Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

189 results about "Multifuel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multifuel, sometimes spelled multi-fuel, is any type of engine, boiler, or heater or other fuel-burning device which is designed to burn multiple types of fuels in its operation. One common application of multifuel technology is in military settings, where the normally-used diesel or gas turbine fuel might not be available during combat operations for vehicles or heating units. Multifuel engines and boilers have a long history, but the growing need to establish fuel sources other than petroleum for transportation, heating, and other uses has led to increased development of multifuel technology for non-military use as well, leading to many flexible-fuel vehicle designs in recent decades.

Internal combustion engine

ActiveUS6990956B2Accurate calculationElectrical controlInternal combustion piston enginesMultifuelEngineering

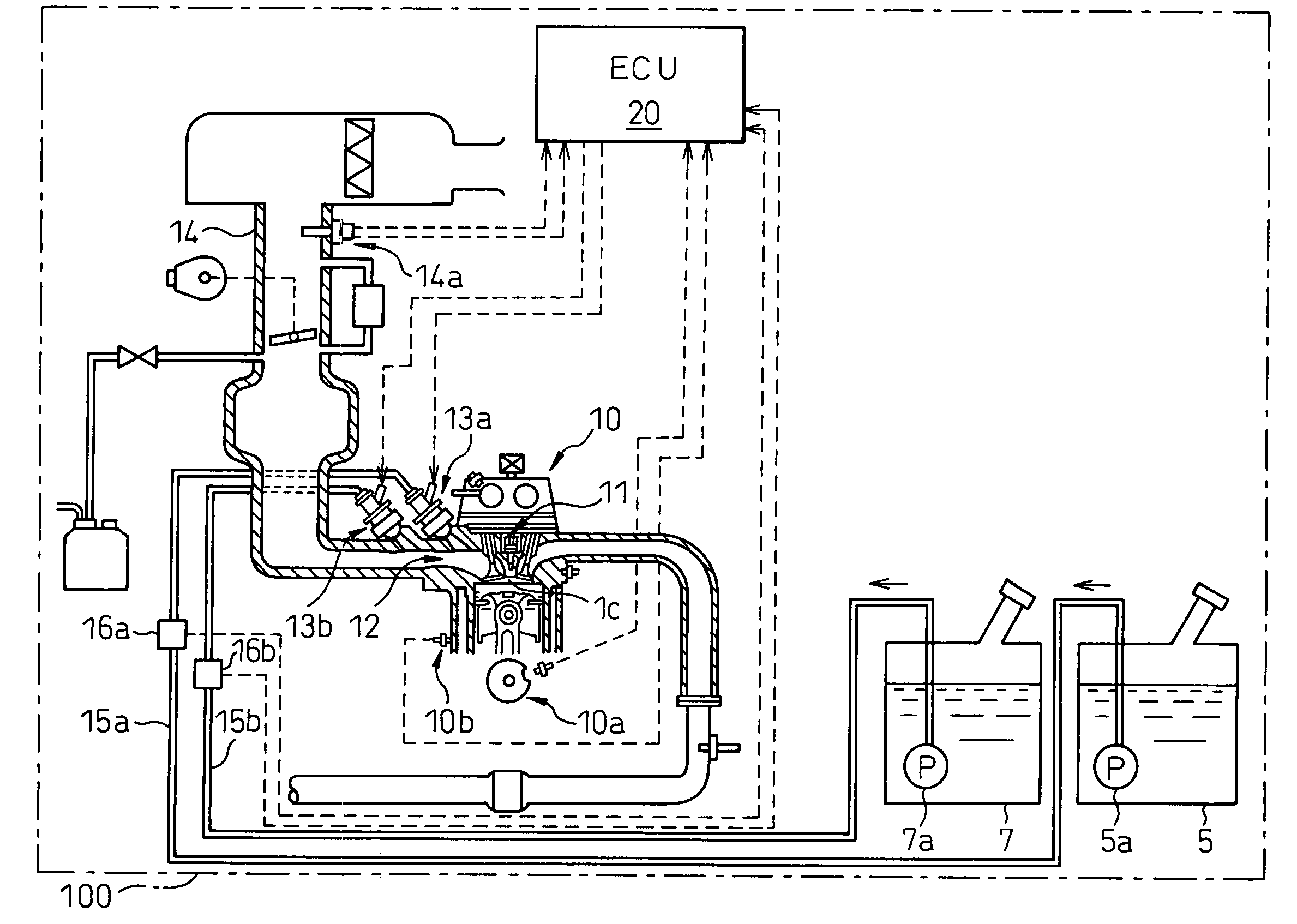

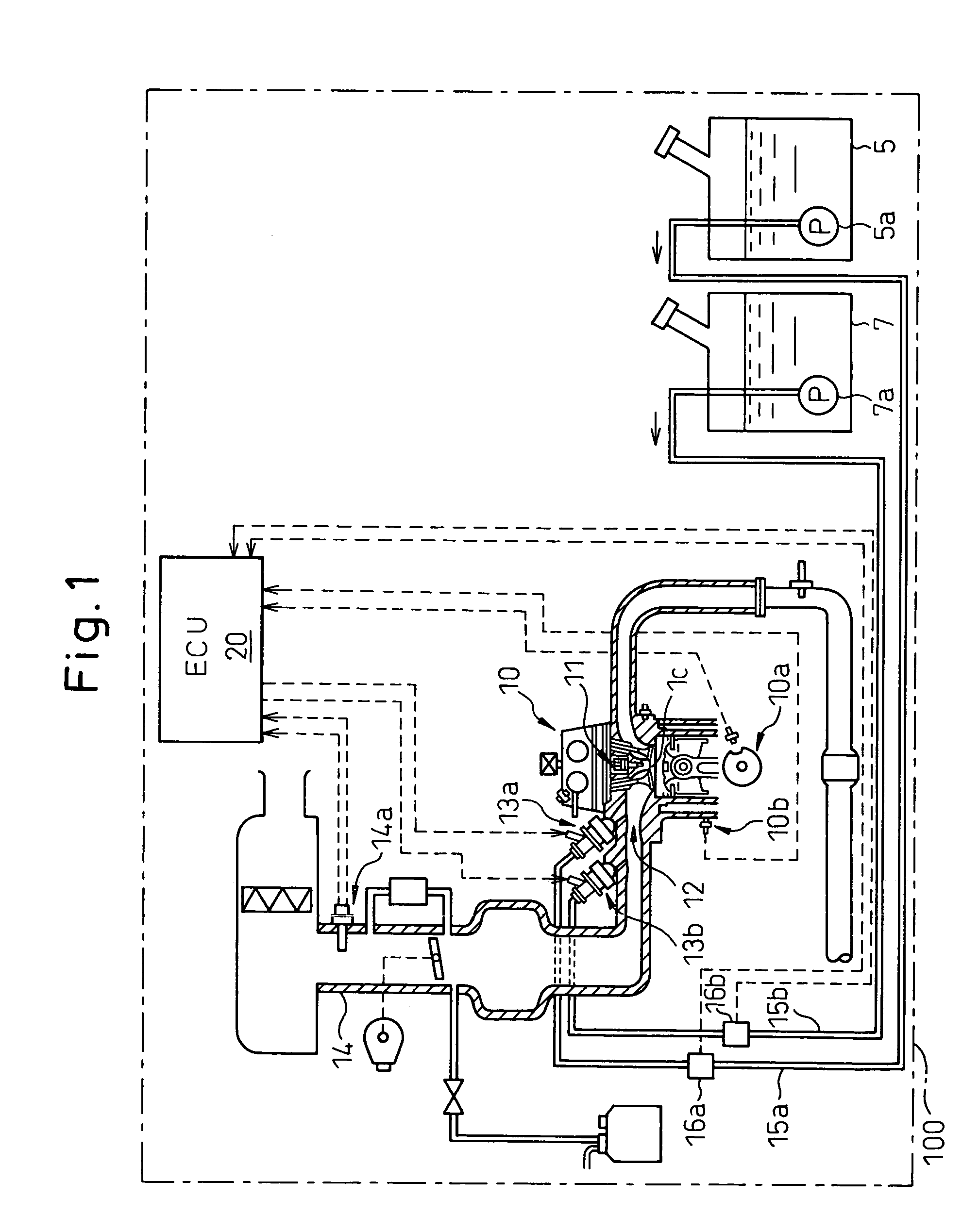

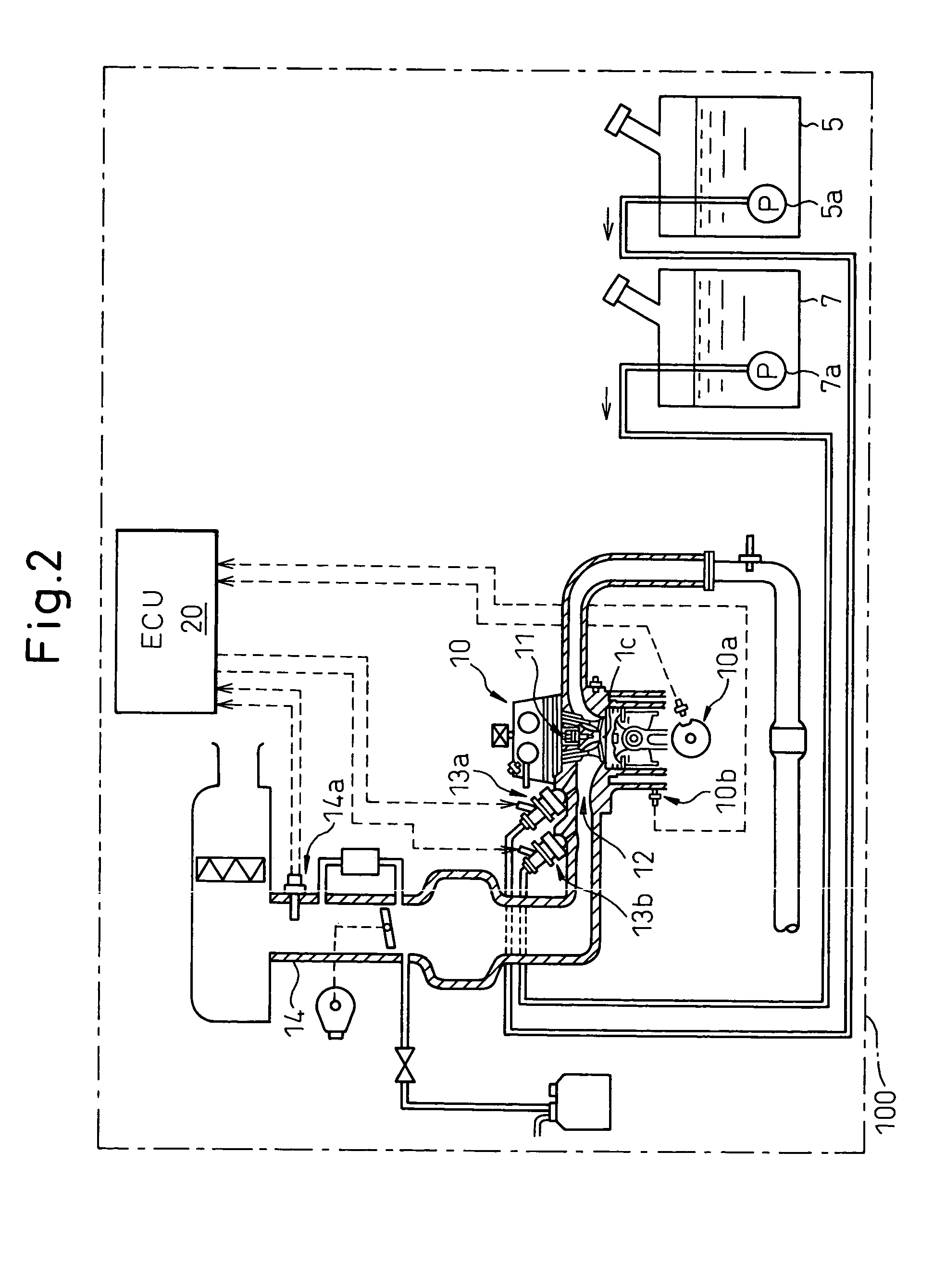

An internal combustion engine, in which multiple kinds of fuels are fed to a cylinder from multiple fuel injectors each corresponding to each of multiple kinds of fuels at a target mixing ratio determined according to a running condition, includes an actual fuel mixing ratio calculator calculating an actual fuel mixing ratio of fuel fed to cylinder. The actual fuel mixing ratio calculator at first calculates actual fuel injection quantity of each fuel injection by adding or subtracting predetermined stuck-on-wall fuel to or from each quantity of fuel injected from each fuel injector, and then calculates an actual fuel mixing ratio of fuel fed to cylinder on the basis of the calculated actual fuel injection quantity of each fuel injector.

Owner:TOYOTA JIDOSHA KK

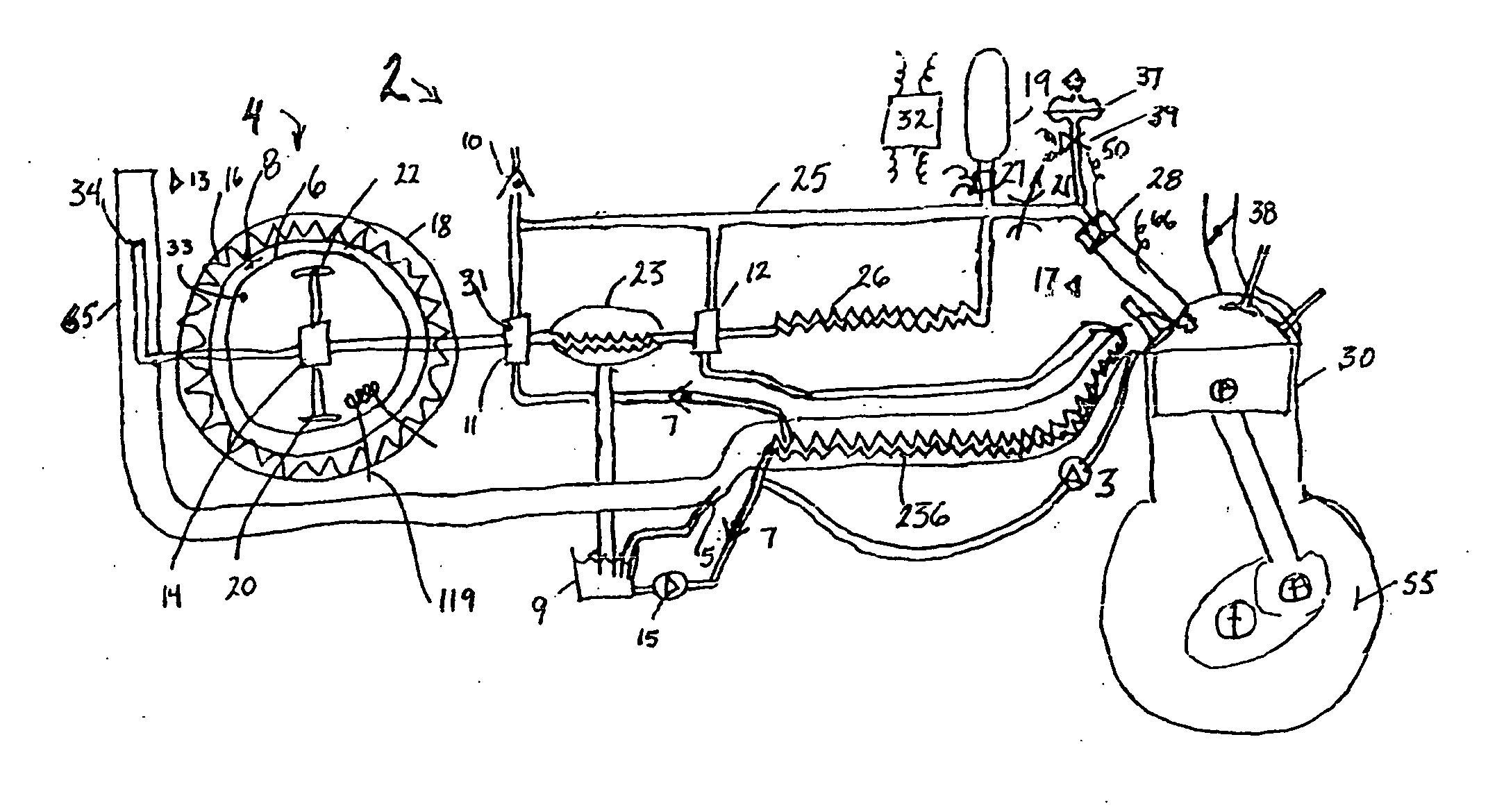

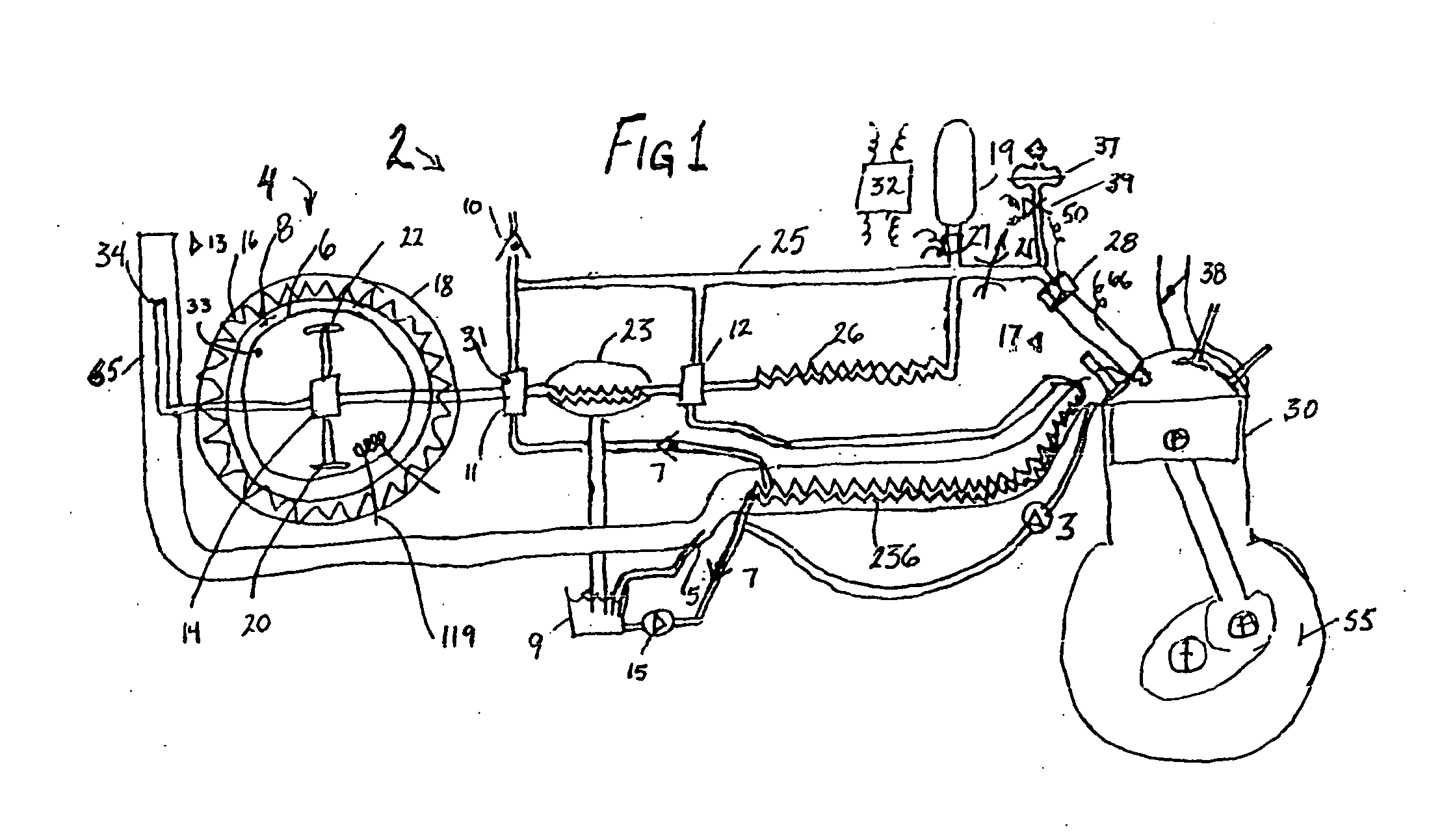

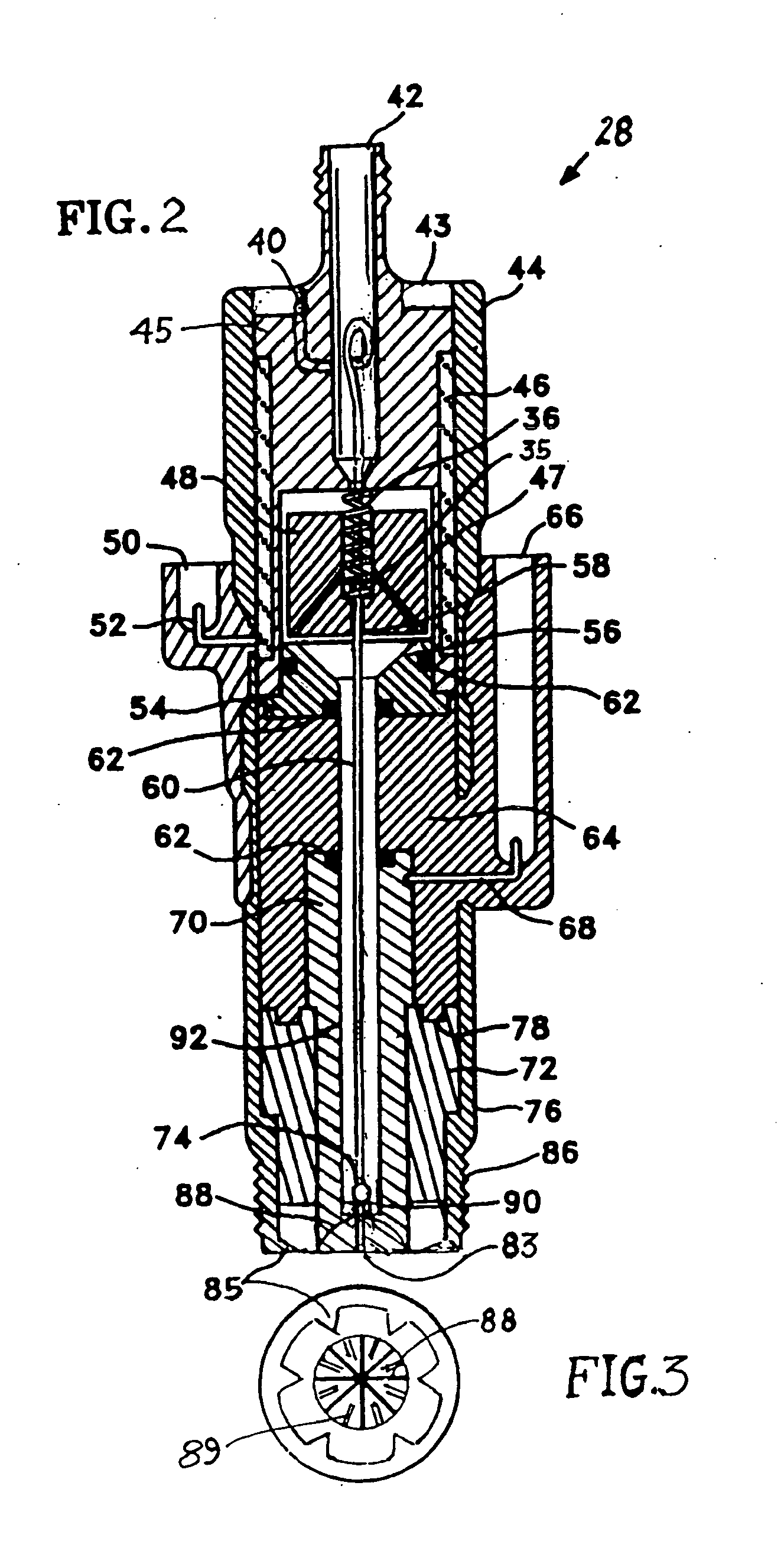

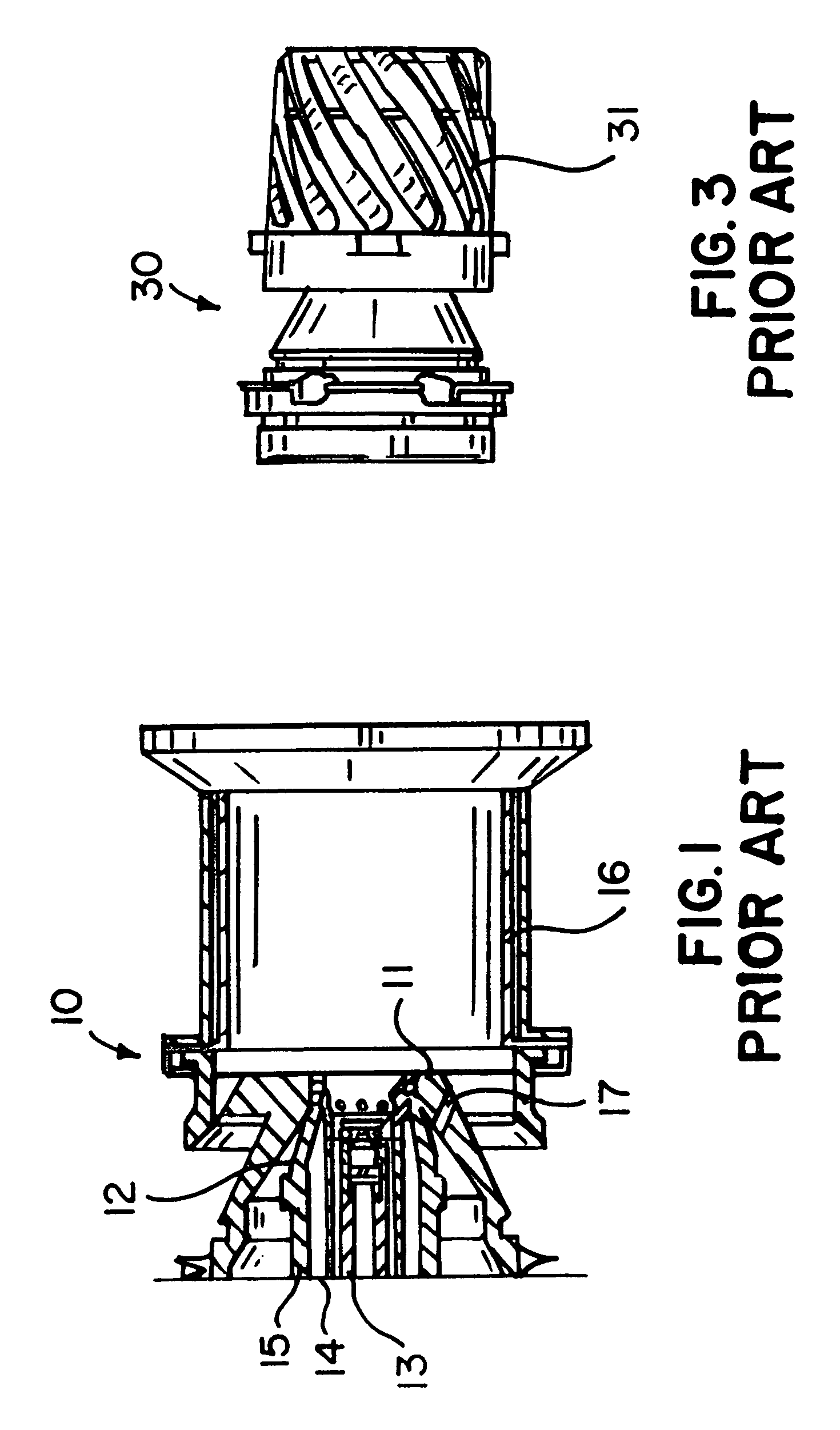

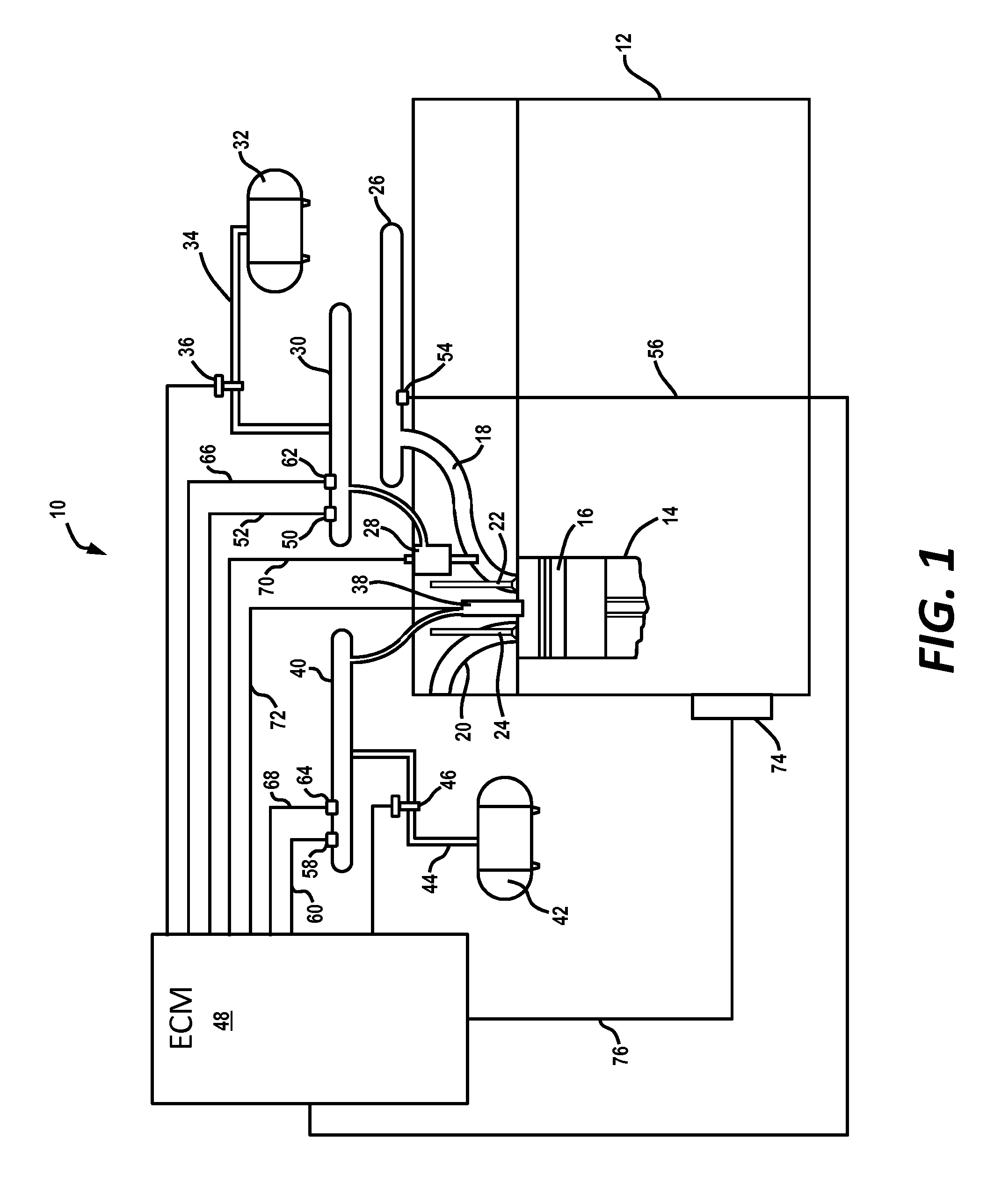

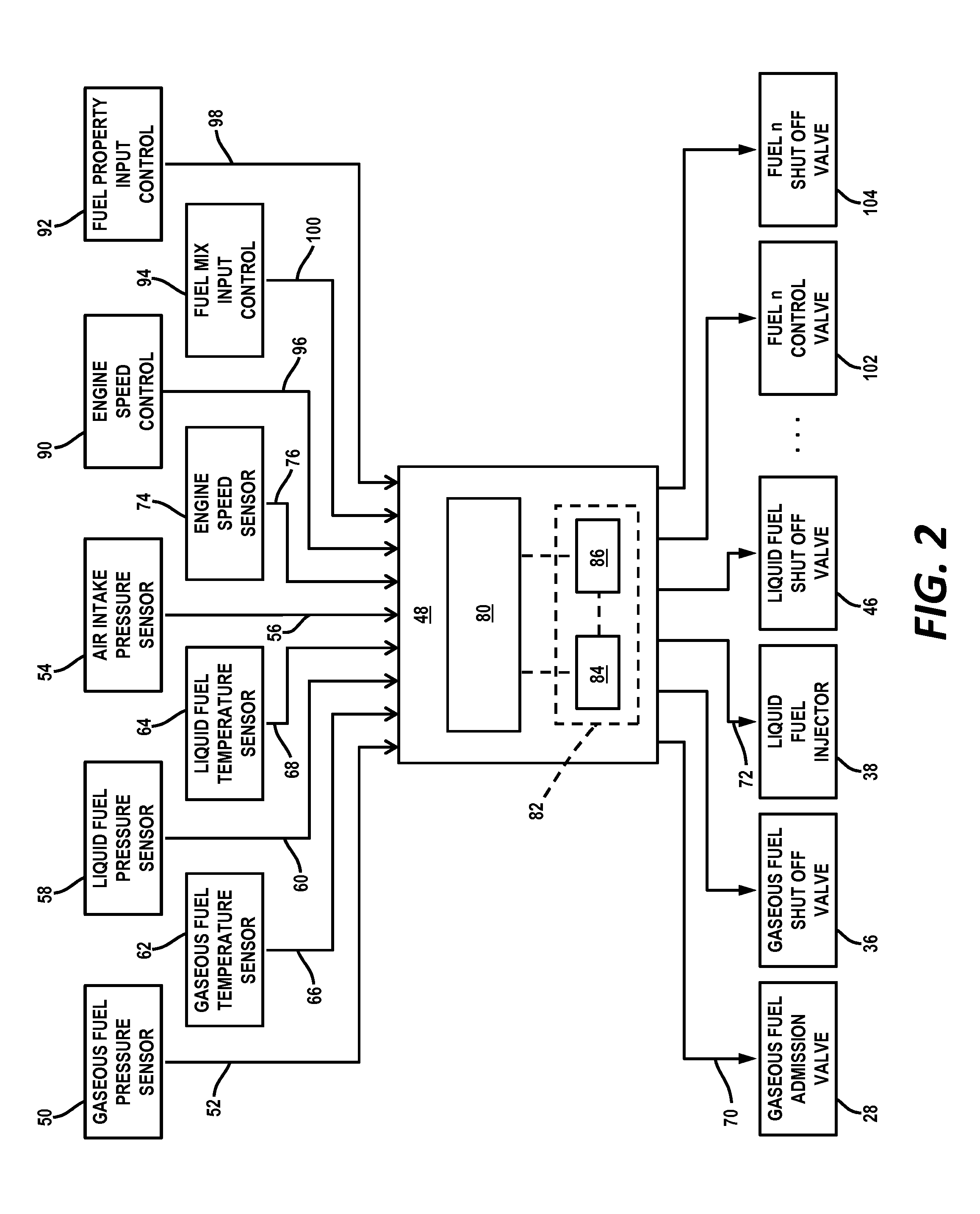

Multifuel storage, metering and ignition system

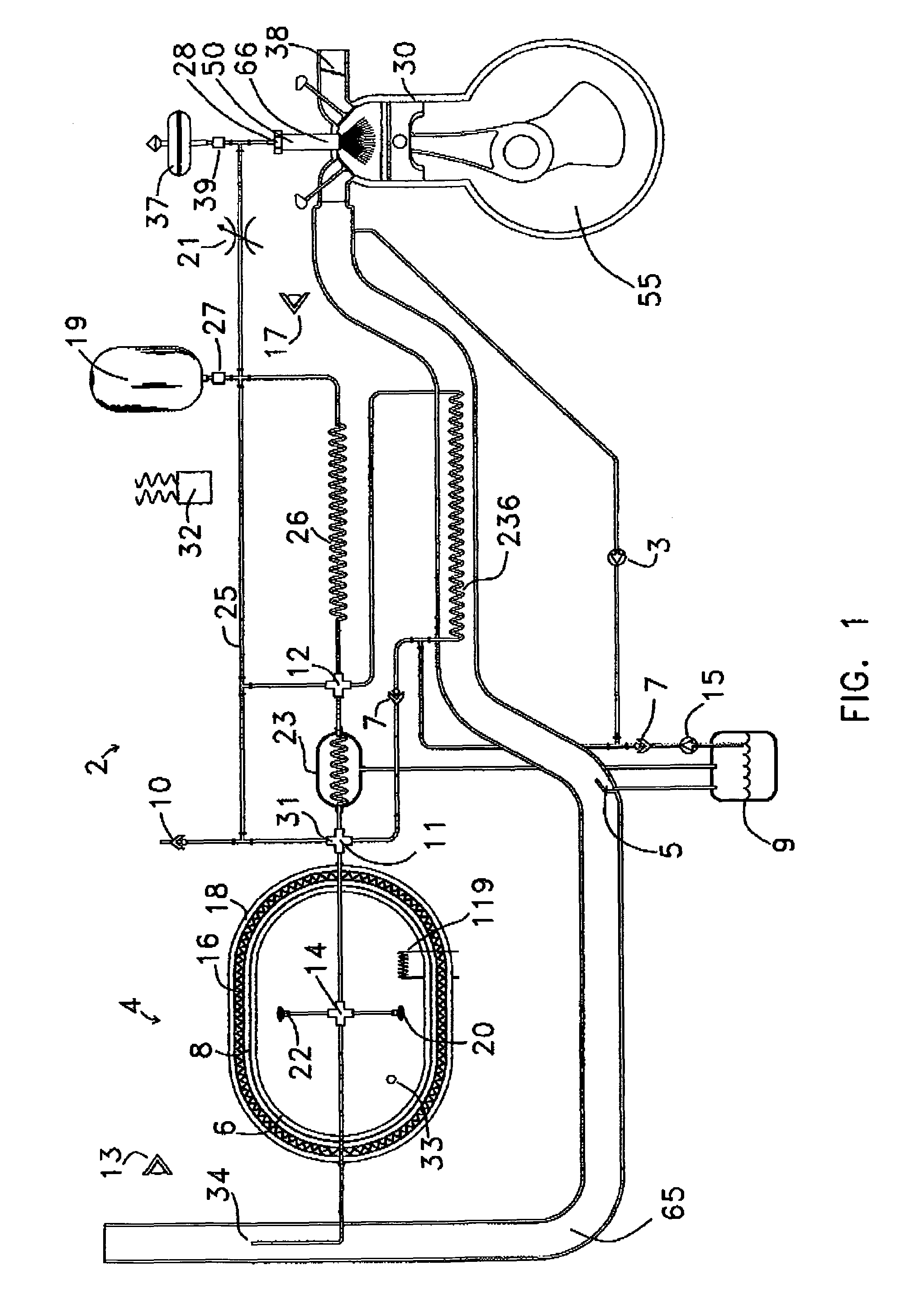

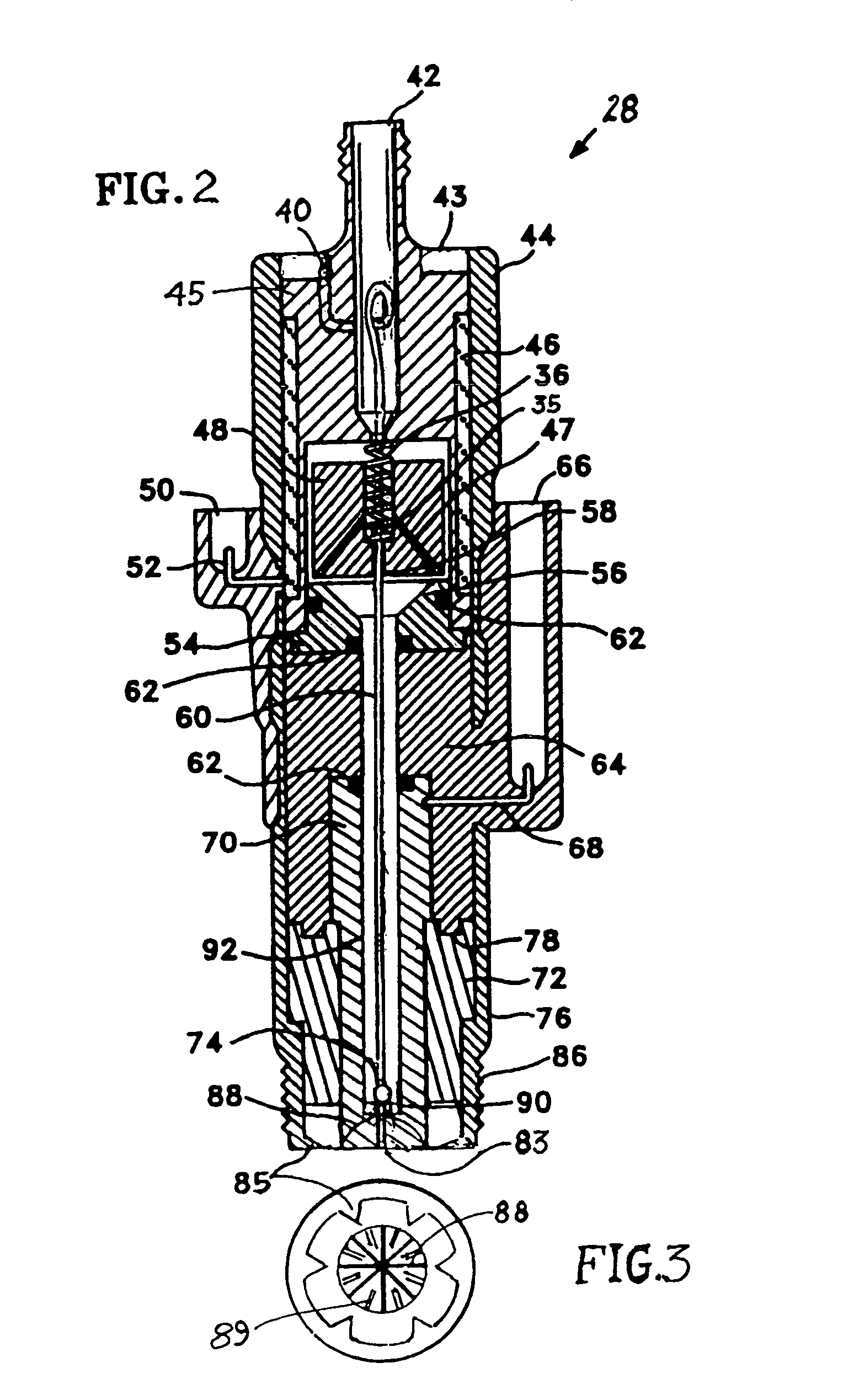

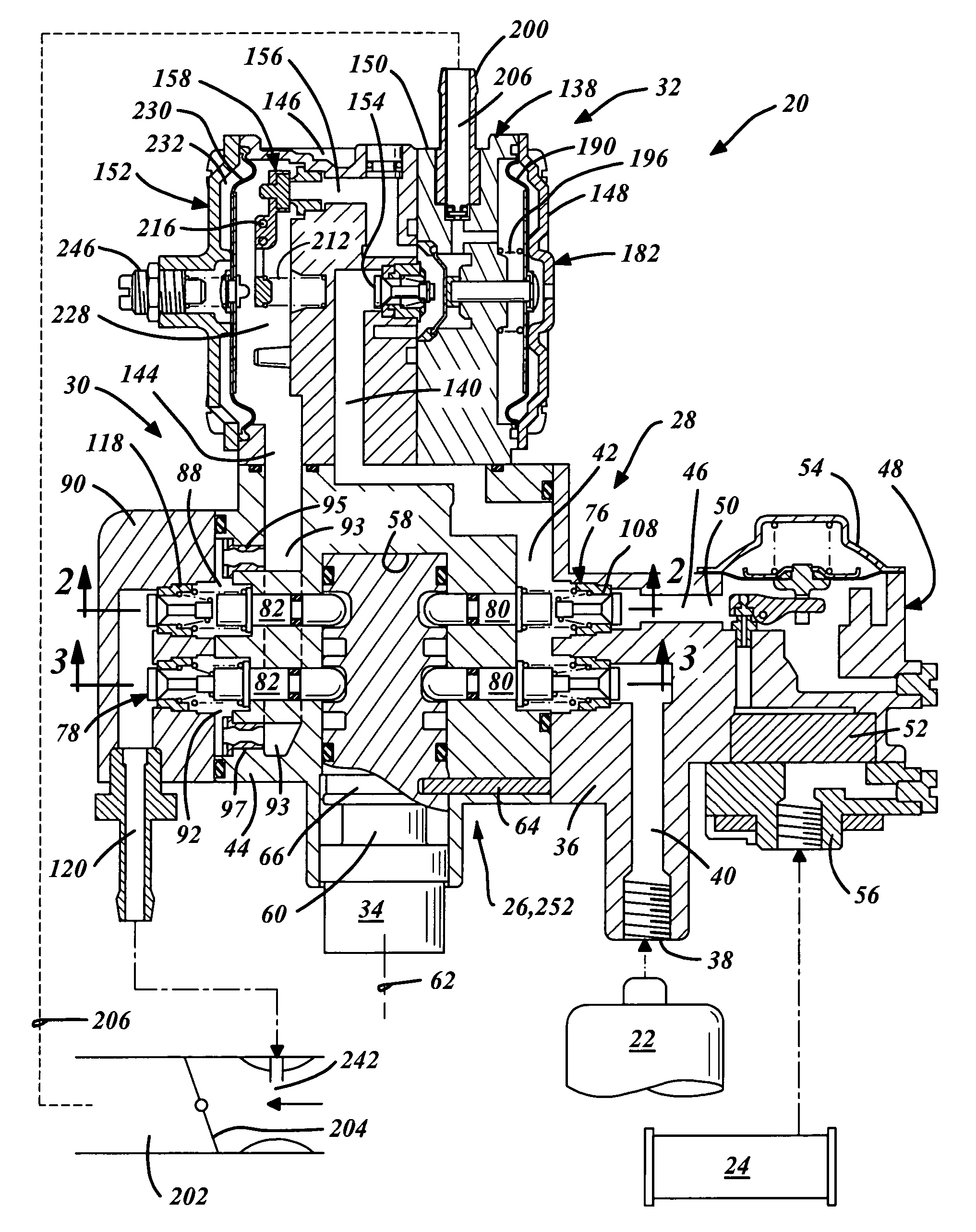

A system for safe storage and efficient utilization of a variety of fuel selections that range in composition and phase from cryogenic mixtures of solids and liquids to elevated temperature gases is provided for unique applications with various types of heat engines and fuel cells including hybridized combinations.

Owner:ADVANCED GREEN INNOVATIONS LLC +1

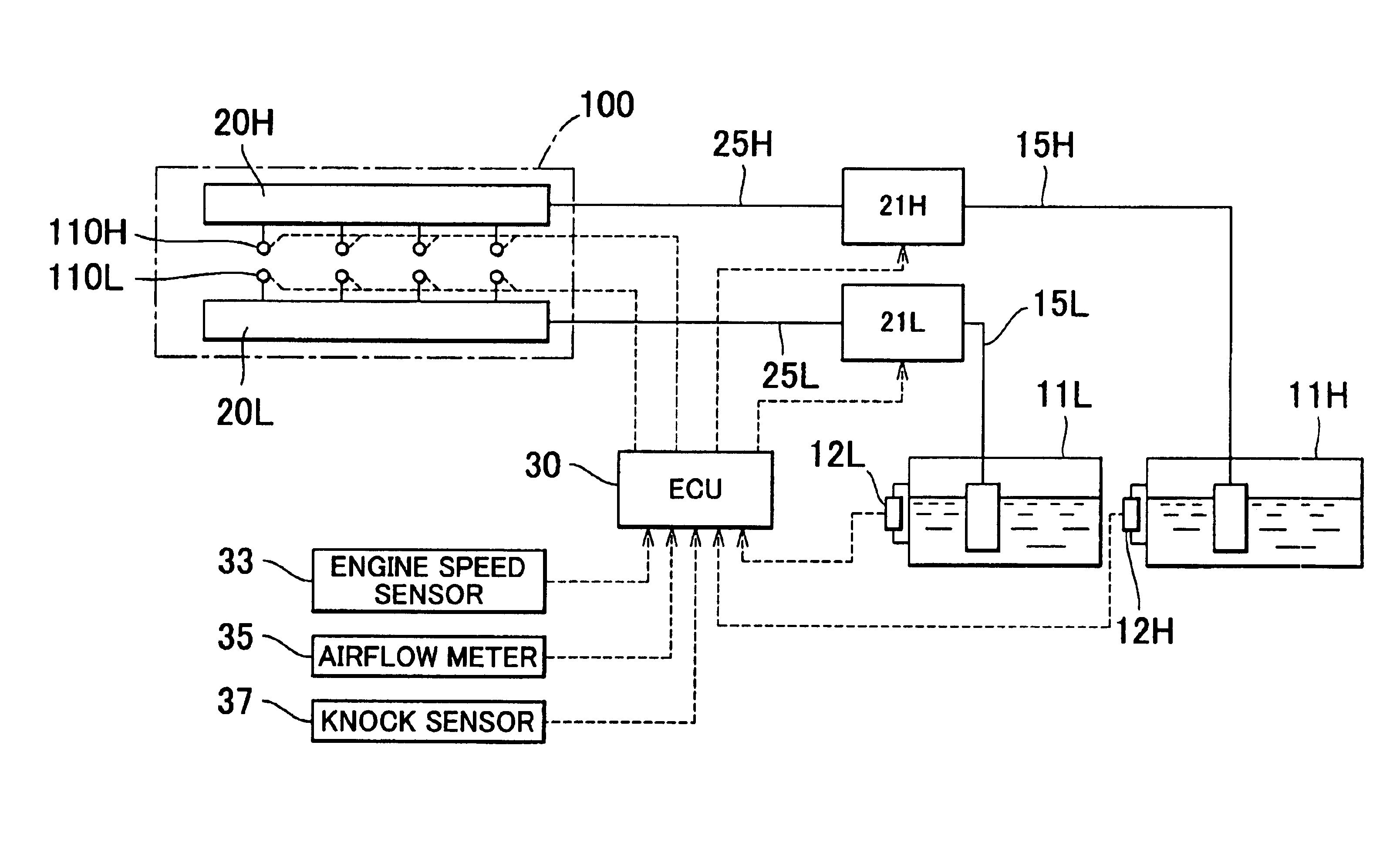

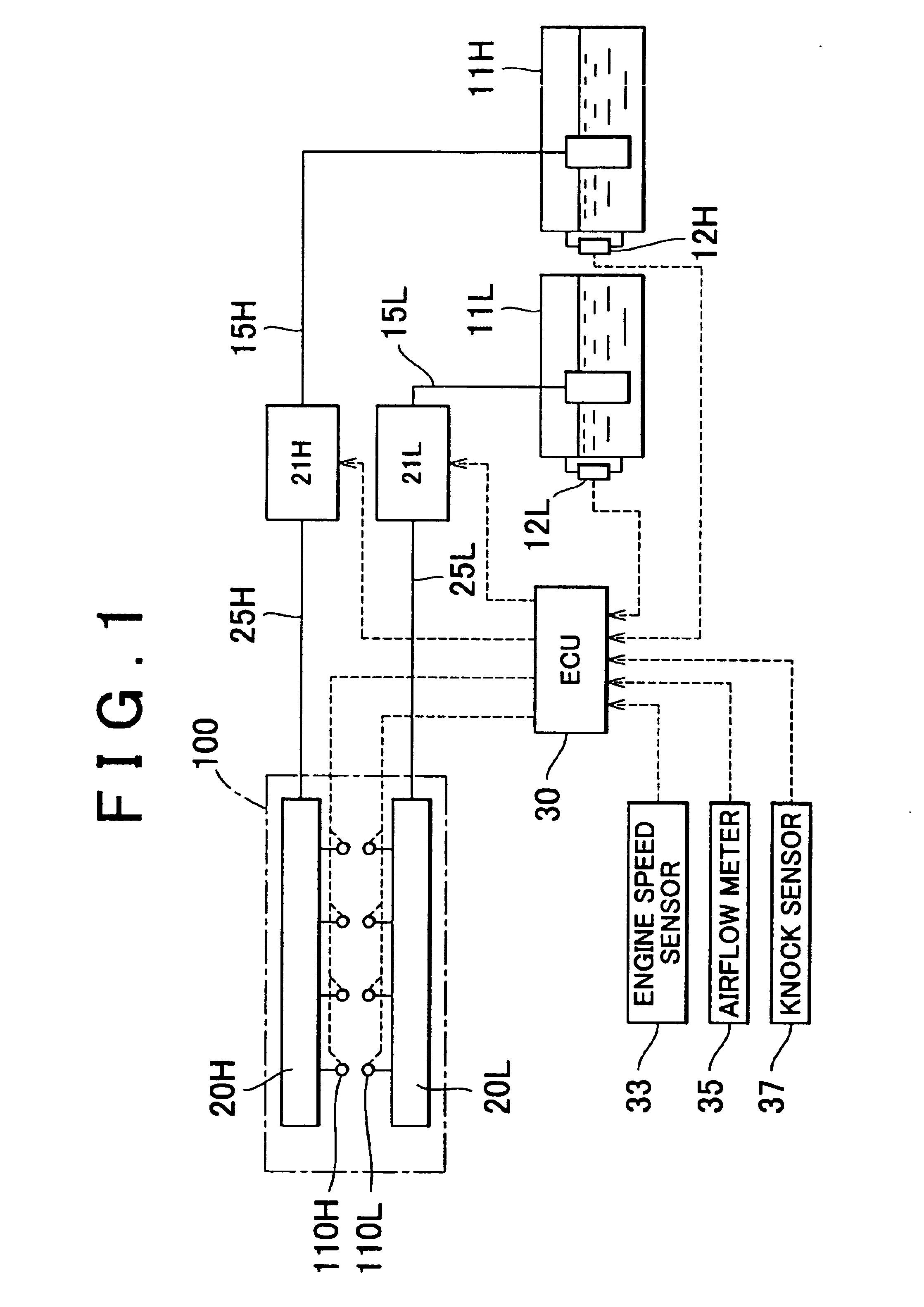

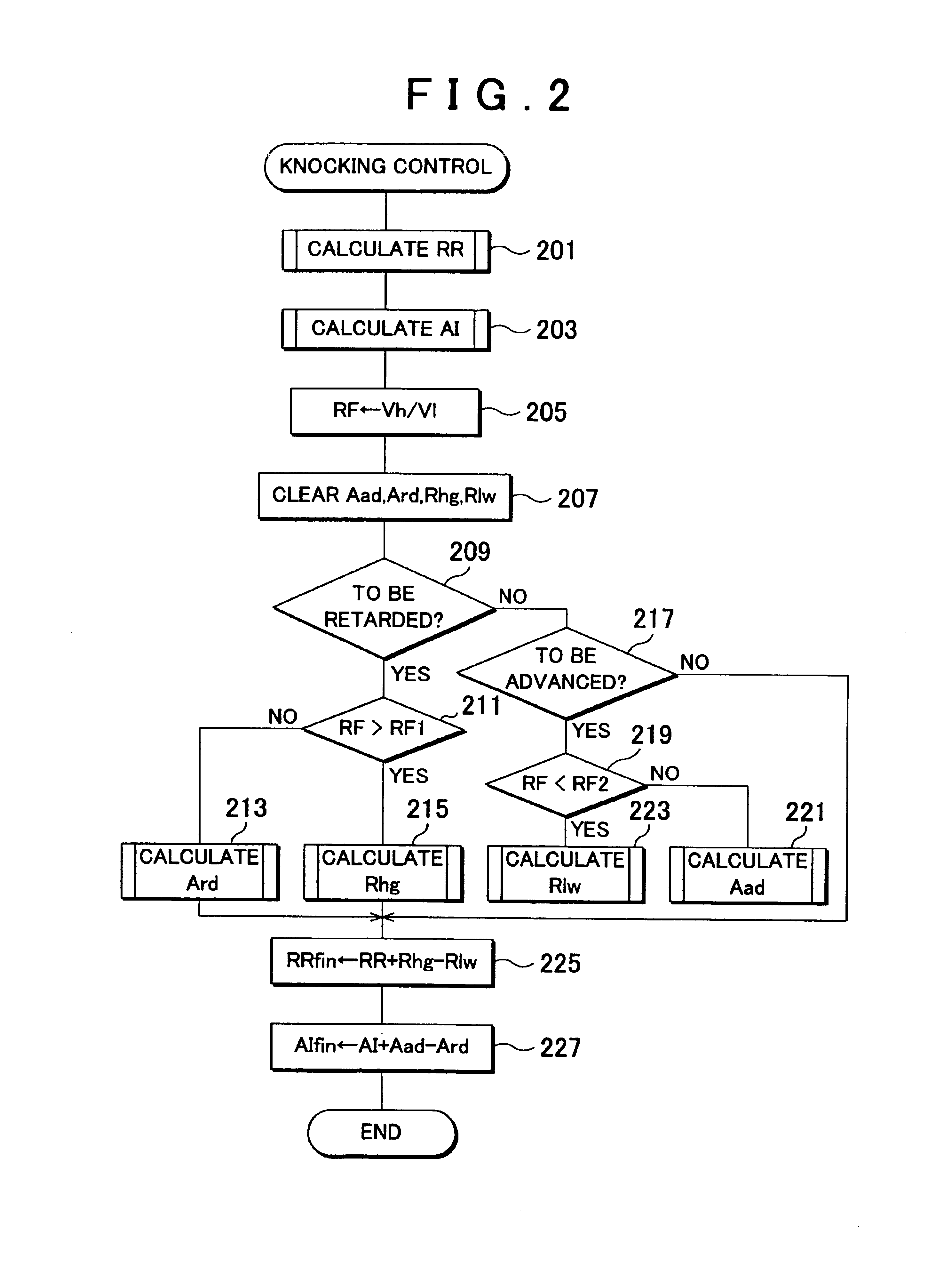

Knocking control system and method for internal combustion engine using multiple fuels

InactiveUS6951202B2Maintain balanceImprove balanceElectrical controlInternal combustion piston enginesMultifuelCombustion chamber

High octane fuel and low octane fuel are supplied into the combustion chamber of an engine from high-octane fuel tank and low octane fuel tank via a high octane fuel injector and a low octane fuel injector. During a knocking control, if the quantity of high and low octane fuels in the respective tanks has been unbalanced, the supply ratio between high octane fuel and low octane fuel is changed 1 to control a knocking occurring in the engine without changing the ignition timing.

Owner:TOYOTA JIDOSHA KK

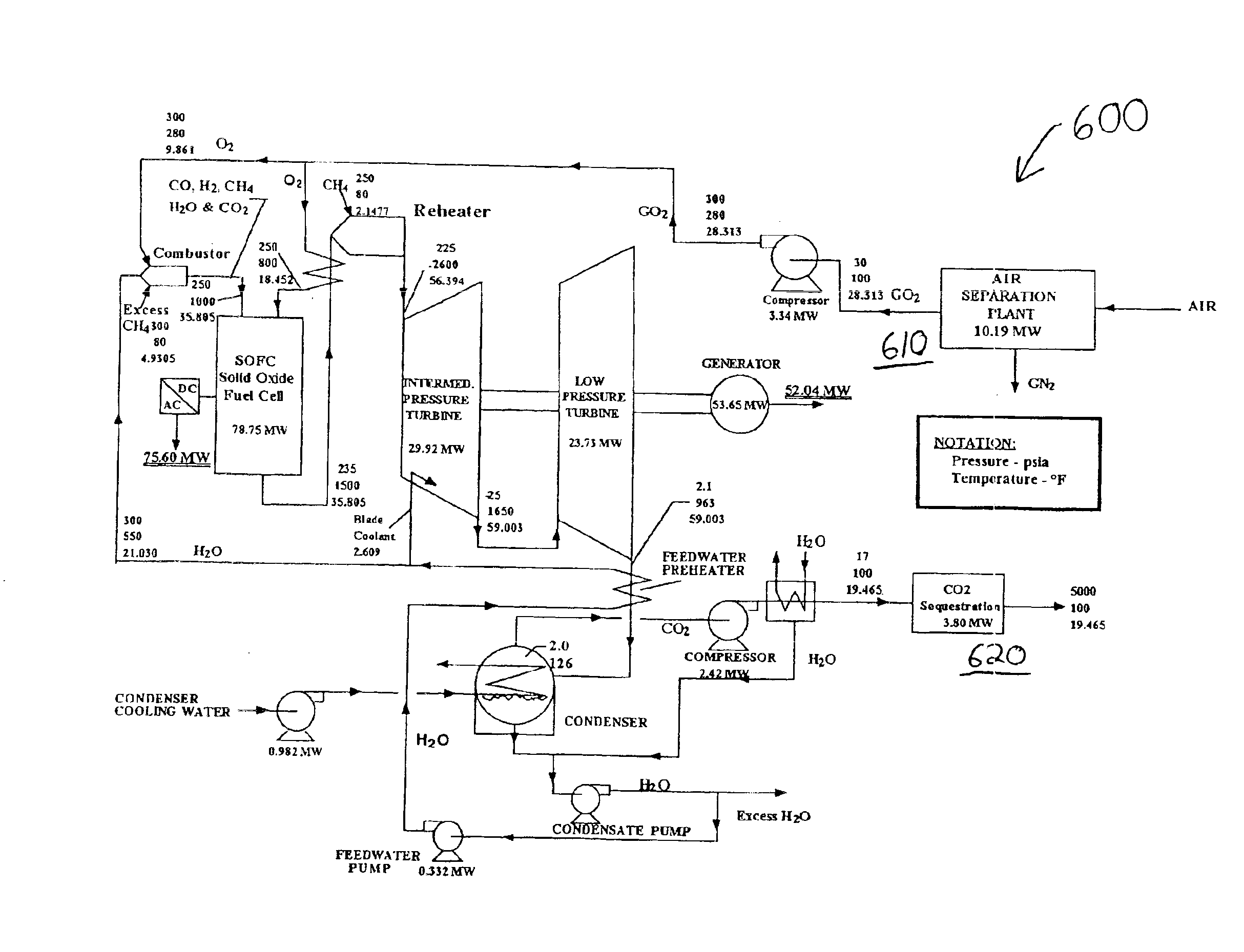

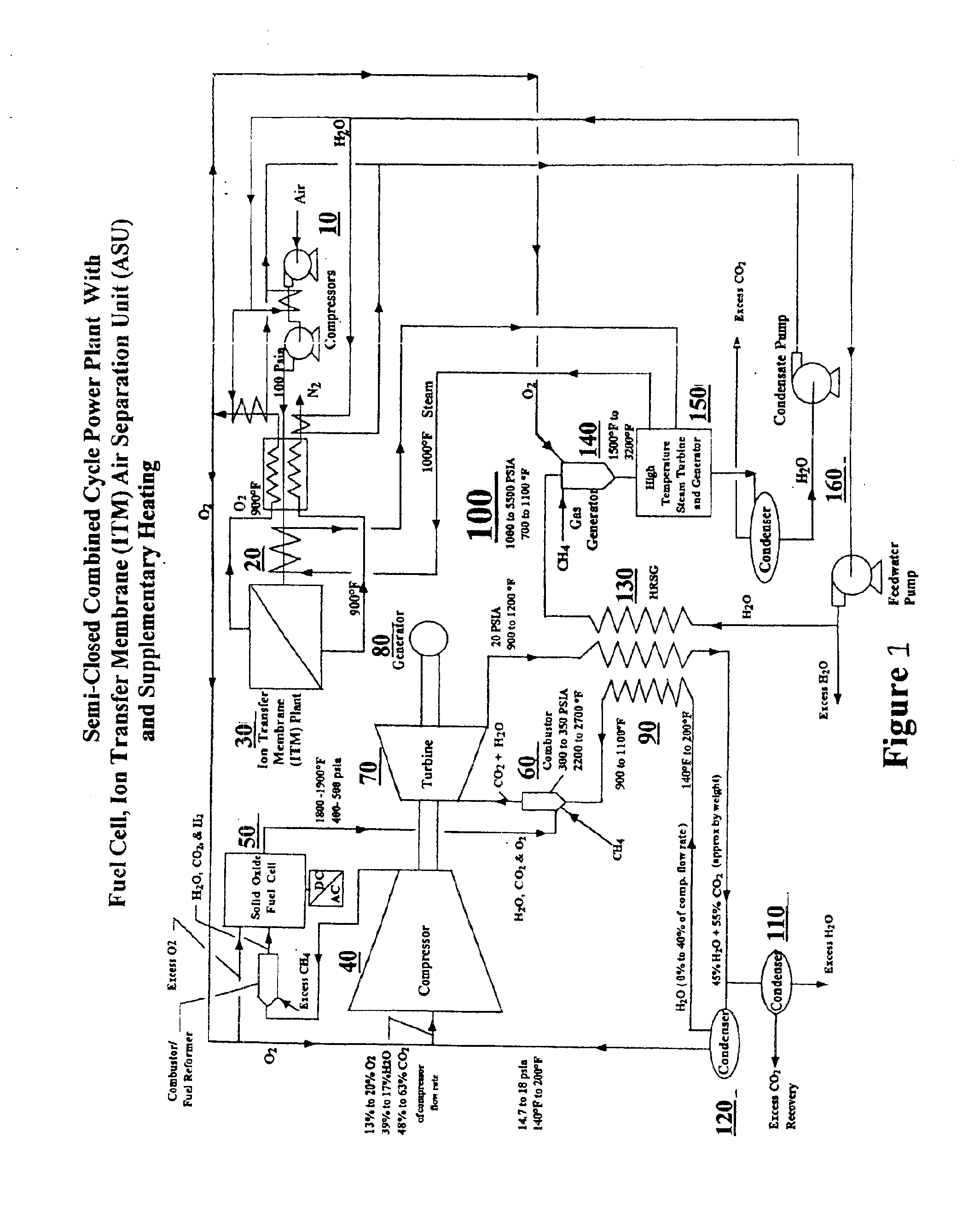

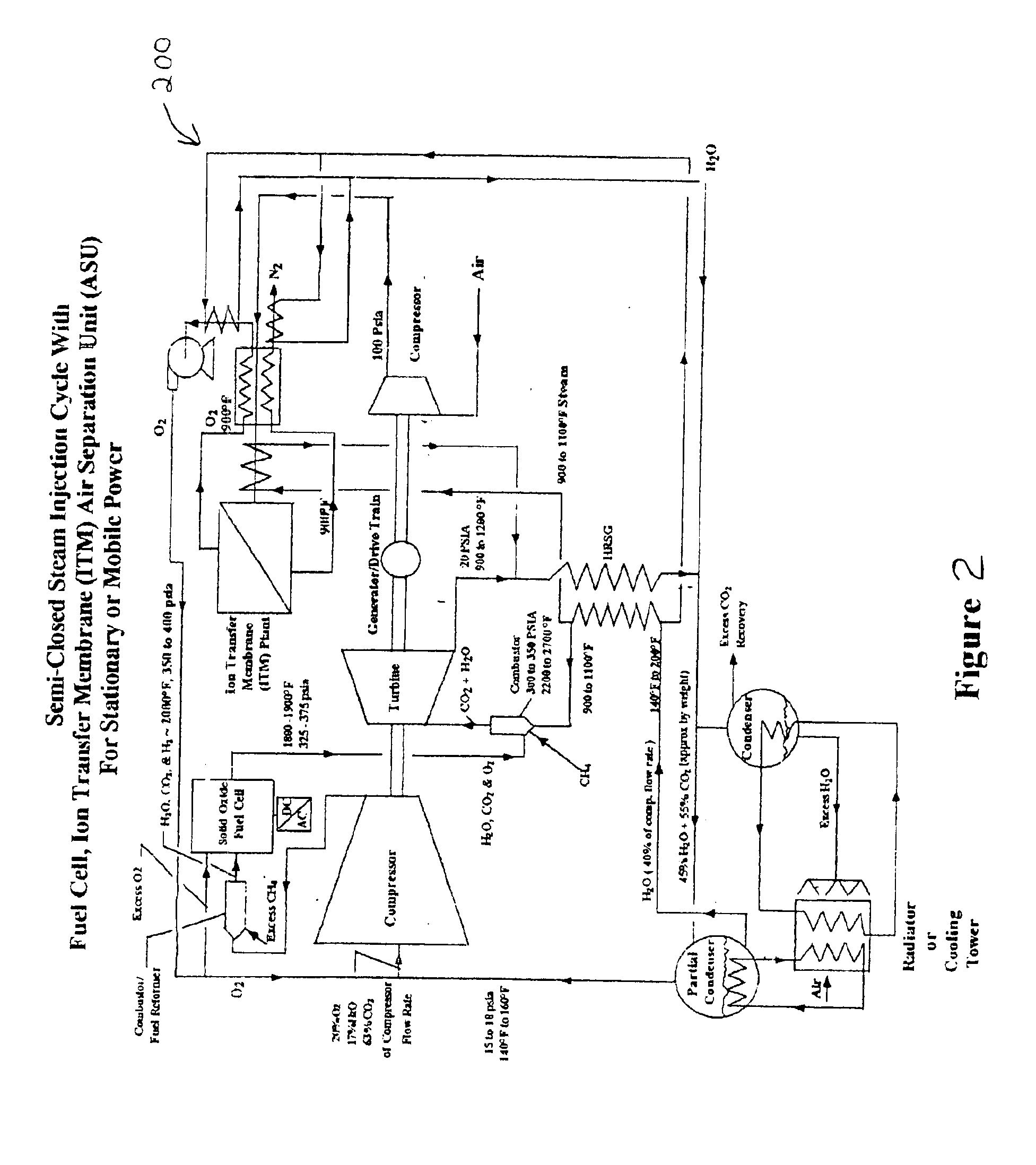

Combined fuel cell and fuel combustion power generation systems

A power generation system is provided which converts chemical energy in one or more fuels into electrical and / or mechanical power. The system includes both fuel cells to directly convert electrical energy in a fuel into electrical power and at lest one combustor and expander to generate mechanical power, optionally than converted to electrical power in a generator. Fuel cell products disclosed from the fuel cell are entered into the combustor to be heated along with products of combustion created in the combustor and expanded in the expander along with the products of combustion.

Owner:CLEAN ENERGY SYST

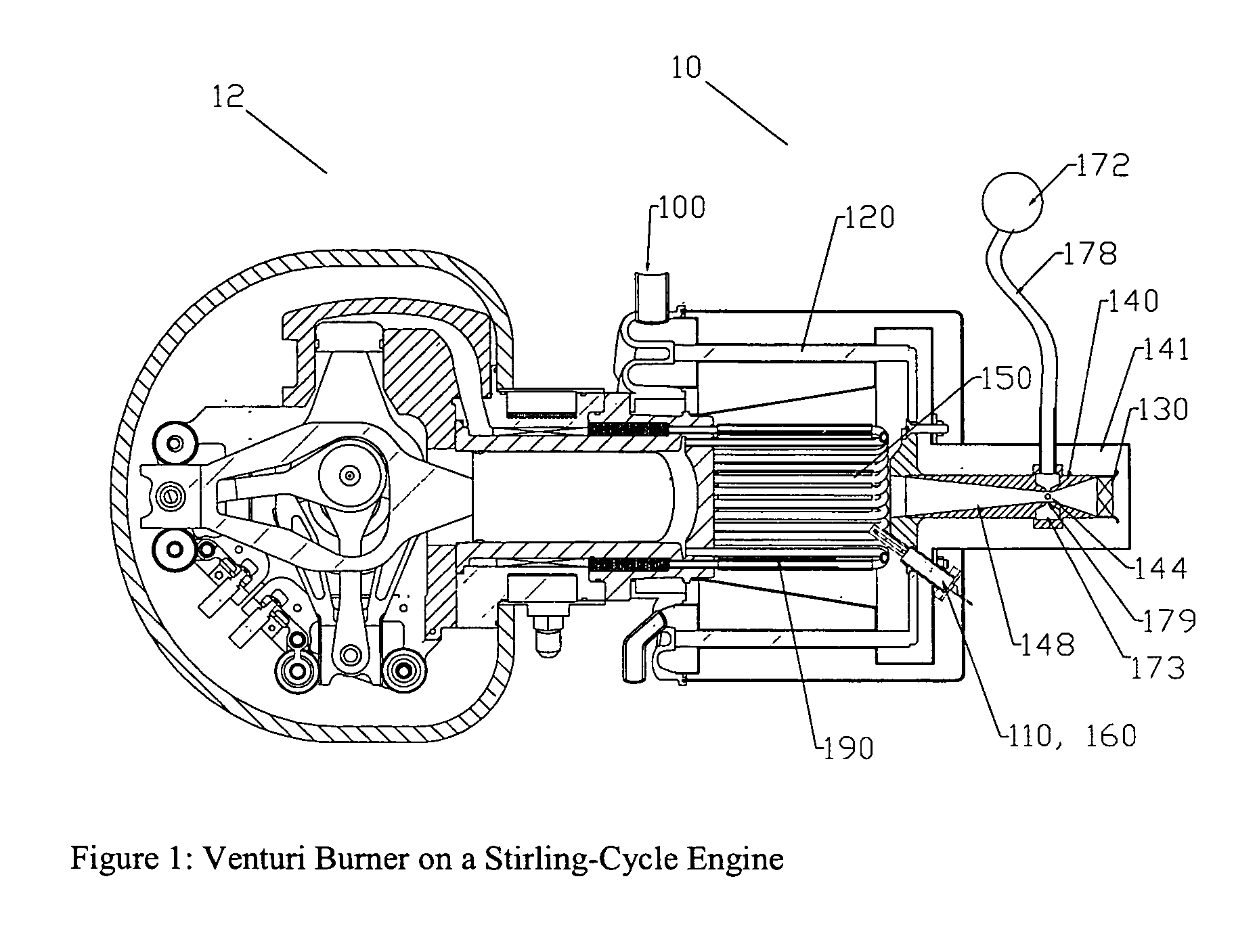

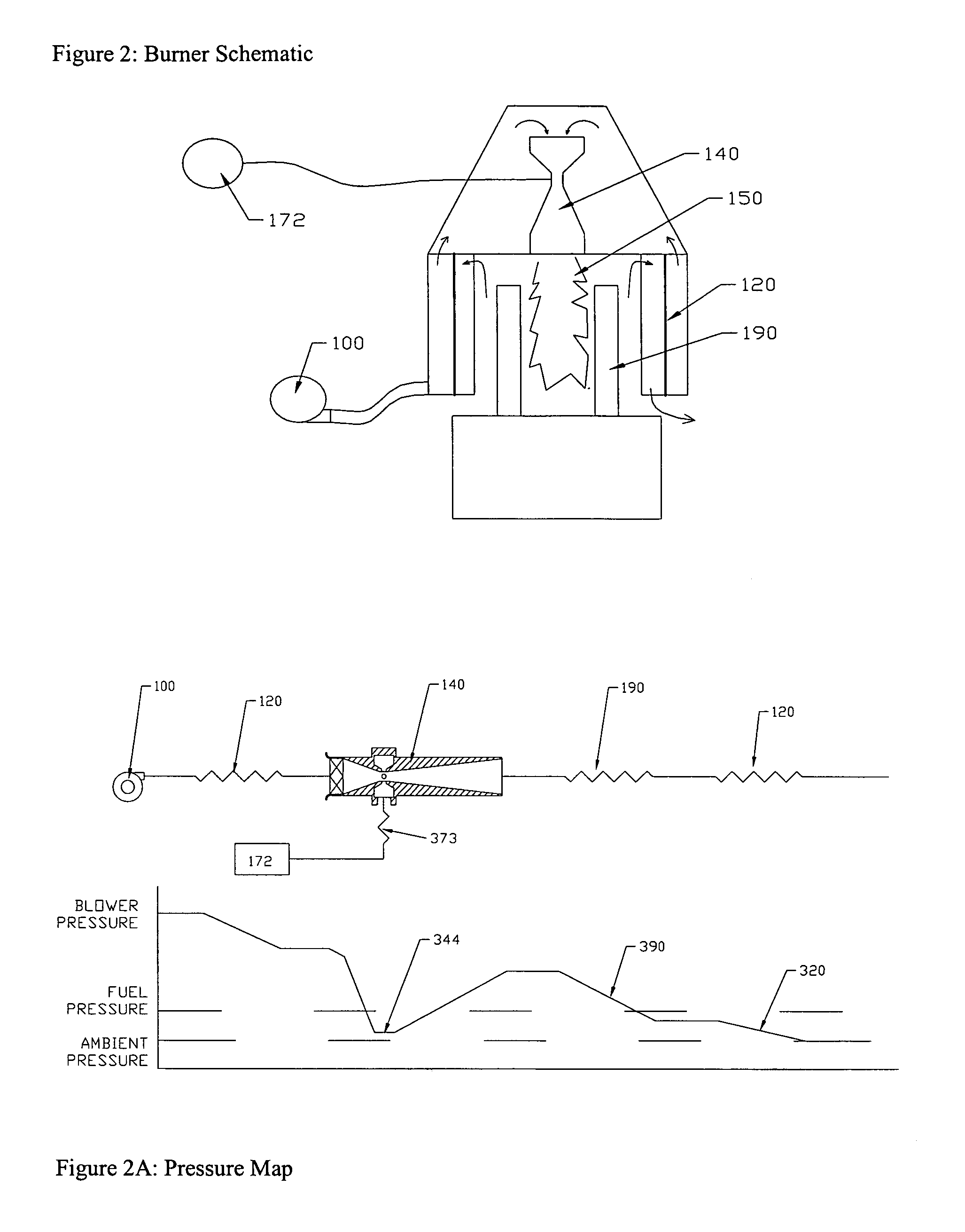

Gaseous fuel burner

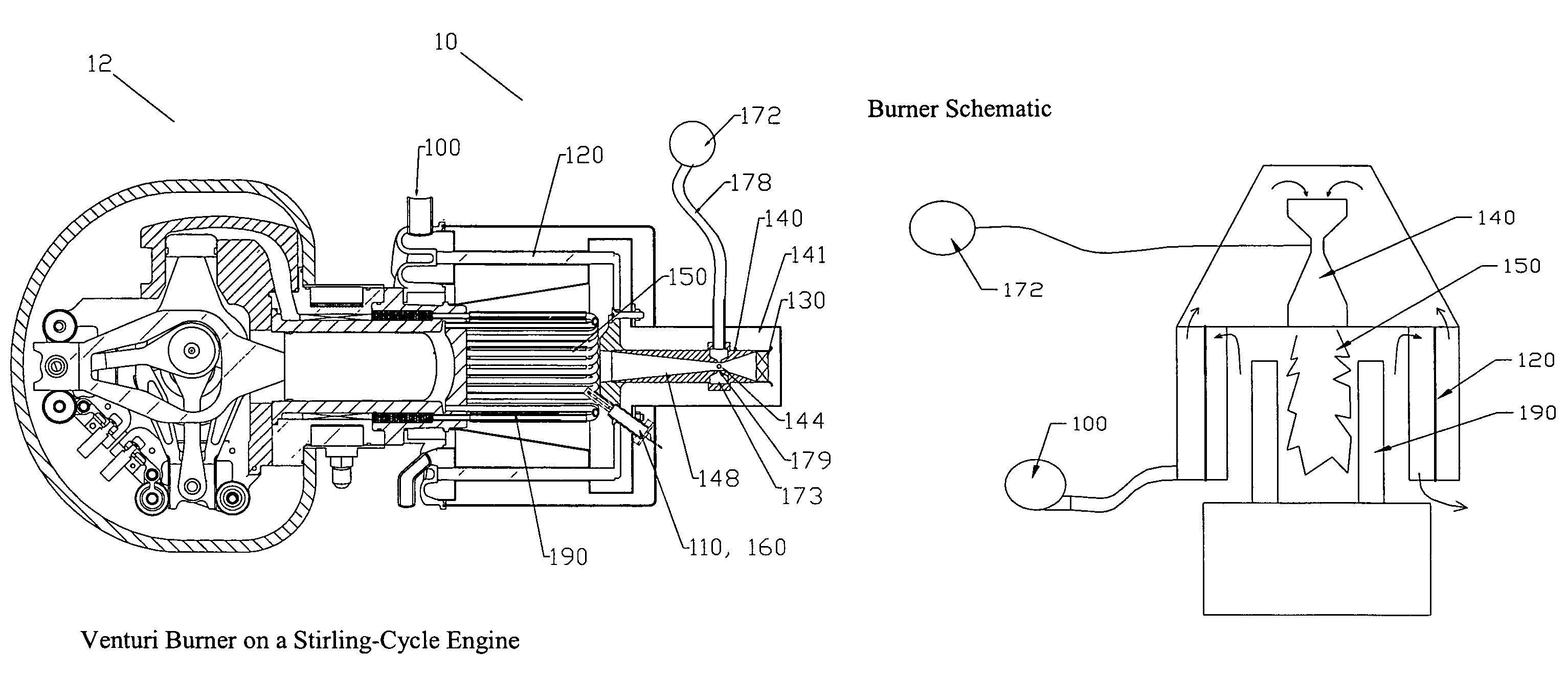

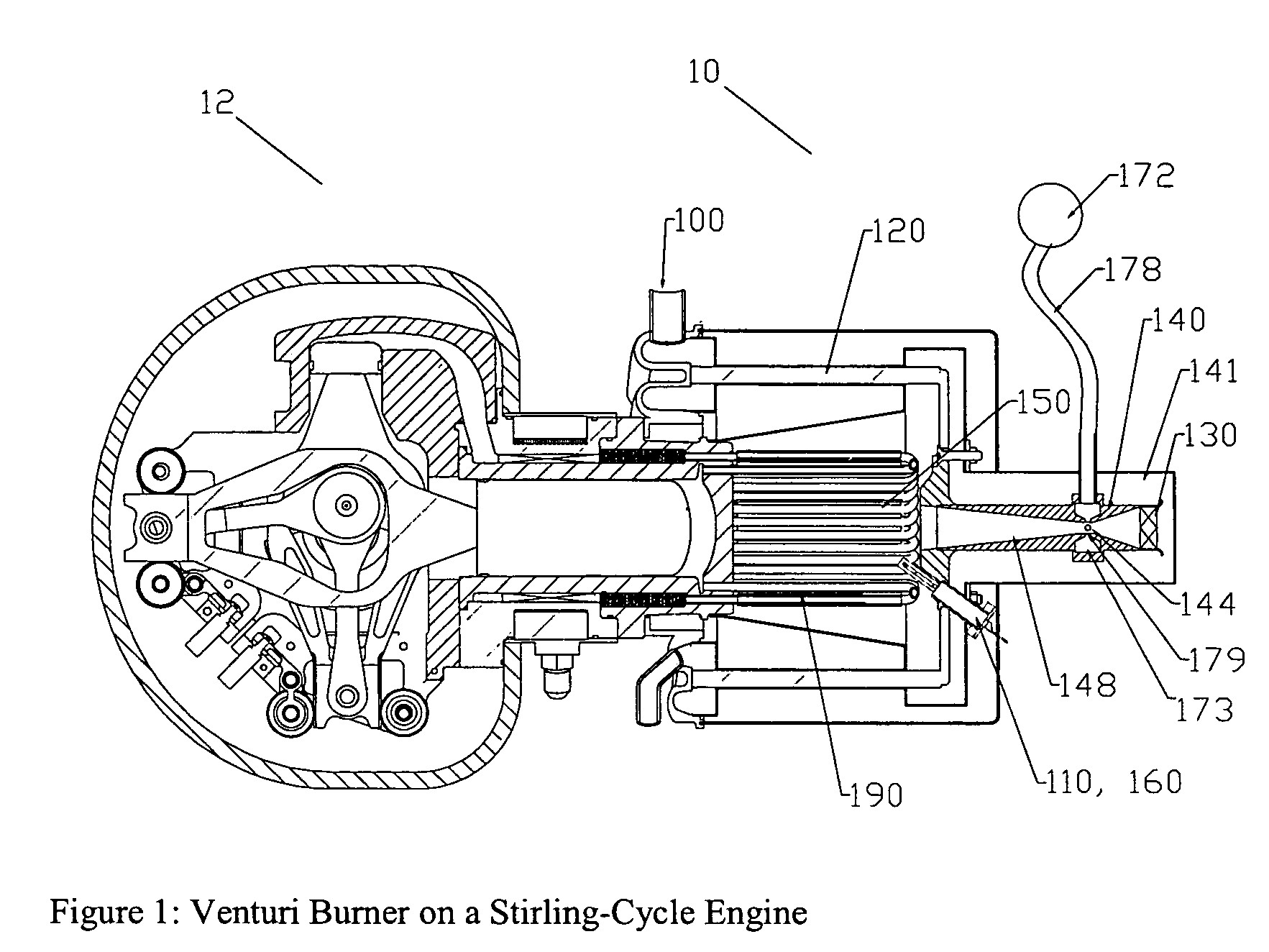

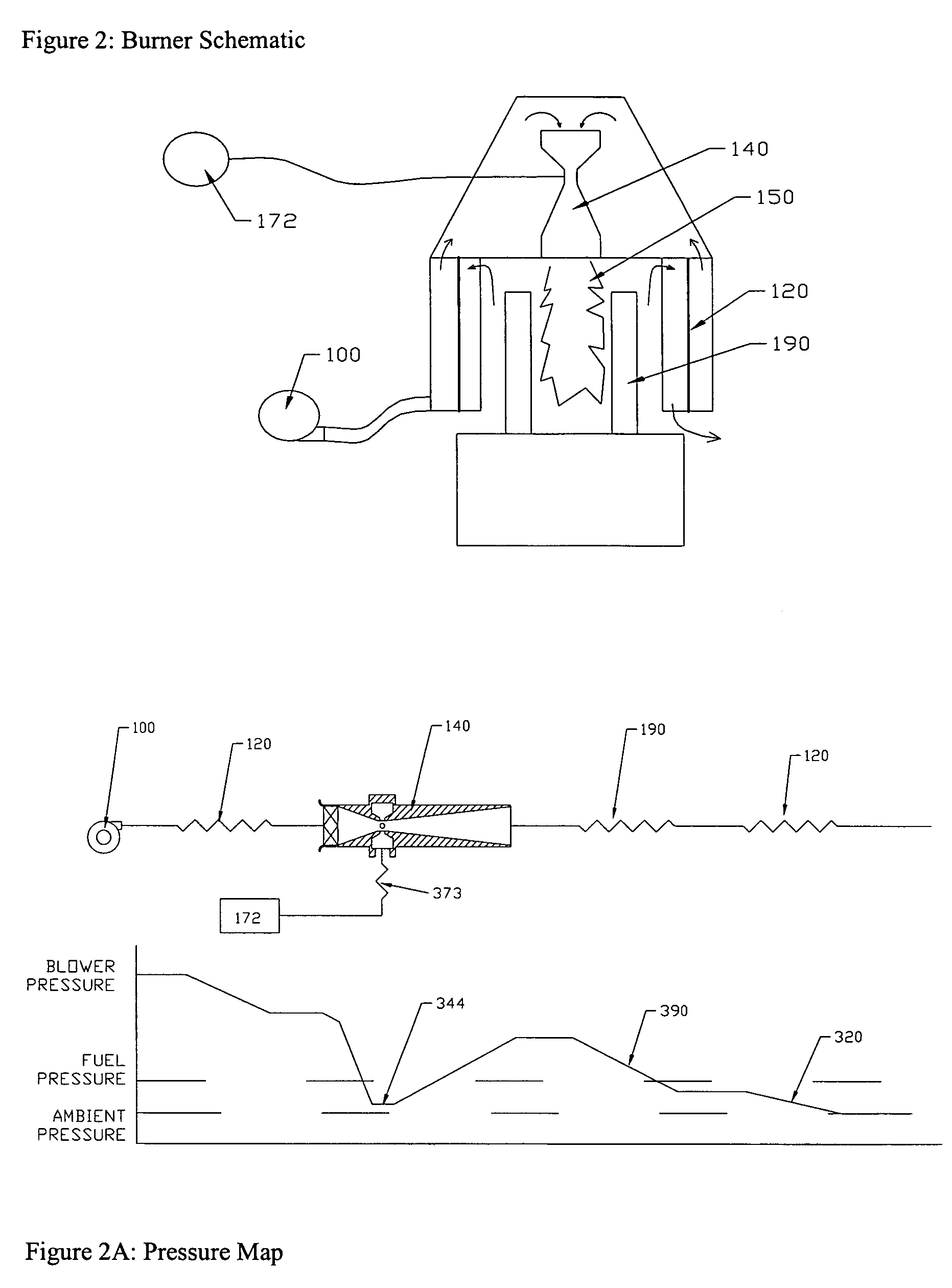

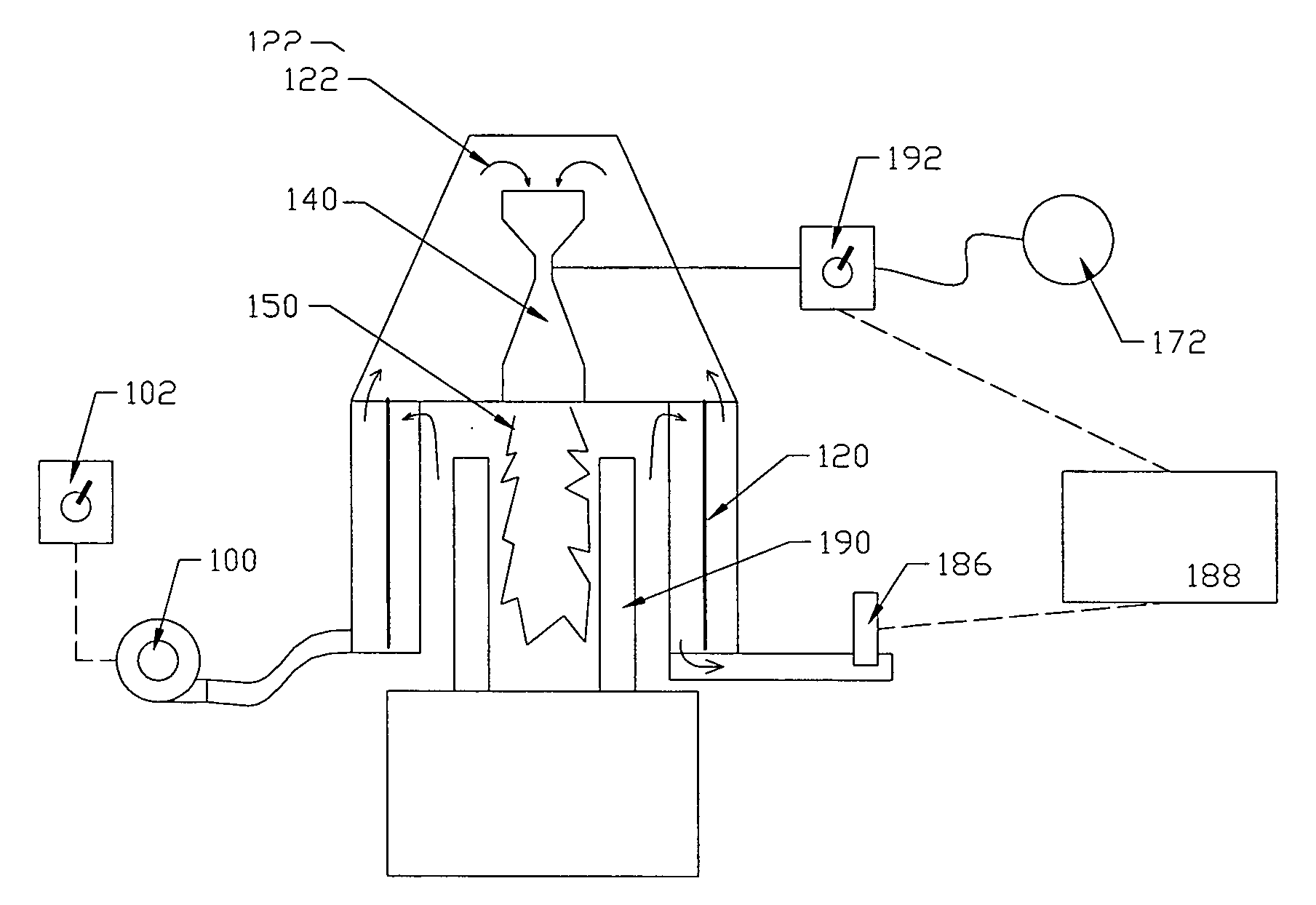

ActiveUS7934926B2Address is challengeEliminate needFuel supply regulationAir supply regulationAir velocityAutomatic control

Owner:NEW POWER CONCEPTS

Gaseous fuel burner

ActiveUS20050250062A1Address is challengeEliminate needFuel supply regulationAir supply regulationAir velocityAutomatic control

An ejector, such as a venturi, facilitates the delivery of gaseous fuel to the combustion chamber of a burner. A blower forces air through the ejector, and the air flow produces a suction that draws fuel from a fuel inlet to produce a fuel-air mixture. The amount of fuel drawn from the fuel inlet is a function of the air flow such that a substantially constant fuel-air ratio is obtained over a range of air flow rates and temperatures without the need for a separate high-pressure fuel pump. The fuel-air mixture may be provided to a combustion chamber for combustion. Air from the blower may be pre-heated prior to entering the ejector, for example, using a heat exchanger that recovers some of the heat from the combusted fuel-air mixture. Air flow through the ejector may be conditioned, for example, by a swirler, to produce a tangential air flow that can increase fuel flow by increasing air velocity across the fuel inlet and / or produce a swirl-stabilized flame in the combustion chamber. The combusted fuel-air mixture may be provided to a thermal load, such as an external combustion engine. Blower speed may be controlled manually or automatically to control power output. Fuel flow to the ejector can be controlled manually or automatically to control fuel-air ratio. The burner can be configured to operate with multiple fuel types, for example, using a fuel selector with fixed or variable restrictors.

Owner:NEW POWER CONCEPTS

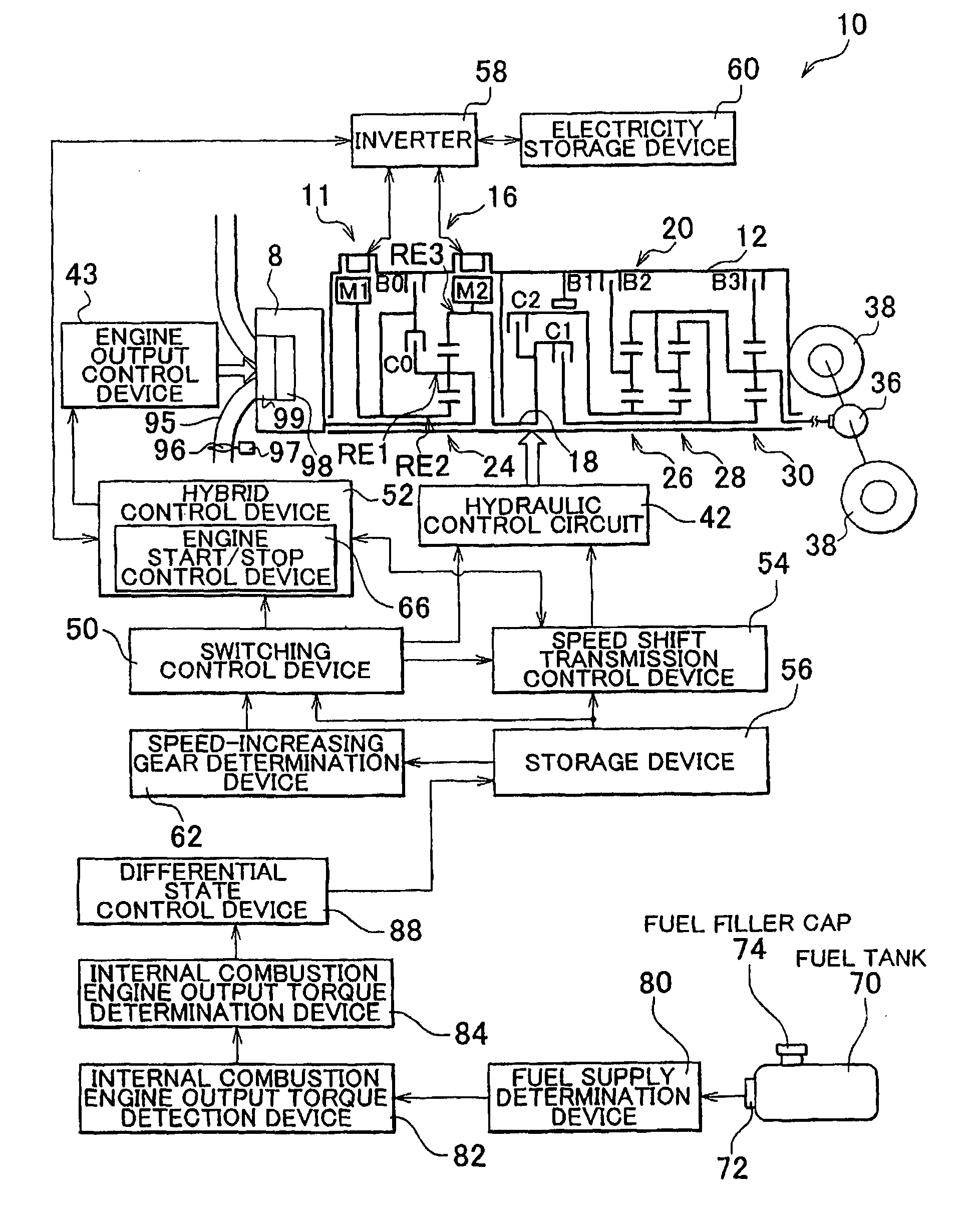

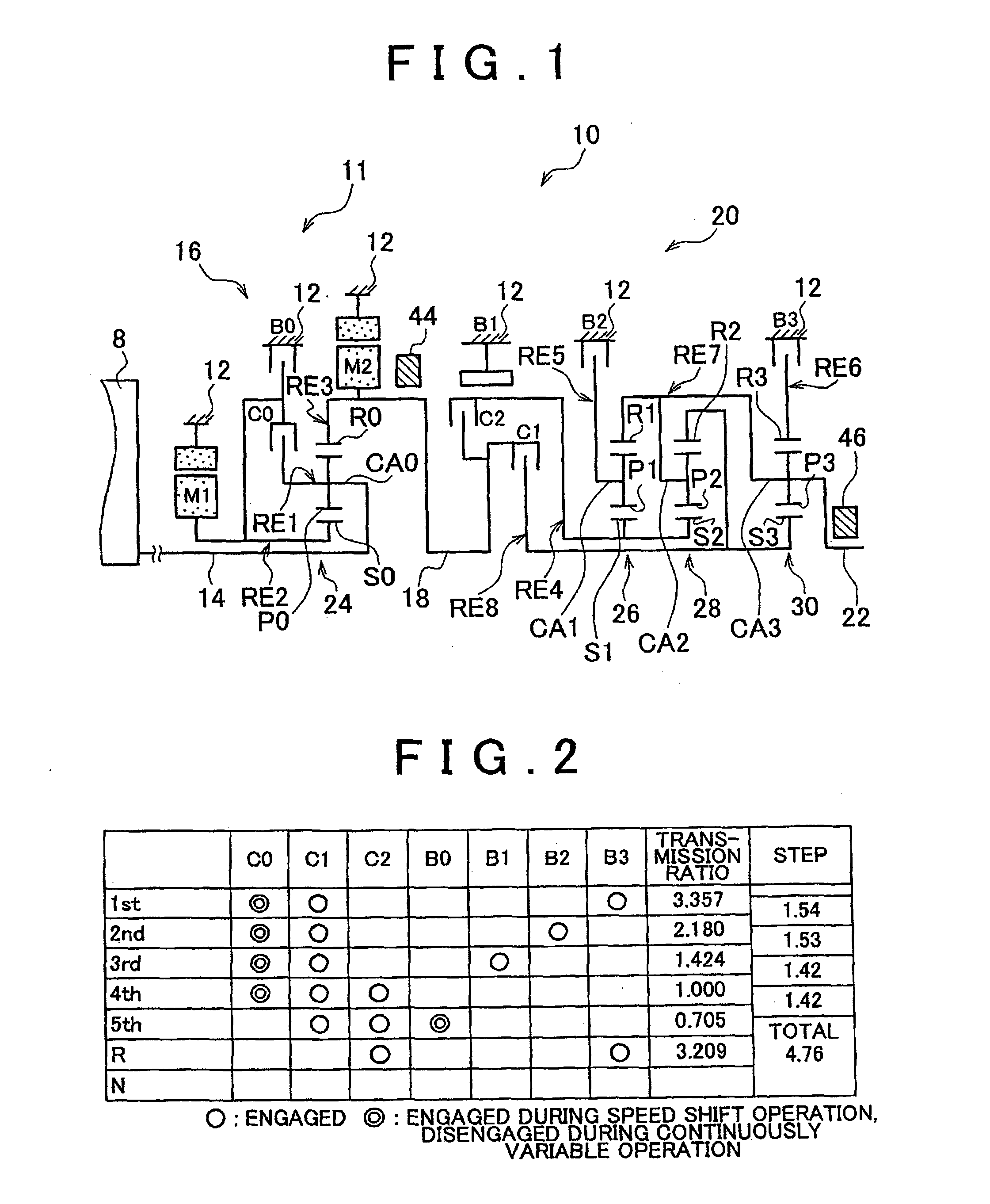

Control device for power transmission device for vehicle

When an engine is driven on a different type of fuel (for example, ethanol-containing fuel) from a reference fuel (for example, gasoline) and the engine torque is thus greater than that produced when the engine is driven on the reference fuel, a differential state control device expands a non-differential range compared to that at the time when the reference fuel is used. Thus, in the case where a plurality of types of fuel including the reference fuel are supplied to the engine, the advantage of switching a power distribution mechanism between a differential enabled state and a non-differential state can be fully utilized in correspondence with engine torque characteristics which may vary in accordance with the type of fuel for the engine. As a result, the fuel consumption rate can be reduced in correspondence with the plurality of types of fuel supplied to the engine, for example.

Owner:TOYOTA JIDOSHA KK

Multifuel storage, metering and ignition system

A system for safe storage and efficient utilization of a variety of fuel selections that range in composition and phase from cryogenic mixtures of solids and liquids to elevated temperature gases is provided for unique applications with various types of heat engines and fuel cells including hybridized combinations.

Owner:ADVANCED GREEN INNOVATIONS LLC +1

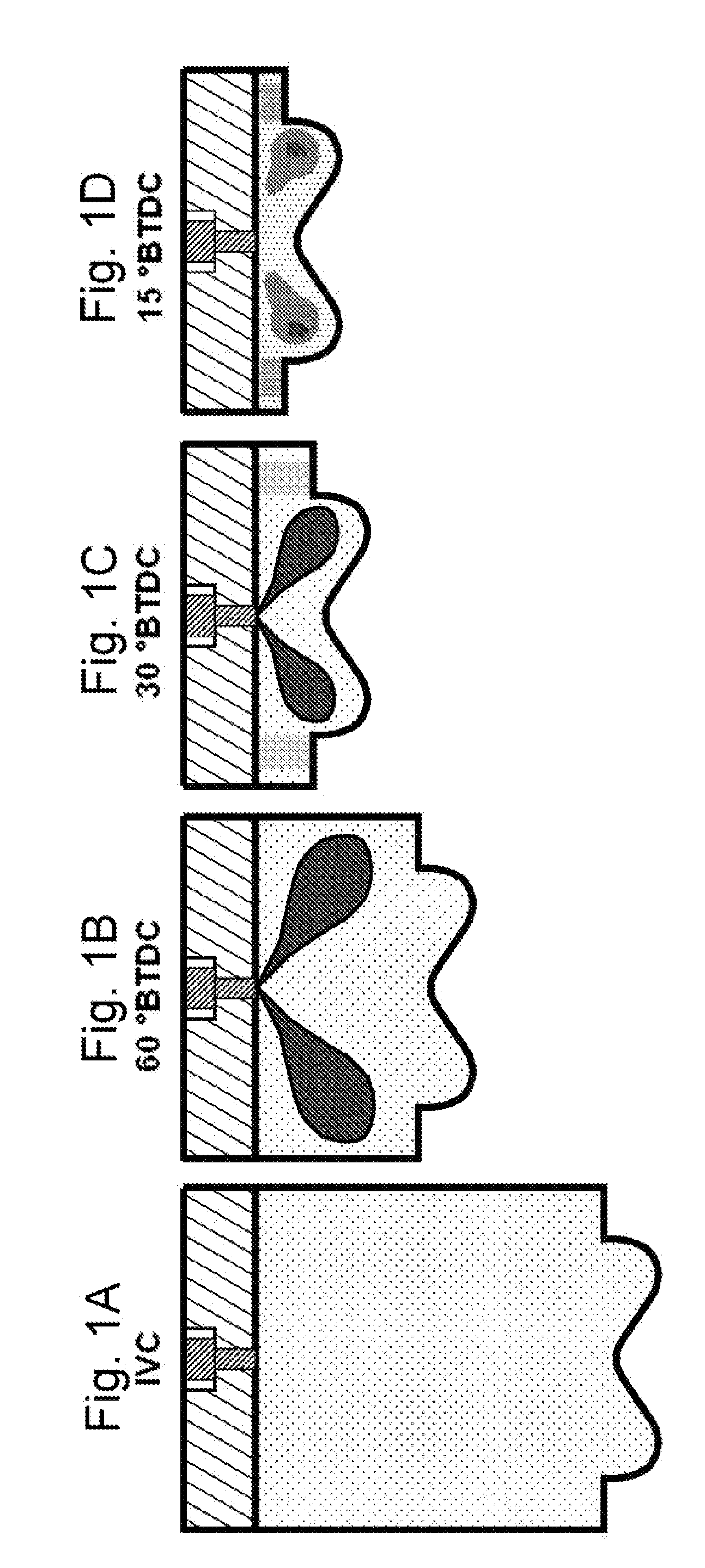

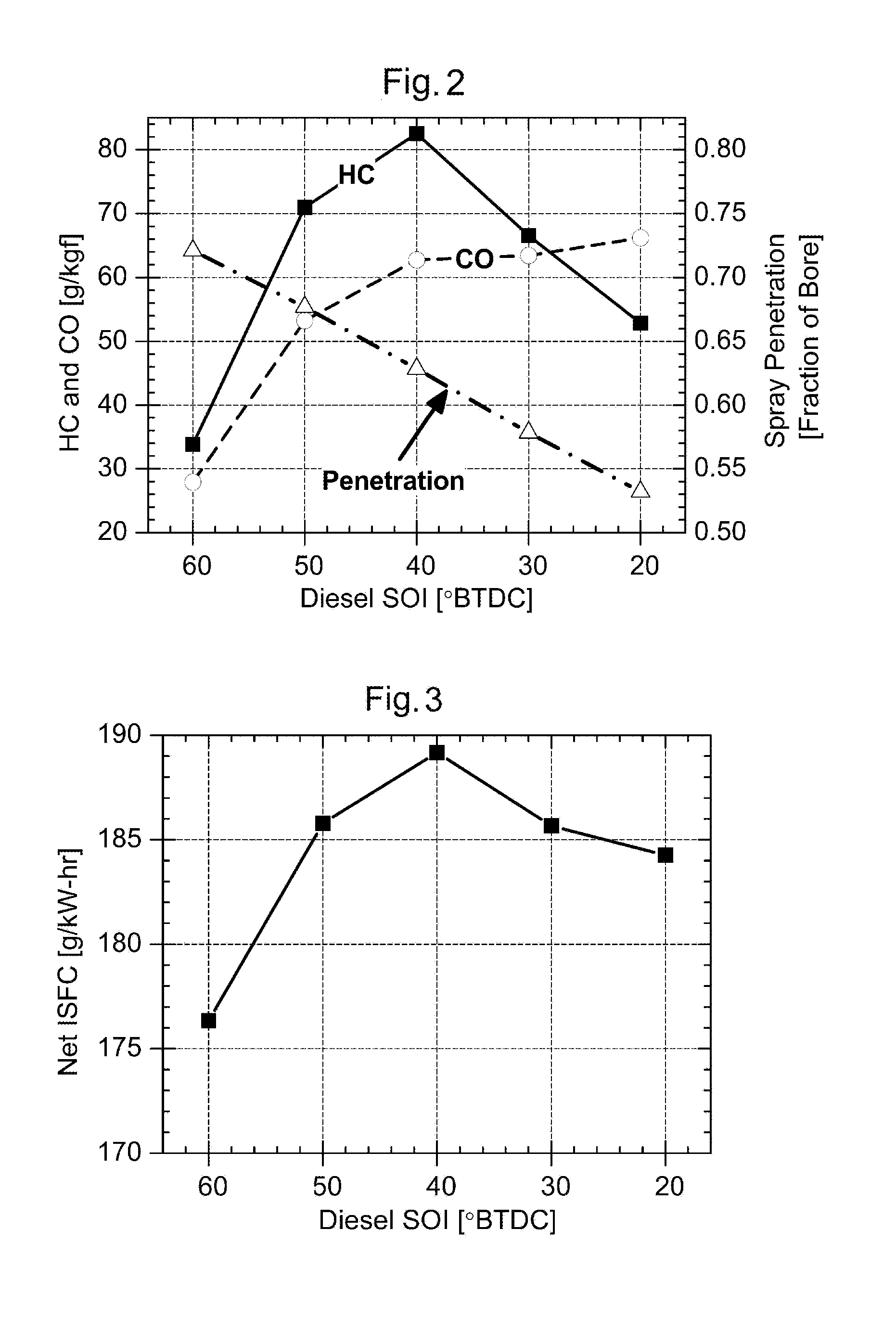

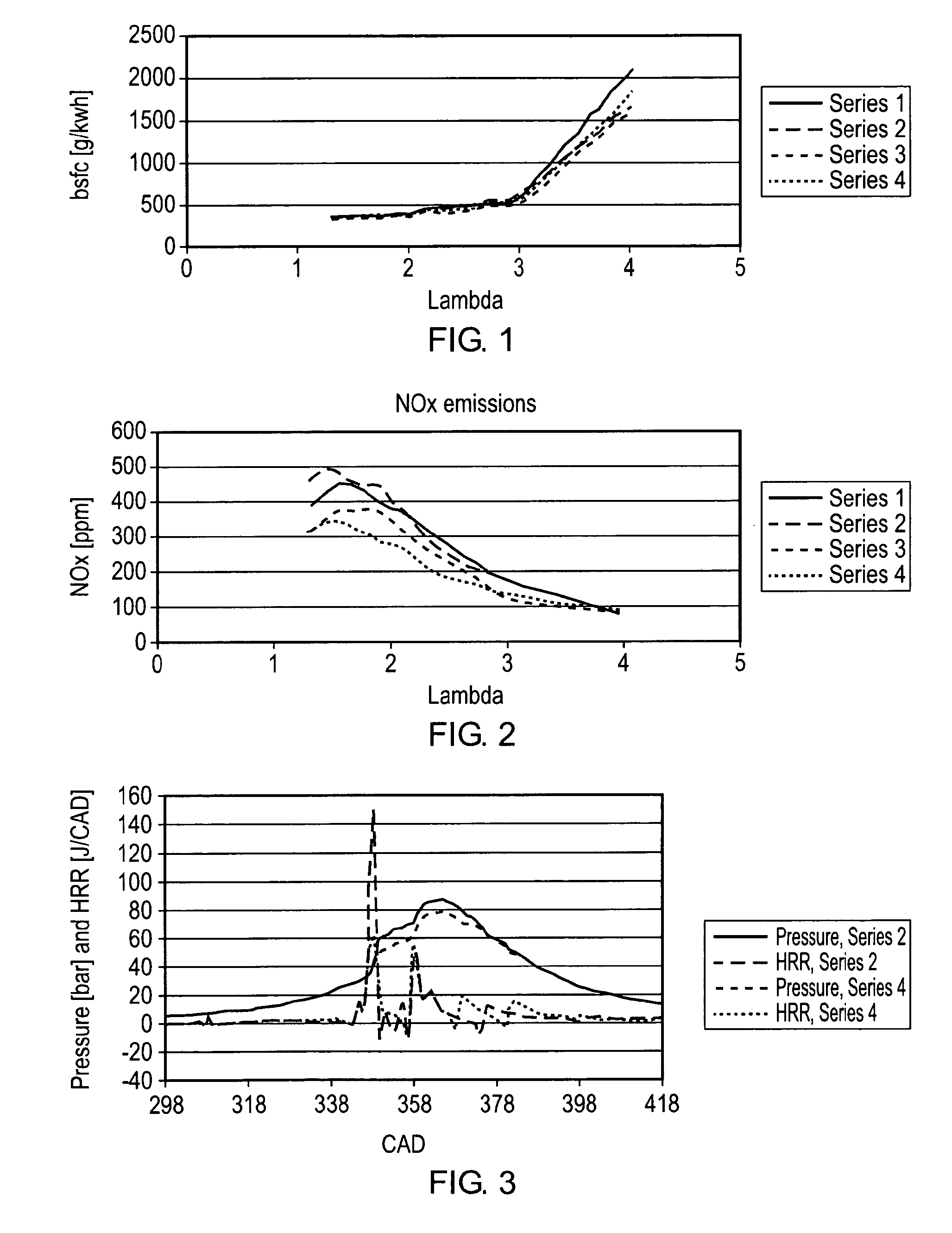

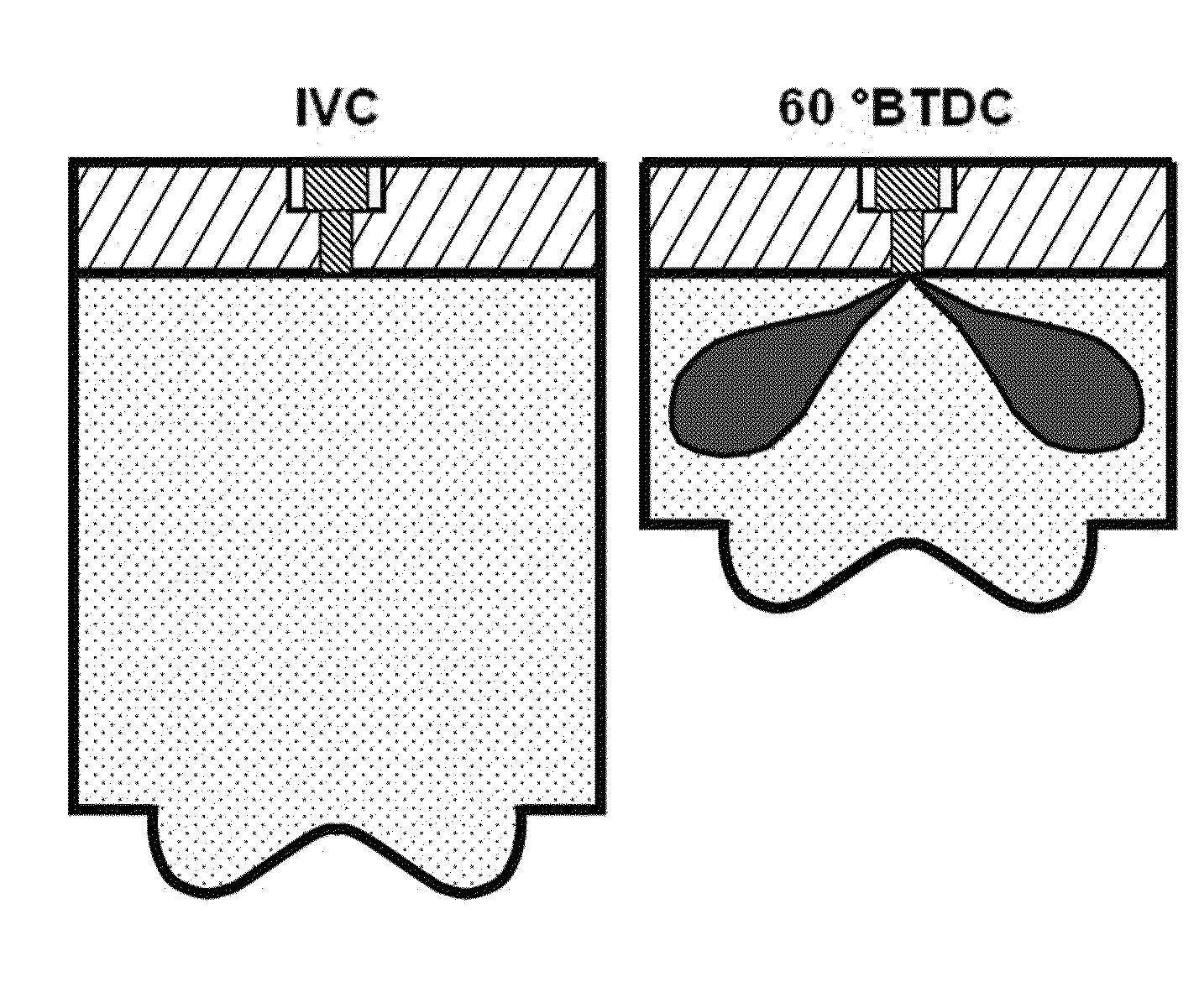

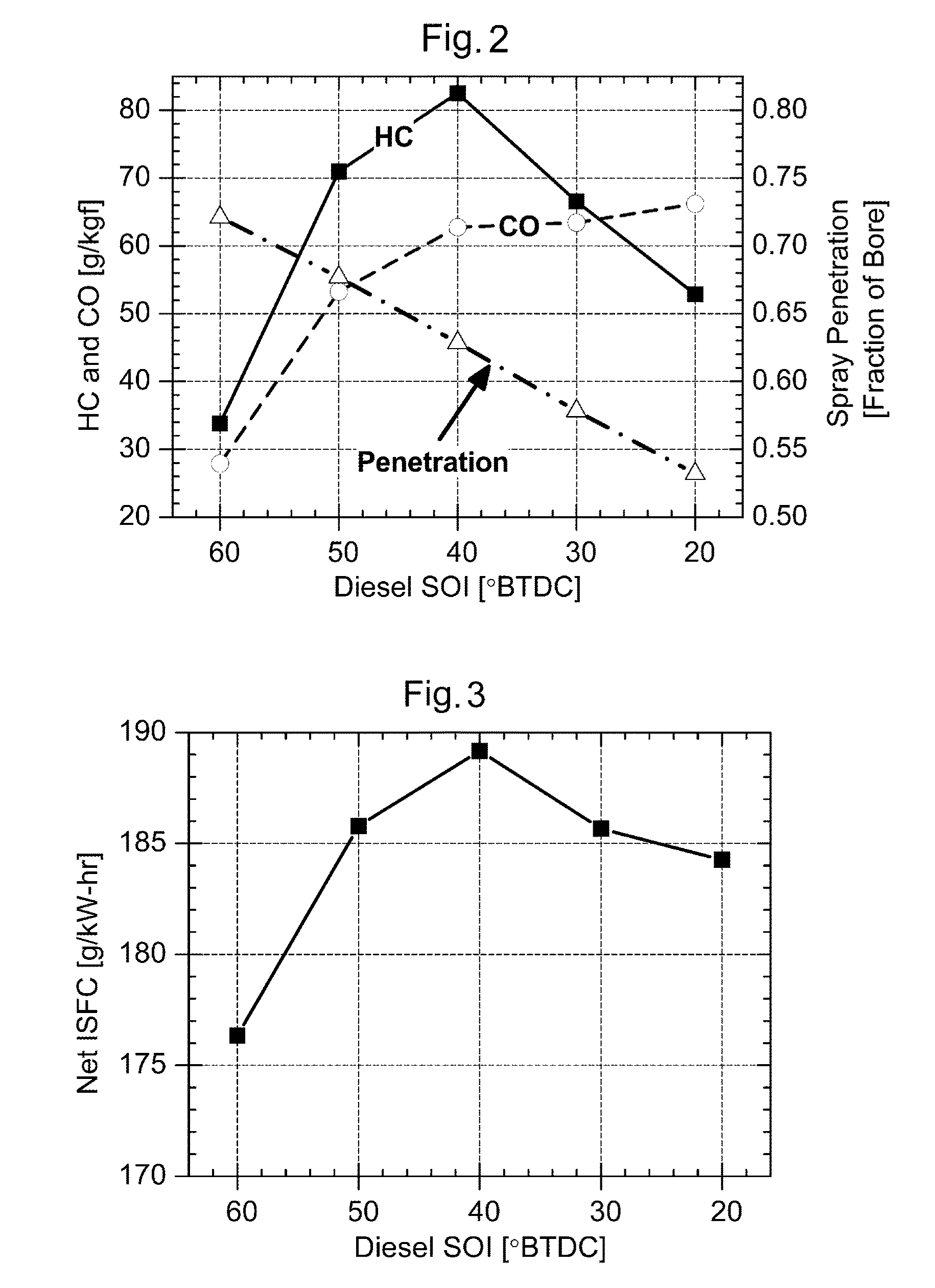

Engine combustion control via fuel reactivity stratification

ActiveUS20110192367A1High and low reactivityConvenience to workElectrical controlInternal combustion piston enginesMultifuelCombustion chamber

A compression ignition engine uses two or more fuel charges having two or more reactivities to control the timing and duration of combustion. In a preferred implementation, a lower-reactivity fuel charge is injected or otherwise introduced into the combustion chamber, preferably sufficiently early that it becomes at least substantially homogeneously dispersed within the chamber before a subsequent injection is made. One or more subsequent injections of higher-reactivity fuel charges are then made, and these preferably distribute the higher-reactivity matter within the lower-reactivity chamber space such that combustion begins in the higher-reactivity regions, and with the lower-reactivity regions following thereafter. By appropriately choosing the reactivities of the charges, their relative amounts, and their timing, combustion can be tailored to achieve optimal power output (and thus fuel efficiency), at controlled temperatures (and thus controlled NOx), and with controlled equivalence ratios (and thus controlled soot).

Owner:WISCONSIN ALUMNI RES FOUND

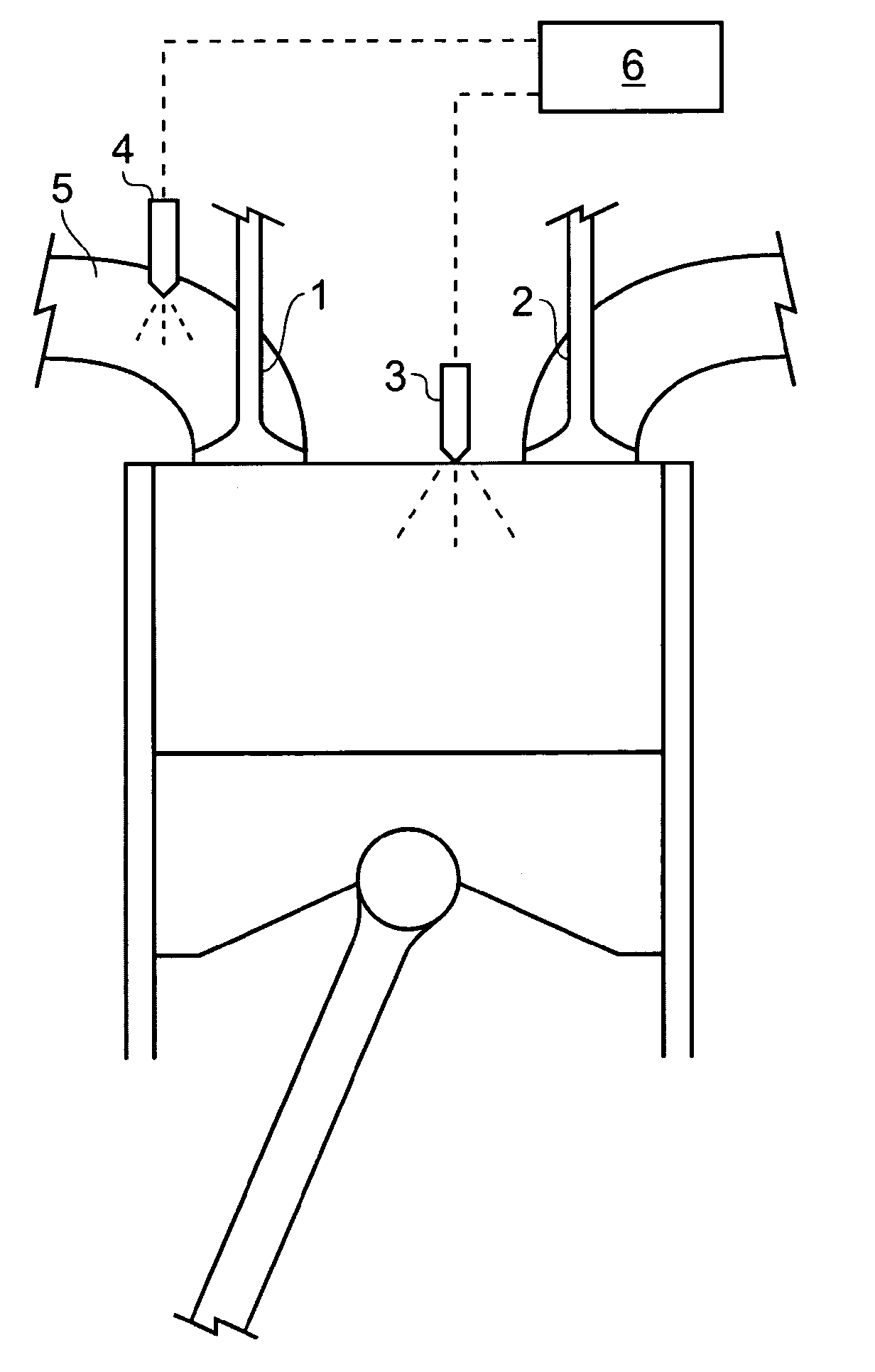

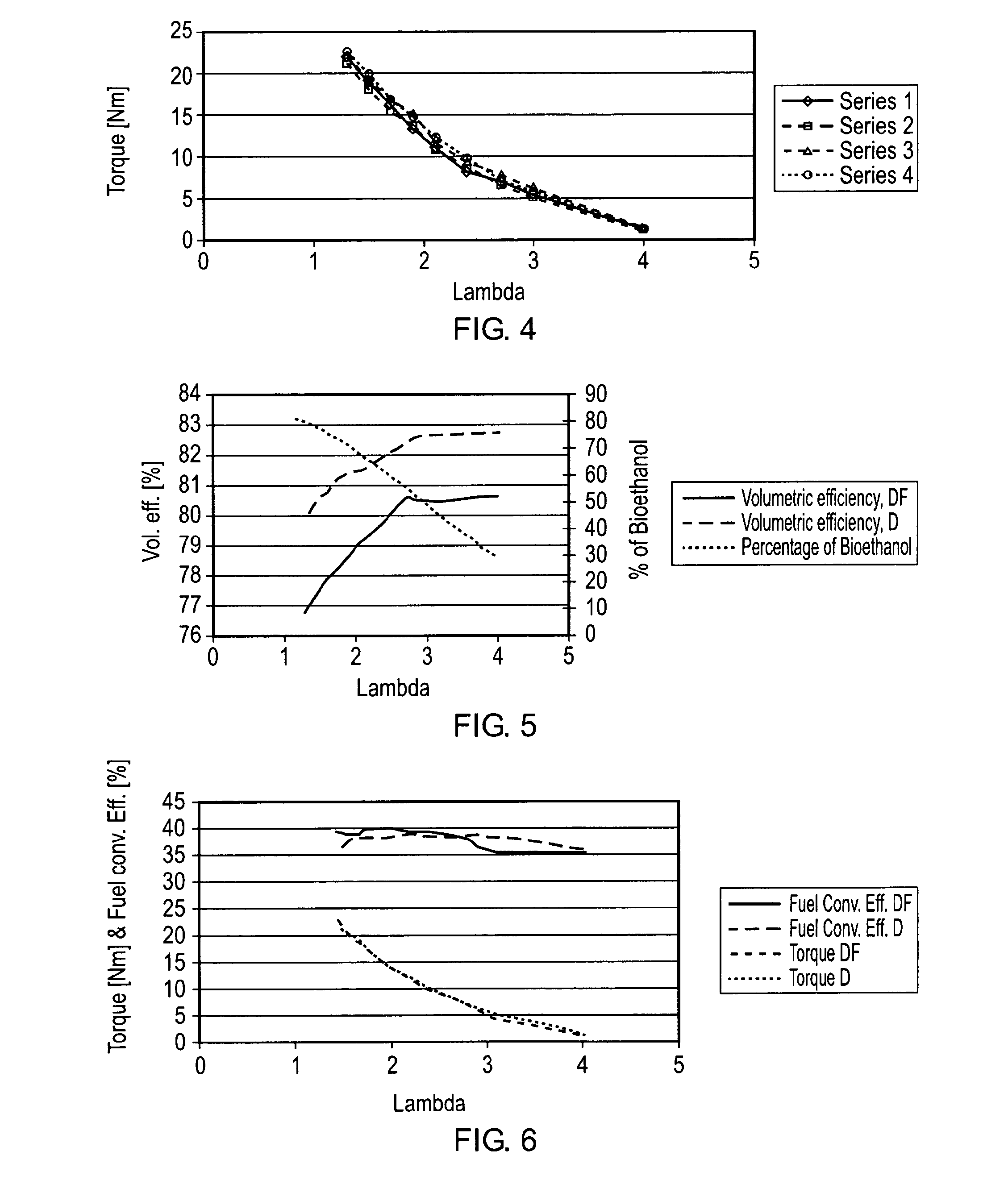

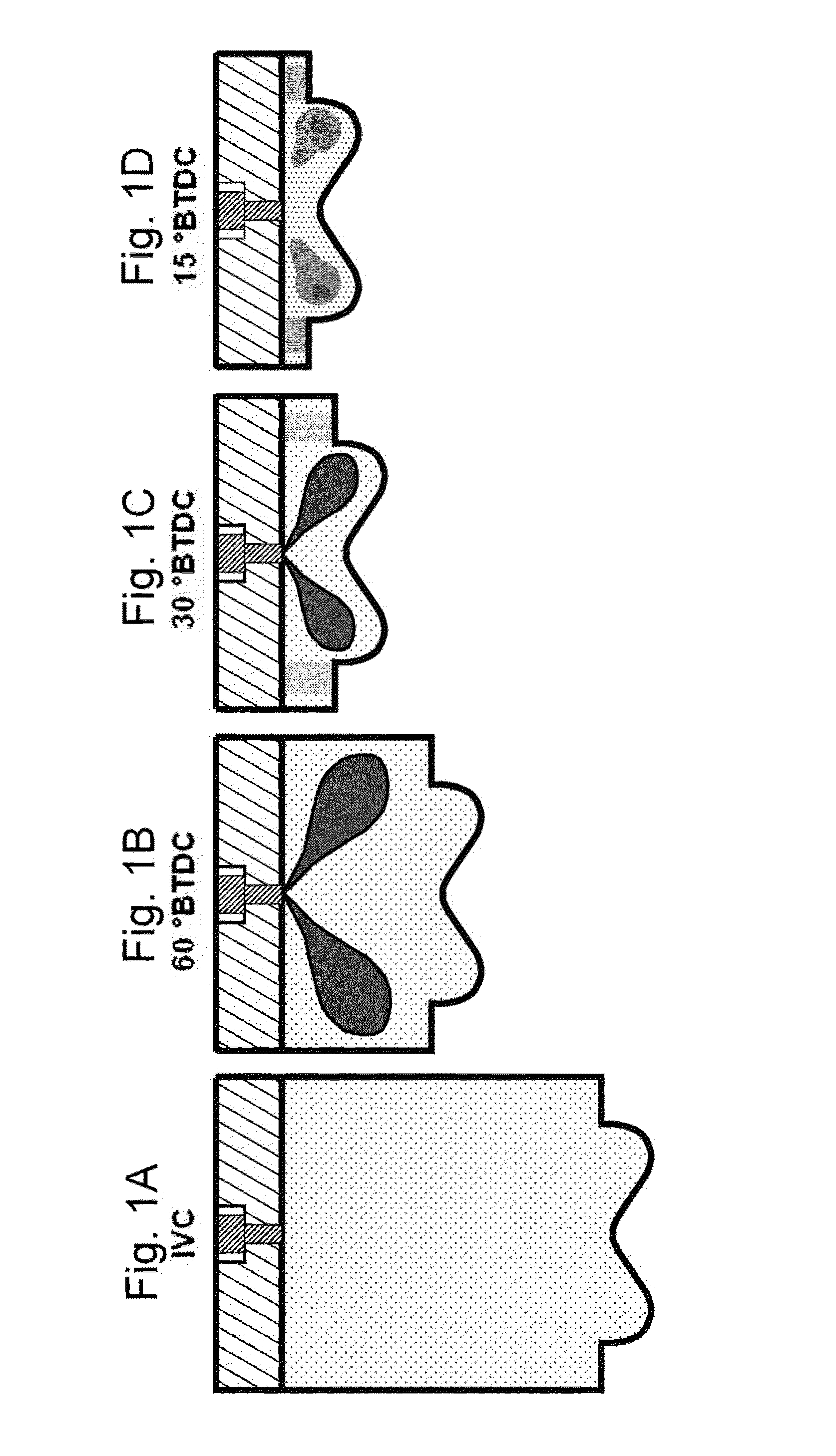

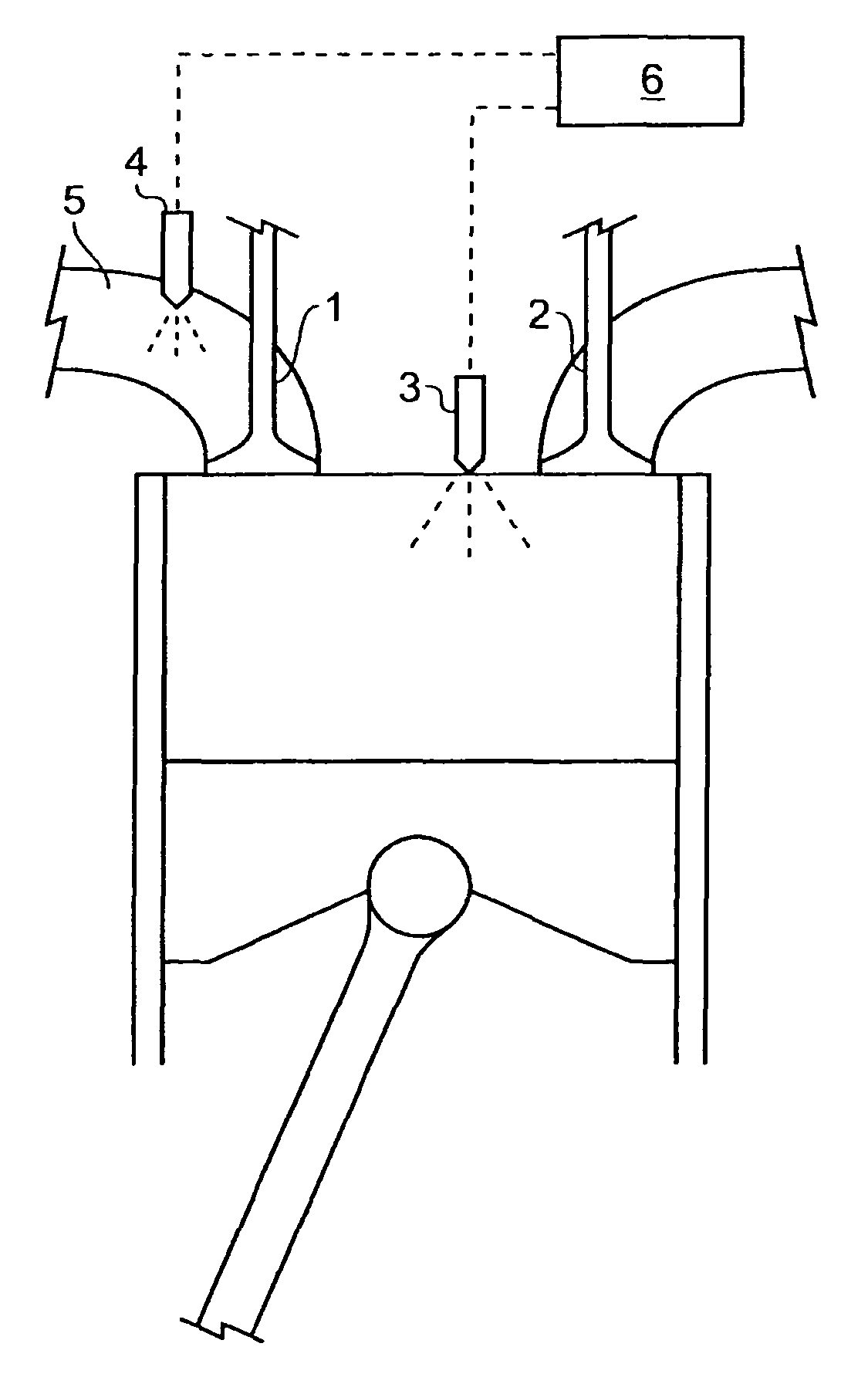

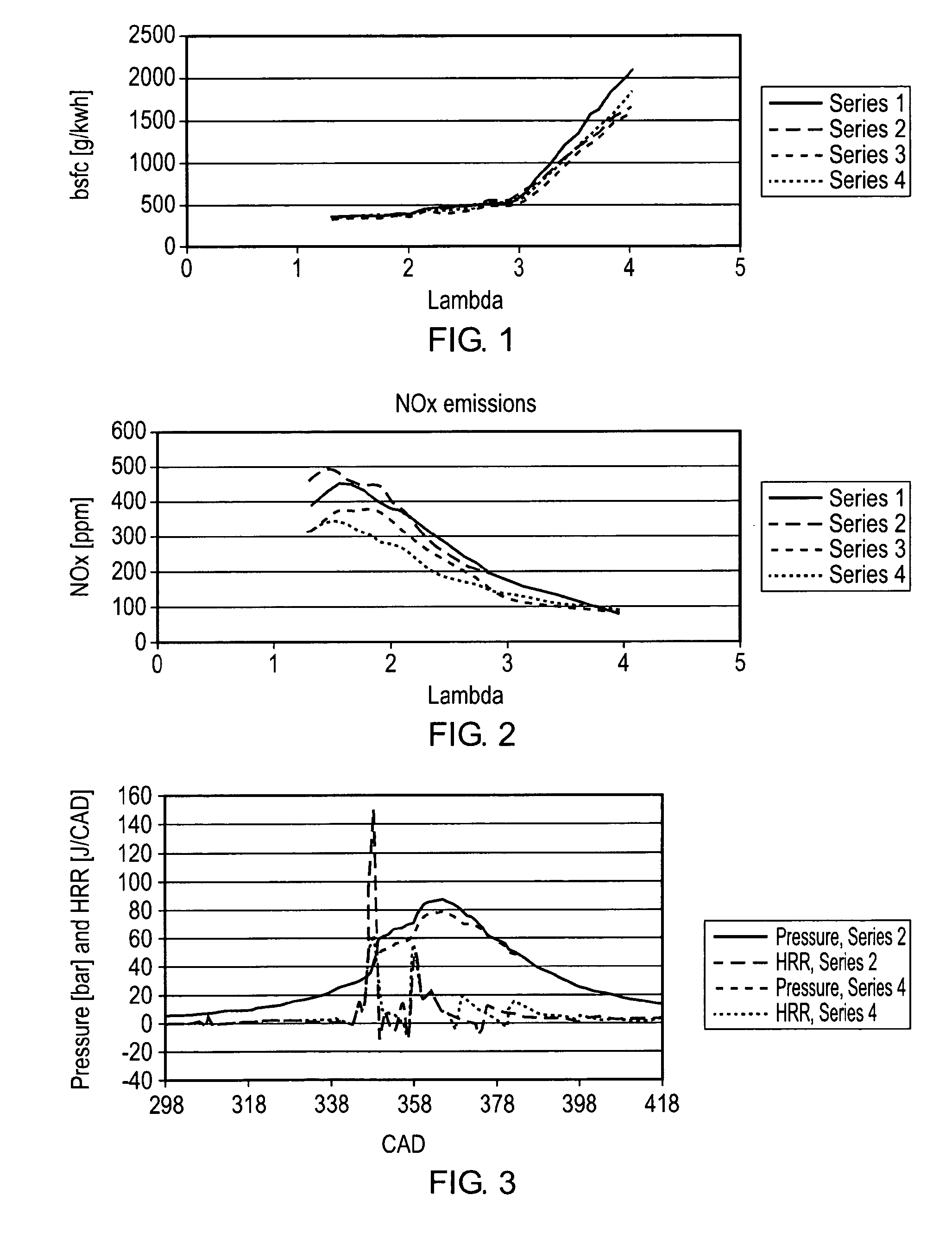

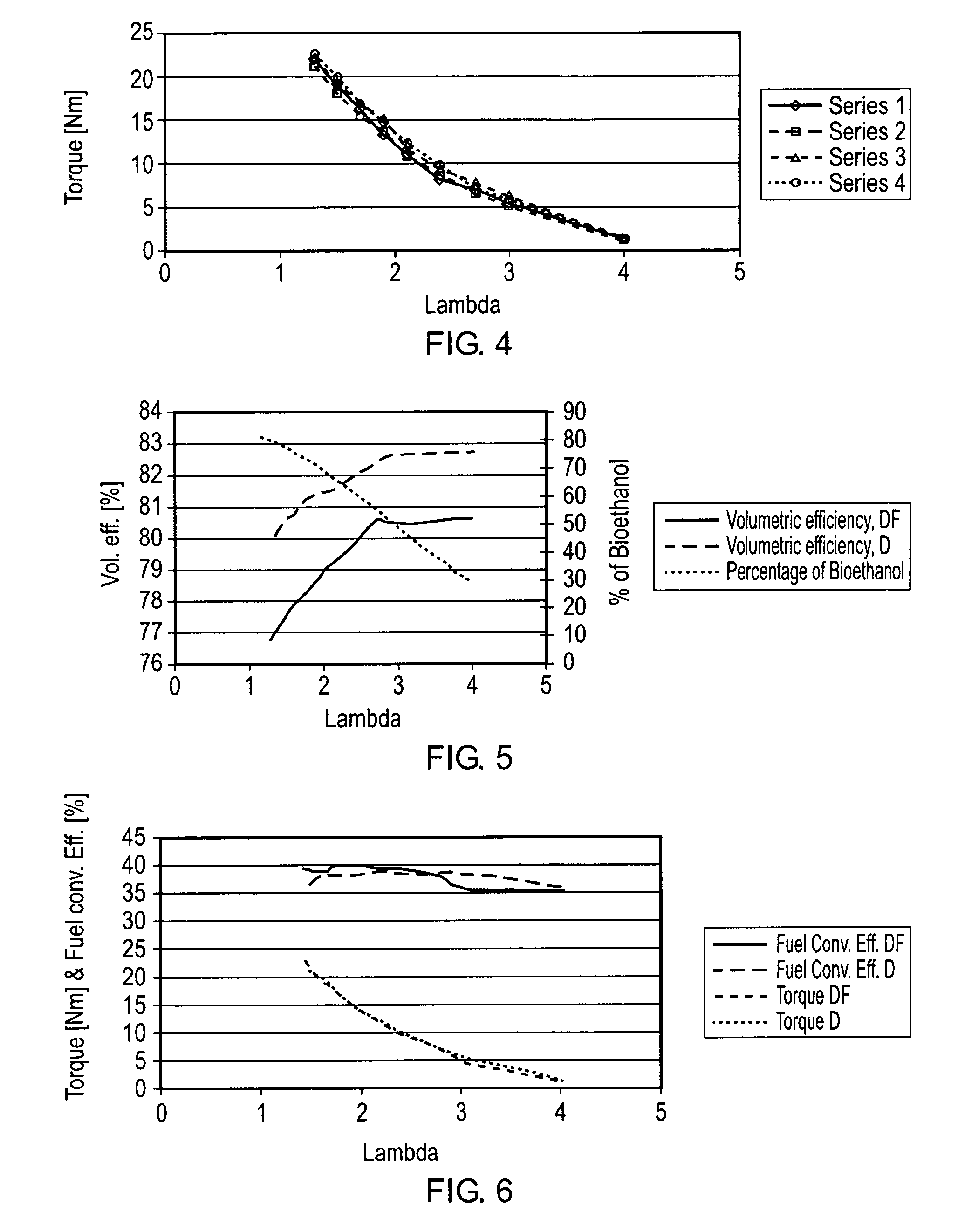

Multi-fuelling an engine

InactiveUS20110088654A1Reduce NOxReduce soot emissionsElectrical controlInternal combustion piston enginesBiodieselCombustion chamber

A compression ignition engine is supplied with a first fuel in a flow of air and a second fuel is injected into the combustion chamber. The first fuel comprises a more volatile fuel than diesel such as ethanol, LPG or other combustible gas; the second fuel comprises diesel or biodiesel; and the second fuel is injected in multiple pulses in each ignition cycle with the first pulse acting as a pilot pulse to trigger ignition, and the timing of the second pulse being such as to modify the temperature through evaporation of the second fuel and thereby reduce the combustion temperature and mitigate knock susceptibility. Preferably the pilot pulse is followed by a single further pulse of the second fuel in the ignition cycle. The engine may be controlled to operate in two different modes, one mode for light and medium load conditions when there is only a pilot pulse injection of the second fuel which reduces NOx and soot emissions, and the other mode for higher load conditions when there is a pilot pulse injection followed by a main pulse injection of the second fuel. The first fuel may comprise bioethanol and or one or more of the following: ethanol, butanol, propanol, lpg, natural gas, hydrogen.

Owner:G VOLUTION

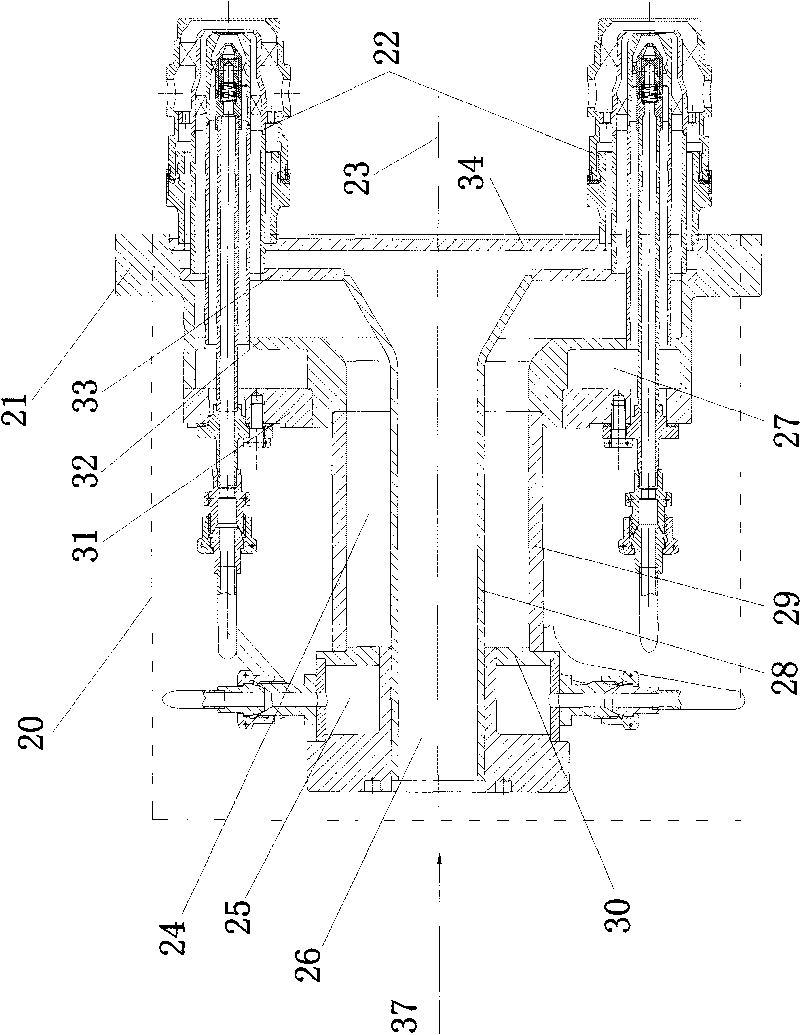

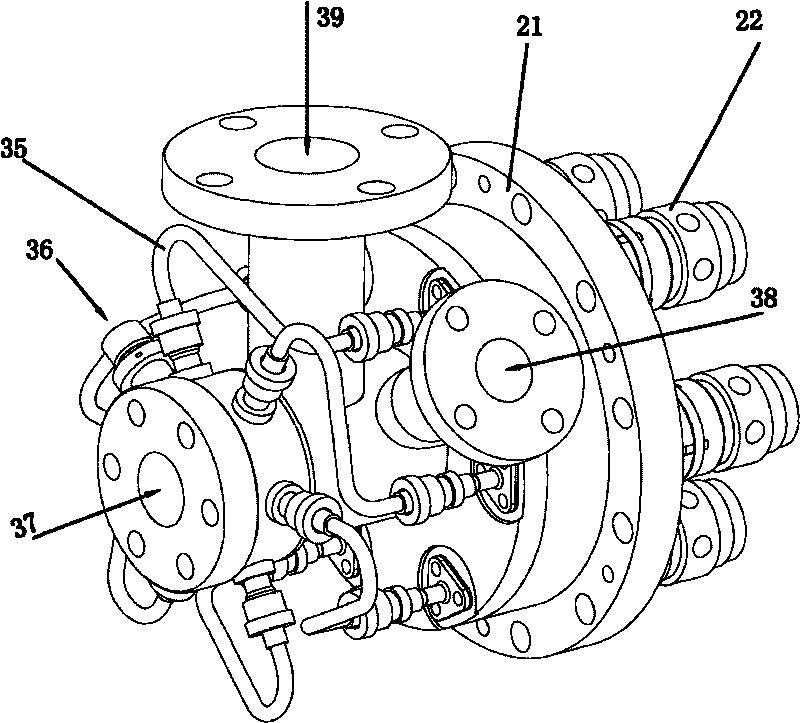

Low-pollution combustor for various fuels

InactiveCN101713546AEmission controlAvoid flashback of premixed combustionContinuous combustion chamberCombustion chamberAir cleaning

The invention discloses a low-pollution combustor for various fuels, which comprises a shunt system, a mounting edge and a plurality of double fuel nozzles, wherein the shunt system is connected with the plurality of double fuel nozzles through the mounting edge into a whole; the shunt system comprises a gas fuel subchannel, a liquid fuel subchannel, a diluent subchannel and an atomized air subchannel; and the double fuel nozzles are arranged circumferentially along the central line of the combustor. The low-pollution combustor for various fuels provided by the invention reduces the dischargeof pollutants such as NOX, solves the problems such as backfire and unstable combustion of premixing combustion of synthetic gases, simplifies an air cleaning and blowing protective system of a combustion chamber, avoids increasing the discharge of carbon monoxide, and can work with low and medium thermal value gas fuel such as coke oven gas, chemical tail gases and synthetic tail gases from IGCCpower plants and high thermal value gas fuel such as diesel oil and natural gas.

Owner:SHENYANG ENGINE DESIGN RES INST CHINA AVIATION IND CORP I

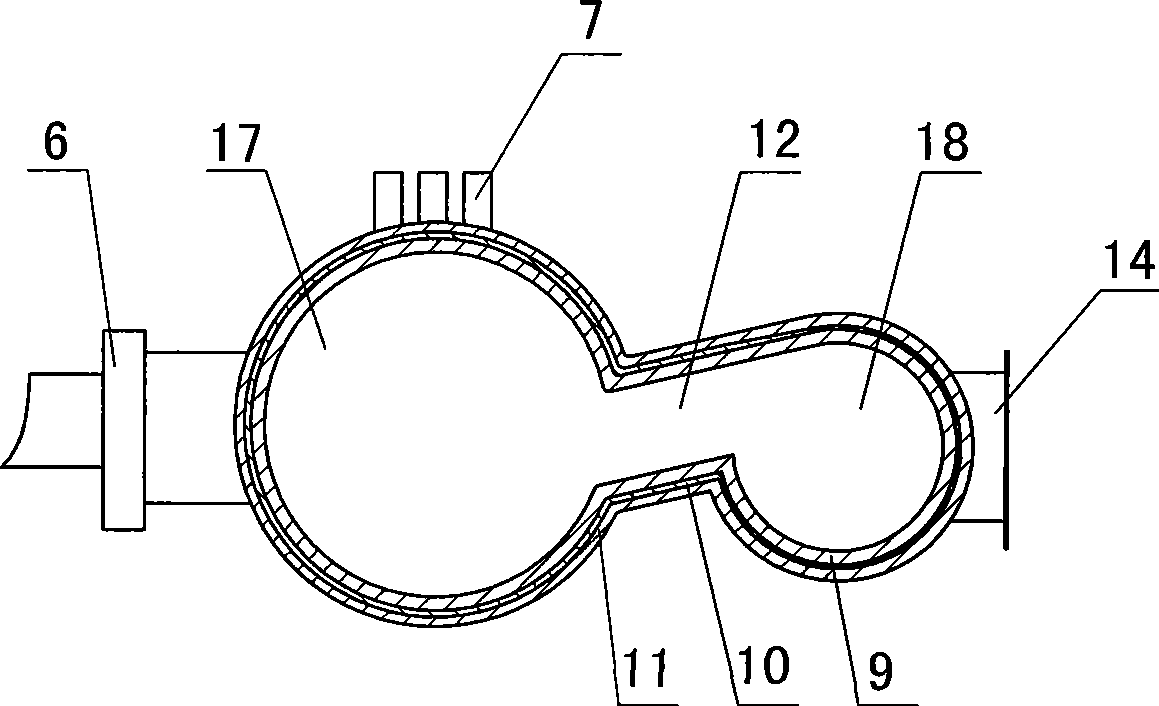

Multifuel internal combustion stirling engine

InactiveUS6457309B1Adequate fuel efficiencyExpensive heat exchanger is avoidedStirling type enginesEngine componentsParticulatesInternal combustion engine

A multifuel internal combustion Stirling engine is described, wherein a compressor piston and a displacer piston reciprocate, within a common cylinder, to enclose a variable air volume, and a variable burned gas volume. Motion of these two pistons, creates a power producing cycle, of compression, combustion, expansion, and scavenge, wherein the burned gases do not contact those cylinder portions over which the compressor piston moves. In this way low engine wear can be obtained when using fuels such as coal, which produces abrasive particulates in the burned gases. A multifuel internal combustion engine of this invention can be readily adapted to operate on a wide variety of fuels, such as, natural gas, diesel fuel, residual petroleum fuel, and coal. Widespread use of these engines would introduce economic competition between these now separately competing fuels. This is a clear route to national energy independence, since coal reserves greatly exceed petroleum reserves, nationally and internationally.

Owner:FIREY JOSEPH CARL

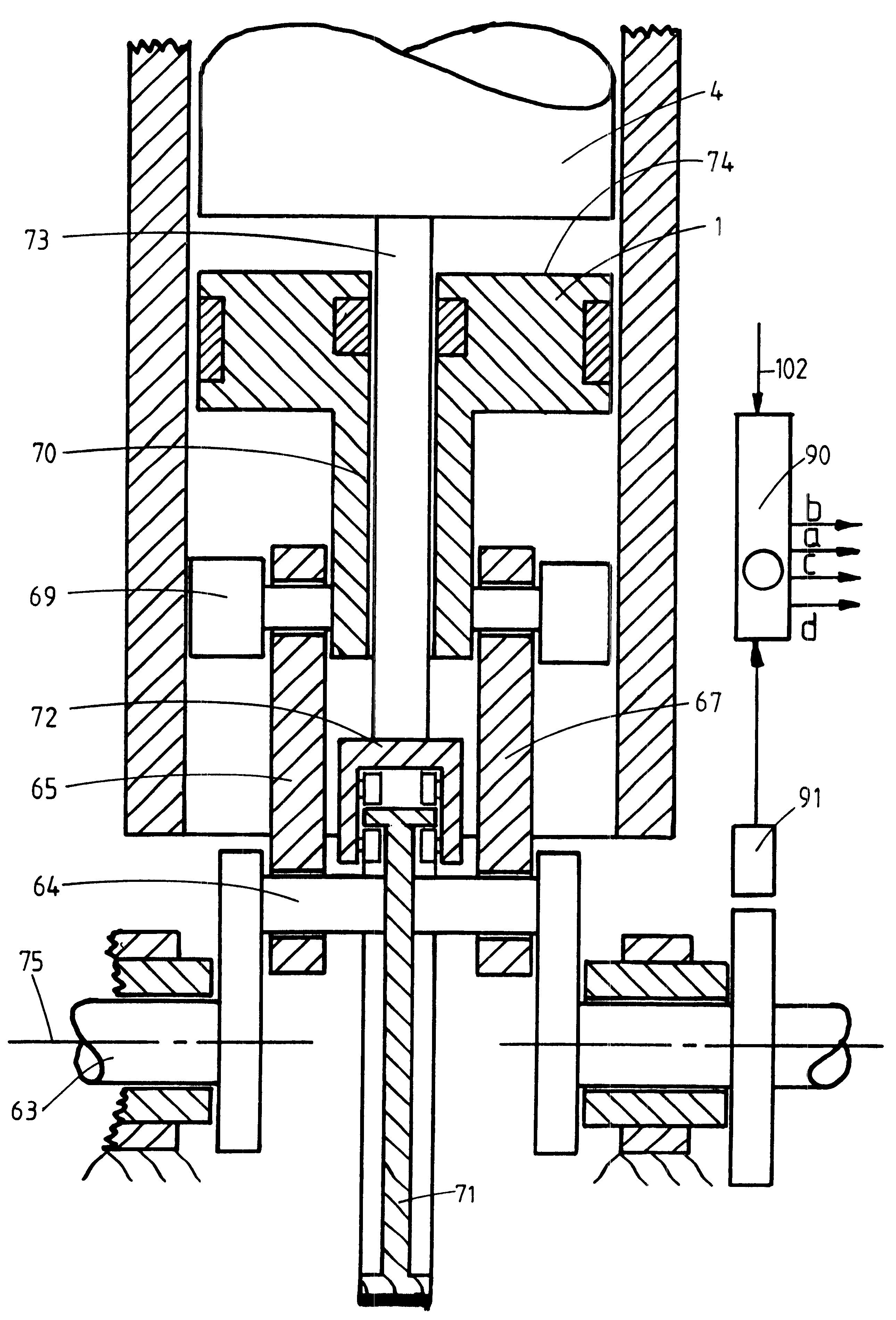

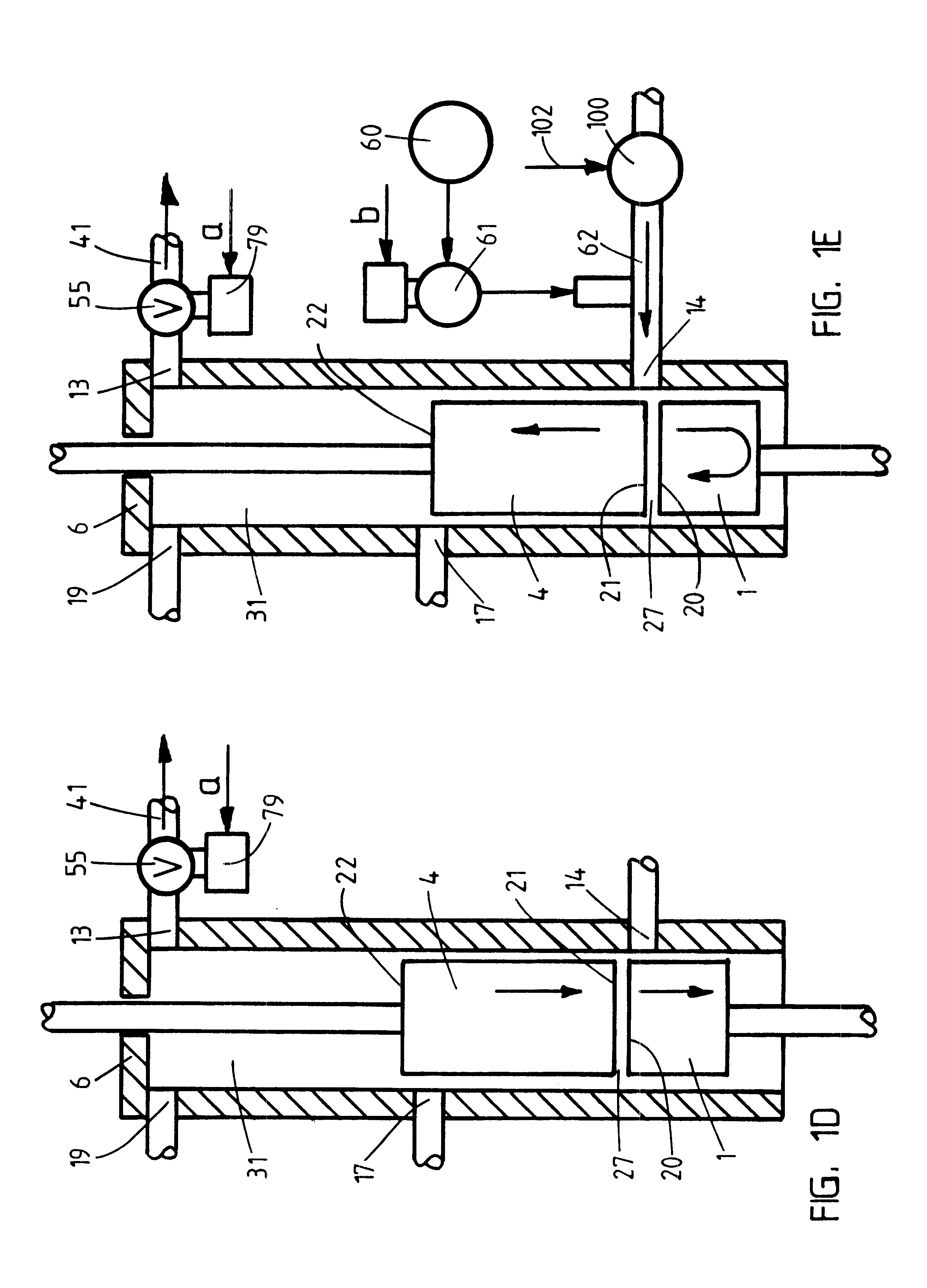

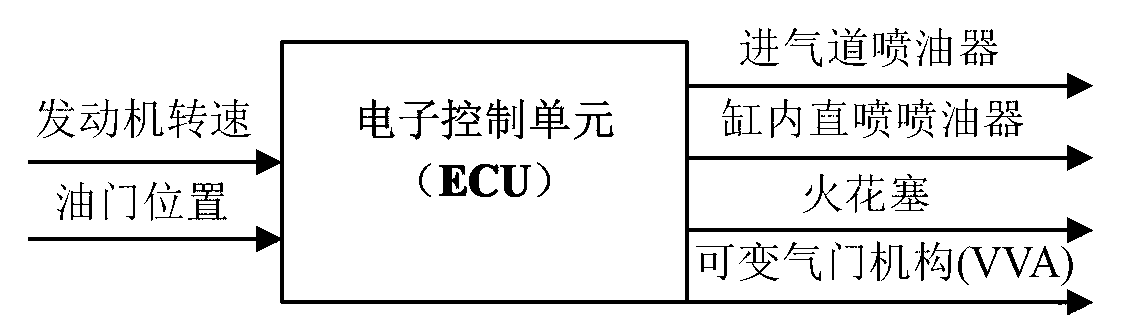

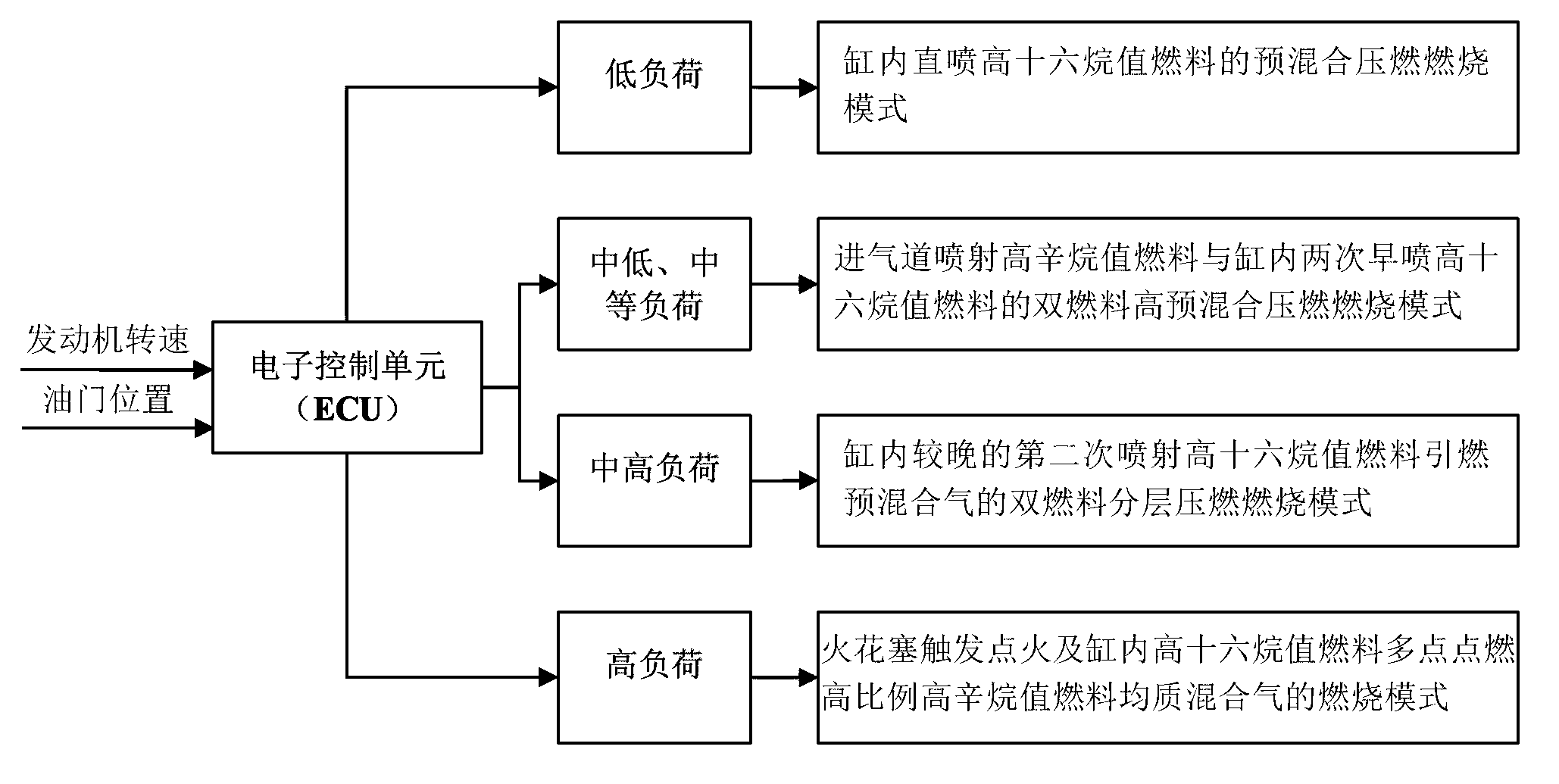

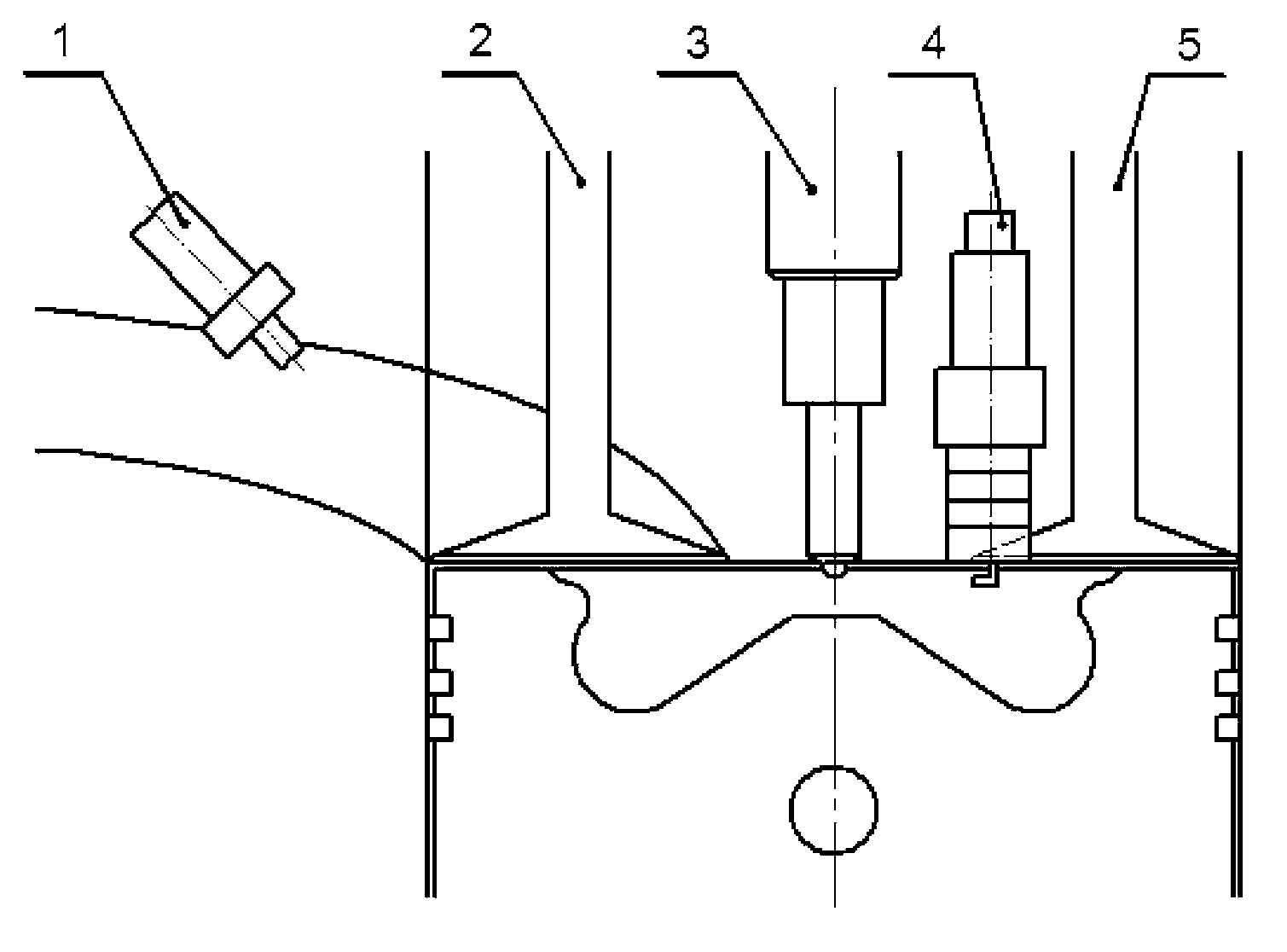

Flexible dual-fuel high pressure combustion chamber (HPCC) engine combustion and discharge control method and deivce

ActiveCN103061908AFlexible and adaptableFlexible and timely controllabilityElectrical controlInternal combustion piston enginesMultifuelCombustion chamber

The invention discloses a flexible dual-fuel high pressure combustion chamber (HPCC) engine combustion and discharge control method and deivce. An engine comprises an air inlet channel oil injector, an air inlet valve, an air cylinder direct injection oil injector, a spark plug, an exhaust valve, a variable valve actuation (VVA) mechanism and an electronic control unit (ECU). The ECU respectively reads engine rotation speed signals and accelerator position signals, judges the engine current operation conditions according to the received engine rotation speed signals and accelerator position signals, determines the combustion mode, and further controls oil injection times, oil injection time and oil injection pulse width of two fuels, spark plug ignition time and VVA actions. According to the flexible dual-fuel HPCC engine combustion and discharge control method and deivce, different combustion modes are adopted for different loads, namely the combustion modes can be controlled timely and flexibly, and the characteristics of fuels in a cylinder can be controlled timely and flexibly; and the device has the advantages of various fuel flexibility and various fuel mode adaptability, and the purpose of effective and clean combustion in the normal working condition range of passenger vehicles can be achieved simply by adopting a diesel engine oxidation and catalyzing postprocessor DOC.

Owner:TIANJIN UNIV

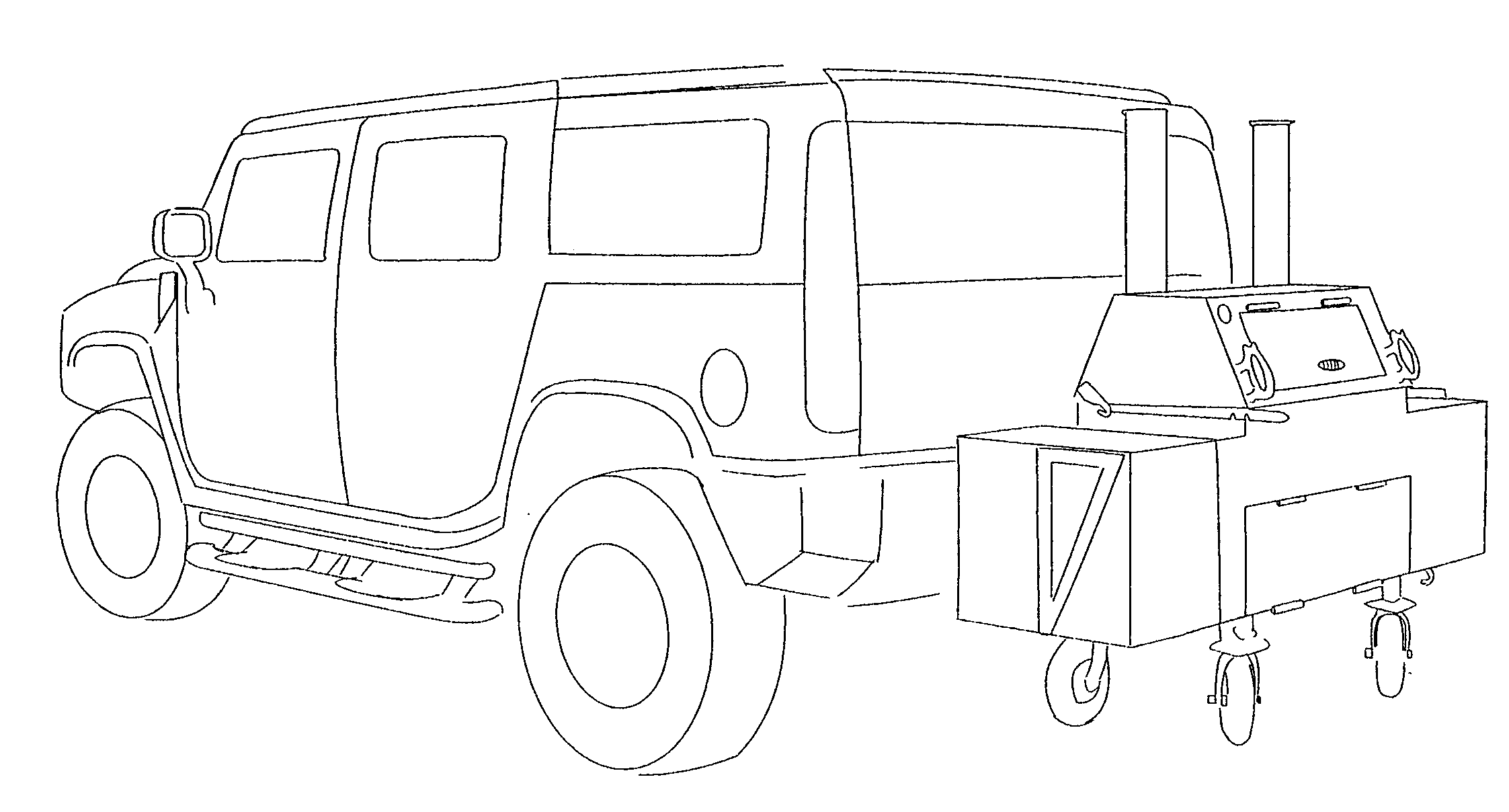

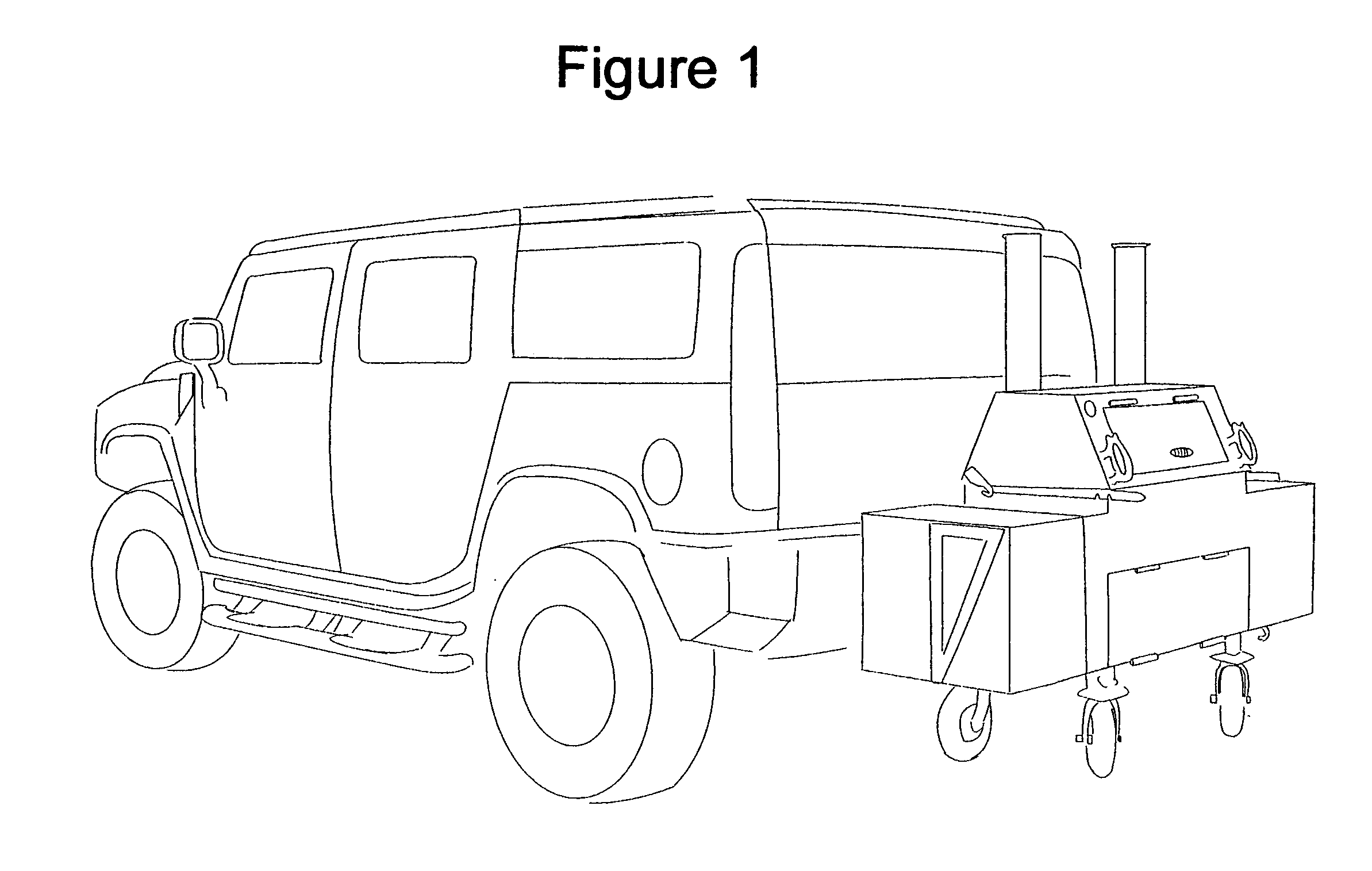

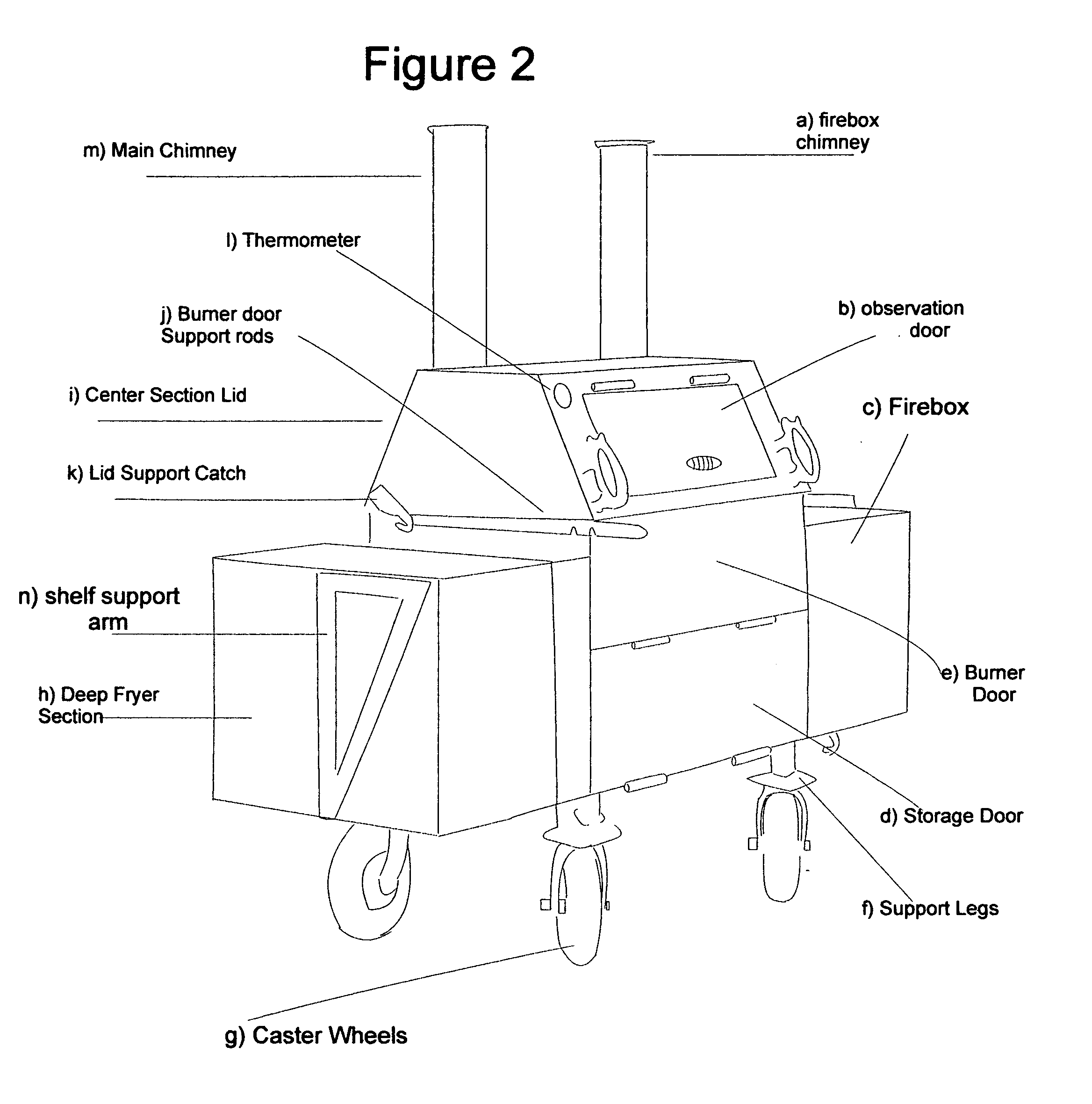

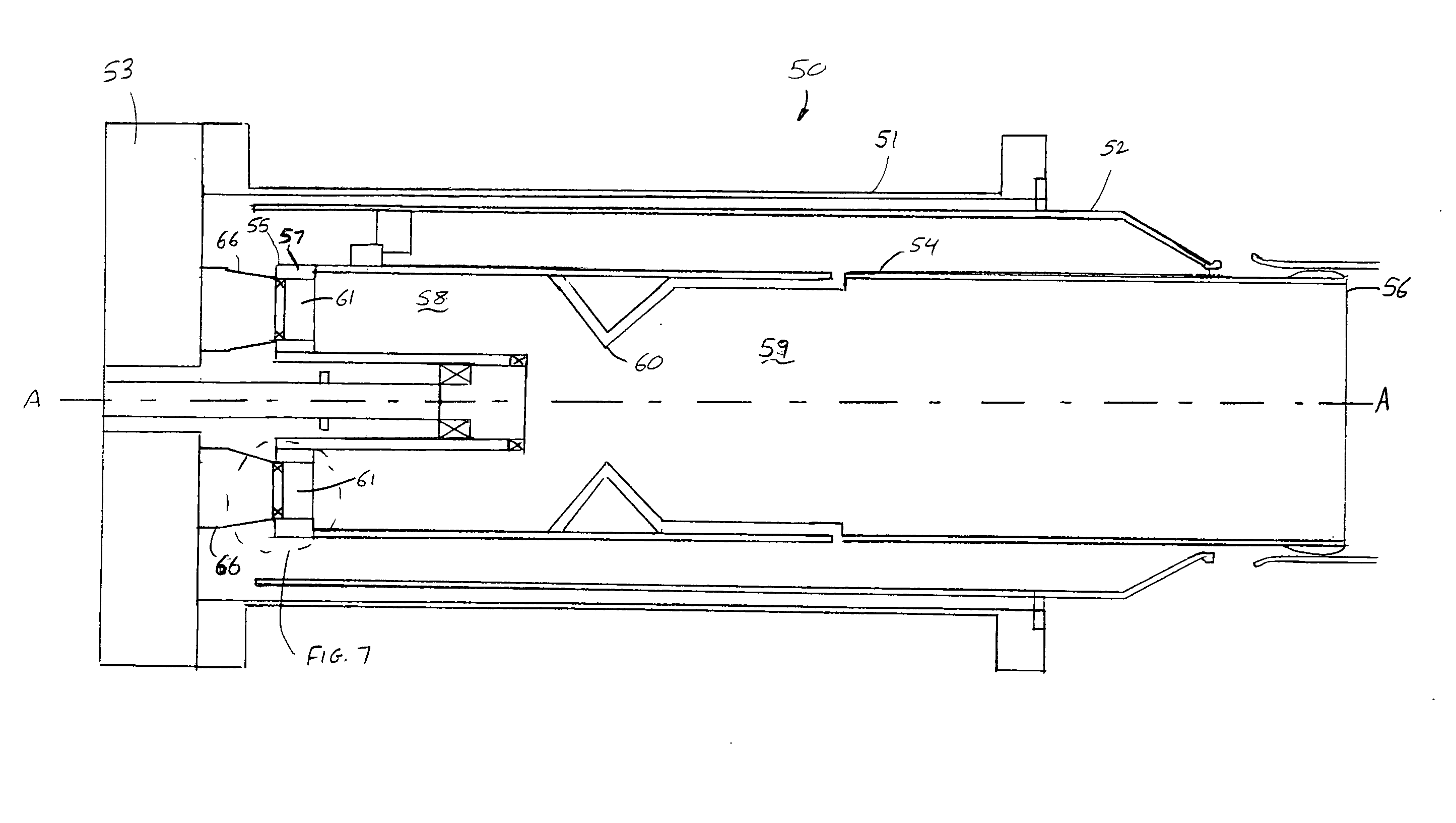

Multi-functional outdoor cooker using multiple fuels and transportable via receiver hitch of vehicle or trailer

InactiveUS20080098902A1Prevent heat lossEasy to checkClimate change adaptationRoasting apparatusEngineeringPropane

A portable grill and cooker which can be transported on a vehicle's trailer hitch, on a separate trailer, or used as a free-standing stationary grill. This grill can also be used to bake, griddle fry, deep fry, boil, steam, smoke, and barbeque different foods. The grill can utilize propane, wood, or charcoal to provide a heat source for cooking. It includes a storage compartment as well as wheels / casters on adjustable-height legs to permit relocation easily, and a trailer hitch adapter which permits easy hookup and raising without the user having to physically lift the grill by hand.

Owner:MANSFIELD PATRICK +1

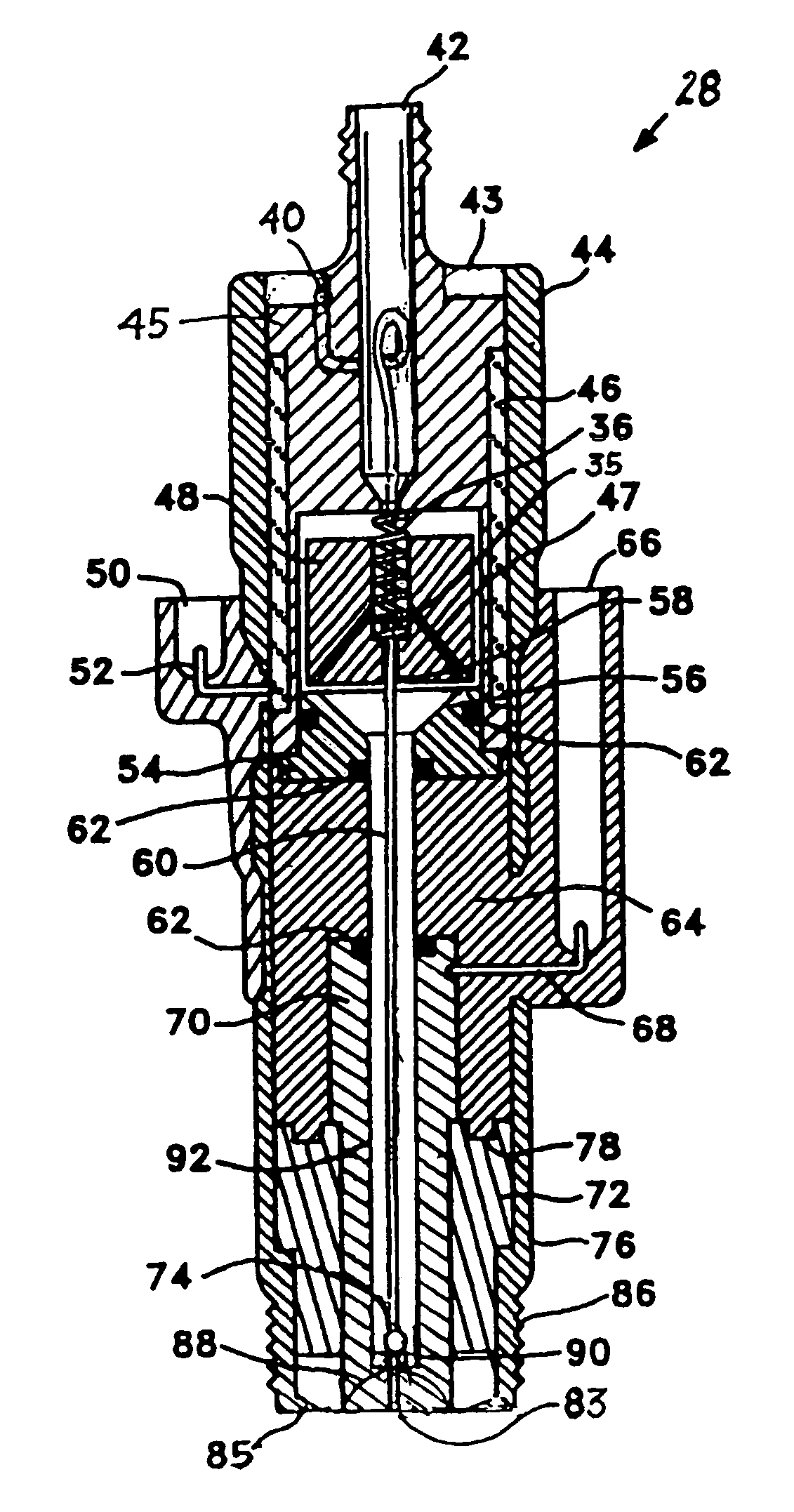

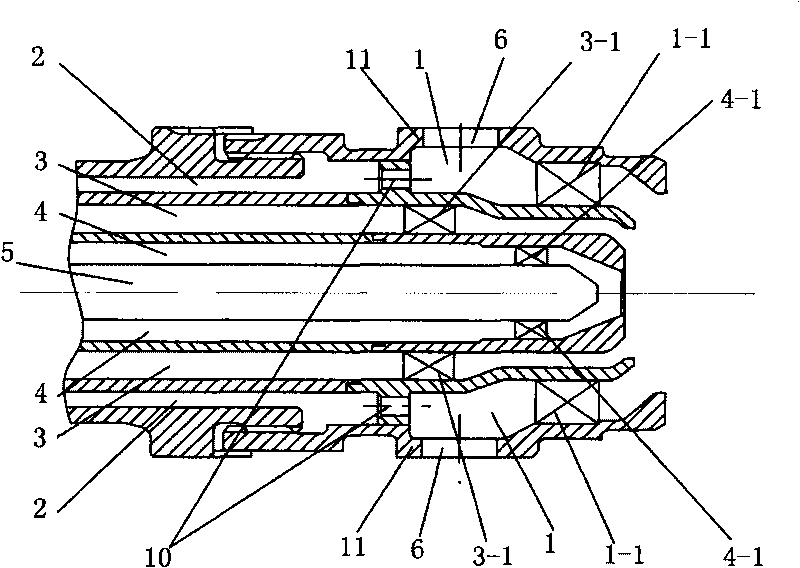

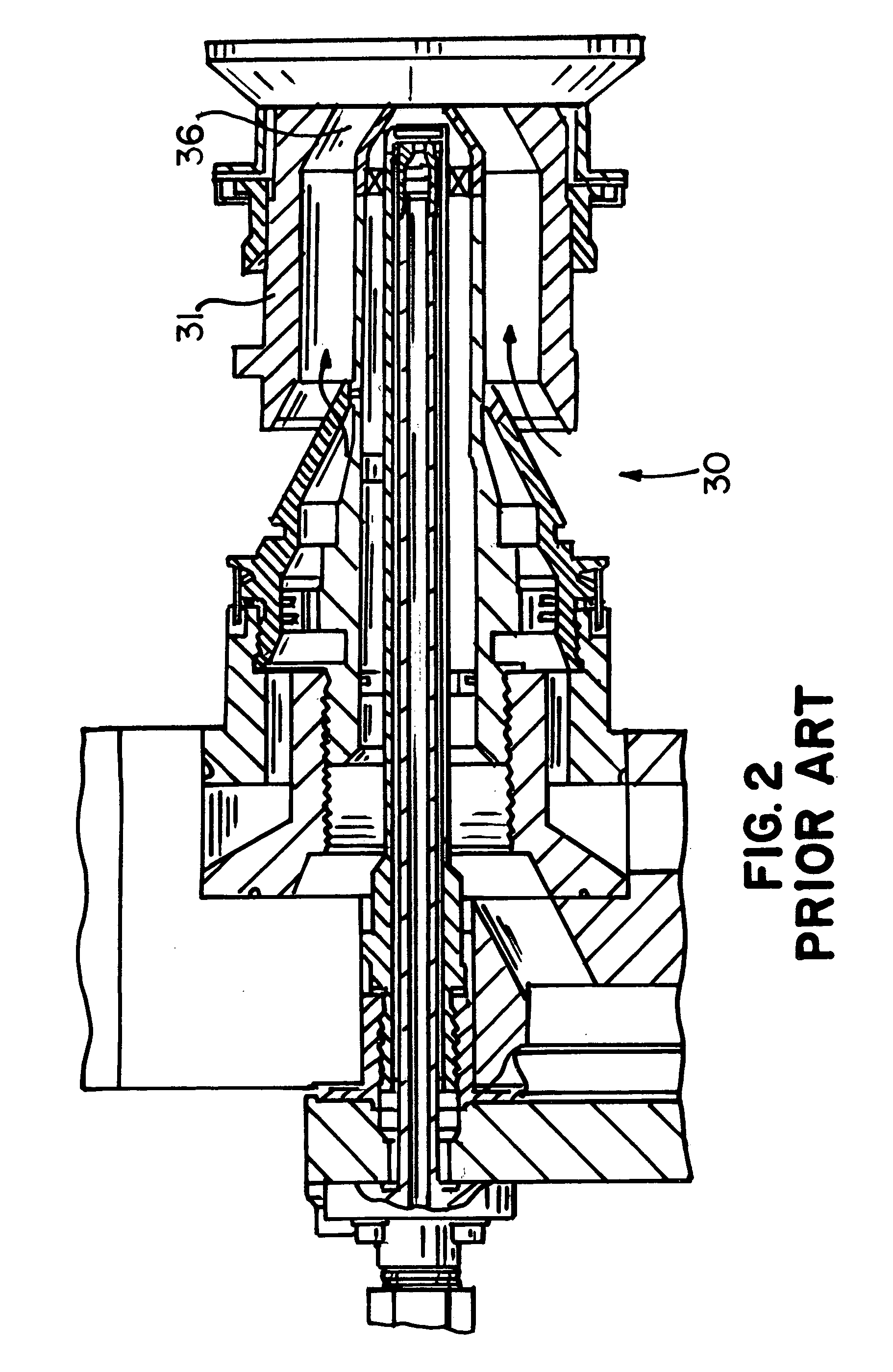

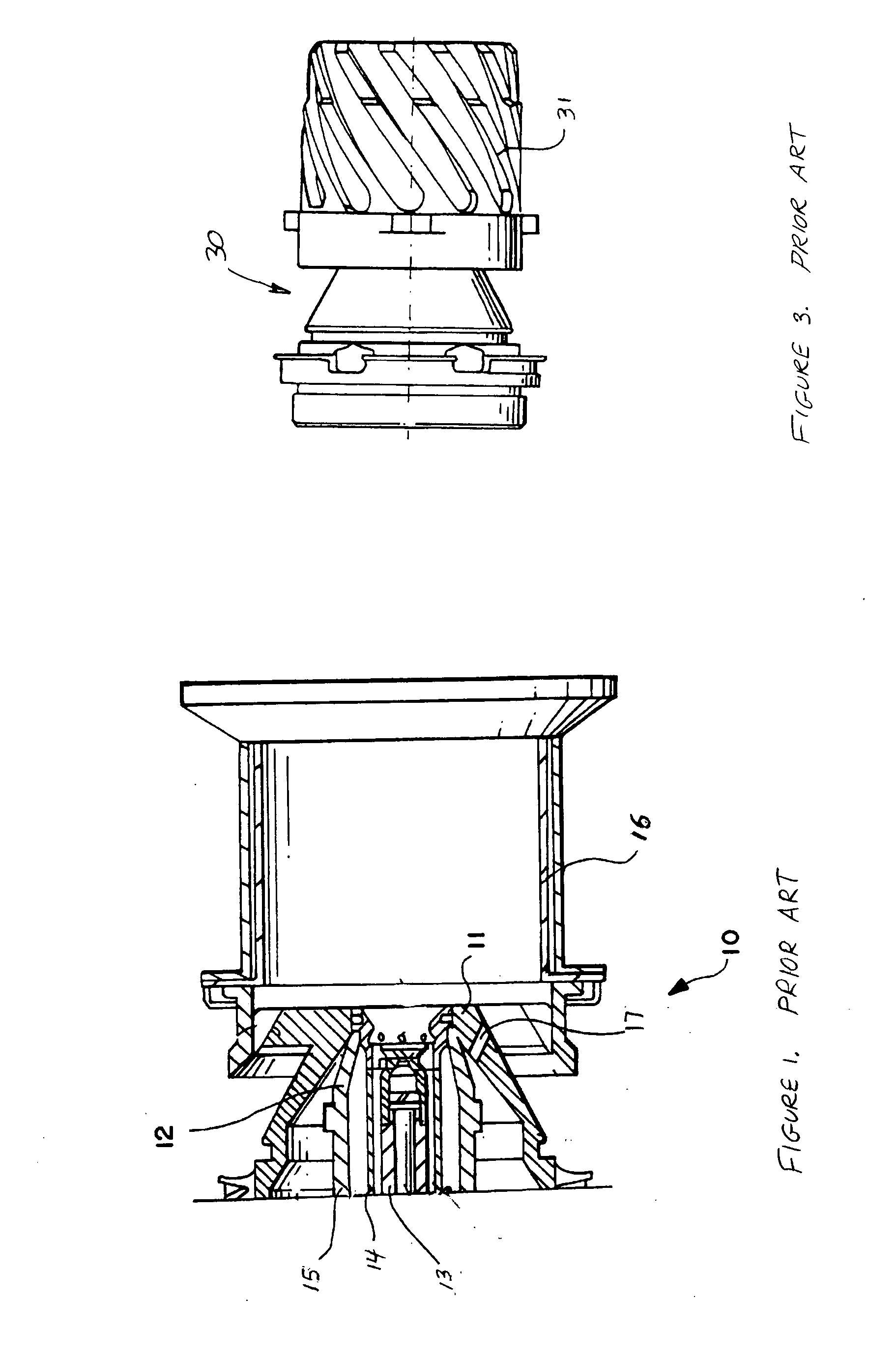

Primary fuel nozzle having dual fuel capability

InactiveUS7000403B2Reduce carbon depositionSimple configurationTurbine/propulsion fuel supply systemsContinuous combustion chamberMultifuelCombustor

A fuel nozzle and gas turbine combustor capable of operating on multiple fuels with reduced carbon build-up to the fuel nozzle and adjacent combustor components is disclosed. The fuel nozzle incorporates a reconfigured gas fuel assembly and mixing tube to eliminate known areas of recirculation. Furthermore, the liquid fuel assembly includes reconfigured spray characteristics to further reduce droplet interaction with the mixing tube.

Owner:ANSALDO ENERGIA SWITZERLAND AG

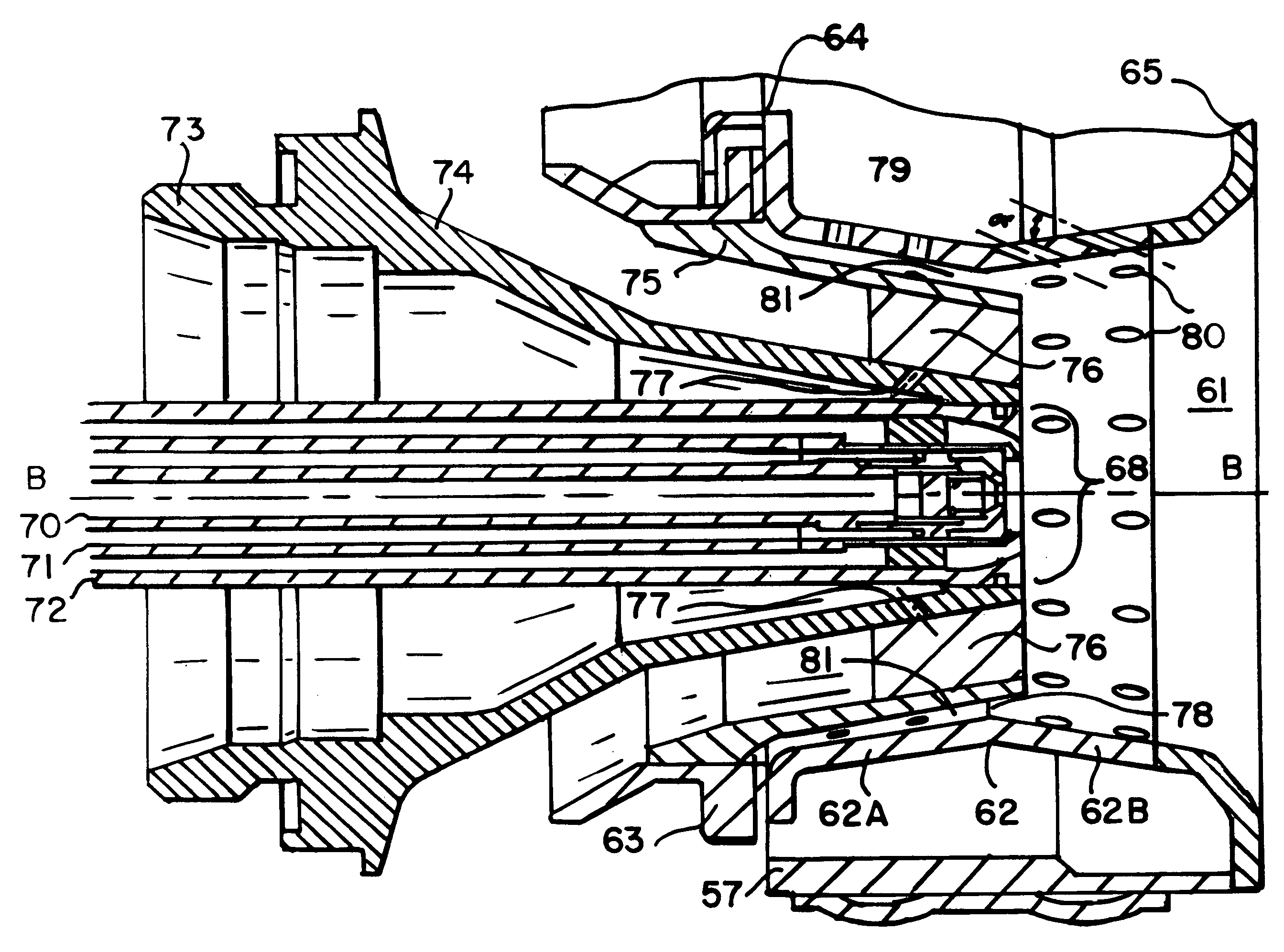

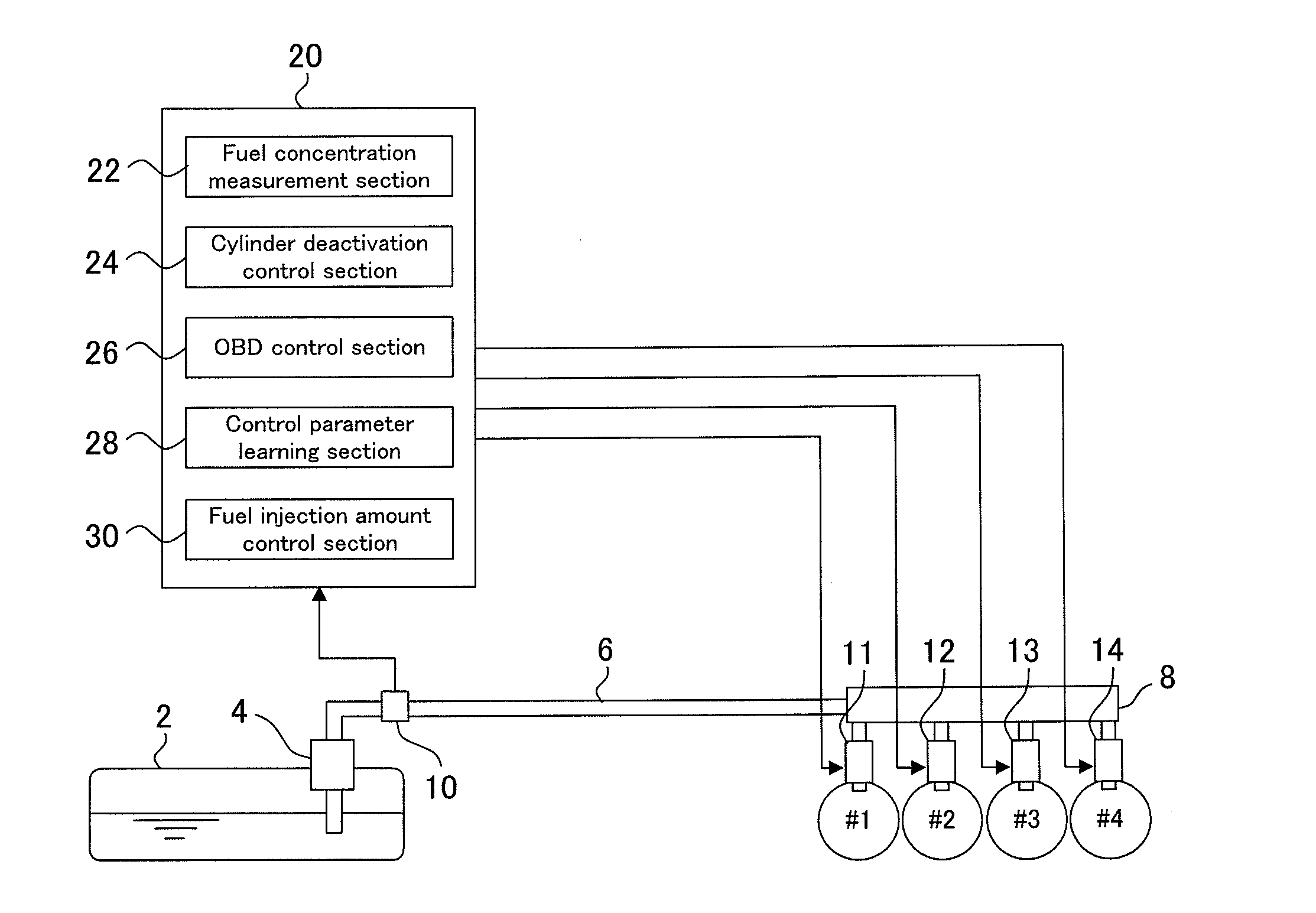

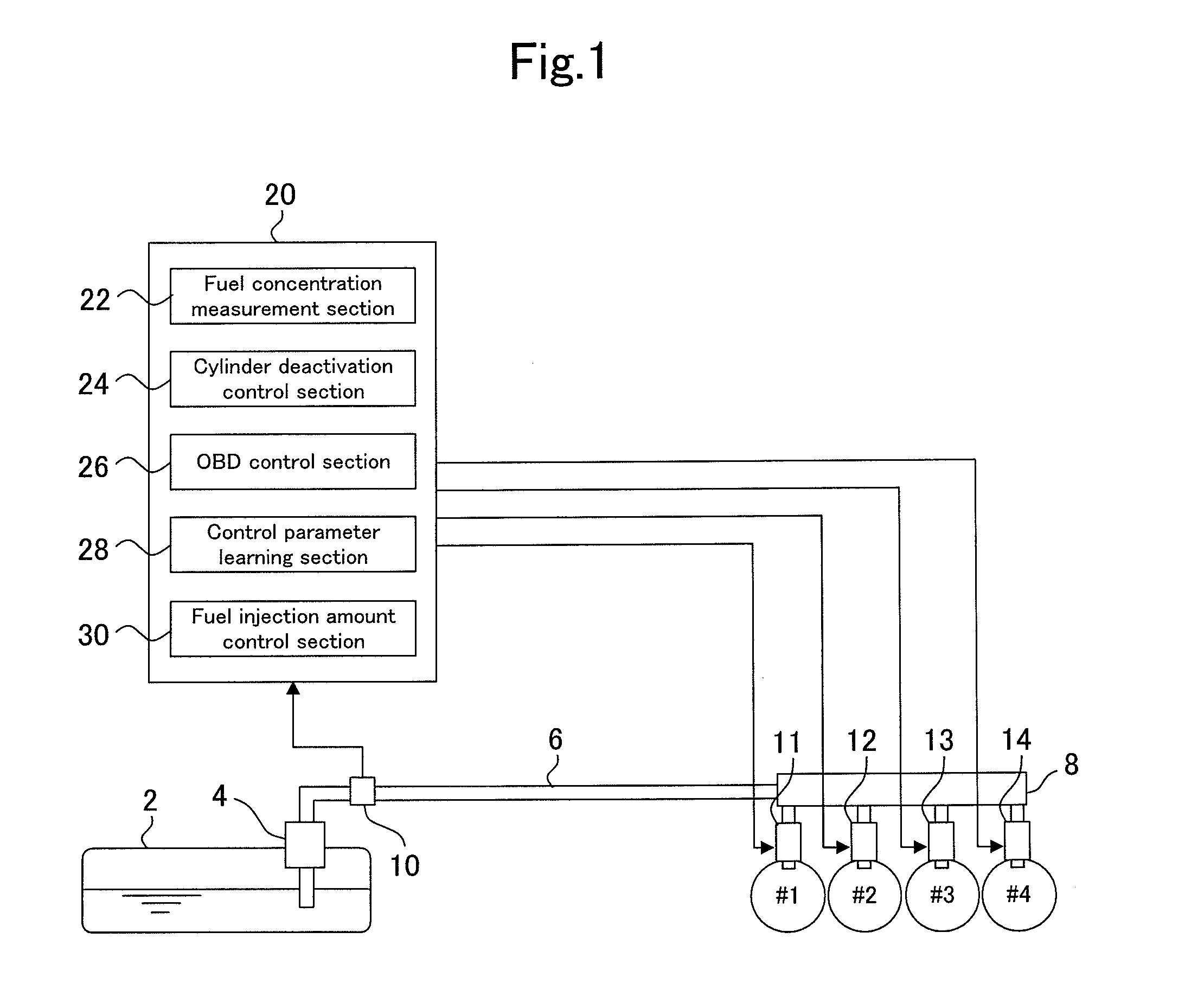

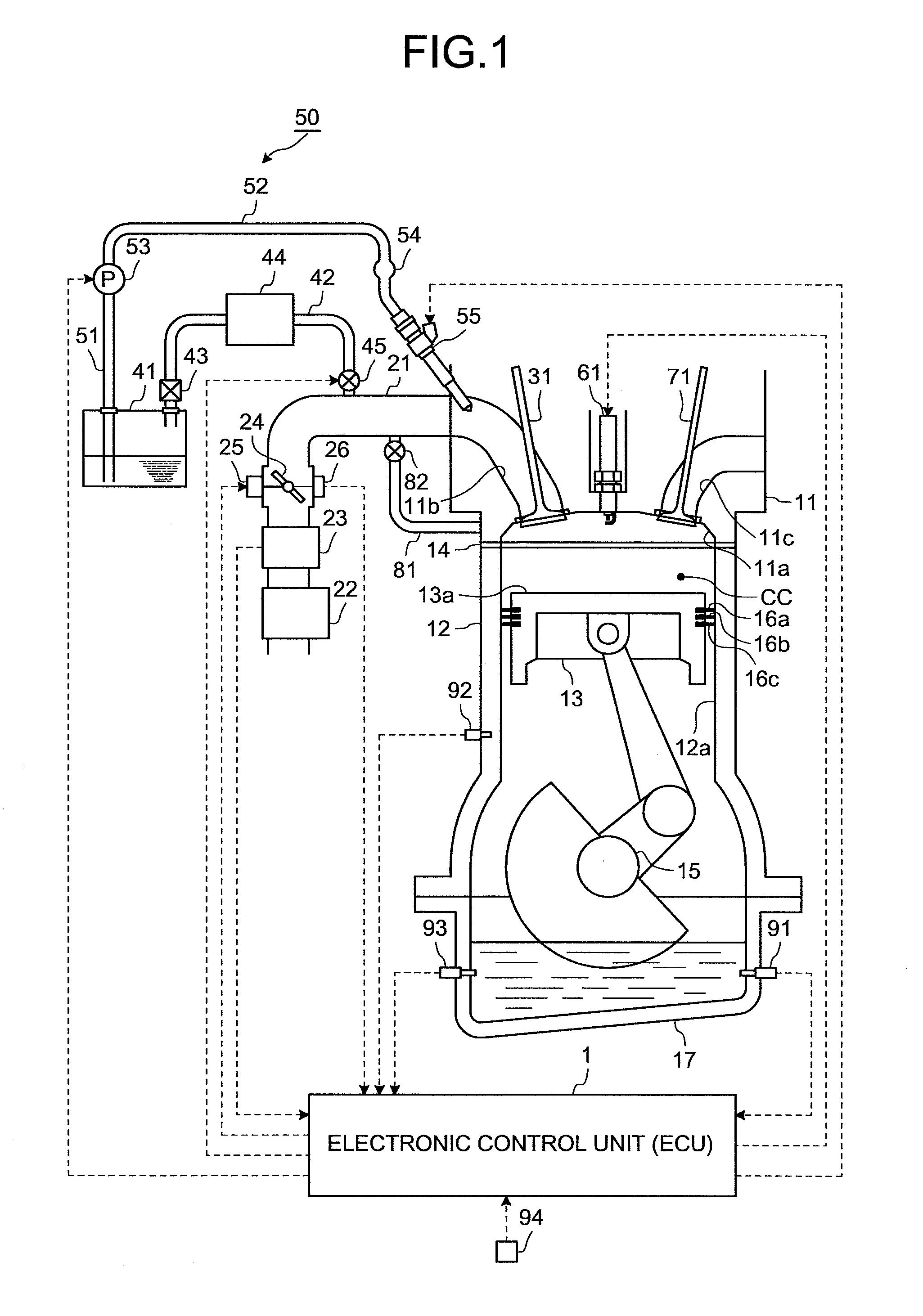

Control device for internal combustion engine

InactiveUS20120103312A1Avoid disagreementReduce the differenceElectrical controlInternal combustion piston enginesMultifuelExternal combustion engine

An object of the present invention is to avoid an air-fuel ratio difference between cylinders upon recovery from a cylinder deactivation in a situation where some of a plurality of cylinders of an internal combustion engine capable of using a plurality of types of fuels having different properties are to be deactivated upon the halt of fuel injection from an injector.To accomplish the object, a control device to which the present invention is applied includes a fuel property sensor that is installed in a fuel line between a fuel tank and a delivery pipe, and detects a fuel property change from a change in a signal of the fuel property sensor. Upon detection of a fuel property change, the control device prohibits the deactivation of a cylinder before the completion of a fuel property change in the delivery pipe.

Owner:TOYOTA JIDOSHA KK

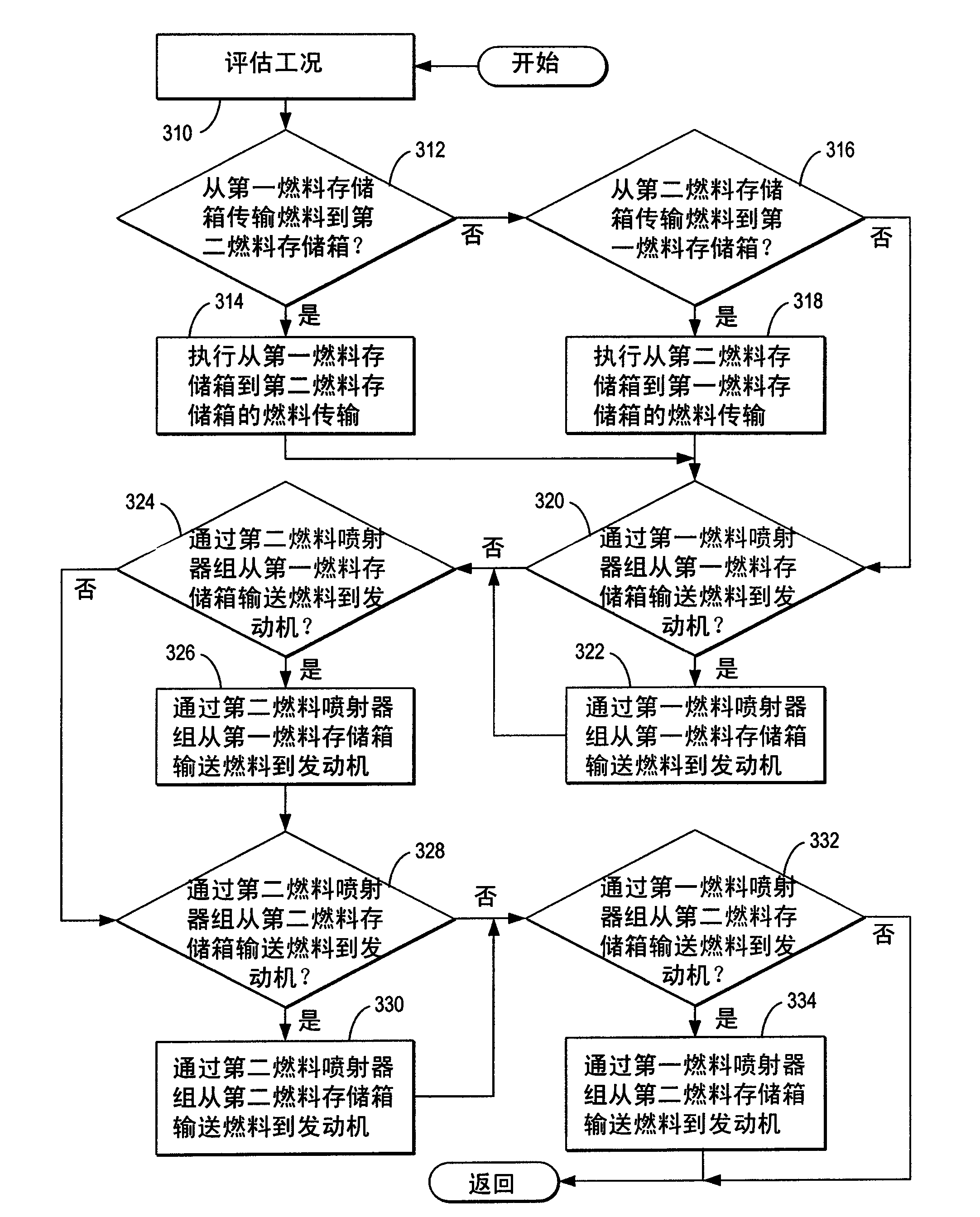

Fuel Apportionment for Multi Fuel Engine System

Owner:CATERPILLAR MOTOREN

Primary fuel nozzle having dual fuel capability

InactiveUS20050198965A1Reduce carbon depositionSimple fuel nozzle configurationContinuous combustion chamberTurbine/propulsion fuel supply systemsMultifuelCombustor

A fuel nozzle and gas turbine combustor capable of operating on multiple fuels with reduced carbon build-up to the fuel nozzle and adjacent combustor components is disclosed. The fuel nozzle incorporates a reconfigured gas fuel assembly and mixing tube to eliminate known areas of recirculation. Furthermore, the liquid fuel assembly includes reconfigured spray characteristics to further reduce droplet interaction with the mixing tube.

Owner:ANSALDO ENERGIA SWITZERLAND AG

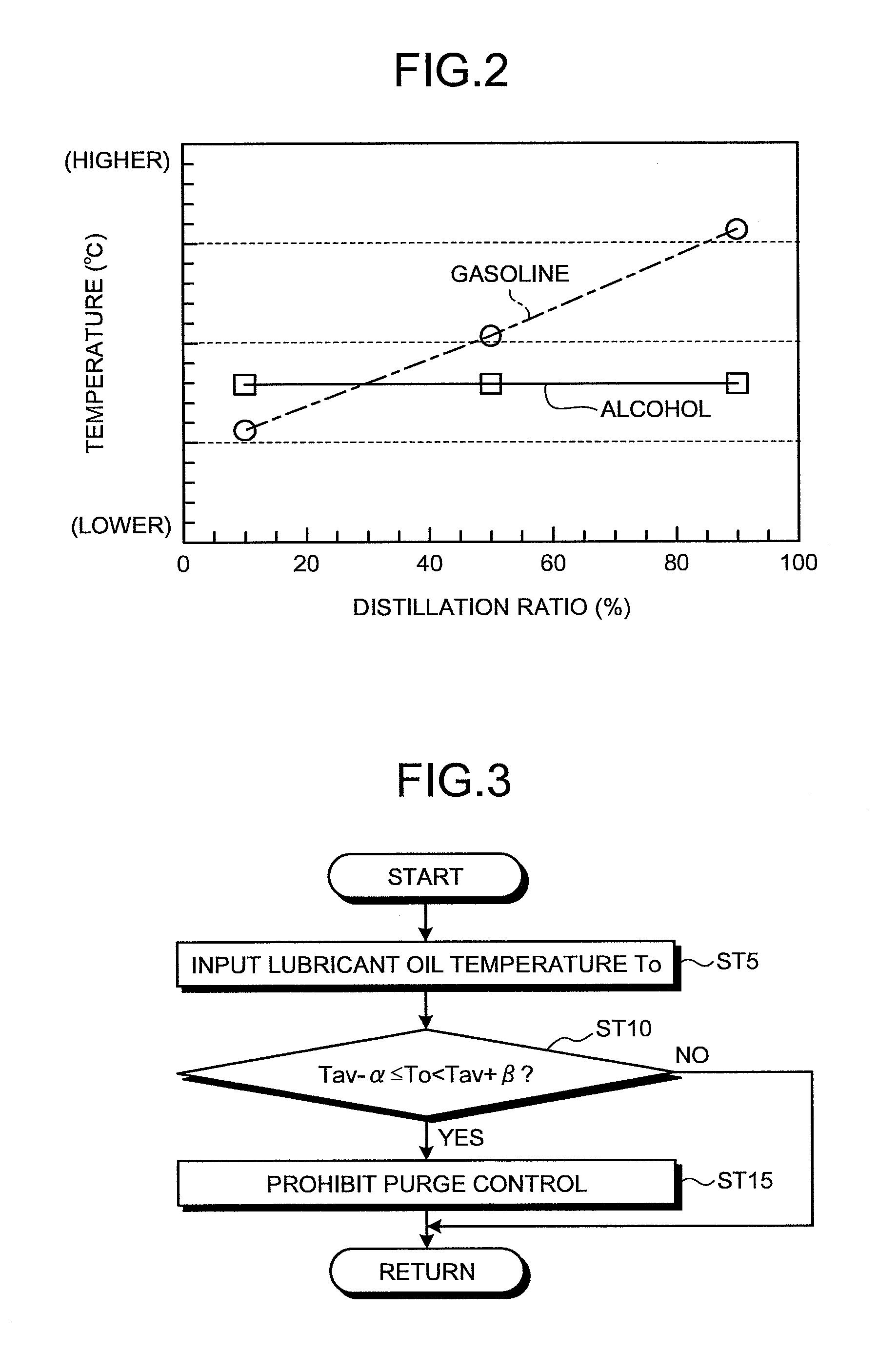

Multifuel internal combustion engine

ActiveUS8113186B2Inhibit deteriorationEasy to driveElectrical controlInternal combustion piston enginesMultifuelExternal combustion engine

Owner:TOYOTA JIDOSHA KK

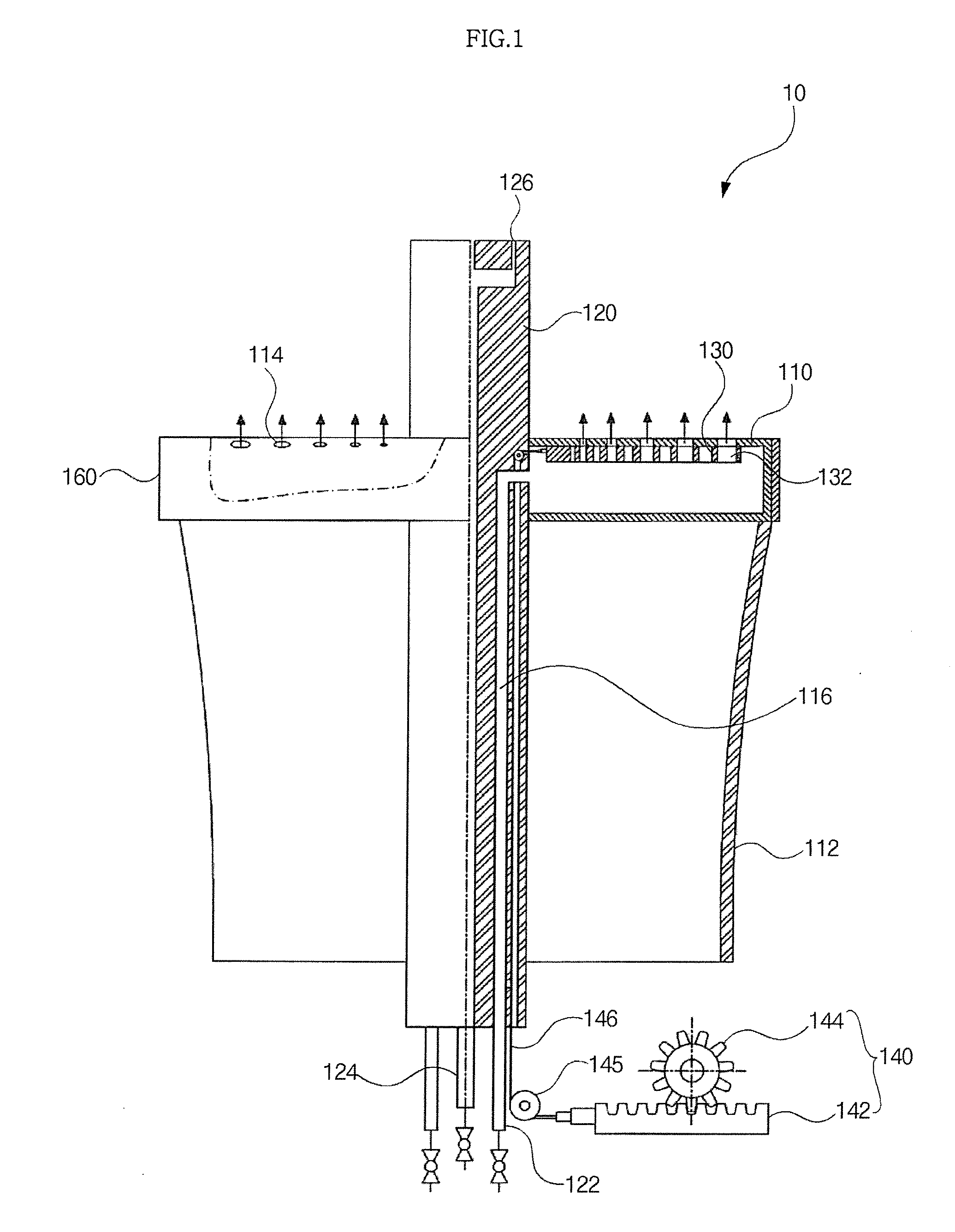

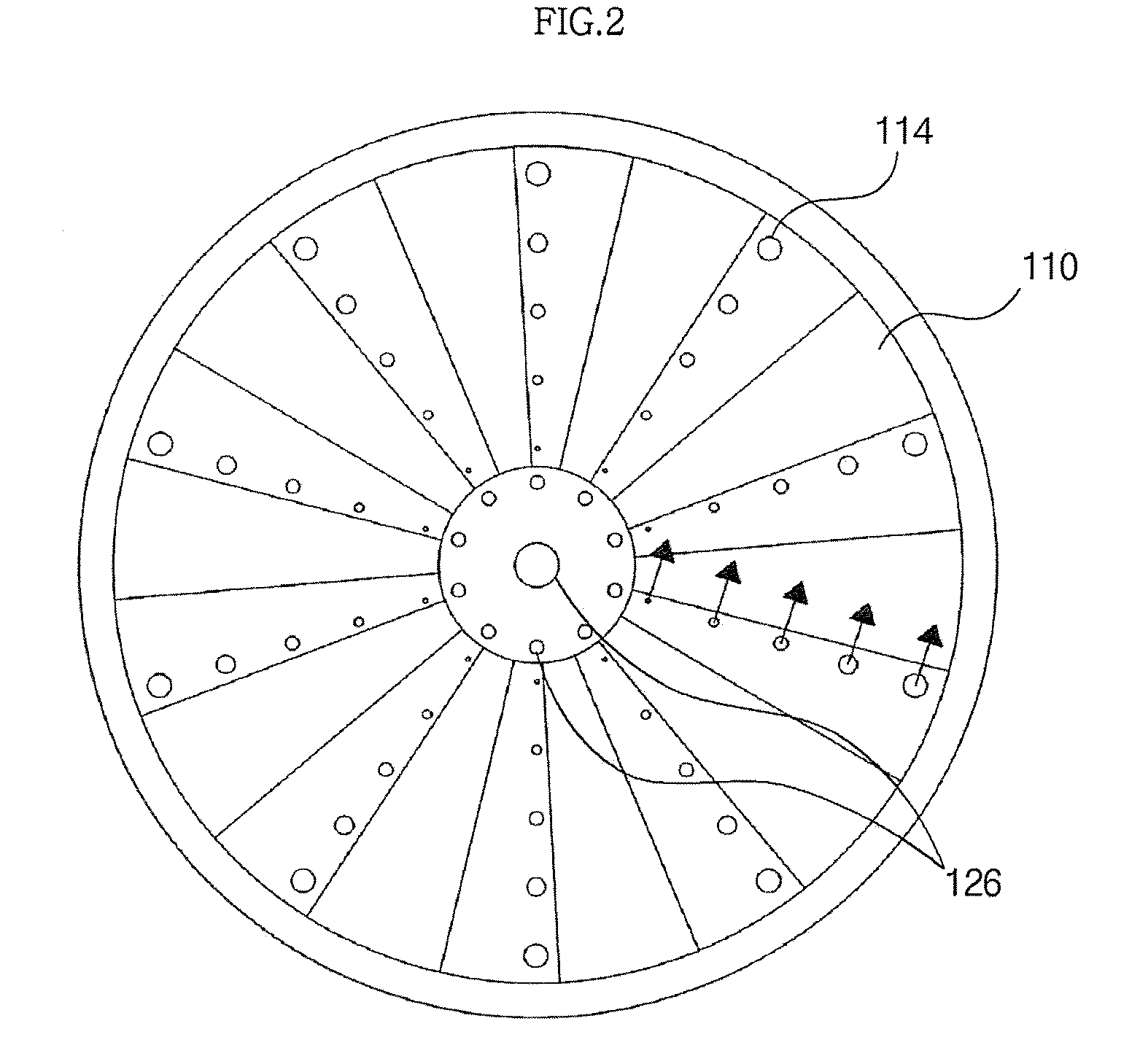

Combustor and multi combustor including the combustor, and combusting method

InactiveUS20080098736A1Increased fuel flexibilityIncrease flexibilityCombustion using gaseous and pulverulent fuelContinuous combustion chamberMultifuelCombustor

A dual fuel nozzle of a gas turbine combustor with a variable jetting hole diameter is disclosed. The combustor includes a plurality of swirling wings disposed along an outer peripheral surface of a central shaft to have at least one main fuel jetting hole, an air duct positioned at the lower side of the swirling wings to supply air to the swirling wings, a pilot fuel injection hole and jetting hole formed to pass through a central portion of the central shaft to supply a pilot fuel, a switching plate disposed inside the swirling wings to vary the size of the main fuel jetting hole, a driving unit disposed to be connected to the switching plate to move a position of the switching plate, and a casing containing the swirling wings, the air duct, the switching plate and the driving unit. It is possible to enhance fuel flexibility in a multiple fuel system for applying two or more fuels to a gas turbine at the same time.

Owner:KOREA ELECTRIC POWER CORP

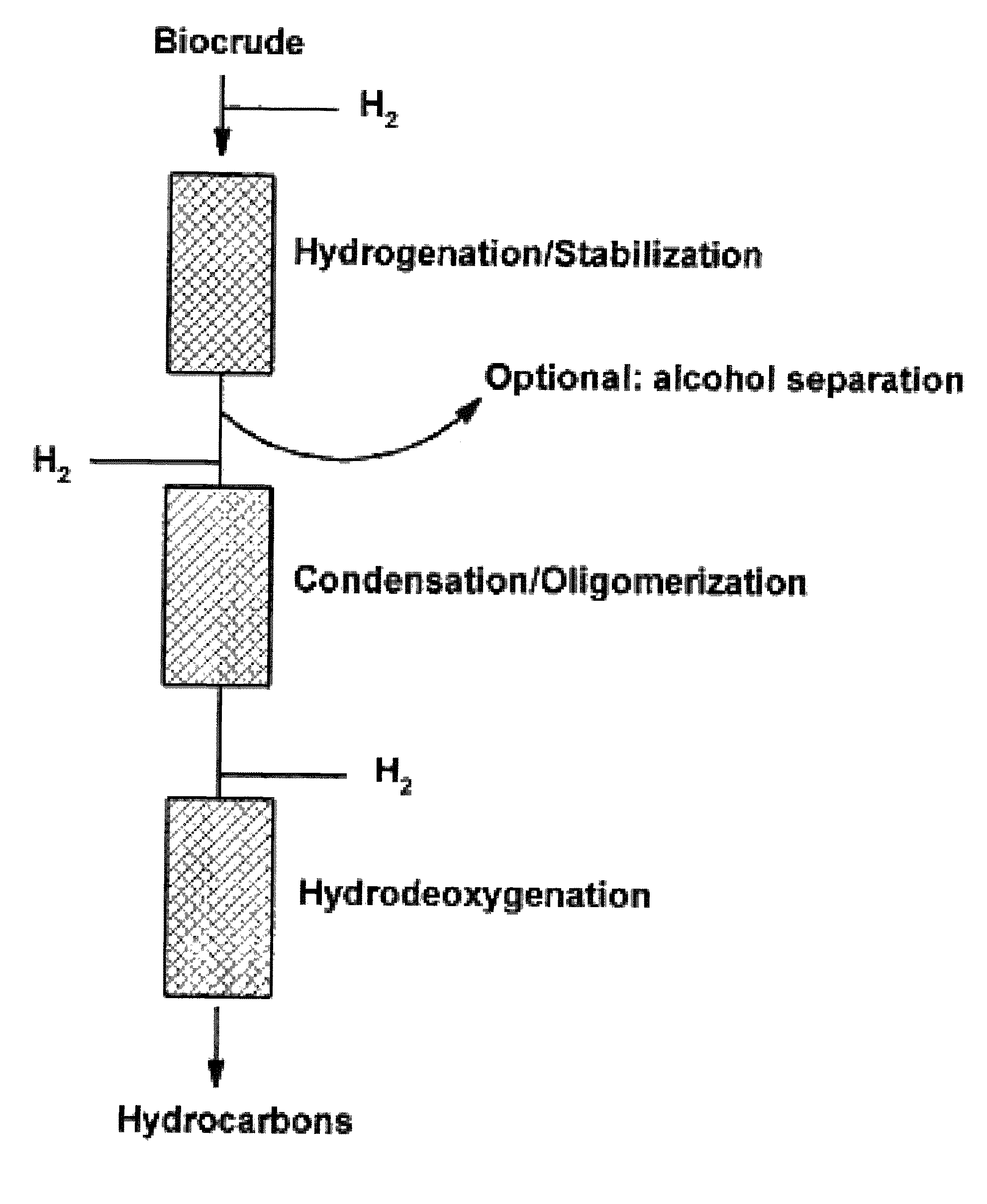

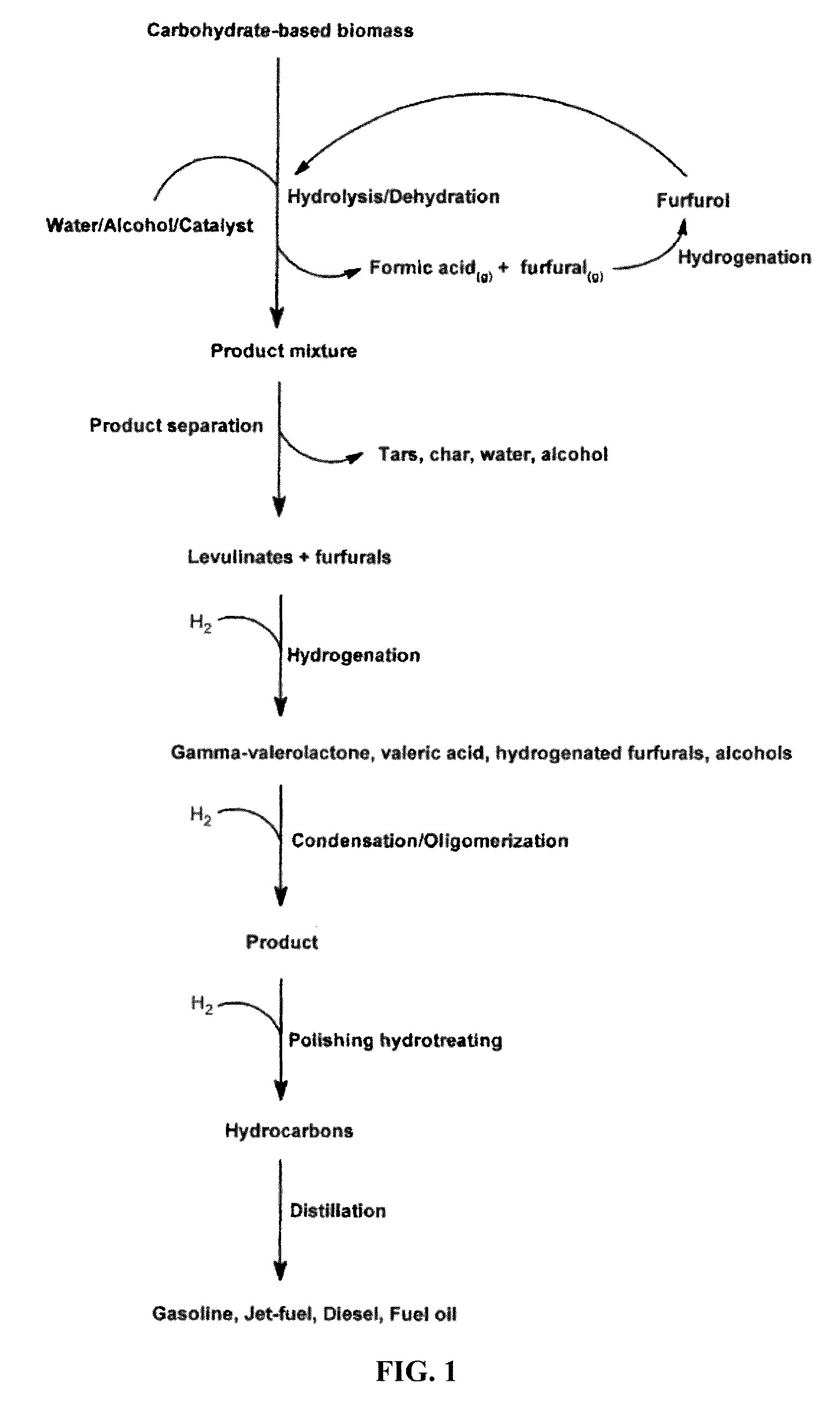

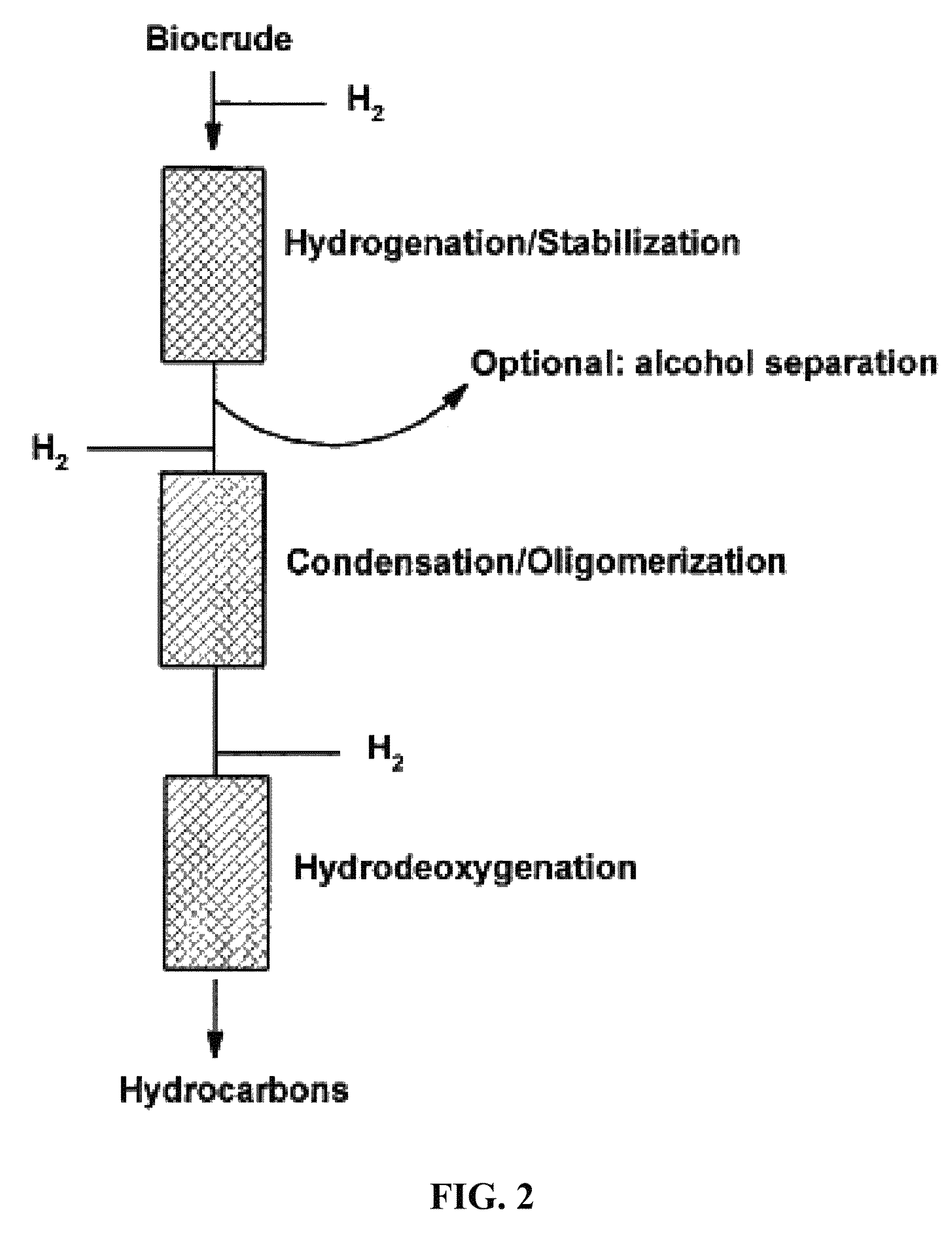

Transportation fuels from biomass oxygenates

ActiveUS8629310B2Liquid hydrocarbon mixtures productionCatalyst activation/preparationOxygenateHydrolysis

Oxygenate feedstocks derived from biomass are converted to a variety of fuels including gas, jet, and diesel fuel range hydrocarbons. General methods are provided including hydrolysis, dehydration, hydrogenation, condensation, oligomerization, and / or a polishing hydrotreating.

Owner:PHILLIPS 66 CO

Engine combustion control via fuel reactivity stratification

ActiveUS8616177B2High and low reactivityConvenience to workElectrical controlInternal combustion piston enginesMultifuelCombustion chamber

A compression ignition engine uses two or more fuel charges having two or more reactivities to control the timing and duration of combustion. In a preferred implementation, a lower-reactivity fuel charge is injected or otherwise introduced into the combustion chamber, preferably sufficiently early that it becomes at least substantially homogeneously dispersed within the chamber before a subsequent injection is made. One or more subsequent injections of higher-reactivity fuel charges are then made, and these preferably distribute the higher-reactivity matter within the lower-reactivity chamber space such that combustion begins in the higher-reactivity regions, and with the lower-reactivity regions following thereafter. By appropriately choosing the reactivities of the charges, their relative amounts, and their timing, combustion can be tailored to achieve optimal power output (and thus fuel efficiency), at controlled temperatures (and thus controlled NOx), and with controlled equivalence ratios (and thus controlled soot).

Owner:WISCONSIN ALUMNI RES FOUND

Multi-fuelling an engine

InactiveUS8327823B2Reduce the temperatureReduce susceptibilityElectrical controlInternal combustion piston enginesBiodieselCombustion chamber

A compression ignition engine is supplied with a first fuel in a flow of air and a second fuel is injected into the combustion chamber. The first fuel comprises a more volatile fuel than diesel such as ethanol, LPG or other combustible gas; the second fuel comprises diesel or biodiesel; and the second fuel is injected in multiple pulses in each ignition cycle with the first pulse acting as a pilot pulse to trigger ignition, and the timing of the second pulse being such as to modify the temperature through evaporation of the second fuel and thereby reduce the combustion temperature and mitigate knock susceptibility. Preferably the pilot pulse is followed by a single further pulse of the second fuel in the ignition cycle. The engine may be controlled to operate in two different modes, one mode for light and medium load conditions when there is only a pilot pulse injection of the second fuel which reduces NOx and soot emissions, and the other mode for higher load conditions when there is a pilot pulse injection followed by a main pulse injection of the second fuel. The first fuel may comprise bioethanol and or one or more of the following: ethanol, butanol, propanol, lpg, natural gas, hydrogen.

Owner:G VOLUTION

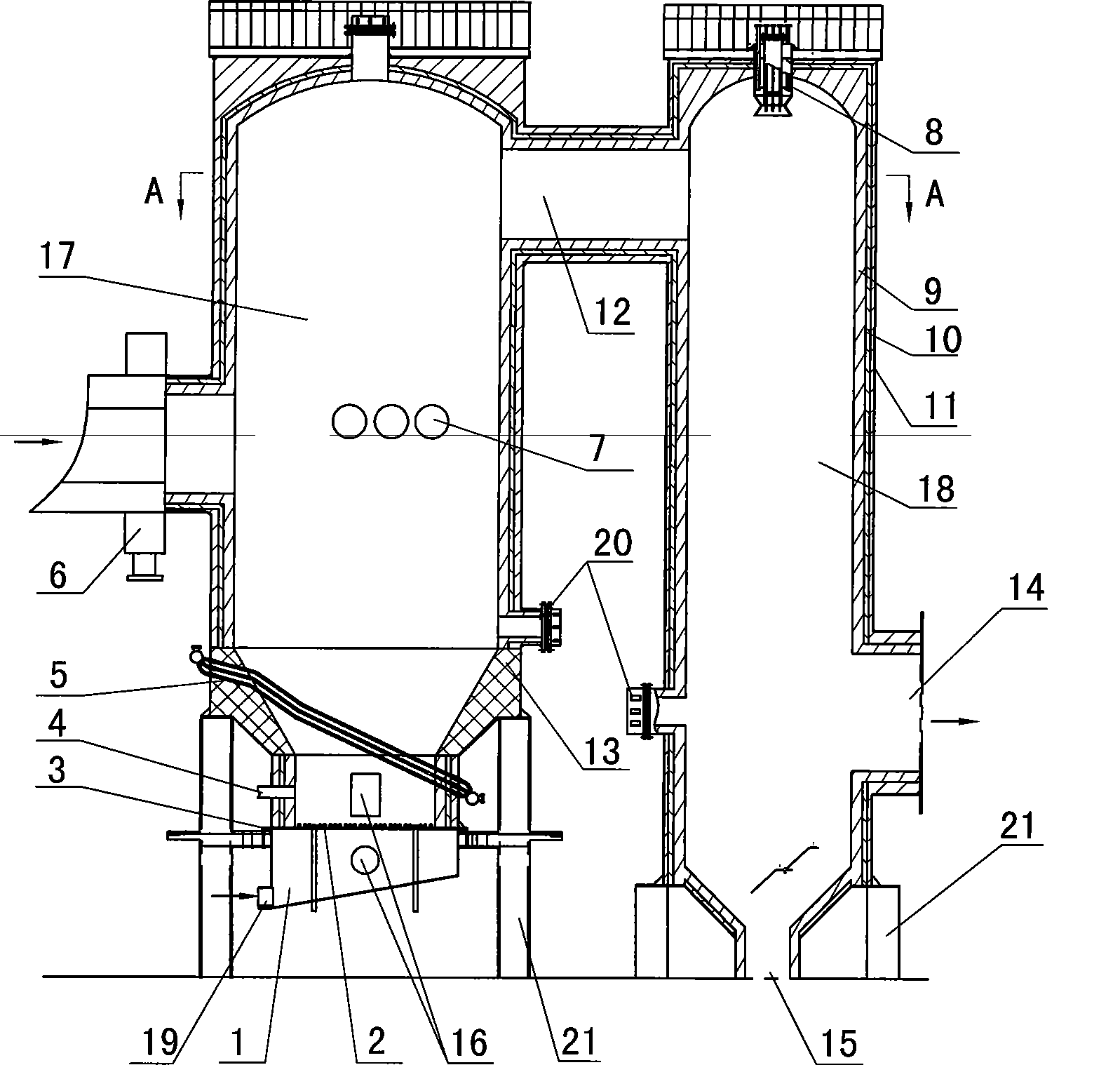

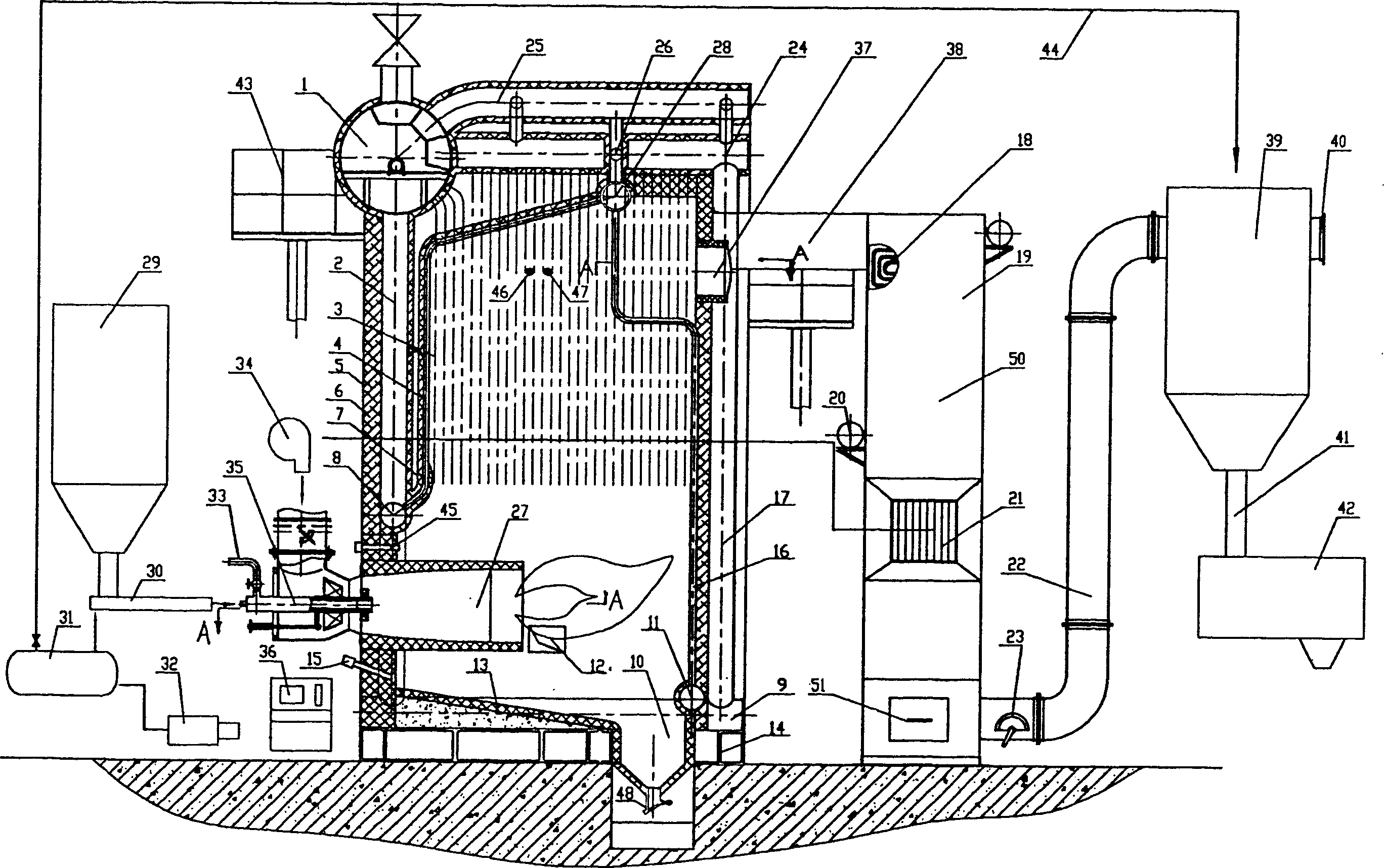

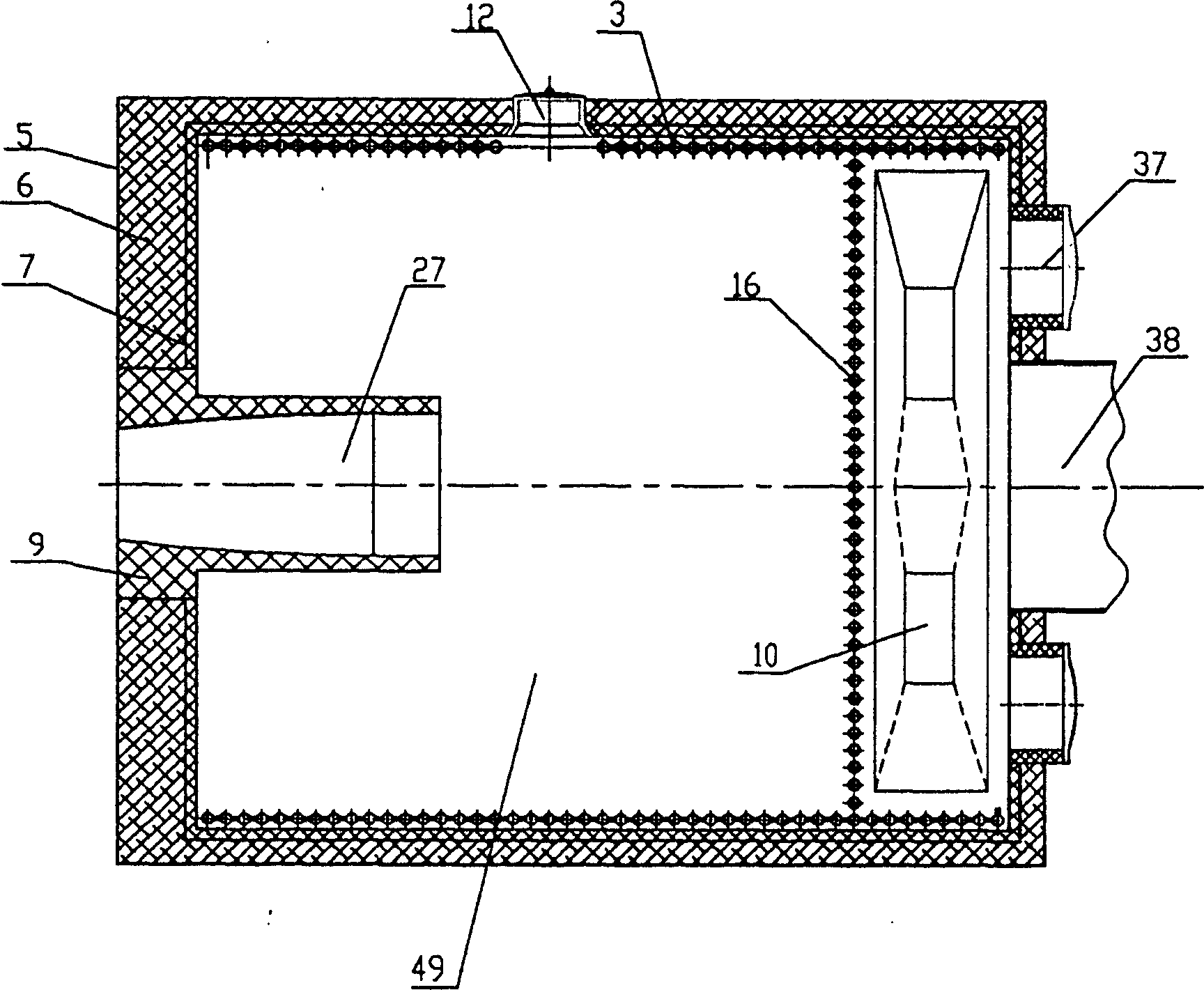

Three-phase multi-functional mixed combustion furnace

ActiveCN101504144AAchieve mutual complementarityReduce resistanceAir/fuel supply for combustionIncinerator apparatusGas phaseHearth

The invention provides a three-phase all-functional multifuel burner, which comprises a main burning furnace for burning coal and waste gas. The bottom of the main burning furnace is provided with a wind chamber; the upper end face of the wind chamber is provided with an air distributing plate; air caps are uniformly distributed on the air distributing plate; a coal burning area on the middle lower part of a hearth of the main combustion furnace is slantwise or vertically provided with a plurality of water pipes which form the water circulation with the outside; the middle part of the hearth is provided with a burning nozzle; and a waste gas inlet on the middle side wall of the main burning furnace is provided with a mixed burner. The burner is characterized in that: an auxiliary burning furnace is arranged; the upper part of the auxiliary burning furnace is tangentially communicated with the main burning furnace through a flue; and the top part of the auxiliary burning furnace is provided with a waste liquid burner, the bottom is an ash outlet, and the side wall on the middle lower part is provided with a heat outlet. The multifuel burner not only can burn coal cinder and the waste gas, but also can use the high temperature generated by the burning to incinerate the waste liquid, and achieve the favorable situation that a gas phase, a liquid phase and a solid phase are burned together. The burner also can be used for dual combination burning of gas-liquid, gas-solid or liquid-solid or can singly burn one fuel, and has good working performance.

Owner:山东本正能源科技有限公司

Transient Event Fuel Apportionment for Multi Fuel Engine System

A method for controlling fuel flow in a multi fuel engine during transient events is disclosed. A specified fuel substitution ratio may be used for apportioning multiple fuels available for providing power to the multi fuel engine to provide input power for operating the engine at a desired engine speed. When a transient event occurs, such as a significant change in the desired engine speed or the load on the engine, a transient event fuel substitution ratio may used instead of the specified fuel substitution ratio to achieve a desired engine response to the event. The transient event may be detected based on, for example, the change in input power or engine speed caused by the event. The transient event fuel substitution ratio may be specified, or may be calculated based on a knock limit air fuel ratio or other factors.

Owner:CATERPILLAR MOTOREN

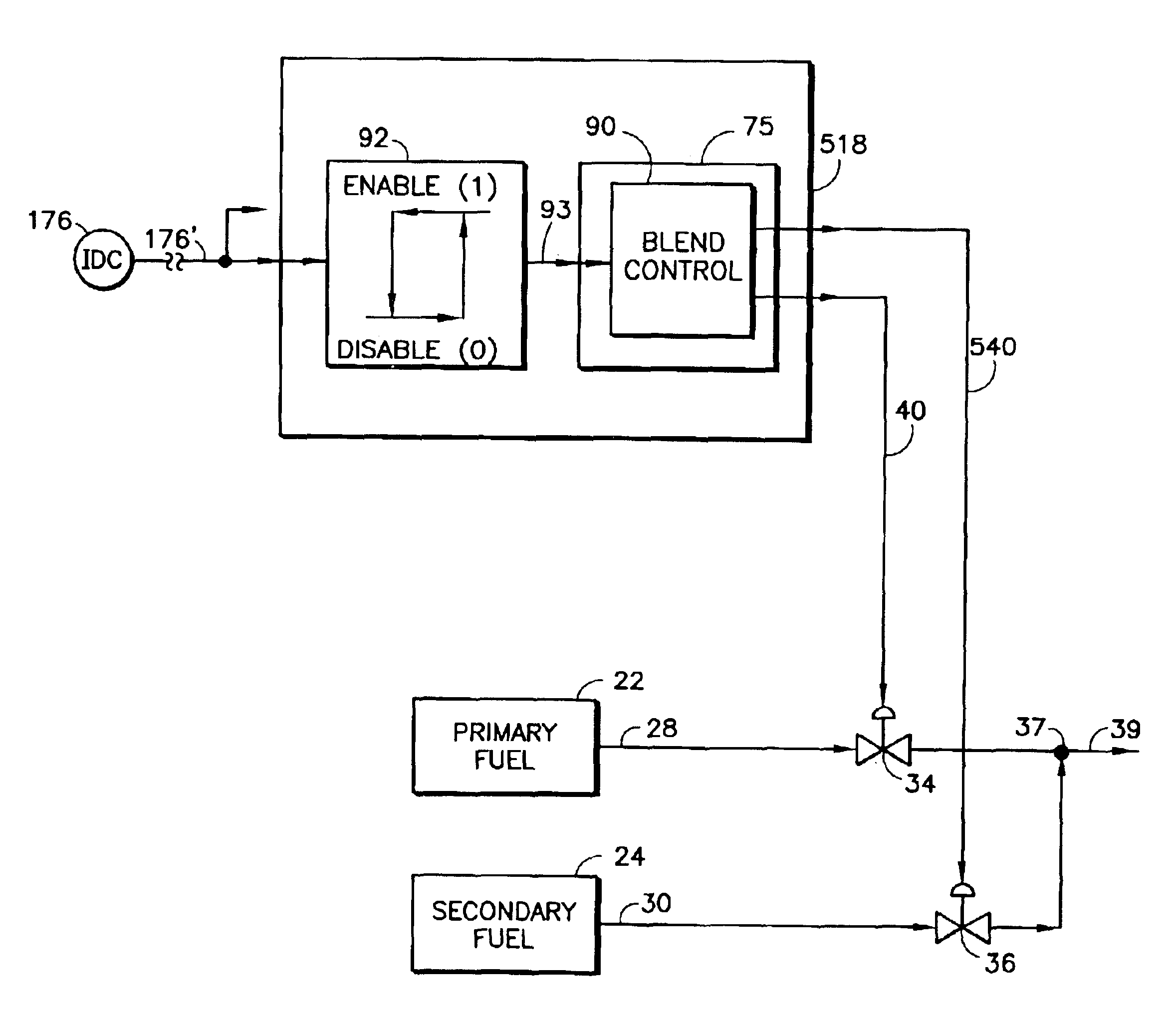

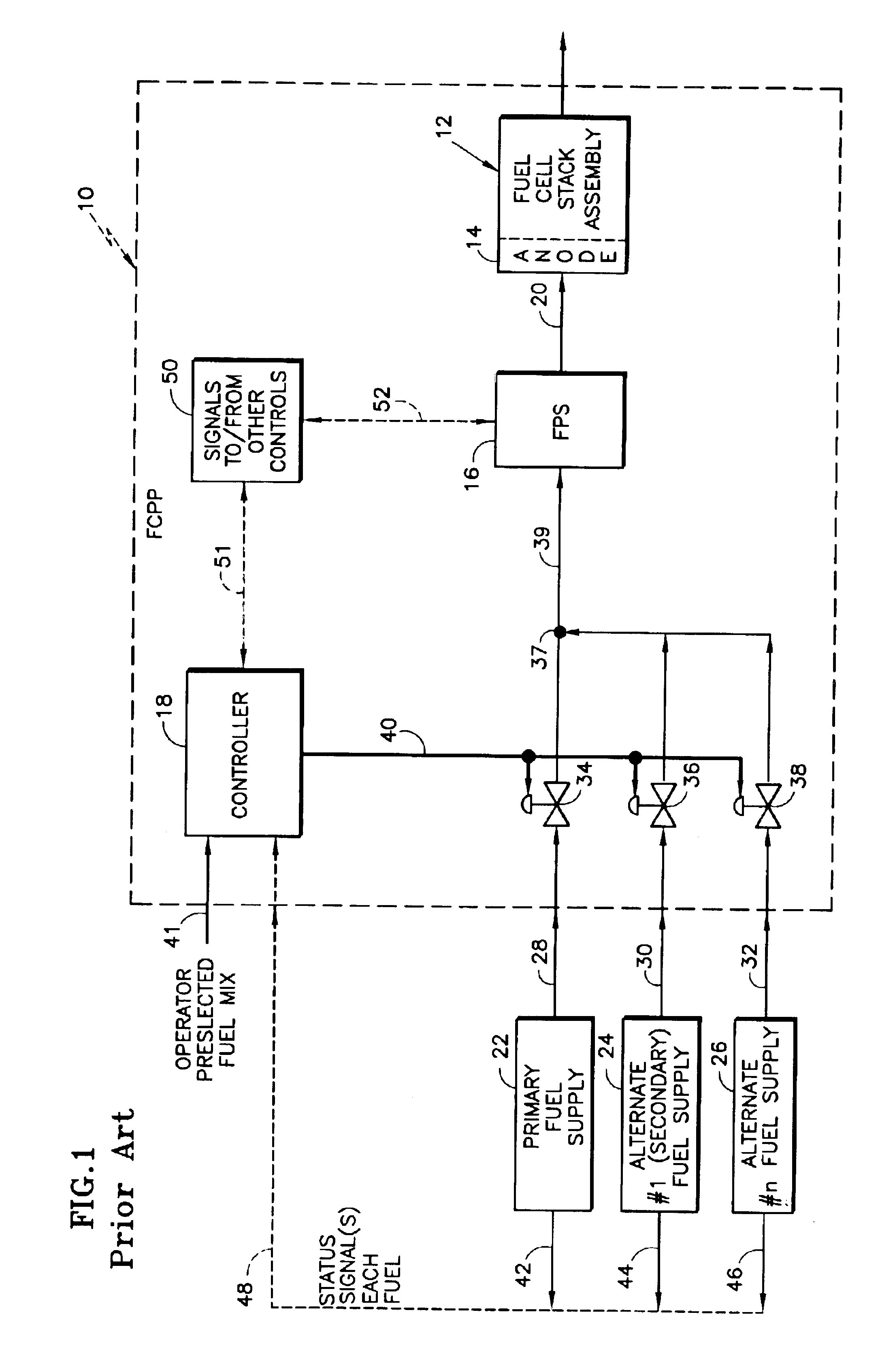

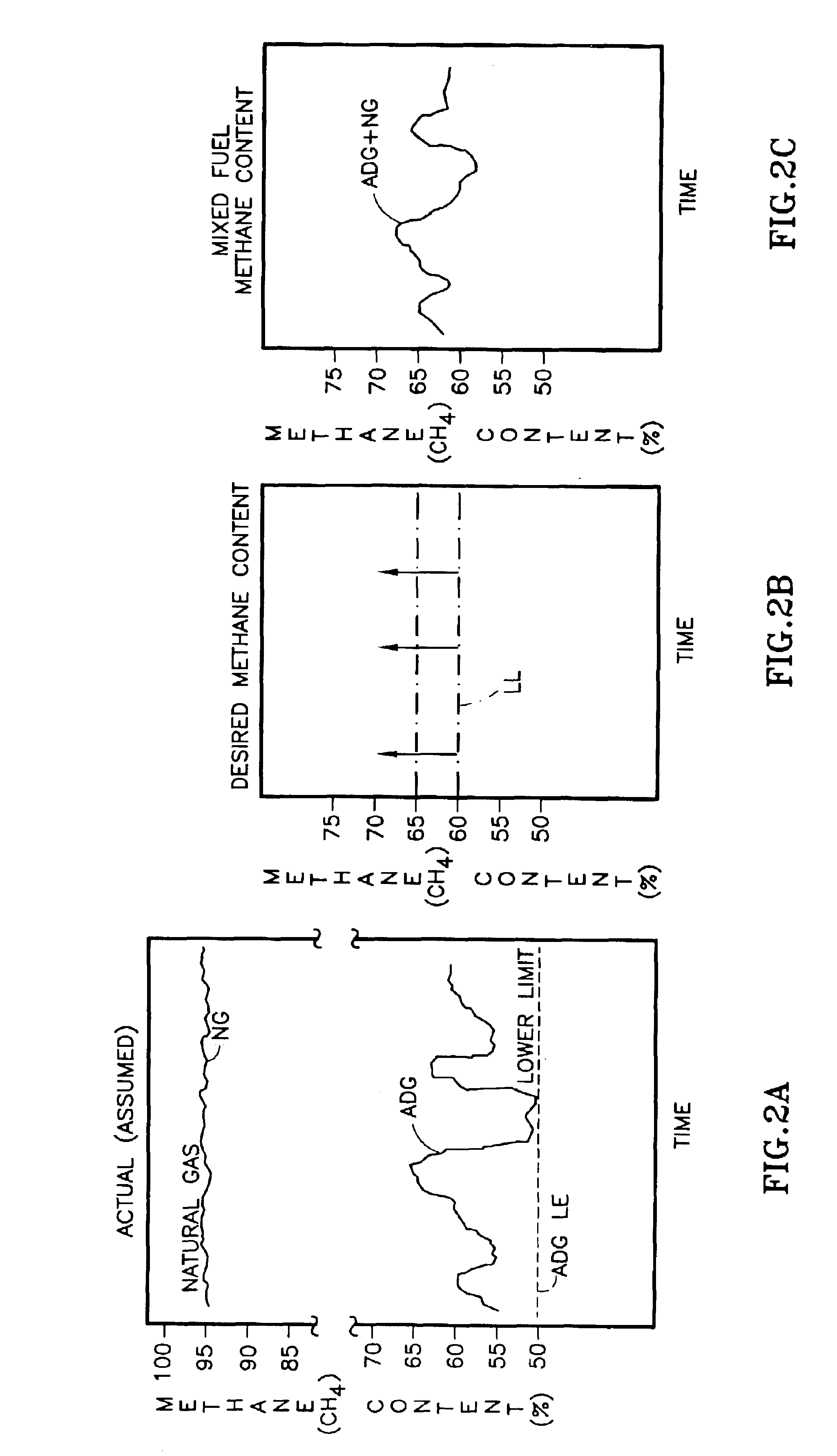

Fuel mixing control for fuel cell power plants operating on multiple fuels

Fuel mixing control arrangements are provided for fuel cell power plants (10) operating on multiple fuels (22, 24, 26). A fuel delivery system (16) supplies hydrogen-rich fuel (20) to the cell stack assembly (CSA) (12) after controlled mixing of a primary fuel (22) and at least a secondary fuel (24), each having a respective “equivalent hydrogen (H2) content”. The relative amounts of the primary fuel (22) and secondary fuel (24) mixed are regulated (18, 34, 36) to provide at least a minimum level (LL) of hydrogen-rich fuel having an equivalent hydrogen content sufficient for normal operation of the CSA (12). The primary fuel (22) is a bio-gas or the like having a limited, possibly variable, equivalent H2 content, and the secondary fuel (22) has a greater and relatively constant equivalent H2 content and is mixed with the primary fuel in an economic, constant relationship that assures adequate performance of the CSA (12). One or more parameters (IDC, P, V, E. C.) of the operating power plant (10) related to the equivalent H2 content of at least the primary fuel may be sensed (72, 26, 78, 84, 176) and used to control (18, 36) the relative amounts of secondary and primary fuels (22, 24) mixed in response thereto.

Owner:INT FUEL CELLS

Multi-gaseous fuel control device for a combustion engine with a carburetor

InactiveUS7395818B2Increase rangeIncrease in sizeInternal combustion piston enginesFuel supply apparatusMultifuelInlet valve

Owner:WALBRO ENGINE MANAGEMENT

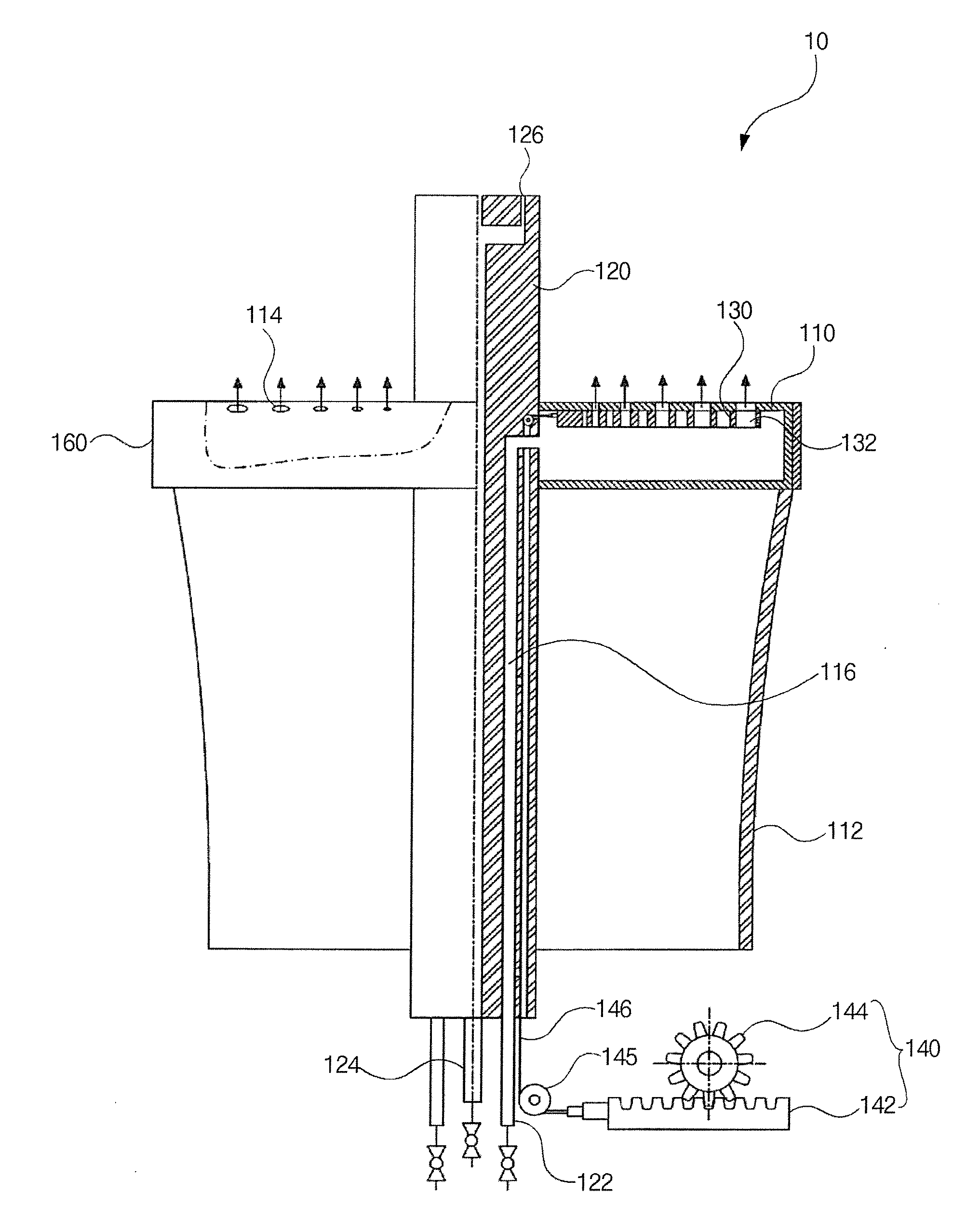

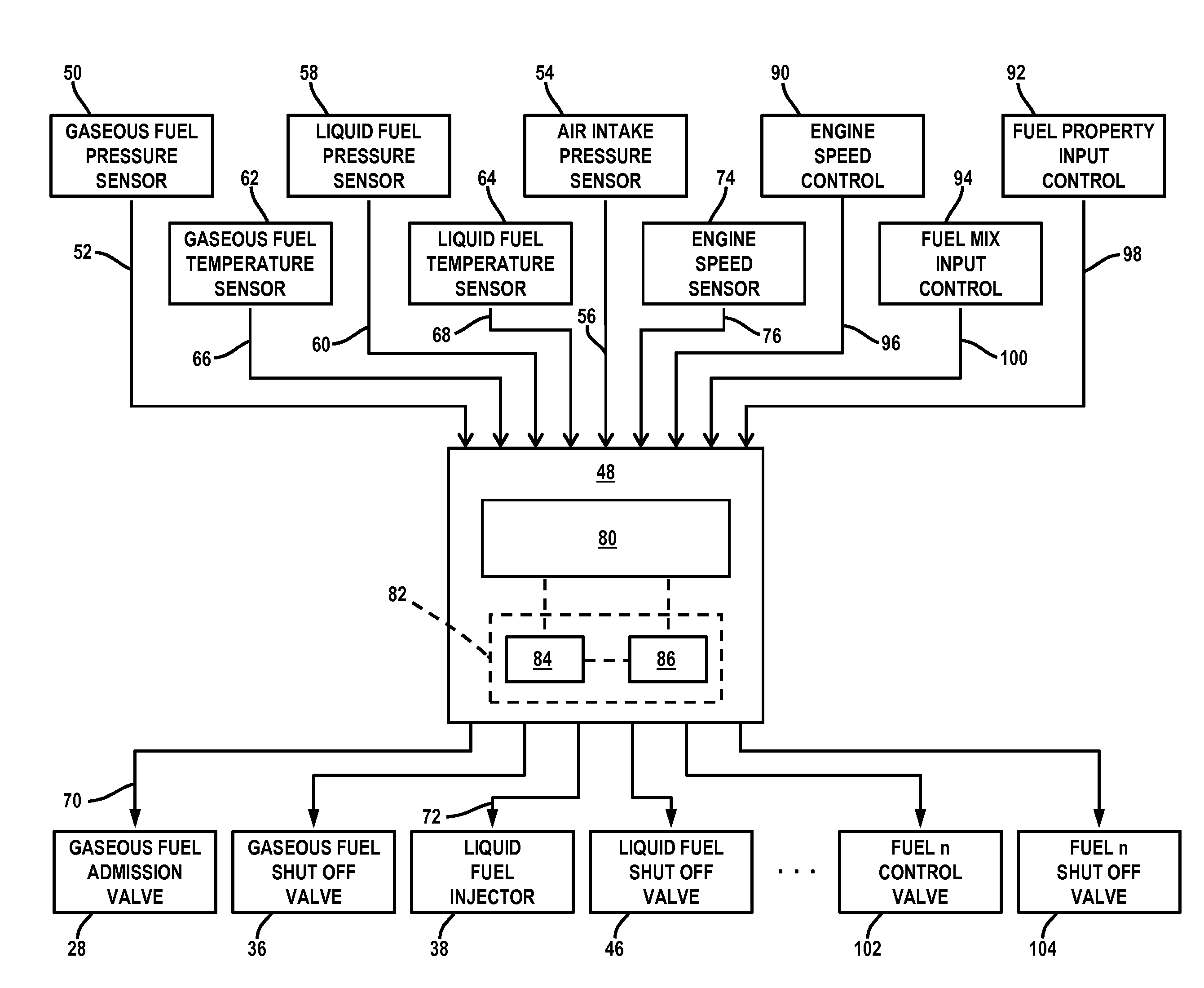

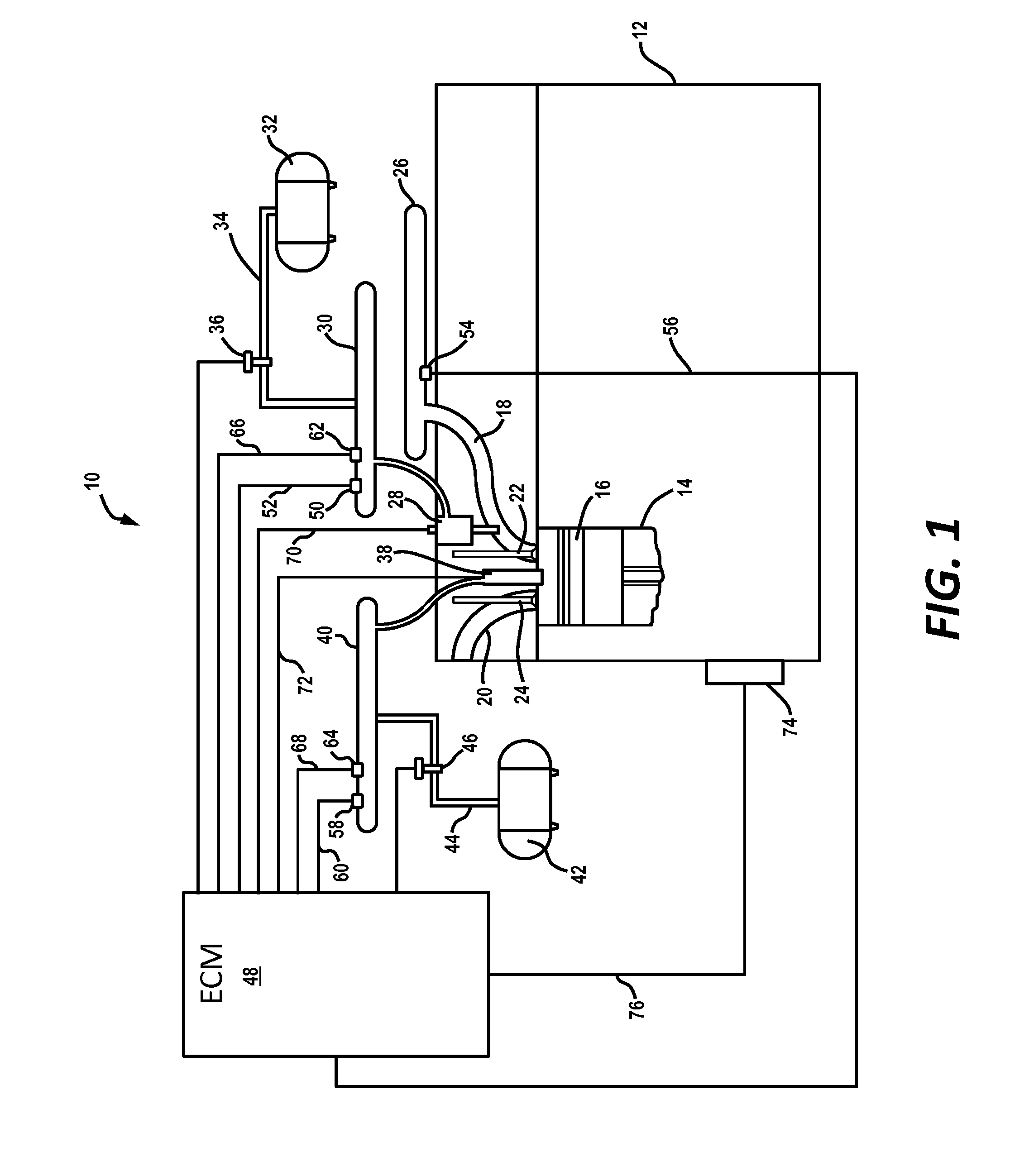

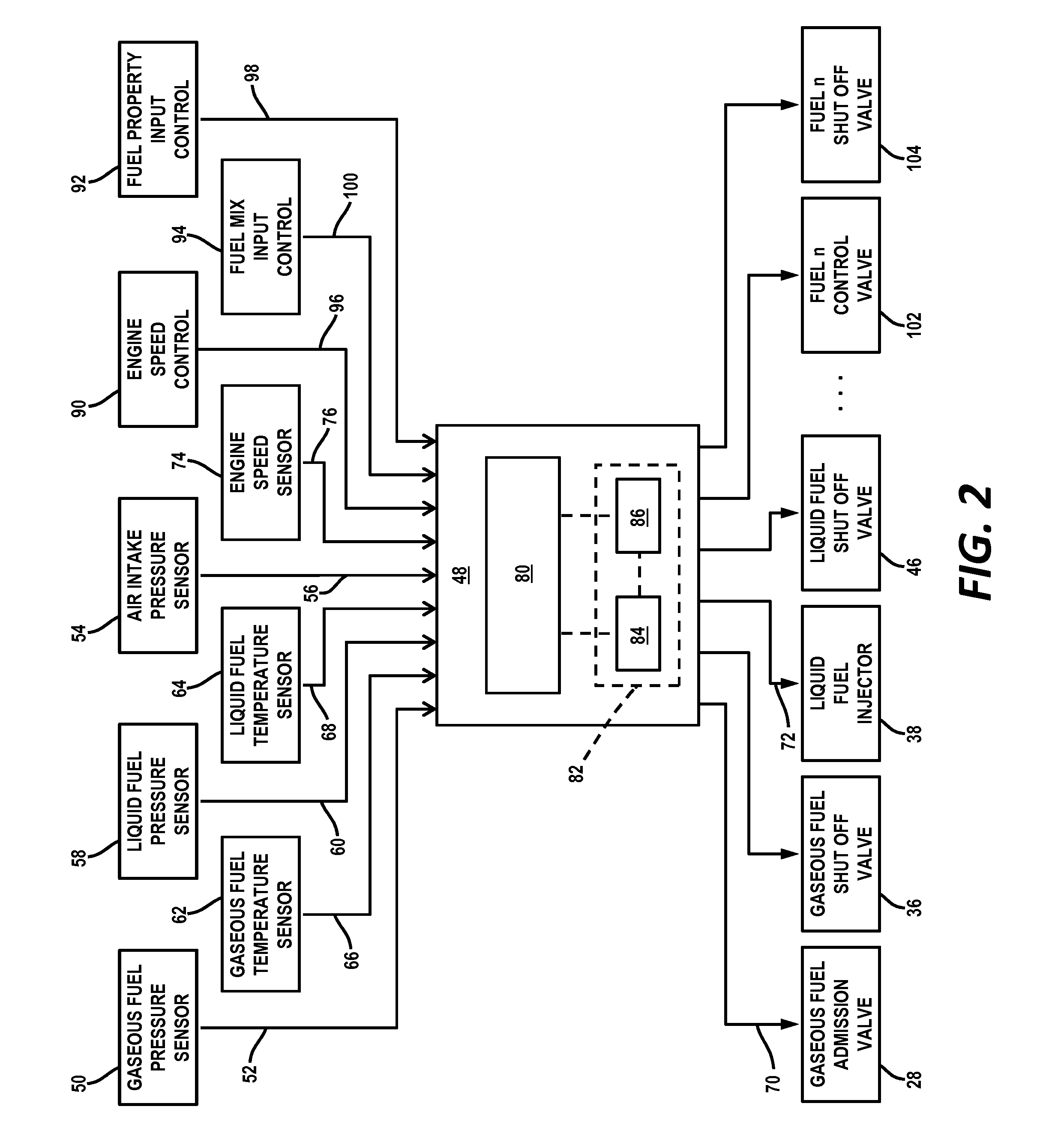

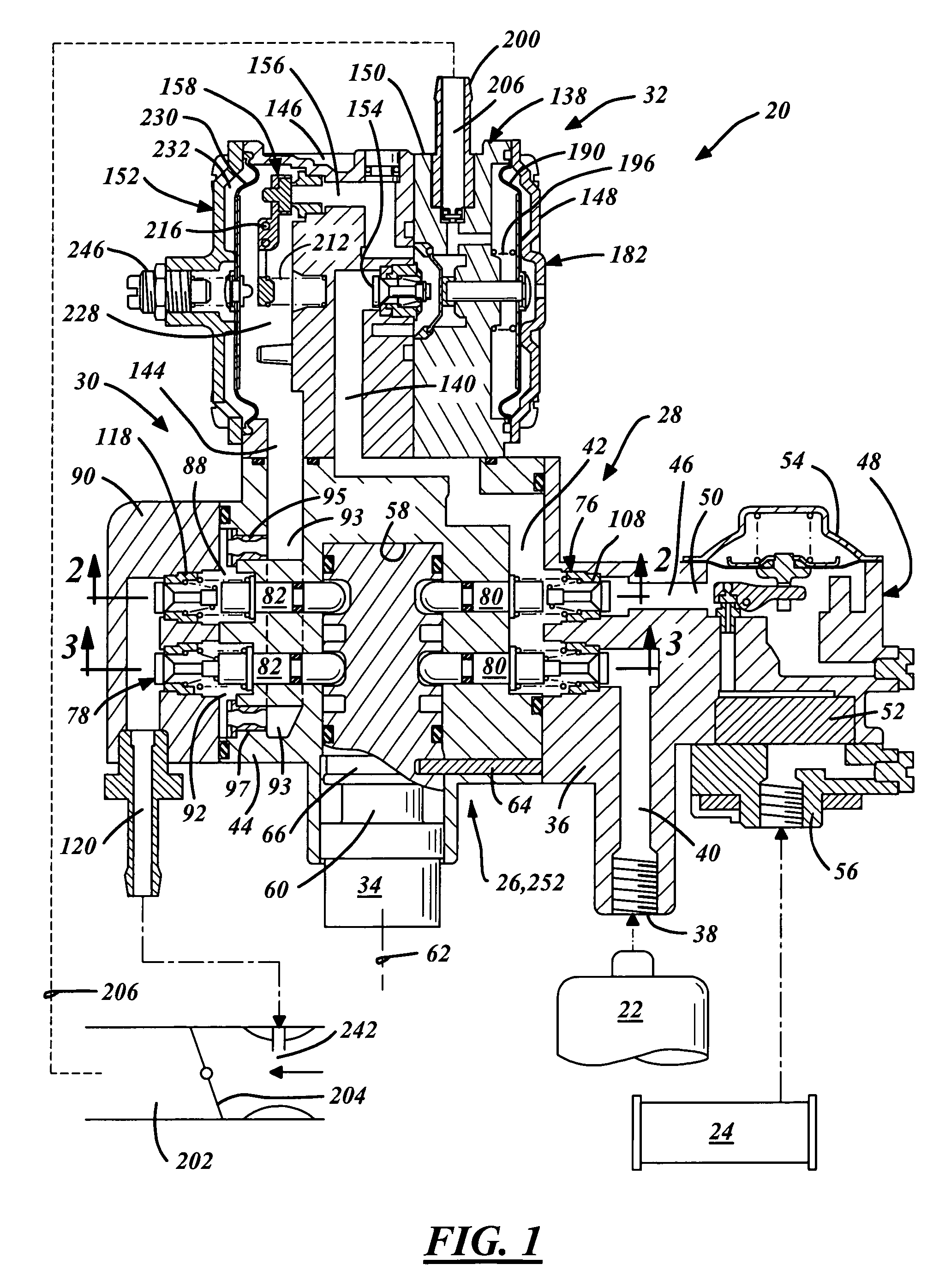

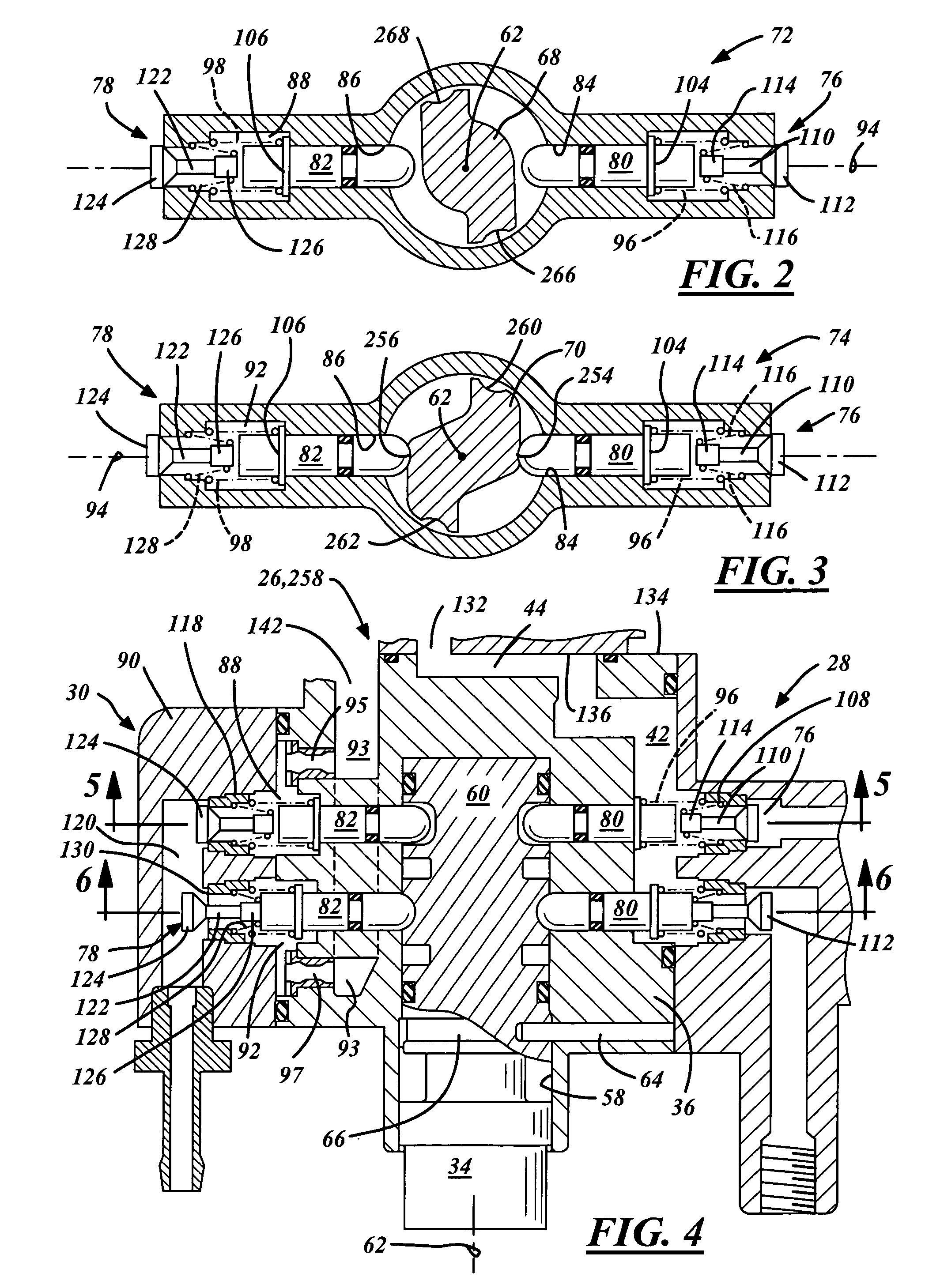

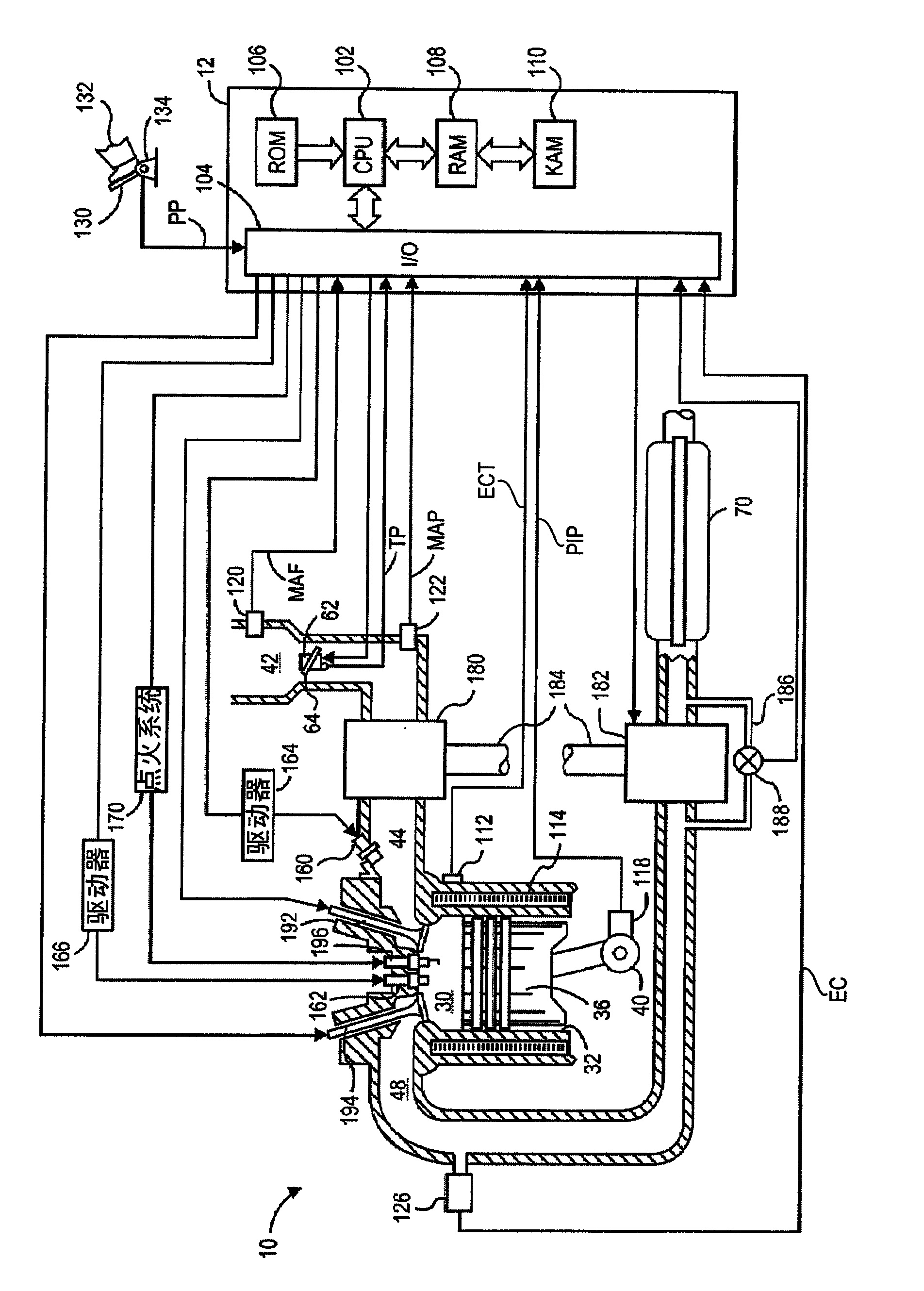

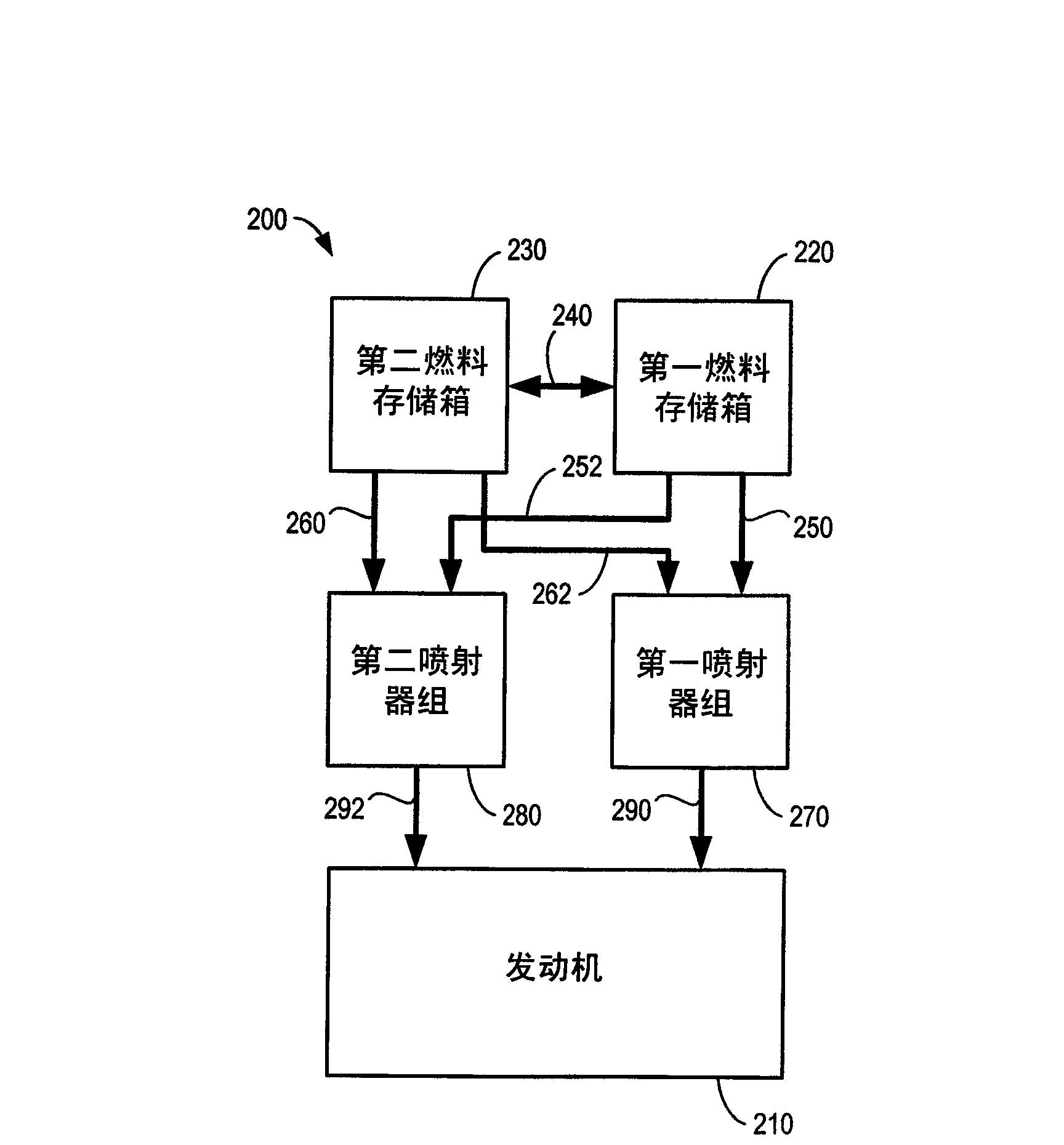

Fuel delivery system for a multi-fuel engine

The invention relates to a fuel delivery system for a multi-fuel internal combustion engine. The fuel delivery system for the multi-fuel internal combustion engine and an approach for operating the fuel delivery system are provided. The fuel delivery system can be operated in two or more different fuel delivery modes according to operating conditions of the engine or fuel delivery system. A first example mode can be performed to concurrently deliver two or more fuels to the engine. A second example mode can be performed to transfer fuel from a first fuel storage tank to a second fuel storage tank. A third example mode can be performed to supply a fuel from a first fuel storage tank to at least two fuel injectors of each cylinder of the engine. In some embodiments, the various modes of operation may be selected by varying a fuel pressure that is provided by the fuel delivery system. The system and the method provided by the invention is good for inhibiting detonation and improving engine operation.

Owner:FORD GLOBAL TECH LLC

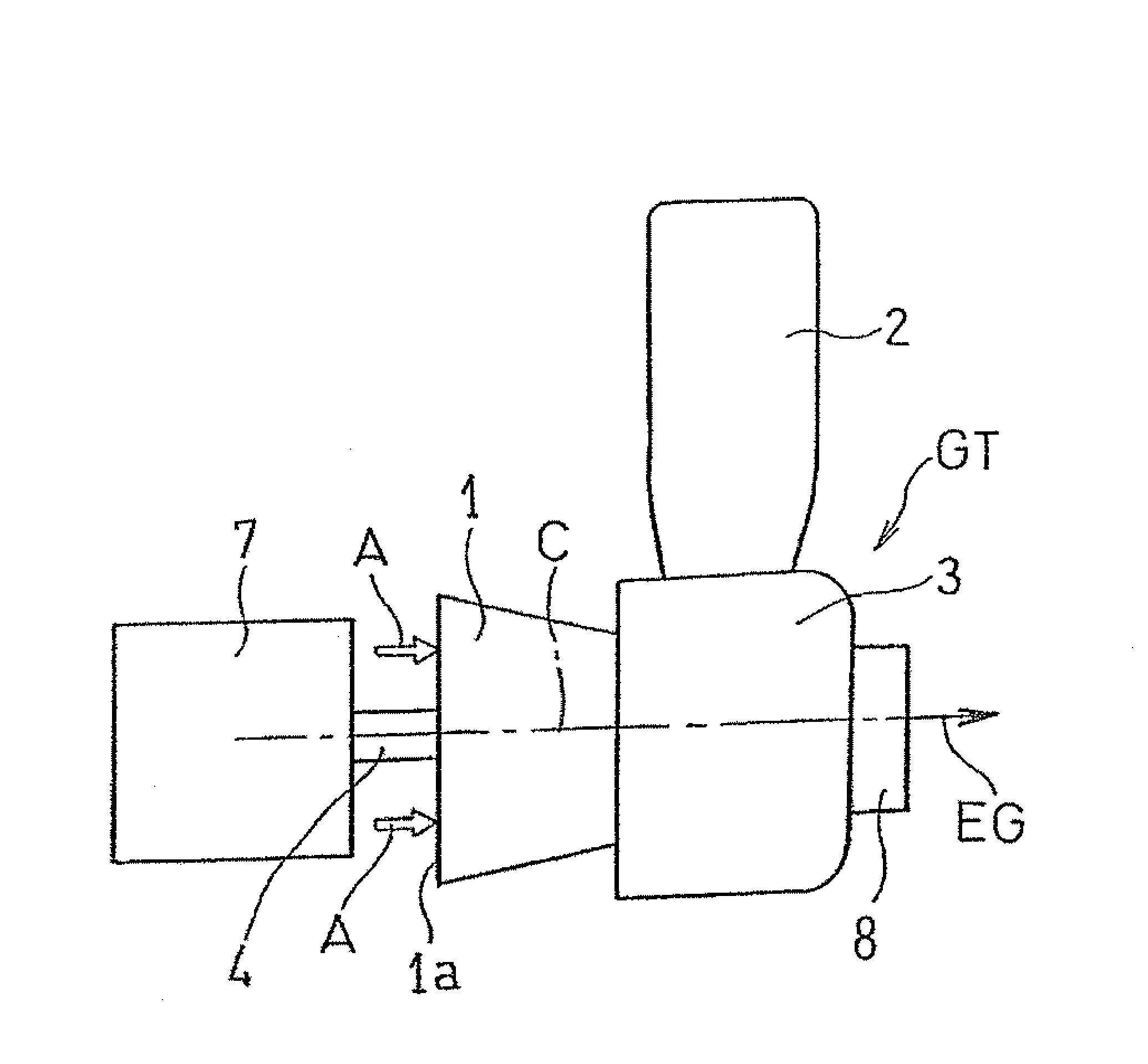

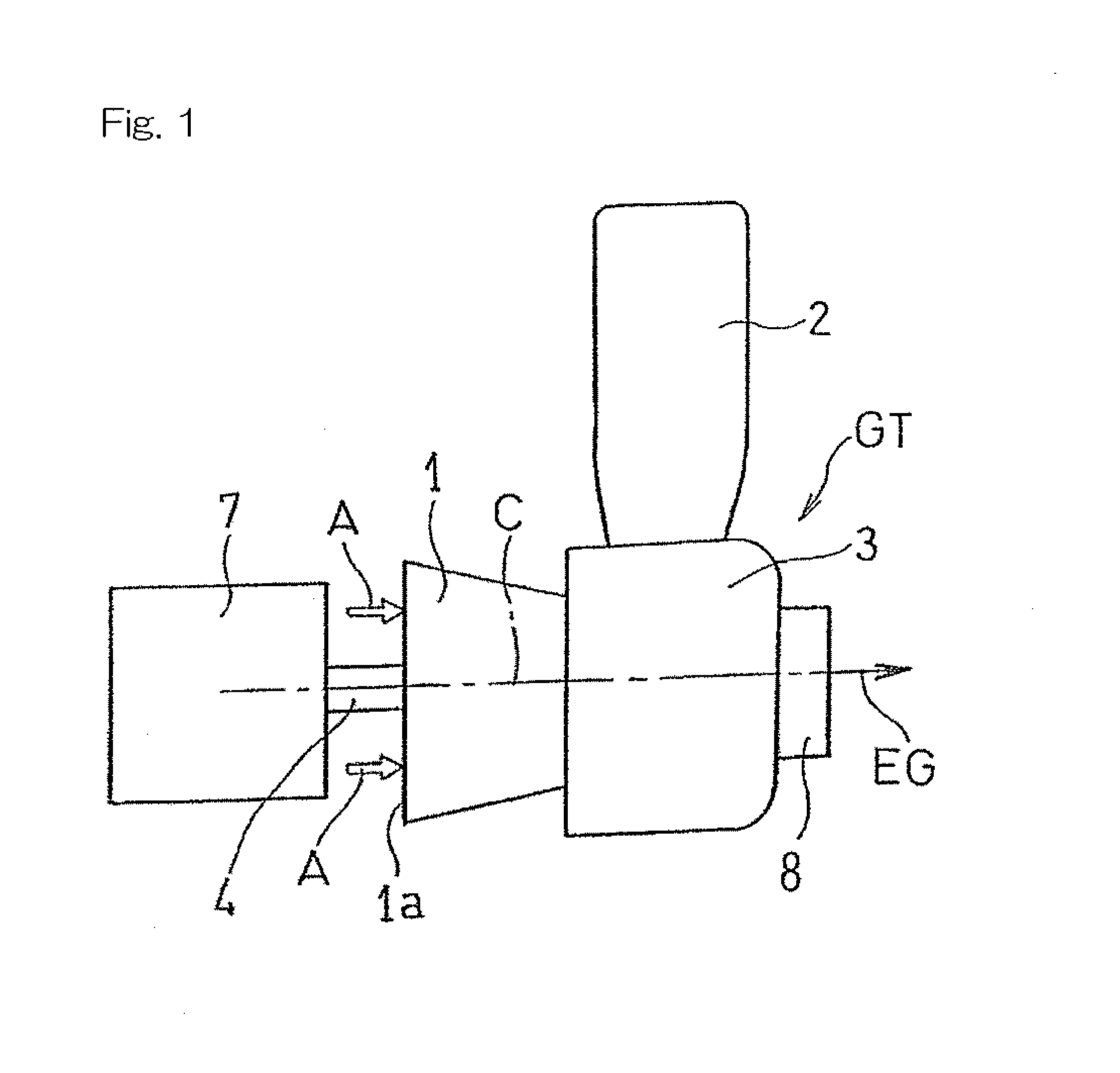

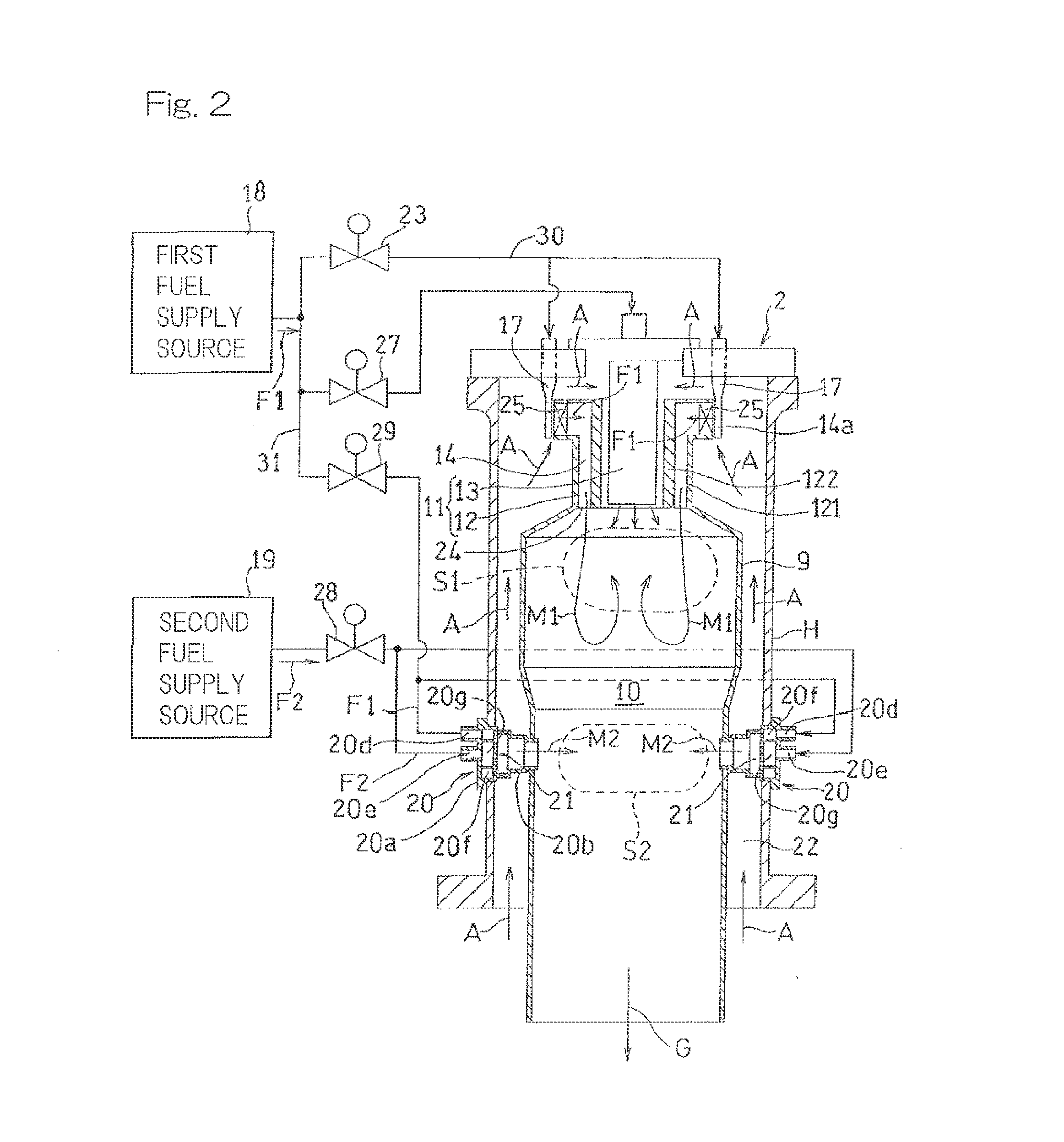

Multifuel gas turbine combustor

ActiveUS20150362194A1Low NOxEmission reductionBurnersContinuous combustion chamberHigh concentrationMultifuel

To provide a multifuel gas turbine combustor capable of combusting gases containing hydrogen in a high concentration with a low NOx while maintaining a low emission performance brought about by the pre-mixture combustion in the main burner, the gas turbine combustor includes a main burner (12) for supplying to and combusting a premixed gas (M), containing a first fuel (F1), within a first combustion region (S1) of a combustion chamber (10), and a supplemental burner (20) for supplying to and combusting a second fuel (F2) of a composition different from that of the first fuel (F1) within a second combustion region (S2) defined downstream of the first combustion region (S1) within the combustion chamber (10). The first fuel (F1) is of a hydrocarbon system and the second fuel (F2) is a gas containing hydrogen in a concentration exceeding the stable combustion limiting concentration of the hydrogen.

Owner:KAWASAKI HEAVY IND LTD

Industrial boiler of multi-fuel burning using ultrafine coal dust as main fuel

InactiveCN1724928AImprove burnout rateFully mixed combustionBurnersCombustion using multiple fuelsMultifuelCoal dust

The invention discloses an industrial boiler fired by multiple mixed fuels with superfine powder coal(water coal slurry) as the primary and natural gas or oil products as the auxiliary, and it is an industrial boiler with the advantages of high firing efficiency, low cost, auto control and reduction of environmental pollution, especially applied to middle-small scale industrial boilers.

Owner:姜政华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com