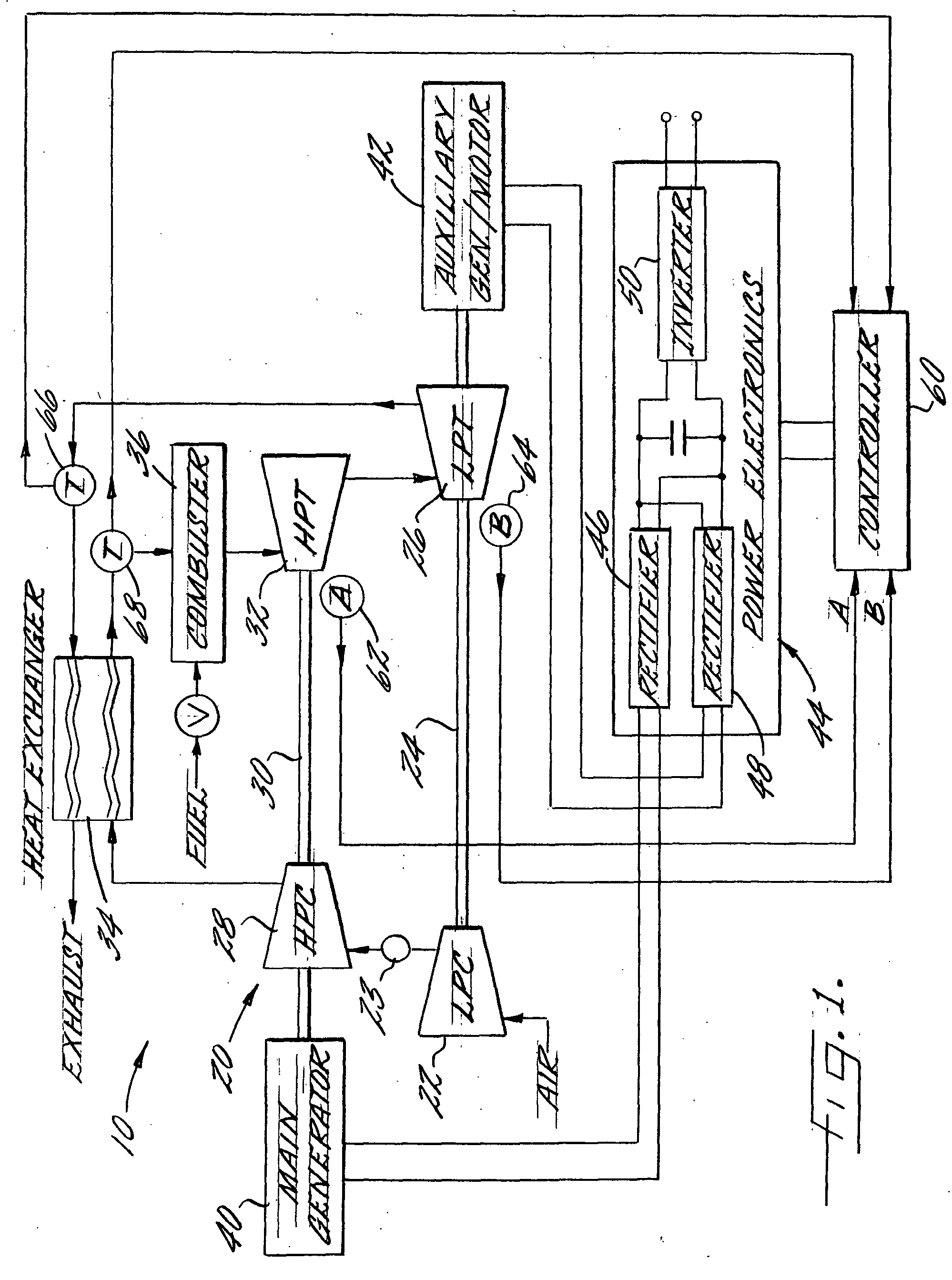

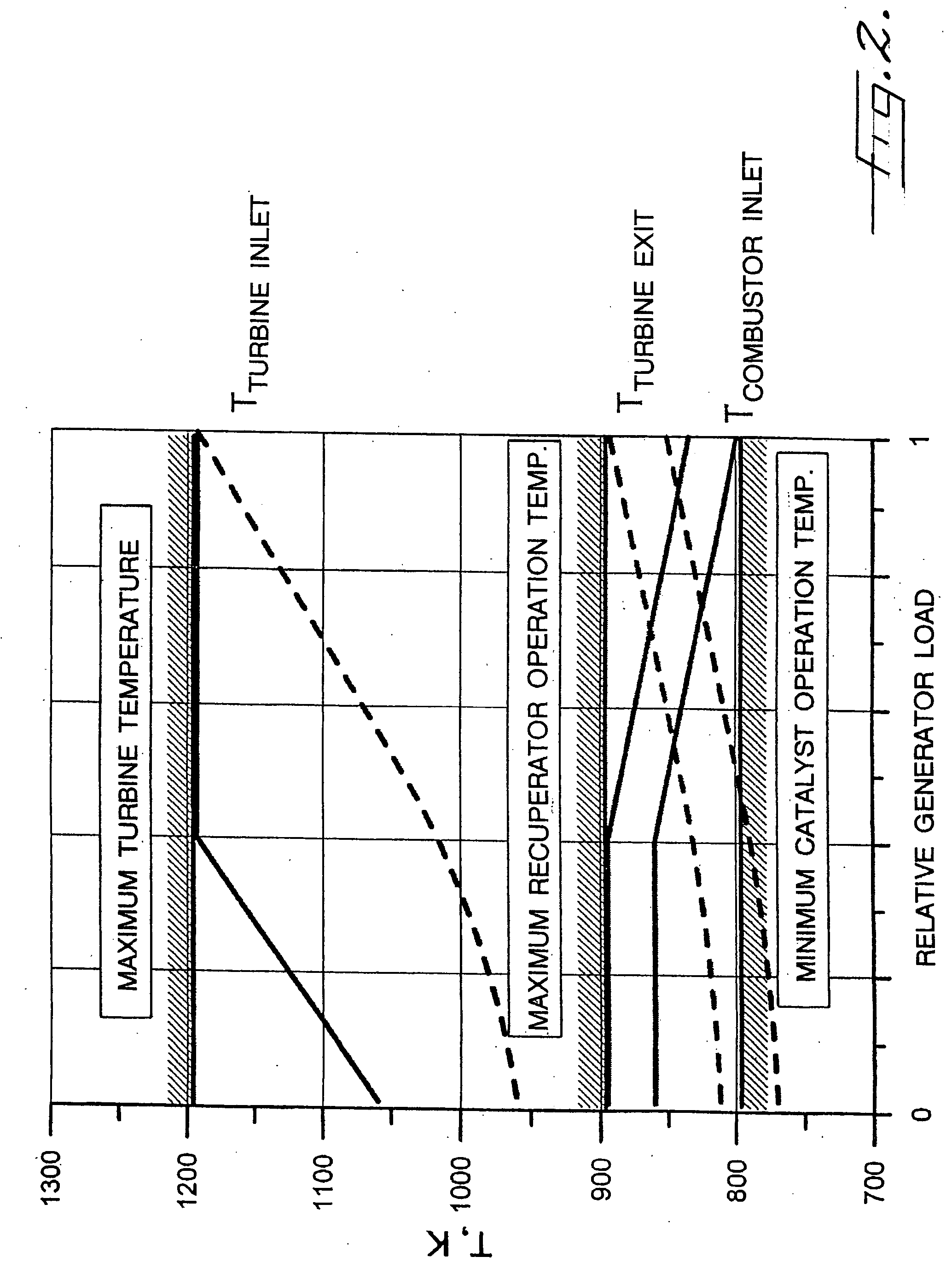

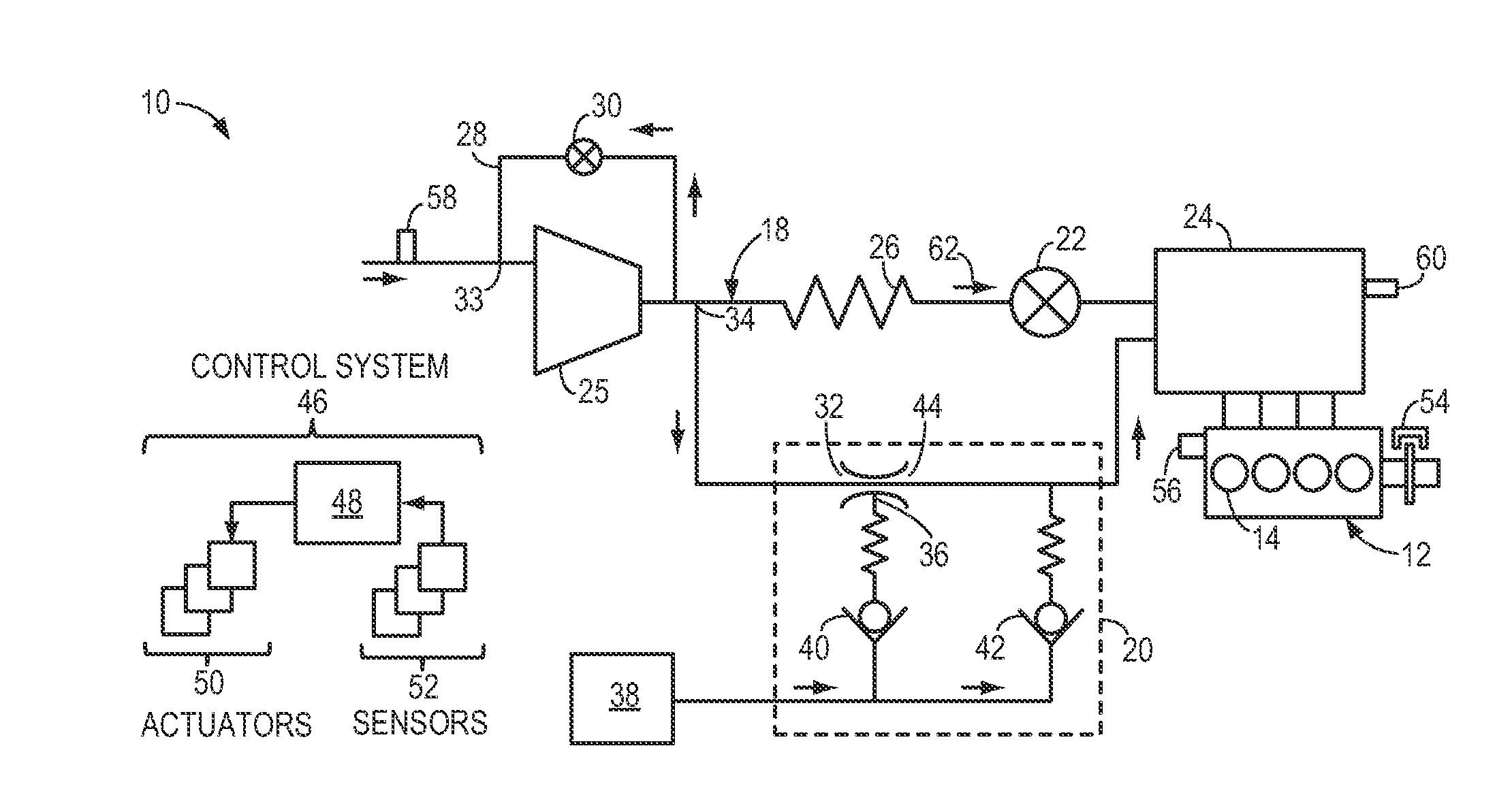

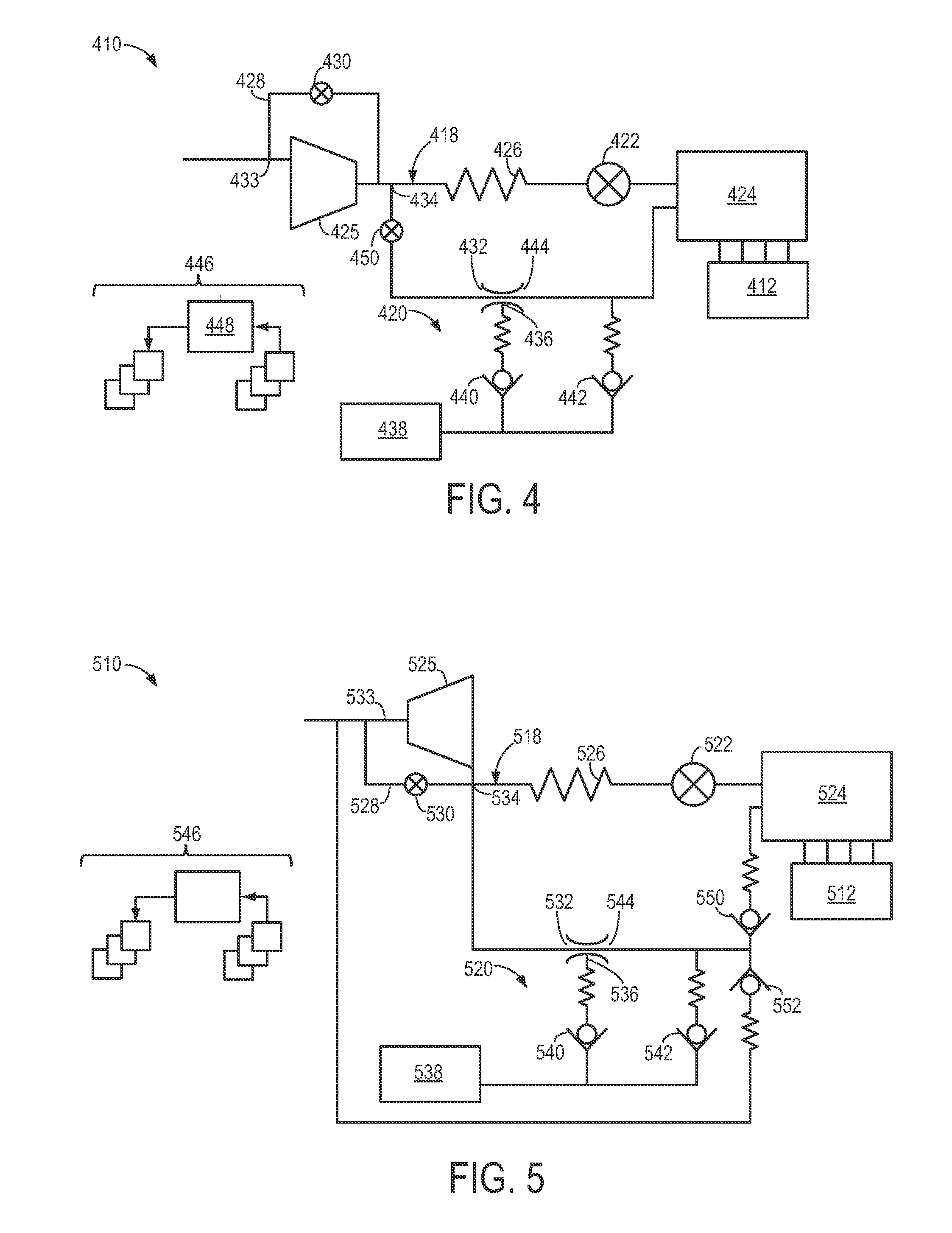

Multi-spool turbogenerator system and control method

ActiveUS20050056021A1Eliminate needMinimize and eliminate needCombustion enginesGas turbine plantsTurbineGas turbines

An electrical power generating system is driven by a multi-spool gas turbine engine including at least first and second spools. The first spool comprises a turbine and a compressor mounted on a first shaft; the second spool has at least a turbine mounted on a second shaft that is not mechanically coupled to the first shaft. A main generator is coupled with one of the spools, and an auxiliary generator / motor is also coupled with one of the spools. Speed control of each of the generators is employed for controlling operation of the engine. The auxiliary generator / motor can operate in either a generation mode to extract power from its spool or a motor mode to inject power into its spool.

Owner:MES INT INC

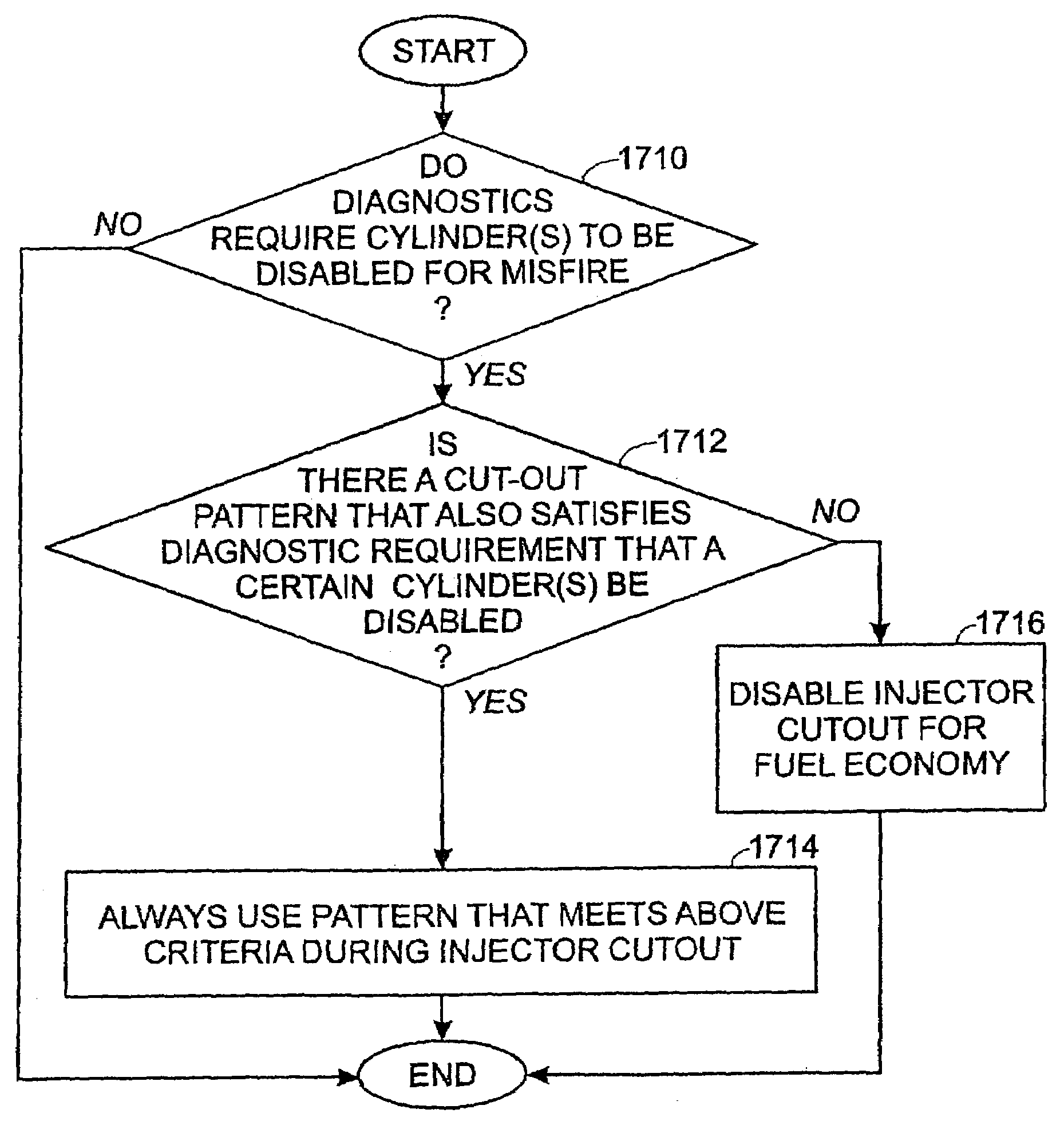

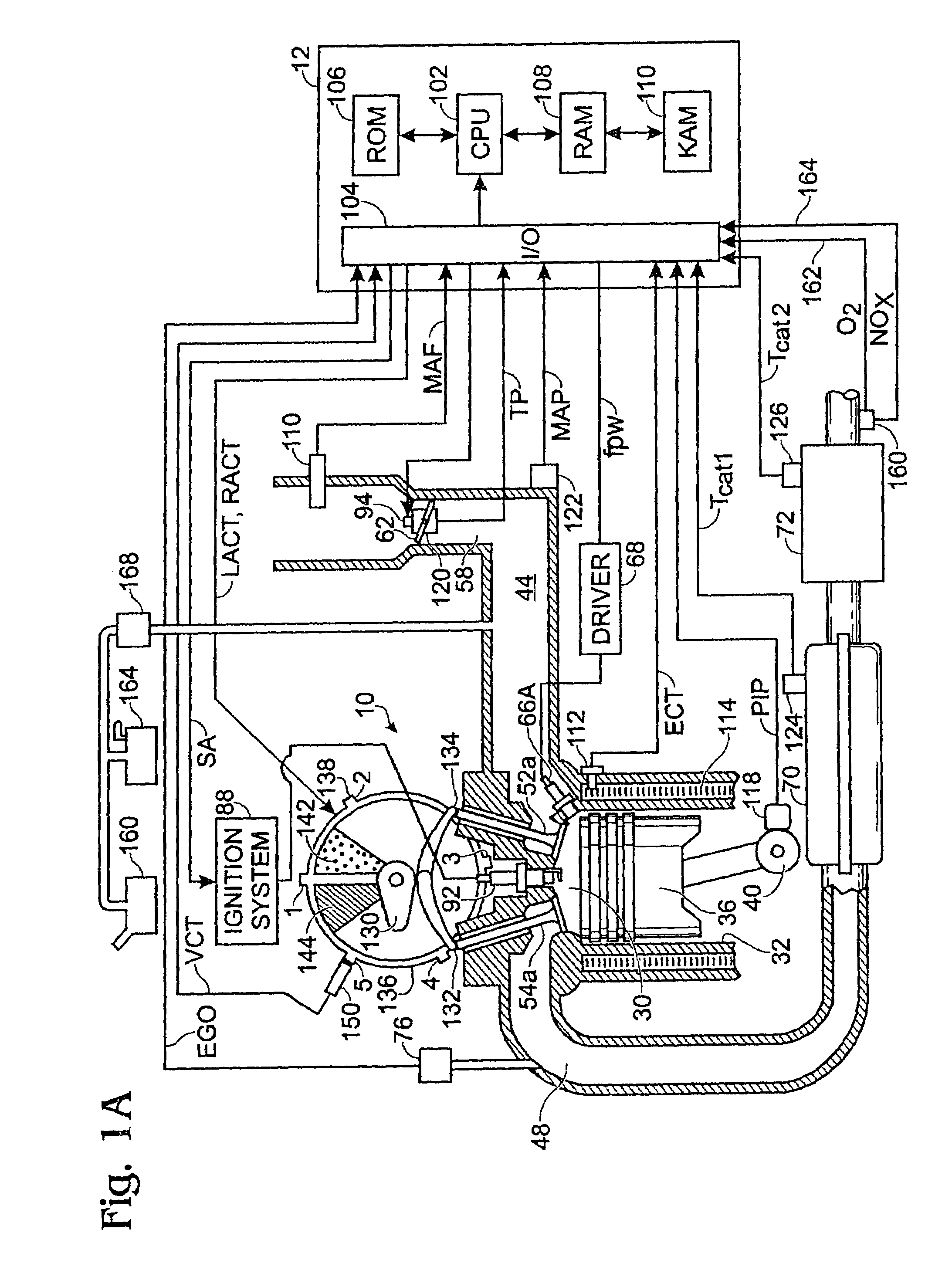

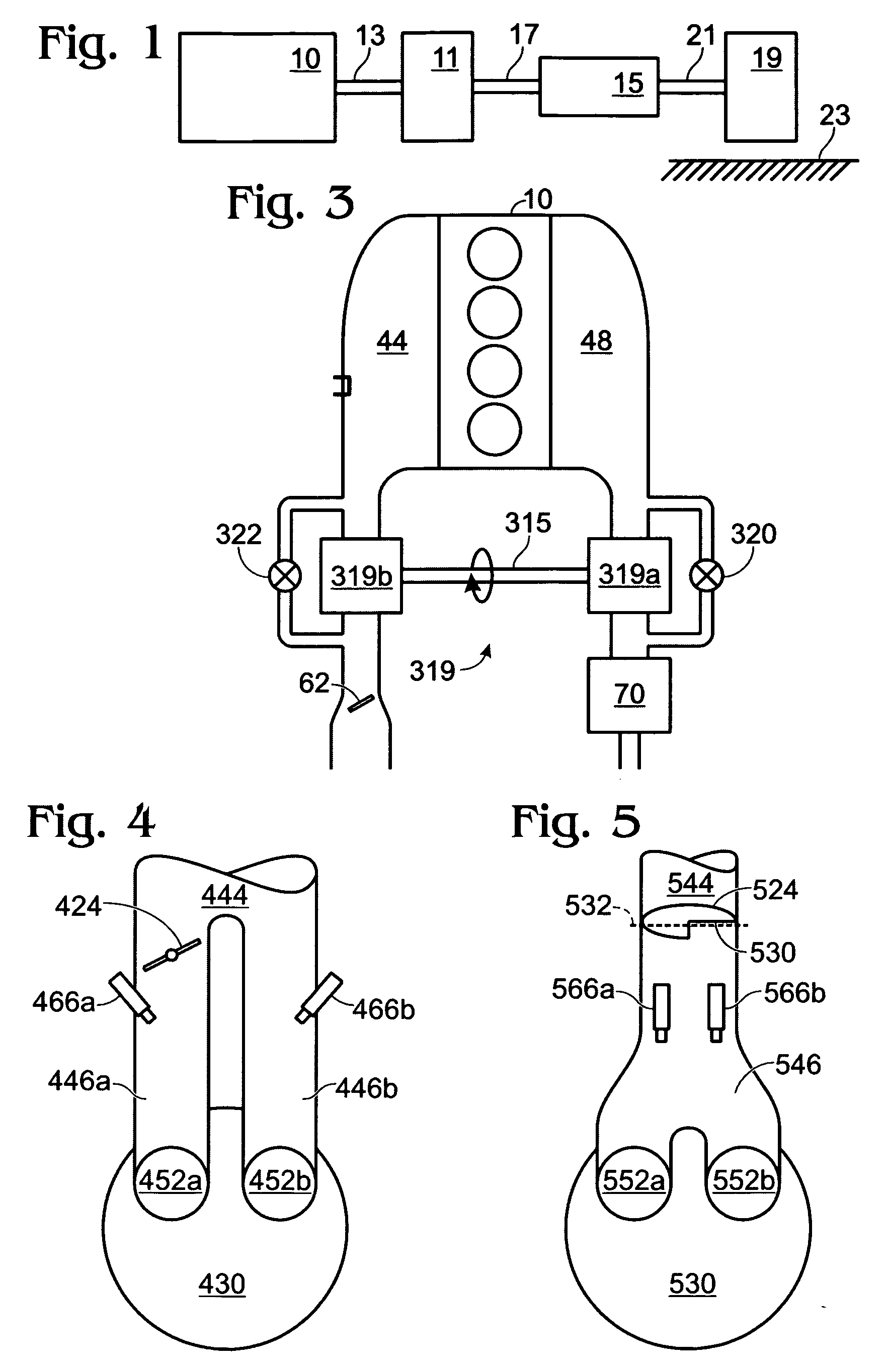

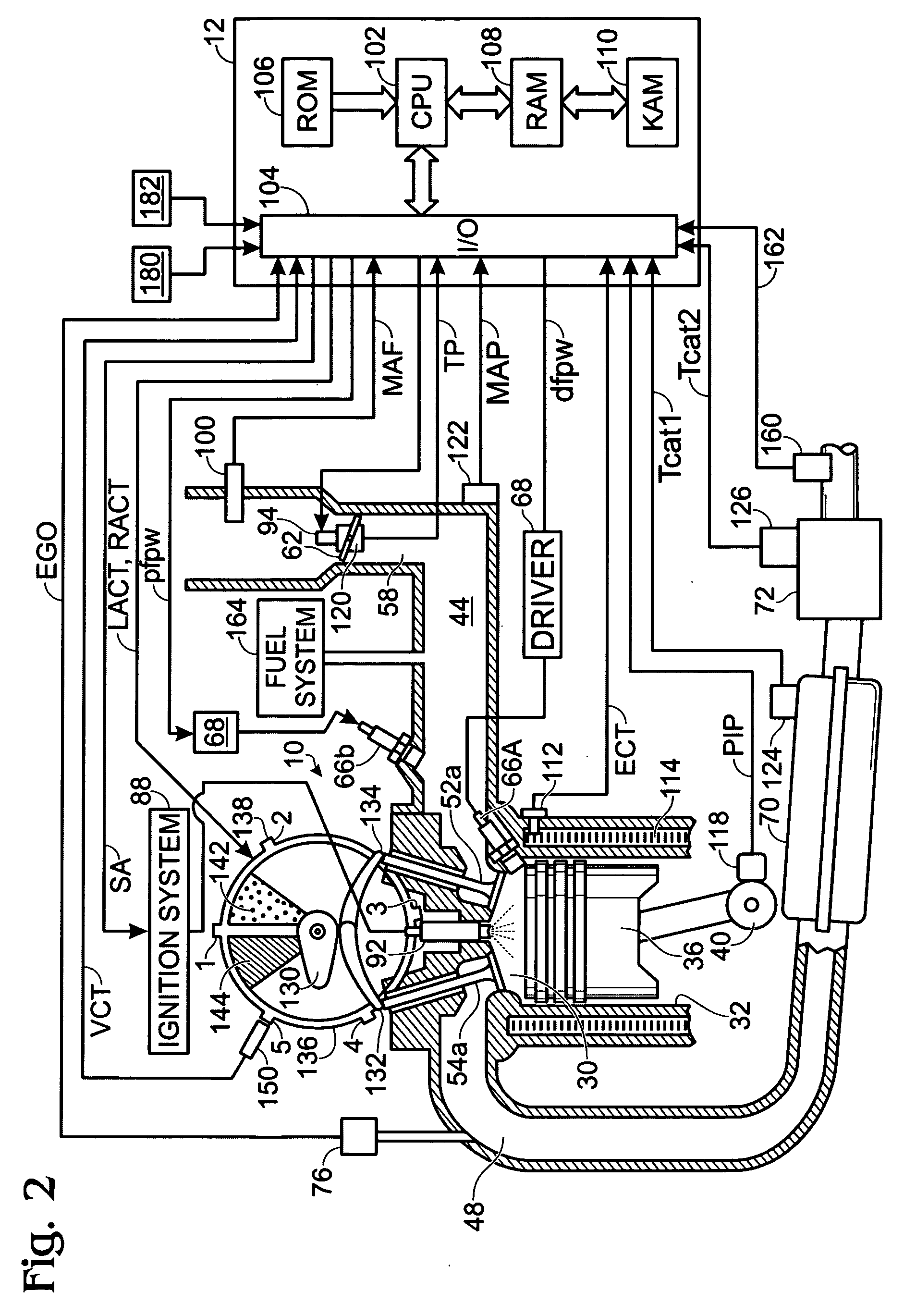

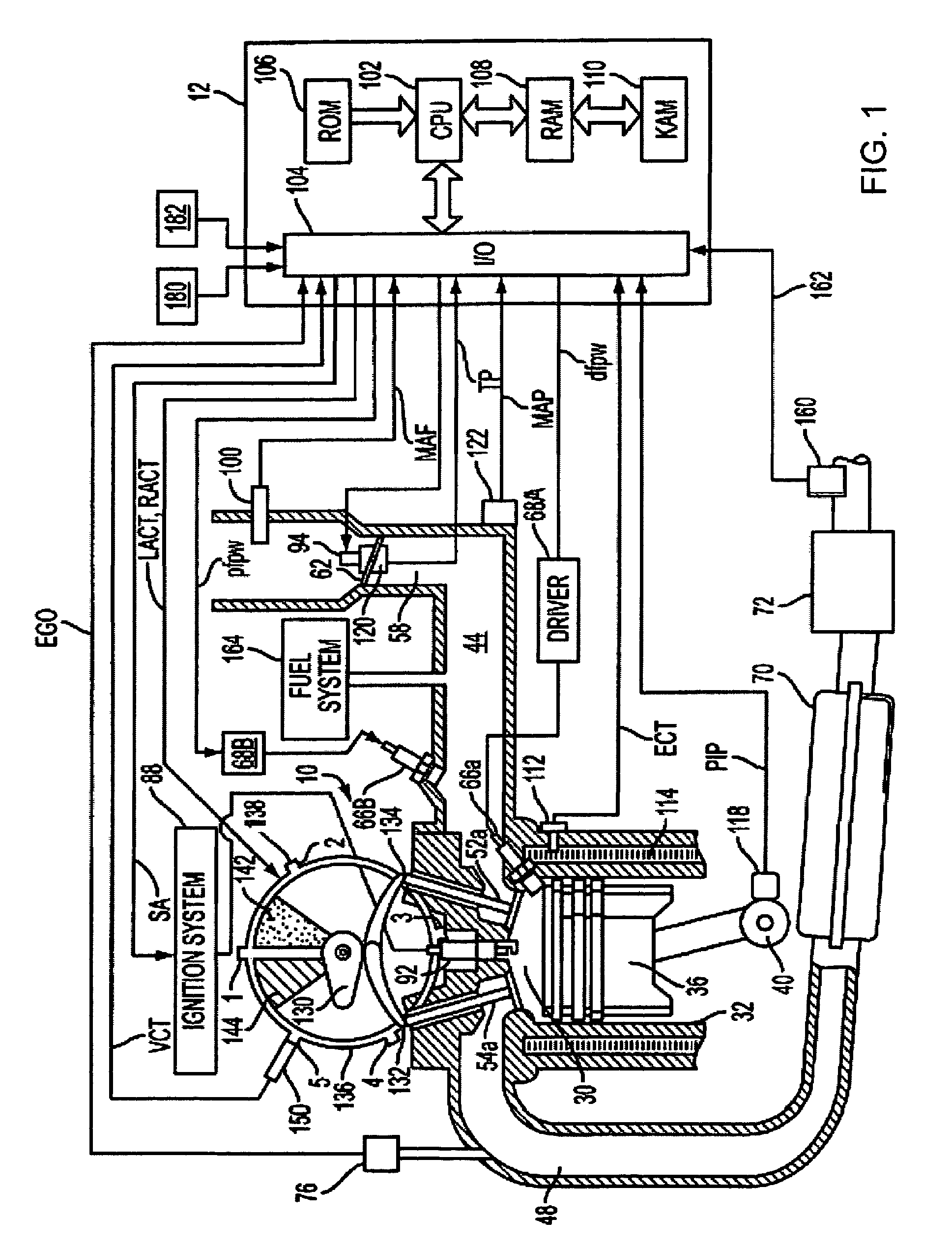

Engine system and method accounting for engine misfire

ActiveUS7086386B2Reducing engine pumping lossesMore efficientCombustion enginesOutput powerSystems designFuel vapor

Various systems and methods are disclosed for carrying out combustion in a fuel-cut operation in some or all of the engine cylinders of a vehicle. Further, various subsystems are considered, such as fuel vapor purging, air-fuel ratio control, engine torque control, catalyst design, and exhaust system design.

Owner:FORD GLOBAL TECH LLC

Intake system including vacuum aspirator

InactiveUS20110132311A1Reduce capacityImprove efficiencyCombustion enginesSpeed sensing governorsEngineeringVacuum aspirator

In some examples, reduced engine displacement reduces an engine's ability to provide brake booster vacuum. The present application relates to intake systems including a vacuum aspirator to generate vacuum.

Owner:FORD GLOBAL TECH LLC

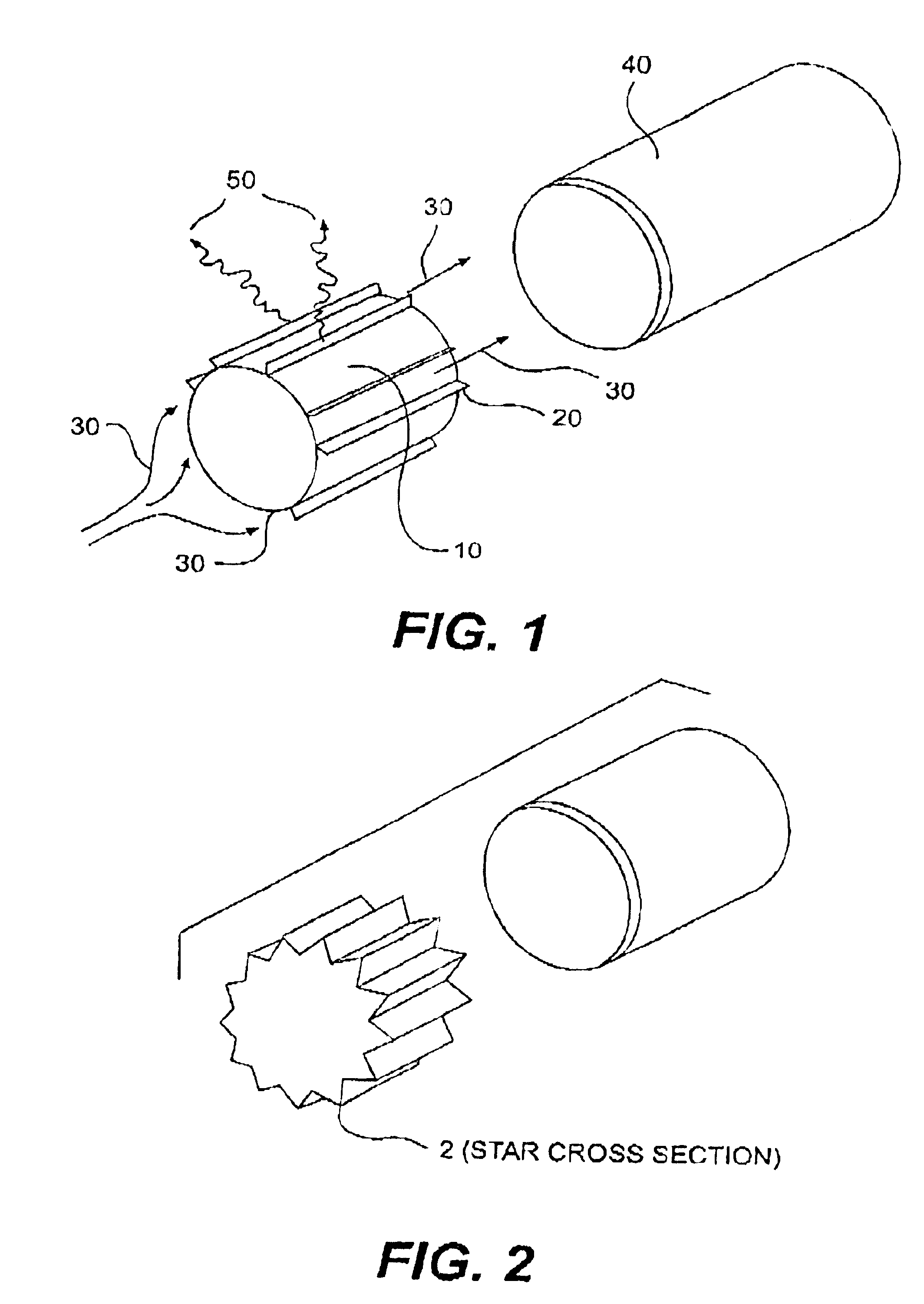

Z-filter media with reverse-flow cleaning systems and methods

A method for cleaning a filter having Z-media includes providing a filter having Z-media and cleaning the media construction by directing a pulse of compressed gas into the media construction through the downstream flow face. Filter elements useable with such methods include elements made of Z-media. An example system utilizing the method includes a gas turbine air intake system.

Owner:DONALDSON CO INC

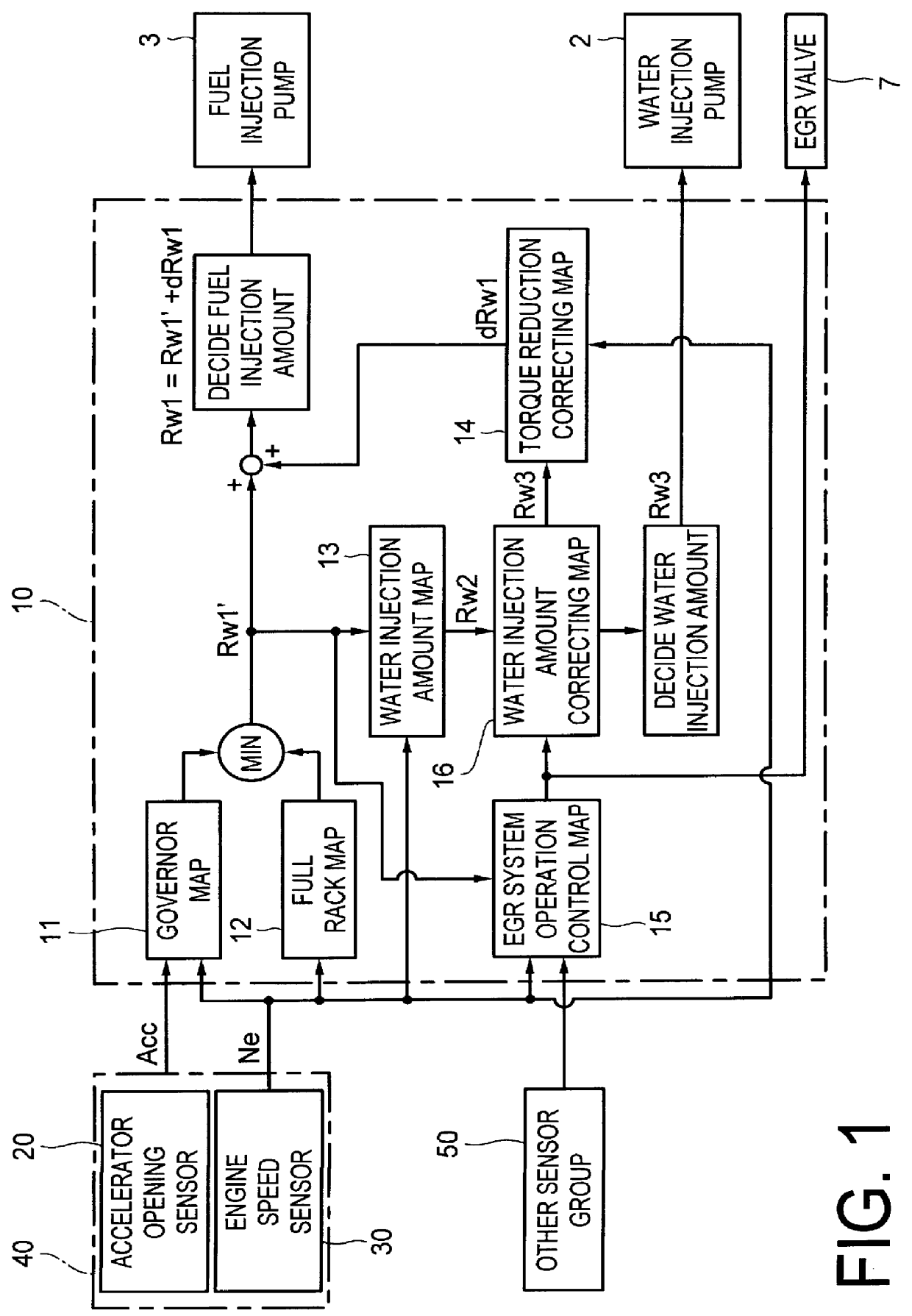

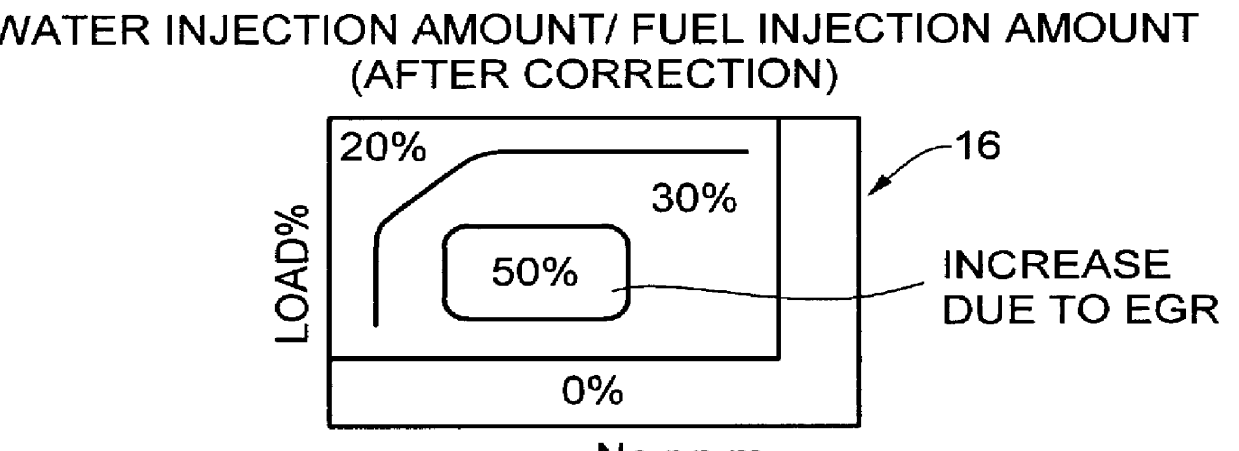

Water injection amount control system for fuel and water injection engine

InactiveUS6112705AEnhance NOx reducing effectImprove reducibilityElectrical controlNon-fuel substance addition to fuelCombustion chamberControl system

A water injection amount control system for a fuel and water injection engine, comprises running state detecting unit for detecting the running state of the engine; an EGR system for recirculating part of exhaust gas of the engine to a combustion chamber of the engine; EGR system operating state detecting unit for detecting or estimating the operating state of the EGR system; water injection amount regulating unit for regulating an amount of water to be injected to the combustion chamber of the engine; and control unit for controlling the operation of the water injection amount regulating unit: wherein the system is arranged to have water injection amount setting unit for deciding a water injection amount based on information from the running state detecting unit and on the operating state of the EGR system detected by the EGR system operating state detecting unit, so that the control unit controls the operation of the water injection amount regulating unit based on the water injection amount decided by the water injection amount setting unit.

Owner:MITSUBISHI FUSO TRUCK AND BUS CORPORATION

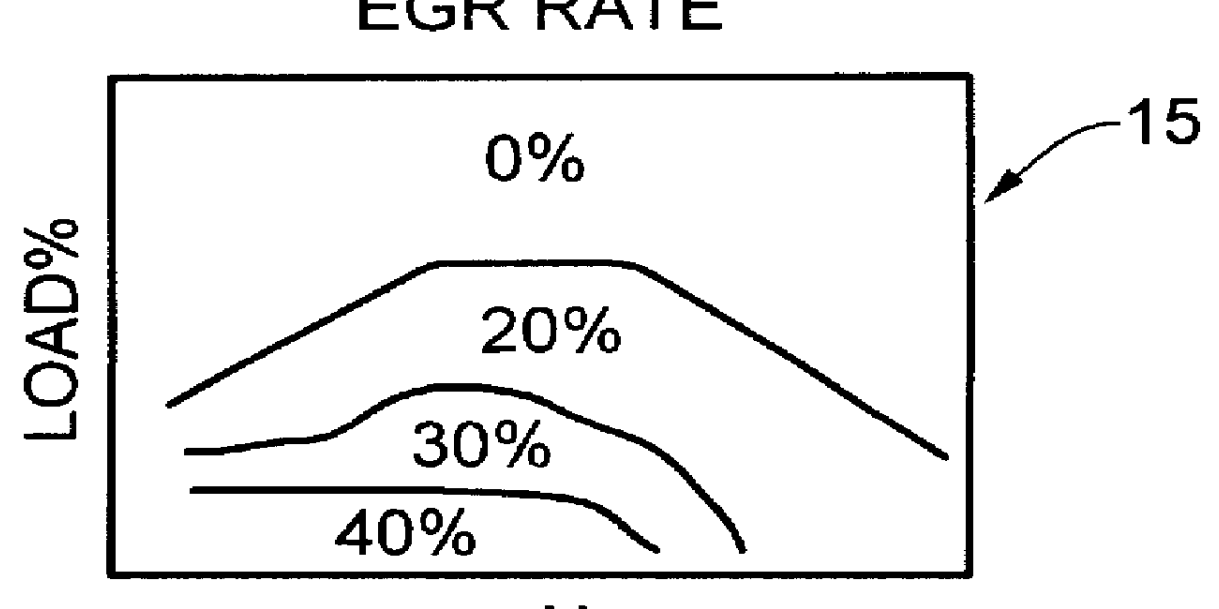

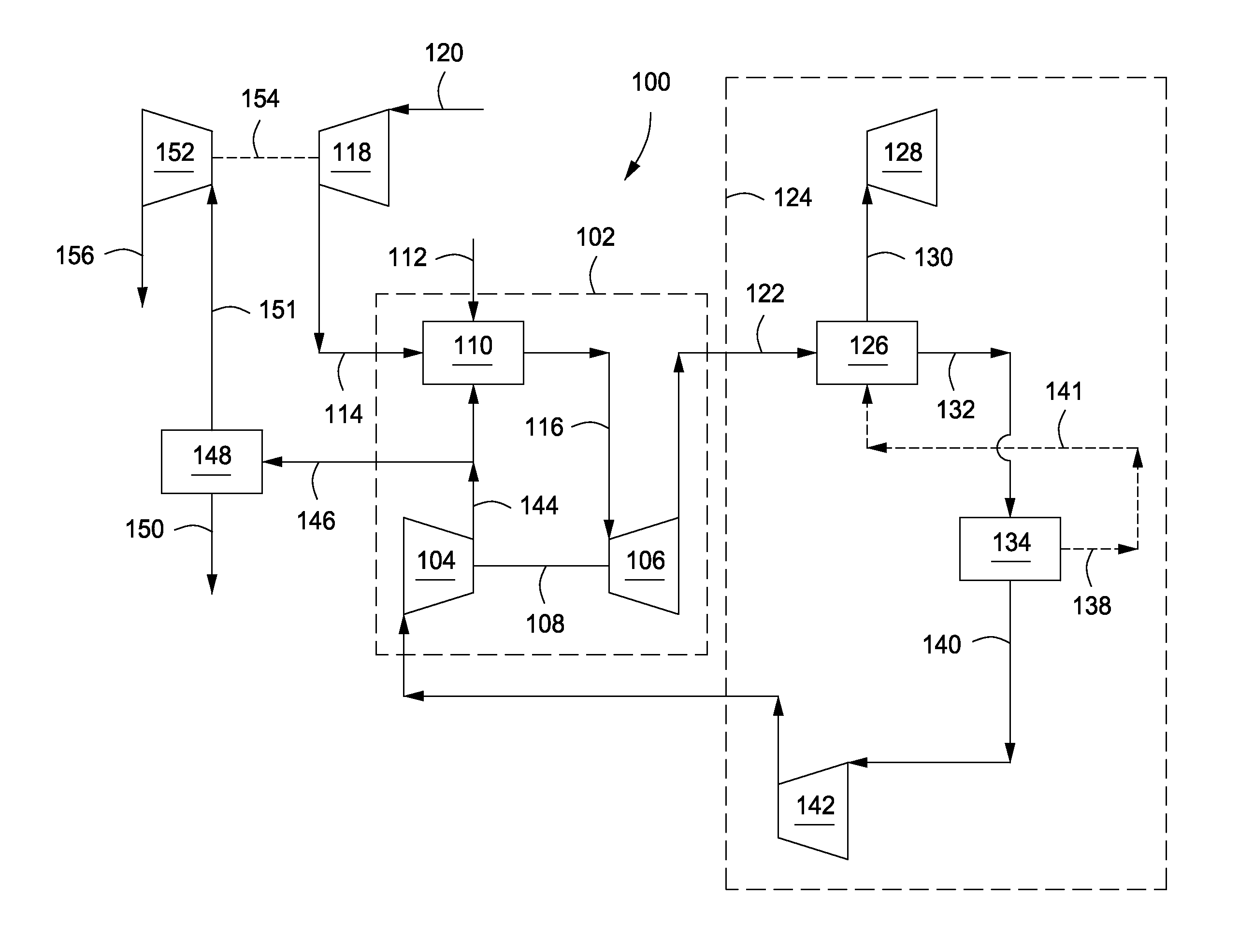

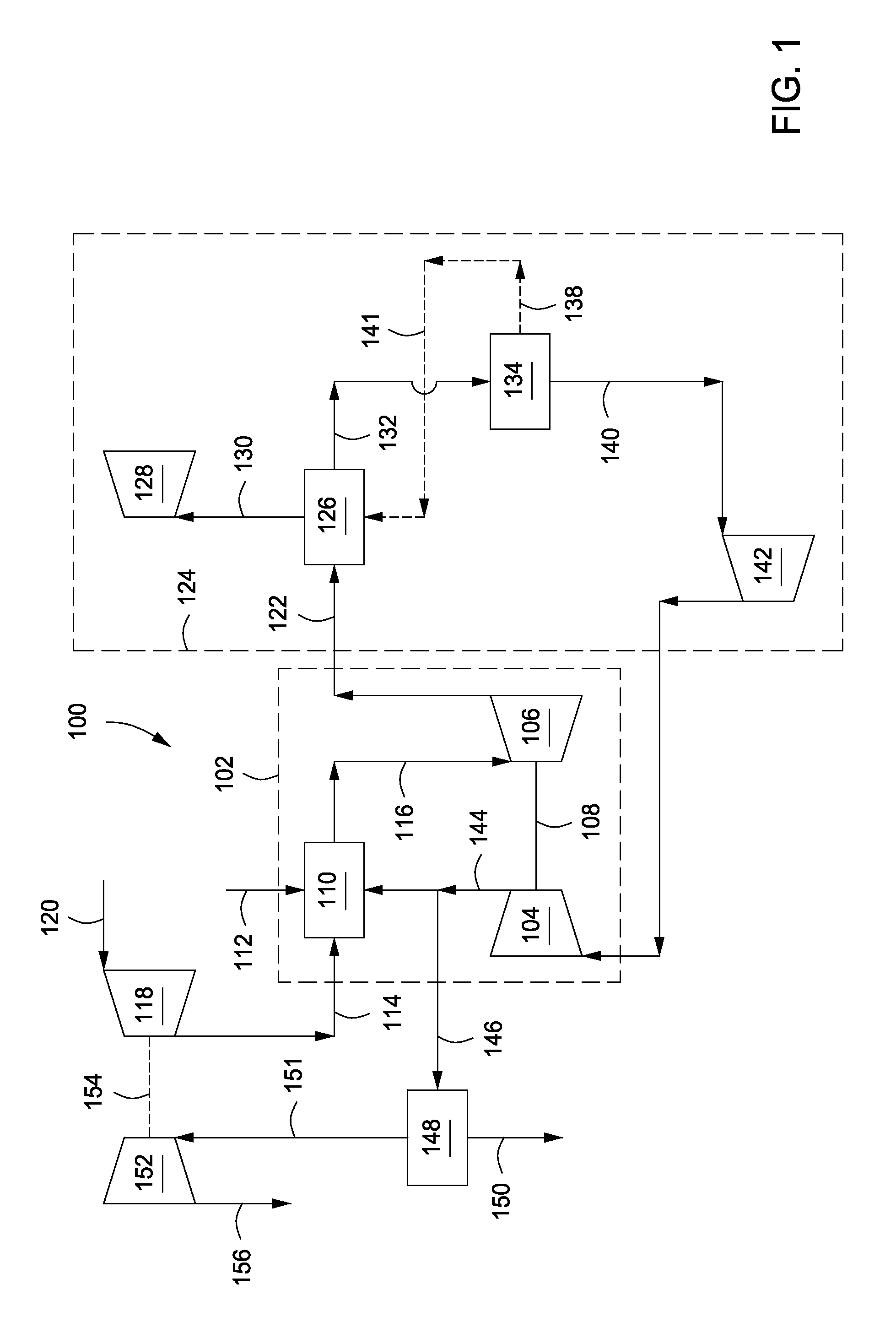

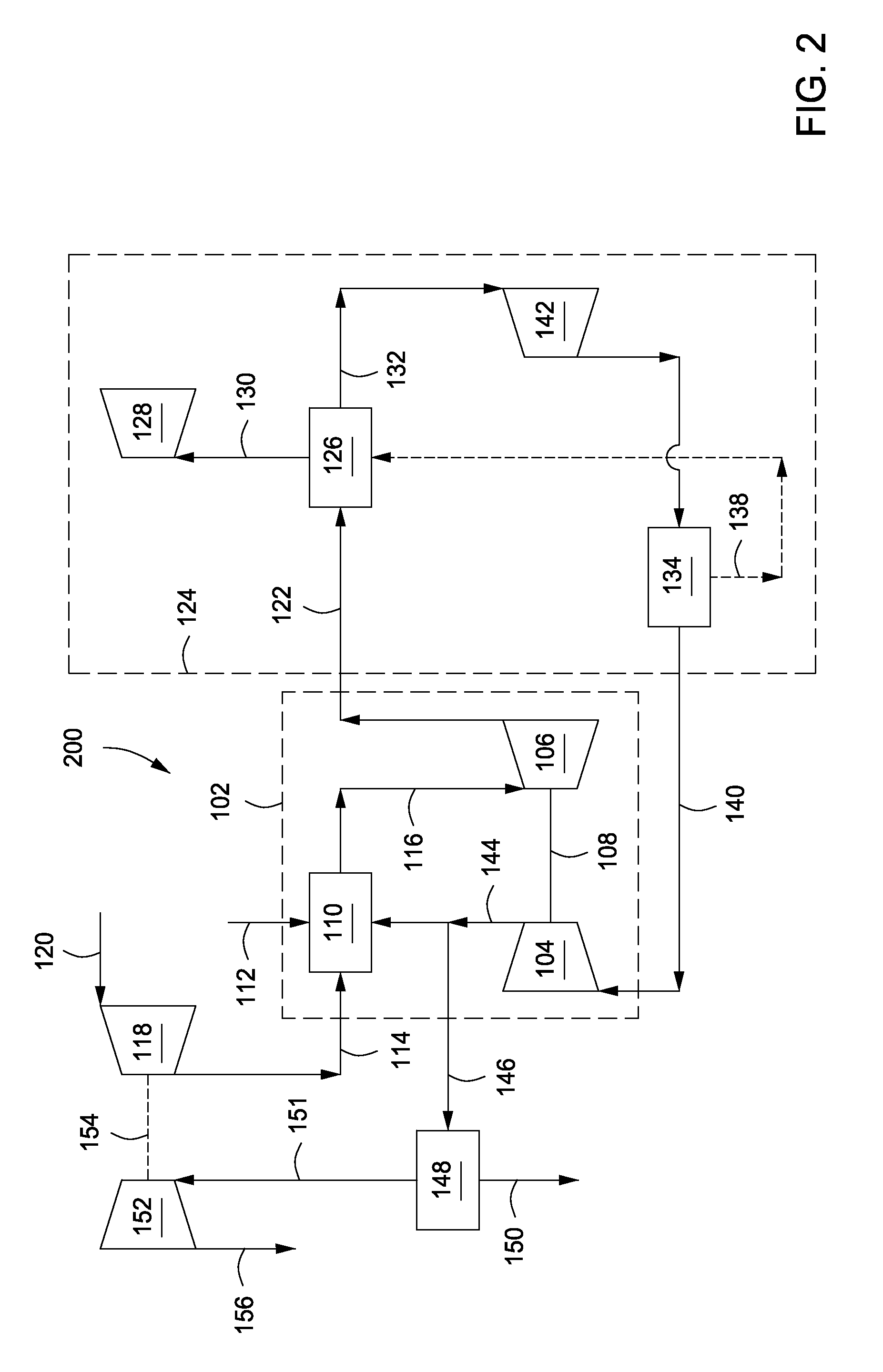

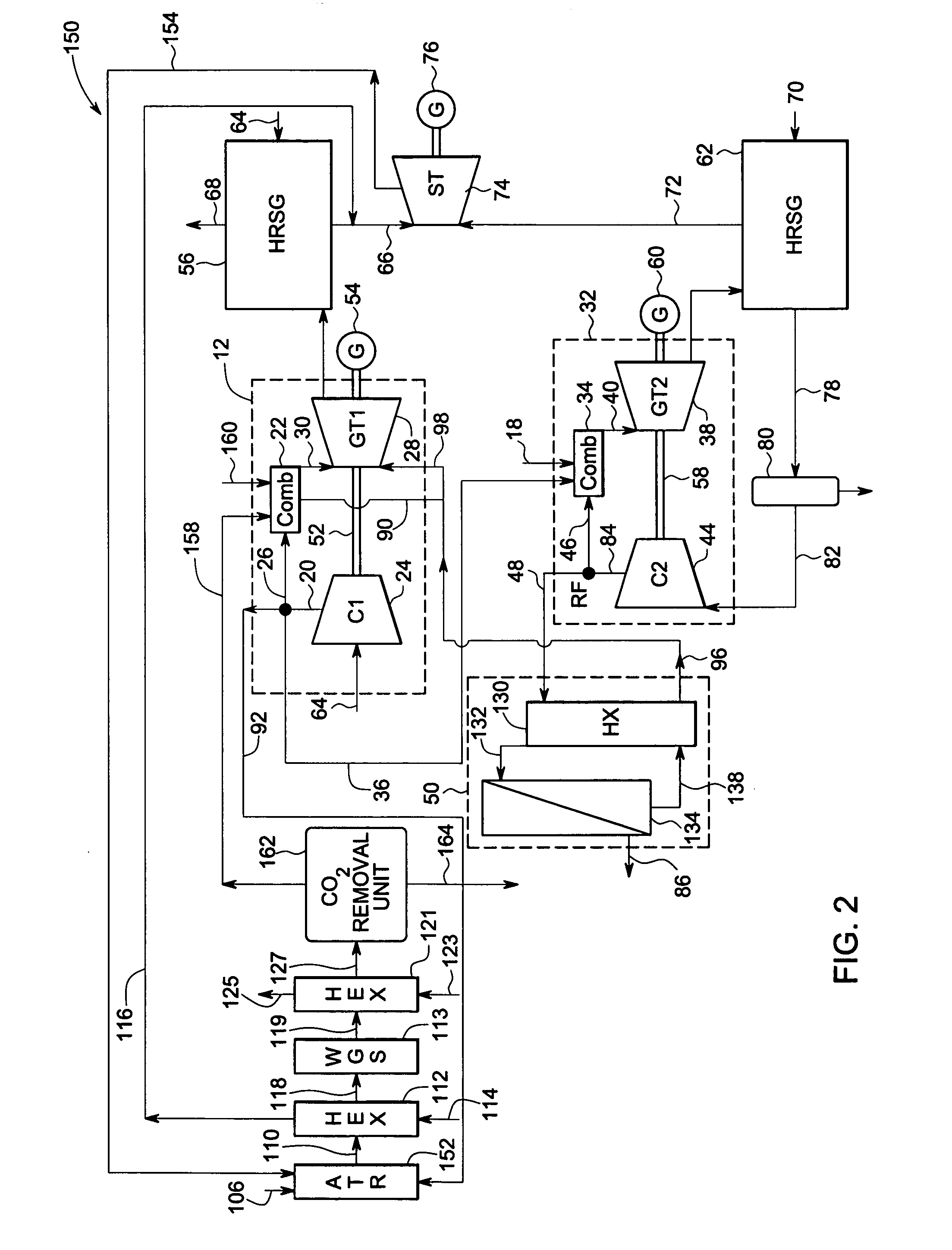

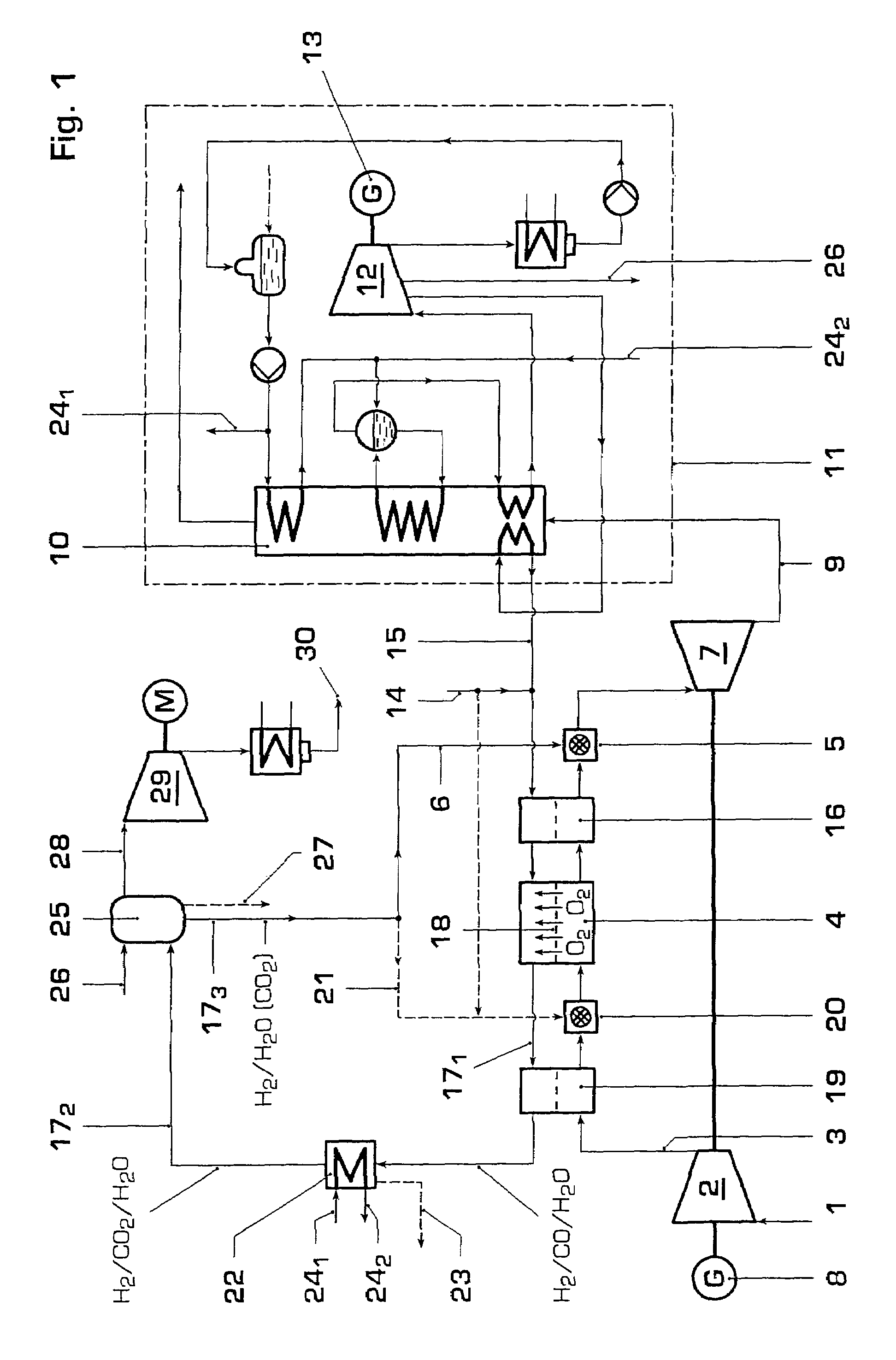

Reforming system for combined cycle plant with partial CO2 capture

A combined cycle system includes, a pre-steam-methane-reformer operating at a temperature of less than about 800 degrees Celsius to reform a mixed fuel stream to generate a first reformate stream, a water-gas-shift reactor to convert carbon monoxide in the first reformate stream to carbon dioxide and form a second reformate stream, a carbon dioxide removal unit for removing carbon dioxide from the second reformate stream and form a carbon dioxide stream and a third reformate stream; wherein less than about 50 percent of the carbon contained in the mixed fuel stream is recovered as carbon dioxide by the removal unit, a gas turbine unit for generating power and an exhaust stream, and a steam generator unit configured to receive the exhaust stream, wherein the heat of the exhaust stream is transferred to a water stream to generate the steam for the mixed fuel stream and for a steam turbine.

Owner:GENERAL ELECTRIC CO

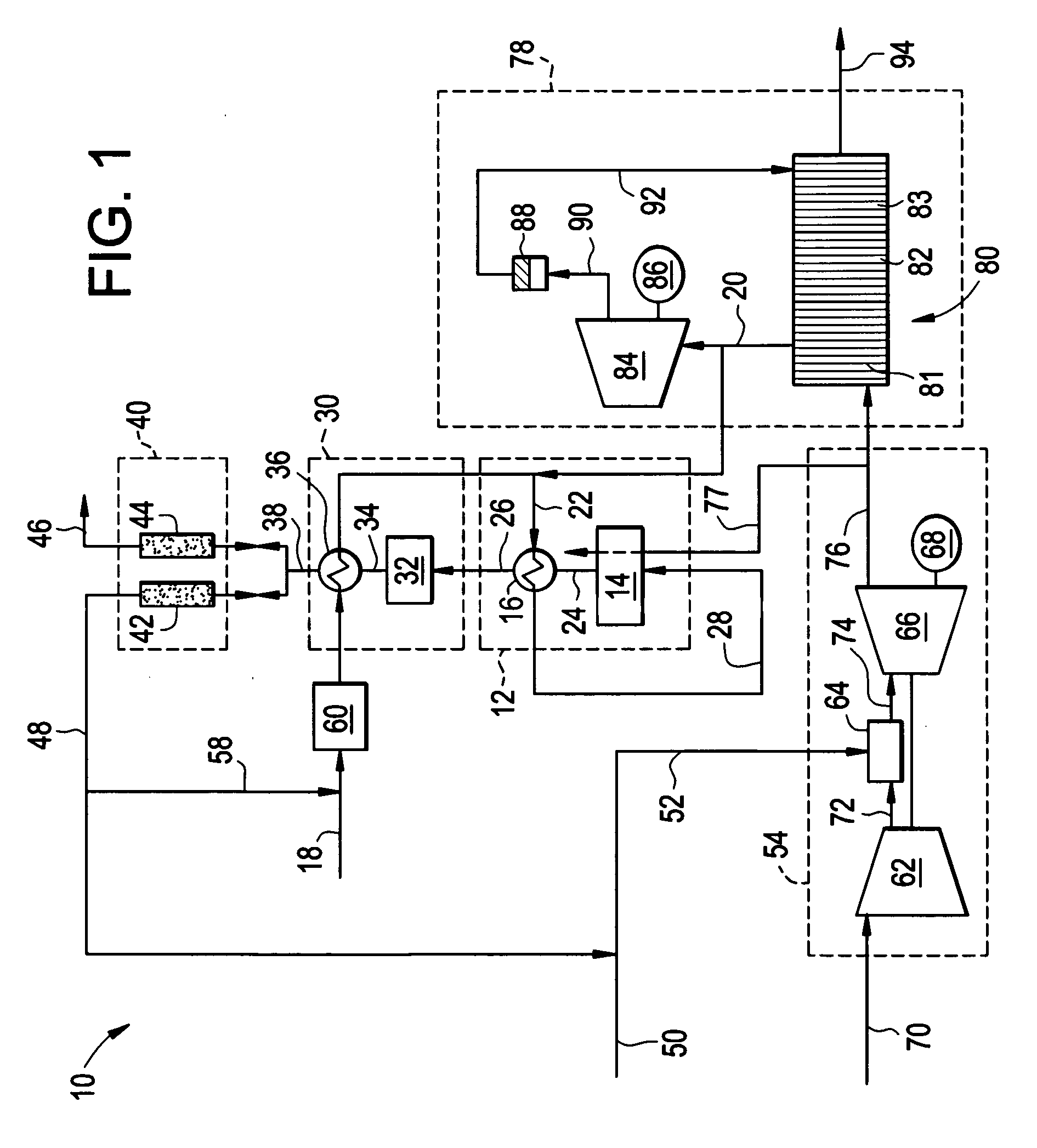

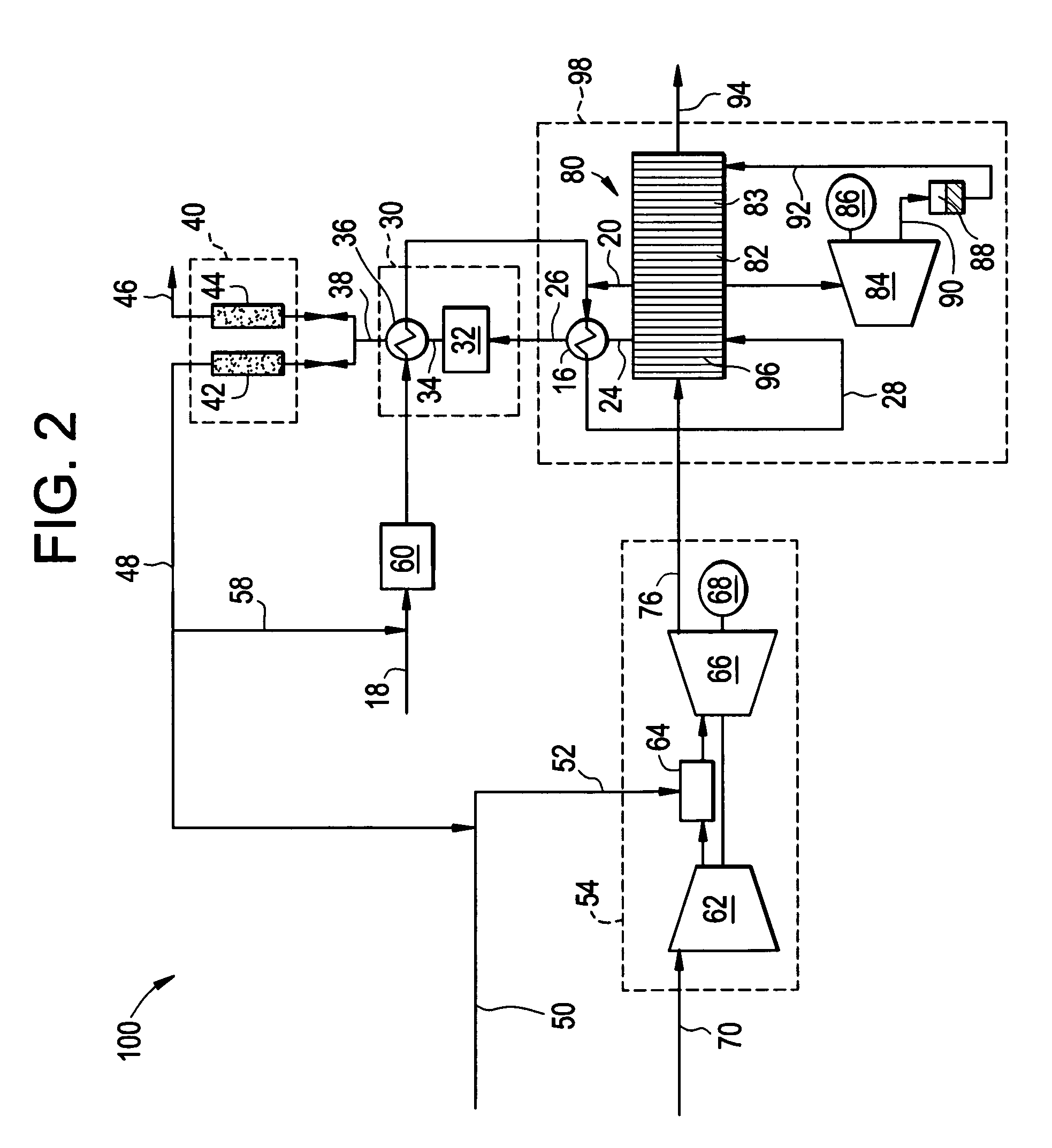

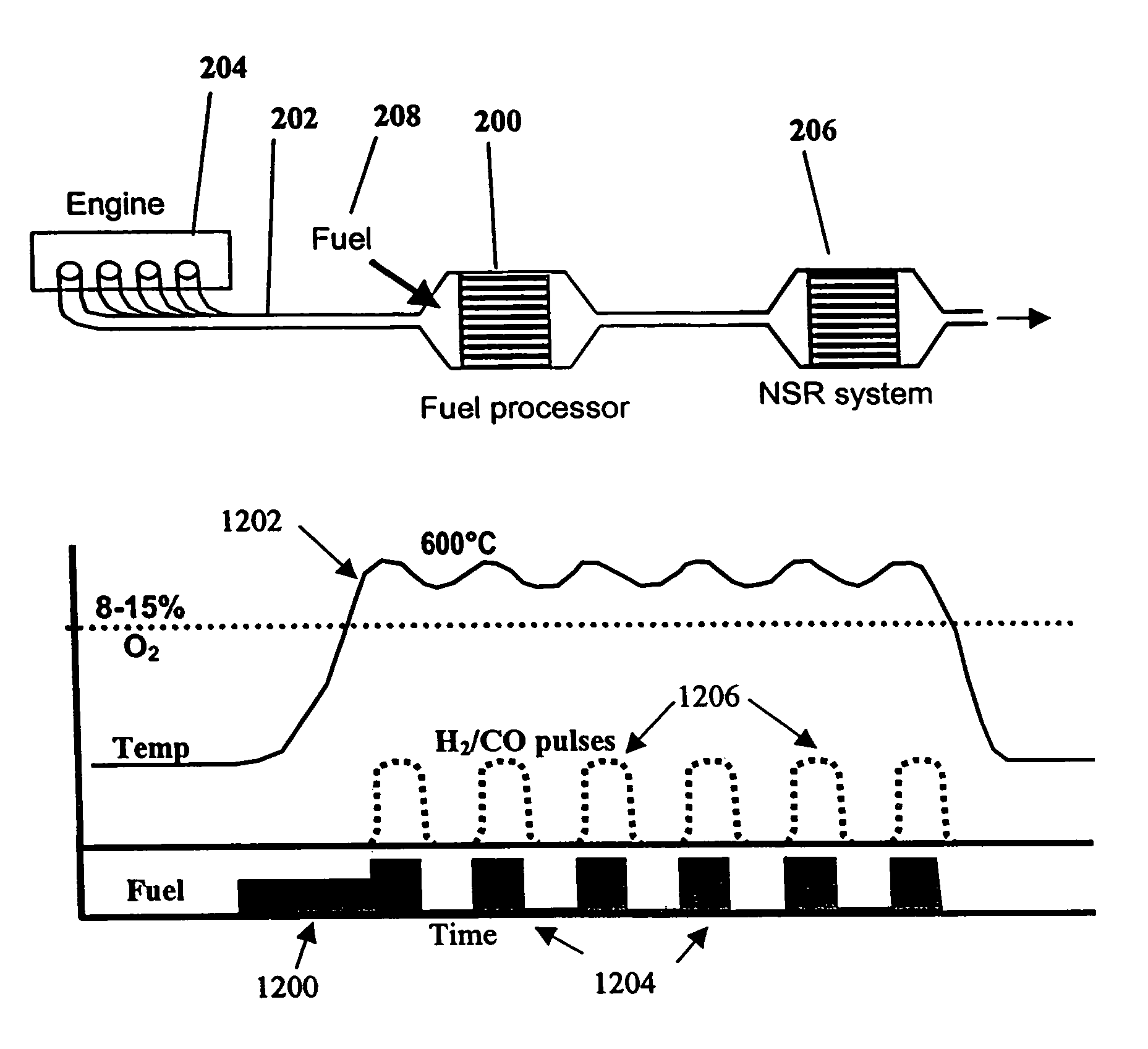

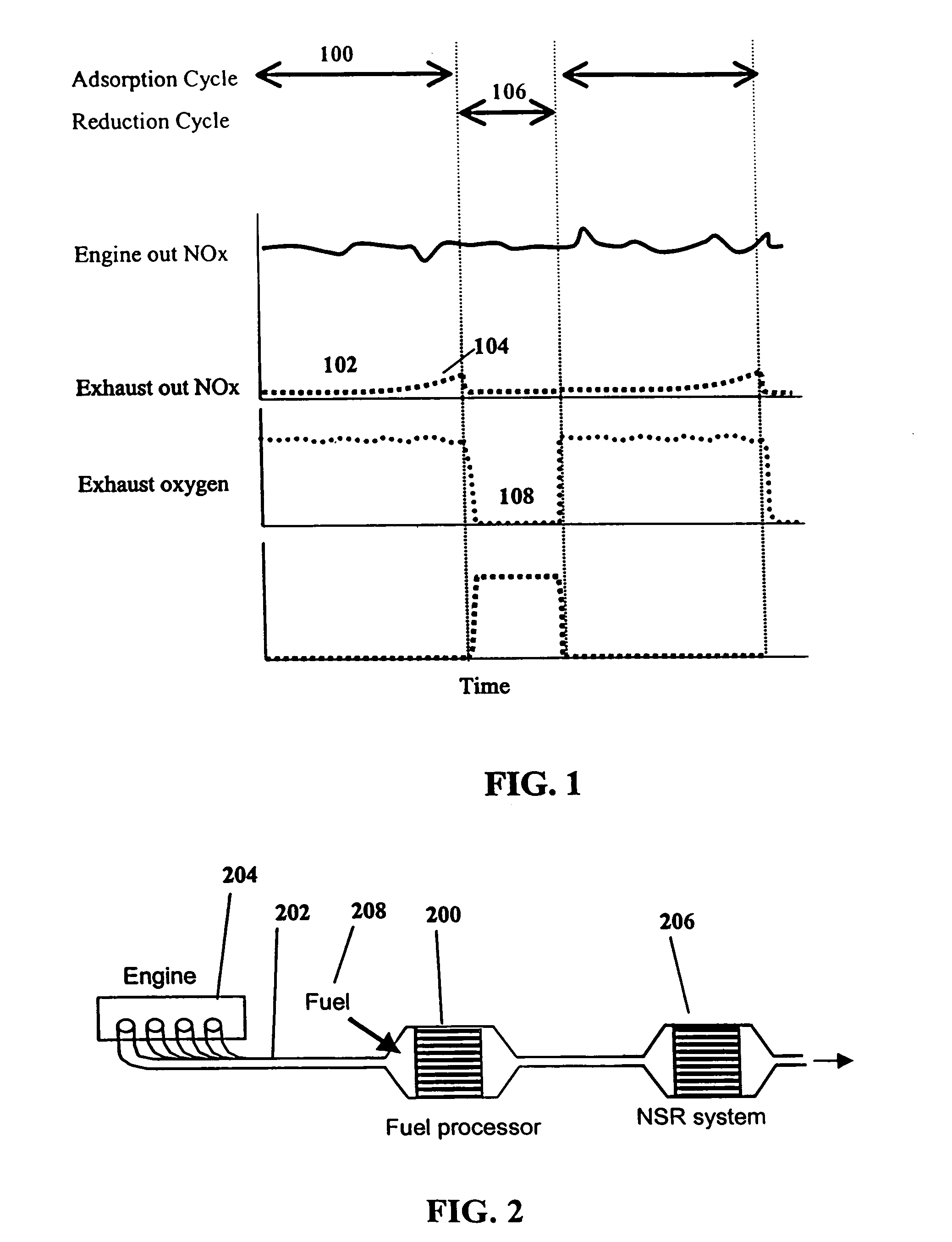

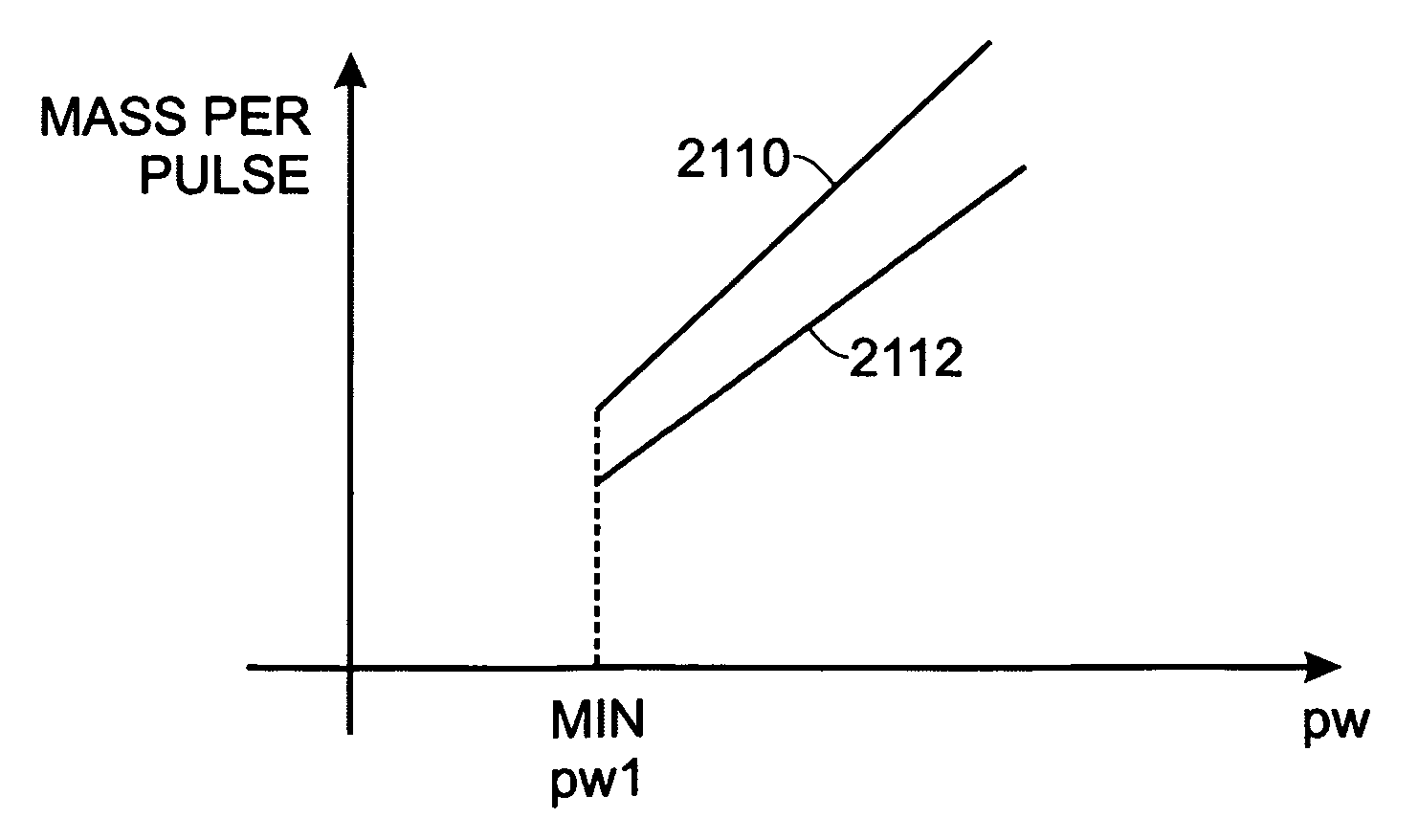

System and methods for improved emission control of internal combustion engines using pulsed fuel flow

InactiveUS7082753B2Save oilReducing greenhouse gas emissionExhaust apparatusCombustion enginesPartial oxidationExternal combustion engine

The present invention provides systems and methods to improve the performance and emission control of internal combustion engines equipped with nitrogen oxides storage-reduction (“NSR”) emission control systems. The system generally includes a NSR catalyst, a fuel processor located upstream of the NSR catalyst, and at least one fuel injection port. The fuel processor converts a fuel into a reducing gas mixture comprising CO and H2. The reducing gas mixture is then fed into the NSR catalyst, where it regenerates the NSR adsorbent, reduces the NOx to nitrogen, and optionally periodically desulfates the NSR catalyst. The fuel processor generally includes one or more catalysts, which facilitate reactions such as combustion, partial oxidation, and / or reforming and help consume excess oxygen present in an engine exhaust stream. The methods of the present invention provide for NSR catalyst adsorbent regeneration using pulsed fuel flow. Control strategies are also provided.

Owner:INT ENGINE INTPROP CO LLC

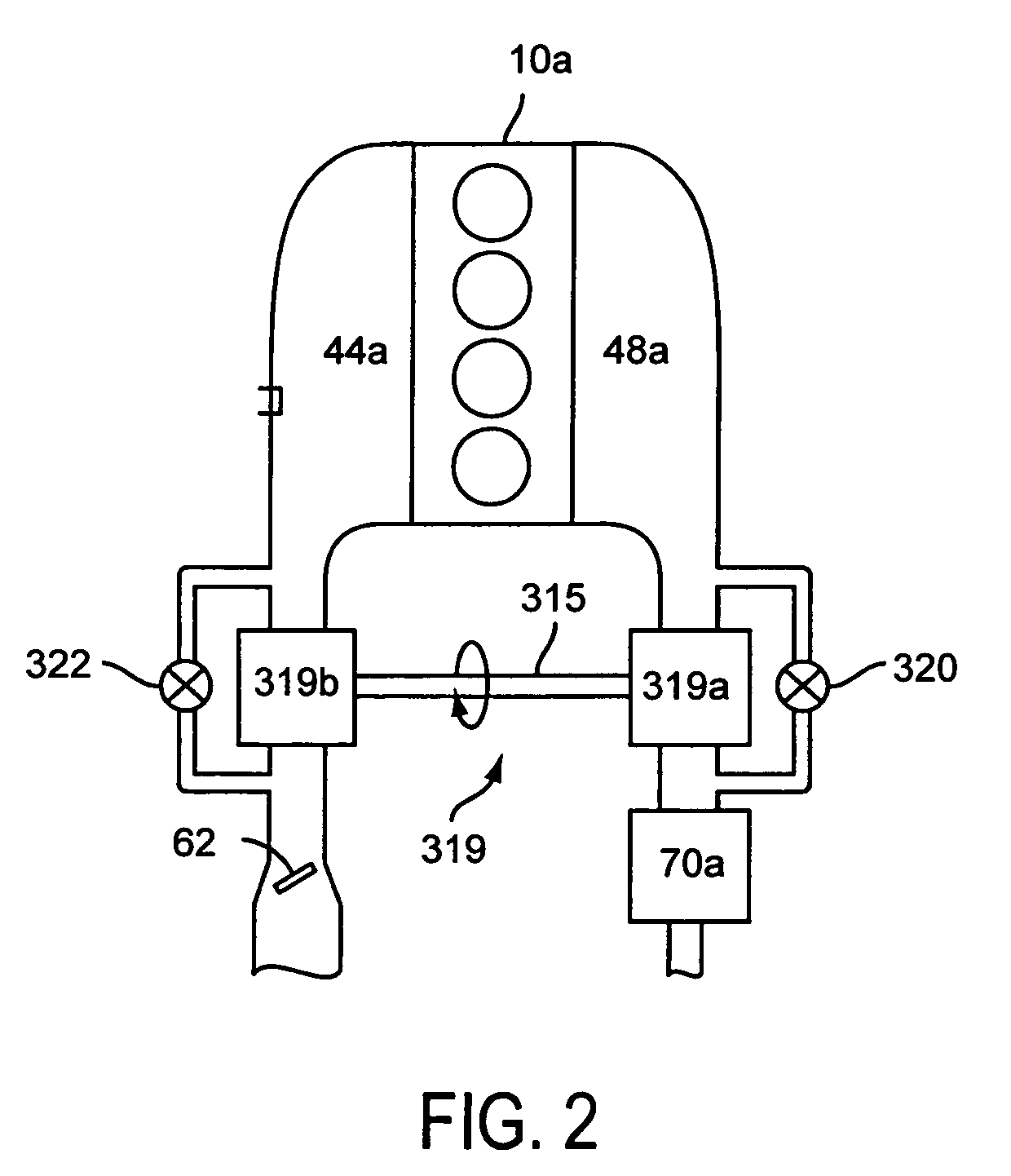

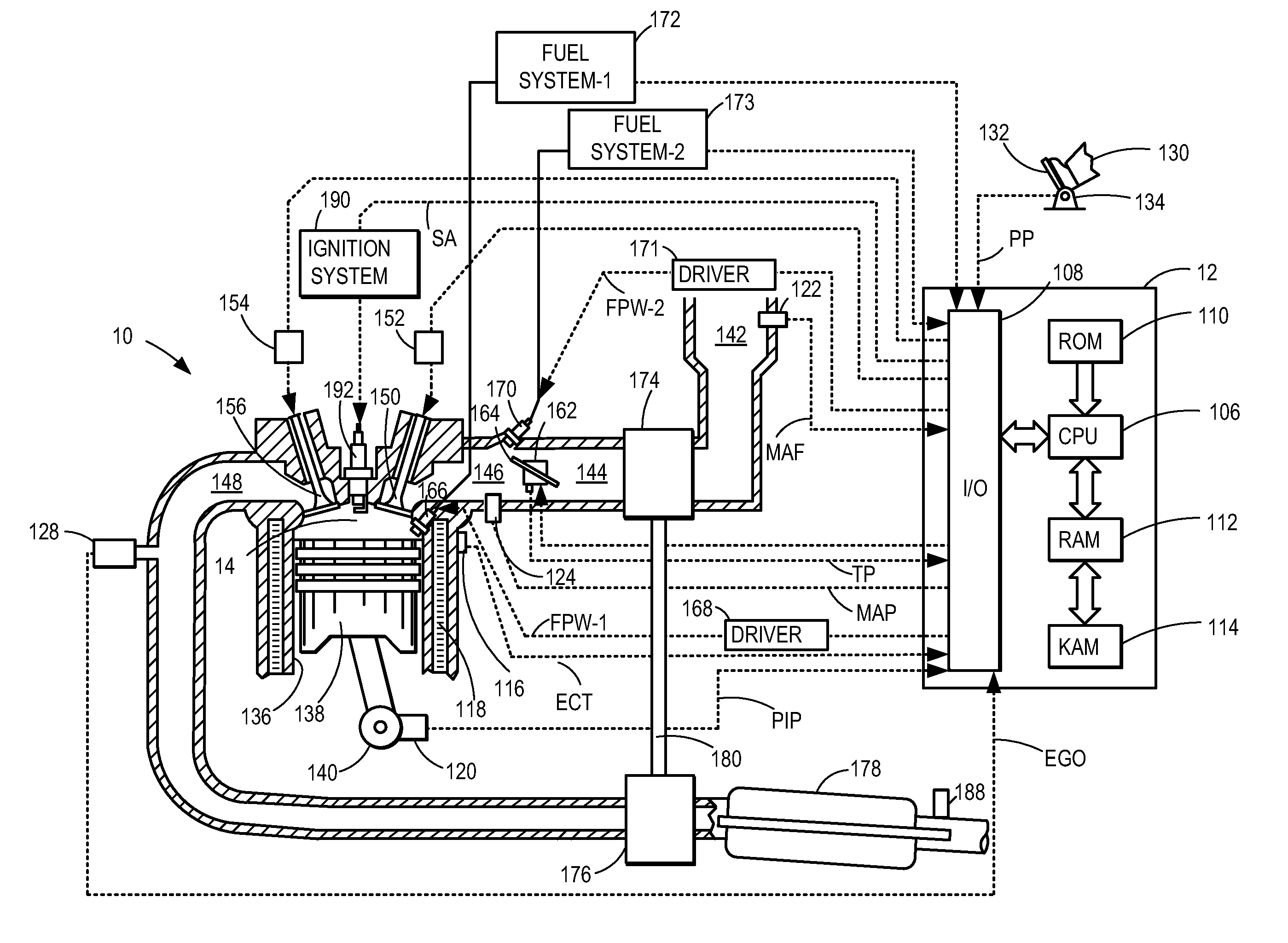

Event based engine control system and method

A system for an engine of a vehicle, comprising of a cylinder of the engine; a first injector configured to inject a first substance to said cylinder; a second injector configured to inject a second substance to said cylinder; and a controller configured to perform injection from said first and second injector in response to a number of combustion events from an engine start.

Owner:FORD GLOBAL TECH LLC

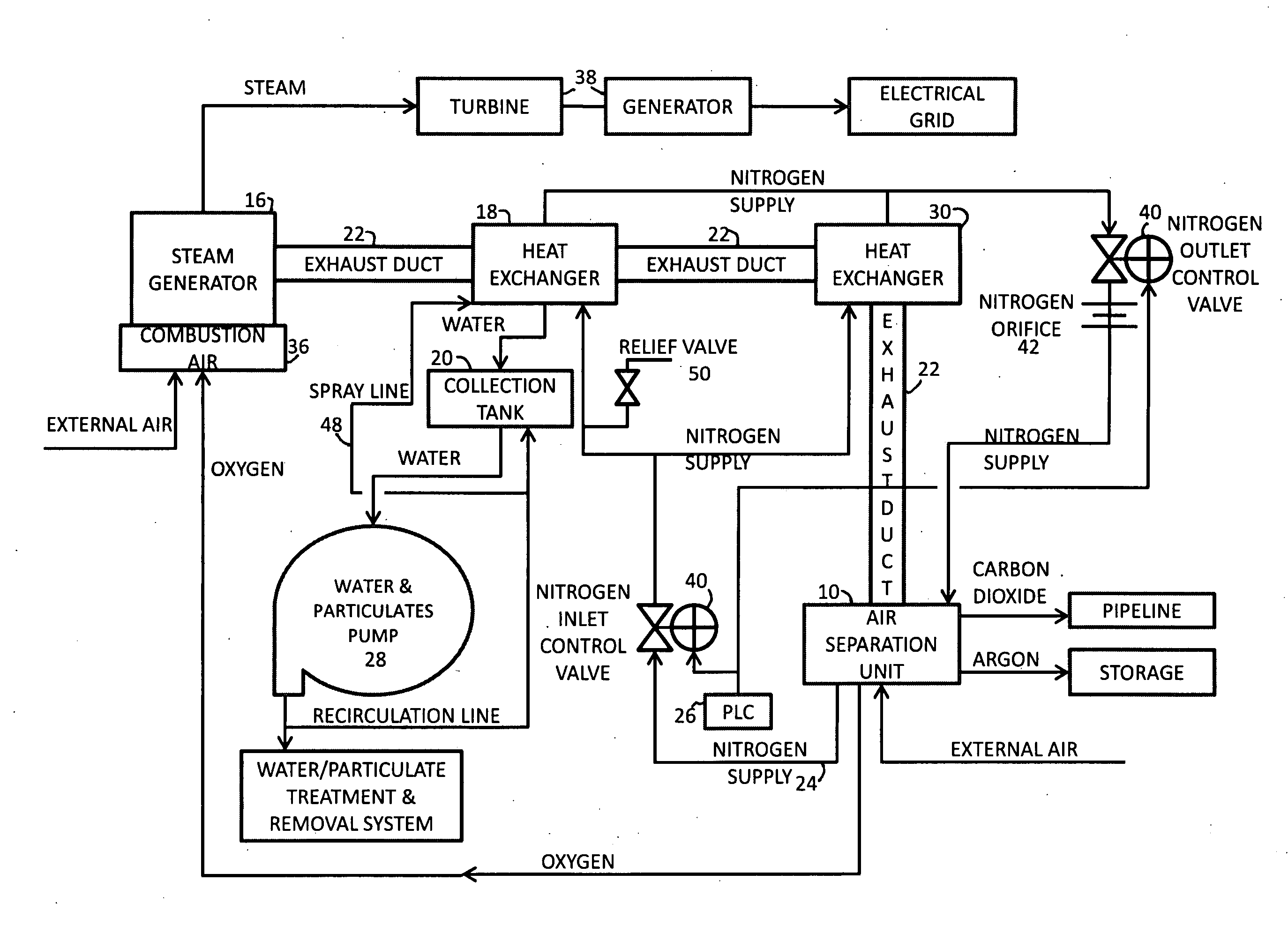

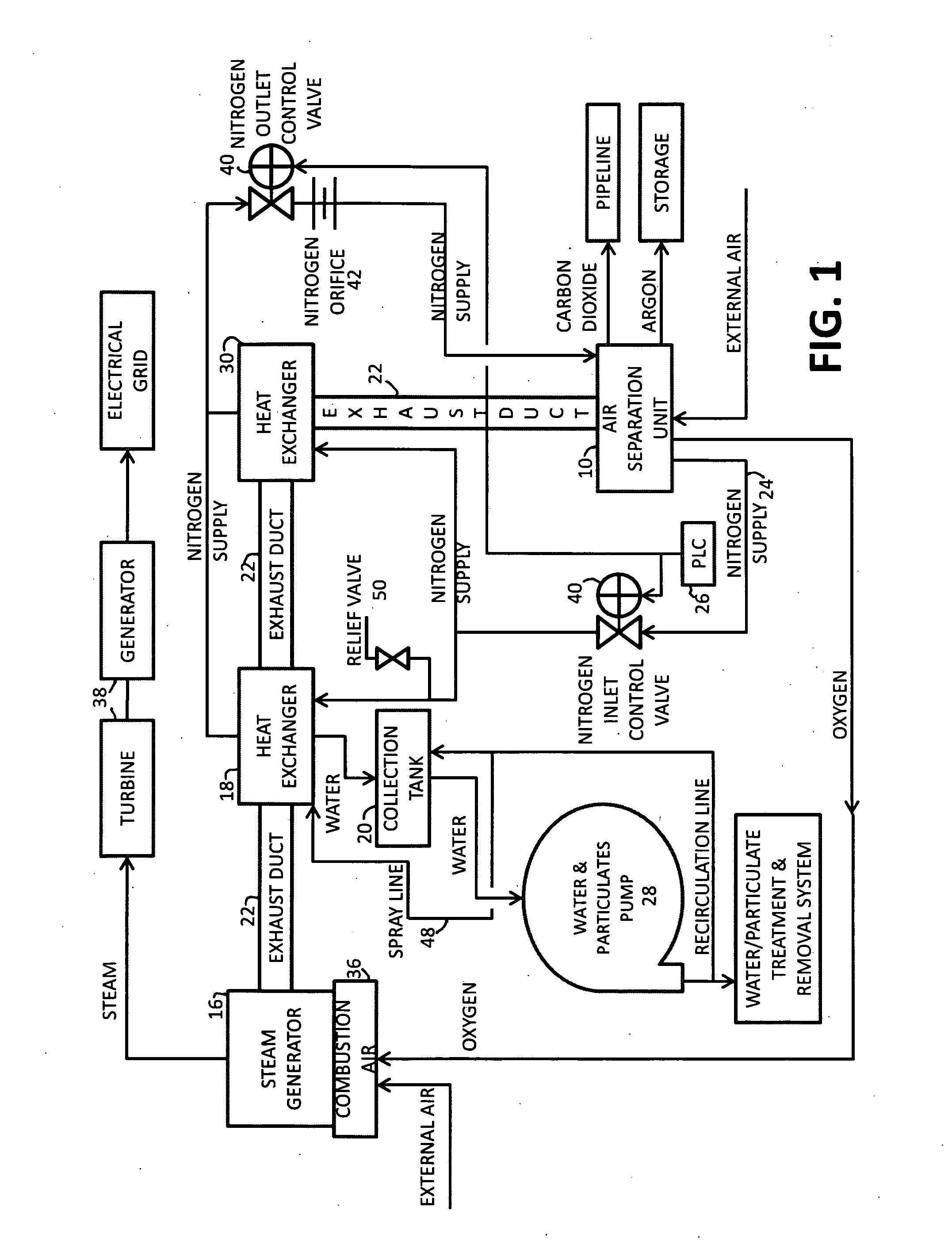

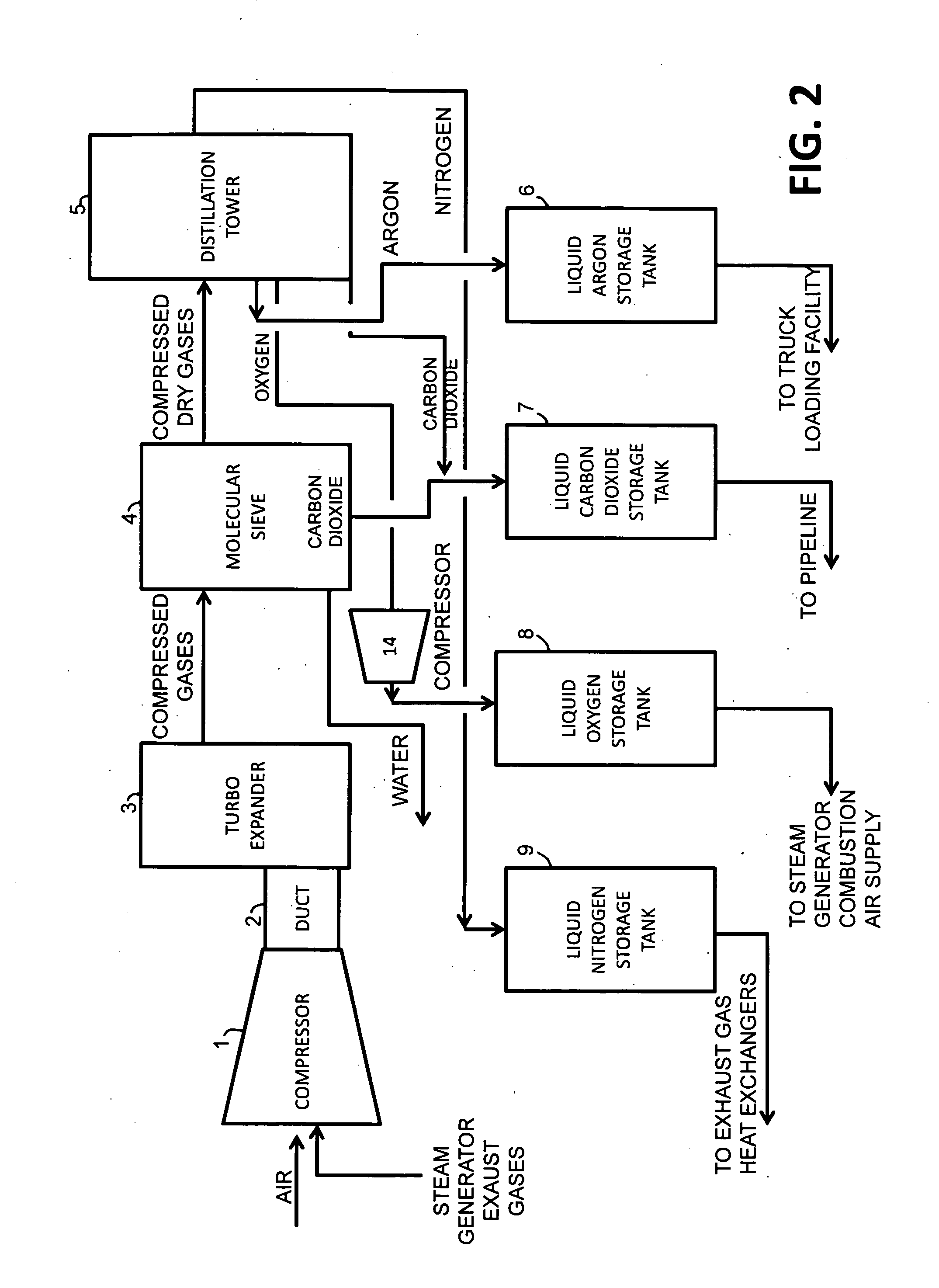

Power plant with emissions recovery

InactiveUS20100018218A1Reduce deliveryEnvironment safetySolidificationLiquefactionParticulatesNitrogen gas

A power plant including an air separation unit (ASU) arranged to separate nitrogen, oxygen, carbon dioxide and argon from air and produce a stream of substantially pure liquid oxygen, nitrogen, carbon dioxide and argon; a steam generator, fired or unfired, arranged to combust a fuel, e.g., natural gas, liquefied natural gas, synthesis gas, coal, petroleum coke, biomass, municipal solid waste or any other gaseous, liquid or solid fuel in the presence of air and a quantity of substantially pure oxygen gas to produce an exhaust gas comprising water, carbon dioxide, carbon monoxide, nitrogen oxides, nitrogen, sulfur oxides and other trace gases, and a steam-turbine-generator to produce electricity, a primary gas heat exchanger unit for particulate / acid gas / moisture removal and a secondary heat exchanger arranged to cool the remainder of the exhaust gases from the steam generator. Exhaust gases are liquefied in the ASU thereby recovering carbon dioxide, nitrogen oxides, nitrogen, sulfur oxides, oxygen, and all other trace gases from the steam generator exhaust gas stream. The cooled gases are liquefied in the ASU and separated for sale or re-use in the power plant. Carbon dioxide liquid is transported from the plant for use in enhanced oil recovery or for other commercial use. Carbon dioxide removal is accomplished in the ASU by cryogenic separation of the gases, after directing the stream of liquid nitrogen from the air separation unit to the exhaust gas heat exchanger units to cool all of the exhaust gases including carbon dioxide, carbon monoxide, nitrogen oxides, nitrogen, oxygen, sulfur oxides, and other trace gases.

Owner:TRIENCON SERVICES

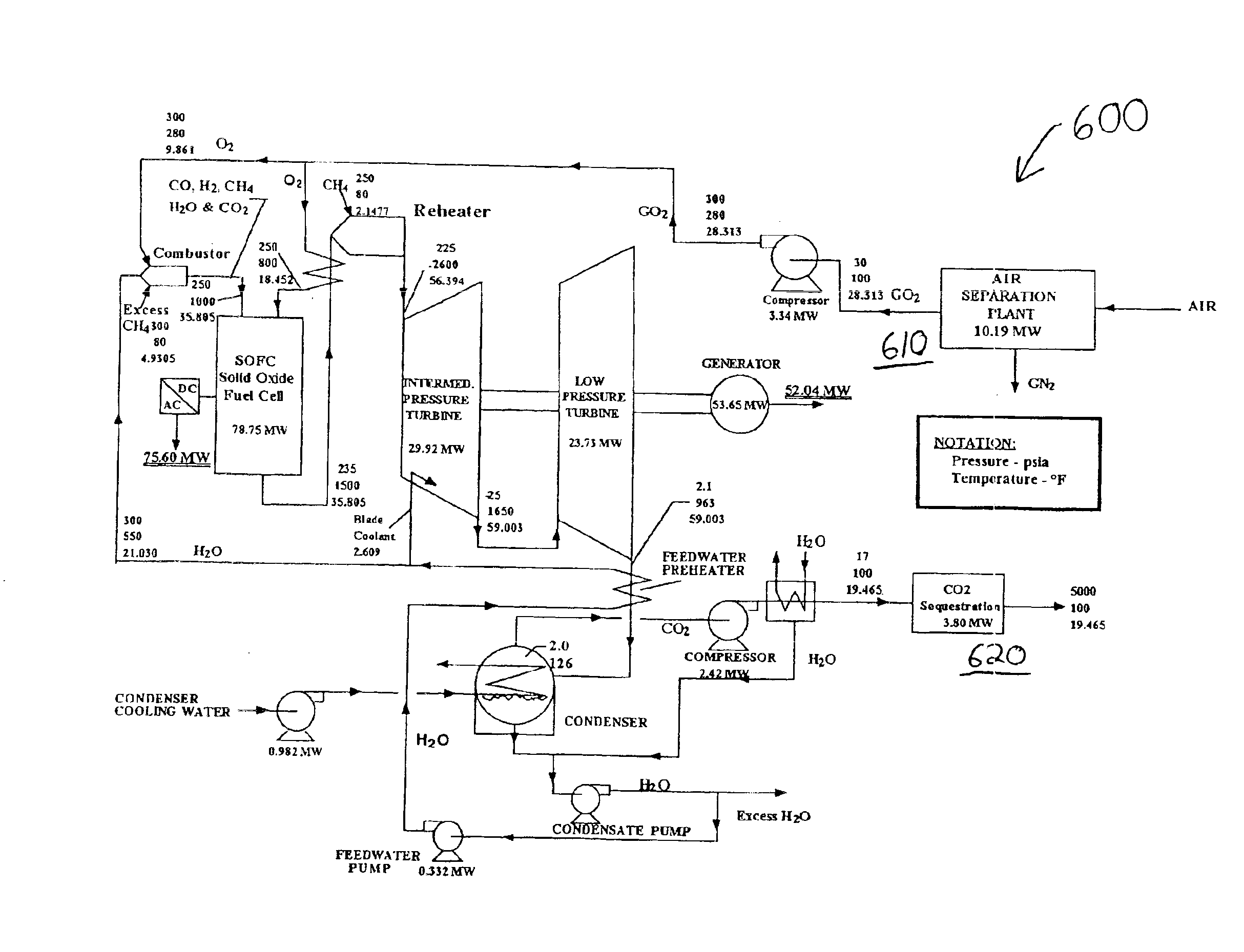

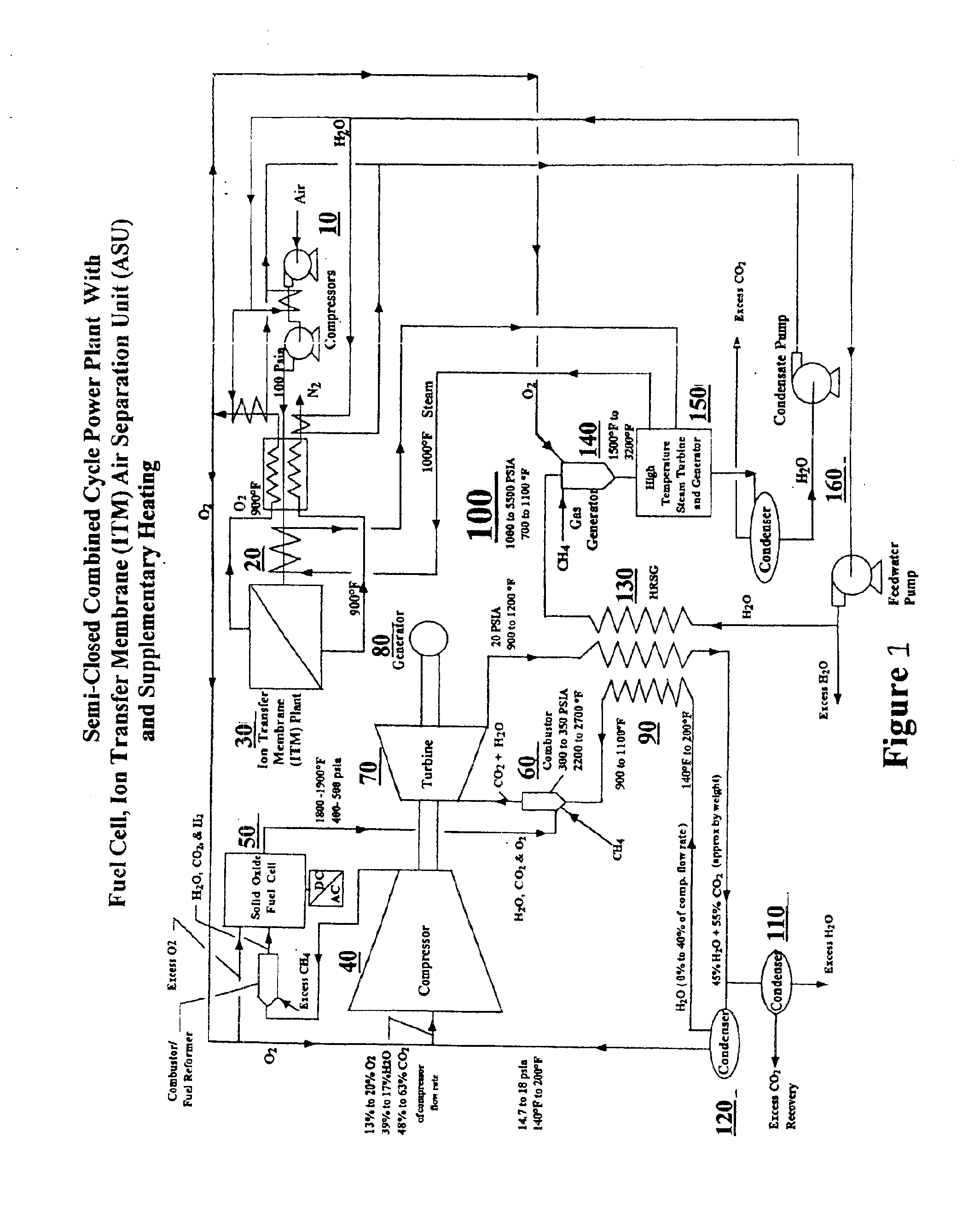

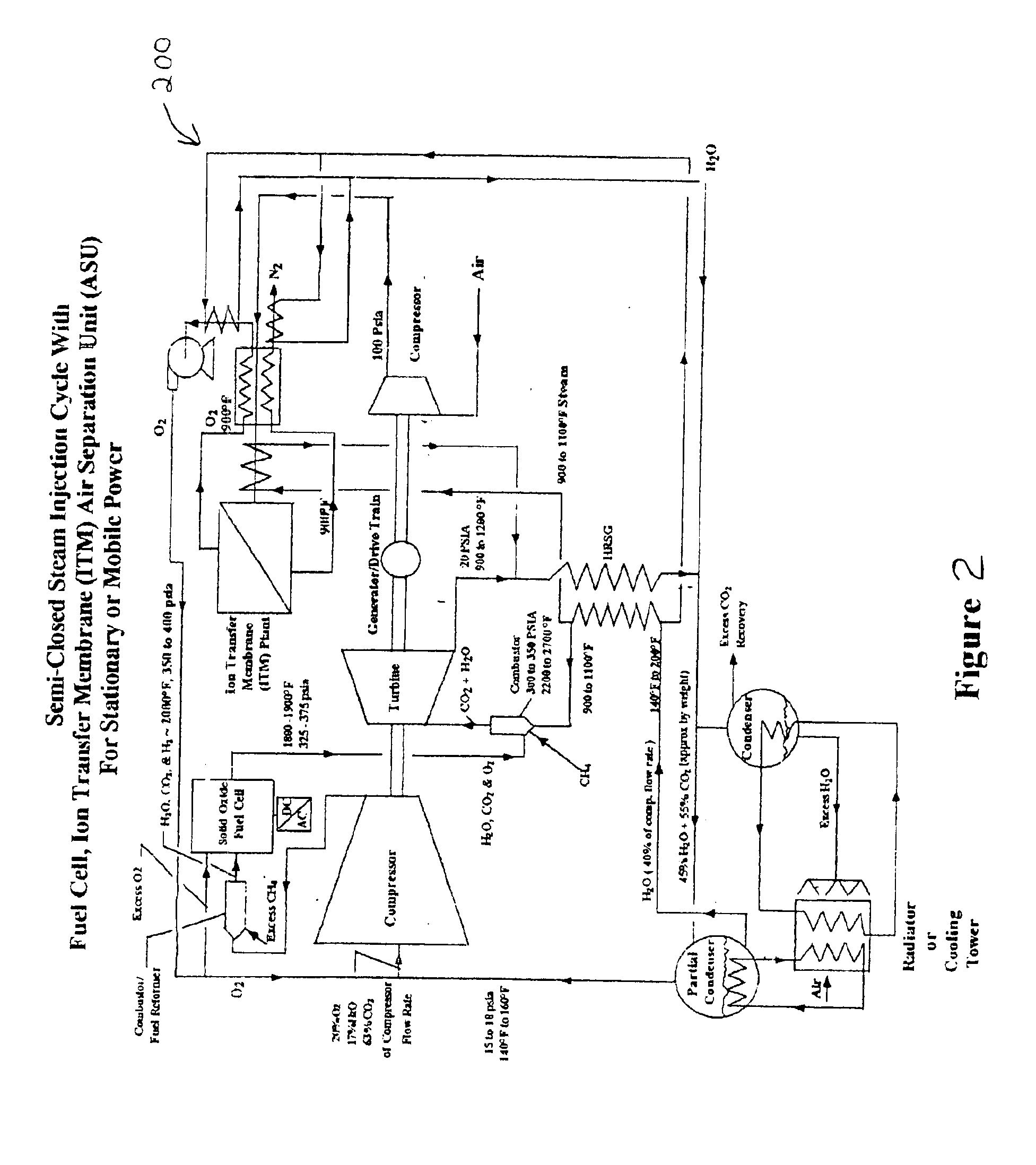

Combined fuel cell and fuel combustion power generation systems

A power generation system is provided which converts chemical energy in one or more fuels into electrical and / or mechanical power. The system includes both fuel cells to directly convert electrical energy in a fuel into electrical power and at lest one combustor and expander to generate mechanical power, optionally than converted to electrical power in a generator. Fuel cell products disclosed from the fuel cell are entered into the combustor to be heated along with products of combustion created in the combustor and expanded in the expander along with the products of combustion.

Owner:CLEAN ENERGY SYST

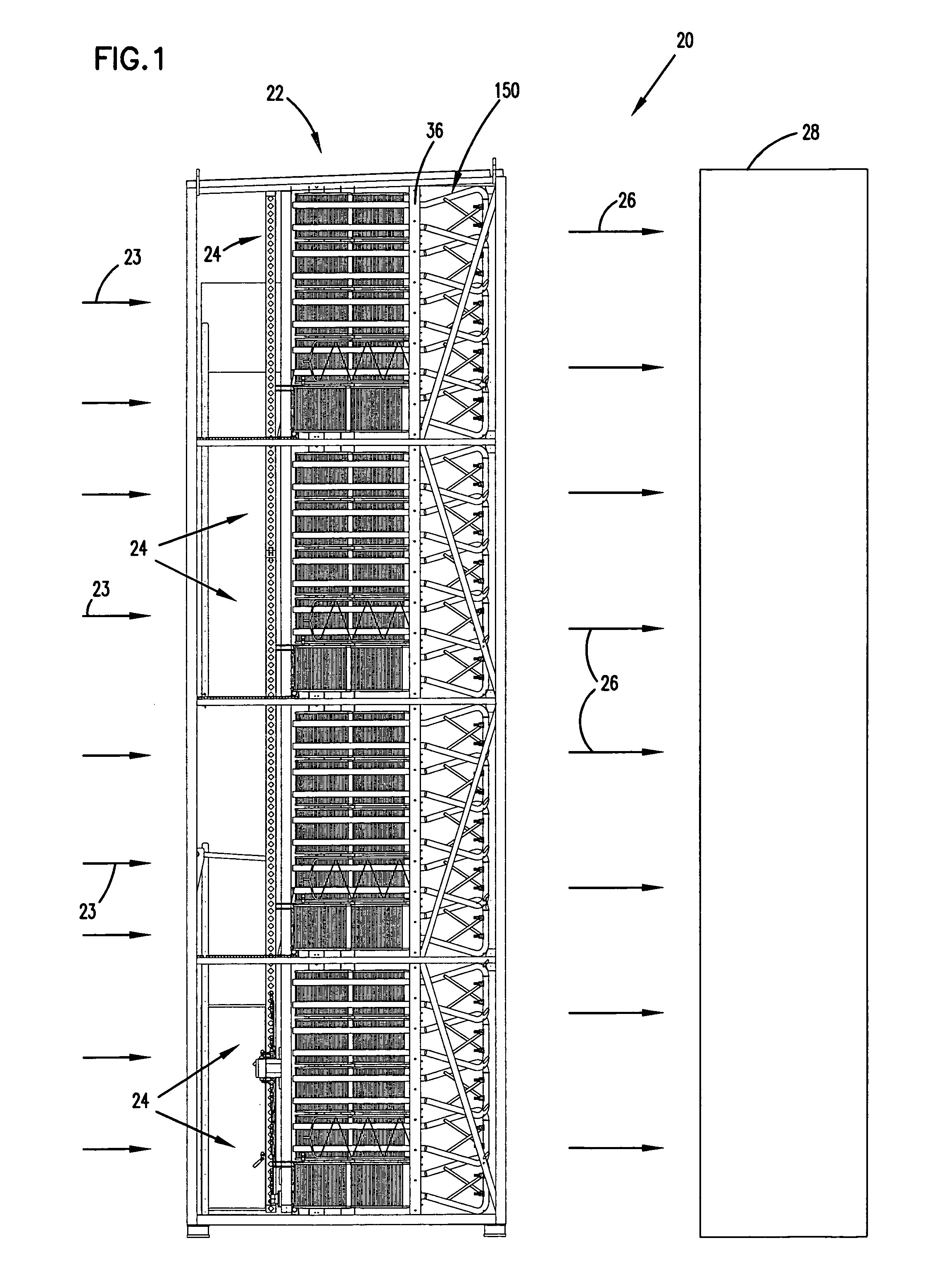

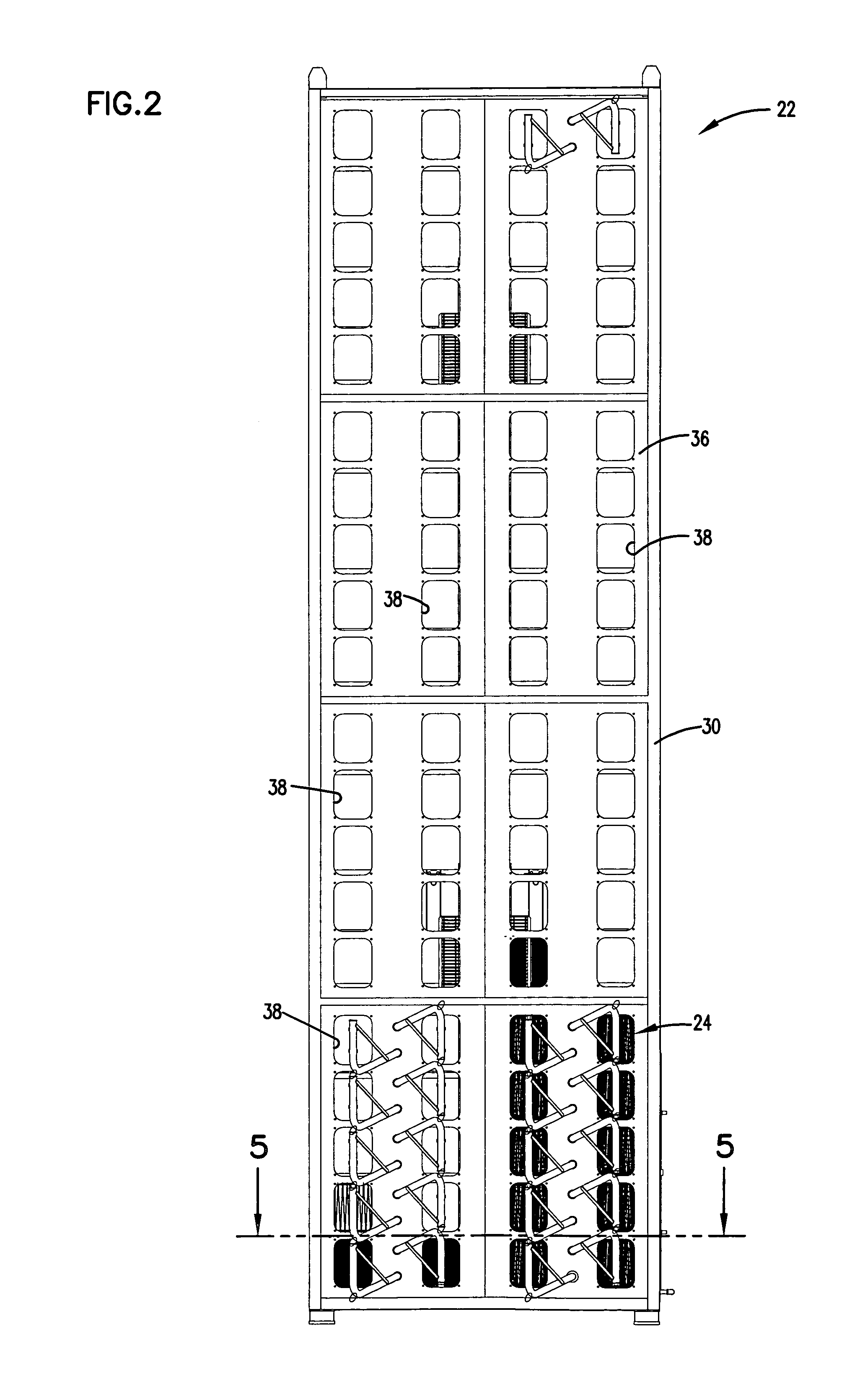

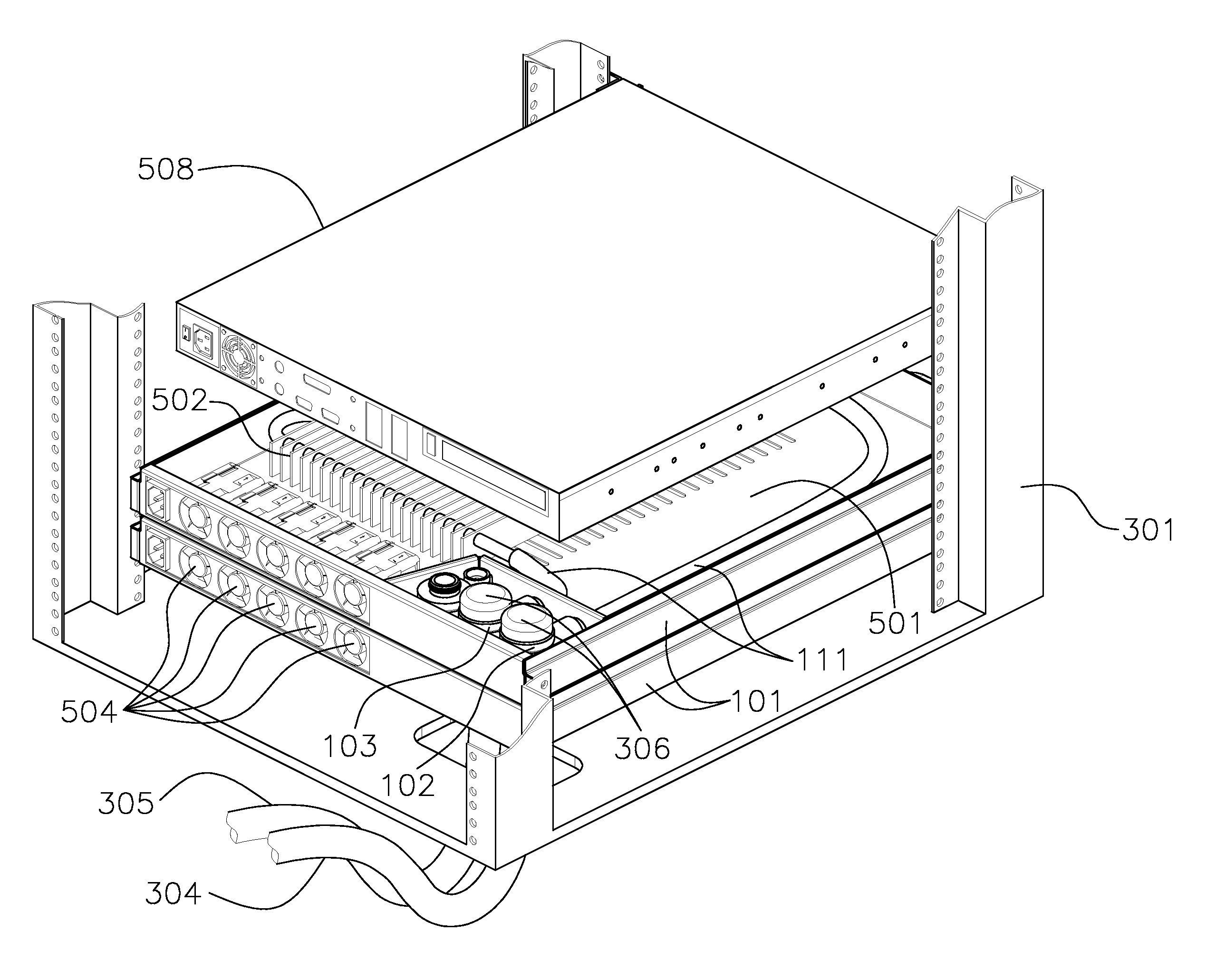

System and method for flowing fluids through electronic chassis modules

InactiveUS20110313576A1Safe removalCombustion enginesFluid dynamicsComputer moduleMonitoring and control

An electronic chassis distributes fluids to adjacent chassis and electronic modules housed within the chassis. Provision is made for the detection, containment, and removal of liquid spilled within the chassis. The fluids may be used as coolants, and provision is made for heat exchanger modules to be included within the chassis. Provision is further made to include fluid sensors and actuators, allowing for monitoring and control of fluid distribution by a controller.

Owner:NICEWONGER MARK RANDAL

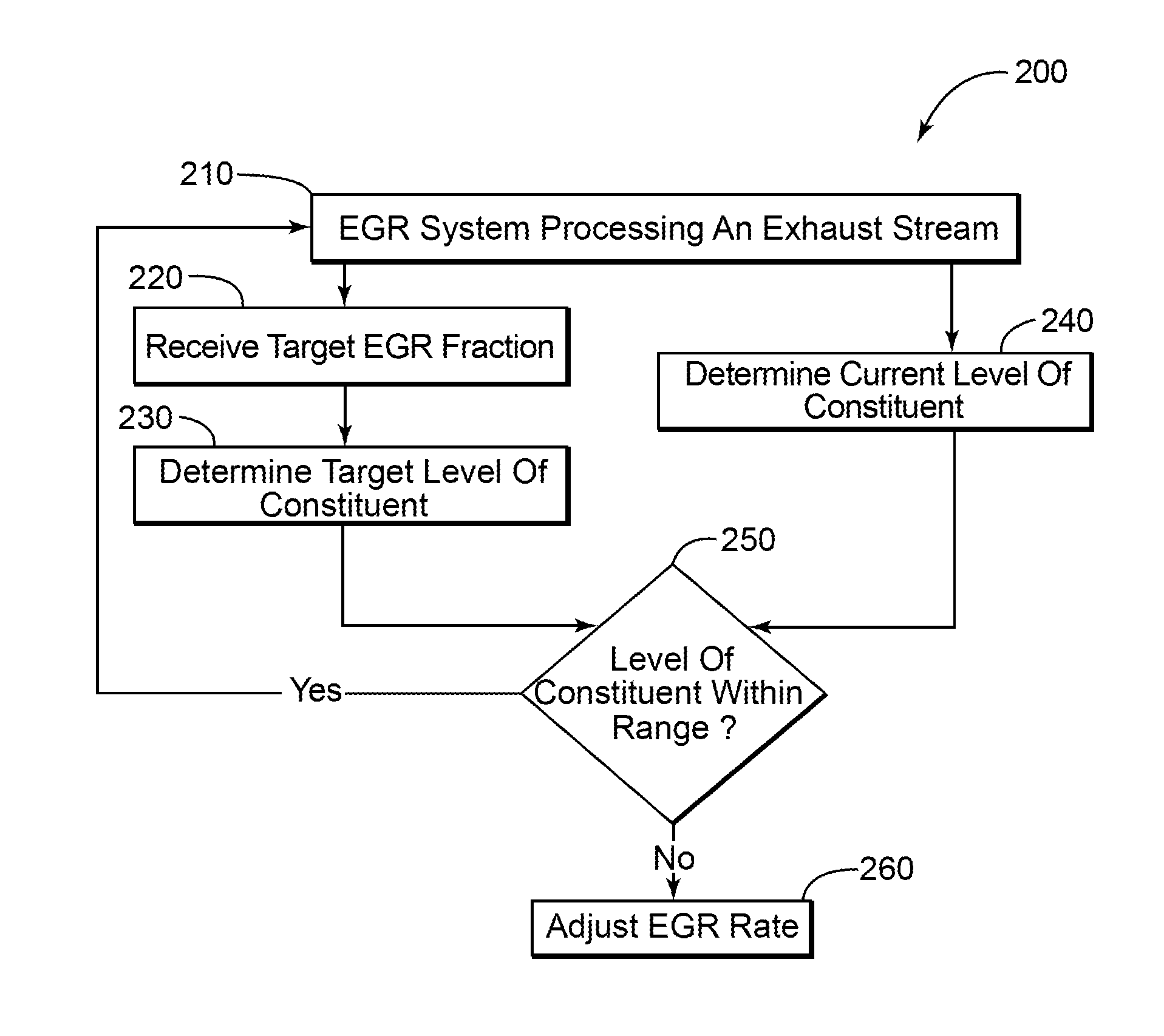

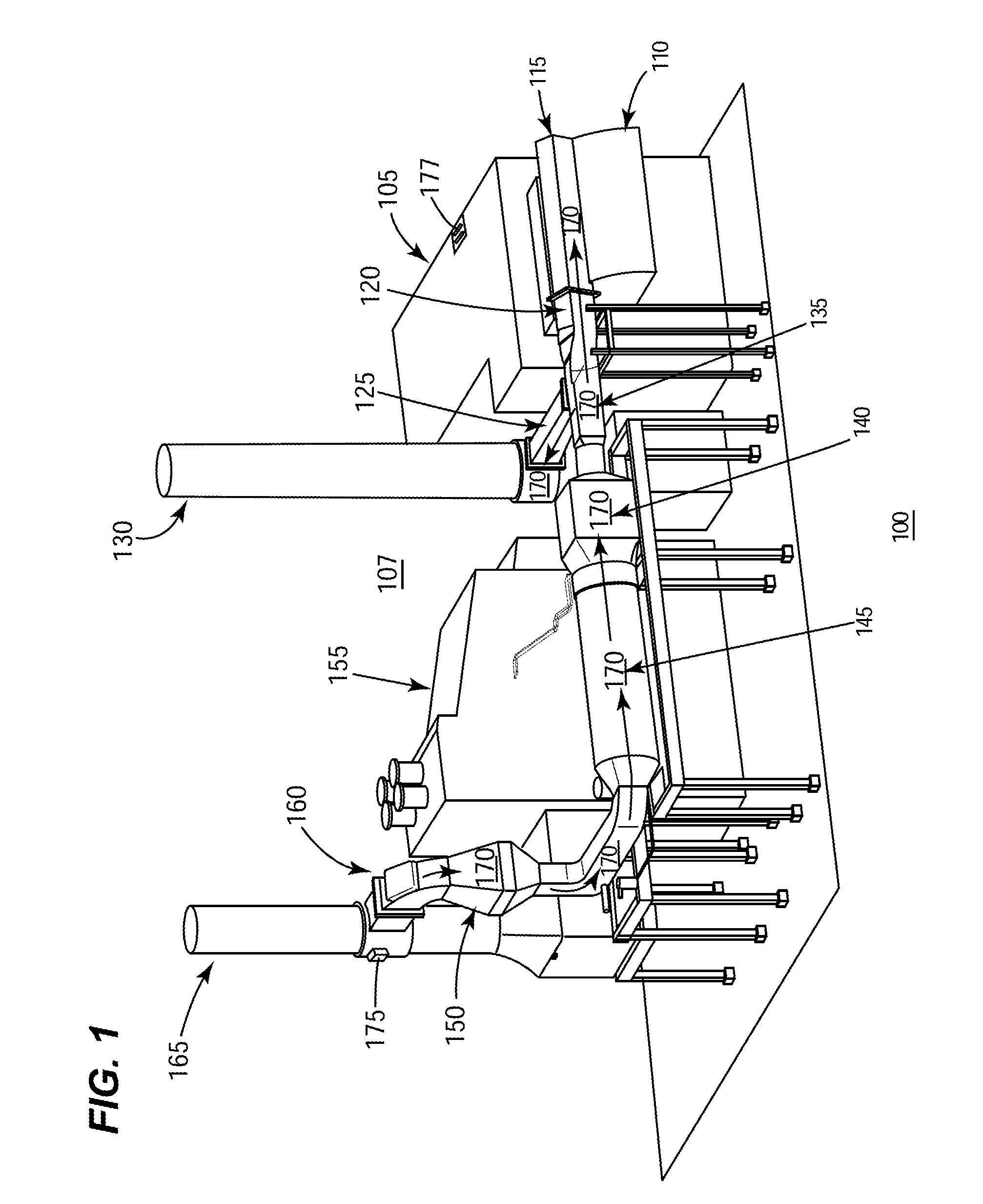

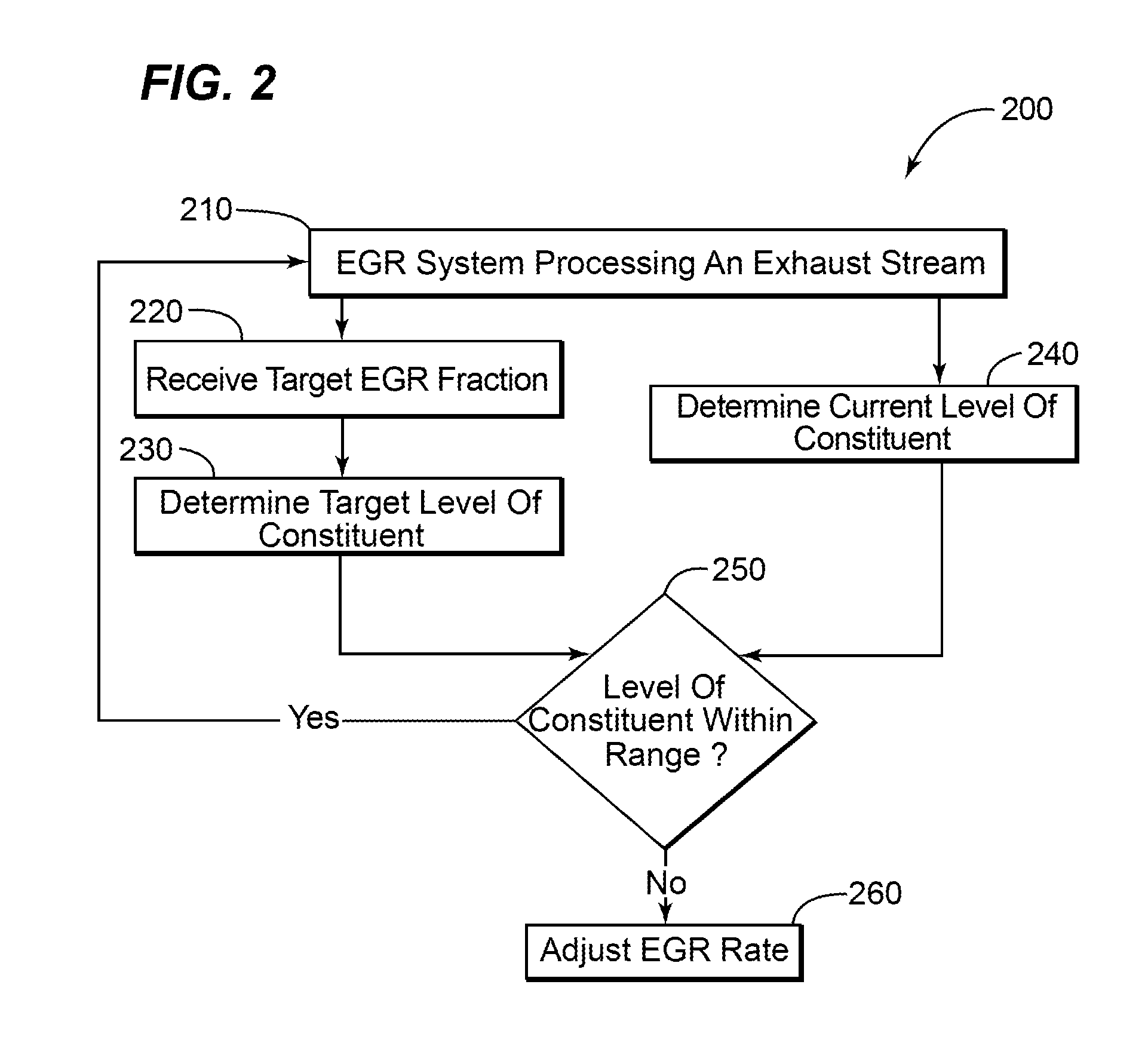

Method and system for controlling a flowrate of a recirculated exhaust gas

ActiveUS7536252B1High trafficAnalogue computers for vehiclesNon-fuel substance addition to fuelStream flowExhaust fumes

A method and system for controlling an exhaust gas recirculation (EGR) system is provided. The EGR system recirculates a portion of an exhaust through an inlet portion of the turbomachine. The EGR system reduces the level of harmful constituents within the exhaust before the recirculation occurs.

Owner:GENERAL ELECTRIC CO

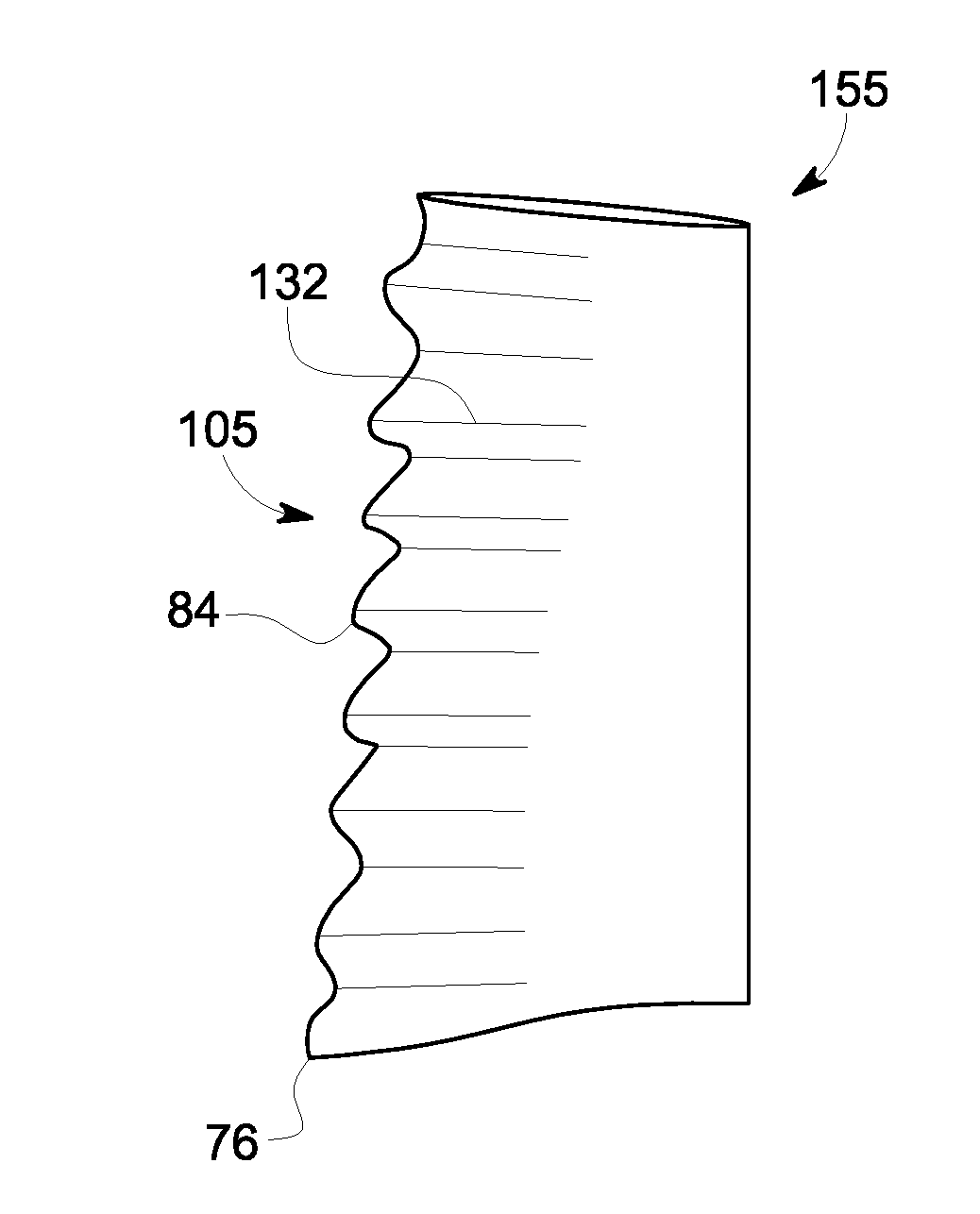

Airfoils for wake desensitization and method for fabricating same

ActiveUS20130164488A1Reducing desensitizationEngine manufacturePump componentsLeading edgeTrailing edge

An airfoil and method of fabricating an airfoil including a first and a second side coupled together at a leading and a trailing edge and extending there between. The airfoil includes a plurality of first chord sections having a first chord length and extending outward from one of the first side or second side of the airfoil at the leading edge and a plurality of second chord sections having a second chord length and extending outward from the one of the first side or the second side of the airfoil at the leading edge. The leading edge including spaced-apart wave-shaped projections defining a waveform. The configuration defining a three-dimensional crenulated airfoil configured to facilitate desensitization of an airfoil unsteady pressure response to at least one impinging upstream generated wake or vortex by decorrelating spatially and temporally and reducing in amplitude an unsteady pressure caused by interaction of the airfoil with the upstream generated wake or vortex.

Owner:GENERAL ELECTRIC CO

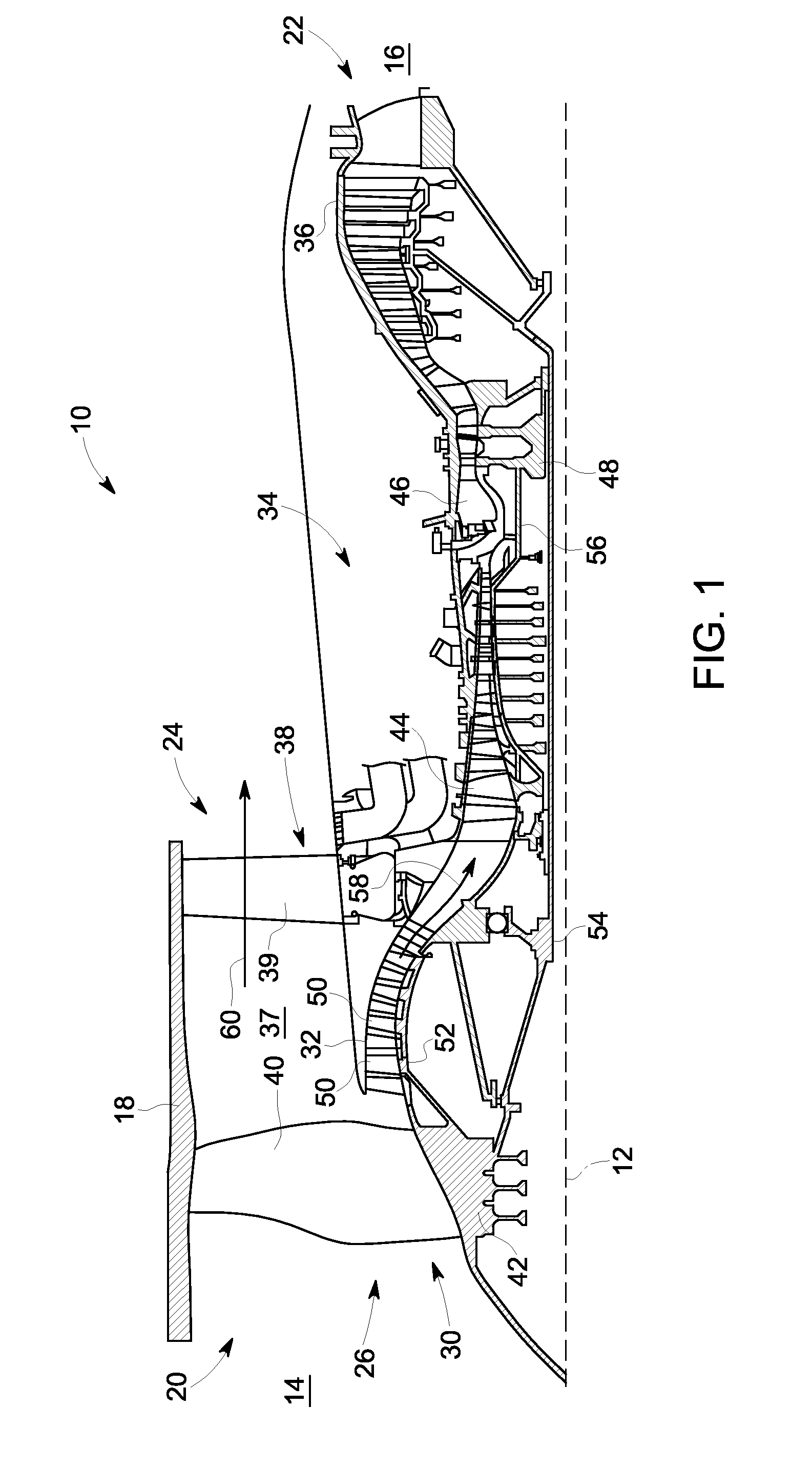

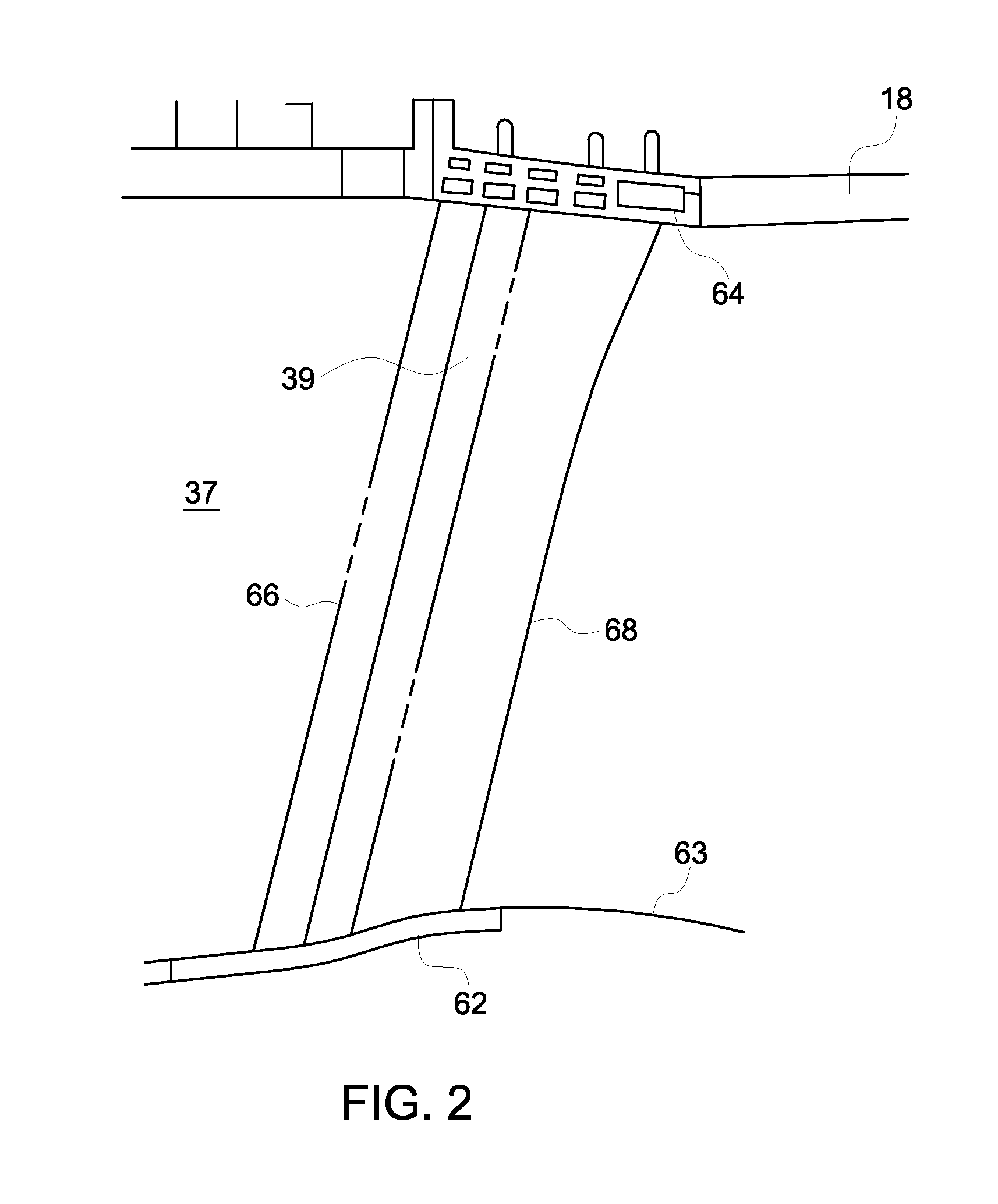

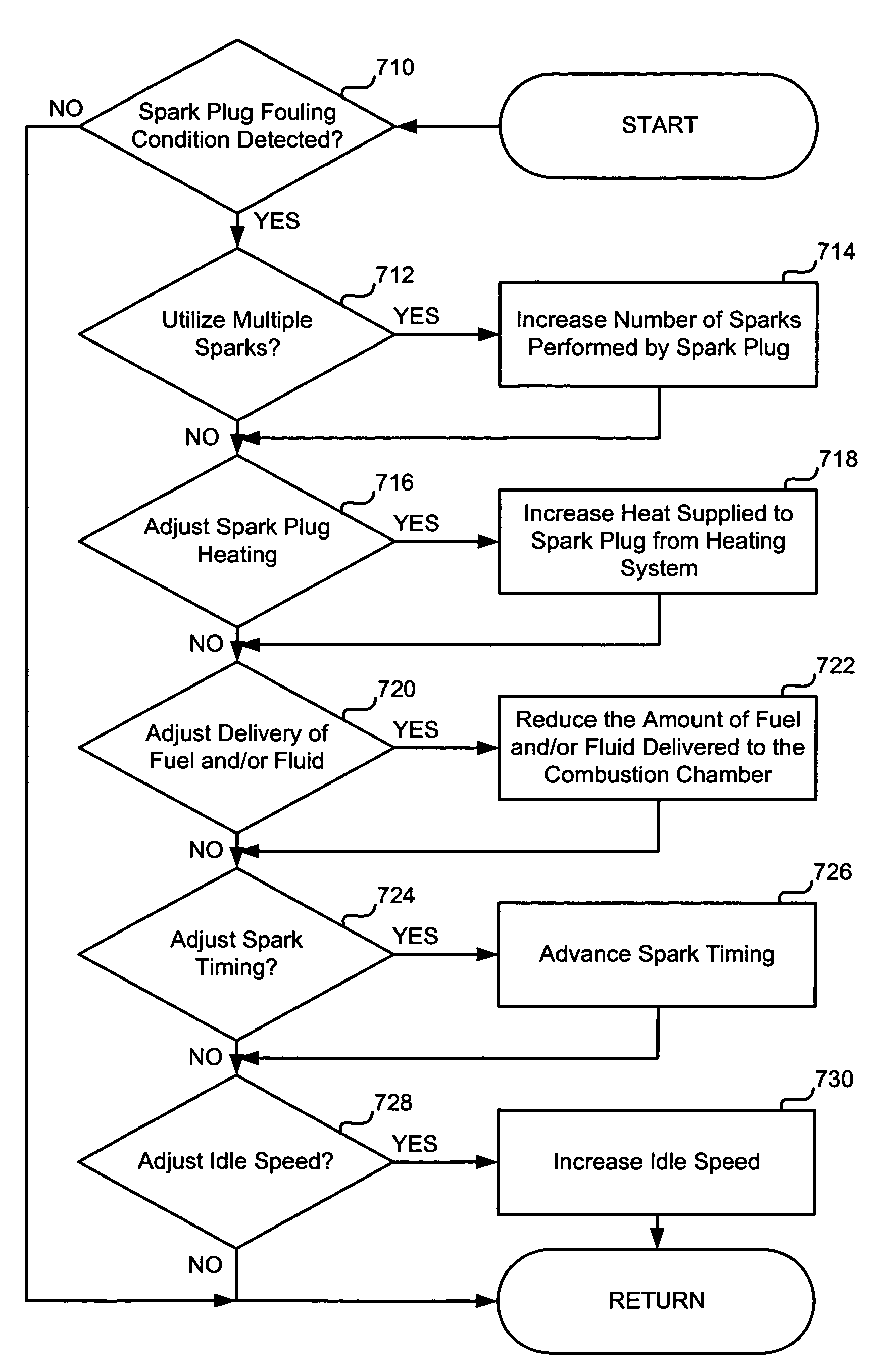

Spark plug heating for a spark ignited engine

A system for an engine of a vehicle, comprising of at least one combustion chamber located in the engine, a delivery system configured to deliver a fuel and a fluid to the combustion chamber, an ignition system including a spark plug configured to ignite the fuel within the combustion chamber, a spark plug heating system configured to supply heat to the spark plug, and a control system configured to vary an amount of heat supplied to the spark plug by the spark plug heating system responsive to a condition of the ignition system.

Owner:FORD GLOBAL TECH LLC

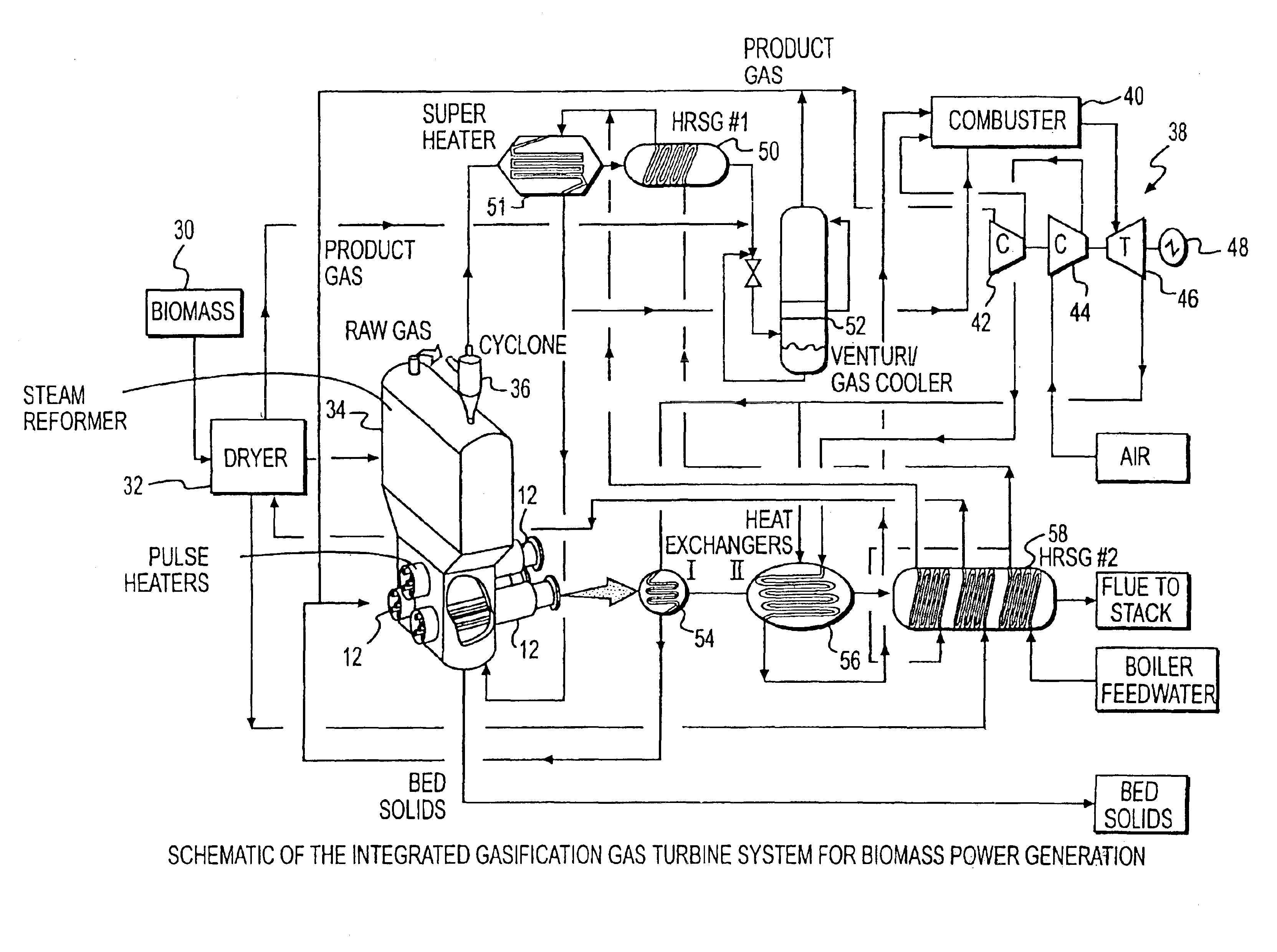

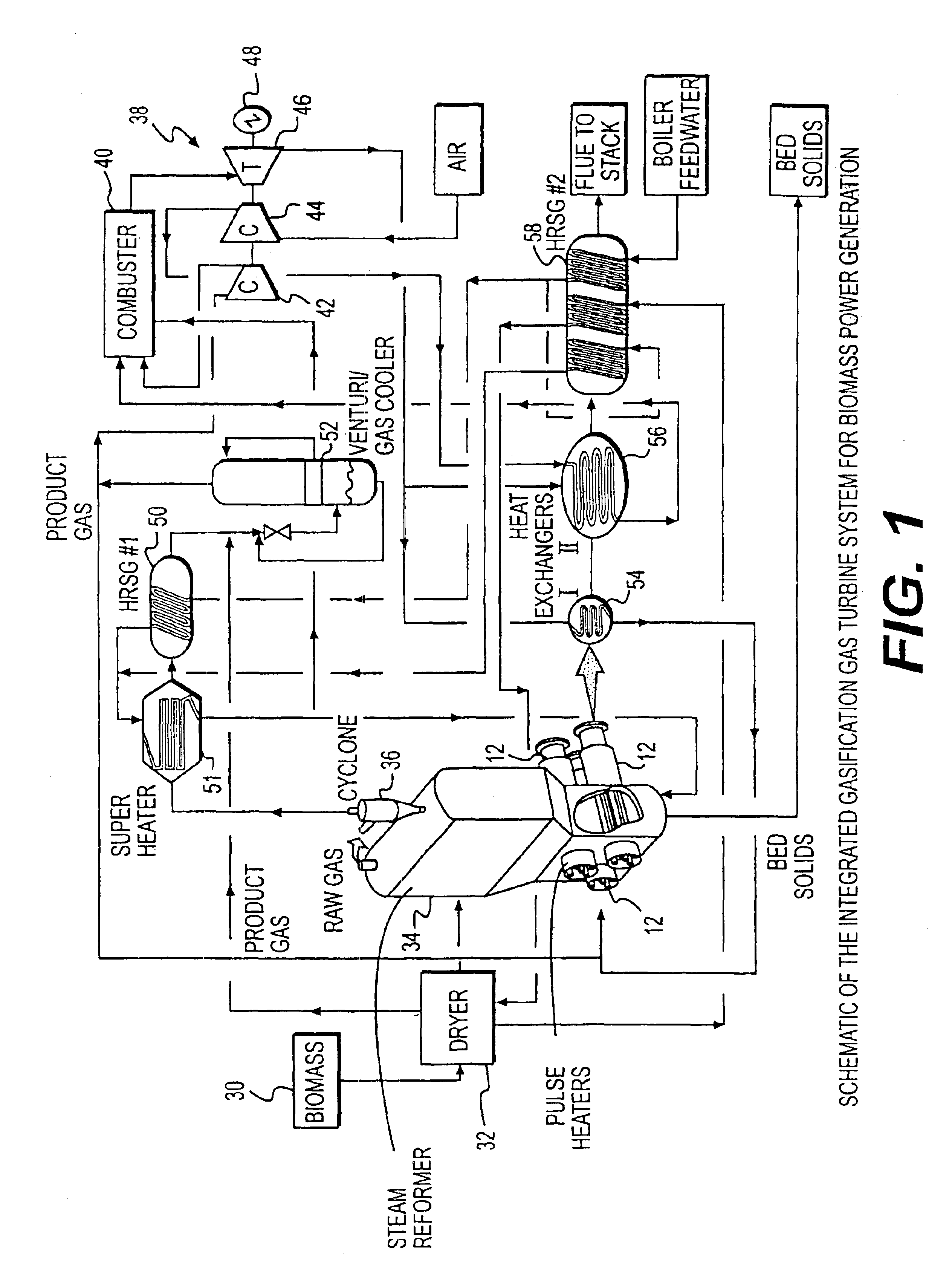

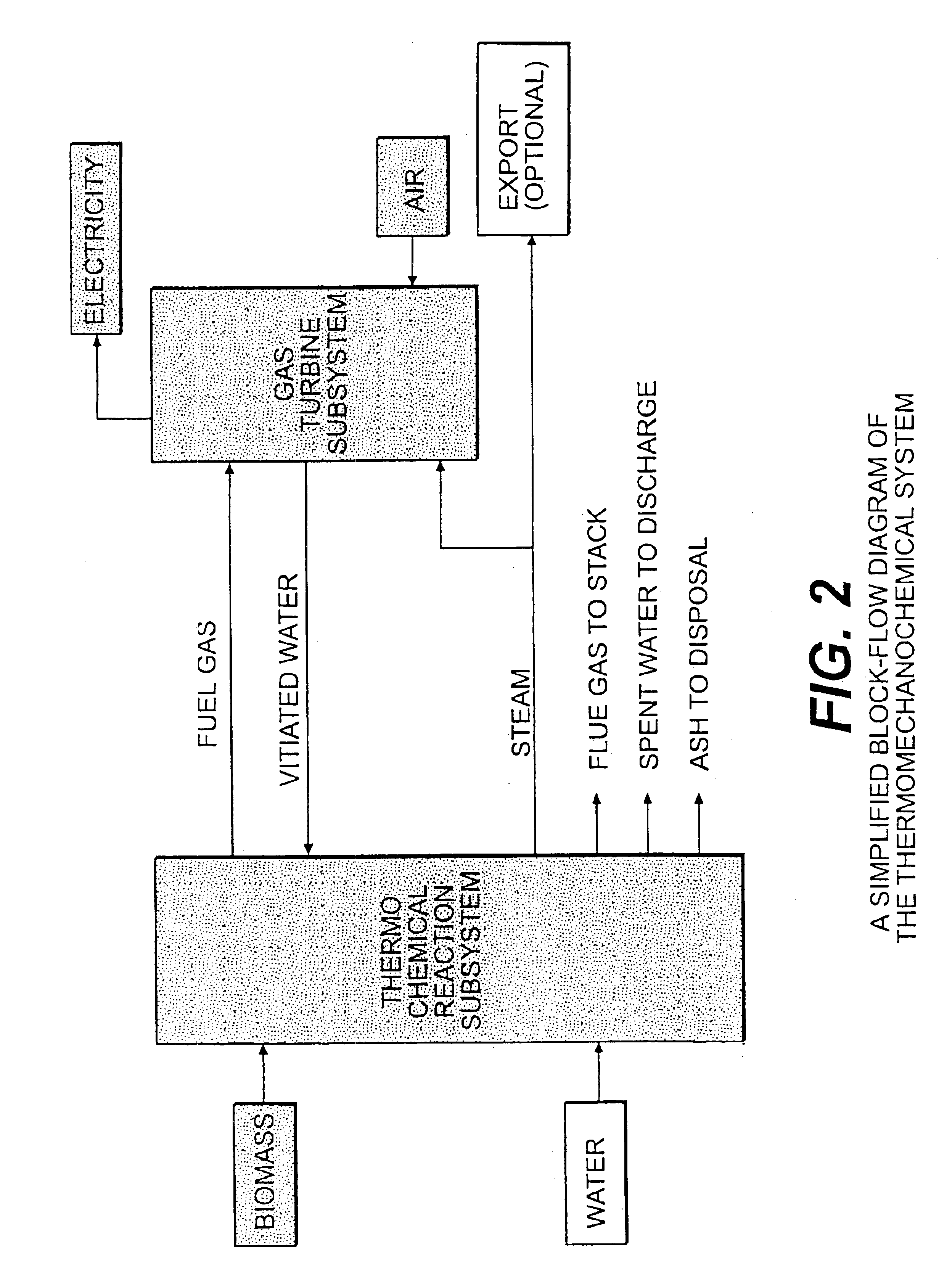

System integration of a steam reformer and gas turbine

A novel process and apparatus for power generation from biomass and other carbonaceous feedstocks are provided. The process integrates a pulse combustor steam reformer with a gas turbine to generate electricity such that (i) efficiency is higher than those of conventional and current advanced power systems, (ii) emissions are lower than those proposed in the new environmental regulations, and (iii) performance is comparable to that of combined cycle, even though a bottoming cycle is not included here. The pulse combustor steam reformer generates a hydrogen-rich, medium-Btu fuel gas that is fired in a gas turbine to generate electricity. The apparatus may be configured to produce only power or combined heat and power.

Owner:THERMOCHEM RECOVERY INT

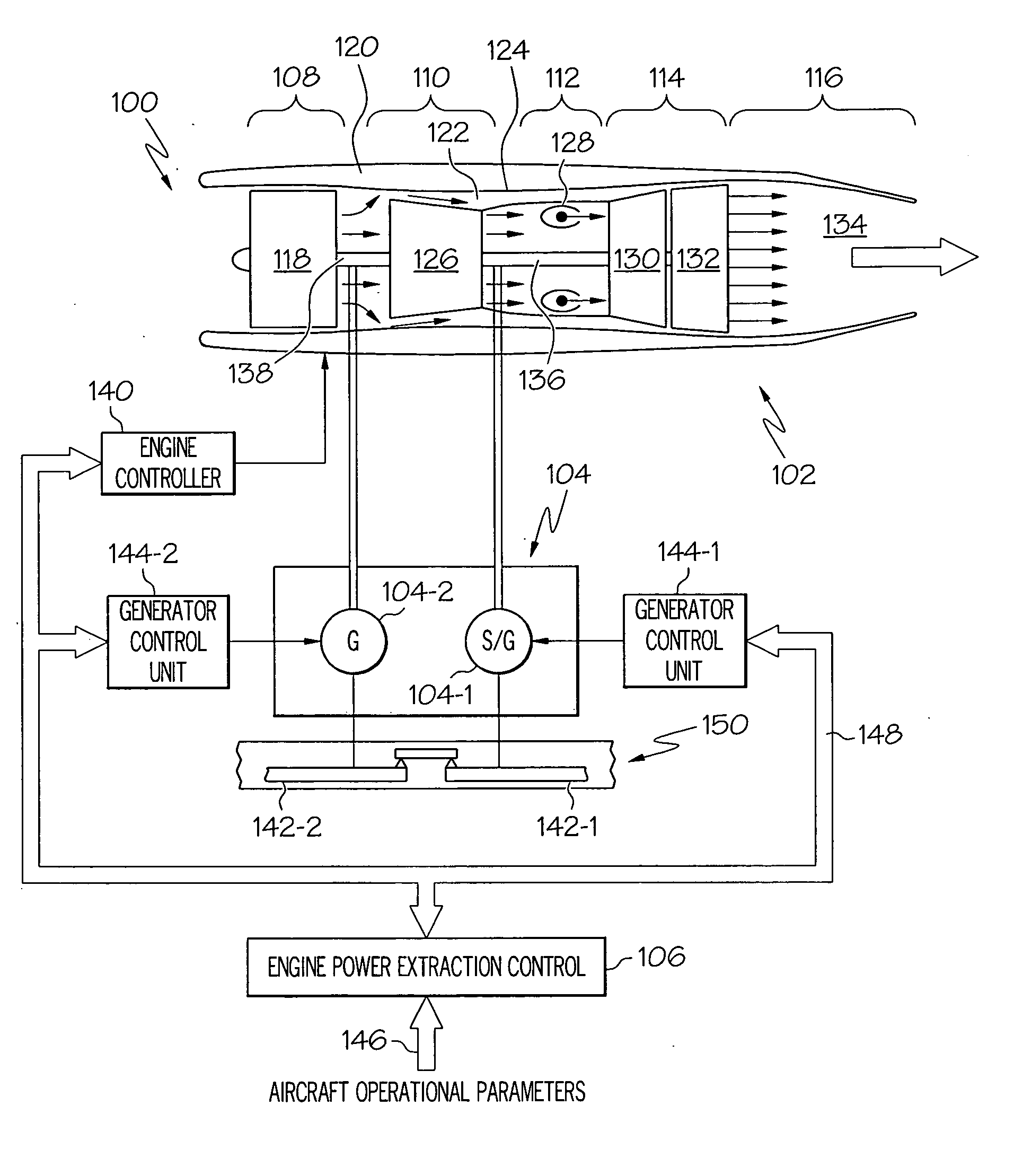

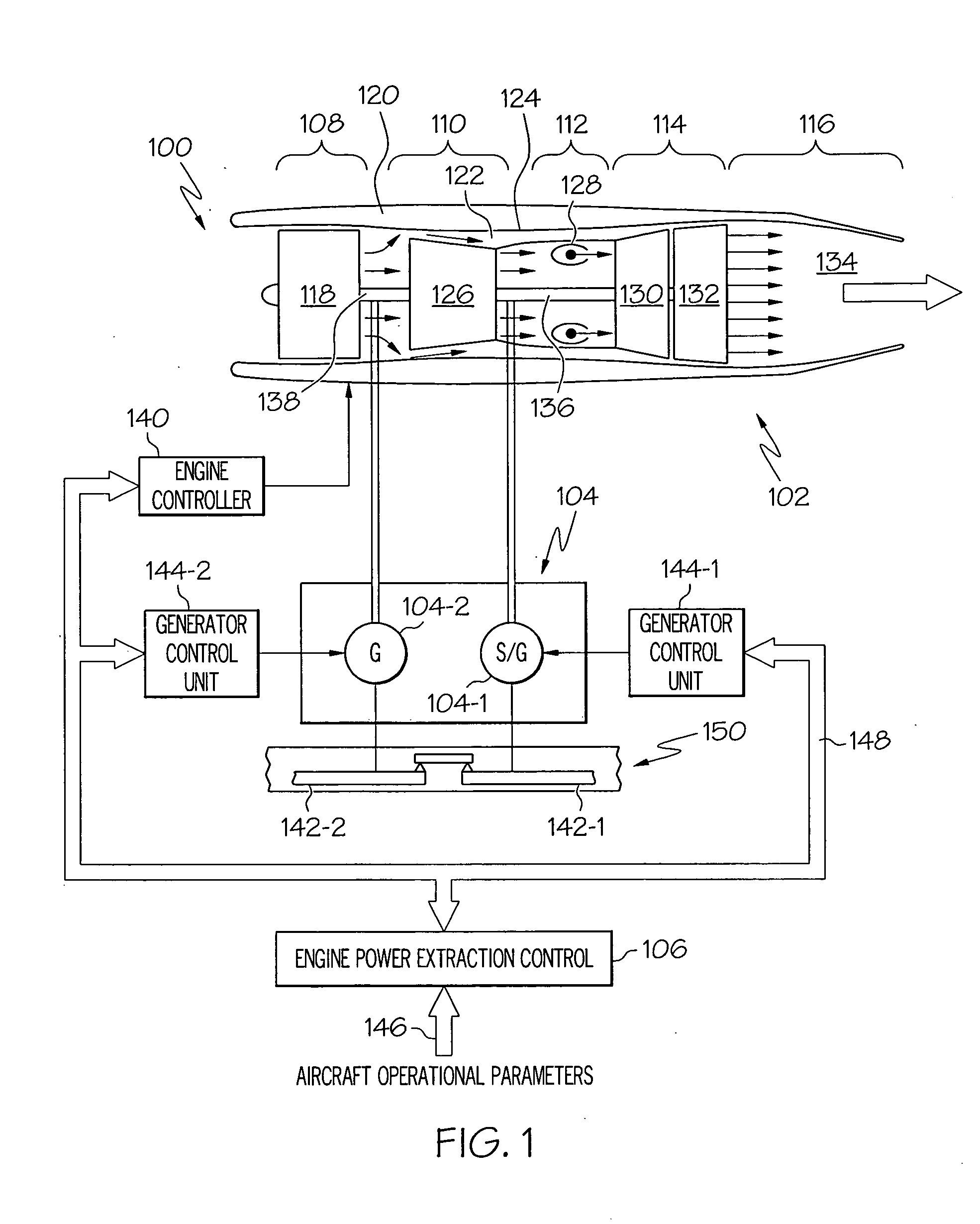

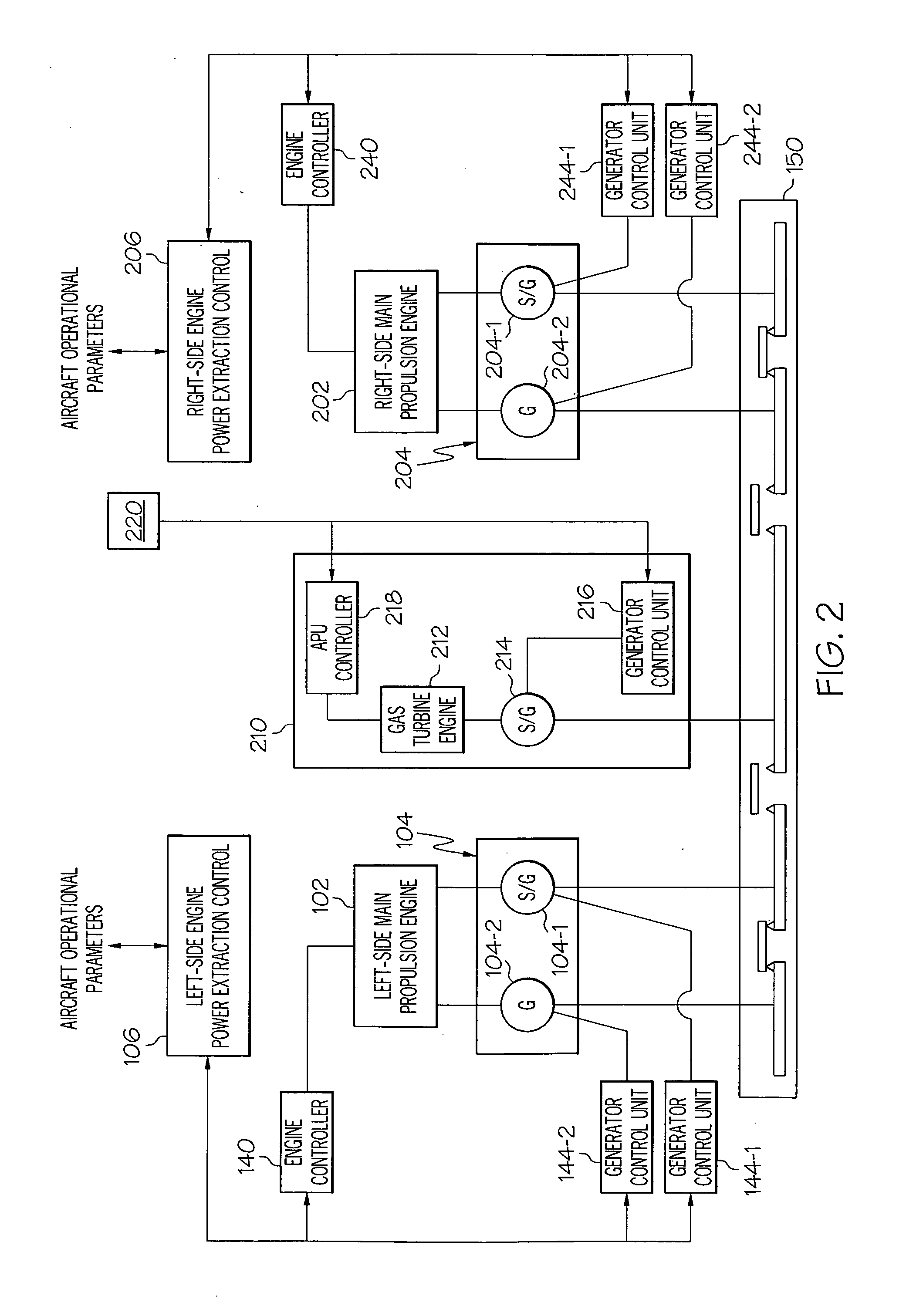

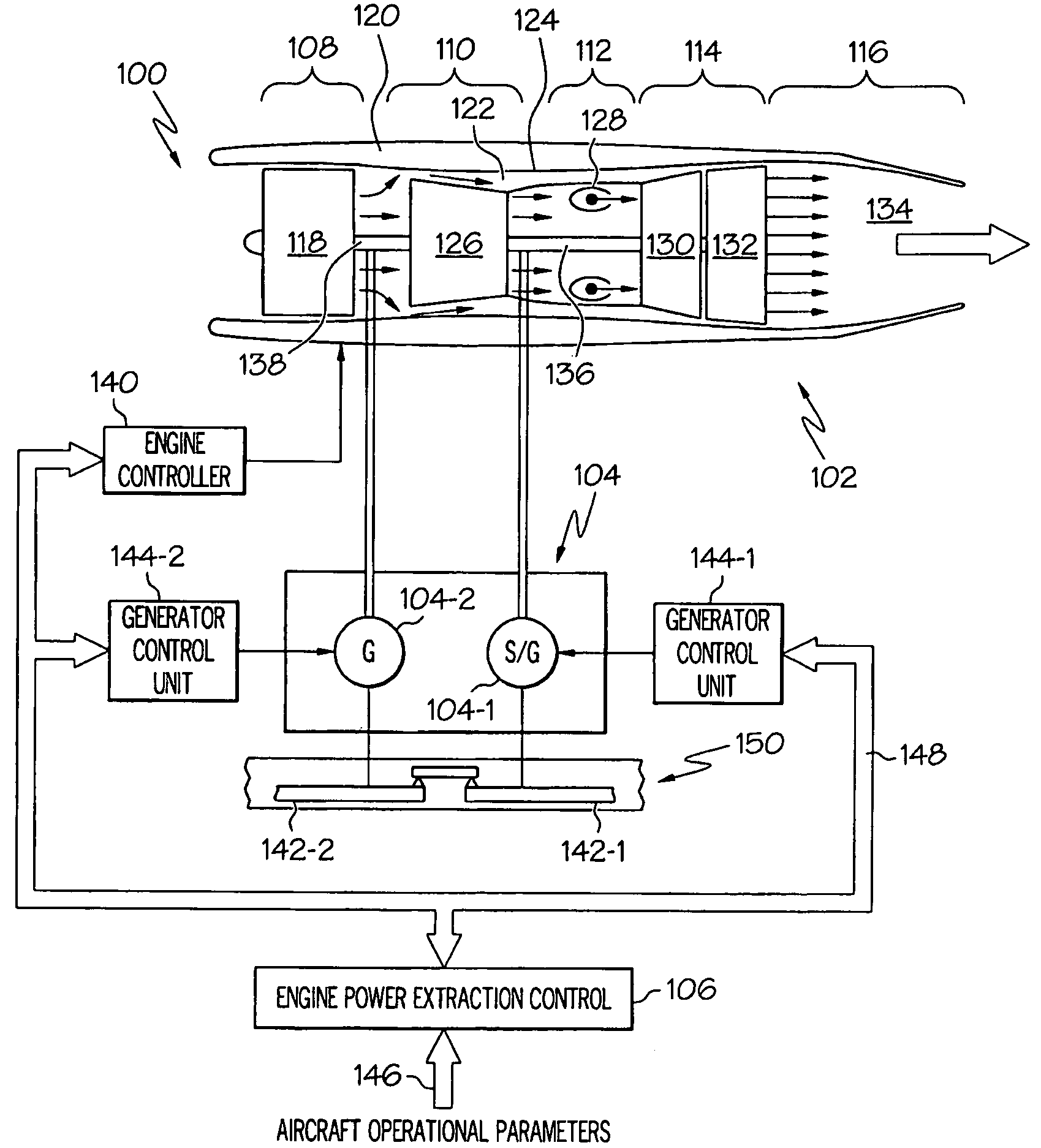

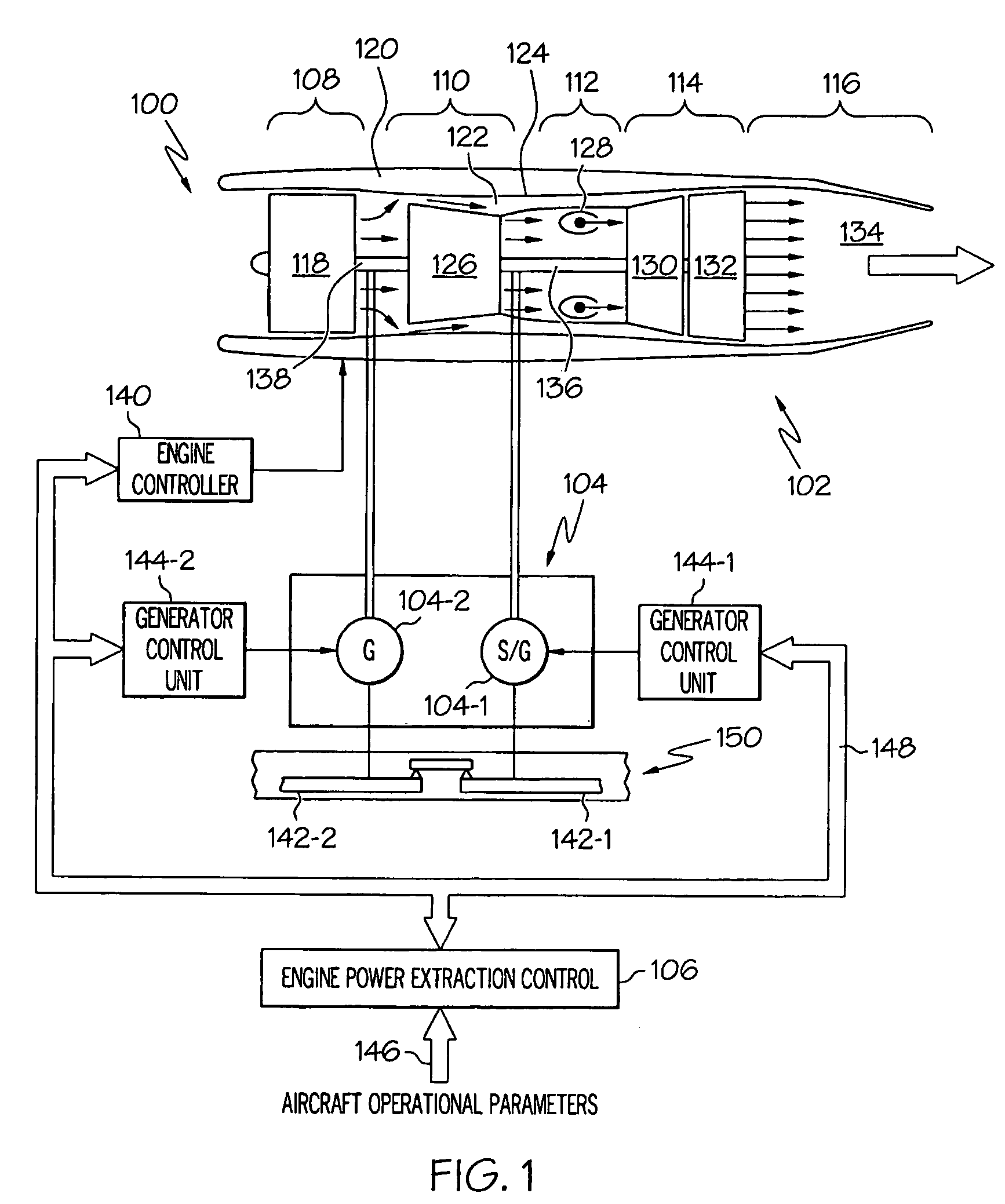

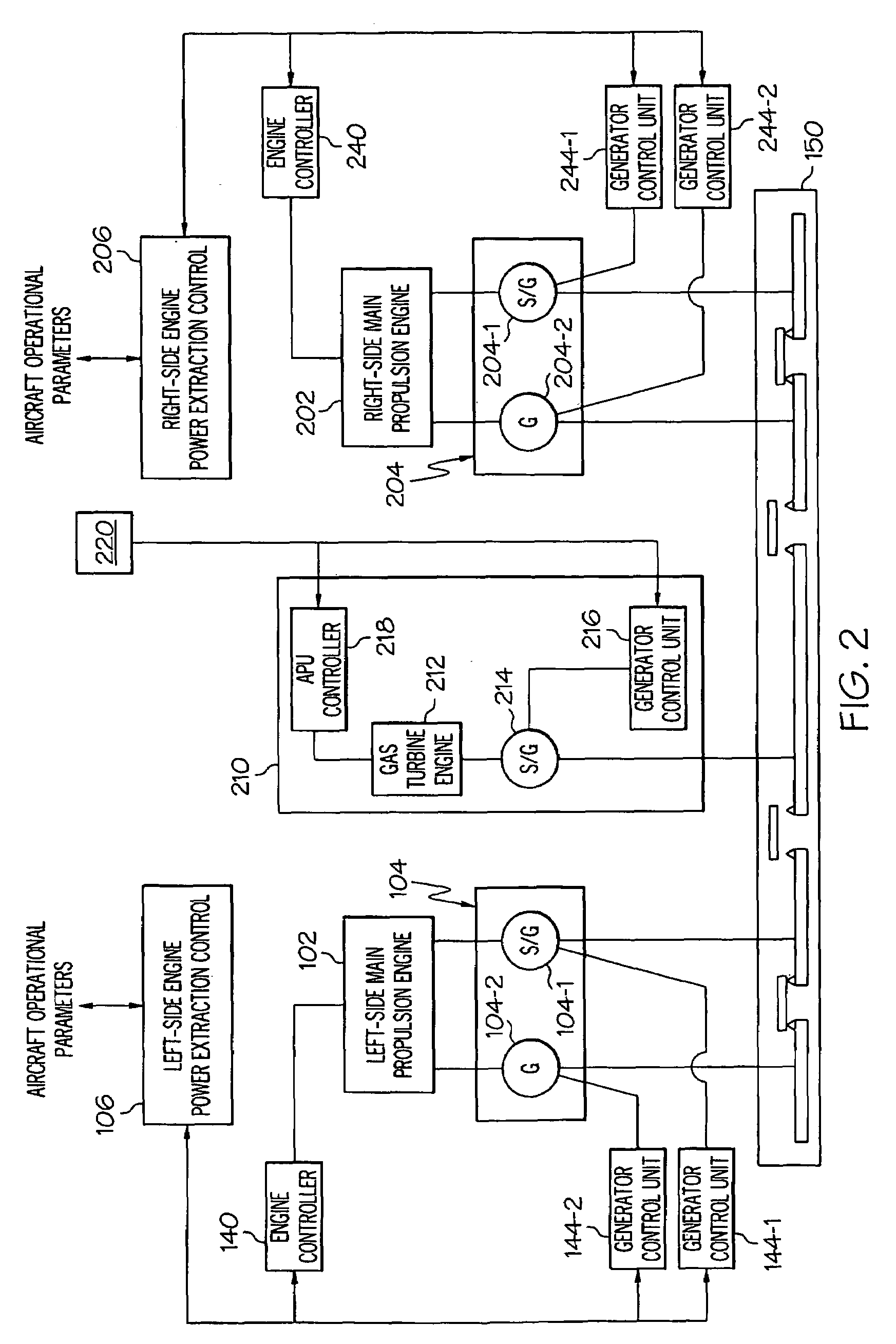

Engine power extraction control system

ActiveUS20060042252A1Increase propulsionEasy to operateReciprocating combination enginesTurbine/propulsion engine ignitionControl systemElectric machine

An engine power extraction control system controls the main propulsion engines and the electrical machines that are coupled thereto to supply an appropriate amount of aircraft thrust and electrical energy to the aircraft. The engines and electrical machines are also controlled so that the propulsion thrust that is generated is split between the various turbines in the main propulsion engines to maintain an adequate surge margin and to minimize residual thrust generation.

Owner:HONEYWELL INT INC

Low Emission Triple-Cycle Power Generation Systems and Methods

Methods and systems for low emission power generation in combined cycle power plants are provided. One system includes a gas turbine system that stoichiometrically combusts a fuel and an oxidant in the presence of a compressed recycle stream to provide mechanical power and a gaseous exhaust. The compressed recycle stream acts as a diluent to moderate the temperature of the combustion process. A boost compressor can boost the pressure of the gaseous exhaust before being compressed into the compressed recycle stream. A purge stream is tapped off from the compressed recycle stream and directed to a C02 separator which discharges C02 and a nitrogen-rich gas which can be expanded in a gas expander to generate additional mechanical power.

Owner:EXXONMOBIL UPSTREAM RES CO

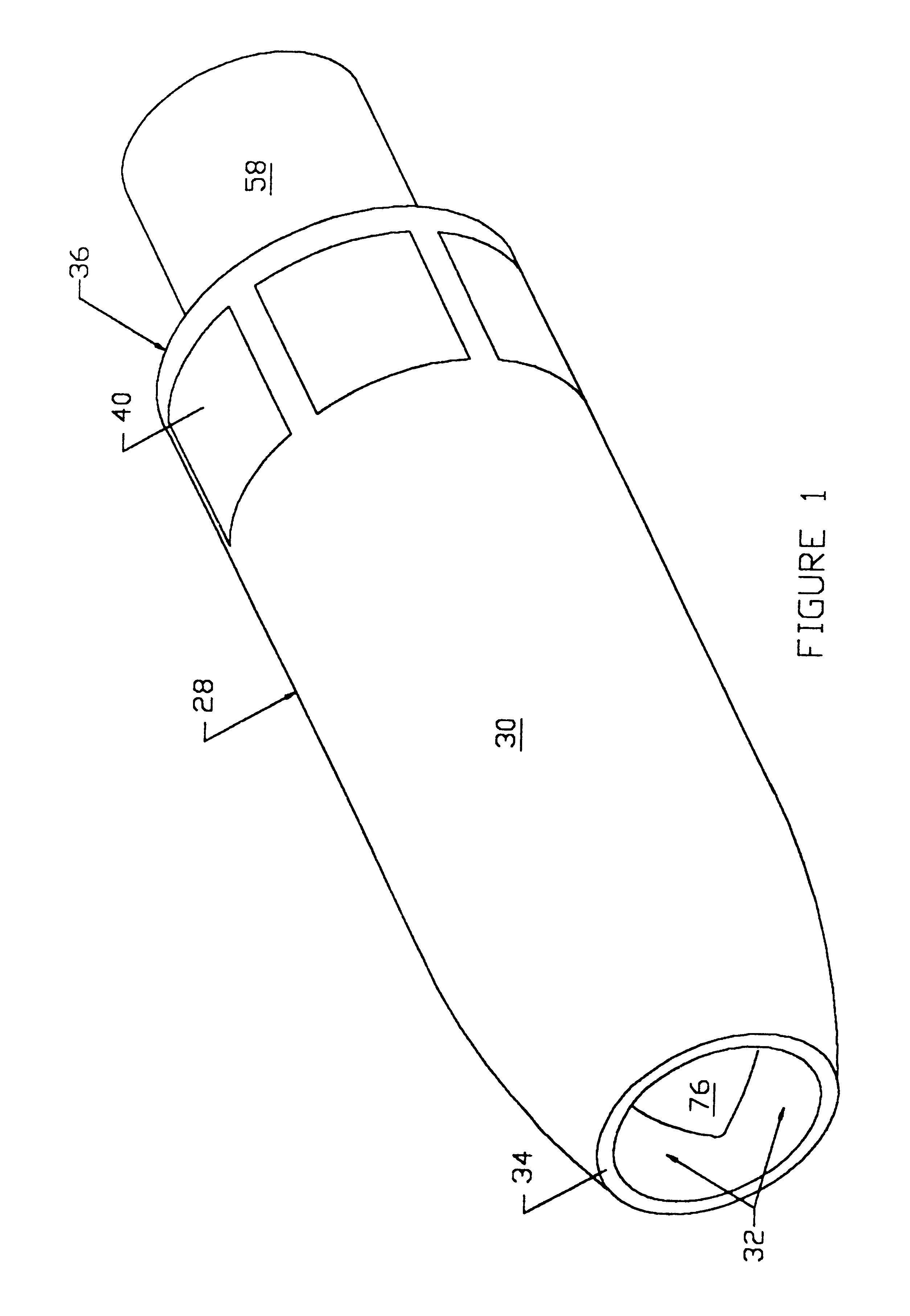

Low drag ducted Ram air turbine generator and cooling system

InactiveUS6270309B1Efficient extractionEnergy efficiencyPump componentsWind motor controlRam air turbineElectric generator

A low drag ducted ram air turbine generator and cooling system is provided. The ducted ram air turbine generator and cooling system has reduced drag while extracting dynamic energy from the air stream during the complete range of intended flight operating regimes. A centerbody / valve tube having an aerodynamically shaped nose is slidably received in a fairing and primary structure to provide a variable inlet area. An internal nozzle control mechanism attached to the valve tube positions nozzle control doors to provide variable area nozzles directing air flow to the turbine stator and rotor blades to maintain optimum generator efficiency. An alternate embodiment includes an annular internal nozzle having interleaved panels to modulate the air flow to the turbine.

Owner:GHETZLER AERO POWER CORP

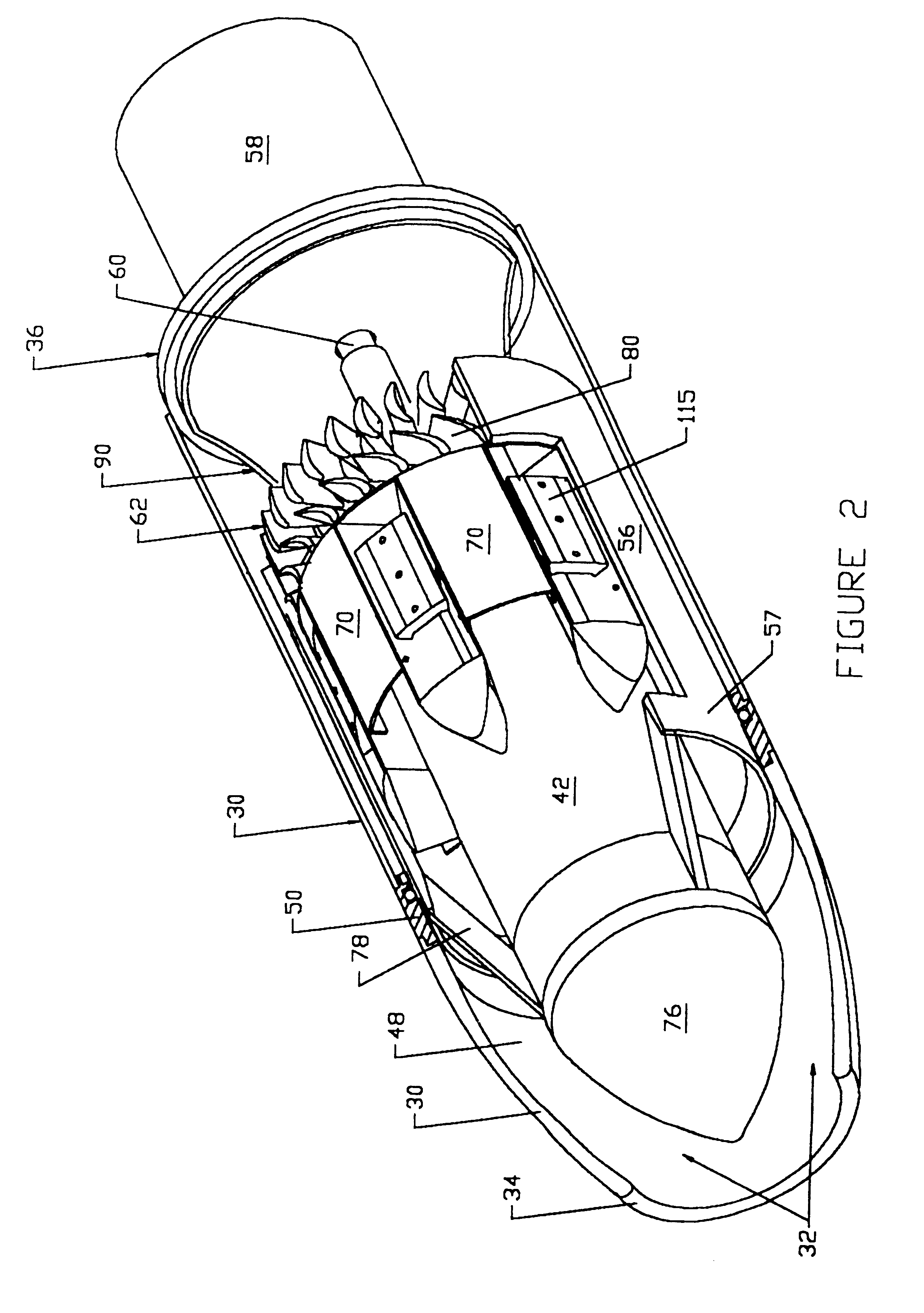

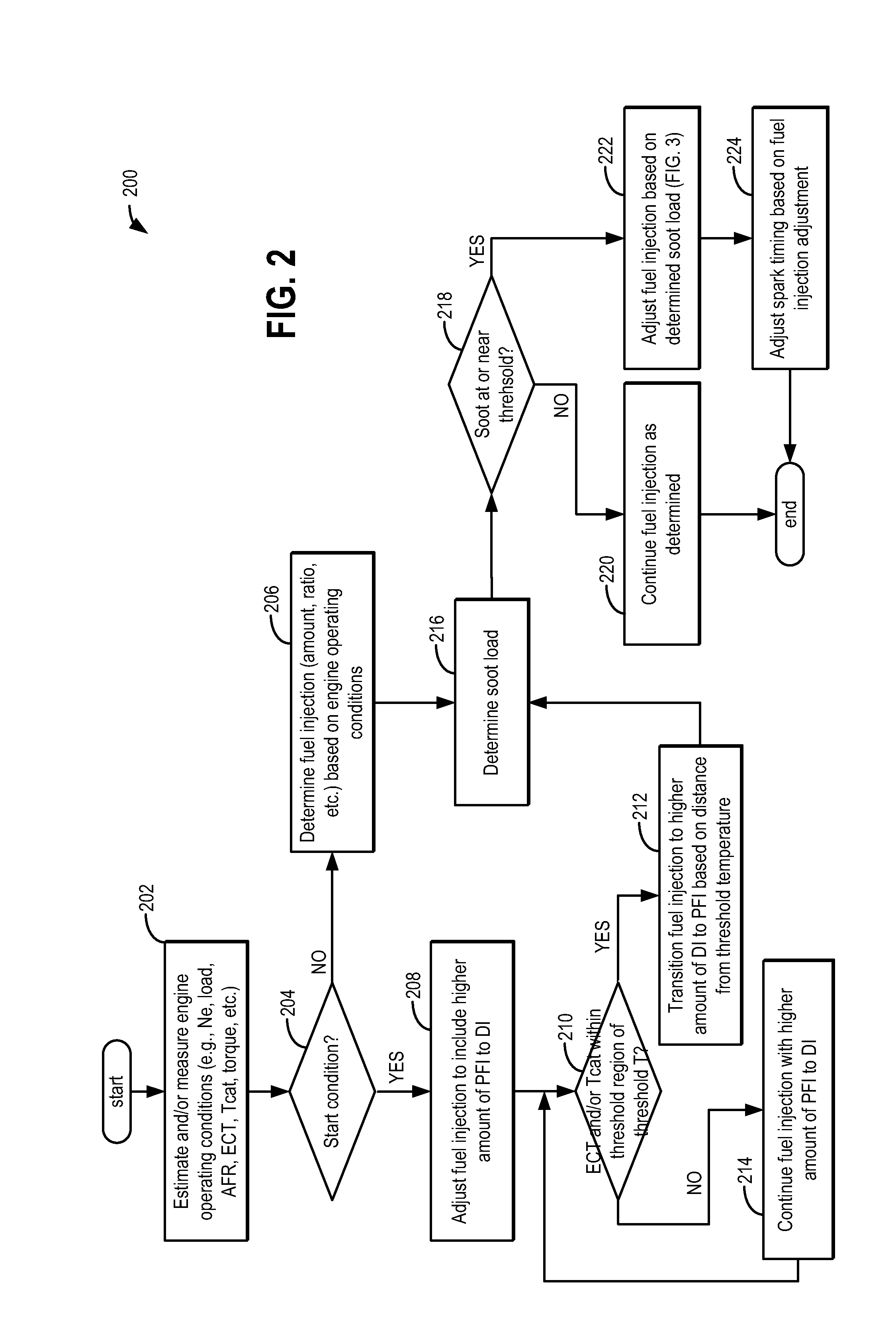

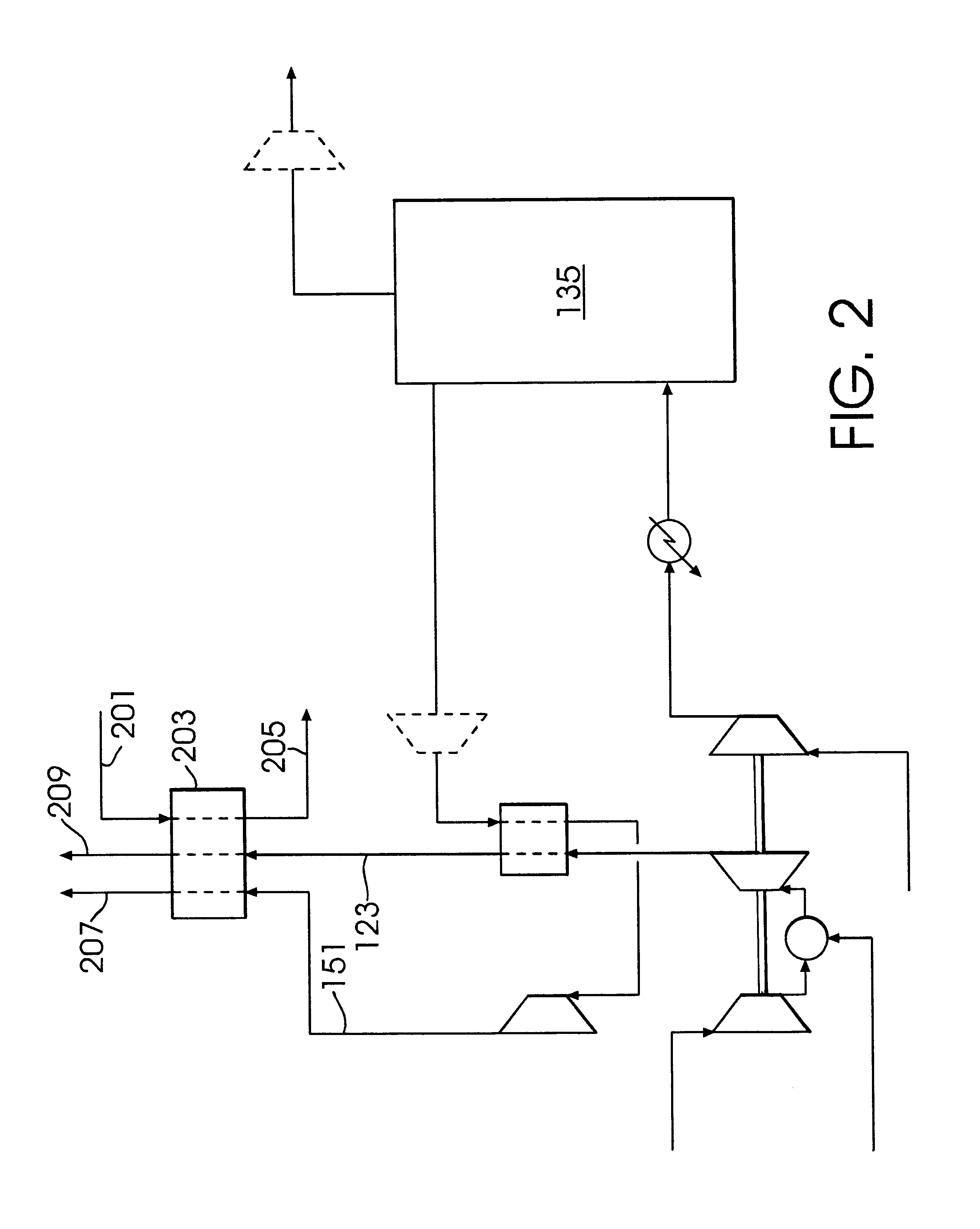

Method and system for engine control

ActiveUS20110162620A1Improve fuel efficiencyImprove cooling effectElectrical controlExhaust apparatusExhaust fumesLoad regulation

Methods and systems are provided for controlling exhaust emissions by adjusting a fuel injection into an engine cylinder from a plurality of fuel injectors based on the fuel type of the injected fuel and further based on the soot load of the engine. Soot generated from direct fuel injection is reduced by decreasing an amount of direct injection into a cylinder as the engine soot load increases.

Owner:FORD GLOBAL TECH LLC

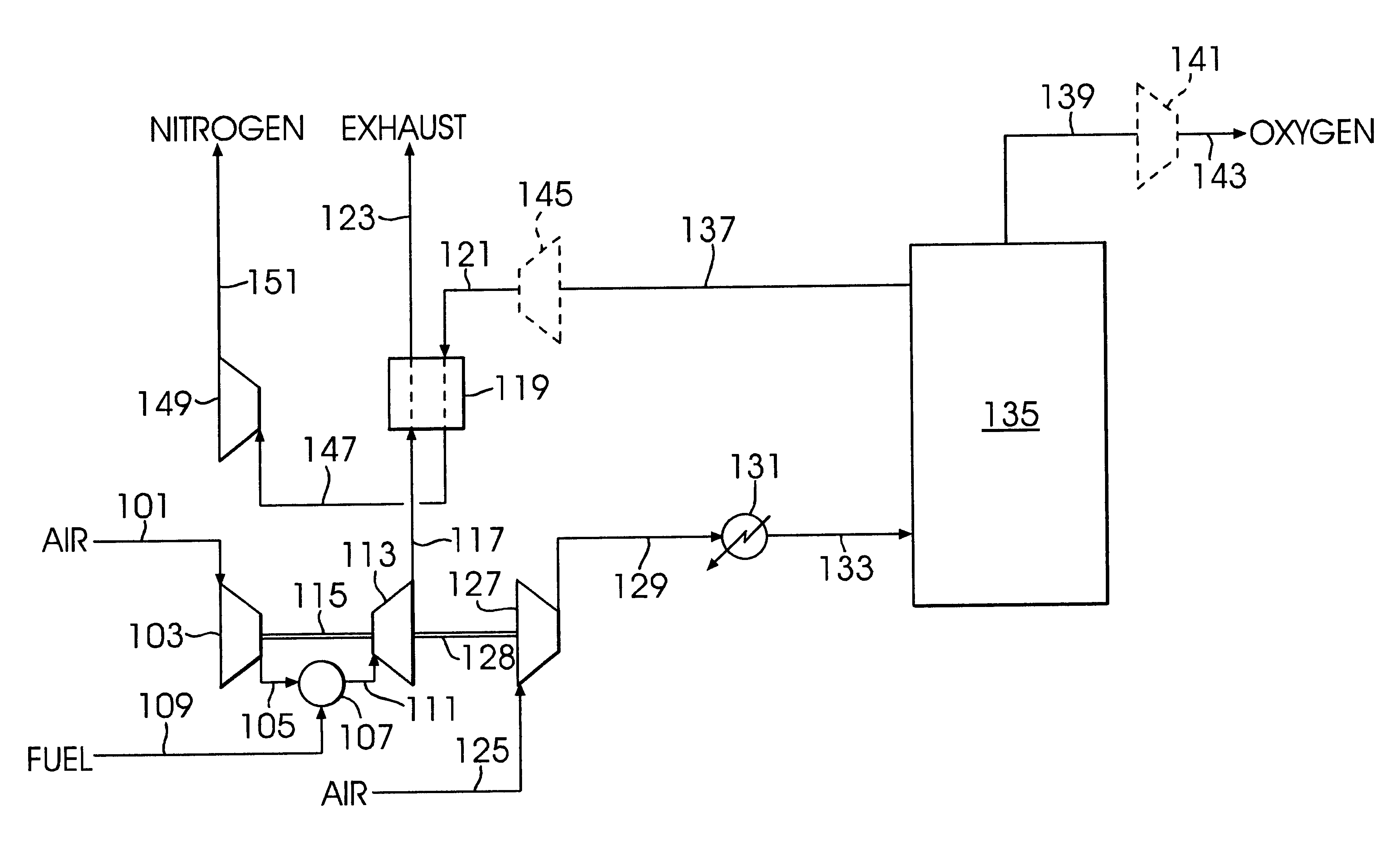

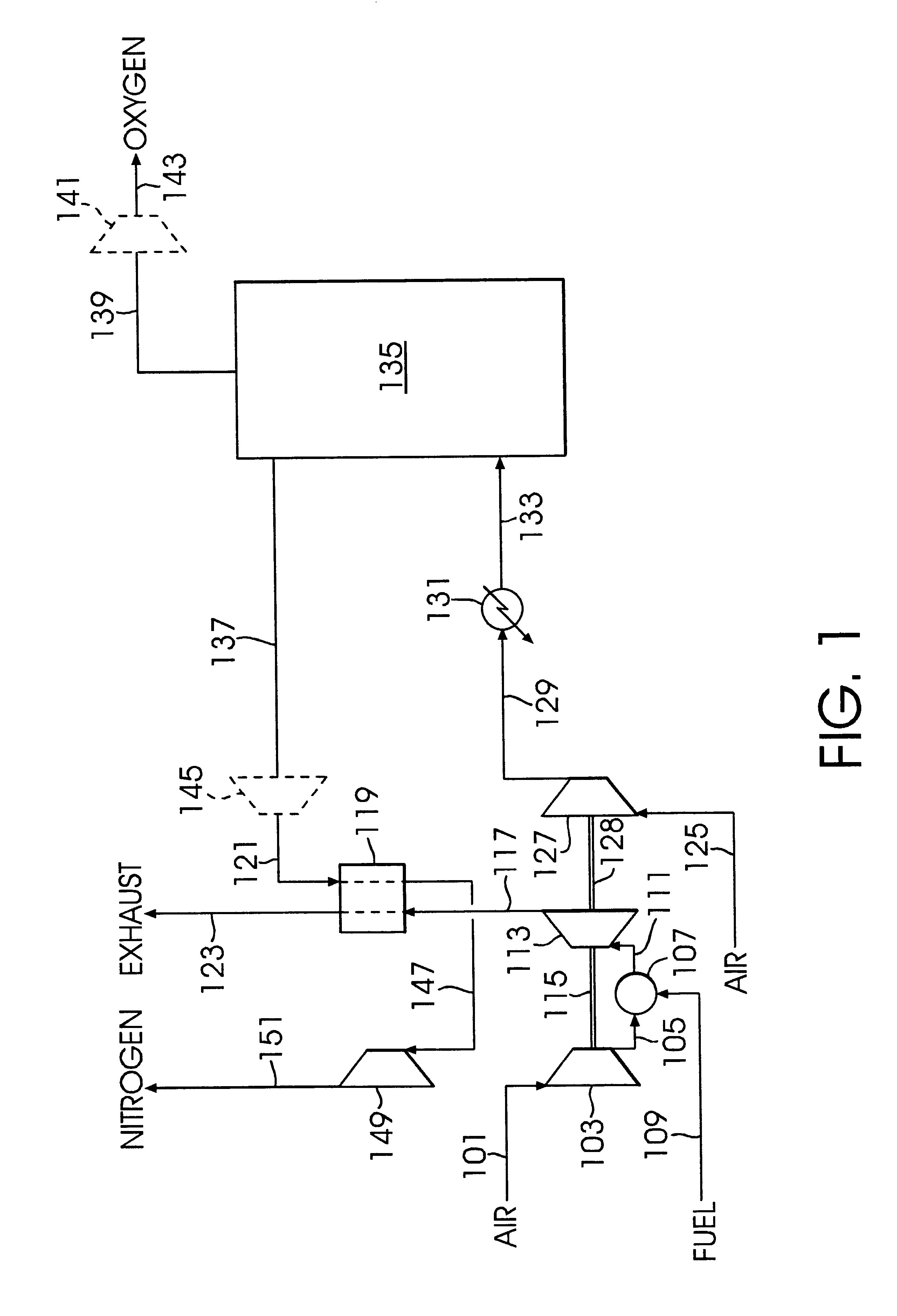

Air separation process integrated with gas turbine combustion engine driver

A method for the separation of a feed gas mixture comprising oxygen and nitrogen in which an oxidant gas and fuel are combusted in a combustion engine to generate shaft work and a hot exhaust gas, the feed gas mixture comprising oxygen and nitrogen is compressed, and the resulting compressed feed gas mixture is separated into two or more product gas streams with differing compositions. The shaft work of the combustion engine is utilized to provide at least a portion of the work required for compressing the feed gas mixture, one of the product gas streams by is heated by indirect heat exchange with the hot exhaust gas from the combustion engine, and the resulting heated product gas is work expanded to generate shaft work and yield an expanded product gas stream. The combustion engine may be a gas turbine combustion engine.

Owner:AIR PROD & CHEM INC

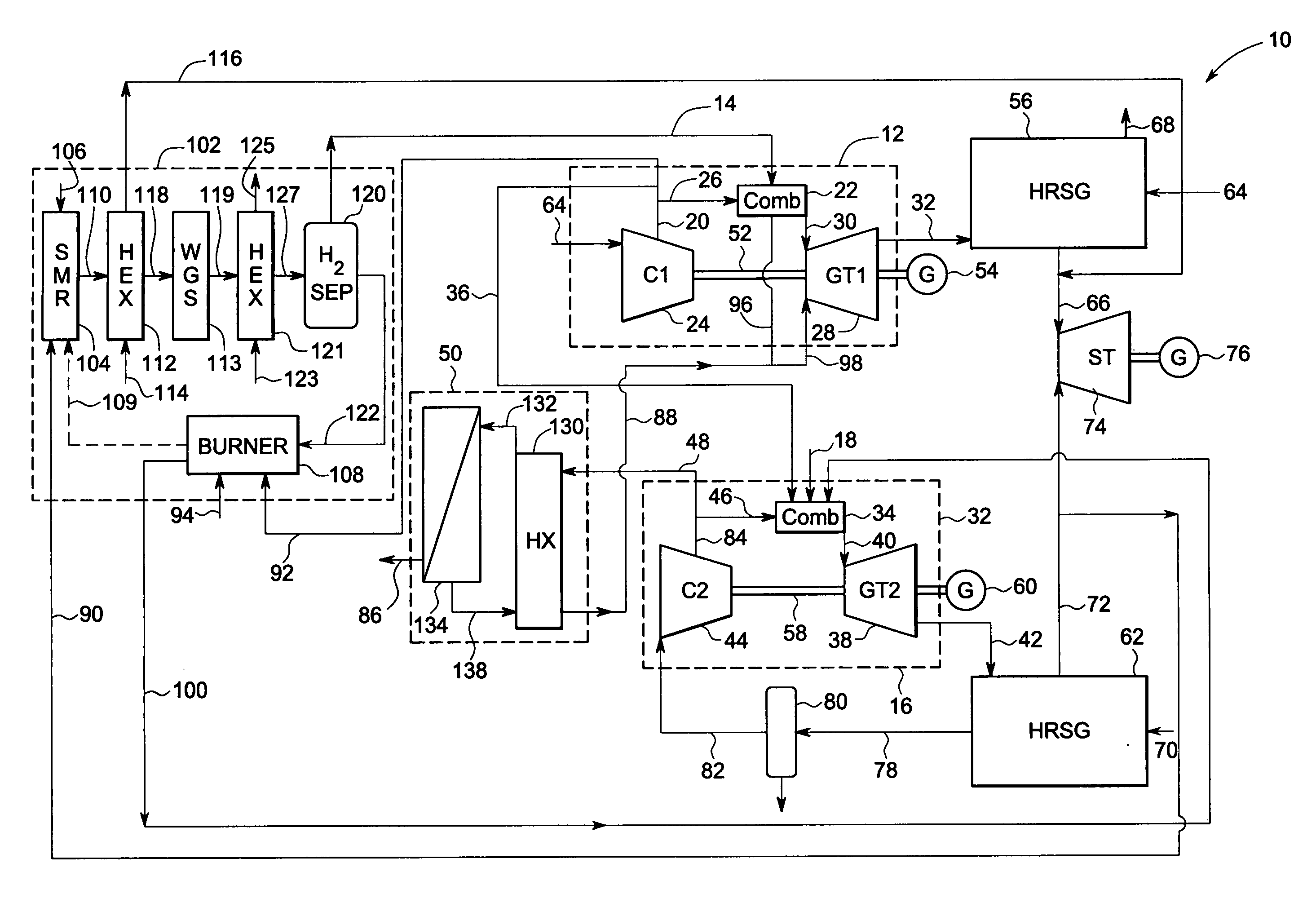

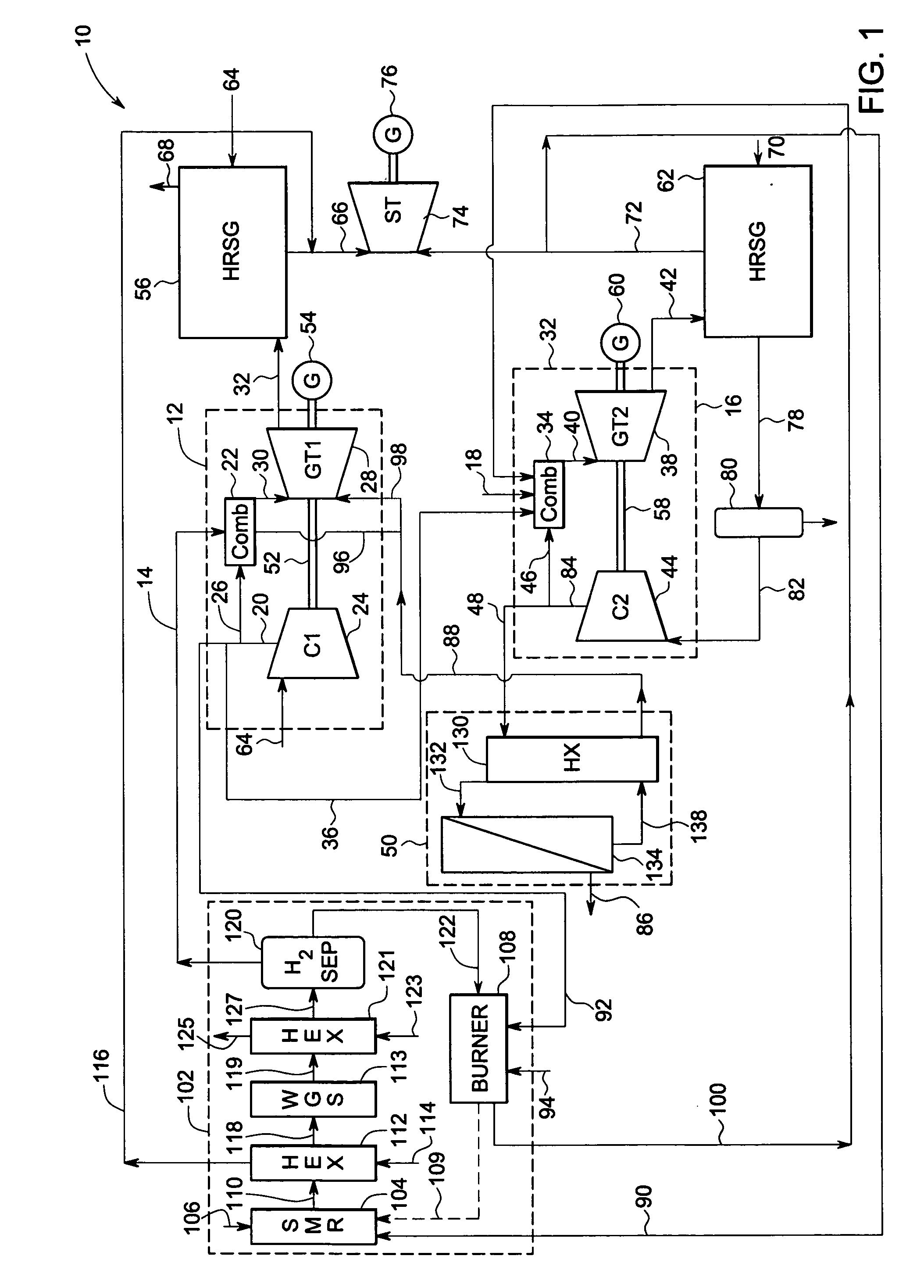

Systems and methods for power generation and hydrogen production with carbon dioxide isolation

A power generation system includes a first gas turbine system. The first turbine system includes a first combustion chamber configured to combust a first fuel stream of primarily hydrogen that is substantially free of carbon-based fuels, a first compressor configured to supply a first portion of compressed oxidant to the first combustion chamber and a first turbine configured to receive a first discharge from the first combustion chamber and generate a first exhaust and electrical energy. The power generation system further includes a second gas turbine system. The second turbine system includes a second combustion chamber configured to combust a second fuel stream to generate a second discharge, wherein the first compressor of the first gas turbine system is configured to supply a second portion of compressed oxidant to the second combustion chamber and a second turbine configured to receive the second discharge from the second combustion chamber to generate a second exhaust and electrical energy. A second compressor is configured to receive the second exhaust comprising carbon dioxide and to discharge a recycle stream to the second combustion chamber and a split stream to a separator system adapted to recover carbon dioxide. The power generation system also includes a hydrogen generation system configured to receive a third fuel and steam to generate the first fuel and a third exhaust gas, wherein the third exhaust gas is recycled into the second combustion chamber.

Owner:GENERAL ELECTRIC CO

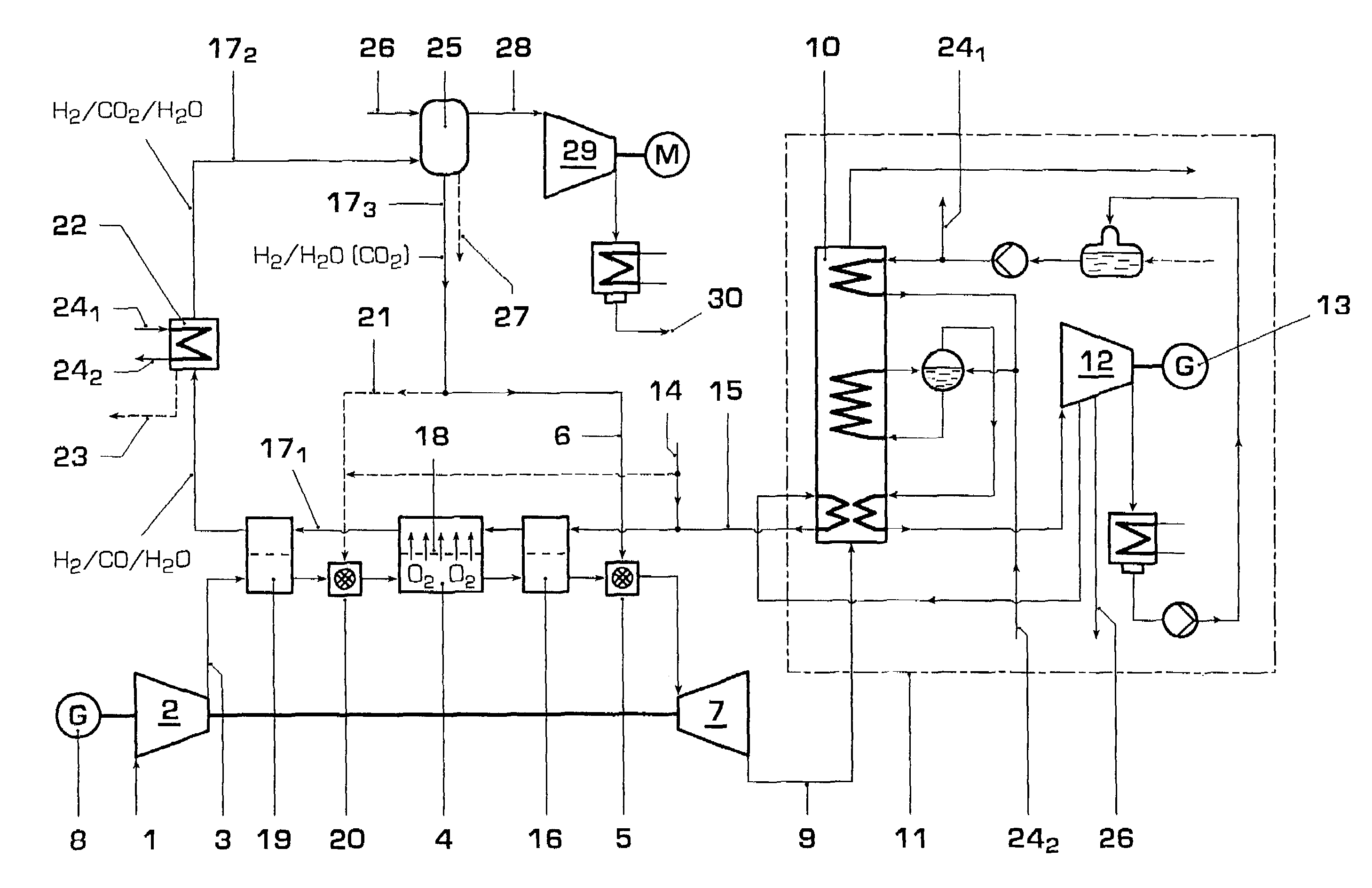

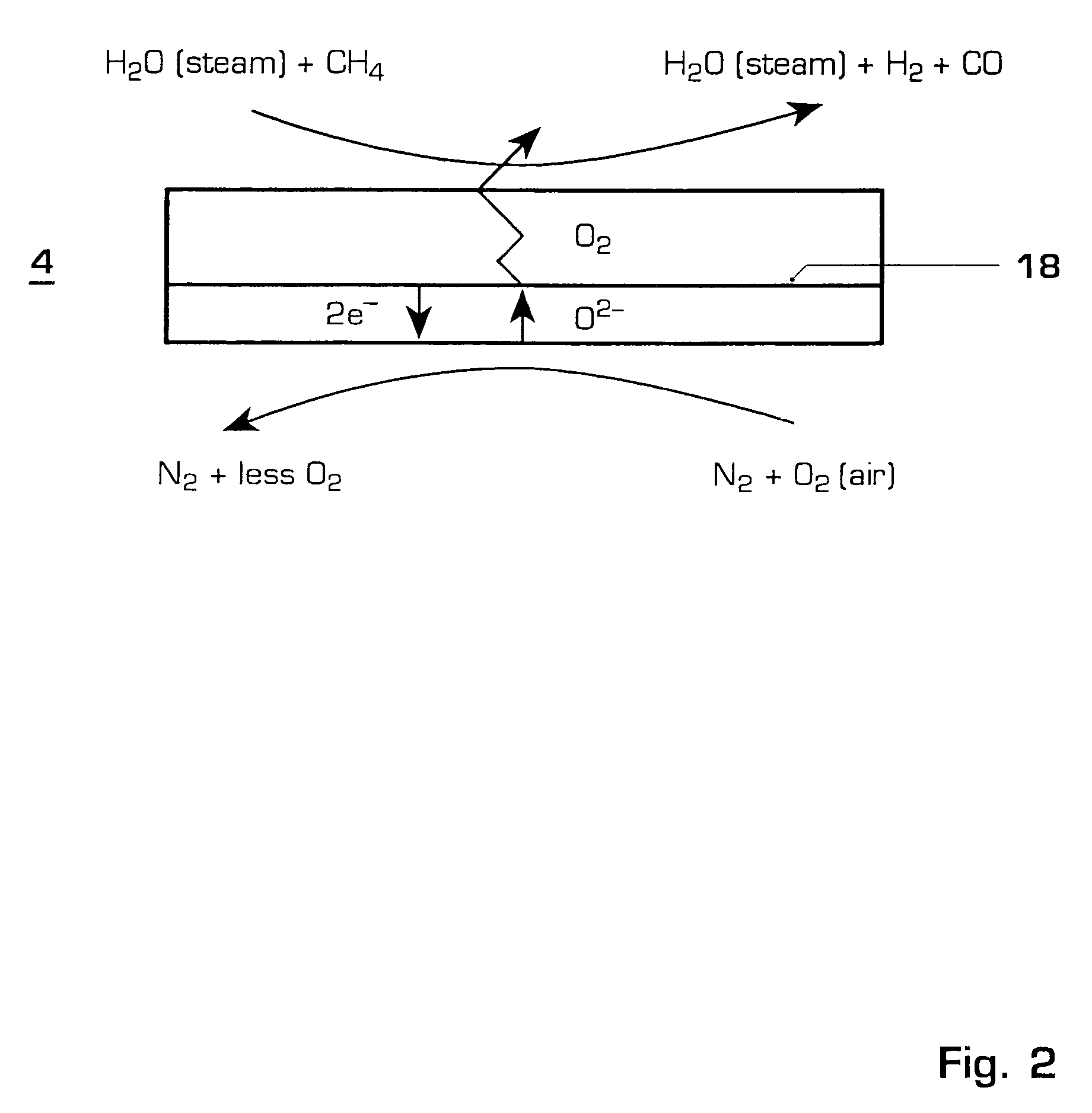

Gas turbine power plant and method of operating the same

InactiveUS7363764B2Improve efficiencyAvoid disadvantagesHydrogenOxygen/ozone/oxide/hydroxideSyngasPartial oxidation

A method of operating a gas turbine power plant and gas turbine power plant are disclosed wherein hydrogen for the combusting process is produced by feeding natural gas mixed with steam through a membrane / partial oxidation reactor and converting the natural gas at least to H2 and CO. Thereby oxygen is transferred from the compressed air through the membrane of the membrane / partial oxidation reactor and the oxygen is used for the partial oxidation process of the natural gas. The process is followed by converting the syngas in a CO shift reactor and a CO shift reactor to a CO2 removal equipment to mainly hydrogen.

Owner:GENERAL ELECTRIC TECH GMBH

Engine power extraction control system

ActiveUS7285871B2Increase propulsionEasy to operateReciprocating combination enginesTurbine/propulsion engine ignitionControl systemEngine power

An engine power extraction control system controls the main propulsion engines and the electrical machines that are coupled thereto to supply an appropriate amount of aircraft thrust and electrical energy to the aircraft. The engines and electrical machines are also controlled so that the propulsion thrust that is generated is split between the various turbines in the main propulsion engines to maintain an adequate surge margin and to minimize residual thrust generation.

Owner:HONEYWELL INT INC

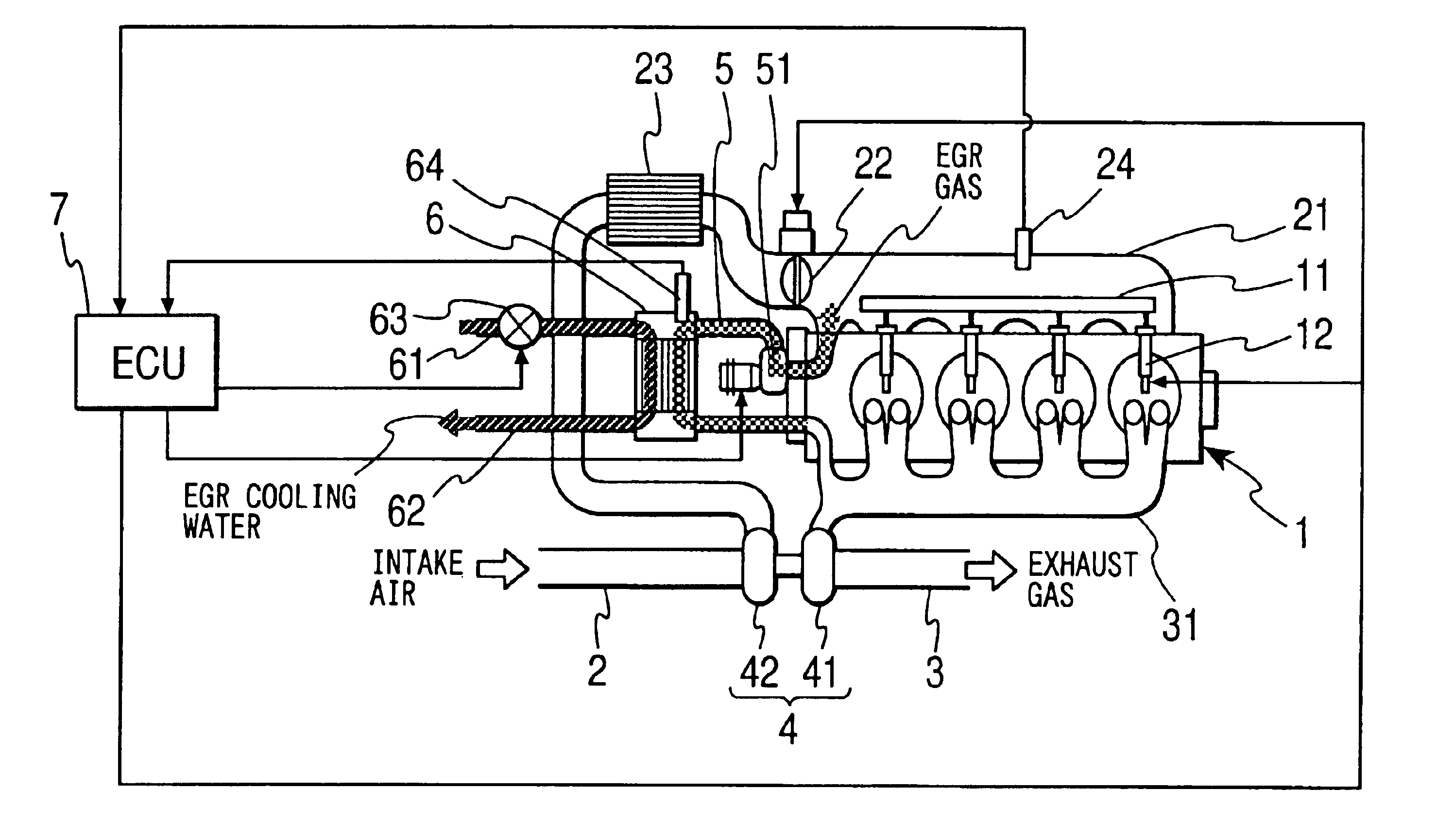

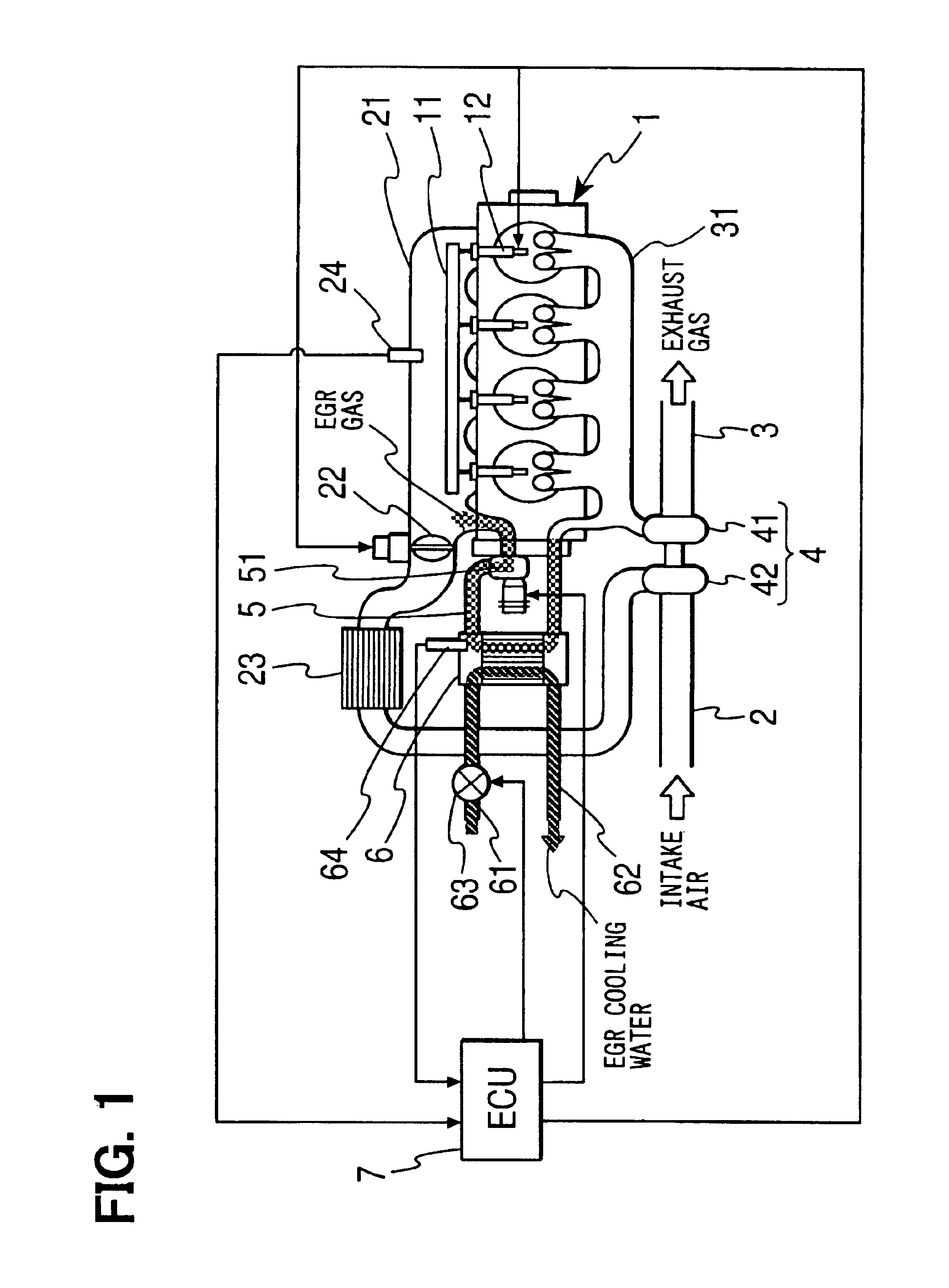

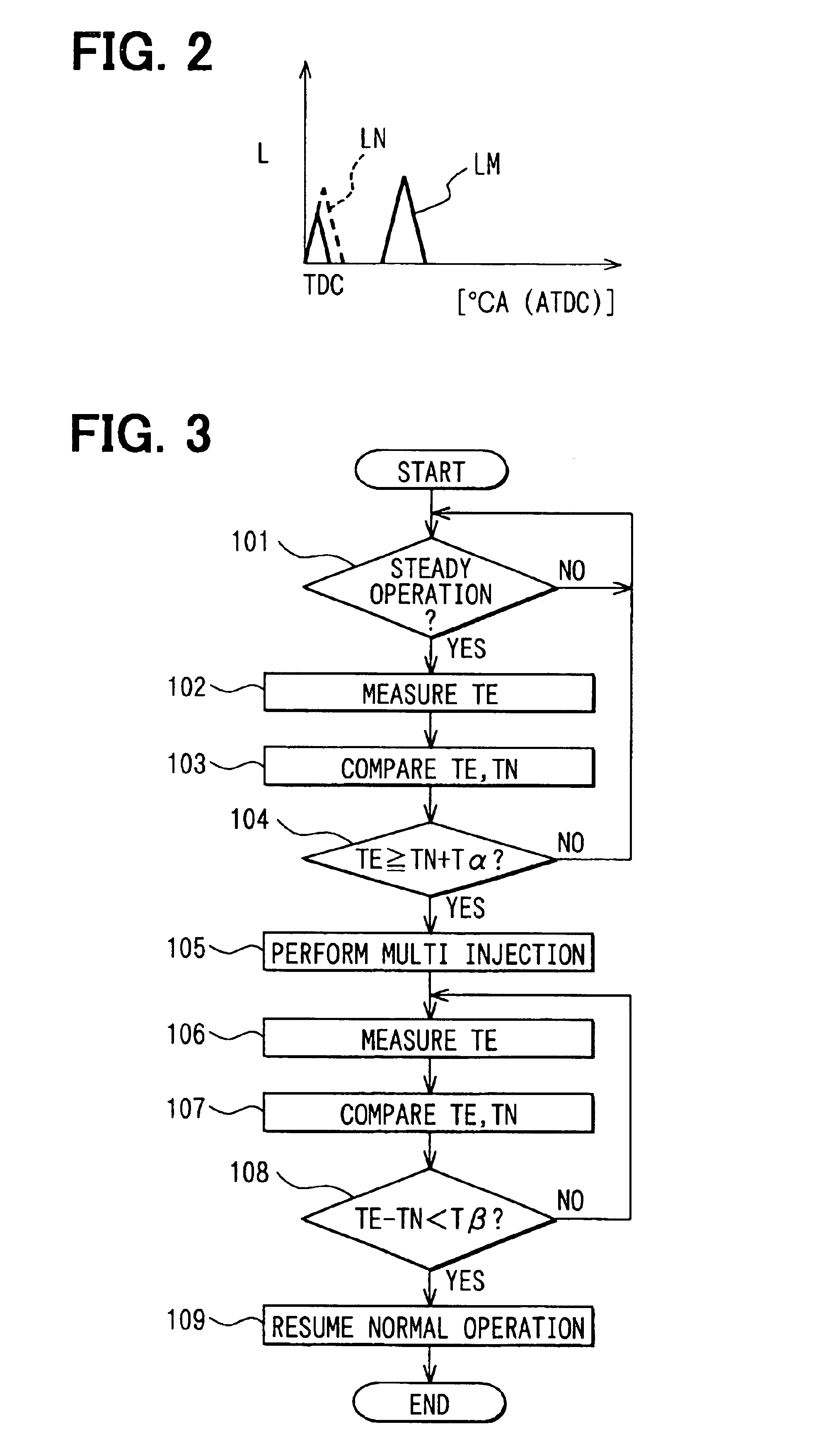

Exhaust gas recirculation system having cooler

InactiveUS6826903B2Improve heat transfer effectElectrical controlNon-fuel substance addition to fuelExhaust fumesExhaust gas recirculation

An exhaust gas recirculation (EGR) system of an internal combustion engine has an EGR cooler in an EGR passage connecting an exhaust manifold with an intake manifold. The EGR cooler cools EGR gas recirculated through the EGR passage. Cooling performance detecting means included in an electronic control unit (ECU) determines that cooling performance of the EGR cooler is degraded when intake pressure measured by an intake pressure sensor is lower than a normal intake pressure by at least a predetermined value. When the degradation of the cooling performance is detected, cooling performance regeneration controlling means included in the ECU increases the temperature inside the EGR cooler by heating the exhaust gas to eliminate soot or unburned hydrocarbon by oxidization. Thus, the cooling performance of the EGR cooler is regenerated.

Owner:DENSO CORP

Popular searches

Electric spark ignition installations Combustion ignition/checking Jet propulsion plants Ignition control Hot gas positive displacement engine plants Semiconductor/solid-state device manufacturing Pipeline systems Chemical vapor deposition coating Drawing-off water installations Thin material handling

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com